Method for predicating surface roughness and surface topography simulation of car milling compound machining

A technology for surface topography and surface machining, which is applied in the field of surface roughness and surface topography simulation and prediction of turning and milling compound cutting, and can solve the problems of inability to accurately describe the turning and milling compound machining process and low degree of bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0115] See Figure 9 , the present invention is a method for simulating and predicting the surface roughness and surface topography of turning-milling composite cutting. The specific steps of the method are as follows:

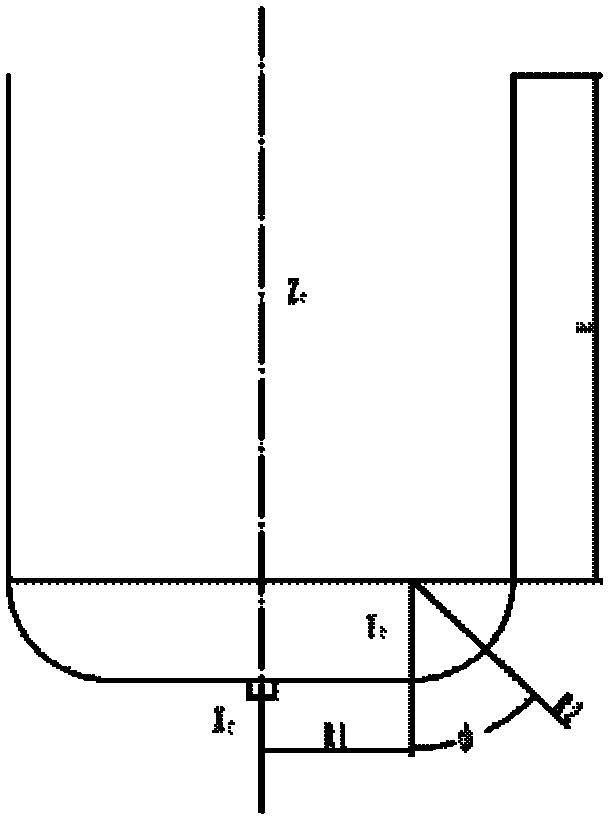

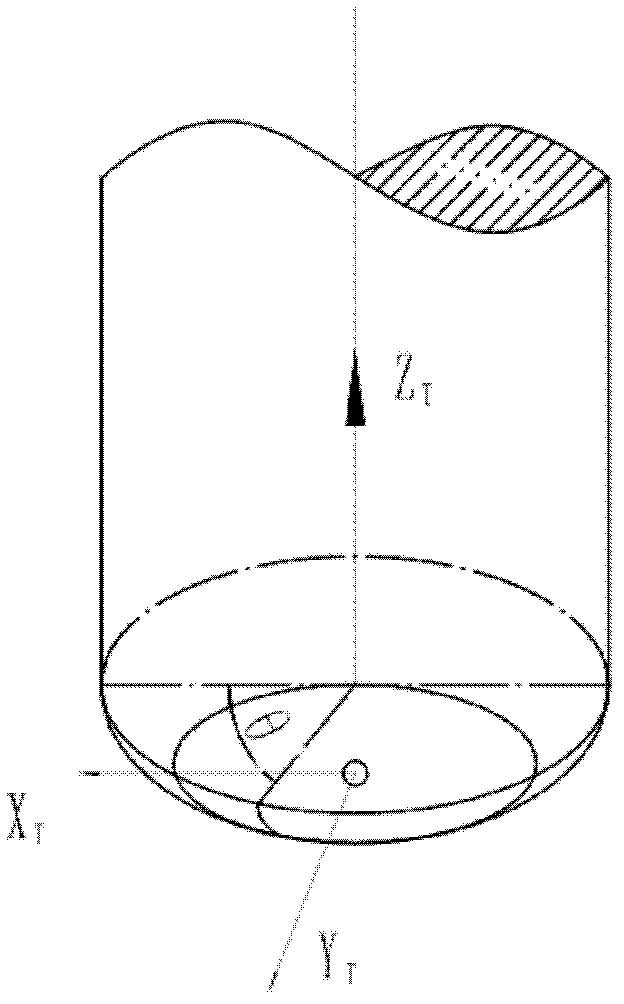

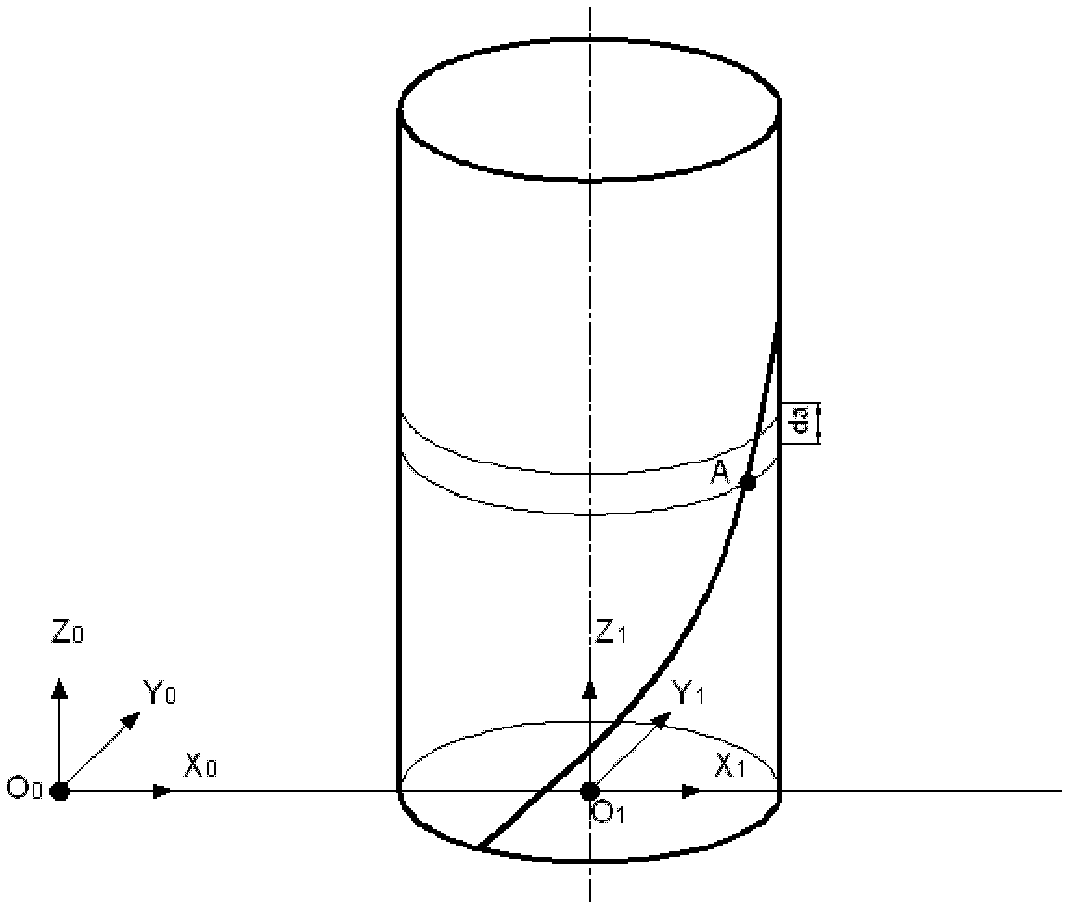

[0116] Step 1: Establish a unified tool position coordinate model for the overall knife and the insert knife

[0117] Solid carbide cutters and insert cutters have their own advantages in actual machining, but in the preliminary geometric modeling, because the milling cutter rotates at a high speed around its own axis, the outer contour of the cutter appears to be continuous after it rotates along the main axis , therefore, the establishment of the model can be carried out uniformly. In this way, the coordinates on the cutting edges of various tools such as ring cutters, ball-end cutters, and plane end mills can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com