Auxiliary laser heating milling device and method

A laser heating and milling processing technology, applied in laser heating assisted milling processing device, processing of difficult-to-machine materials, and laser heating assisted milling processing field, can solve the difficulty of combining laser and milling, and the relative position of laser and milling cutter cannot be adjusted and restricted. Technical application scope and other issues, to achieve the effect of simple and convenient system establishment, easy operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

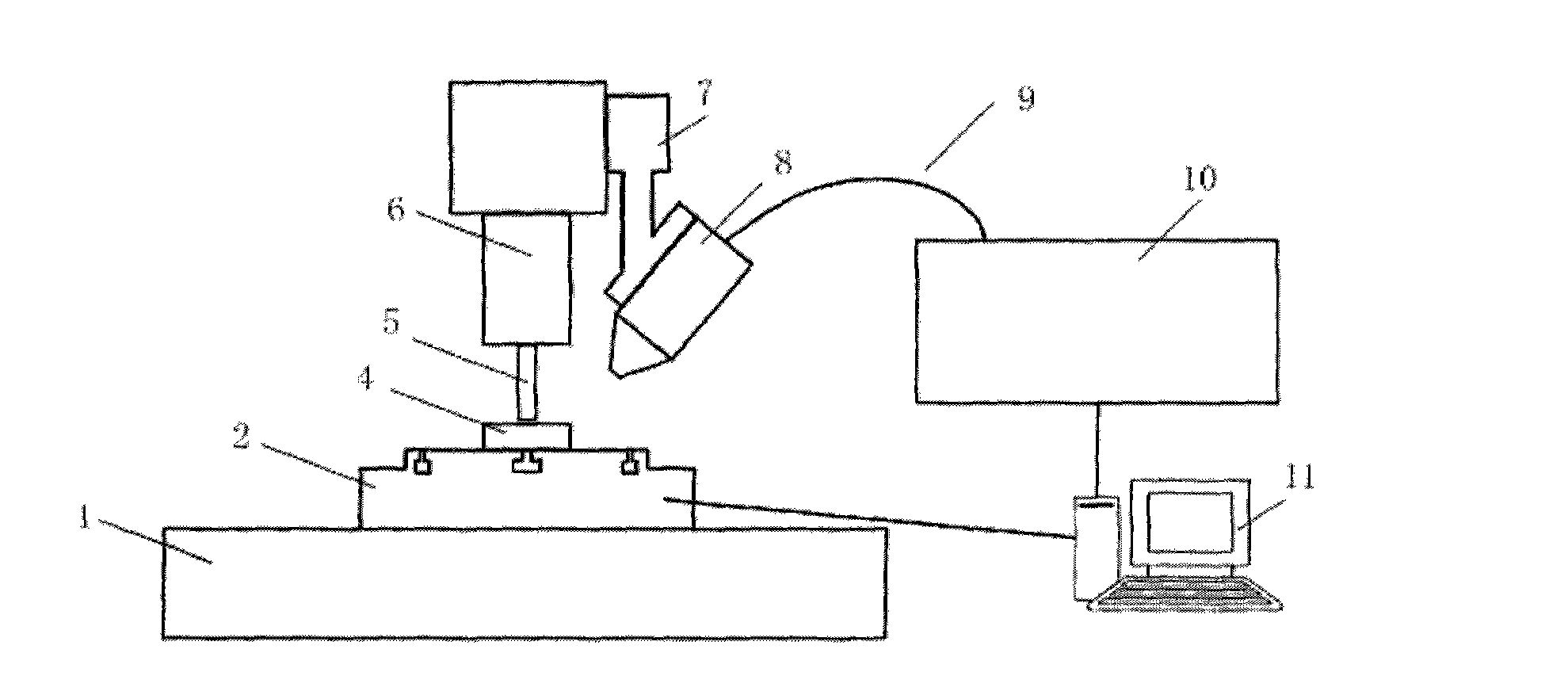

[0030] Embodiment 1: For processing straight lines, the processing accuracy is not high or the existing milling machine cannot meet the requirements. The schematic diagram of the method device is as figure 1 As shown, the system is simple to set up by adopting this scheme. It is enough to add a rotating worktable 2 on an ordinary CNC milling machine. First, adjust the position and process in one direction. When the processing direction needs to be changed, the milling cutter 5 is lifted, the shutter is closed, and the work is rotated. The table 2 is rotated to the next position so that the processing direction is the same as the incident direction of the laser. At the same time, the work table 1 is moved to the rotated processing position, and the milling cutter 5 is lowered to perform processing at the next position. However, since the relative position of the laser incidence cannot be adjusted at any time during the processing, only straight-line trajectories can be processed....

Embodiment approach 2

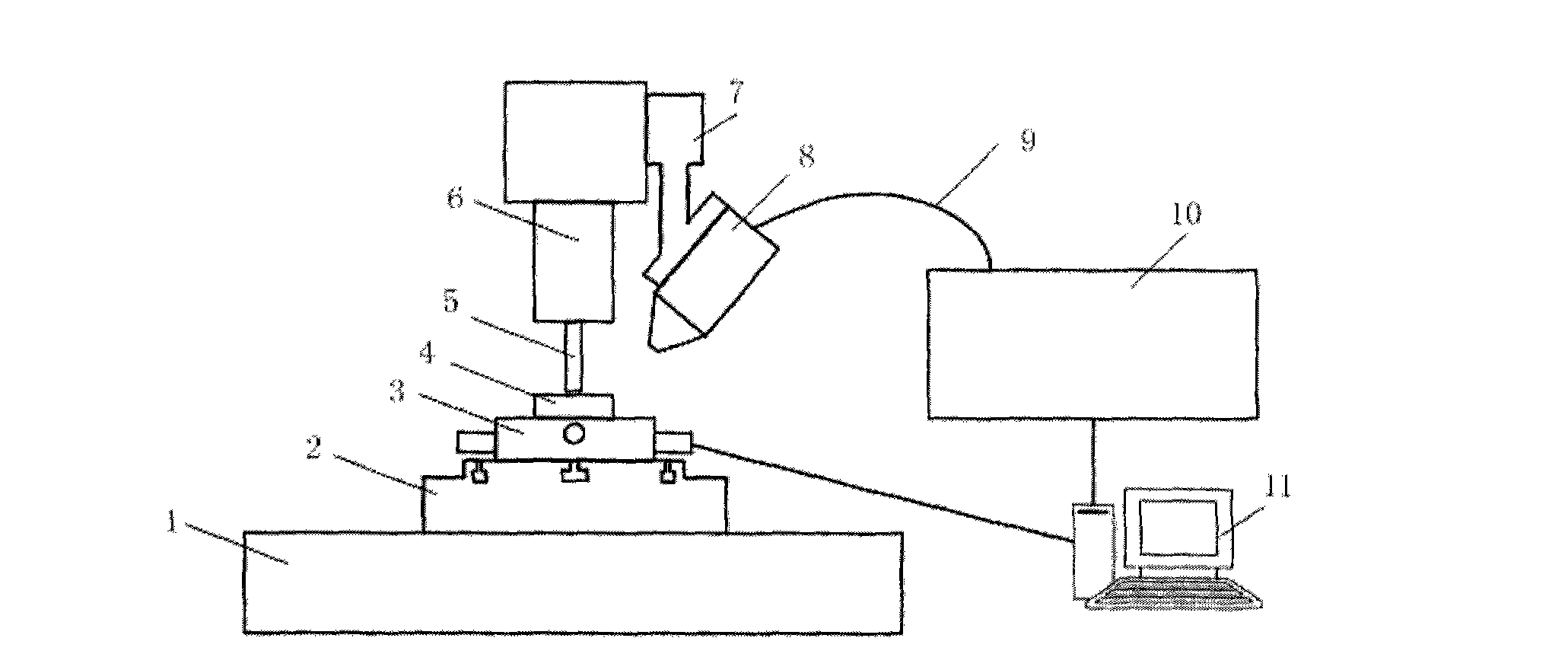

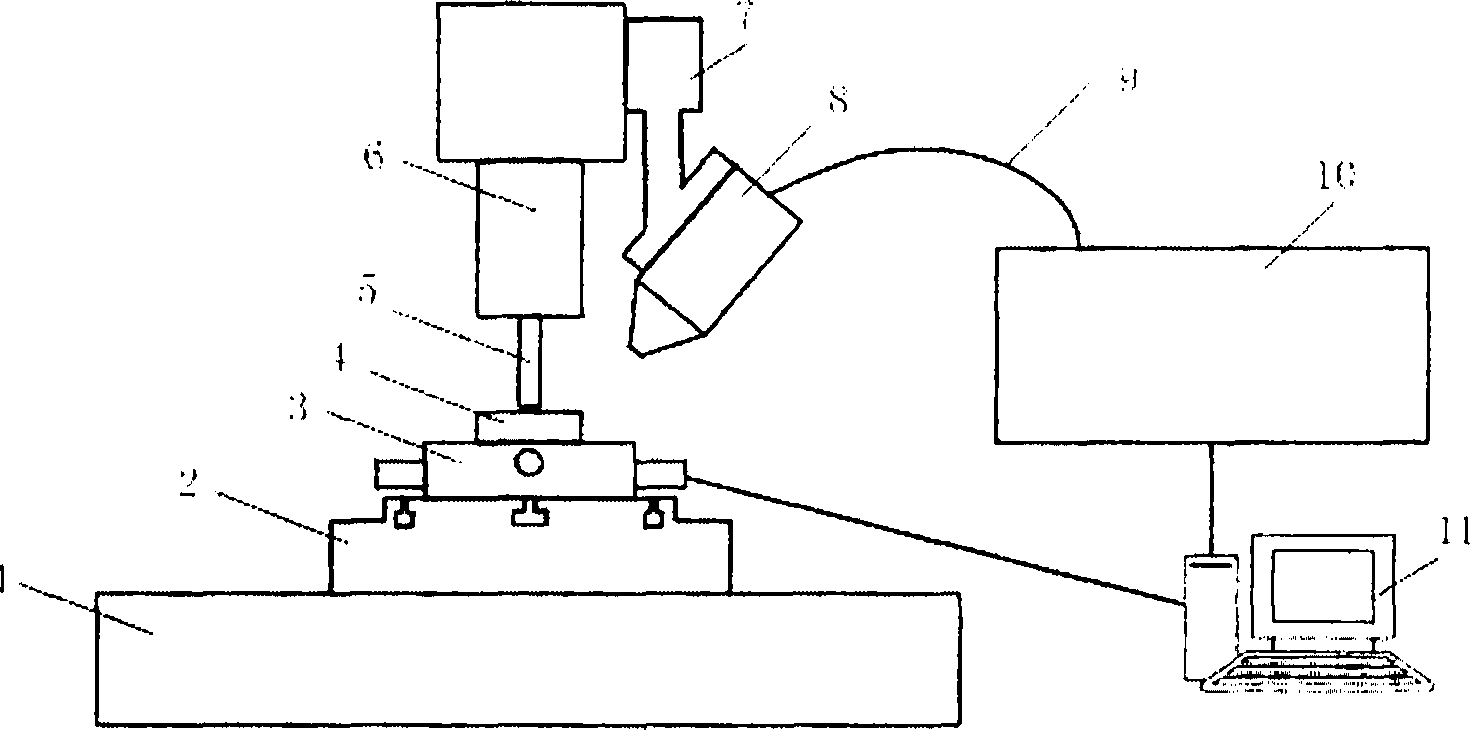

[0031] Embodiment 2: For occasions that require processing curves, processing brittle materials, or high processing accuracy requirements. The schematic diagram of the method device is as figure 2 As shown, the two-dimensional moving table 3 is placed on the rotating table 2, the machine spindle 6 is coaxial with the center of the rotating table 2, and the rotating table 2 only changes the processing direction during the rotation, without changing the milling cutter 5 Relative to the position of the moving worktable 3, the two-dimensional moving worktable 3 and the z-axis of the milling machine constitute three axes in the milling process. At this time, it can be ensured that the relative position of the laser incident can be adjusted at any time during the processing, so the processing requirements of the curved track can be met. During the processing, the workpiece moves with the moving table 3, and the relative angle between the laser incident position and the workpiece is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com