Patents

Literature

439 results about "Cnc milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

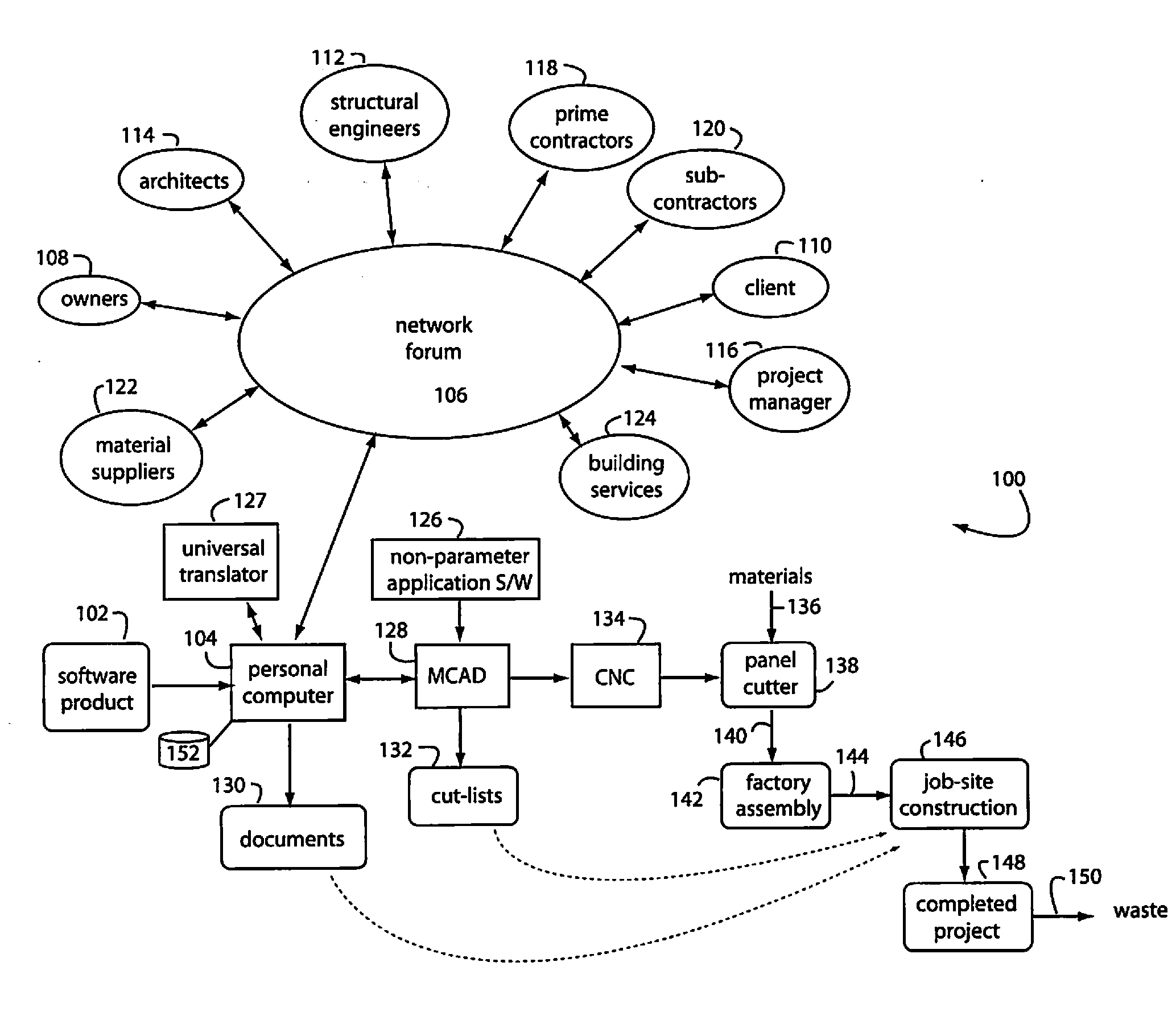

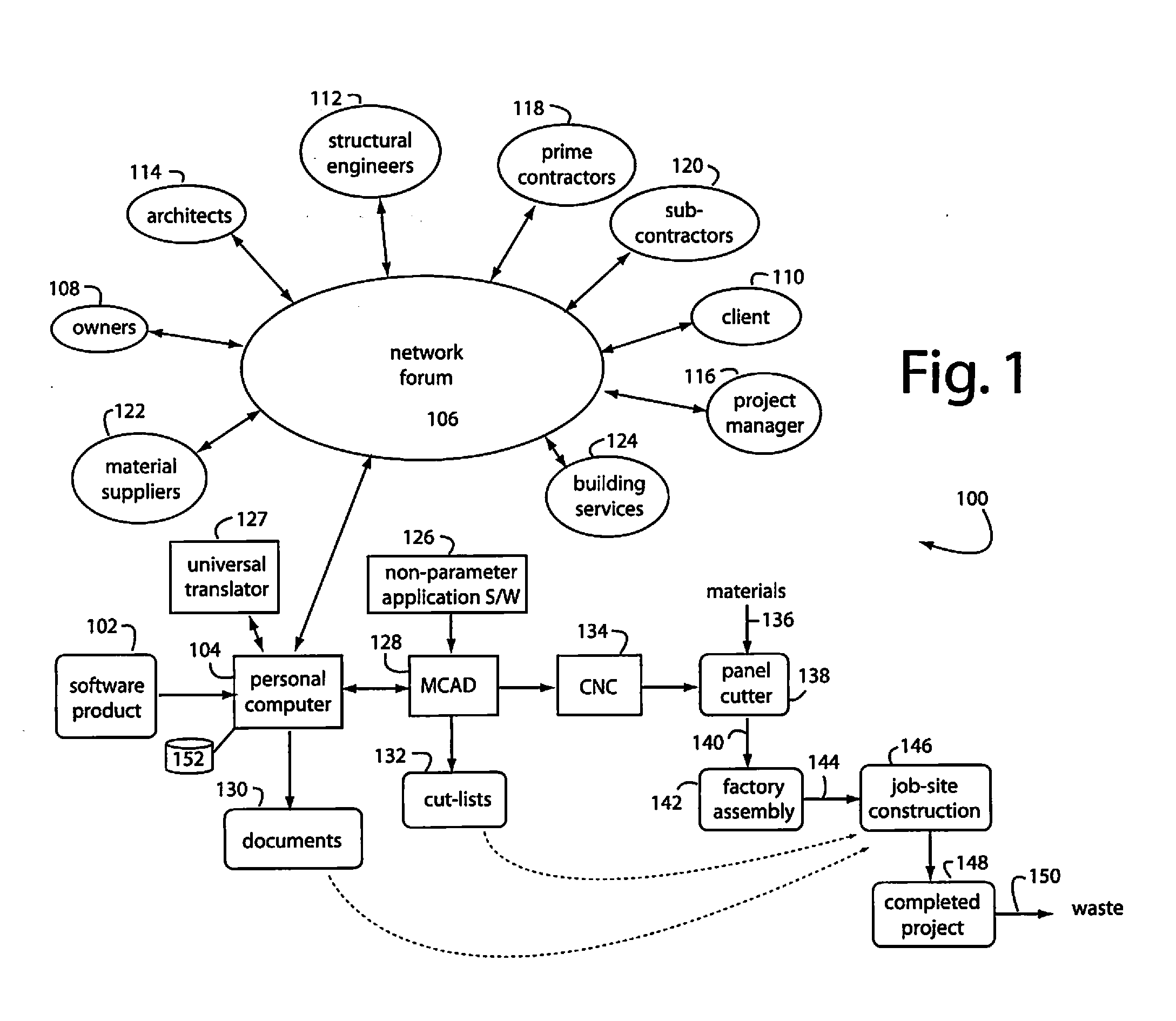

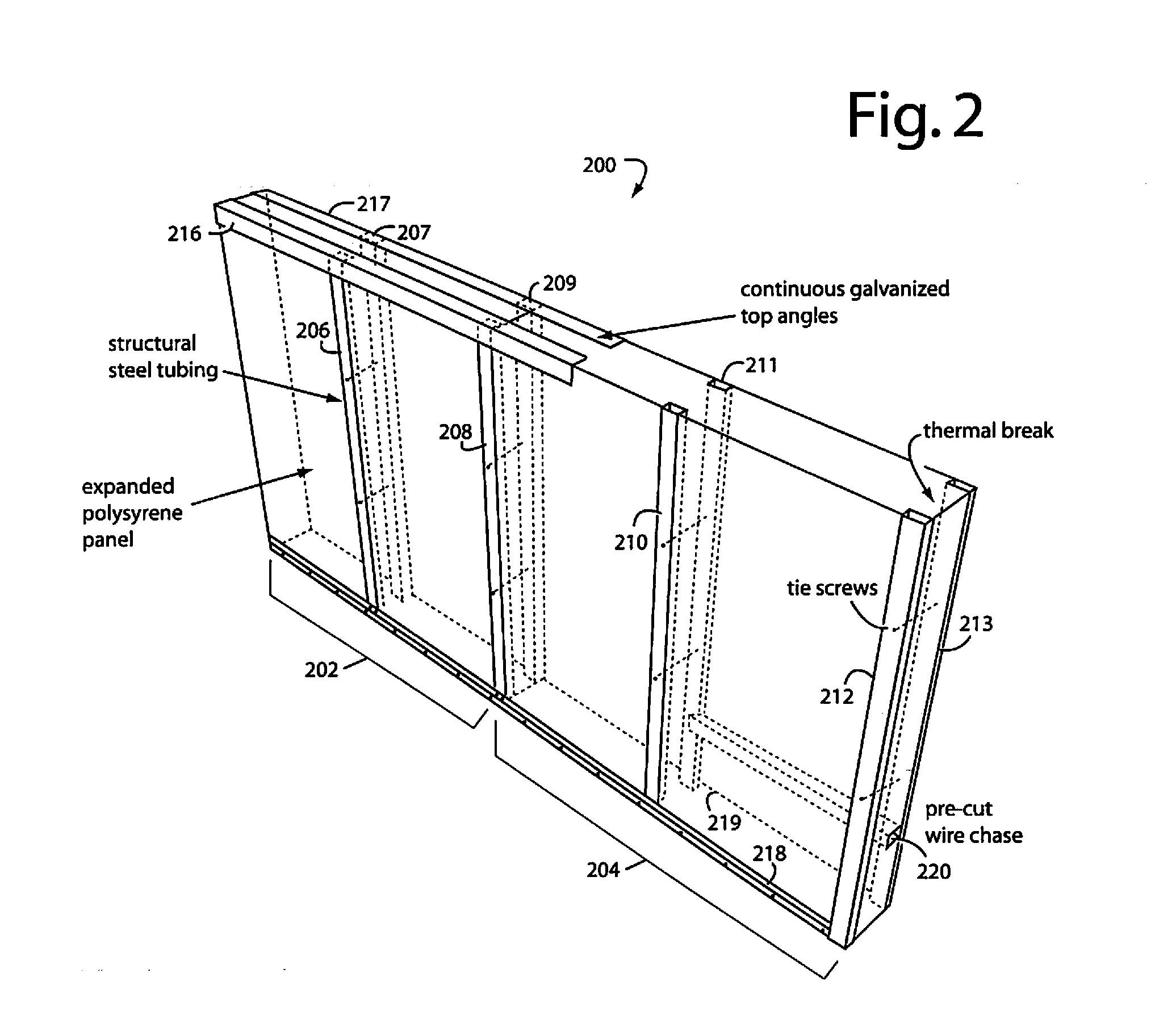

Building Construction Software and System

ActiveUS20110054652A1Input/output for user-computer interactionGeometric CADNumerical controlComputer Aided Design

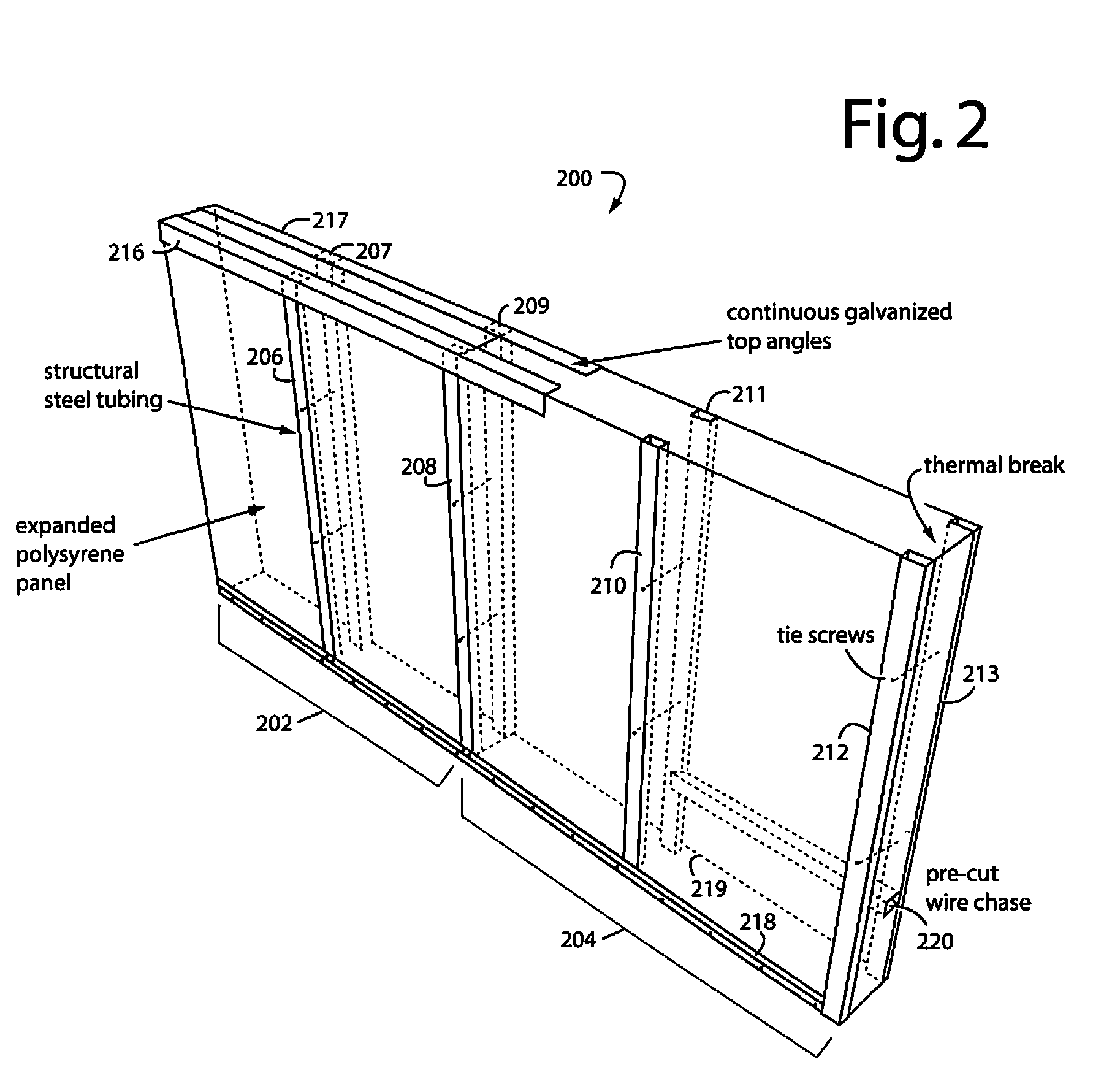

A method of building construction includes designing a building with software for execution on a computer such that an envelope of the building principally comprises expanded polystyrene foam panels, and the software is used to automatically generate a plan with reference numbers that identify substantially all the component pieces of the building. The software and computer are coupled to a computer aided design (CAD) program for generating computer numerical controlled (CNC) milling commands for expanded polystyrene foam panels, and a cut-list for steel reinforcing studs to fit into matching slots milled into the expanded polystyrene foam panels. At least the expanded polystyrene foam panels and matching steel reinforcing studs are marked with identifying numbers corresponding to the reference numbers. The expanded polystyrene foam panels are milled with a CNC machine and panel cutter according to CNC milling commands from the CAD program.

Owner:COMPASS PROPERTY GRP

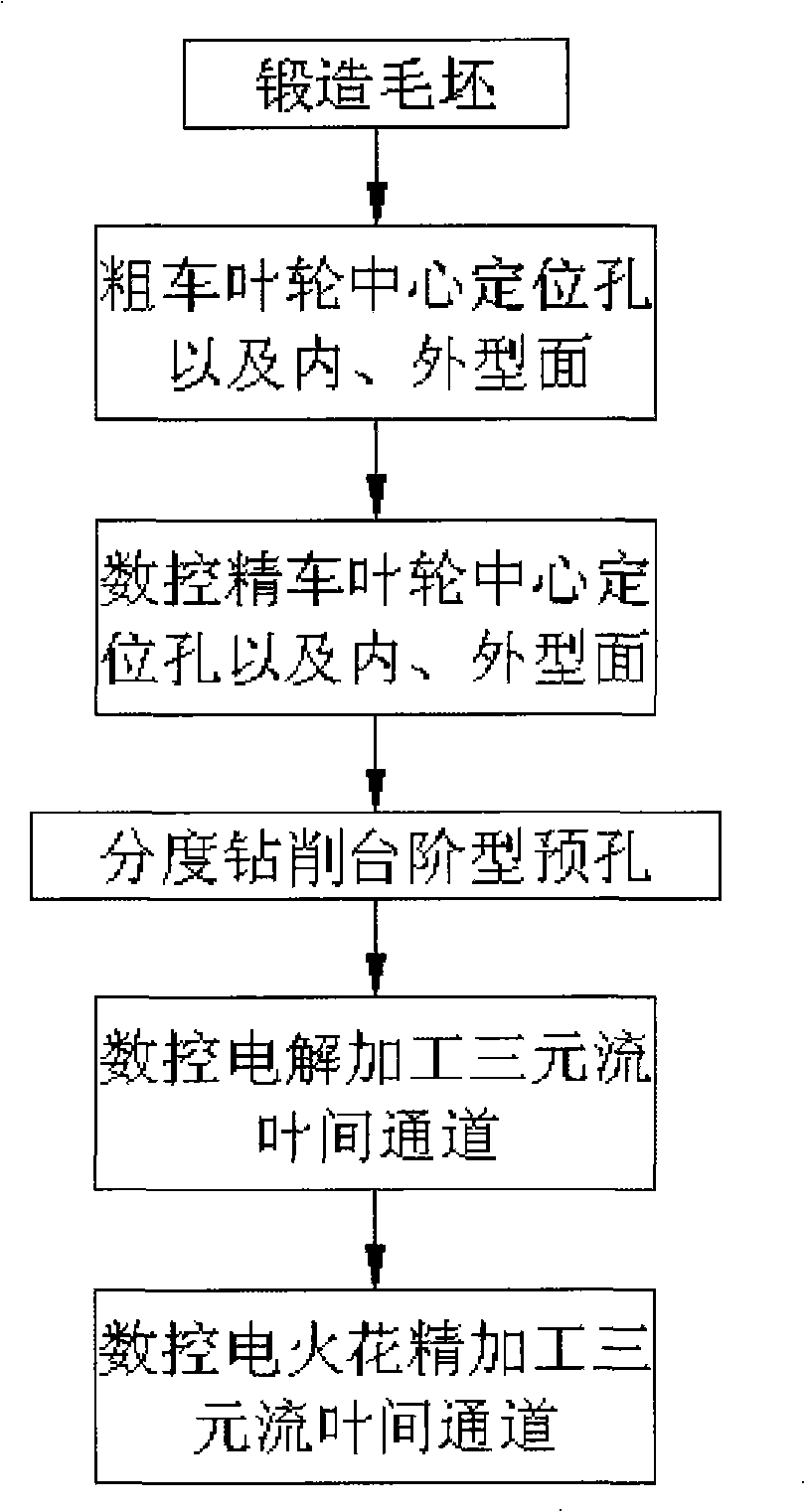

Method for manufacturing three-dimensional flow enclosed-type impeller inter-impeller passage and special clamp thereof

InactiveCN101524805AImprove efficiencyAvoid the phenomenon that is prone to blind spots in processingImpellerEngineering

The invention relates to a method for manufacturing a three-dimensional flow enclosed-type impeller inter-impeller passage and a special clamp thereof. A specially designed and manufactured molding or quasi-molding tool cathode is used for numerical control electrolytic processing to remove most remainder, then a specially designed and manufactured molding or quasi-molding tool electrode is used for numerical control electric spark precision processing to achieve the design requirement, thereby the three-dimensional flow enclosed-type impeller inter-impeller passage that can not be processed resulting from interference of numerical control milling cutter and undercutting can be manufactured, besides, the method has the technical and economical characteristics of high precision and efficiency, and low cost compared with the prior three manufacturing methods of integral casting, divided processing rewelding and numerical control milling.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

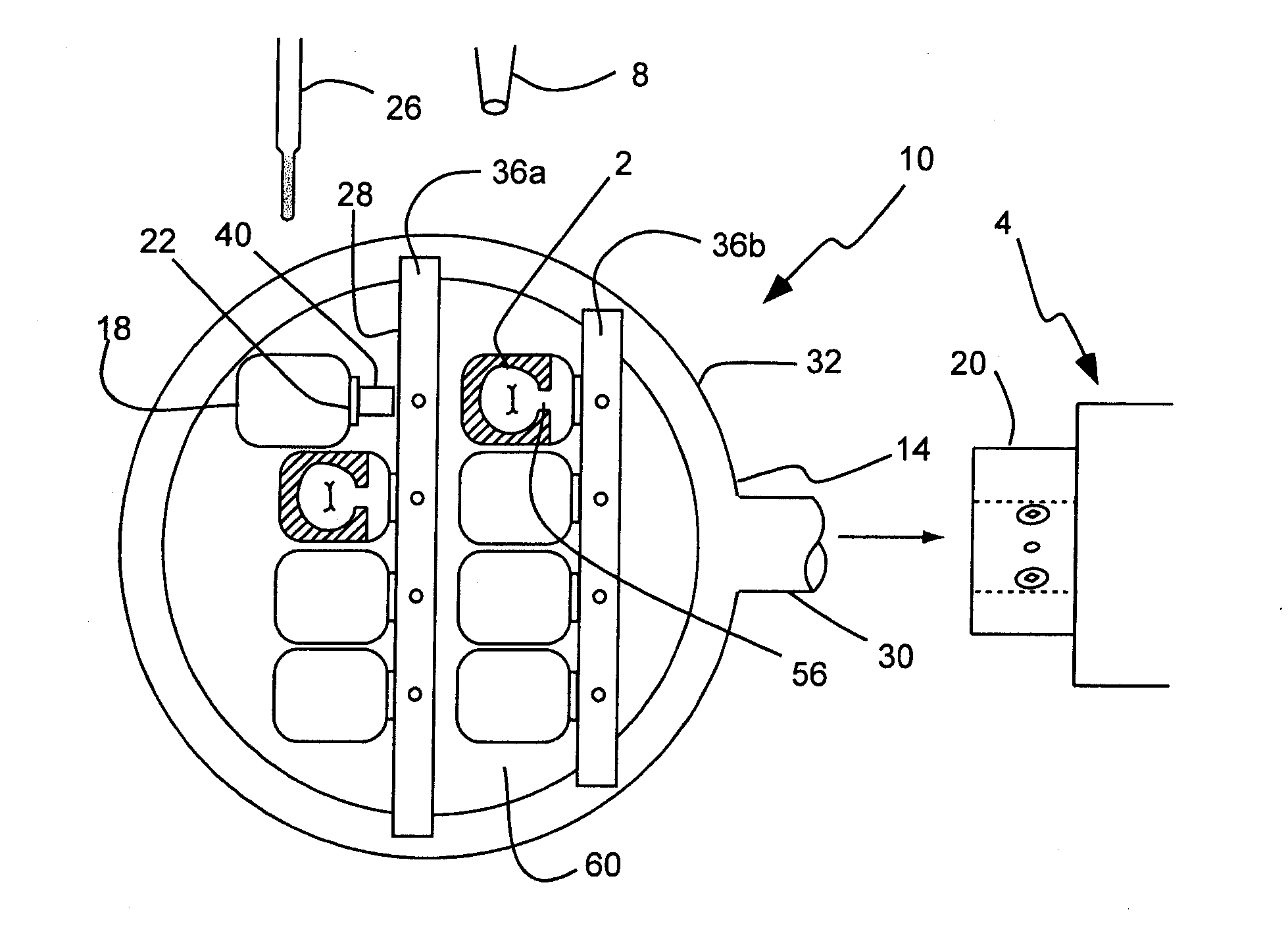

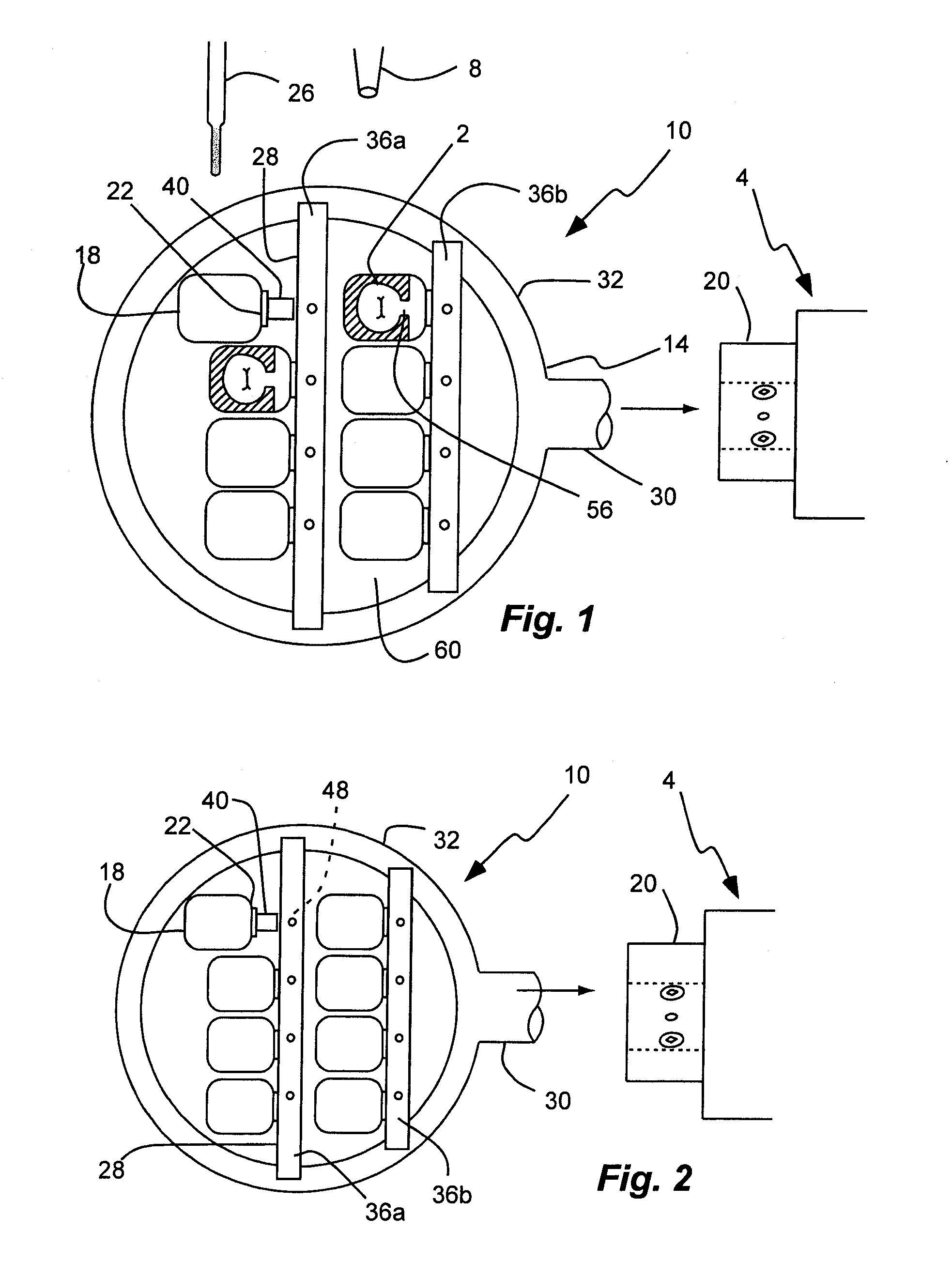

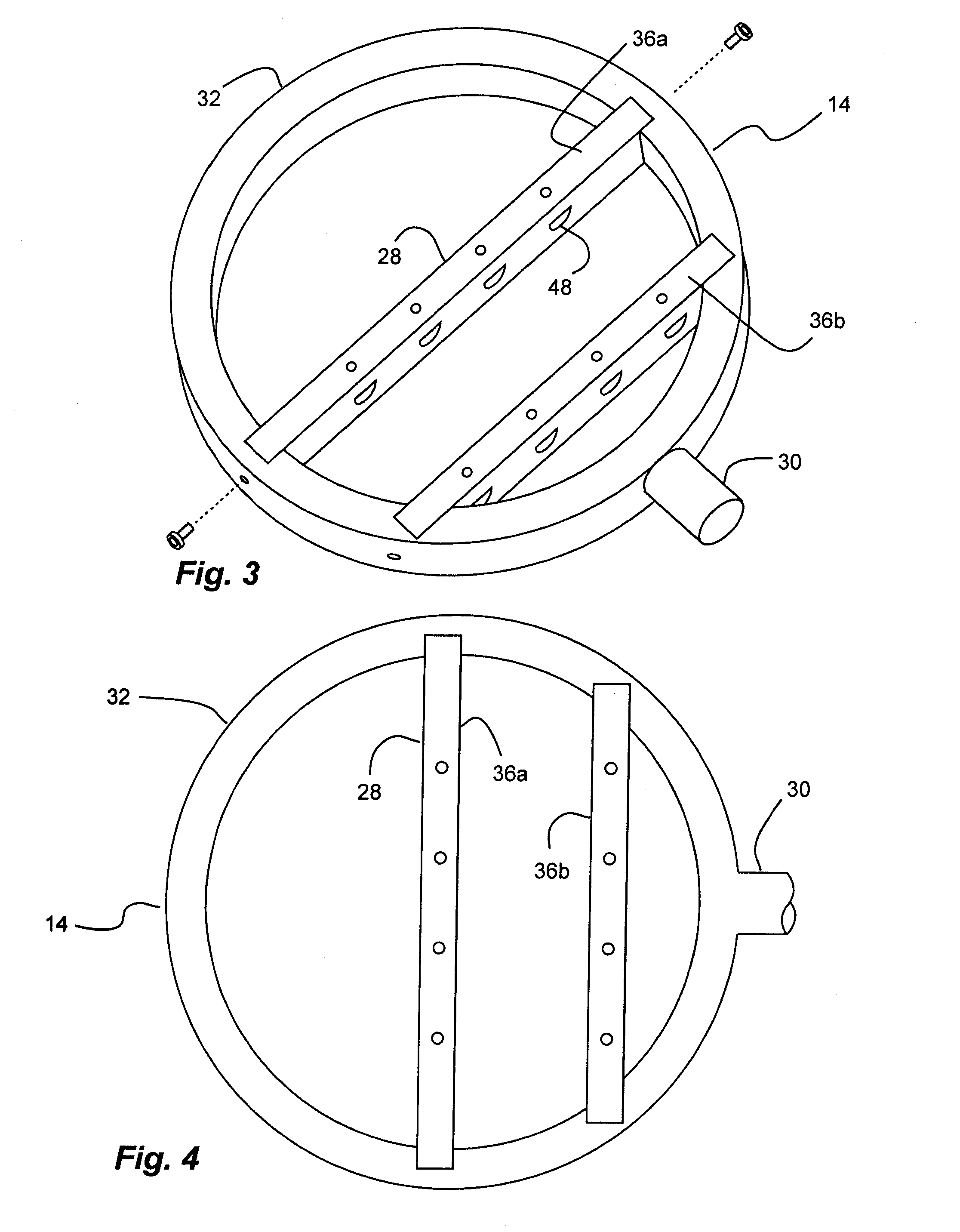

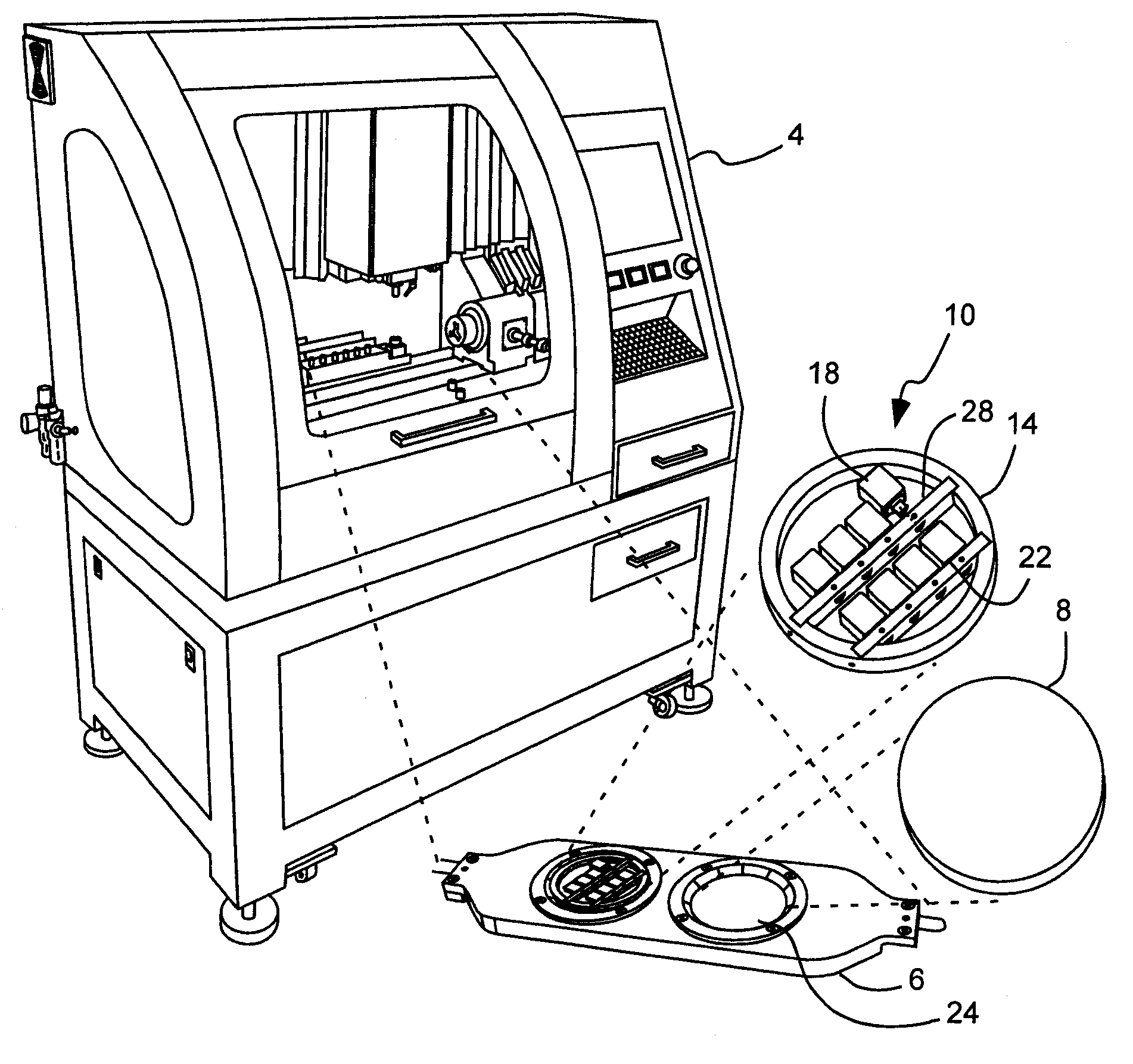

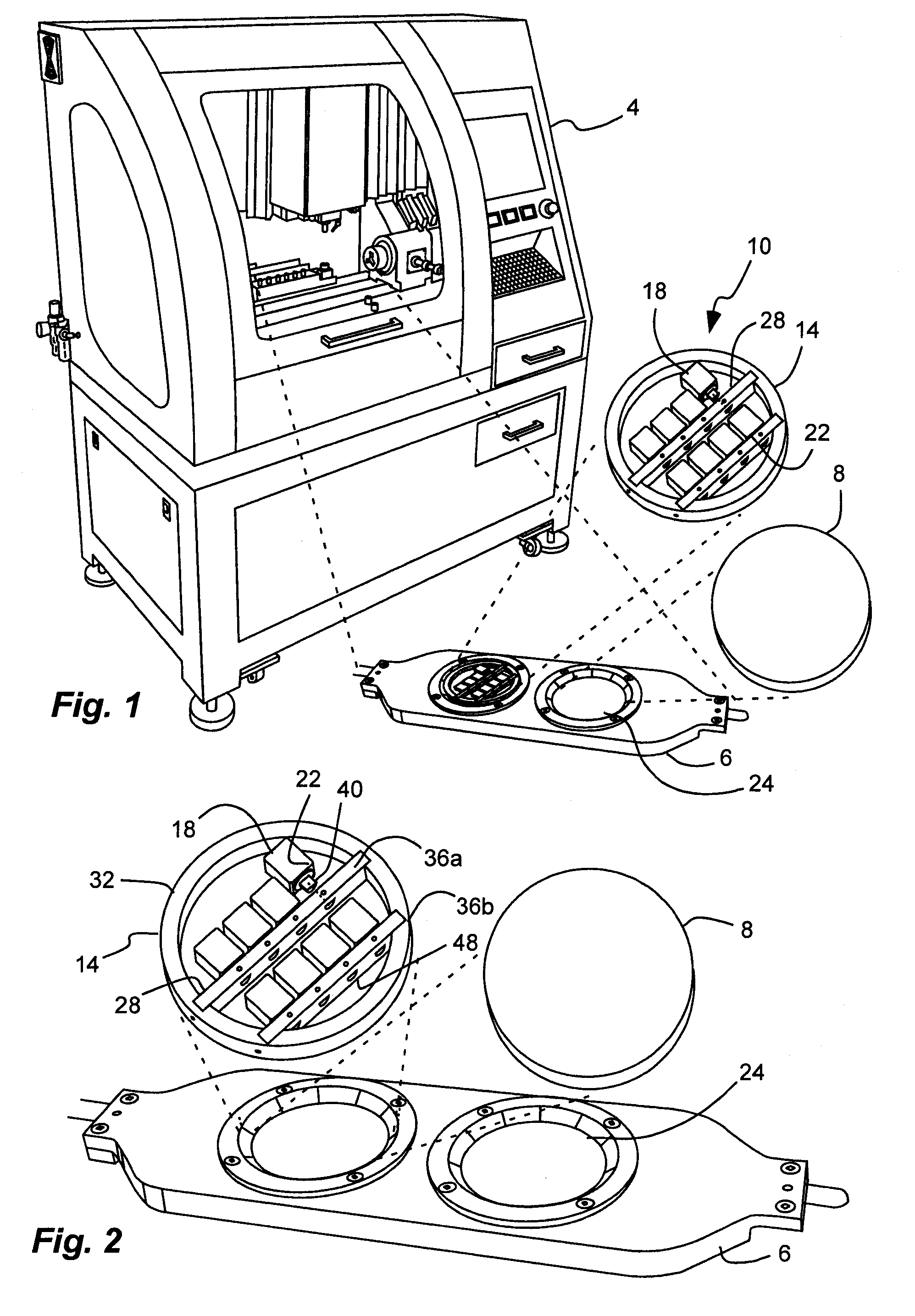

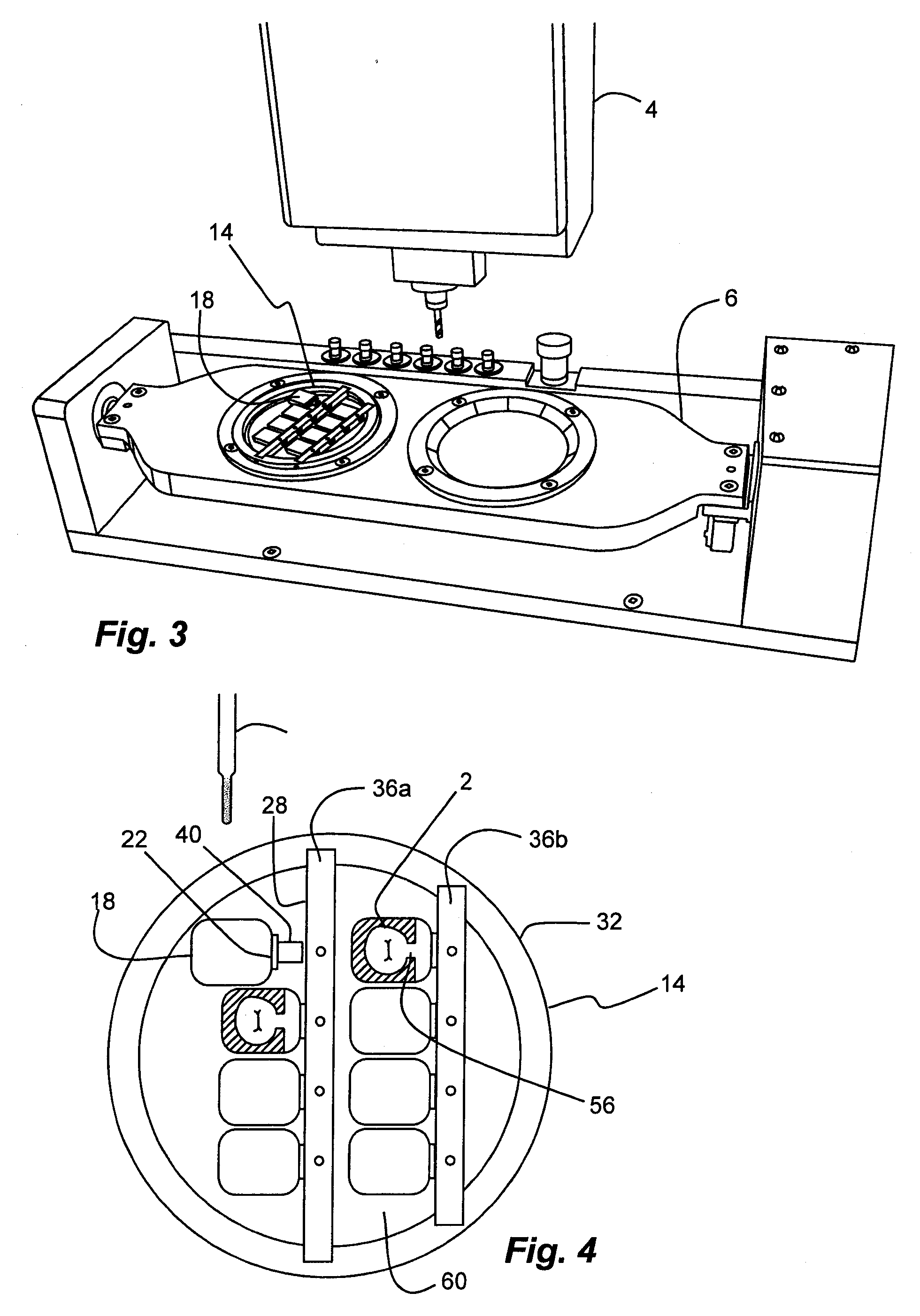

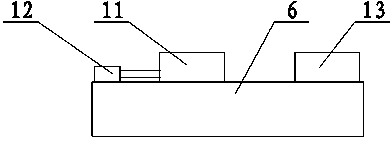

System and Method for Securing Multiple Ceramic Dental Blocks for Milling

A system and method for milling dental prostheses in a CNC milling includes affixing a lateral side of each of a plurality of ceramic millable dental blanks to a lateral wall of a fixture; securing the fixture to a chuck of the milling machine; wet milling a single dental prosthesis in each of the plurality of ceramic millable dental blanks with a diamond burred cutter; and removing the plurality of ceramic millable dental blanks from the fixture.

Owner:JUNG YUNOH +1

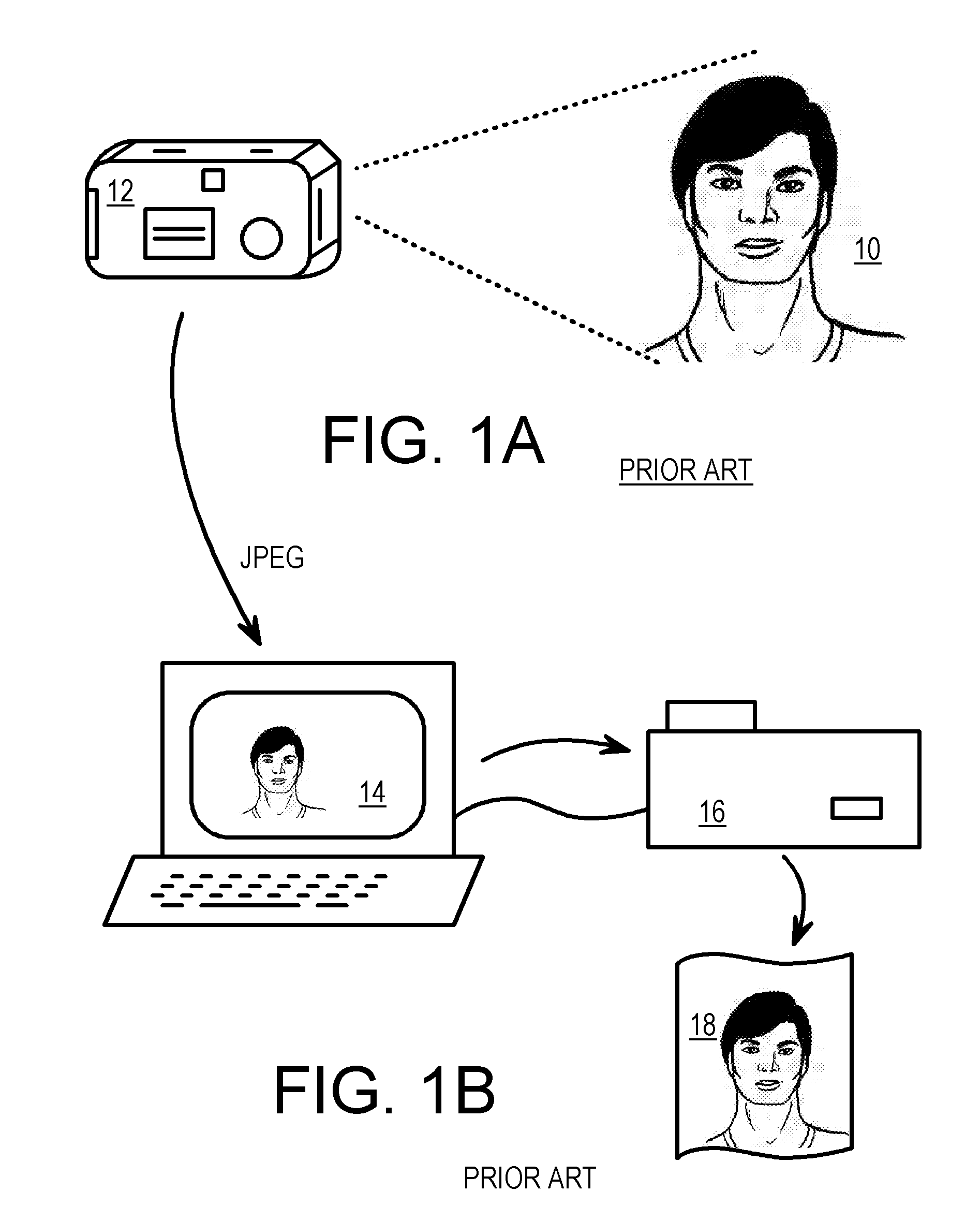

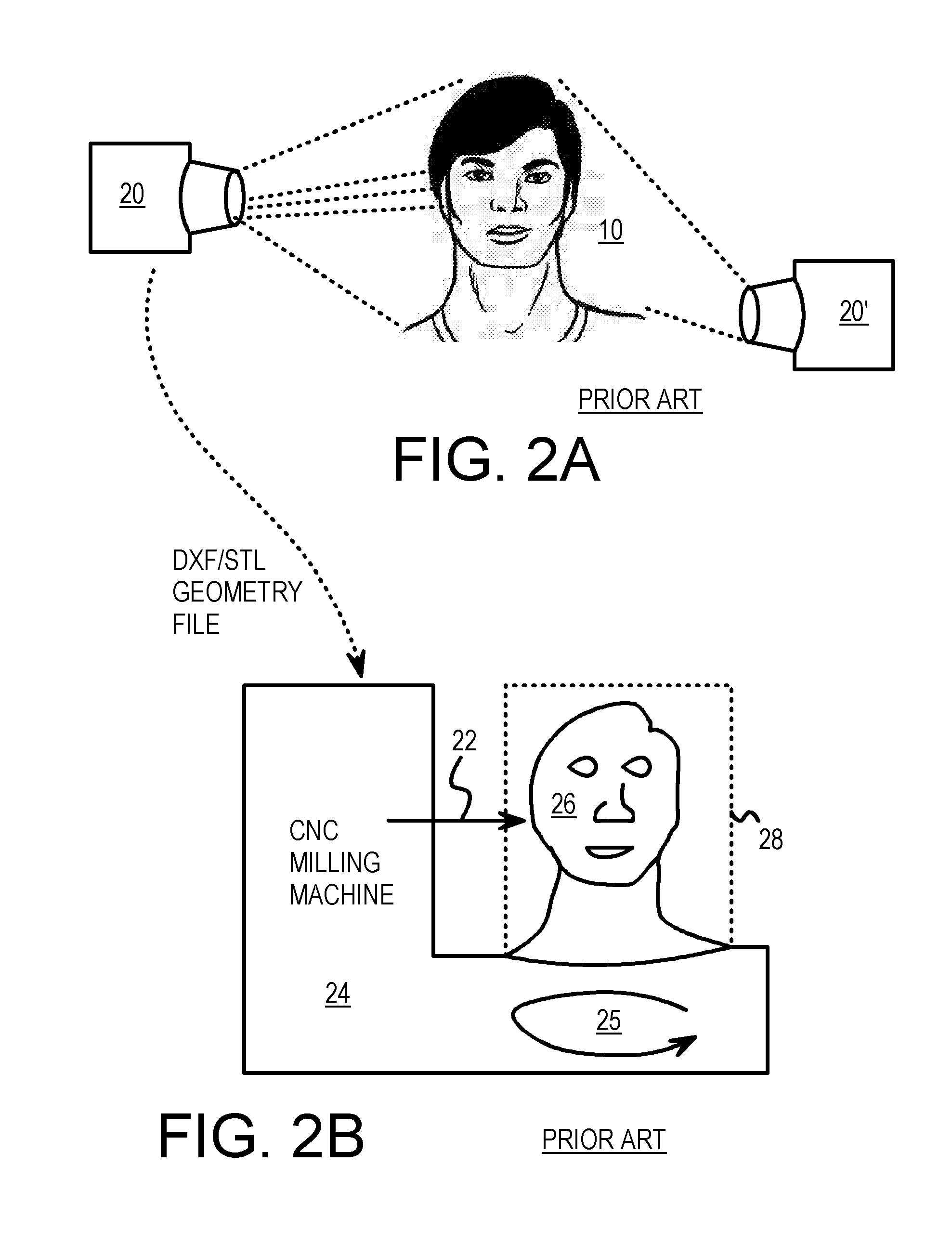

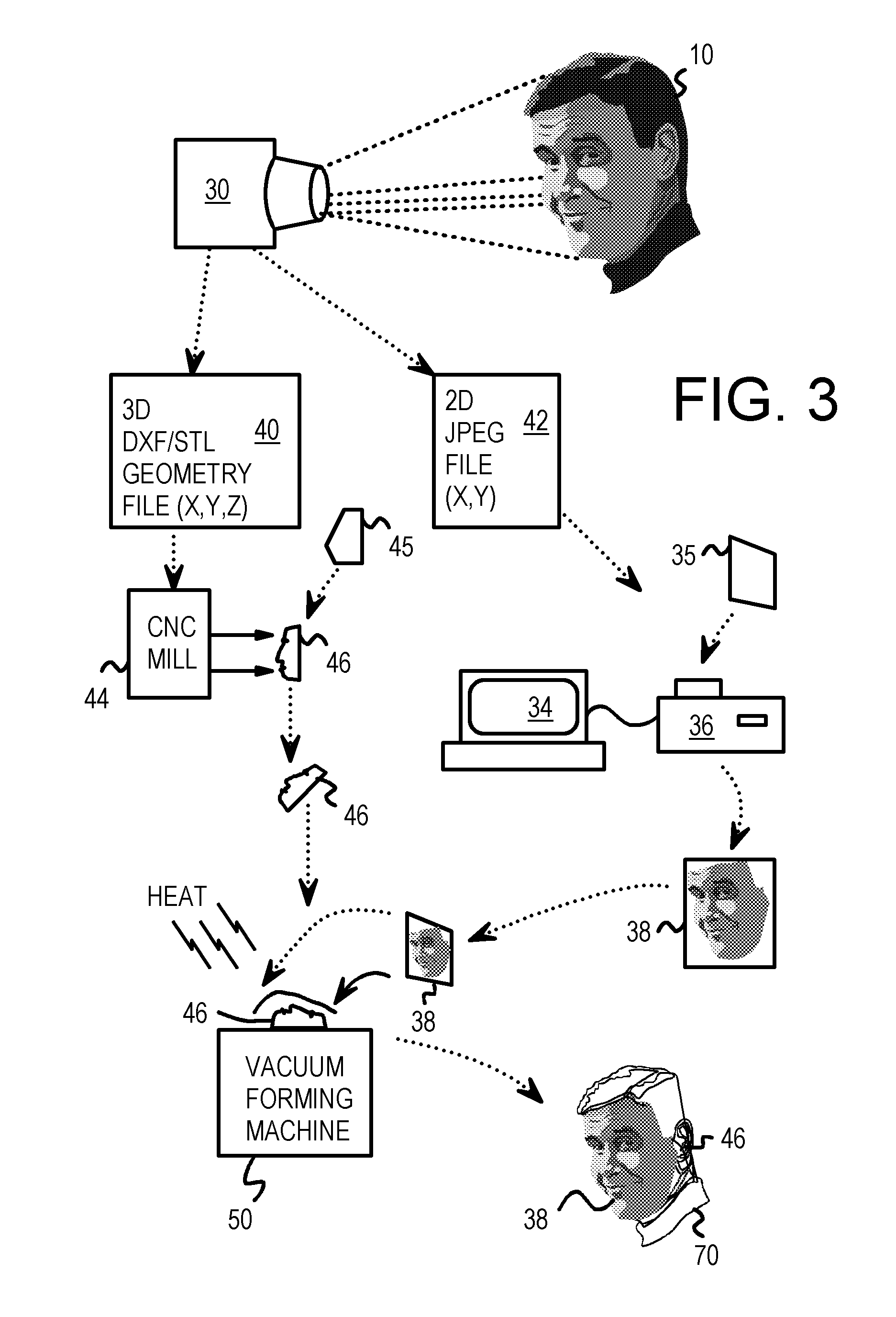

Custom 3-D Milled Object with Vacuum-Molded 2-D Printout Created from a 3-D Camera

A 3D copy of a 3D subject is made by combining a 3D custom milled shape and a 2D printed 2D image sheet molded to the contours of the 3D custom milled shape. A 3D camera captures 3D details of the 3D subject and also captures a multi-color 2D image of the 3D subject. The 3D camera outputs a geometry file to a CNC milling machine that cuts a milling blank to make a custom milled shape. The 3D camera also outputs a 2D image file to a personal computer that prints the 2D image onto a plastic sheet. The custom milled shape is placed as a mold on a vacuum-forming machine. The plastic sheet is aligned to the custom milled shape and heat and vacuum pressure applied. The 2D image is molded into the 3D shape of the custom milled shape.

Owner:TSENG TAN

Method for fabricating a custom implant abutment

InactiveUS20120214133A1Facilitate precision millingSimple manufacturing processDental implantsTooth crownsCNC routerBiomedical engineering

A system and method for fabricating custom implant abutments uses an implant abutment connector to secure a partial blank with respect to a milling tool of a CNC milling machine. The implant abutment connector has an implant interface geometry of an implant. The partial blank can have a prefabricated implant abutment interface geometry of the implant abutment; and can thus mate with the implant, and the implant interface geometry of the implant abutment connector.

Owner:B & D DENTAL

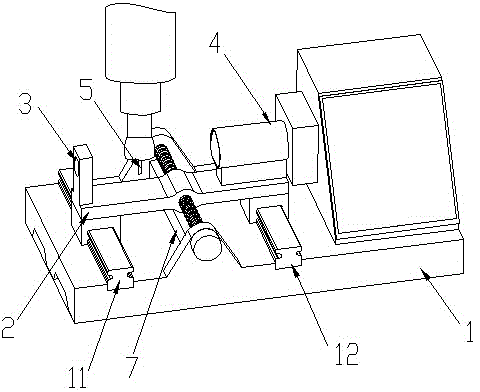

Automobile hub bore numerical control milling device

ActiveCN103273123AIncrease storage spaceGuaranteed uptimeMilling machinesFeeding apparatusNumerical controlControl engineering

The invention discloses a hub bore numerical control milling device aiming at improving the automobile hub bore processing efficiency and meeting the demand of high precision processing. The automobile hub bore coefficient numerical control milling device is convenient to use, flexible in bore processing and capable of well meeting the market demand. The automobile hub bore numerical control milling device disclosed by the invention comprises a base, an upright, a sliding saddle, a tool changer, a spindle motor, a spindle and a spindle box, wherein a Y-axis lead screw is arranged on the base along the front-back direction and is connected with a Y-axis motor, a Y-axis sliding platform is also arranged on the base, a 360-degree overturning working platform is arranged on the Y-axis sliding platform, an X-axis lead screw is also arranged on the upright along the left-and-right direction of the base, a Z-axis lead screw is also arranged on the sliding saddle along the vertical direction of the base and connected with a Z-axis motor, a sliding block is matched with the Z-axis lead screw through a nut seat, the spindle, the spindle motor and the spindle box are arranged on the sliding block, and the sliding block, the sliding saddle are assembled through Z-axis sliding rails and a Z-axis sliding block.

Owner:JIANGSU SLD PRECISION TECH

Device and Method of Securing Dental Material for Production of Dental Prosthesis

A system and method for milling dental prostheses in a CNC milling machine includes a larger millable dental blank receivable in a primary fixture of a milling machine and capable of being machined to form one or more dental prostheses; a plurality of smaller millable dental blanks each capable of being machined to form a dental prosthesis; and lateral affixing means for affixing a lateral side of the plurality of smaller millable dental blanks in a space defined by the larger millable dental blank in the primary fixture, when the larger millable dental blank is removed.

Owner:JUNG YUNOH +1

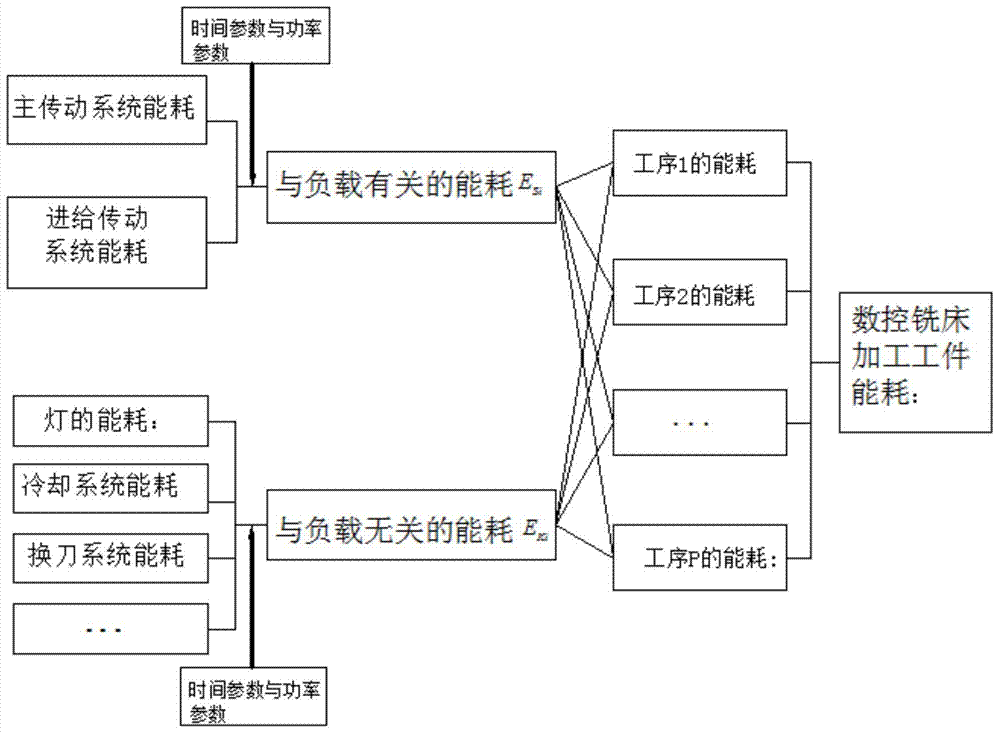

Method for predicting energy consumption of CNC milling machine based on time parameters

ActiveCN103941644ACalculate energy consumptionHigh feasibilityProgramme controlComputer controlWork timeTransmission system

The invention discloses a method for predicting the energy consumption of a CNC milling machine based on time parameters. The method includes the steps that (a) an energy consumption prediction model is established for the machining process of the CNC milling machine; (b) the no-load power, the additional power, the cutting power and the feeding power of a feed shaft of each component process are detected, and meanwhile the time parameters including the idle time of a main transmission system, the milling time and the working time of the feed shaft are acquired respectively through NC codes; (c) all the obtained power parameters and the obtained time parameters are substituted into the energy consumption prediction model, and the overall energy consumption prediction technological process is correspondingly executed. By the adoption of the method, the energy consumption prediction process of the CNC milling machine can be rapidly and accurately realized only by inputting the cutting data and the time parameters of each process, the method is high in feasibility, and optimization and support can be provided for solving a series of problems of process selection, energy consumption prediction, energy consumption evaluation, energy saving and emission reduction of the machine and the like in workpiece machining process of the CNC milling machine.

Owner:重庆亿如电子有限公司

Machining method for numerical control milling of thin-wall curved-surface irregular parts

ActiveCN105382313AGuarantee product qualityIncrease productivityMilling equipment detailsNumerical controlEngineering

A machining method for numerical control milling of thin-wall curved-surface irregular parts aims at providing a technological scheme and a clamping method used in the machining process of the thin-walled curved-surface irregular parts. According to the machining method, an upper irregular curved-surface area and a lower irregular curved-surface area are divided in a blocked mode and technological clamping blocks are reserved by reasonably arranging the technological process and dividing a cutting area, positioning tools and rough and finish milling numerical control machining procedures are designed, and cutting tool selecting and cutting parameters are determined, linear cutting machining of the like products is replaced by milling machining, the machining cost is reduced, and the machining efficiency and product quality are improved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

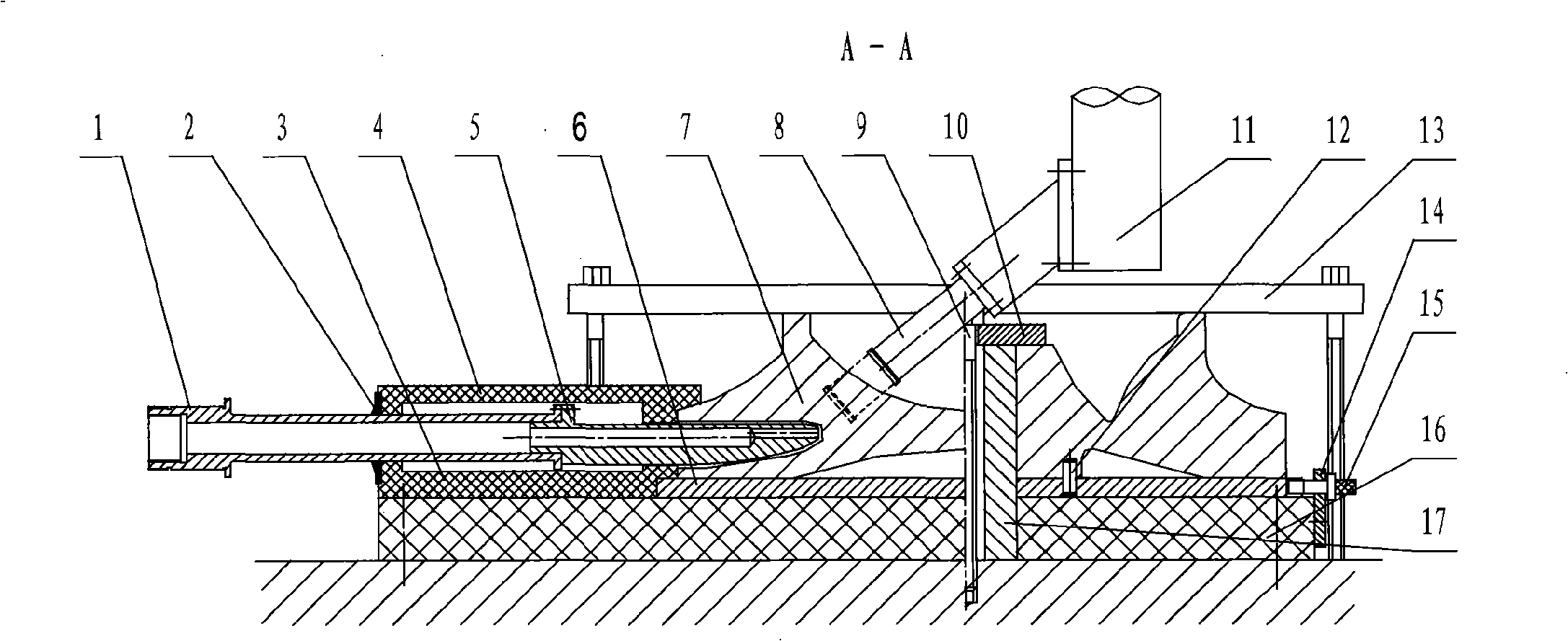

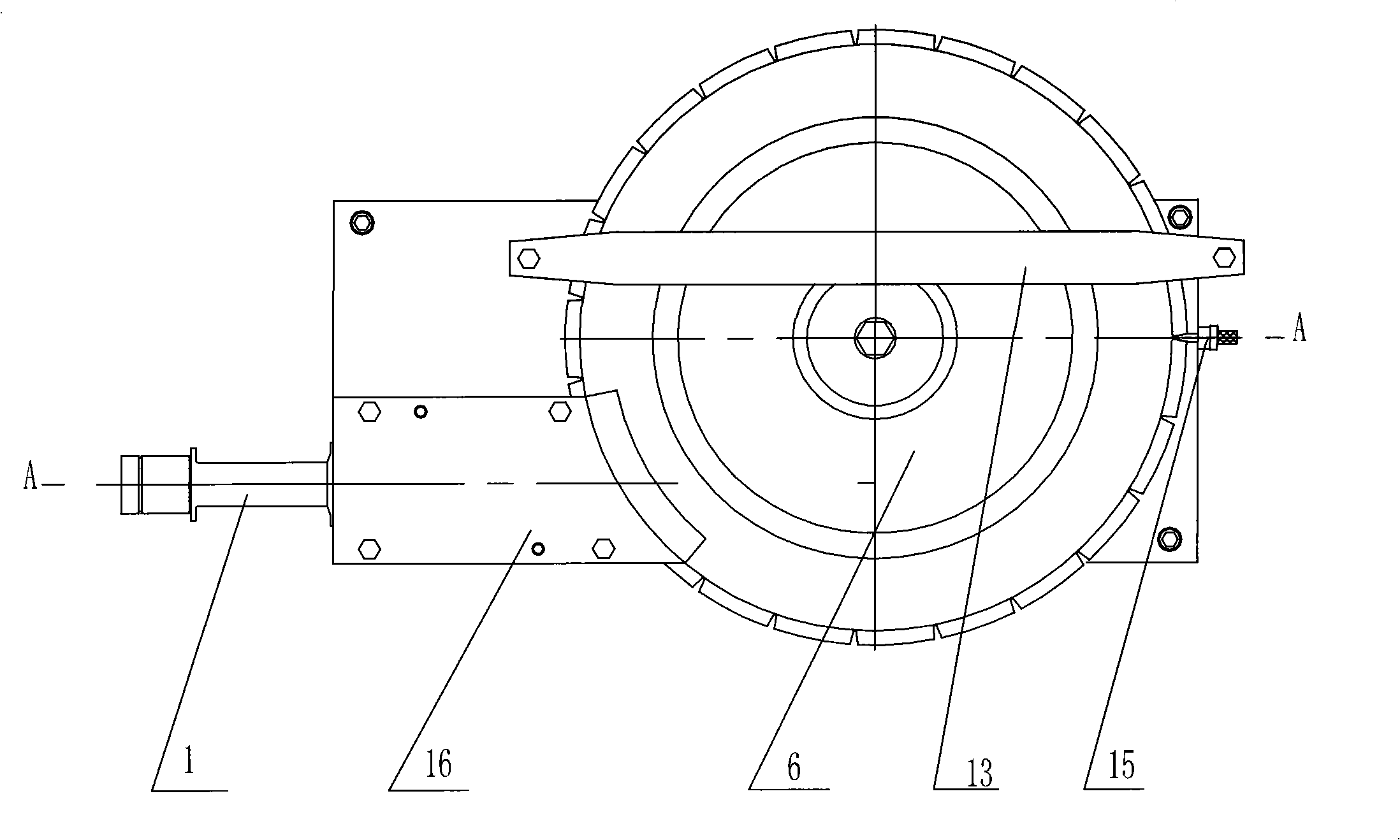

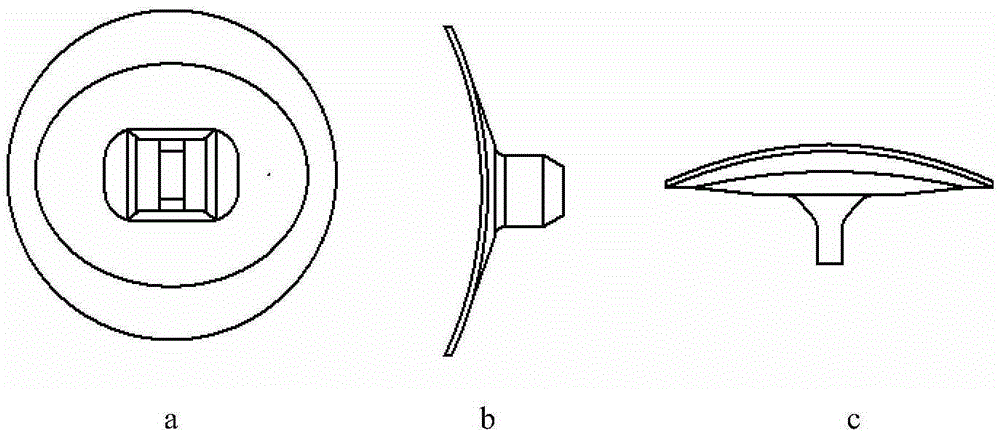

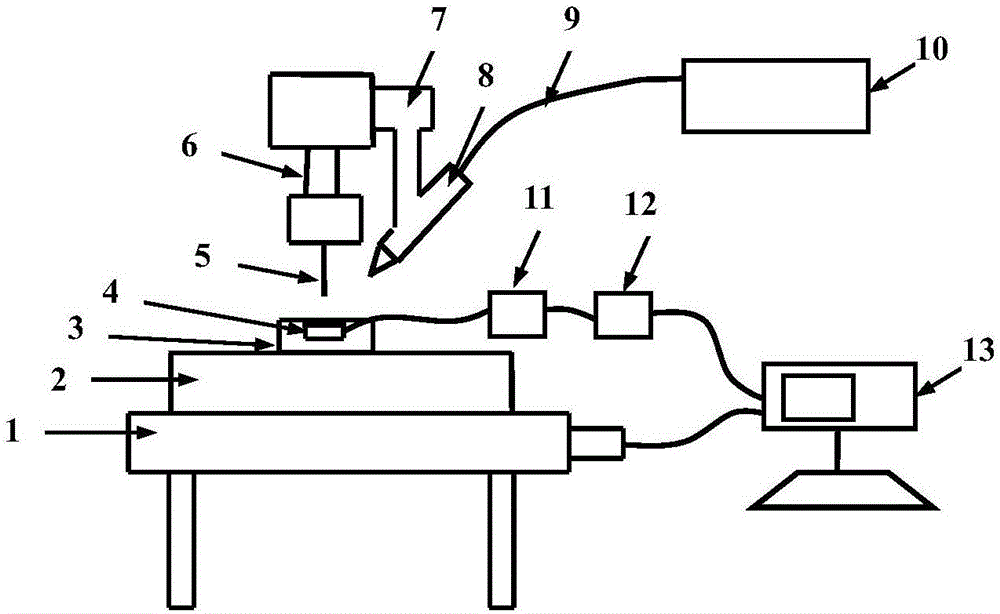

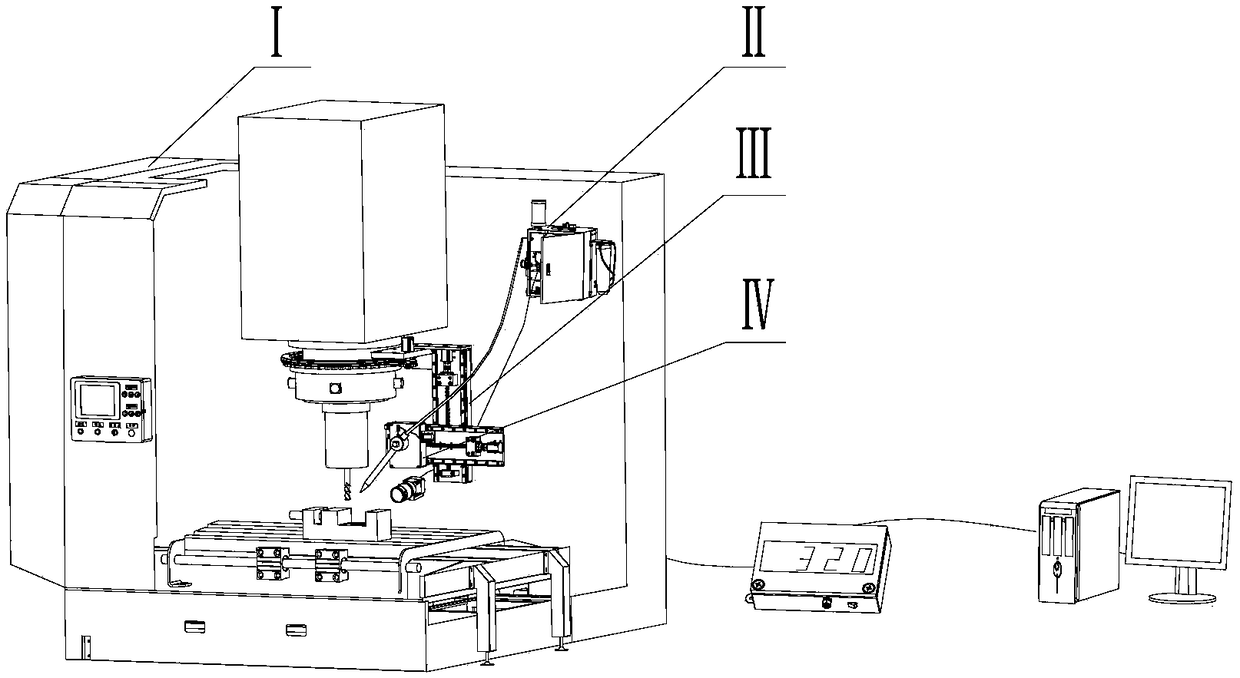

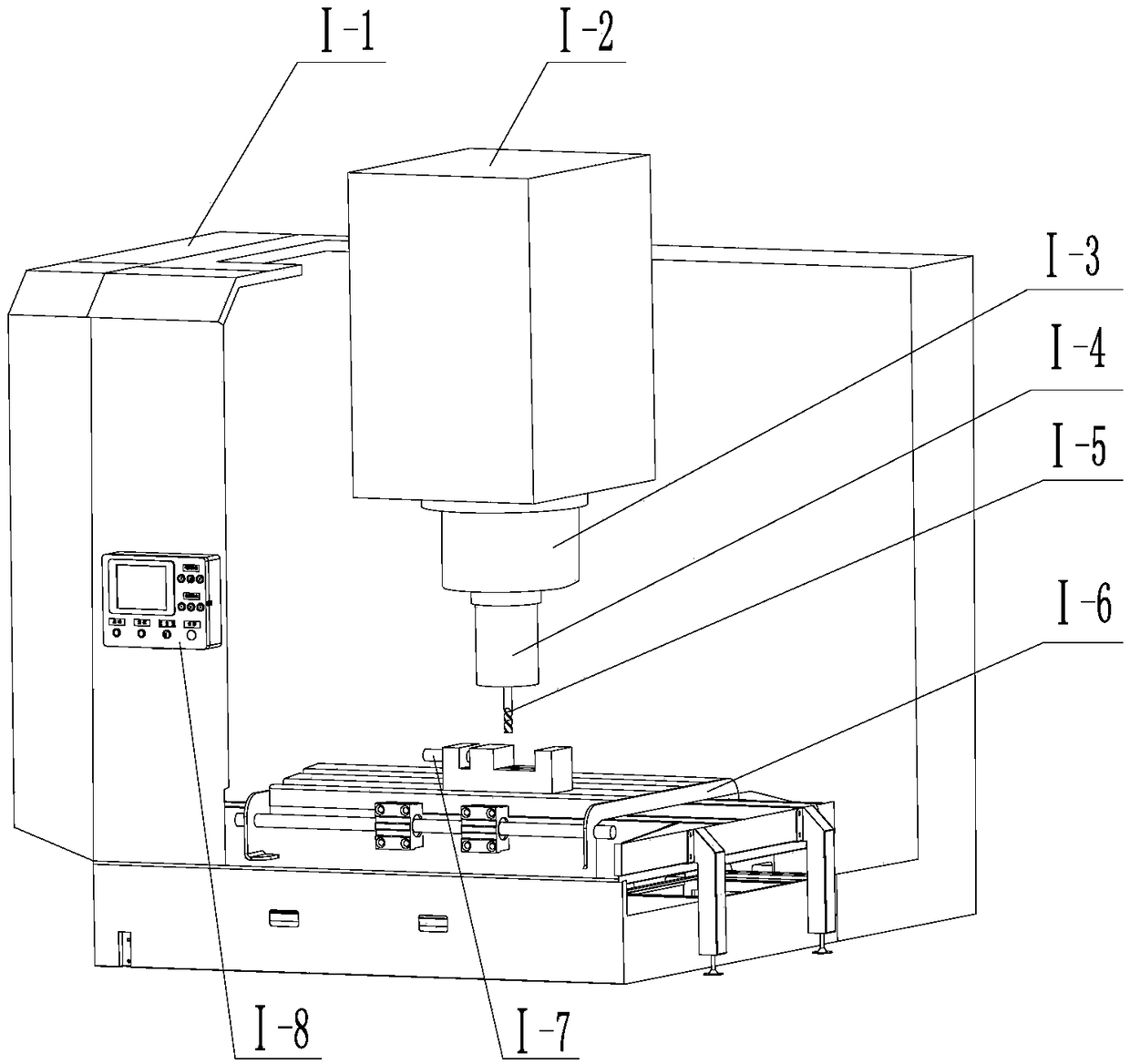

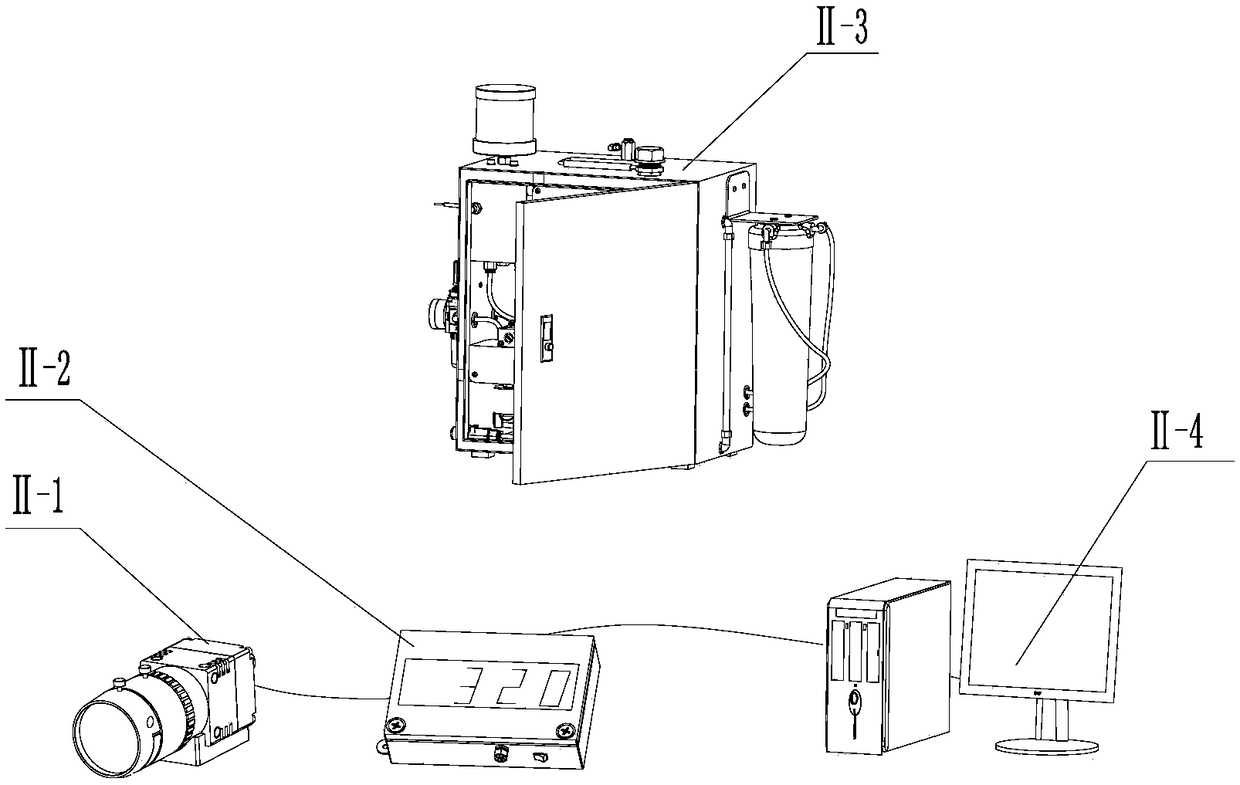

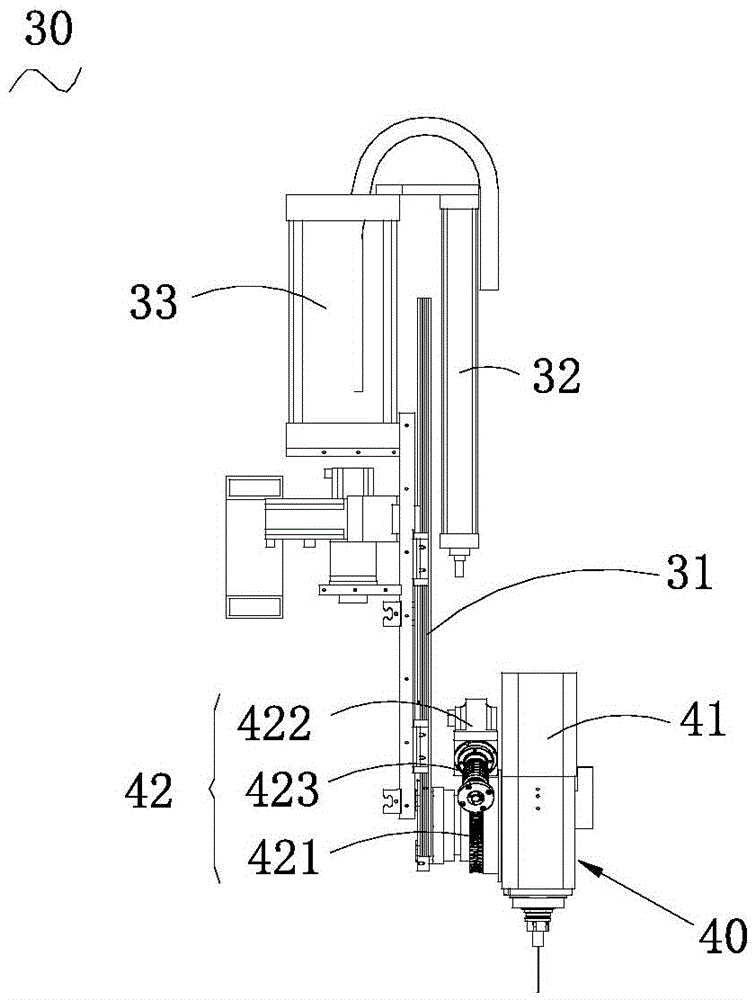

Laser heating-assisted milling device capable of real-time monitoring tool wear

ActiveCN106216745AEasy to monitor onlineImprove efficiencyMeasurement/indication equipmentsMilling equipment detailsNumerical controlMilling cutter

The invention discloses a laser heating-assisted milling device capable of real-time monitoring tool wear. The laser heating-assisted milling device capable of real-time monitoring tool wear comprises a milling device, a laser heating device and a real-time monitoring device. The milling device comprises a CNC (Computer Numerical Control) milling machine table, a milling cutter and a workpiece fixed to the CNC milling machine table; the laser heating device comprises a laser focus head; a laser light is incident on the surface of the workpiece through the laser focus head; the real-time monitoring device comprises a plurality of acoustic emission sensors, a signal processing module, a data acquisition processing module and an industrial personal computer; the acoustic emission sensors are arranged on the workpiece and are used for detecting acoustic emission signals of the milling cutter at a milling state; the acoustic emission signals are processed through the signal processing module and the data acquisition processing module and then are stored in the industrial personal computer; and through processing and analyzing, the real-time wear condition of the milling cutter is obtained.

Owner:HARBIN INST OF TECH

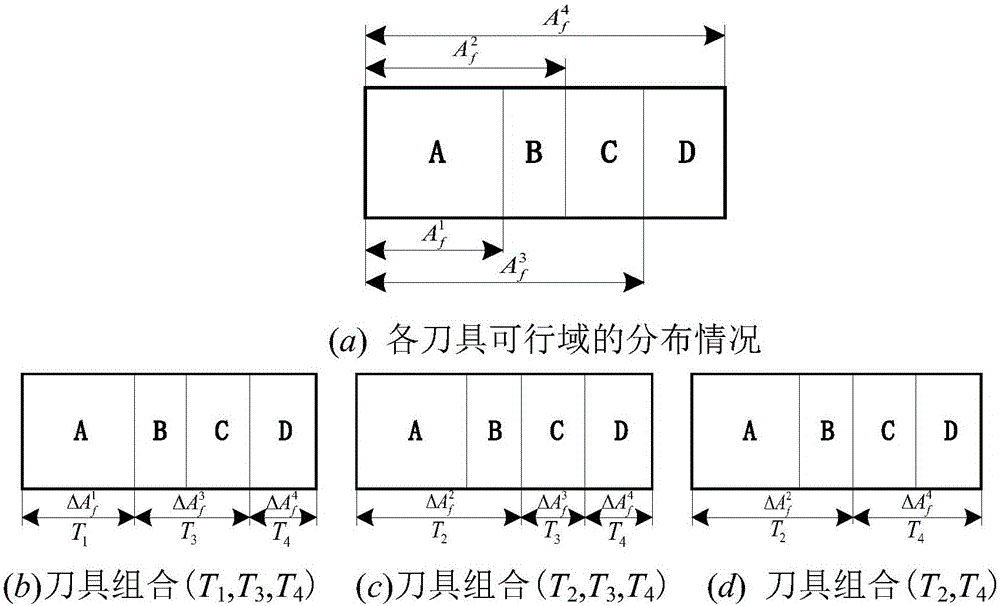

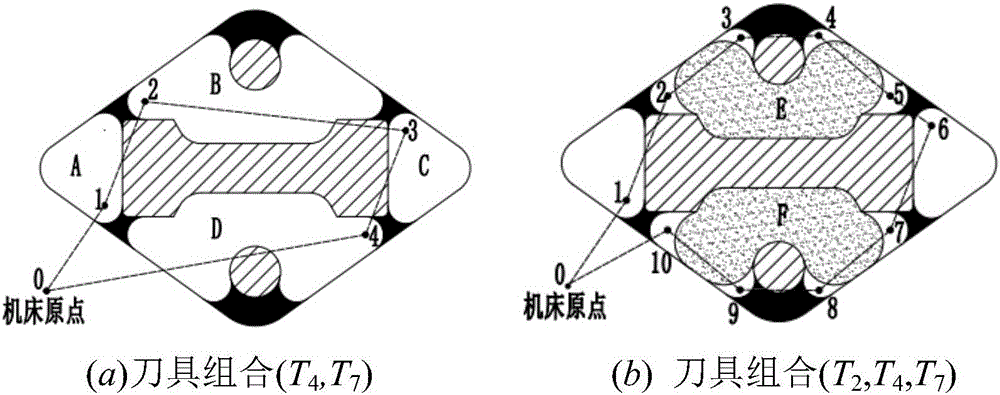

Energy-consumption-oriented cavity numerical control milling cutter combination optimization method

ActiveCN105785912AReduce energy costsReduce processing costsNumerical controlNumerical controlHigh energy

The invention is to solve the problem of high energy consumption and cost due to inappropriate selection of cutter combination in the 2.5 D cavity-type part milling, and discloses an energy-consumption-oriented cavity numerical control milling cutter combination optimization method. The method comprises the following steps: to begin with, systematically analyzing a mapping relation between the cutter combination and energy consumption in numerical control milling proves, revealing influence of the cutter diameter and cutter feasible region on milling energy consumption, and establishing a multi-cutter numerical control milling energy consumption function; based on this, establishing a numerical control milling cutter combination multi-objective optimization model with feasible cutters being optimization variables and energy consumption and cost being optimization objectives; providing a cutter combination optimization solution method, constructing a feasible cutter set, determining a feasible region of each cutter, and solving the optimization model through a digraph and a Dijkstra algorithm; and finally, carrying out cavity milling through the obtained optimum cutter combination.

Owner:CHONGQING UNIV

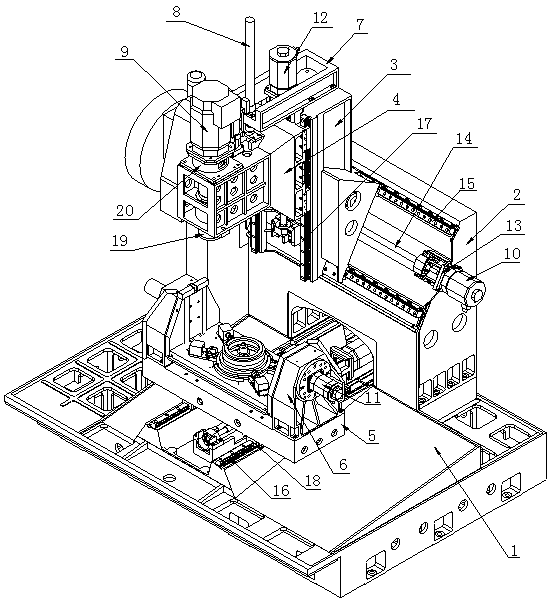

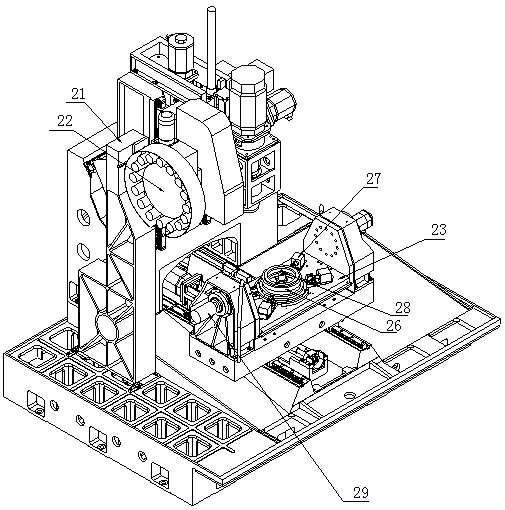

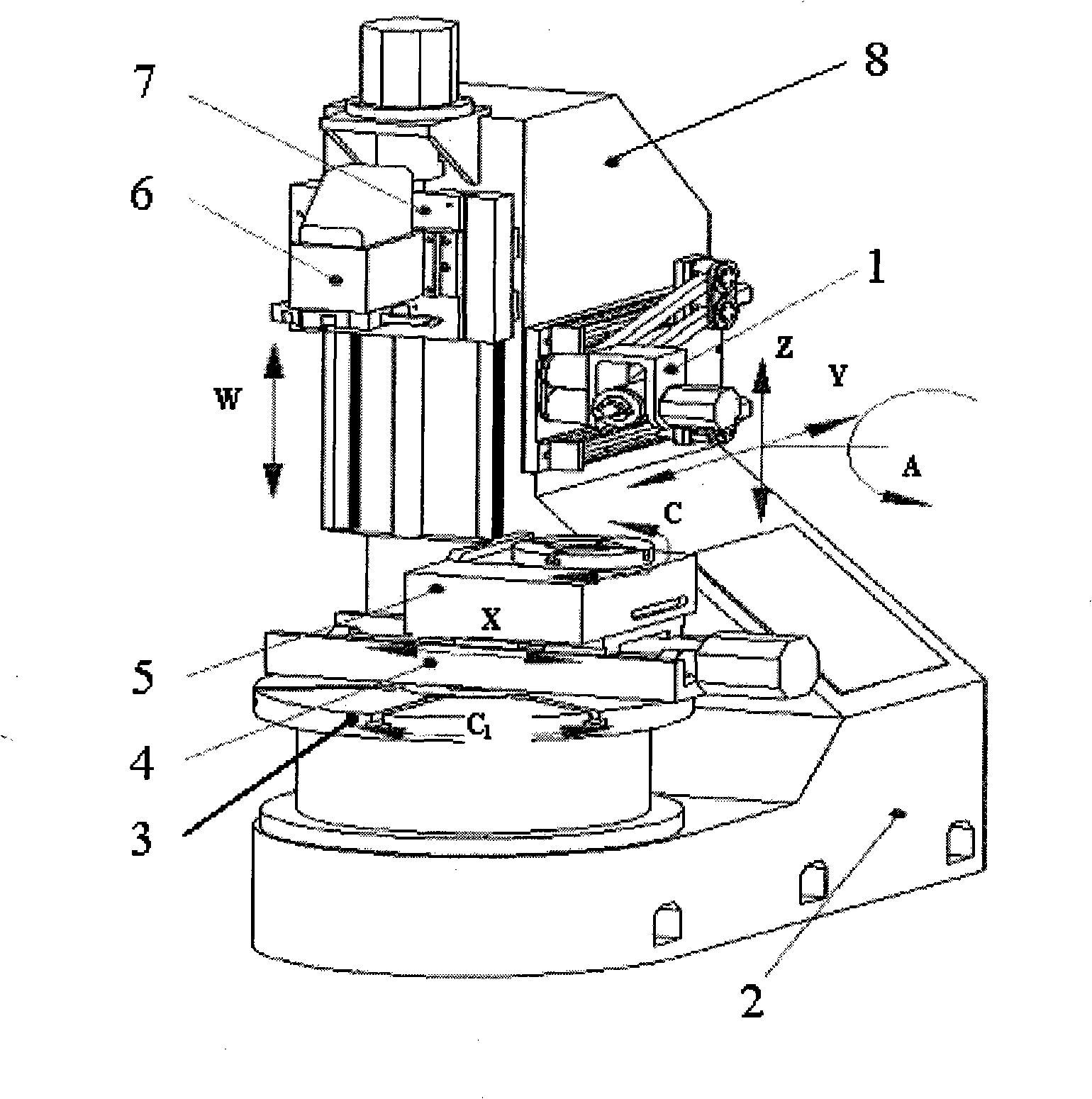

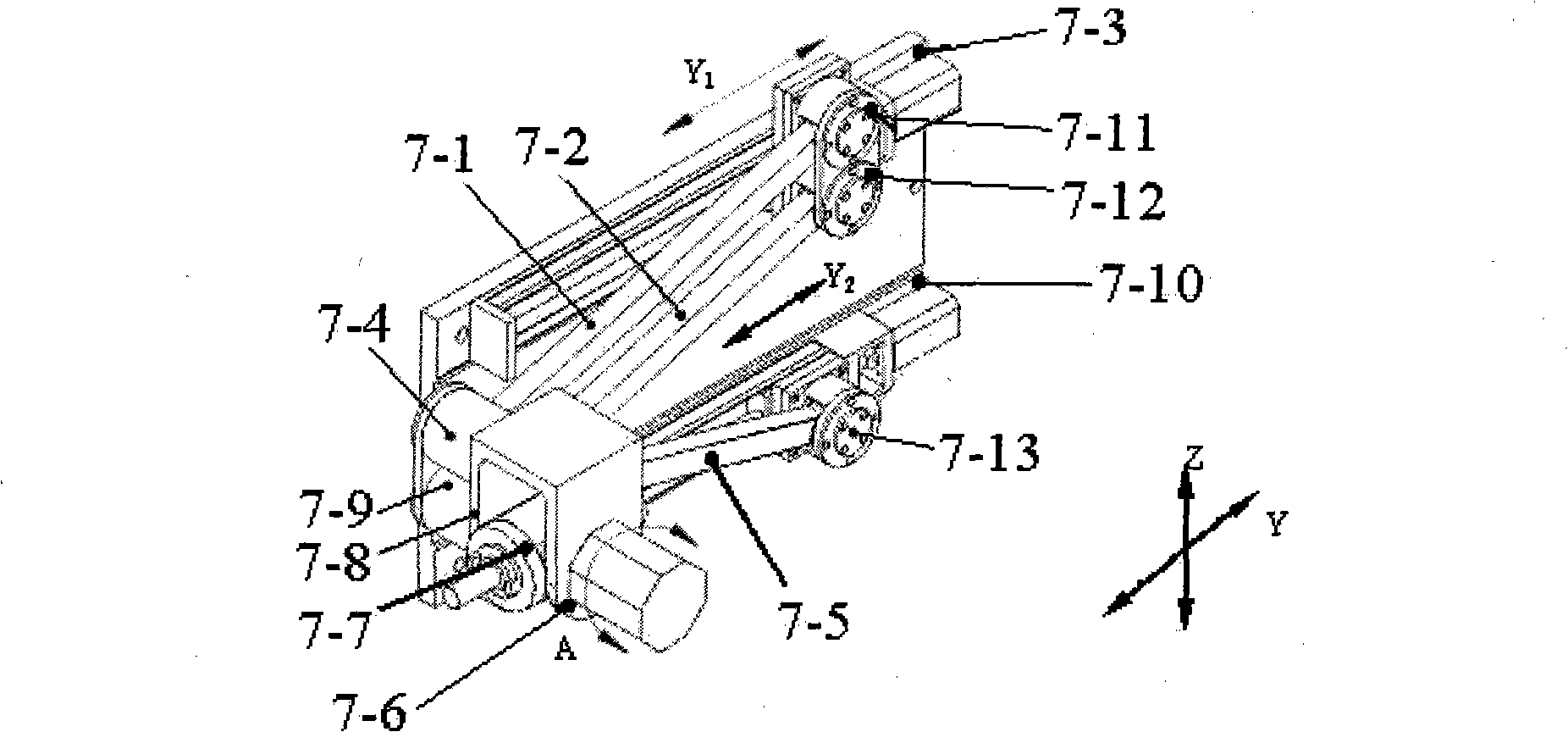

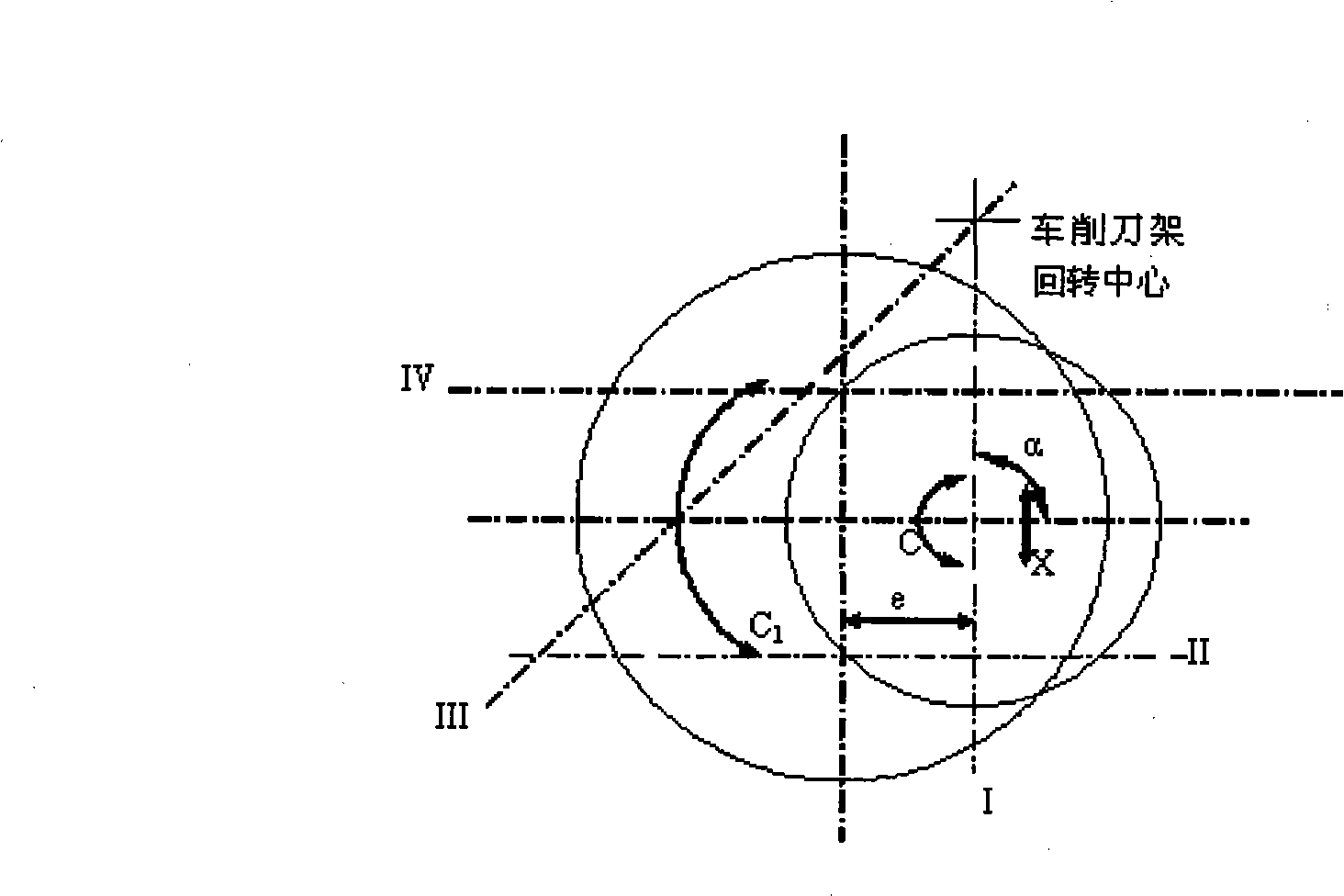

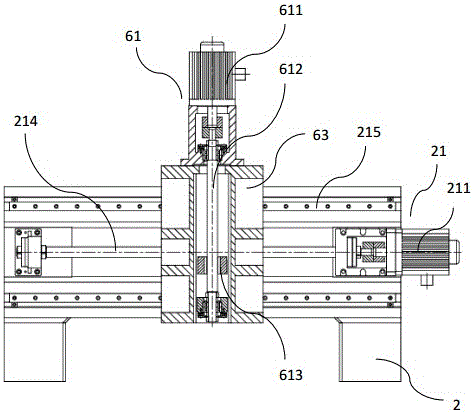

Parallel-series principle milling vehicle combined numerically controlled machine

InactiveCN101279422AChange positionChange directionOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine tool

The invention discloses a milling vehicle composite numeral control machine based on the principle of parallel series, which comprises a lathe bed. A column and an indexing table are respectively arranged on the lathe bed and a triaxial parallel series milling spindle head is arranged horizontally along the direction of the Y axis on one side wall of the column; a W shaft component which can move along the Z direction is arranged on the side wall of the column close to the indexing table and a turning head is arranged on the W shaft component; an X axis component which is eccentrically arranged is arranged on the indexing table and the upper side of the X axis component is connected with a rotary table of a C shaft by a guide pair. The composite numeral control machine of the invention can realize the functions of the 5-axis CNC milling machining, high-speed milling vehicle machining of the complex rotary moulding surface by four-axis simultaneous motion and milling machining by three-axis spontaneous motion, and the function of enlarging the range of machining dimension by using small stroke to process large workpieces.

Owner:XIAN UNIV OF TECH

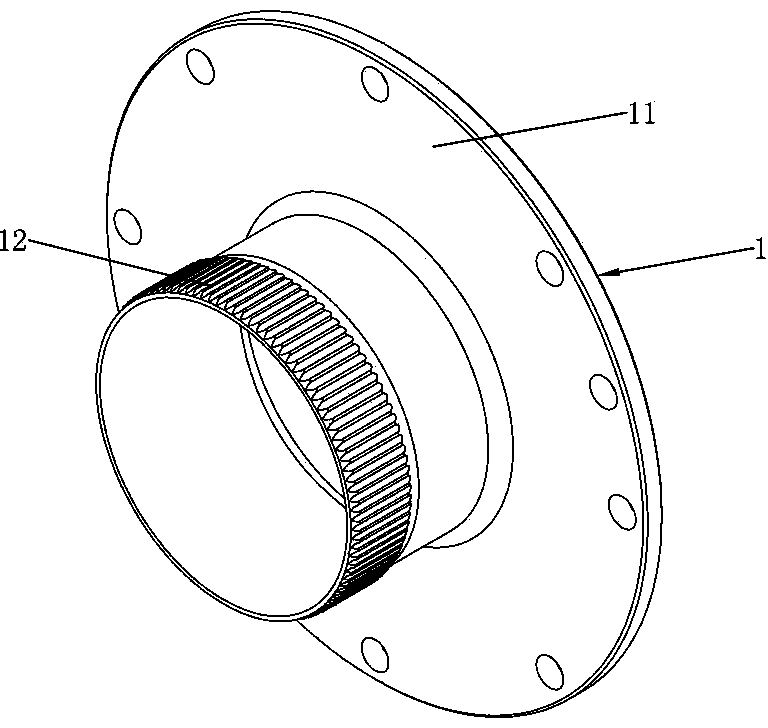

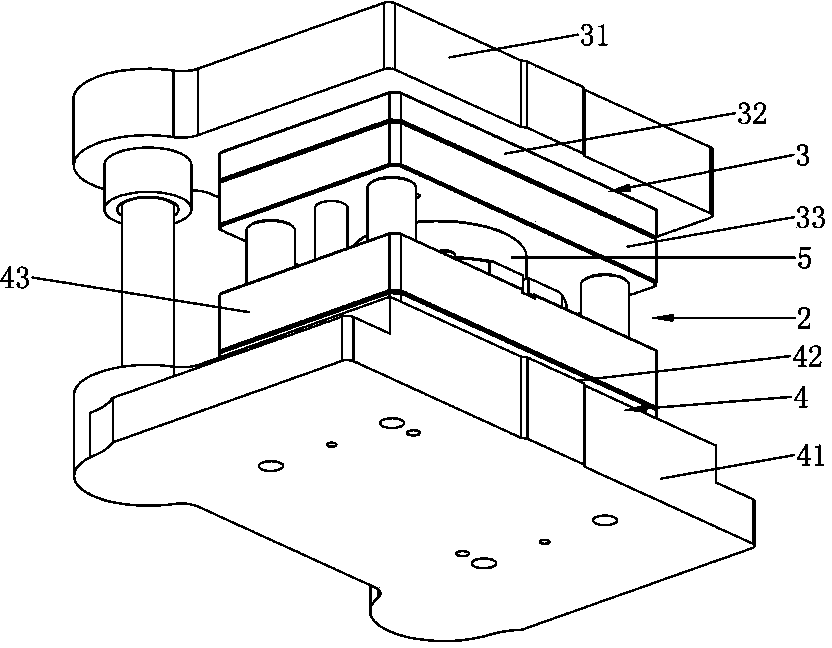

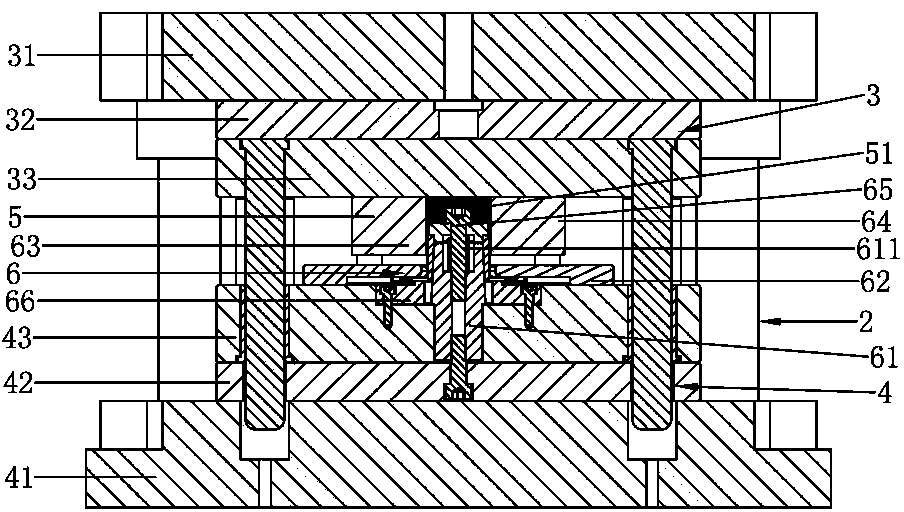

Method for processing harmonic reducer flexible wheel

The invention discloses a method for processing a harmonic reducer flexible wheel. The method sequentially includes processes of blanking, forging and shaping, normalizing for heat treating, spinning, turning in a CNC (computer numerical control) lathe, gear-shaping in a CNC milling machine and punching and shaping. The process of punching and shaping is performed through matching of a punching machine and a punching and shaping die, an upper die base, an upper padding plate, an upper fixing plate, a lower die base, a lower padding plate, a lower fixing plate, an upper shaping die, a positioning column, a pressing plate, a tightening ring, a tightening-ring pressing plate and a locking screw are arranged on the punching and shaping die, and an inner shaping gear hole is formed in a core portion of the upper shaping die. The pressing plate clamps and fixes a fixed portion of the semi-finished flexible wheel, the positioning column, the tightening ring, the tightening-ring pressing plate and the locking screw cooperatively fix a center hole of the semi-finished flexible wheel, and the inner shaping gear hole performs shaping upon a profile of an outer gear portion. Therefore, flexible-wheel processing can be completed through a universal machine tool, financial burden of manufacturers can be reduced on one hand, and on the other hand, processing precision of the flexible wheel can be guaranteed.

Owner:DONGGUAN XINTUO INTELLIGENT MACHINERY TECH

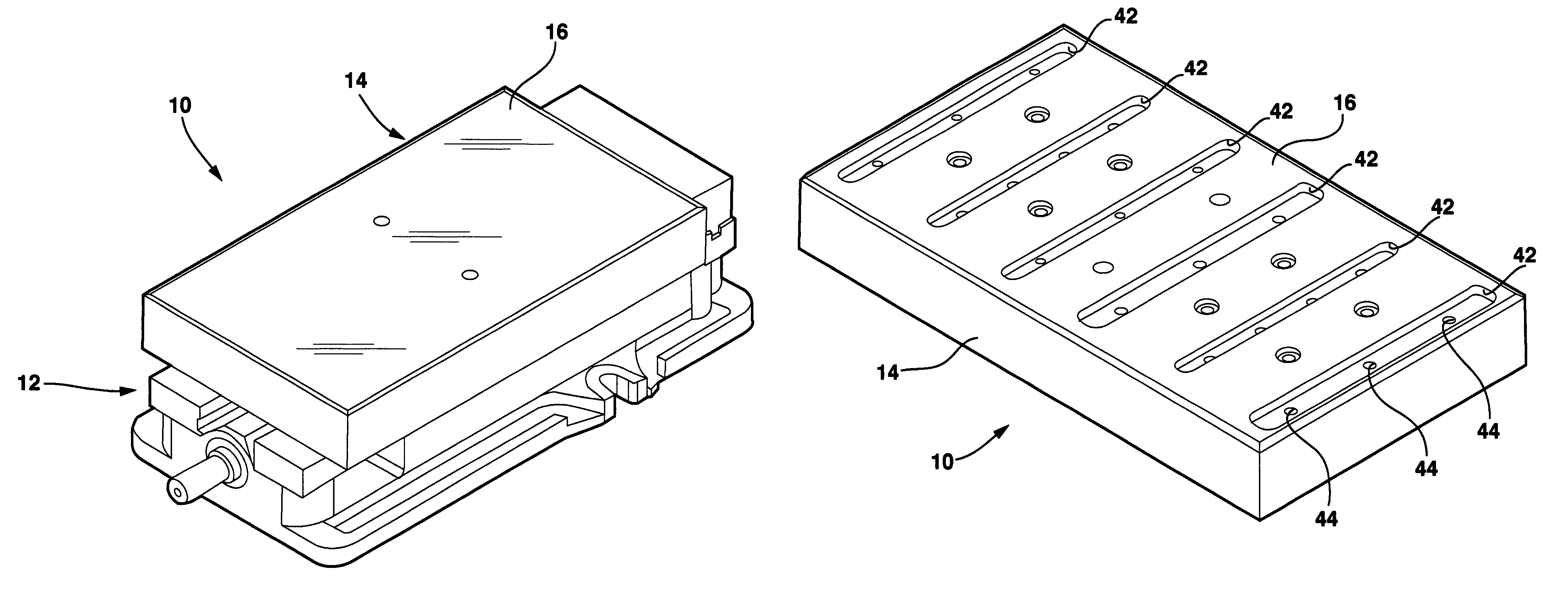

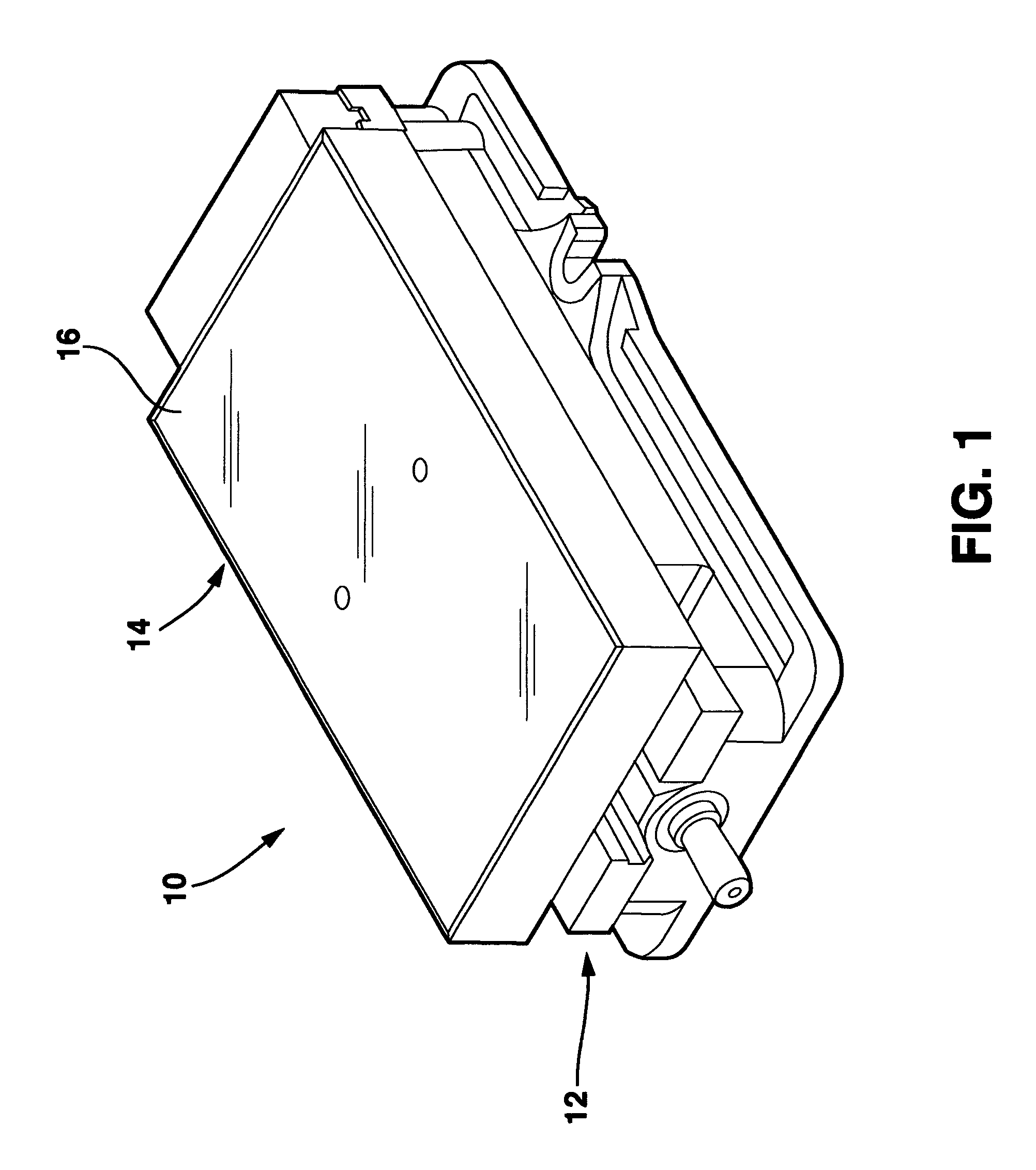

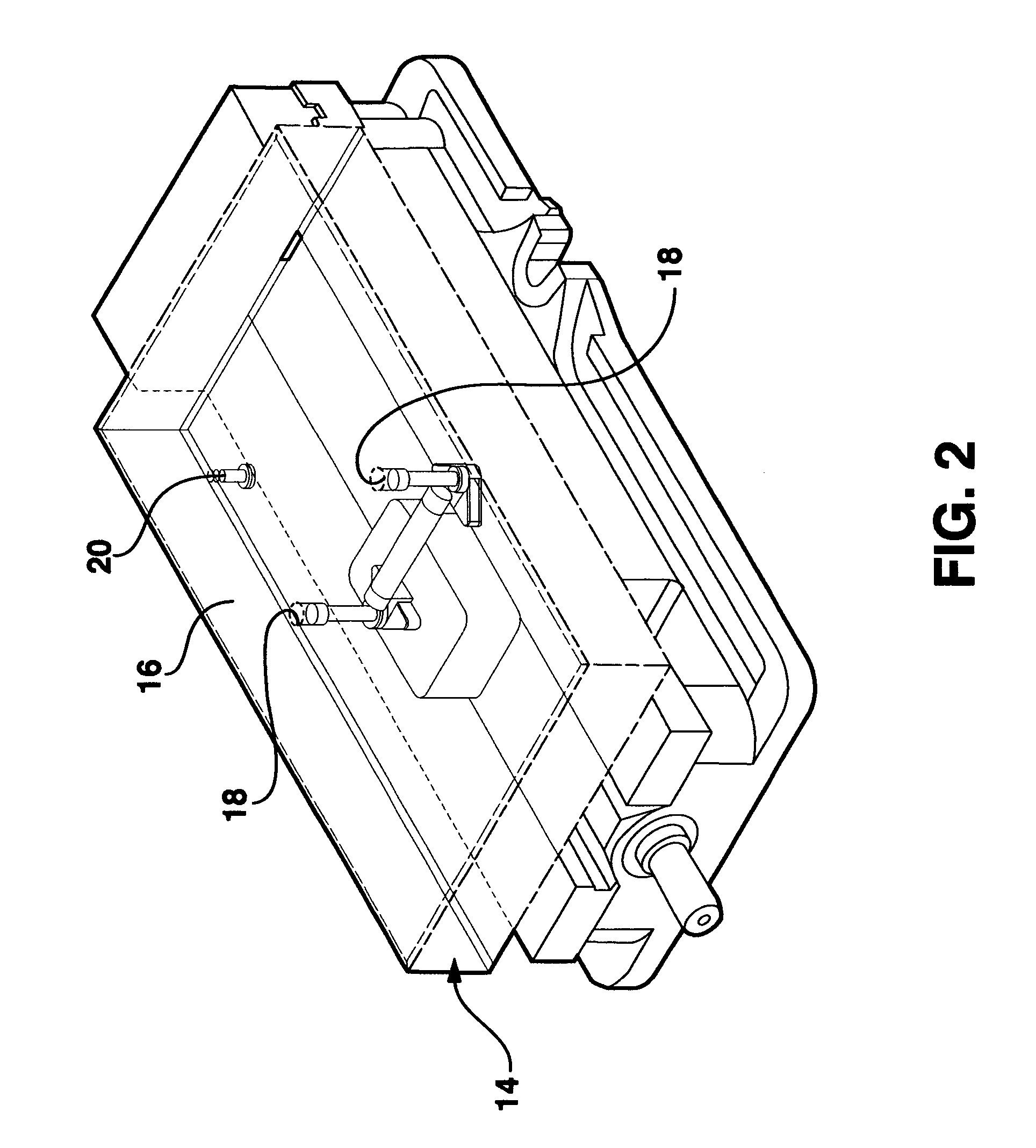

Vise attachable fixture plate for use with CNC milling equipment

A fixture plate for use with a CNC milling machine. The fixture plate is constructed of a generally rectangular block having a top surface, a bottom surface and a forward edge. The bottom surface of the block is positioned to rest on the support surface with the forward edge of the block resting against the fixed jaw. The bottom surface of the block includes a cavity in which is mounted a clamping pin for coupling with the vise hook nut. When the machine screw is manipulated to move the mounting block toward the fixed jaw, the block is clamped to the vise between the fixed jaw and the vise hook nut. The top surface of the block is provided with grooves shaped to conform to the peripheral shape of each of the multiple workpieces. Clamping nuts, recessed in the grooves, are used for clamping the multiple workpieces to the block.

Owner:LOVAS STEPHEN R

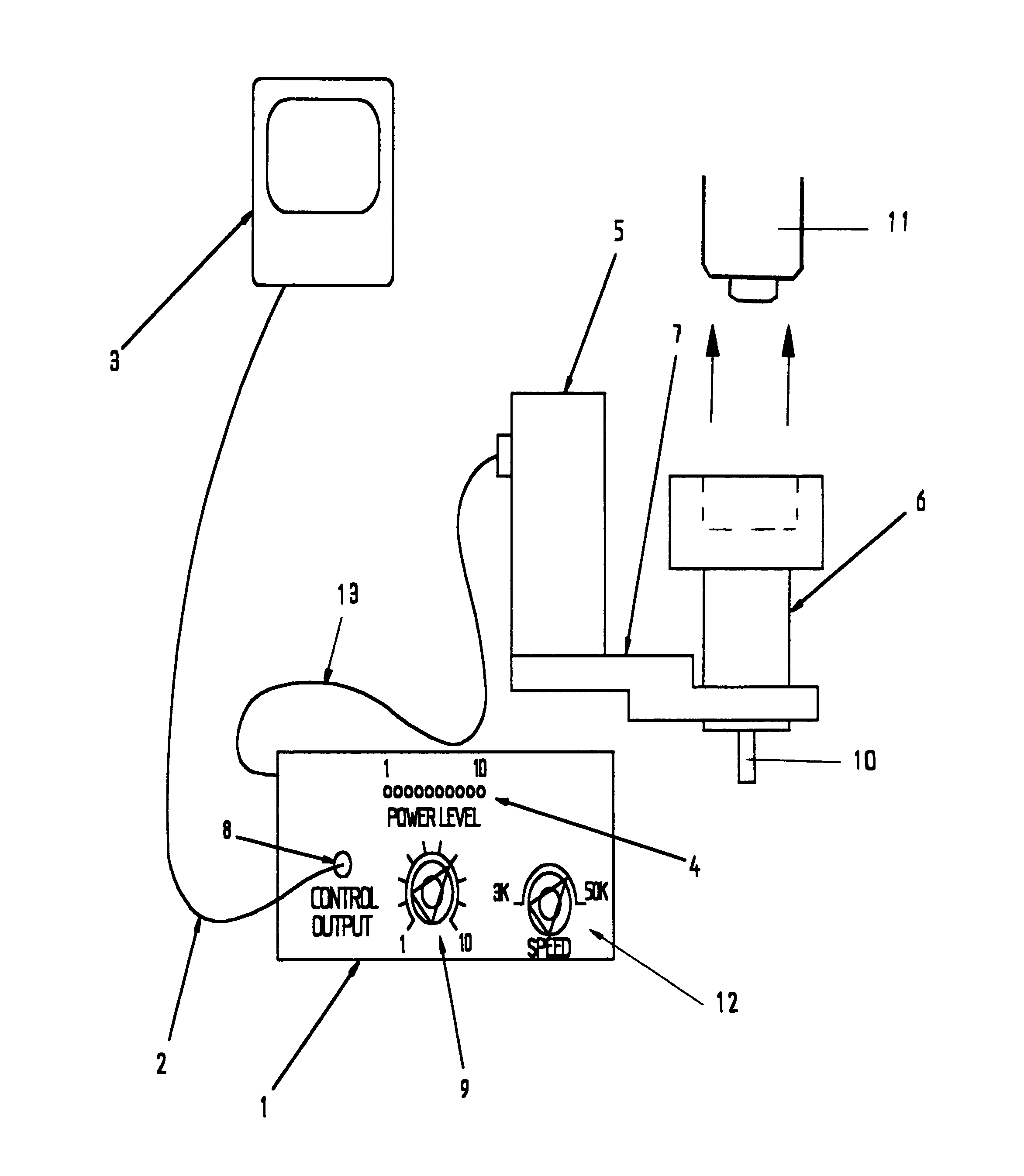

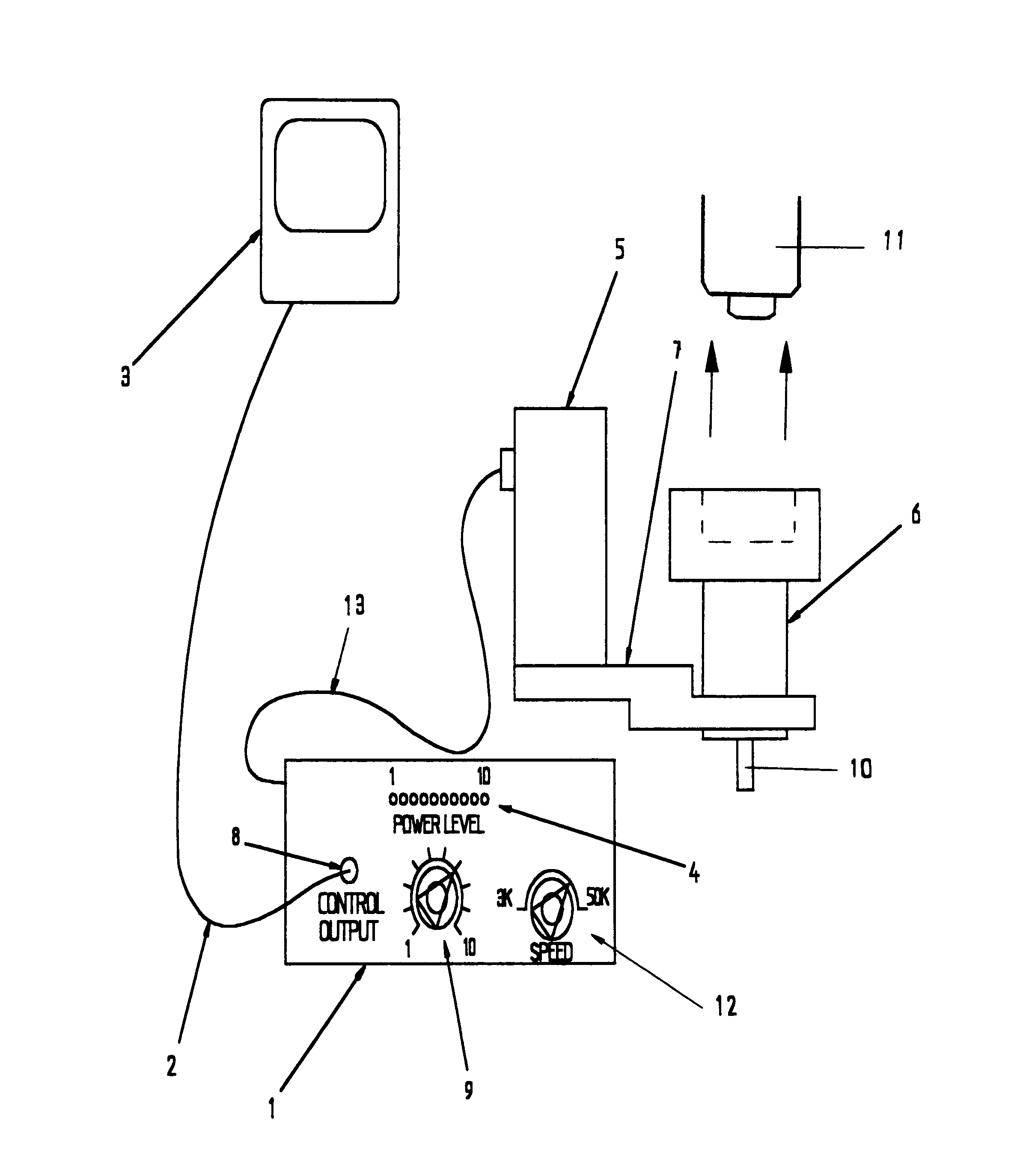

Controller for the electric motor of a high-speed spindle attachment used with computer-controlled milling machines

InactiveUS6874980B1Lower levelProvide protectionThread cutting machinesMilling machinesMaximum levelElectronic controller

An improved electronic controller for the motor of a high-speed spindle attachment used in conjunction with a cnc milling machine. The controller comprises preventative circuitry that protects the spindle assembly of the attachment from overload accruing as a result of relatively moderate increases in torque demand during use. The controller senses the power level being used by the motor while it causes high-speed spindle rotation, and when it identifies a power consumption rate by the spindle that exceeds the operator pre-set maximum level determined to be safe for avoiding catastrophic spindle damage, the electronic controller sends a signal back to the computer controlling the axes of the cnc milling machine that is sufficient to slow, pause, and / or stop the feed-rate.

Owner:NOELLE JOHN A +1

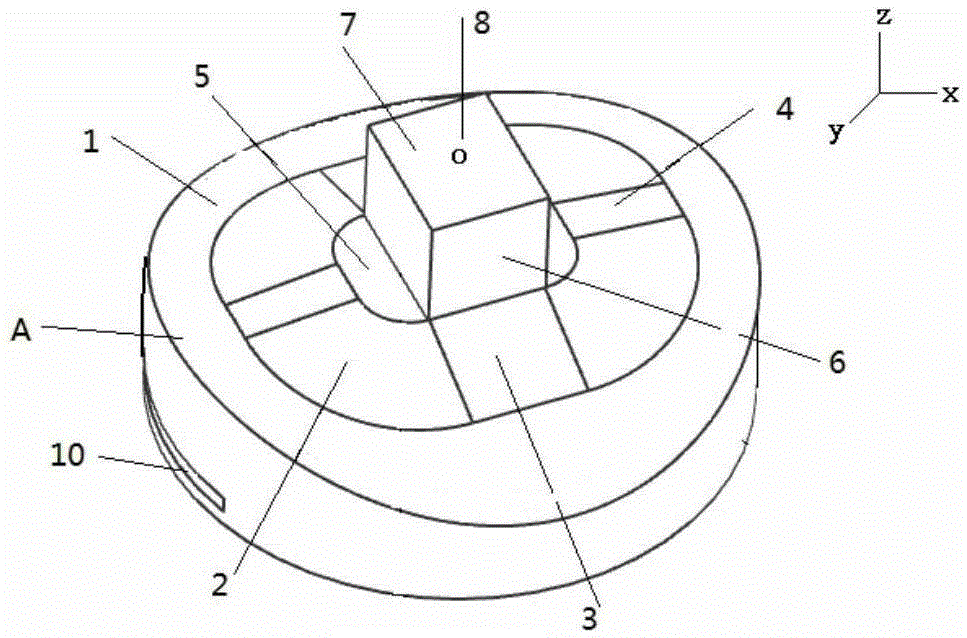

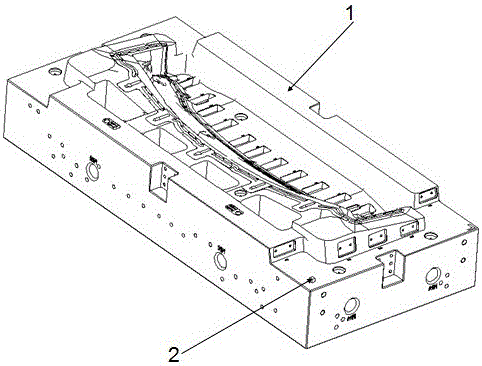

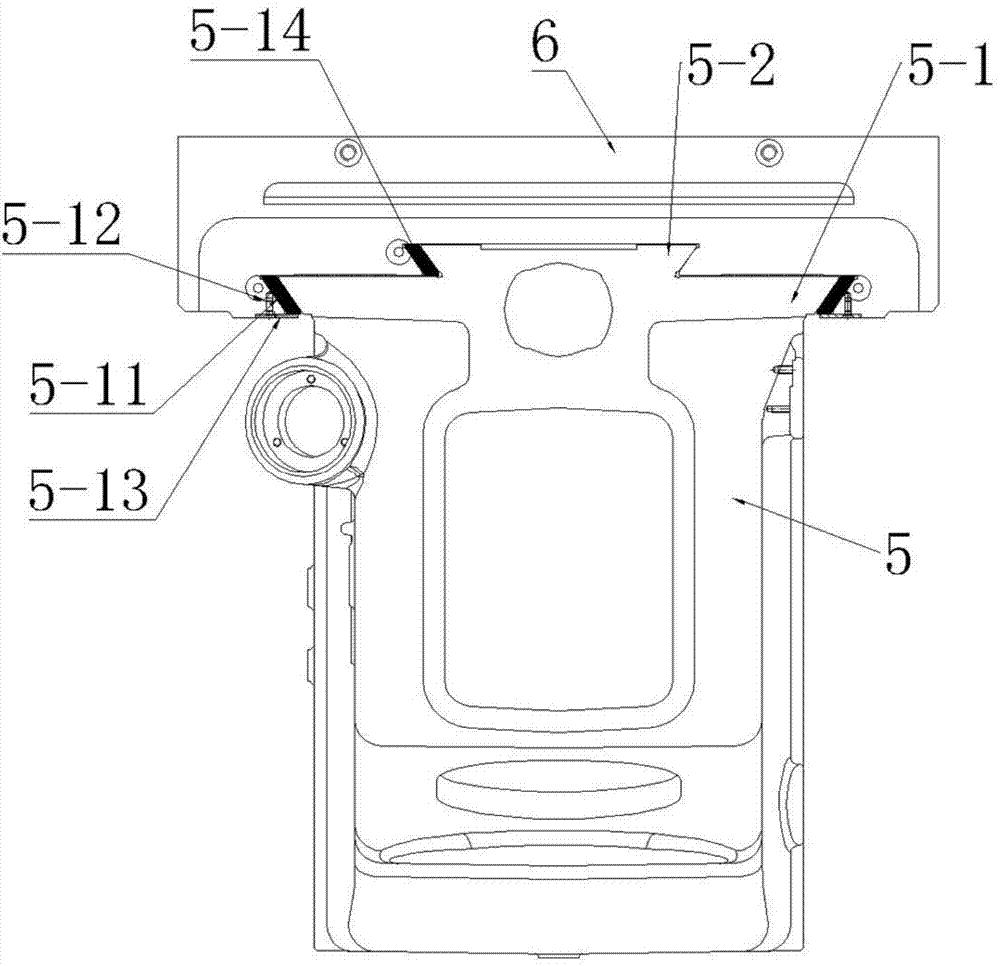

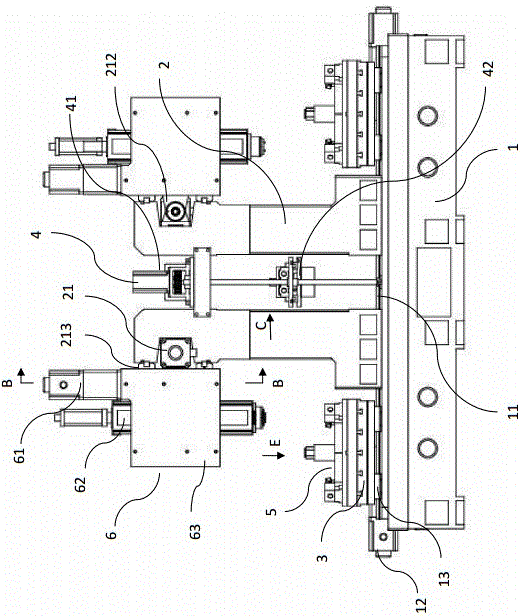

Minimum quantity lubrication multi-freedom-degree intelligent spray head system based on CNC milling machine

InactiveCN109108723AThe spray angle is effectively controllableEffective Controllable DistanceMaintainance and safety accessoriesMulti degree of freedomMachining system

The invention discloses a minimum quantity lubrication multi-freedom-degree intelligent spray head system based on a CNC milling machine. The system comprises a CNC milling machine system connected with a nozzle multi-directional movement system and a nozzle angle automatic adjustment system. The nozzle multi-directional movement system comprises an XZ face rotation mechanism, a Y-direction movingmechanism and an X-direction moving mechanism. A nozzle is mounted on the X-direction moving mechanism and is further connected with the nozzle angle automatic adjustment system. The X-direction moving mechanism is used for driving the nozzle to move in the direction X. The nozzle angle automatic adjustment system is used for adjusting the angle of the nozzle. Under drive of the Y-direction moving mechanism, the X-direction moving mechanism can move in the direction Y along the Y-direction moving mechanism, and therefore X-direction movement of the nozzle is achieved. Under drive of the XZ face rotation mechanism, the X-direction movement mechanism can do XZ face rotation movement along the XZ face rotation mechanism, and therefore XZ face rotation movement of the nozzle is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

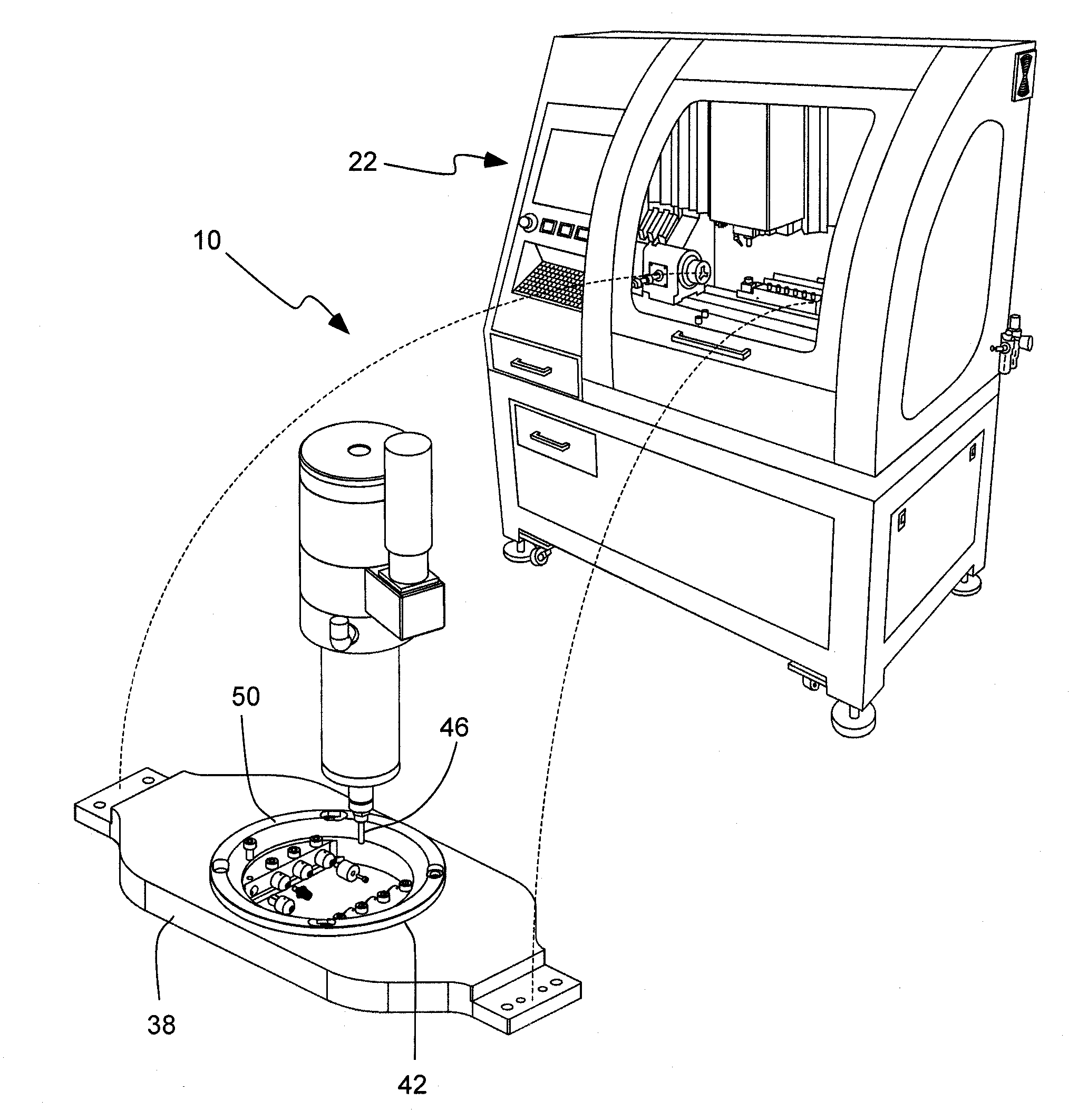

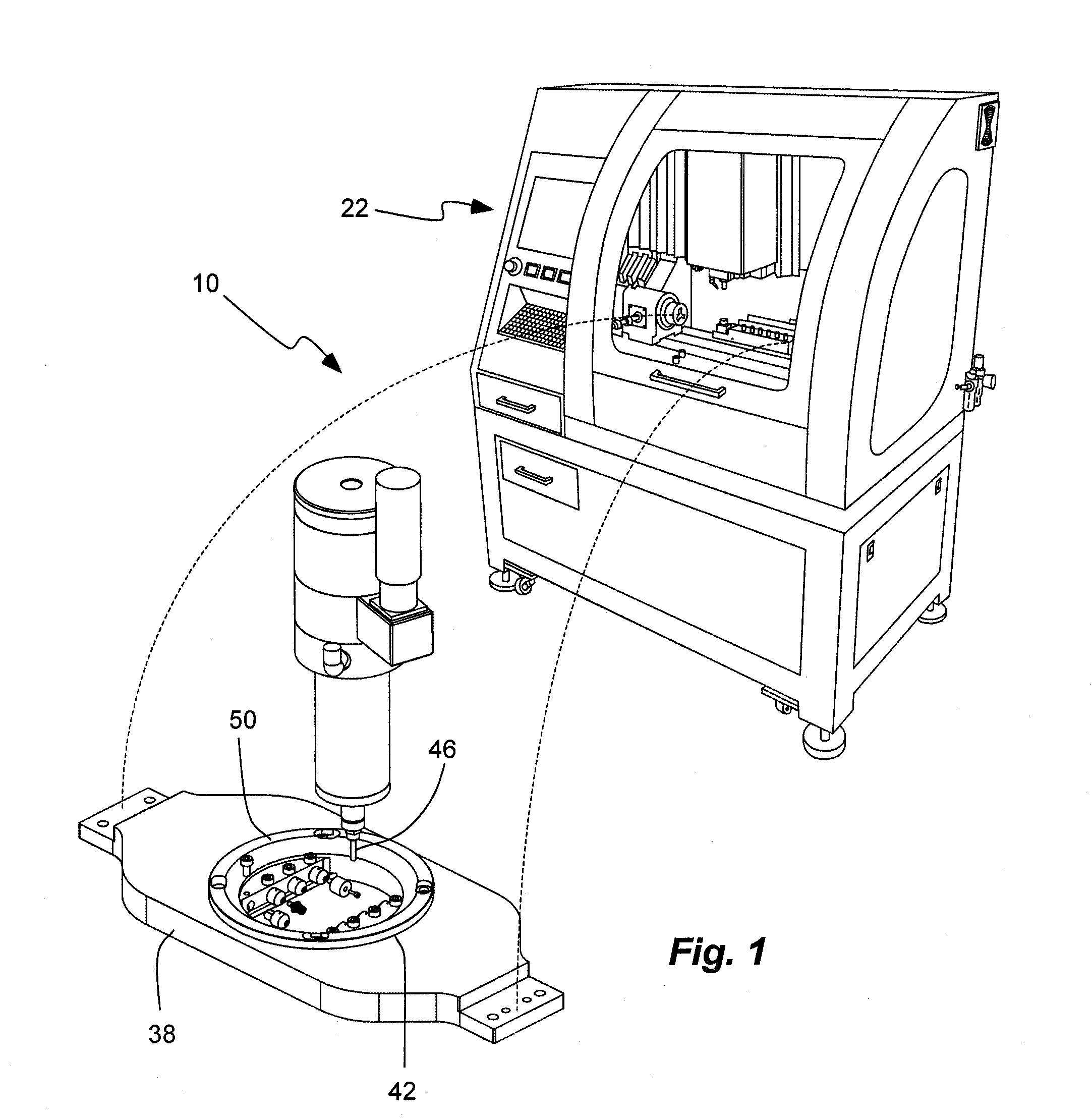

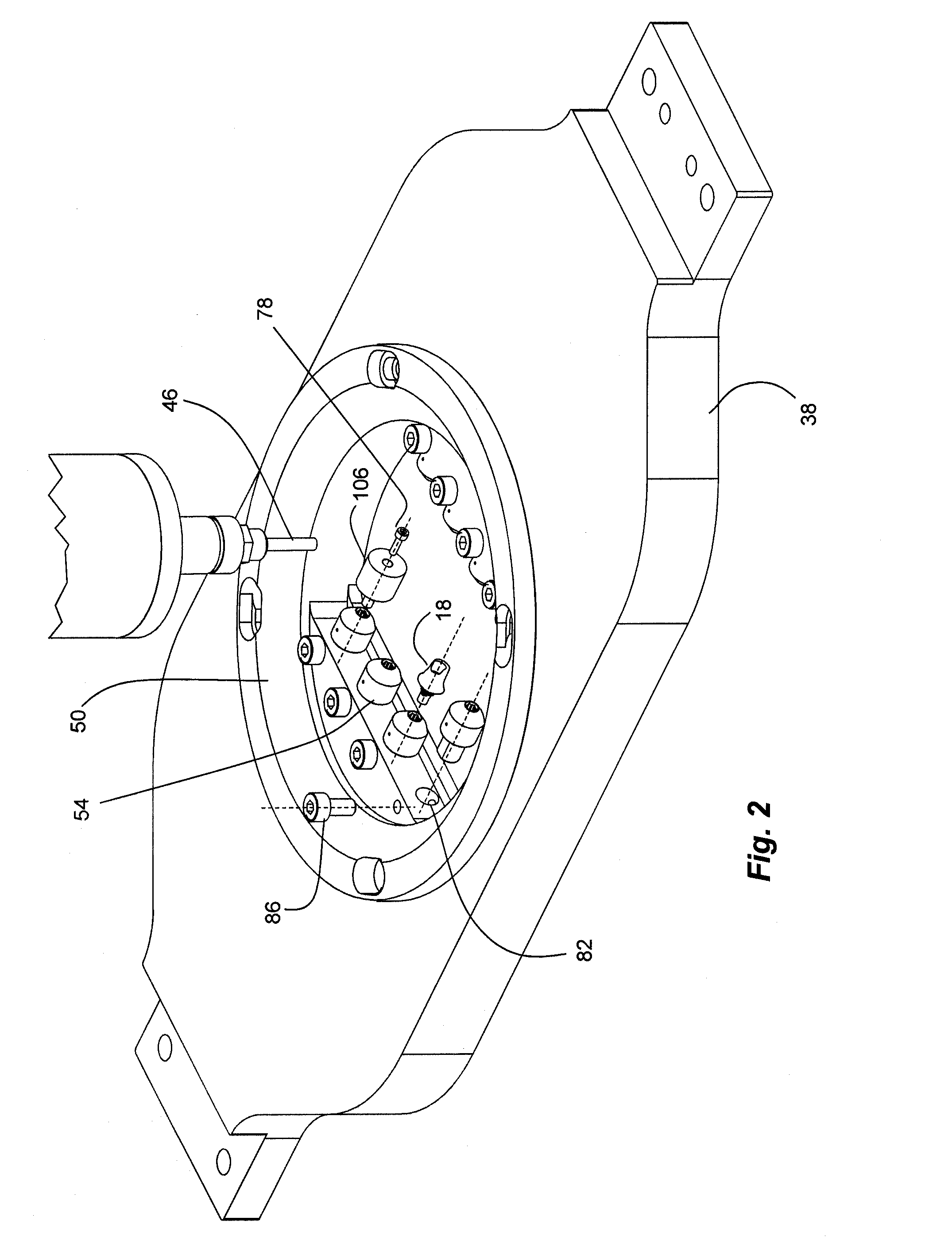

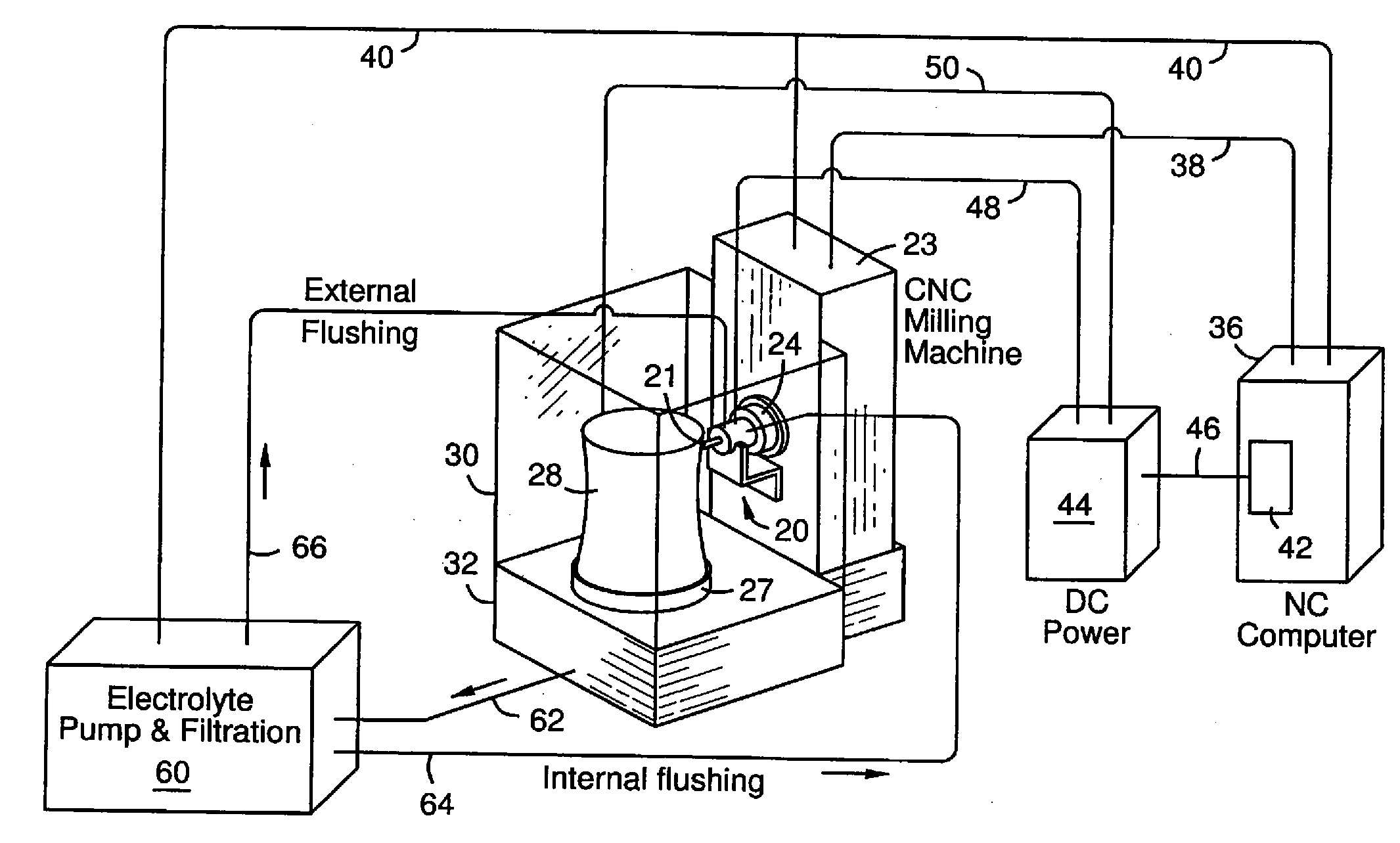

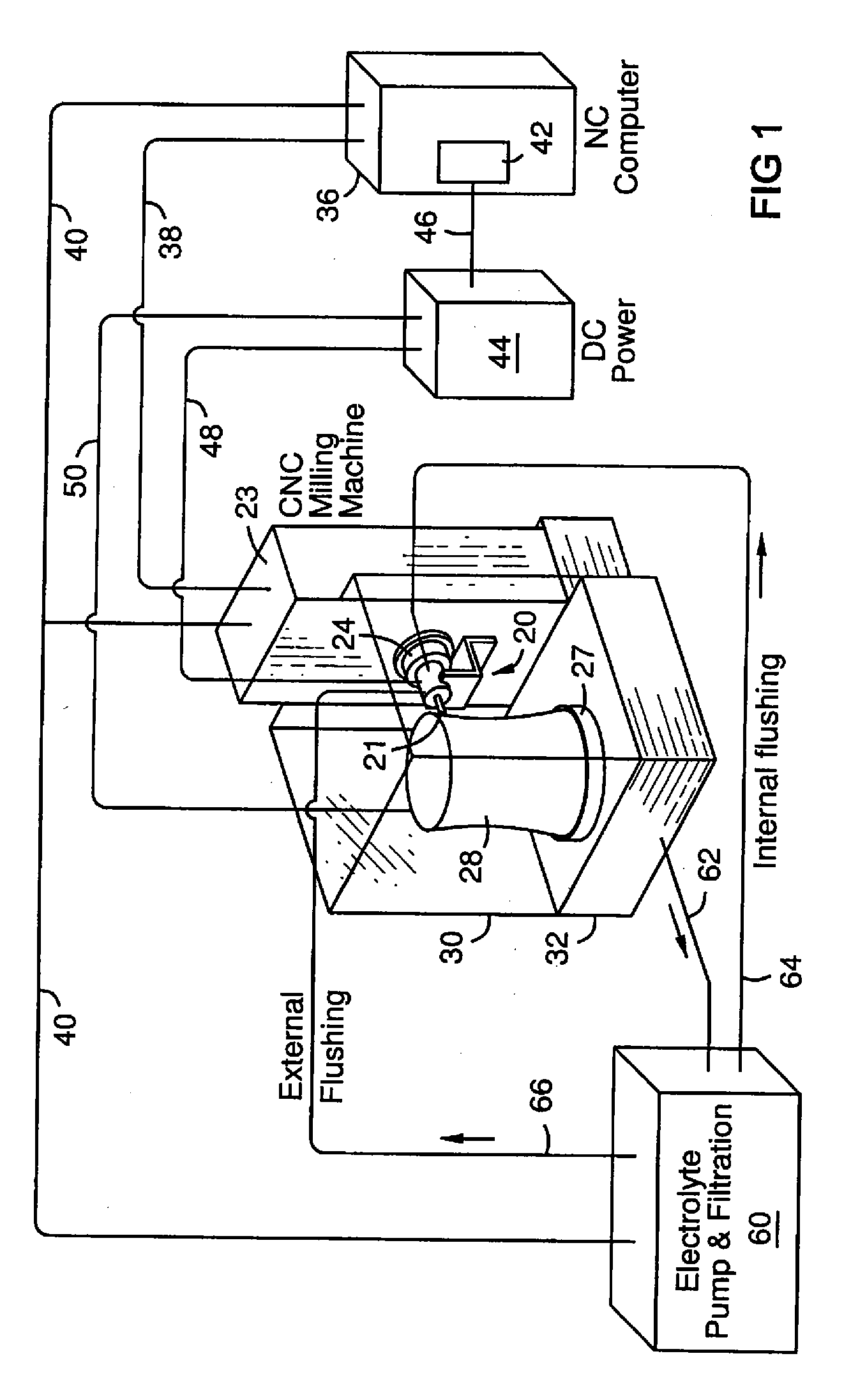

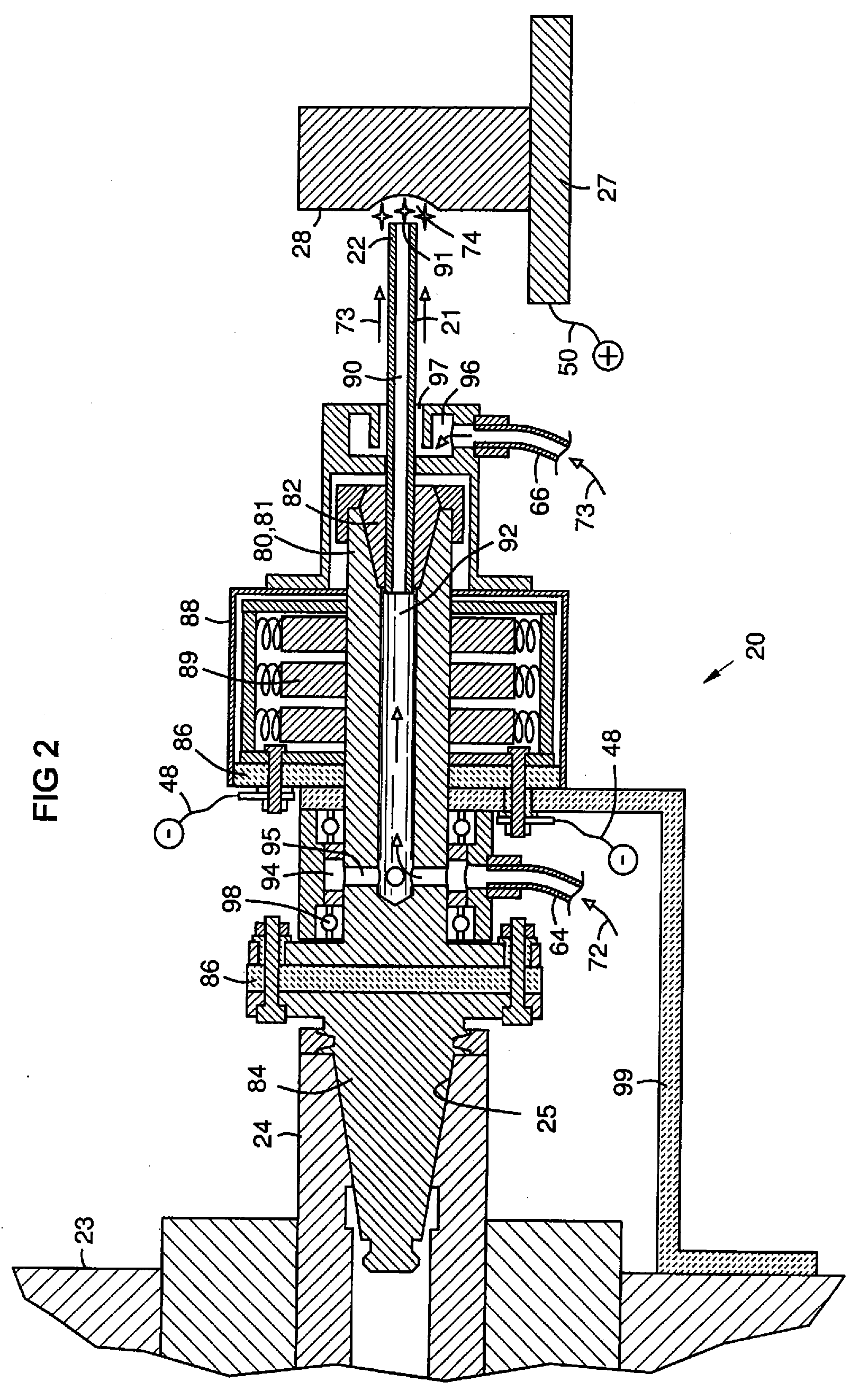

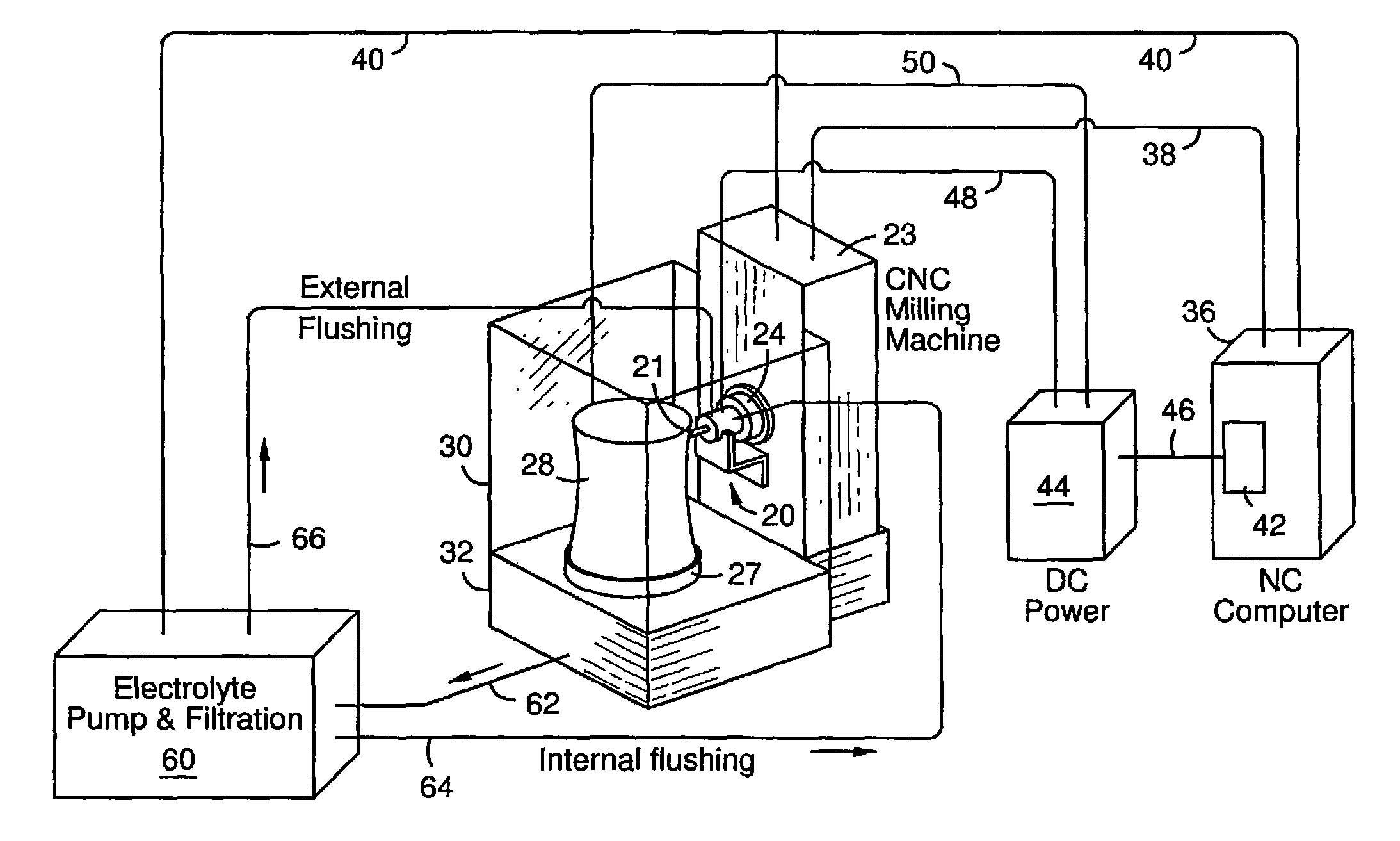

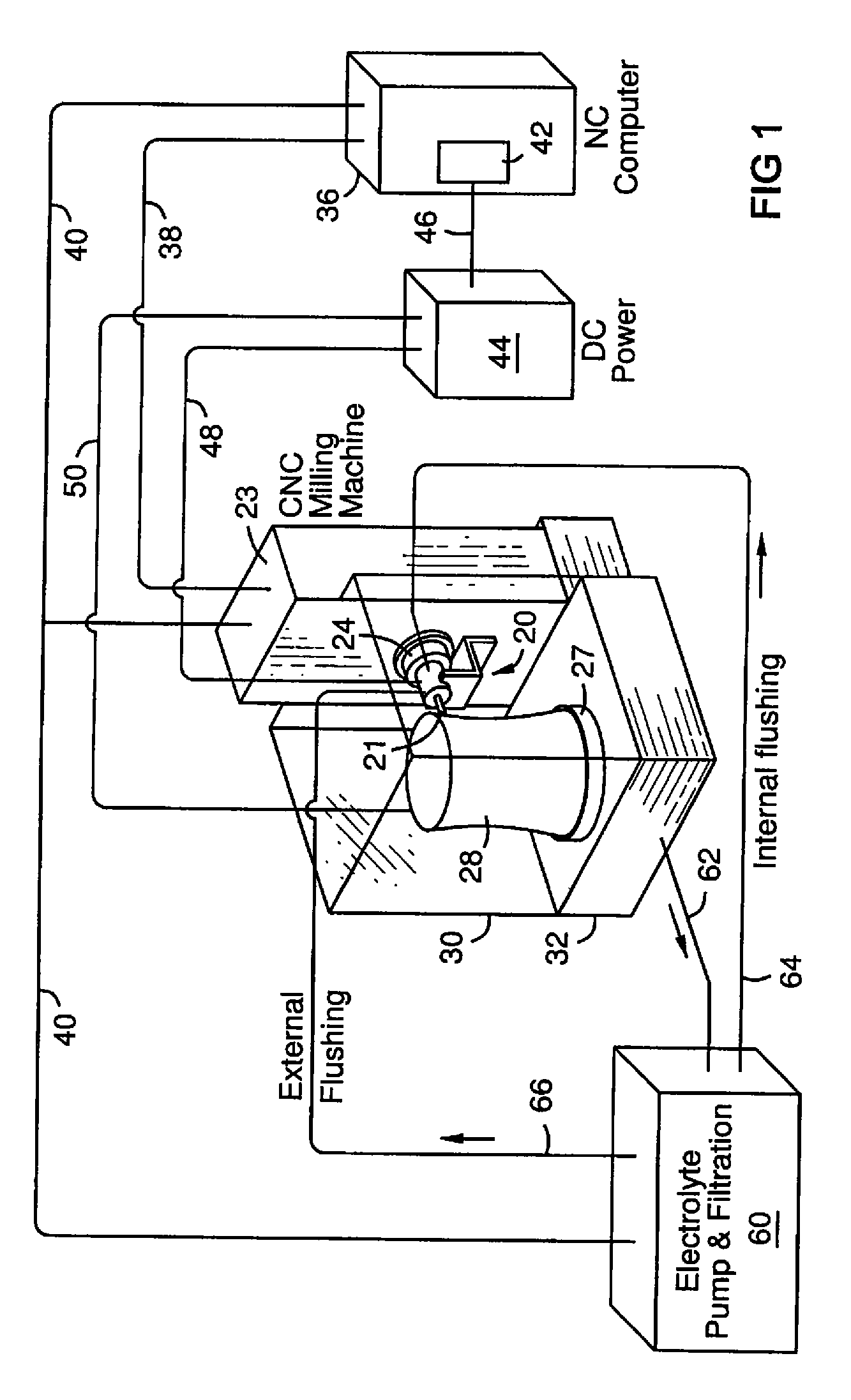

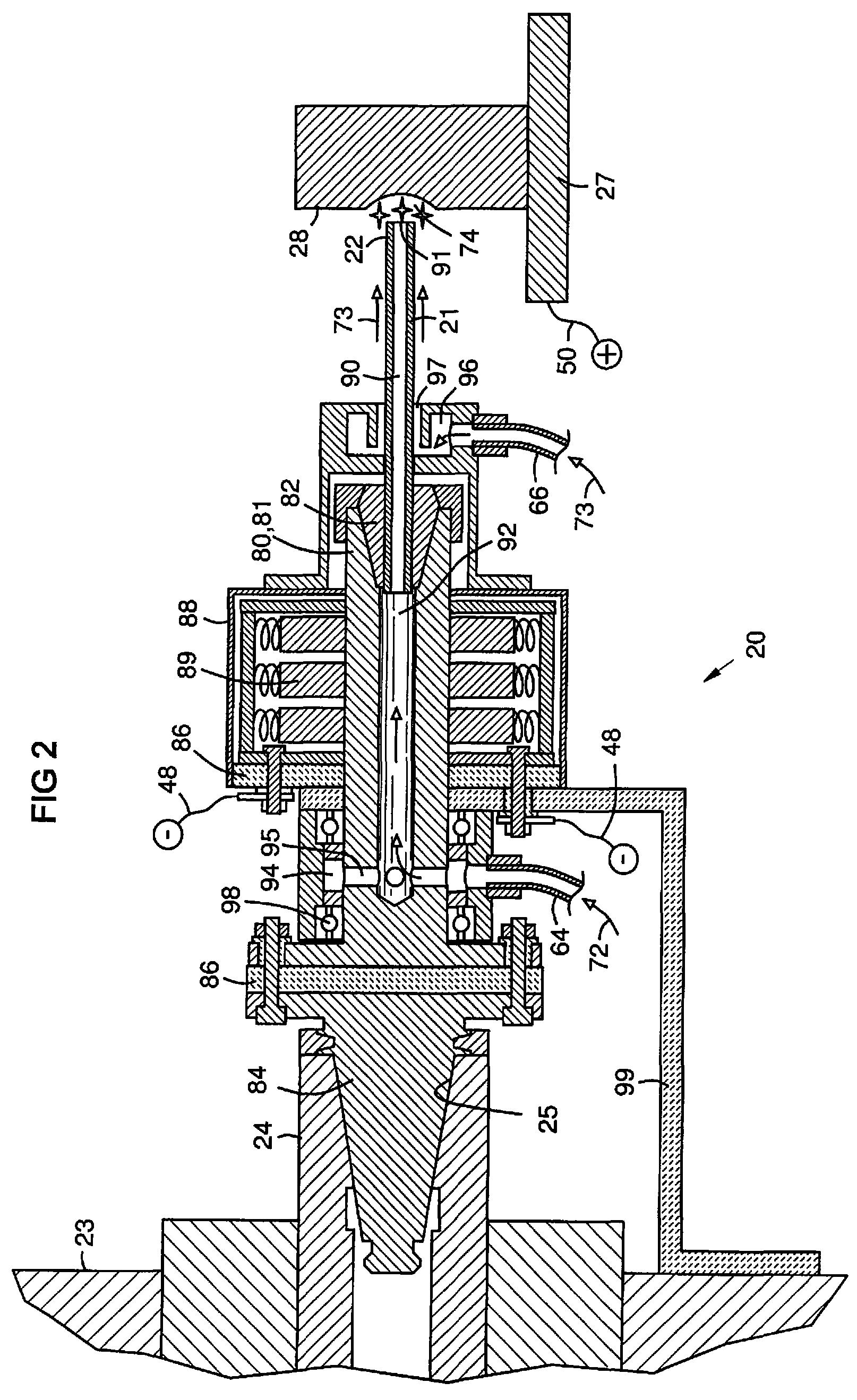

Adaptive Spindle Assembly For Electroerosion Machining On A CNC Machine Tool

An apparatus and method for adapting a CNC milling machine for electroerosion machining. The apparatus includes a tubular electrode on the distal end of an adapter shaft. A tool holder on the proximal end of the adapter shaft is mountable in the chuck of a cutter spindle in the milling machine. The adapter shaft is rotatably mounted within a bearing and an electrical brush contact subassembly, both of which are supported by a bracket. The bracket is attached to the milling machine but insulates it from the tool electrode. The bearing supports the adapter shaft in alignment with the CNC spindle. An electrical power supply energizes the electrode and the workpiece for electroerosion in a gap between them. Electrolyte is circulated through the spinning tool electrode during operation. The CNC computer is configured to operate the machine, power supply, and electrolyte flow for electroerosion machining.

Owner:GENERAL ELECTRIC CO

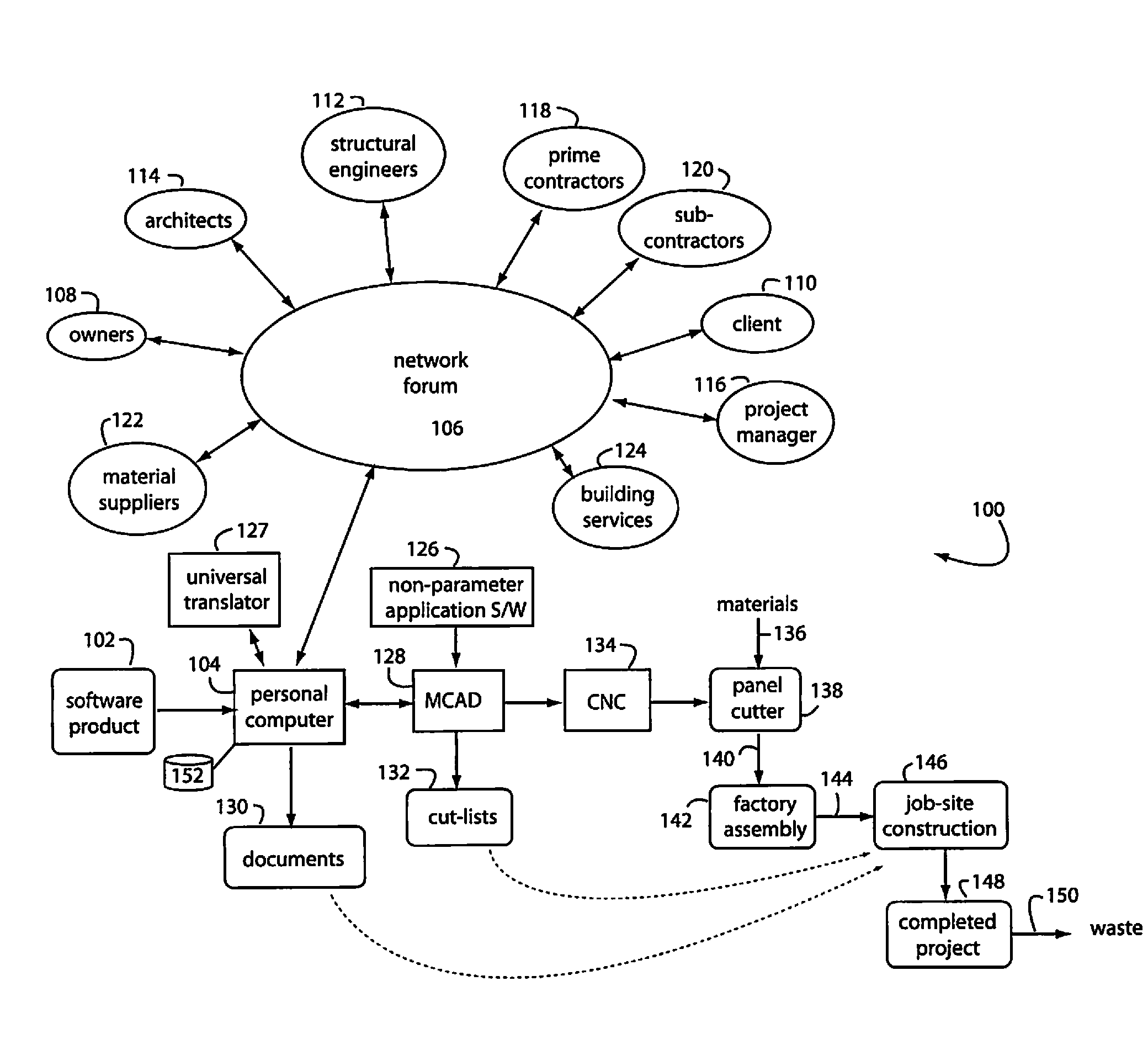

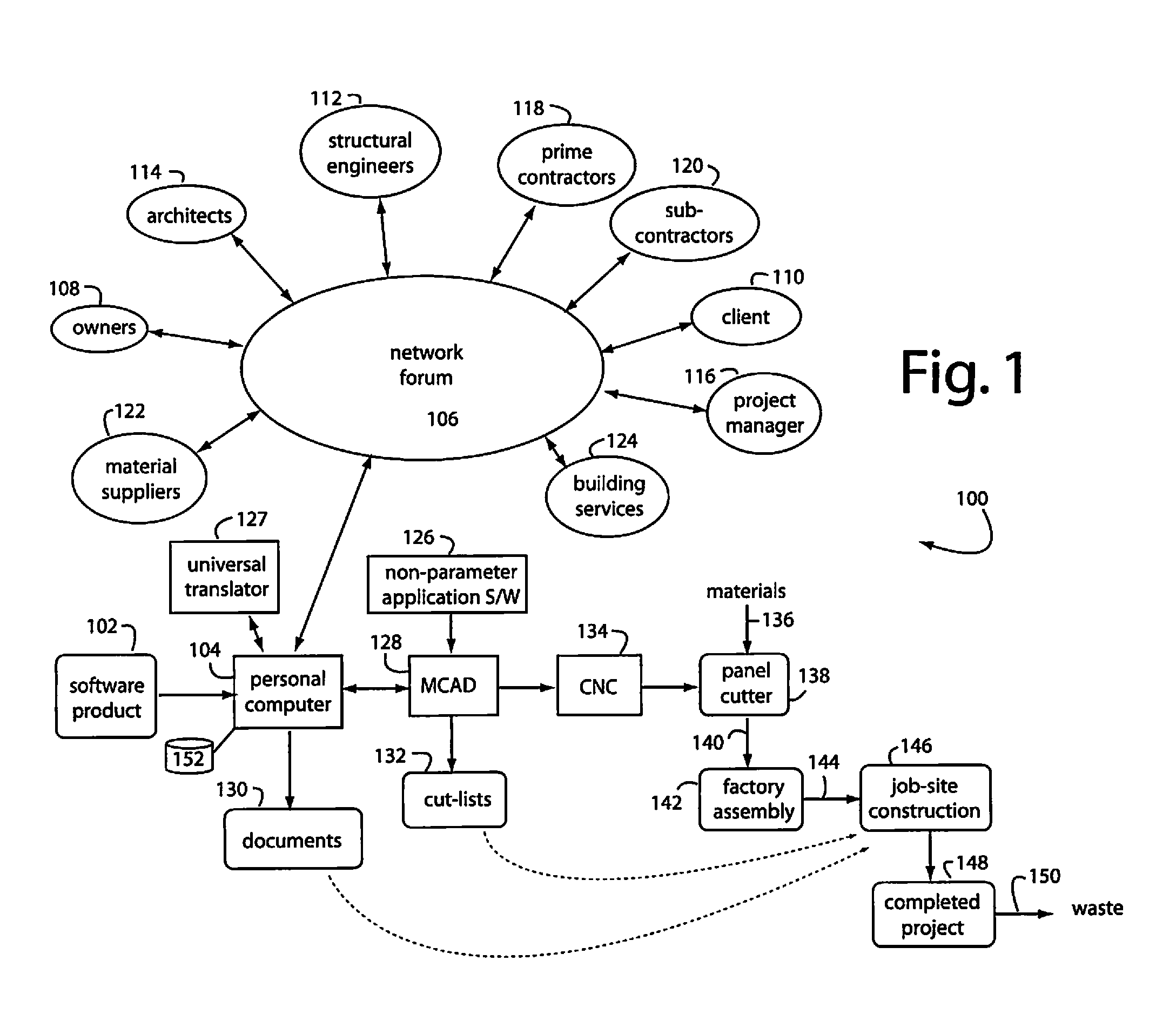

Building construction software and system

ActiveUS8204619B2Geometric CADSpecial data processing applicationsNumerical controlComputer Aided Design

A method of building construction includes designing a building with software for execution on a computer such that an envelope of the building principally comprises expanded polystyrene foam panels, and the software is used to automatically generate a plan with reference numbers that identify substantially all the component pieces of the building. The software and computer are coupled to a computer aided design (CAD) program for generating computer numerical controlled (CNC) milling commands for expanded polystyrene foam panels, and a cut-list for steel reinforcing studs to fit into matching slots milled into the expanded polystyrene foam panels. At least the expanded polystyrene foam panels and matching steel reinforcing studs are marked with identifying numbers corresponding to the reference numbers. The expanded polystyrene foam panels are milled with a CNC machine and panel cutter according to CNC milling commands from the CAD program.

Owner:COMPASS PROPERTY GRP

Adaptive spindle assembly for electroerosion machining on a CNC machine tool

An apparatus and method for adapting a CNC milling machine for electroerosion machining. The apparatus includes a tubular electrode on the distal end of an adapter shaft. A tool holder on the proximal end of the adapter shaft is mountable in the chuck of a cutter spindle in the milling machine. The adapter shaft is rotatably mounted within a bearing and an electrical brush contact subassembly, both of which are supported by a bracket. The bracket is attached to the milling machine but insulates it from the tool electrode. The bearing supports the adapter shaft in alignment with the CNC spindle. An electrical power supply energizes the electrode and the workpiece for electroerosion in a gap between them. Electrolyte is circulated through the spinning tool electrode during operation. The CNC computer is configured to operate the machine, power supply, and electrolyte flow for electroerosion machining.

Owner:GENERAL ELECTRIC CO

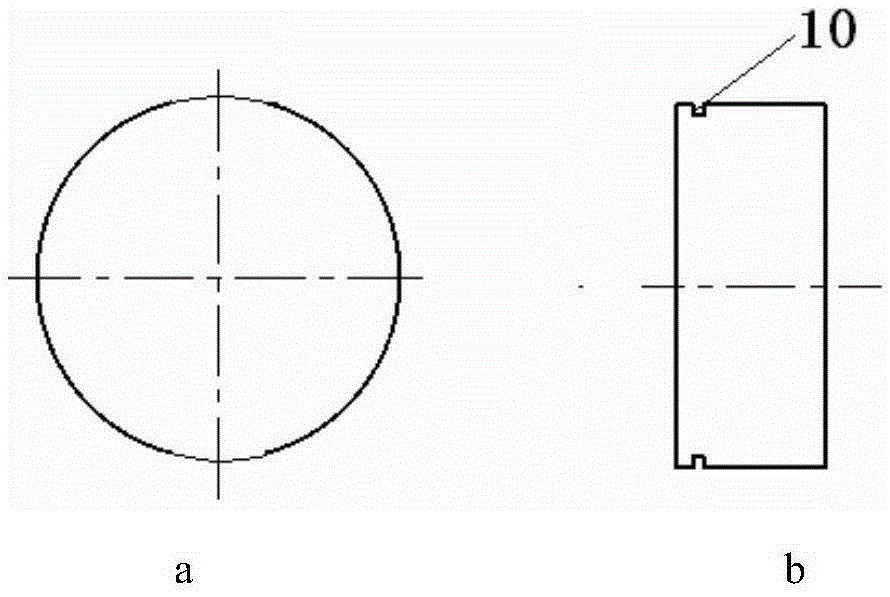

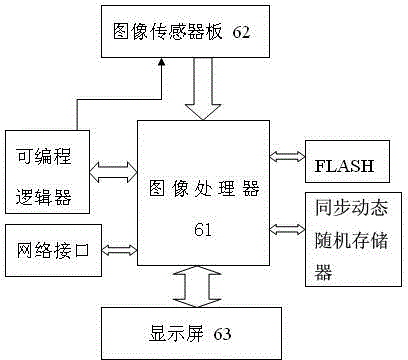

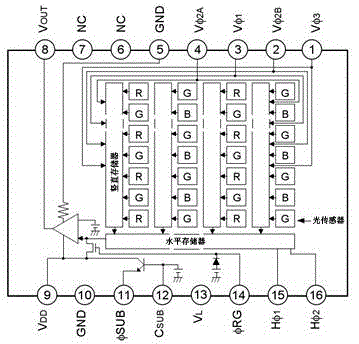

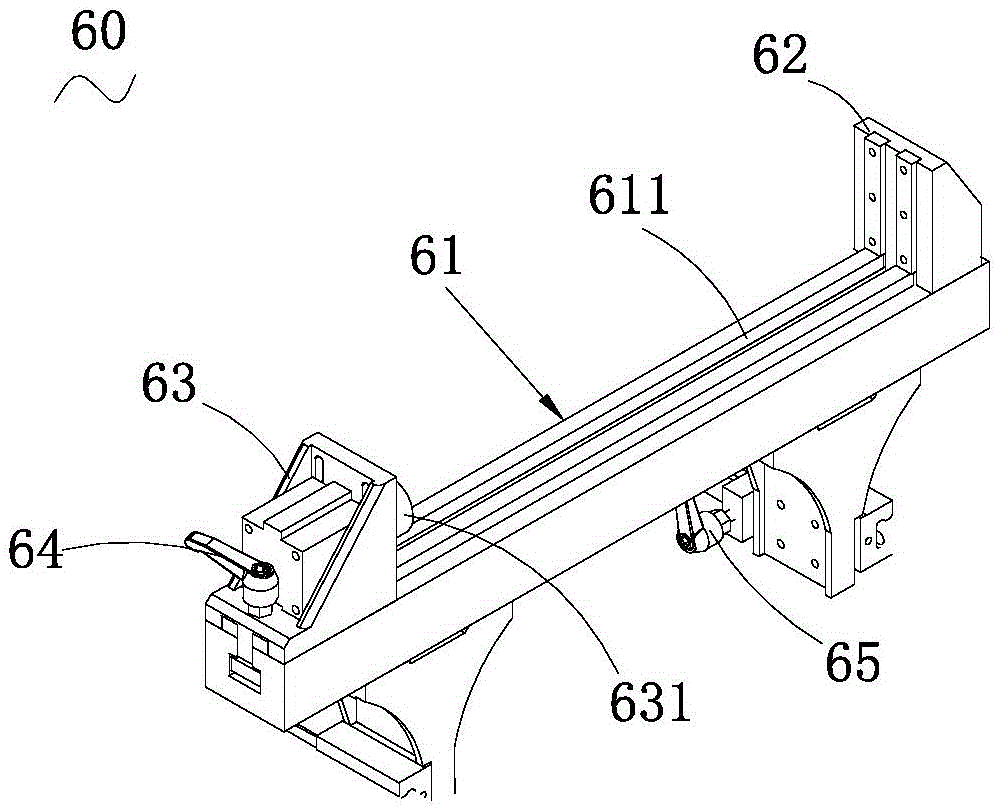

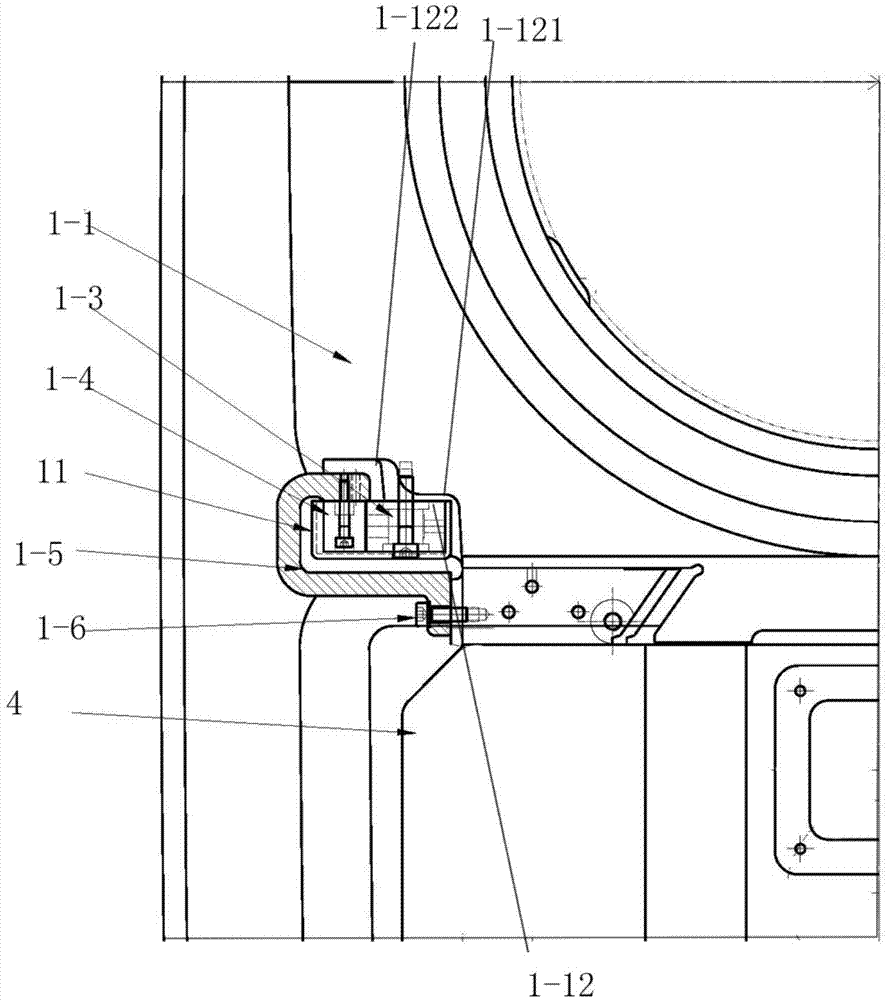

Portable detector of CNC milling machine cutter

ActiveCN104596422ARealize automatic tool settingEasy to handleUsing optical meansNumerical controlEngineering

The invention relates to the field of detection equipment and discloses a portable detector of an CNC (Computer Numerical Control) milling machine cutter. The portable detector comprises a holder device, a cutter imaging system and an image analyzing system; the holder device can be installed nearby the milling machine cutter on the operating platform of the CNC milling machine and longitudinally moved; the cutter imaging system is installed on the holder device, horizontally moved and used for dynamically photographing images of the milling machine cutter; the image analyzing system is fixed to the holder device, connected with the cutter imaging system and used for converting the images of the milling machine cutter into parameters of the milling machine cutter. The detector is a small portable detector, images are formed by the cutter imaging system, and the images and parameters of the milling machine cutter are analyzed by the image analyzing system to achieve online detection and presetting of the milling machine cutter. The detector further comprises an offline detection cutter frame, and the holder device, the cutter imaging system and the image analyzing system are positioned on the offline detection cutter frame through an offline detection cutter frame simulation machine tool to achieve offline detection and cutter presetting.

Owner:深圳市眼之杰光电科技有限公司

CNC machining technological method

ActiveCN106180829AImprove efficiencyImprove processing qualityMeasurement/indication equipmentsMilling machinesMachine partsSurface roughness

The invention discloses a CNC machining technological method. The CNC machining technological method comprises the following steps: (1) selecting a tool suitable for self-machining steel types, and testing and recording attrition values, before and after machining, of the tool in a process of machining different kinds of steel; (2) testing tool attrition data values, selecting a finish machining tool to firstly fine machine part features after machining in rough machining is completed, reserving 0.2-mm steel at periphery for being not machined, carrying out canonical data finish machining after parts are integrally machined, wherein high-quality tool meets a + / -0.02mm machining tolerance range; and (3) dividing a CNC milling mode into a down milling mode and an up milling mode, wherein surface roughness of up milling machining is superior to that of down milling machining. The machining technological method disclosed by the invention can be widely applied to various machining fields, can improve efficiency of machinery within short time according to conditions of factor equipment, further can improve machining quality, can shorten the machining period, and can reduce the production cost.

Owner:SHENZHEN BAOHONG PRECISION MOLD

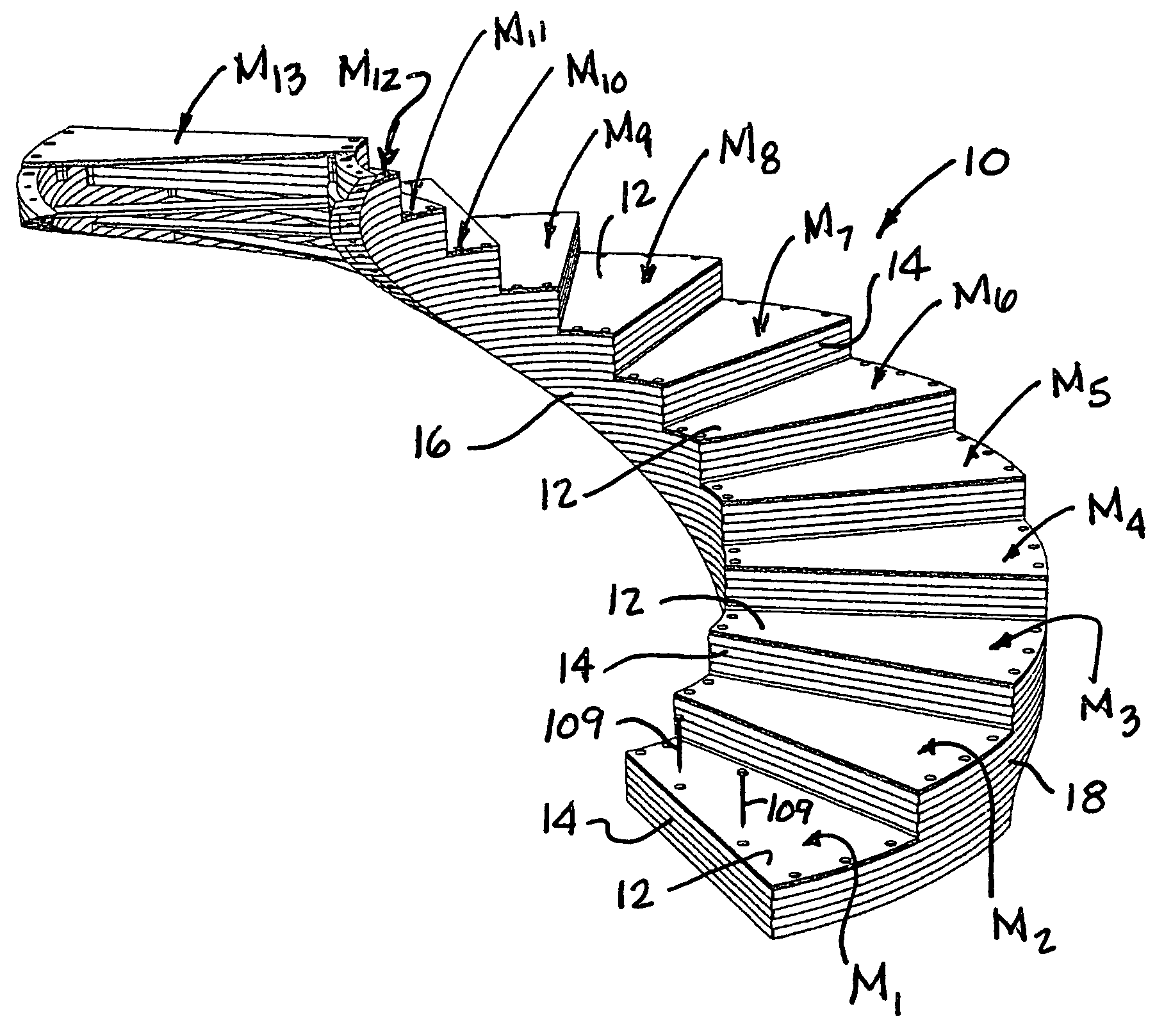

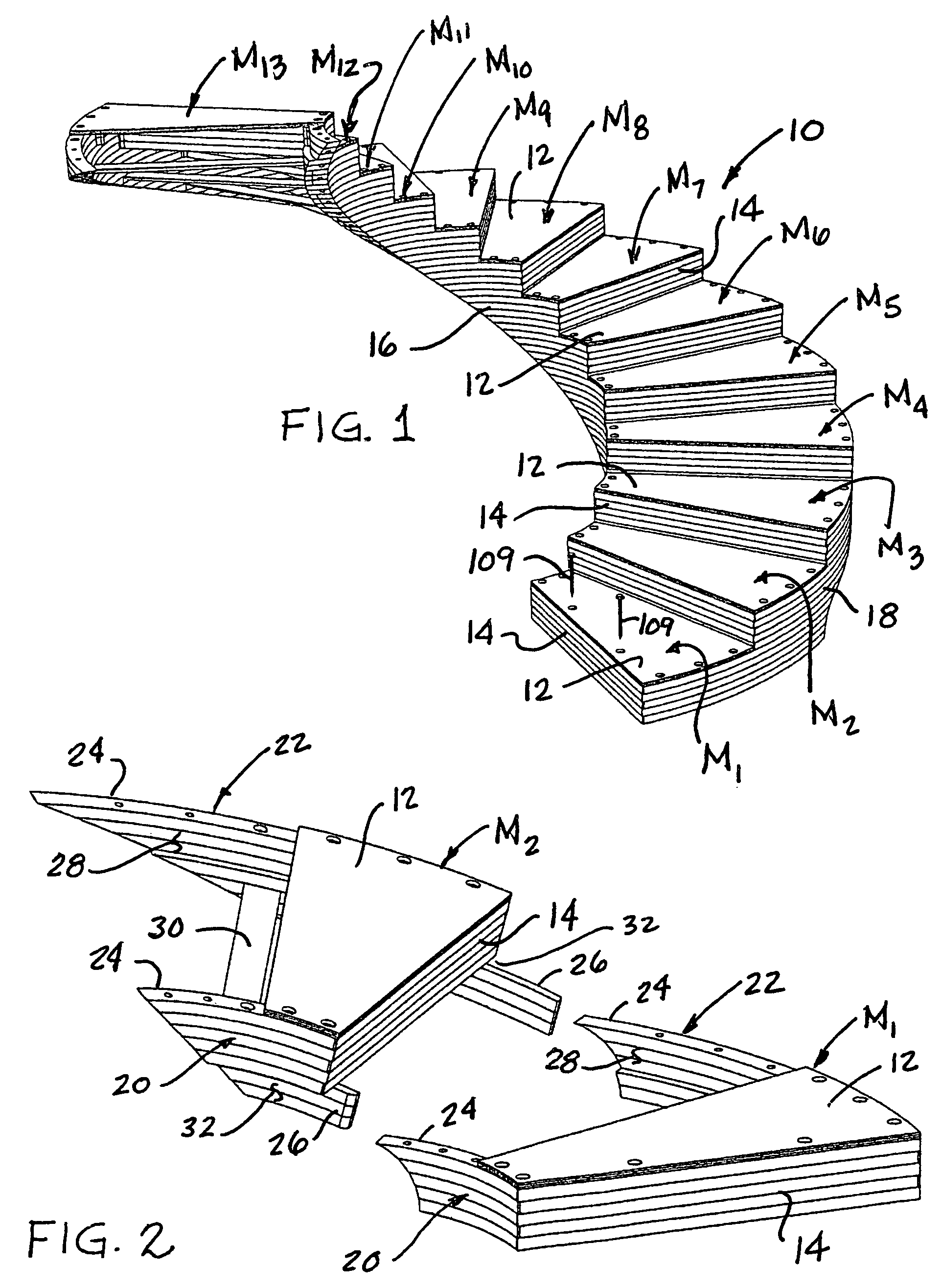

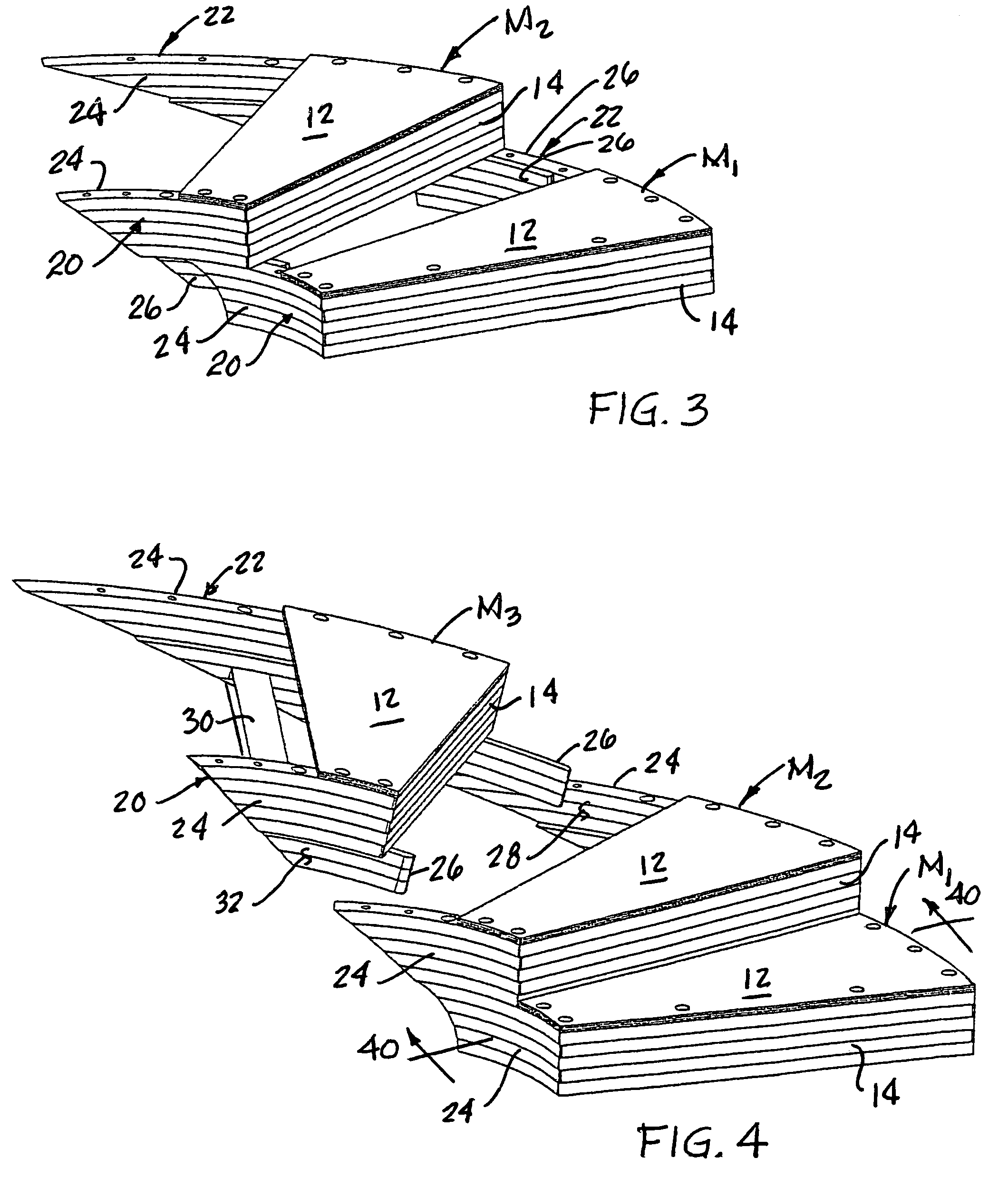

Modular staircase construction

A staircase structure, representatively at least partially curved, is constructed from longitudinal modules each having tread, riser and stringer portions. In one embodiment of the construction technique, stringer portions of the modules are longitudinally telescoped with one another and then intersecured so that the interfitted modules form successive longitudinal portions of the assembled staircase structure. In another embodiment of the construction technique, stringer portions of the modules are vertically stacked and then intersecured. Illustratively, the riser and stringer portions of each module are of a laminated wooden construction shaped in situ on the underside of module tread portion by a CNC milling machine.

Owner:SMITH LYNN H

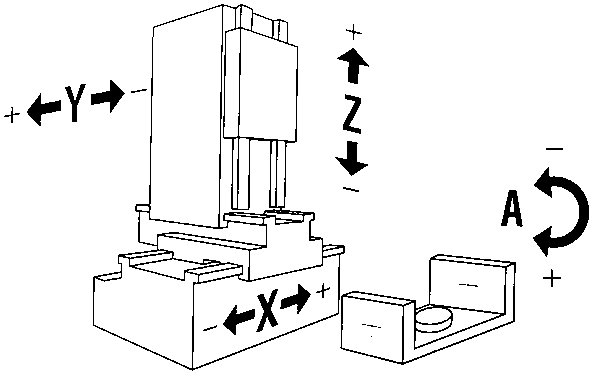

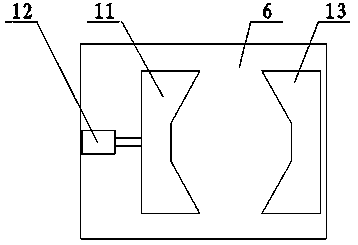

Four-axis CNC drilling and milling machine

ActiveCN103551854AGuaranteed uptimePrecise processingFeeding apparatusOther manufacturing equipments/toolsEngineeringTurbine

The invention provides a four-axis CNC milling machine, which comprises a base, wherein an X-axis guide rail is arranged on the base, and a sliding seat is arranged on the X-axis guide rail; a Y-axis guide rail and a cutting device erected on the Y-axis guide rail are arranged on the sliding seat, and a Z-axis guide rail is arranged on the cutting device; a cutting mechanism is arranged on the Z-axis guide rail and comprises a cutting head and a turbine device, and the turbine device comprises a turbine and a rotating arm motor; the turbine is erected on the Z-axis guide rail, and the rotating arm motor is fixedly arranged on the cutting head; an output shaft of the rotating arm motor is sleeved with a worm, and the worm is meshed with the turbine. The cutting head can move in X-axis, Y-axis and Z-axis directions and rotate at 0 degree to 180 degrees, so that workpieces are clamped once to complete the processing of there to five sides, a structurally complicated product can be processed, the operation is stable, the processing is precise, and the efficiency is high.

Owner:佛山金皇宇企业孵化器有限公司

Precision machining process of motor shaft

InactiveCN104439996AImprove processing efficiencyReduce processing difficultyShaftsNumerical controlElectric machinery

The invention discloses a precision machining process of a motor shaft. The process includes the steps of 1, performing rough milling; 2, thermal treatment; 3, performing forming grinding; 4 performing wire-cut electrical discharge machining; 5, performing forming milling; 6, performing CNC (computer numerical control) turning; 7, performing CNC milling; 8, performing electrical discharge machining; and 9, checking the size. The precision machining process helps improve machining efficiency, decrease machining difficulty and improve economic benefit and is convenient and safe to operate.

Owner:广州博捷电机有限公司

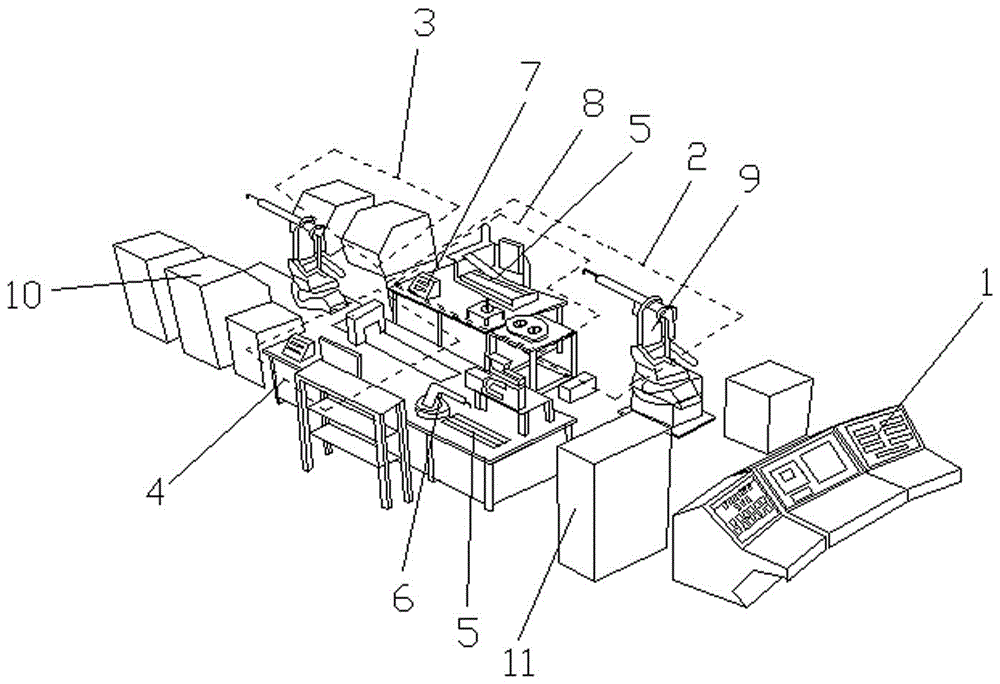

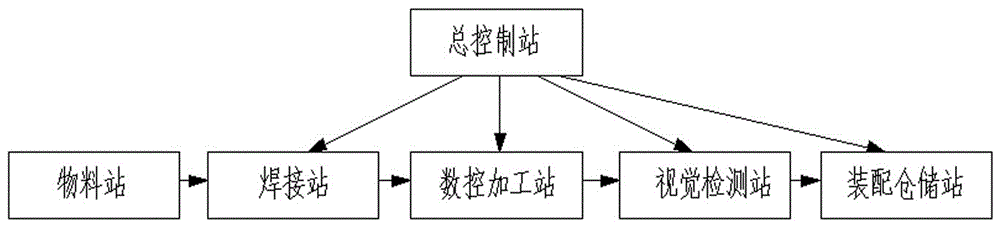

Flexible manufacturing system experimental equipment based on industrial robots

PendingCN106205266ACosmonautic condition simulationsEducational modelsFlexible manufacturing systemRobot hand

The invention relates to flexible manufacturing system experimental equipment based on industrial robots. A master control station comprises a PLC main console and conveying equipment controlled by the PLC main console; the conveying equipment comprises a conveying track, a transfer robot is arranged on the conveying track and connected with a stepping motor; the transfer robot transfers workpieces into a welding station, a material station is connected with a welding table, work is controlled by an electrical control cabinet, a welding robot is controlled by the master control station to transfer the workpieces to a CNC milling machine in a digital machining station for drilling, and the CNC milling machine is connected with a visual detection station; the visual detection station comprises a conveying belt, the workpieces conveyed by the CNC milling machine on the conveying belt are shot into images through cameras fixed beside the conveying belt, and unqualified workpieces are removed through a portal robot hand. Through the equipment, relevant practical training can be provided for the industrial robot application technology, the electromechanical maintenance and management specialty, the mechatronics specialty, the electric automation specialty, the machinery manufacturing and automation specialty and the like.

Owner:魏志丽

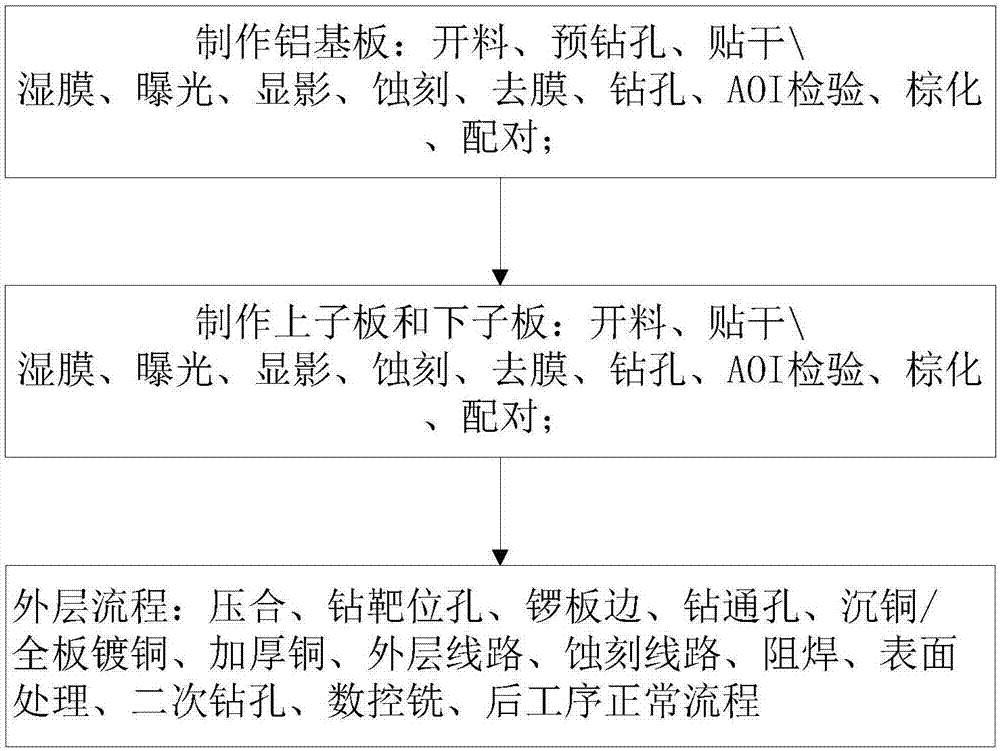

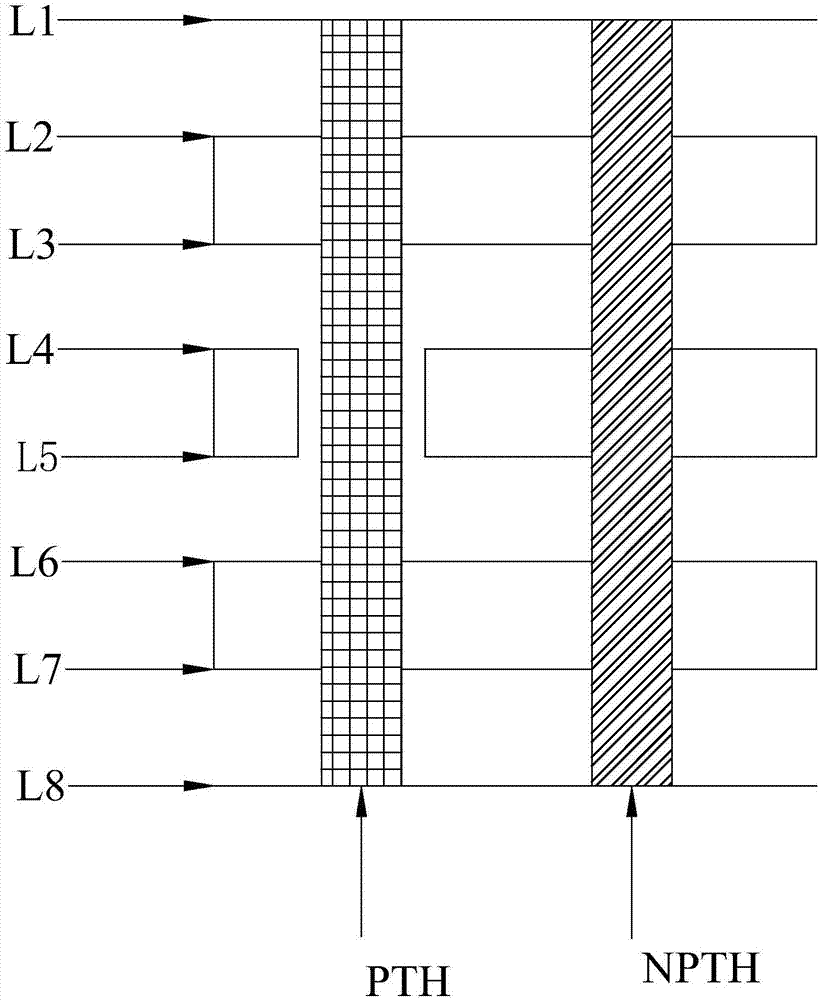

Thick copper sandwiched aluminum substrate manufacturing method

ActiveCN107484356AAvoid short circuitReduce defective rateMetal core circuit manufactureCopper platingEconomic benefits

The invention discloses a thick copper sandwiched aluminum substrate manufacturing method, which comprises the following steps: (1) making an aluminum substrate: opening a material, pre-drilling, dry or wet film sticking, exposing, developing, etching, hole drilling, AOI testing, browning, and pairing; (2) making an upper board and a lower board: opening the material, dry or wet film sticking, exposing, developing, etching, film removing, hole drilling, AOI testing, browning, and pairing; (3) and performing outer layer processing: pressing and fitting, drilling a target position hole, gonging plate edge, drilling a through hole, copper sinking / full plate copper plating, thickening copper, outer line wiring, etching lines, soldering, surface treating, secondary drilling, CNC milling, and process-post normal processes. The method pre-drills a hole on an aluminum substrate to prevent the short circuit between the copper clad layer and the aluminum base during drilling, thereby reducing the product defect rate and possessing good economic benefits.

Owner:深圳明阳电路科技股份有限公司

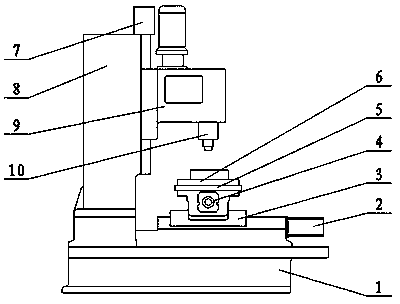

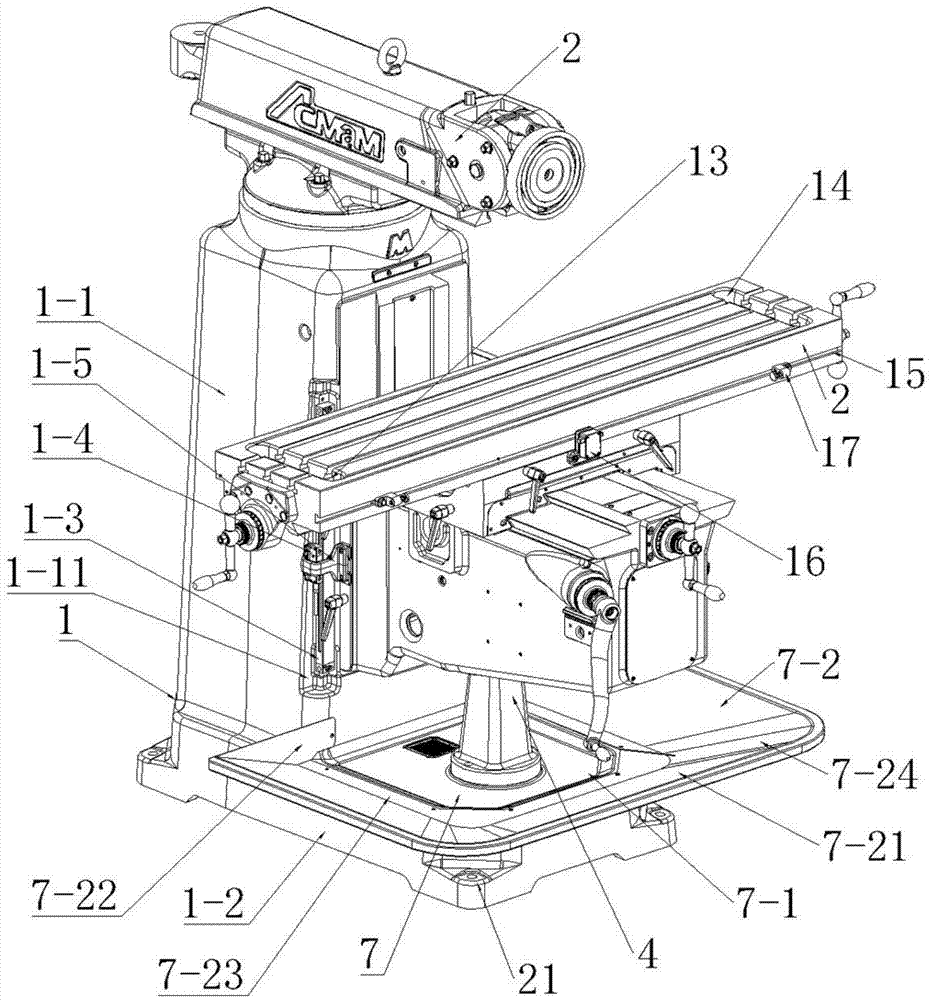

CNC milling machine

InactiveCN103920914AEasy to disassembleEasy maintenanceMilling machinesLarge fixed membersEngineeringMachine tool

The invention provides a CNC milling machine. The CNC milling machine comprises a machine body and a CNC system for controlling the machine body, wherein the machine body comprises a base and a stand column fixed on the base, a Y-axis slide rail is arranged on the base, a Y-axis slide table is arranged on the Y-axis slide rail, a Y-axis drive device for controlling the Y-axis slide table to slide on the Y-axis slide rail left and right is arranged between the Y-axis slide table and the base, an X-axis slide rail is arranged on the Y-axis slide table, an X-axis slide table is arranged on the X-axis slide rail, an X-axis drive device for controlling the X-axis slide table to slide on the X-axis slide rail front and back is arranged between the X-axis slide table and the Y-axis slide table, a worktable is arranged at the top of the X-axis slide table, a clamp is arranged at the top of the worktable, a Z-axis slide rail vertically arranged is arranged on the left side of the stand column, a milling head box is mounted on the Z-axis slide rail in a sliding manner, and a Z-axis drive device for driving the milling head box to move up and down is arranged at the top of the stand column. With the adoption of the technical scheme, the CNC milling machine can be conveniently detached and maintained, the detaching and maintaining time is reduced, large-scale machining and production is realized, and the production efficiency is improved.

Owner:句容市石狮冲压件厂

CNC milling machine

InactiveCN103934697AReduce labor intensityReduce cloggingMeasurement/indication equipmentsMilling machinesNumerical controlGrating

The invention discloses a CNC milling machine. The CNC milling machine comprises a numerical control device, a machine body, a milling mechanism, a workbench, a transverse feeding mechanism, a lifting table and a cooling and lubricating system, wherein the milling mechanism, the workbench, the transverse feeding mechanism, the lifting table and the cooling and lubricating system are arranged on the machine body. The machine body is composed of a lifting table seat and a milling machine base. The milling mechanism is mounted on the top of the lifting table seat through a rotary disk. The milling machine base is provided with a liquid receiving groove. The CNC milling machine is characterized in that the milling machine base is provided with a liquid collection tank, a filtering device, a circulating pipeline and a circulating water pump, the liquid collection tank, the filtering device and the circulating pipeline are connected with the liquid receiving groove, and the circulating water pump is connected with the circulating pipeline; the lifting table seat is provided with a grating scale, a grating scale reading head and a reading head seat, the grating scale reading head is arranged on the reading head seat, the reading head seat is arranged on the lifting table, and the lifting table seat is provided with a recess for containing the grating scale; a guide rail seat is provided with a dovetail rail, and the dovetail rail is provided with a dovetail guide portion; a carrying table is arranged at the front end of the workbench, and a stop mechanism is arranged at the rear end of the workbench; the four corners of the lifting table seat are respectively provided with an L-shaped supporting leg. The CNC milling machine is simple in structure, convenient to use and high in production efficiency.

Owner:FOSHAN FENGBAO PRECISION MACHINE

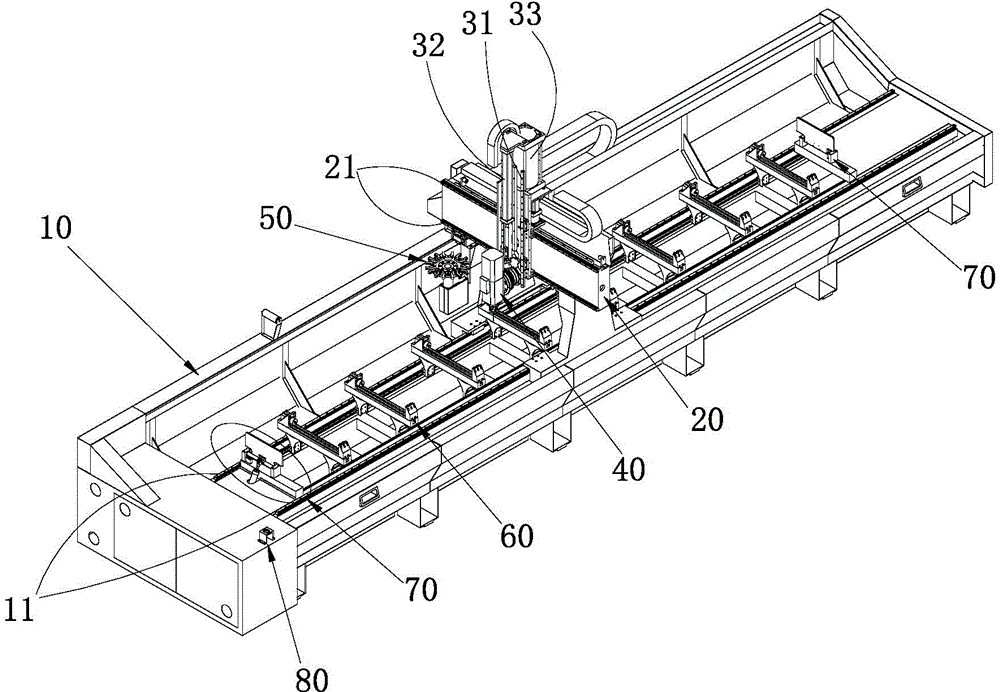

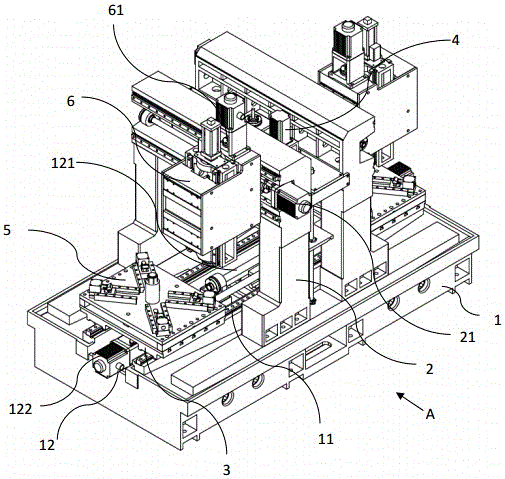

Gantry type double-head computer numerical control (CNC) milling machine for hub machining

ActiveCN106624084AHigh degree of automationSmall footprintMilling machinesLarge fixed membersNumerical controlSmall footprint

The invention provides a gantry type double-head computer numerical control (CNC) milling machine for hub machining, comprising a bedplate and characterized in that two symmetrical gantry racks are arranged on the bedplate; vertical milling head devices are installed at the reverse positions of the two gantry racks, and longitudinal guide rails are arranged on the bedplate, and run through the two gantry racks; two workbenches are installed on the longitudinal guide rails movably, and fixtures able to clamp workpiece are arranged on the workbenches; a workpiece delivery device is arranged between the two gantry racks, and comprises a clamping device and a lifting device able to drive the clamping device to move upward or downward; the workpiece on the left workbench can be delivered to the right workbench through transition of the workpiece delivery device. The CNC milling machine provided by the invention is mainly used for the hub machining, and the workpiece can be clamped automatically by the fixtures. The workpiece roughly machined is delivered to the right workbench through the workpiece delivery device for fine machining. The CNC milling machine provided by the invention has the advantages of high level of automation and small occupied area.

Owner:NINGBO DEMA INTELLIGENT MACHINERY CO LTD

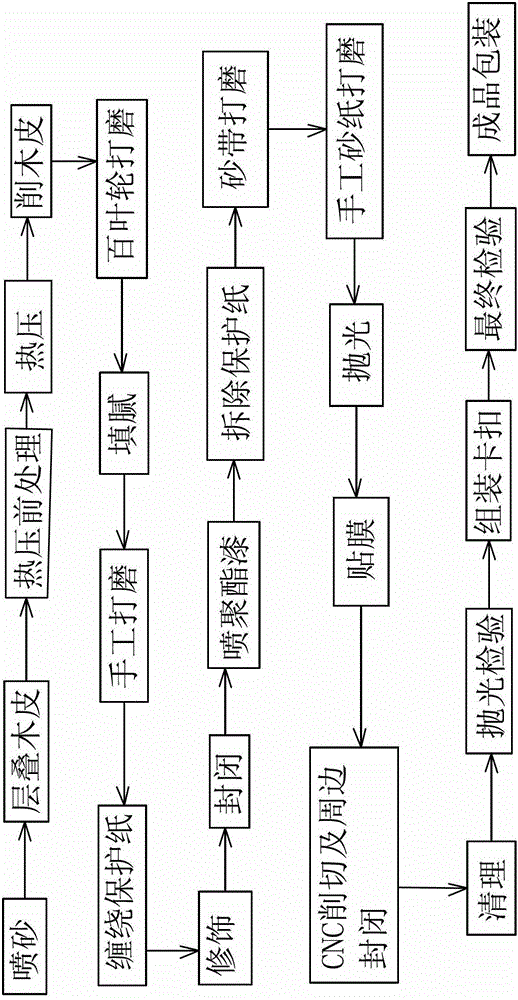

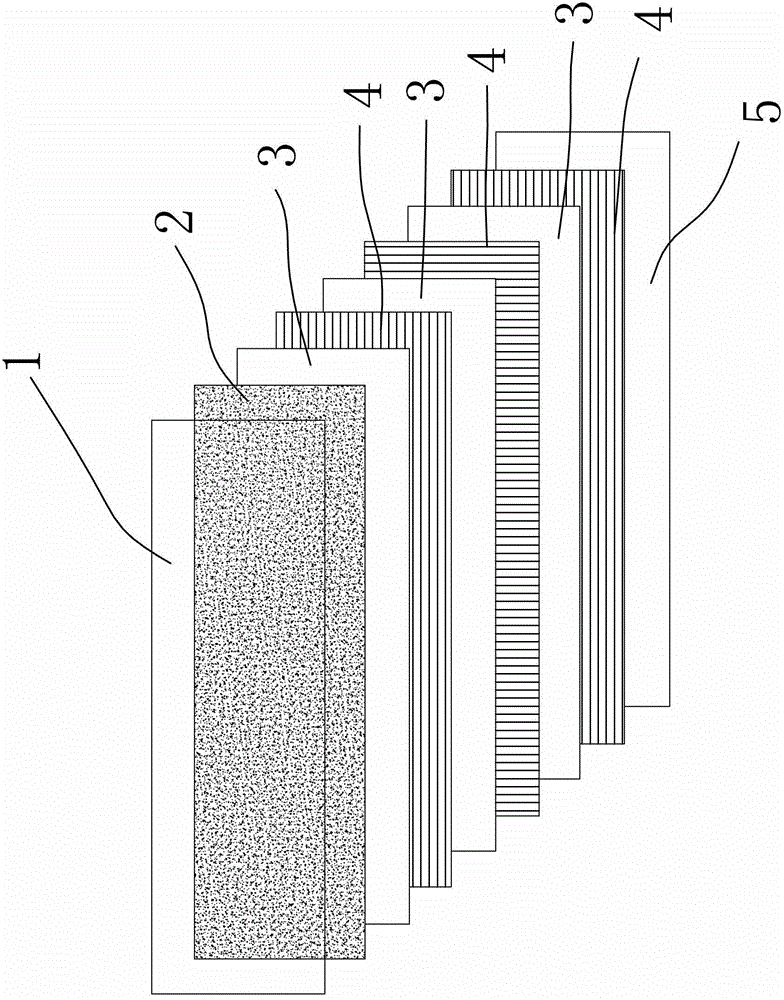

Making technology of hot-pressed xylary automobile ornament

ActiveCN103332057AWrinkle freeNo stratificationLayered productsSpecial ornamental structuresWood veneerPolyester

The invention belongs to the technical field of automobile components, and provides a making technology of a hot-pressed xylary automobile ornament. The matrix of an automobile ornament is compounded with a wood veneer. The technology comprises the following steps: sandblasting; laminating the wood veneer; carrying out hot-pressing pretreatment; hot-pressing; chipping off the wood veneer; polishing and filling with a putty; winding with protection paper and modifying; closing; spraying with a polyester paint; dismantling the protection paper and polishing; buffing; pasting a film and carrying out CNC milling and surrounding closing; and clearing, carrying out buffing examination, assembling buckles, finally examining, and packaging the obtained finished product. The technology is simple, allows the automobile ornament to have a xylary or synthetic-wood interior decoration through increasing the wood veneer structure on the automobile ornament matrix, guarantees no defects comprising wrinkling, layering, damages, cracking or the like after the hot pressing of the automobile ornament and the wood veneer, and realizes a perfect effect in the comfort level and appearance.

Owner:宁波劳伦斯汽车内饰件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com