Patents

Literature

40 results about "CNC router" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A computer numerical control (CNC) router is a computer-controlled cutting machine related to the hand-held router used for cutting various hard materials, such as wood, composites, aluminium, steel, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut mortises and tenons.

Method for fabricating a custom implant abutment

InactiveUS20120214133A1Facilitate precision millingSimple manufacturing processDental implantsTooth crownsCNC routerBiomedical engineering

A system and method for fabricating custom implant abutments uses an implant abutment connector to secure a partial blank with respect to a milling tool of a CNC milling machine. The implant abutment connector has an implant interface geometry of an implant. The partial blank can have a prefabricated implant abutment interface geometry of the implant abutment; and can thus mate with the implant, and the implant interface geometry of the implant abutment connector.

Owner:B & D DENTAL

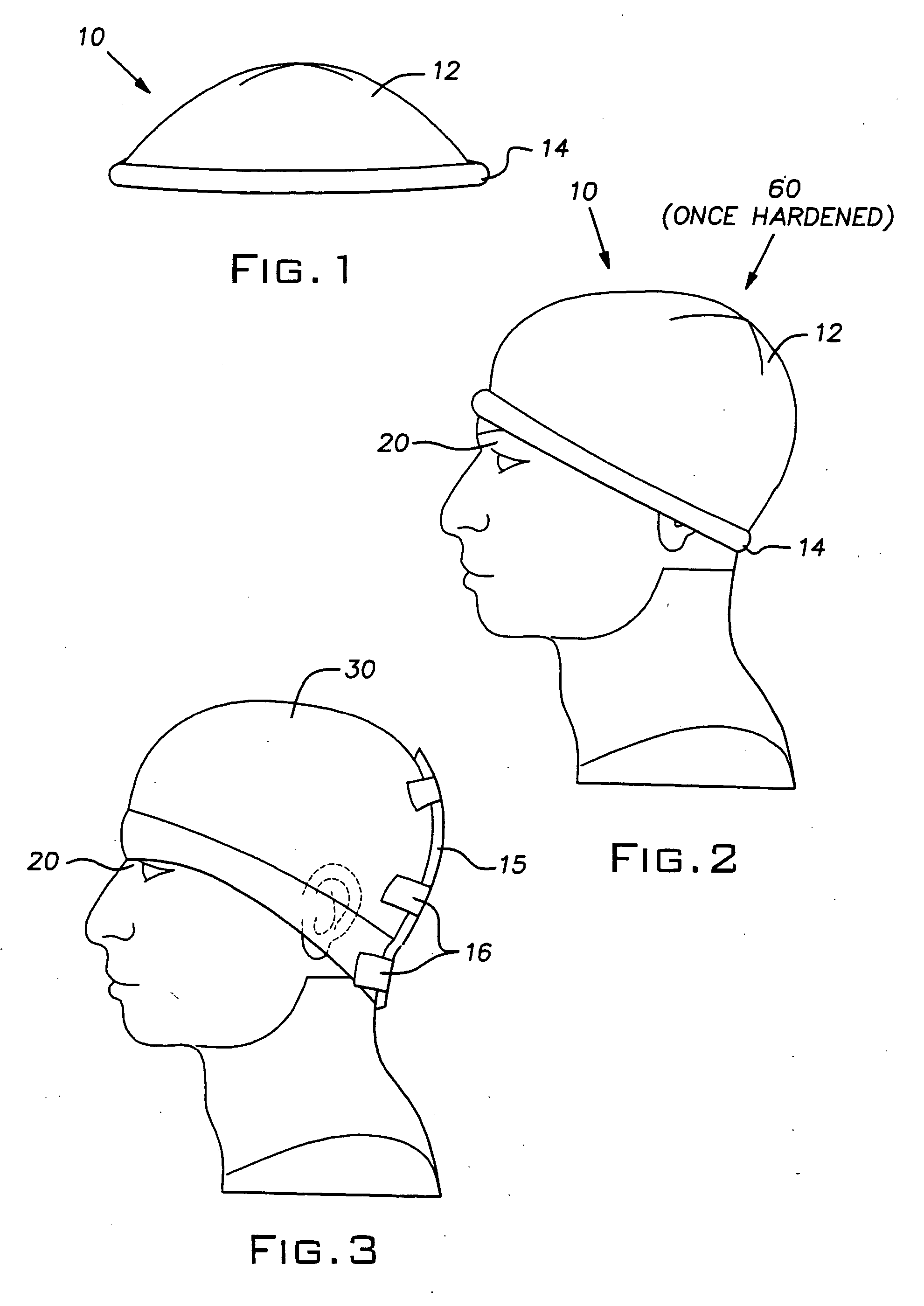

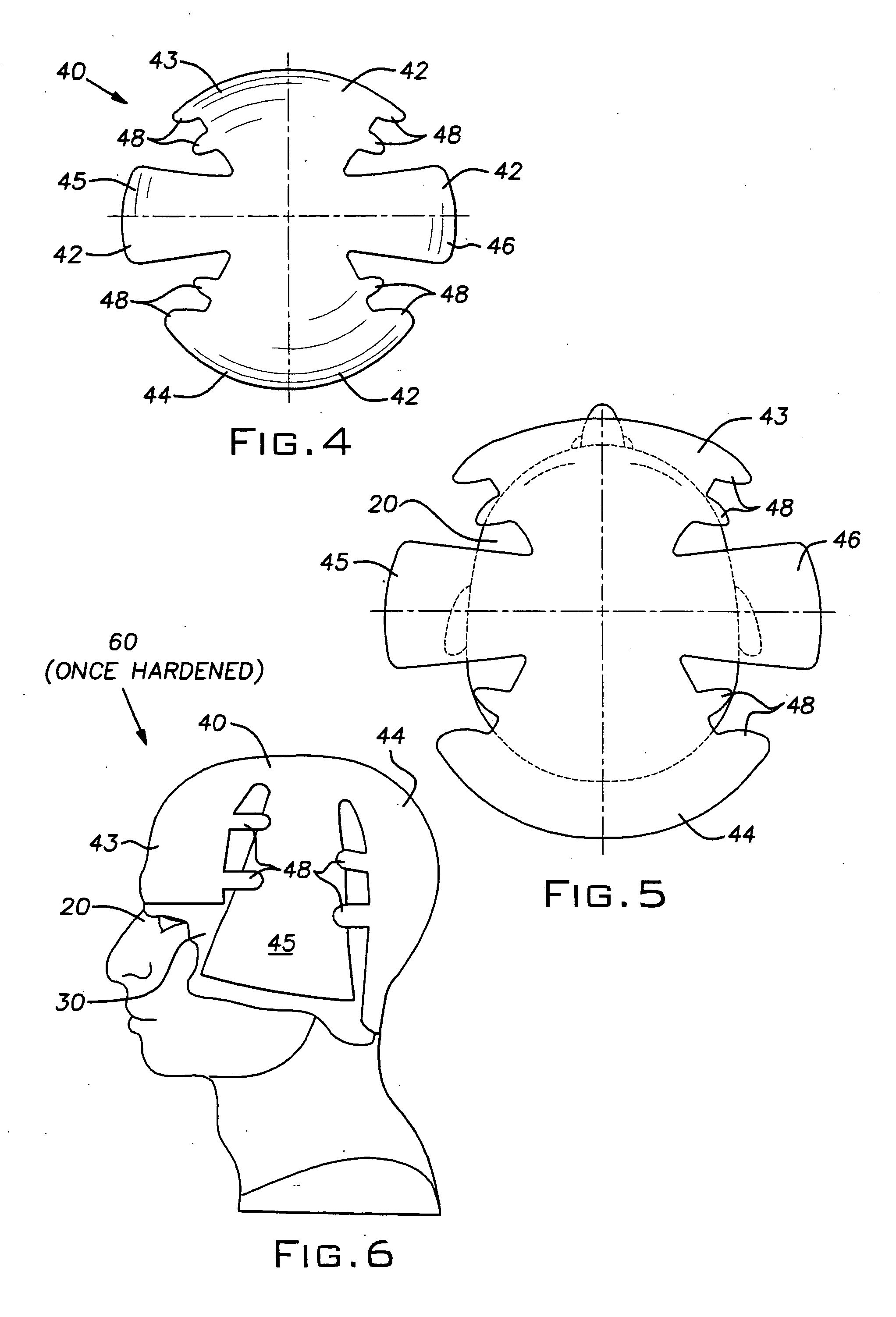

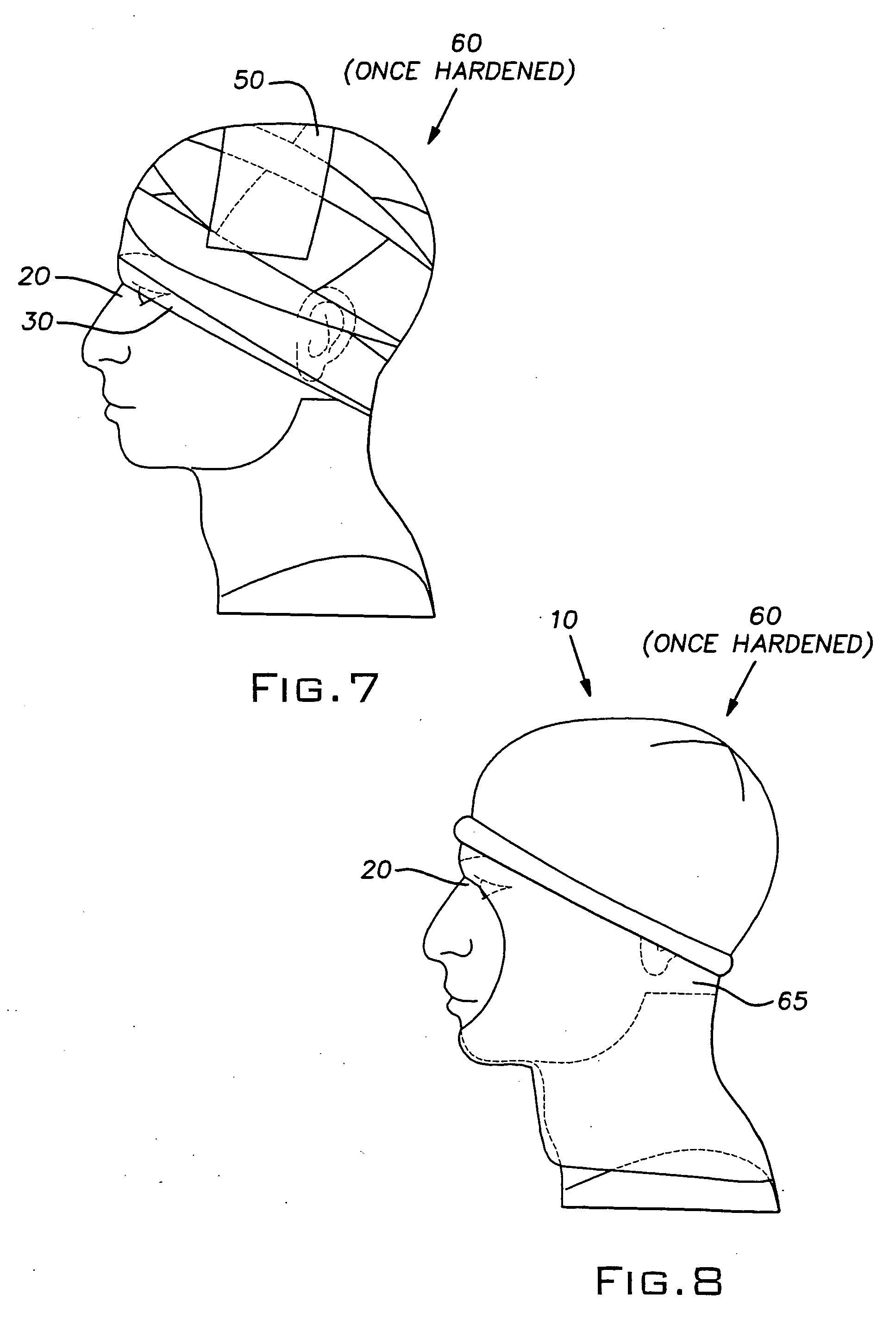

Custom fitted helmet and method of making the same

A helmet that is custom-fitted to a wearer's head, and methods of making the helmet, are provided A method includes the steps of positioning a shape-forming means over the wearer's head, and hardening the shape-forming means to provide a hardened headform that substantially conforms to the shape of the wearer's head. The shape-forming means can be a stretchable beanie cap that is coated or impregnated with a curable polymeric material, a heat-softenable plastic sheet, or a strip or plurality of strips of curable tape that are wrapped about the wearer's head to provide a headwrap. Once the hardened headform has been made, it can be used to cast a hardened plaster fixture for use as the “male” member in a mold for casting an energy absorbing foam liner for a helmet which has an inner surface substantially conforming to the shape of the wearer's head. Alternatively, the hardened headform can itself be used as the “male” member of the liner casting mold. In a further alternative, the hardened headform can be digitized to produce computer-readable data from which a suitable machine, such as a CNC router, can machine a pre-made energy absorbing liner “blank” so as to provide an inner surface thereof having a complementary contour to the wearer's head.

Owner:INTPROP HLDG

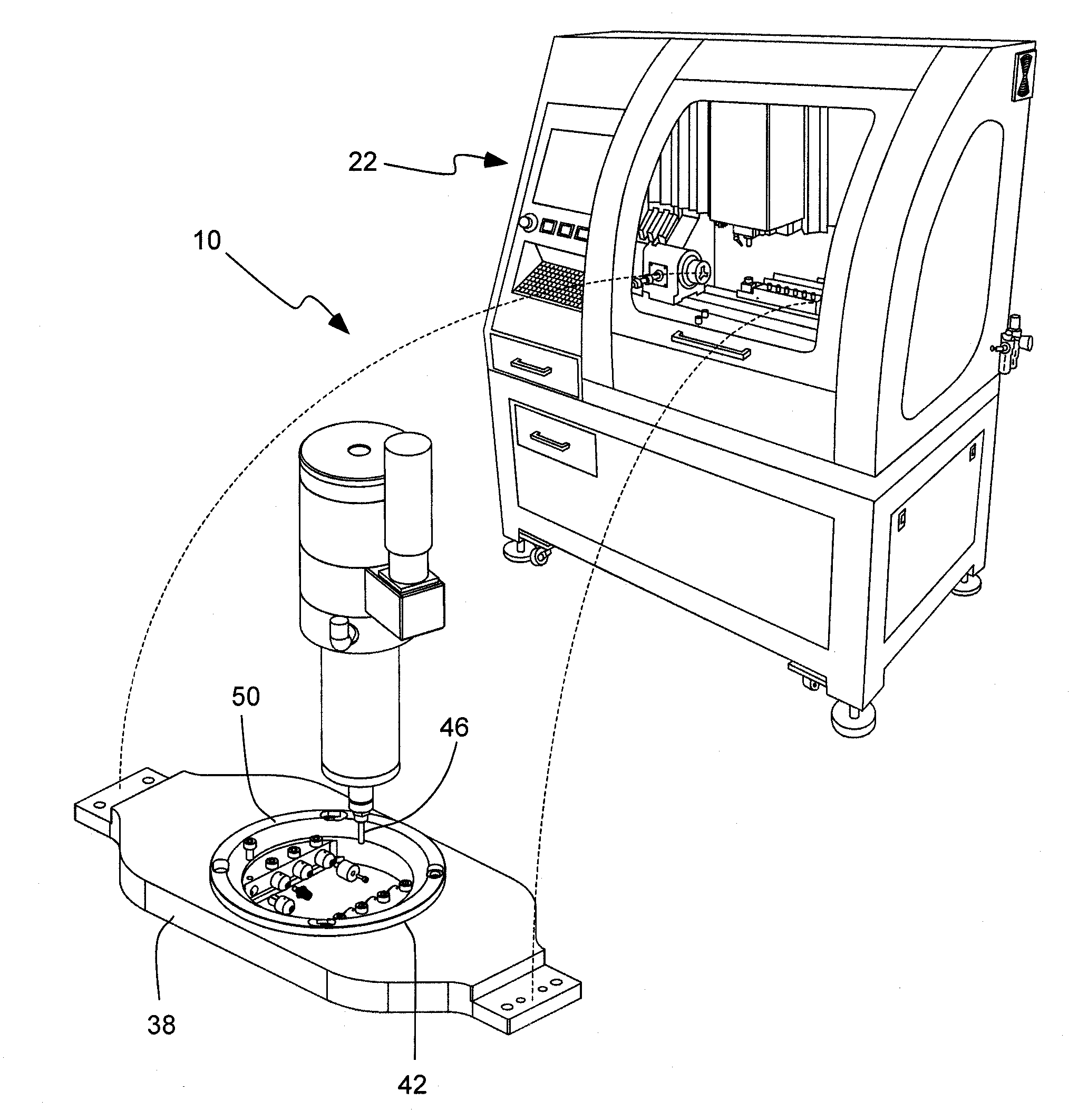

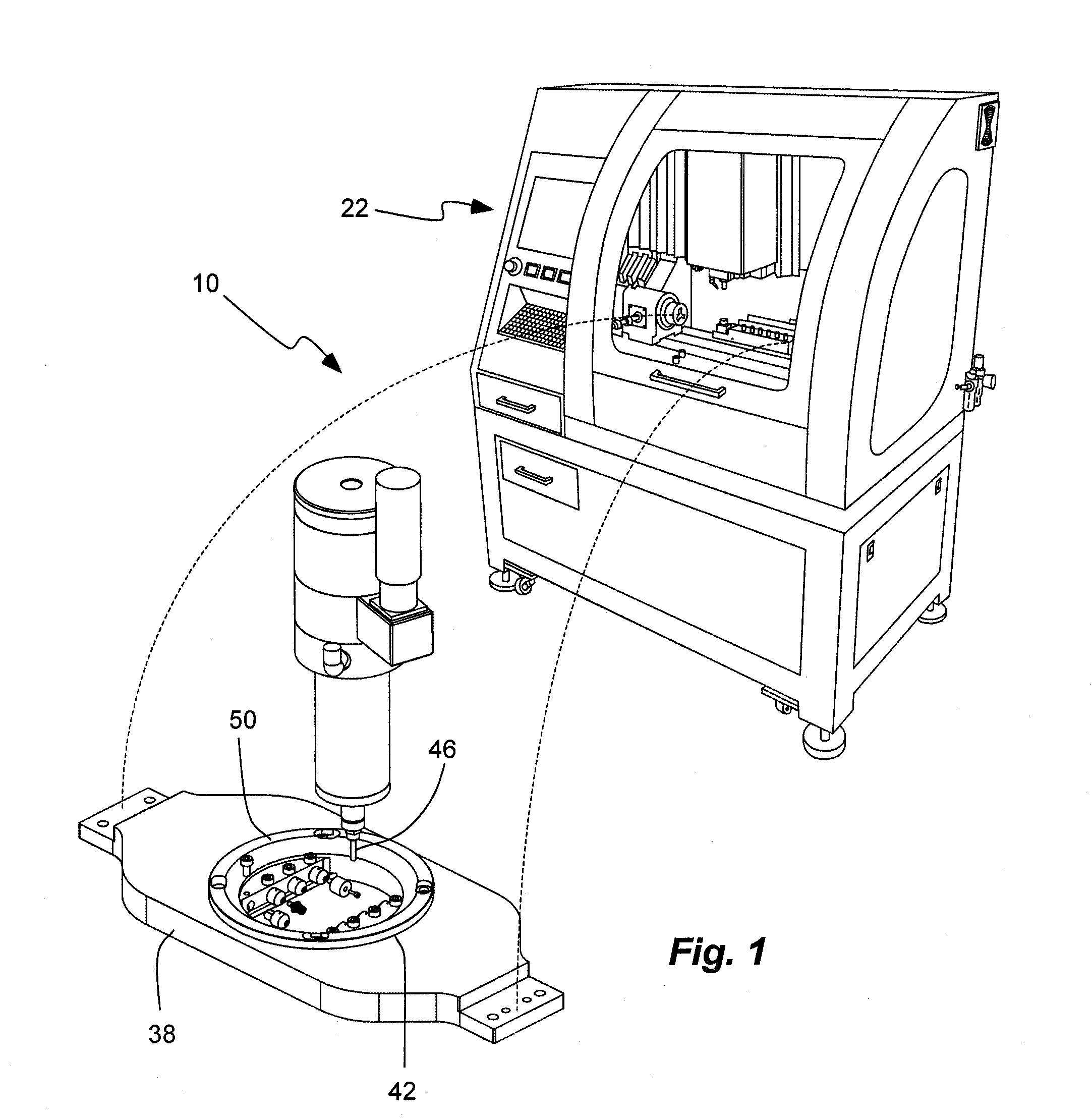

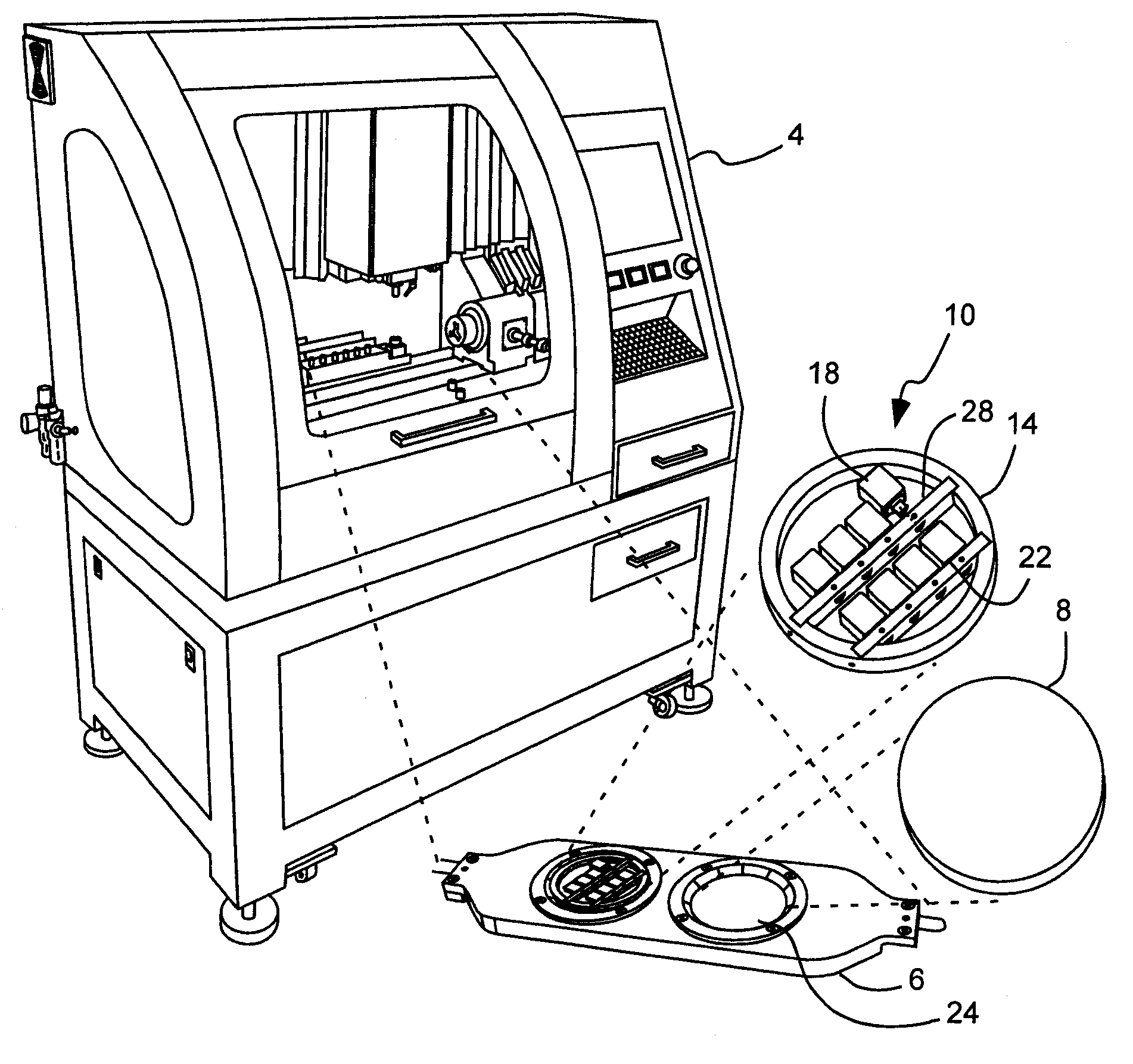

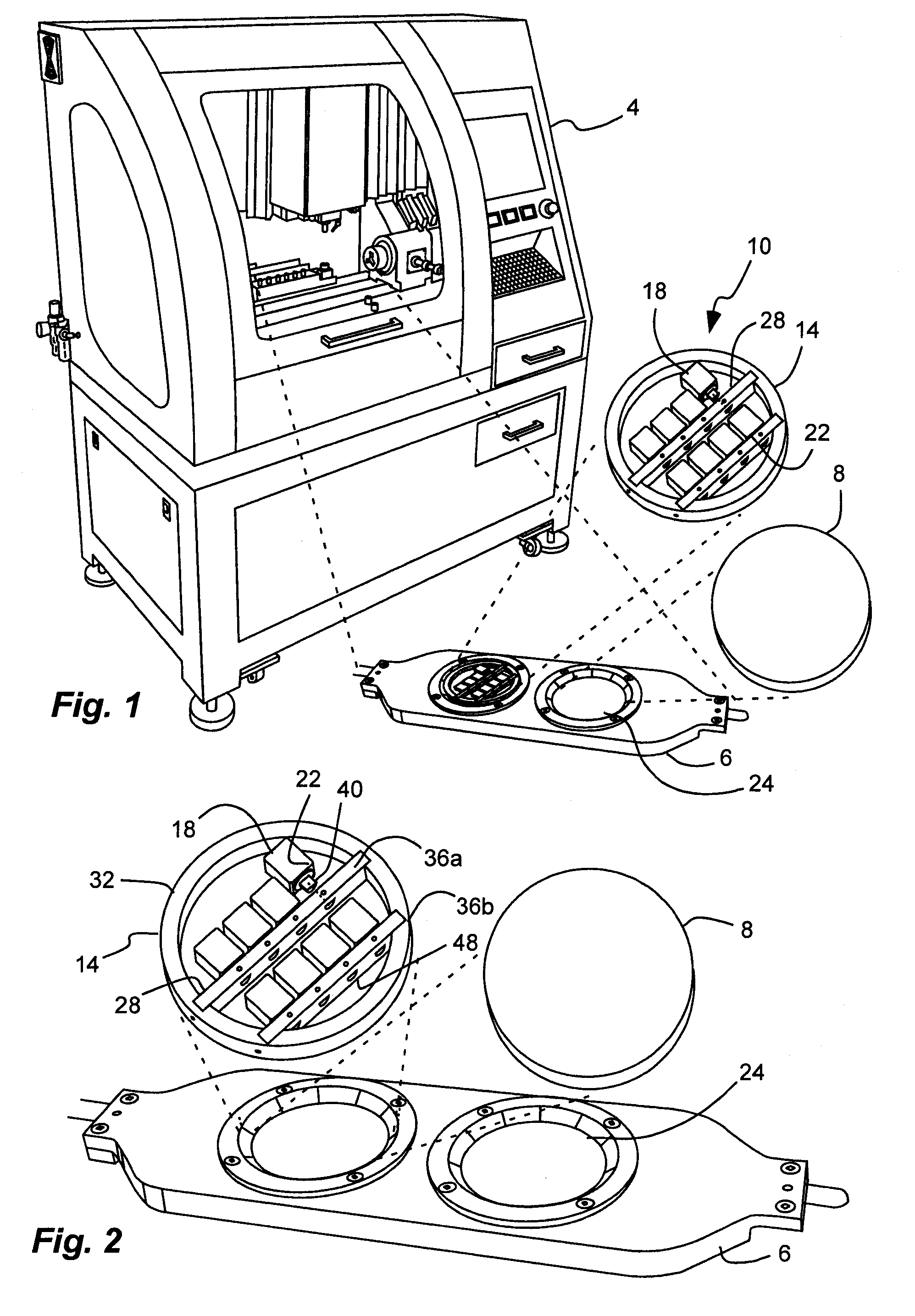

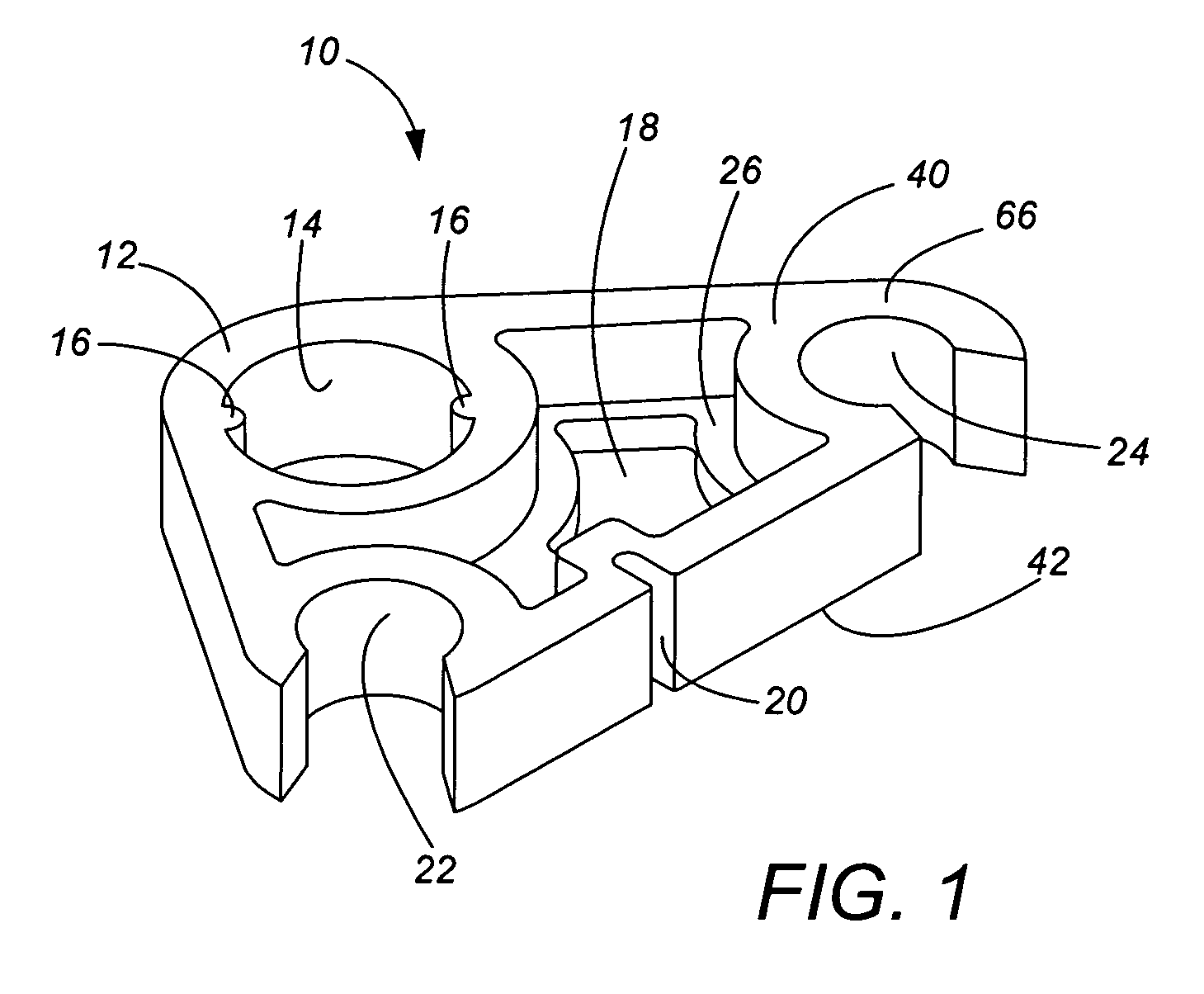

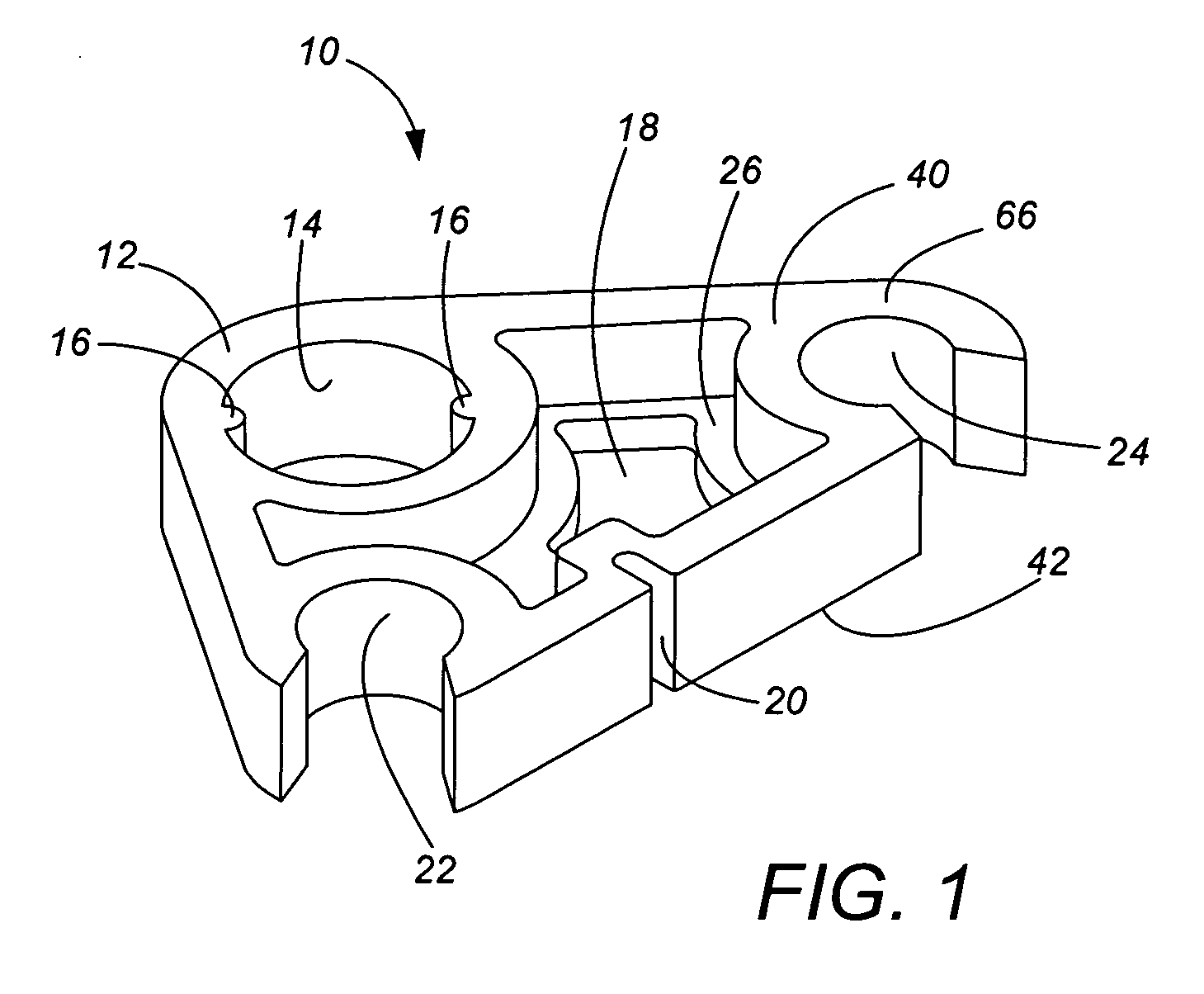

Device and Method of Securing Dental Material for Production of Dental Prosthesis

A system and method for milling dental prostheses in a CNC milling machine includes a larger millable dental blank receivable in a primary fixture of a milling machine and capable of being machined to form one or more dental prostheses; a plurality of smaller millable dental blanks each capable of being machined to form a dental prosthesis; and lateral affixing means for affixing a lateral side of the plurality of smaller millable dental blanks in a space defined by the larger millable dental blank in the primary fixture, when the larger millable dental blank is removed.

Owner:JUNG YUNOH +1

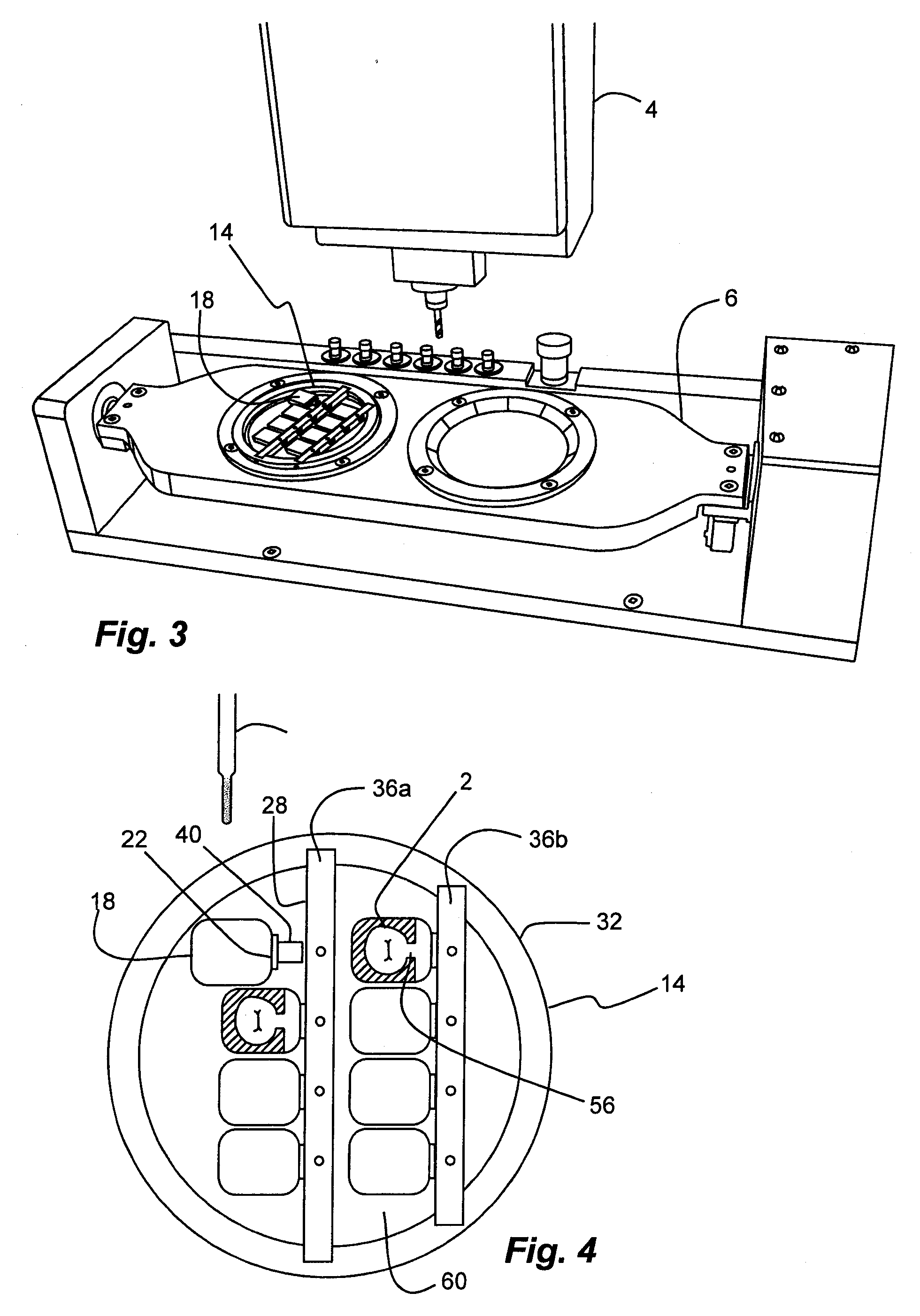

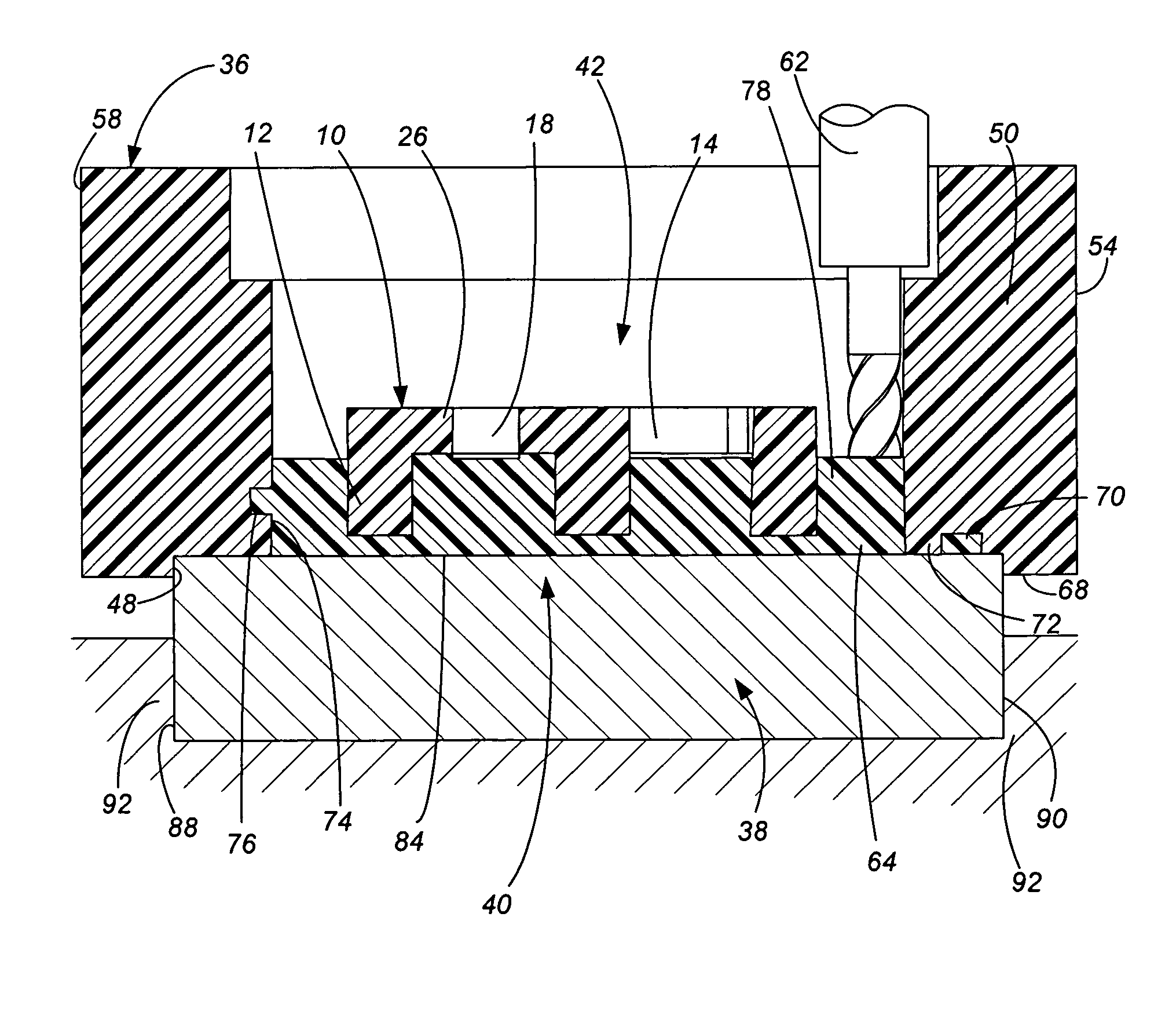

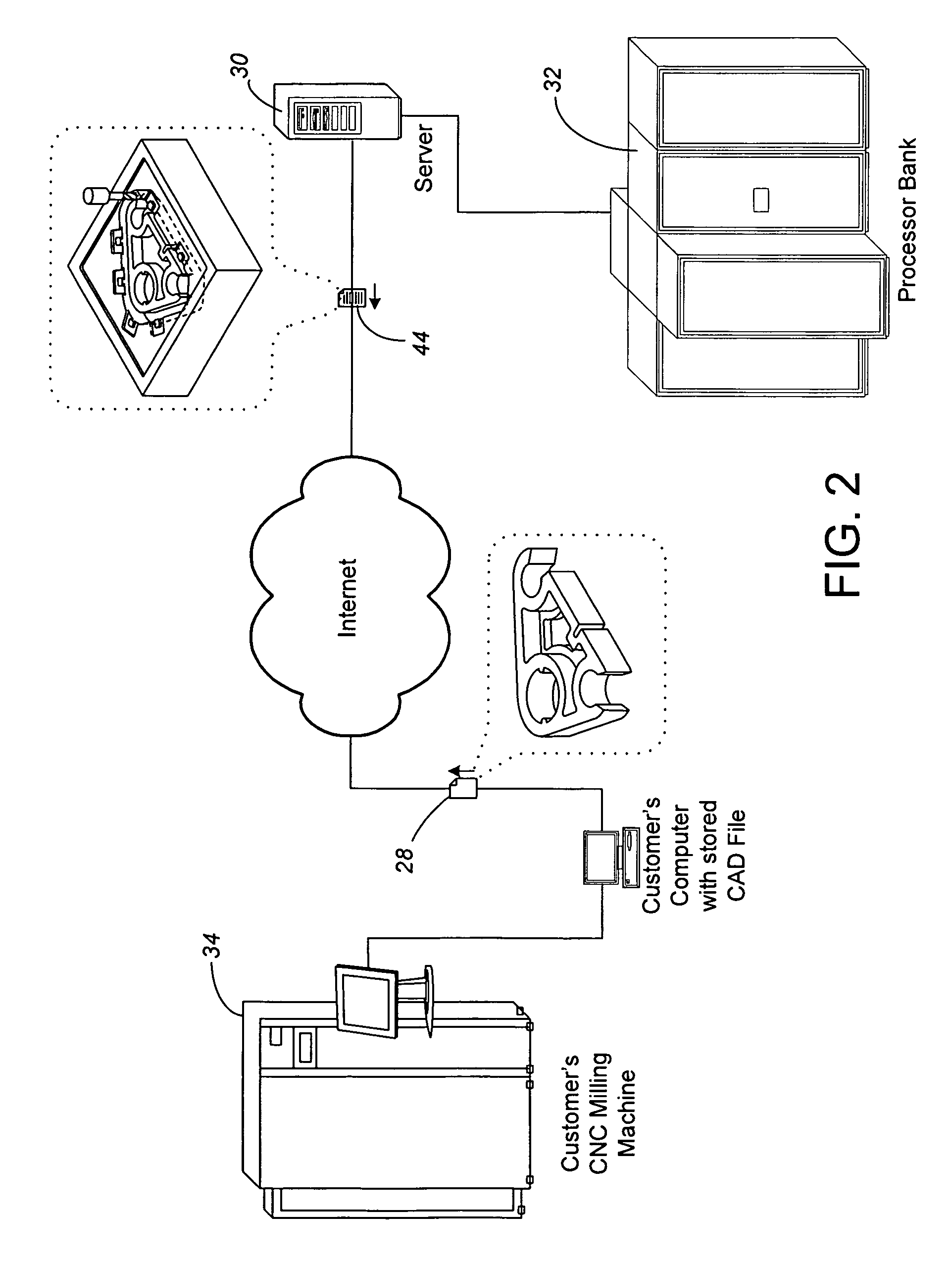

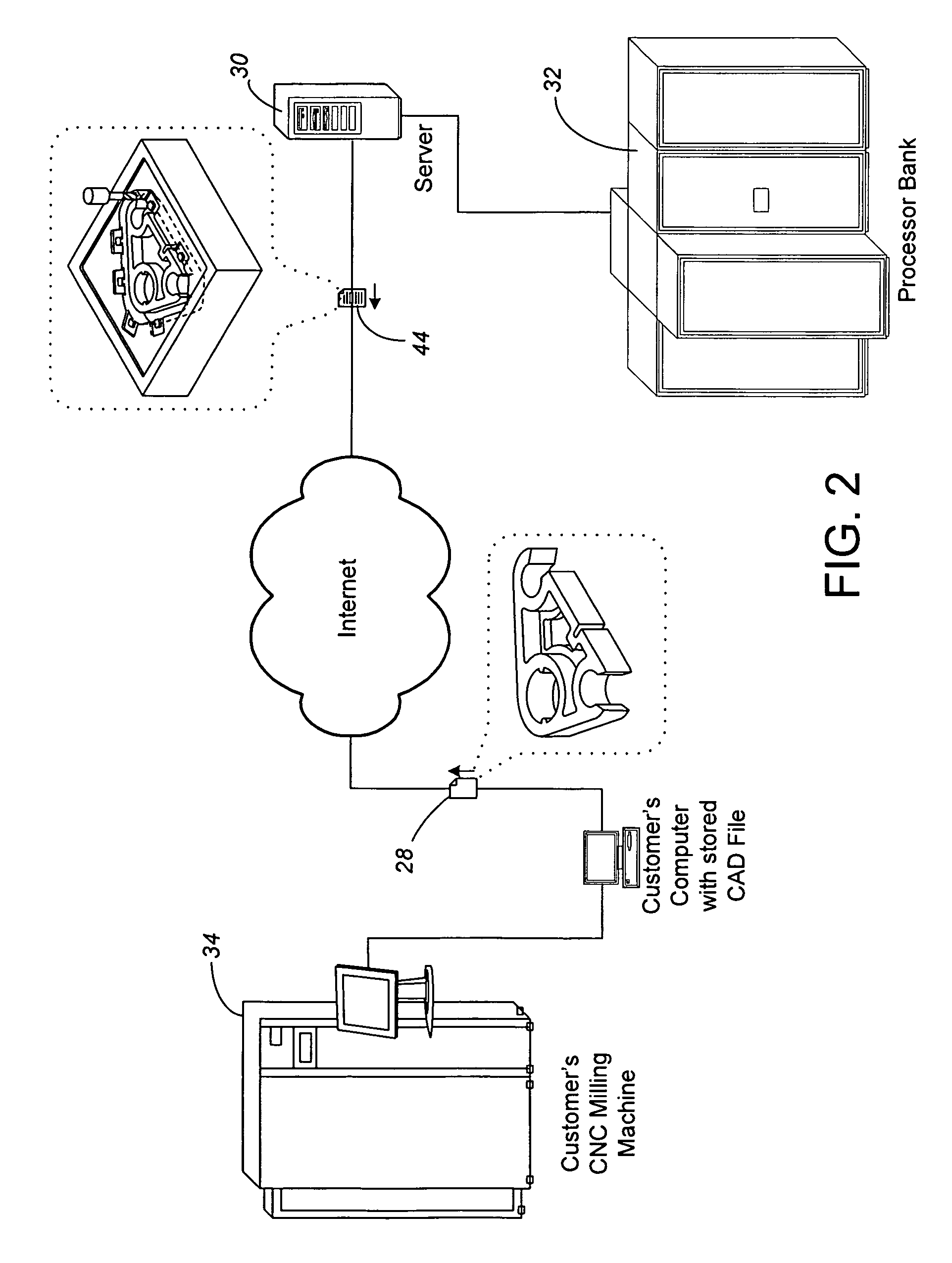

CNC instructions for solidification fixturing of parts

A customer transmits their 3D CAD file for a part to be total profile machined. Computer analysis of the transmitted CAD file produces CNC machining instructions, which are transmitted back to an address defined by the customer. The customer can then use the transmitted CNC machining instructions to total profile machine their own part using their own CNC mill at the location where the part is likely needed. The transmitted instructions include not only the tool paths for CNC machining of the total profile of the part, but also for additional features formed into the encircling portion of a material block from which the part is to be total profile machined. For instance, the CNC machining instructions transmitted back to the customer can define a registration recess and / or channels or undercuts for fluid support material on an A-side of a material block. After the A-side of the block is machined, the customer adds and solidifies fluid support material into the machined recess. The CNC mill is then used to machine a support surface into a portion of the solidified support material surface. A registration fixture is applied into contact with the support surface CNC machining on the B-side of the material block is then performed while the part is supported by the solidified support material, substantially separating the part from the encircling block of material. The support material is then removed, such as by dissolving, freeing the part from the encircling block of material.

Owner:PROTOLABS INC

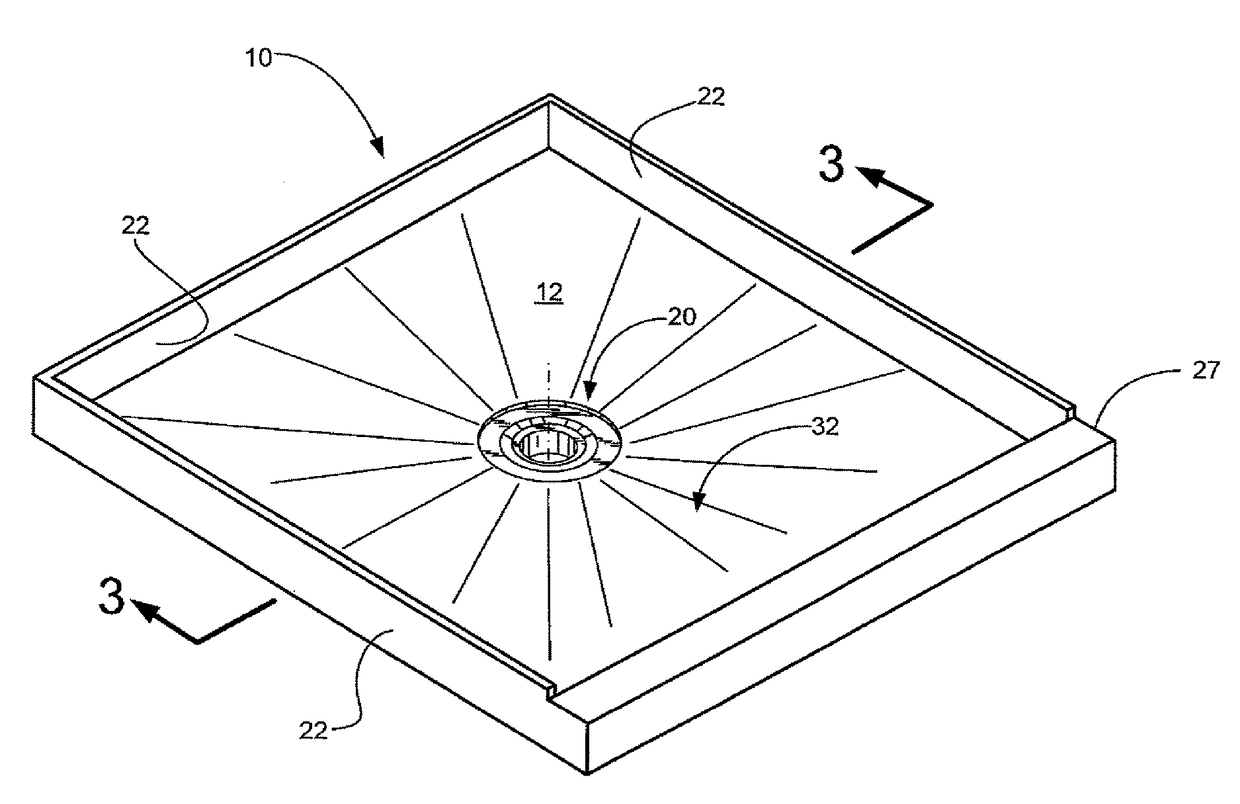

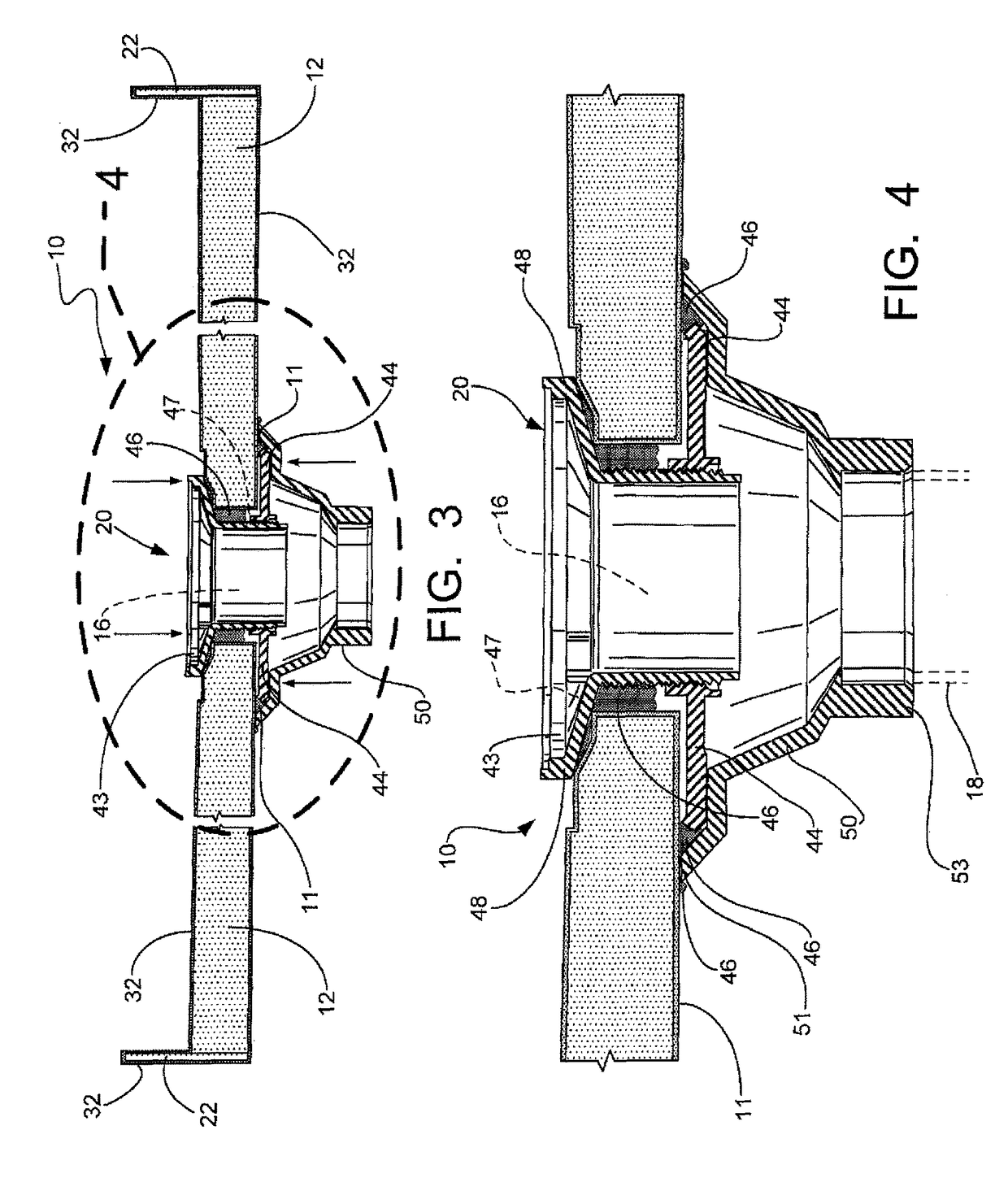

One piece shower pan and method of making same

InactiveUS9107545B1Absorbs very little or no waterSewerage structuresClimate change adaptationPolystyreneEngineering

A one piece shower drain pan, encapsulated in a water proof membrane, and the method of fabricating the one piece open drain shower pan, the method which includes providing extruded polystyrene (XPS) foam of the type which absorbs very little water; shaping the section of extruded polystyrene foam with a CNC router to obtain the desired slope in the floor; cutting a hole in the foam to produce the drain hole; cutting a curb from the XPS foam and gluing the foam to a pan base on the open sides. Splash walls are then cut from concrete wall board and glued to the sides having no curb, so that the glue serves as a bonding agent and provides a waterproof seal between the parts; after the glue has cured, spraying the entire pan assembly with a polyurethane or polyurea coating to completely encapsulate the entire pan with a waterproof membrane, which provides strength and rigidity and defines a one piece drain pan ready for installation.

Owner:TILE REDI

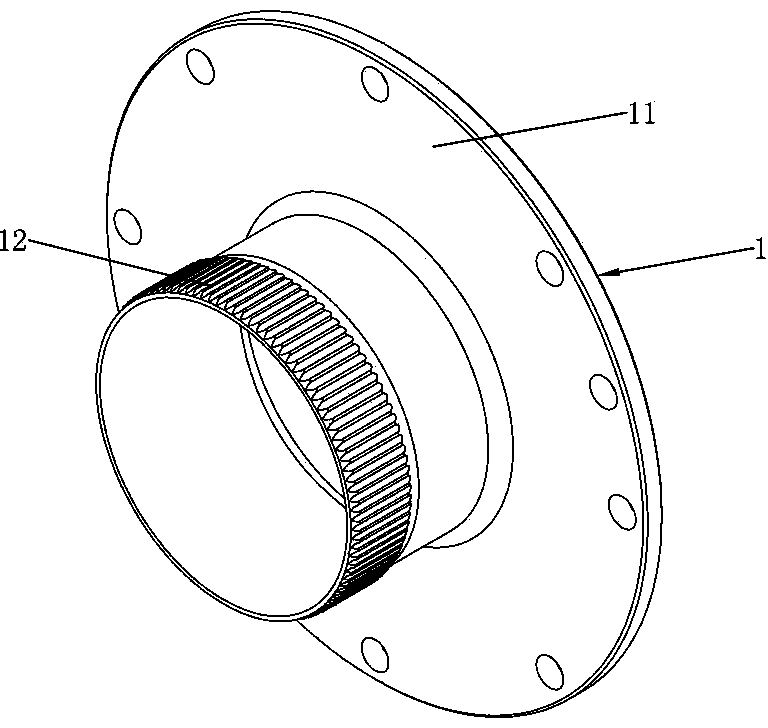

Method for processing harmonic reducer flexible wheel

The invention discloses a method for processing a harmonic reducer flexible wheel. The method sequentially includes processes of blanking, forging and shaping, normalizing for heat treating, spinning, turning in a CNC (computer numerical control) lathe, gear-shaping in a CNC milling machine and punching and shaping. The process of punching and shaping is performed through matching of a punching machine and a punching and shaping die, an upper die base, an upper padding plate, an upper fixing plate, a lower die base, a lower padding plate, a lower fixing plate, an upper shaping die, a positioning column, a pressing plate, a tightening ring, a tightening-ring pressing plate and a locking screw are arranged on the punching and shaping die, and an inner shaping gear hole is formed in a core portion of the upper shaping die. The pressing plate clamps and fixes a fixed portion of the semi-finished flexible wheel, the positioning column, the tightening ring, the tightening-ring pressing plate and the locking screw cooperatively fix a center hole of the semi-finished flexible wheel, and the inner shaping gear hole performs shaping upon a profile of an outer gear portion. Therefore, flexible-wheel processing can be completed through a universal machine tool, financial burden of manufacturers can be reduced on one hand, and on the other hand, processing precision of the flexible wheel can be guaranteed.

Owner:DONGGUAN XINTUO INTELLIGENT MACHINERY TECH

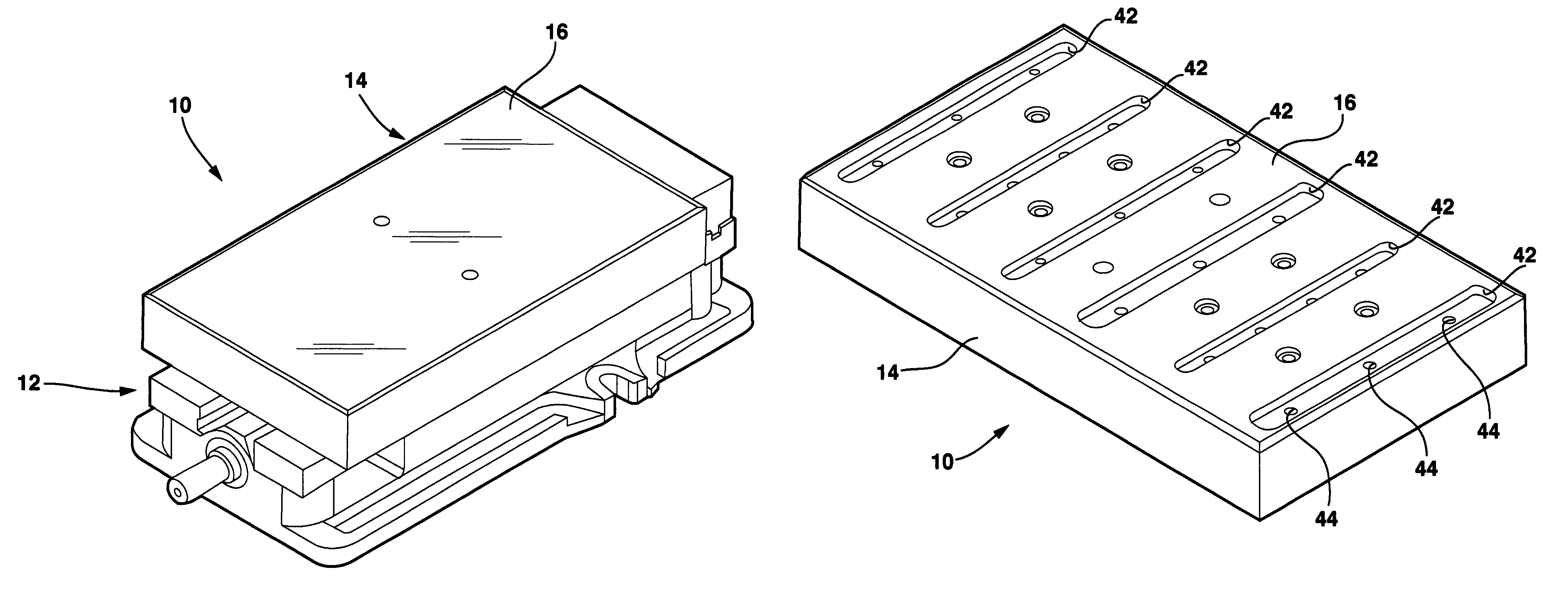

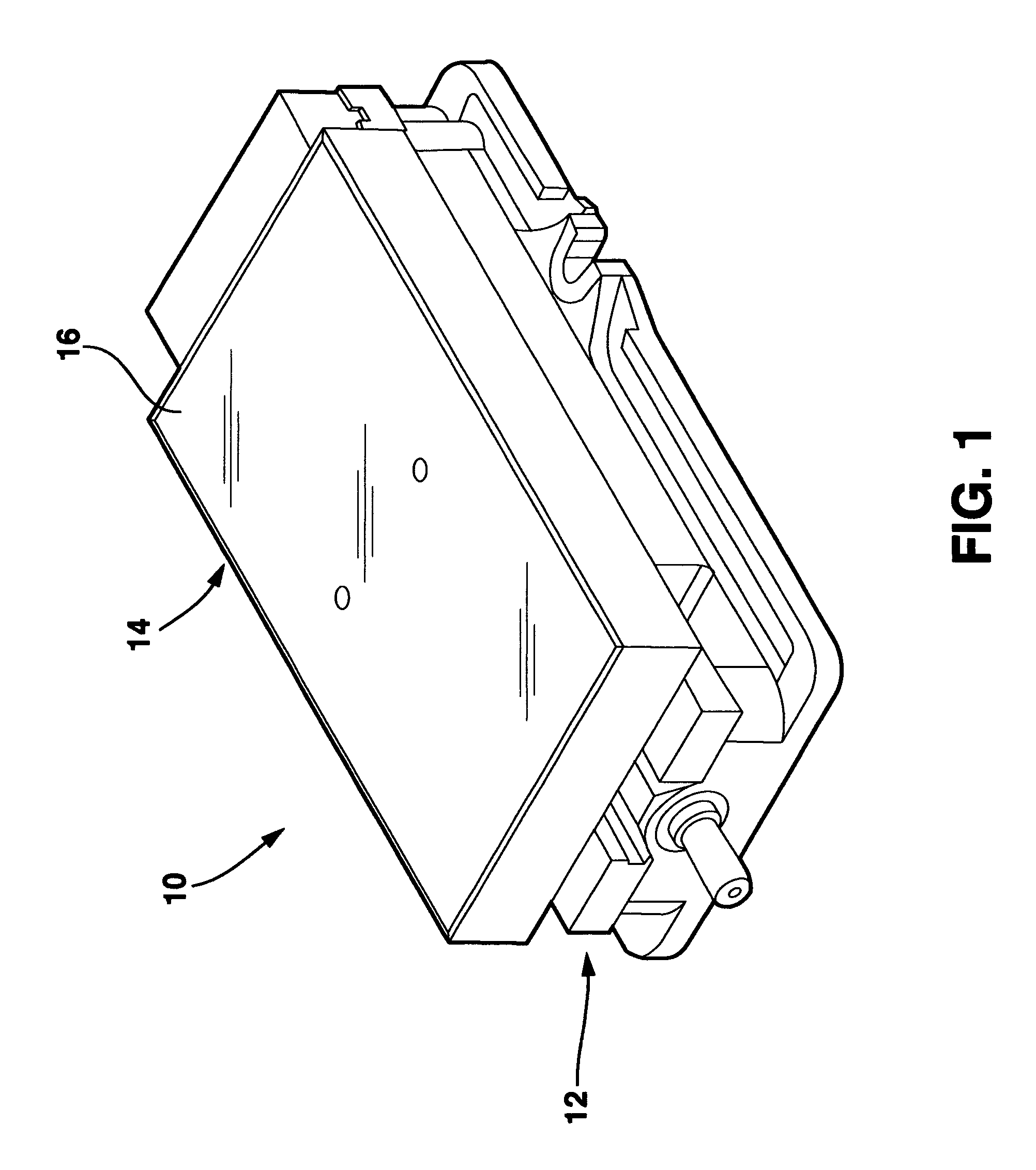

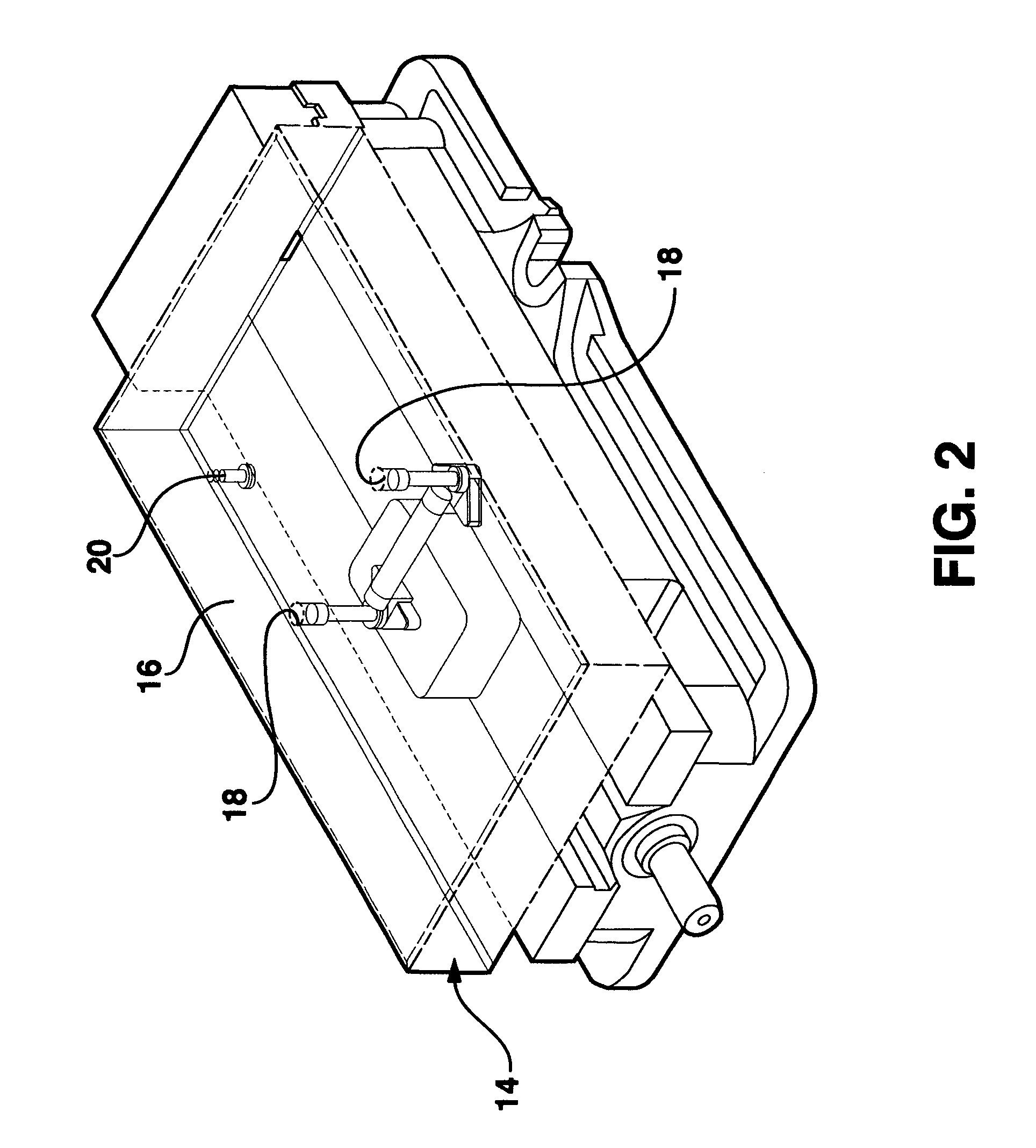

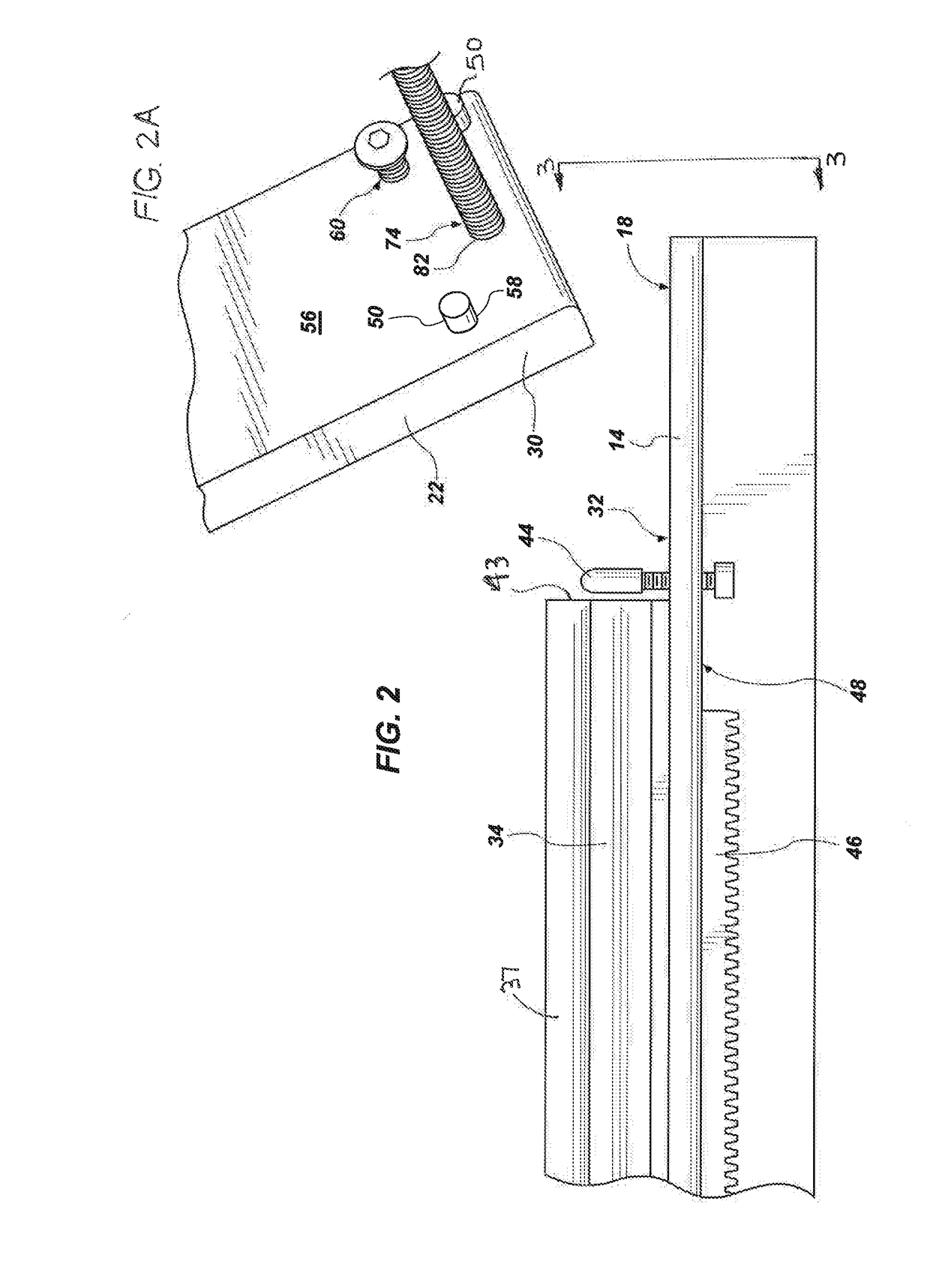

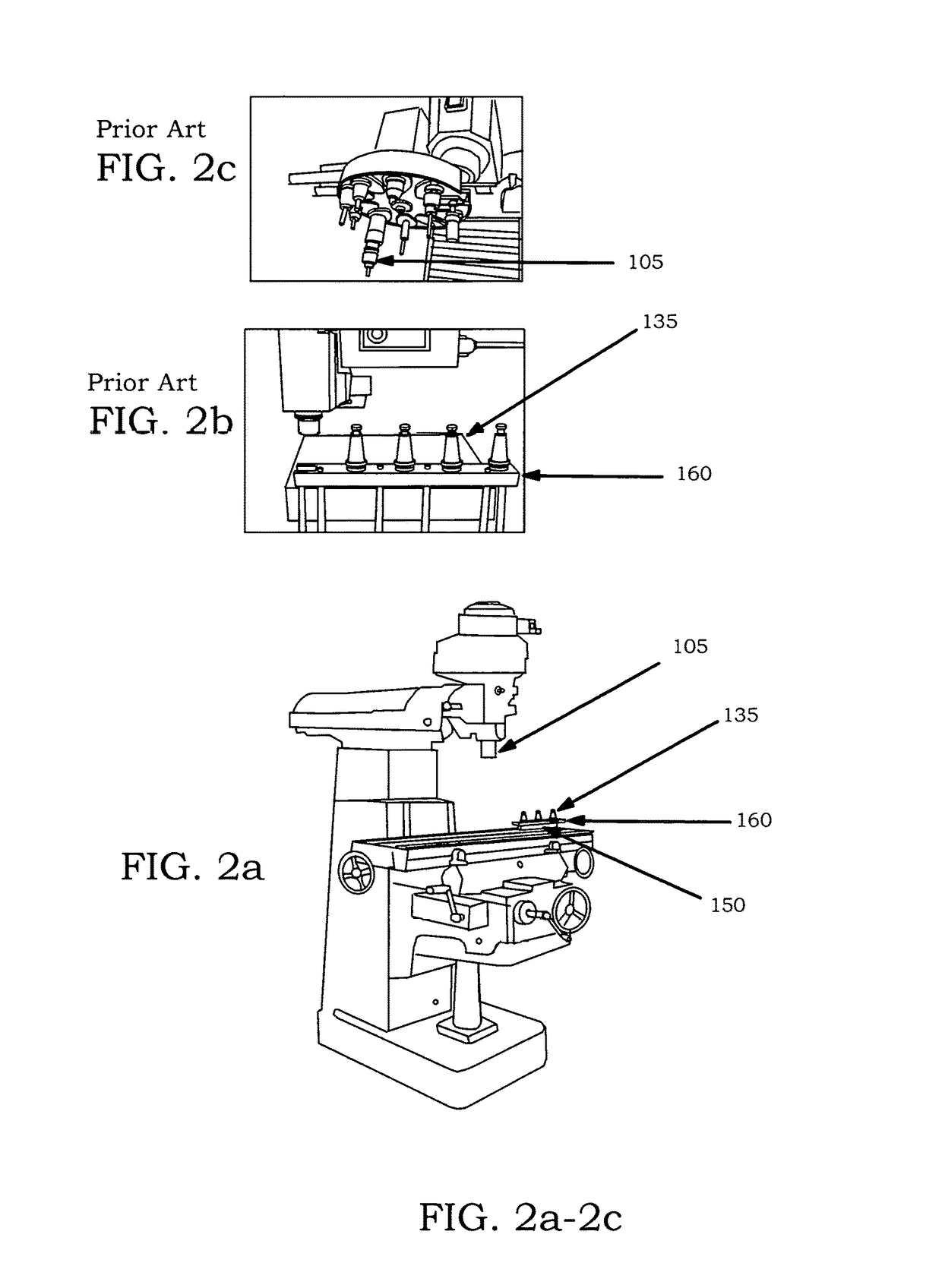

Vise attachable fixture plate for use with CNC milling equipment

A fixture plate for use with a CNC milling machine. The fixture plate is constructed of a generally rectangular block having a top surface, a bottom surface and a forward edge. The bottom surface of the block is positioned to rest on the support surface with the forward edge of the block resting against the fixed jaw. The bottom surface of the block includes a cavity in which is mounted a clamping pin for coupling with the vise hook nut. When the machine screw is manipulated to move the mounting block toward the fixed jaw, the block is clamped to the vise between the fixed jaw and the vise hook nut. The top surface of the block is provided with grooves shaped to conform to the peripheral shape of each of the multiple workpieces. Clamping nuts, recessed in the grooves, are used for clamping the multiple workpieces to the block.

Owner:LOVAS STEPHEN R

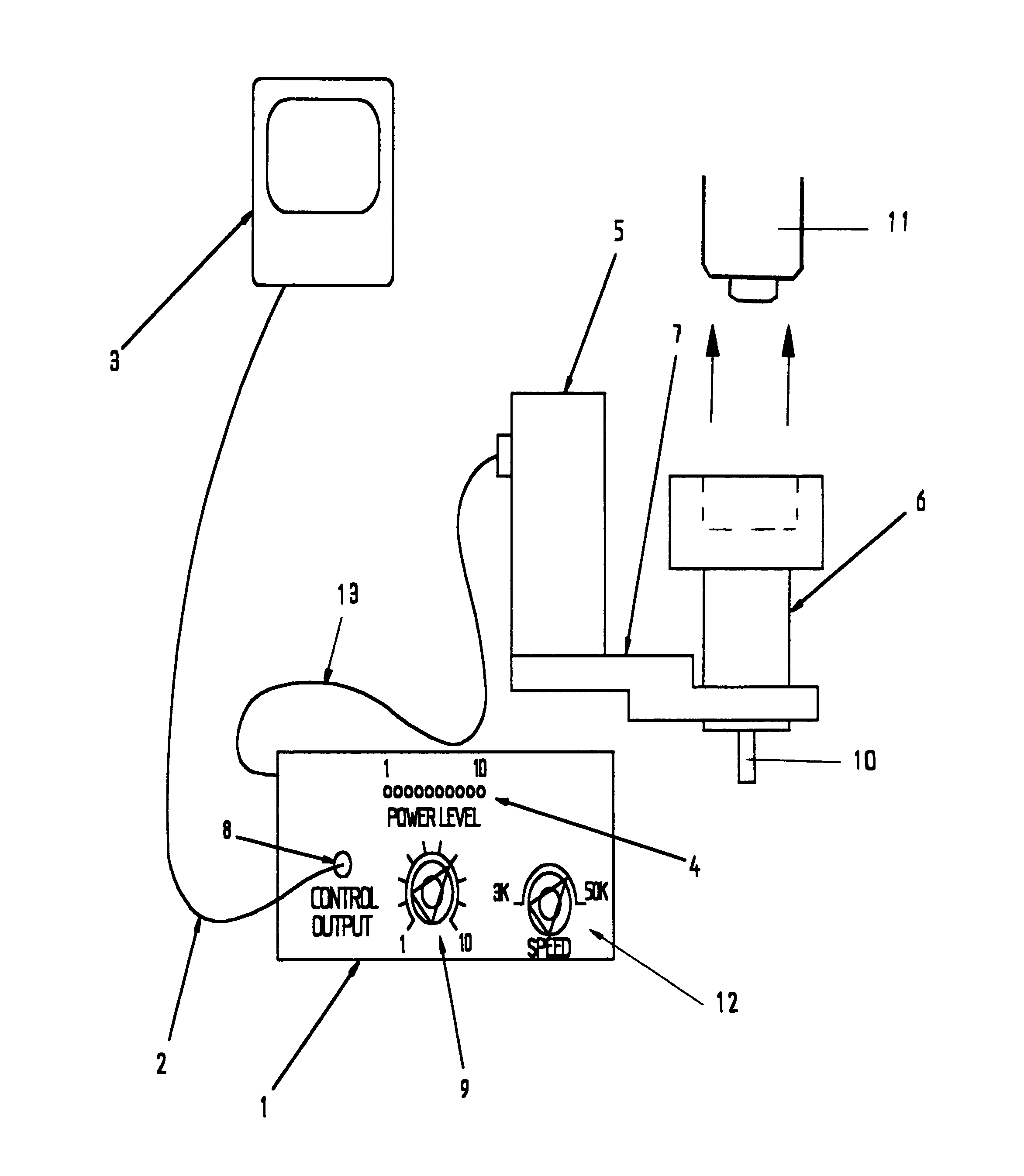

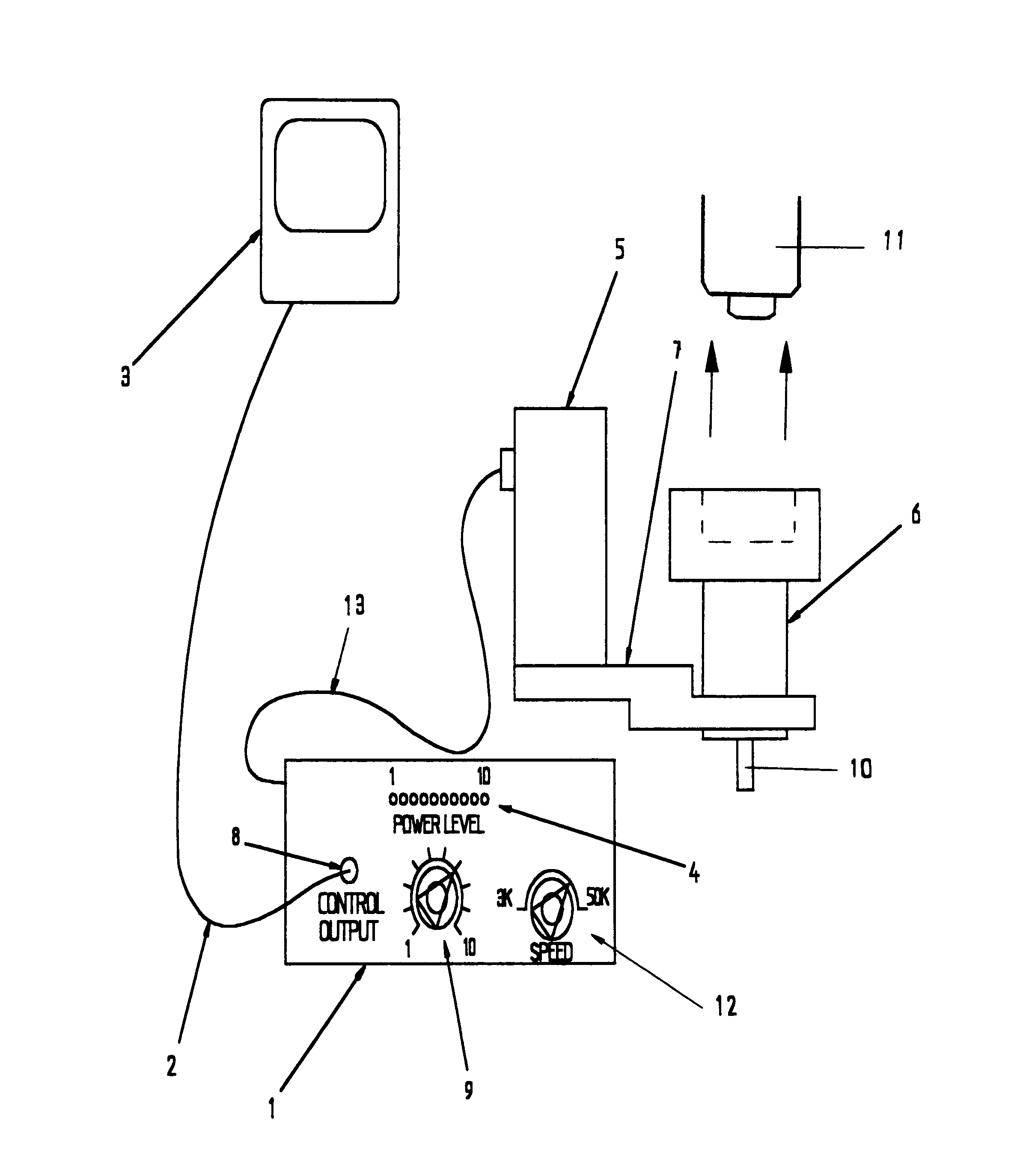

Controller for the electric motor of a high-speed spindle attachment used with computer-controlled milling machines

InactiveUS6874980B1Lower levelProvide protectionThread cutting machinesMilling machinesMaximum levelElectronic controller

An improved electronic controller for the motor of a high-speed spindle attachment used in conjunction with a cnc milling machine. The controller comprises preventative circuitry that protects the spindle assembly of the attachment from overload accruing as a result of relatively moderate increases in torque demand during use. The controller senses the power level being used by the motor while it causes high-speed spindle rotation, and when it identifies a power consumption rate by the spindle that exceeds the operator pre-set maximum level determined to be safe for avoiding catastrophic spindle damage, the electronic controller sends a signal back to the computer controlling the axes of the cnc milling machine that is sufficient to slow, pause, and / or stop the feed-rate.

Owner:NOELLE JOHN A +1

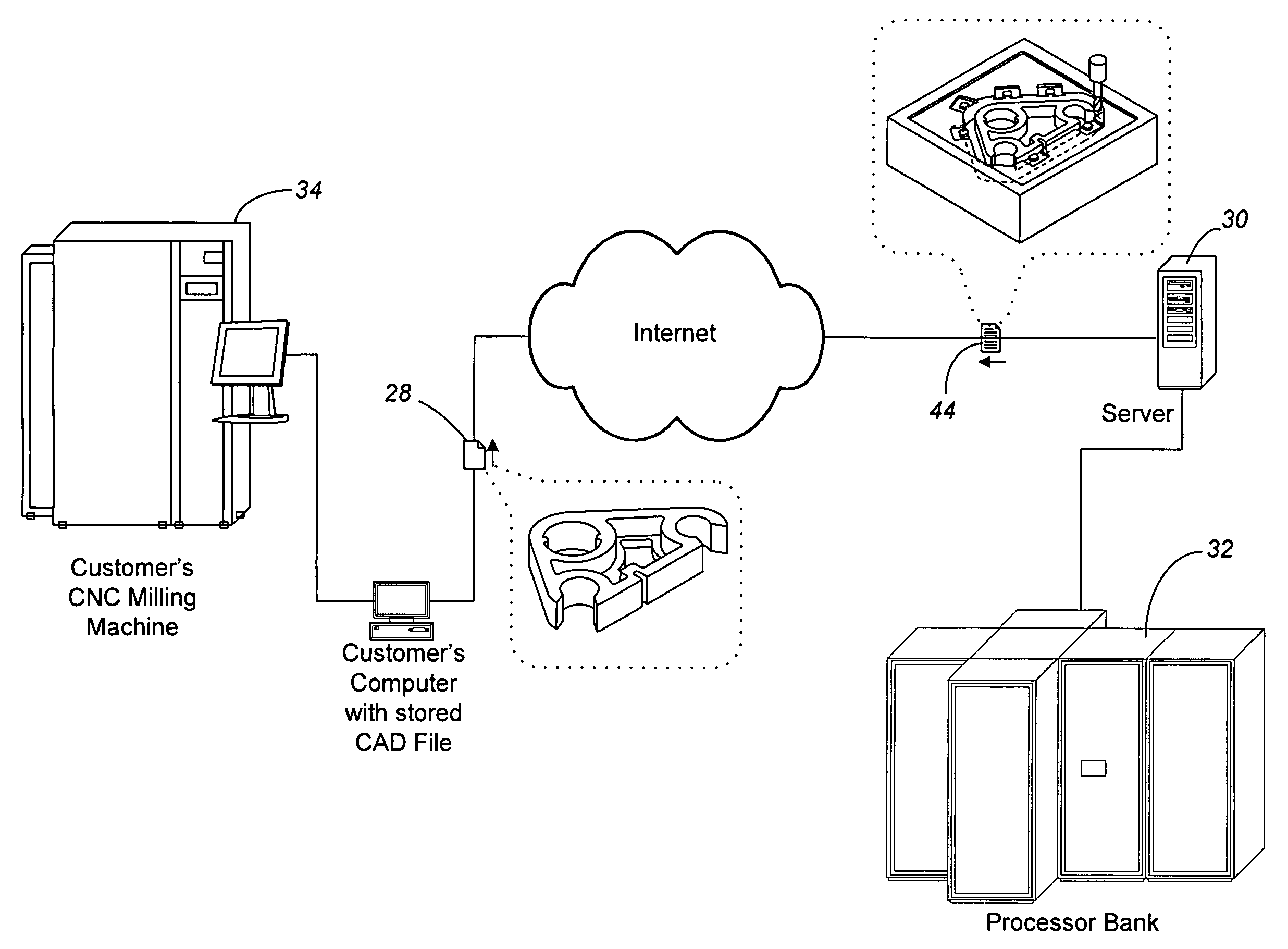

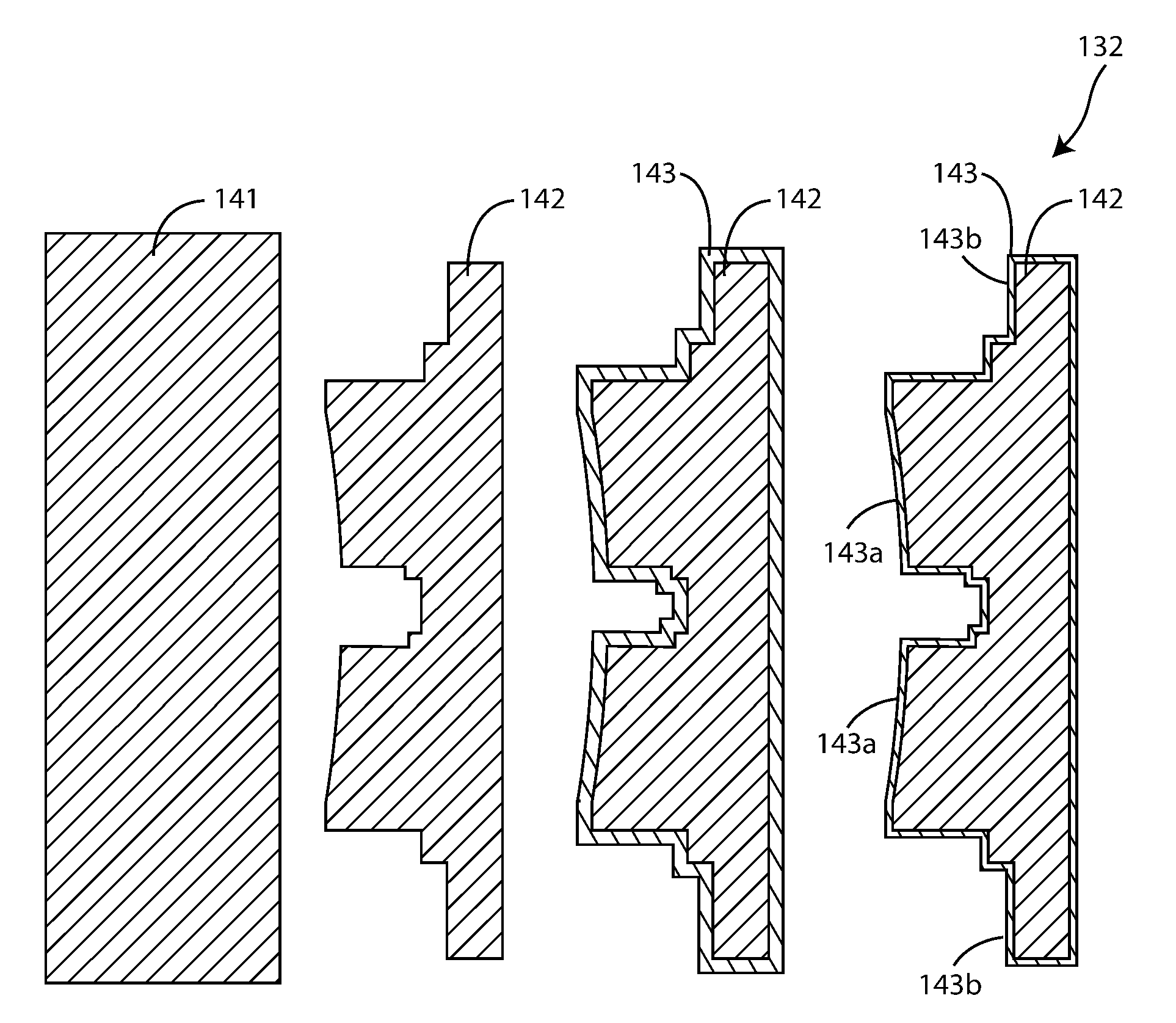

CNC Instructions For Solidification Fixturing Of Parts

ActiveUS20090302496A1Computation using non-denominational number representationCommerceMachine instructionCNC router

A customer transmits their 3D CAD file for a part to be total profile machined. Computer analysis of the transmitted CAD file produces CNC machining instructions, which are transmitted back to an address defined by the customer. The customer can then use the transmitted CNC machining instructions to total profile machine their own part using their own CNC mill at the location where the part is likely needed. The transmitted instructions include not only the tool paths for CNC machining of the total profile of the part, but also for additional features formed into the encircling portion of a material block from which the part is to be total profile machined. For instance, the CNC machining instructions transmitted back to the customer can define a registration recess and / or channels or undercuts for fluid support material on an A-side of a material block. After the A-side of the block is machined, the customer adds and solidifies fluid support material into the machined recess. The CNC mill is then used to machine a support surface into a portion of the solidified support material surface. A registration fixture is applied into contact with the support surface CNC machining on the B-side of the material block is then performed while the part is supported by the solidified support material, substantially separating the part from the encircling block of material. The support material is then removed, such as by dissolving, freeing the part from the encircling block of material.

Owner:PROTOLABS INC

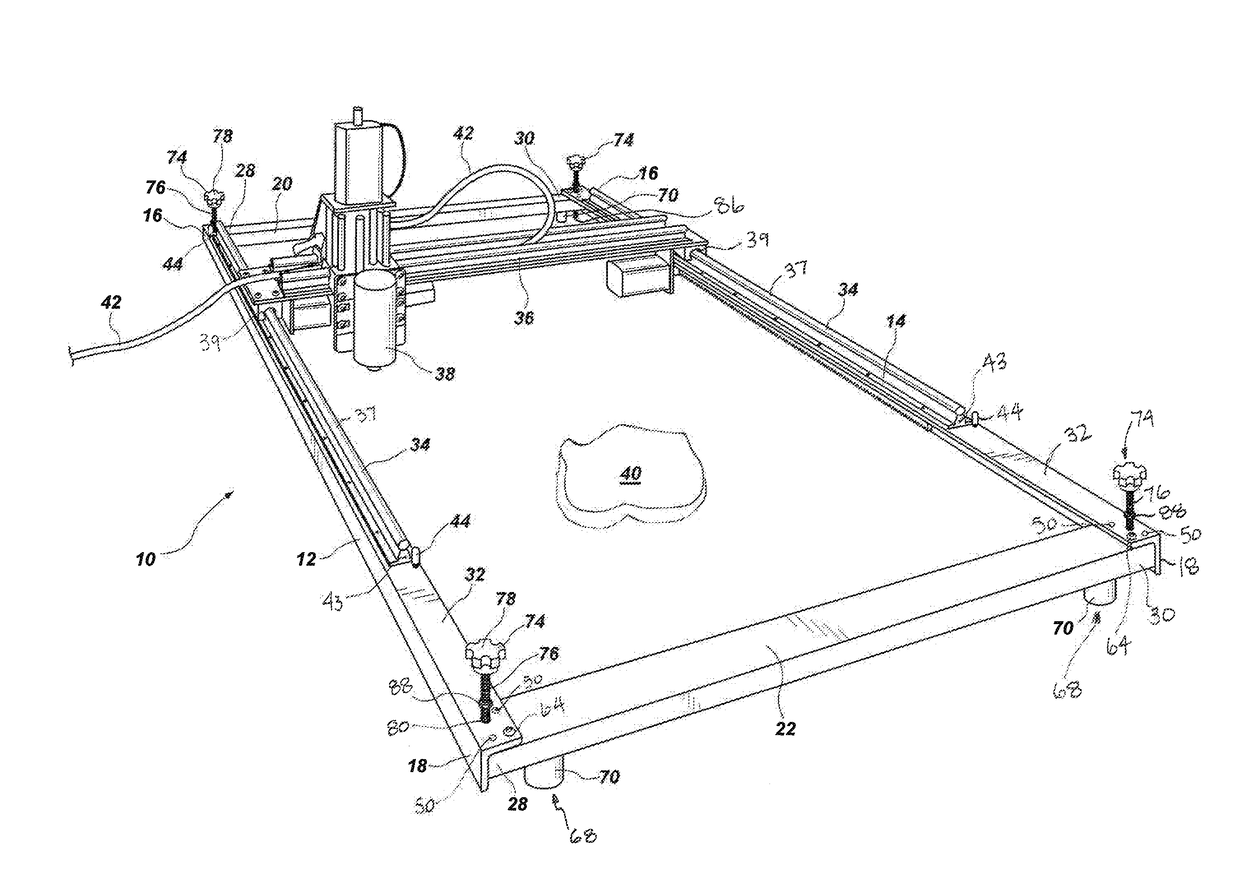

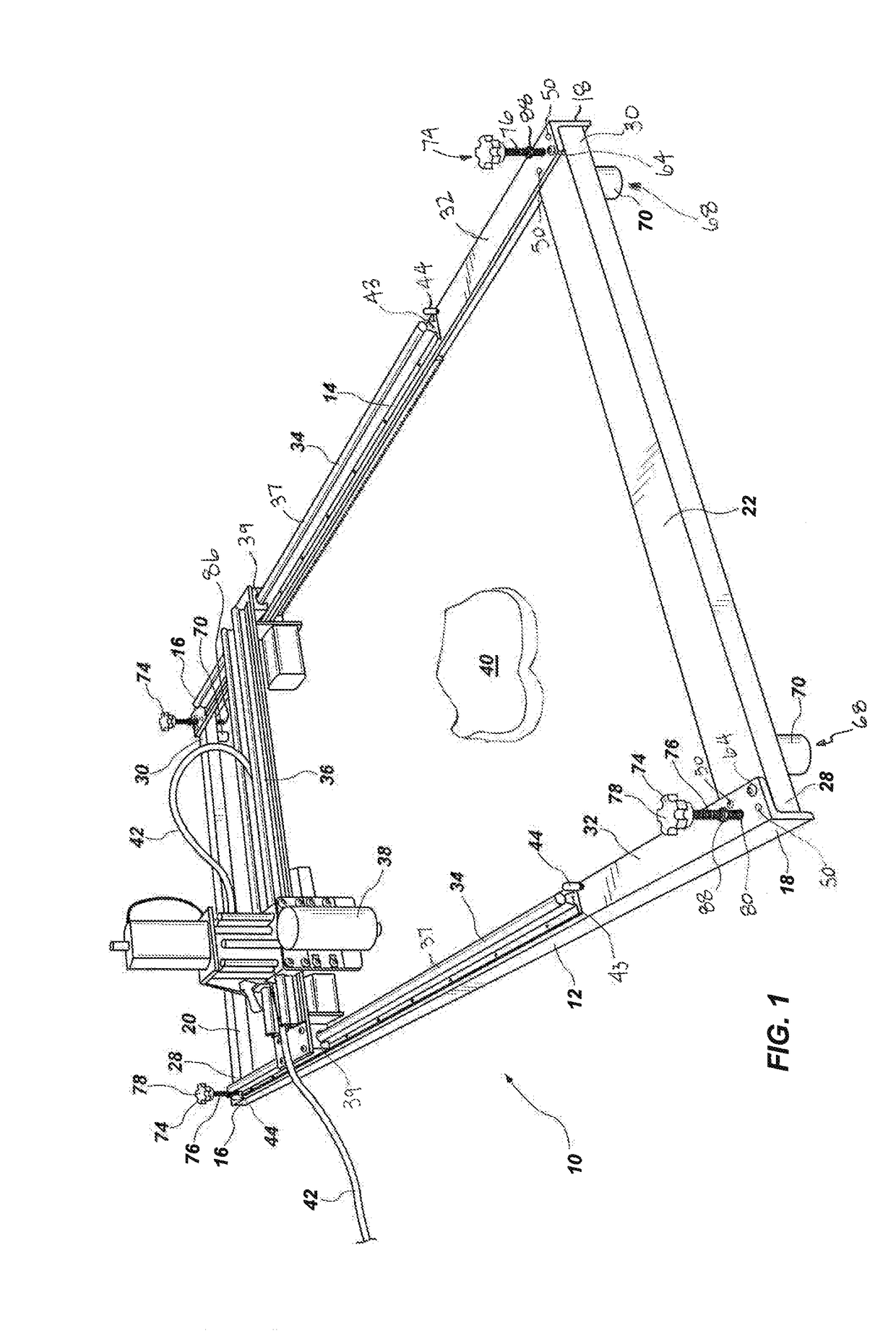

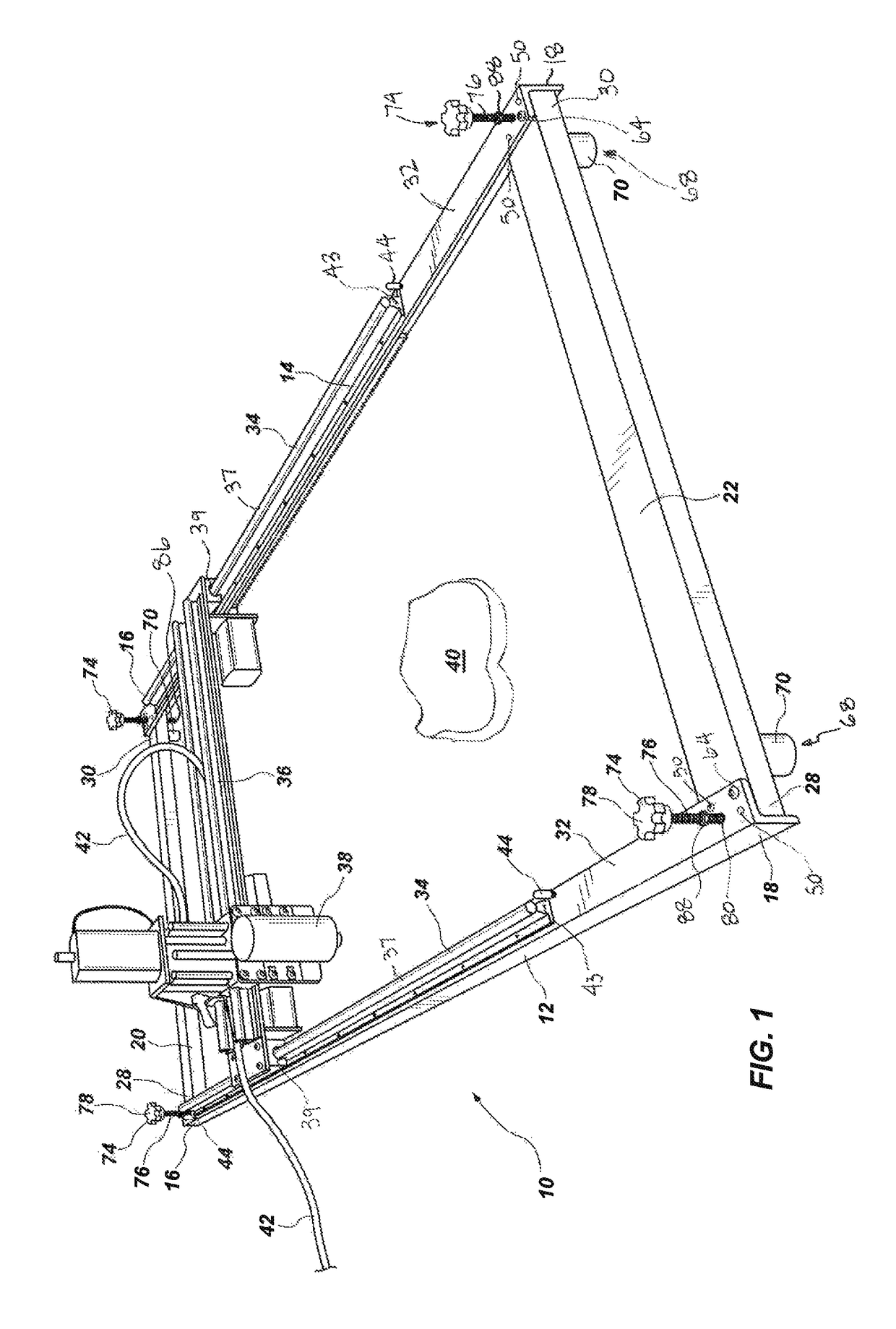

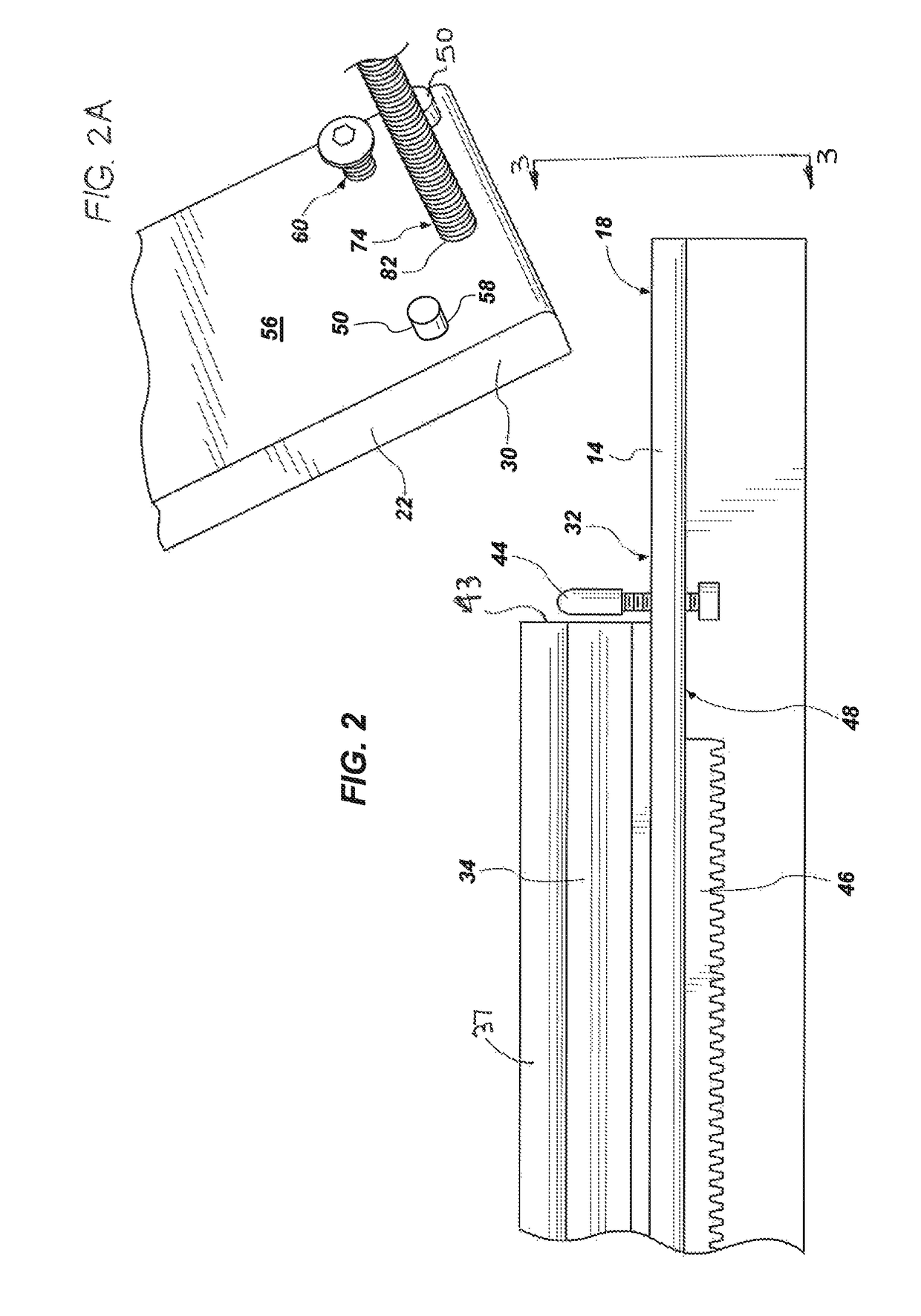

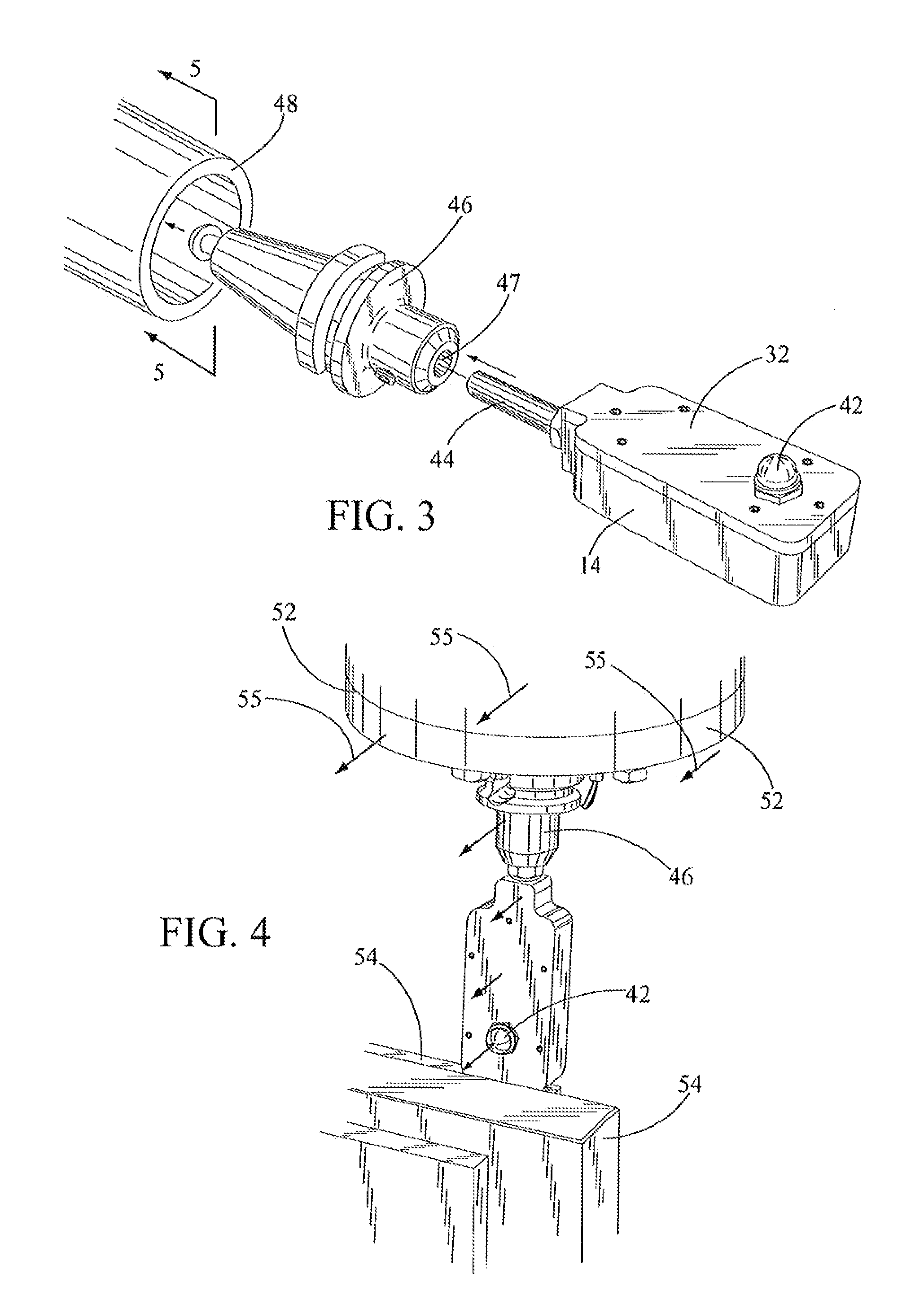

Portable rail system for mounting an engraving device

A portable rail system for mounting an engraving device includes rails and crossbar members that are precisely joined, and include height adjustment devices for incrementally adjusting the height of the rail system relative to a work surface or contact surface, thus making the portable rail system capable of being assembled and disassembled at a work site to enable the use of an engraving device, such as a CNC router engraving systems, in situ, or on-site, rather than in a workshop. The portable rail system enables the use of a CNC router device or other engraving device on vertical surfaces.

Owner:REDART TECH LLC

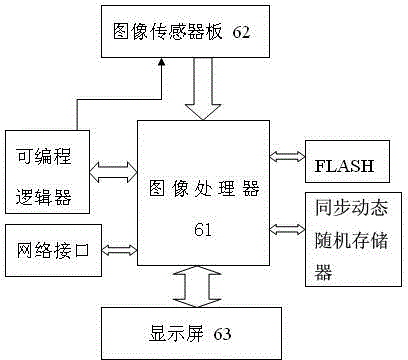

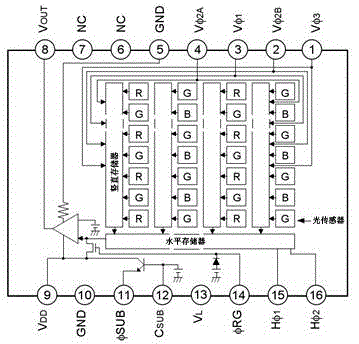

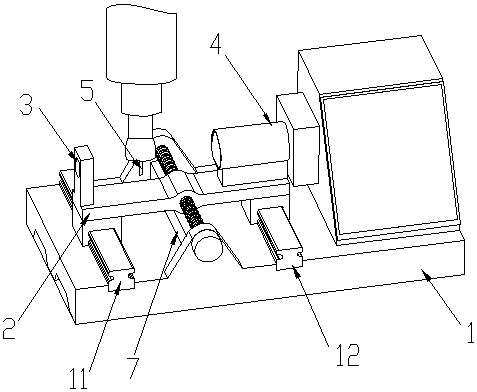

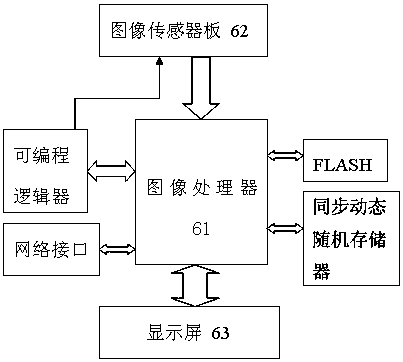

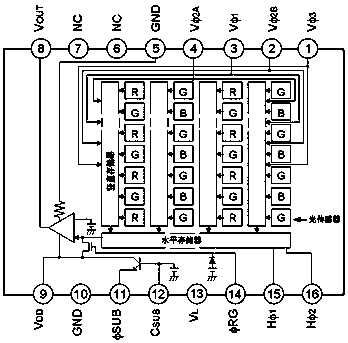

Portable detector of CNC milling machine cutter

ActiveCN104596422ARealize automatic tool settingEasy to handleUsing optical meansNumerical controlEngineering

The invention relates to the field of detection equipment and discloses a portable detector of an CNC (Computer Numerical Control) milling machine cutter. The portable detector comprises a holder device, a cutter imaging system and an image analyzing system; the holder device can be installed nearby the milling machine cutter on the operating platform of the CNC milling machine and longitudinally moved; the cutter imaging system is installed on the holder device, horizontally moved and used for dynamically photographing images of the milling machine cutter; the image analyzing system is fixed to the holder device, connected with the cutter imaging system and used for converting the images of the milling machine cutter into parameters of the milling machine cutter. The detector is a small portable detector, images are formed by the cutter imaging system, and the images and parameters of the milling machine cutter are analyzed by the image analyzing system to achieve online detection and presetting of the milling machine cutter. The detector further comprises an offline detection cutter frame, and the holder device, the cutter imaging system and the image analyzing system are positioned on the offline detection cutter frame through an offline detection cutter frame simulation machine tool to achieve offline detection and cutter presetting.

Owner:深圳市眼之杰光电科技有限公司

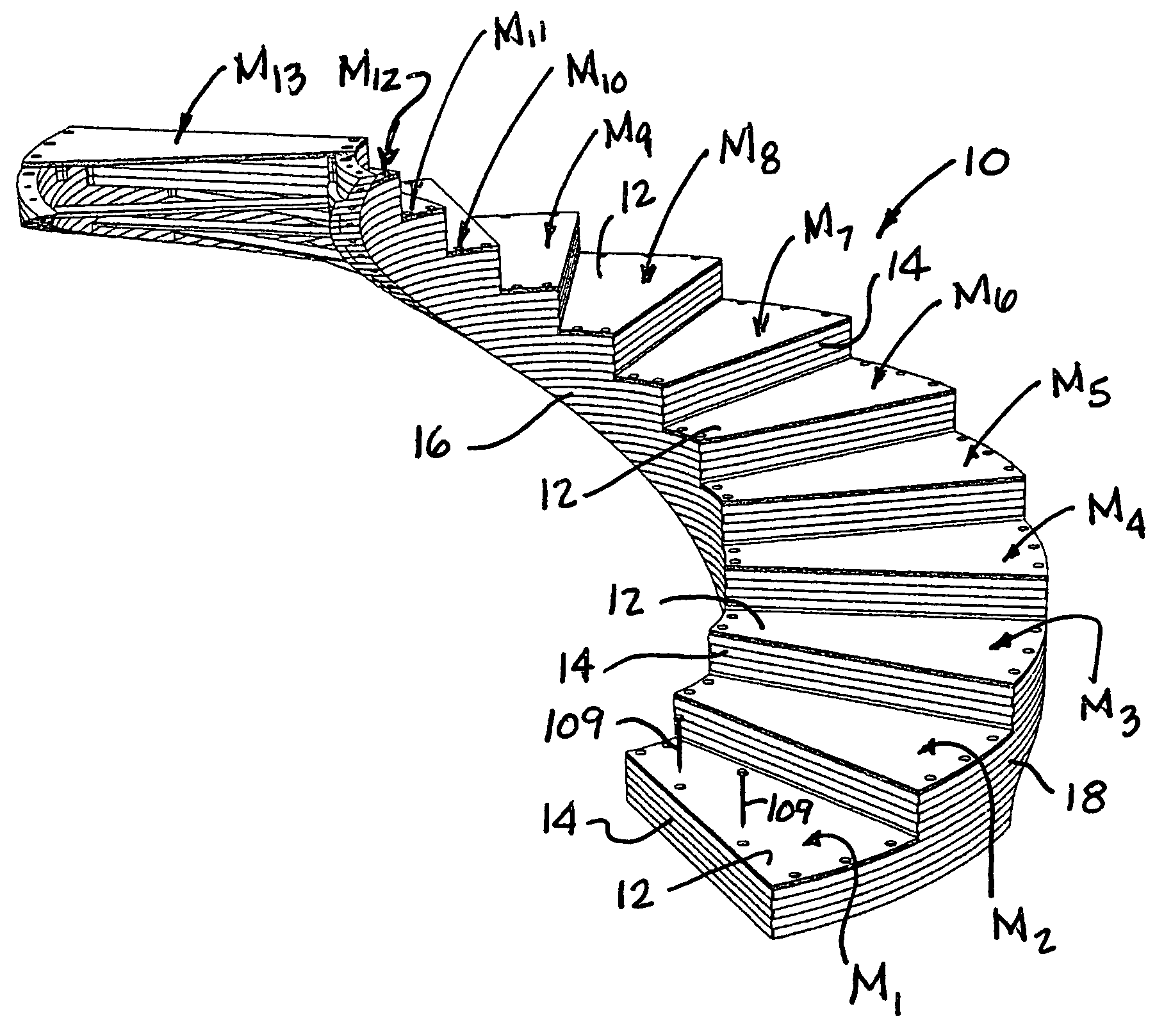

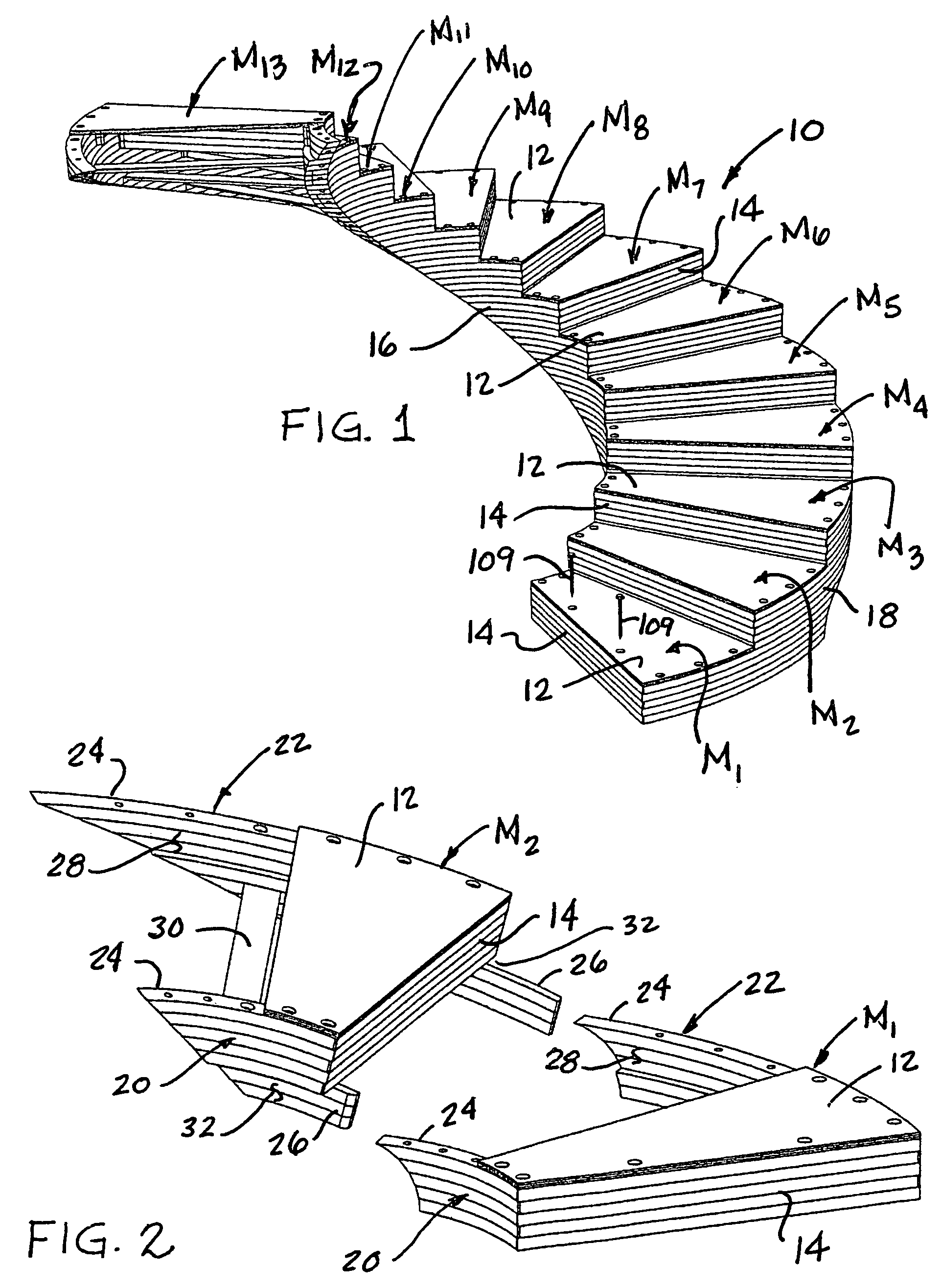

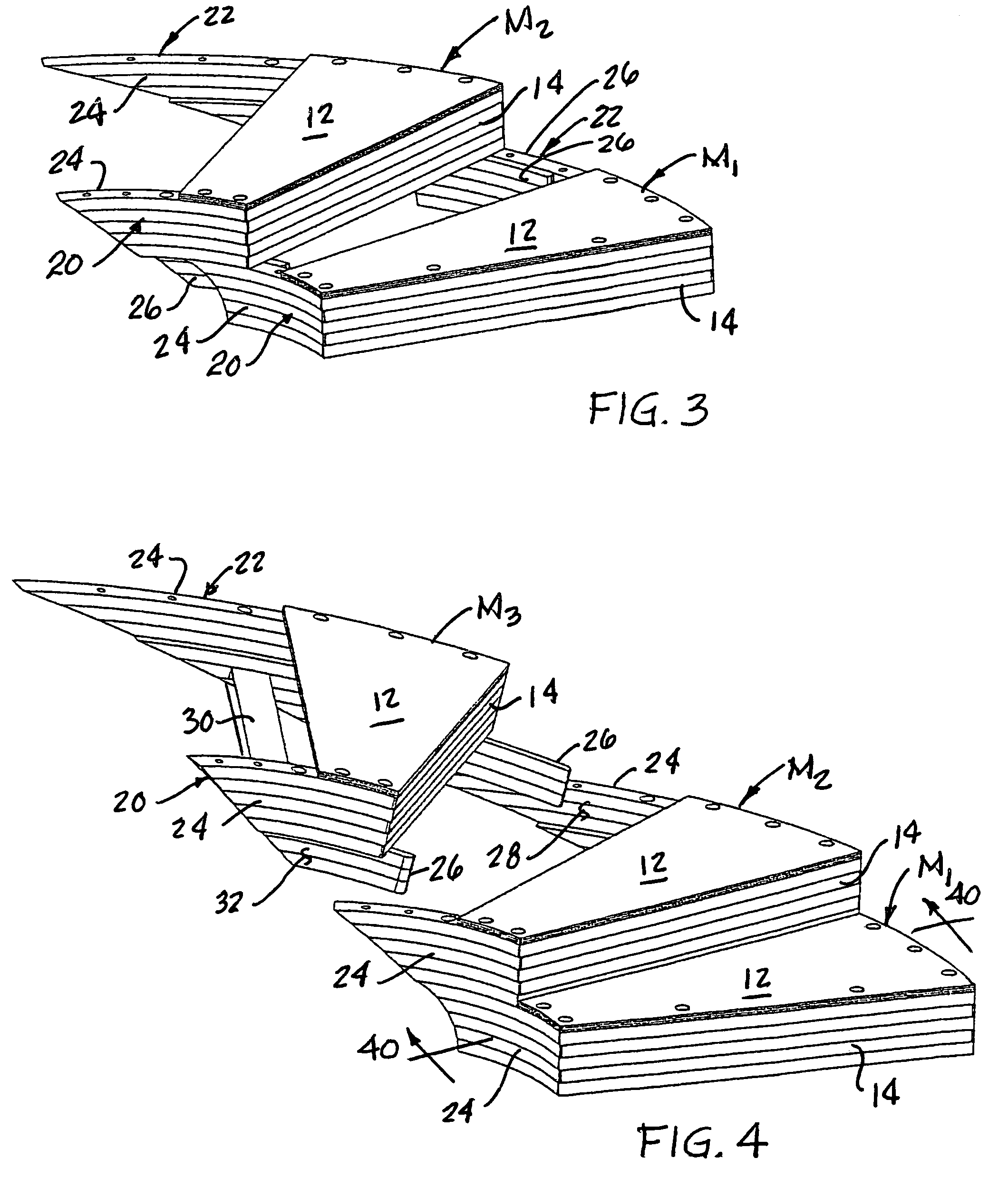

Modular staircase construction

A staircase structure, representatively at least partially curved, is constructed from longitudinal modules each having tread, riser and stringer portions. In one embodiment of the construction technique, stringer portions of the modules are longitudinally telescoped with one another and then intersecured so that the interfitted modules form successive longitudinal portions of the assembled staircase structure. In another embodiment of the construction technique, stringer portions of the modules are vertically stacked and then intersecured. Illustratively, the riser and stringer portions of each module are of a laminated wooden construction shaped in situ on the underside of module tread portion by a CNC milling machine.

Owner:SMITH LYNN H

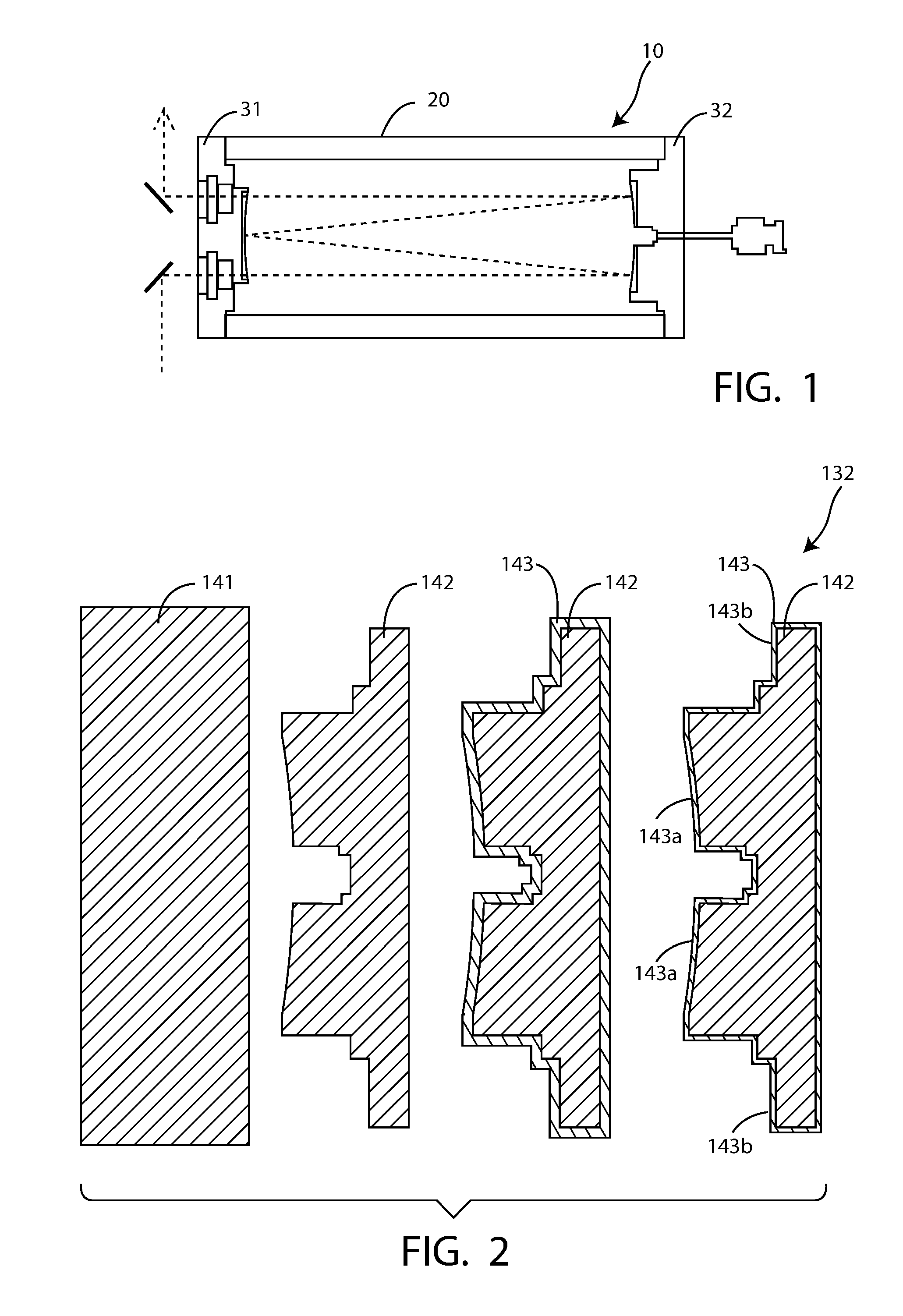

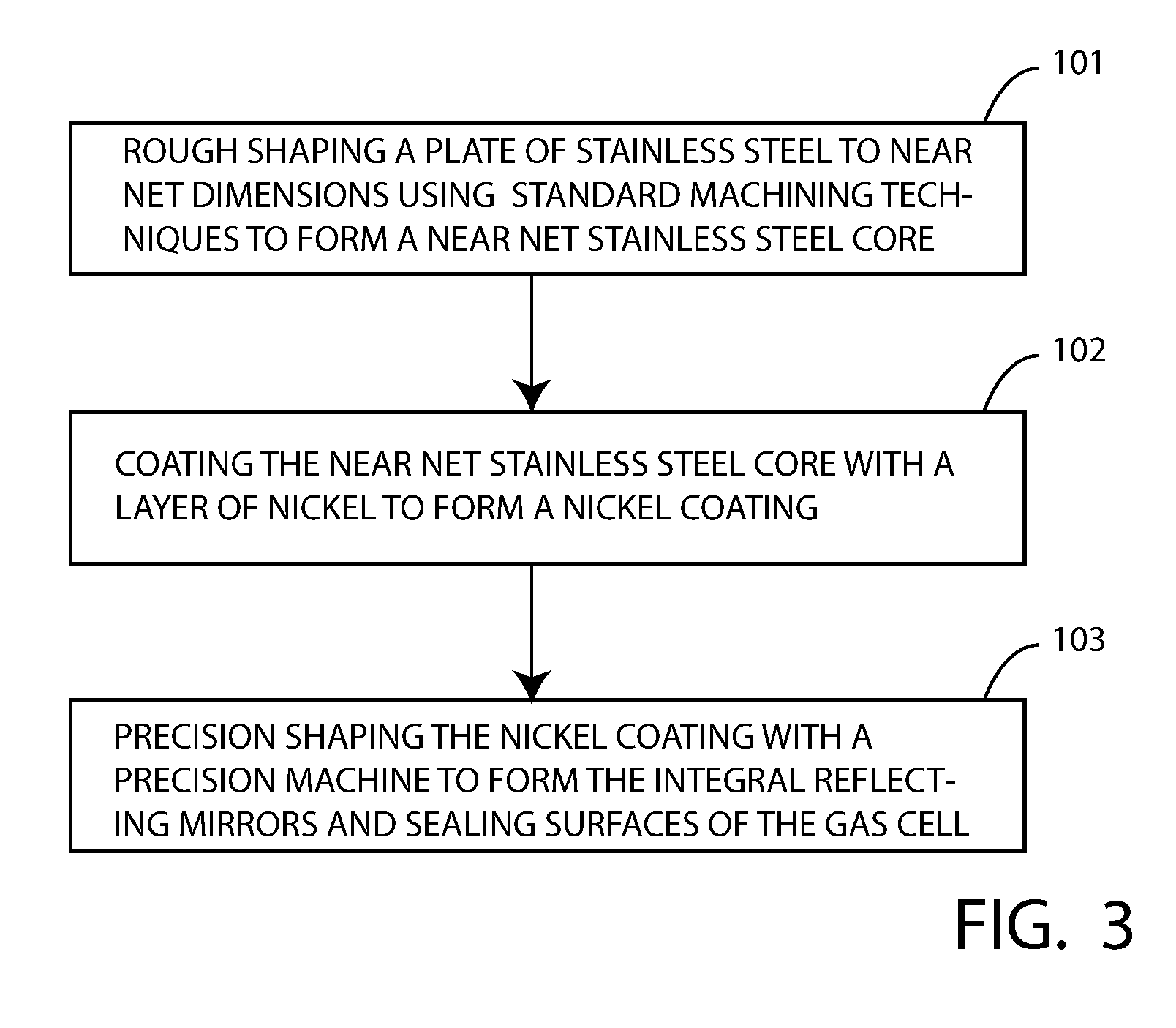

Corrosion Resistant Gas Cell Formed From Nickel Plated Stainless Steel

InactiveUS20120156368A1Efficient and cost-effective manufacturingMaterial analysis by optical meansPretreated surfacesCNC routerMaterials science

Method of making a corrosion resistant gas cell including an end cap having integral reflecting mirrors and sealing surfaces, the method involving the steps of: rough shaping a plate of stainless steel to near net dimensions using a standard-precision CNC milling machine and standard cutting bits to form a near net stainless steel core; coating the near net stainless steel core with a layer of nickel that is at least 0.002″ thick by immersing the near net stainless steel core in a bath of nickel sulfamate for at least eight hours; and precision shaping the coating of nickel with a precision milling machine to form the integral reflecting mirrors and sealing surfaces of the gas cell

Owner:MIDAC

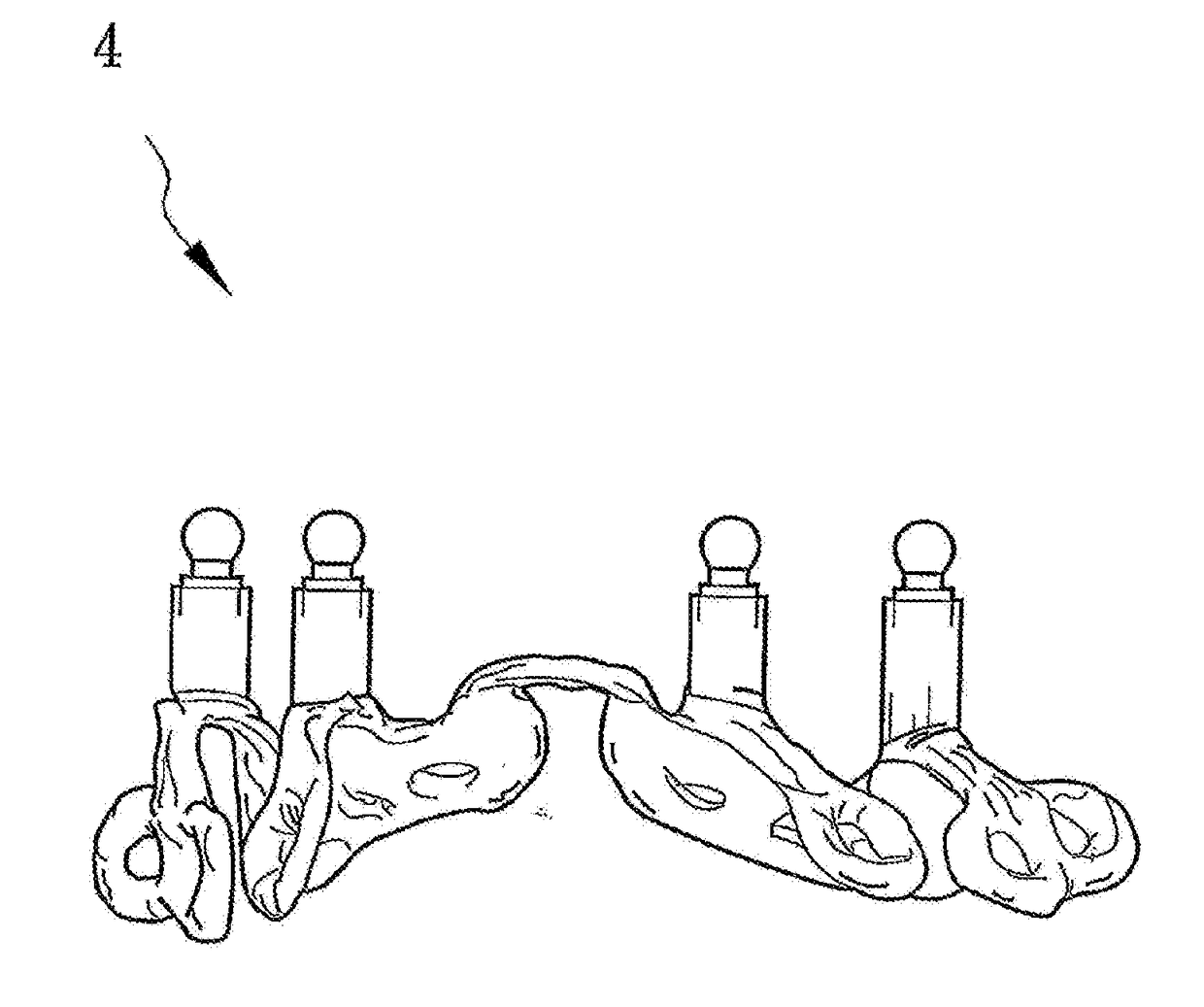

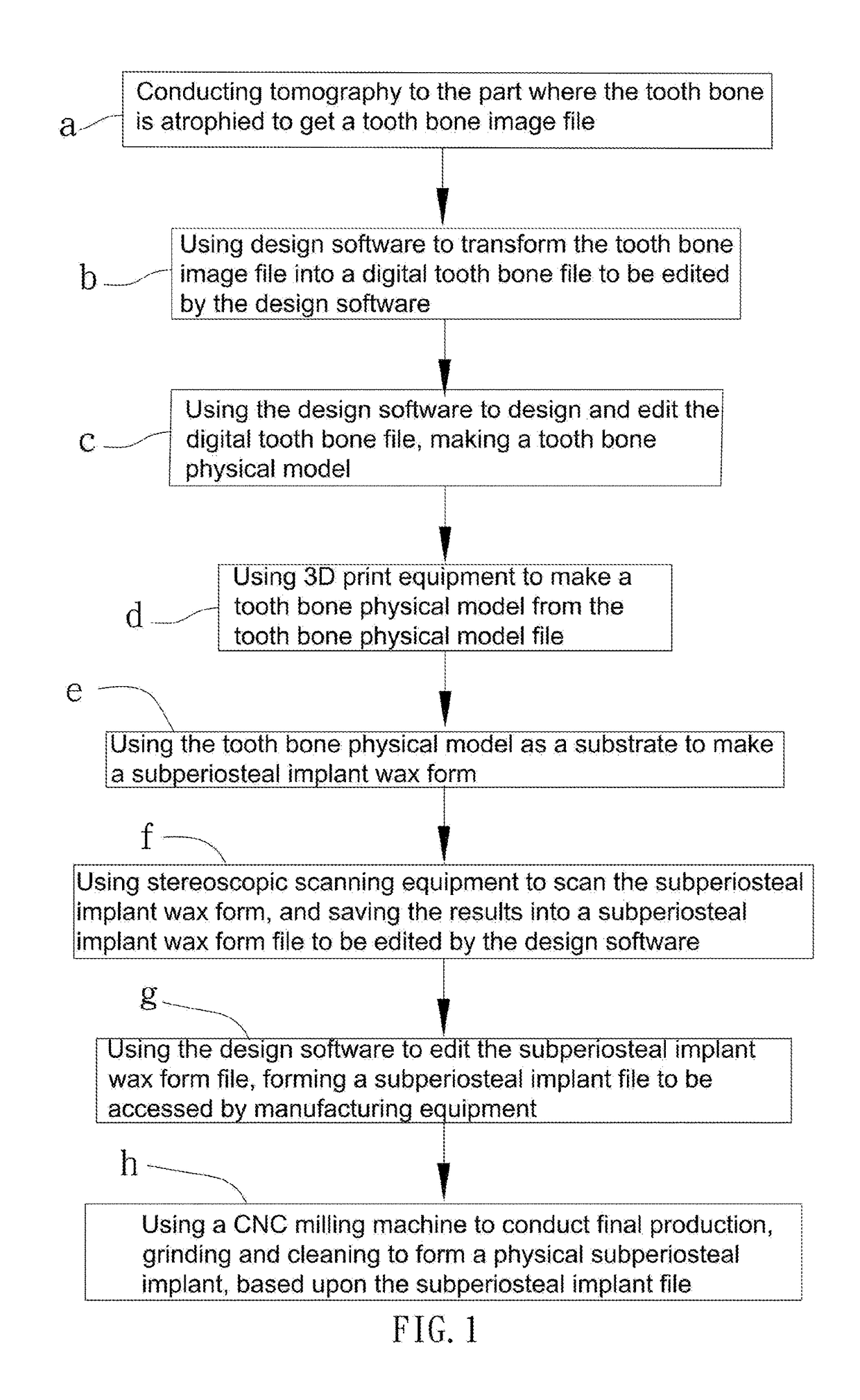

Tooth implantation technique and a subperiosteal implant manufacturing method for the solution of extreme atrophy of a tooth bone

InactiveUS20170312057A1Poor precisionHigh failure rateDental implantsImpression capsData transformationPhysical model

A tooth implantation technique and a subperiosteal implant manufacturing method for the solution of extreme atrophy of a tooth bone are disclosed, primarily using steps of tomography, data transformation, software design, 3D printing of a physical model, making a subperiosteal implant wax form, wax form scanning and design, and manufacturing with a CNC milling machine, so as to make a subperiosteal implant that fits with a patient, thereby improving the shortcomings in a conventional manufacturing procedure of an implant.

Owner:CHENG JUNG CHUAN

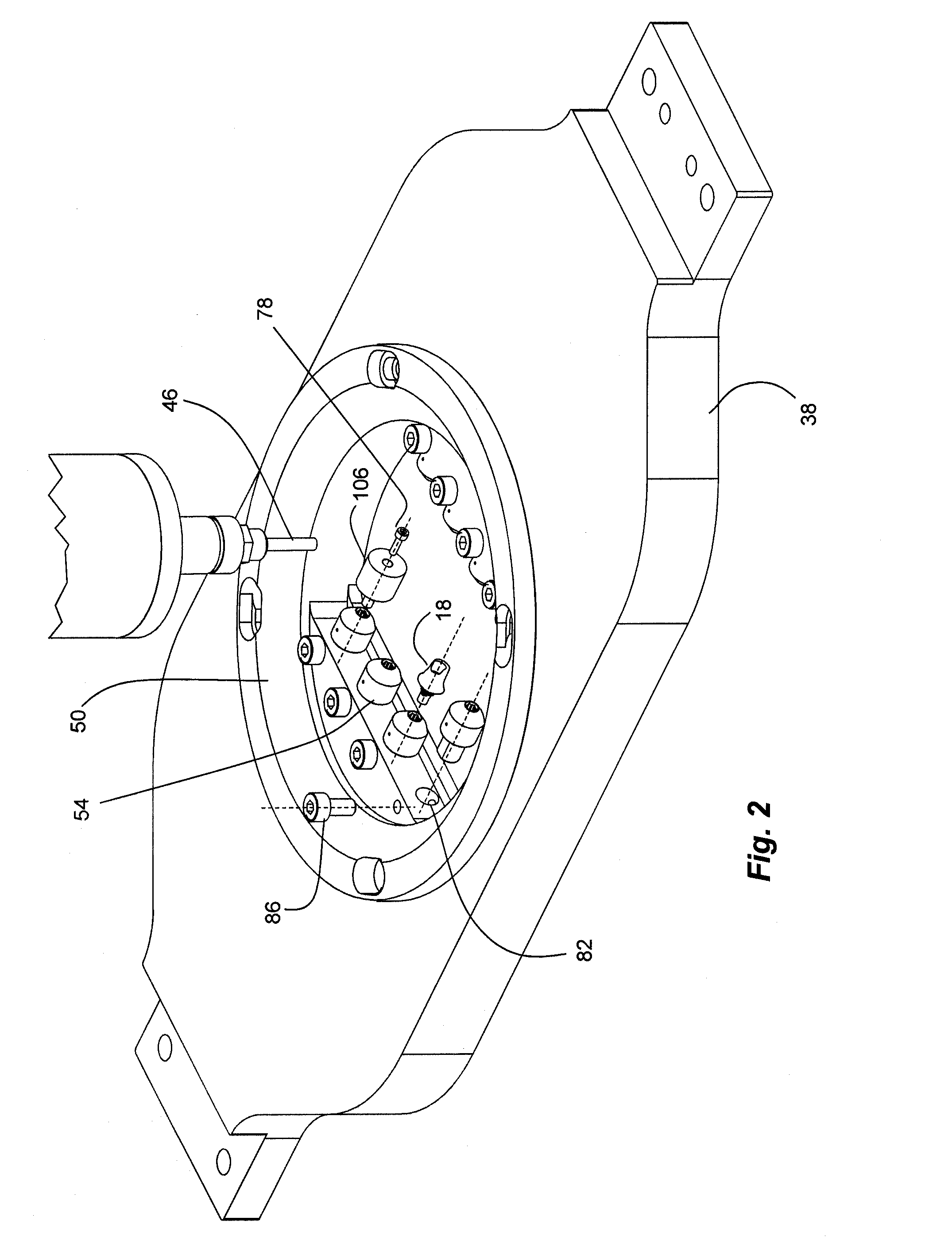

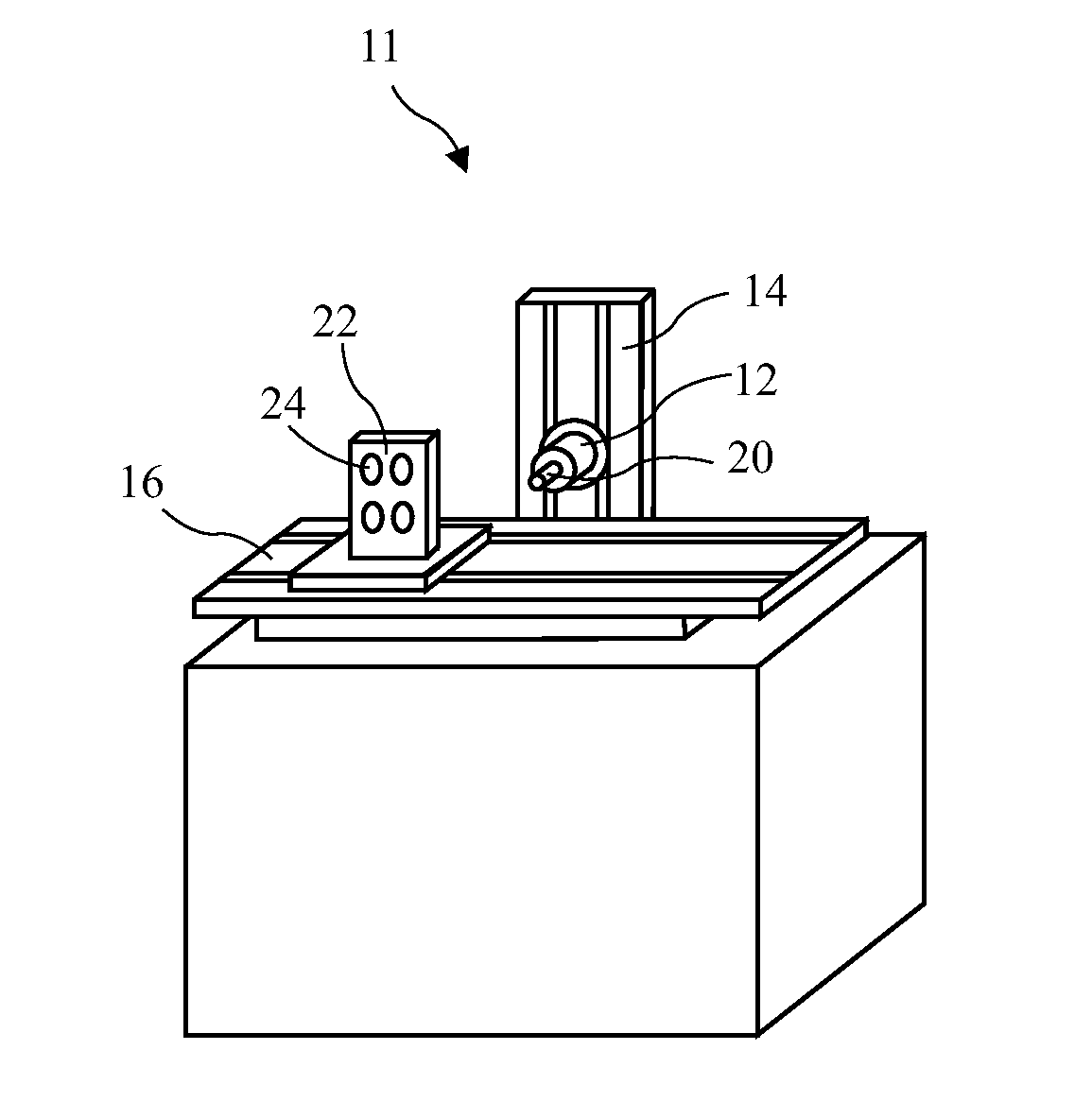

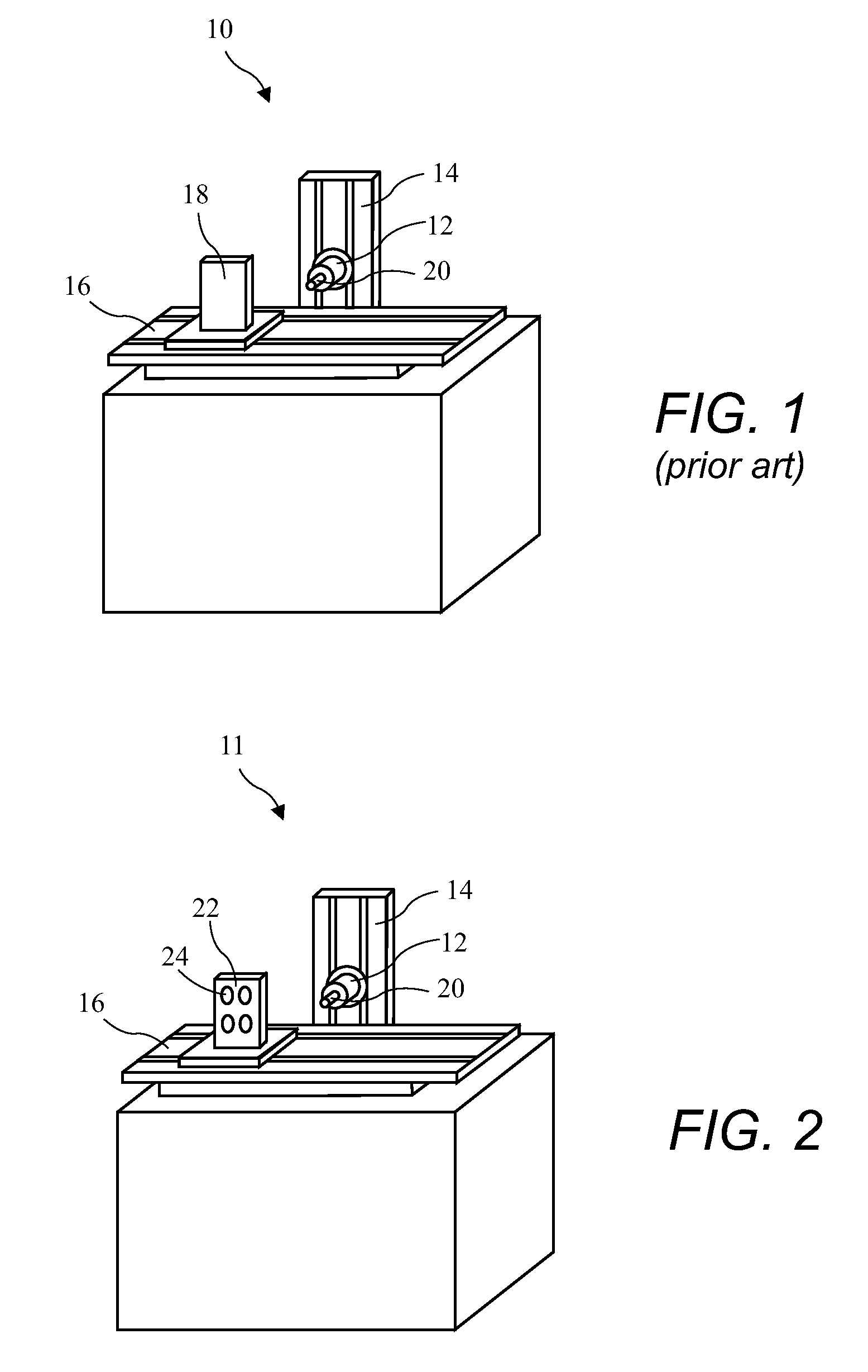

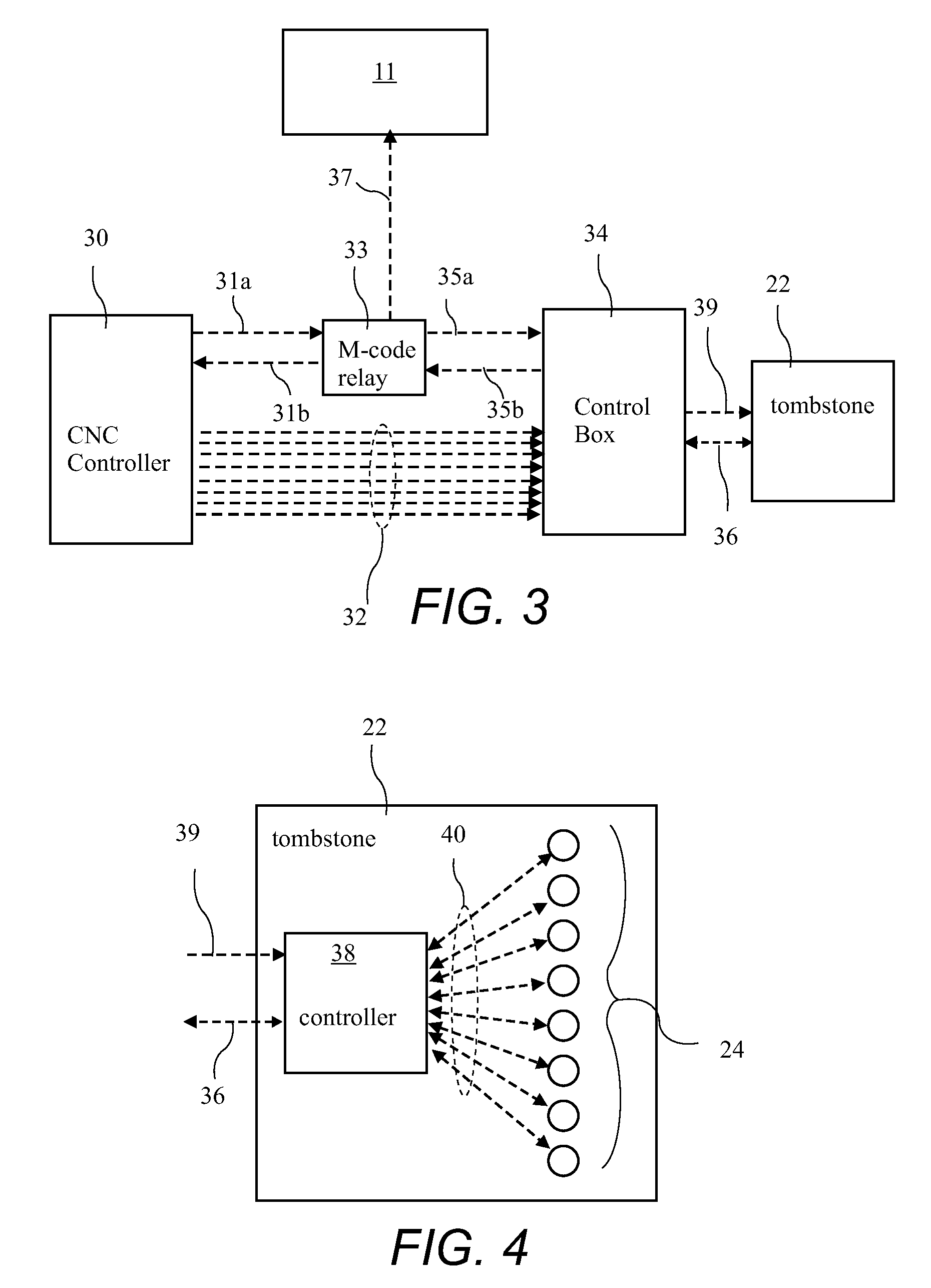

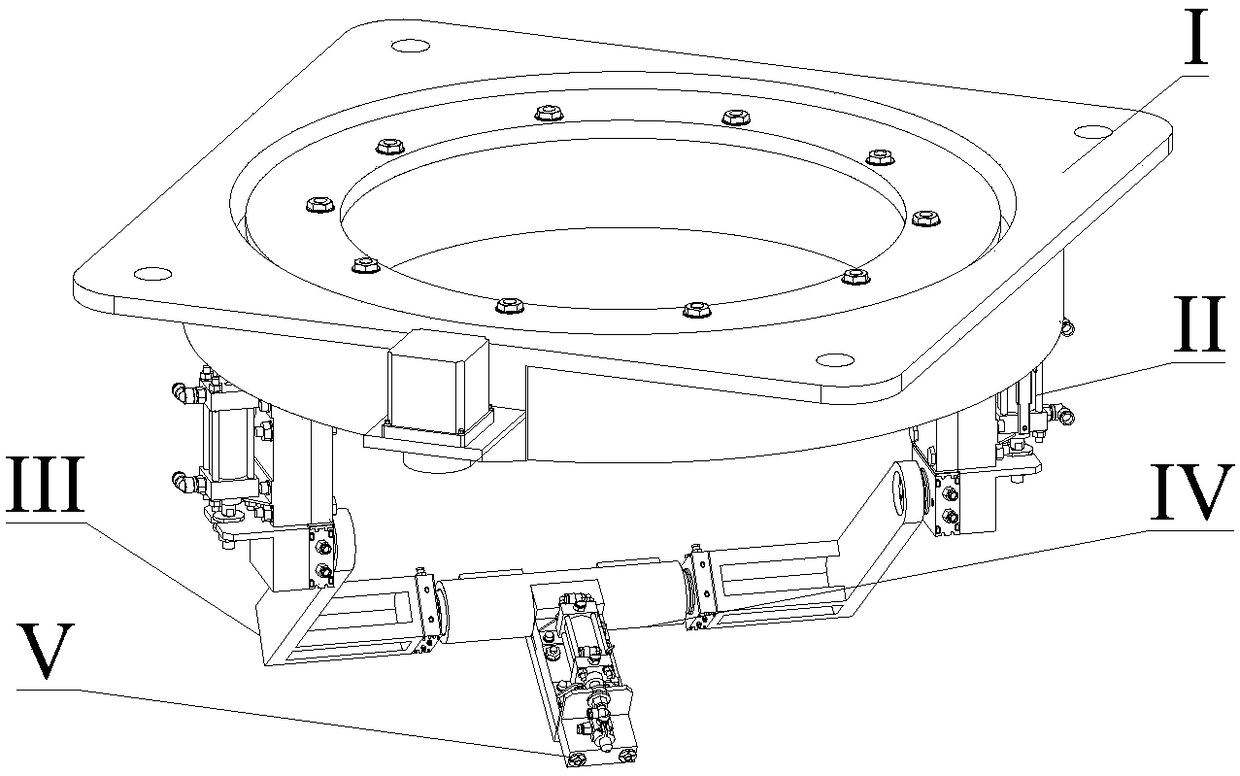

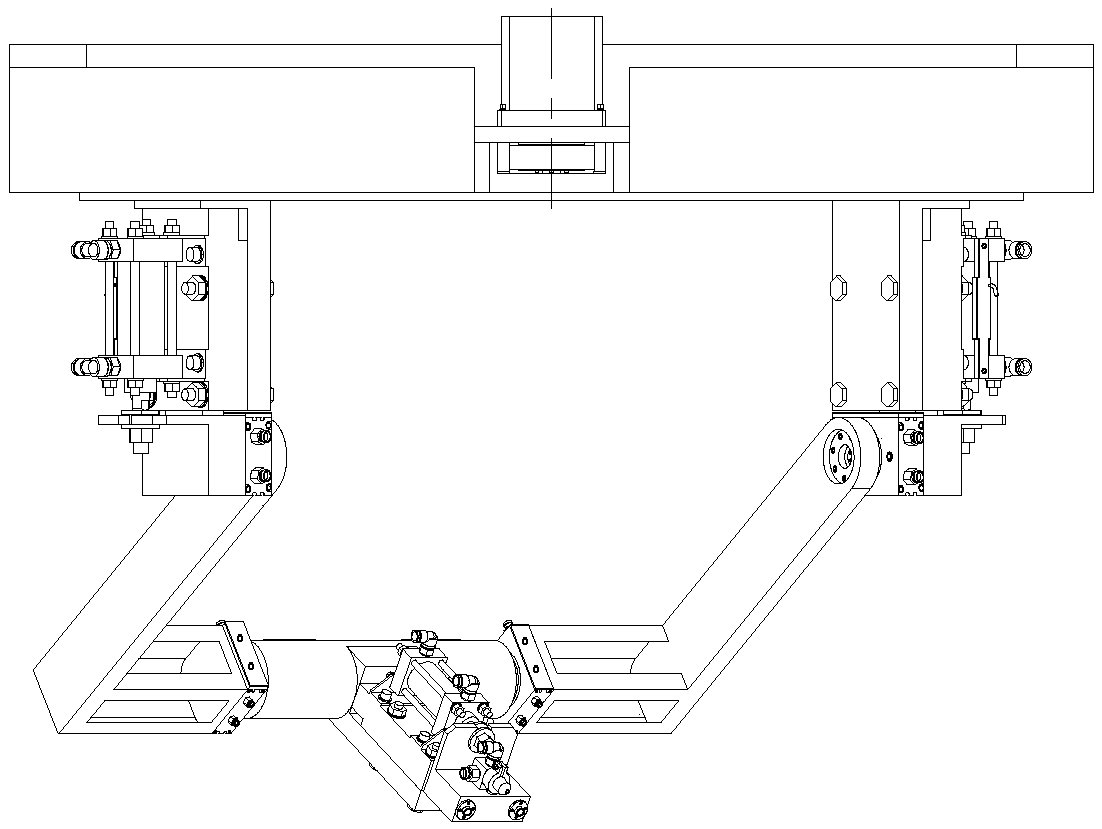

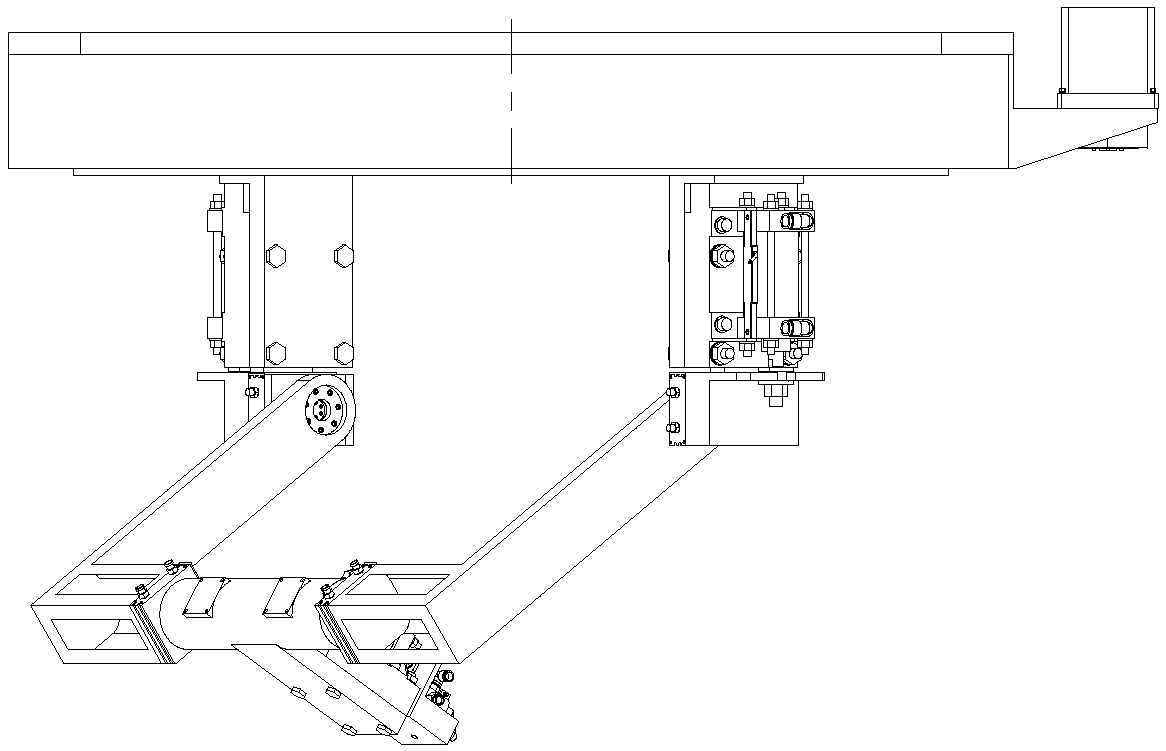

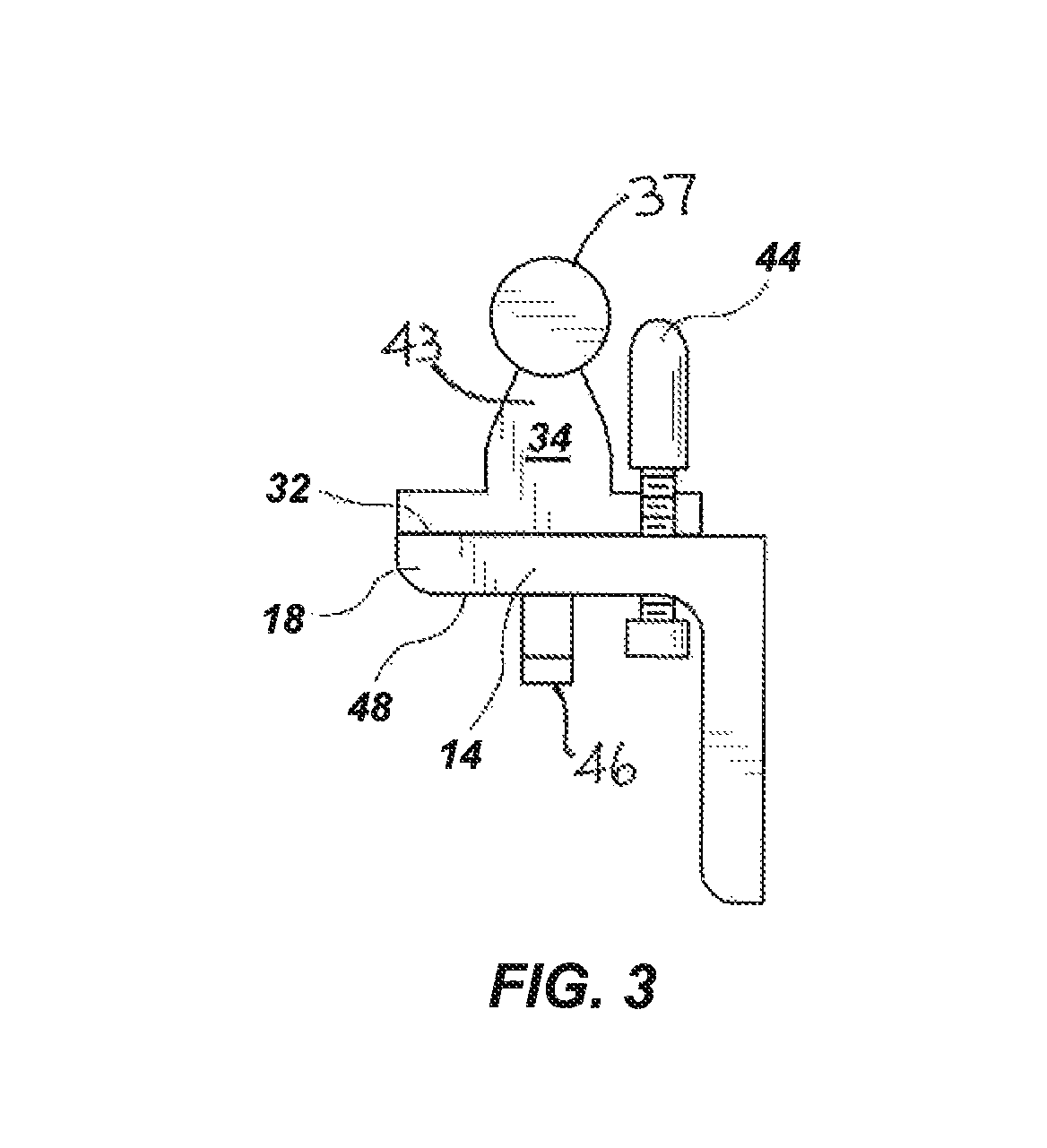

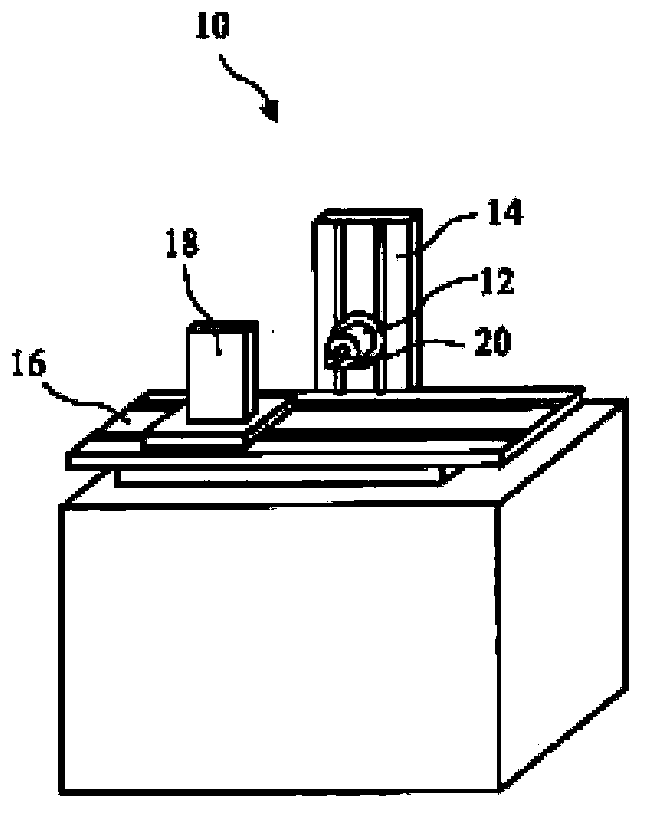

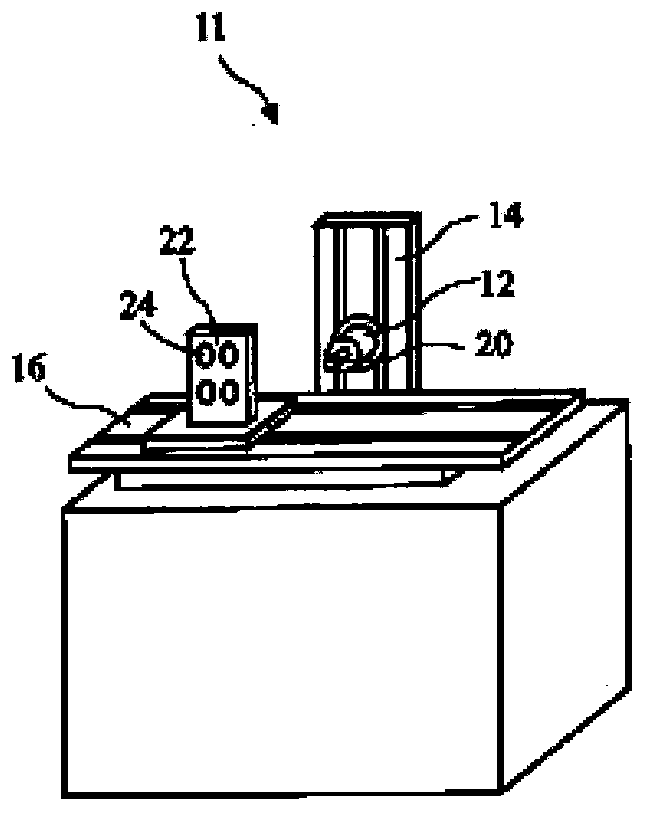

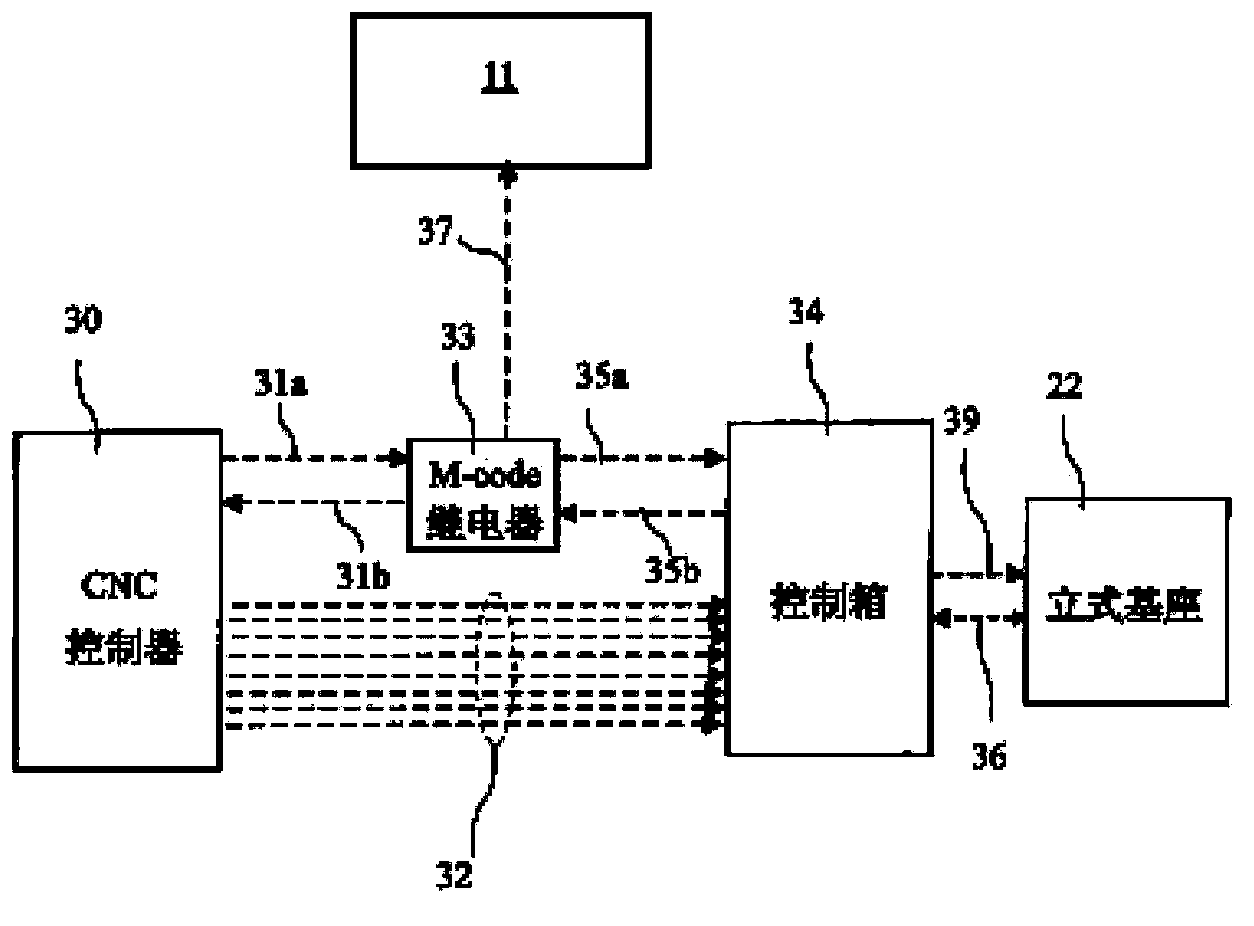

CNC controlled rotating work piece holding fixtures for a horizontal mill

ActiveUS8977381B1Low gear ratioLower ratioMilling machinesLarge fixed membersMultiplexingEngineering

A CNC controlled rotating workpiece holding fixture is attached to a tombstone of a horizontal mill. The rotating workpiece holding fixture(s) allows workpieces to be independently rotated to allow milling of various surface of the workpiece thereby providing a five axis CNC capability. As many as eight rotating workpiece holding fixtures may be attached to a single tombstone. Each rotating workpiece holding fixture may be formed by a harmonic drive driven by a servo motor which provides a compact configuration and a very low gear ratio in the harmonic drive combined with the inherent braking of the servo motor provides stability. The rotating workpiece holding fixtures may be controlled using existing auxiliary outputs (e.g., M-Codes), present in CNC milling machines. The M-Codes are preferably created by an operator, multiplexed, sent to the tombstone, de-multiplexed, and used to control each rotating workpiece holding fixture.

Owner:MEZZASALMA JEROME +1

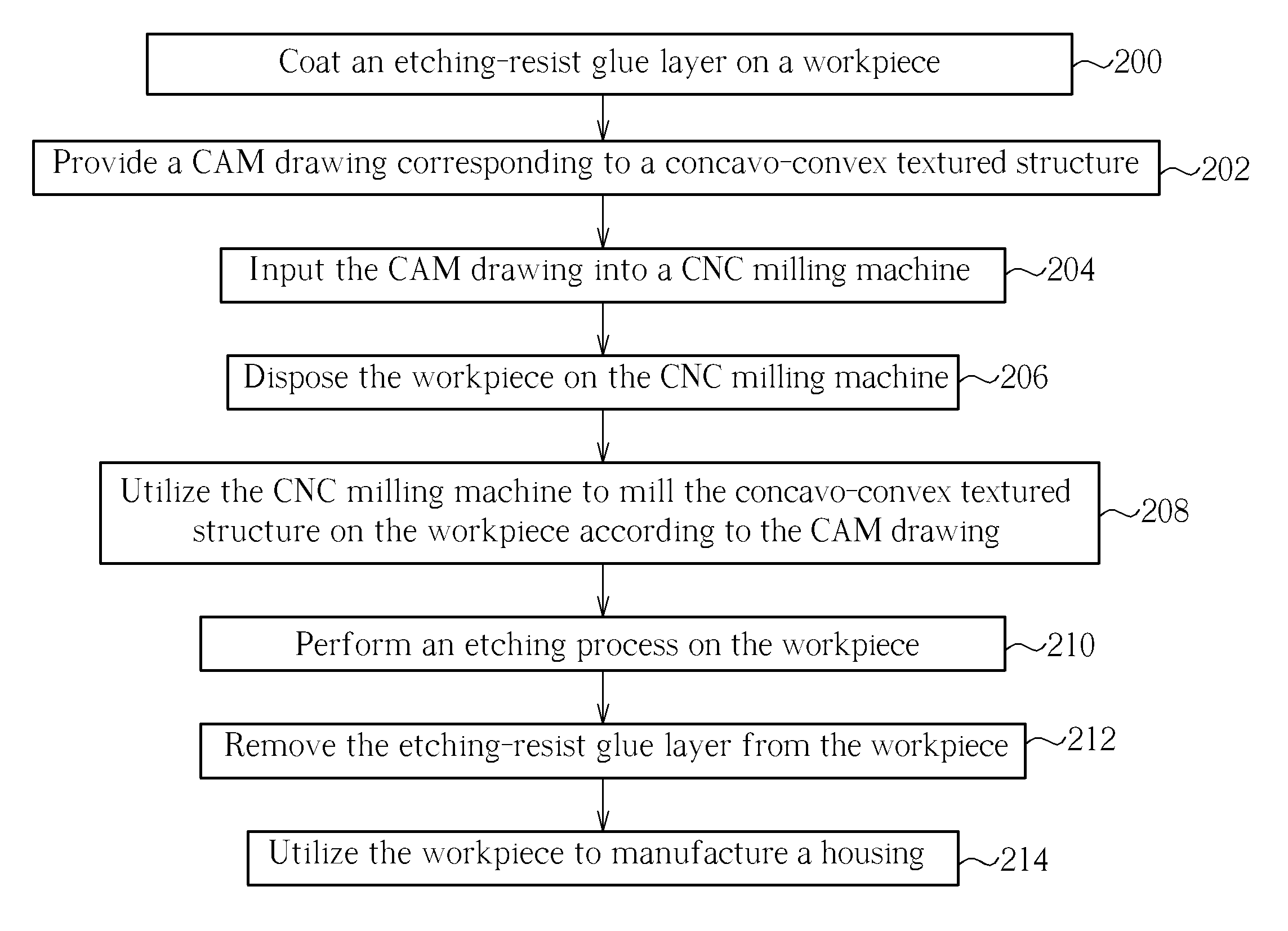

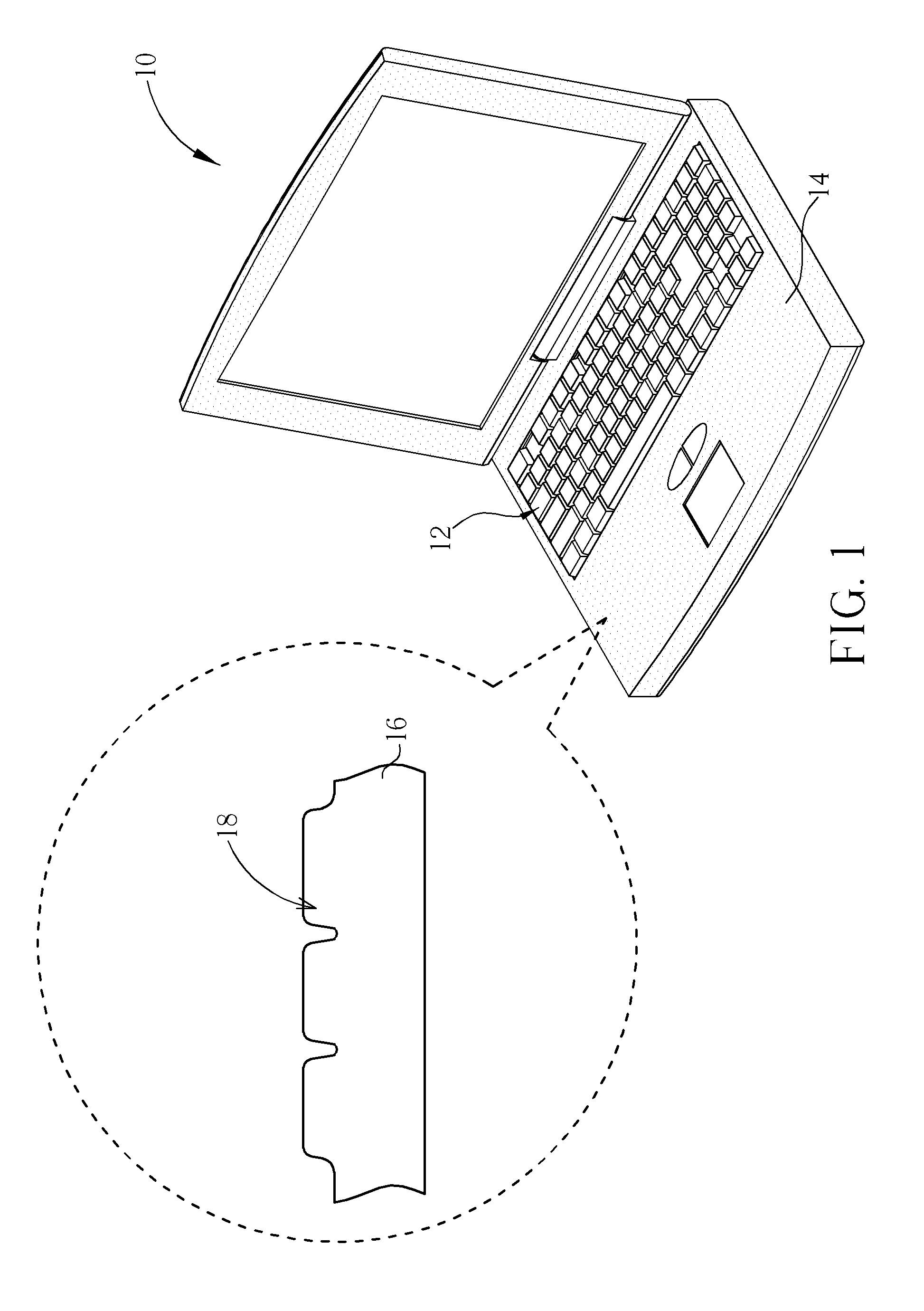

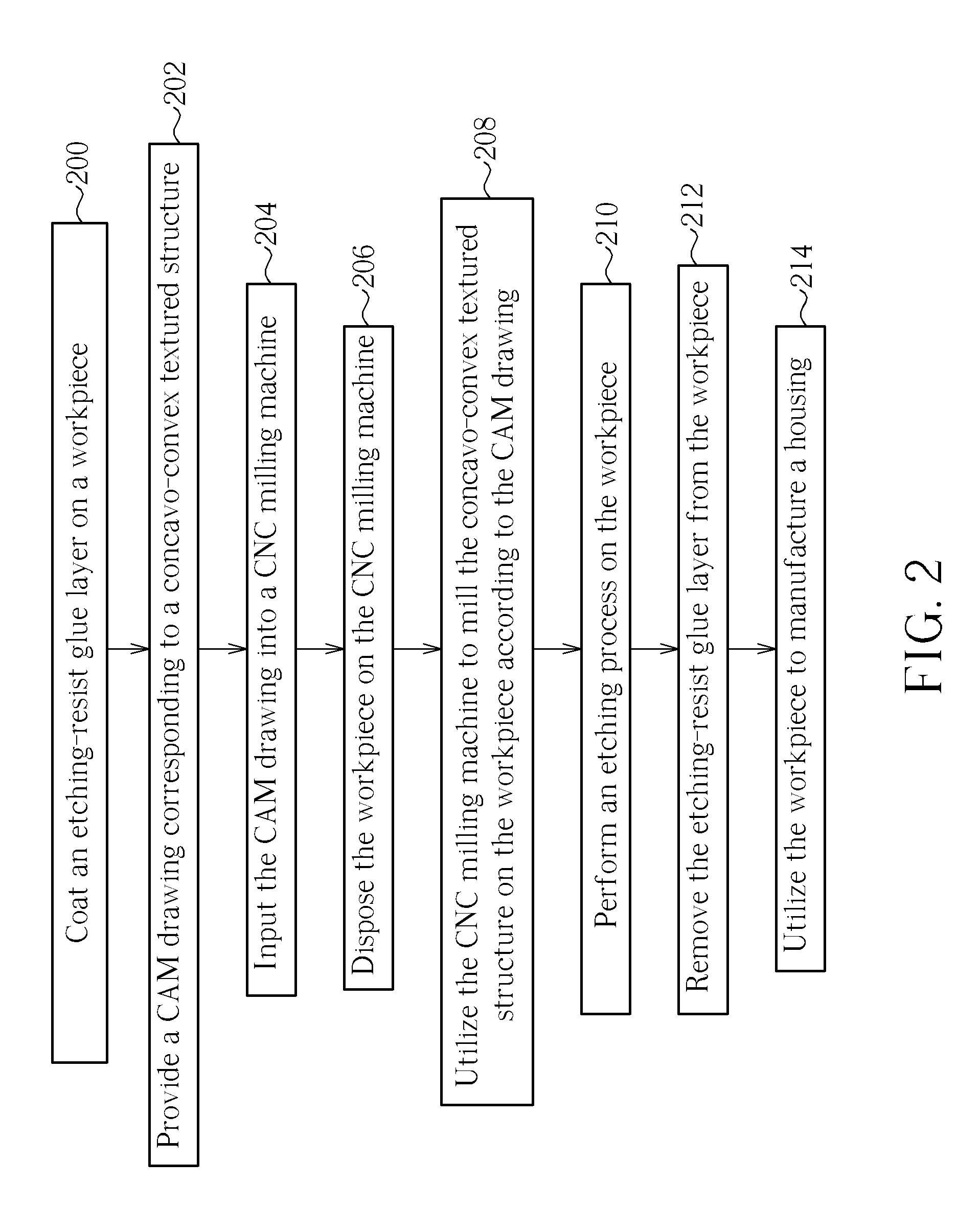

Method for forming a concavo-convex textured structure on a housing of an electronic device and related structure

A method is used for forming a concavo-convex textured structure on a housing of an electronic device. The method includes providing a CAM (Computer-Aided Manufacturing) drawing corresponding to the concavo-convex textured structure, inputting the CAM drawing into a CNC (Computer Numerical Control) milling machine, disposing a workpiece on the CNC milling machine, and utilizing the CNC milling machine to mill the concavo-convex textured structure on the workpiece according to the CAM drawing, and utilizing the workpiece to manufacture the housing of the electronic device.

Owner:WISTRON CORP

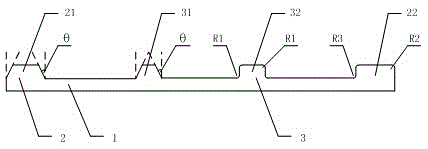

Processing method of specially-shaped thick and thin Clip parts

The invention relates to a processing method of specially-shaped thick and thin Clip parts. The processing method of the special-thickness Clip part comprises the following steps: S1, preparing plates; S2, punching for a first time; S3, carrying out precise CNC; and S4, punching for a second time. The invention adopts a novel processing and manufacturing process, wherein the novel processing and manufacturing process comprises the steps of punching specially-shaped plates, subsequently carrying out precise CNC milling machine processing for a first time, then punching for a second time. The specially-shaped calendaring technique is used in the punching process, so that a bulge part of a Clip part and a substrate part form an integrated structure; the problem of incomplete lamination is avoided, so that the influence on the design function of the product can be avoided. In addition, all the processing techniques in the processing method of specially-shaped thick and thin Clip parts are controllable processes which are widely used in the prior art, so that the size of the product and the stability of various process parameters can be effectively ensured; the manufactured product can meet various design requirements; meanwhile, the yield of the processed product can also be greatly improved; the production cost of the processing enterprise can be reduced.

Owner:SUZHOU UIGREEN MICRO & NANO TECH CO LTD

One piece shower pan and method of making same

A one piece shower drain pan, encapsulated in a water proof membrane, and the method of fabricating the one piece open drain shower pan, the method which includes providing extruded polystyrene (XPS) foam of the type which absorbs very little water; shaping the section of extruded polystyrene foam with a CNC router to obtain the desired slope in the floor; cutting a hole in the foam to produce the drain hole; cutting a curb from the XPS foam and gluing the foam to a pan base on the open sides. Splash walls are then cut from concrete wall board and glued to the sides having no curb, so that the glue serves as a bonding agent and provides a waterproof seal between the parts; after the glue has cured, spraying the entire pan assembly with a polyurethane or polyurea coating to completely encapsulate the entire pan with a waterproof membrane, which provides strength and rigidity and defines a one piece drain pan ready for installation.

Owner:TILE REDI

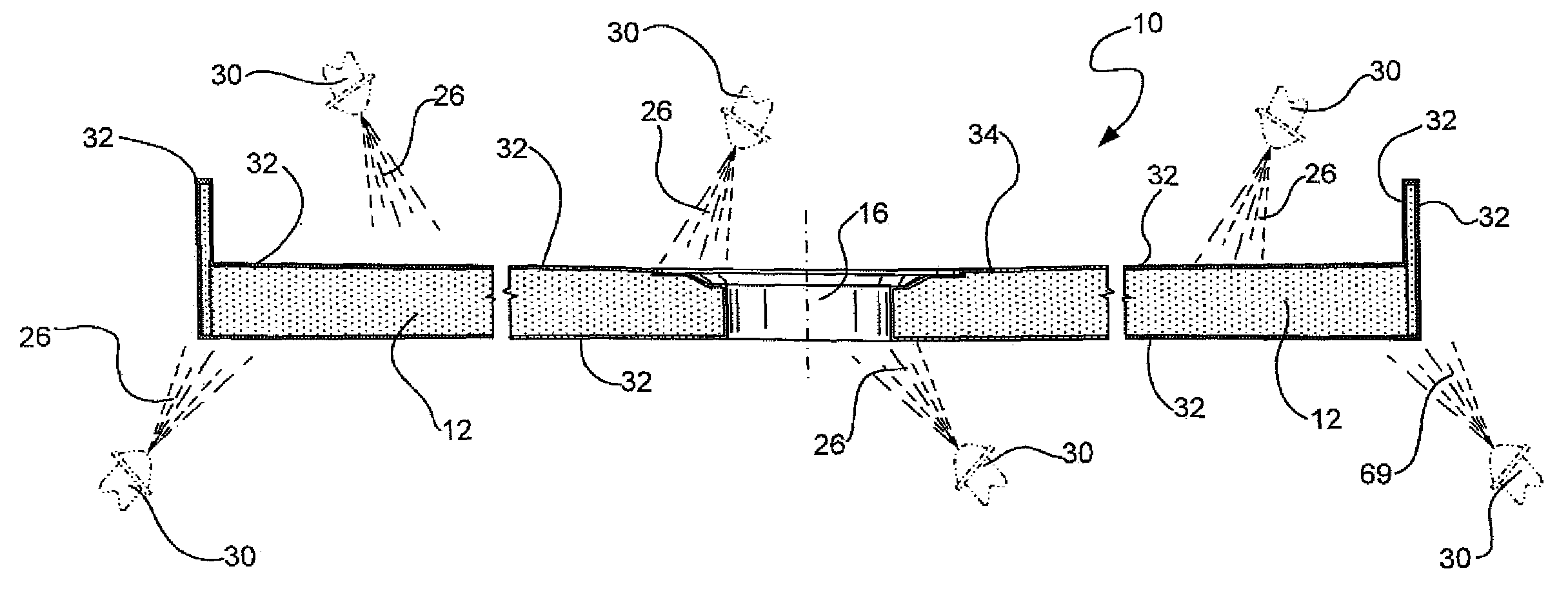

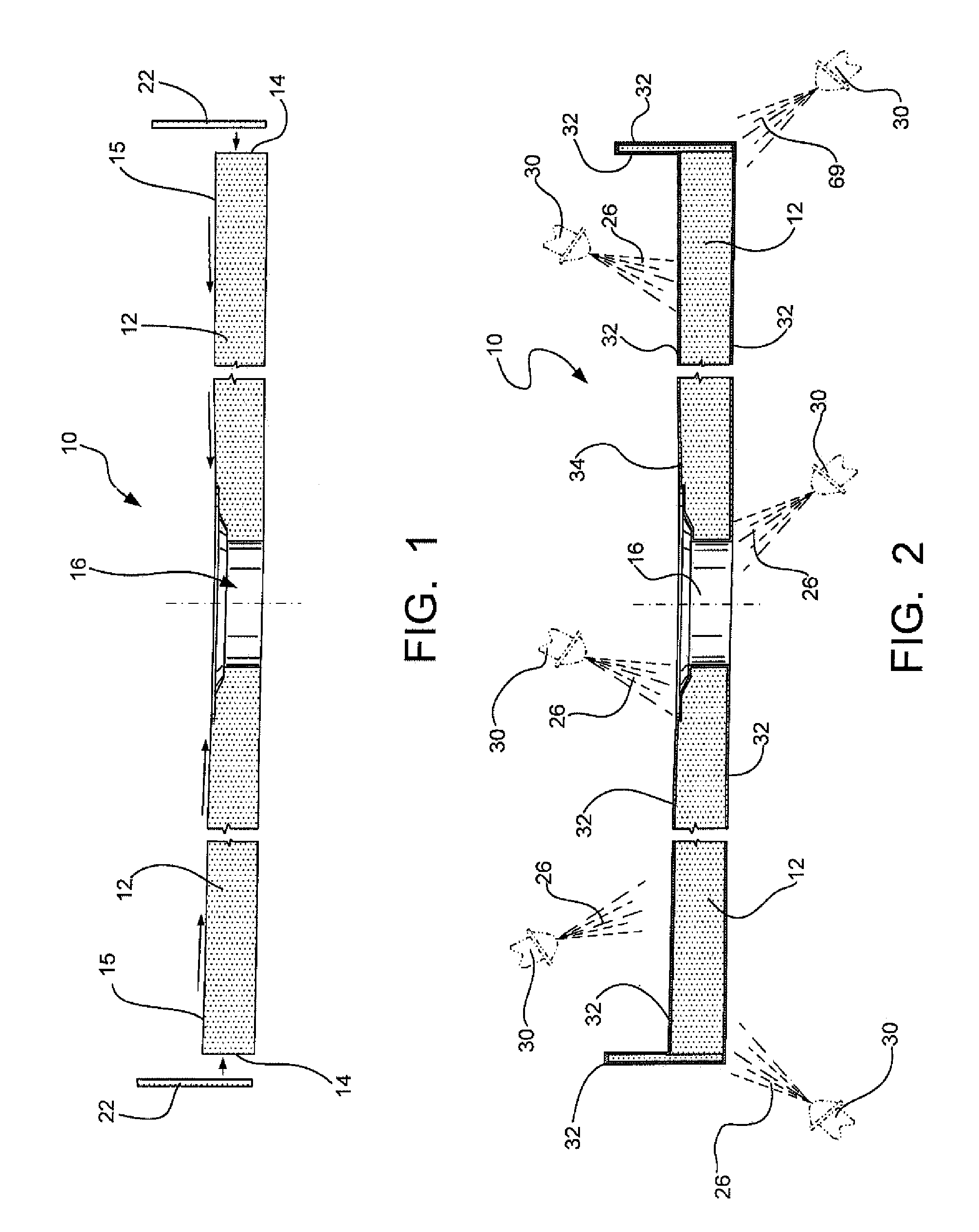

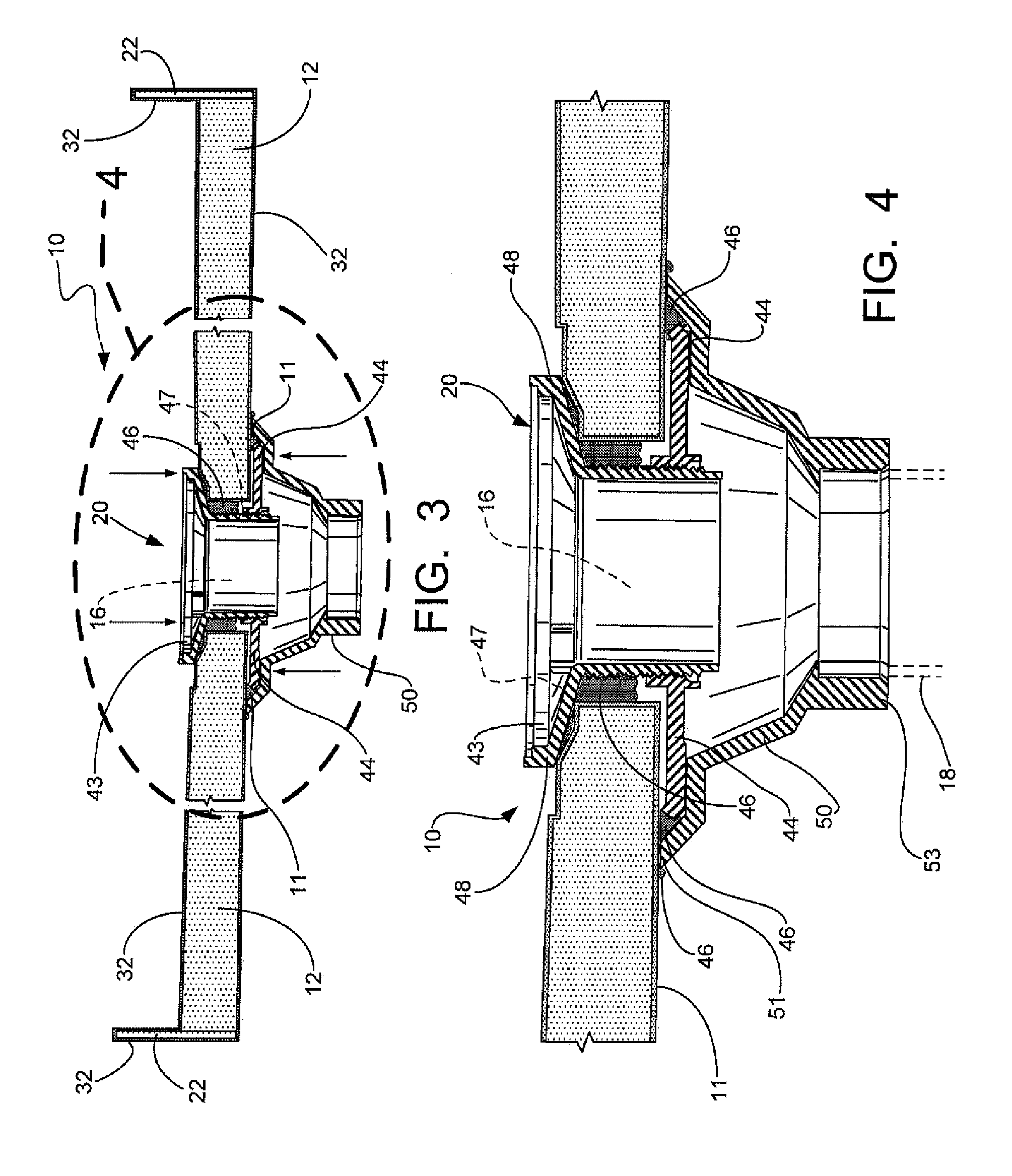

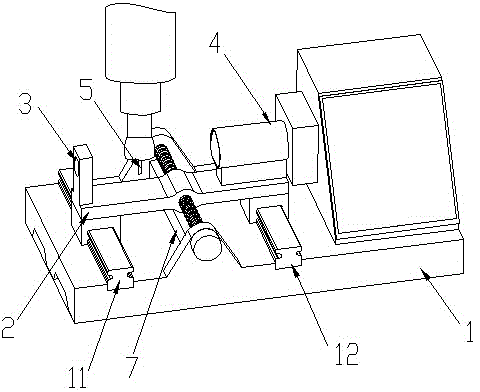

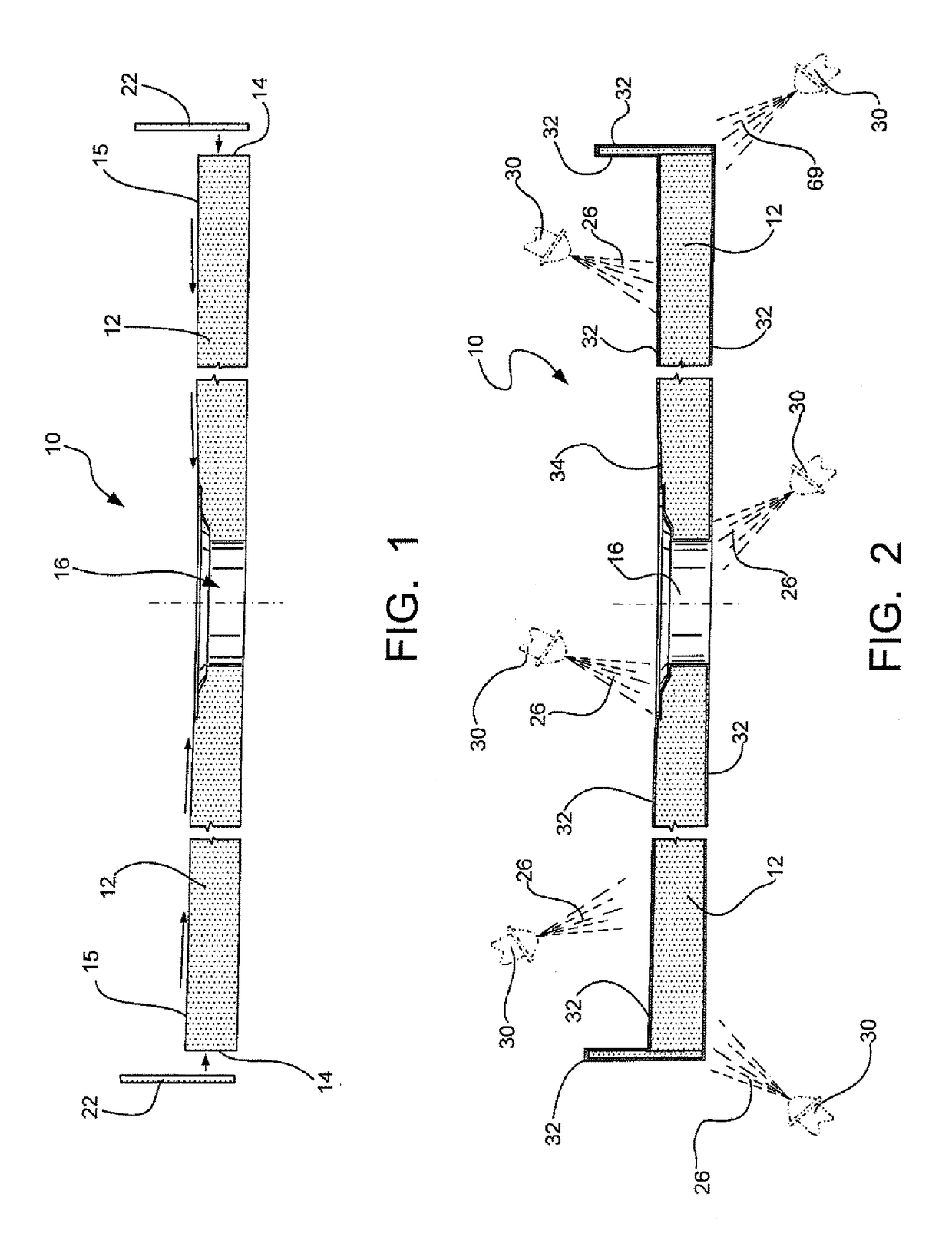

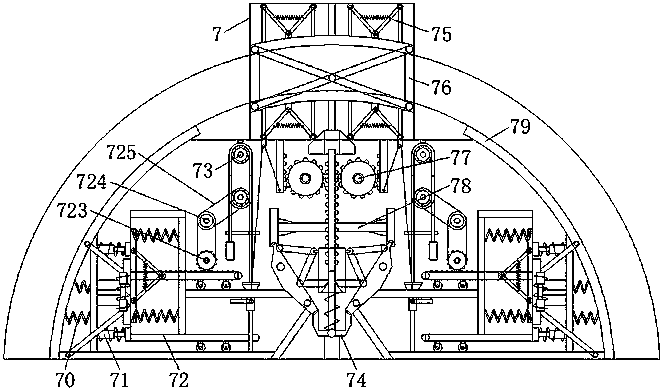

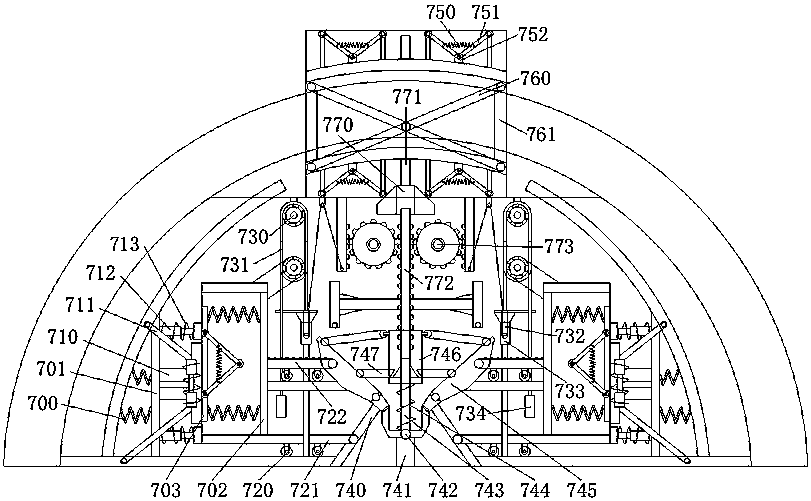

Multi-degree-of-freedom micro lubricating intelligent spray head system for CNC milling machine

ActiveCN108555685AReal-time acquisitionSolve wastePrecision positioning equipmentMovable spraying apparatusRotary stageLiquid ratio

The invention discloses a multi-degree-of-freedom micro lubricating intelligent spray head system for CNC milling machine. The multi-degree-of-freedom micro lubricating intelligent spray head system comprises a ring-shaped rotary table, a longitudinal telescopic part, a rotary part, an intelligent spray head mounting table and an information acquisition system, wherein the ring-shaped rotary tablecomprises a rotary part which rotates in the horizontal peripheral direction; the bottom of the rotary part is connected with at least one longitudinal telescopic part; the lower end of the longitudinal telescopic part is connected with the rotary part; the rotary part takes a connecting point of the longitudinal telescopic part as a shaft center, and rotates within a set angle range; the intelligent spray head is connected with the rotary part and moves along with the rotary part; and the information acquisition system is mounted on the intelligent spray head mounting table. The angle of thespray head is reasonably regulated through processing data, and a gas-liquid ratio is reasonably set, so that a processed workpiece is sprayed by the spray head with a reasonable angle, the defect that a conventional cutting fluid spray head is fixed and is limited in spraying angle is solved, and the problem that a cutting surface has a dead corner and cutting fluid is wasted is solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Portable rail system for mounting an engraving device

A portable rail system for mounting an engraving device includes rails and crossbar members that are precisely joined, and include height adjustment devices for incrementally adjusting the height of the rail system relative to a work surface or contact surface, thus making the portable rail system capable of being assembled and disassembled at a work site to enable the use of an engraving device, such as a CNC router engraving systems, in situ, or on-site, rather than in a workshop. The portable rail system enables the use of a CNC router device or other engraving device on vertical surfaces.

Owner:REDART TECH LLC

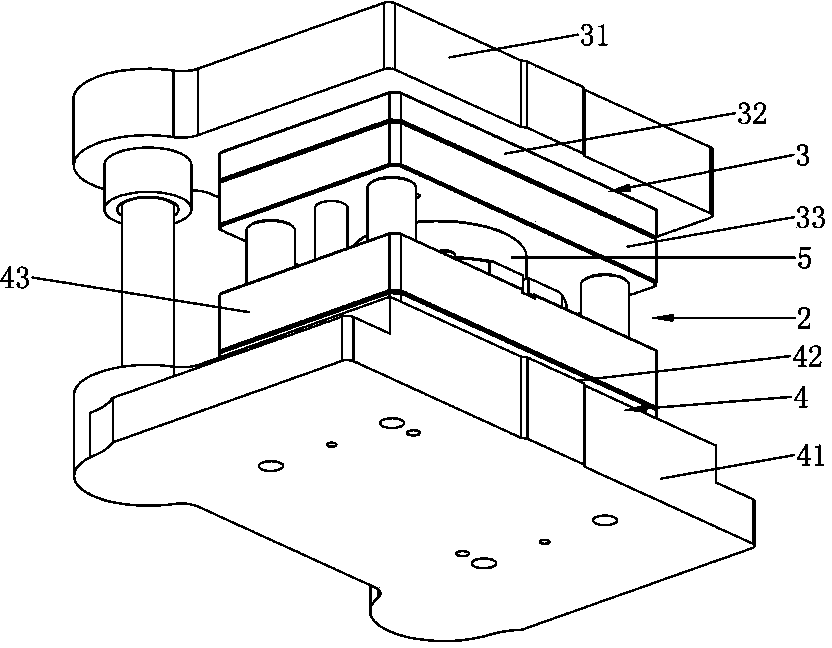

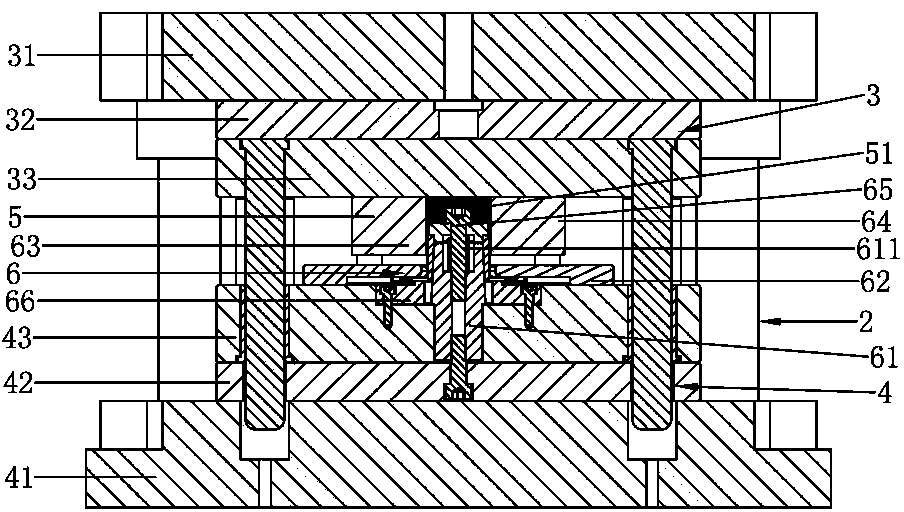

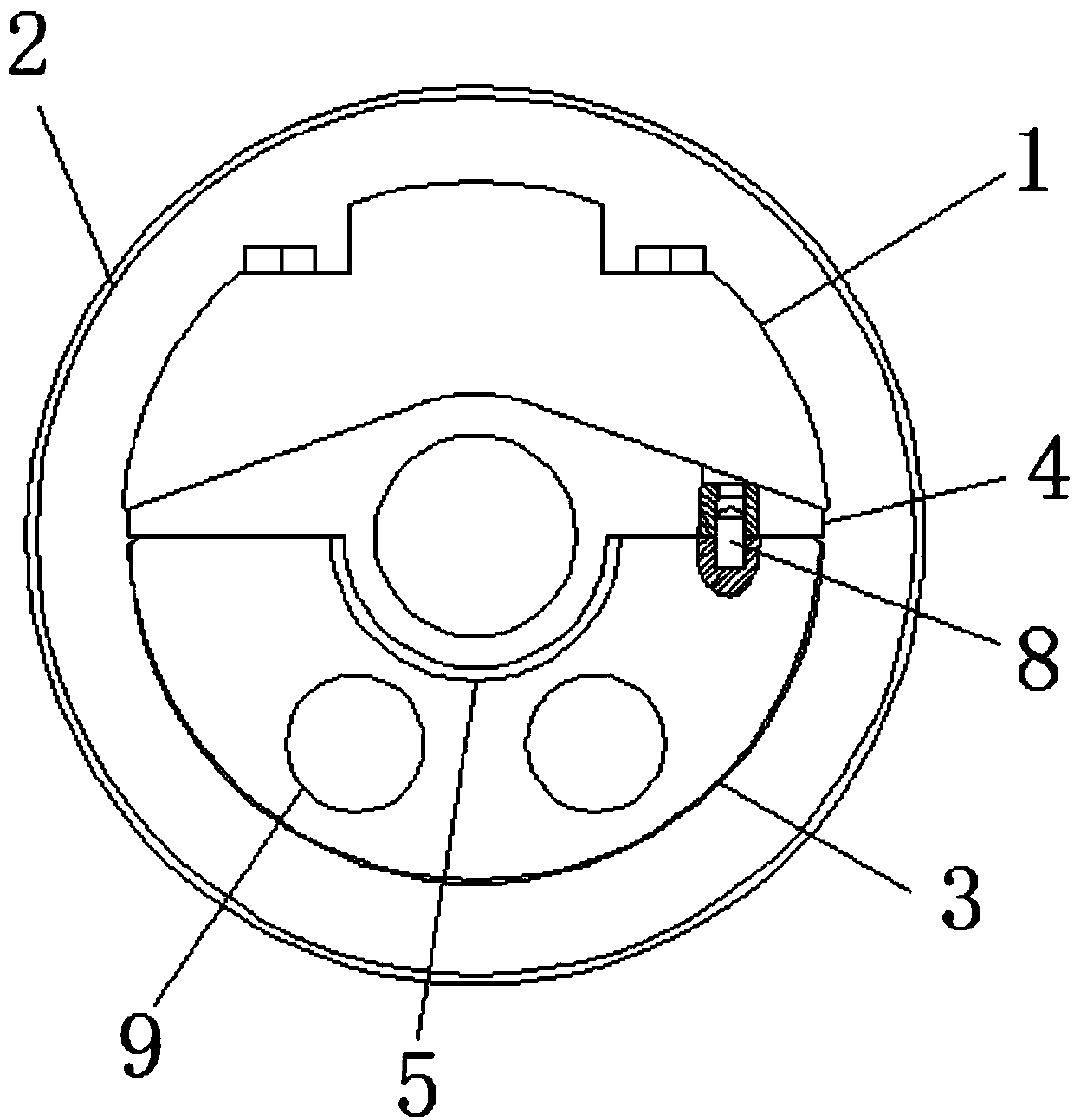

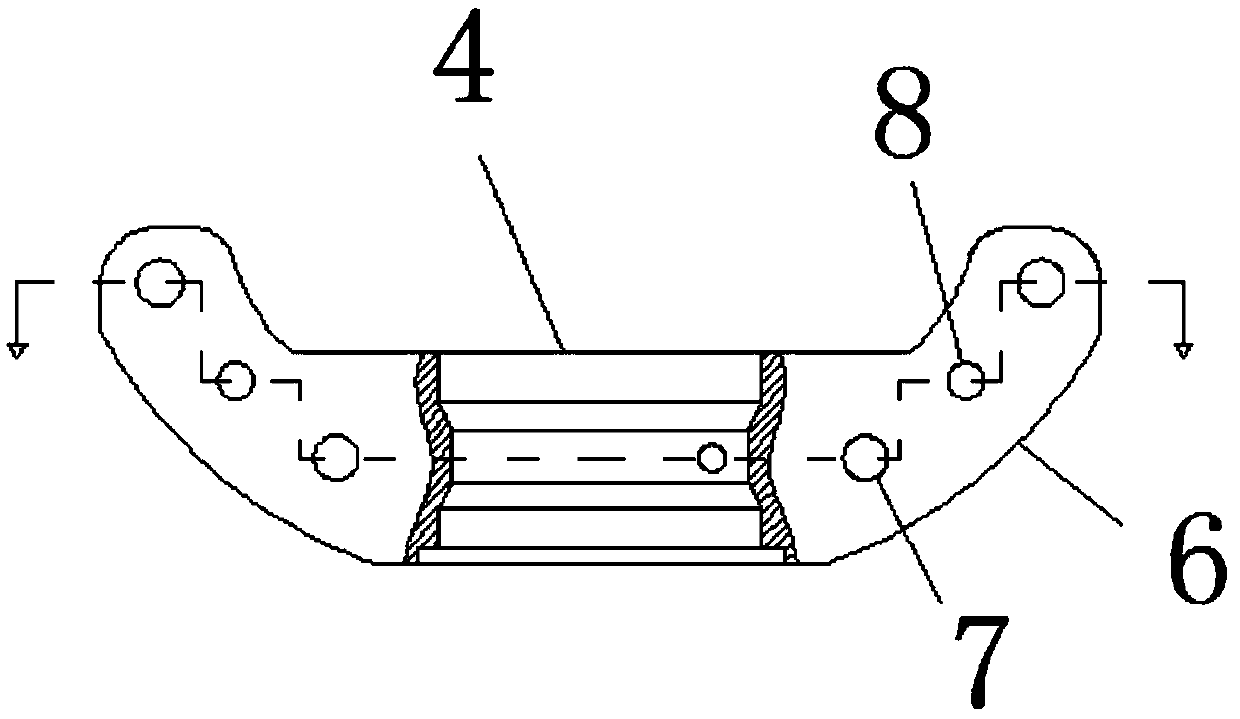

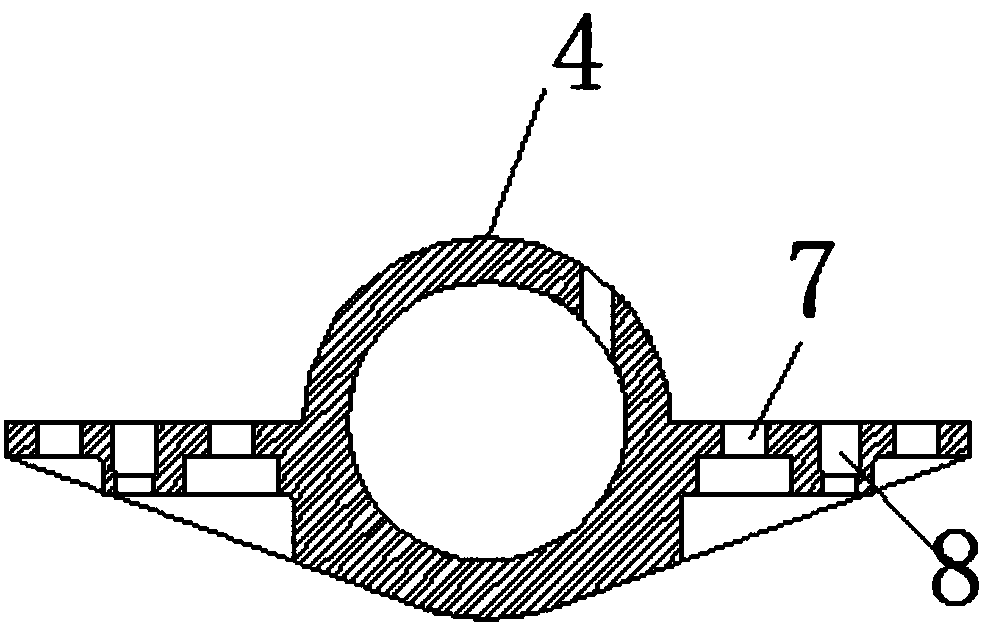

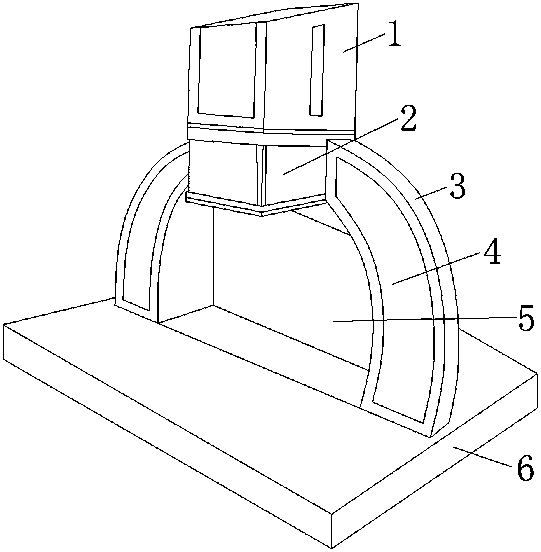

CNC (computer numerical control) rotating workpiece fixing and clamping device used for horizontal milling machine

ActiveCN103894877AOverall small sizeTransmission ratio is smallProgramme controlAutomatic control devicesNumerical controlEngineering

The invention relates to a CNC (computer numerical control) rotating workpiece fixing and clamping device used for a horizontal milling machine. The CNC rotating workpiece fixing and clamping device is arranged on a vertical base of the horizontal milling machine and can enable multiple workpieces to independently rotate respectively, and each surface of each workpiece can be cut, so that five-shaft CNC processing performance can be realized by the horizontal milling machine. Eight rotating workpiece fixing and clamping devices can be arranged on a single vertical base. Each rotating workpiece fixing and clamping device can be formed by a harmonic speed reducer driven by a servo motor, thereby being ingenious in structure, and an extremely-low transmission ratio can be provided in the harmonic speed reducer by combining special braking performance of the servo motor, so that stability can be realized. The rotating workpiece fixing and clamping device can be controlled by an existing auxiliary output device (namely M-Code) arranged in the CNC milling machine. Preferably, the M-Code is used for controlling each rotating workpiece fixing and clamping device after being set by an operator, multiplexed, transmitted to the vertical base and de-multiplexed.

Owner:梅札萨尔马·杰罗姆 +1

Machining process of special-shaped bearing

InactiveCN109531285AAccurate positioning accuracyImprove machining accuracyOther manufacturing equipments/toolsUltra fineEngineering

The invention relates to the technical field of special-shaped bearing machining processes, and discloses a machining process of a special-shaped bearing. The machining process comprises the followingsteps that a bar is blanked, and blanking operation is carried out on the bar by adopting a sawing machine; forging is performed, and a hot forging mode is adopted; spheroidizing annealing is carriedout; datum plane machining, bearing inner ring machining and outer ring rough machining are carried out, a CNC milling machine machining reference plane is adopted, and an inner ring and an outer ring of the bearing are subjected to rough machining; a datum hole is machined, and linear cutting is adopted to machine a datum hole; the reference surface is finely ground, a grinding machine is adopted, the datum plane is subjected to finish machining, and meanwhile burrs at the hole opening of the datum hole are ground; finish machining is carried out on the inner ring of the bearing, the reference plane and the datum hole are taken as the positioning reference, ultra-fine grinding are carried out on the channel, the inner diameter and the slope surface of the bearing inner ring by a lathe; and the outer ring of the bearing is machined, the outer ring of the bearing is subjected to ultra-fine grinding machining by taking the inner diameter and the reference surface of the bearing as a machining reference, and the lathe is adopted for carrying out ultra-fine grinding on the outer ring of the bearing. The machining process of the special-shaped bearing has the advantages of being accurate in positioning accuracy and high in product machining precision.

Owner:GUIZHOU TIANMA HONGSHAN BEARING CO LTD

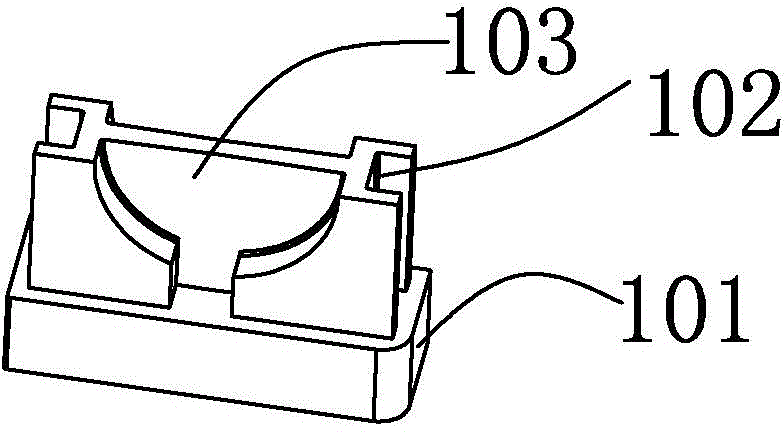

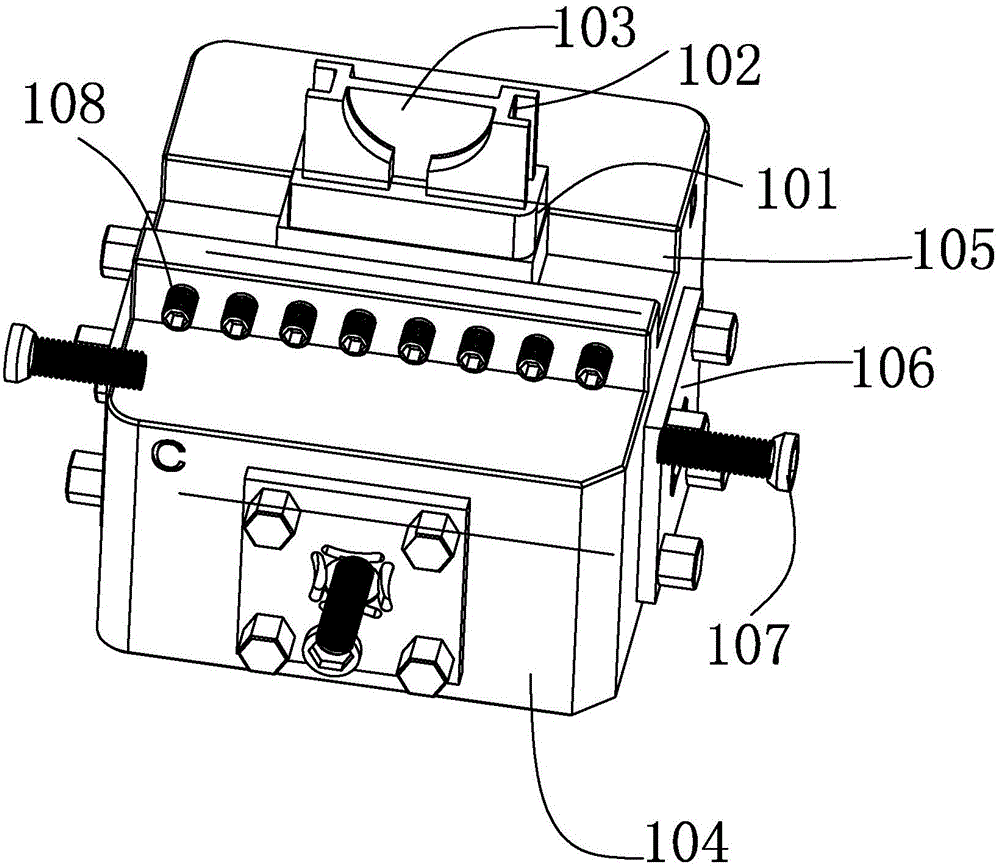

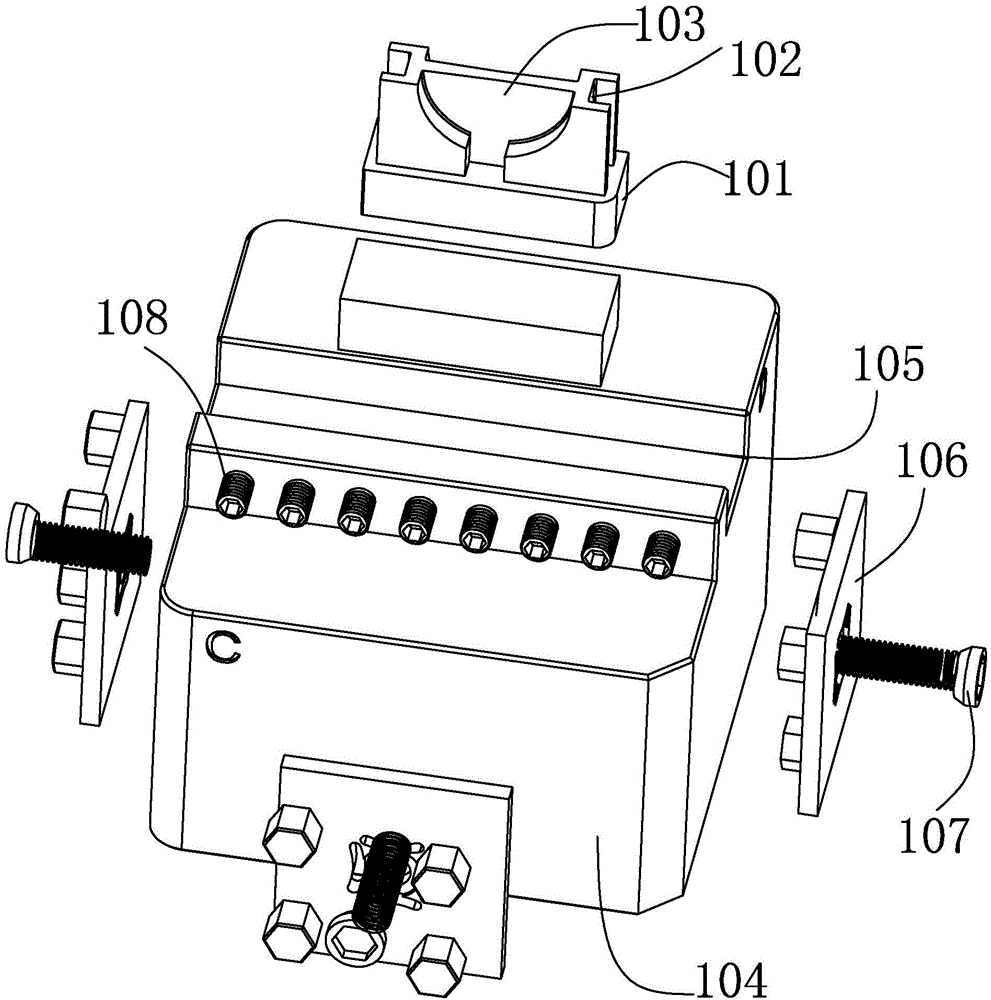

Fixture structure

ActiveCN105081837AReduce processing costsSave on-site meter calibration timePositioning apparatusMetal-working holdersSet screwWire cutting

The invention discloses a fixture structure, which is used for clamping a stepped workpiece having a rectangular groove or a semicircular groove. The fixture structure is arranged on a CNC milling machine, and comprises a base, washers and set screws, wherein the base is provided with a top surface, a bottom surface, a left side surface, a right side surface, a front surface and a back surface, the top surface is provided with a workpiece groove, and a workpiece is clamped in the workpiece groove; the washers are respectively arranged at the bottom surface, the left side surface, the right side surface, the front surface and the back surface; certain ends of the set screws are fixed onto the washers, and the other ends of the set screws are free ends. By adoption of the structure, the stepped workpiece having the rectangular groove or the semicircular groove can be obtained through the CNC milling machine. Hence, through the steps, the meter calibration time in the field can be saved, and the processing efficiency is high; a wire cutting processing is not needed, so that the processing cost is low; a special chamfering tool is not needed, so the processing cost brought by the tool is reduced.

Owner:SUZHOU MITAC PRECISION TECH

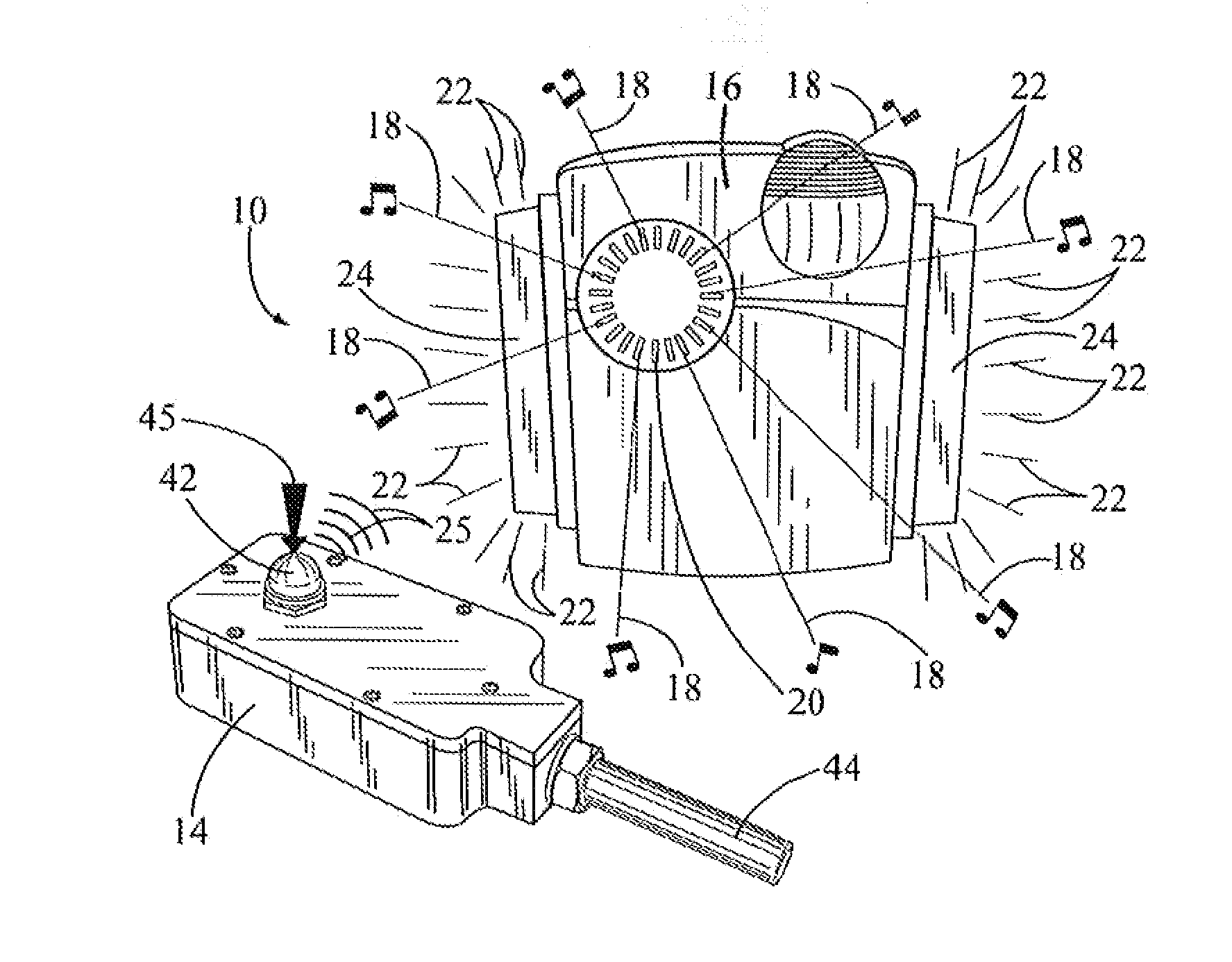

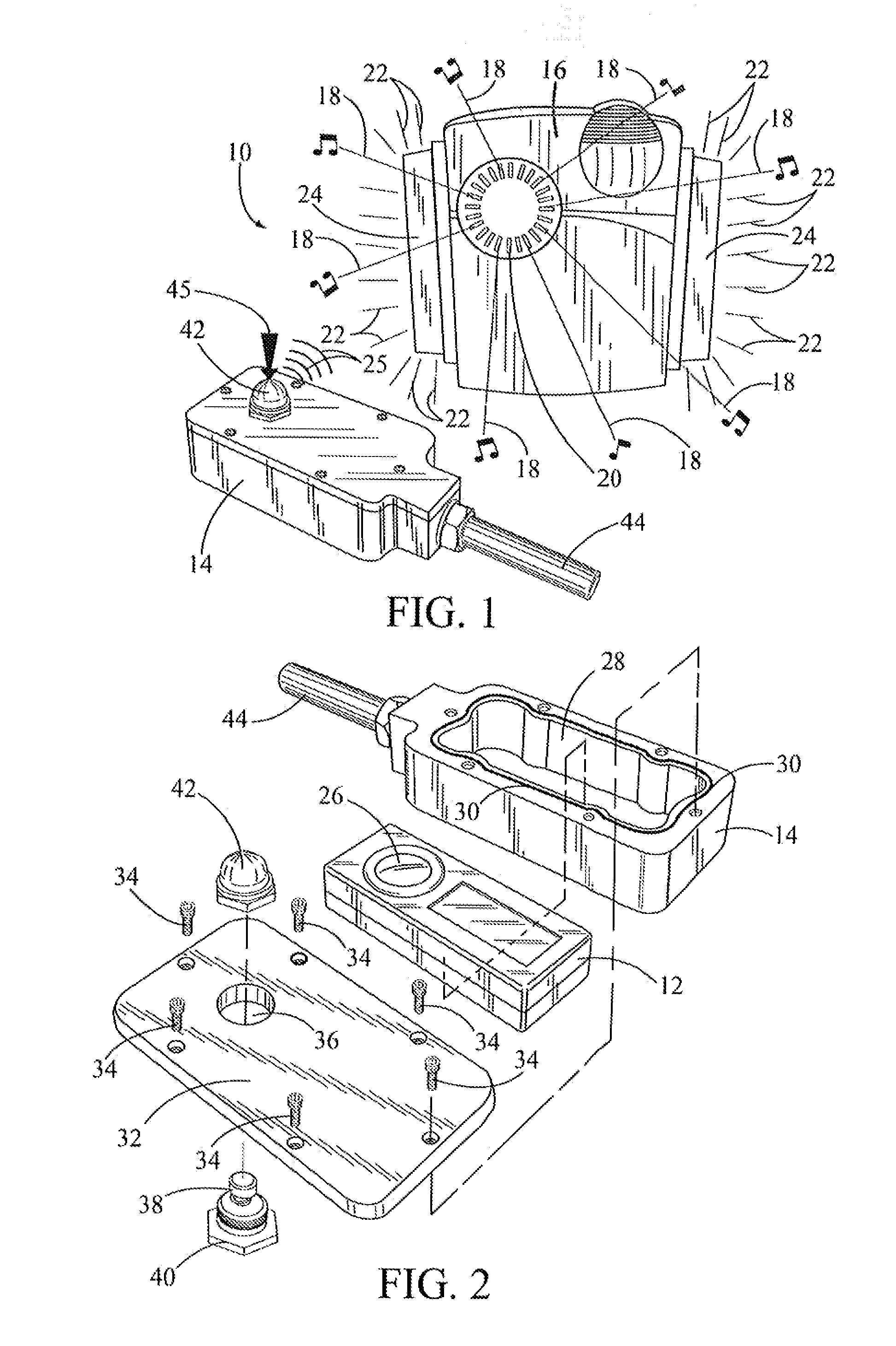

Portable Alarm System for CNC Milling Machine

InactiveUS20150158135A1Easy to useGreat work piece productivityMachine tool componentsTool changing apparatusWork cycleRadio frequency signal

An alarm system including a battery powered transmitter received in a watertight housing. The housing includes an outwardly extending shank. The shank is adapted for receipt in a tool holder stored in tool change magazine. The magazine is mounted inside a high speed CNC milling machine. When the milling machine completes a work cycle on a work piece, it is programmed to activate an automatic tool changer that retrieves the tool holder with transmitter from the magazine and attaches them to a tool spindle. The movement of the machine is then used to activate a radio signal button on the transmitter and send a radio frequency signal to a battery powered receiver disposed outside the milling machine. The receiver than activates an alarm. The operator is then alerted that the milling machine has stopped operating and needs to be attended.

Owner:RYAN THOMAS F

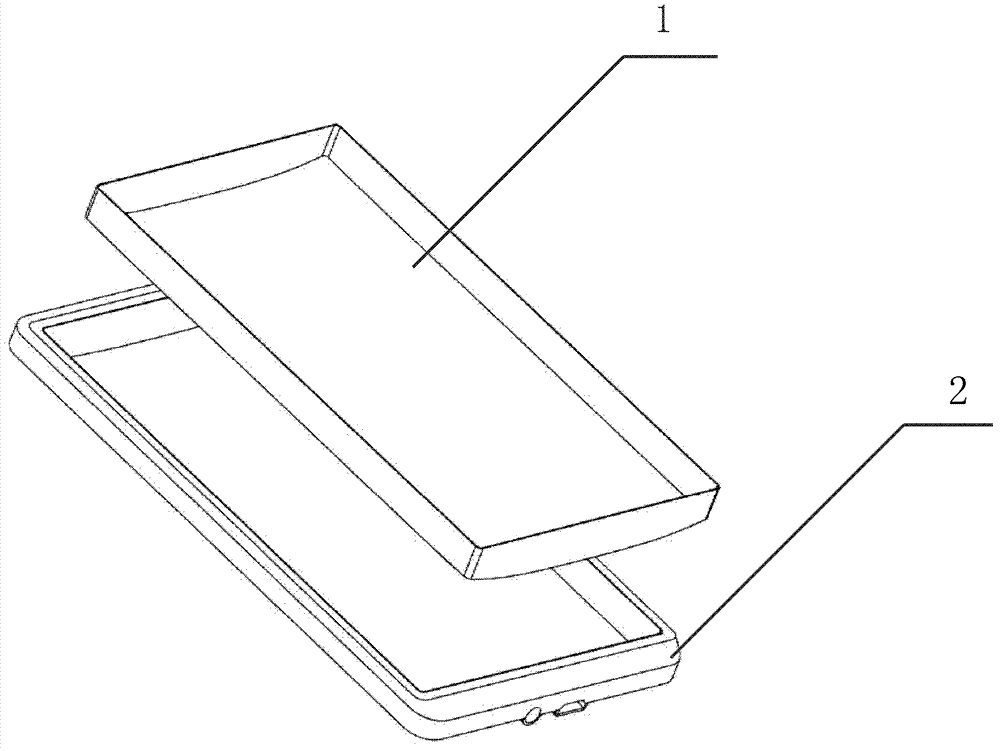

Bamboo cellphone shell with integral body

InactiveCN103369072AGuaranteed CorrosionGuaranteed firmnessTelephone set constructionsEngineeringGraphite

Disclosed is a bamboo cellphone shell which is characterized in that: (1) the whole cellphone shell adopts a whole piece of bamboo, which undergoes a special processing, as a production raw material; (2) after one face of the bamboo, as a display screen of the cellphone, is sculptured, internal electronic parts which use a CNC router can be placed; (3) the external-layer bamboo cellphone shell is fused with a plastic base plate with a hard bottom so that flintiness and abradability of the whole shell body are ensured; (4) when other five outer-layer faces of the cellphone are sculptured, the CNC router can be used; and (5) adding a waterproof adhesive film on surfaces of the whole bamboo shell to make sure that an internal part of the cellphone is not corroded when subjected to moisture. A short growth cycle of the bamboo further ensures an adequate supply of the raw material and the bamboo can be decomposed by organisms completed and recycled; the bamboo has higher malleability than metals and higher compressibility than coagulations and higher signal receiving ratio than graphite; cellphone made of the bamboo is more ornamental and signal sending and receiving of the cellphone are not affected; and combination with the hard plastic base plate ensures a best strength of the cellphone.

Owner:上海的沃网络科技有限公司 +2

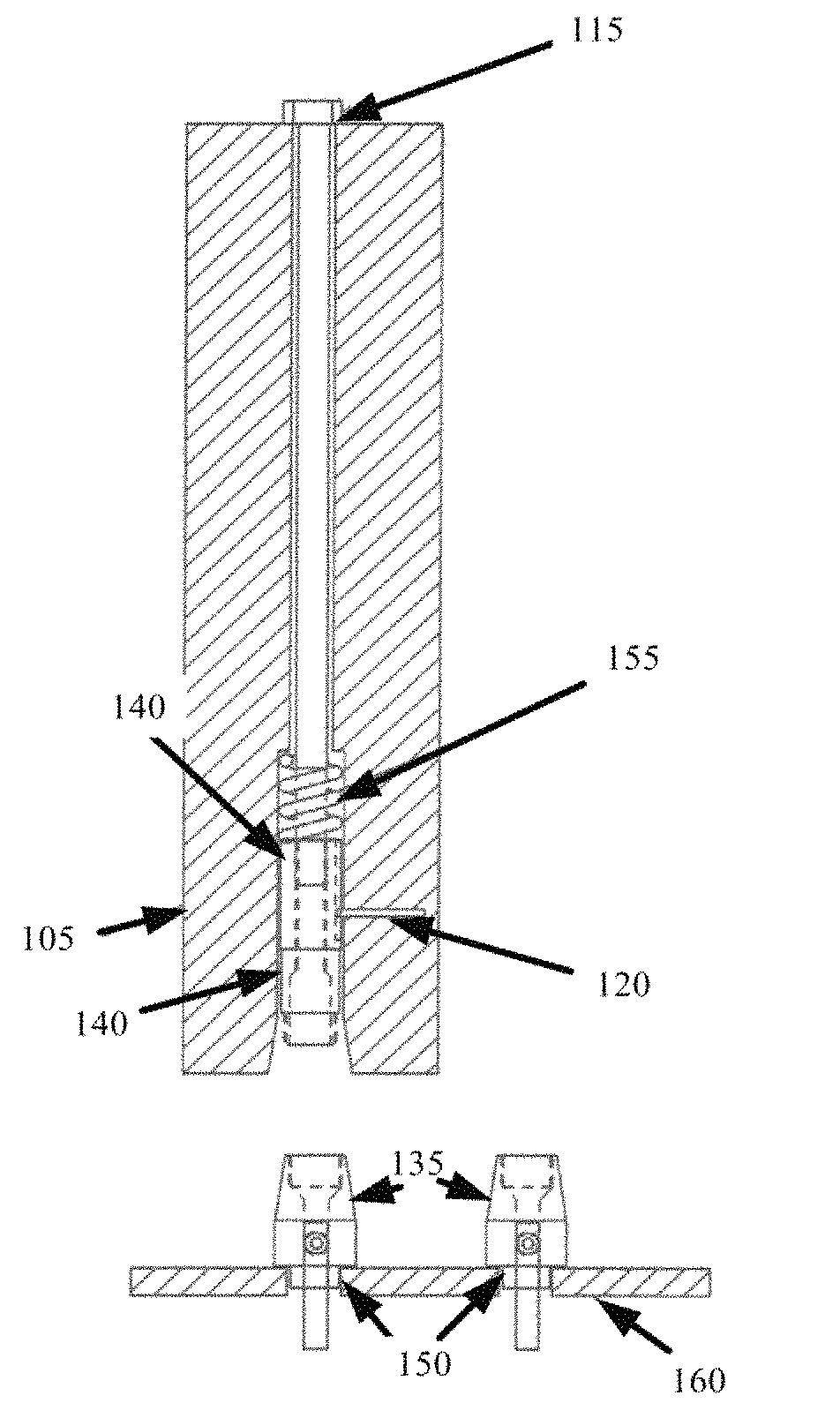

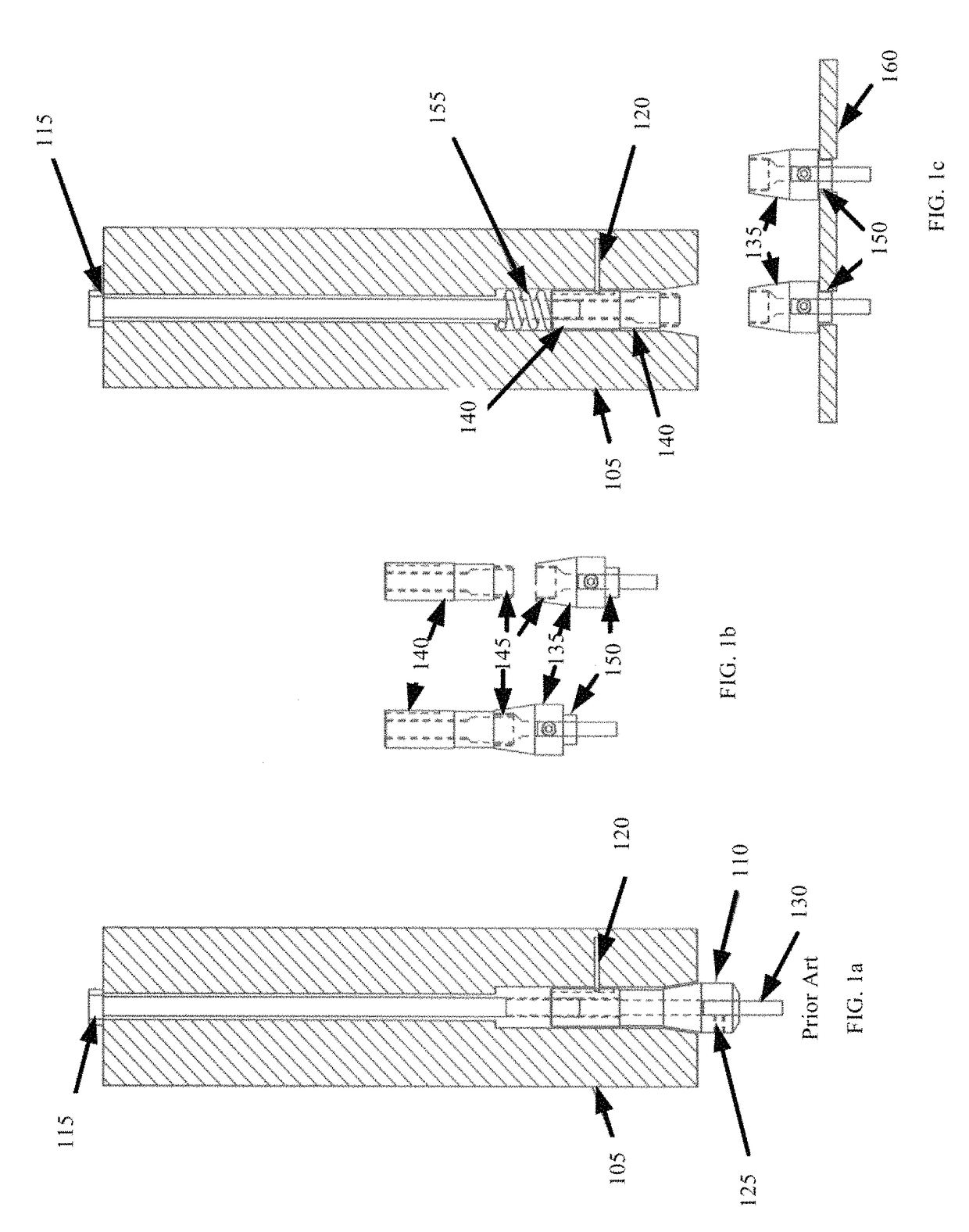

Apparatus and a system for automatic tool change by threading engagement for a CNC milling machine

An apparatus and a system comprise a collet comprising a top portion and a bottom portion. The top portion comprises a threading means. The bottom portion at least comprises means for holding the collet from rotating and means for retaining an end mill. A master comprises a top portion and a bottom portion. The top portion is configured for engagement with a spindle of a milling machine. The bottom portion comprises a threading means for engagement with the threading means of the collet, wherein the master is retained by the spindle and the collet engages and disengages the master by rotation of the spindle. The milling machine operates under computer control during engagement and disengagement of the collet from the master.

Owner:URIARTE JORGE

Clamping fixture

InactiveCN103042405AStable clampingAvoid compromising stabilityPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a clamping fixture which comprises a square seat. The clamping fixture is characterized by further comprising a fixed clamping jaw and a horizontal movable clamping jaw, the fixed clamping jaw and a slide are arranged on the square seat, the bottom of the horizontal movable clamping jaw is inserted into the slide and can horizontally move along the slide, the fixed clamping jaw and the horizontal movable clamping jaw are positioned on the same straight line, and bayonets of the fixed clamping jaw and the horizontal movable clamping jaw are opposite. The clamping fixture solves the problems that a three-jaw chuck in the prior art only clamps circular products, materials in other shapes need to be machined by a CNC (computerized numerical control) milling machine, a machining process is complicated, working efficiency is low, and time and money are wasted. The clamping fixture is simple in structure, convenient to use and capable of clamping products in optional shapes.

Owner:KUSN MAIZHI FIXTURE TECH

Portable cnc milling machine tool detector

ActiveCN104596422BEasy to handleRealize online detectionUsing optical meansNumerical controlEngineering

The invention relates to the field of detection equipment and discloses a portable detector of an CNC (Computer Numerical Control) milling machine cutter. The portable detector comprises a holder device, a cutter imaging system and an image analyzing system; the holder device can be installed nearby the milling machine cutter on the operating platform of the CNC milling machine and longitudinally moved; the cutter imaging system is installed on the holder device, horizontally moved and used for dynamically photographing images of the milling machine cutter; the image analyzing system is fixed to the holder device, connected with the cutter imaging system and used for converting the images of the milling machine cutter into parameters of the milling machine cutter. The detector is a small portable detector, images are formed by the cutter imaging system, and the images and parameters of the milling machine cutter are analyzed by the image analyzing system to achieve online detection and presetting of the milling machine cutter. The detector further comprises an offline detection cutter frame, and the holder device, the cutter imaging system and the image analyzing system are positioned on the offline detection cutter frame through an offline detection cutter frame simulation machine tool to achieve offline detection and cutter presetting.

Owner:深圳市眼之杰光电科技有限公司

Portable cutter detecting instrument for CNC milling machine

InactiveCN108581634ARealize buckle fasteningRealize local detectionMeasurement/indication equipmentsEngineeringCNC router

The invention discloses a portable cutter detecting instrument for a CNC milling machine. The portable cutter detecting instrument for the CNC milling machine structurally comprises a mounting head, adetecting instrument rotating head, a fixing covering frame, a detecting instrument body, a frame position, a base and a reinforcing device, wherein the fixing covering frame is vertical to the base;a slotted strip of the detecting instrument body is connected to a track of the base; the fixing covering frame is provided with the frame position and fits the detecting instrument body. According to the portable cutter detecting instrument for the CNC milling machine, a cutter upwards moves to drive transmission so as to realize rotating detecting, and thus whether the cutter is damaged can beuniversally detected; the cutter downwards moves to drive transmission to realize local detection, and thus a detection area can be reasonably matched, and the working quality can be accurately detected; an upward pushing transmission mechanism is subjected to X shape transmission and fixing during transmission, so that the overall transmission sensitivity and stability can be effectively improved; a first damping device, a second buffering device, a first fastening assisting mechanism and a second fastening assisting mechanism are provided, so that the damage rate of the detecting instrumentin fixing and separating can be minimized.

Owner:长沙熙迈机械制造有限公司

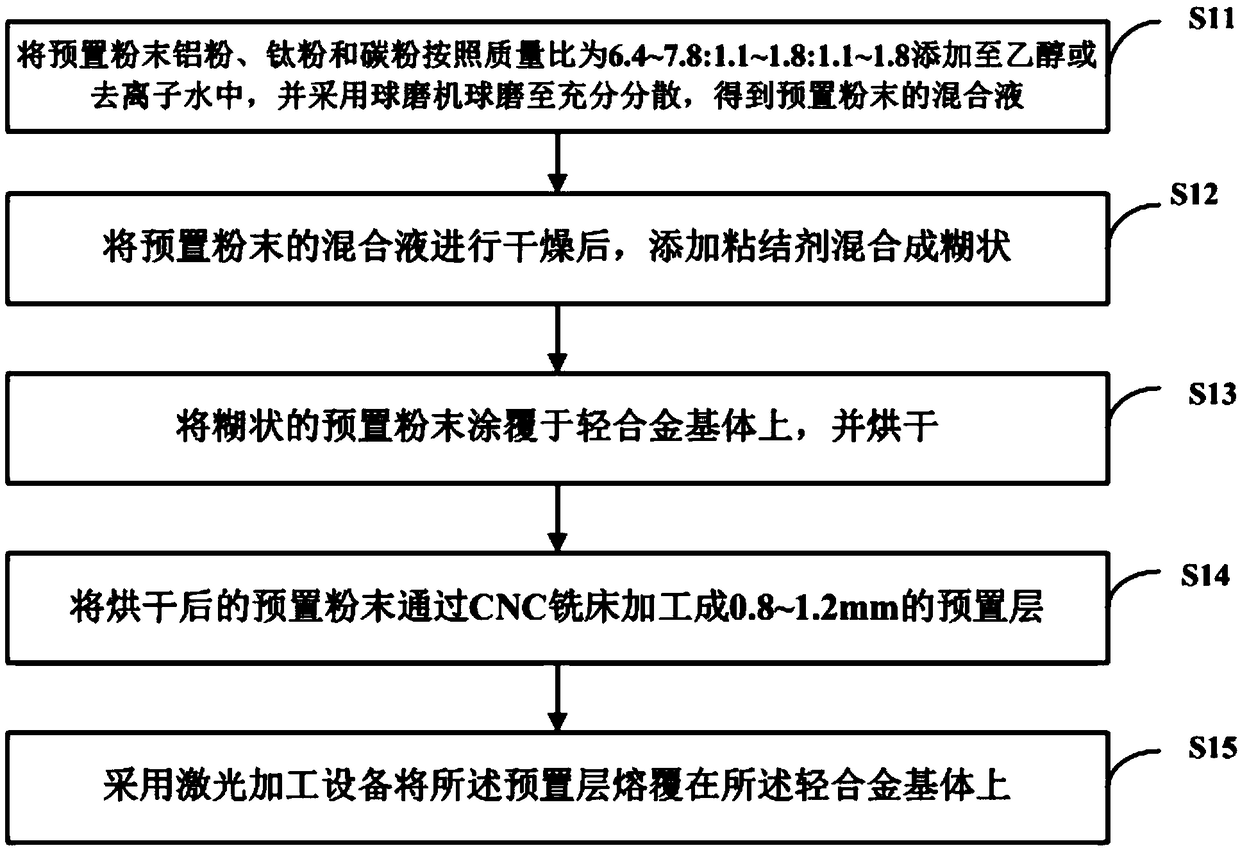

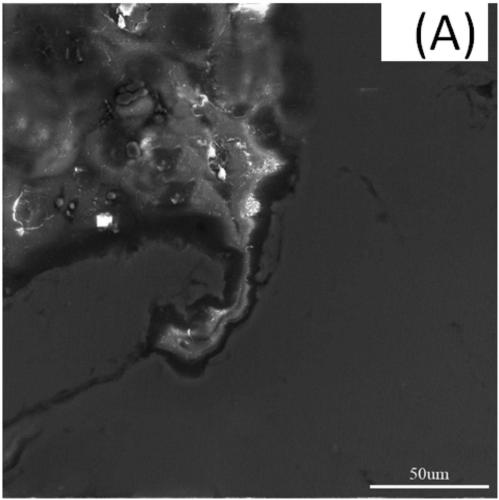

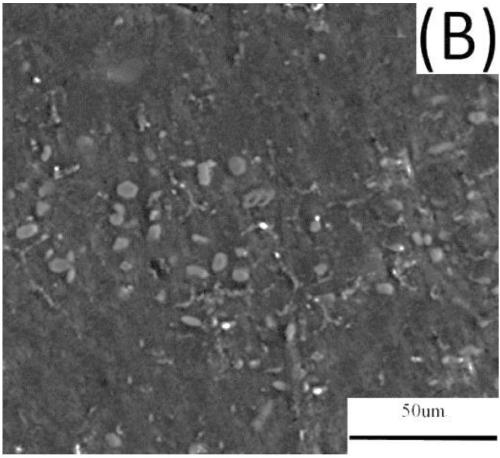

Preparation method of laser cladding coating

InactiveCN109055931AQuality assuranceHigh strengthMetallic material coating processesAluminium powderAlloy

The invention discloses a preparation method of a laser cladding coating. The preparation method comprises the steps that pre-prepared aluminum powder, titanium powder and carbon powder are added intoethyl alcohol or deionized water according to the mass ratio being 6.4-7.8:1.1-1.8:1.1-1.8 and subjected to ball milling through a ball mill to be sufficiently dispersed, and mixed liquid of the pre-prepared powder is obtained; the mixed liquid of the pre-prepared powder is dried, and mixed with a binding agent to be pasty; a light alloy matrix is coated with the pasty pre-prepared powder and dried; the dried pre-prepared powder is machined by a CNC milling machine to be a pre-prepared layer with the thickness of 0.8-1.2mm; and the pre-prepared layer is clad to the light alloy matrix throughlaser machining equipment. In the embodiment, the pre-prepared aluminum powder, titanium powder and carbon powder are sufficiently dispersed and mixed and mixed with the binding agent to be pasty to be arranged on the surface of the light alloy in a coating mode to form the pre-prepared layer, the CNC milling machine is adopted for strictly controlling the thickness of the pre-prepared layer, thethickness at all positions is uniform, and the quality of the cladding coating is ensured.

Owner:JIANGXI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com