Patents

Literature

2725results about "Belts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

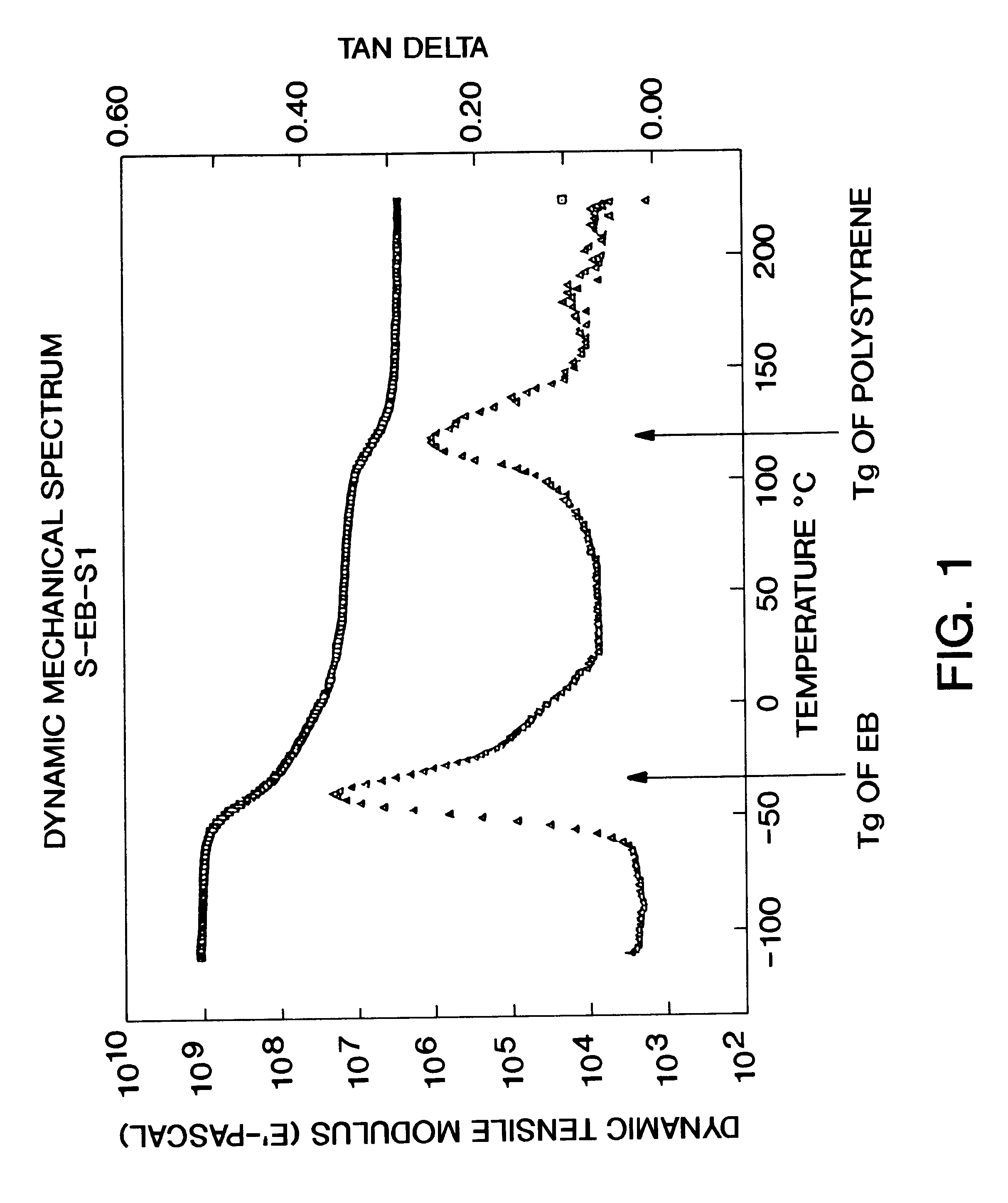

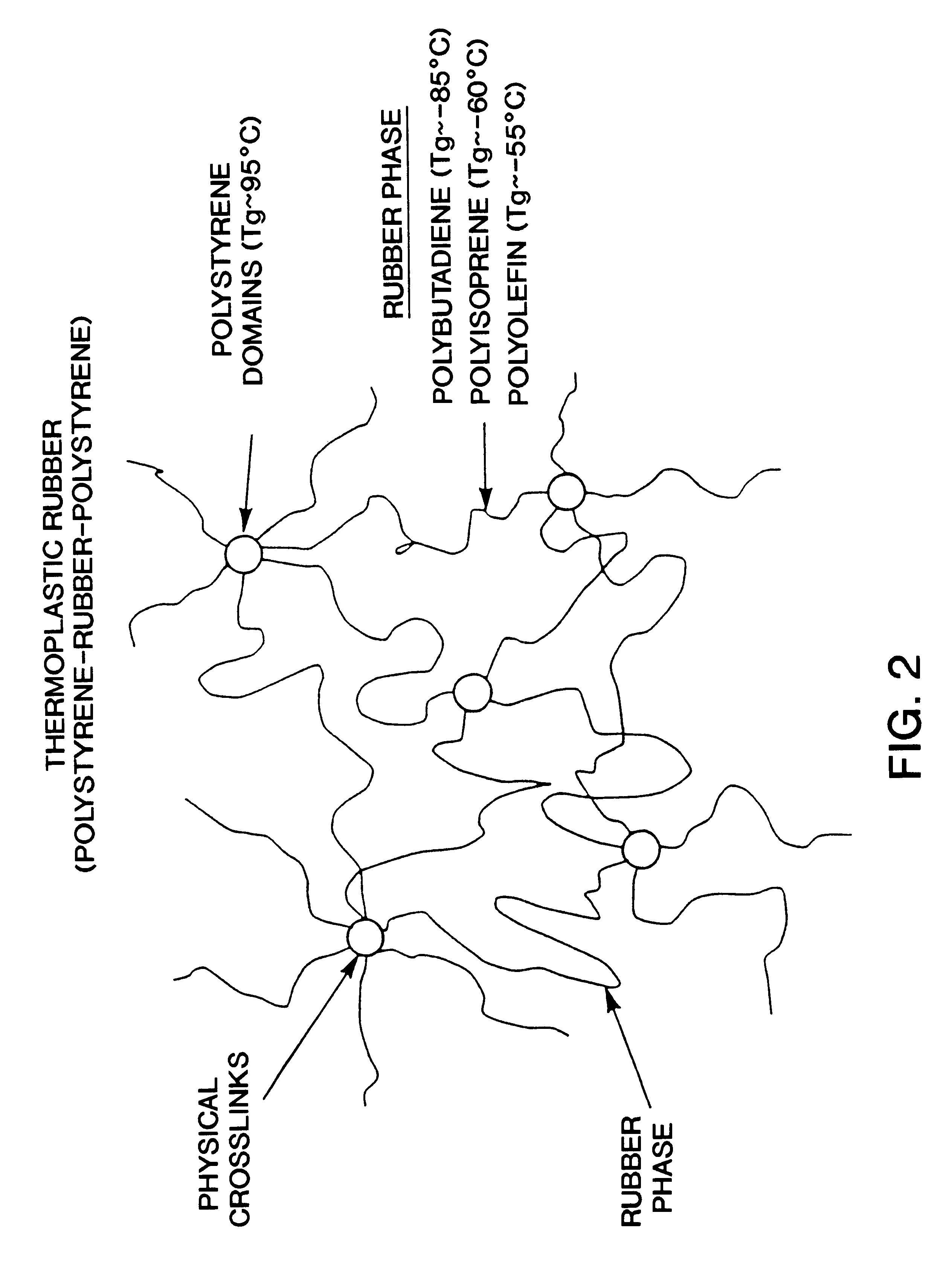

Dimensionally stable, breathable, stretch-thinned, elastic films

A method for producing a stretch-thinned elastic article having dimensional stability over time and at elevated temperatures in which a thermoplastic block copolymer is melt-processed into a stretchable article such as a film or fiber. The article is then conditioned at an elevated temperature greater than or equal to a glass transition temperature (Tg) of a hard phase of the thermoplastic block copolymer. The article is stretch-thinned at the elevated temperature to a desired percentage stretch, forming a stretch-thinned article, after which it is cooled to a temperature below the glass transition temperature of the hard phase of the thermoplastic block copolymer. Films produced by this method are suitable for use in durable and disposable articles including personal care articles such as diapers, incontinence wear, training pants, and feminine care articles, as well as wound dressings, wipes, towels, napkins, and protective apparel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

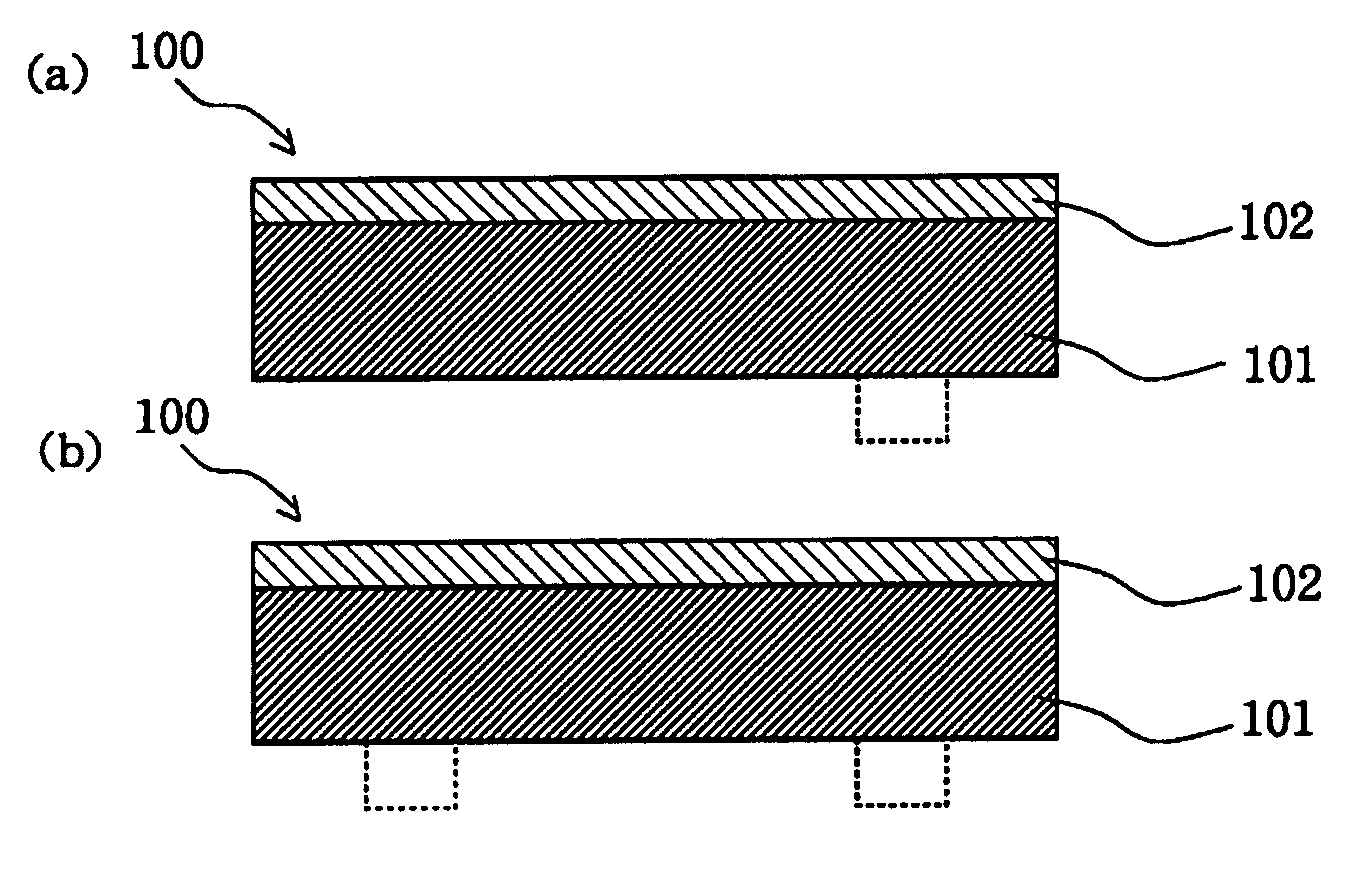

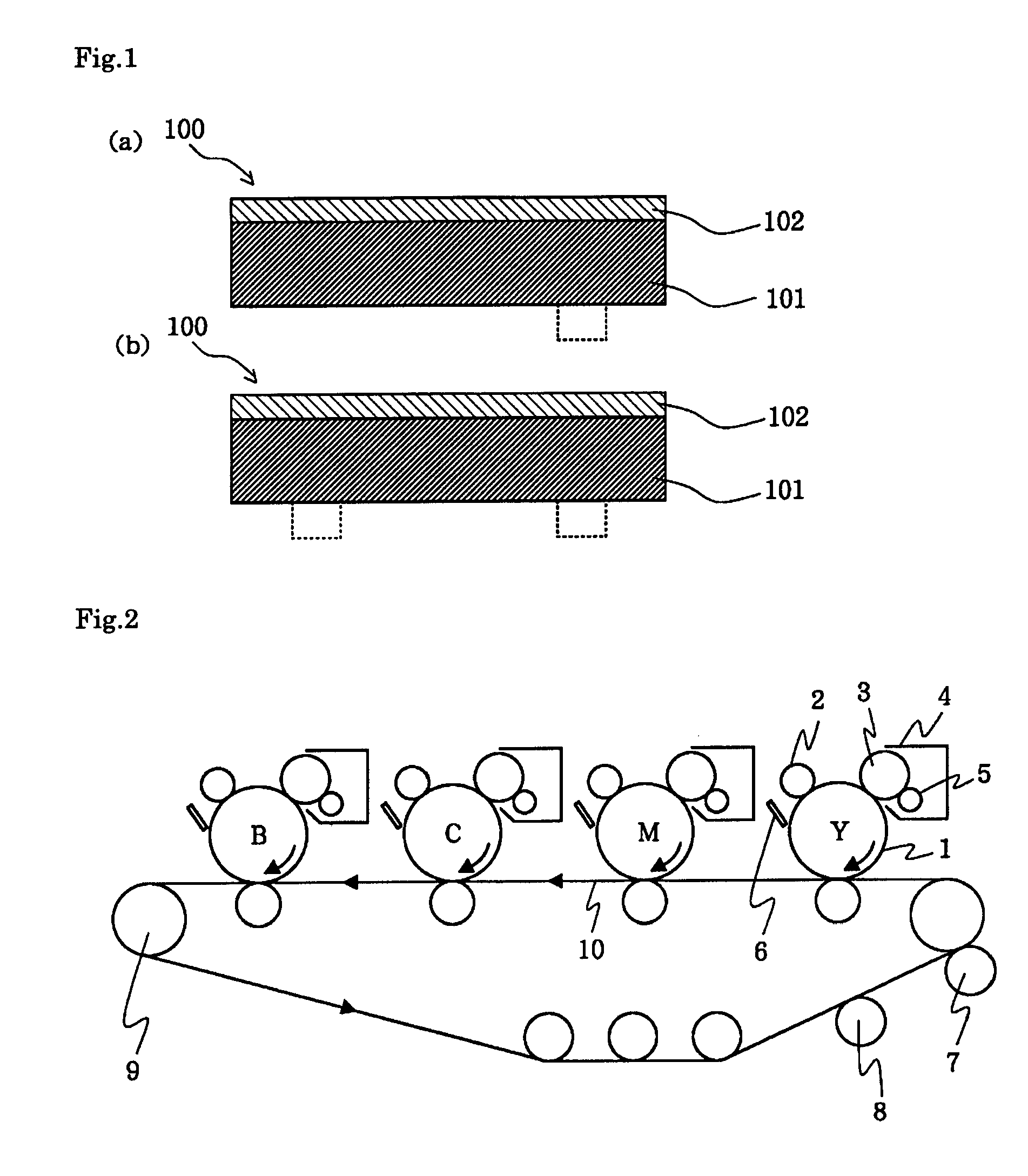

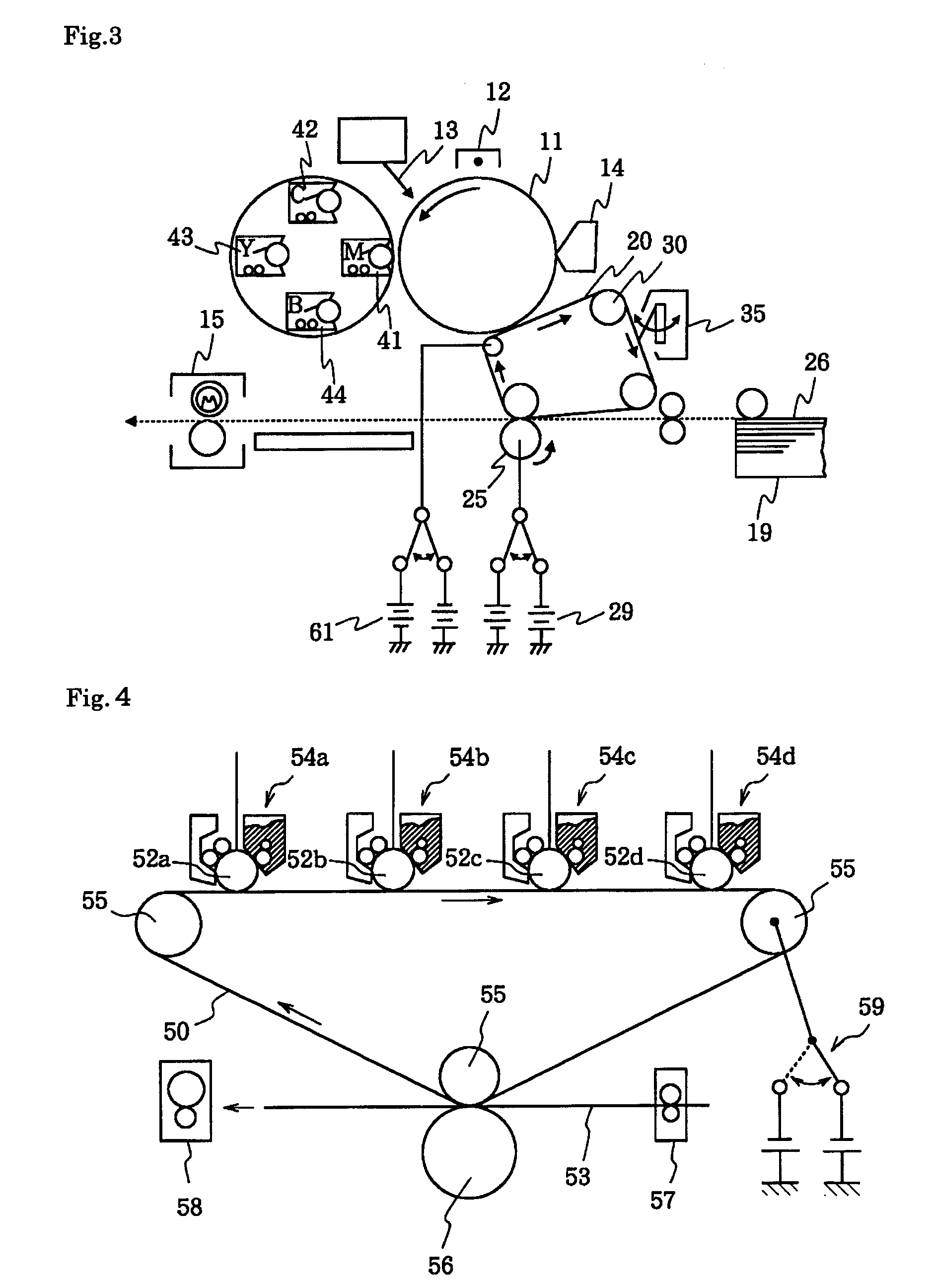

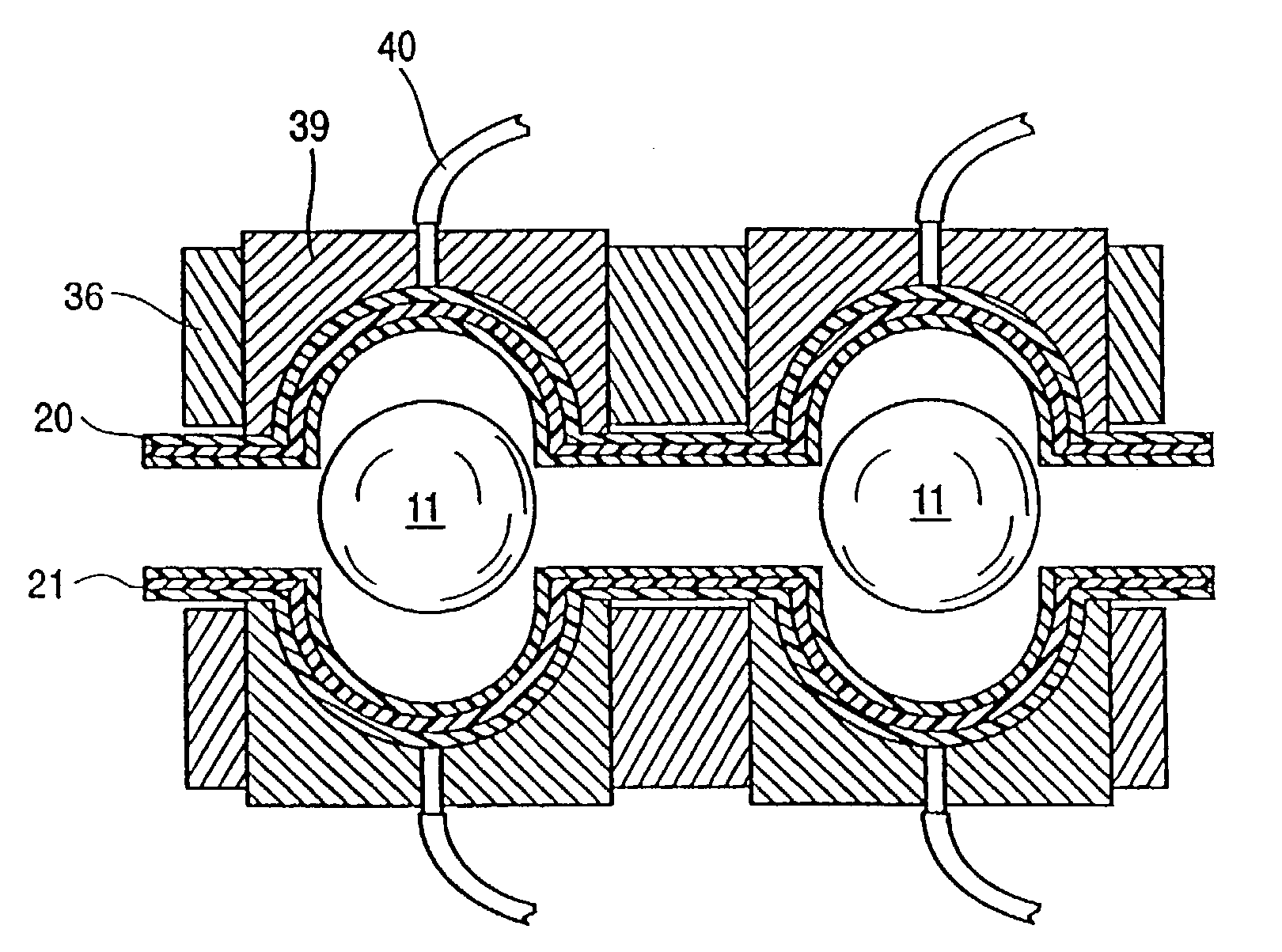

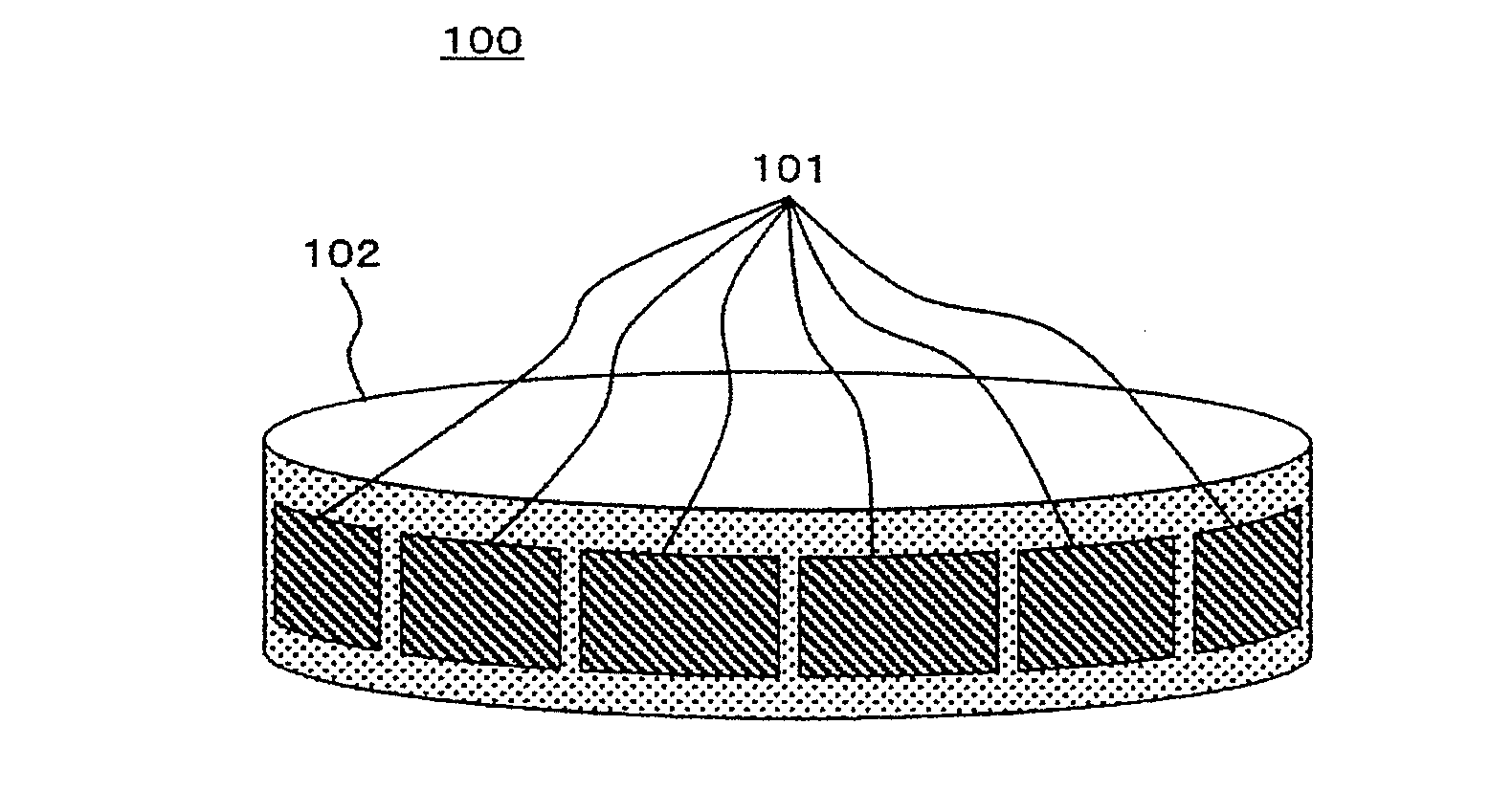

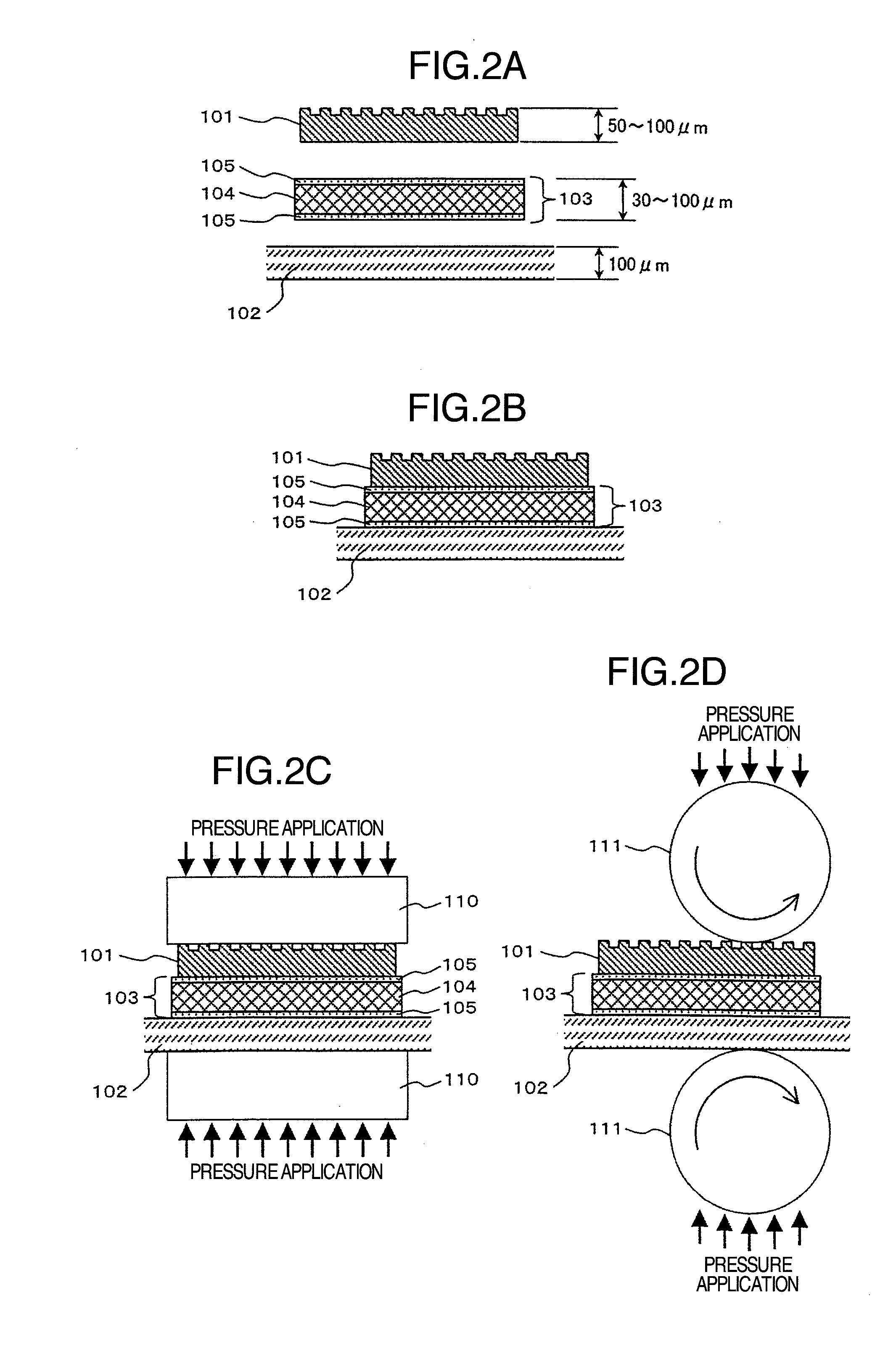

Conductive Endless Belt, Method For Producing Same, And Image Forming Apparatus Employing Same

InactiveUS20070286957A1Fast and easy and reliable curingStable productionPretreated surfacesElectrographic process apparatusImage formationUltraviolet

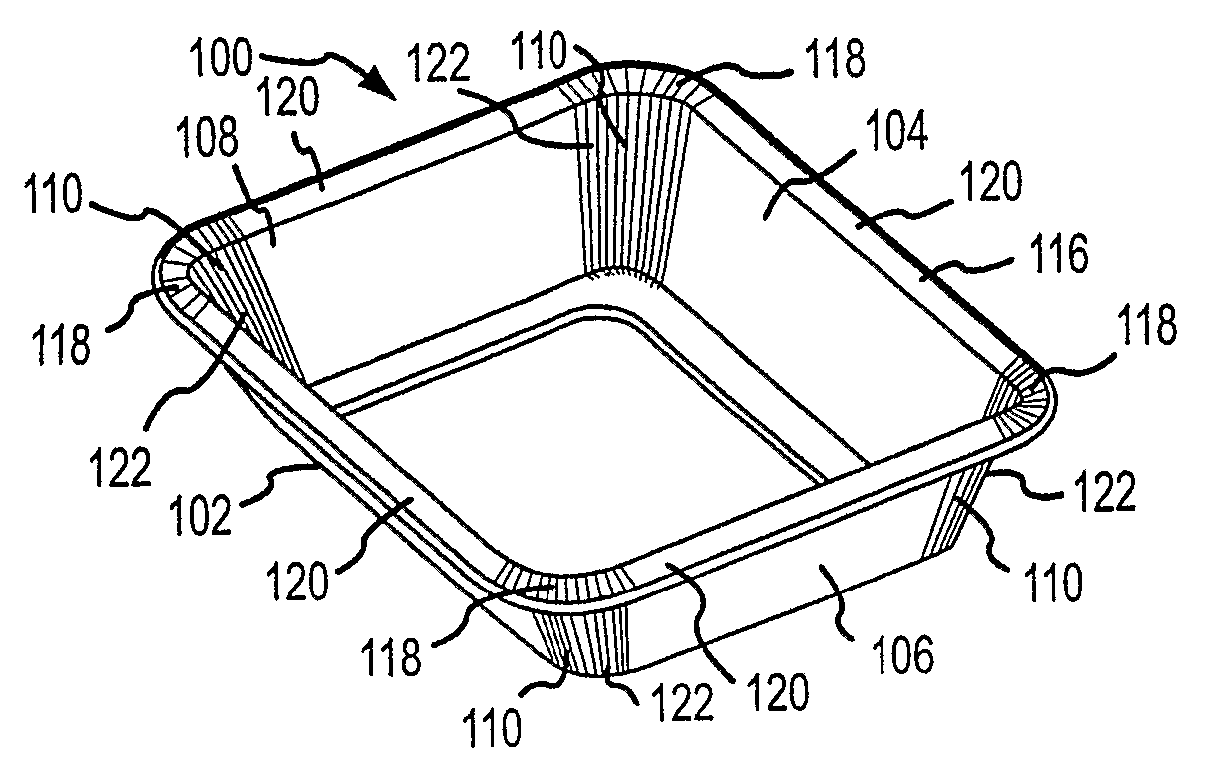

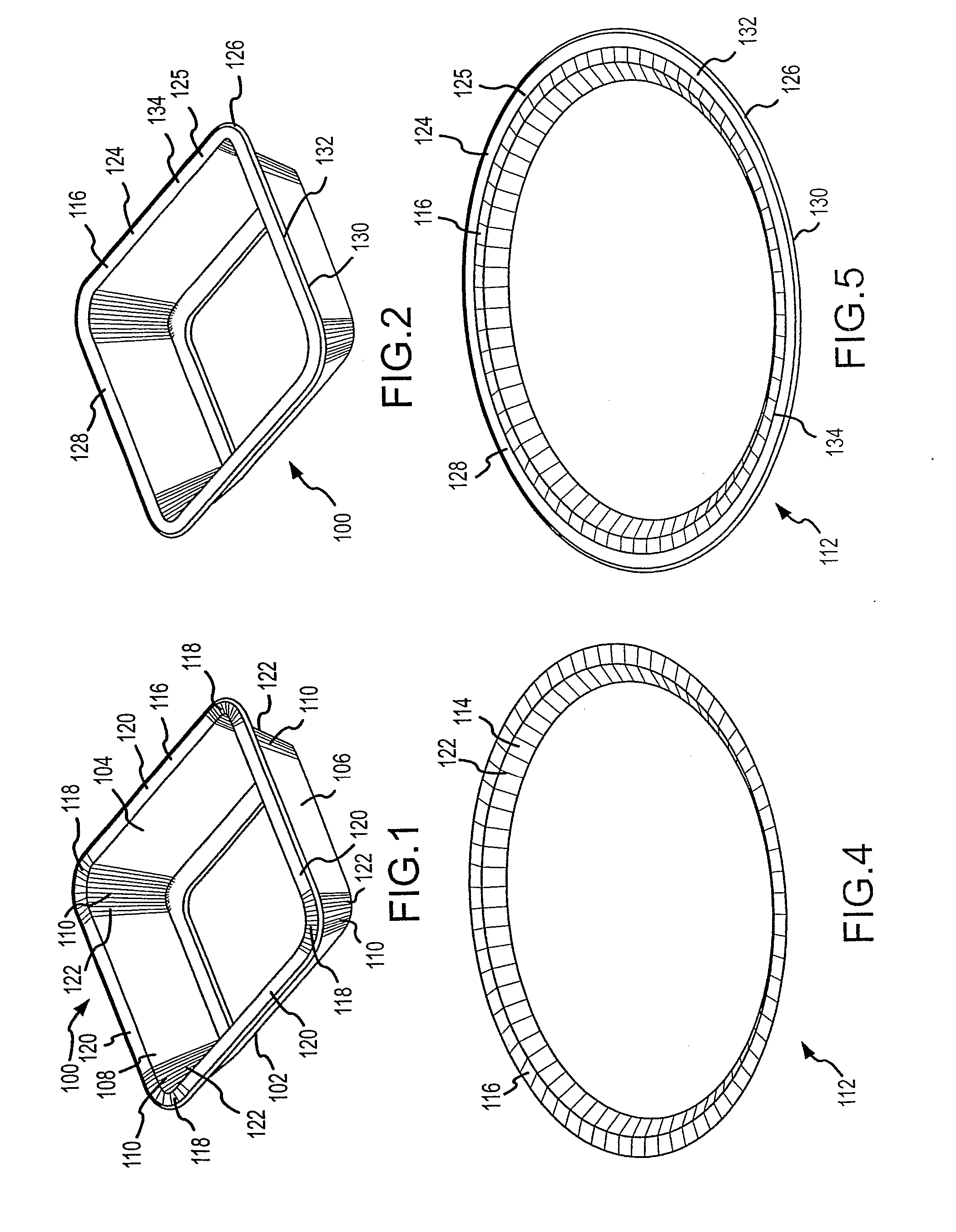

Provided are a conductive endless belt, a method of producing the same, and an image forming apparatus employing the same, the conductive endless belt having both desirable intended belt properties and surface properties, and being producible without known problems in terms of cost and quality. A conductive endless belt 100 is used as a transfer / transport conductive endless belt for a tandem system in which the conductive endless belt is circularly driven by a drive member so as to transport a recording medium held by the belt through electrostatic attraction to four differing image forming bodies, in which the toner images are sequentially transferred onto the recording medium. The conductive endless belt 100 is composed of a belt base 101 having thereon a resin layer 102, the resin layer 102 containing an ultraviolet or electron beam curable resin. The resin layer 102 preferably contains a conductive agent, specifically carbon black.

Owner:BRIDGESTONE CORP

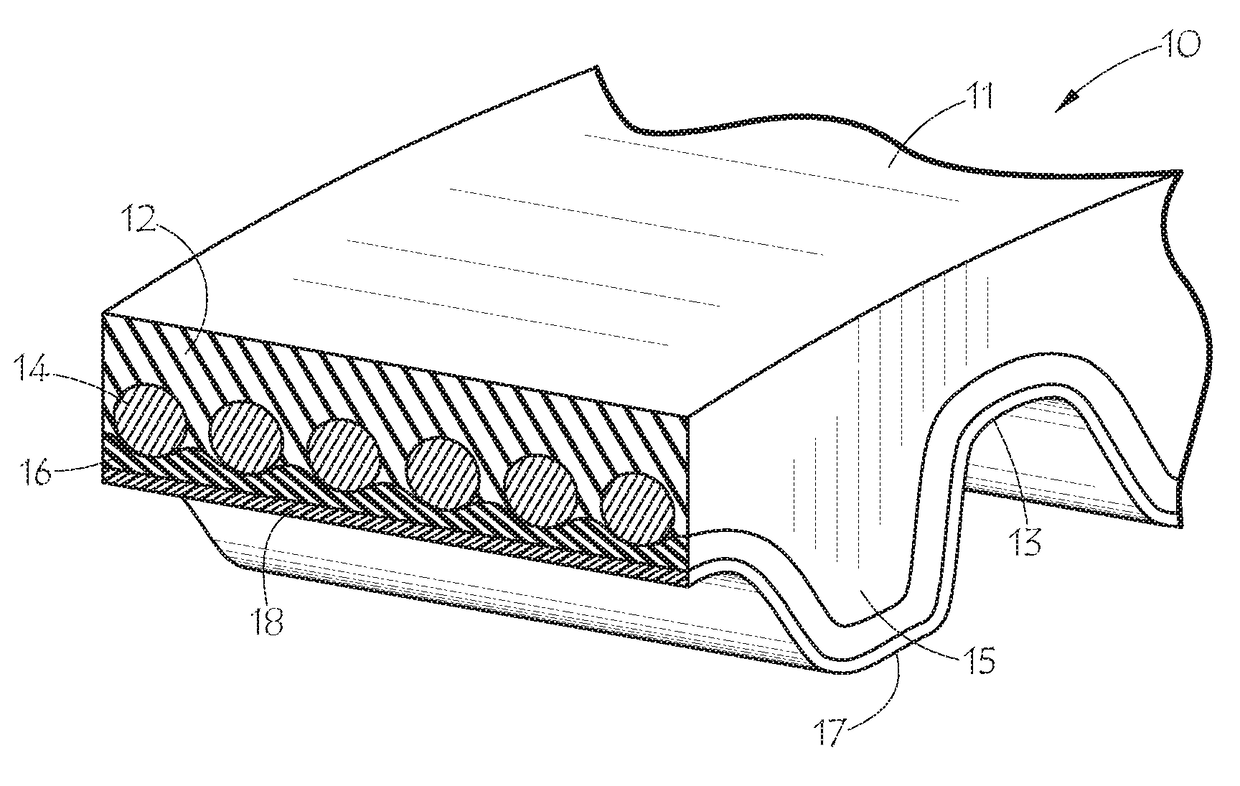

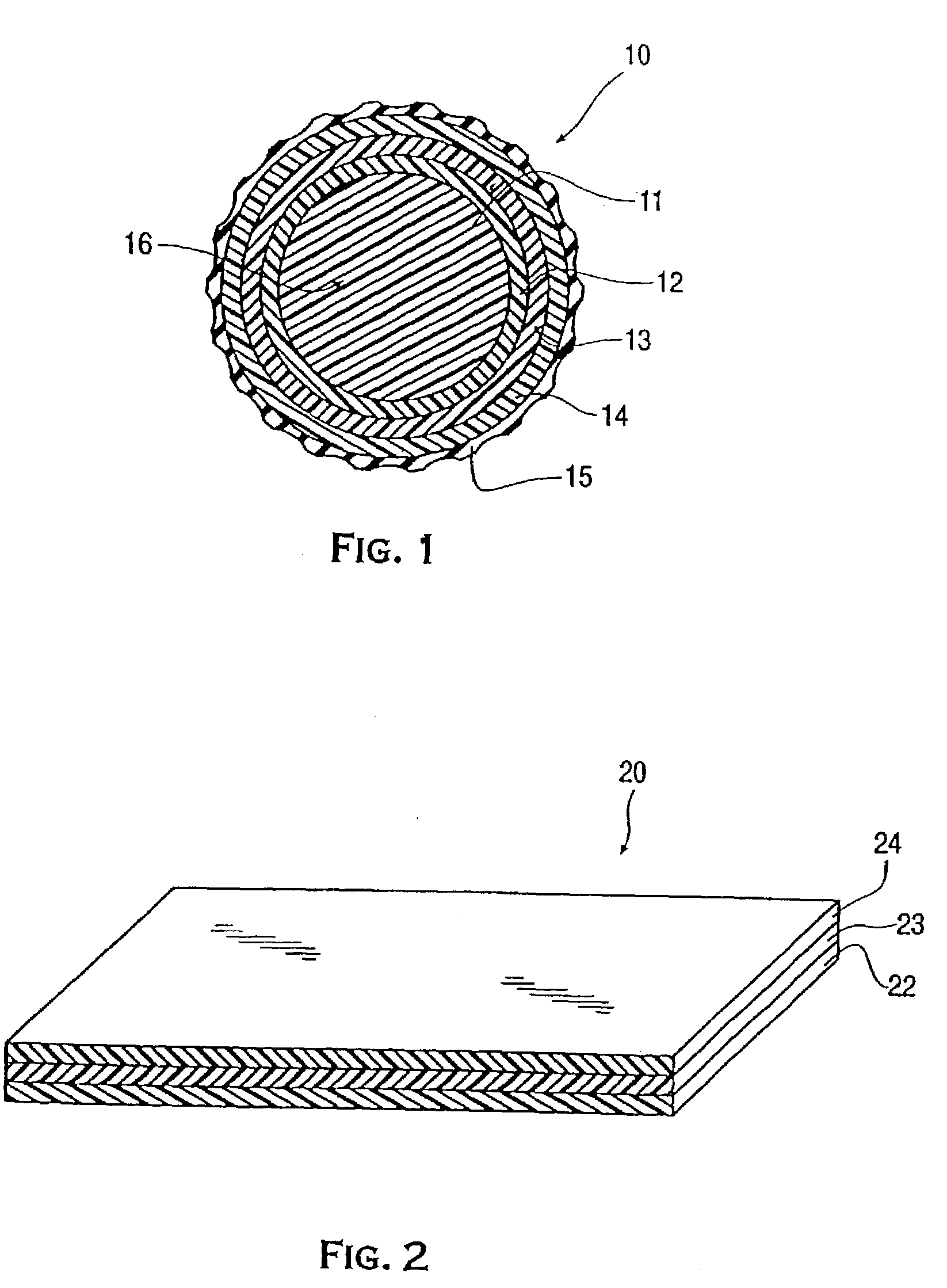

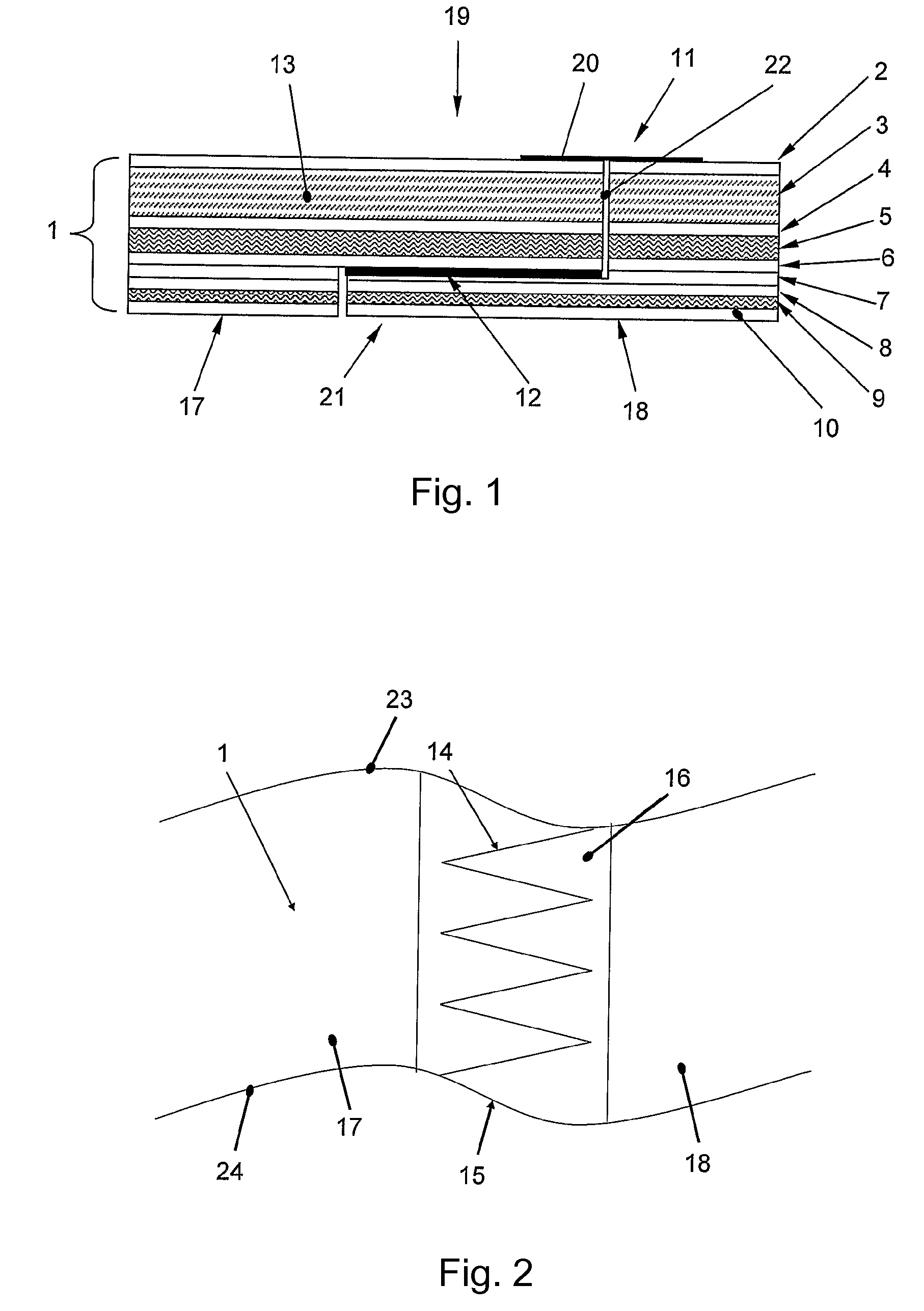

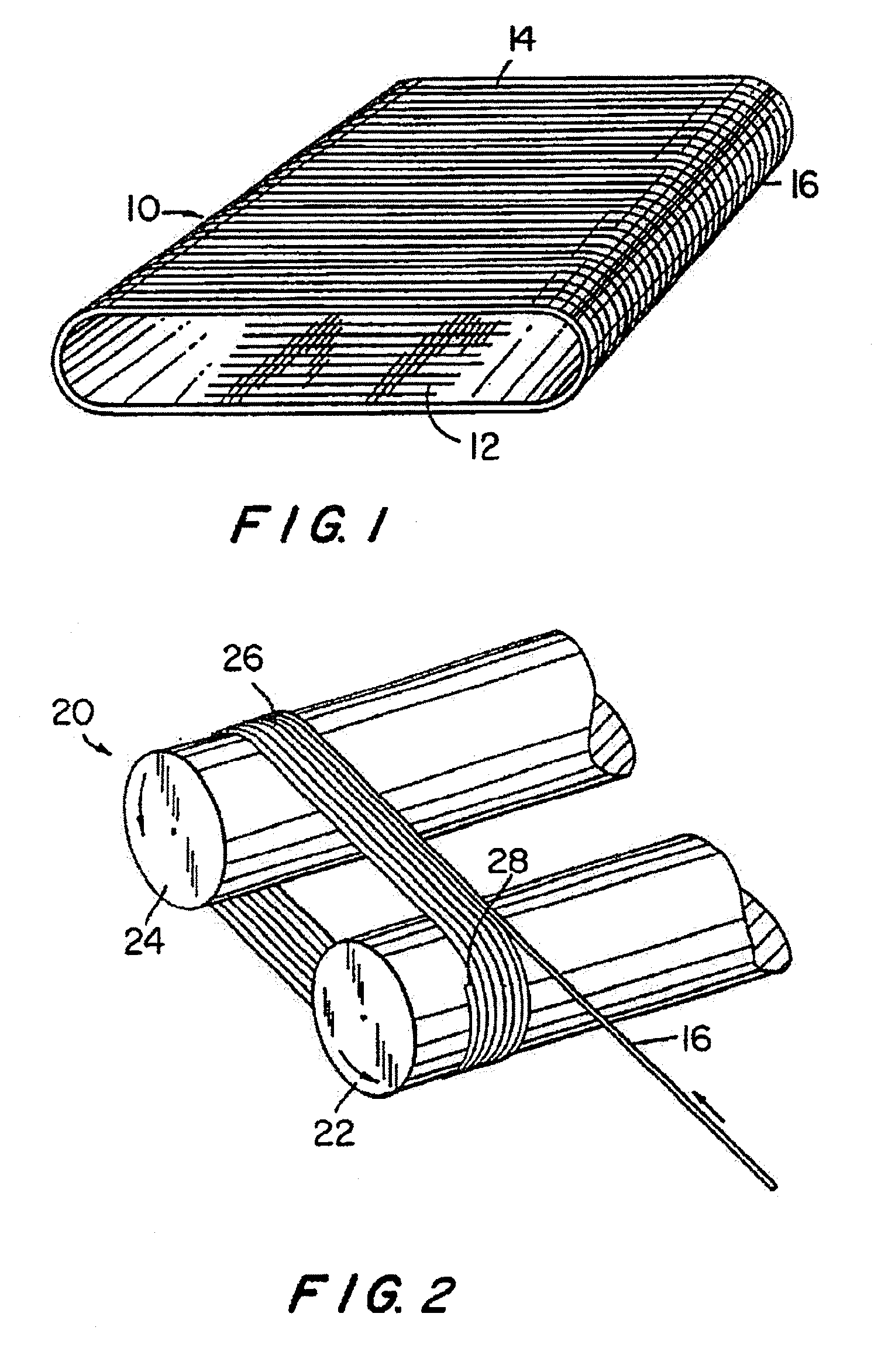

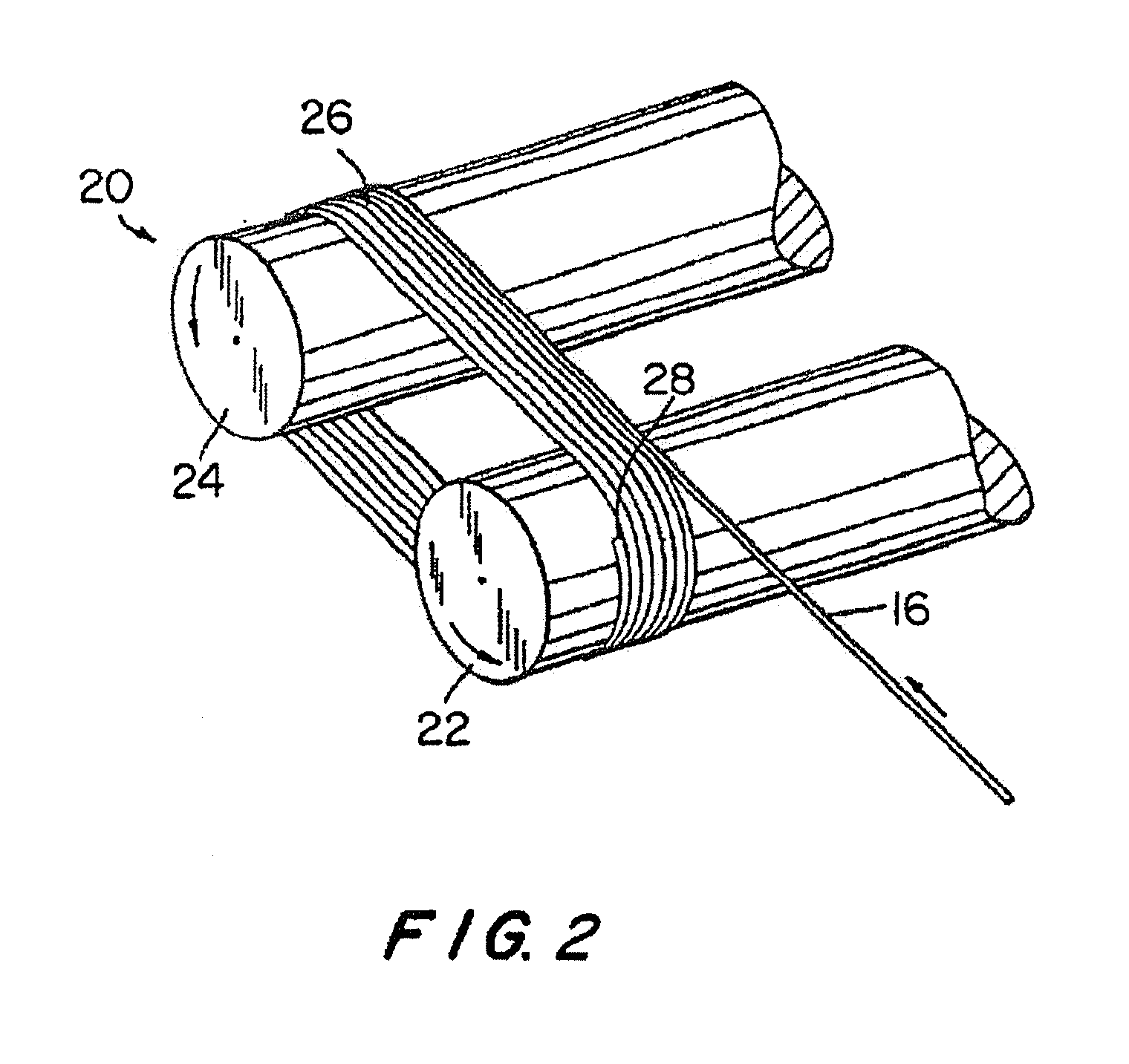

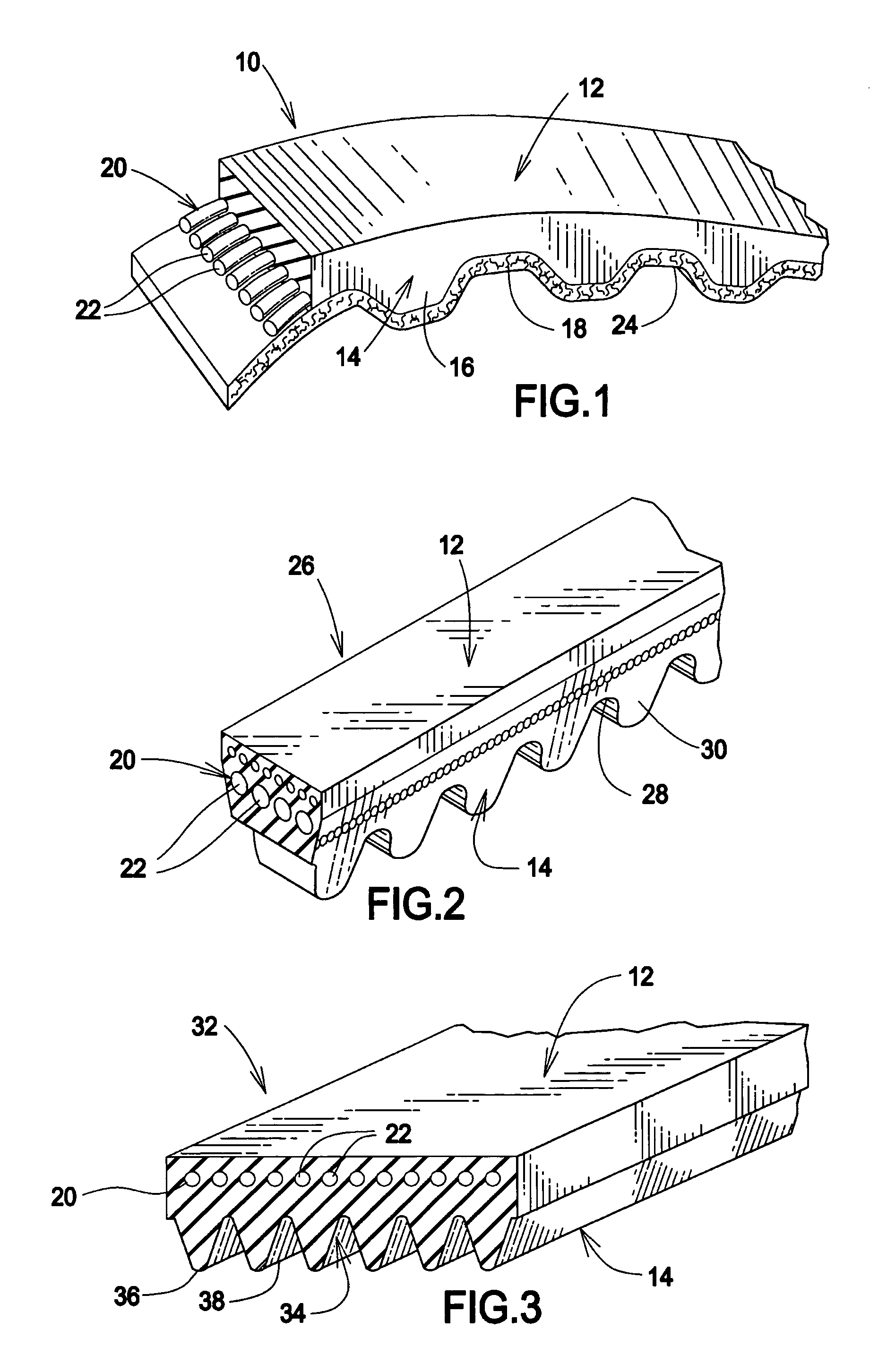

Electrically conductive power transmission belt

A belt made up of an elastomeric belt body, an electrically conductive tensile cord such as carbon fiber cord in a cord layer reinforcing the belt body, an outer layer of electrically conductive thermoplastic material such as polypropylene film, and an electrically conductive fabric layer residing between the tensile cord layer and the outer layer and providing electrical continuity between the outer layer and the tensile cord. An electrically conductive thread may be woven in the fabric and may present at both surfaces of the fabric and contact both the outer layer and the tensile cord to provide the electrical continuity there between.

Owner:THE GATES CORP

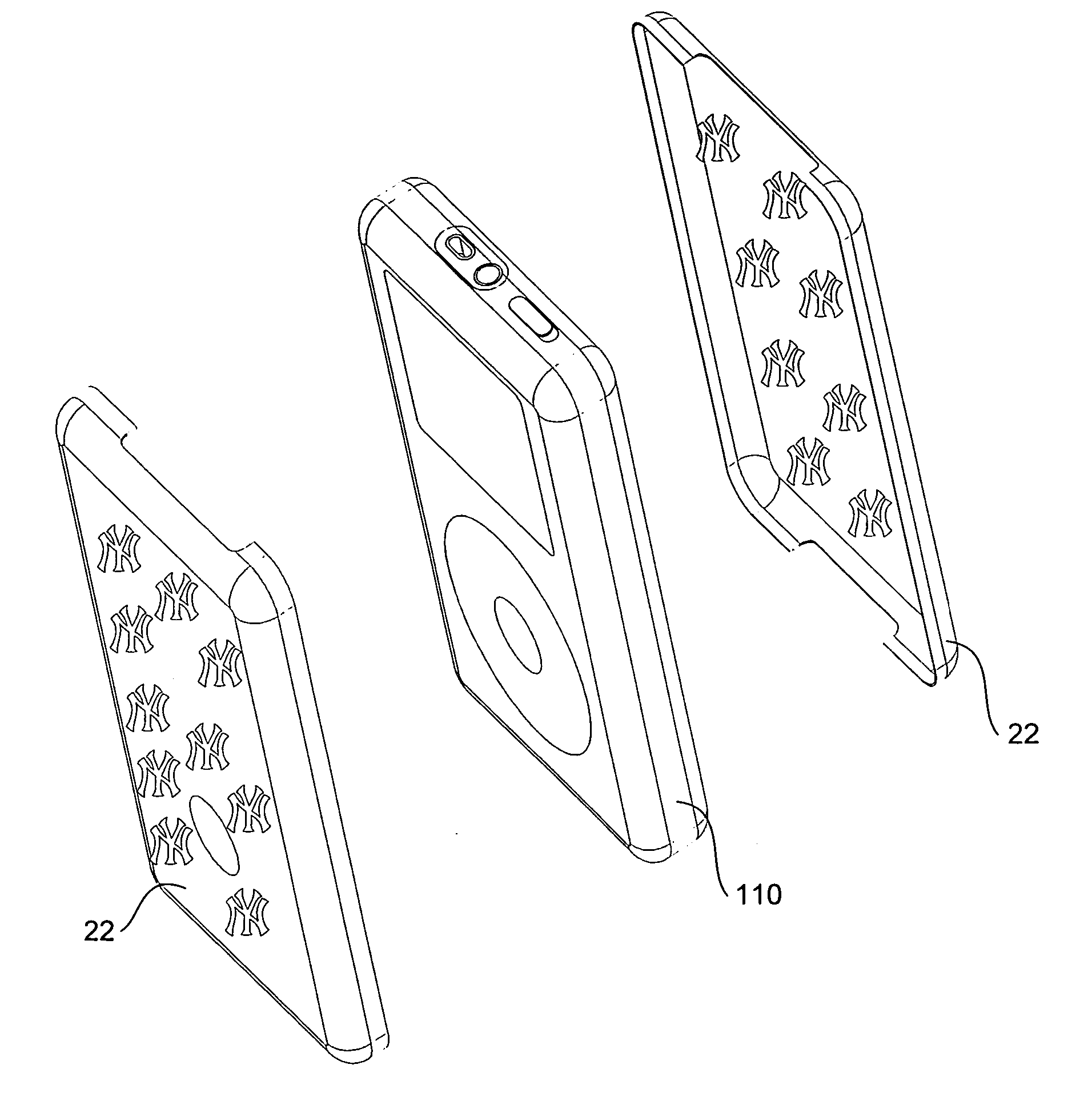

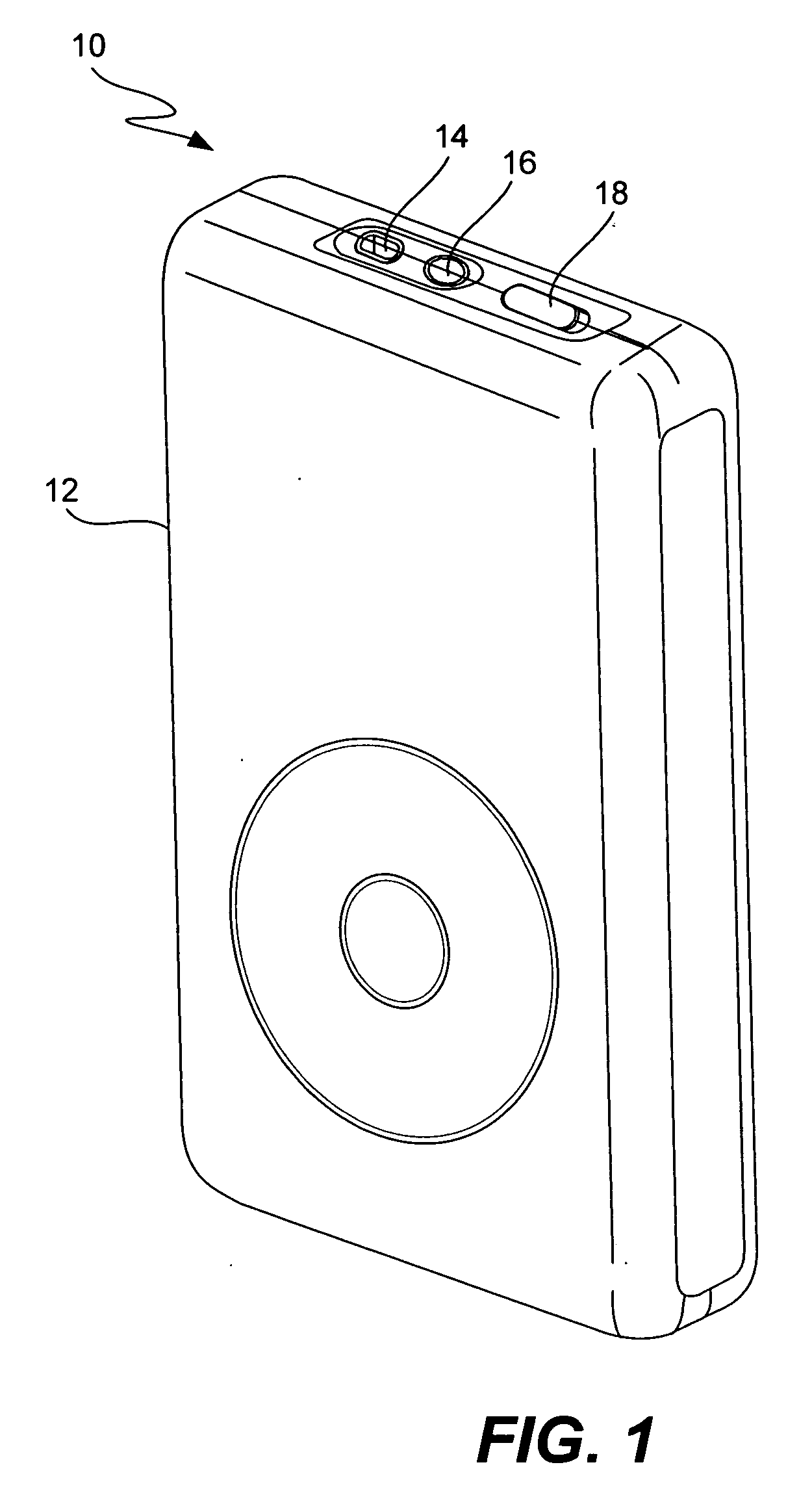

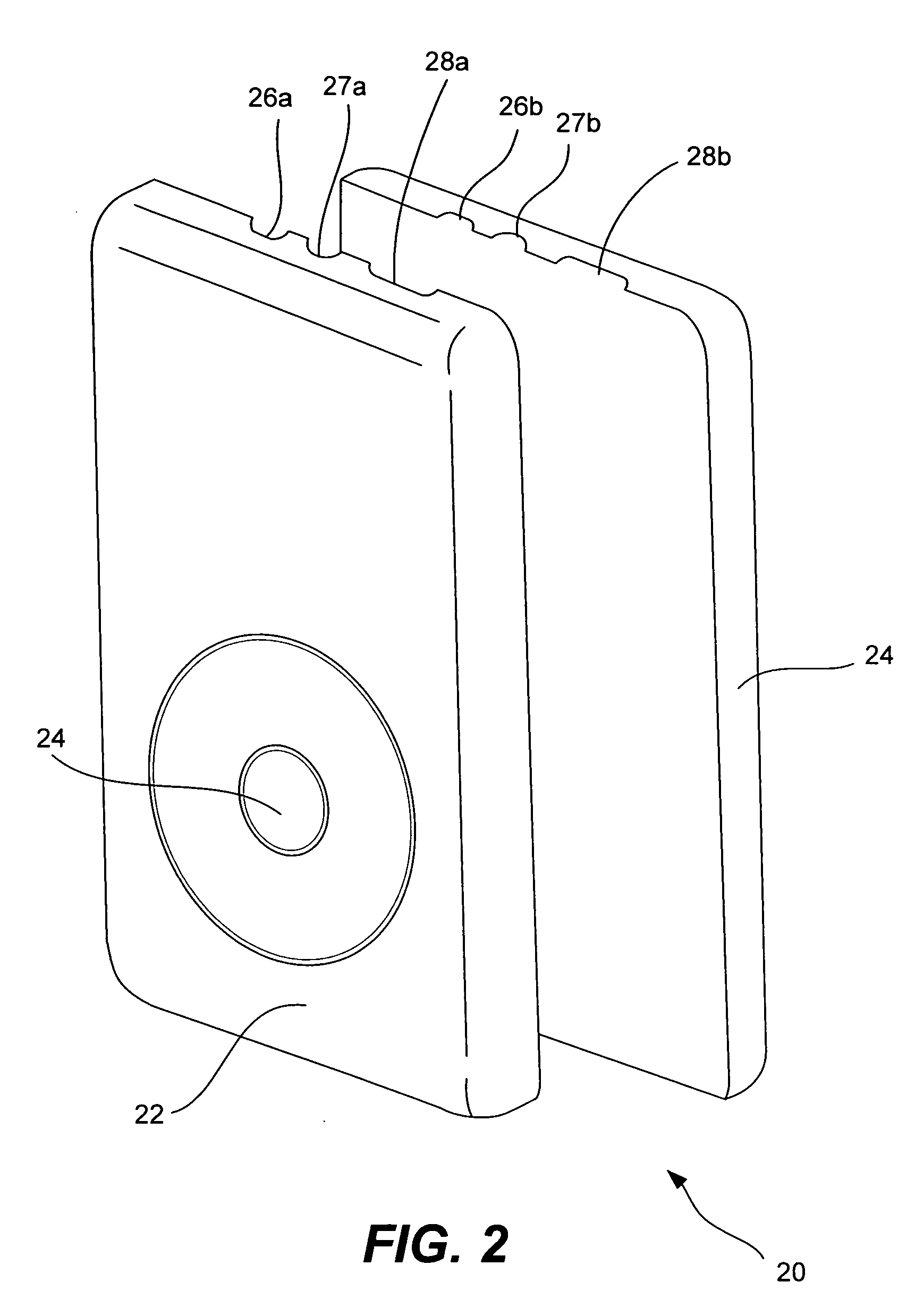

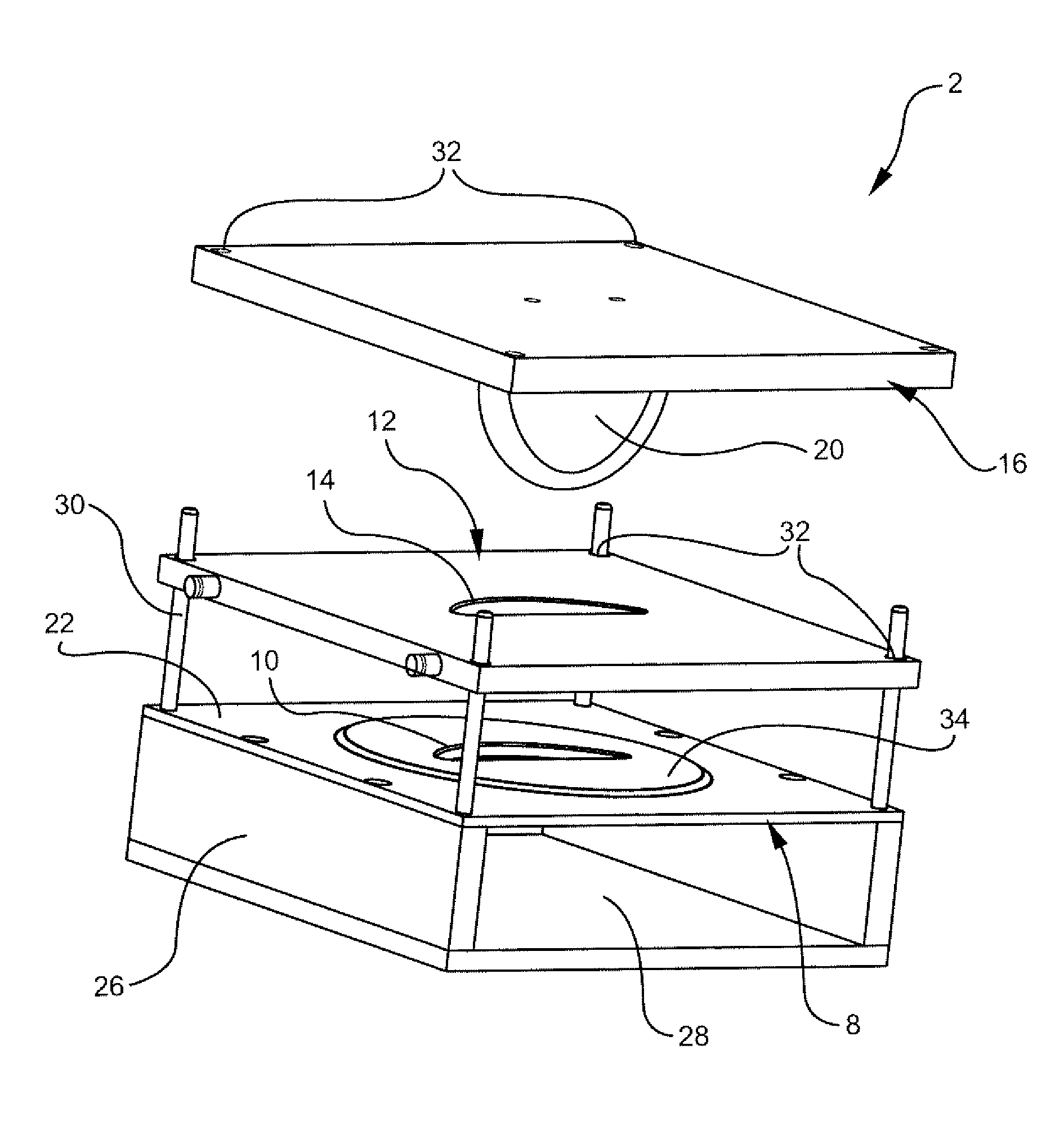

Apparatus and method for making form-fitted molded protective cases for products

A method and apparatus for making inexpensive, form-fitted, protective cases of thermal plastic or polycarbonate material that can be easily printed with decorative imagery and / or electronic circuitry for a variety of products, such as portable music players or radios, cell phones, lap-top computers, and the like. The method involves creating a tool having substantially the same surface dimensions of a product. An element is then molded from bulk film of thermoplastic material using the tool. Once the element is molded, it is trimmed from the bulk film. The resulting apparatus is a protective case intended to form-fit over the surface features and dimensions of the actual product used to define the tool.

Owner:SIK

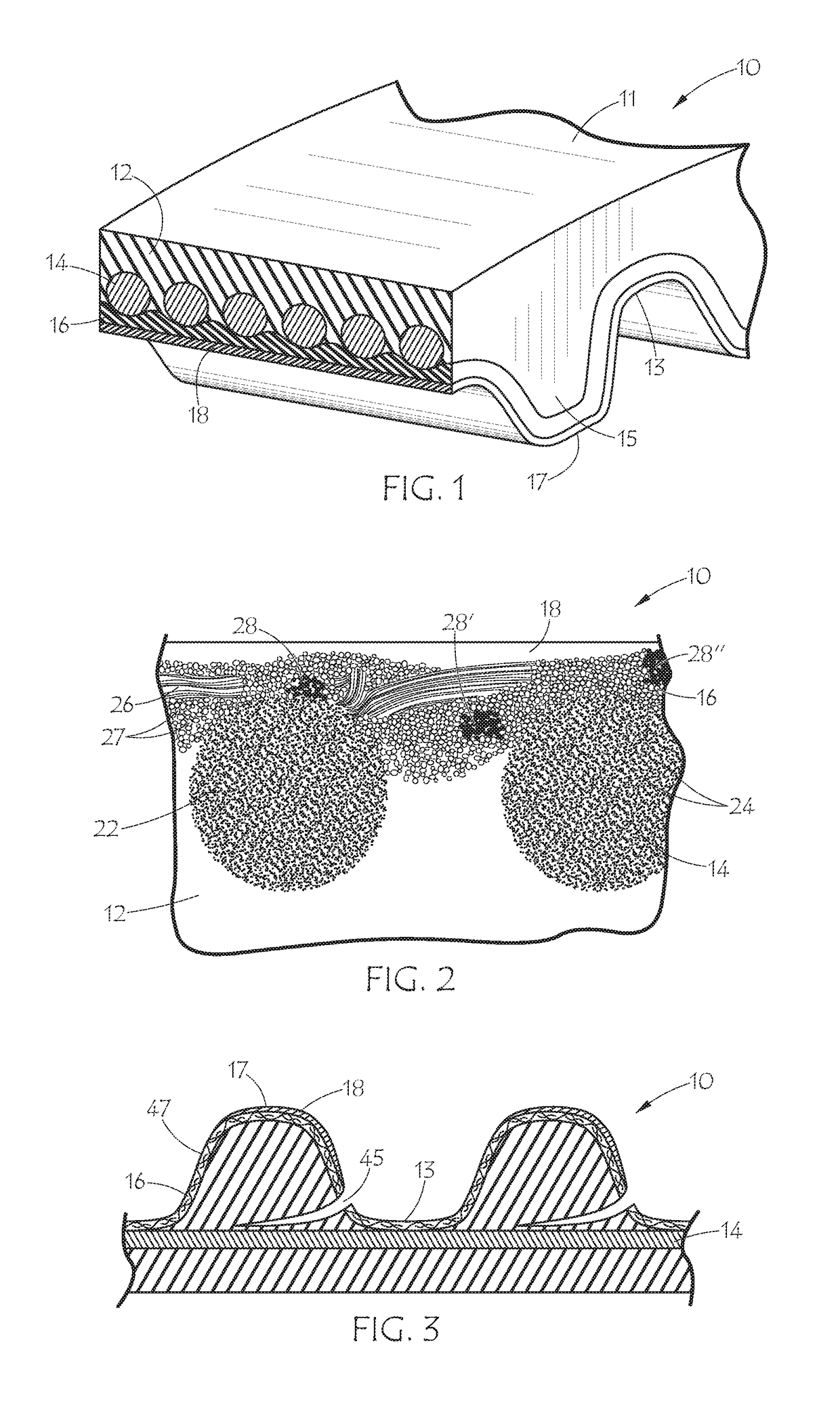

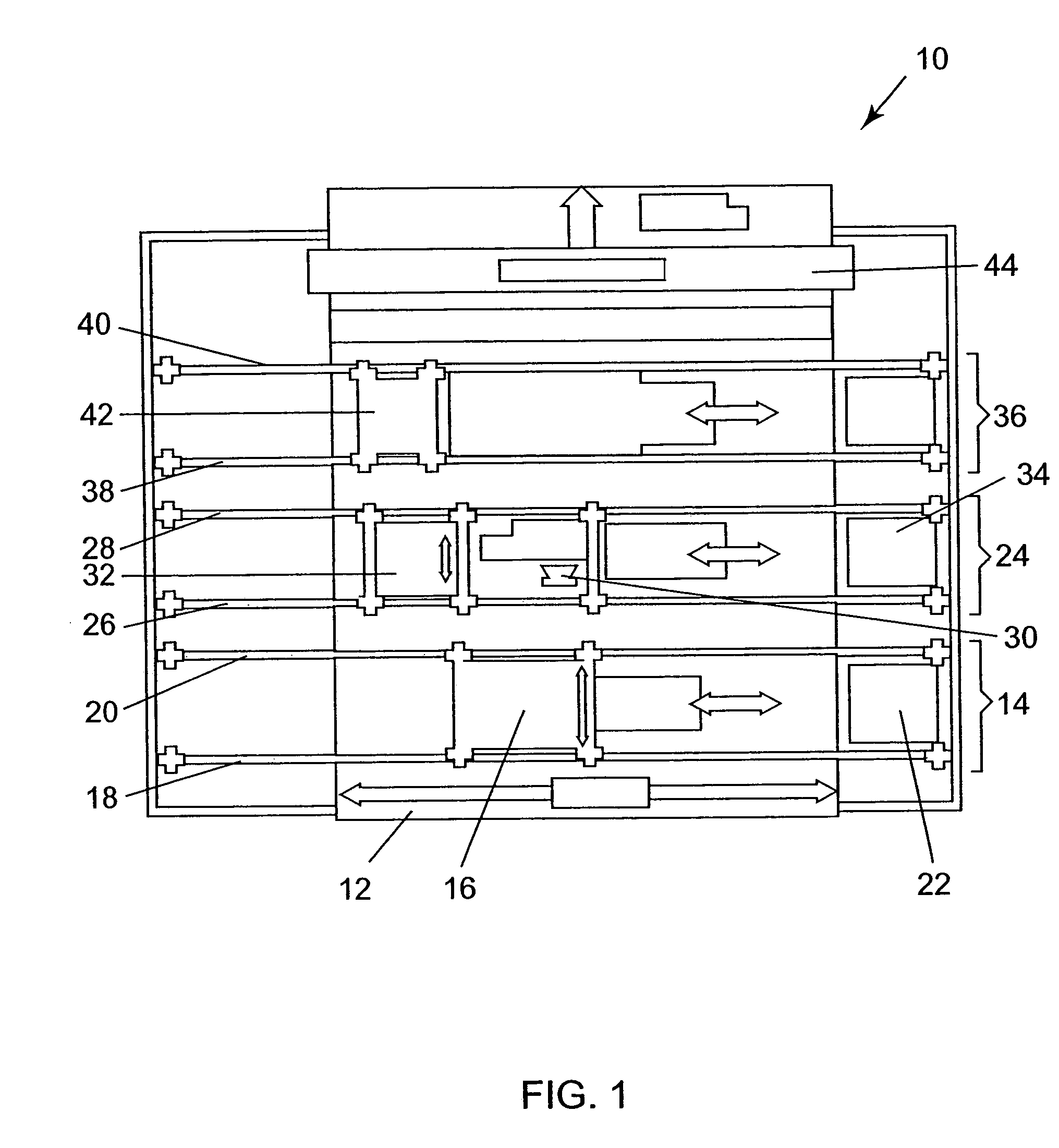

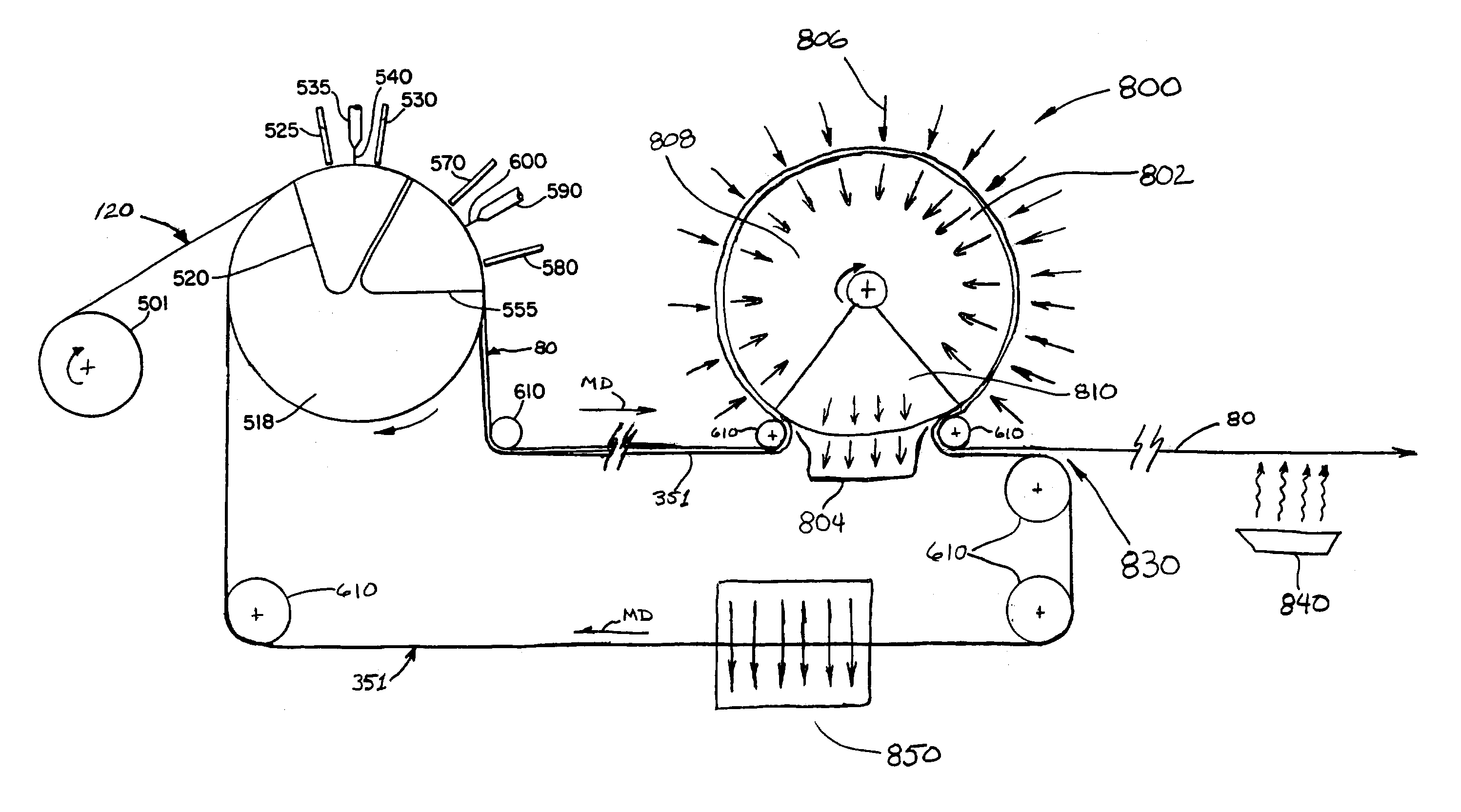

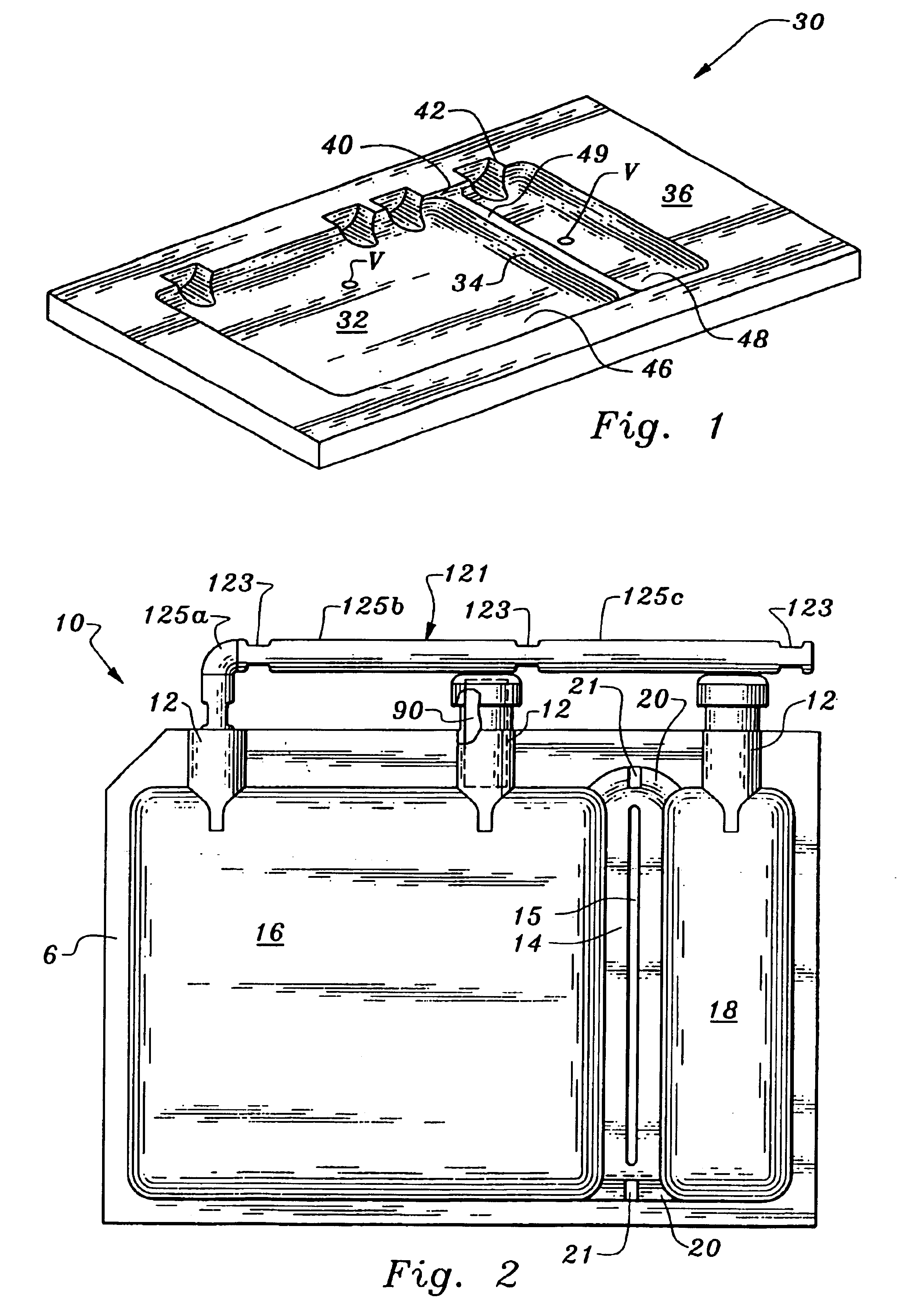

Industrial fabric for producing tissue and towel products, and method of making thereof

ActiveUS8454800B2Reduce the amount of solutionIncrease rangeNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringNonwoven fabric

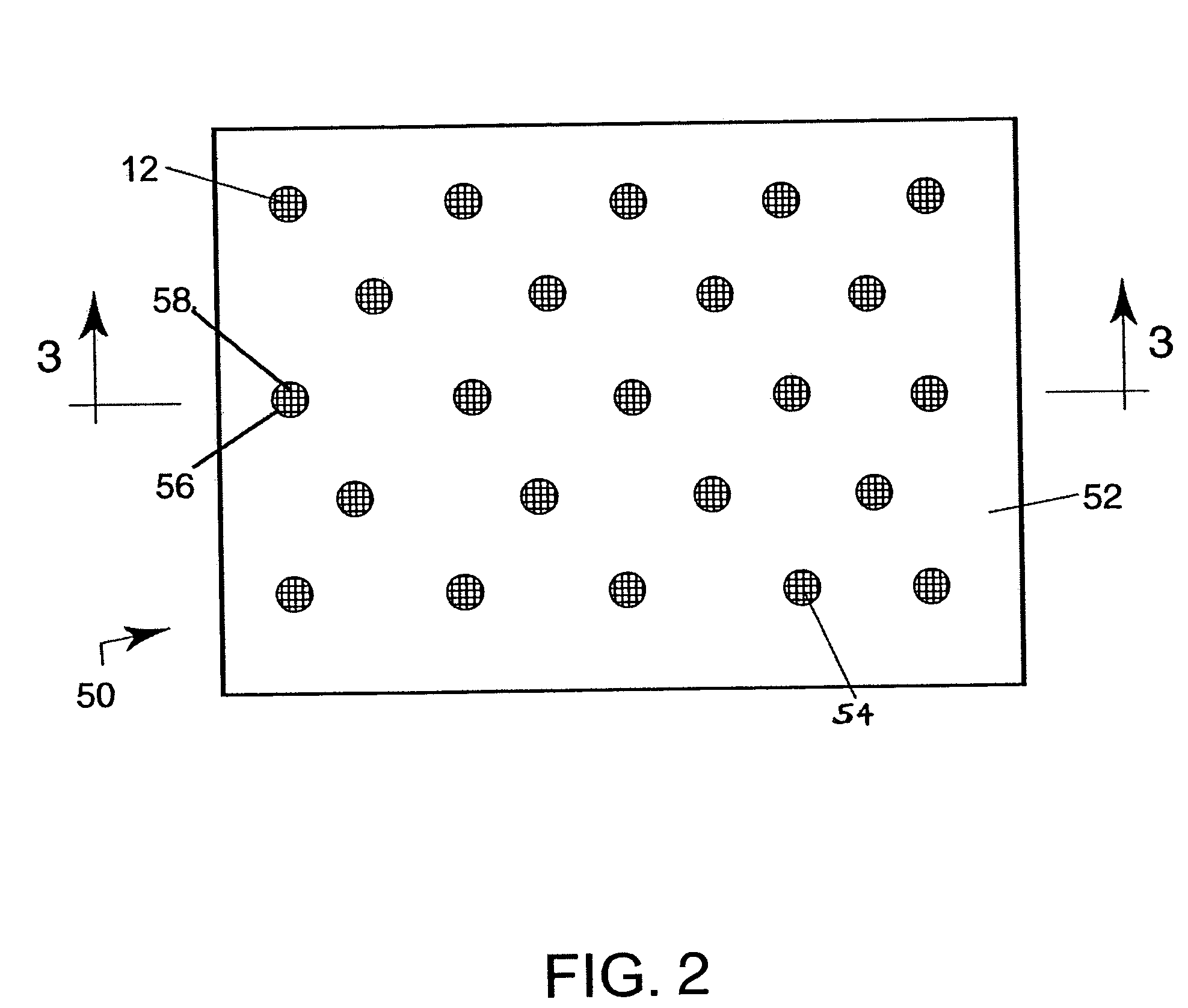

A nonwoven fabric includes a plurality of through voids, where each of the voids has a first opening associated with a top surface of the fabric and a first raised edge circumferentially adjacent to the first opening. The voids may each further include a second opening associated with a bottom surface of the fabric and a second raised edge circumferentially adjacent to the second opening, such that the first opening may have a surface area that is larger than or the same as the second opening.

Owner:ALBANY INT CORP

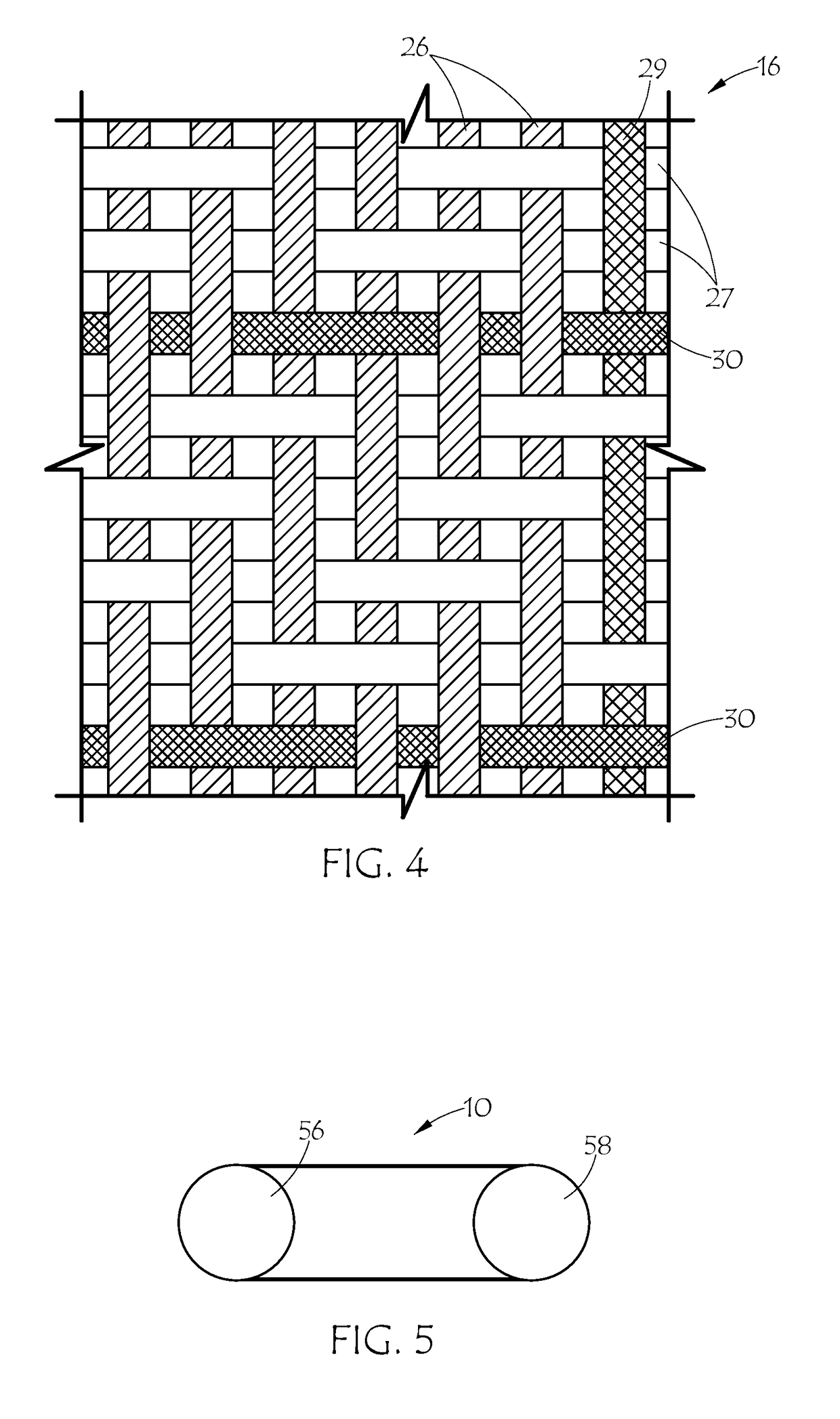

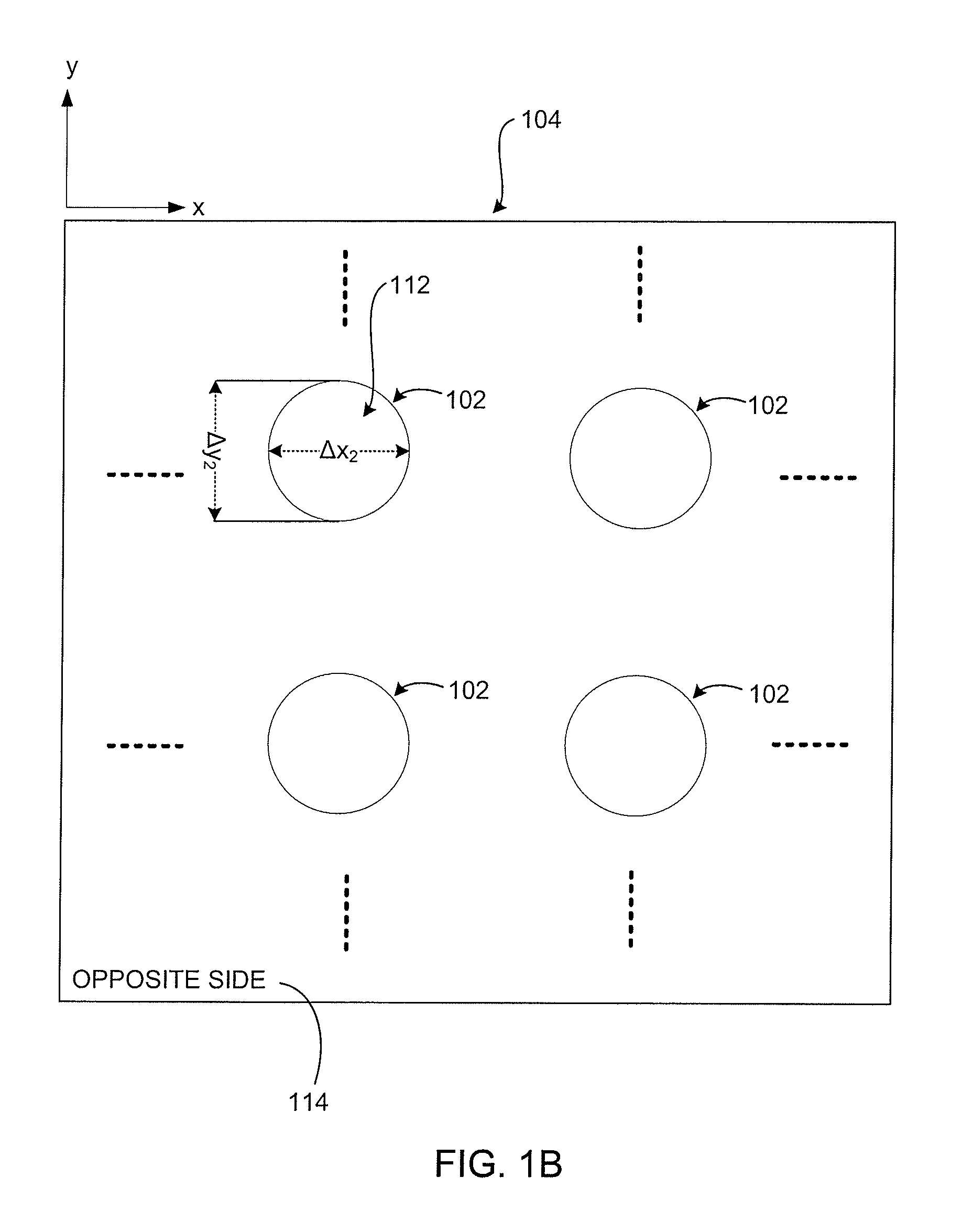

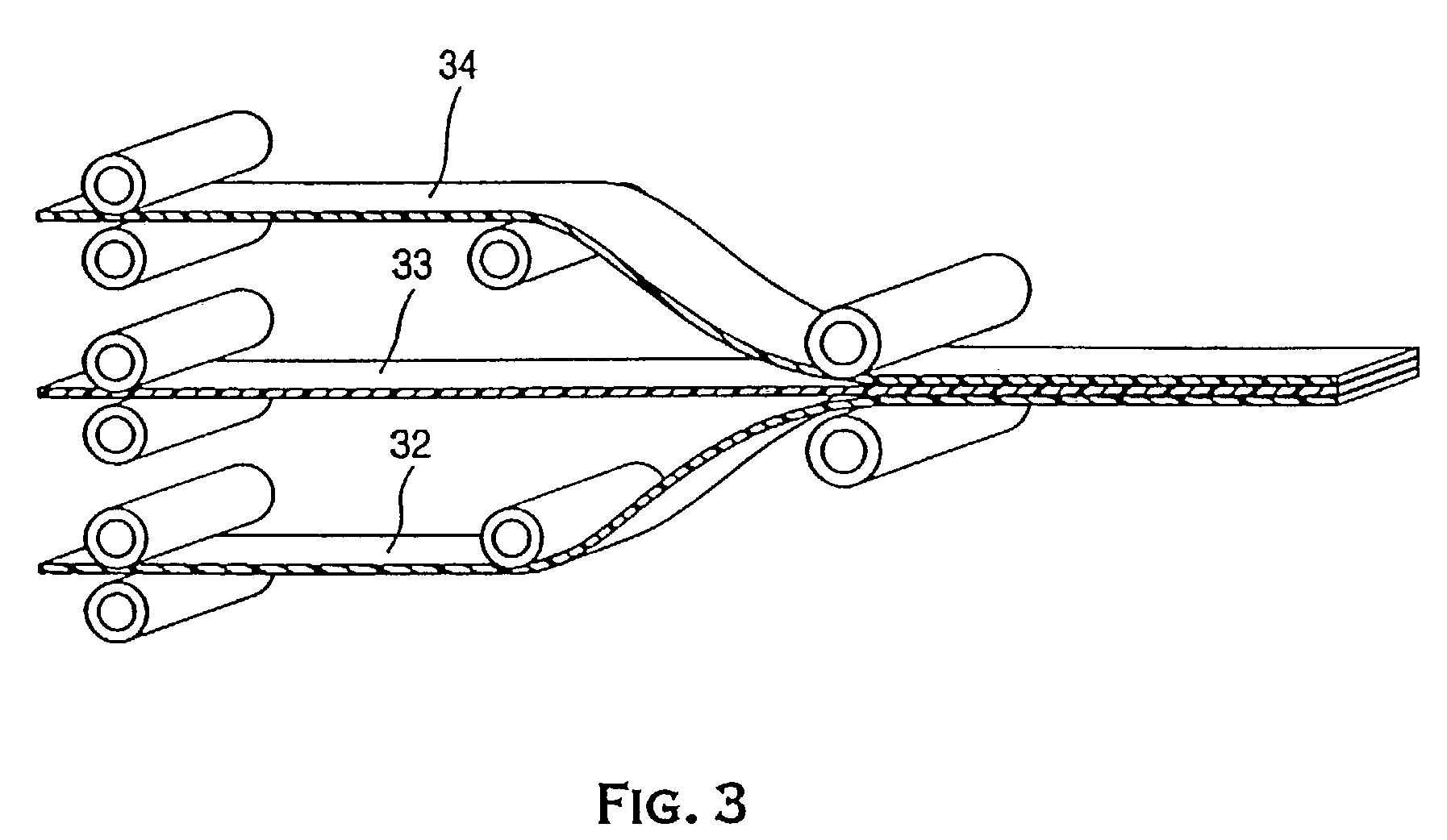

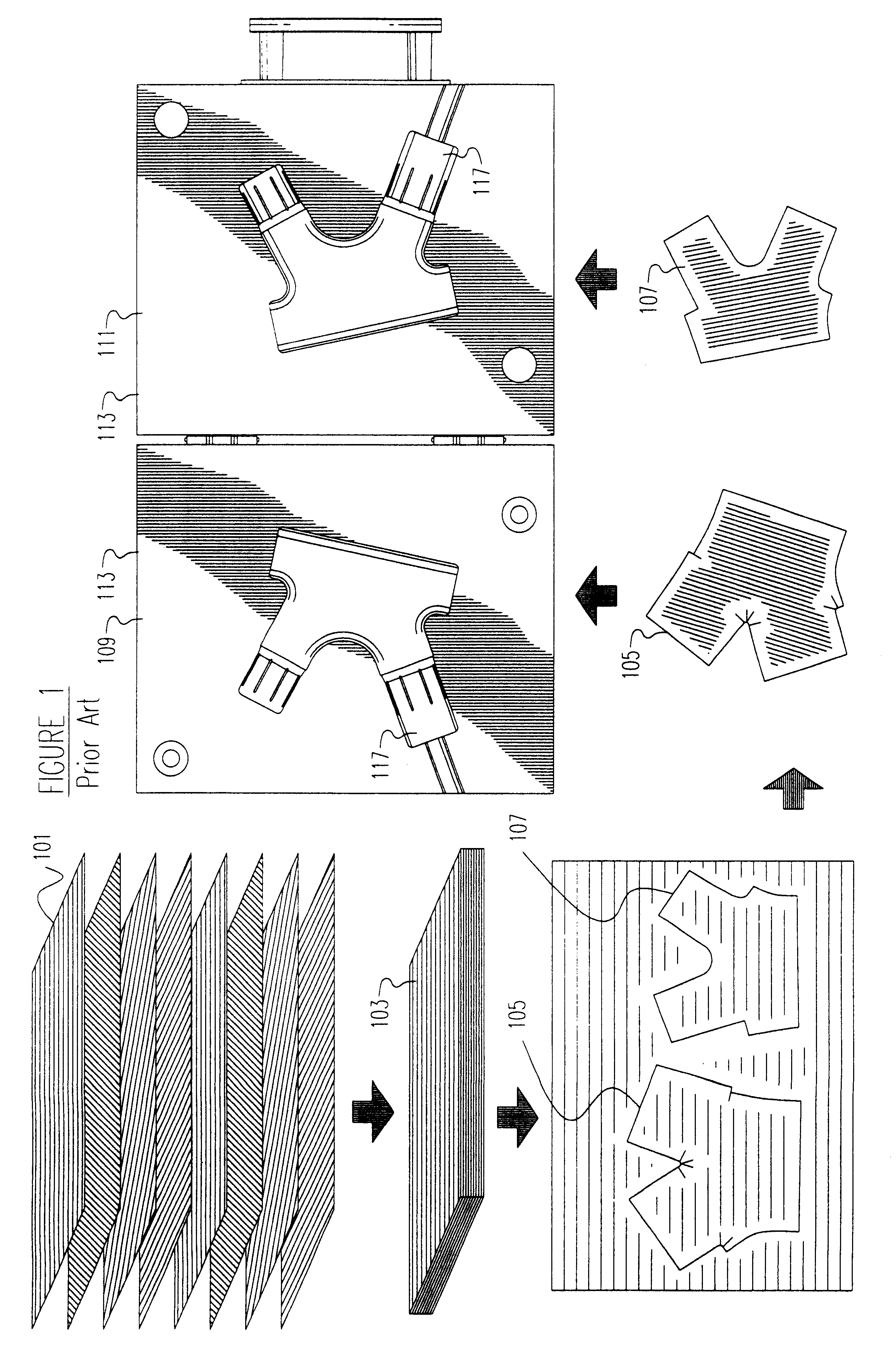

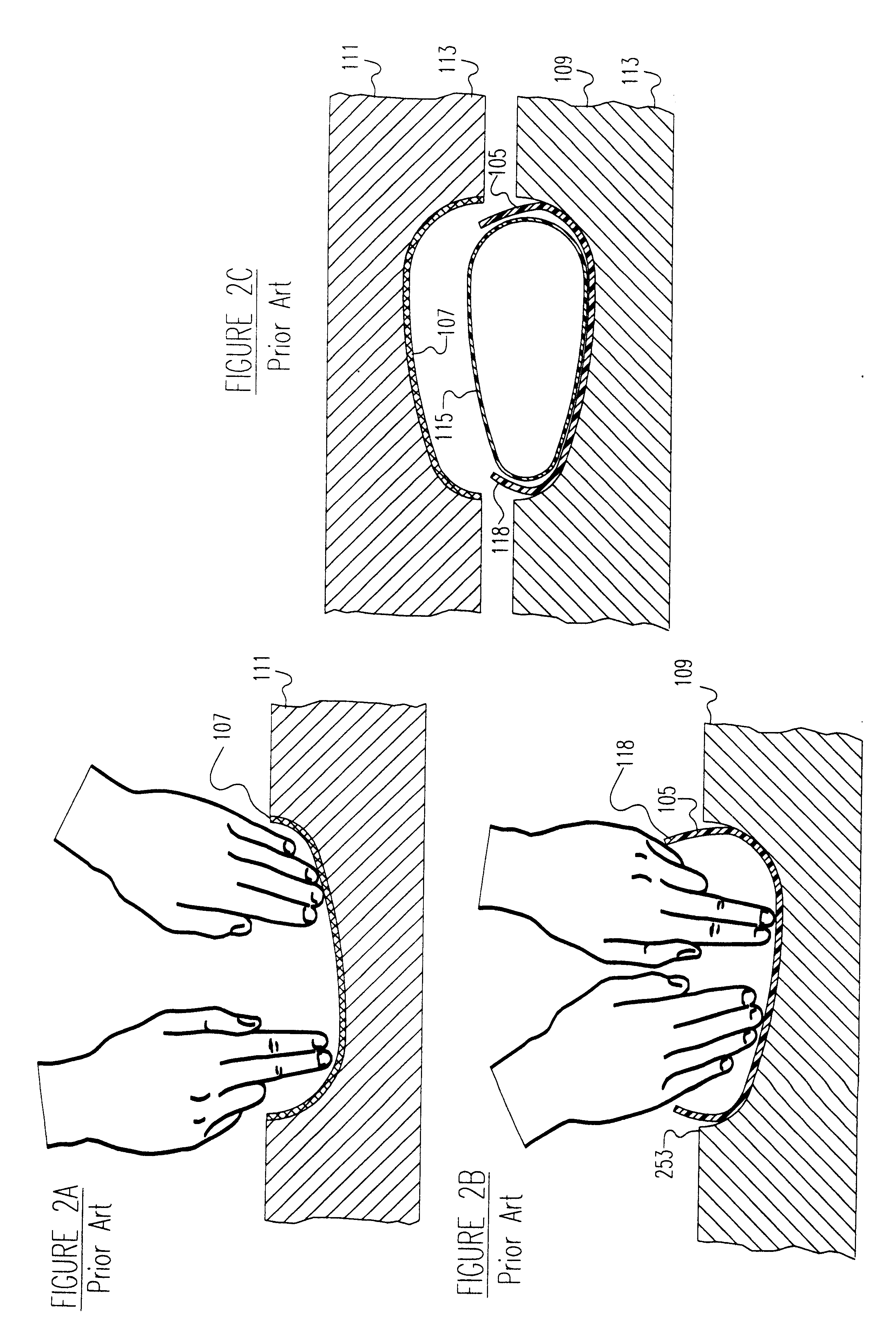

Method of fabricating a belt and a belt used to make bulk tissue and towel, and nonwoven articles and fabrics

InactiveUS7005044B2Accurate storageUniform thicknessNon-fibrous pulp additionNatural cellulose pulp/paperPolymer resinMechanical engineering

In a method for manufacturing a belt and a belt for use in the production of bulk tissue and towel, and of nonwoven articles and fabrics, a polymeric resin material is applied onto the surface of a base substrate in a precise predetermined pattern which is to be imparted onto products manufactured with the belt. The polymeric resin material is deposited in droplets having an average diameter of 10μ (10 microns) or more. The polymeric resin material is then set by means appropriate to its composition, and, optionally, may be abraded to provide the belt with a uniform thickness, and a smooth, macroscopically monoplanar surface.

Owner:ALBANY INT CORP

Container Having a Rim or other Feature Encapsulated by or Formed From Injection-Molded Material

ActiveUS20070267374A1Strengthen and stabilizeProvide supportClosure lidsTurning machine accessoriesHermetic sealEngineering

Owner:GRAPHIC PACKAGING INT

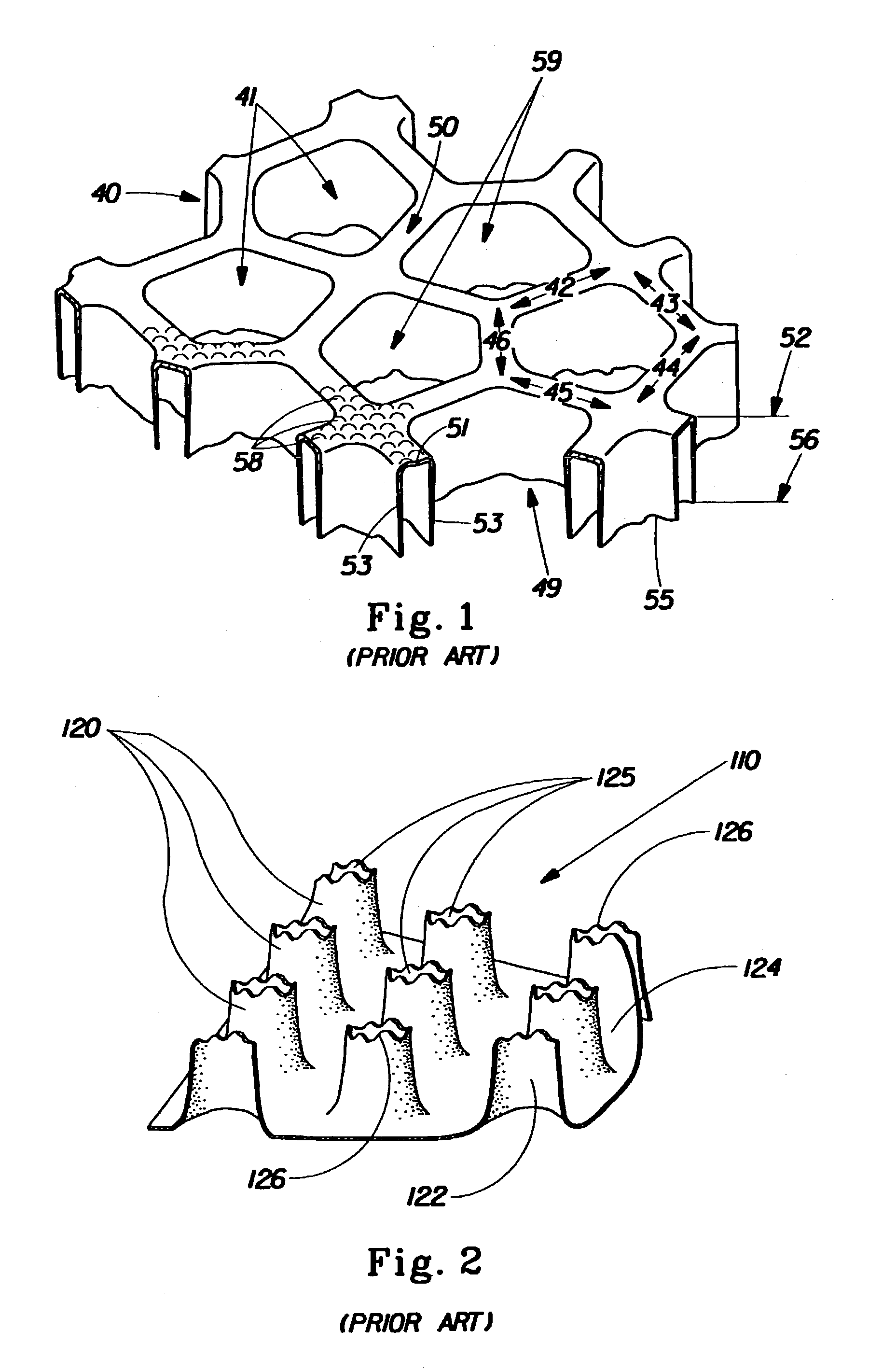

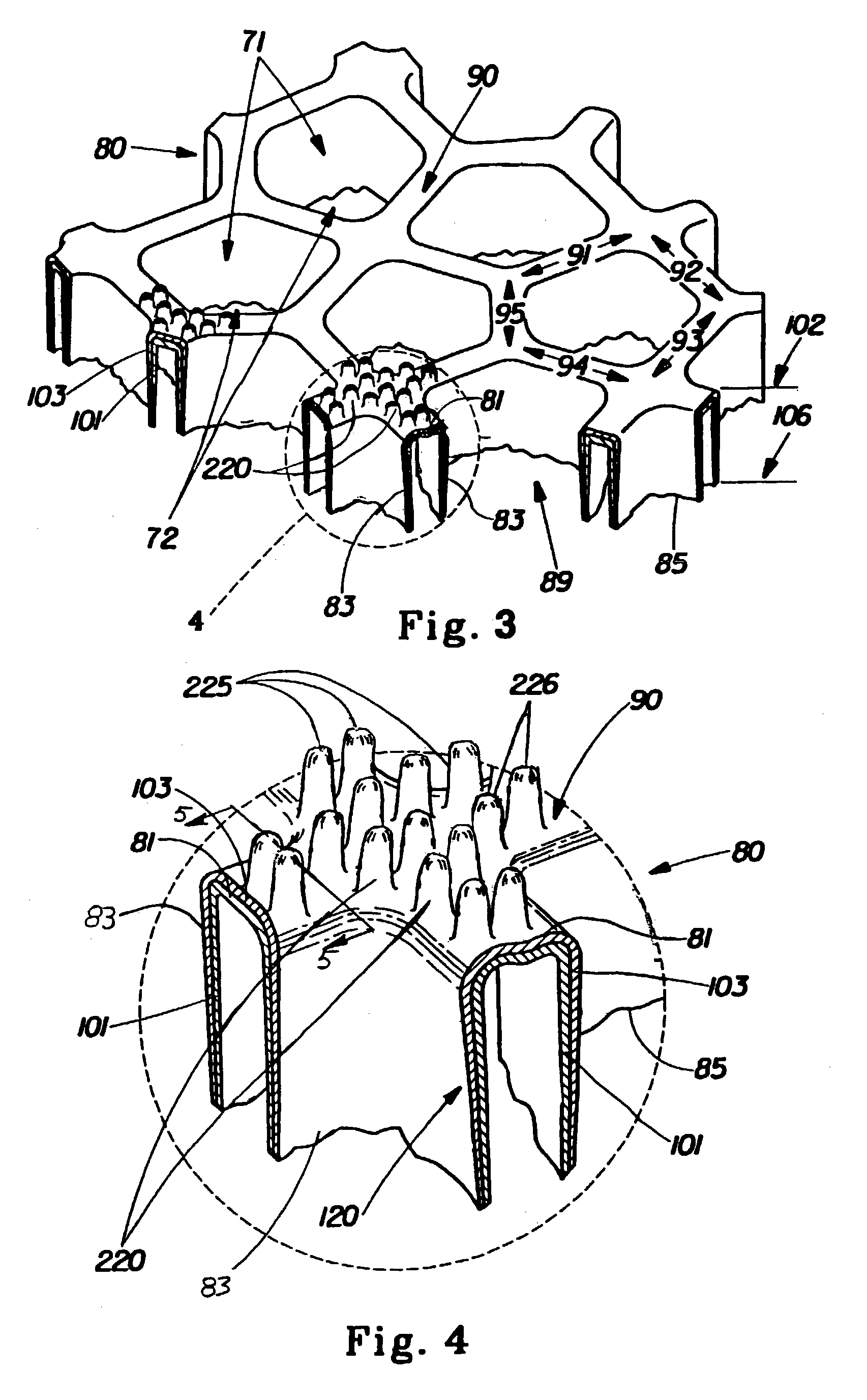

Method of making a polymeric web exhibiting a soft and silky tactile impression

A polymeric web exhibiting a soft and silky tactile impression on at least one side thereof is disclosed. The silky feeling side of the web exhibits a pattern of discrete hair-like fibrils, each of the hair-like fibrils being a protruded extension of the web surface and having a side wall defining an open proximal portion and a closed distal portion. The hair-like fibrils exhibit a maximum lateral cross-sectional diameter of between 2 and 5 mils, and an aspect ratio from 1 to 3. Methods and apparatus for making the polymeric web utilize a three-dimensional forming structure having a plurality of protrusions being generally columnar forms having an average aspect ratio of at least about 1.

Owner:THE PROCTER & GAMBLE COMPANY

Rubber composition and product thereof

The invention relates to a rubber combination, which comprises: 100 pars of rubber being a major constituent, 0-60 parts of anti-polyolefine, 1-5 parts of zinc oxide, 1-4 parts of stearic acid, 0.5-2 parts of age inhibitor, 0.5-2 parts of paraffinum, 20-150 parts of modification filling, 1-5 parts of process oil, 0.5-20 parts of softener, 0.5-3 parts of promoter, and 0.5-3 parts of sulfur. The rubber combination is molded, shaped, vulcanized so as to obtain various corresponding high performance products, in particular to tyre products, cord ply adhesive tapes and conveyor belt and has extensive use.

Owner:严晓敏

Method of making a golf ball with a multi-layer core

InactiveUS7153467B2Uniform thicknessWell formedSynthetic resin layered productsCeramic shaping apparatusHardnessEngineering

A method for making a multilayer golf ball including a solid center having a center hardness, a plurality of laminates cut into a plurality of shapes formed around the center to create an inner ball, and a cover formed around the inner ball, wherein the plurality of layers can include at least a first layer having a hardness greater than the center hardness and a second layer having a hardness greater than the first layer hardness, and optionally a third layer disposed between the first and the second layers having a hardness greater than the first layer hardness.

Owner:ACUSHNET CO

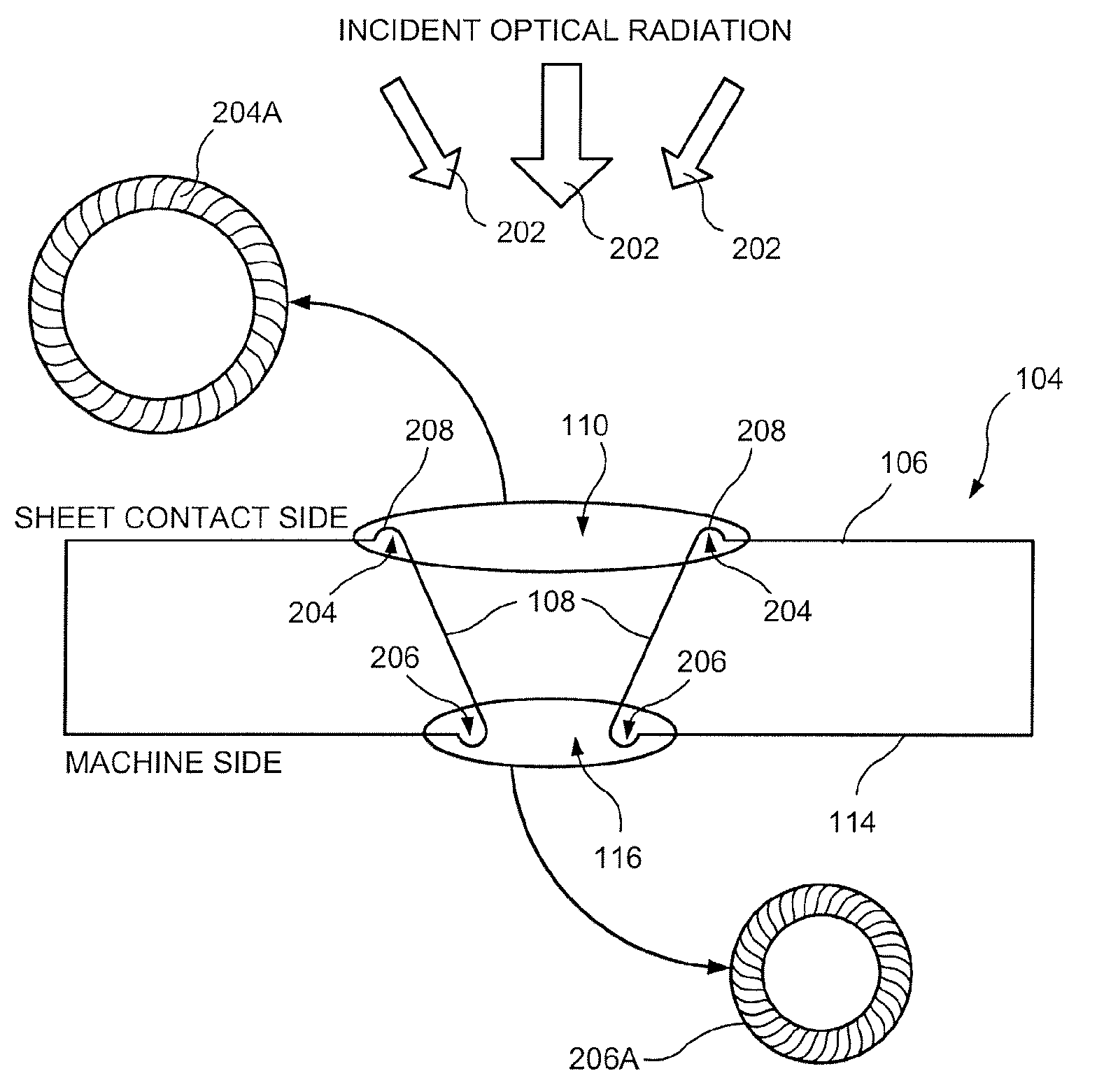

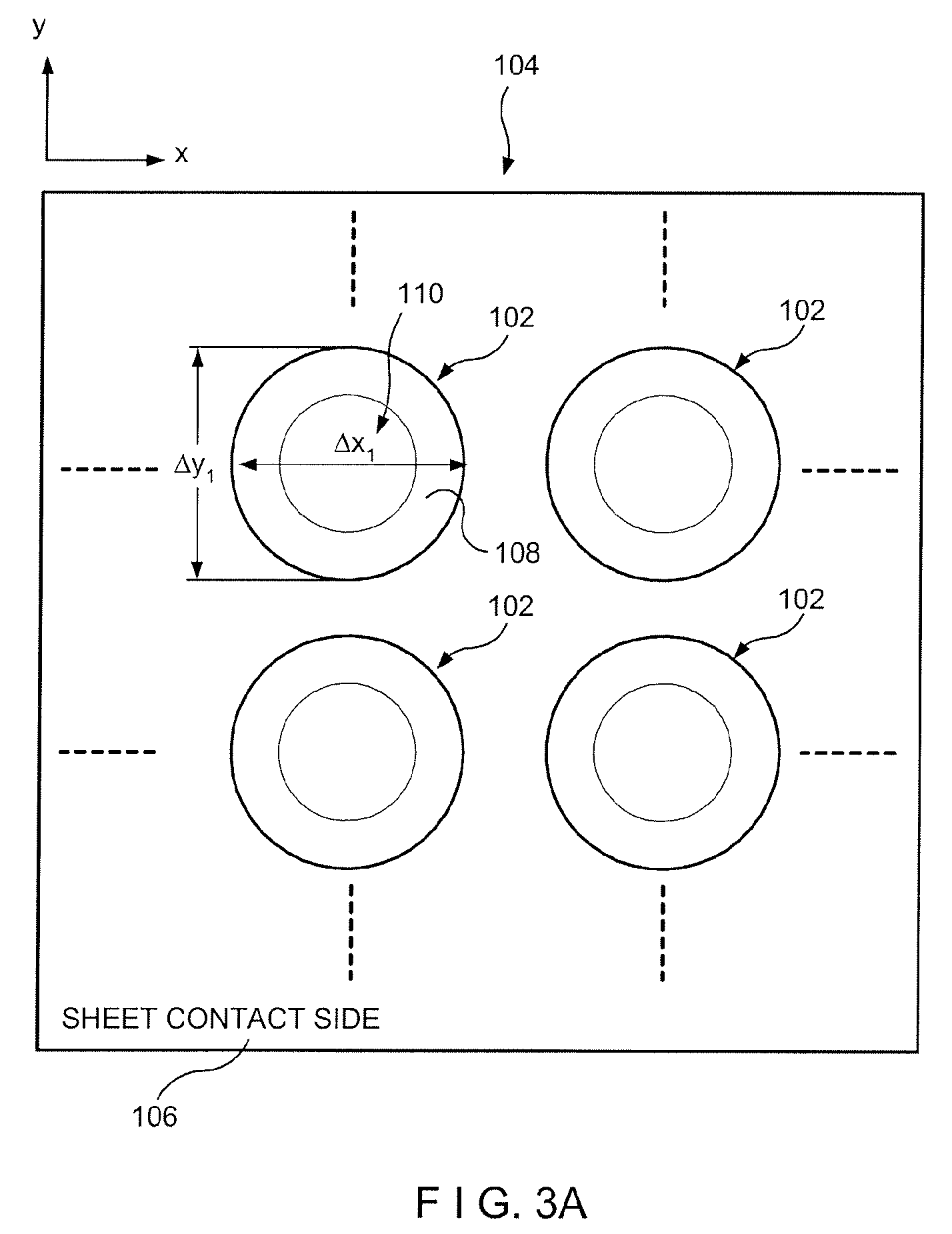

Industrial fabric, and method of making thereof

ActiveUS8822009B2Wet shapingEasy to cleanPattern makingSynthetic resin layered productsEngineeringMaterial Perforation

A support member such as a belt or sleeve includes a topographical pattern on its sheet contact side. A plurality of land areas, corresponding depressions, through voids, and / or groove areas are formed on the top surface of the support member to produce the topographical pattern. The land areas, corresponding depressions, through voids, and / or groove areas may be formed by graving, cutting, etching, embossing, mechanical perforation or a combination thereof. The improved belt or sleeve imparts desired physical characteristics, such as bulk, appearance, texture, absorbency, strength, and hand to a nonwoven product produced thereon.

Owner:ALBANY INT CORP

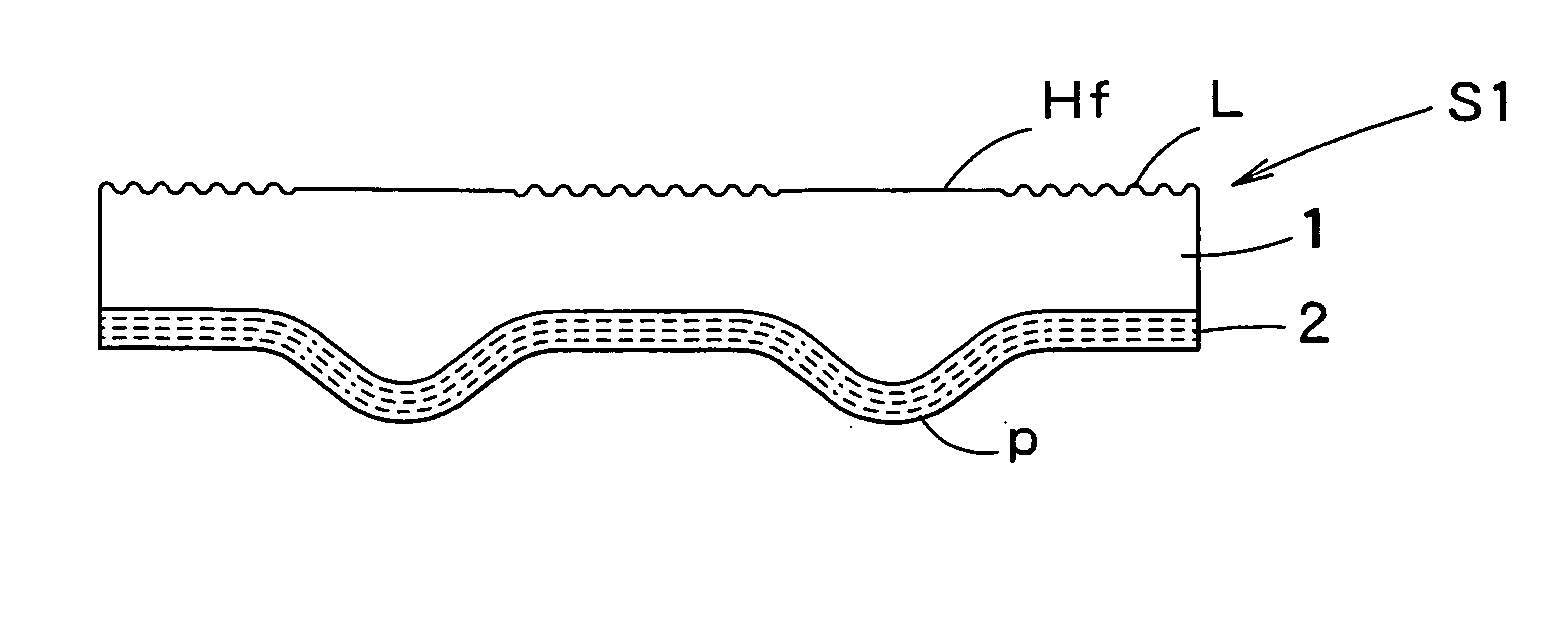

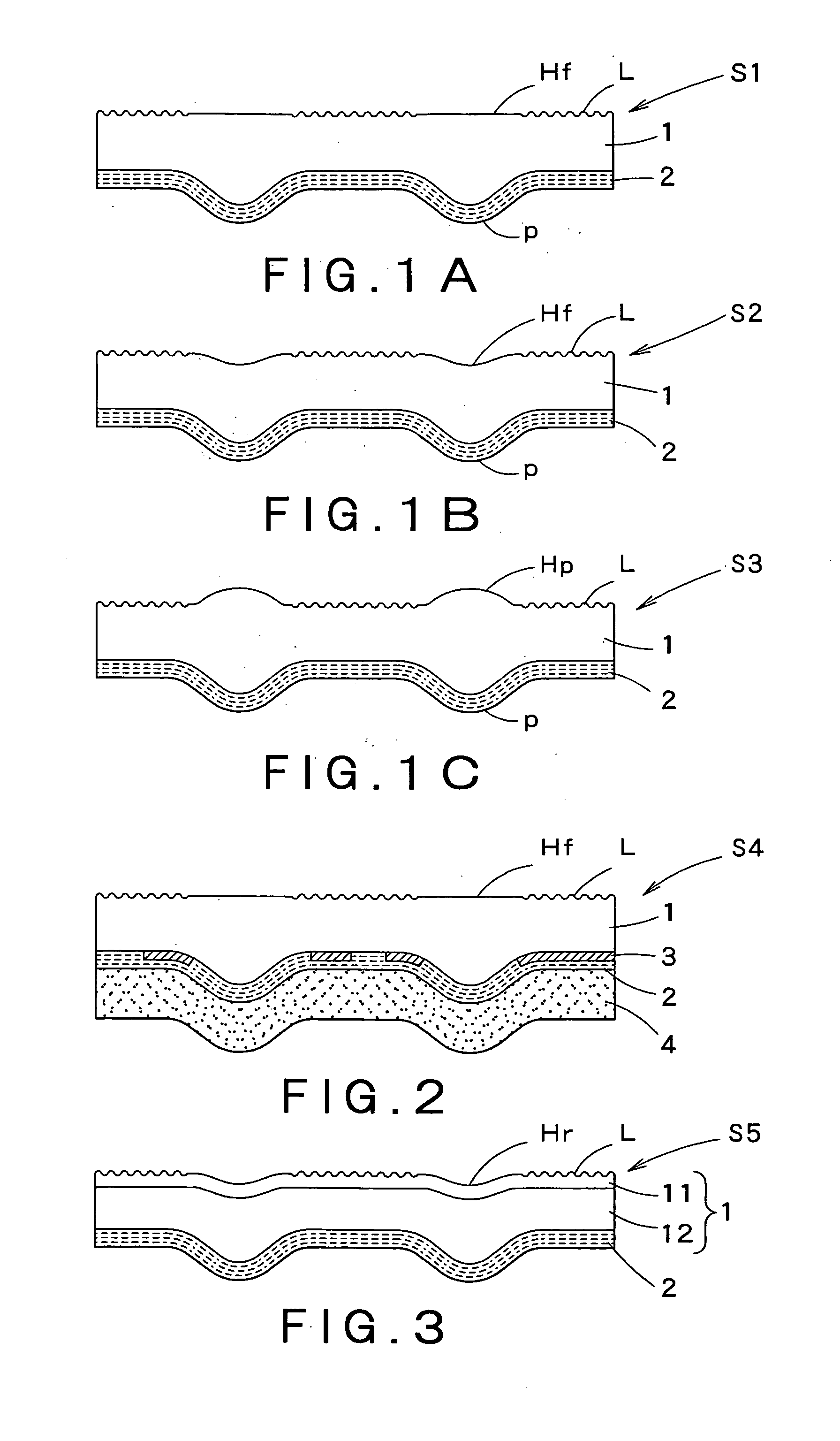

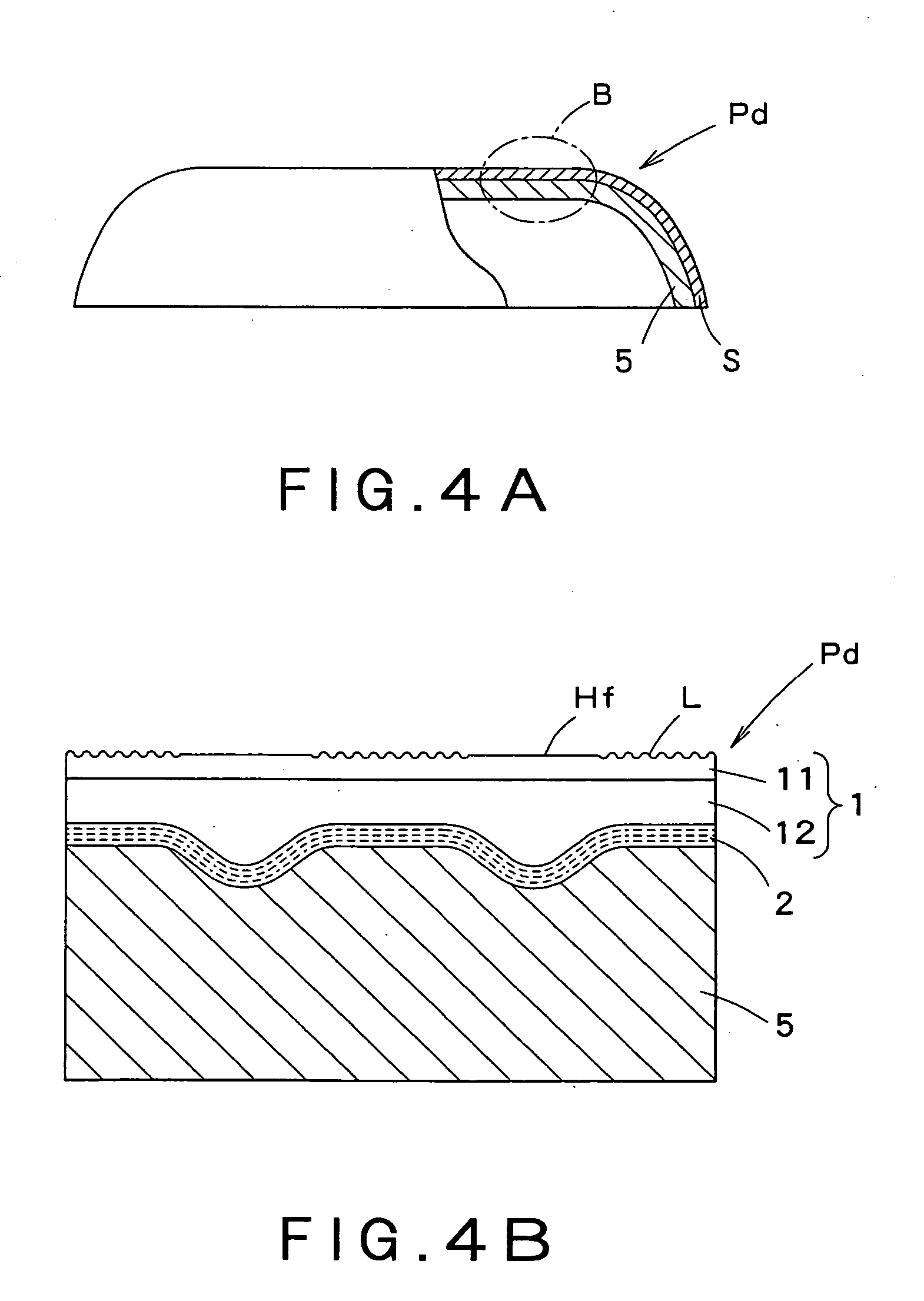

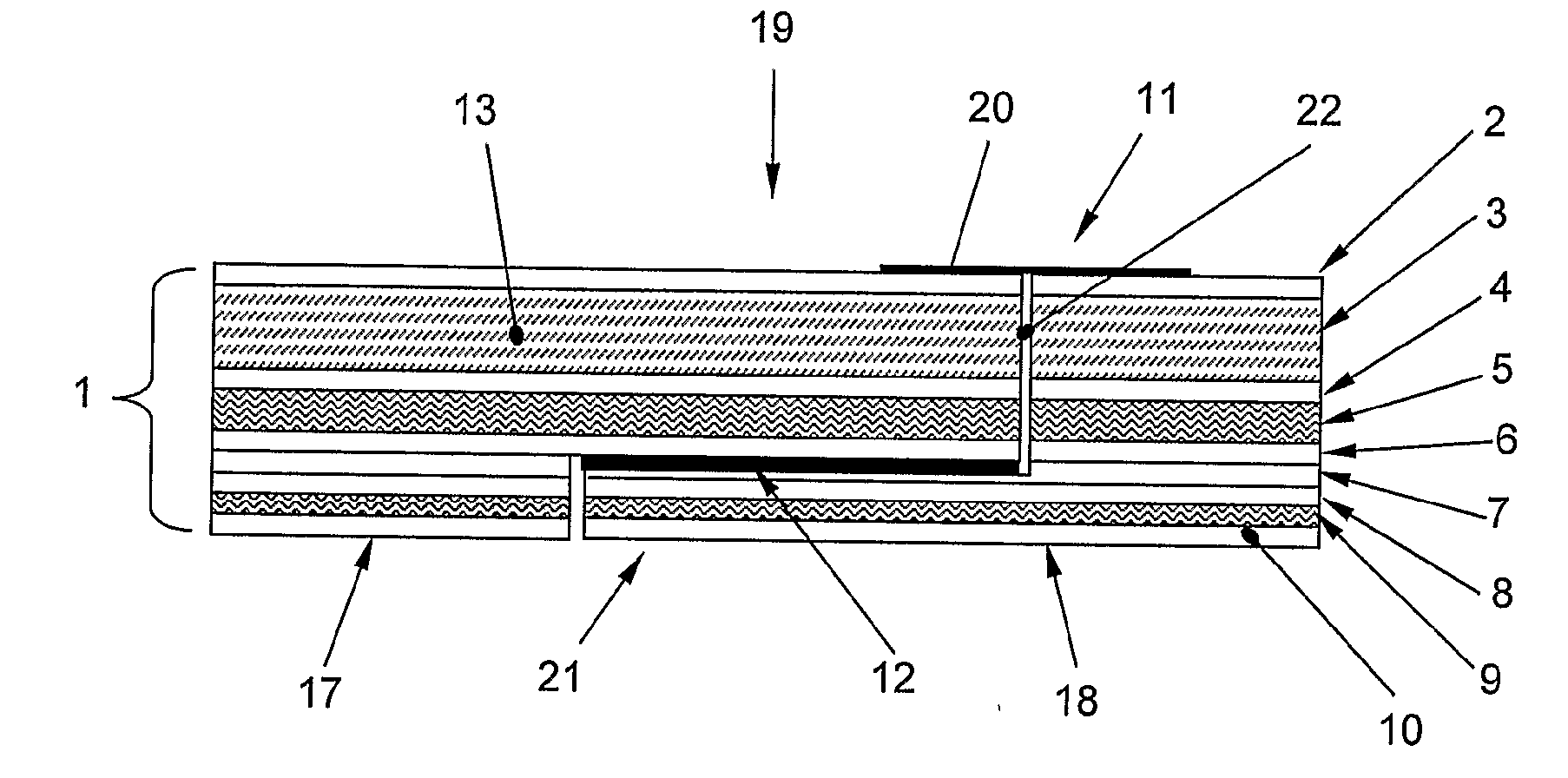

Decorating sheet, decorating molded article and in-mold decorating injection molding

ActiveUS20070026197A1Easy to manufactureOrnamental structuresSpecial ornamental structuresShell moldingEngineering

A decorating sheet comprises a transparent resin substrate sheet 1 and a glossy layer 2 laminated to the back surface of the transparent resin substrate sheet 1, and the front surface of the transparent resin substrate sheet 1 is divided into high-gloss portions H and low-gloss portions L. The transparent resin substrate sheet 1 is thick at the high-gloss portions and thin at the low-gloss portions, and, owing to these portions, the decorating sheet can provide a pattern that is visually sensed as if it were a three-dimensional pattern. This transparent resin substrate sheet 1 is composed of two layers, a crystalline resin layer 11 and a non-crystalline resin layer 12. A decorated molded product Pd can be obtained by laminating this decorating sheet to a resin molded product 5.

Owner:DAI NIPPON PRINTING CO LTD

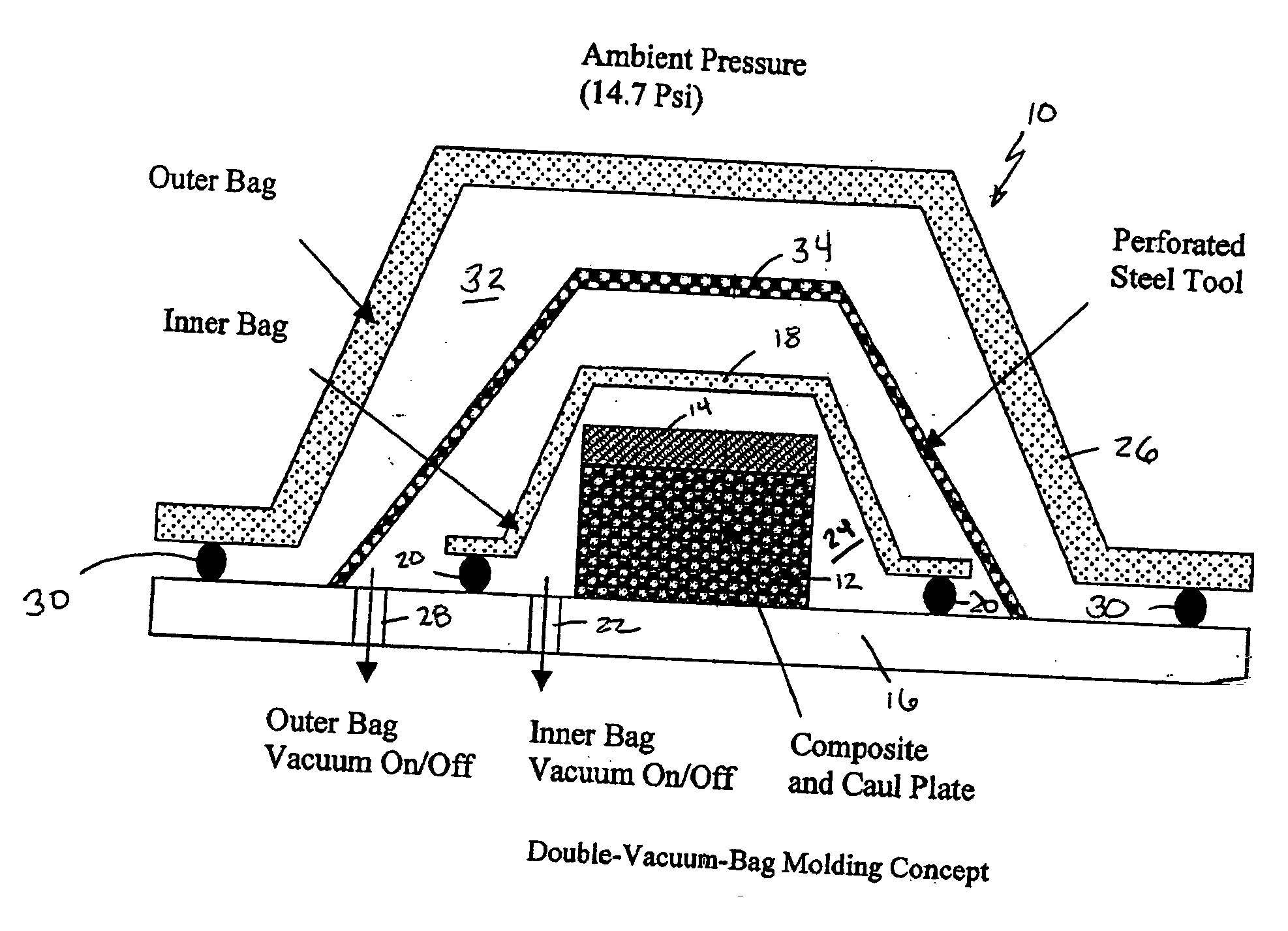

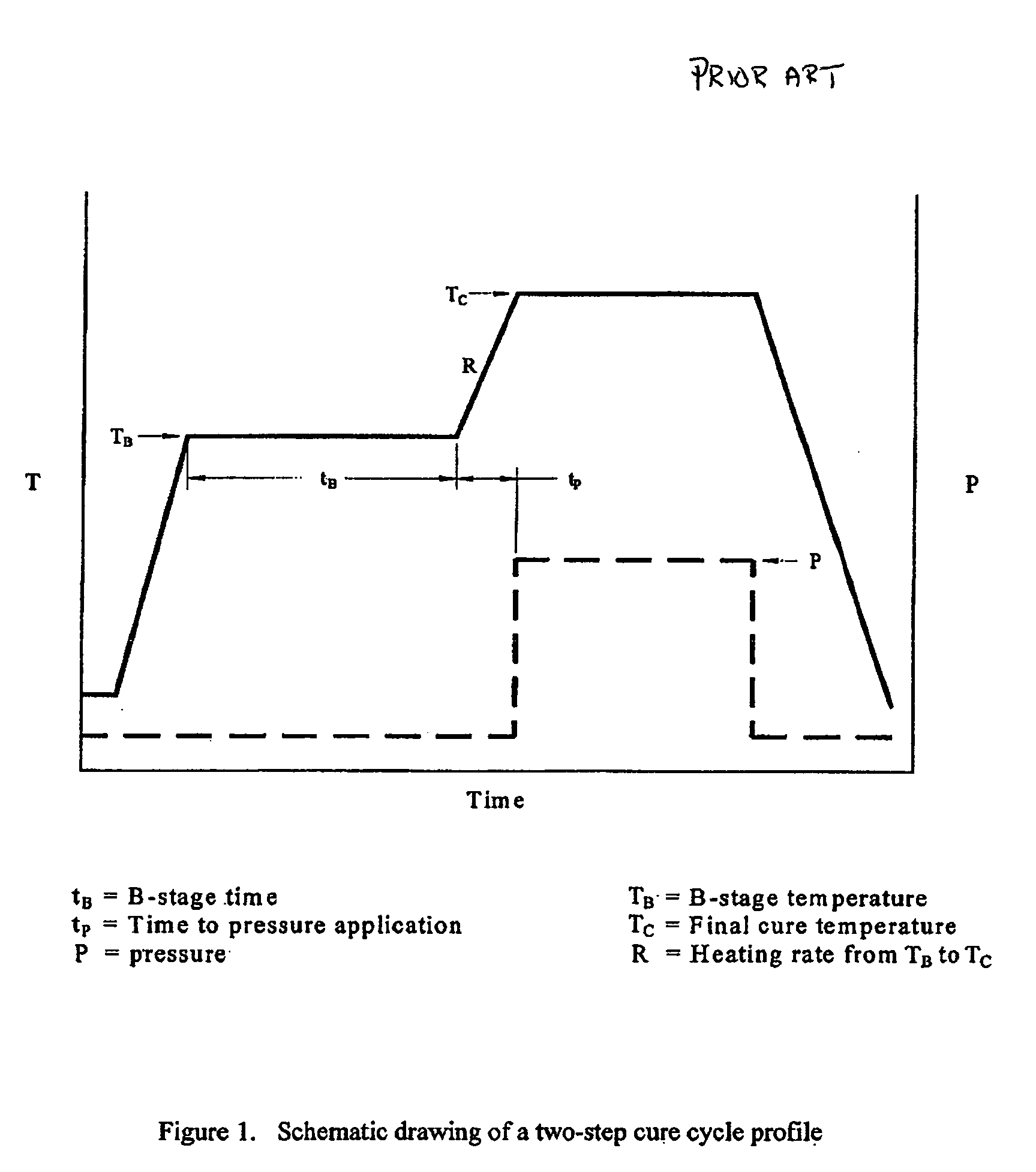

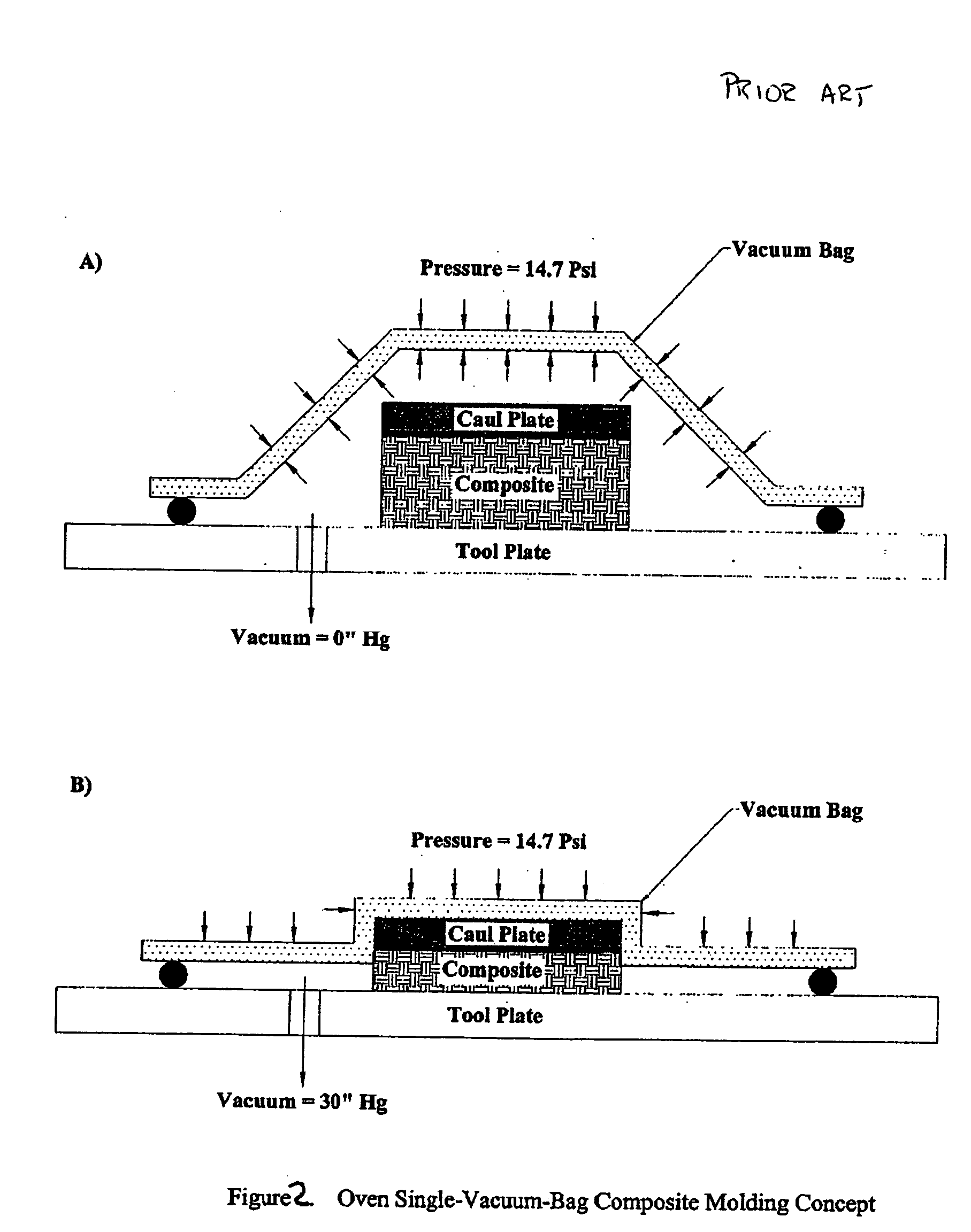

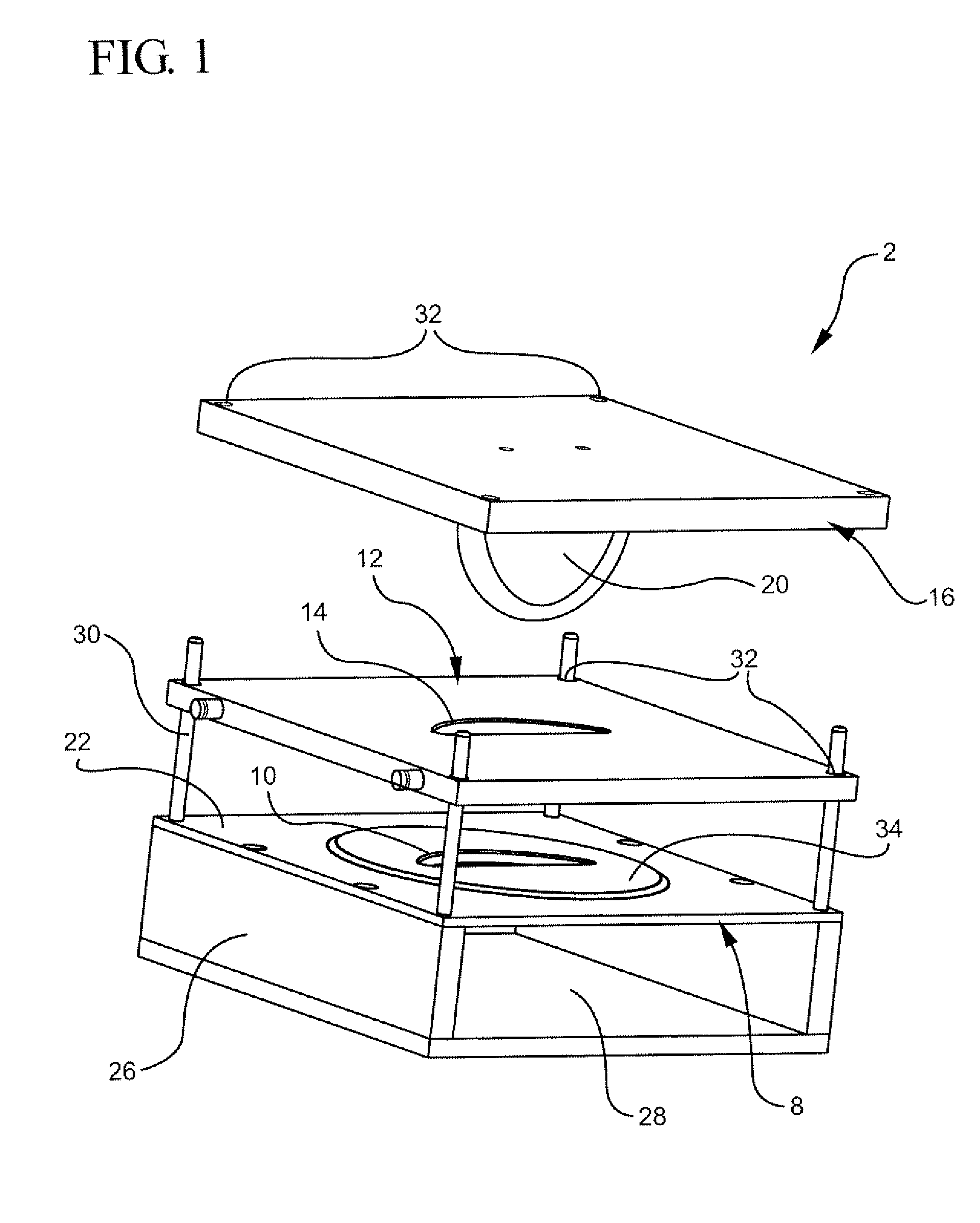

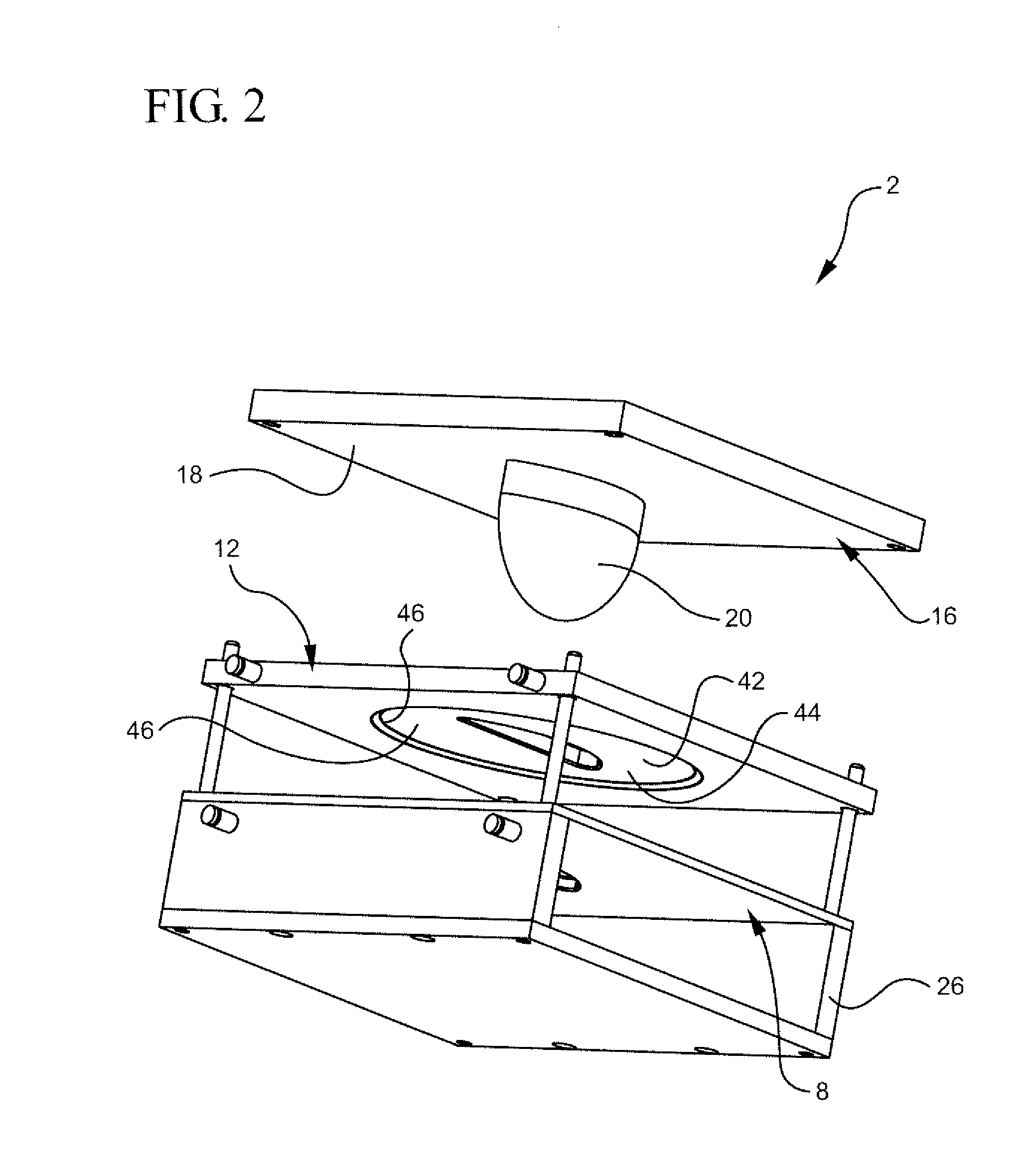

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

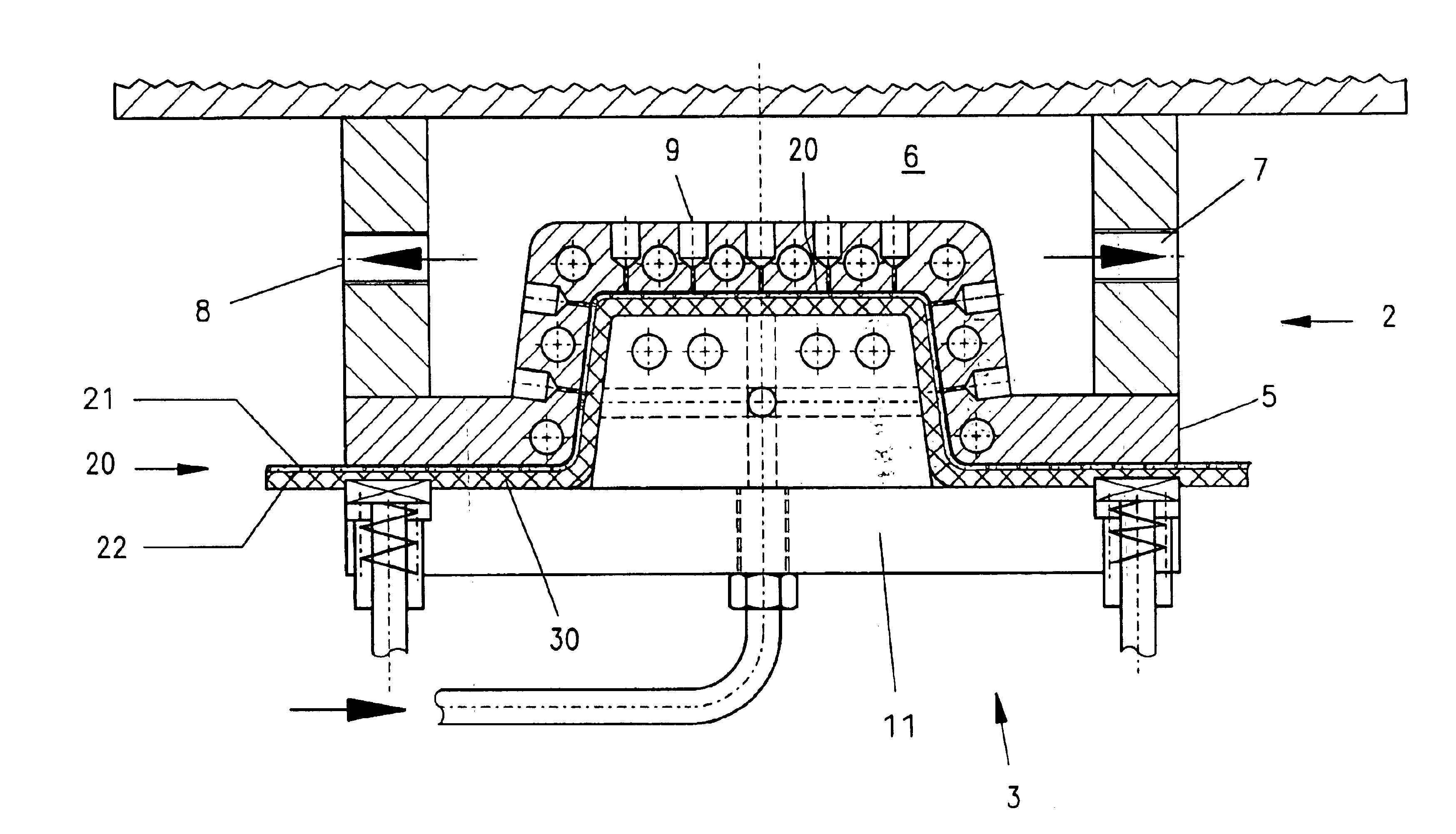

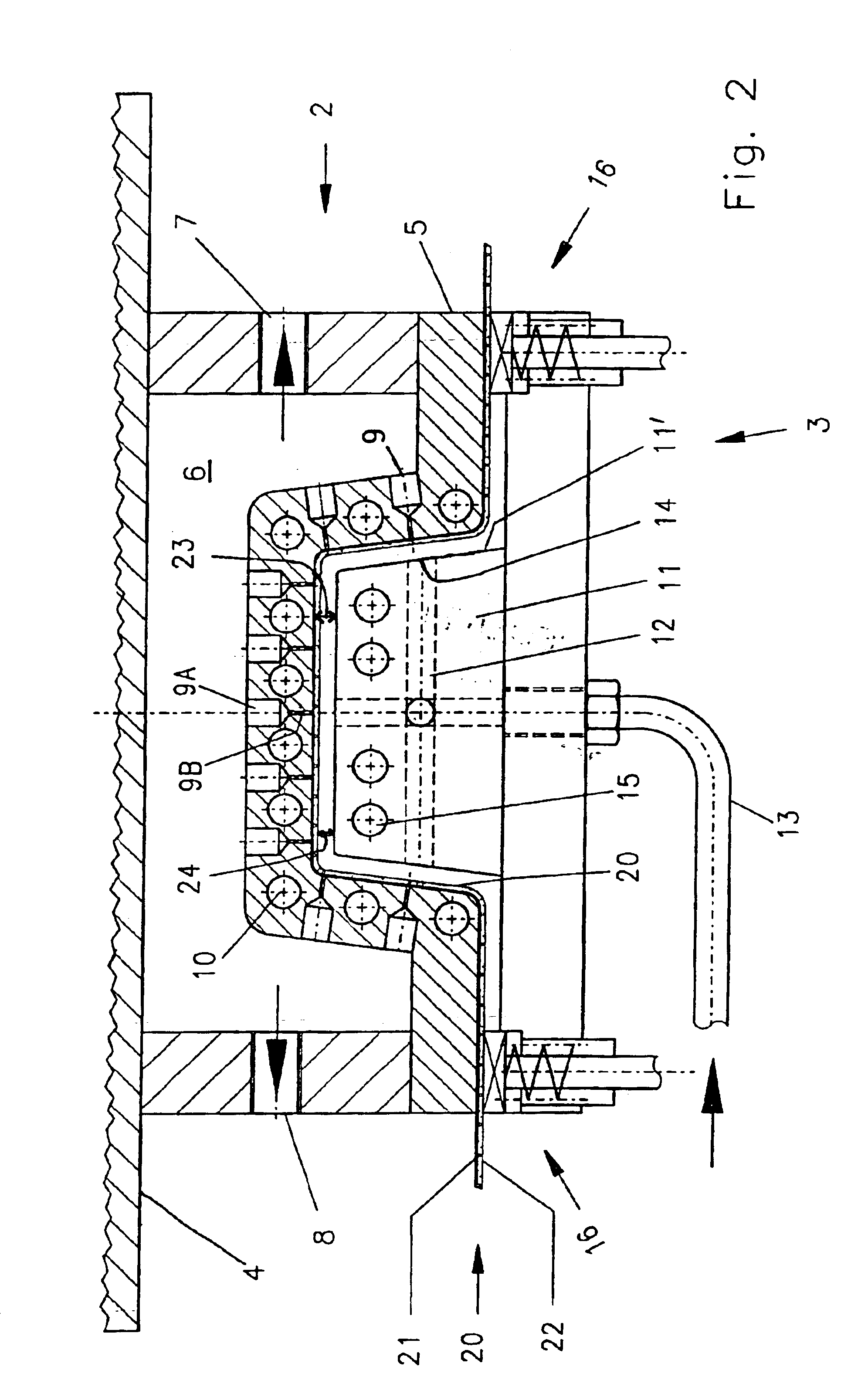

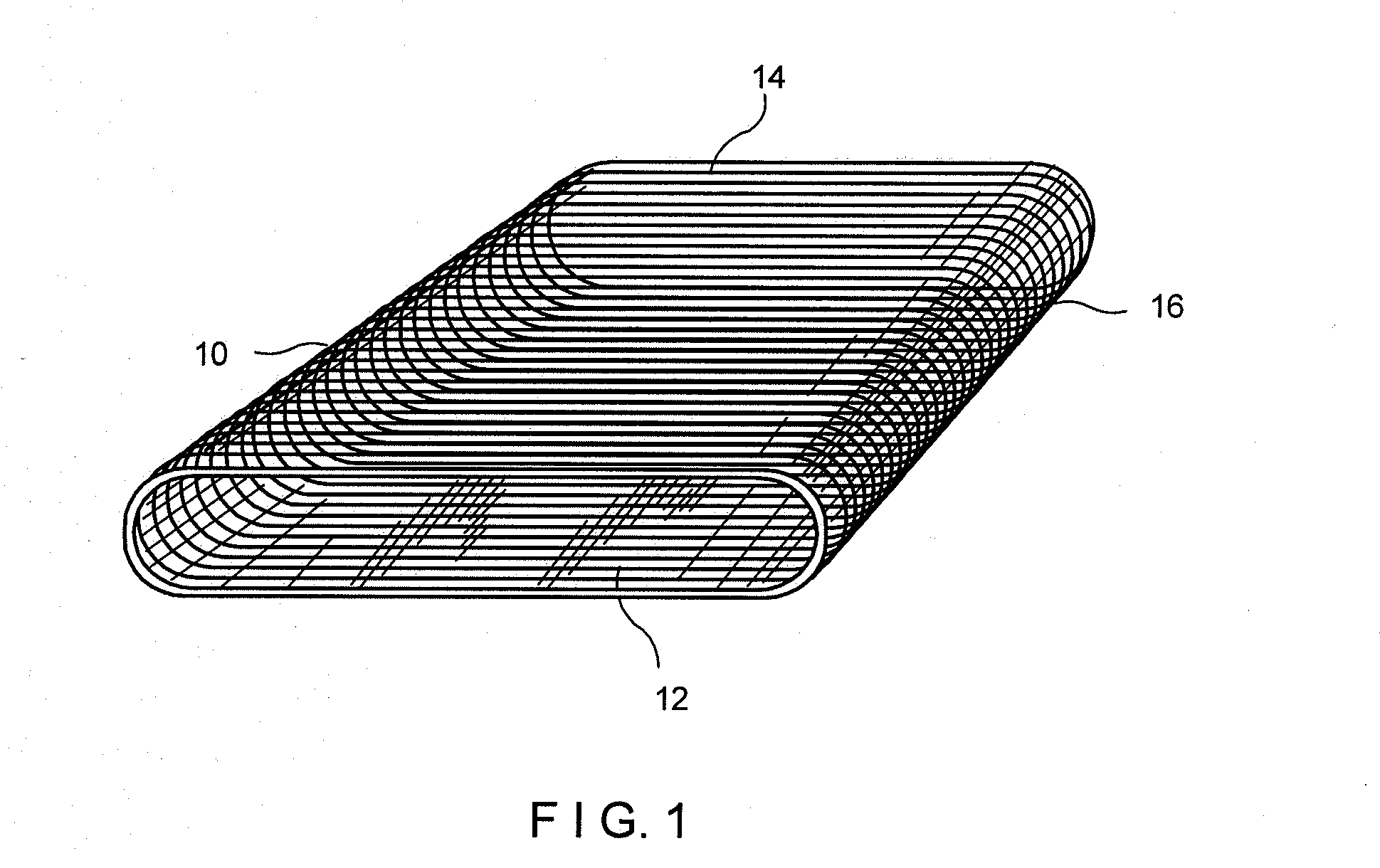

Multi-layered belt

InactiveUS20090098385A1Reliable and durable mechanical propertyReduce stress exertedConveyorsSynthetic resin layered productsEngineeringLeather belt

A multi-layered belt, in particular a continuous running and / or transport and / or processing belt, includes a traction layer and a functional layer that contains a gel. To reduce the stress placed on the transported goods, in particular persons, the gel is an unplasticized gel and the functional layer consist of a coating containing the interspersed gel. In addition, to a method for producing a belt of this type is provided, in which the gel is poured in a continuous method onto the traction layer and a mixer and delivery unit is guided back and forth in a reversible manner perpendicular to the displacement direction of the traction layer in such a way that a gel layer with a uniform thickness is applied to the traction layer. Furthermore, the use of said belt as a running belt for persons, in particular as a running belt for training and / or fitness equipment is described.

Owner:FORBO SIEGLING +1

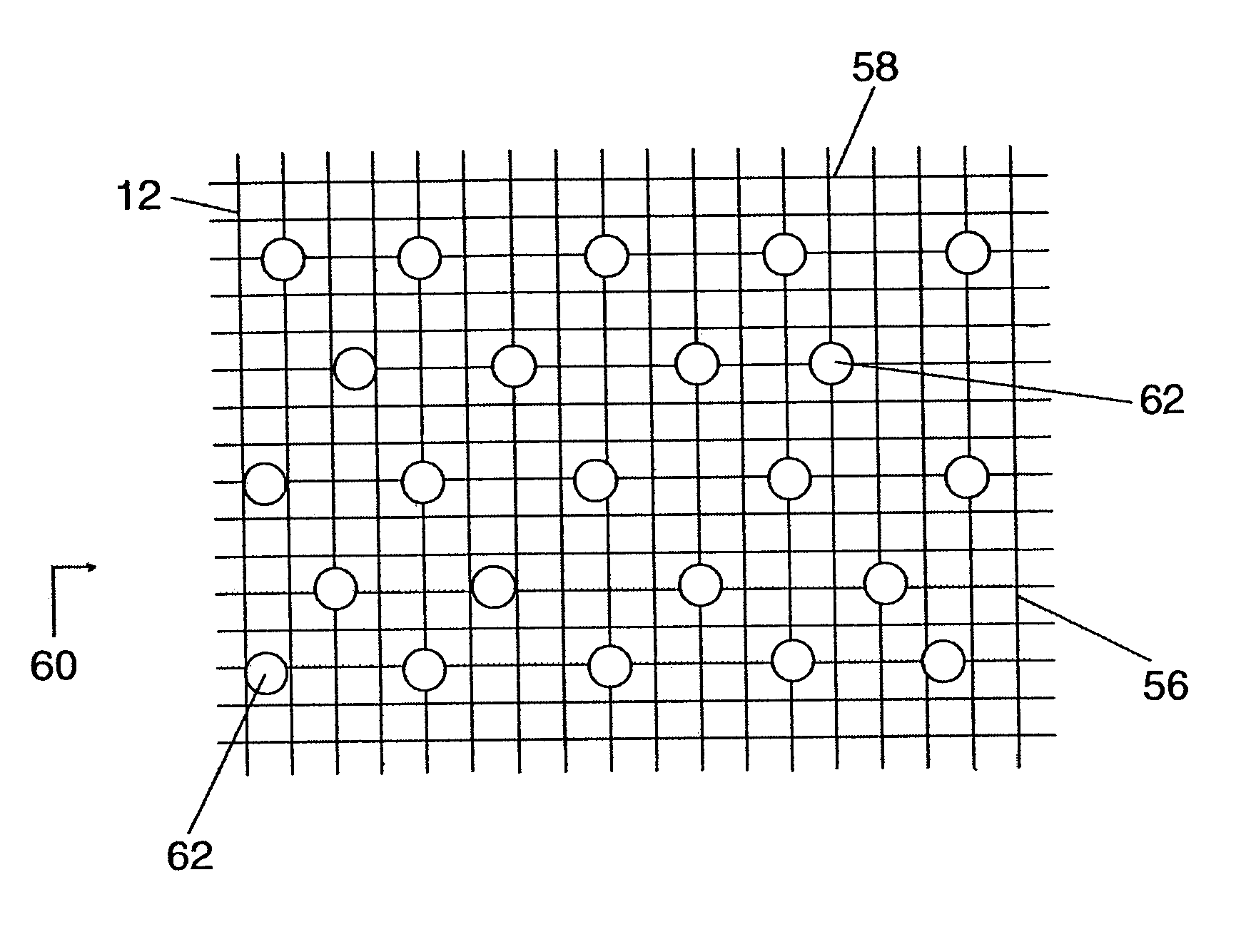

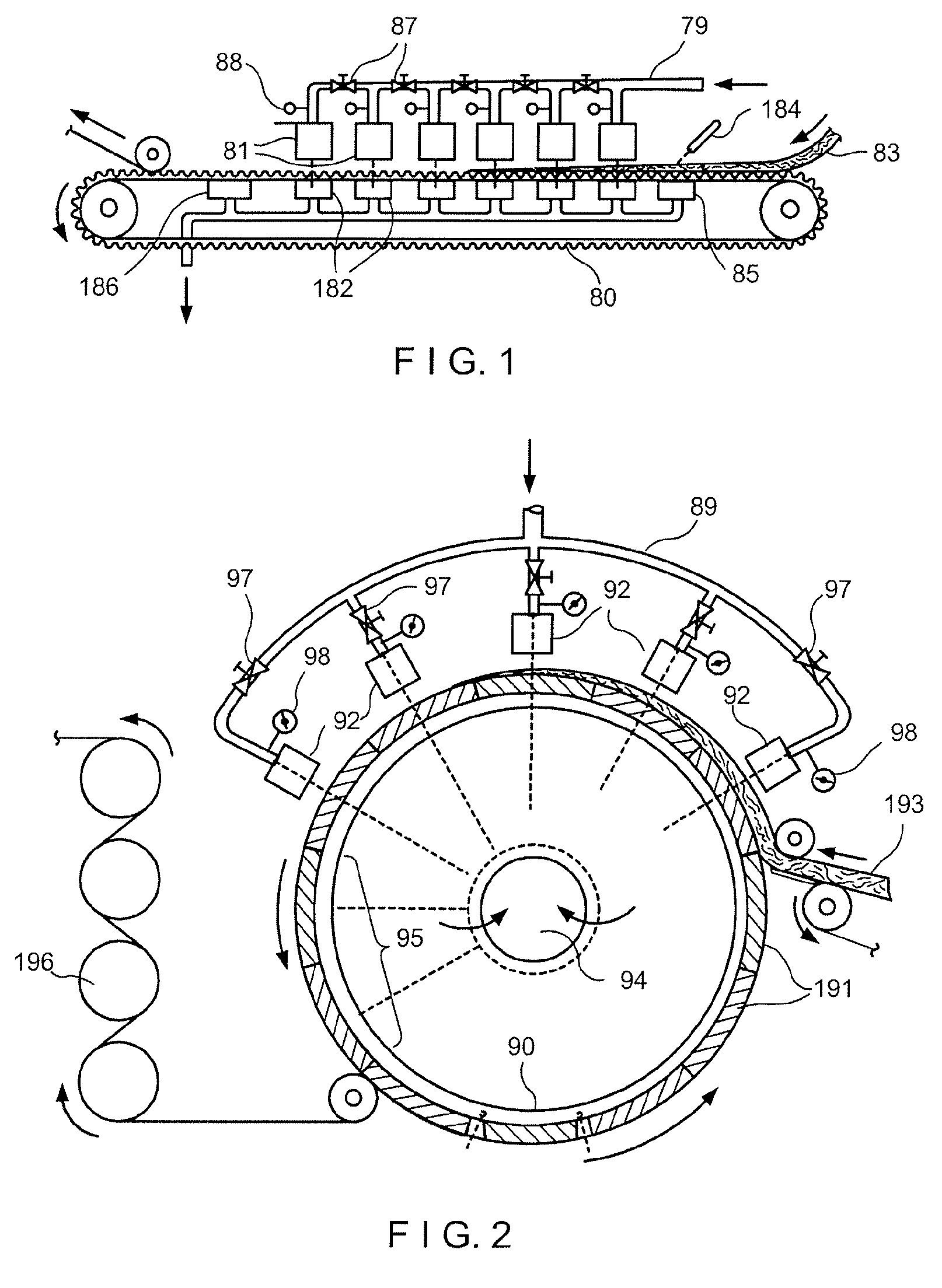

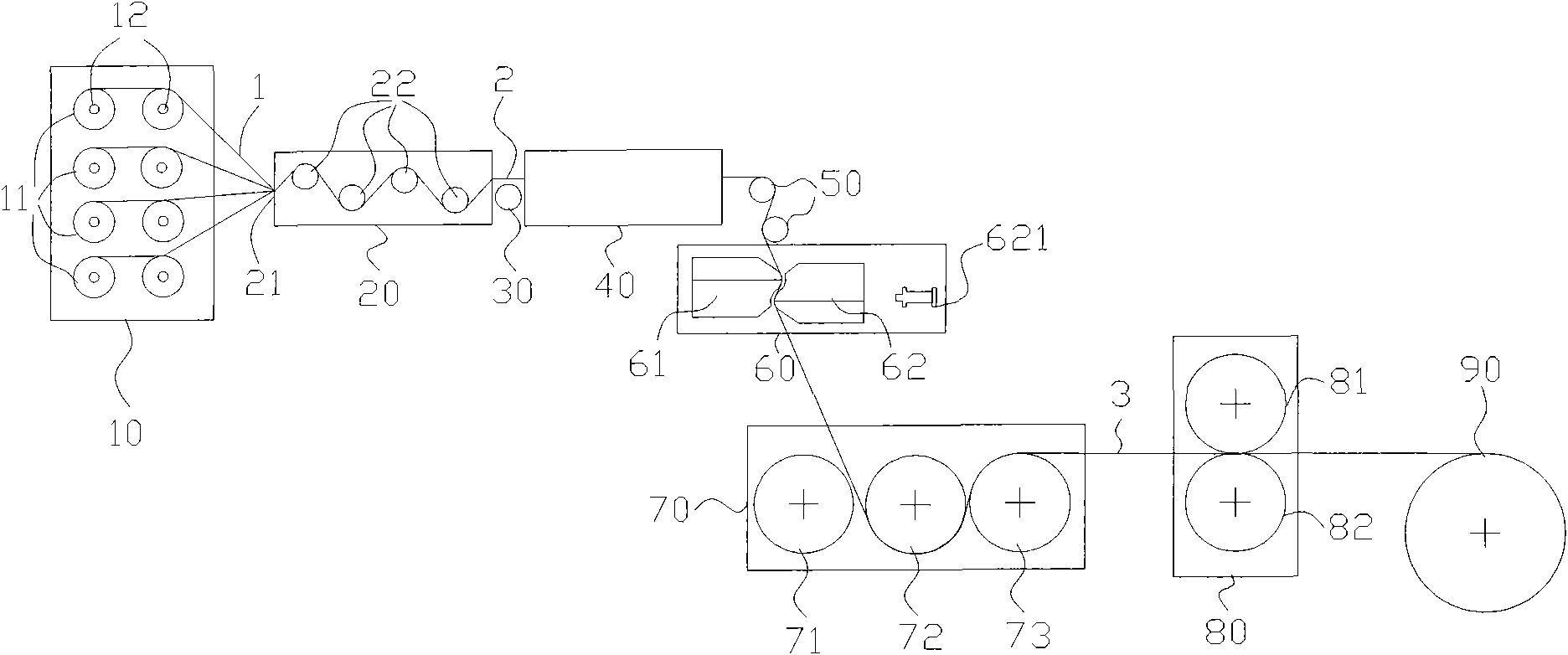

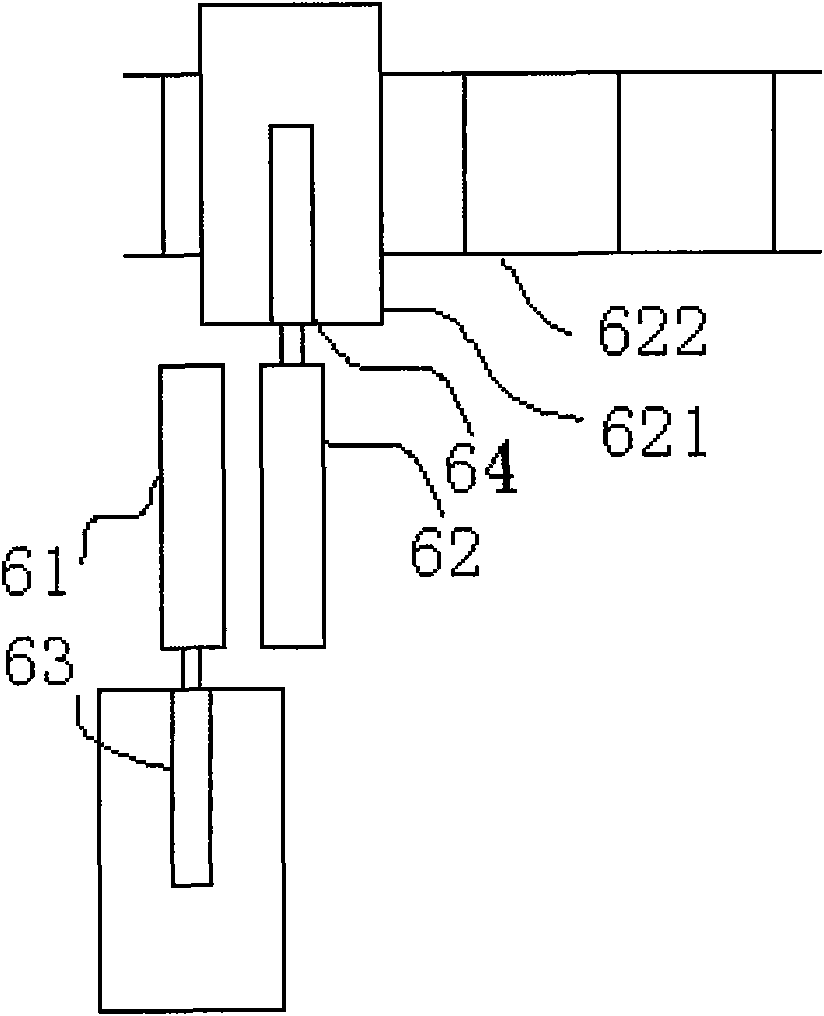

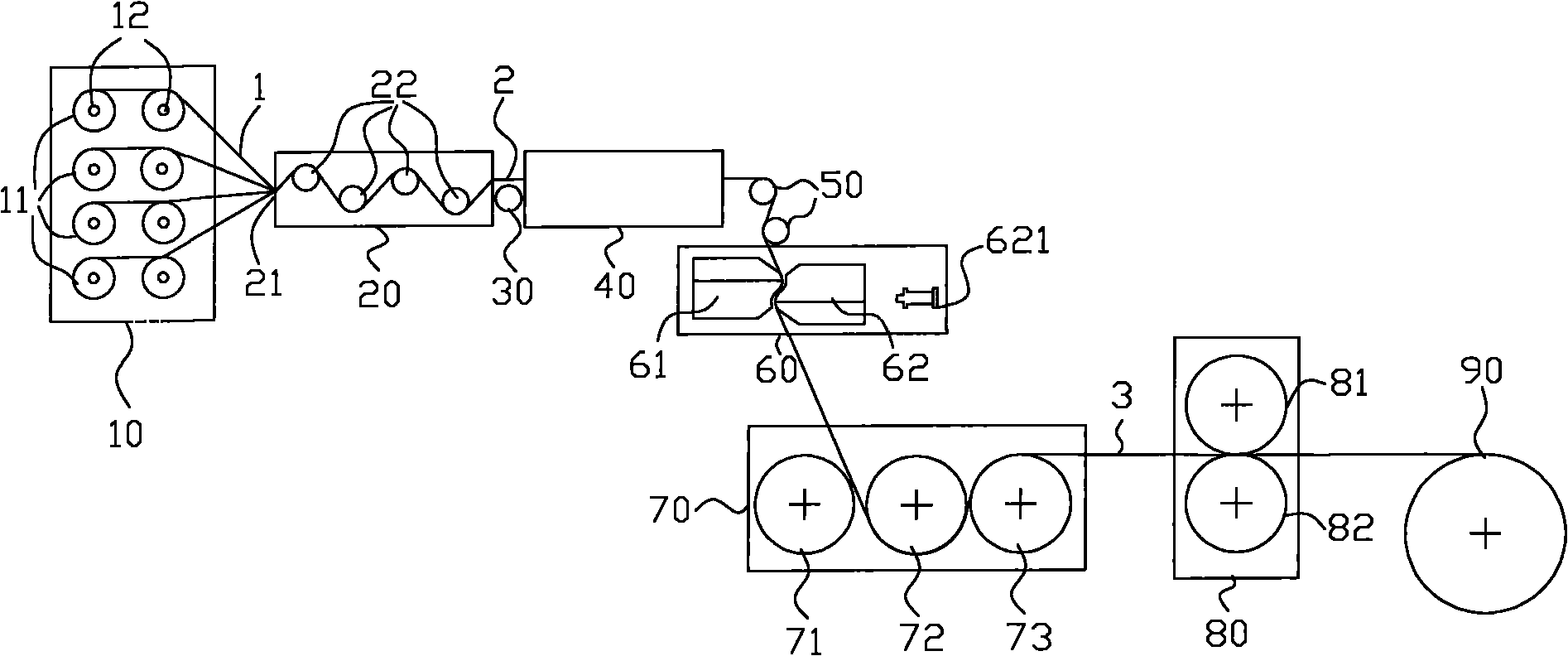

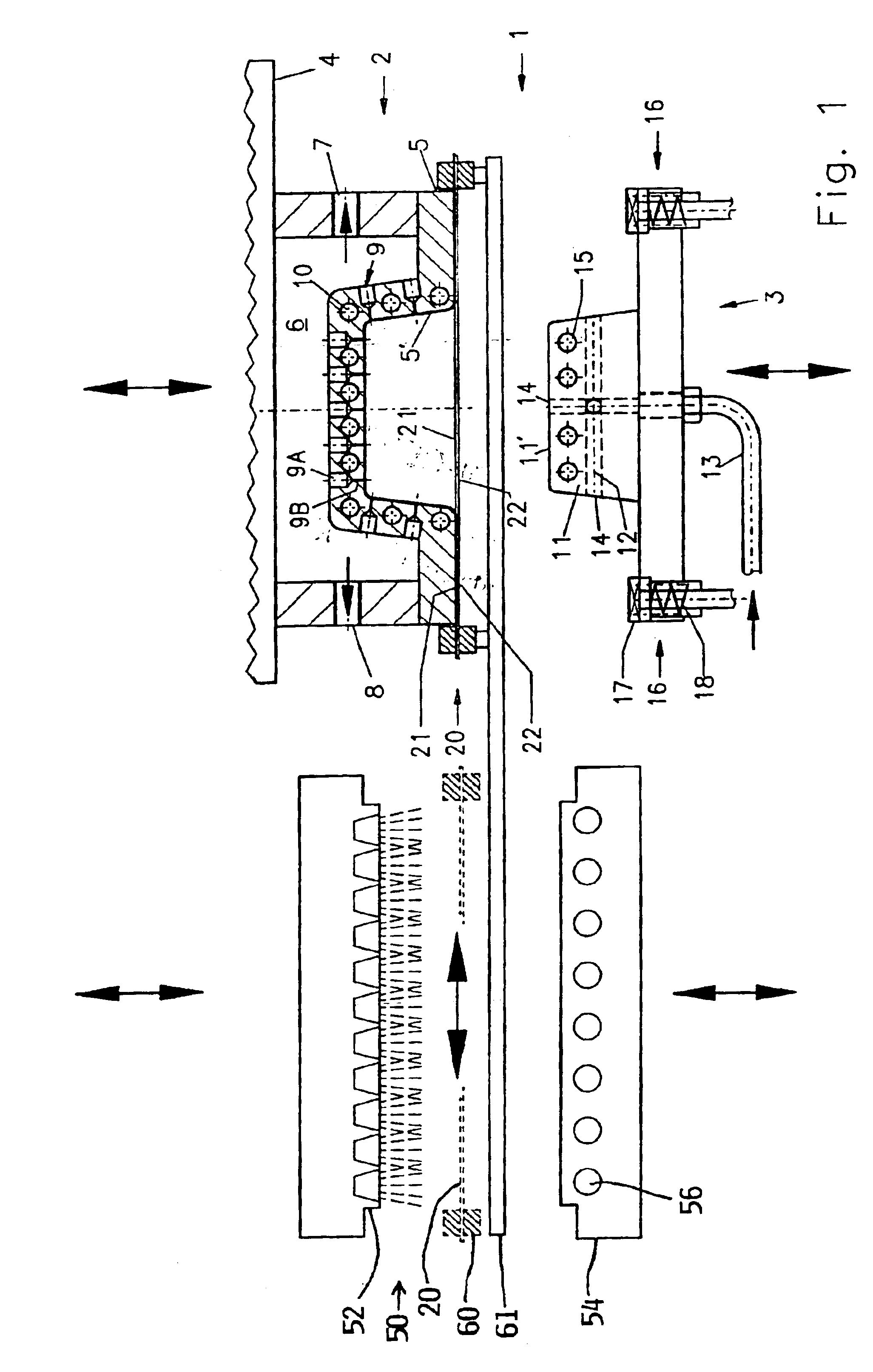

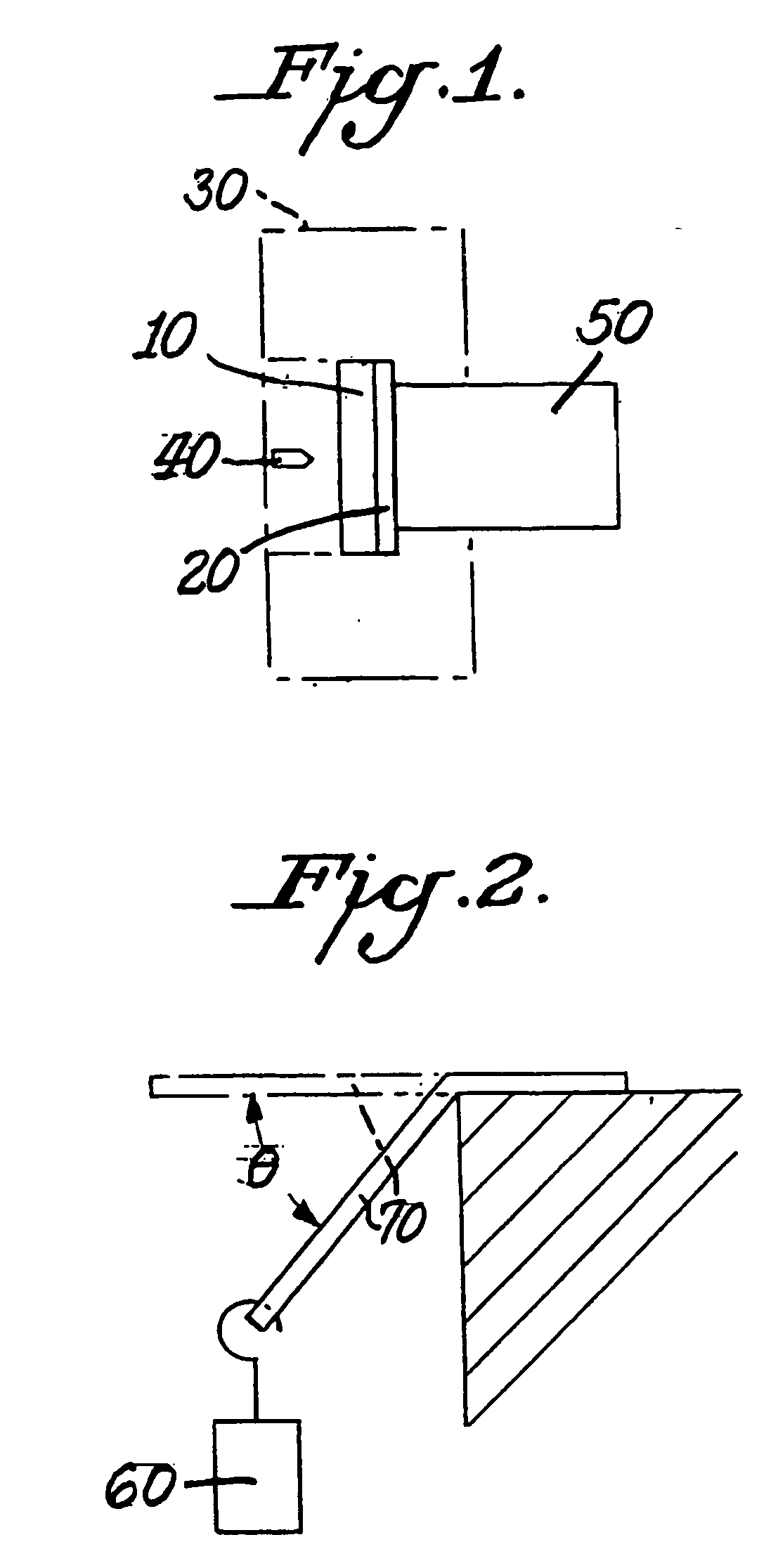

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Light guide plate made of transparent resin, molding method thereof, insert block, mold assembly, and area light apparatus

InactiveUS20020181224A1Accurately reliably formedCorrect formatMechanical apparatusMouldsLight guideMechanical engineering

A light guide plate which is made of a transparent resin and has a first main surface and a second main surface opposite to said first main surface, said first main surface having a surface portion provided with convex portions having a height of 5x10-7 m to 6x10-5 m each and a pitch of 5x10-7 m to 4x10-4 m, each convex portion having a tip portion, and the convex portions of at least 80% of the total convex portions having the tip portions having a radius of curvature of 2x10-6 m or less.

Owner:MITSUBISHI ENG PLASTICS CORP

Process for producing a water soluble package

InactiveUS6281183B1Prevent overflowLess-weak spotCosmetic preparationsToilet preparationsShell moldingEngineering

A process for producing a thermoformed package comprises the steps of placing a first sheet of film over a forming die having at least one cavity, heating the film to mould the film into the at least one cavity thereby forming at least one recess in the film, placing a composition in the at least one formed recess, and sealing a second sheet of film across the at least one formed recess to produce at least one closed package. Once formed, the or each recess is substantially retained in its formed orientation by the application of a vacuum through the or each cavity.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Industrial fabric including spirally wound material strips

ActiveUS20100230064A1Improved fiber supportFacilitated releaseFilament handlingNeedling machinesStrappingUltrasonic welding

An industrial fabric, belt or sleeve and a method of making the fabric, belt or sleeve are disclosed. The industrial fabric, belt or sleeve is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric, belt or sleeve may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

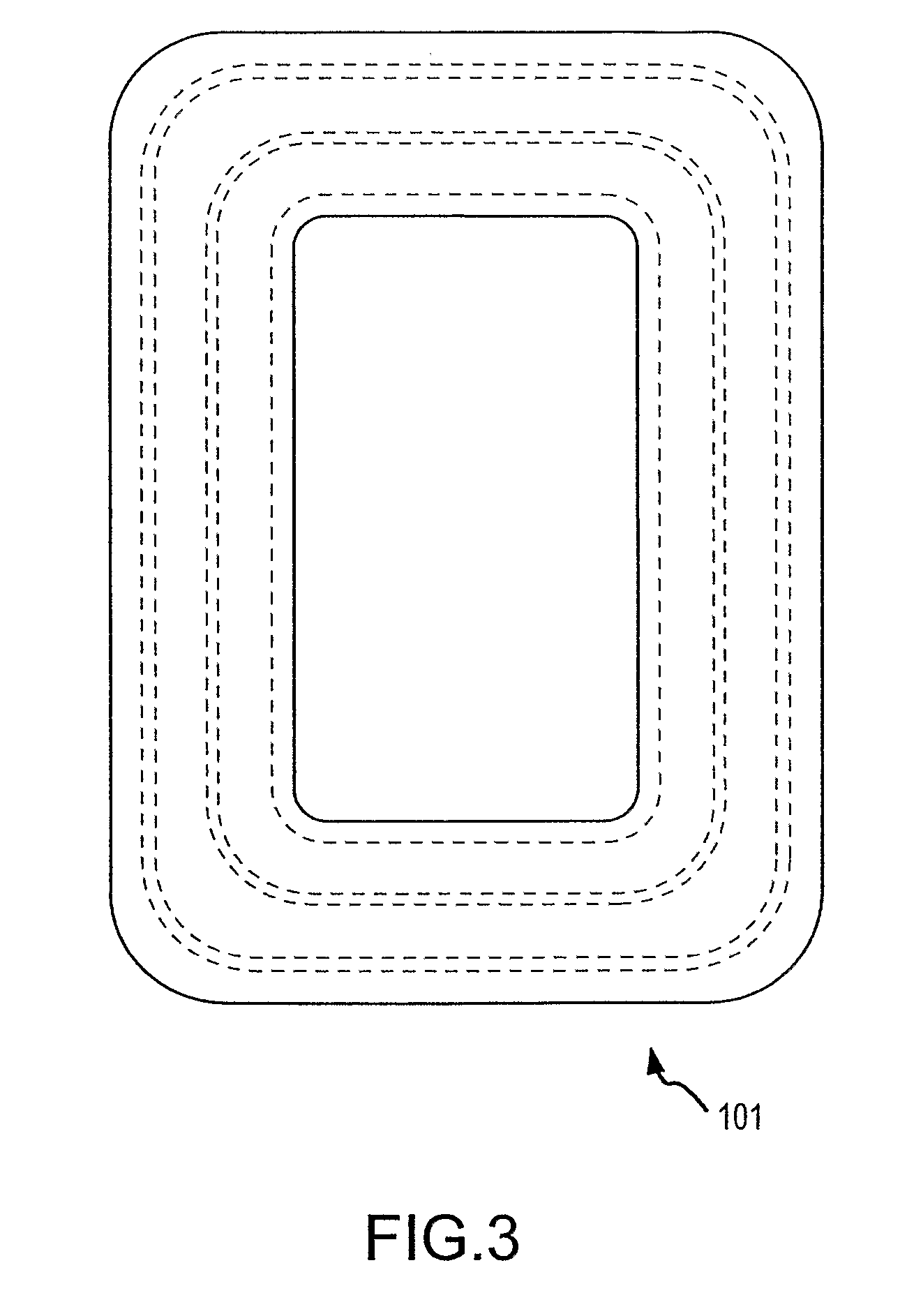

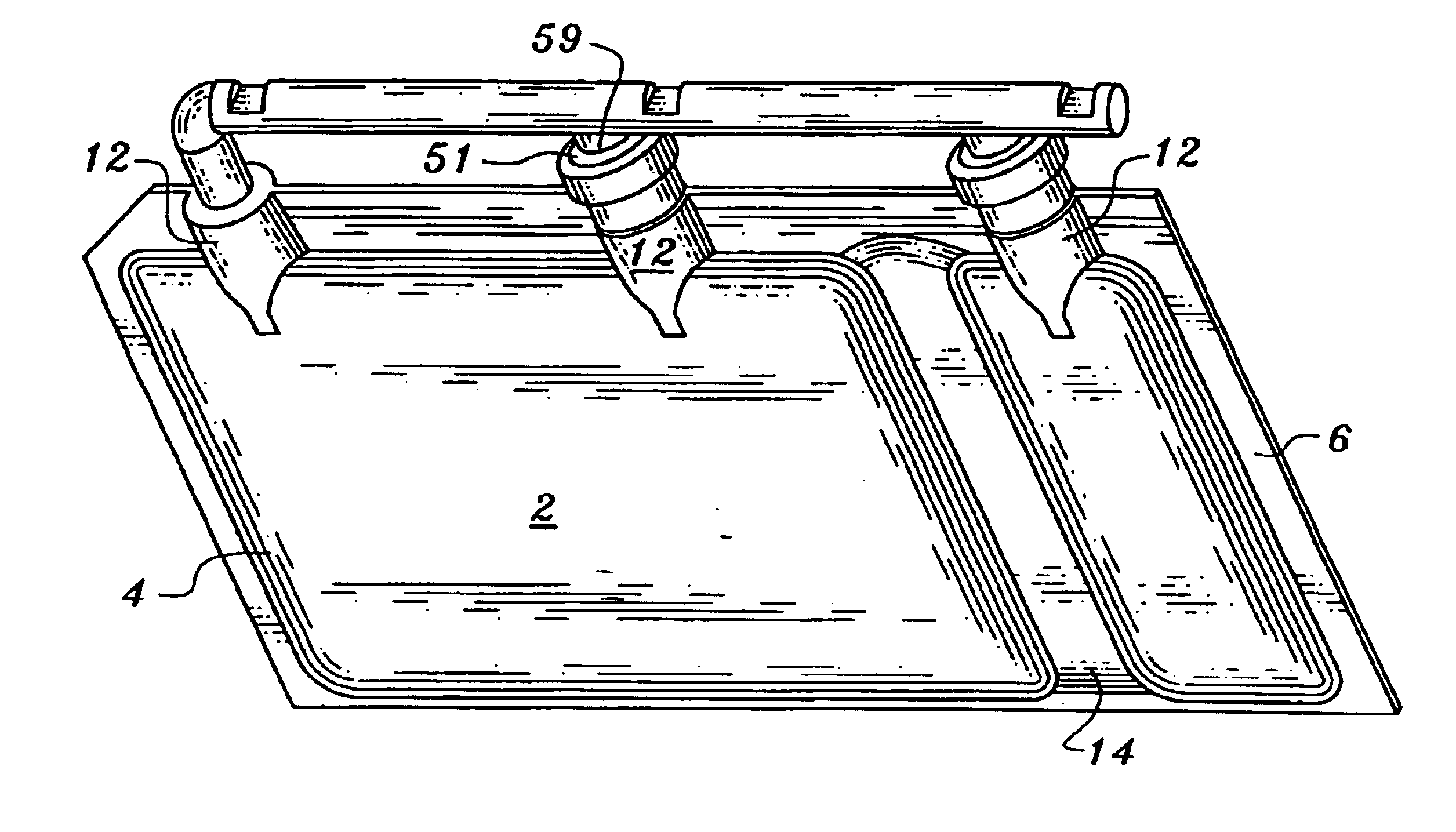

Freezing and thawing bag, mold, apparatus and method

InactiveUS6808675B1High strengthImprove integrityBioreactor/fermenter combinationsBiological substance pretreatmentsStress relievingFreeze and thaw

A bag, method of manufacture and process are disclosed for the cryopreservation of thermolabile substances. The bag is characterized as having substantially uniform thickness throughout its length and height. The bag features a radiused peripheral edge wall for stress relief and to provide the constant cross-section. A peripheral flashing circumscribes the radiused edge wall and provides a suitable purchase area for sealing so that the thus formed bag is less susceptible to fracture particularly when exposed to cryogenic temperatures. The uniform thickness of the bag promulgates uniform heat transfer to and from the contents of the bag in relation to any surrounding medium at a different temperature. The bag affords more space for efficient storage and reduces heat invasion into the contents of the bag when a plurality of bags are placed with their larger planar surfaces in contact with each other.

Owner:CESCA THERAPEUTICS

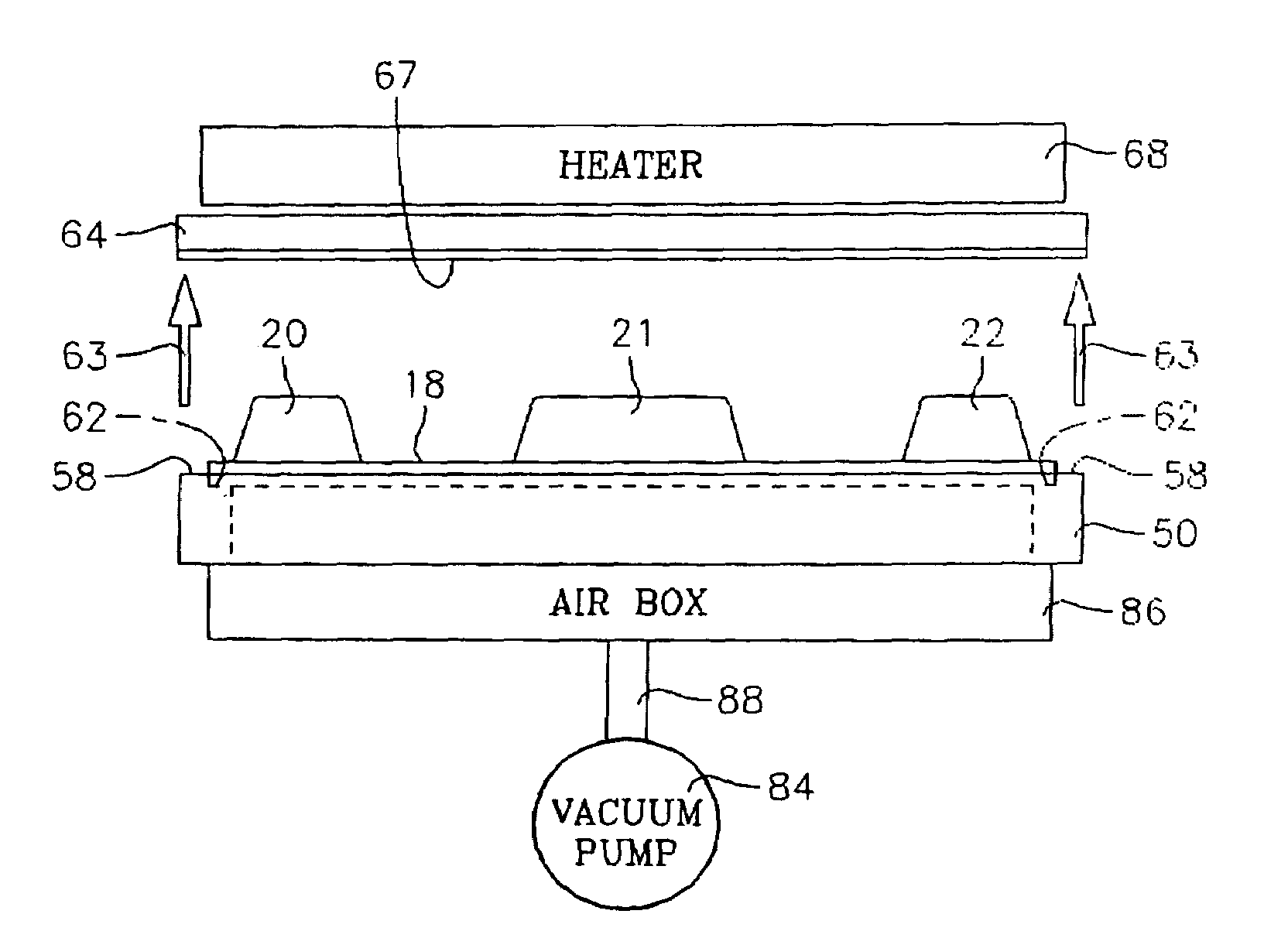

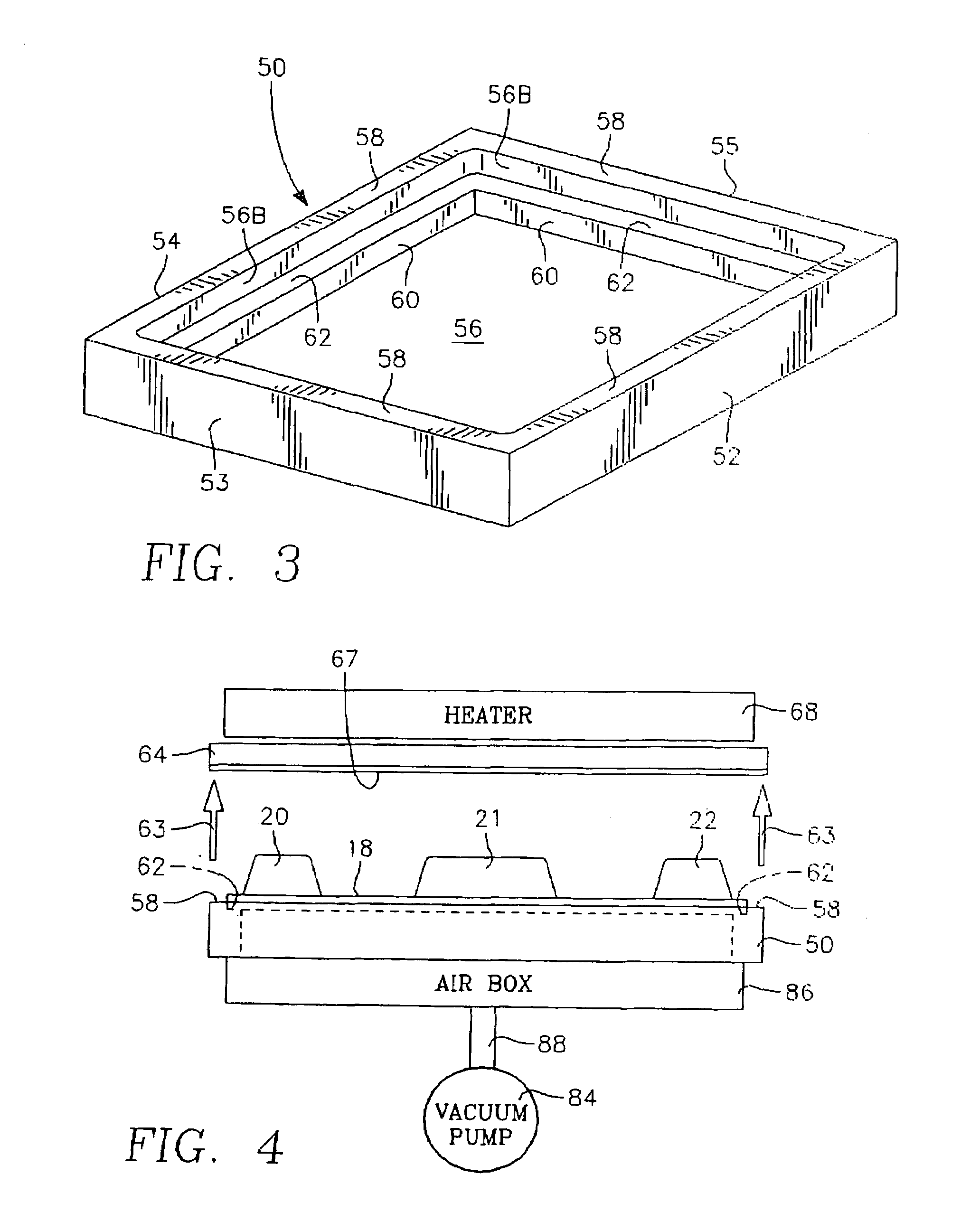

Method and apparatus for molding components with molded-in surface texture

An automobile interior trim component includes a molded substrate laminated onto a cover sheet including a foam backing and a skin film having a surface texture. The cover sheet is preheated so the skin film is in a melted viscous liquid state above its melting temperature, and the foam backing remains in a solid elastic foam state below its melting temperature. The preheated cover sheet is mechanically pre-molded by a back mold into a front mold. Pressurized air is applied through the back mold, to blow-mold the cover sheet against the front mold, so the melted skin film reproduces a surface texture of the front mold surface while the solid foam backing acts as a buffer and air barrier layer. Vacuum is applied through the front mold surface. The mold is opened, a substrate is introduced, and the back mold then molds and thermally laminates the substrate against the foam backing of the cover sheet.

Owner:HERBERT OLBRICH

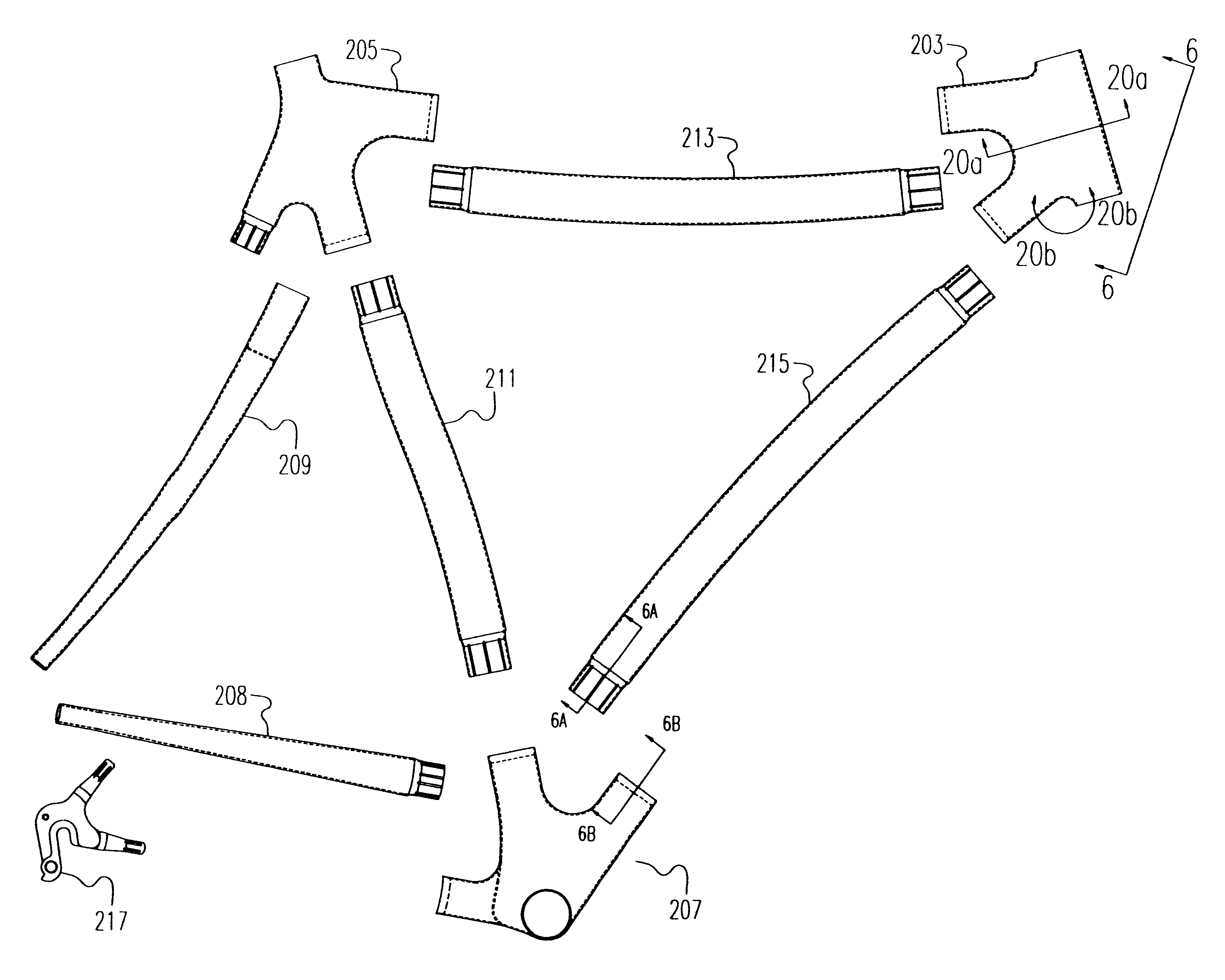

Composite bicycle frame and method of construction thereof

InactiveUS6340509B1Avoiding extra weightInhibition strengthPassenger cyclesChildren cyclesFiberVehicle frame

Bicycle frame components without laps made by a method comprising;shaping a fluid-removable core in the general form of the component,placing a flexible inflatable bladder around the core,wrapping over the assembly of core and bladder at least one ply of fiber impregnated with a curable resin, forming a cured part by inflating the bladder while the assembly of core, bladder, and impregnated fiber is in a mold to force the plies against the inner surfaces of the mold, such that compaction of the fiber against the mold is predominantly from the bladder inflation and not from the core, and heating to cure the resin to form a cured part, removing the bladder and the fluid-removable core from the interior of the cured part by disintegrating the fluid-removable core with a fluid sufficient to allow removal of the core and the bladder.

Owner:RADIUS ENG

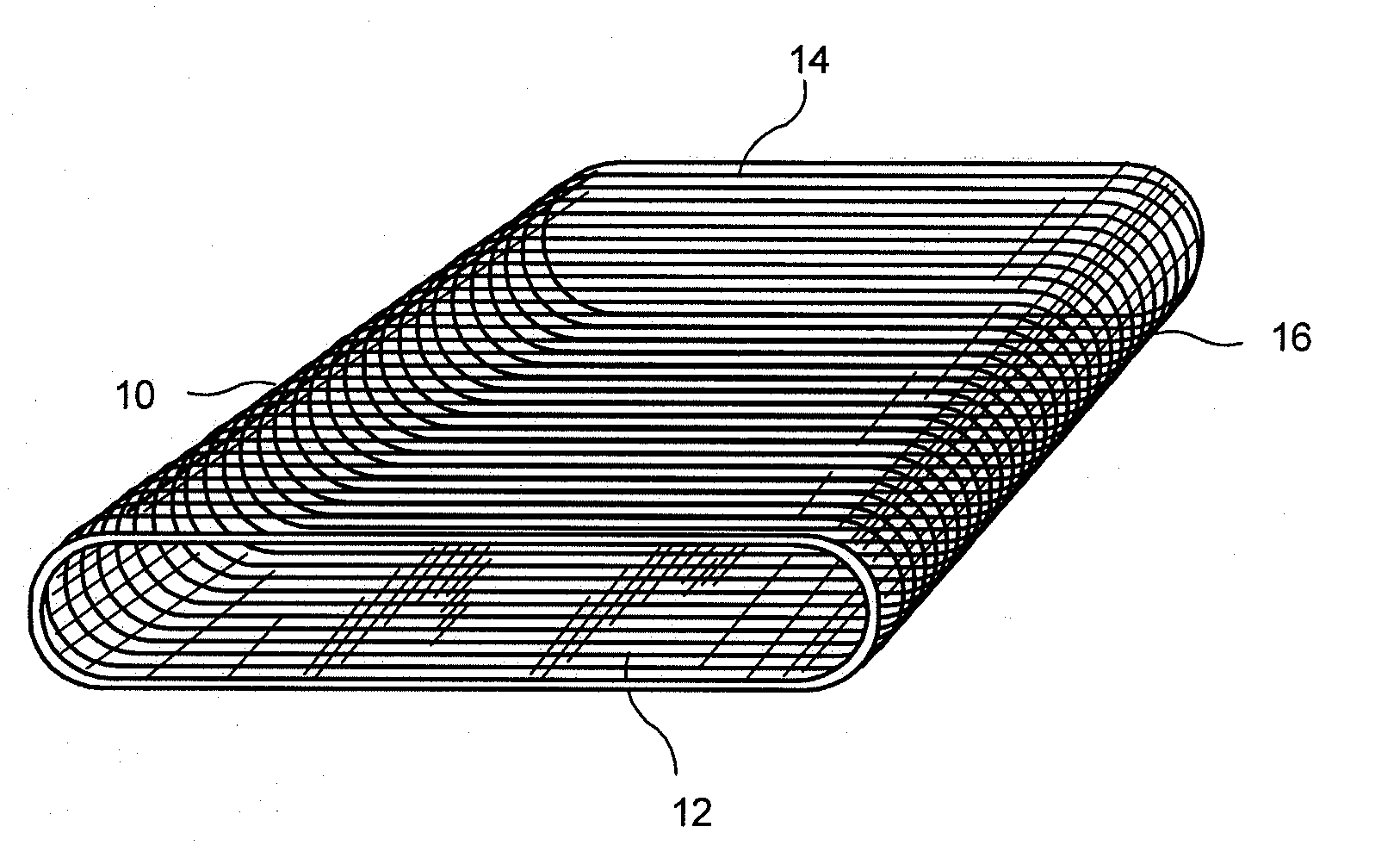

Industrial fabric including spirally wound material strips

ActiveUS20100236034A1Facilitated releaseStable supportNon-fibrous pulp additionNatural cellulose pulp/paperUltrasonic weldingStrapping

An industrial fabric such as an endless belt or sleeve for use in the production of nonwovens, and a method of making thereof are disclosed. The industrial fabric is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

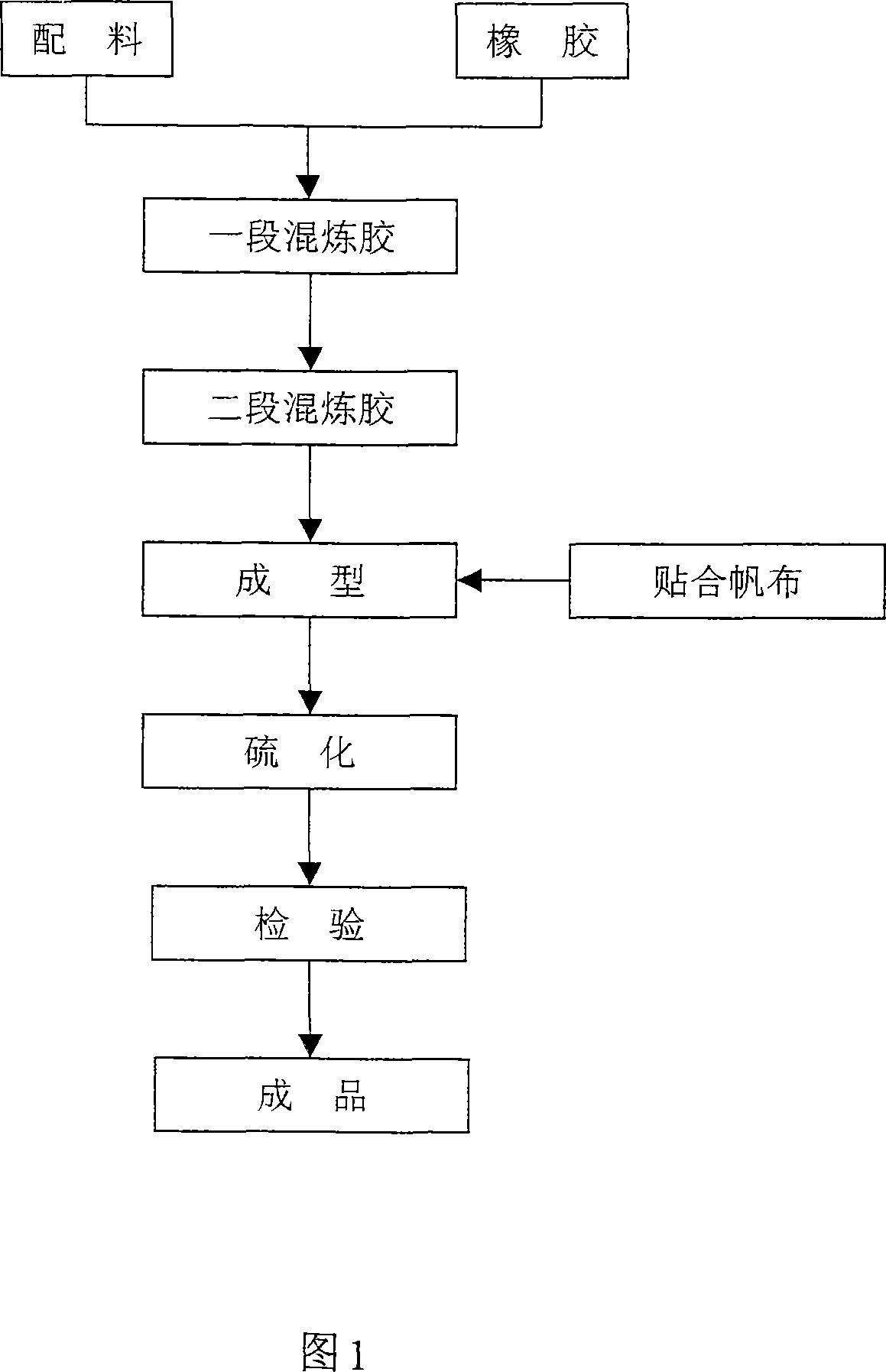

High-temperature-resisting conveyer belt

ActiveCN101028888AImprove heat resistanceExtended service lifeConveyorsBeltsCross-linkPolymer science

A refractory conveying belt is prepared from the dibasic ethylene propylene rubber, or dibasic ethylene propylene rubber and ternary ethylene propylene rubber through pre-pugging, adding heat conducting agent and anti-ageing agent, pugging, adding reinforcing agent, softening agent and short aramid fibers, pugging, adding cross-linking agent and cross-linking aid, heating, calendering to become sheet, attaching it onto tension-resistant canvas, rolling and sulfurizing.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Preformed support device and method and apparatus for manufacturing the same

ActiveUS20090240342A1Increase the cross-sectional areaEliminate needConfectioneryWood working apparatusMammalian tissueEngineering

A device for making a seamless, anatomically contoured, prosthetic device for supporting or maintaining the position of mammalian tissue, organ or structure or a replacement thereof, such as a breast implant, includes a support plate, an ironing plate or a clamping plate and a core plate, each of which is made from a thermally conductive material. The support plate and the ironing or clamping plates have openings formed through the thickness thereof. The core plate has a core extending outwardly from a lower surface thereof which is received through the openings in the ironing or clamping plate and the support plate.

Owner:ETHICON INC

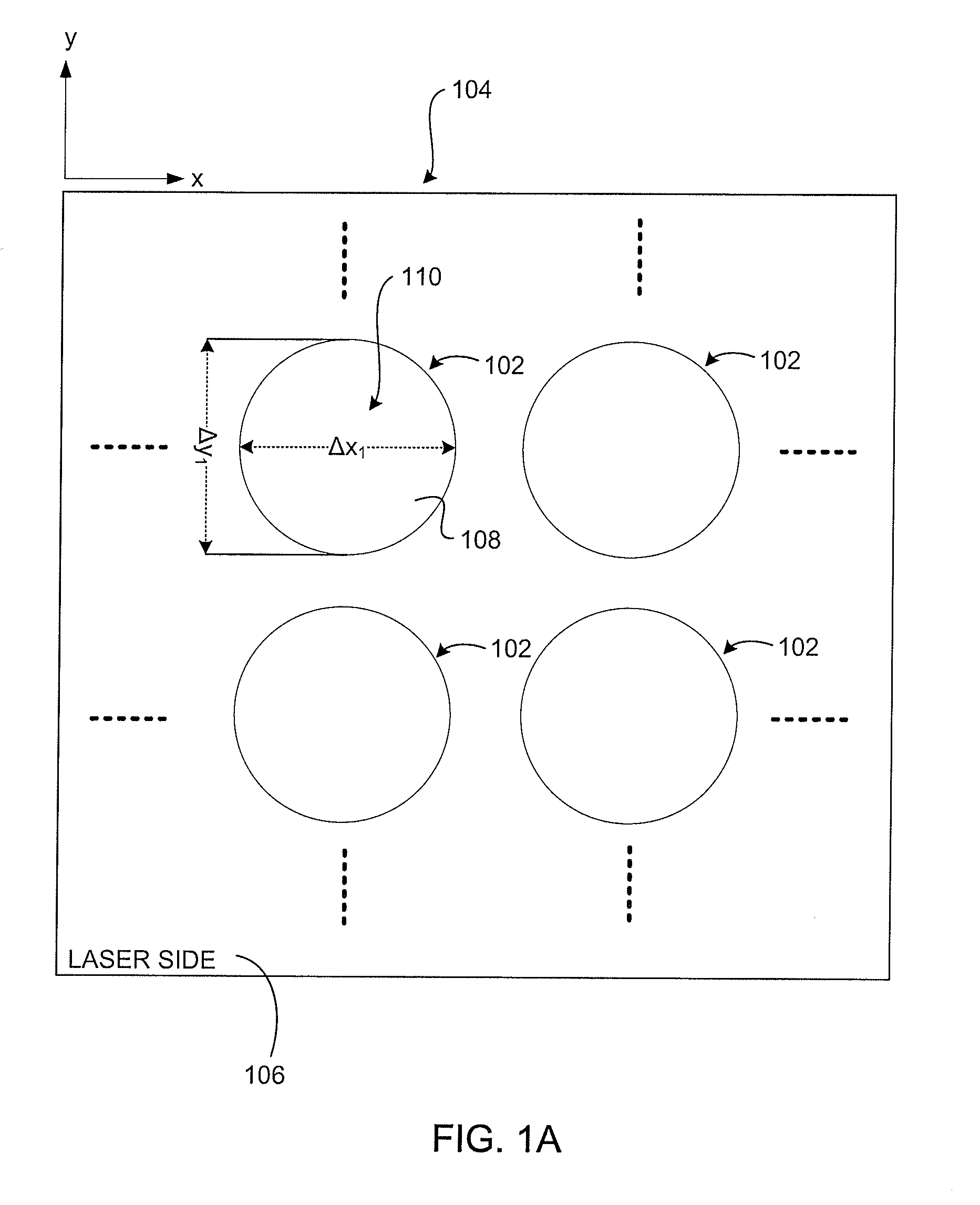

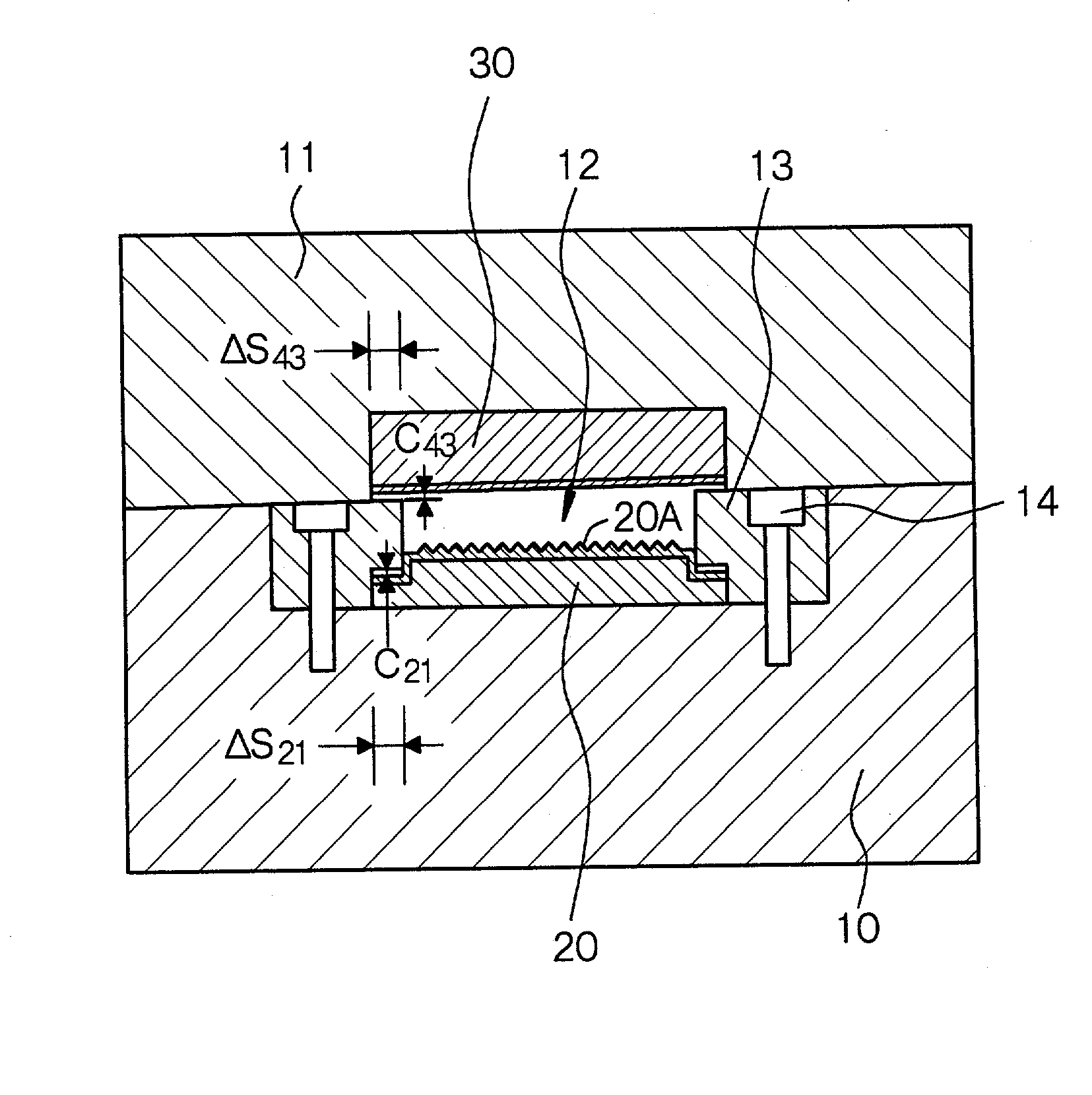

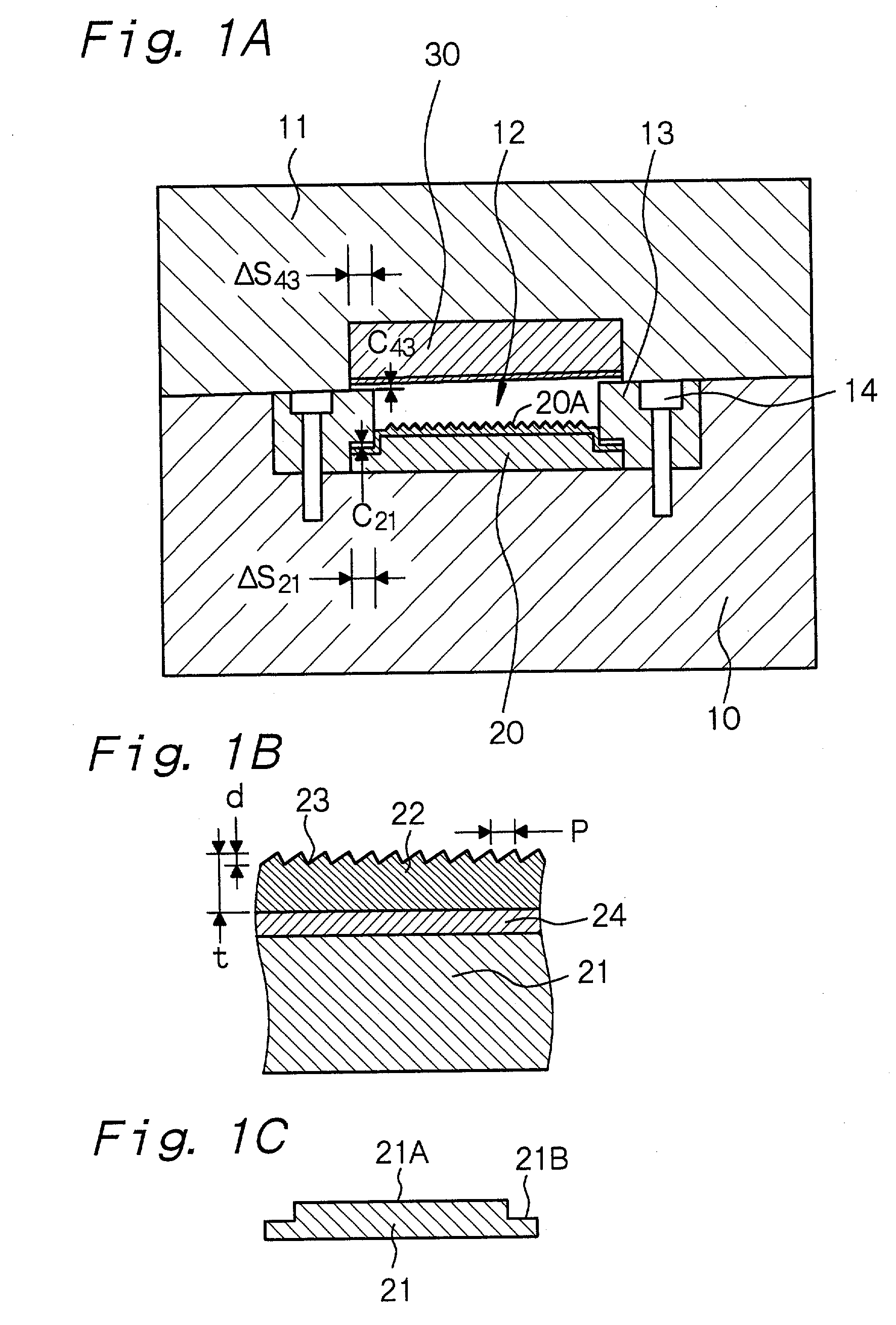

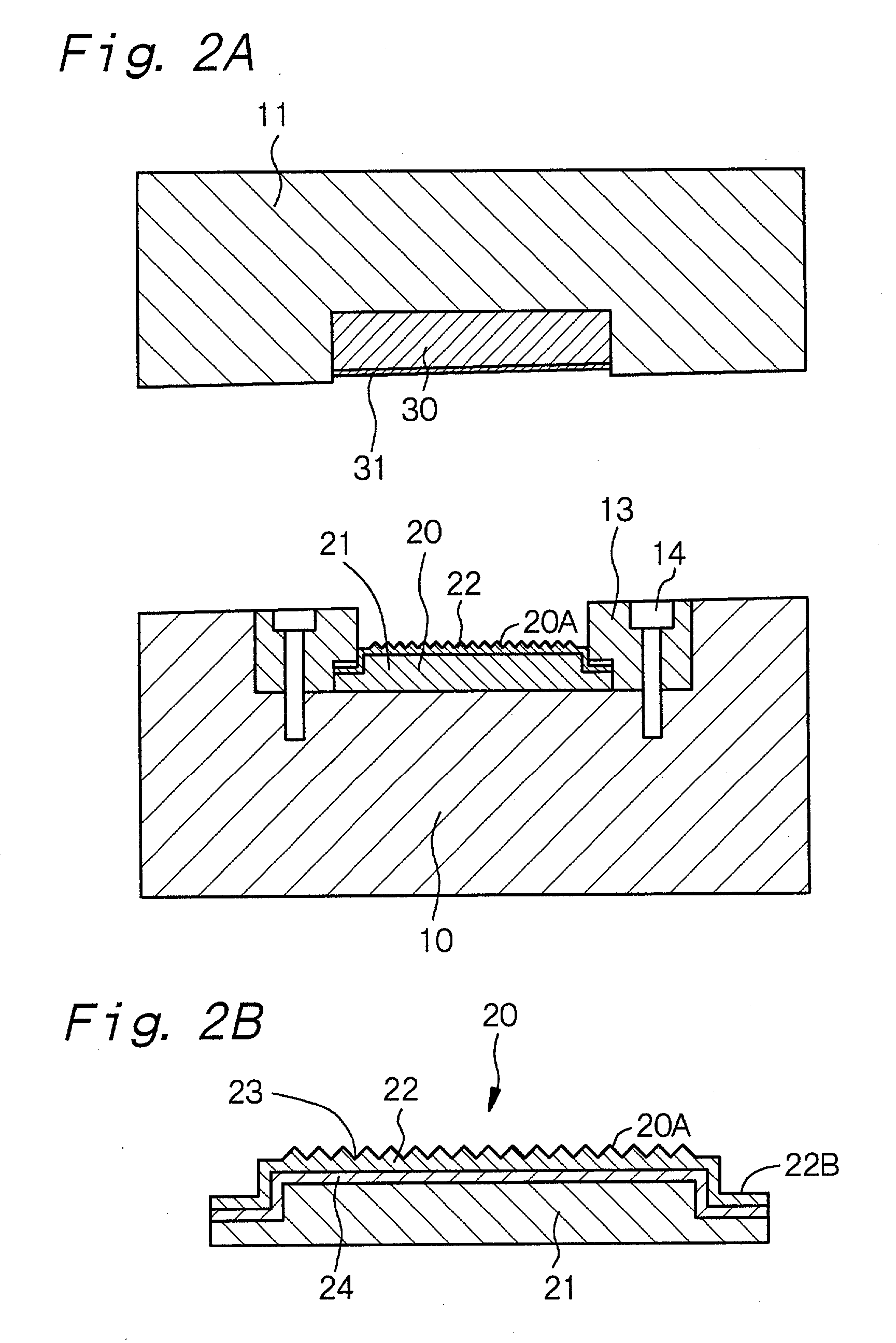

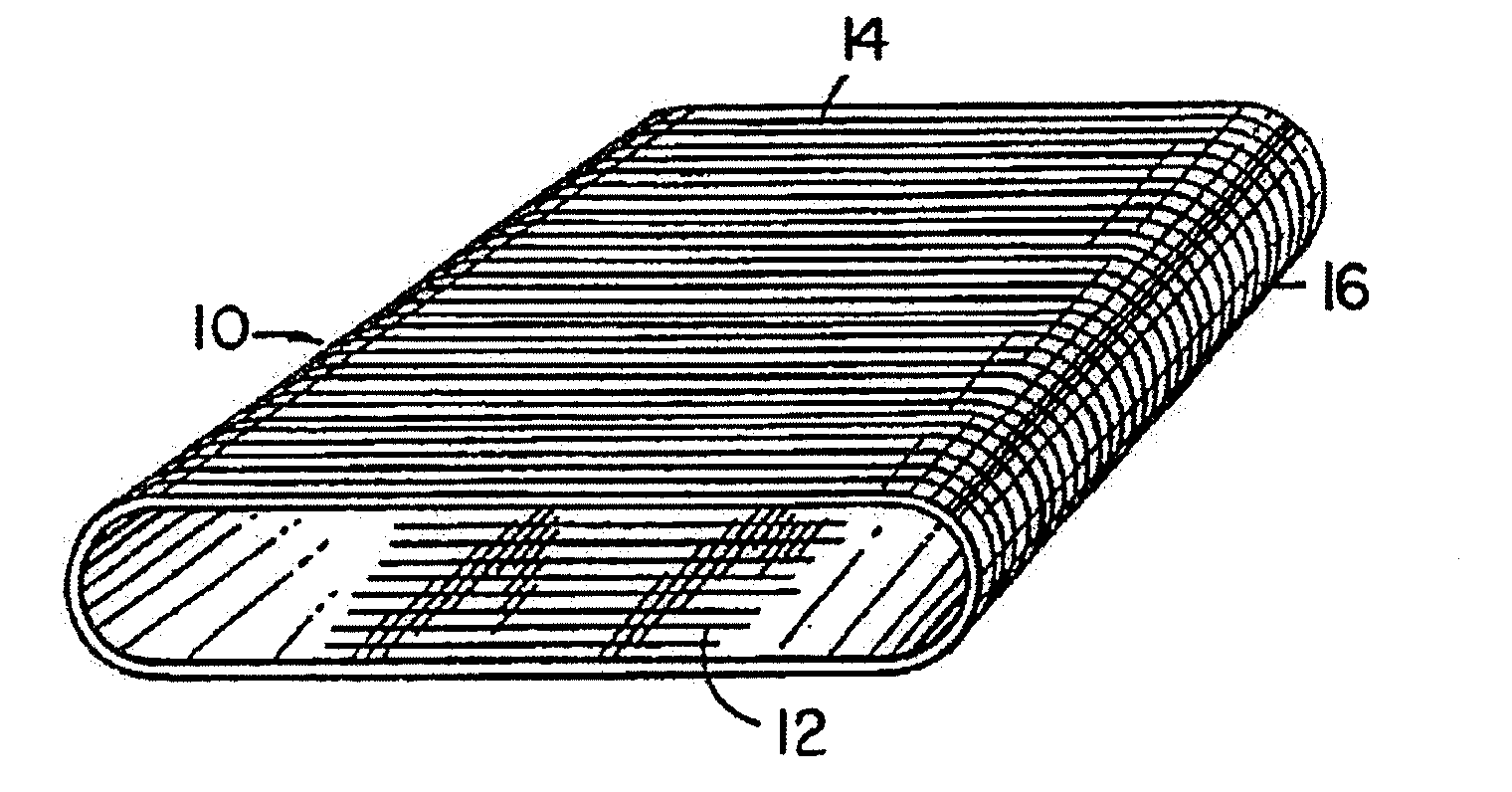

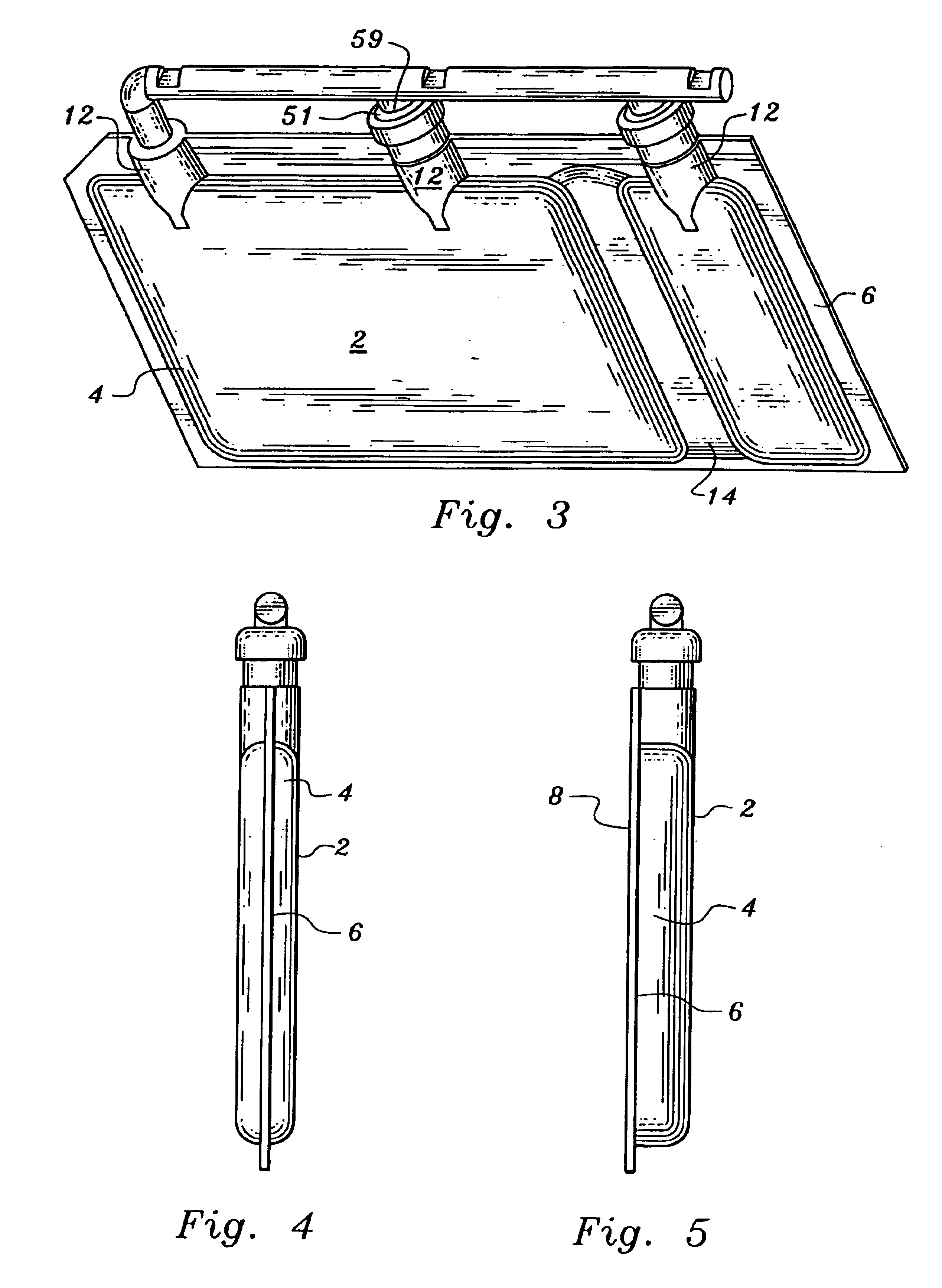

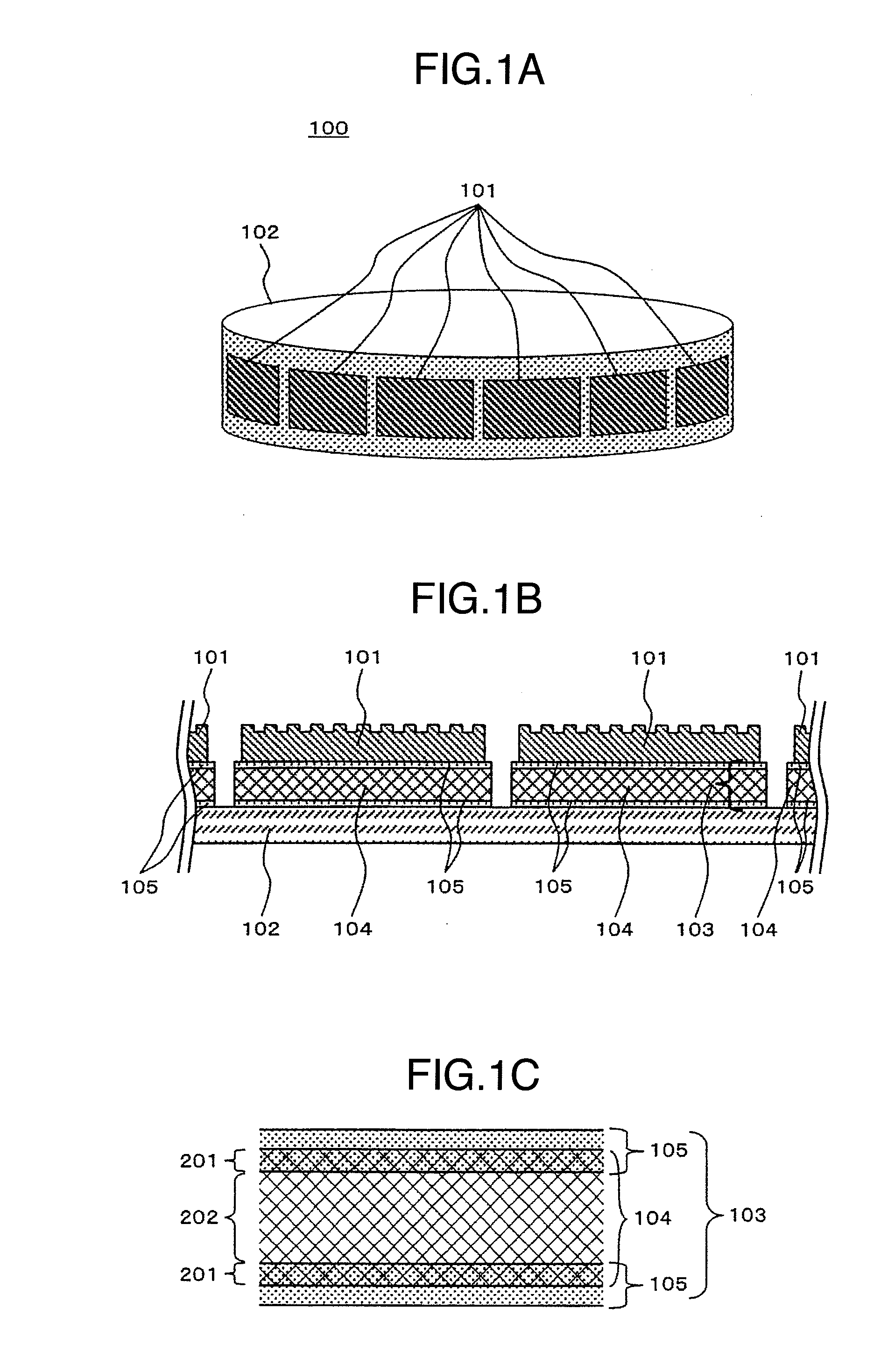

Belt-shaped mold and nanoimprint system using the belt-shaped mold

InactiveUS20090087506A1High aspect ratioFormed rapidly and stablyNanoinformaticsConfectioneryFine structureTransfer system

There is provided a fine pattern transfer, belt-shaped mold, with which a fine structure having a high aspect ratio can be formed rapidly and stably using nanoimprinting, and a fine pattern transfer system (a nanoimprint system) that employs this mold. According to the present invention, a nanoimprint mold includes: a belt-shaped support member; a plurality of stampers, for each of which a fine convex-and-concave pattern, to be transferred, is formed on one surface; and an adhesive member, to which the belt-shaped support member and the stampers are to be securely adhered, wherein the adhesive member includes a porous member and adhesive layers, which are deposited on either face of the porous member, for impregnating one part of the porous member, and wherein, for the porous member, a porous area that is not impregnated with the adhesive layers, is provided and positioned so as to sandwich the porous member between portions impregnated with the adhesive layers.

Owner:HITACHI LTD

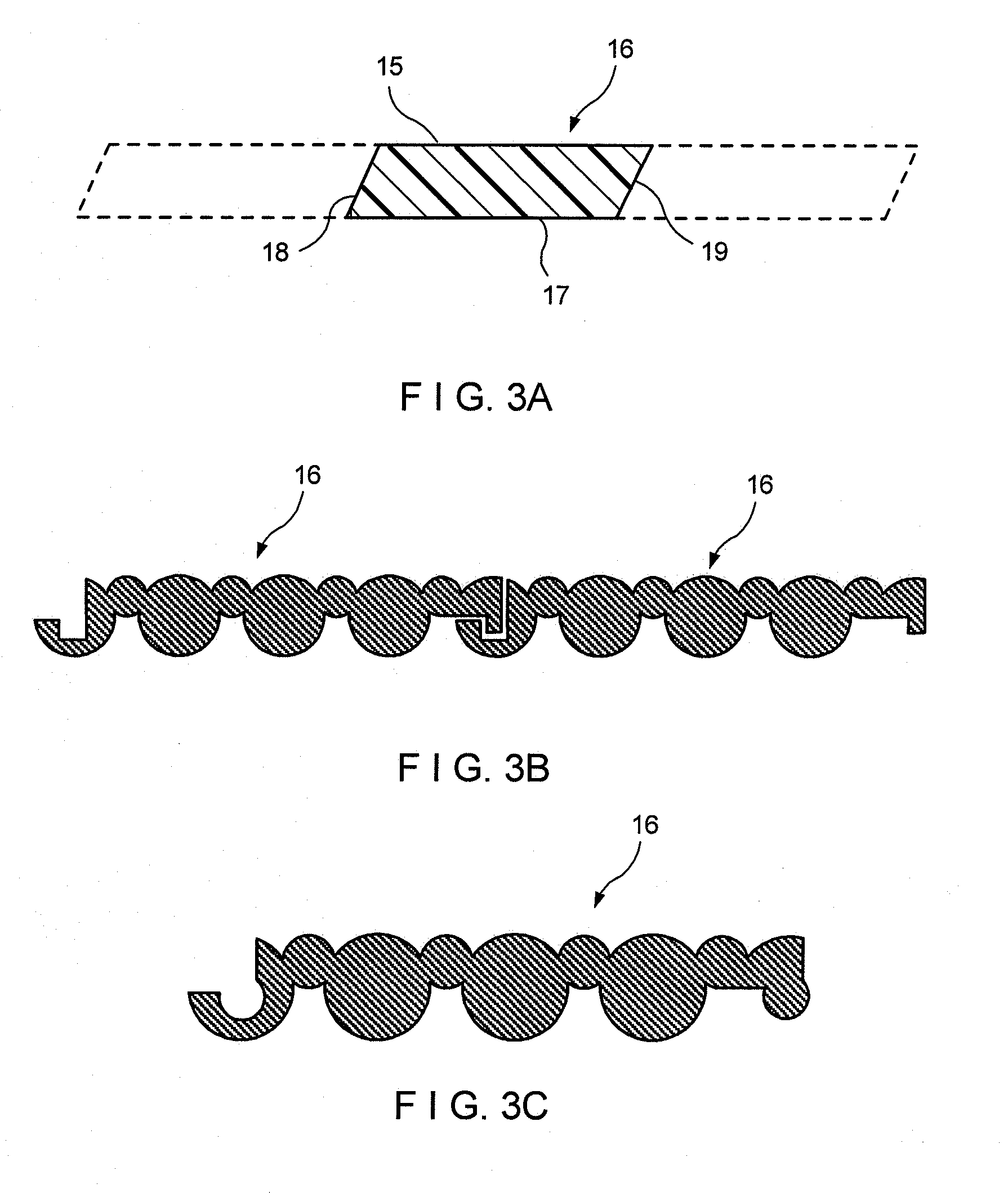

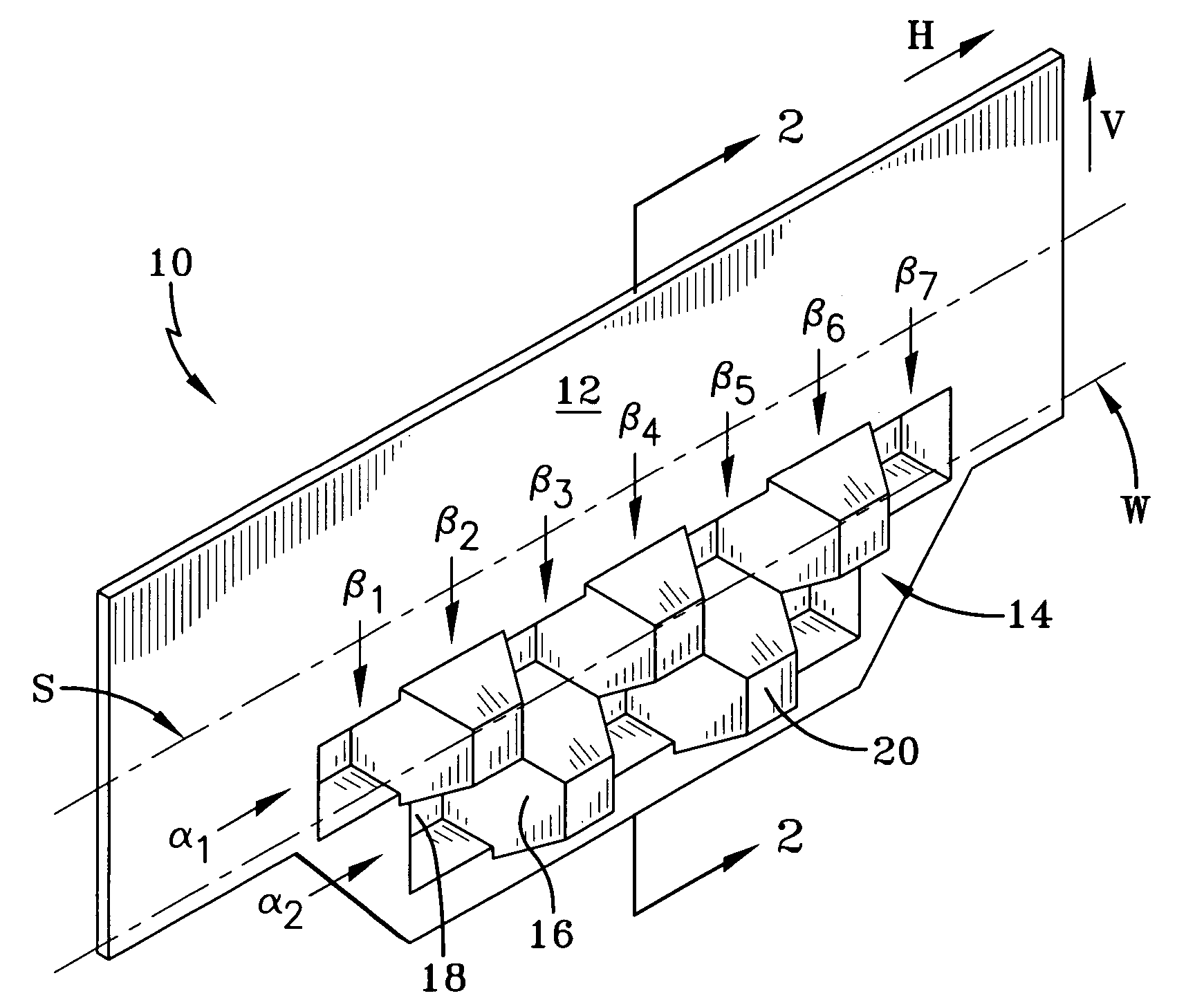

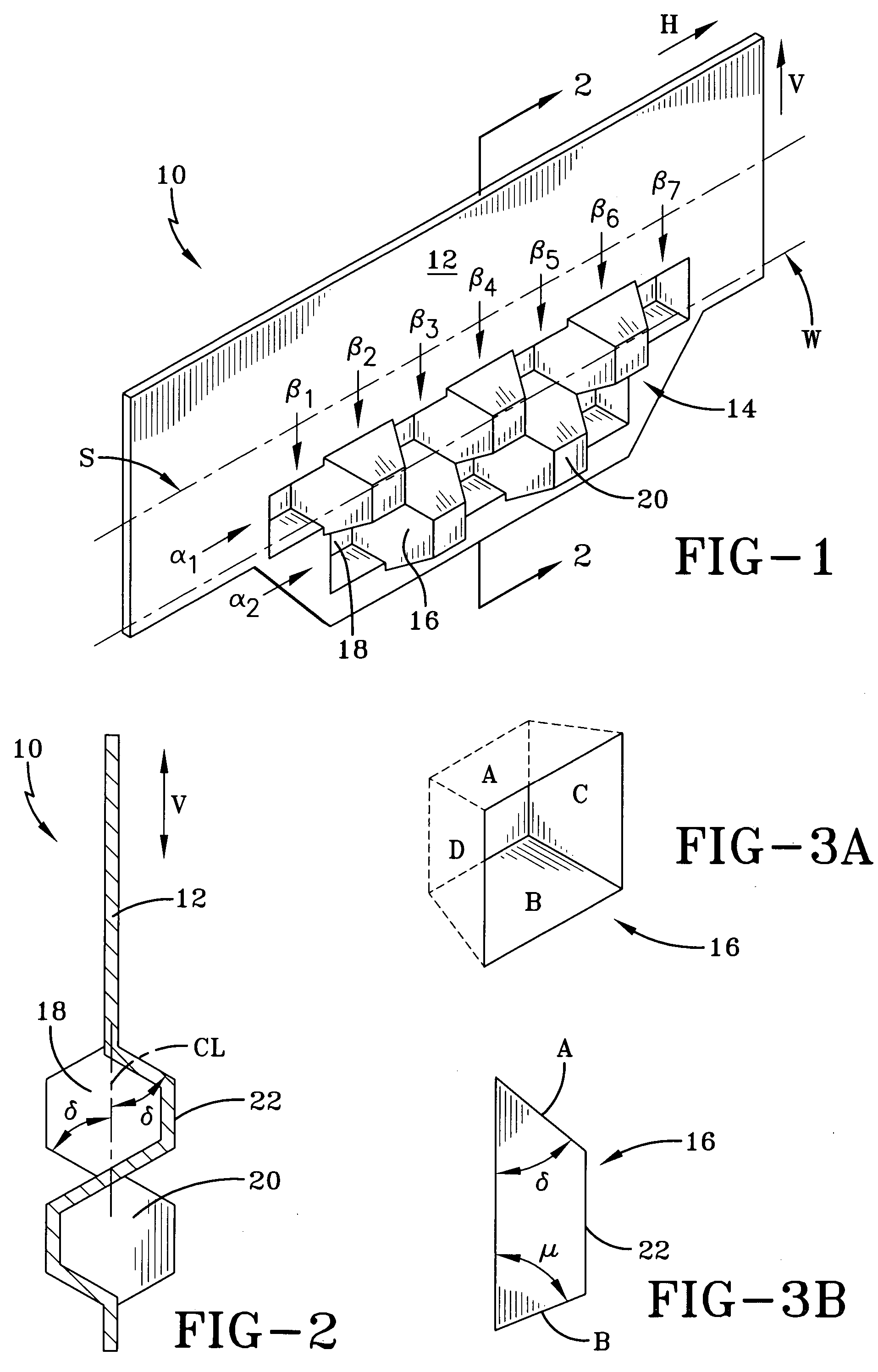

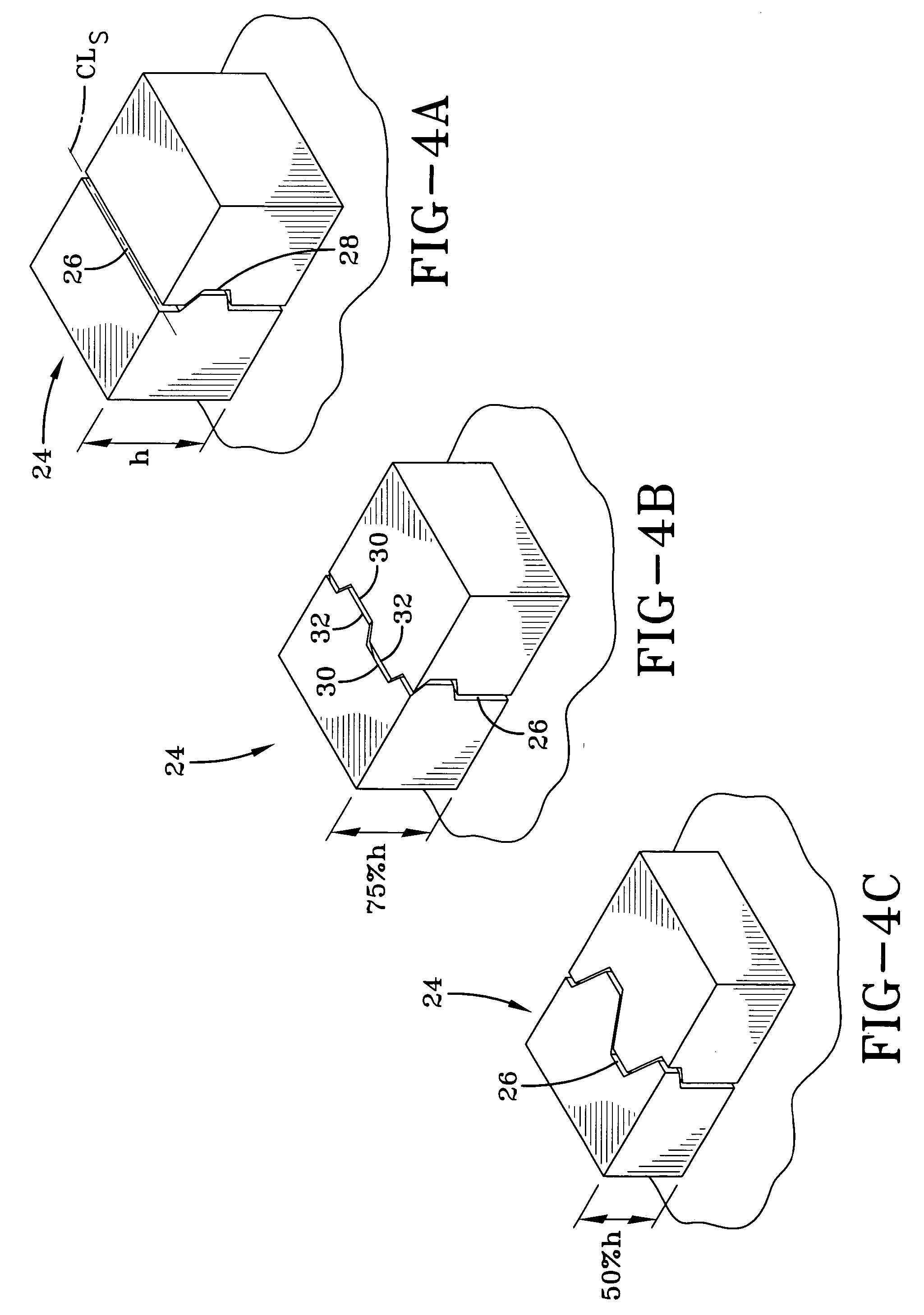

Three-dimensional sipes for treads

ActiveUS20050109438A1Good traction characteristicsPrevent slippingTyresTyre tread bands/patternsEngineeringKnife blades

Both a mold blade for forming sipes and the sipe so formed in a tire tread element have three dimensional portions. In the formed sipe, the three dimensional portion creates a constant interlocking of the opposing sipe faces. The blade and the sipe have at least one row of alternating polygonal shaped recesses and protrusions. The recesses and protrusions terminate in a vertex; the vertex has a planar, or two-dimensional, configuration that is parallel to either-the blade centerline or the sipe centerline.

Owner:THE GOODYEAR TIRE & RUBBER CO

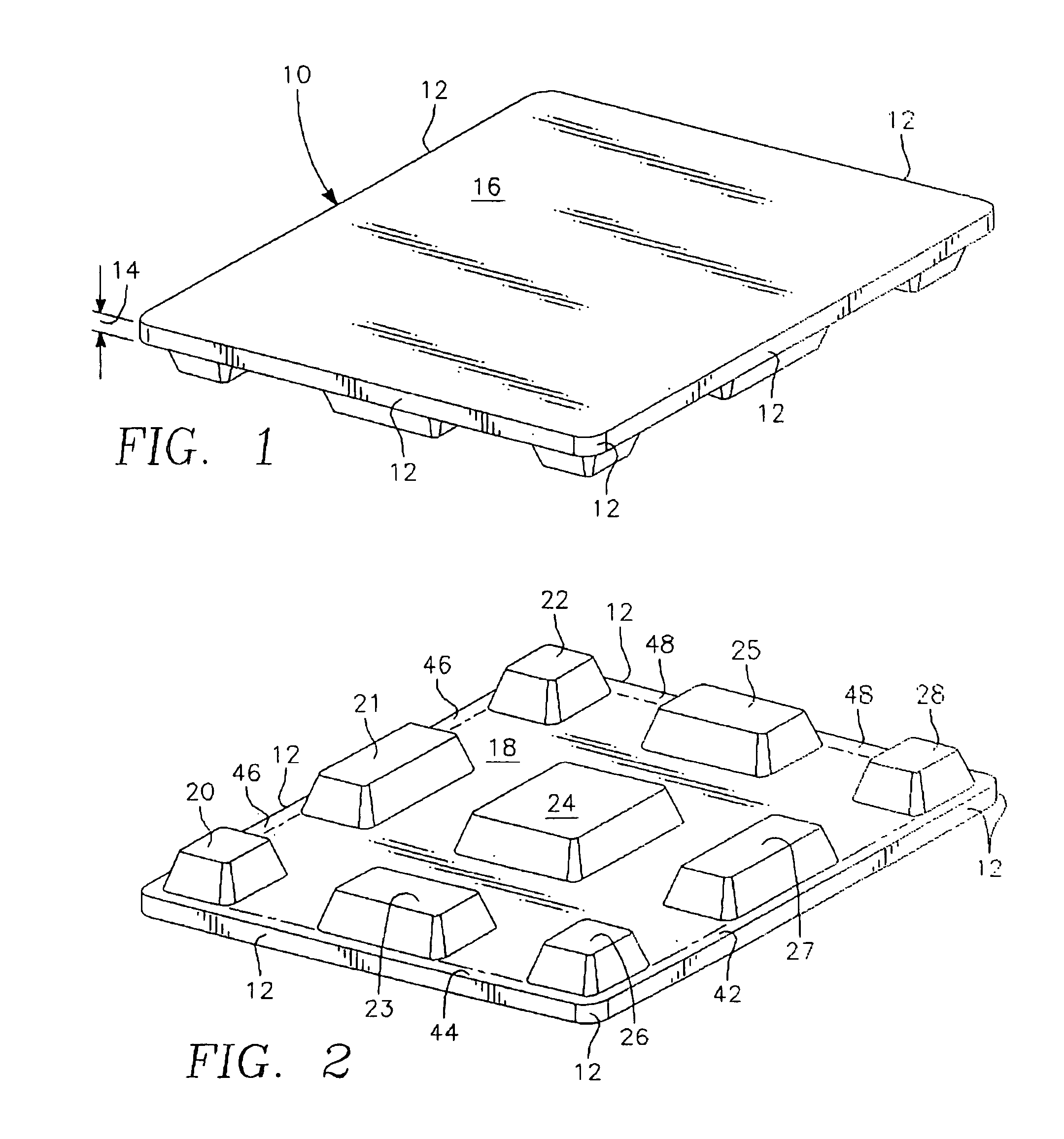

Dunnage platform

InactiveUS7128797B2Easy to moveAdhesive processesMechanical working/deformationDunnageChemical combination

A dunnage platform is in the general shape of a rectangular slab with legs extending form one side. The dunnage platform is made from an expanded polystyrene core. A chemical combination process is used to chemically combine portion of the core proximal to its surface with high impact polystyrene. In a first of two parts of the combination process, the core is placed in a forming mold with one of its two sides and two thirds of its thickness extending therefrom. A heated sheet of high impact polystyrene is brought into contact with the portion of the core extending from the mold. In a similar manner, the other of the two sides of the core is made to extend from the forming mold for contact with a heated sheet of high impact polystyrene.

Owner:AIRDEX CORP

Advanced body armor utilizing shear thickening fluids

InactiveUS20060234577A1High strengthNot impede fabric flexibilityWarp knittingCircular knitting machinesPuncture resistanceBody armor

An armor composite material has been invented which contains a fabric which has been impregnated with shear thickening fluid. This invention offers a ballistic resistant material that is more flexible and less bulky than comparable, conventional ballistic fabric. The material in the alternative can be puncture resistant. The invented material offers superior ballistic performance and / or puncture resistance compared to conventional ballistic fabric-based materials of equal thickness. The invented material can be applied to applications requiring armor that is compact and / or flexible, such as body armor, protective clothing and flexible protective devices and shields, and stab resistant clothing and devices.

Owner:UNIVERSITY OF DELAWARE

High temperature polyurethane/urea elastomers

InactiveUS6964626B1High and low temperature resistance propertiesHigh and low temperature resistance propertyV-beltsRopes and cables for vehicles/pulleyElastomerPolyester

The present invention relates to molded polyurethane / urea elastomers, and specifically to improved polyurethane / urea elastomers having high temperature stability to about 140–150° C. and low temperature flexibility at about −35–(−40)° C., for use in dynamic applications. These elastomers are particularly useful for application in belts, specifically in automotive timing or synchronous belts, V-belts, multi V-ribbed or micro-ribbed belts, flat belting and the like. The polyurethane / urea elastomers of the present invention are prepared by reacting polyisocyanate prepolymers with symmetric primary diamine chain extenders, mixtures of symmetric primary diamine chain extenders and secondary diamine chain extenders, or mixtures of symmetric primary diamine chain extenders and non-oxidative polyols, which are all chosen to eliminate the need for catalysts via standard molding processes, and to improve phase separation. The polyisocyanate prepolymers are reaction products of polyols which are nonoxidative at high temperatures, such as polycarbonate polyols, polyester polyols, or mixtures thereof, with organic polyisocyanates which are either compact, symmetric and aromatic, such as para-phenylene diisocyanate, 1,5-naphthalene diisocyanate, and 2,6-toluene diisocyanate, or are aliphatic and possess trans or trans,trans geometric structure, such as trans-1,4-cyclohexane diisocyanate and trans,trans-4,4′-dicyclohexylmethyl diisocyanate.

Owner:THE GATES CORP

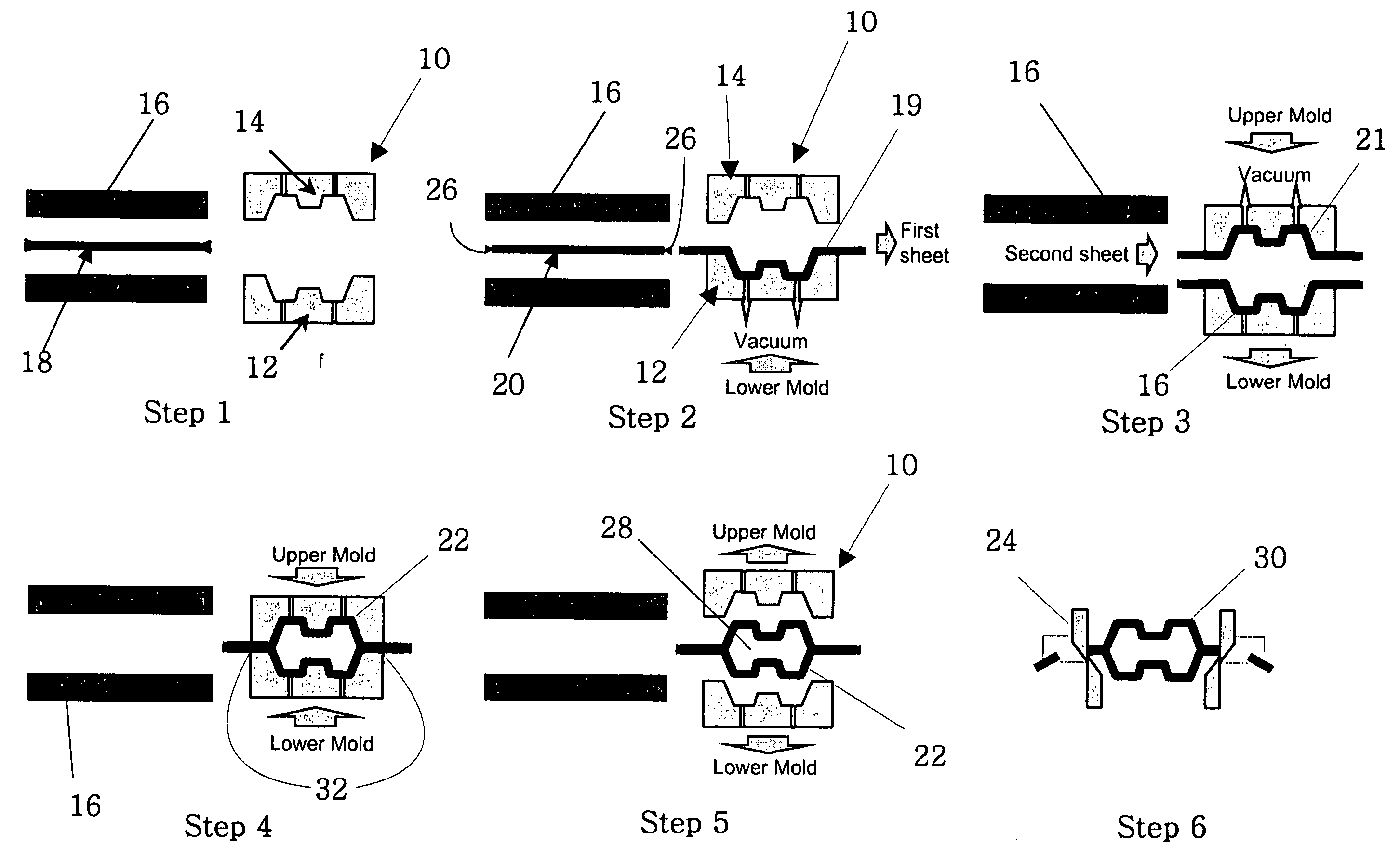

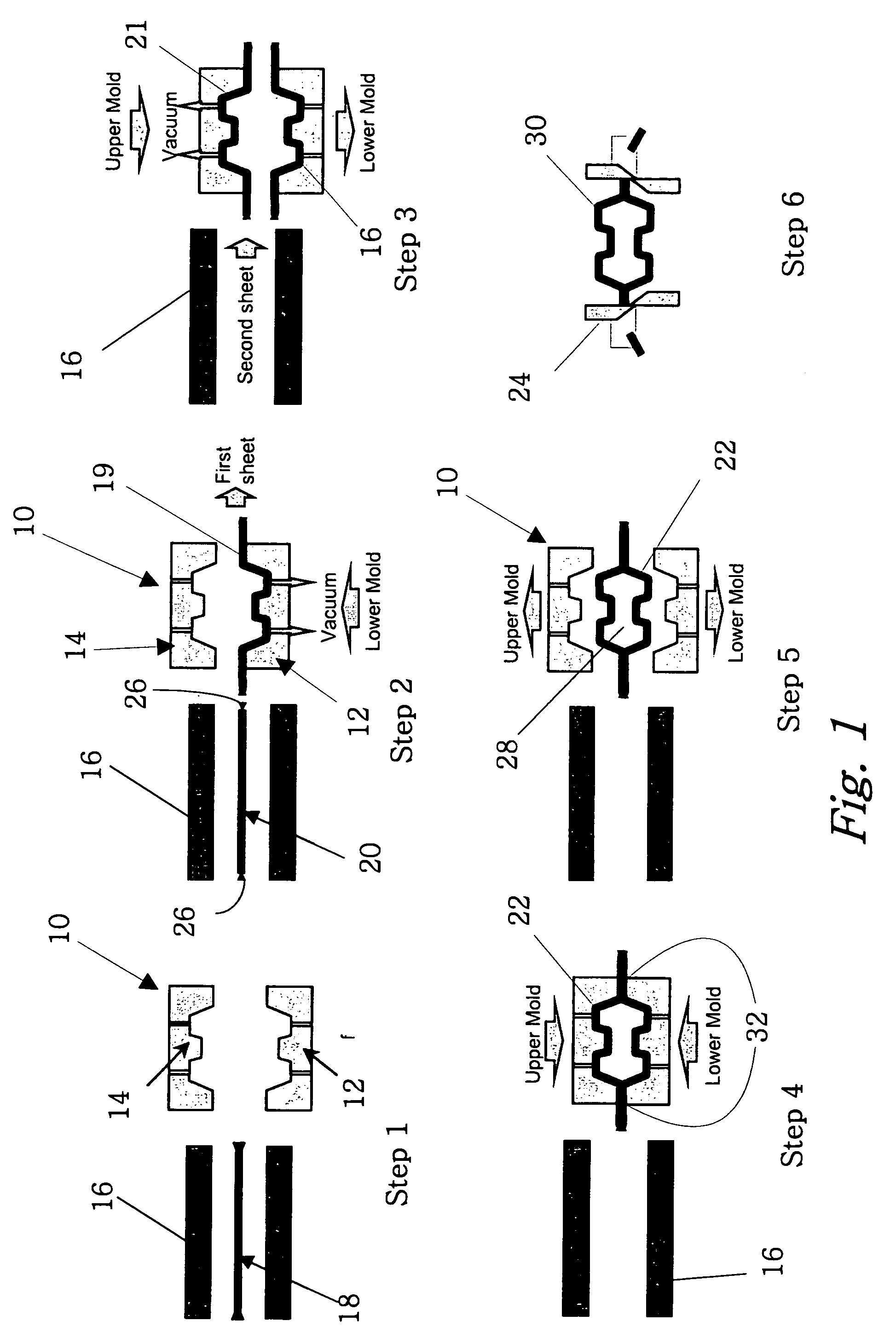

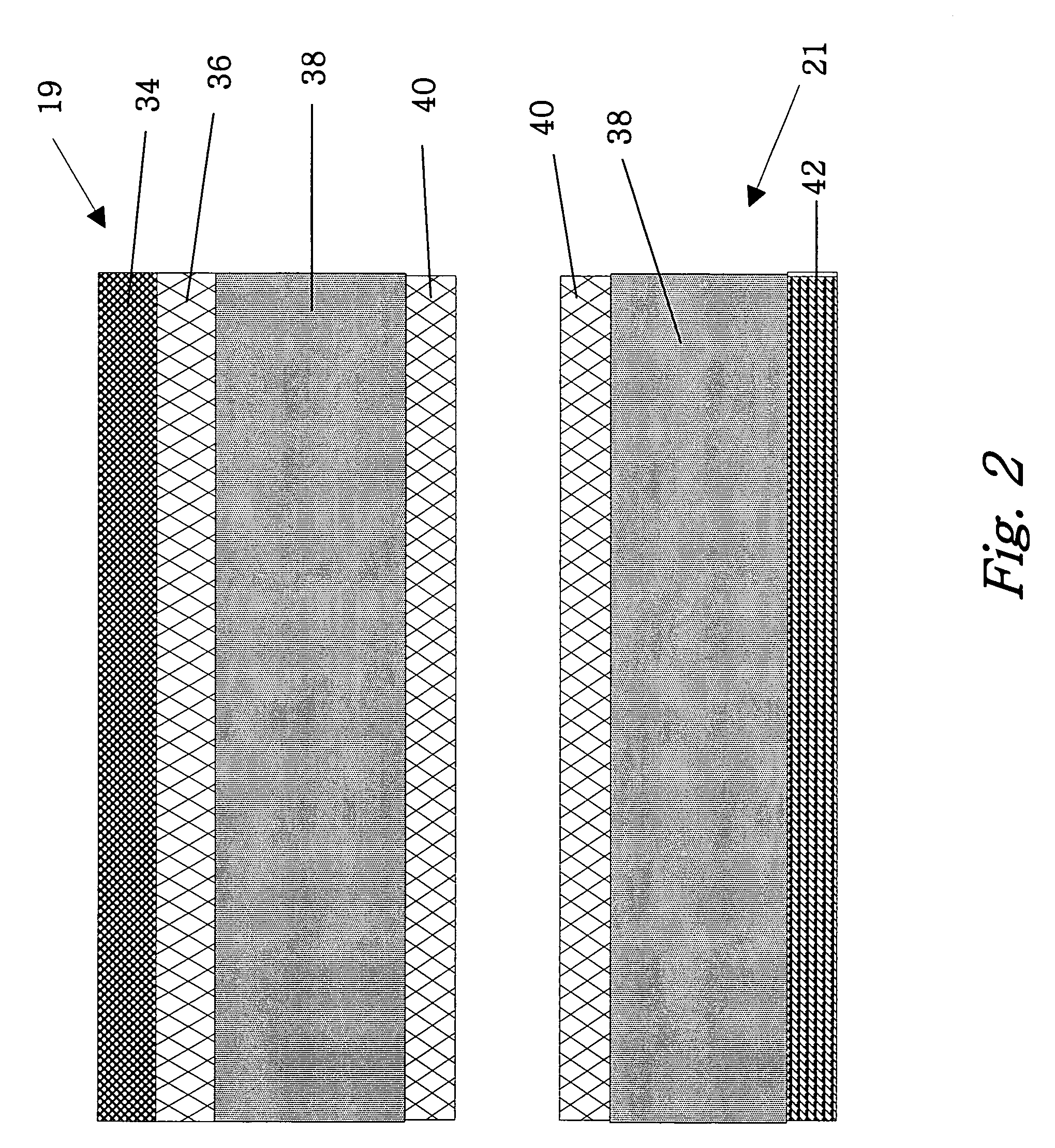

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com