Patents

Literature

1326results about "Record carriers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

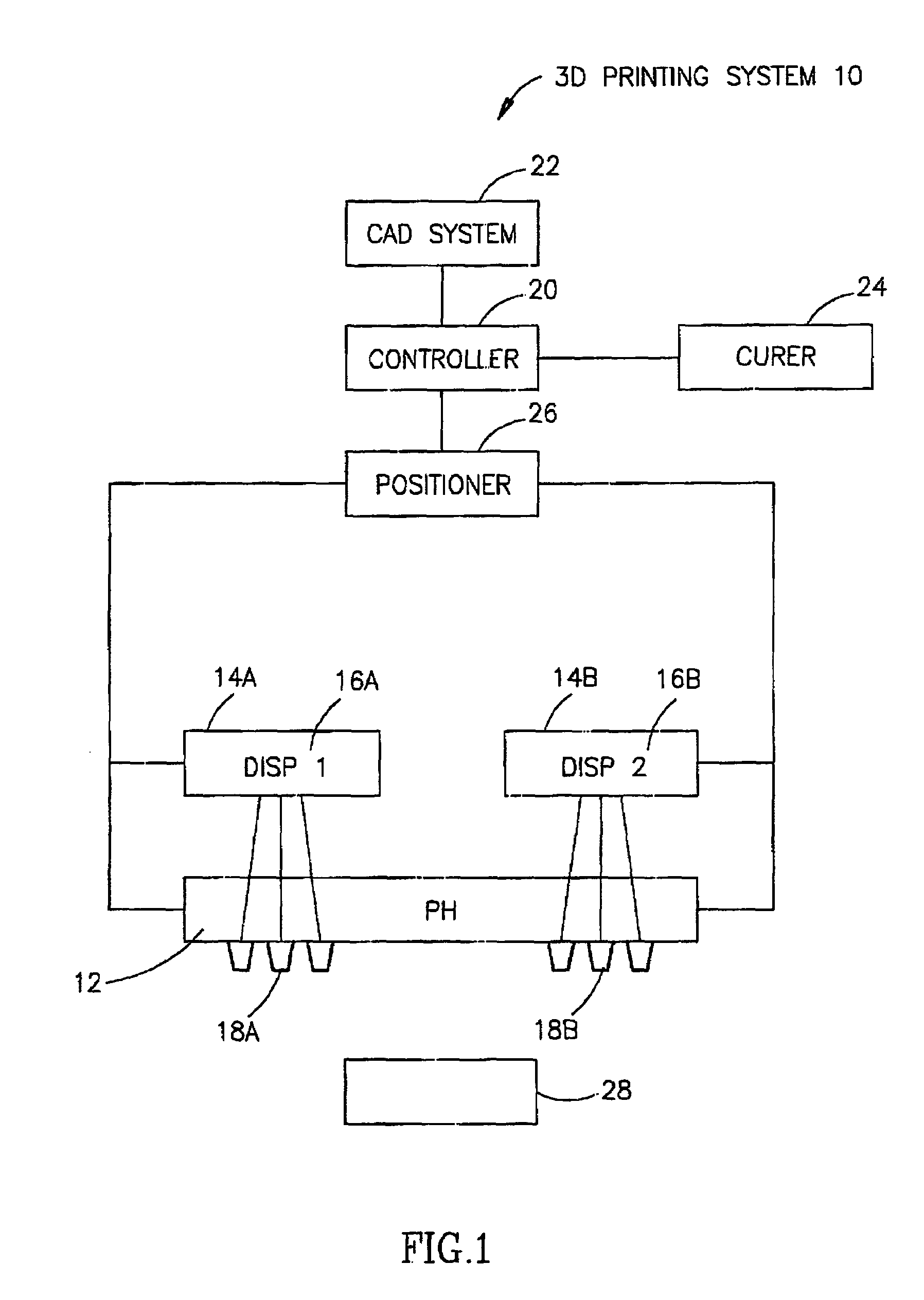

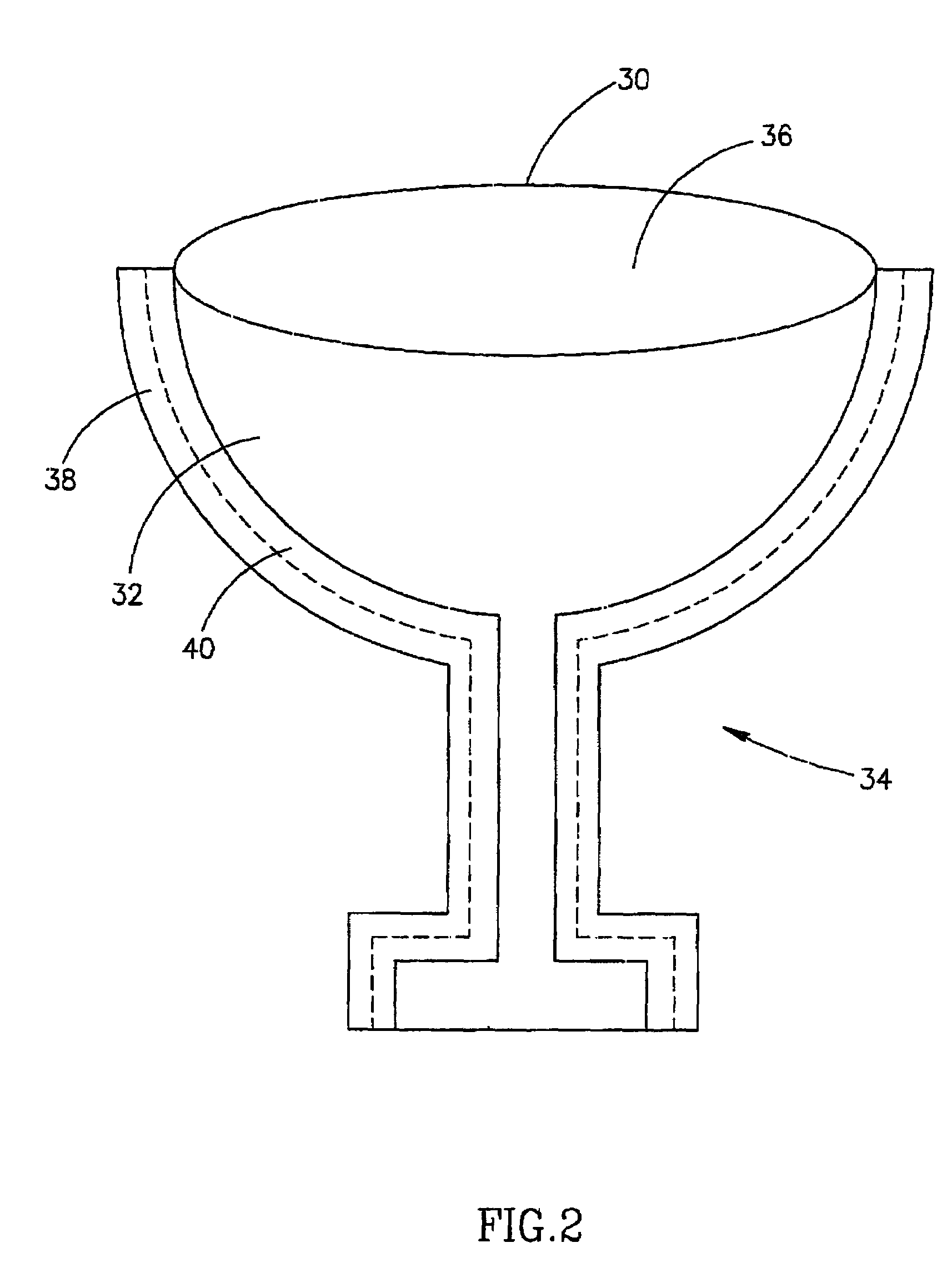

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

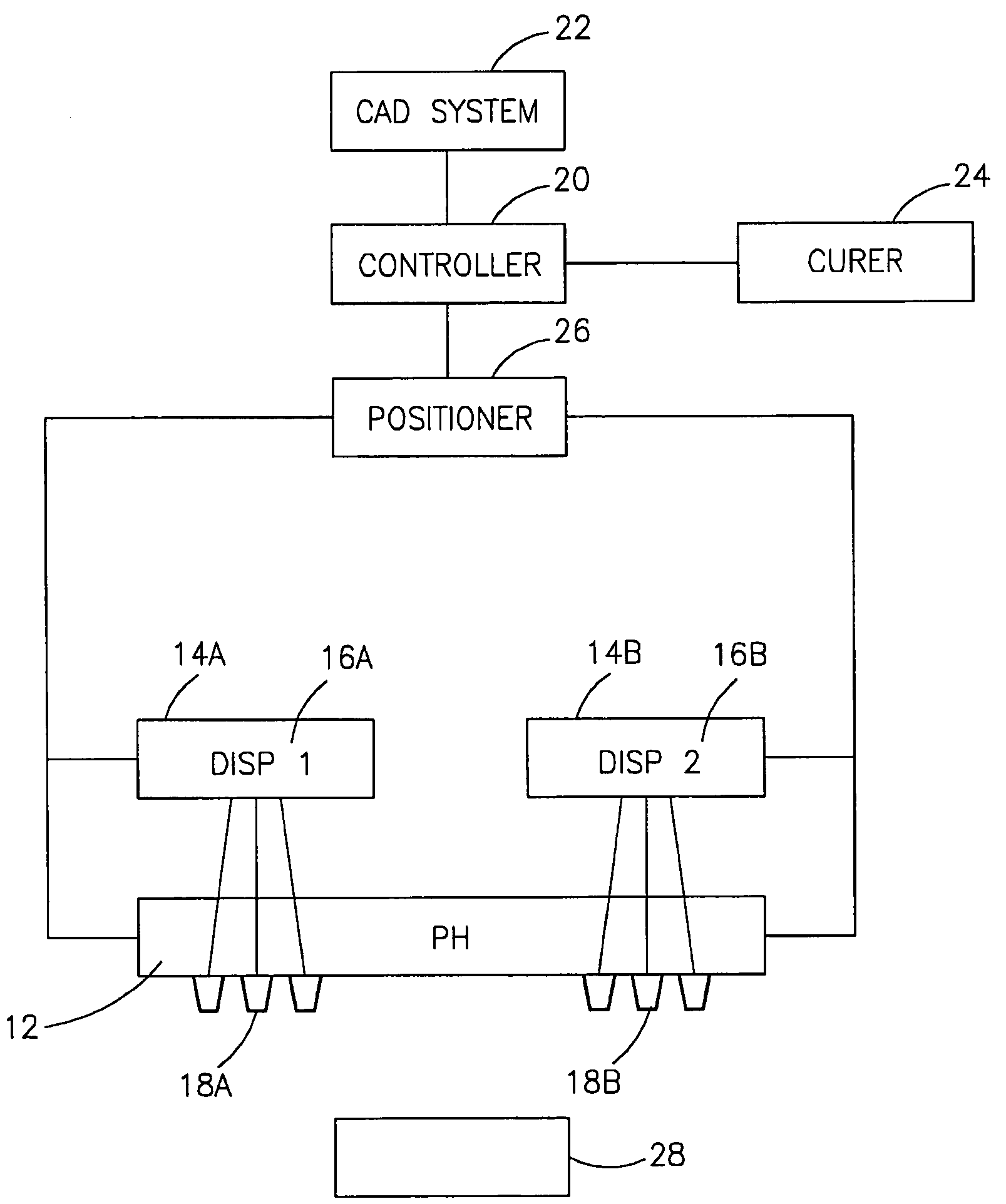

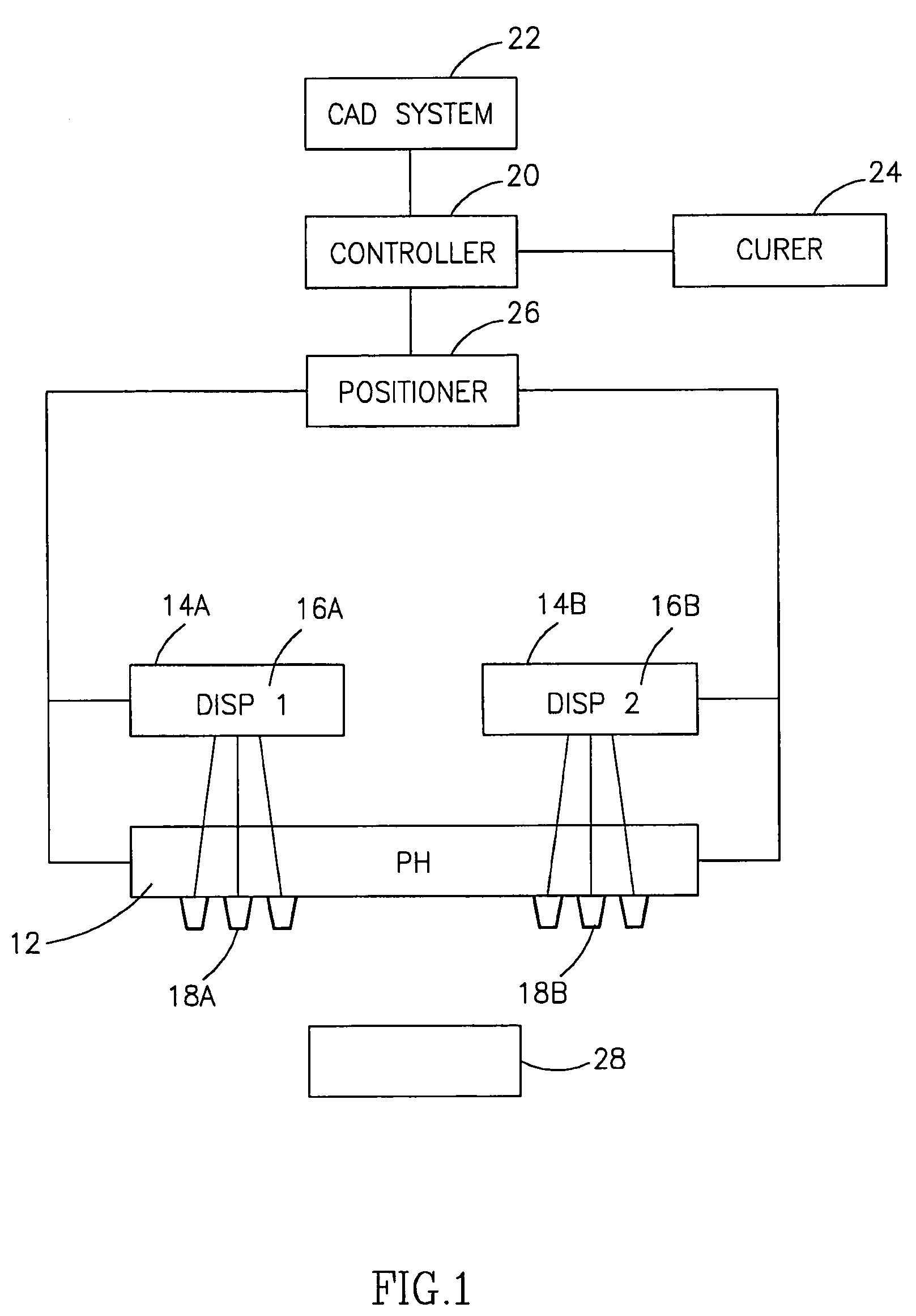

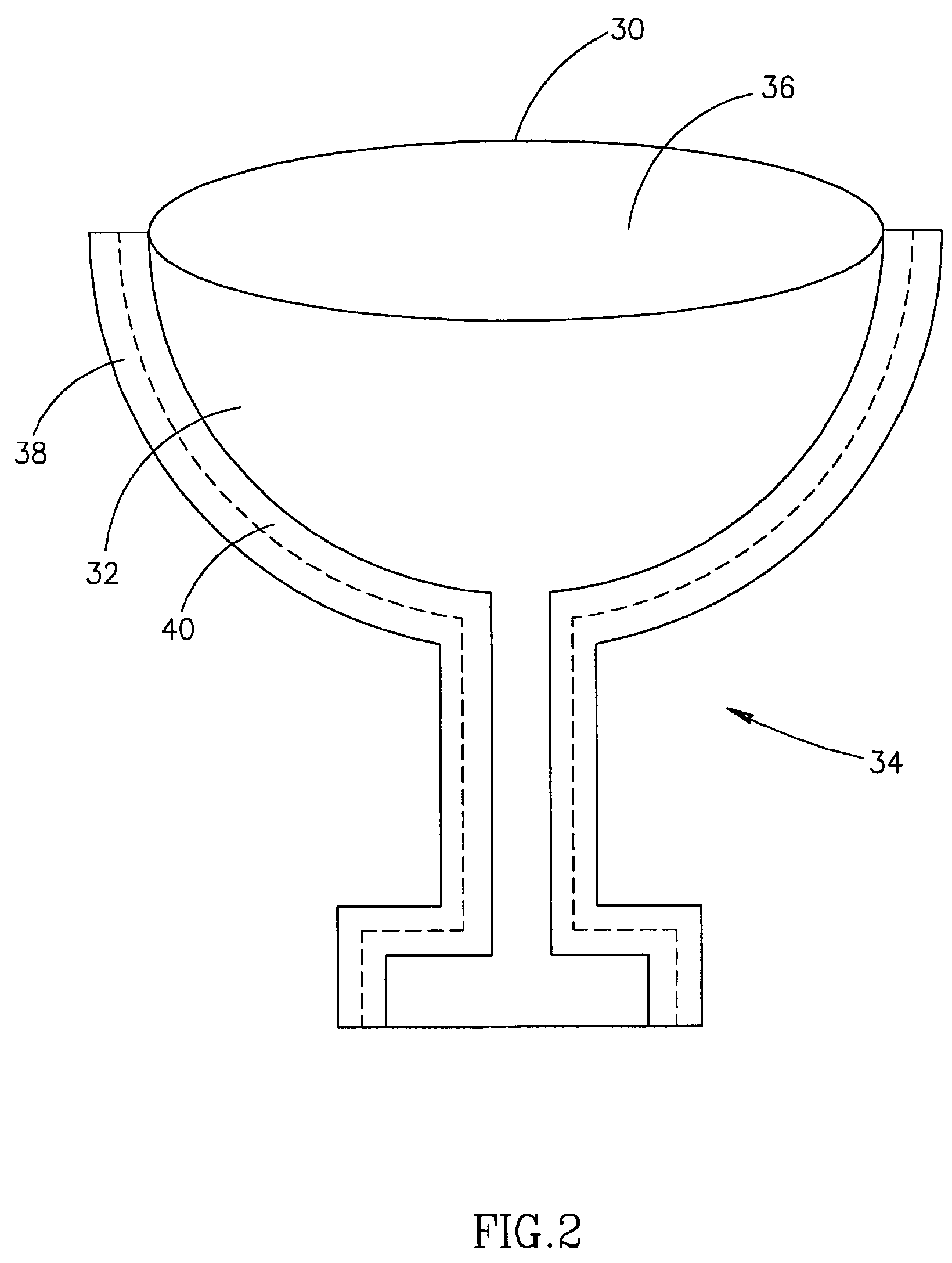

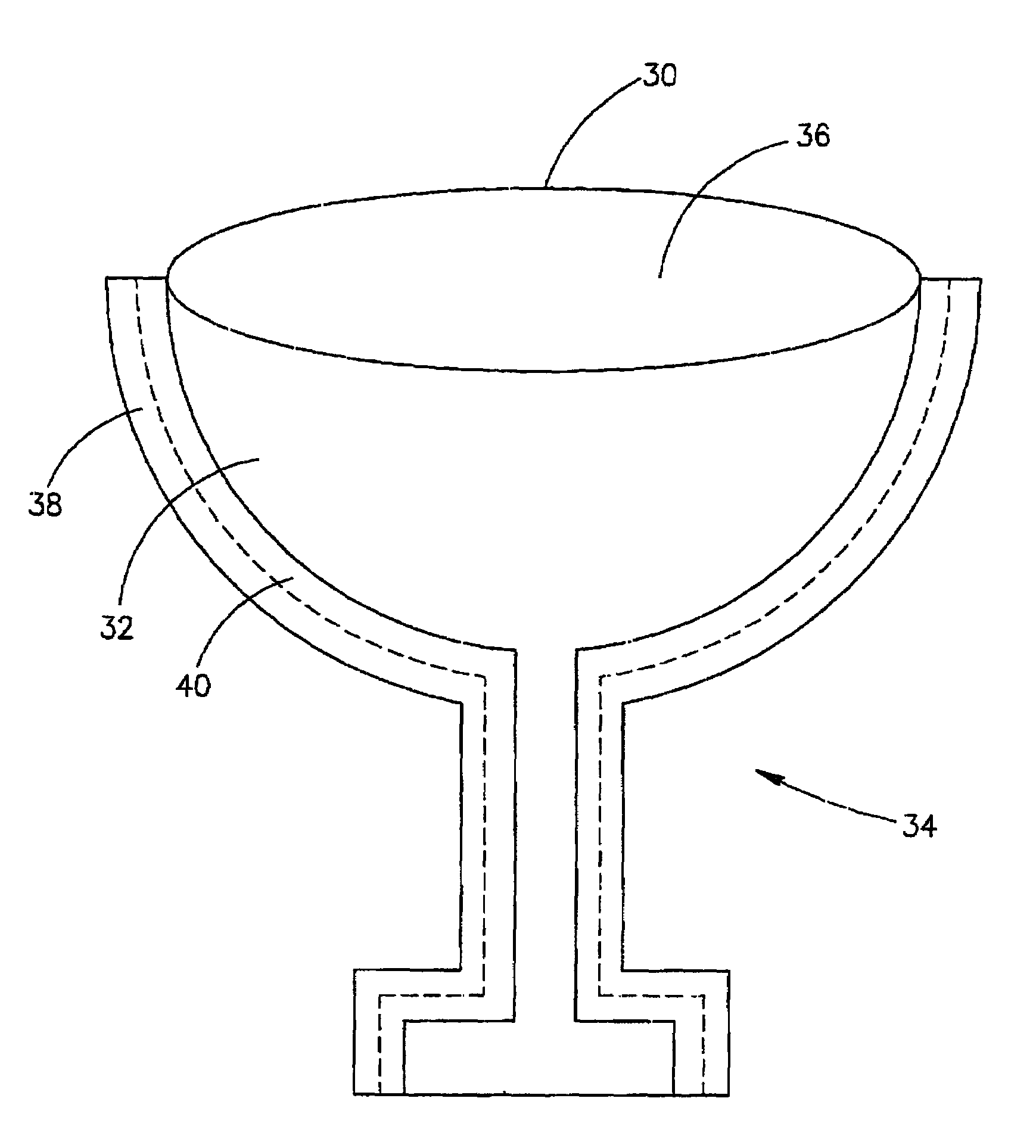

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

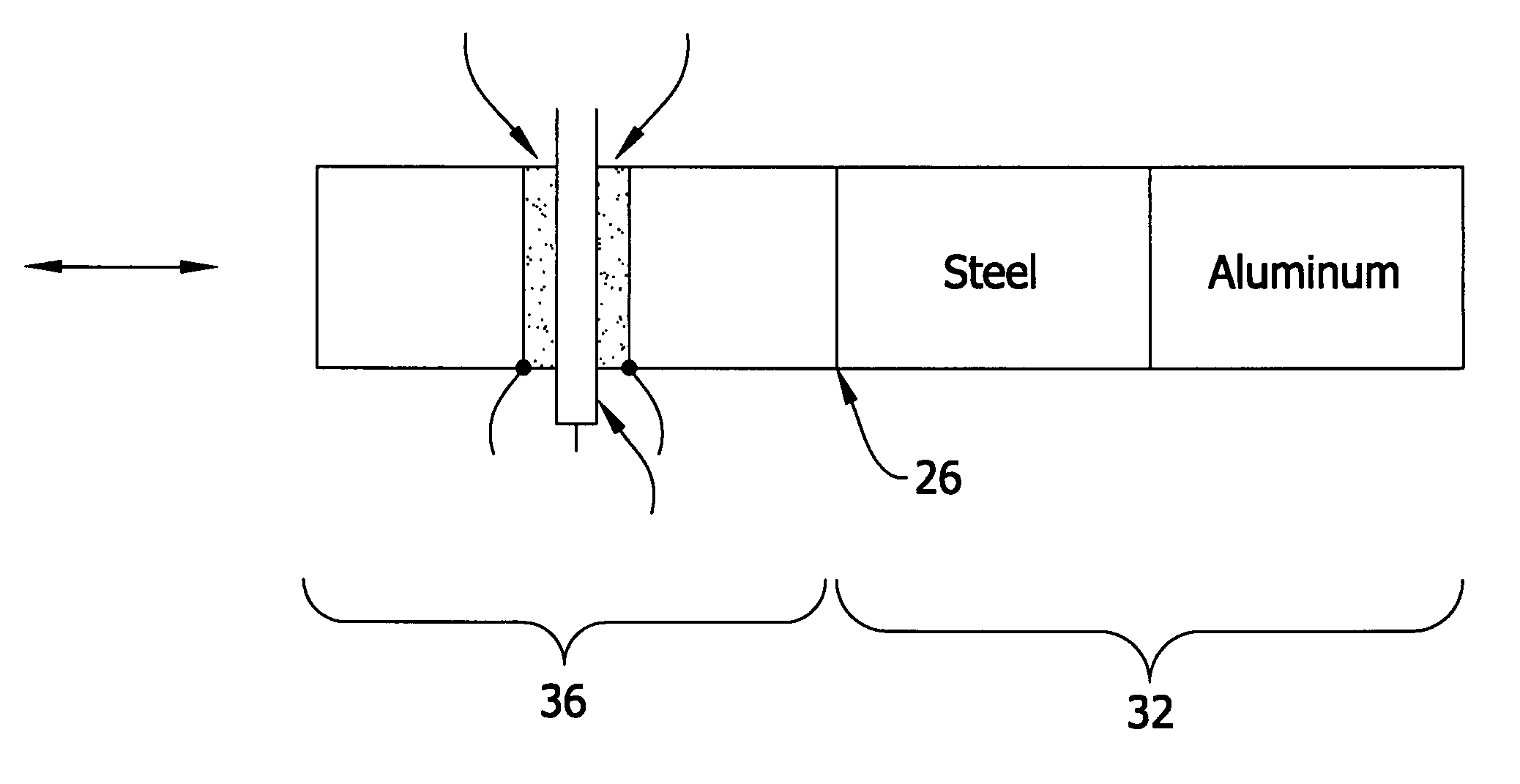

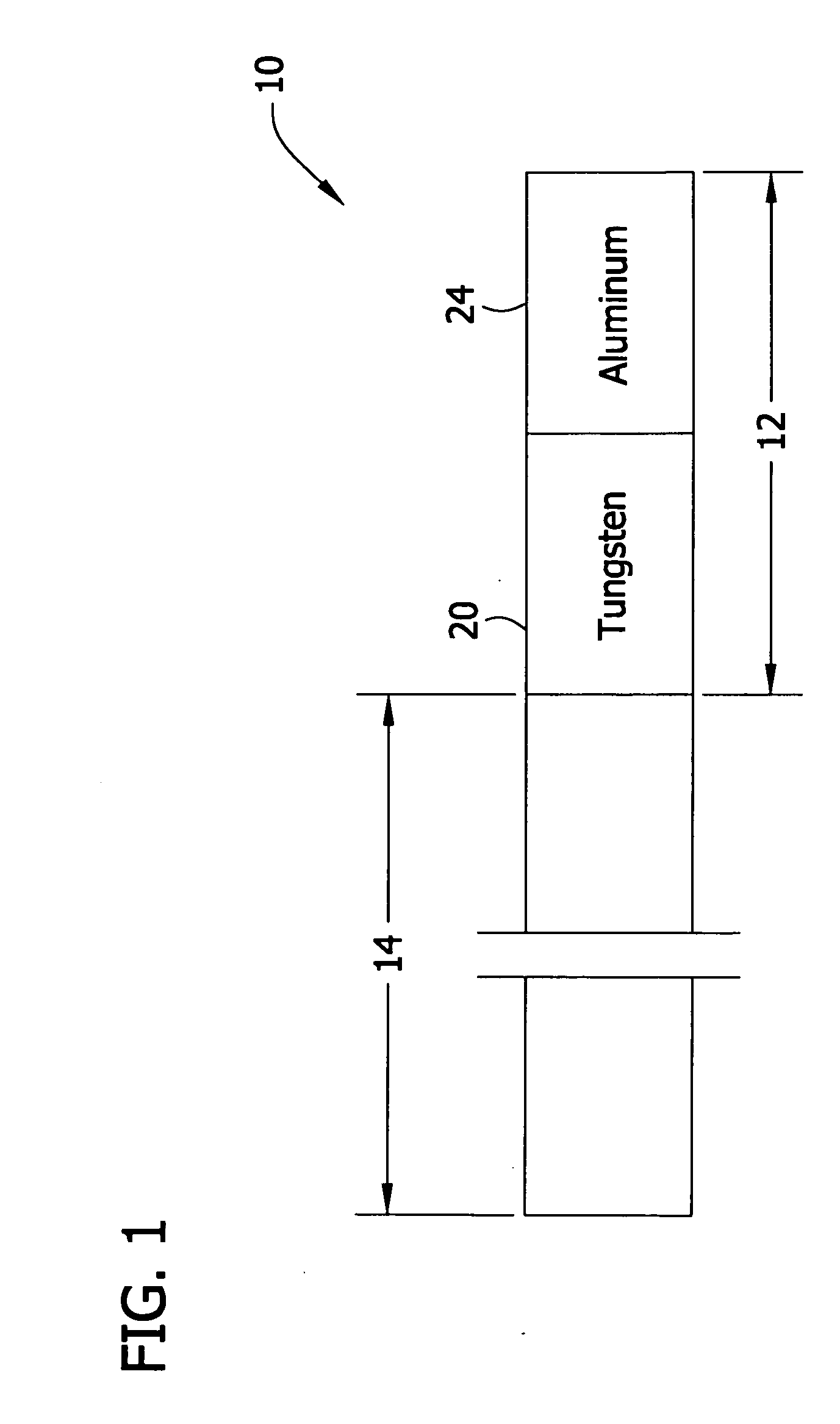

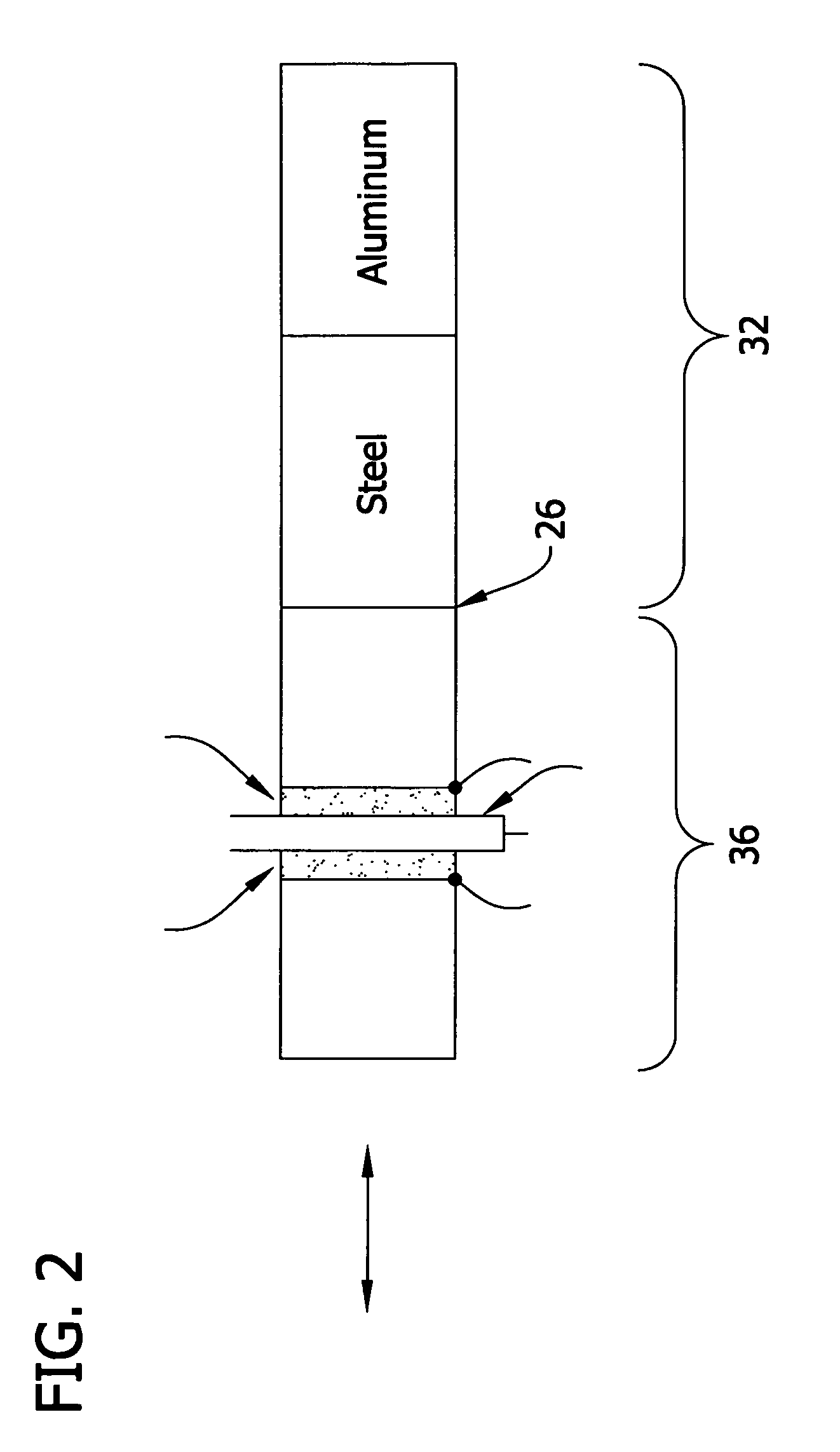

Methods for producing ultrasonic waveguides having improved amplification

InactiveUS20070130771A1High magnificationReduce stressElectrical transducersMaterial analysis using sonic/ultrasonic/infrasonic wavesAcousticsWaveguide

Methods for manufacturing ultrasonic waveguides having improved velocity gain are disclosed. Additionally, methods for manufacturing ultrasonic medical devices including the ultrasonic waveguides are disclosed. Specifically, the ultrasonic waveguides comprises a first material having a higher acoustic impedance and a second material having a lower acoustic impedance.

Owner:KIMBERLY-CLARK WORLDWIDE INC

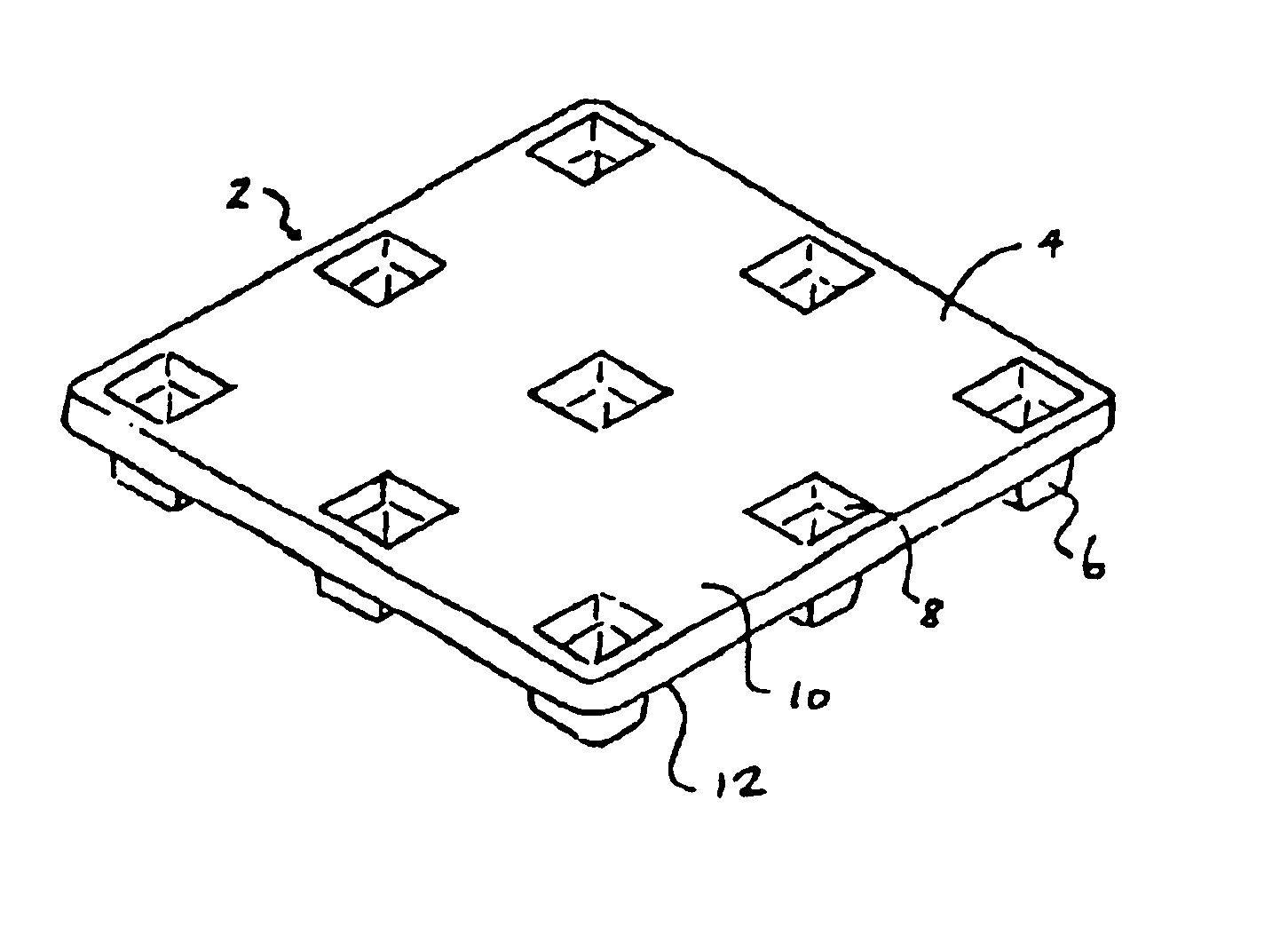

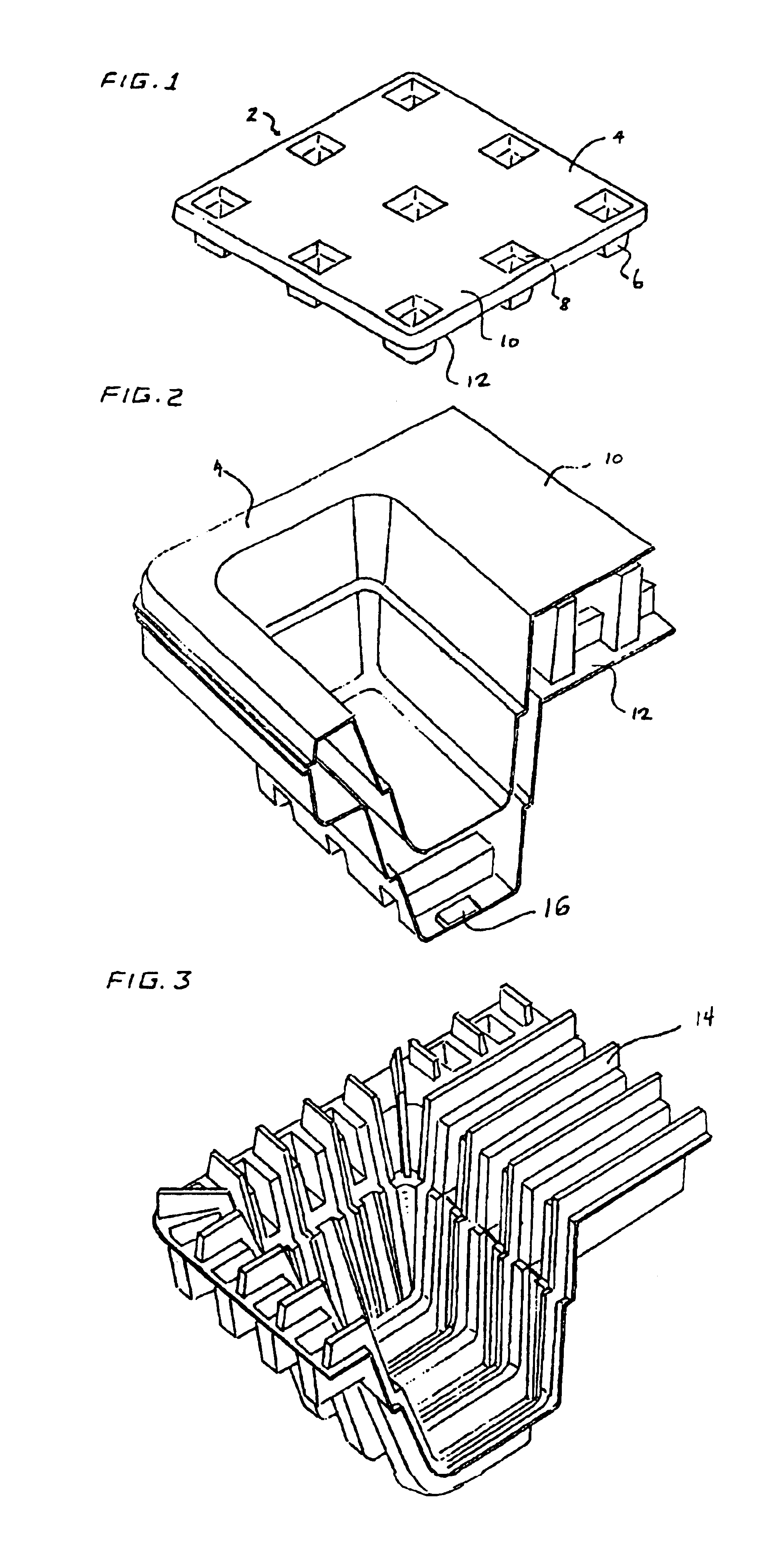

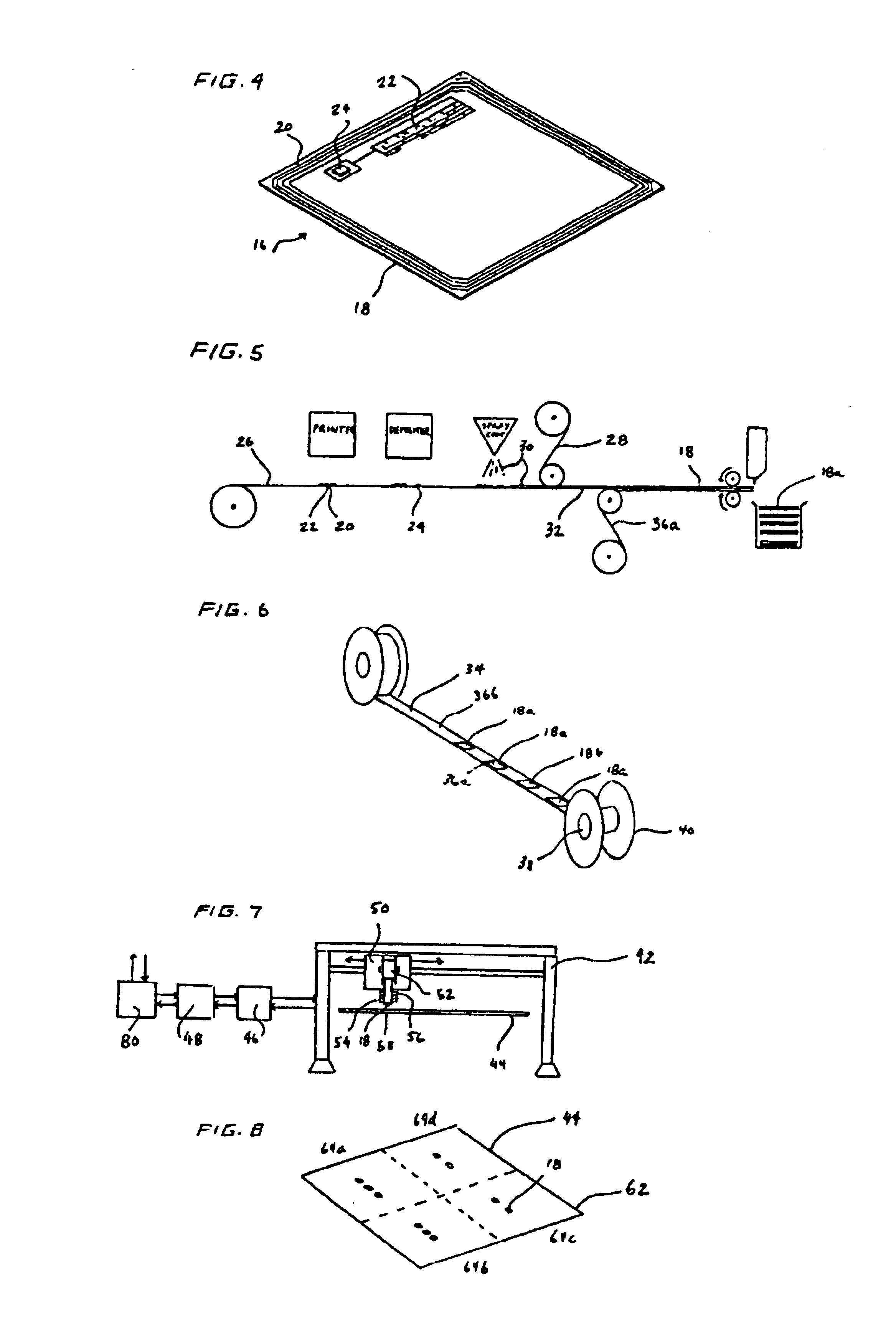

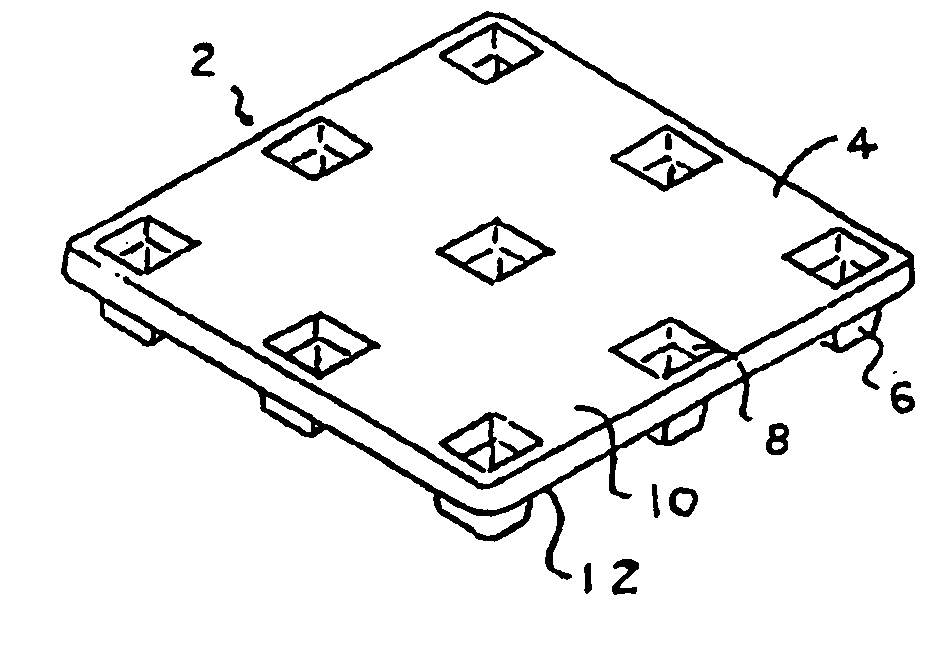

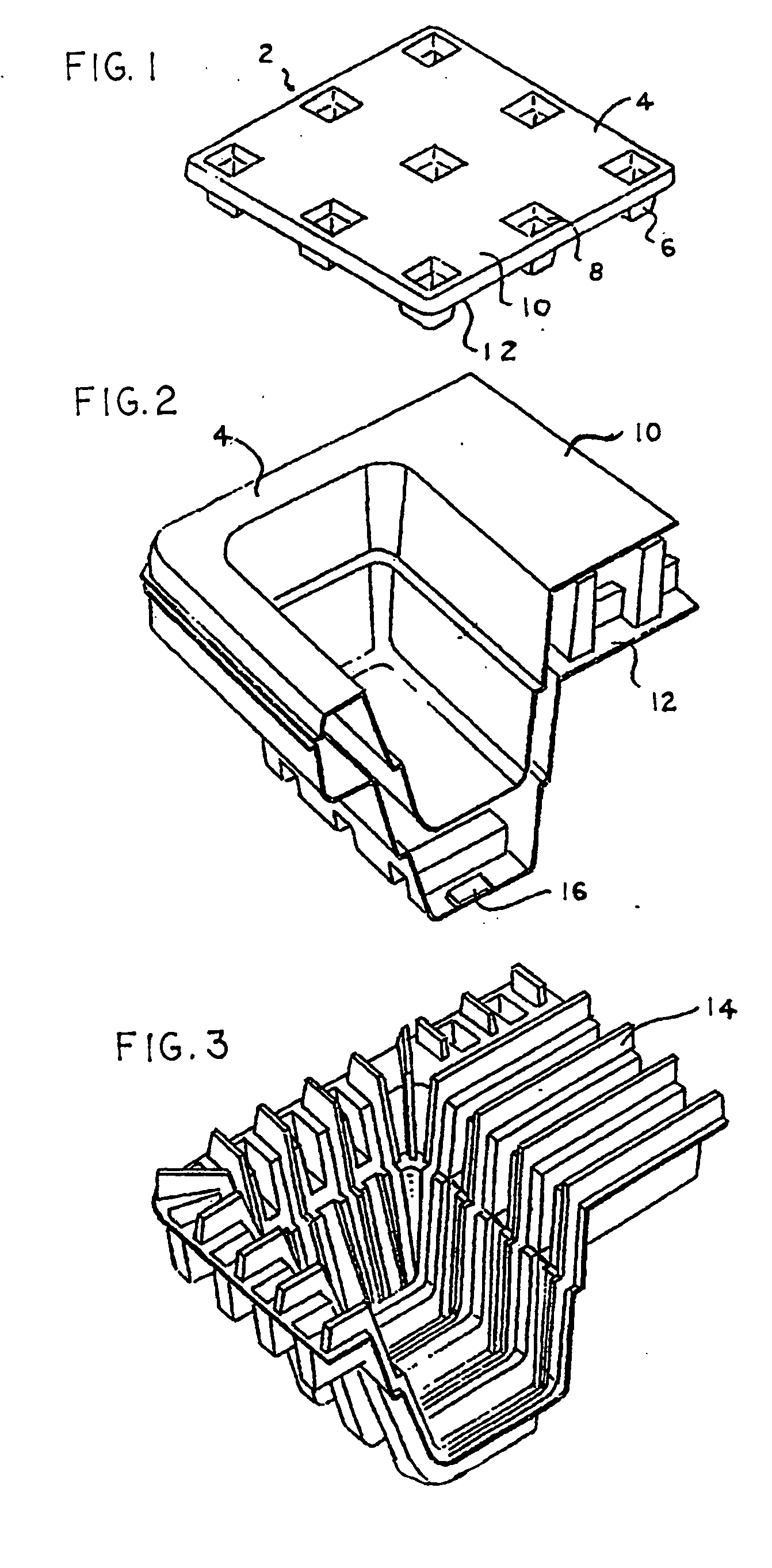

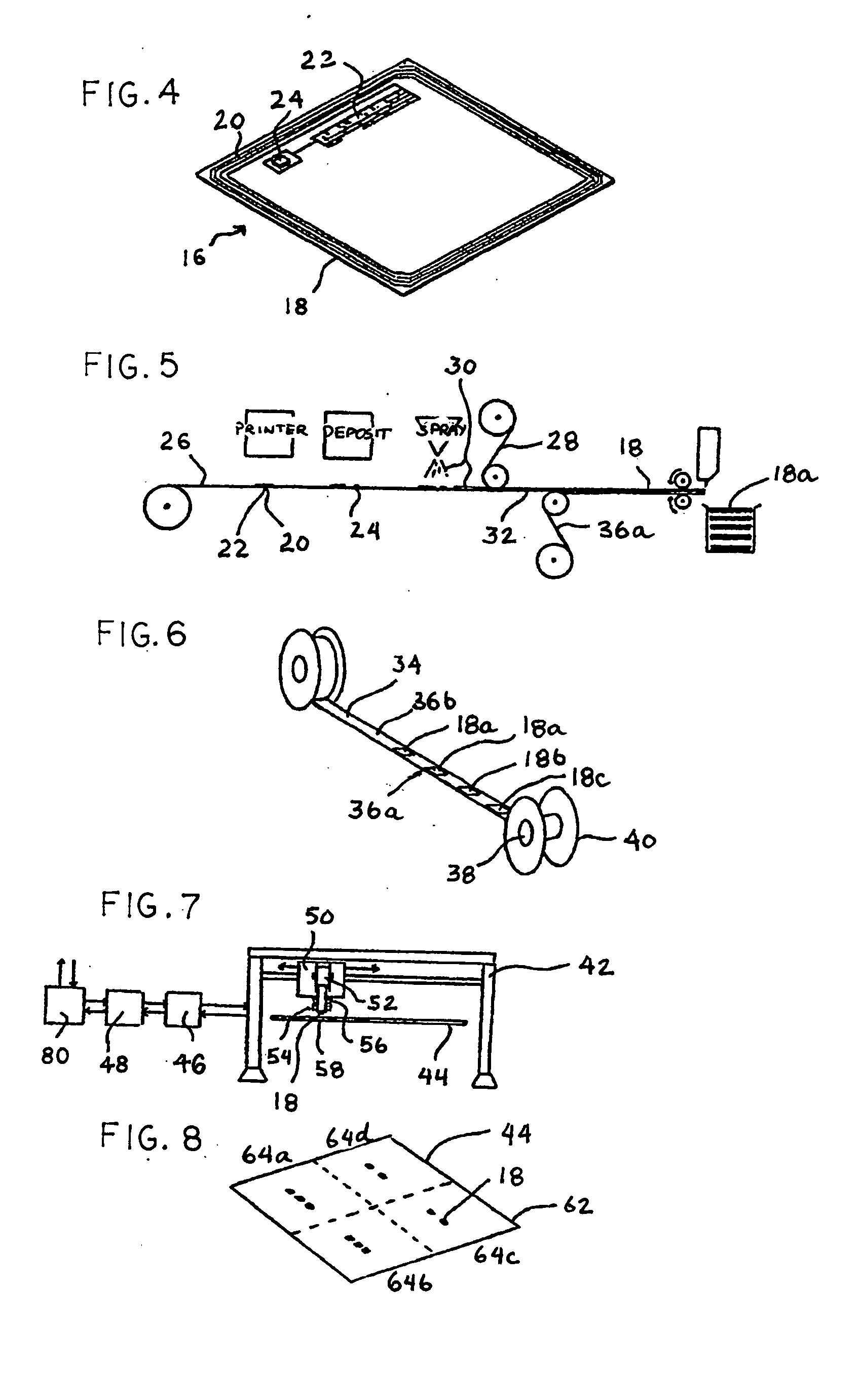

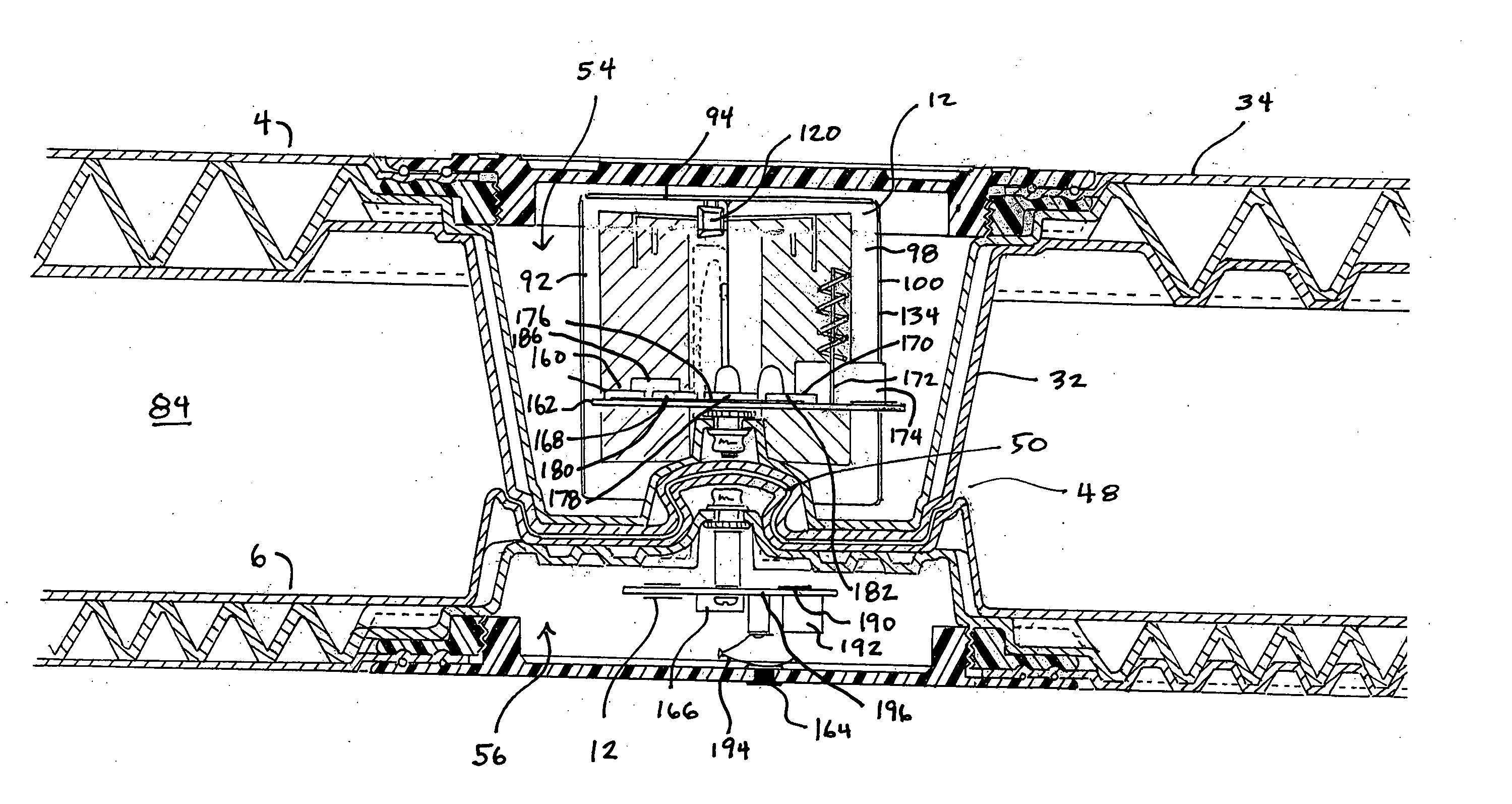

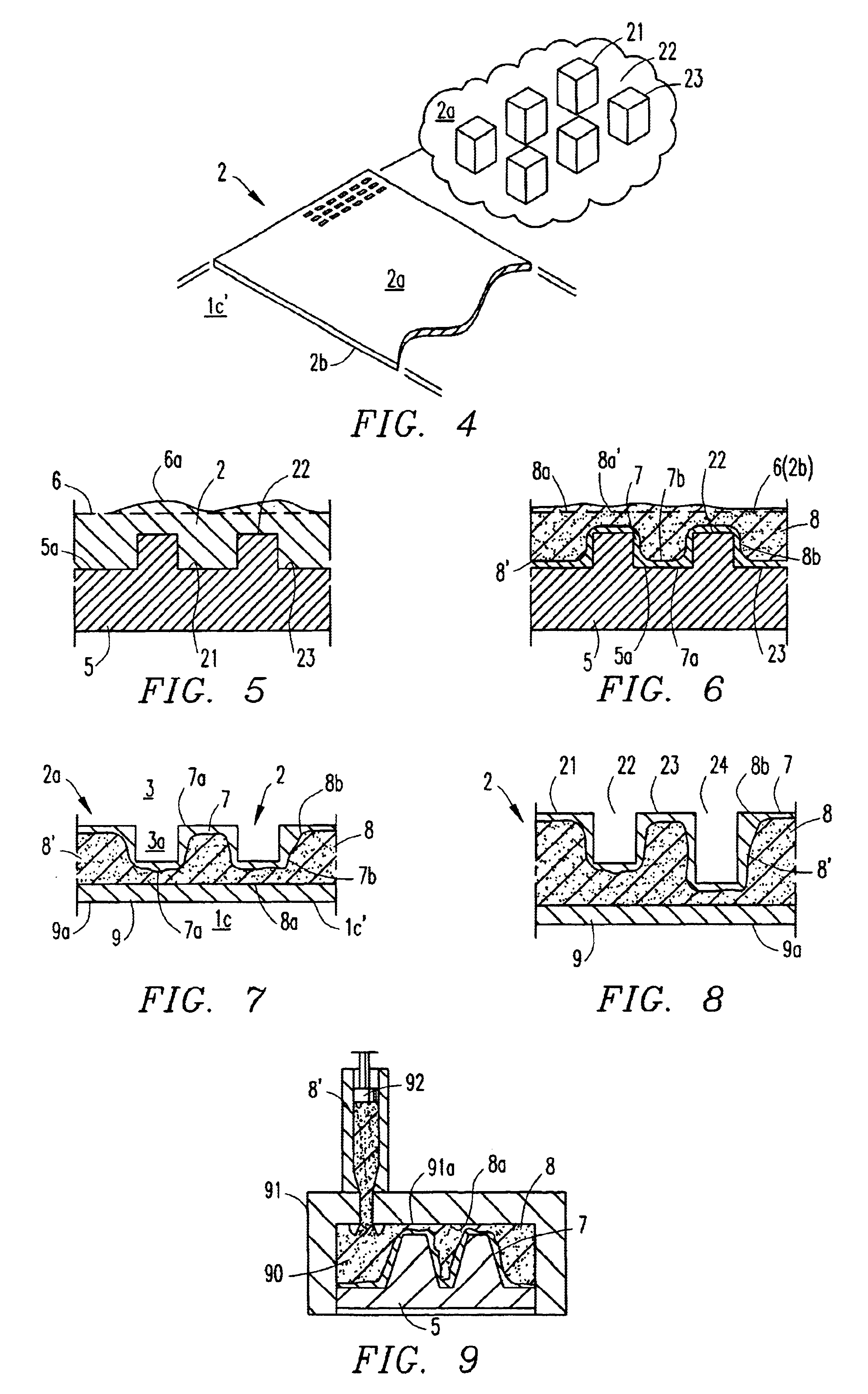

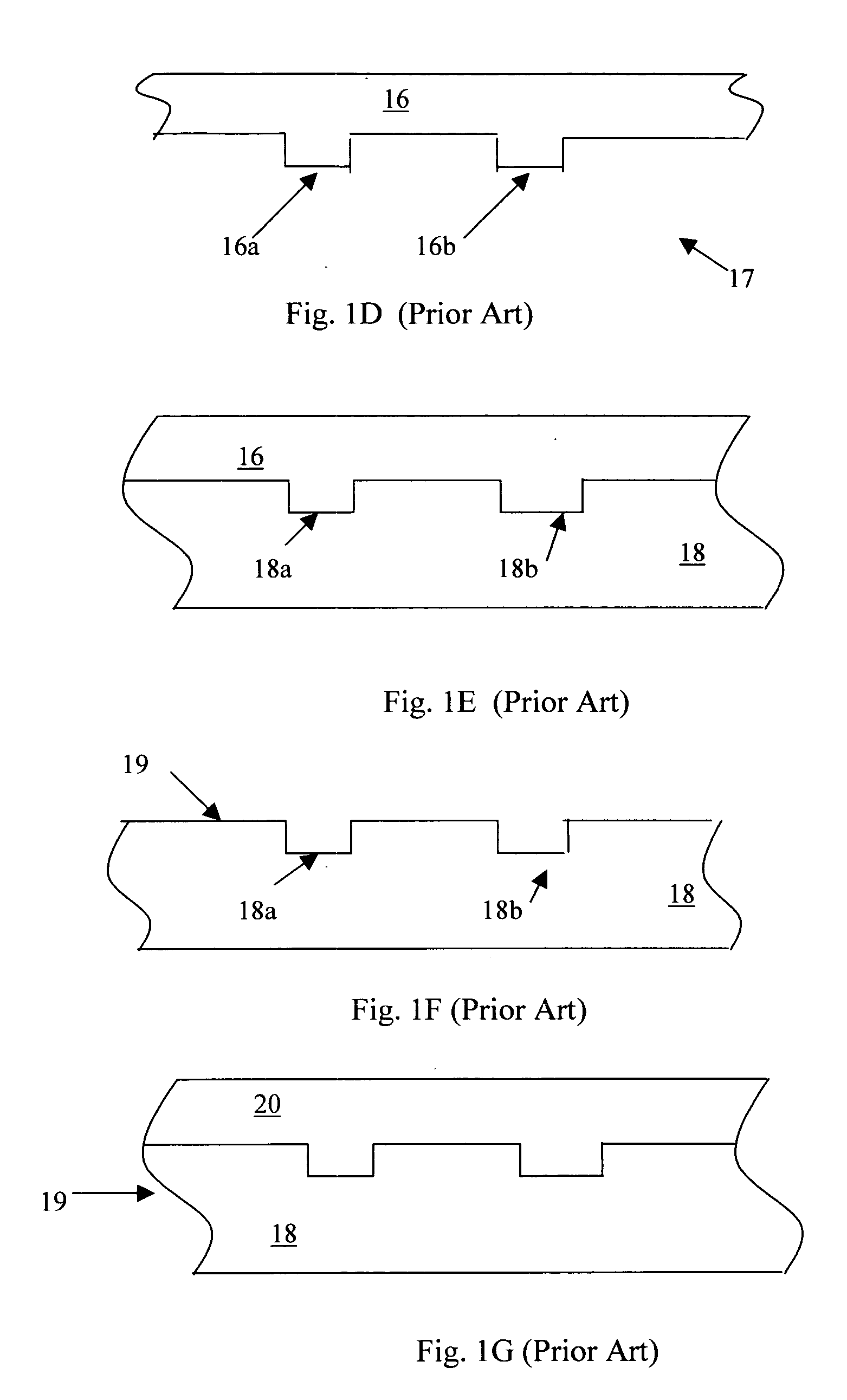

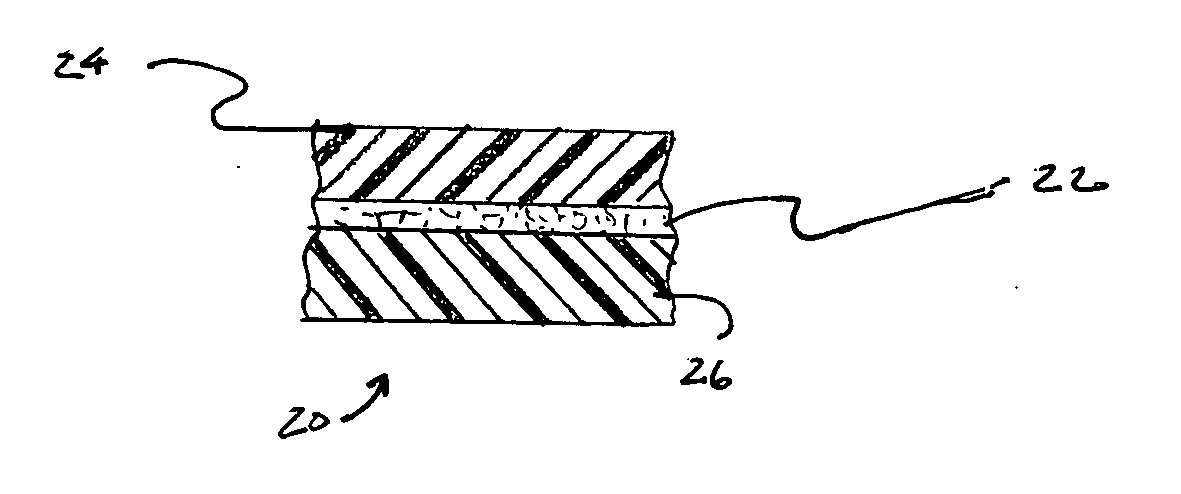

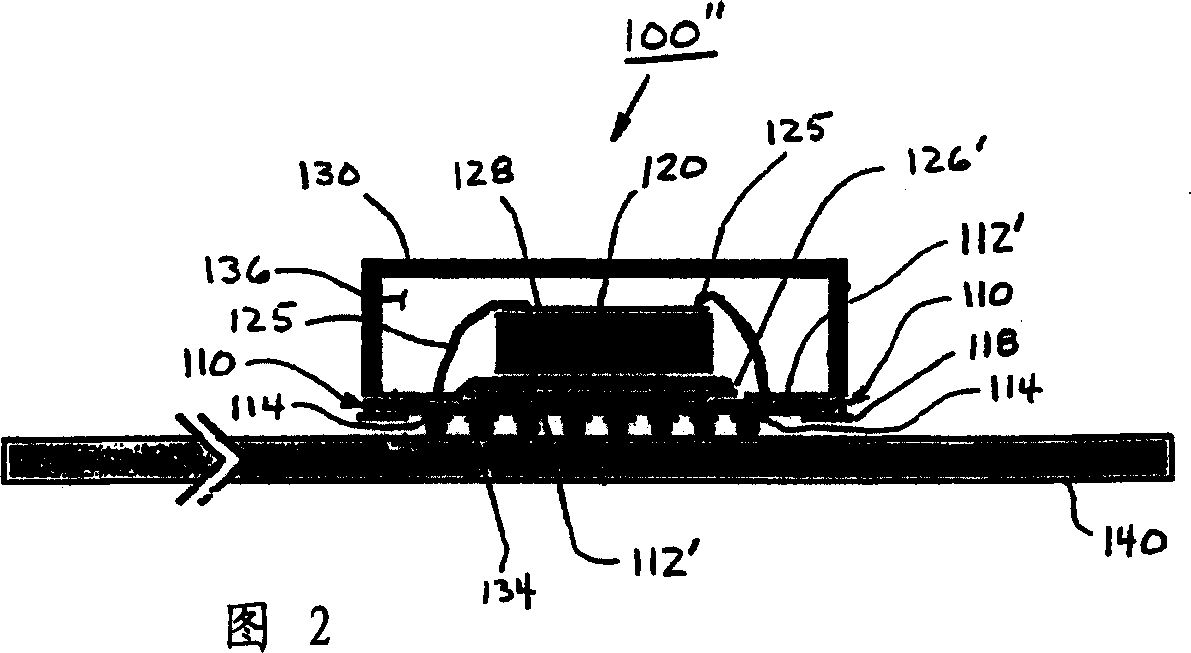

Thermoformed apparatus having a communications device

InactiveUS6943678B2Improve protectionIncreased durabilityRecord carriersDigital data processing detailsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

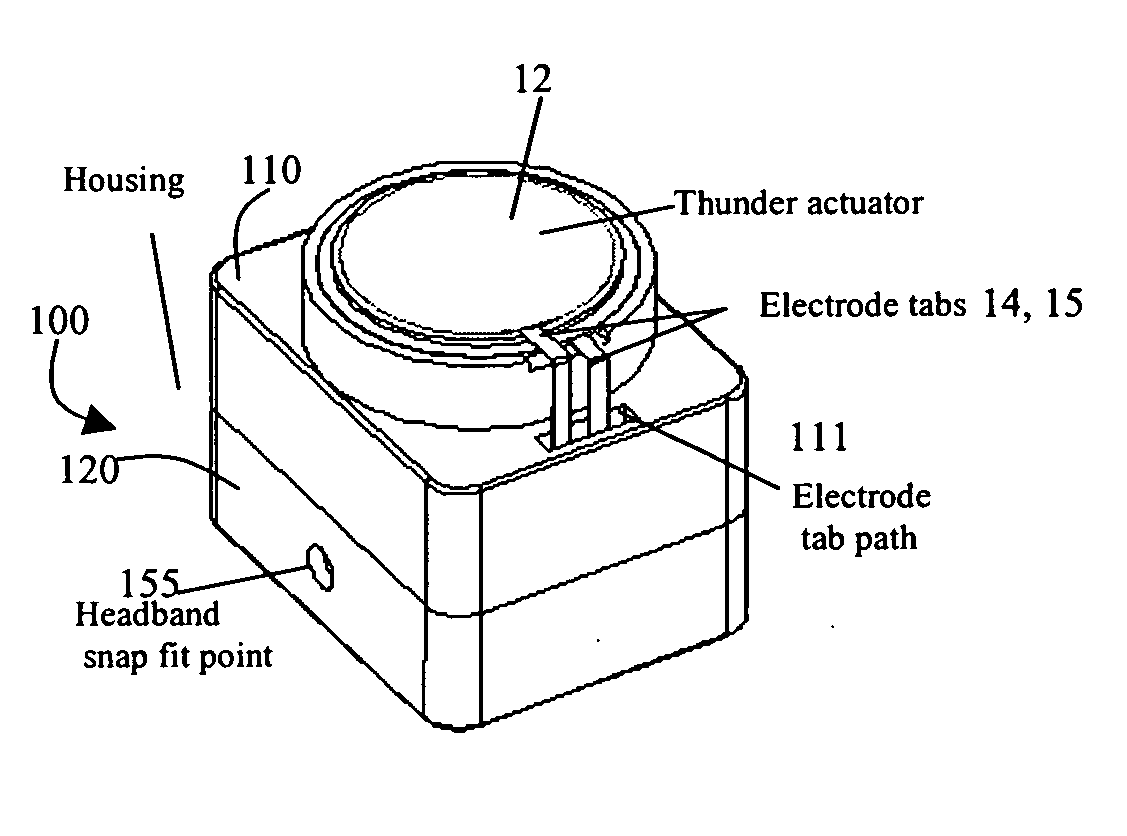

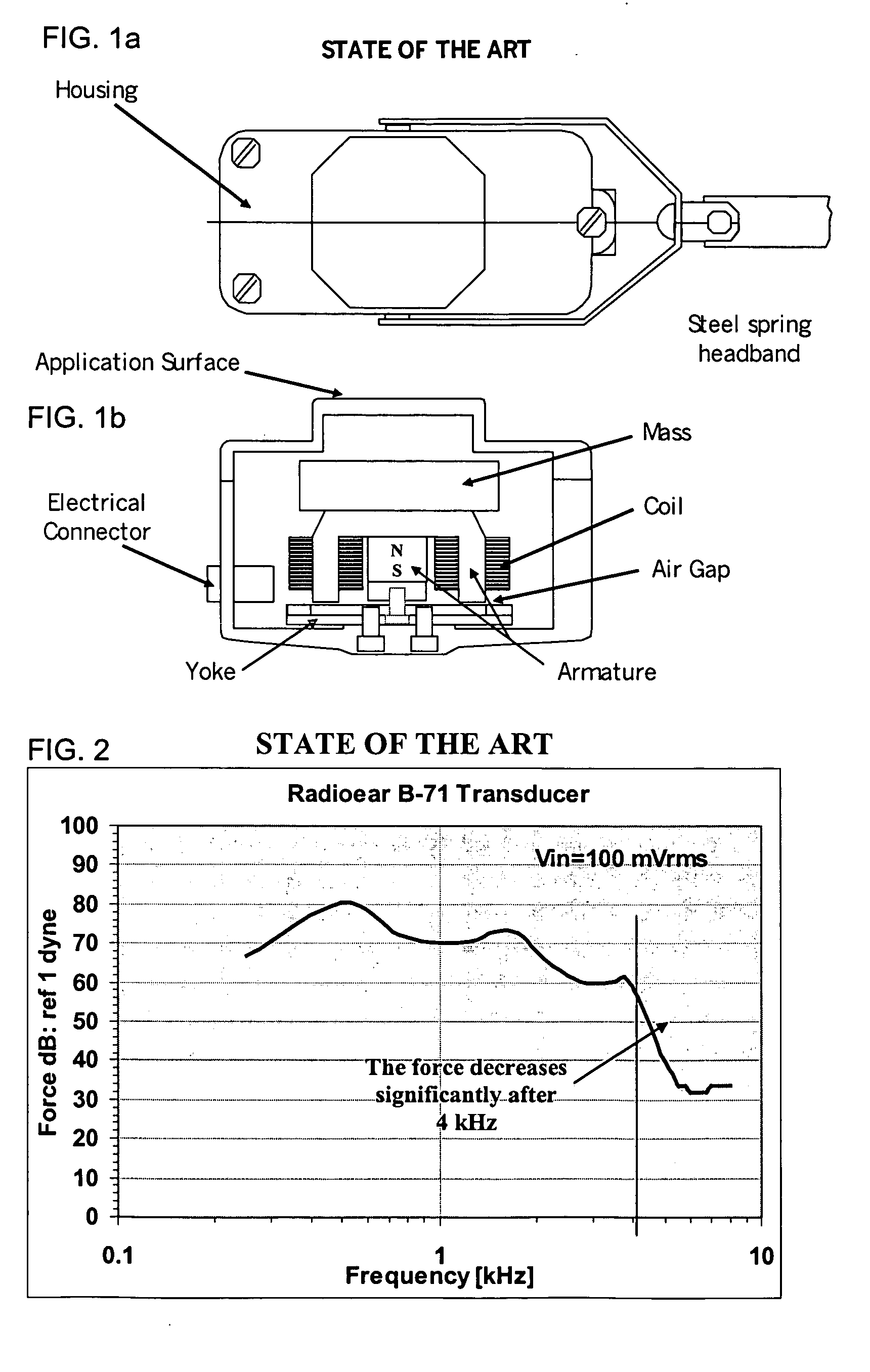

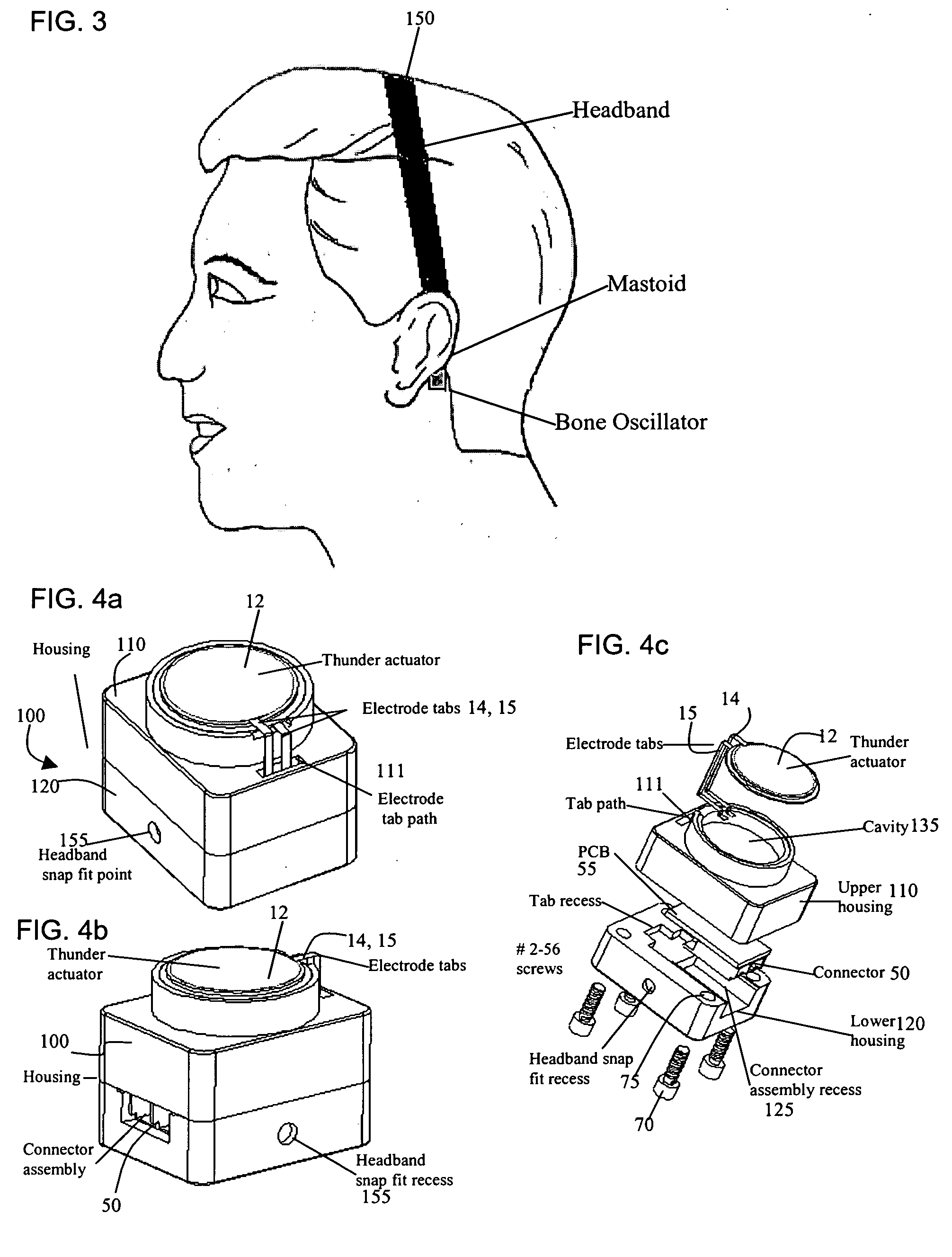

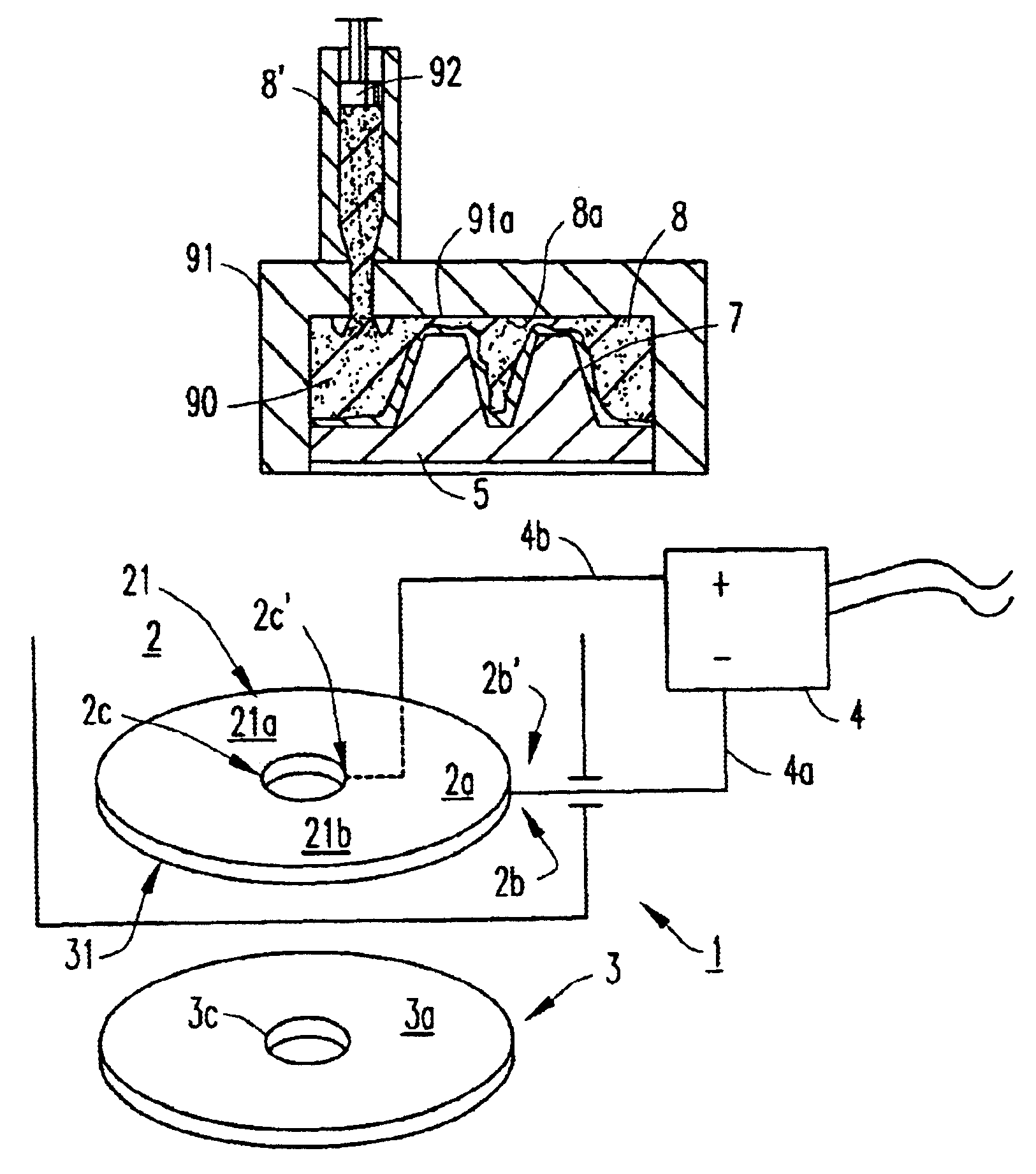

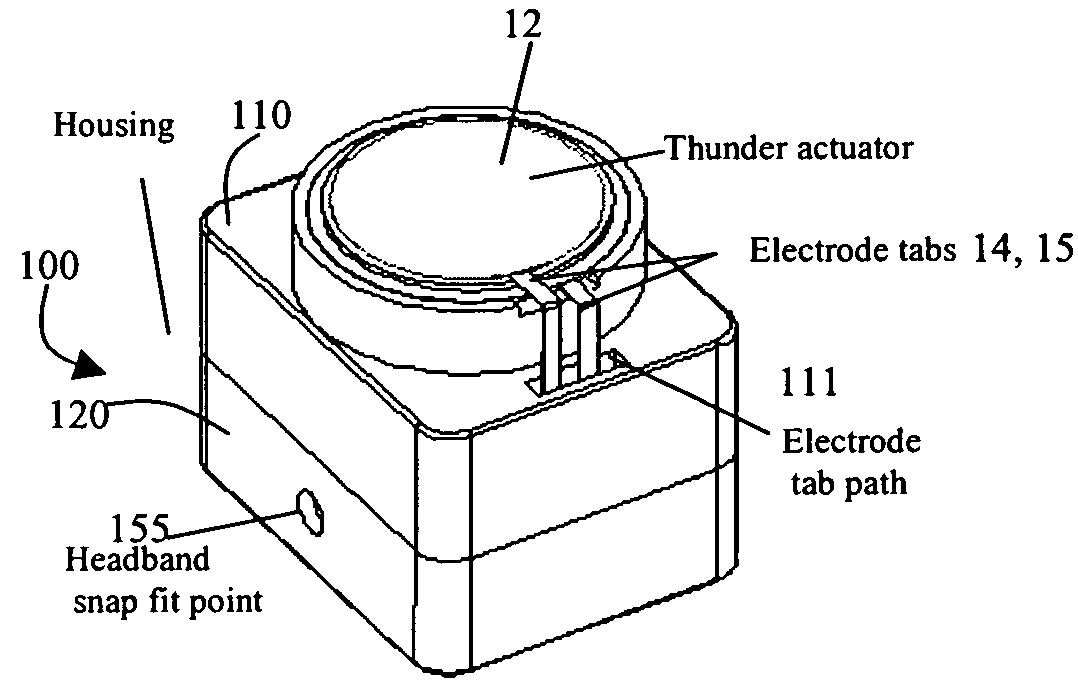

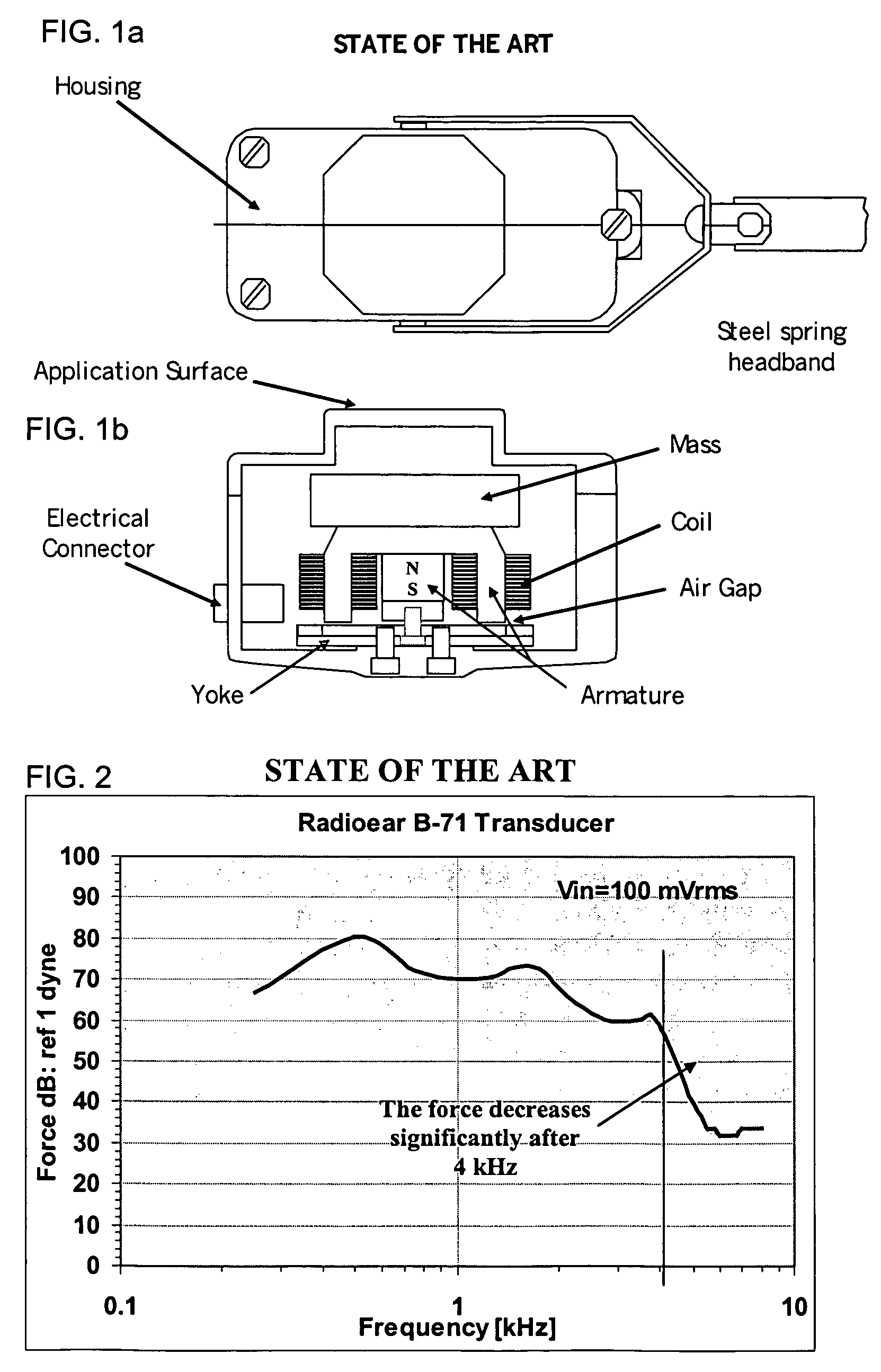

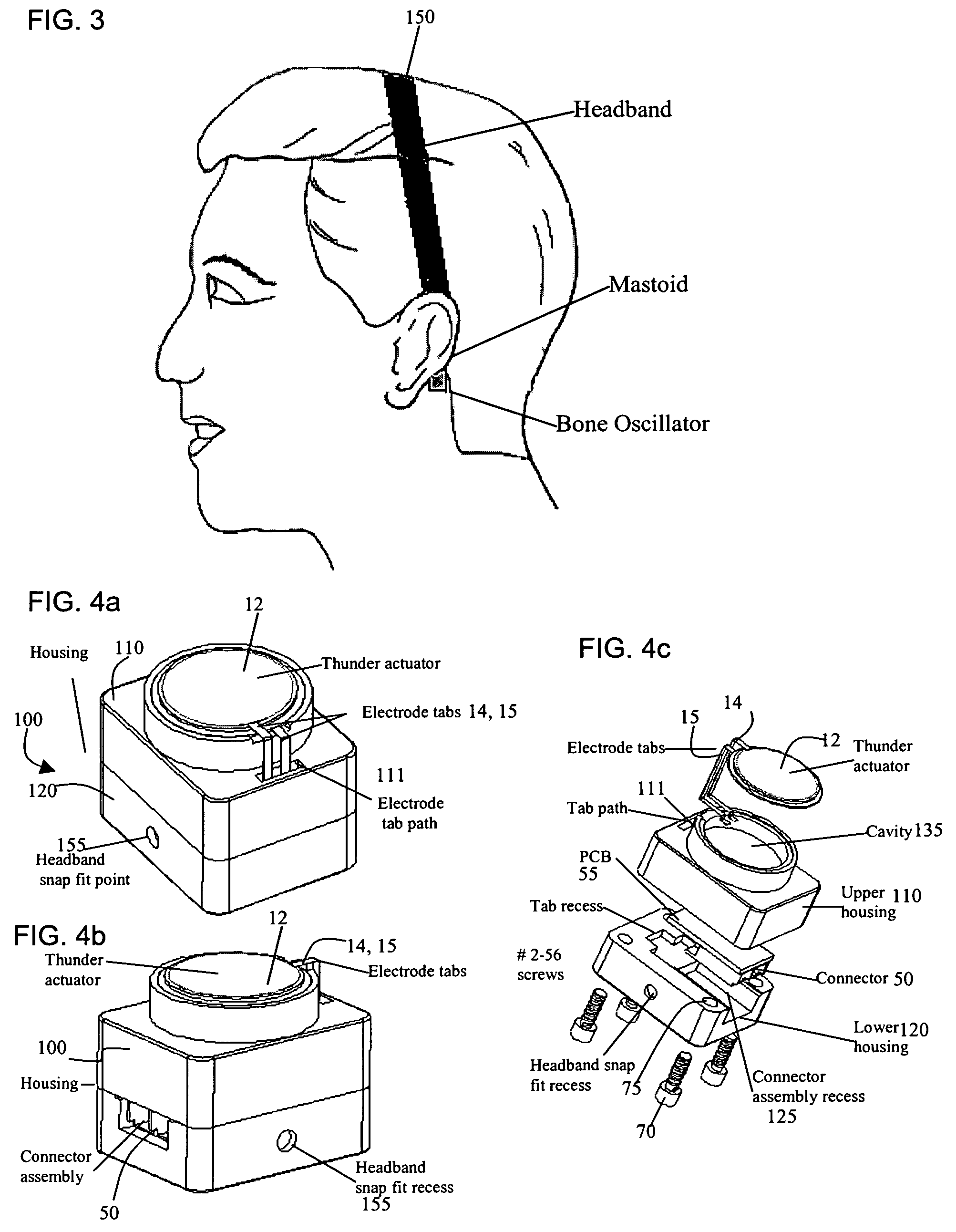

Bone-conduction hearing-aid transducer having improved frequency response

InactiveUS20070041595A1Eliminates soldering wireEliminate useRecord carriersPiezoelectric/electrostrictive transducersFrequency spectrumBone structure

A hearing-aid device and a method for transmitting sound through bone conduction are disclosed. The hearing-aid device comprises a piezoelectric-type actuator, housing and connector. The piezoelectric actuator is preferably a circular flextensional-type actuator mounted along its peripheral edge in a specifically designed circular structure of the housing. During operation, the bone-conduction transducer is placed against the mastoid area behind the ear of the patient. When the device is energized with an alternating electrical voltage, it flexes back and forth like a circular membrane sustained along its periphery and thus, vibrates as a consequence of the inverse piezoelectric effect. Due to the specific and unique designs proposed, these vibrations are directly transferred trough the human skin to the bone structure (the skull) and provide a means for the sound to be transmitted for patients with hearing malfunctions. The housing acts as a holder for the actuators, as a pre-stress application platform, and as a mass which tailors the frequency spectrum of the device. The apparatus exhibits a performance with a very flat response in the frequency spectrum 200 Hz to 10 kHz, which is a greater spectrum range than any other prior art devices disclosed for bone-conduction transduction which are typically limited to less than 4 kHz.

Owner:FACE INT

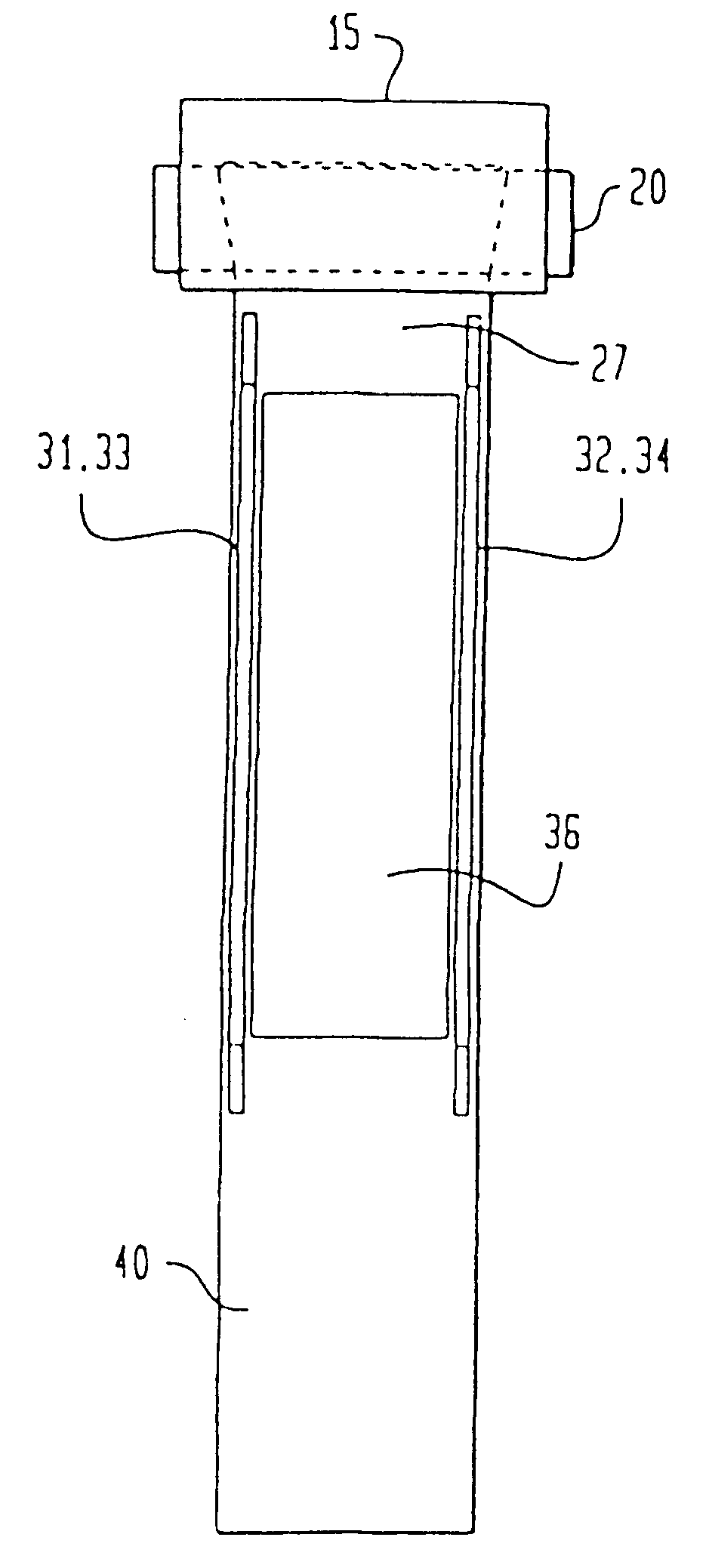

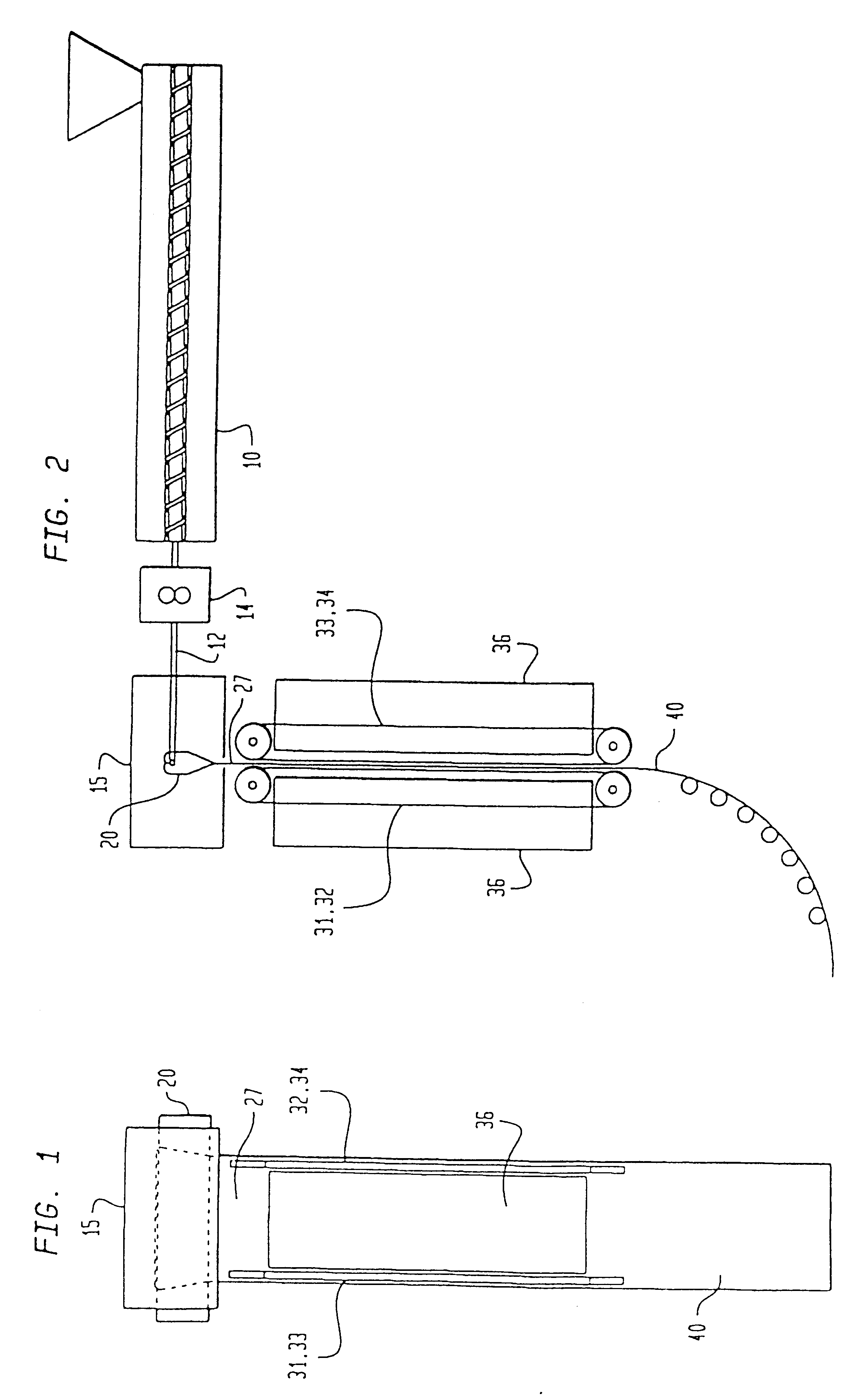

Thermoformed platform having a communications device

InactiveUS20050241548A1Improve protectionImprove reliability and durabilityContainer decorationsLevel indicationsThermoformingEngineering

An apparatus has a communications device associated therewith. In another aspect of the present invention, a pallet is made from thermoformed polymeric sheets with an attached communications device. A further aspect of the present invention provides a radio frequency identification device attached to an apparatus. In still another aspect of the present invention, a communications device is incorporated into one or more sheets of a pallet or other container prior to forming. Methods of making and using a thermoformed pallet and container, having a communications device, are also provided.

Owner:NEXTREME

RF-enabled pallet

InactiveUS20050237184A1Small sizeContainer decorationsLevel indicationsElectrostatic couplingEngineering

The inventions involve material handling apparatus developed to operate in radio frequency rich environments. Articles are provided having at least one large compartment capable of enclosing at least one electronic device or a package populated with a plurality of devices. RFID tags are also provided having three antenna arrays situated on three planes to improve electromagnetic and electrostatic coupling with an external distributed network of devices. Pallets are provided with cellular communications devices to provide track and trace functionality. Sensors and actuators are used in connection with the material handling apparatus.

Owner:NEXTREME

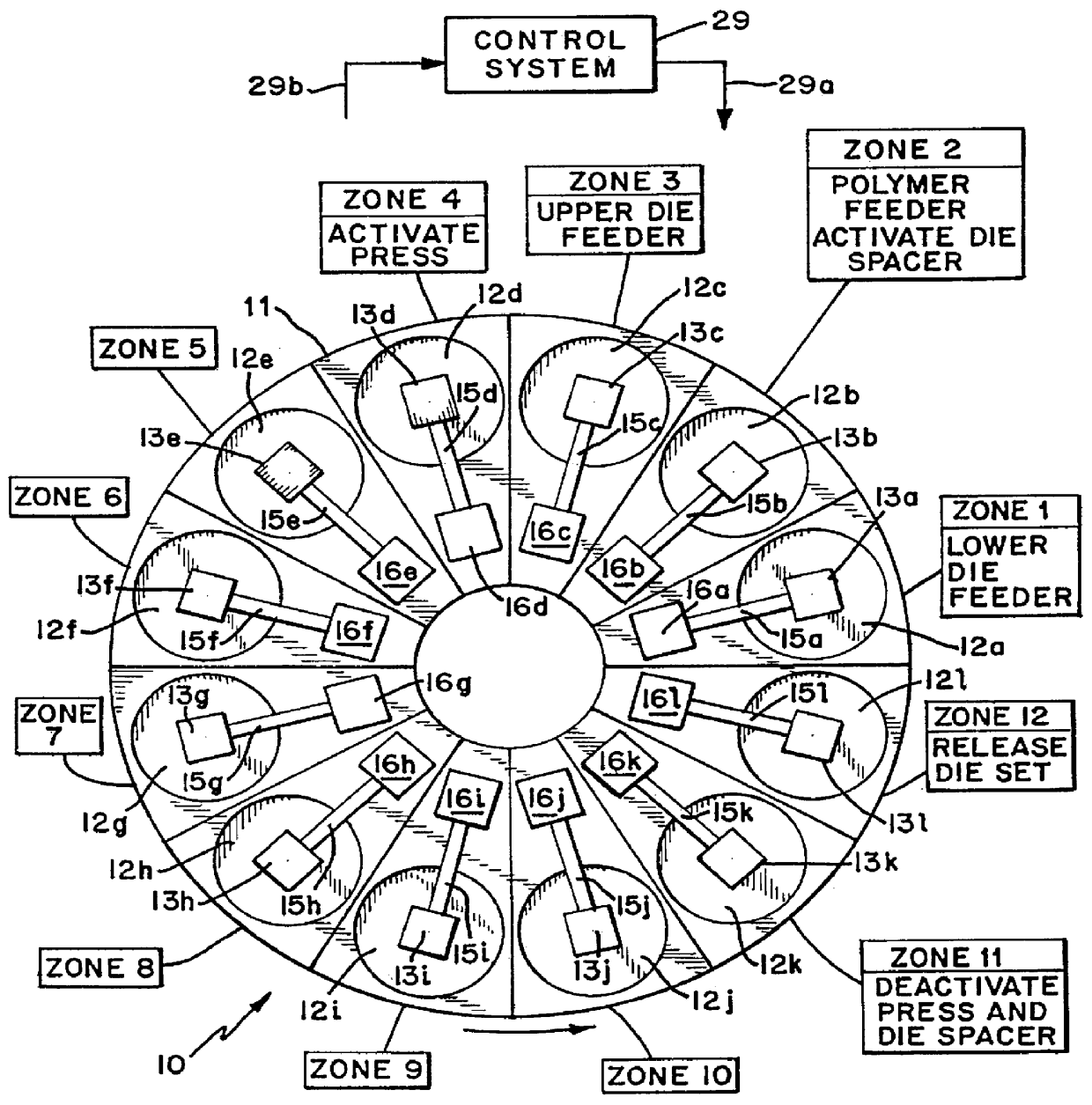

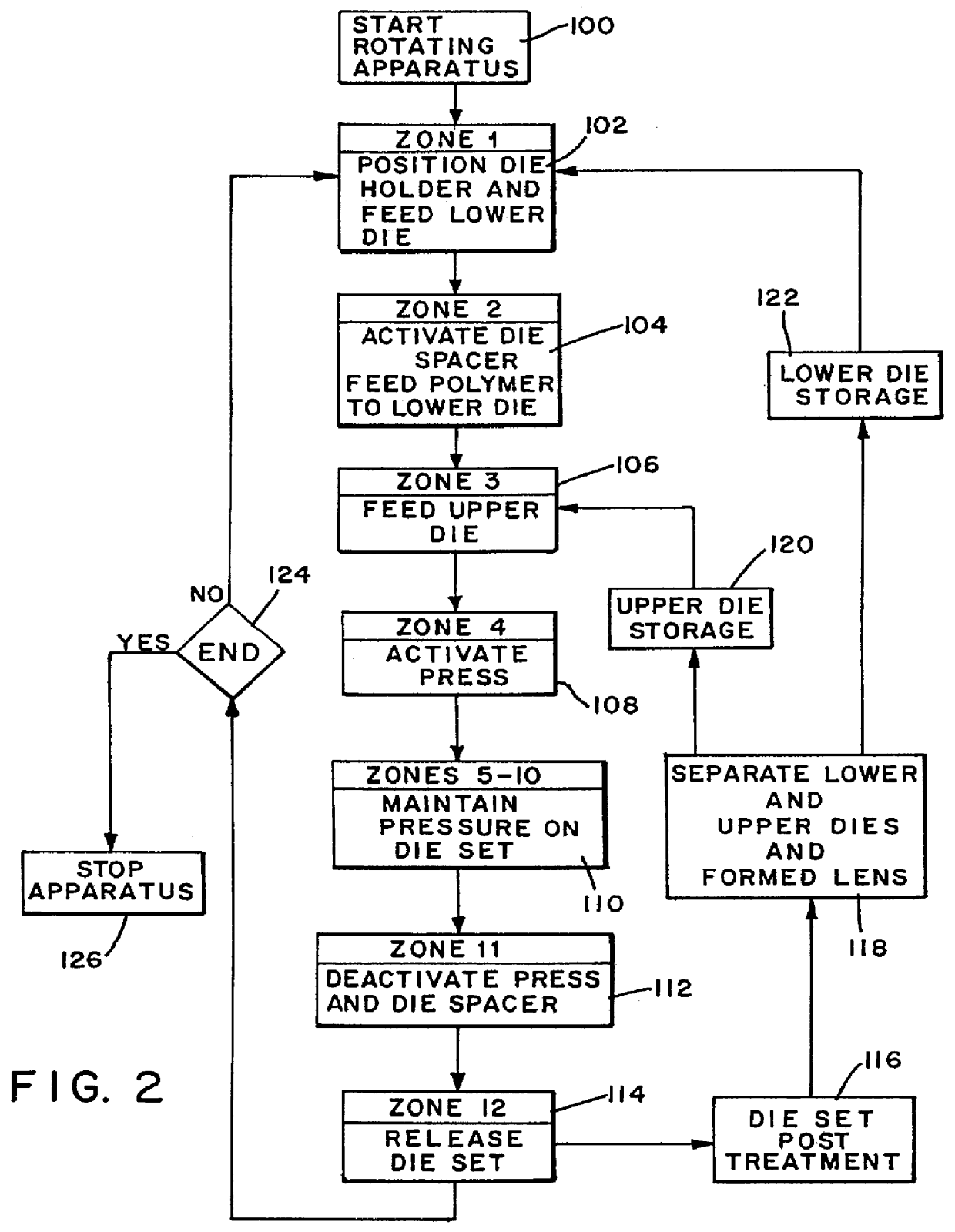

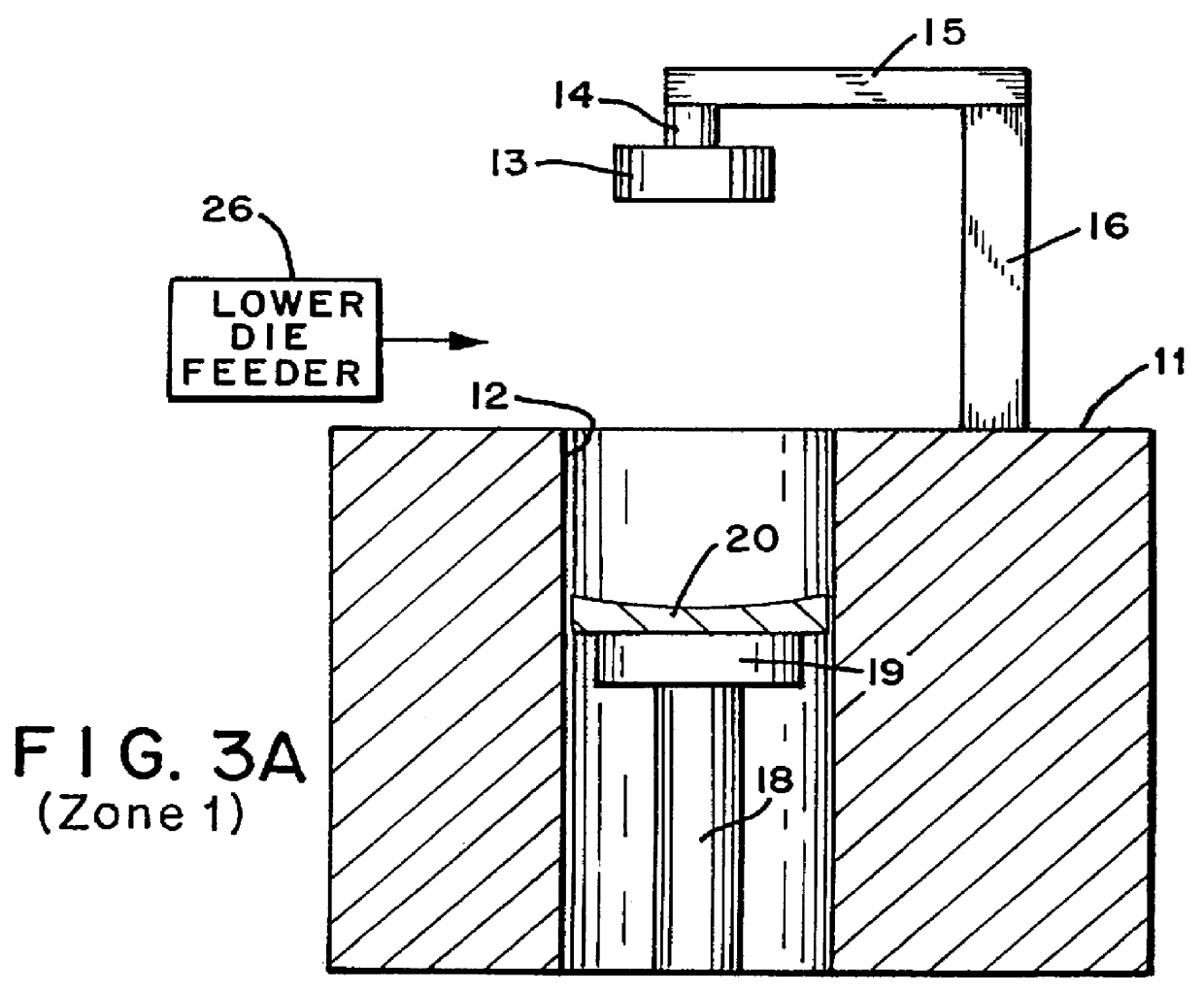

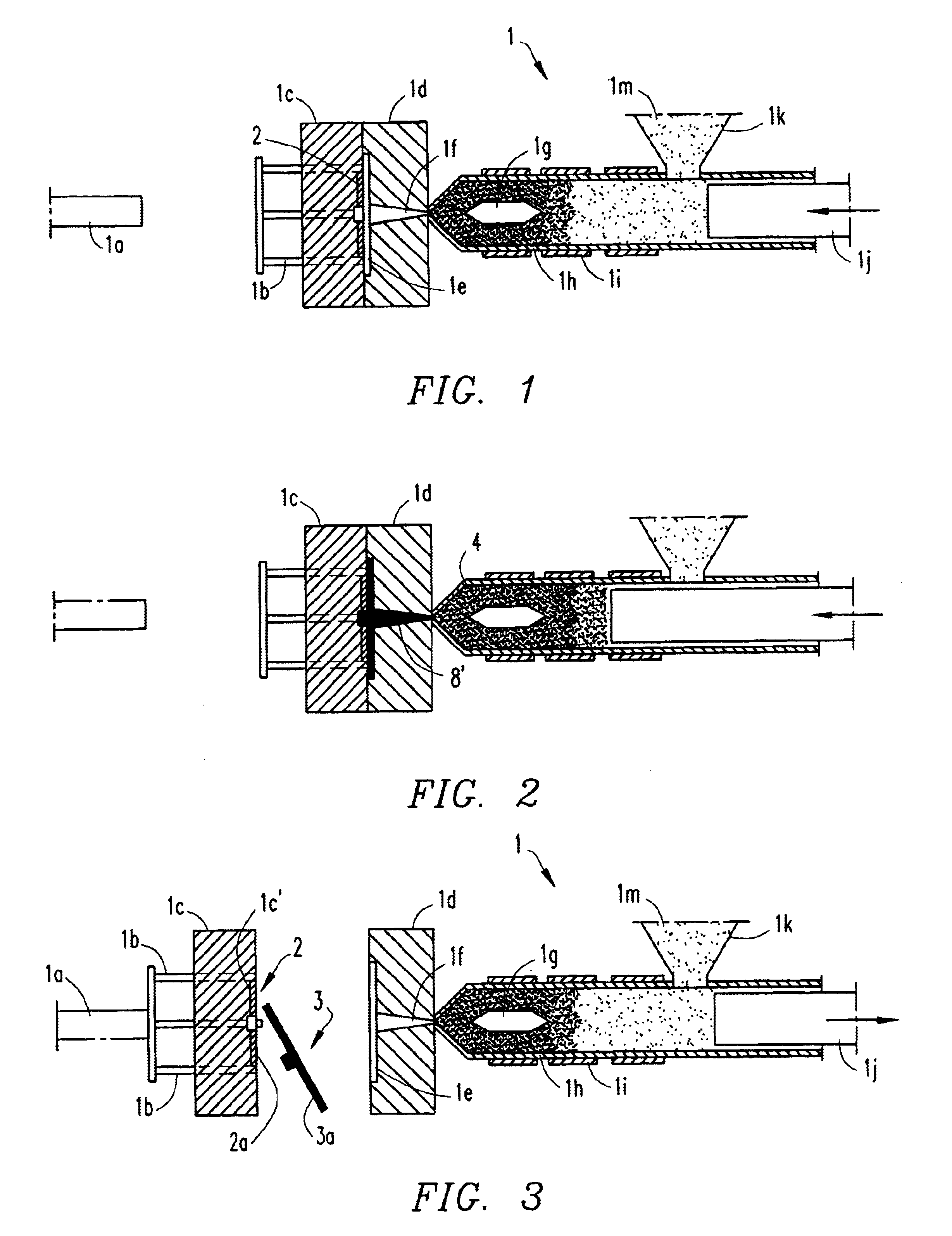

Continuous extrusion-compression molding process for making optical articles

InactiveUS6042754AEasy to processLong lastingRecord carriersConfectioneryCompression moldingShell molding

The present invention relates to making optical articles such as opthalmic lenses by molding and, in particular, to using a continuous extrusion-compression molding method to make plastic lenses whereby a polymer melt is fed from an extruder or melting apparatus to a first die of a plurality of rotating or conveyed sequentially processed compression die sets comprising a first die and a second die. The die sets are positioned on die supports on a rotating turntable or conveying system, the lenses formed by compressing the die sets with pressing means associated with each die support, the lenses separated from the dies and the dies recycled to die loading and the melt feed step of the process and the process repeated until the desired number of lenses or other optical articles such as compact disk substrates are produced.

Owner:FOREVER VISION

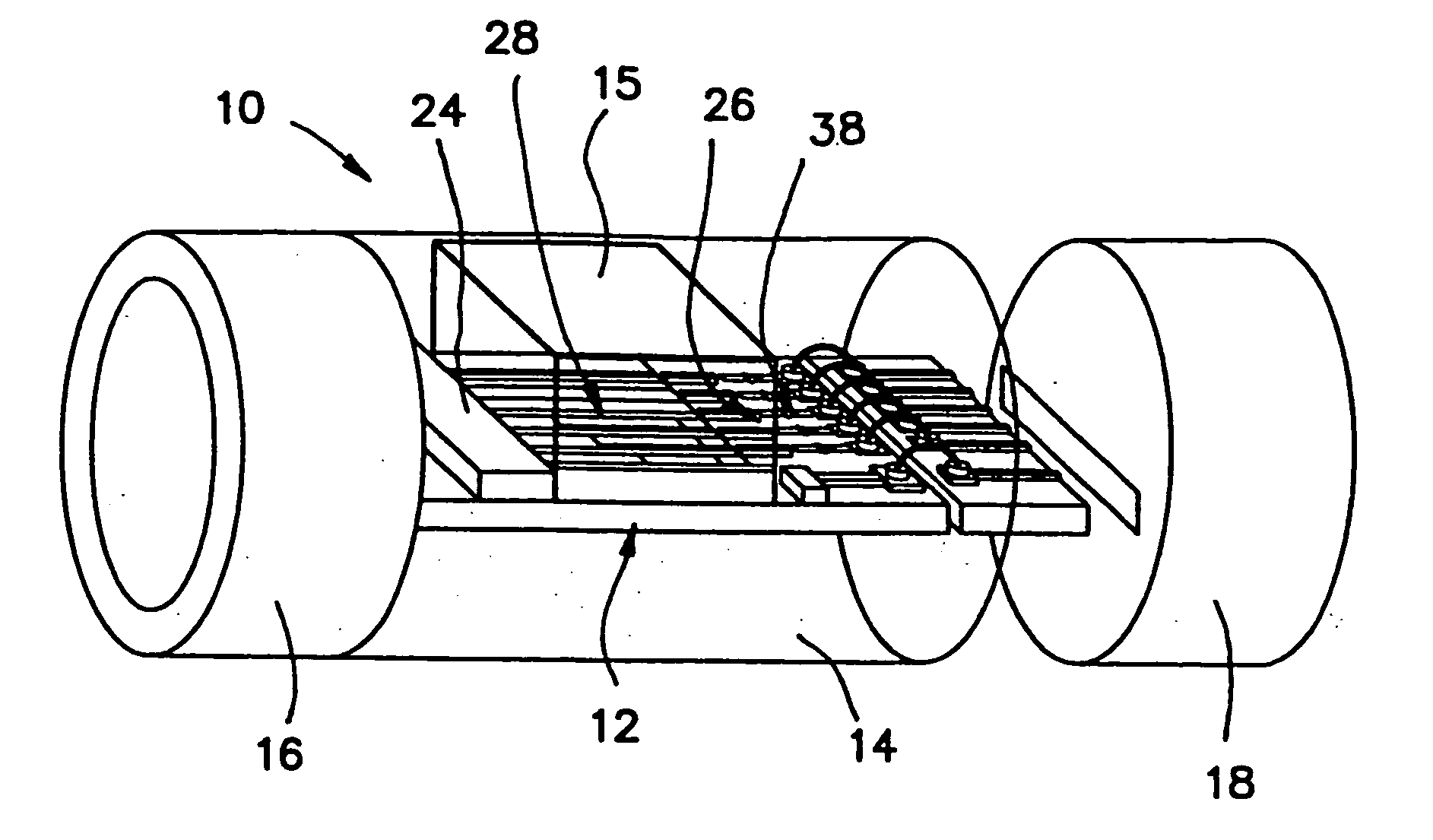

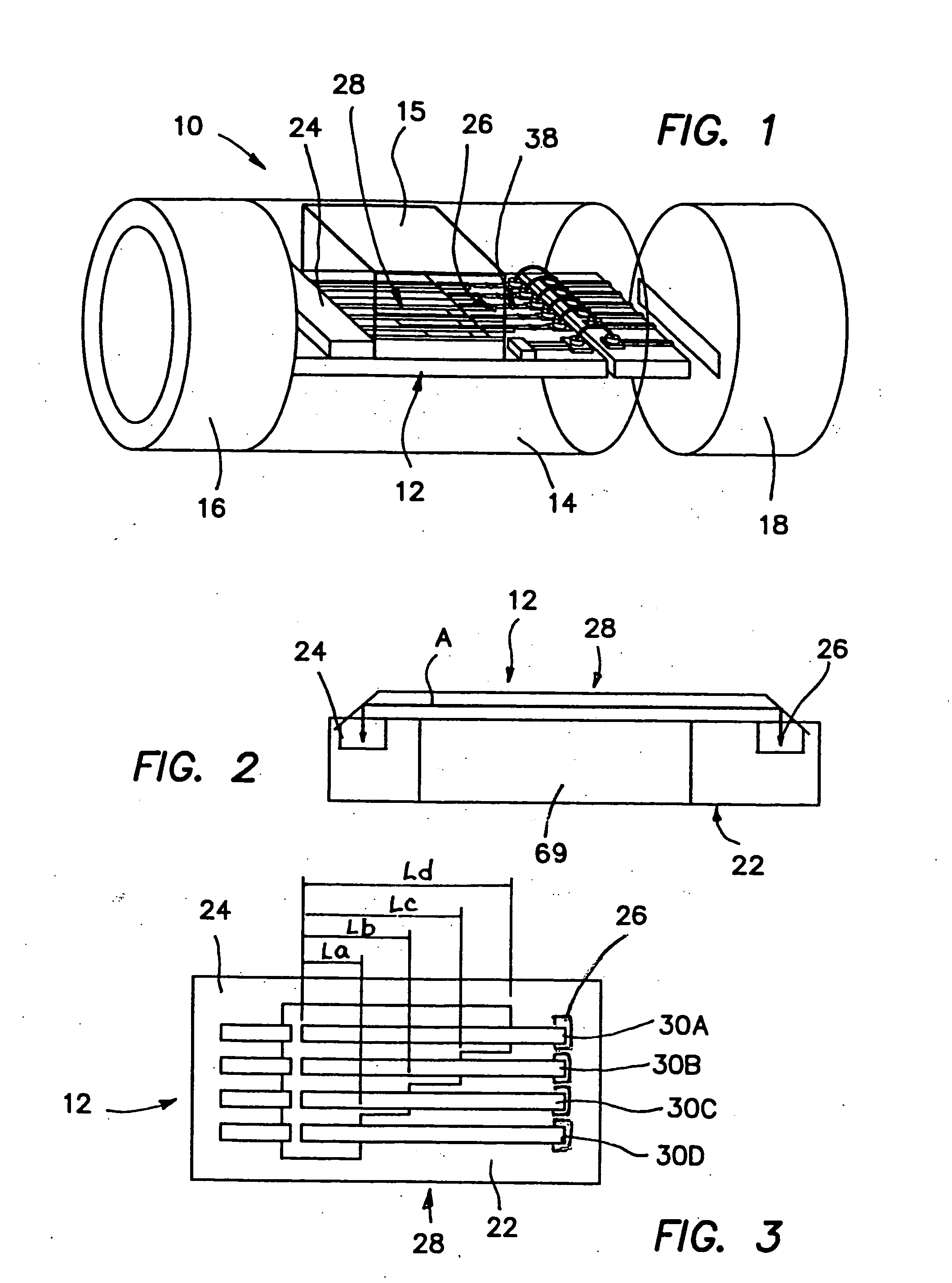

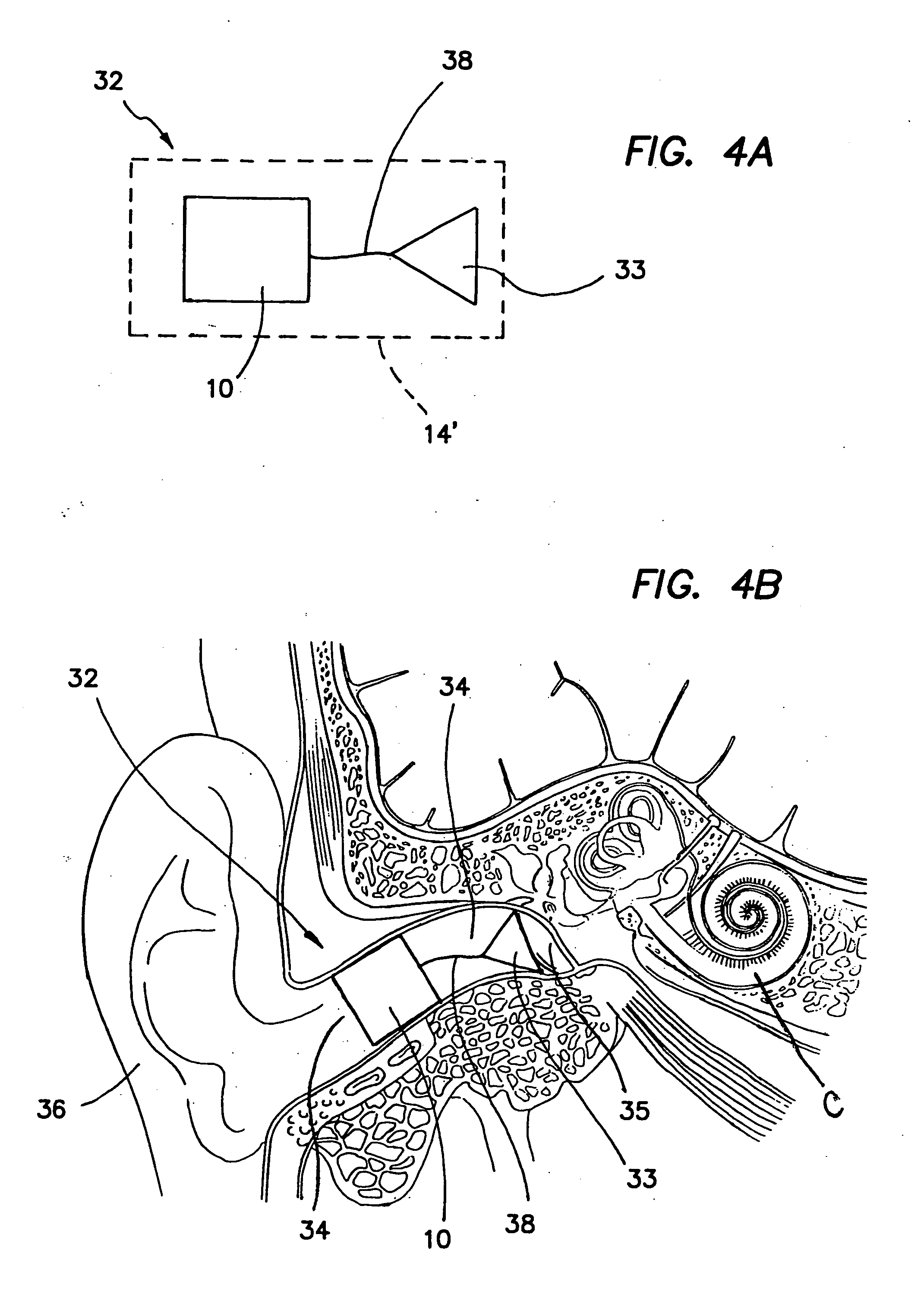

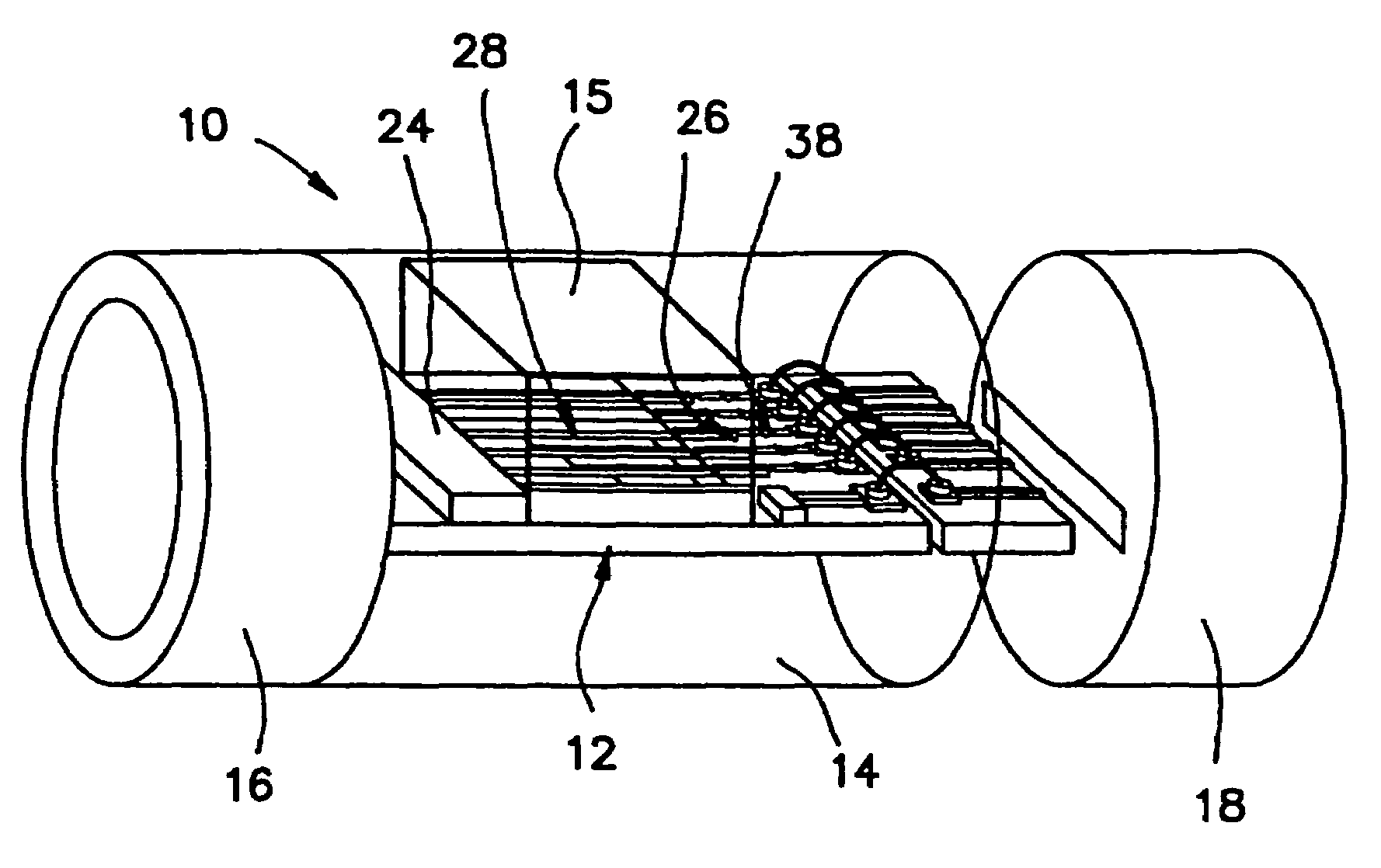

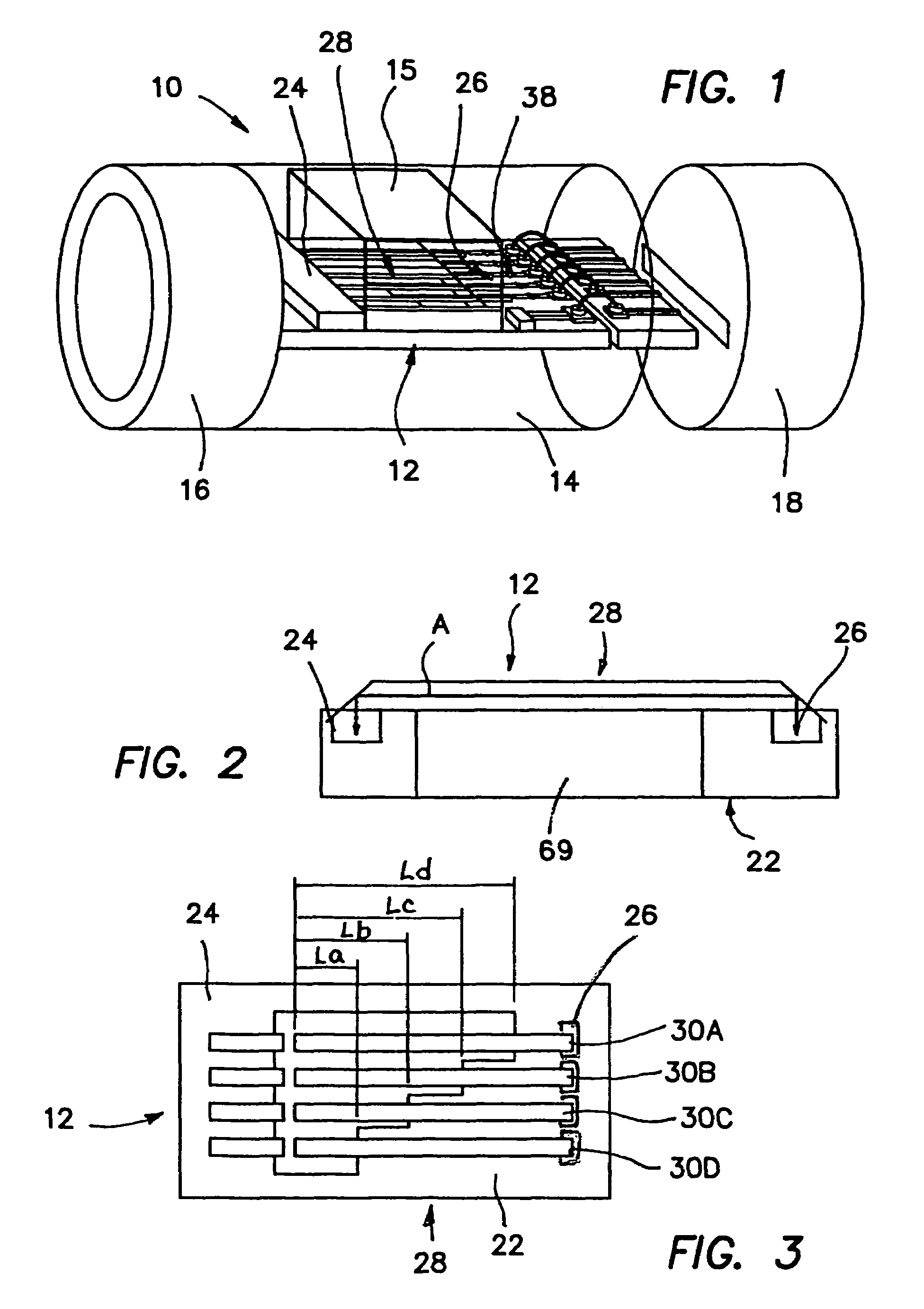

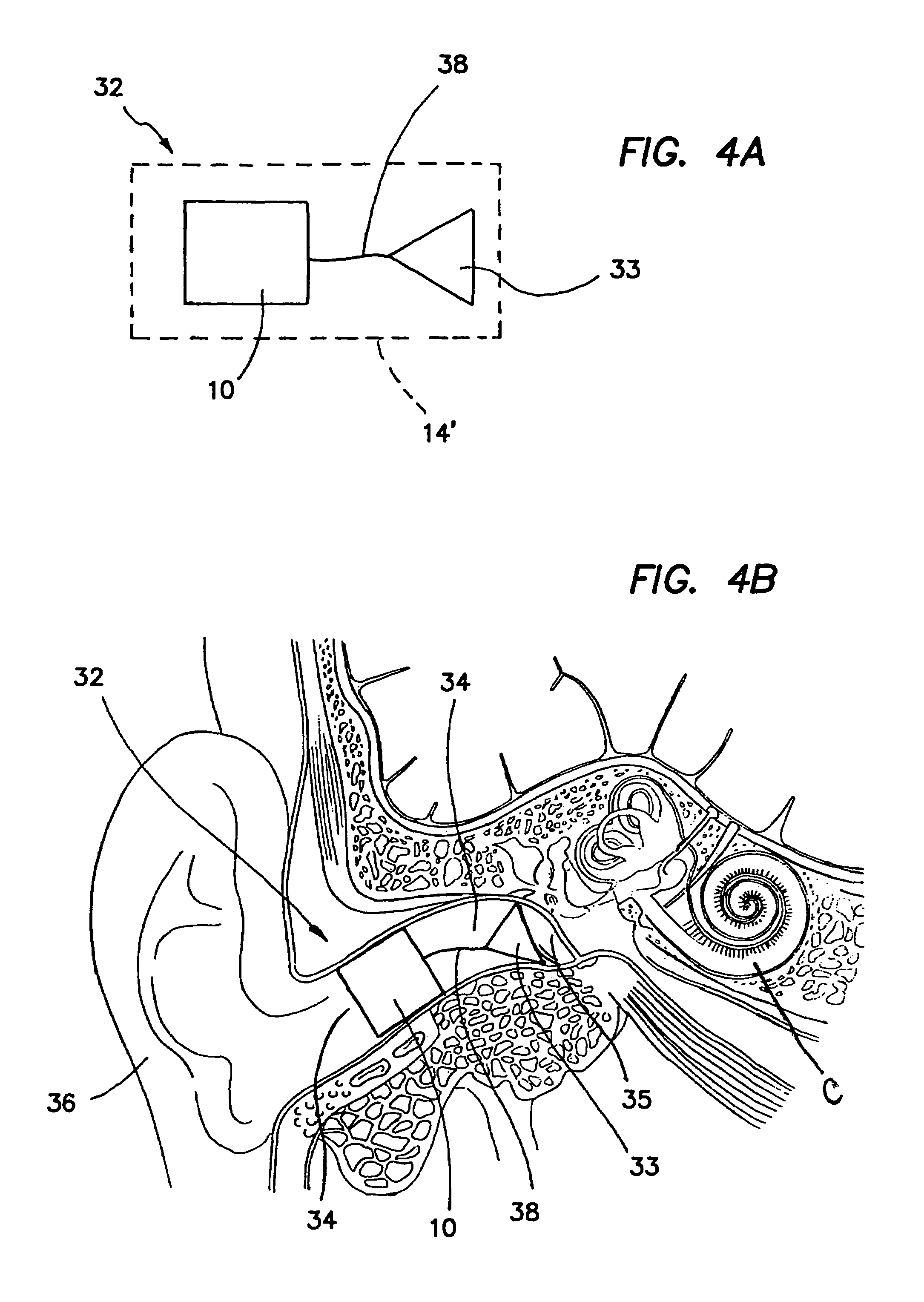

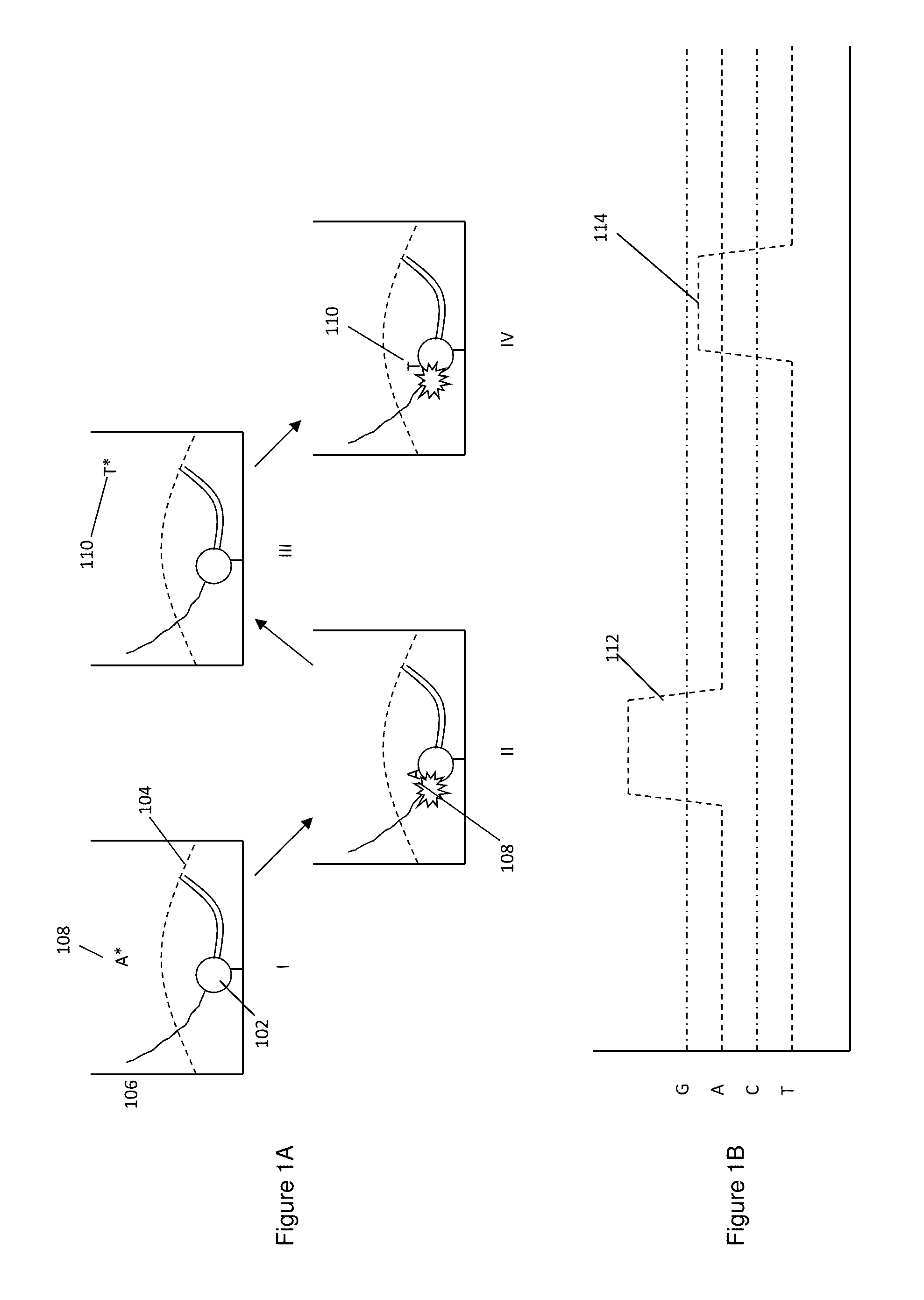

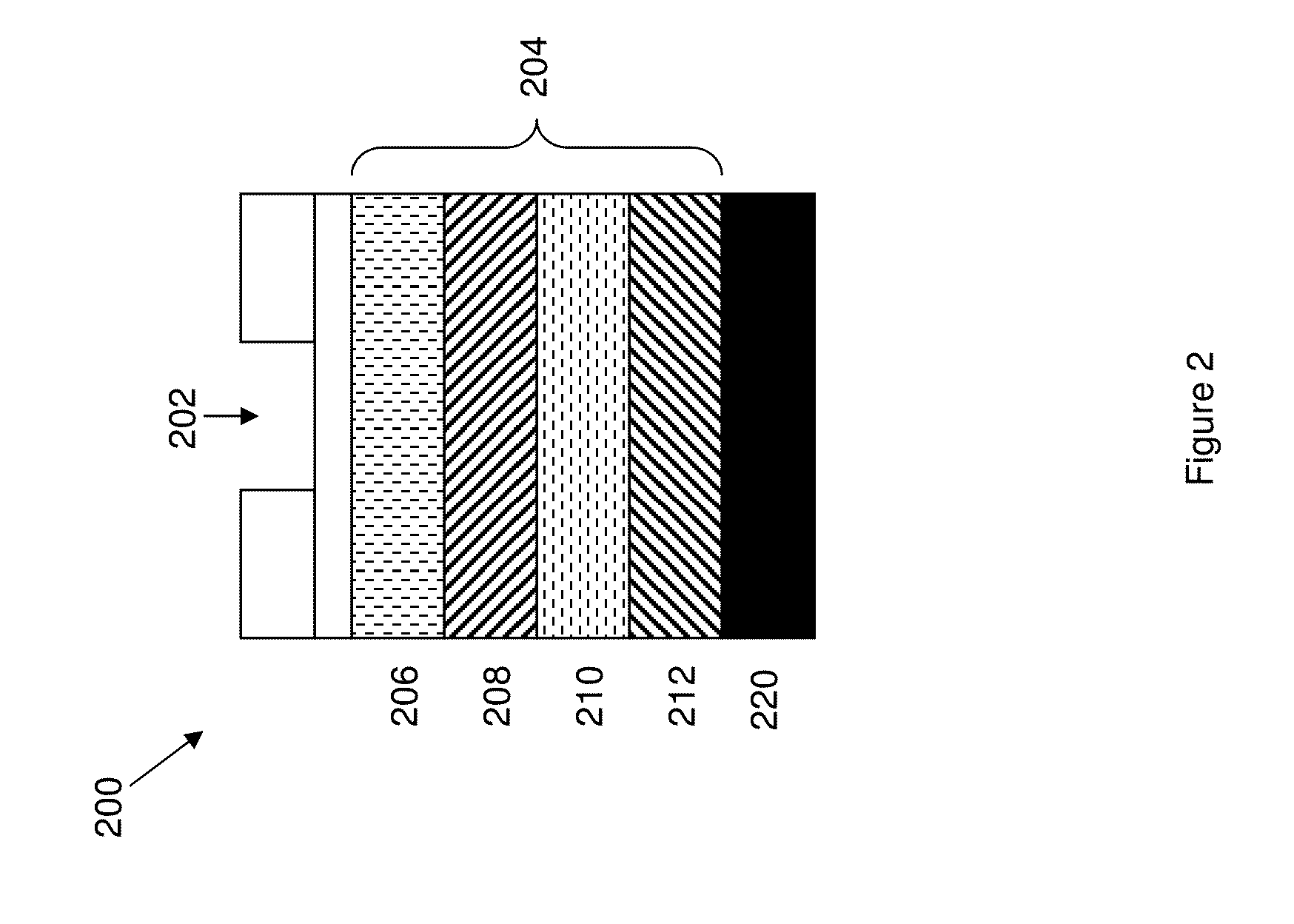

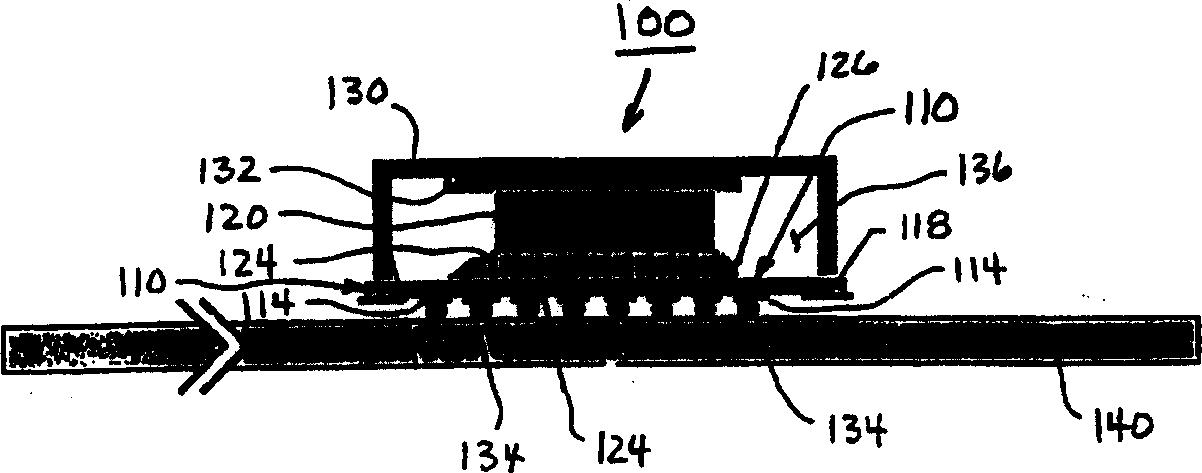

Optical waveguide vibration sensor for use in hearing aid

InactiveUS20060107744A1Improve hearingVibration measurement in solidsRecord carriersPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

Matrix and method of producing said matrix

The invention relates to a matrix suitable for use in the replication of a plastic element having a positive microstructure, comprising a first wear-resistant layer that is supported by a carrier element, wherein the matrix comprises a heating means for supplying electrical heat energy through the wear-resistant layer or carrier element. The invention further relates to a plastic element producing machine and a method for the manufacture of a plastic element having a surface with a positive microstructure.

Owner:GYROS

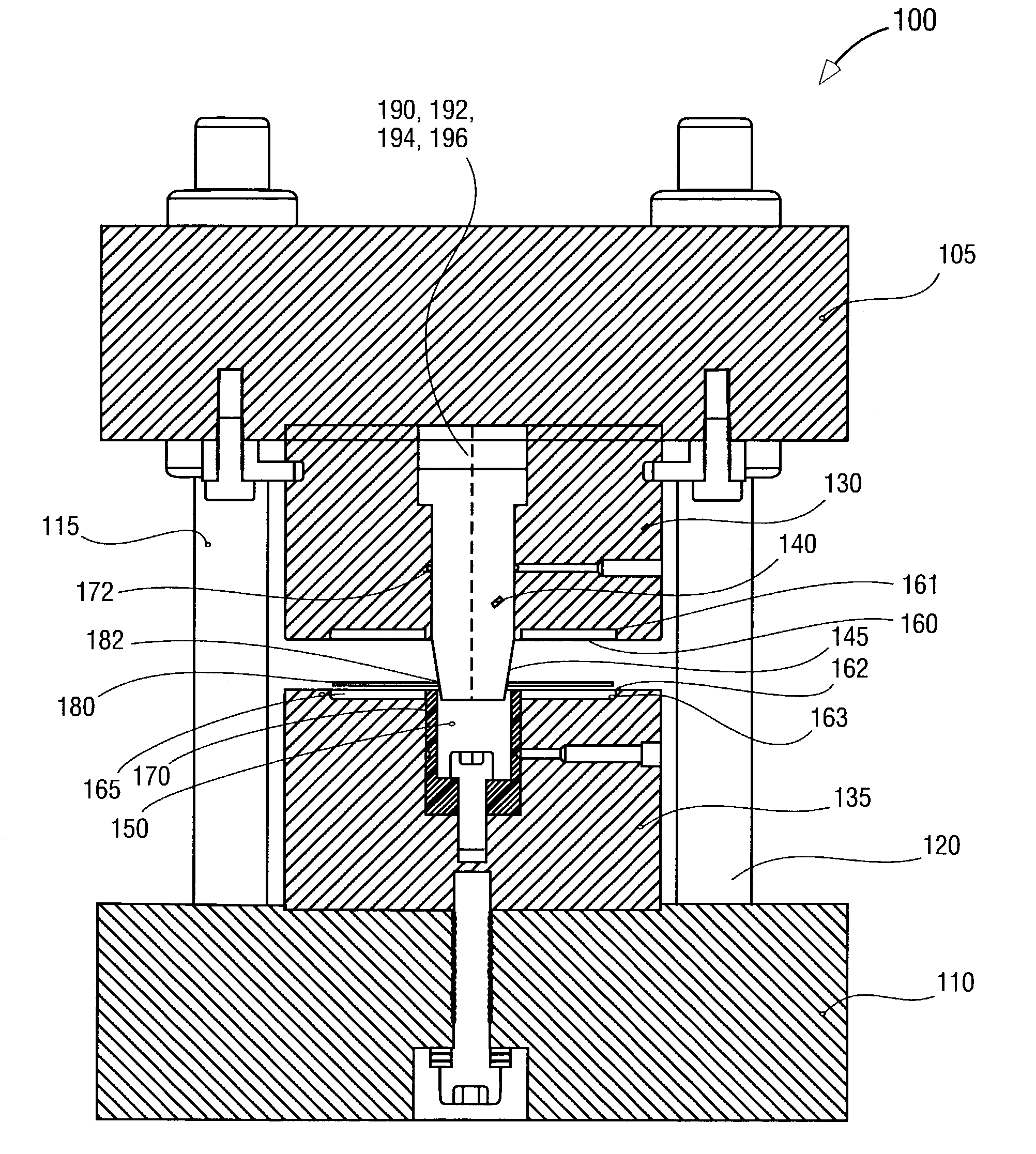

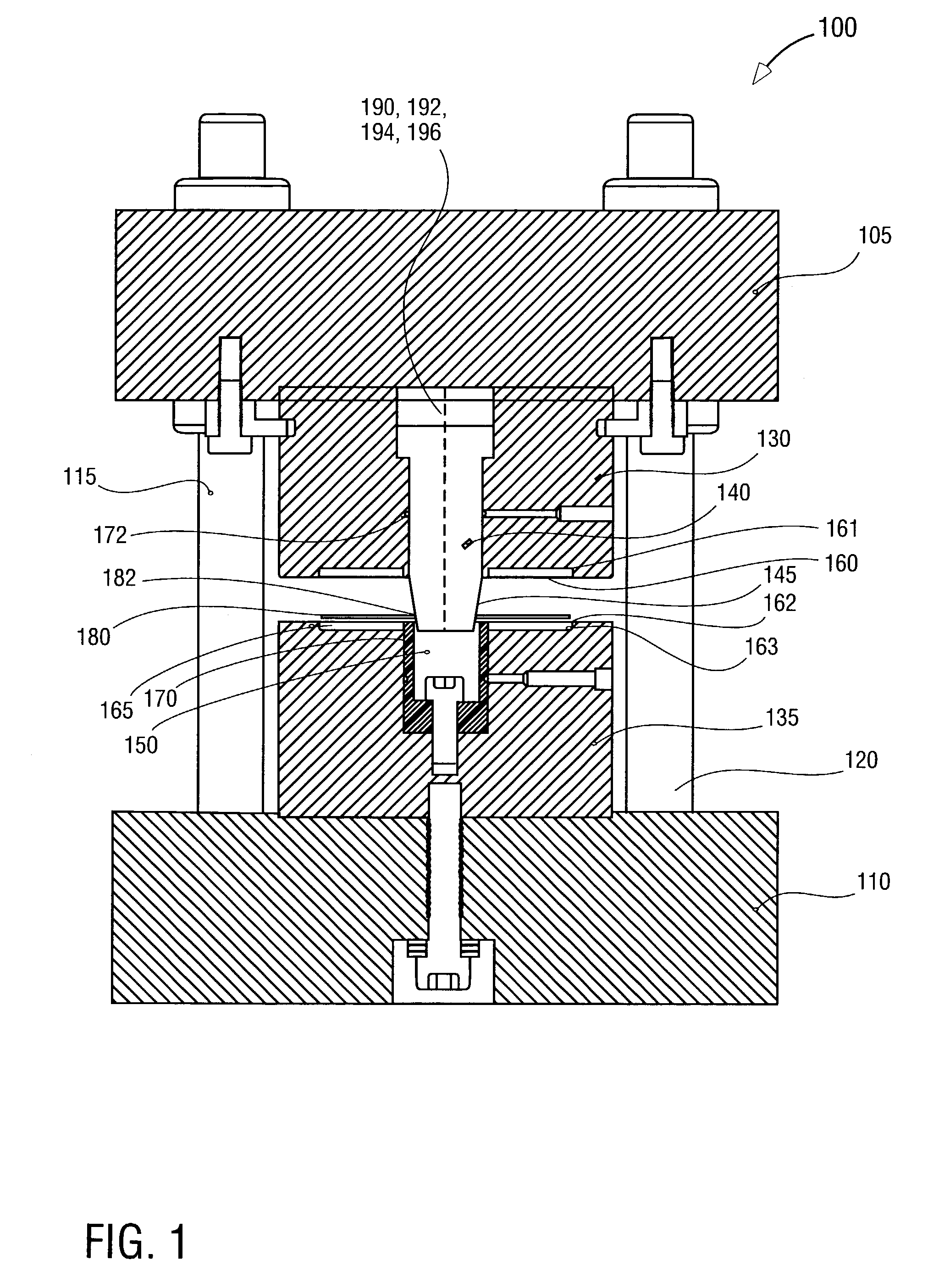

Disk alignment apparatus and method for patterned media production

An apparatus and method for aligning a disk with an imprinting surface are described. In one embodiment, the apparatus has a die which includes an air-bearing mandrel having a tapered nose to engage an ID of the disk, a circular imprinting surface having a centerline concentric with the air-bearing mandrel, and an air-bearing cavity to position the disk. The axial movement of the top die towards the bottom die guides the ID of the disk into coincident alignment with the centerline of the top die.

Owner:WD MEDIA

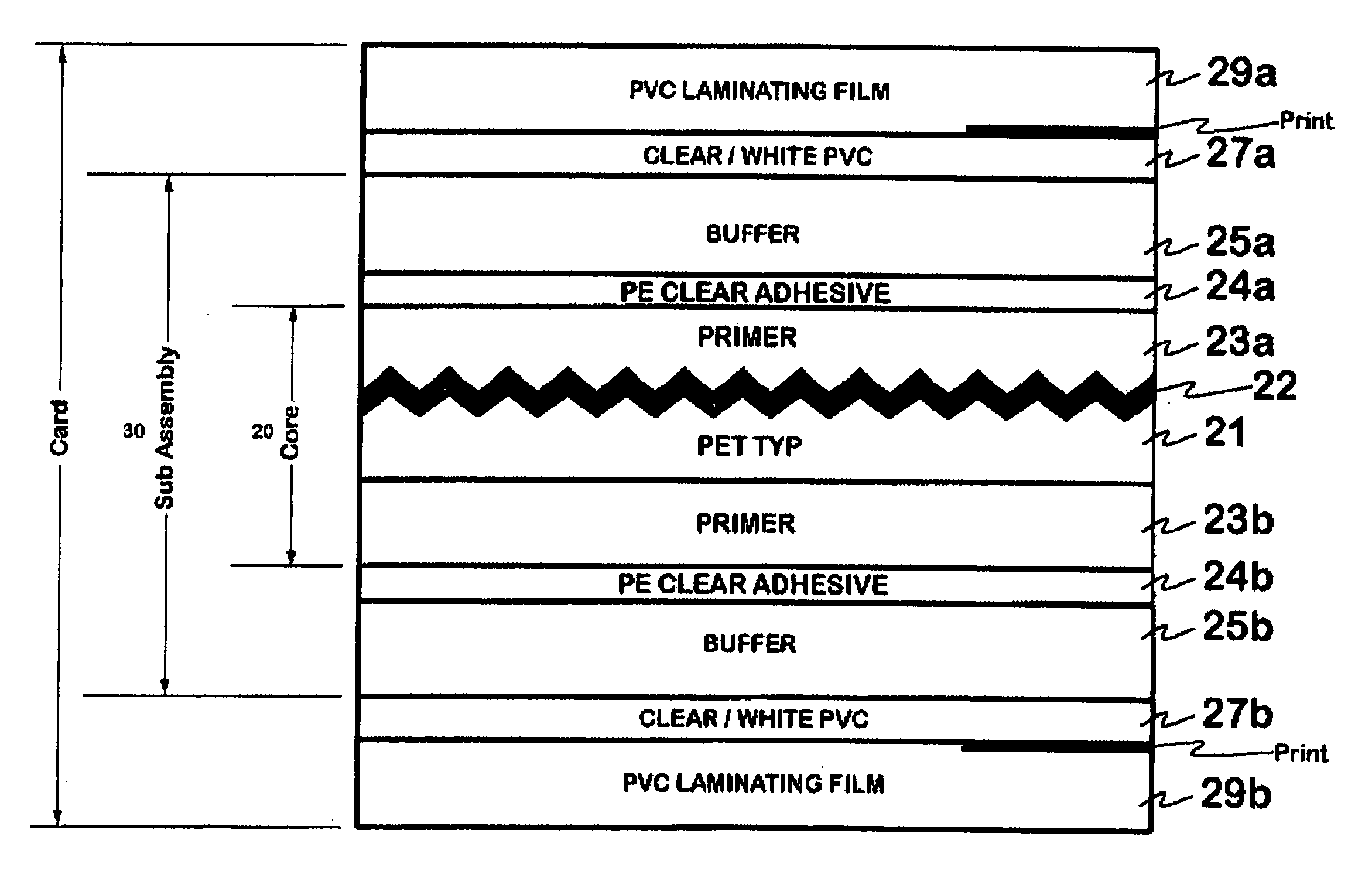

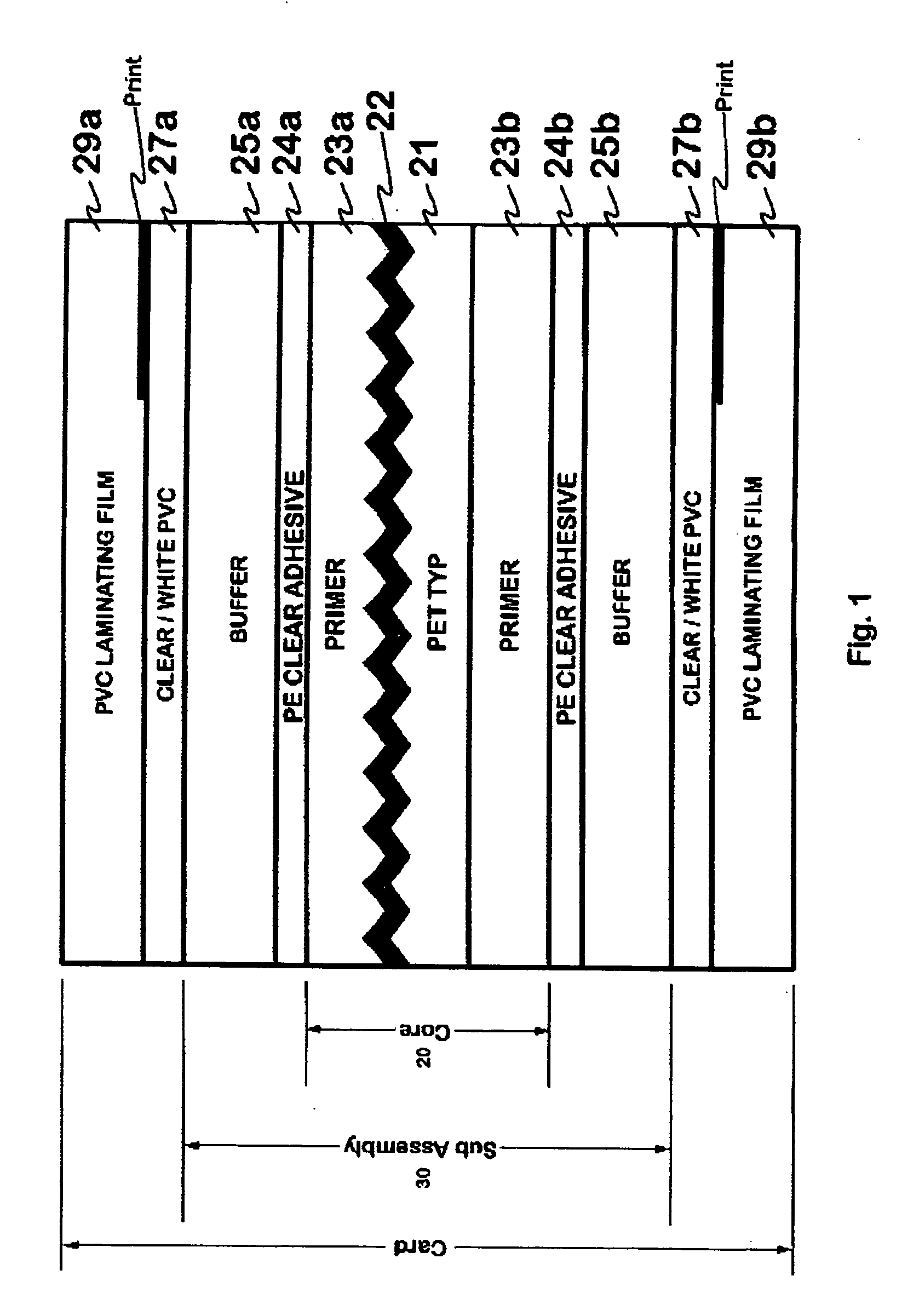

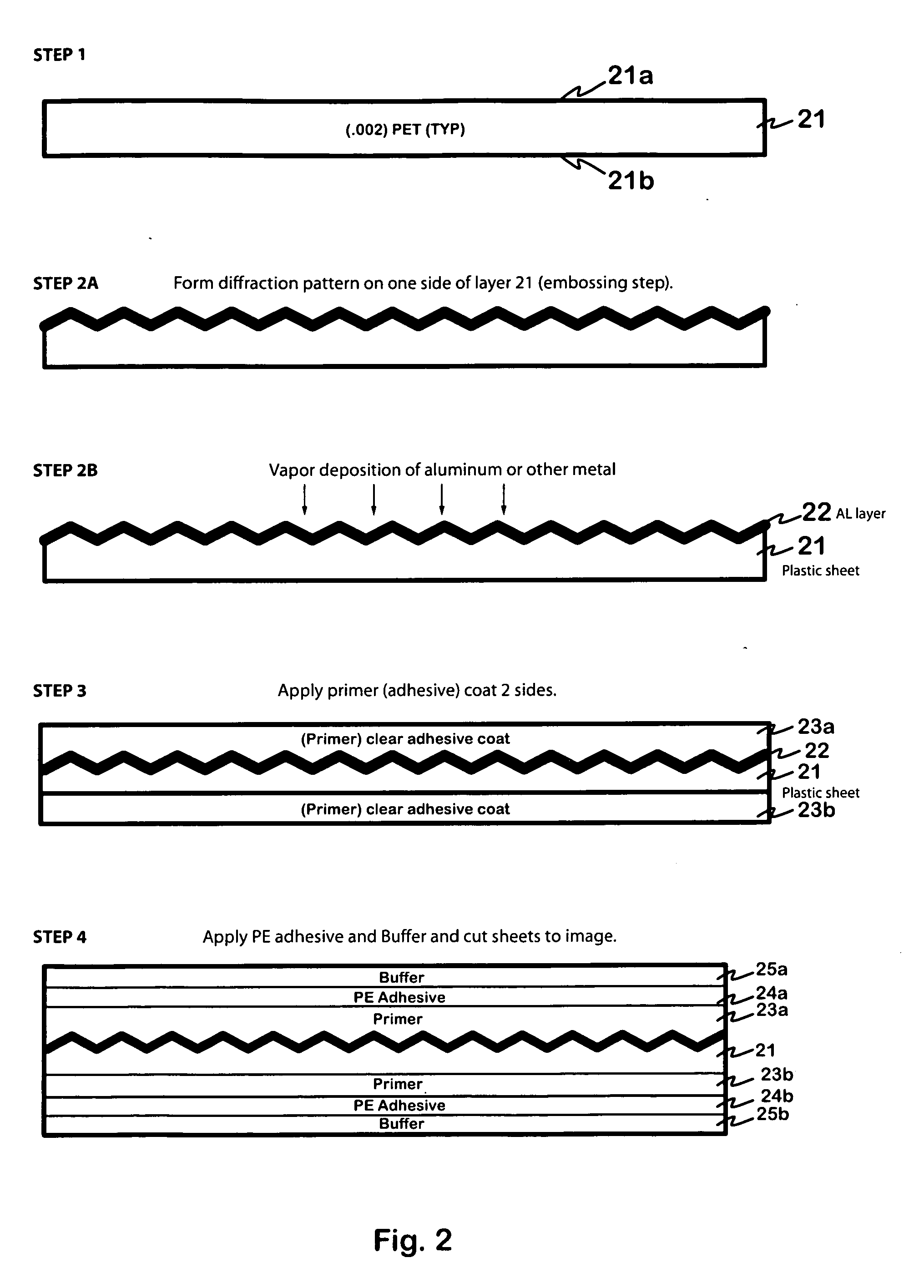

Foil composite card

Composite cards formed in accordance with the invention include a security layer comprising a hologram or diffraction grating formed at, or in, the center, or core layer, of the card. The hologram may be formed by embossing a designated area of the core layer with a diffraction pattern and depositing a thin layer of metal on the embossed layer. Additional layers may be selectively and symmetrically attached to the top and bottom surfaces of the core layer. A laser may be used to remove selected portions of the metal formed on the embossed layer, at selected stages of forming the card, to impart a selected pattern or information to the holographic region. The cards may be “lasered” when the cards being processed are attached to, and part of, a large sheet of material, whereby the “lasering” of all the cards on the sheet can be done at the same time and relatively inexpensively. Alternatively, each card may be individually “lasered” to produce desired alpha numeric information, bar codes information or a graphic image, after the sheets are die-cut into cards.

Owner:COMPOSECURE LLC

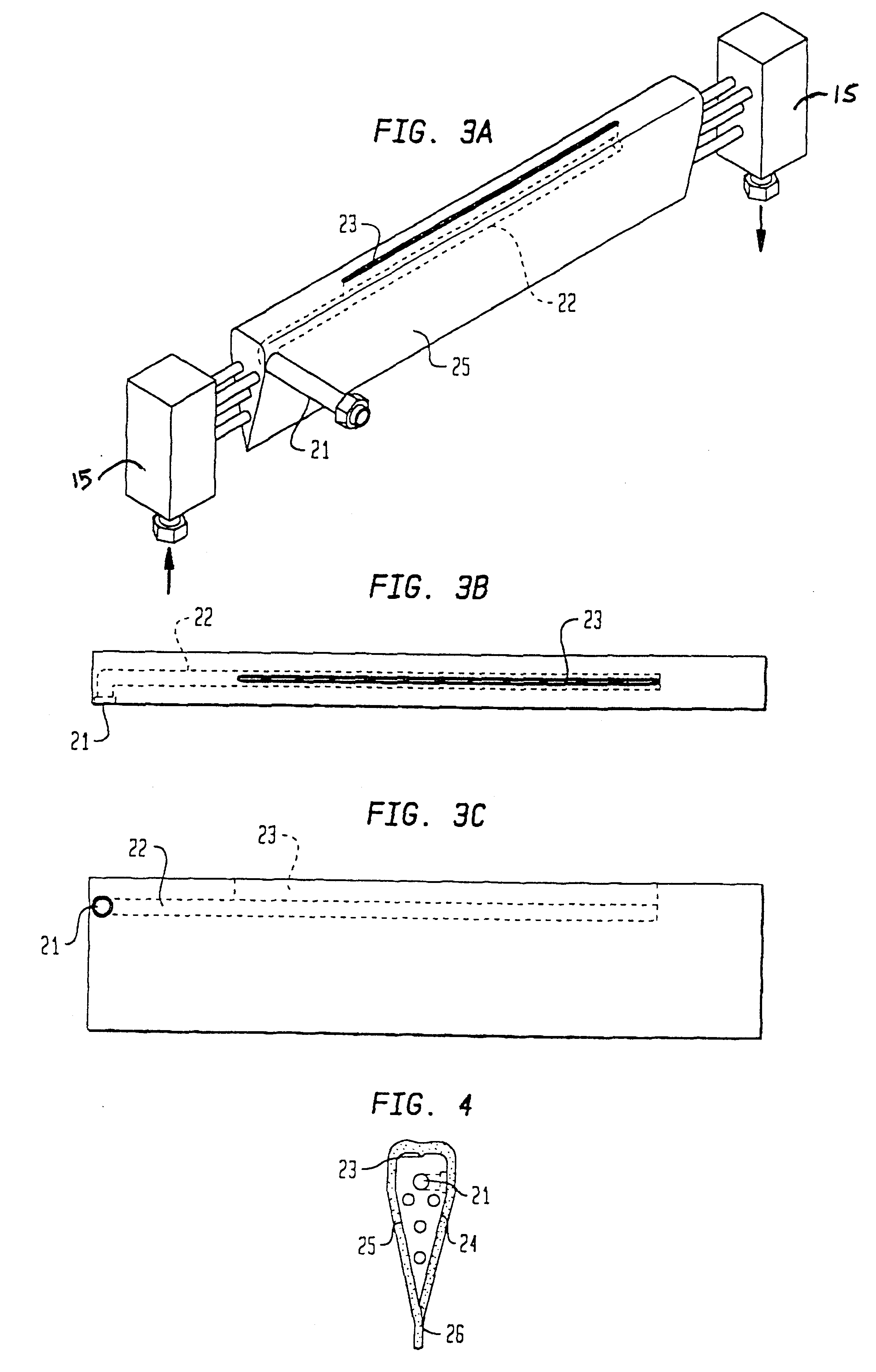

Process and apparatus for forming plastic sheet

InactiveUS6183829B1Avoid mistakesLow birefringenceRecord carriersPhotosensitive materialsEngineeringMechanical engineering

Owner:ROHM & HAAS CO

Optical waveguide vibration sensor for use in hearing aid

InactiveUS7444877B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

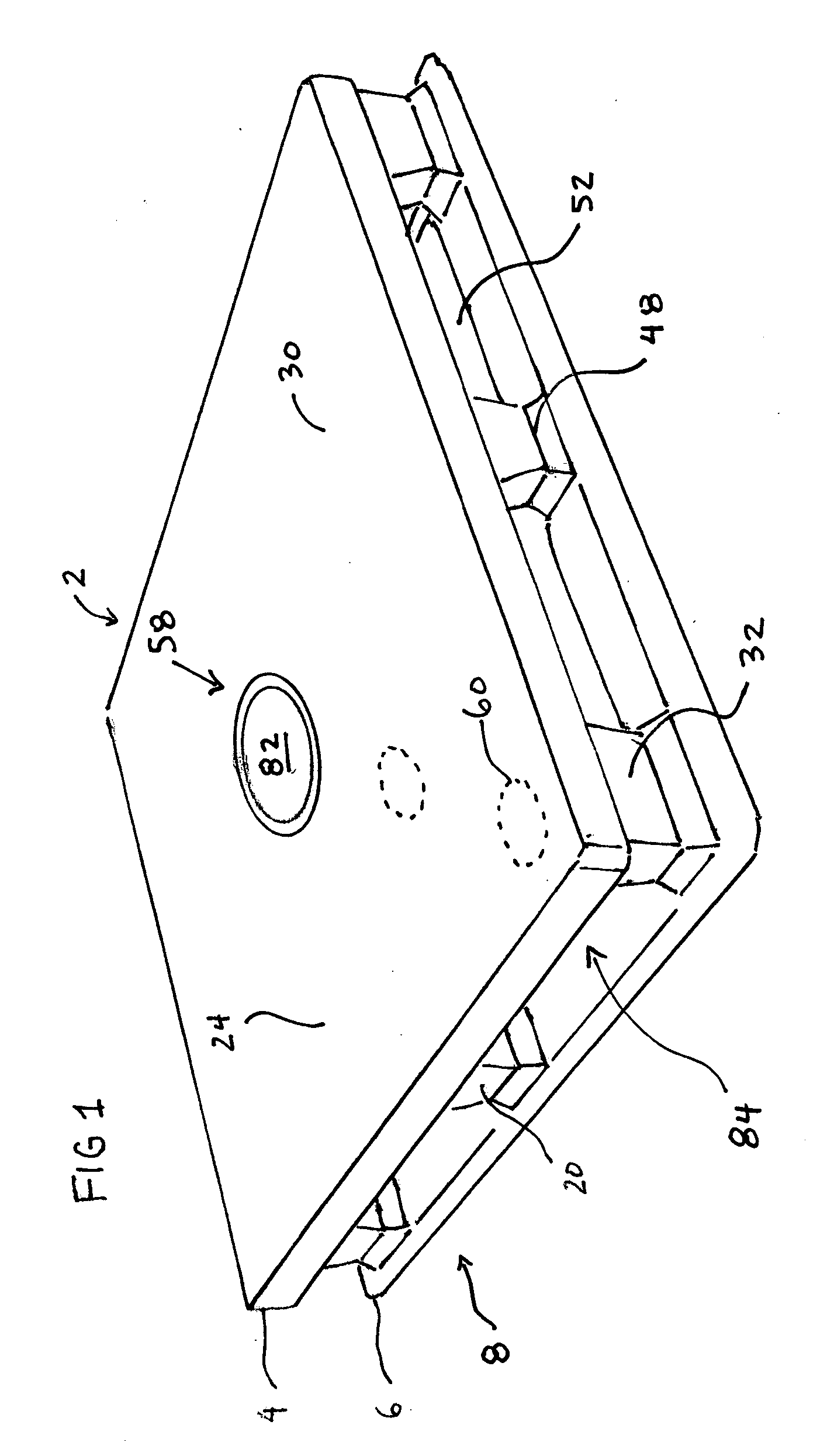

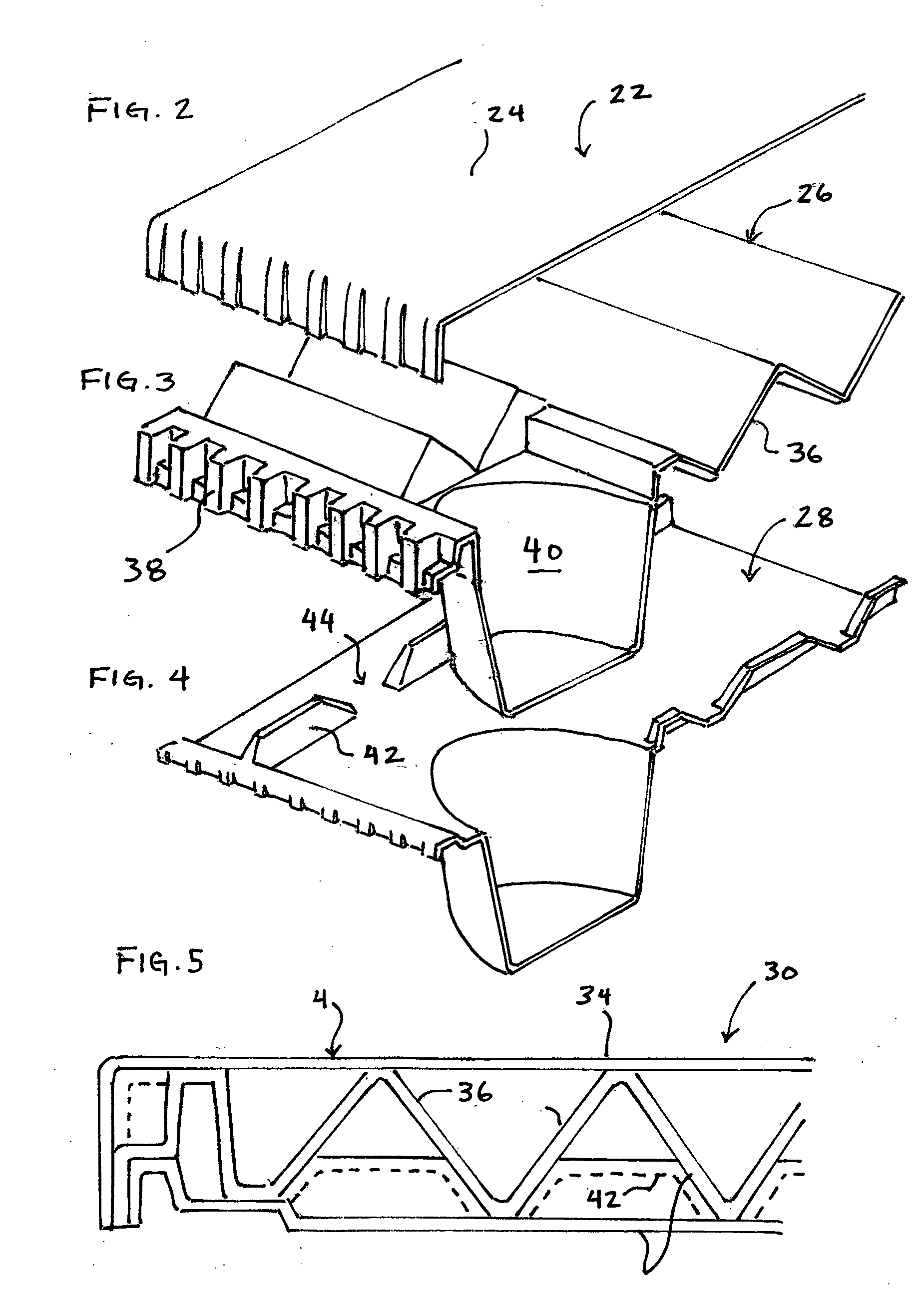

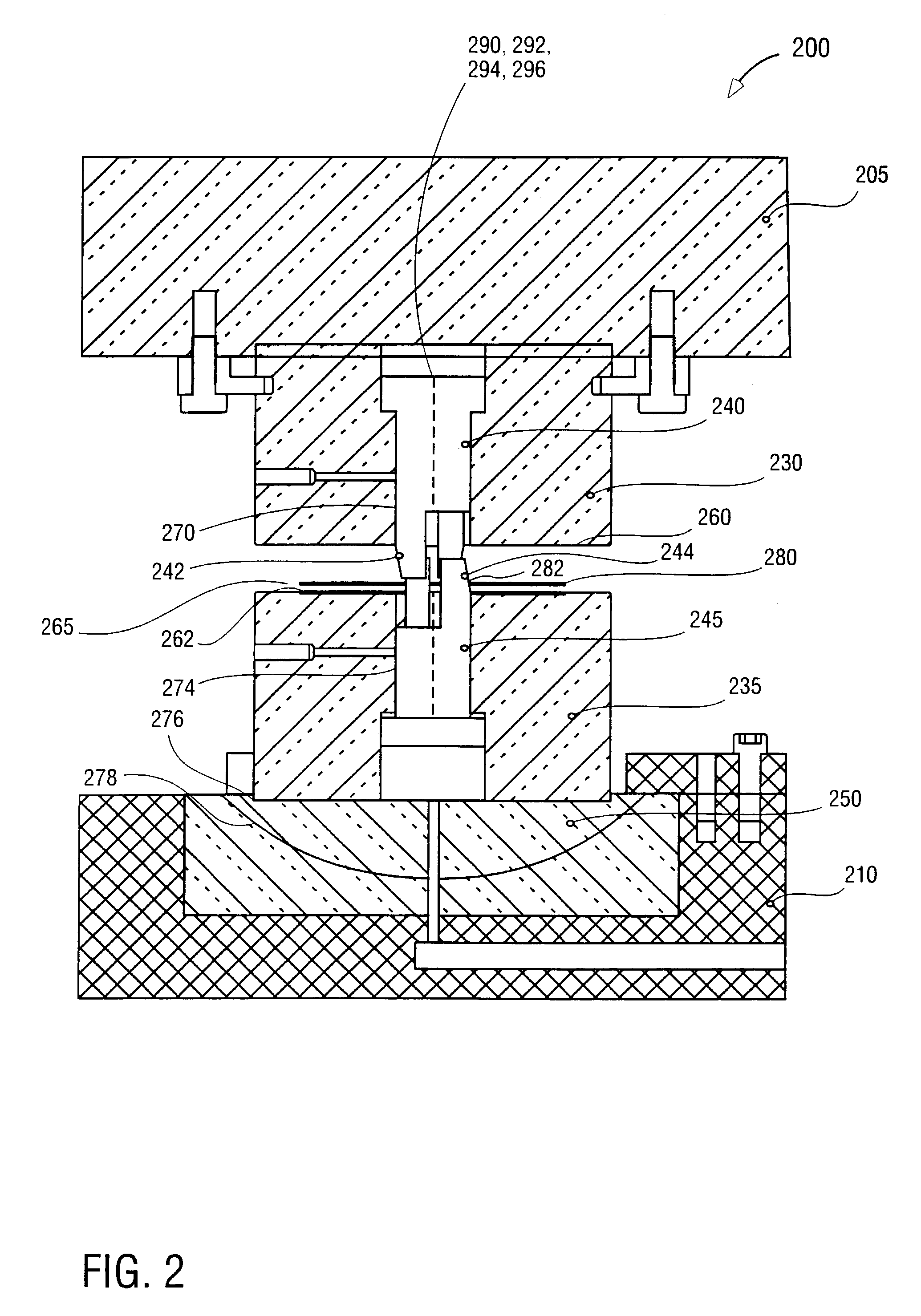

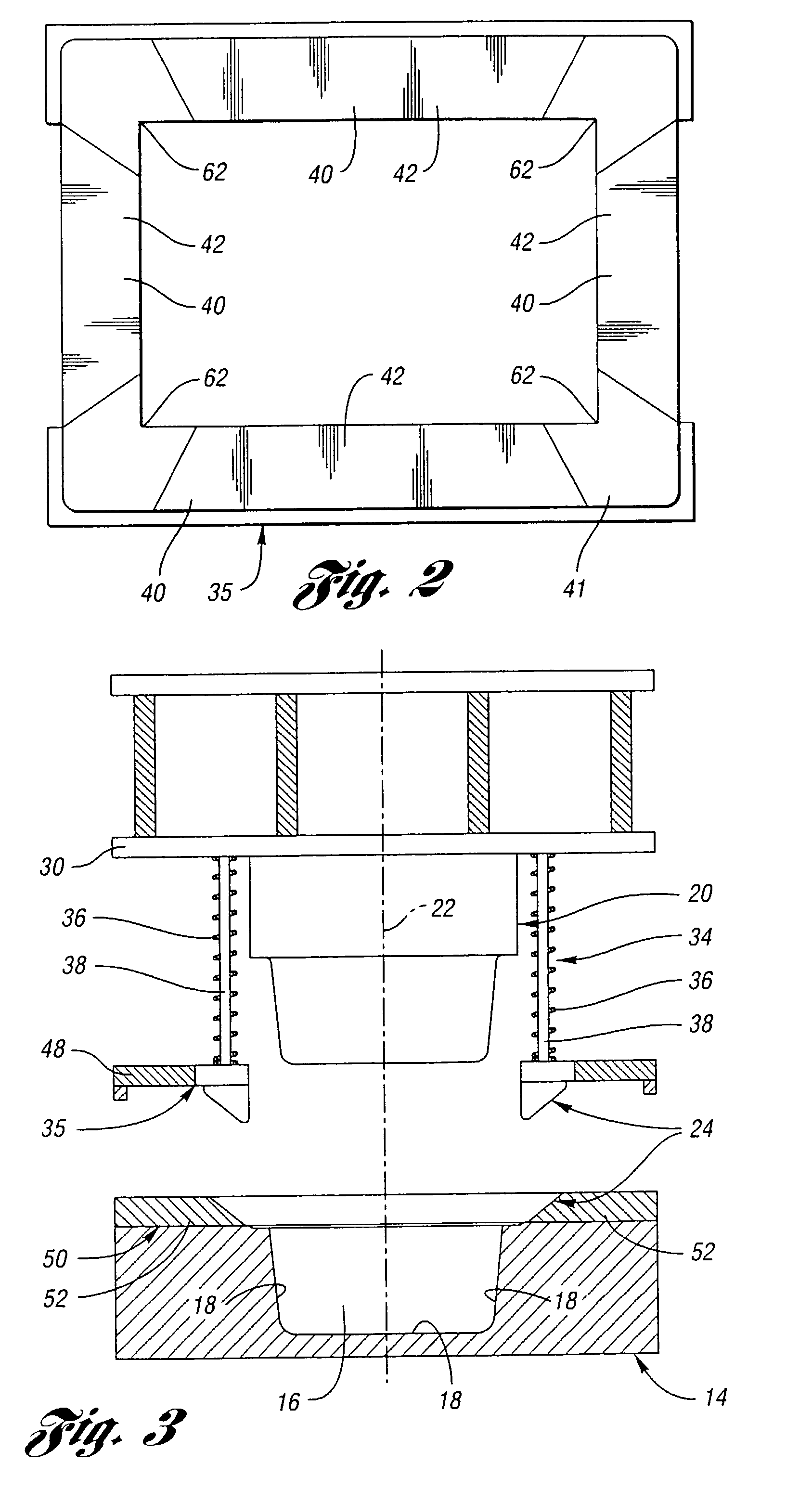

System for molding thermoplastic sandwich material and deep-drawn article produced thereby

A method and system for molding thermoplastic sandwich material to form a deep-drawn article utilizing a unique clamping technique and mechanism are described. The method includes the steps of positioning a blank of thermoplastic sandwich material having a cellular core over a female die having an article-defining cavity defined by inner surfaces of the female die. Then, an inner portion of the blank is forced into the female die along a substantially vertical axis and against the inner surfaces of the female die to obtain deep-drawn material. During the step of forcing at least one outer portion of the blank immediately adjacent the female die is clamped to guide the at least one outer portion of the blank to travel into the article-defining cavity at an acute angle with respect to the vertical axis. Thickness of at least one side wall of the deep-drawn material is substantially the same as thickness of the blank of thermoplastic sandwich material. The deep-drawn material does not significantly stretch or tear during the step of forcing due to the clamping technique and mechanism.

Owner:GLOBAL IP HLDG

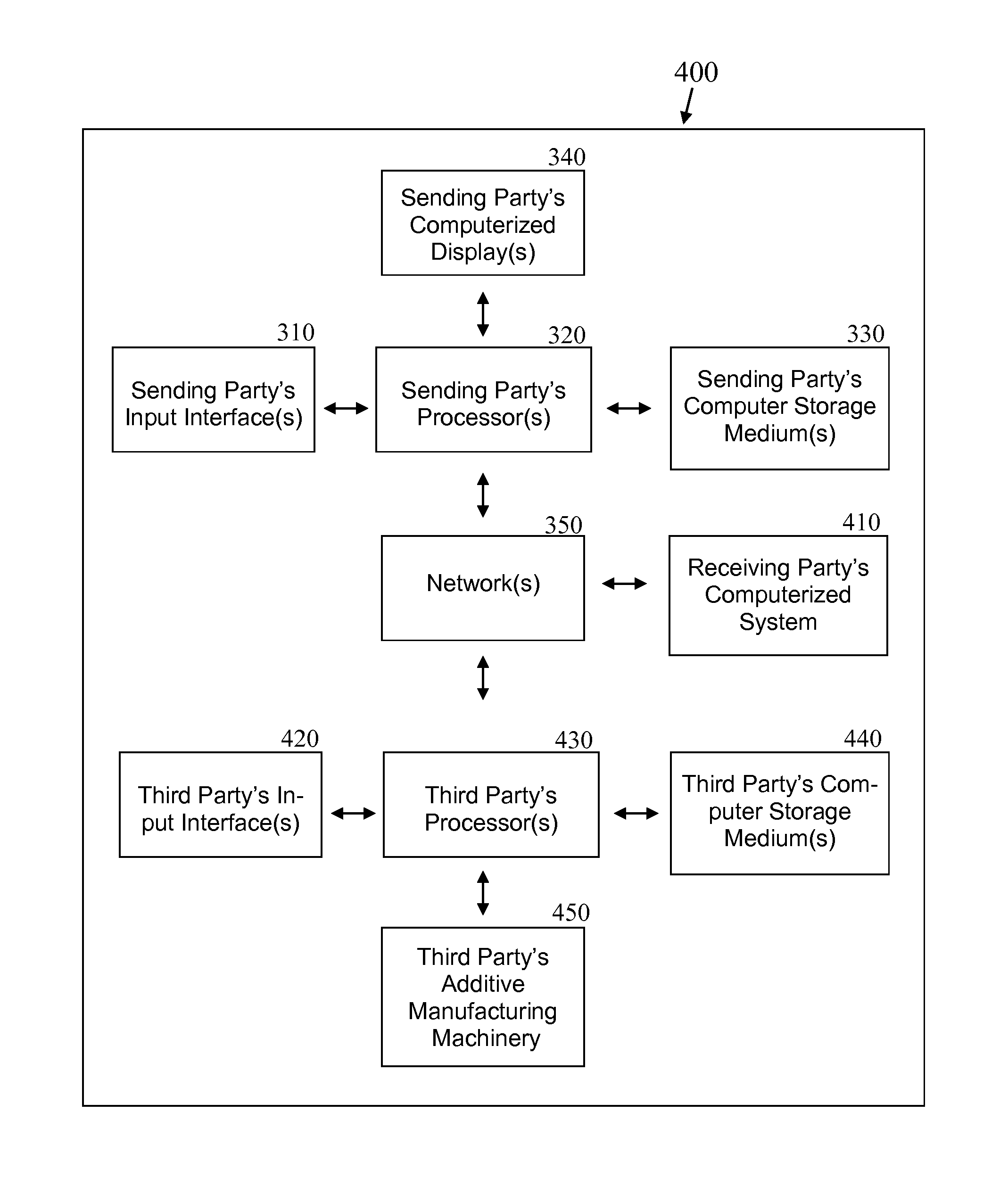

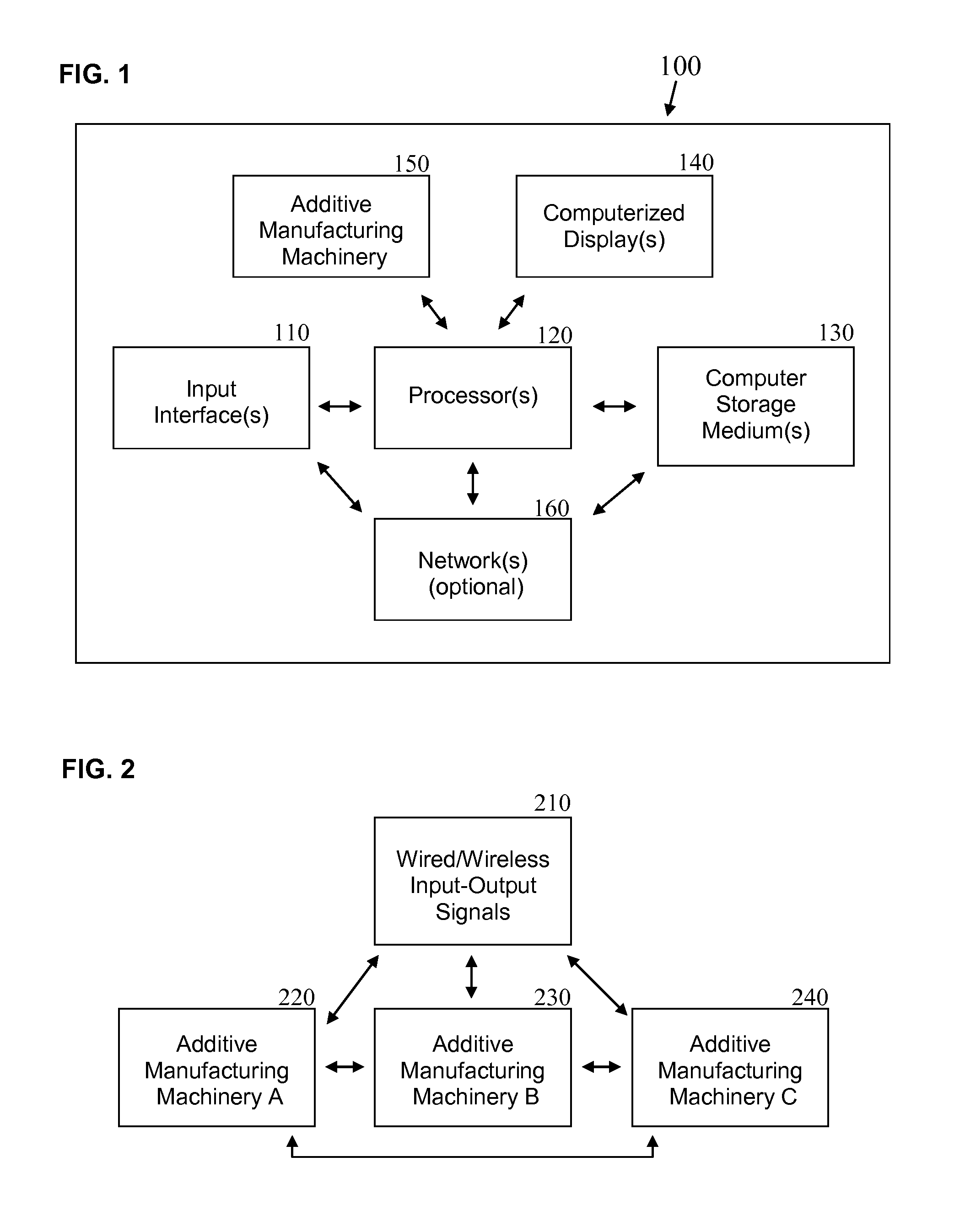

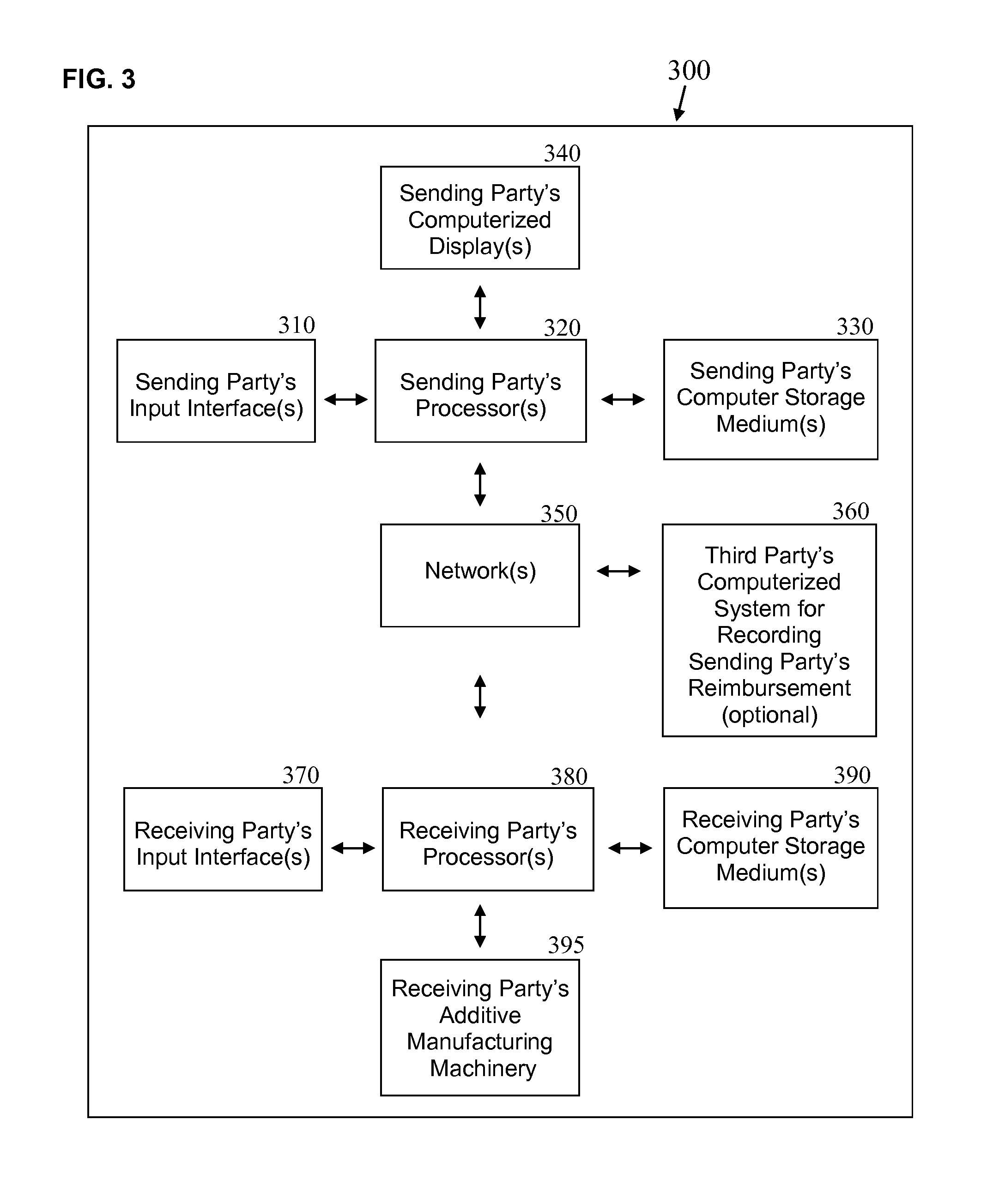

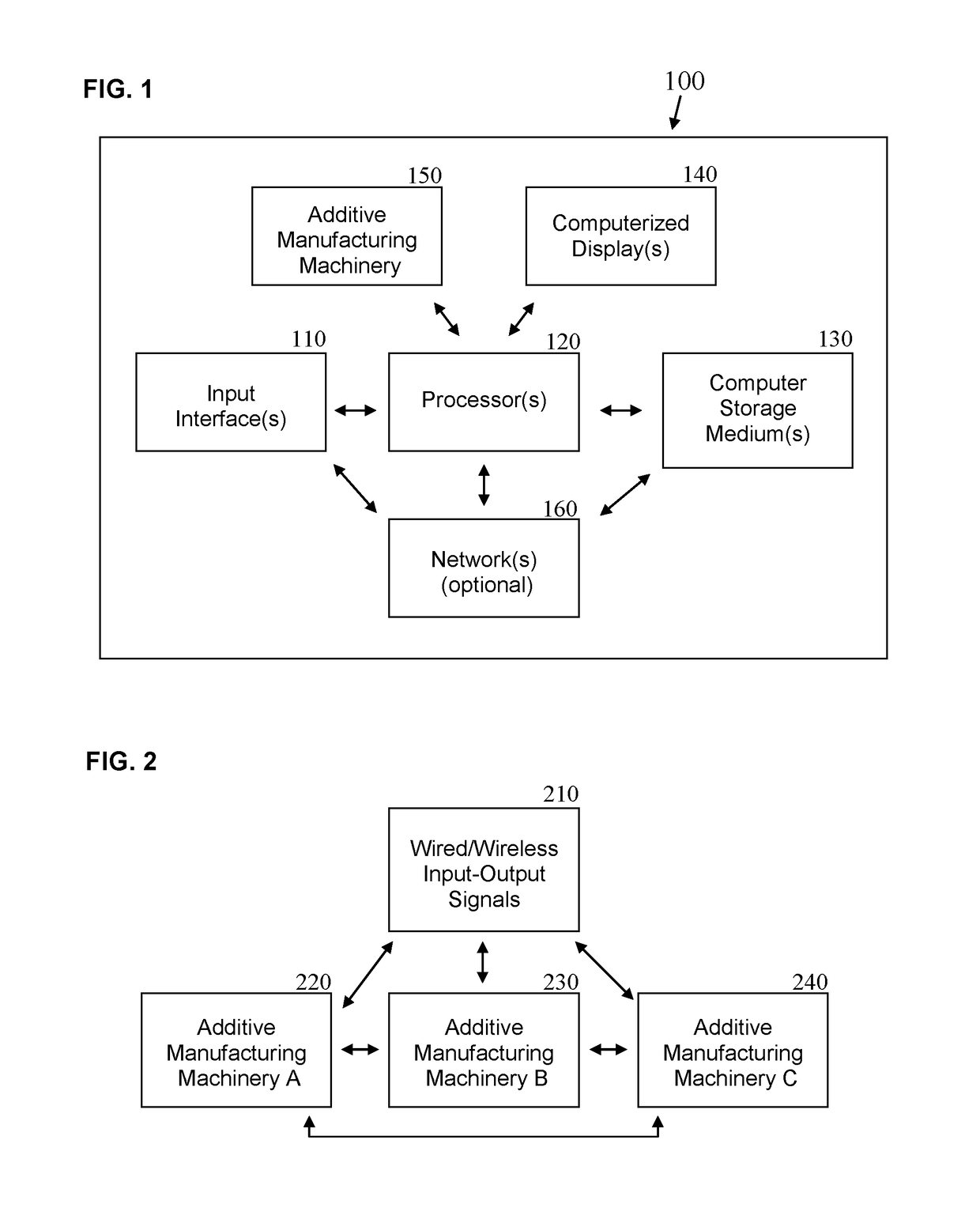

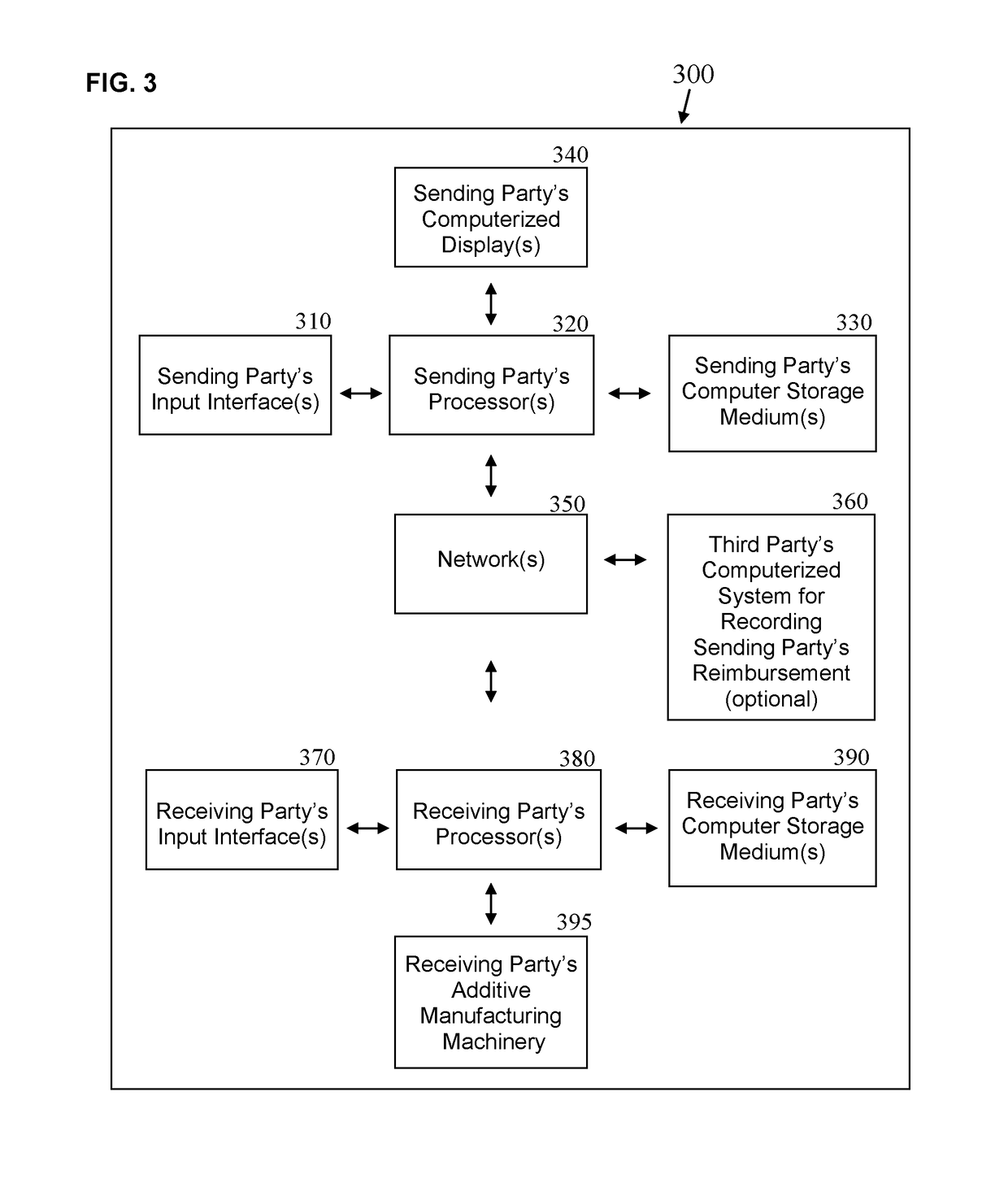

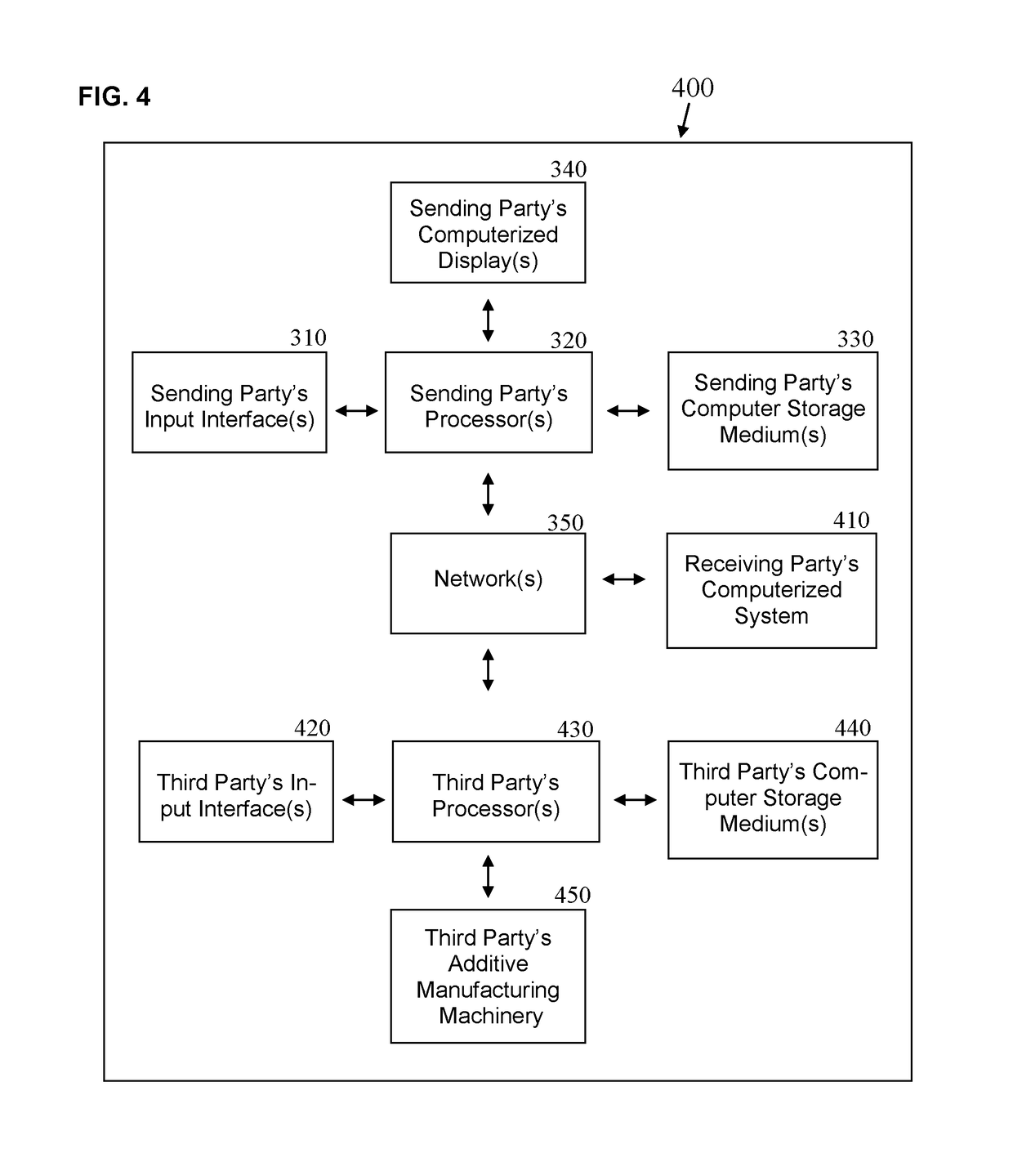

Game object advances for the 3D printing entertainment industry

Embodiments describe constructing game-related objects through additive manufacturing systems. At least one construction configuration for building a game-related object is advanced at least partly due to at least one game task result being attained by a user and / or due to when an object is constructed and / or arranged to be built. Several embodiments demonstrate select game task results leading to determined construction configurations instead of alternative construction configurations, causing, for instance, a differing design, complexity, function, and / or number of constructed object portions. Game task results in certain embodiments lead to multiple distinct portions of one or more objects being constructed concurrently and / or successively, at one or more locations. Selected methods and systems disclose objects constructed as awards, puzzles, other assembly challenges, educational challenges, wagering elements, electronic game elements, in multiple inseparable portions, and / or for other entertainment purposes.

Owner:NEVINS JOEL

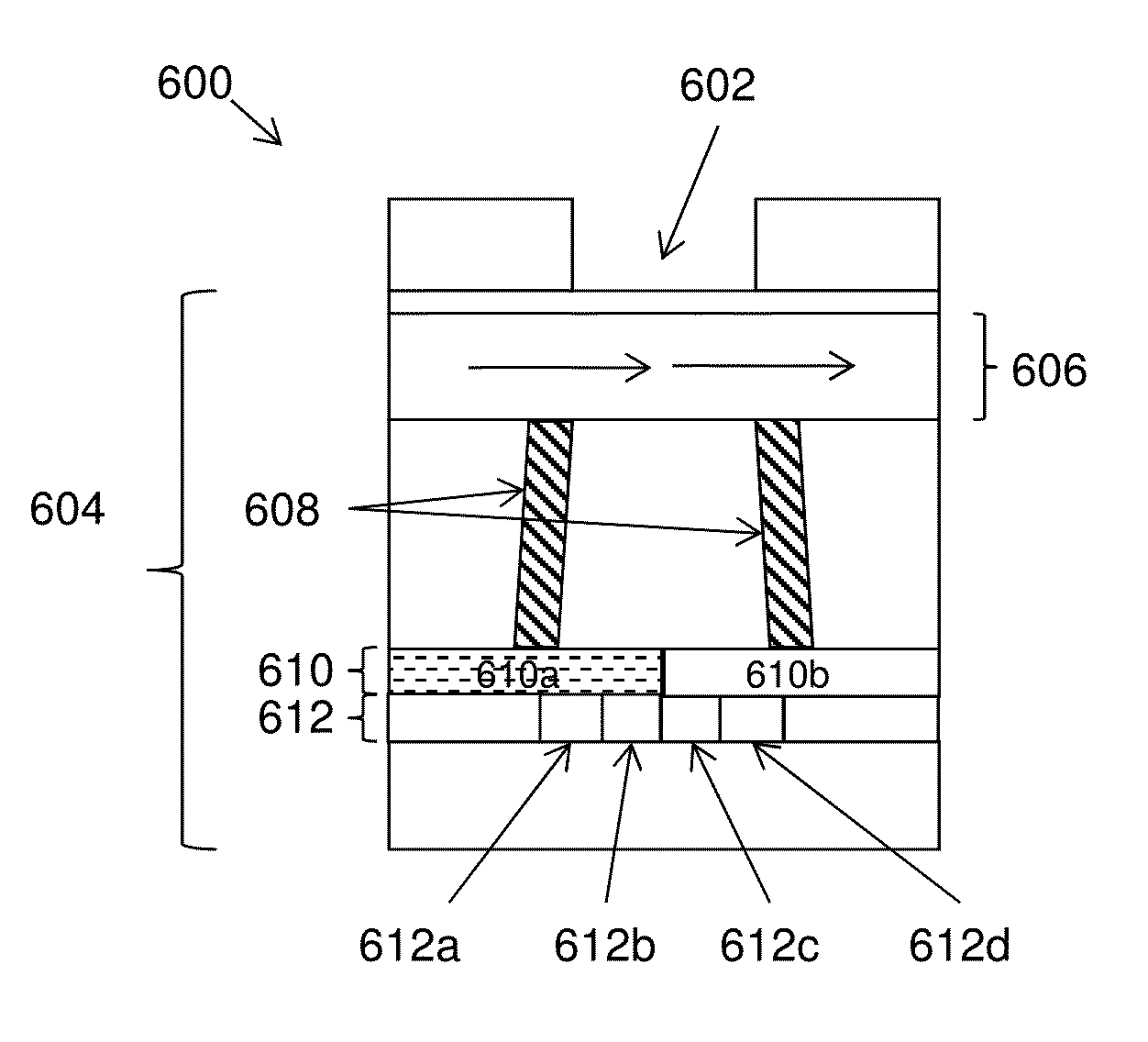

Arrays of integrated analytical devices and methods for production

Arrays of integrated analytical devices and their methods for production are provided. The arrays are useful in the analysis of highly multiplexed optical reactions in large numbers at high densities, including biochemical reactions, such as nucleic acid sequencing reactions. The integrated devices allow the highly sensitive discrimination of optical signals using features such as spectra, amplitude, and time resolution, or combinations thereof. The arrays and methods of the invention make use of silicon chip fabrication and manufacturing techniques developed for the electronics industry and highly suited for miniaturization and high throughput.

Owner:PACIFIC BIOSCIENCES

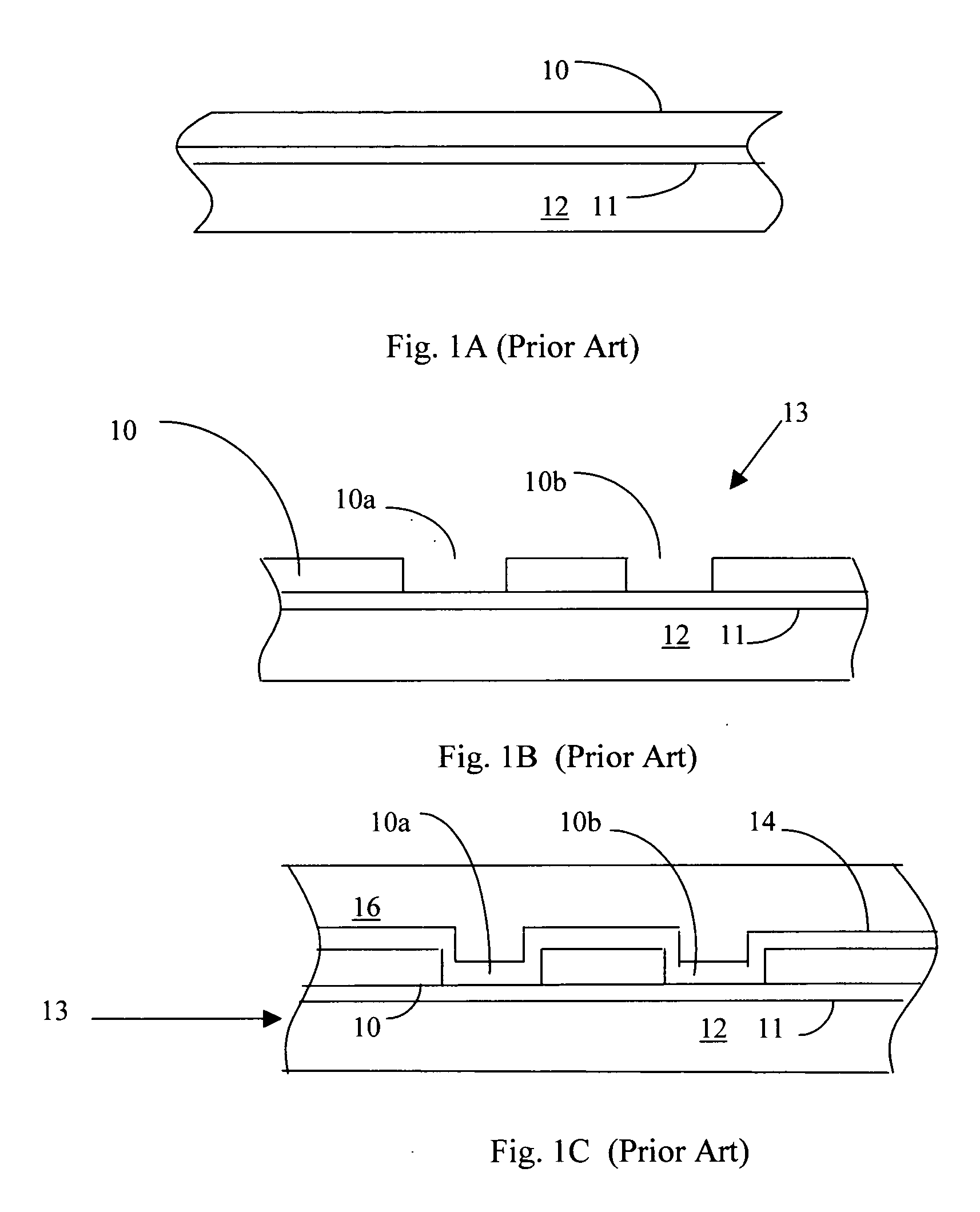

Method and apparatus for making a stamper for patterning CDs and DVDs

InactiveUS20050167867A1Good resistance stabilityUnnecessary to performRecord carriersConfectioneryResistCompact Disc manufacturing

A method for forming a stamper used in the manufacture of CDs, DVDs, and other types of optical disks comprises forming a substrate by rolling. A layer of material is deposited (e.g. by plating) onto the substrate. Thereafter, a resist layer is formed on the layer of material and patterned. Because the substrate is formed by rolling, it is relatively inexpensive to form the substrate to a desired thickness. Because the layer of material is formed by deposition (e.g. plating), it is relatively inexpensive to ensure that the layer has a very smooth surface (i.e. without necessitating a great deal of polishing).

Owner:WD MEDIA

Magneto-active adhesive systems

A magneto-active adhesive and method of adhesive bonding by magnetic field. The method includes steps of providing at least two adherends to be bonded, providing a magneto-active adhesive system between the at least two adherends, the magneto-active adhesive system comprising a plurality of magnetic particles and an adhesive; and applying a non-cyclically varying magnetic field or a cyclically varying magnetic field induced by an alternating current having a frequency of less than 100 hz to the magneto-active adhesive system to change the adhesion of the magneto-active adhesive system to at least one of the adherends. Various carriers for microelectronic devices including magneto-active adhesive contact surfaces are also described within the scope of the invention.

Owner:ENTEGRIS INC

Method and apparatus for making a stamper for patterning CDs and DVDs

InactiveUS20050151283A1Reduced and no sacrifice in data storage densityHuge savingsRecord carriersOptical articlesResistCompact Disc manufacturing

A method for forming a stamper used in the manufacture of CDs, DVDs, and other types of optical disks comprises forming a substrate by rolling. A layer of material is deposited (e.g. by plating) onto the substrate. Thereafter, a resist layer is formed on the layer of material and patterned. Because the substrate is formed by rolling, it is relatively inexpensive to form the substrate to a desired thickness. Because the layer of material is formed by deposition (e.g. plating), it is relatively inexpensive to ensure that the layer has a very smooth surface (i.e. without necessitating a great deal of polishing).

Owner:WD MEDIA

Synchronizing instructional media with object builds to advance the 3D printing industry

Methods and systems are described for constructing media-synchronized objects through additive manufacturing means. At least one construction configuration for at least one object is at least partly synchronized with at least one segment of at least one associated instructional media presentation viewed by a user through at least one media presentation device. Various embodiments demonstrate successive object portions synchronized with successive media presentation segments, at least partly automated object construction synchronized with one or more media presentation segments, and / or user assembly of multiple object portions configured to modify media presentation aspects. In select embodiments, object design modifications by the user are configured to change media presentation aspects. Certain embodiments permit accelerated and / or decelerated object construction being configured to accelerate, decelerate, lengthen, and / or truncate associated media presentations.

Owner:NEVINS JOEL

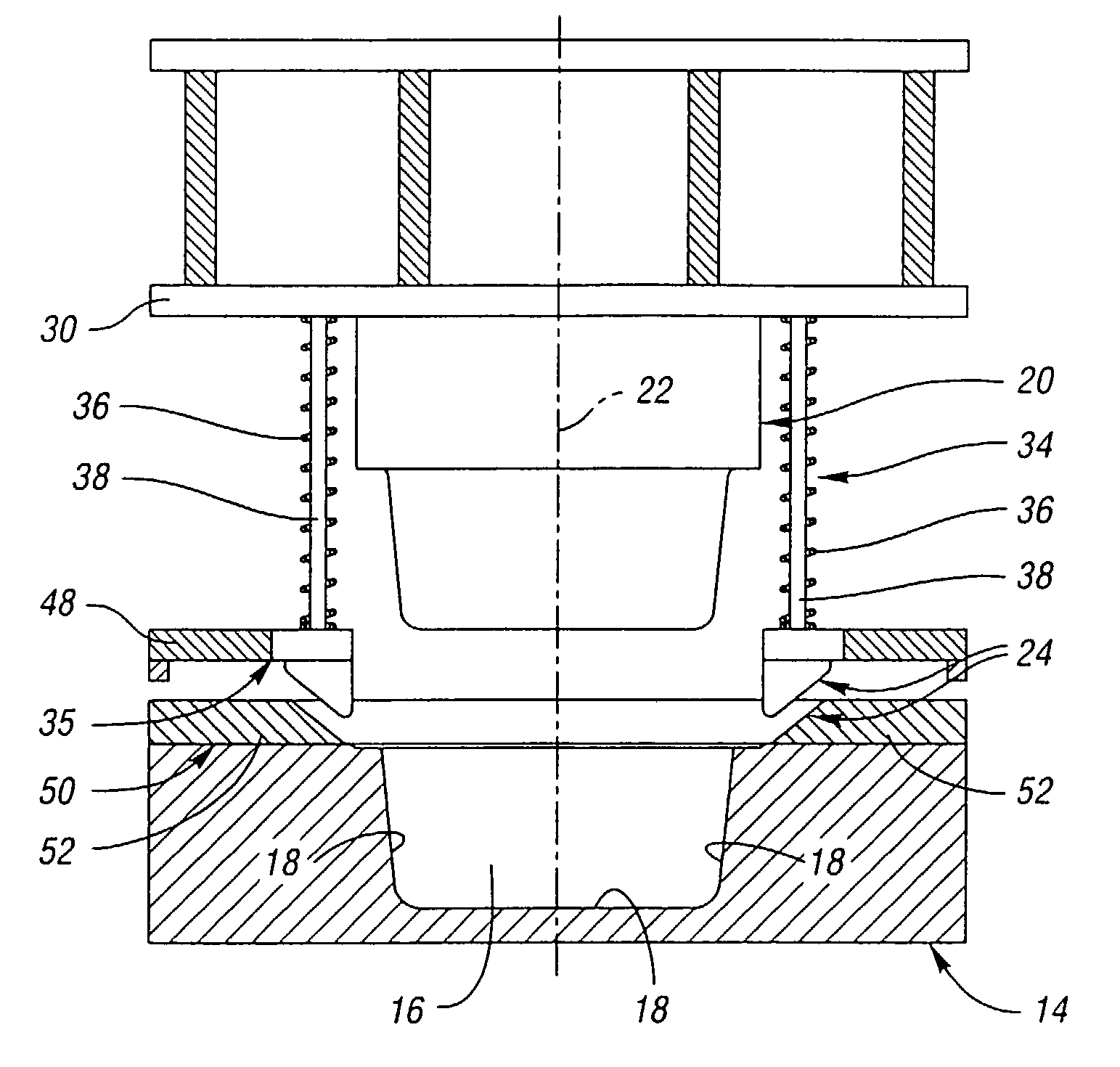

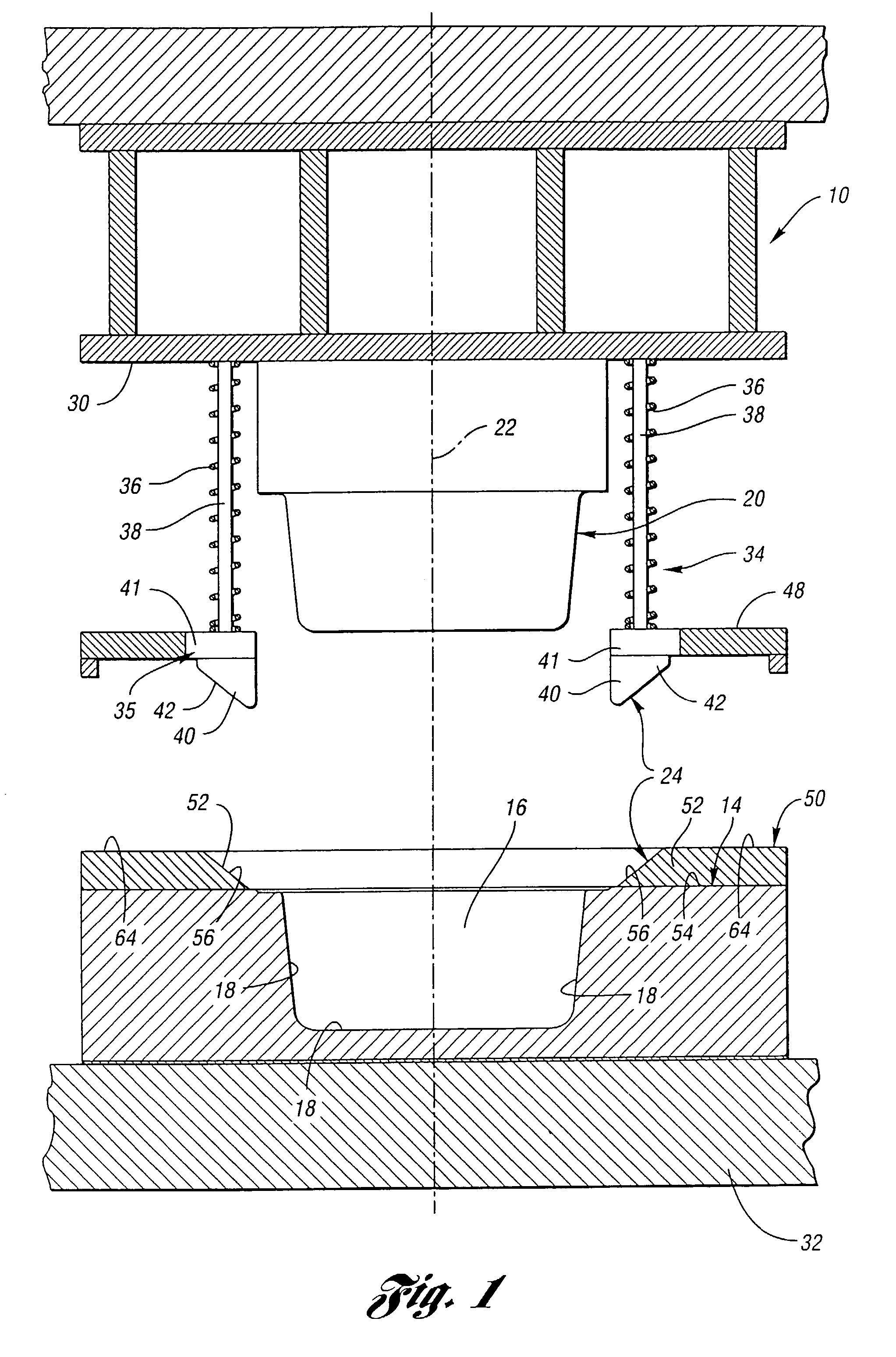

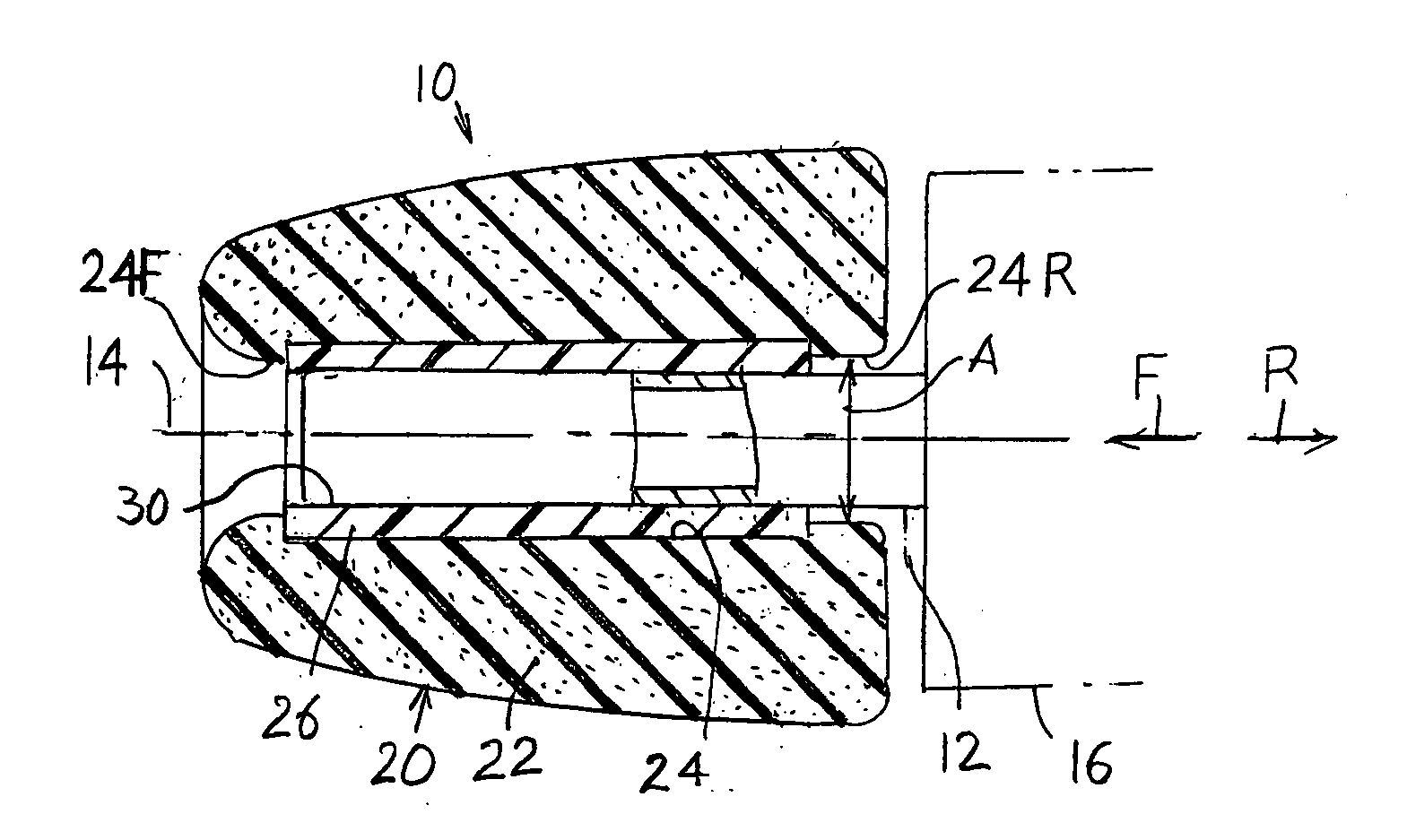

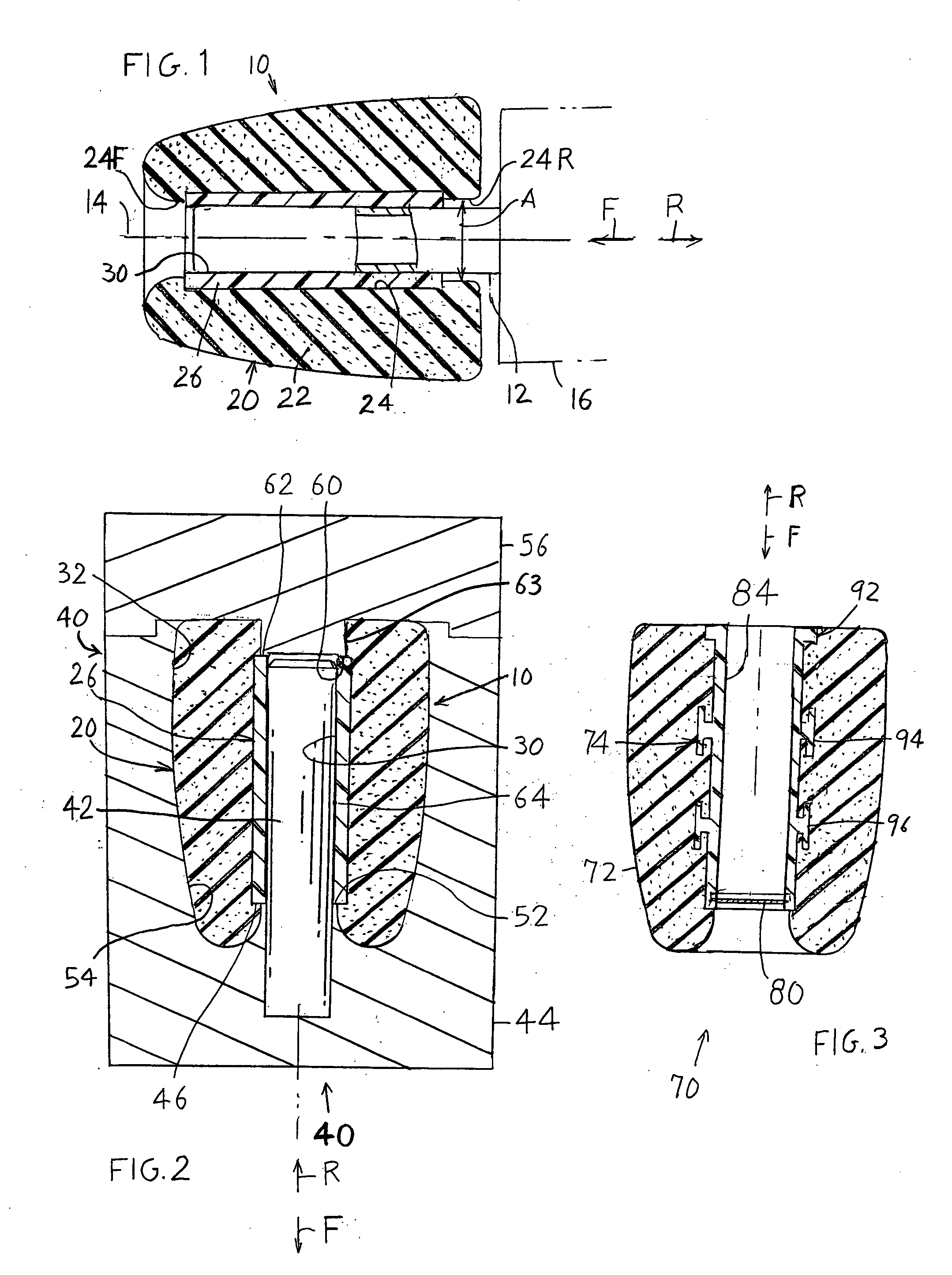

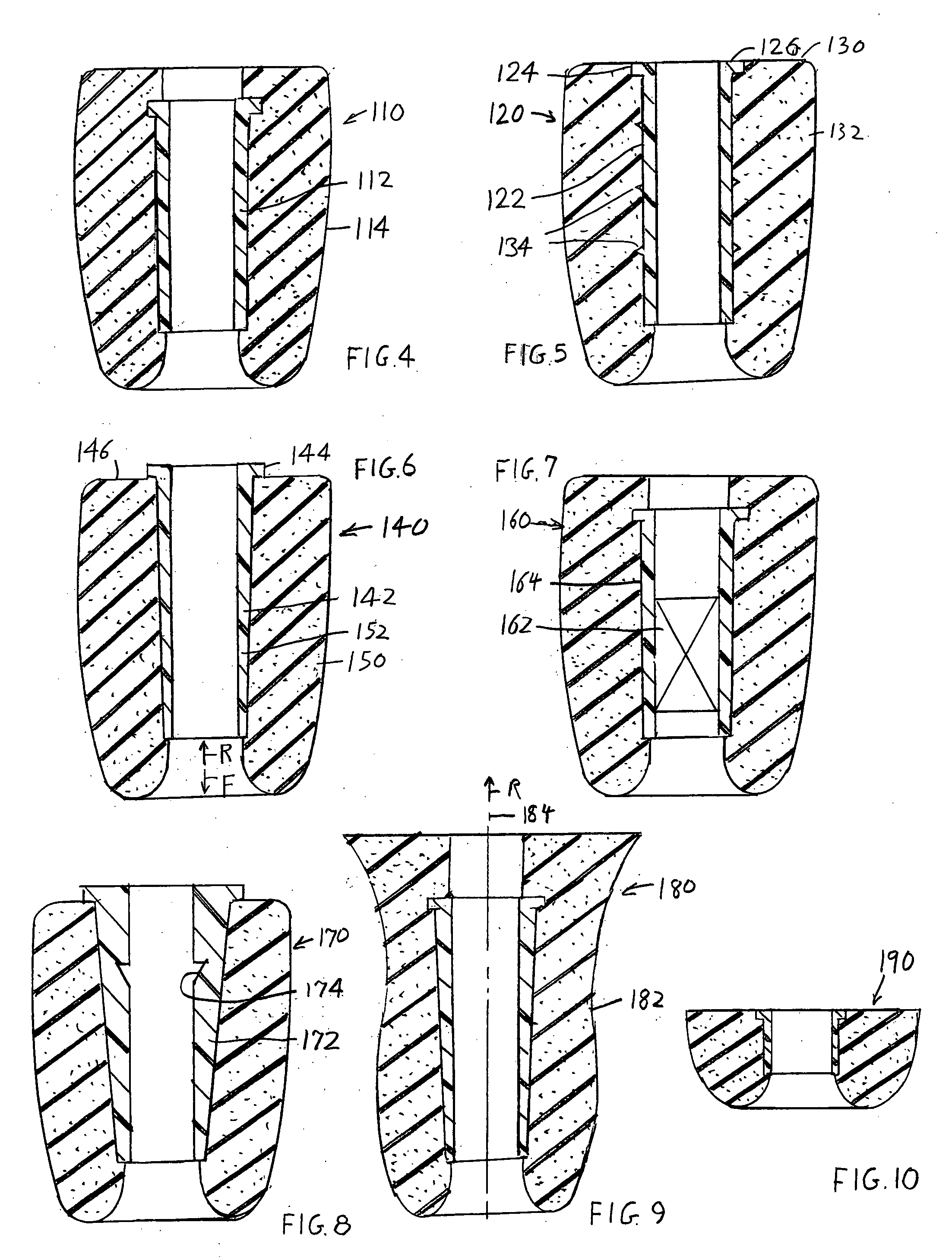

Earbud and method of manufacture

InactiveUS20080187161A1Reliable and attractiveReduce construction costsRecord carriersMouldsAdhesiveBiomedical engineering

An earbud (10) for carrying sound from a source (16) to a person's ear canal, includes a soft foam body (20) and a sleeve (26) of stiffer material lying within the body. The body is molded around the sleeve and is chemically bonded to the sleeve without an adhesive between them. The earbud is molded around the sleeve by placing the sleeve on a mandrel pin (42) within a mold cavity (32), placing foamable material in the mold and closing the mold. The mold has shoulders with one mold shoulder (52) that abuts one end (46) of the sleeve and another mold shoulder (60) that lies within 0.1 millimeter of the other sleeve end (62), to prevent foaming material from leaking into the space (64) between the mandrel pin and the sleeve passage.

Owner:HONEYWELL SAFETY PROD USA INC

Colored optical discs and methods for making the same

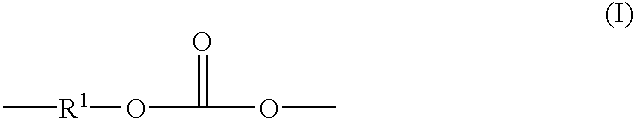

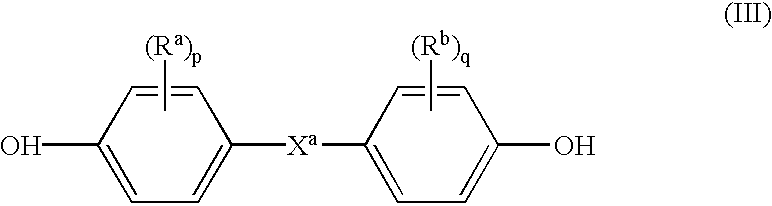

Embodiments of optical discs and methods for making the same are disclosed. In one embodiment, the optical disc comprises: at least two plastic substrates comprising a bonding layer and a data layer disposed therebetween, wherein at least one of the substrates is a read side substrate comprising greater than or equal to about 0.05 wt % colorant, based upon the total weight of the read side substrate, and wherein the read side substrate has a UV Bonding Index of greater than or equal to about 0.5. One method for making the optical disc comprises: forming a first plastic substrate comprising greater than or equal to about 0.05 wt % colorant, based upon the total weight of the first plastic substrate, wherein a UV Bonding Index of the first plastic substrate is controlled to be greater than or equal to about 0.5, disposing a data layer between the first plastic substrate and a second substrate, bonding the first plastic substrate to the second plastic substrate with a bonding layer, and curing the bonding layer.

Owner:SABIC INNOVATIVE PLASTICS IP BV

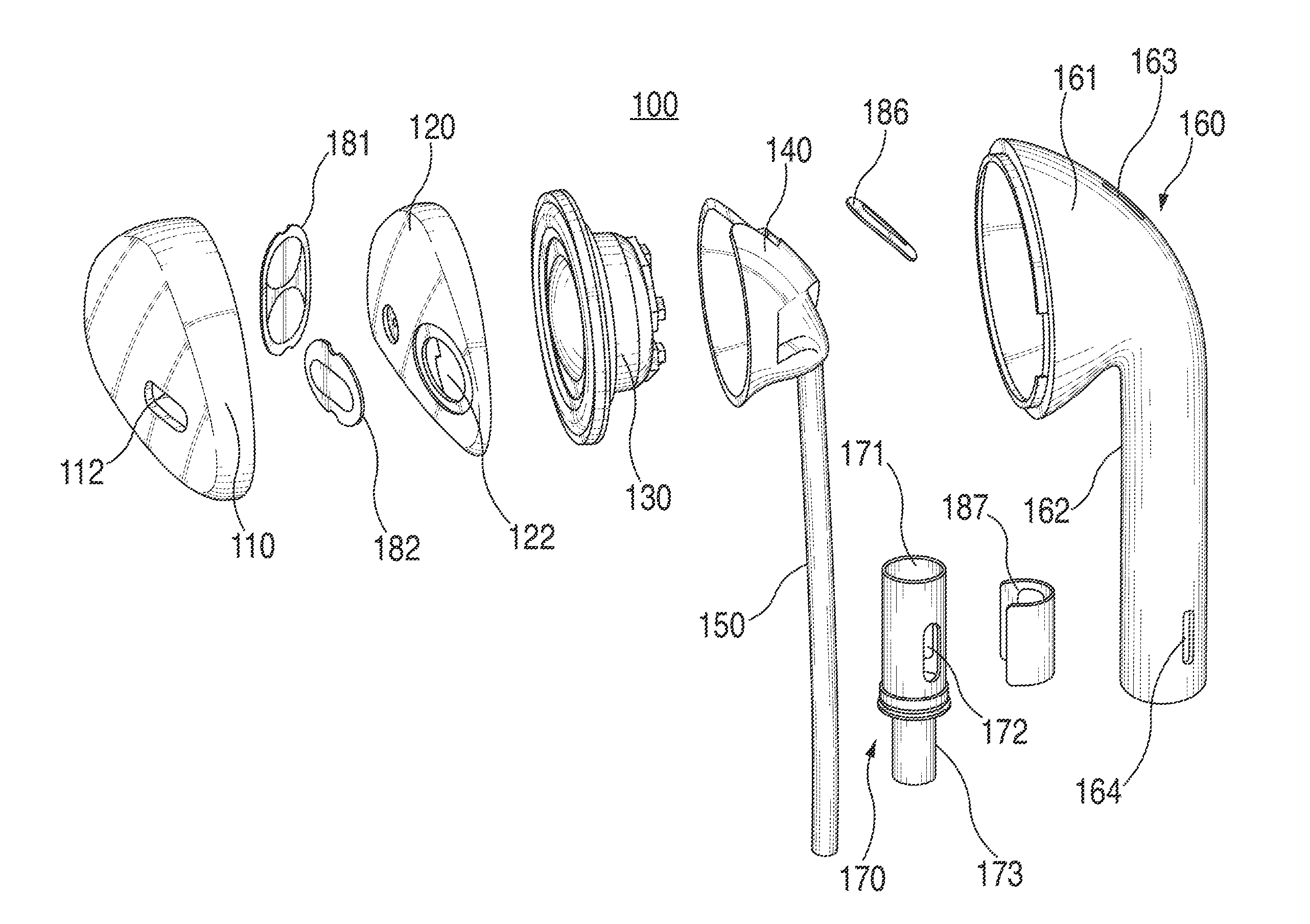

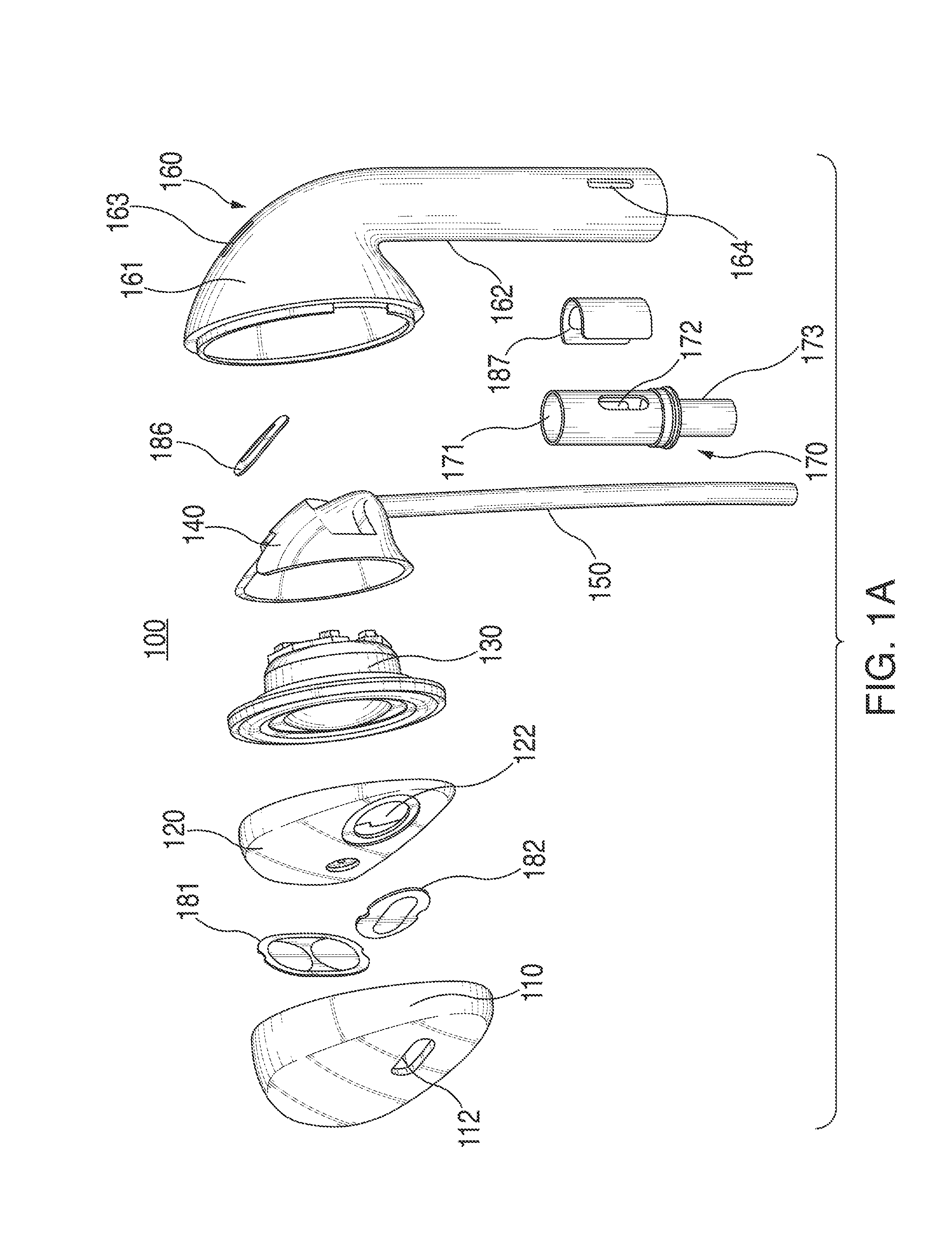

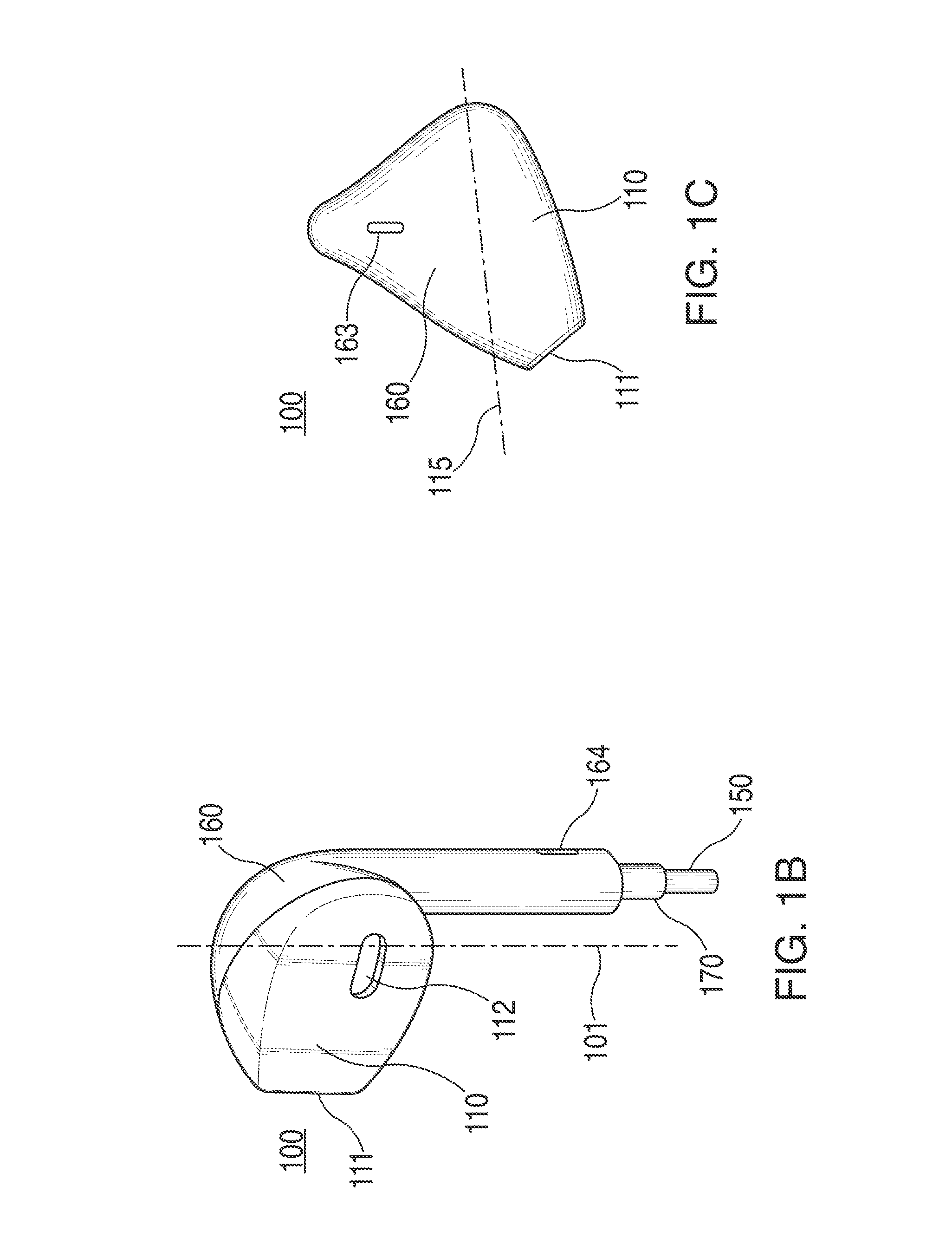

Systems and methods for assembling non-occluding earbuds

ActiveUS20140068944A1Improve performanceDesired performanceAutomatic control devicesRecord carriersEngineeringDirectional sound

Systems and methods for assembling non-occluding earbuds are disclosed. The earbud includes a non-occluding housing having a directional sound port offset with respect to a center axis of the earbud. The housing can have an asymmetric shape amenable to in-the-ear retention. Additionally, the housing can have a seamless or nearly seamless construction even though two or more parts are joined together to form the housing.

Owner:APPLE INC

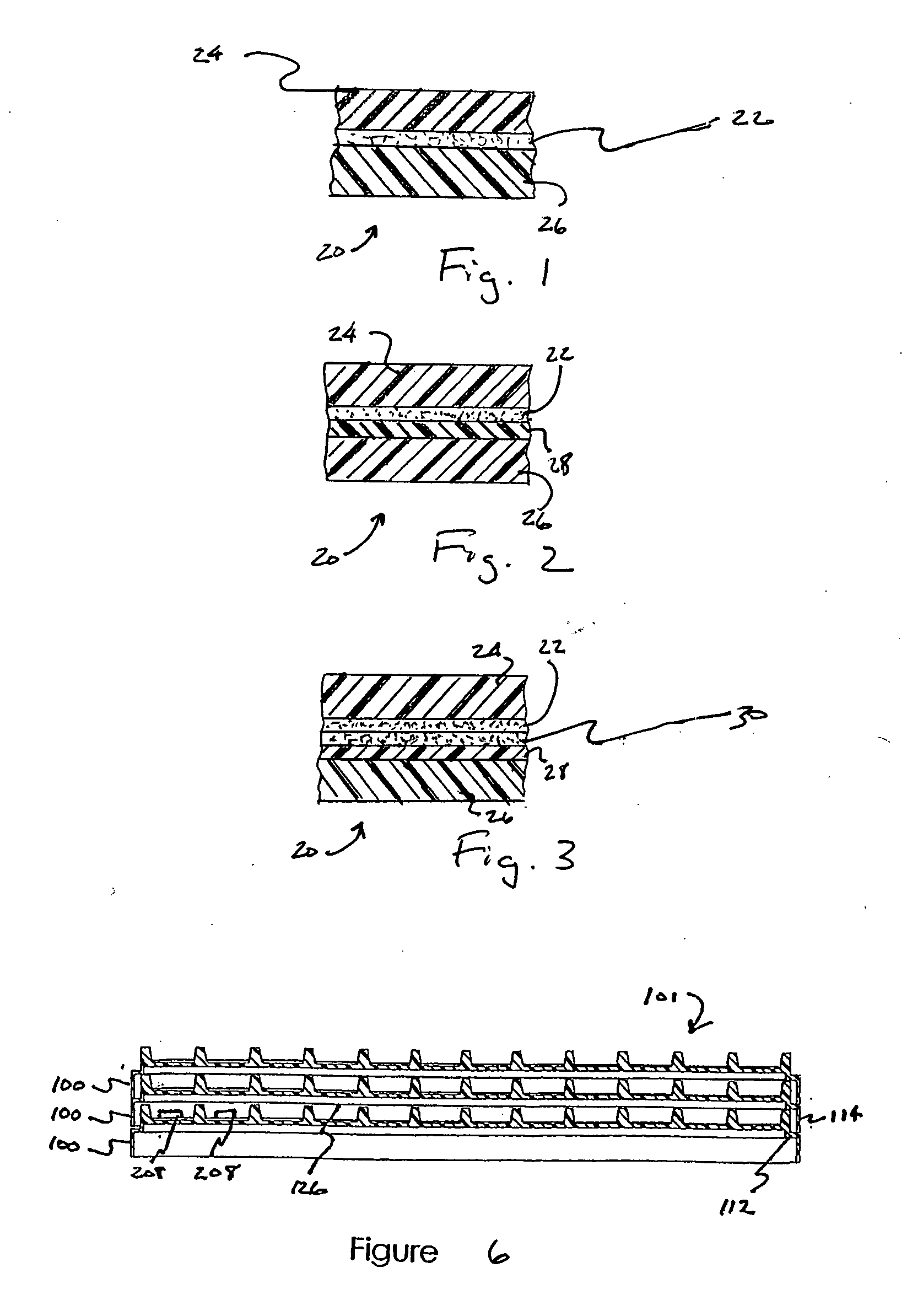

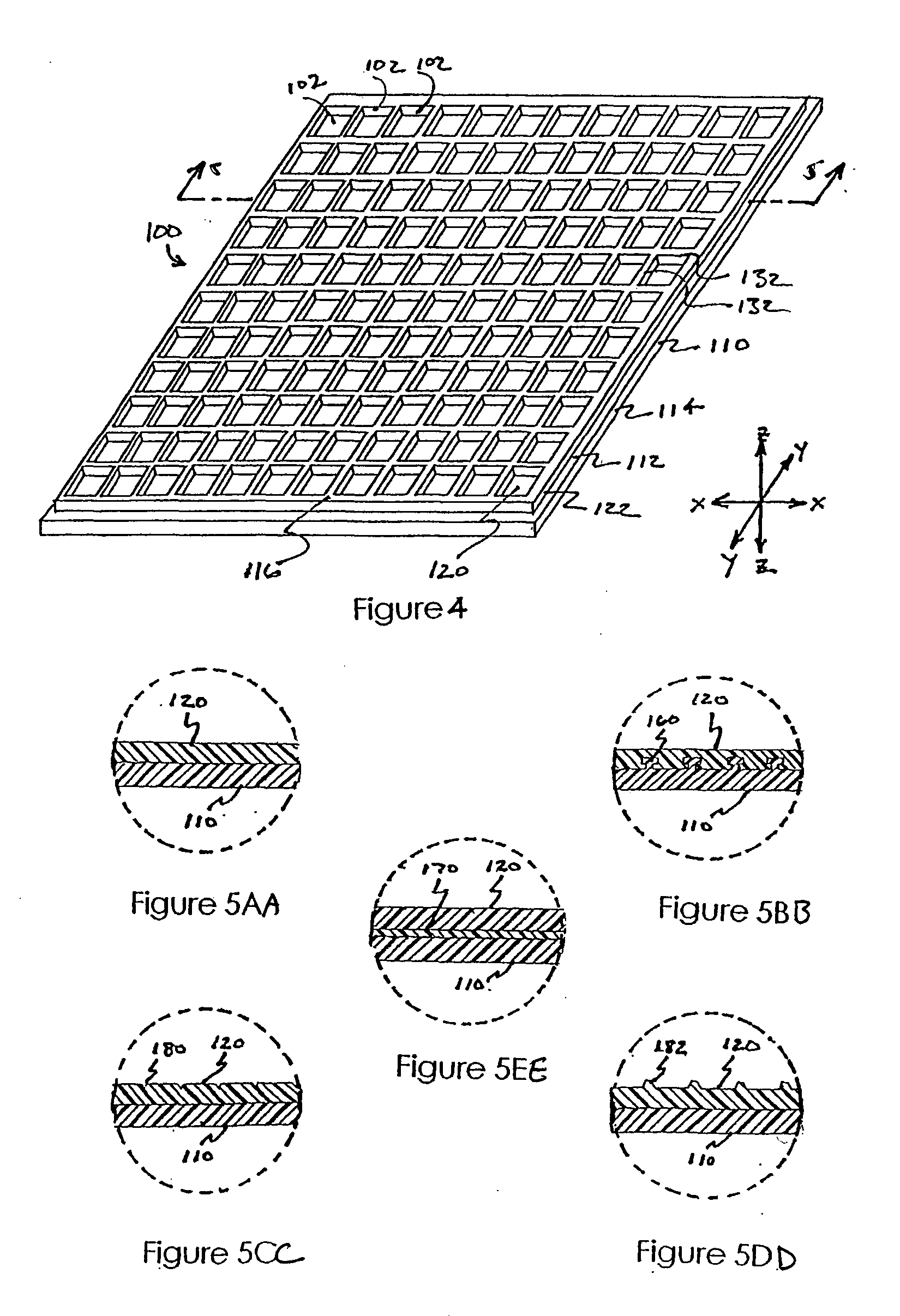

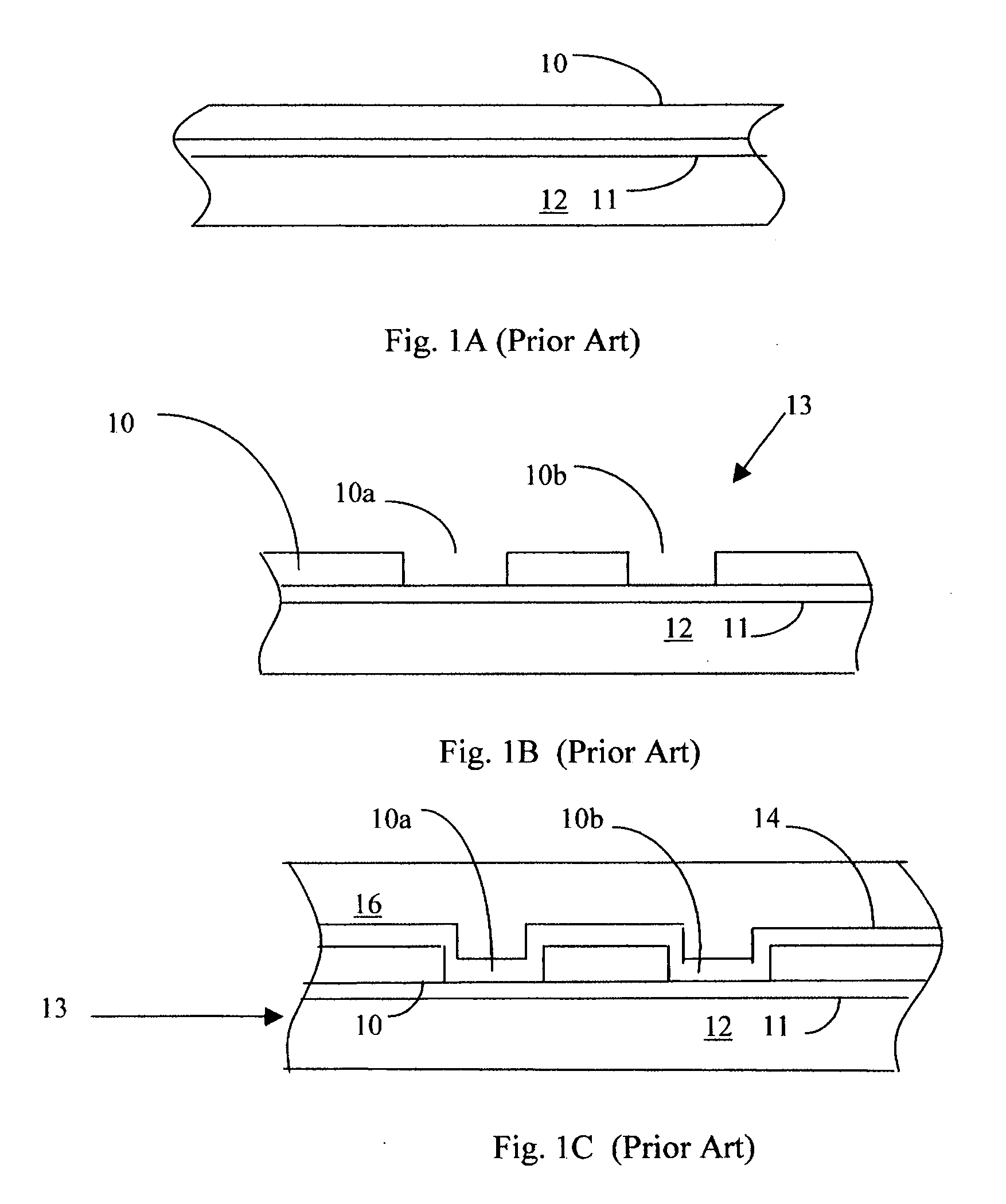

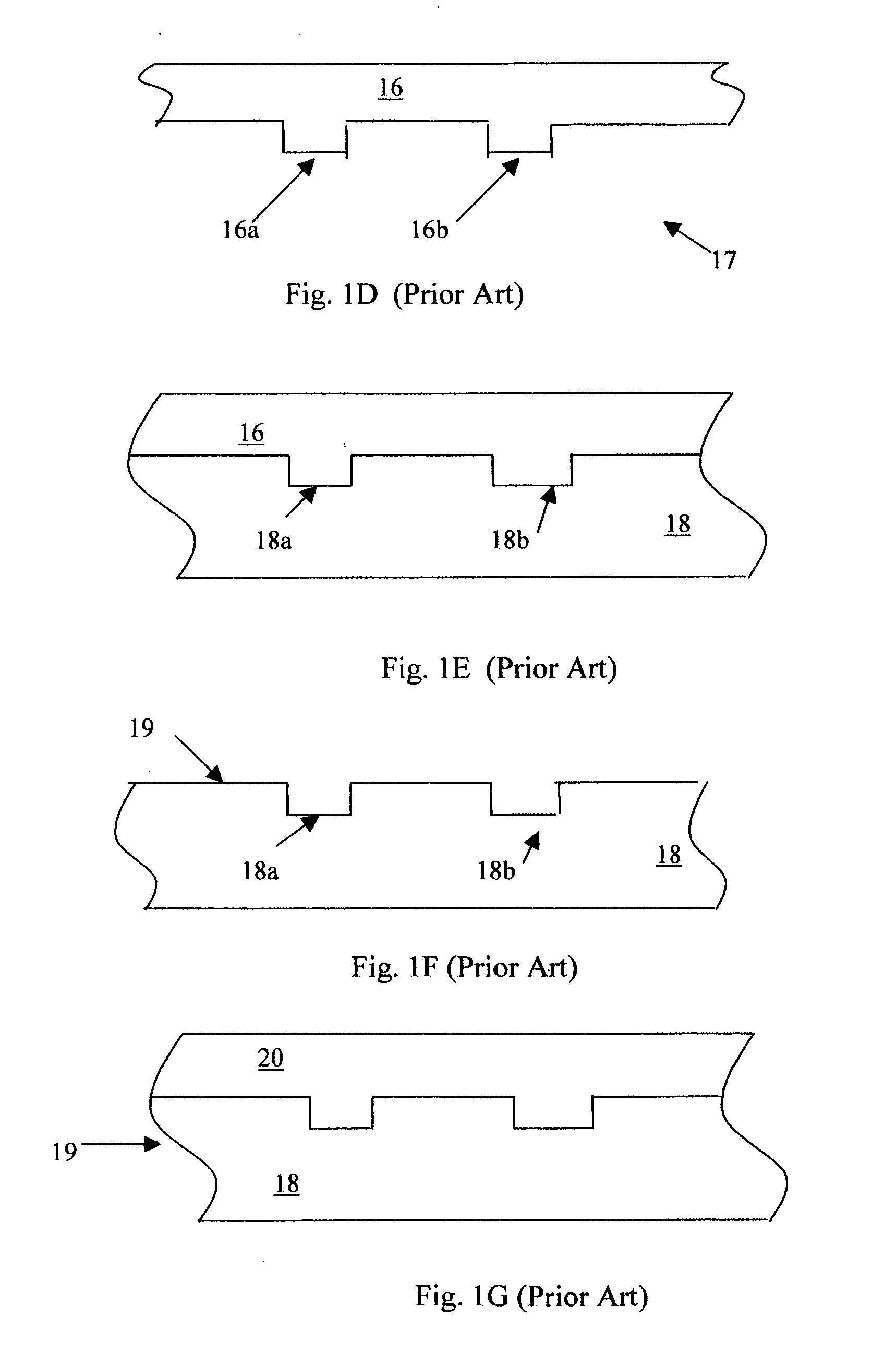

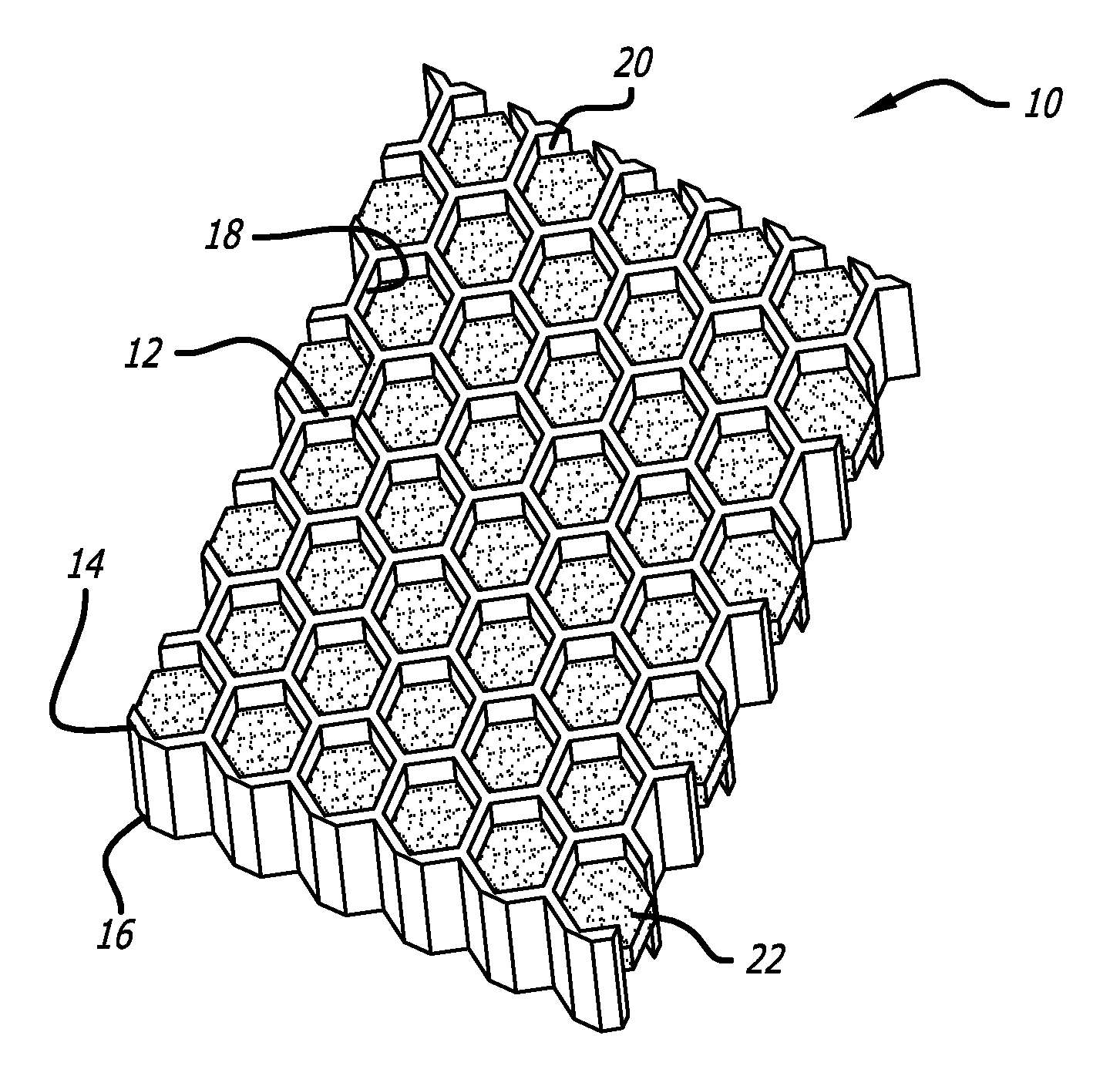

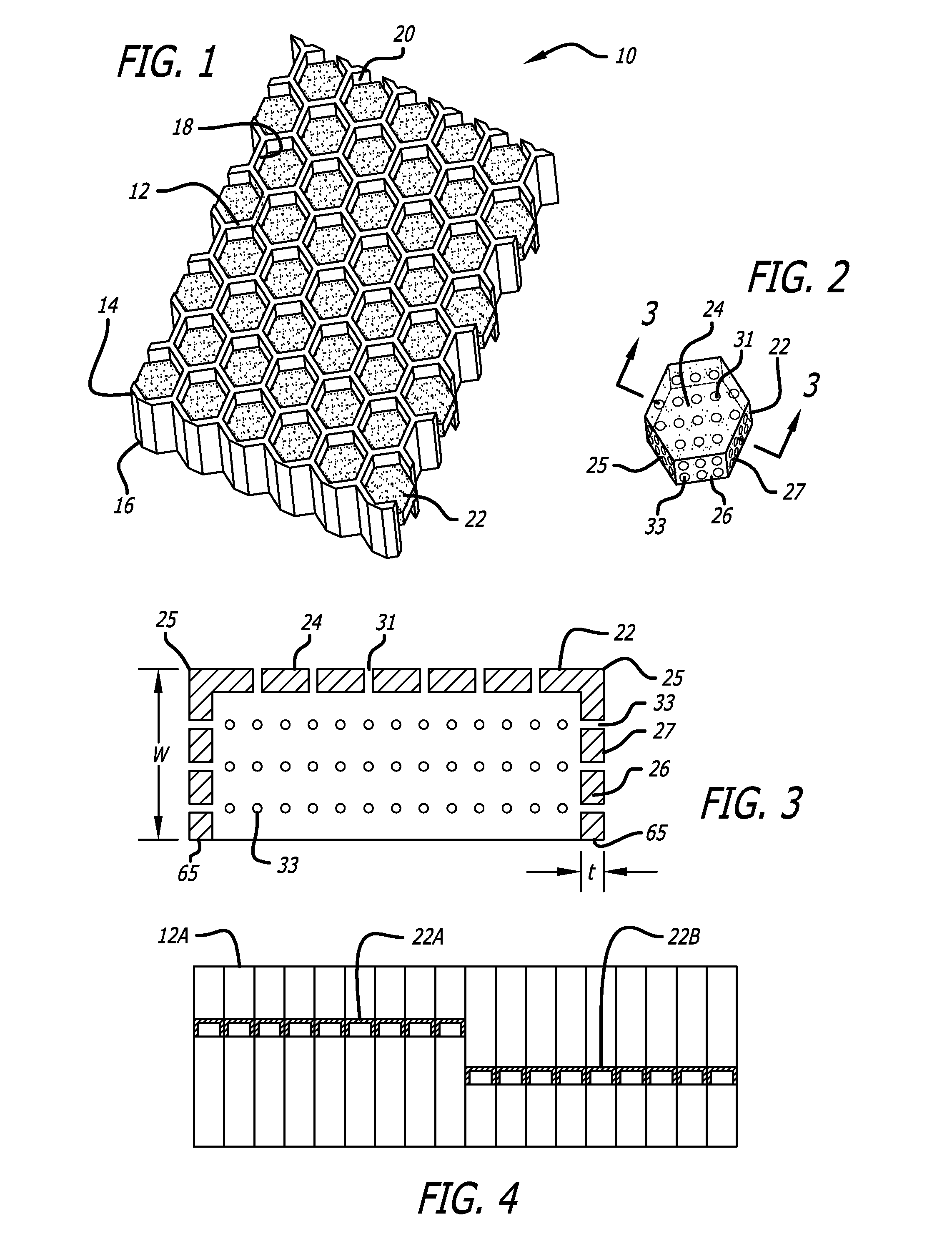

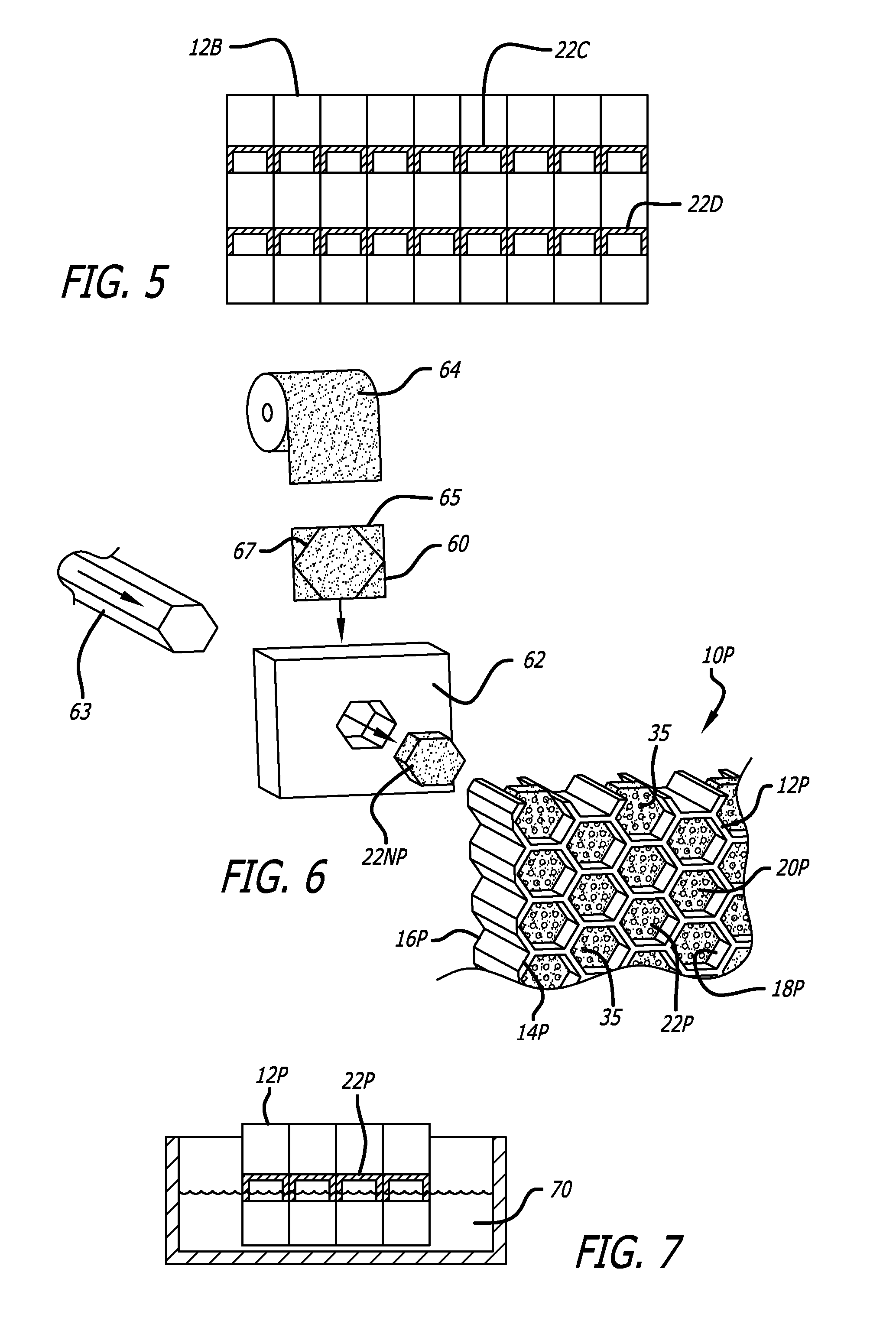

Acoustic honeycomb with perforated septum caps

ActiveUS20120037449A1Lean structureReduced flexibilityElectrical transducersRecord carriersAdhesiveEngineering

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of flexible material that may be perforated before or after the material is inserted into the honeycomb. The flexible material is sufficiently flexible to allow folding into the shape of a septum cap. The flexible material is also sufficiently stiff to provide frictional engagement and locking of the septum cap to the honeycomb cell when the cap is inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXCEL

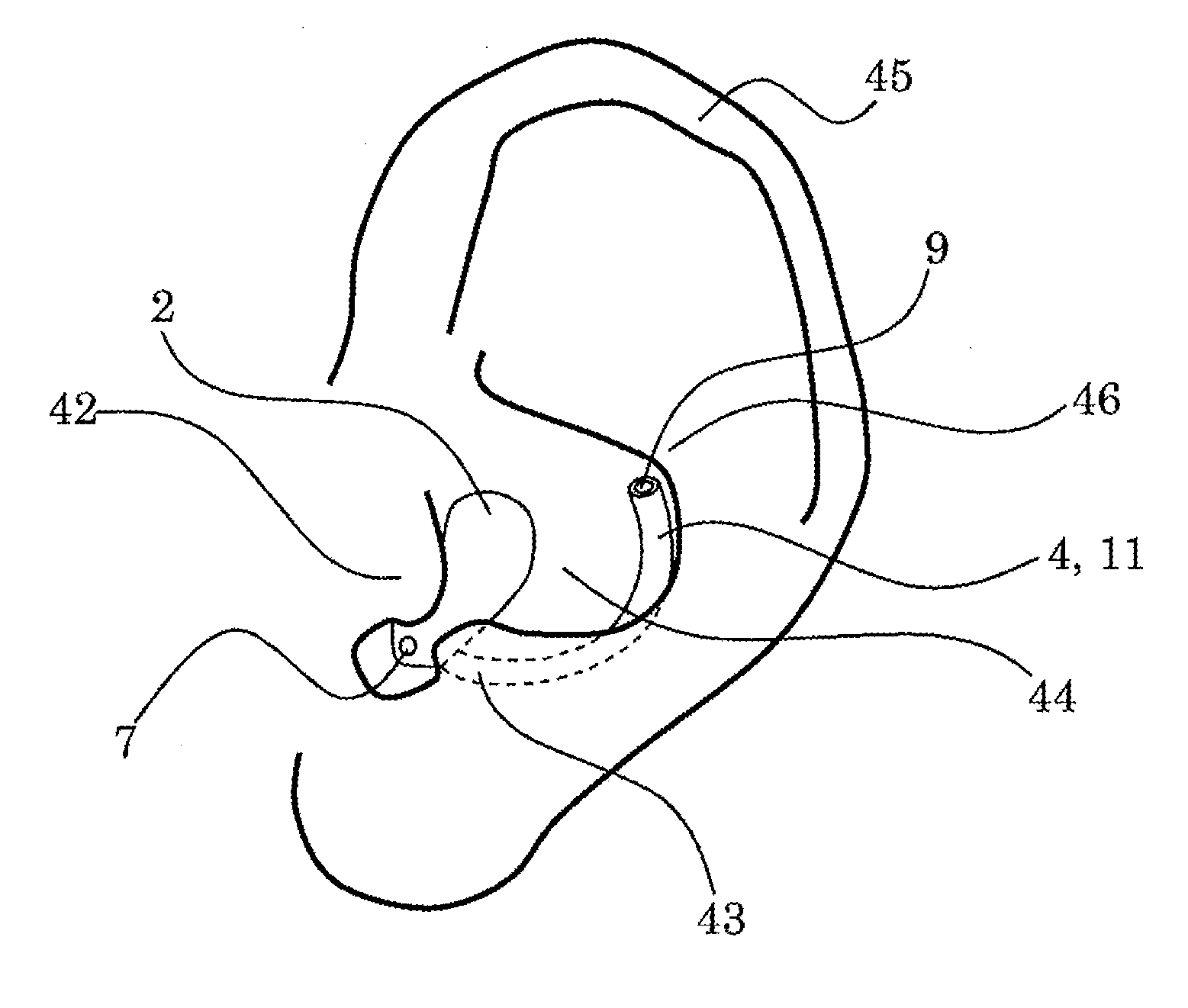

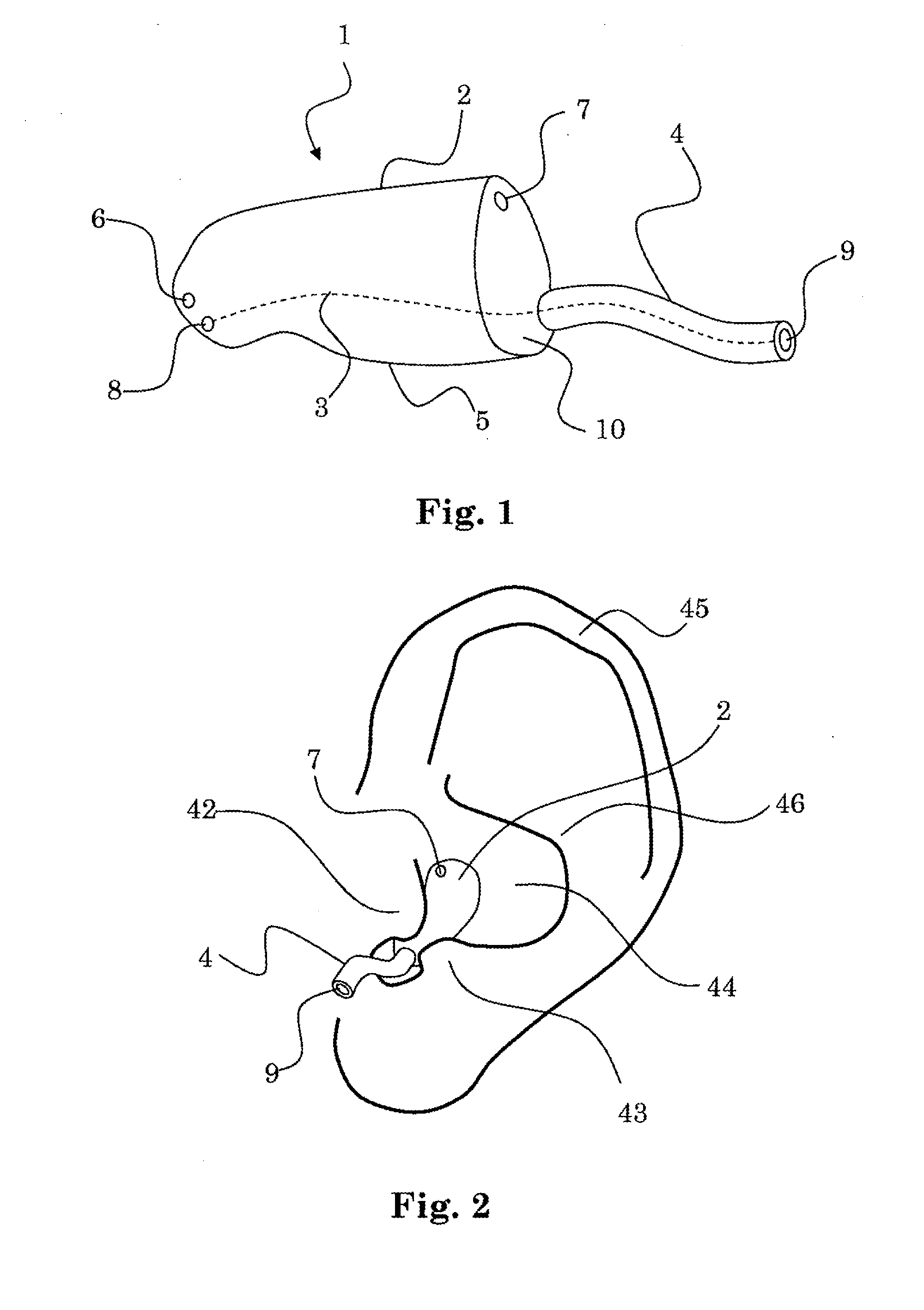

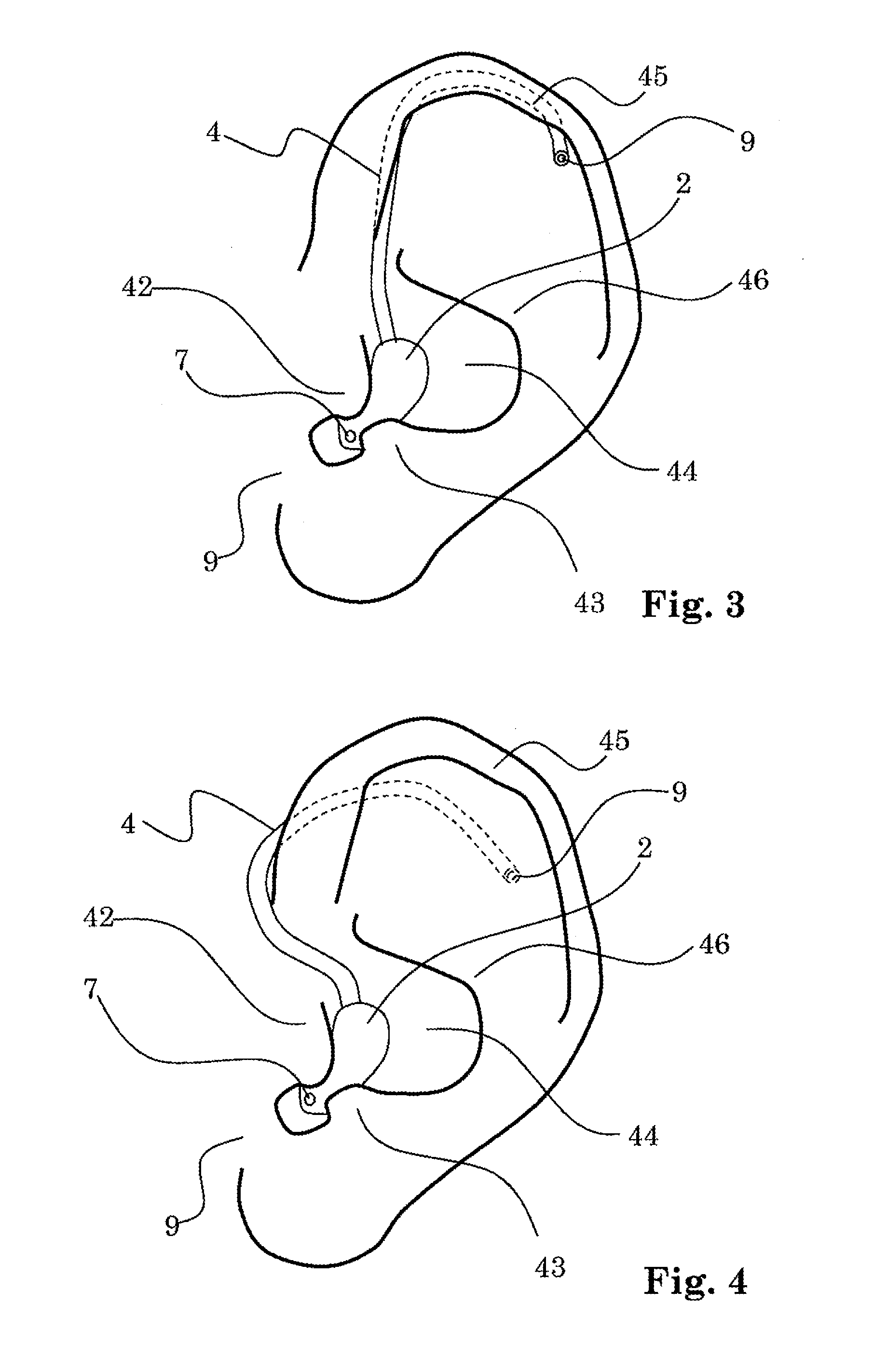

Hearing device with a vent extension and method for manufacturing such a hearing device

InactiveUS20120140967A1Equally distributedConvenient ArrangementElectrical transducersRecord carriersEngineeringHearing perception

The hearing device comprises an ear-piece (1) which is designed to be worn at least partially in an ear canal of a user of the hearing device. The ear-piece (1) comprises a vent passage (3) connecting the ear canal with the atmosphere. The vent passage (3) has an inner opening (8) towards the ear-canal and an outer opening (9) towards the atmosphere. The ear-piece (1) further comprises a vent extension (4). The vent extension (4) is a protrusion extending the vent passage (3) beyond the body (2) of the ear-piece (1). The vent extension (4) is adapted for abutting on a surface of the body of the user and is thereby inconspicuous and / or contributes thereby to retention. A method for manufacturing such a hearing device is also disclosed.

Owner:SONOVA AG

Bone-conduction hearing-aid transducer having improved frequency response

InactiveUS7822215B2Simplified component countRecord carriersBone conduction transducer hearing devicesBone structureFrequency spectrum

A hearing-aid device and a method for transmitting sound through bone conduction are disclosed. The hearing-aid device comprises a piezoelectric-type actuator, housing and connector. The piezoelectric actuator is preferably a circular flextensional-type actuator mounted along its peripheral edge in a specifically designed circular structure of the housing. During operation, the bone-conduction transducer is placed against the mastoid area behind the ear of the patient. When the device is energized with an alternating electrical voltage, it flexes back and forth like a circular membrane sustained along its periphery and thus, vibrates as a consequence of the inverse piezoelectric effect. Due to the specific and unique designs proposed, these vibrations are directly transferred through the human skin to the bone structure (the skull) and provide a means for the sound to be transmitted for patients with hearing malfunctions. The housing acts as a holder for the actuators, as a pre-stress application platform, and as a mass which tailors the frequency spectrum of the device. The apparatus exhibits a performance with a very flat response in the frequency spectrum 200 Hz to 10 kHz, which is a greater spectrum range than any other prior art devices disclosed for bone-conduction transduction which are typically limited to less than 4 kHz.

Owner:FACE INT

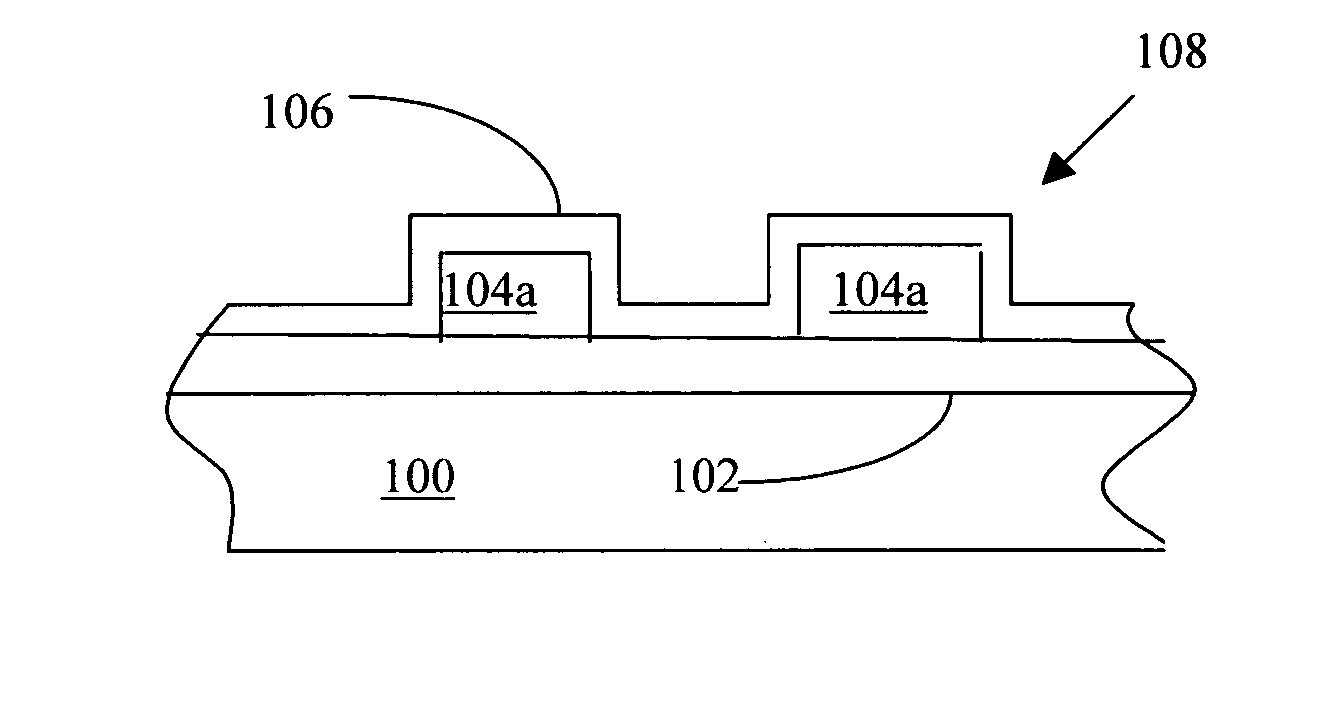

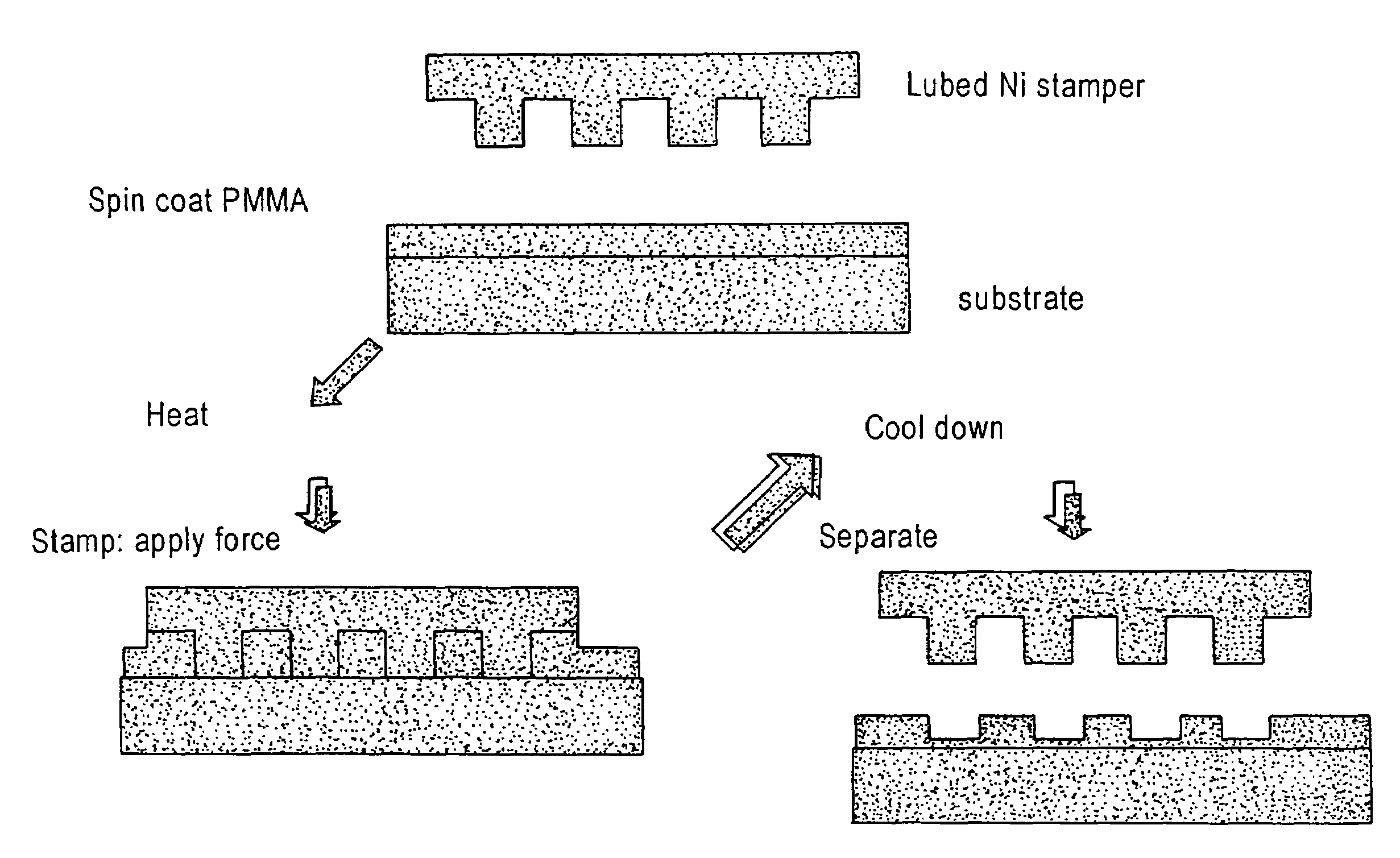

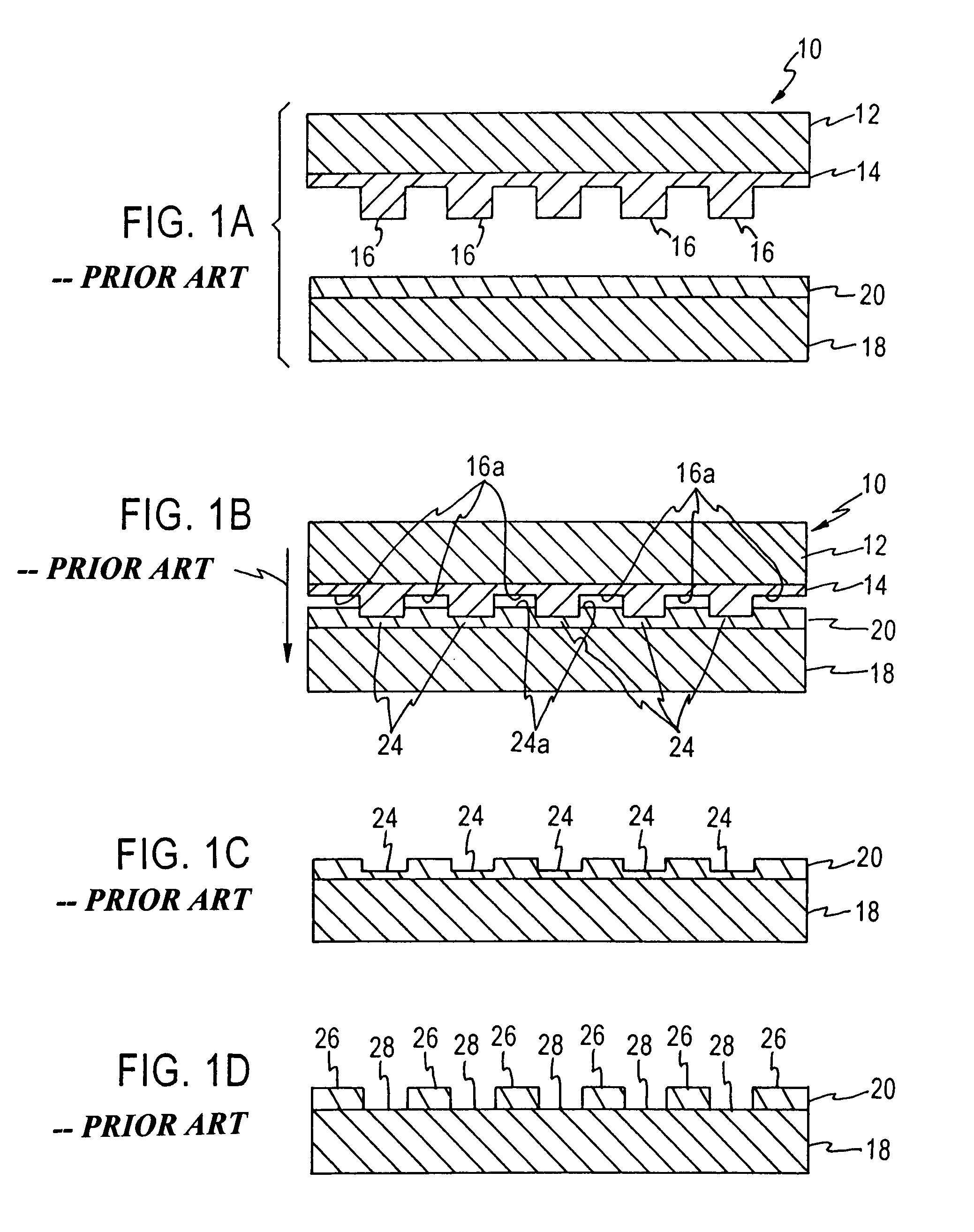

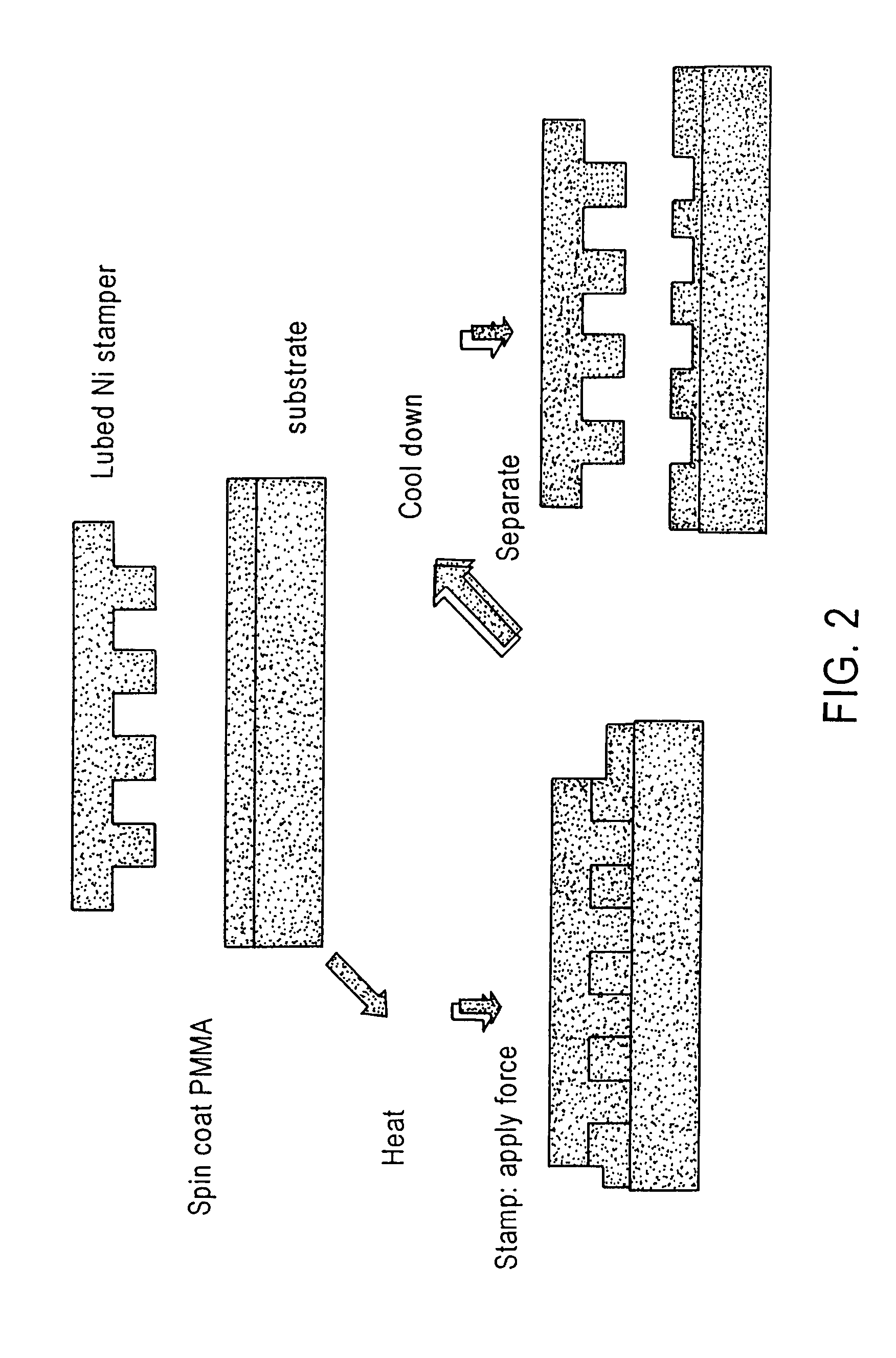

Surface modified stamper for imprint lithography

InactiveUS7294294B1Good release effectMinimize peelingRecord carriersNanoinformaticsLithographic artistEngineering

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH LLC

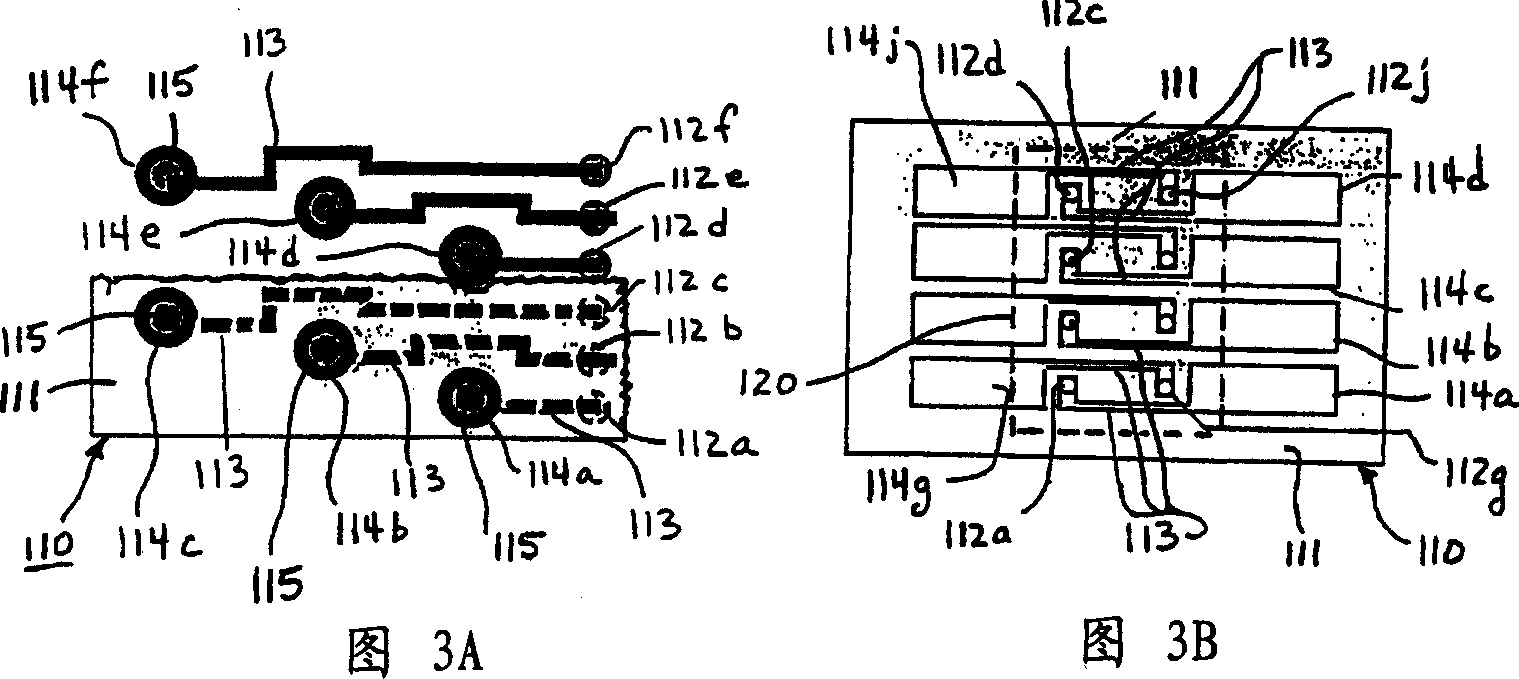

High-density electronic package and method for making same

InactiveCN1352804ARecord carriersSemiconductor/solid-state device detailsElectrical conductorHigh density

A high density electronic package includes a low-modulus-of-elasticity flexible adhesive interposer substrate to which an electronic device, such as a semiconductor chip or die or other component, is attached. The flexible adhesive interposer substrate includes a sheet or layer of a molecularly flexible adhesive having via holes therein in which are built up conductive vias to which contacts of the electronic device connect. A thin layer of metal foil on one surface of the flexible adhesive sheet is patterned to provide contacts and to connect electrically to the conductive vias. The electronic device may be covered by a lid or by an encapsulant attached to the flexible adhesive interposer substrate and / or the electronic device. An electronic package may include a plurality of electronic devices and respective flexible adhesive interposers that are electrically interconnected.

Owner:AMERASIA INT TECH

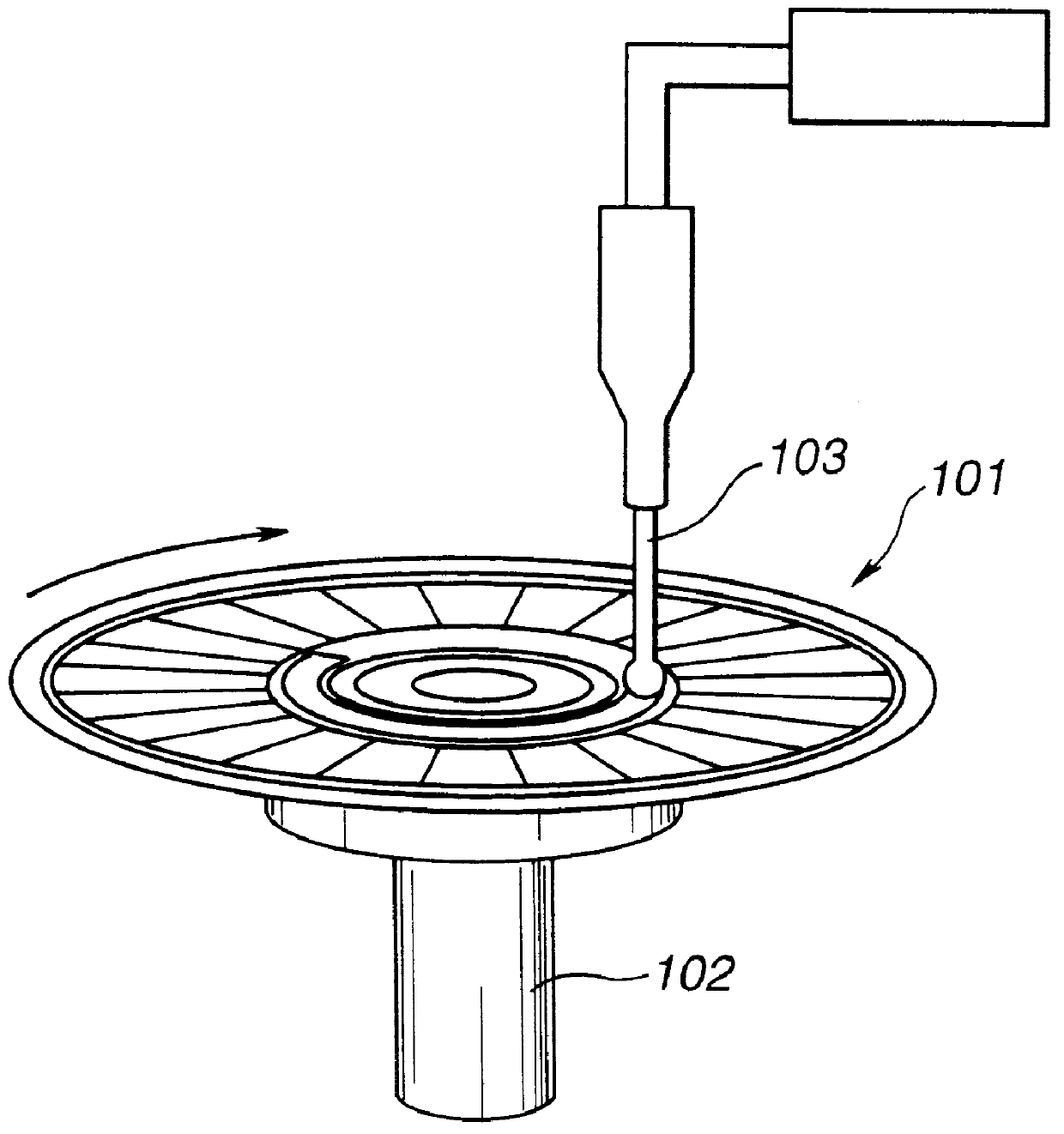

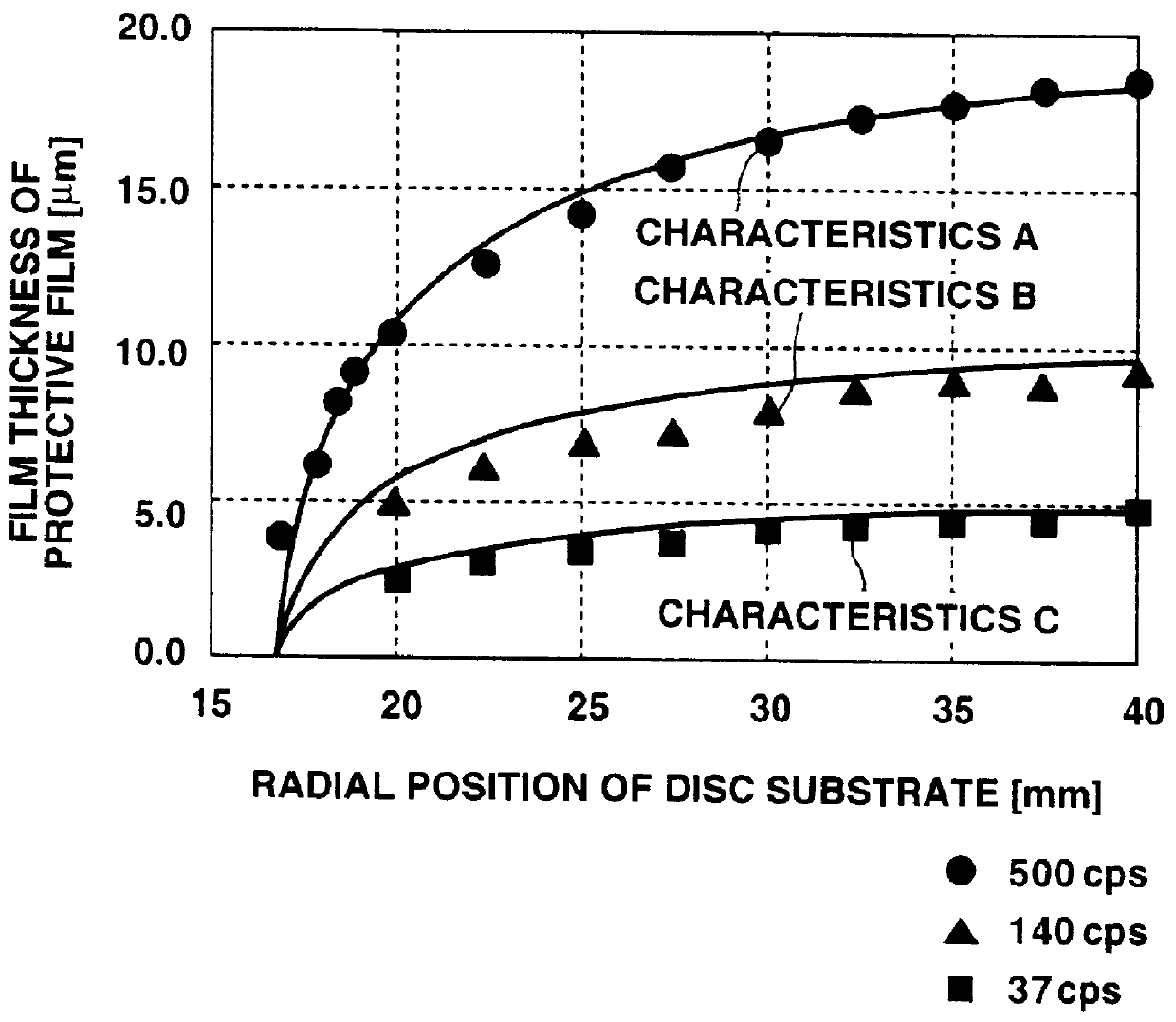

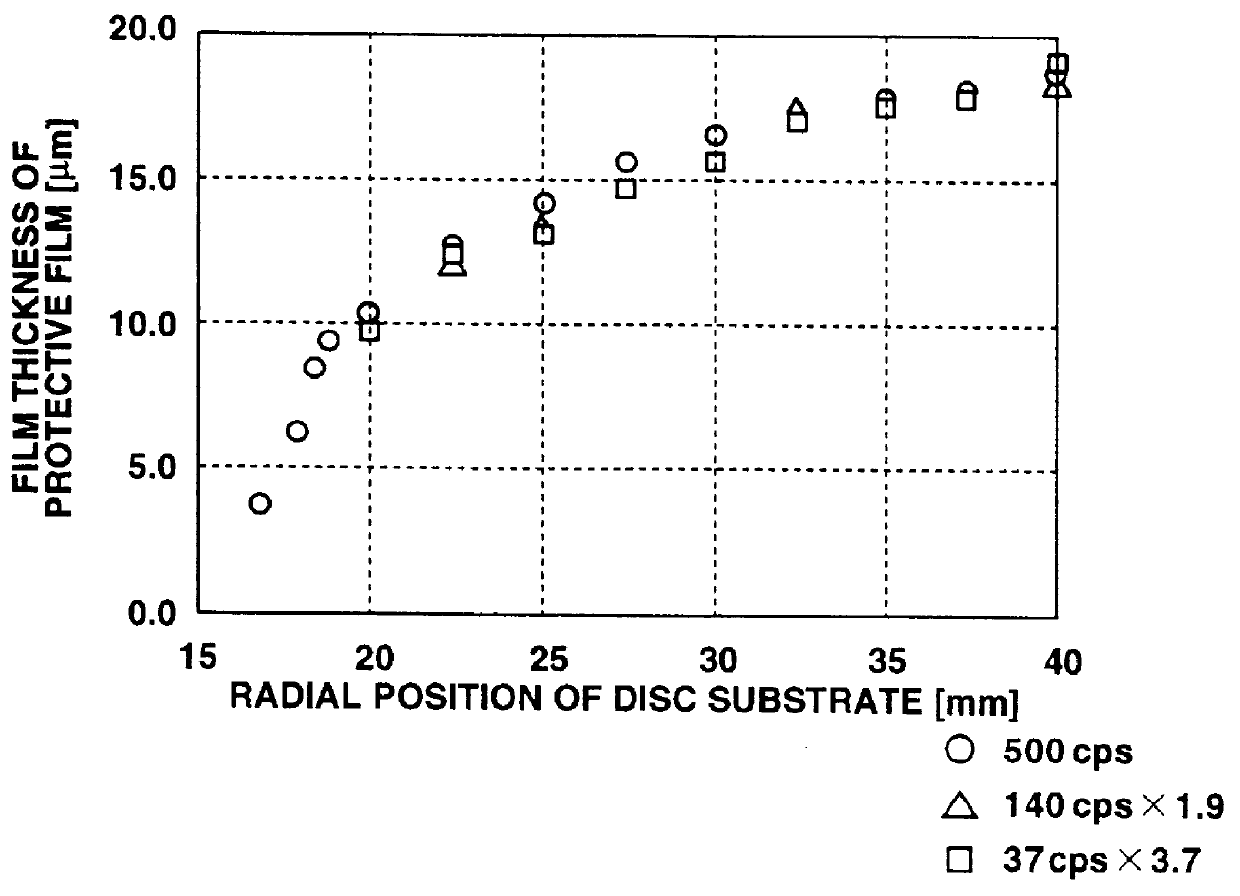

Method and apparatus for manufacturing disc-shaped recording medium

InactiveUS6077349ALarge diameterSuppress mutationRecord carriersSpraying apparatusCircular discEngineering

When applying a coating film by a spin coating method on a disc-shaped recording medium, the film thickness difference between the inner rim and the outer rim of the disc has to be suppressed. To this end, a coating liquid is supplied to a center portion of the disc-shaped recording medium and a rotary disc, as a center shaft of a rotary disc is inserted into a recess formed in a turntable on which the disc-shaped recording medium is set and the disc-shaped recording medium and a rotary disc are run in rotation. The coating liquid is spread under the centrifugal force caused by rotation for forming a coating film on the disc-shaped recording medium.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com