Patents

Literature

73 results about "Compact Disc manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compact disc manufacturing is the process by which commercial compact discs (CDs) are replicated in mass quantities using a master version created from a source recording. This may be either in audio form (CD-Audio) or data form (CD-ROM). This process is used in the mastering of read-only compact discs; CD-Rs, CD-RWs, and DVDs are made somewhat differently, though the methods are broadly similar.

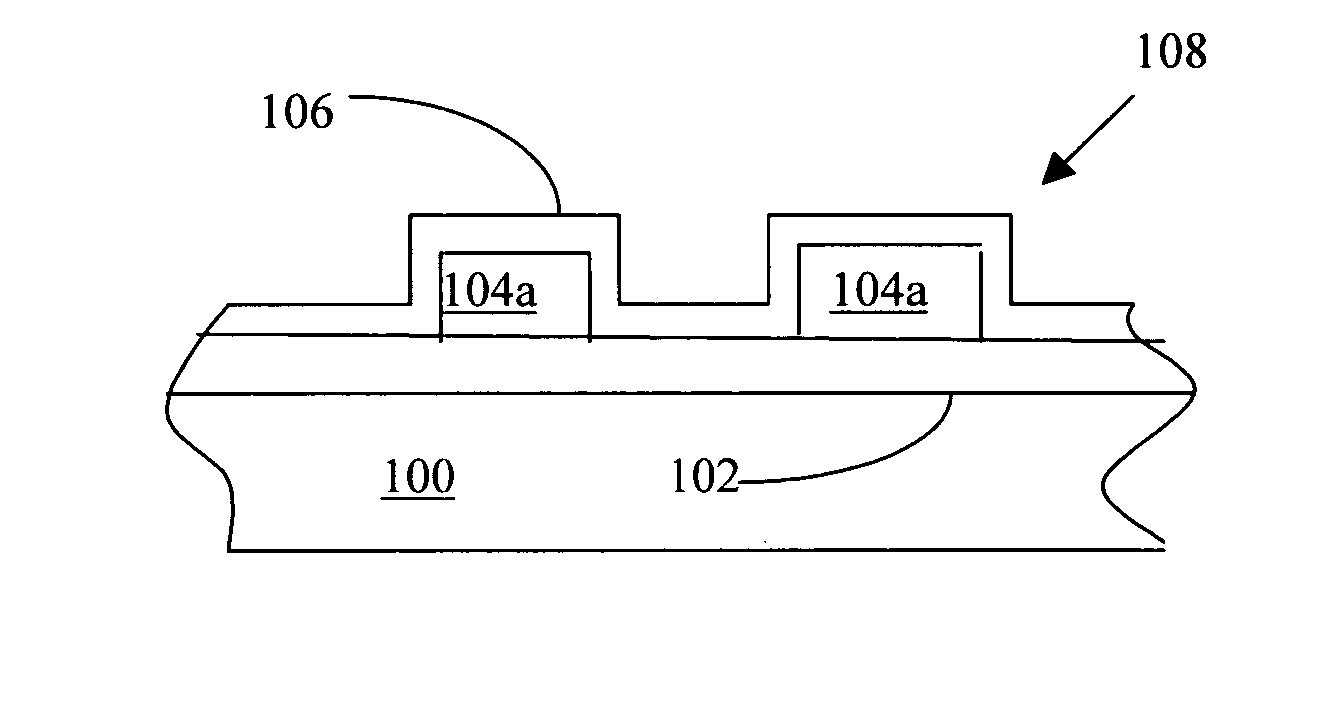

Method and apparatus for making a stamper for patterning CDs and DVDs

InactiveUS20050167867A1Good resistance stabilityUnnecessary to performRecord carriersConfectioneryResistCompact Disc manufacturing

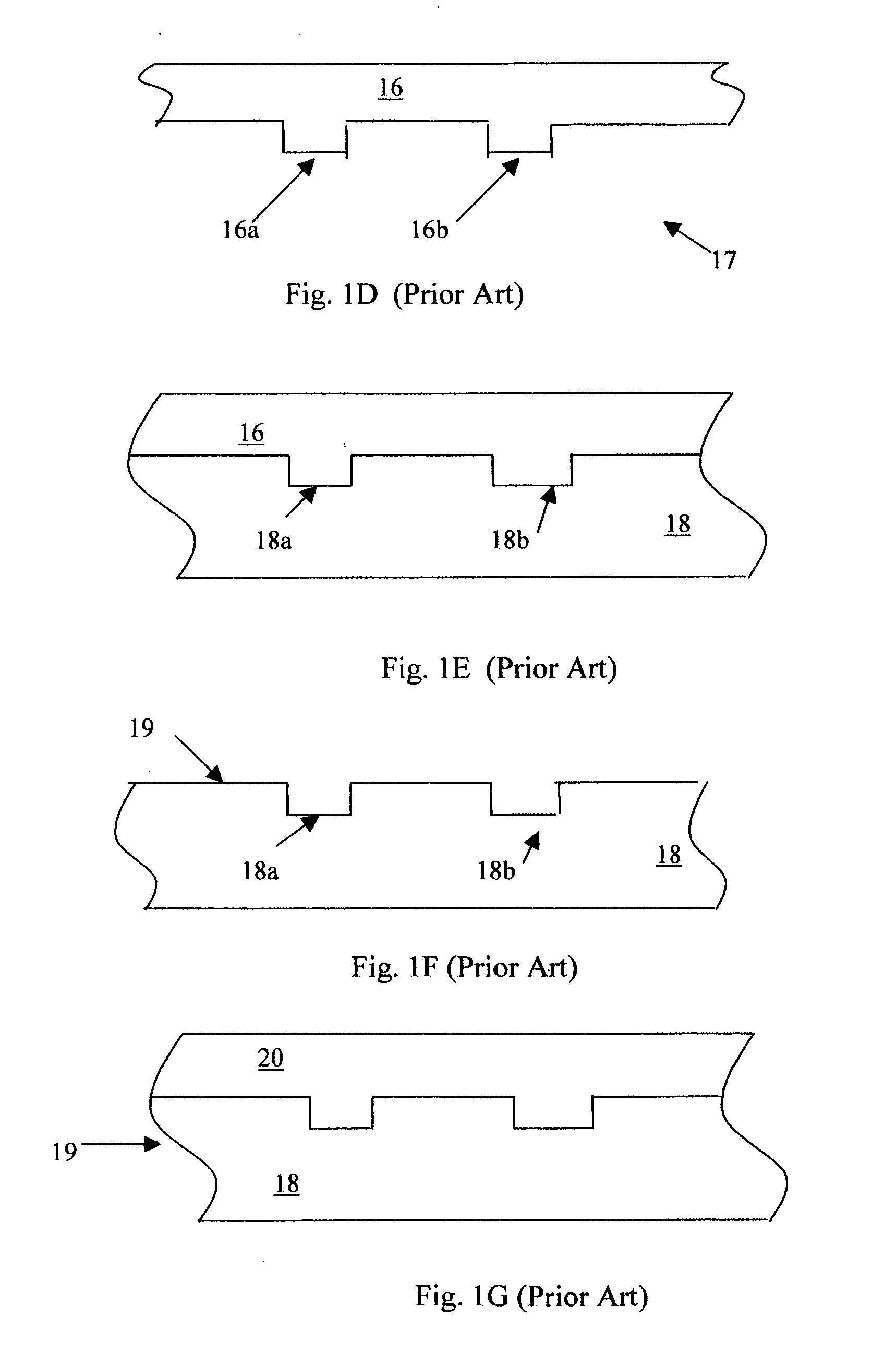

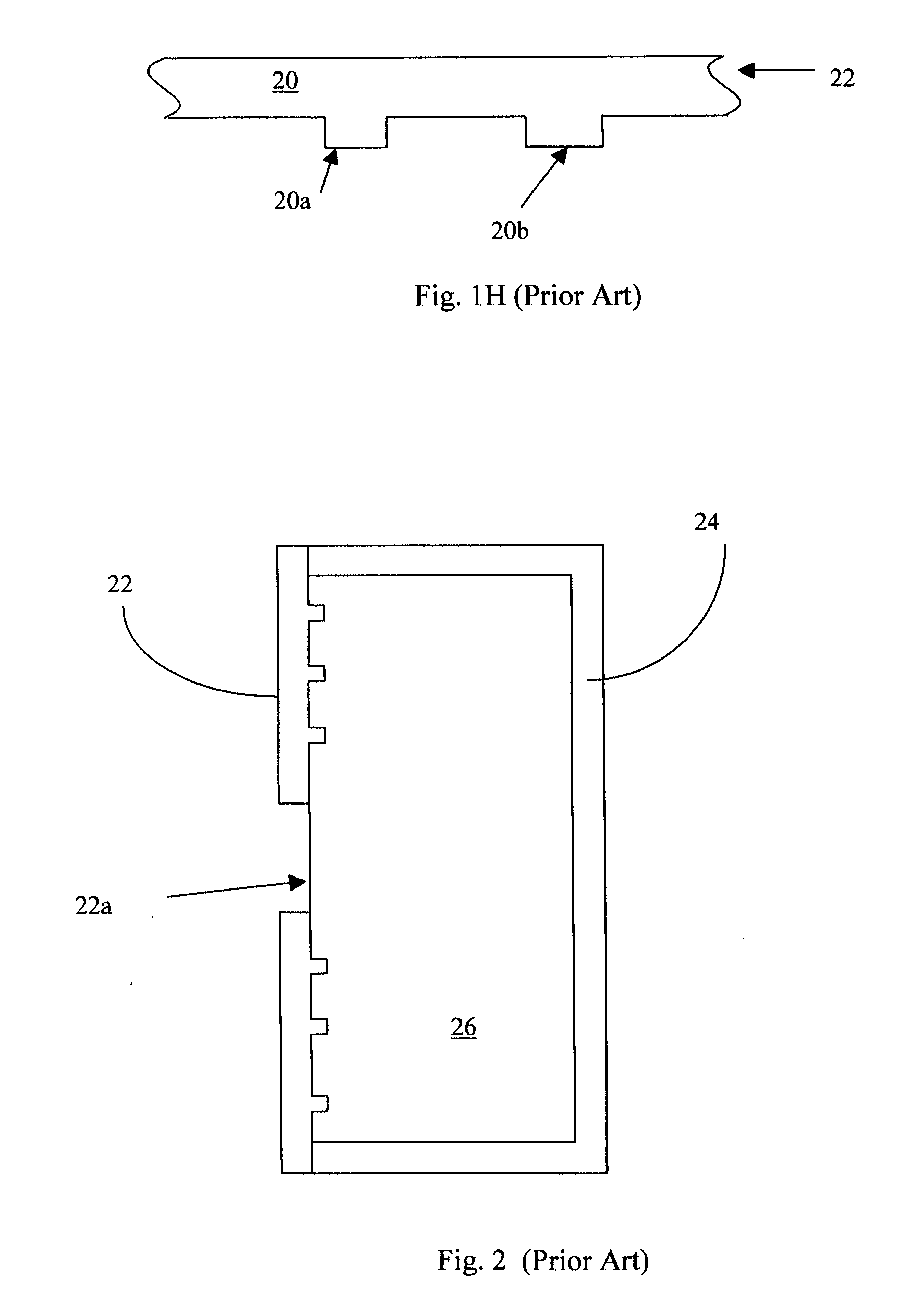

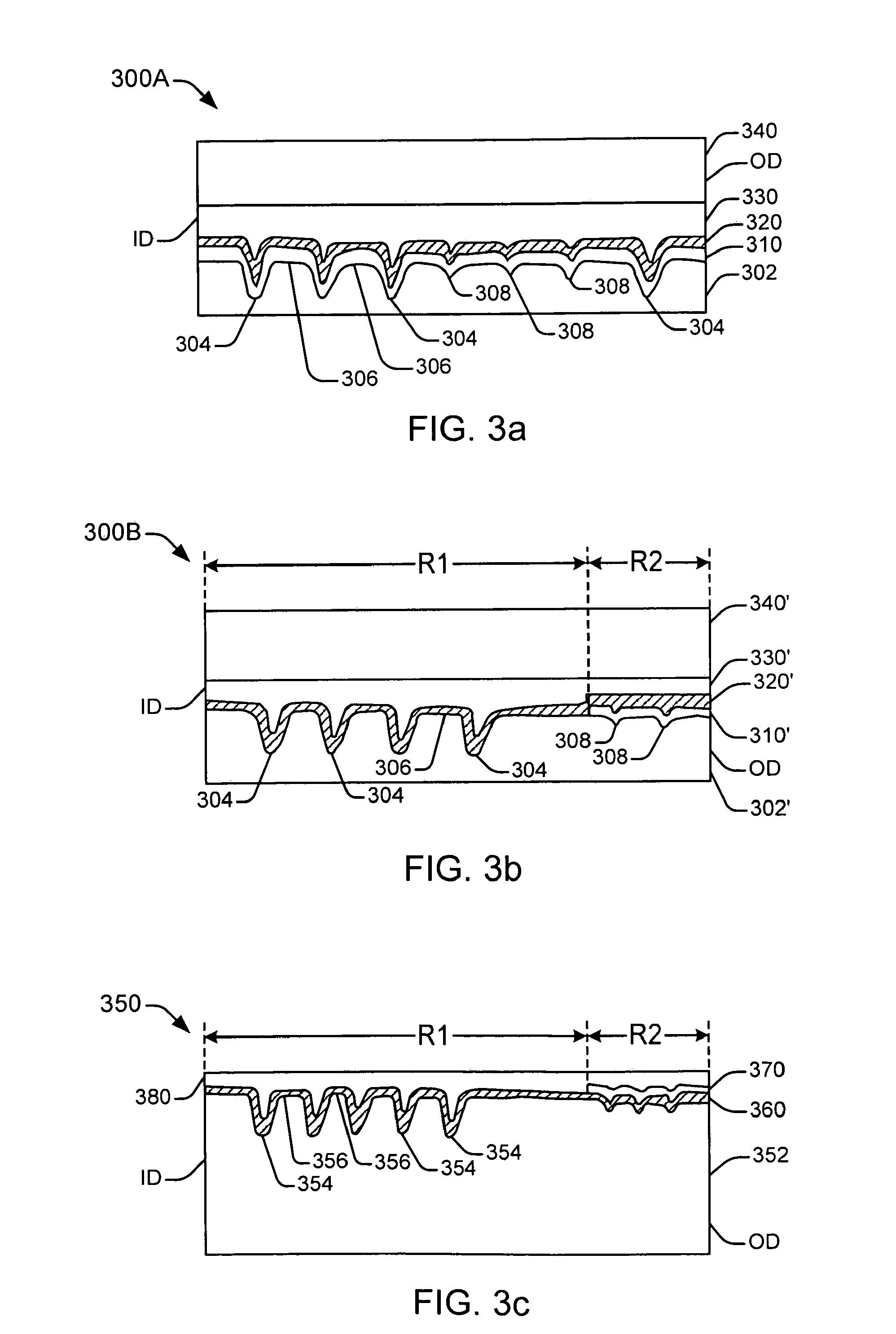

A method for forming a stamper used in the manufacture of CDs, DVDs, and other types of optical disks comprises forming a substrate by rolling. A layer of material is deposited (e.g. by plating) onto the substrate. Thereafter, a resist layer is formed on the layer of material and patterned. Because the substrate is formed by rolling, it is relatively inexpensive to form the substrate to a desired thickness. Because the layer of material is formed by deposition (e.g. plating), it is relatively inexpensive to ensure that the layer has a very smooth surface (i.e. without necessitating a great deal of polishing).

Owner:WD MEDIA

Method and apparatus for making a stamper for patterning CDs and DVDs

InactiveUS20050151283A1Reduced and no sacrifice in data storage densityHuge savingsRecord carriersOptical articlesResistCompact Disc manufacturing

A method for forming a stamper used in the manufacture of CDs, DVDs, and other types of optical disks comprises forming a substrate by rolling. A layer of material is deposited (e.g. by plating) onto the substrate. Thereafter, a resist layer is formed on the layer of material and patterned. Because the substrate is formed by rolling, it is relatively inexpensive to form the substrate to a desired thickness. Because the layer of material is formed by deposition (e.g. plating), it is relatively inexpensive to ensure that the layer has a very smooth surface (i.e. without necessitating a great deal of polishing).

Owner:WD MEDIA

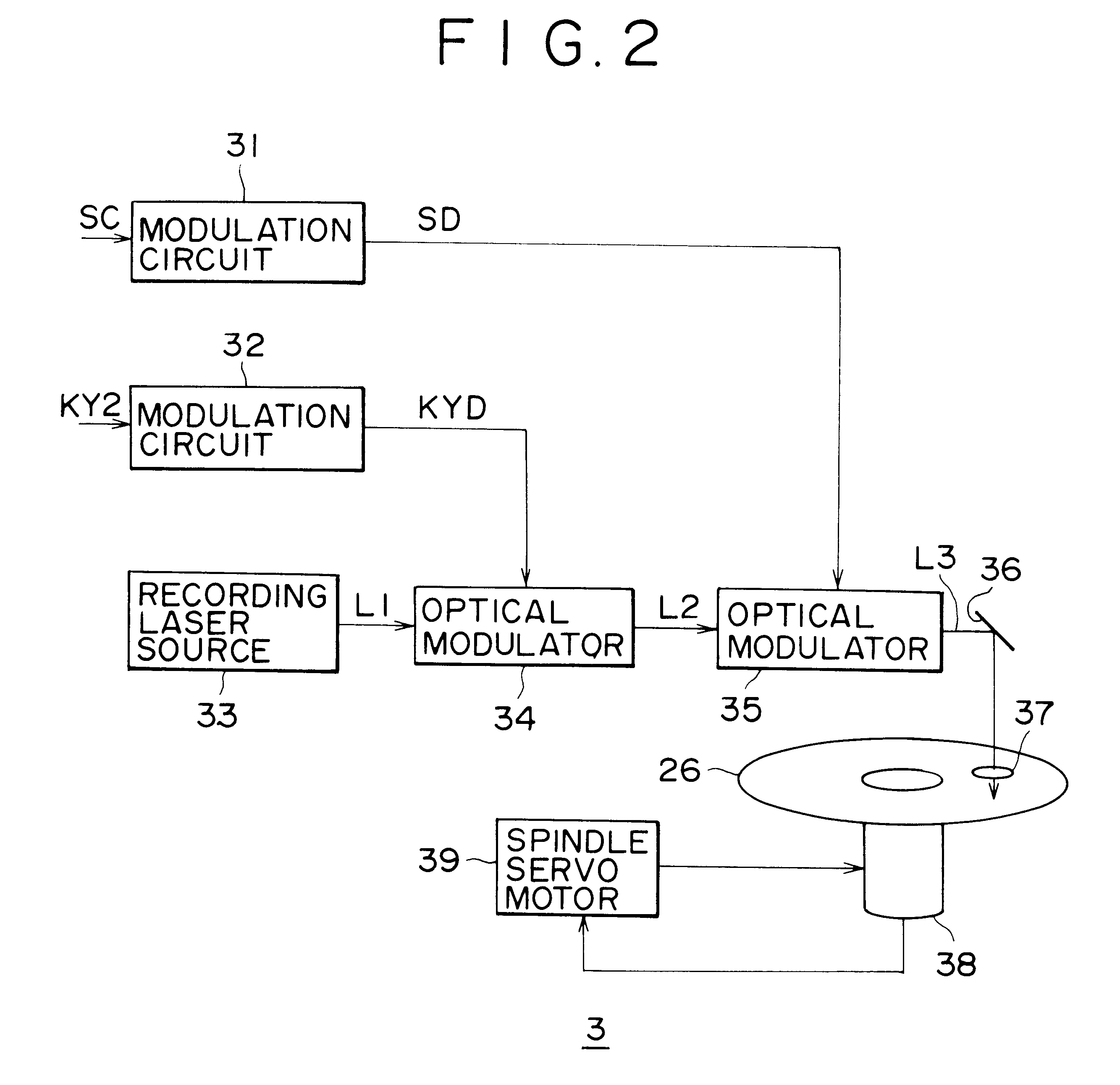

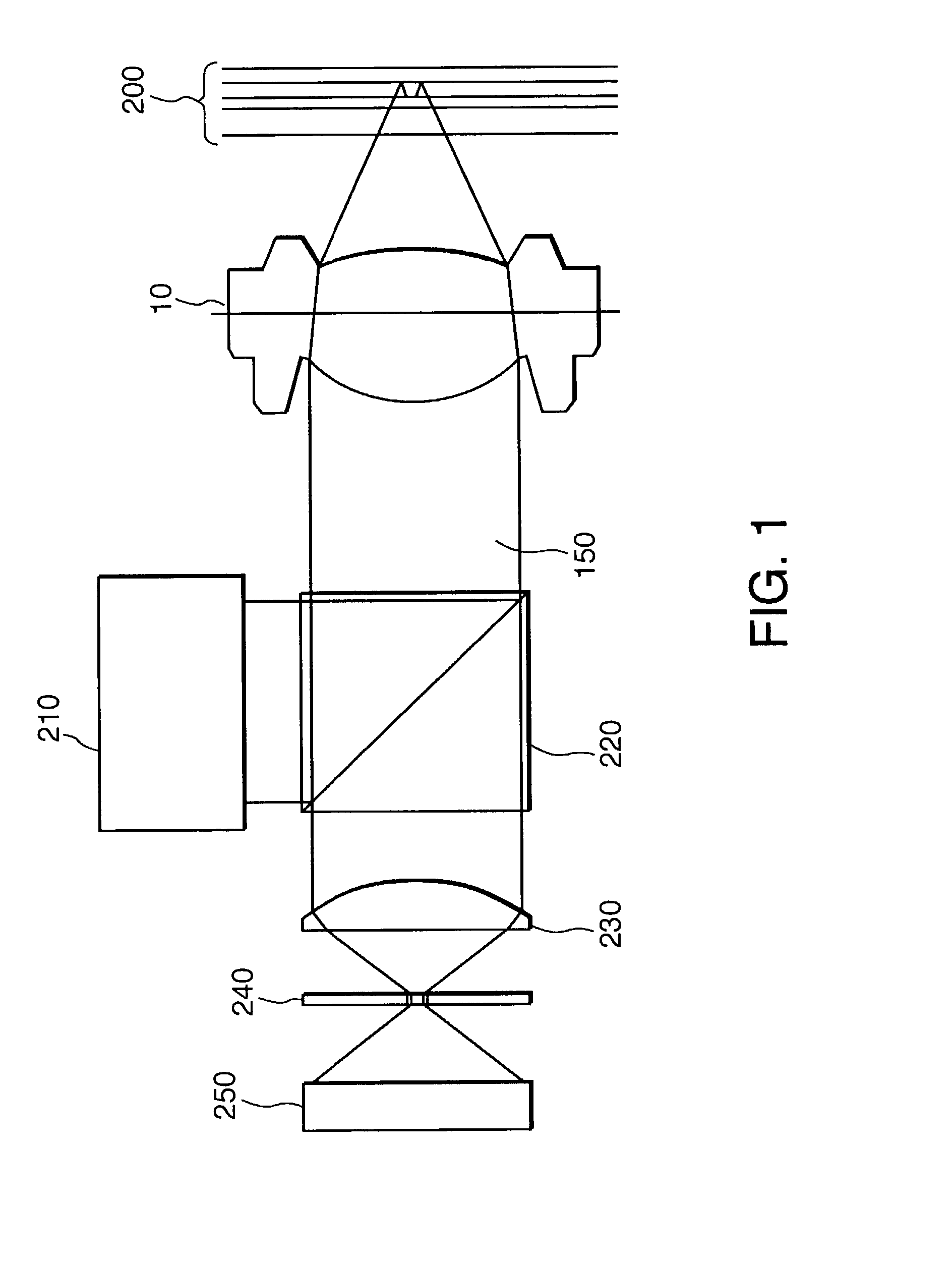

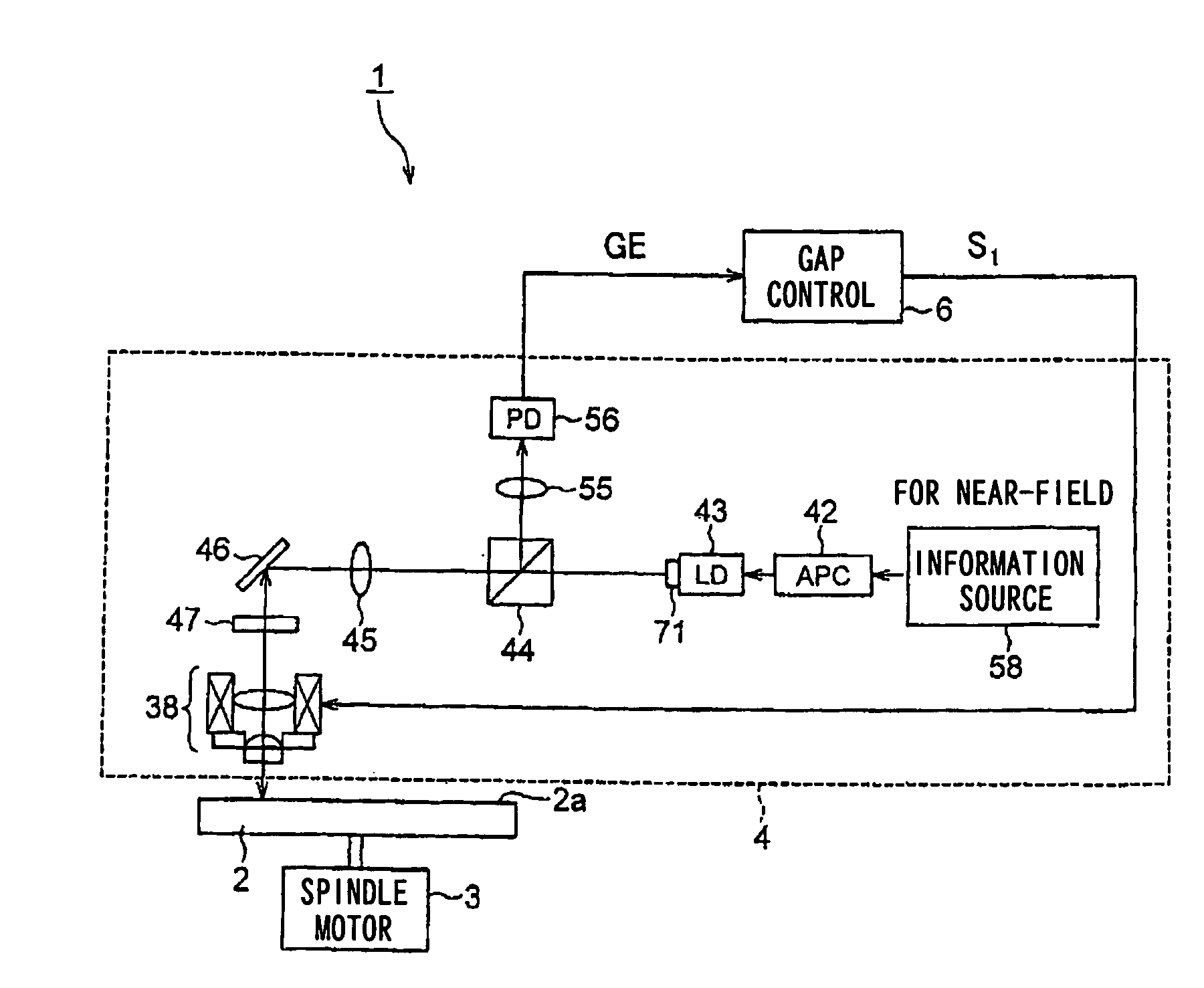

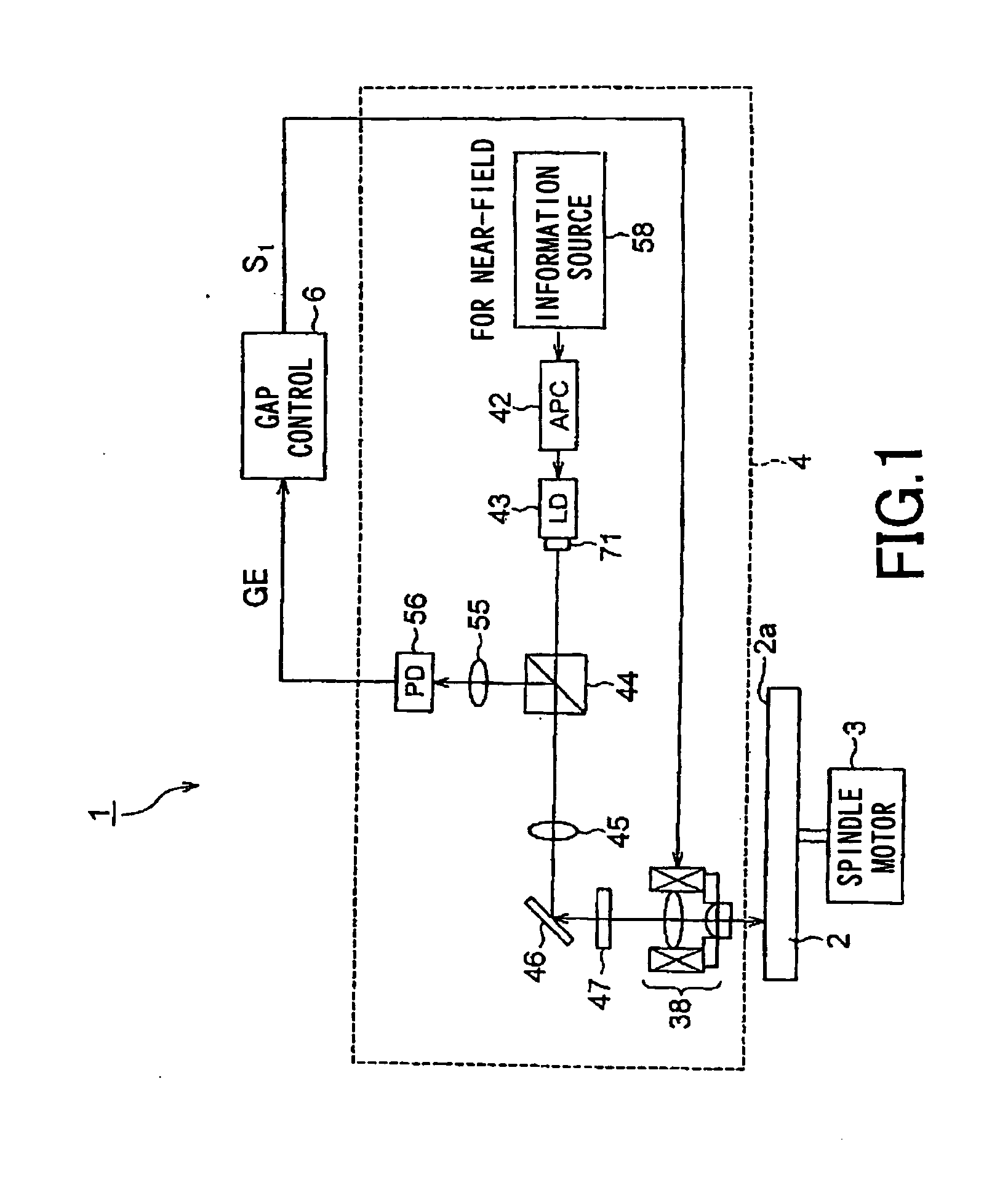

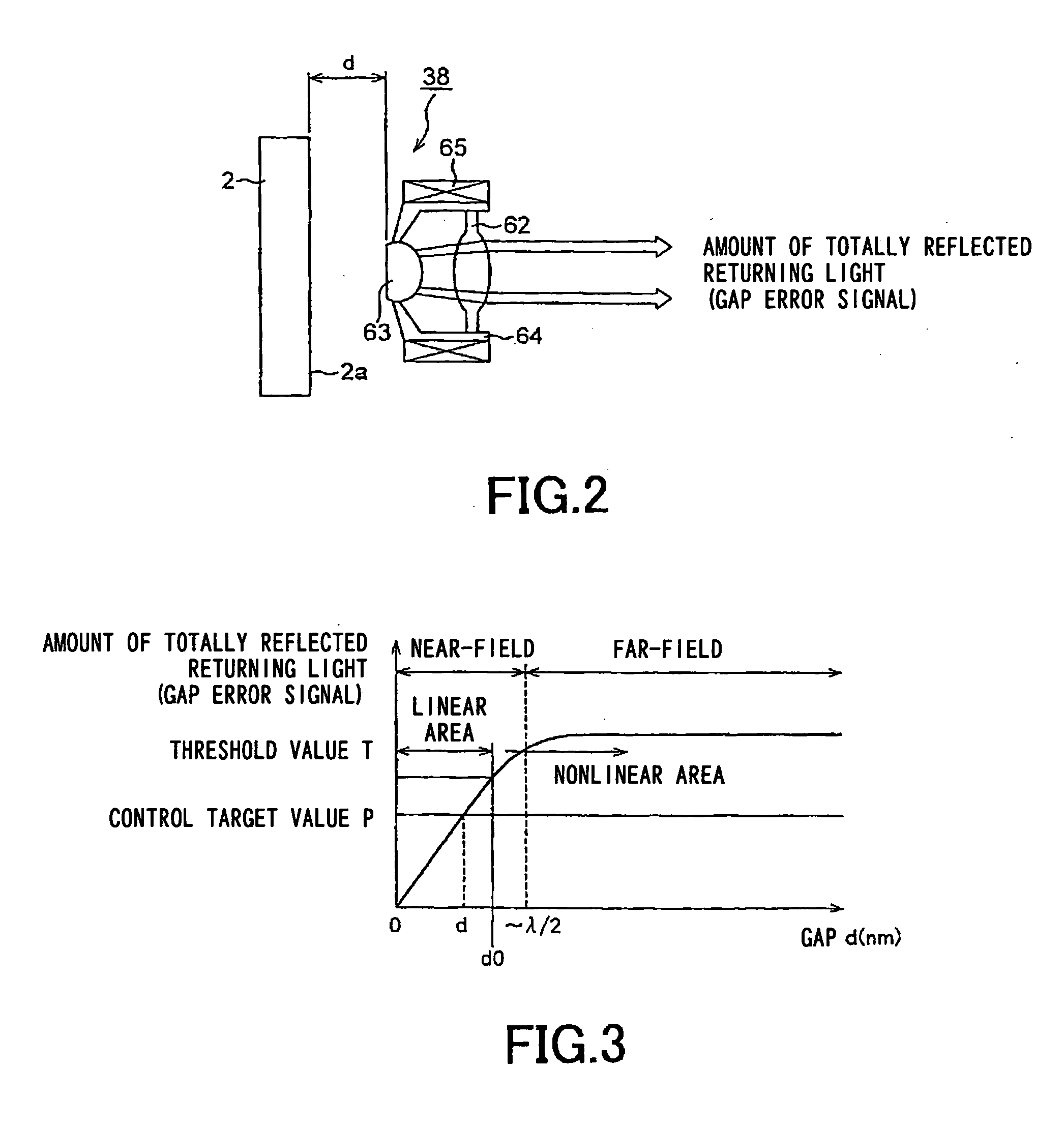

Apparatus and method for manufacturing optical disks, apparatus and method for recording data on optical disks, apparatus and method for reproducing data from optical disks, and optical disk

InactiveUS6665240B1Television system detailsAccessories for auxillary signalsDigital dataCompact Disc manufacturing

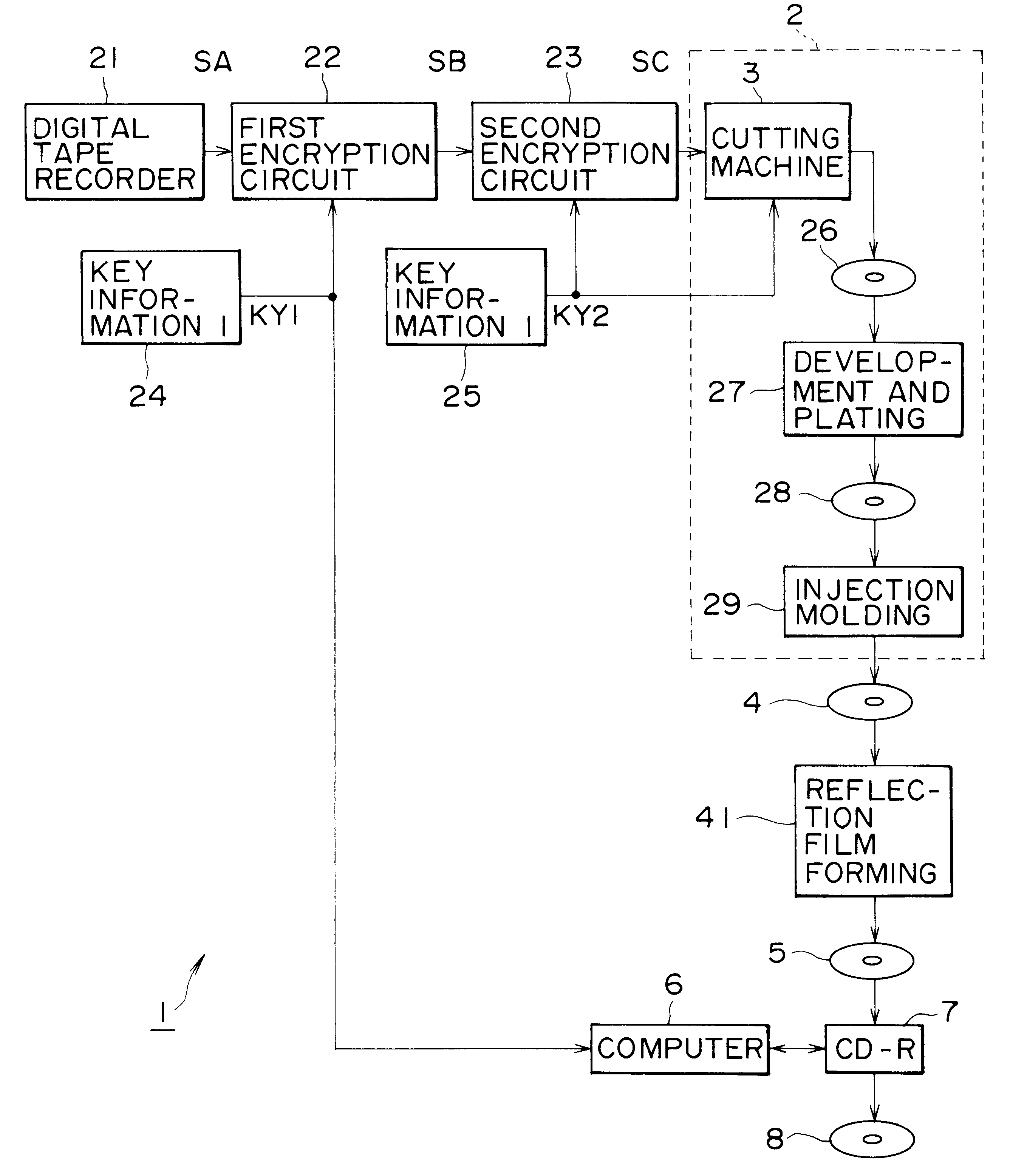

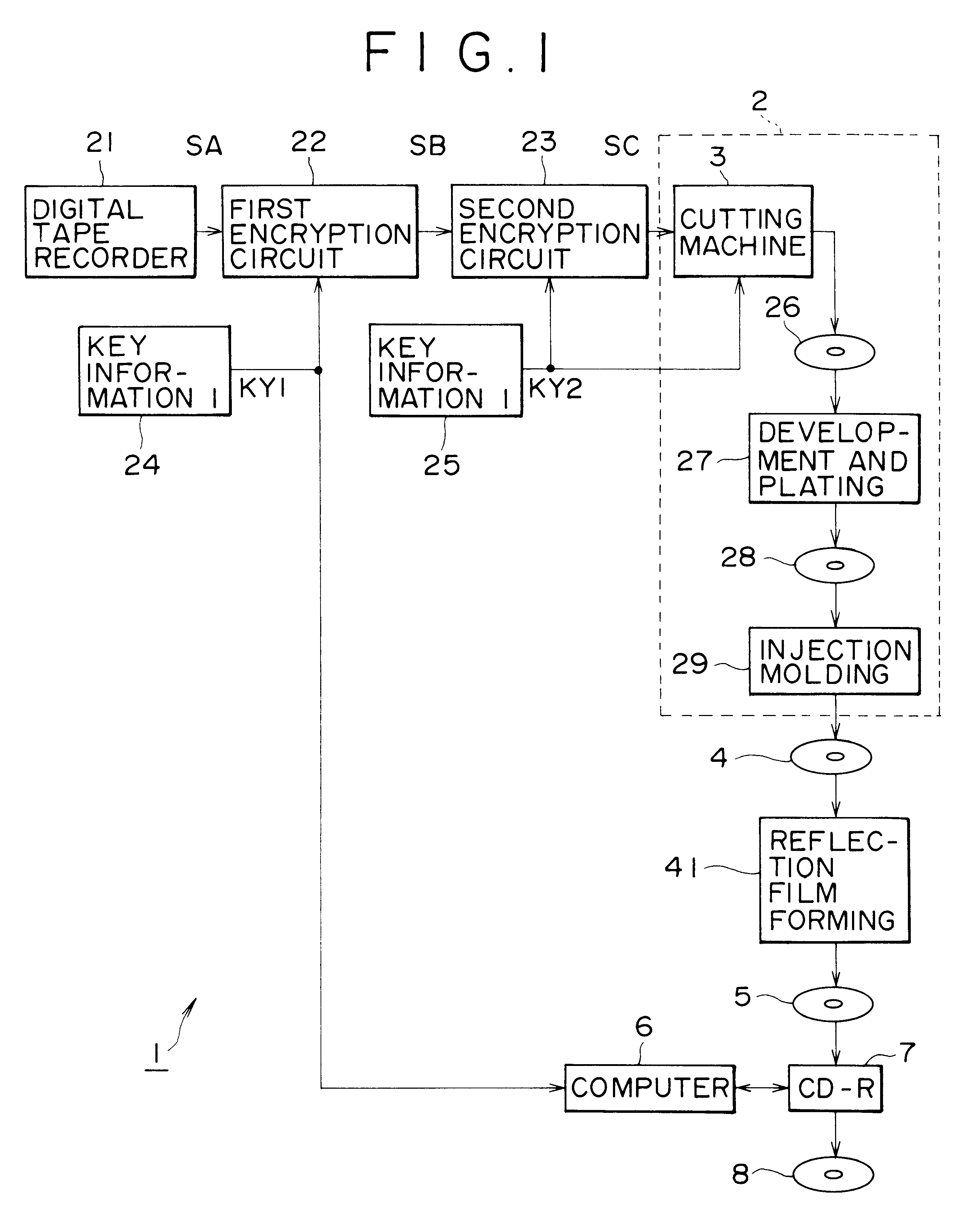

Described herewith is an optical disk manufacturing apparatus for reading recorded digital data from an optical disk, comprising an encryption unit (22, 23) for encrypting entered digital data according to a plurality of key information; an optical disk substrate manufacturing unit 2 for manufacturing an optical disk substrate 4 on which the encrypted digital data and key information are recorded in the form of physical form changes; a reflection film forming unit 41 for forming a reflection film on the optical disk substrate 4; and a key information recording unit 7 for recording key information on the optical disk substrate on which the reflection film is formed. The reflection factor of the optical disk is changed locally, thereby giving a jitter to the position information of each pit edge, and desired data is recorded additionally according to this jitter. Pits, etc. are disposed so as to be deviated from the track center towards the inner / outer region of the optical disk 2, thereby recording such subdata as key information KY, etc.

Owner:SONY CORP

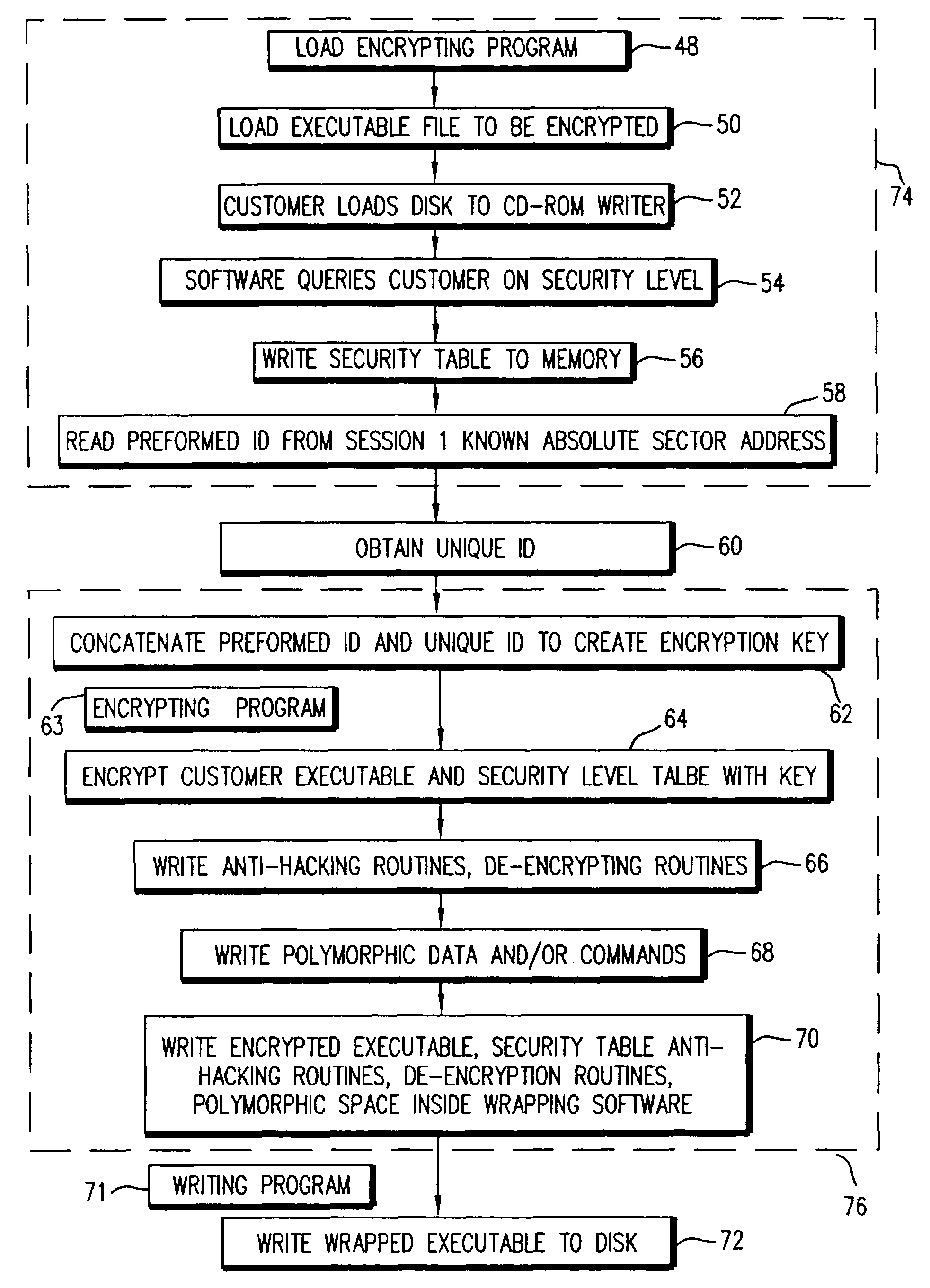

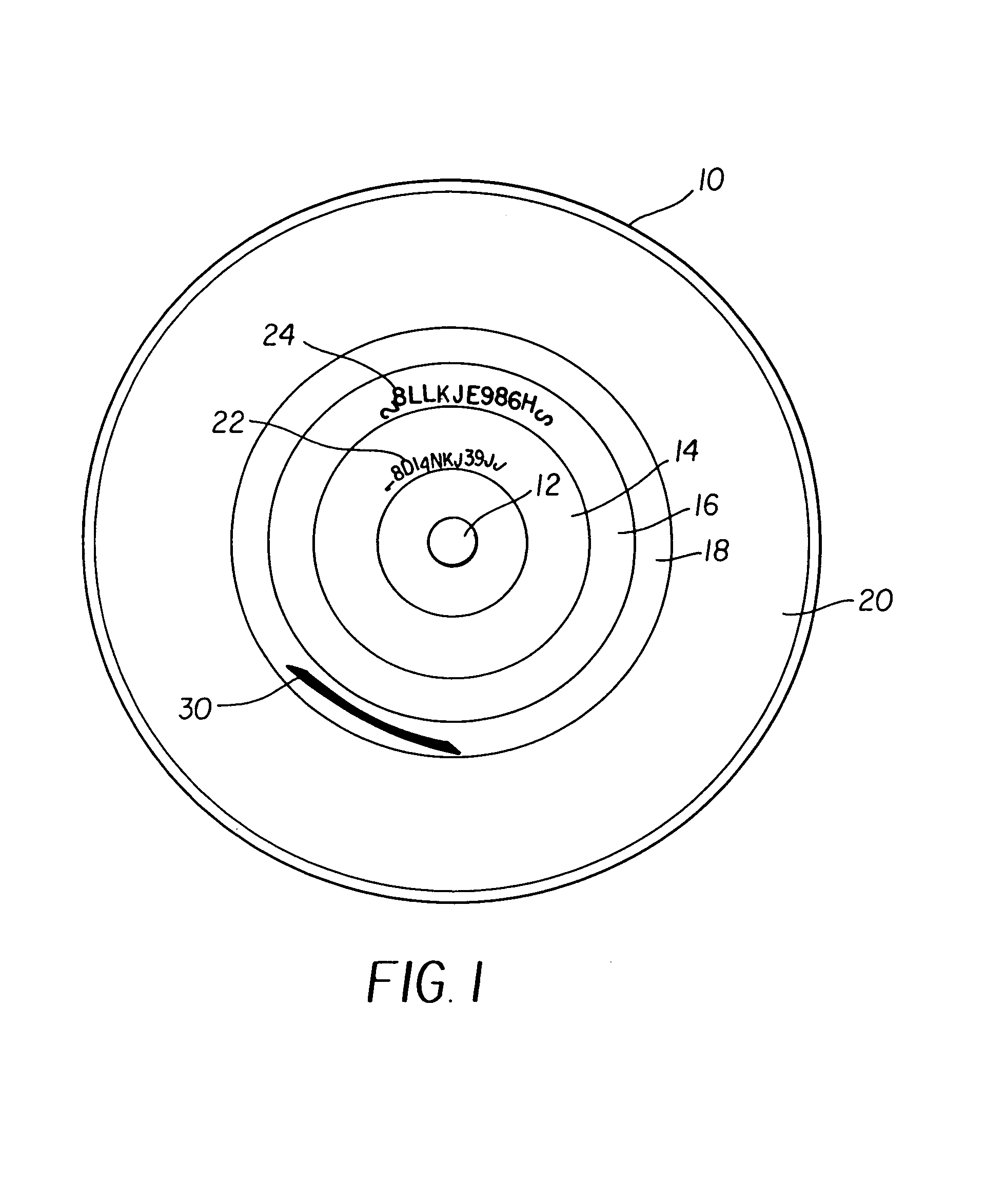

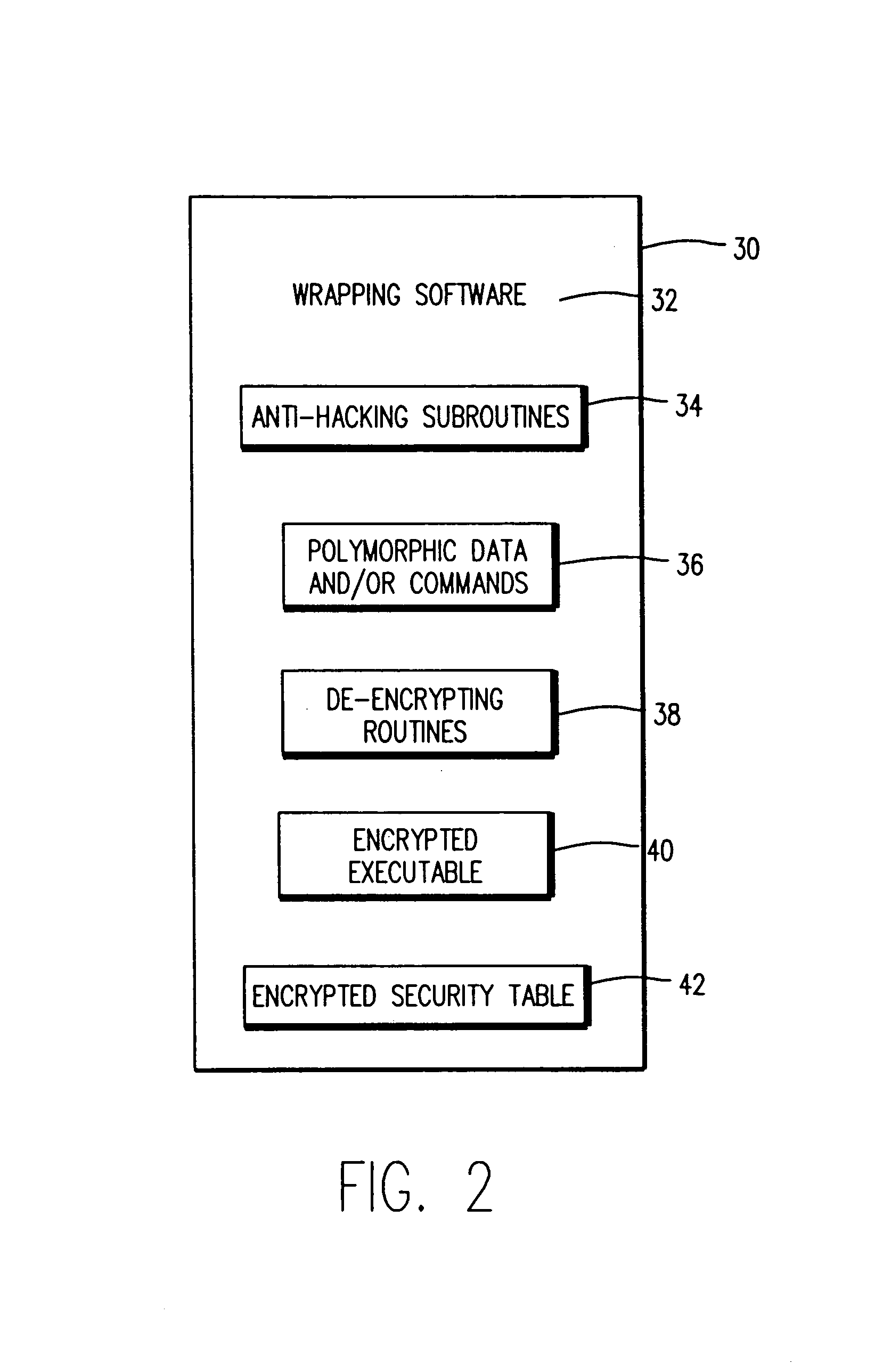

Copy protection using multiple security levels on a programmable CD-ROM

InactiveUS7057993B2Easy to copyNumber of EliminationsTelevision system detailsRecord information storageComputer hardwareCompact Disc manufacturing

A copy-protected optical disc, including a preformed identification number (ID) in the ATIP signal and the subcode which is impressed upon the optical disc and a number of other optical discs during optical disc manufacture, a unique identification number for the optical disc which was written on the optical disc after it is manufactured; and an encrypted program written onto the optical disc wherein the encryption of such program is based upon the preformed ID and the unique ID and includes two or more selectable security levels.

Owner:EASTMAN KODAK CO

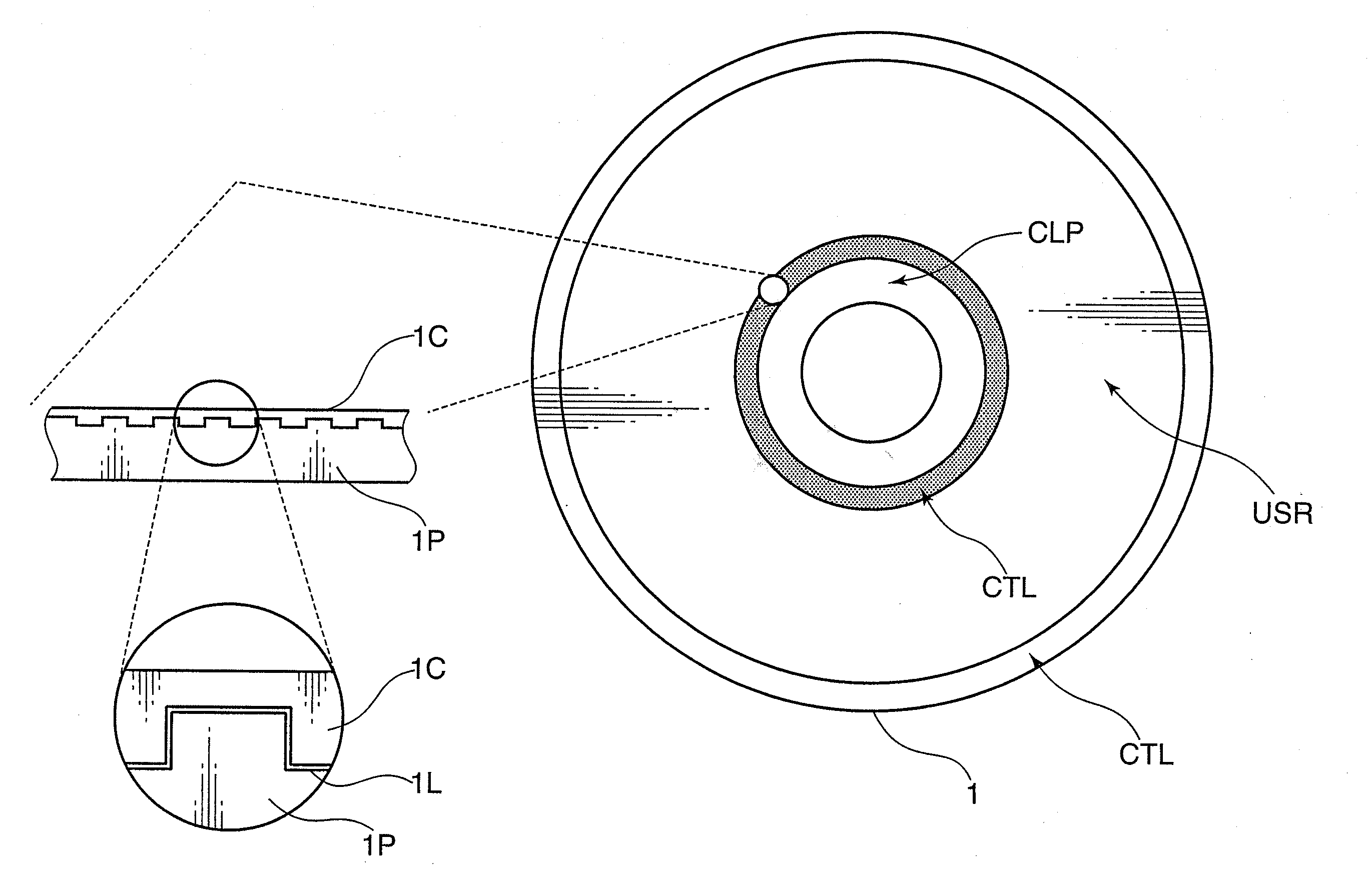

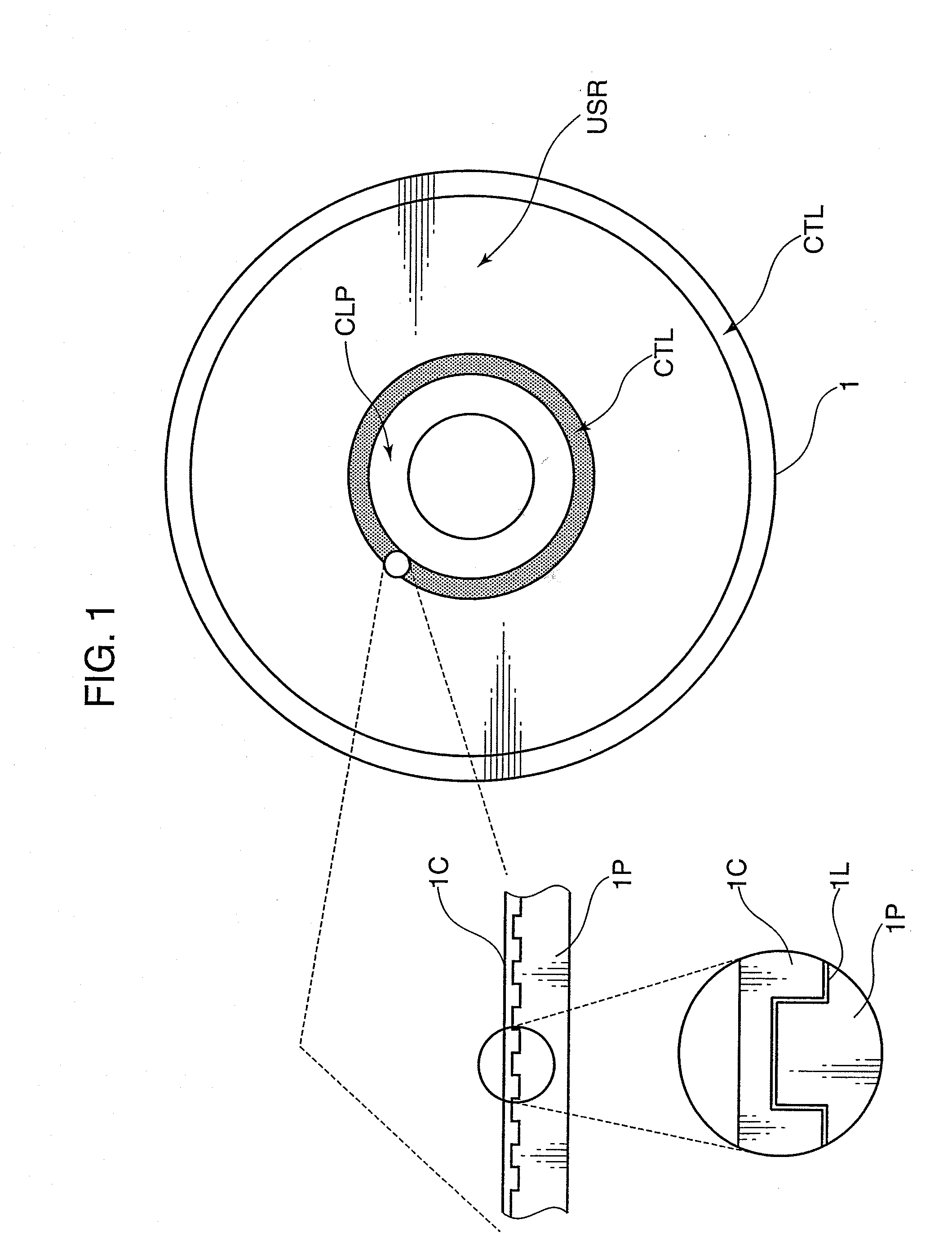

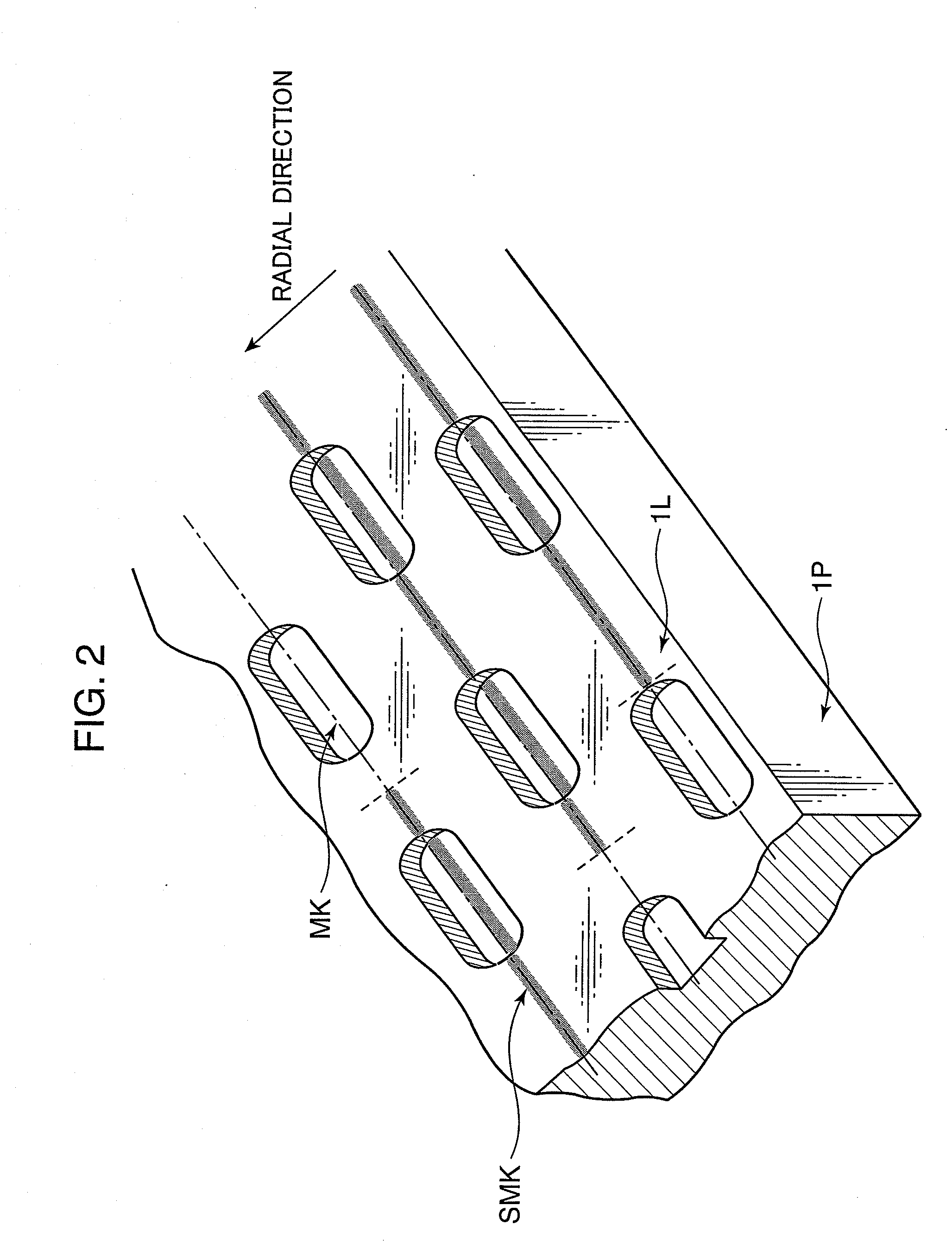

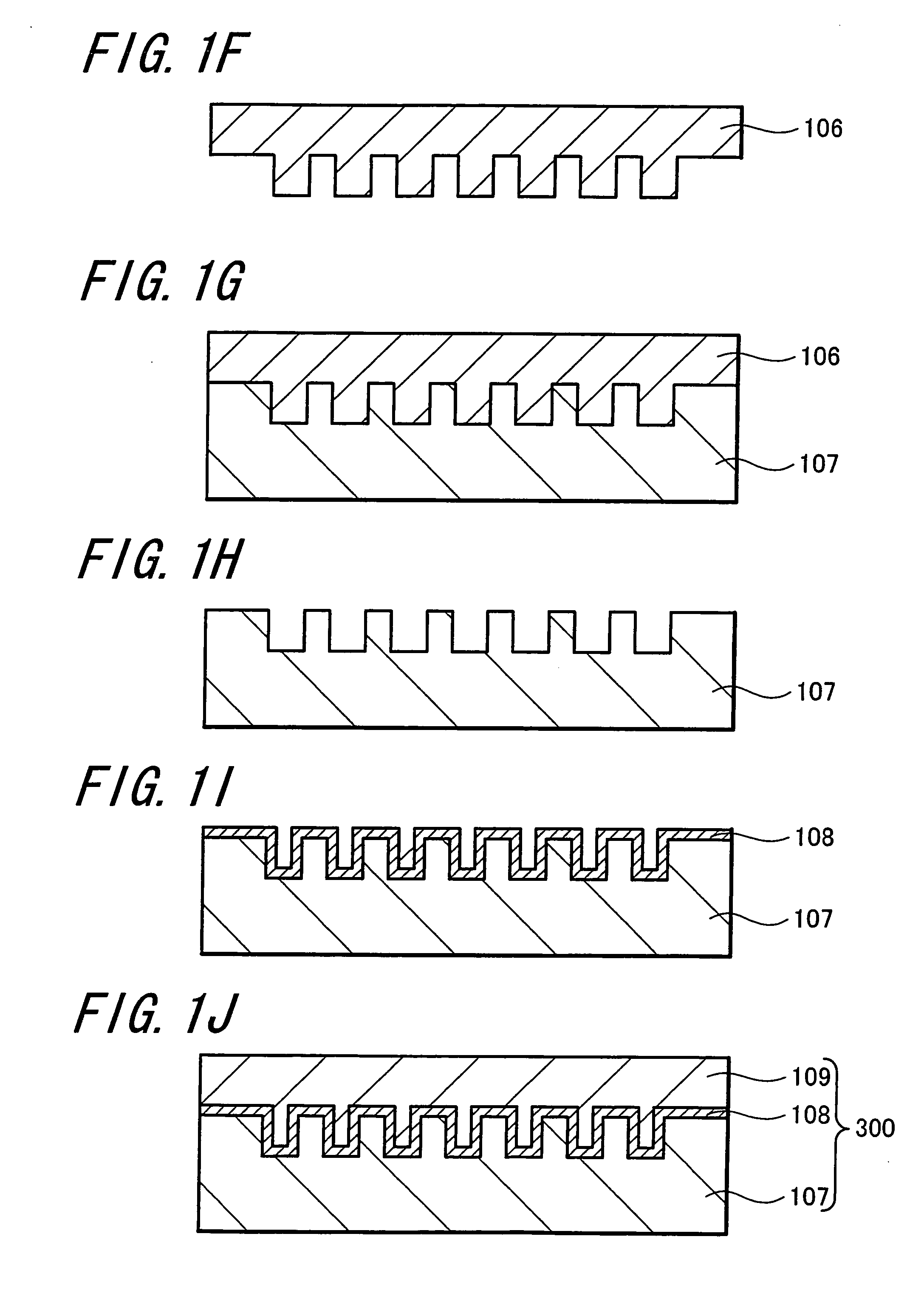

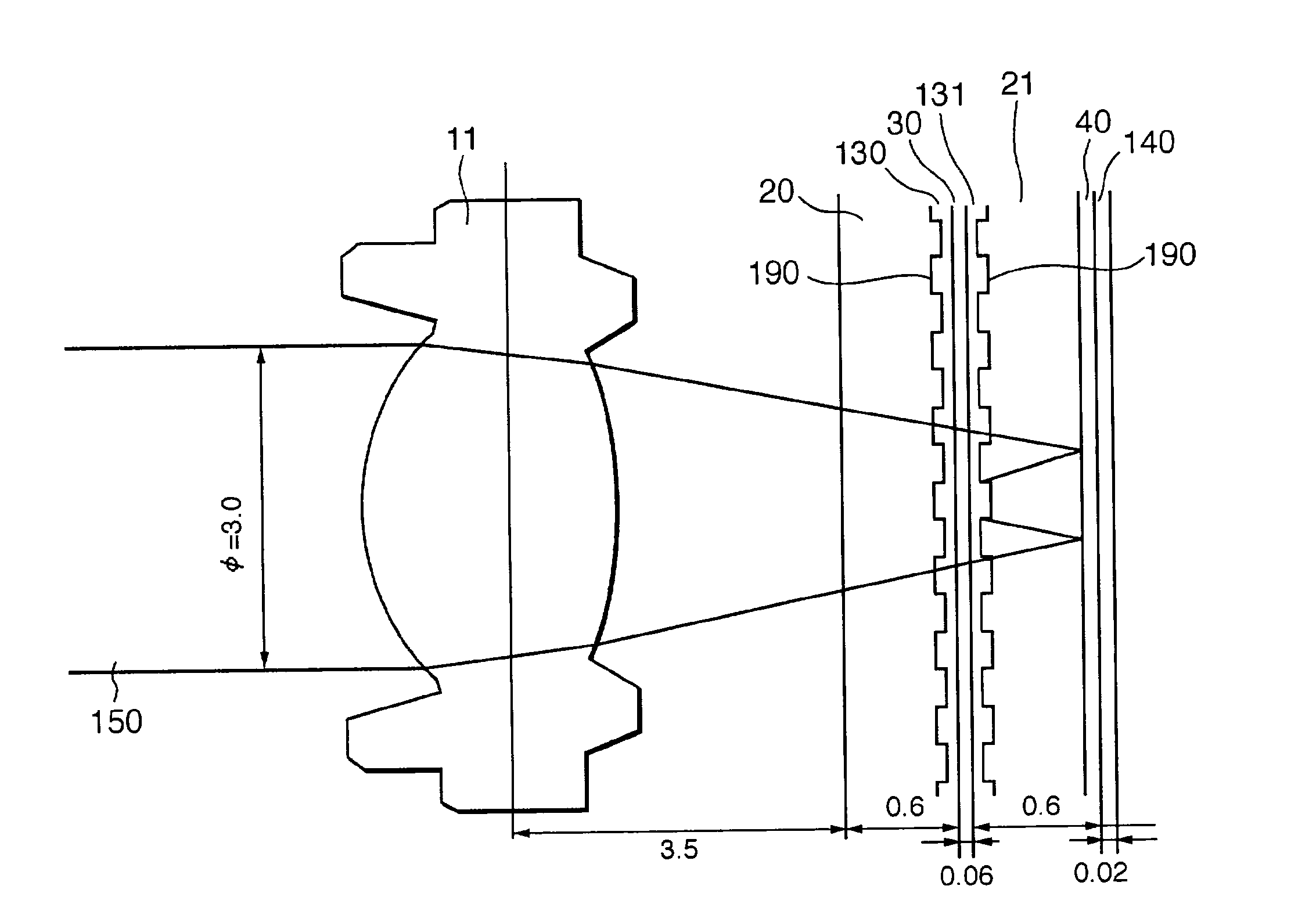

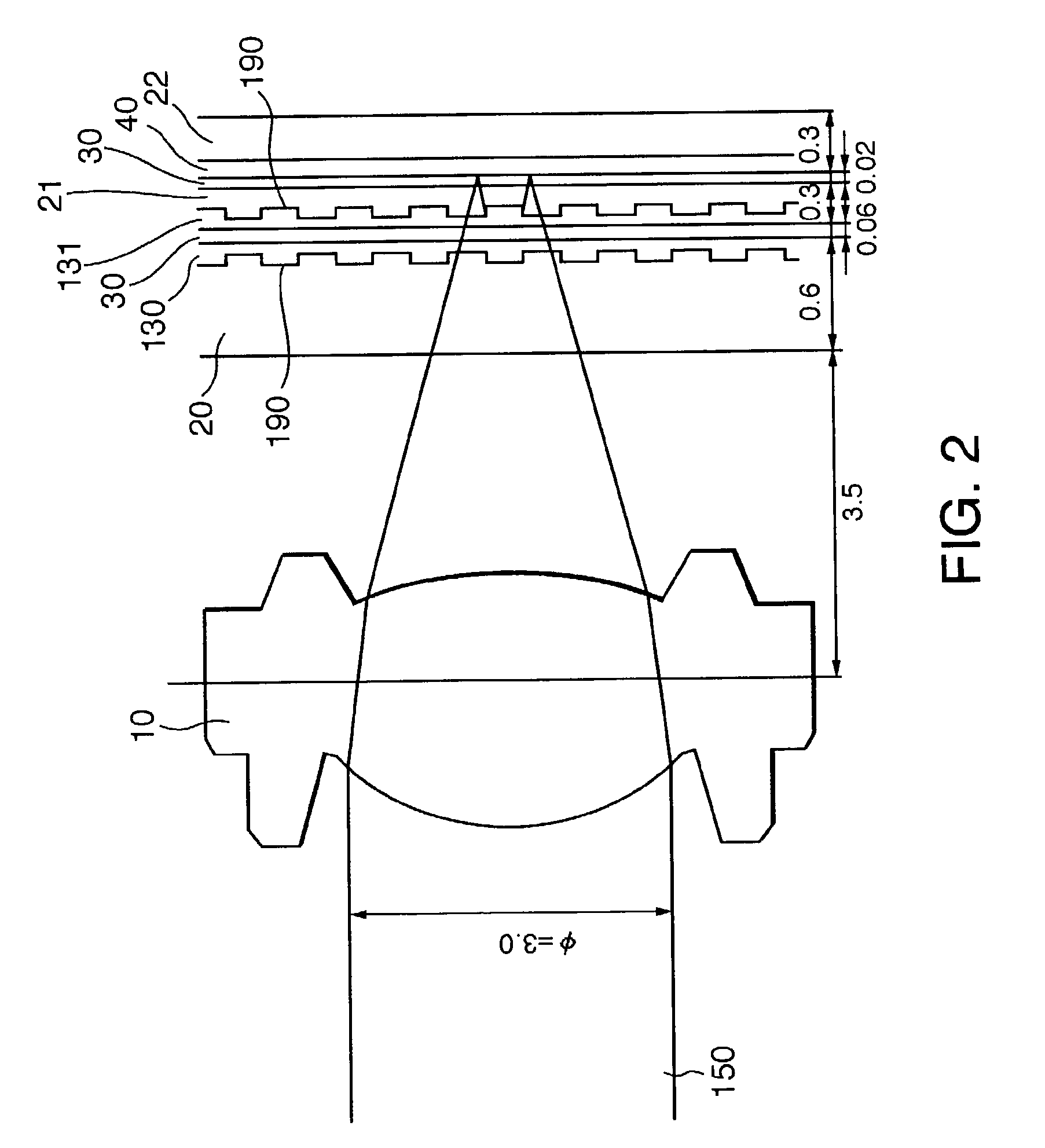

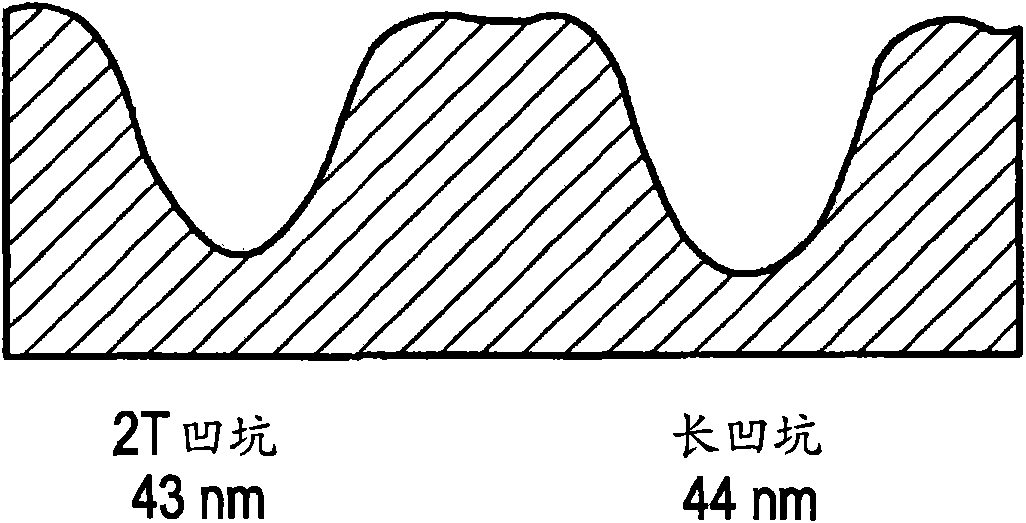

Optical disc, optical disc manufacturing method, optical disc recording device and optical disc reproduction device

ActiveUS20090196140A1Illegal duplication can be preventedAvoid duplicationRecord information storageRecord carrier typesOptical propertyCompact Disc manufacturing

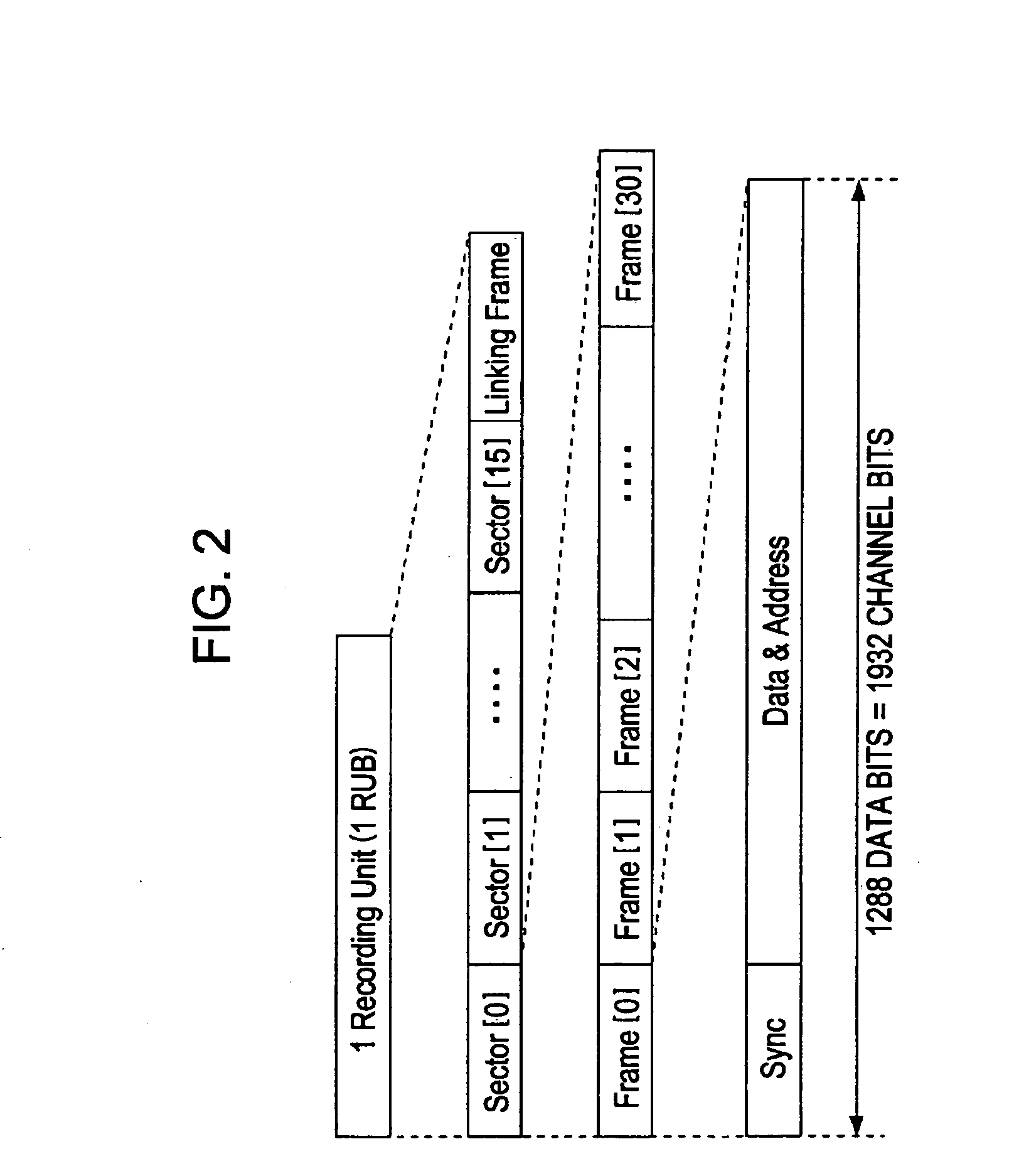

Sub-information necessary to reproduce main information is recorded without deteriorating the reading accuracy of the main information, so that the illegal duplication of an optical disc is prevented. An optical disc 1 is produced by forming a reflective film 1L on concave and convex marks MK after the concave and convex marks MK synchronized with the integral multiple of a channel bit length are formed in accordance with modulated main information. Thereafter, continuous or intermittent laser light synchronized with the integral multiple of the channel bit length is irradiated at intervals longer than the longest one of the concave and convex marks MK in accordance with a spiral track formed in a circumferential direction of the concave and convex marks MK, whereby an optical characteristic of the reflective film 1L is changed to form a recordable mark SMK and sub-information necessary to reproduce the main information is recorded in a superimposition manner.

Owner:PANASONIC CORP

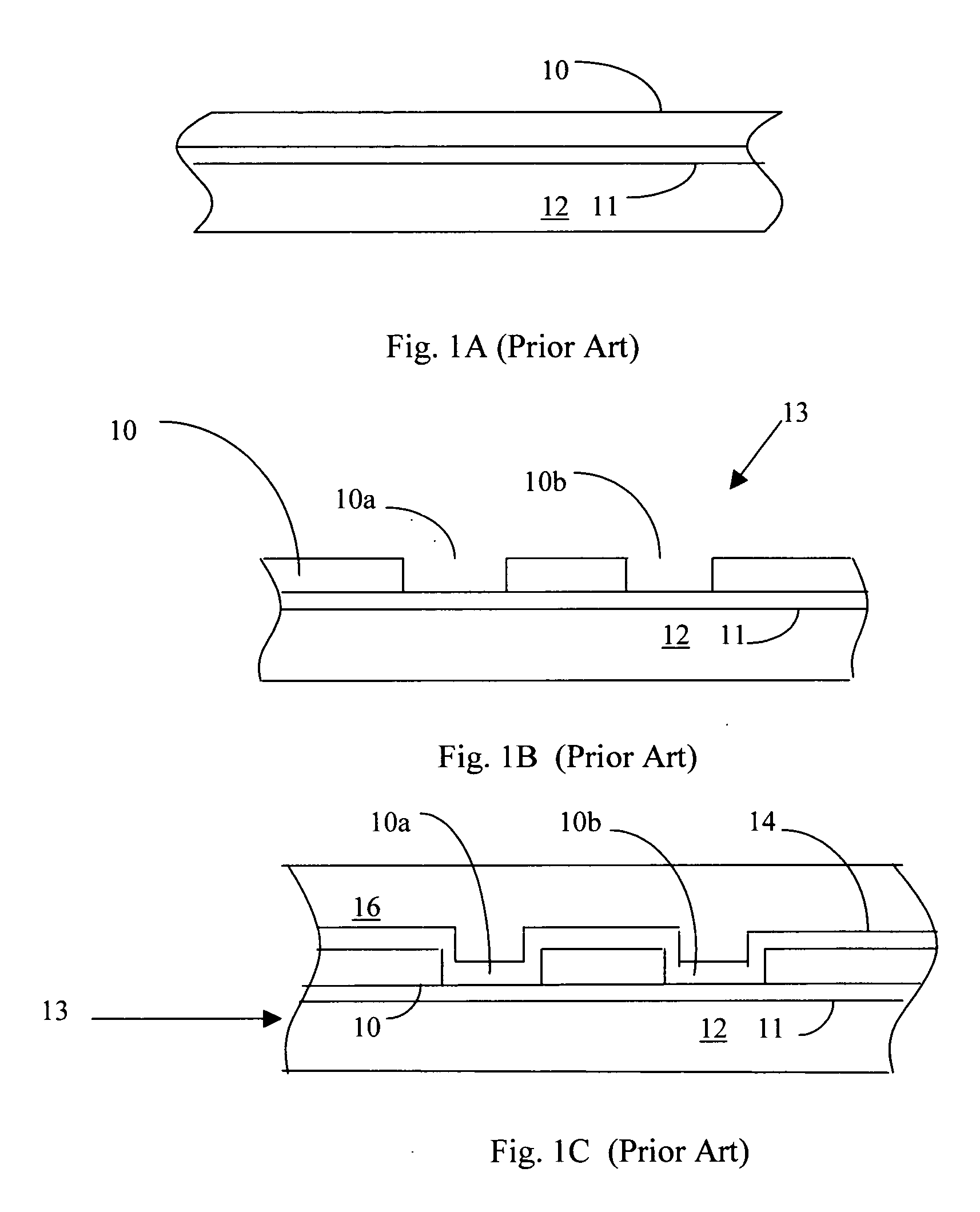

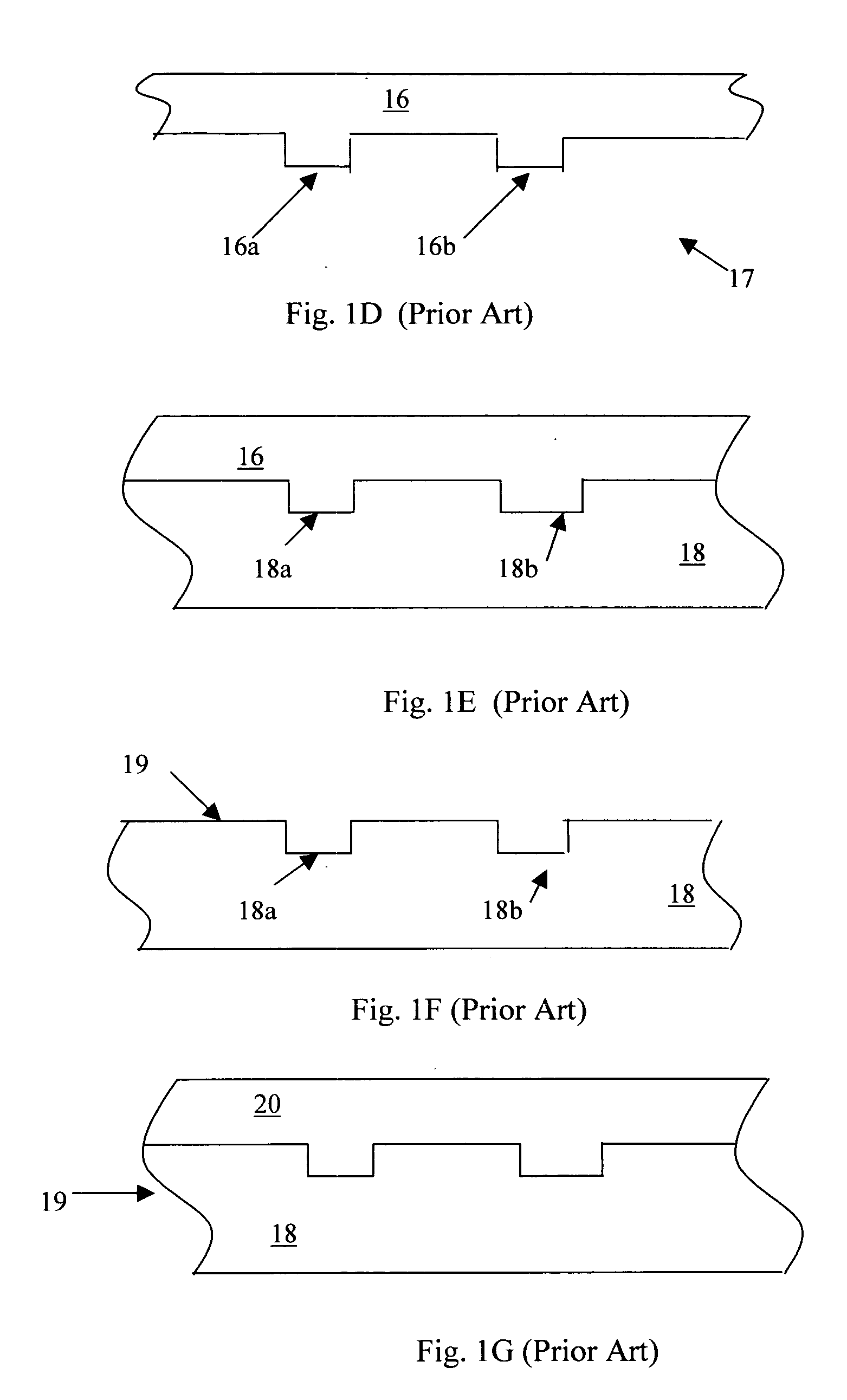

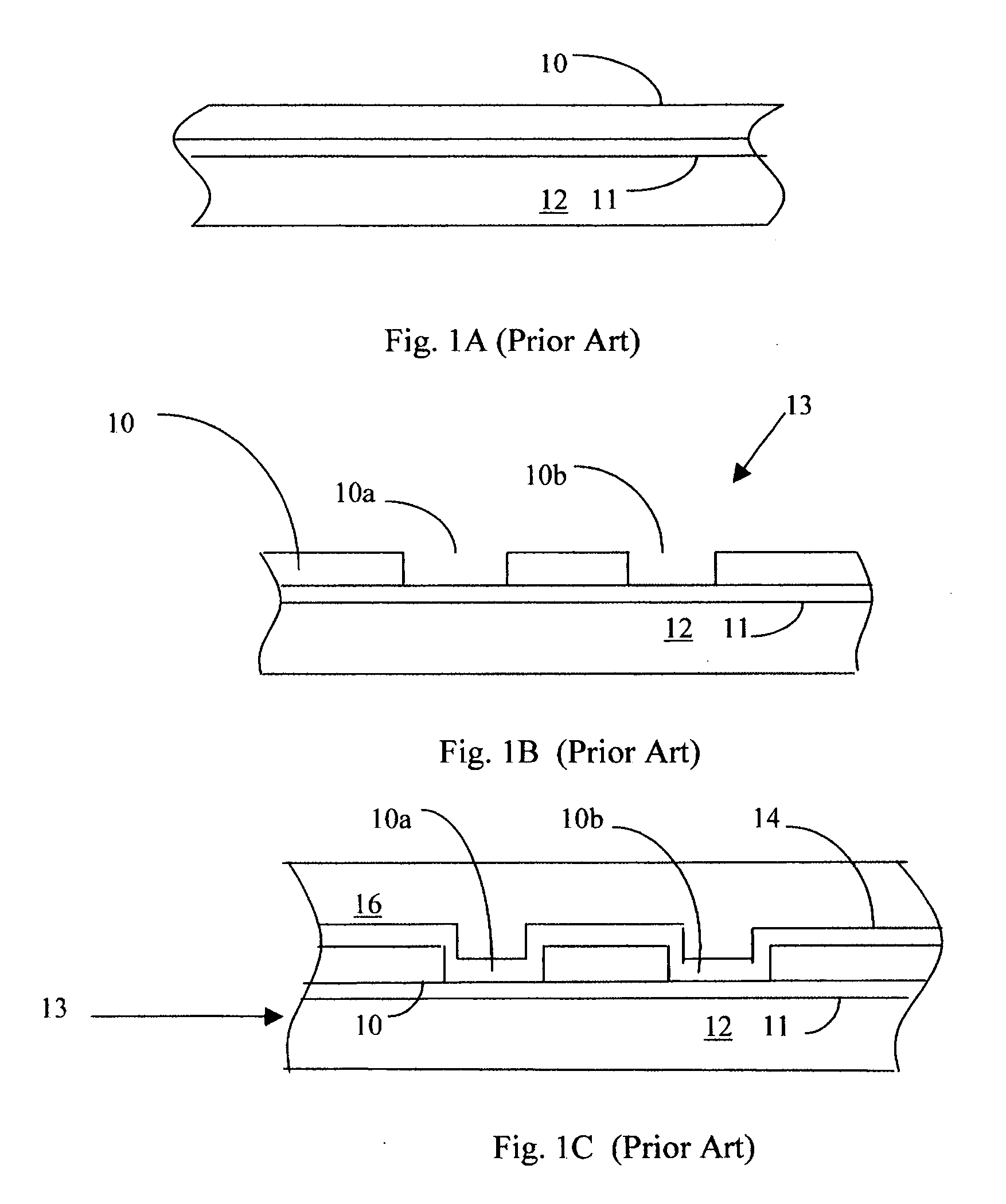

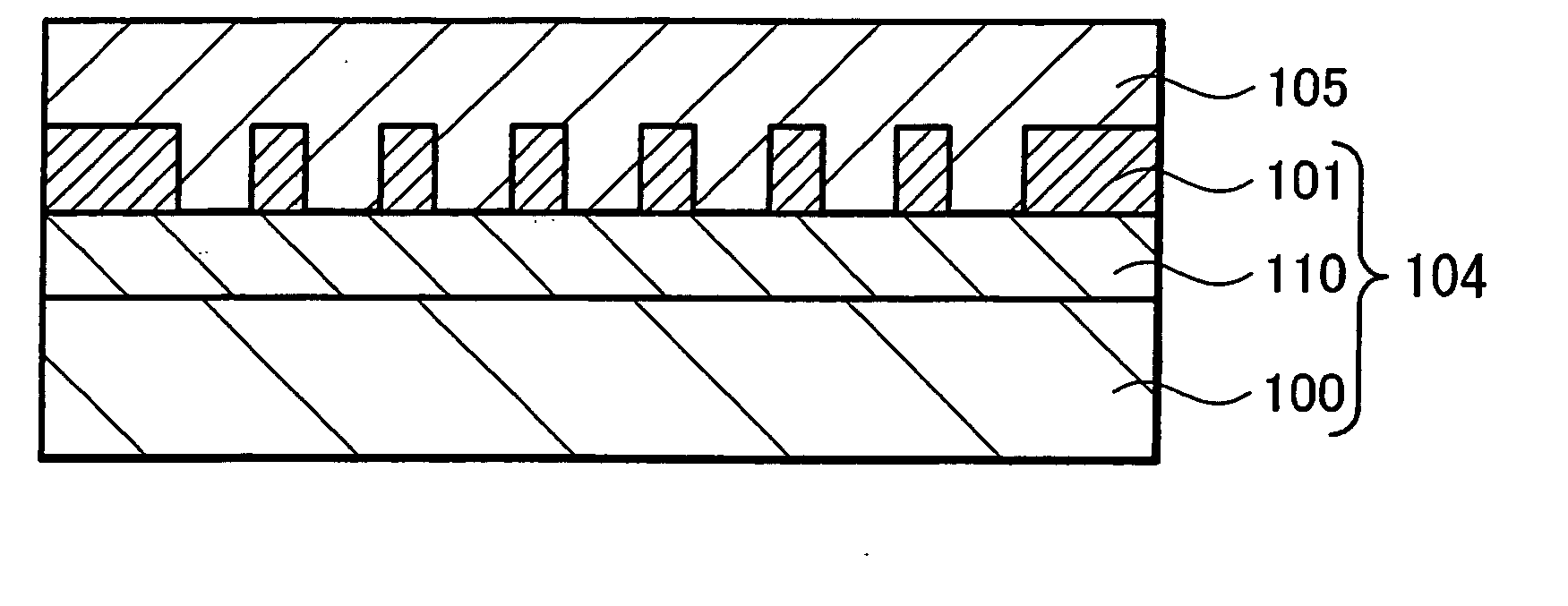

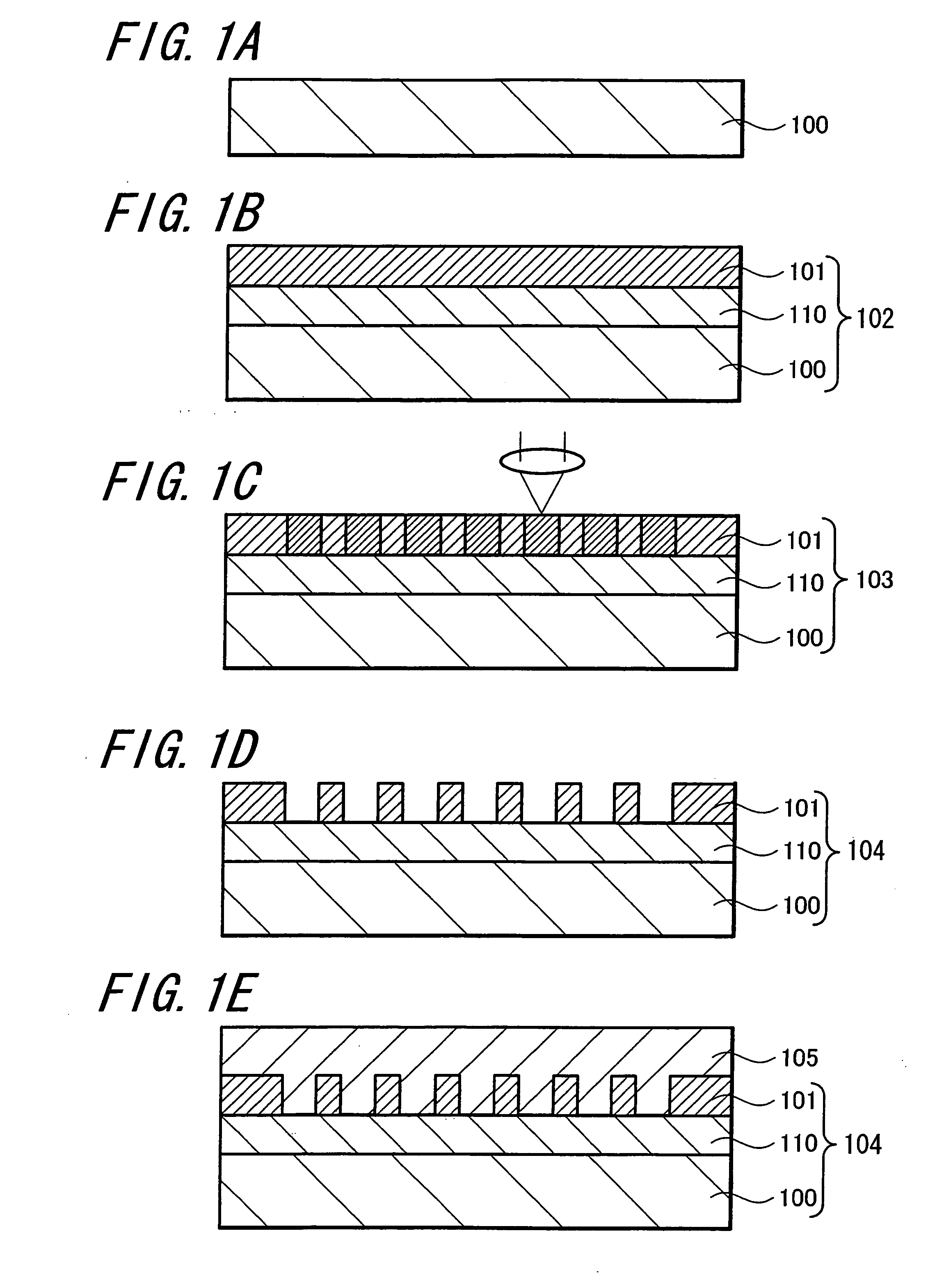

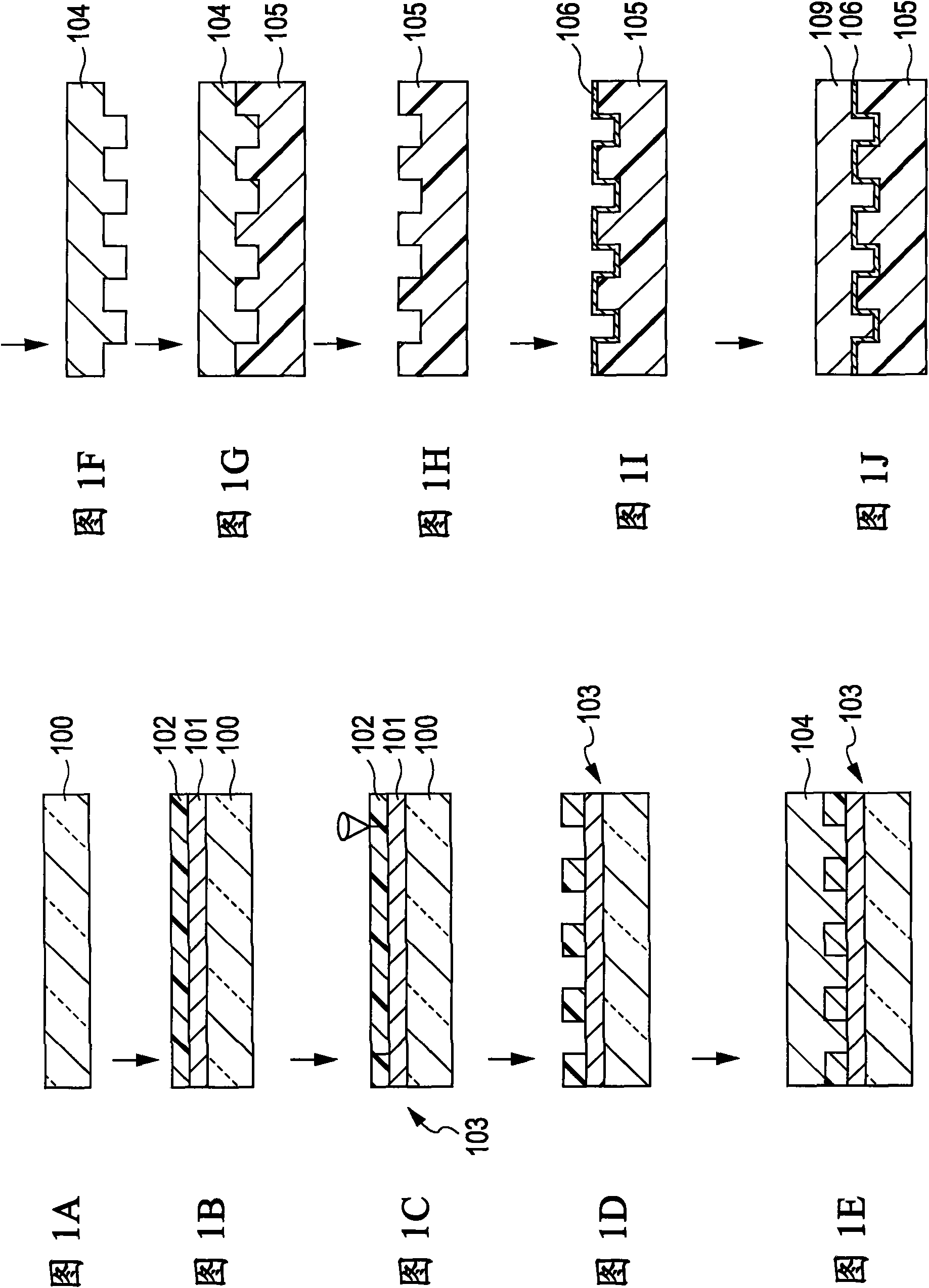

Method for producing stamper used for producing optical disc and optical disc producing method

InactiveUS20050128926A1Improve productivityHigh conforming rateOptical beam sourcesRecord information storageResistControl power

The method of the present invention includes an exposing step in which a laser beam for recording modulated by an information signal corresponding to an information signal of an information concave and convex pattern formed on the optical disc is applied to an inorganic resist layer 101 formed on a substrate 100 to form an exposed pattern corresponding to the information concave and convex pattern on the optical disc, and a development step in which a concave and convex pattern corresponding to the information concave and convex pattern by the inorganic resist layer is formed. By applying a laser beam for estimation to a predetermined area on the inorganic resist layer in the exposing step to estimate recorded signal characteristics of the exposed pattern by the inorganic resist layer using reflected light of the laser beam for estimation, and controlling power of the laser beam for recording based on the estimated result, the aimed information recording on the optical disc can reliably be obtained.

Owner:SONY CORP

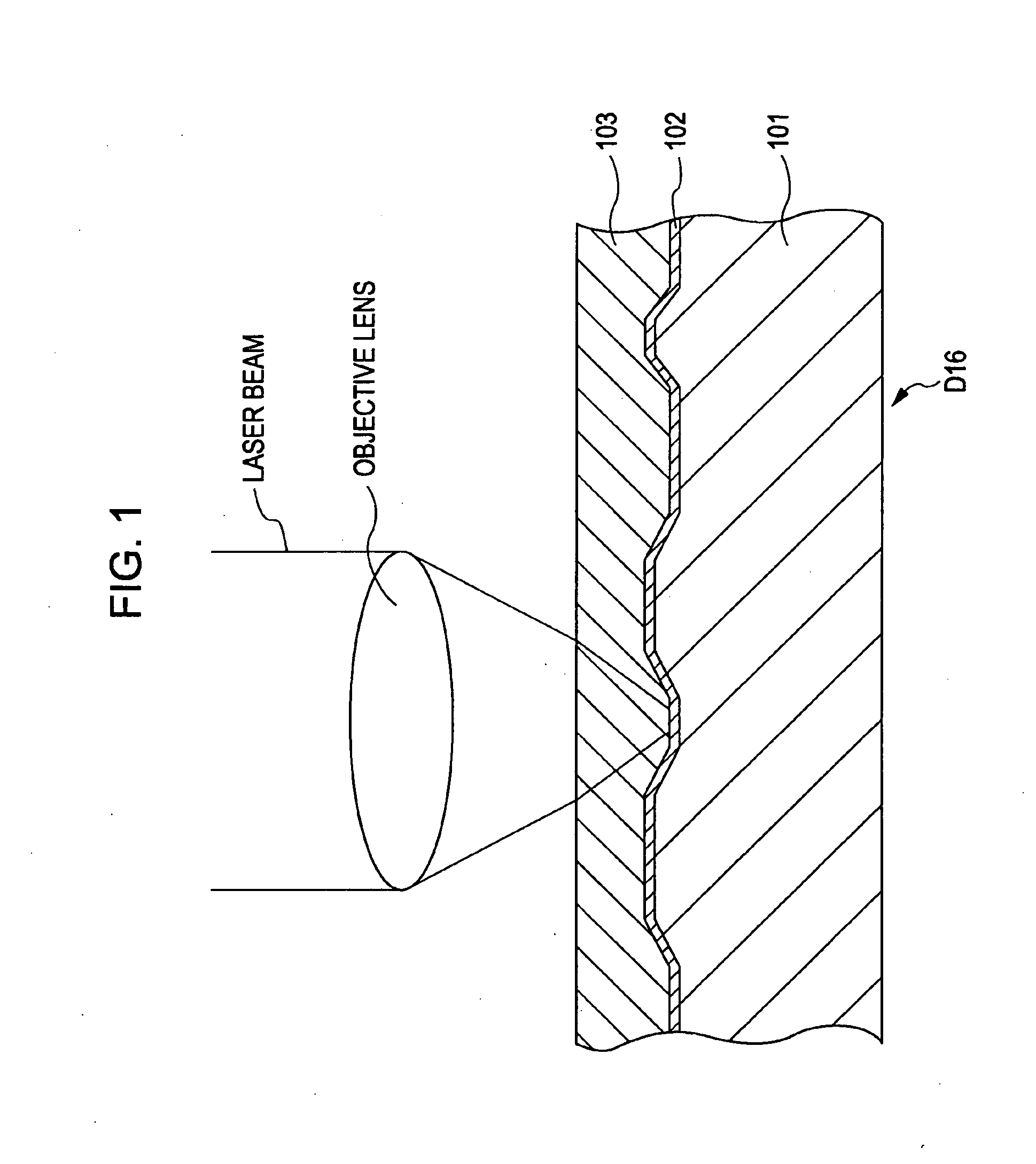

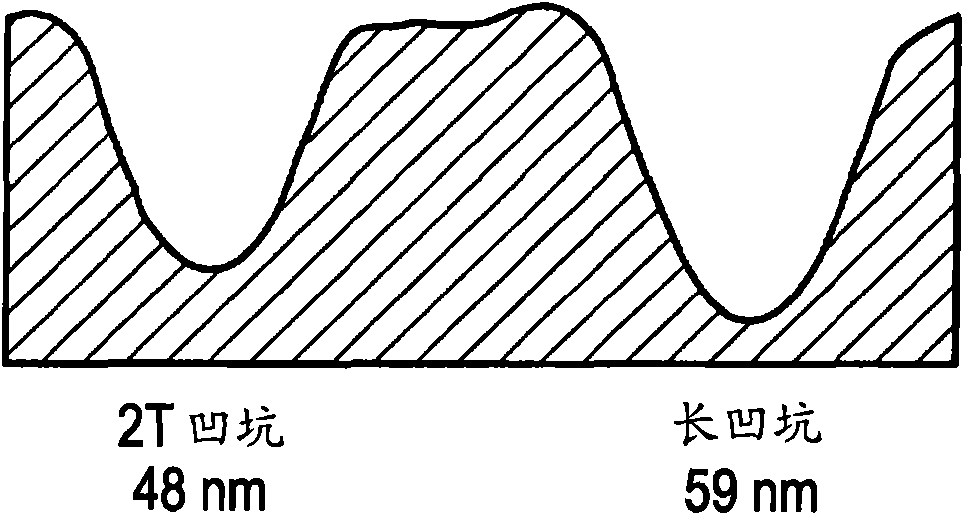

Evaluation apparatus, evaluation method, and optical disk manufacturing method

InactiveUS20060285461A1Combination recordingModification of read/write signalsCompact Disc manufacturingSignal on

An evaluation apparatus for evaluating the recording quality of secondary data recorded on an optical disk recording medium on which primary data is recorded as combinations of pits and lands includes the following elements: a reading unit operable to read a signal on the basis of reflected light information of a laser beam of playback power irradiated onto the optical disk recording medium; a binarizing unit operable to slice the signal read by the reading unit at a predetermined level and output the result as a binary signal; and a jitter calculating unit operable to calculate a jitter of edge shift amounts on the basis of a standard deviation and an average of the edge shift amounts and information on a predetermined minimum shift amount determined as the minimum amount of shift that can be detected by a binary decision as an edge shift.

Owner:SONY CORP

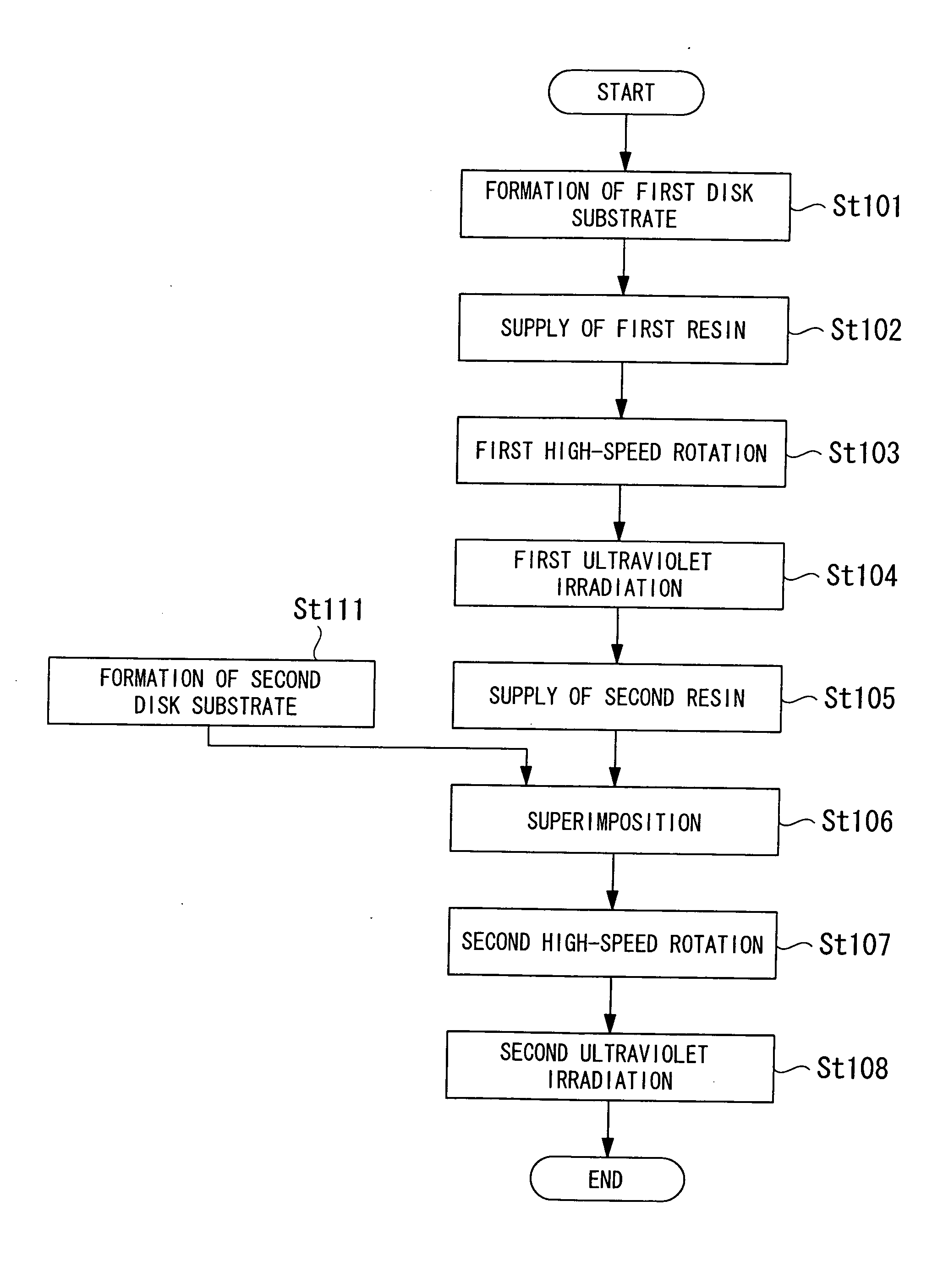

Optical disk and optical disk manufacturing method and device

InactiveUS20060153054A1Easy to optimizeReduce errorsRecord information storageOptical record carriersCompact Disc manufacturingEngineering

Owner:ORIGIN ELECTRIC CO LTD

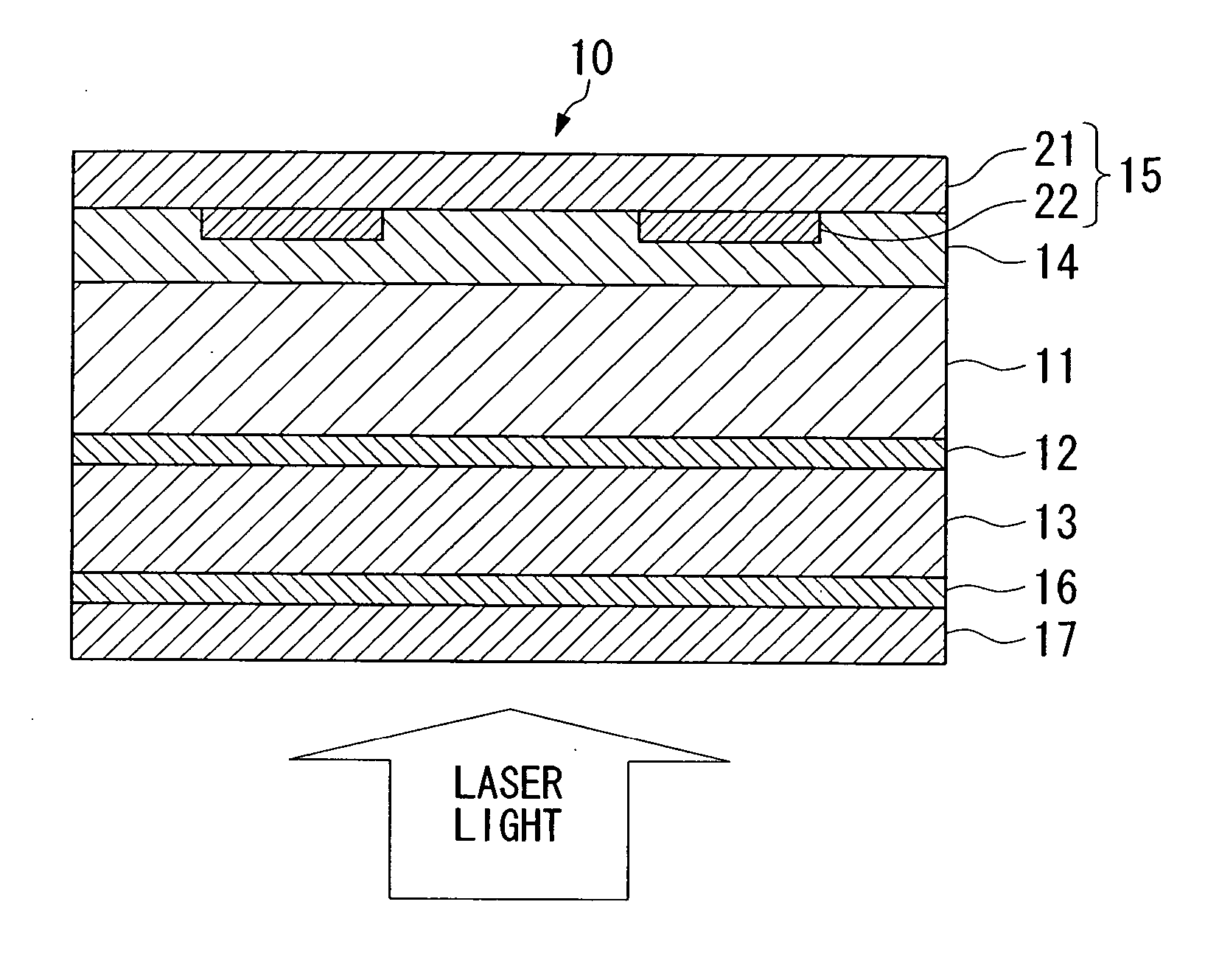

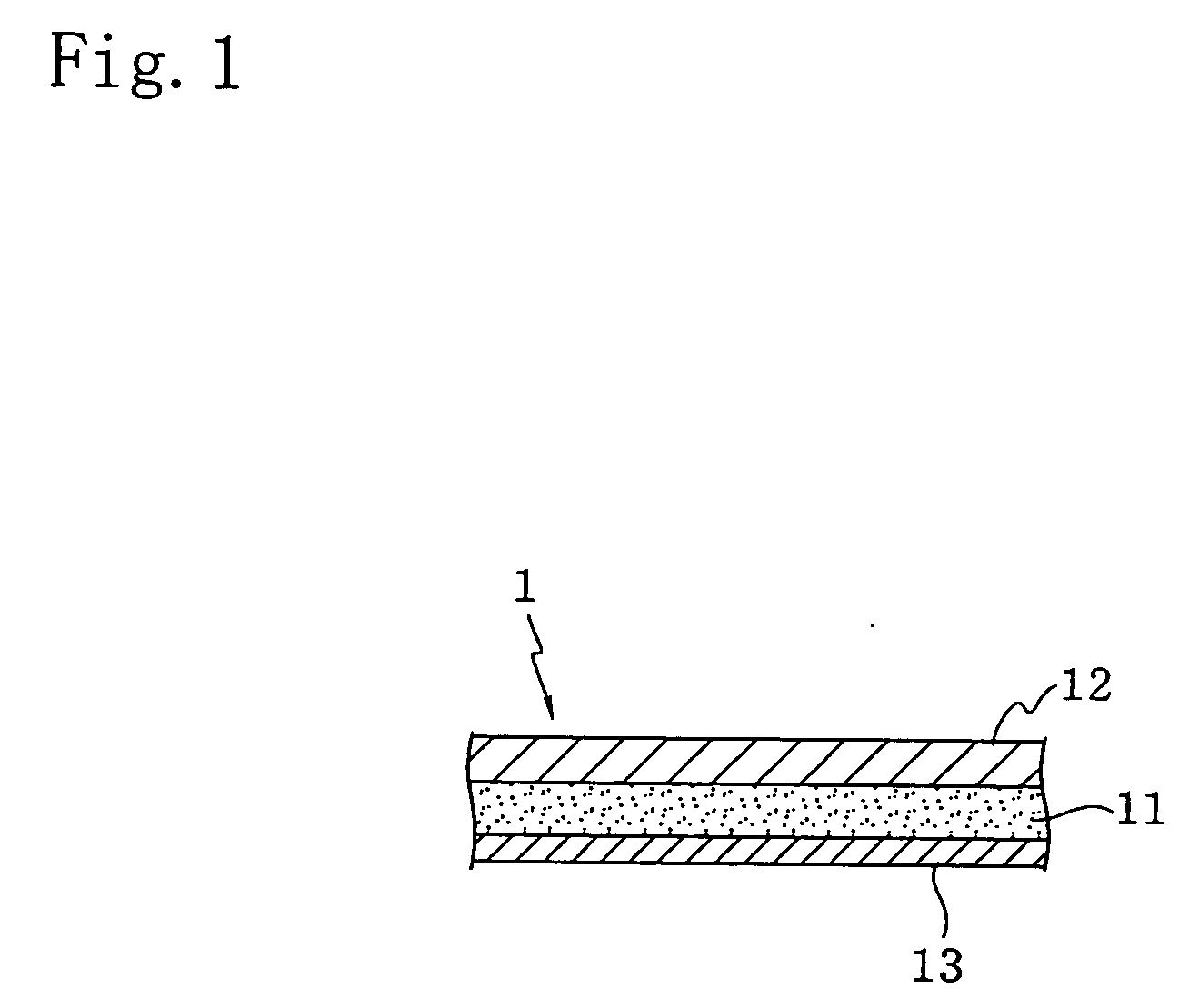

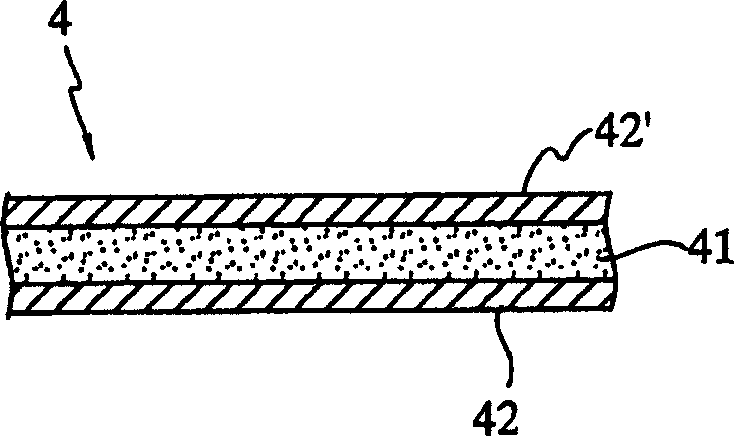

Optical disk and its manufacturing method

InactiveUS20060133256A1Little substrate warpingLow production costRecord information storageRecord carrier materialsCompact Disc manufacturingEngineering

An optical disk (10) of the present invention has a substrate (11) included a resin-impregnated paper, in which resin is impregnated into paper, or resin-coated paper, in which the paper surface is coated with a resin, and a recording layer (13) formed on at least one side of the substrate (11). This type of optical disk (10) has performance equal to that of conventional optical disks and has a minimal effect on the environment during disposal. In addition, a manufacturing method of an optical disk of the present invention has a recording layer sheet fabrication step in which a recording layer sheet is fabricated by forming tracks on a recording layer base material, and a recording layer sheet lamination step in which a recording layer (13) included the recording layer sheet is provided on a substrate (11) included resin-impregnated paper or resin-coated paper by laminating the recording layer sheet with the resin-impregnated paper in which a resin is impregnated into paper or the resin-coated paper in which the surface of the paper is coated with a resin. This type of manufacturing method of an optical disk allows optical disk (10) to be produced inexpensively.

Owner:SONY CORP +1

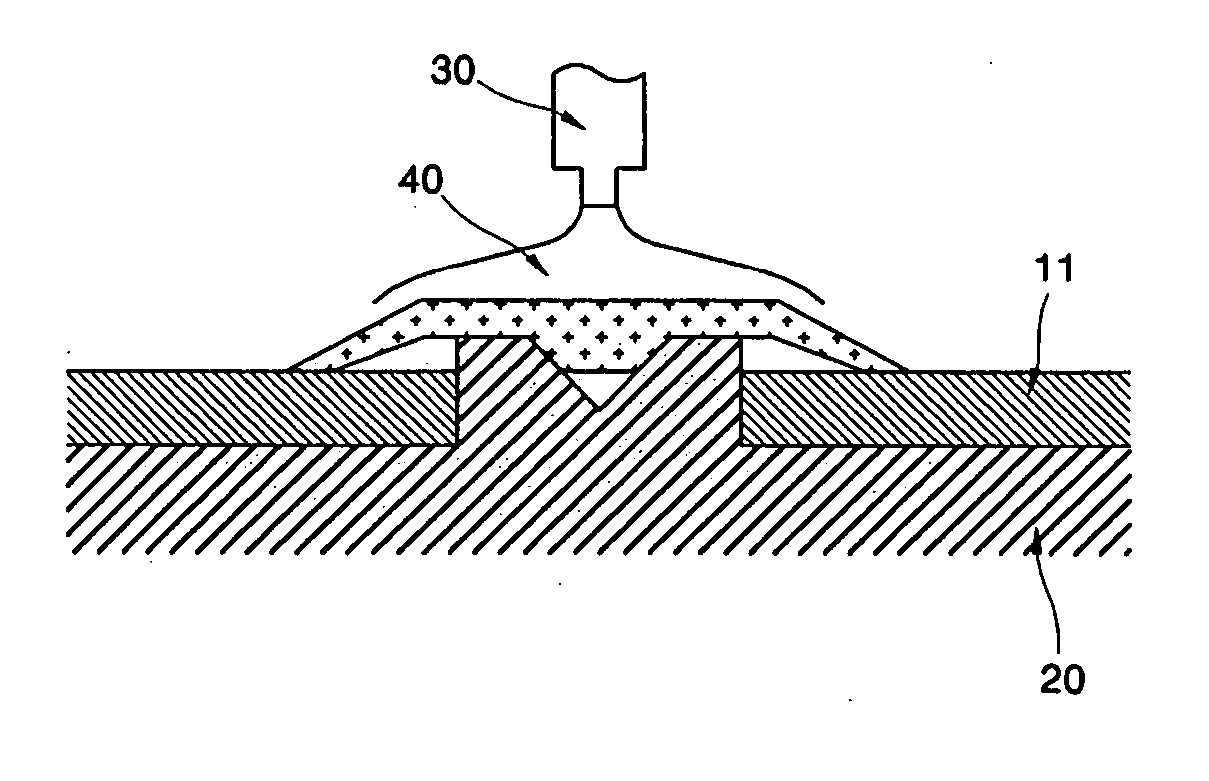

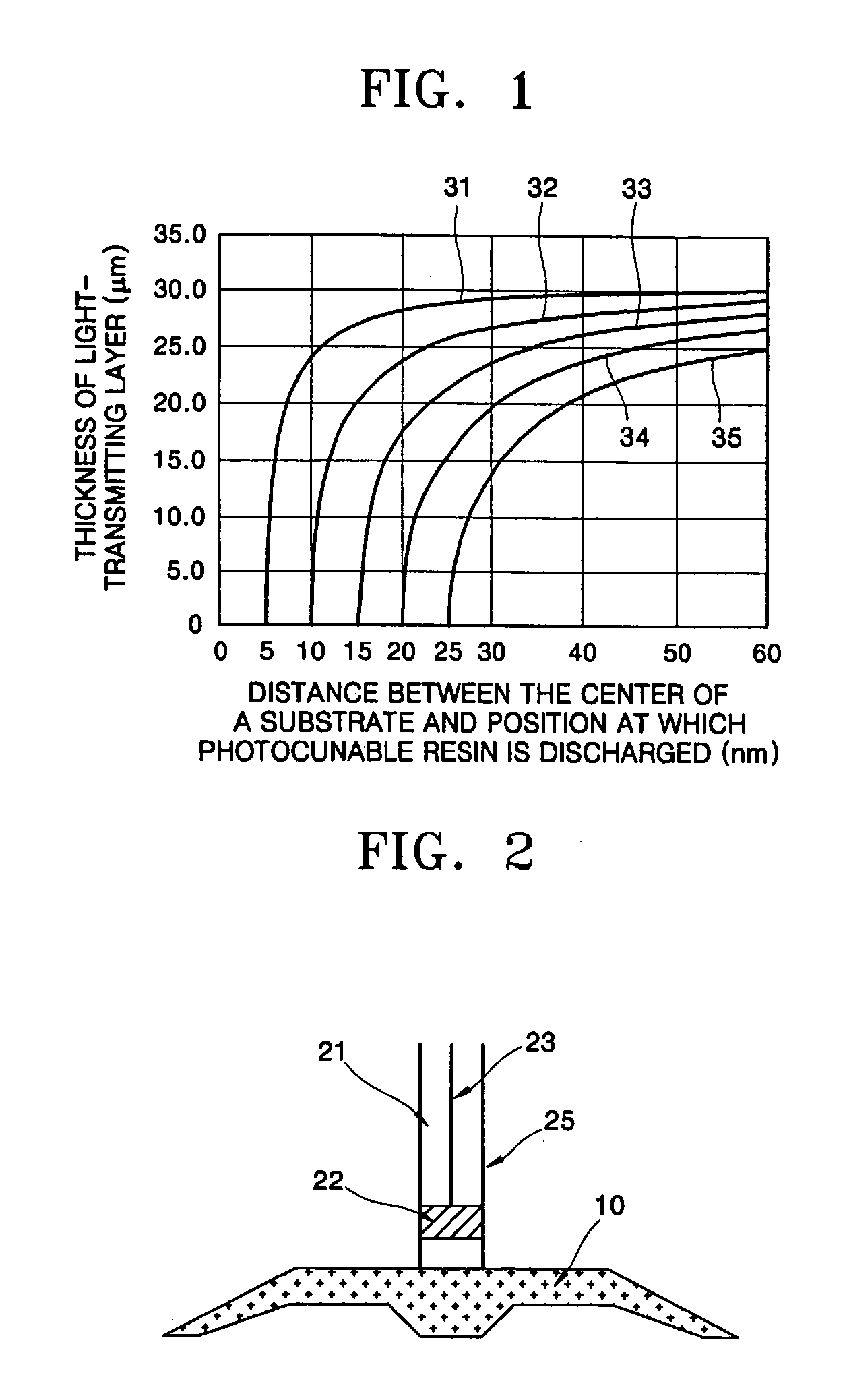

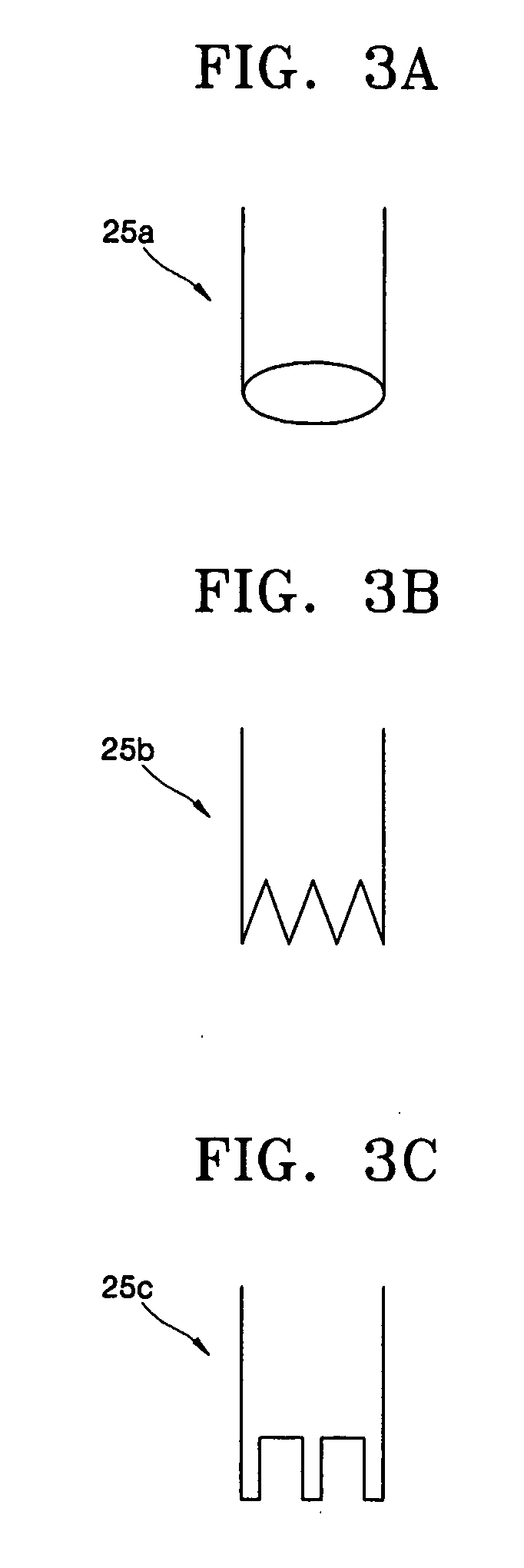

Spin coater, temperature controlling method of the same, optical disc production apparatus, and optical disc production method

InactiveUS20100062155A1Efficiently formedUniform thicknessPretreated surfacesRecord information storageTemperature controlCompact Disc manufacturing

The present invention provides a spin coater including a rotation table that rotatably holds the disc substrate, a spin-cup that surrounds the outer circumference of a disc substrate held on the rotation table, a dripping unit configured to drip an ultraviolet-curable resin composition onto the surface of the disc substrate, a rotating unit configured to rotate the disc substrate via the rotation table to spread the ultraviolet-curable resin composition over the surface of the disc substrate, a heating unit configured to heat the ultraviolet-curable resin composition on the disc substrate, and a temperature controlling unit configured to control a reaching temperature of the spin cup which is increased by the heating unit each time the ultraviolet-curable resin composition is spread, so as to be constant over multiple spin coating processes.

Owner:RICOH KK

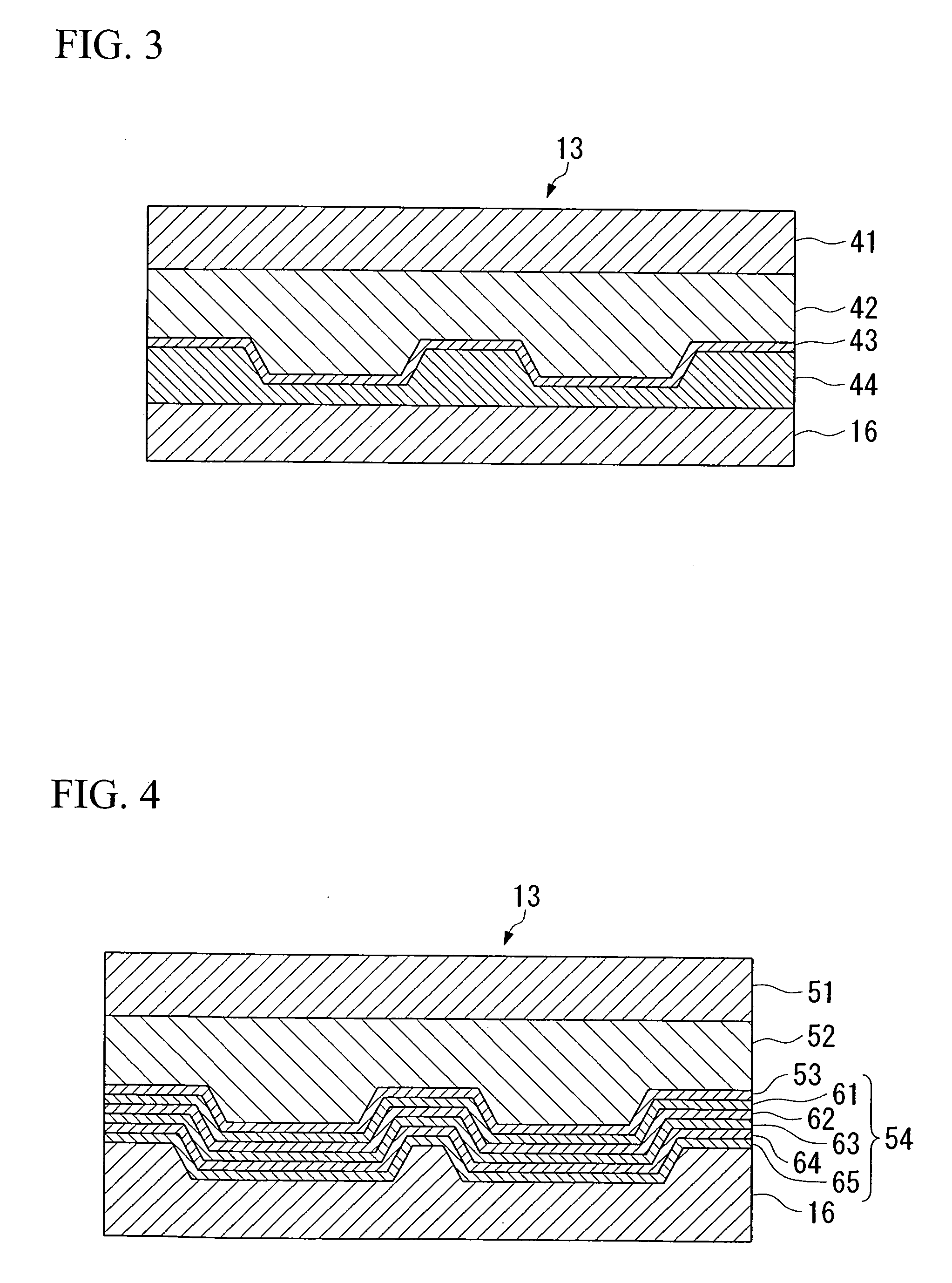

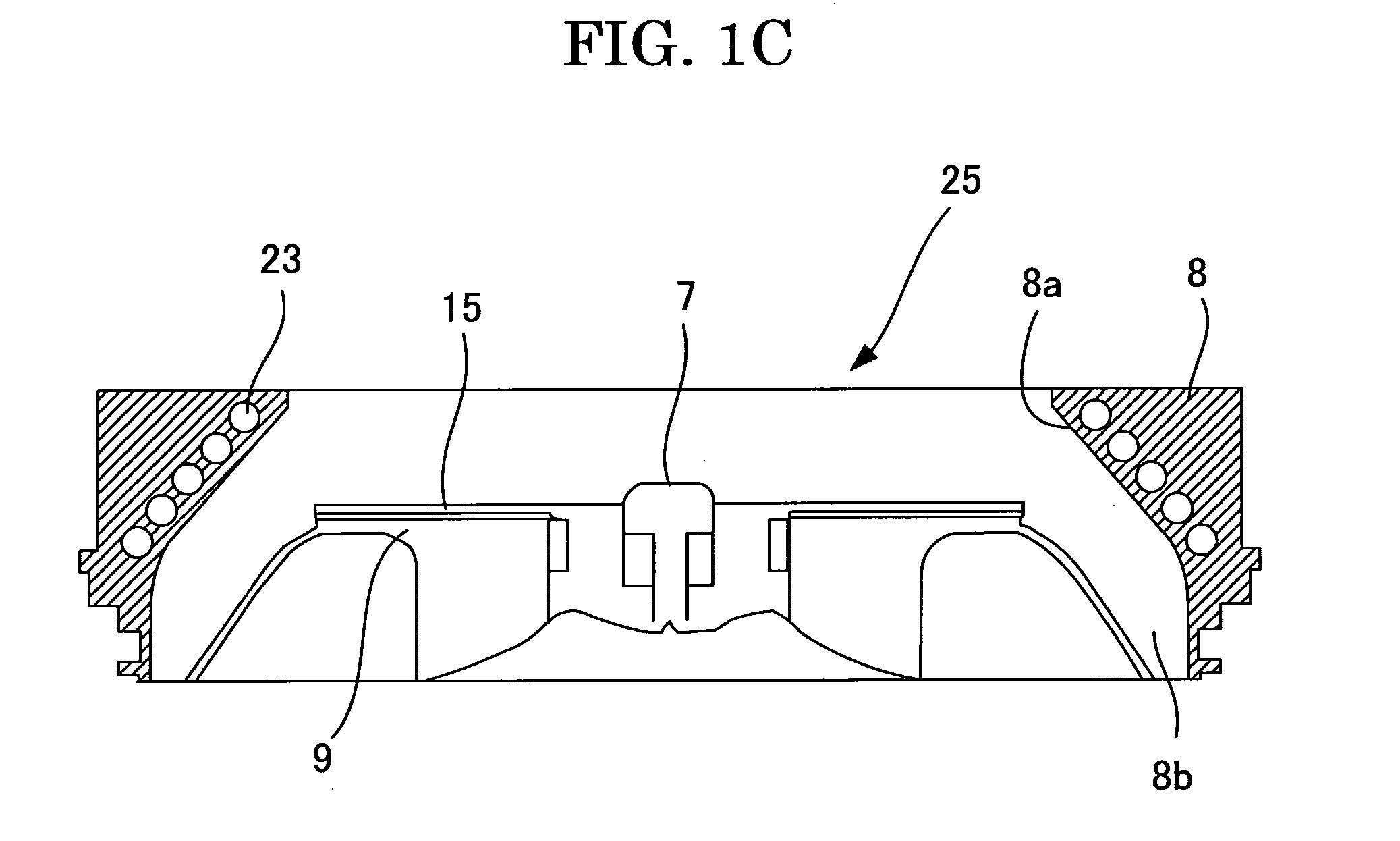

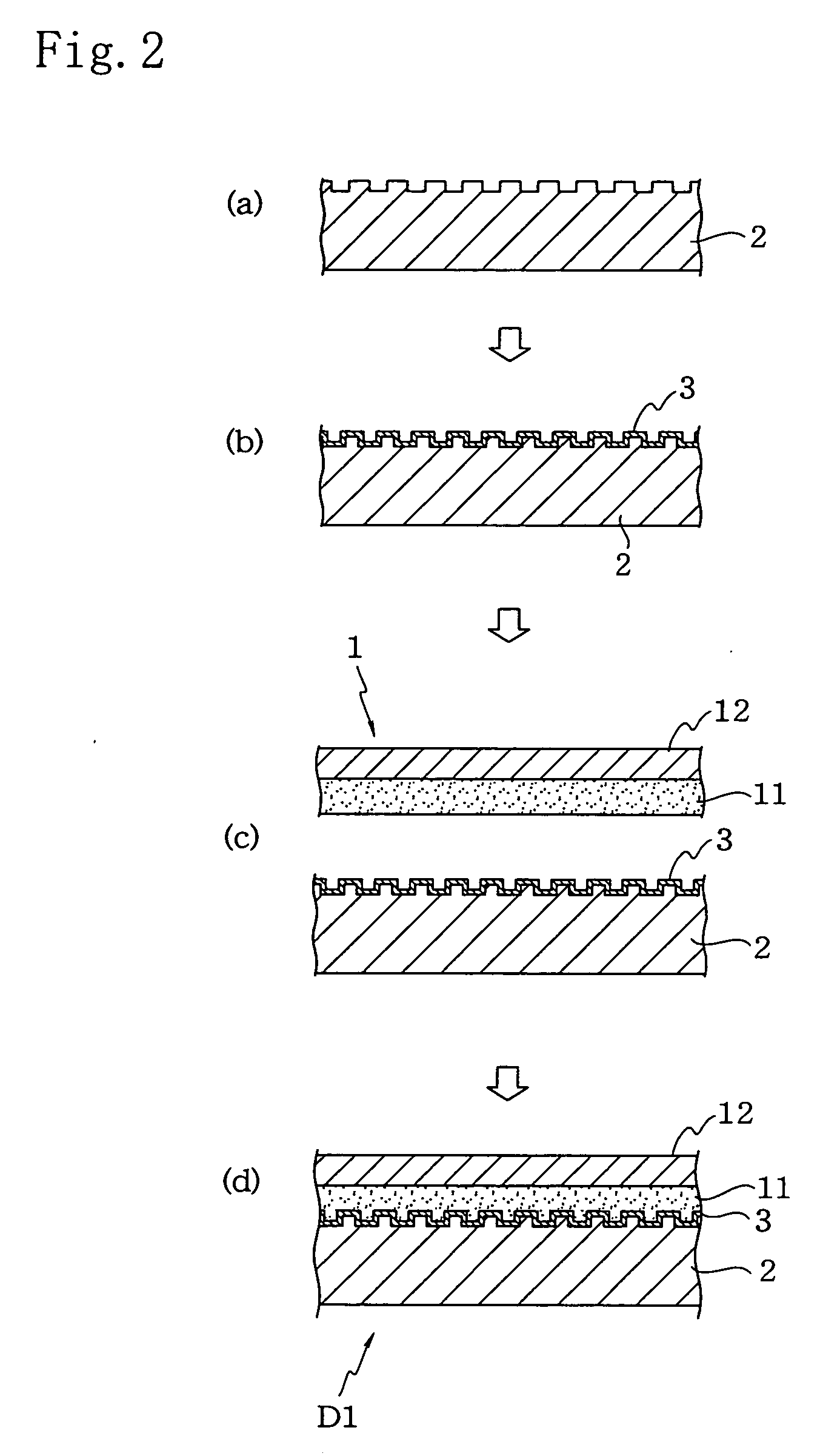

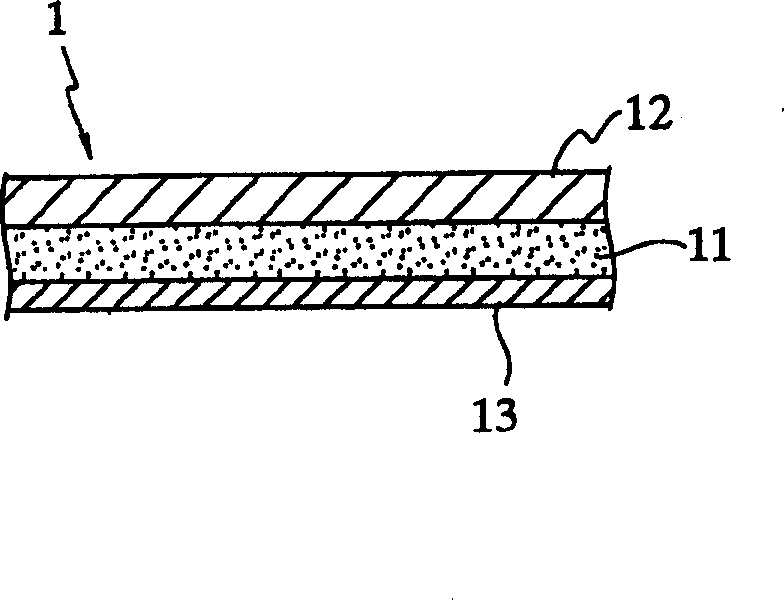

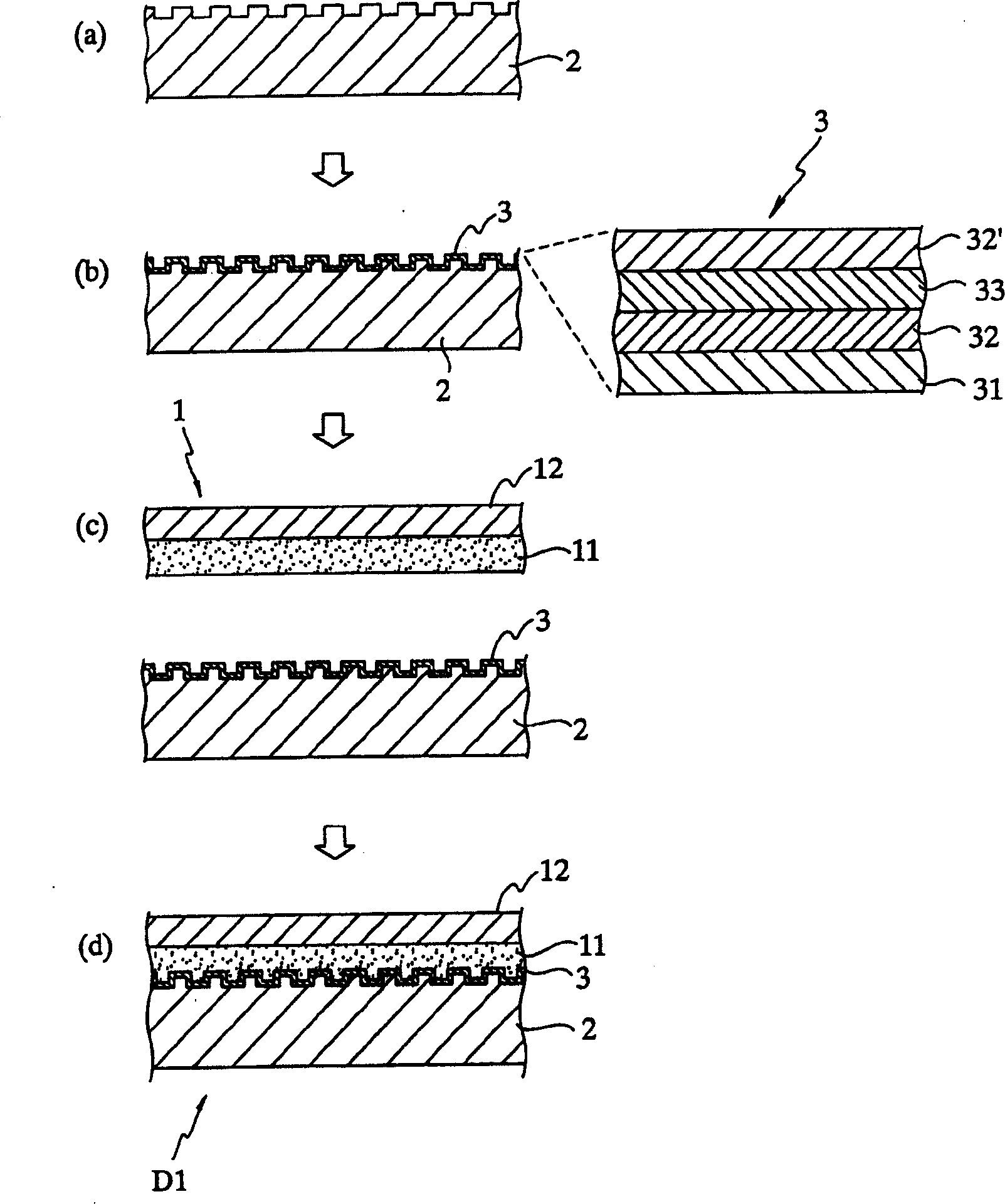

Sheet for manufacturing optical disk and optical disk

InactiveUS20060280110A1Uniform thicknessMechanical record carriersRecord information storageCompact Disc manufacturingEngineering

Optical disc manufacturing sheet 1 comprising protective sheet 12 and curable adhesive layer 11 with a pre-curing storage elastic modulus of 103 to 106 Pa and a post-curing storage elastic modulus of 107 to 1011 Pa is laminated on reflective layer 3 formed on optical disc substrate 2. In the optical disc D1 obtained in this way, adhesive layer 11 has a uniform thickness and protective sheet 12 is resistant to pressure imprint.

Owner:LINTEC CORP

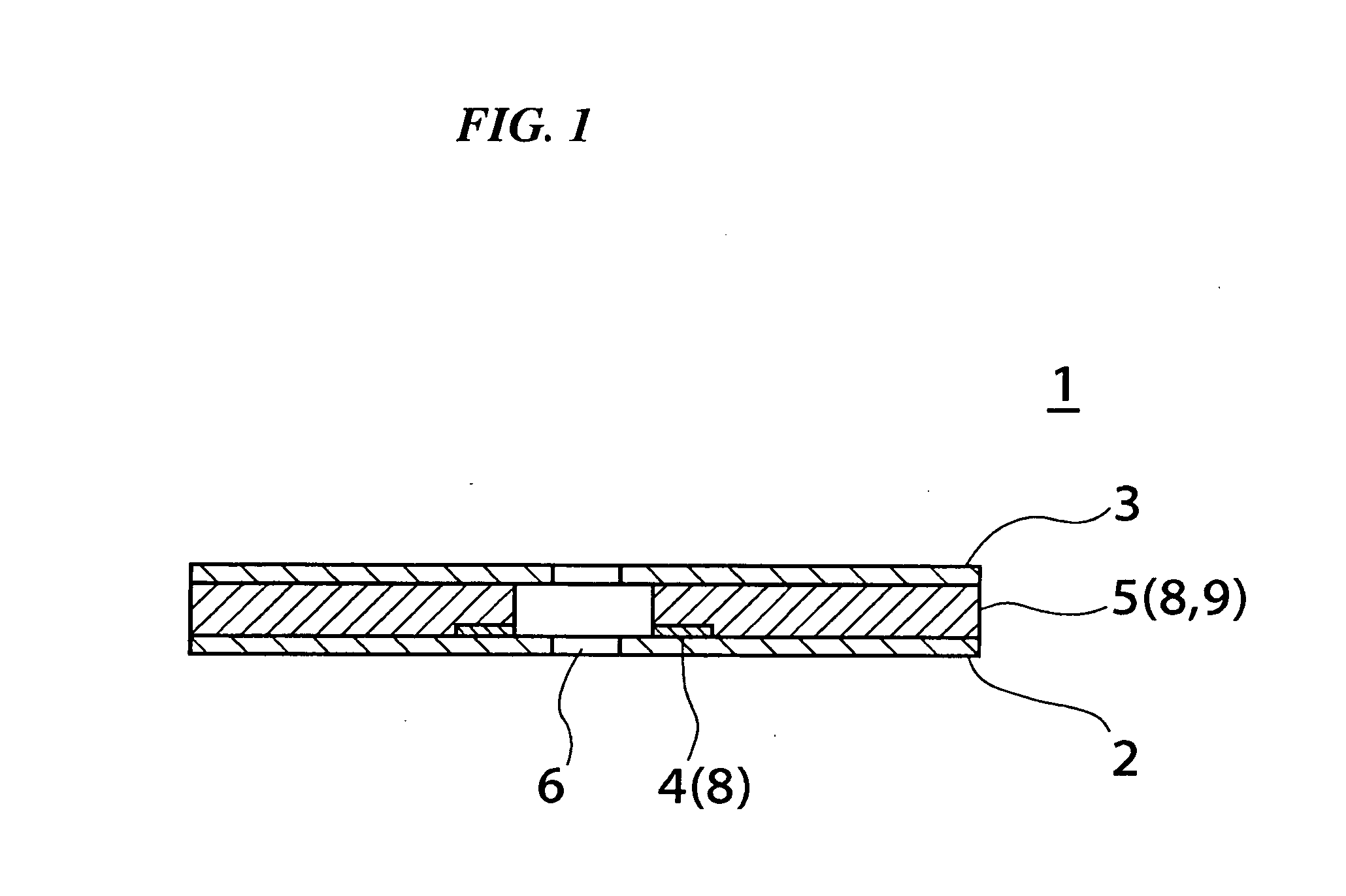

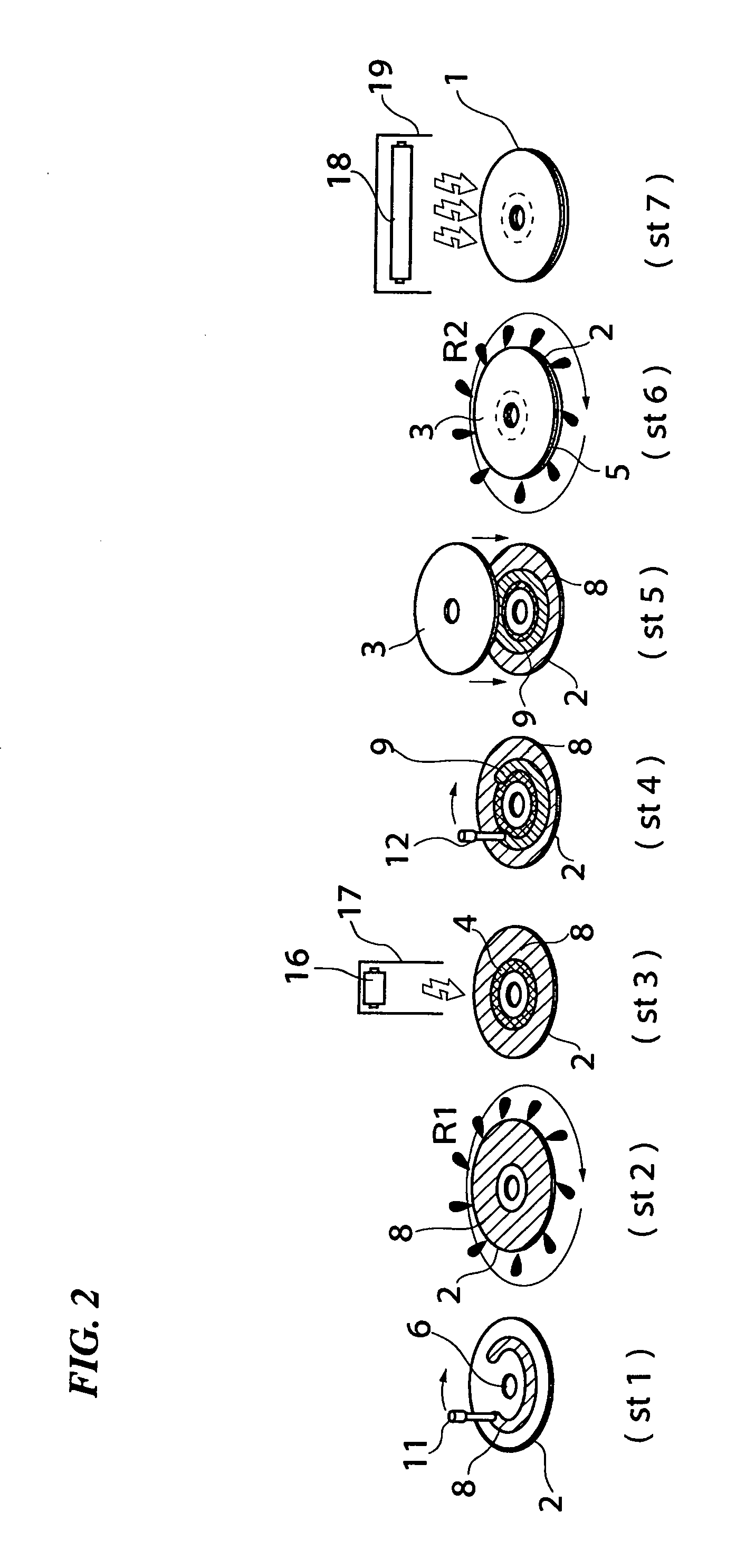

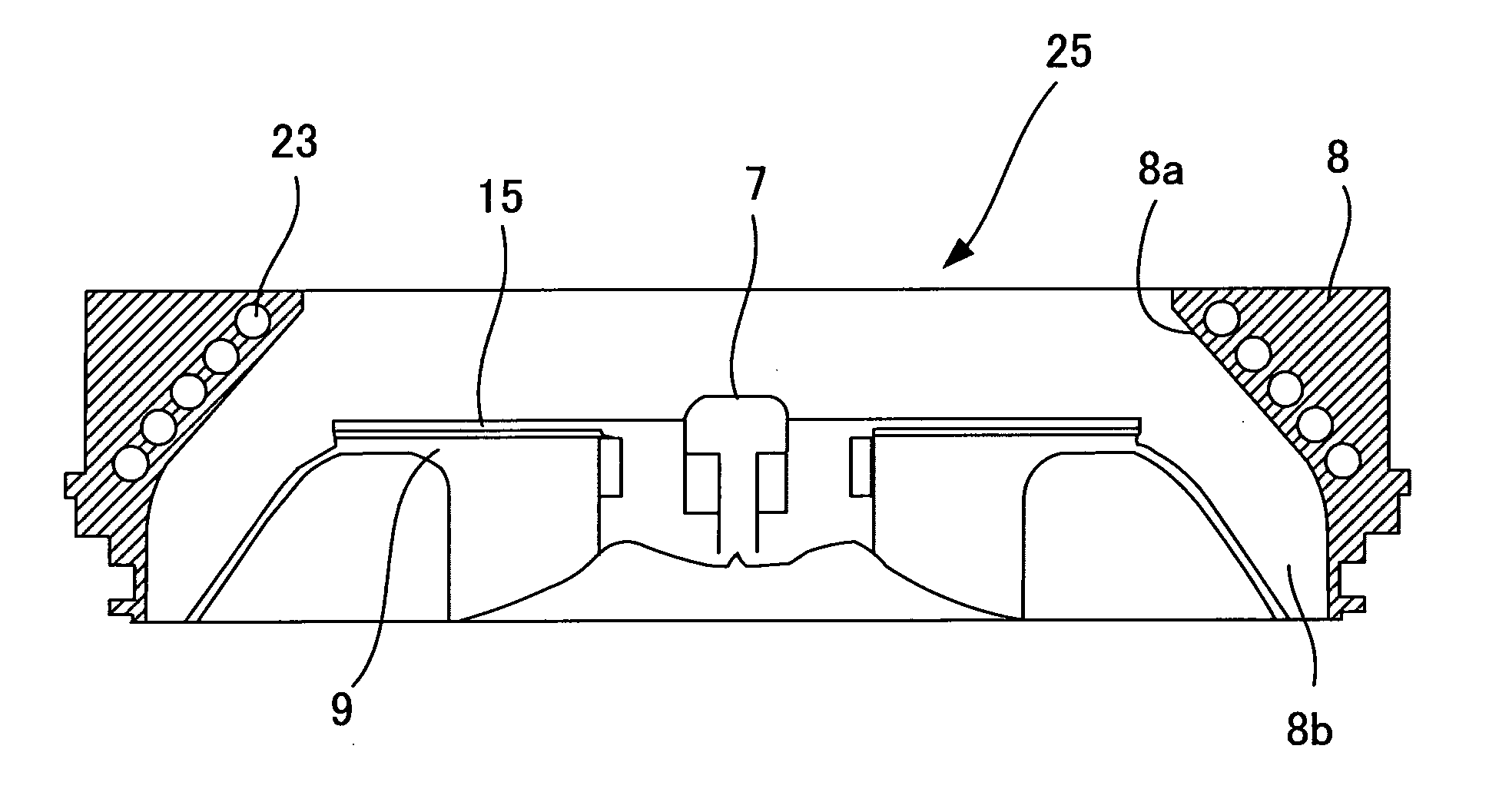

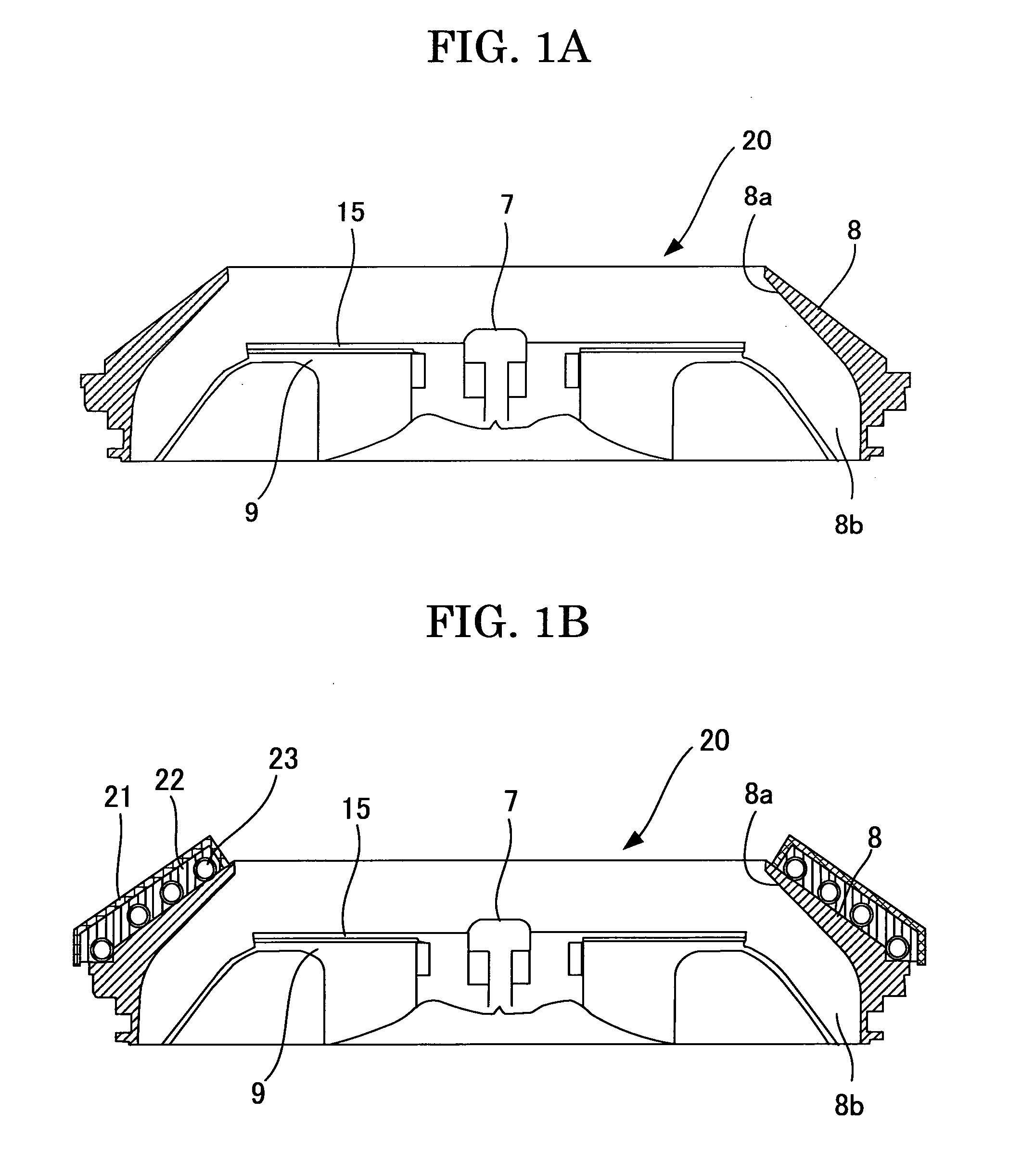

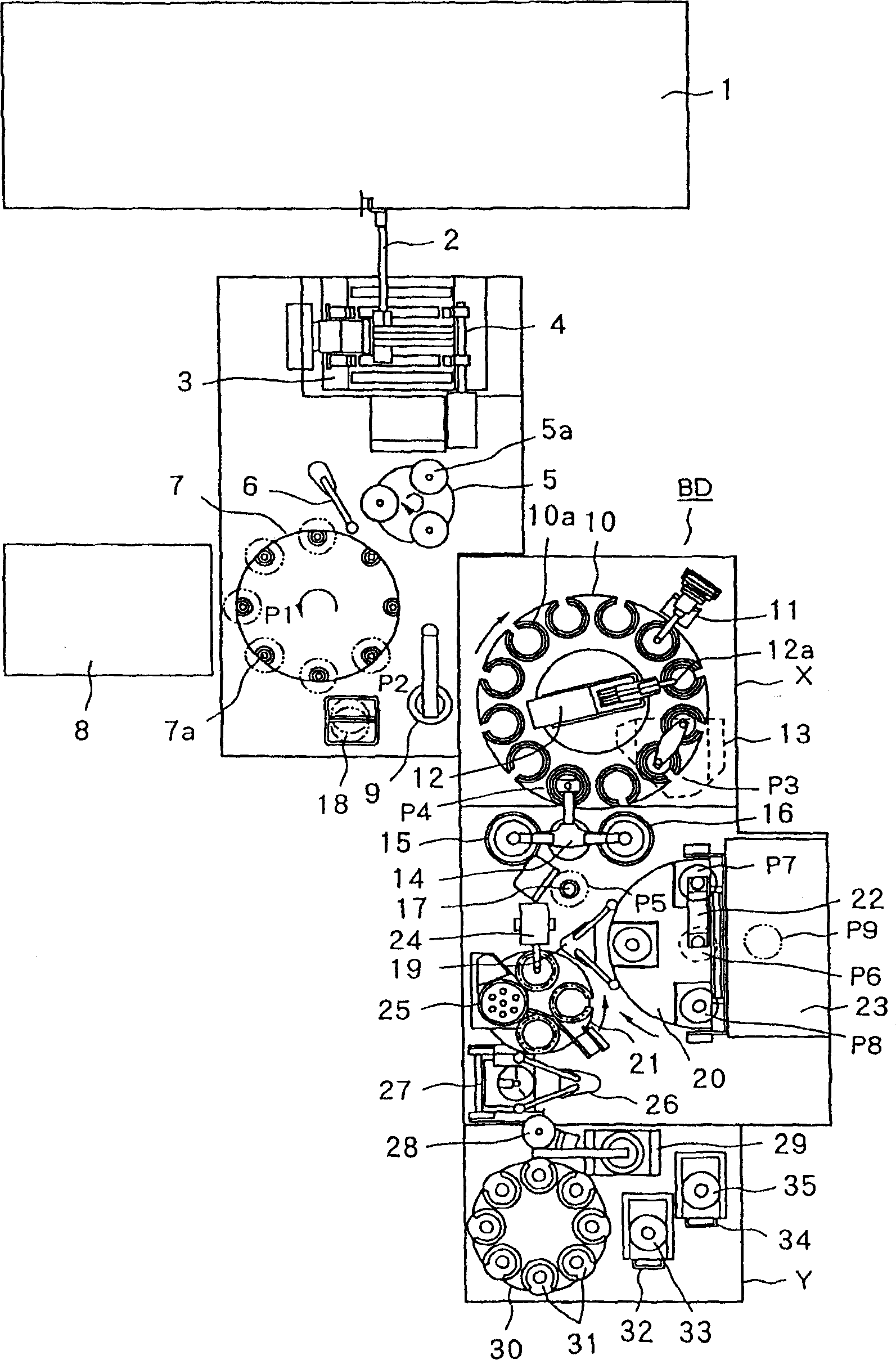

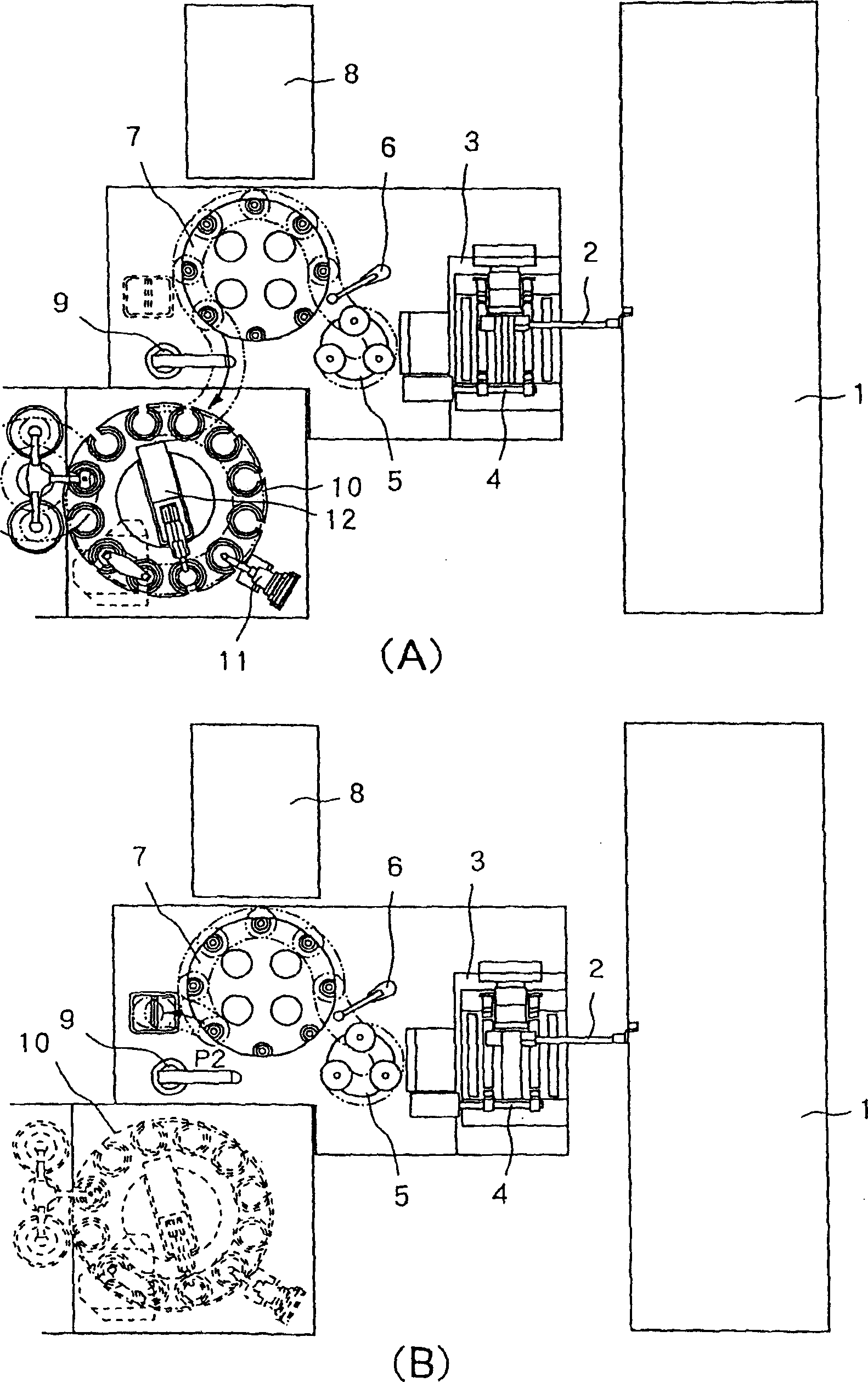

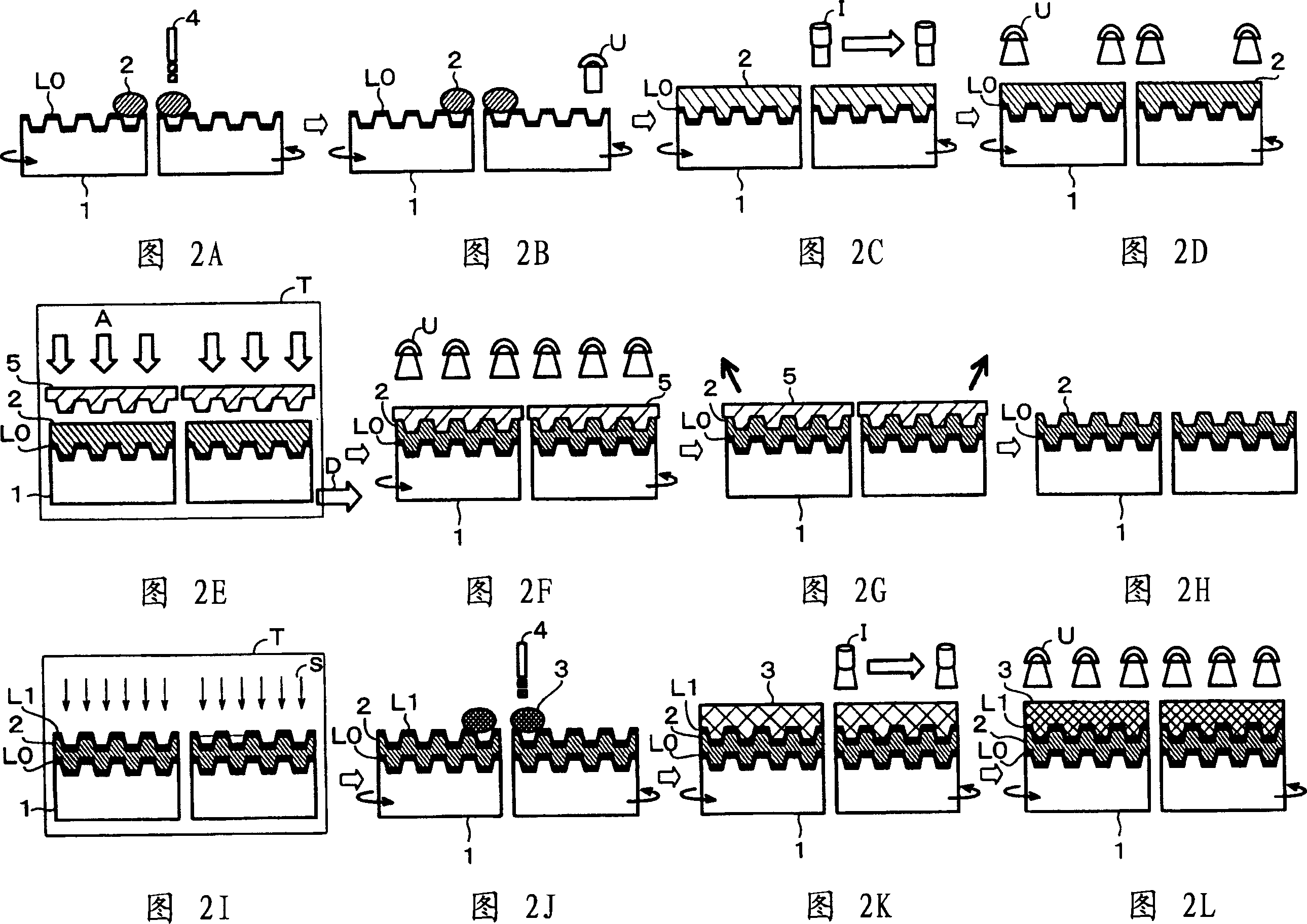

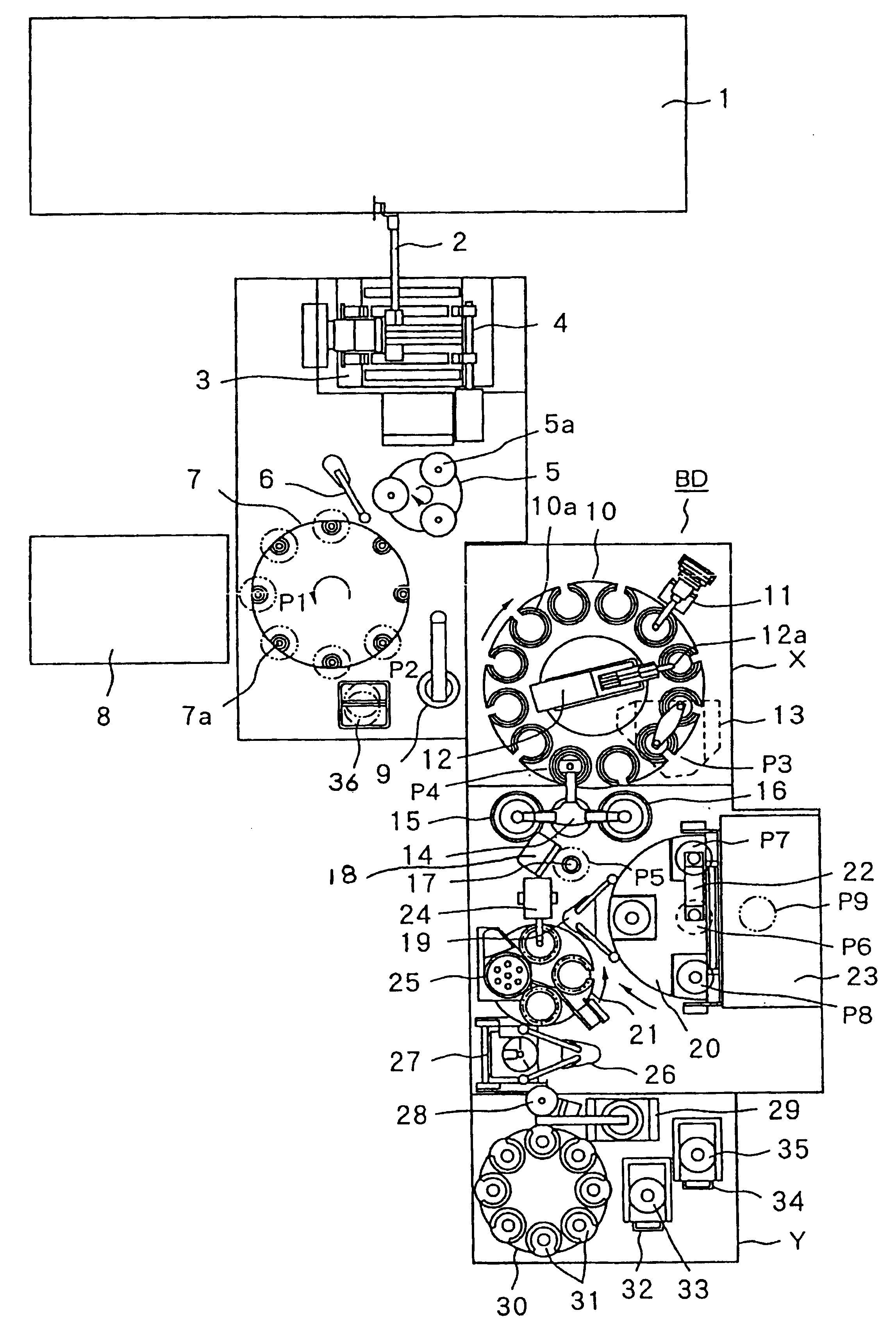

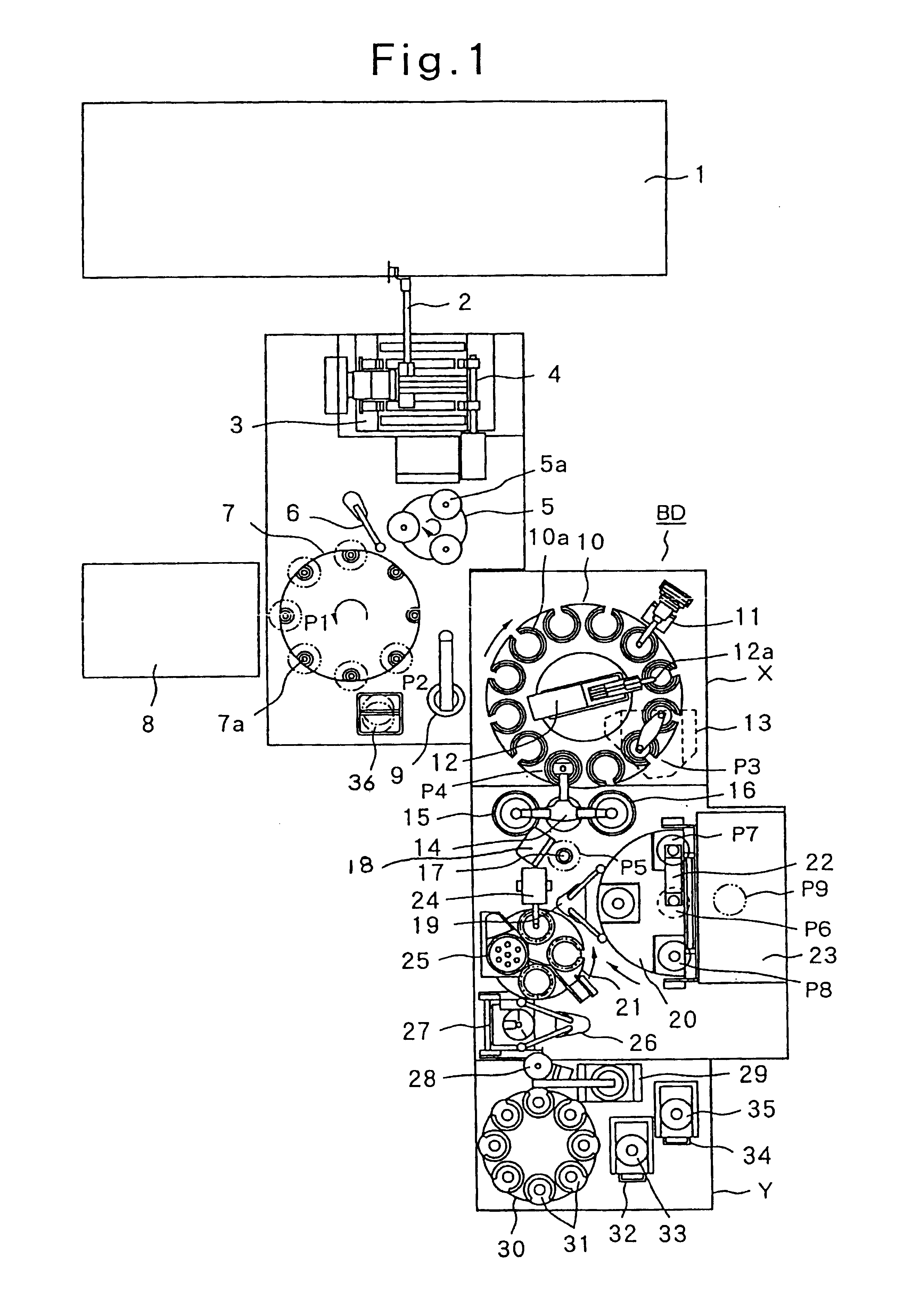

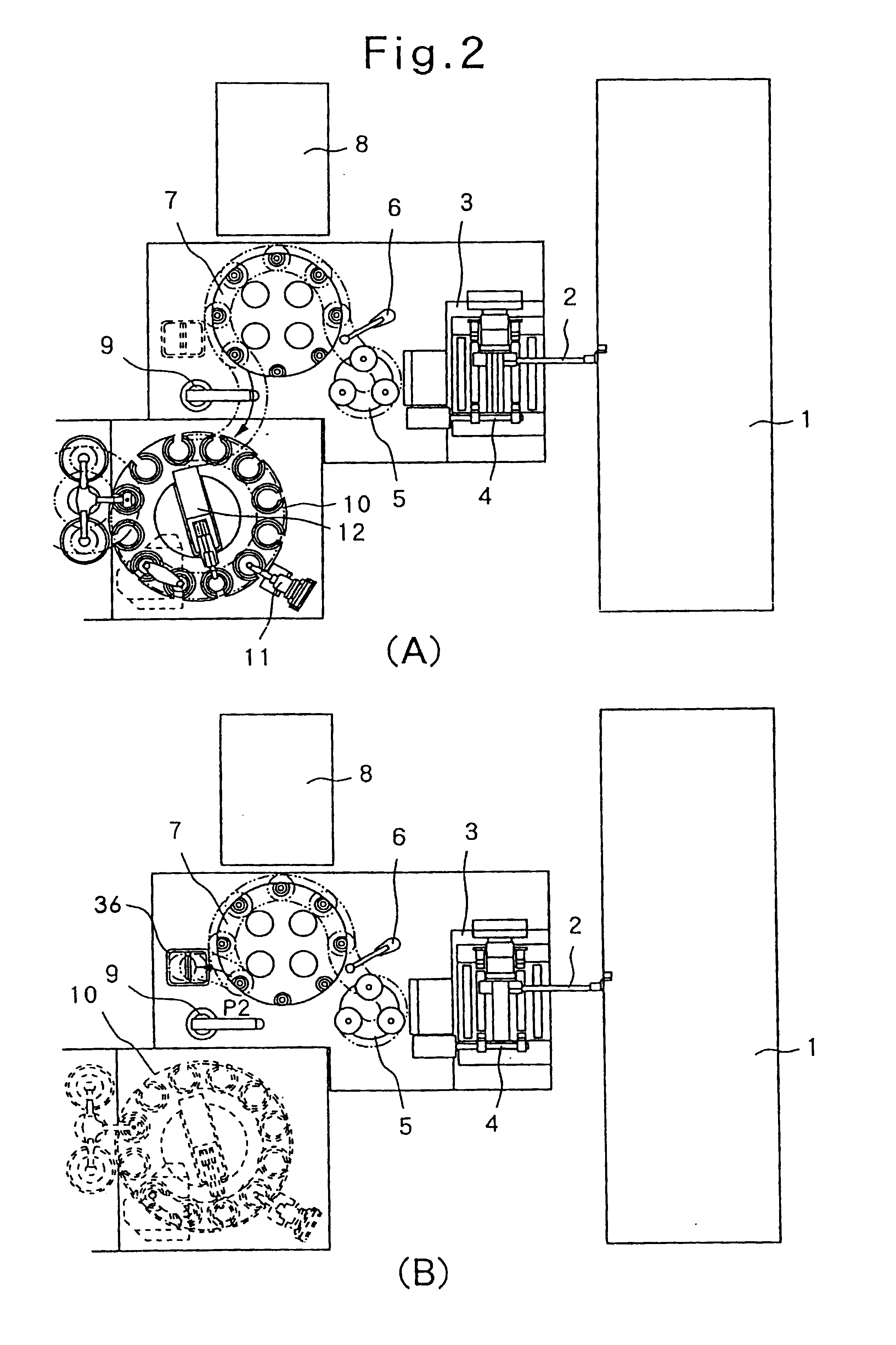

Optical disc producing device and producing method

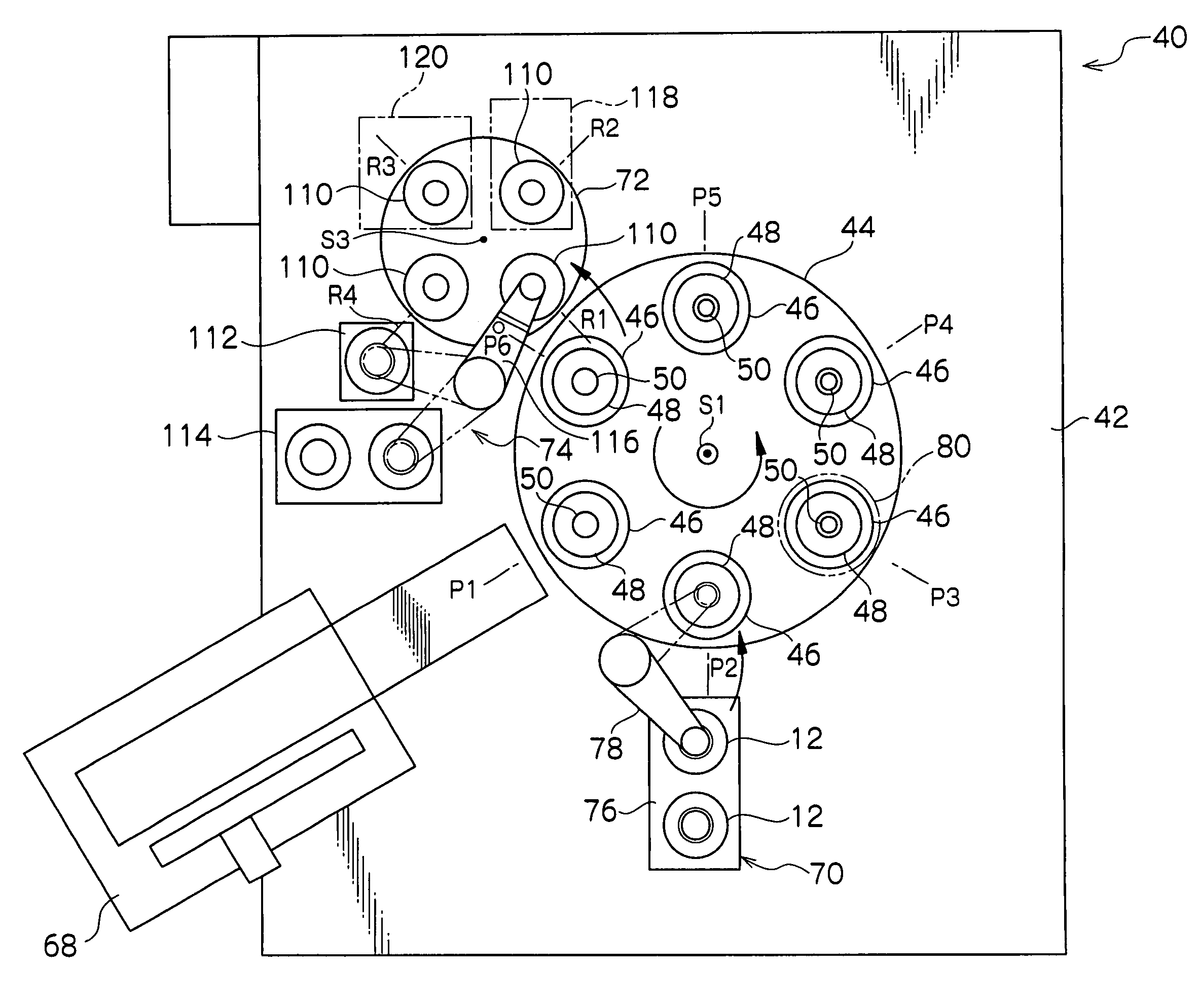

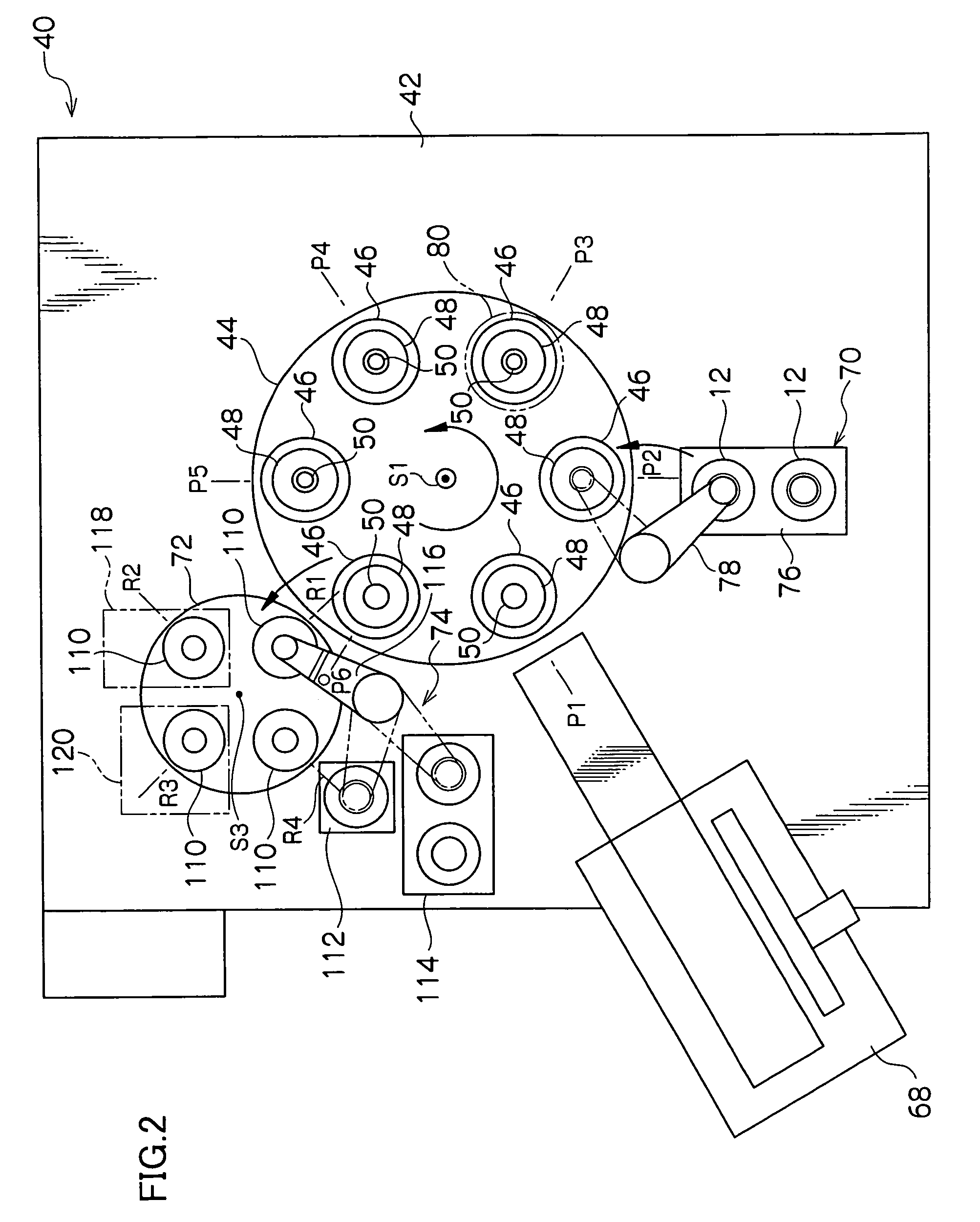

A molding machine 1 which molds two sheets of disc substrates on which the information is recorded simultaneously, a cooling mechanism 3 for cooling each of the disc substrates, first movably mounting means 2 for movably mounting the disc substrate from the molding machine onto the cooling mechanism, and a second movably mounting means 4 for mounting each of the disc substrates onto a receiving portion of the turn table 5 are provided. In addition, a film forming device 8 for receiving sequentially each of the disc substrates from this movably mounting means 6 and forming a reflective film on one of the surfaces of each of the received disc substrates on which the information is recorded; a turn table 10 having a plurality of receiving portions on which the disc substrates are mounted and which rotates intermittently through each constant angle; a reversing mechanism 11 which reverses 180 degrees each of the disc substrates; and an overlapping mechanism for overlapping the reversed disc substrates over the other disc substrates are provided. Furthermore, spinners 15, 16 for rotating the overlapped two sheets of disc substrates and a curing device 23 which radiates ultra-violet rays onto the disc substrates which are rotated by the spinners to cure the liquid adhesive. According to the above-described structure, an optical disc which is compact, is fast in a production speed, and has a high quality can be achieved.

Owner:ORIGIN ELECTRIC CO LTD

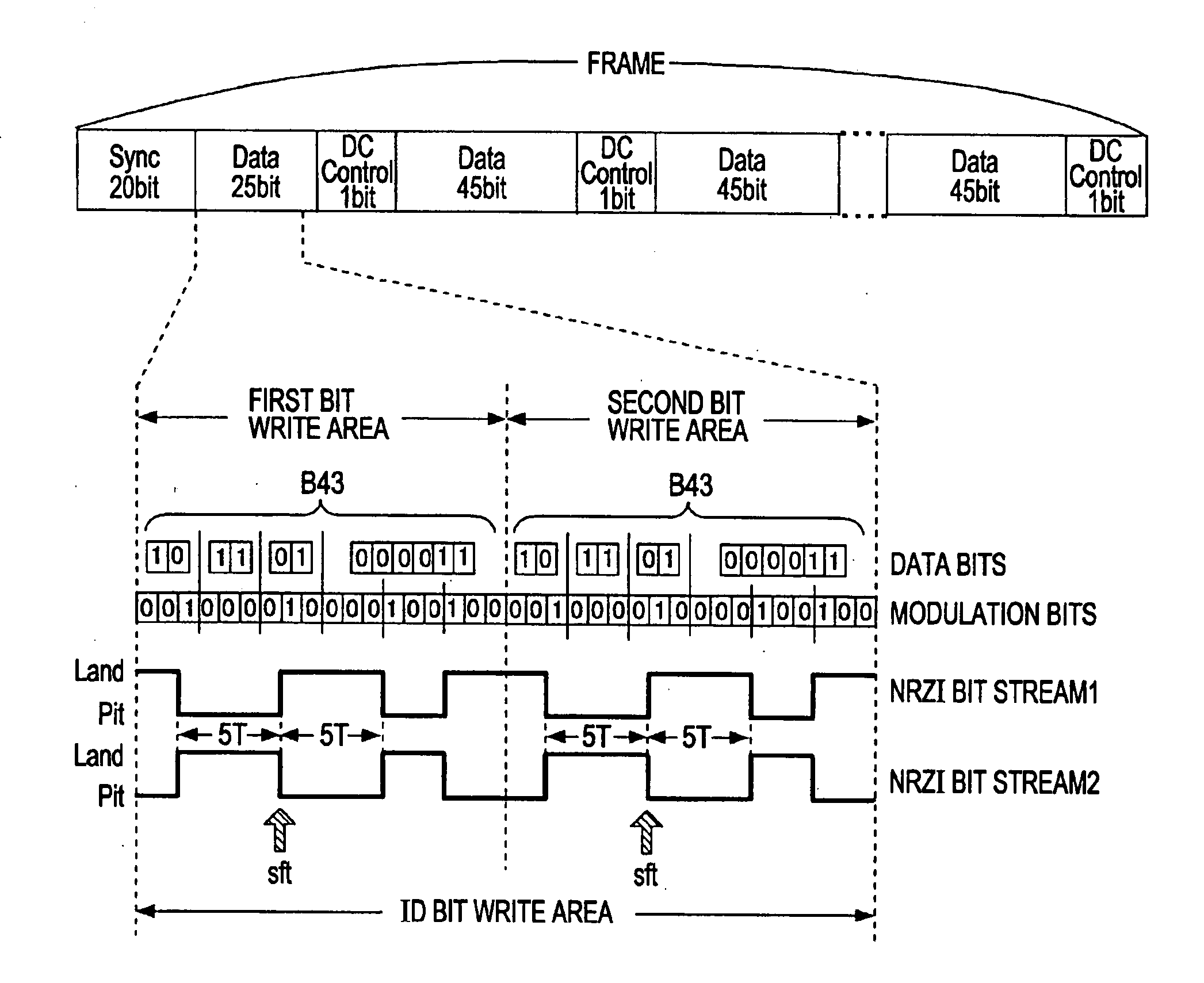

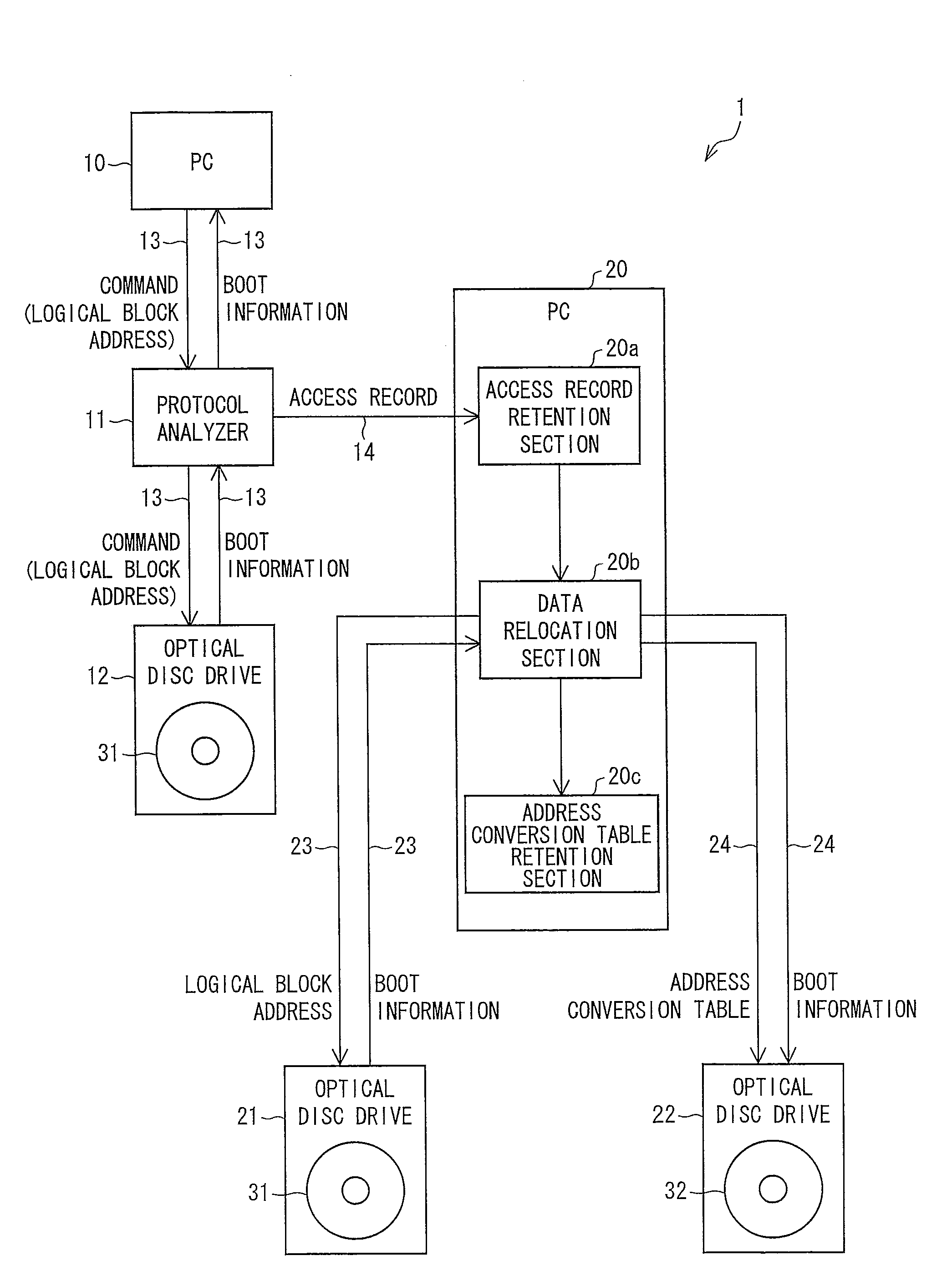

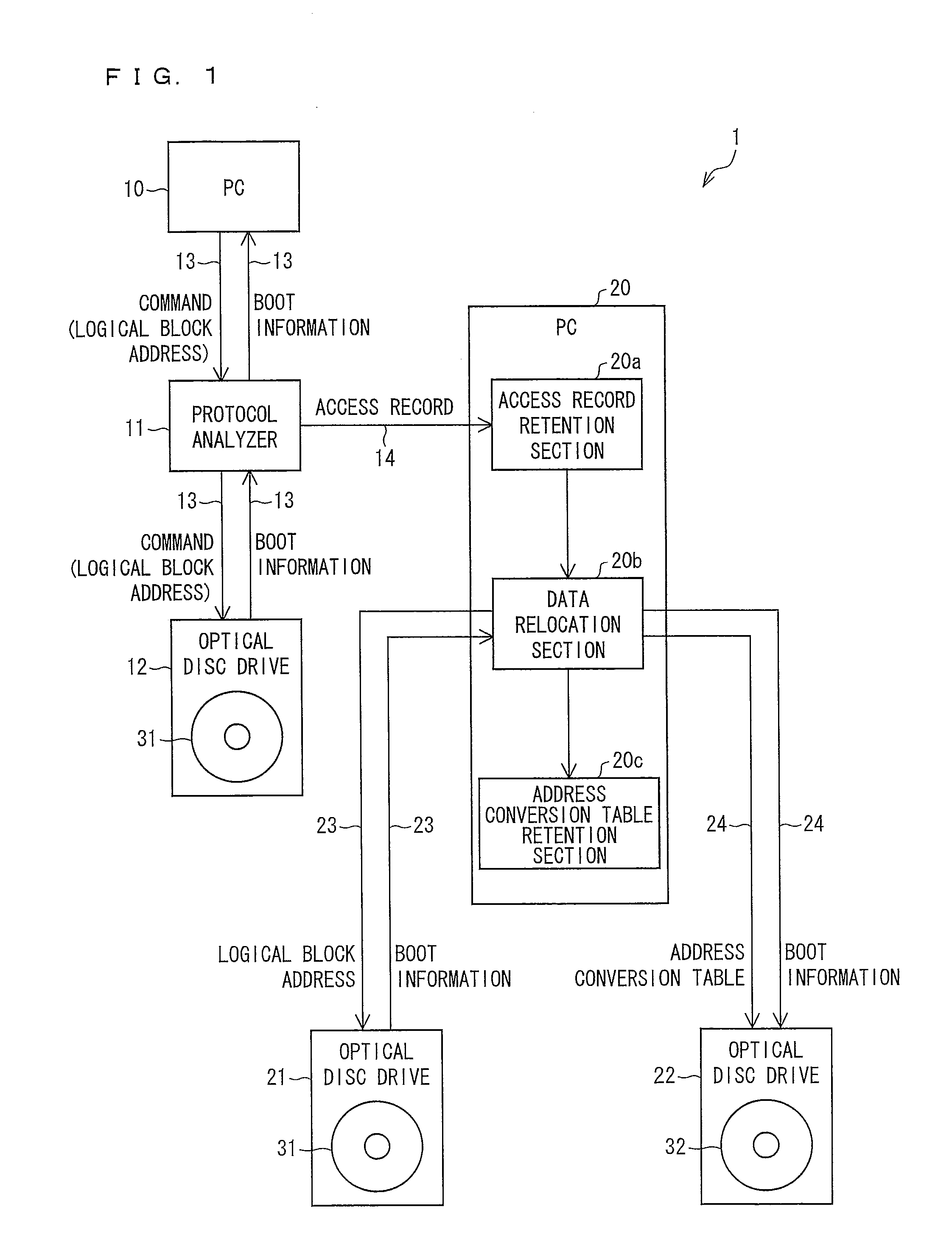

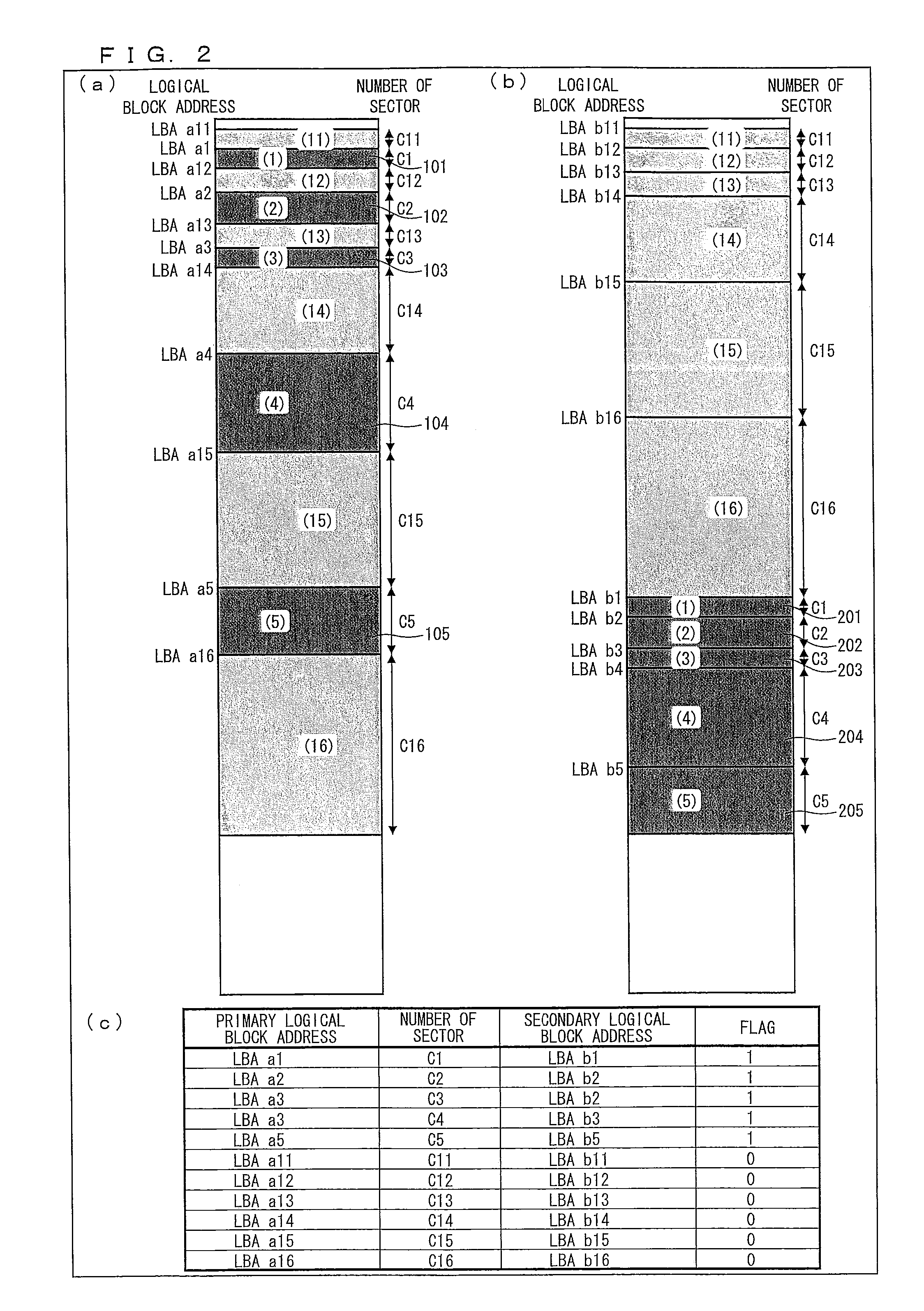

Recording method, recording device, optical disc, optical disc manufacturing method, and optical disc drive device

InactiveUS20110038238A1Increased start-up timeShorten the timeElectronic editing digitised analogue information signalsRecord information storageComputer hardwareCompact Disc manufacturing

In a recording system (1), a personal computer (20) reads out boot information from an optical disc (31) in a predetermined order and records elements of the boot information in contiguous areas on the optical disc (32). In order to thus operate, the personal computer (20) refers to access records before reading out the boot information from the optical disc (31). The access records are generated by a protocol analyzer (11) at a start-up of a personal computer (10). Further, for each of the elements indicated by the access records, the personal computer (20) records, on the optical disc (32), an address conversion table in which that area on an optical disc (31) in which the element is recorded and that area on the optical disc (32) in which the element is recorded are correlated with each other.

Owner:SHARP KK

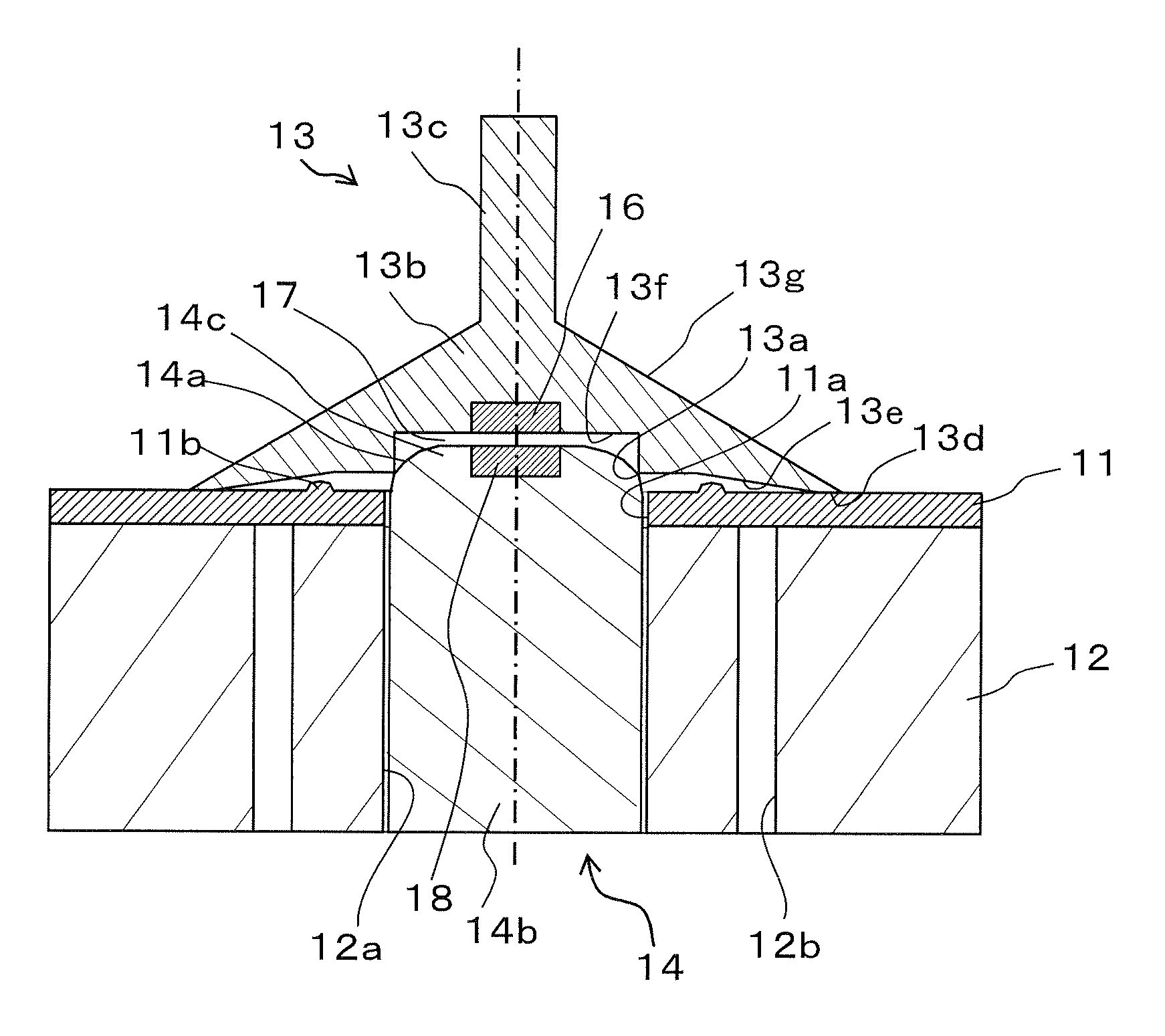

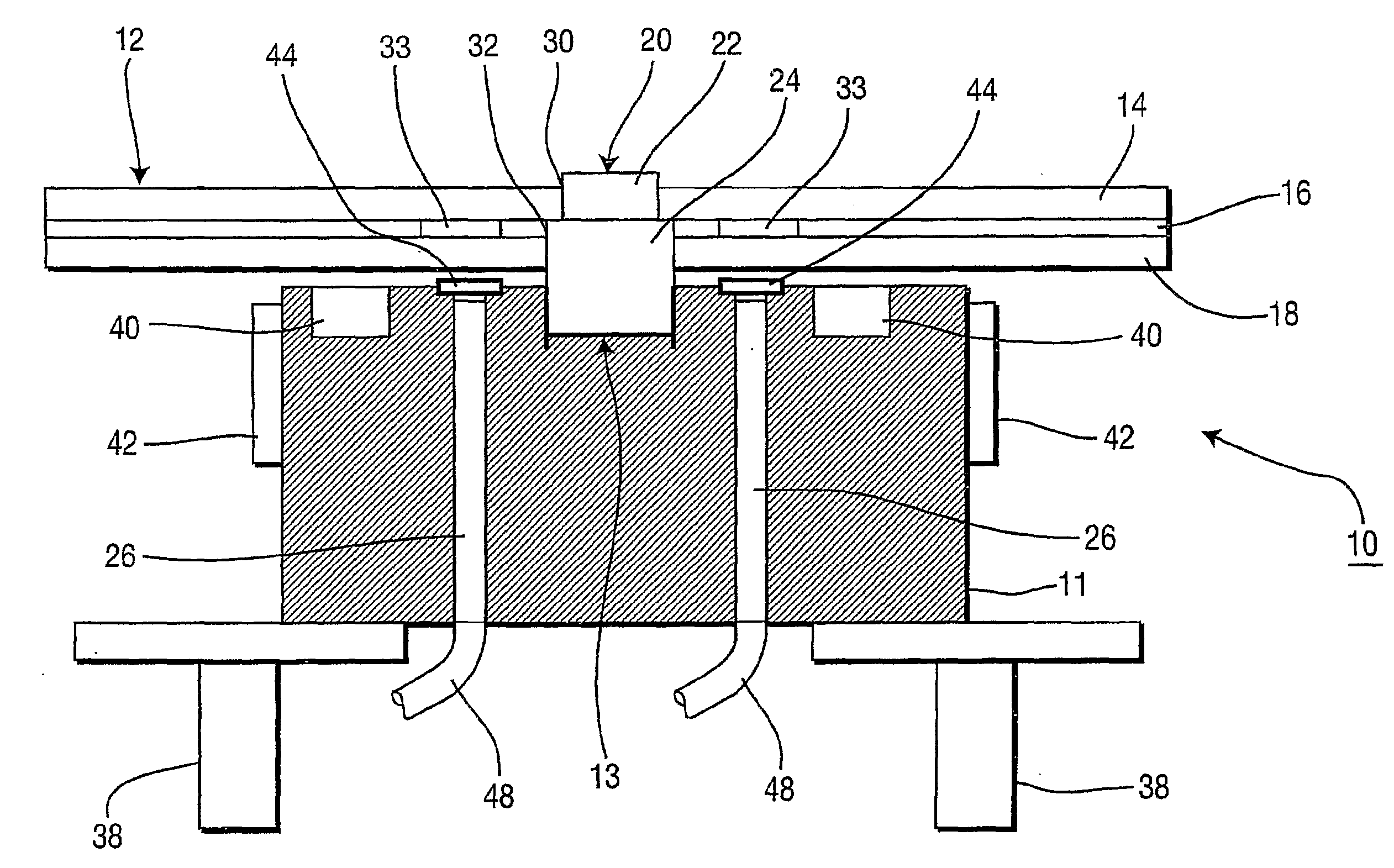

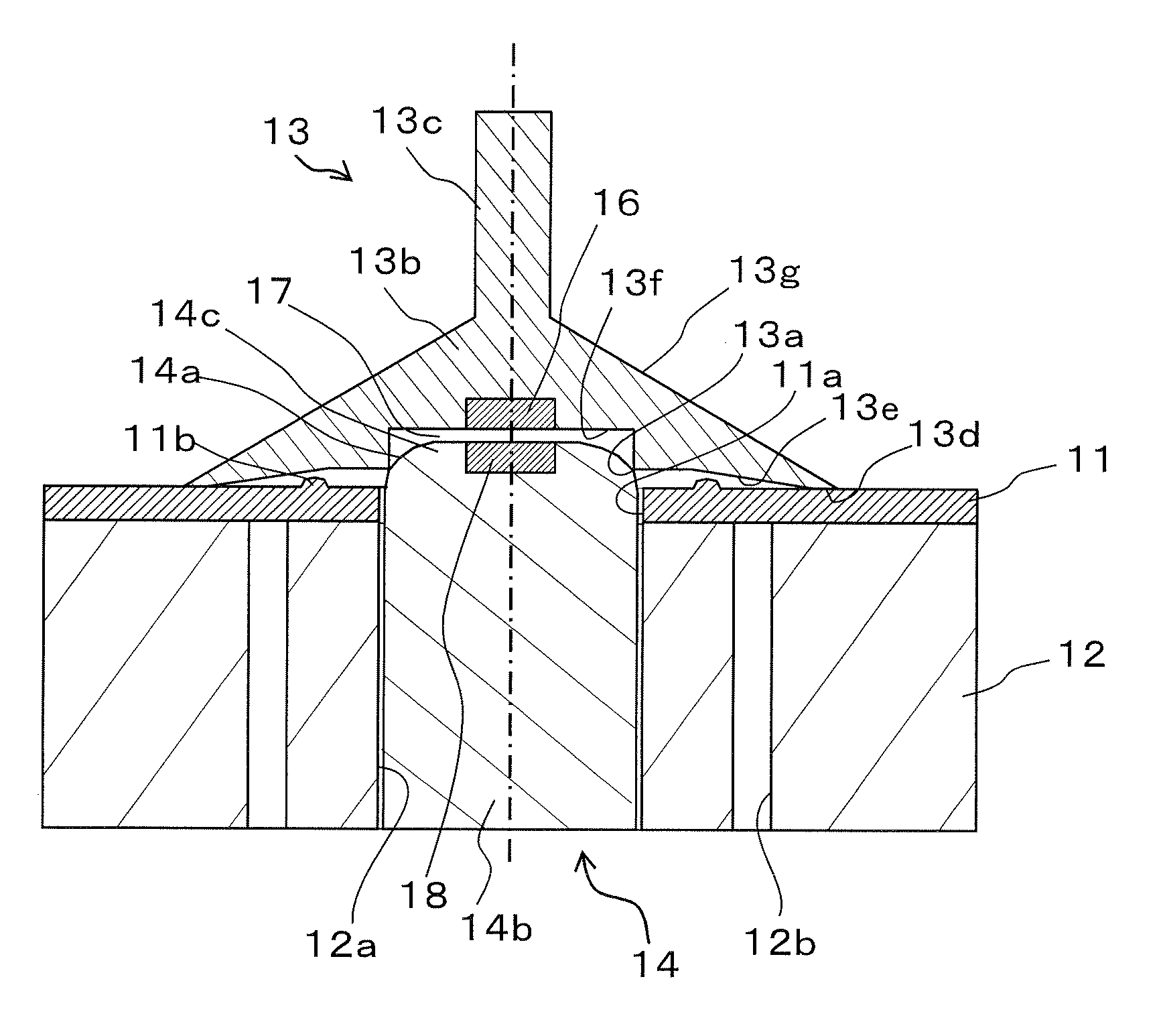

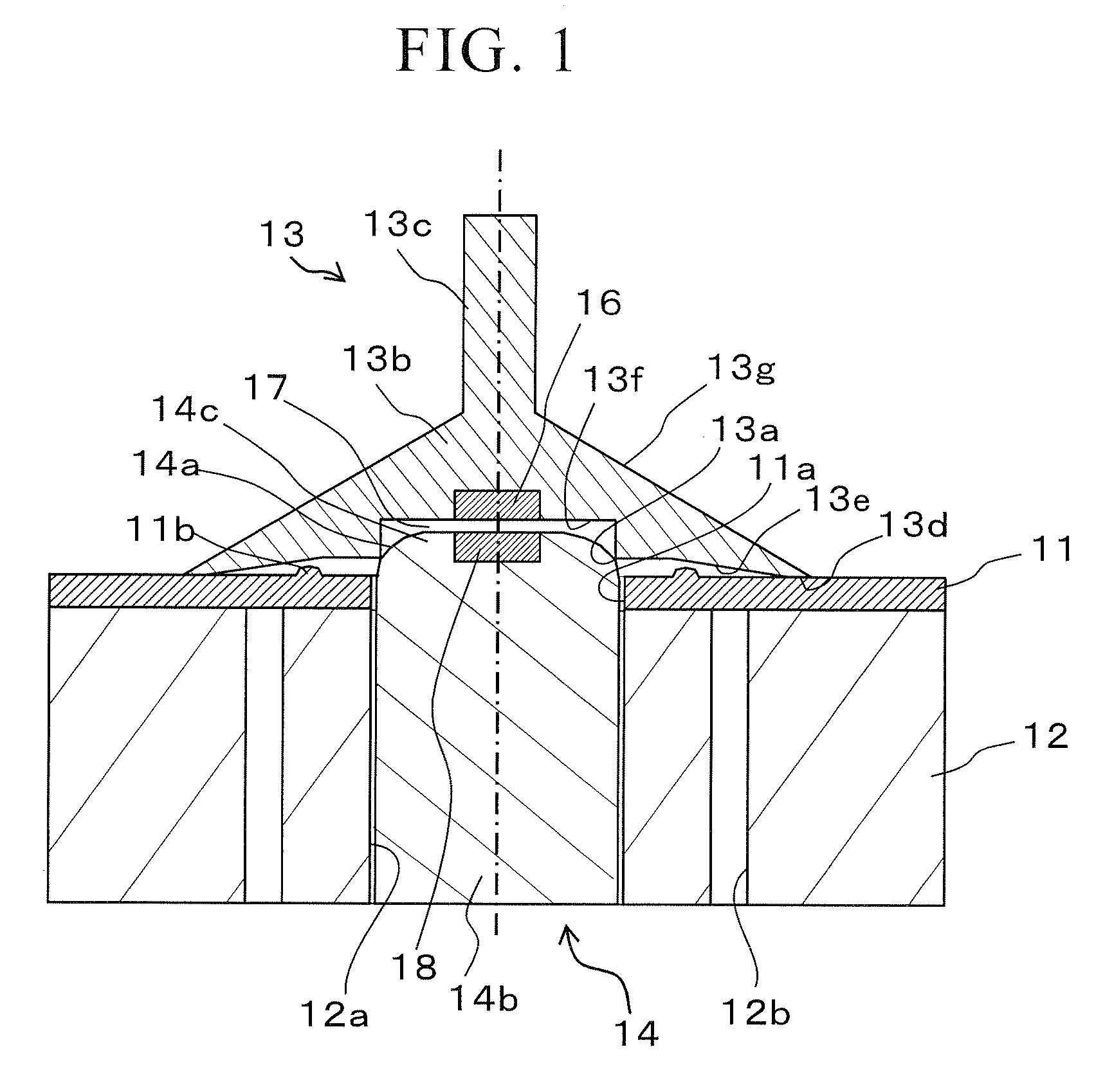

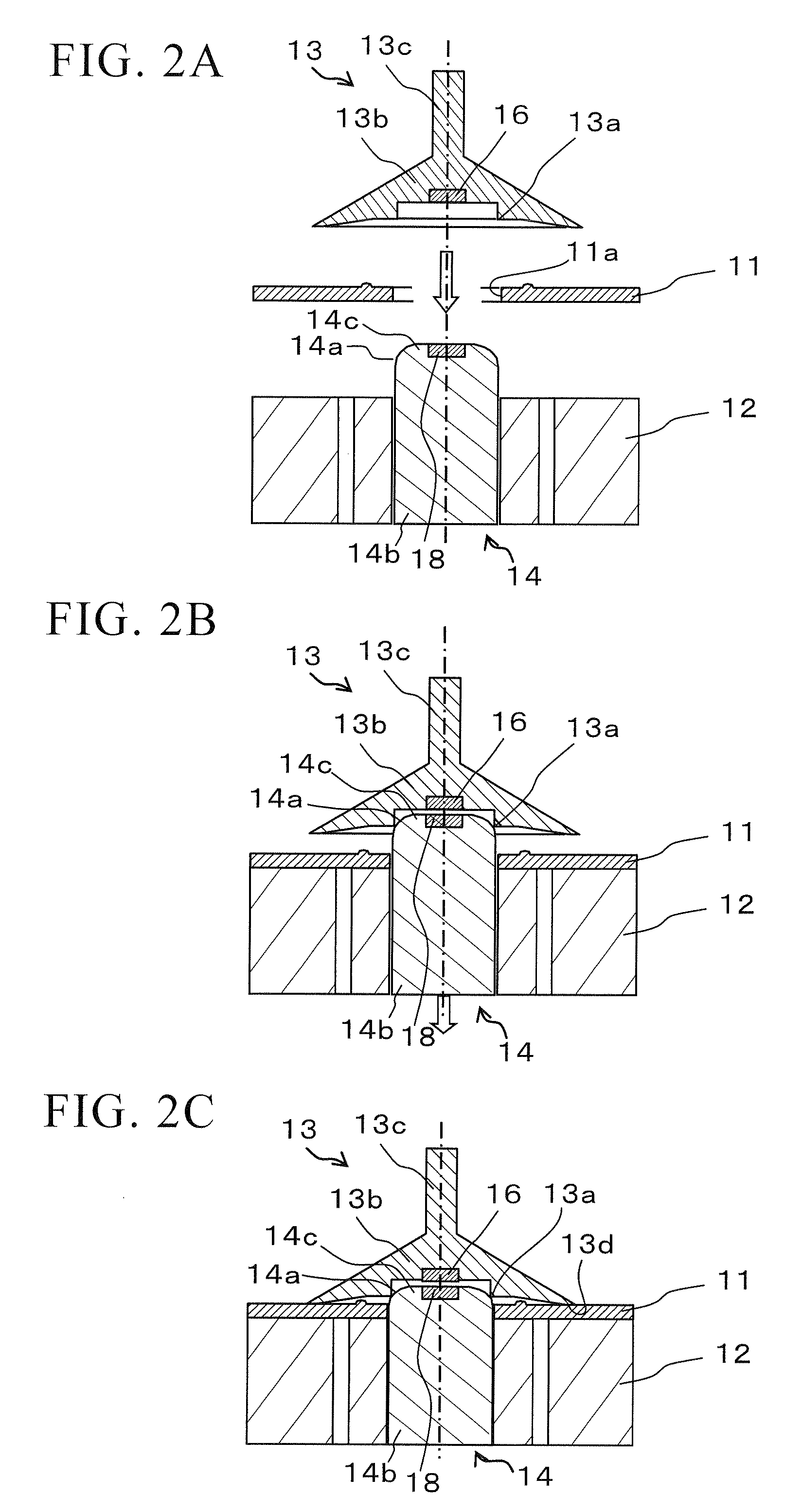

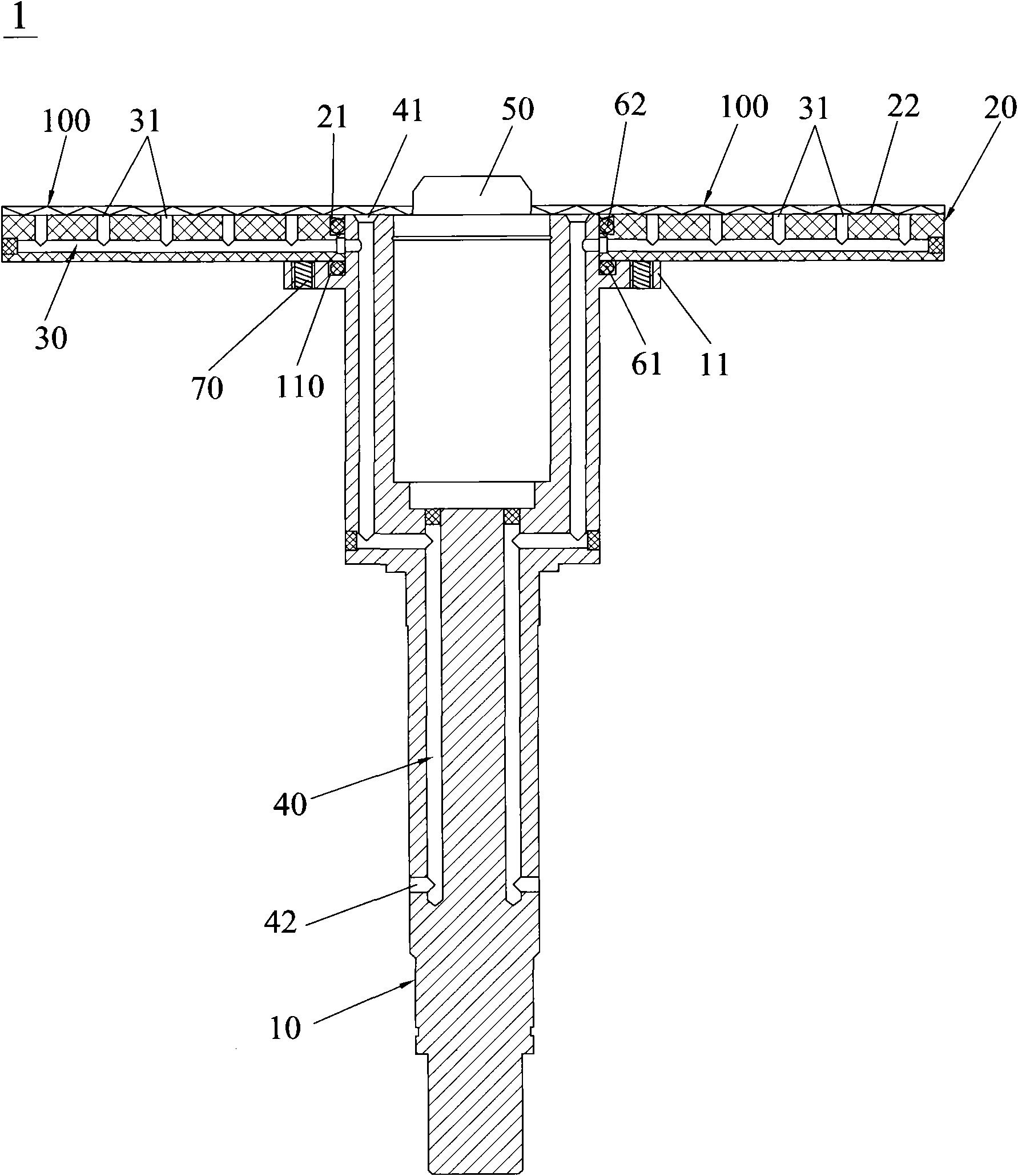

Manufacturing device and manufacturing method for optical disc

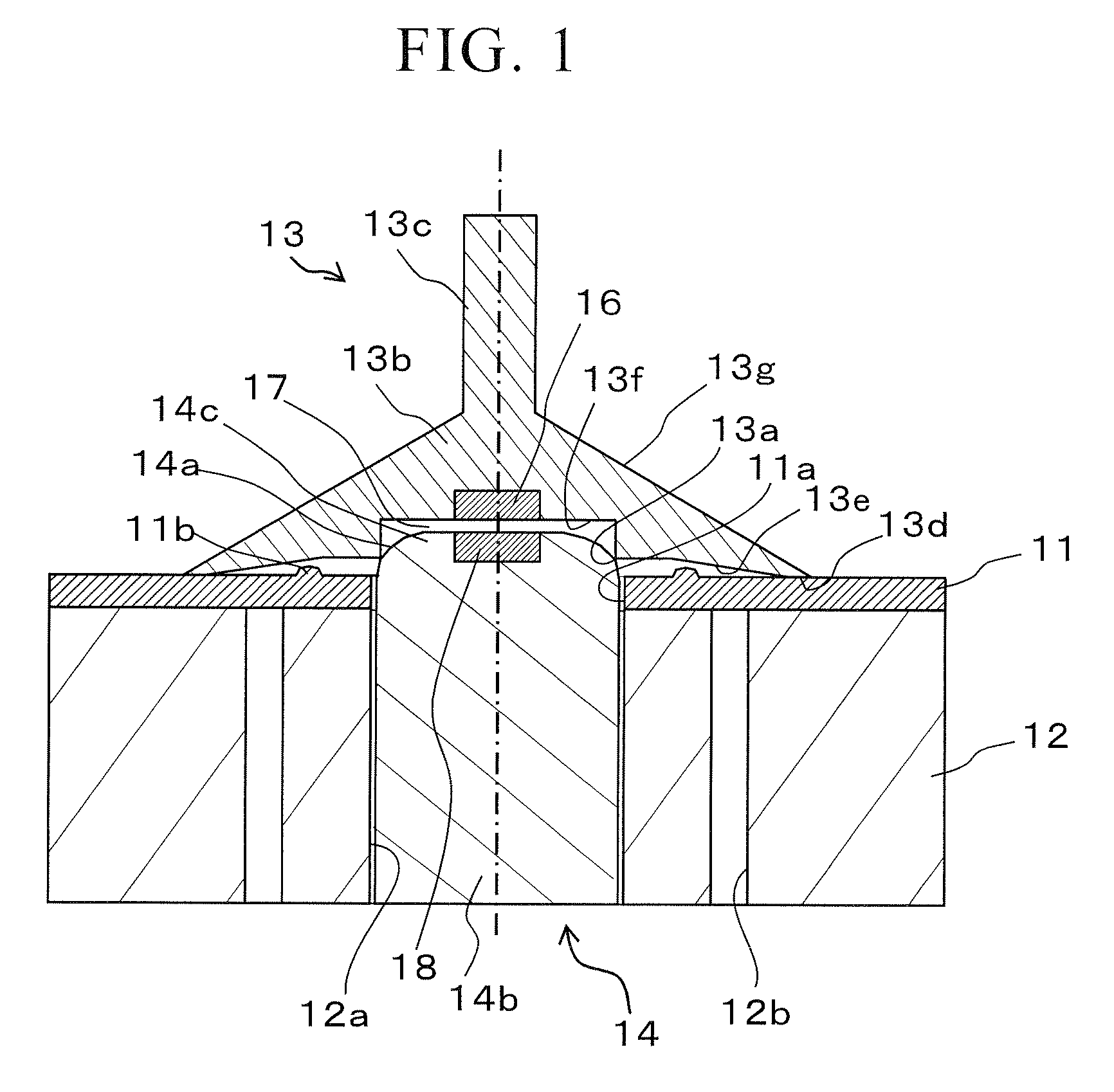

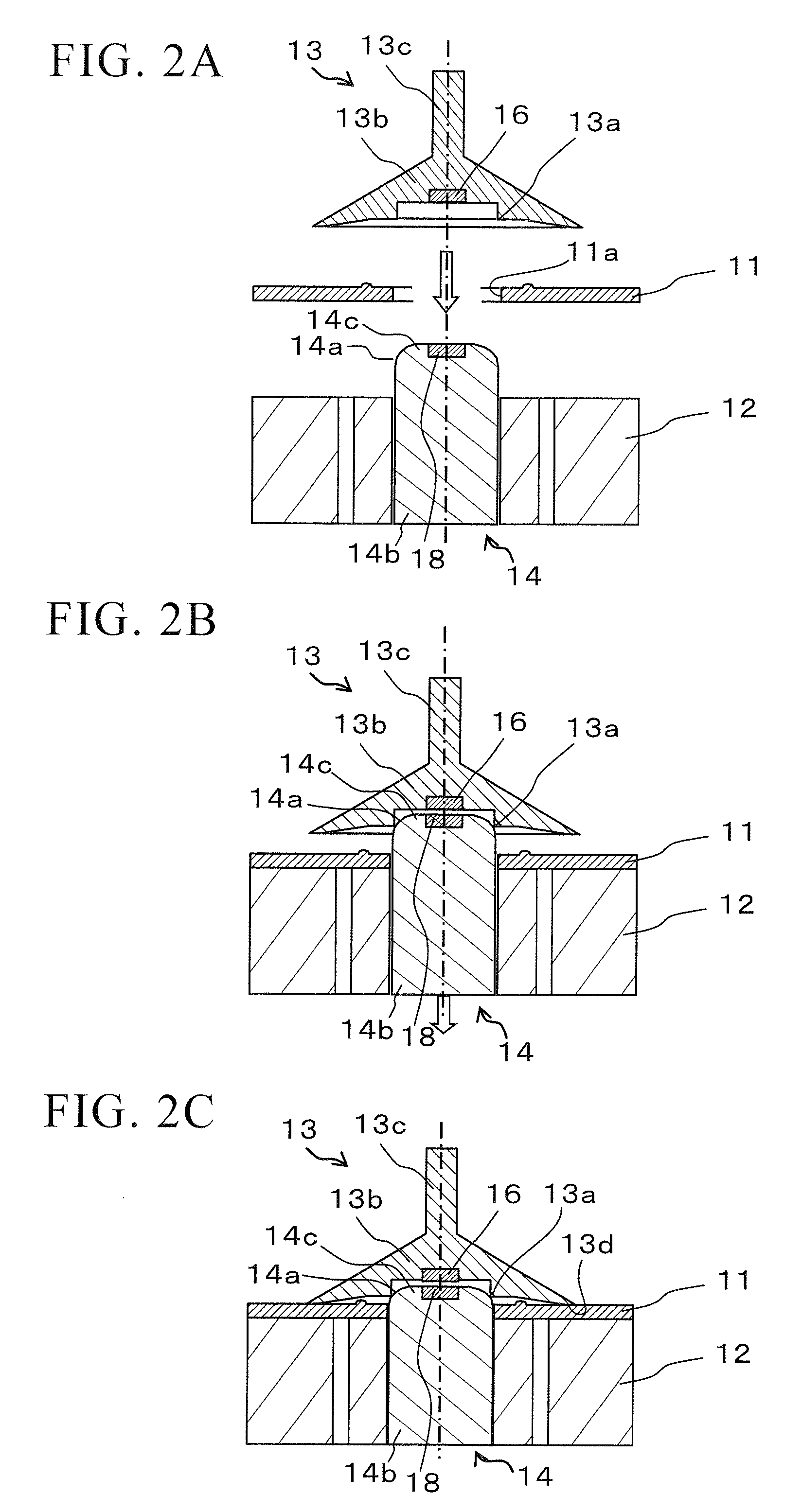

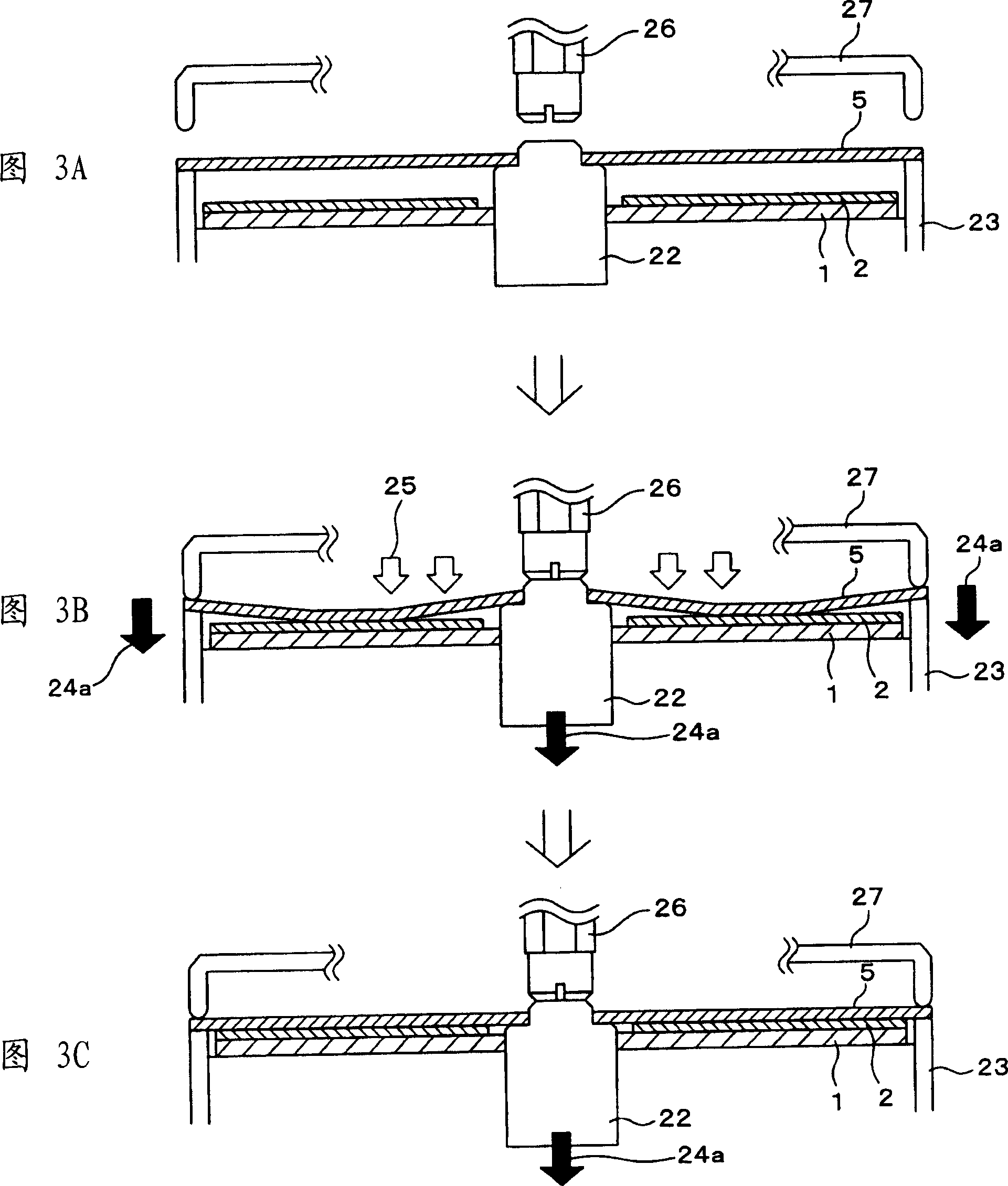

InactiveUS7910161B2Easily follow flatnessSmooth connectionMechanical working/deformationRecord carriersCompact Disc manufacturingEngineering

This manufacturing device for an optical disc includes: a disc-supporting base on which a disc substrate is mounted; a pin-shaped member arranged at a center of the disc-supporting base, and is movable in the vertical in a center hole of the disc substrate; and a capping member which is slidably placed on a top of the pin-shaped member, and closes the center hole of the disc substrate, wherein when the capping member placed on the top of the pin-shaped member is lowered such that a back face of the capping member contacts an around of the center hole of the disc substrate mounted on the disc-supporting base, the capping member slides on the top of the pin-shaped member.

Owner:ORIGIN ELECTRIC CO LTD

Manufacturing method of optical disk and its manufacturing apparatus

A manufacturing method of an optical disk in which information recording layers are formed onto a resin layer laminated on a substrate surface. The substrate surface is coated with the resin layer. The substrate and a stamper are arranged into a vacuum chamber so that the resin layer surface and the stamper surface with concave / convex portions face almost in parallel. The chamber is set into an almost vacuum state while holding the facing state of the substrate and the stamper. The chamber is changed from the almost vacuum state to an atmospheric pressure or higher. The substrate and the stamper are overlaid. The stamper is pressed by a differential pressure between the almost vacuum pressure and the atmospheric pressure or higher, thereby adhering the substrate and the stamper and transferring the concave / convex portions to the resin layer. The resin layer with the transferred concave / convex portions is hardened.

Owner:SONY CORP

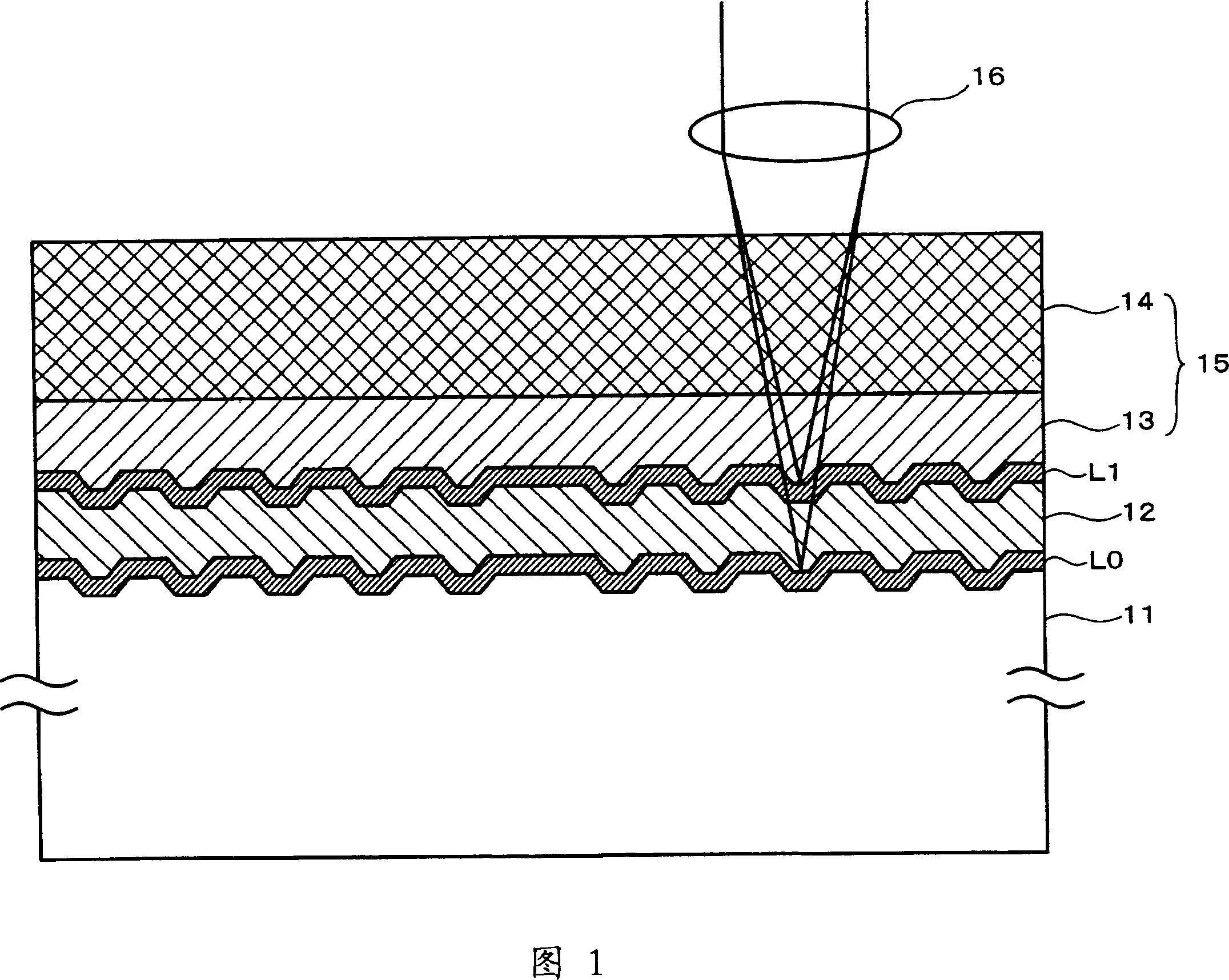

Optical disk having multiple write layers, optical disk manufacturing method, optical disk device and optical disk write/read method

InactiveUS20030031110A1Mechanical record carriersRecord information storageCompact Disc manufacturingLight beam

An optical disk, a method for manufacturing an optical disk, an optical disk device and a method for writing / reading an optical disk, wherein the optical disk is of a write / read type having two layers of write films, enabling the state of the write / read beam to be kept constant when writing onto or reading out of a second write film without being affected by variations in the write state of a first write film, is to be provided. In an optical disk configured by stacking, enumerated in the direction of incidence of a write / read beam, a disk substrate, a first write film, an adhesive layer, a second write film, another disk substrate and an aluminum reflective layer, when performing read / write onto or out of a write film which is the second write film, the write / read beam is focused on the second write film after being transmitted by the disk substrate, the first write film, the adhesive layer, the second write film and the other disk substrate and reflected by the aluminum reflective layer.

Owner:NEC CORP

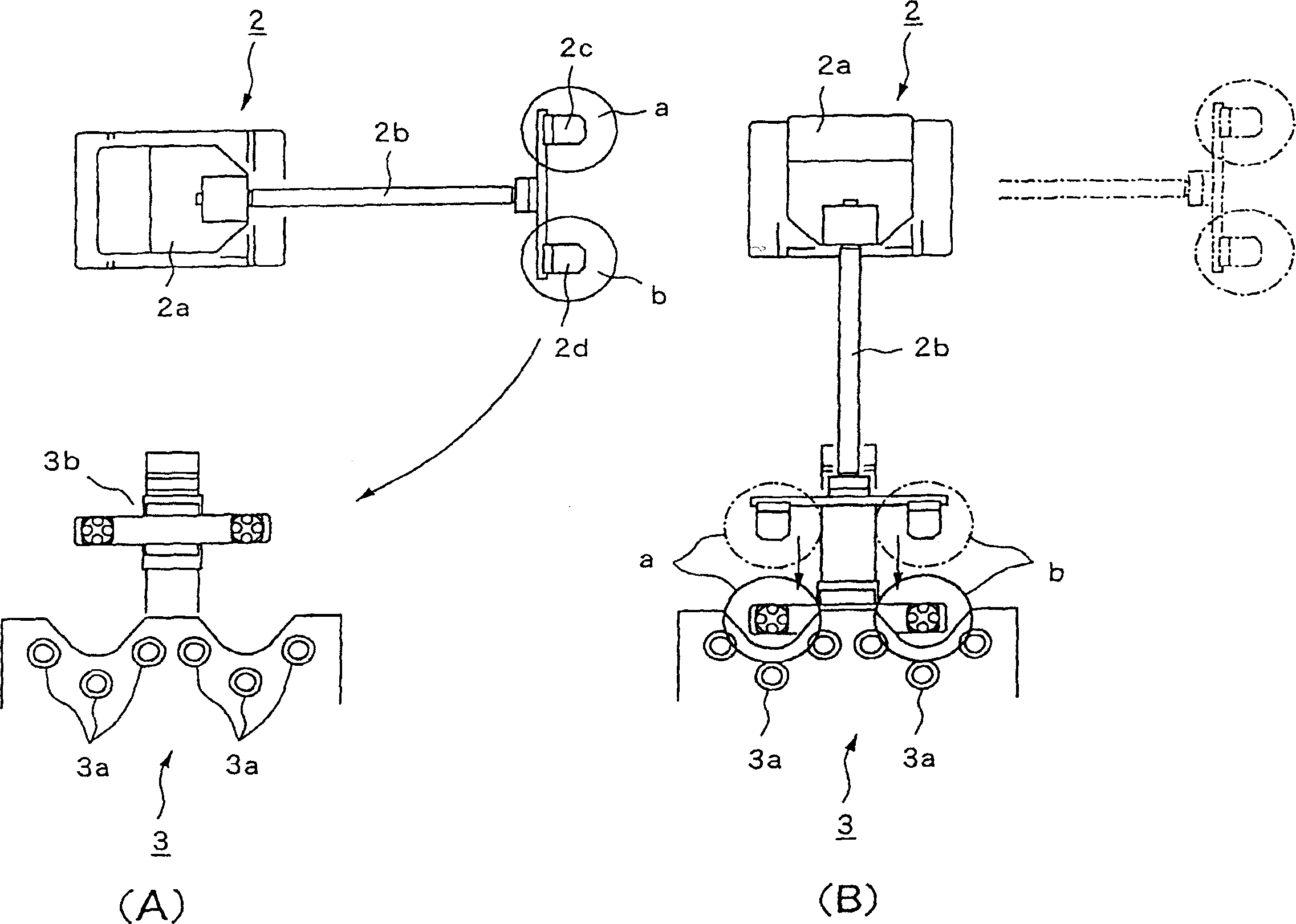

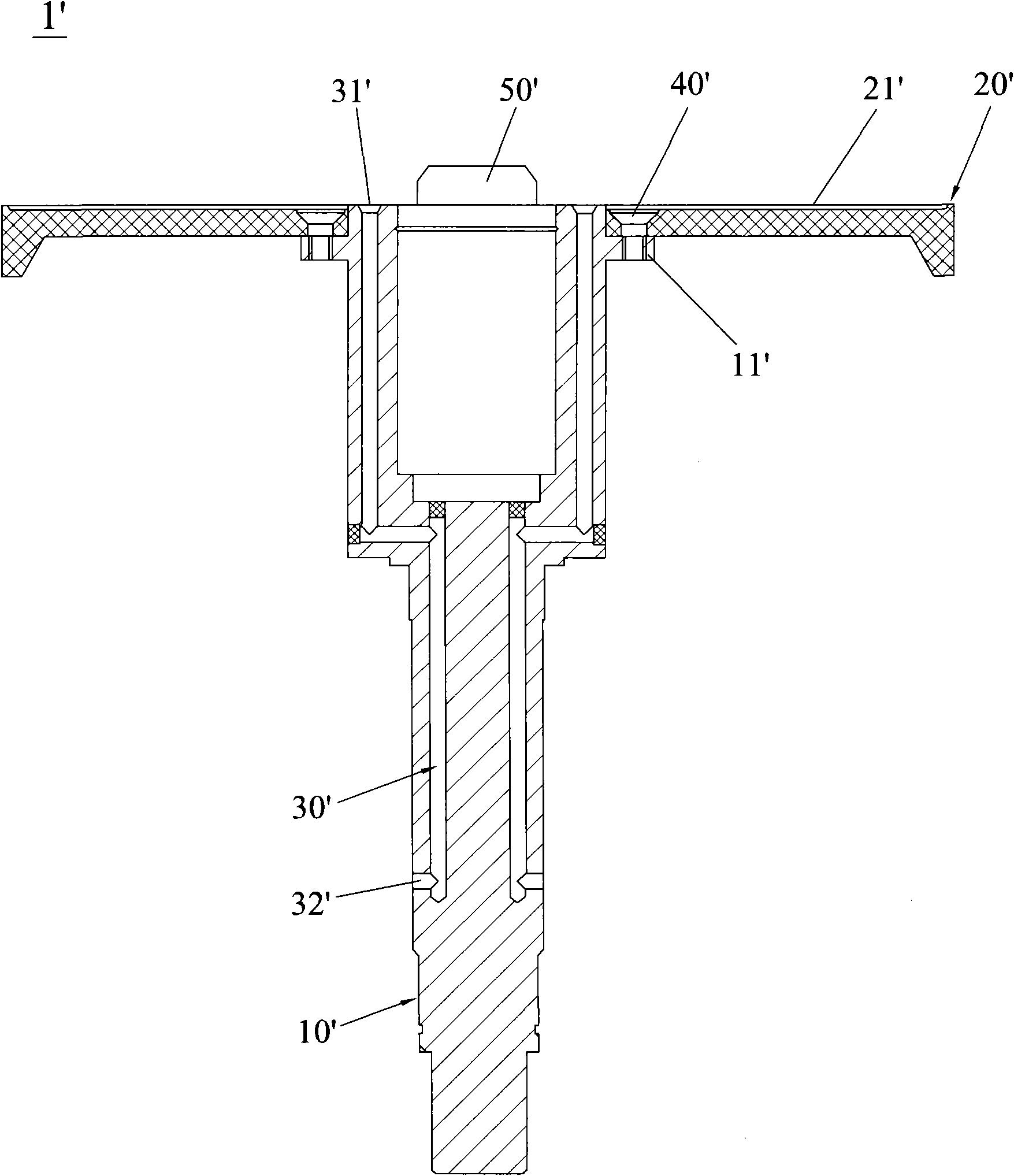

Alignment device for fabricating optical disk

InactiveUS7337819B2Satisfactory accuracyPrecise positioningMechanical working/deformationRecord carriersCompact Disc manufacturingEngineering

In an optical disc fabricating apparatus, when the disc substrate is lowered from the tip of a disc inserting portion at a center pin down to a disc supporting portion, a disc urging portion of an alignment lever is pressed by a disc substrate, to be thus pushed in toward an inner periphery and a sheet urging portion is pushed out toward an outer periphery, so as to press the inner peripheral surface of a cover sheet so that both of the cover sheet and the disc substrate are urged in an alignment direction. Thus, it is possible to eliminate play generated between the inner peripheral surface of the cover sheet and the outer peripheral surface of a sheet inserting portion and play generated between the inner peripheral surface of the disc substrate and the outer peripheral surface of the disc inserting portion.

Owner:FUJIFILM HLDG CORP +1

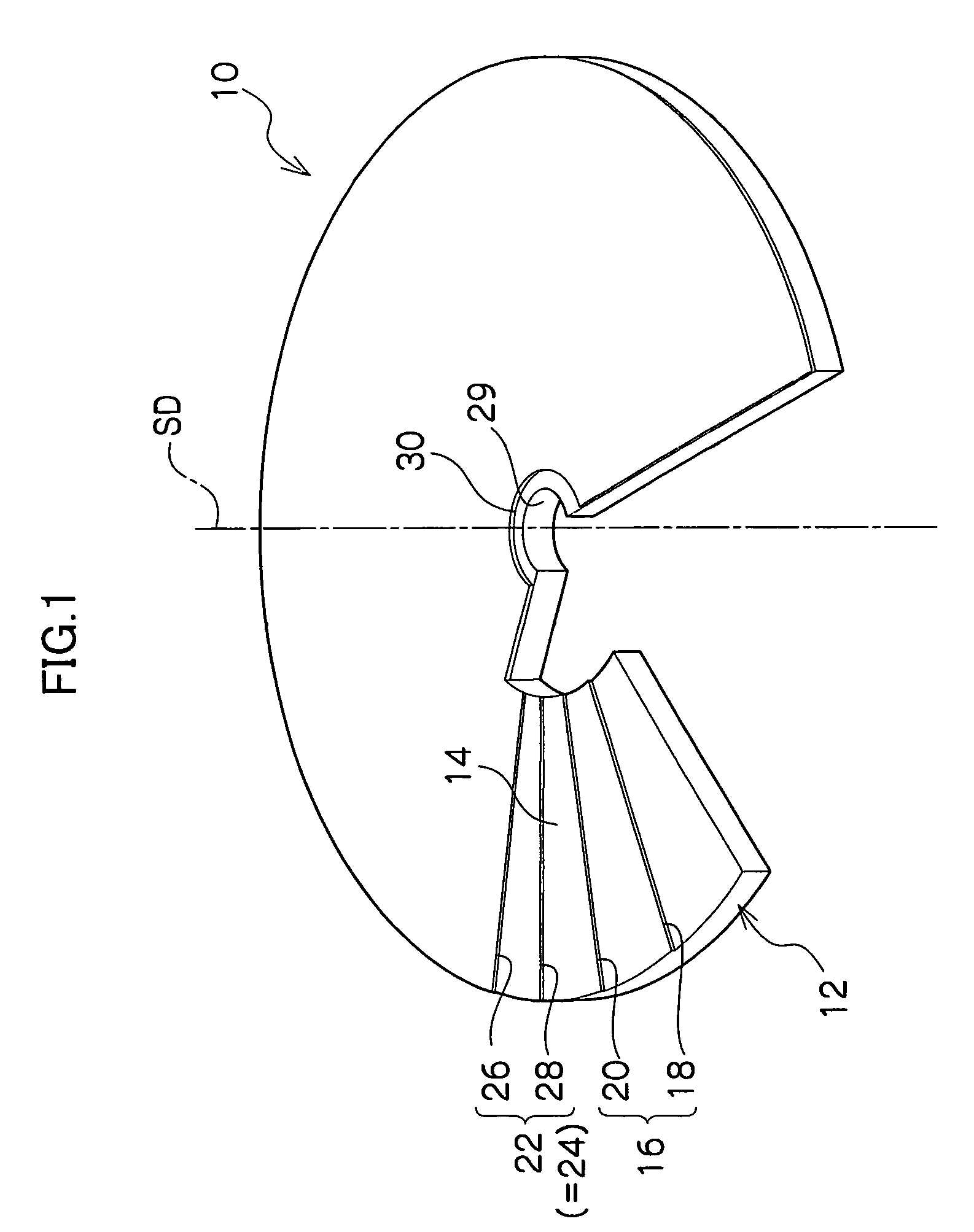

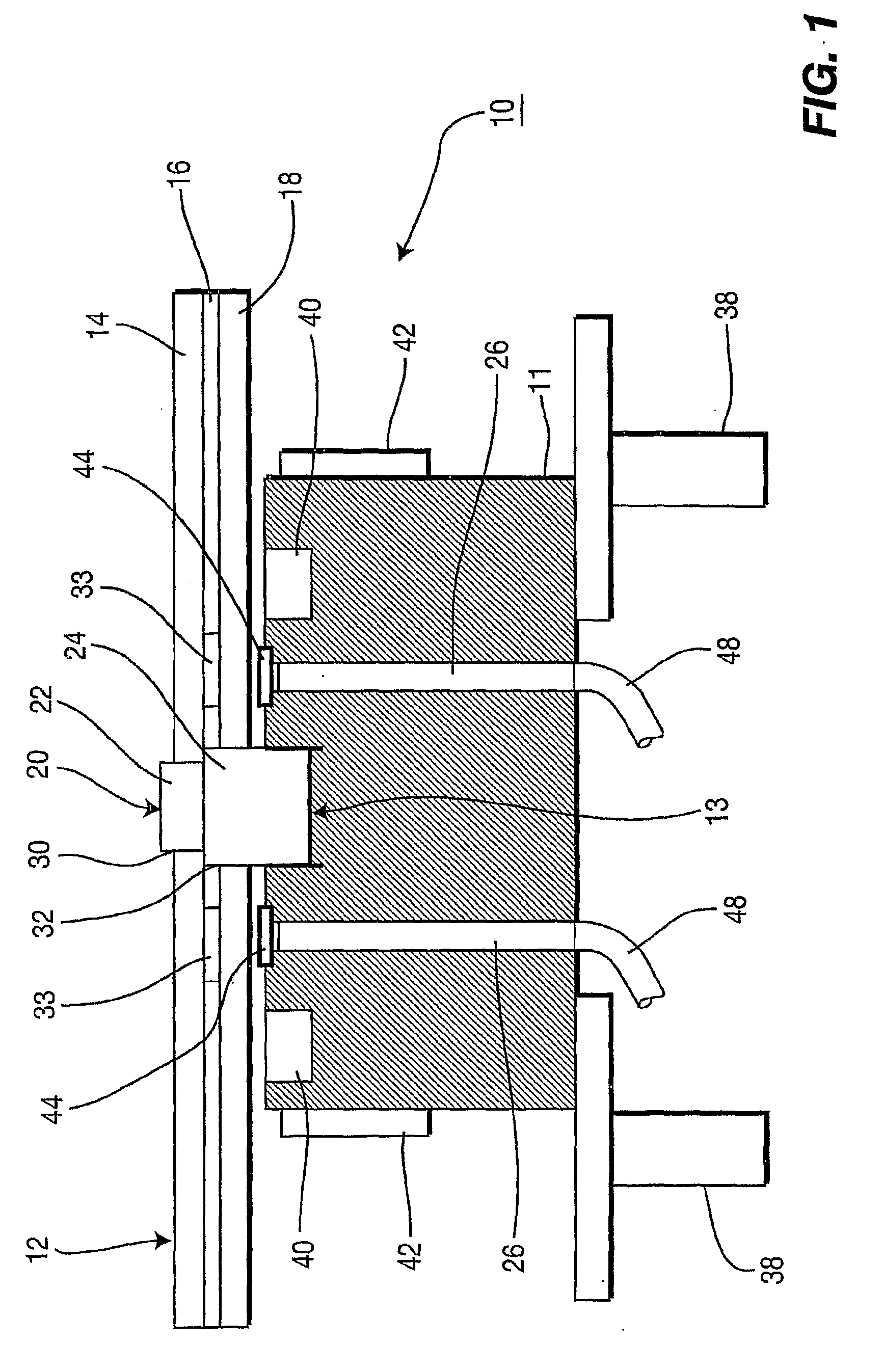

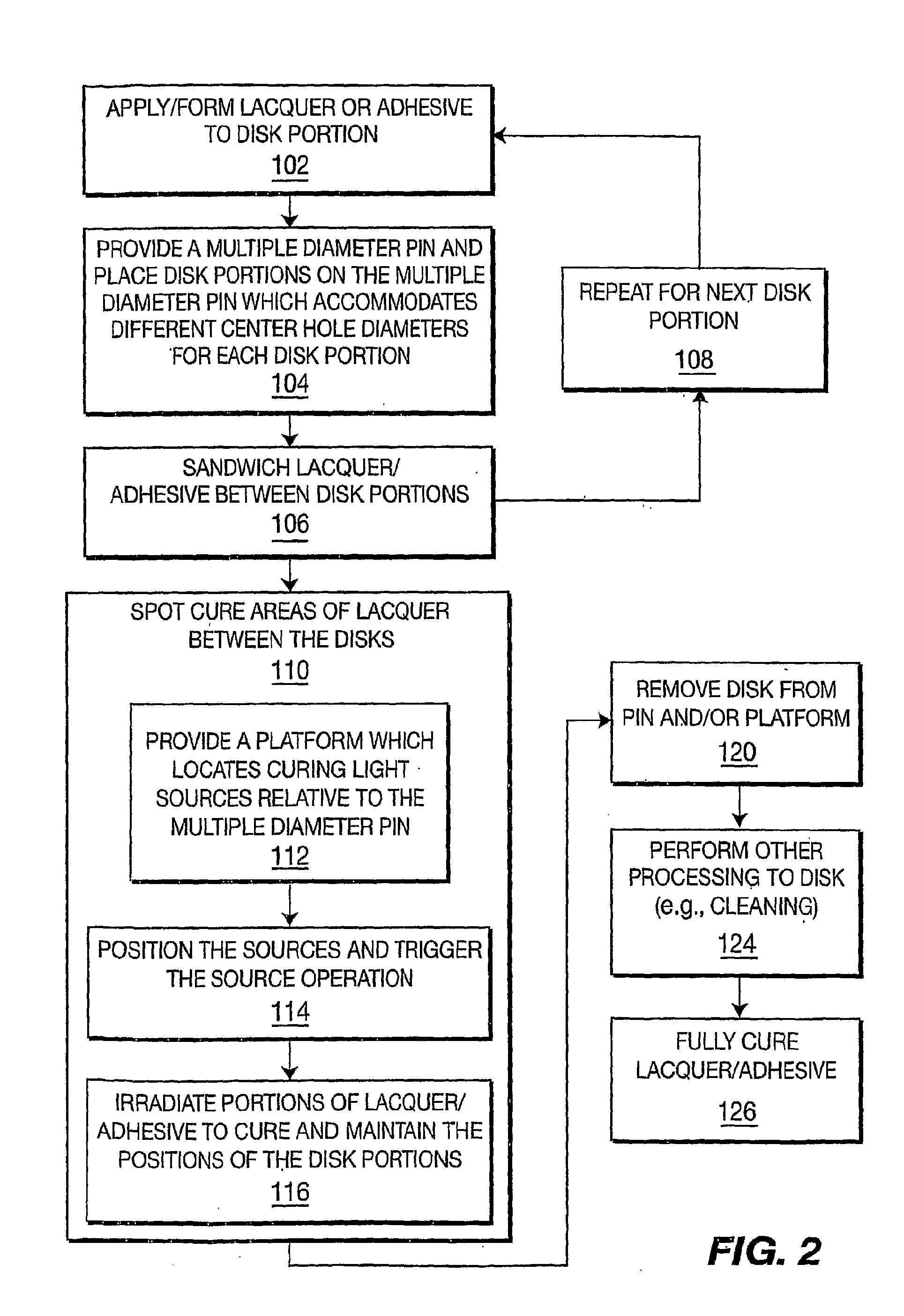

Apparatus and Method for Improving Center Hole Radial Runout Control in Optical Disk Manufacturing

InactiveUS20080149266A1Record carriersMechanical working/deformationCircular discCompact Disc manufacturing

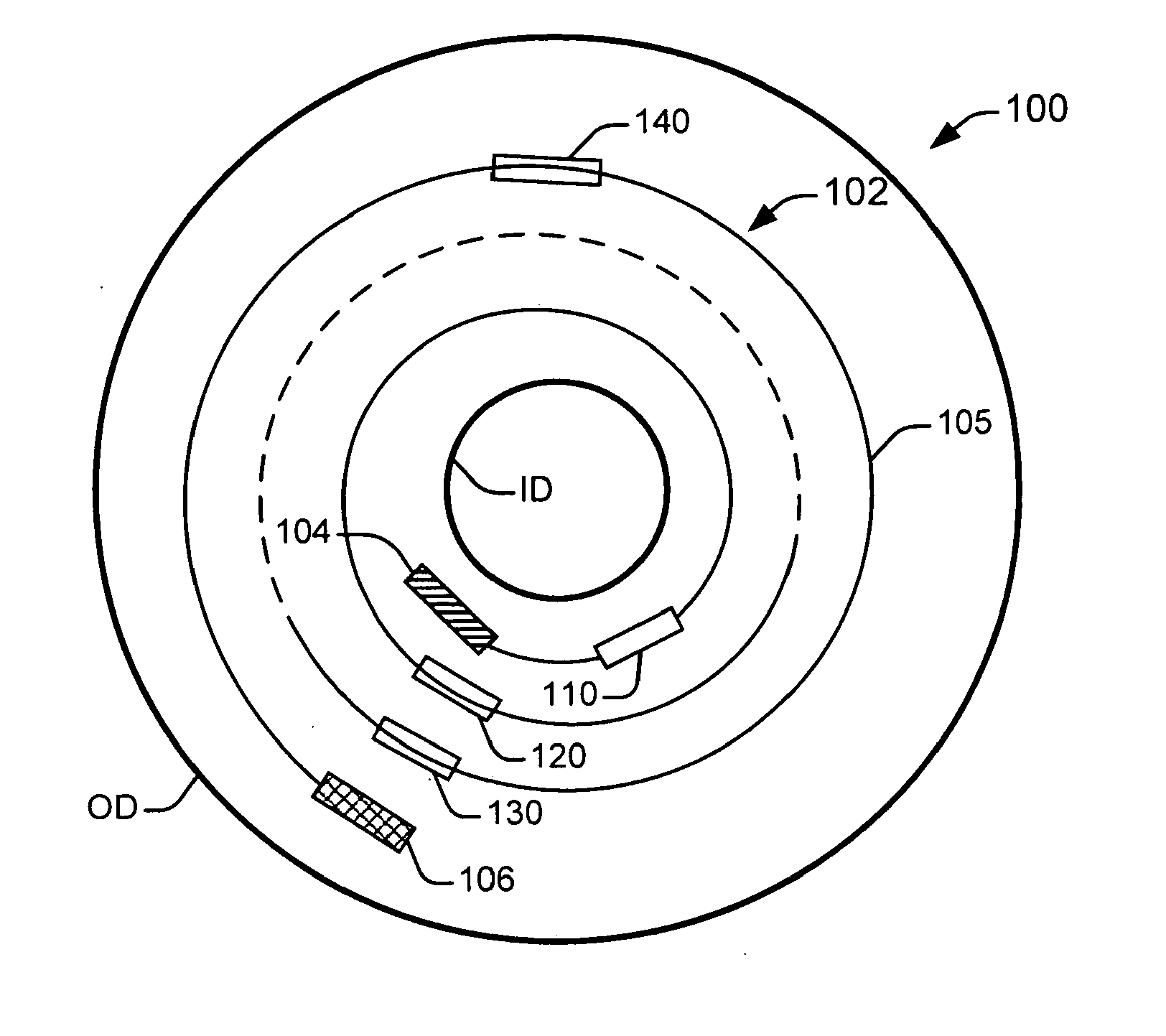

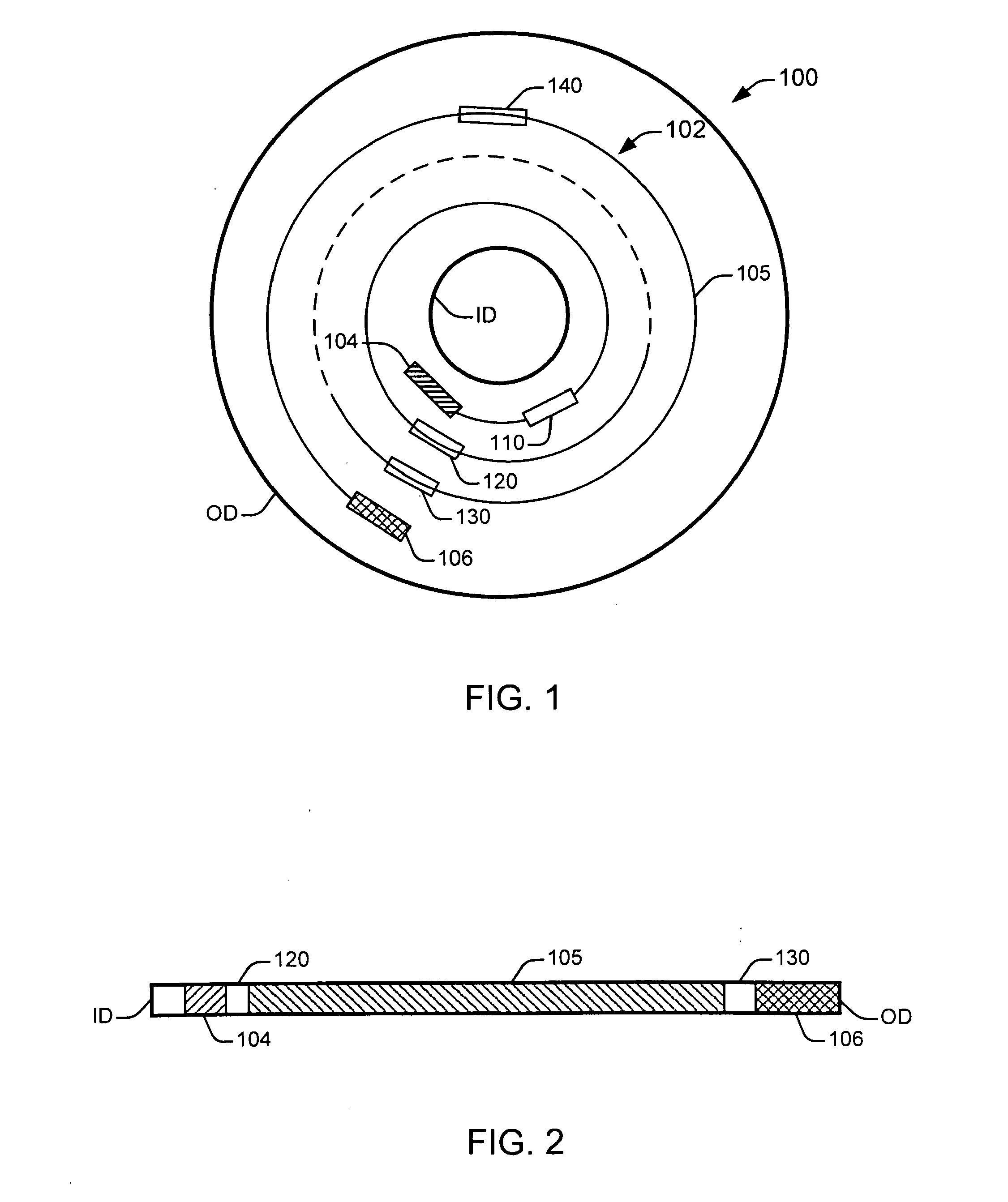

An apparatus and method for controlling radial runout between stacked disk portions (14, 18) and providing a cylindrical pin (20) having at least two diameters (22, 24). The pin is dimensioned and configured to permit the disk portions, which have different center hole dimensions, to be indexed such that a center hole of each disk portion is received by a separate diameter of the pin. The disk portions are maintained in spatial relationship as provided by the pin by spot curing a portion of the adhesive.

Owner:TECHNICOLOR INC

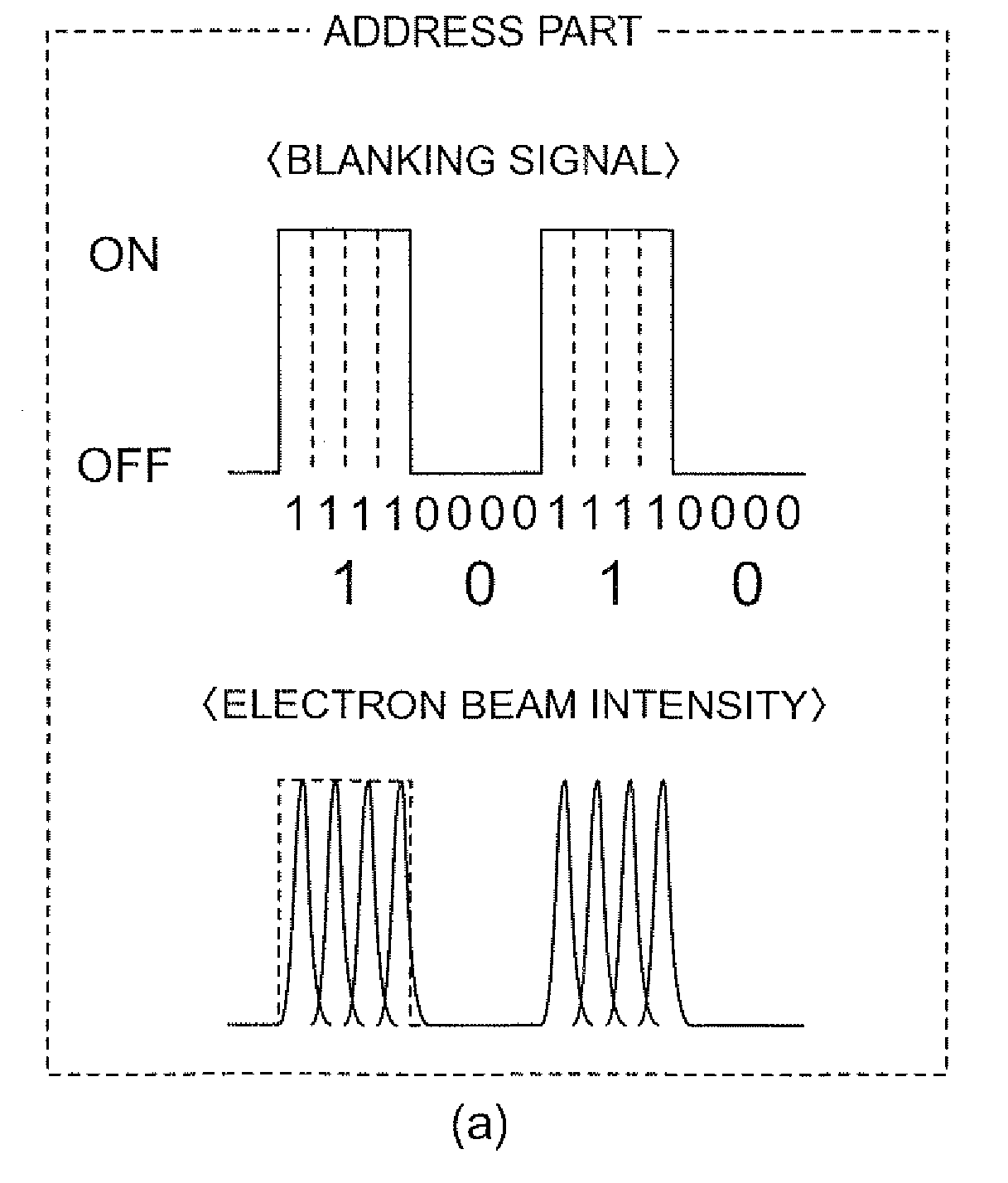

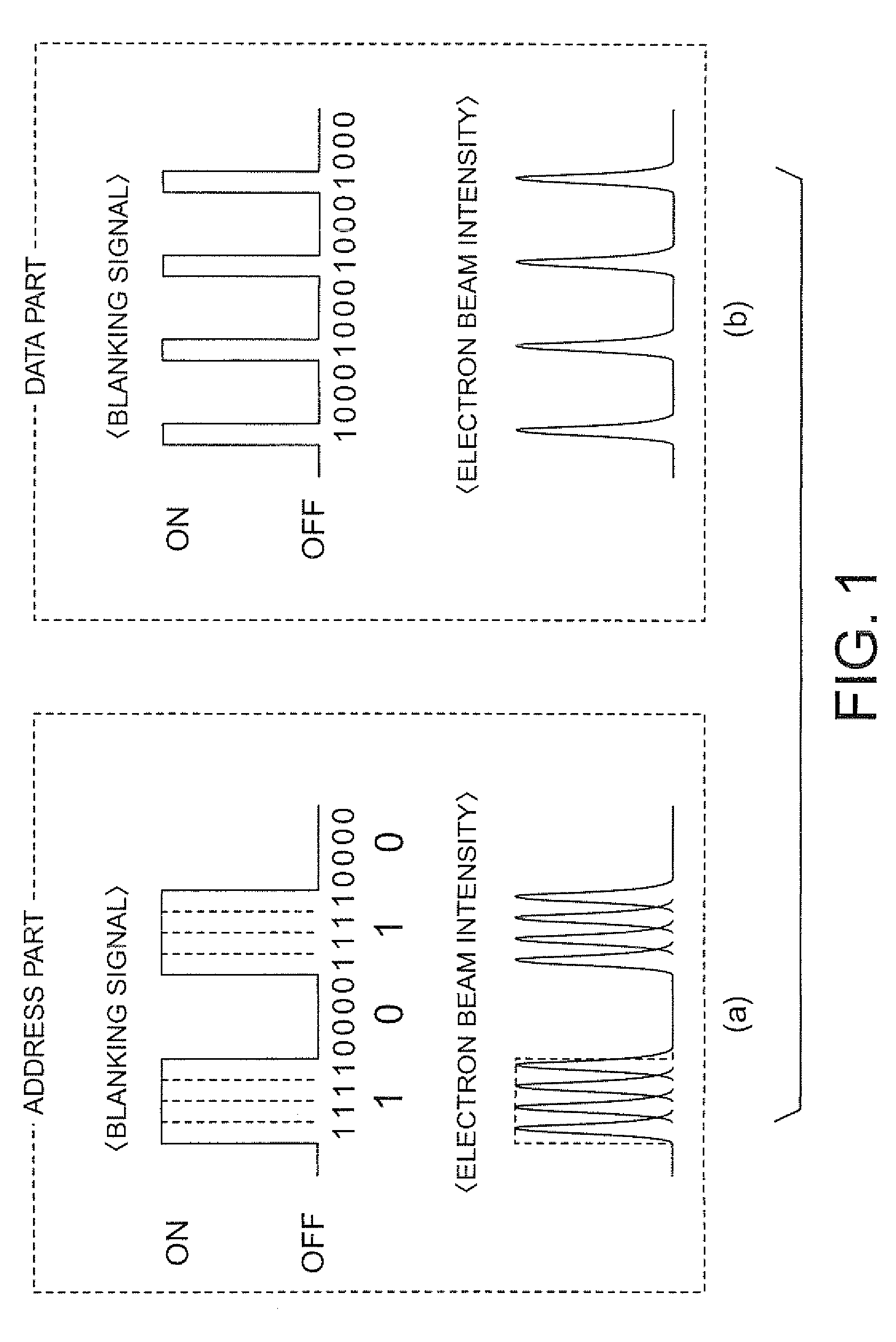

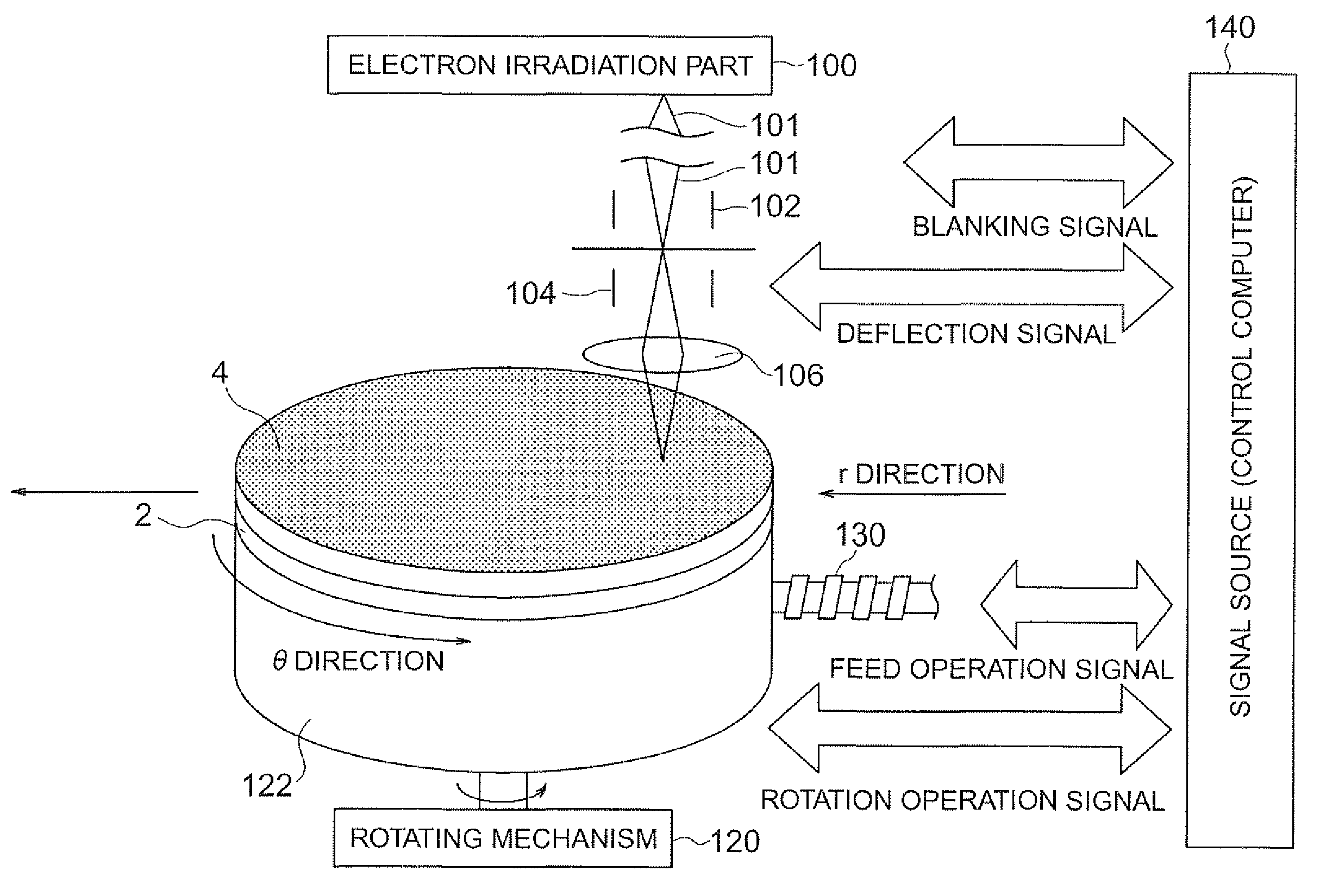

Original disk fabrication method, magnetic recording medium manufacturing method and magnetic recording medium

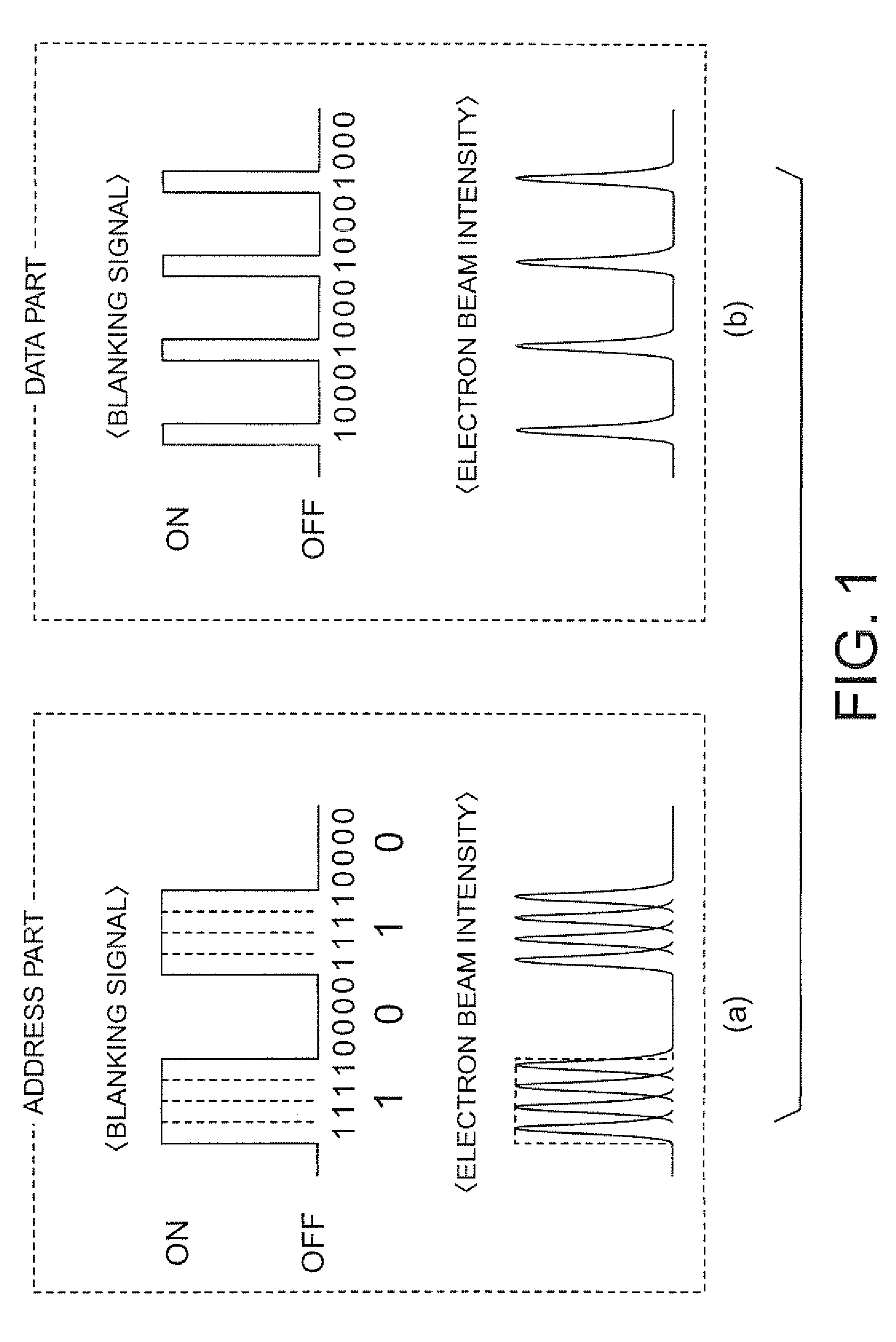

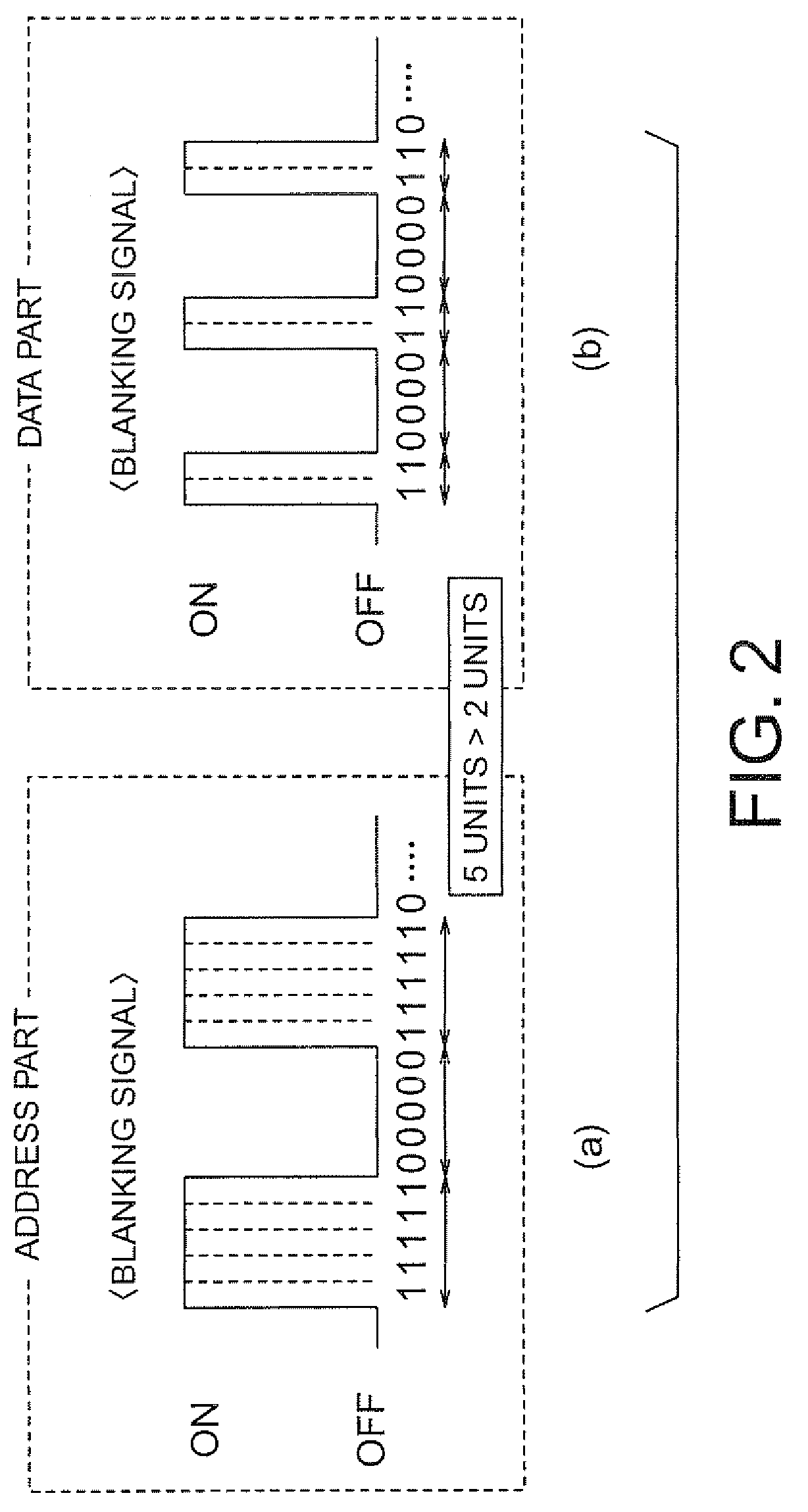

InactiveUS20080204935A1Favorable address decipheringImprove recording densityElectron beam carrier recordingElectric discharge tubesCompact Disc manufacturingEngineering

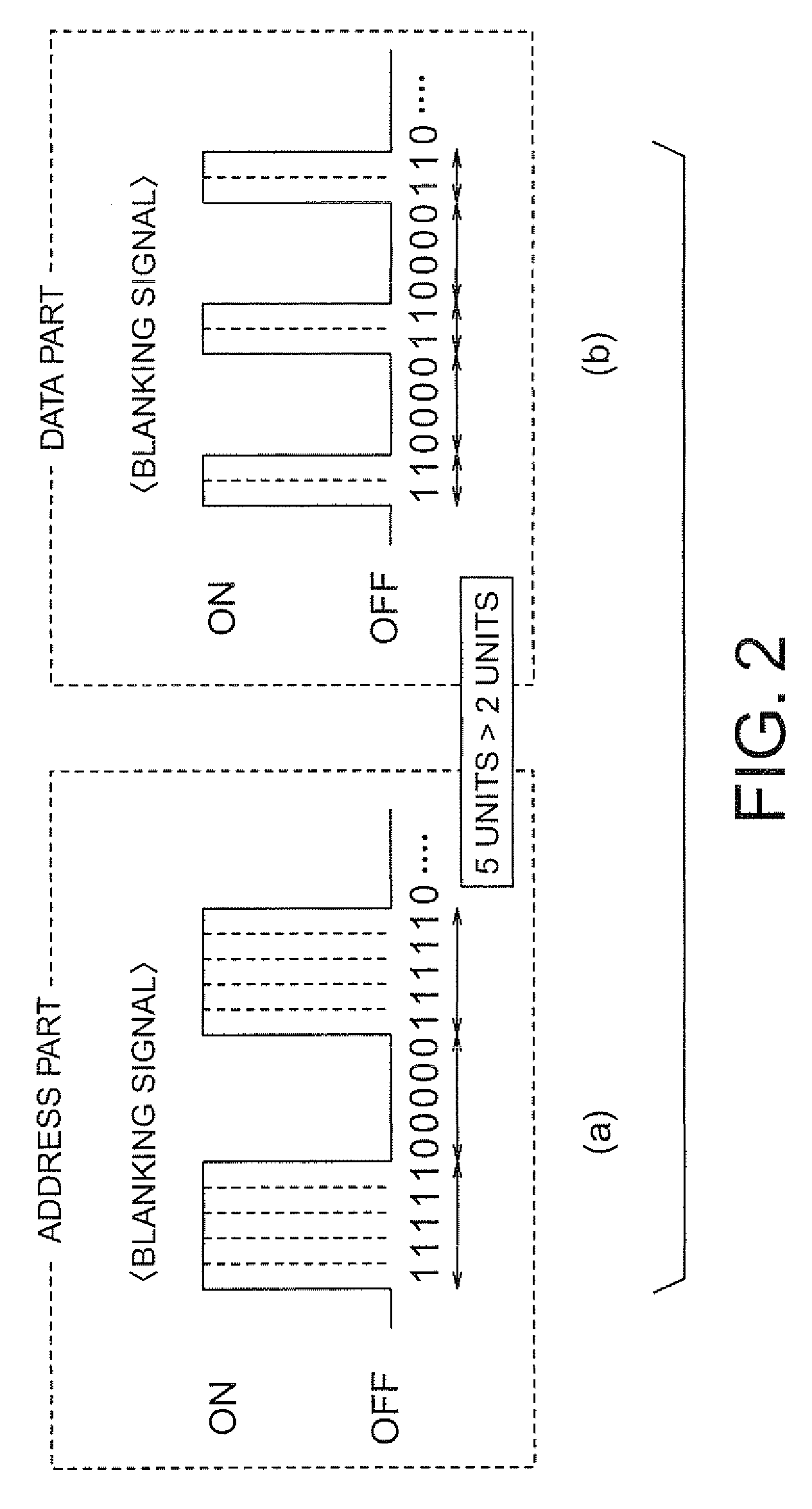

It is made possible to fabricate a bit-patterned magnetic recording medium having a high recording density and making favorable address deciphering possible. An original disk fabrication method for irradiating a photosensitive resin film with an electron beam to draw a pattern, the method includes: irradiating the electron beam by using a plurality of blanking signals every rotation of a stage per bit unit, when drawing the pattern in a part corresponding to an address part on a photosensitive resin film.

Owner:KK TOSHIBA

Optical disc with pre-recorded and recordable regions and method of forming the disc

InactiveUS20100322055A1ConfectioneryRecord information storageComputer hardwareBiological activation

An optical disc having a region with pre-recorded data and a recordable region, a method of fabricating the disc, a stamper for forming a disc master, and a recording device for use with the disc are disclosed. Data recorded in the recordable region may be used for activation of the disc, providing unique identification or enhancing program content on the disc.

Owner:MAGNOLIA LICENSING LLC

Disc Recording Medium, Disc Drive, and Manufactuing Method of Optical Disc

InactiveUS20080062854A1Increasing the thicknessHigh recording processingDriving/moving recording headsOptical overwritingComputer hardwareCompact Disc manufacturing

The present invention relates to an optical disc on which an information signal can be rewritten. Guide grooves (81a) for tracking control are formed on respective tracks of the rewritable area where an information signal can be rewritten. A recording layer (83) onto which an information signal is to be written is laminated on a substrate on which the guide grooves (81a) have been formed. The information signal can be rewritten on the recording layer (83) at least in the rewritable area using near-field light based on multibeam. Concave portions (85a) are formed on the outermost surface of the disc recording medium in correspondence with the positions of the guide grooves (81a).

Owner:SONY CORP

Optical disk producing device and producing method

InactiveUS6960270B2Quality improvementSmall sizeMechanical working/deformationTurning machine accessoriesCompact Disc manufacturingAdhesive

A molding machine 1 which molds two sheets of disc substrates on which the information is recorded simultaneously, a cooling mechanism 3 for cooling each of the disc substrates, first movably mounting means 2 for movably mounting the disc substrate from the molding machine onto the cooling mechanism, and a second movably mounting means 4 for mounting each of the disc substrates onto a receiving portion of the turn table 5 are provided. In addition, a film forming device 8 for receiving sequentially each of the disc substrates from this movably mounting means 6 and forming a reflective film on one of the surfaces of each of the received disc substrates on which the information is recorded; a turn table 10 having a plurality of receiving portions on which the disc substrates are mounted and which rotates intermittently through each constant angle; a reversing mechanism 11 which reverses 180 degrees each of the disc substrates; and an overlapping mechanism for overlapping the reversed disc substrates over the other disc substrates are provided. Furthermore, spinners 15, 16 for rotating the overlapped two sheets of disc substrates and a curing device 23 which radiates ultra-violet rays onto the disc substrates which are rotated by the spinners to cure the liquid adhesive. According to the above-described structure, an optical disc which is compact, is fast in a production speed, and has a high quality can be achieved.

Owner:ORIGIN ELECTRIC CO LTD

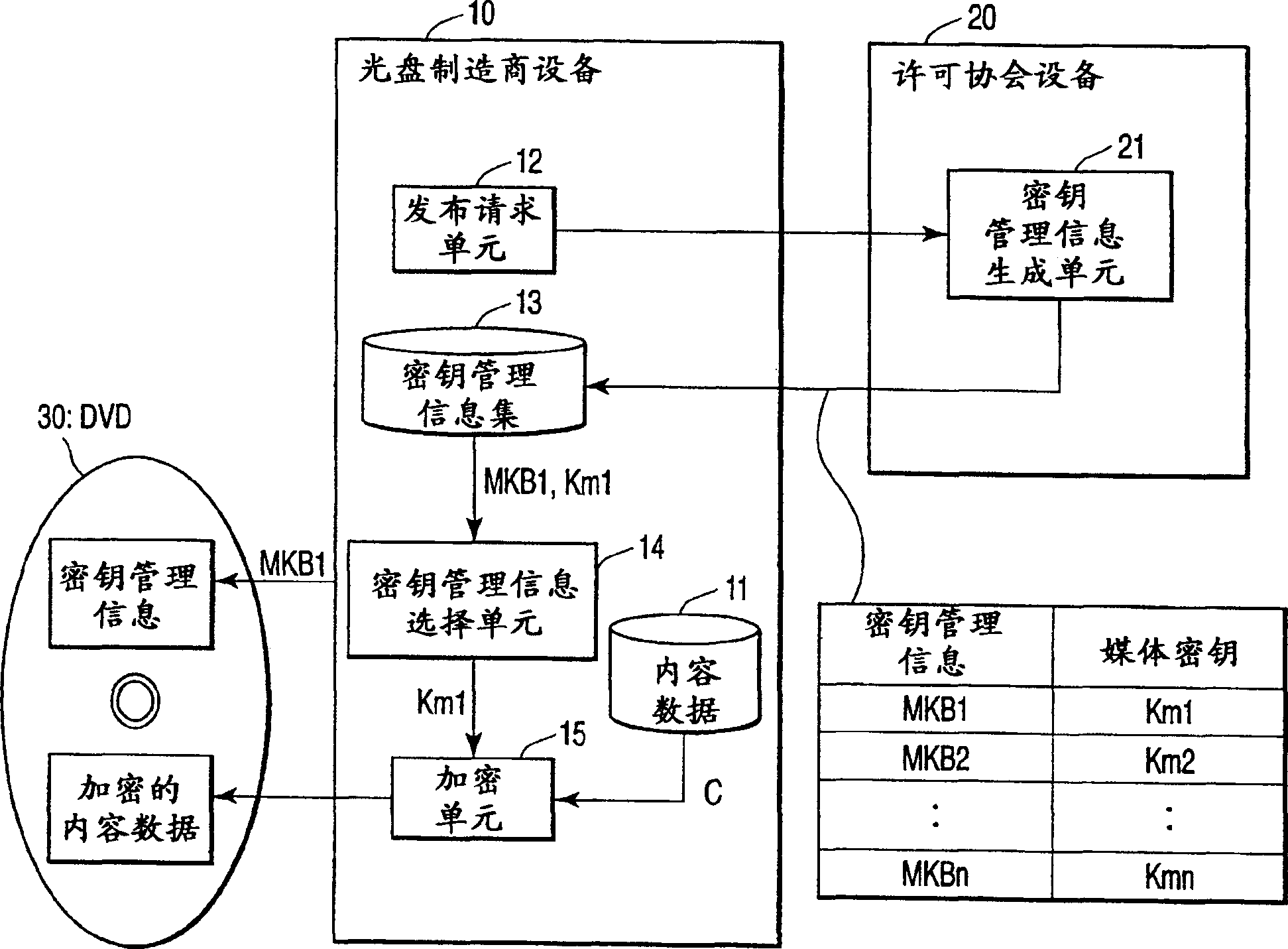

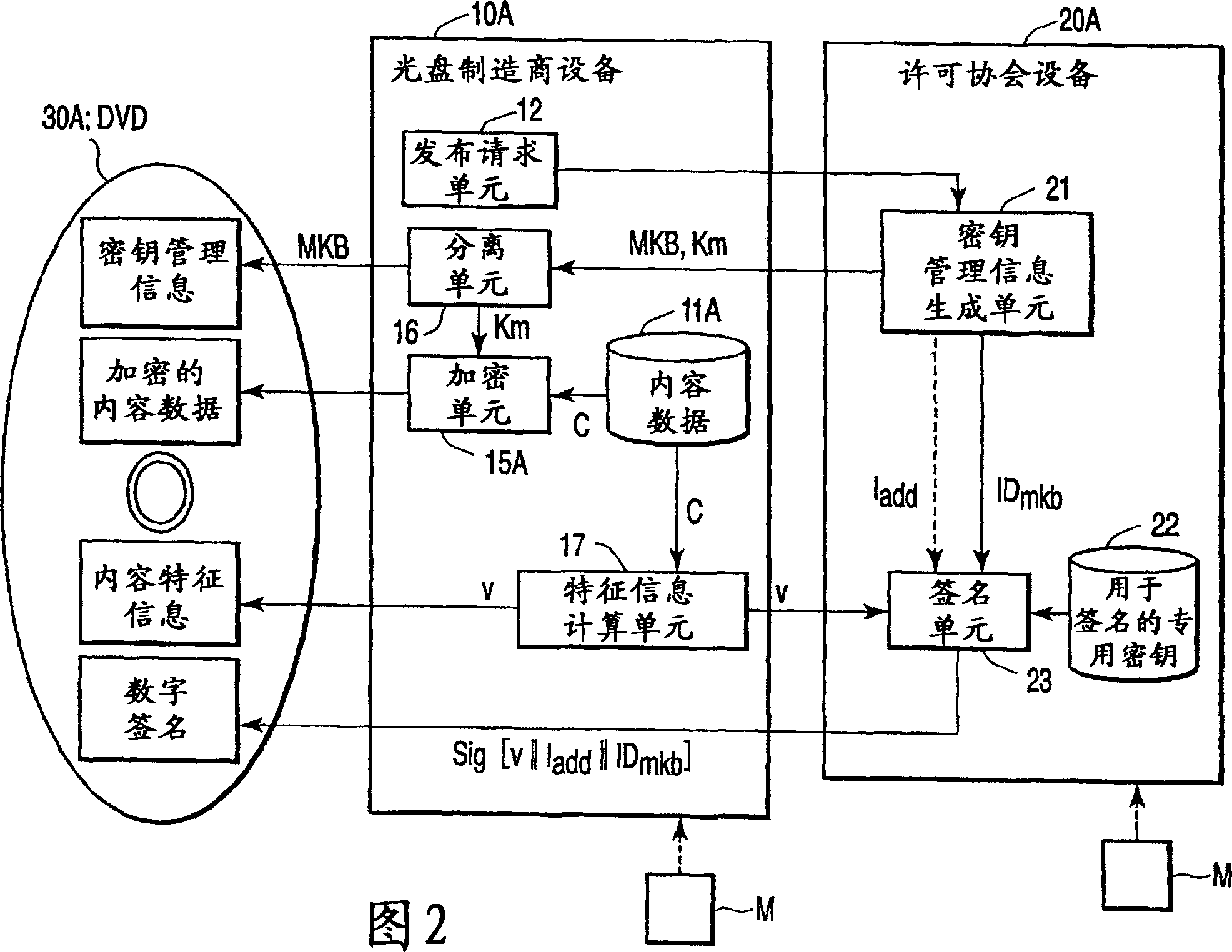

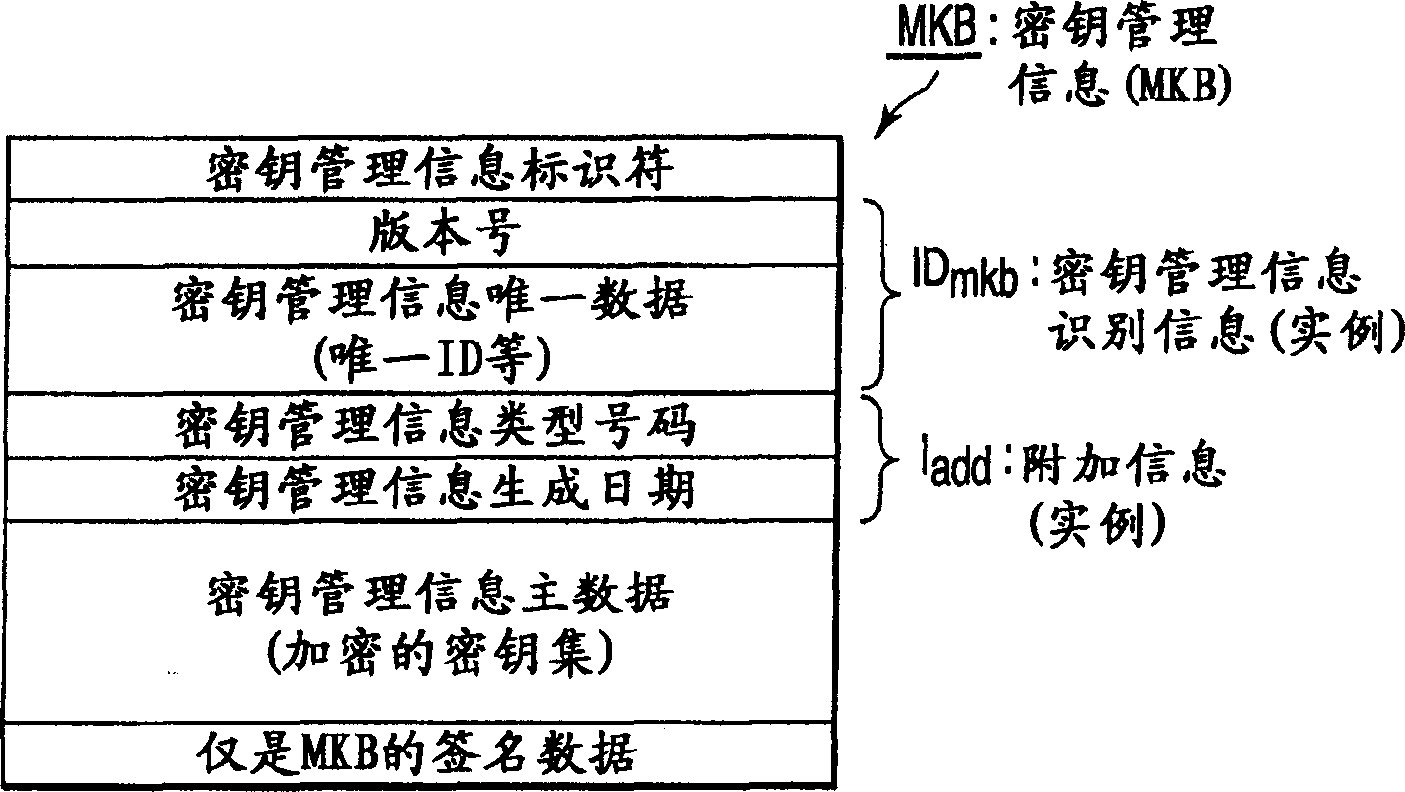

Method, device and programme for protecting content

InactiveCN1716426AImprove accuracyUnauthorized memory use protectionRecord information storageCompact Disc manufacturingDigital signature

Owner:KK TOSHIBA

Apparatus for attaching and detaching cap for optical disc spin-coating, apparatus for optical disc spin-coating comprising the same, method of manufacturing optical disc using the apparatus for attaching and detaching cap for optical disc spin-coating

InactiveUS20050287291A1Easily attach and detach capAvoid pollutionPretreated surfacesRecord information storageCompact Disc manufacturingEngineering

Provided are an apparatus for attaching and detaching a cap for optical disc spin-coating that can be easily attached to and detached from the cap for covering a center hole of an optical disc by including a permanent magnet when contaminated by a photocurable resin, an apparatus for spin-coating including the same, and a method of manufacturing an optical disc using the apparatus for attaching and detaching a cap for optical disc spin-coating. By using the apparatus for attaching and detaching a cap for optical disc spin-coating, the cap can be easily attached to and detached from the optical disc before and after the spin coating even when the viscosity of the photocurable resin is high. In addition, the use of the apparatus for optical disc spin coating and the method of manufacturing the optical disc results in high manufacturing efficiency.

Owner:LG CHEM LTD

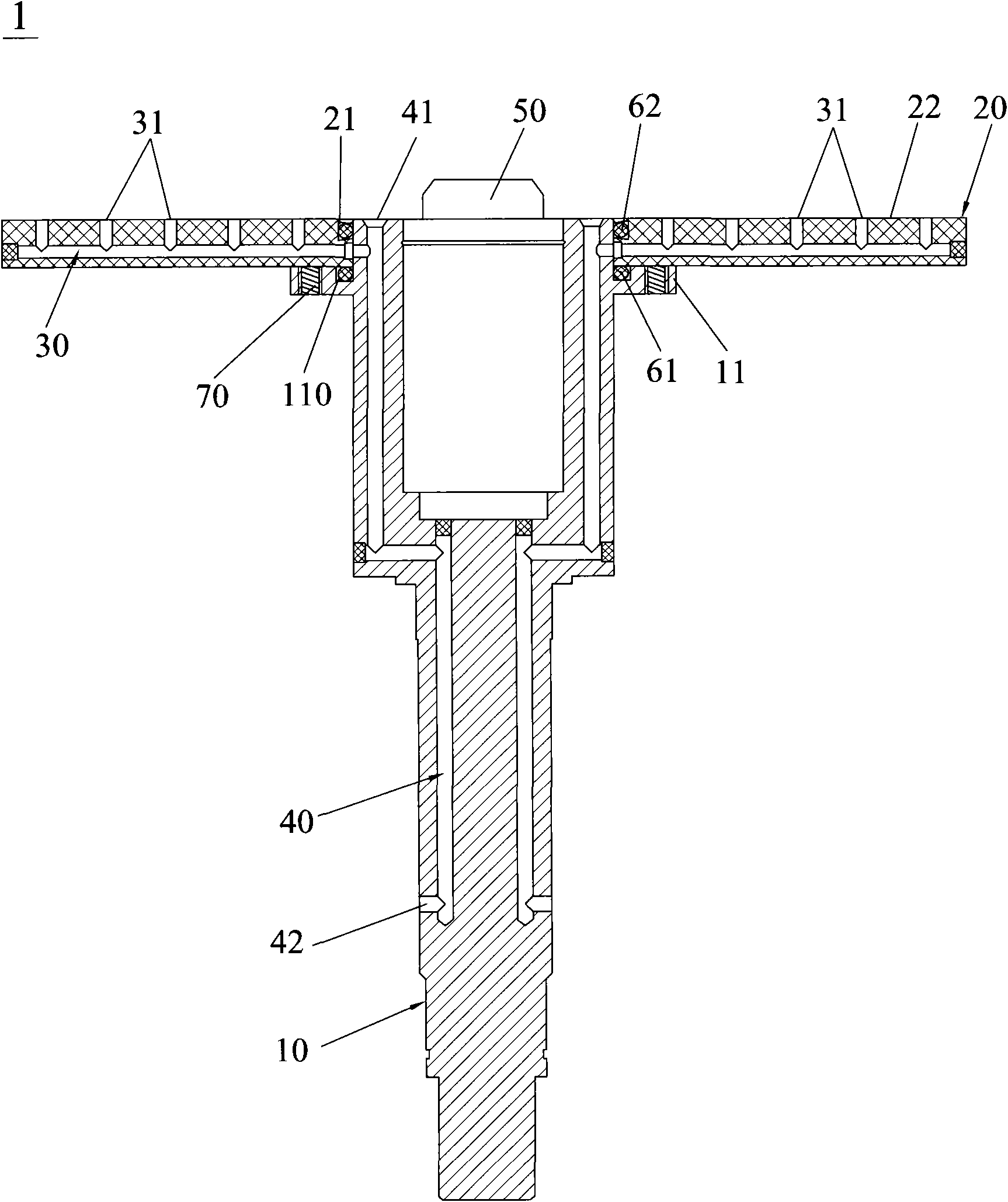

Manufacturing device and manufacturing method for optical disc

InactiveUS20080093755A1Easily follow flatnessSmooth connectionMechanical working/deformationRecord carriersCompact Disc manufacturingEngineering

This manufacturing device for an optical disc includes: a disc-supporting base on which a disc substrate is mounted; a pin-shaped member arranged at a center of the disc-supporting base, and is movable in the vertical in a center hole of the disc substrate; and a capping member which is slidably placed on a top of the pin-shaped member, and closes the center hole of the disc substrate, wherein when the capping member placed on the top of the pin-shaped member is lowered such that a back face of the capping member contacts an around of the center hole of the disc substrate mounted on the disc-supporting base, the capping member slides on the top of the pin-shaped member.

Owner:ORIGIN ELECTRIC CO LTD

CD-fixing device

InactiveCN101783152AImprove adsorption capacityRapid positioningOptical record carrier manufactureCompact Disc manufacturingDrive shaft

The invention discloses a compact disk (CD)-fixing device which comprises a turnplate, a rotating shaft and an absorption pipeline system. The lower end of the rotating shaft is connected with an external driving device; the upper end of the rotating shaft penetrates through a central hole of the turnplate and is hermetically and fixedly connected with the turnplate, the absorption pipeline system comprises a plurality of mutually communicated bypass vacuum pipelines and a central vacuum pipeline which penetrates into the rotating shaft, one end of the central vacuum pipeline penetrates through the upper end of the rotating shaft to form central suckers which are evenly distributed in equal diameters by using the rotating shaft as a center, and the other end of the central vacuum pipeline penetrates through the rotating shaft to form a central interface and is communicated with an external vacuumizing device. The bypass vacuum pipelines penetrate into the turnplate, one end of each bypass vacuum pipeline is communicated with the central vacuum pipeline, the other end of each bypass vacuum pipeline penetrates through the upper surface of the turnplate to form side suckers which are evenly distributed at stages by using the rotating shaft as a center, and the side suckers and the central suckers are arranged on the same plane. The invention aims to provide the CD-fixing device which has strong adsorption force, safety, reliability, convenient manufacture and maintenance and simple structure and is suitable for fixing a CD in the CD manufacture process.

Owner:HENAN KAIRUI DIGITAL

Optical disc manufacturing method, disc master manufacturing method, and optical disc

InactiveCN101567199AImprove productivityImprove reflectivityRecord information storageOptical record carrier manufactureResistProduction rate

An optical-disc manufacturing method including the steps of: fabricating a pre-exposure disc master by forming, on a substrate, a heat accumulation layer having a thickness of 17% or less of a recording-laser wavelength and forming an inorganic resist layer; performing exposure of a recording-signal pattern having pits and spaces with respect to the inorganic resist layer of the disc master, by performing recording-laser light irradiation; fabricating a disc master having a pit-array shape having pits and spaces, by performing development processing after the exposure; manufacturing a stamper to which the pit-array shape is transferred, by using the disc master having the pit-array shape; and manufacturing an optical disc having a predetermined layer structure including a recording layer to which the pit-array shape of the stamper is transferred and in which a silver or silver-alloy reflective film is formed on the pit-array shape.

Owner:SONY CORP

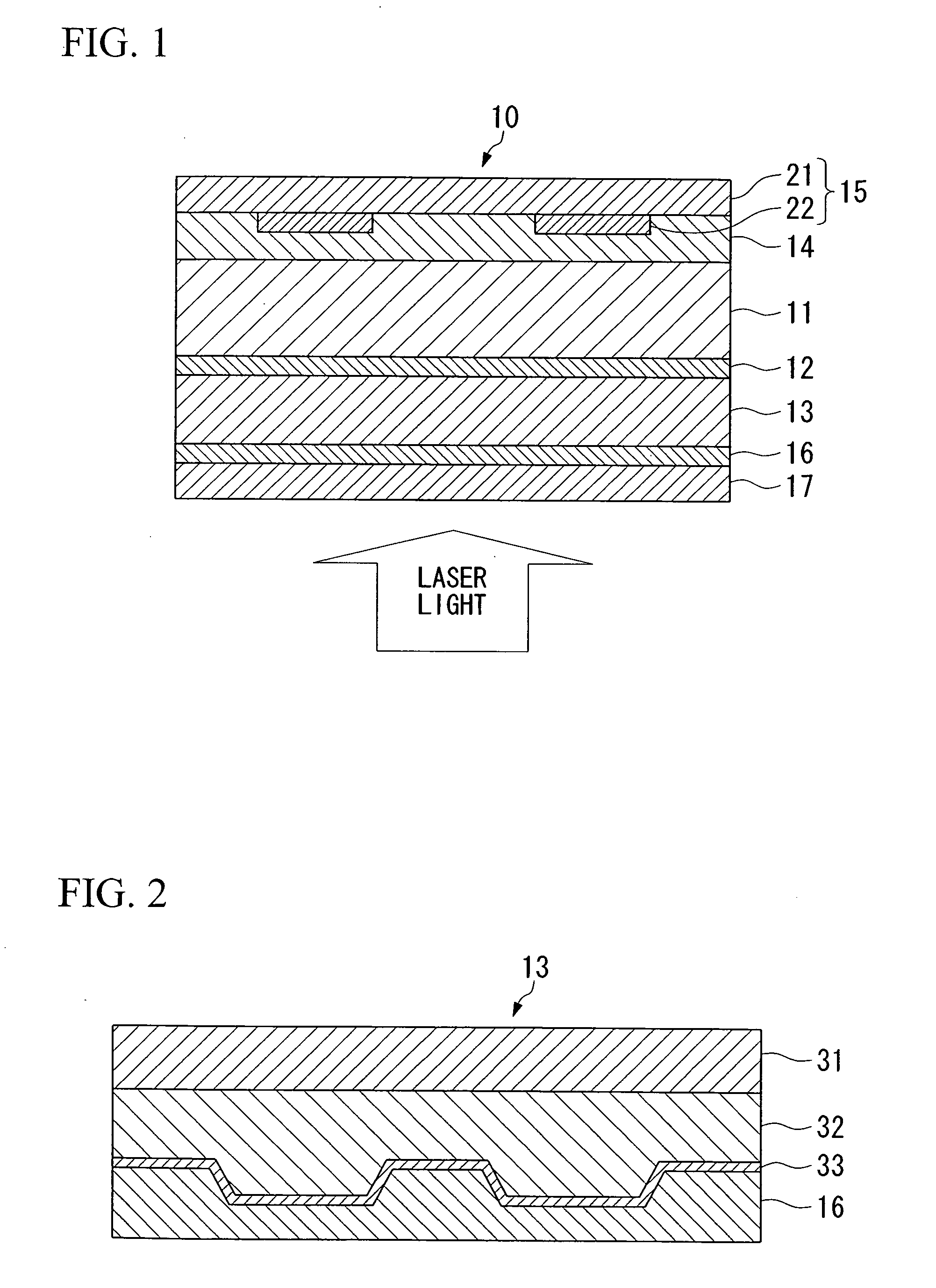

Optical recording medium-producing sheet and optical recording medium

InactiveCN1571046AExact reproductionLayered productsRecord information storageCompact Disc manufacturingPhase change

An optical disc-producing sheet 1, which has an adhesive layer 11 having a specific heat capacity after curing of not more than 1.9 J / g. DEG C at 80 DEG C and a protective sheet 12, is laminated onto an information recording layer 3 (a laminate of a reflecting layer 31, a dielectric layer 32, a phase change layer 33 and a dielectric layer 32') formed on an optical recording medium substrate 2. According to this optical disc, recorded information can be reproduced accurately even in the case that recording / erasure or reproduction of information has been carried out repeatedly.

Owner:LINTEC CORP +1

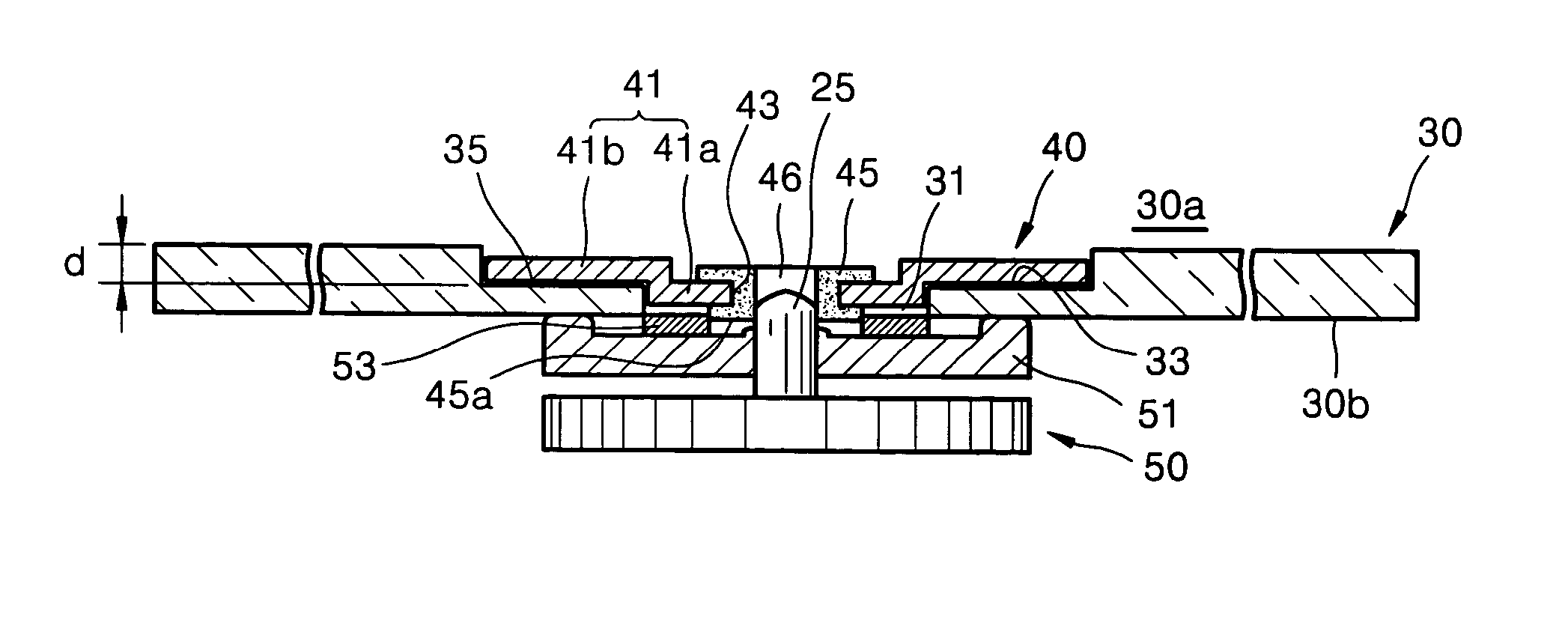

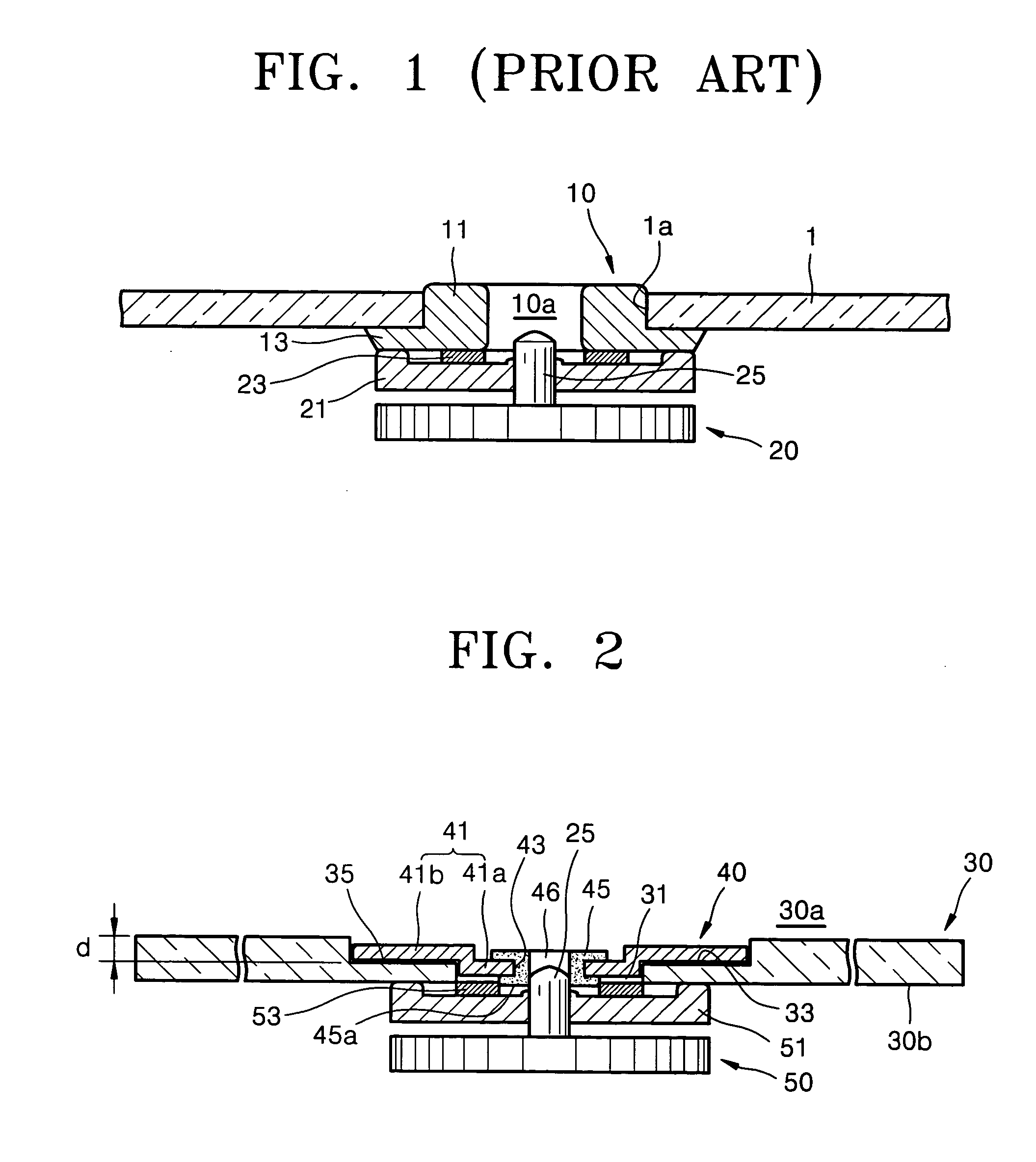

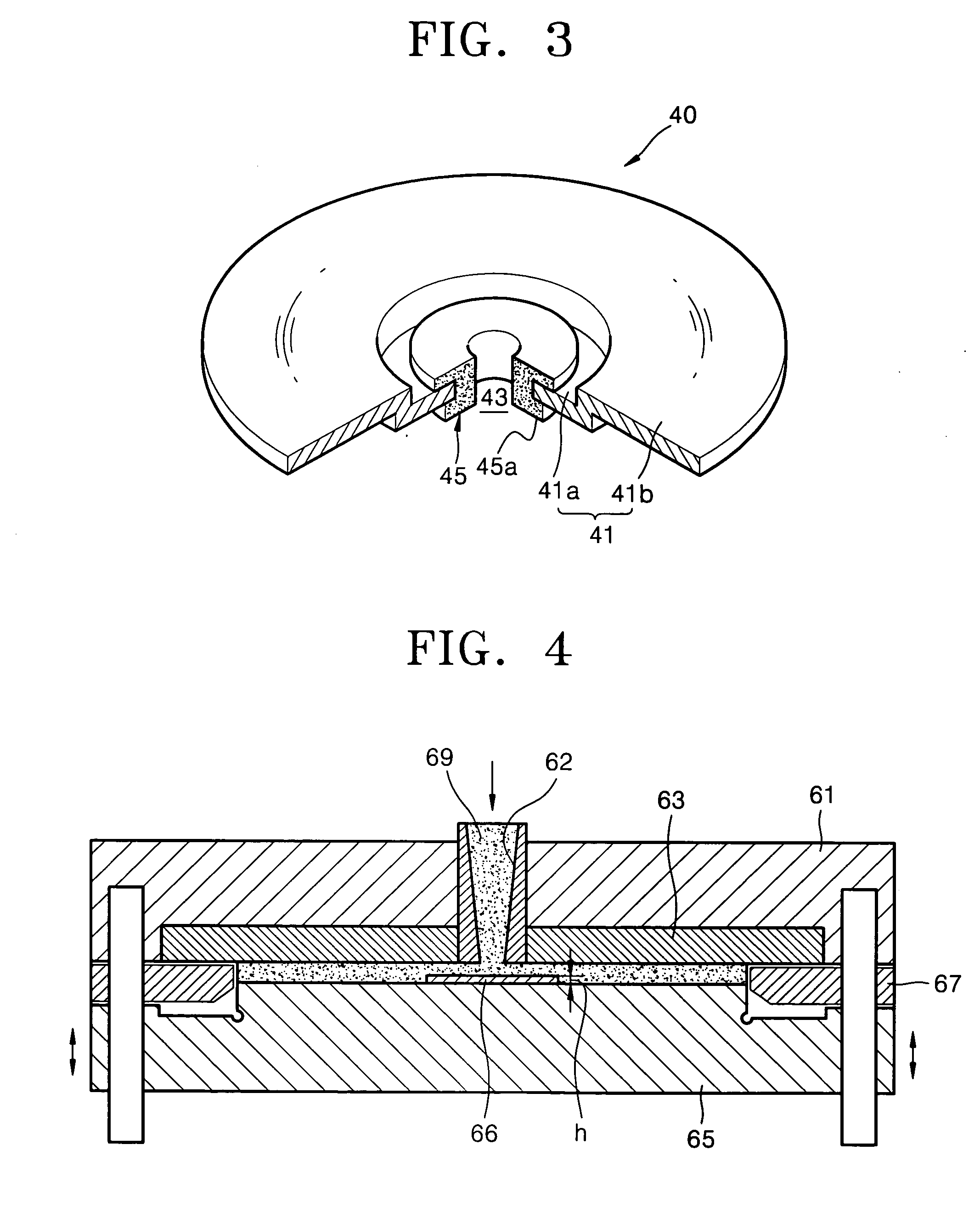

Hub-mounted optical disk, method for fabricating optical disk, and injection molding die for manufacturing optical disk substrate

InactiveUS20050086680A1Reduce the overall heightApparatus for flat record carriersRecord information storageCompact Disc manufacturingEngineering

A hub-mounted optical disk to eliminate the need for a separate stack ring while decreasing the overall height, a method of fabricating the optical disk, and an injection molding die for manufacturing an optical disk substrate. The hub-mounted optical disk includes a substrate having a hollow and an indented portion engraved to a predetermined depth on the inside of a non-recording surface where no information is recorded; and a hub including a plate that has a fitting hole therein and is engaged into the hollow and the indented portion and a central ring that is inserted into the fitting hole. The method of fabricating the hub-mounted optical disk includes mounting the hub onto a magnetic chuck, applying an ultra-violet (UV) hardening resin on the indented portion of the substrate, operating the magnetic chuck so that the plate is in contact with the indented portion, and curing the UV hardening resin by irradiating it with UV light. The injection molding die for manufacturing the optical disk substrate includes a stationary plate having an injection nozzle that allows resin forming the substrate to be injected, a stamper that has a predetermined information recording pattern, and a moving plate having a projecting portion at the center.

Owner:SAMSUNG ELECTRONICS CO LTD

Original disk fabrication method, magnetic recording medium manufacturing method and magnetic recording medium

InactiveUS7817377B2Improve recording densityFavorable address decipheringElectron beam carrier recordingElectric discharge tubesCompact Disc manufacturingEngineering

It is made possible to fabricate a bit-patterned magnetic recording medium having a high recording density and making favorable address deciphering possible. An original disk fabrication method for irradiating a photosensitive resin film with an electron beam to draw a pattern, the method includes: irradiating the electron beam by using a plurality of blanking signals every rotation of a stage per bit unit, when drawing the pattern in a part corresponding to an address part on a photosensitive resin film.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com