Patents

Literature

11128 results about "Molding machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

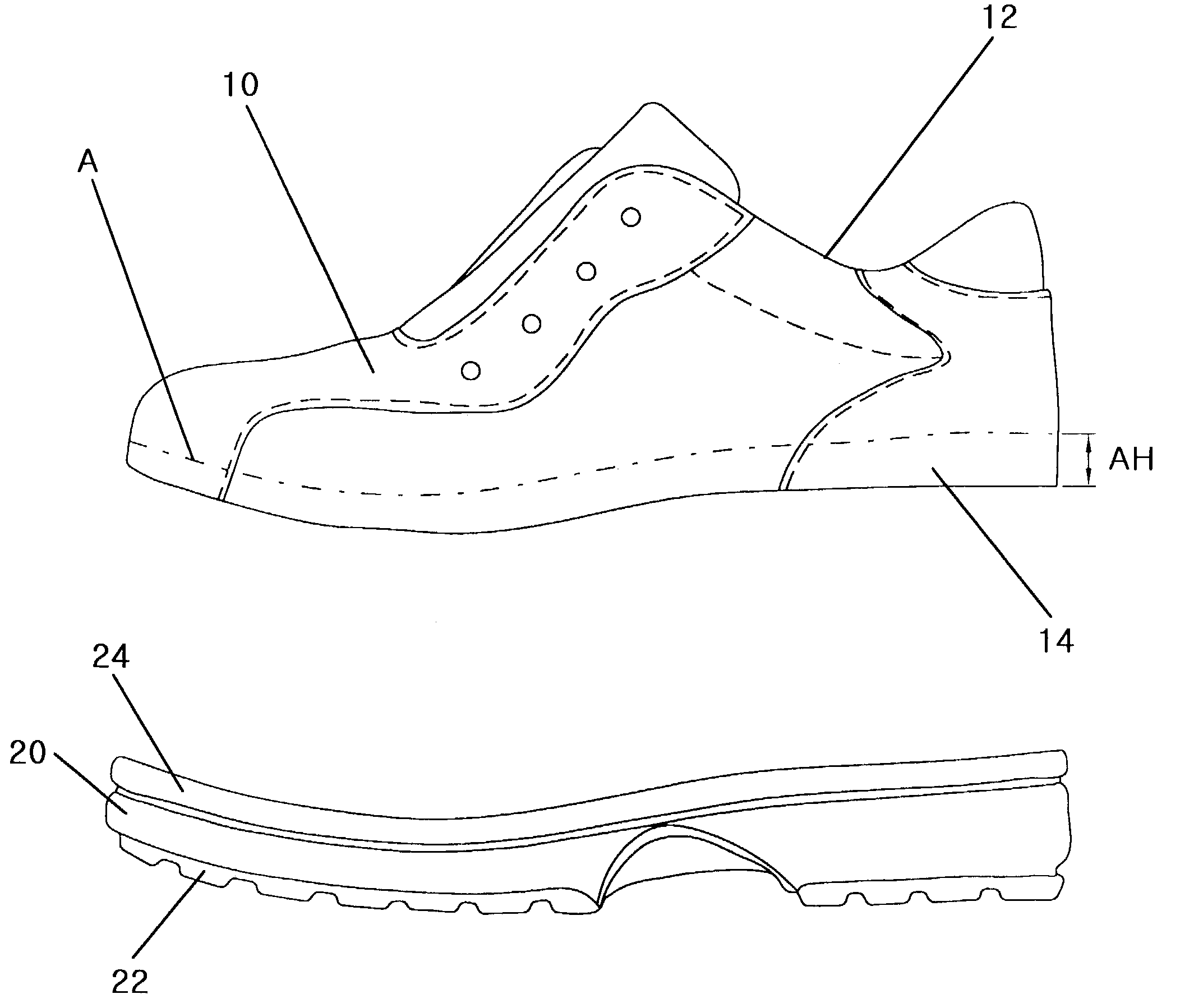

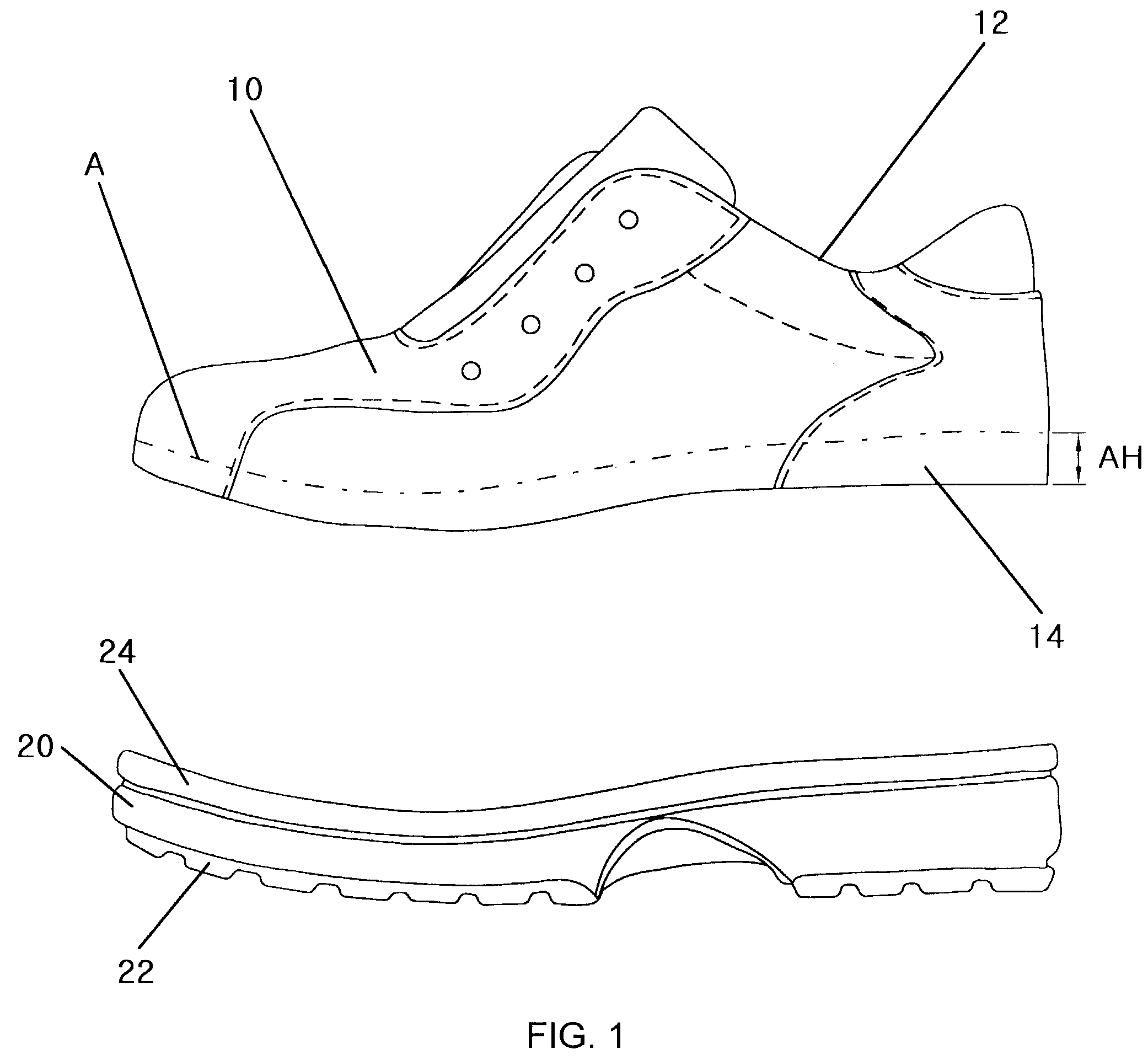

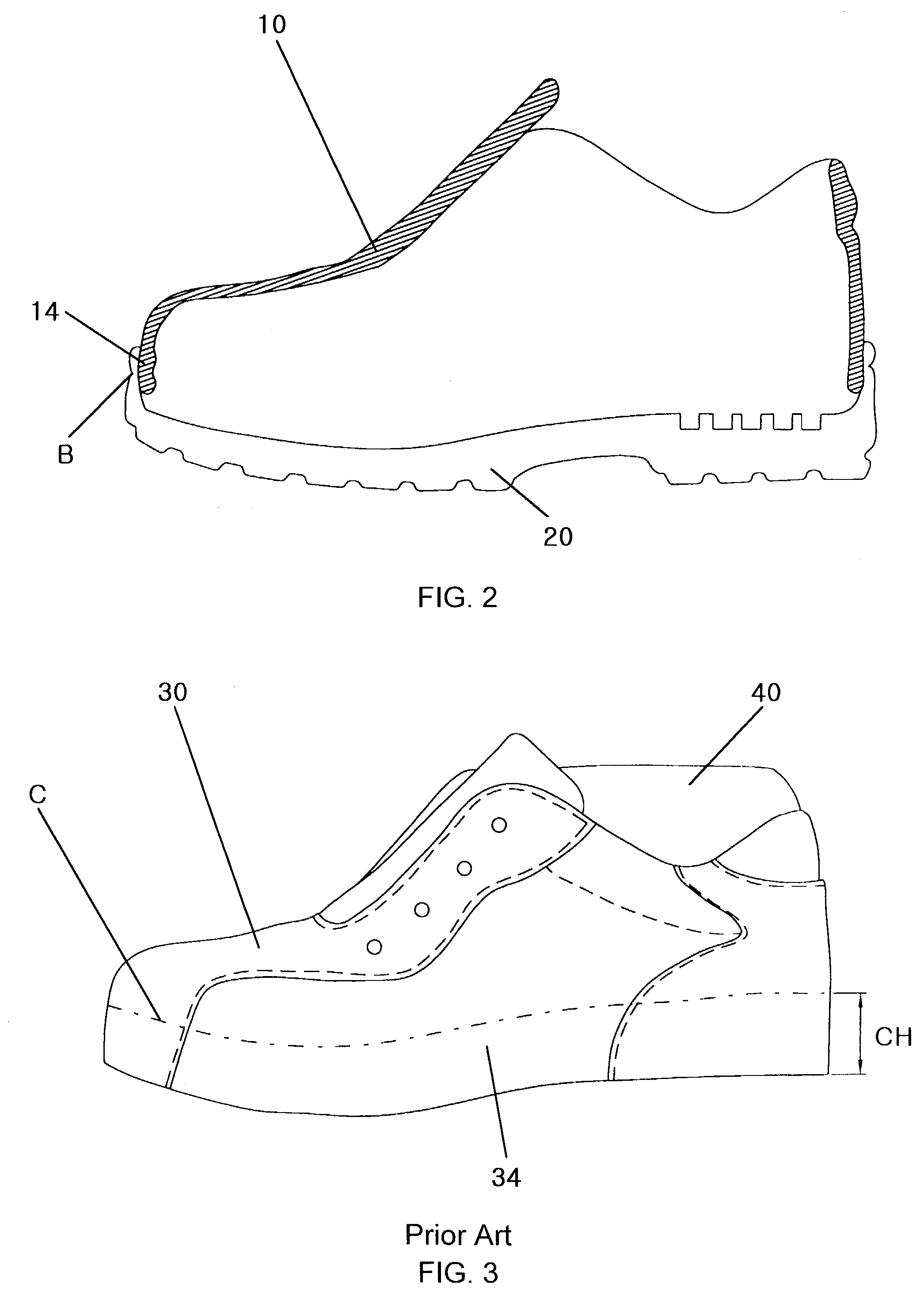

Method for manufacturing shoes and shoes manufactured by the method

InactiveUS6978557B2Reduce the amount requiredShorten the timeSolesDomestic footwearMolding machineEngineering

A method for manufacturing shoes is provided. The method includes preparing an upper and an outsole, applying an adhesive agent to the outer surface of an upper seal portion and the inner surface of an outsole seal portion, stitching together the outer surface of the upper seal portion and inner surface of the outsole seal portion, activating the adhesive agent by applying heat to the stitched seal portions, and molding the upper and the outsole by using a molding machine. Therefore, since the amount of the upper can be reduced and a separate insole is not necessary, the total weight of the shoes can also be reduced. The flexibility of shoes can also be enhanced.

Owner:JUNG IN LEE

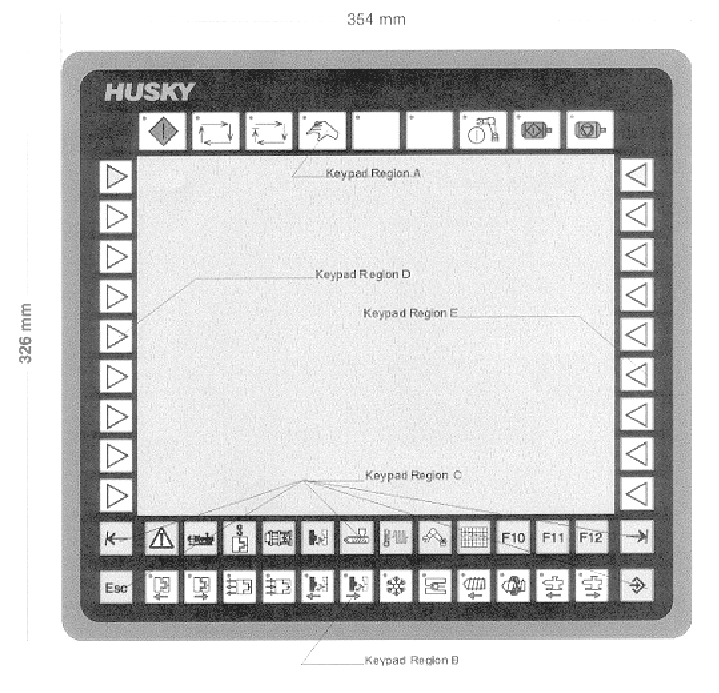

Method of simplifying machine operation

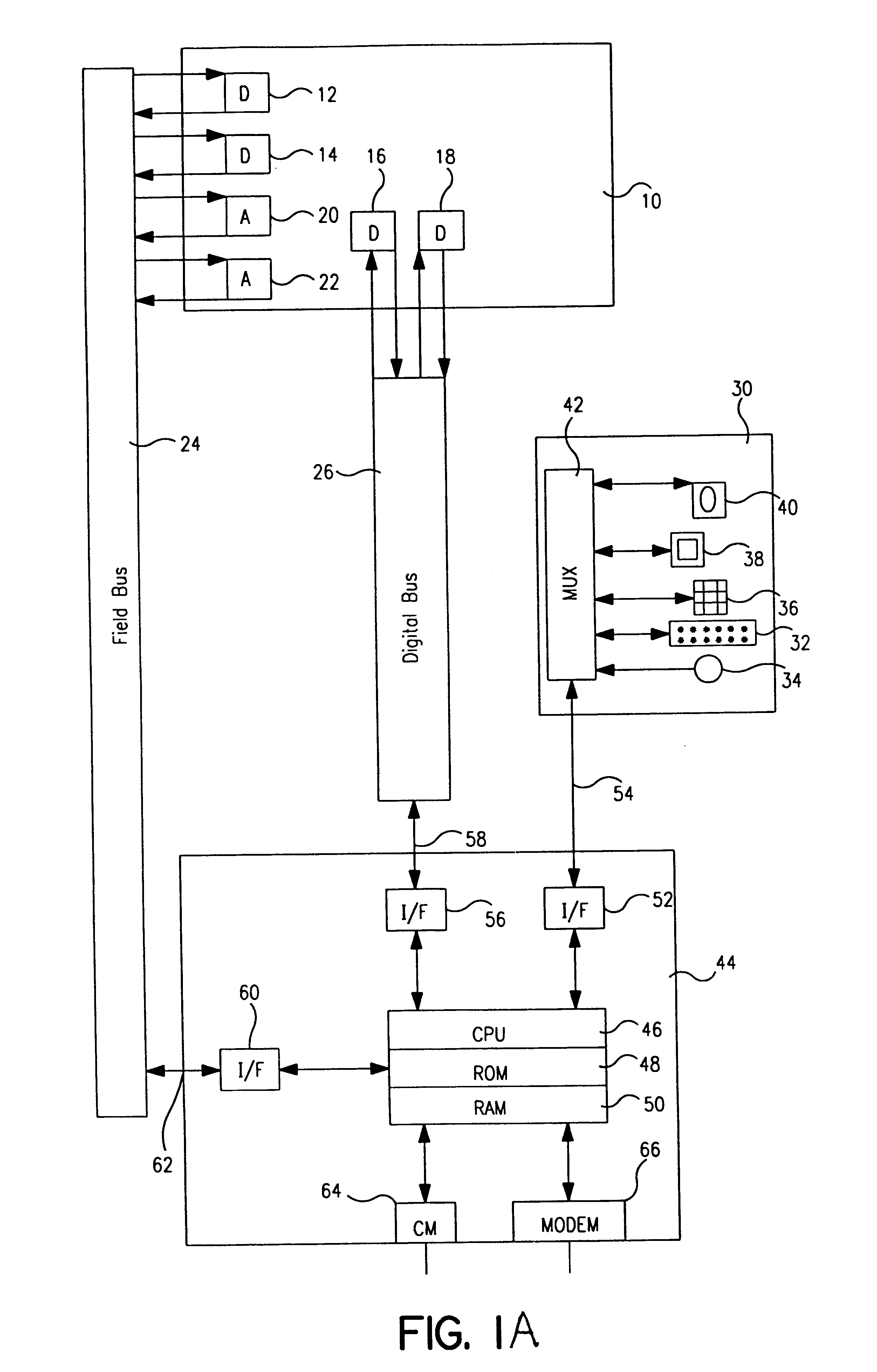

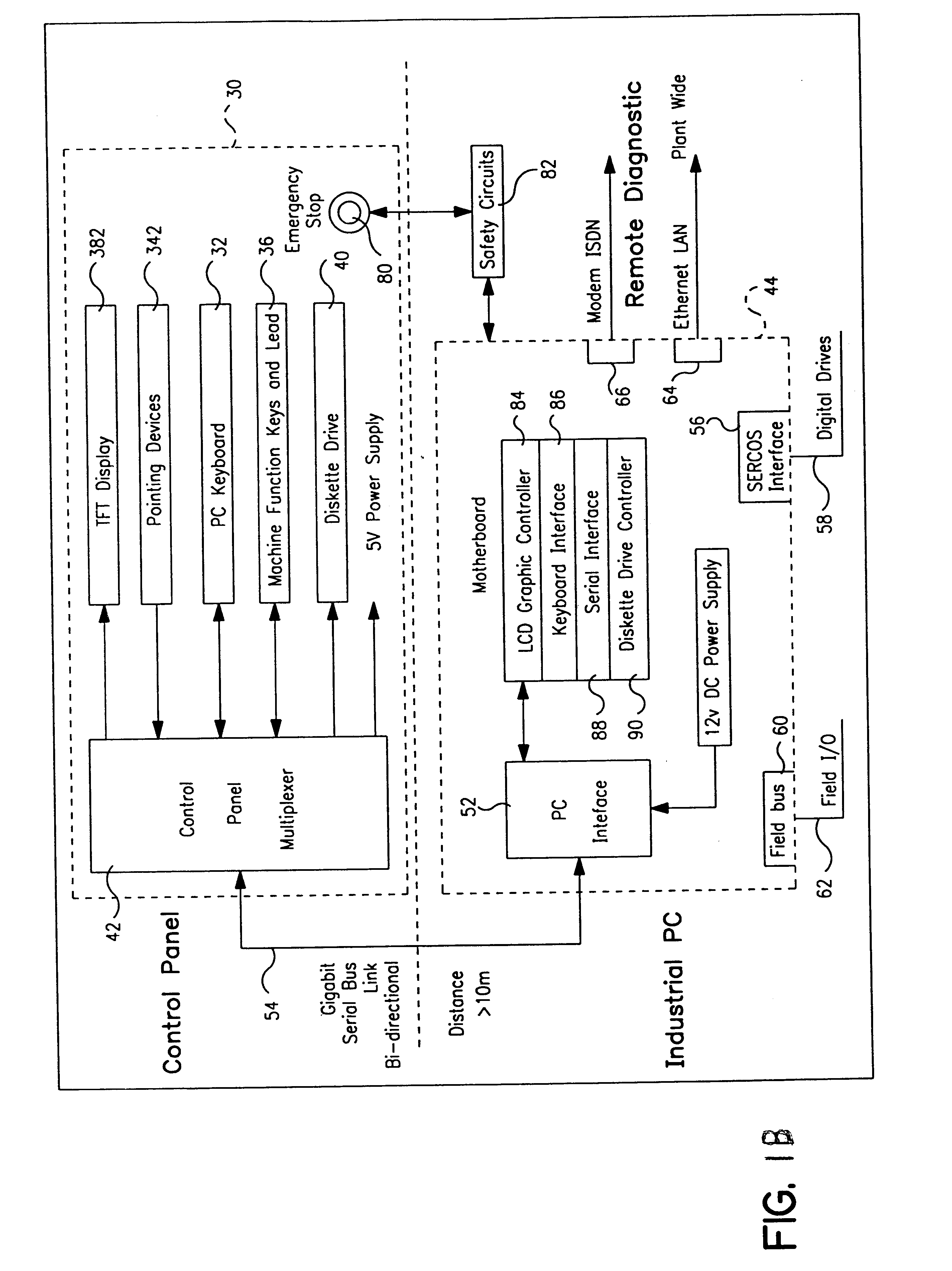

InactiveUS6684264B1Reduce learning and trainingEasy to operateProgramme controlComputer controlHuman–machine interfaceMolding machine

Apparatus and method for controlling a molding machine includes structure and function for a human machine interface control panel having: (i) a flat panel display screen; (ii) a pointing device; (iii) a plurality of pushbuttons overlaid with or without icons; (iv) a housing containing the above and the associated electronics; (v) structure to uniquely identify each users preferred configuration; (vi) structure to connect to a remote controller for both digital information and video signal communication; (vii) a connection for receiving external power to drive the panel's electronics and display; and (viii) software running in the remote controller to provide all the operating functions of the human machine interface.

Owner:HUSKY INJECTION MOLDING SYST LTD

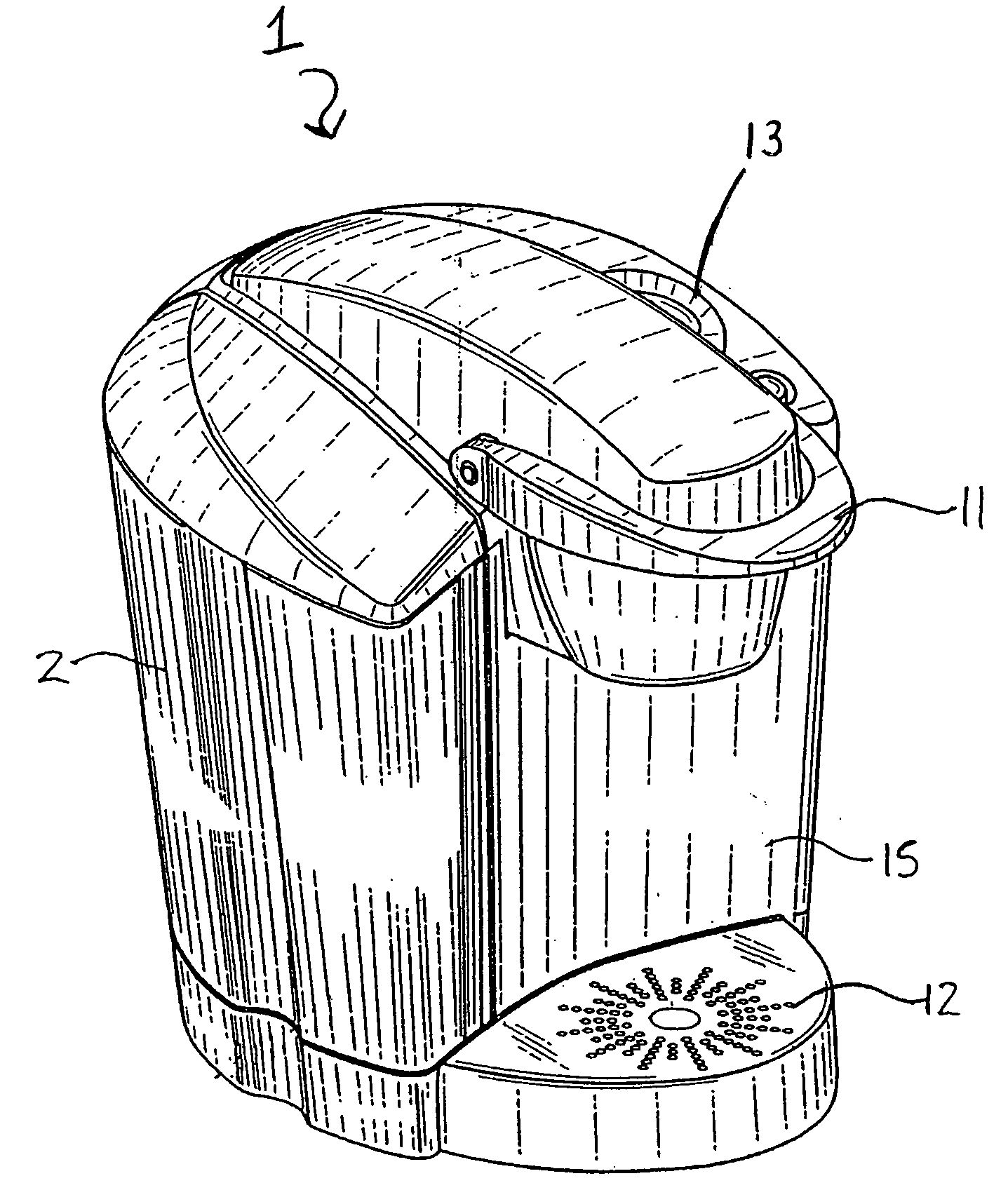

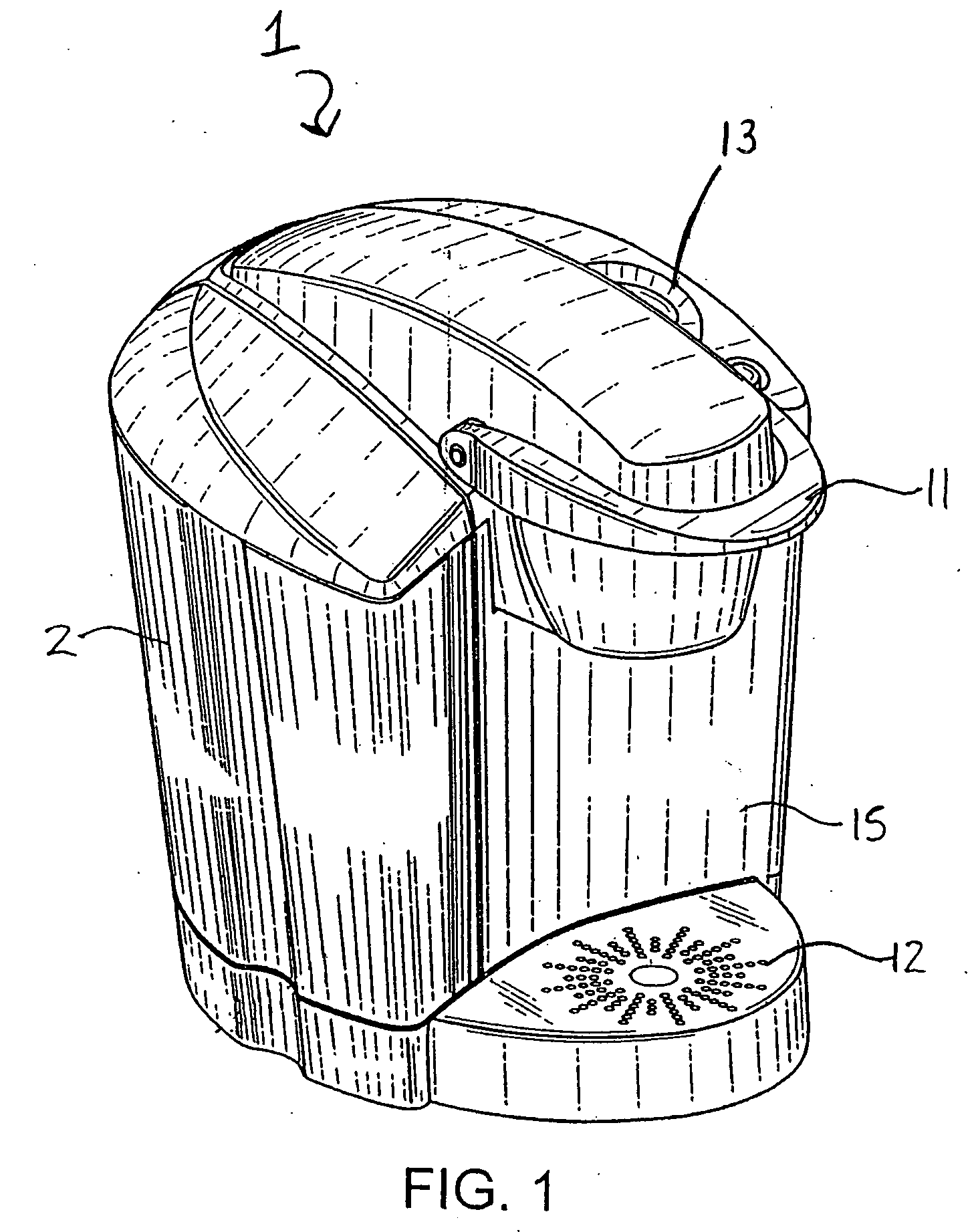

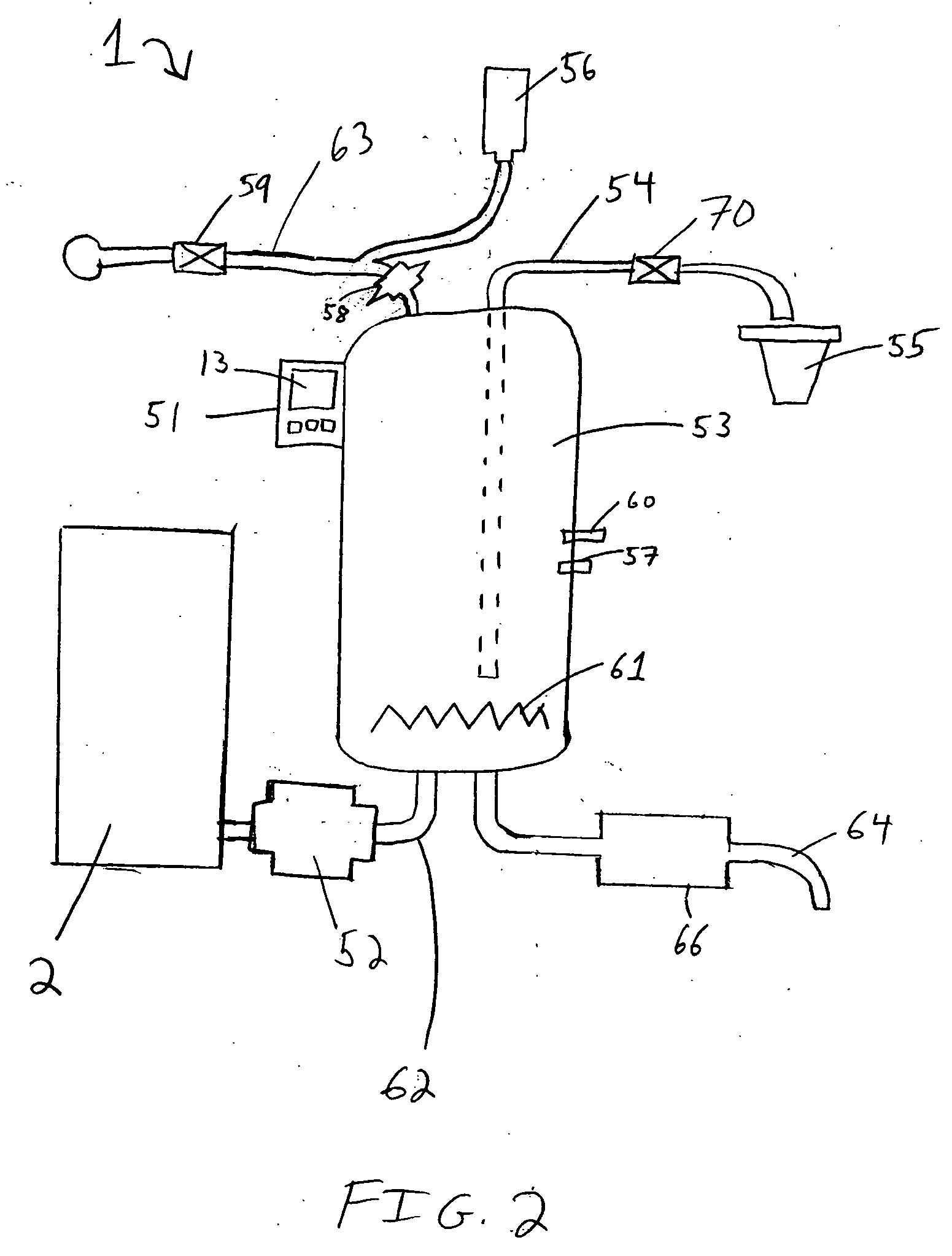

Drain for beverage forming machine

ActiveUS20070056994A1Easy to drainVolume measurement and fluid deliveryBeverage vesselsMolding machineEngineering

A method and apparatus for draining a component of a beverage forming system such as a coffee brewer. A tank used for holding and / or heating a beverage precursor liquid may be automatically drained. A beverage forming machine including a drain system may be self-contained in that the liquid drained from the tank is held by another tank that is part of the beverage forming machine. The tank into which the drained liquid is deposited may be removable from the beverage forming machine.

Owner:KEURIG GREEN MOUNTAIN INC

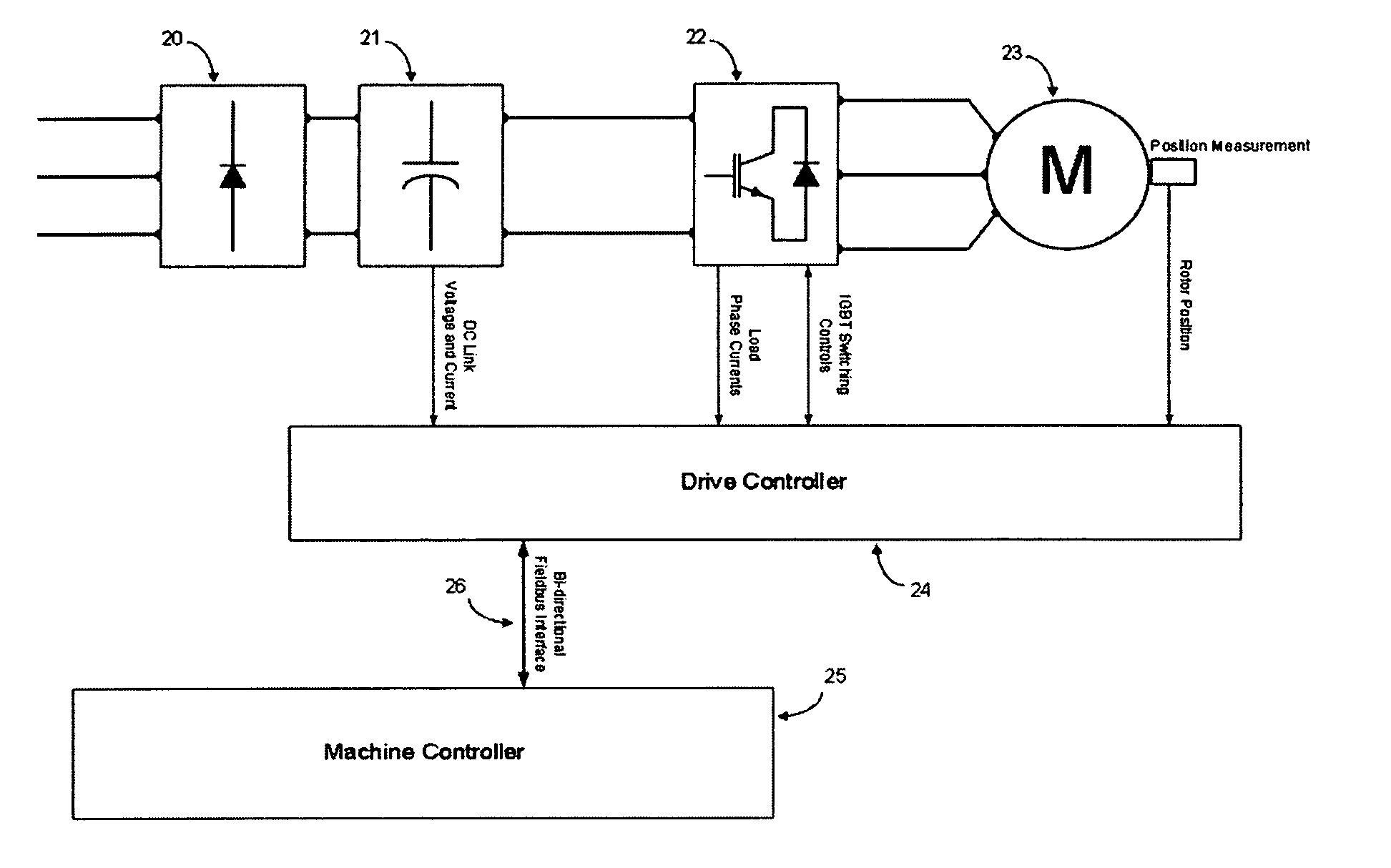

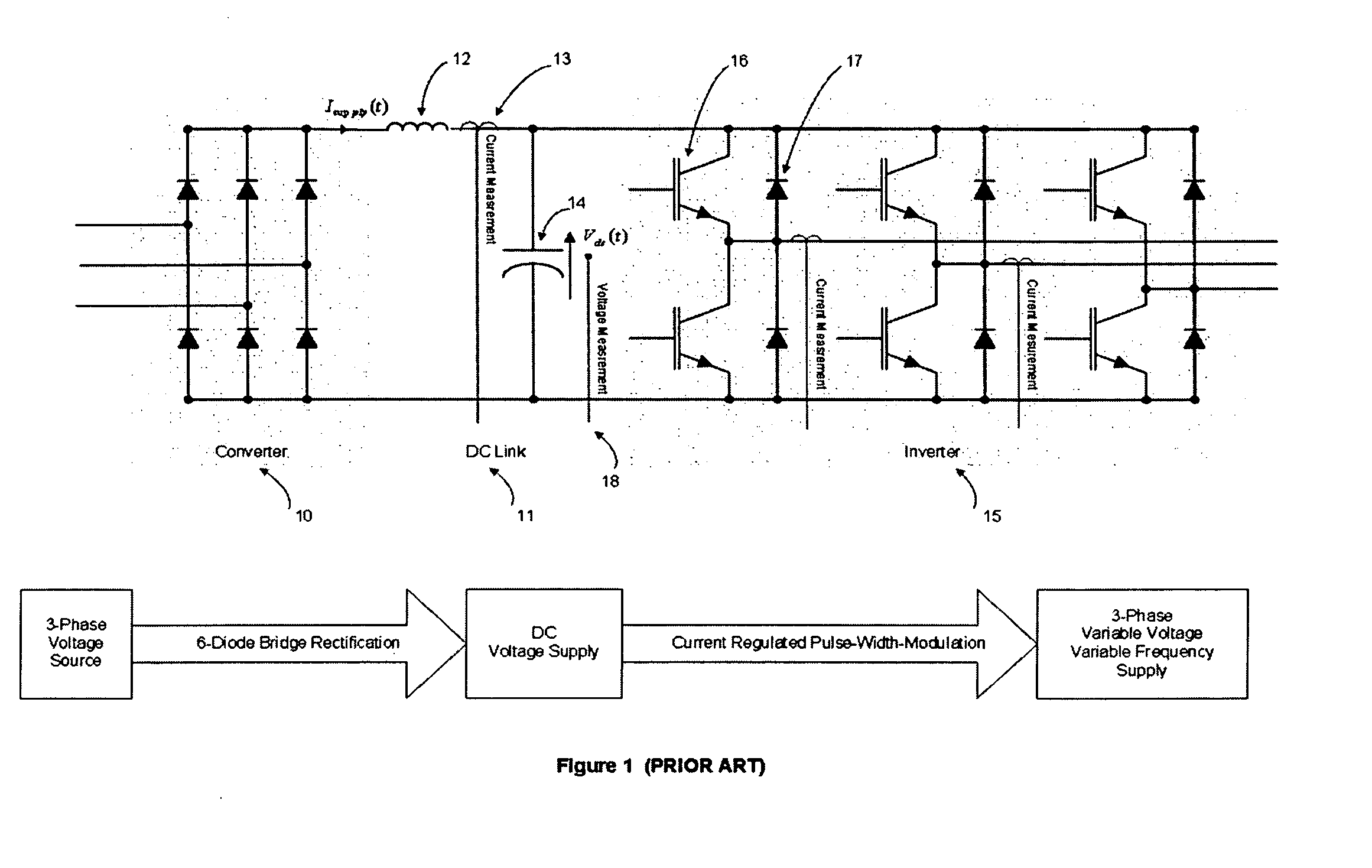

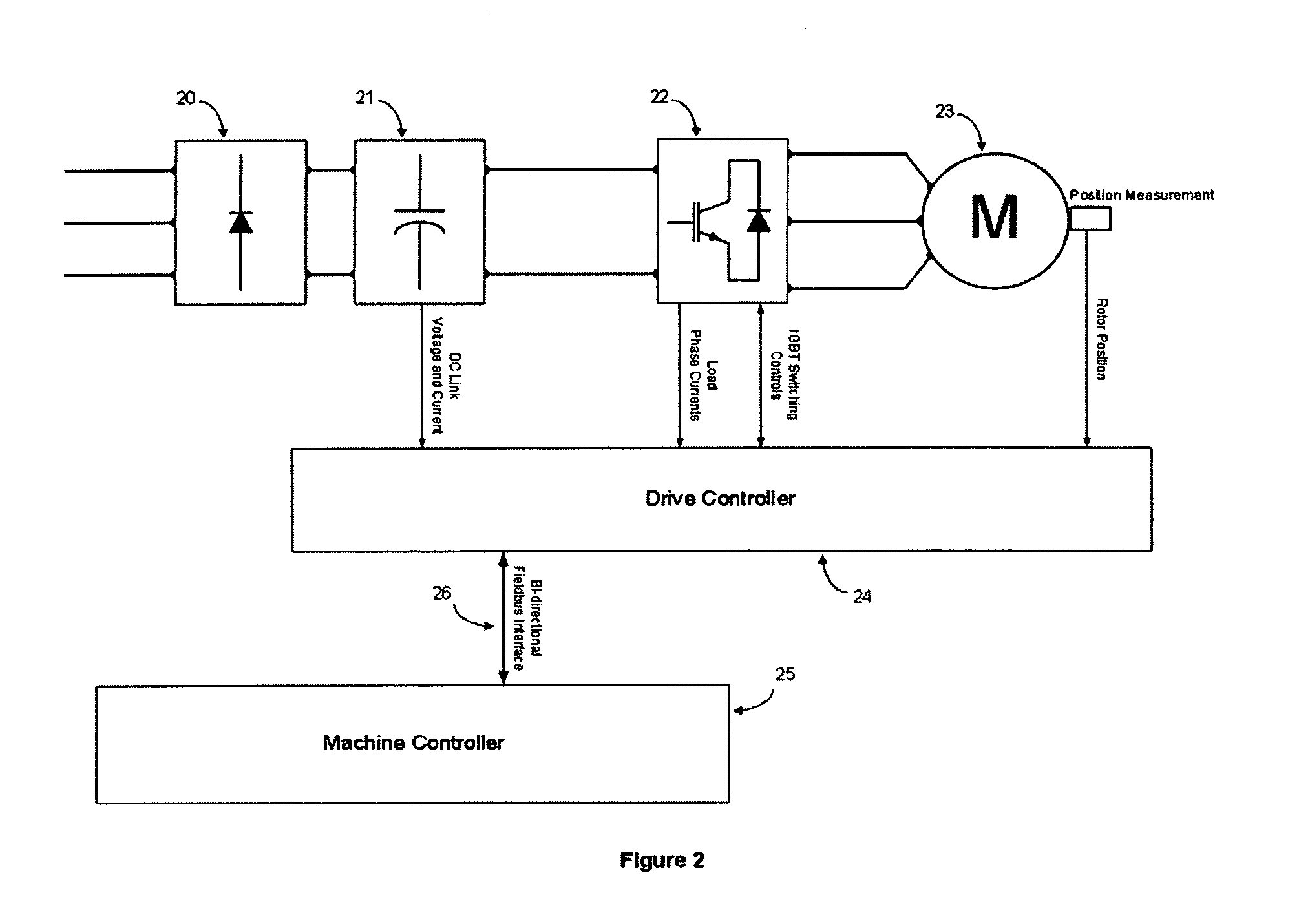

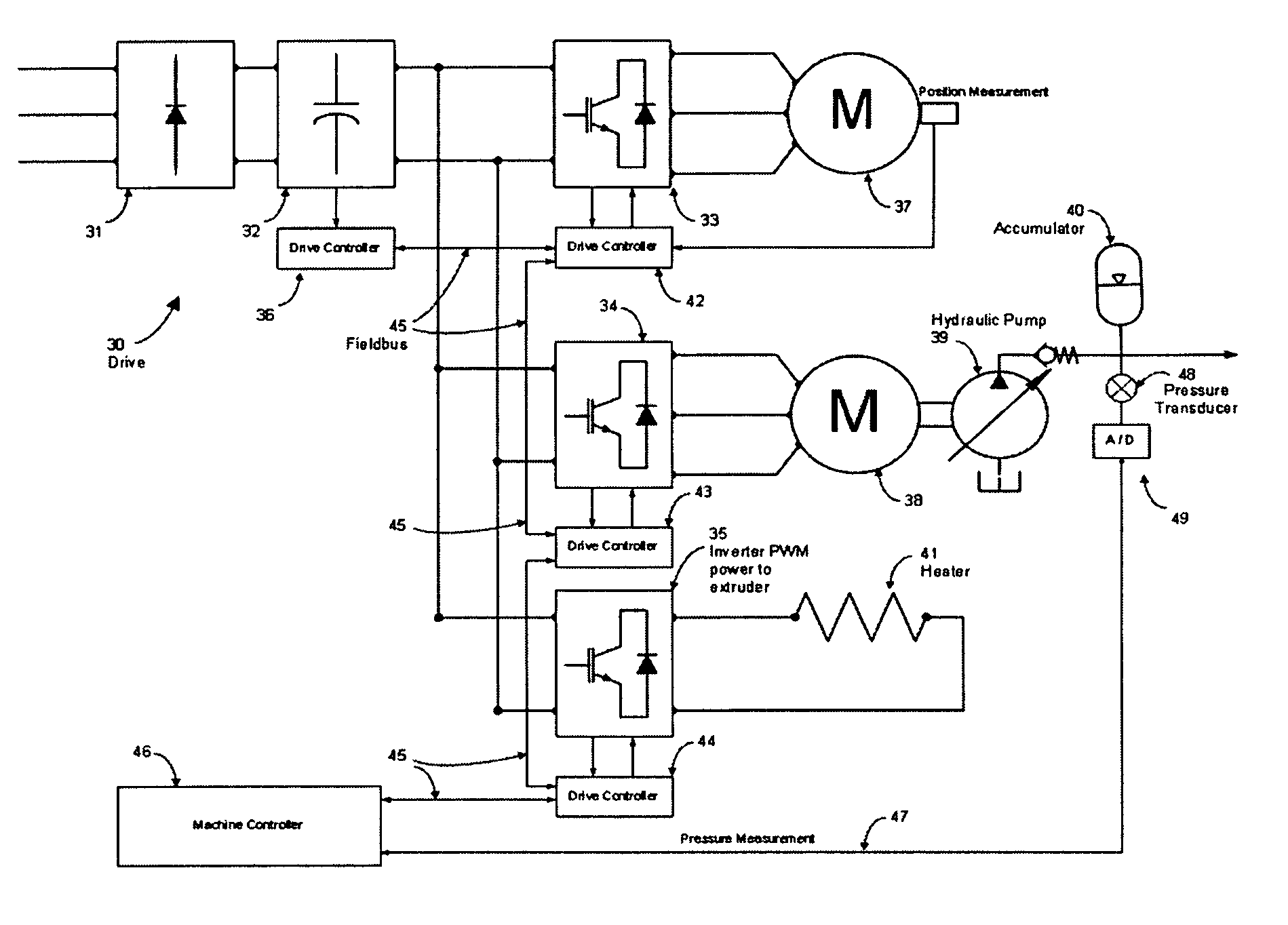

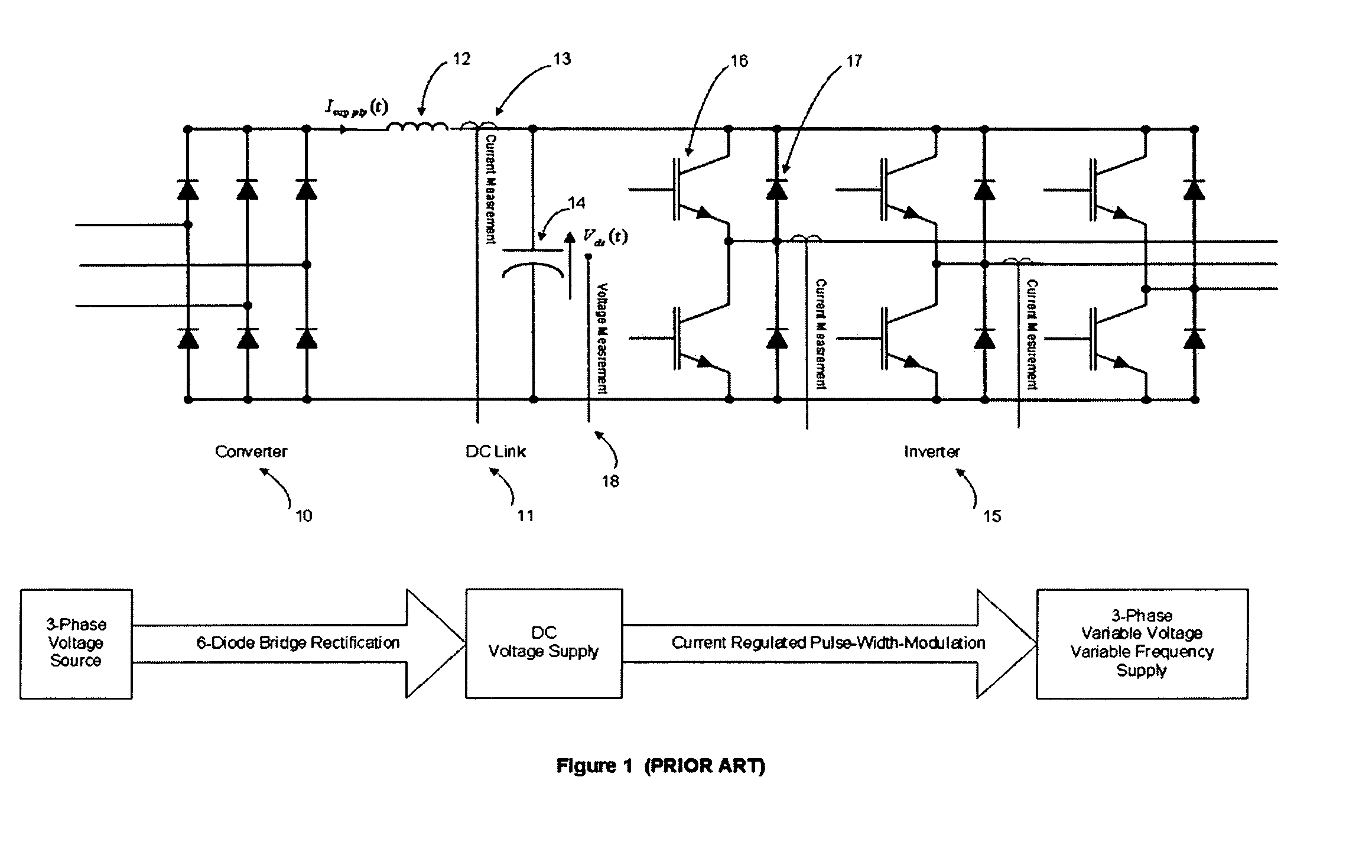

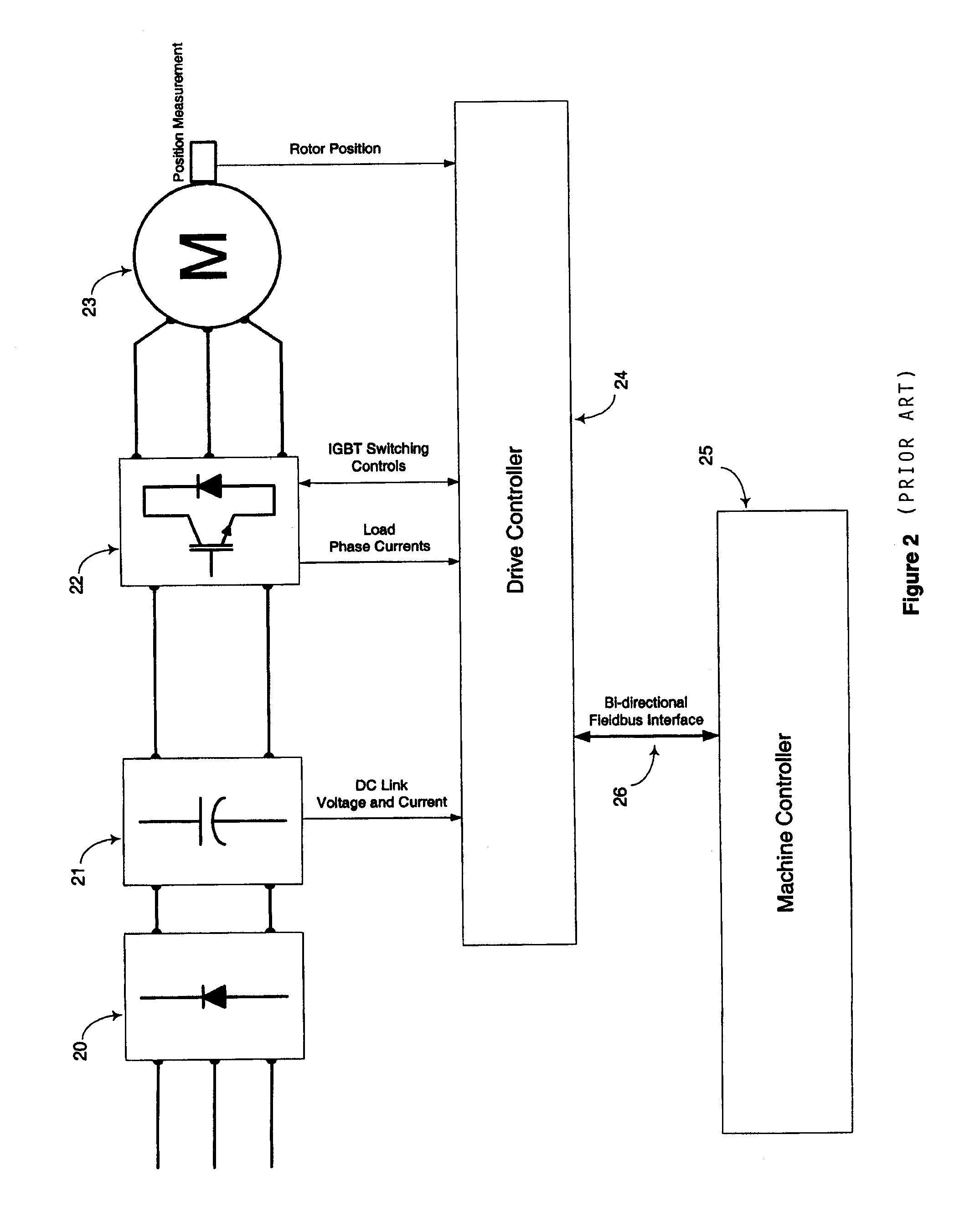

Energy management apparatus and method for injection molding systems

ActiveUS20050258795A1Reduce processing needsLowering speed profileComputer controlSimulator controlElectricityMolding machine

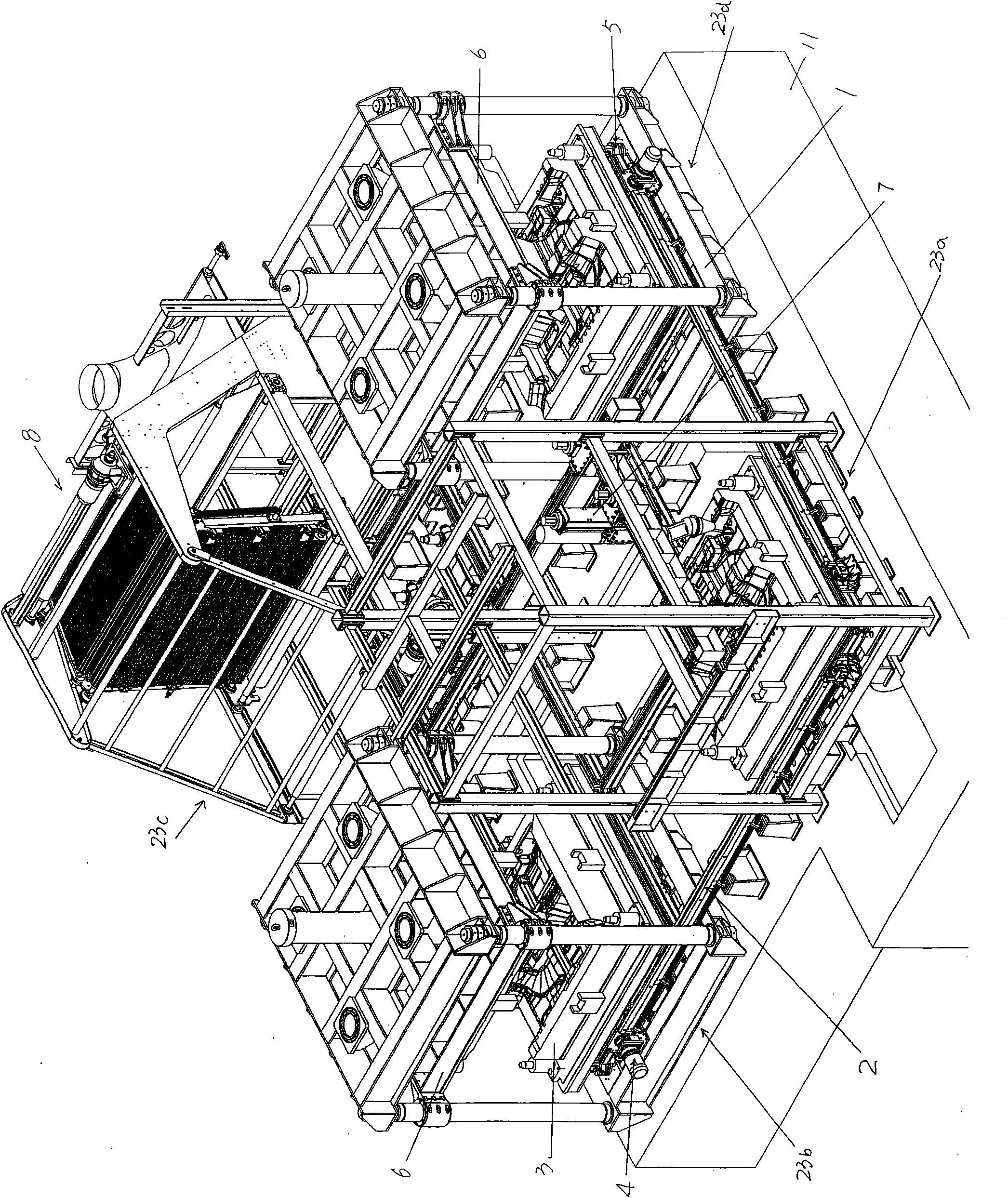

An energy management control apparatus for a molding machine that includes a first electrically-driven prime mover configured to drive at least a first molding machine device, and a second electrically-driven prime mover configured to drive at least a second molding machine device, includes a common DC link configured to provide DC energy to the first electrically-driven prime mover and to the second electrically-driven prime mover. A slave axis is configured to supply and absorb energy from to / from the common DC link. A machine controller is configured to (i) communicate with the first electrically-driven prime mover, the second electrically-driven prime mover, the common DC link, and the slave axis, (ii) cause the slave axis to supply energy to the common DC link in response to input from at least one of the first electrically-driven prime mover and the second electrically-driven prime mover, and (iii) cause the slave axis to absorb energy from the common DC link in response to input from at least one of the first electrically-driven prime mover and the second electrically-driven prime mover.

Owner:HUSKY INJECTION MOLDING SYST LTD

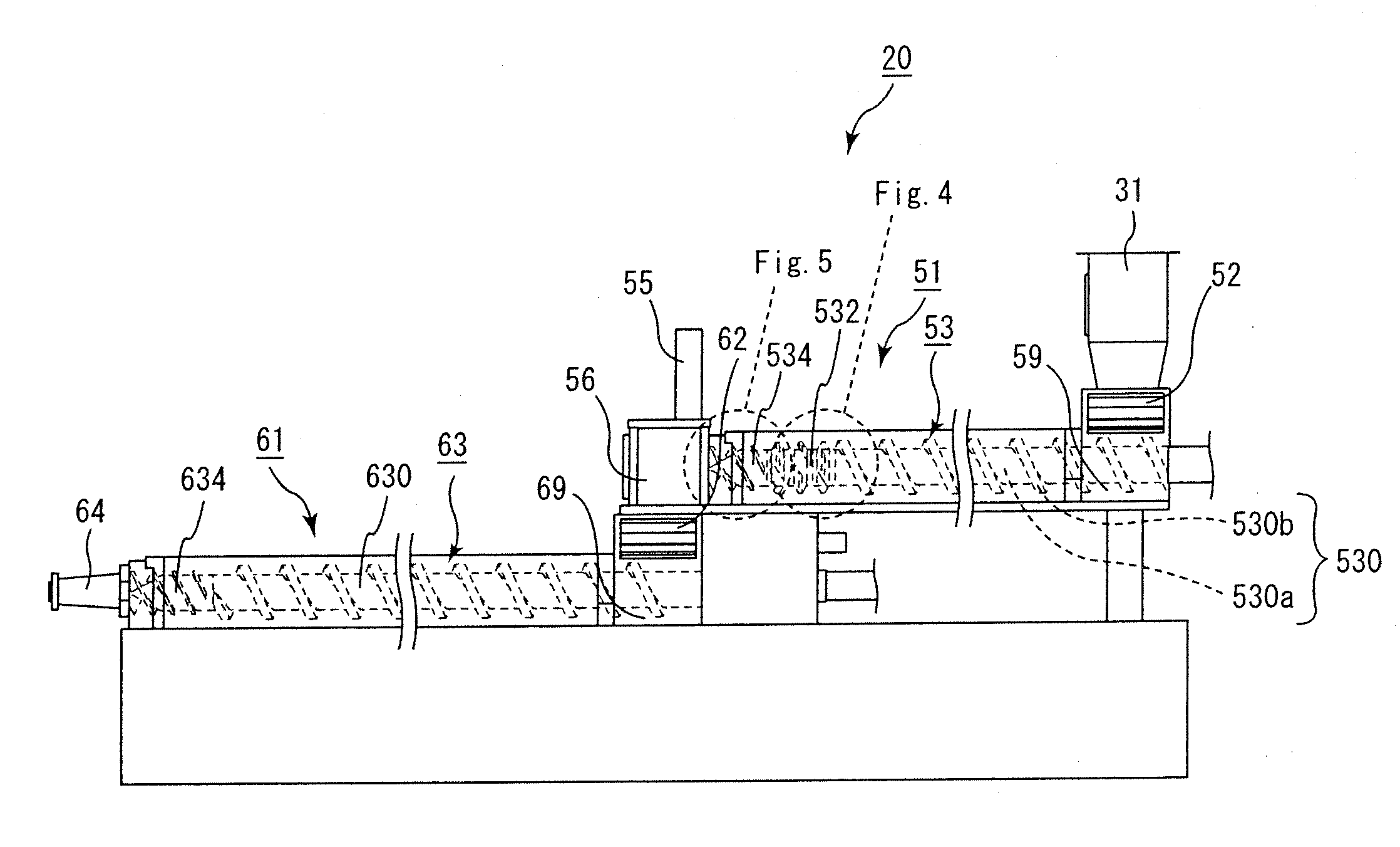

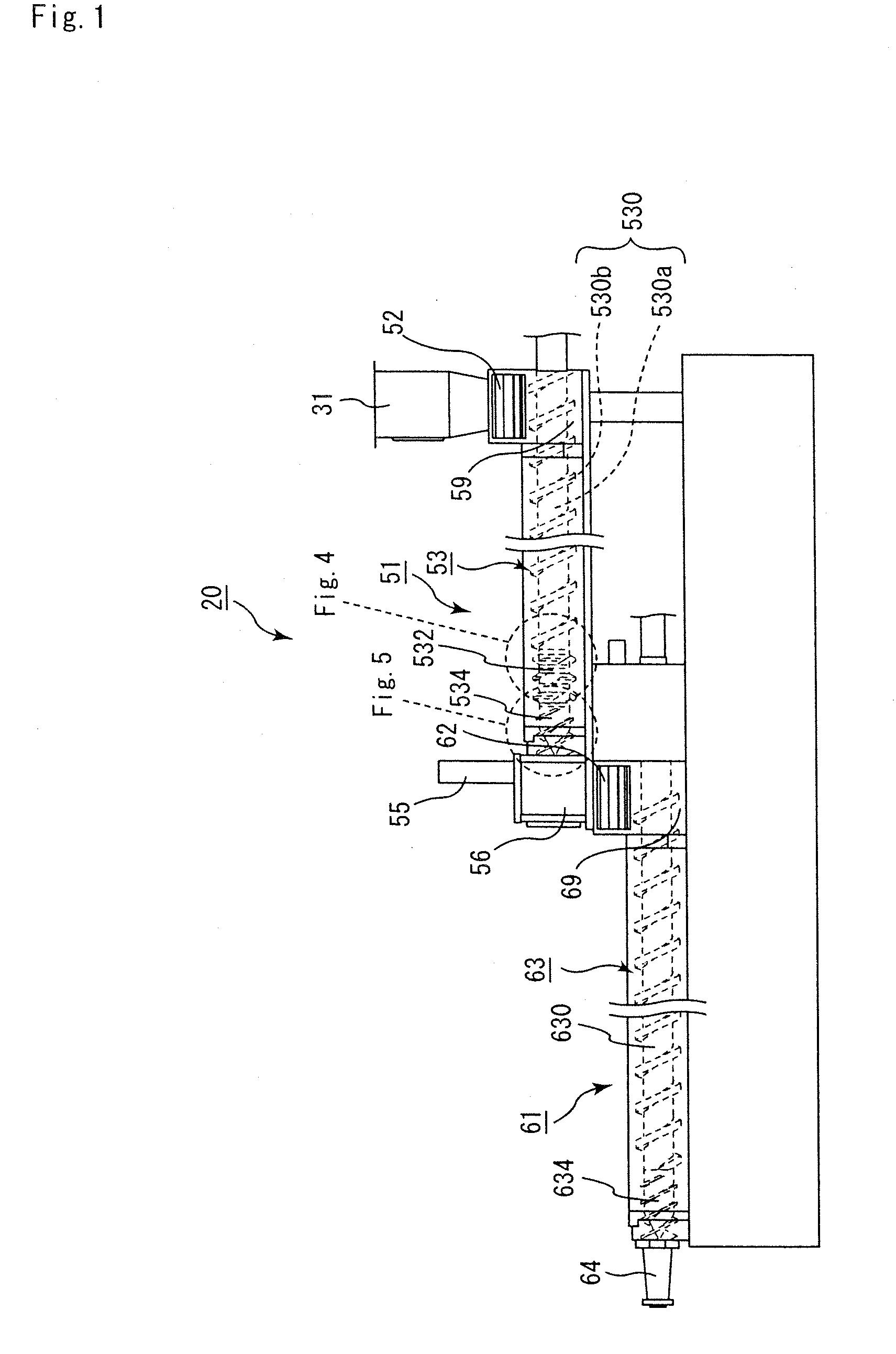

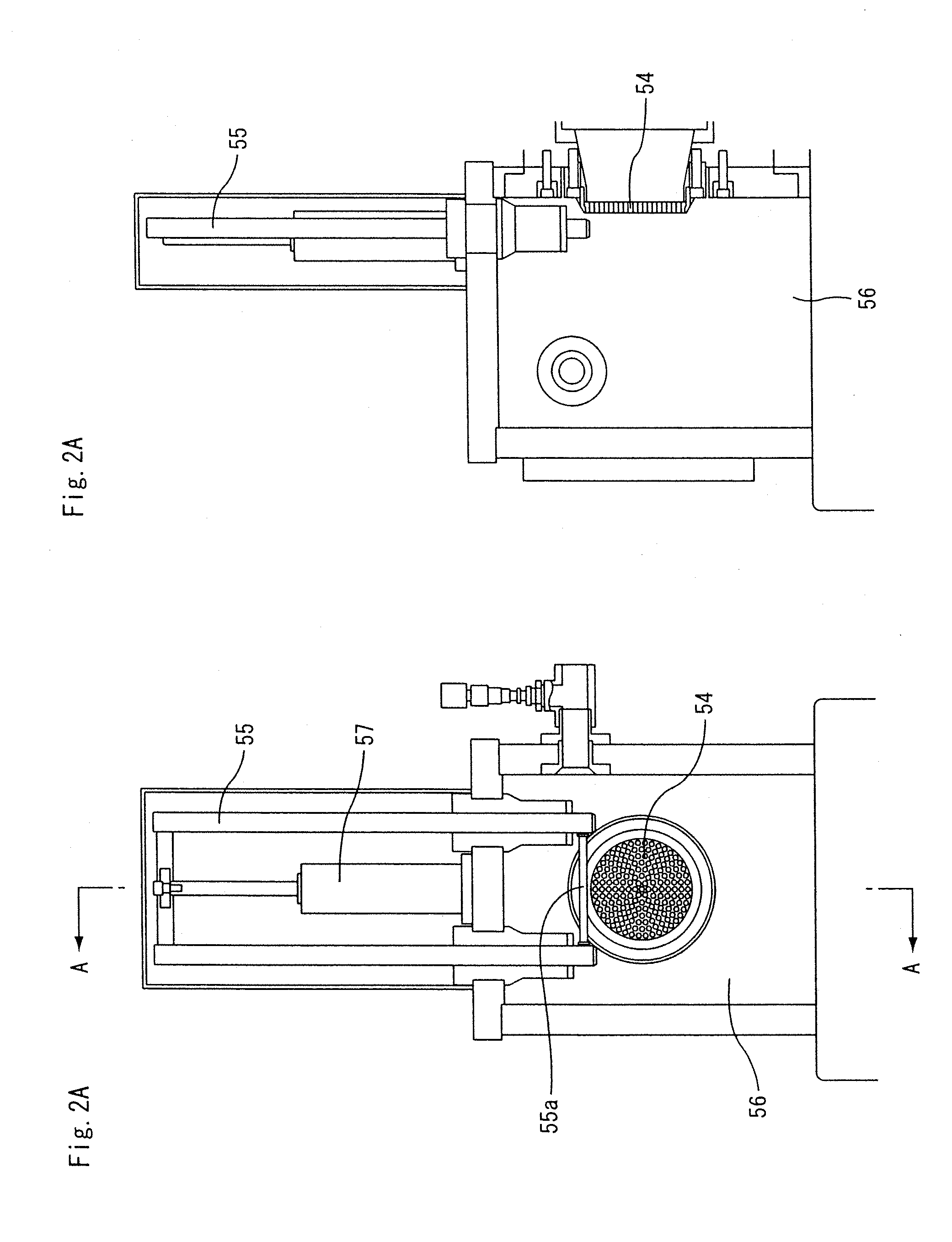

Extrusion-molding machine, extrusion-molding method, and method for manufacturing honeycomb structured body

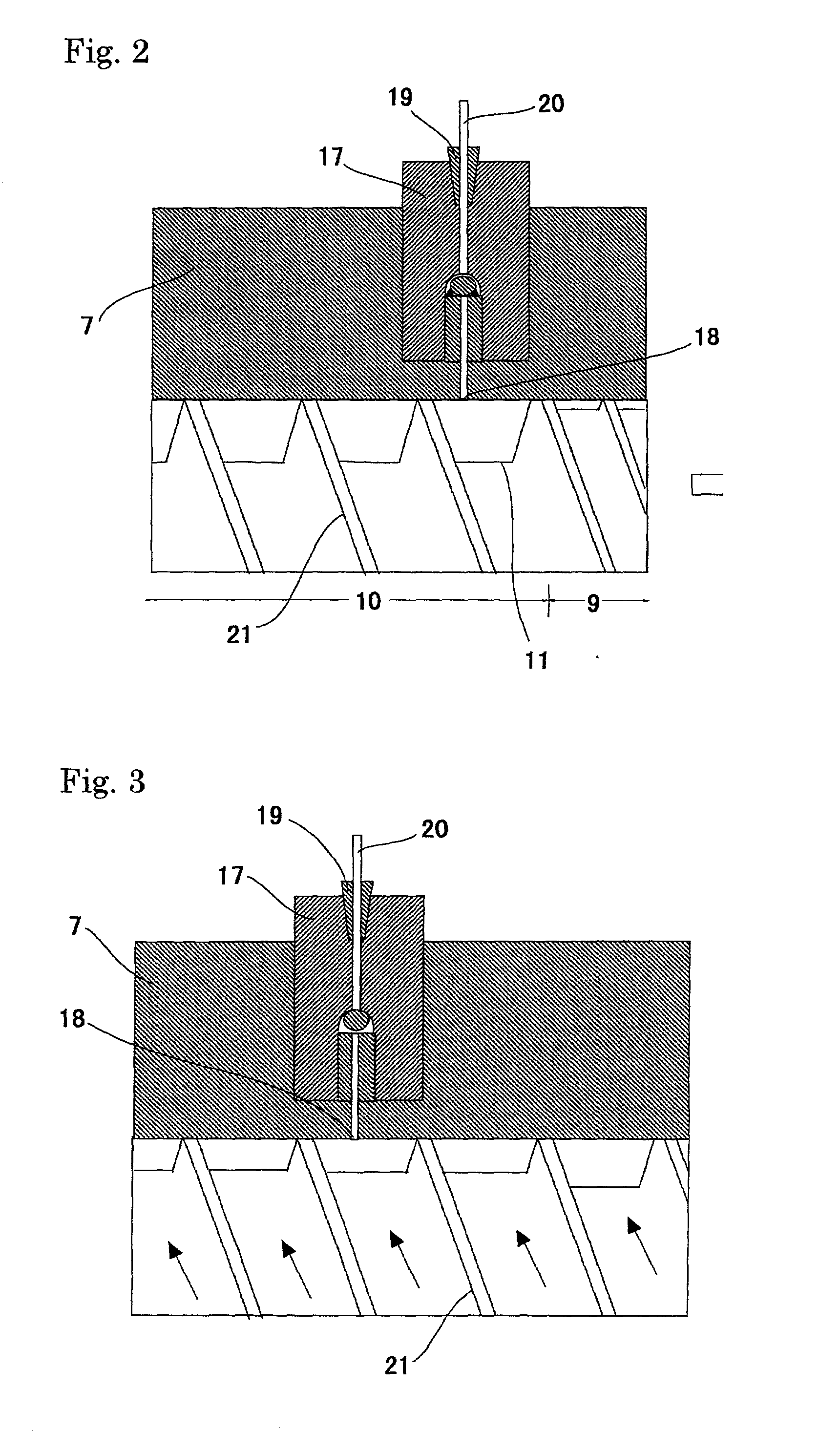

An extrusion-molding machine according to the present invention comprises: a screw having a blade portion for extruding a molding material, the screw disposed in a tightly-closed space; and a die for molding an extruded molding material, wherein the space is maintained in a reduced-pressure atmosphere, and a high-hardness coat layer is formed at least on the blade portion.

Owner:IBIDEN CO LTD

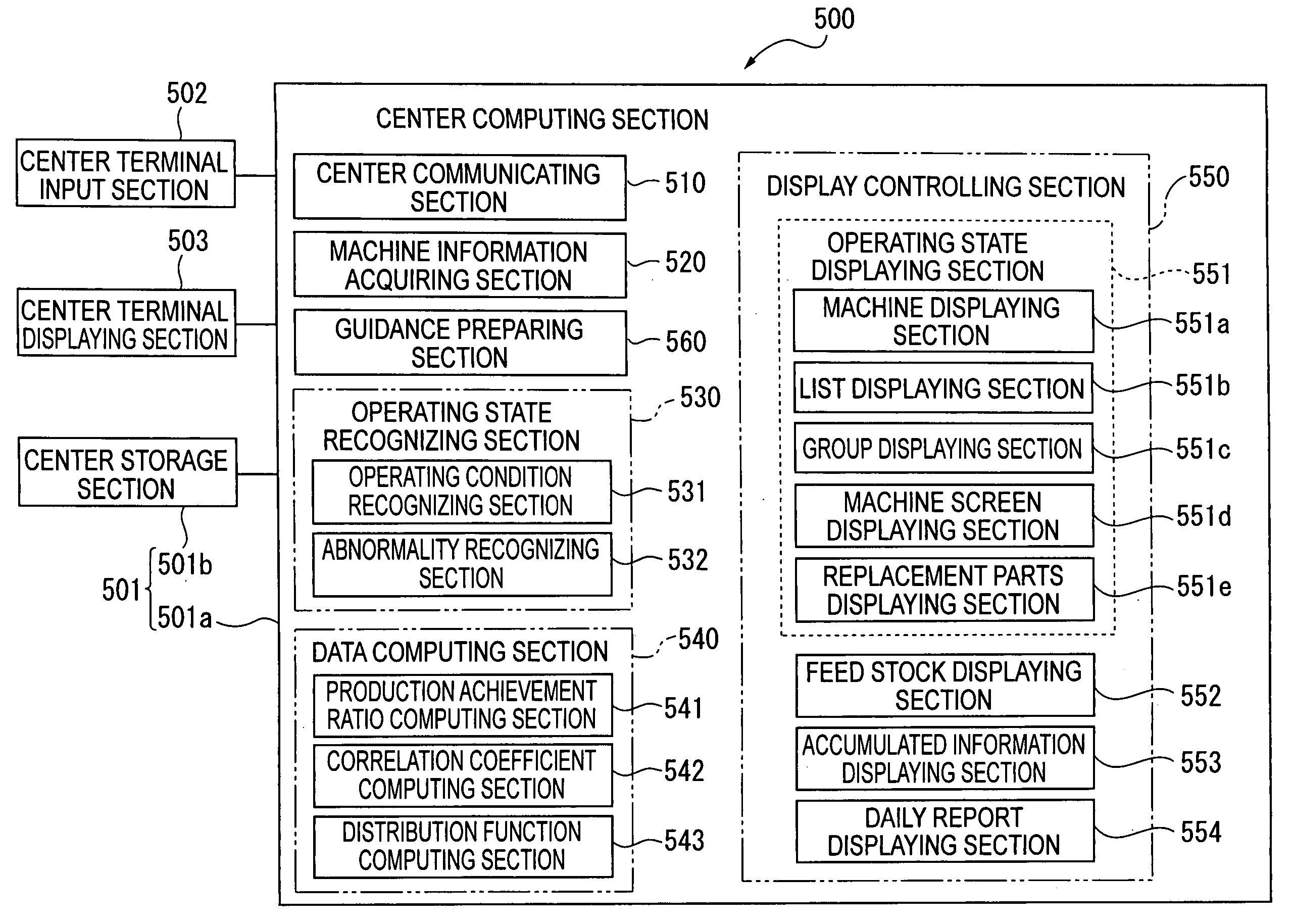

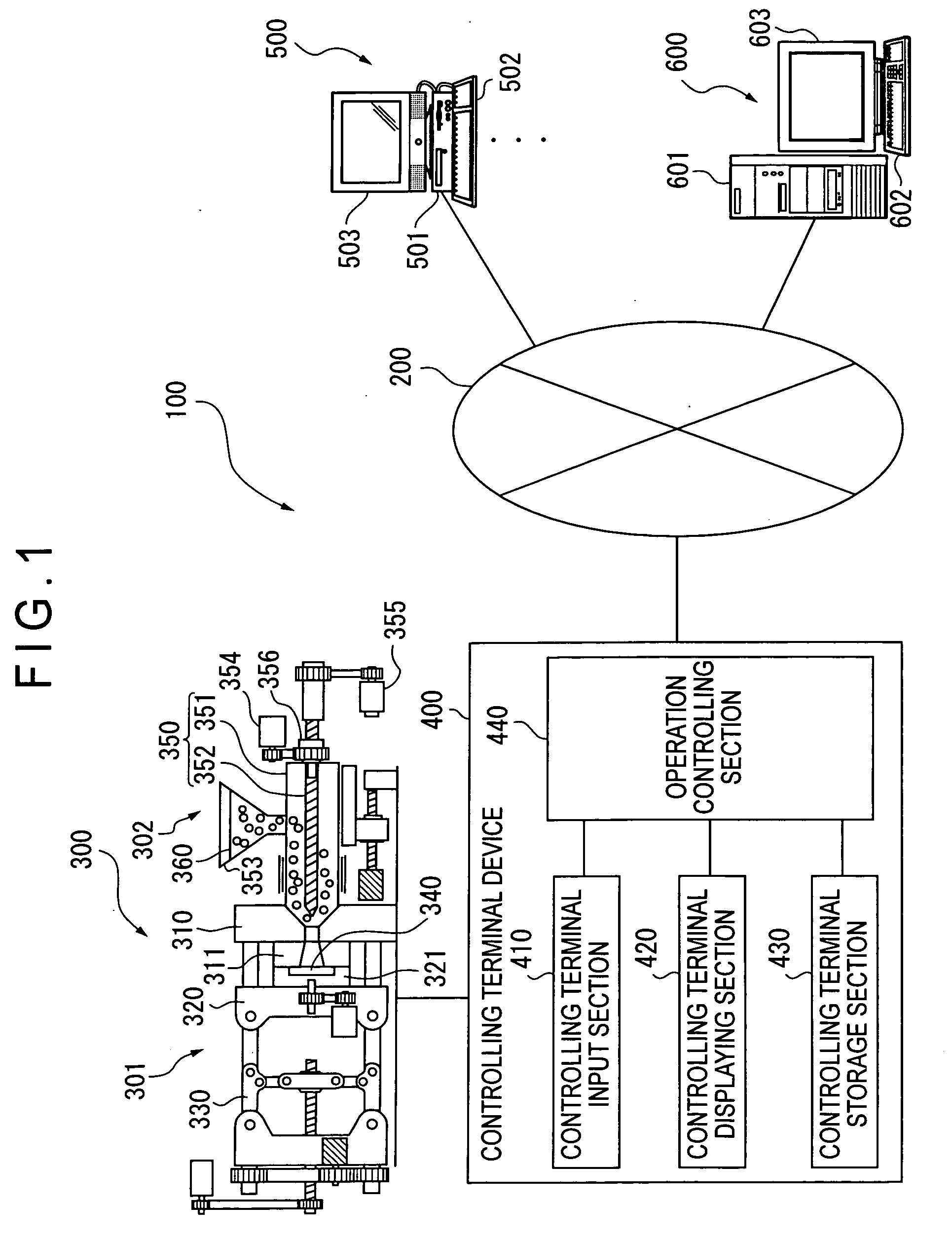

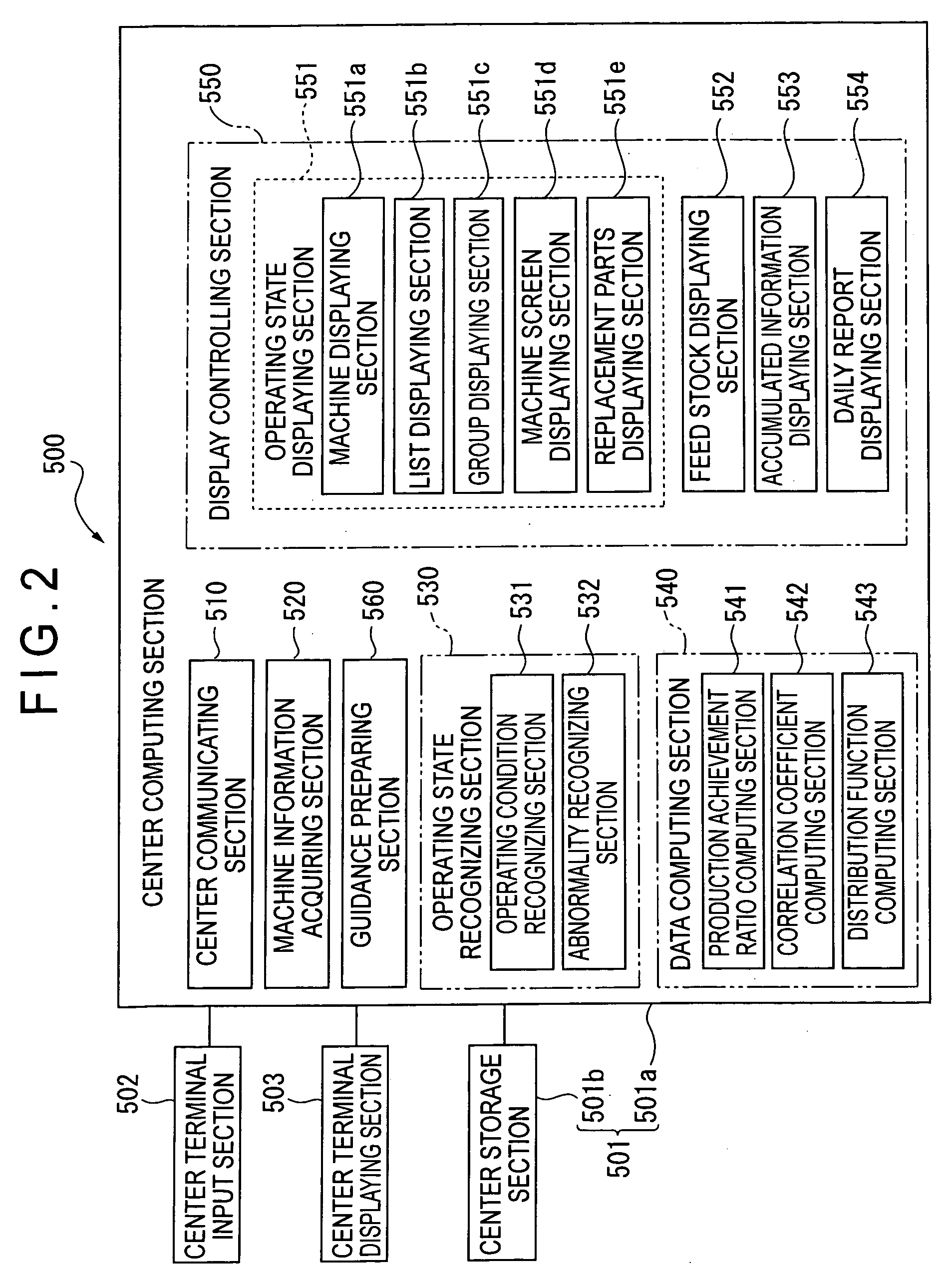

Management supporting apparatus, management supporting system, management supporting method, management supporting program, and a recording medium with the program recorded therein

ActiveUS20040148136A1Efficient replacementEasy to manageProgramme controlComputer controlSupporting systemManagement support systems

Operation state information for each cycle of manufacturing operations of each of injection molding machines 300 is acquired by a center management terminal device 400 via a network from a plurality of controlling terminal device 400 for controlling the injection molding machines 300. Cumulative utilization of replacement parts of each injection molding machine 300 put into practical operation is recognized by the operating condition recognizing section of the center management terminal device 400 based on the parts state information for the replacement parts of each injection molding machine 300 included in the operating state information. Based on the cumulative utilization, availability of the parts is recognized with reference to lifetime information concerning lifetime of the parts previously stored in the center storage section, and situation of the availability is displayed with a different display format on the center terminal displaying section 503.

Owner:TOSHIBA MASCH CO LTD

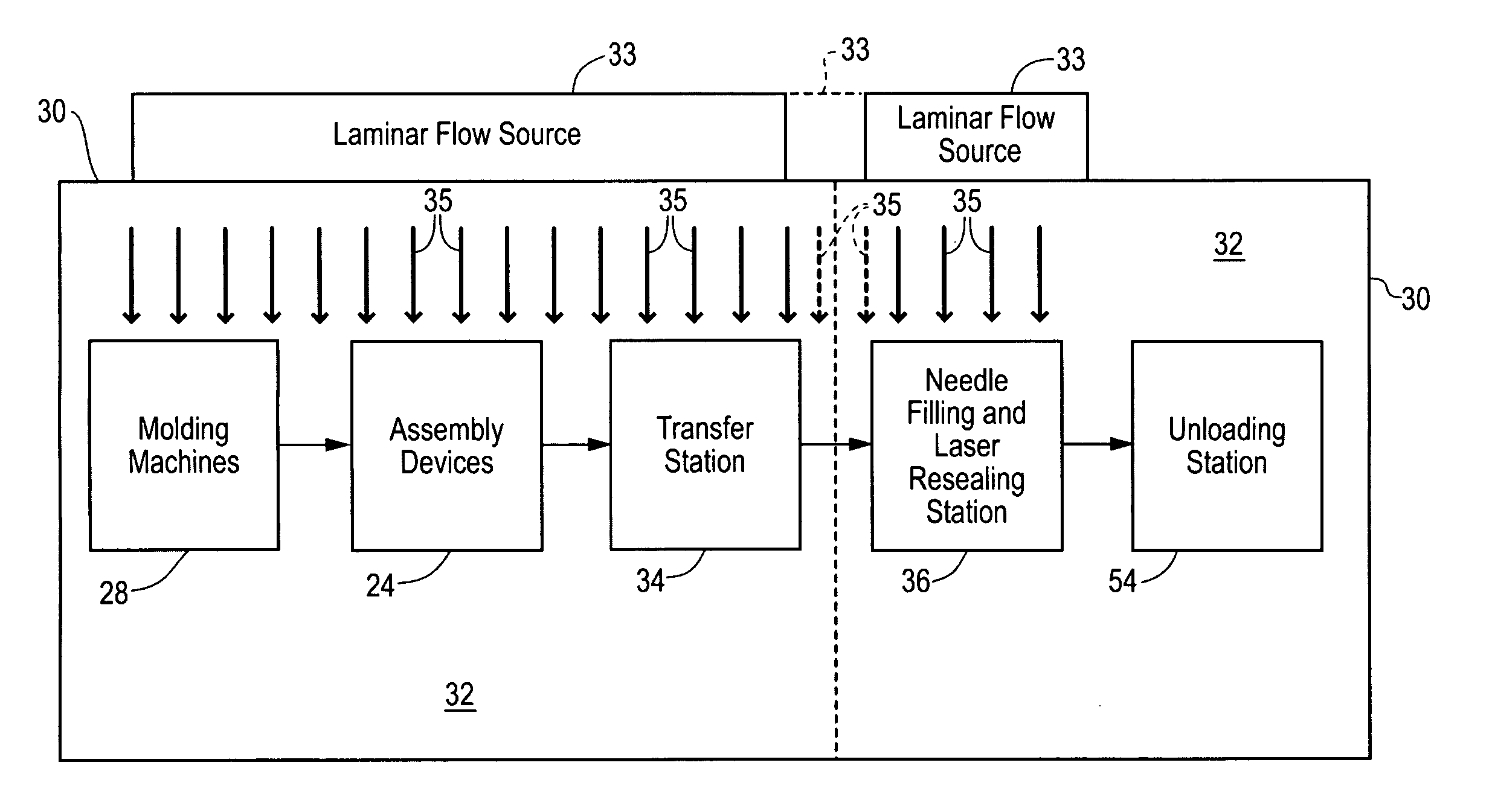

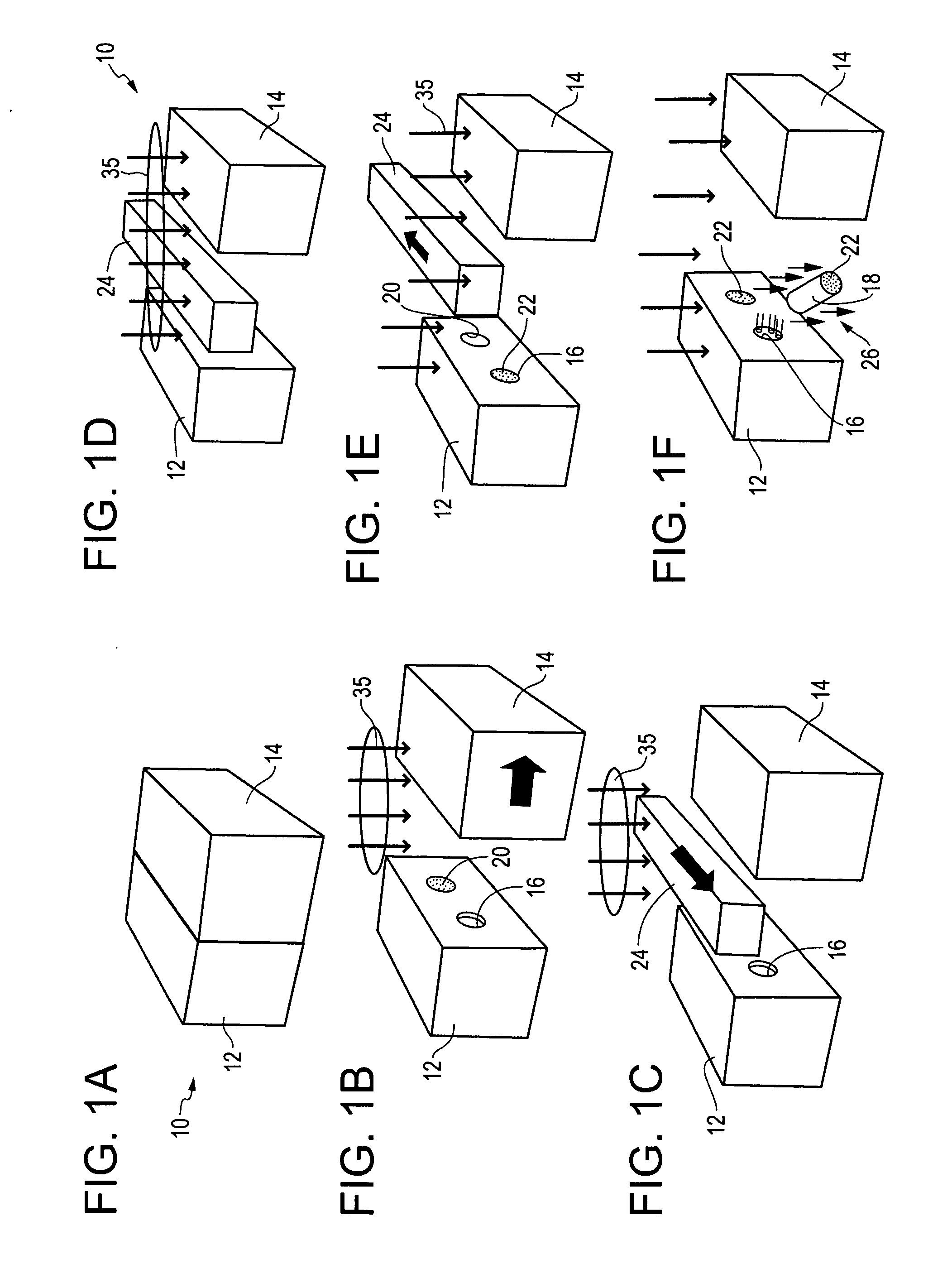

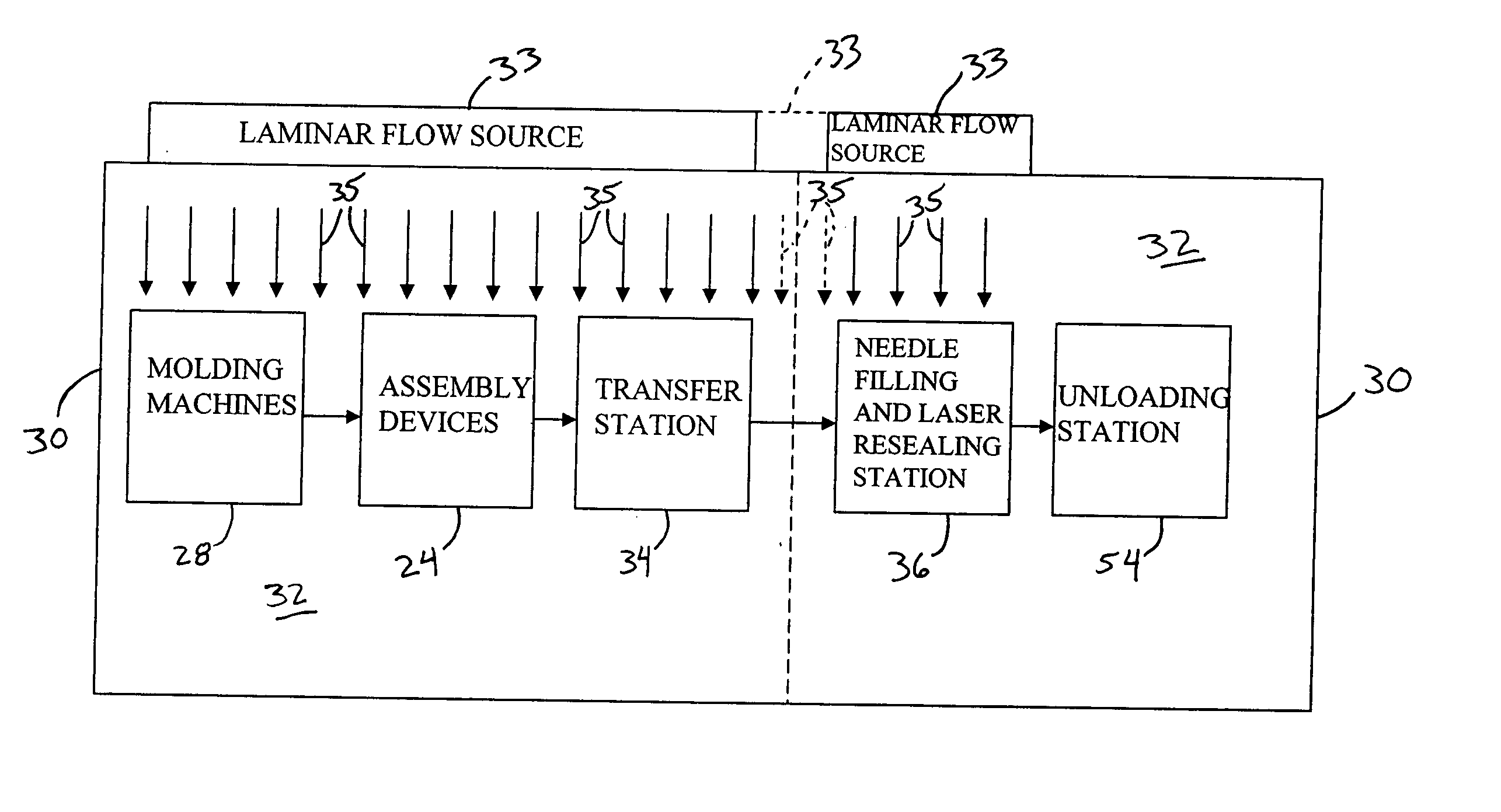

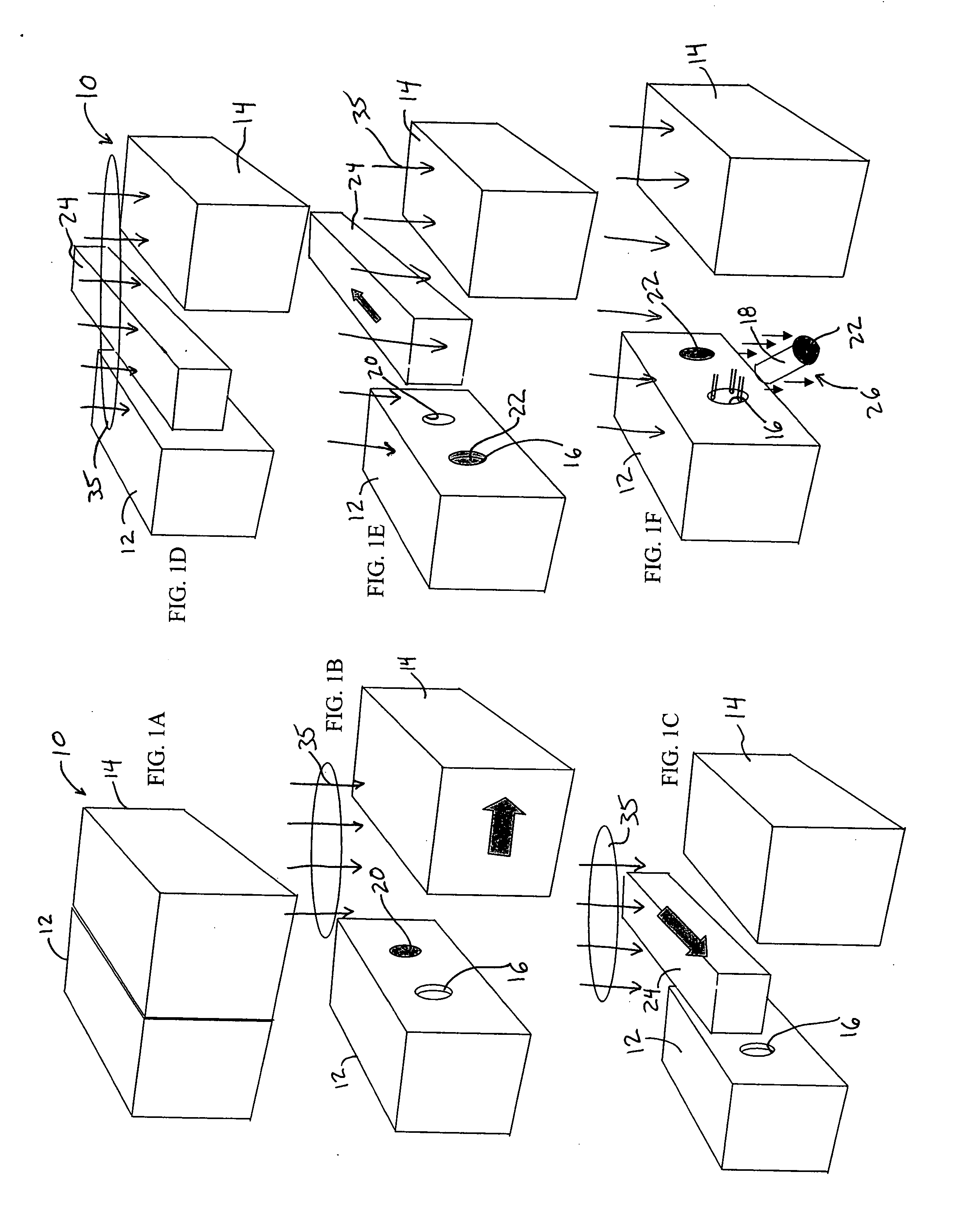

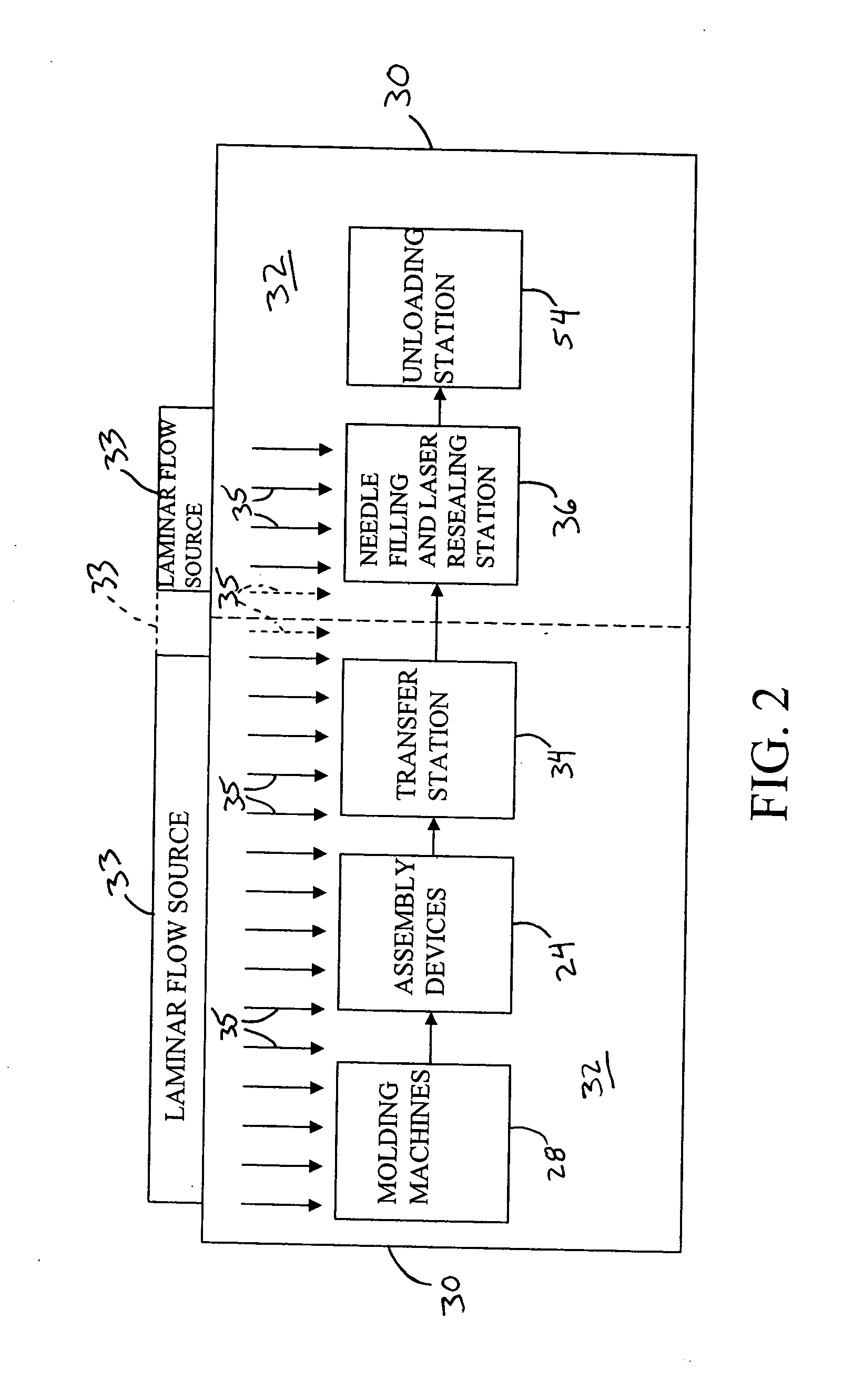

Apparatus for molding and assembling containers with stoppers and filling same

InactiveUS20050223677A1Package sterilisationPackaging under vacuum/special atmosphereMolding machineMechanical engineering

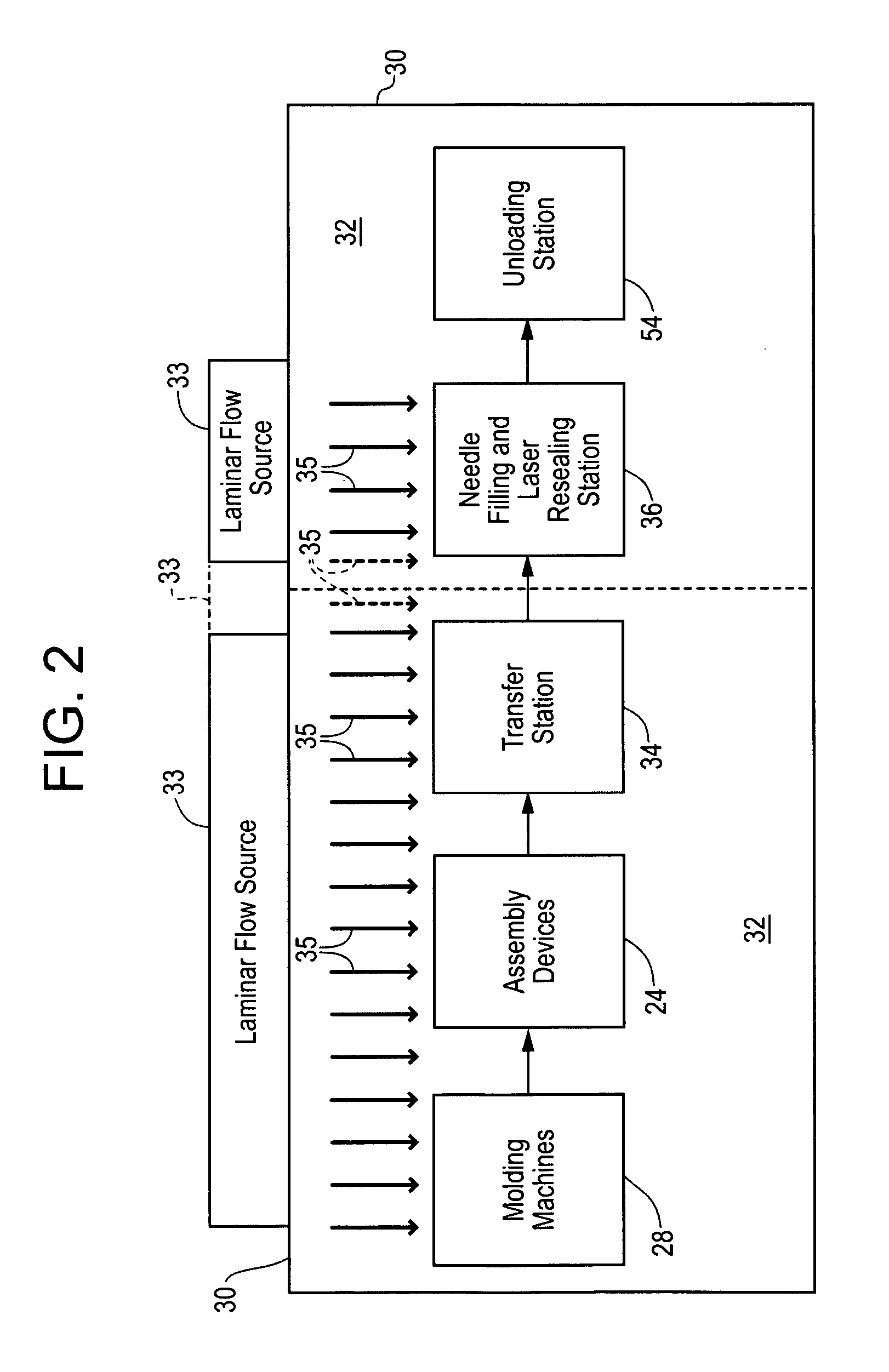

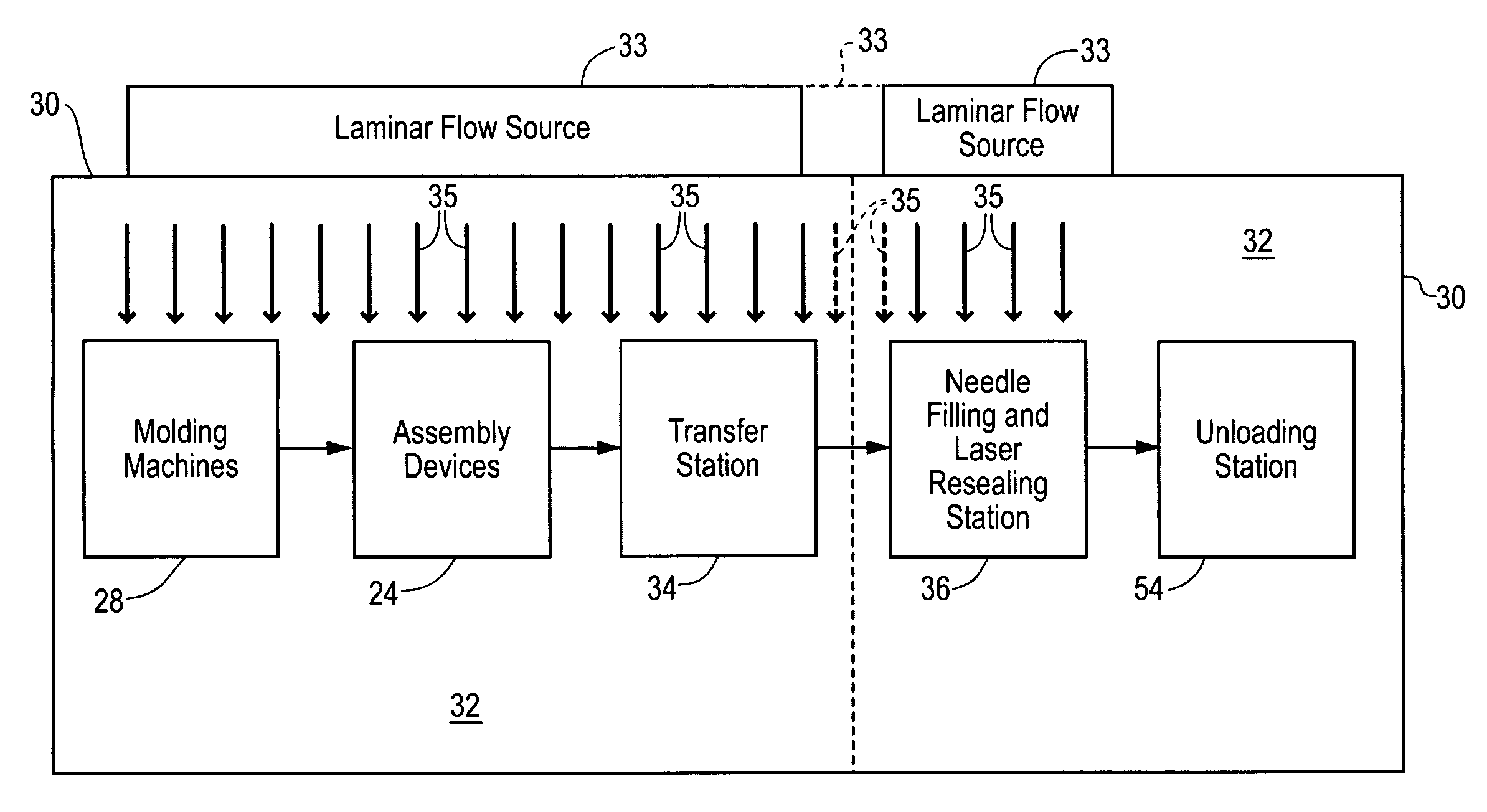

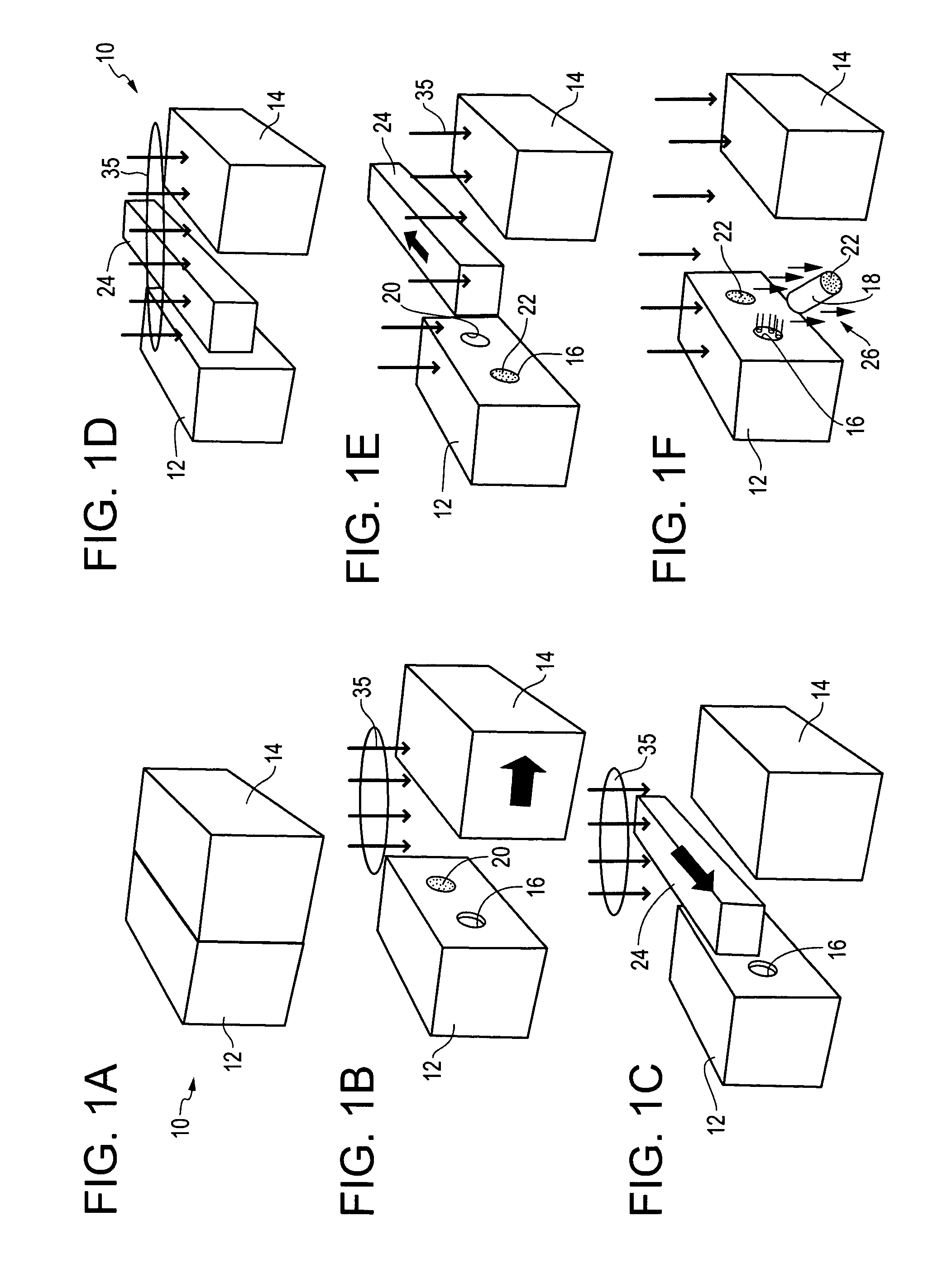

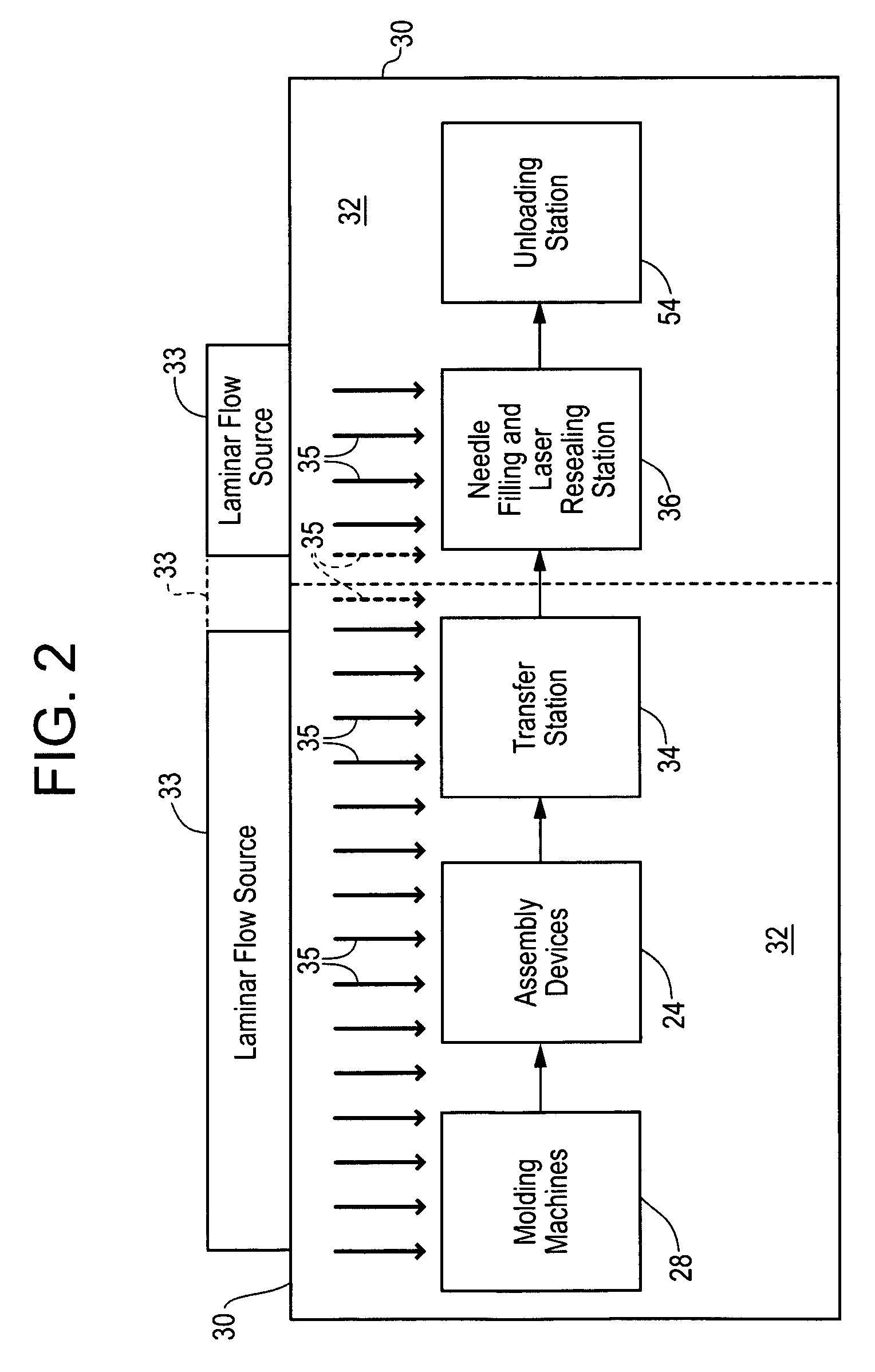

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

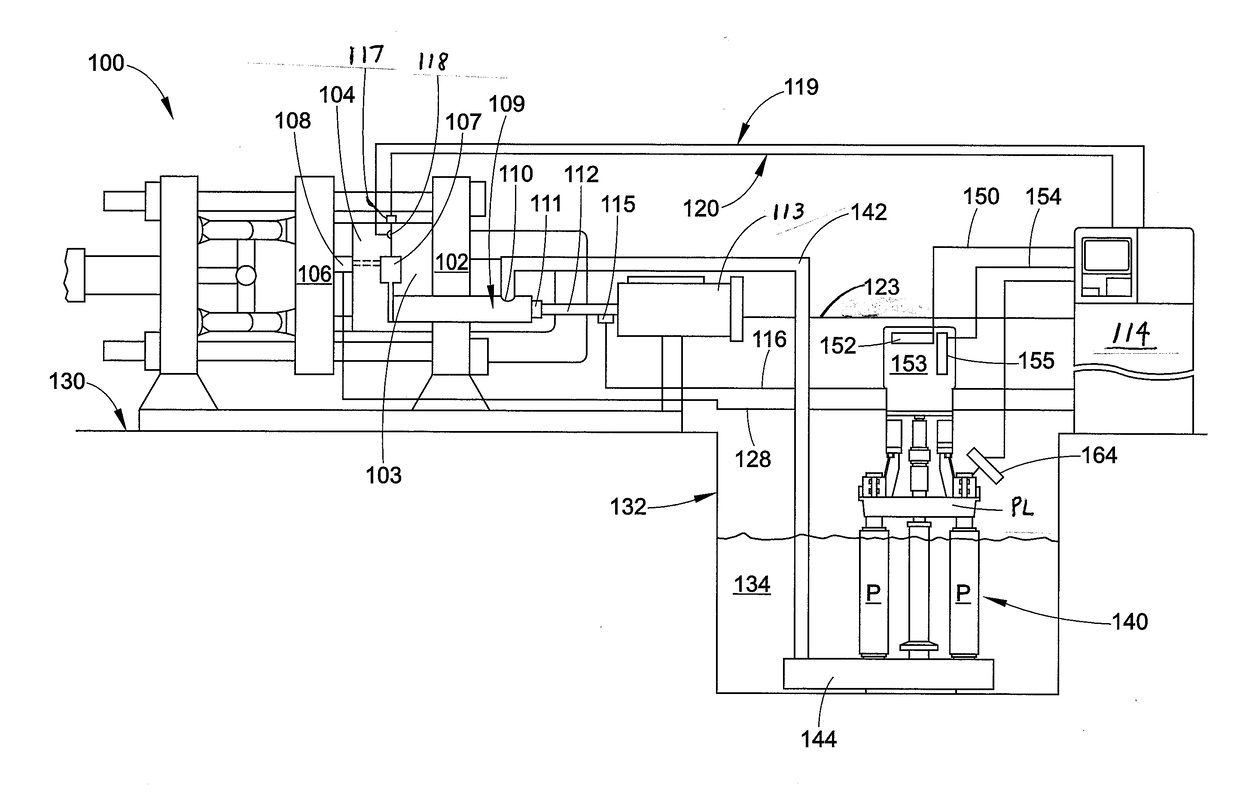

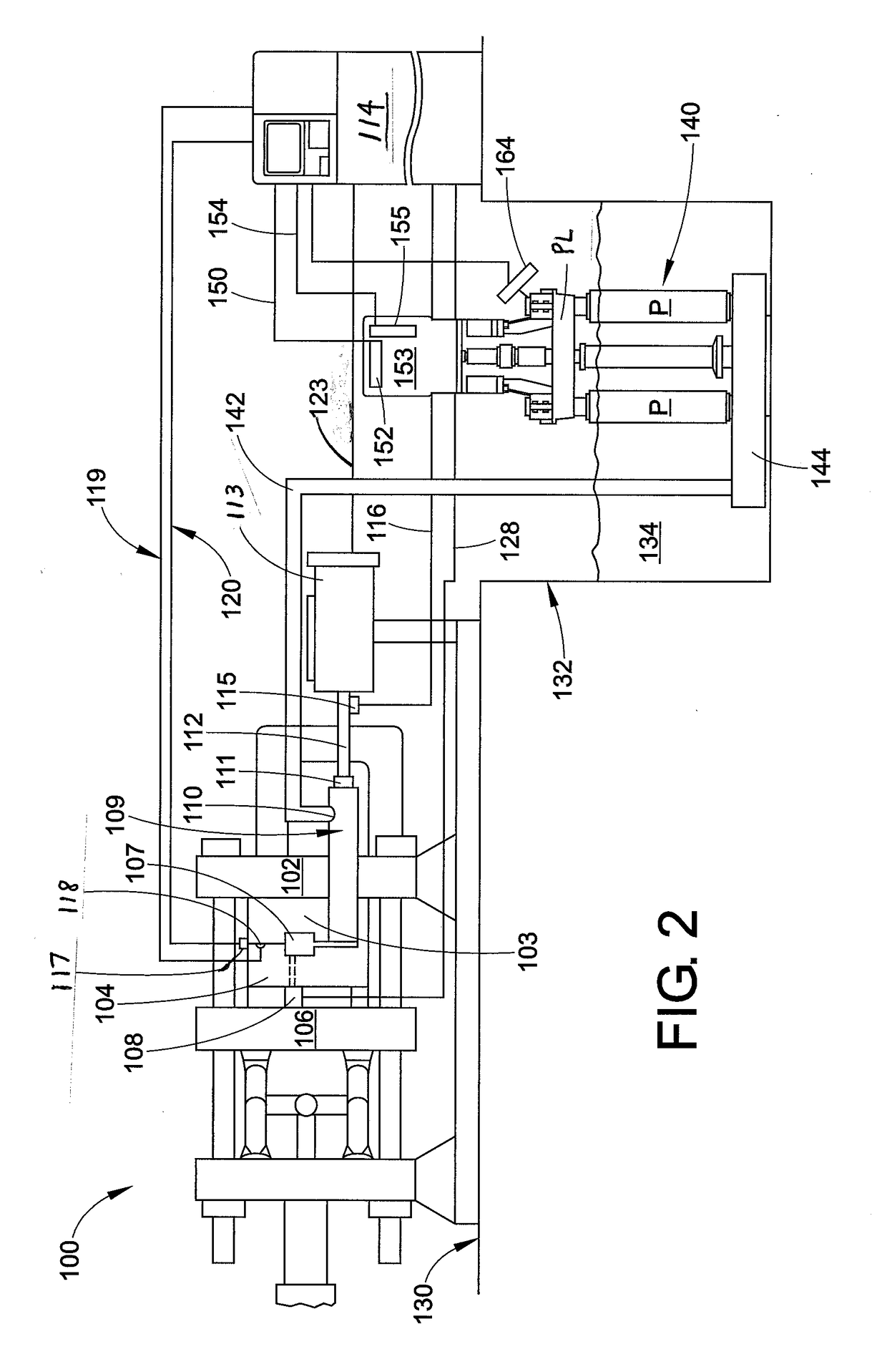

Intelligent molding environment and method of configuring a molding system

ActiveUS20060082009A1Easy to operate and controlReduce complexityAuxillary shaping apparatusMolding machineEngineering

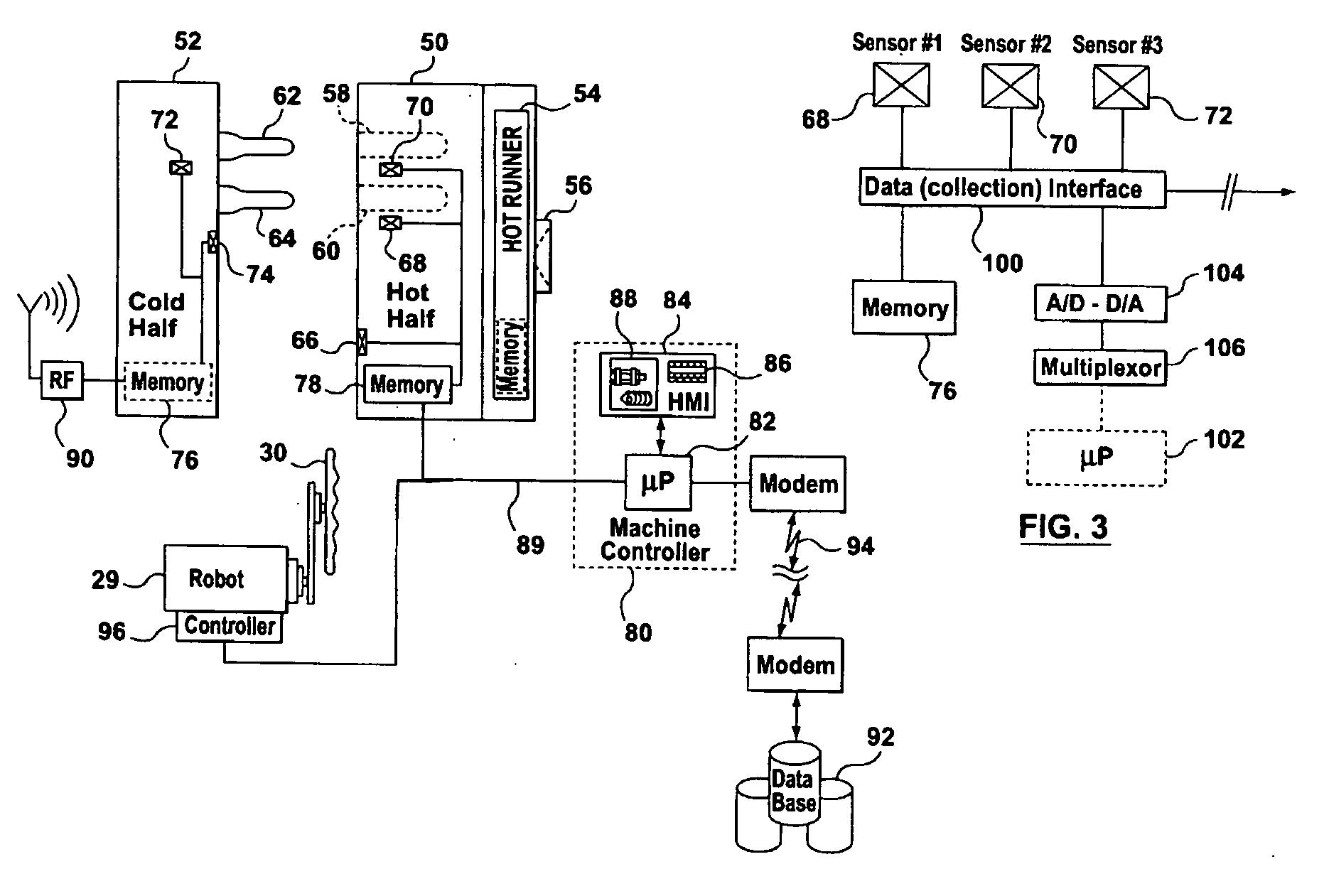

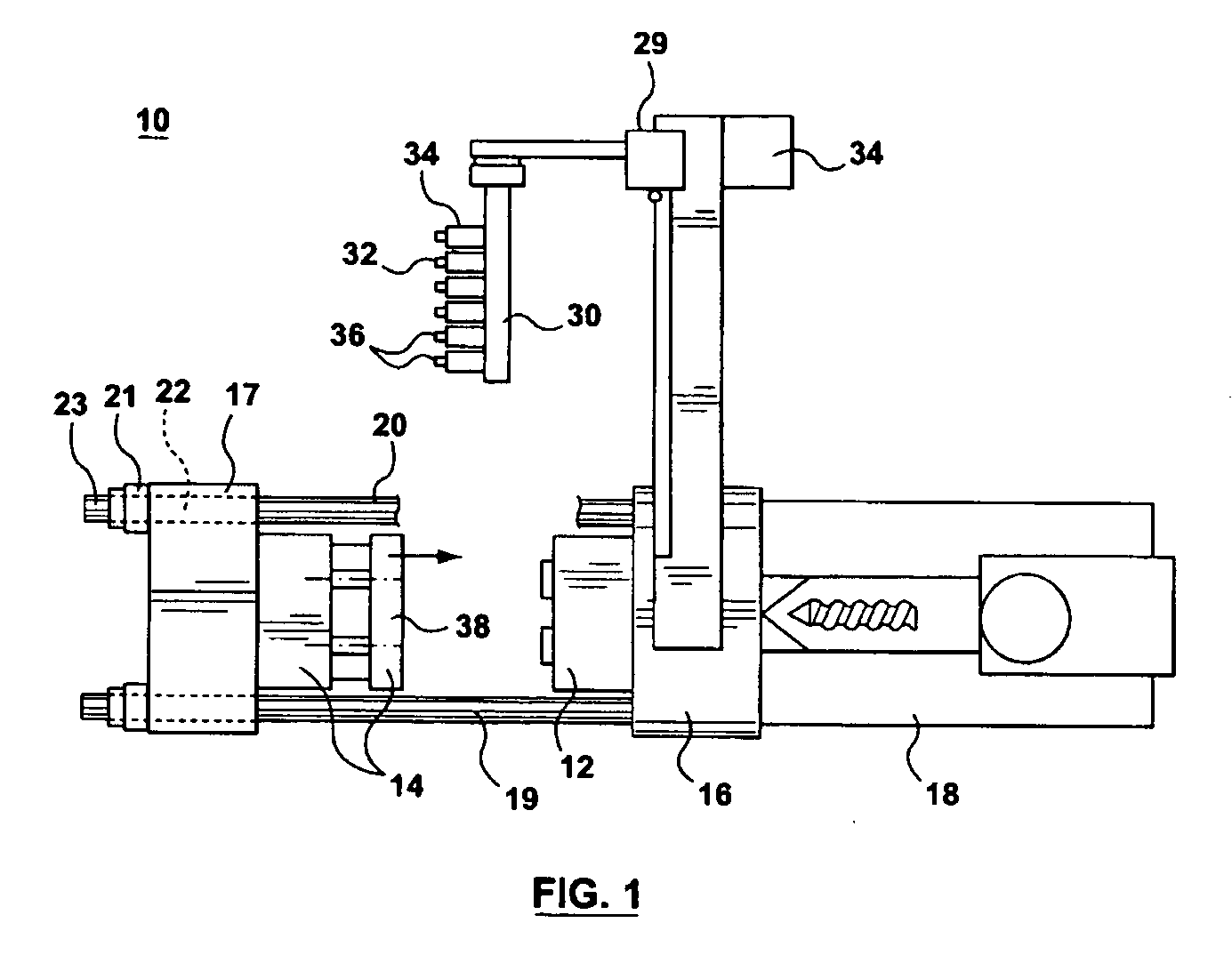

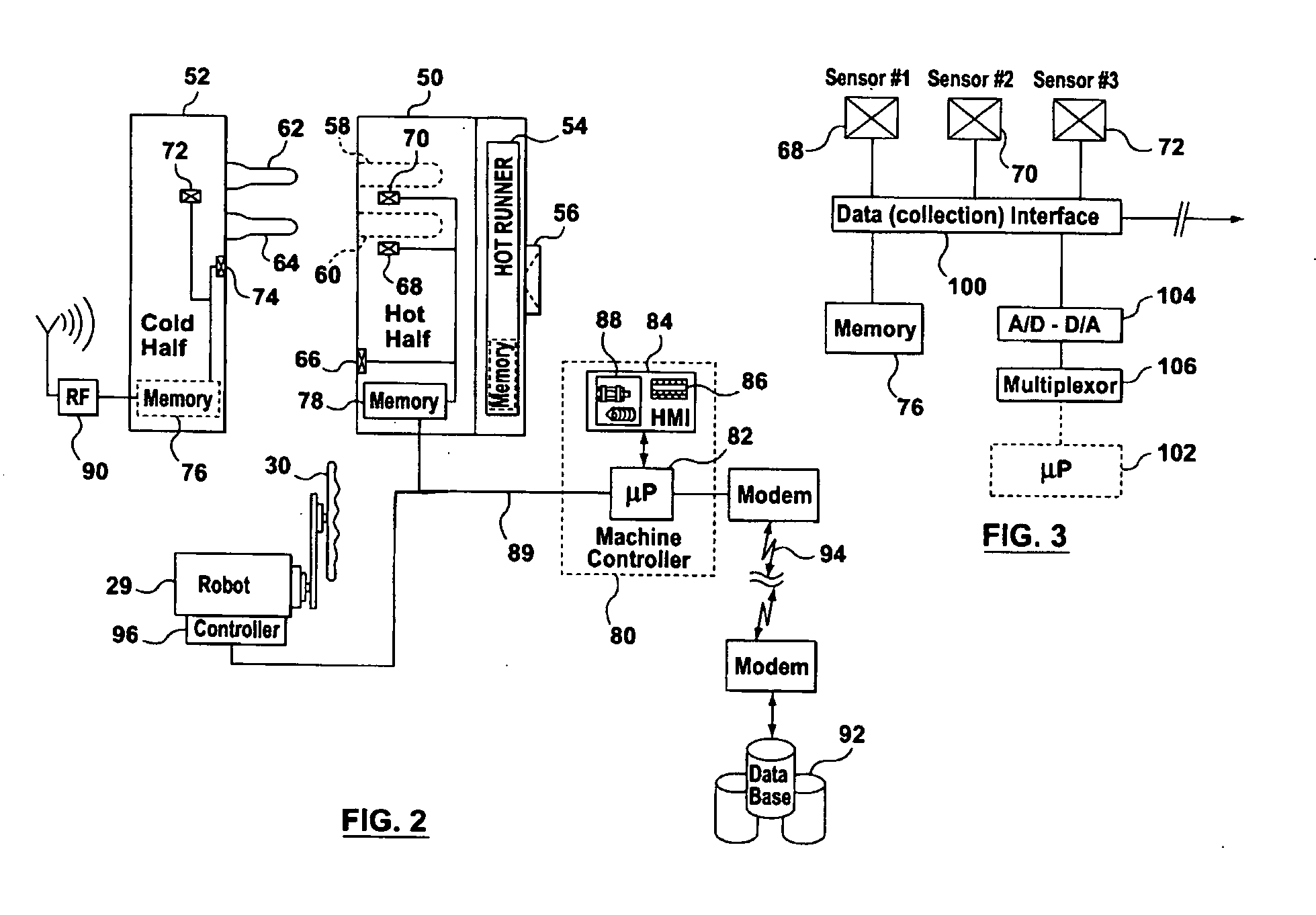

An intelligent molding system (FIG. 2) is provided that makes use of data directly associated with a molding environment or particular mold (50, 52). Accessible data, typically stored locally in an in-mold memory device (76, 78) or input via an HMI (86), identifies parameters germane to mold set-up and machine operation. Upon receiving such data, a machine controller (80) operates to configure a molding machine (10) to an initial set-up defined by the data considered close to an optimal operating condition for the mold. Mold set-up data can include information relating to a fill profile for a molded article that is partitioned into different zones having different thicknesses and geometries. Weighting factors for the various zones compensate for differing cooling and flow characteristics. The memory (76, 78) can also be used to store historical data pertaining to mold operation, settings and alarms.

Owner:HUSKY INJECTION MOLDING SYST LTD

Method for molding and assembling containers with stoppers and filling same

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

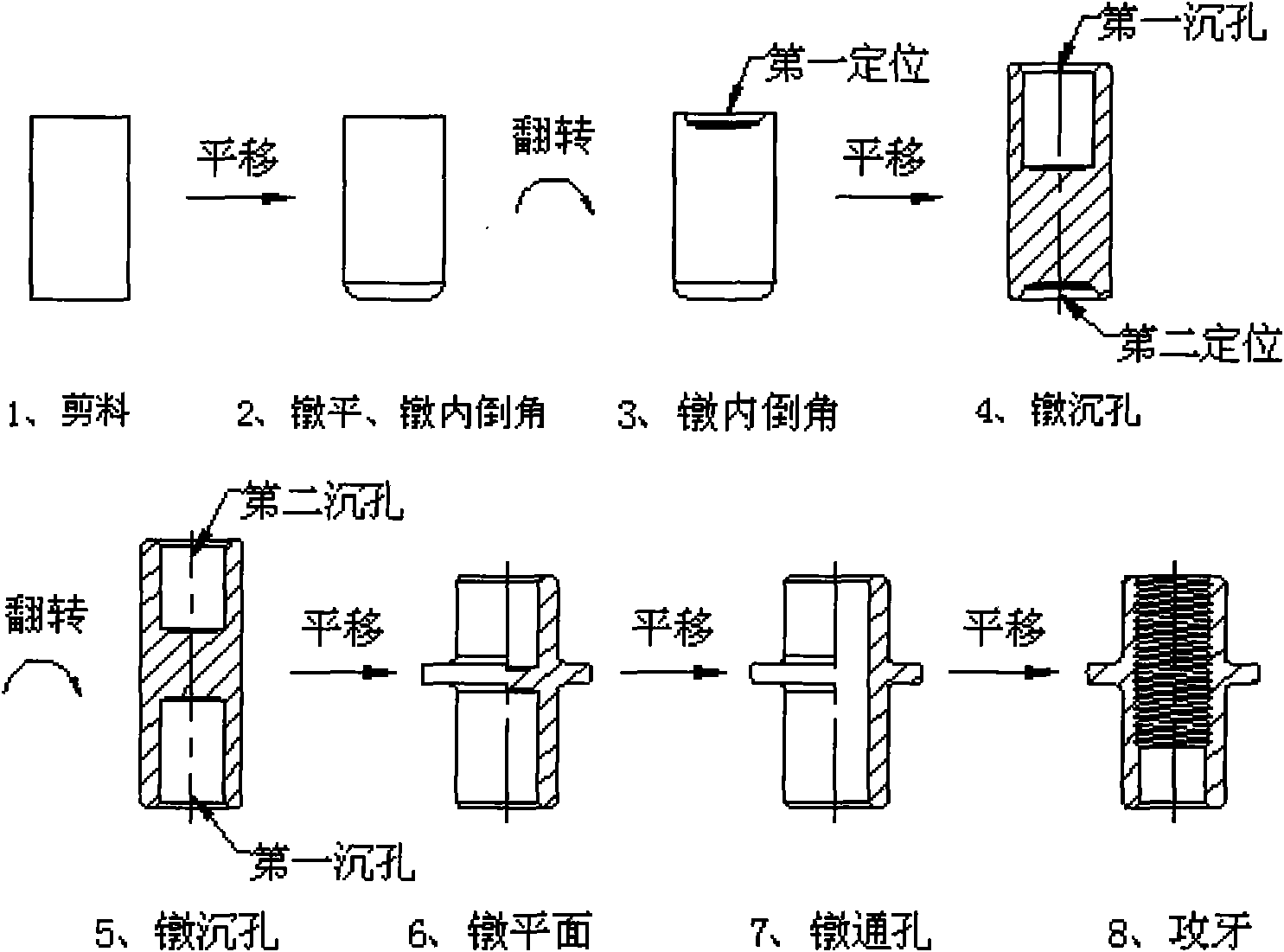

Manufacturing process of adjusting nut

InactiveCN101618498ALess consumablesCompact structureNutsMetal-working apparatusWire rodMolding machine

The invention discloses a manufacturing process of an adjusting nut. The steel billet raw materials are manufactured into wire rod materials, surface treatment is performed on the wire rod materials by using phosphate, spheroidizing annealing, phosphating and fine-drawing and sizing treatment are respectively performed on the wire rod materials after roughing, and finally, the molding working procedure of the adjusting nut is carried out in a cold-heading molding machine; the molding working procedure of the adjusting nut comprises the following steps: material fracturing; material shaping and upsetting, upsetting an inner chamfer at the upper end; material turning, shaping and upsetting a positioning hole at the upper end and an inner chamfer at the lower end; material translating, upsetting a counterbore at the front end and a positioning hole at the rear end; material turning, upsetting a counterbore at the other end; material translating, upsetting a plane in the middle by using the PKO male die technology; discharging the residual scrap iron at a middle hole out and manufacturing a through hole product; and performing tapping to an inner hole of a blank of the adjusting nut. The invention is molded at one time by adopting a cold heading machine, thereby improving the production efficiency and the product quality of the adjusting nut, saving the raw material and reducing the manufacturing cost.

Owner:NINGBO ANCHOR FASTENERS INDAL

Apparatus for molding and assembling containers with stoppers and filling same

InactiveUS7707807B2Package sterilisationPackaging under vacuum/special atmosphereMolding machineShell molding

A stopper and container body are molded in the same molding machine. An assembly device, such as a pick and place robot, transfers the stopper from one mold cavity into the opening in the container body located within another mold cavity, or vice versa, to assemble the stopper and container body. Then, the assembled container body and stopper are removed from the molding machine and transported to a needle filling and laser resealing station for filling and laser resealing. A laminar flow source directs a substantially laminar flow of air or sterile gas over the mold surfaces, stoppers and container bodies, and assembly device, to prevent contamination during assembly.

Owner:MEDINSTILL DEV

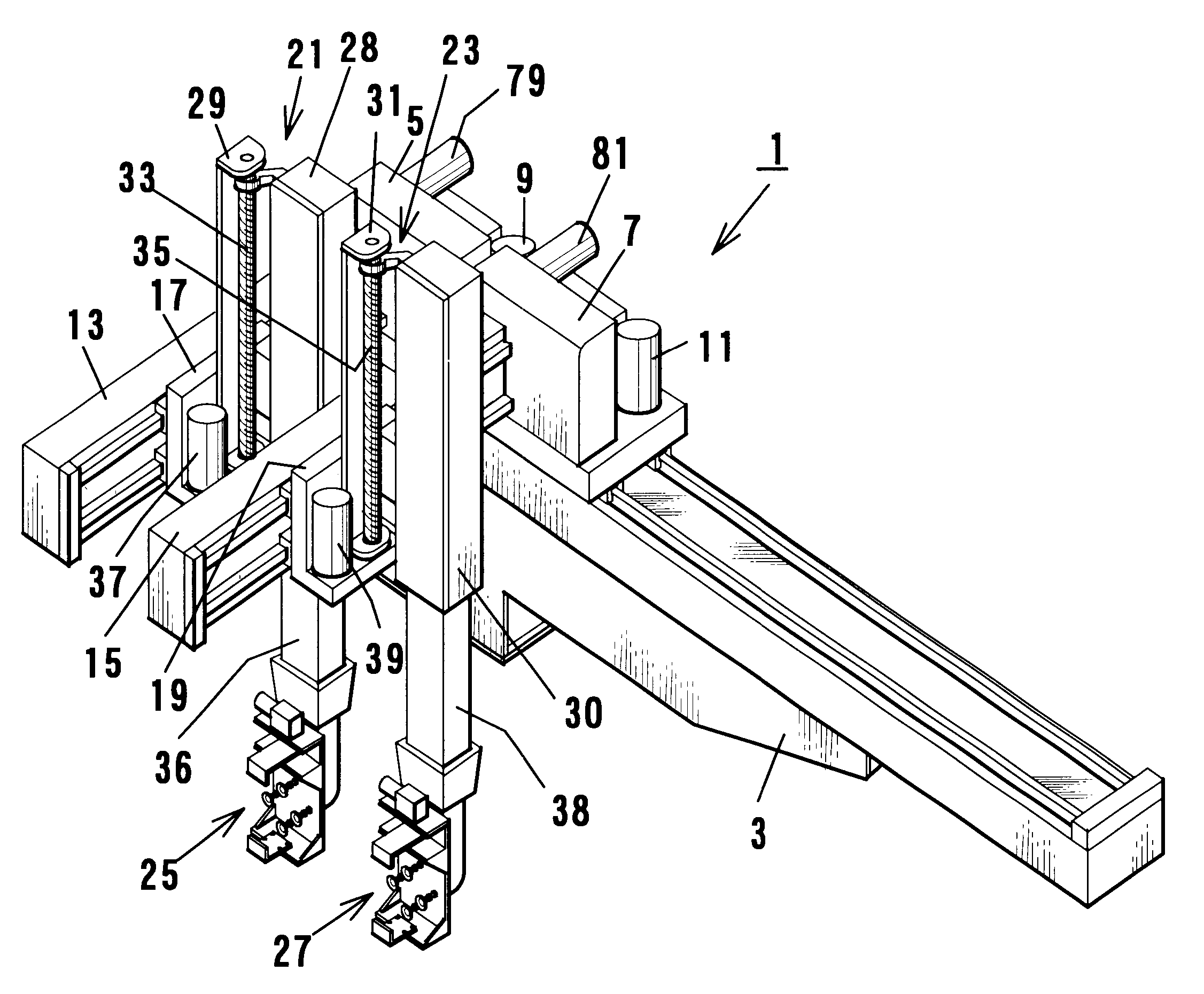

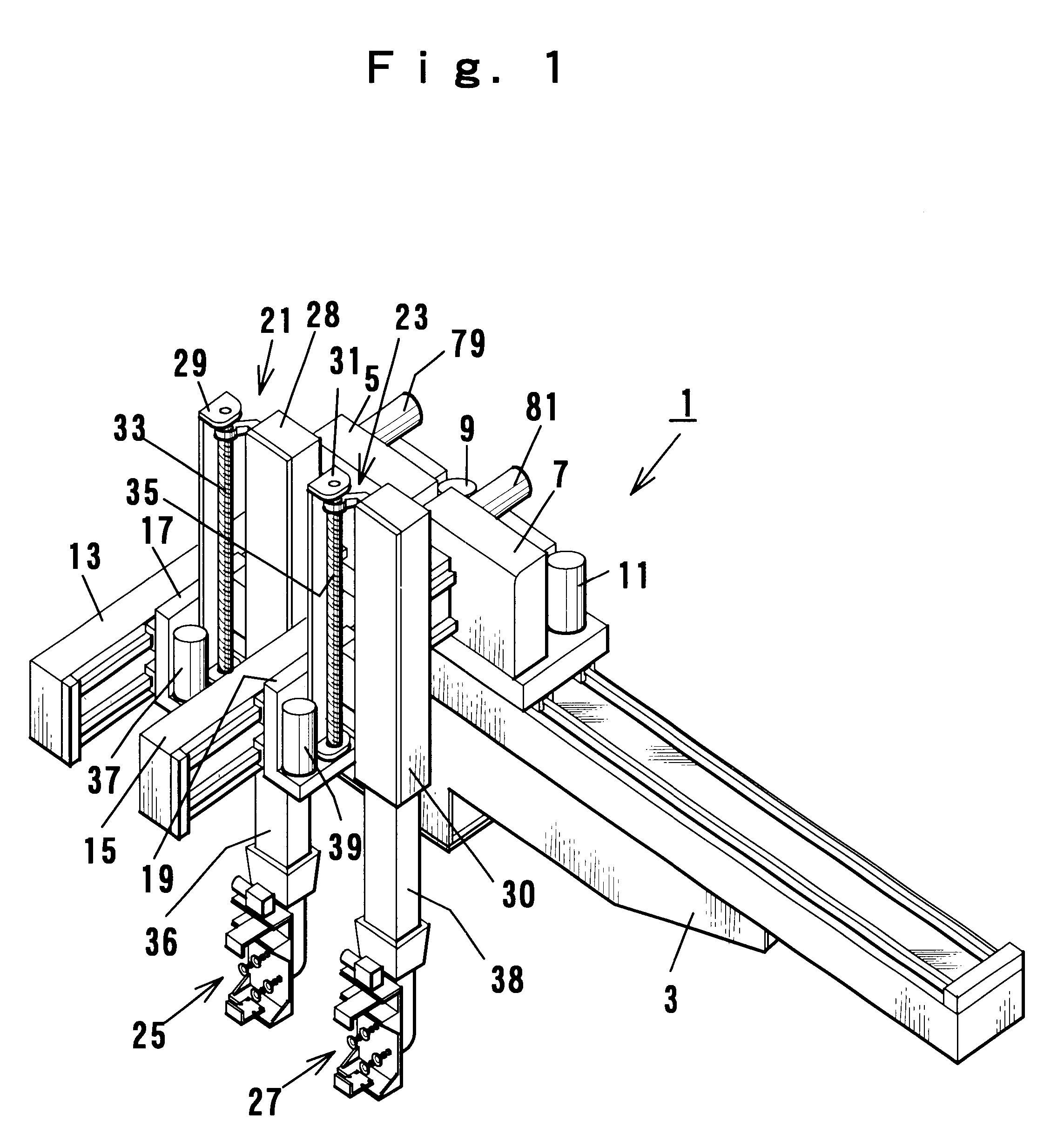

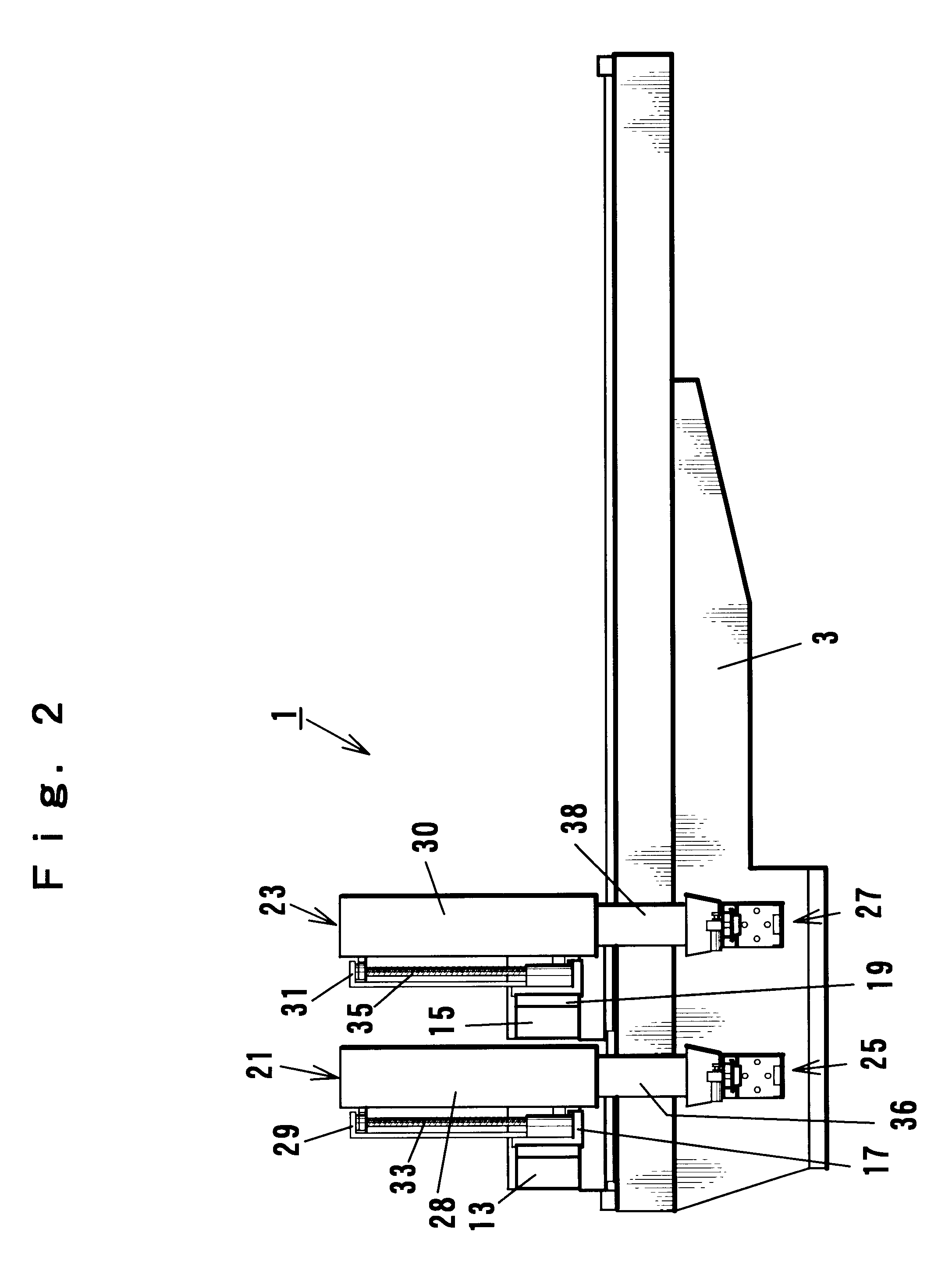

Removal apparatus for molded product and method for removing molded products

A removal apparatus is provided which includes a travelling frame, first and second carriages provided on the travelling frame, first and second cross frames provided on the first and second carriages, first and second cross carriages provided on the first and second cross frames, first and second vertical units provided on the first and second cross carriages, and first and second chucking units secured to the first and second vertical units. In addition, a control unit is provided for synchronously controlling the movement of the first and second carriages, the first and second cross carriages, and the first and second vertical units so as to enable the first and second chucking units to be moved in three dimensions for removal of a molded product from a molding machine.

Owner:STAR SEIKI

Coking coal dust shaping technique

A process method of coking coal dust forming chiefly aims at settling the problem about a second dust emission in the course of transportation. First, the large quantity of small smut produced by a fluidized bed can be collected by a dust precipitator, be conveyed to a smut collecting storehouse, and constantly transmitted into a high pressure molding machine by an incessant closed conveyer. The feeding mouth of the high pressure molding machine is provided with a repressing screw to ensure the smut entering a high pressure rolling pair to be with certain pressure. Then the smut can be extruded into effigurate briquette, which at last is conveyed into a production coal conveying system after the molding. The process can prevent the production coal from producing the second dust emission during the transportation, thus reducing the engineering investment and environmental pollution with the advantages of less floor space and increasing the coke yield produced by coke oven.

Owner:SHANDONG IRON & STEEL CO LTD

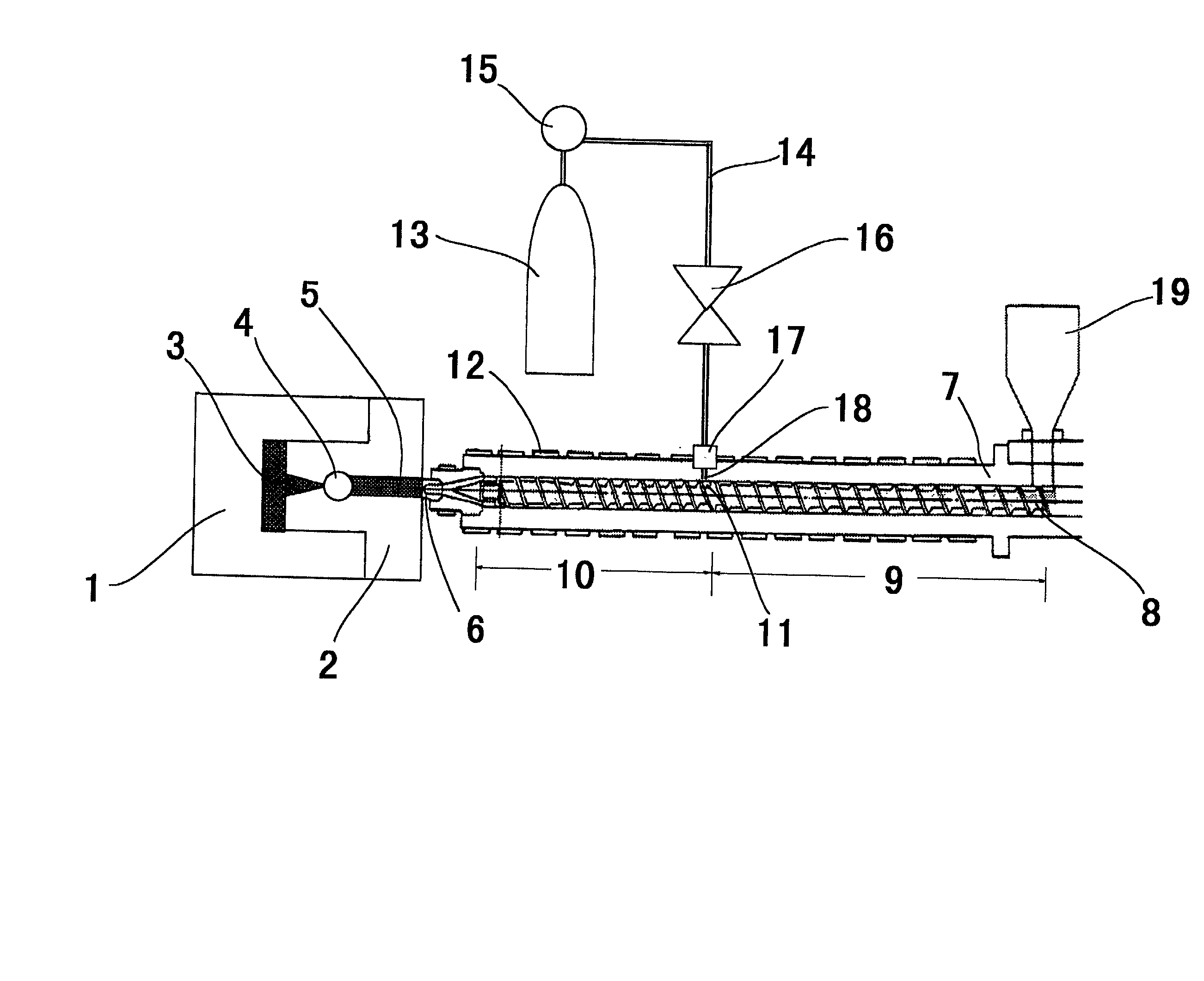

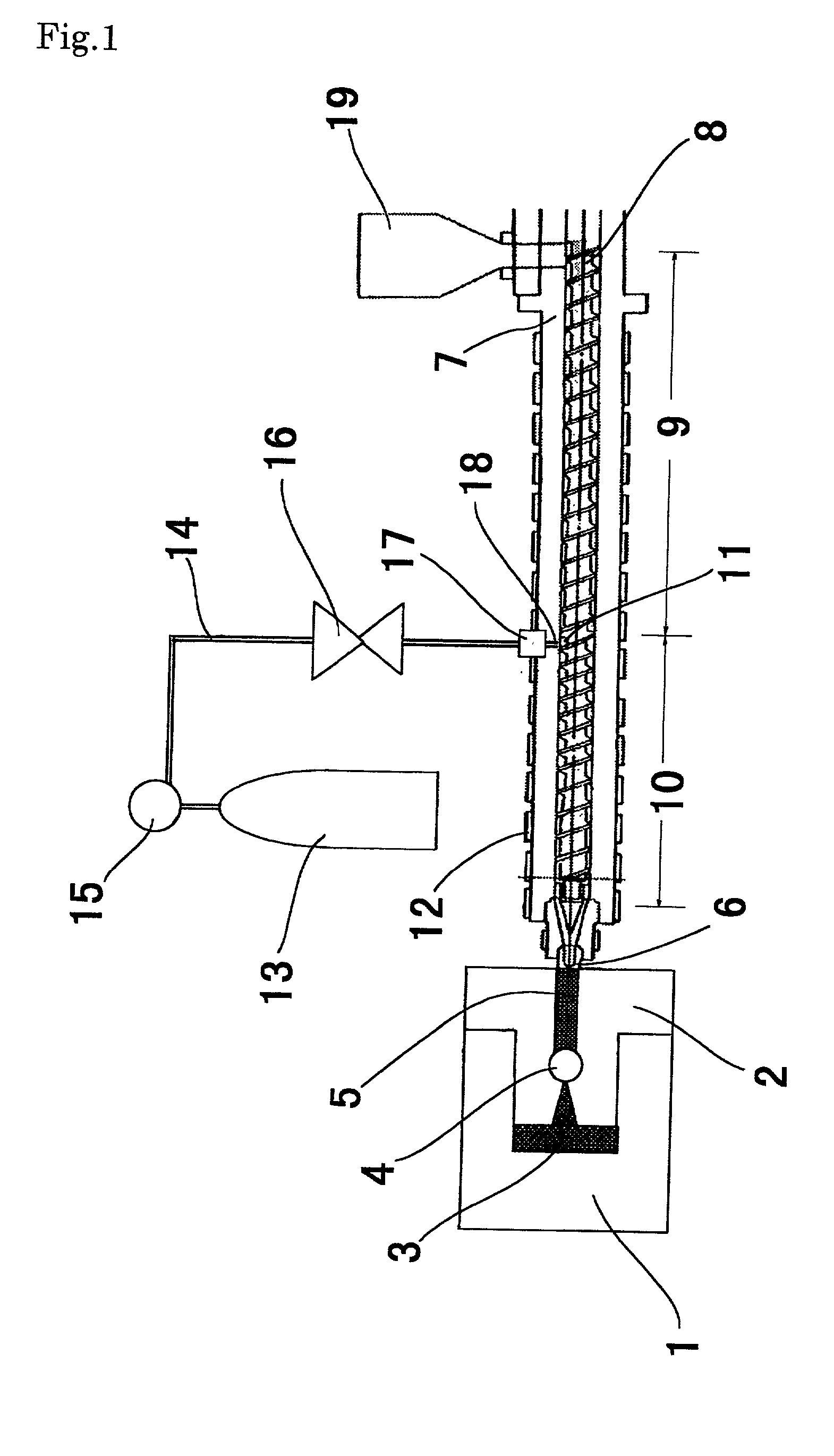

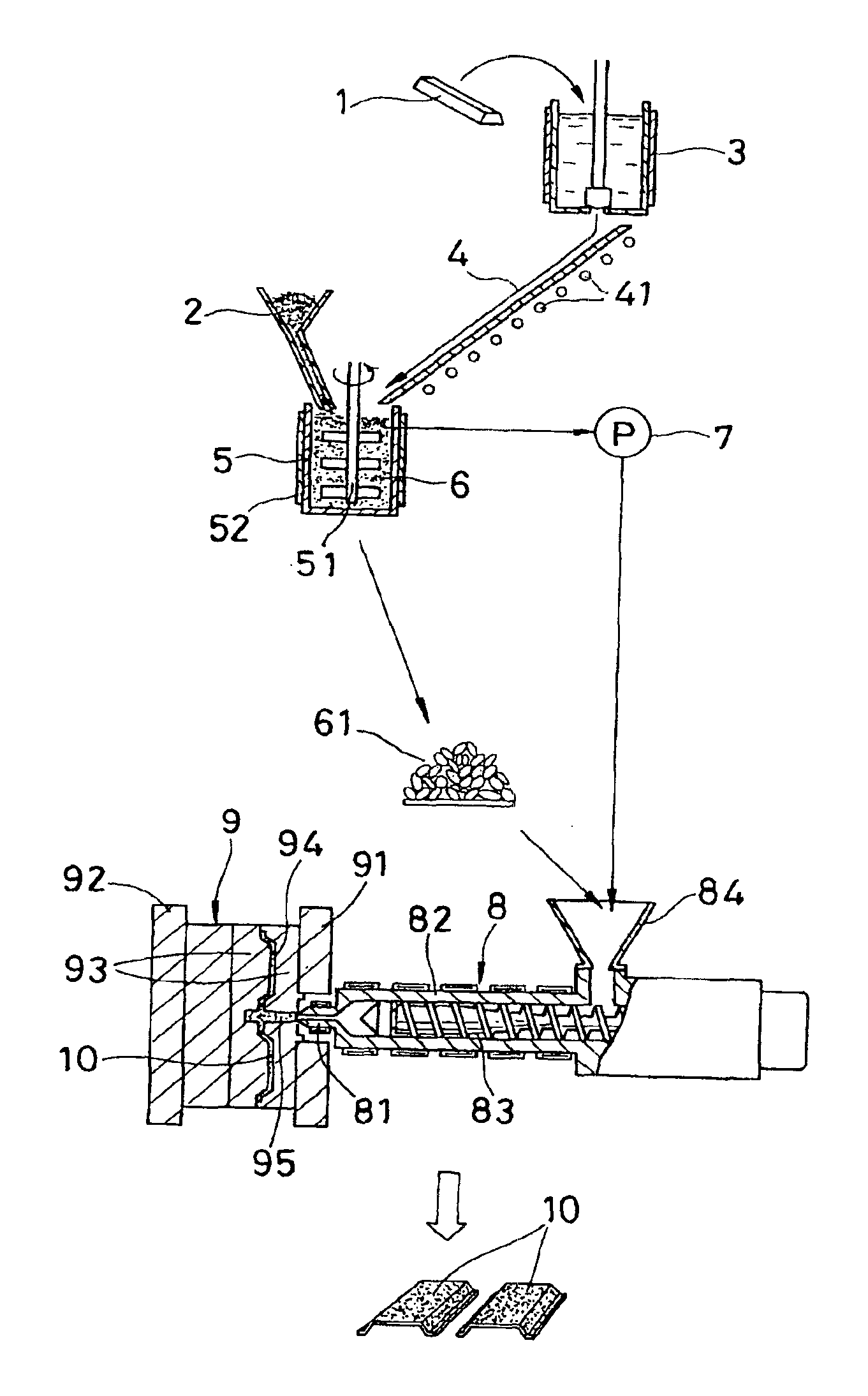

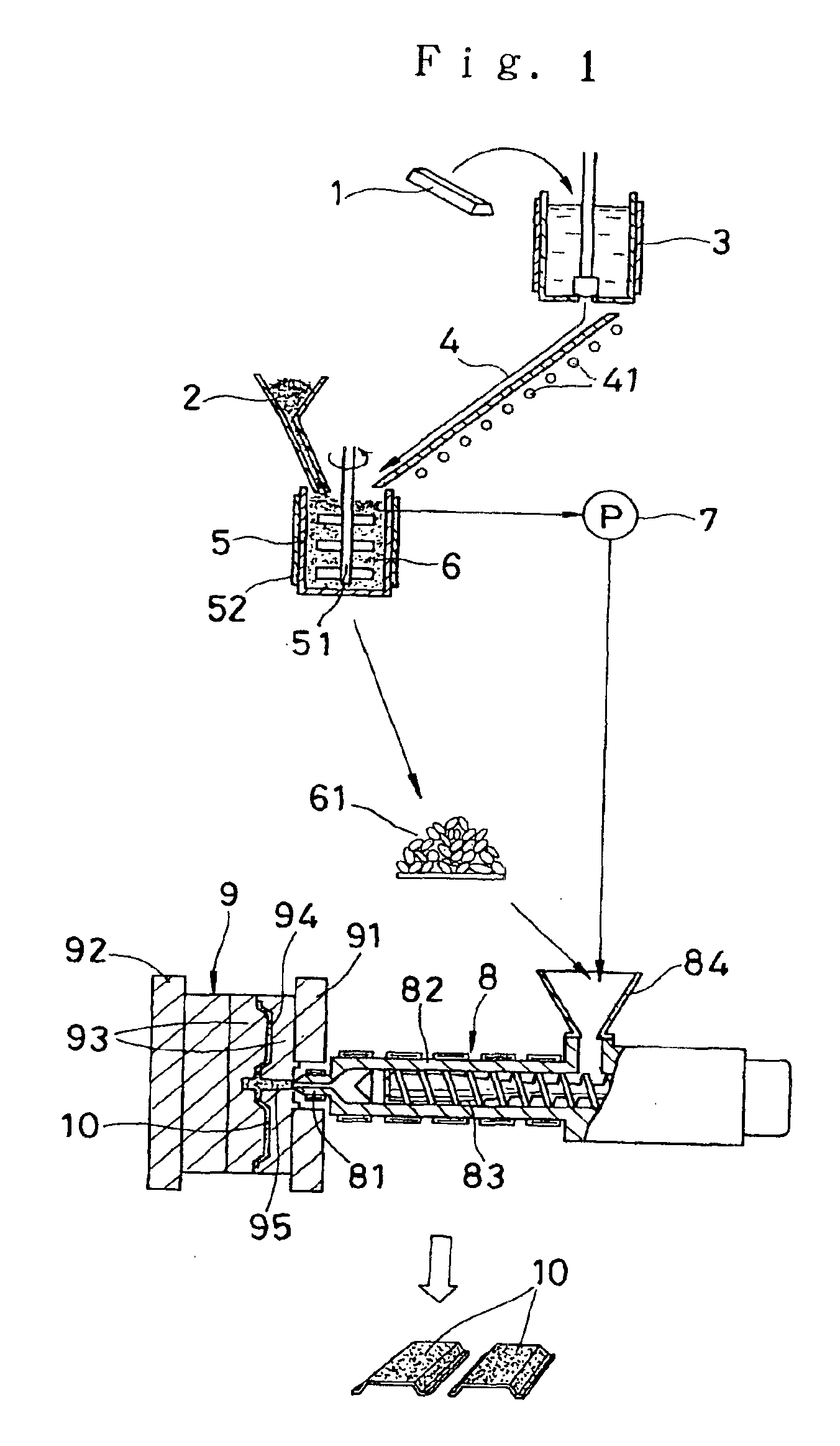

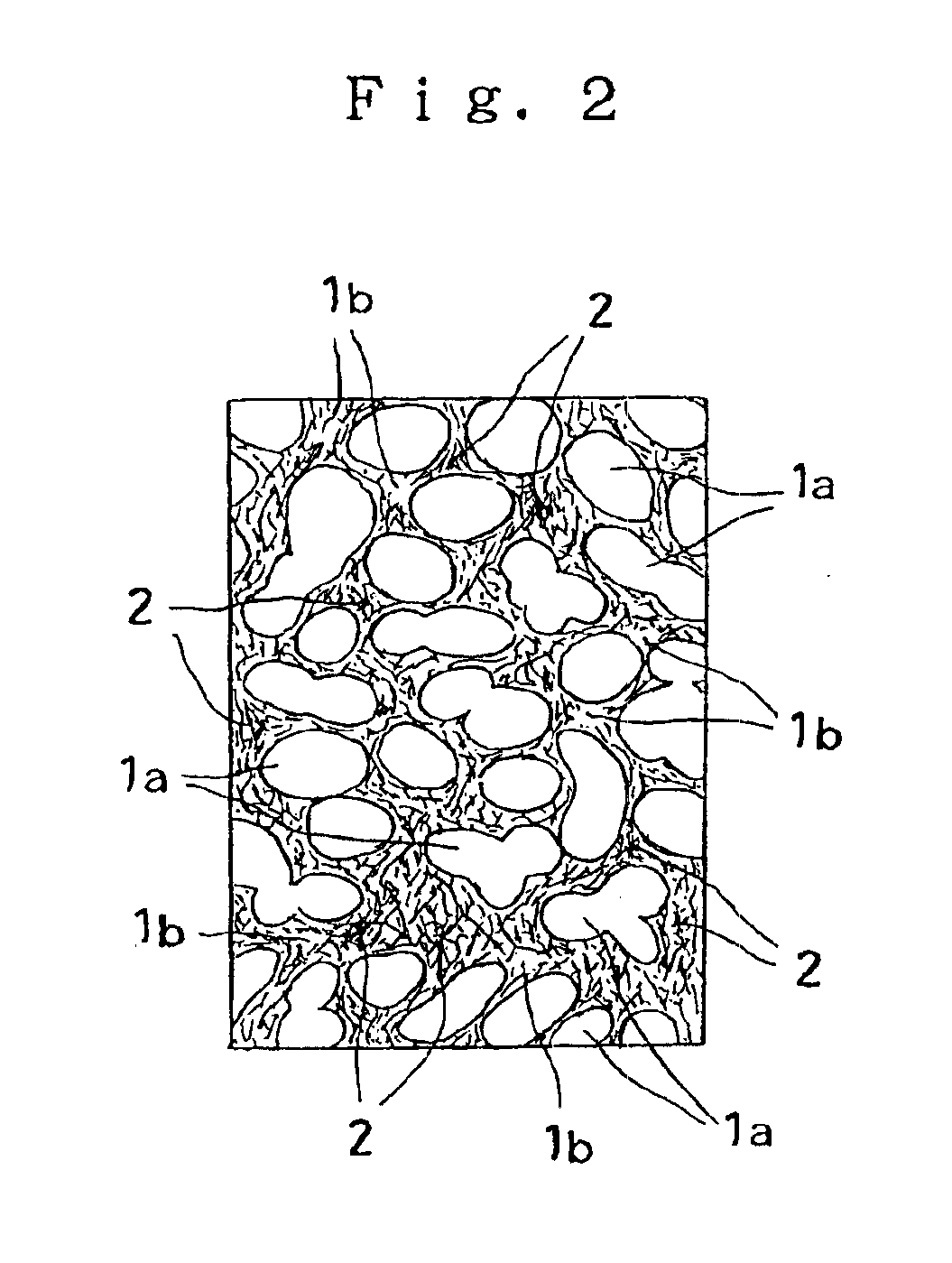

Process for injection foaming, and machine and composition therefore

A process for injection-foaming a thermoplastic resin by using an injection molding machine with a two-stage-compression screw, injecting a physical foaming agent into the cylinder of the machine at a pressure lower than the storage pressure of the physical foaming agent, mixing it with a melted resin and expanding the volume of the cavity of the mold at the time of injection, and an injection molding machine and resin composition suitable therefore.

Owner:MITSUI CHEM INC

Method for producing a composite metal product

A low melting point metal material is made to a thixotropic state in which liquid phases and solid phases coexists. In the thixotropic state of the low melting point metal material, a carbon nano material is kneaded with the low melting point metal material and forms a composite material. Thus obtained composite material is supplied to a metal molding machine and injected into a mold in a thixotropic state or a completely molten state of the metal so that the composite material fills the mold, thereby the composite material is molded to a composite metal product. With the above process, it is possible to injection mold the composite metal product to which the characteristics of the carbon nano material are applied.

Owner:NISSEI PLASTIC IND CO LTD

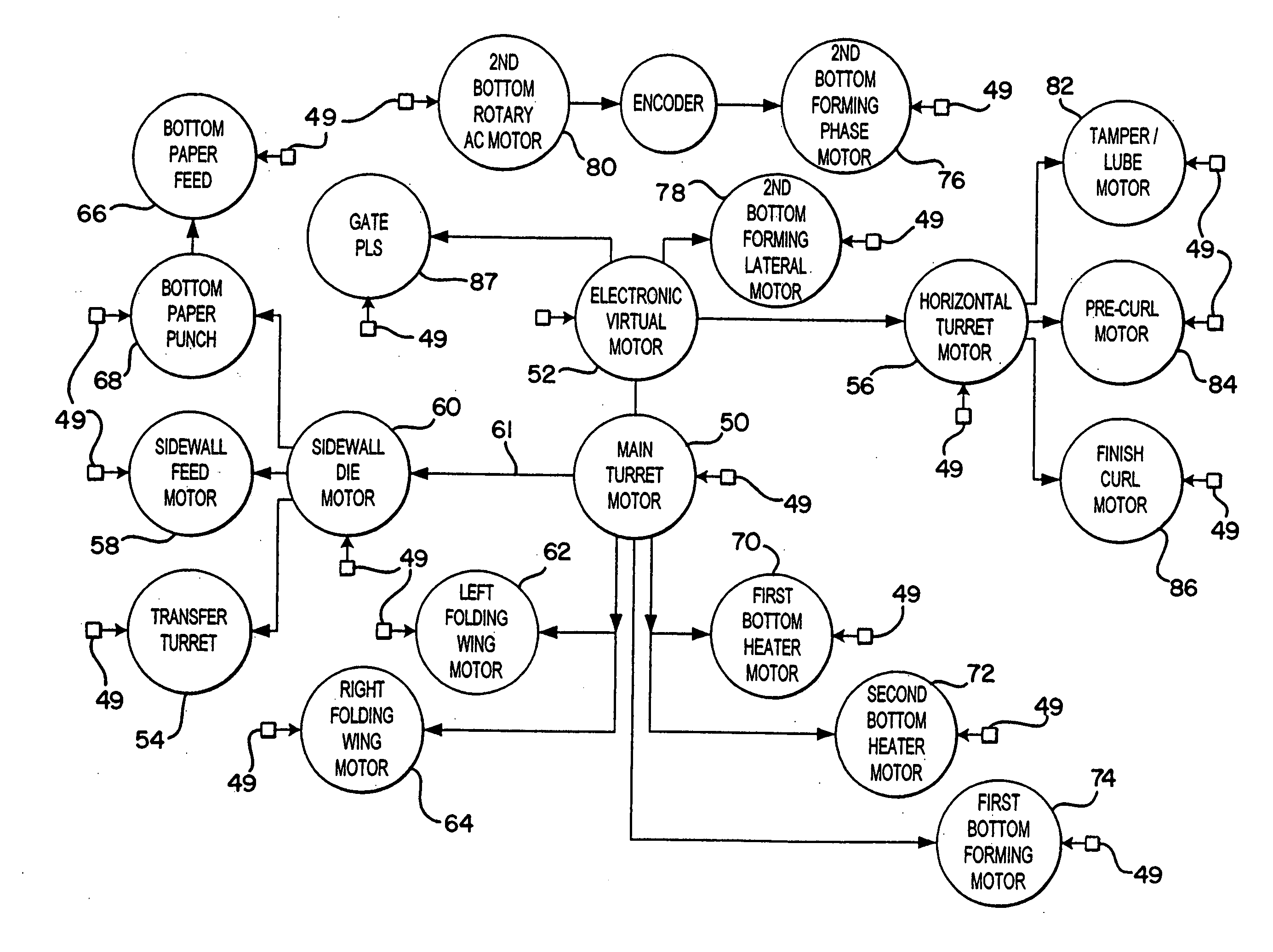

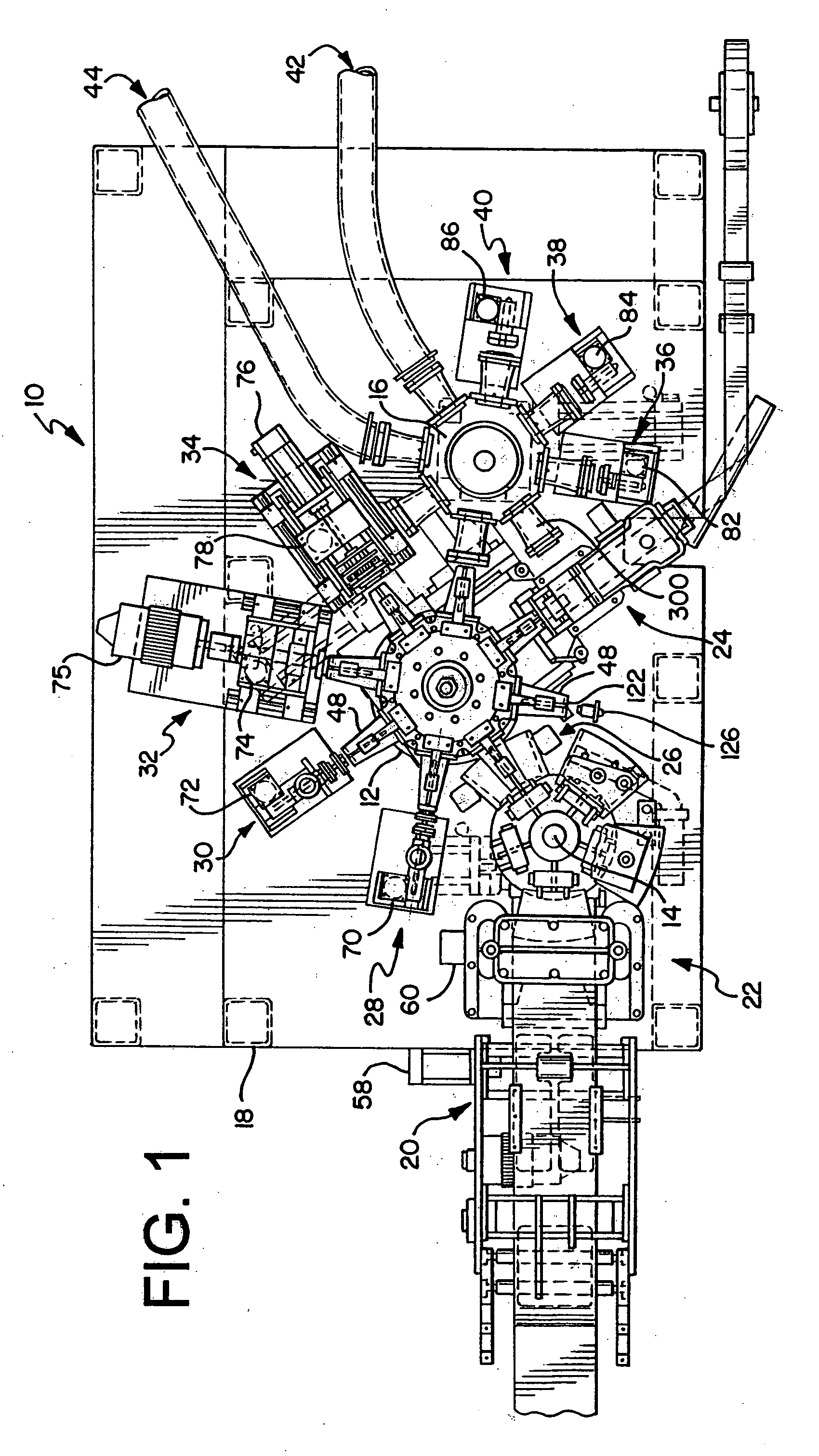

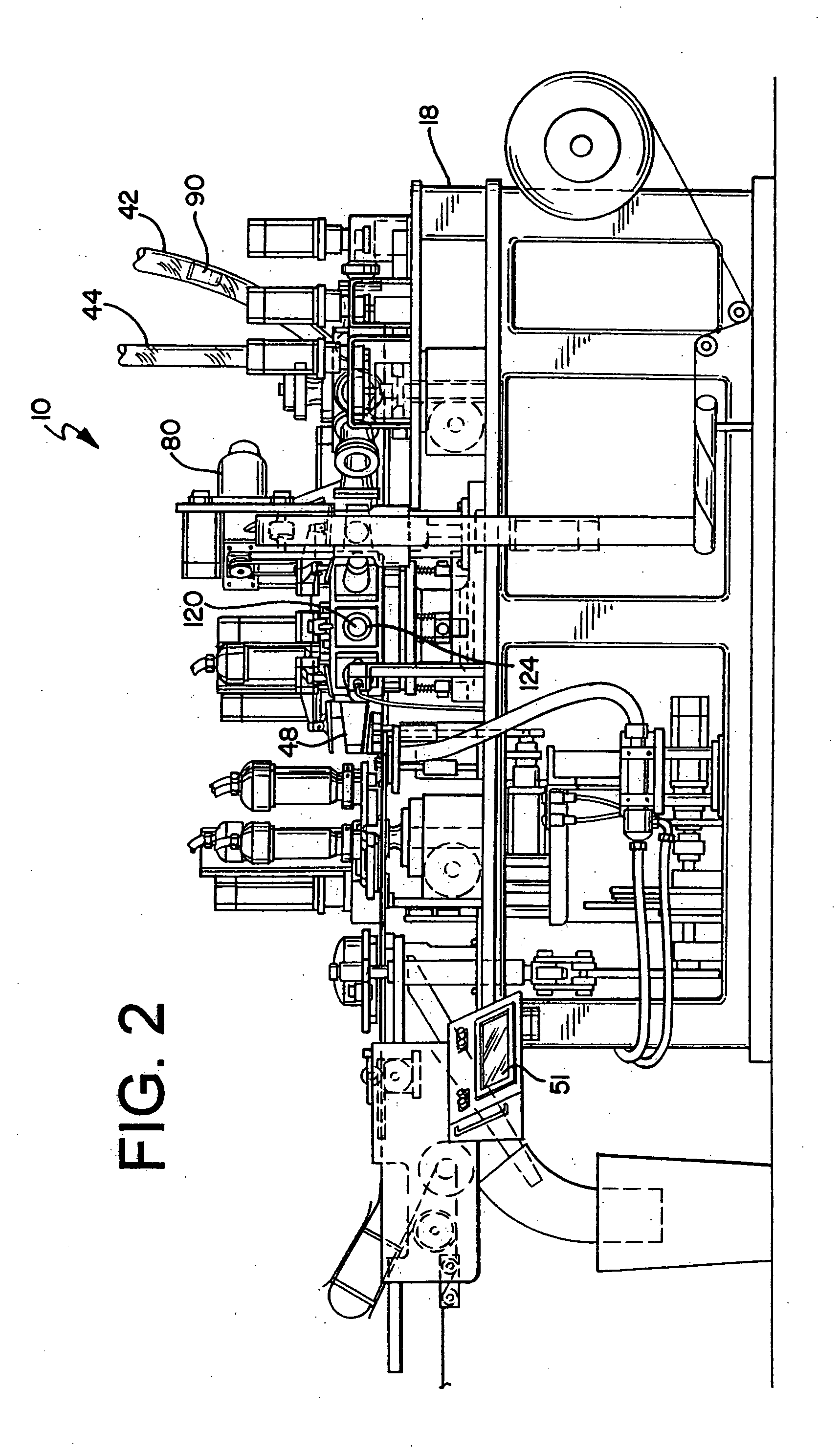

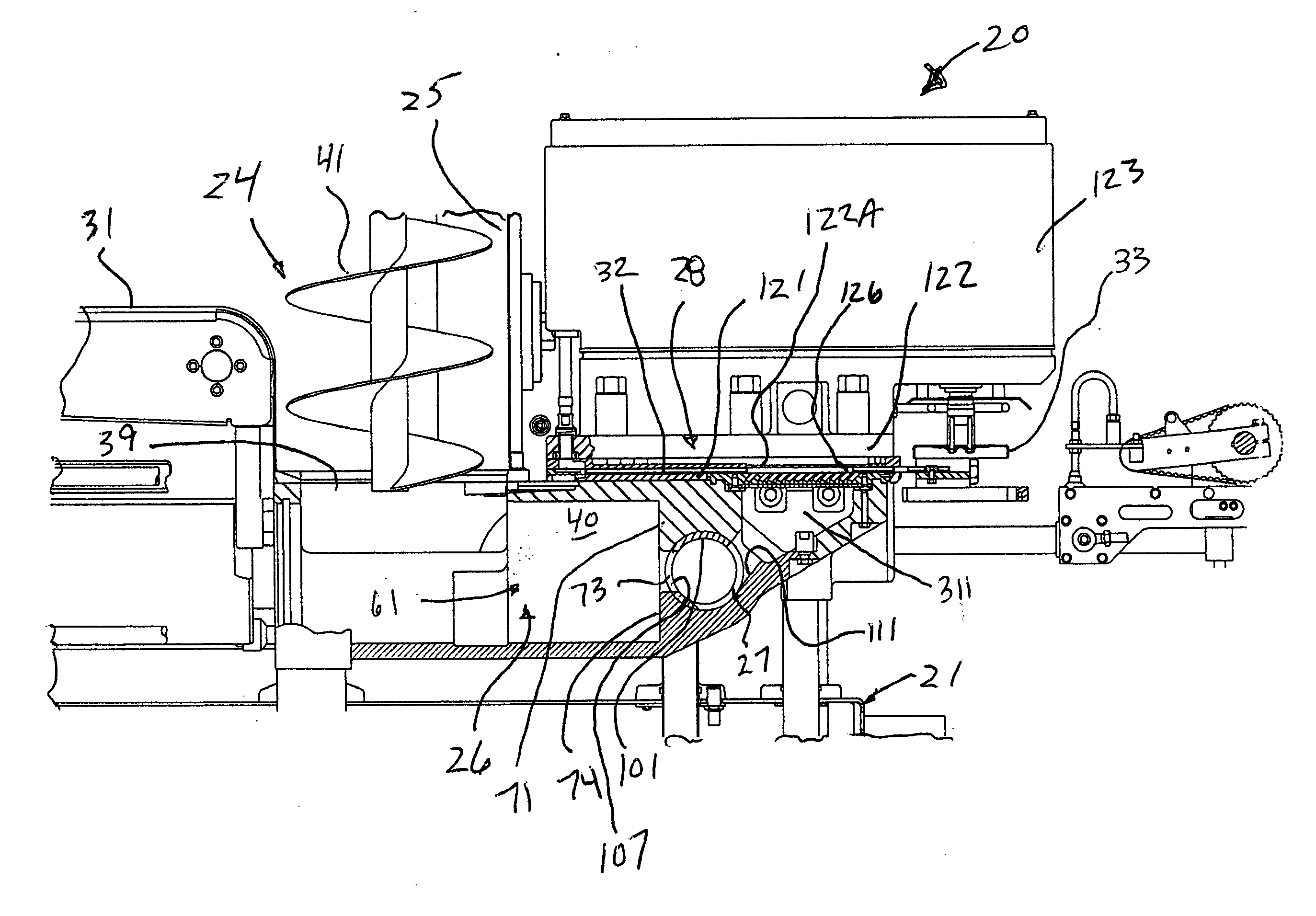

Computer controlled cup forming machine

A computer controlled cup forming machine is provided. The computer controlled cup forming machine has a main motor, a main controller, and a plurality of workstations having individual motors electrically connected to the main motor and the main controller. The main controller develops electrical signals of a drive or motion profile that are sent to the individual motors, and the main motor sends additional electrical signals to the individual motors to initiate the drive profiles at the individual motors. The main controller also has an input station to quantitatively control each of the individual motors.

Owner:SOLO CUP OPERATING CORP

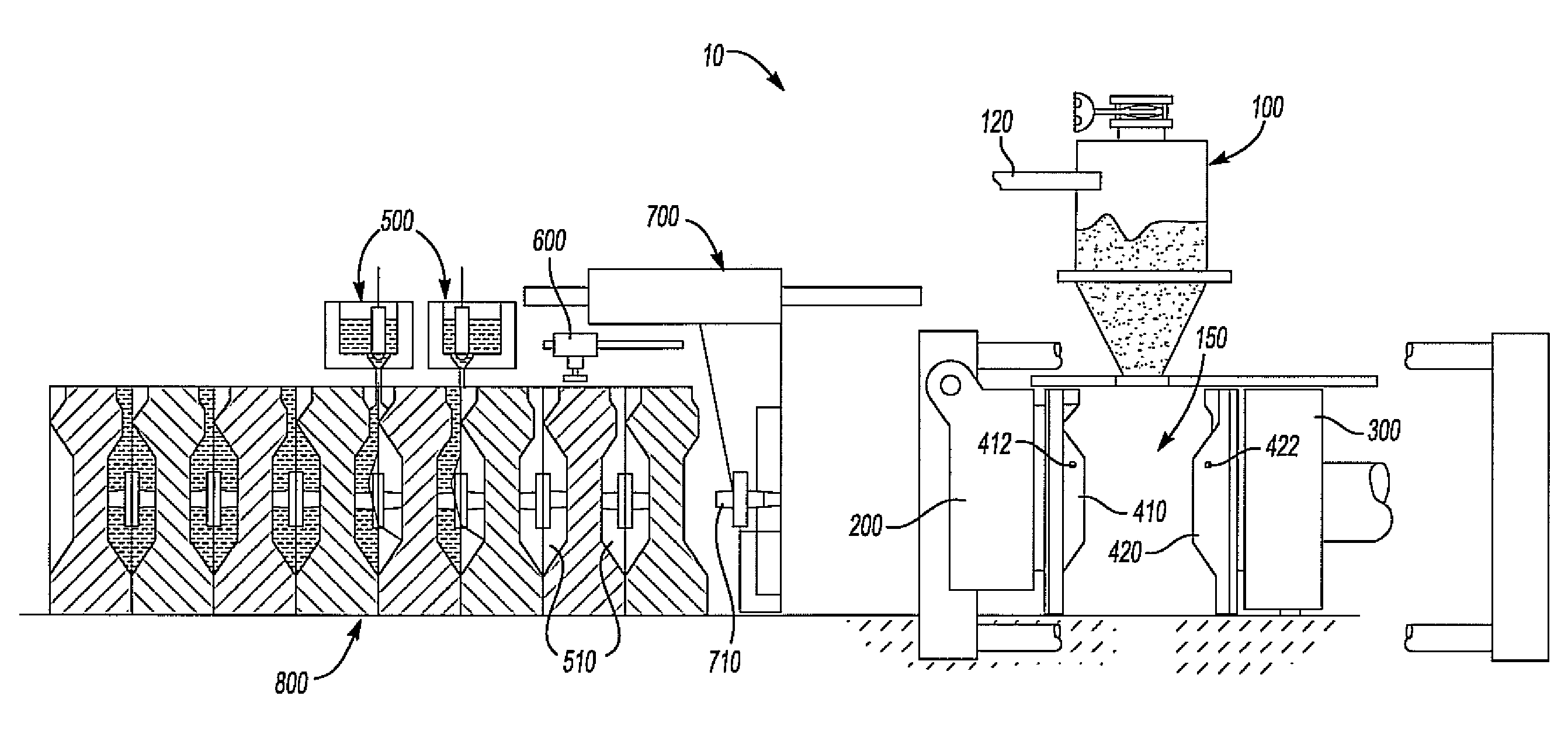

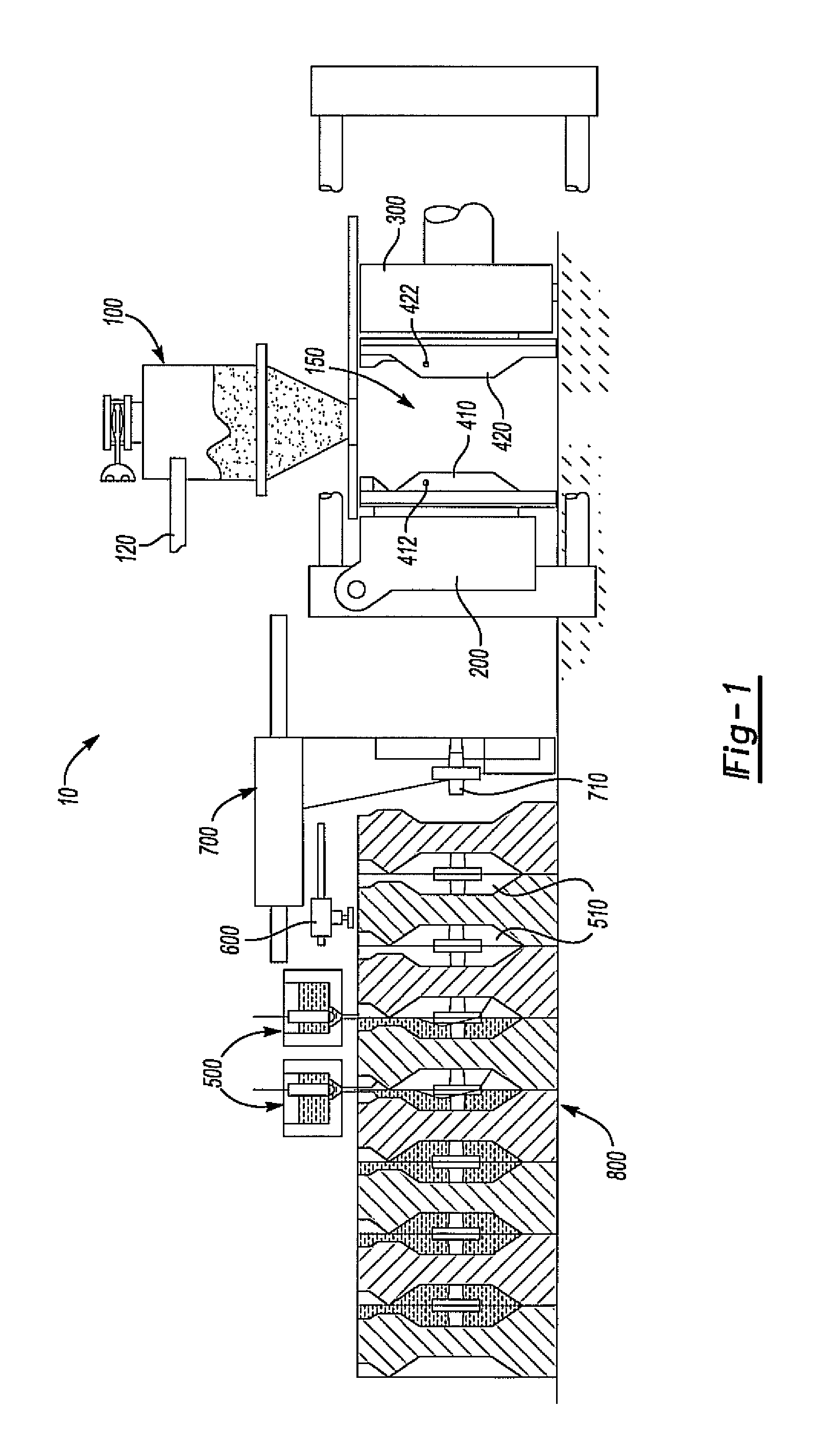

Angled fill ports and seal-off arrangement for patty-forming apparatus

ActiveUS20070098862A1Eliminates minimizesEfficient fillingConfectioneryMeat processingMolding machineEngineering

A food patty molding machine has a reciprocating mold plate. A moldable food product is pumped through a fill passage into cavities of the mold plate when the mold plate is in its fill position. A fill plate, interposed in the fill passage immediately adjacent the mold plate, has a multiplicity of fill orifices distributed in a predetermined pattern throughout an area aligned with the mold cavity when the mold plate is in its fill position. The fill orifices define paths through the fill plate, wherein the paths each have an inlet portion that is perpendicular to a fill side face of the mold plate that is connected to an outlet portion that is obliquely angled to a fill side face of the mold plate. A seal-off stripper plate is interposed in the fill passage immediately adjacent the face of the fill plate opposite the mold plate. The stripper plate is movable along a path transverse to the mold plate path between a fill location and a discharge location. The stripper plate has a multiplicity of fill openings aligned one-for-one with the fill orifices as extensions thereof when the stripper plate is in its fill location.

Owner:PROVISUR TECHNOLOGIES INC

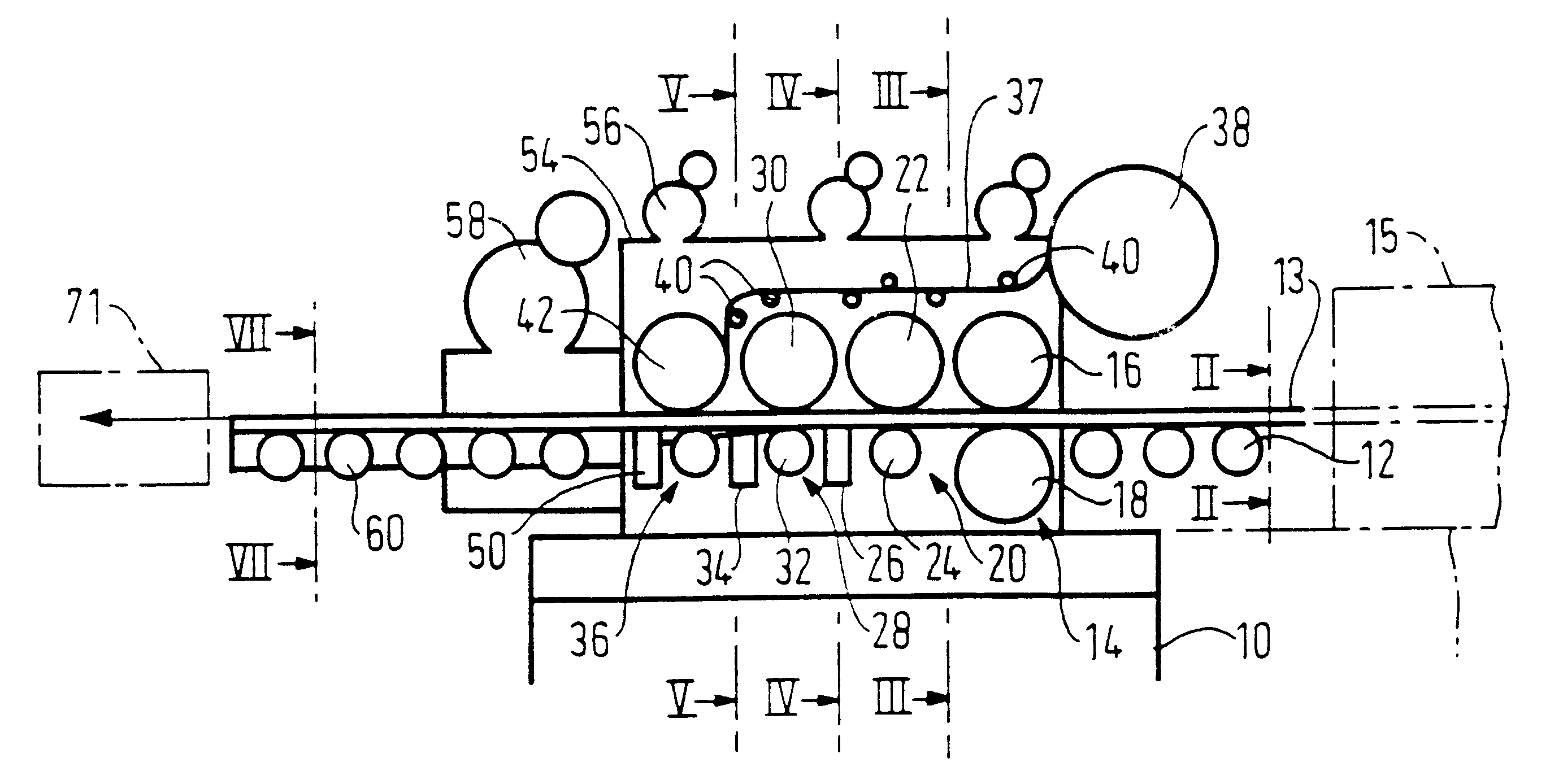

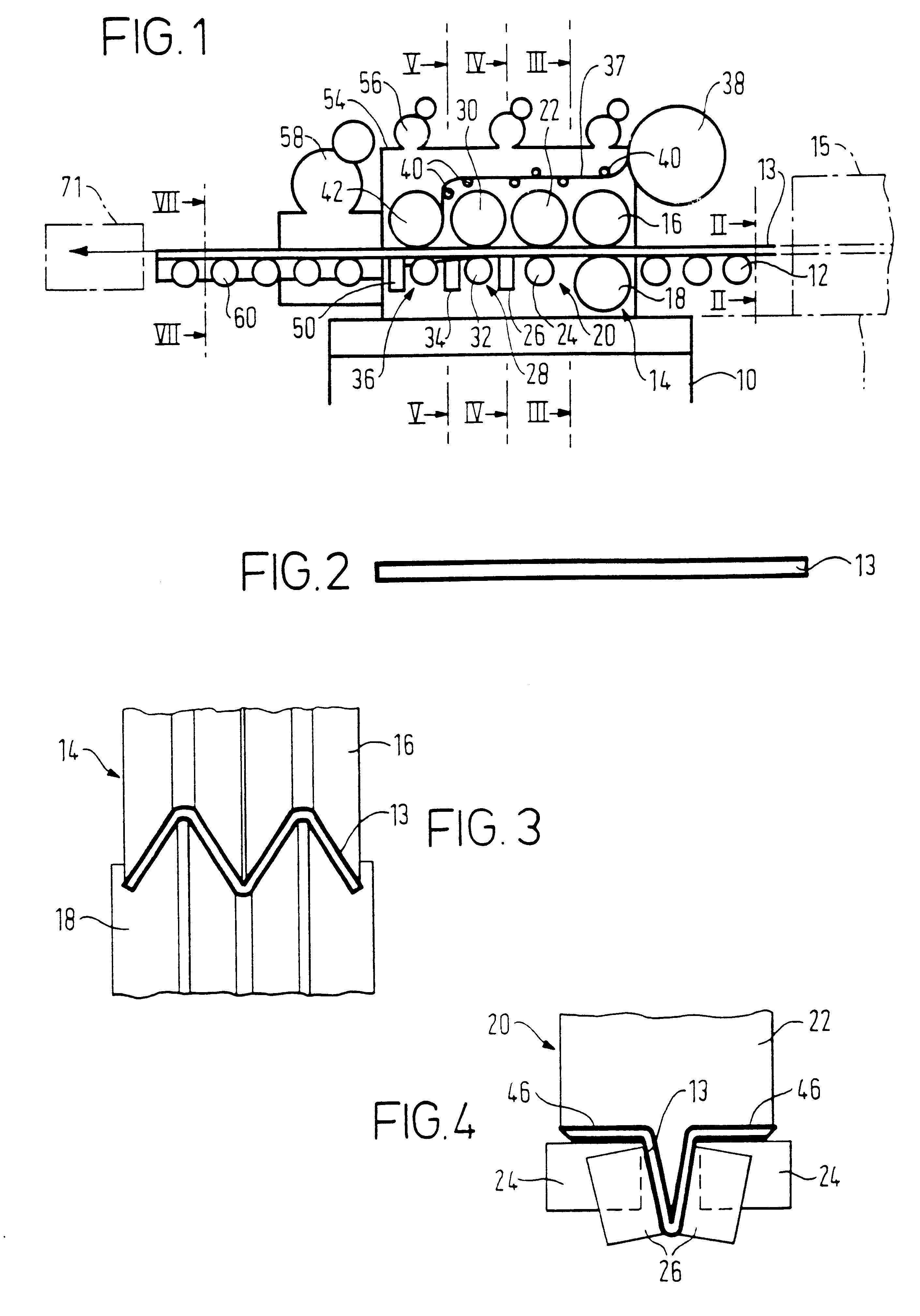

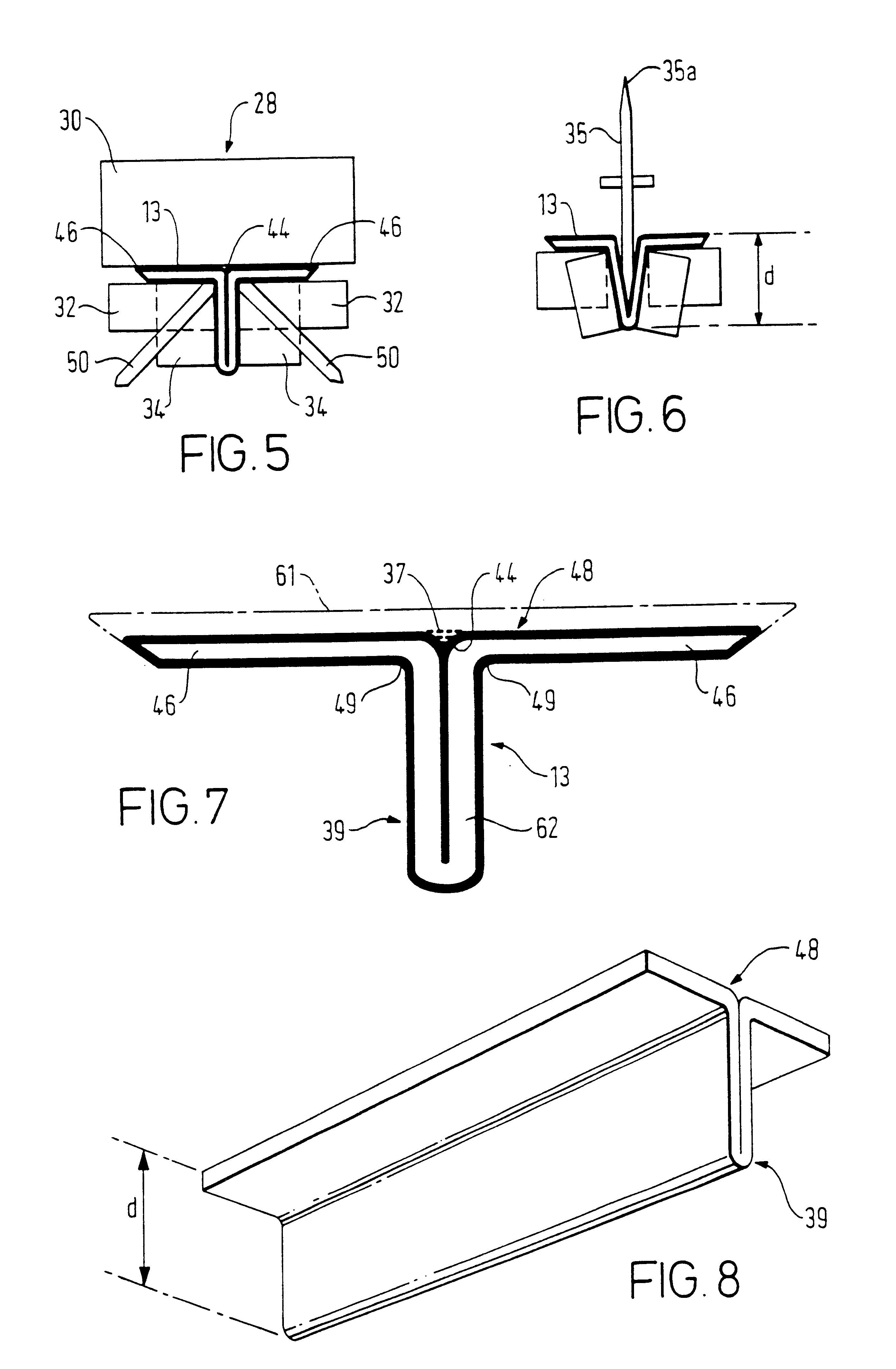

Roll forming machine

The roll forming machine comprise a series of rollers 14, 20, 28 and 36 for shaping a fabric 13 such as a fabric impregnated with a curable matrix. A feed roller 36 is provided for feeding a length of material 37 such as a tow of fibres onto the fabric during or subsequent to the shaping process. The roll forming process is particularly useful in the manufacture of blade stiffeners for an aircraft wing.

Owner:AIRBUS OPERATIONS LTD

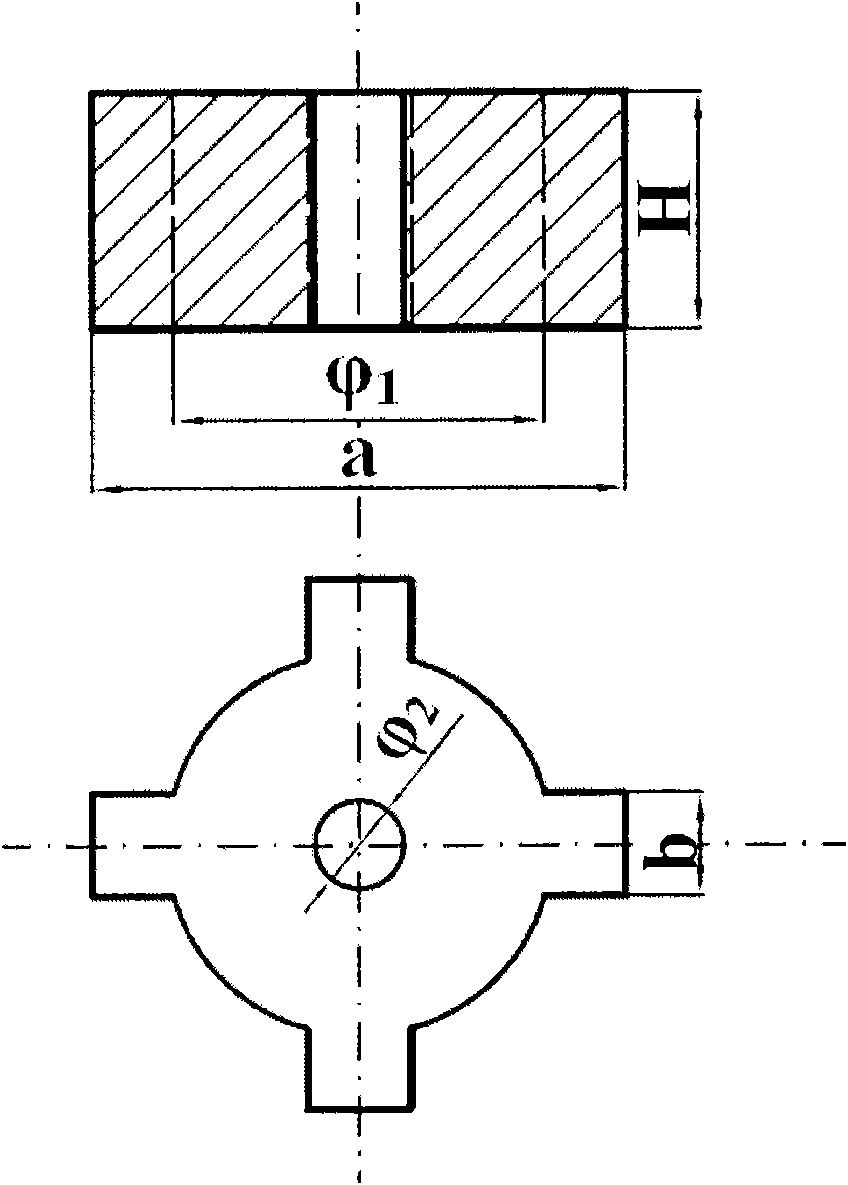

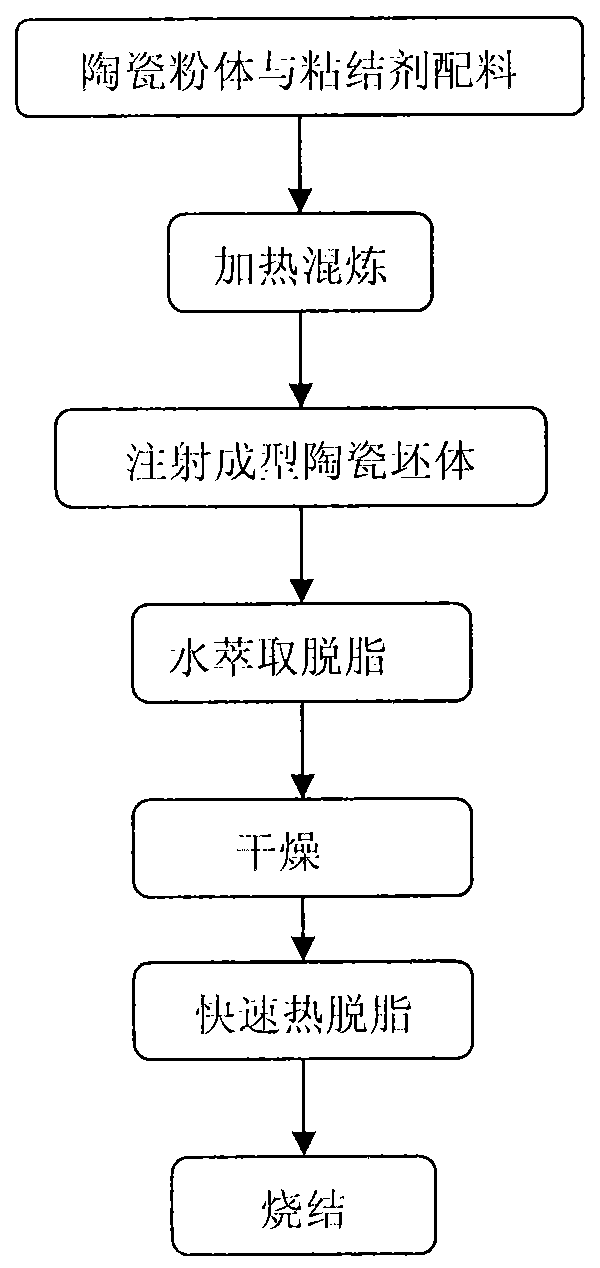

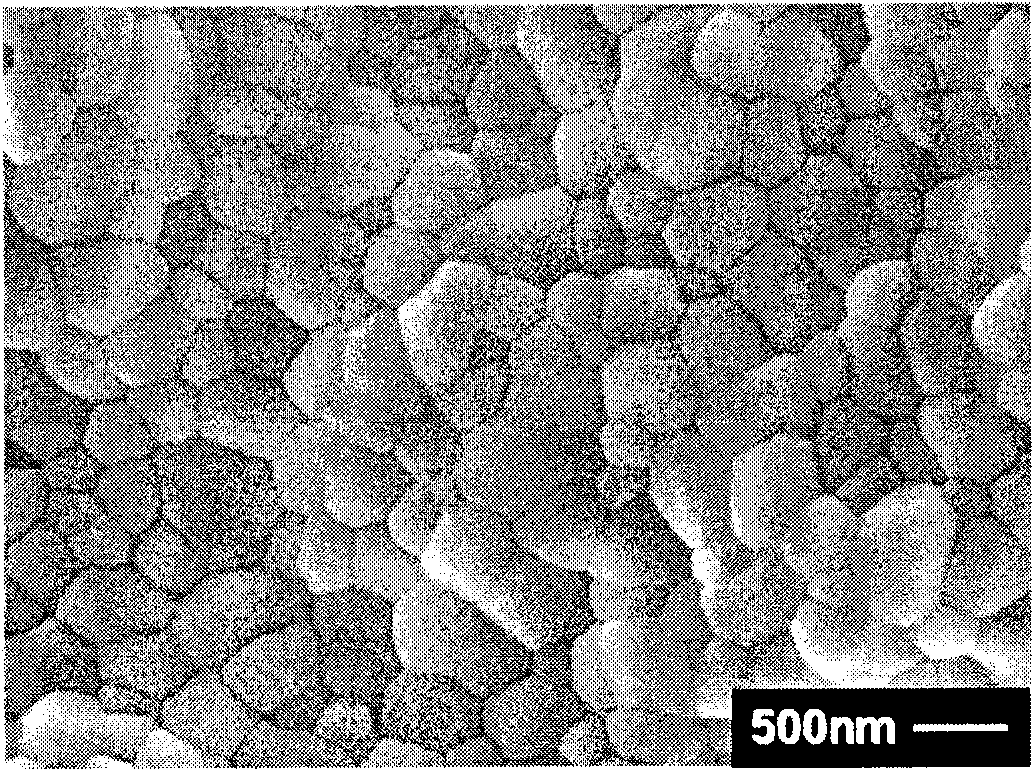

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

Nutritional porridge mixture and preparation method thereof

InactiveCN104351659AEasy to changeBalanced NutrientsClimate change adaptationFood preparationFood additiveAdditive ingredient

The invention relates to a nutritional porridge mixture and a preparation method thereof, belonging to the technical field of production and processing of nutritional foods. The food mixture consists of coarse cereals, vegetables, fruits, dried fruits, nuts, seeds, beans, funguses, alga and special foods. According to various characters and different qualities of the foods, the foods are treated by a method and a process of washing, soaking, washing, airing, steaming, boil-drying, air drying and sun drying, then the dried food products are mixed together, milled in a flour mill and sent to a molding machine to be prepared into oatmeal, and finally the products are subjected to vacuum packaging under the illumination of an ultraviolet sterilizing lamp. The nutritional porridge disclosed by the invention is free of any food additives, anti-corrosive agents, sugar, salt and the like, so the original taste and flavor as well as the natural nutritional ingredients and effects of the foods are retained.

Owner:杨征宇

Energy management apparatus and method for injection molding systems

ActiveUS7176648B2Uniform heating powerReduce processing needsSynchronous motors startersAC motor controlElectricityMolding machine

Owner:HUSKY INJECTION MOLDING SYST LTD

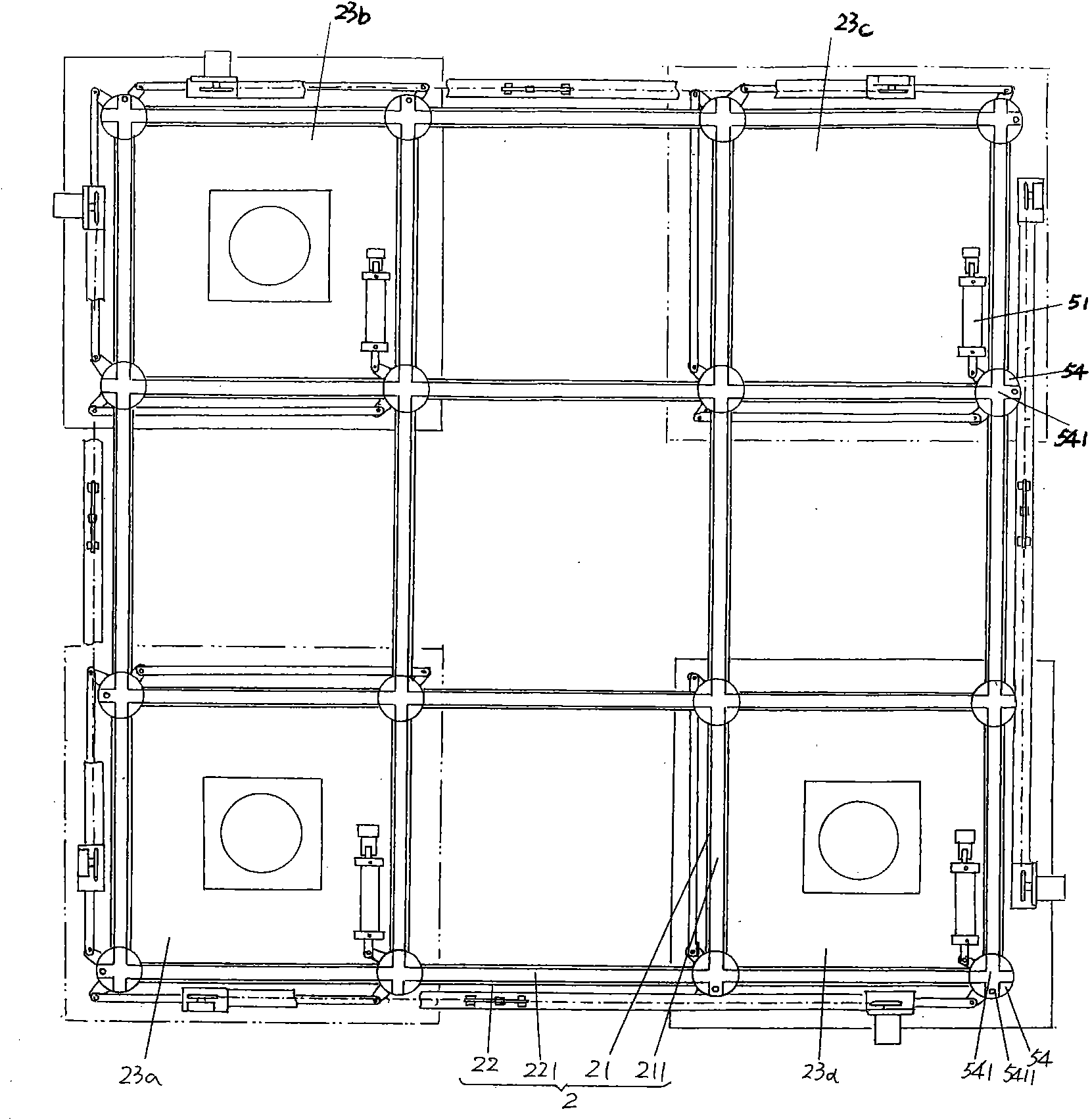

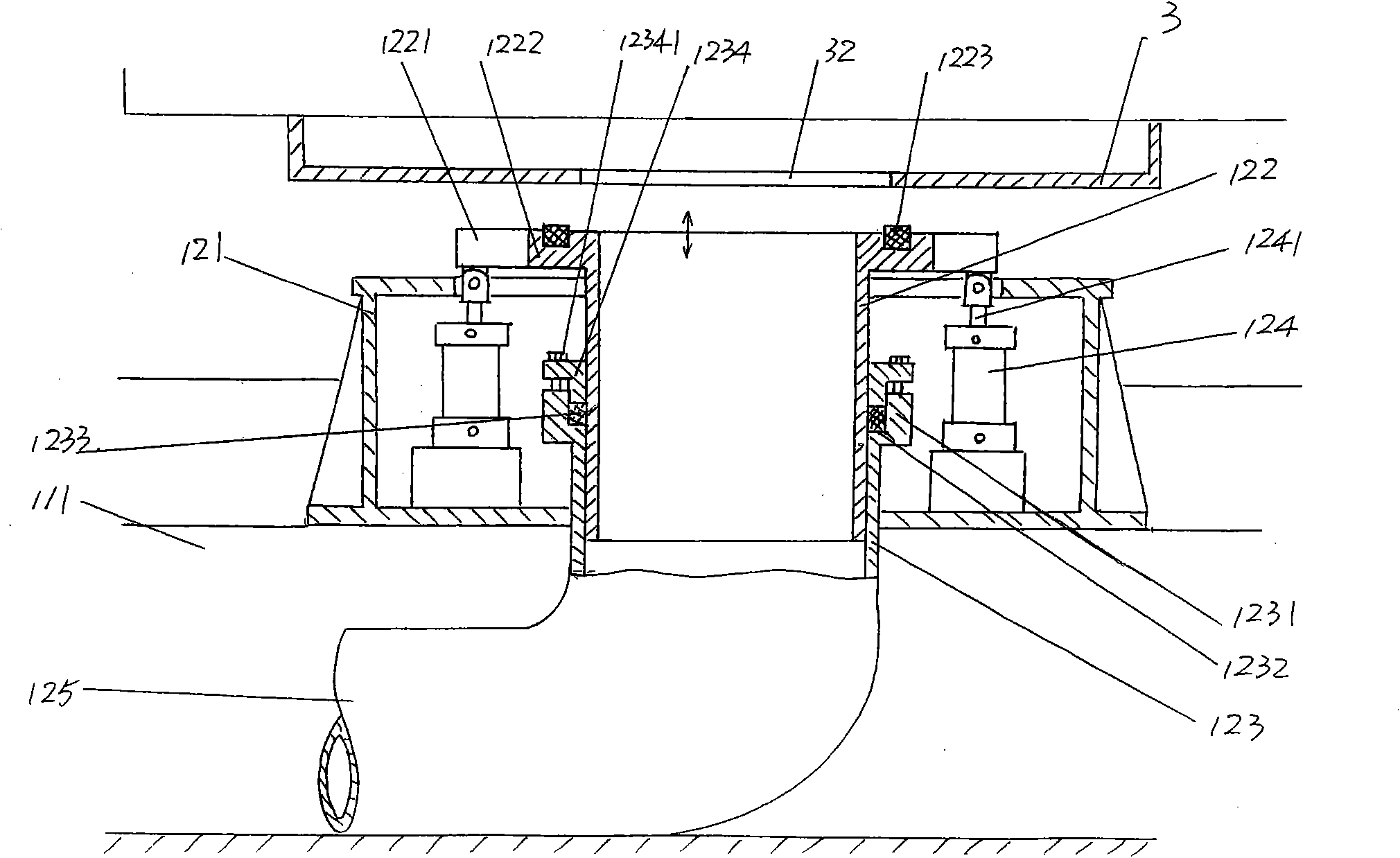

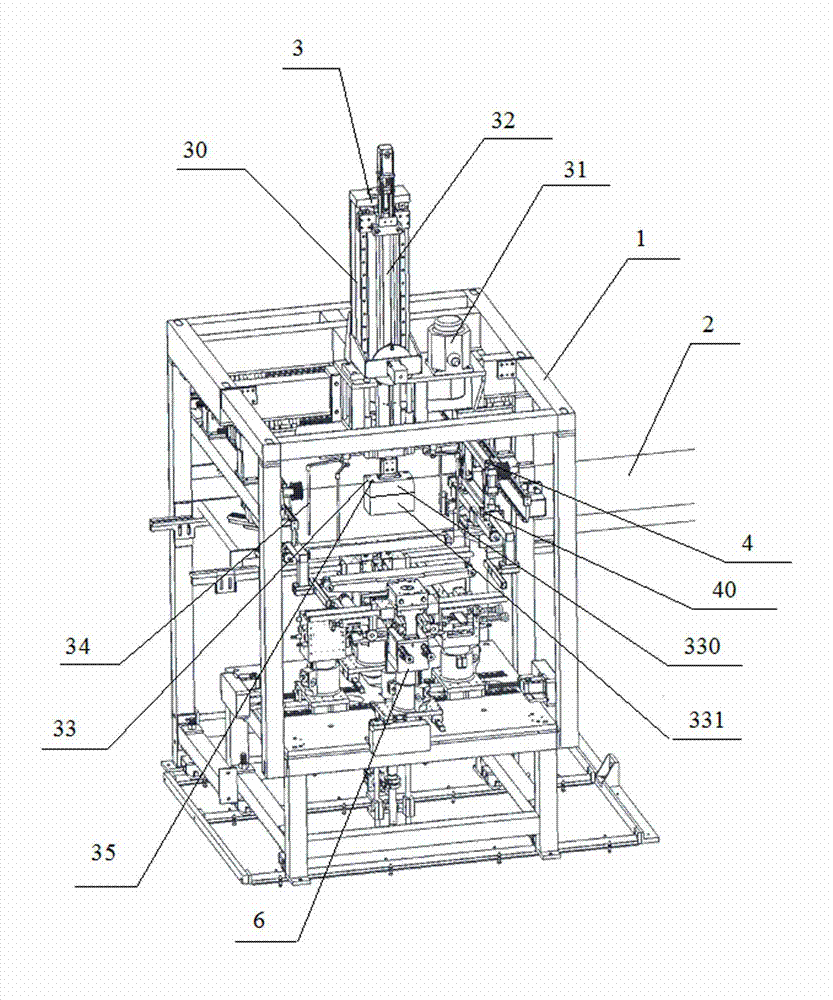

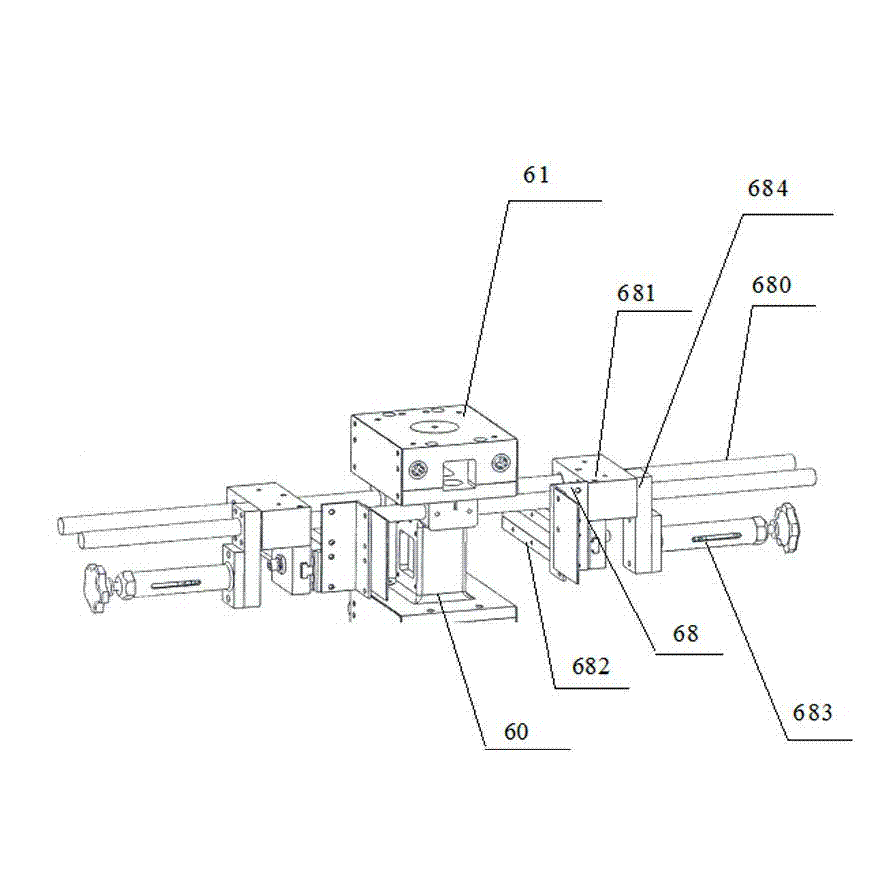

Automatic molding machine for automobile interior part felt

InactiveCN101775708AHigh degree of collectionIncrease productivityFelting apparatusFrame basedMolding machine

The invention discloses an automatic molding machine for an automobile interior part felt and belongs to molding machinery of automobile interior parts. The automatic molding machine comprises a frame base, a rail assembly, three lower molds, a group of lower mold station moving mechanisms, a group of lower mold station reversing mechanisms, a pair of pressing upper molds, a feed supplementing mechanism and a net laying mechanism. The rail assembly consists of a group of longitudinal guide rails and a group of transverse guide rails, and is arranged on the frame base, and the longitudinal guide rails and the transverse guide rails are vertically staggered to form a feed complementing station, a pre-pressing station, a net laying station and a molding station. The three lower molds which are provided with a lower mold base are arranged on the rail assembly. The group of lower mold station moving mechanisms are arranged on the frame base. The group of lower mold station reversing mechanisms are arranged on the frame base and matched with the intersection formed by vertically intersecting the transverse guide rails and longitudinal guide rails. The pair of pressing upper molds which is provided with the upper mold base is arranged on the frame base, wherein one pressing upper mold corresponds to the upper part of the pre-pressing station, and the other pressing upper mold corresponds to the upper part of the molding station. The feed complementing mechanism is arranged on the frame base and corresponds to the upper part of the feed complementing station. The net laying mechanism is arranged on the frame base and corresponds to the upper part of the net laying station. The automatic molding machine for the automobile interior part felt has the advantages of high integration degree, small occupancy area, a few on-line workers, high production efficiency and energy conservation.

Owner:常熟市双龙无纺设备有限公司

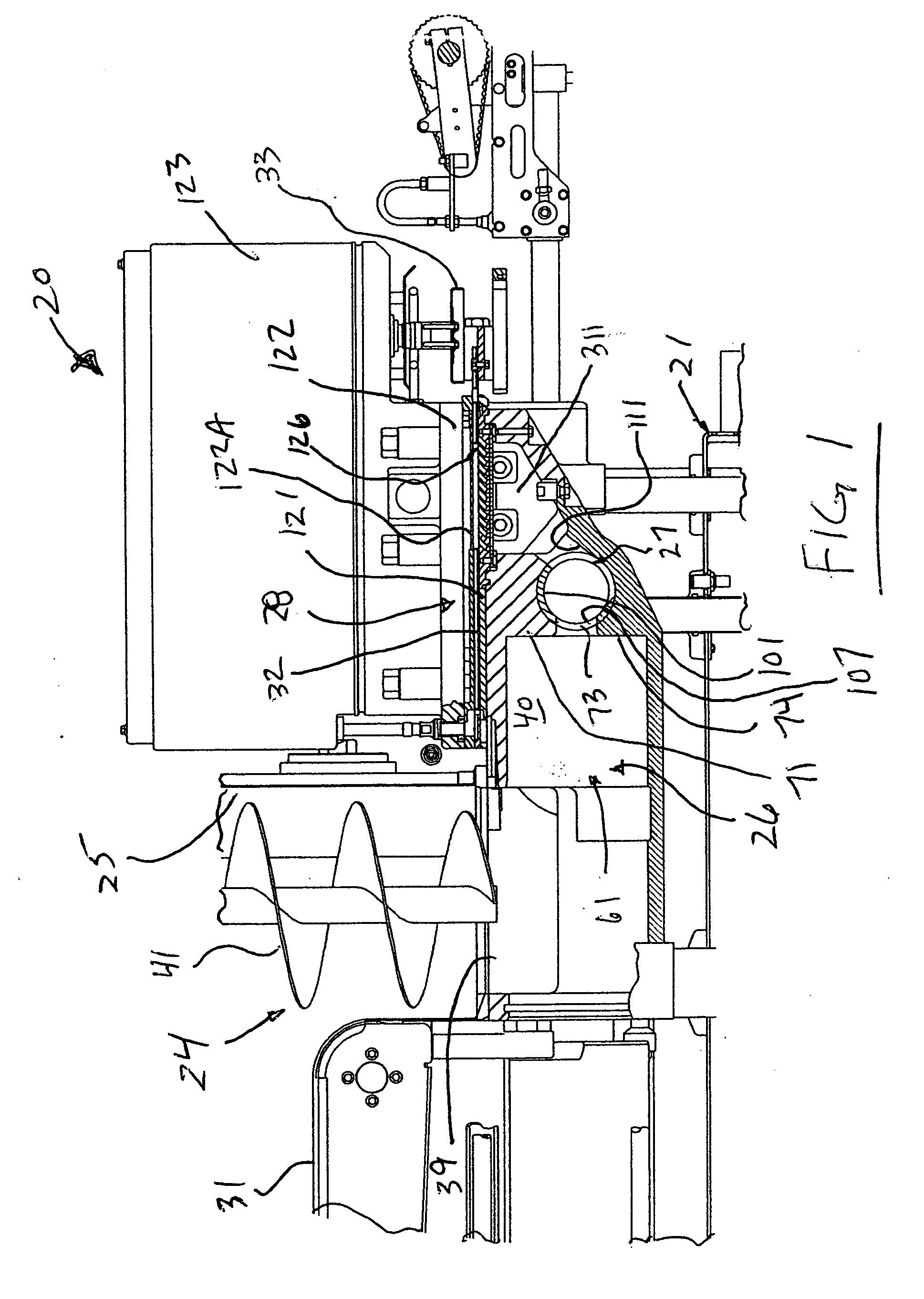

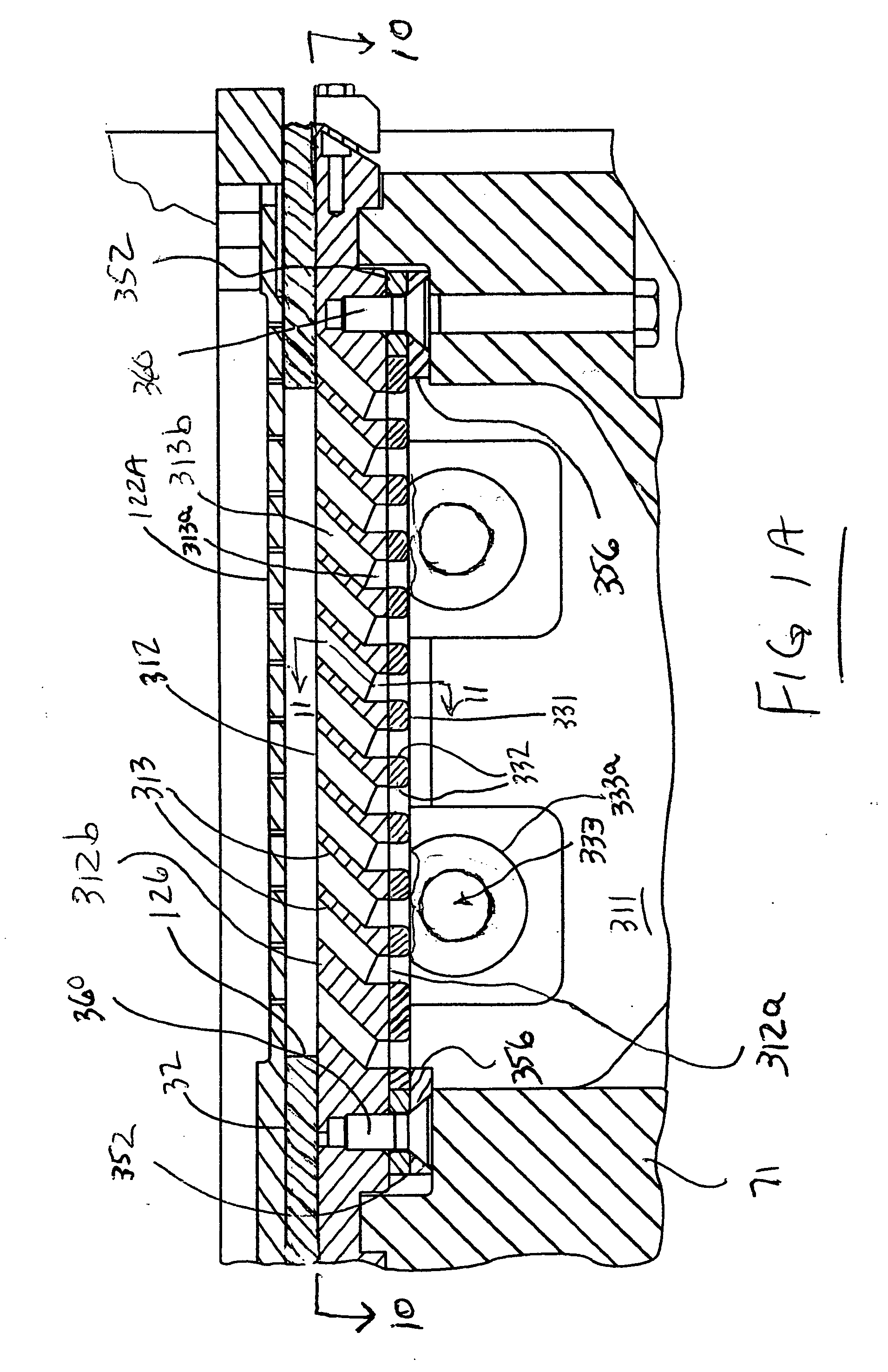

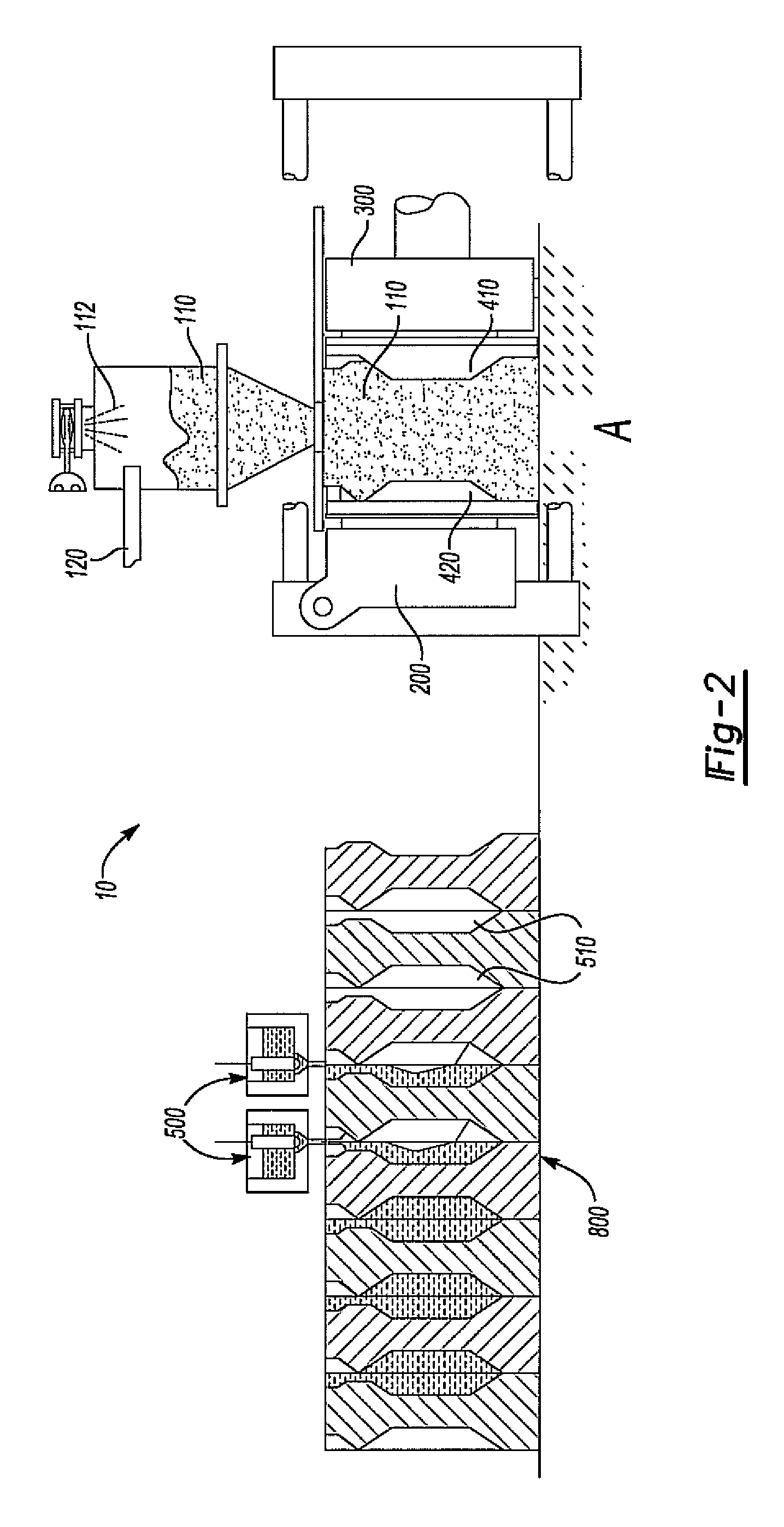

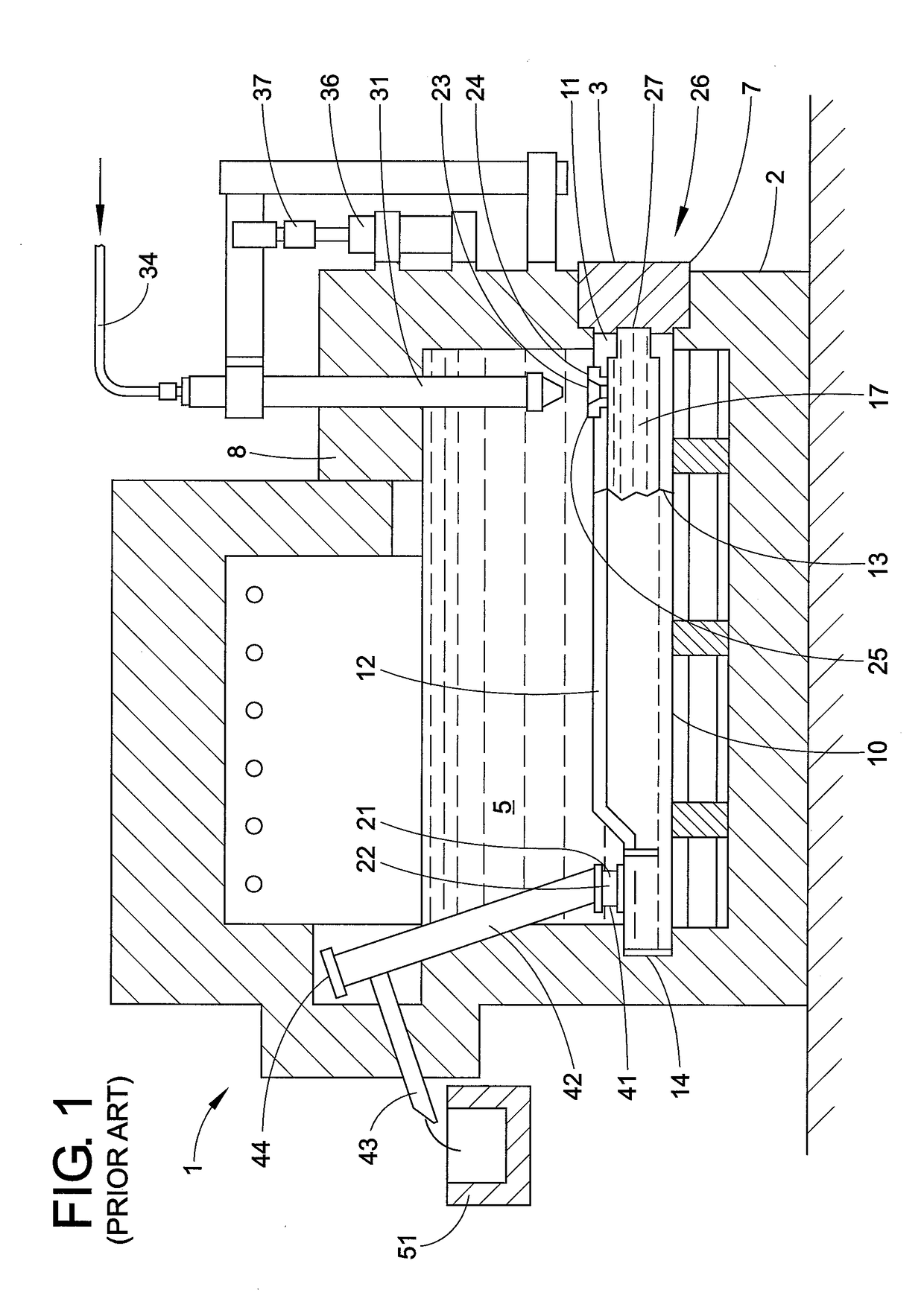

Molding and casting machine

ActiveUS20080135205A1Improved swing movementEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

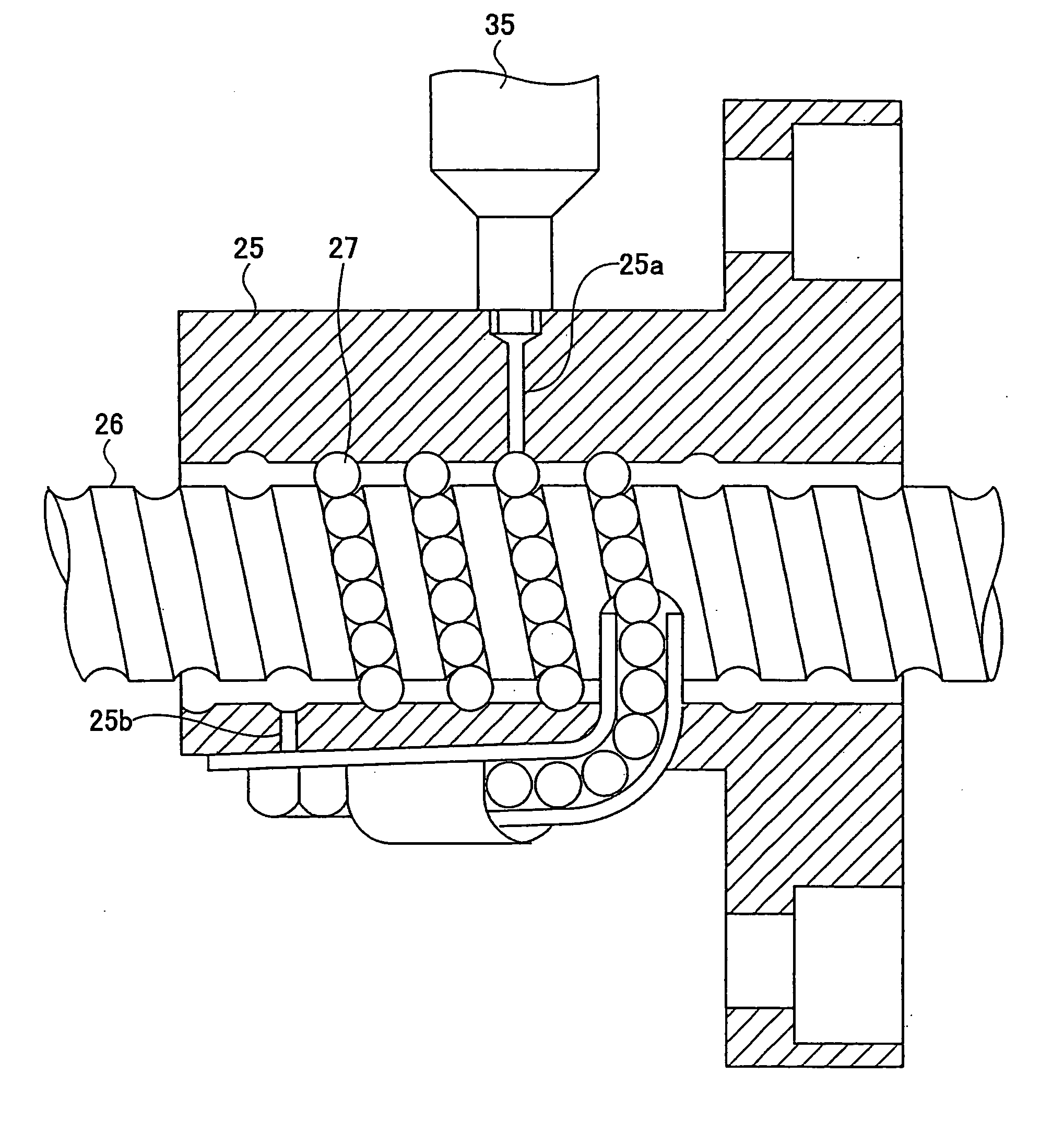

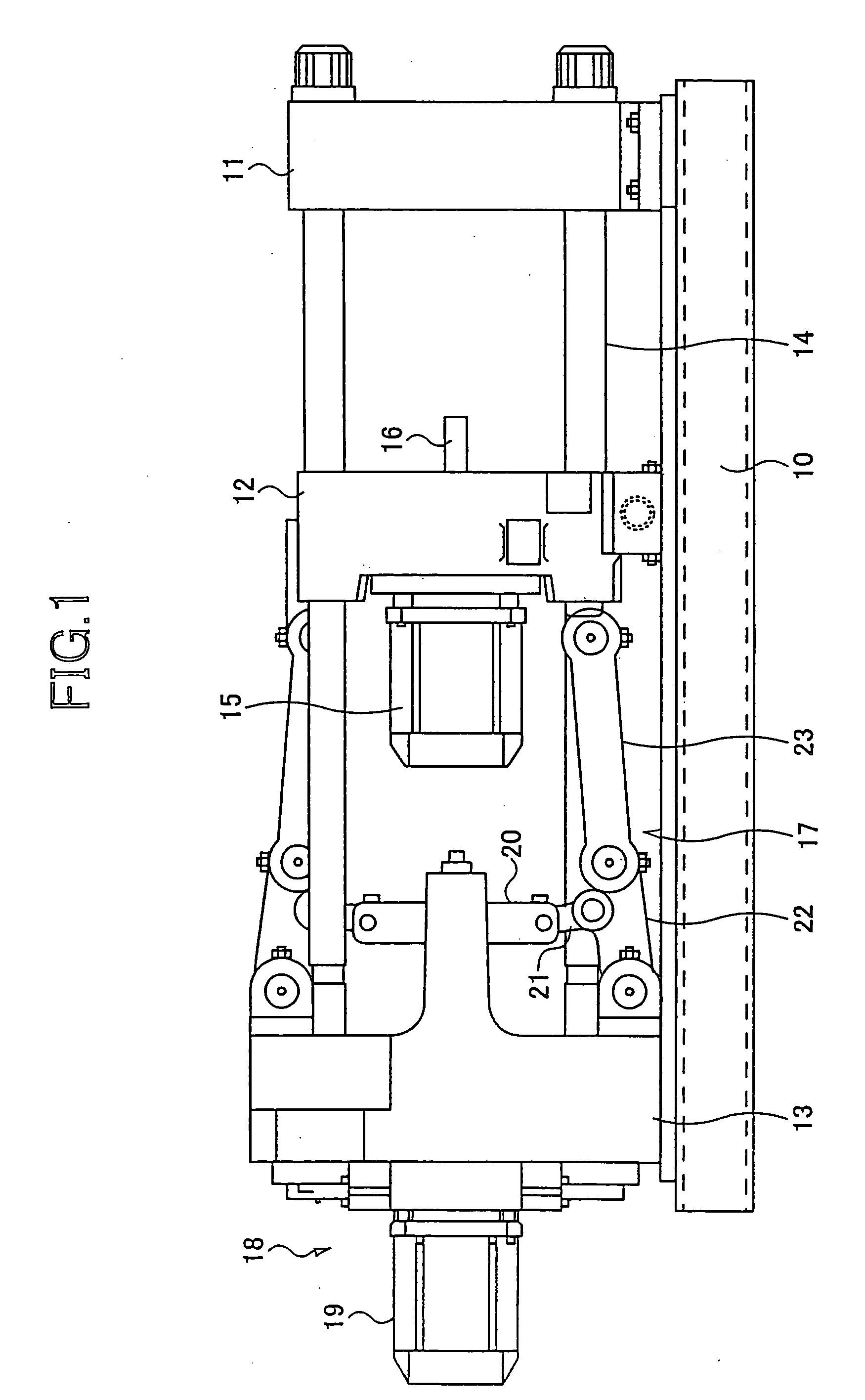

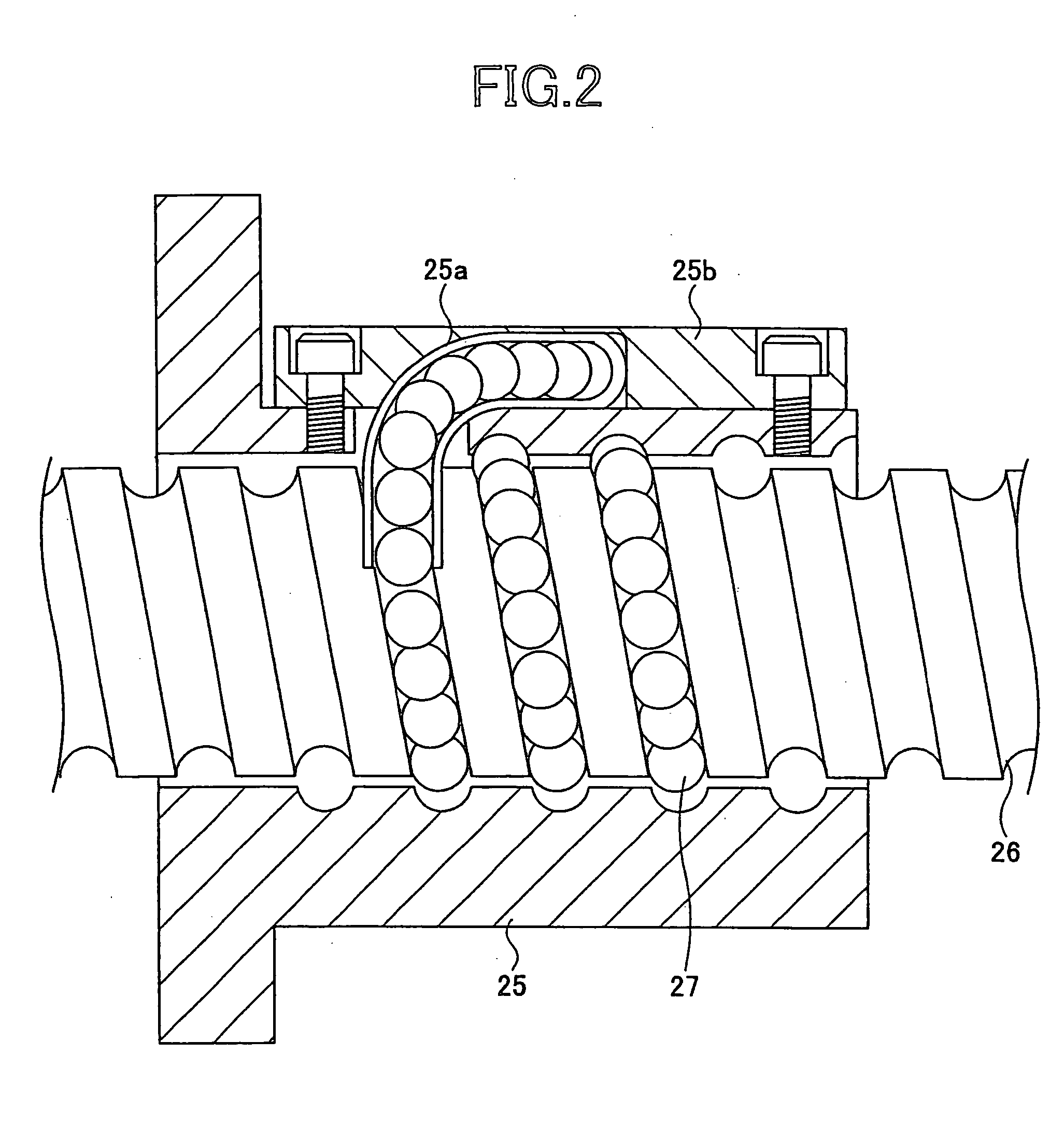

Injection machine having a lubrication mechanism and a lubrication method of an injection machine

InactiveUS20050255186A1Fully lubricatedInhibit temperature riseGear lubrication/coolingToothed gearingsMolding machineBall screw

A molding machine having a lubrication mechanism according to the present invention can effectively rubricate a ball screw and elongate a service life of the ball screw. In a clamping apparatus of an electric injection molding machine, a rotational movement of a rotational shaft of a motor is converted into a linear movement in an axial direction by a ball screw mechanism. Atomized lubrication oil is directly sprayed inside the ball screw nut from a spray nozzle. The lubrication oil, which has been sprayed from the spray nozzle, is recovered and reused.

Owner:SUMITOMO HEAVY IND LTD

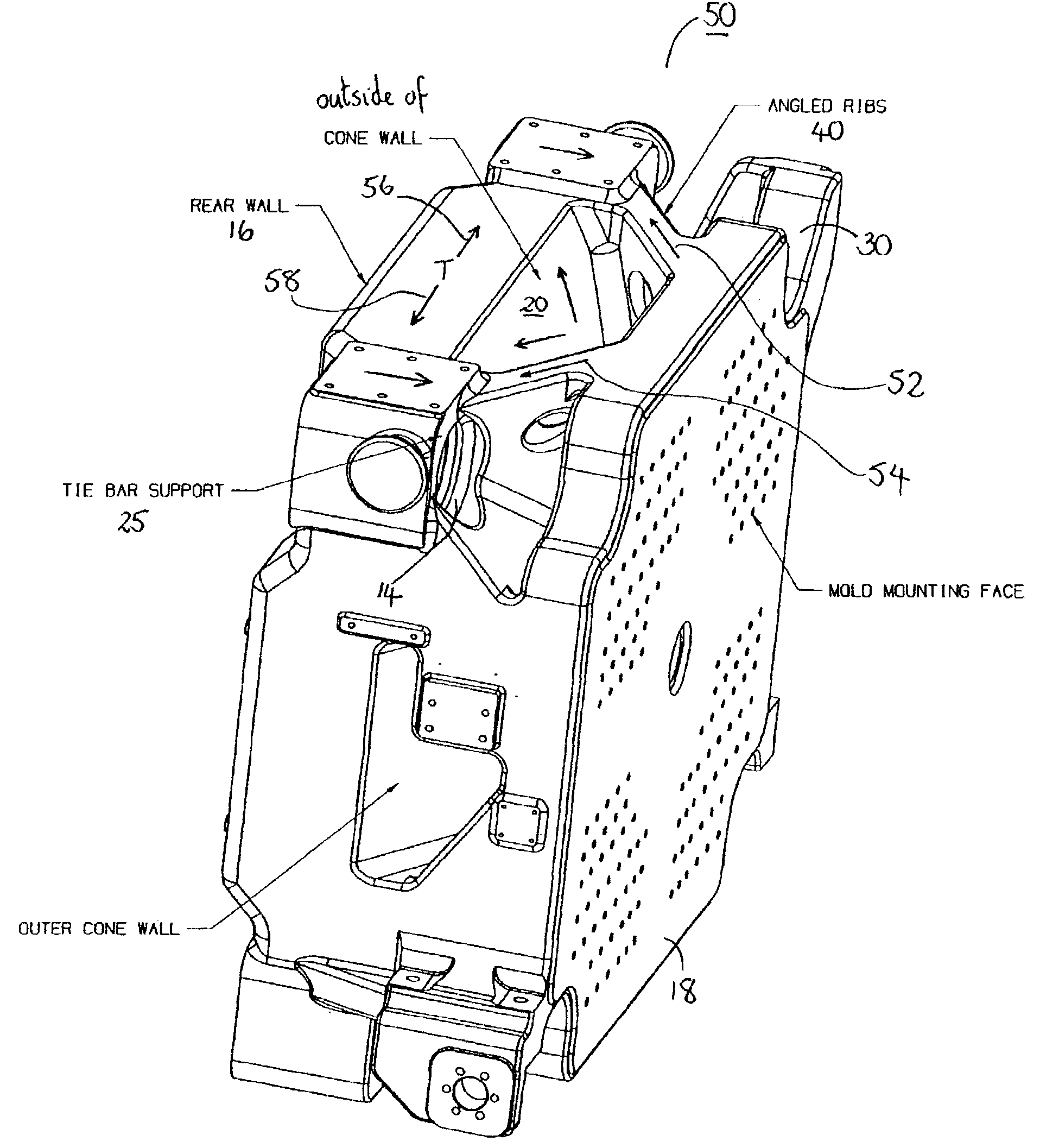

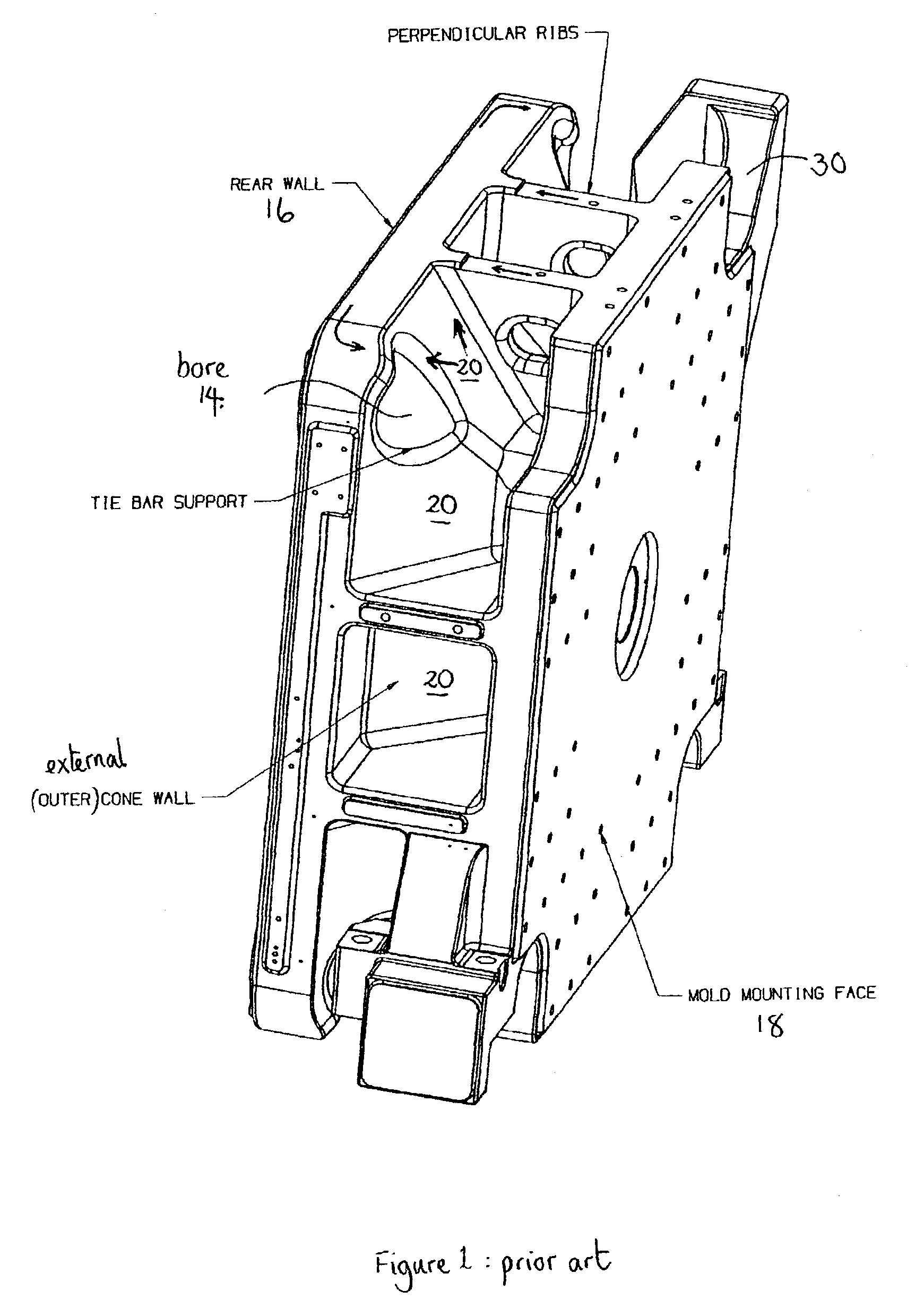

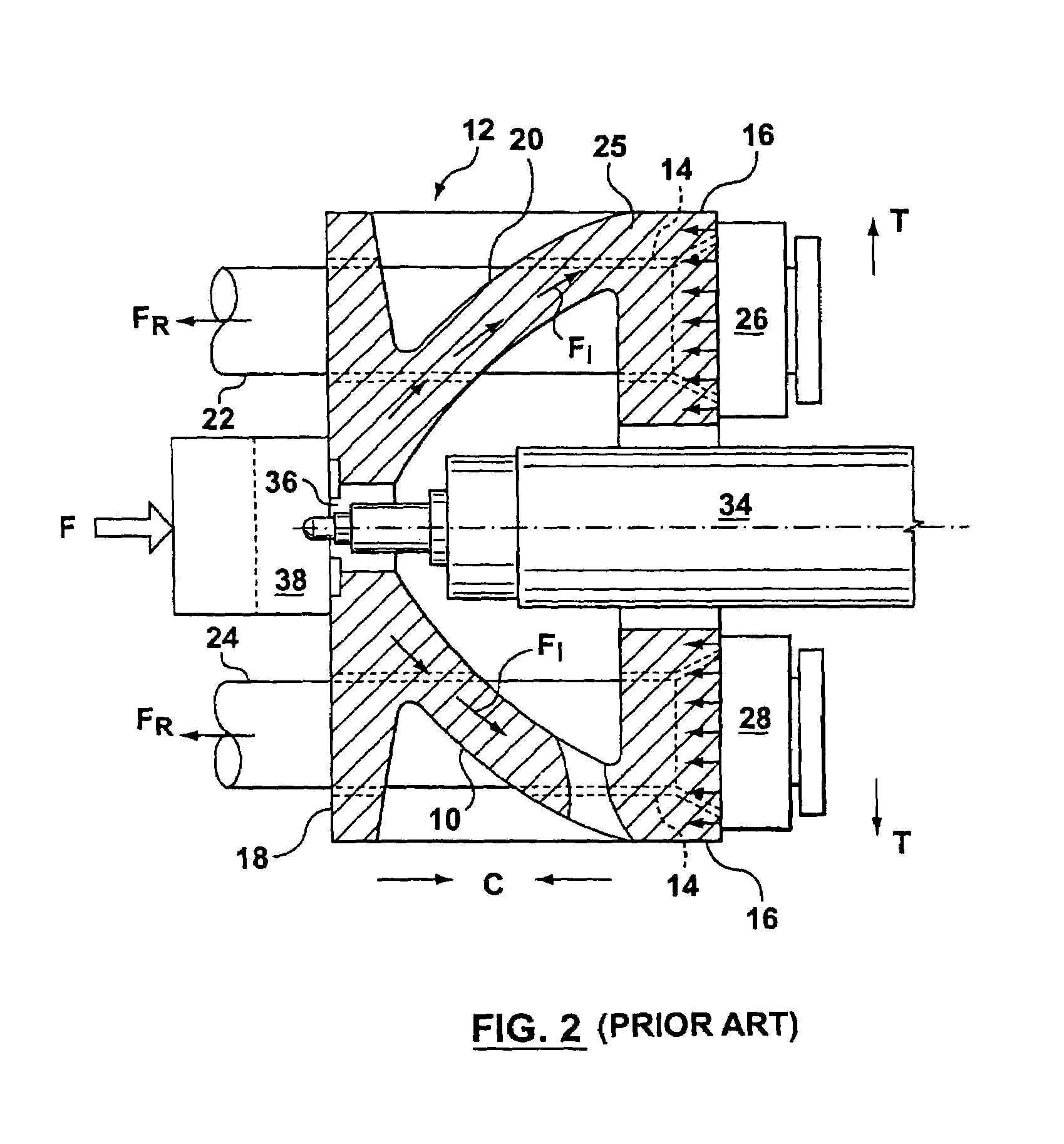

Platen

ActiveUS7080978B2Efficient couplingMaintenance of the flatness of the arrangementWelding/cutting auxillary devicesLaminationMolding machineCoupling

A platen (50) for a molding machine includes an intermediate support structure (20) between two planar walls (16, 18) having ribs (40) arranged at a non-normal angle β to a first wall (18). The ribs (40) couple forces from the first wall (18) to the second wall (16) in such a way that bending of the second wall (16) is resisted. This adds to the rigidity of the second wall (16) and hence the platen (50), adding to flatness of the arrangement. Gussets (42) may be provided extending between the ribs (40) and the intermediate support structure (20). This has the effect of surrounding and supporting an injection bore (14) and further adding to the coupling of forces to the edge portions of the second wall (16) to resist forces acting to bend the wall.

Owner:HUSKY INJECTION MOLDING SYST LTD

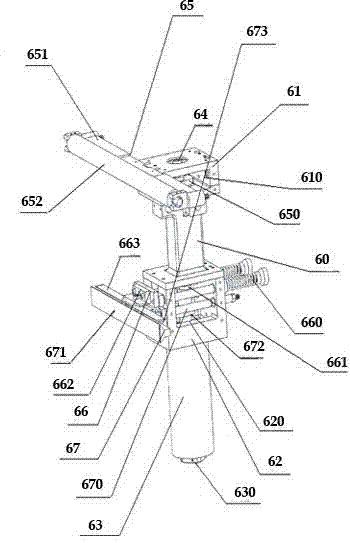

Mold pump

PendingUS20170246681A1Specific fluid pumpsMolten metal supplying equipmentsMolding machineGuide tube

A molding machine for molding material is provided. The machine includes a cavity to be filled with molten metal and a conduit system leading to the cavity, thus forming a system of interconnected hollow spaces. At least one pressure member is moveable in at least part of the conduit system. A centrifugal pump in fluid communication with a reservoir of molten metal is provided, the pump providing molten metal to the hollow space receiving the at least one pressure member.

Owner:PYROTECK INC

Light ground mass industrial machine-shaping process technology

InactiveCN101253845AReduce labor intensityProtect environmentBio-organic fraction processingBiofuelsEcological environmentEngineering

A technology for industrialized processing and molding of a light matrix includes the steps of crushing agricultural and forest waste first, composting the waste with beneficial microbes, namely EM bacteria for fermentation, conducting rational sifting and matrix matching, using a light-matrix processing and molding machine to process the scattered matrix into an enteroid matrix container with a diameter of 35mm to 50mm, and then cutting the matrix container into small sections, namely matrix sections in the length of 80mm to 100mm, thereby suiting both the cultivation of eucalyptus grafts and the upper bag of the seedling container for tissue-culture rooting. The technology, which can be used for industrialized matrix production, greatly reduces labor intensity and protects ecological environment. The matrix, belonging to composite matrix, can be used for seeding, cuttage and transplant of plants and for the cultivation of other seedlings for greening purpose, with a high survival rate and robust root systems.

Owner:CHINA EUCALYPT RES CENT

Fully automatic carton molding machine

InactiveCN103085316AStable jobWork flexiblyContainer making machineryMolding machineProgrammable logic controller

Provided is a fully automatic carton molding machine. The fully automatic carton molding machine comprises a rack, a transmission belt which is arranged on the rack and extends outward, a box pressing device which is arranged above the transmission melt, a box holding device which is arranged on two sides of the box pressing device, and a molding machine head device which is arranged below the transmission belt. The fully automatic carton molding machine further comprises a programmable logic controller (PLC) controlling system for controlling the transmission belt, the box pressing device, the box holding device, and the molding machine head device. The molding machine head device comprises four molding machine heads and the molding machine heads can independently complete molding work, so that the fully automatic carton molding machine is stable at work. Lifting-dropping barrel bodies are arranged on all the molding machine heads, the lifting-dropping barrel bodies can independently lift and drop, a shovel device and a plate pressing device of the molding machine heads can rotate and tilt, and thus the fully automatic carton molding machine is flexible at work. Due to the fact that the PLC controlling system for controlling is the transmission belt, the box pressing device, and the molding machine head device, automatic production is achieved, and thus production efficiency and product pass percent are improved.

Owner:广东力顺源智能自动化有限公司

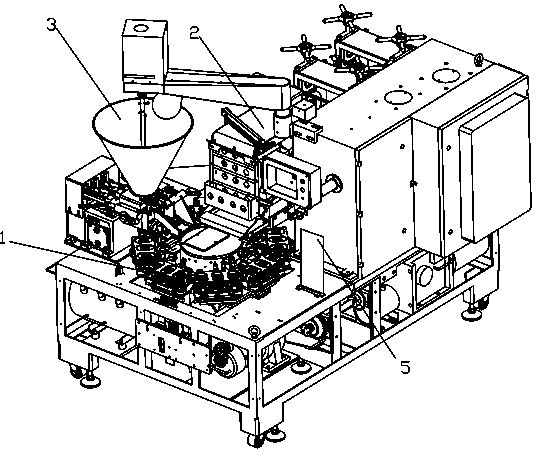

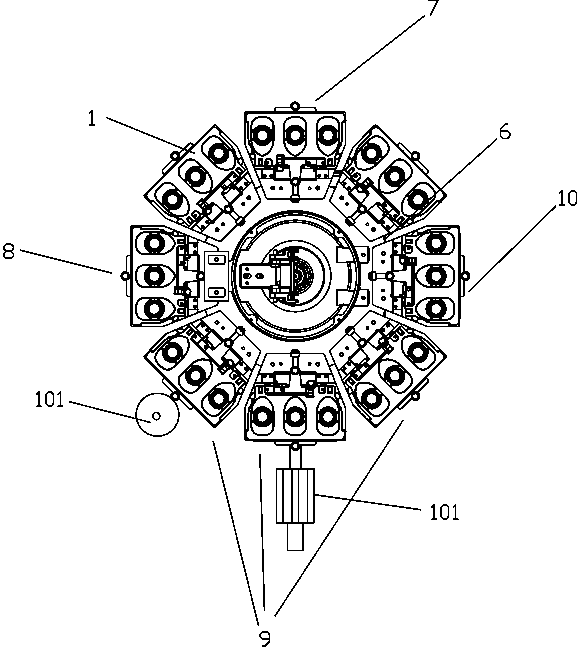

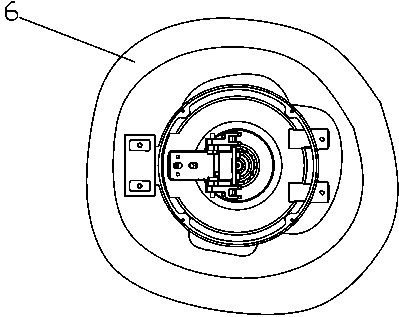

Farci food forming machine

The invention belongs to the technical field of food processing, and particularly relates to a farci food forming machine. The farci food forming machine comprises a stander and a flour wrapper transporting device, a stuffing feeding device, a flour wrapper receiving plate, a withdrawing device and an annular track arranged on the stander, wherein the flour wrapper transporting device, the stuffing feeding device and the withdrawing device are respectively and fixedly arranged on the flour receiving station, the stuffing injecting station and the withdrawing station of the annular track, the flour wrapper receiving plate capable of moving around the annular track is arranged on the annular track, a die assembly device is arranged under the flour wrapper receiving plate, the die assembly device of the farci food forming machine can provide a persistent press force when the farci food is processed, so that the compactness of the fit part of the flour wrapper of the farci food can be guaranteed, and the flour wrapper can not be opened after being pressed for a long time, so that the yield of the farci food can be guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com