Patents

Literature

91results about How to "High precision manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

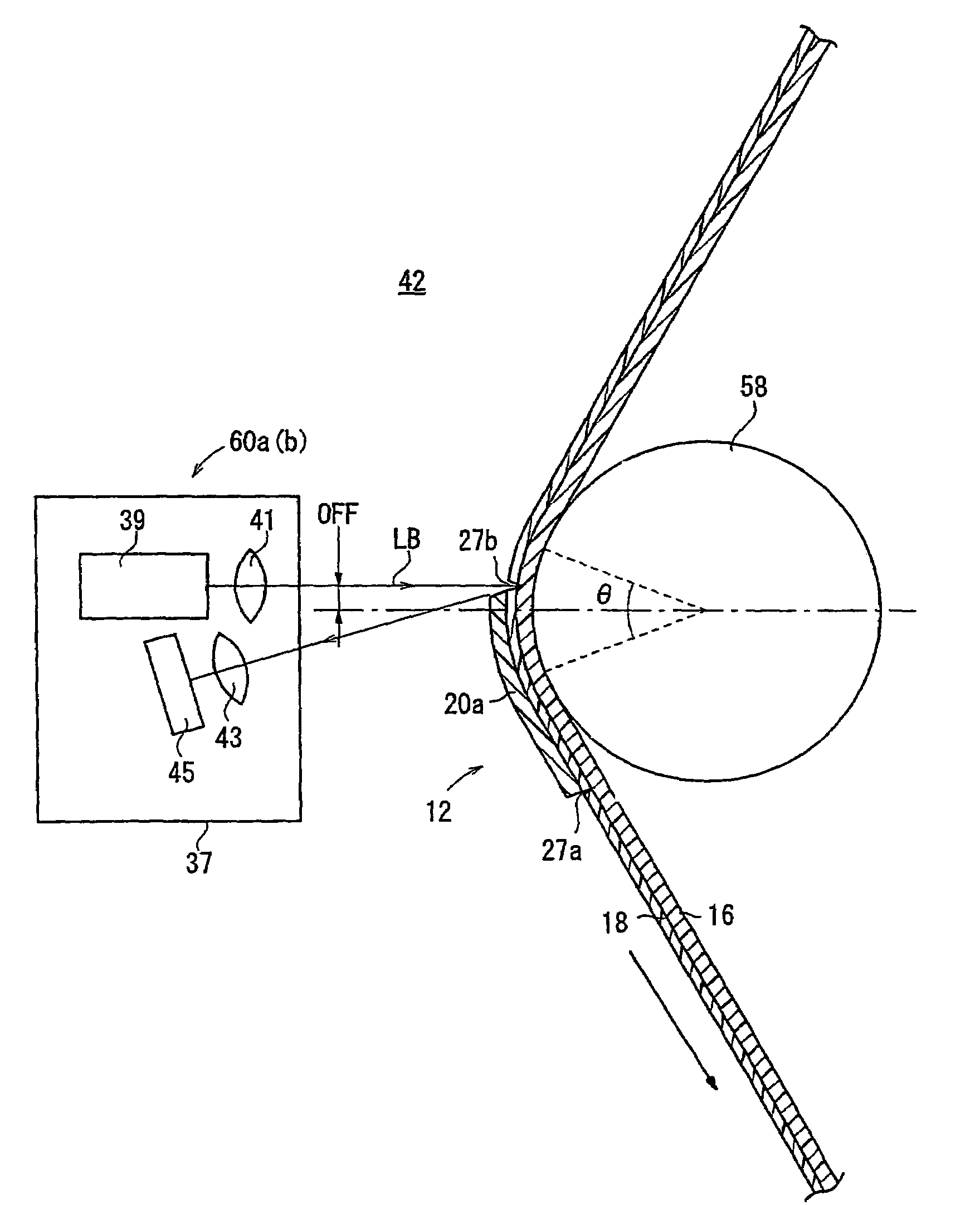

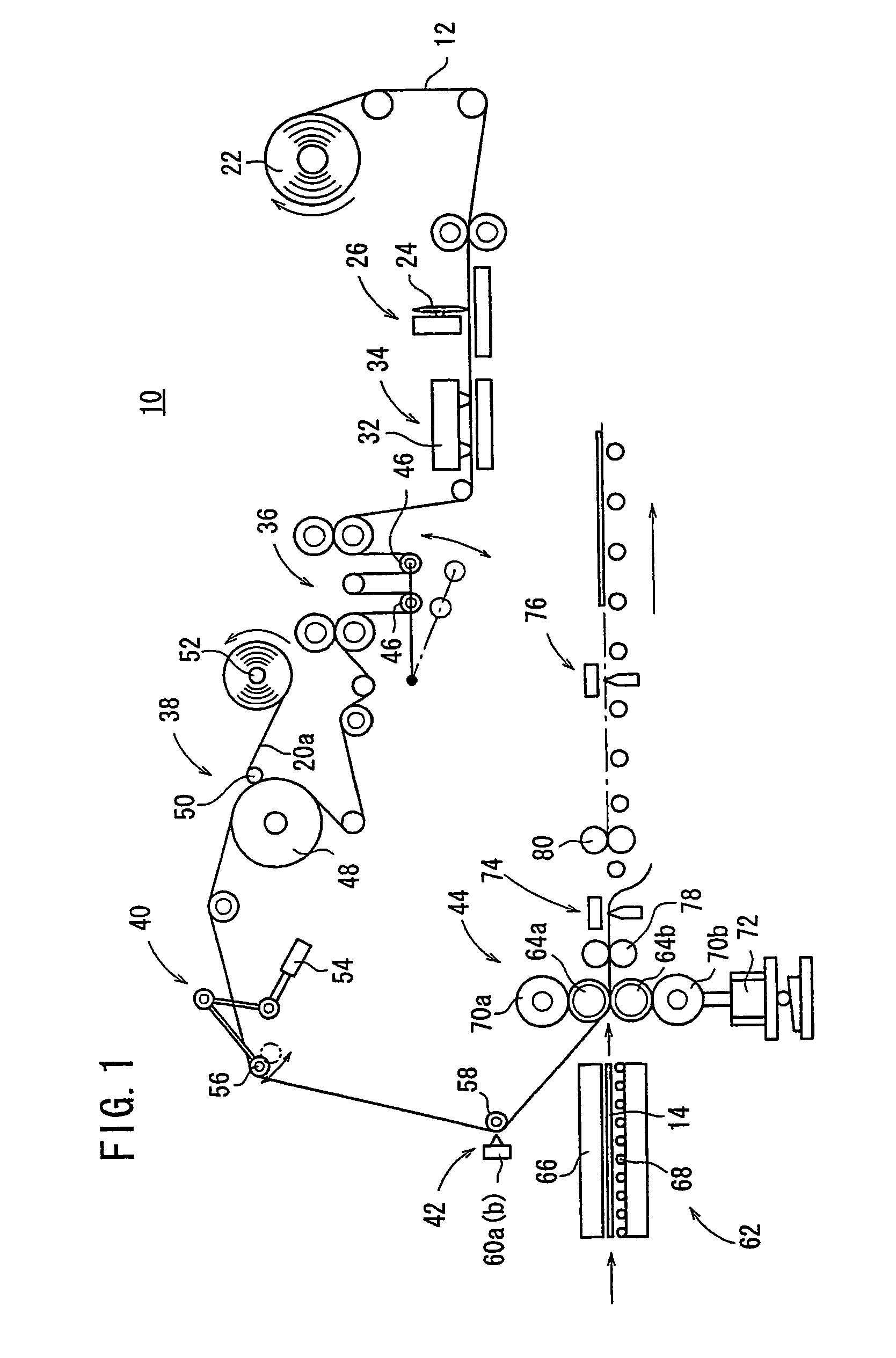

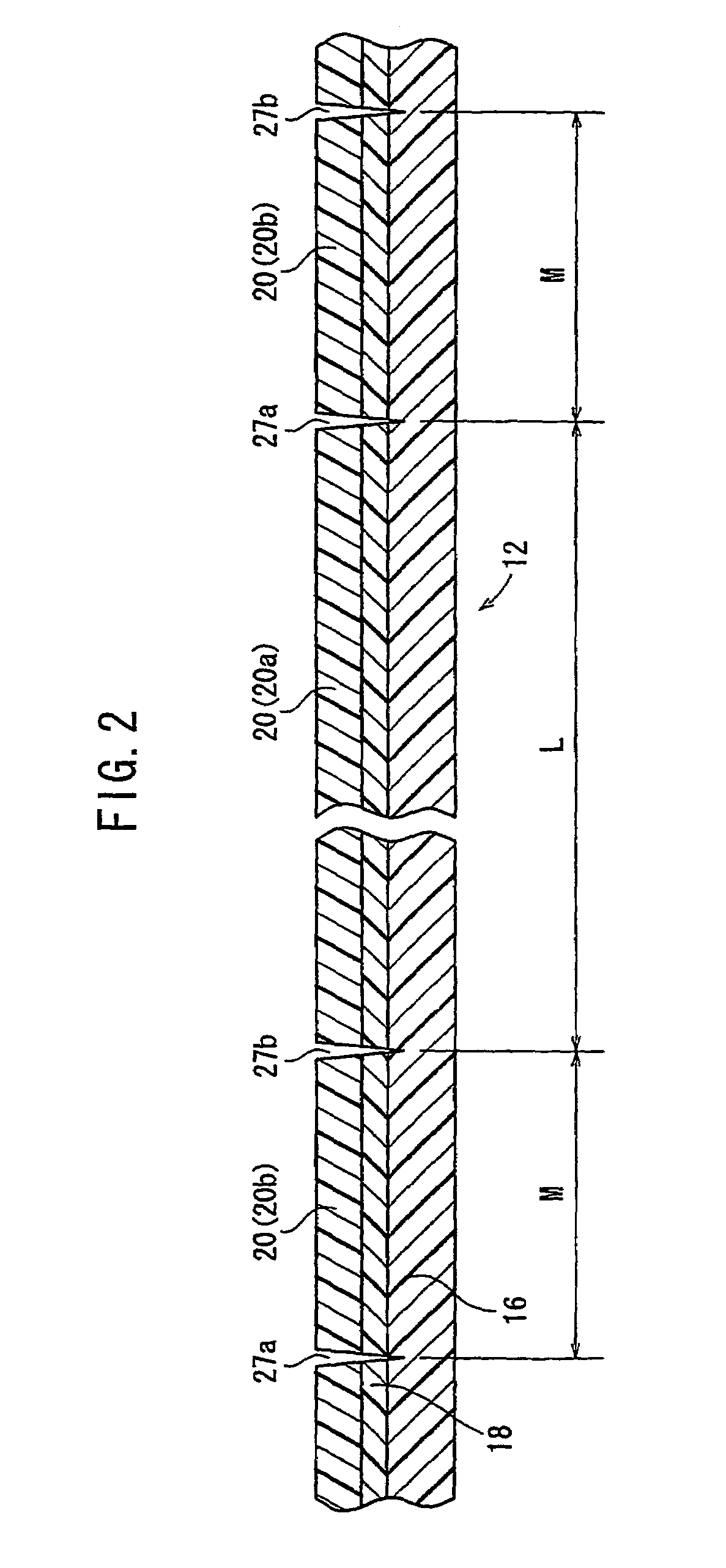

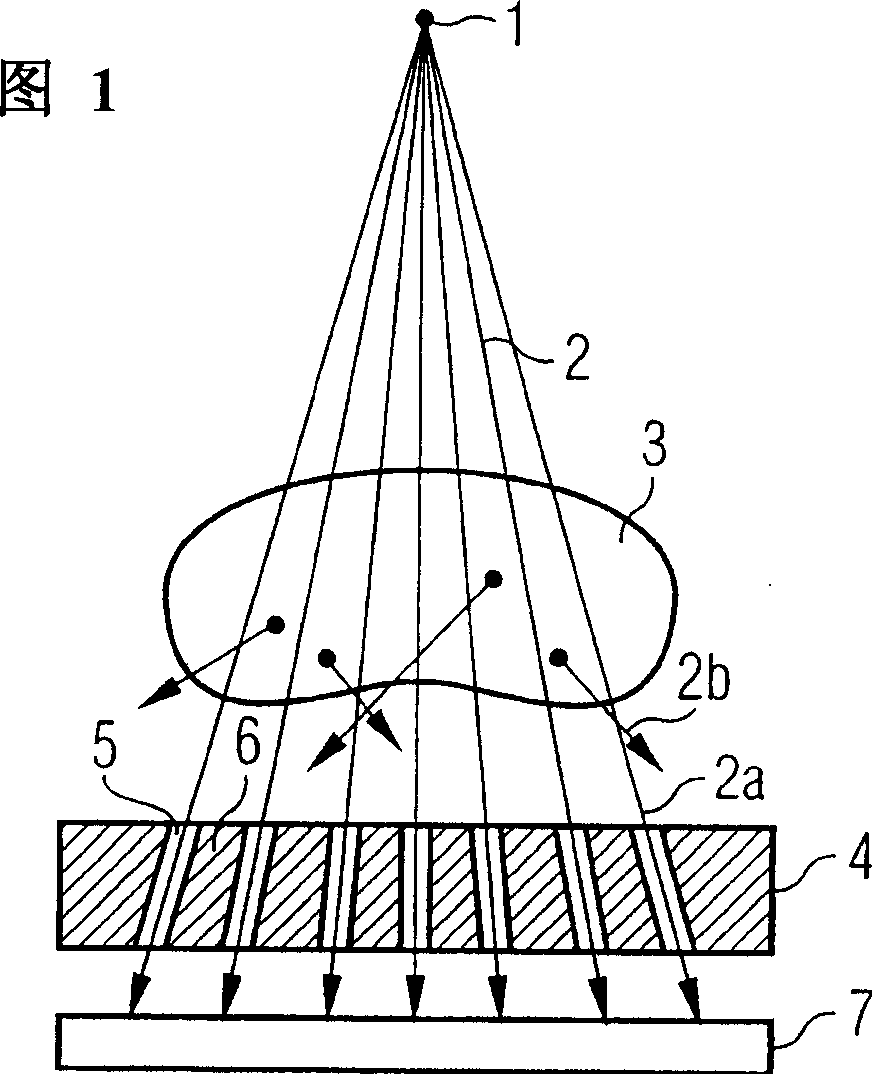

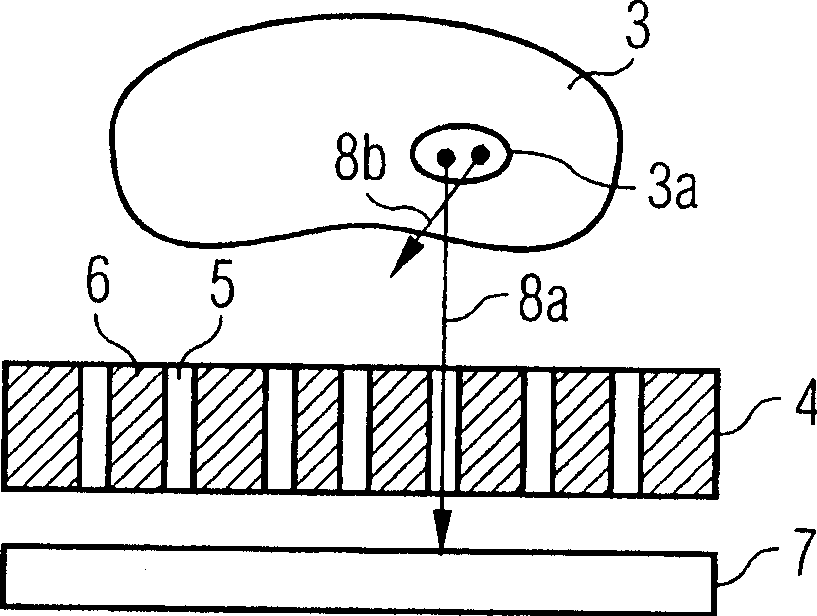

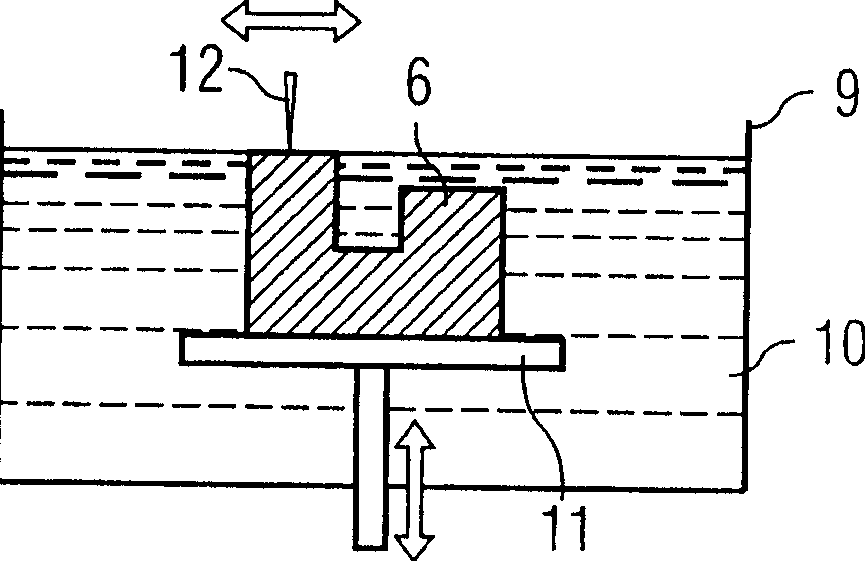

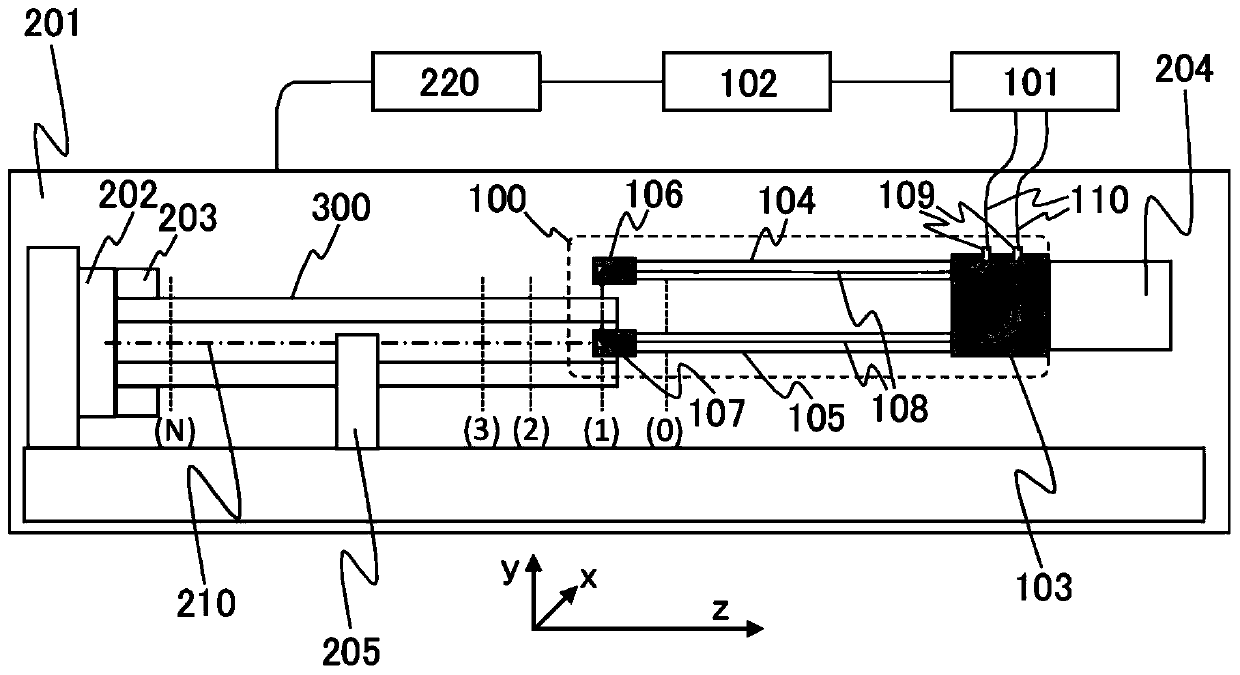

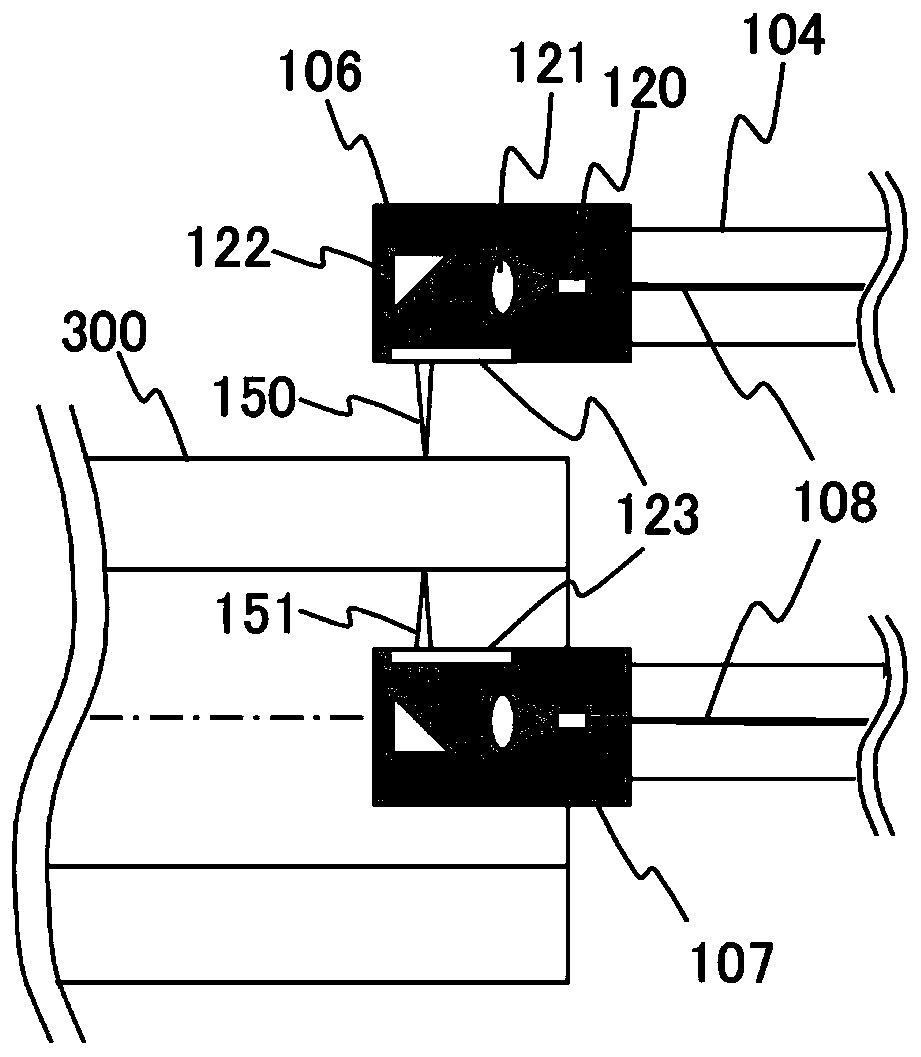

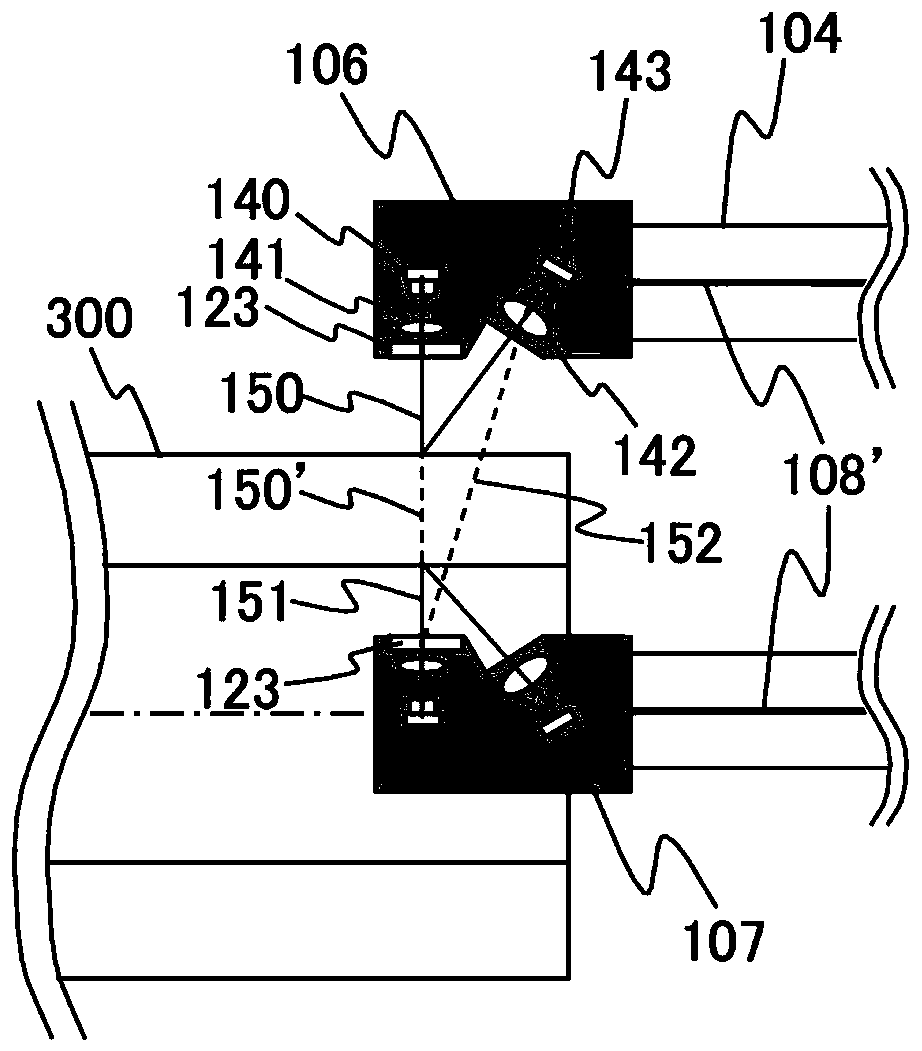

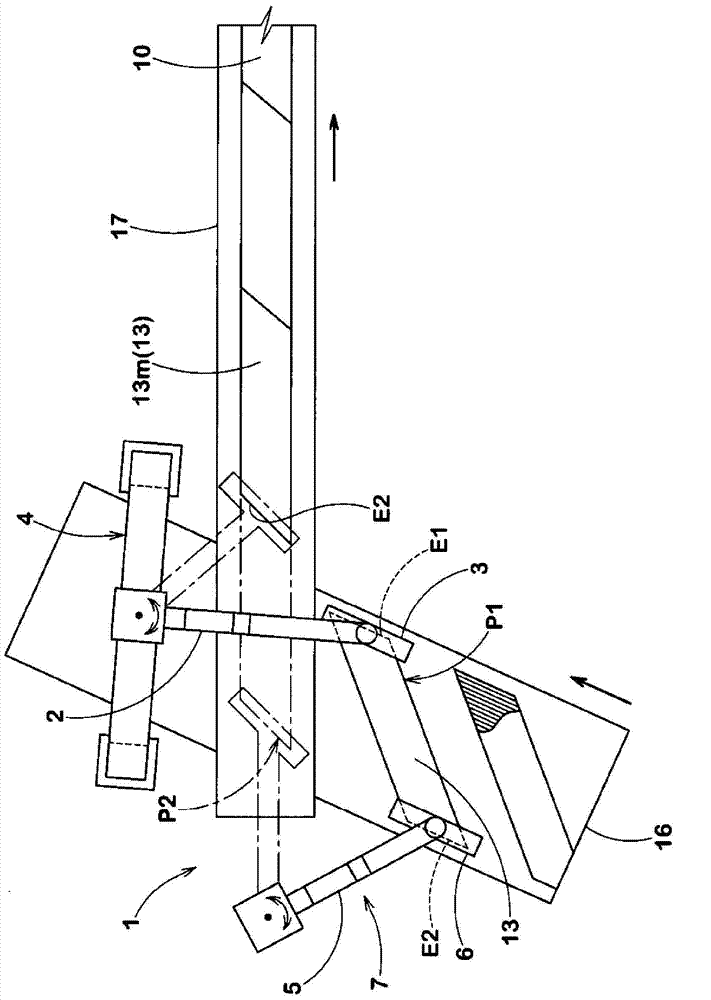

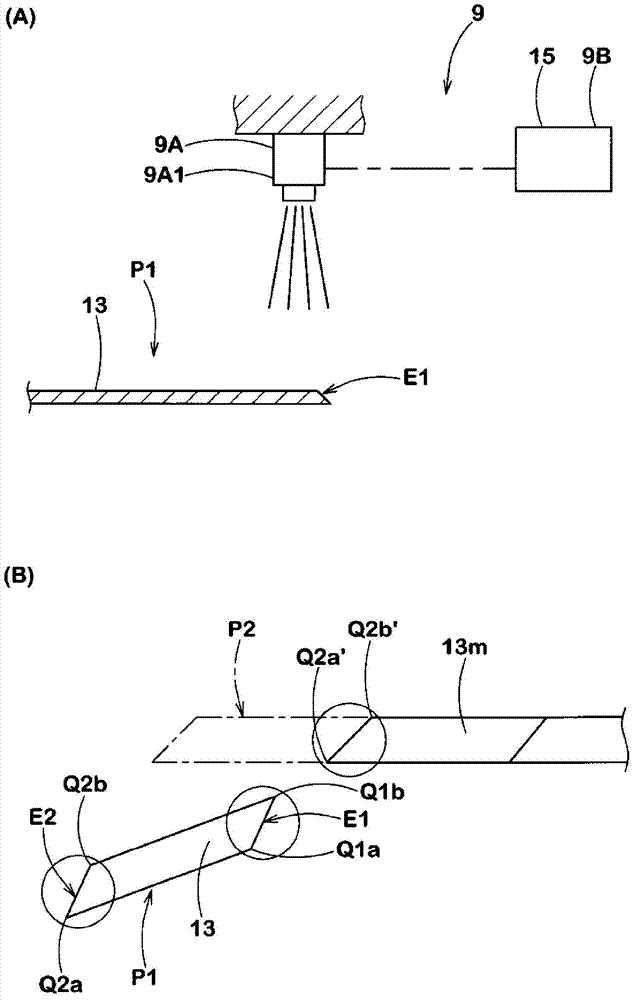

Detecting device and laminated body manufacturing apparatus employing such detecting device

InactiveUS7534989B2Simple and inexpensive structureReliable detectionInvestigating moving sheetsCounting objects on conveyorsSheet filmManufactured apparatus

A laser beam emitted from a laser diode of each of detectors is applied to a partly cut region of a photosensitive sheet film which is spread toward the detectors by a film bending roller. Part of the laser beam which is reflected from the partly cut region is detected by an amount-of-light sensor. The laser beam that is applied to a surface of the photosensitive sheet film other than the partly cut region is reflected outside of a light-detecting area of the amount-of light sensor, and is not detected by the amount-of-light sensor.

Owner:FUJIFILM CORP

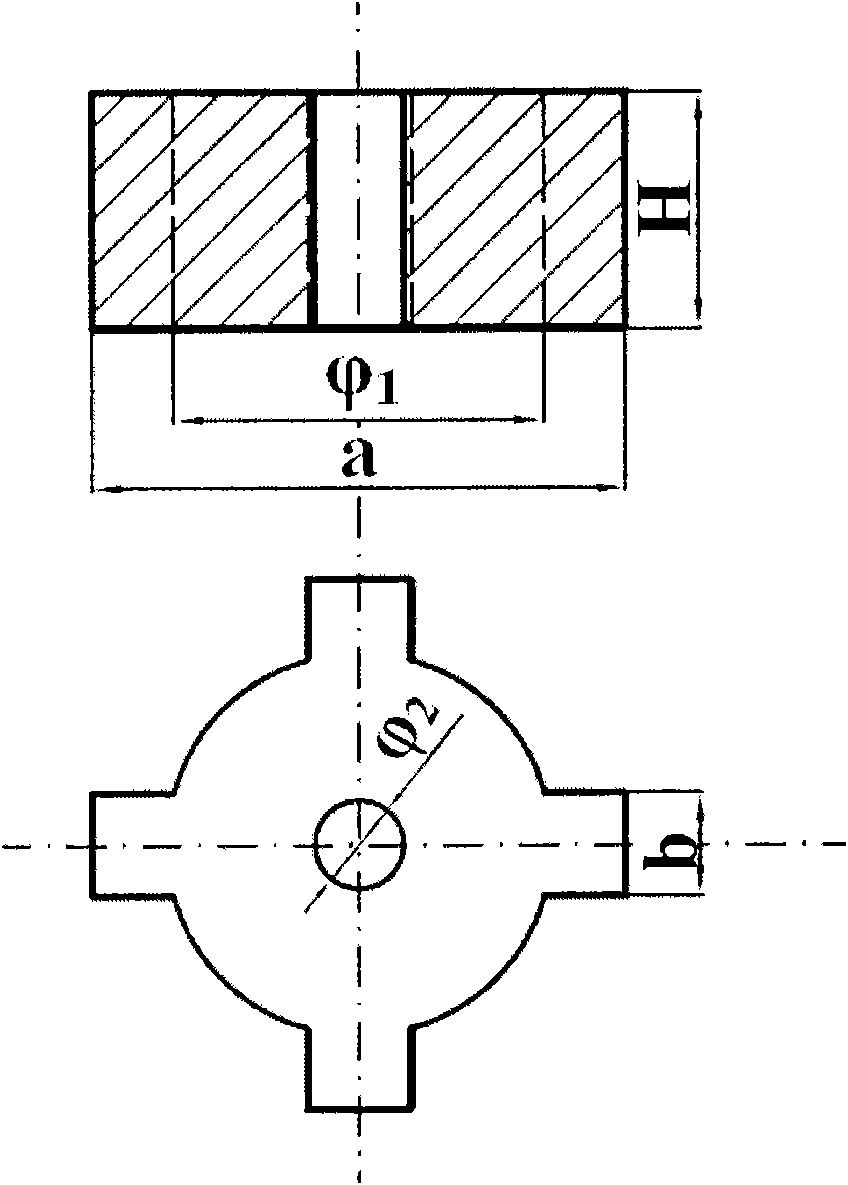

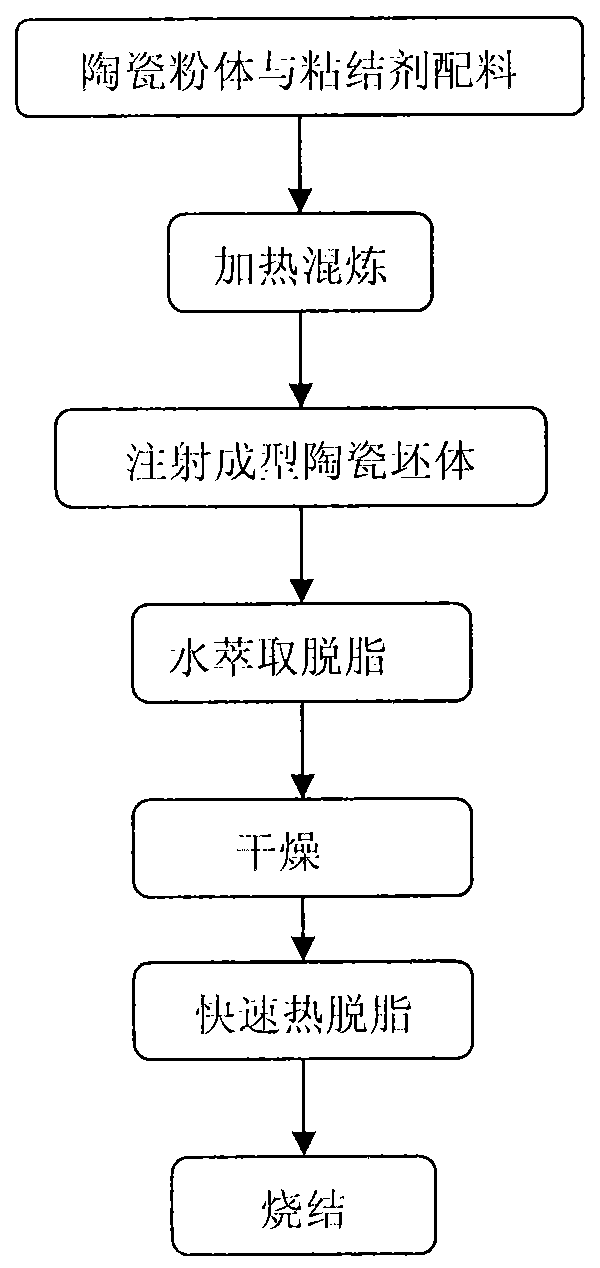

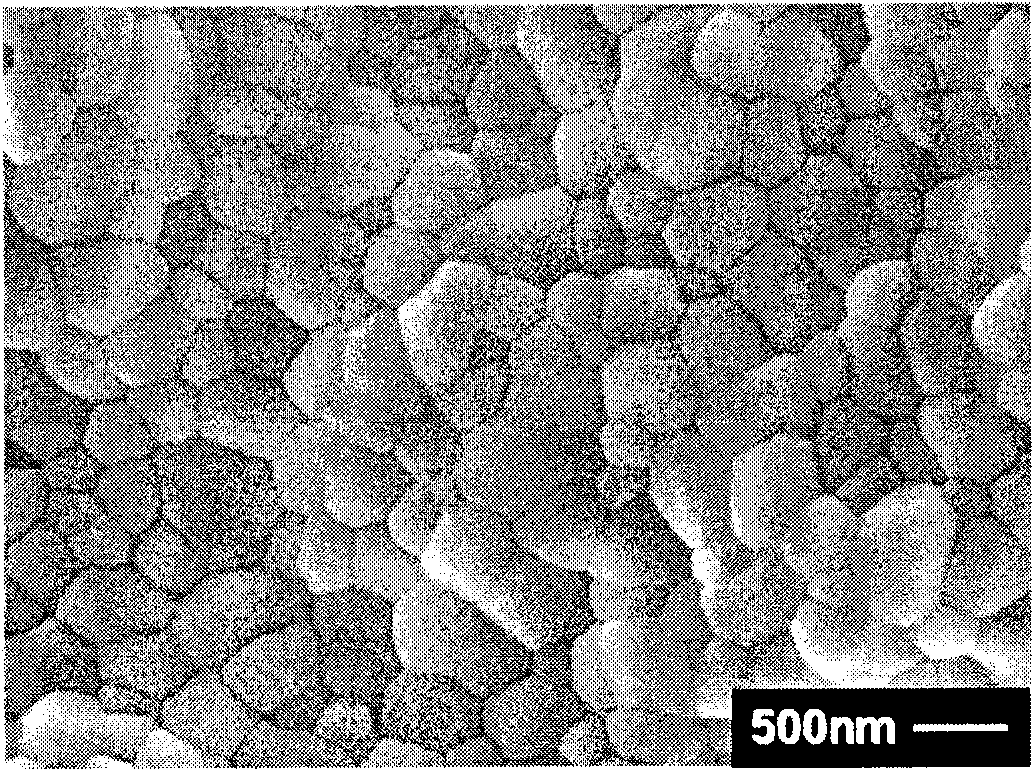

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

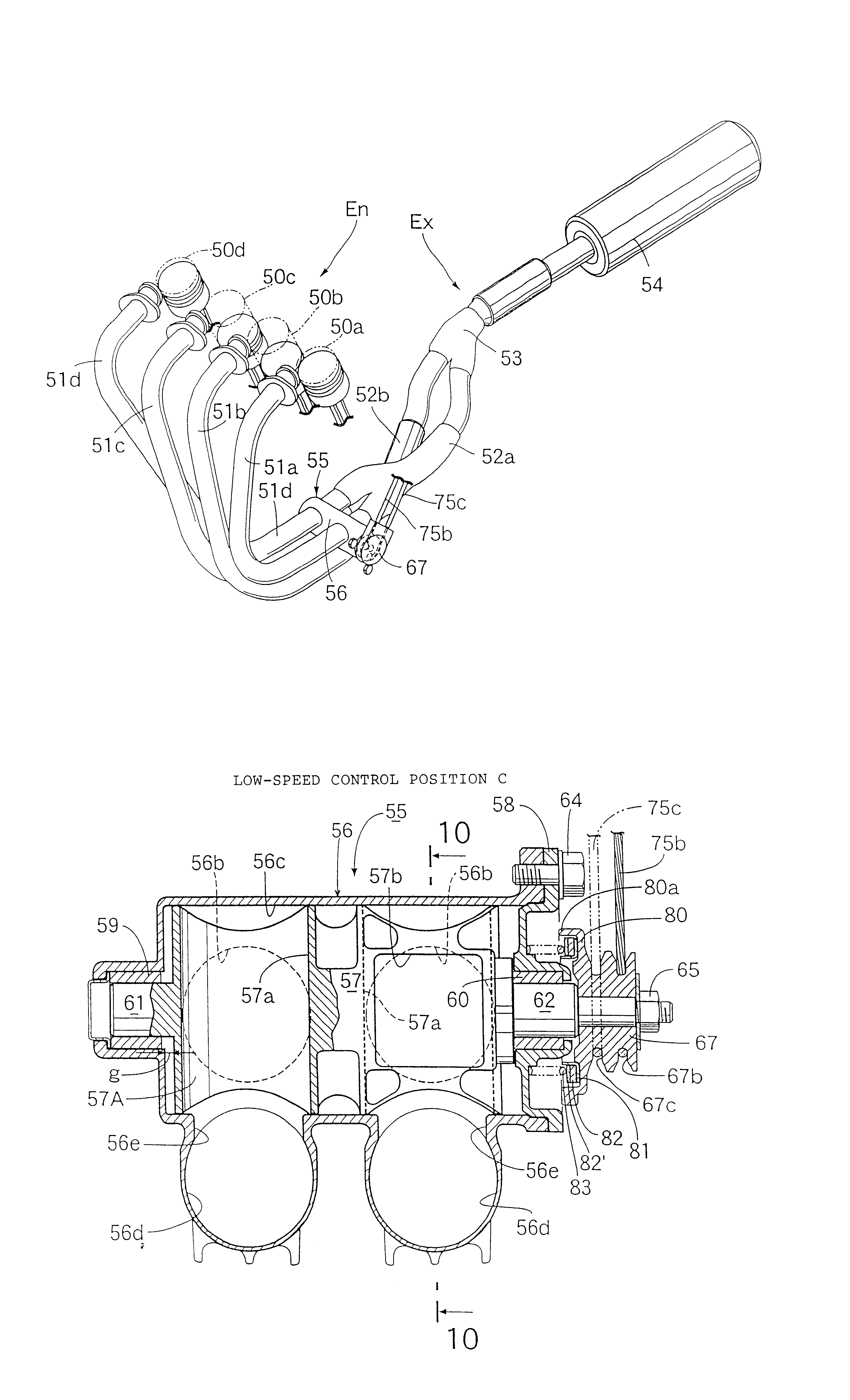

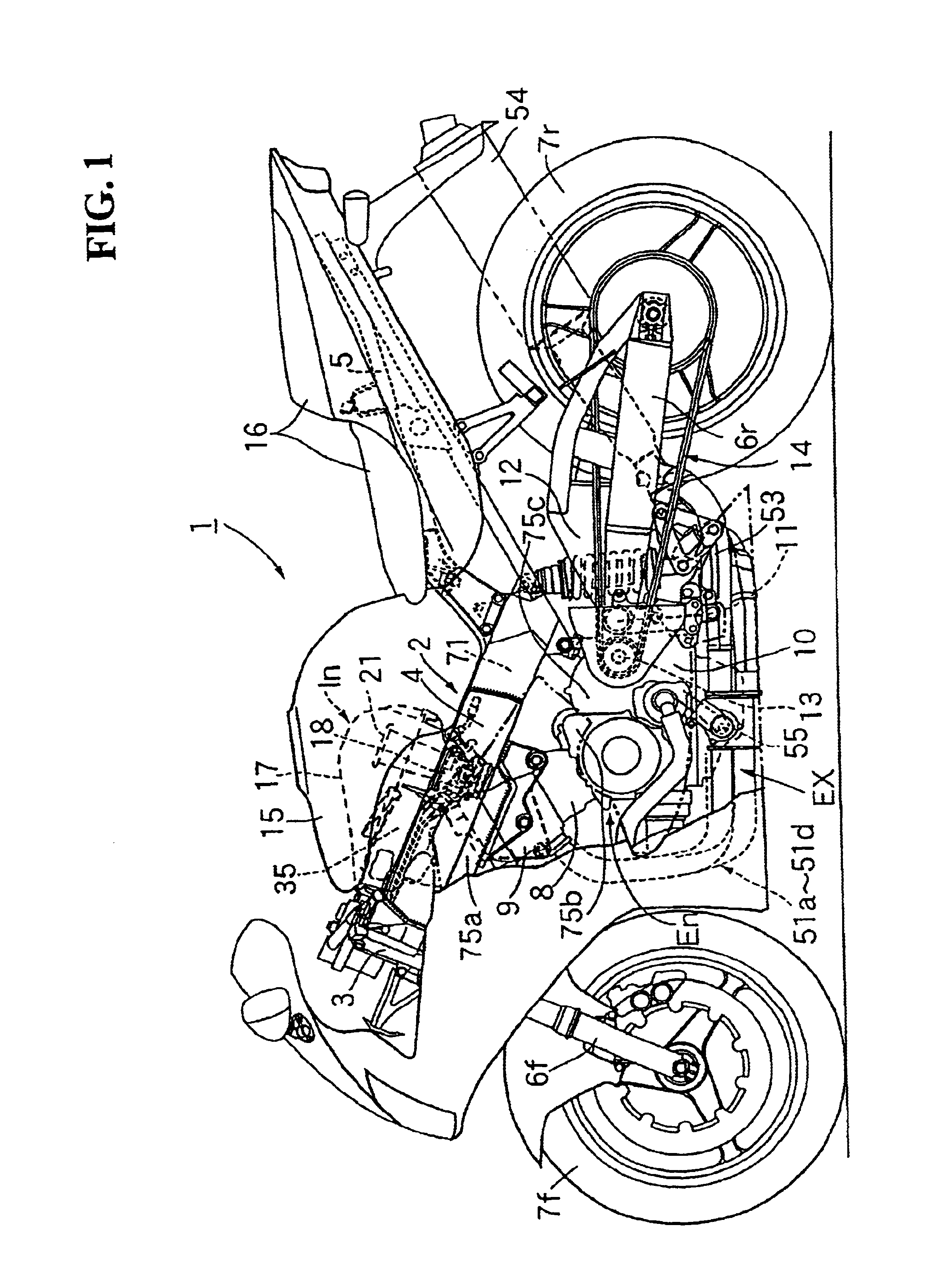

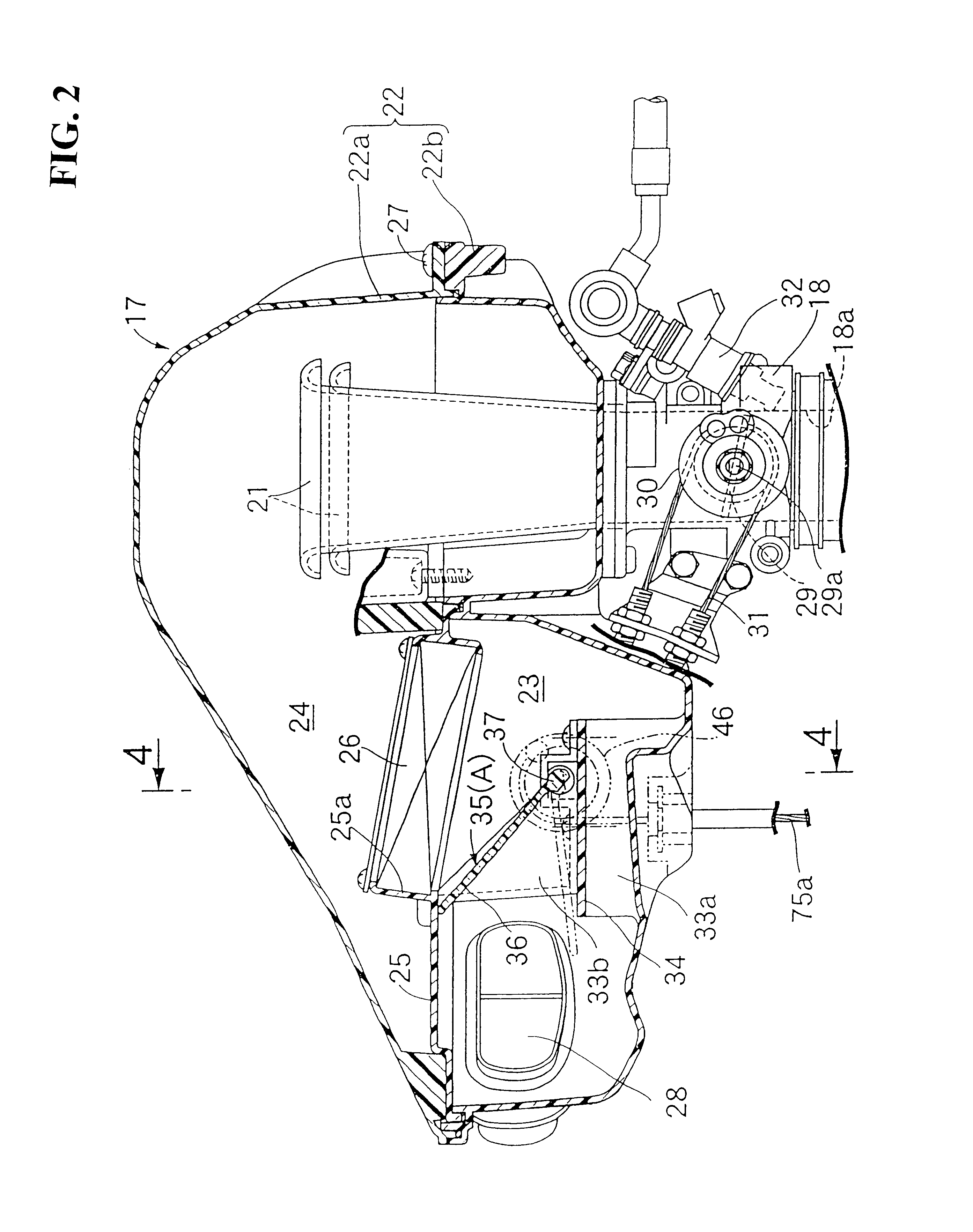

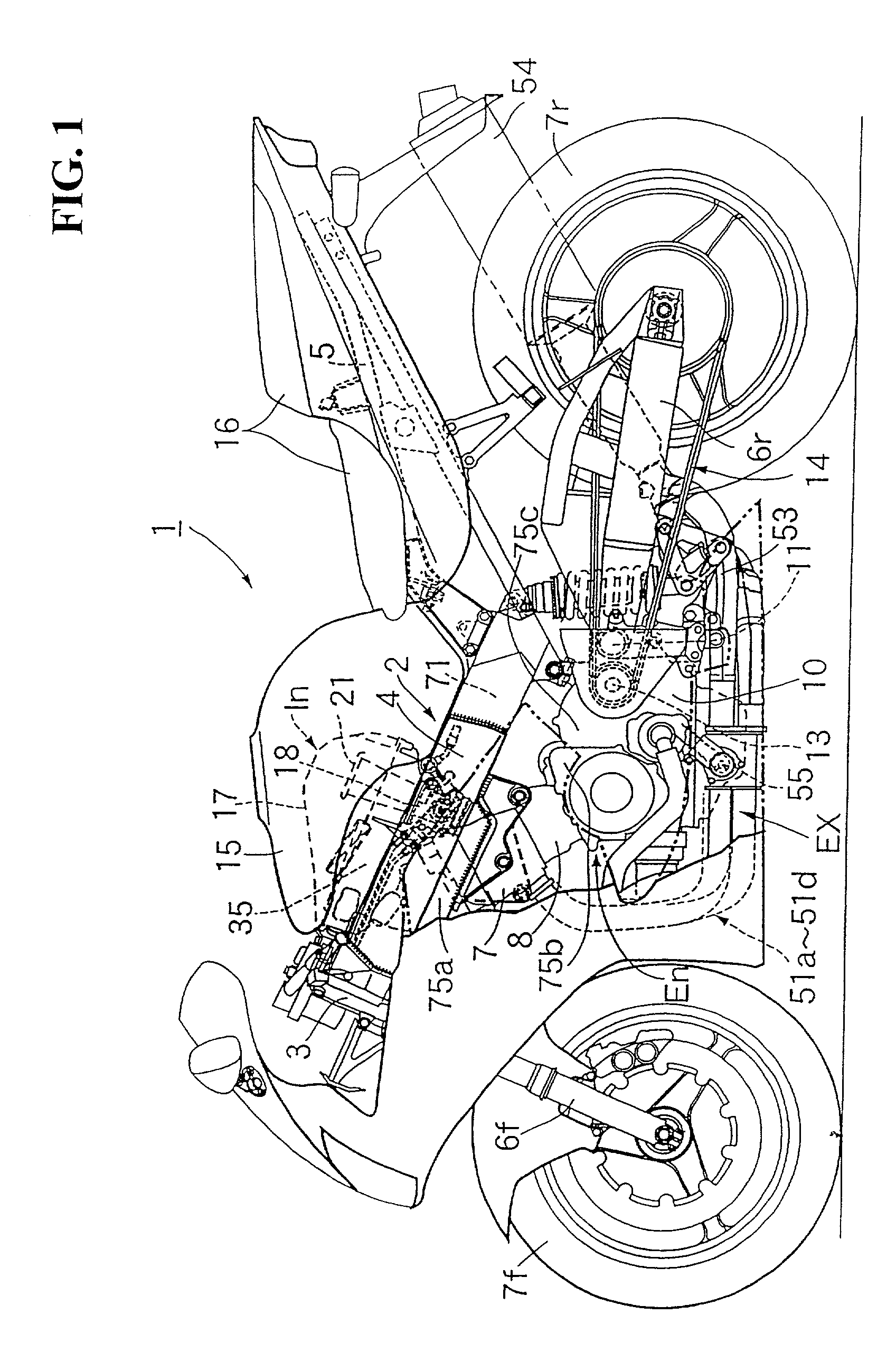

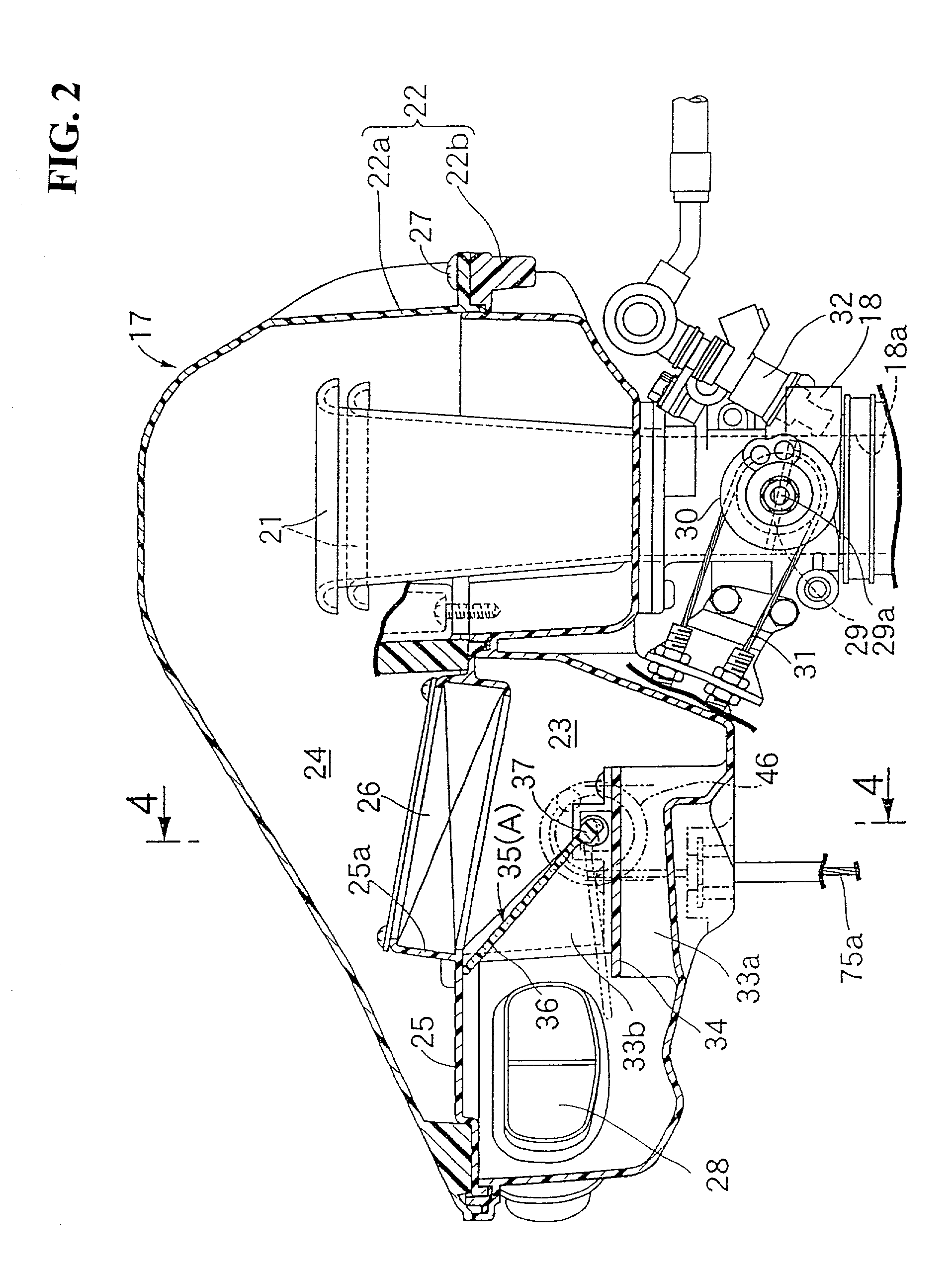

Exhaust control valve

InactiveUS6655134B2High precision manufacturingPrevent thermal deformationPlug valvesOperating means/releasing devices for valvesControl valvesVALVE PORT

An exhaust control valve has a valve housing and a valve body rotatably contained within the valve housing. The valve body cooperates with the valve housing for controlling the flow of exhaust gas. A transmission member rotationally drives a valve shaft of the valve body. The valve body is formed in a cylindrical shape and coaxially with an axis line of the valve shaft. The valve body and the valve shaft are made from a one-piece body by casting. This arrangement provides an exhaust control valve for an engine having a valve body that provides excellent sealing properties, demonstrates high response to driving torque and is easy to manufacture through casting.

Owner:HONDA MOTOR CO LTD

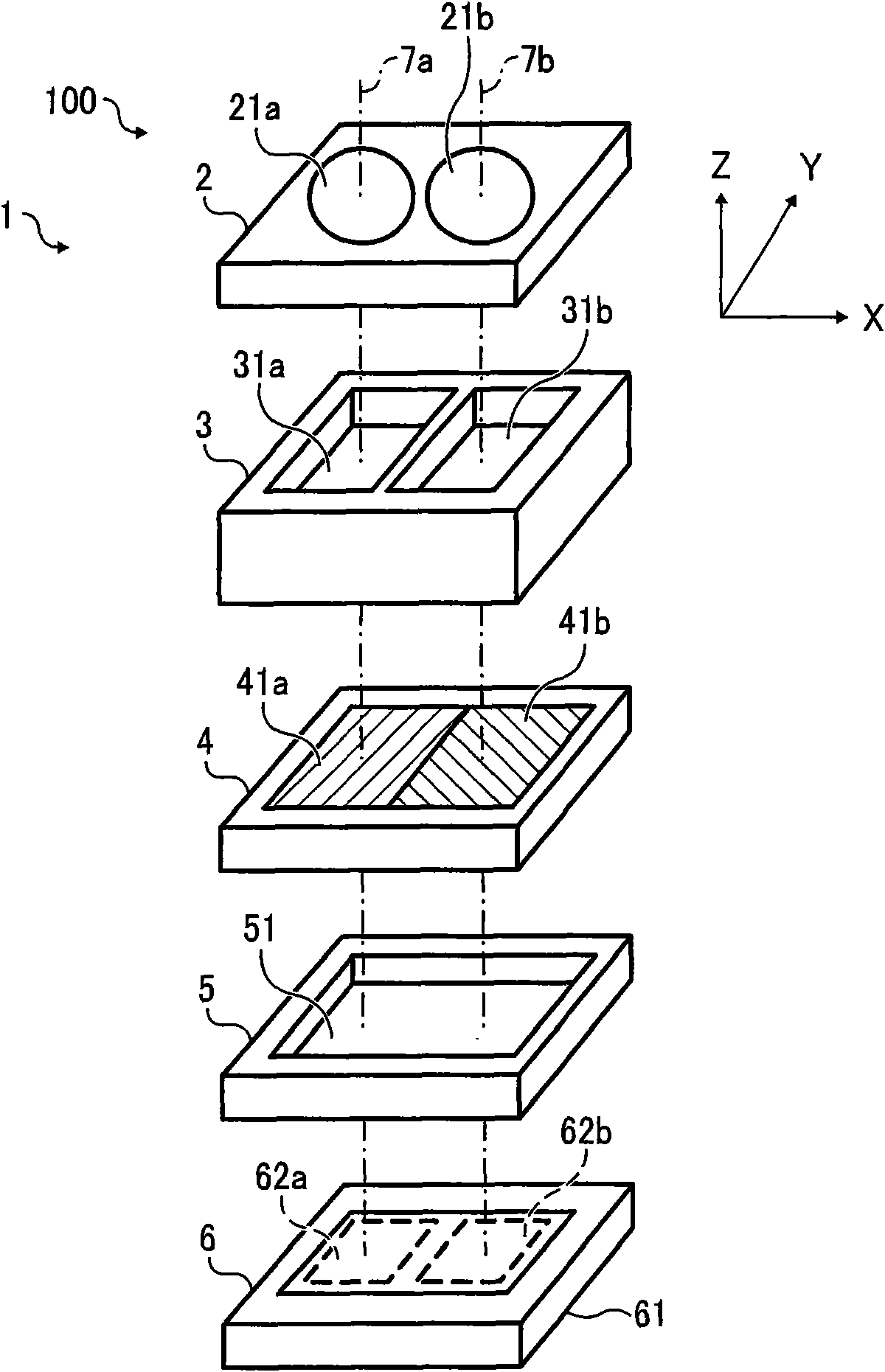

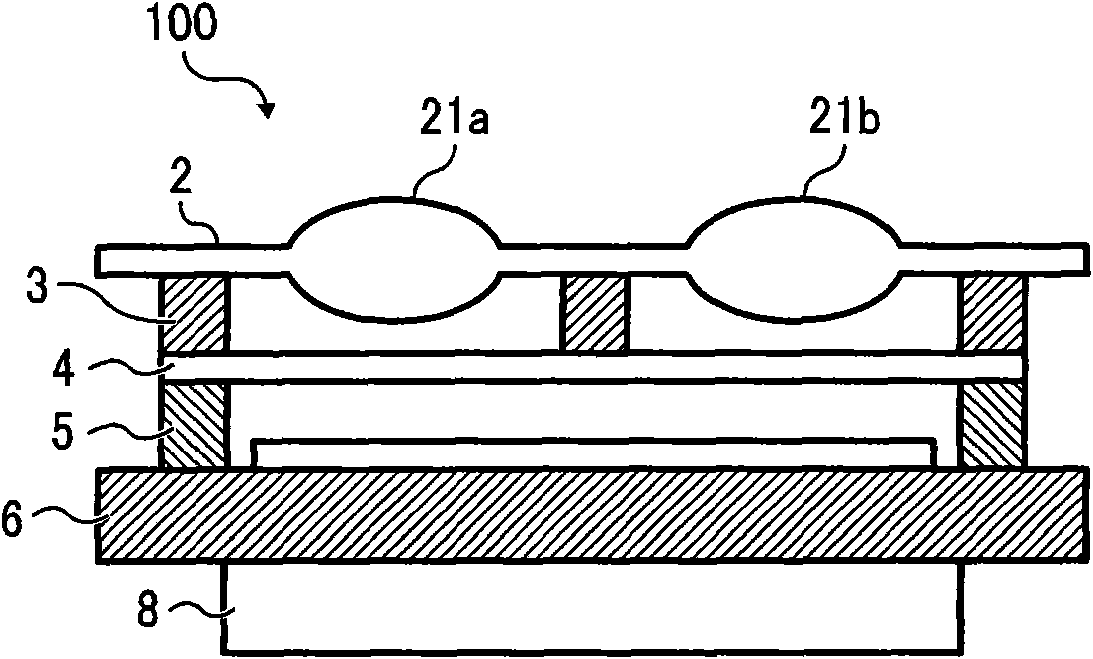

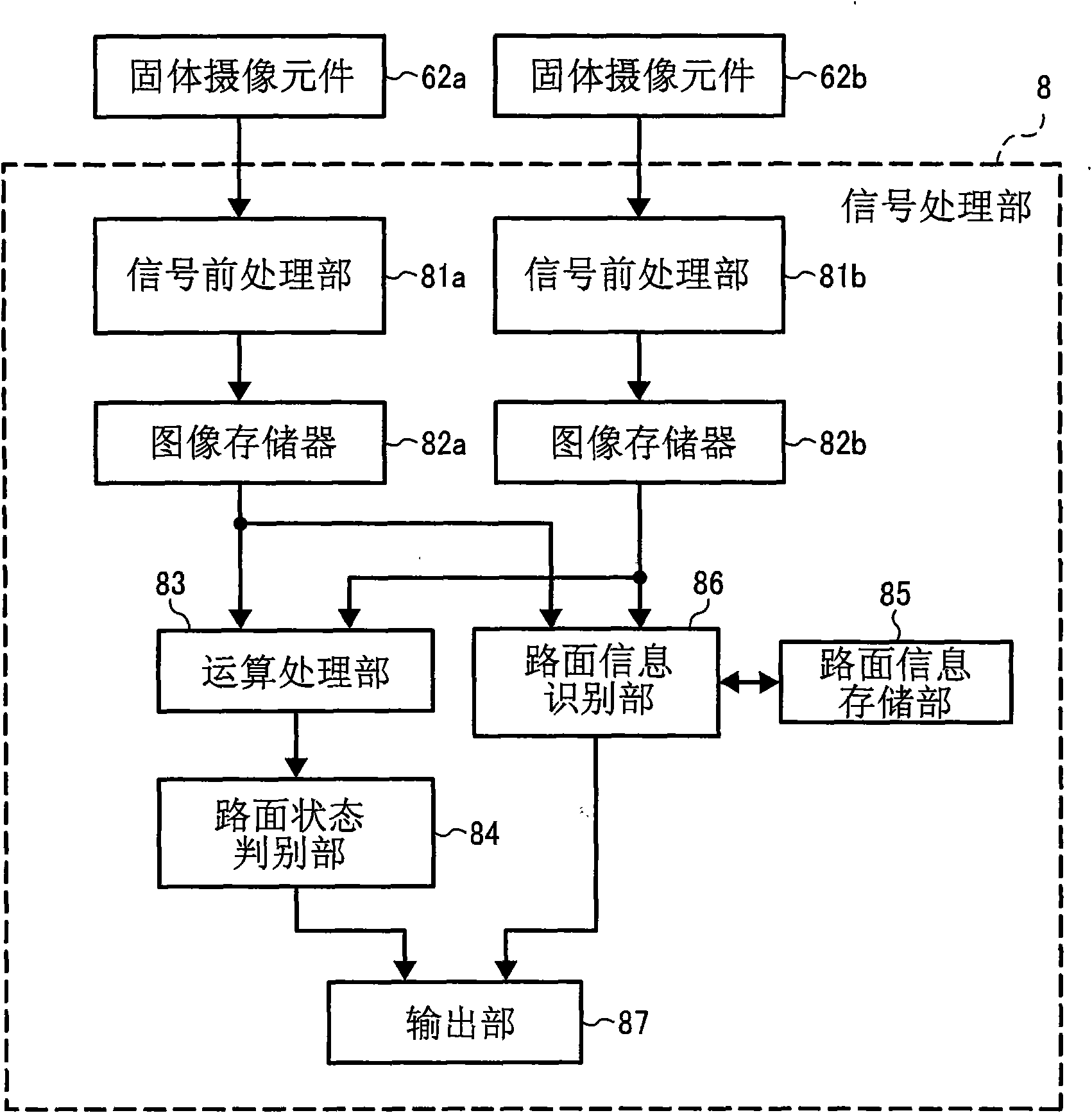

Image pickup and method of detecting road status

InactiveCN101610357AAdd supportAchieve thinningTelevision system detailsPolarisation-affecting propertiesLight beamMiniaturization

The invention relates to an image pickup and a method of detecting the road status. The image pickup (100) includes a lens array (2) having two lenses (21a,21b); a filter (4) including at least two polarizer areas (41a,41b) with respective perpendicular axes which are separated according to beams of light which have passed through the respective lenses (21a,21b) of the lens array (2); an image pickup unit (6) including multiple image pickup areas (62a,62b) that shoots images of an object by receiving the beams of light which have passed through the respective corresponding polarizer areas (41a,41b) of the filter (4). The image pickup (100) shoots the vertical polarized light image and the horizontal polarized light image and judges the road status based on the polarized light ratio of theshot vertical polarized light image and the horizontal polarized light image, thus realizing the apparatus miniaturization. The image pickup is easily installed in the vehicles and detects the road status even in running.

Owner:RICOH KK

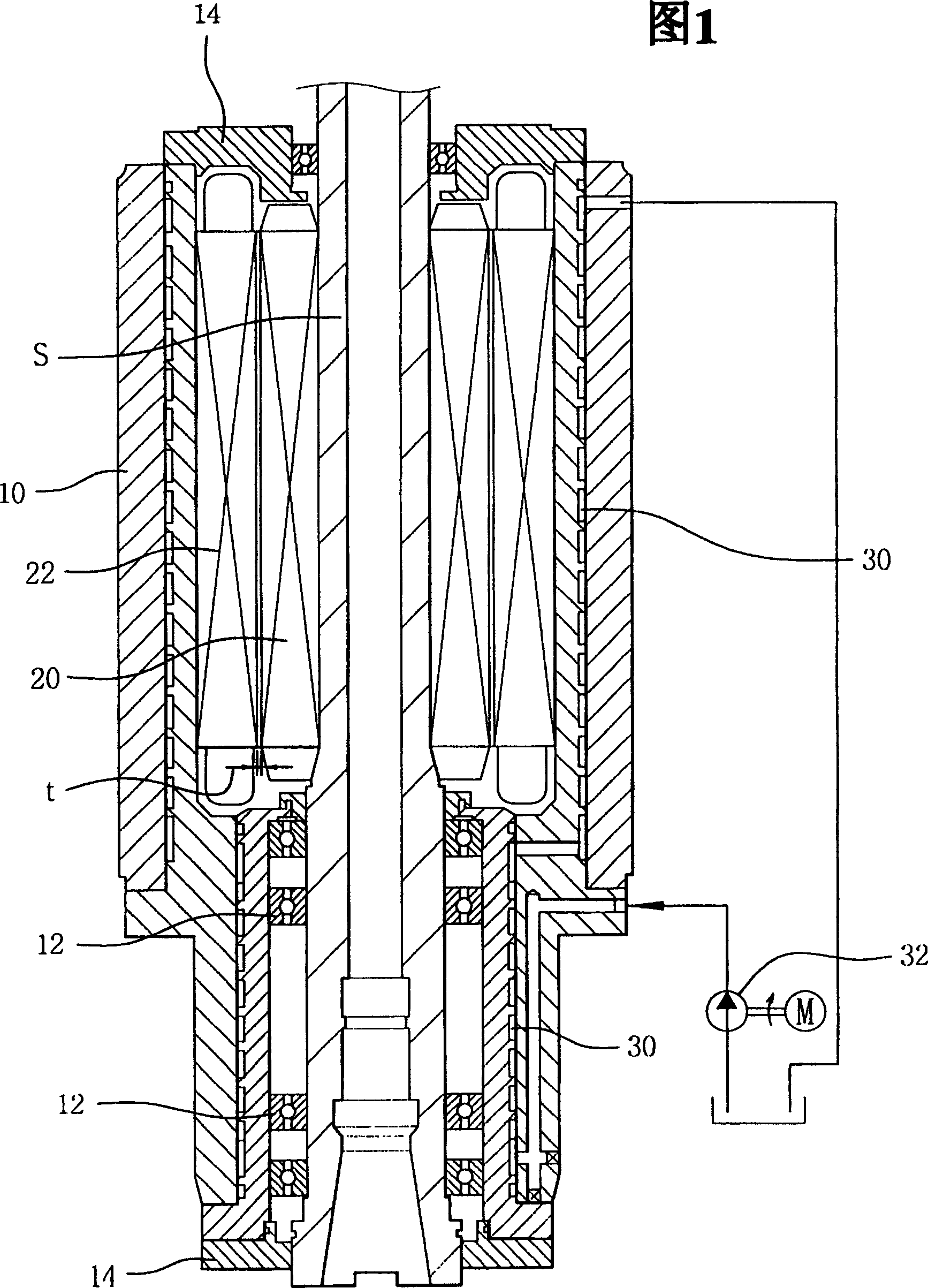

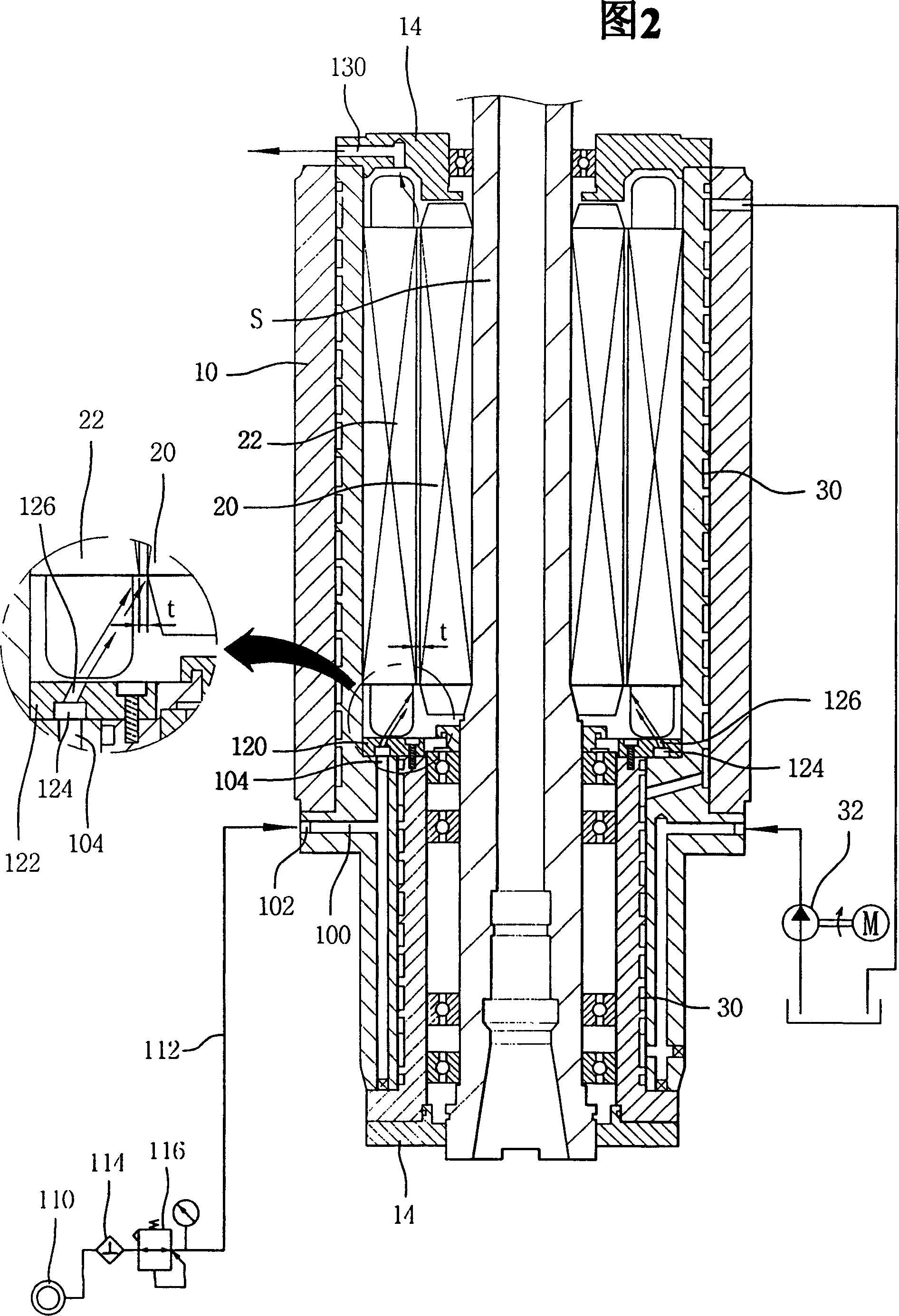

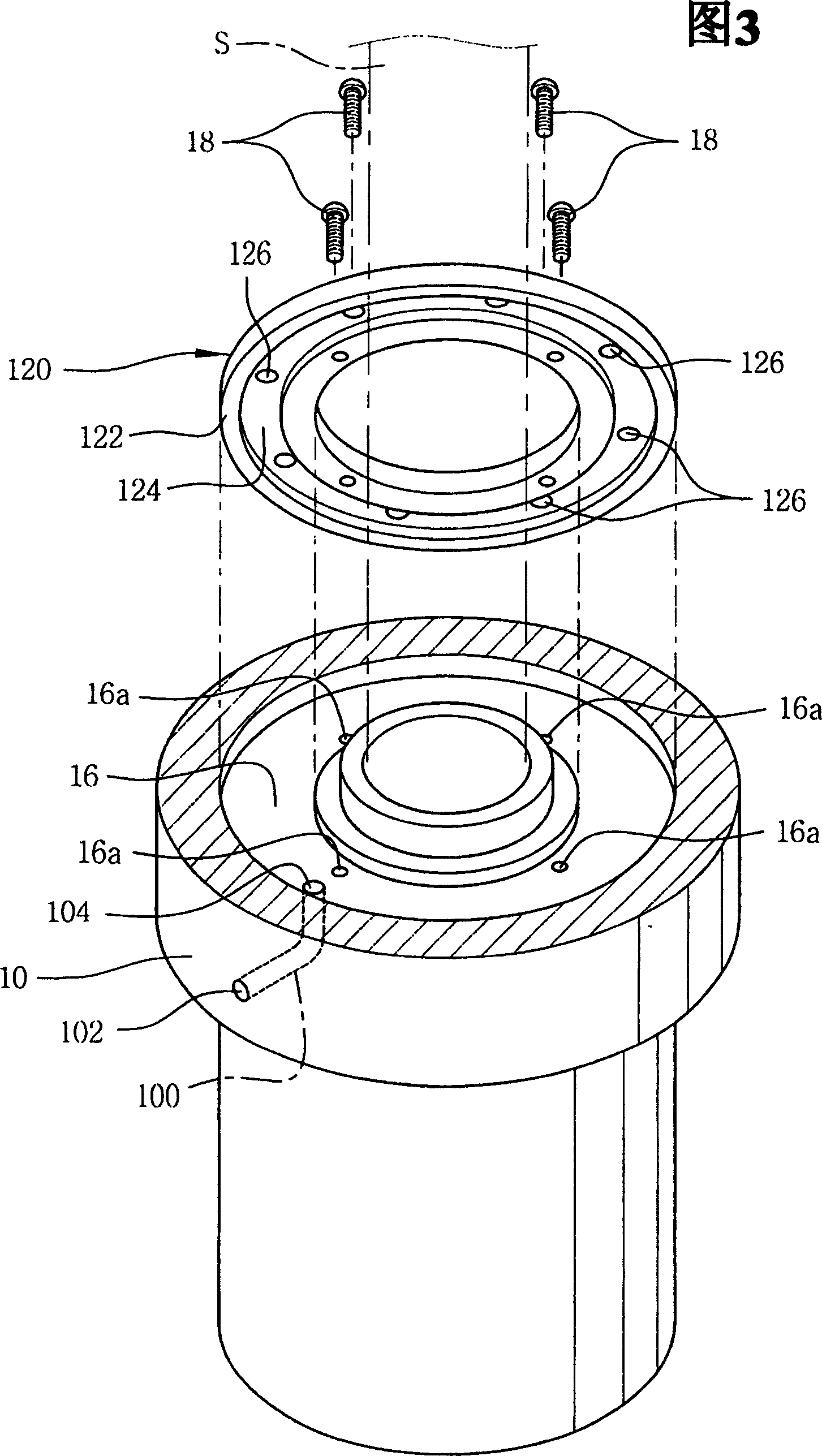

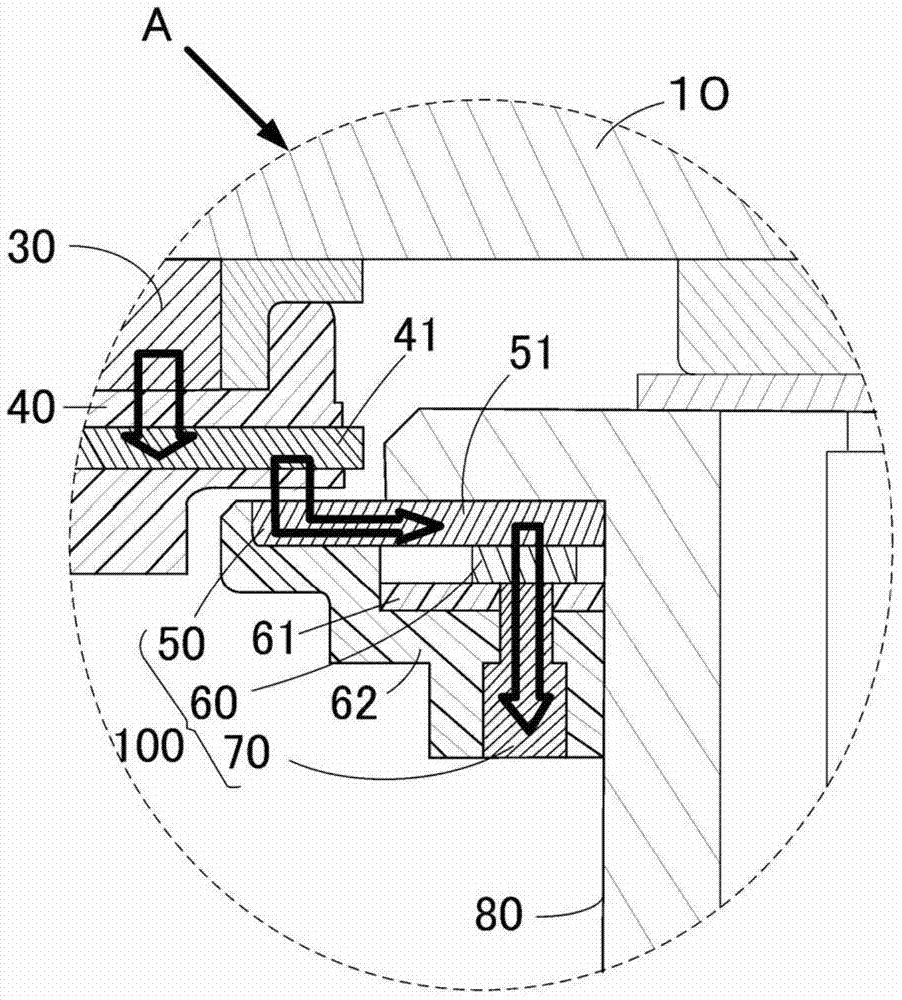

Cooling device for built-in-spindle type spindle motor of machine tool

ActiveCN1630166AImprove cooling effectBlock transmission toMechanical energy handlingCooling/ventillation arrangementEngineeringMachine tool

A cooling device for cooling a built-in shaft type spindle motor of a machine tool, wherein the spindle motor includes a motor casing enclosing the spindle, a rotor fixed around the spindle, and a stator fixed on the inner peripheral surface of the motor casing around the rotor, between the rotor and the stator forming a gap, wherein the cooling device includes: a cooling air supply device for supplying cooling air; a motor housing having a cooling air introduction passage for introducing cooling air supplied from the cooling air supply device to one side of the rotor and the stator; And a cooling air injection nozzle, which is detachably installed in the motor housing and has one or more nozzle openings that can inject cooling air into the gap between the rotor and the stator.

Owner:DN SOLUTIONS CO LTD

Exhaust control valve

InactiveUS20010027648A1High precision manufacturingPrevent thermal deformationPlug valvesOperating means/releasing devices for valvesEngineeringControl valves

An exhaust control valve has a valve housing and a valve body rotatably contained within the valve housing. The valve body cooperates with the valve housing for controlling the flow of exhaust gas. A transmission member rotationally drives a valve shaft of the valve body. The valve body is formed in a cylindrical shape and coaxially with an axis line of the valve shaft. The valve body and the valve shaft are made from a one-piece body by casting. This arrangement provides an exhaust control valve for an engine having a valve body that provides excellent sealing properties, demonstrates high response to driving torque and is easy to manufacture through casting.

Owner:HONDA MOTOR CO LTD

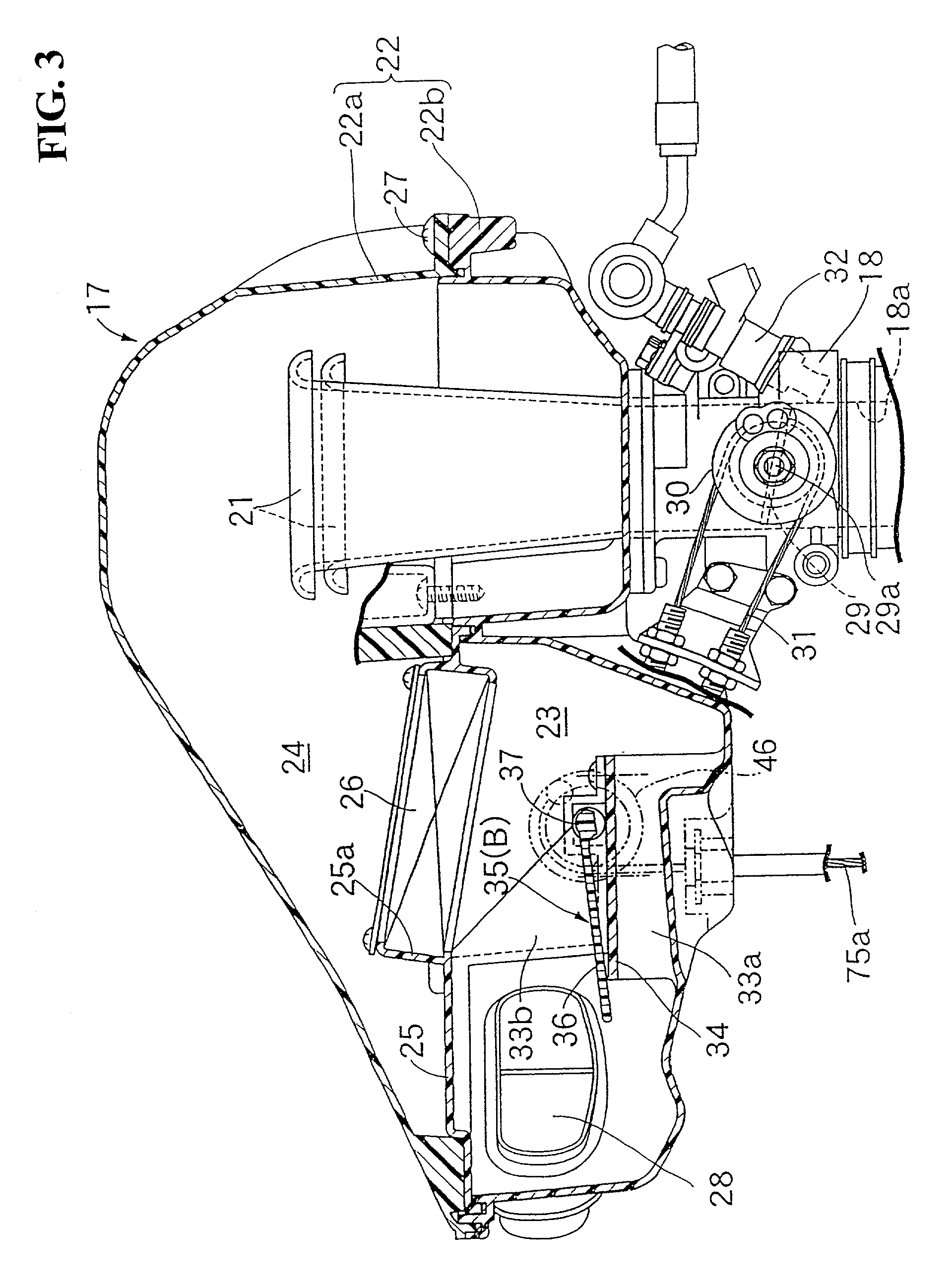

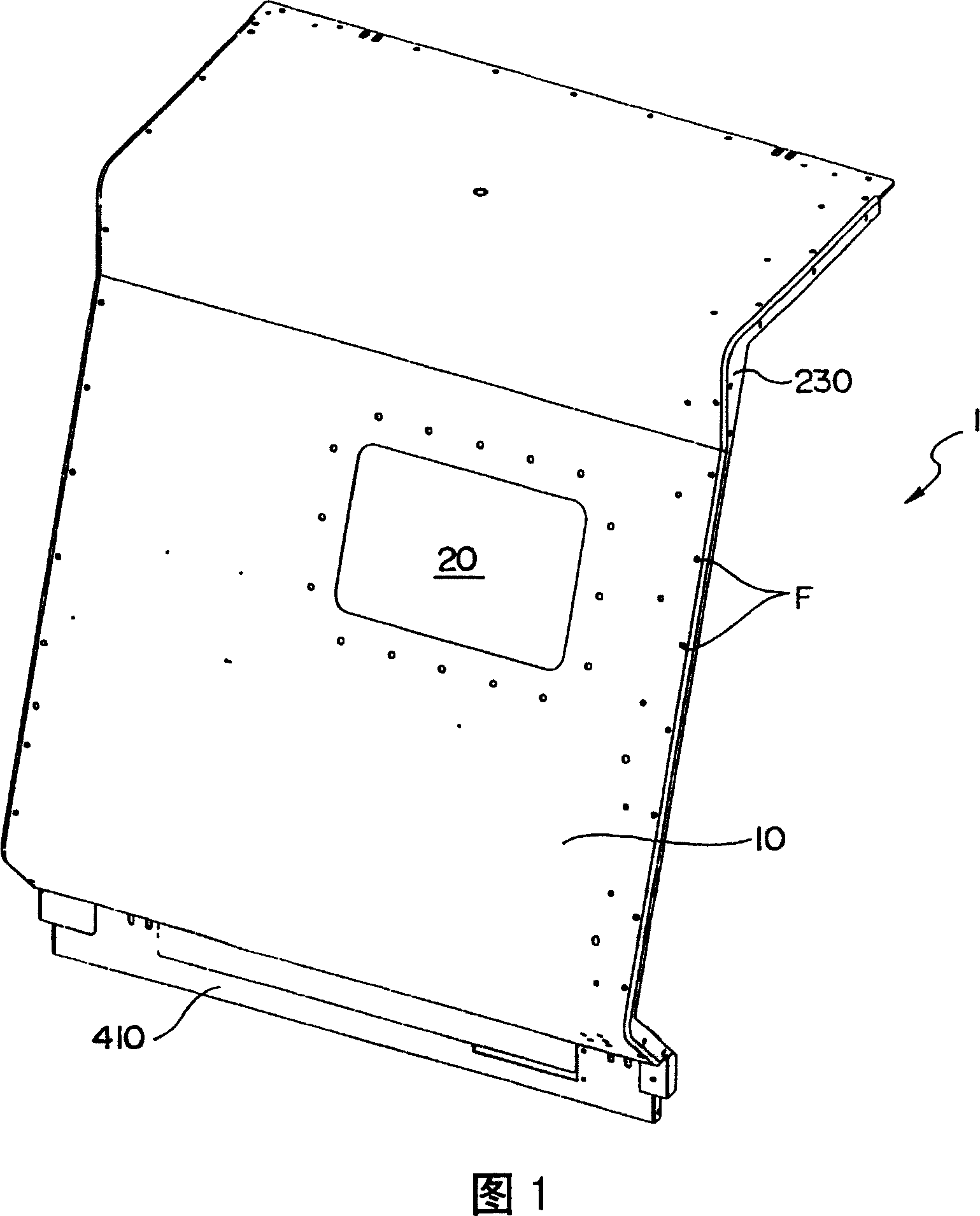

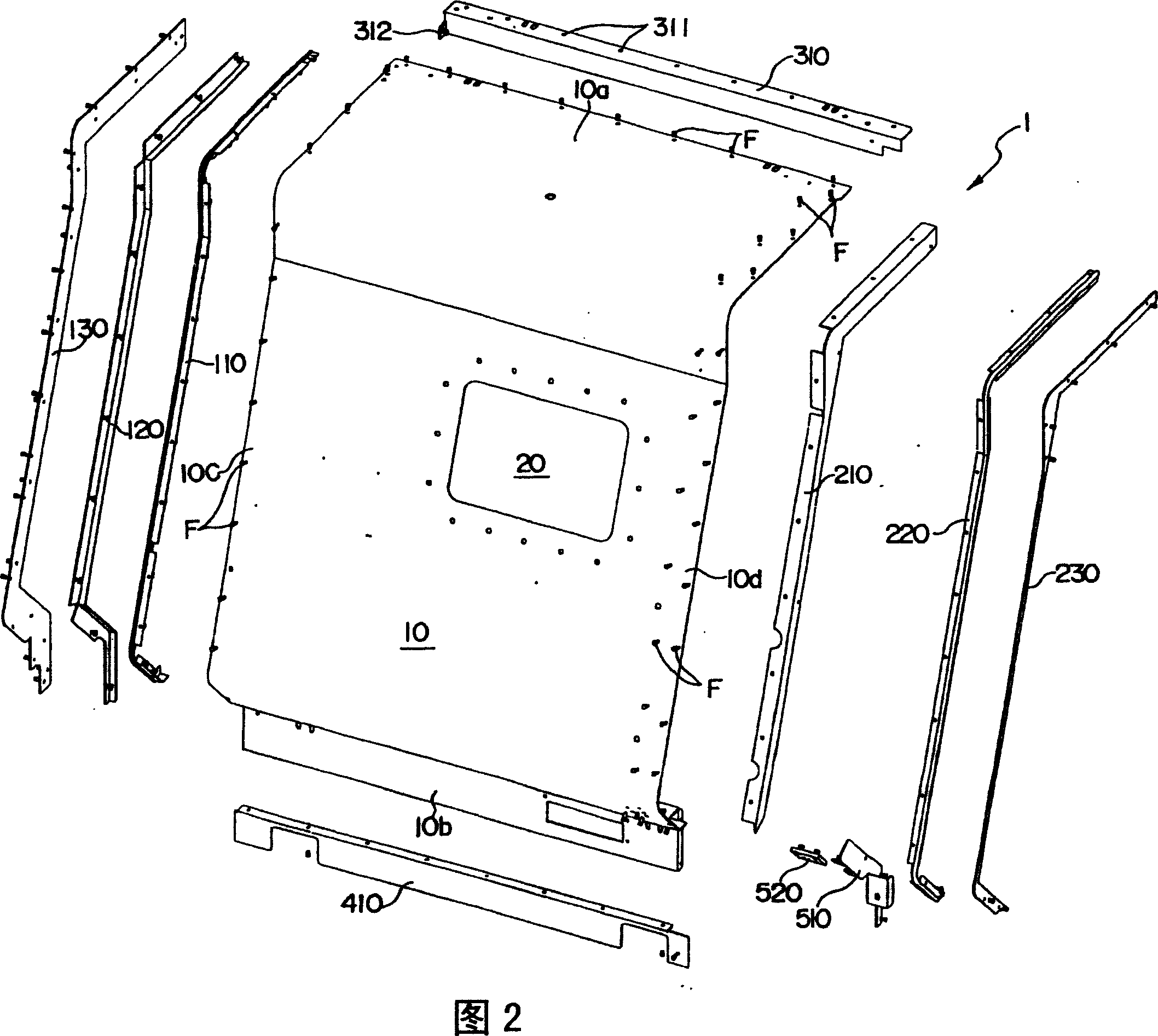

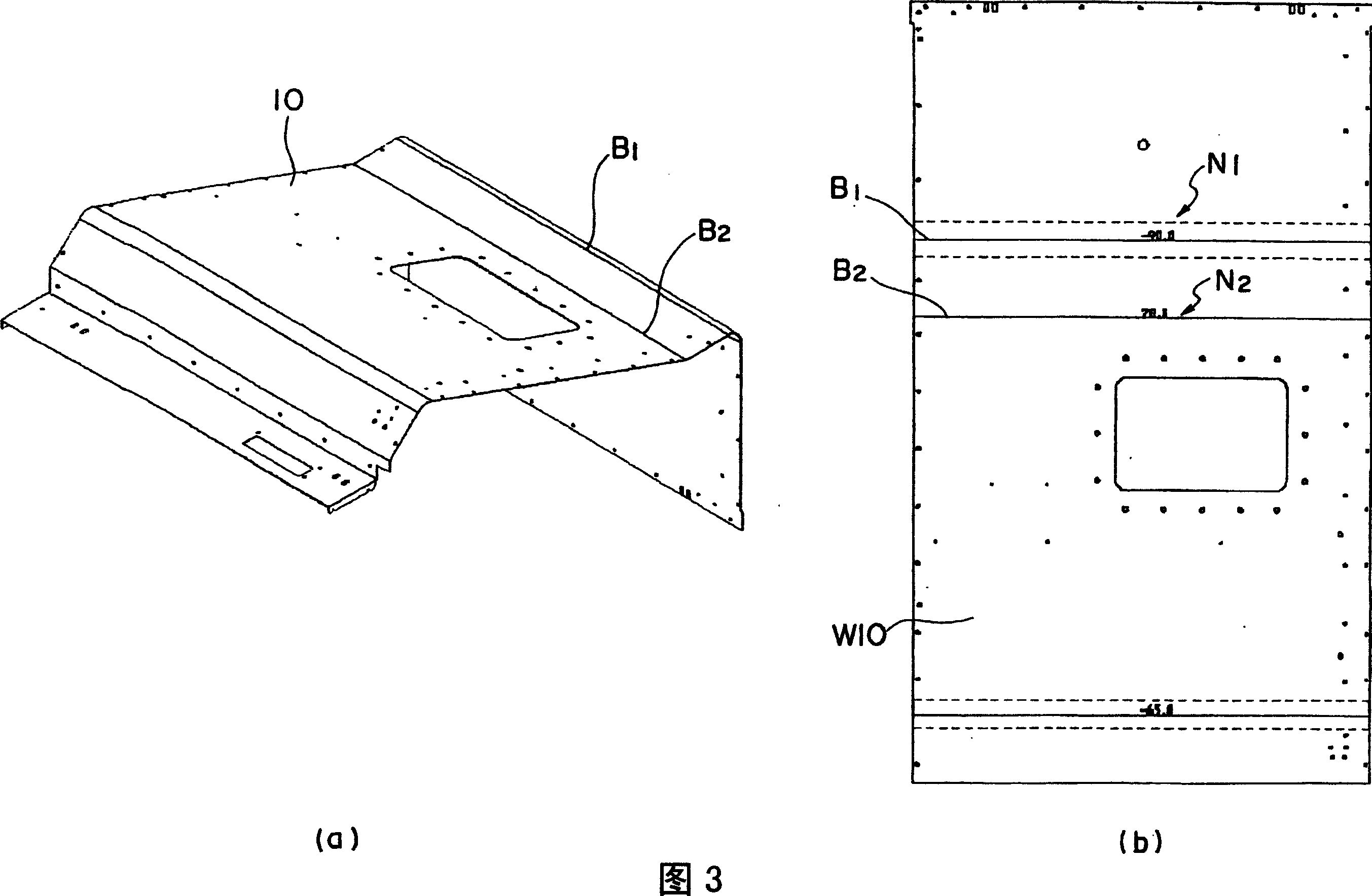

Method for fabricating sheet metal product having three-dimensional shape, and product

InactiveCN101041219AReduce welding processHigh precisionMachine framesOther manufacturing equipments/toolsLaser processingLaser beam machining

To provide a method of manufacturing a large-size sheet metal product with a three-dimensional shape such as a cover for a machine tool without a welding step, and also to provide its product. A cover unit 1 for a machine tool is manufactured by fixing edge members 110, 120, 130, 210, 220, 230 on the periphery of a cover sheet 10 by a fixing tool such as a bolt or a nut. In the cover sheet 10 or the respective edge members, the flat development based on data of a three-dimensional solid model of the cover unit 1 is nested on the sheet metal material on a laser beam machine, and laser beam machining is carried out. In the laser beam machining, the respective members are marked with information on bending lines, bending angles, or the like necessary for post processes. The members which have been precisely laser beam machined are subjected to necessary bending works, and assembled by the fixing tool, so as to obtain the large-size sheet metal product with the three-dimensional shape without the welding step.

Owner:YAMAZAKI MAZAK KK

Method for producing scattering ray raster or collimator with ray absorption material

InactiveCN1707699AHigh precision manufacturingReduce processing stepsRadiation measurementHandling using diaphragms/collimetersPresent methodGrating

The invention relates to a method for producing a scattered radiation grating or collimator (4) for a radiation type, the scattered radiation grating or collimator consisting of at least one geometrically predeterminable base body (6) The base body (6) has a channel or a channel groove (5) extending between its two opposing surfaces for the passage of the primary beam of the beam type. The method is characterized in that the base body ( 6 ) is formed by die-casting or stereolithography from a structural material that absorbs strongly this type of radiation. The use of the method allows the production of scattered radiation gratings or collimators with high precision using only a small number of method steps.

Owner:SIEMENS AG

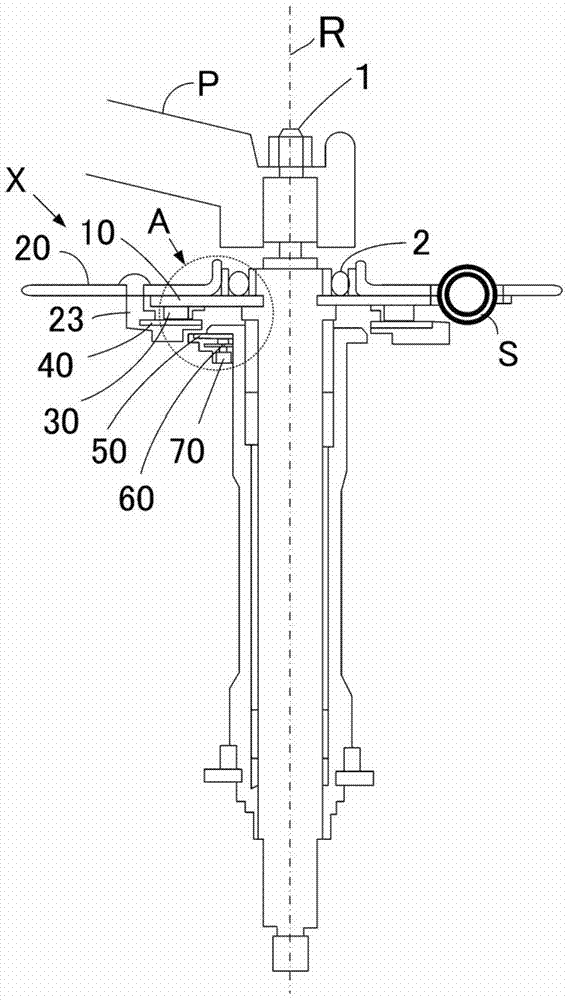

Relative rotational angular displacement detection device, torque detection device, torque control device, and vehicle

InactiveCN103673868AHigh precision manufacturingHigh precision assemblyCycle equipmentsWork measurementMagnetic polesEngineering

The present invention provides a relative rotational angular displacement detection device, a torque detection device, a torque control device, and a vehicle. A relative rotational angular displacement detection device includes a pair of rotatable members relatively rotatable in a circumferential direction. A permanent magnet is attached to one of the rotatable members and includes magnetic poles magnetized in an axial direction of the axis of rotation and arranged to alternate in polarity in the circumferential direction. A magnetic flux inducing ring includes an annular ring body attached to the other of the rotatable members and is arranged coaxially with the axis of rotation, and a plurality of protrusions having a circumferential width smaller than a circumferential width of a magnetic pole. A magnetic detection portion is configured to detect a magnetic flux of the ring body of the magnetic flux inducing ring. The flux inducing ring is magnetized depending on a relative positions the protrusions and positions of the magnetic poles.

Owner:YAMAHA MOTOR CO LTD

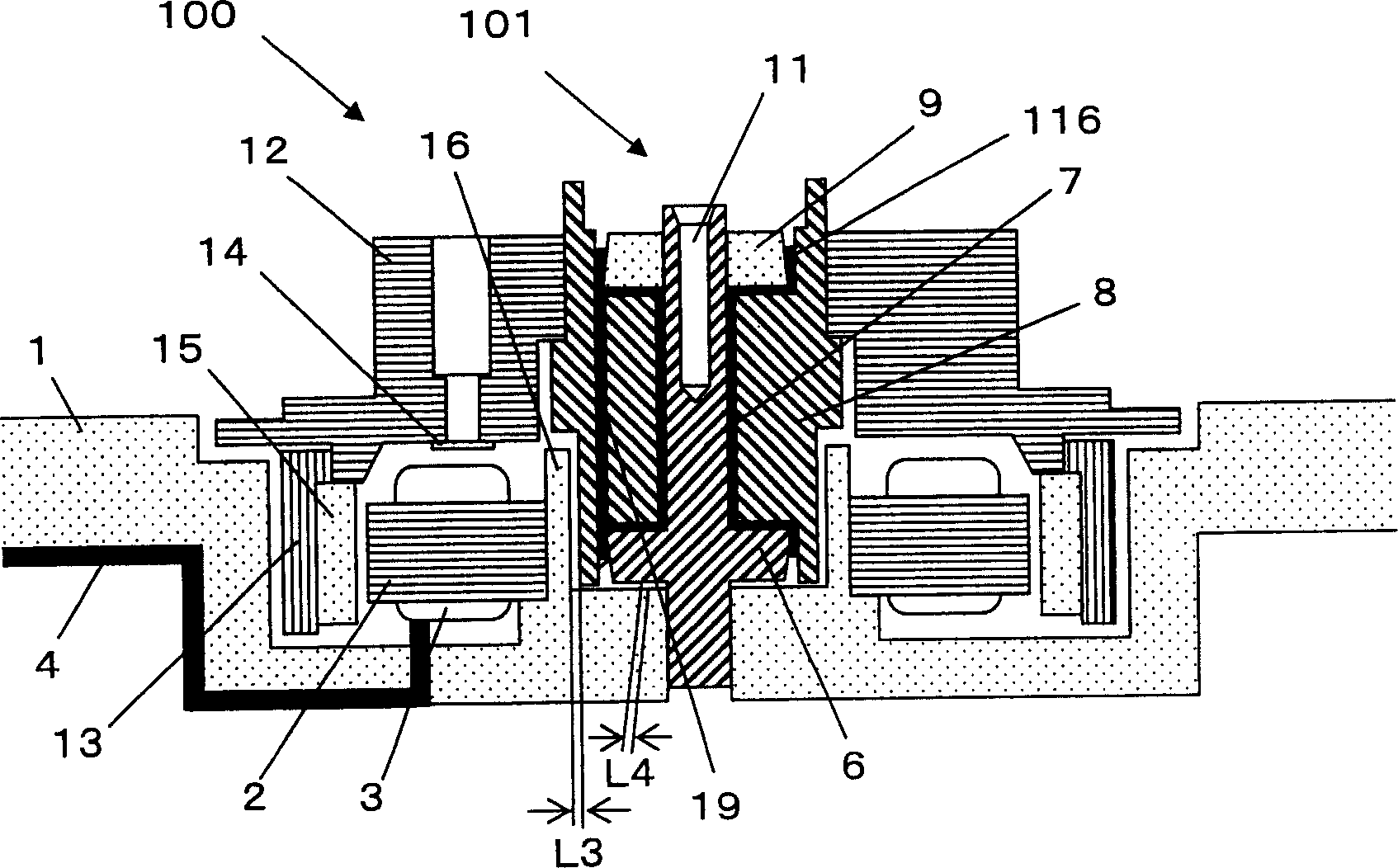

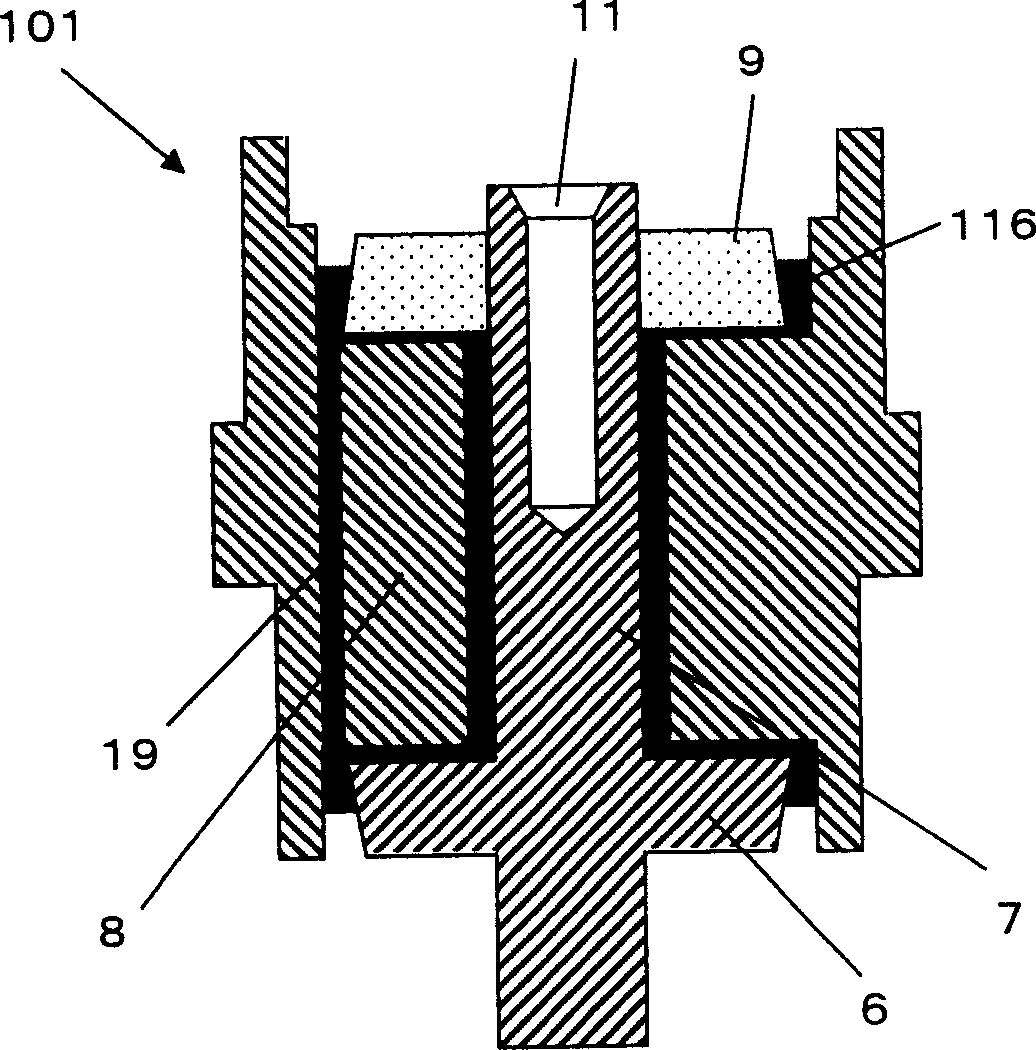

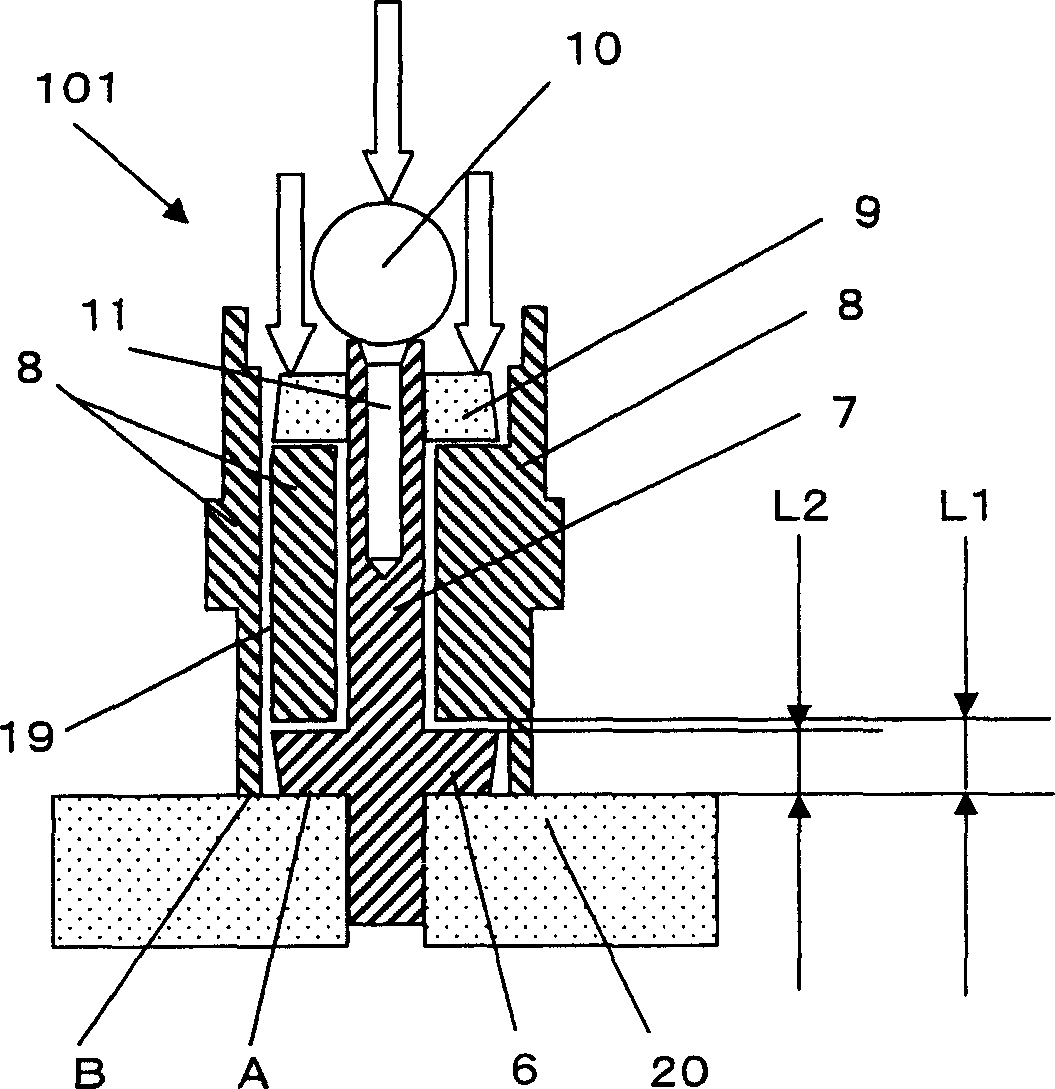

Hydrodynamic bearing and method for manufacturing the same, and spindle motor and method for manufacturing the same

ActiveCN1831347ASuppression of scatteringHigh precision manufacturingSliding contact bearingsSynchronous machines with stationary armatures and rotating magnetsEngineeringCam

The invention relates to a dynamic liquid bearing which can confirm axial space needed in working, and relative production, and main axle motor, wherein said bearing (101) at least comprises axle (7), an axle sleeve (8) rotationally relative to the axle (7), the first cam element (6) fixed on the axle (7), and the second cam element (9) fixed on the axle (7). In addition, said production comprises: 1, sheathing axle sleeve (8) on the axle (7); inserting second cam element (9) into axle (7); 2, pushing the axial upper end of second cam element (9); 3, holding said pushing operation, welding axle (7) and the second cam element (9), to fix the second cam element (9) on the axle (7).

Owner:PHC HLDG CORP

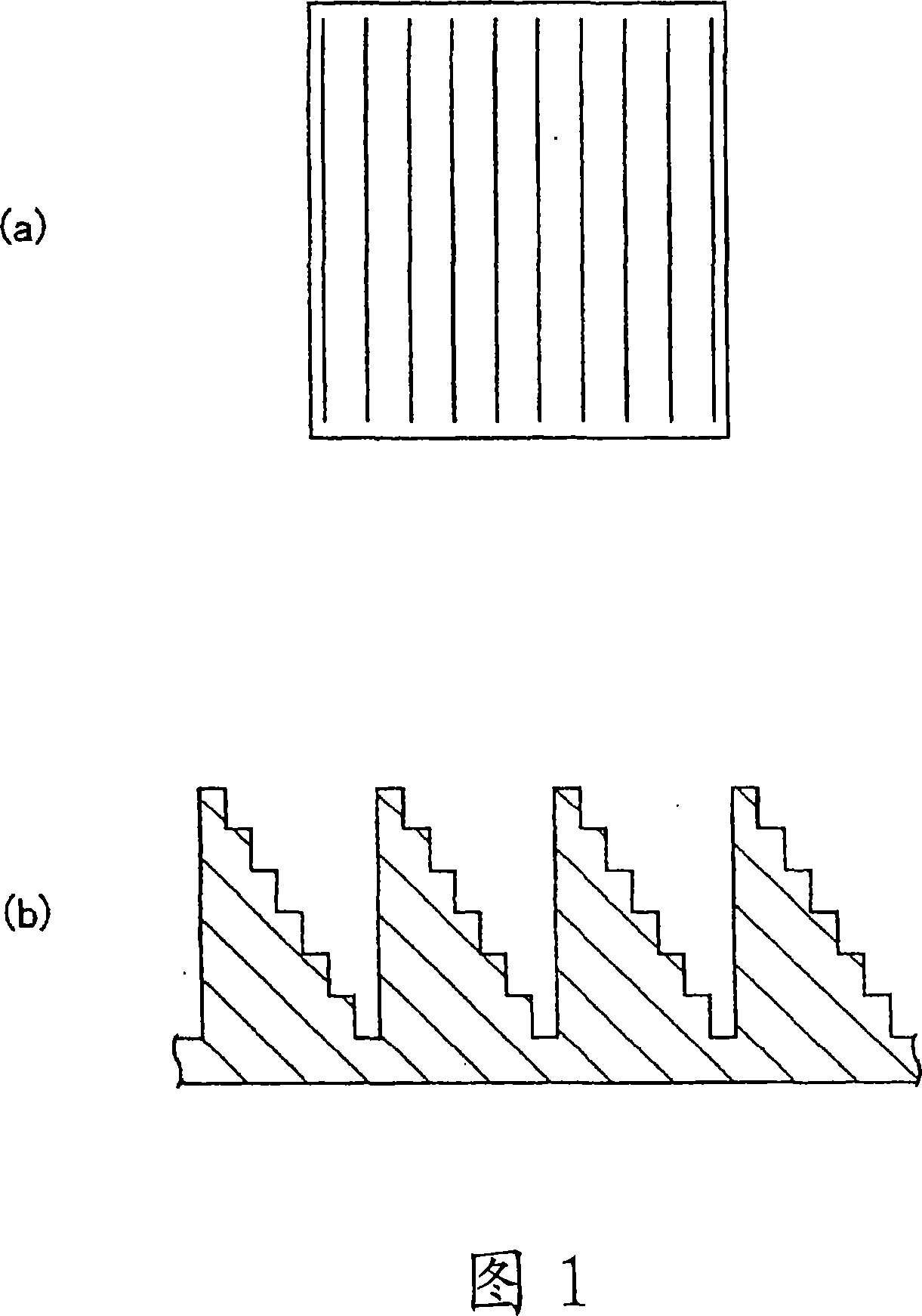

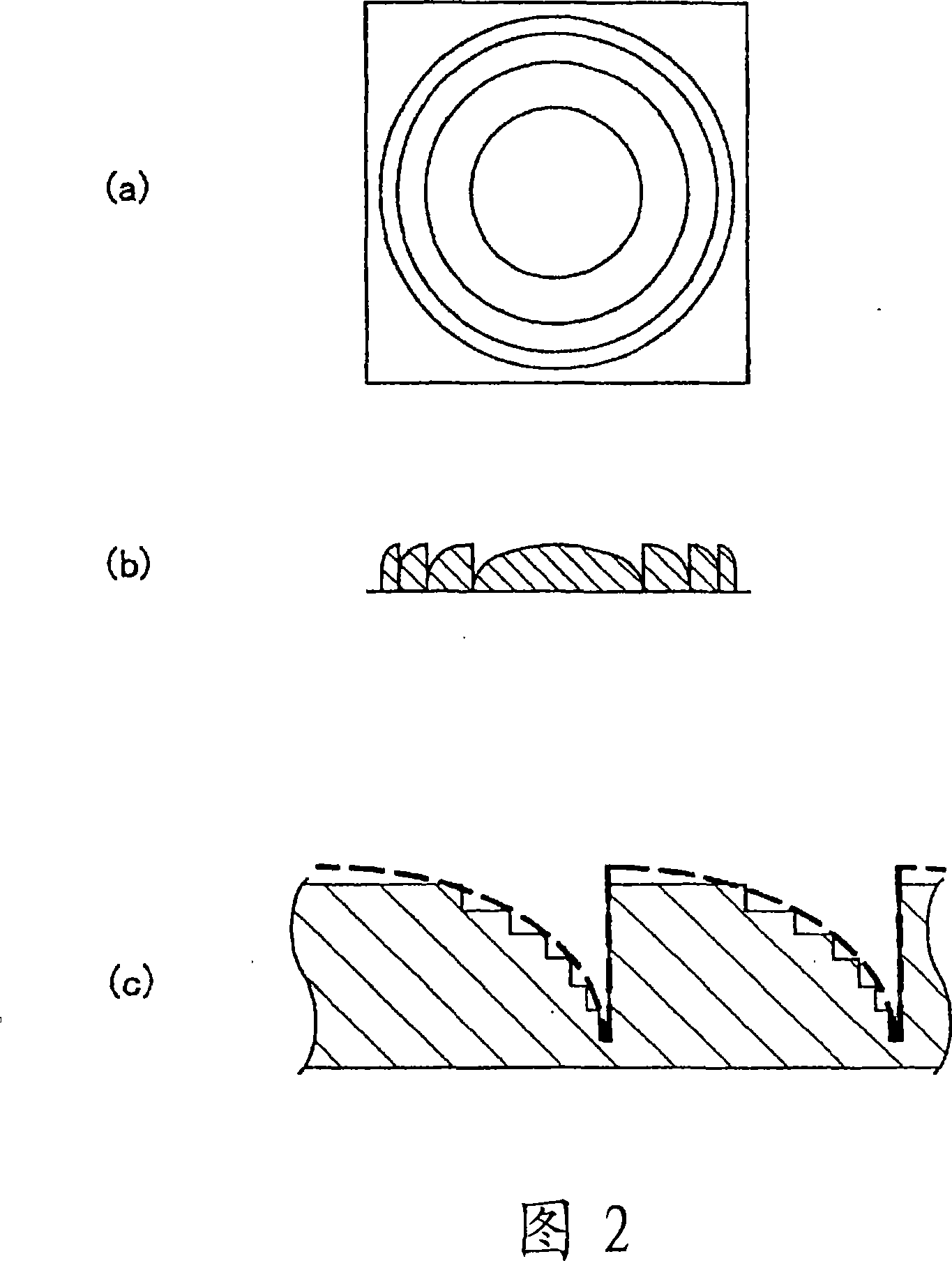

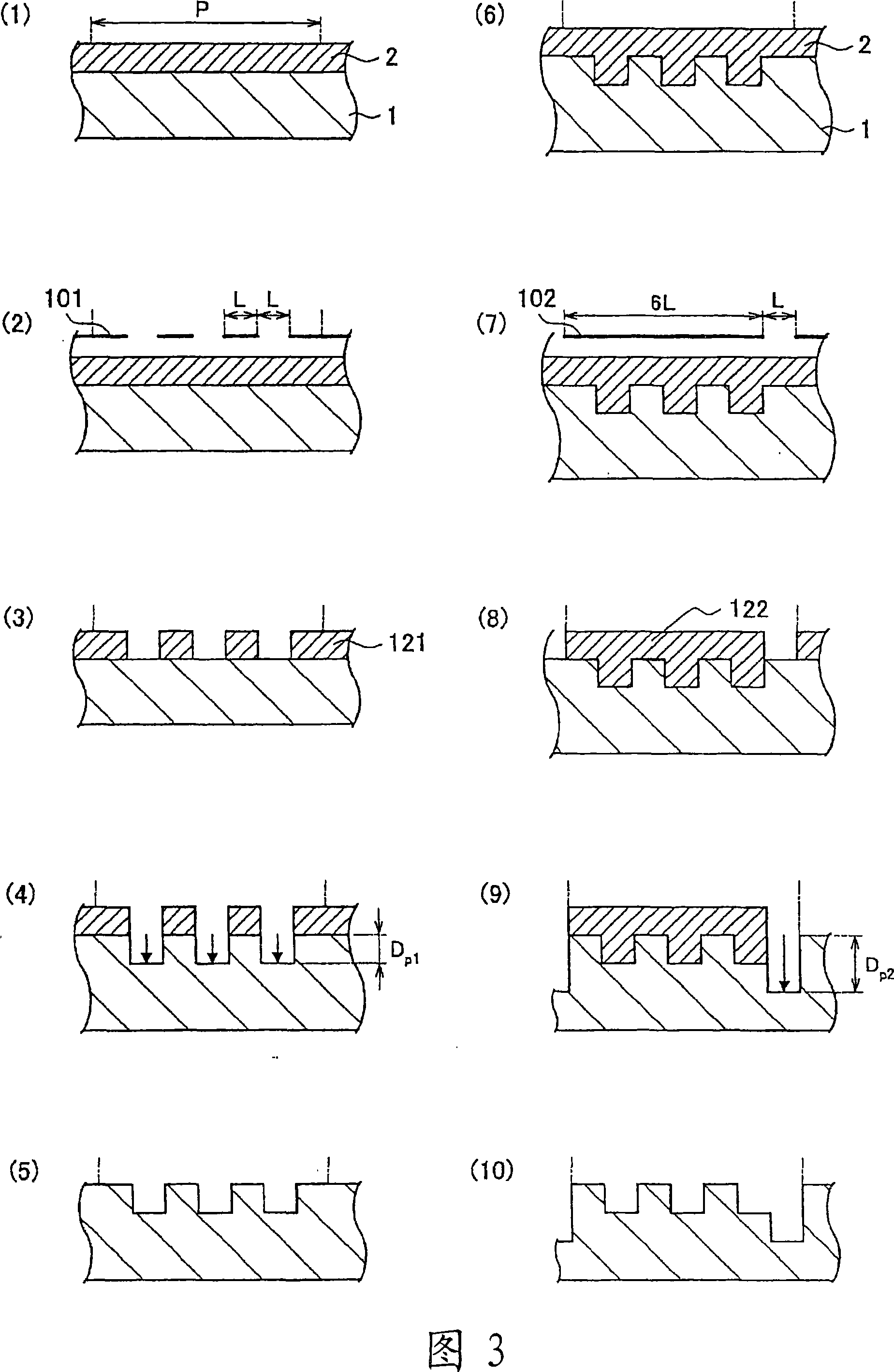

Diffractive optical component making method

InactiveCN101171534AHigh precision manufacturingHigh diffraction efficiencyPhotomechanical apparatusDiffraction gratingsResistDiffraction optics

To provide a method for fabricating a high precision diffraction optical element capable of enhancing diffraction efficiency. [MEANS FOR SOLVING PROBLEMS] A diffraction optical element having a periodical stepwise profile is fabricated by repeating a series of processes for exposing and developing a substrate (1) coated with resist (2) through a mask to form a resist pattern and then etching the resist pattern. In the first process, a pattern having a width identical to that of the step is formed and then the width of the pattern is increased in the subsequent processes. When fabricating a seven-step diffraction optical element assuming the level difference of step is D, the second, fourth and sixth step portions are etched with depth D in the first process the ninth step portion is etched with depth 2D in the second process, the fifth, sixth and seventh step portions are etched with depth 2D in the third process, and the third, fourth, fifth, sixth and seventh step portions are etched with depth 2D in the fourth process.

Owner:OKI ELECTRIC IND CO LTD

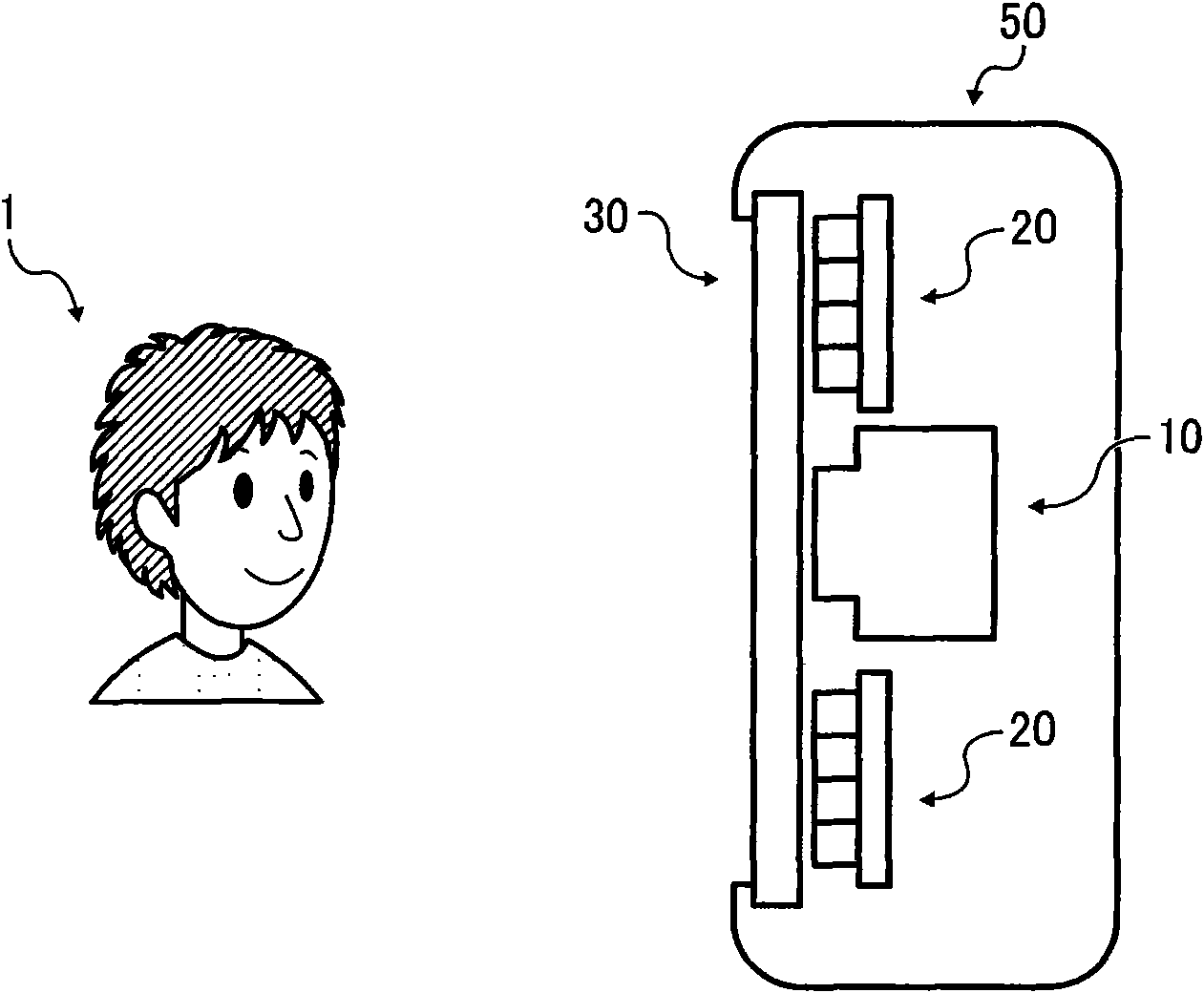

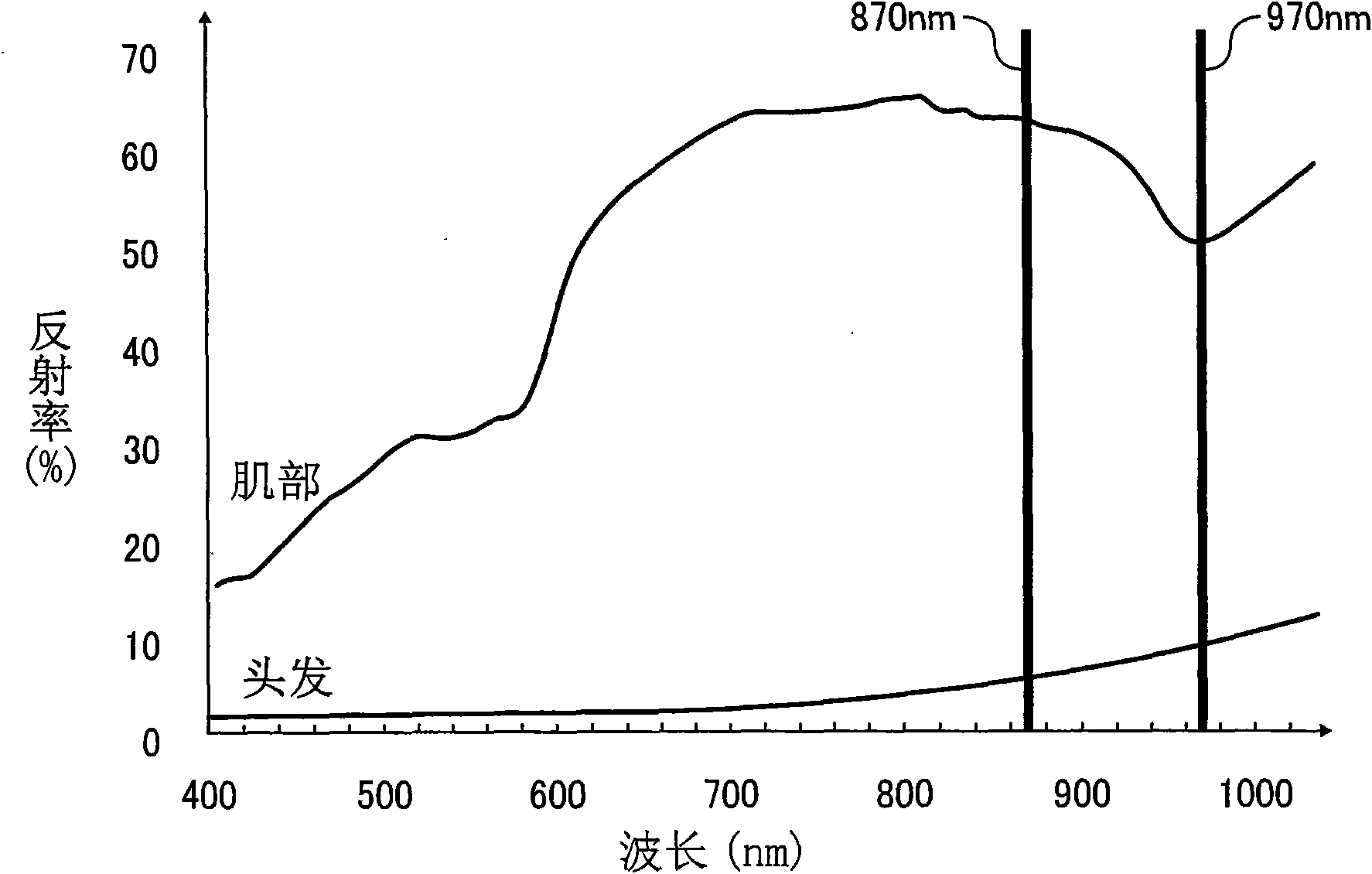

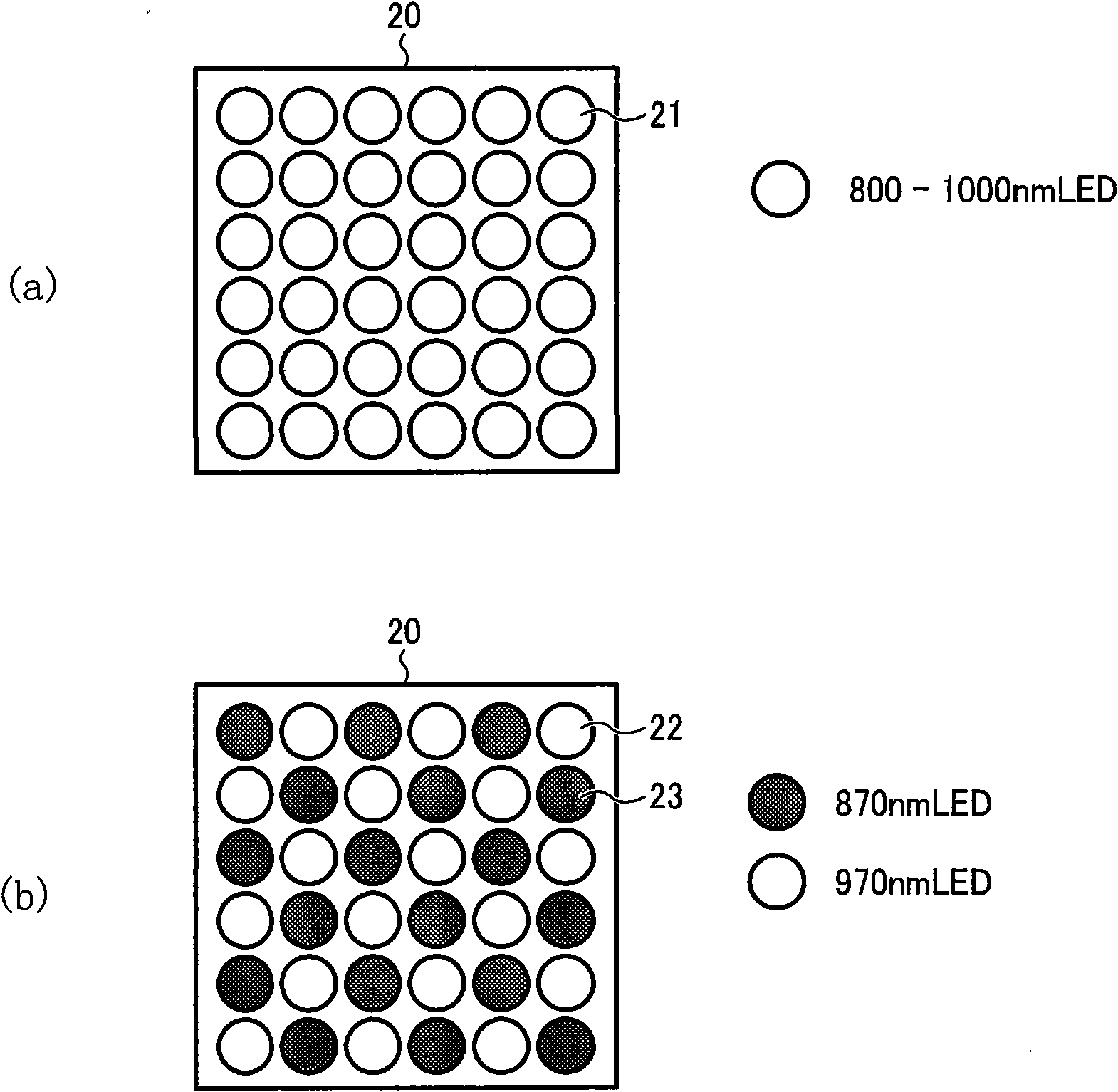

Image pickup

InactiveCN101631194ARaise attentionPrompt attentionTelevision system detailsColor television detailsLight beamLength wave

An image pickup including a light emission portion (20) that irradiates an object with near infrared; and an image pickup portion (10) that receives a reflection light image of the object by the near infrared. The image pickup portion includes a lens array containing a substrate on which multiple lenses to respectively receive the reflection light image of the object by the near infrared are arranged; a light shield spacer that shields beams of light that have passed through the lens array from each other; a color filter separated into areas according to beams of light that pass through the light shield spacer, each of which transmits only particular beams of near infrared depending on the wavelengths thereof; and an image pickup element that simultaneously obtains multiple images of the object which are formed of each of the particular beams of near infrared having independent wavelengths that have passed through each of the areas of the color filter.

Owner:RICOH KK

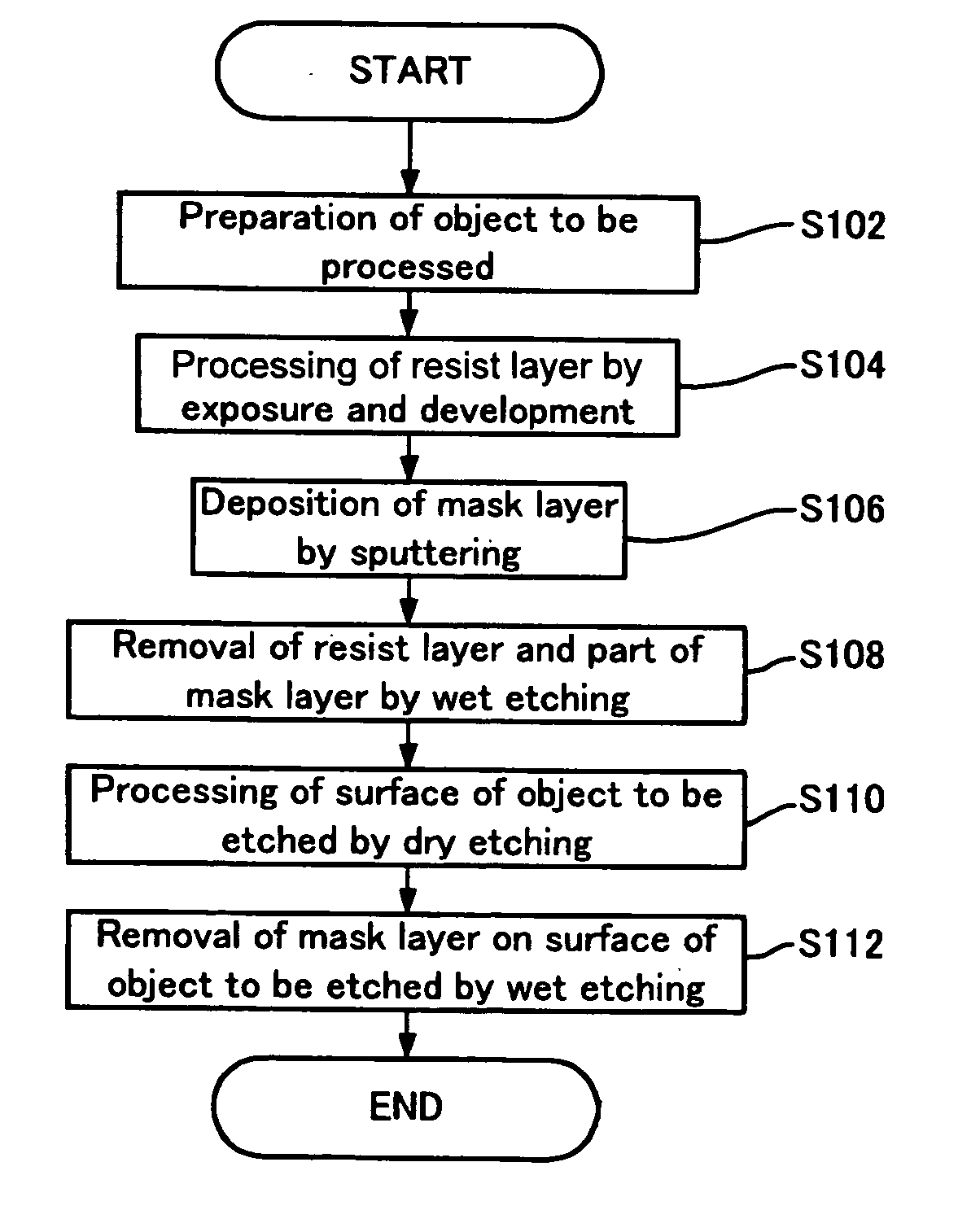

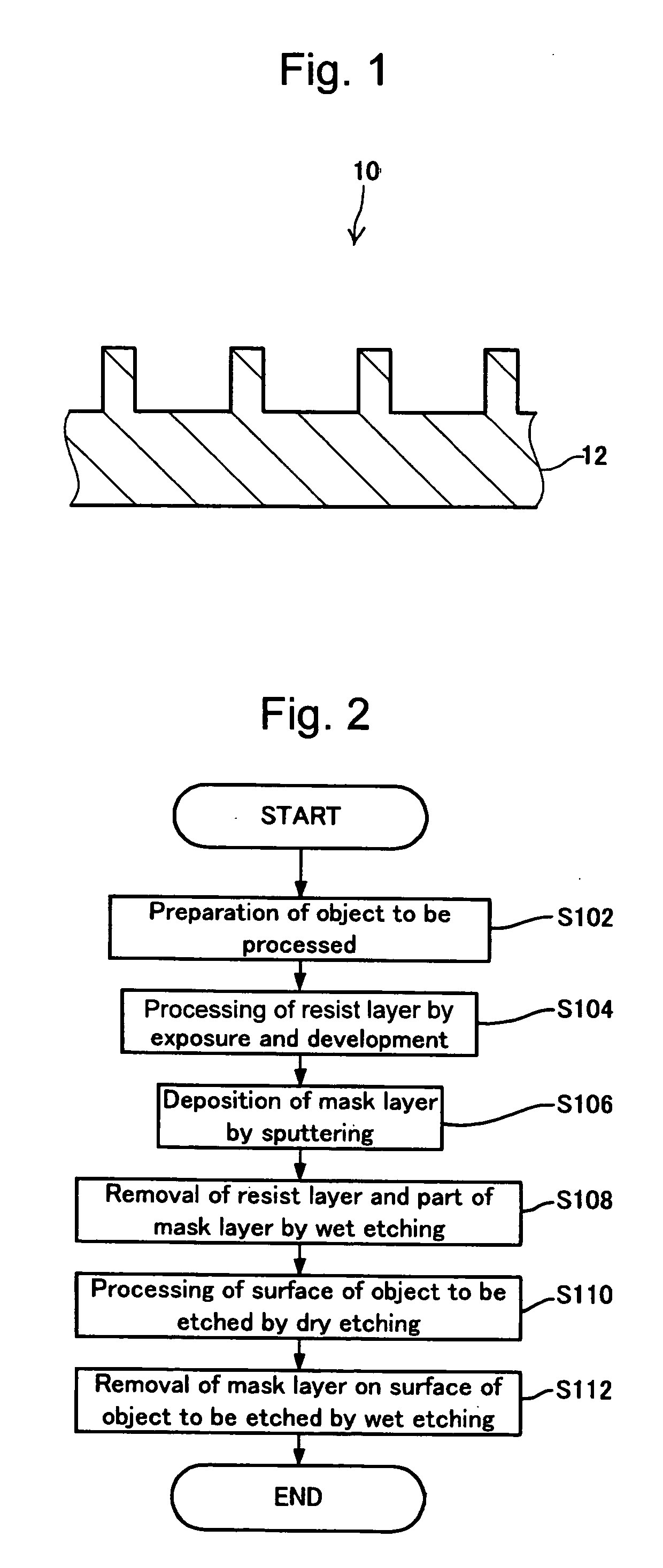

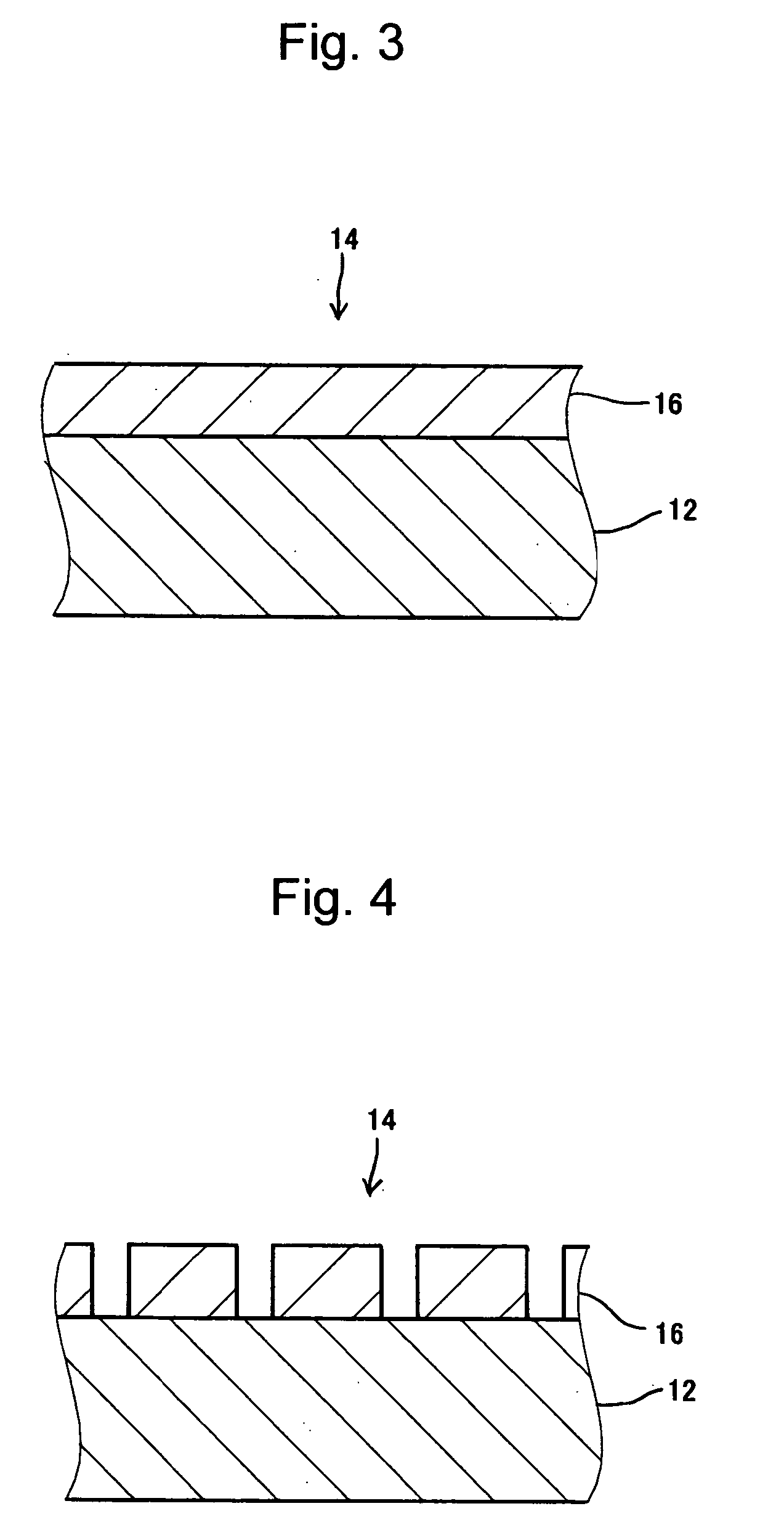

Master for concavo-convex pattern transfer and method for manufacturing stamp for manufacturing information recording medium

InactiveUS20050127032A1Efficient preparationImprove accuracyDecorative surface effectsNanoinformaticsResistEngineering

A method for manufacturing a master for concavo-convex pattern transfer, which enables highly accurate manufacture of a master carrying a concavo-convex pattern including a convex portion at a large aspect ratio, and a method for manufacturing a stamp using the master are provided. A mask layer is formed in a predetermined pattern on an object to be etched having a higher rigidity than that of a resist material. The object to be etched is then etched so as to form a concavo-convex pattern on the surface thereof to obtain a master for concavo-convex pattern transfer. A material having a lower etching rate than that of the resist material and that of the object to be etched is used as a material of the mask layer.

Owner:TDK CORPARATION

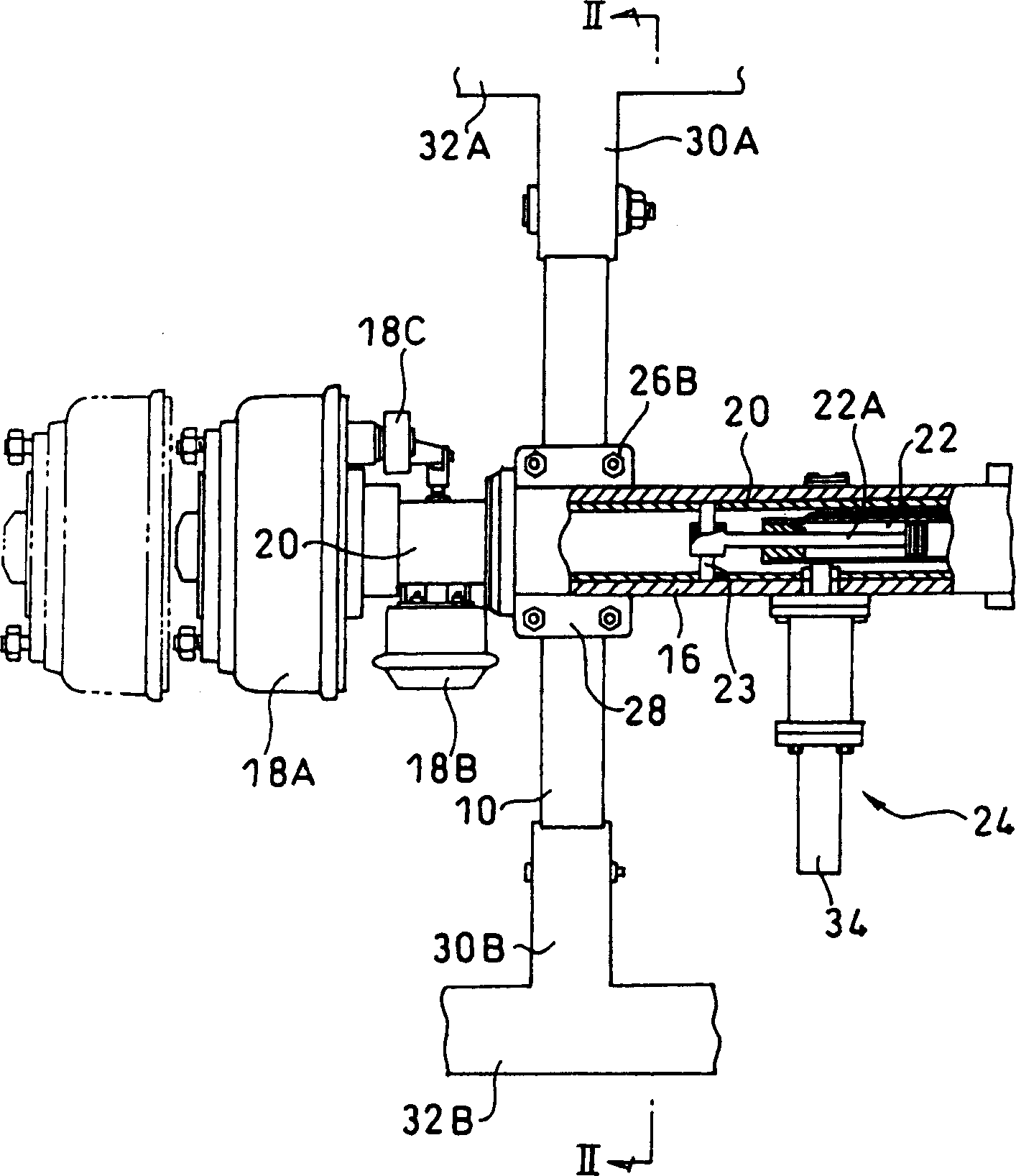

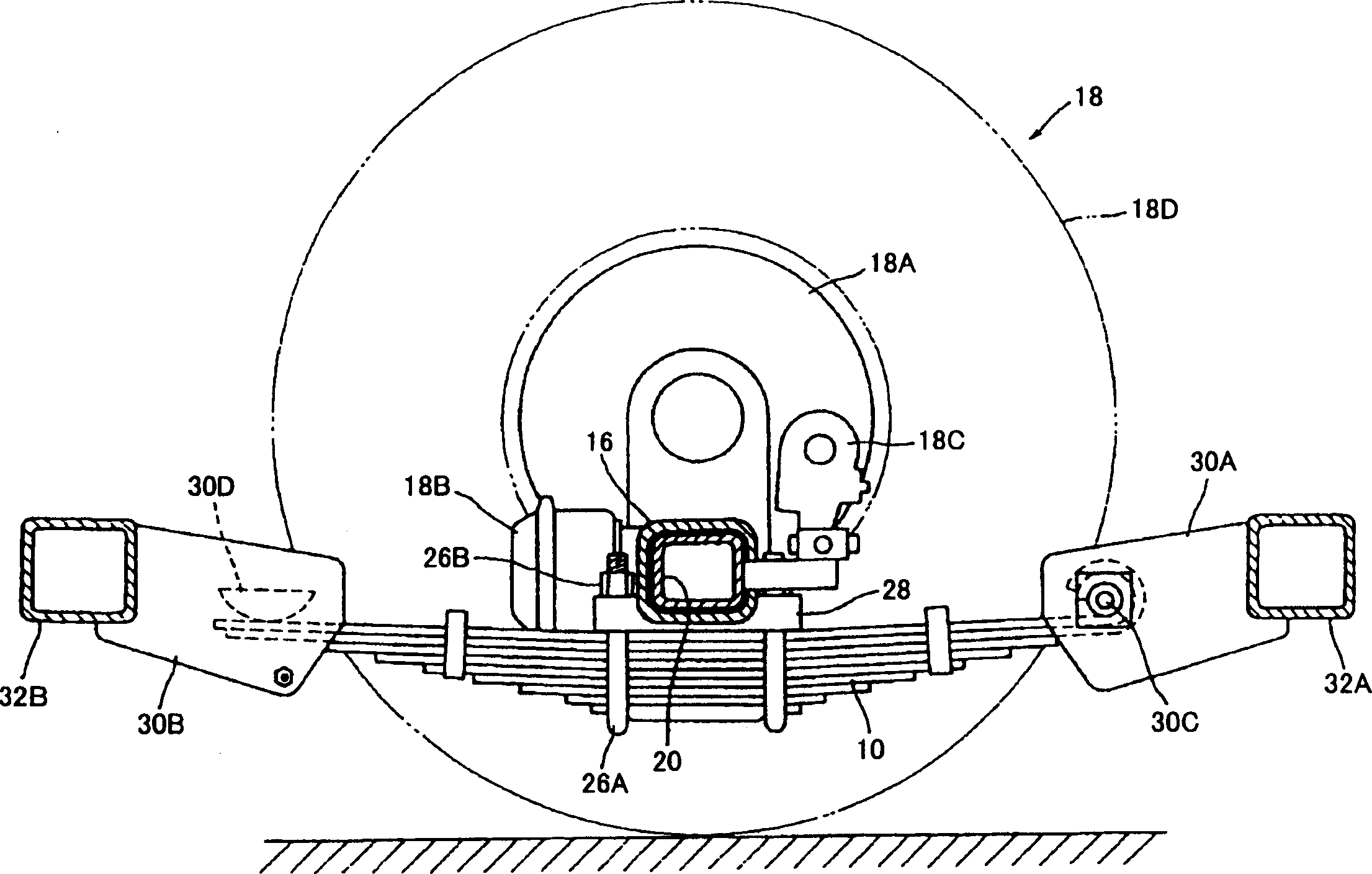

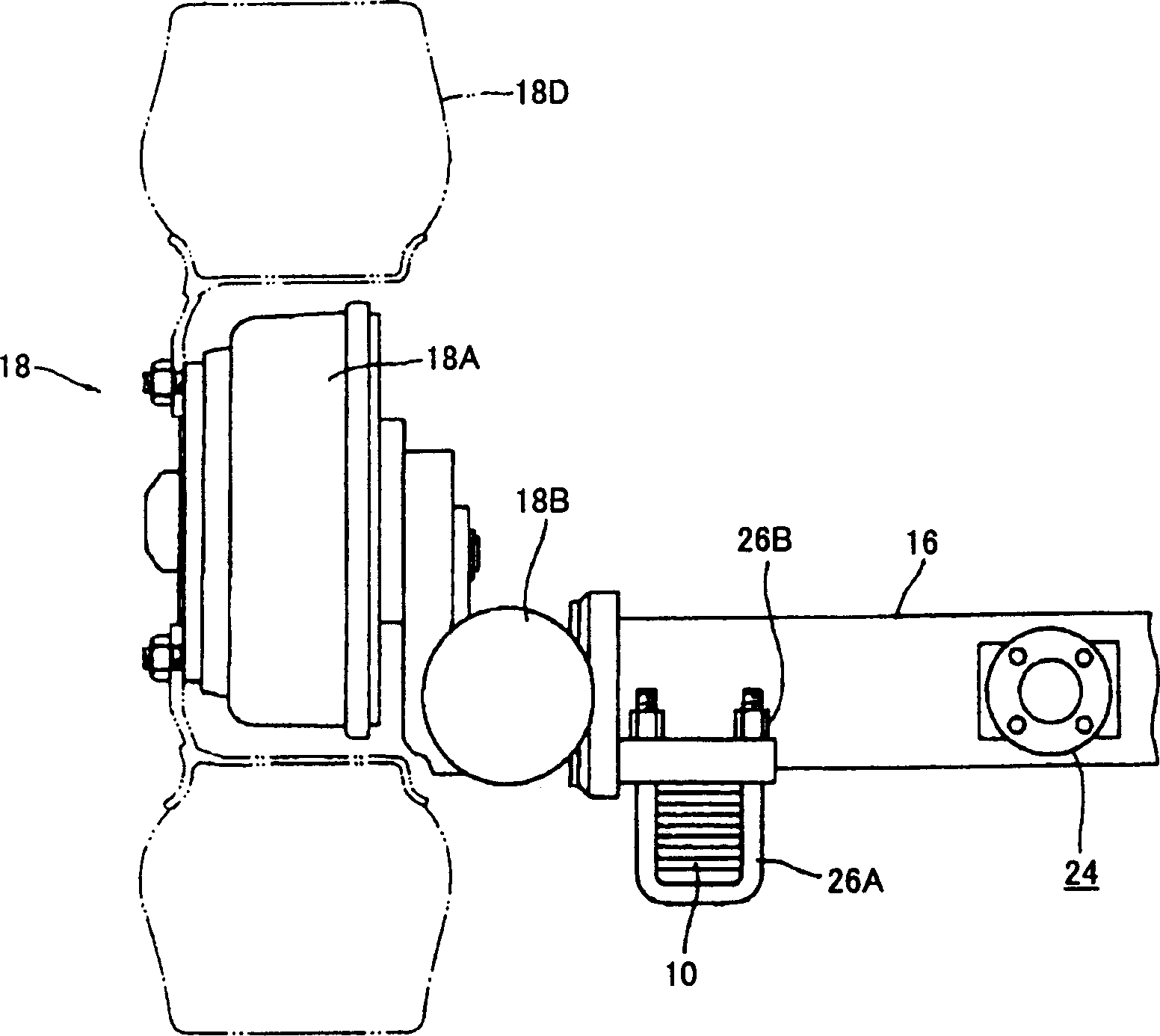

Wheel center distance variable axle of trailer

The invention provides variable-tread axles of trailer, in the state of freely advancing and retreating of inside axle relative to outside axle and in the variable-tread axles, realizing stopping the rotation of inside axle and needing no spline to position vehicle at the same time, in addition, realizing enlarging the widening amount of the tread. It has: the outside axle supported on the bodywork by plate springs, the inside axle supporting the wheel, the hydraulic cylinder device driving the inside axle in the axial direction and the locking device fixing the inside axle..

Owner:株式会社滨名沃克斯

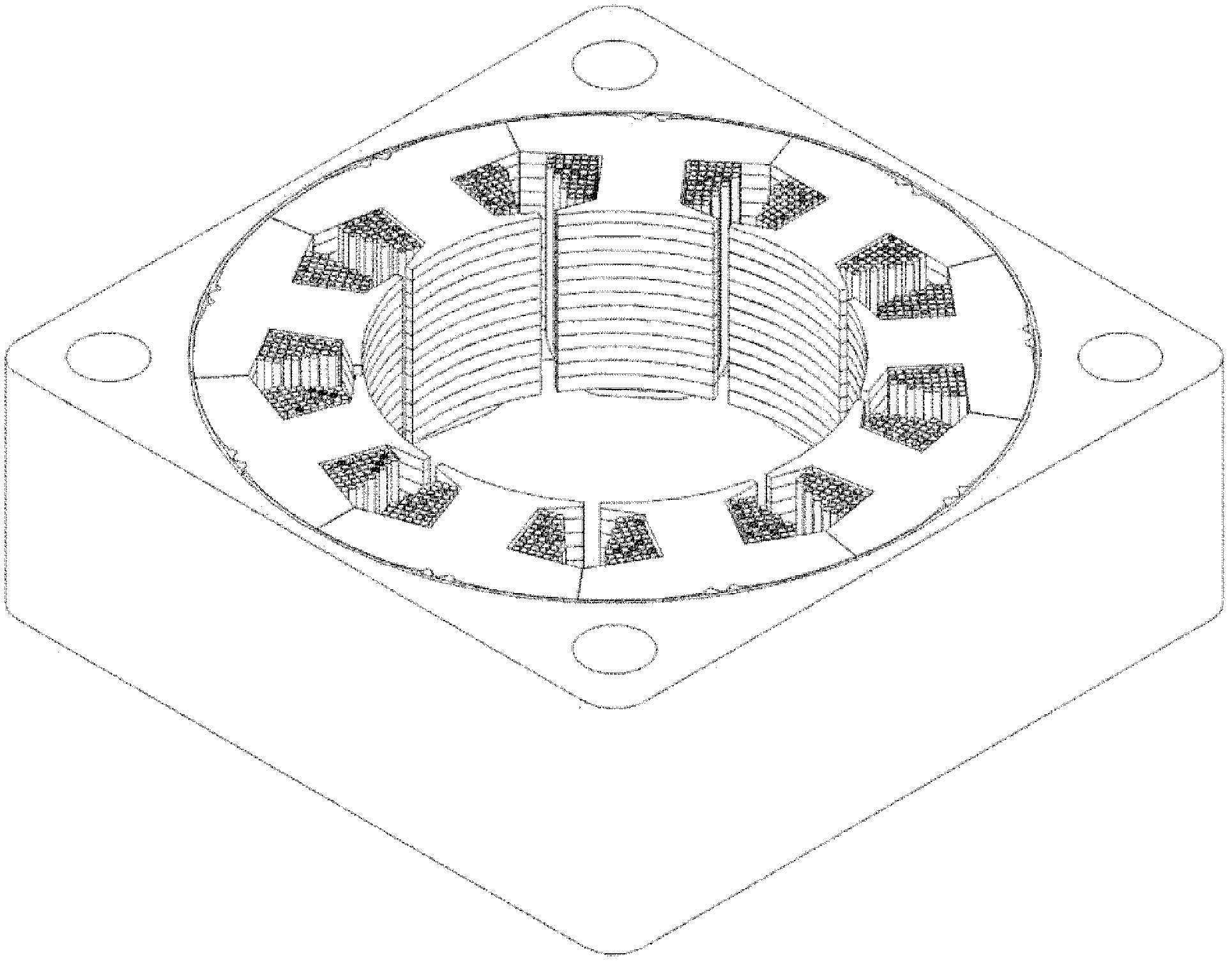

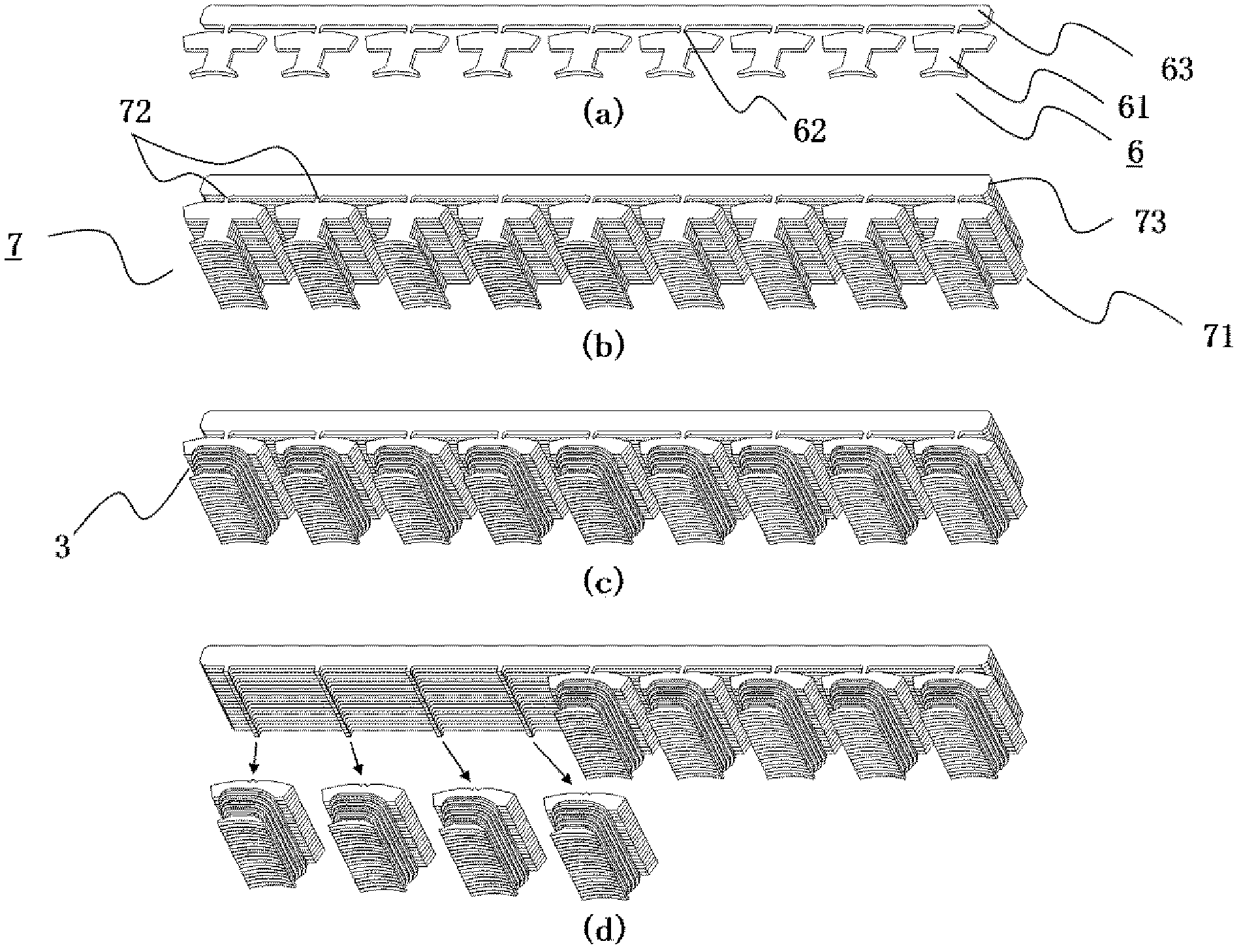

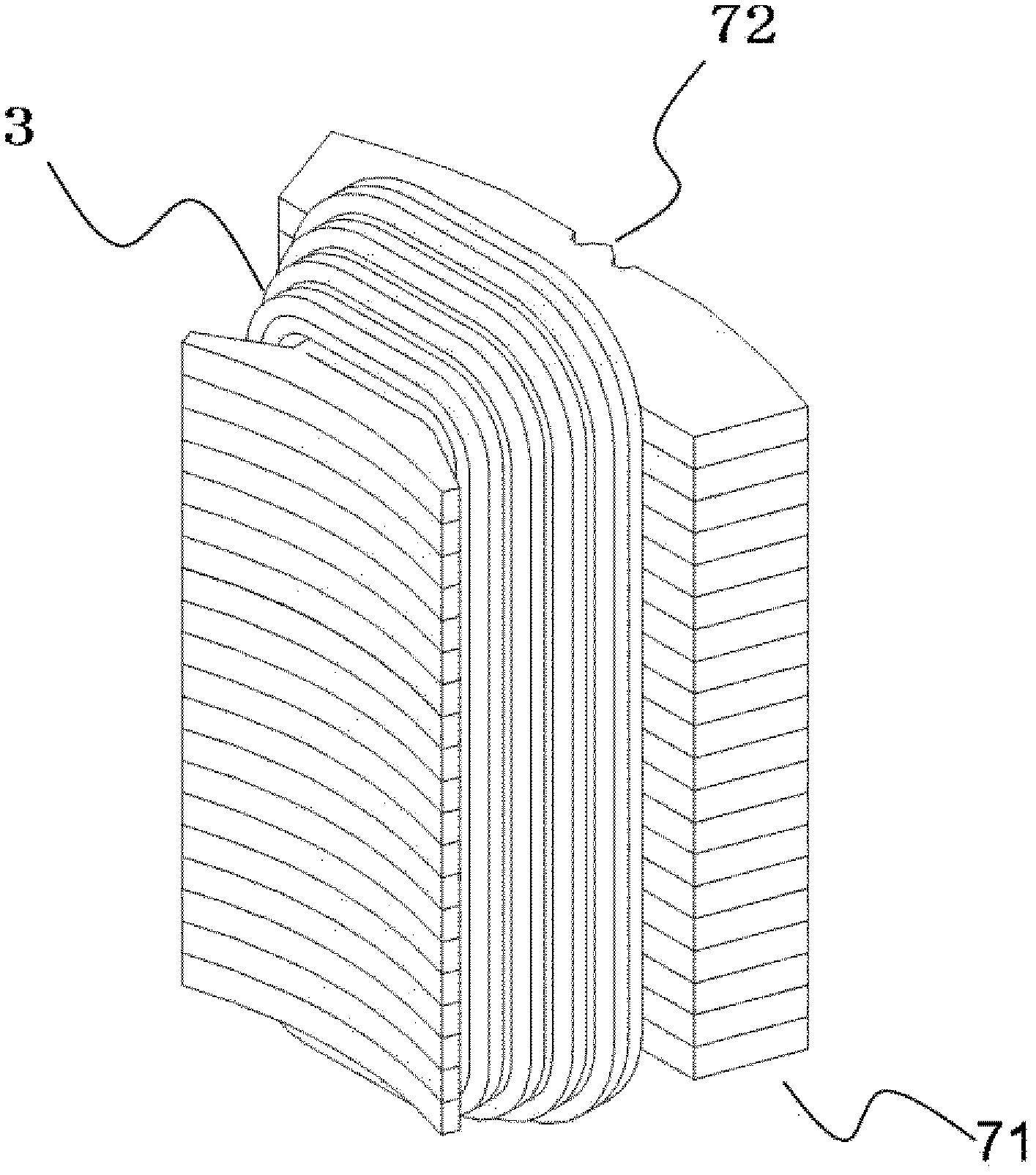

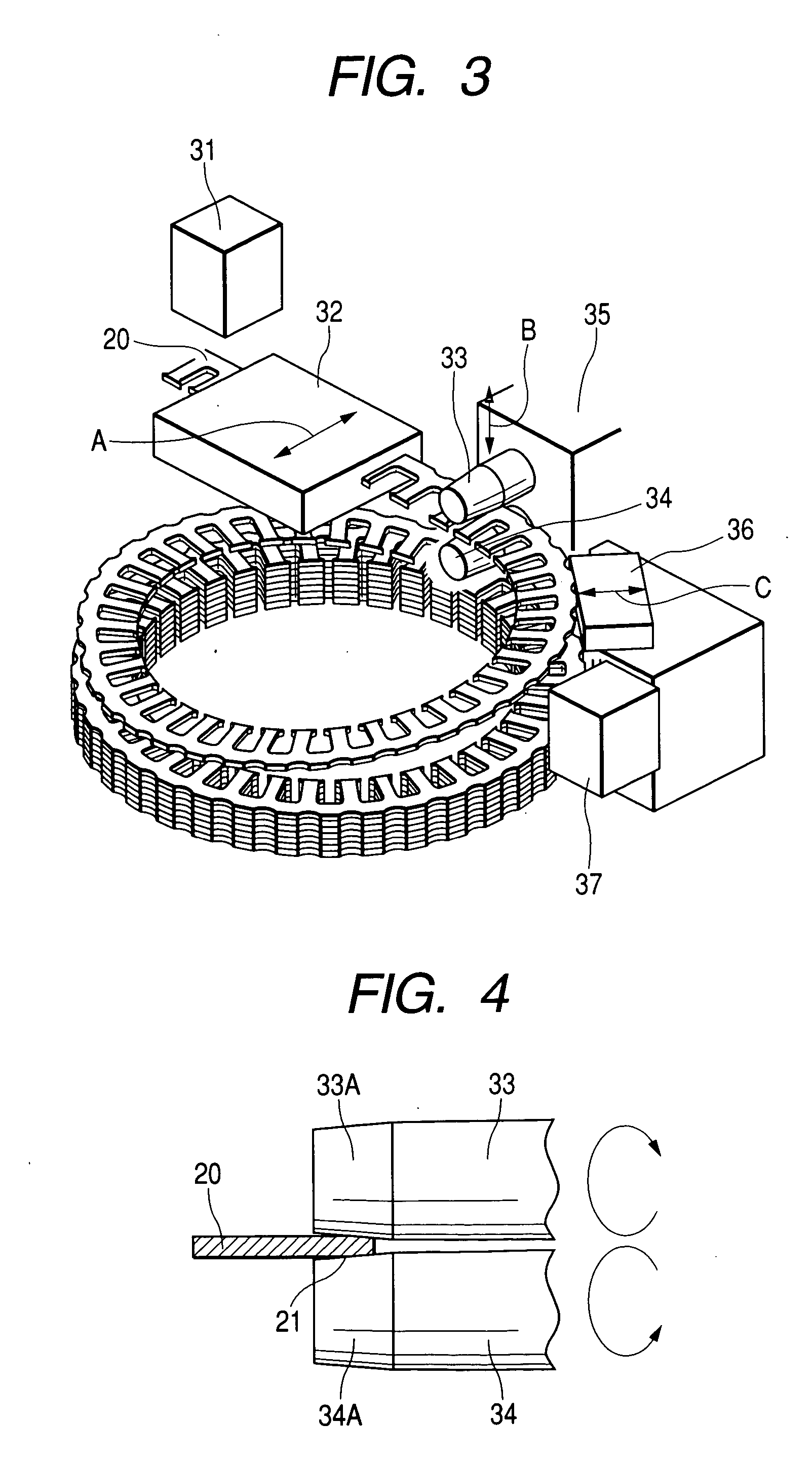

Method of manufacturing molded stator of dynamo electric machine

InactiveCN102549881AReduce stressHigh precision manufacturingWindingsMagnetic circuit stationary partsElectric machineEngineering

A method of manufacturing the molded stator of a dynamo electric machine comprises a lamination step for constituting a split lamination core group structure (7) by laminating a plurality of core sheets (6) in each of which a plurality of core pieces (61) are bonded to one coupling part through a bridge (62), a winding step for winding a coil around the tooth of each split lamination core (71) of the split lamination core group structure (7), a cutting step for cutting the split lamination core (71), around which a coil is wound, at the bridge and separating the split lamination core, a temporary fixing step for shaping a plurality of split lamination cores (71) into an annular stator (2) and fixing the stator temporarily, and a molding step for setting the stator (2) in a die by inserting a mold mandrel (10) to the inner circumferential side of the stator, and fixing the outer circumferential surface of the stator (2) with resin.

Owner:MITSUBISHI ELECTRIC CORP

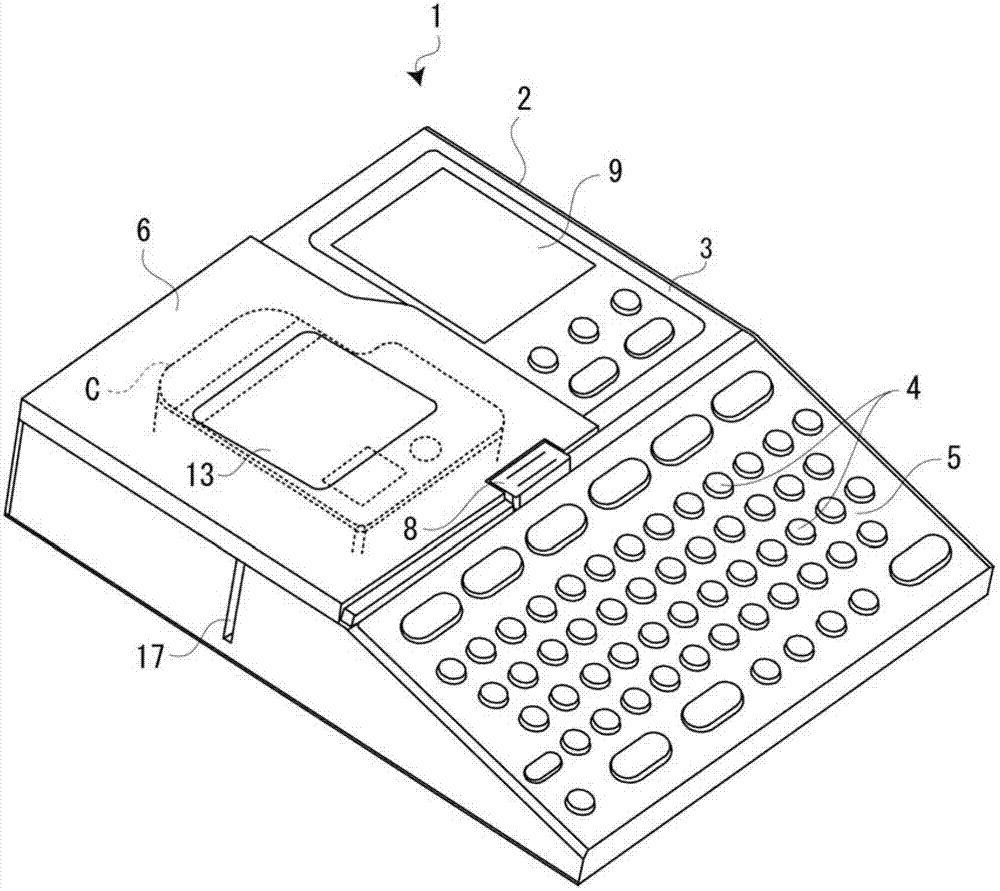

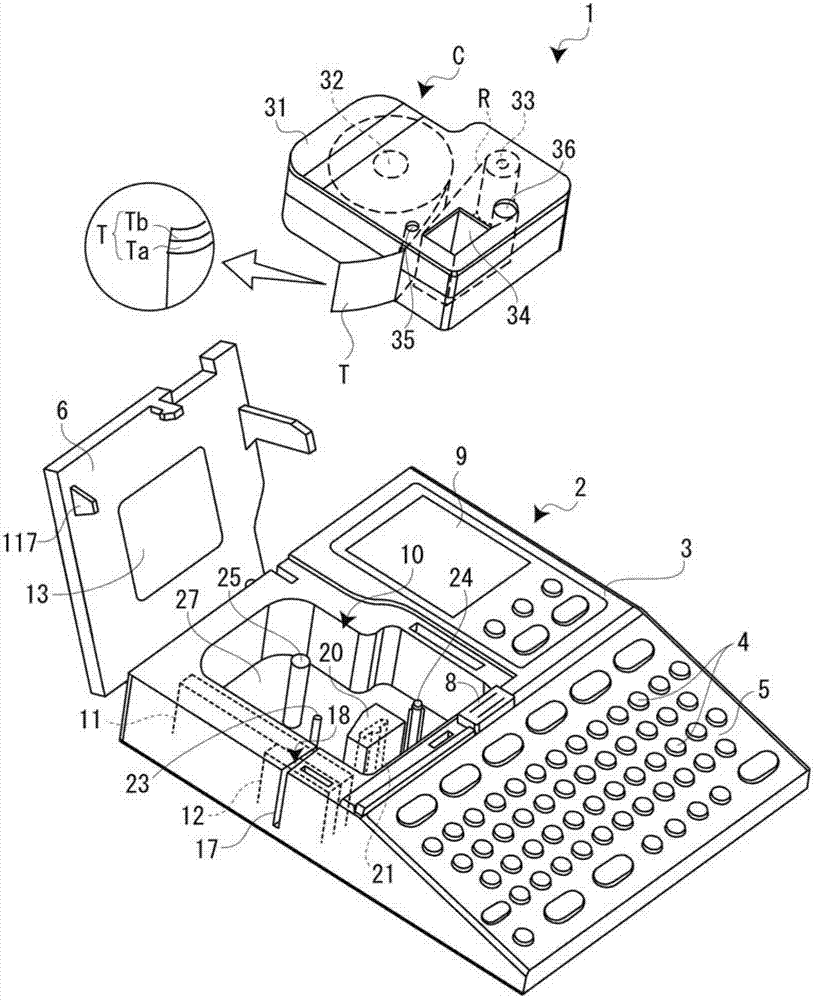

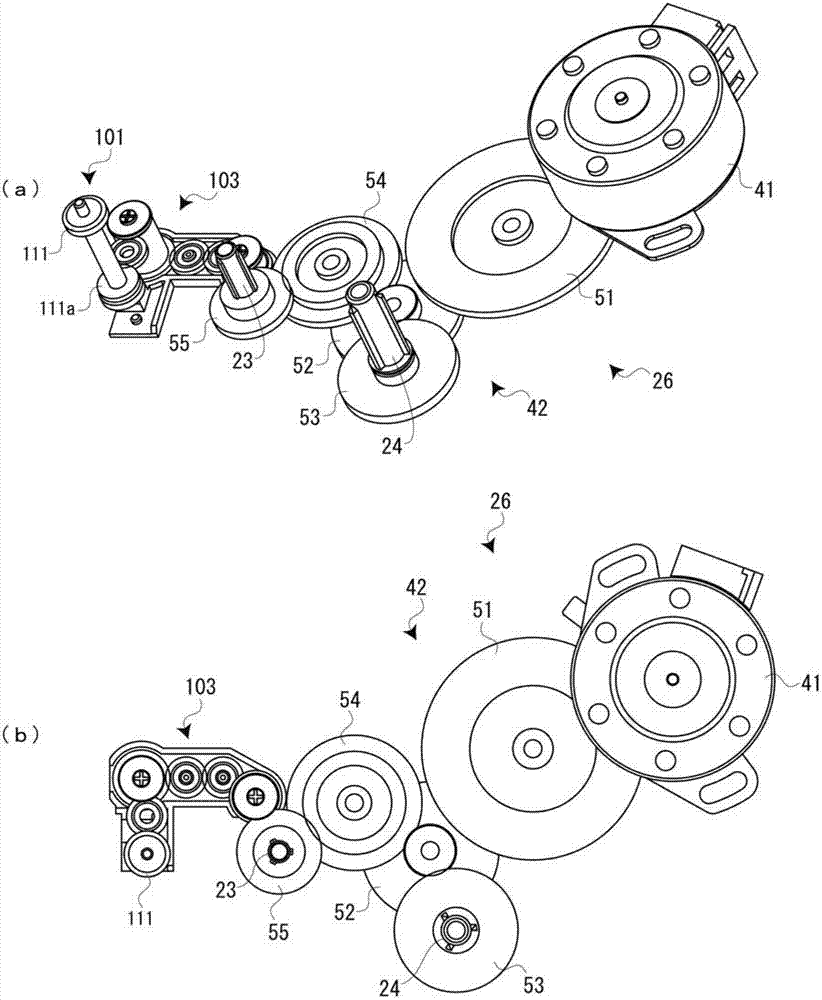

Tape cutting apparatus, tape printing apparatus having the same, and method of controlling stepping motor

ActiveCN102806782AEasy to makeSimple structure and high precision productionOther printing apparatusElectric machineryMotor control

The invention provides a tape cutting apparatus, a tap printing apparatus having the same, and a method of controlling a stepping motor. The tape cutting apparatus includes: a half cutter (62) configured to cut a body tape (Ta) or a release tape (Tb) with respect to a processed tape (T) having the release tape (Tb) adhered to the body tape (Ta); a stepping motor (63) configured to cause the half cutter (62) to perform a cutting operation; and a motor control unit (200) configured to control the stepping motor (63), wherein the motor control unit (200) is configured to continue the cutting operation until the stepping motor (63) loses steps.

Owner:SEIKO EPSON CORP

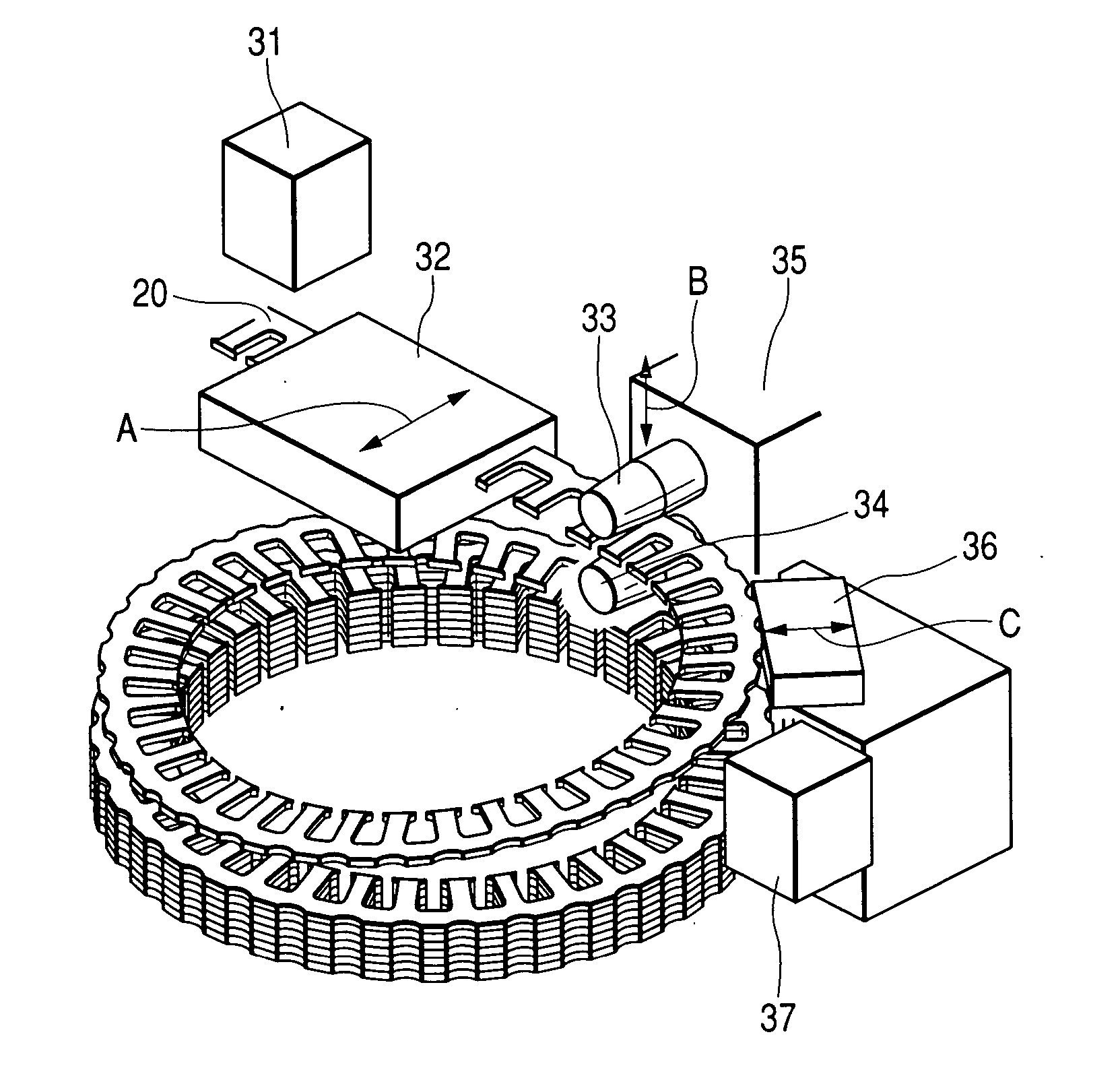

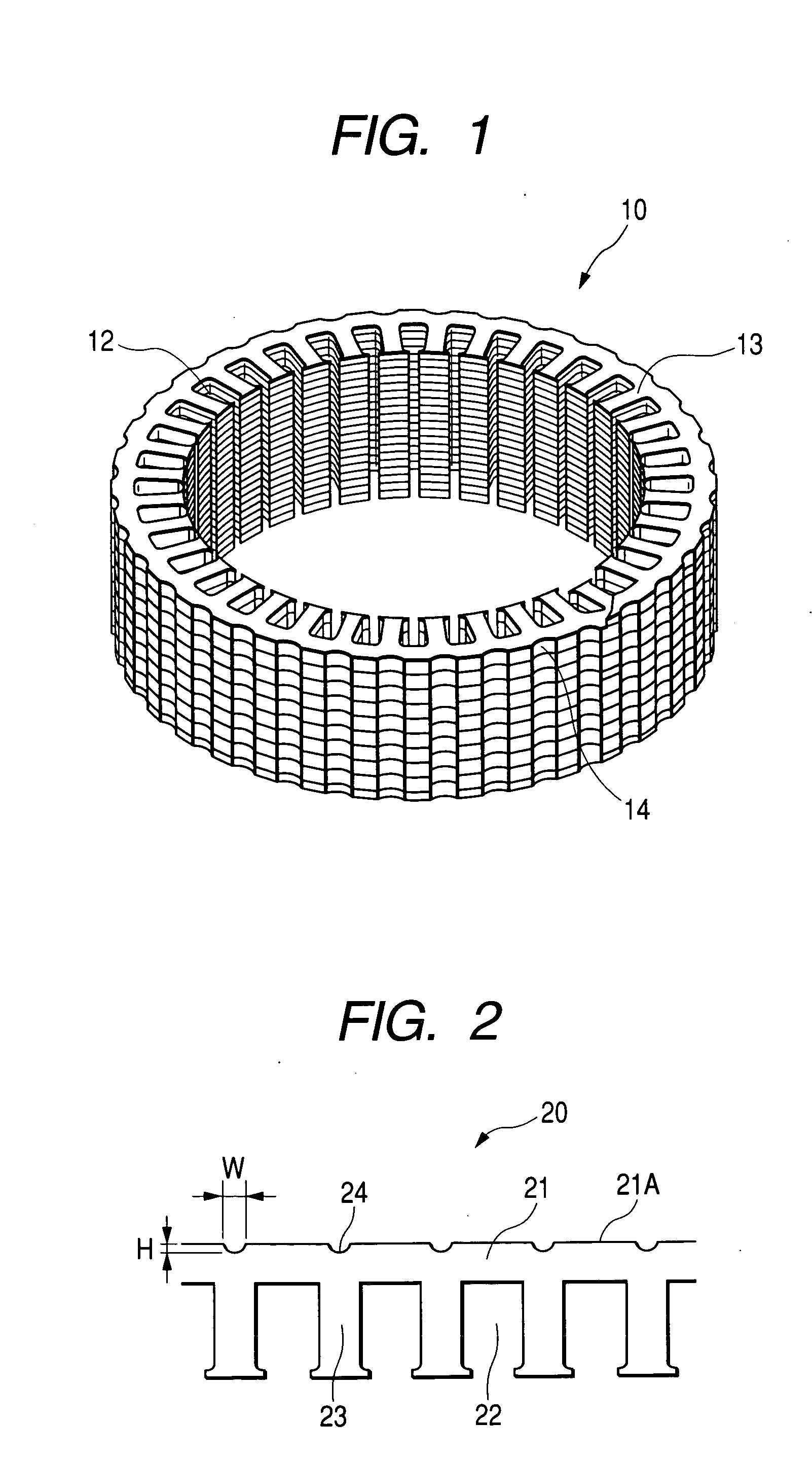

Iron core and method of manufacturing the same and apparatus for manufacturing the same

ActiveUS20050061046A1High precision manufacturingMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringPosition control

An apparatus for manufacturing an iron core comprising: a plate thickness measurement unit for measuring a thickness of the strip as an intermediate product of the iron core; an inlet guide for positioning the strip in a widthwise direction thereof; a mil roll unit for performing a rolling-bending process to the strip fed out of the inlet guide; a restraint jig for shaping the strip fed out of the mil unit and holding a curvature thereof constant; and a curvature measurement unit for measuring a curvature of the strip to which the rolling-bending process has been performed by using said mill roll. Position control of the inlet guide, the pressure roll unit, and the restraint jig is performed based on at least one of the plate thickness and the curvature of the strip.

Owner:HITACHI ASTEMO LTD

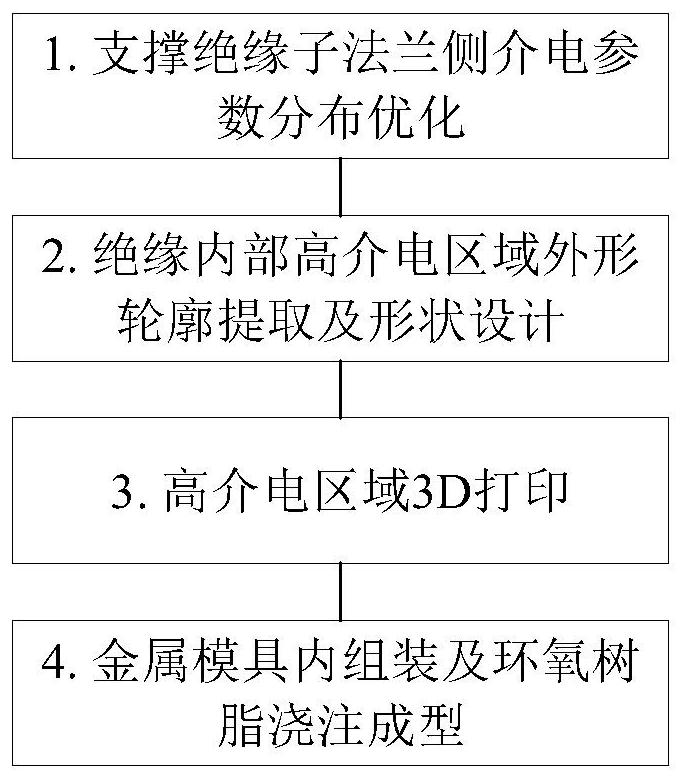

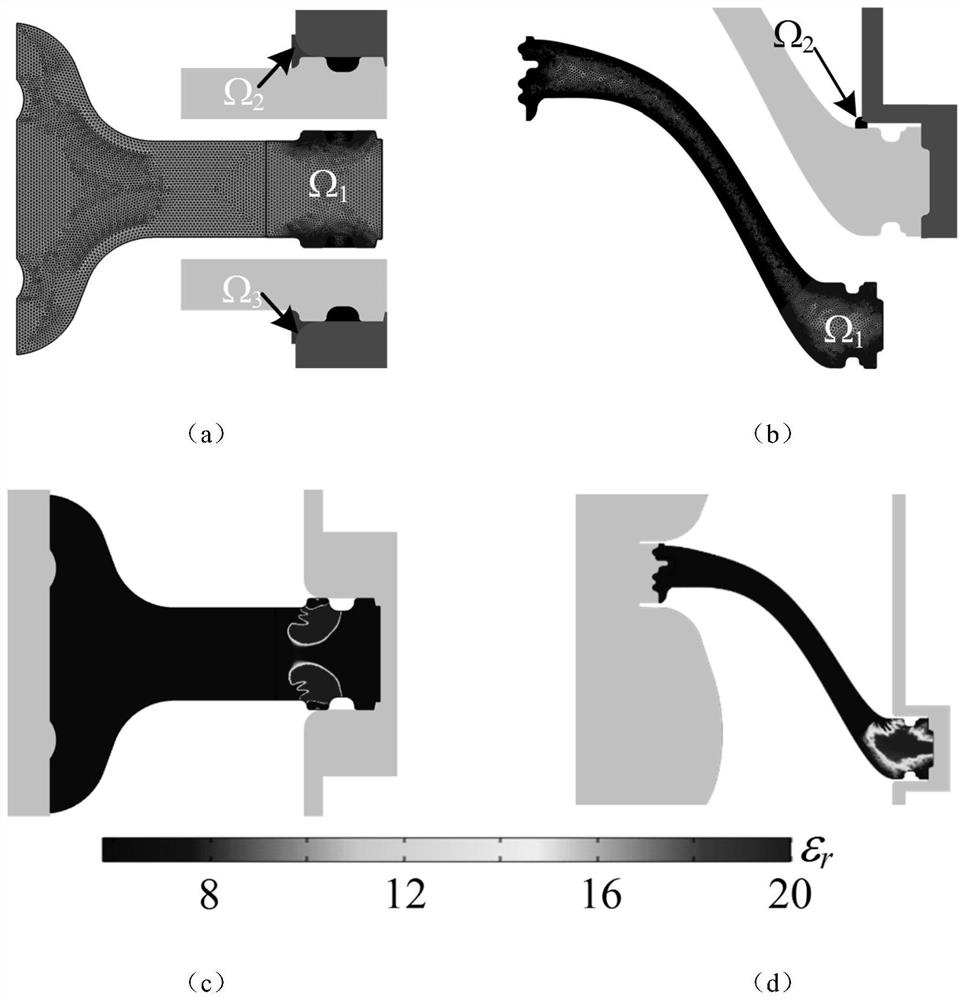

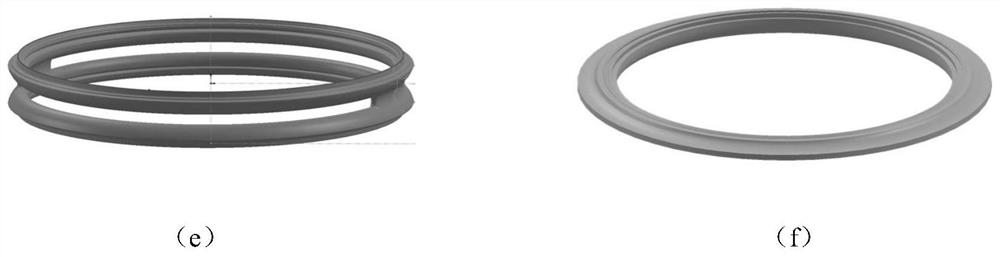

Suppression method for partial discharge at flange of GIS/GIL supporting insulator

ActiveCN113470907AHigh-precision manufacturingGood compatibilityImage enhancementAdditive manufacturing apparatusPhysicsPartial discharge

The invention discloses a suppression method for partial discharge at a flange of a GIS / GIL supporting insulator. According to the invention, reduction of electric field intensity in a flange-side local air gap area is taken as an optimization target, and optimal space distribution of flange-side insulation internal dielectric parameters of supporting insulator is solved by using a variable density or level set algorithm; and extracting the geometric contour of a high-dielectric region by using an image segmentation algorithm, and acquiring a CAD drawing of the geometric shape of the high-dielectric region through a parameter modeling mode. According to the invention, dielectric functional gradient material distribution is introduced in consideration of the mechanical properties and interface bonding strength of a cast workpiece, the structural design of a high-dielectric area workpiece is improved; a high-dielectric composite material is prepared in a high-dielectric filler / polymer blending mode, and manufacturing of the workpiece is completed through 3D printing; and finally, the high-dielectric workpiece is put into a traditional epoxy pouring metal mold, and thermocuring epoxy resin is poured to complete manufacturing of the supporting insulator.

Owner:XI AN JIAOTONG UNIV

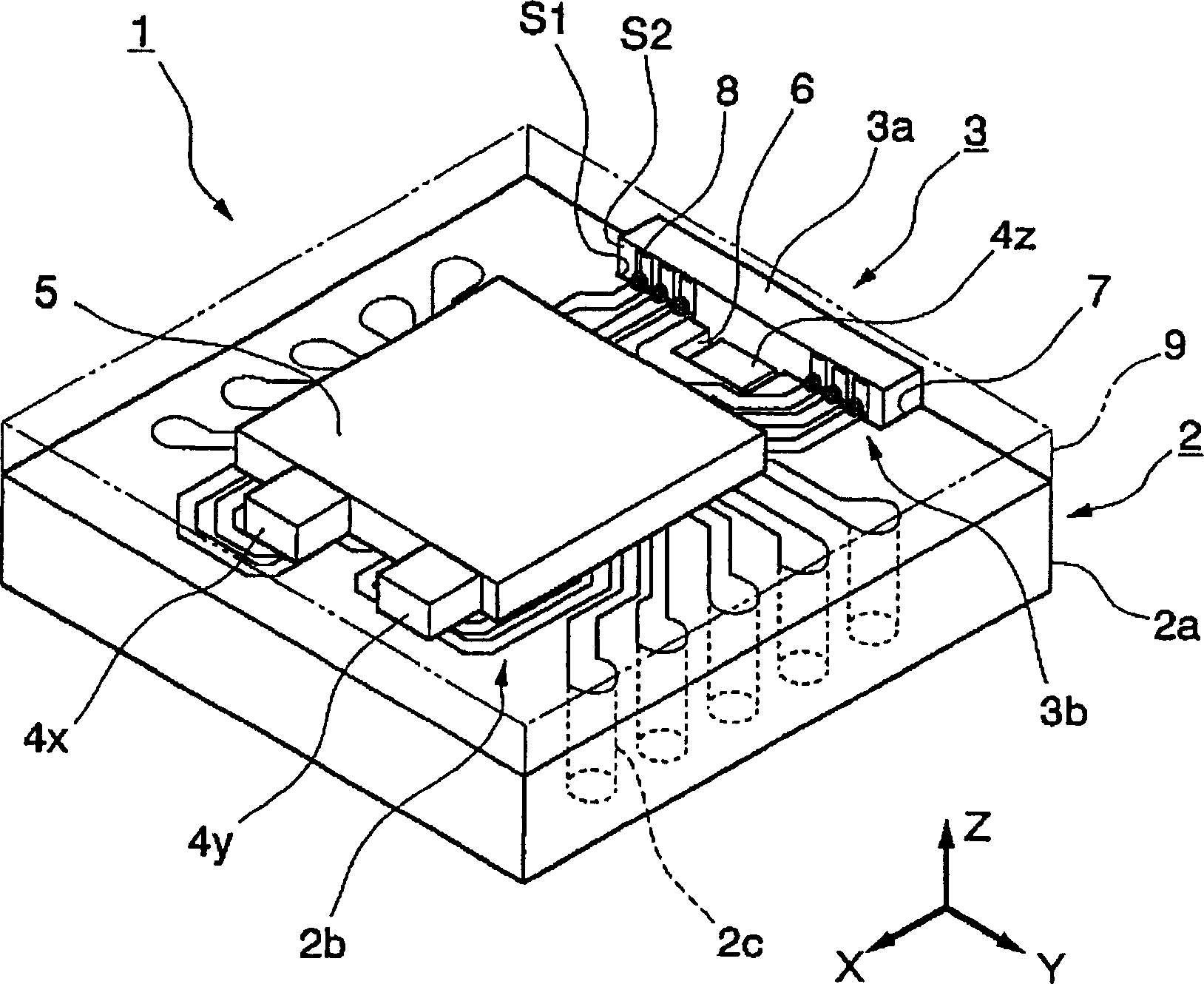

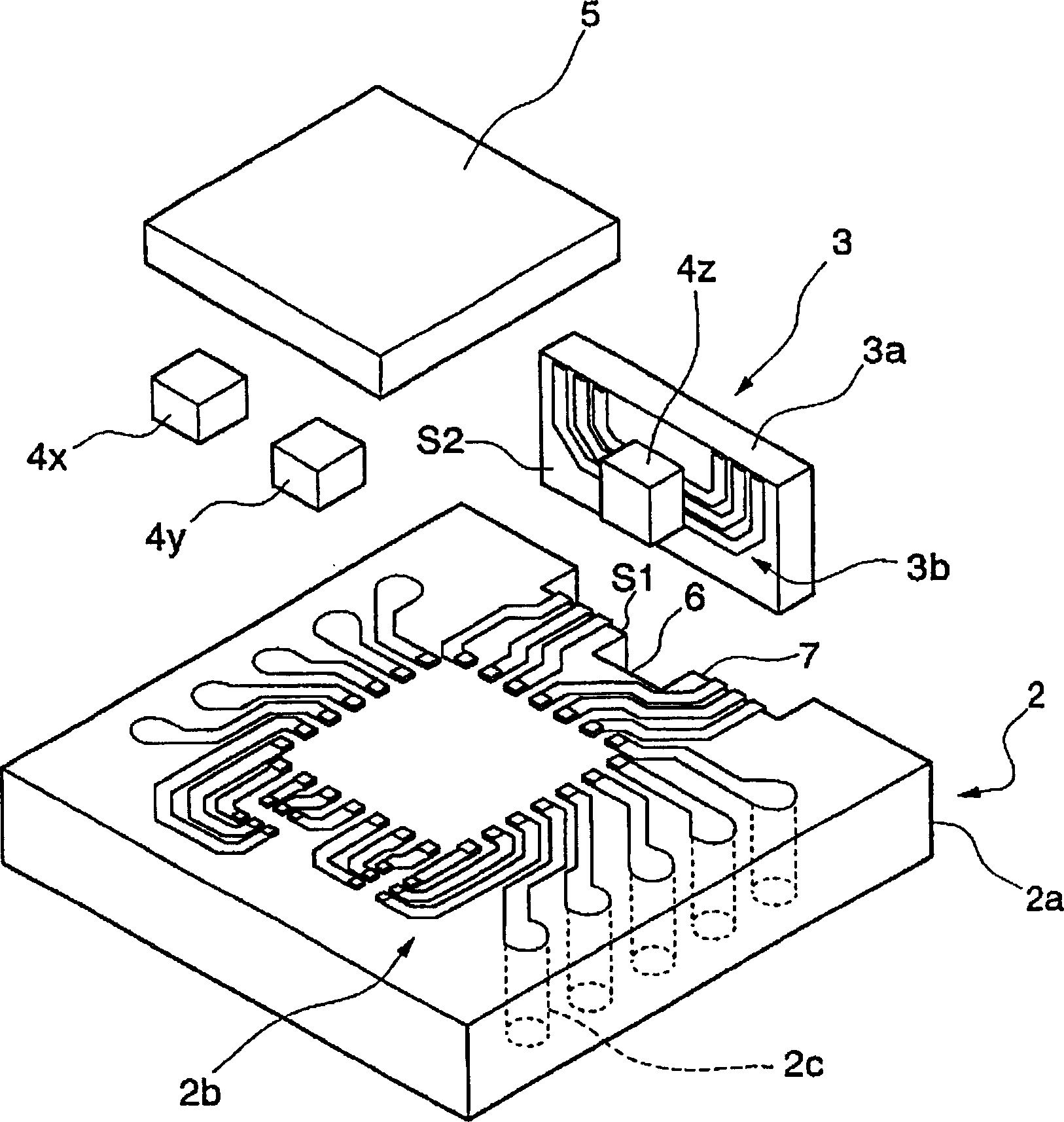

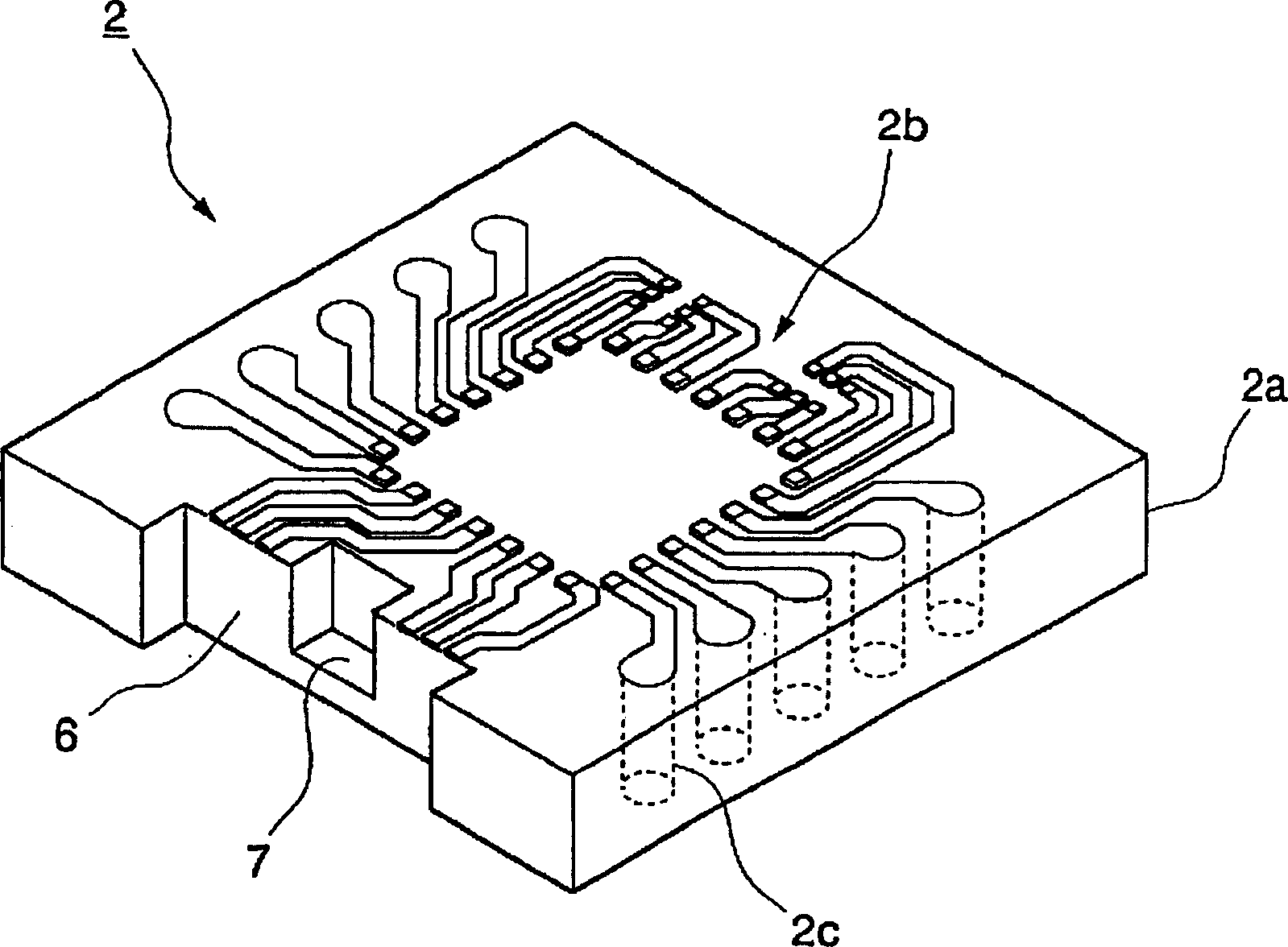

Three-dimensional circuit module and method of manufacturing the same

InactiveCN1822747AEasy to achieve angle formationHigh precision manufacturingSemiconductor/solid-state device detailsPrinted circuit aspectsElectronic componentDepth direction

A three-dimensional circuit module has a three-dimensional structure in which a second board is bonded to a first board at a predetermined angle. The first board has a first notched concave part formed at an edge to be a bonding surface S1 and a second notched concave part formed at an edge of the first notched concave part in the depth direction thereof. The second board has an electronic component mounted on a surface thereof opposite to the bonding surface of the first board and is engaged with the first notched concave part in a state in which the electronic component is disposed in the second notched concave part.

Owner:ALPS ALPINE CO LTD

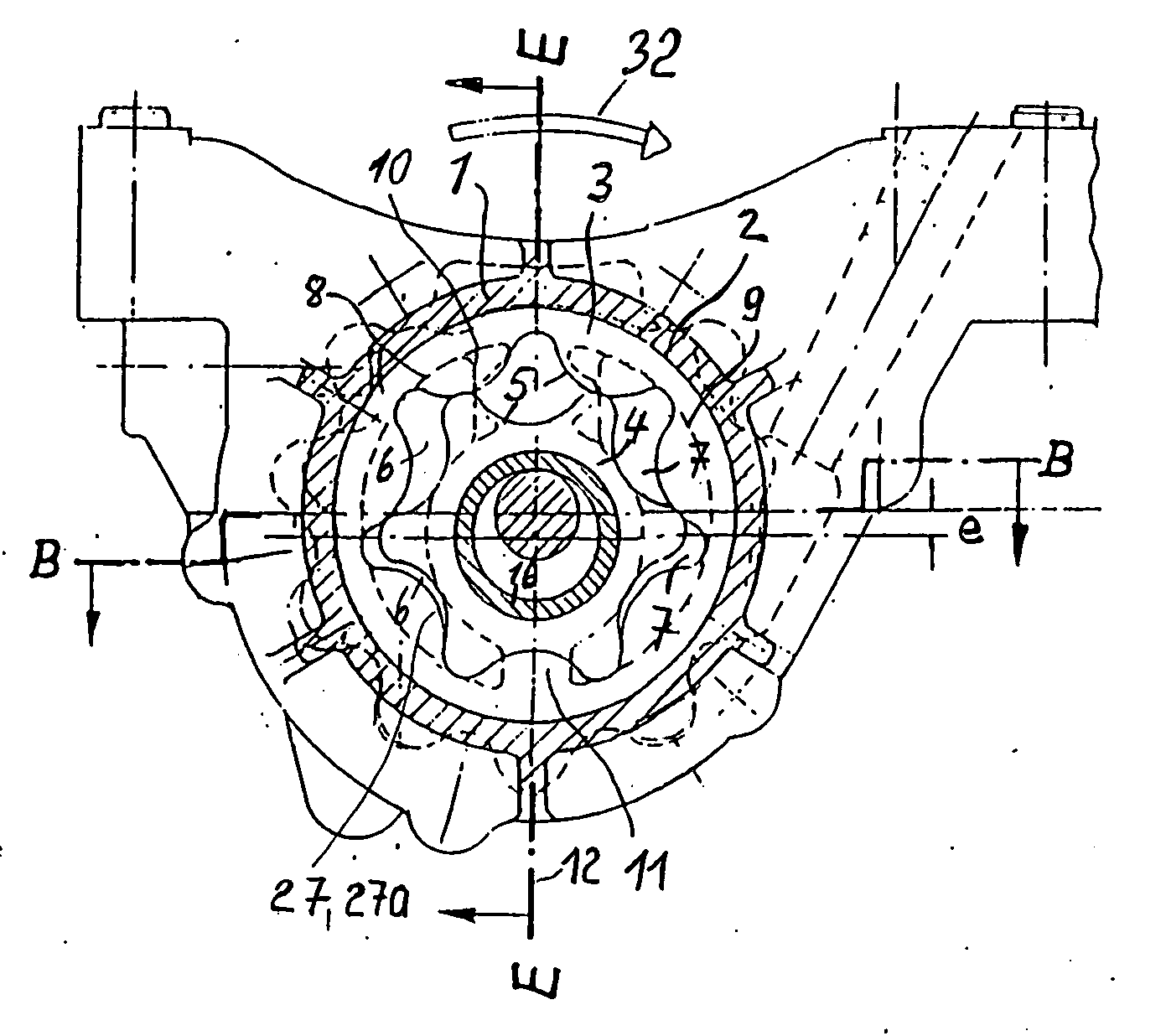

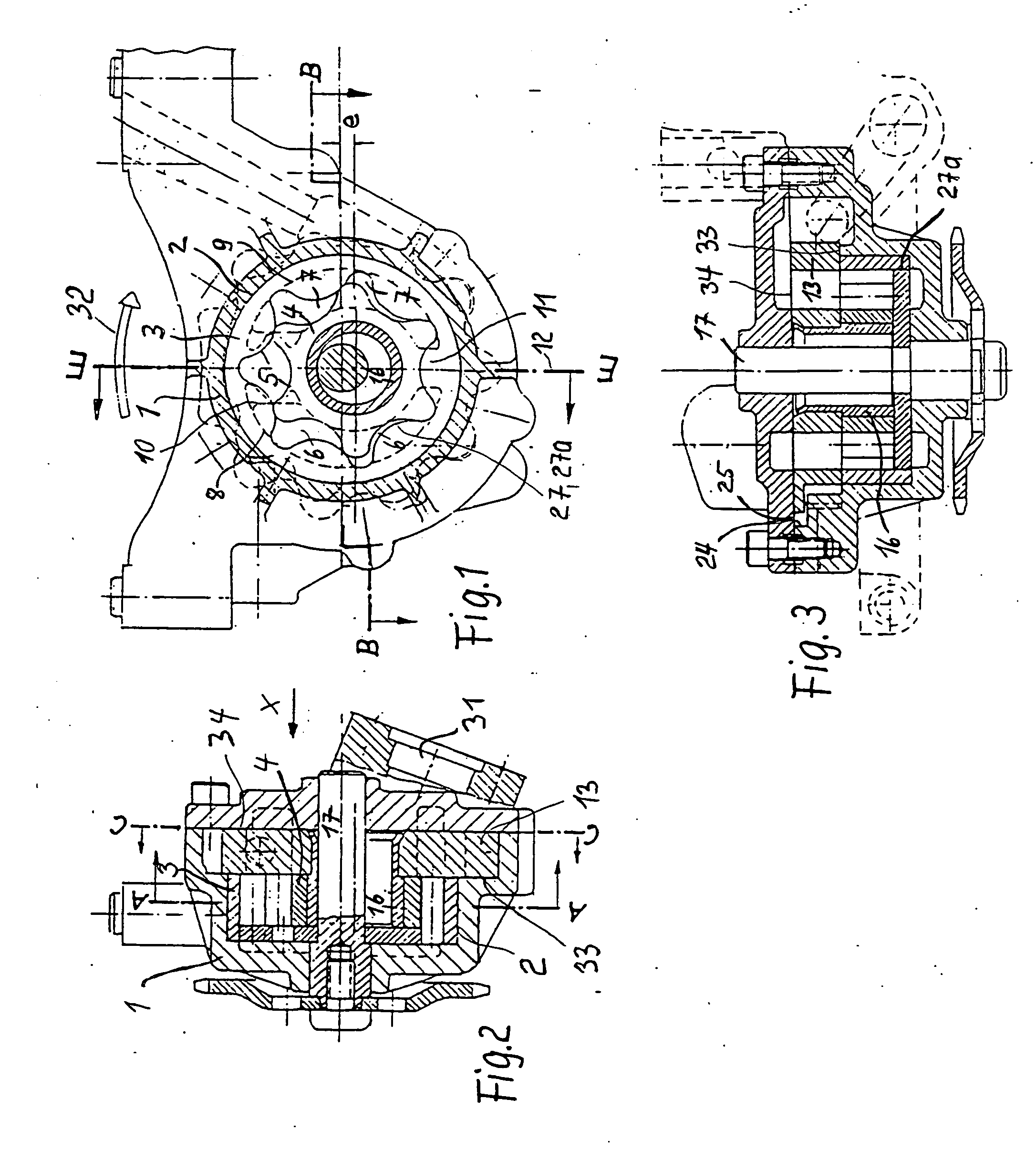

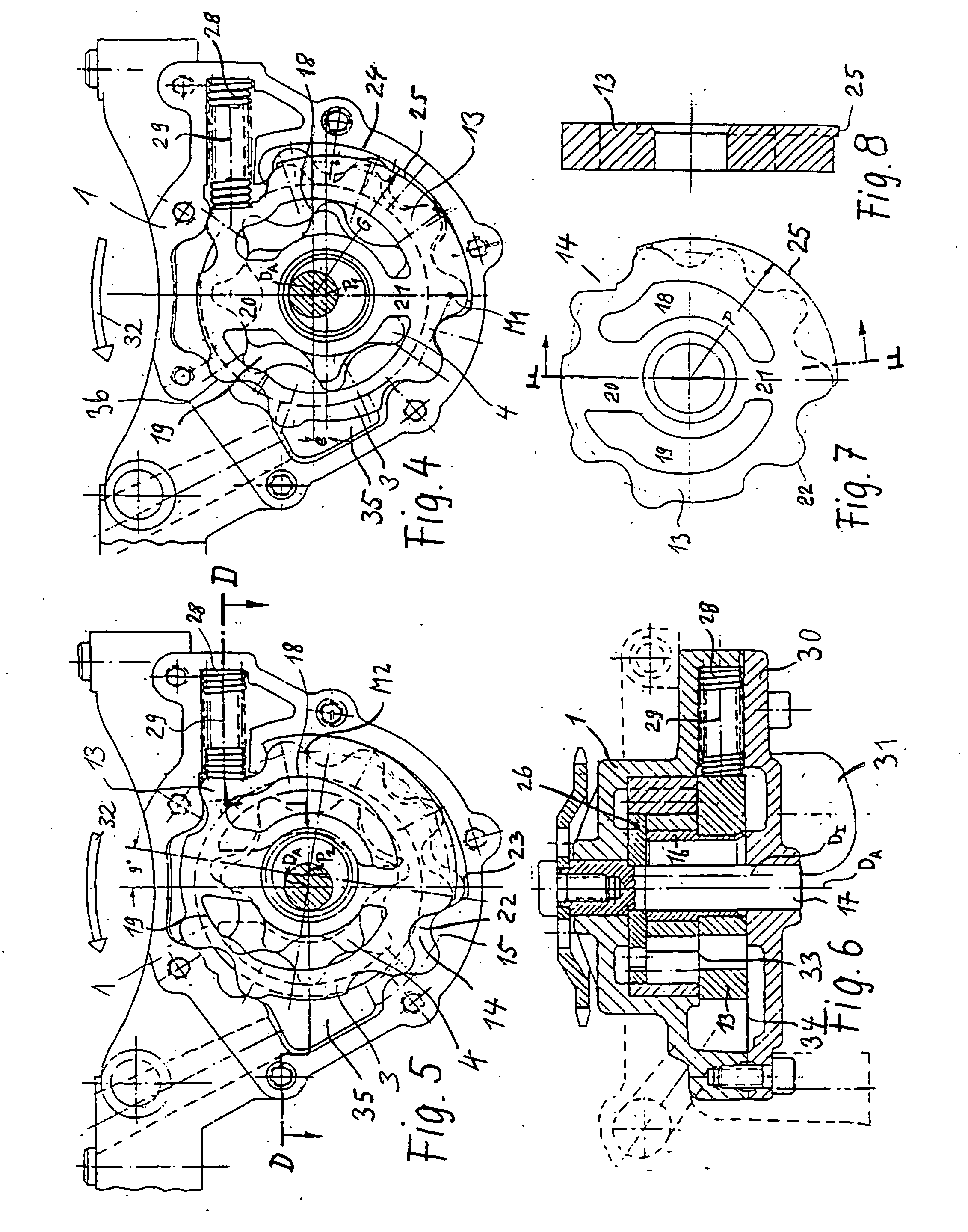

Displacement pump with variable volume flow

InactiveUS20050214149A1Reduced design spaceGreat suctionValve arrangementsEngine of arcuate-engagement typeRotational axisHigh pressure

A displacement pump with variable volume flow having a casing; a chamber with an inlet opening on a low pressure side and an outlet opening on a high pressure side for a fluid; an internal rotor capable of rotation about a rotational axis (DI); a ring having a central ring axis (DA) surrounding the internal rotor and forming together with the ring, at least one delivery cell in which fluid is delivered from a low pressure side to a high pressure side of the pump; and an adjusting device which, during an adjusting movement, rolls off on the casing without slipping is provided. The internal rotor is fixed to the adjusting device and rotatble about the rotational axis (DI), and the position of the rotational axis (DI) relative to the central ring axis (DA) of the ring is adjusted by the adjusting movement of the adjusting device.

Owner:HARLE HERMONN +1

Measurement system and method of manufacturing shaft with hole

InactiveCN110953996AHigh precision manufacturingHigh precision measurementCaliper-like sensorsMeasurement/indication equipmentsMeasuring instrumentEngineering

Owner:PROTERIAL LTD

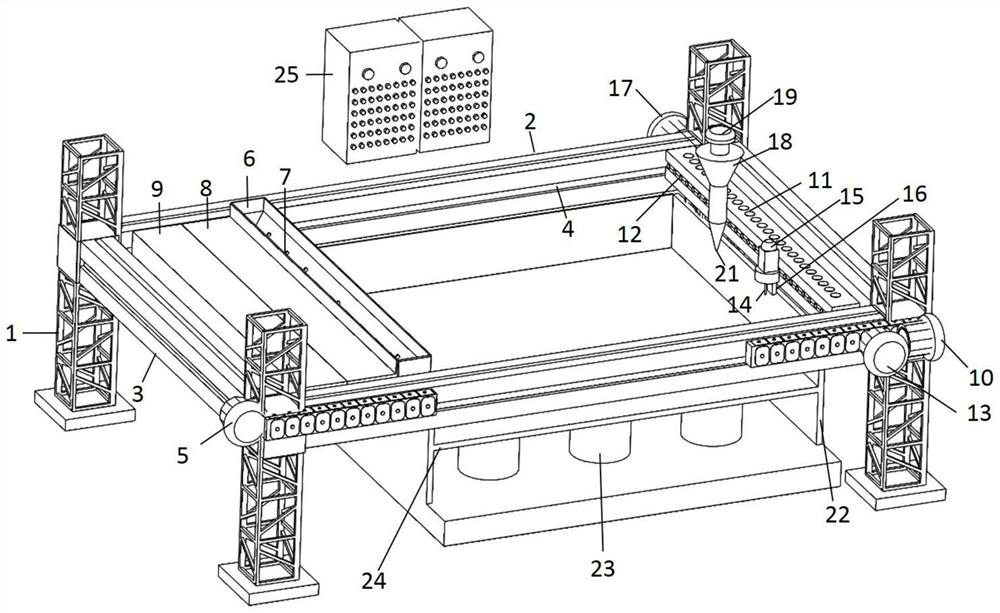

Powder bonding 3D printing equipment and method for preparing complex geologic model

InactiveCN112172139ARealize simultaneous printingHigh precision3D object support structuresAdditive manufacturing with solidsControl systemPhysical model

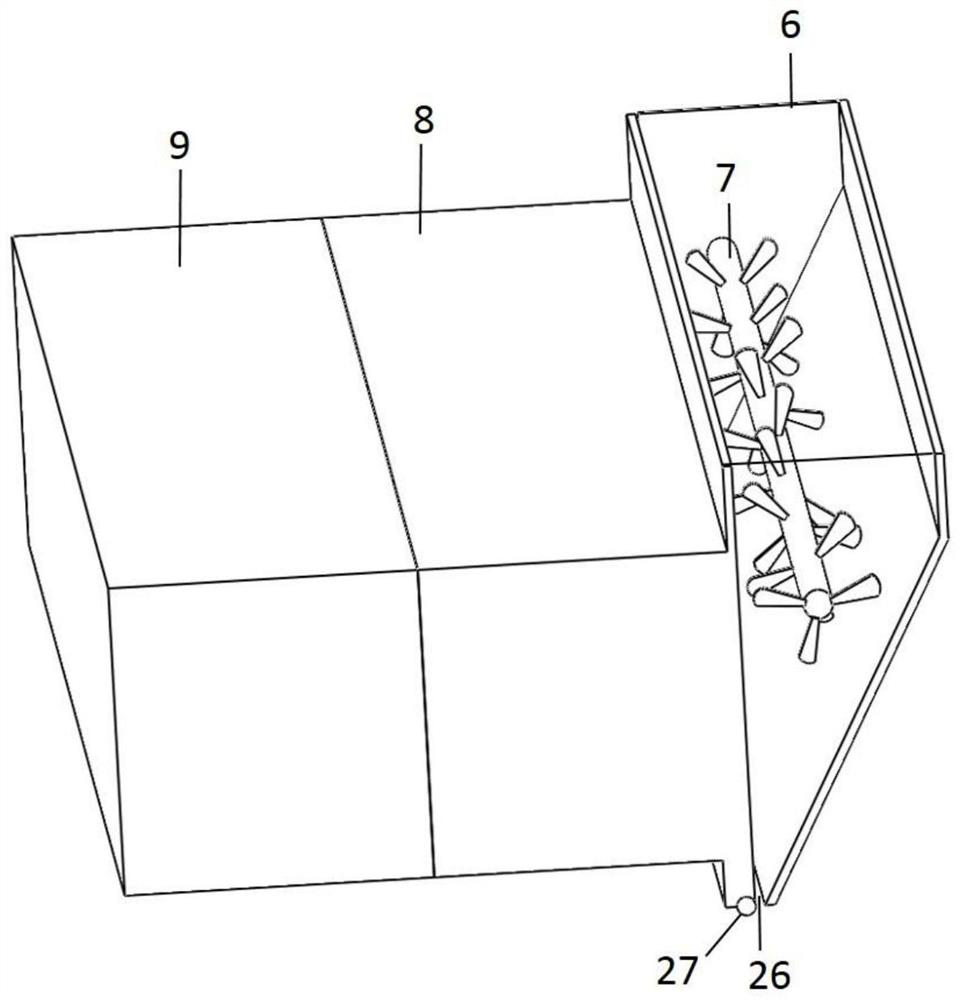

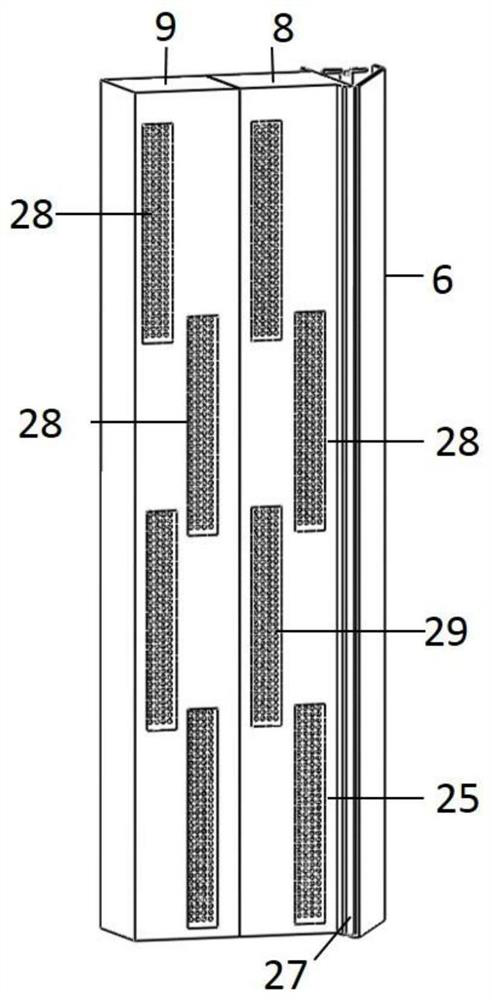

The invention discloses powder bonding 3D printing equipment and method for preparing a complex geological model. The equipment comprises a rack, a transverse guide rail, a powder laying and bonding assembly stepping motor, a powder laying and bonding assembly, a small longitudinal beam stepping motor, a small longitudinal beam, a longitudinal guide rail, a crack cutting device stepping motor, a crack cutting device, a crack filling device stepping motor, a crack filling device, a lifting forming chamber and a control system. According to the powder bonding 3D printing equipment, through cooperative work among the steps of powder laying, binder injection bonding and forming, crack cutting, crack filling, lifting platform movement and the like, simultaneous printing of hard rock, soft rockand other multi-strength rock materials and a complex crack network is achieved for the first time through a layer-by-layer stacking method, and a high-precision complex geological model is prepared;and the problem of manufacturing a three-dimensional physical model of a complex geological structure is solved.

Owner:HEBEI UNIV OF TECH

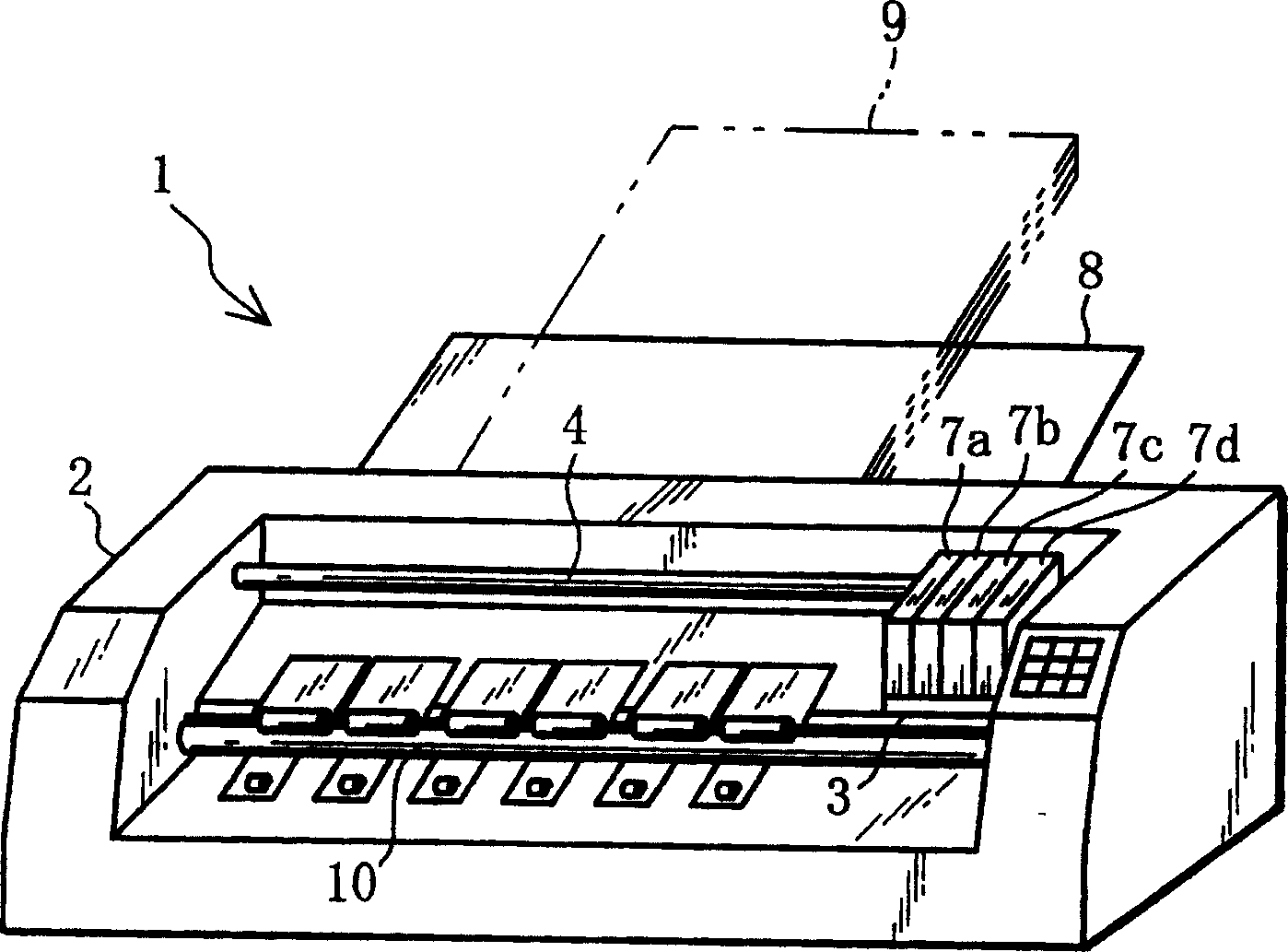

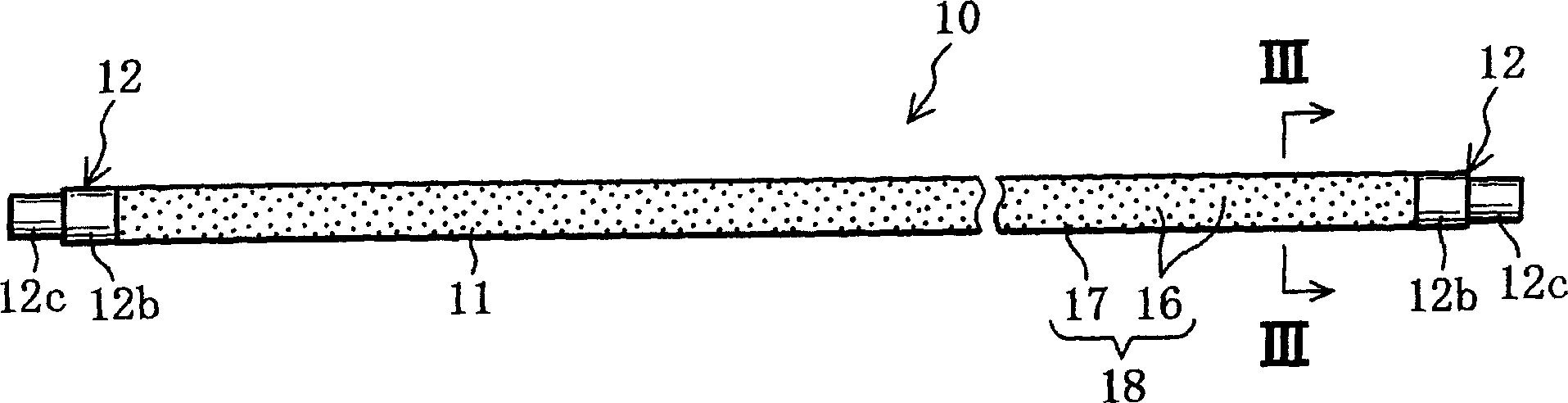

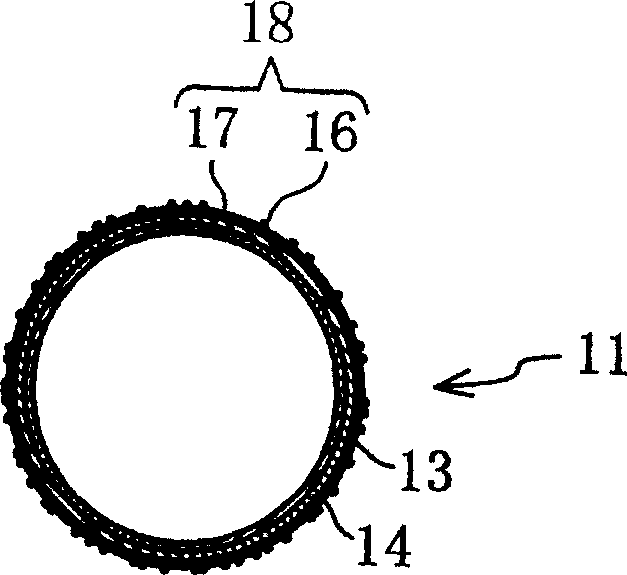

Paper feed roller

InactiveCN1915778AEasy curingShorten the timeArticle feedersWebs handlingPulp and paper industrySynthetic resin

A paper feed roller capable of assuring a rigidity and an accuracy and reducing a machining cost and a material cost and a method of manufacturing the roller, the paper feed roller comprising a hollow pipe-like member having a paper feed part for feeding paper formed thereon and a pair of shaft members coaxially fixed to both end parts of the pipe-like member, the pipe-like member further comprising a hollow steel pipe, a synthetic resin cover material for covering the outer peripheral surface of the steel pipe, and a synthetic resin friction coat layer containing hard particles formed on the outer peripheral surface of the cover material, wherein a steel pipe covered with the synthetic resin cover material can be used as the material of the pipe-like member.

Owner:SANCALL CORP

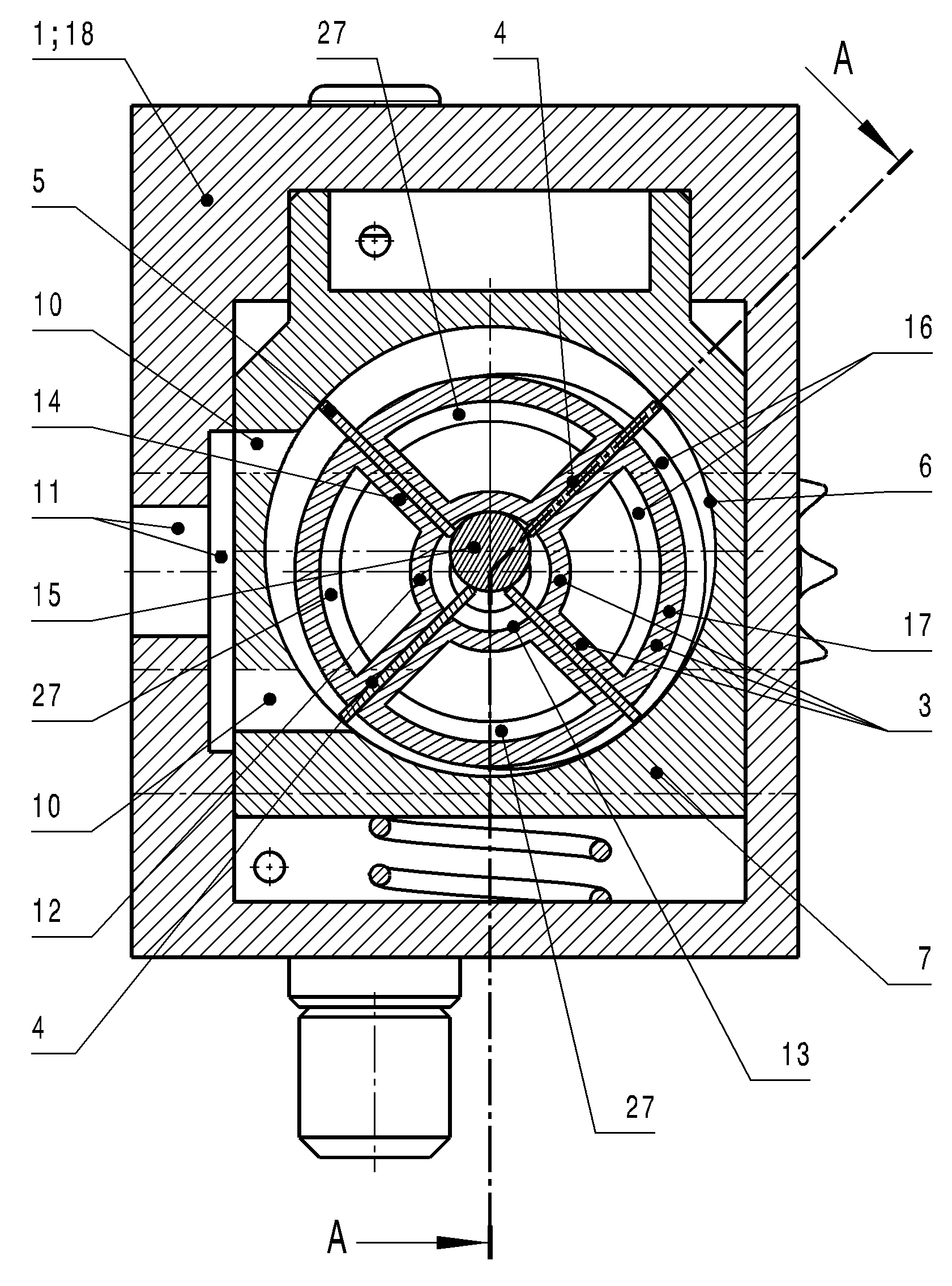

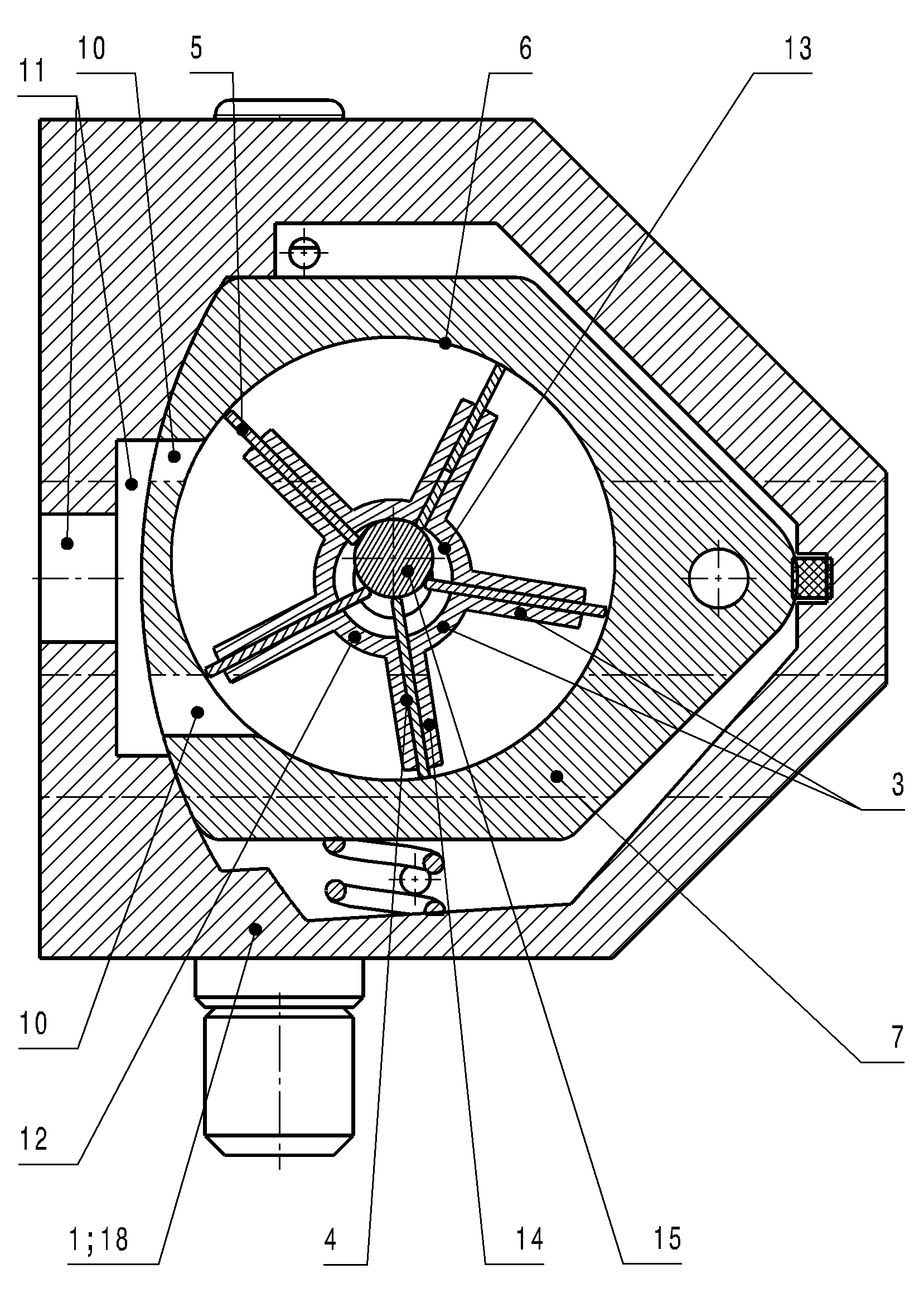

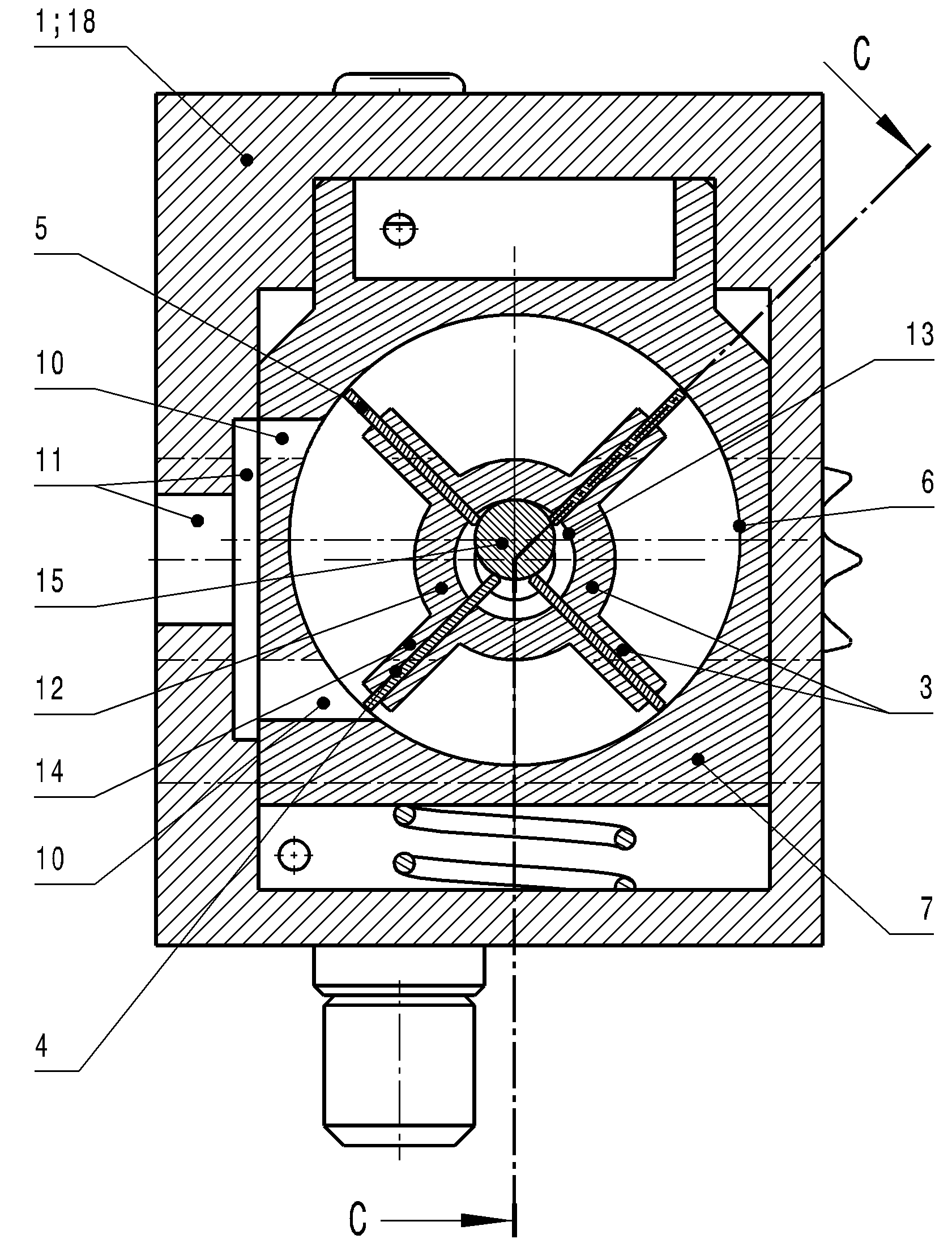

Vane pump

InactiveCN103221690AImprove stabilityEasy to fillRotary piston pumpsRotary piston liquid enginesPump chamberEngineering

The invention relates to a vane pump, comprising a rotor, which is supported in a pump housing and driven by a shaft, a plurality of vane plates supported in the rotor in a radially movable manner, and an outer ring that surrounds the rotor and the vane plates, the outer ring being arranged either directly in the pump housing or in an adjusting ring that can be moved in the pump housing along specified paths. The invention is based on the aim of developing a vane pump that among other things lowers the frictional and leakage losses, ensures the pump chambers are filled and drained optimally in regard to flow, in the lower rotational speed ranged as well as in the upper rotational speed range, significantly reduces the power losses, also is easy to manufacture and assemble in regard to production and significantly reduces the production costs, at the same time is insensitive to particles, minimizes the wear of the assemblies, and ensures the reliability and service life and a high specific delivery volume flow at high volumetric efficiency, both at low rotational speeds and high rotational speeds. The vane pump according to the invention is characterized in particular in that a cylinder guide (13) is arranged in the hollow rotor shaft (24), in which cylinder guide a freely rotating synchronizing cylinder (15) that is not rigidly connected to the adjacent assemblies is guided, wherein vane-shaped vane plate guide webs (14), which are associated with bearing grooves (4) arranged in the wall of the hollow rotor shaft (24) and which radially protrude beyond the hollow rotor shaft (24) in the vicinity of said bearing grooves (4) by approximately 0.75 to 1.8 times the diameter of the synchronizing cylinder (15) and which have bearing grooves (4), are rigidly arranged on the hollow rotor shaft (24) in such a way that the hollow rotor shaft (24) forms a vane rotor (3) together with vane plate guide webs (14), and outlet opening(s) (10), which extend completely through the adjusting slide and which extend radially with respect to the inner cylinder (6) and which are opposite the inlet nodule(s) (9) arranged in the side walls of the pump housing (1) on the pump side, are arranged in the adjusting slide (7).

Owner:欧根·施密特博士仪器和泵制造有限责任公司

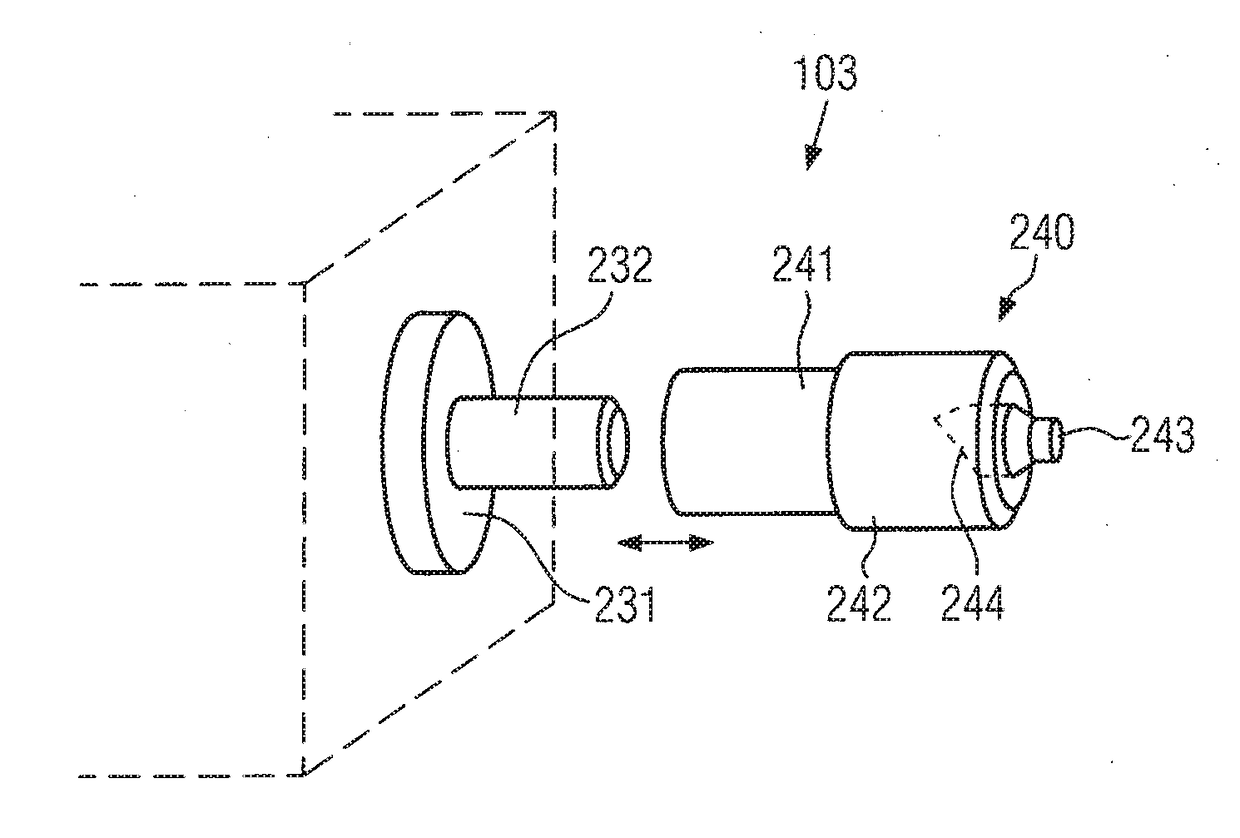

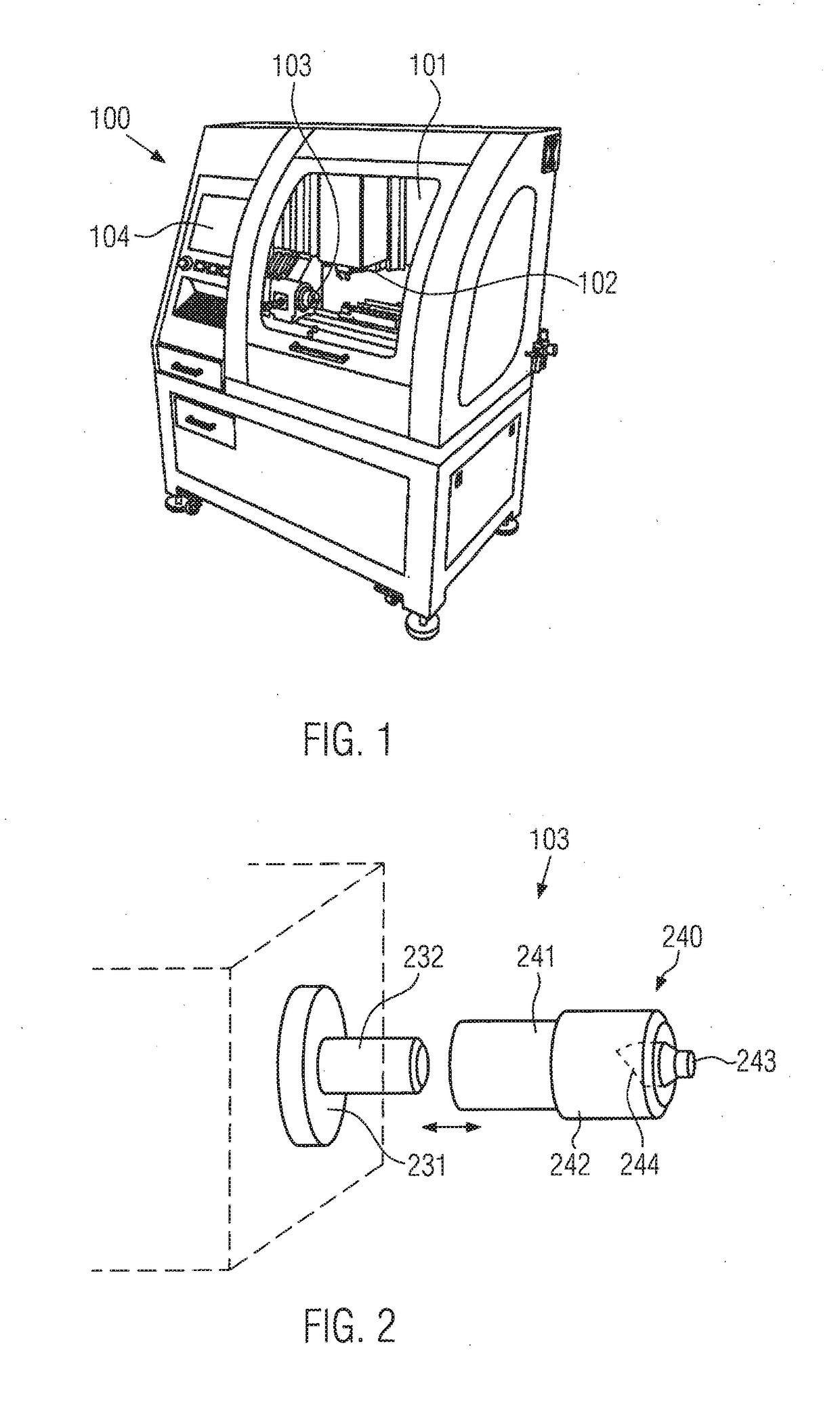

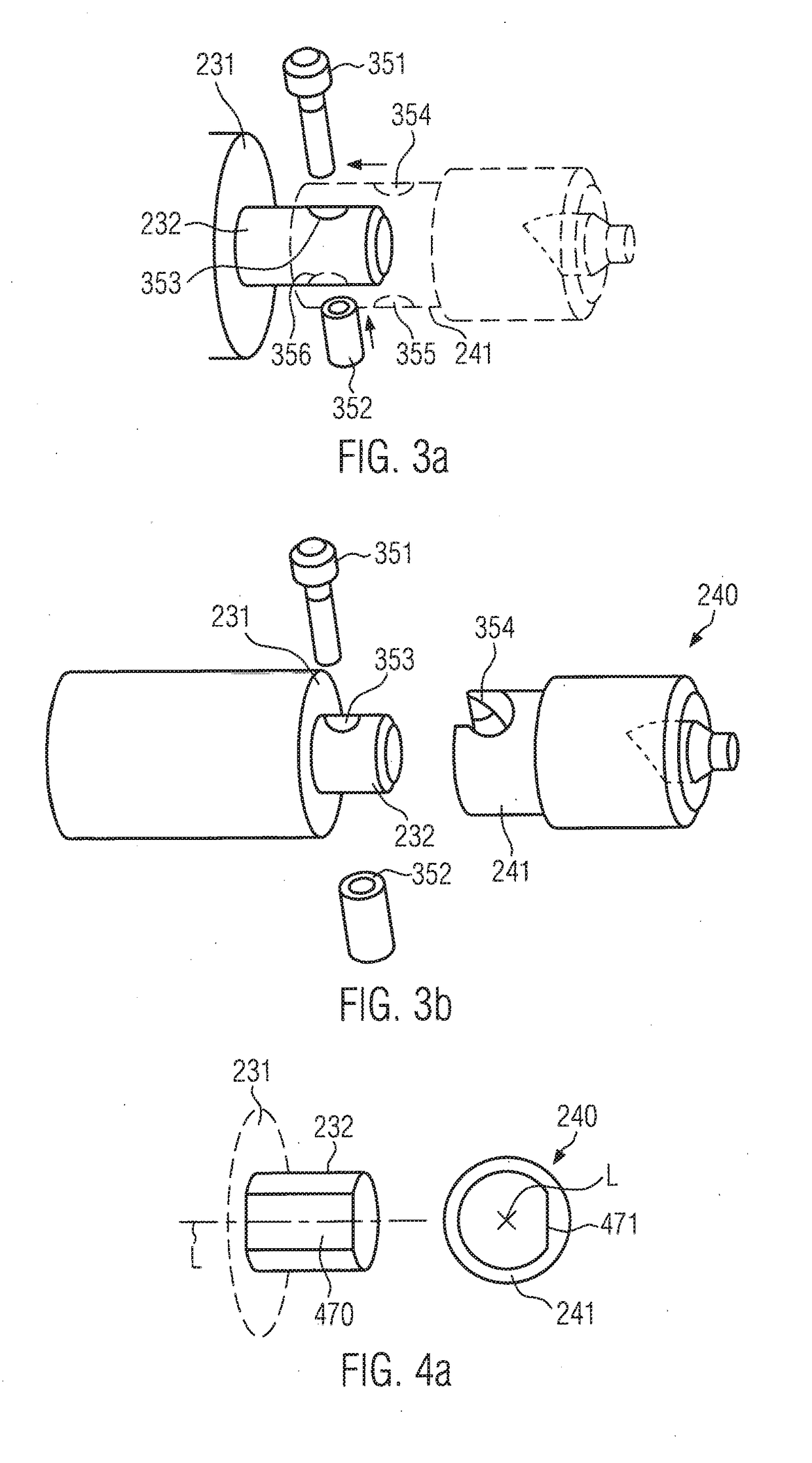

Milling Machine and Blank for a Dental Component

ActiveUS20170319303A1Reduce productionReduce failureSleeve/socket jointsTooth crownsAbutmentMechanical engineering

The invention relates to a milling machine for producing a dental component, such as a crown or an abutment for example, from a blank. The milling machine includes a stop and a holder for the blank. The invention is characterized in that the holder is designed such that the holder can be surrounded by a mounting, which surrounds the holder, of the blank, and the surrounding mounting of the blank can be brought into contact with the stop for positioning purposes. The invention further relates to a corresponding blank.

Owner:AMANN GIRRBACH

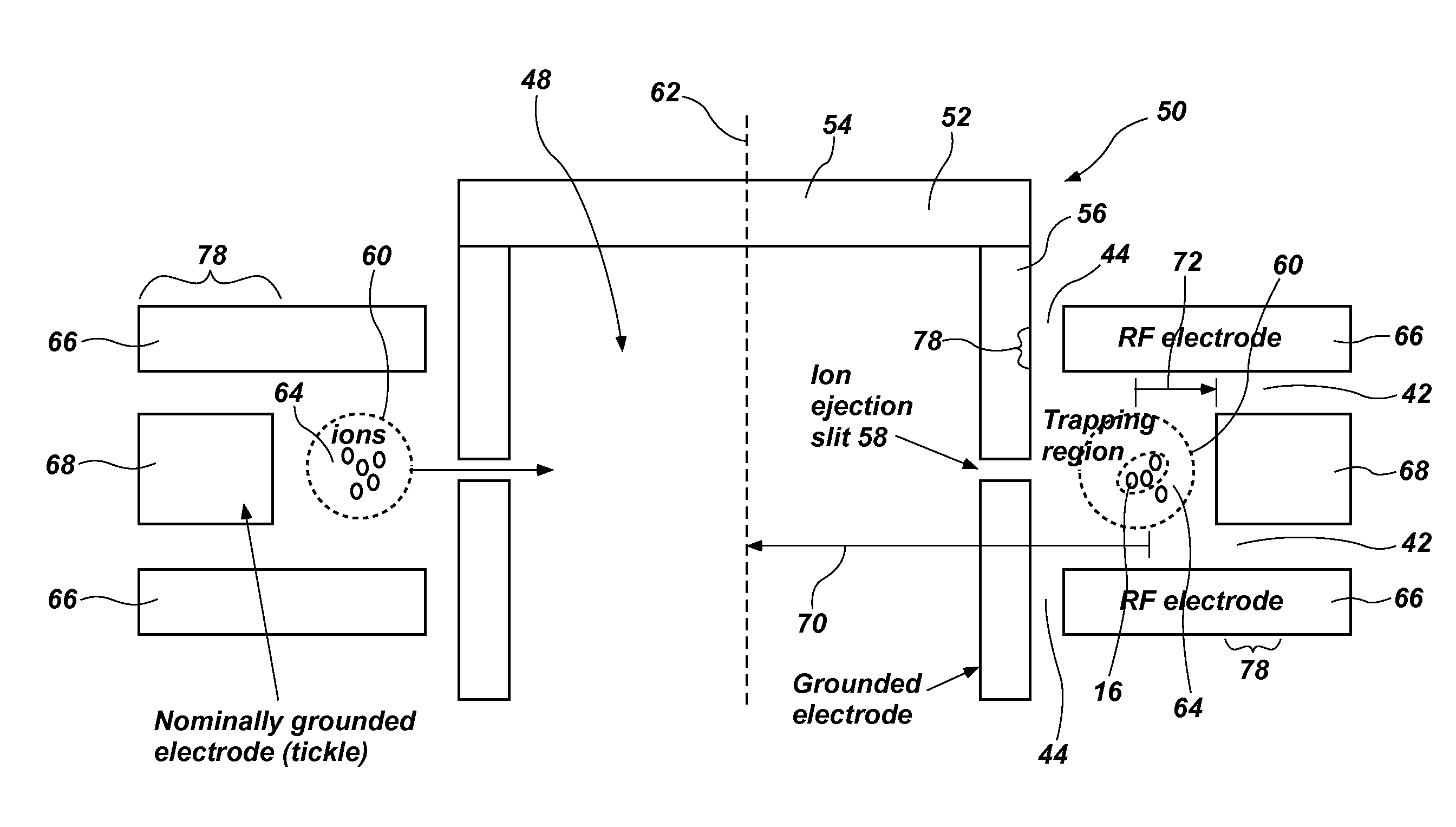

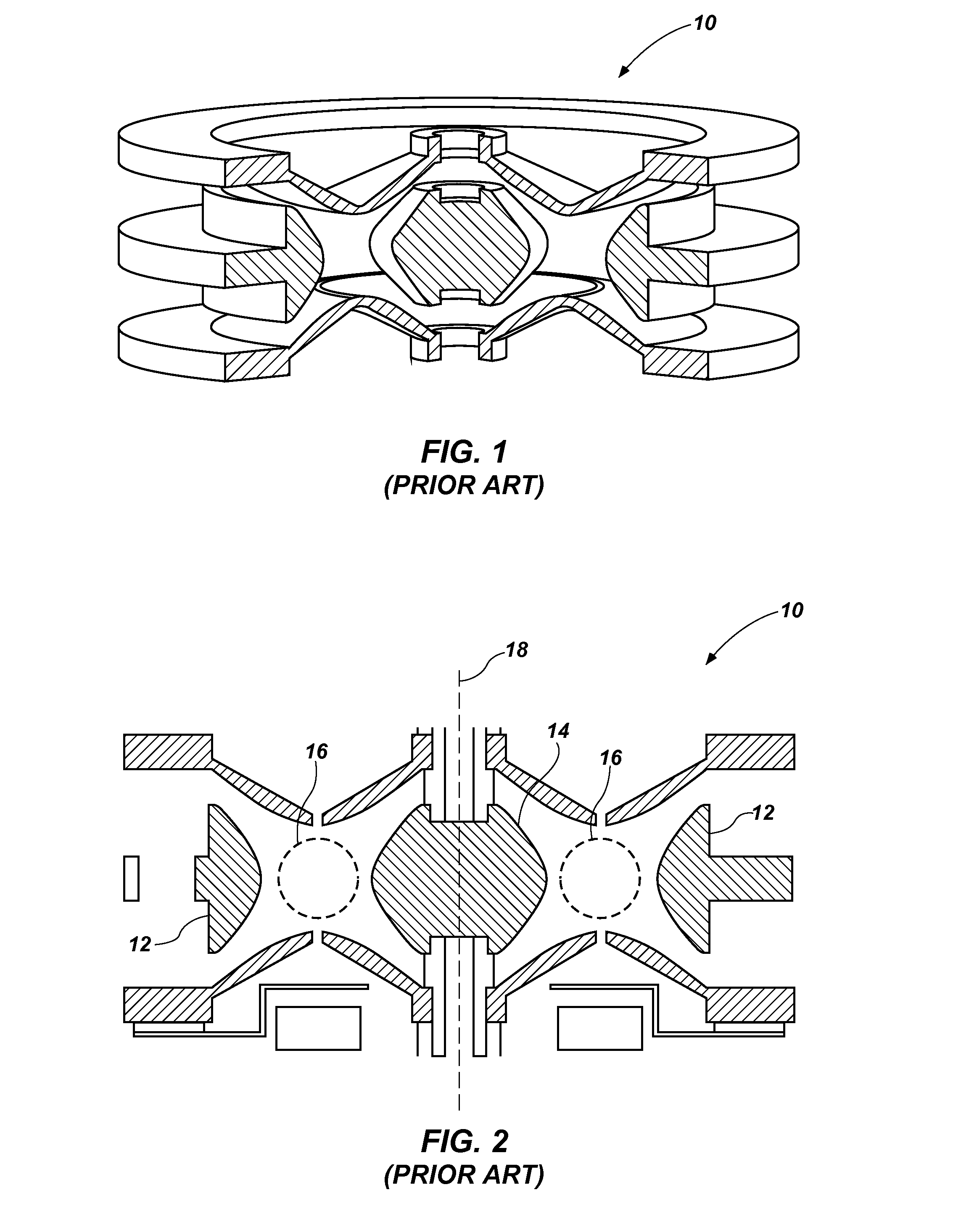

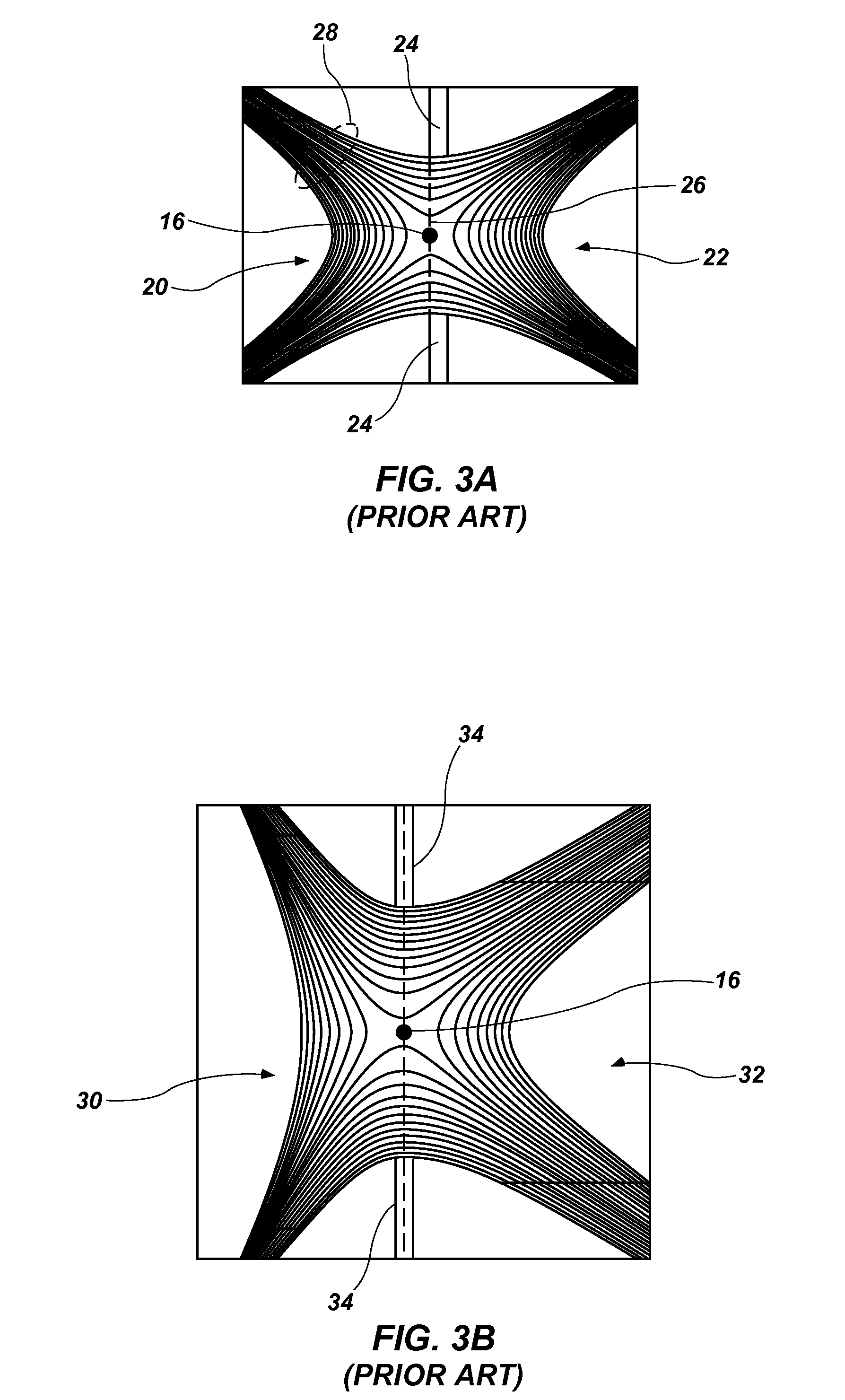

Toroidal ion trap mass analyzer with cylindrical electrodes

ActiveUS20130214152A1High precision manufacturingImprove detectionMiniaturised spectrometersIsotope separationElectric fieldCylindrical electrode

A combination of electrodes that are cylindrical and an asymmetric arrangement of cylindrical and planar electrodes are used to create electric fields that compensate for toroidal curvature in a toroidal ion trap, the design lending itself to high precision manufacturing and miniaturization, converging ion paths that enhance detection, higher pressure operation, and optimization of the shape of the electric fields by careful arrangement of the electrodes.

Owner:BRIGHAM YOUNG UNIV

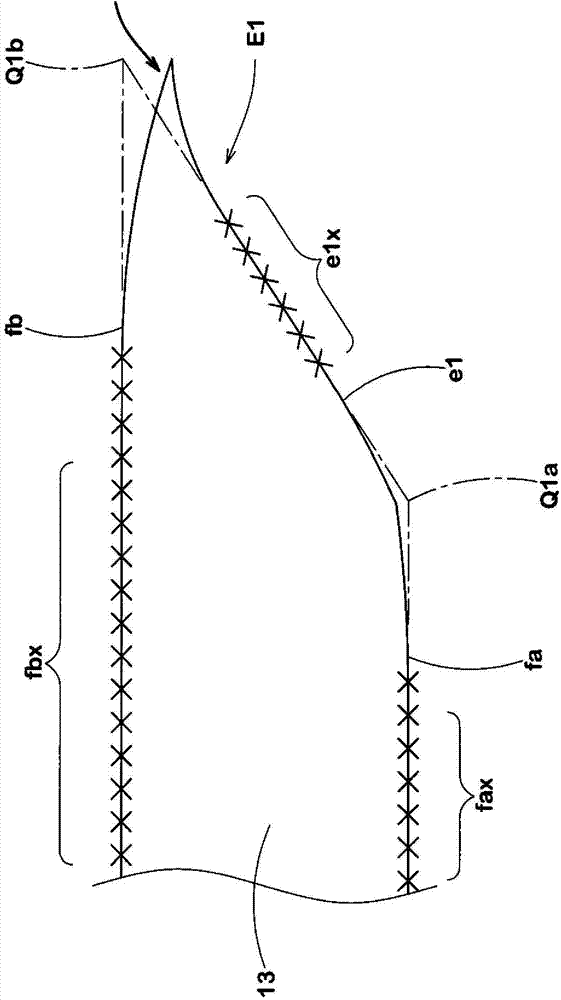

Manufacturing device for tire ply material

The device for manufacturing tire ply material efficiently and with high precision is equipped with: a first gripping-moving device provided with a first gripping tool, which grips the first connection edge of a cut piece at the emplacement position, on the tip of a first robot arm; and a second gripping-moving device provided with a second gripping tool, which grips the second connection edge, on the tip of a second robot arm. The first gripping tool comprises a gripping means on one side that grips the end portion on one side of the first connection edge of the cut piece and a gripping means on the other side that grips the end portion on the other side of the cut piece, and is provided with a stretching means that draws the gripping means away from each other to stretch the cut piece gripped therewith.

Owner:SUMITOMO RUBBER IND LTD

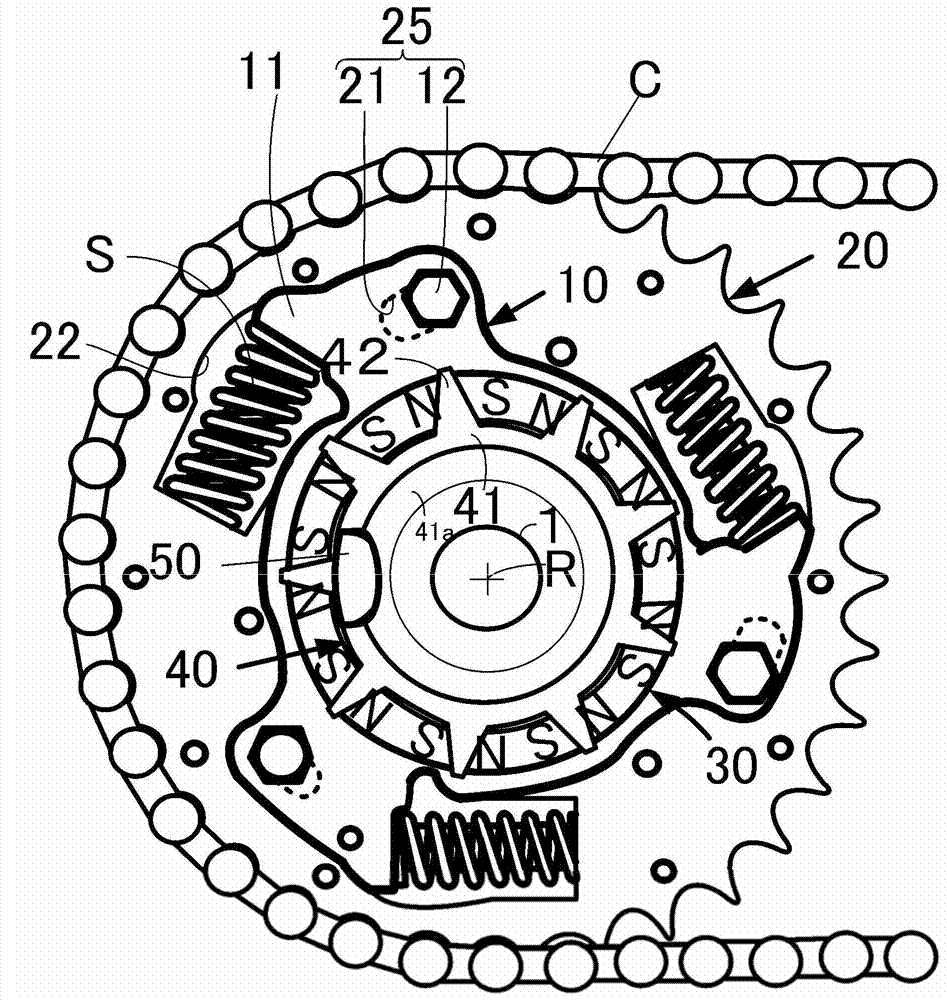

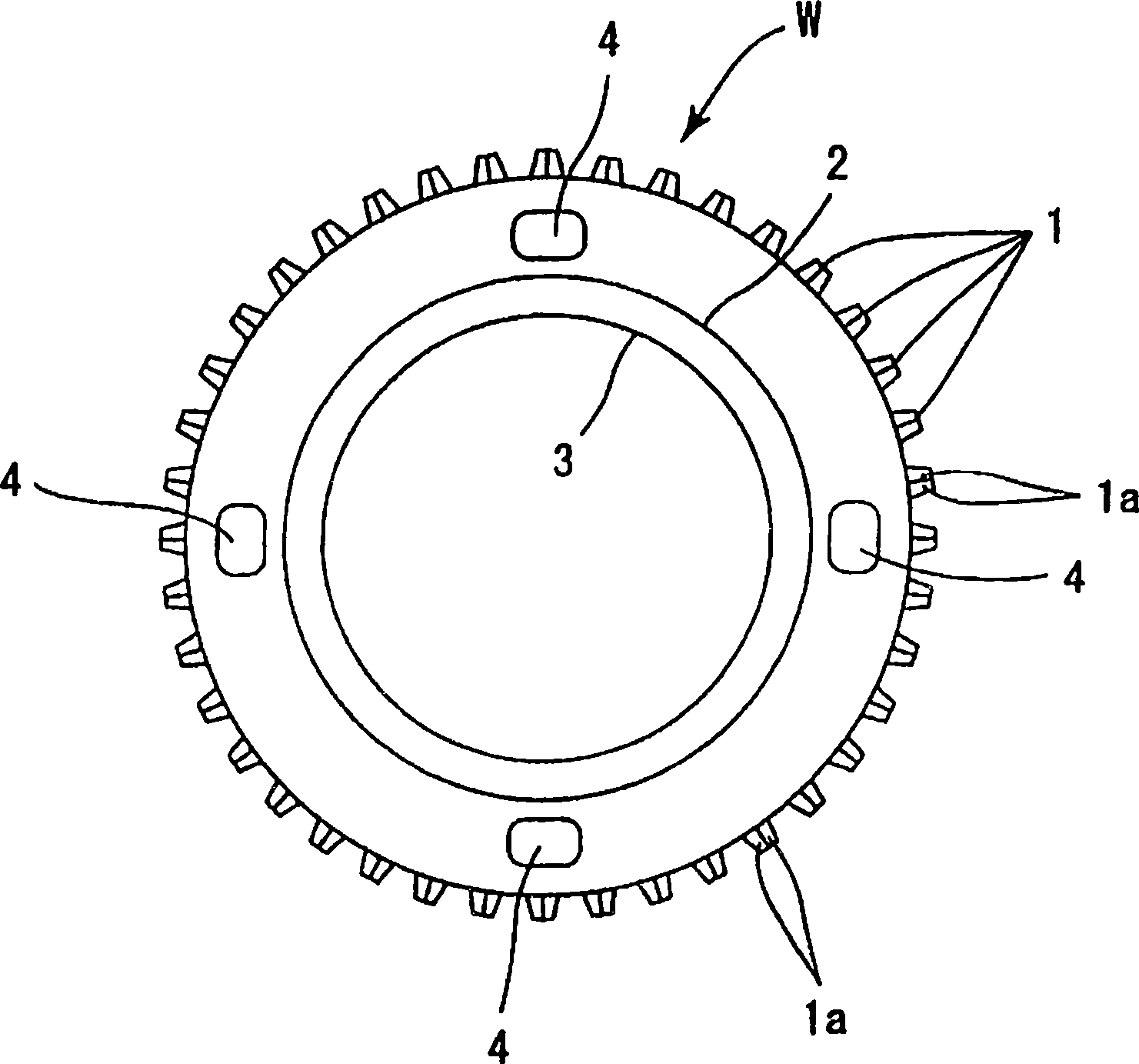

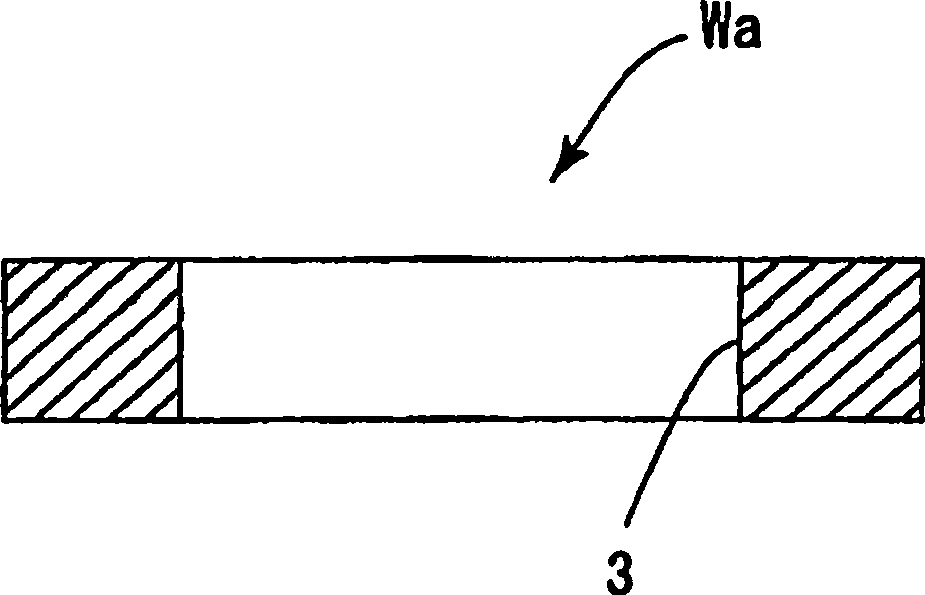

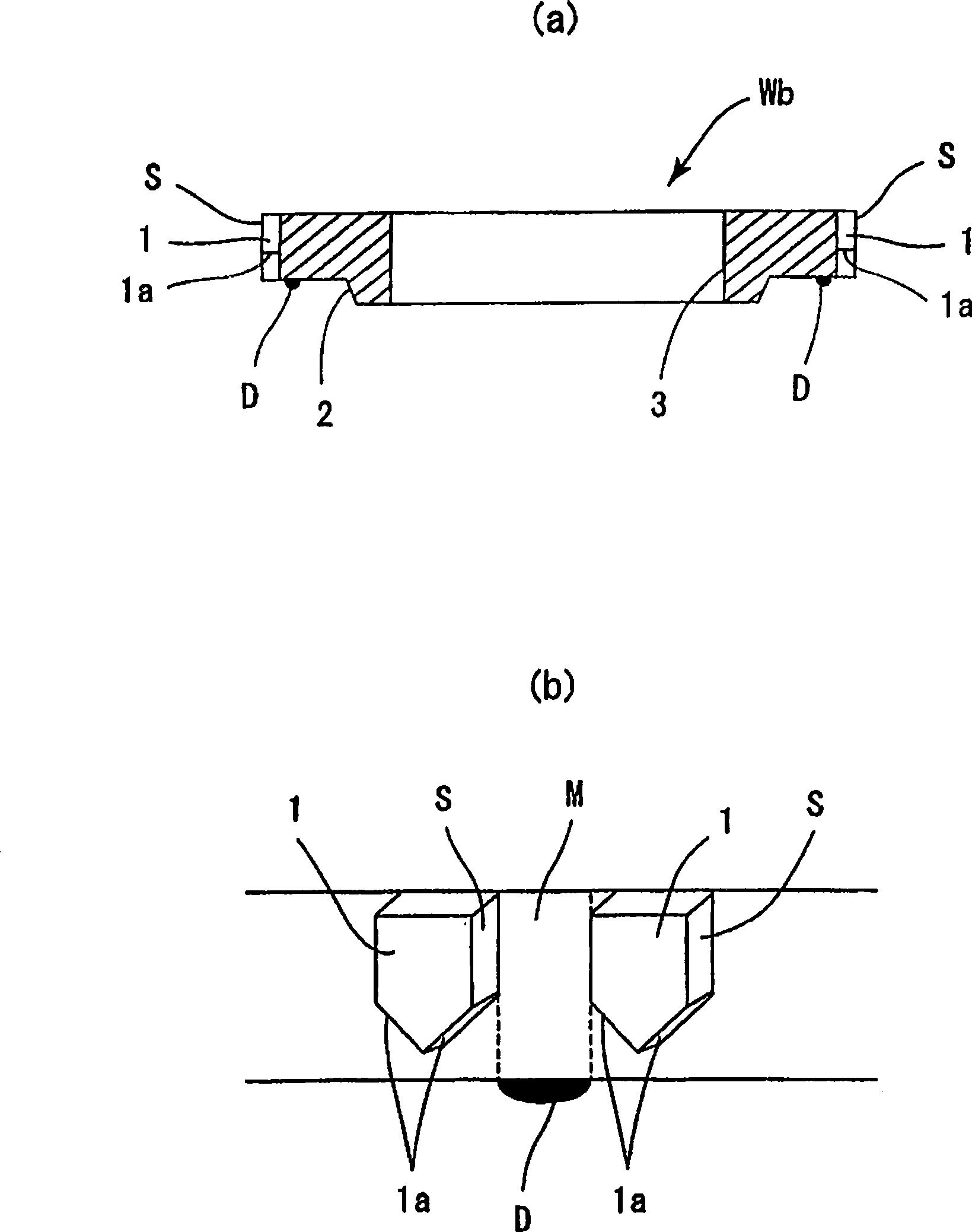

Clutch gear manufacturing apparatus and clutch gear manufacturing method

ActiveCN101362181AHigh precision manufacturingAvoid deformationForging/hammering/pressing machinesWheelsClutchGear manufacturing

The invention provides a clutch gear manufacturing apparatus of the clutch gear for restraining the increase of process number, while manufacturing multiple tapered synchronization device and a clutch gear manufacturing method. The clutch gear manufacturing apparatus includes a die (16) that allows a clutch gear primary product (Wb), which has spline teeth (1) with chamfers (1a) formed in an outer peripheral surface of the primary product (Wb), to be disposed in the die (16), and includes a blade(16a) capable of forming reverse tapers (1b) at the spline teeth (1); a punch (18) capable of pressing down the primary product (Wb) disposed in the die (16) so that the spline teeth (1) are pressed by the blade (16a); a knockout sleeve (17) that receives the primary product (Wb) which is pressed down by the punch (18); and a punch pin (31) that forms a cone hole (4) in a side surface of the primary product (Wb) while the spline teeth (1) are pressed by the blade (16a).

Owner:NISSAN MOTOR CO LTD

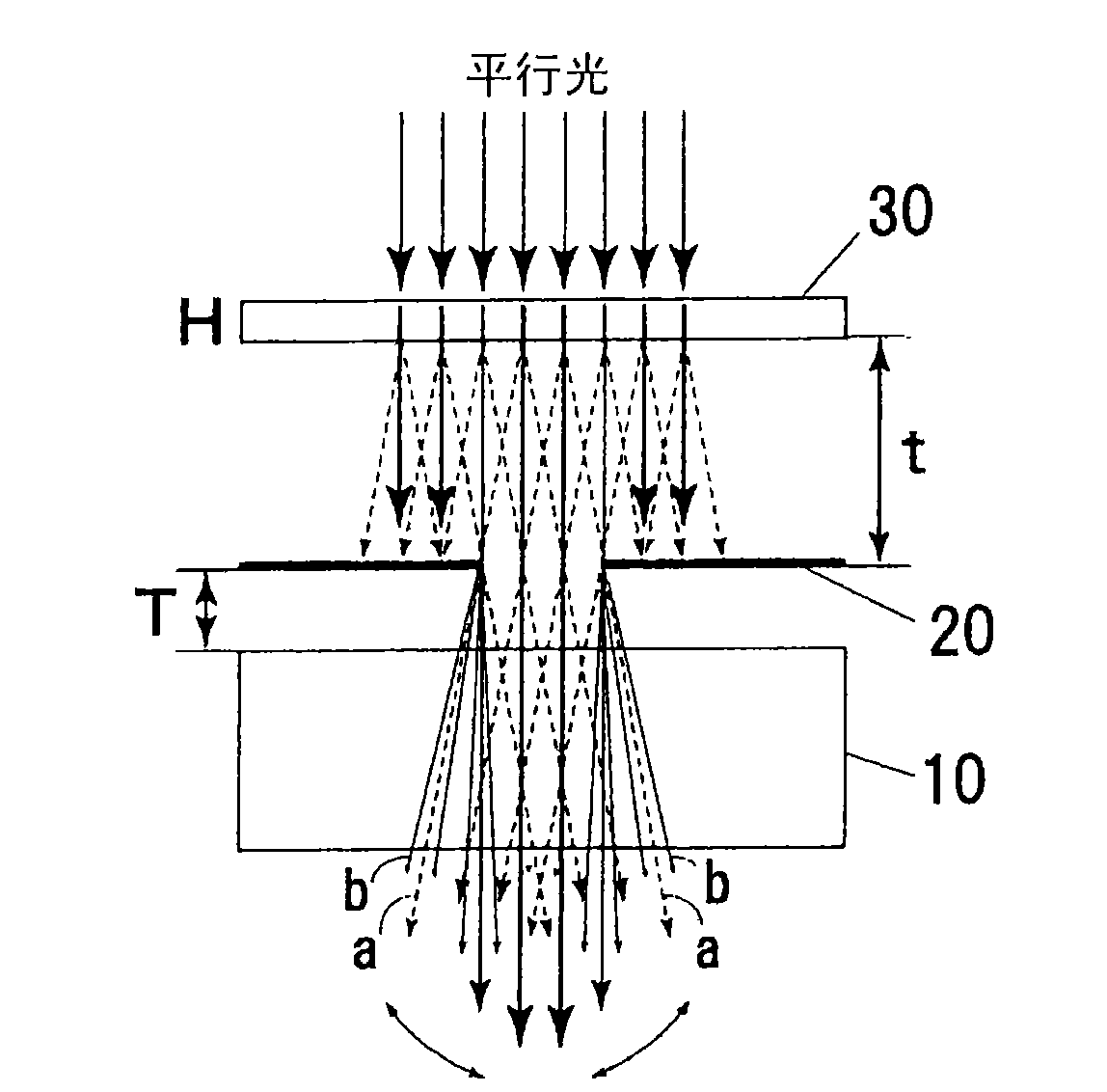

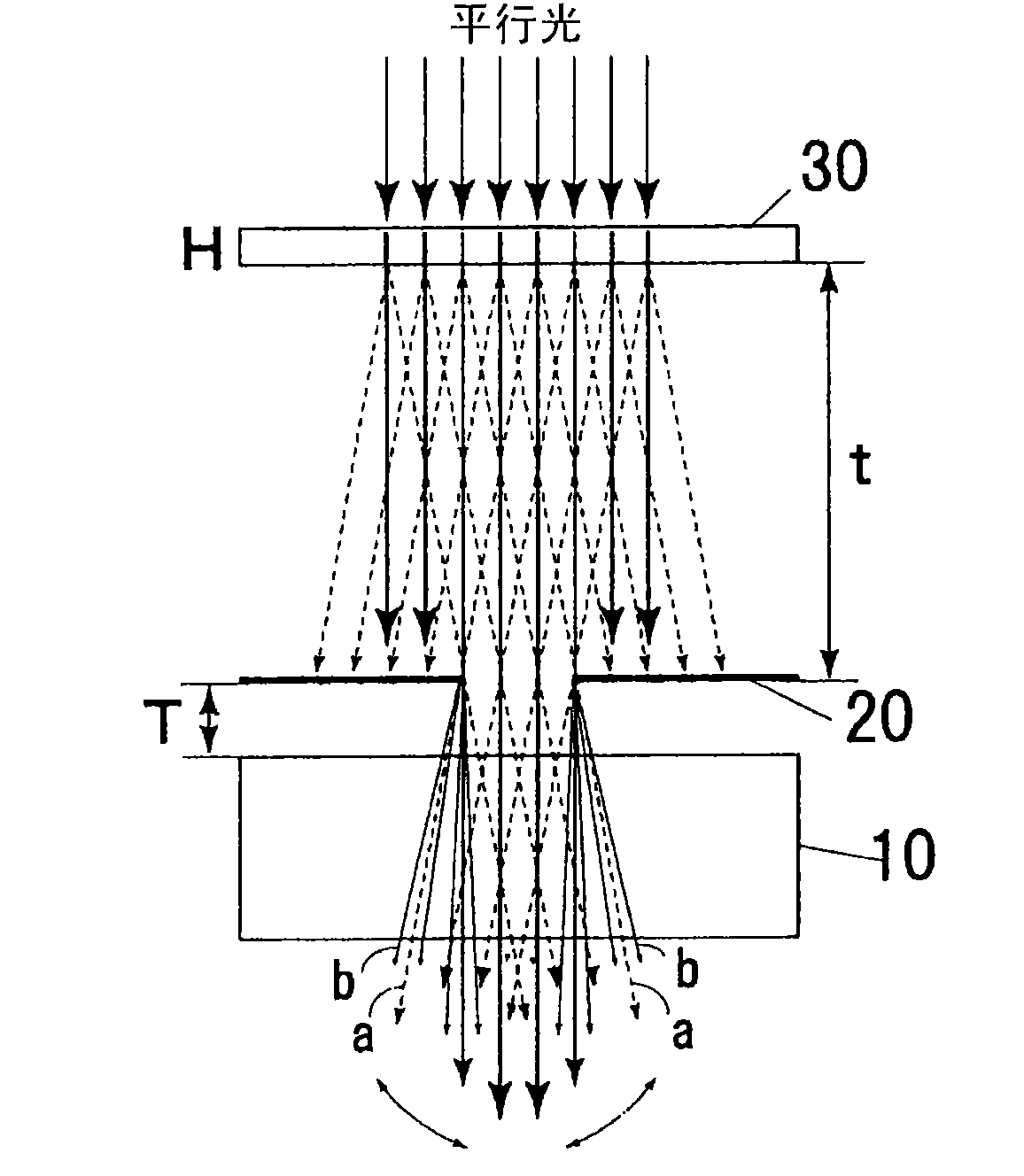

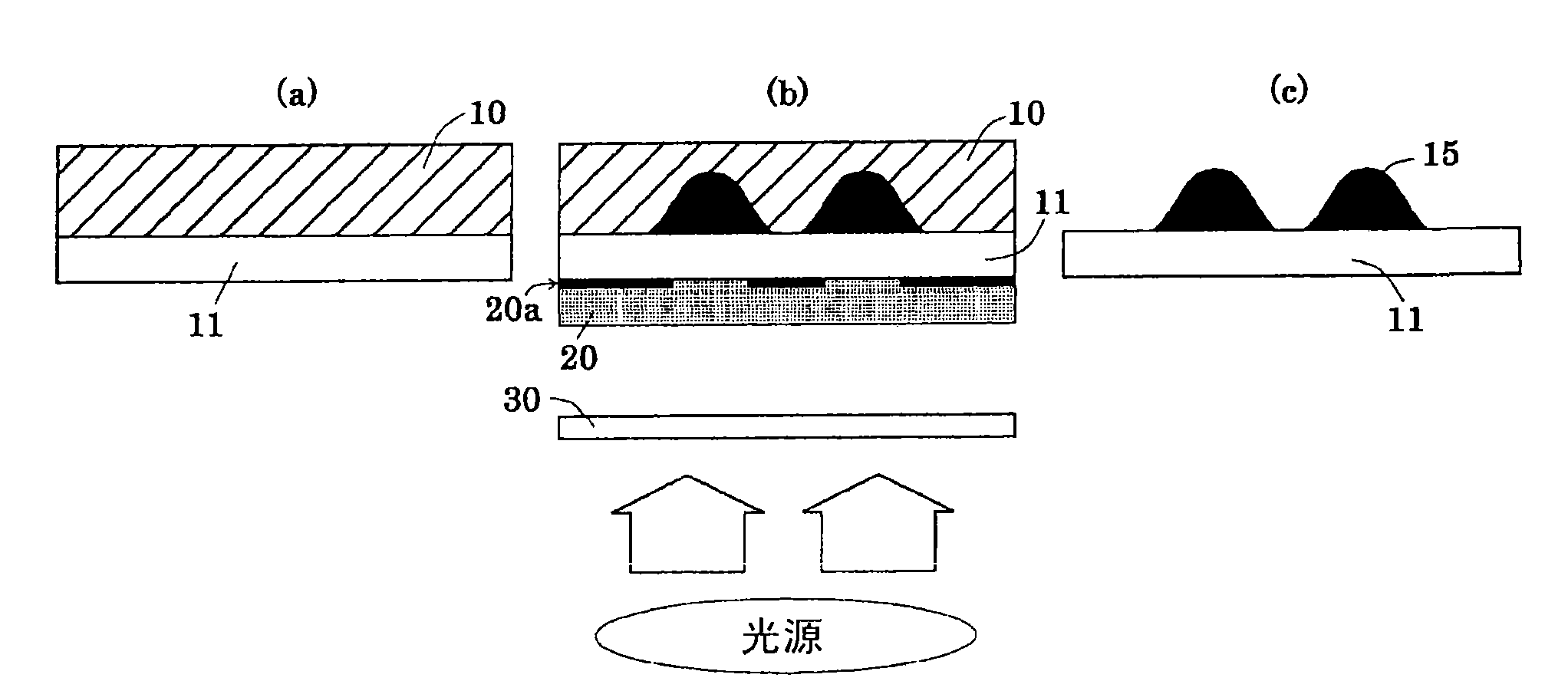

Method for manufacturing surface unevenness

InactiveCN101636671AHigh precision manufacturingDiffusing elementsPhotomechanical apparatusEngineeringPhotomask

The inventon provides a method for manufacturing surface unevenness, by which a desired uneven shape can be formed easily at a high accuracy by using a photomask. On one side of a photosensitive film (10) composed of a photosensitive resin composite, a mask member (20) having a light permeable section and a non light permeable section is arranged at an interval from the photosensitive film (10), and a light diffusing member (30) is arranged on the side opposite to the photosensitive film (10) of the mask member (20). Light is applied from a light source arranged on the side opposite to the mask member (20) of the light diffusing member (30), and a photosensitive film (10) is exposed through the light diffusing member (30) and the light permeable section of the mask member (20). An exposedsection or unexposed section of the photosensitive film (10) is removed by development, and unevenness determined by the shape of the exposed section or the unexposed section is formed on the photosensitive film (10). In the exposure, exposure conditions such as haze of the light diffusing member (30) are controlled, and the shape of the exposed section or the unexposed section is controlled.

Owner:KIMOTO CO LTD

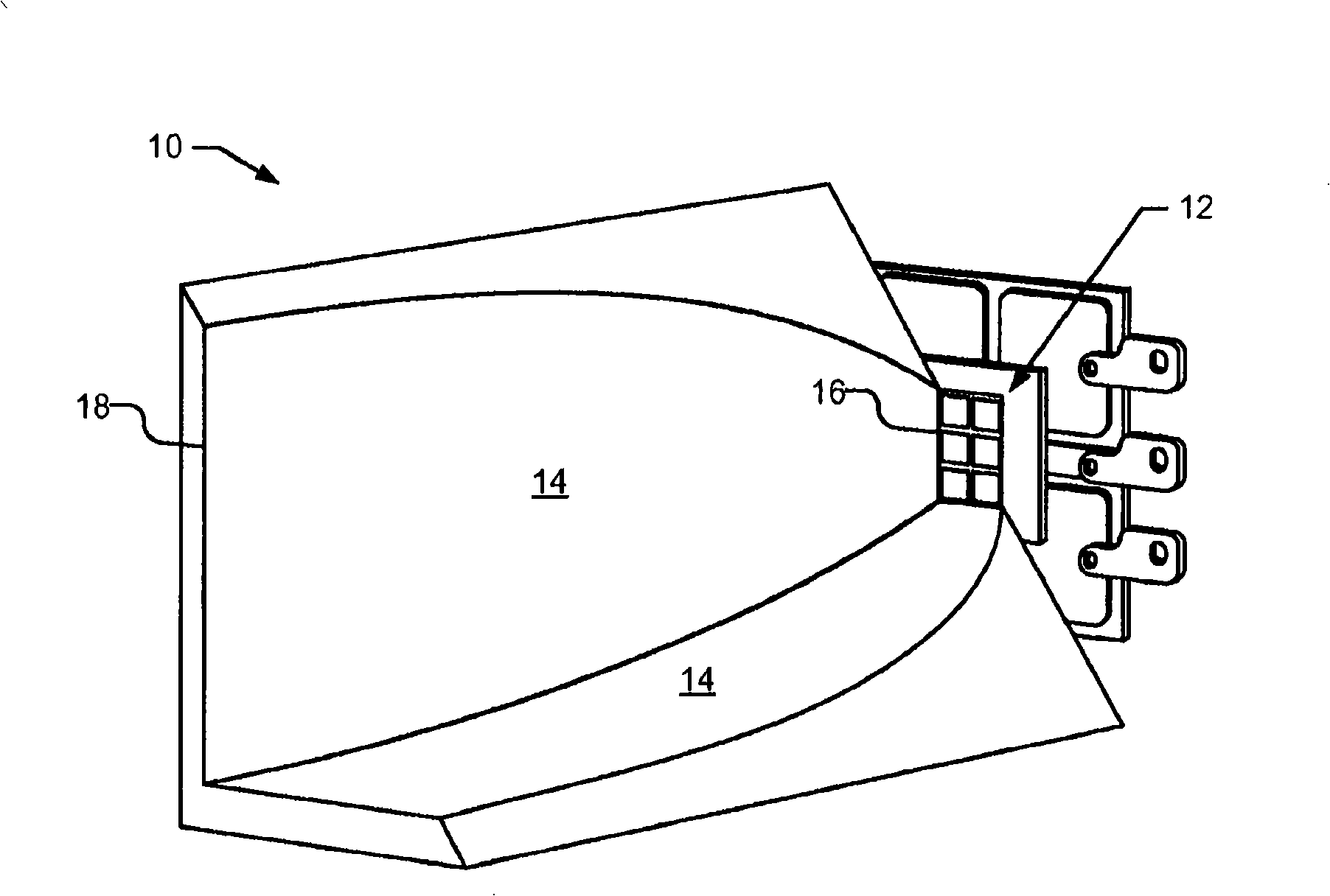

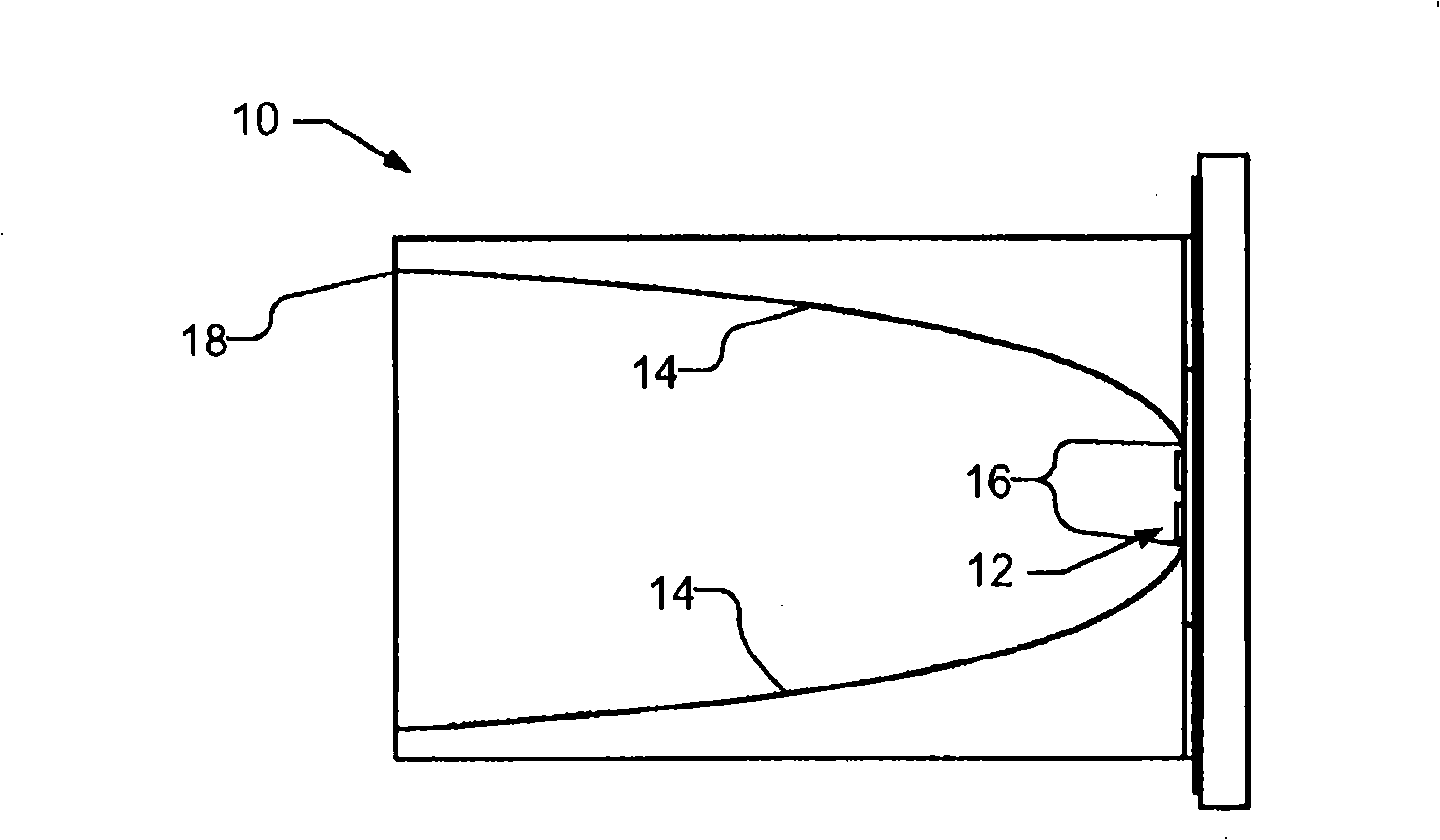

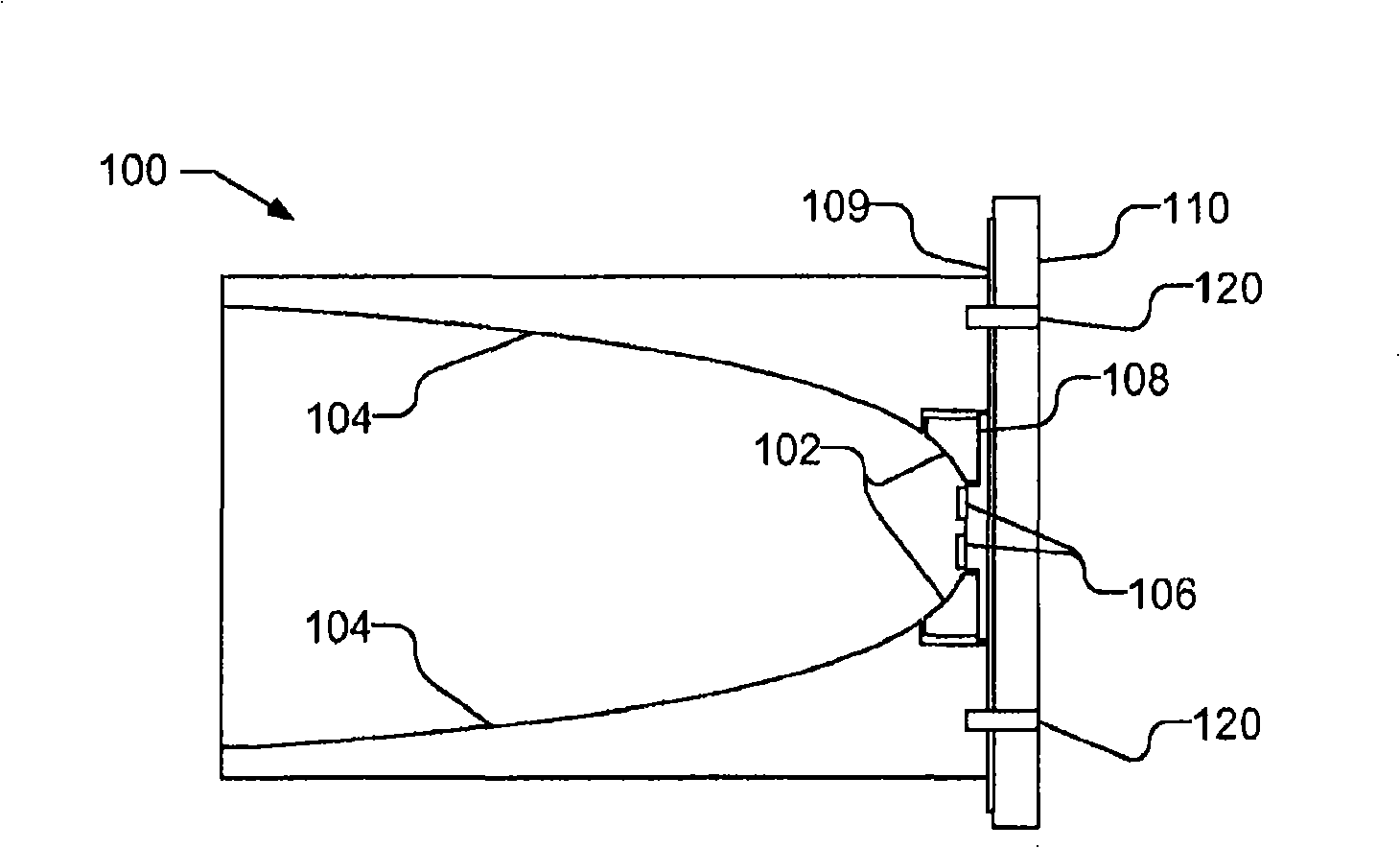

Multiple piece reflective angle transformer

ActiveCN101297153AHigh precision manufacturingPoint-like light sourceDisplay meansTransformerLight-emitting diode

Collection optics (10) are used with one or more light emitting diodes (106) to produce, e.g., collimated light. The collection optics (10) are produced in multiple pieces including a small reflective ring (102) that surrounds the one or more light emitting diodes (106). The reflective ring (102) may be positioned relative to the LEDs (106), using a mesa (112) upon which the LEDs (106) are mounted, as a lateral positioning guide. A separate upper reflector (104) uses the reflective ring (102) as a lateral positioning guide during assembly. The reflective ring (102) and the upper reflector (104) include reflective sidewalls that are approximately continuous when the reflective ring (102) and upper reflector (104) are assembled.

Owner:SIGNIFY NORTH AMERICA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com