Vane pump

A technology of vane pumps and vane plates, applied in pumps, pump components, pump control, etc., can solve problems such as high processing and assembly costs, and achieve the effects of improving sealing, reducing friction radius, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

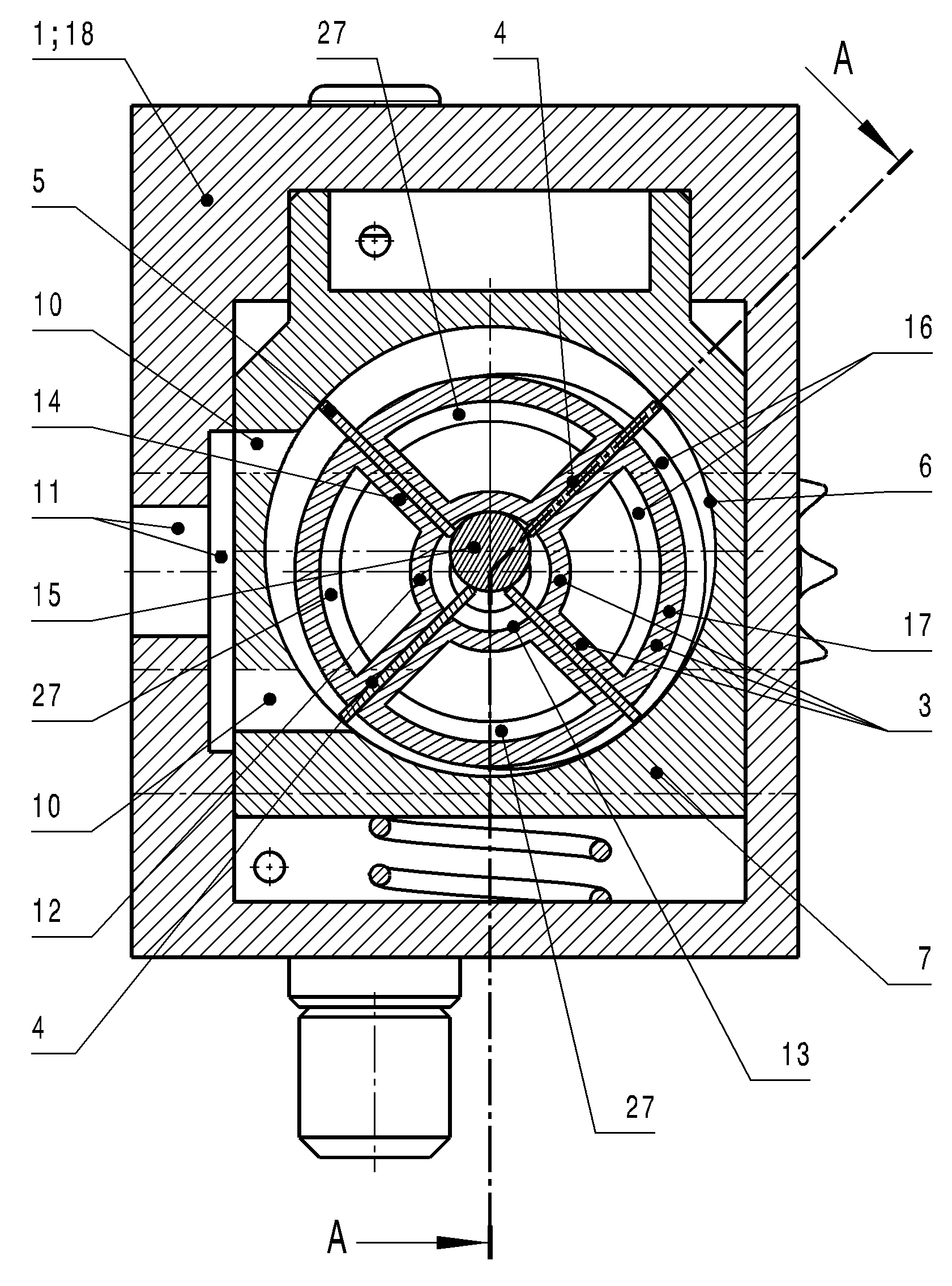

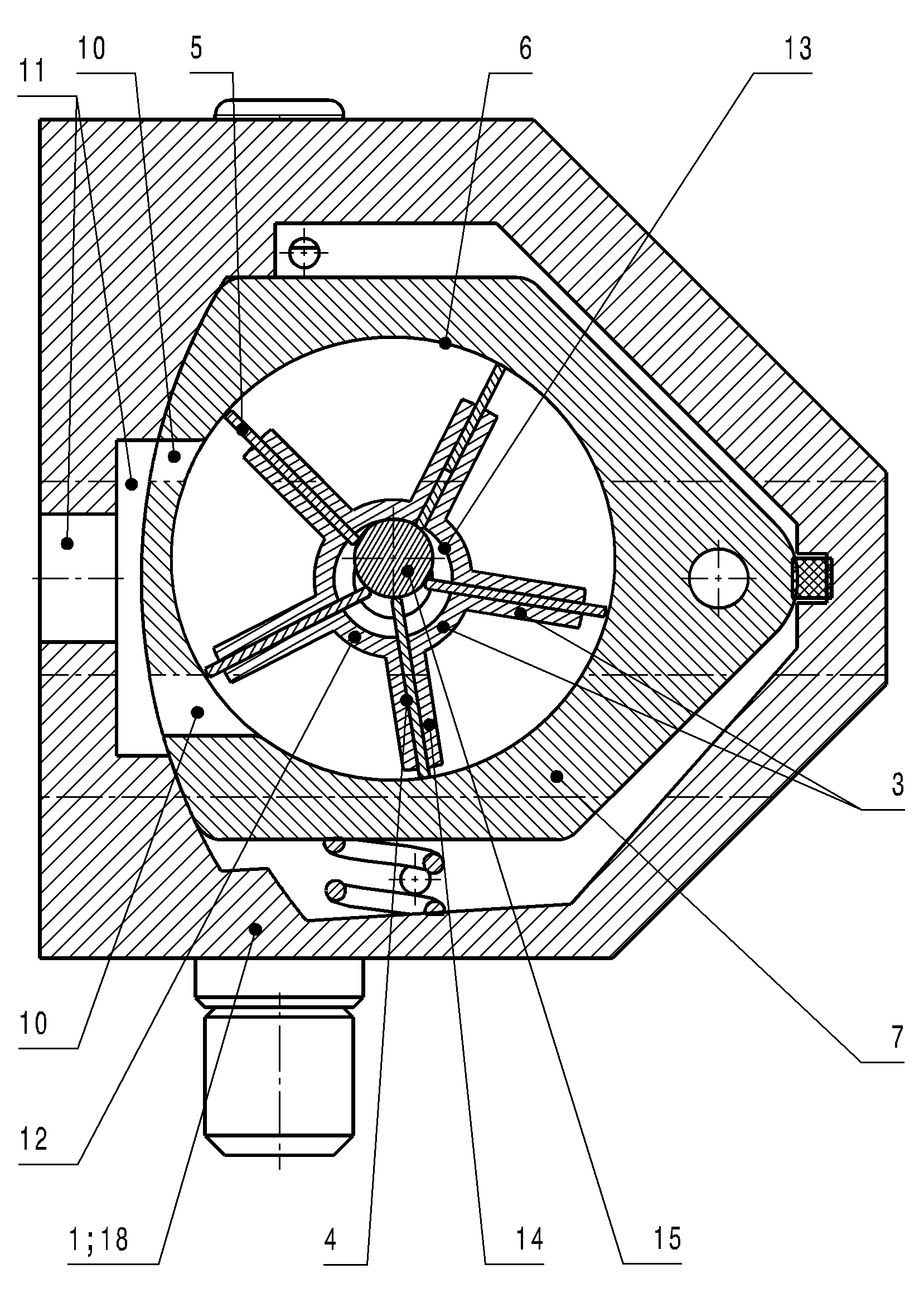

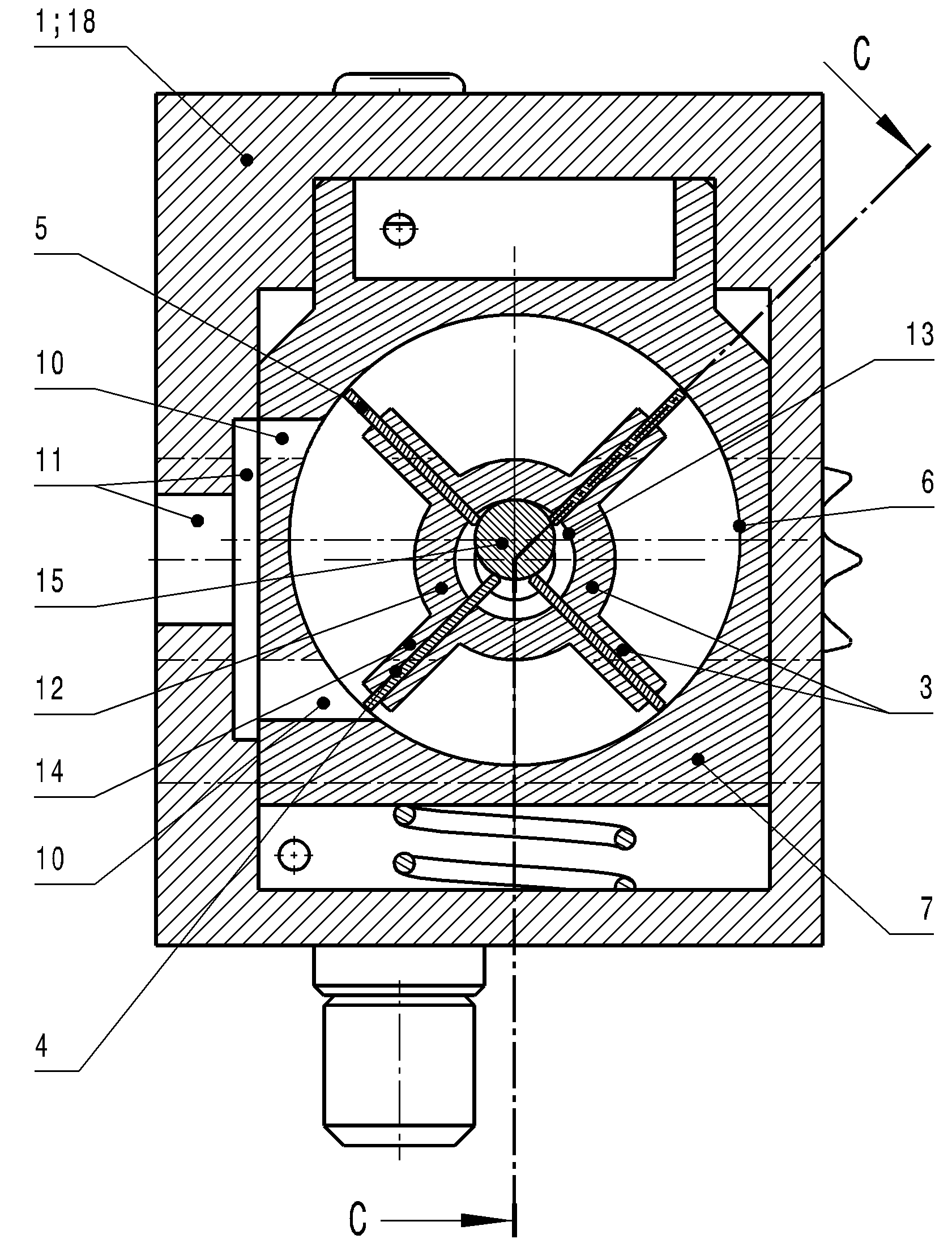

[0054] Four of the possible designs of the vane pump according to the invention are shown in FIGS. 1 to 6 with two different designs of the adjusting slide 7 .

[0055] Common to all designs here is that the rotor shaft 12 is arranged in the pump housing 1 .

[0056] The rotor shaft 12 comprises a drive shaft 2 mounted in the pump housing 1 and a hollow rotor shaft 24 connected to the drive shaft 2 .

[0057] All constructions are characterized in that a cylindrical guide 13 is arranged in the rotor hollow shaft 24 , in which a freely surrounding synchronous cylinder 15 which is non-rigidly connected to adjacent components is guided .

[0058] What is essential according to the invention here is that the blade-shaped, associated bearing groove 4 arranged in the wall of the rotor hollow shaft 24 is arranged so rigidly on the rotor hollow shaft 24 that in the region of this bearing groove 4 there is Approximately 0.75 to 1.8 times the diameter of the synchronizing cylinder 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com