Patents

Literature

315results about How to "Reduce leakage loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

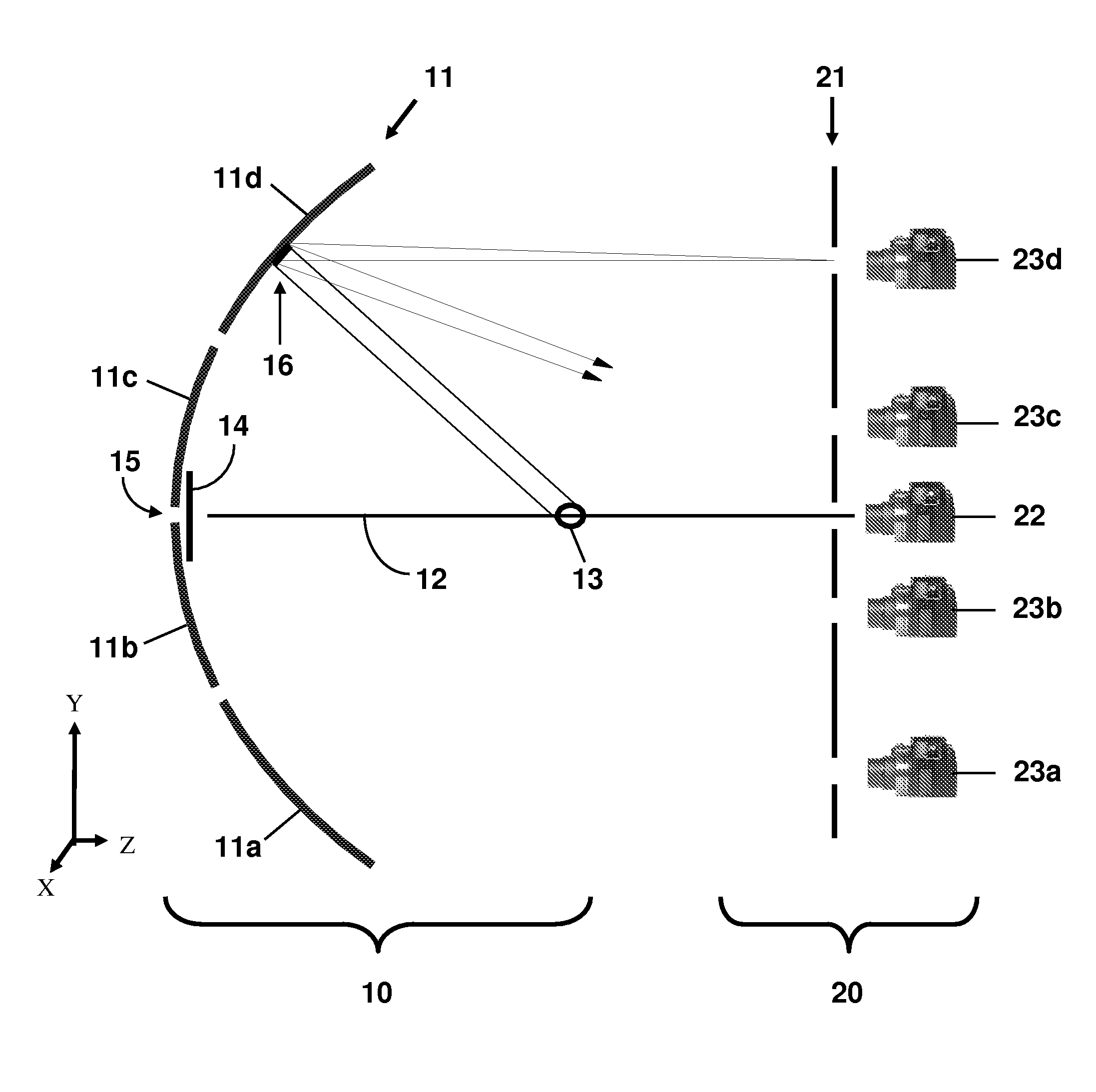

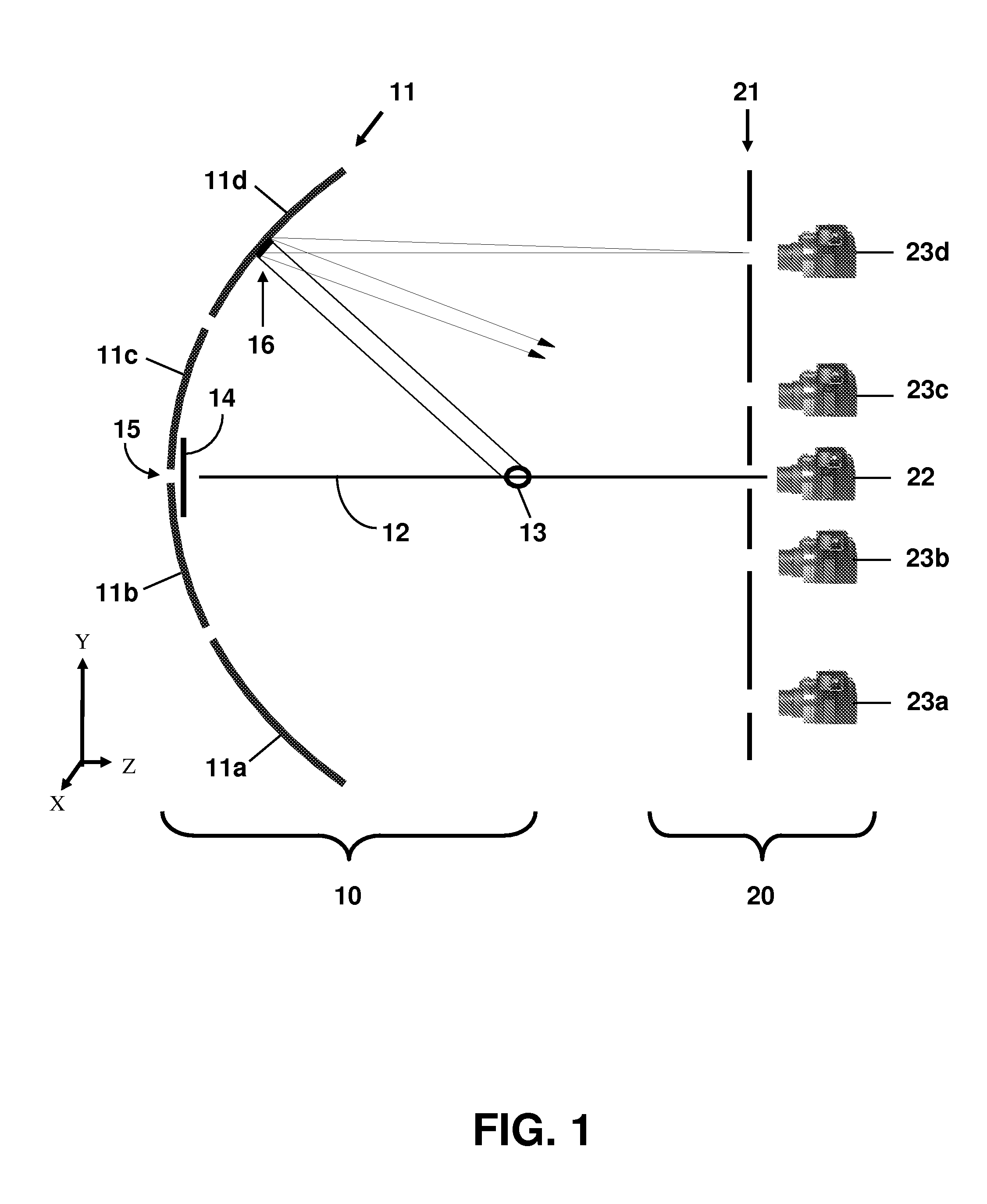

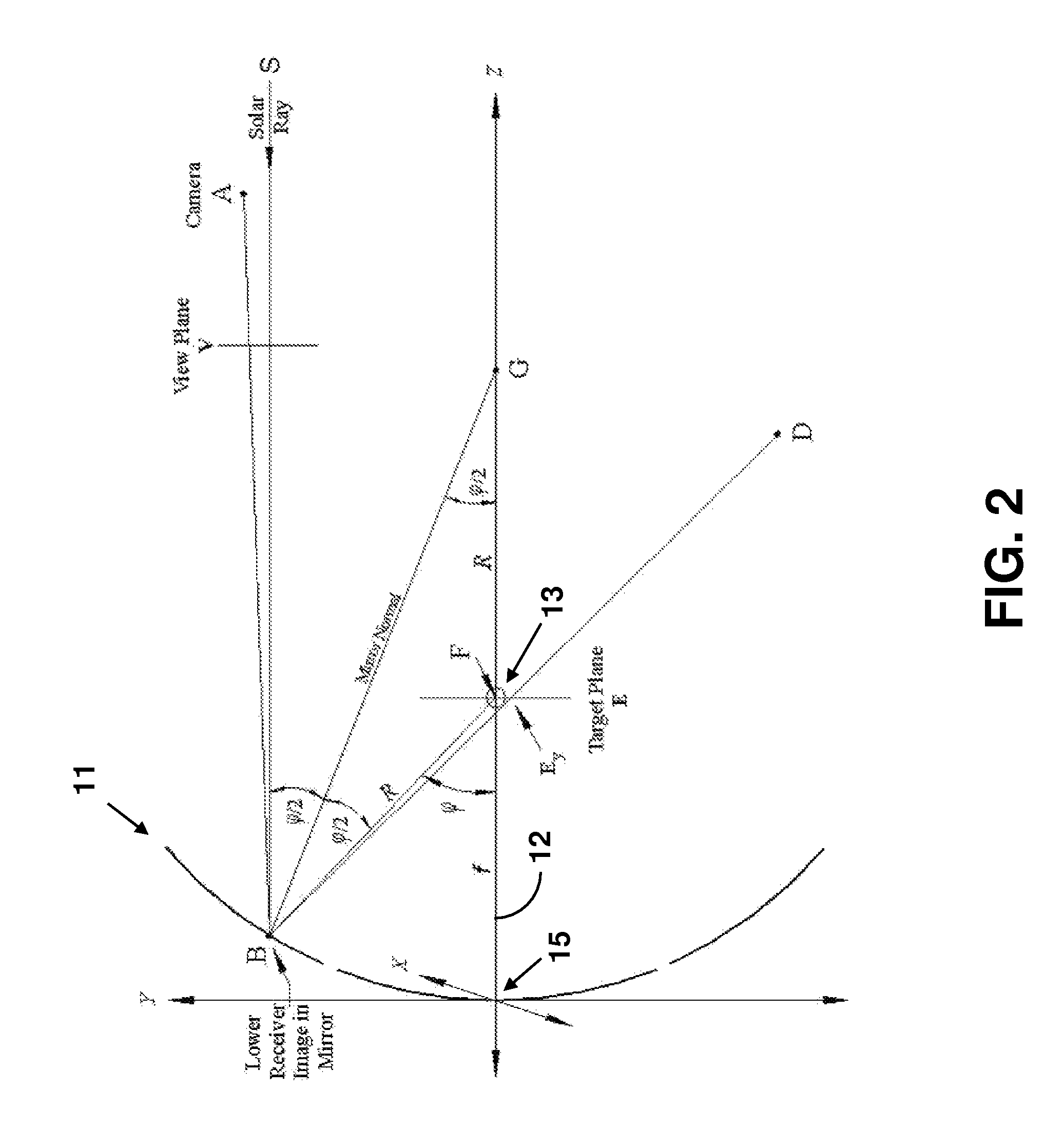

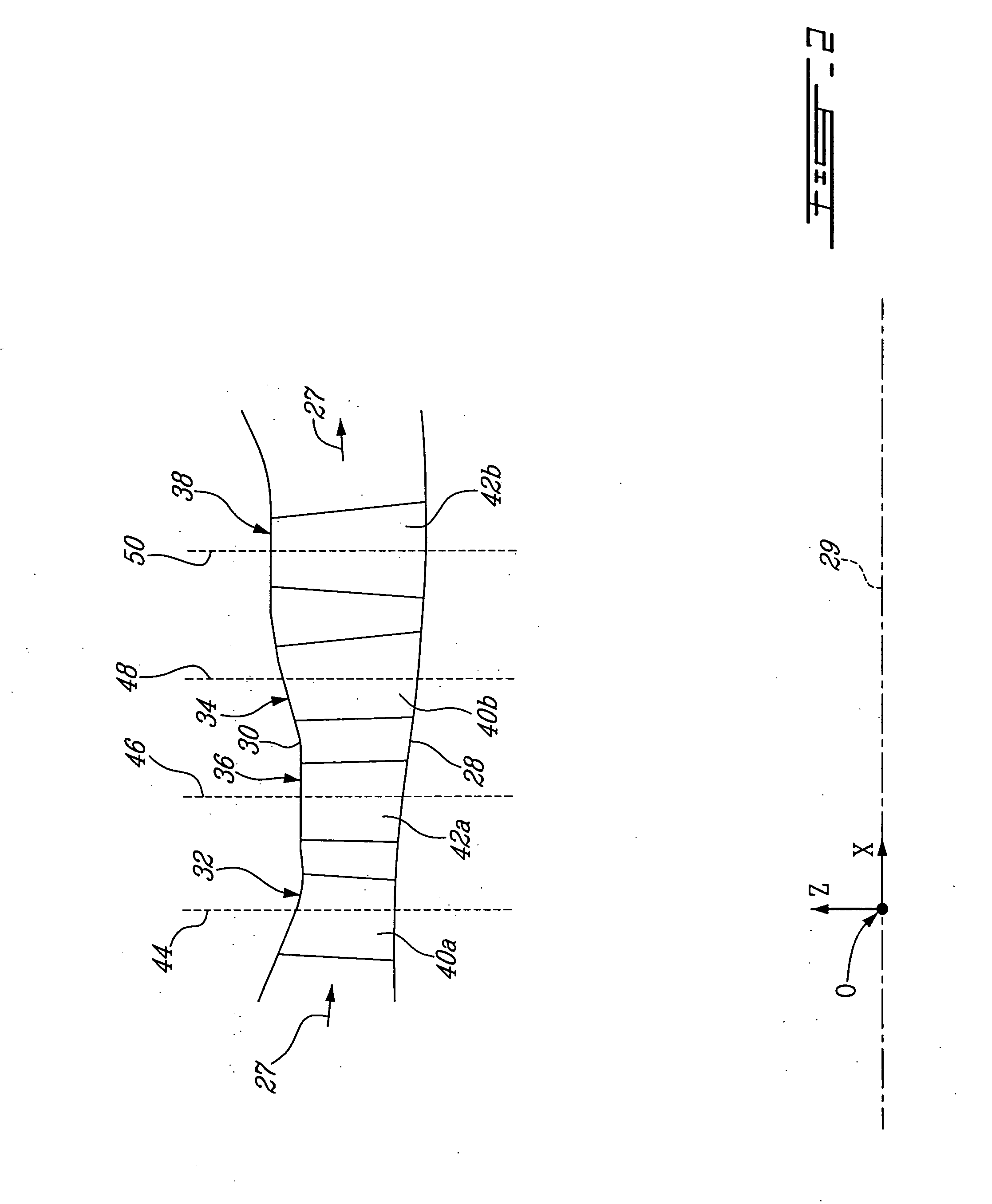

Alignment method for parabolic trough solar concentrators

ActiveUS7667833B1Good optical performanceAlignment accuracyAngle measurementSolar heating energyEngineeringSolar concentrator

A Theoretical Overlay Photographic (TOP) alignment method uses the overlay of a theoretical projected image of a perfectly aligned concentrator on a photographic image of the concentrator to align the mirror facets of a parabolic trough solar concentrator. The alignment method is practical and straightforward, and inherently aligns the mirror facets to the receiver. When integrated with clinometer measurements for which gravity and mechanical drag effects have been accounted for and which are made in a manner and location consistent with the alignment method, all of the mirrors on a common drive can be aligned and optimized for any concentrator orientation.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

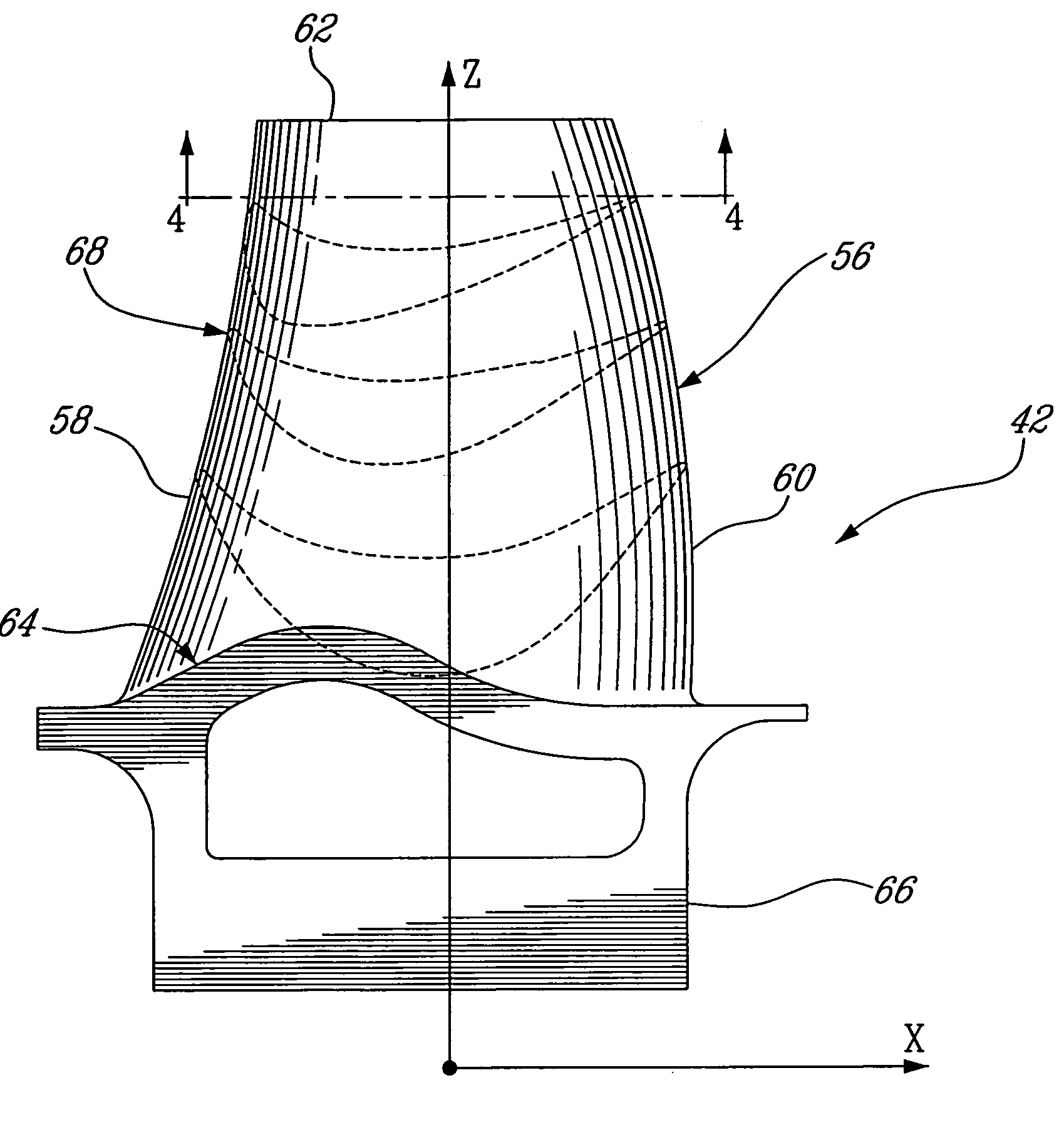

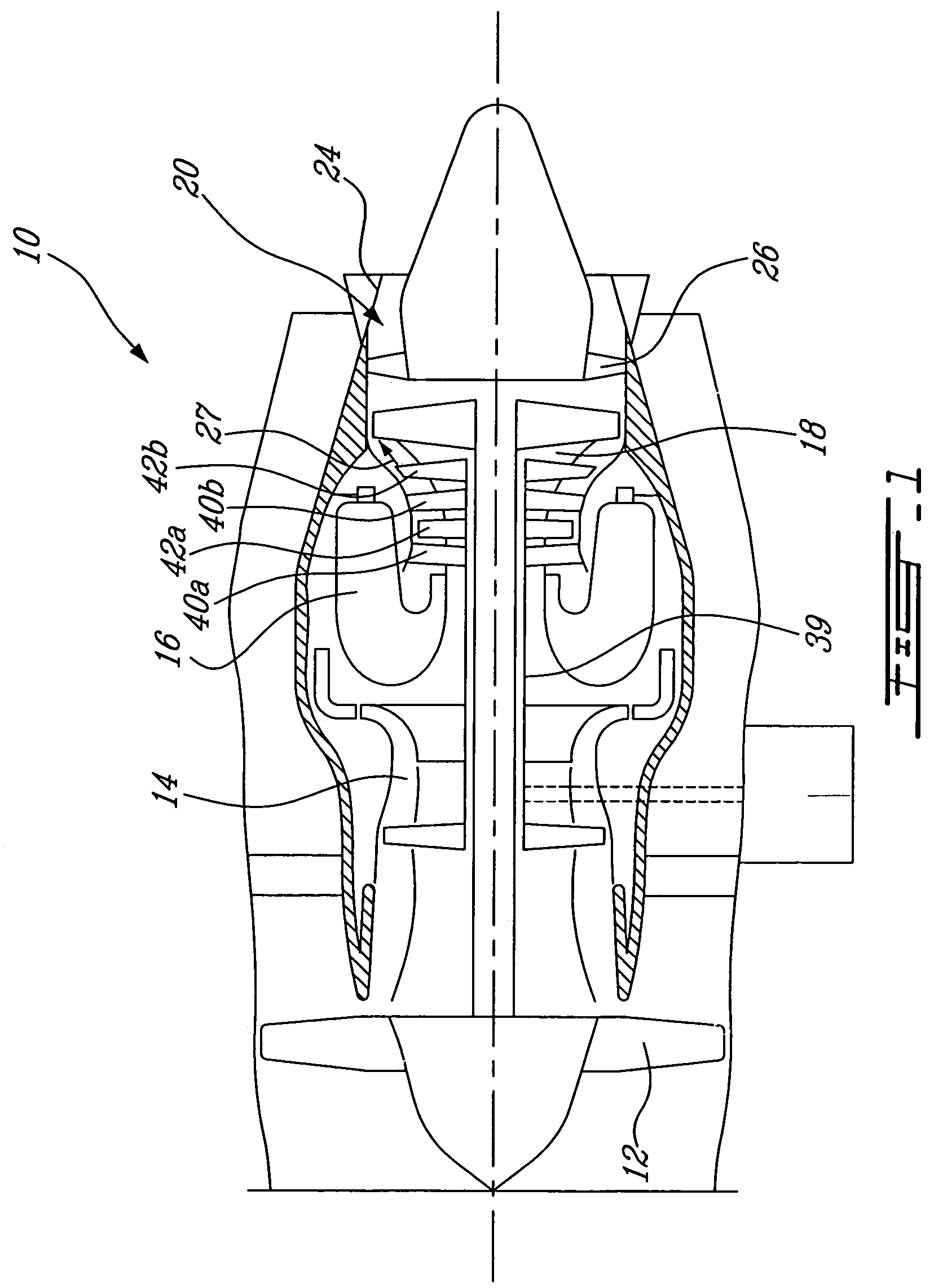

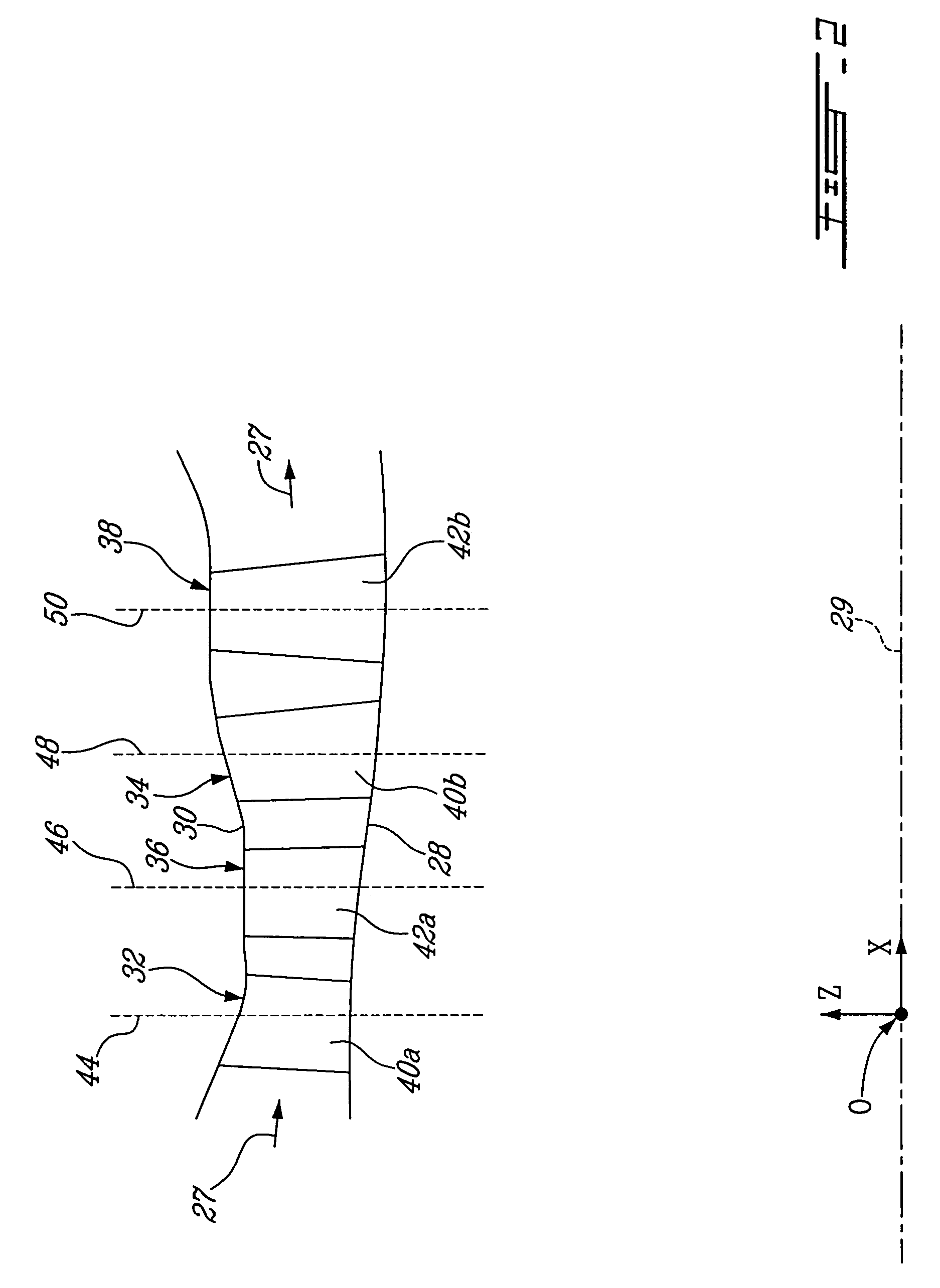

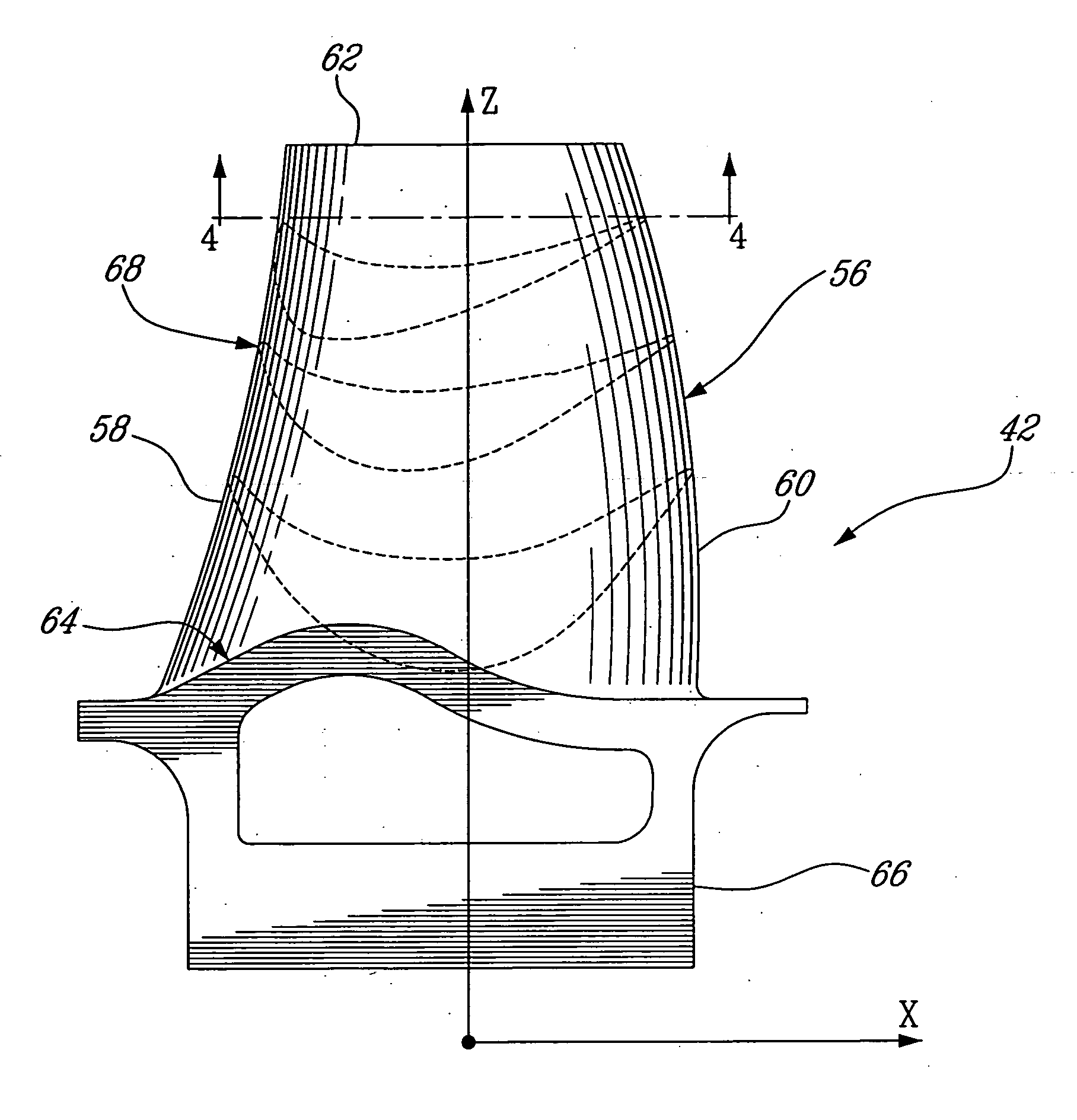

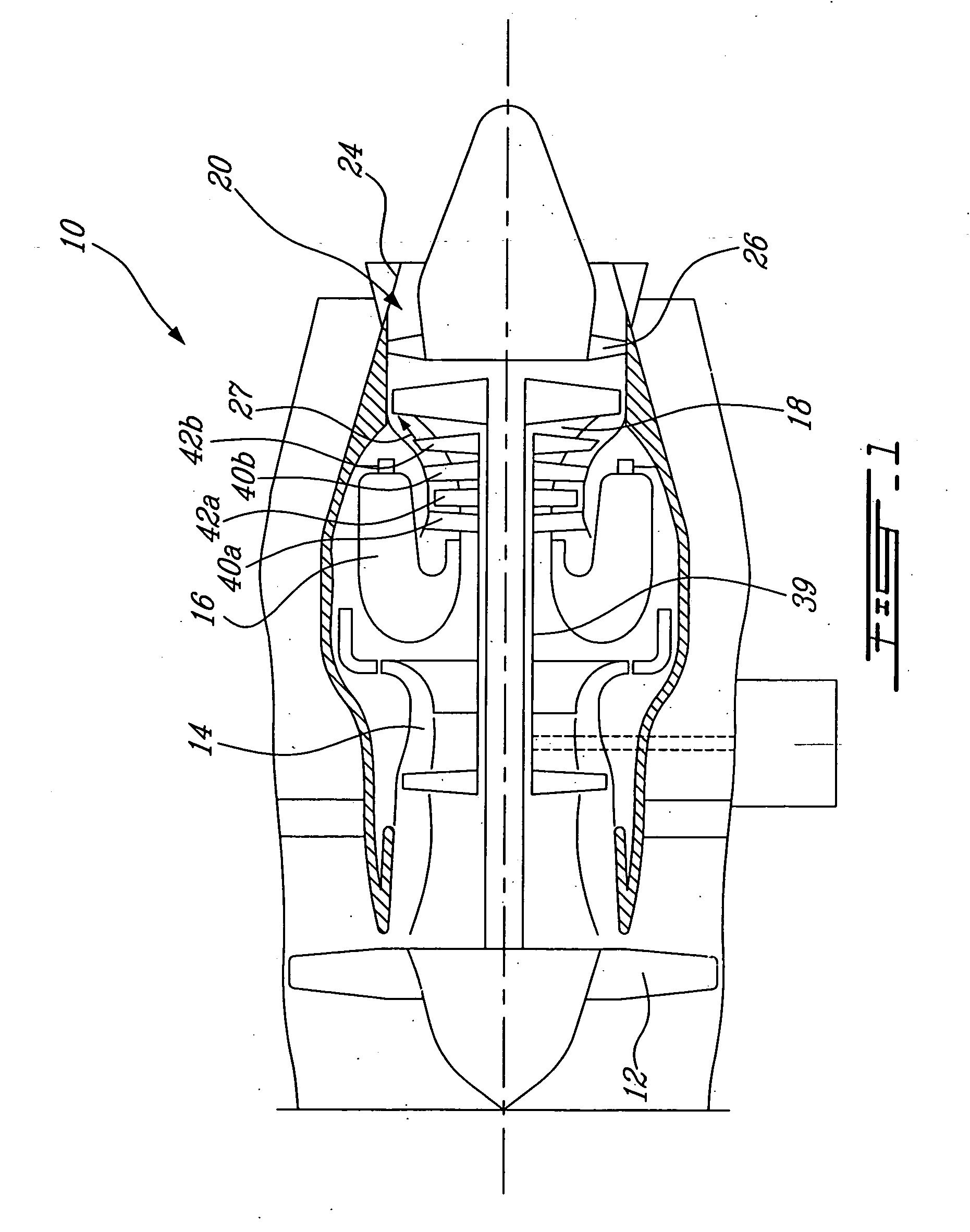

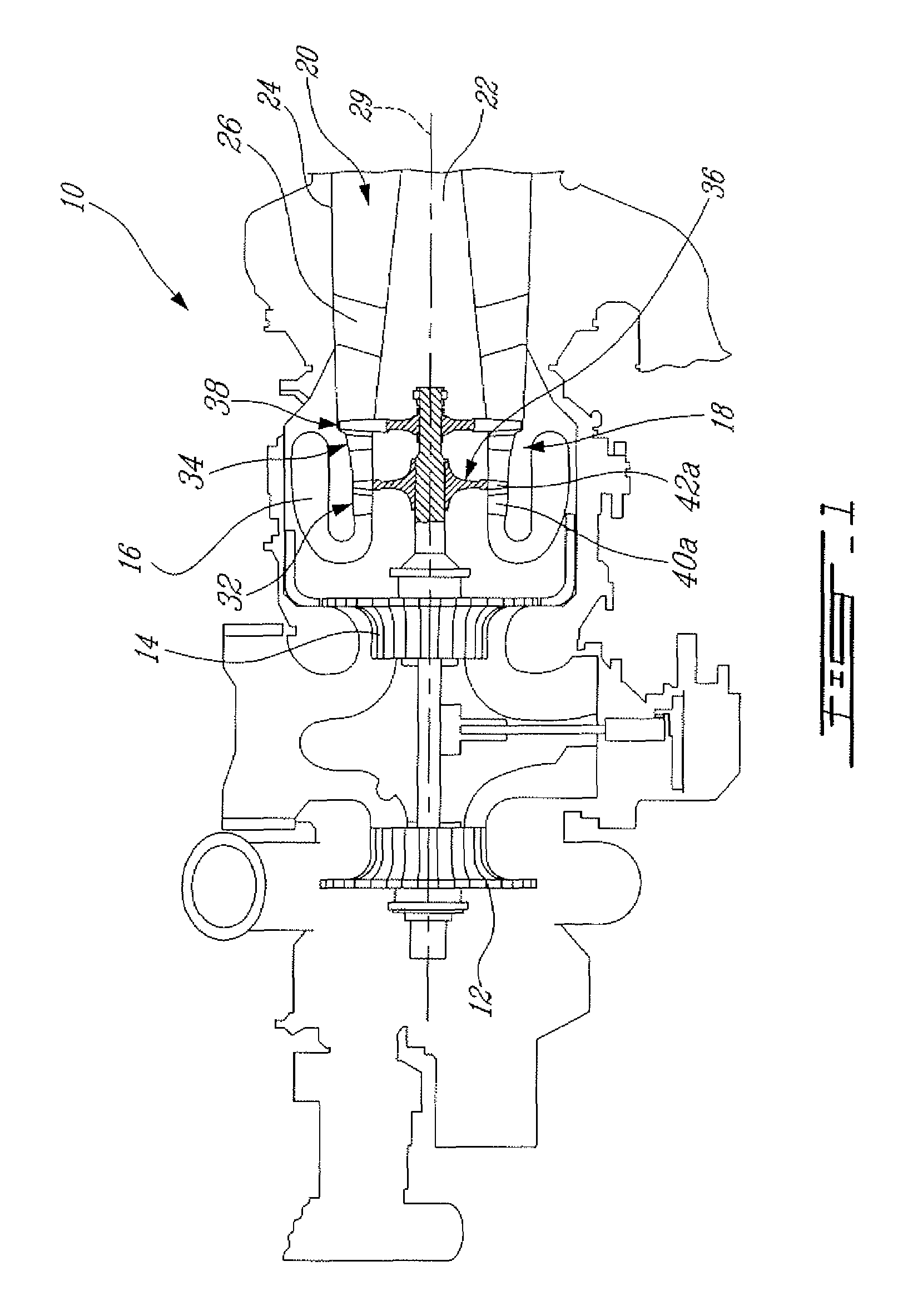

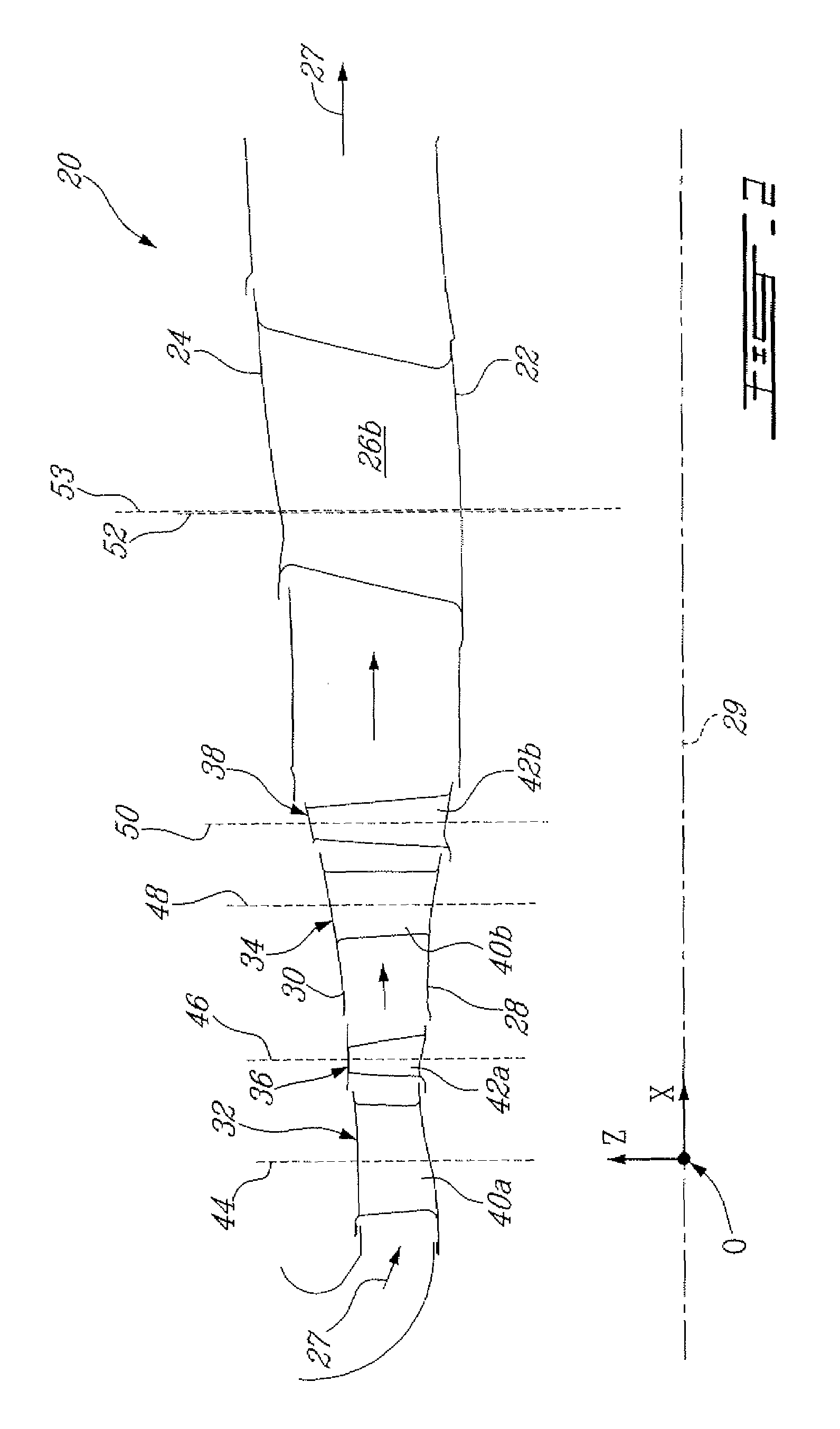

HP turbine blade airfoil profile

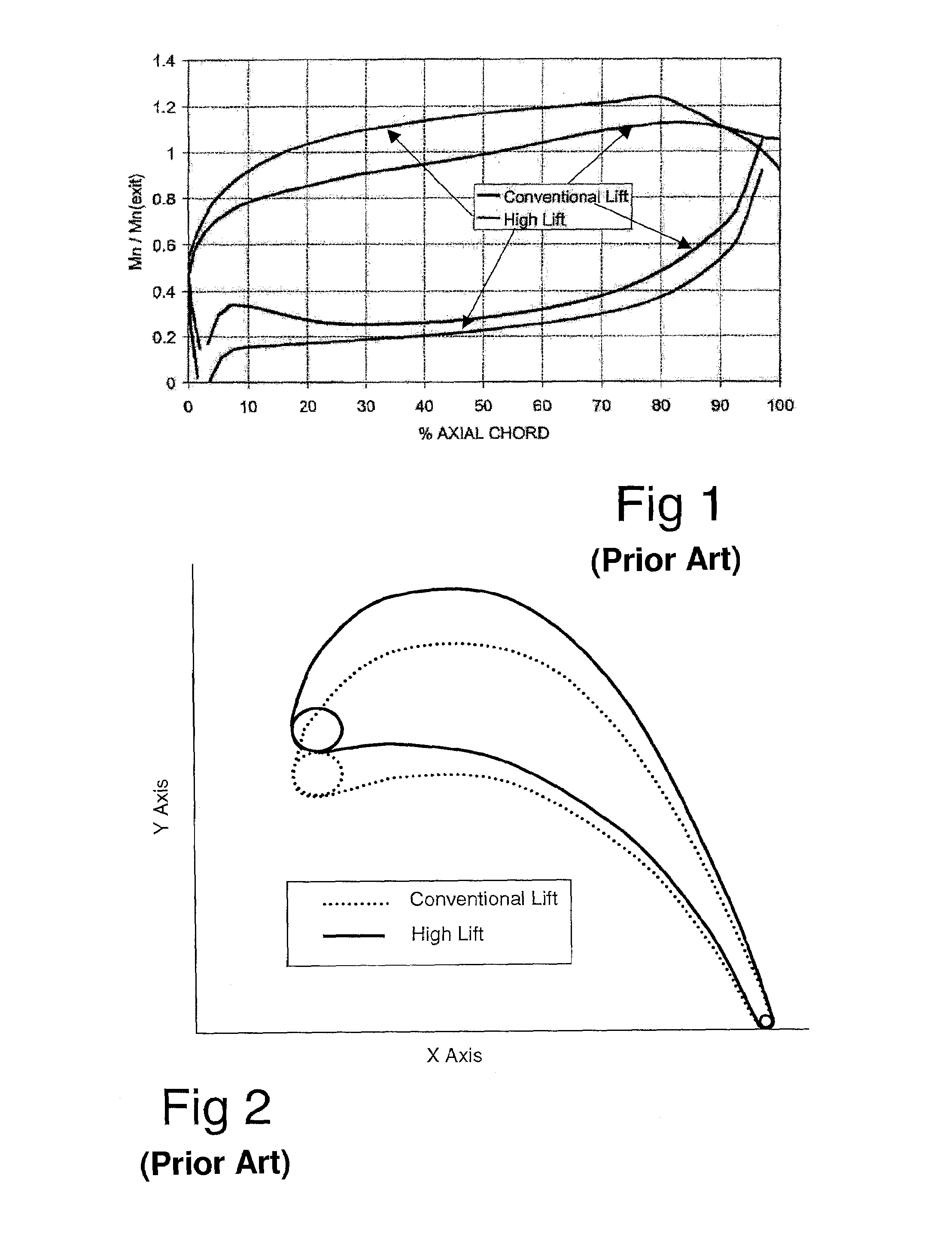

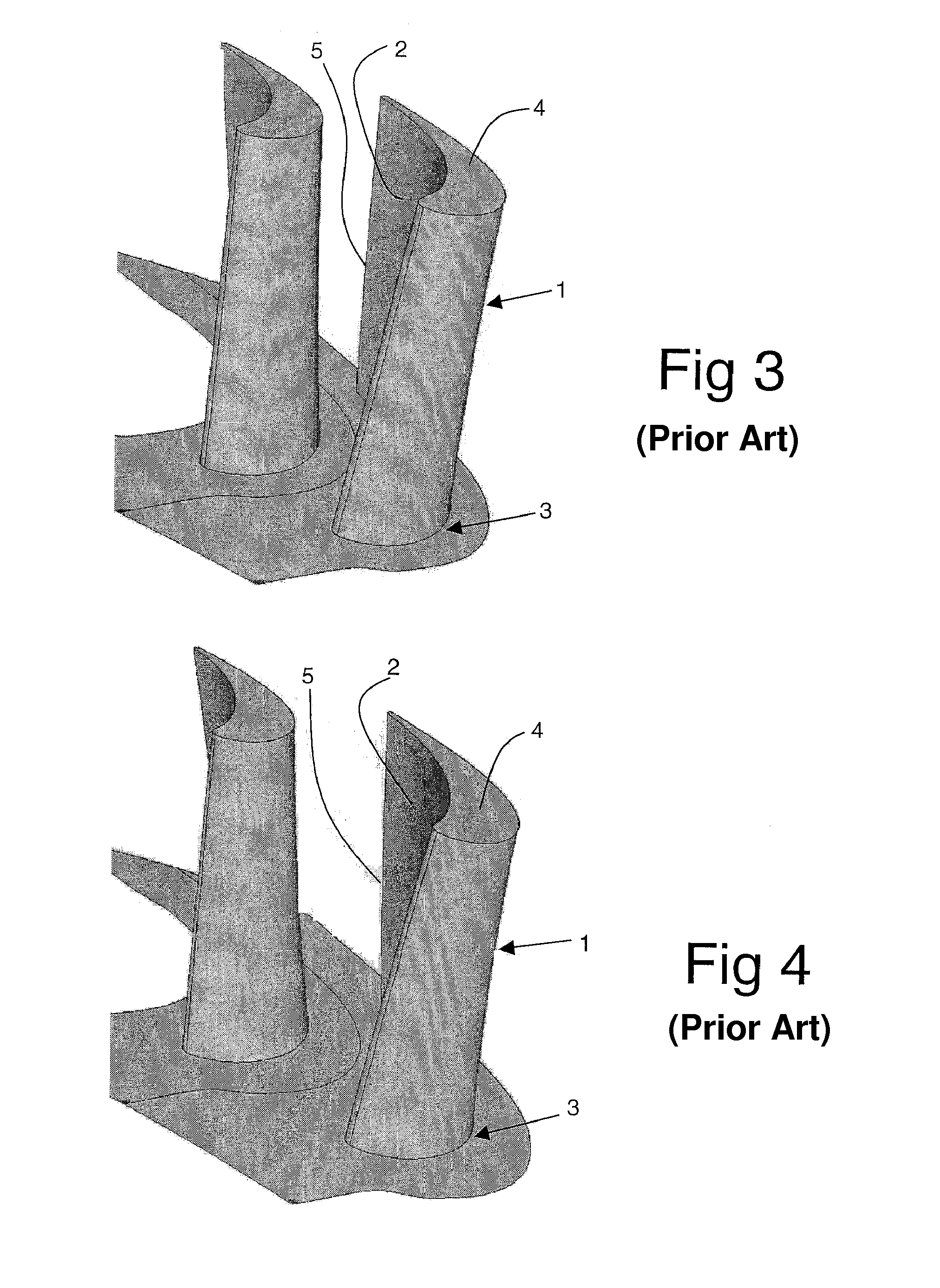

ActiveUS7520726B2Reduce disadvantagesReduce secondary flow lossEngine manufactureBlade accessoriesTurbine bladeHigh pressure

A first stage blade of a two-stage high pressure turbine includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

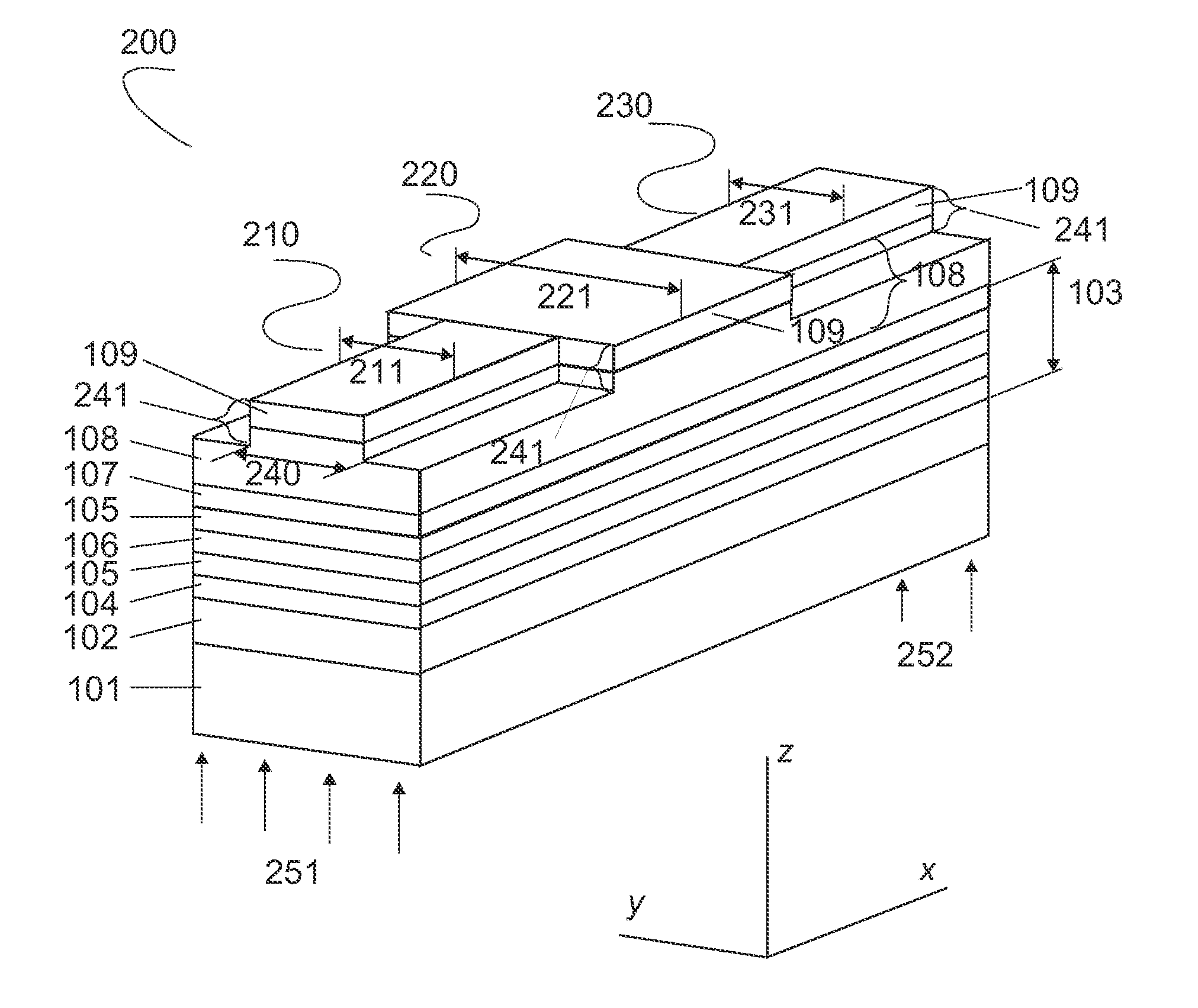

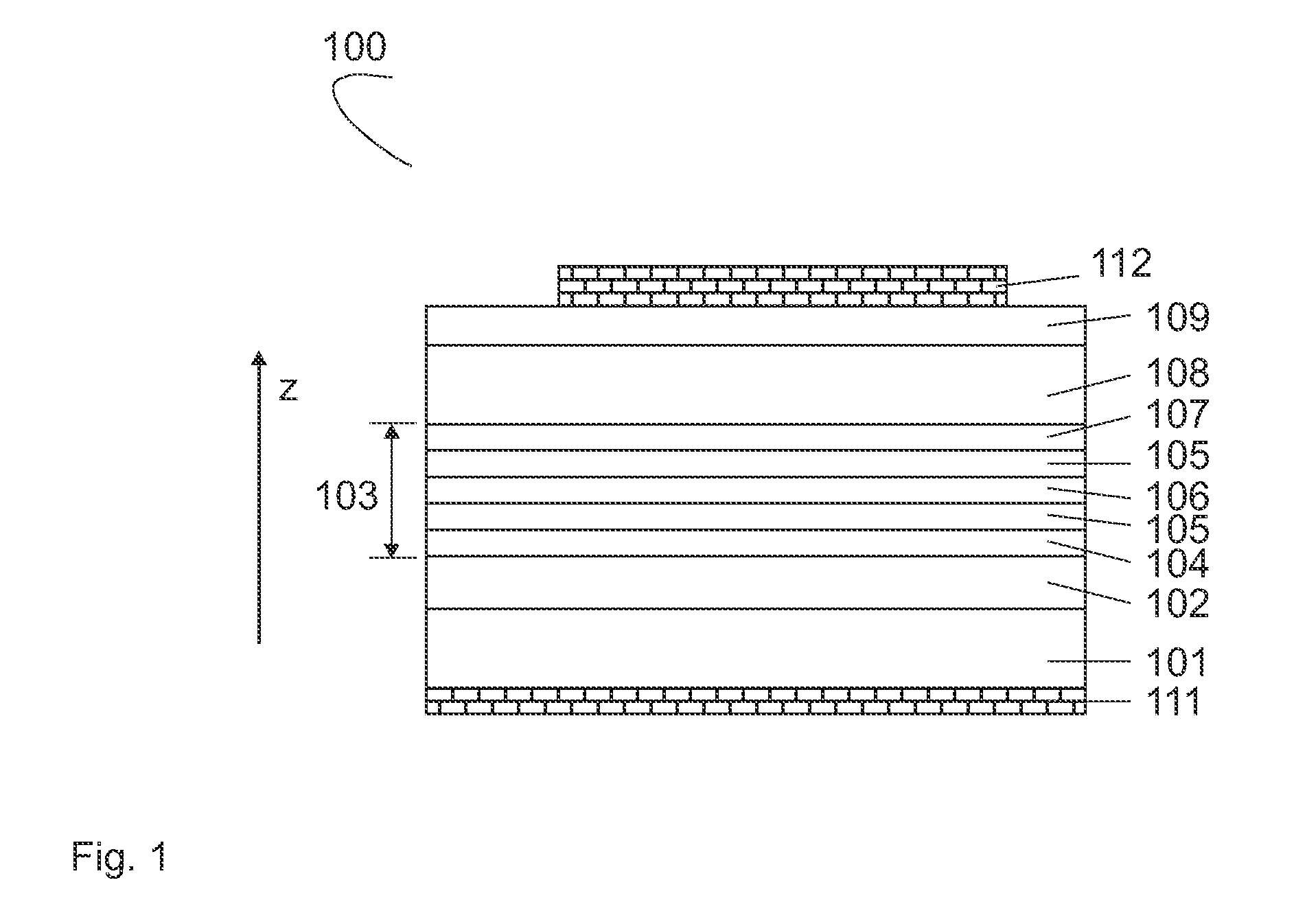

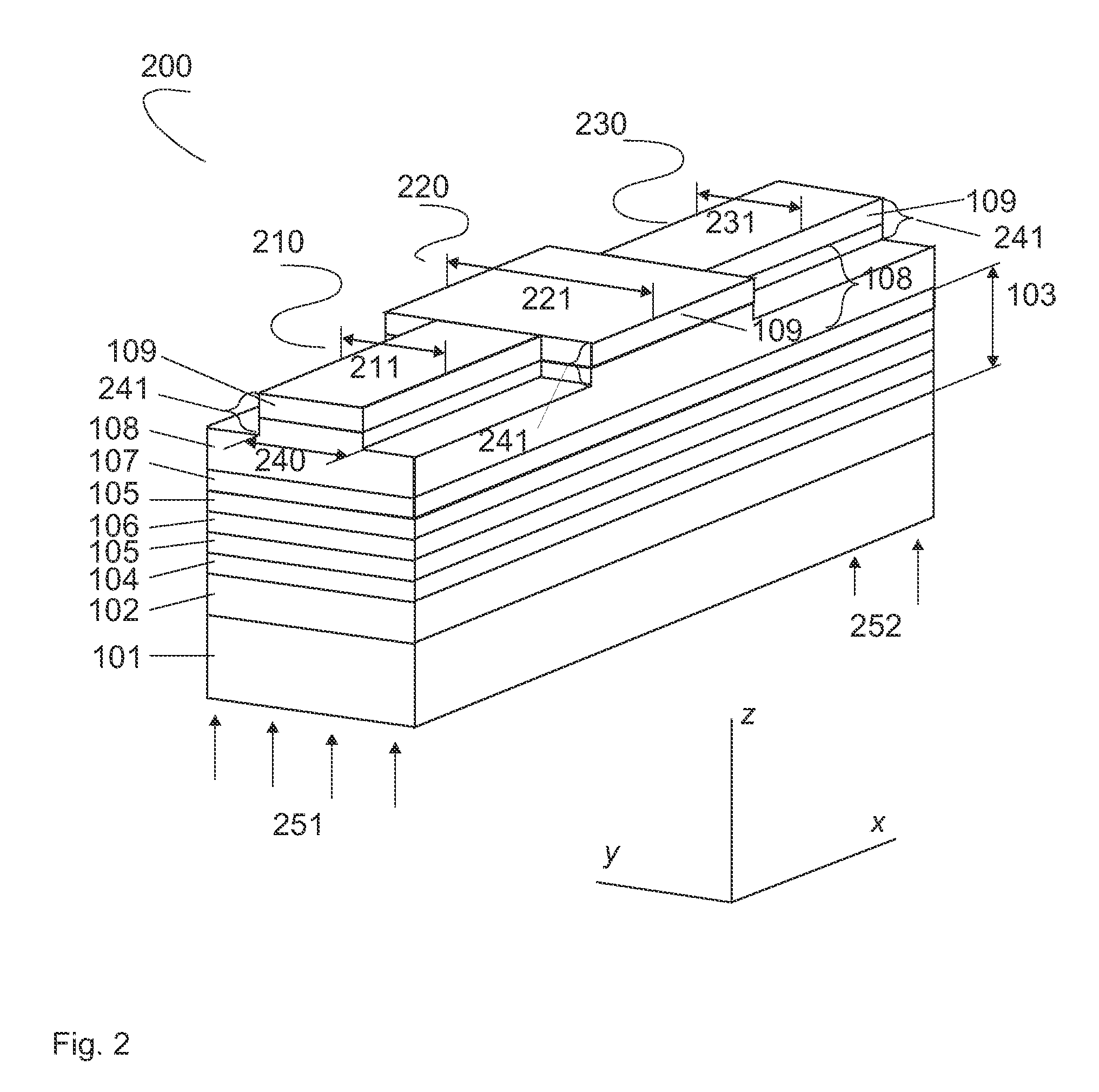

High-Power Optoelectronic Device with Improved Beam Quality Incorporating A Lateral Mode Filtering Section

InactiveUS20070223549A1Simplified method of fabricatingLeakage losses is still relatively largeOptical wave guidanceLaser detailsLight beamWaveguide

An optoelectronic device includes a planar active element, a vertical waveguide surrounding the active element in the vertical direction, and a lateral waveguide comprising at least one active section and at least one filter section following each other in the longitudinal direction. At least part of the active element within the active section generates optical gain in response to above-threshold pumping. The broad lateral waveguide in the active section can localize multiple lateral optical modes. In the filter section, no lateral confinement is provided for the lateral optical modes. The device further comprises means to ensure low absorption loss in the filter section and, therefore, ensure high efficiency. In one embodiment low absorption loss is achieved by pumping of at least part of the active element within the filter section. In another embodiment, the active element has small overlap with the vertical optical modes.

Owner:INNOLUME

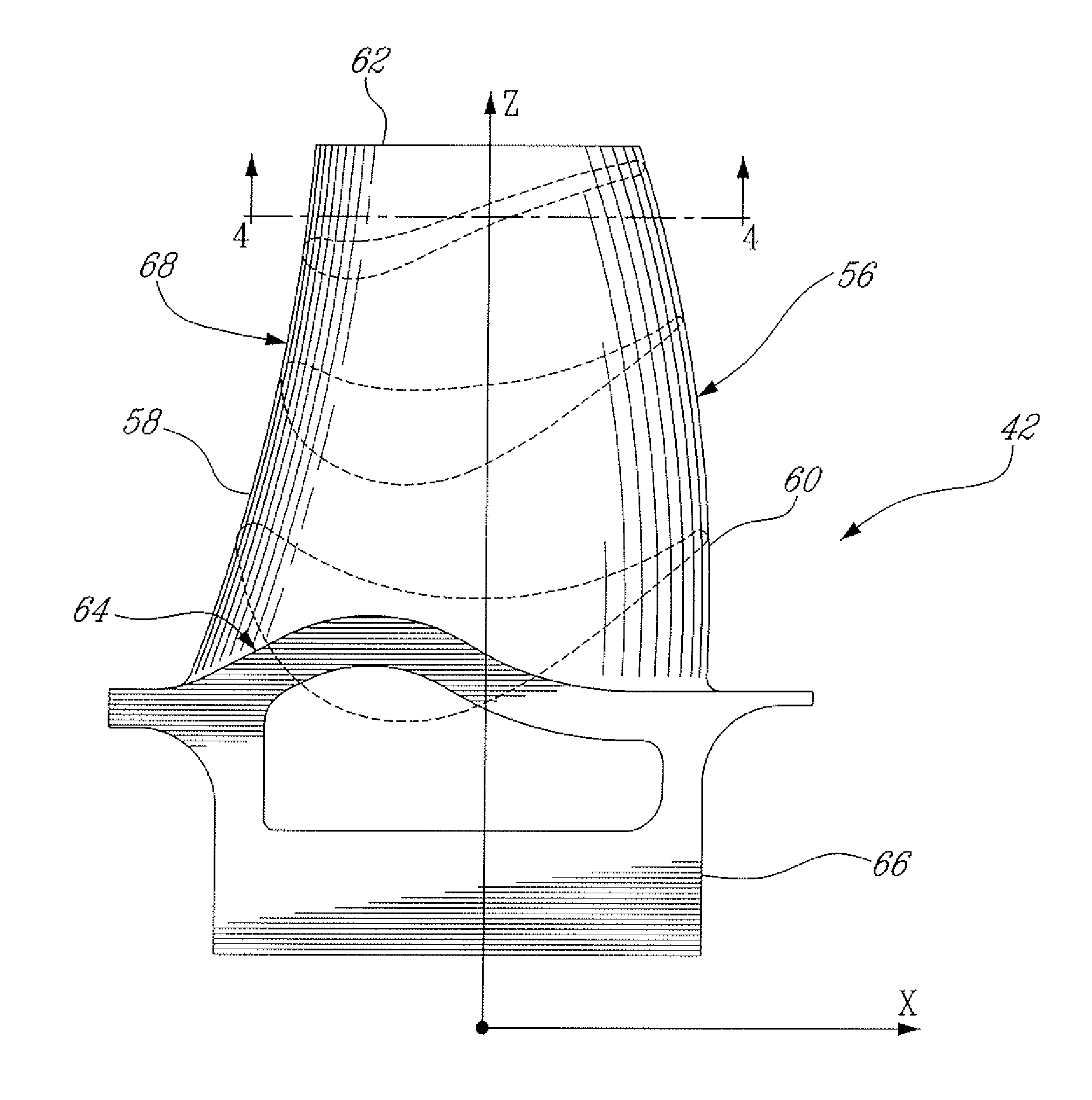

HP turbine blade airfoil profile

ActiveUS20080063530A1Minimizing flow separation disadvantageReduce secondary flow lossEngine manufactureBlade accessoriesTurbine bladeHigh pressure

A first stage blade of a two-stage high pressure turbine includes an airfoil having a profile substantially in accordance with at least an intermediate portion of the Cartesian coordinate values of X, Y and Z set forth in Table 2. The X and Y values are distances, which when smoothly connected by an appropriate continuing curve, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape.

Owner:PRATT & WHITNEY CANADA CORP

HP turbine blade airfoil profile

ActiveUS7632074B2Without any adverse effect on LPT performanceReduce interactionPropellersEngine manufactureSingle stageTurbine blade

Owner:PRATT & WHITNEY CANADA CORP

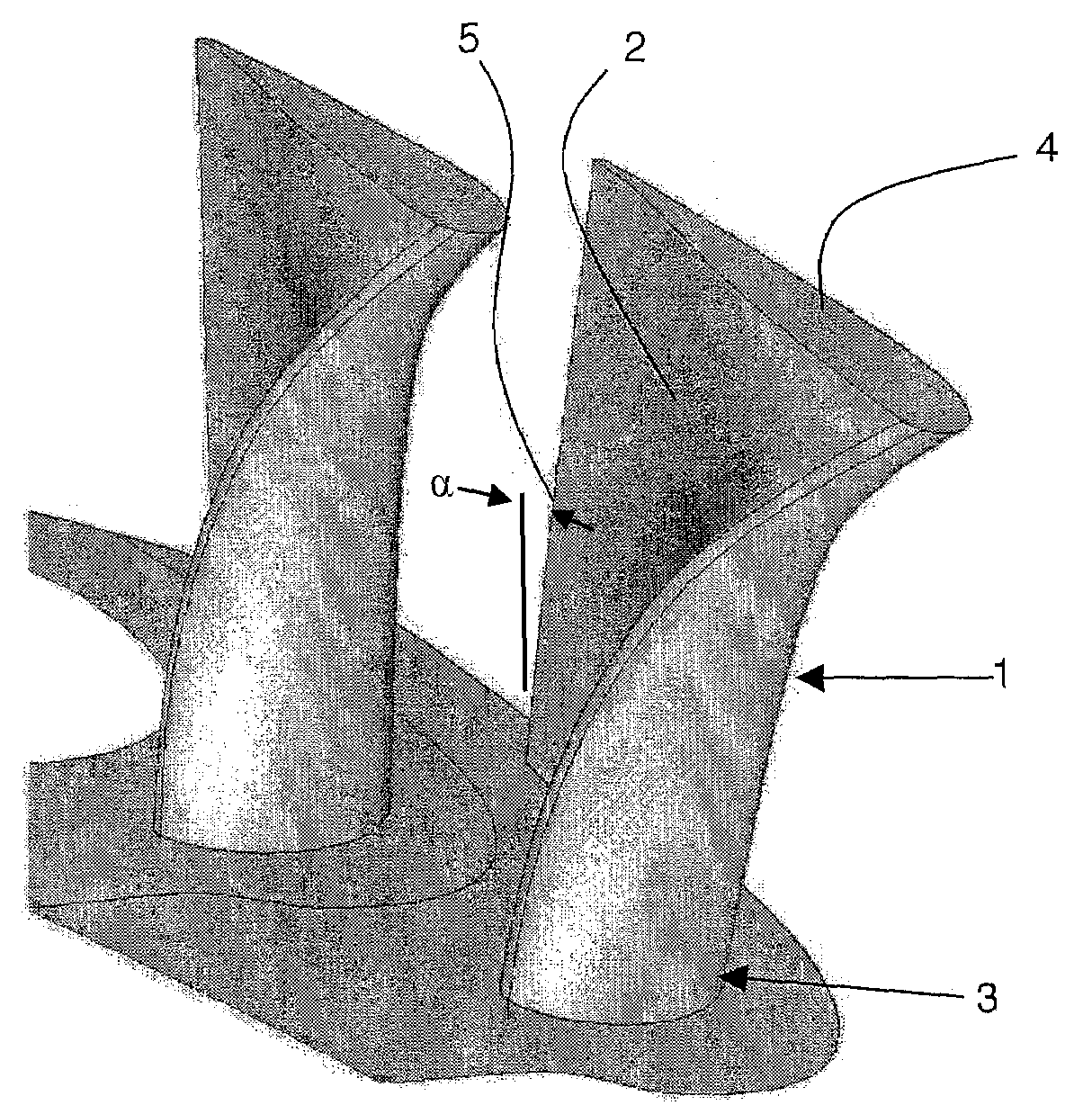

Turbine rotor blade for gas turbine engine

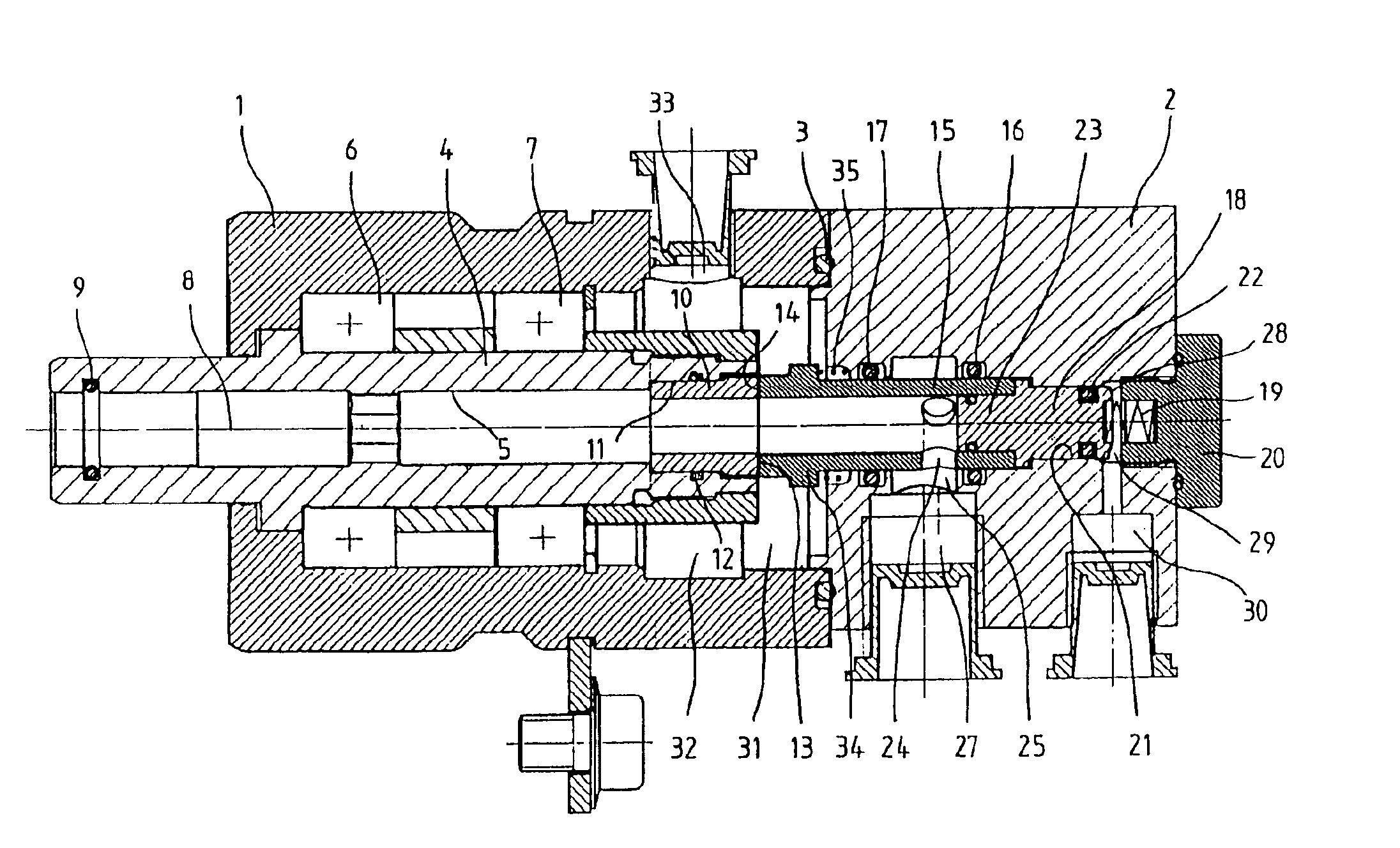

InactiveUS7217101B2Reduce leakage lossReduce manufacturing costPropellersEngine manufactureLeading edgeTurbine blade

A rotor blade for a gas turbine engine includes a blade root (3) and an aerofoil projecting therefrom, the aerofoil having a leading edge and a trailing edge (5), a generally concave pressure surface (2) and a generally convex suction surface (1). The aerofoil shape of the blade varies in section along the length thereof such that:the chord-wise convex curvature of the rear suction surface decreases towards the tip (4) of the blade;the convex curvature of the early to mid suction surface increases towards the tip;the stagger of the aerofoil section increases towards the tip; andthe trailing edge (5) is a straight line.

Owner:ANSALDO ENERGIA SWITZERLAND AG

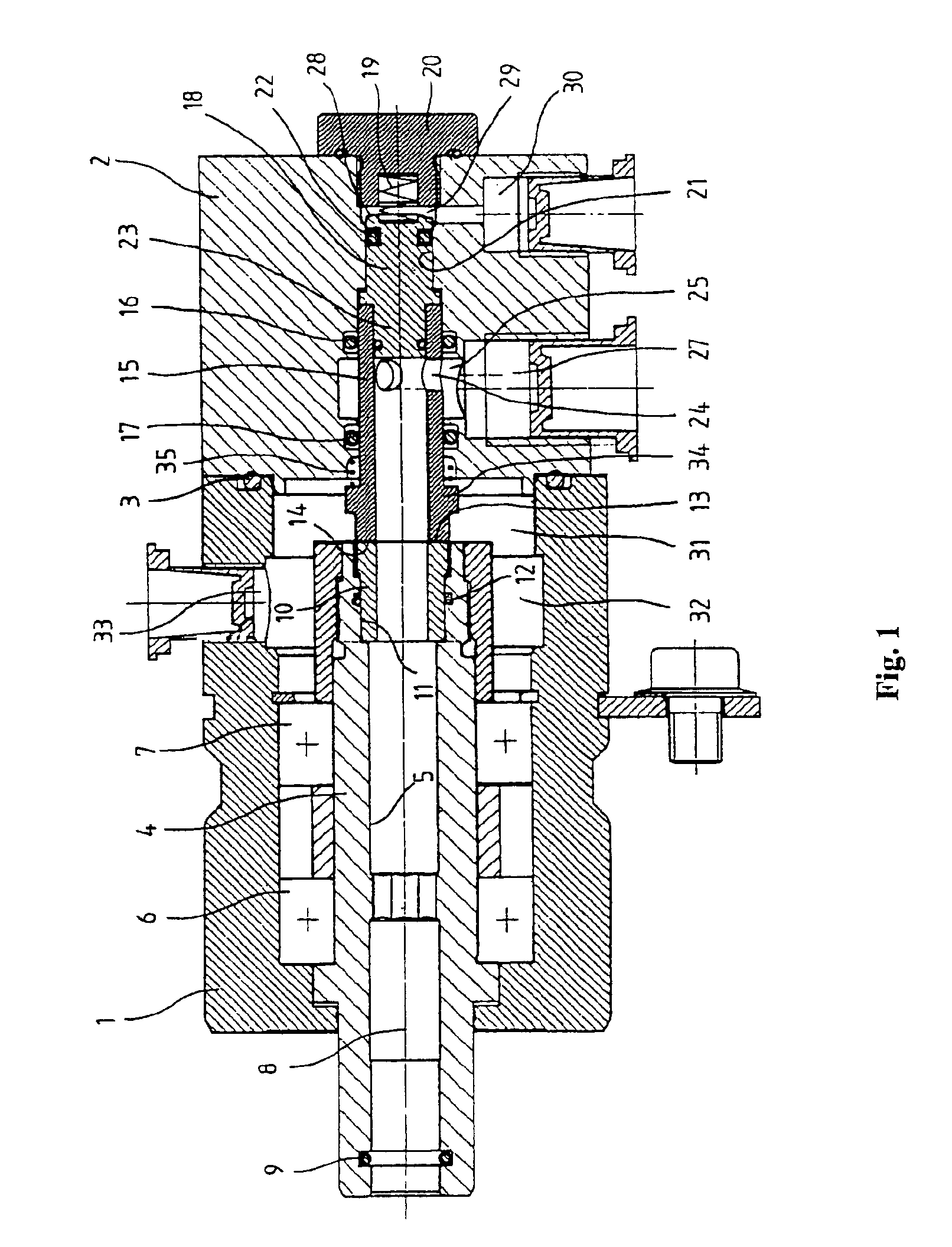

Rotary feed-through

InactiveUS6929099B2Easy constructionReduce wearAdjustable jointsMachines/enginesLine tubingContact pressure

A rotary feed-through, which contains a hollow shaft, which is supported in a first housing part so that it can rotate, with a first sealing surface and a sealing bushing, which is arranged rotationally fixed within a second housing part and which is coaxial with the hollow shaft, with a second sealing surface for contact to the first sealing surface. In order to also enable lower leakage losses, in addition to less wear, with the supply of cooling lubricants and compressed air, the second housing part contains a first lateral supply channel, which can be attached to a coolant supply line or a compressed air supply line, for the supply of cooling lubricant or compressed air via at least one radial opening of the sealing bushing and a second supply channel, which is charged during the supply of cooling lubricant, for the supply of cooling lubricant to a pressure piston, which closes the rear end of the sealing bushing, to increase the contact pressure of the sealing surfaces.

Owner:OTT JAKOB & SPANNTECHN

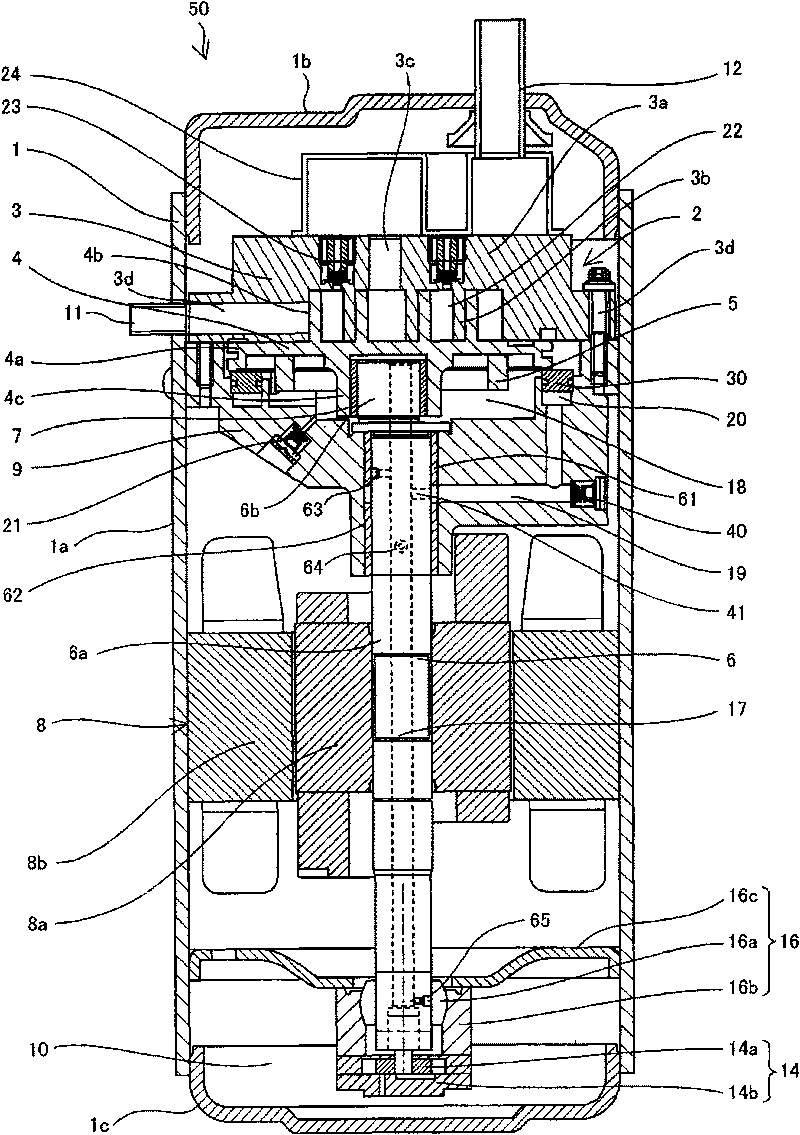

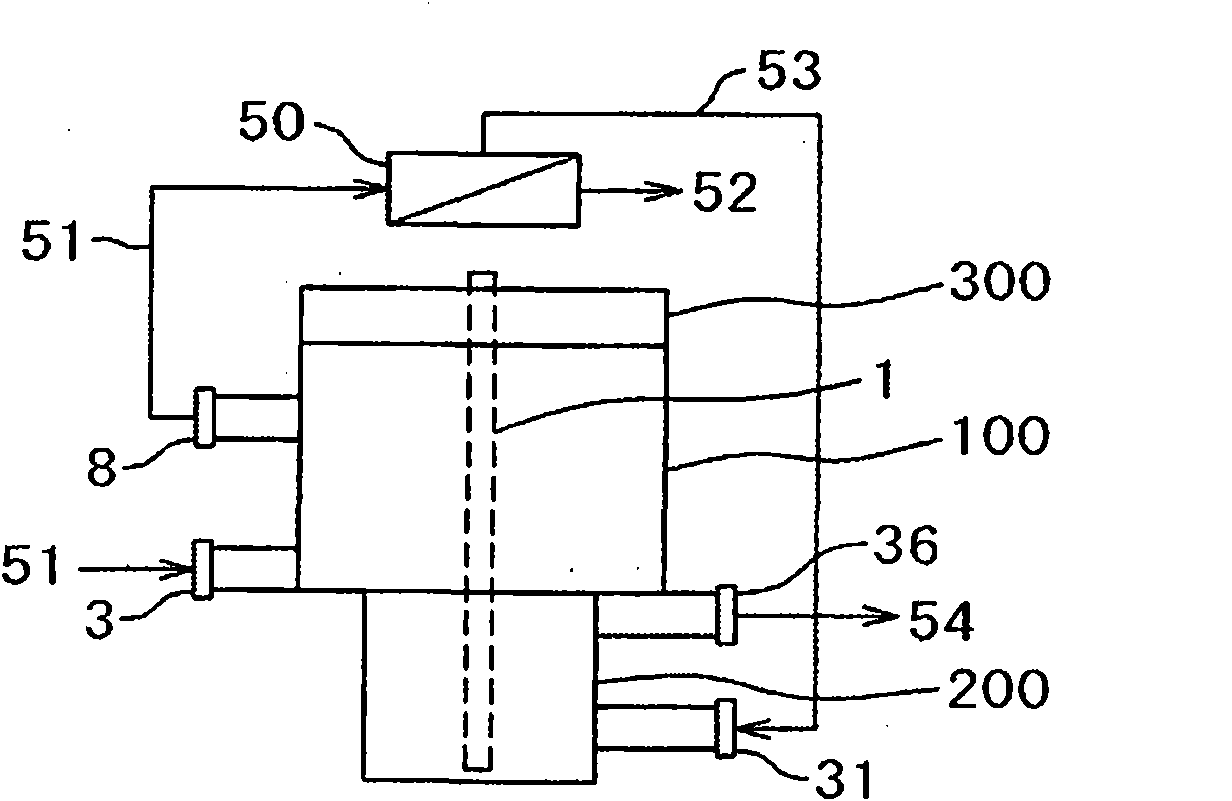

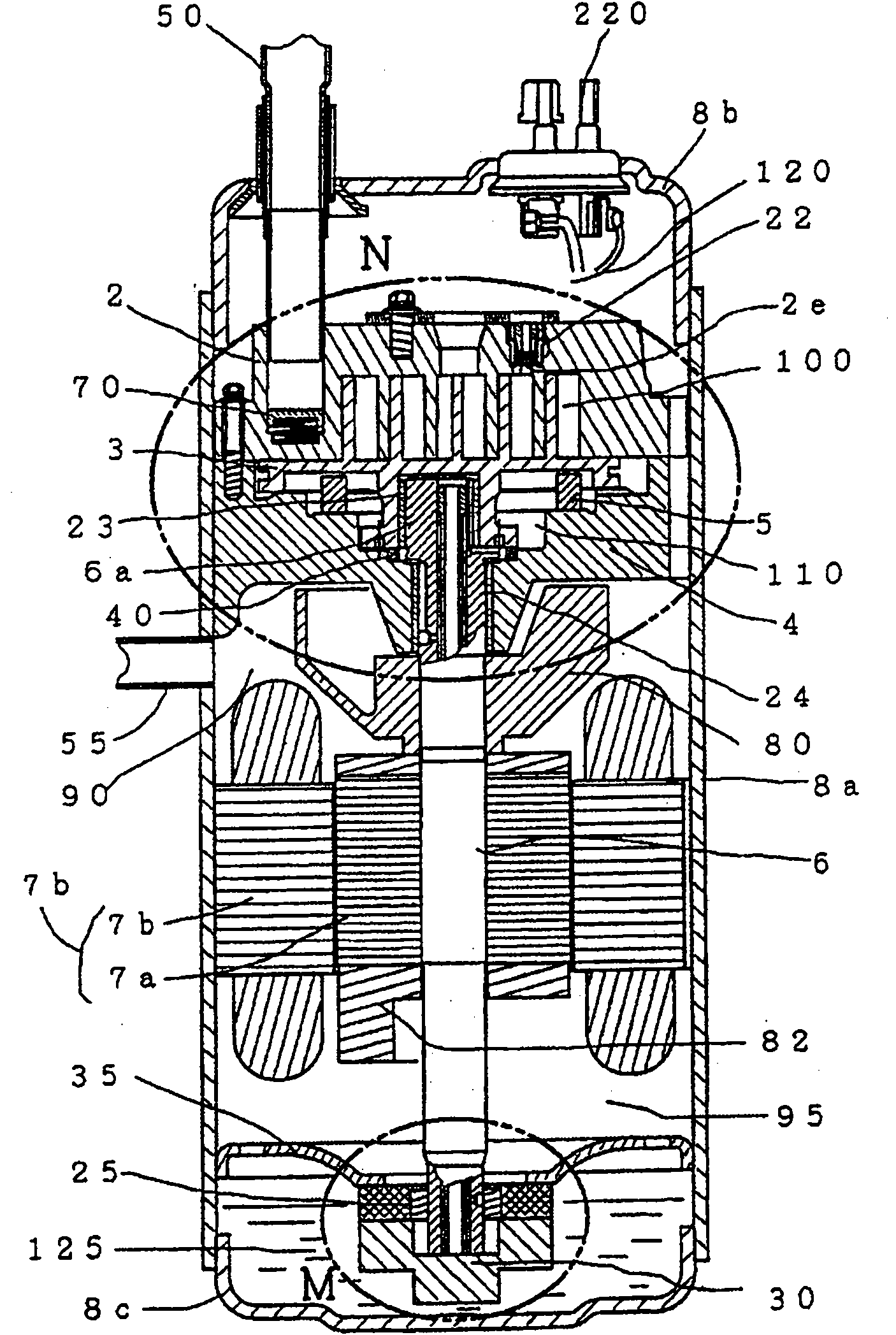

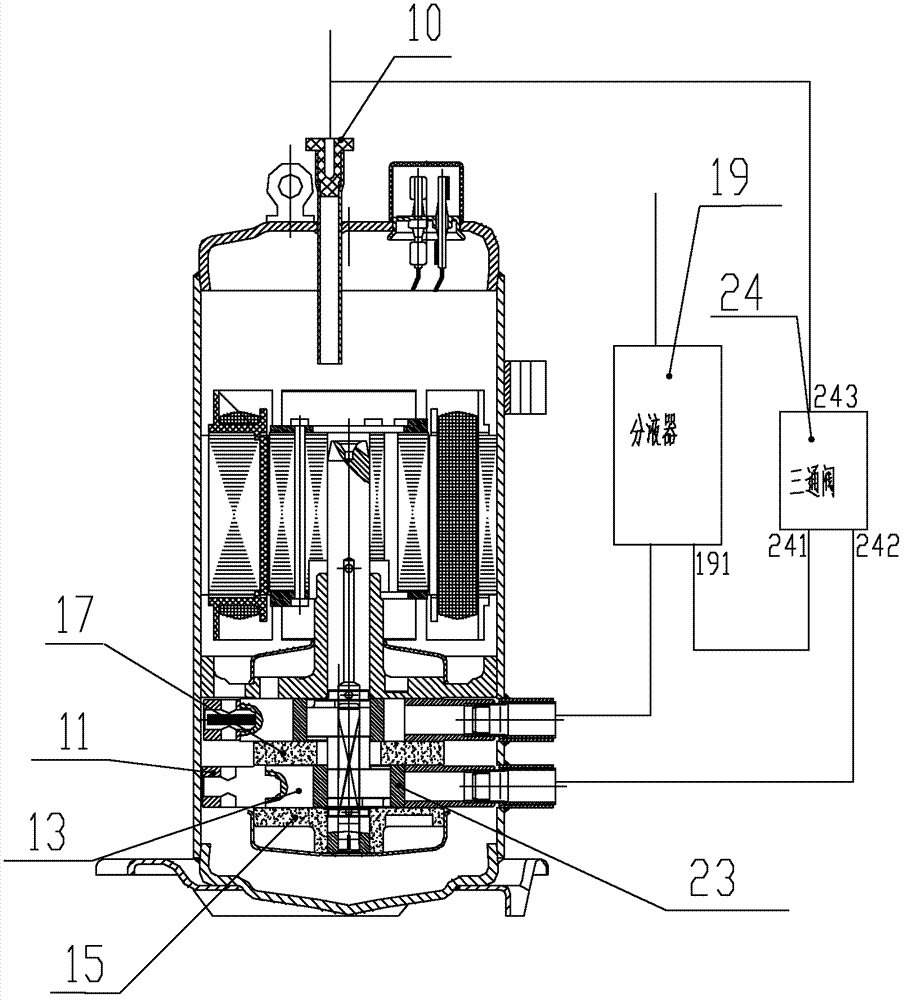

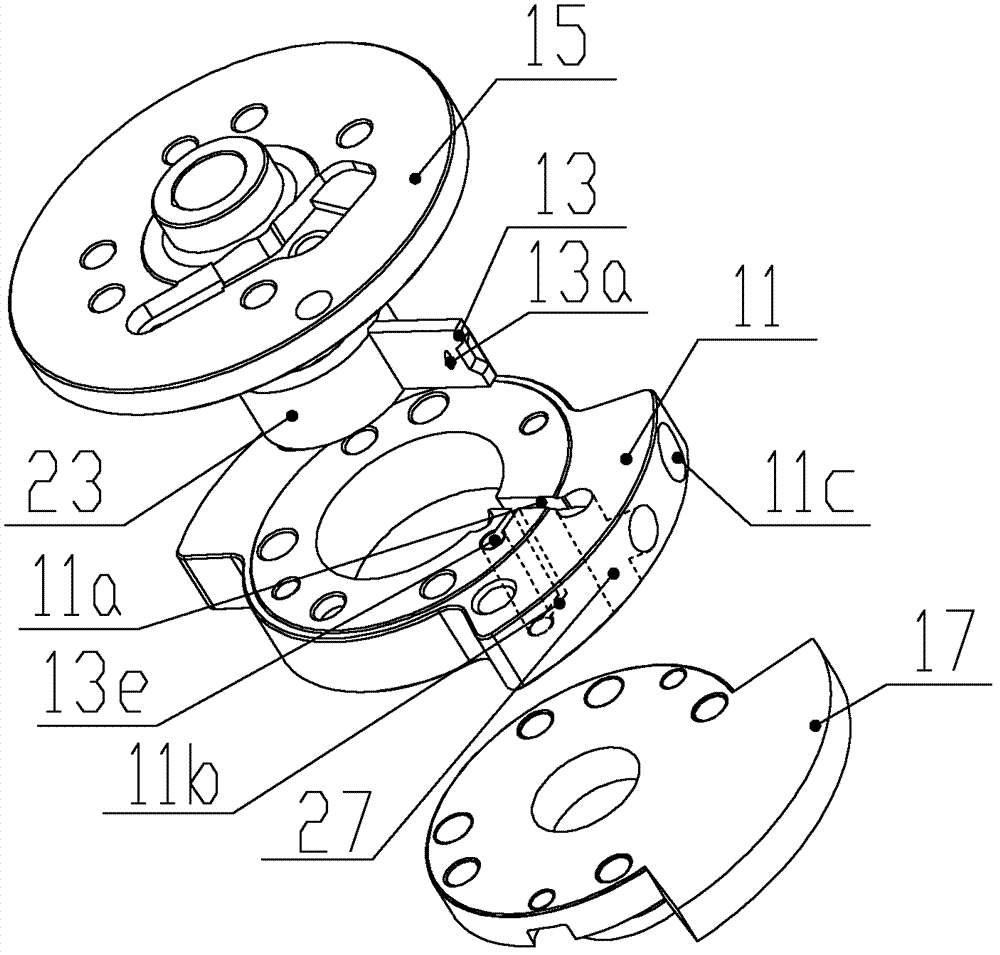

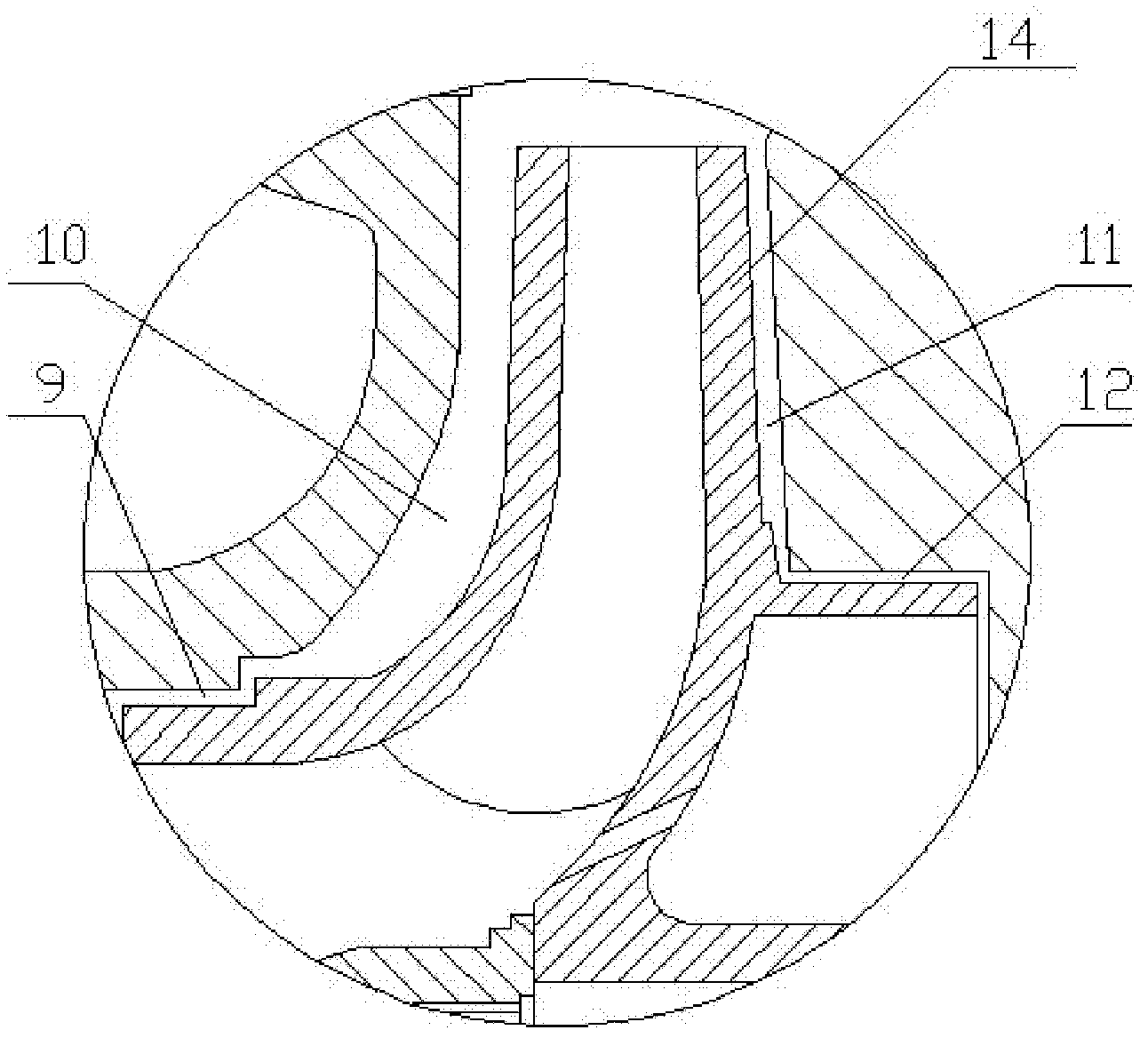

Scroll compressor

ActiveCN101749234AReduce leakage lossShorten run-up timeRotary piston pumpsRotary piston liquid enginesCyclotronCrankshaft

The invention discloses a scroll compressor, which can reduce the leakage between a cyclotron scroll pan and an immobile scroll pan and the mechanical loss in a larger running range, and shorten the running rise time. The scroll compressor (50) has, in a sealed container (1), a compressing mechanism part (2) with the immobile scroll pan (3) and the cyclotron scroll pan (4), and a motor to drive the cyclotron scroll pan (4) by a crankshaft (6). A thrust collar (30) is arranged at the back side of the cyclotron scroll pan (4), a circular backpressure chamber (20) is arranged at the back side of the thrust collar (30), an oil storage part (10) for storing a lubricating oil is arranged in the sealed container (1), and an oil supply mechanism for supplying the lubricating oil in the oil storage part (10) by the rotating of the crankshaft (6) is provided. The lubricating oil supplied by the oil supply mechanism is guided into the circular backpressure chamber (20) so as to press the thrust collar (30).

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

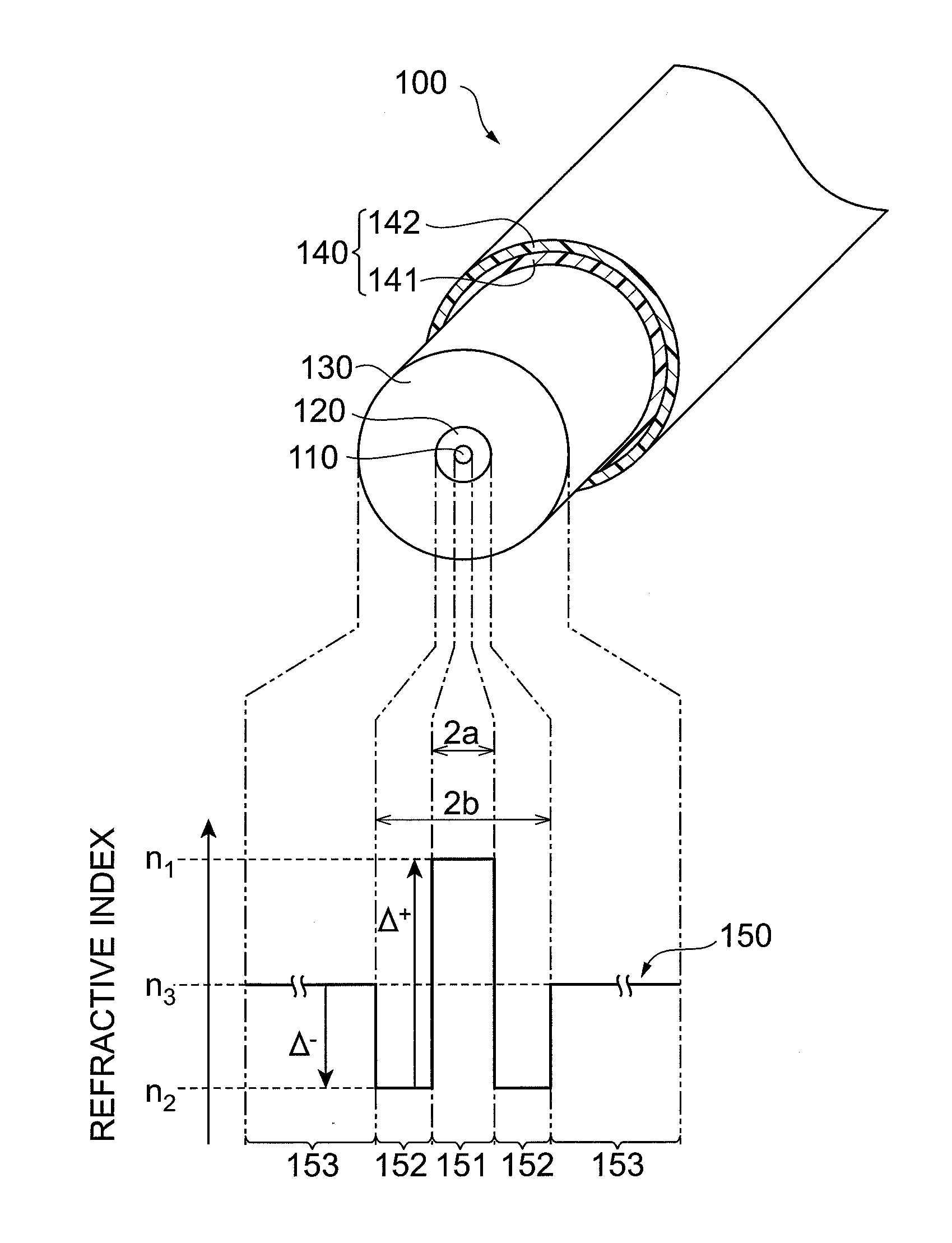

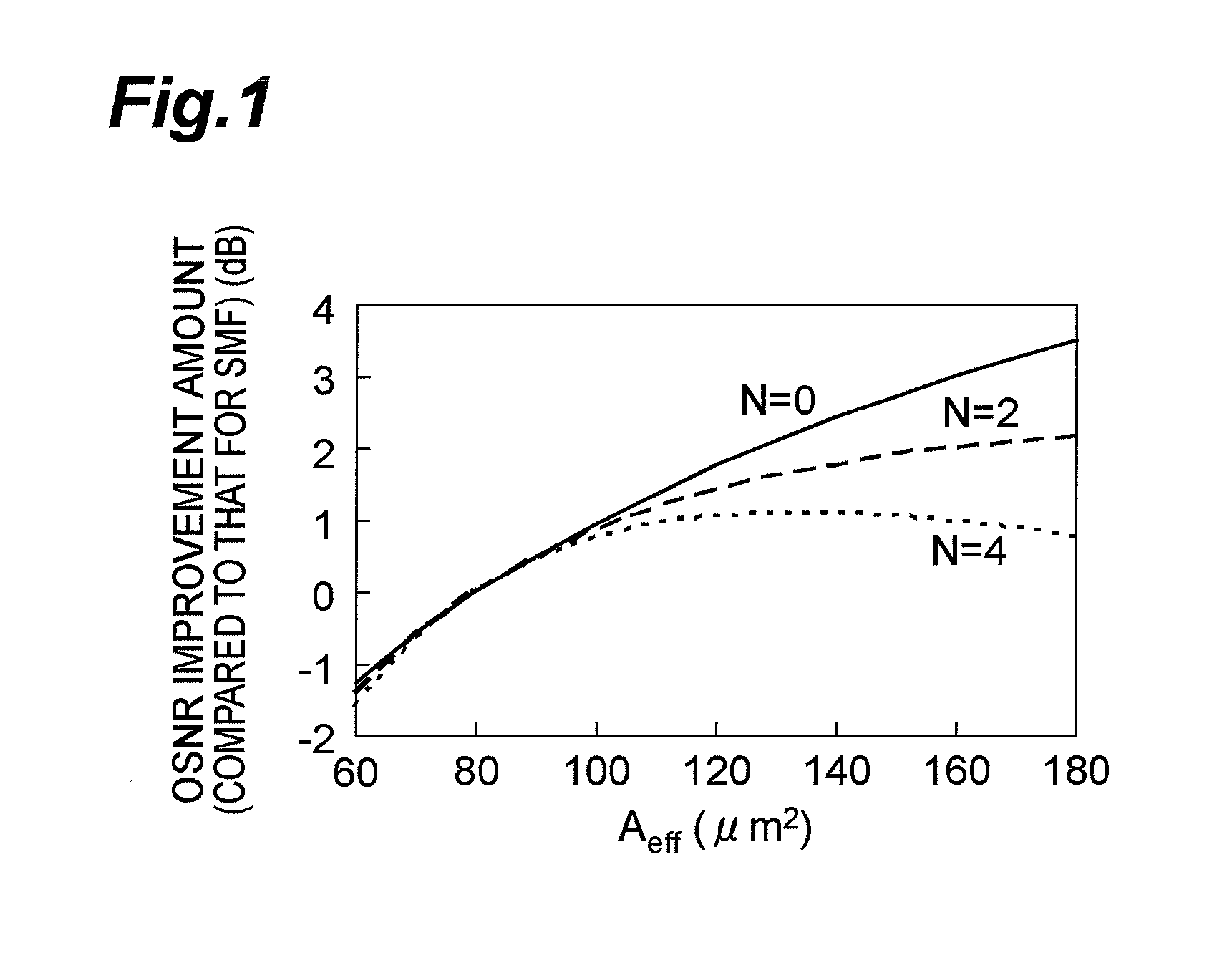

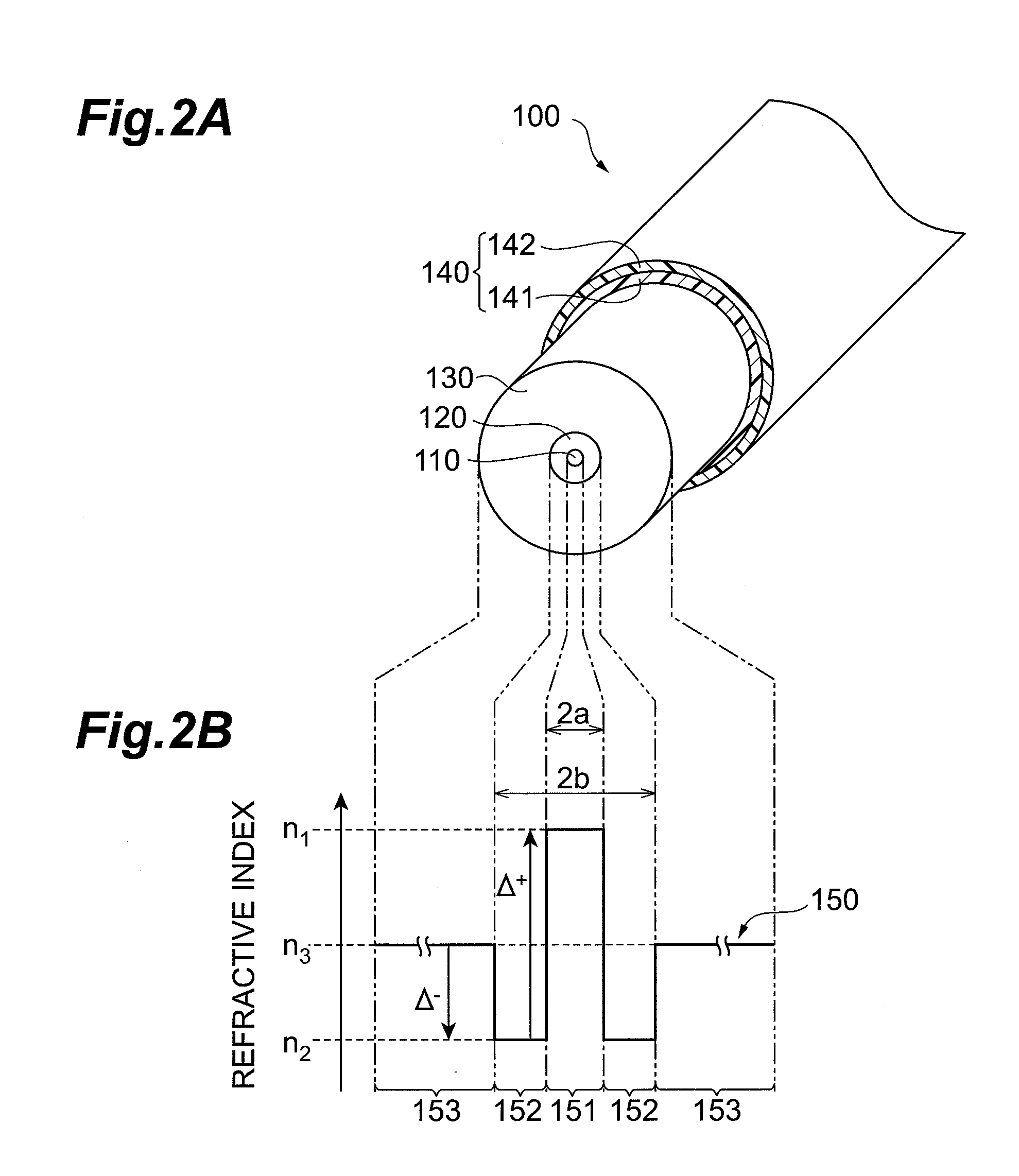

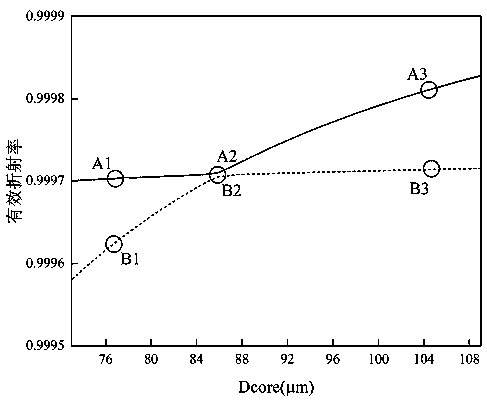

Optical fiber and optical communication system including same

ActiveUS20110211788A1High powerEnhance the imageGlass optical fibreCoupling light guidesPhysicsRefractive index profile

The invention relates to an optical fiber employable in an optical communication system using Raman amplification and adapted to improve OSNR and suppress bending loss at the same time, and the like. The optical fiber is a silica-based optical fiber having a depressed refractive index profile constituted by at least a core, an inner cladding having a low refractive index, and an outer cladding, an effective area Aeff of 110 μm2 or more at the wavelength of 1550 nm, and a fiber cutoff wavelength λC of 1.3 μm or more but 1.53 μm or less. The depressed refractive index profile is designed such that the ratio Ra(=2b / 2a) of the diameter of the inner cladding to the diameter of the core is 2.5 or more but 3.5 or less and that the relative refractive index difference Δ− of the inner cladding with respect to the outer cladding is at least the relative refractive index difference Δ−min where the bending loss at the wavelength for use is minimized but not exceeding (Δ−min+0.06) %.

Owner:SUMITOMO ELECTRIC IND LTD

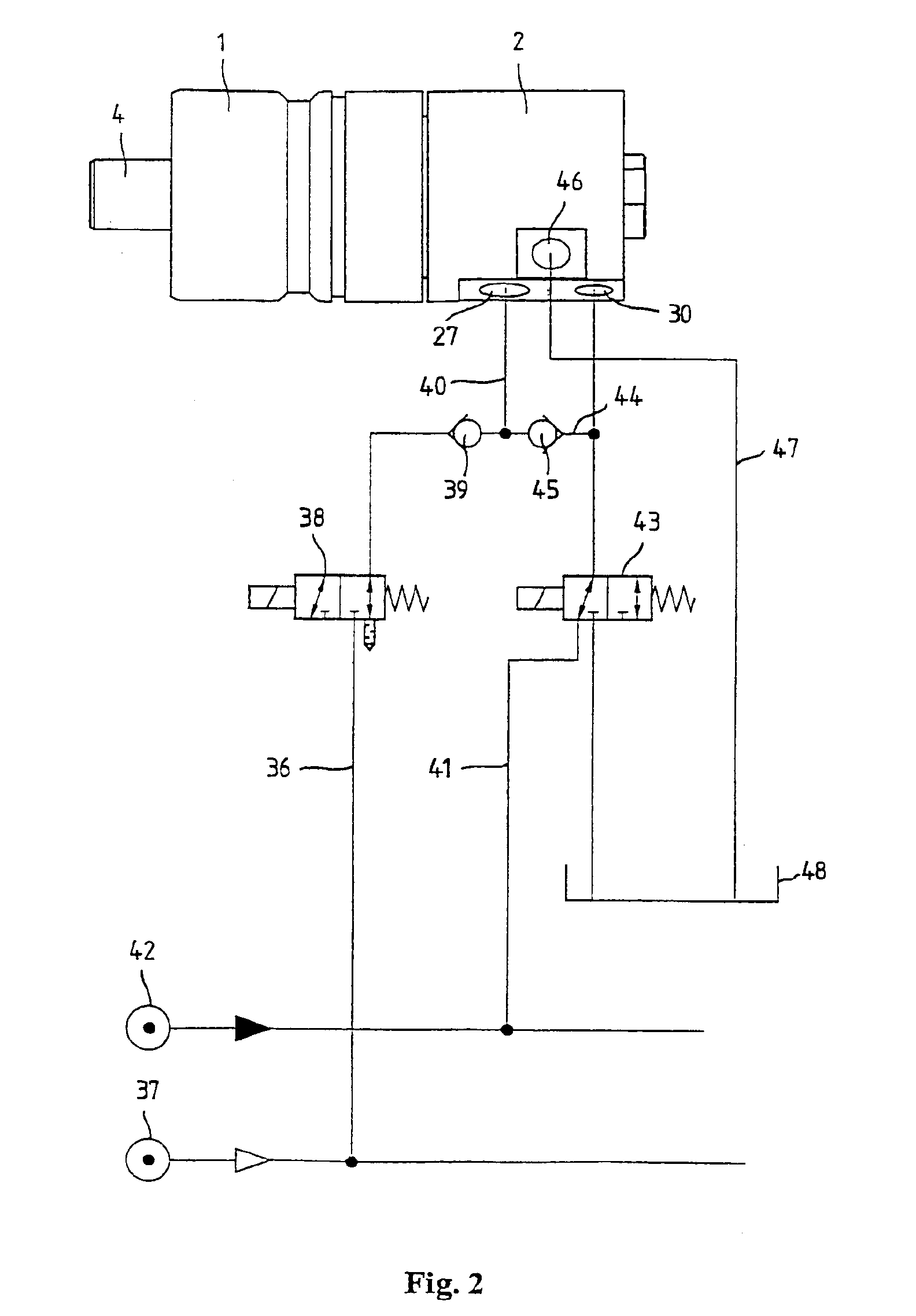

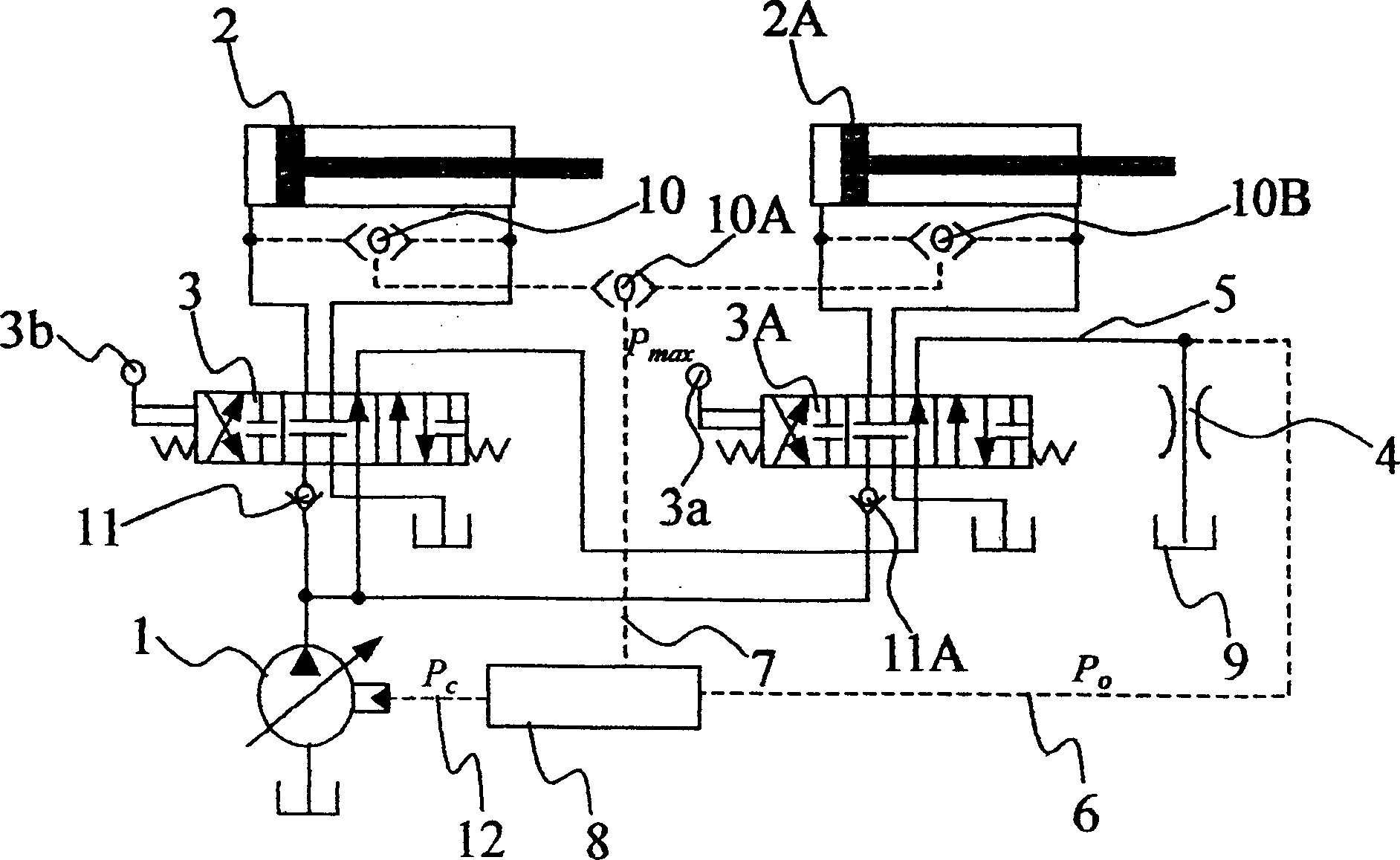

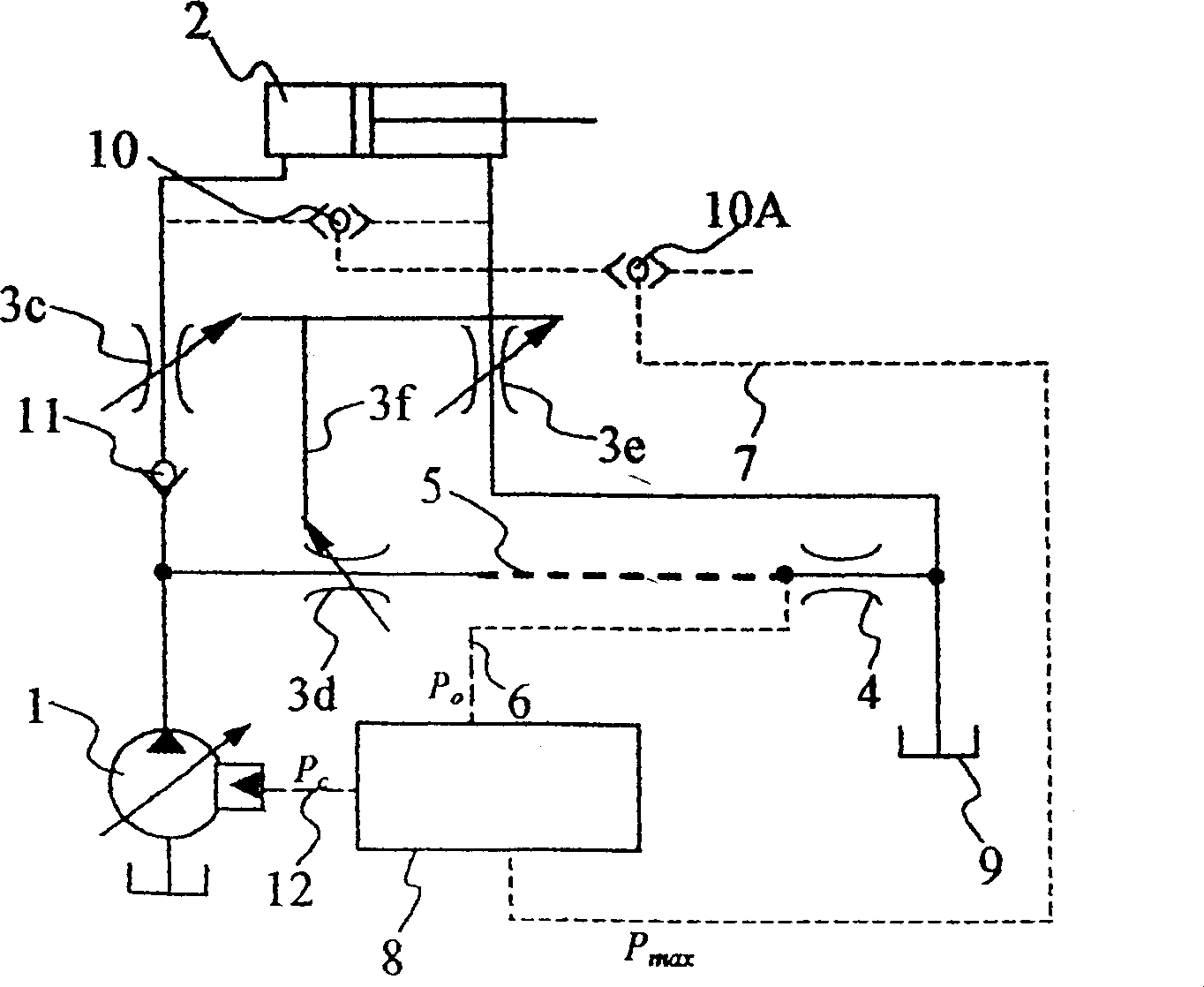

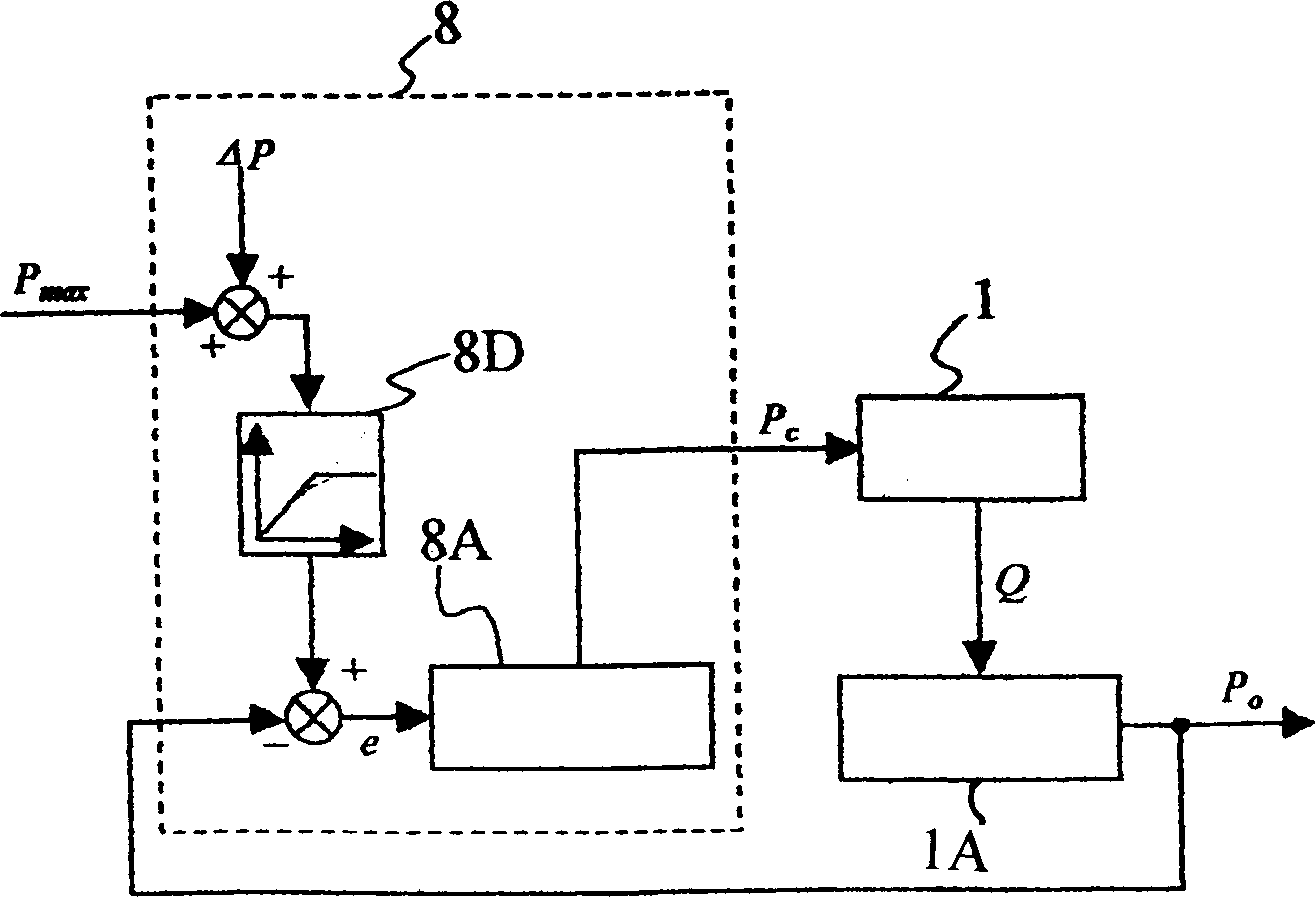

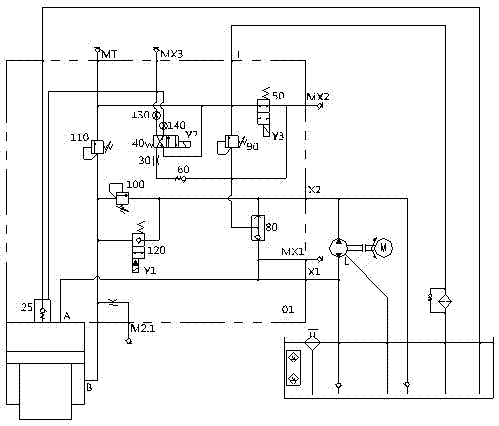

Load sensing hydraulic system for controlling six-way multiple unit valve

InactiveCN1405458AReduce consumptionImprove protectionServomotor componentsFluid-pressure actuator componentsLoad sensingHydraulic pump

A load sensing hydraulic system used in six-way valve. Using displacement-controllable variable delivery pump and six-way valve, multiple hydraulic load can be controlled. The loade limit can be checked by pressure detector set on the oil mouth of six way valve. On the bypass loop of six-way valve, a flow detector is set between the six-way valve group and the hydraulic oil tank to detect the oil flow of the rear oil-return tank. Because of the flow detector, the loss of flow through the bypass loop can be greatly lowered, also because of the check of load pressure in the system, the output pressure of hydraulic pump can be controlled.

Owner:ZHEJIANG UNIV

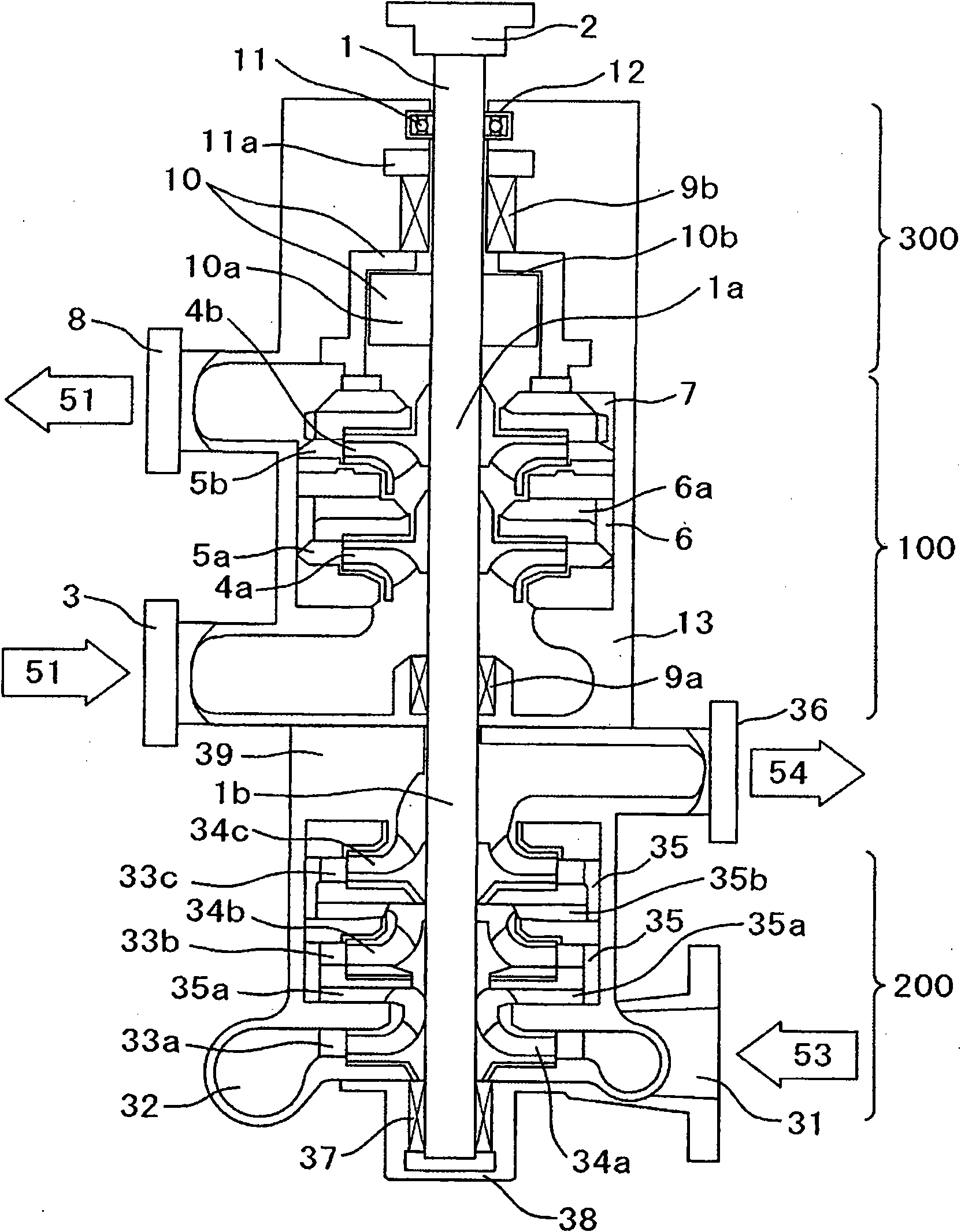

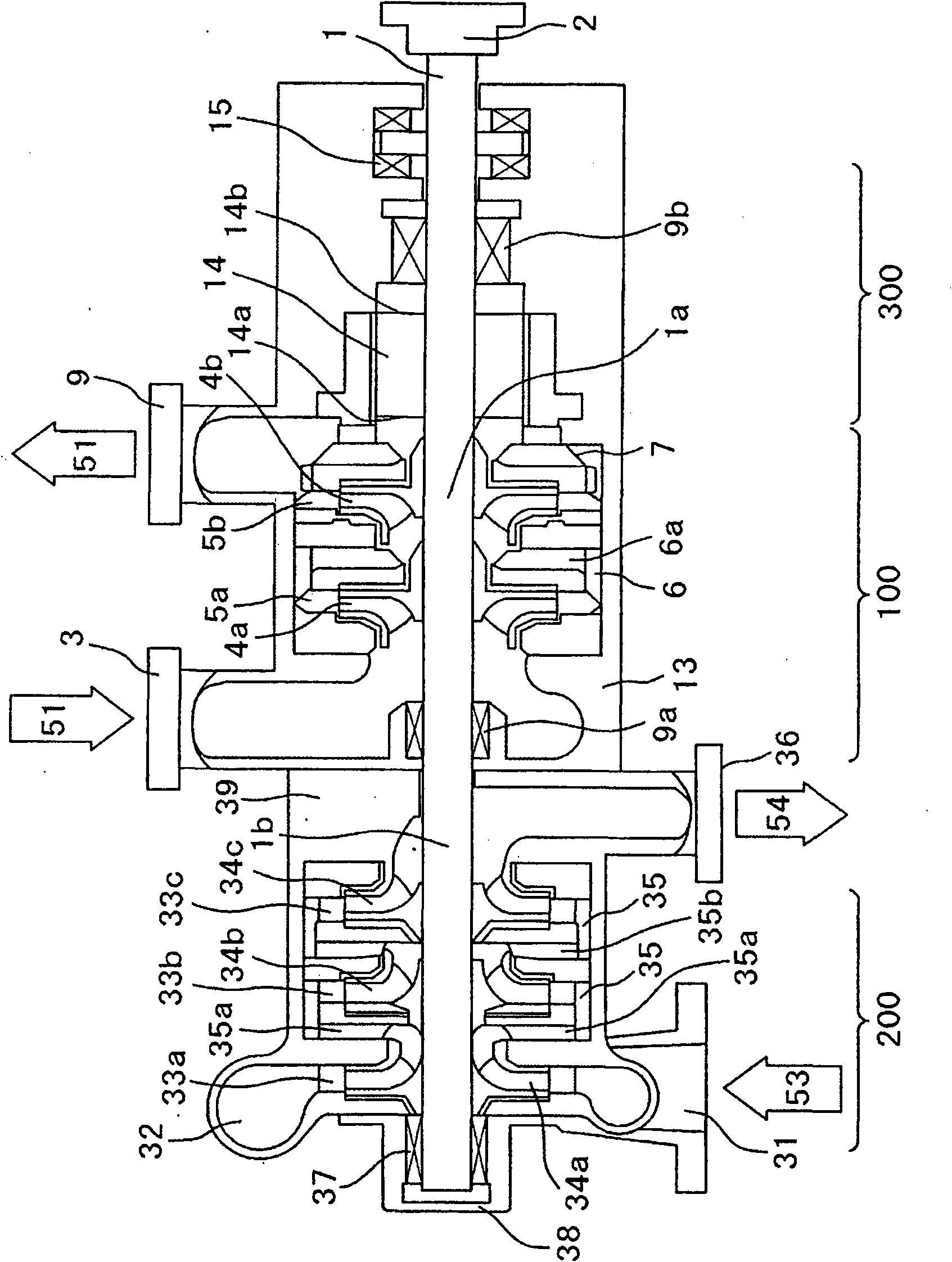

Pump system having energy recovery apparatus

InactiveCN102032194AEasy to ensure suction performanceLower the setting surface heightPump componentsHydro energy generationImpellerTurbine wheel

A compact, efficient, reliable, low-cost pump system having an energy recovery apparatus is provided for a large capacity desalination plant using a reverse osmosis membrane. The pump system in a desalination plant using a reverse osmosis membrane, the system includes a seawater pressurization pump and an energy recovery apparatus that recovers energy from high-pressure concentrated waste water through the reverse osmosis membrane to use the energy as a driving force for the pressurization pump. Hydro turbine impellers and pump impellers are disposed opposite each other coaxially with a pump shaft of the pressurization pump to reduce an axial thrust. A thrust direction of the shaft is supported by a single axial thrust support device. A radial direction of the shaft is supported by multiple radial submerged bearings.

Owner:HITACHI LTD

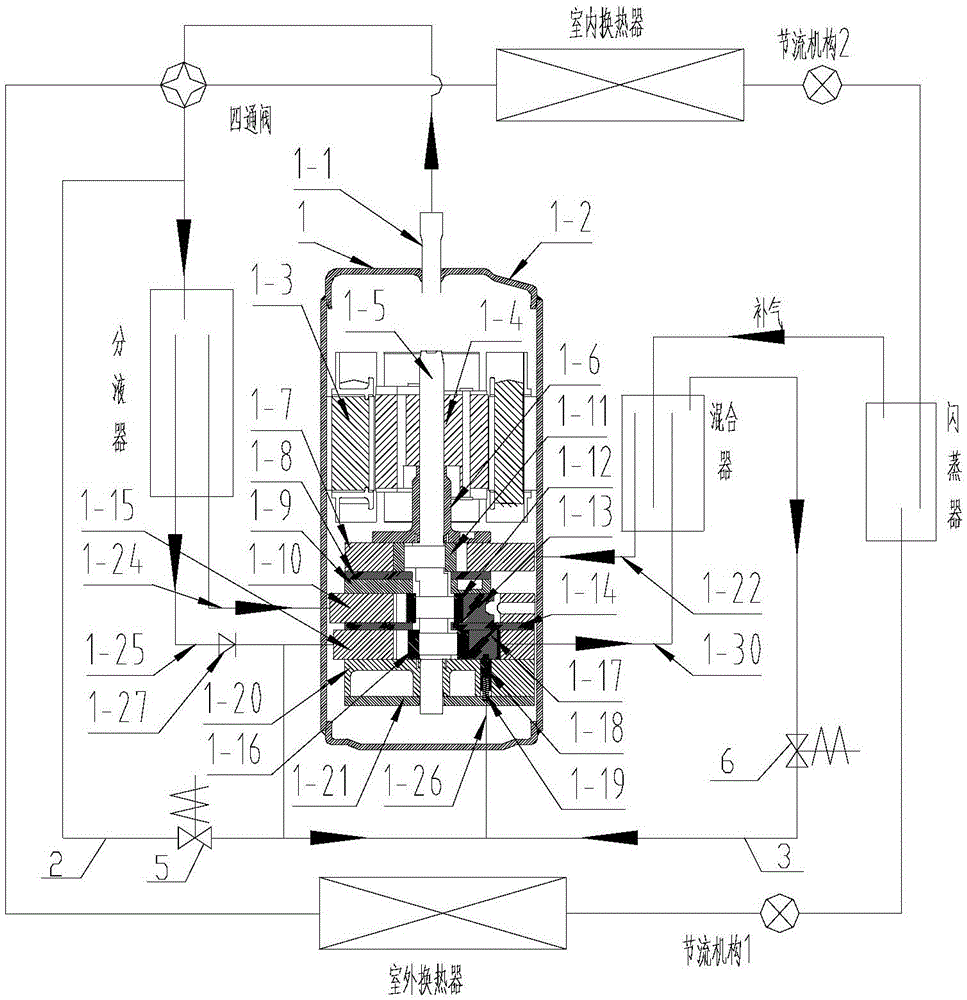

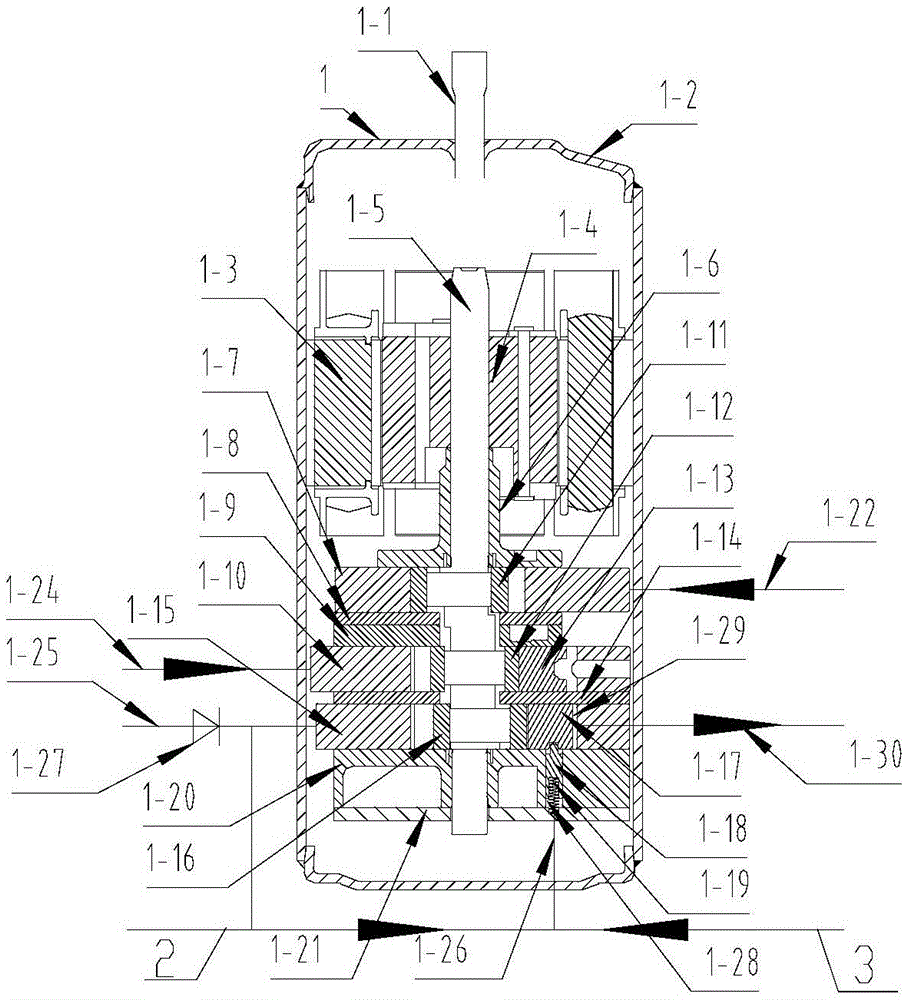

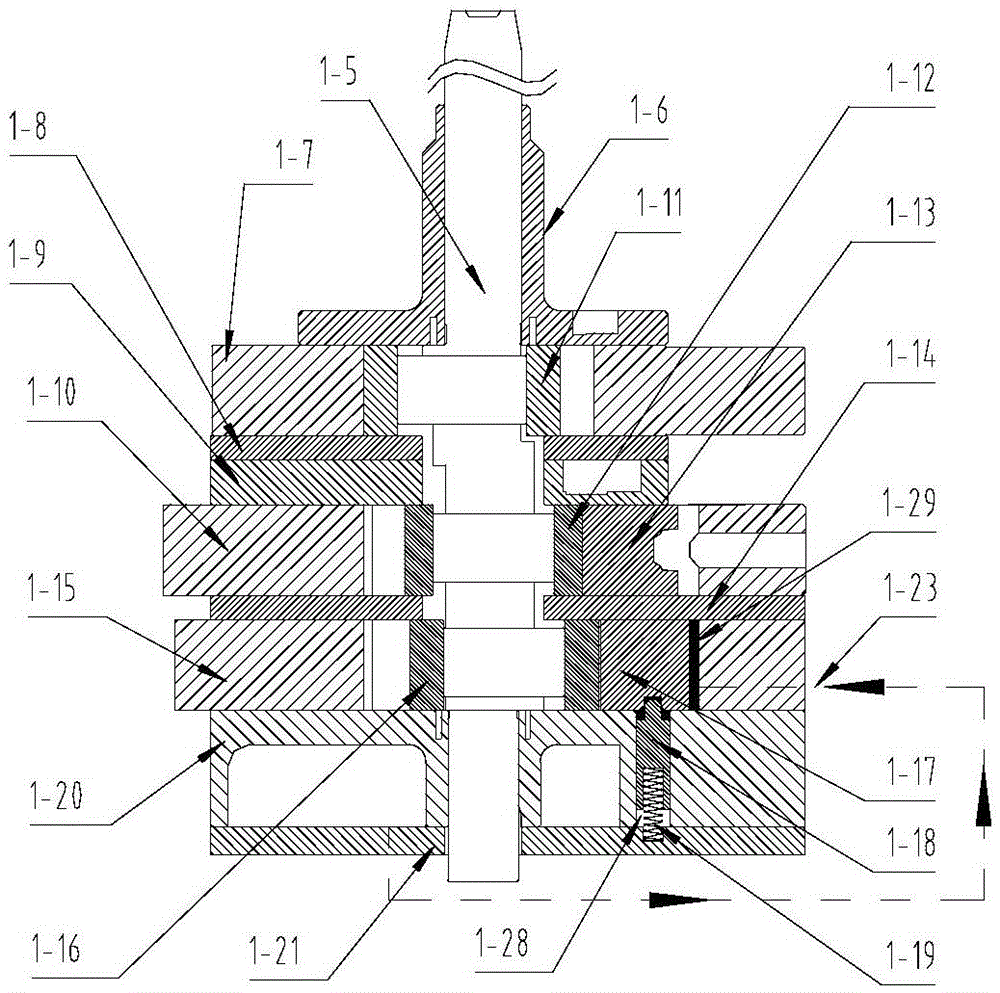

Multi-cylinder two-stage variable-capacity compressor system and control method of switching of running modes thereof

ActiveCN105545742AReduce front and rear pressure differenceImprove operational efficiencyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDifferential pressureEngineering

The invention provides a multi-cylinder two-stage variable-capacity compressor system. The multi-cylinder two-stage variable-capacity compressor system comprises a compressor in which a plurality of sets of rotating type compression mechanism parts are contained, wherein the compression mechanism parts comprise at least one high-pressure-stage rotating type compression mechanism part and at least two low-pressure-stage rotating type compression mechanism parts; one compression mechanism part in the low-pressure-stage compression mechanism parts is provided with a variable-capacity switching mechanism and further comprises an intermediate communicating pipeline introducing air suction pressure or intermediate pressure of the compressor to the variable-capacity switching mechanism. Air suction pressure or intermediate pressure is introduced to the variable-capacity mechanism by the multi-cylinder two-stage variable-capacity compressor so that the running modes of the variable-capacity compressor can be changed, the front and back pressure difference (between the head and the tail of a pin nail) of the variable-capacity mechanism is reduced, leakage loss caused by pressure difference is reduced, and the running efficiency of the compressor can be improved. The invention further relates to a control method of switching of running modes of the multi-cylinder two-stage variable-capacity compressor system.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

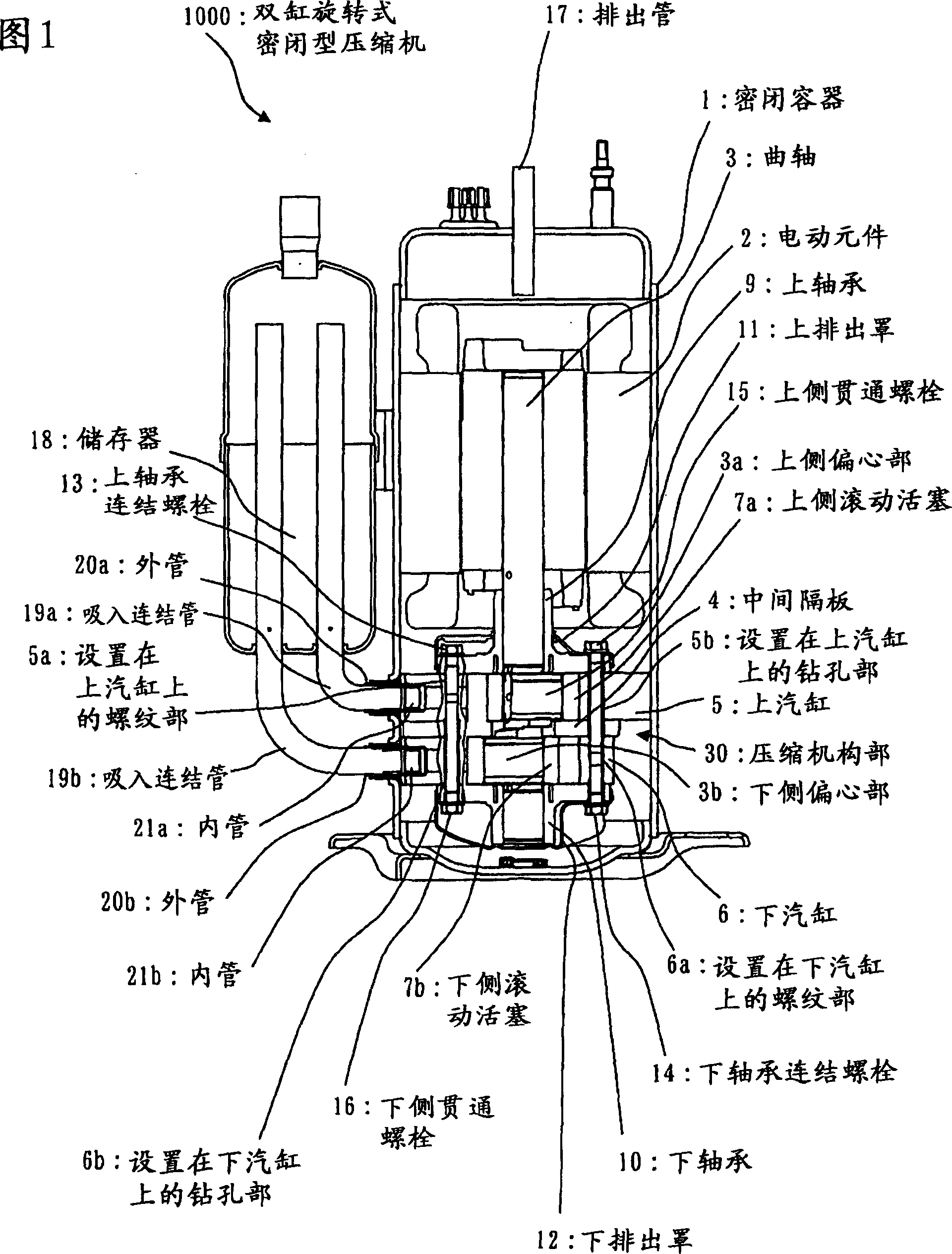

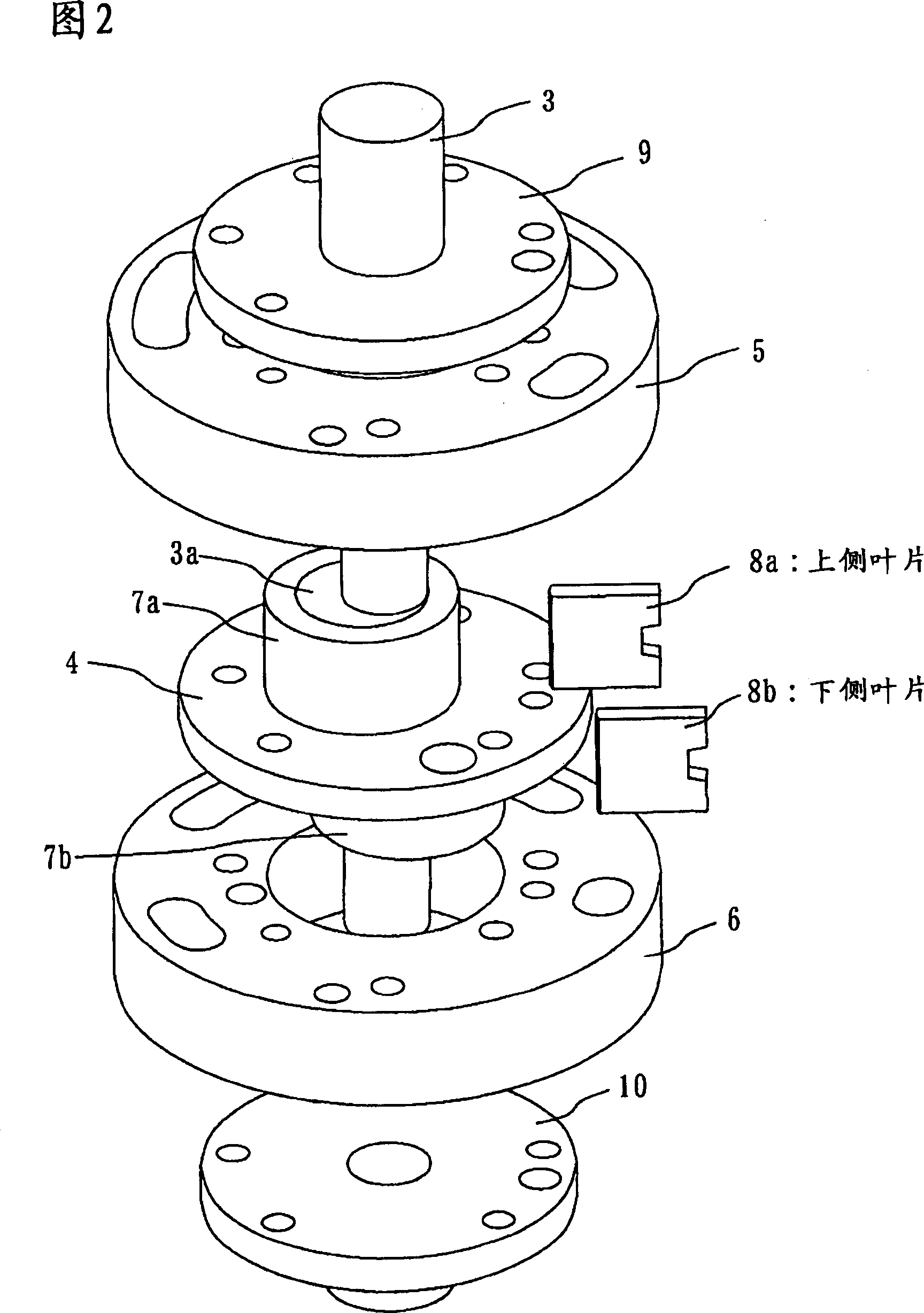

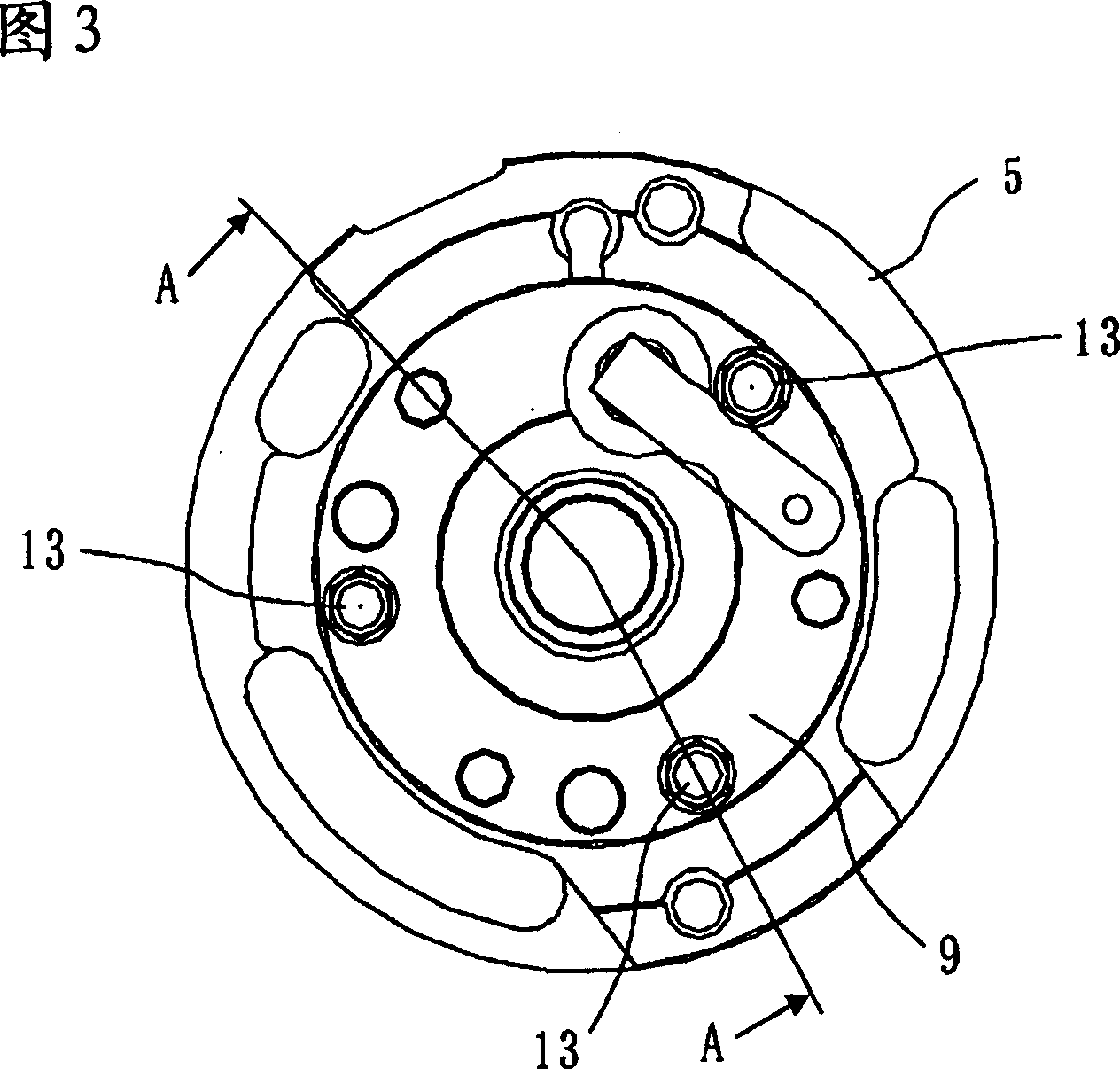

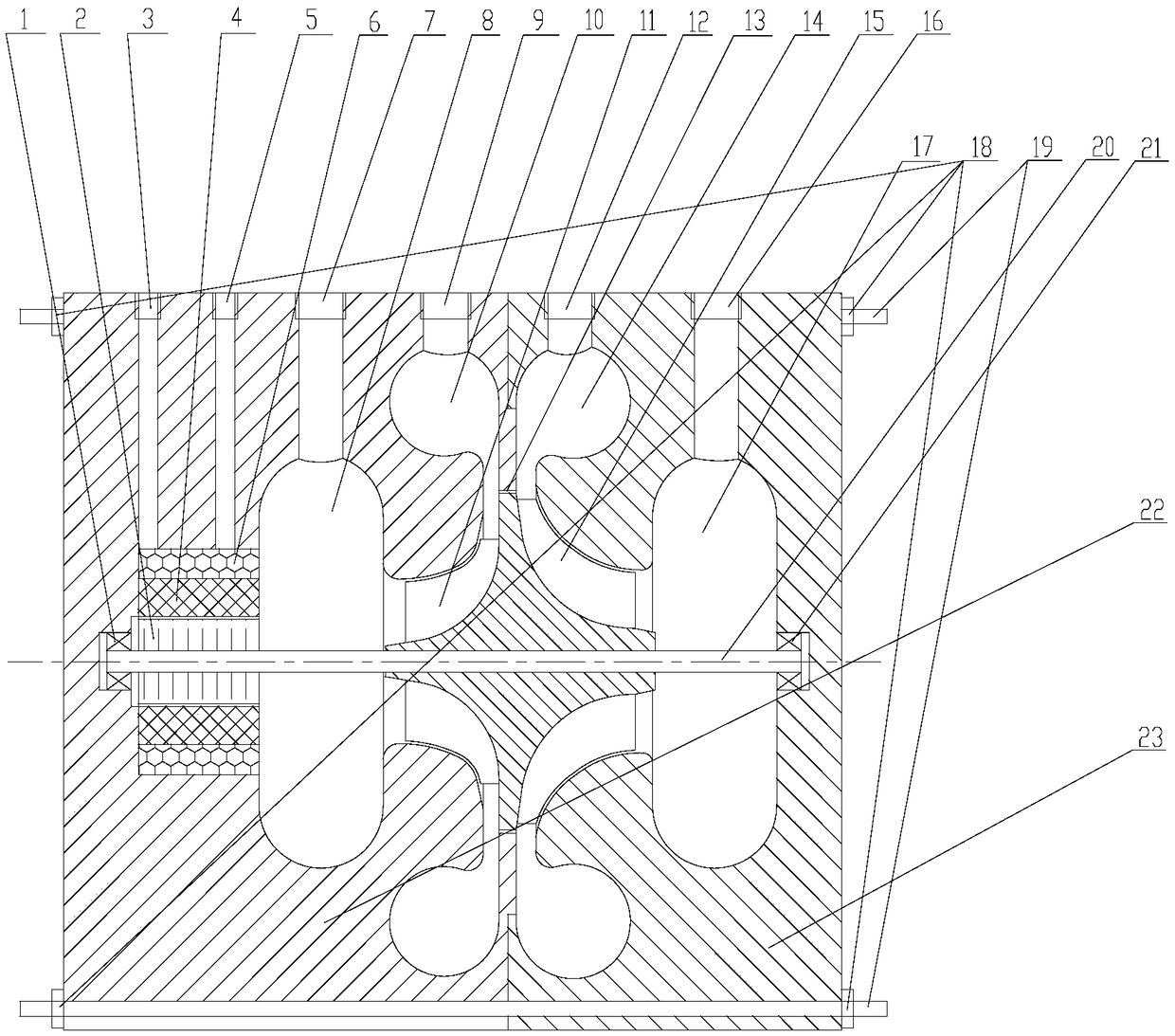

Double-cylinder rotary sealing type compressor and manufacturing method thereof

ActiveCN1991178AIncrease compression powerLow priceRotary/oscillating piston combinations for elastic fluidsMachines/enginesEngineeringMechanical engineering

The invention provides a dual-cylinder rotating close-type compressor comprising an electromotion element being held at the upper part of a close housing; a compression mechanism section being held at the lower part of the close housing and comprising an upper bearing, an upper cylinder, a central clapboard, a lower cylinder and a lower bearing, and being driven by the electromotion element via a crankshaft; the upper transfixion bolts for fixing the upper bearing, the upper cylinder, the central clapboard to the lower cylinder from the upper bearing side; and lower transfixion bolts for fixing the lower bearing, the lower cylinder, the central clapboard to the upper cylinder from the lower bearing side, and in addition, at least two lower transfixion bolts and two lower transfixion bolts are alternately arranged along the circumferential direction of the crank shaft rotation direction.

Owner:MITSUBISHI ELECTRIC CORP

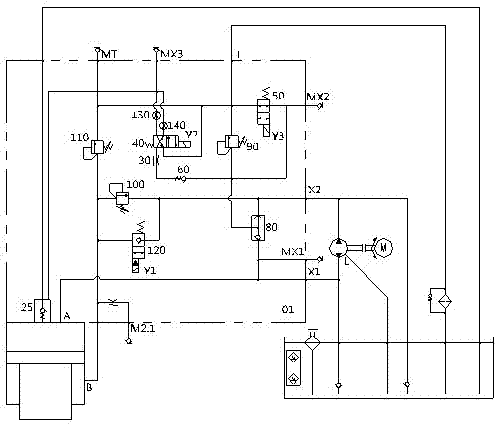

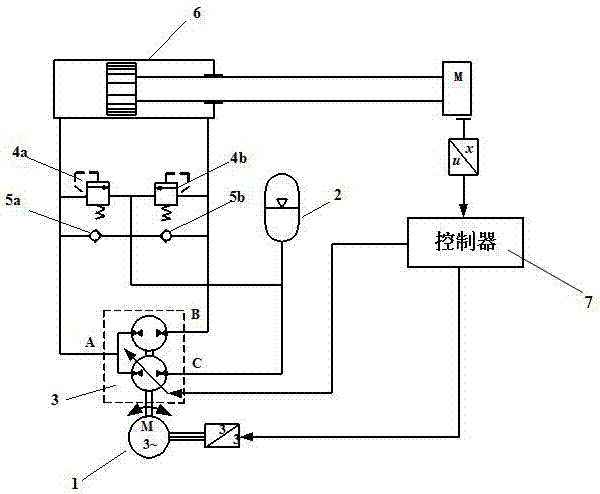

Hydraulic control system for novel servo pump control bending machine

ActiveCN102513413AReduce drag lossReduce leakage lossFluid-pressure actuator componentsSystem pressureNumerical control system

The invention belongs to the technical field of hydraulic control and particularly relates to a hydraulic control system of a novel bending machine, i.e. a servo pump control system. The hydraulic control system comprises a motive power source and a control valve group, wherein the motive power source is connected with a numerical control system. The hydraulic control system is characterized in that the motive power source comprises a servo motor, a bidirectional quantitative pump and an oil tank, the bidirectional quantitative pump and the oil tank are connected with the servo motor, the control valve group comprises a shuttle valve, a pressure valve, an unloading valve, a one-way valve, a reversing valve, a back pressure valve, a poppet valve, a safety valve and a liquid filling valve, the pressure valve is used for regulating the system pressure, an oil inlet and outlet of the bidirectional quantitative pump is controlled by the shuttle valve, a positive oil outlet is directly connected with an upper cavity of an oil cylinder, a reverse oil outlet is connected with a lower cavity of the oil cylinder through the poppet valve and the back pressure valve, an oil inlet and outlet of the bidirectional quantitative pump is connected with the oil tank through the one-way valve, the reversing valve and the liquid filling valve, the liquid charging valve is connected with the control valve, and the safety valve is connected between the oil tank and the lower cavity of the oil cylinder. The hydraulic control system has the characteristics that efficiency is high, the energy is saved, and the synchronous precision is high.

Owner:NANJING ESTUN AUTOMATION CO LTD

Cyclone compressor

InactiveCN101900115ALittle changeHigh overall thermal insulation efficiencyRotary piston pumpsRotary piston liquid enginesCycloneFriction loss

To stabilize the pressure of a back pressure chamber arranged on the back face of a cyclone component to reduce variation of a force for pushing one cyclone component against the other cyclone component so as to implement high efficiency of a cyclone compressor. On the root of teeth of one cyclone component, a compression chamber side communication port of a back pressure communication channel is arranged at a position facing to the compression chamber of two systems, and the internal line of the cyclone component equipped with the compression chamber side communication port is of a tooth shape that the compression of the compression chamber is performed in advance. Thereby, the variation amplitude of the pressure in the compression chamber communicated with the compression chamber side communication port is reduced, and the variation amplitude of corresponding back pressure is reduced. By means of restraining the variation of the back pressure, the deformation variation of the cyclone component is restrained; leakage loss is reduced by improving sealability of the clearance between two cyclone components, such that a total adiabatic efficiency is improved by restraining interference and reducing friction loss.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

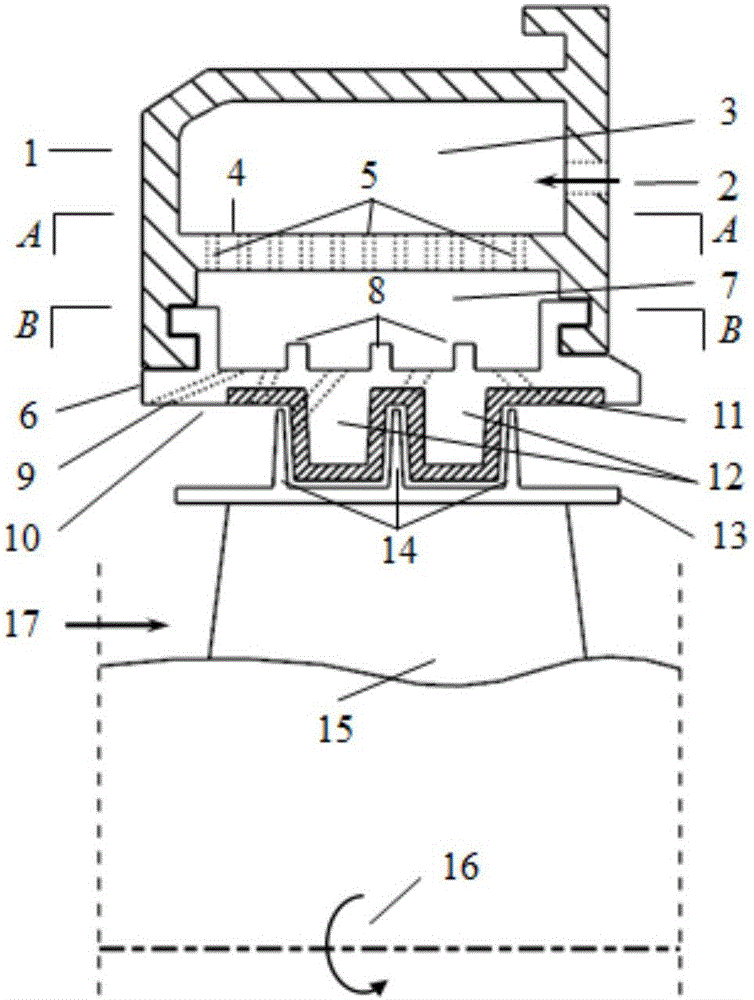

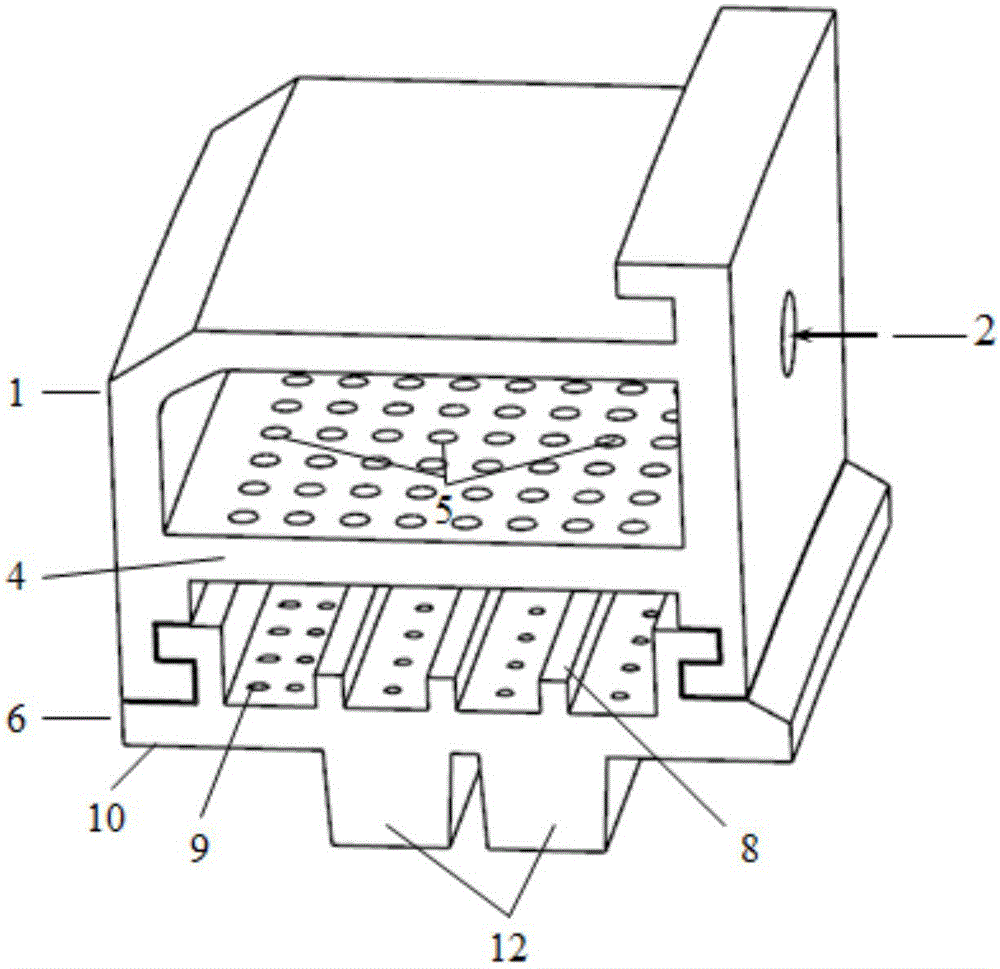

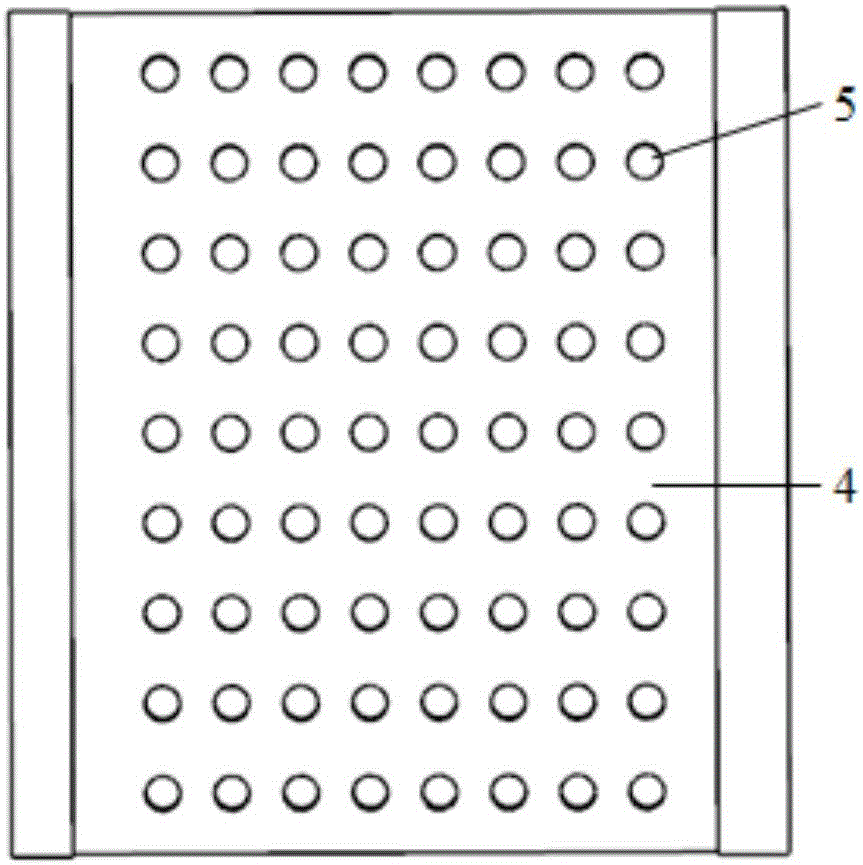

Casing structure with leaf apex interval control and leaf tip flow control

ActiveCN107435563AReduce the temperatureReduce radial deformationLeakage preventionMachines/enginesCold airCooling effect

The invention discloses a casing structure with leaf apex interval control and leaf tip flow control. A turbine casing and an impact plate form a first cavity, multiple impact holes are limited in the impact plate, a turbine outer ring form a second cavity, multiple turbulent structures, and an air film hole structure and a leak-proof structure are limited on the outer ring; cold air flow enters the first cavity through an air incoming hole, enters the second cavity through an impact hole structure to impact the outer ring, fully cools the turbine outer ring through the turbine structures and flows out from the air film hole structure of the outer ring to form a cooling air film to be finally mixed with main fuel gas; a boss structure on the turbine outer ring is mainly used for blocking formation and development of leaf tip leakage vortex. Heat exchange effect of cooling airflow inside the casing is enhanced, the air film hole structure has good cooling effect on the surface of the turbine casing and a leaf tip position in direct contact with high-temperature fuel gas, the leakage-proof structure effectively lowers leaf tip leakage loss, and turbine efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

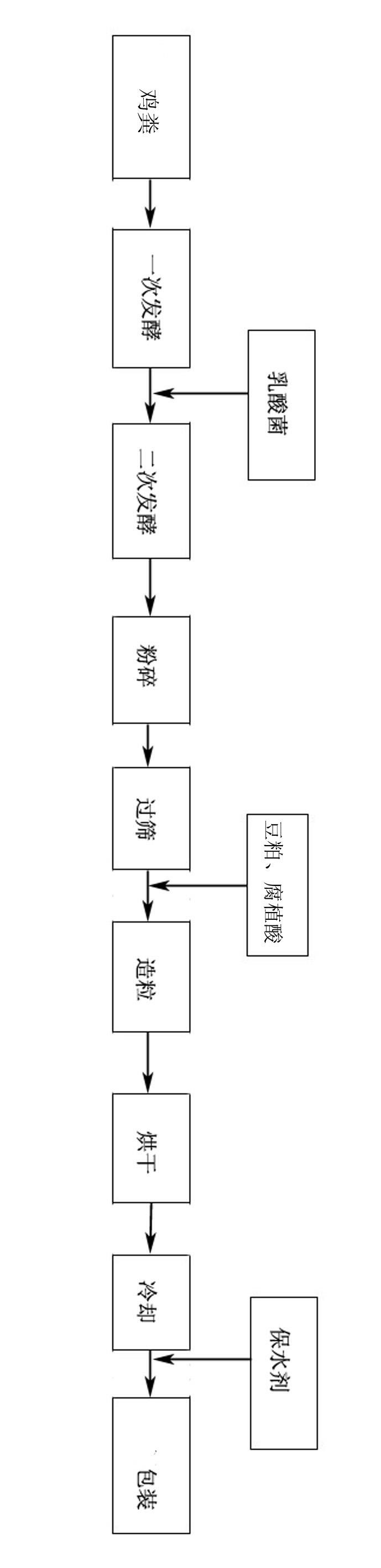

Biological bacterium water-retaining organic fertilizer and preparation method thereof

InactiveCN102674969AThermal insulationIncrease moisture contentBio-organic fraction processingOrganic fertiliser preparationBiotechnologyLactic acid bacterium

The invention relates to an organic fertilizer technology and specifically relates to biological bacterium organic fertilizer and in particular to biological bacterium water-retaining organic fertilizer and a preparation method thereof, which solves the problem that the conventional organic fertilizer cannot help soil to resist drought and retain water. The biological bacterium organic fertilizer is prepared from the following raw materials in part by weight: 150 to 170 parts of chicken manure, 210 to 230 parts of humic acid, 60 to 70 parts of bean pulp, 15 to 18 parts of lactic acid bacteria and 50 to 60 parts of water-retaining agent, wherein the humic acid is one or a mixture of any one of sodium humate, potassium humate, phosphamidon humate, ulmic acid and grass carbon soil in any ratio. The biological bacterium organic fertilizer is prepared by the following steps: (1), placing the chicken manure into a fermenting tank and performing primary fermentation at normal temperature, wherein the fermentation time is 4 days and the raw materials are turned over for three times every day during fermentation; (2), adding the lactic acid bacteria and mixing uniformly; and (3), spreading the raw materials and performing secondary fermentation.

Owner:FENYANG JINTUDI BIOLOGICAL TECH ORGANIC FERTILIZER

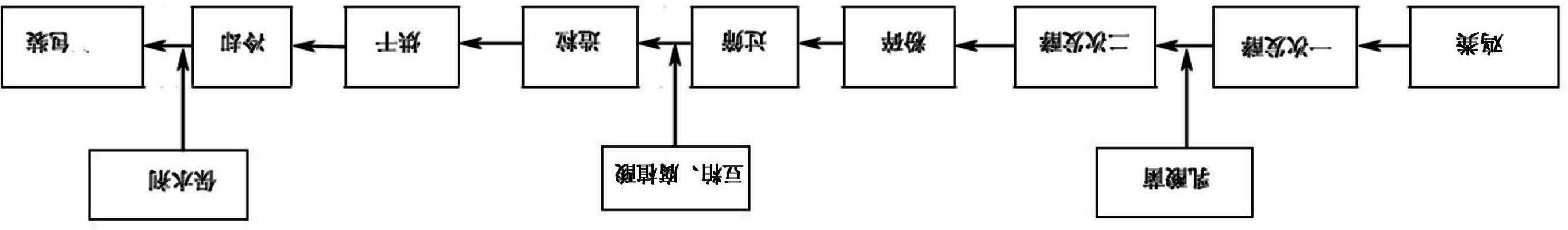

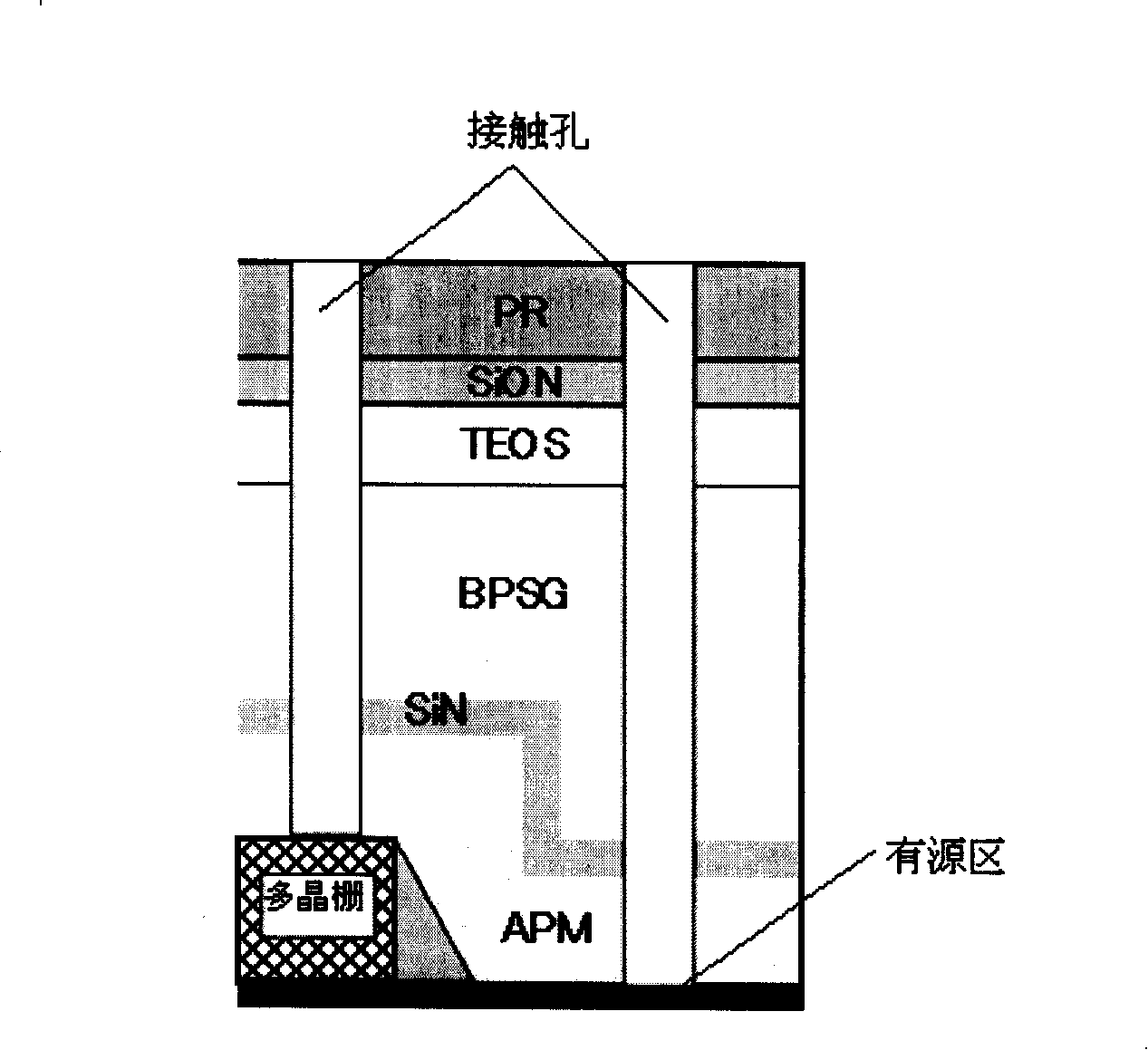

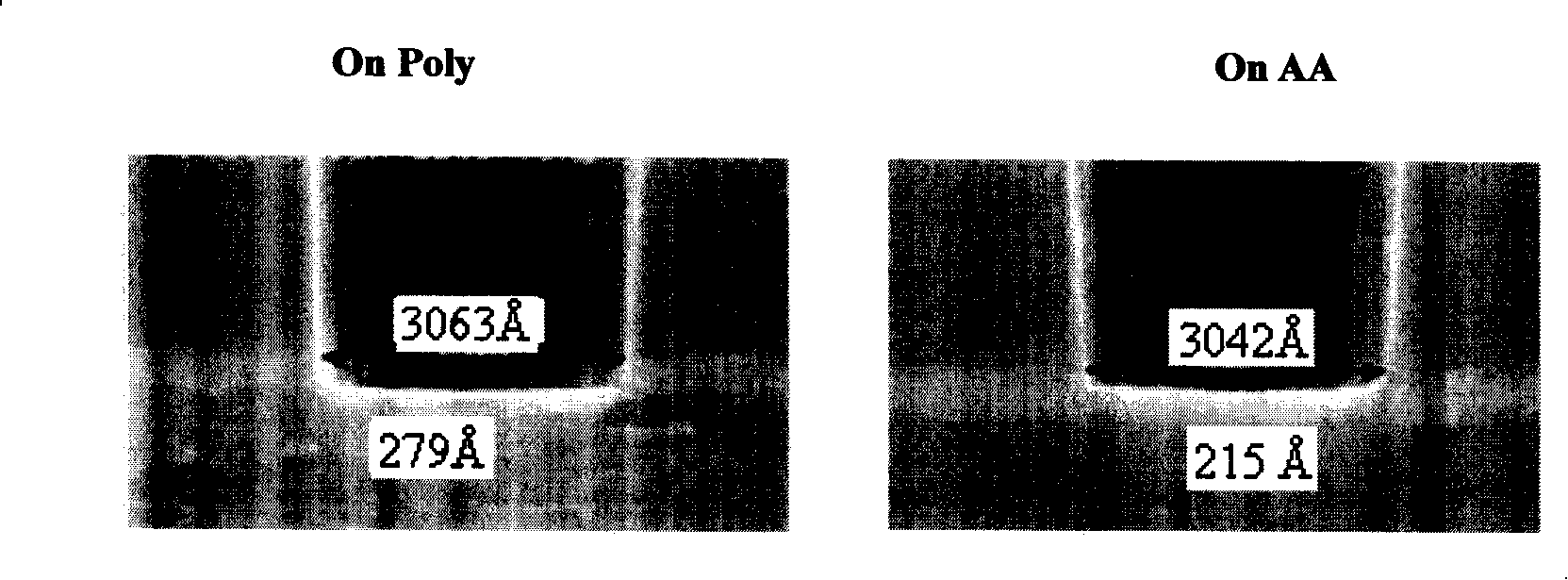

Method for etching suspending type etch blocking layer contact hole in embedded flash memory device

ActiveCN101202243AReduce lossesReduce depthSemiconductor/solid-state device manufacturingSalicideSilicon oxide

The invention discloses an etching method for contact holes of a suspended type etching barrier layer of an embedded flash memory device and comprises the following steps: the first step is the etching of top silicon oxy-nitride; the second step is the fast main etching of an oxide film; the third step is the slow main etching of the oxide film: in the step, the selectivity-ratio of silicon oxide to silicon nitride is bigger than 20:1, while the etching rate is relatively slower; the fourth step is to remove polymers which are produced in the previous three steps and are left at bottom parts of the contact holes; the fifth step is to remove the suspended type etching barrier layer of the nitride silicon; the sixth step is the etching of the oxide film at the bottom part. The invention solves the problem of excessive loss of metal contact silicide on the top part of a poly gate due to no etching barrier layer; at the same time, the invention can effectively avoid excessive etching and communication of the poly gate and an isolated edge of a shallow groove caused by deviation of exposing positions, thus the loss of electric leakage of the device can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

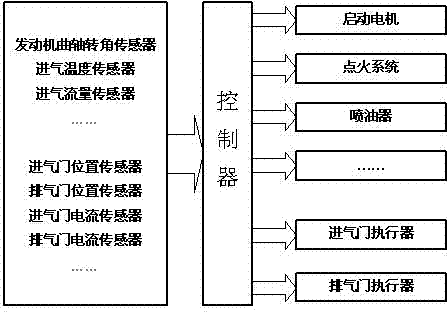

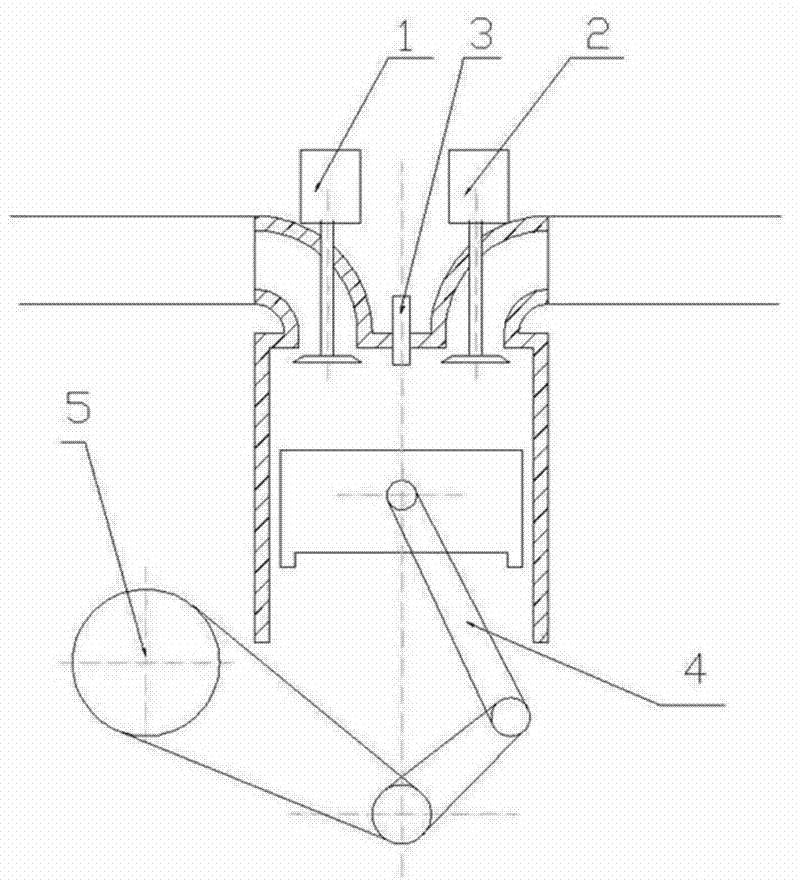

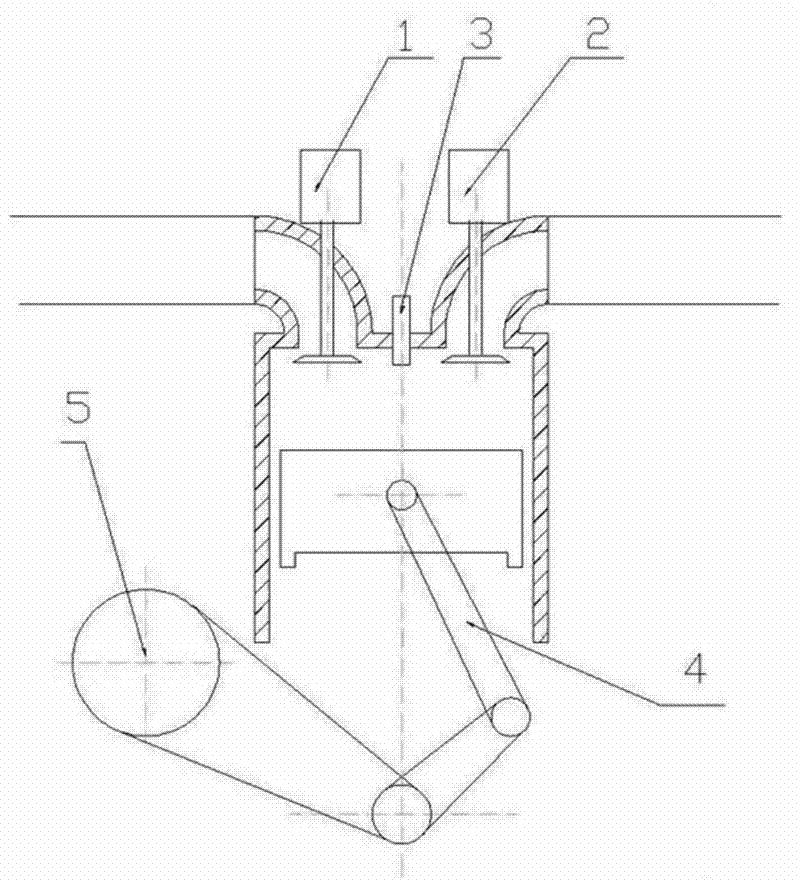

Efficient and quick starting method of engine applying solenoid-driven valves

InactiveCN102477877AGood for starting a fireShort transition timeOutput powerElectric motor startersClosed loop feedbackElectric machine

The invention discloses a control method for efficiently and quickly starting an engine. The engine applies a solenoid-driven inlet valve and a solenoid-driven exhausting valve, and is subjected to positioning and electric current double closed-loop feedback control by an engine electric control unit, so as to achieve the independent, continuously variable and real-time regulation of the opening moment, the closing moment, the lift range and the motion rule of the inlet valve and the exhausting valve of the engine; as in the process that the rotational speed of the engine rises step by step, the inlet valve basically keeps an opening state and stops the oil spraying and the ignition of each cylinder until a set rotational speed is reached, under the same power of a starting motor, the transition time can be obviously shortened; and the energy-saving performance and the environment-friendly performance of the engine can be improved.

Owner:NANJING UNIV OF SCI & TECH

Gain photon crystal fiber guide and its device

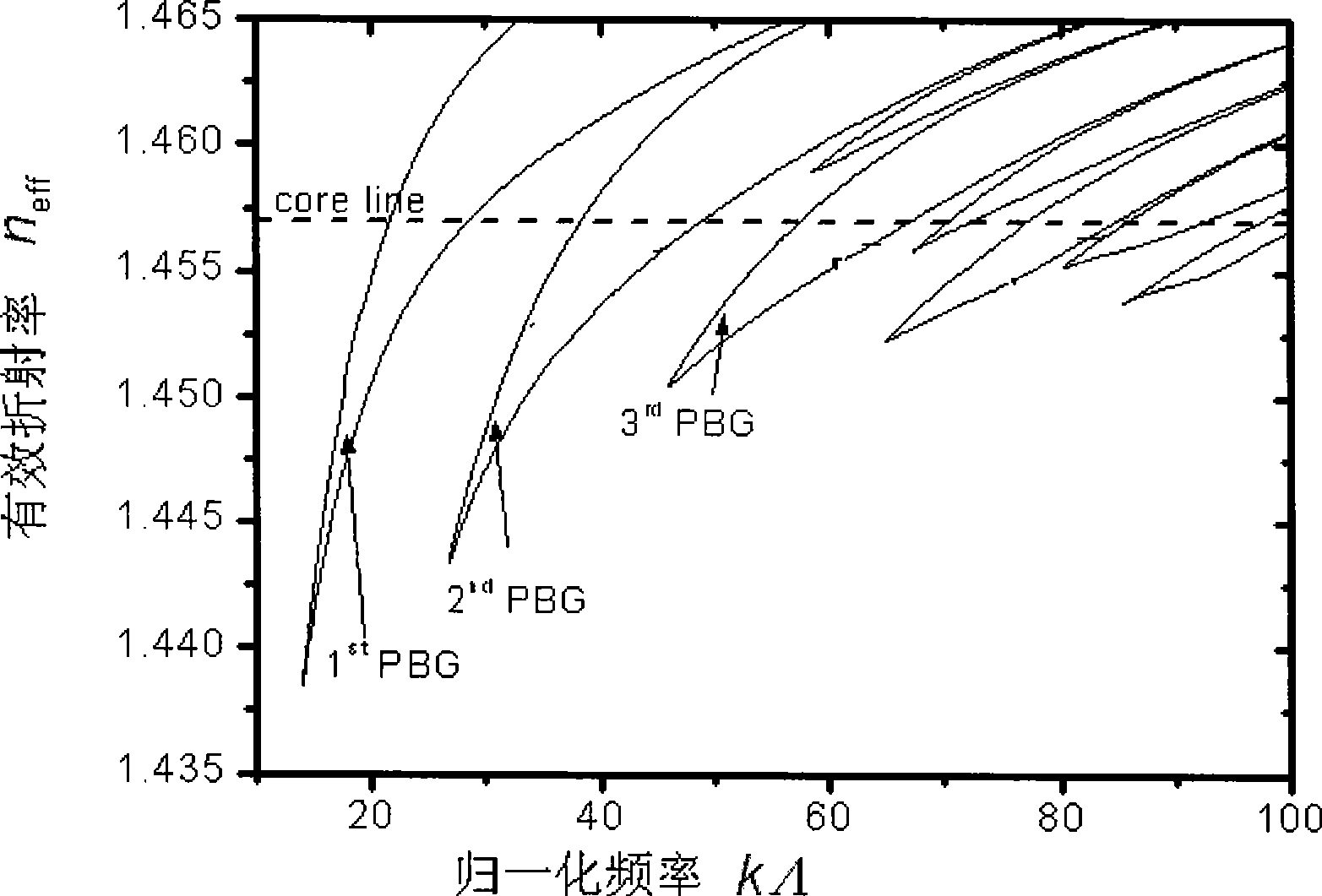

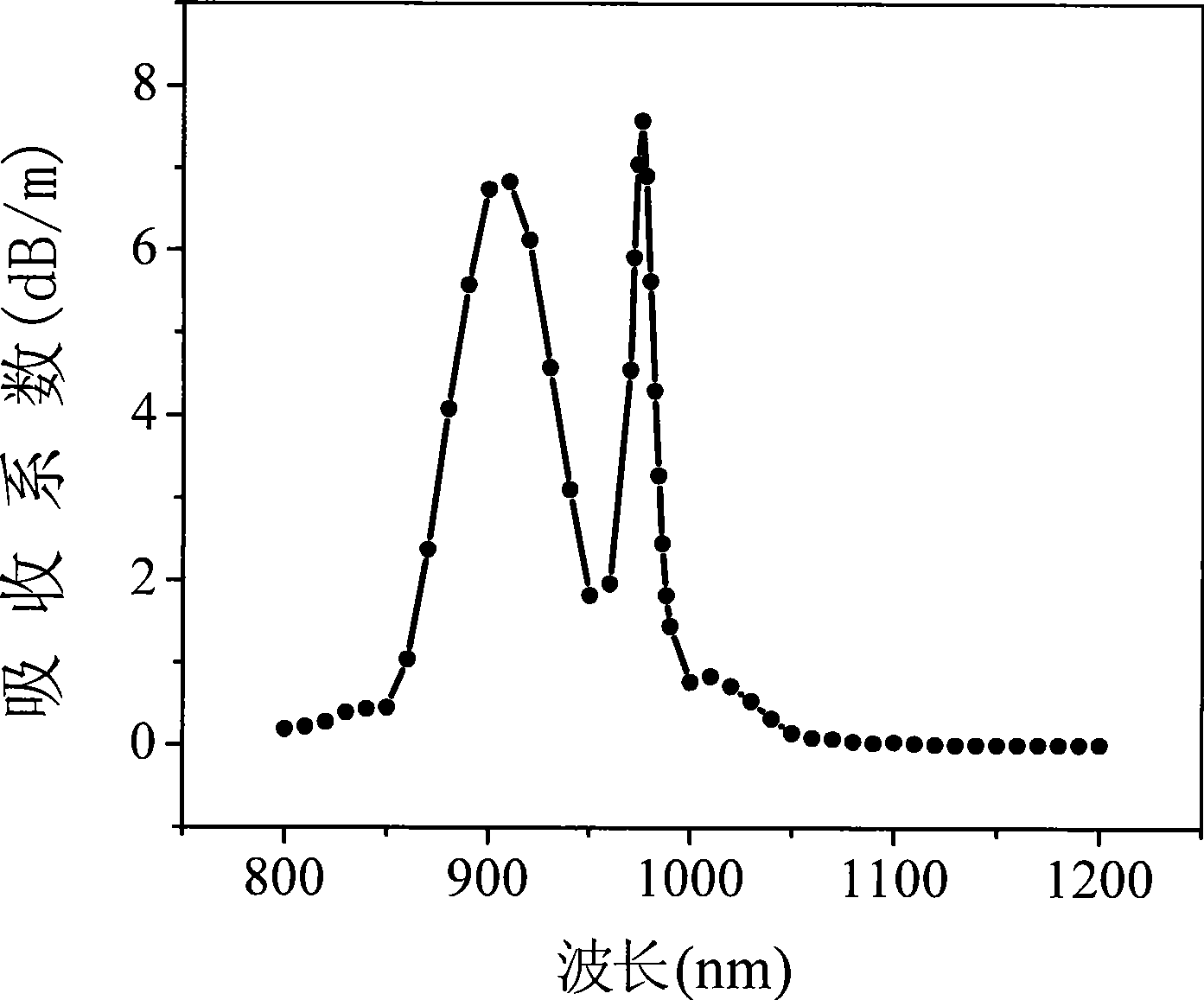

ActiveCN101369035AIncreased Laser Damage ThresholdImprove coupling efficiencyOptical fibre with multilayer core/claddingActive medium shape and constructionHigh power lasersLaser light

The invention relates to a gain photon crystal optical fiber waveguide, which is composed of a core layer and a coating layer which surrounds the core layer. The inner coating layer of the optical fiber comprise solid microstructure point lattice which is formed by germanium-doped silica column, and forms outer bandgap of the gain optical fiber, the function thereof is that the multimode pump light can be strictly restricted in a second fiber core region which is provided with rare earth dopant ion, and improves the utilizing efficiency of the pump light; the second fiber core of the optical fiber is composed of the solid microstructure point lattice which is formed the rare earth ion silica column to form the inner bandgap of the gain optical fiber, the function thereof is that through the multimode pump light, the generated laser light can be strictly restricted in a first fiber core region which is formed by high pure silica glass. Adopting the solid gain photon crystal optical fiber can greatly improve the utilization efficiency of the pump light, improve beam quality of output laser light, enhance output power of the optical fiber laser, and reduce nonlinear effect of the high-power laser device.

Owner:FENGHUO COMM SCI & TECH CO LTD

Double-rotor variable-volume compressor

ActiveCN103244412AImprove performanceImprove stabilityRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsPull forceLocking mechanism

The invention provides a double-rotor variable-volume compressor, comprising a first air cylinder group and a second air cylinder group. The first air cylinder group comprises a first air cylinder, a first sliding sheet and a locking mechanism, wherein the first air cylinder is provided with a first sliding groove; the first sliding sheet is arranged in the first sliding groove and is provided with a positioning hole or a positioning groove; the locking mechanism is provided with a locking piece; the locking piece is provided with a locking position and an unlocking position, wherein the locking position extends into the first sliding groove and is matched with the positioning hole or the positioning groove so as to lock the first sliding sheet, and the unlocking position is used for unlocking the first sliding sheet. The double-rotor variable-volume compressor provided by the utility model can convert between single-cylinder operation and double-cylinder operation, and has higher operation stability and reliability. Meanwhile, a sliding sheet of a second air cylinder is not stressed by a pull force towards the outer side of the air cylinder in the double-cylinder operation, so that the sliding sheet is tightly adhered to a roller; the leakage loss and the like can be reduced; and the properties of the compressor can be improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

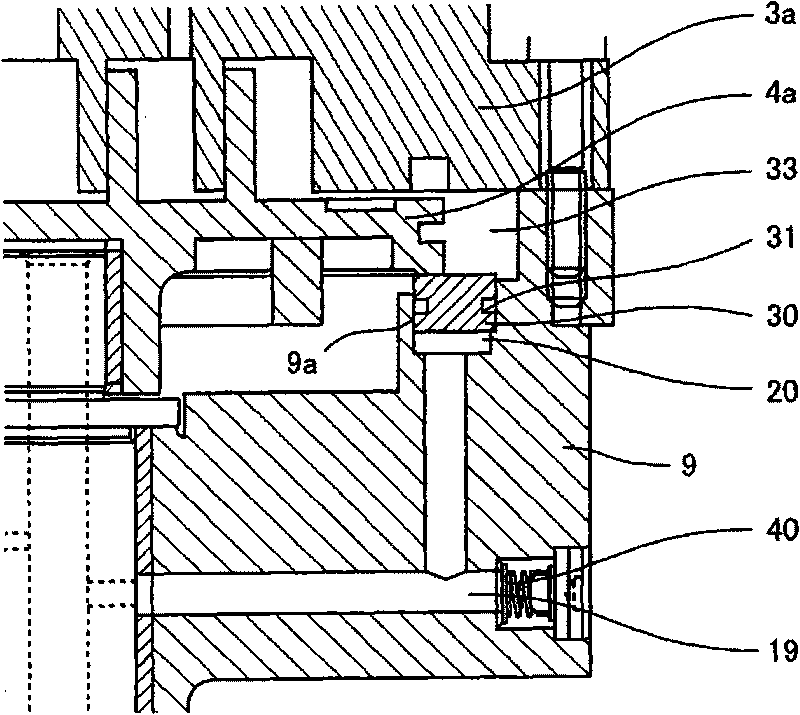

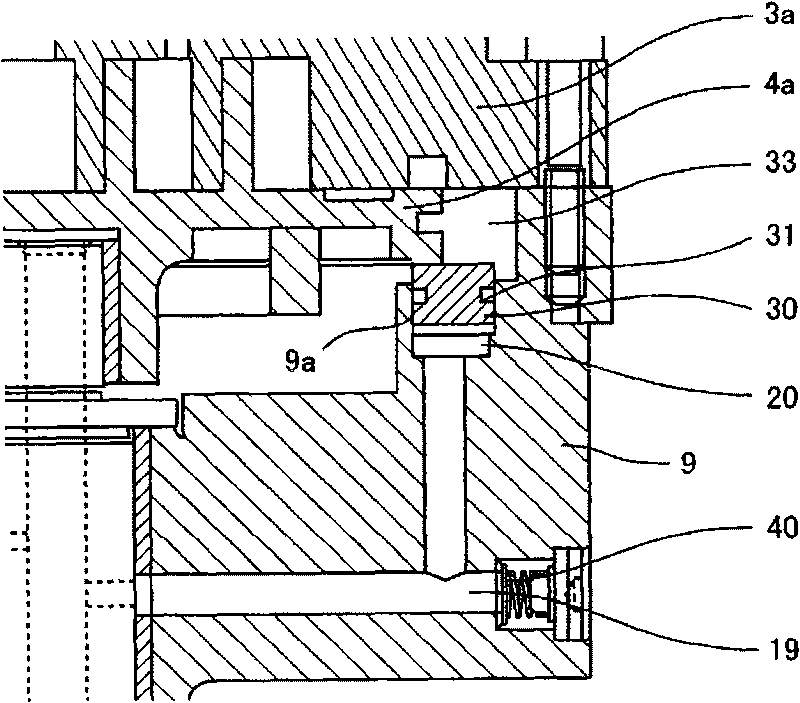

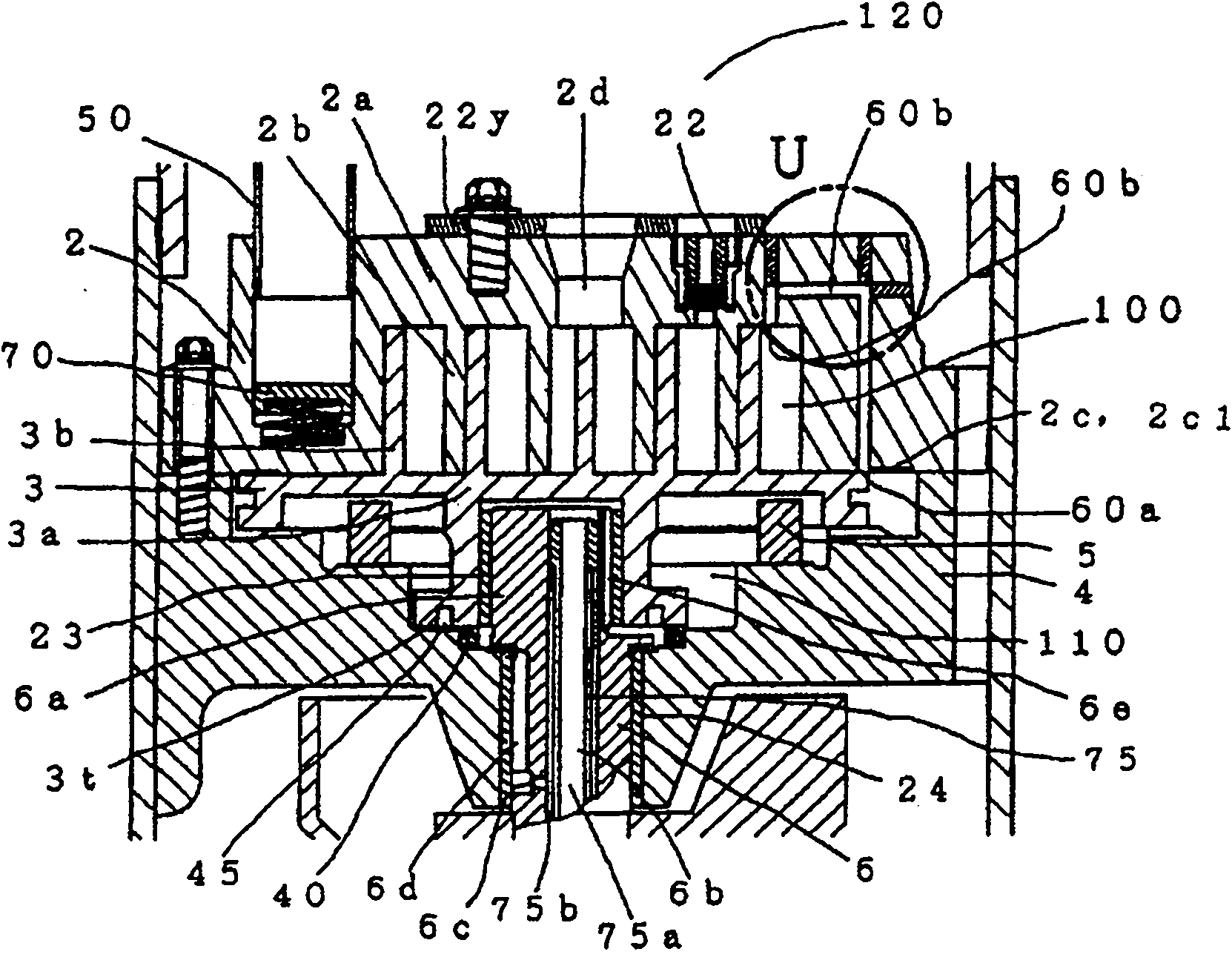

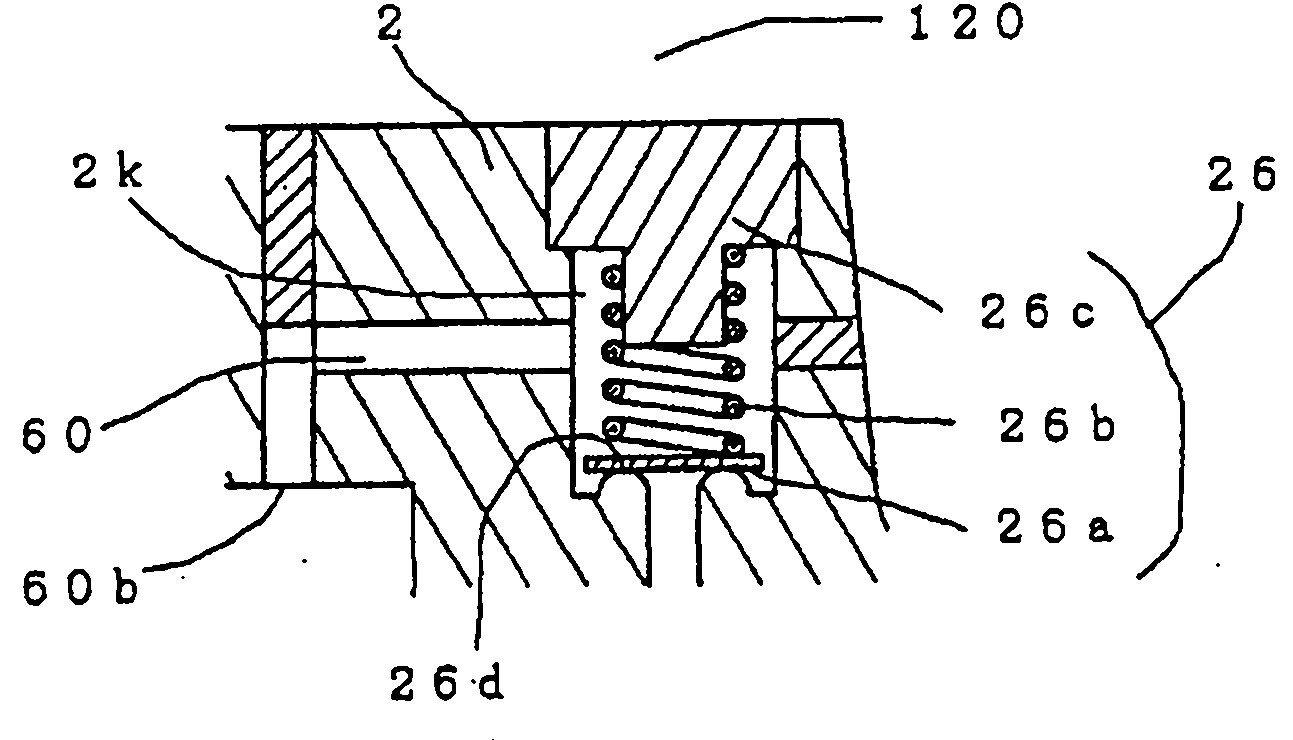

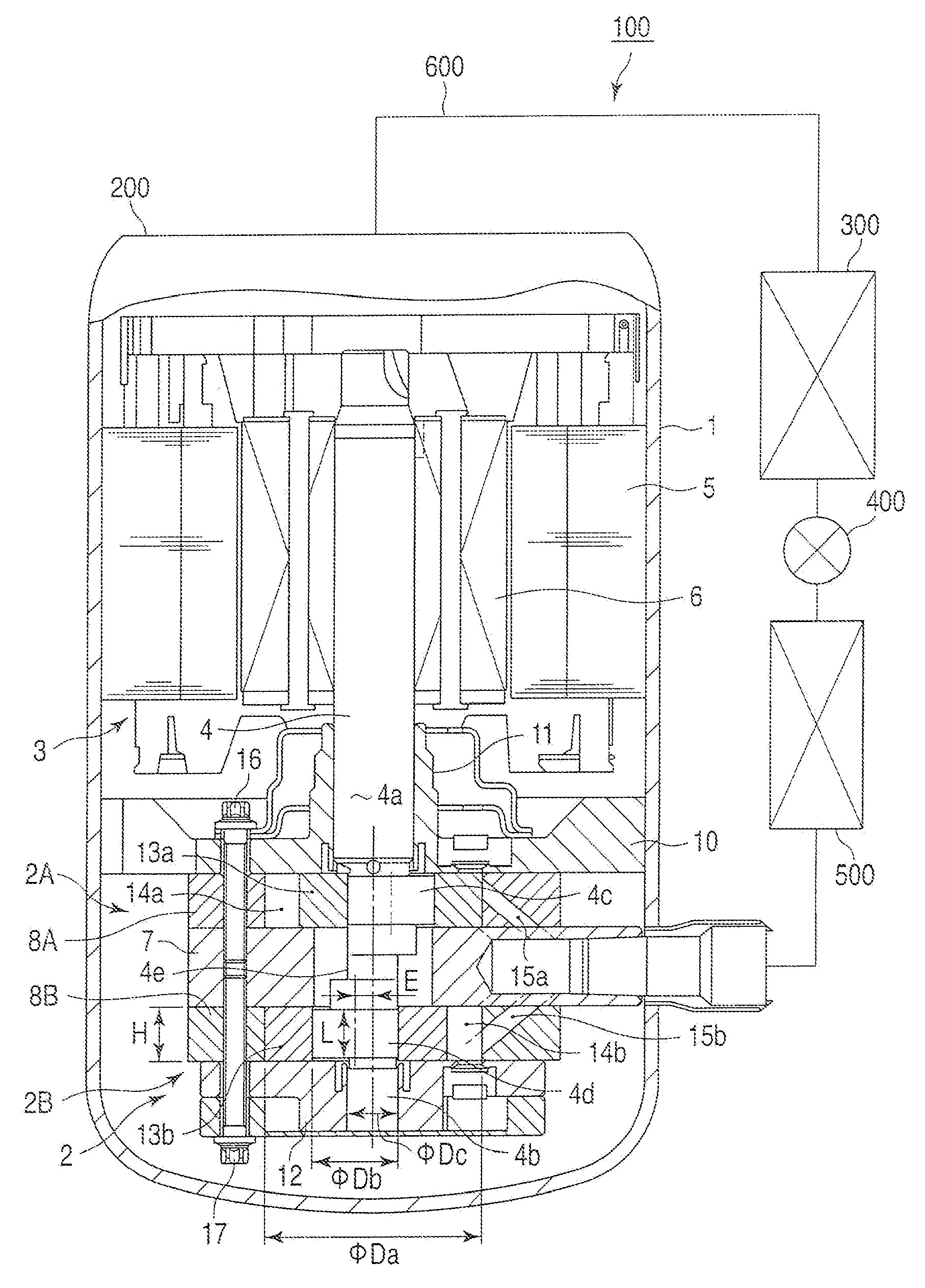

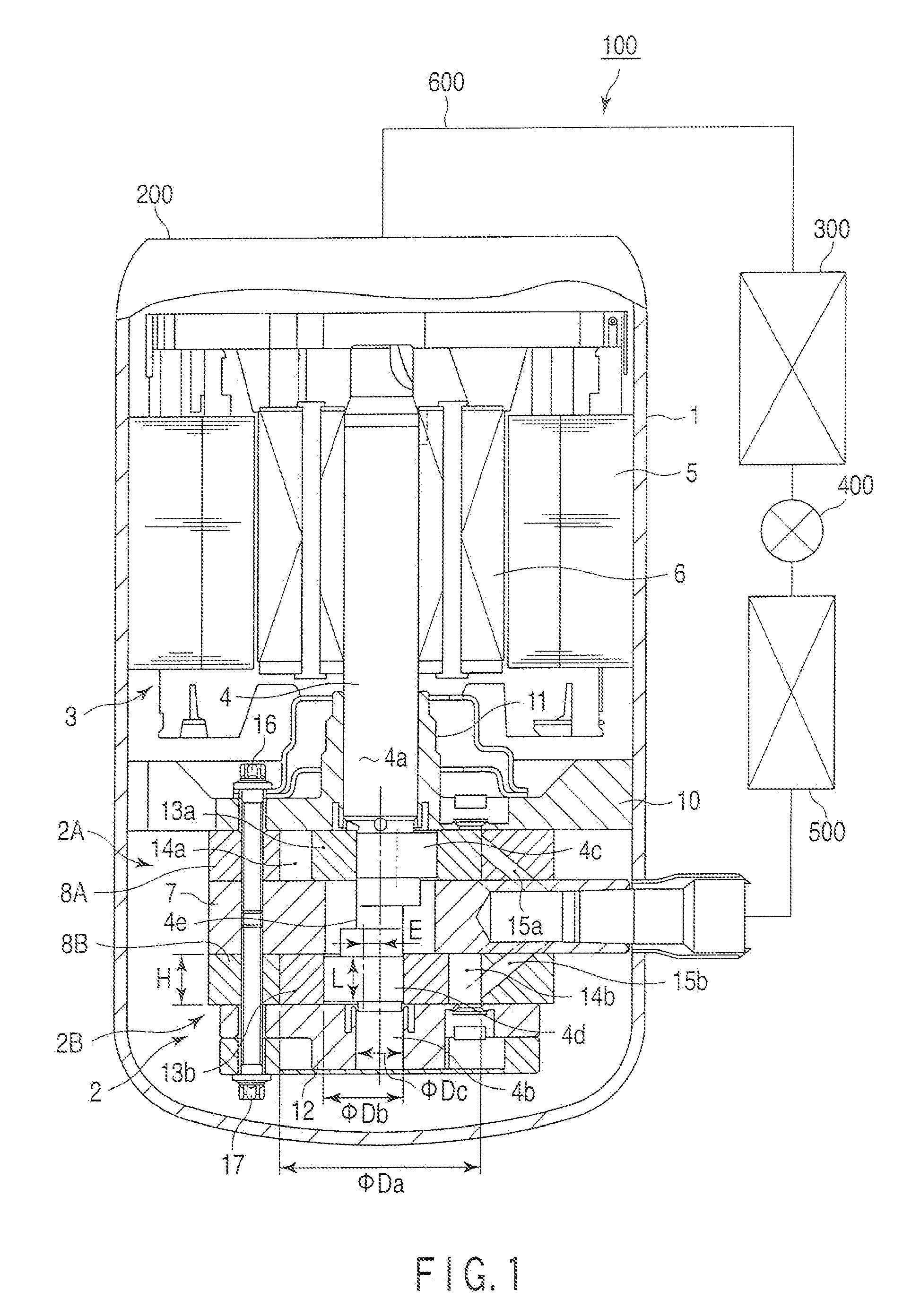

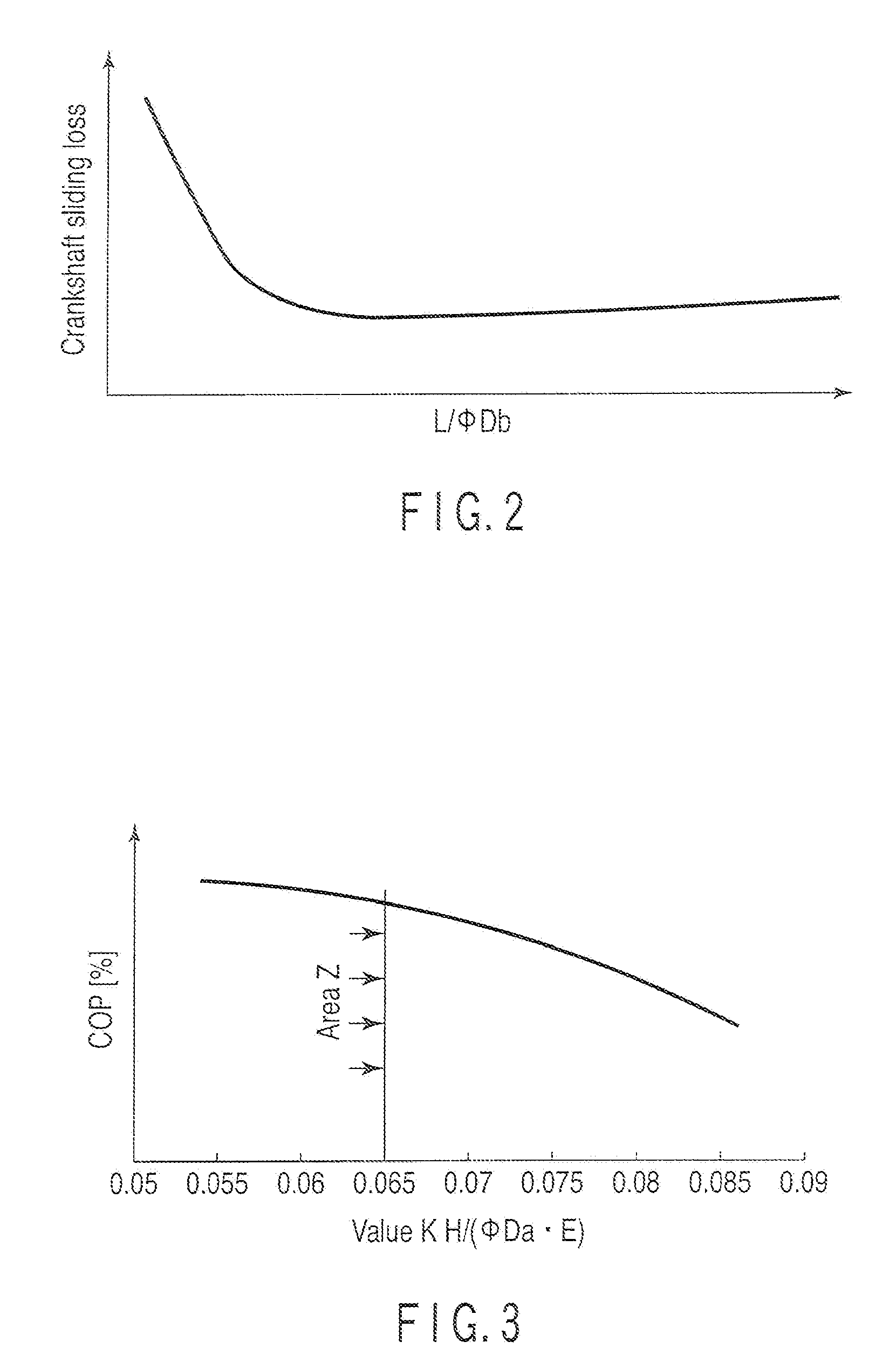

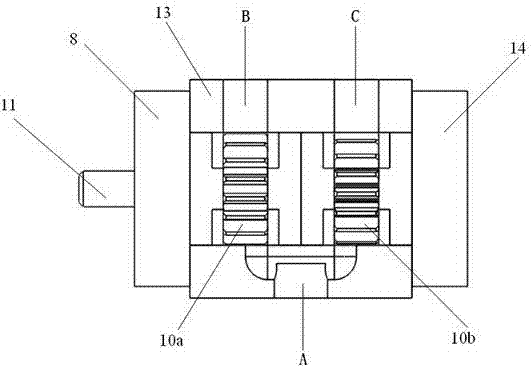

Rotary compressor and refrigeration cycle equipment

ActiveUS20100147020A1Reduce leakage lossImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A rotary compressor, which contains a motor unit and compression mechanism in a sealed case, transmits the rotational power of the motor to the compression mechanism through a rotary shaft and crankshafts eccentrically provided in the rotary shaft, and compresses a refrigerant in the compression mechanism, wherein the rotary compressor is configured to have H / (φa•E)=K, and K≦0.065, and the formula 0.35+0.07•K•H≦L / φDb≦0.45+0.07•K•H, assuming that the inside diameter of the cylinder forming the compression mechanism is φDa [mm], the cylinder height is H [mm], the crankshaft eccentricity is E [mm], the crankshaft diameter is φDb [mm], and the sliding lengths of the crankshaft and a roller fitted over the crank are set to L [mm].

Owner:TOSHIBA CARRIER CORP

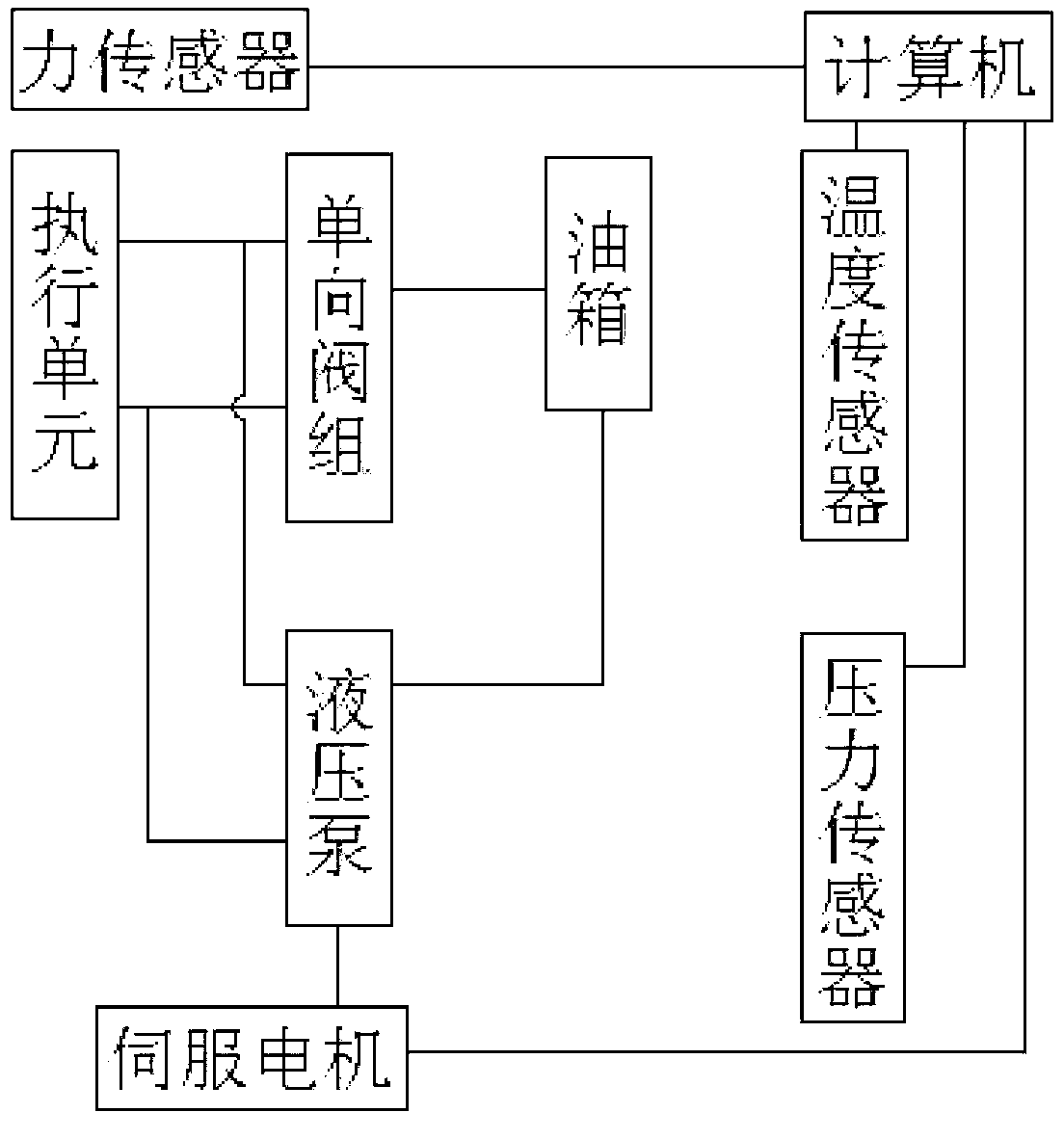

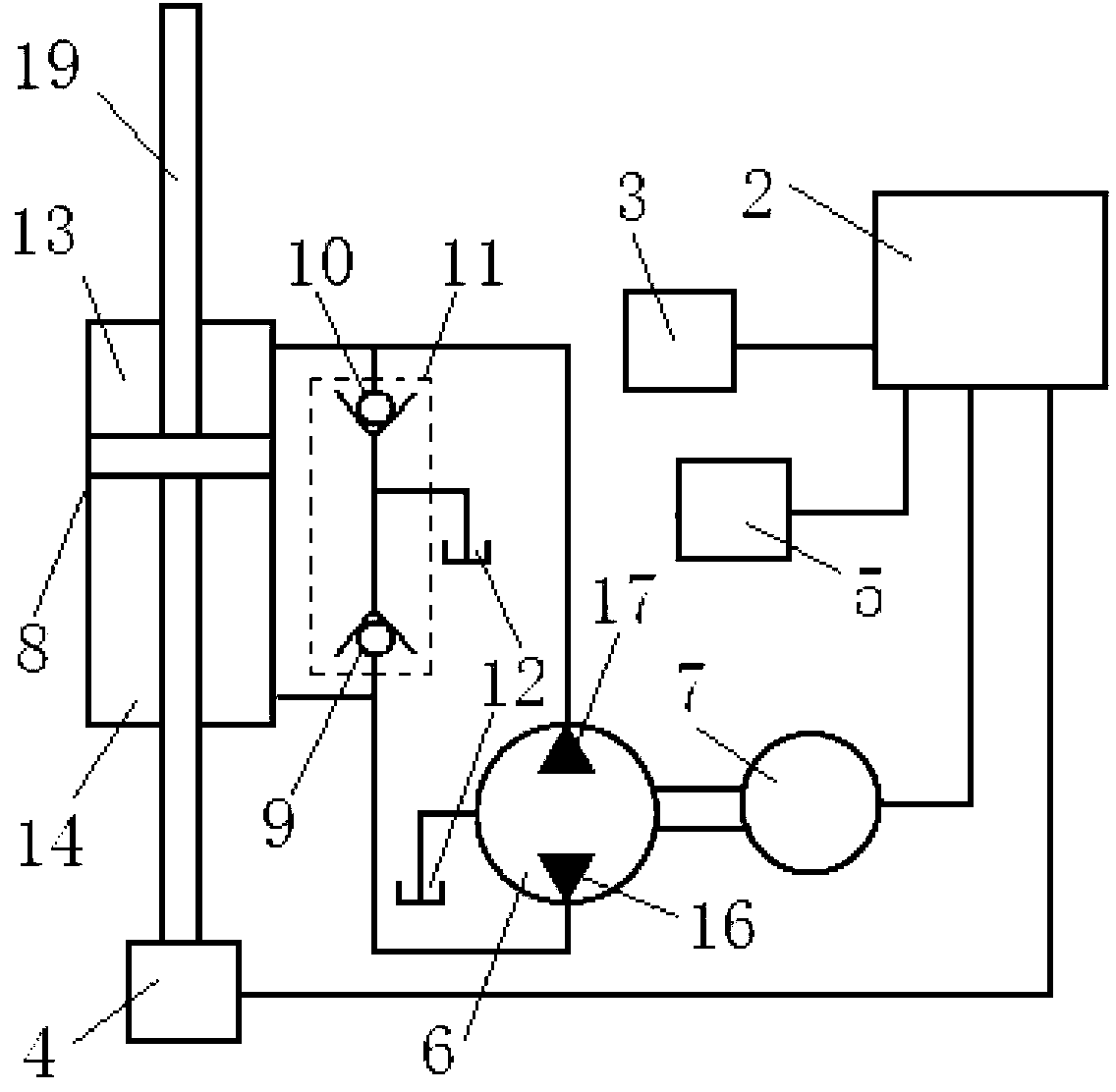

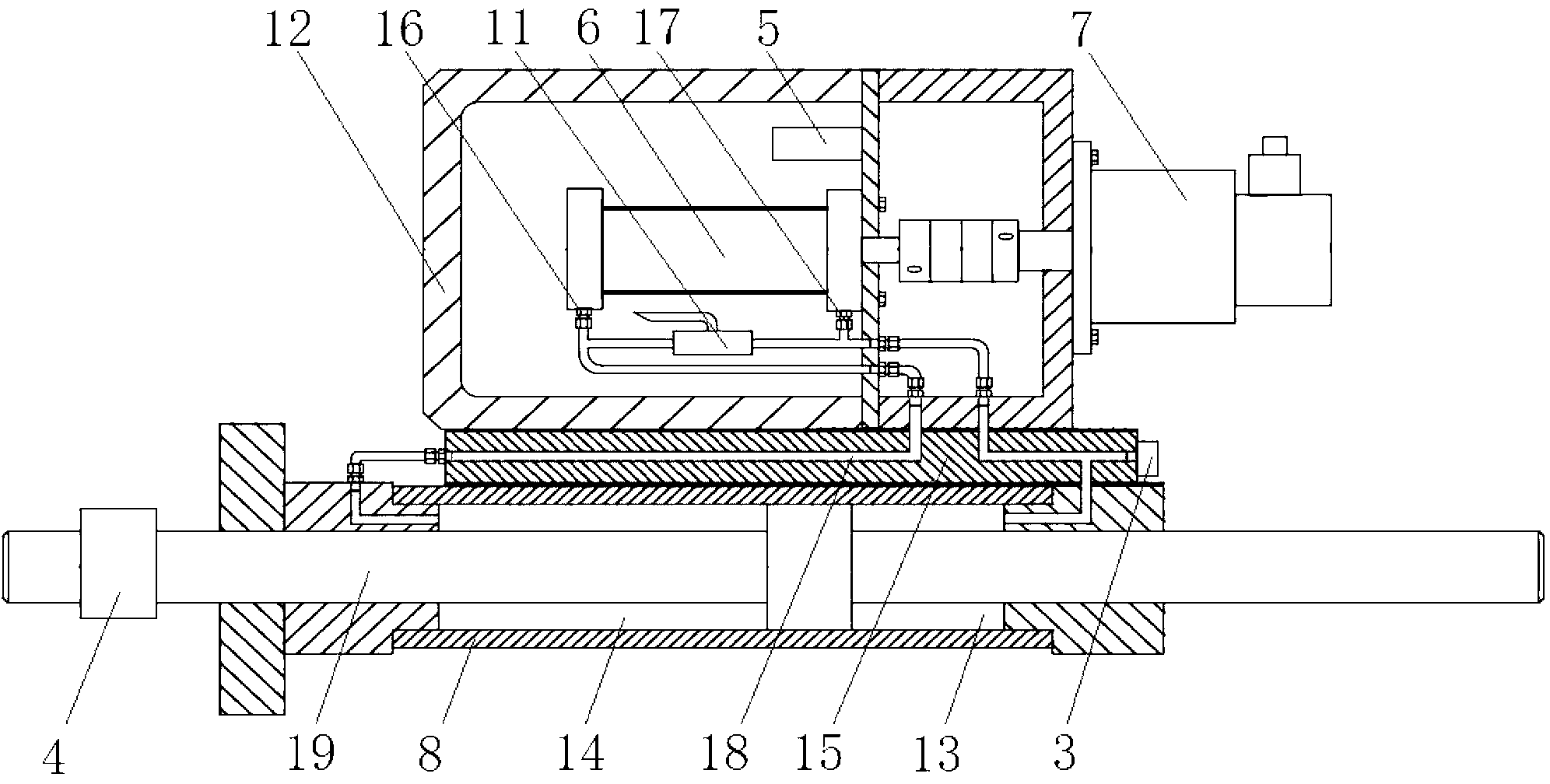

Integrated type energy-saving and environment-friendly hydraulic servo system

InactiveCN103264521AReduce space consumptionReduce loss along the wayFluid-pressure actuator componentsPressesHydraulic cylinderHydraulic pump

The invention discloses an integrated type energy-saving and environment-friendly hydraulic servo system, and belongs to the technical field of machinery assemblies. The integrated type energy-saving and environment-friendly hydraulic servo system comprises a computer, a data collecting part, a power output control part, a one-way valve set, a connecting block and an executing unit. The data collecting part comprises a force sensor, a pressure sensor and a temperature sensor. The power output control part comprises a hydraulic pump, a servo motor and an oil tank. The one-way valve set comprises a first one-way valve and a second one-way valve. An oil channel is placed inside the connecting block. A hydraulic cylinder is adopted in the executing unit, and is composed of a pressurizing cavity, a pressure releasing unit and a piston rod. The computer is connected with the force sensor, the pressure sensor and the temperature sensor. The servo motor is connected with the computer and the hydraulic pump, the hydraulic pump is installed inside the oil tank, and the servo motor is installed outside the oil tank. The oil tank is fixedly connected with a hydraulic cylinder body through the connecting block in a sealing mode, the hydraulic pump is communicated with the hydraulic cylinder through the connecting block, the oil inlet ends of the one-way valves are communicated with the oil tank, and the oil outlets of the one-way valves are communicated with the hydraulic pump.

Owner:NORTHEASTERN UNIV

Supercritical carbon dioxide closed type circulating turbine compressor

ActiveCN108643979AReduce leakage lossImprove structural strengthPump componentsBlade accessoriesAutomotive engineeringImpeller

The invention provides a supercritical carbon dioxide closed type circulating turbine compressor which comprises a power generation assembly unit, a gas compressor impeller, a turbine, a gas compressor end shell and a turbine end shell. The power generation assembly unit, the gas compressor turbine and the turbine are sequentially arranged coaxially and located in a cavity formed by the gas compressor end shell and the turbine end shell in a closed manner. The gas compressor impeller and the turbine are integrated and arranged in a back-to-back manner. The supercritical carbon dioxide closed type circulating turbine compressor is located in the closed space, and the leakage loss is reduced. The gas compressor impeller and the turbine are integrated and arranged in a back-to-back manner, and the structural strength is good.

Owner:CHINA NORTH ENGINE INST TIANJIN

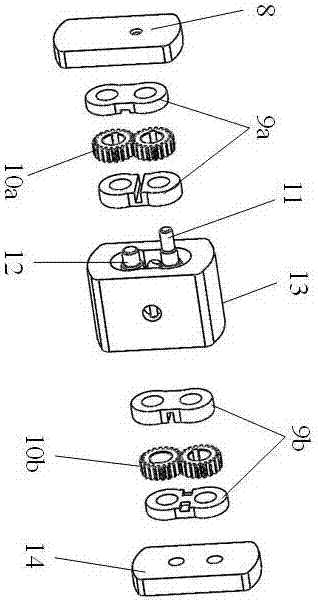

Closed pump control single out rod hydraulic cylinder static and dynamic flow real-time matching system

ActiveCN107882786ARealize dynamic matchingSimple control structureServomotorsFluid-pressure actuator componentsHydraulic cylinderGear pump

The invention relates to a closed pump control single out rod hydraulic cylinder static and dynamic flow real-time matching system, and belongs to electrohydraulic control systems. A servo motor and avariable displacement asymmetric gear pump are coaxially connected, a first working oil opening of the variable displacement asymmetric gear pump is connected with a rodless cavity of a single out rod hydraulic cylinder, a second working oil opening of the variable displacement asymmetric gear pump is connected with a rod cavity of the single out rod hydraulic cylinder, and a third working oil opening of the variable displacement asymmetric gear pump is connected with an energy accumulator; and the energy accumulator is communicated with oil inlets of a first one-way valve and a second one-way valve and oil outlets of a first overload valve and a second overload valve, an oil outlet of the first one-way valve is communicated with the rodless cavity of the single out rod hydraulic cylinder, an oil outlet of the second one-way valve is communicated with the rod cavity of the single out rod hydraulic cylinder, an oil inlet of the first overload valve is communicated with the rodless cavity of the single out rod hydraulic cylinder, and an oil inlet of the second overload valve is communicated with the rod cavity of the single out rod hydraulic cylinder. According to the closed pump control single out rod hydraulic cylinder static and dynamic flow real-time matching system, asymmetric flow generated by differential motion cylinder area difference can be compensated, and flow dynamic matching between the single out rod hydraulic cylinder and the asymmetric gear pump is achieved.

Owner:TAIYUAN UNIV OF TECH

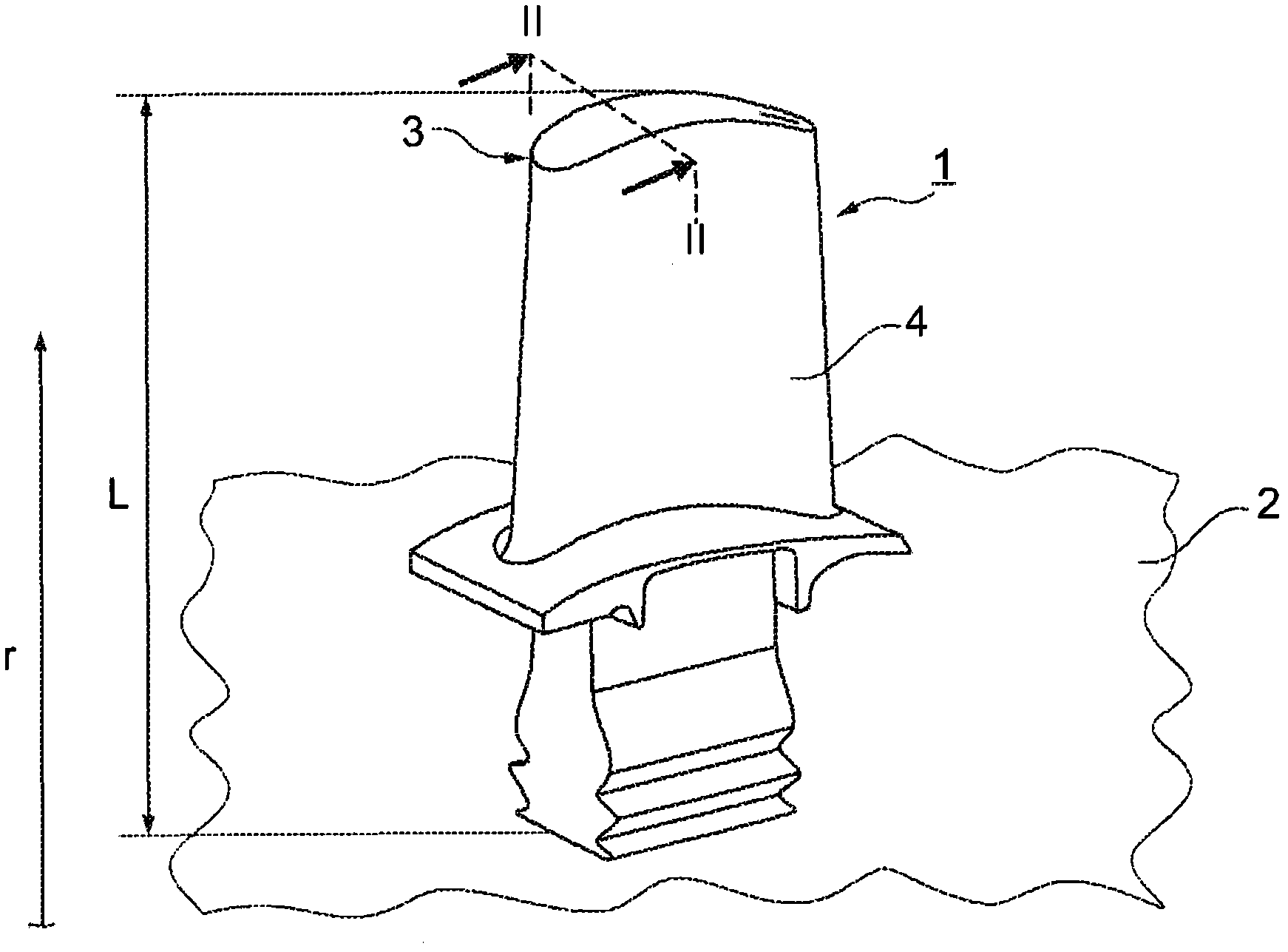

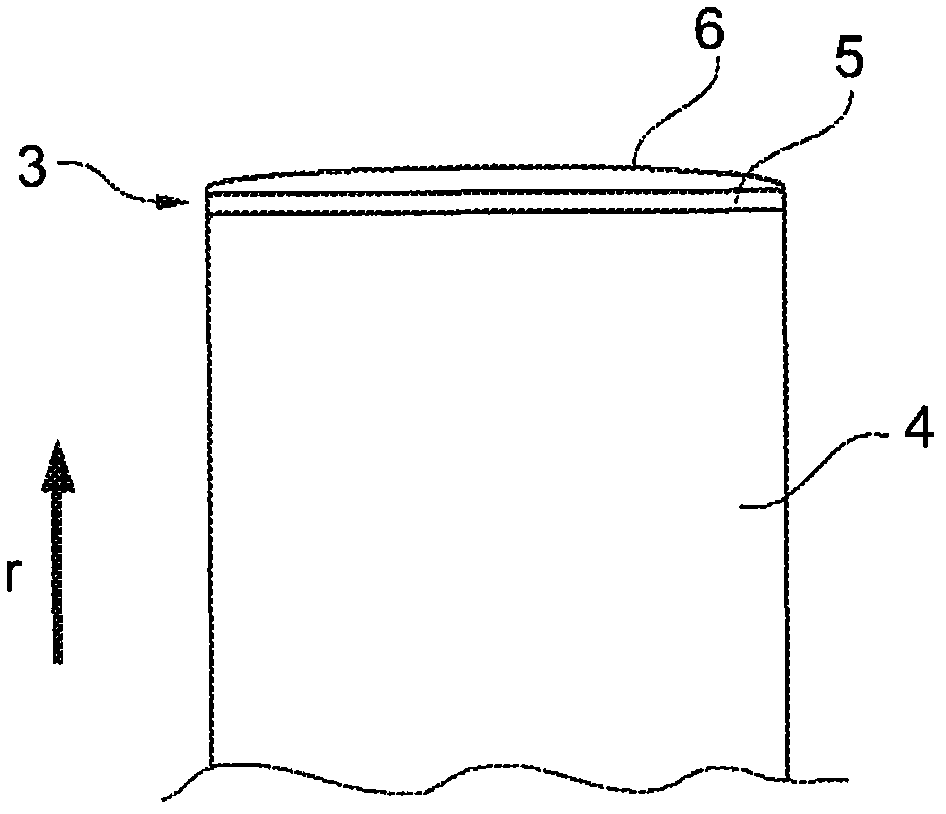

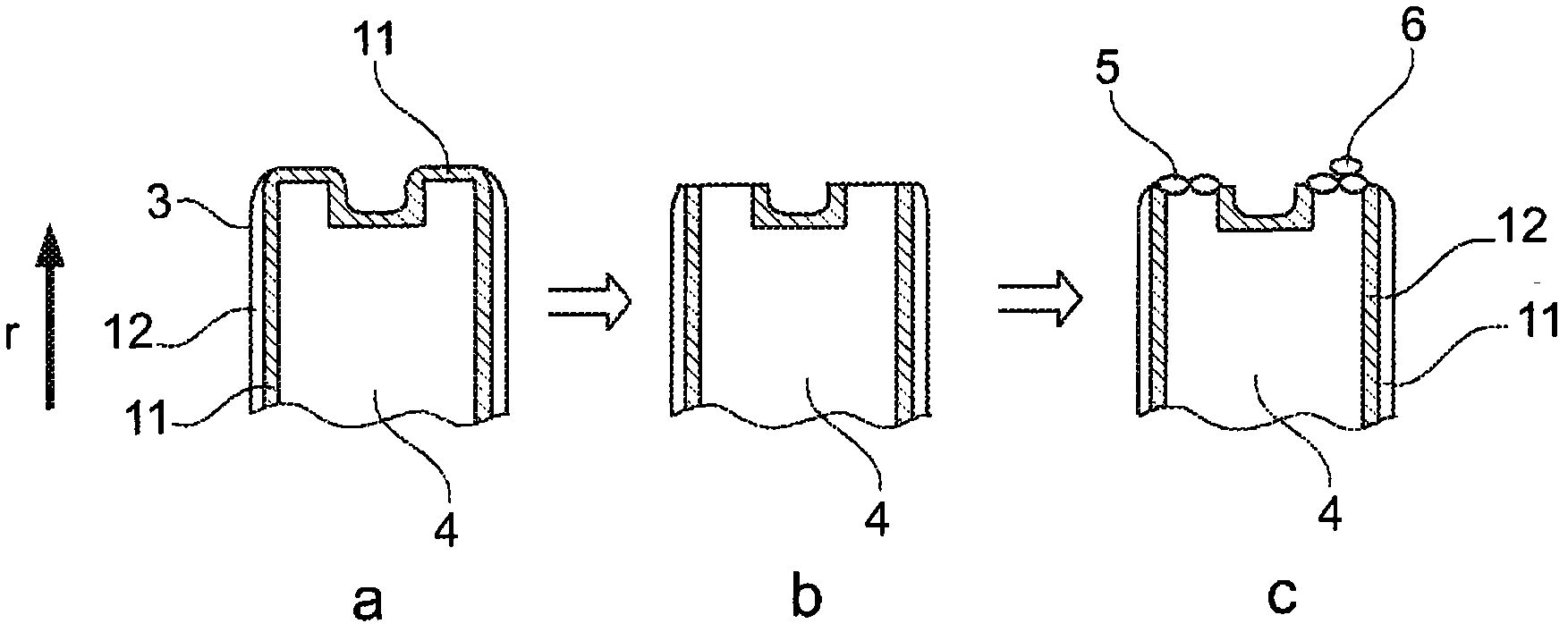

Abrasive single-crystal turbine blade

ActiveCN102052094AImprove service lifeReduce leakage lossTurbinesBy zone-melting liquidsOxidation resistantWear resistant

The invention relates to an abrasive single-crystal turbine blade, in detail, relates to a turbine blade (1) used for a turbine rotor (2).A turbine blade for a turbine rotor, is provided having a single-crystal basic body which has a blade tip and extends in the radial direction. The turbine blade includes at least one oxidation-resistant intermediate coating, which is applied by laser metal forming and is epitaxially bonded to the basic body, is arranged on the radially outer blade tip, and in that an at least single-layer, wear-resistant and oxidation-resistant coating, which is applied by laser metal forming and consists of oxidation-resistant binder material and abrasive particles embedded therein, is arranged on at least certain regions of said epitaxial intermediate coating.

Owner:ANSALDO ENERGIA IP UK LTD

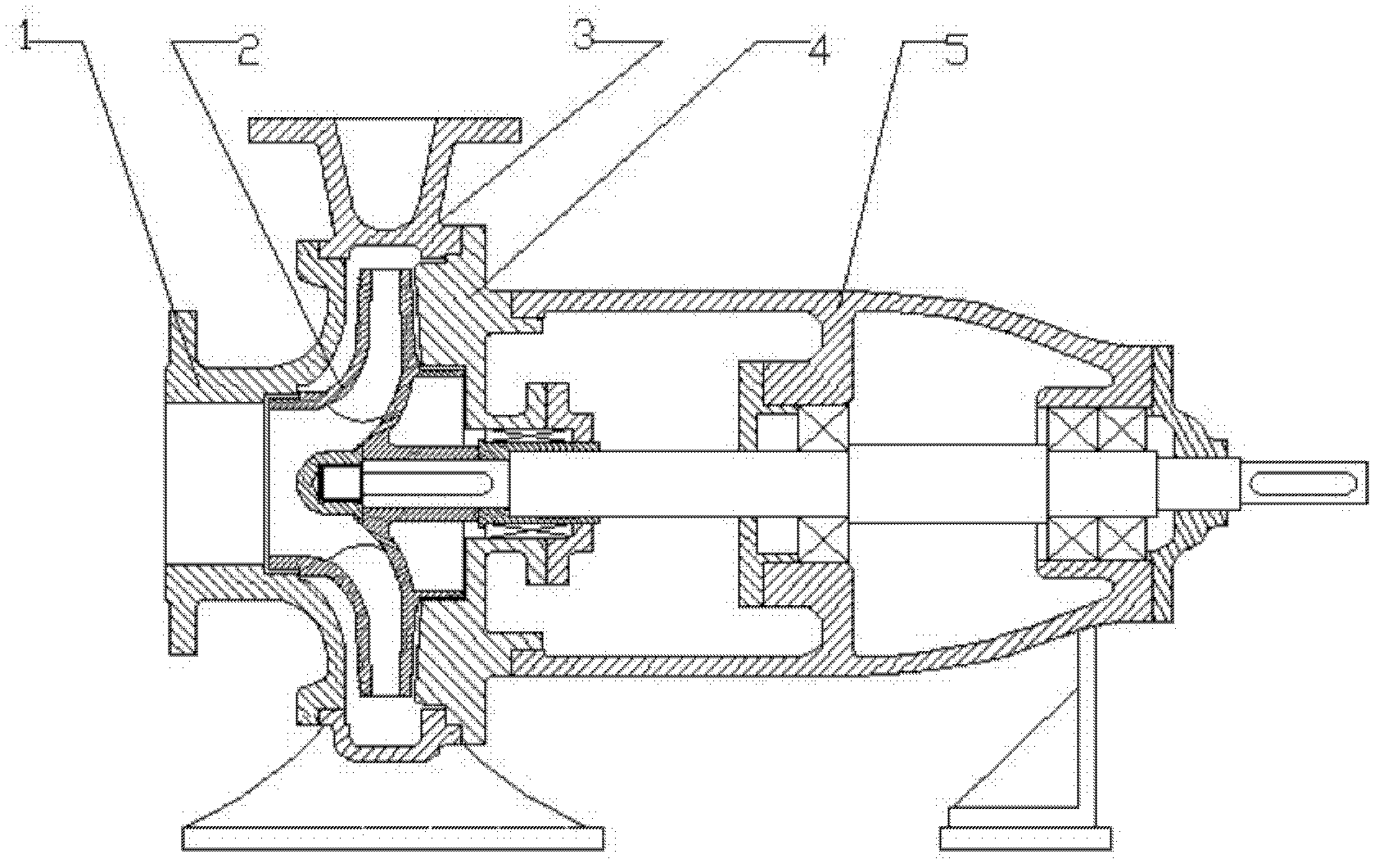

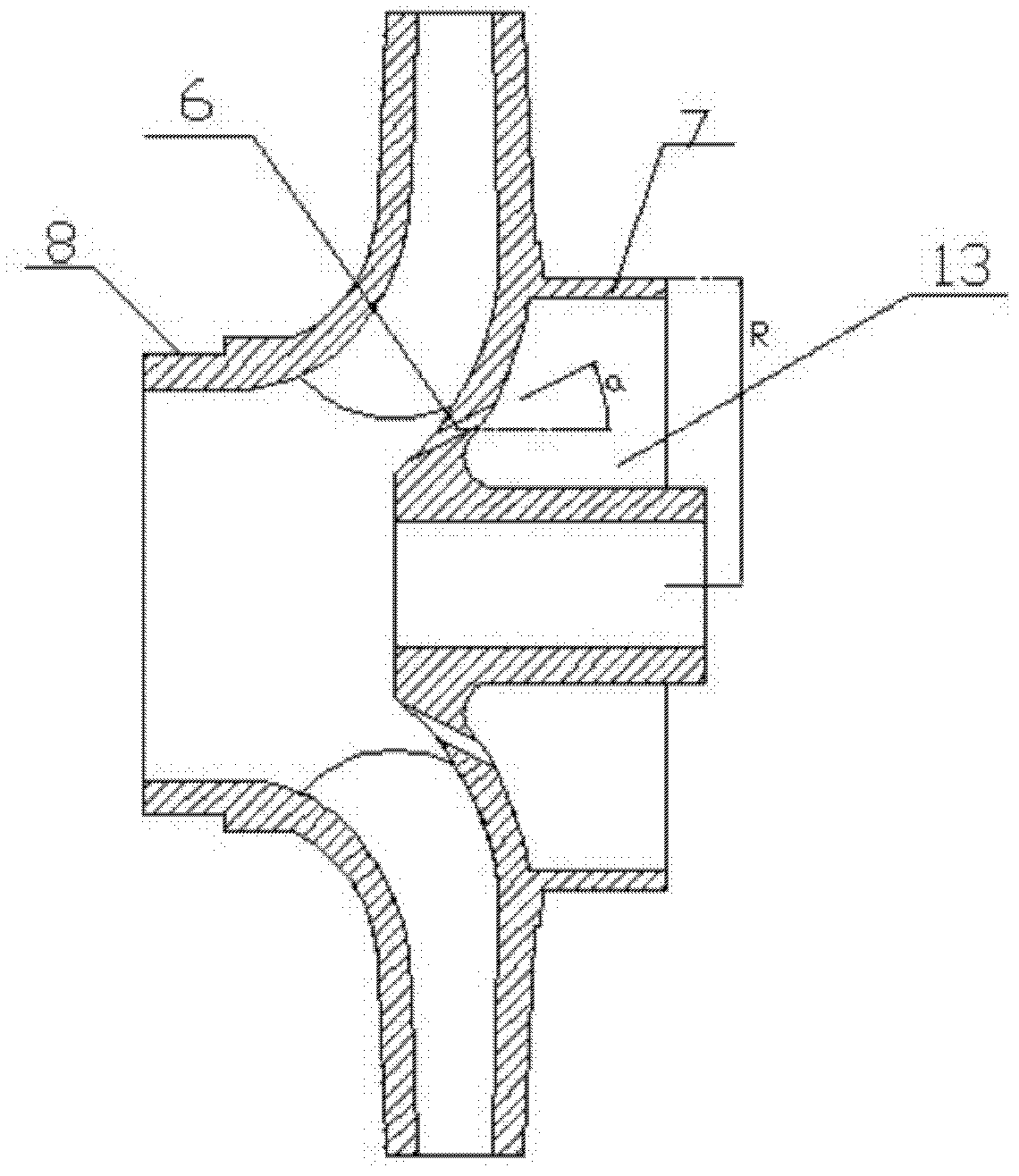

Single-stage centrifugal pump with balanced axial force

The invention discloses a single-stage centrifugal pump with a balanced axial force, which comprises a pump body, a front pump cover, an impeller, a rear pump cover, a rear cover plate opening ring and a bearing body, wherein a balancing chamber is formed by the rear part of a rear cover plate; the balancing chamber of the rear cover plate is communicated with an impeller suction port; the impeller is provided with an inclined balancing hole; one end of the balancing hole, which is positioned at the impeller suction port, is close to the position of a hub; one end of the balance hole, which is positioned on the balance chamber, is away from the position of the hub; an angle is formed by a center line of the balancing hole and the axial line of the hub; the diameter of a rear opening ring of the impeller is greater than that of a front opening ring of the impeller; and the length of the rear opening ring is greater than that of the front opening ring. According to the single-stage centrifugal pump disclosed by the invention, the balance of the axial force can be better achieved.

Owner:ZHEJIANG UNIV OF TECH

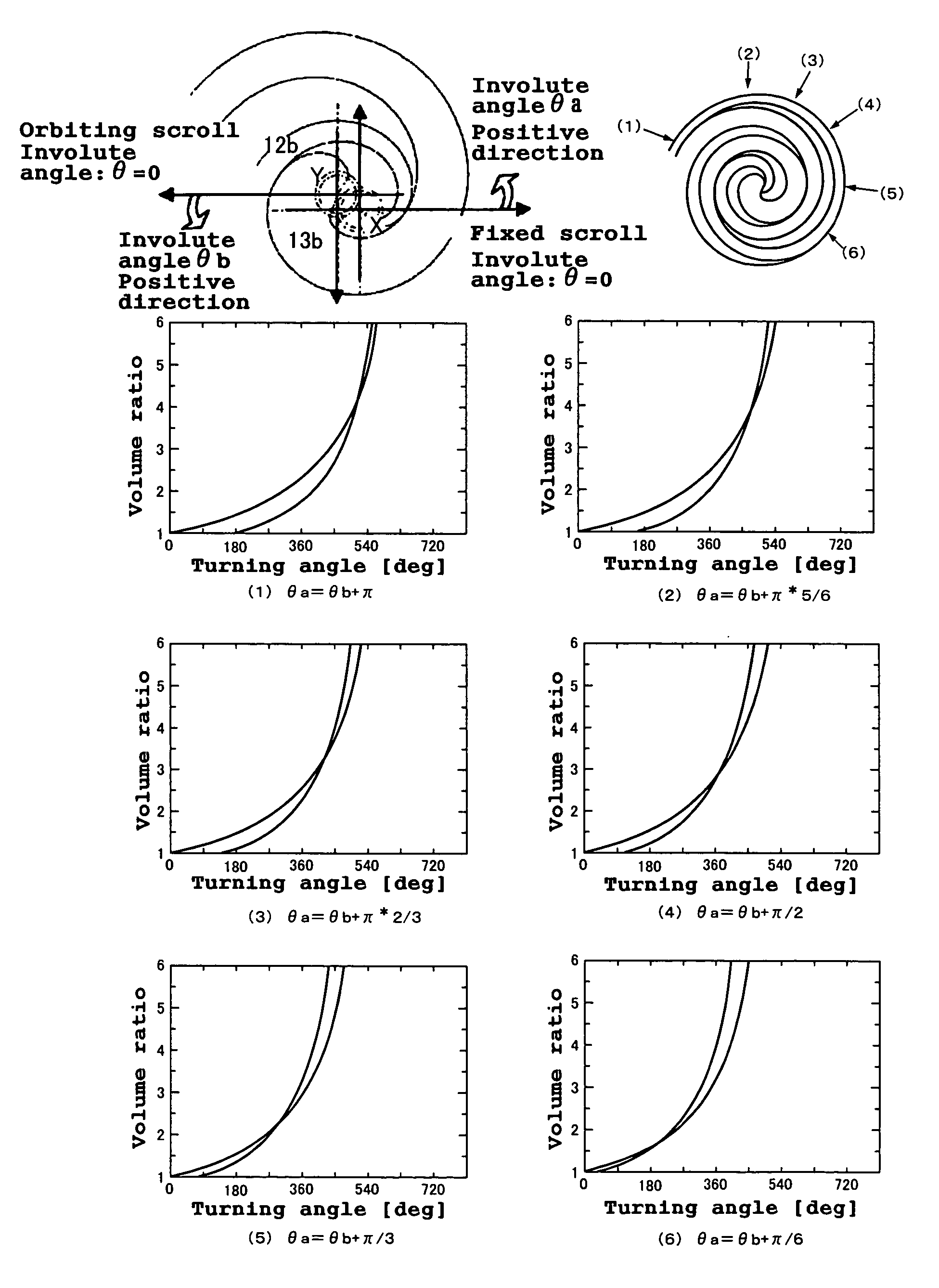

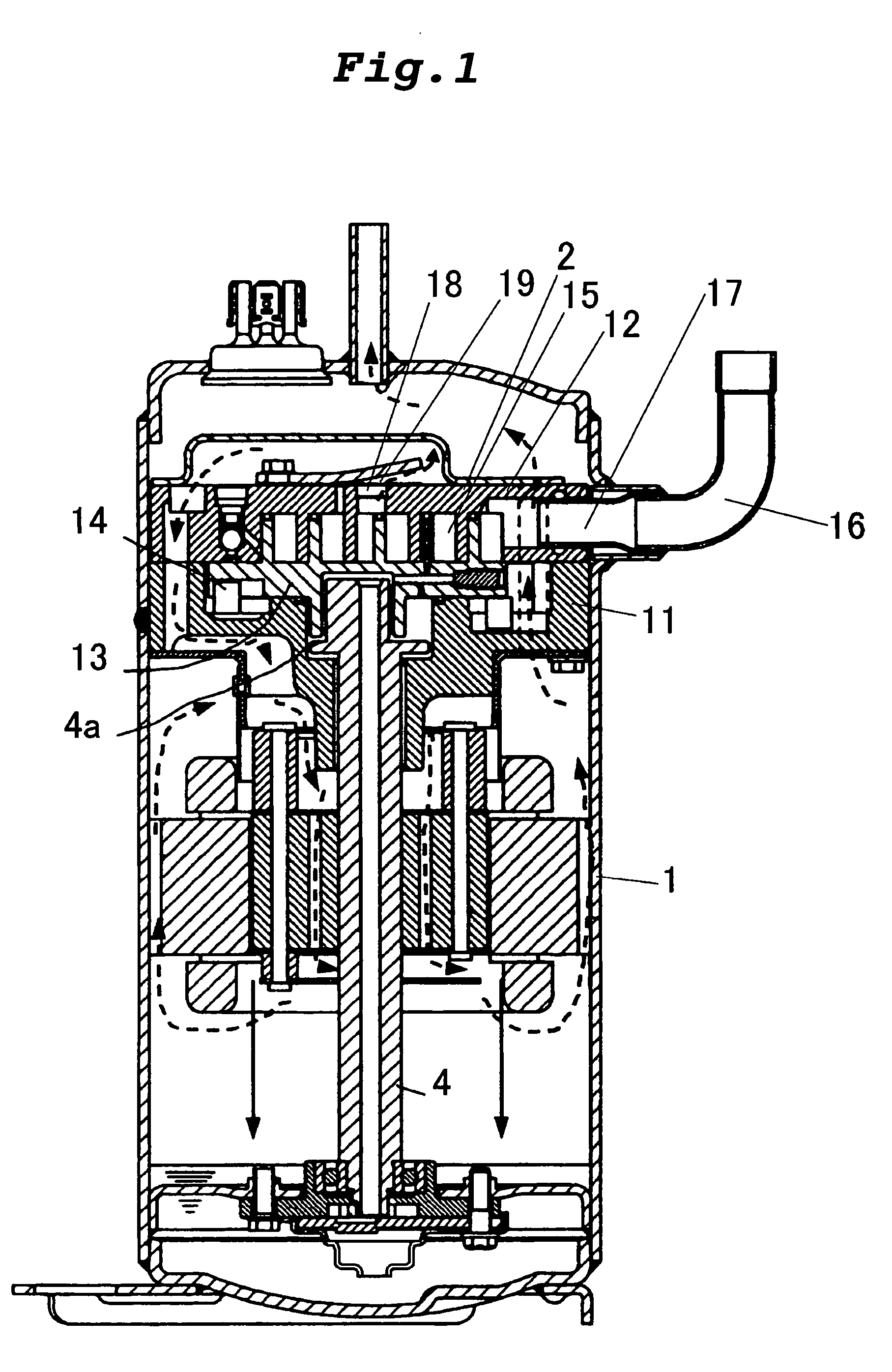

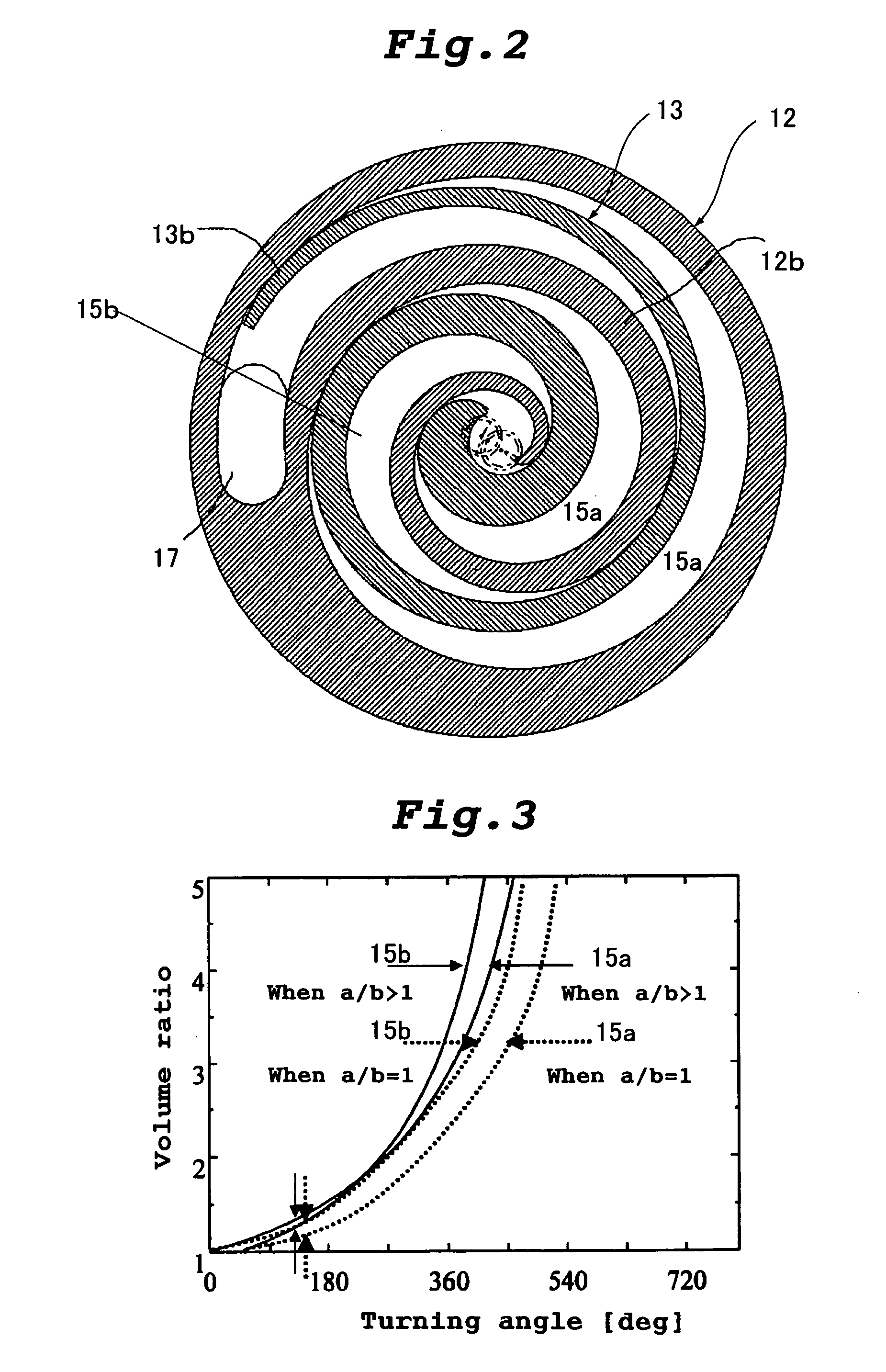

Scroll compressor

ActiveUS20060115371A1Leakage loss during compression process can be reducedSecure strengthRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInvoluteEngineering

In a scroll compressor, an outer wall curve of a scroll lap of a fixed scroll and an inner wall curve of a scroll lap of an orbiting scroll are formed of involute curves whose basic circle radius is defined as “a”, an inner wall curve of the scroll lap of the fixed scroll and an outer wall curve of the scroll lap of the orbiting scroll are formed of involute curves whose basic circle radius is defined as “b”, and a value of a / b which is a ratio of the basic circle radius a and the basic circle radius b is set to a value exceeding 1.0 and less than 1.5. With this structure, a compression chamber formed on the side of the inner wall of the scroll lap of the orbiting scroll is compressed faster than a compression chamber formed on the side of the outer wall of the scroll lap of the orbiting scroll, and leakage loss during compression process can be reduced.

Owner:PANASONIC CORP

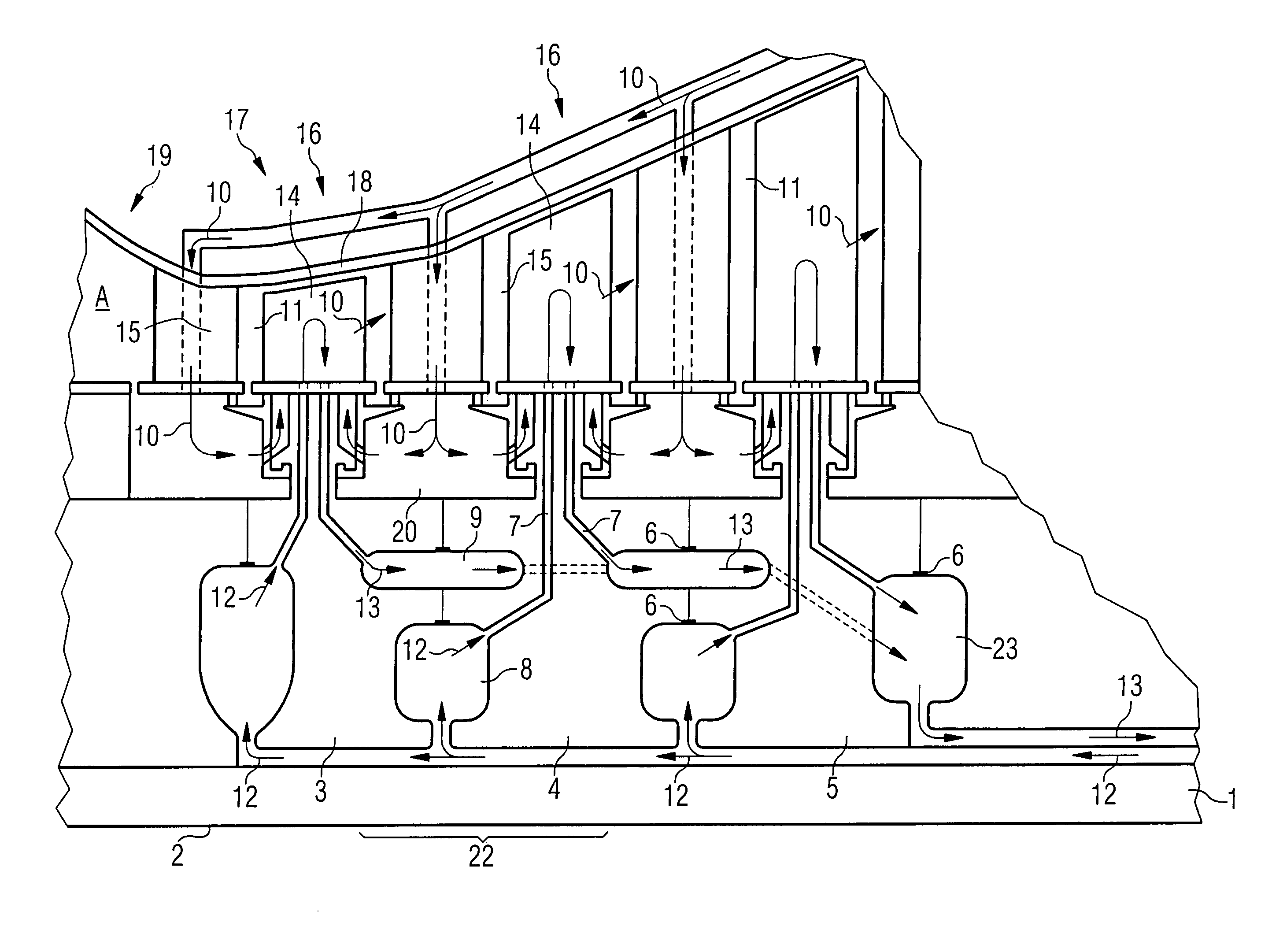

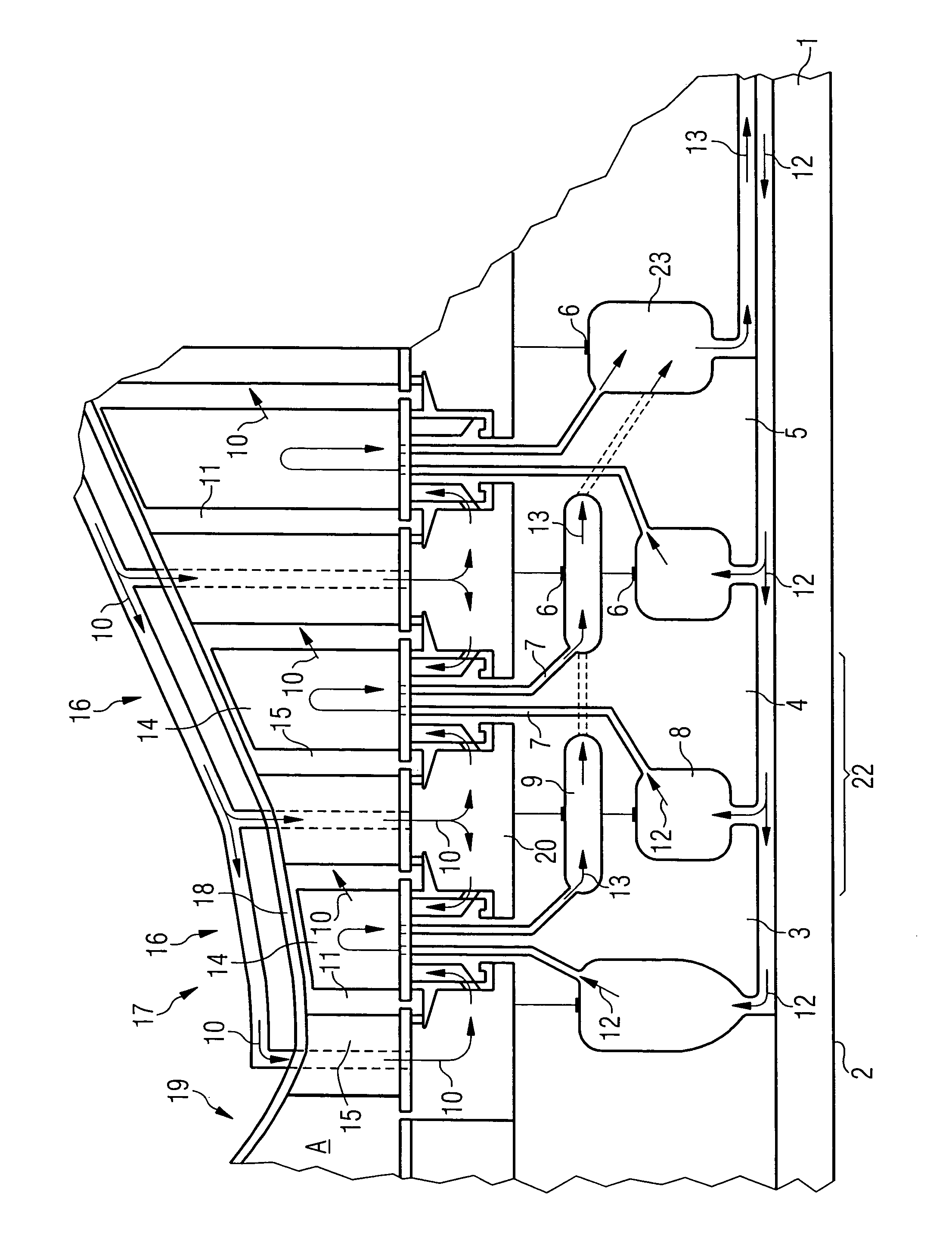

Turbine engine and a method for cooling a turbine engine

InactiveUS7131813B2Improve turbine efficiencyReduce operational riskPump componentsTurbine/propulsion engine coolingKnife bladesTurbine

A turbine engine with a turbine shaft which has a number of disks arranged adjacent to one another, to each of which a number of blades are fastened in a star arrangement, wherein these blades can be cooled with at least one coolant which flows through coolant channels inside the blades is provided.

Owner:SIEMENS AG

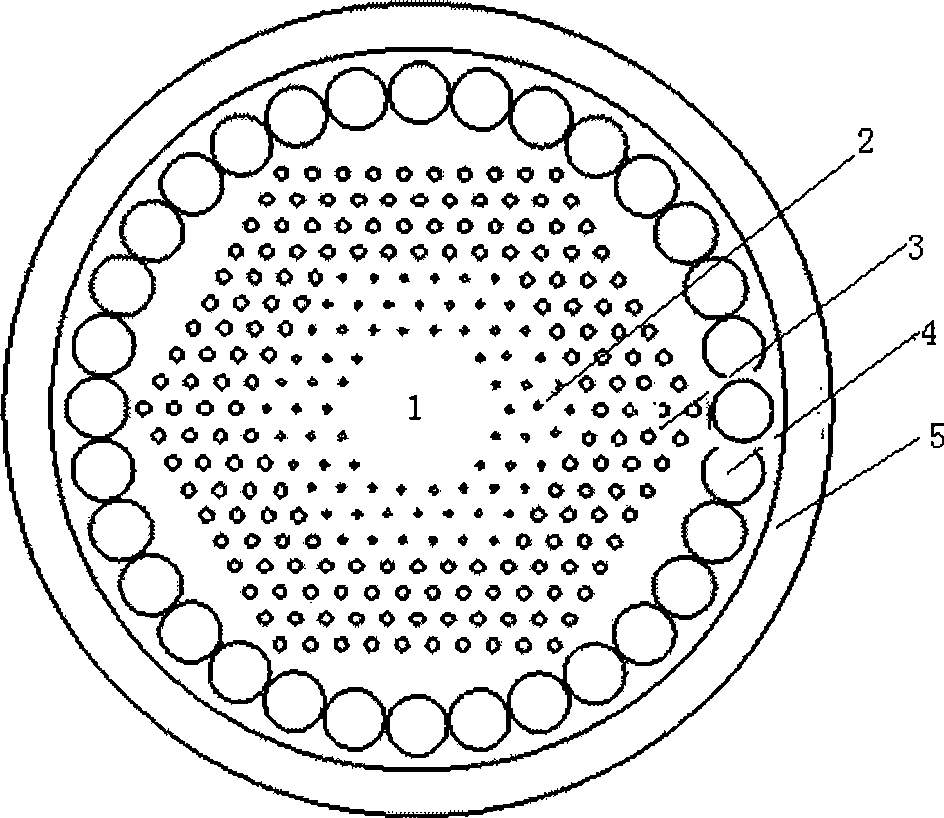

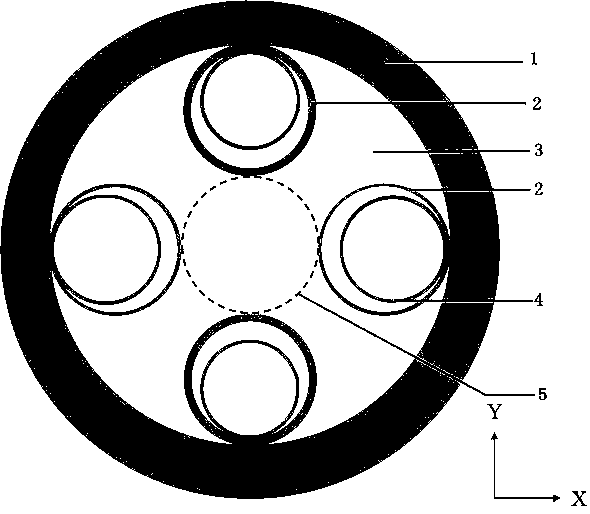

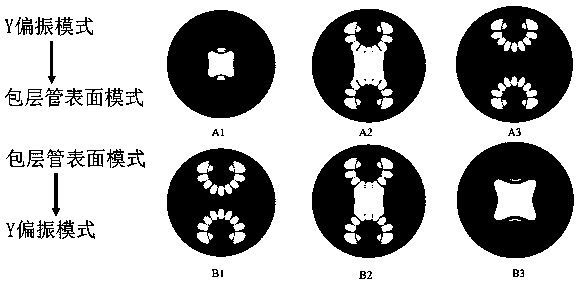

Single-mode single-polarization hollow negative curvature optical fiber

ActiveCN111458787APolarizedSimple structureCladded optical fibreOptical waveguide light guideFiberInterior space

The invention discloses a single-mode single-polarization hollow negative curvature optical fiber. The invention discloses a hollow negative curvature optical fiber, which belongs to the technical field of hollow negative curvature optical fibers and comprises an outer cladding, four cladding tubes, a fiber core area, nesting tubes and a fiber core, wherein the four cladding tubes are uniformly arranged around the circle center of the outer cladding and cling to the inside of the outer cladding; the nesting tubes are respectively arranged in the cladding tubes and uniformly arranged around thecircle center of the outer cladding; the outer diameters of the four cladding tubes are equal, the wall thicknesses of the two cladding tubes in the Y direction are the same, the wall thicknesses ofthe two cladding tubes in the X direction are the same, the wall thickness of the cladding tubes in the Y direction is larger than that of the cladding tubes in the X direction, and the gaps between the adjacent cladding tubes in the circumferential direction are equal; the nesting tubes are tightly attached to the interiors of the cladding tubes and correspond to the position where the outer cladding is tightly attached to the cladding tubes; and the core area and other internal spaces are filled with air. At the working wavelength, the single-mode characteristic is good, the material is purequartz, the structure is simple, the effective mode field area is large, and the manufacturing efficiency is high.

Owner:四川天府江东科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com