Patents

Literature

2293 results about "Shuttle valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A shuttle valve is a type of valve which allows fluid to flow through it from one of two sources. Generally a shuttle valve is used in pneumatic systems, although sometimes it will be found in hydraulic systems.

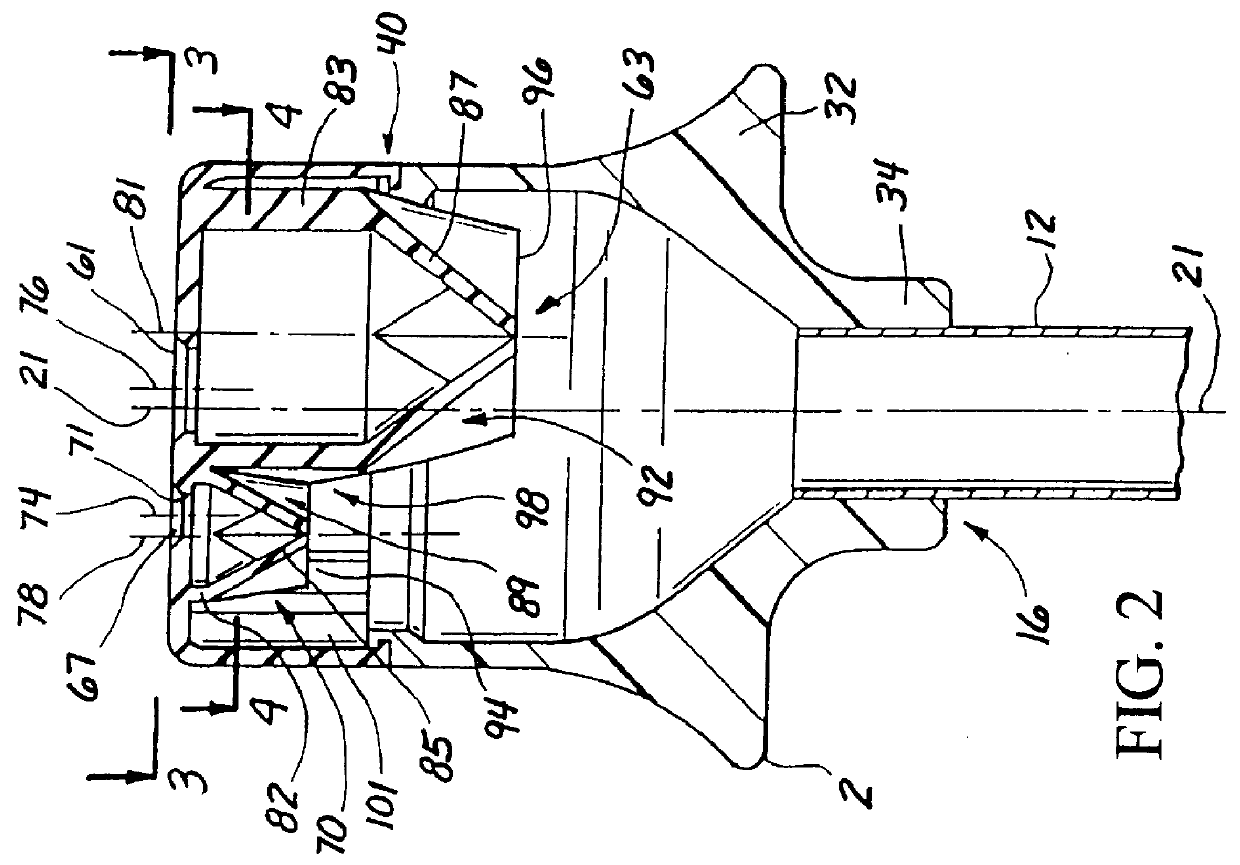

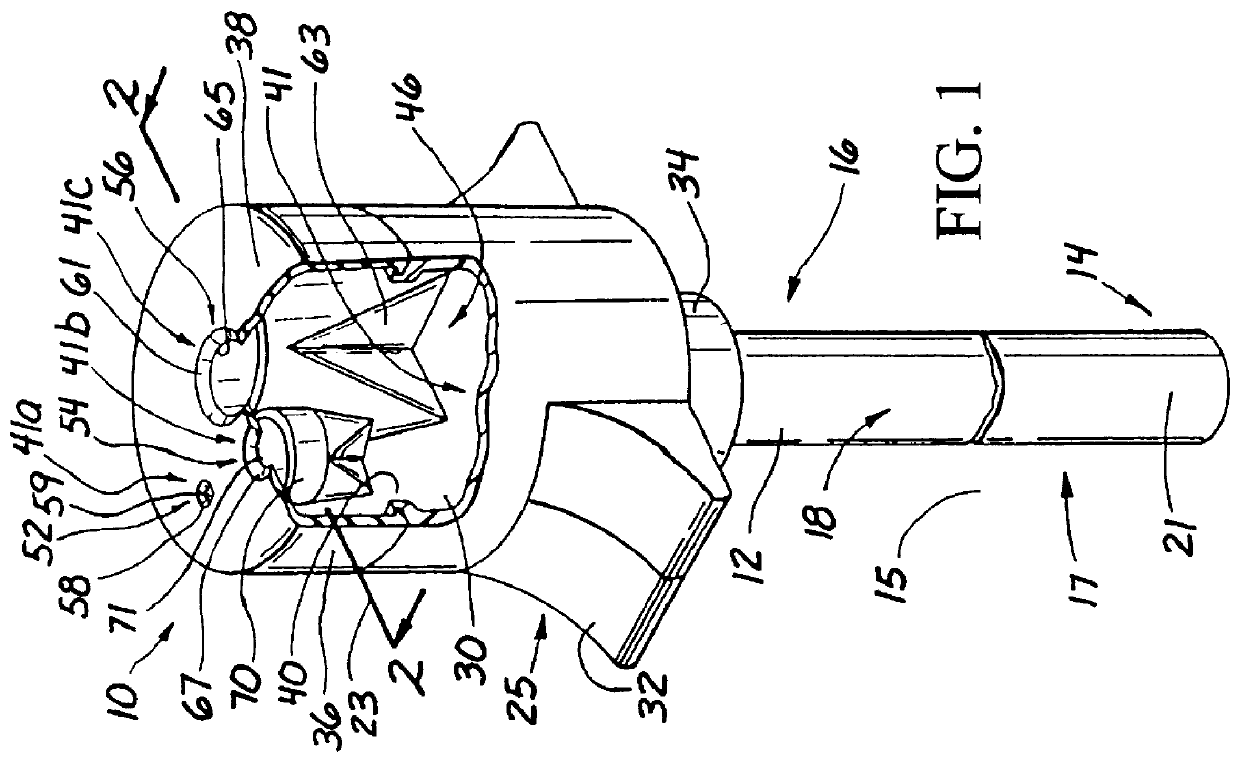

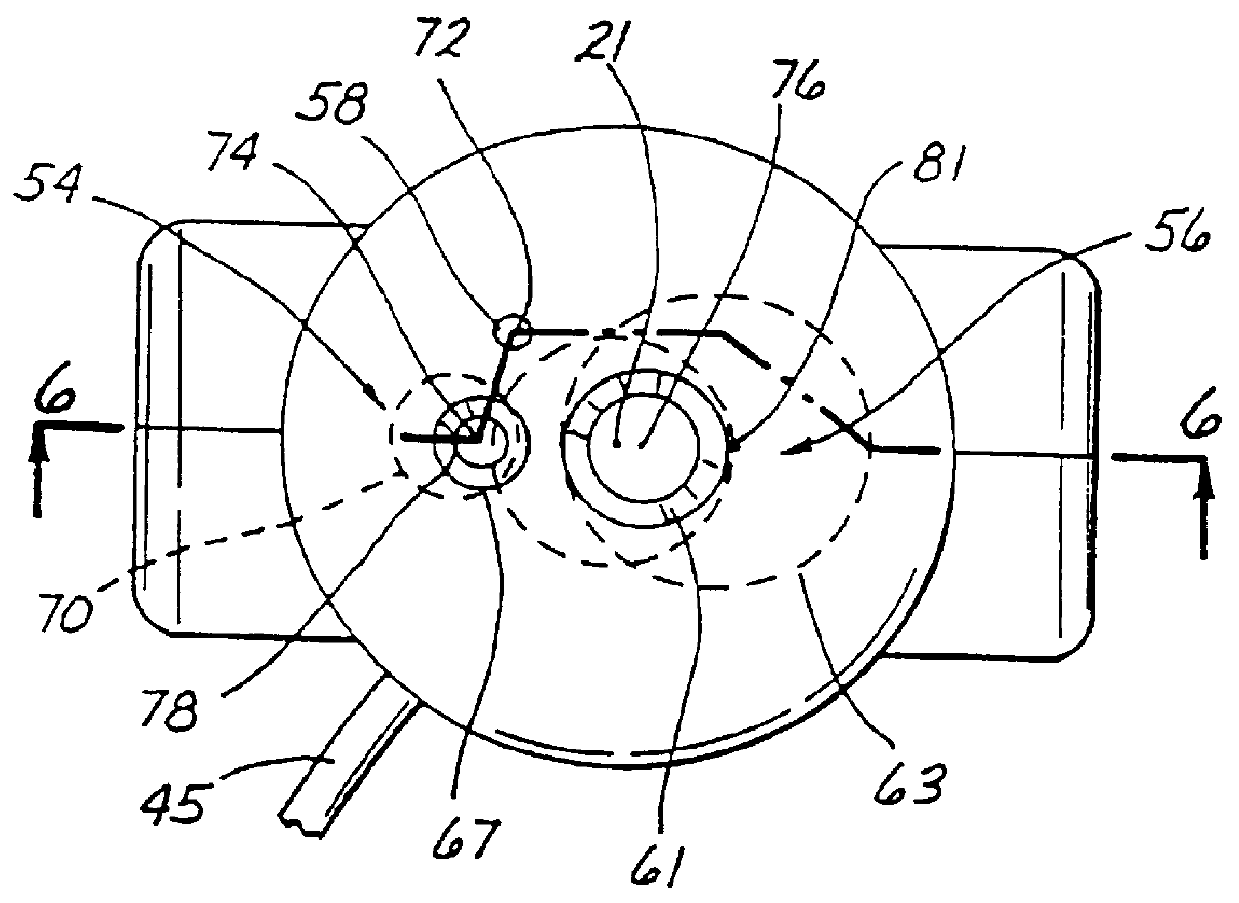

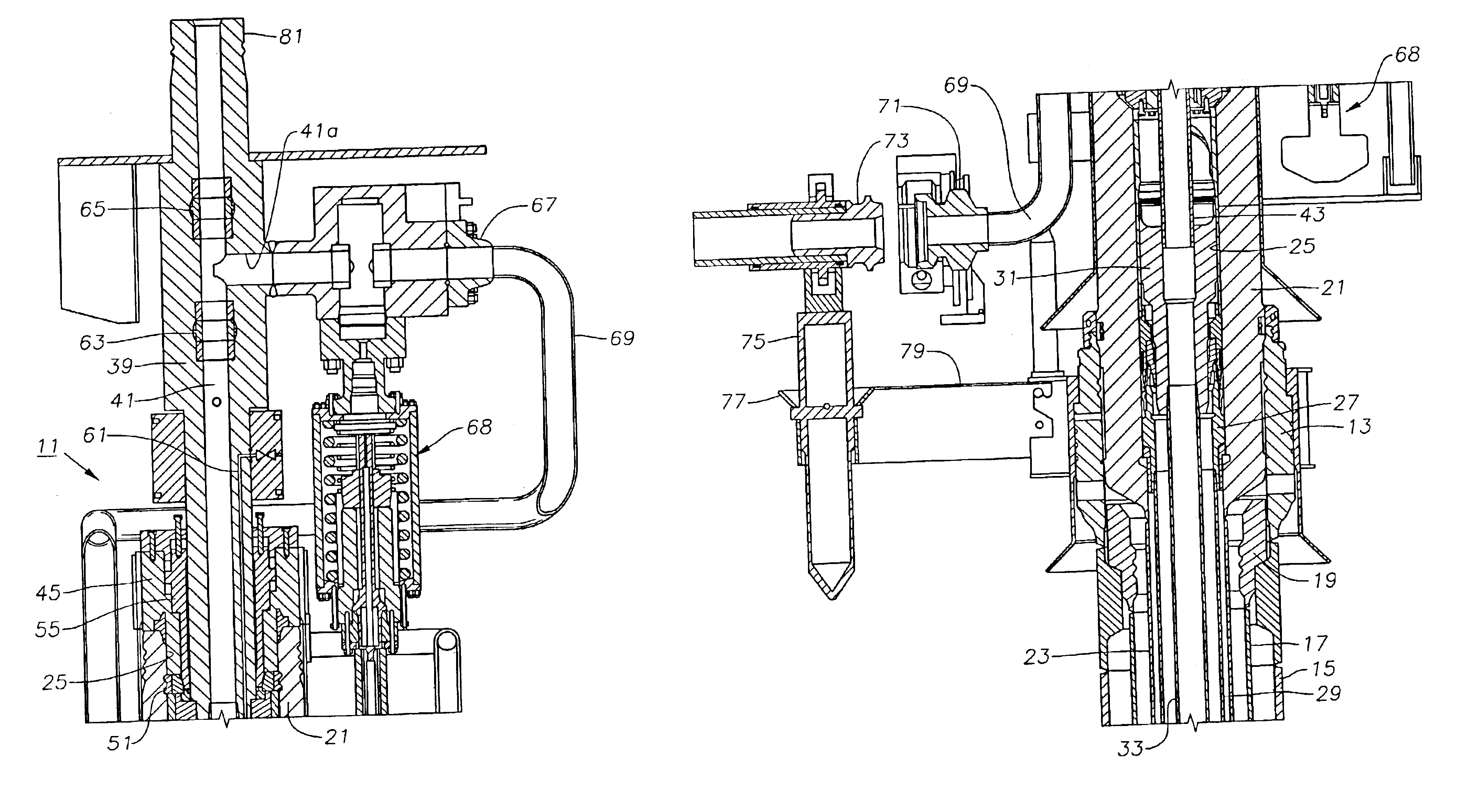

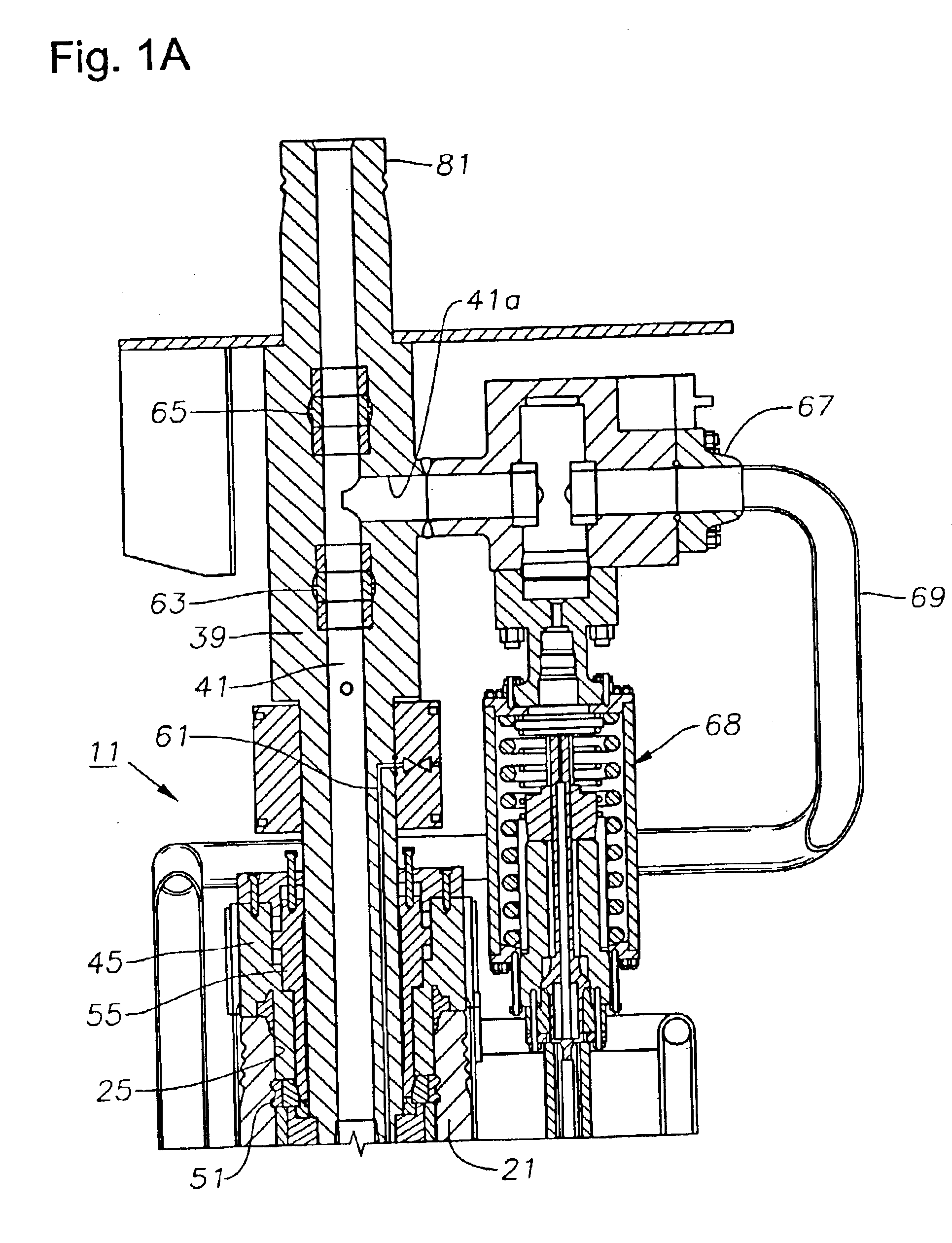

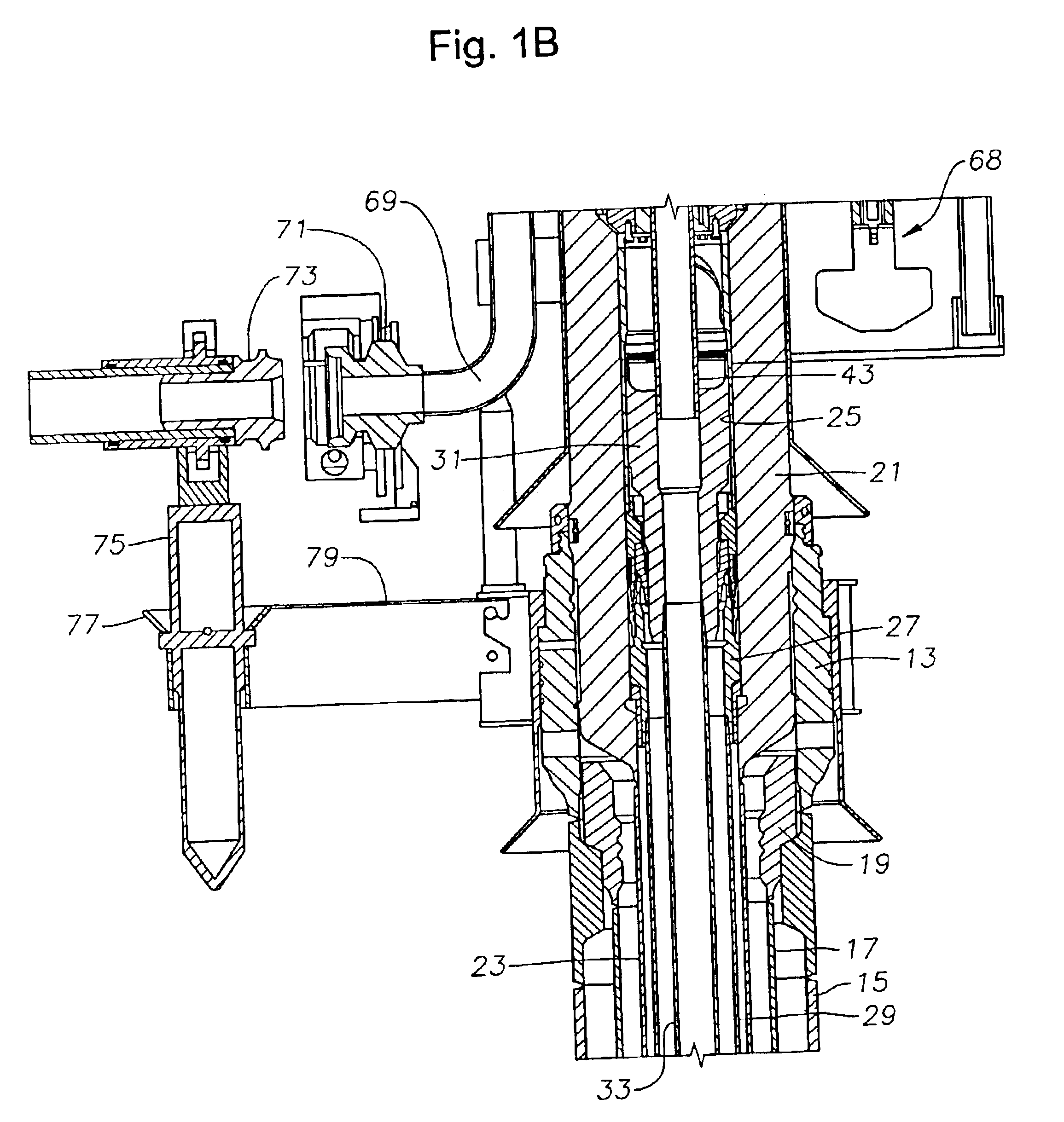

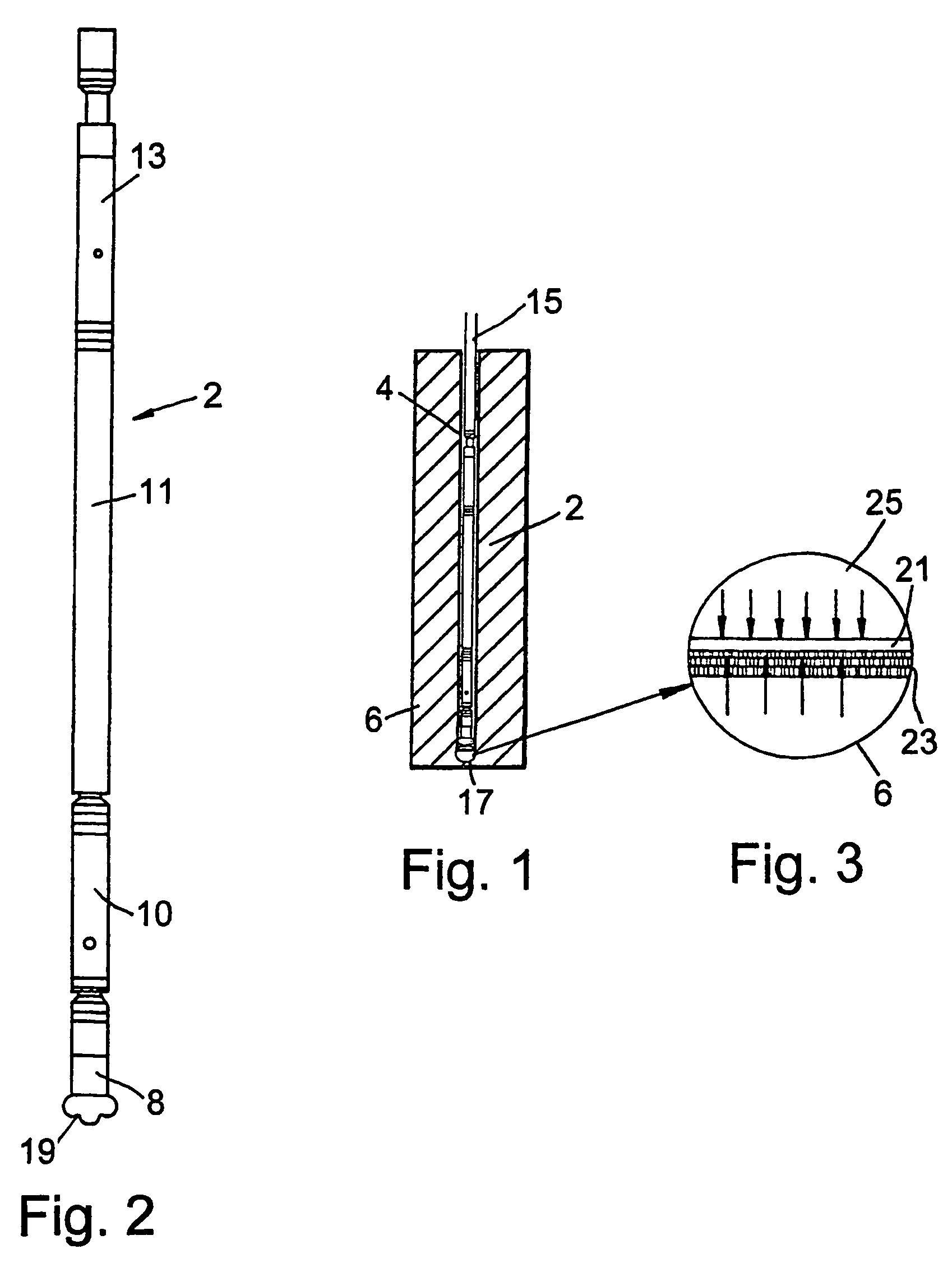

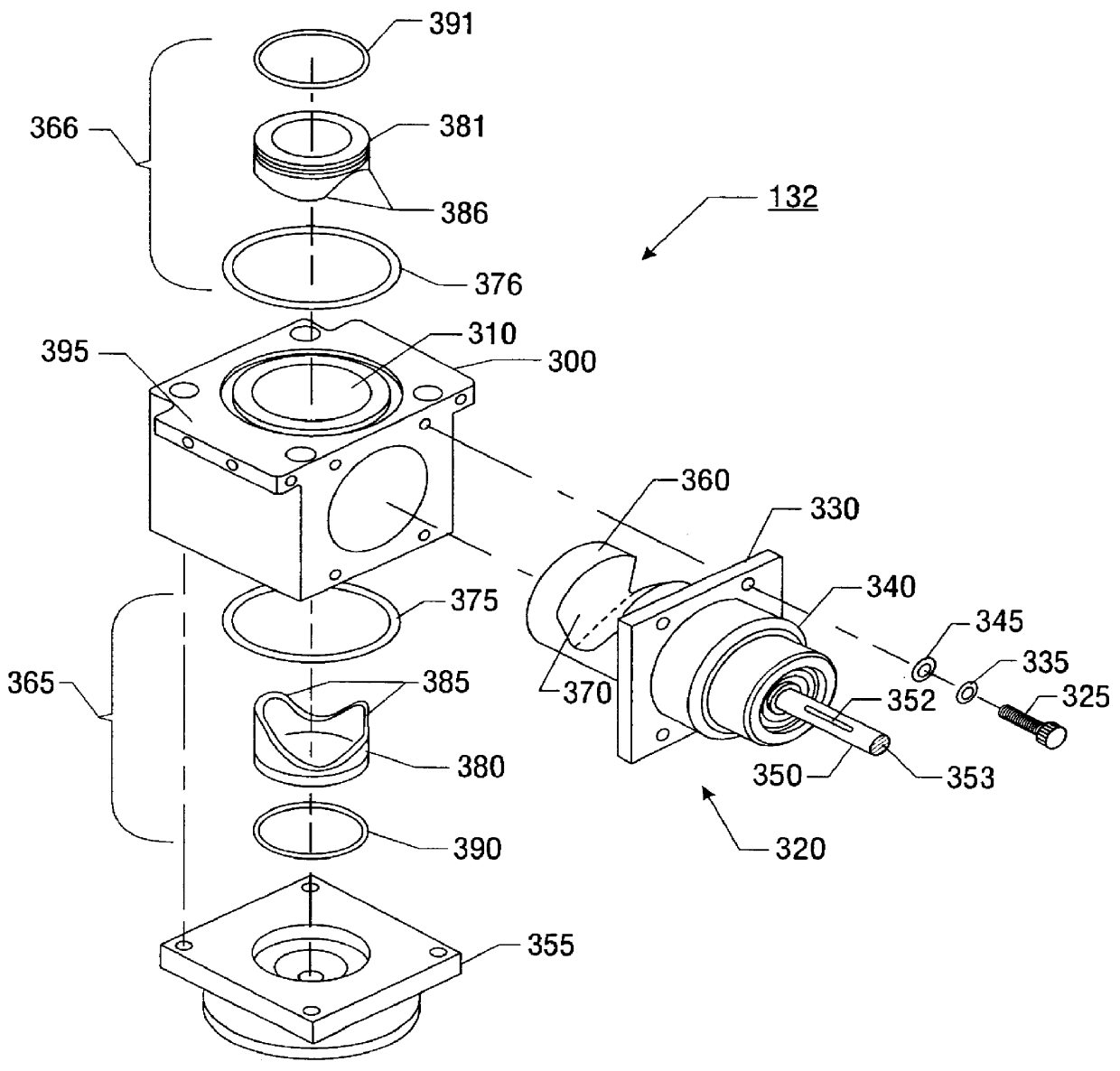

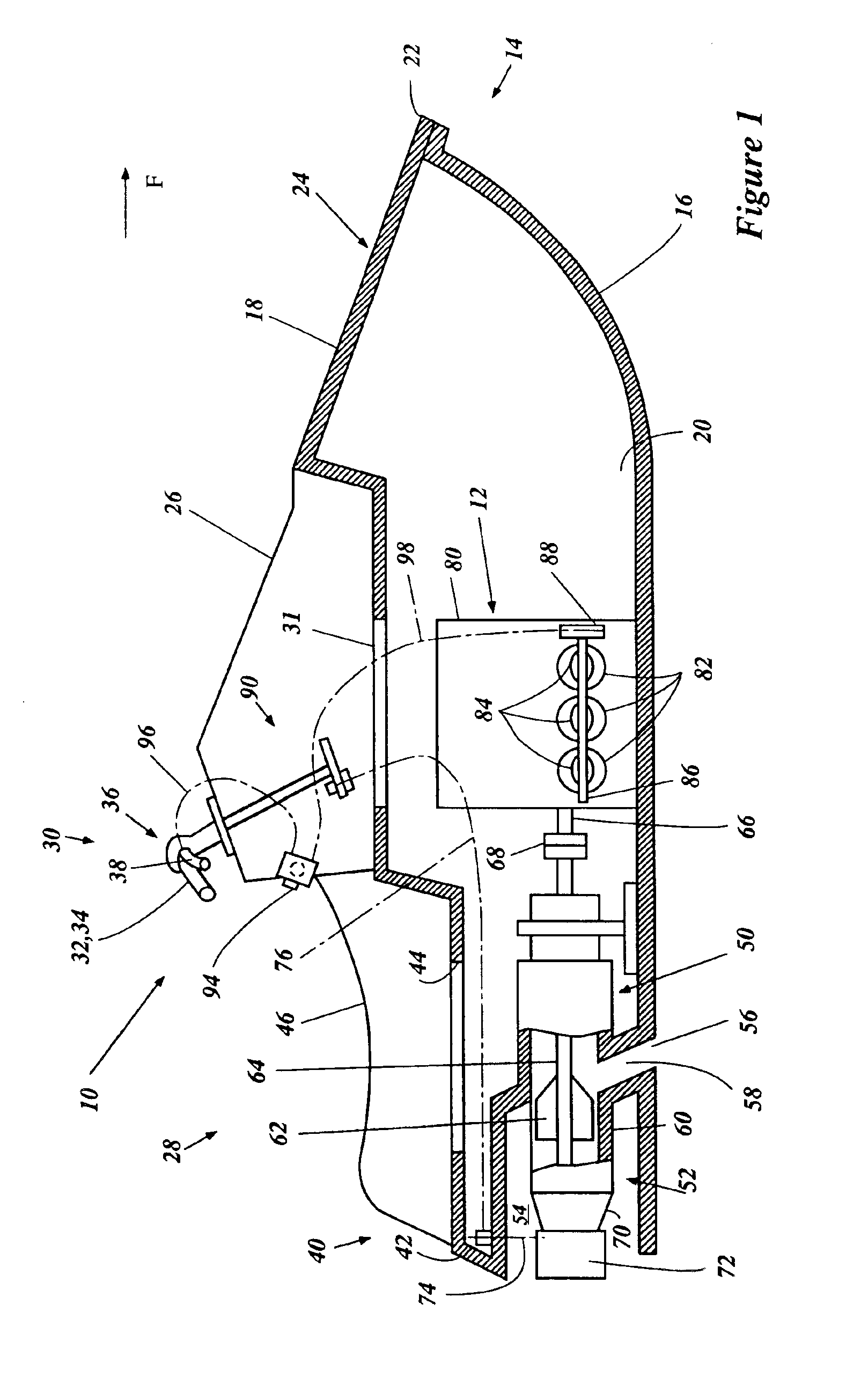

Multiport access device

A trocar having a cannula and a valve housing with a polygonal configuration, provides for a floating septum where the float is encouraged in a first direction and restricted in a second direction. The septum includes multiple septum valves which may function with a comnron zero-closure valve, or individually in a valve assembly with an associated zero-closure valve. Various seals can be configured to prevent blow-back. Cup valves, check valves, and reciprocating valves are contemplated, along with various skirt configurations for maintaining pressurized air within the trocar.

Owner:APPL MEDICAL RESOURCES CORP

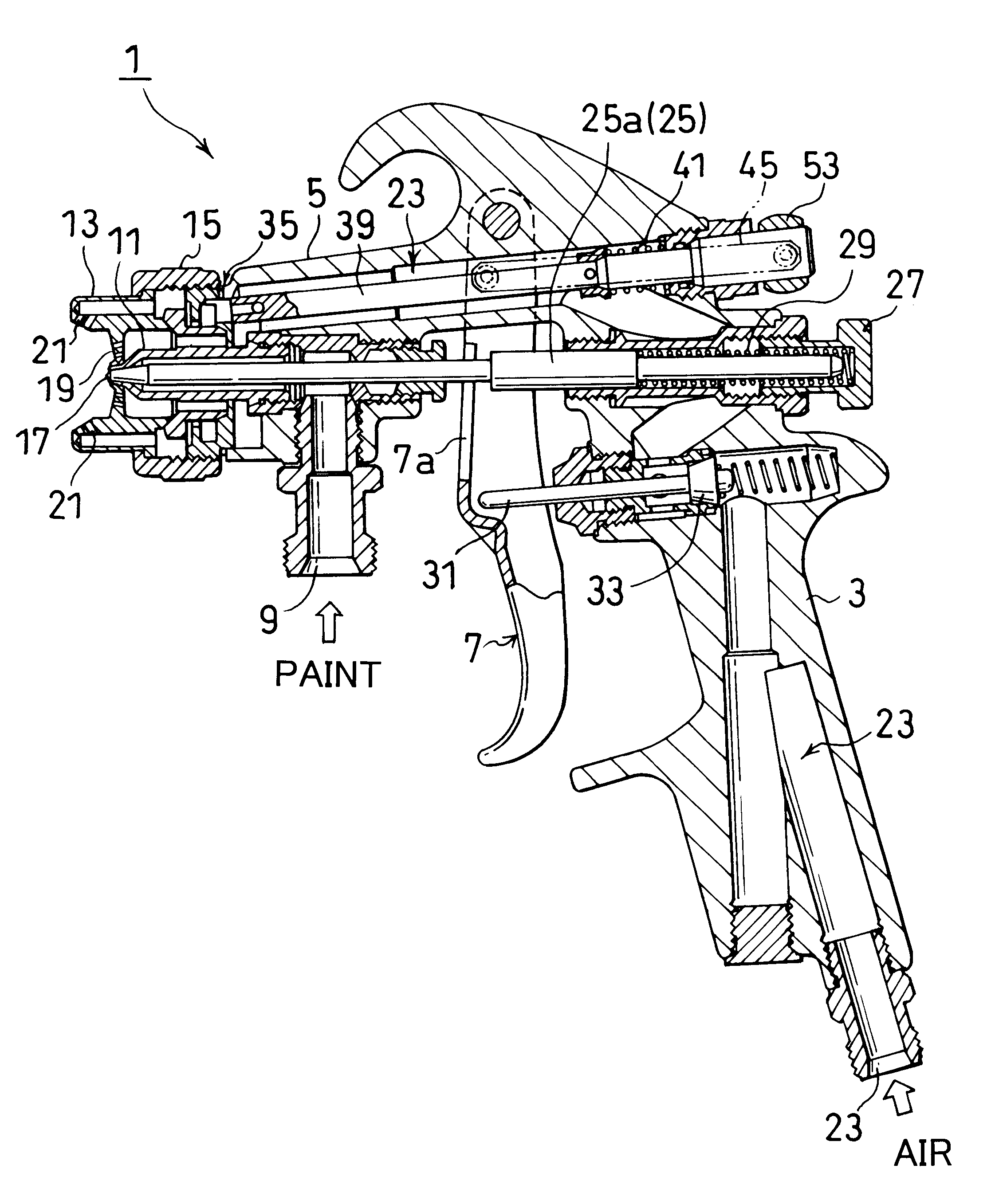

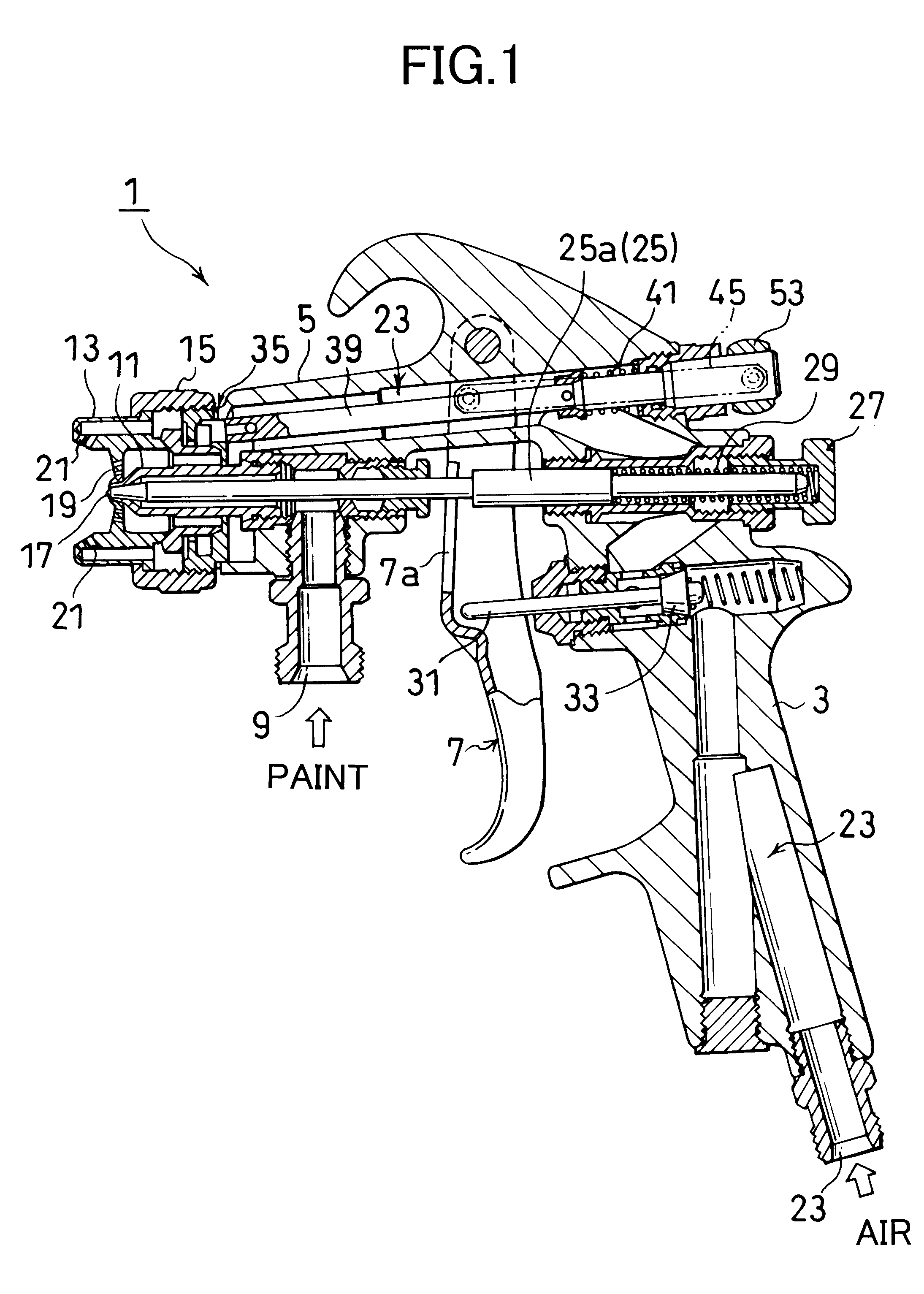

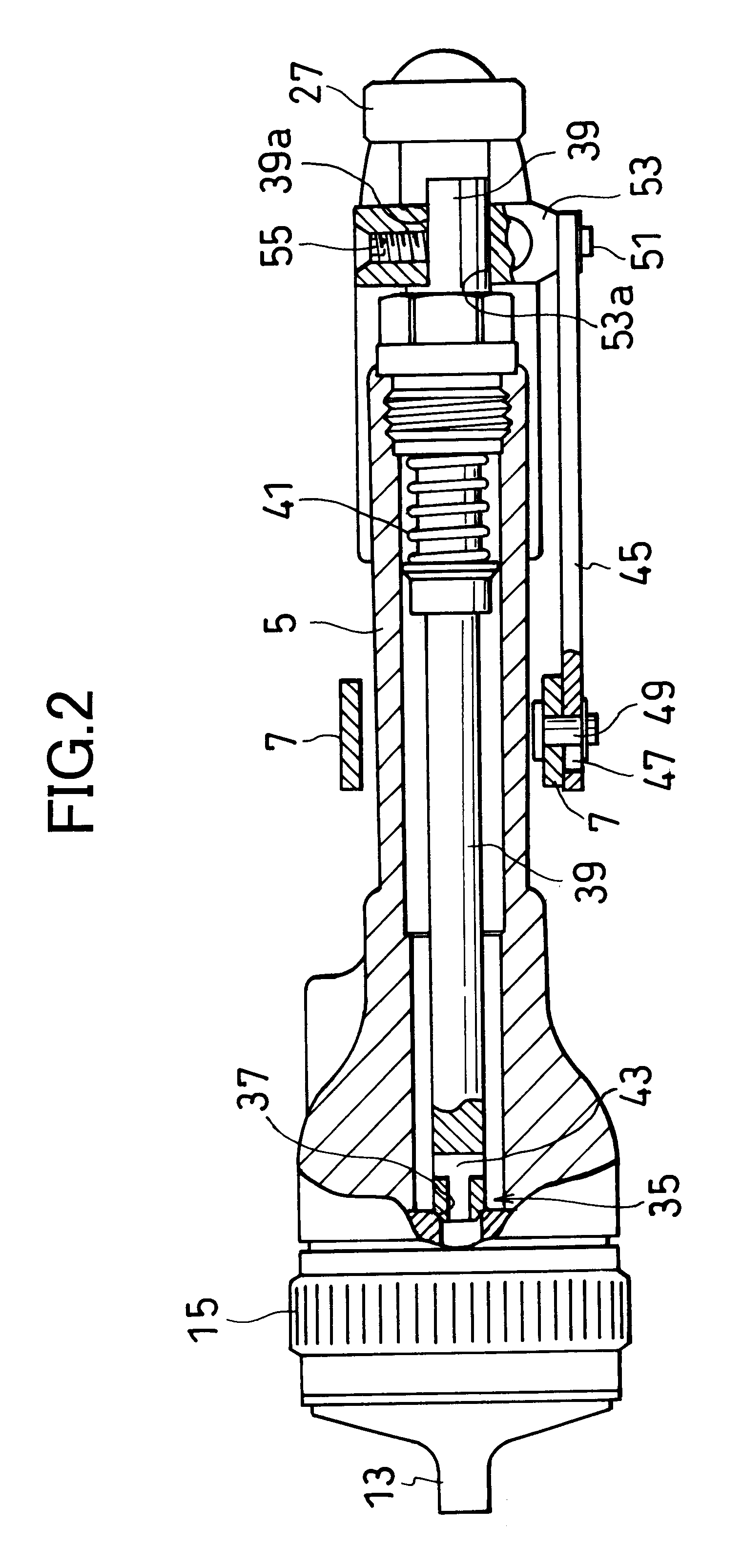

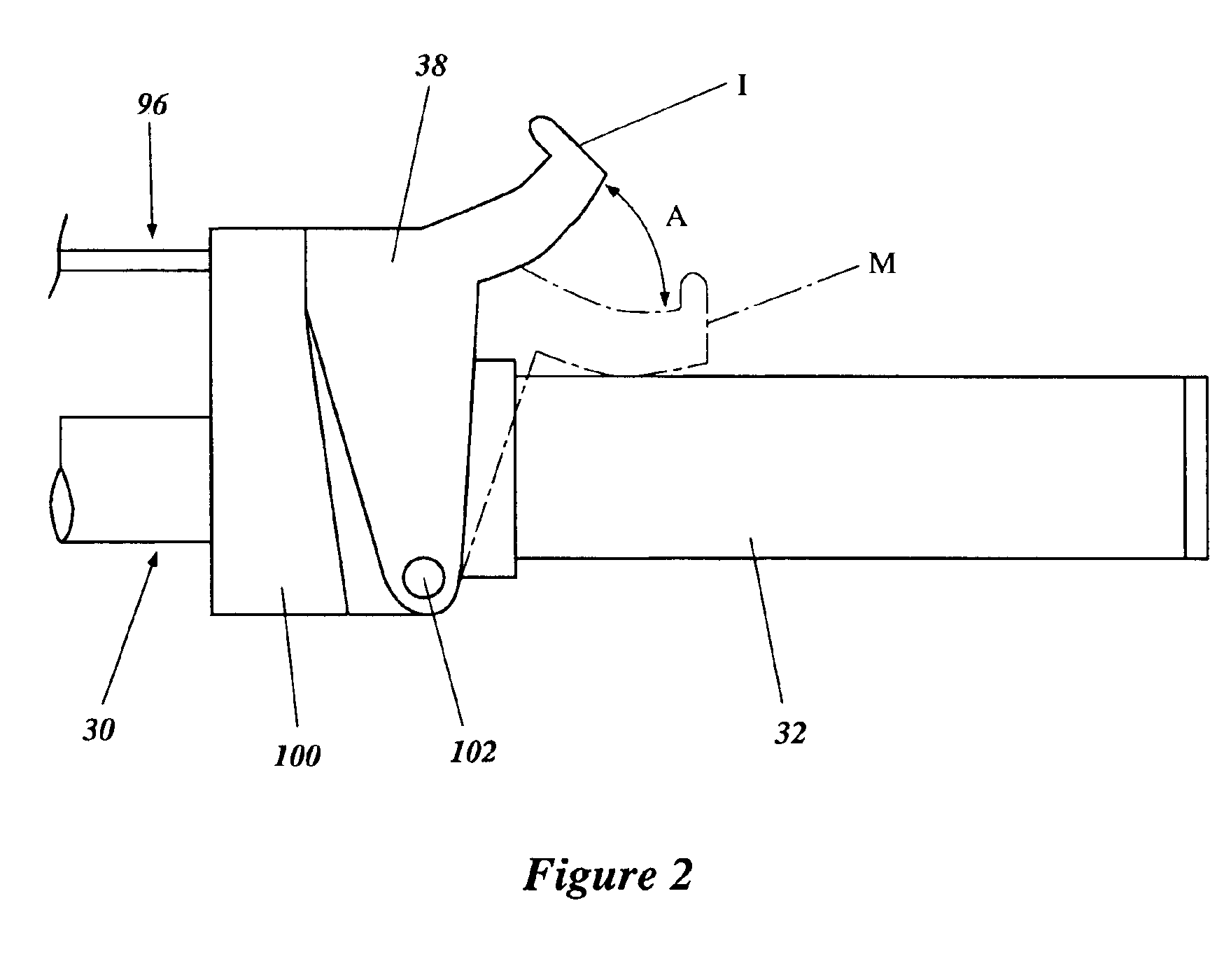

Aerosol spray gun

InactiveUS6402058B2Reduce in quantityLiquid spraying apparatusGaseous fuel burnerAerosol sprayCoupling

An aerosol spray gun used selectively in two spraying modes of small and large patterns is provided. The aerosol spray gun has a throttle valve, an air duct, and a coupling link. The throttle valve has an internal air duct for supplying pressurized air to a patterning air outlet which shapes a paint spraying stream jetted out from the aerosol spray gun, and has a movable valve element to which a compressed spring applies force to open the valve. The air duct created at the tip of the movable valve element supplies a small volume of air from the internal air duct to the patterning air outlet while the movable valve element seats on a valve seat. The coupling link, coupling the movable valve element to the trigger, has an elongated hole to disconnect the trigger from the movable valve element without cooperative relation between them from an initial stage where an operator begins to squeeze the trigger to an intermediate stage before the operator fully squeezes the trigger.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

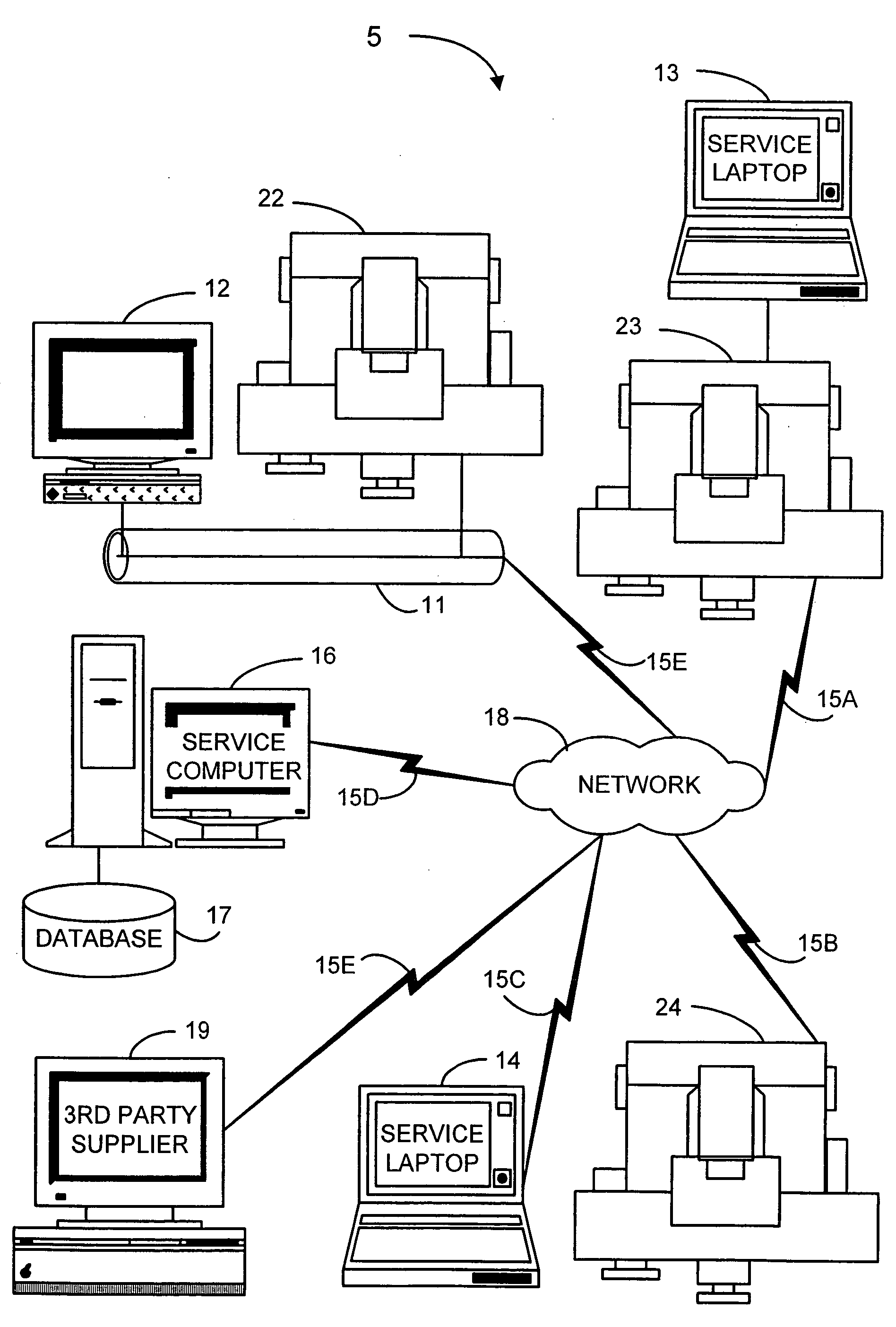

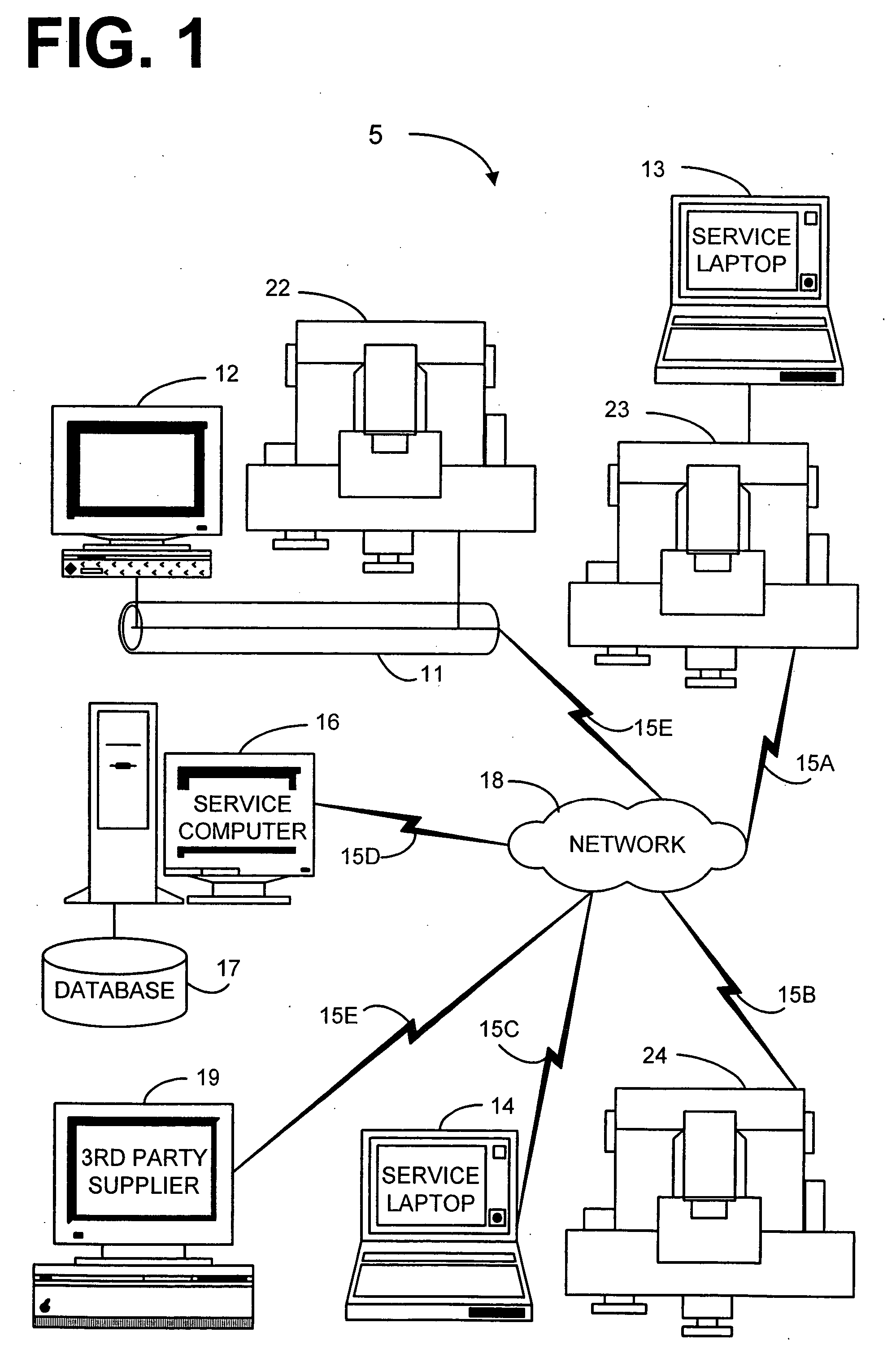

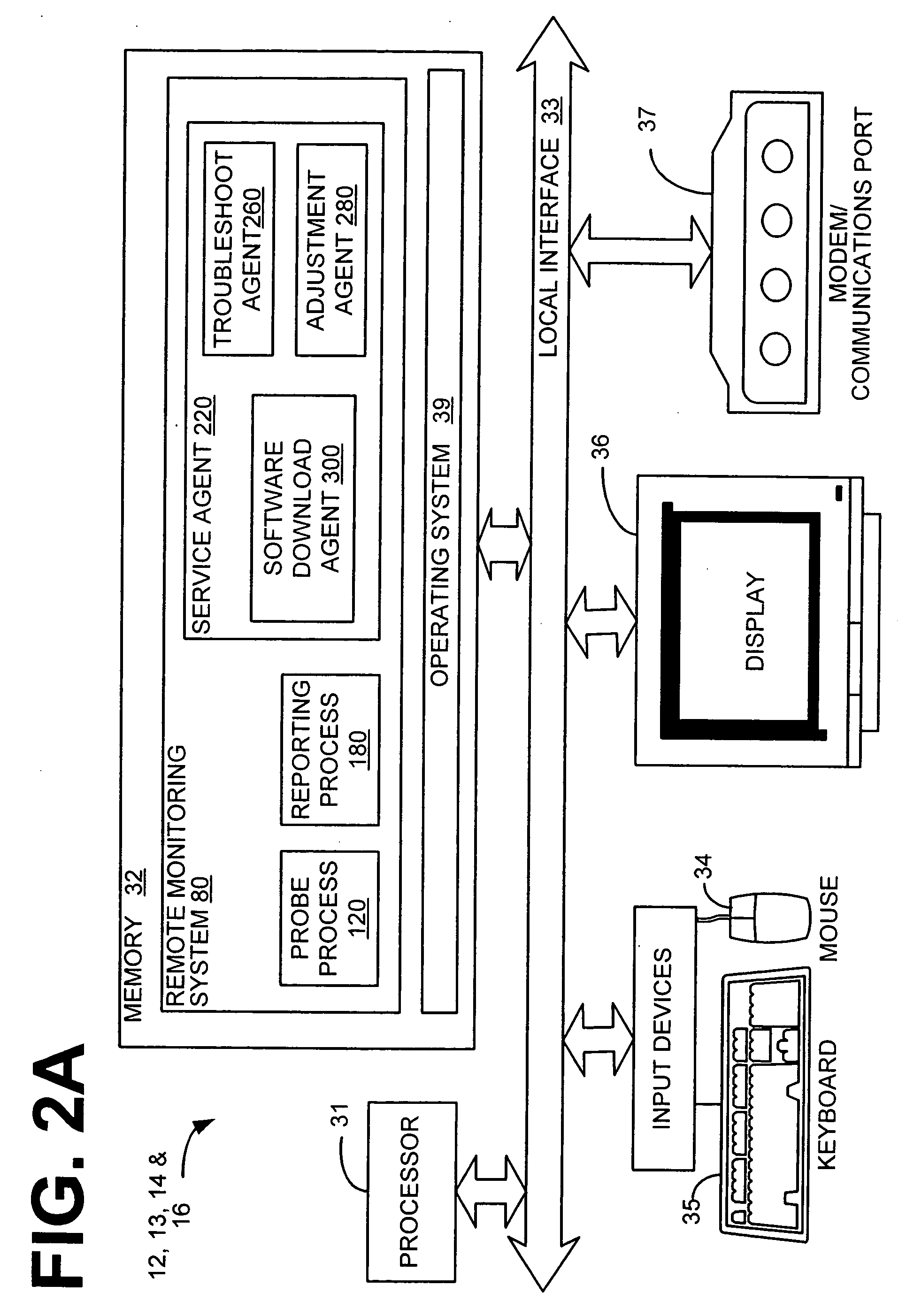

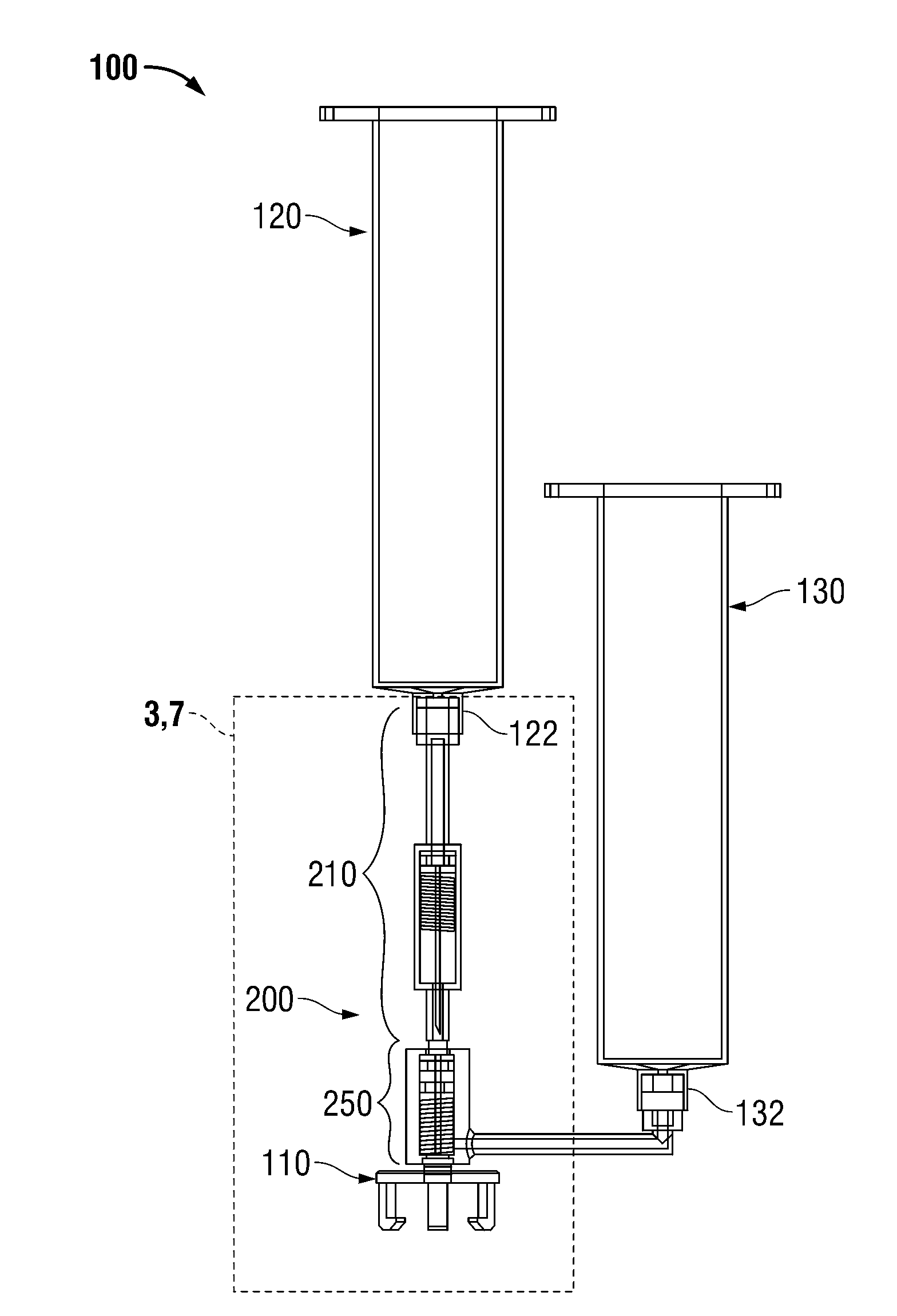

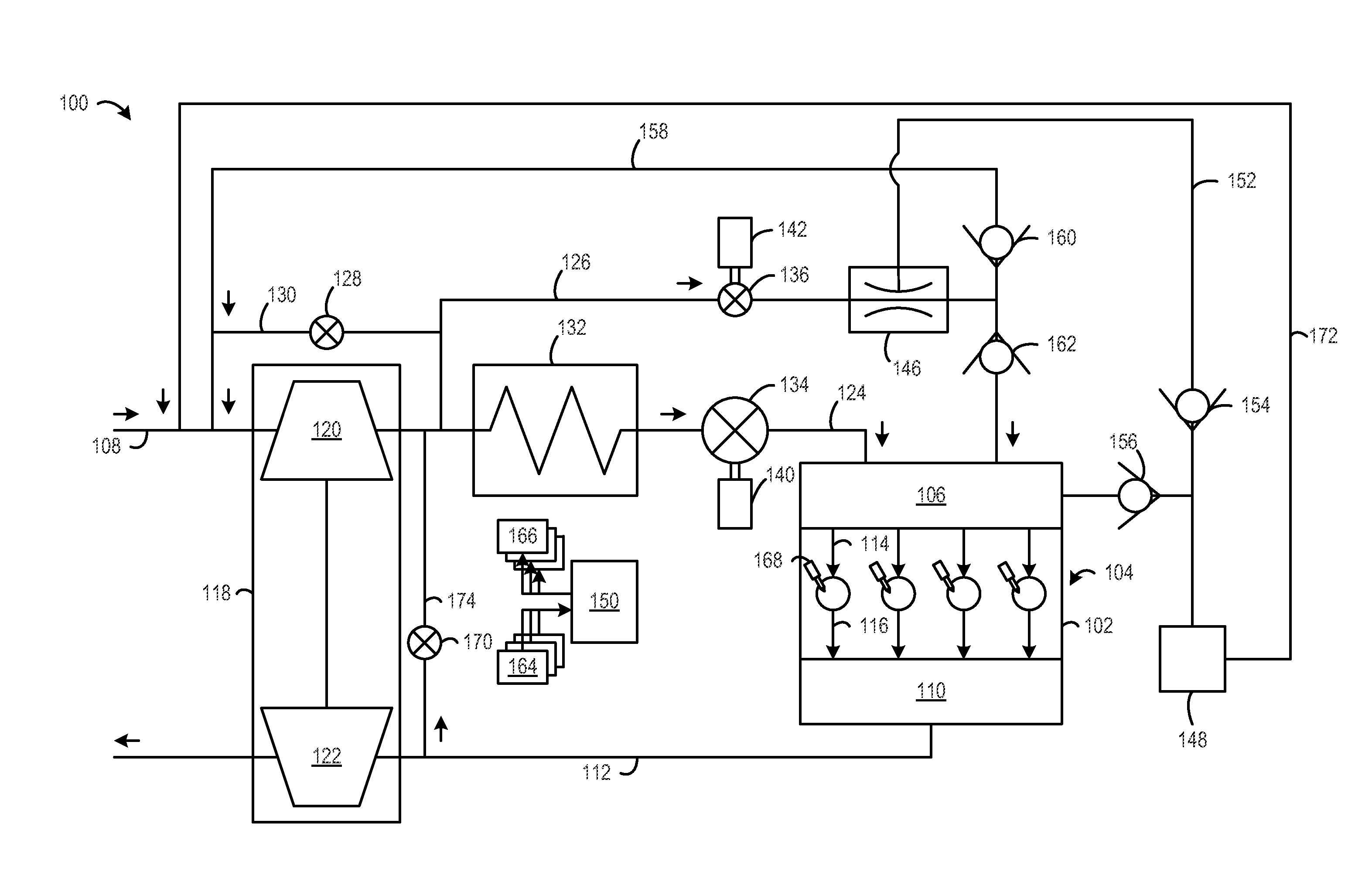

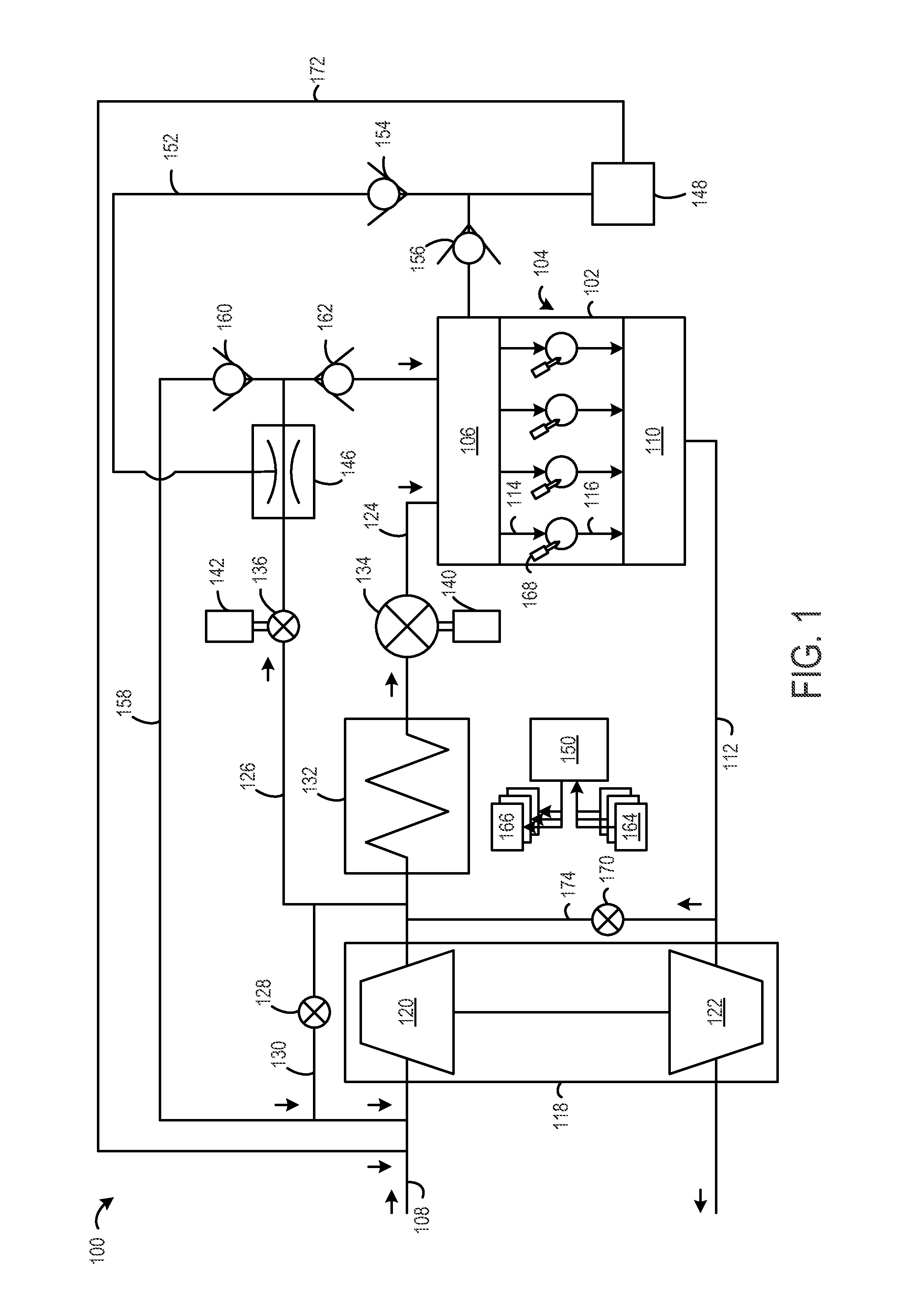

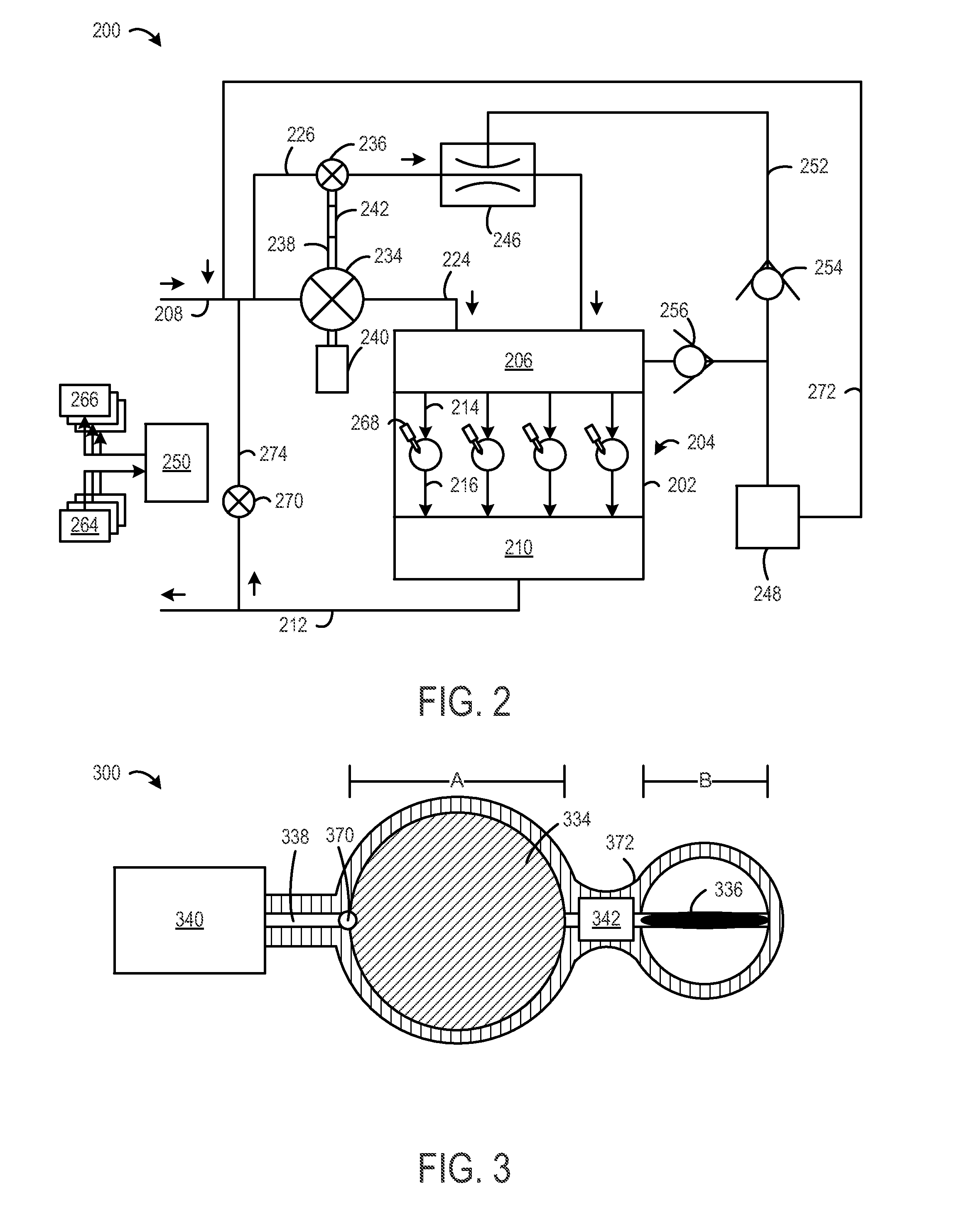

Operational control system and a system providing for remote monitoring of a manufacturing device

ActiveUS20050010323A1Maintain tensionReduce the impactSafety arrangmentsComputer controlTransceiverSystems design

A system and method for providing operational control and / or remote monitoring of a manufacturing device as in a foam dispenser device such as a foam-in-bag dispensing device. In architecture, the remote monitoring system includes a server device containing a remote monitoring system. The remote monitoring system further includes a transceiver to receive an indication of a help condition, connect to the manufacturing device; and receive data from the manufacturing device. The present invention can also be viewed as a method for providing remote monitoring of a manufacturing device. The method operates by (1) receiving an indication of a help condition; (2) connecting to the manufacturing device; and (3) receiving data from the manufacturing device. The operational control system is designed to control operation of one or more sub-systems of the manufacturing device as in a foam dispenser's chemical supply (proper temperature and pressure) and solvent supply as well as performance of a reciprocating valve device. With a foam-in-bag system, the control system provides for additional control over, for example, film feed and tensioning, bag edge and end seals as well as dispenser output into the bag. In a preferred embodiment, the operational control system and remote monitoring control interface with each other.

Owner:PREGIS INTELLIPACK CORP

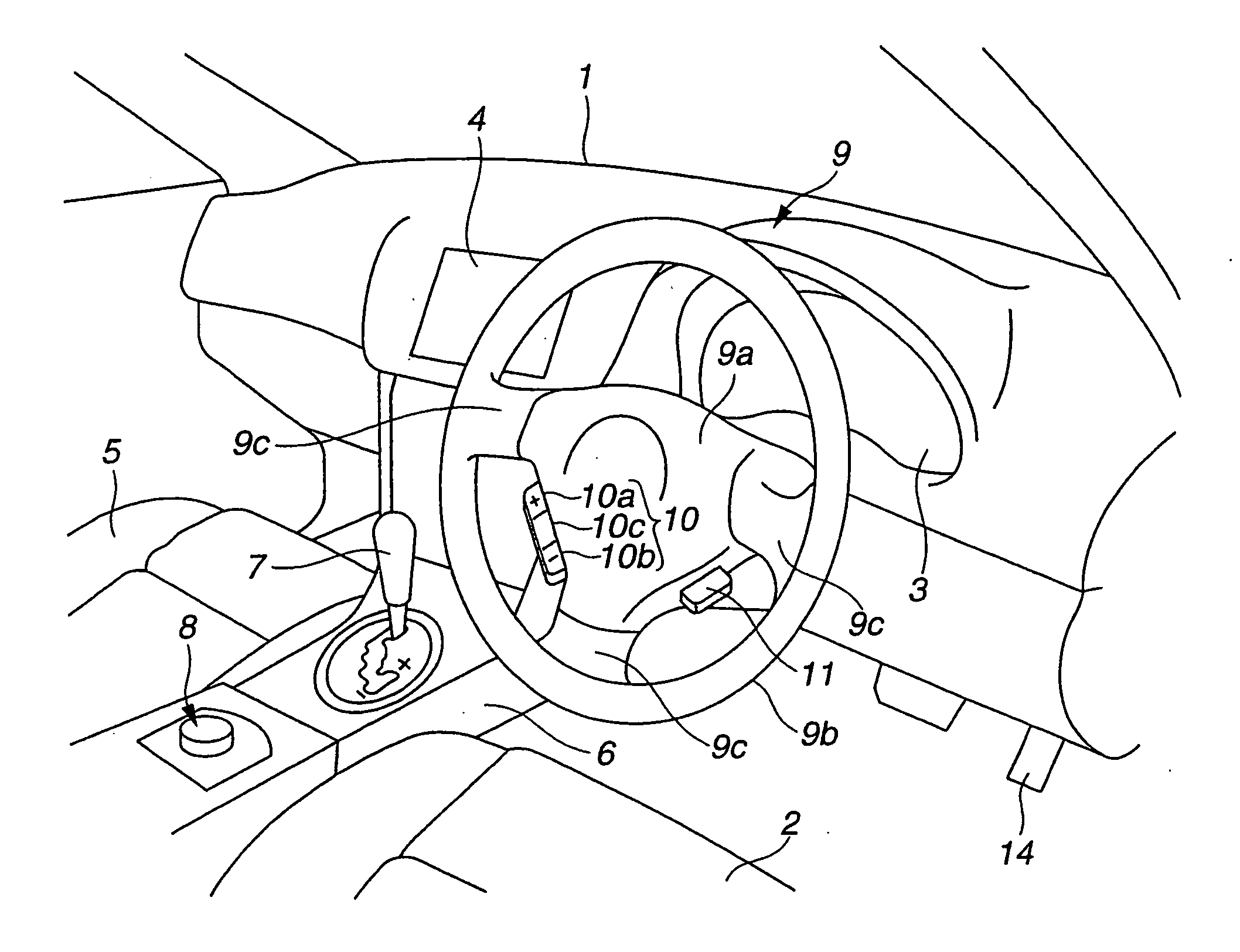

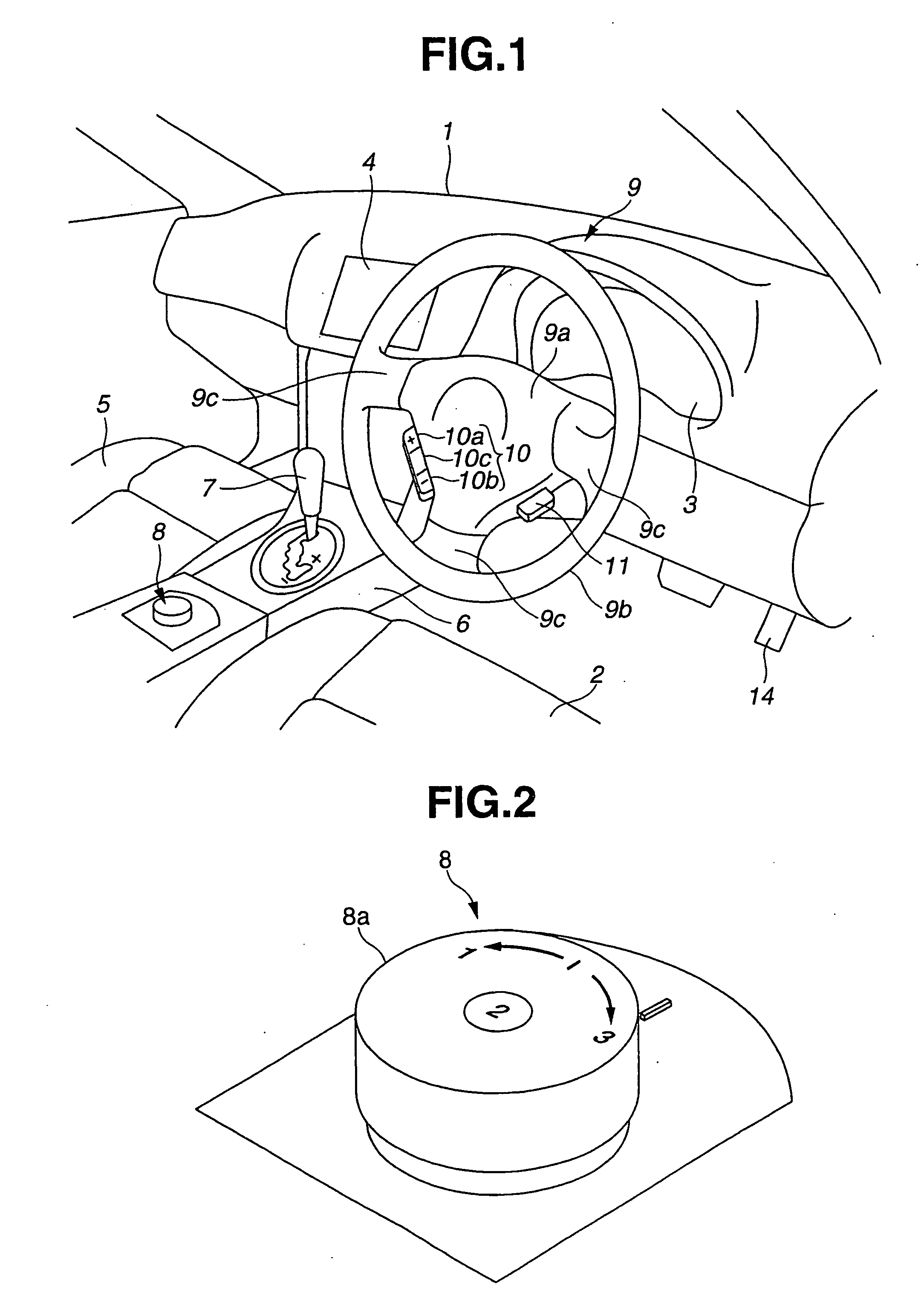

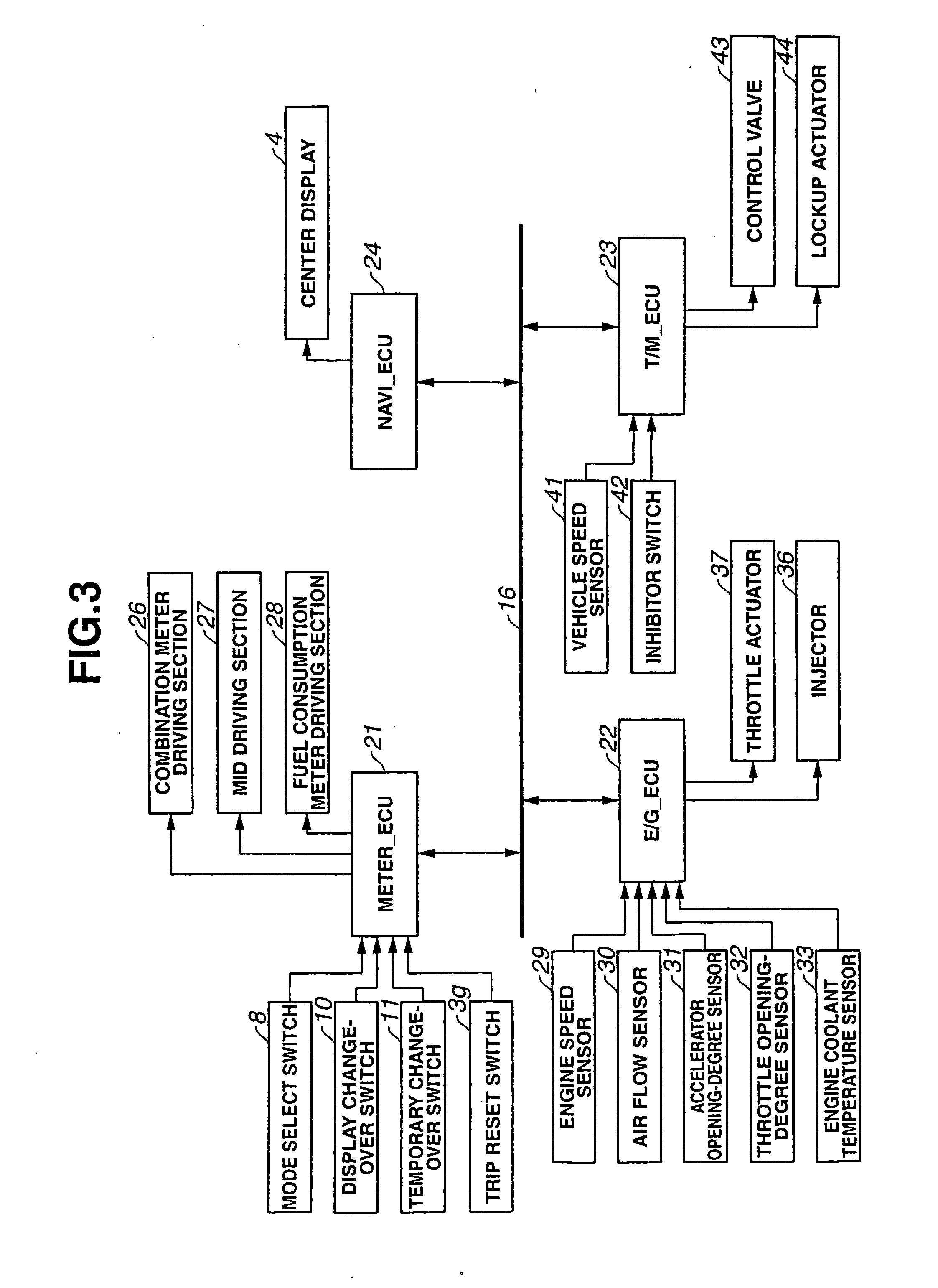

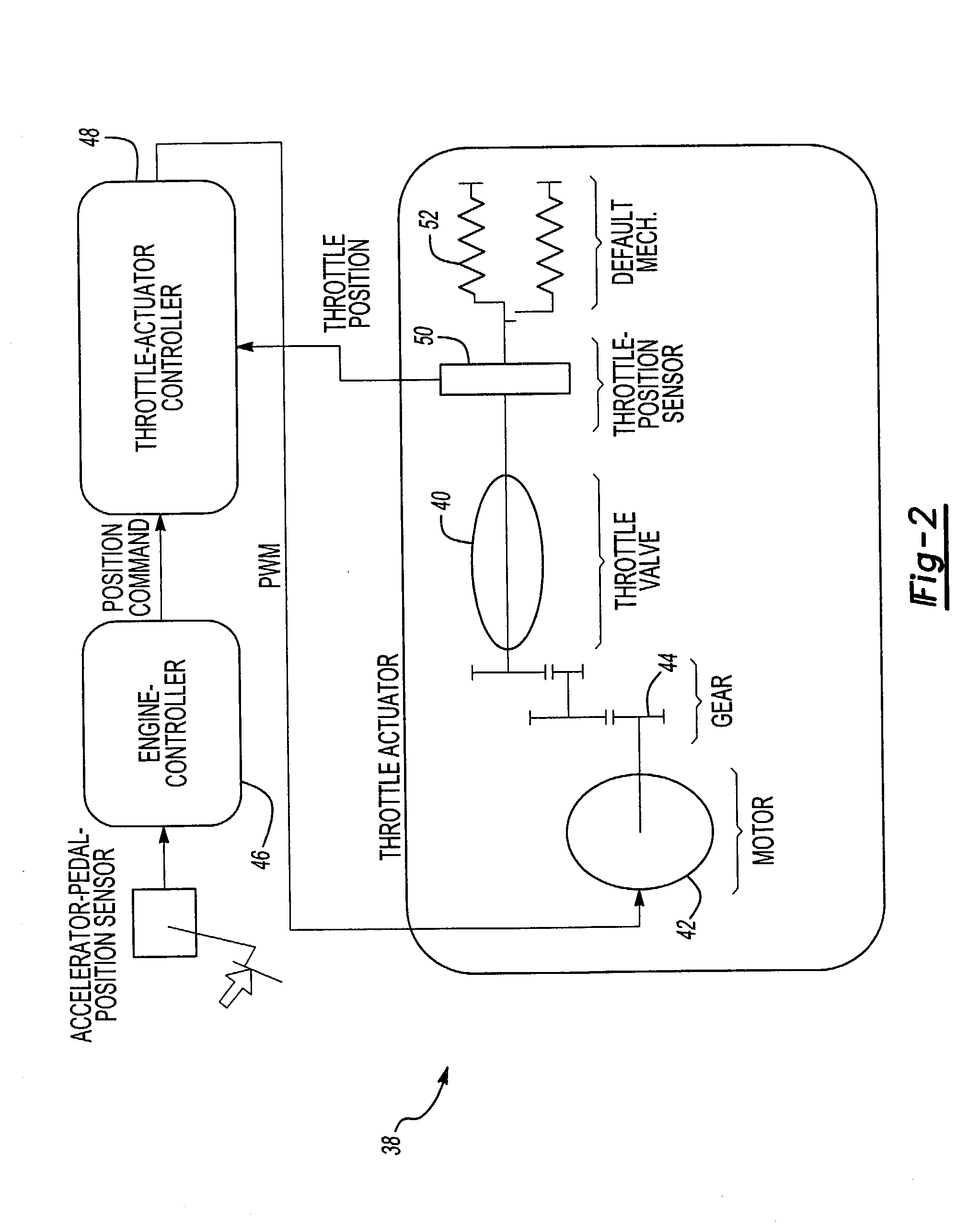

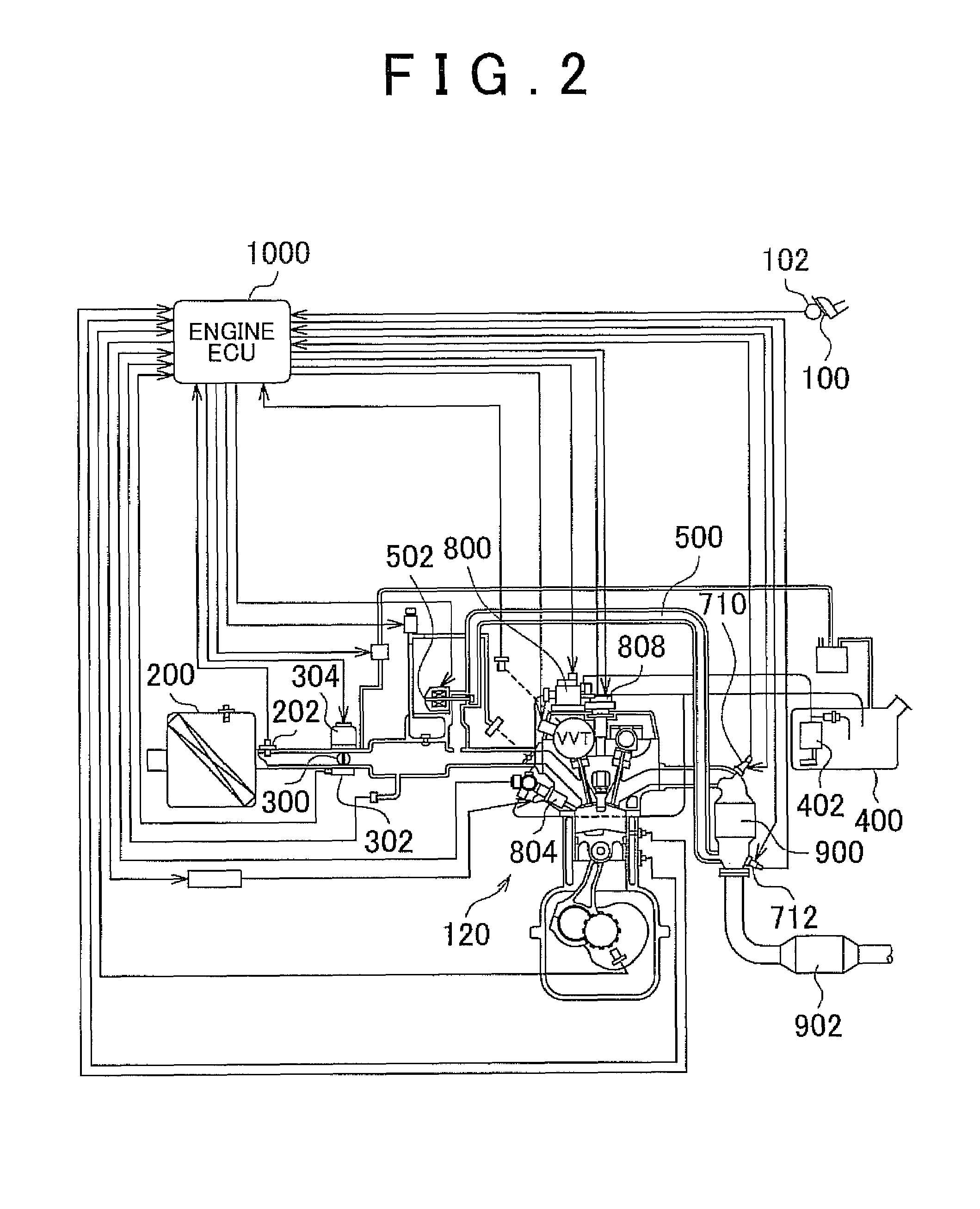

Engine control apparatus

ActiveUS20080300768A1Improve driving effectImprove startupAnalogue computers for vehiclesElectrical controlActuatorControl theory

A storage unit provided in an engine control device stores three kinds of mode maps having different engine output characteristics. One of the mode maps is selected in accordance with the driving conditions, and a target torque is set by referring to the selected mode map using an engine speed and an accelerator opening-degree as parameters. A throttle opening-degree signal corresponding to the target torque is output to a throttle actuator, and an operation of opening or closing the throttle valve is performed in response to the throttle opening-degree signal.

Owner:SUBARU CORP

Tubing annulus valve

InactiveUS6840323B2Increased durabilityGuaranteed uptimeWaste water treatment from quariesDrilling rodsOcean bottomTubing hanger

A subsea wellhead assembly has a tubing hanger with a tubing annulus passage and a production passage. A metal-sealing shuttle valve is mounted in the tubing hanger for blocking upward flow through the tubing annulus passage. The shuttle valve has a retention mechanism that prevents the shuttle from moving to the open position when fluid pressure is applied from above. The retention mechanism is released by the running tool after testing has been completed, causing the shuttle to close. The tree has an engaging member that can be stroked downward into the tubing hanger annulus passage to move the shuttle valve to the open position for communicating with the annulus.

Owner:VETCO GRAY

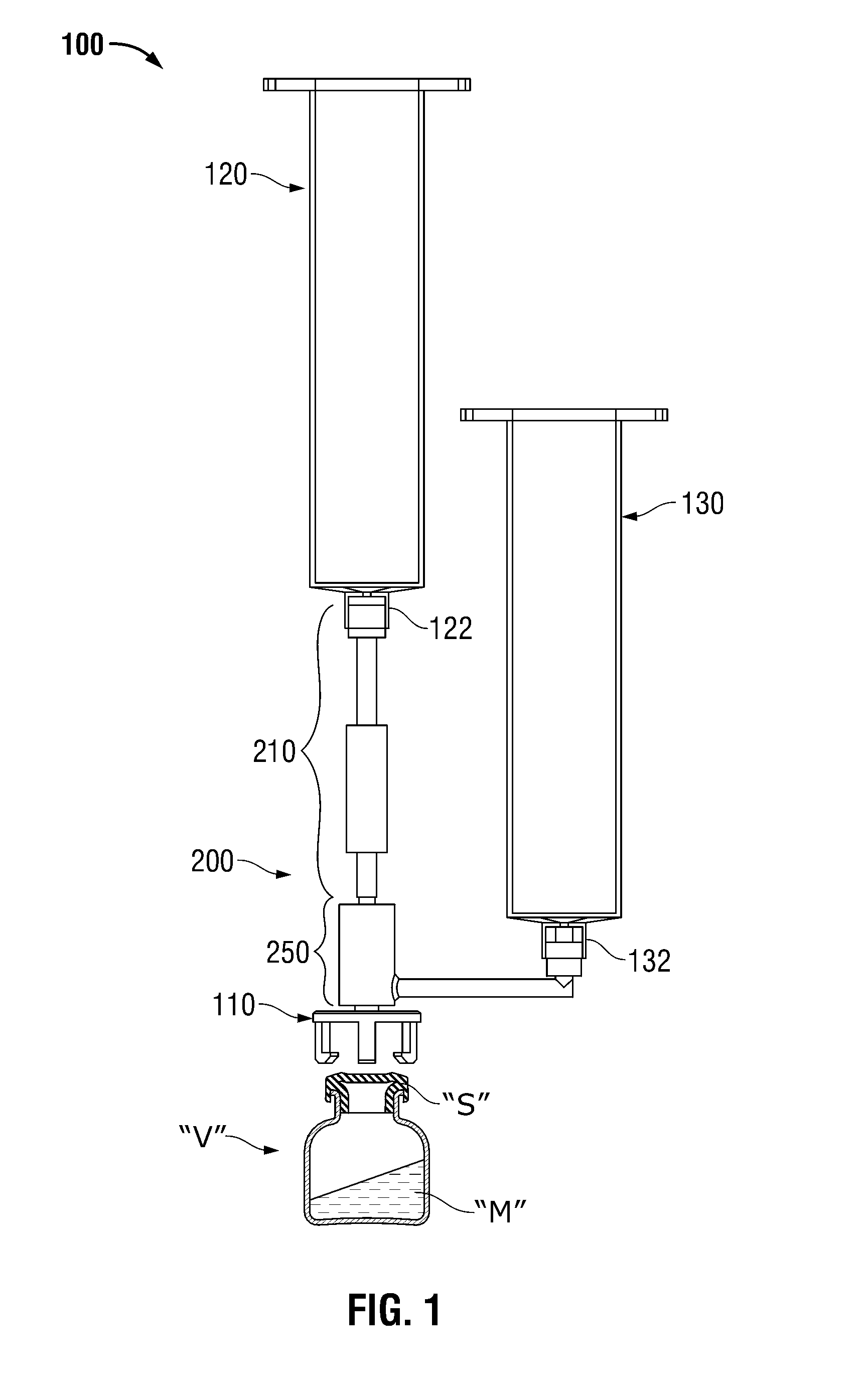

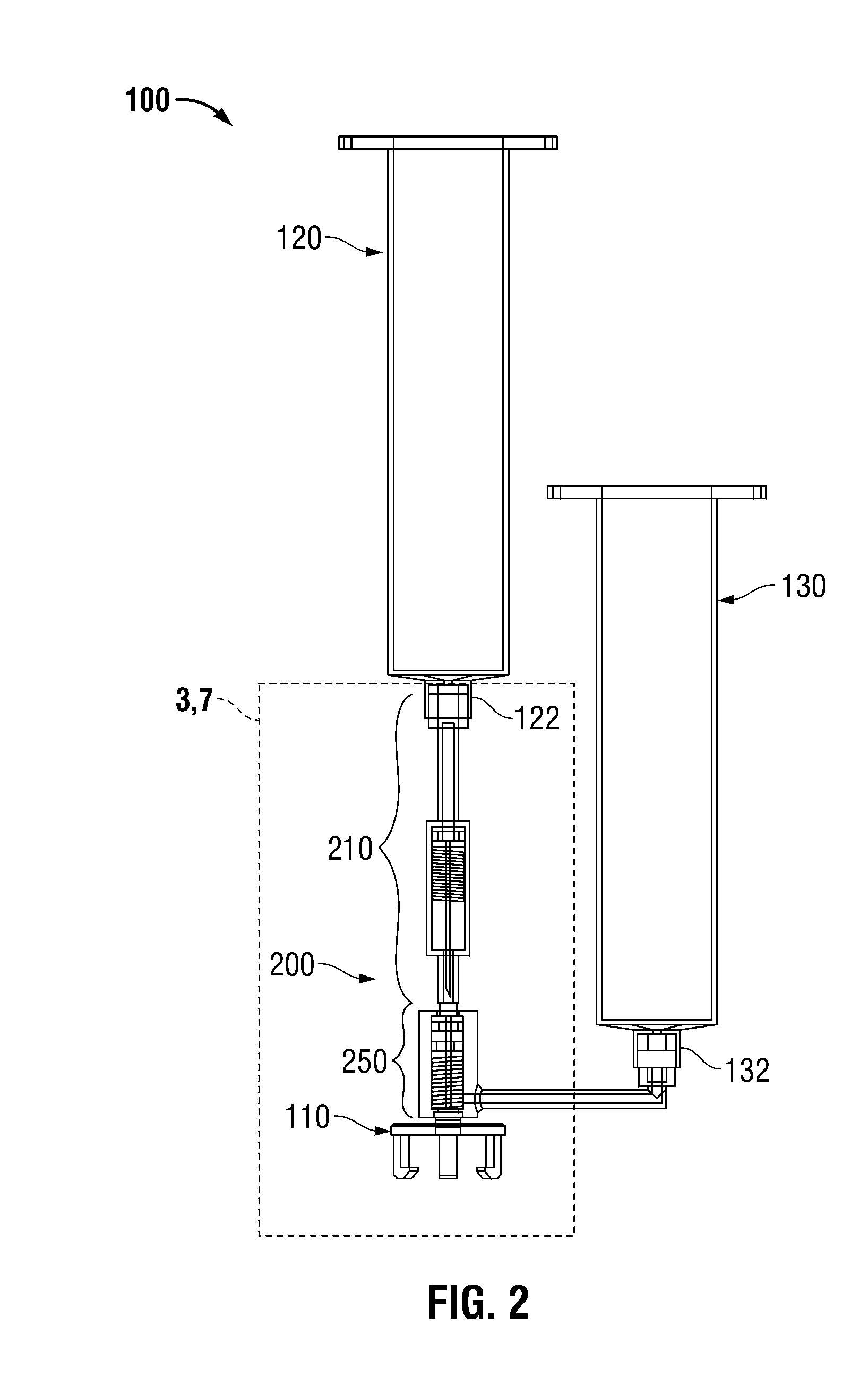

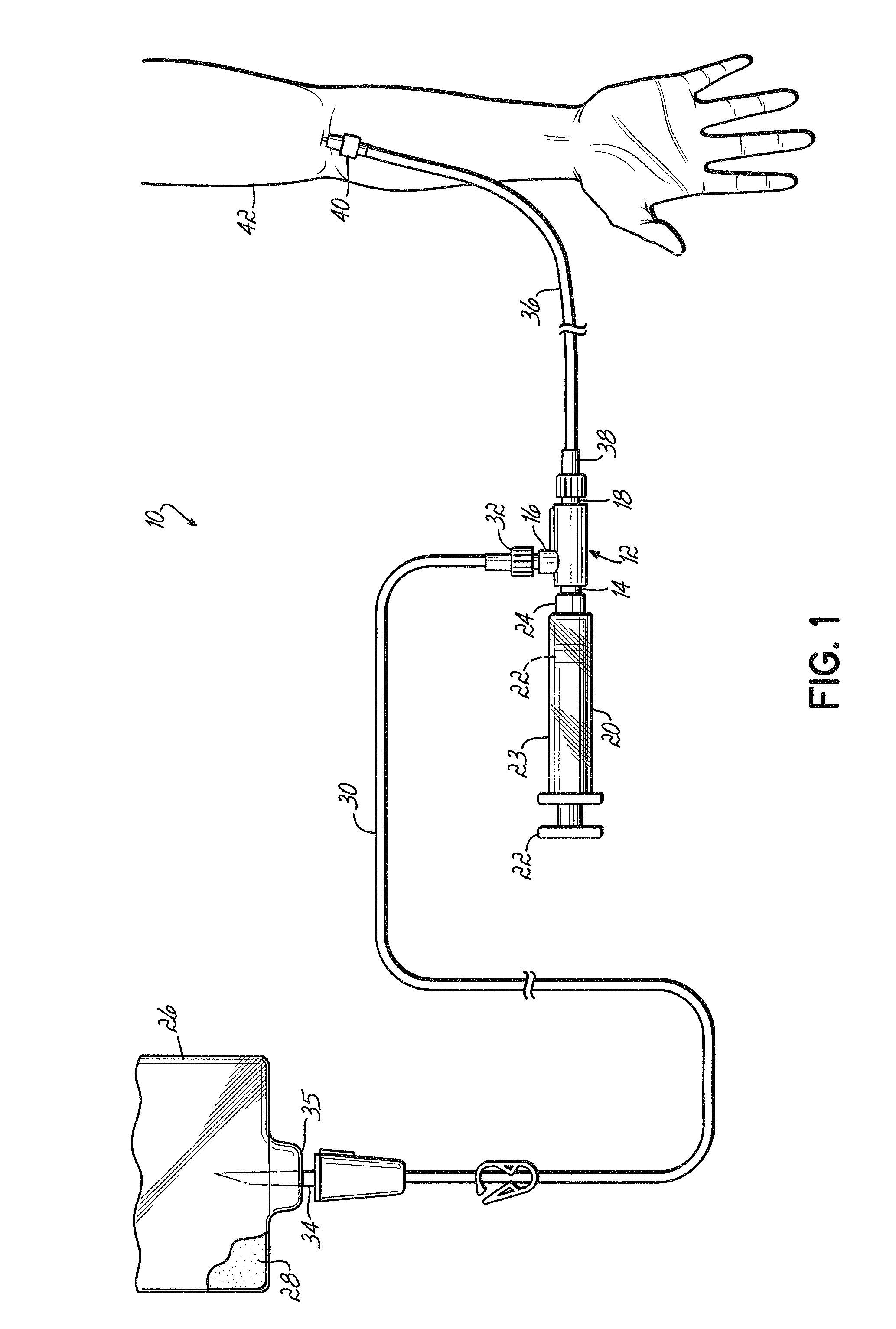

Systems and methods for safe medicament transport

A medicament transport system includes a syringe adapter assembly; and a vial adapter assembly including a base defining an opening having a seal member disposed therewithin, a stem extending from the base and defining a lumen therethrough and an opening through a wall thereof, a needle shuttle valve slidably disposed within the lumen of the stem and supporting a transfer needle and a vacuum needle; and a vacuum cup slidably supported on the stem, wherein a vacuum chamber is defined in the space between the base, the stem and the vacuum cup. The medicament transport system includes a condition where the transfer needle and the vacuum needles penetrate the seal member of the vial adapter assembly, and the vacuum cup is moved to draw a vacuum through the vacuum needle. An automation system is provided that utilizes a medicament transport system for forming a medicament solution from a liquid / non-liquid solution.

Owner:CORVIDA MEDICAL INC

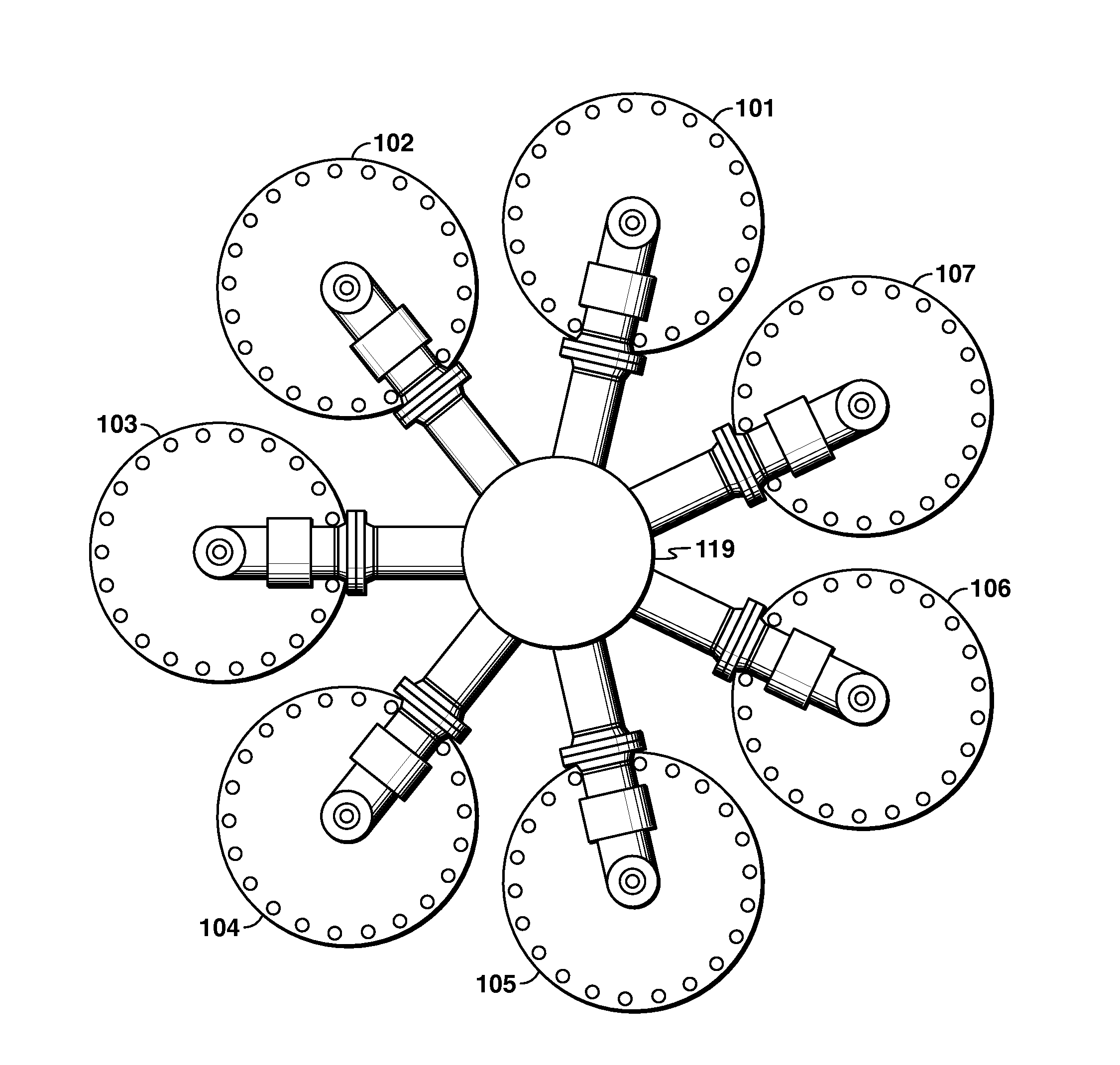

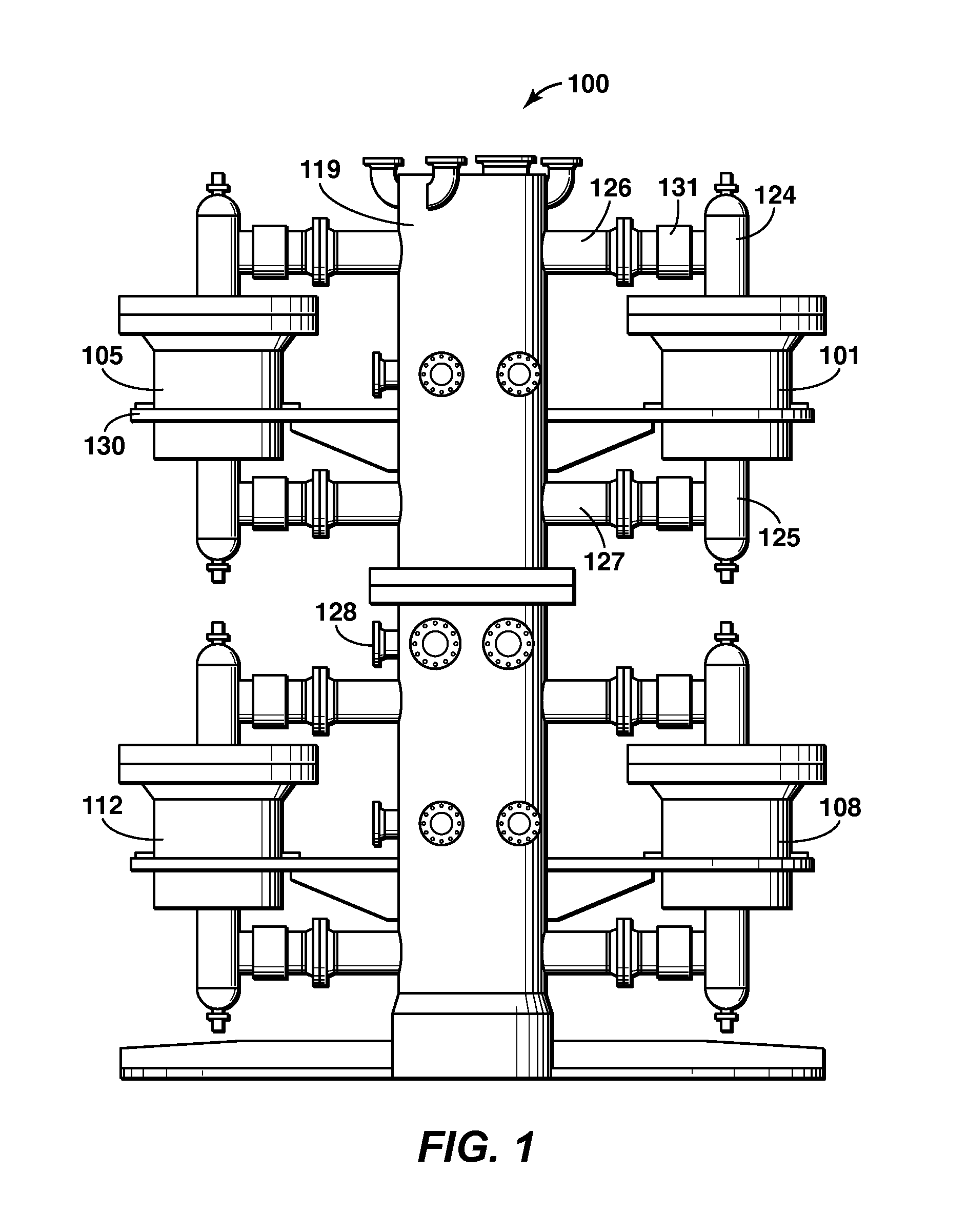

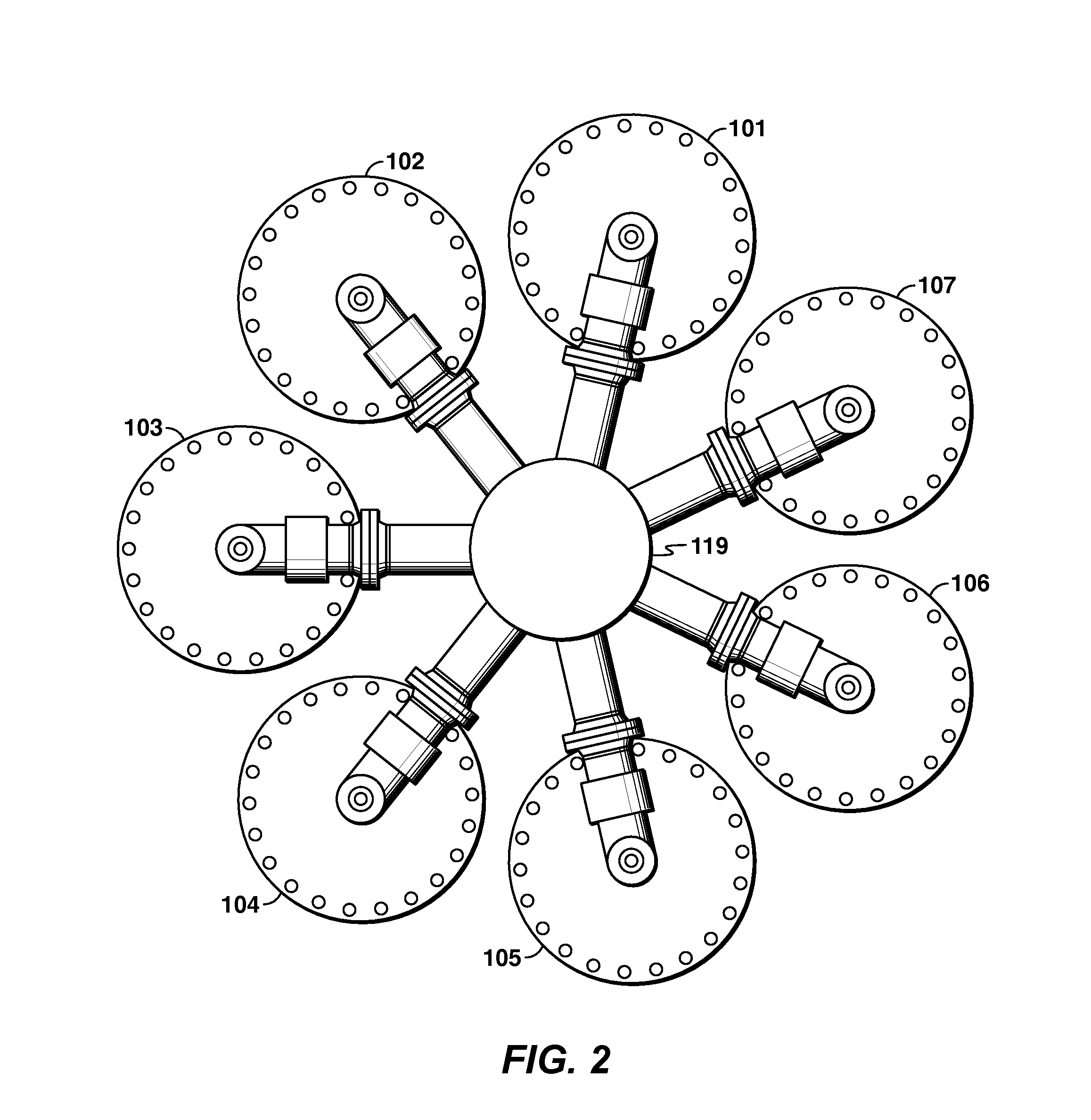

Apparatus and Systems Having a Rotary Valve Assembly and Swing Adsorption Processes Related Thereto

Provided are apparatus and systems having a rotary valve assembly integrated with a reciprocating valve assembly to perform swing adsorption processes. The rotary valve assembly is utilized with the reciprocating valve assembly to manage the flow of streams through the system in an enhanced manner.

Owner:EXXONMOBIL UPSTREAM RES CO

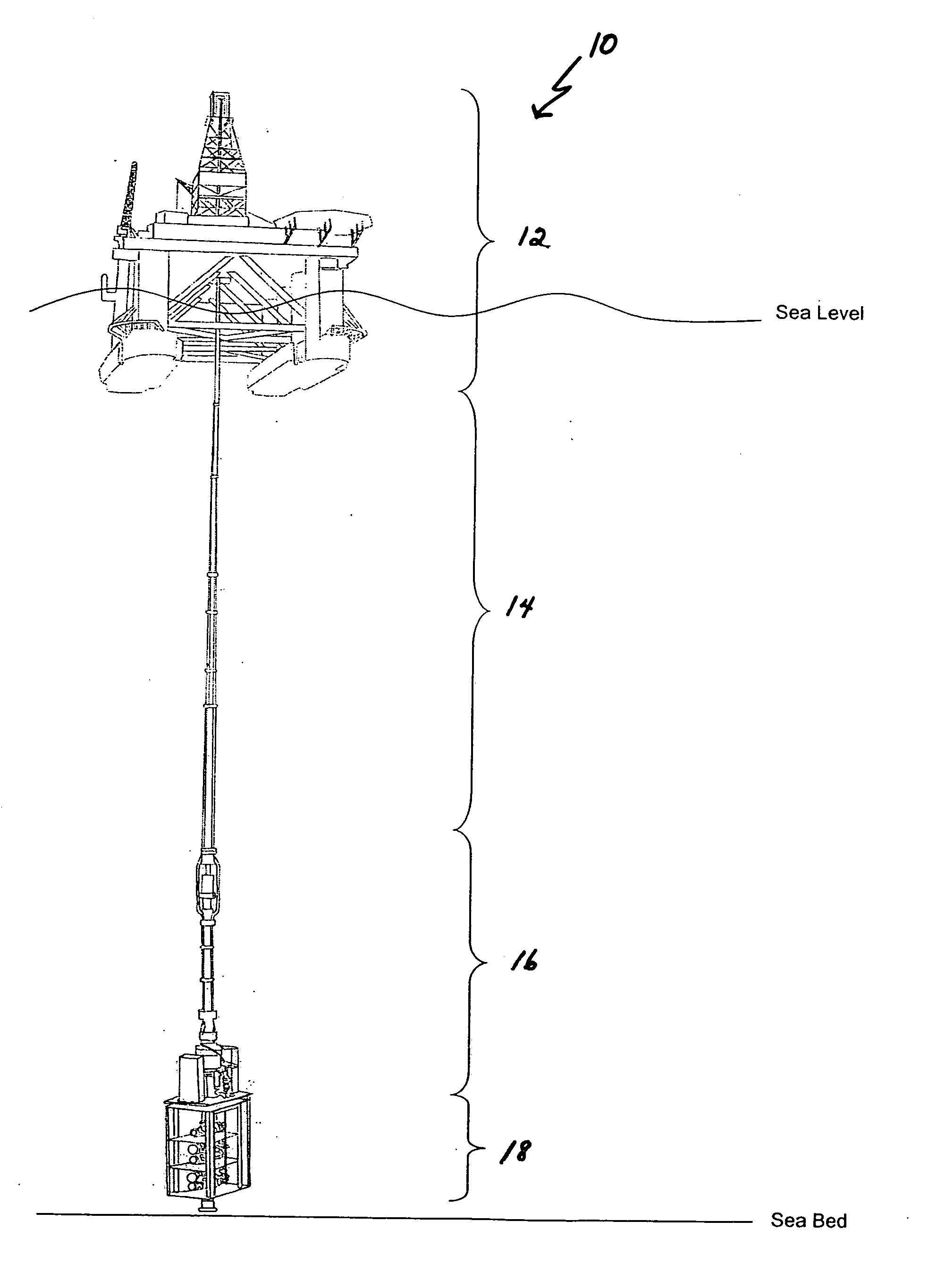

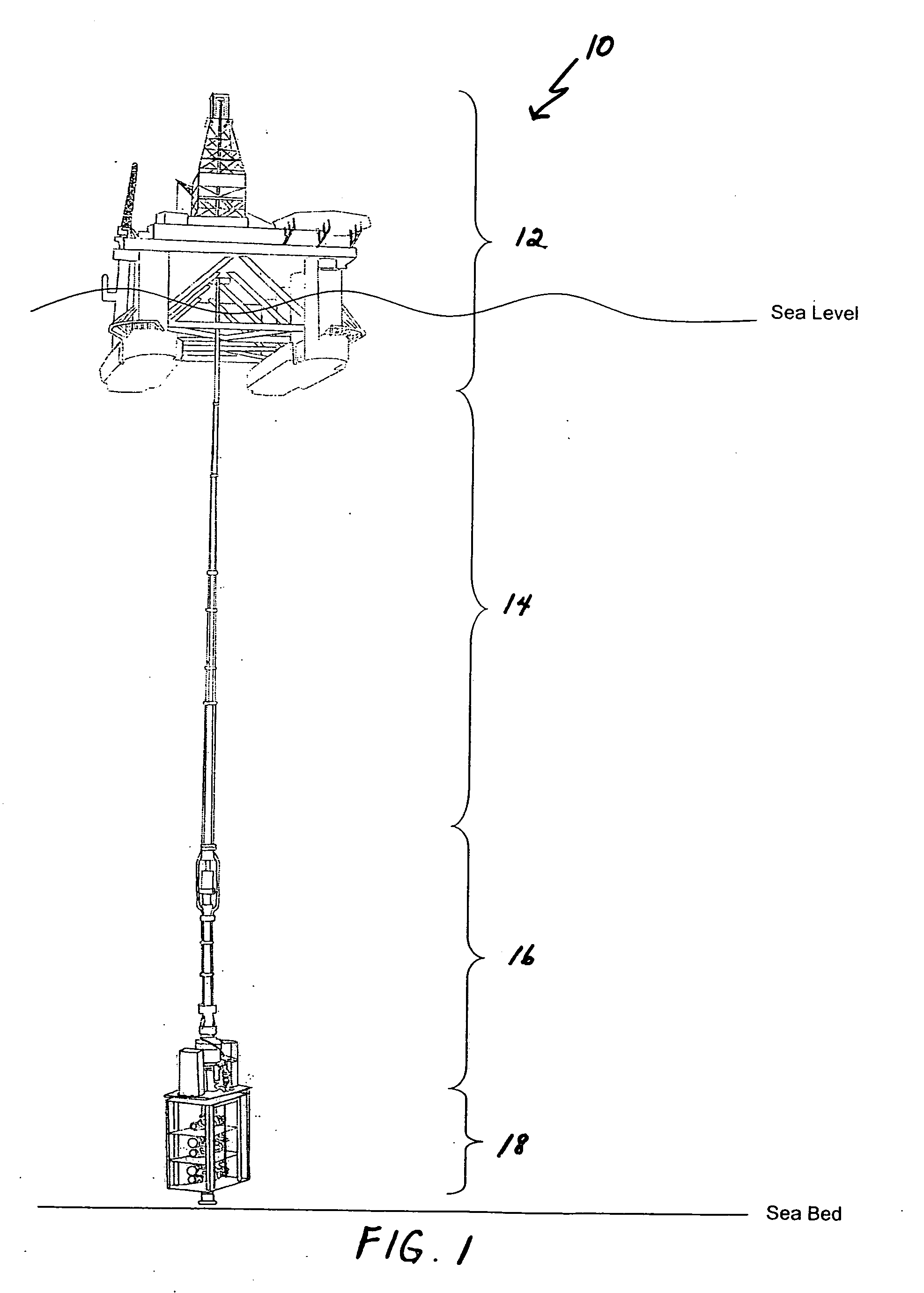

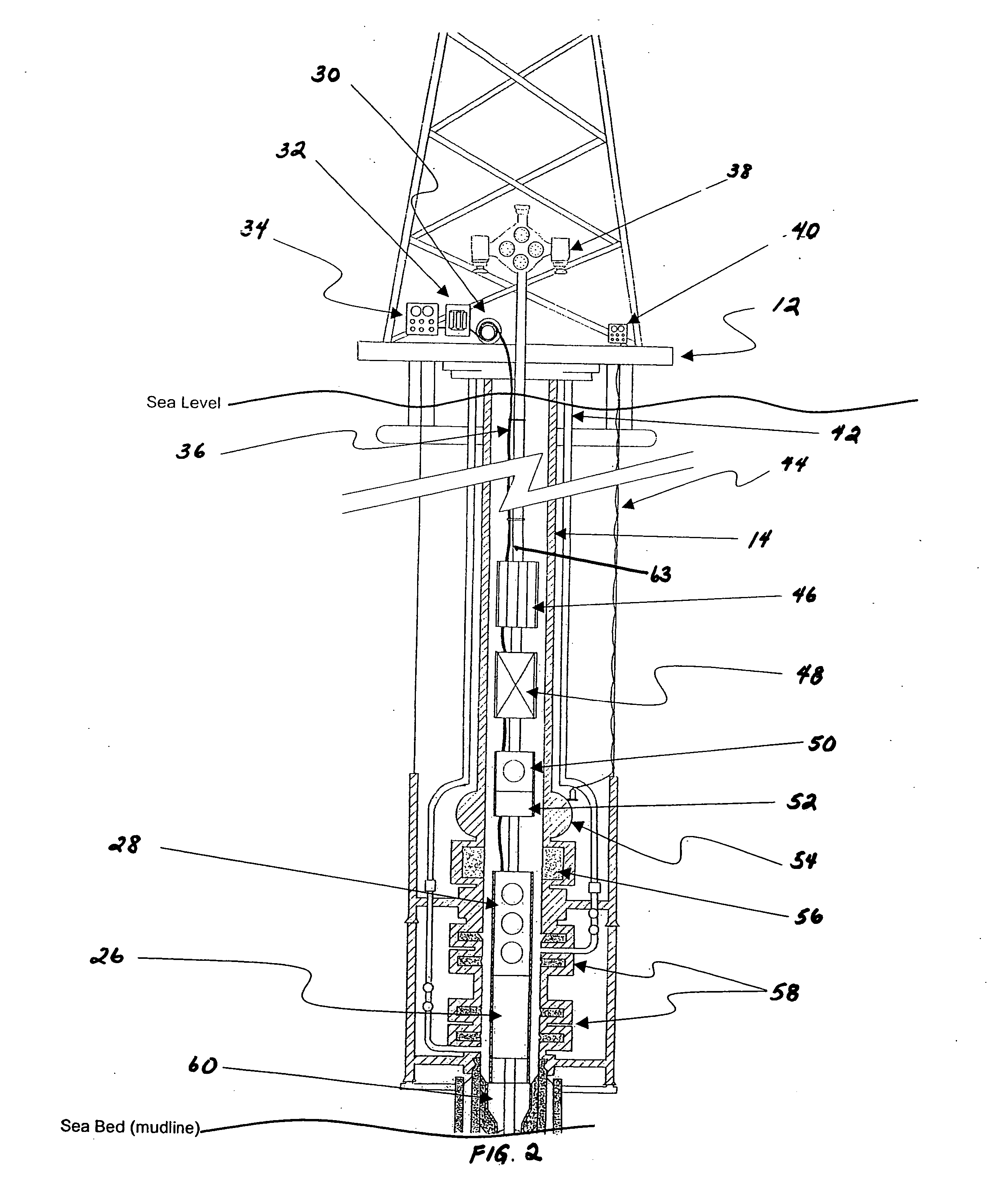

Tubing hanger running tool and subsea test tree control system

InactiveUS20050217845A1Reduced rig timeImprove securityFluid removalWell/borehole valve arrangementsControl systemTubing hanger

A system for providing power to elements down-hole in a subsea well includes a control pod having at least one shuttle valve, a down-hole hydraulically-actuated device having at least one internal porting mechanism in fluid communication with the at least one shuttle valve, a blowout preventer stack connected to the down-hole device, the blowout preventer stack including a first ram and a second ram, and a choke line in fluid communication with an area between the first ram and the second ram. The at least one shuttle valve controls distribution of hydraulic pressure applied through the choke line to the internal porting mechanism for selective distribution of power to the hydraulically-actuated device.

Owner:MCGUIRE LINDELL V

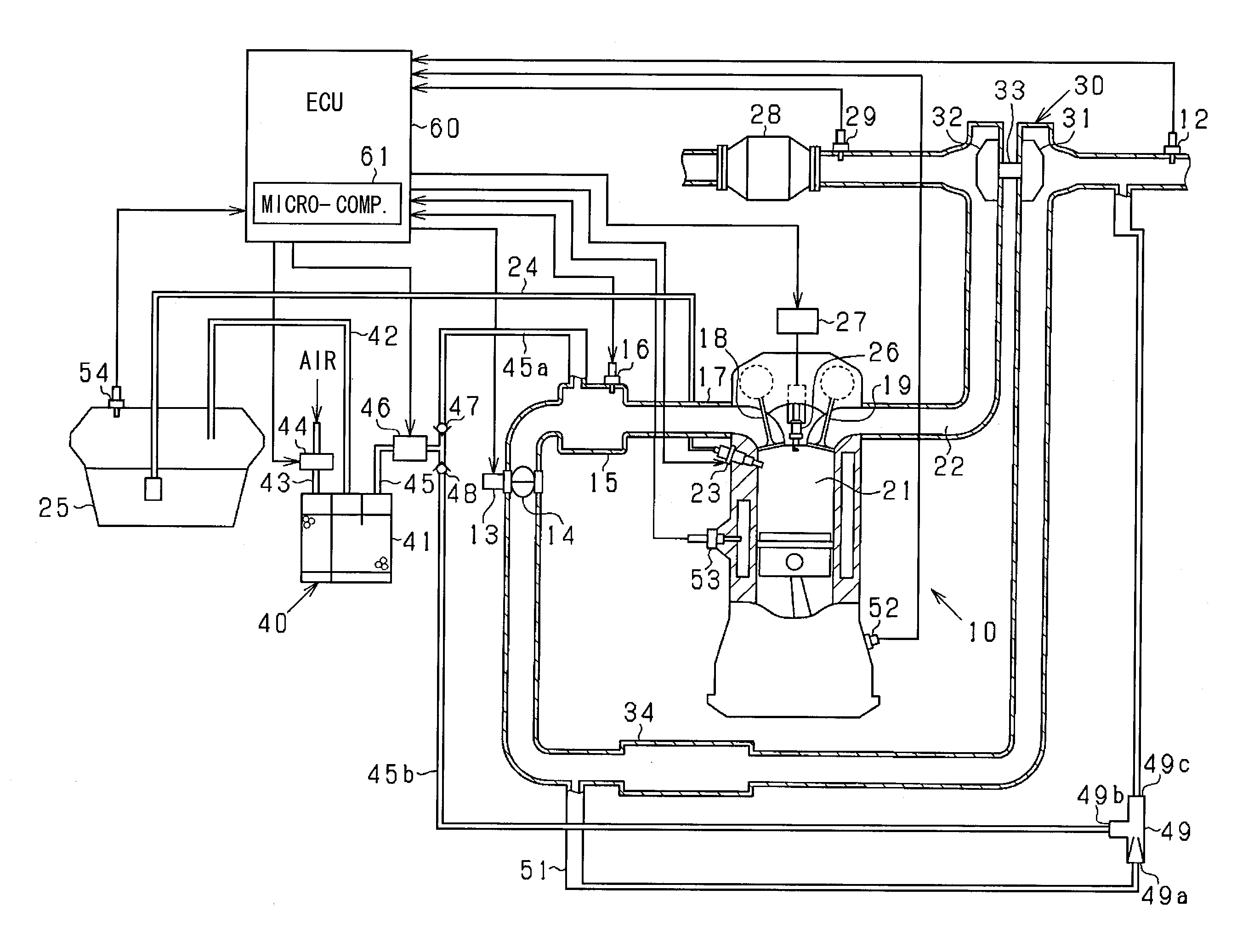

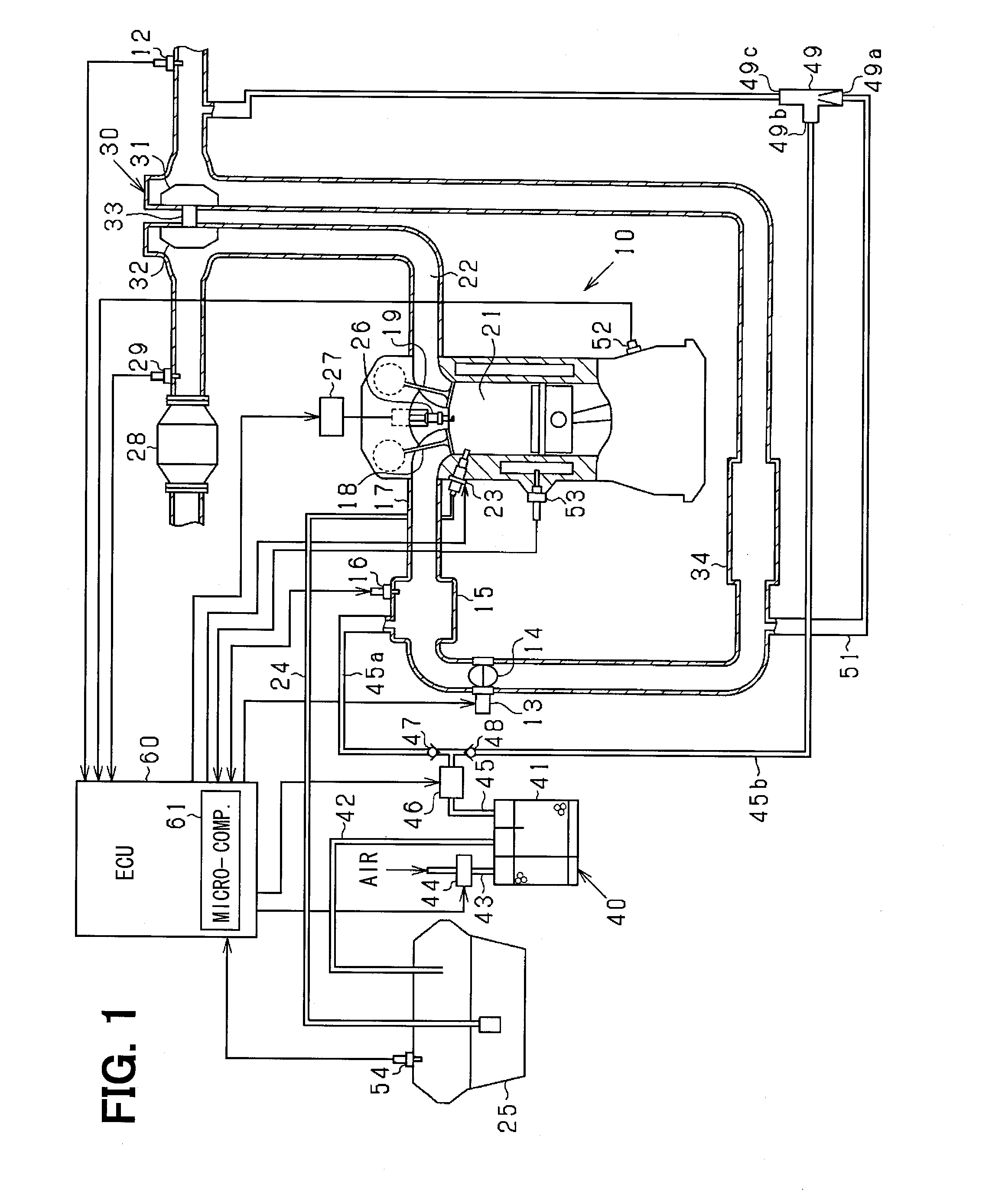

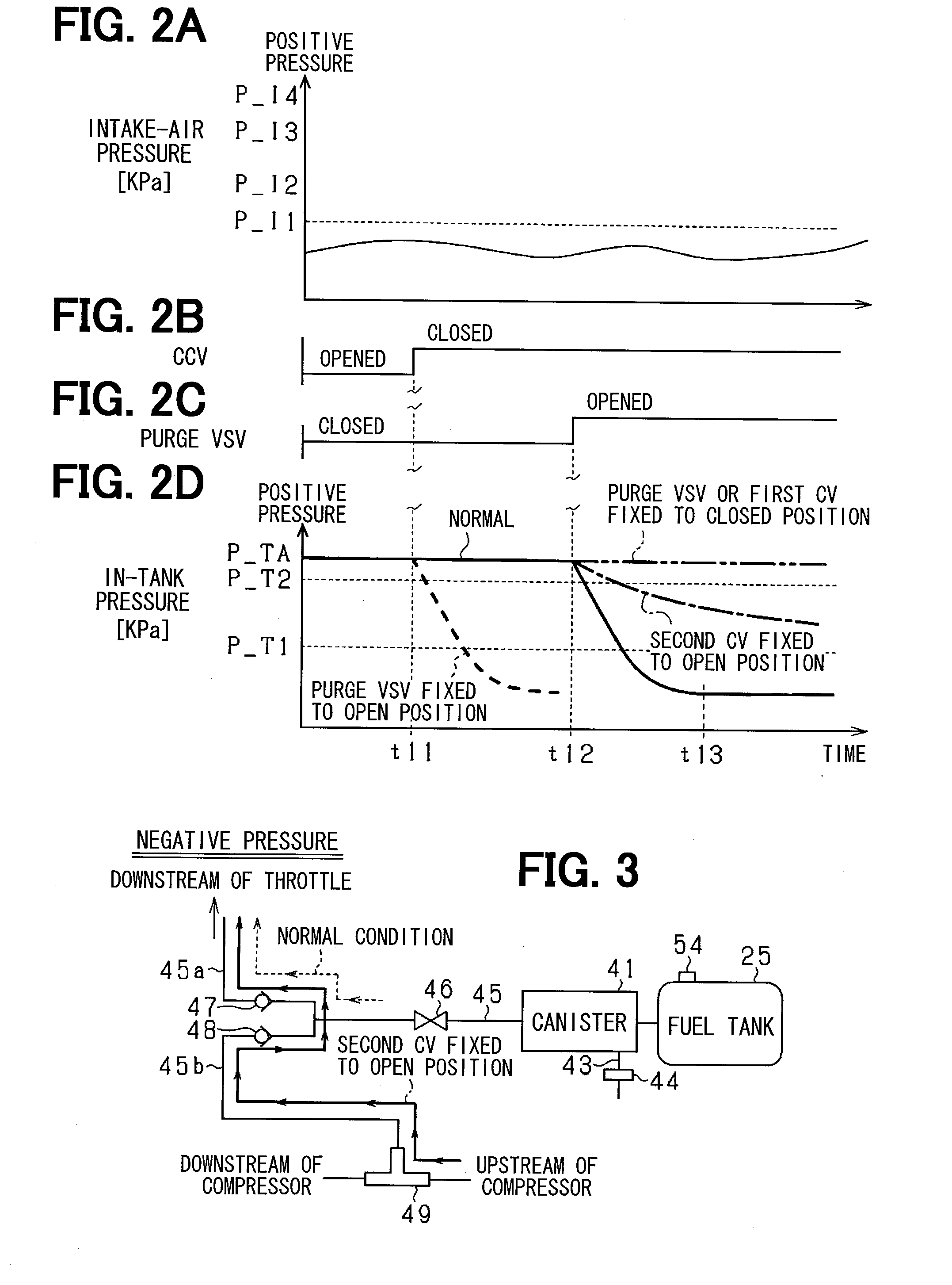

Vaporized-fuel processing system

ActiveUS20130199504A1Improve accuracyNon-fuel substance addition to fuelMachines/enginesFuel tankEngineering

A first purge passage is connected to an intake-air passage at a downstream side of a throttle valve. A second purge passage is connected to the intake-air passage at an upstream side of a supercharging device. A first and a second check valve are respectively provided in the first and second purge passages. A control unit determines to which operating condition (from a first to a third operating condition) engine operation corresponds, based on downstream-side and upstream-side pressure of the throttle valve. A change of in-tank pressure of a fuel tank is detected in a condition that an air-communication valve is closed but a purge control valve is opened. The control unit diagnoses which of the valves is not normally operated and whether such valve is fixed to a valve opened or a valve closed position, based on the change of in-tank pressure for each of engine operating conditions.

Owner:DENSO CORP

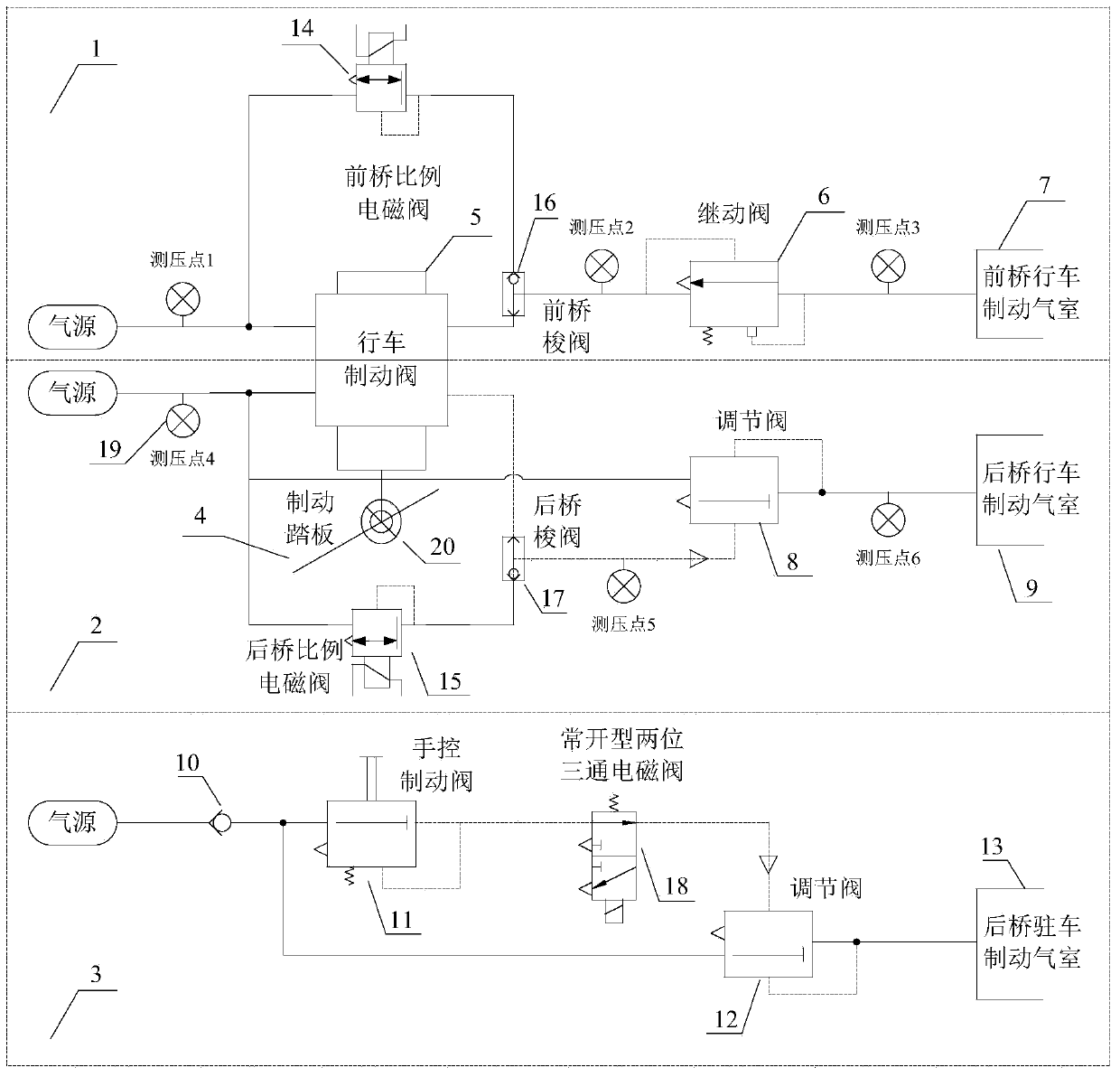

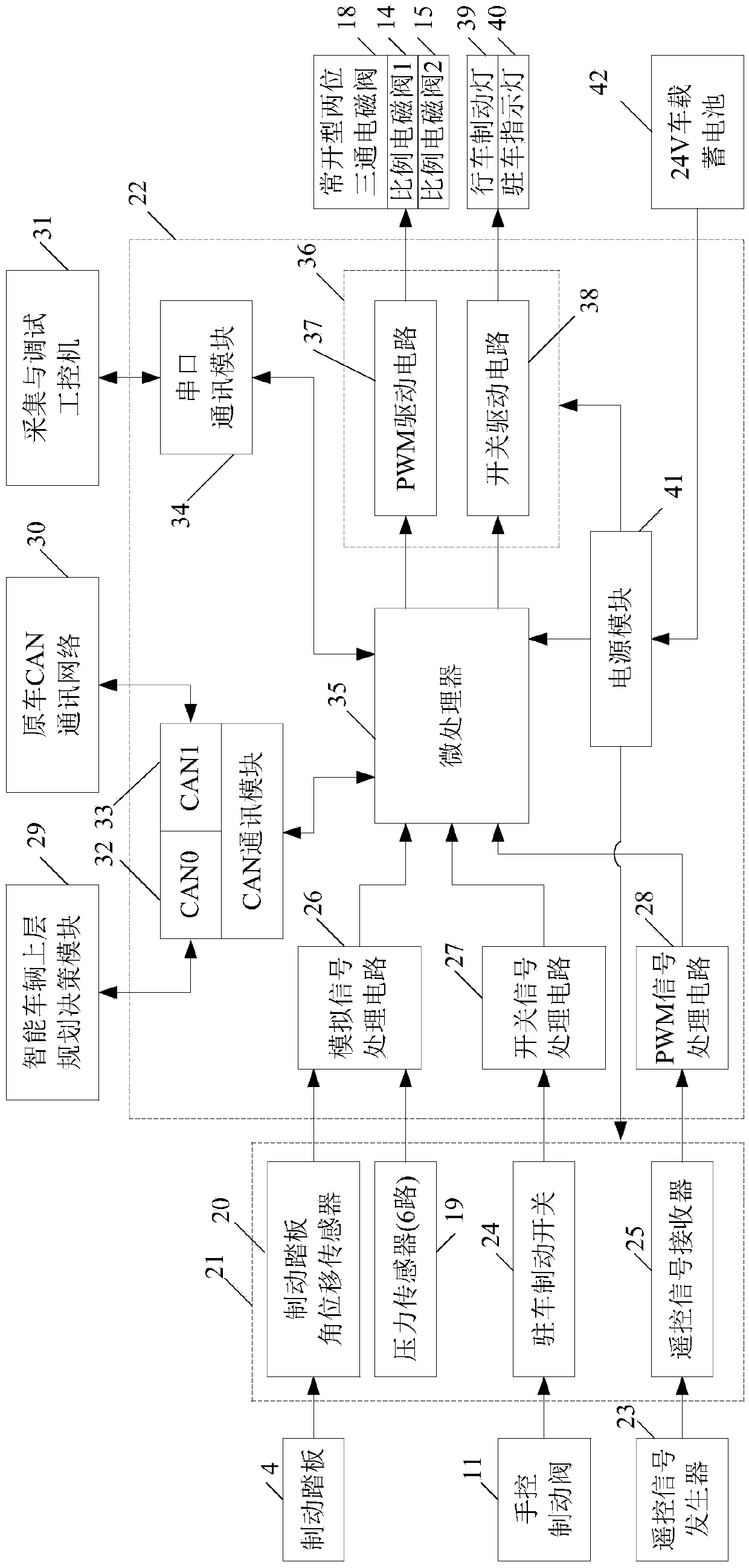

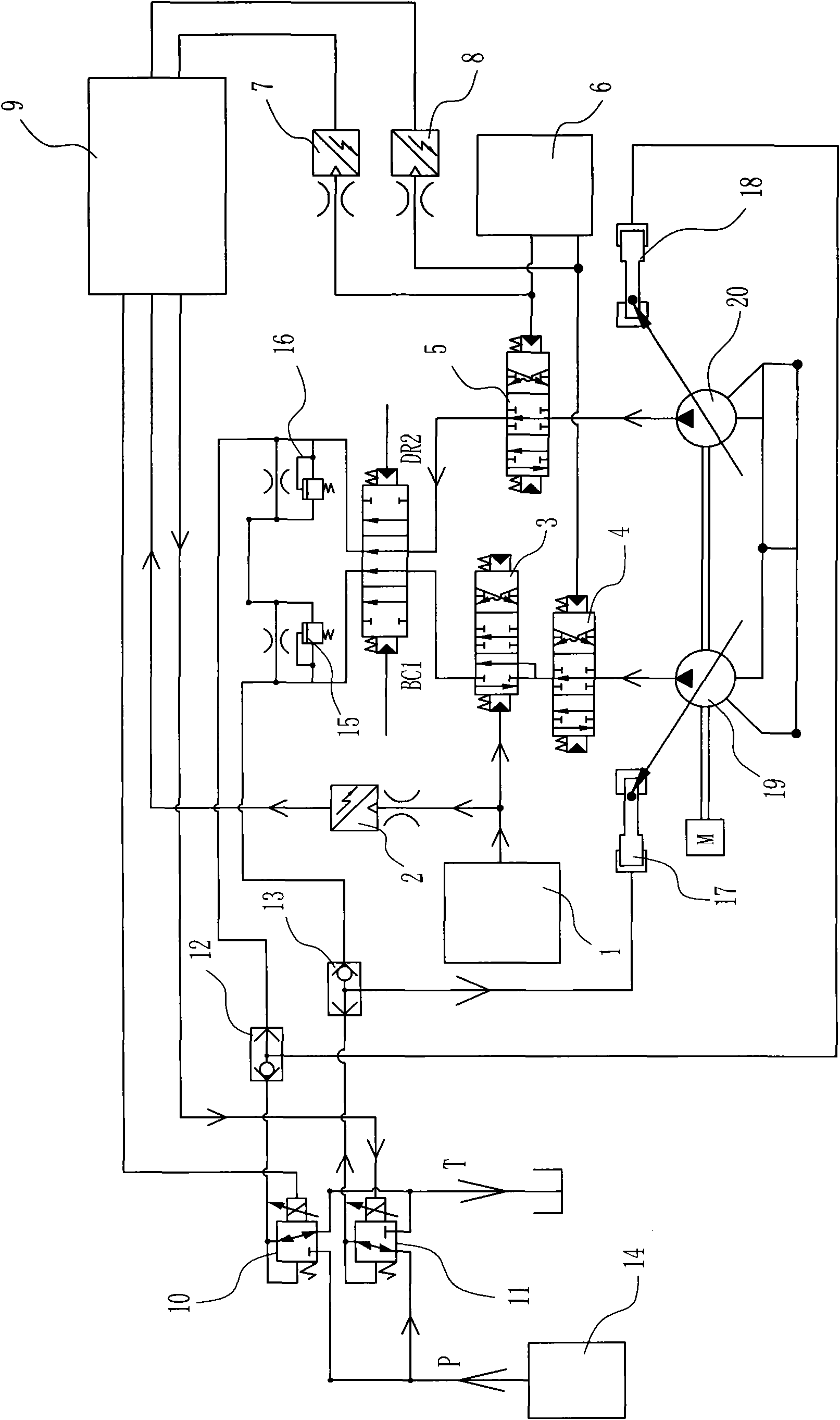

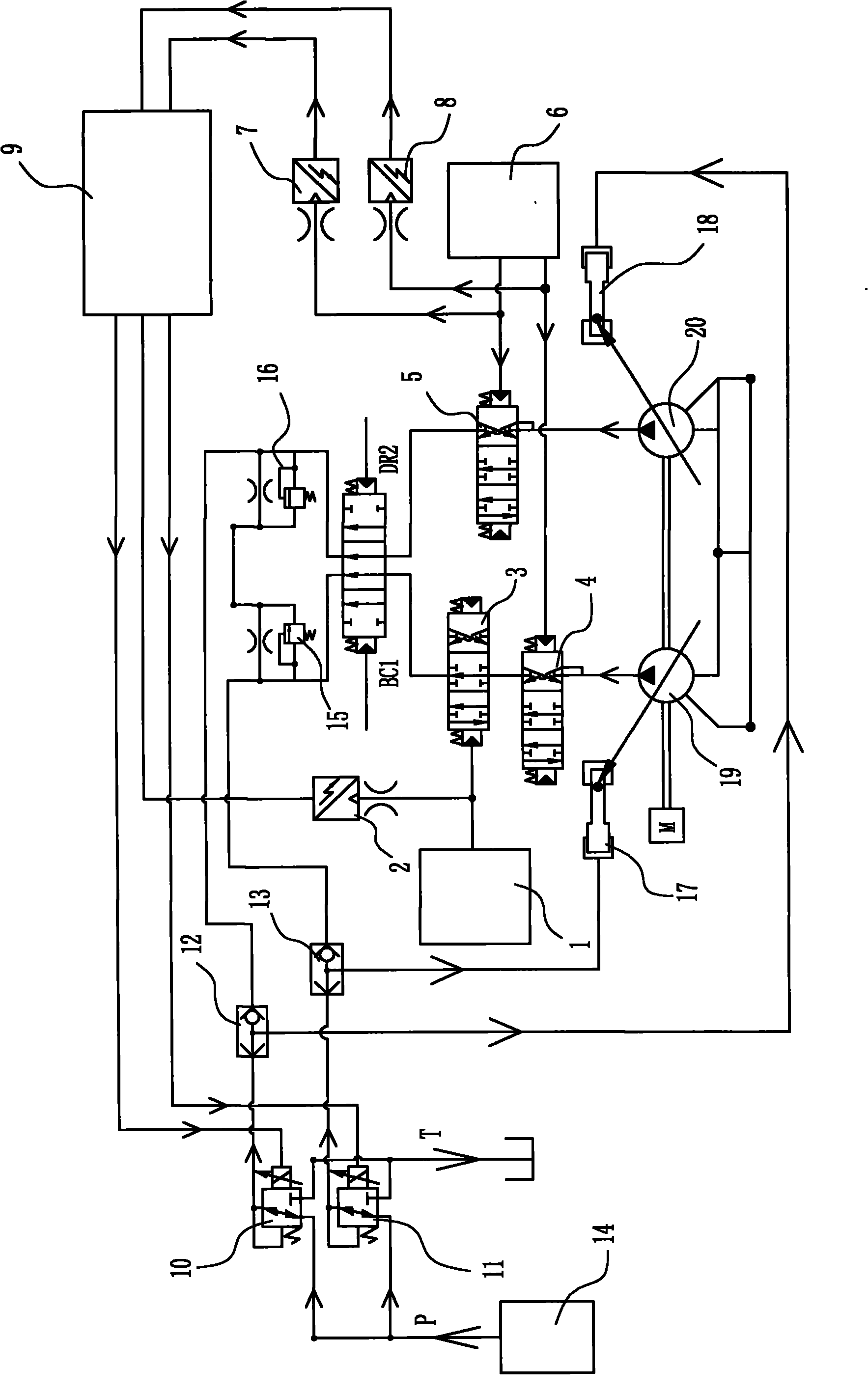

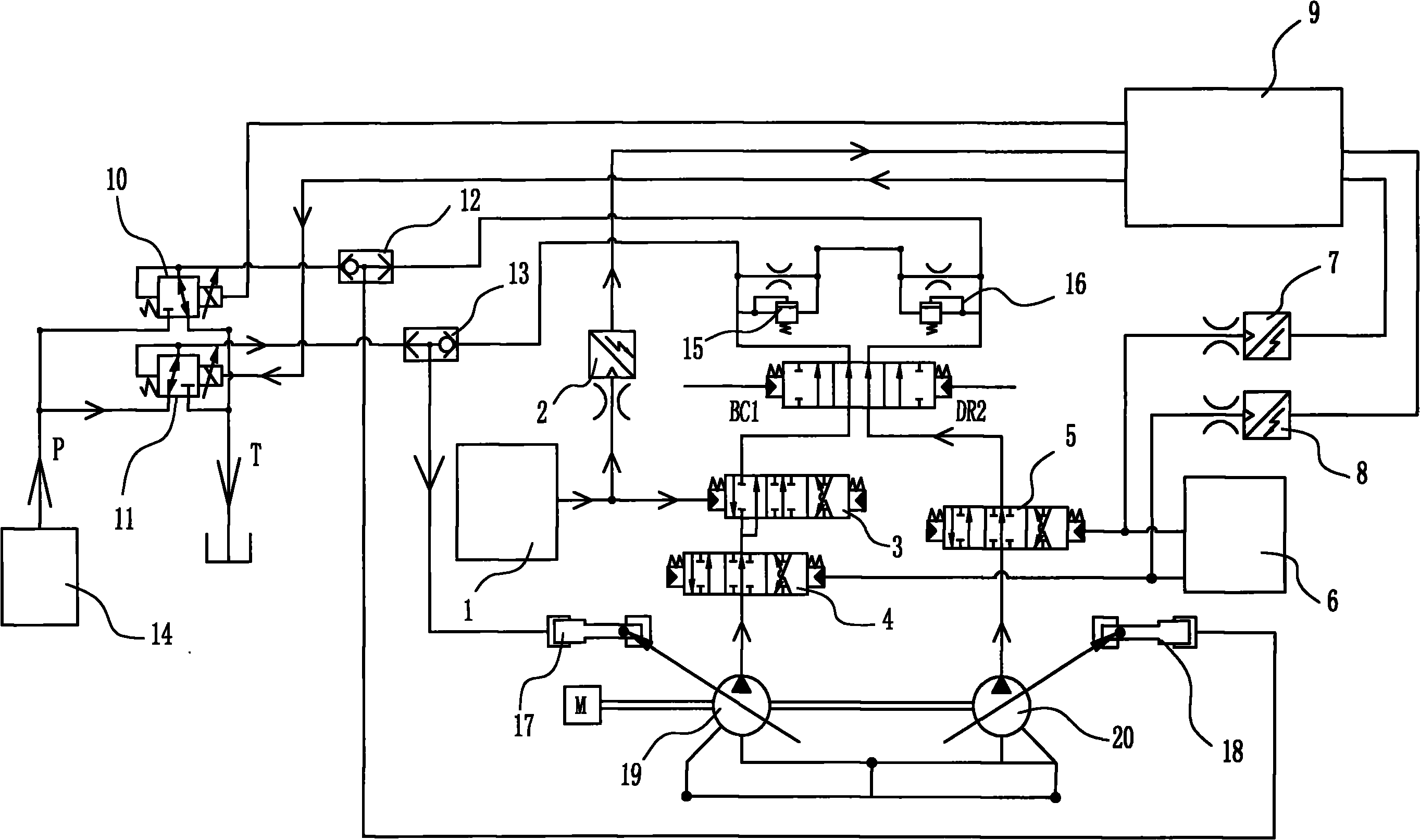

Electrically controlled pneumatic braking system of vehicle

ActiveCN104192114AFlexible switchingActive manual parking brakeBraking action transmissionRemote controlSolenoid valve

The invention provides an electrically controlled pneumatic braking system of a vehicle. The system retains a manual braking function of a manual driving mode while achieving an electrically controlled braking function of an unmanned driving mode of the intelligent vehicle, the manual driving mode and the unmanned driving mode can be switched flexibly, and a remote control braking function is achieved on emergency circumstances. The system comprises a braking controller, a front axle proportional solenoid valve, a front axle shuttle valve, a rear axle proportional solenoid valve, a rear axle shuttle valve and a normally open type two-position three-way solenoid valve. The braking controller is used for receiving upper planning decision commands of the intelligent vehicle; when electrically controlled driving braking needs to be conducted, the braking controller controls the front axle proportional solenoid valve and the rear axle proportional solenoid valve to act, the air pressure output by the front axle shuttle valve is made to be the air pressure of an output port of the front axle proportional solenoid valve, and the air pressure output by the rear axle shuttle valve is made to be the air pressure of an output port of the rear axle proportional solenoid valve; when manual driving braking needs to be conducted, the braking controller enables the front axle proportional solenoid valve and the rear axle proportional solenoid valve to be powered off.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

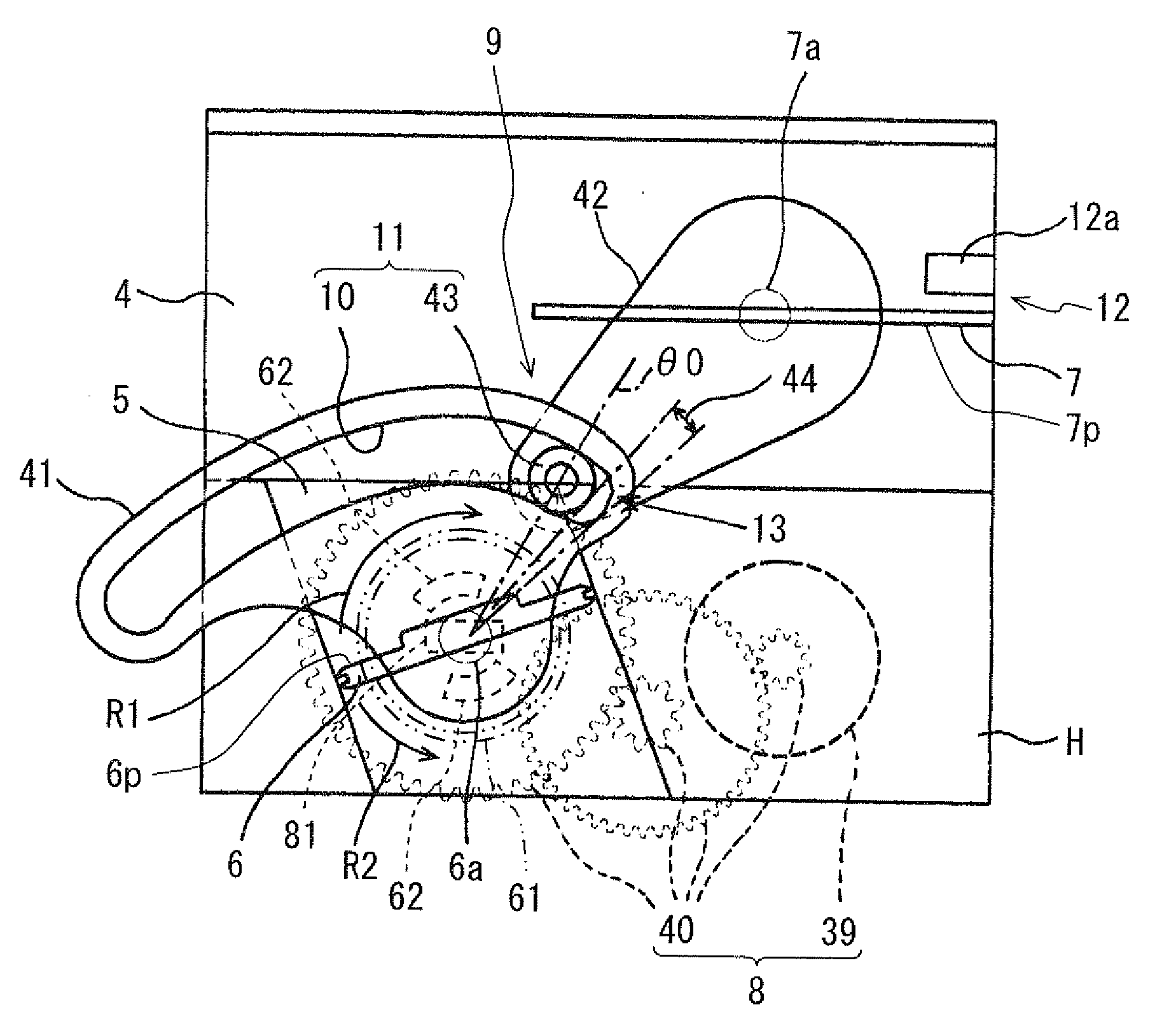

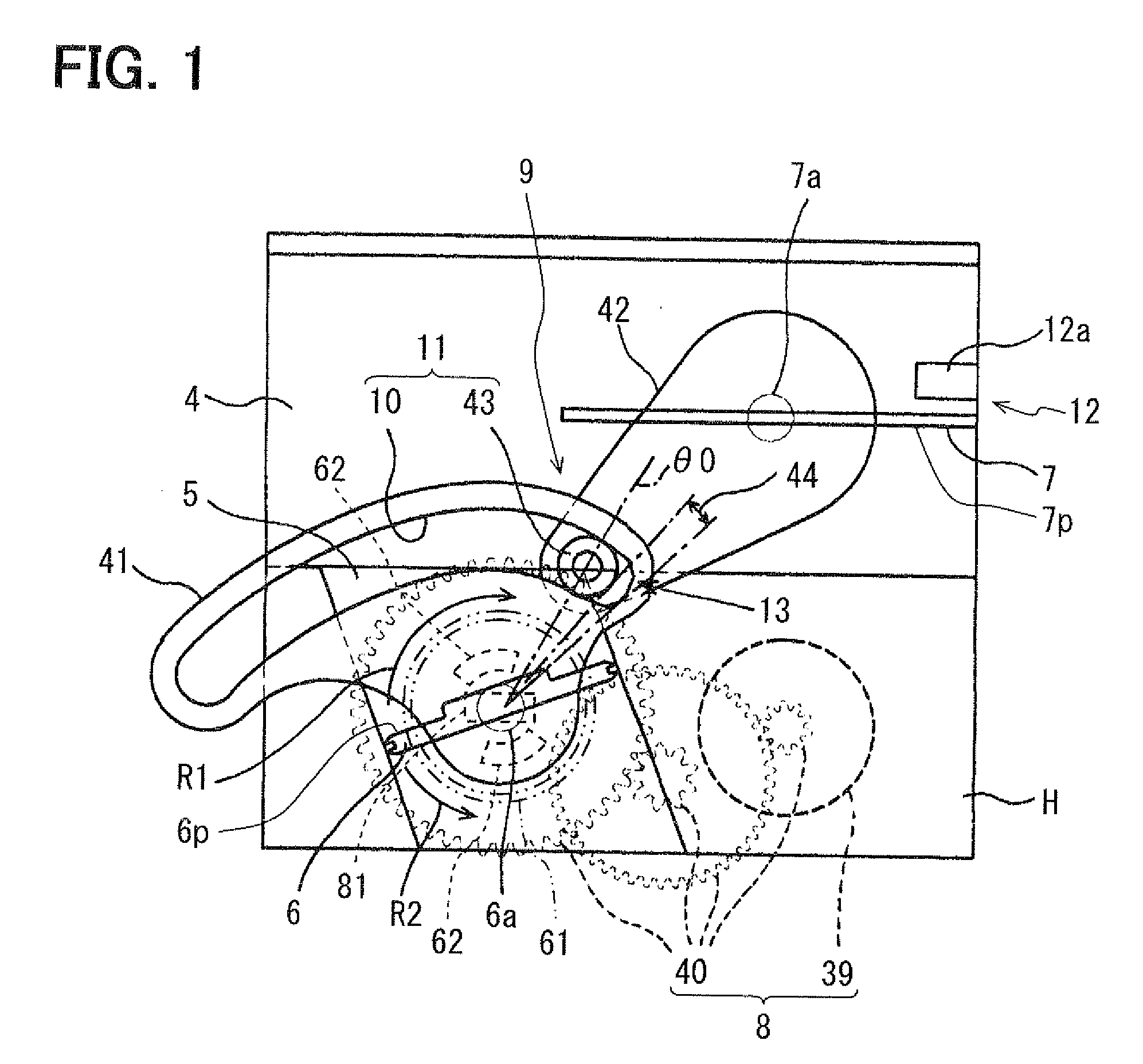

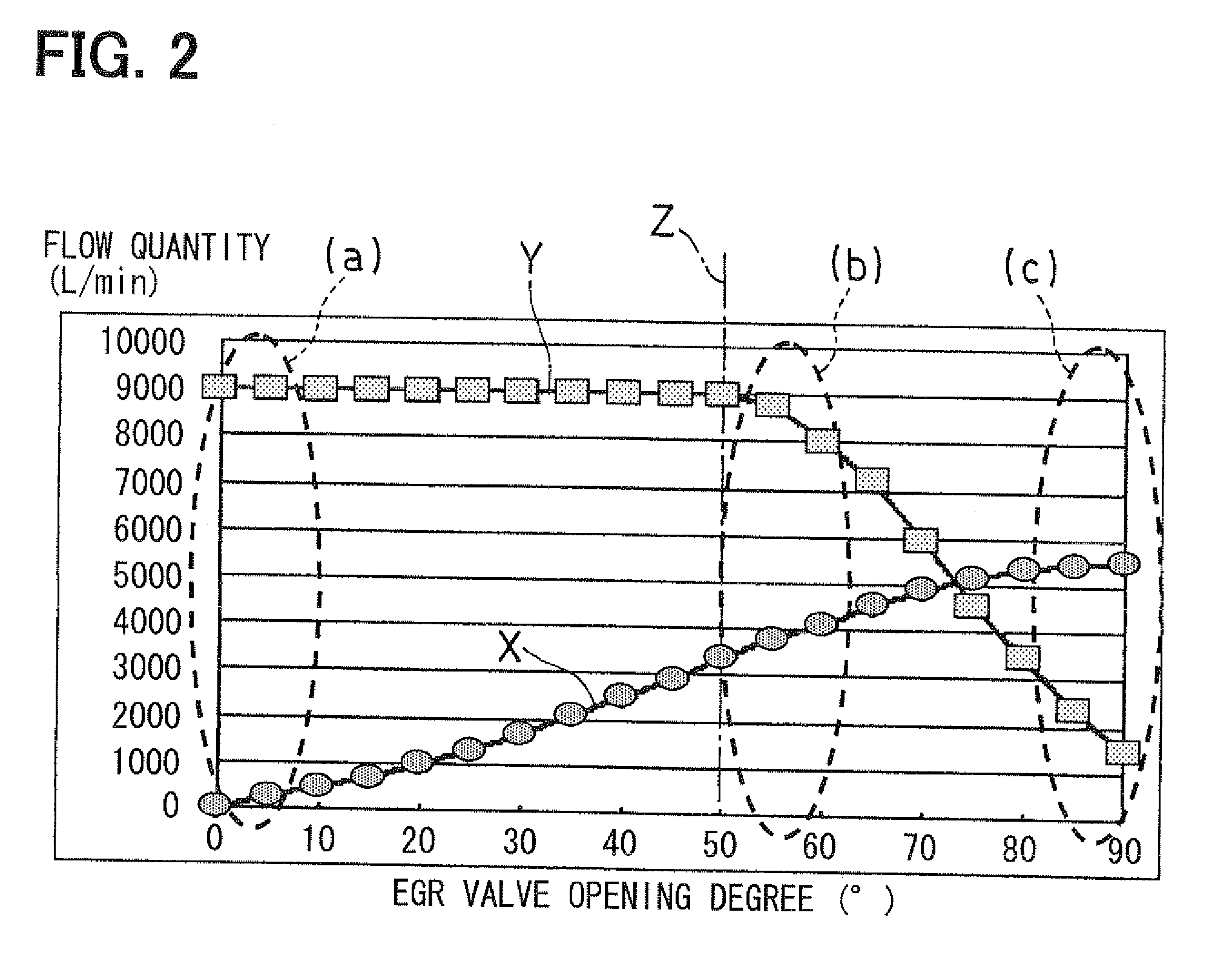

Low pressure exhaust gas recirculation apparatus

ActiveUS20110023846A1Reduce the degree of openingHigh trafficNon-fuel substance addition to fuelInternal combustion piston enginesExhaust gas recirculationActuator

A low pressure EGR regulating valve is driven by an electric actuator, and an output of the electric actuator is transmitted to an intake air throttle valve through a link device. An ECU executes a failure determination to determine presence of a failure in a case where a sensed opening degree, which is sensed with a low pressure EGR opening degree sensor, is other than an opening degree that corresponds to a maximum opening degree of the throttle valve limited by a mechanical stopper. The ECU executes the failure determination after the energization of the electric actuator is stopped in response to stopping of the engine.

Owner:DENSO CORP

Chatter resistant shuttle valve

InactiveUS20050028864A1Extended opening timePrevent openingMultiple way valvesSlide valveMarine engineeringStructural engineering

A chatter resistant shuttle valve is provided to direct fluid flow from at least two sources of pressurized fluid to a downstream apparatus. The shuttle valve includes a valve body with a shuttle valve member movably mounted inside. A dampening chamber is provided which dampen opening movement of the shuttle as it moved from a closed position on one side of the shuttle toward a closed position on the other end of the shuttle. One or more dampening chambers may be provided.

Owner:PROSERV OFFSHORE INC +1

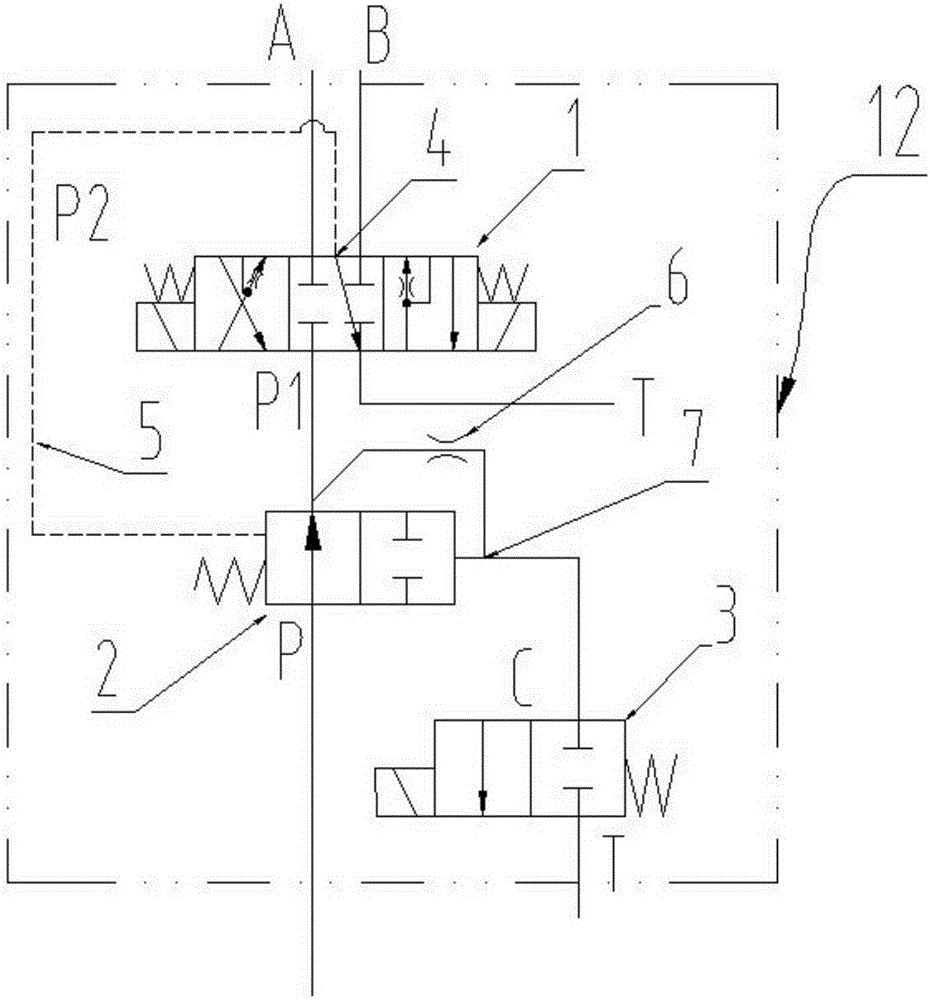

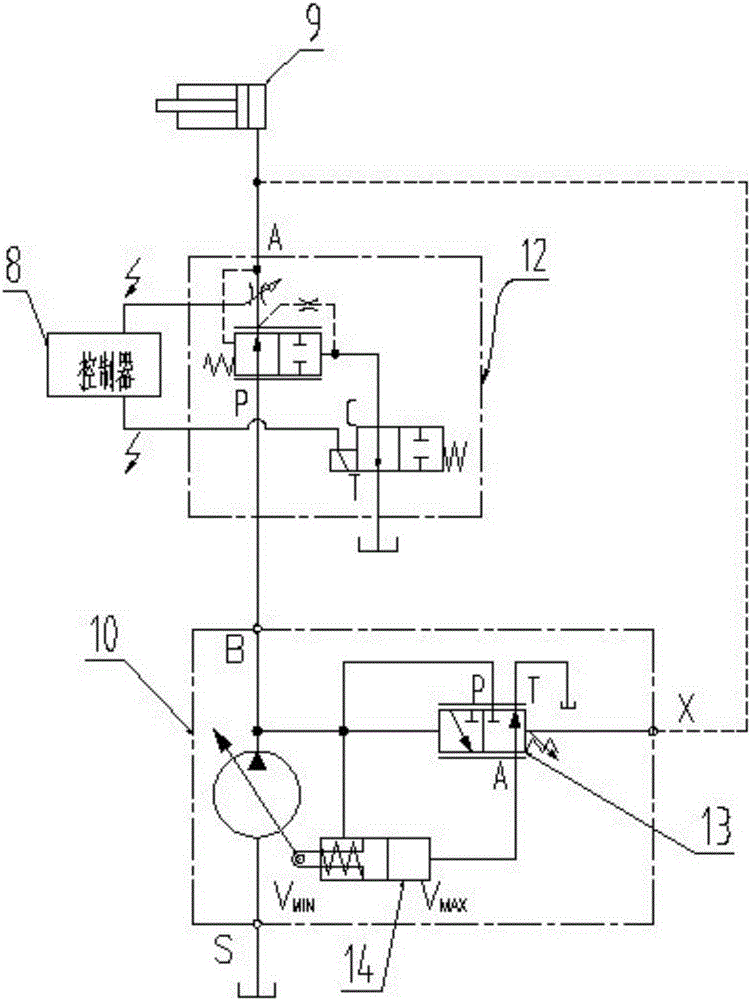

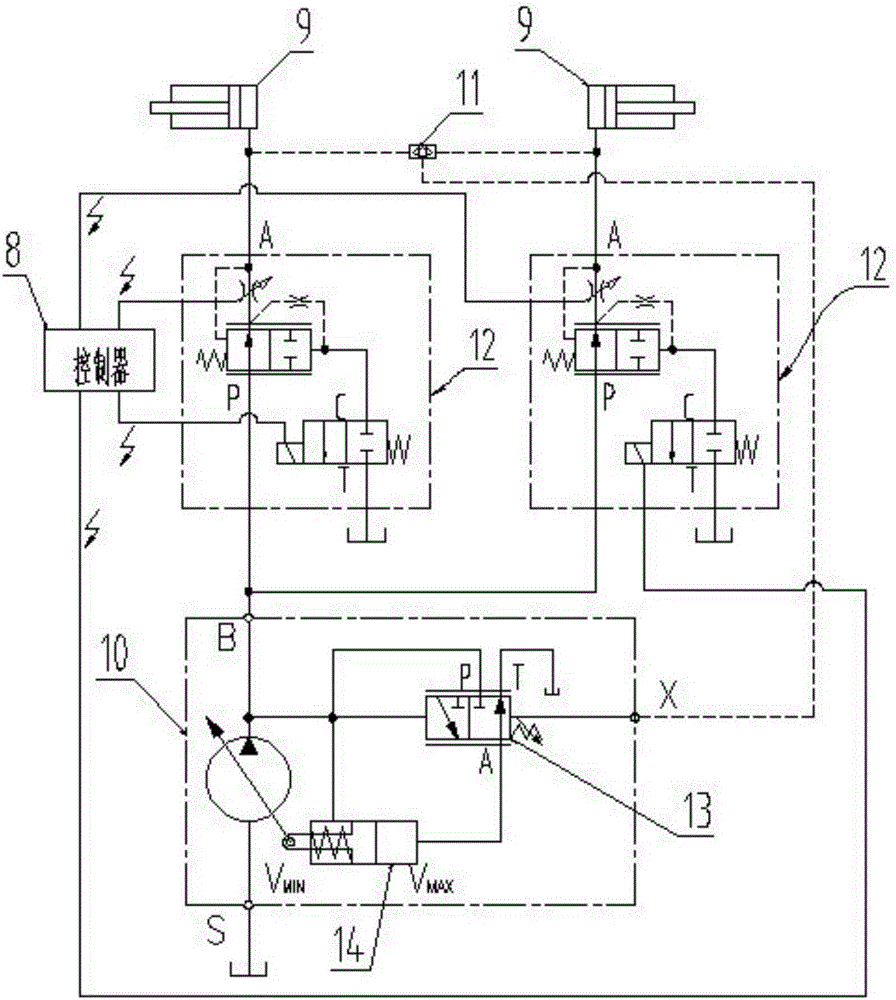

Hydraulic excavator flow rate control method and control loop

InactiveCN102011416AAvoid damageImprove work efficiencyServomotorsSoil-shifting machines/dredgersNegative feedbackElectric control

The invention discloses a hydraulic excavator flow rate control loop which comprises a hydraulic and electric control loop. The hydraulic excavator flow rate control loop is characterized by comprising two electromagnetic proportional valves and two or-gate type three-way shuttle valve, wherein the electric control ends of the proportional valves are respectively connected with the controller, the input end is connected with a pilot pressure pump of an excavator, the output end is connected with a input opening P1of one three-way shuttle valve, input openings P2 of the two three-way shuttle valves are respectively connected with a front negative feedback valve core and a back negative feedback valve of the excavator, and output openings A of the three-way shuttle valves are respectively connected with a front negative feedback regulator and a back negative feedback regulator. A method comprises the following steps of: receiving sensor signals by a controller; sending electromagnetic proportional valve electric control signals; opening proportional valve and shuttle valve paths; controlling the corresponding negative feedback regulators through the pressure of the proportional valves; and finally controlling the delivery capacity of the pump. The method realizes the limitation on the system delivery capacity through controlling the delivery capacity of the pump by using the electromagnetic proportional valves, so the flow rate maintains the normal state when a rotating or walking device works singly, and the damage to a motor caused by high flow rate is avoided.

Owner:SANY HEAVY MACHINERY

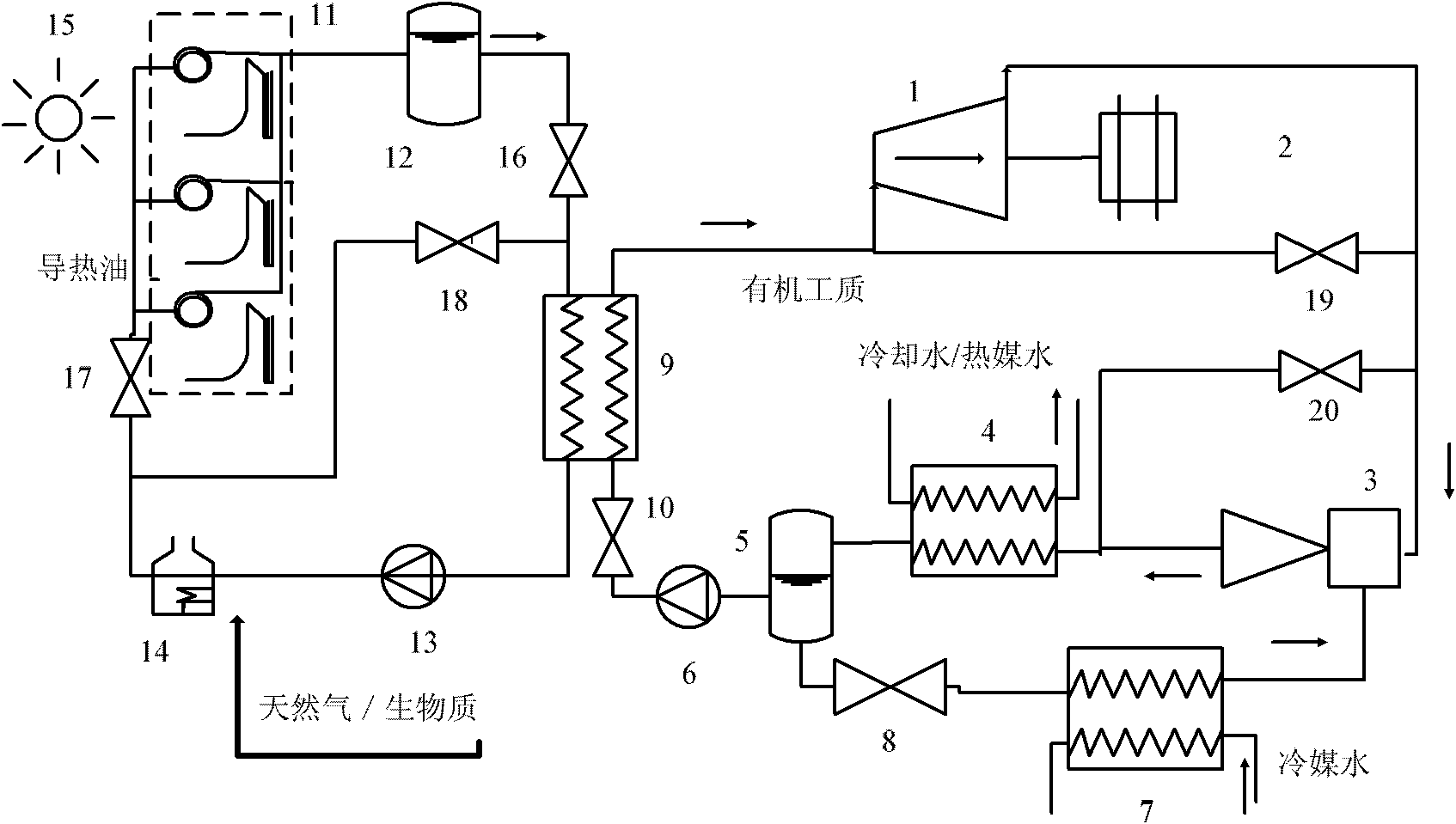

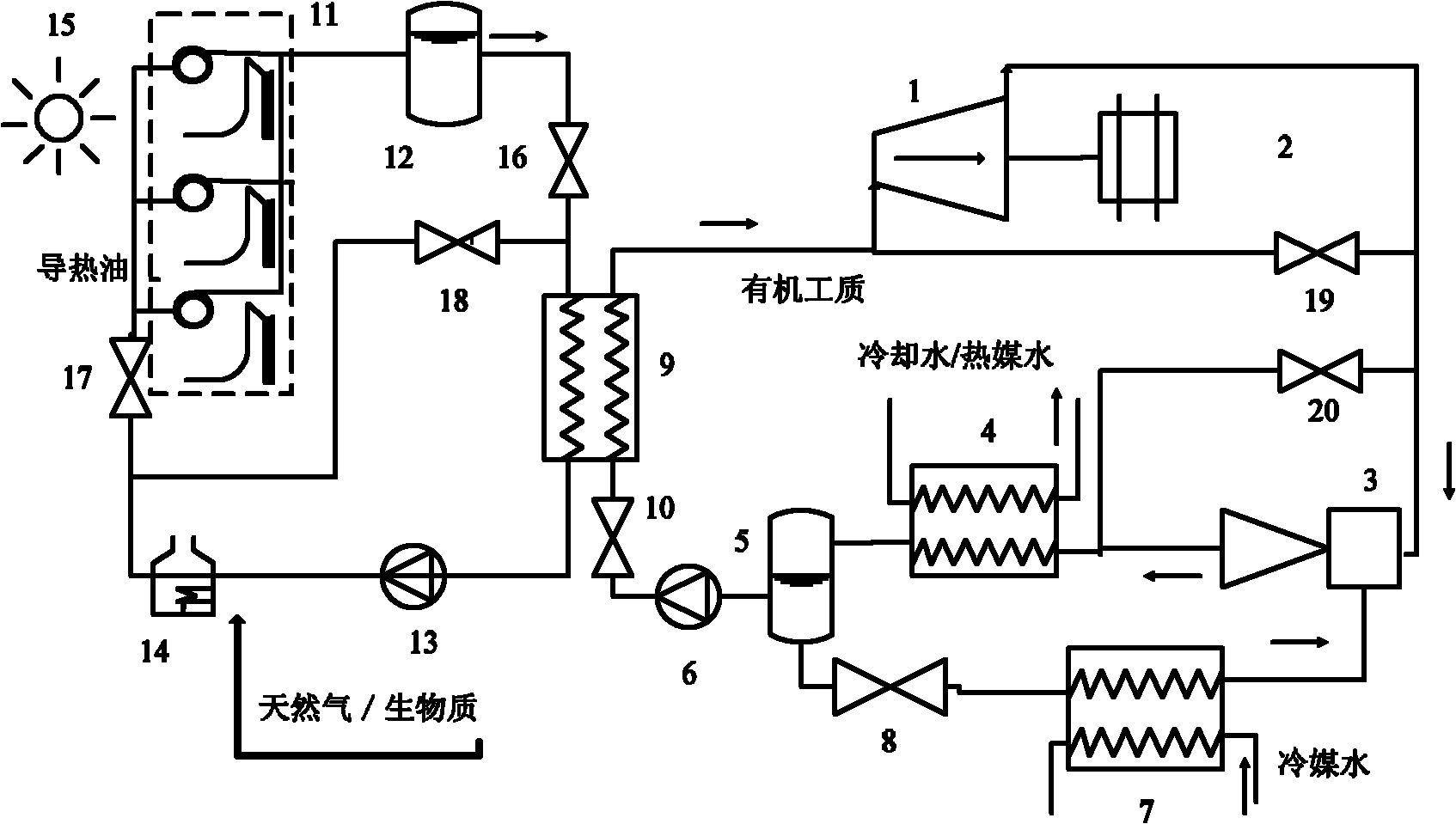

Solar energy-natural gas complementary injection type distributed combined cold heat and power supply device

InactiveCN101871440AImprove cooling effectSimple structureFrom solar energySolar heat devicesCyclic processShuttle valve

The invention provides a solar energy-natural gas complementary injection type distributed combined cold heat and power supply device, comprising a turbine expansion engine, a generator, an ejector, a condenser, a working medium storage tank, a working medium pump, a refrigerating evaporator, a throttle valve, a heat source exchanger, a first valve, a solar thermal collector, a conduction oil storage tank, an oil pump, an afterburner, a second valve, a third valve, a fourth valve, a first bypass valve and a second bypass valve. Electric powder required by the whole circulating process can be supplied by the system self, and extra electric energy and cold can be outputted to meet the load requirement of a user of a cold and power supply distributed energy supply system.

Owner:SHANGHAI JIAO TONG UNIV

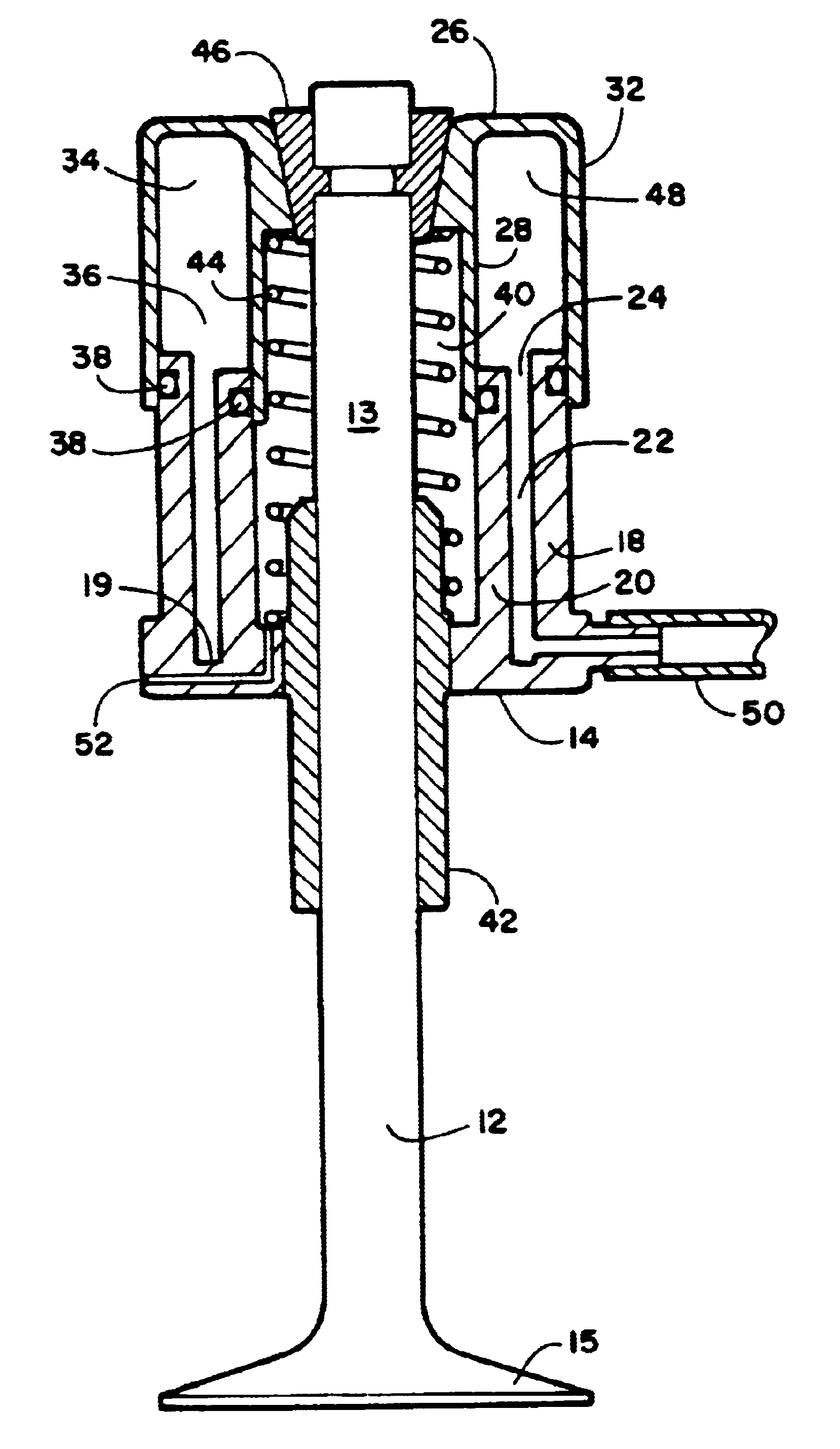

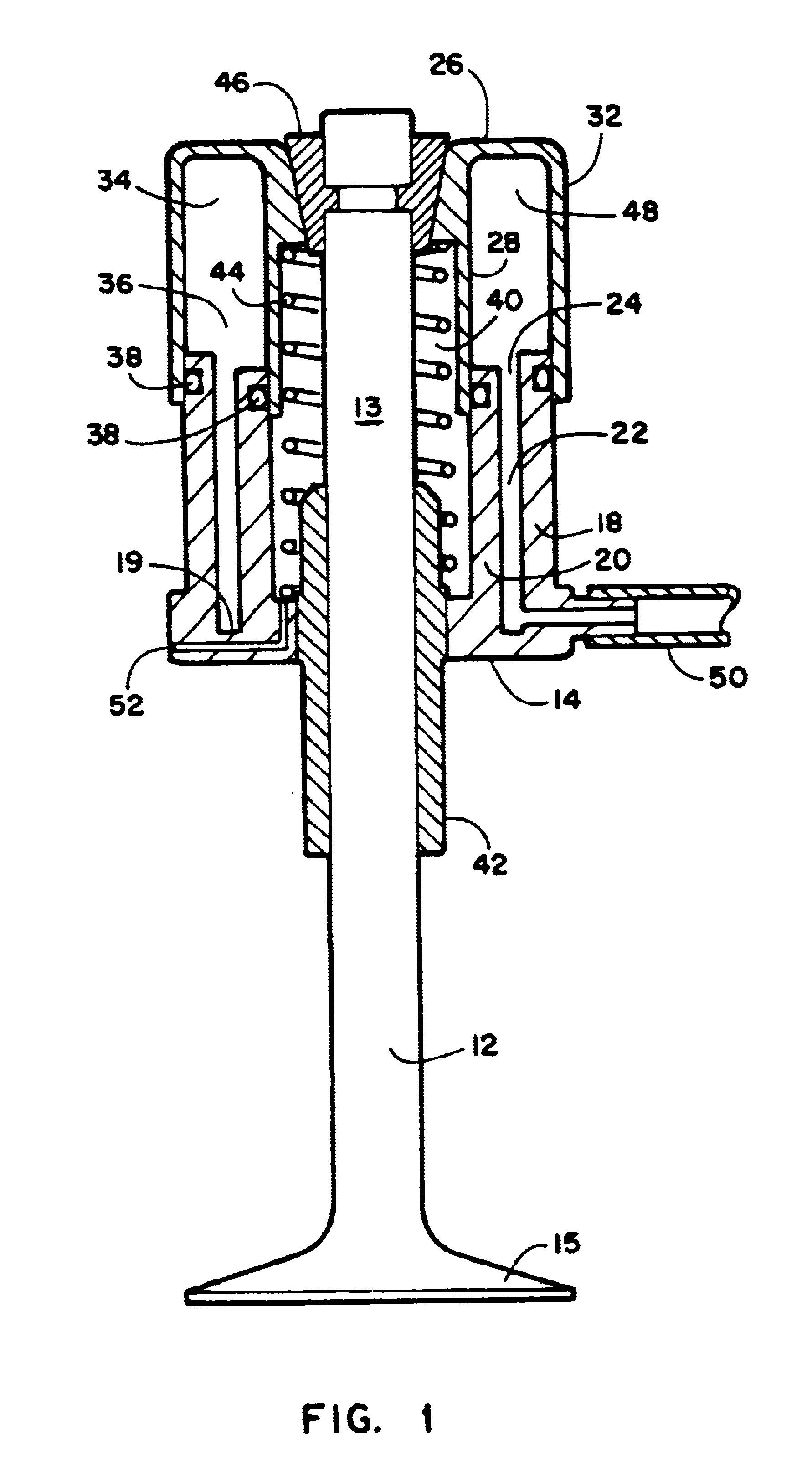

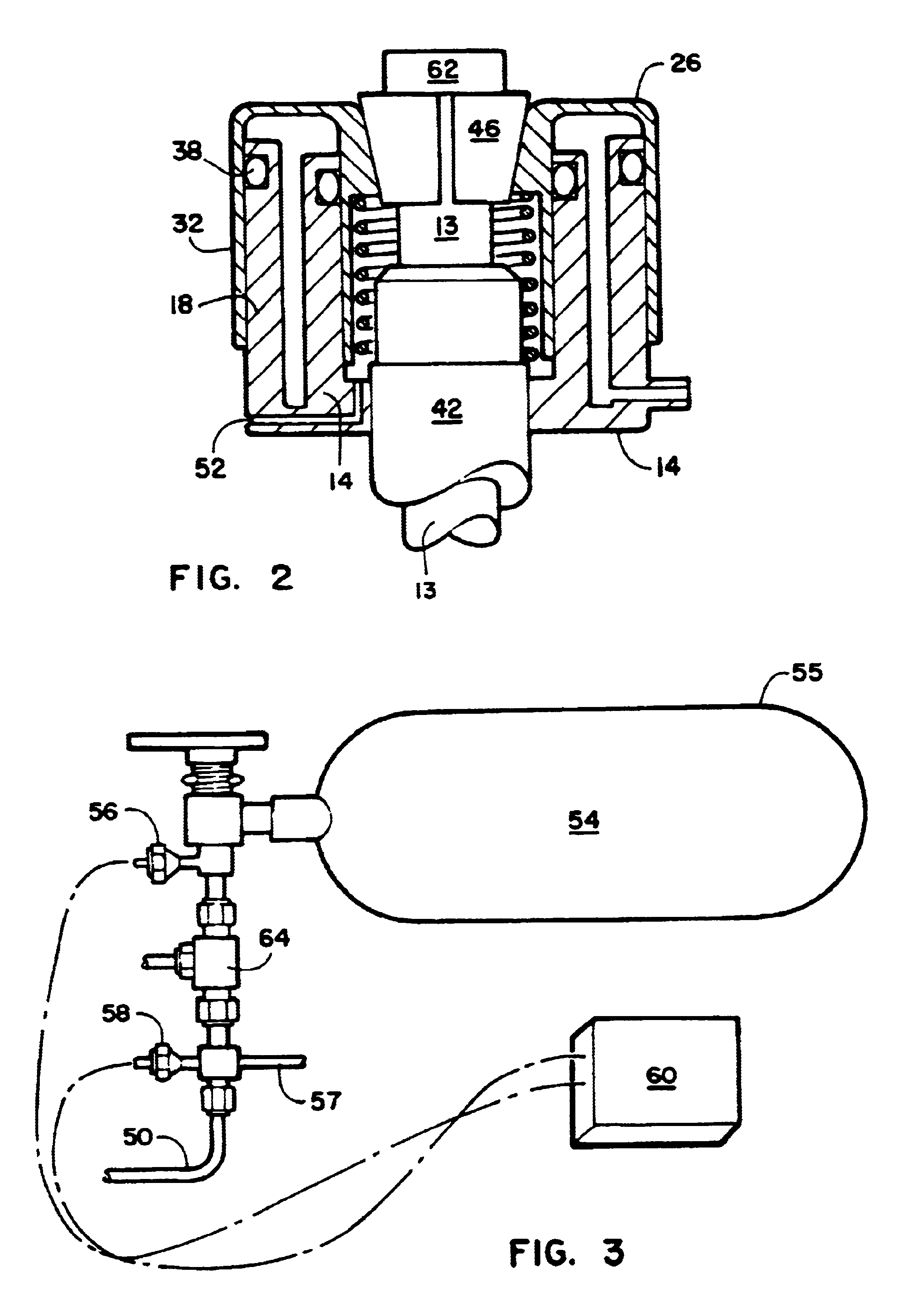

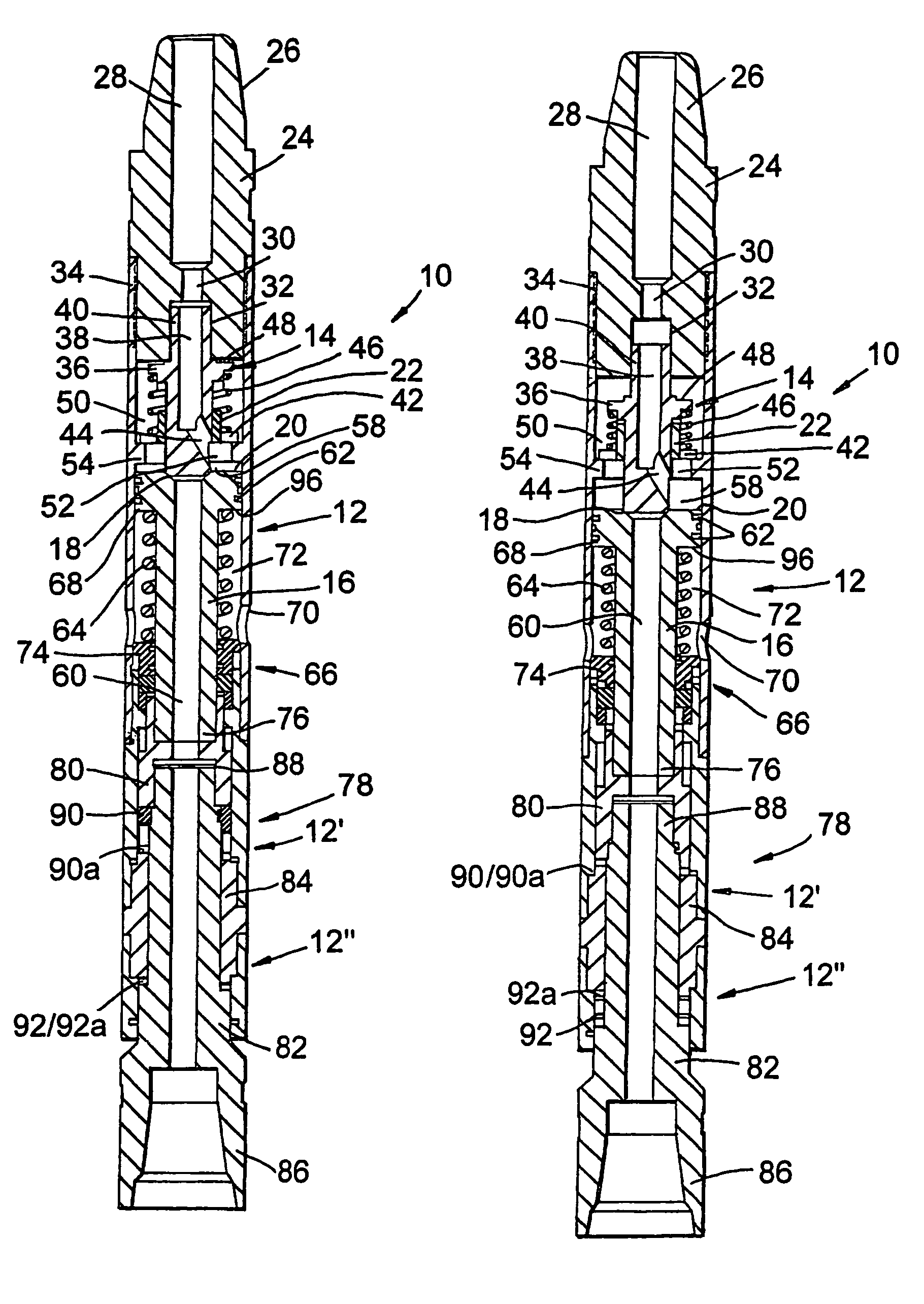

Pneumatic valve return spring

InactiveUS6745738B1Simple installation and constructionImprove economyMachines/enginesLift valveEngineeringPneumatic valve

A valve spring device using pressurized gas for use in biasing a reciprocating valve which moves between a seated position and open position. The device features a static housing having a static chamber what is translateably engaged with dynamic housing. Chambers inside both housings are sealably engaged such that the dynamic housing translates away from the static housing when pressurized gas is communicated to the engaged sealed chambers thereby biasing the dynamic housing away from the static housing and moving the attached valve. Timing of oscillation of the translation and resulting valve timing is controlled by a controller activating a control valve between a pressurizing state and a venting state. The timing may be adjusted to accommodate the engine timing through varying the controller's activation of the control valve and optionally varying the pressure of the gas using a regulator.

Owner:BOSSCHER RICHARD J

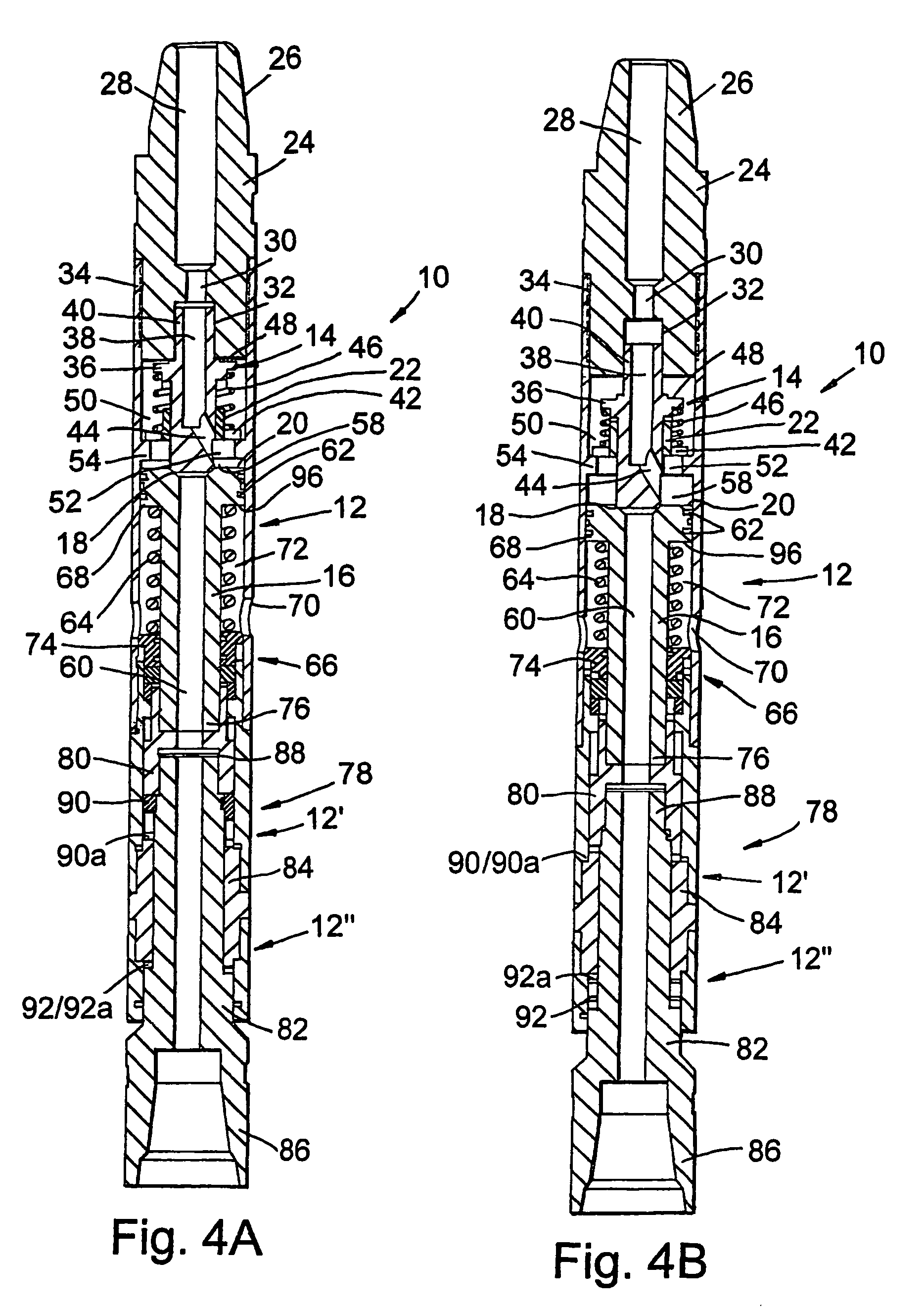

Downhole tool

InactiveUS7073610B2Improve efficiencyIncrease ratingsDrill bitsReciprocating drilling machinesShuttle valveMechanical engineering

A downhole tool for generating a longitudinal mechanical load. In one embodiment, a downhole hammer is disclosed which is activated by applying a load on the hammer and supplying pressurizing fluid to the hammer. The hammer includes a shuttle valve and piston that are moveable between first and further position, seal faces of the shuttle valve and piston being released when the valve and the piston are in their respective further positions, to allow fluid flow through the tool. When the seal is releasing, the piston impacts a remainder of the tool to generate mechanical load. The mechanical load is cyclical by repeated movements of the shuttle valve and piston.

Owner:ROTECH GROUP

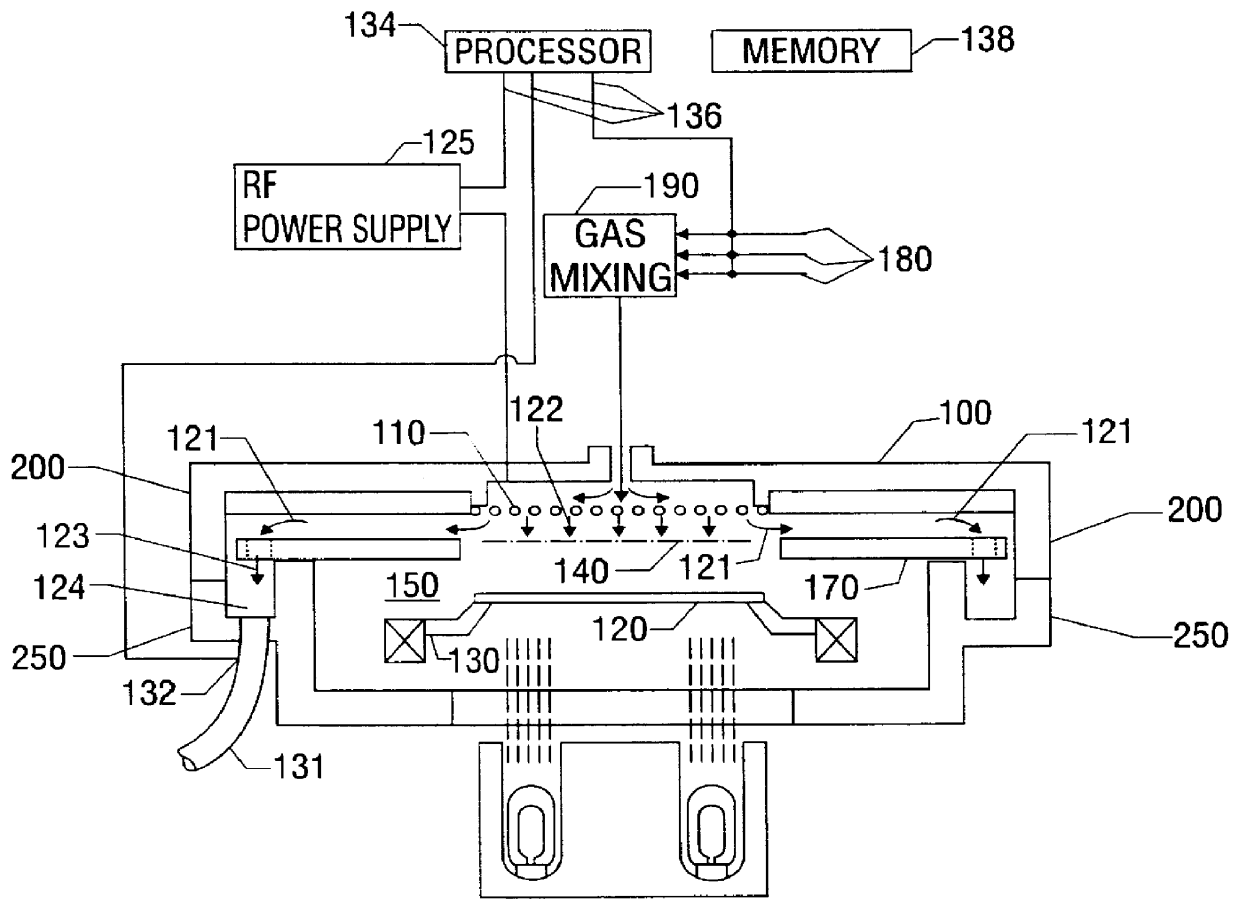

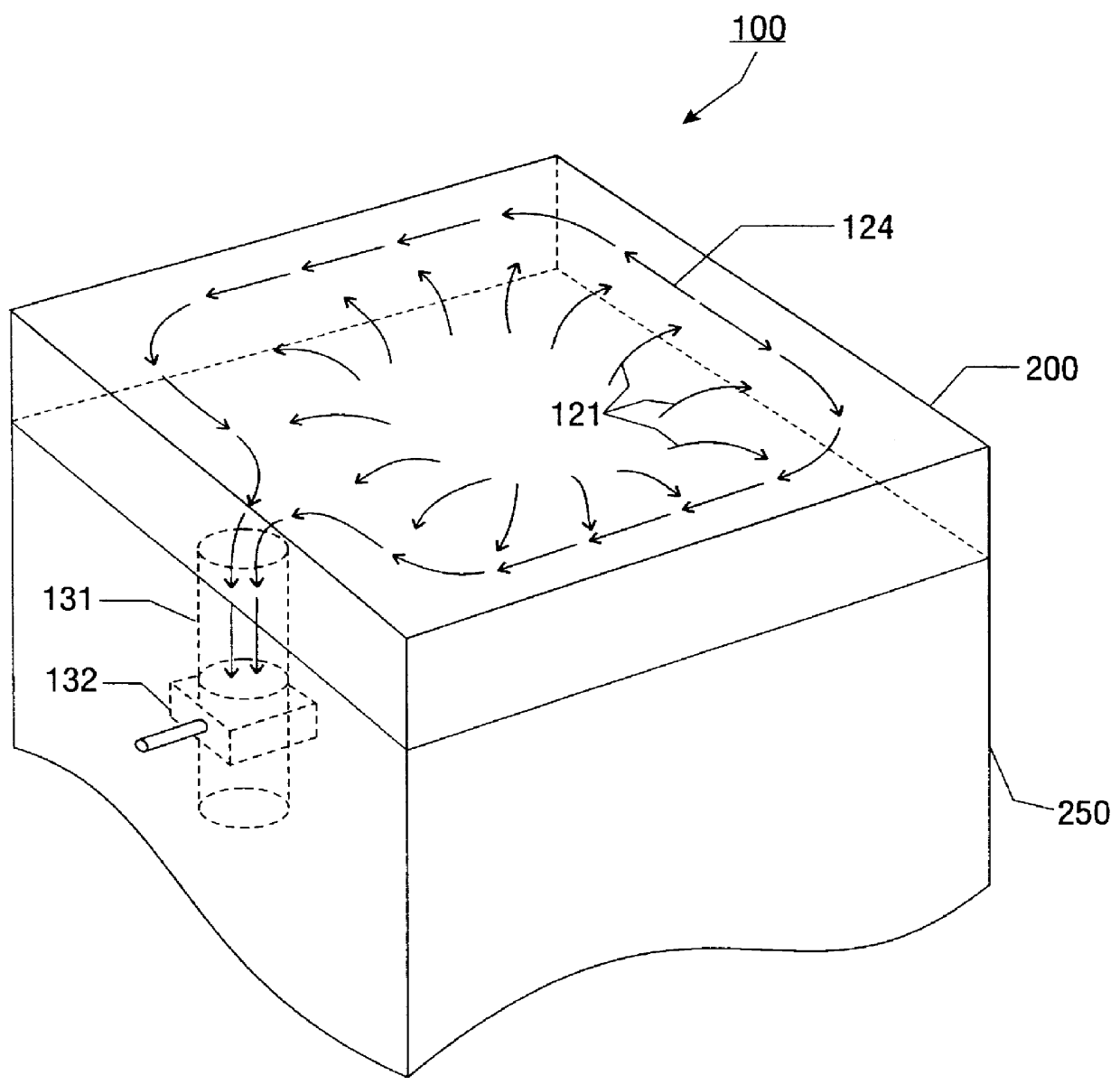

Throttle valve providing enhanced cleaning

InactiveUS6090206APlug valvesSemiconductor/solid-state device manufacturingControl theoryShuttle valve

A throttle valve assembly is provided, including a throttle valve housing having a bore therethrough and a throttle valve plug assembly. The throttle valve plug assembly includes a shaft rotatably mounted on the throttle valve housing and a throttle valve plug having a concave cut-out portion. The throttle valve plug is mounted on the shaft within the throttle valve housing and substantially perpendicular to the bore. The throttle valve plug has at least two fully open positions and a closed position.

Owner:APPLIED MATERIALS INC

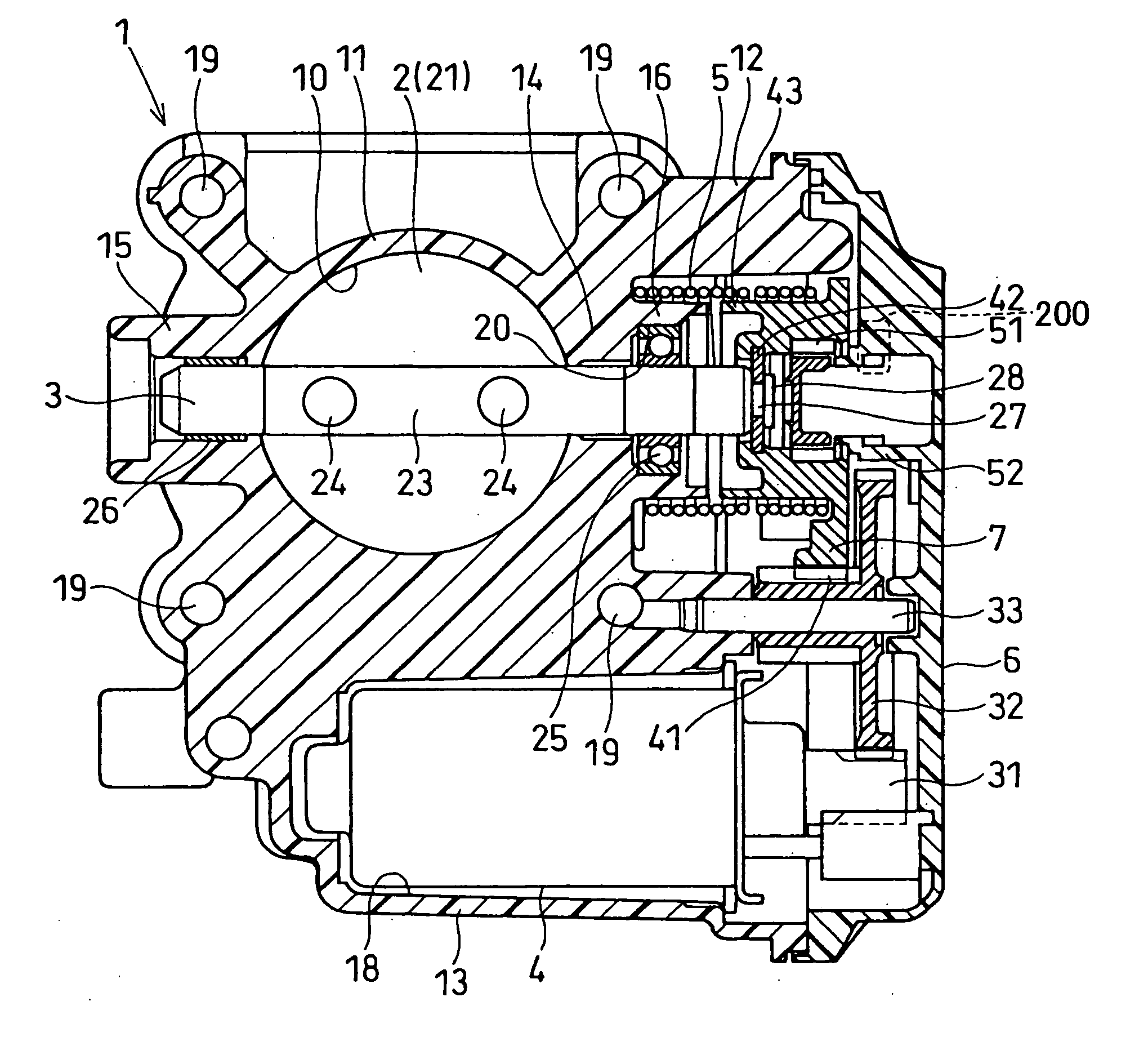

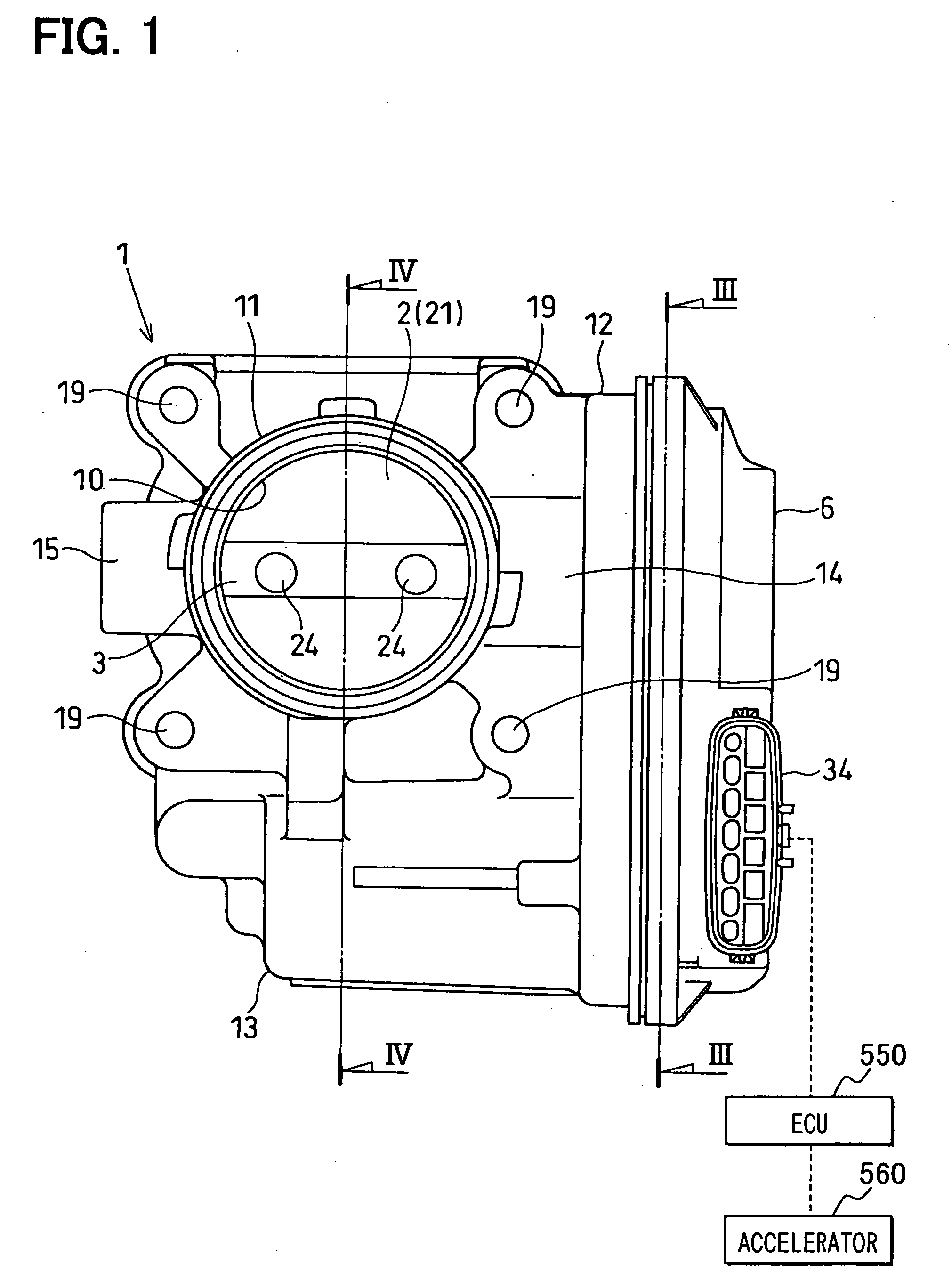

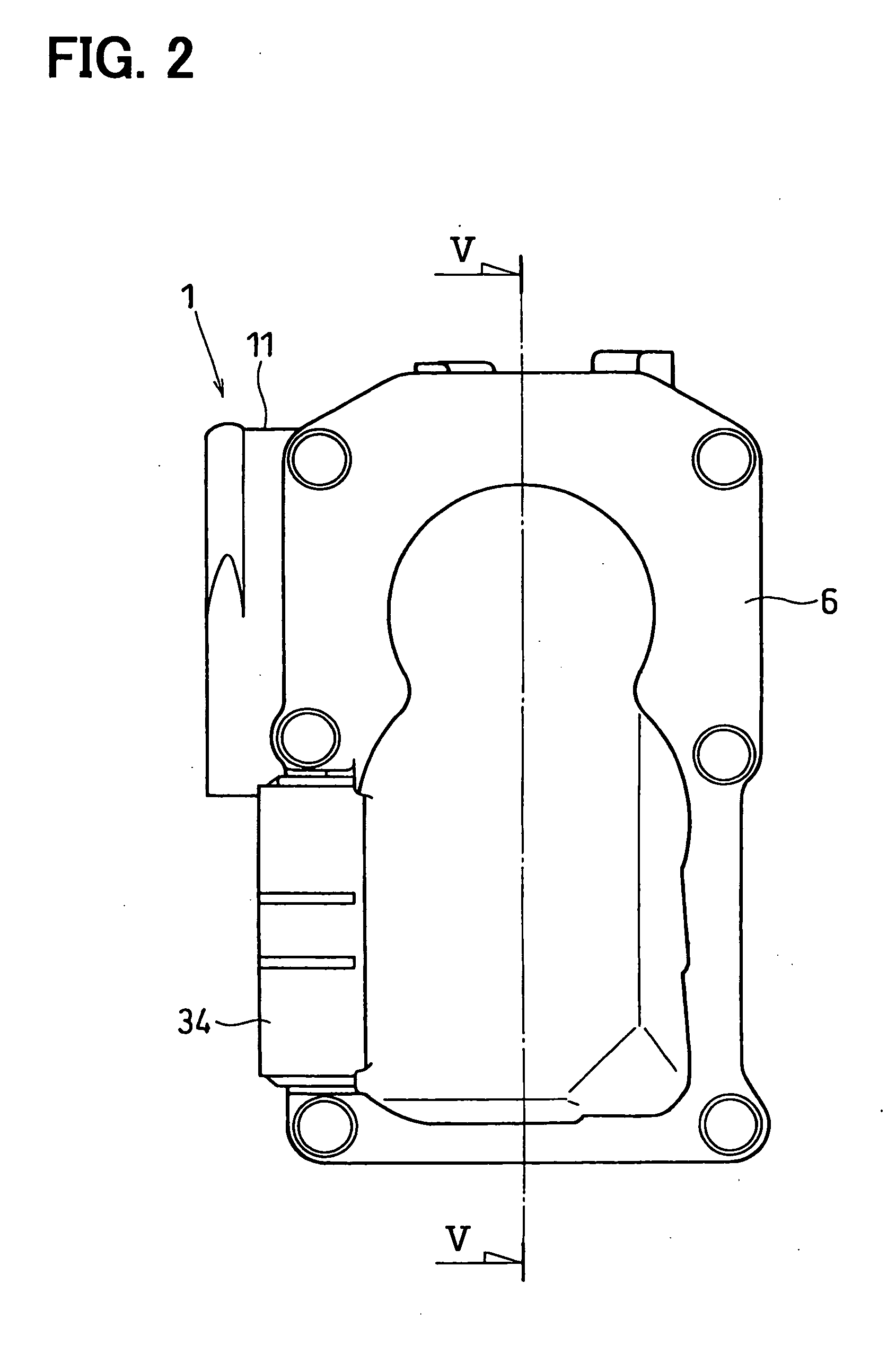

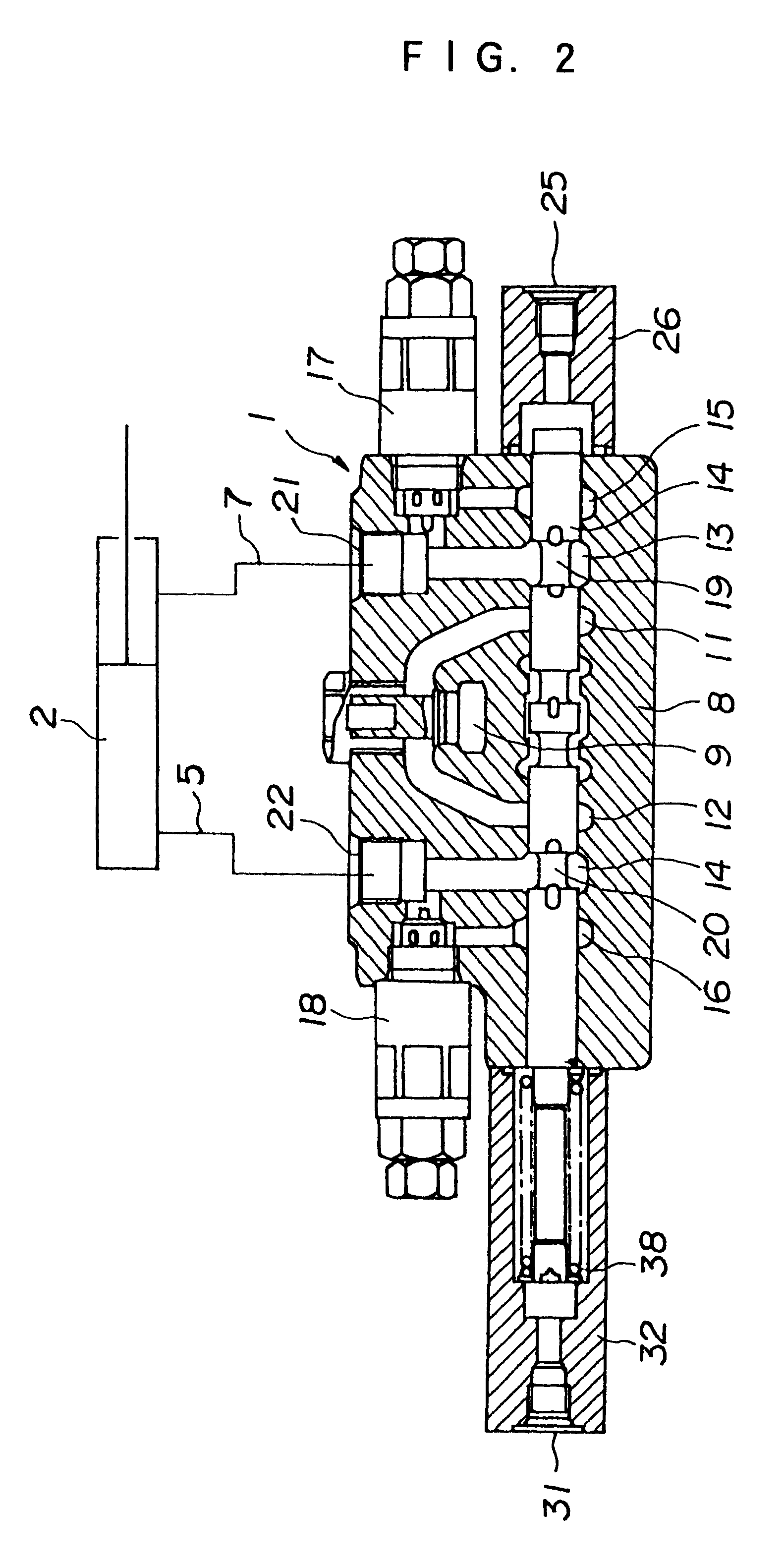

Intake control device for internal combustion engine

ActiveUS20060000443A1Clearance adjustableShort working hoursEngine controllersMachines/enginesExternal combustion engineCoupling

An intake control device for an engine includes a throttle body that defines a throttle bore, which is substantially circular-shaped in cross section, through which intake air flows. A throttle valve is rotatably assembled in the throttle bore of the throttle body. The throttle valve rotates integrally with a shaft. One axial end of the shaft is connected to a rotary driver, so that the rotation angle of the throttle valve is changed via the shaft. The rotary driver defines a fitted hole, to which the one axial end of the shaft is clearance fitted. The rotary driver defines a fitting recess dented radially outward from the hole wall surface of the fitted hole. The one axial end of the shaft includes a coupling that is crimped and fixed to the rotary driver in the state of being fitted to the fitted hole.

Owner:DENSO CORP

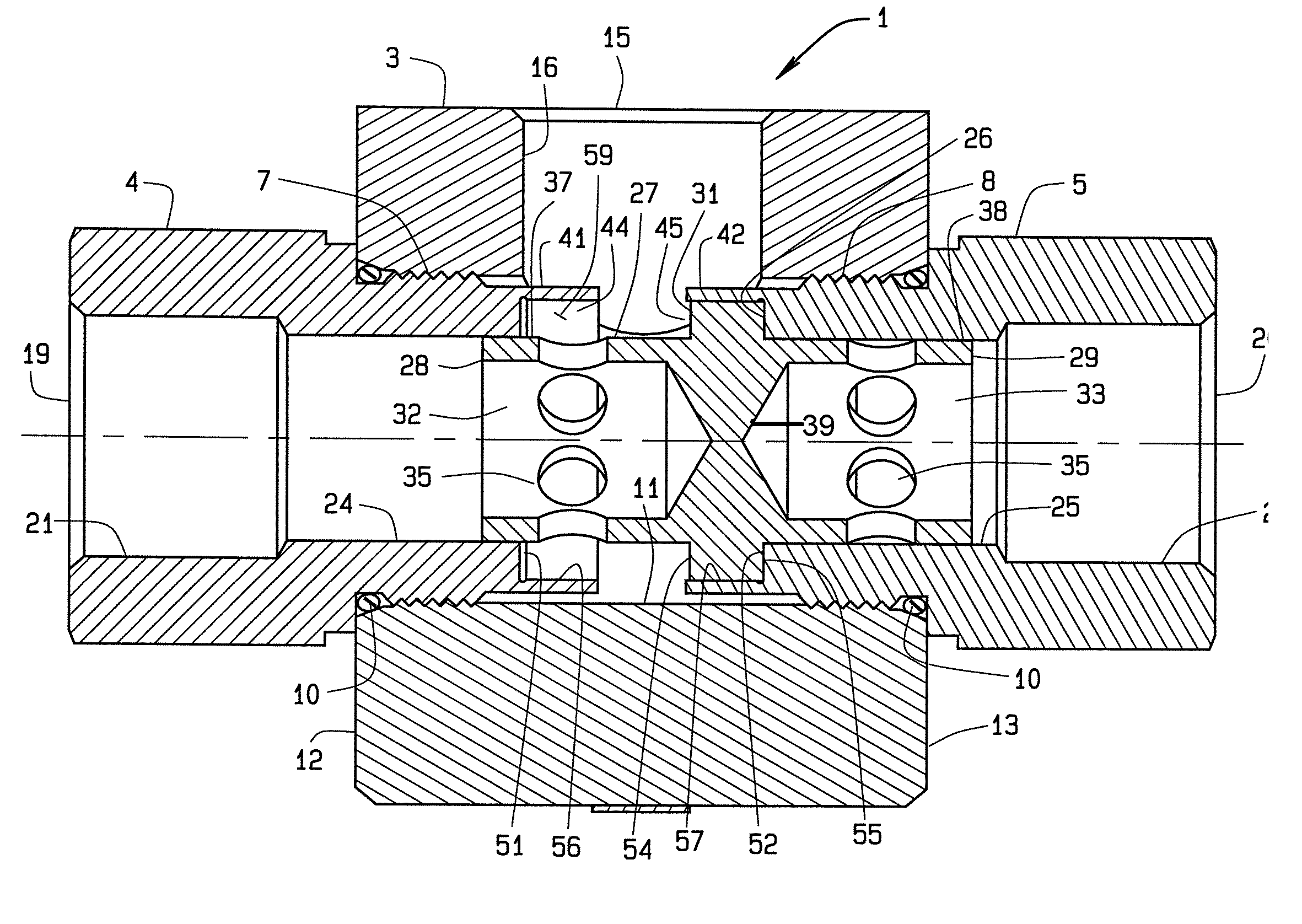

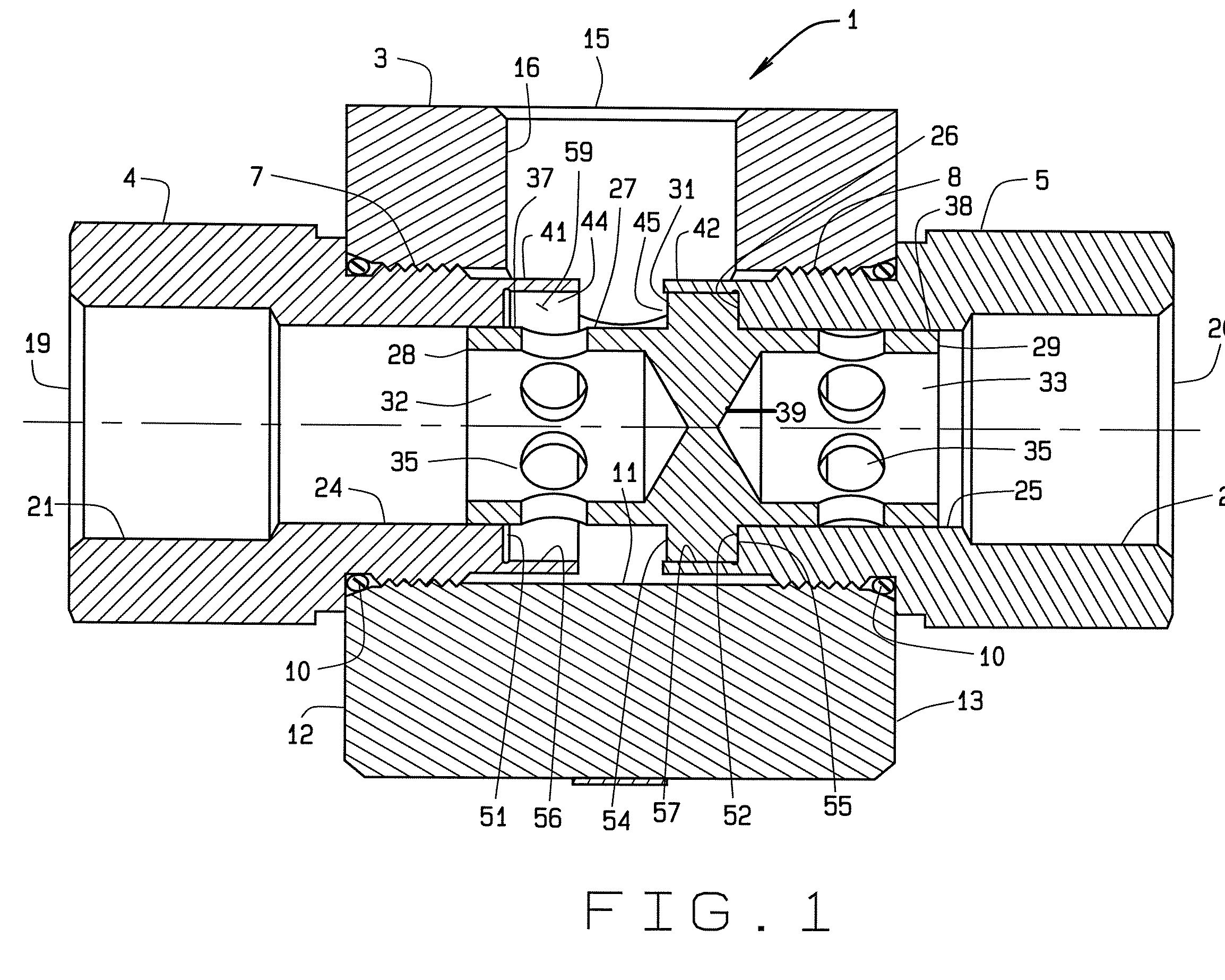

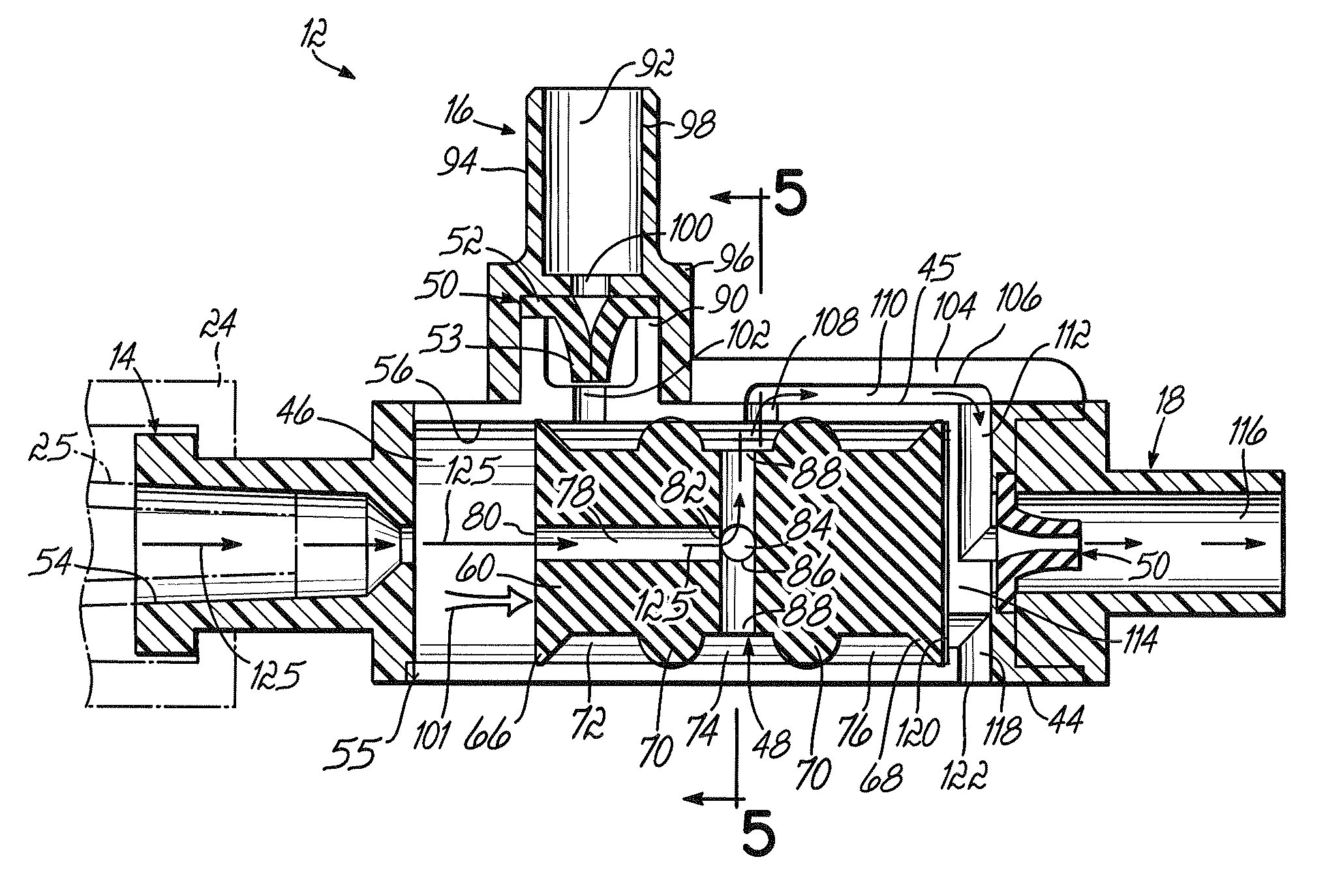

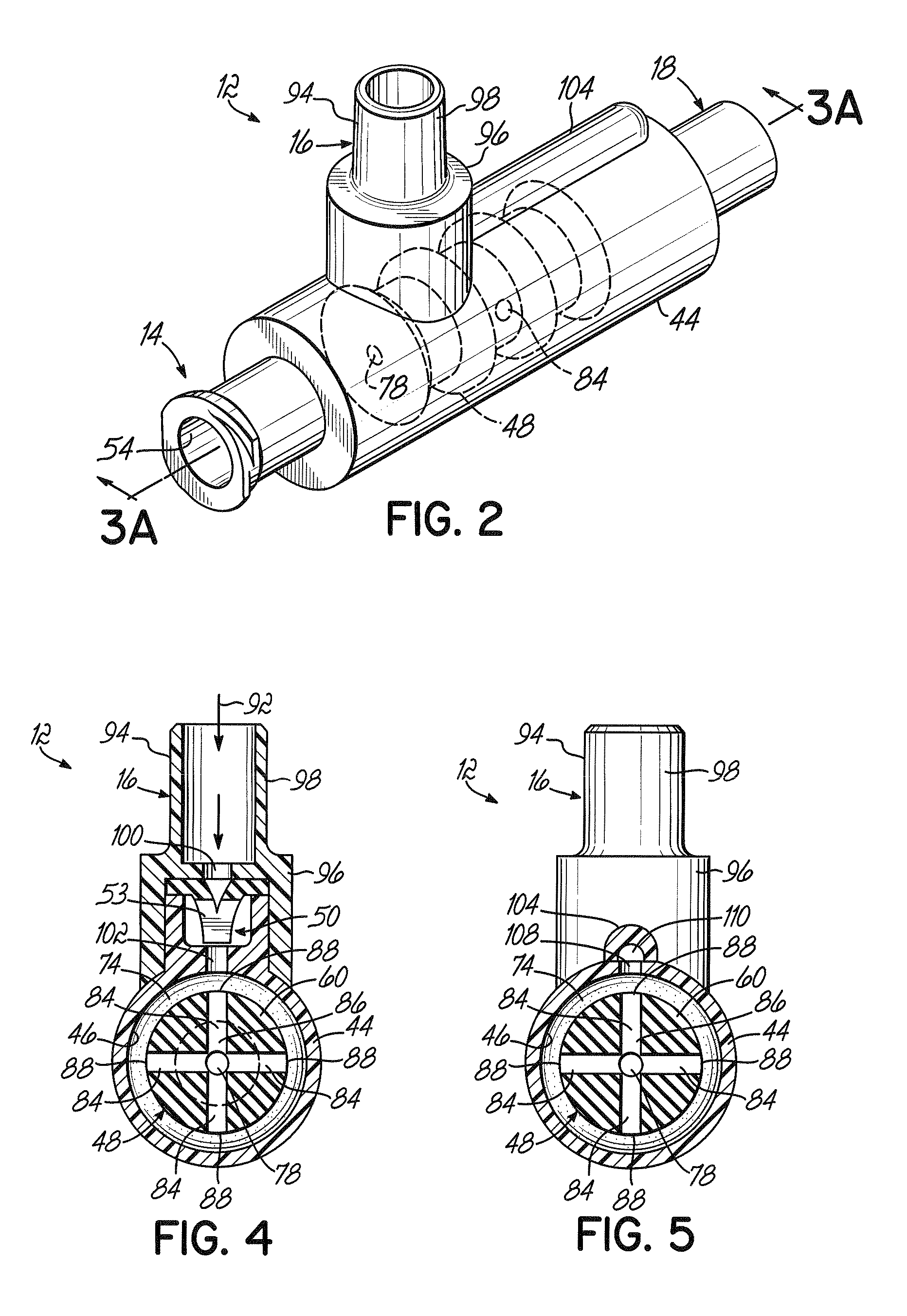

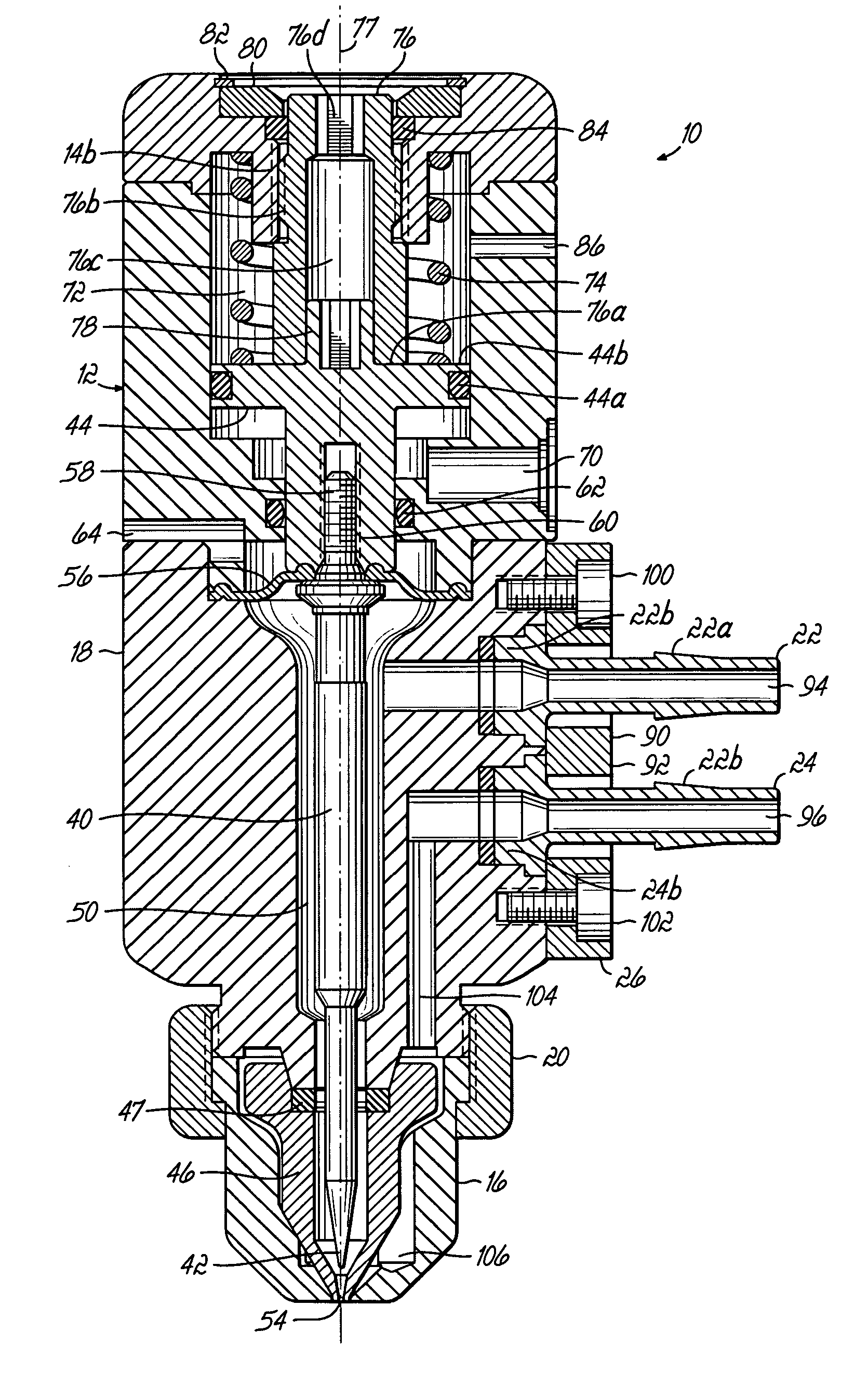

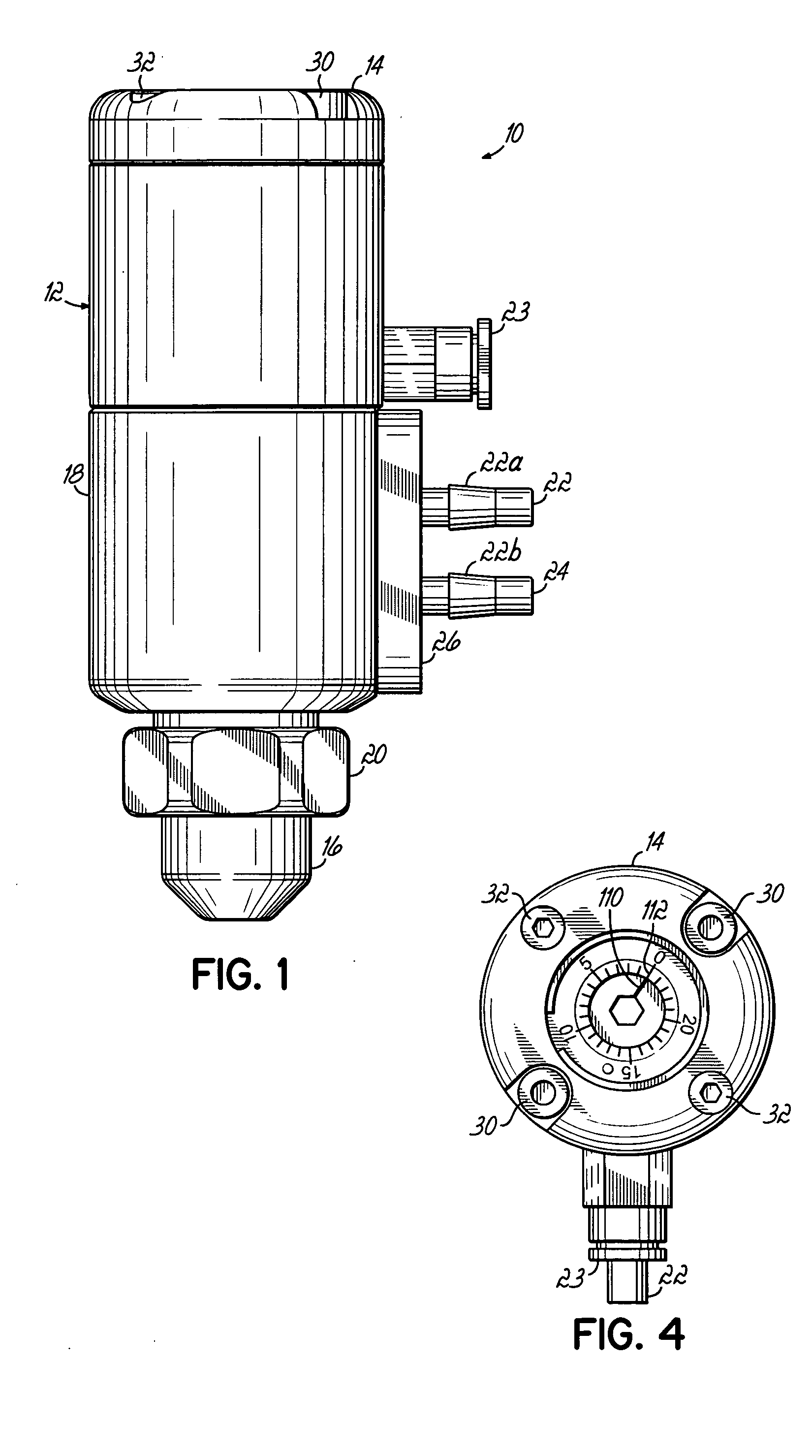

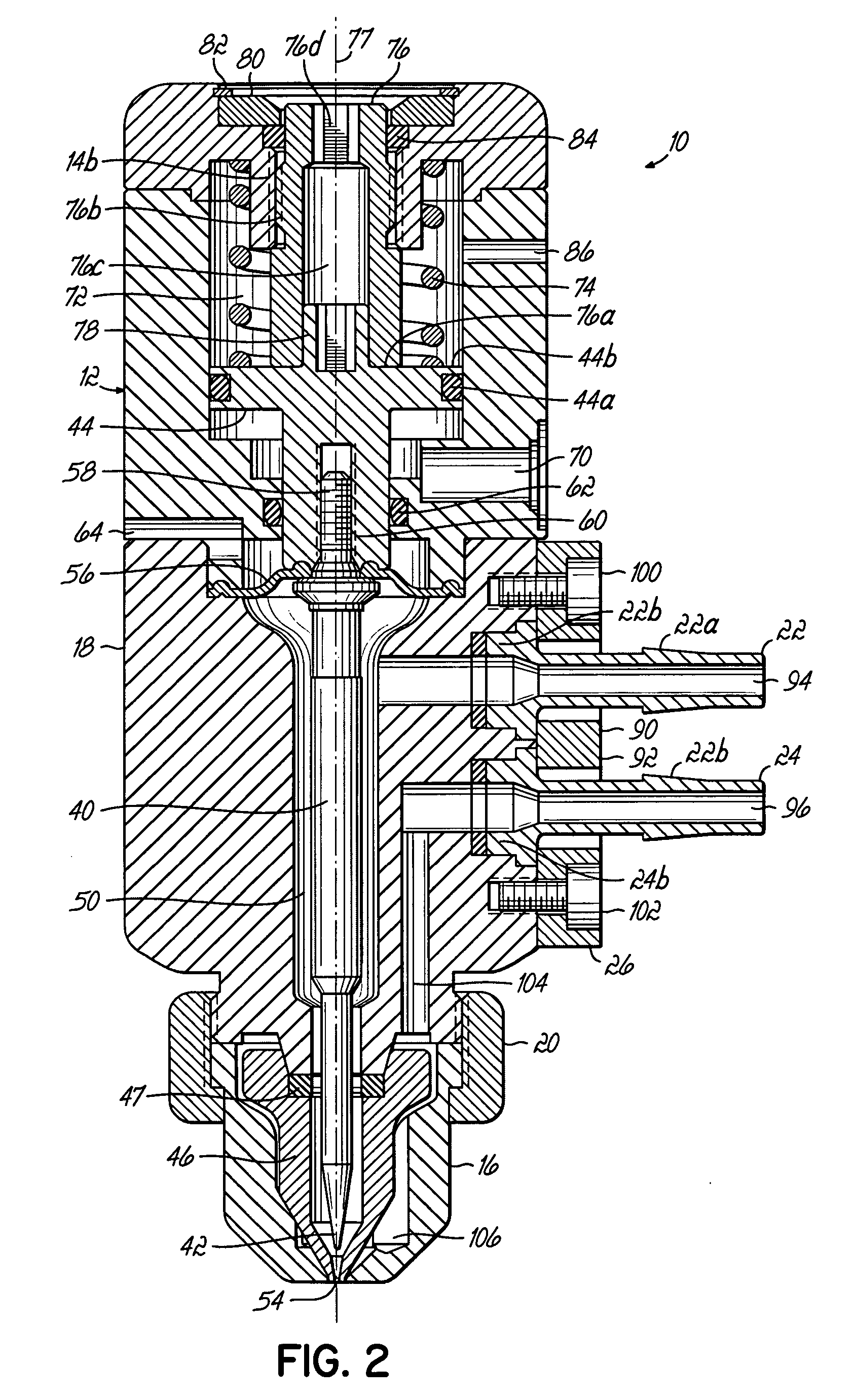

Shuttle valve

InactiveUS7637279B2Easily fill and emptyReduce fluid pressureLevel controlCheck valvesEngineeringCheck valve

A shuttle valve (12,150,230) is provided having a body (44,152,232) defining an interior chamber (46,154,234). The valve (12,150,230) includes inlet (16,158,238), outlet (18,160,240) and common (14,156,236) ports that are coupled to the body (44,152,232). A shuttle (48, 162,242) is translatably disposed within the chamber (46,154,234) between a first position wherein the inlet (16,158,238) and common (14,156,236) ports are fluidicly coupled and the common (14,156,236) and outlet (18,160,240) ports are fluidicly uncoupled, and a second position wherein the outlet (18,160,240) and common (14,156,236) ports are fluidicly coupled and the common (14,156,236) and inlet (16,158,238) ports are fluidicly uncoupled. A first check valve (50,50,50) coupled to the inlet port (16,158,238) to permit fluid flow through the inlet port (16,158,238) into the chamber (46,154,234) and to prevent fluid from discharging therethrough. A second check valve (50,50,50) is coupled to the outlet port (18,160,240) in a manner to permit fluid to discharge from the chamber (46,154,234) through the outlet port (18,160,240) and to prevent fluid from flowing through the outlet port (18,160,240) into the chamber (46,154,234).

Owner:SMITHS MEDICAL ASD INC

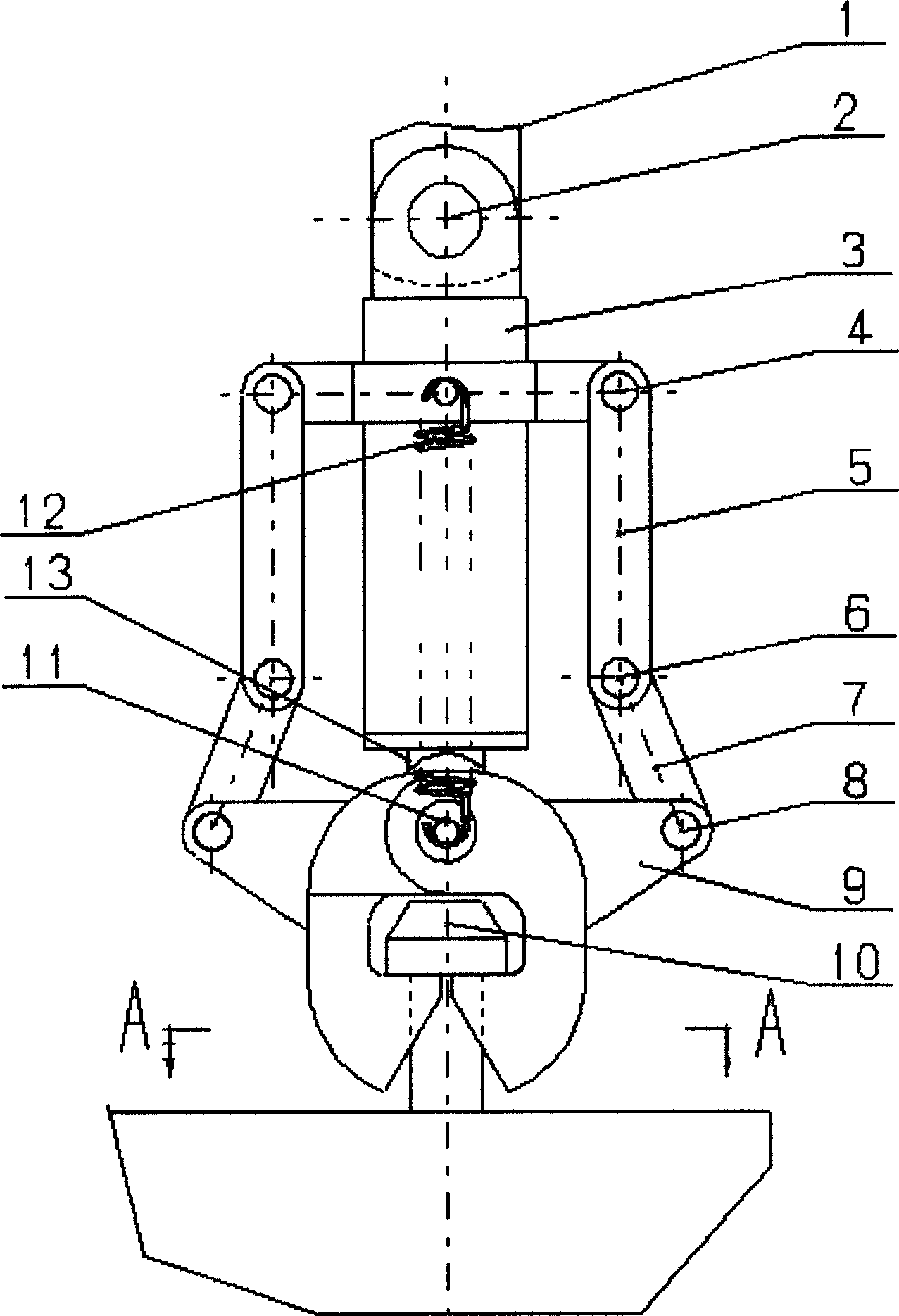

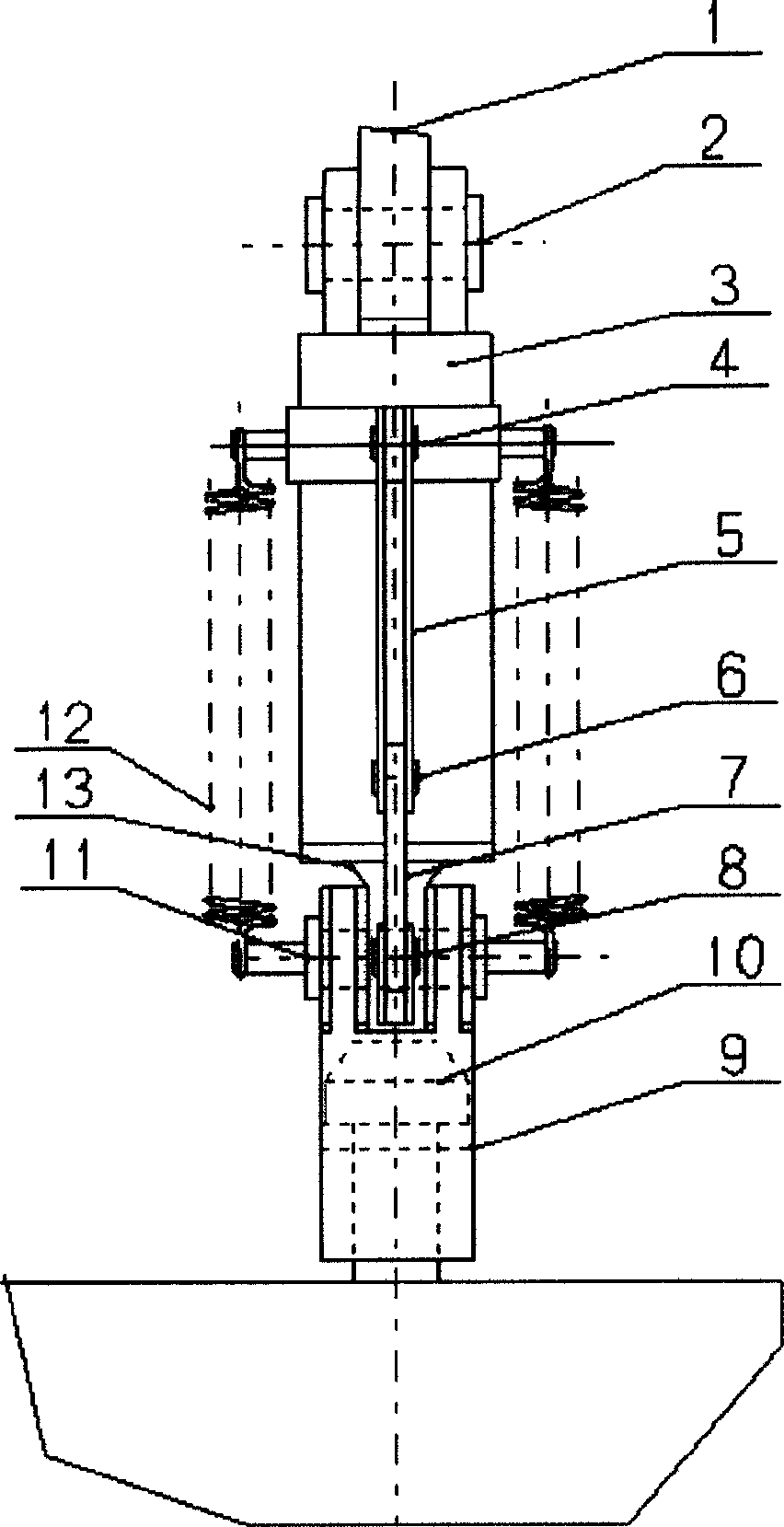

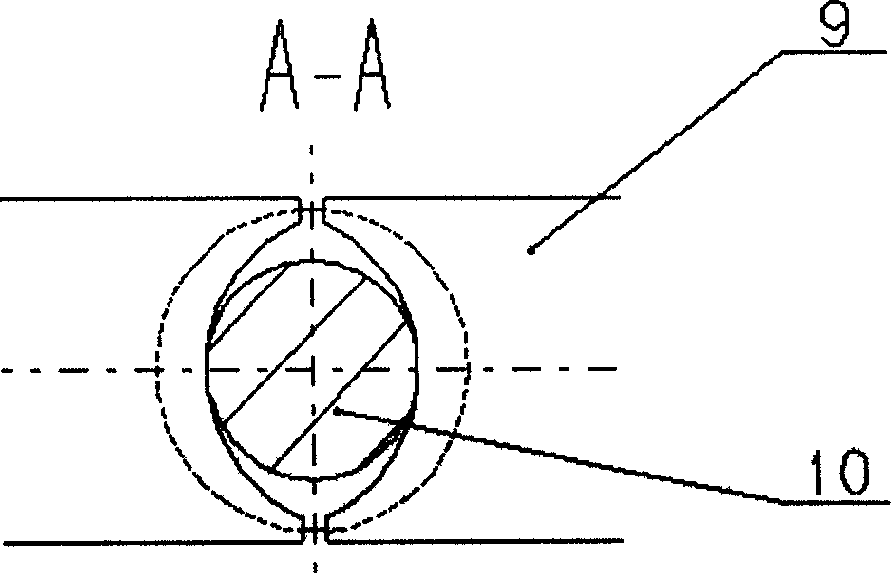

Hydraulic tripper of strong rammer and its tripping method

InactiveCN1587542AReduce wearQuick and complete decouplingLoad-engaging elementsSoil preservationHydraulic cylinderControl system

The present invention belongs to the field of engineering machinery technology, and the hydraulic tripper of strong rammer includes mechanical unit and hydraulic control system. The mechanical unit consists of oil hydraulic cylinder, link rod, lifting lug, and spring; and the hydraulic control system consists of cartridge inserted valve, non-return valve, oil tank, throttle valve, overflow valve and electromagnetic change-over valve. The present invention needs no manual hanging operation in controlling the rammer descent from any lifted height. The rammer descent is synchronous with tripping course, and tripping is fast, complete, small in impact, and low in the wear of the lifting lug. The present invention is suitable for geotechnical engineering.

Owner:DALIAN UNIV OF TECH

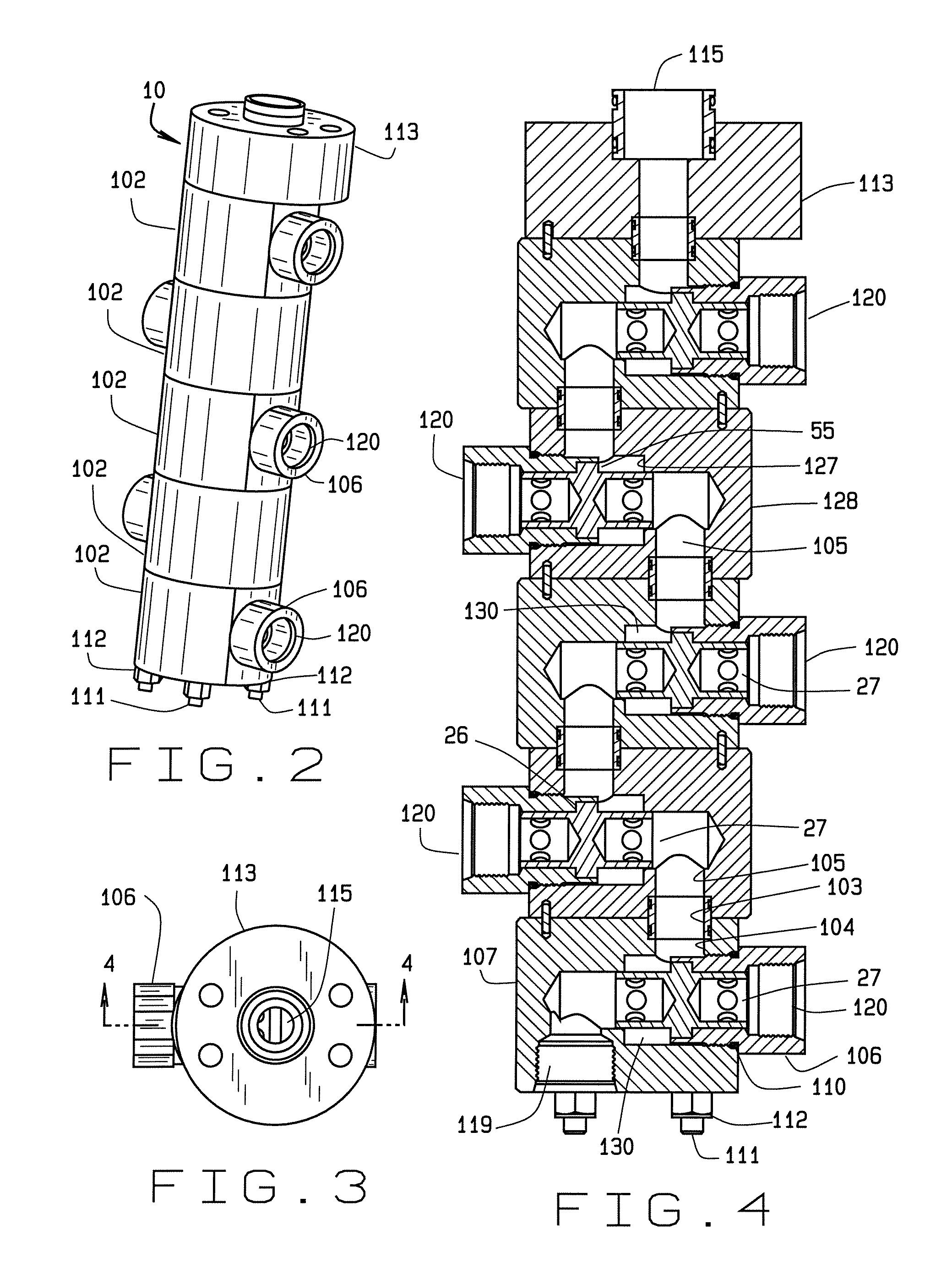

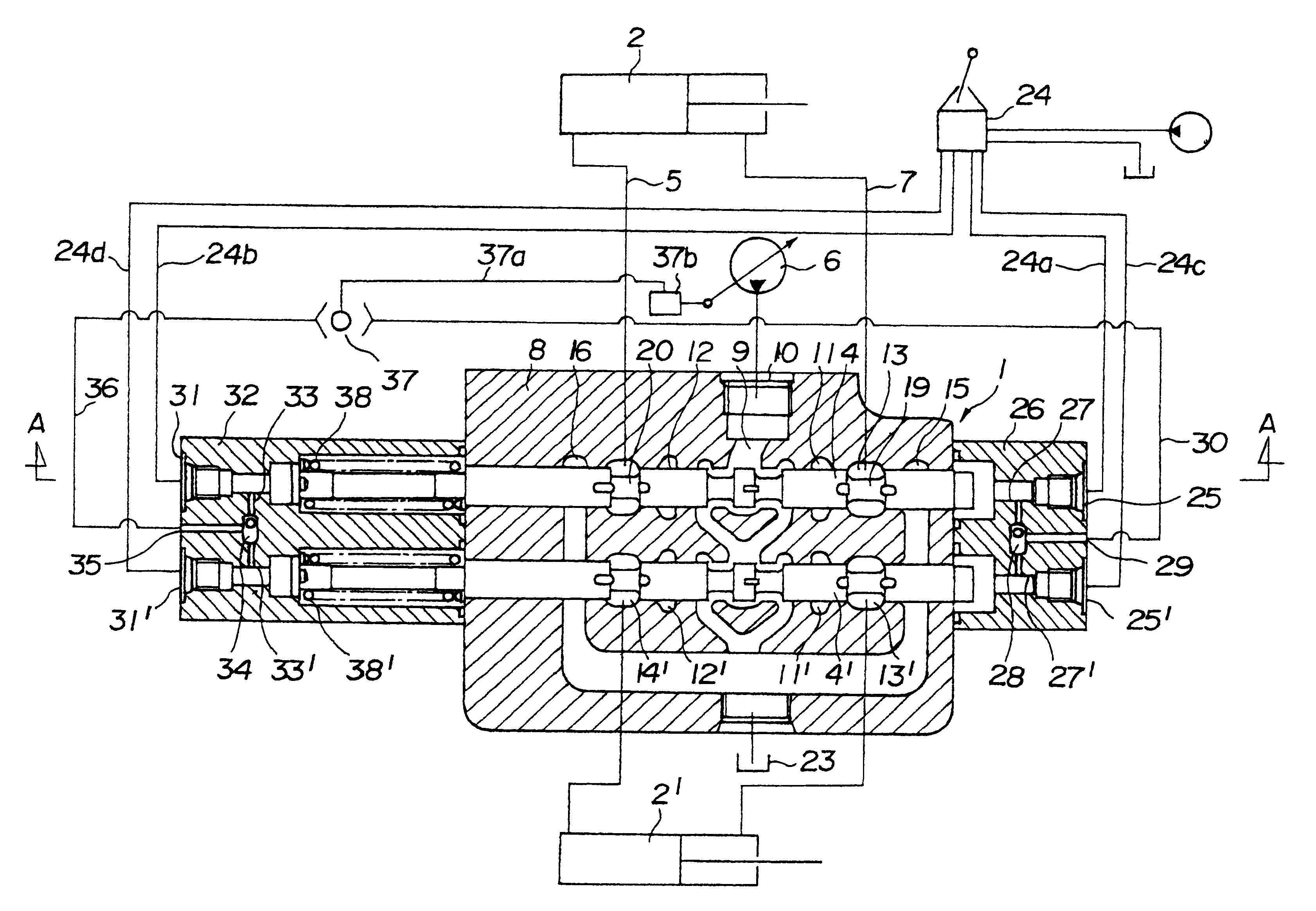

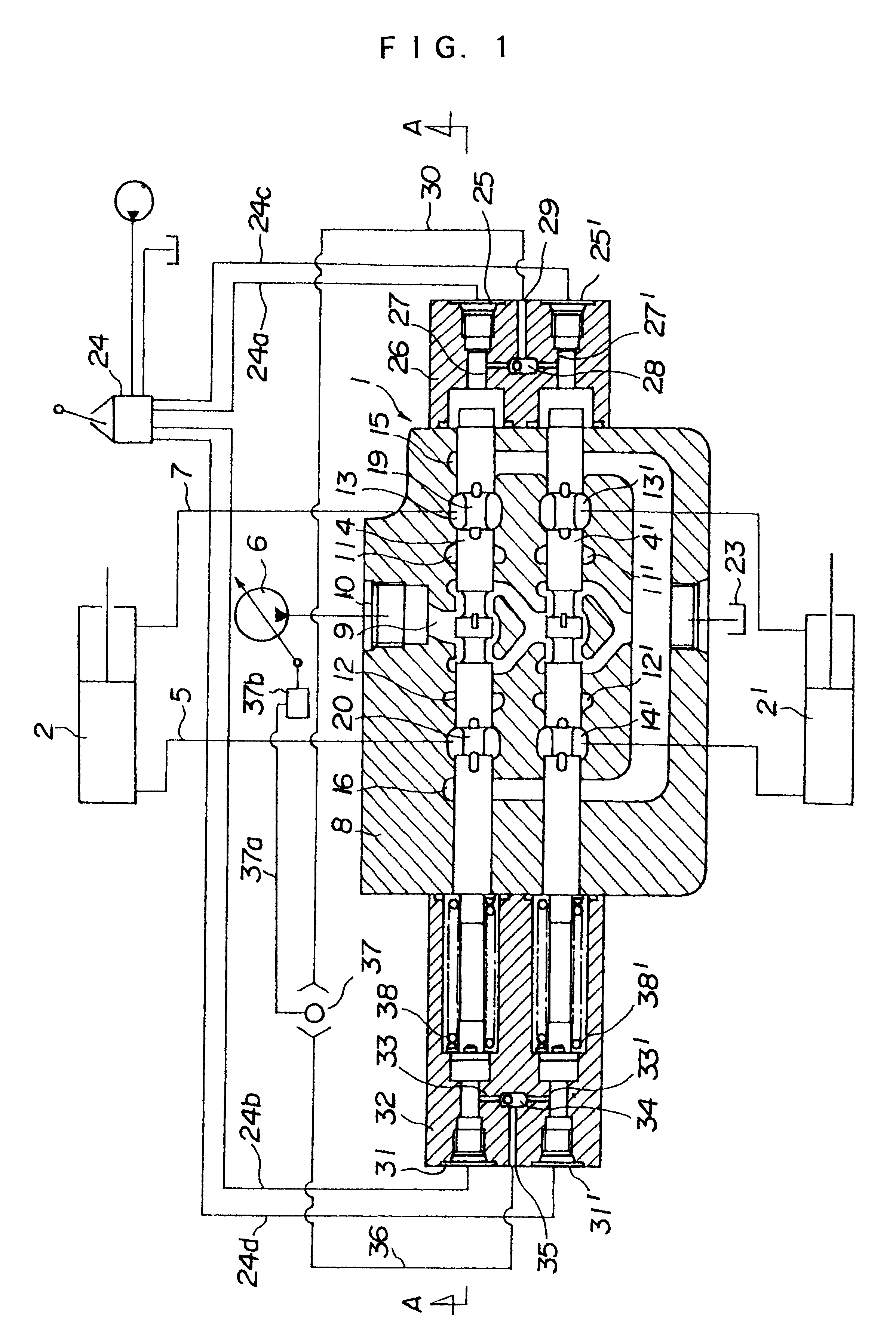

Control valve

It is an object of the present invention to provide a control valve which can reduce the number of external lines connected to a hydraulic remote control valve. A control valve 1 for controlling hydraulic cylinders 2,2' is provided, in one 26 of spool covers, with fluid passages 27,27', a shuttle valve 28 for selecting higher one of pilot pressures to be transmitted to these fluid passages 27,27', and a fluid passage 29 for transmitting the pressure selected by the shuttle valve 28. The fluid passages 27,27' are in communication with pressure fluid ports 25,25' as connection ports for pilot lines 24a,24c. The control valve 1 is also provided, in the other spool cover 32, with fluid passages 33,33', a shuttle valve 34 for selecting higher one of pilot pressures to be transmitted to these fluid passages 33,33', and a fluid passage 35 for transmitting the pressure selected by the shuttle valve 34. The fluid passages 33,33' are in communication with pressure fluid ports 31,31' as connection ports for pilot lines 24b,24d.

Owner:NIHON KENKI CO LTD

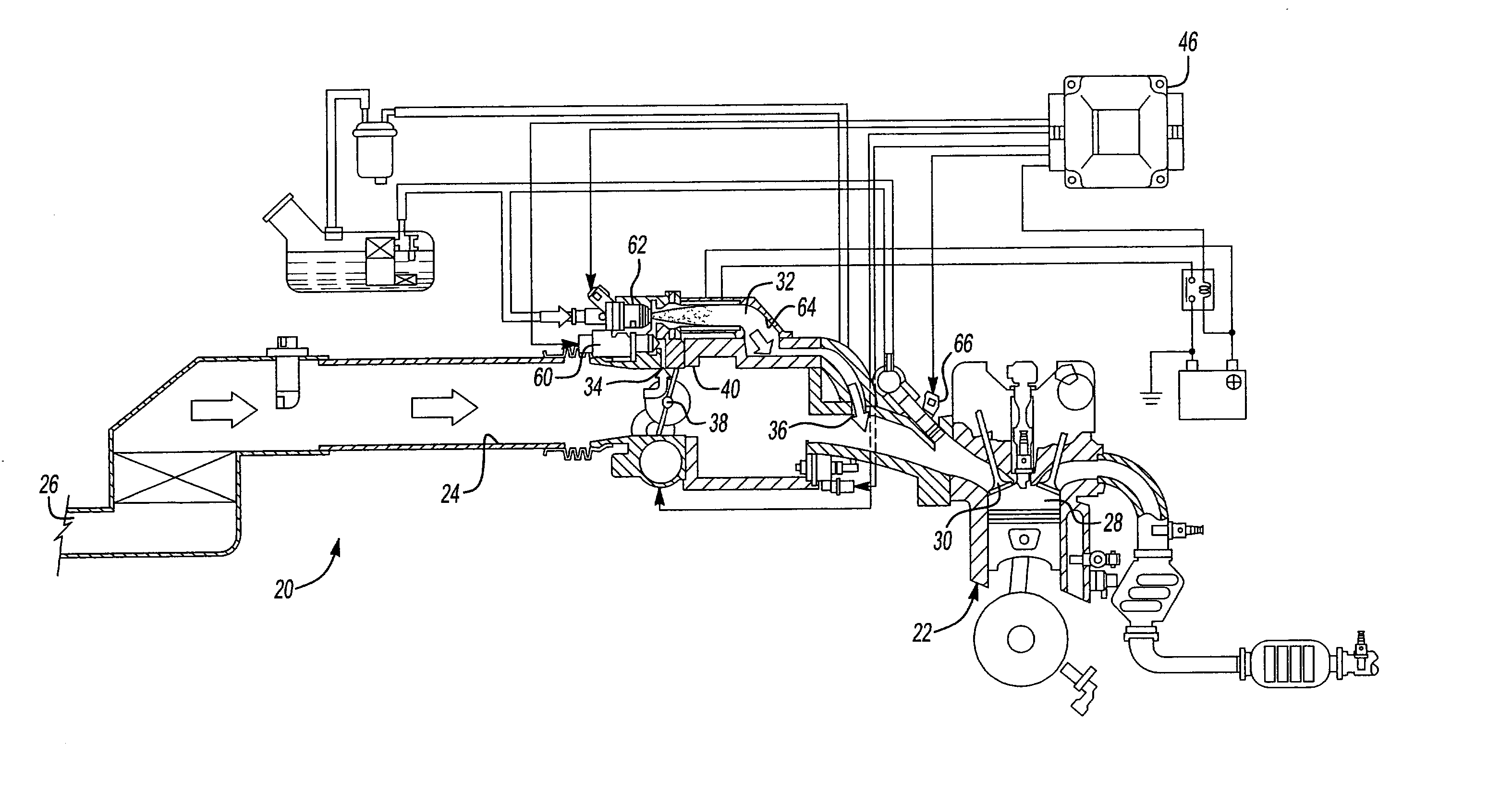

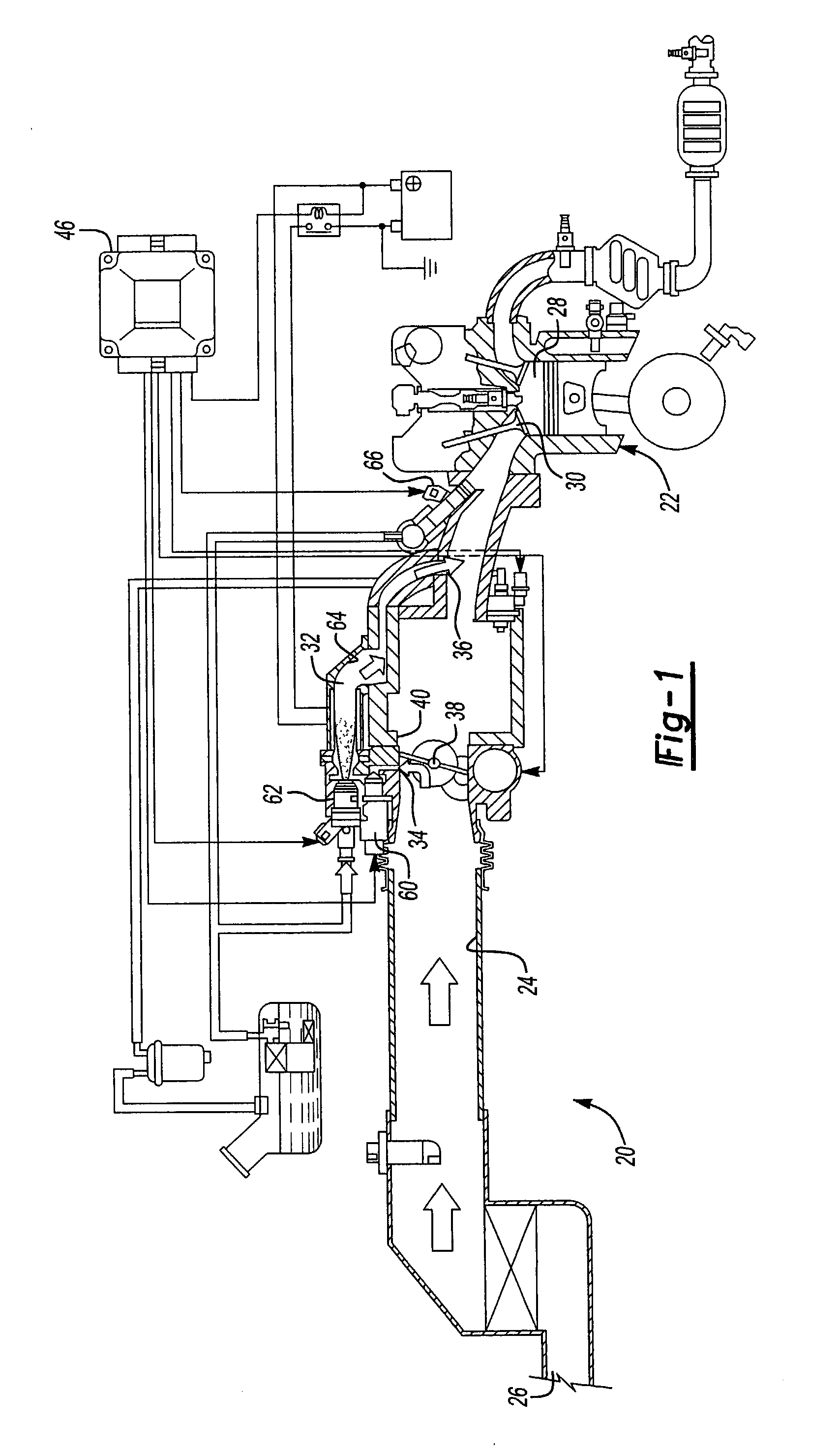

Fuel delivery system for an internal combustion engine

InactiveUS20040025837A1Improved vaporizationElectrical controlNon-fuel substance addition to fuelEngine efficiencyIdle speed control

A fuel delivery system for an internal combustion engine of the type having an intake manifold selectively fluidly connected to a combustion chamber and a bypass gas flow passageway having an inlet open to the intake manifold and an outlet open to the intake manifold downstream for the inlet is disclosed. The system includes an electronically controlled throttle valve operatively disposed in the intake manifold and movable between an open and a closed position to control air flow through the intake manifold. An idle speed control valve is operatively disposed within the bypass gas flow passageway, and the idle speed control valve is also movable between an open and a closed position to control air flow through the bypass gas flow passageway. A control system controls the actuation of both the throttle valve and idle speed control valve to control the delivery of a combustible charge to the internal combustion engine to maximize engine efficiency and minimize noxious emissions. Optionally, a cold start fuel injector is disposed within the bypass gas flow passageway to provide the fuel charge to the engine during a cold start condition. In an alternate form of the invention, two electronically controlled throttle valves are disposed within the intake manifold to control both the air flow through the intake manifold as well as the air flow through the bypass gas flow passageway.

Owner:HITACHI LTD

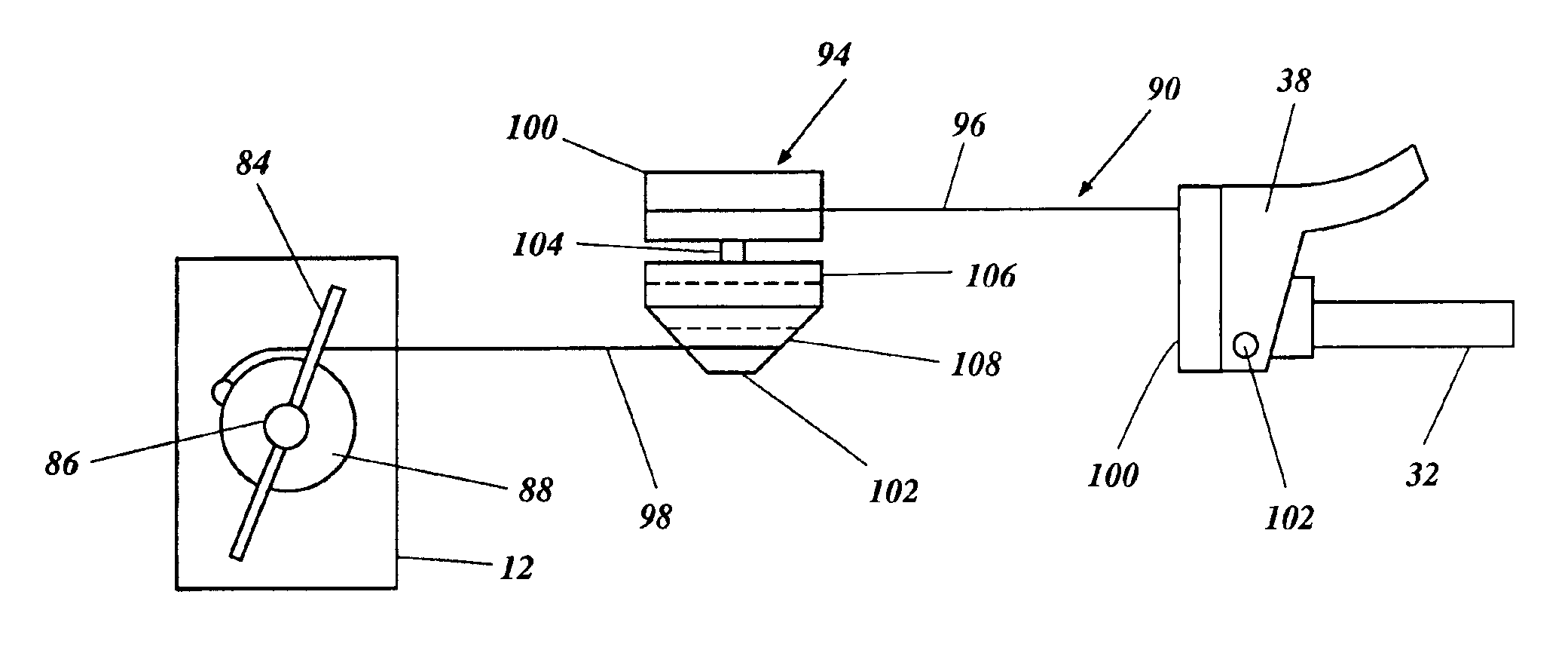

Apparatus for dispensing precise amounts of a non-compressible fluid

InactiveUS20050072815A1Easy to useMaterial is facilitatedContracting/expanding measuring chambersMovable measuring chambersMotor driveEngineering

A dispensing apparatus has a motor drive that moves an output member along an axis in a first chamber. A shuttle valve controls flow between a first chamber and either a reservoir of material or an output port. Extending the output member discharges precise volumes of material through an output port. Retracting the output member fills the first chamber.

Owner:CAREW DENNIS +2

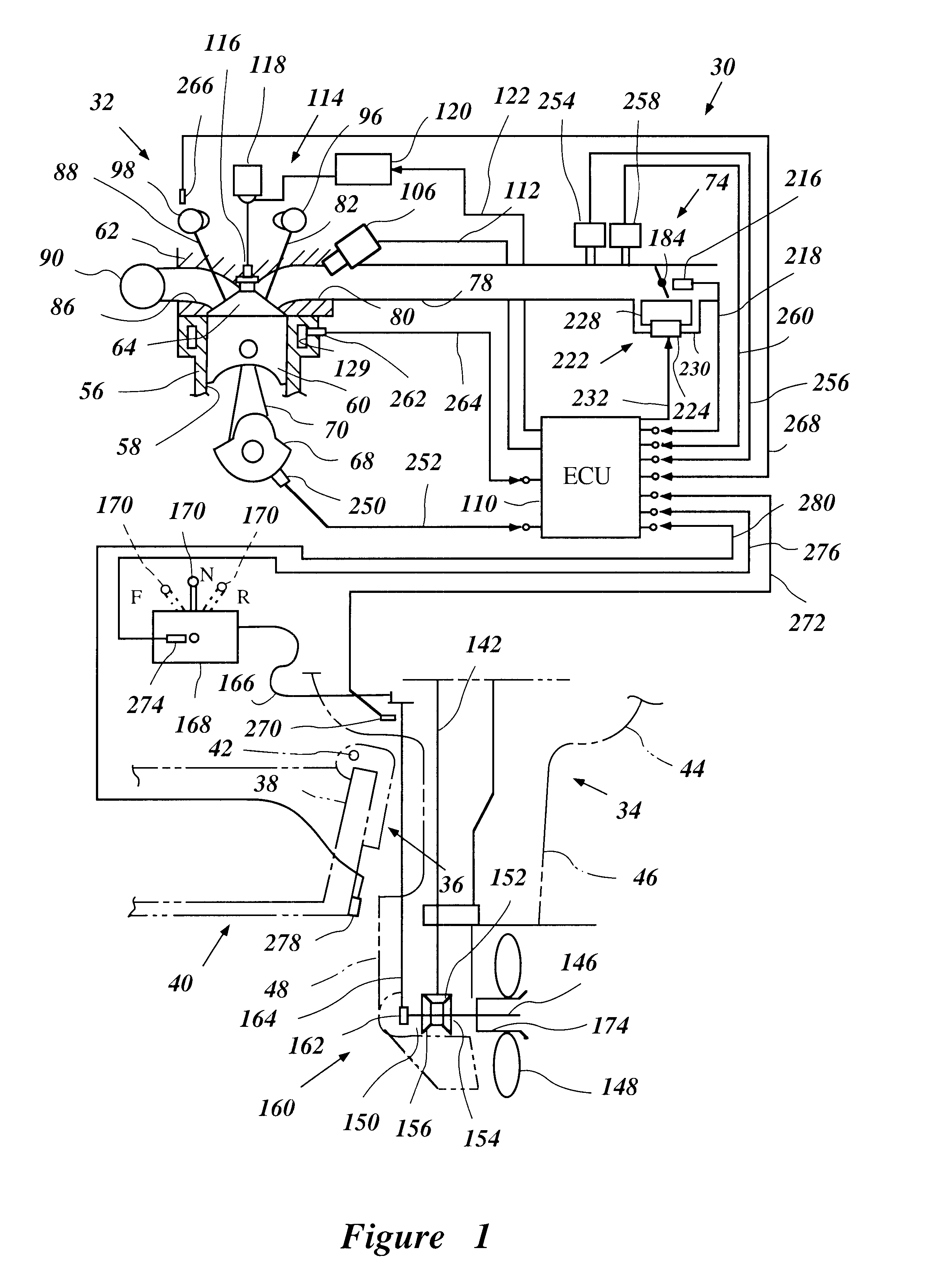

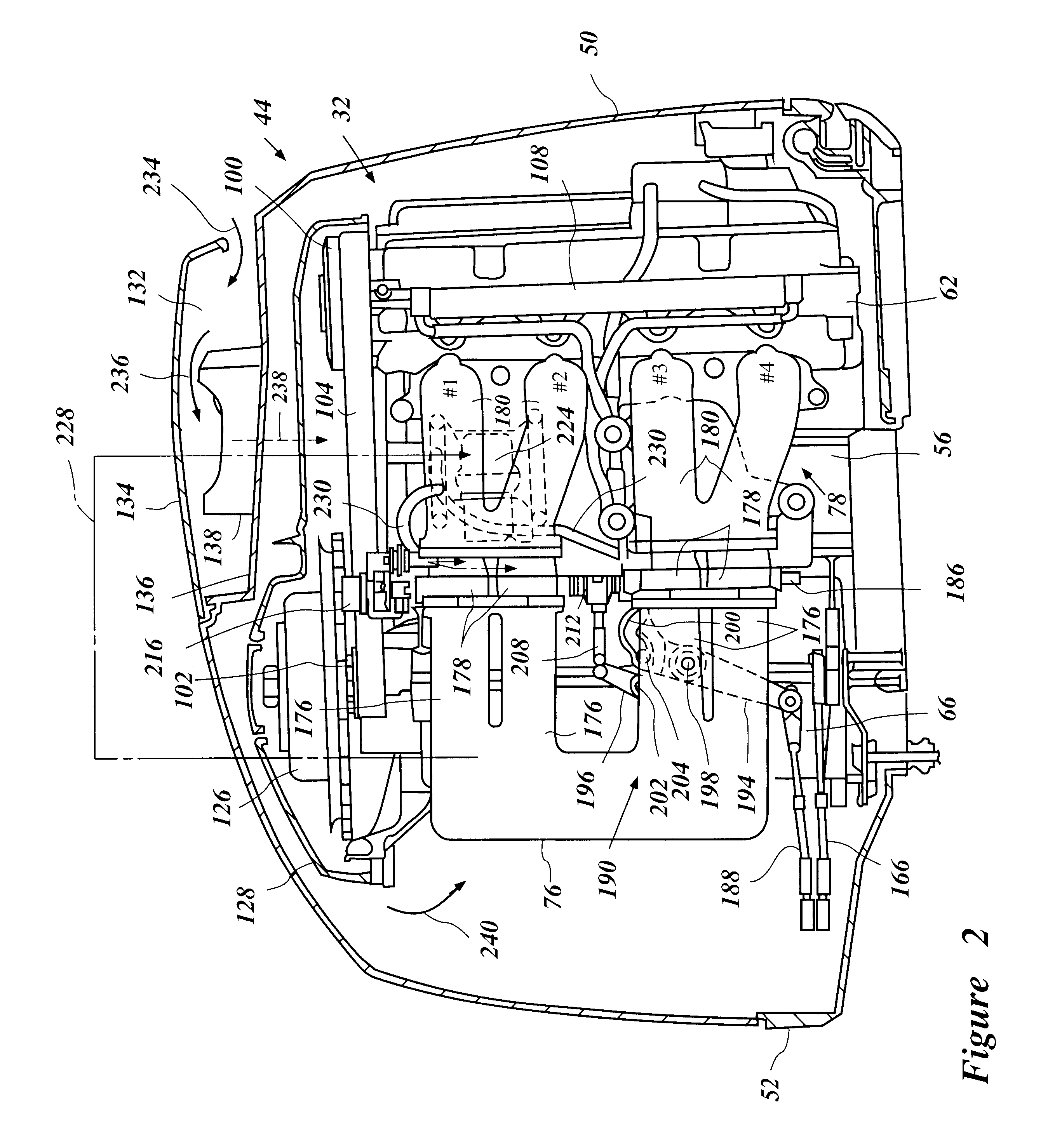

Engine control device for water vehicle

InactiveUS6886529B2Avoid flowPropulsion power plantsCombustion-air/fuel-air treatmentProportional controlOutput device

A watercraft includes an engine output control device that can adjust the maximum output of the engine. The output device can be constructed of mechanical devices for adjusting the relationship between the movement of a throttle lever and a throttle valve, an electronic device for proportionally controlling the position of throttle valves in relation to the movement of the throttle lever, are other devices for controlling engine speeds in other ways.

Owner:YAMAHA MARINE KK

Throttle valve system for an engine

InactiveUS20130233276A1Low production costElectrical controlInternal combustion piston enginesControl theoryShuttle valve

An embodiment of an engine is described. The engine includes a first throttle valve. The first throttle valve is provided in a first intake passage coupled to an intake manifold. The first throttle valve has a default closed position. The engine further includes a second throttle valve. The second throttle valve is provided in a second intake passage coupled to the intake manifold. The second throttle valve has a default open position. The engine further includes a venturi pump that is provided between the second throttle valve and the intake manifold. When the second throttle valve is in the default open position, intake air flows through the venturi pump.

Owner:FORD GLOBAL TECH LLC

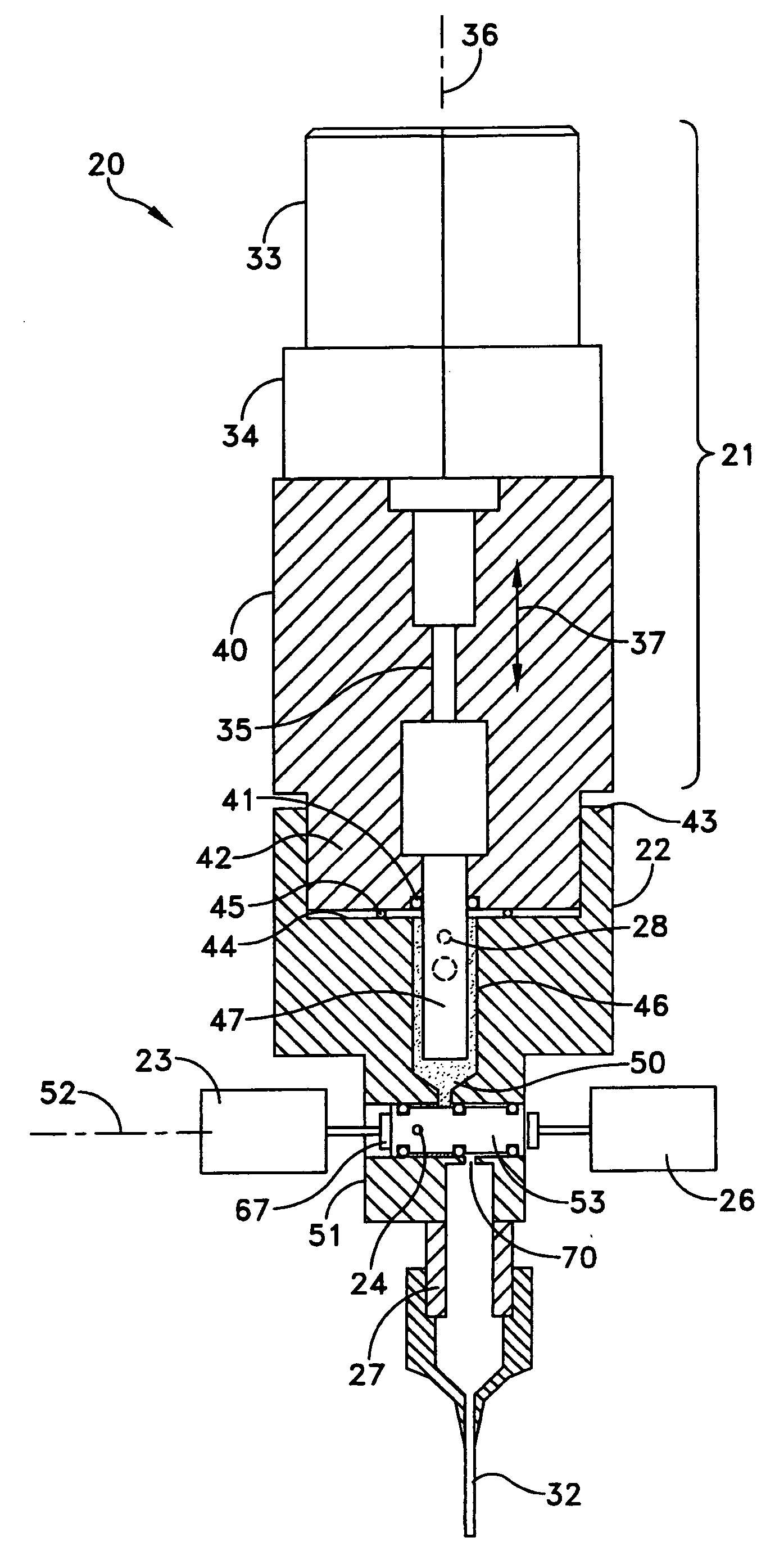

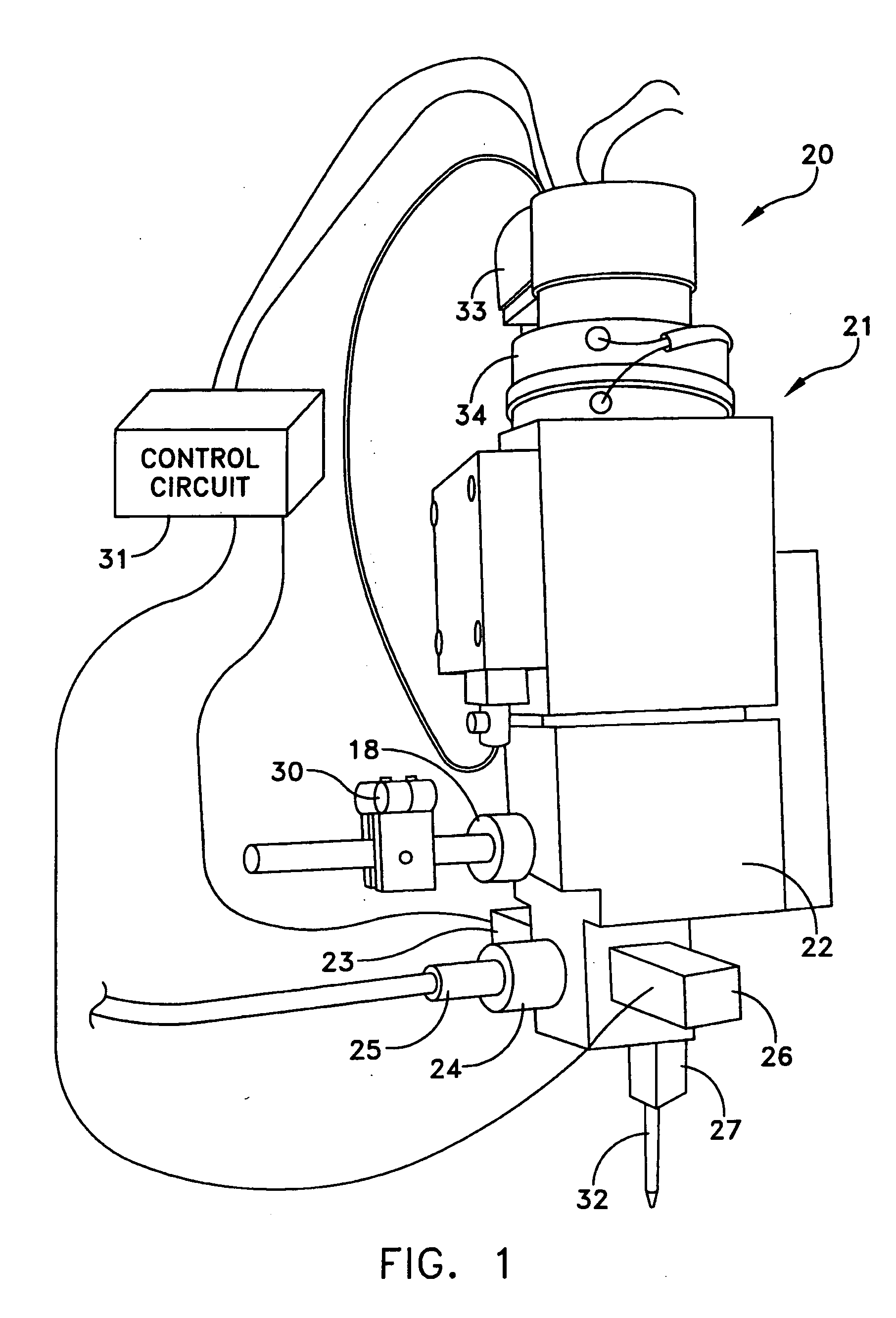

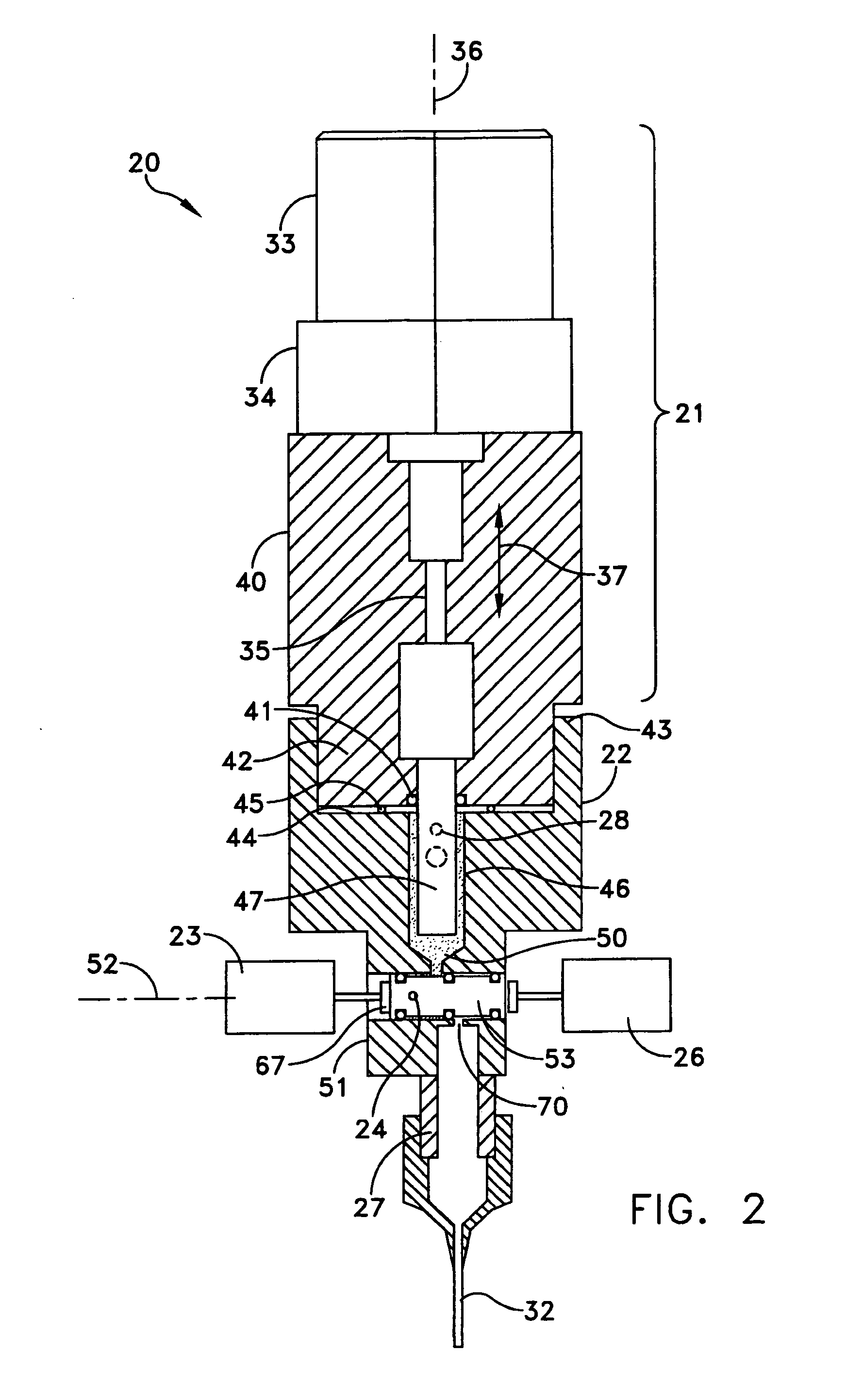

Liquid dispensing valve and method with improved stroke length calibration and fluid fittings

A liquid dispensing valve includes a valve body, a valve seat, and a reciprocating valve member engageable with the valve seat for controlling flow through a liquid outlet. A calibration device includes a rotatable stroke control stop member and a rotatable reference ring. The reference ring and stop member may be initially rotated to a zero position and, subsequently, the stop member may be rotated to set the desired stroke length. One or more fluid fittings are provided and sealed against the valve body using a clamp plate.

Owner:NORDSON CORP

Load-sensitive valve and load-sensitive hydraulic system

ActiveCN105221506AImprove general performanceReduce throttling lossServomotor componentsServomotorsElectricityFuel tank

A load-sensitive valve comprises a proportional reversing valve, a pressure compensation valve and an enable reversing valve. An oil outlet of the pressure compensation valve is communicated with an oil inlet of the proportional reversing valve, a spring valve of the pressure compensation valve is communicated with a downstream pressure opening of the proportional reversing valve through a downstream pressure detection oil way, and a throttler is arranged on a load feedback oil way of the pressure compensation valve. An oil inlet of the enable reversing valve is communicated with the load feedback oil way of the pressure compensation valve. A single-load sensitive hydraulic system is provided. An oil inlet of the load-sensitive valve is communicated with an oil tank through a load-sensitive pump, and an electronic control opening of the load-sensitive valve is electrically connected with a controller. According to a multi-load sensitive hydraulic system, the oil inlet of the load-sensitive valve in each load execution unit is communicated with the oil tank through the load-sensitive pump, the electronic control opening of the load-sensitive valve in each load execution unit is electrically connected with the controller, and pressure detection openings of the load-sensitive valves are communicated through shuttle valves. Energy losses can be reduced under the work condition that only one execution mechanism works in a system.

Owner:徐州中新机械科技有限公司

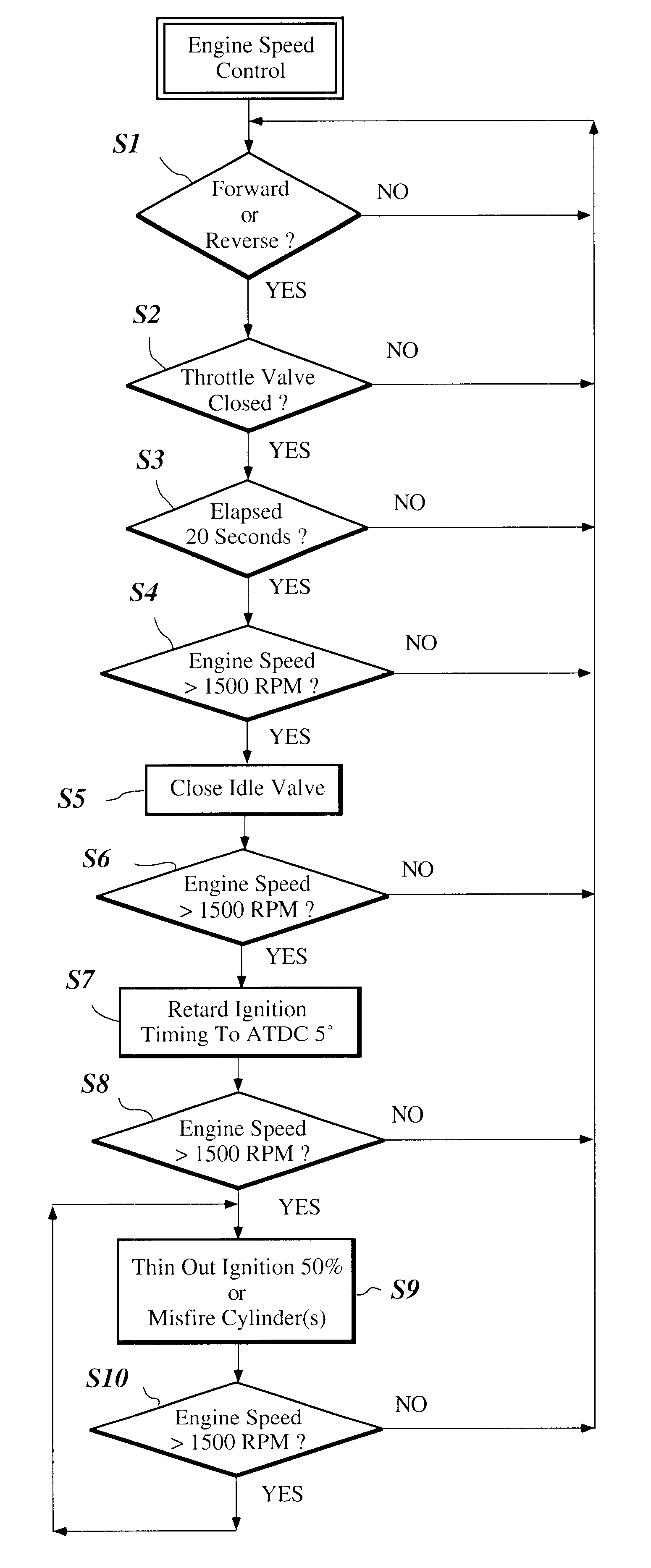

Engine control system

An engine control system includes an improved construction that can release an engine from an abnormal engine speed so that, for example, the operator can operate a shift actuator without any overload. The engine includes an air induction system that introduces air to the combustion chamber and includes a throttle valve. The throttle valve admits the air to flow through the air induction system unless placed in a closed position. A throttle valve position sensor is arranged to sense the position of the throttle valve. An engine speed sensor is also arranged to sense a rotational speed of the crankshaft. A control device is provided for slowing down the engine speed based upon a throttle position signal from the throttle valve position sensor and a speed signal from the engine speed sensor. In one operating mode, the slow down control is made when the throttle position signal indicates that the throttle valve is generally at the closed position and the speed signal indicates that the engine speed exceeds a preset speed.

Owner:SANSHIN KOGYO CO LTD

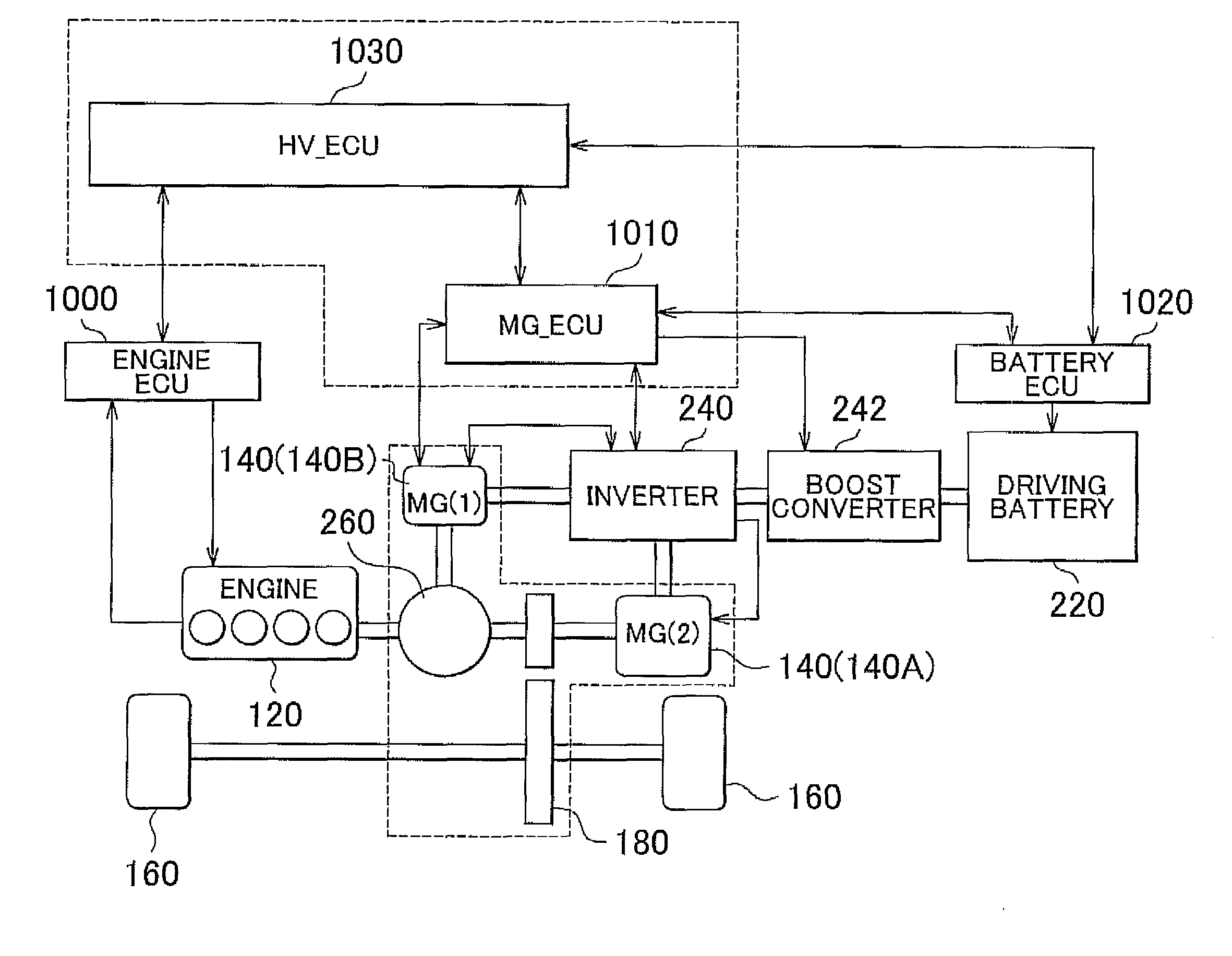

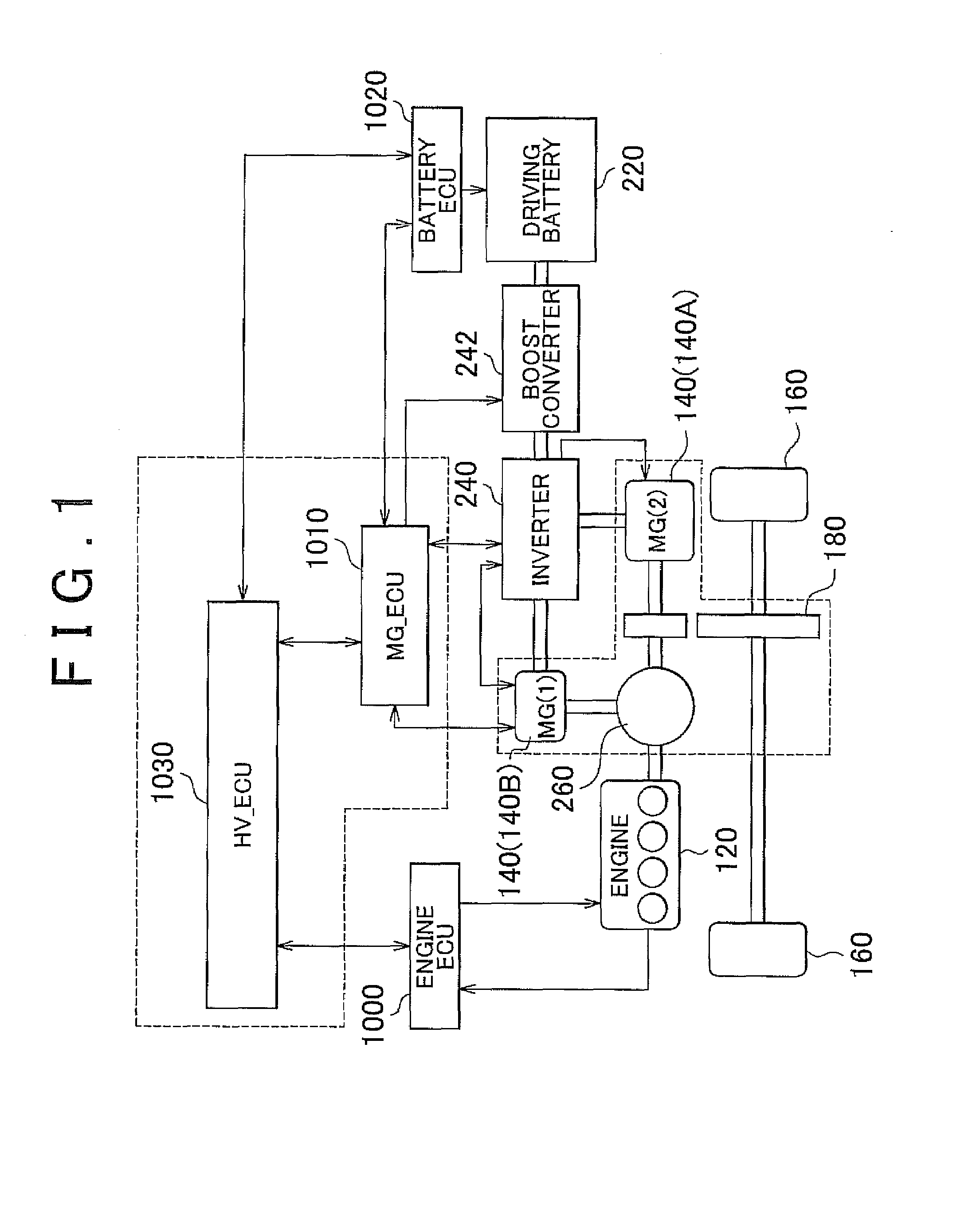

Control apparatus and method for hybrid vehicle

ActiveUS20100070122A1Improve fuel efficiencyImprove drivabilityInternal combustion piston enginesDigital data processing detailsThrottle controlRegenerative brake

A control apparatus for a hybrid vehicle, which outputs motive power to a drive shaft from an internal combustion engine and motor generators as motive power sources, including: a recirculating gas control portion that performs valve opening control on a recirculation valve so that an amount of recirculating exhaust reaches a control target valve, and that closes the recirculation valve completely when a deceleration request by a driver is detected; a throttle control portion that performs valve closing control on a throttle valve so that the amount of air circulating through an intake pipe decreases at a predetermined speed when the deceleration request issued by the driver is detected; and a braking control portion that controls regenerative braking forces of the motor generators so that at least one of the motor generators absorbs the motive power generated by the engine while valve closing control is executed on the throttle valve.

Owner:TOYOTA JIDOSHA KK

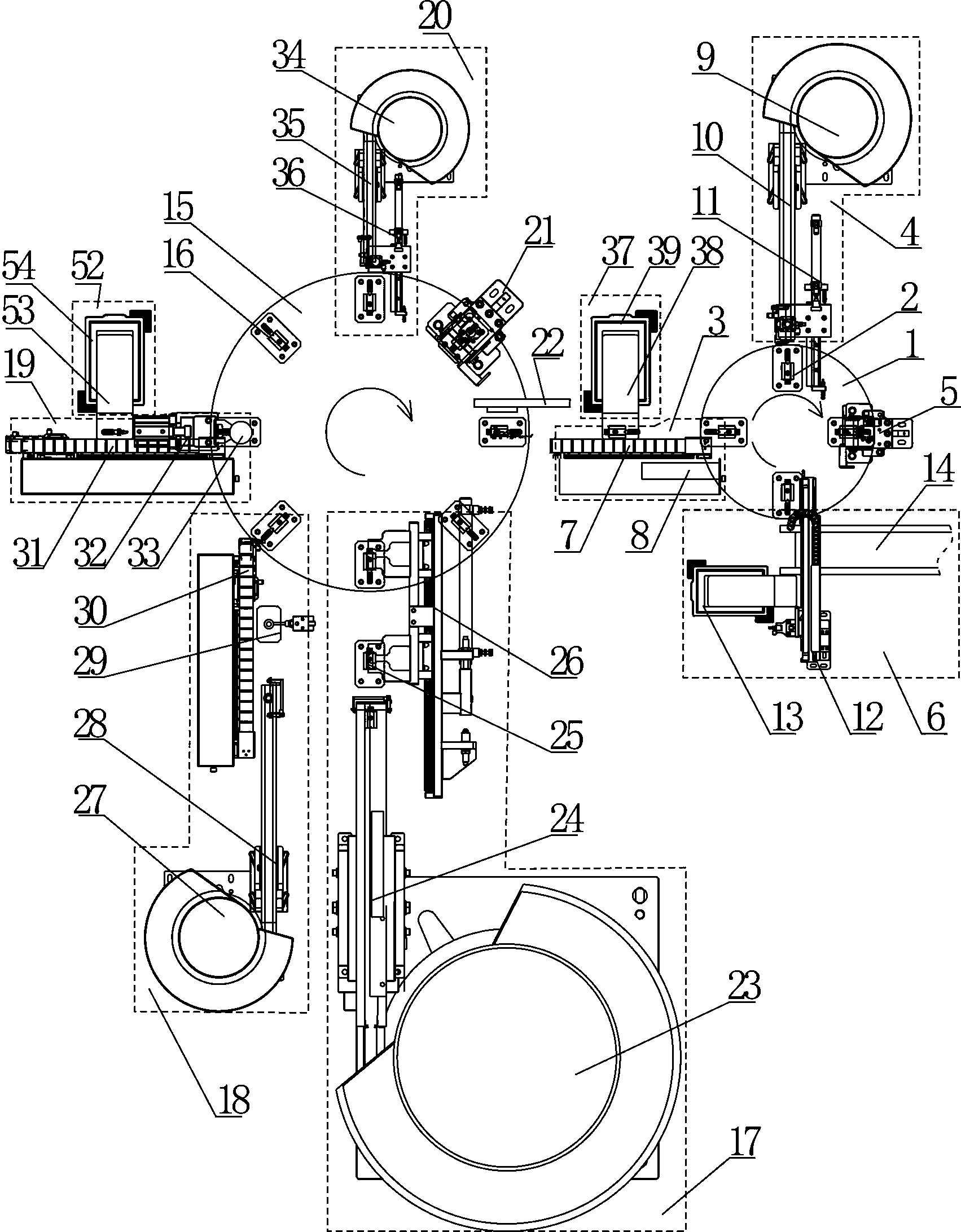

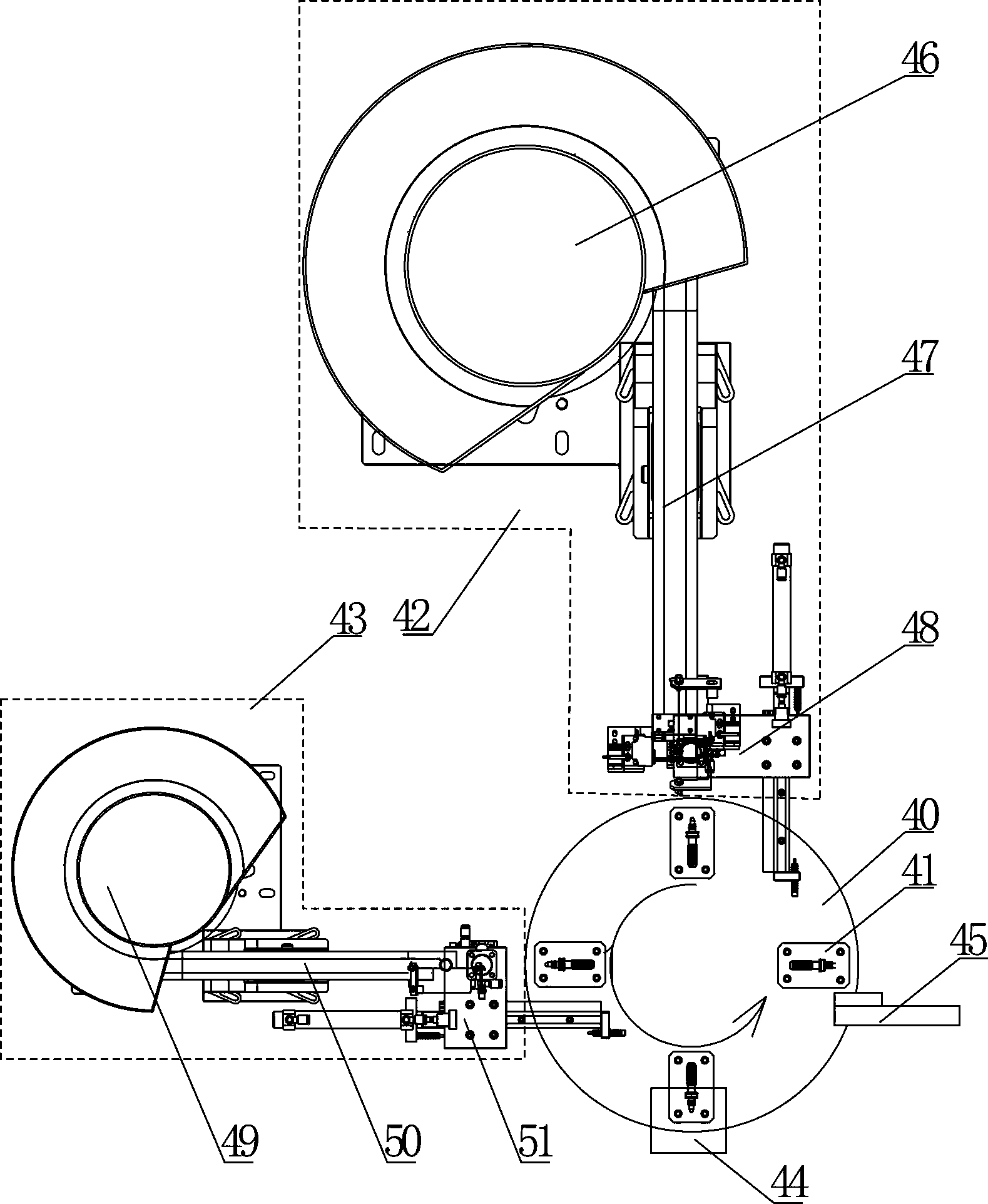

Automatic assembly machine for kettle valve of coffee maker

InactiveCN103707060AAutomate operationIncrease productivityAssembly machinesEngineeringShuttle valve

The invention discloses an automatic assembly machine for a kettle valve of a coffee maker. The automatic assembly machine comprises an intermittent rotating plate uniformly provided with four jigs along the periphery of the intermittent rotating plate, and a valve body assembly loading device, a seal ring loading device, a seal ring on-line detecting device and a valve body assembly taking-out device are sequentially arranged around the intermittent rotating plate and correspond to the jigs. The intermittent rotating plate conveys the jigs to stations to carry out valve body assembly loading, seal ring loading, seal ring on-line detecting and valve body assembly taking-out. In addition, a valve body sub-assembly assembling device and a valve element assembly assembling device are arranged. Automatic operation of all processes is achieved, automatic production is achieved by controlling mechanical mechanisms through various sensors and electric components, the production efficiency is improved, and the manual operation is simplified.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com