Patents

Literature

2812results about How to "Automate operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

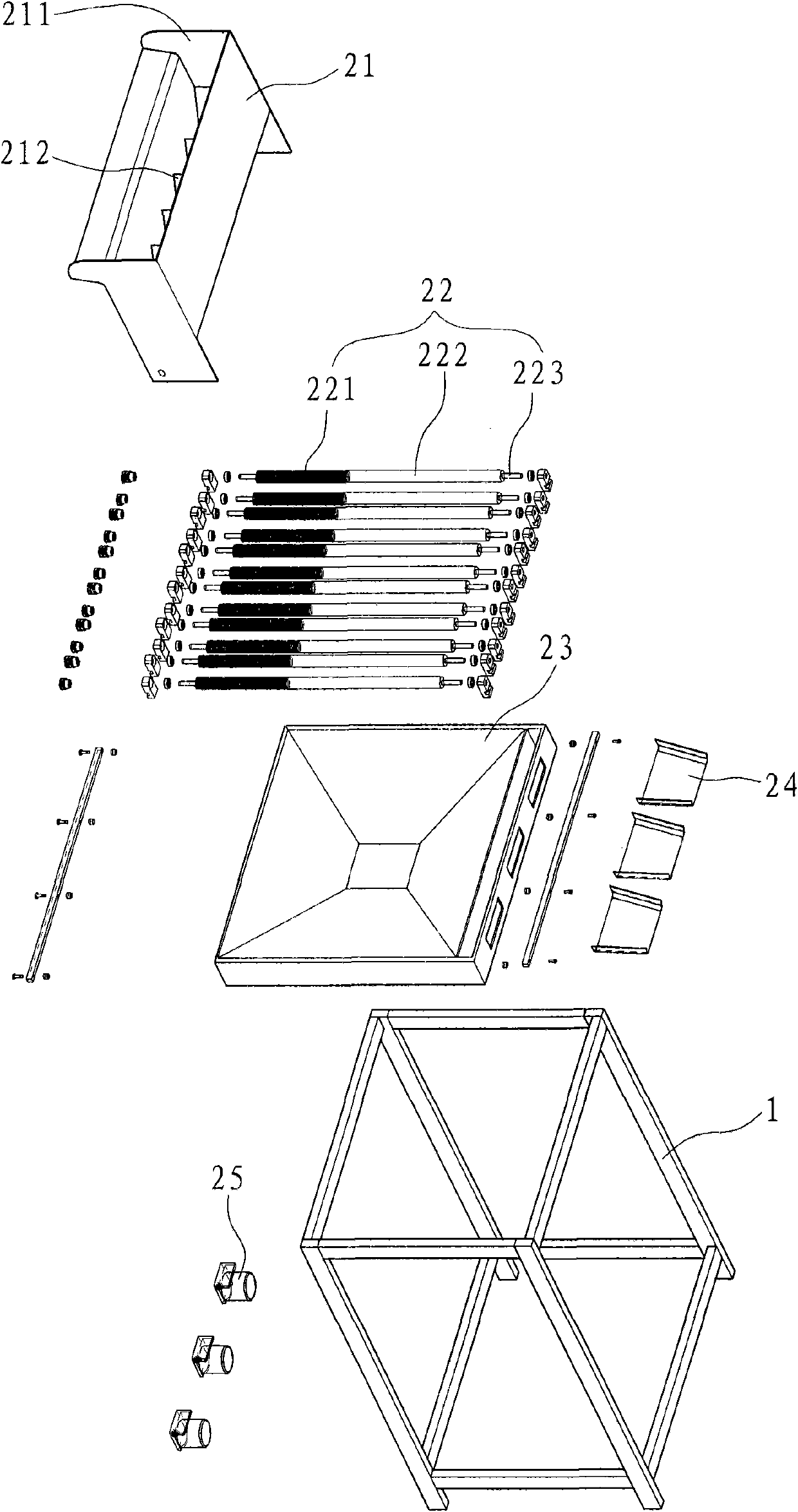

Enzyme-linked immune analysis method and fully-automatic enzyme-linked immune analyzer

ActiveCN102116771AUnique structural shapeNo wasteMaterial analysis by optical meansBiological testingTemperature controlControl system

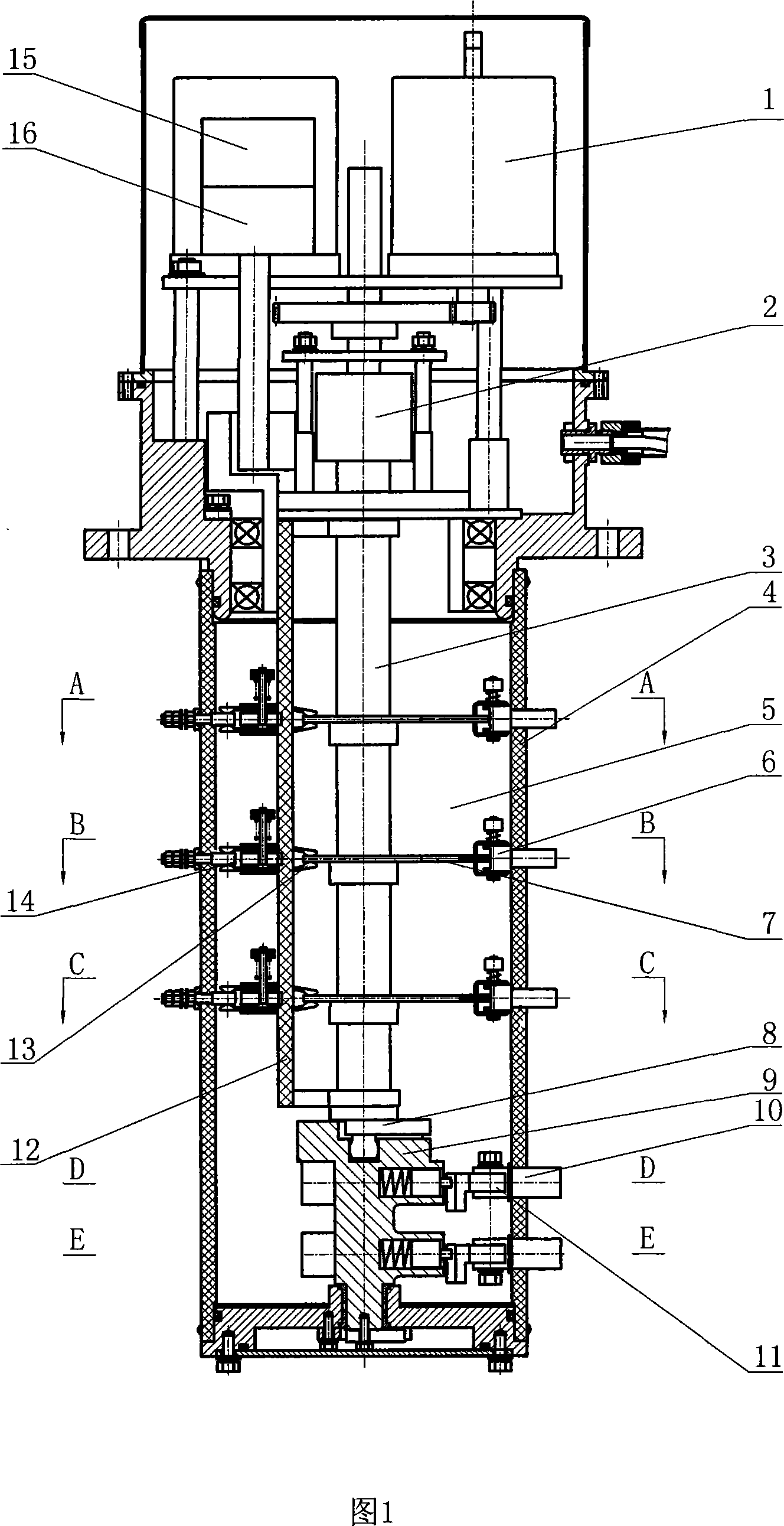

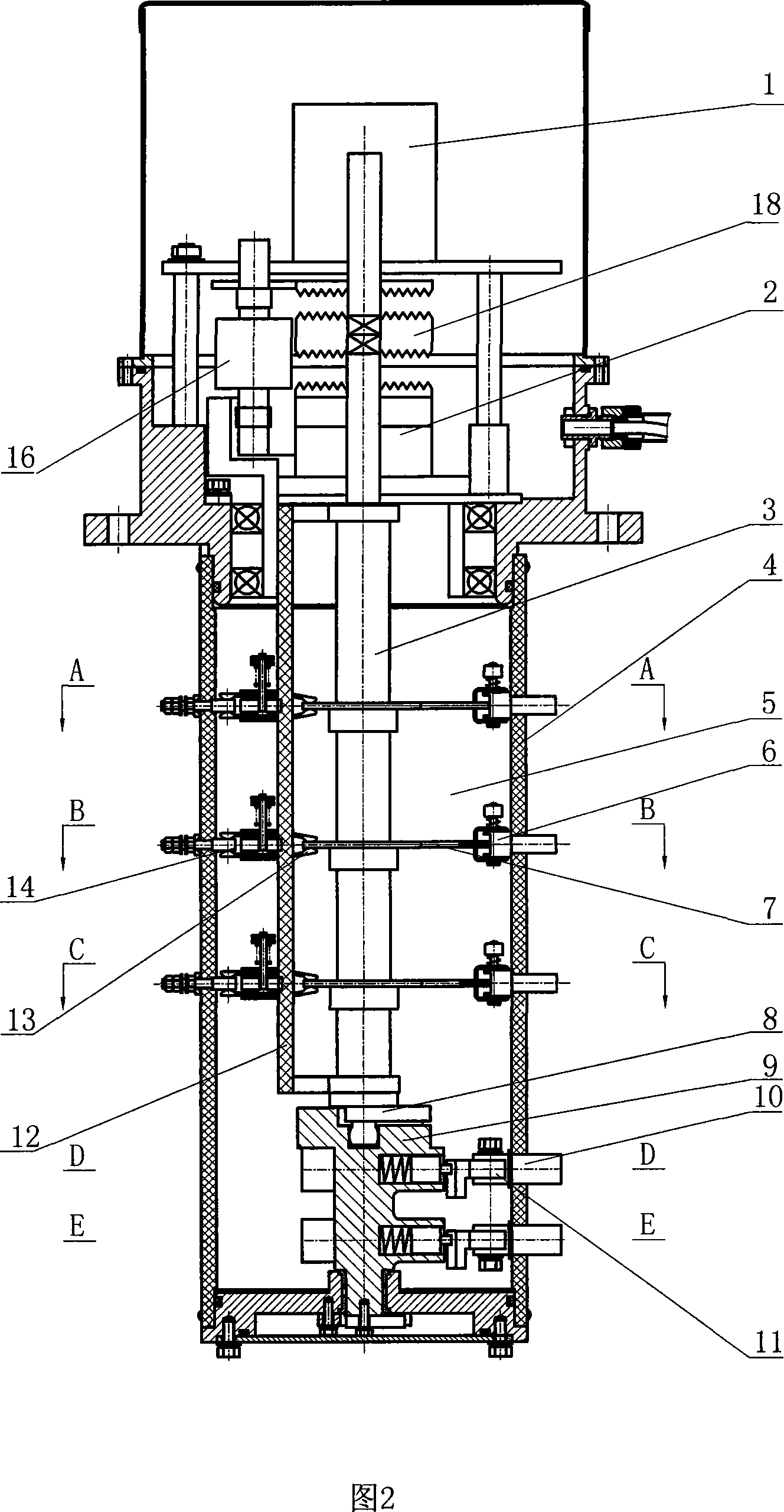

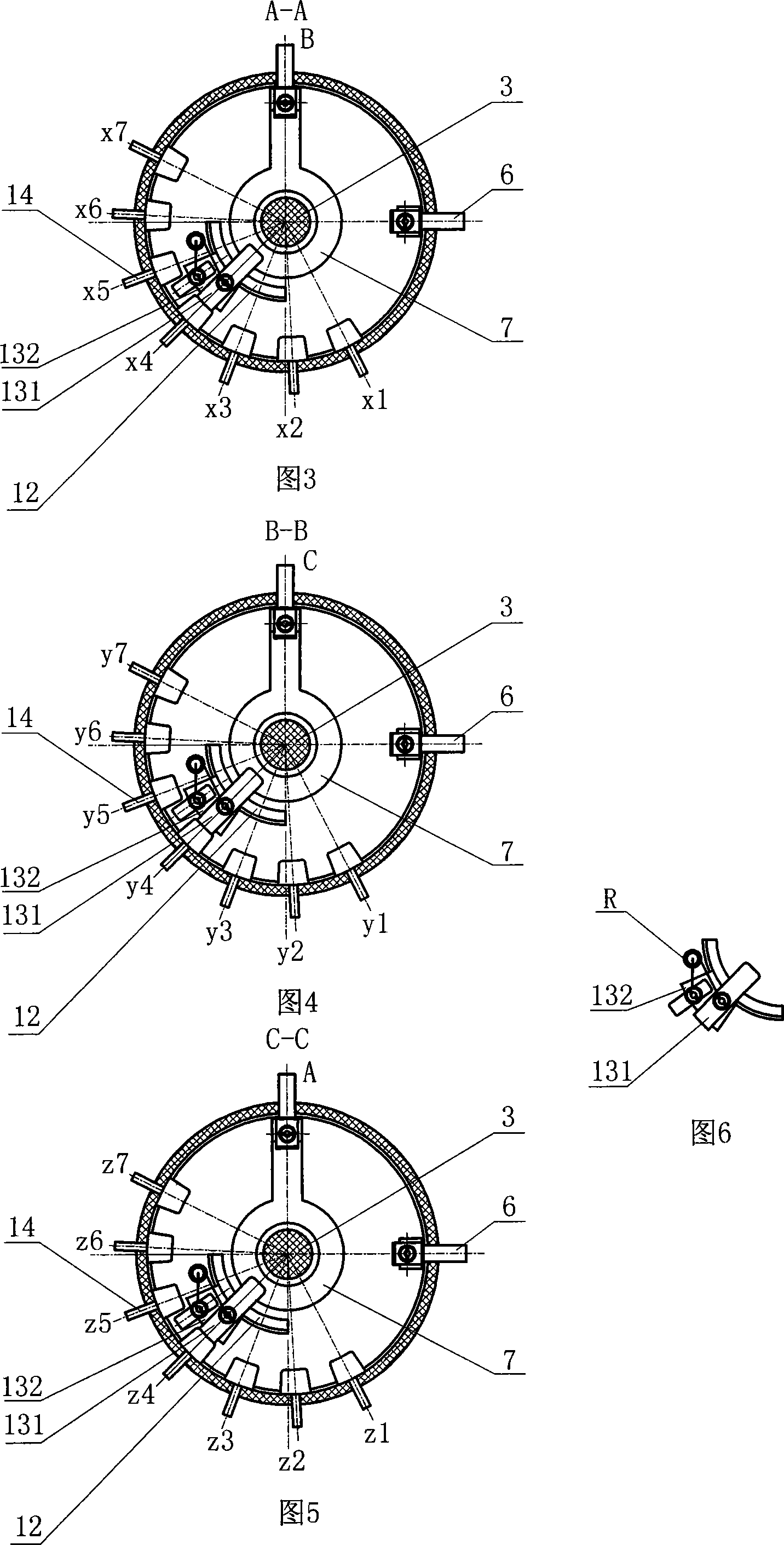

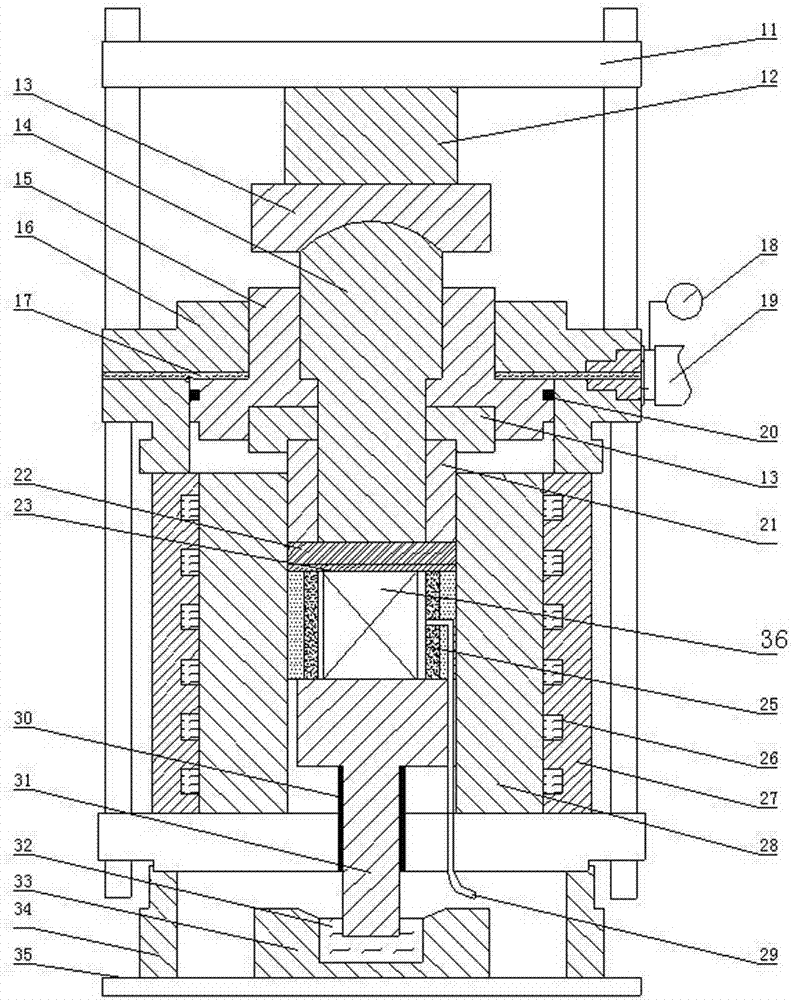

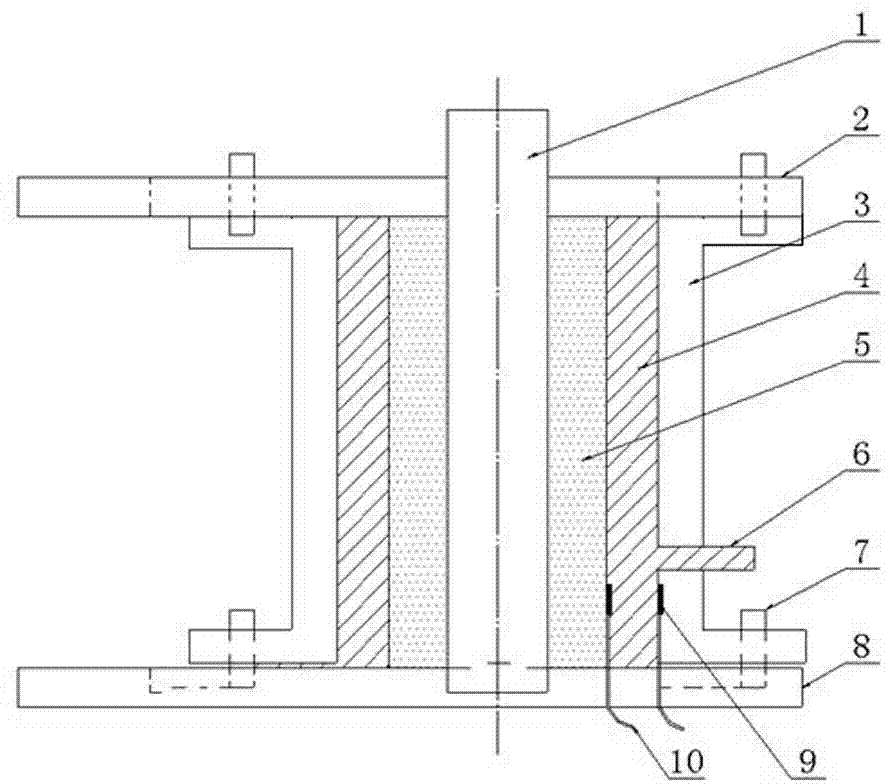

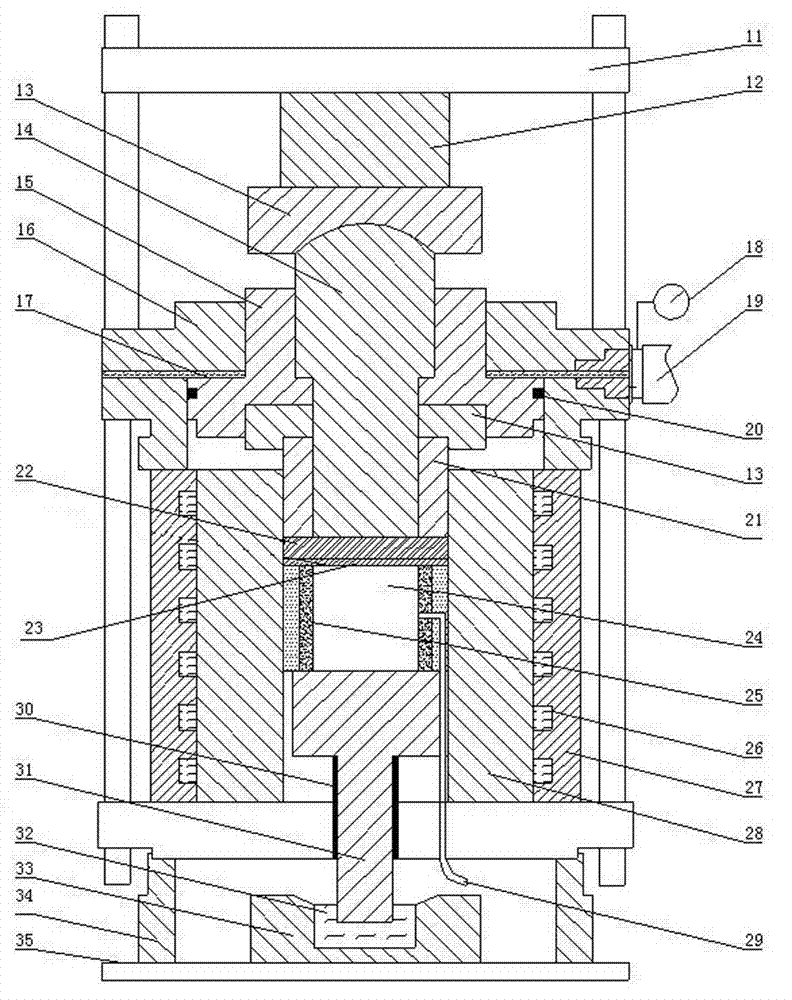

The invention relates to an enzyme-linked immune analysis method and a fully-automatic enzyme-linked immune analyzer. The analyzer comprises a rack component, a washing component, a sample adding / reagent adding component, a heating and temperature control component, a fluid path system, an input and output device, an optical measurement component and a control system, wherein the rack component comprises a rack soleplate; a pillar is arranged on the rack soleplate; a lower fixed plate and an upper fixed plate are arranged on the pillar from bottom to top in sequence; a circular reaction plate is arranged between the lower fixed plate and the upper fixed plate; the circular reaction plate is connected with the upper fixed plate and the lower fixed plate through a central shaft; a first motor is fixedly arranged at the lower part of the lower fixed plate; and the first motor is used for driving the circular reaction plate to rotate through a first transmission mechanism. When in use, the enzyme-linked immune analysis method and the fully-automatic enzyme-linked immune analyzer can carry out the detection of corresponding projects without wasting reagent through only one sample; and detection reagents need not to be respectively contained in different reagent bottles, so that the operation is very convenient, and the operation error is not easily caused, thereby ensuring the accuracy of the detection results.

Owner:SHENZHEN YHLO BIOTECH

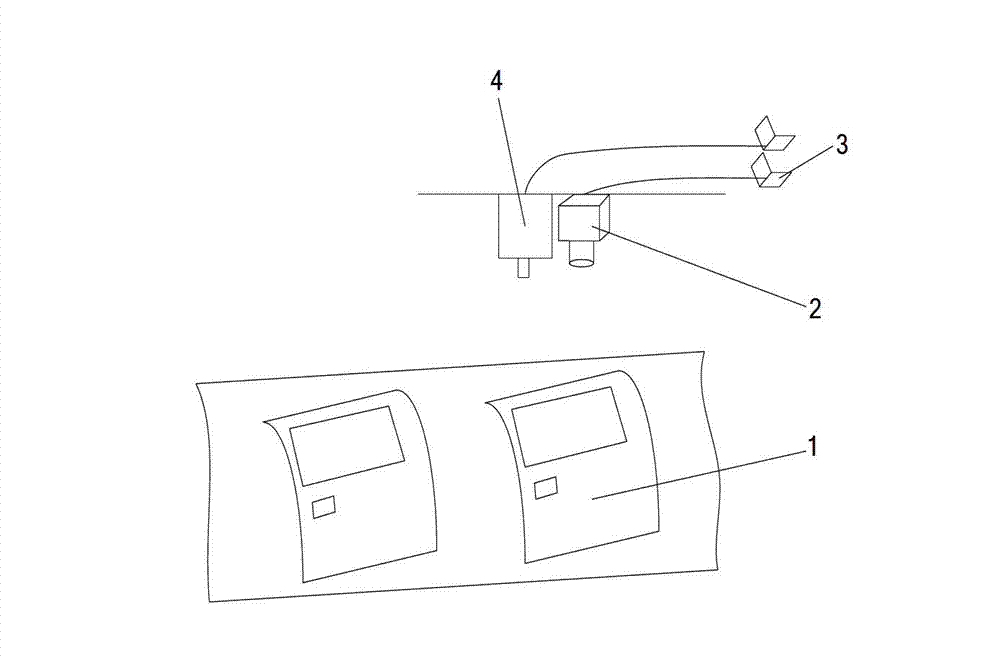

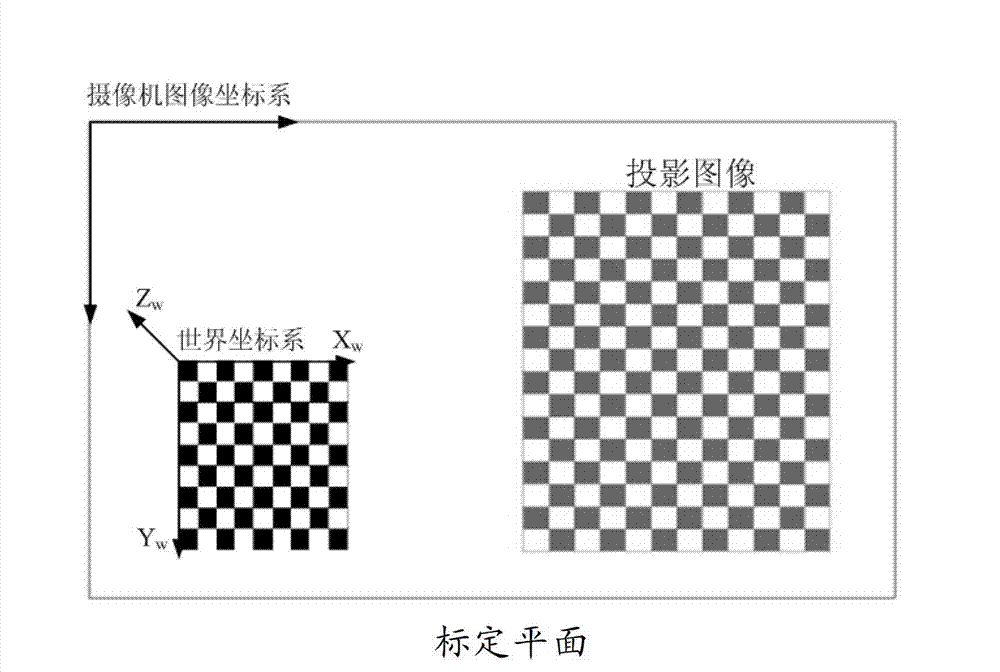

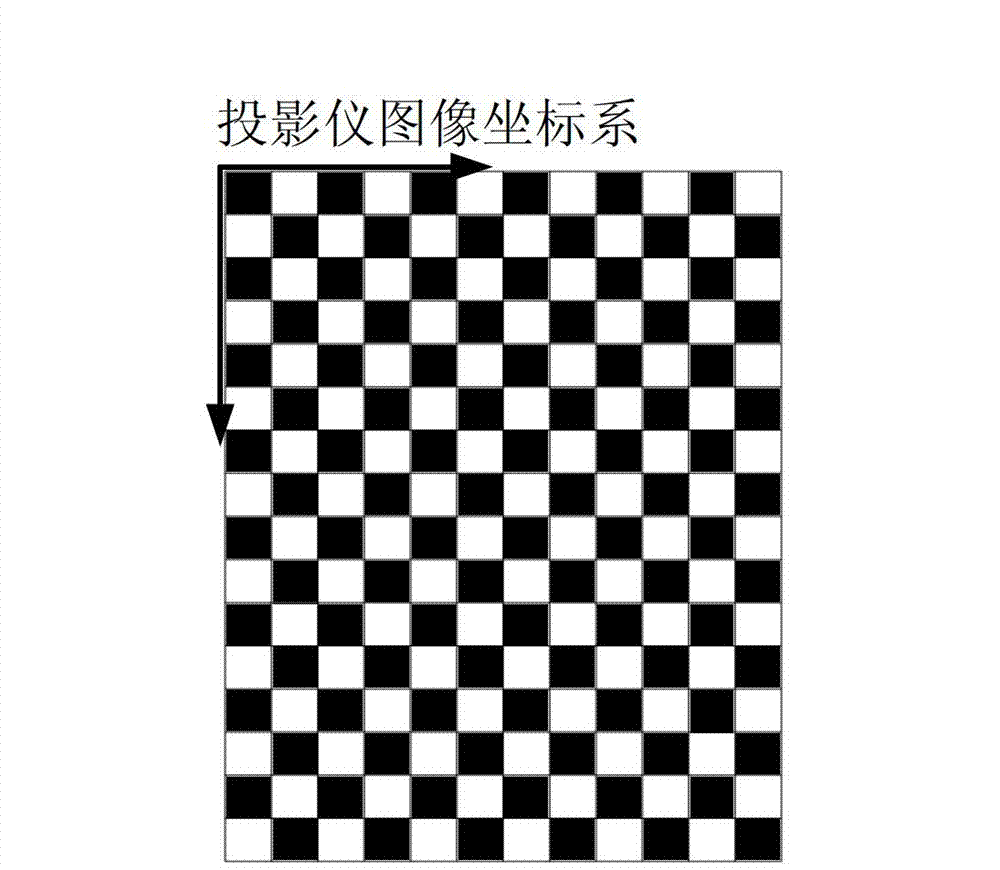

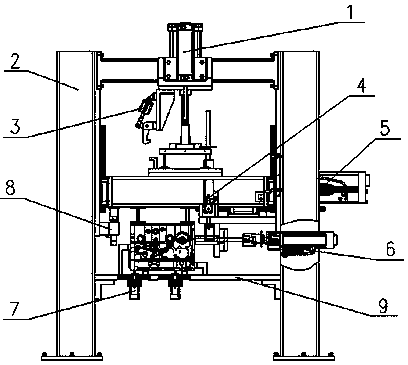

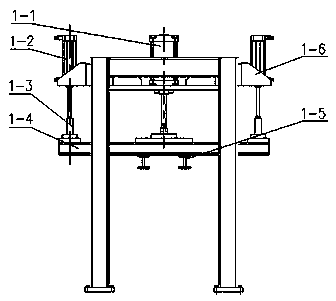

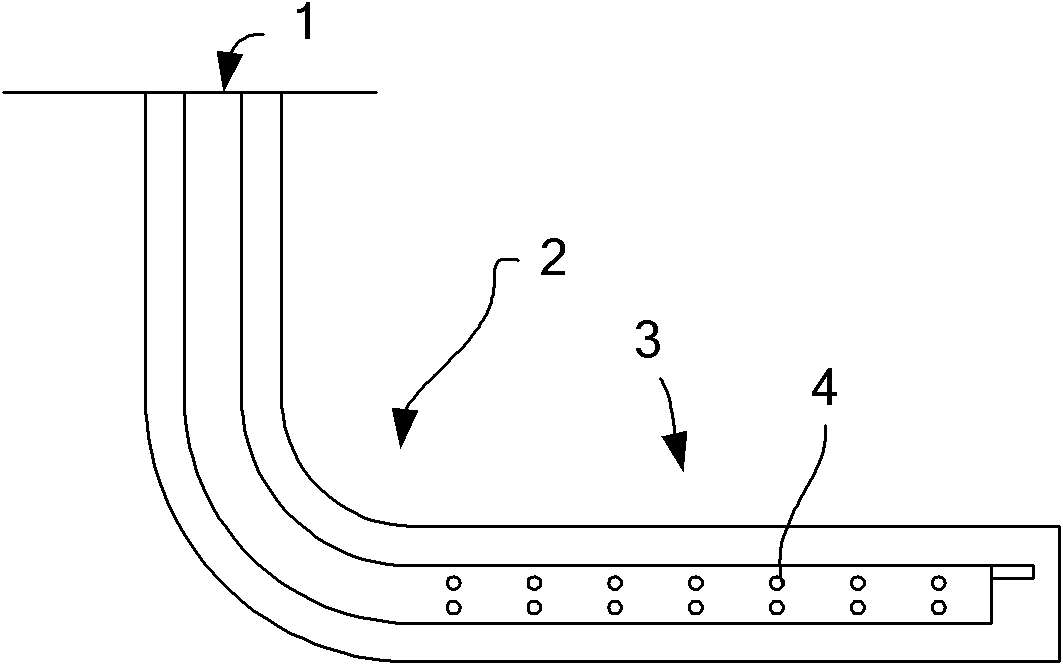

Method for detecting vehicle door outer plate shape and size based on single-projection encoding structured light

InactiveCN103047943AAutomate operationThe detection process is fastImage analysisUsing optical meansCar doorLinear relation

The invention discloses a method for detecting vehicle door outer plate shape and size based on single-projection encoding structured light and aims to break through the condition that structured light visual detecting technology is rarely applied to online detection on the vehicle door outer plate shape and size. The method comprises the following steps of 1, calibrating a structured light detecting system, i.e. calibrating a camera (2) and a projector (4), and establishing corresponding non-linear relation between a space position and an image coordinate; 2, designing an encoding projection template; 3, decoding and identifying a detecting image, i.e. projecting the encoding projection template to the surface of a vehicle door outer plate by using the projector (4), shooting a surface image of the vehicle door outer plate by using the camera (2), and transmitting the shot image to a computer to be processed and identified; and 4, calculating a space point cloud coordinate and evaluating an error, i.e. 1) calculating a three-dimensional space coordinate of surface projection image characteristic points of the vehicle door outer plate, and 2) matching and rectifying a detecting point cloud obtained through calculation and a point cloud model measured by a three-coordinate measuring machine.

Owner:JILIN UNIV

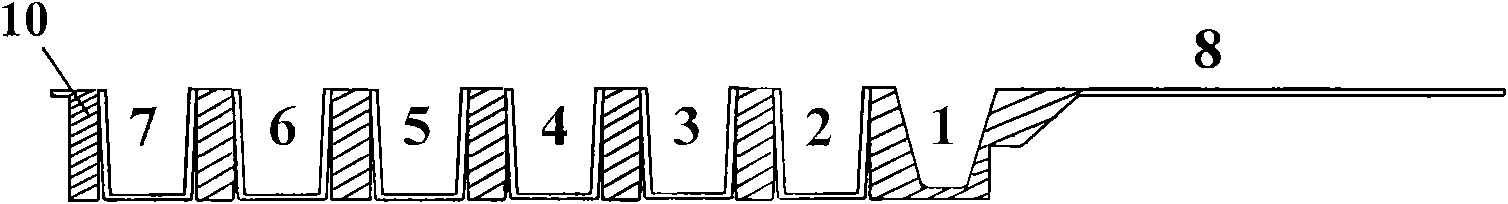

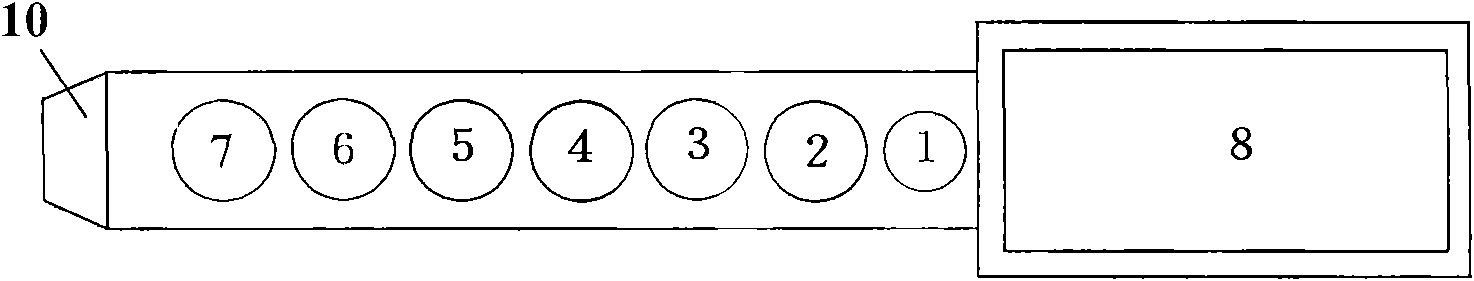

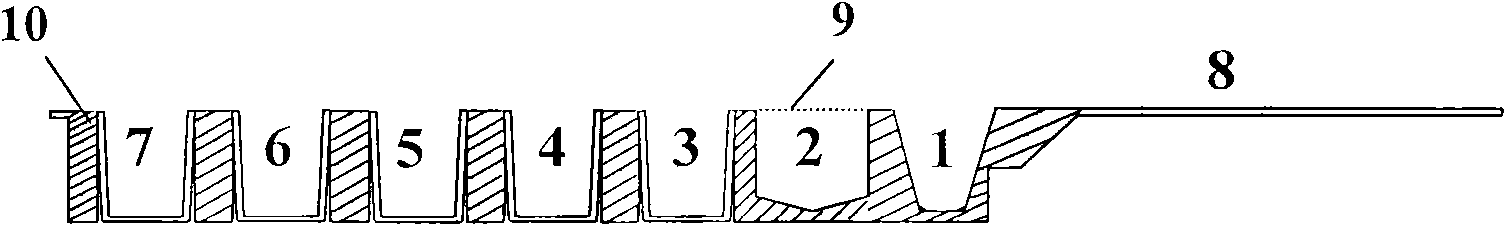

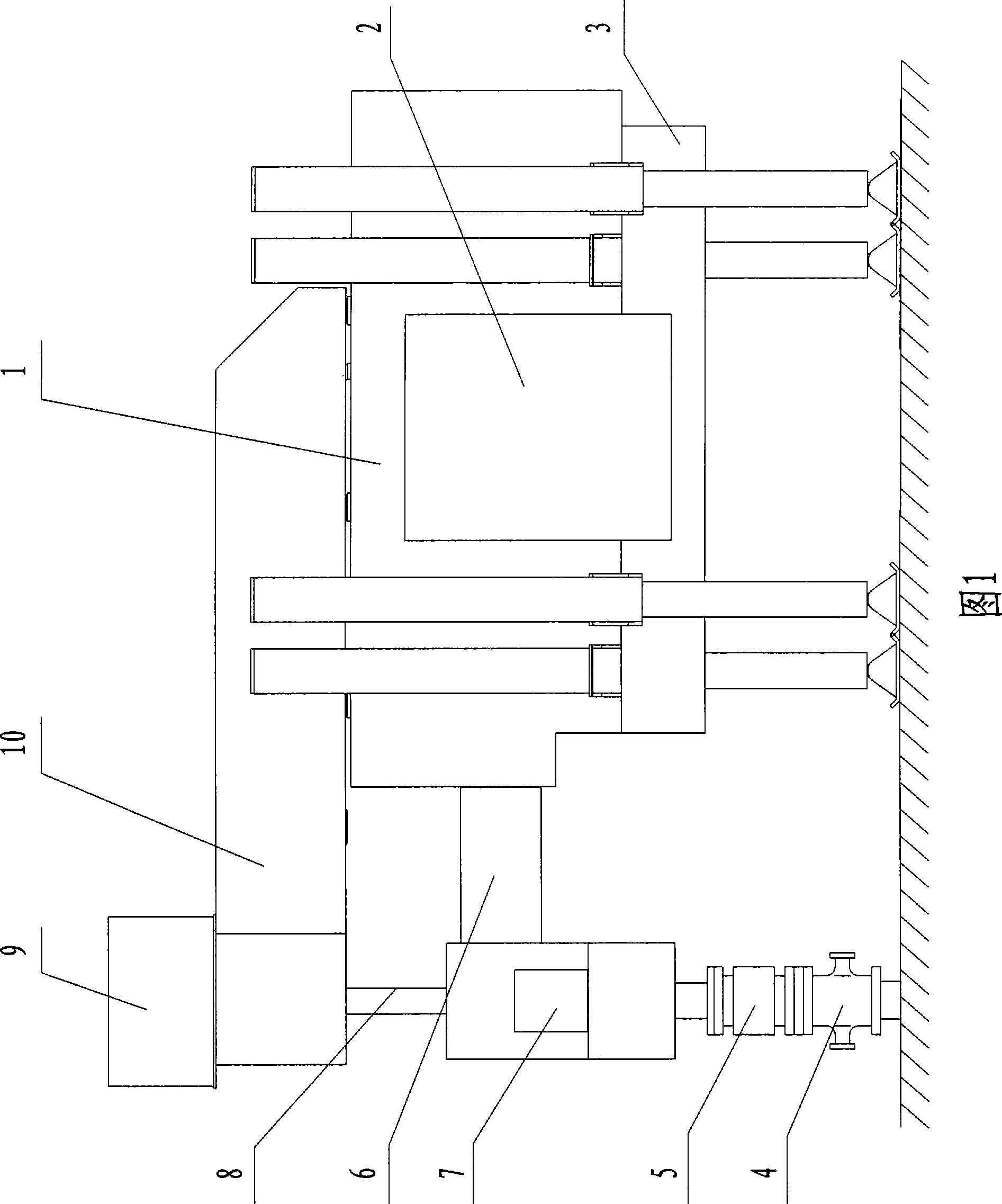

Pressing machine for liner

ActiveCN104028999APrevent slippingAvoid violent collisionsMetal working apparatusControl systemProgrammable logic controller

A pressing machine for a liner comprises a programmable logic controller (PLC) control system, a frame, a clamping mechanism, a plugging mechanism, a feeding mechanism, a pushing mechanism and a pressing mechanism. The clamping mechanism is arranged on the upper portion of the frame. A working platform is arranged on the lower portion of the frame. The plugging mechanism is fixedly arranged on the lower end surface of the working platform and corresponding to a positioning hole of the working platform. The pushing mechanism is arranged on a pressing plate of the clamping mechanism. The pressing plate is provided with a transversal linear slide. The feeding mechanism and the pressing mechanism are matched and respectively connected with the pushing mechanism through a mounting plate. The clamping mechanism, the plugging mechanism, the feeding mechanism, the pushing mechanism and the pressing mechanism are all controlled by the PLC control system. The pressing machine is adaptable to assembling of the liner of an oil pump cylinder body of an engine, and capable of realizing automatic operation, improving working efficiency, reducing labor intensity and improving products quality.

Owner:长城汽车股份有限公司平湖分公司

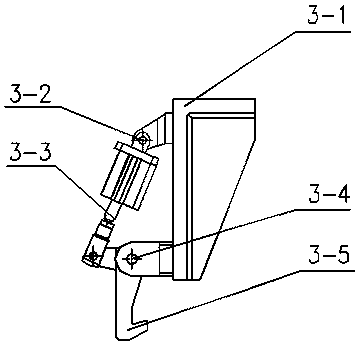

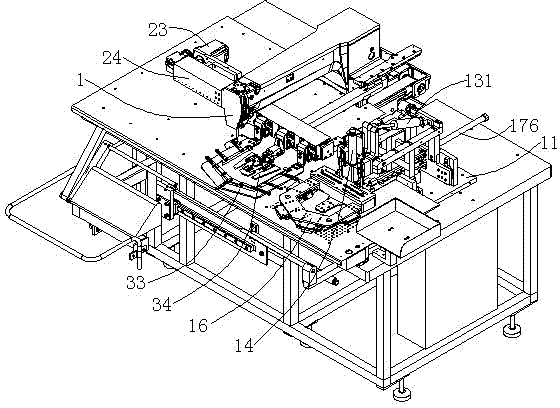

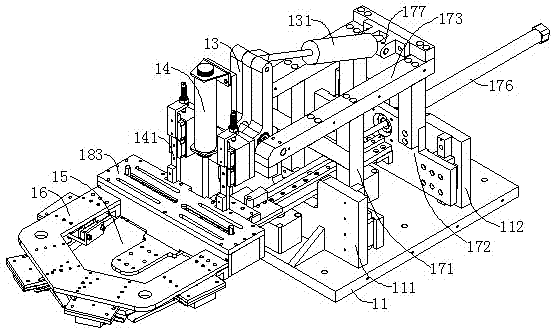

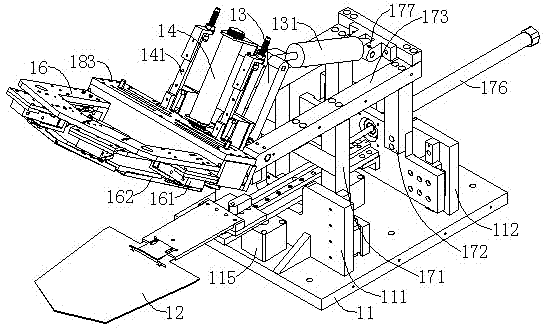

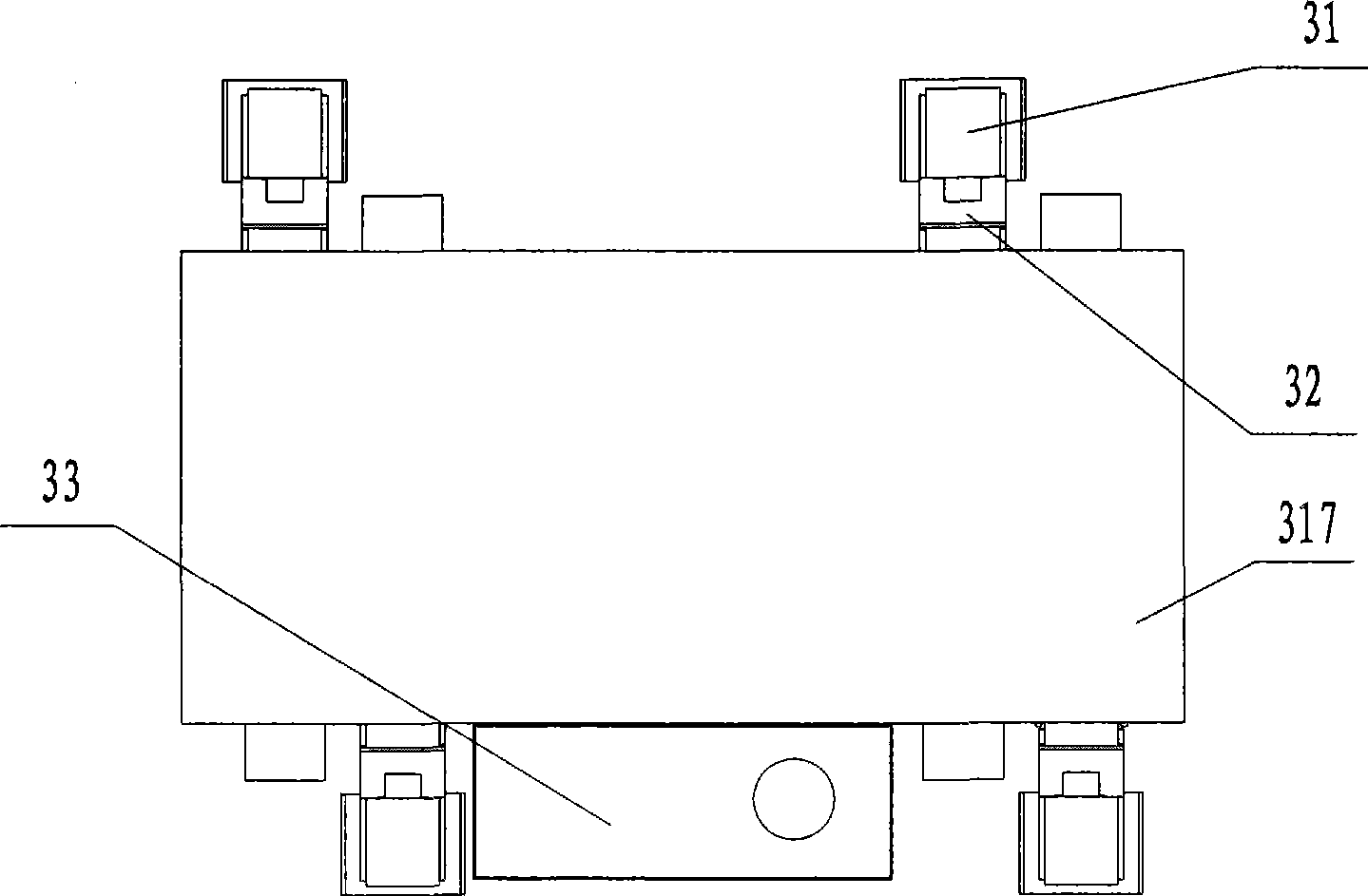

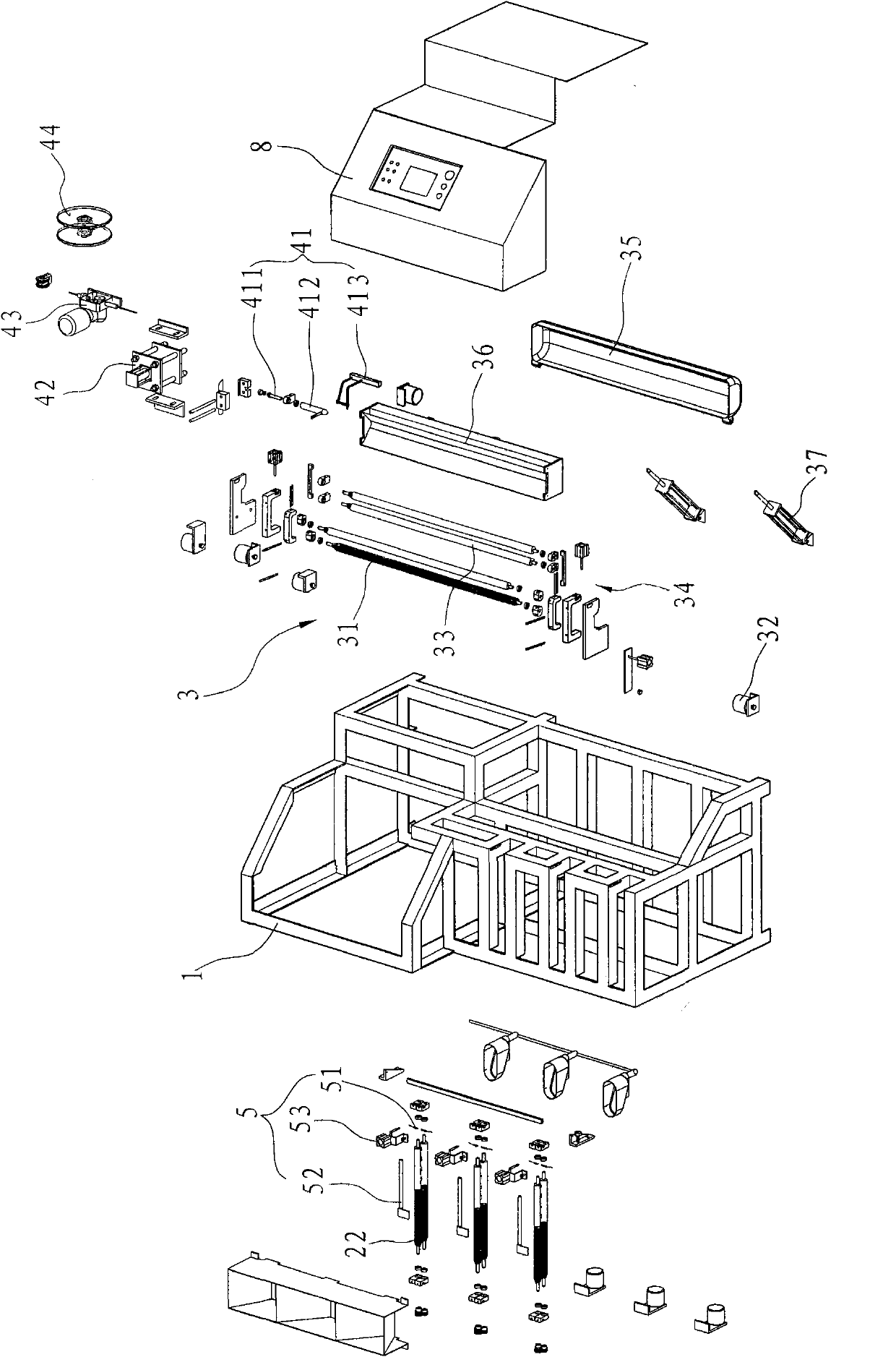

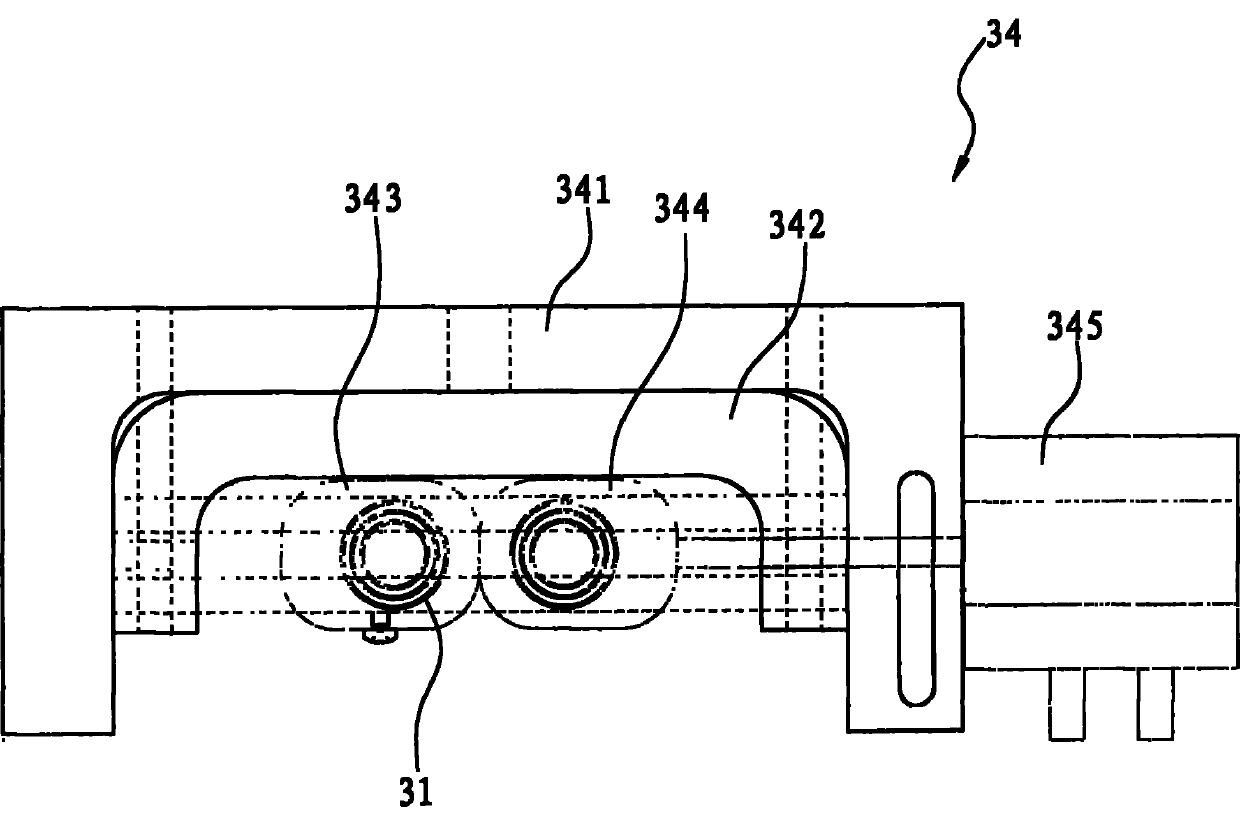

Full-automatic patch pocket machine

ActiveCN102899817ACompact structureSave installation spaceWork-feeding meansPressersEngineeringSewing machine

The invention discloses a full-automatic patch pocket machine which comprises a sewing machine head, a folding device, a pressing device and a feeding device, wherein the folding device comprises a mounting bracket which is capable of vertically moving and is arranged on a fixed base plate; a template for loading a pocket piece is arranged on the mounting bracket; the template can horizontally stretch relative to the mounting bracket; a pressing plate and a folding bracket are fixedly connected with a moveable bracket; the pressing plate is used for pressing by matching with the template; thefolding bracket is provided with a folding cylinder; a feeding mounting plate which is connected with the feeding device is arranged on the pressing device; an auxiliary pressing foot and a pressing frame are arranged on the feeding mounting plate; the auxiliary pressing foot is used for pressing the pocket piece on the template; the pressing frame is used for pressing cloth; pressing blocks are distributed on the periphery of the pressing frame; and the feeding device is used for driving the pressing device to send the pressed pocket piece and cloth to a sewing position of the sewing machinehead. The full-automatic patch pocket machine can be used for folding the pocket piece into a pocket and sewing on the corresponding cloth and solving the problems of complex pocket processing structure and low working efficiency of the prior art.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

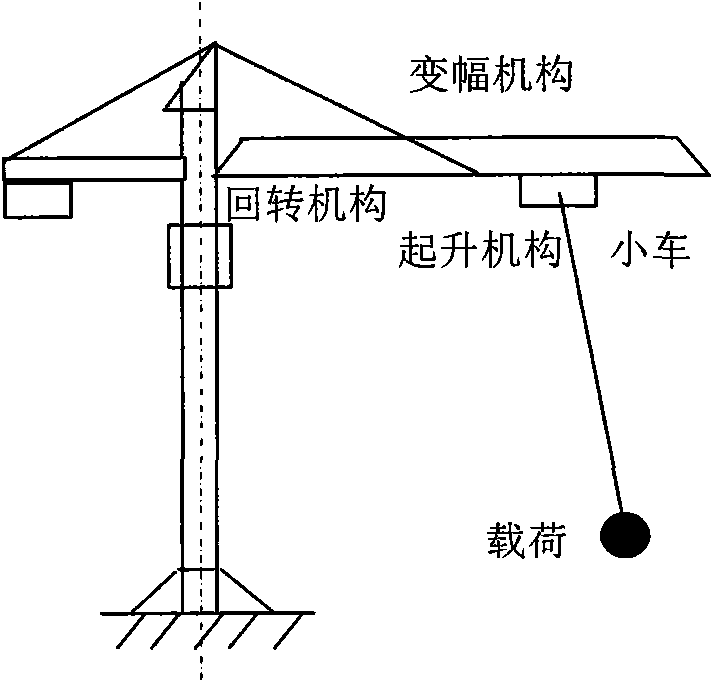

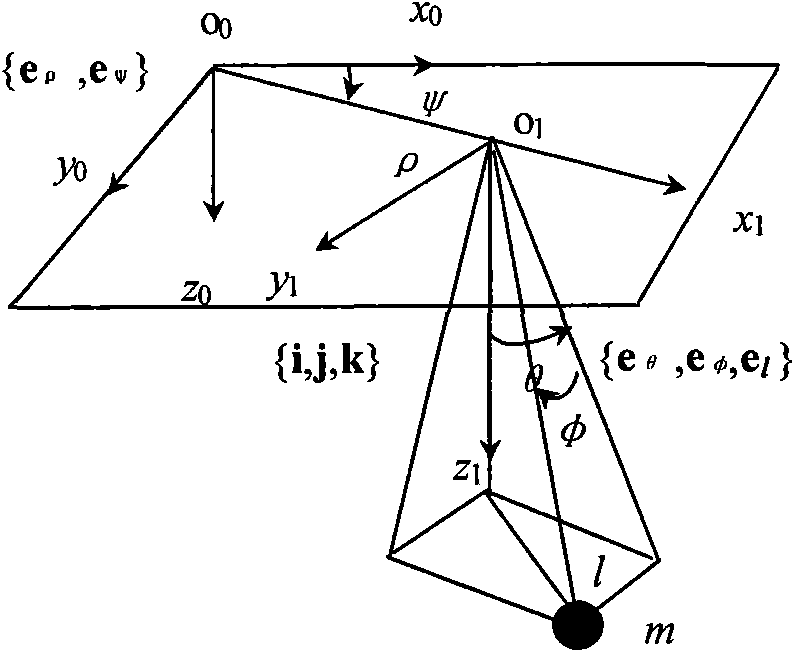

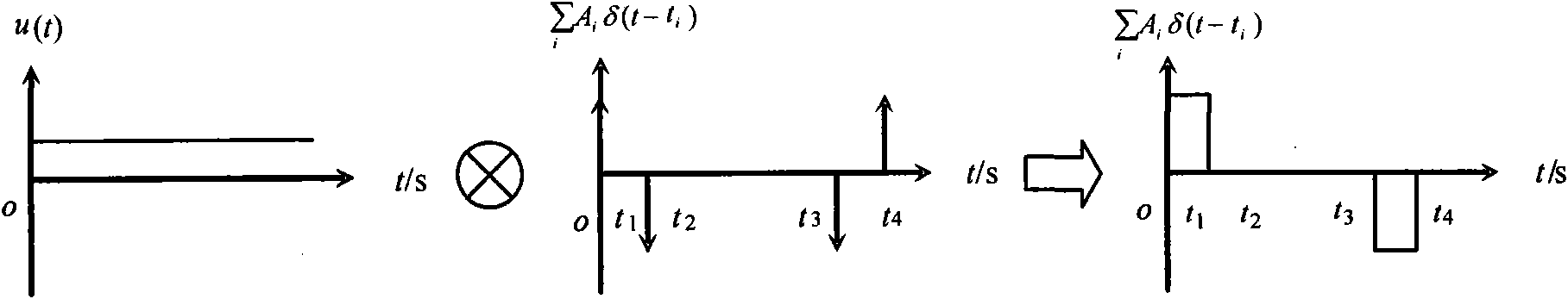

PLC frequency-converting speed-governing control system for eliminating tower-type crane load

InactiveCN101659375AImprove work efficiencyImprove securityLoad-engaging elementsDynamic modelsControl system

The invention discloses a PLC frequency-converting speed-governing control system for eliminating tower-type crane load, based on an E1 time-delayed filter, which is developed by the following steps:establishing an inertia pole coordinate system, a non-inertia cartesian coordinate system and a non-inertia sphere coordinate system; establishing a nonlinear dynamics model and a linear dynamics model of a tower-type crane. The control system comprises an operation console, a controller, a PLC, a frequency-converting set, a hoisting mechanism motor, a brake, a hoisting mechanism, an amplitude varied mechanism motor, an amplitude varied mechanism, a swing mechanism motor and a swing mechanism. The controller consists of a load swing frequency and damping ratio calculation unit, a system parameter calculation unit and a time-delayed filter calculation unit. The invention provides the PLC frequency-converting speed-governing control system based on the dynamic property and the time-delayed filter principle of the tower-type crane, which has simple structure, low cost, convenient operation and effective elimination of load swing.

Owner:SHANDONG JIANZHU UNIV

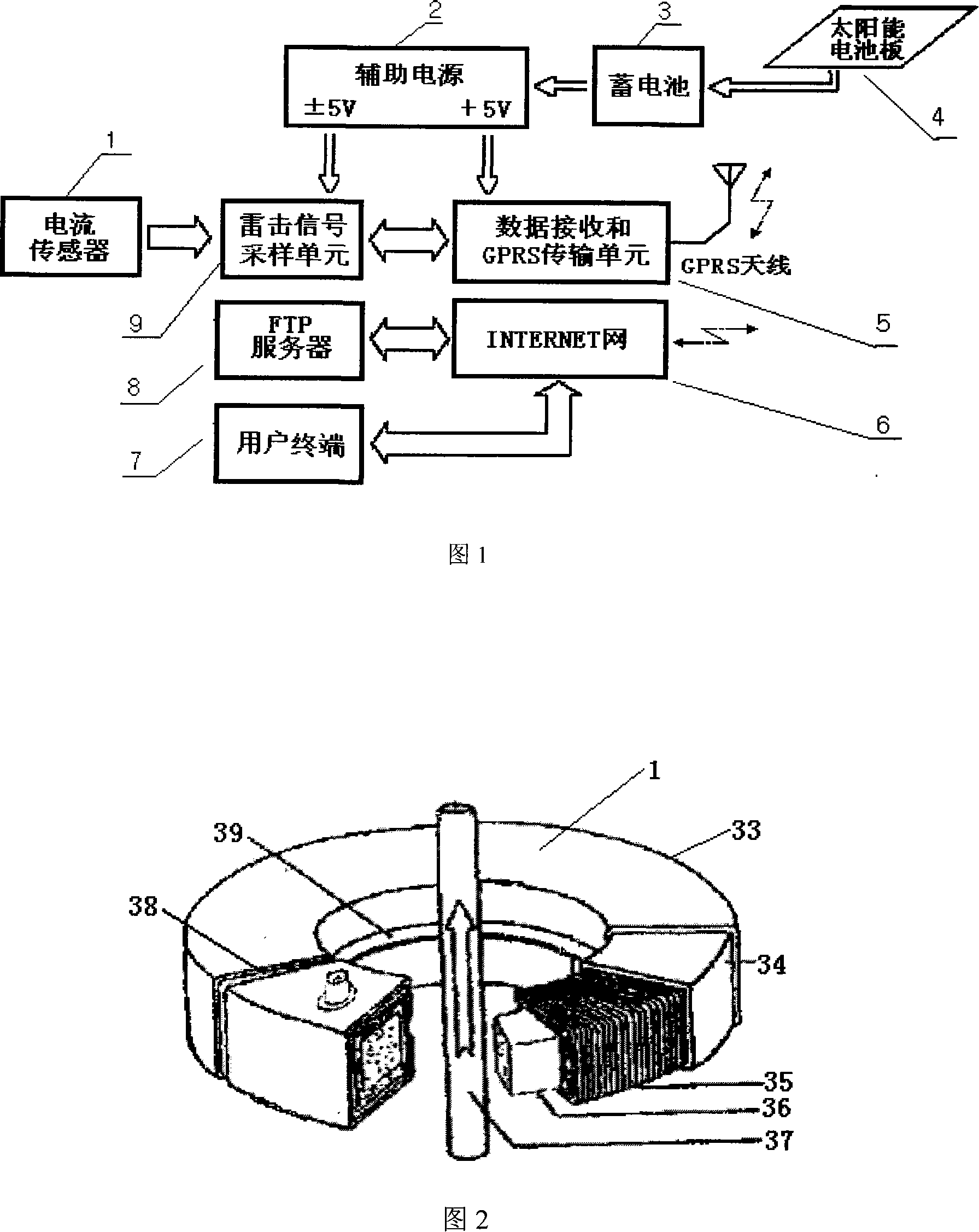

Transmission line lightning stroke on-line monitoring system

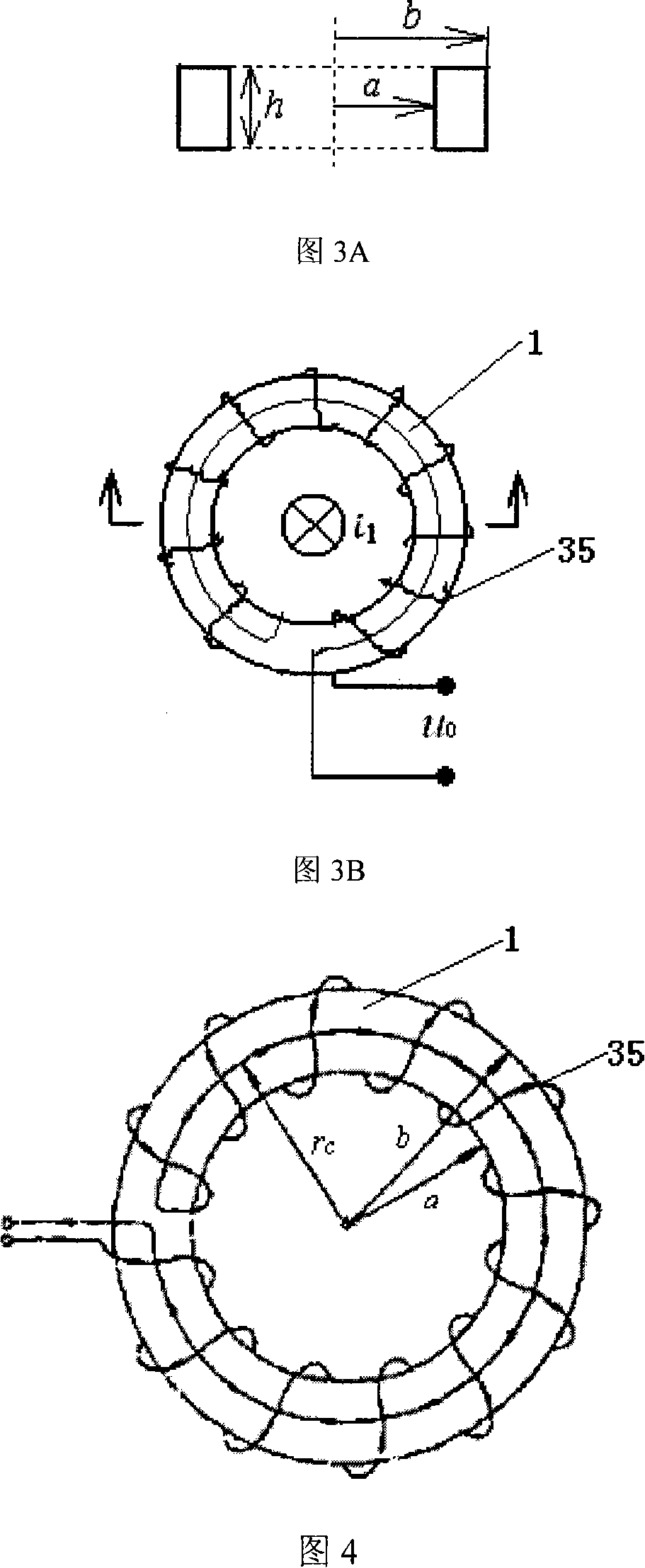

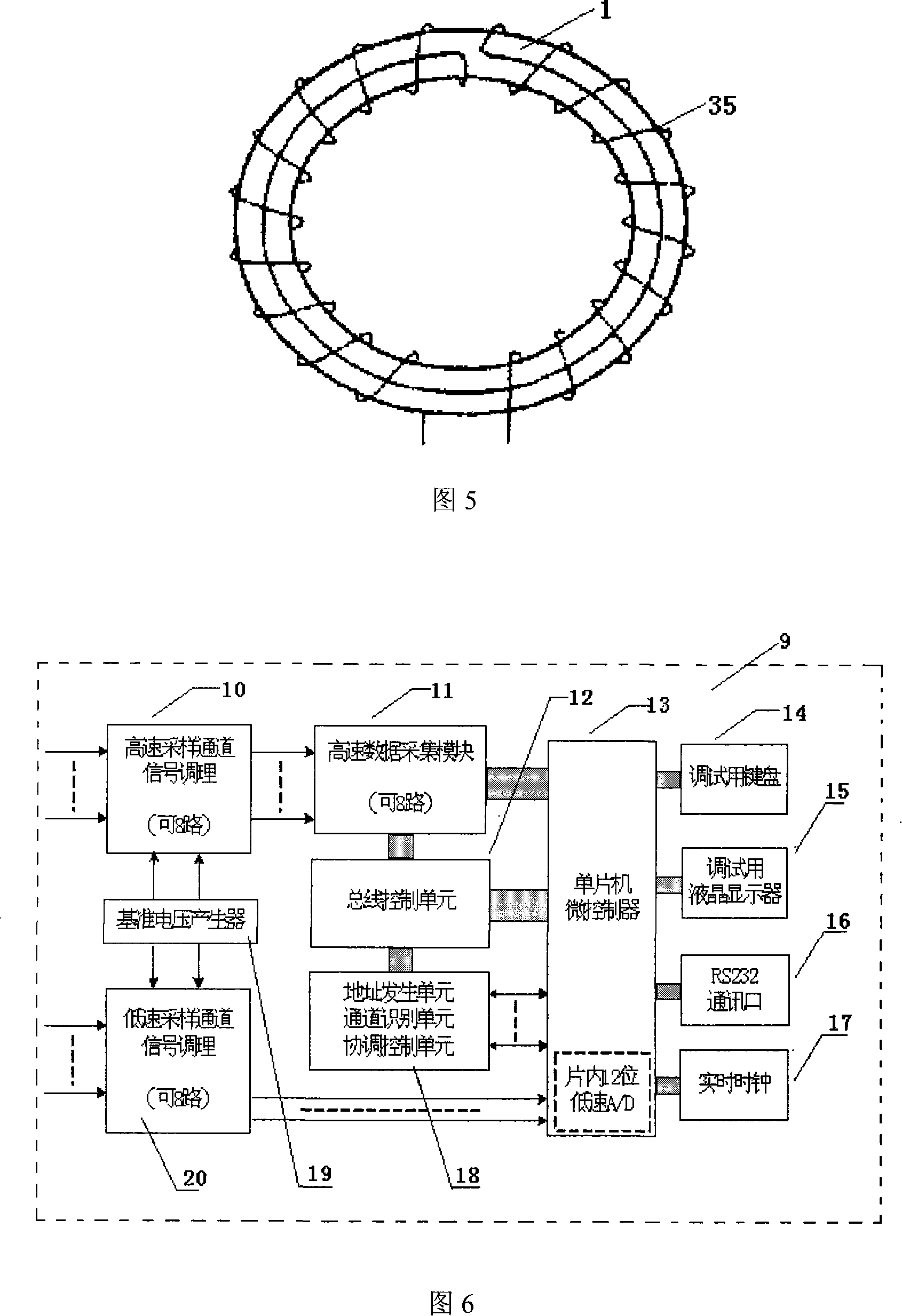

ActiveCN101149400AWon't flow throughForm of intelligent judgmentElectric signal transmission systemsDirection of current indicationThe InternetCurrent sensor

This invention discloses a kind of transmit electricity circuit lightning strike online monitor system, it includes the current sensor, the lighting strike signal collection cell, the Russell loop, the accumulator links with the solar battery, the pressure converter separately, the pressure converter links with the lighting strike signal collection cell, data receive and GPRS transmission cell separately, the lighting strike signal collection cell links with the current sensor, data receive and GPRS transmission cell separately, the lighting strike signal collection cell A / D sends the gained thunderstorm current data to the data receive and GPRS transmission cell through the RS232 interface after collecting, the data receive and GPRS transmission cell sends the data gained by each thunderstorm current sensor to the internet by handset network, then to the FTP server, links with the user terminal by the server use network line. The structure of this invention is simple, the operation is automatic, the measurement is stable, the data is correct.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +1

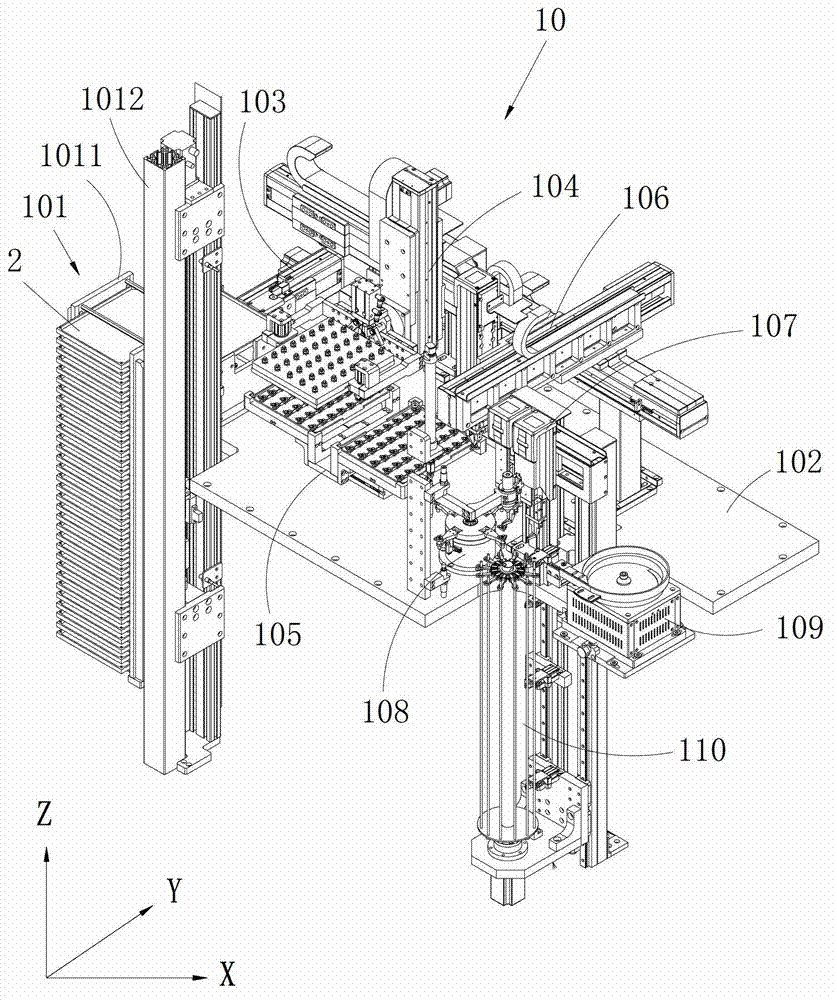

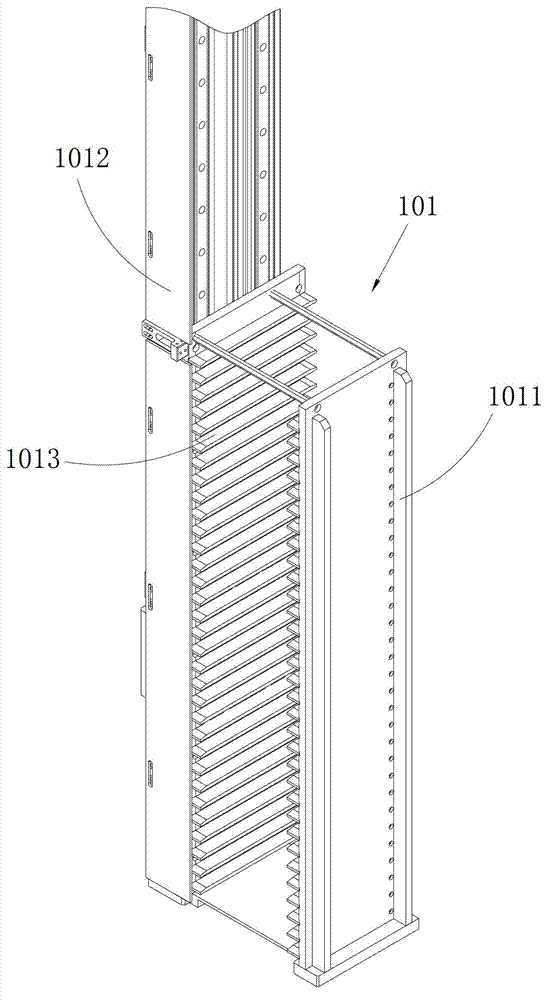

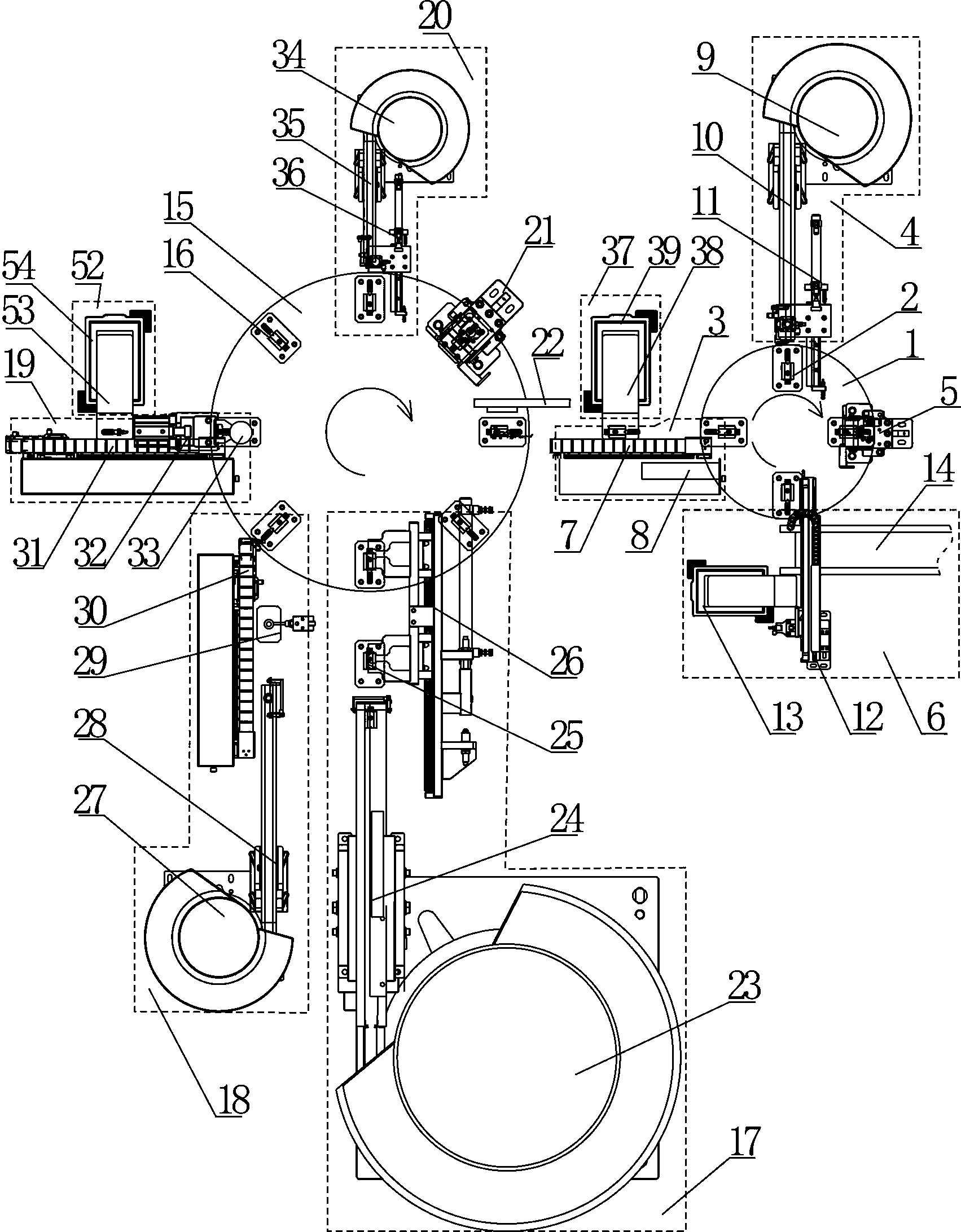

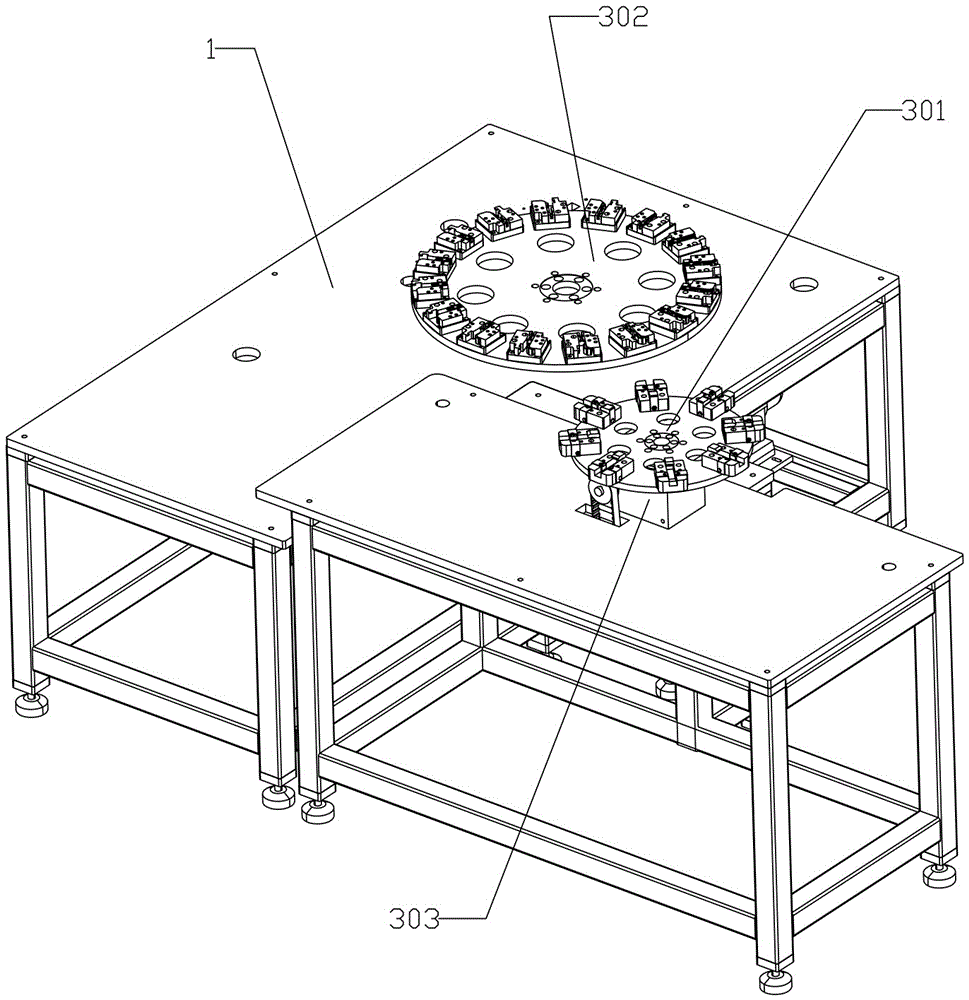

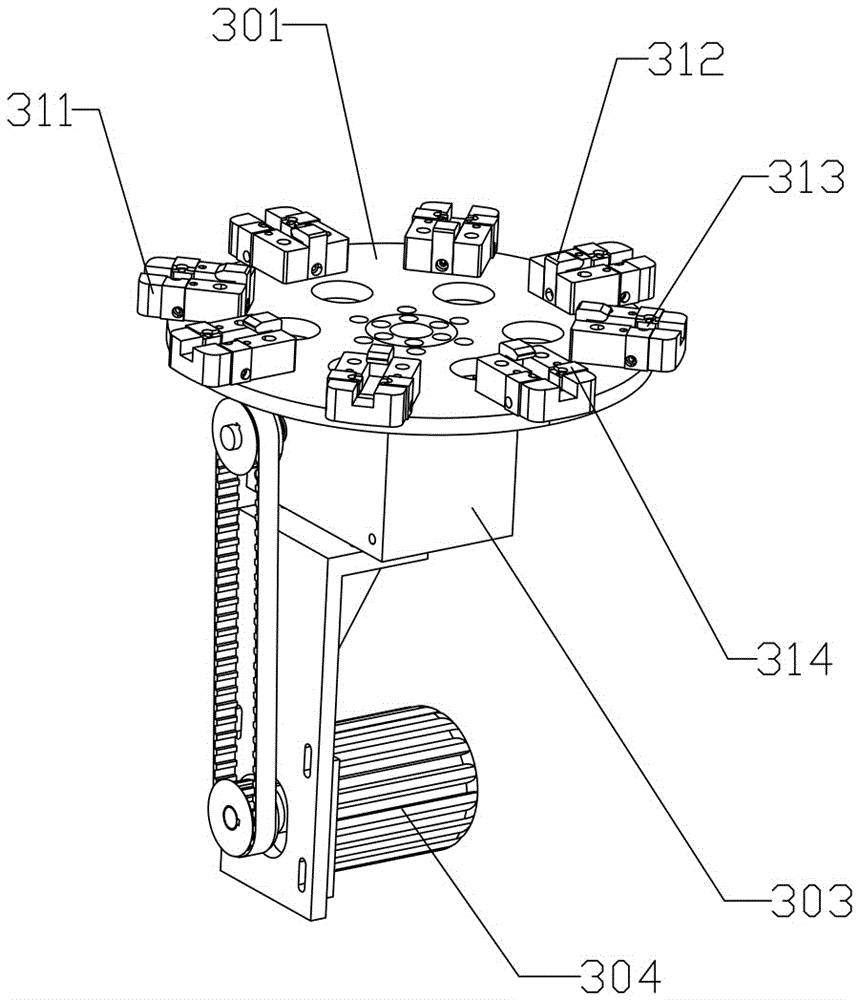

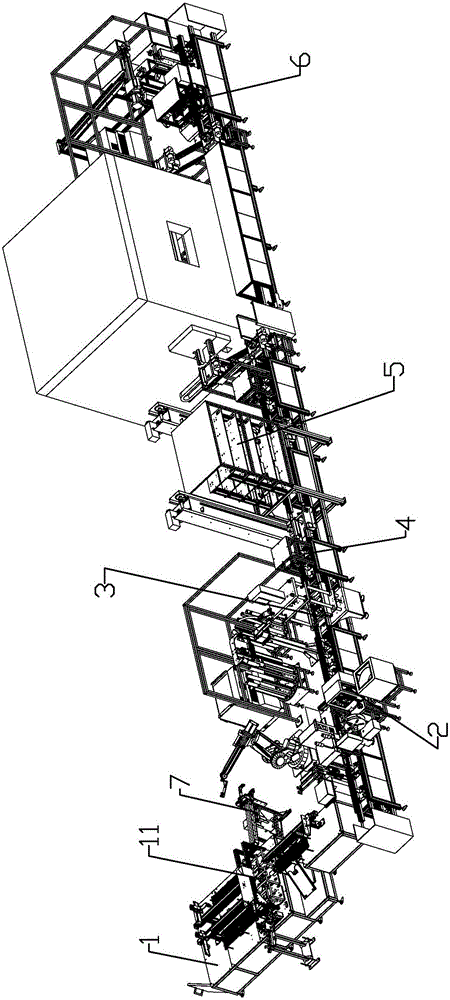

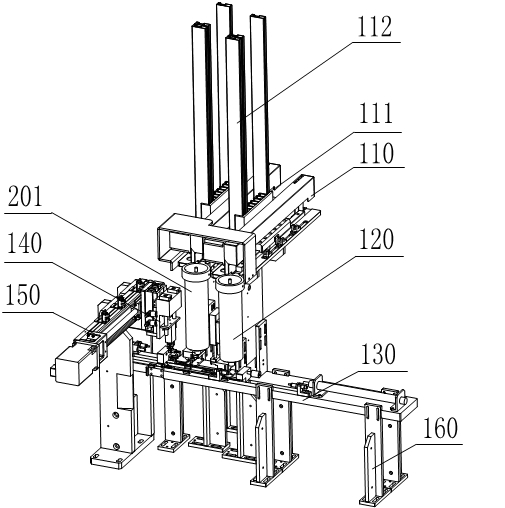

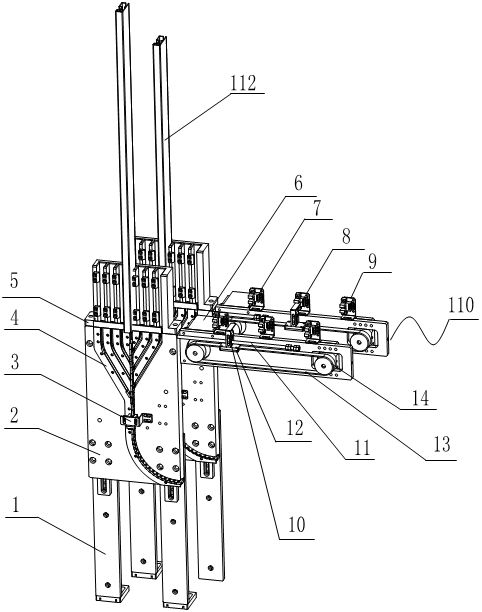

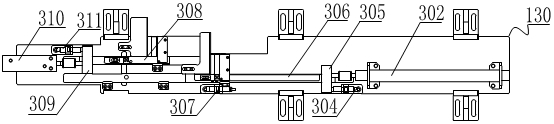

Loading equipment

The invention relates to the technical field of mechanical equipment and discloses loading equipment. The loading equipment comprises a charging tray mechanism, a tray moving mechanism, a middle transition mechanism, a turning conveying mechanism, a first part taking mechanism, a rotary platform, a second part taking mechanism and a sleeved mechanism. The charging tray mechanism is used for placing a charging tray, the tray moving mechanism is used for taking out of the charging tray in the charging tray mechanism, the middle transition mechanism is used for placing the charging tray, the turning conveying mechanism is used for grabbing a material plate in the middle transition mechanism, enabling the material plate and the charging tray to be overlapped, and enabling the overlapped material plate and charging tray turning to be arranged on the middle transition mechanism, and the first part taking mechanism and the rotary platform are used for grabbing blades on the charging tray. The second part taking mechanism is used for grabbing blades on the rotary platform and gaskets in a vibration platform, and the sleeved mechanism is used for being sleeved on the blades and the gaskets which are grabbed by the second part taking mechanism. The whole operation process of sleeved equipment is controlled by a control center, achieves automatic operation, does not need manual participation, greatly improves operation efficiency, does not need staff cost, reduces cost, avoids misoperation phenomenon of operation of staff due to adopting of automatic operation, and therefore guarantees quality of the blades.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

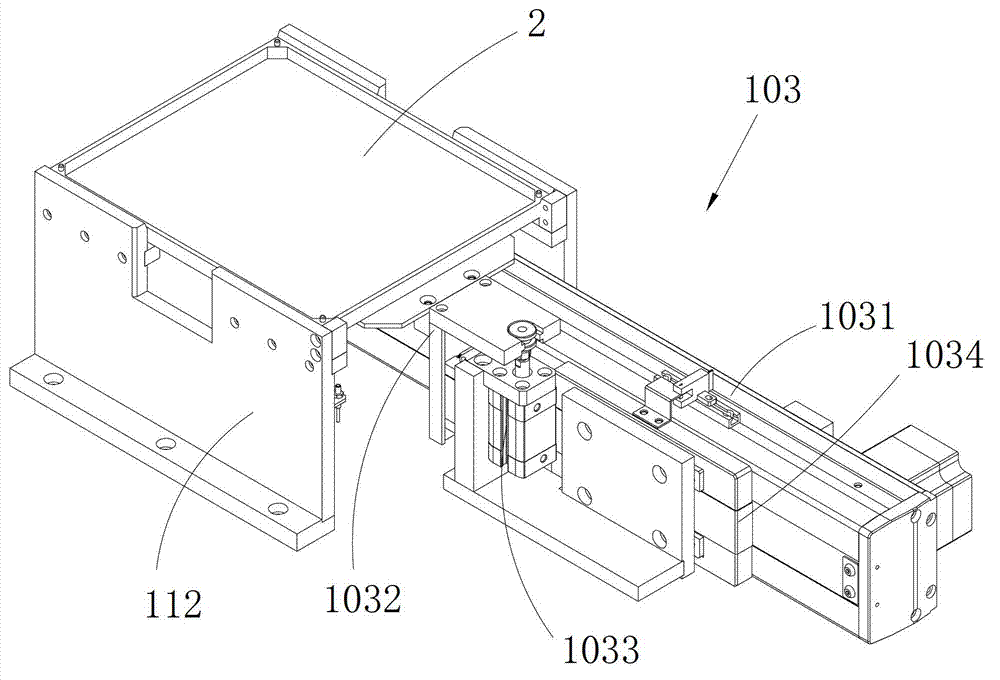

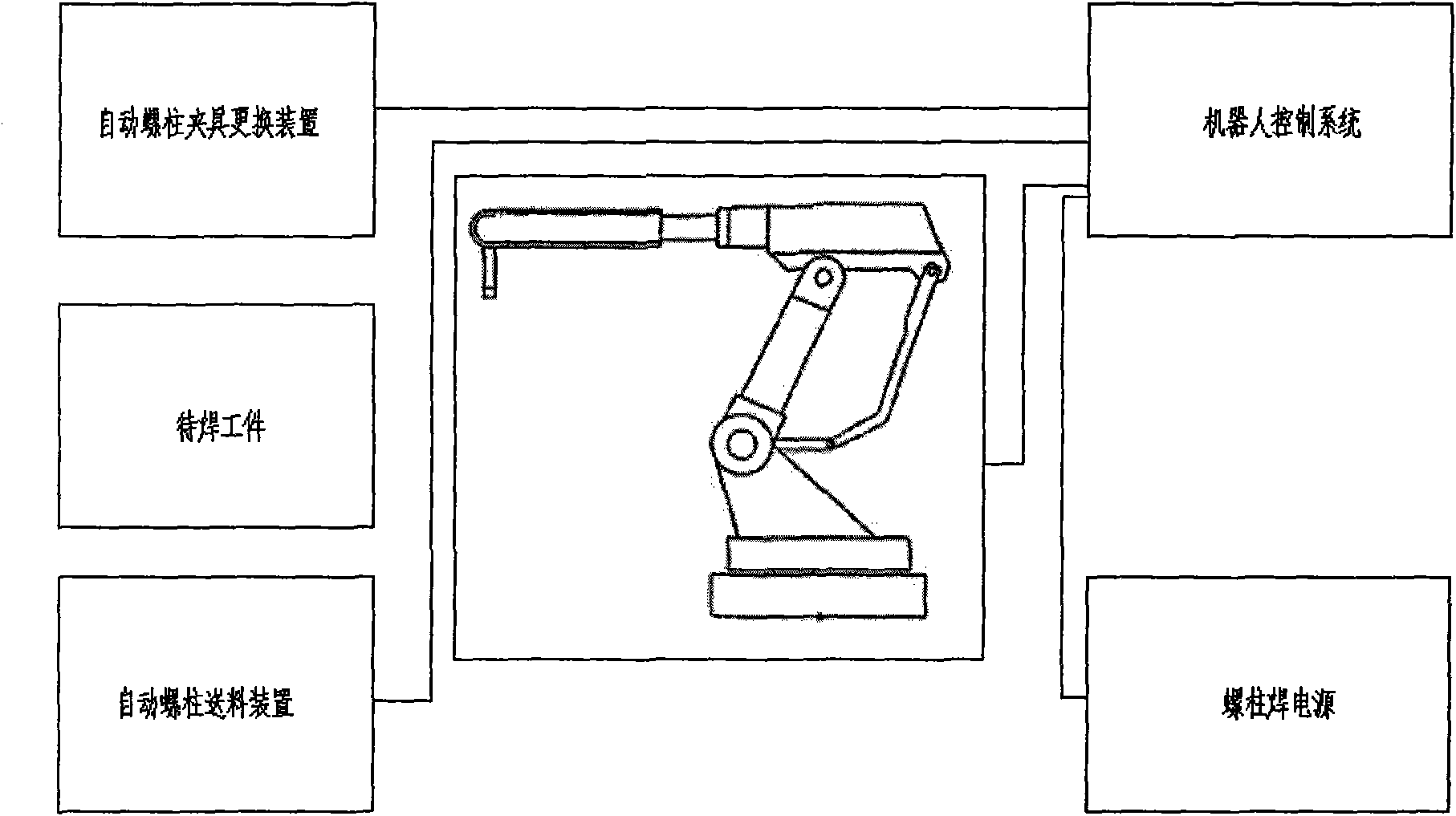

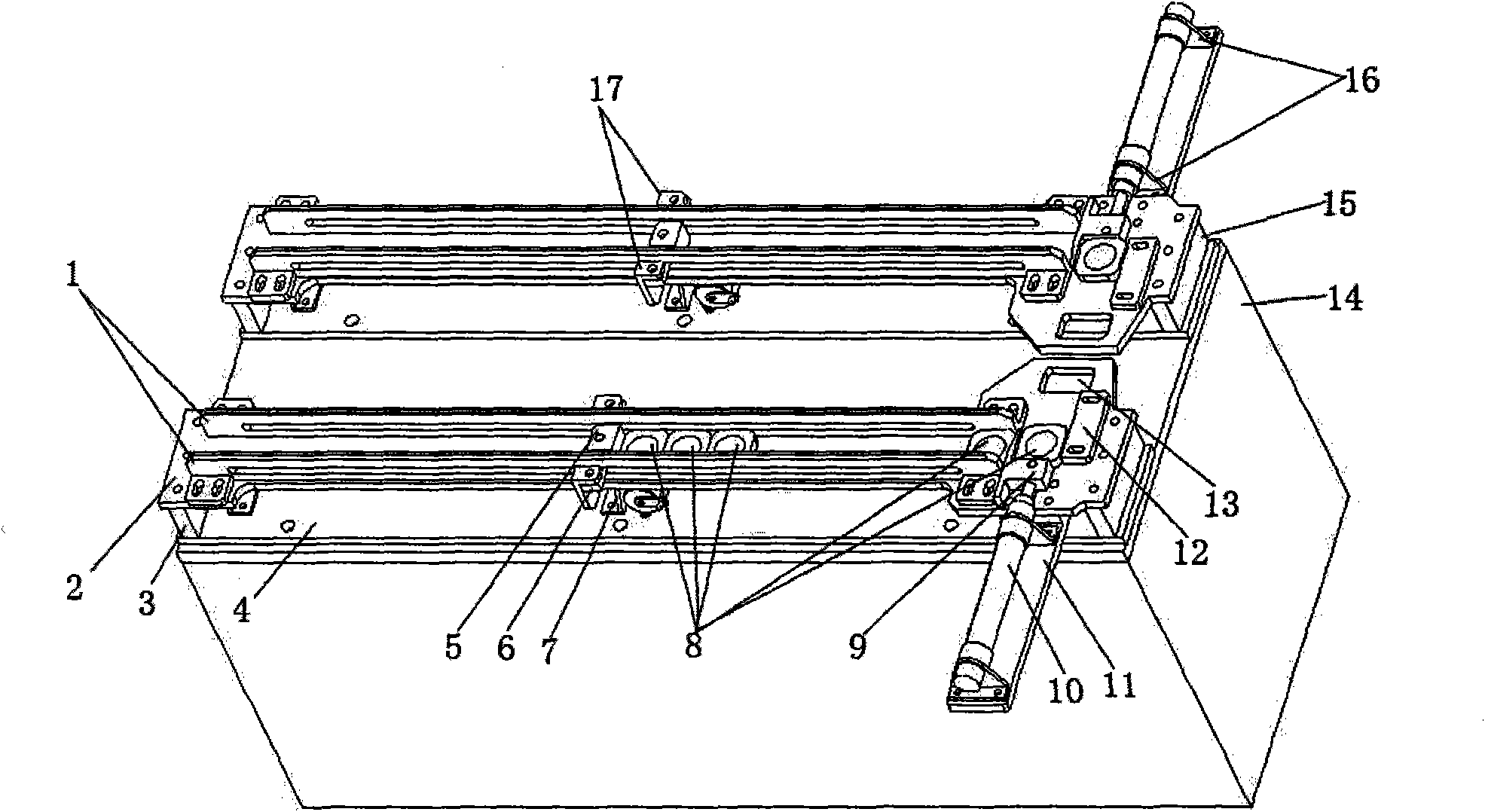

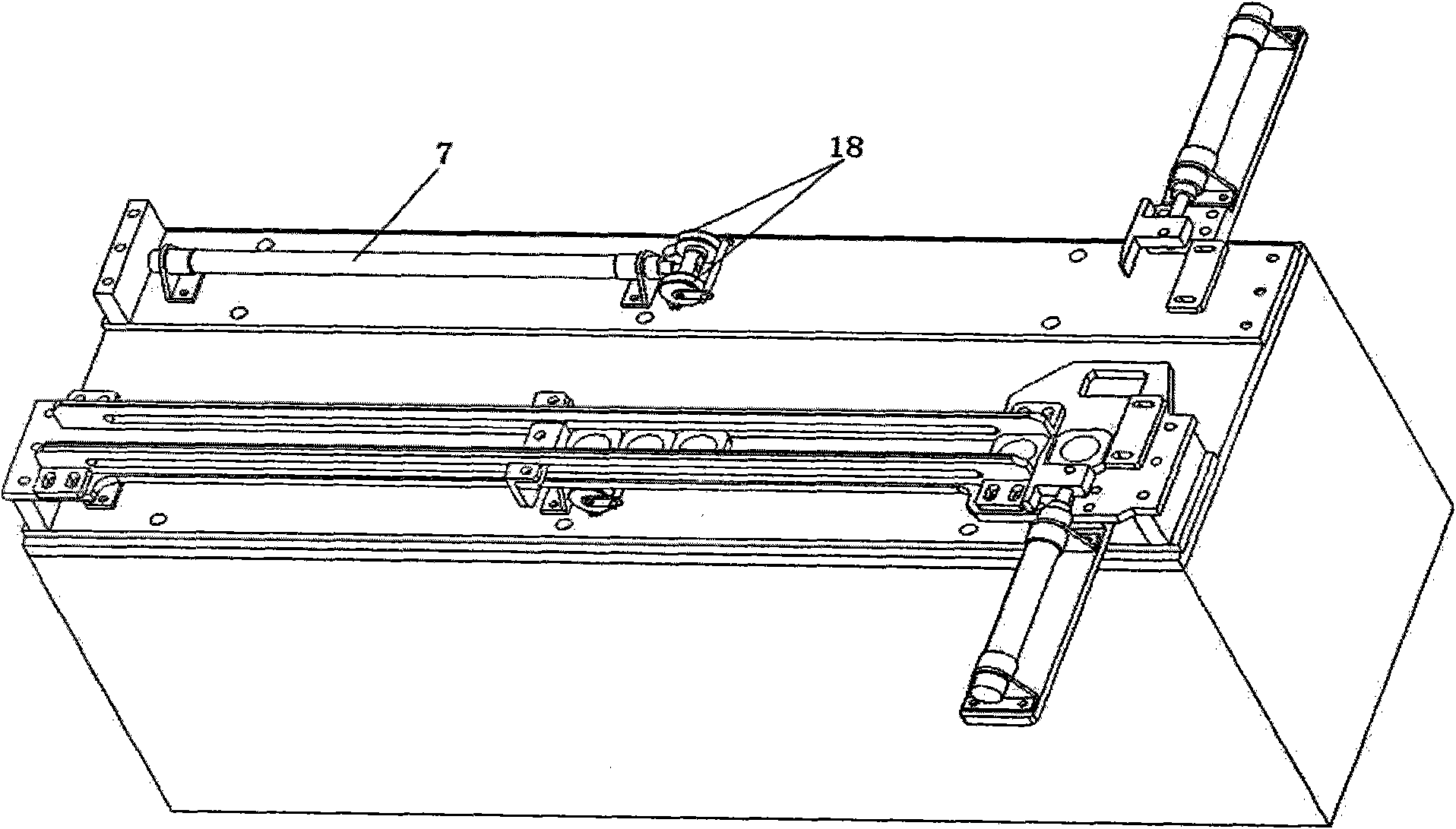

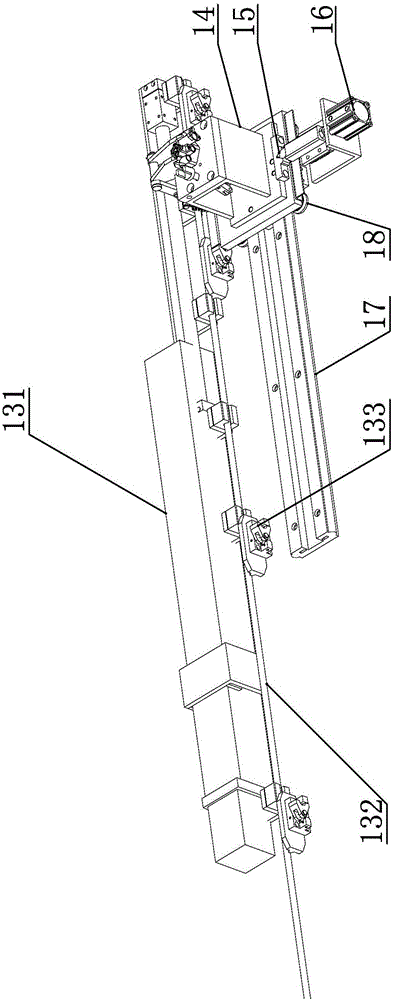

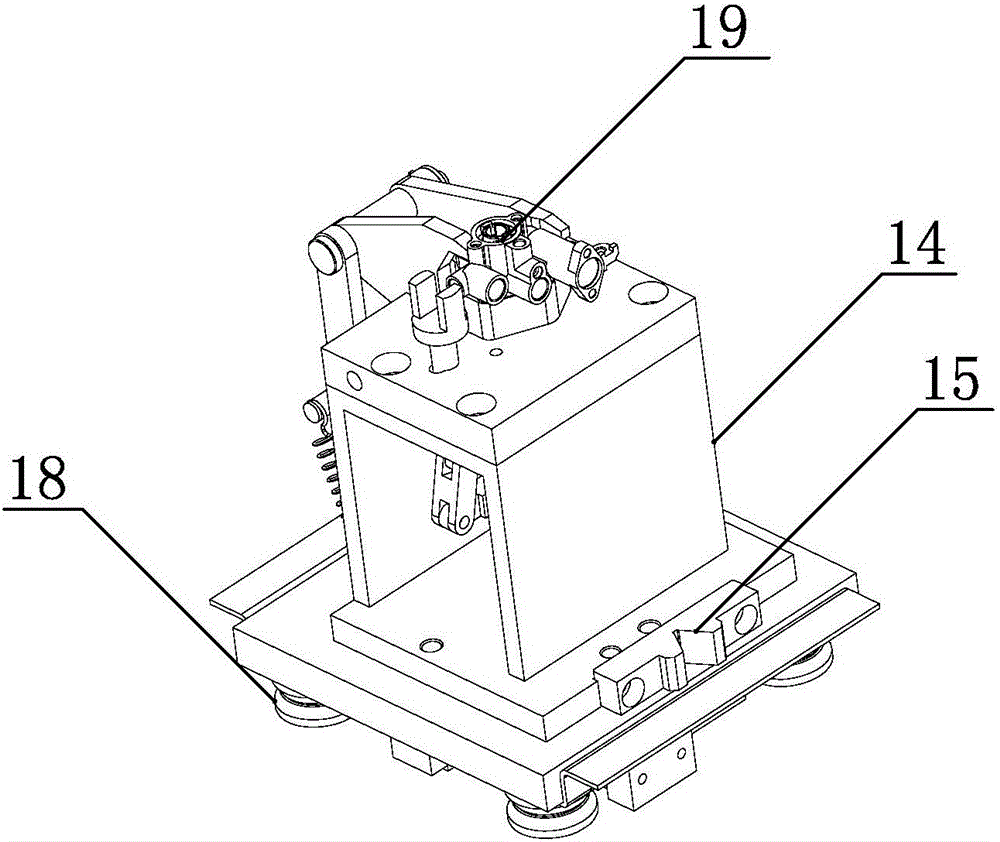

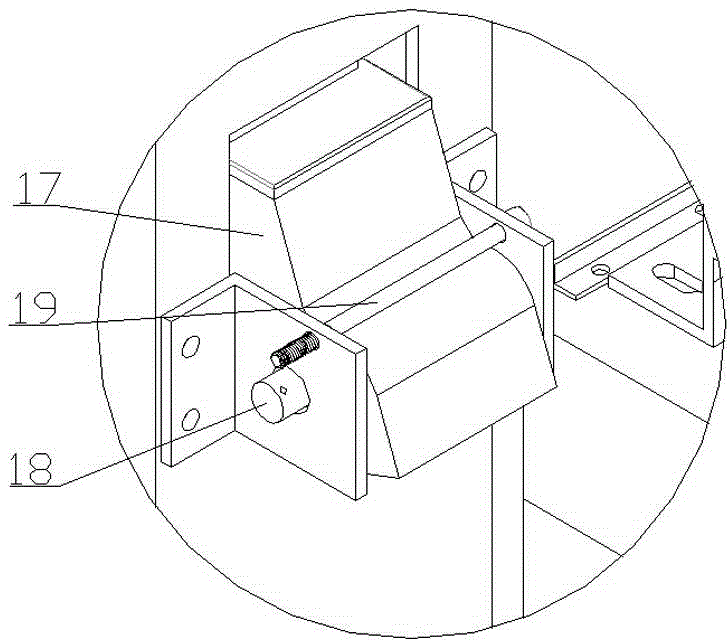

Stud flexible welding device and method

ActiveCN102114568ARealize automatic clampingLarge size spanArc welding apparatusControl systemControl signal

The invention discloses a stud flexible welding device and method. The stud flexible welding device comprises a welding robot, a robot control system, an automatic stud welding gun, an automatic stud feeding device, an automatic stud welding and clamping device and an automatic stud welding jig replacing device, wherein the welding robot, the automatic stud welding gun, the automatic stud feeding device, the automatic stud welding and clamping device and the automatic stud welding jig replacing device are connected with the robot control system to receive a control signal of the robot control system; the automatic stud feeding device is used for conveying studs; the automatic stud welding and clamping device is used for setting precompression amount required in an automatic clamping and welding process of studs and ceramic rings; and the automatic stud welding jig replacing device is used for assembling and disassembling the automatic stud welding and clamping device. The invention can be used for carrying out automatic feeding.

Owner:NANJING UNIV OF SCI & TECH

Load capacity and pressure regulating switch for transformer

ActiveCN101090034AAdjust capacityAdjust the output voltageContact mechanismsVariable inductancesCapacitanceDistribution transformer

This invention relates to a load capacitance and voltage regulation switch characterizing in the following structure: a voltage-regulation static contactor is mounted on an insulated drum of a load capacitance-regulation part, a voltage -regulating bracket is set in the drum, a voltage-regulation dynamic contactor and a transition resistor are set on the bracket to integrate the load capacitance and voltage regulation, a set of operation unit is used between the quick unit of the capacitance and the voltage regulation parts by an electromagnetic clutch and an electric control box is set for adjusting capacitance and voltage automatically according to the change of loading current and voltage of a transformer.

Owner:SHENYANG KEQI ELECTRICAL EQUIP

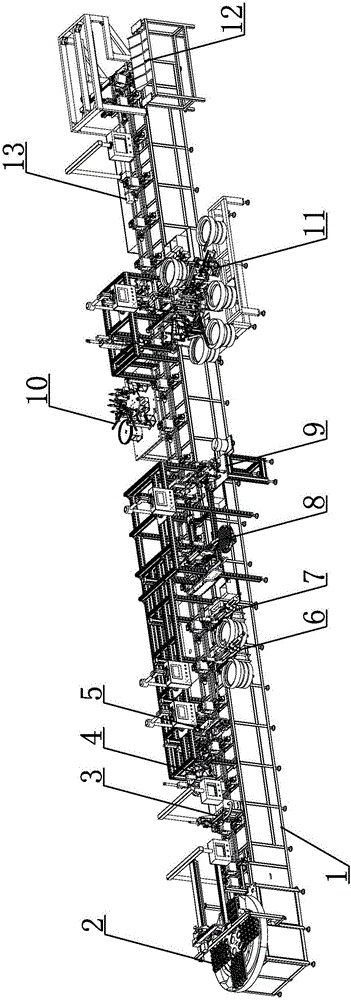

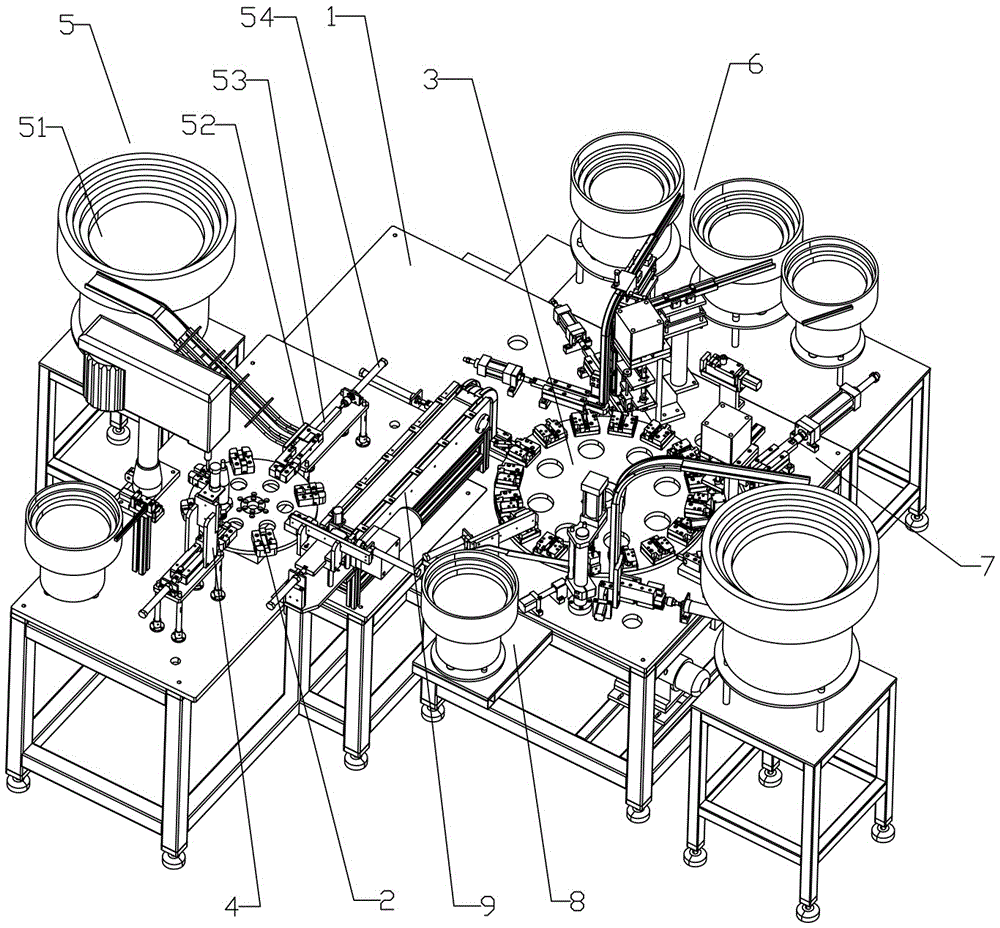

Assembly line for gas valves

PendingCN105855870ARealize blankingAutomate operationAssembly machinesAssembly lineElectromagnetic valve

The invention discloses an assembly line for gas valves, relates to an industrial assembly line for assembling gas valves, and aims to provide a full-automatic valve assembly line capable of improving the assembling efficiency of the gas valves and promoting large-scale production. The assembly line for the gas valves comprises a rack, wherein a main slide is arranged on the rack, a main assembly line is mounted on the rack, a pallet capable of moving horizontally is arranged on the main assembly line and is used for fixing valve bodies of the valves, and following stations are sequentially arranged on the main assembly line: a valve body front feeding station, a body dust collection station, a closed direction-distinguishing and oiling station, a closed oiling and rotating station, a cock direction-distinguishing and assembling station, a small screw locking station, a large screw locking station, a short copper joint locking station, a long copper joint locking station, an electromagnetic valve assembling and locking station, a fine-adjustment valve core assembling and locking station, a valve core assembly assembling station, a switch axle assembly assembling station, a cover plate assembling and locking station and a finished product discharging station.

Owner:NANJING AIMEIQING INTELLIGENT TECH CO LTD

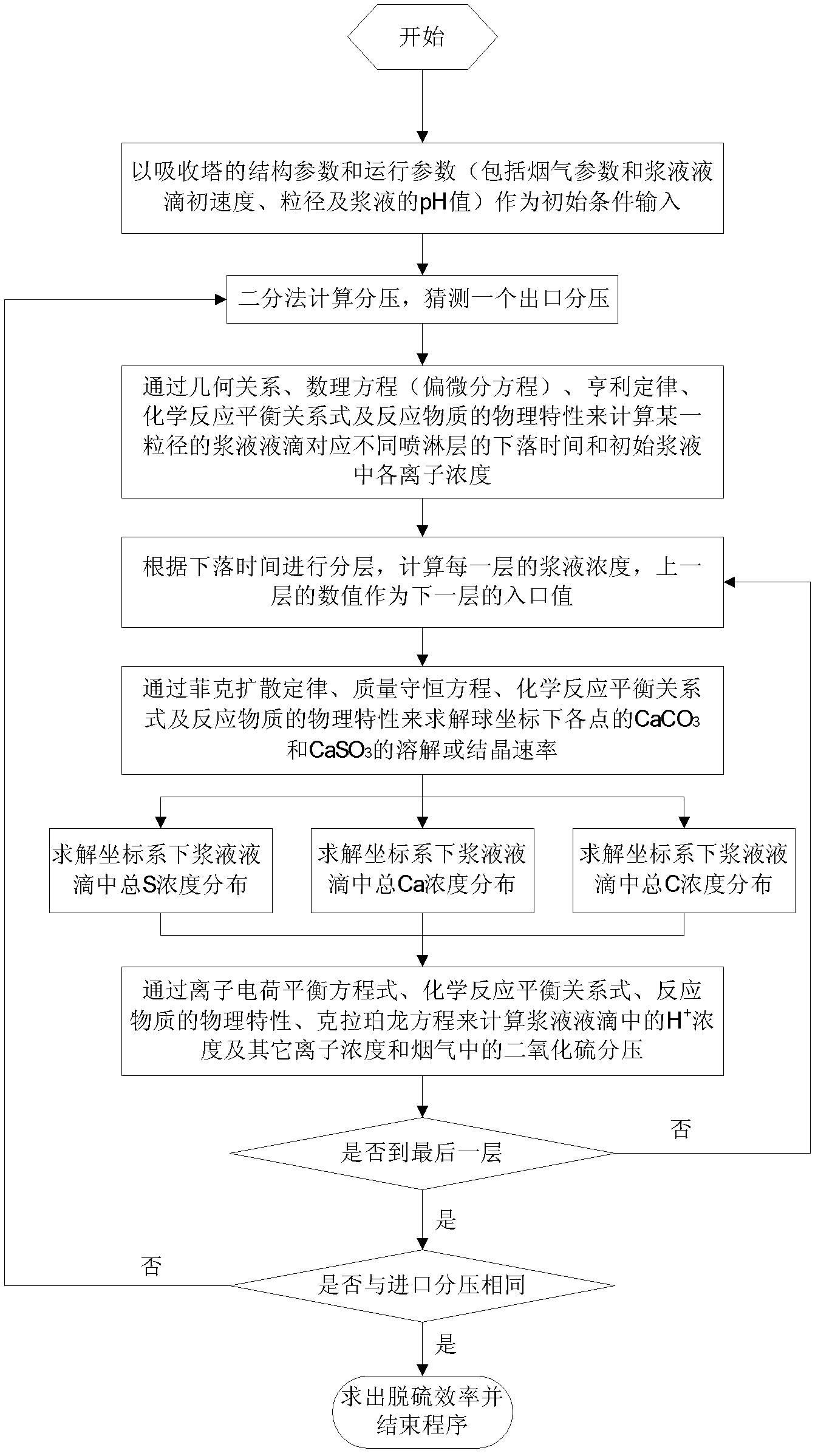

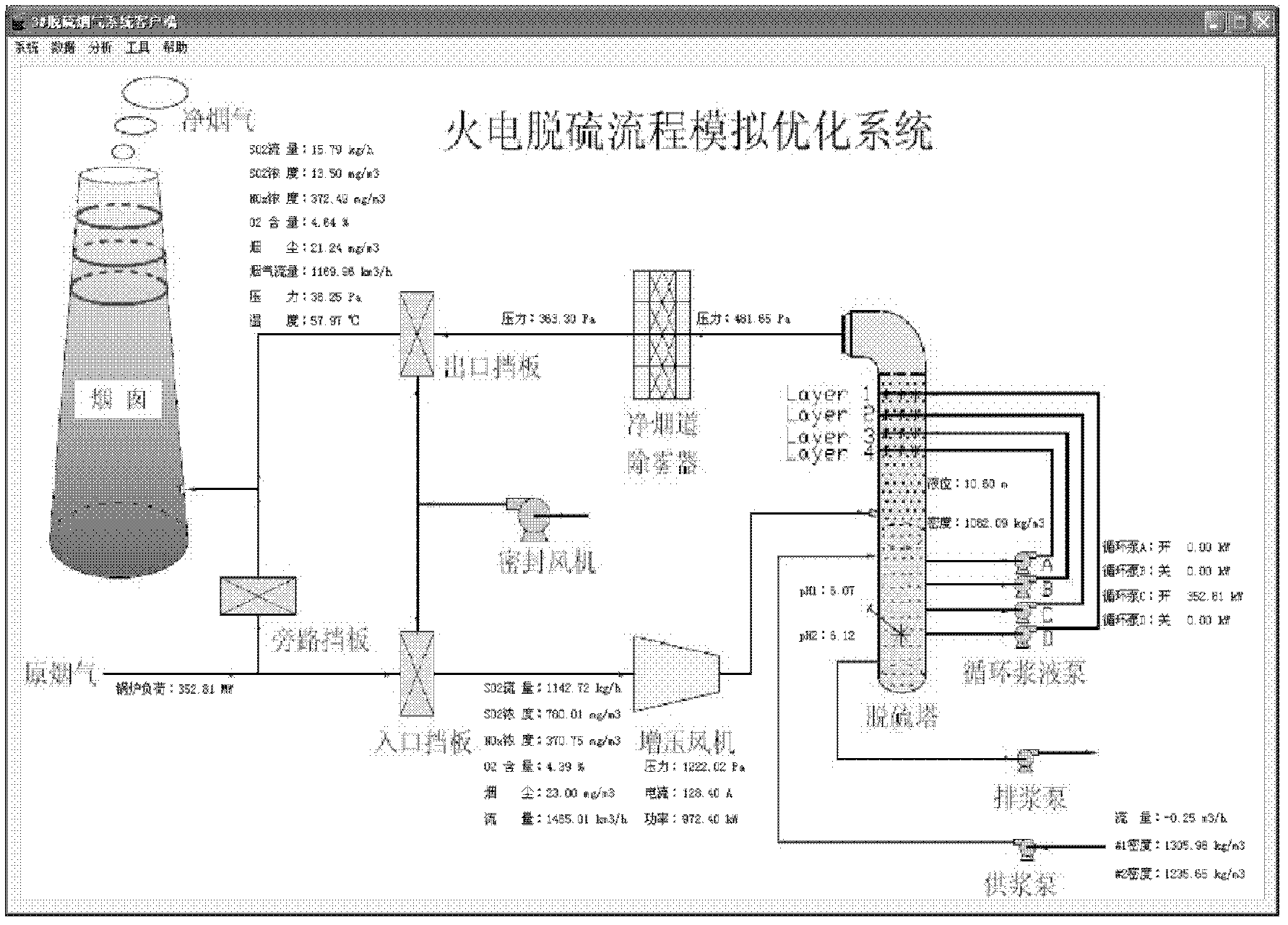

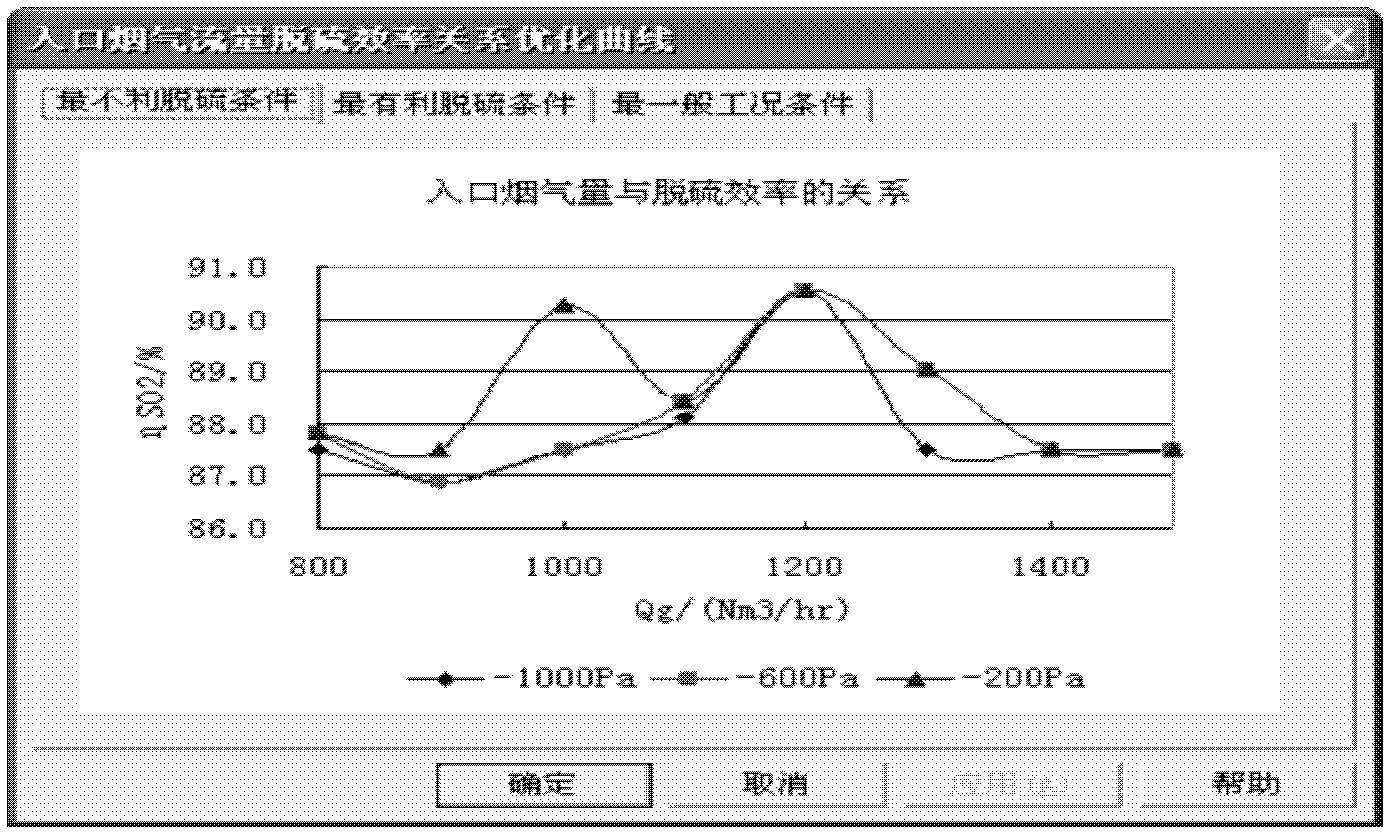

Simulation and optimization system of flue gas desulfurization process of thermal power plant

InactiveCN102580513ARapid responseSmall hysteresisSimulator controlDispersed particle separationOperational systemData file

The invention discloses a simulation and optimization system of a flue gas desulfurization process of a thermal power plant. The simulation and optimization system is composed of a server and a client. A limestone-gypsum wet fuel gas desulfurization model is firstly established to realize simulation of the desulfurization process; and a multi-objective normalized optimization method is used for optimizing and simulating artificially set work conditions so as to sieve an optimal operating condition under each work condition and package the optimal operating condition as an optimized operation database. The server monitors a real-time data document of a DCS (Distributed Control System) sent by an SIS (Supervisory Information System) database, finds matched records in the optimized operation database via a way of database retrieval and then sends the real-time data and relevant advices to the client for a user to check. The server and the client realize connection and user management through an LAN (Local Area Network). The simulation and optimization system, disclosed by the invention, has the advantages of providing an optimization control platform for the desulfurization system of the thermal power plant, providing optimized operation advices and early warnings for operators without directly operating the DCS system and thereby improving normal running rate, desulfurization efficiency and SO2 discharge concentration attainment rate of the desulfurization system.

Owner:FUJIAN PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI

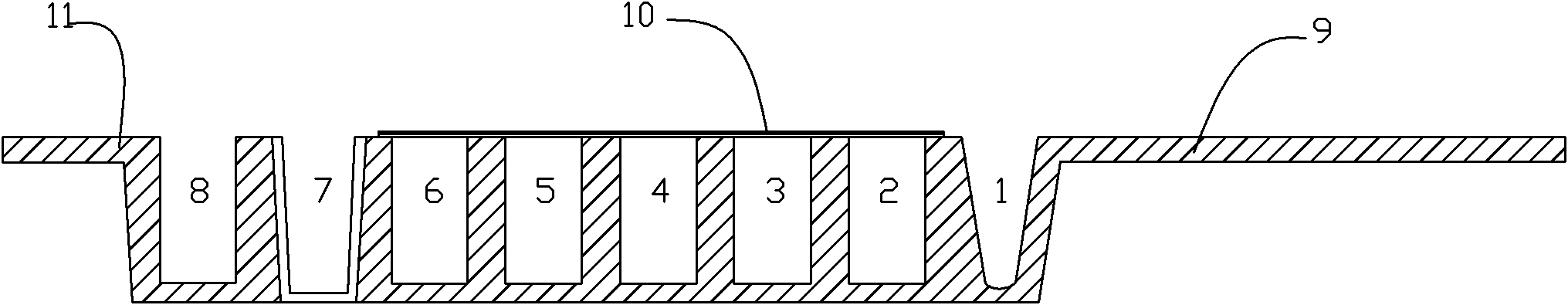

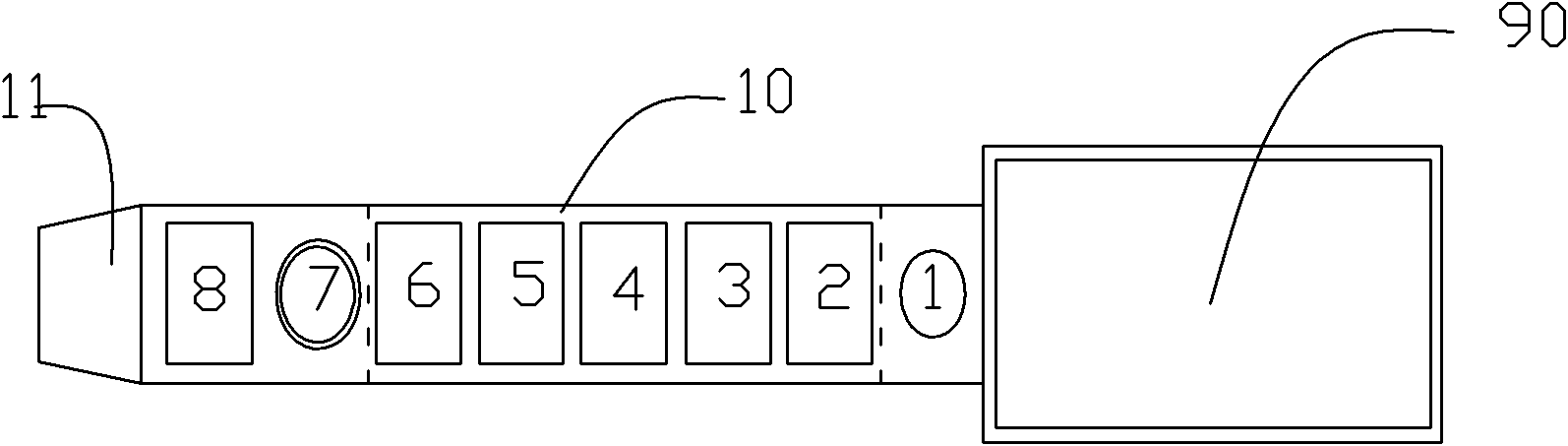

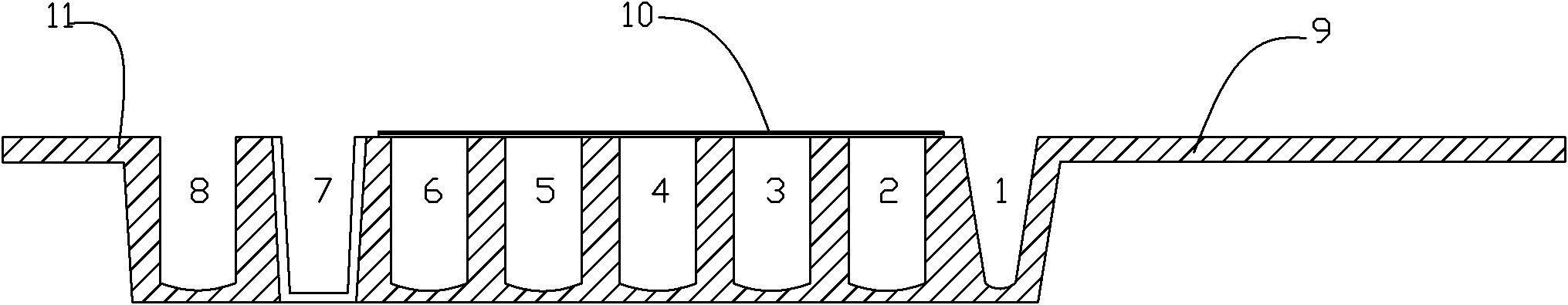

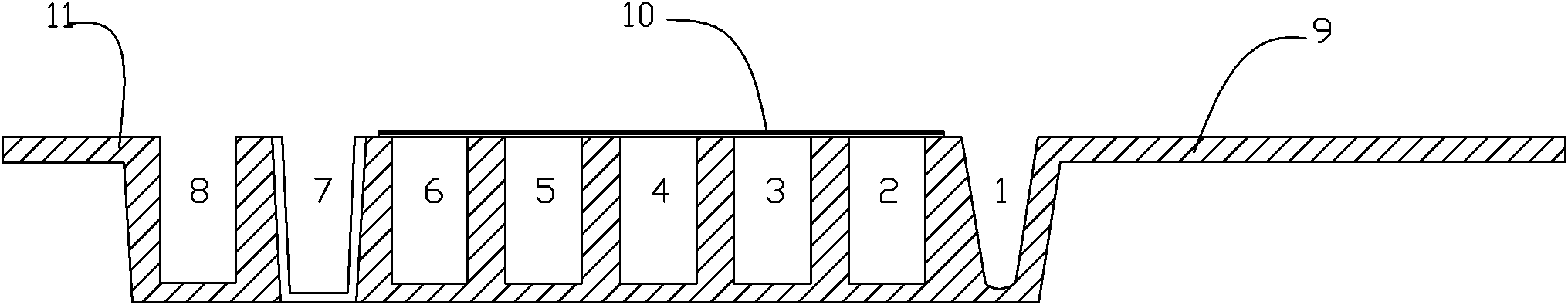

Method for testing anti-SmD1 antibody IgG and reagent device

The invention provides a method for immunologically detecting an anti-SmD1 antibody IgG on the basis of an enzyme-linked immunosorbent assay principle and a reagent device , which relate to an analysis method used for enzyme-linked immunosorbent assay of the anti-SmD1 antibody IgG independently, individually and disposably, a reagent device and a matched reagent. In the method, a plurality of reagents required in the enzyme-linked immunosorbent assay of the anti-SmD1 antibody IgG can be contained in one analyzing device; and according to the method, relevant immunological tests can be conveniently conducted according to using requirements on the tested project, and better basis is provided for clinical practice.

Owner:SHENZHEN YHLO BIOTECH

Cement sheath structural integrity mechanics experiment device

The invention relates to a cement sheath structural integrity mechanics experiment device which is composed of a cement sheath maintenance die and a three-shaft stress maintenance kettle. The cement sheath maintenance die is arranged inside an inner cavity of the three-shaft stress maintenance kettle. The cement sheath maintenance die comprises an adjustable eccentricity upper flange cover, a simulation well wall, a simulation well wall outer protective barrel, a casing pipe and an adjustable eccentricity lower flange plate. The three-shaft stress maintenance kettle comprises a barrel-shaped container, a confining pressure oil cylinder, an oil cylinder piston, an axial load piston, a confining pressure piston, an annular heating element and an electrode. The confining pressure piston is arranged inside the barrel-shaped container, the confining pressure oil cylinder is arranged on the upper end face of the barrel-shaped container in a sitting mode, a silicone oil cavity is formed between the confining pressure oil cylinder and the oil cylinder piston, an axial load sensor is connected with the axial load piston, a pressing machine upper plate is arranged at the upper end of the axial load sensor, the annular heating element is arranged inside the barrels-shaped container, the lower end face of the annular heating element presses the electrode, and the annular heating element is connected with a thermoelectric coupler. The cement sheath structural integrity mechanics experiment device can simulate the actual working condition of the oil-gas well construction, and the measured cement strength of a cement interface conforms to the actual site work better and more accurately.

Owner:NORTHEAST GASOLINEEUM UNIV

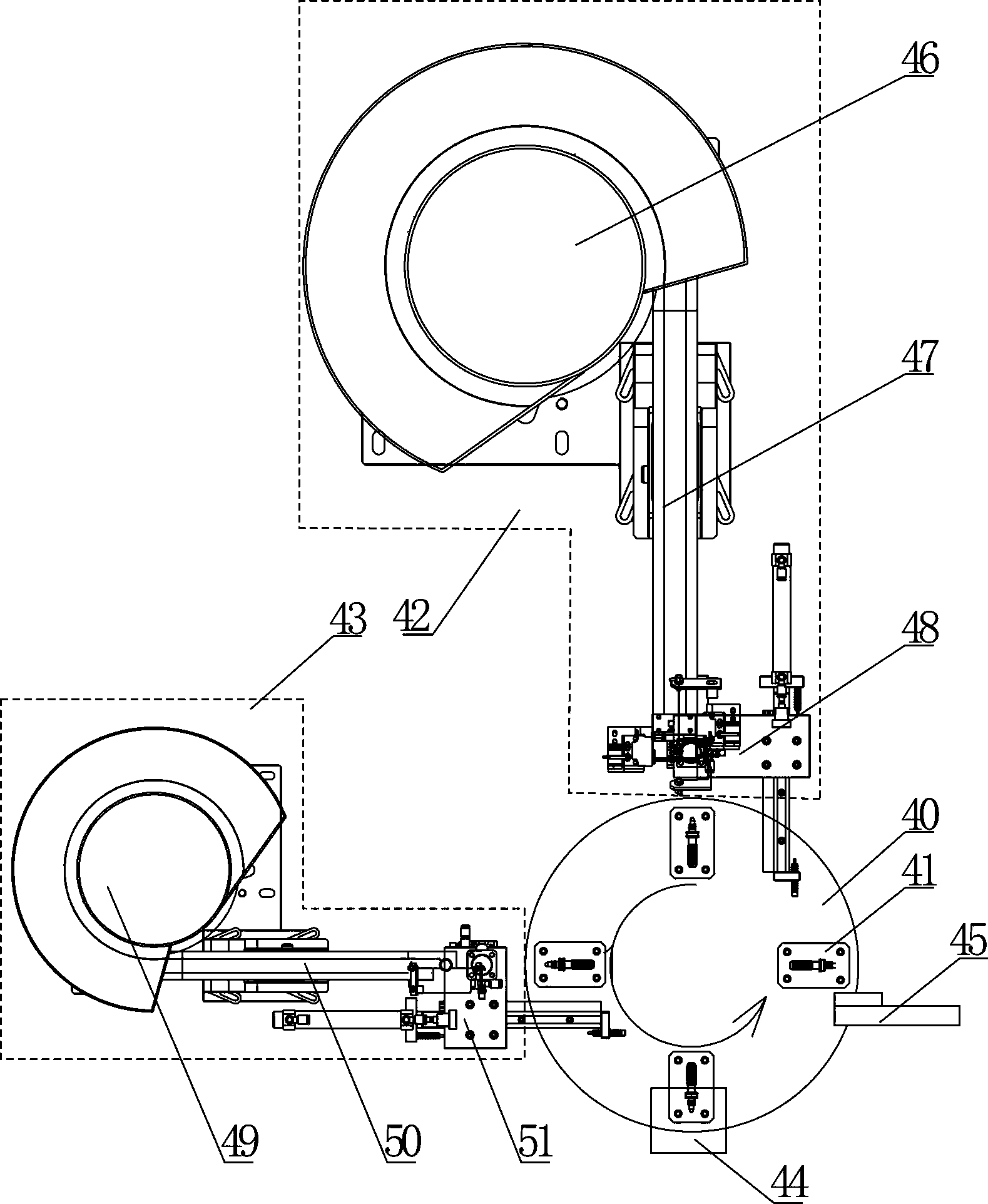

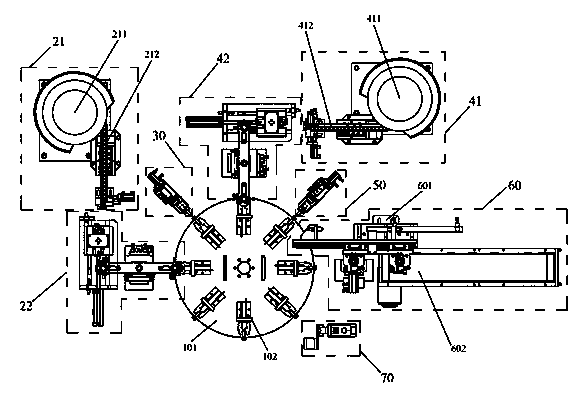

Automatic assembly machine for kettle valve of coffee maker

InactiveCN103707060AAutomate operationIncrease productivityAssembly machinesEngineeringShuttle valve

The invention discloses an automatic assembly machine for a kettle valve of a coffee maker. The automatic assembly machine comprises an intermittent rotating plate uniformly provided with four jigs along the periphery of the intermittent rotating plate, and a valve body assembly loading device, a seal ring loading device, a seal ring on-line detecting device and a valve body assembly taking-out device are sequentially arranged around the intermittent rotating plate and correspond to the jigs. The intermittent rotating plate conveys the jigs to stations to carry out valve body assembly loading, seal ring loading, seal ring on-line detecting and valve body assembly taking-out. In addition, a valve body sub-assembly assembling device and a valve element assembly assembling device are arranged. Automatic operation of all processes is achieved, automatic production is achieved by controlling mechanical mechanisms through various sensors and electric components, the production efficiency is improved, and the manual operation is simplified.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

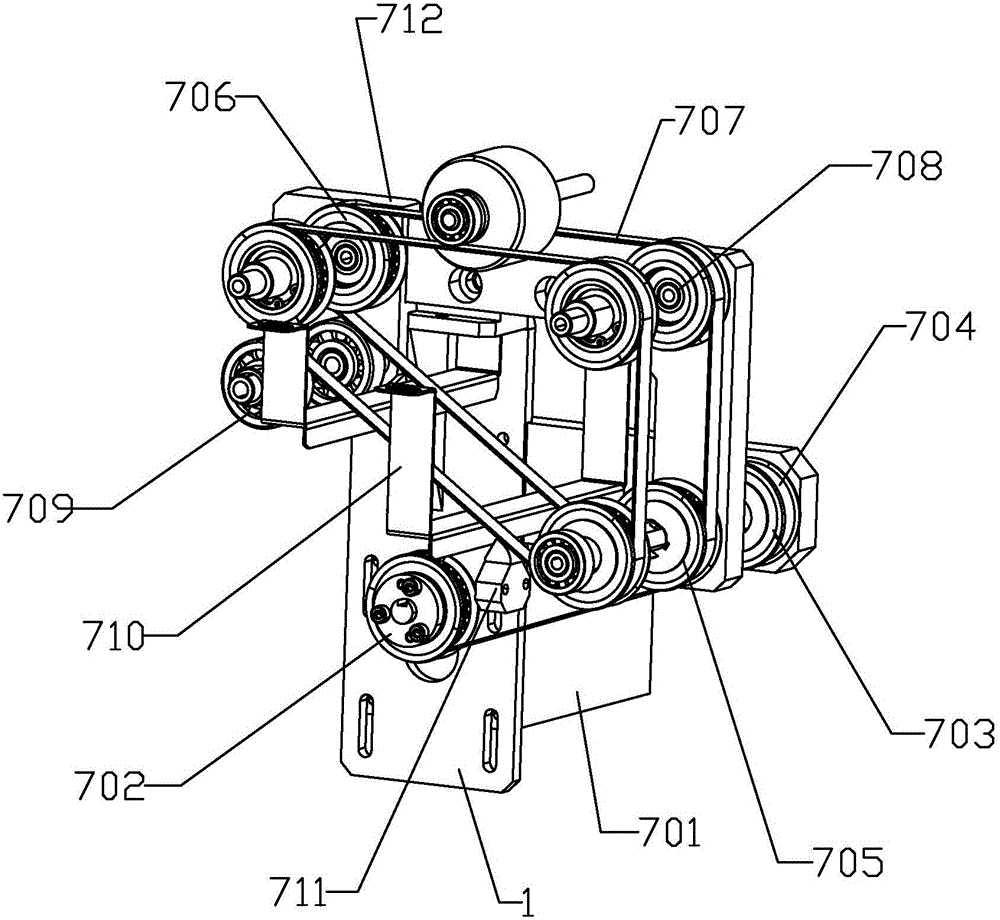

Automatic hinge assembly equipment

InactiveCN105522381AHigh degree of automationImprove stabilityPrecision positioning equipmentAssembly machinesTorsion springAutomation

The invention discloses automatic hinge assembly equipment. The automatic hinge assembly equipment comprises a frame, and is characterized in that the frame is provided with a rotating transmission mechanism with an assembly station, and a screw screwing mechanism, an adjusting block assembly mechanism, a torsion spring rocking rod assembly mechanism, a crank assembly mechanism and a hinge cup assembly mechanism arranged around the rotating transmission mechanism in sequence. The automatic hinge assembly equipment is high in stability and automation degree.

Owner:QINGYUAN SACA PRECISION MFG CO LTD

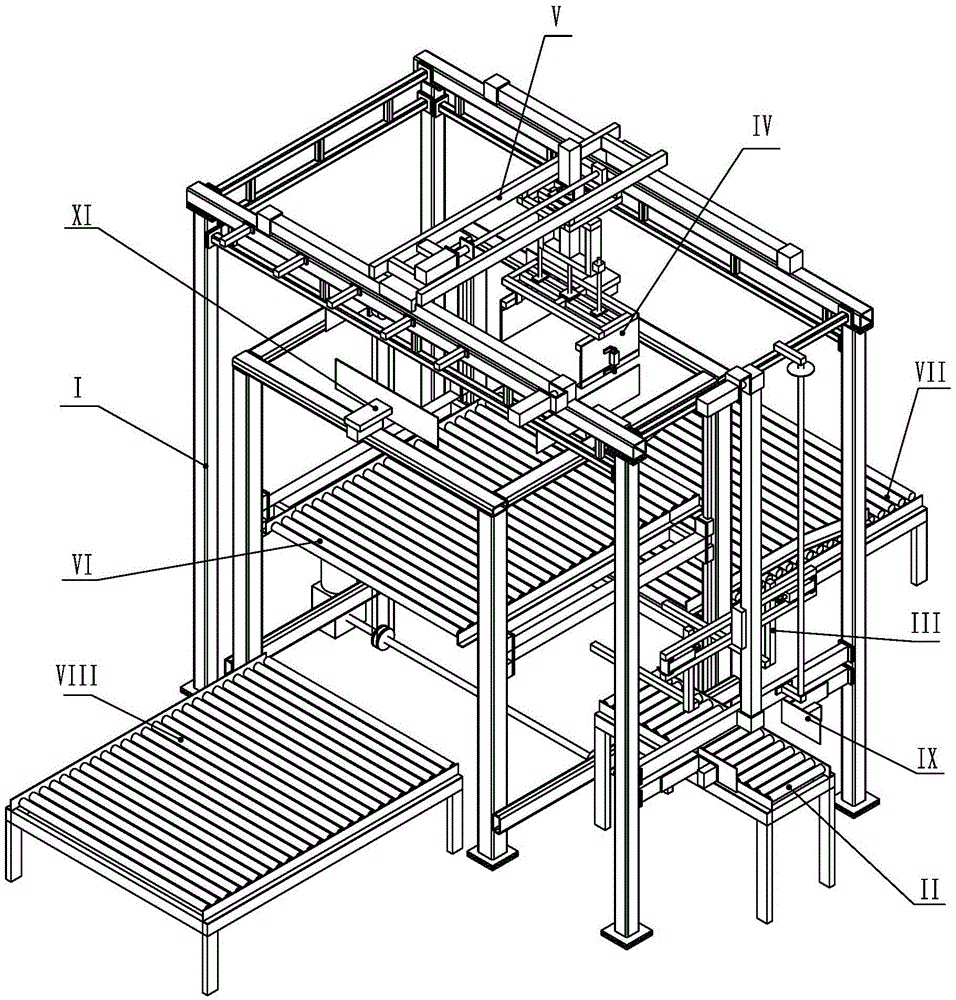

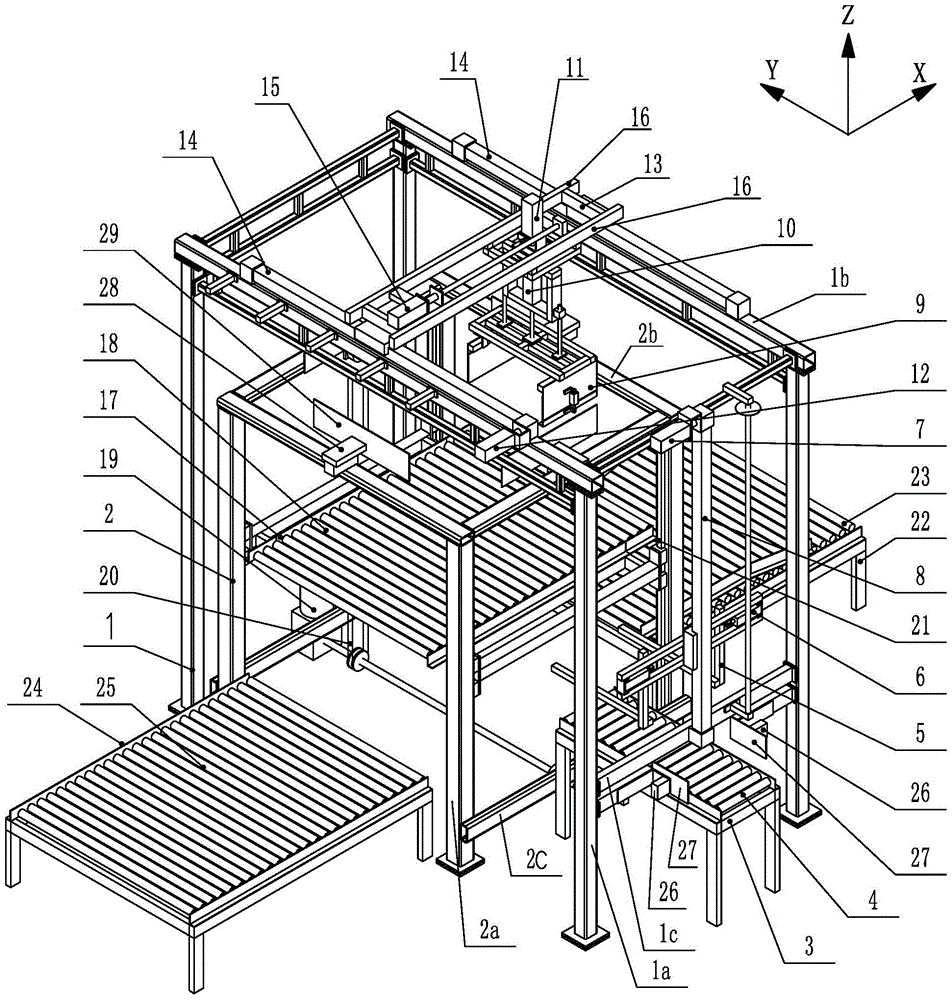

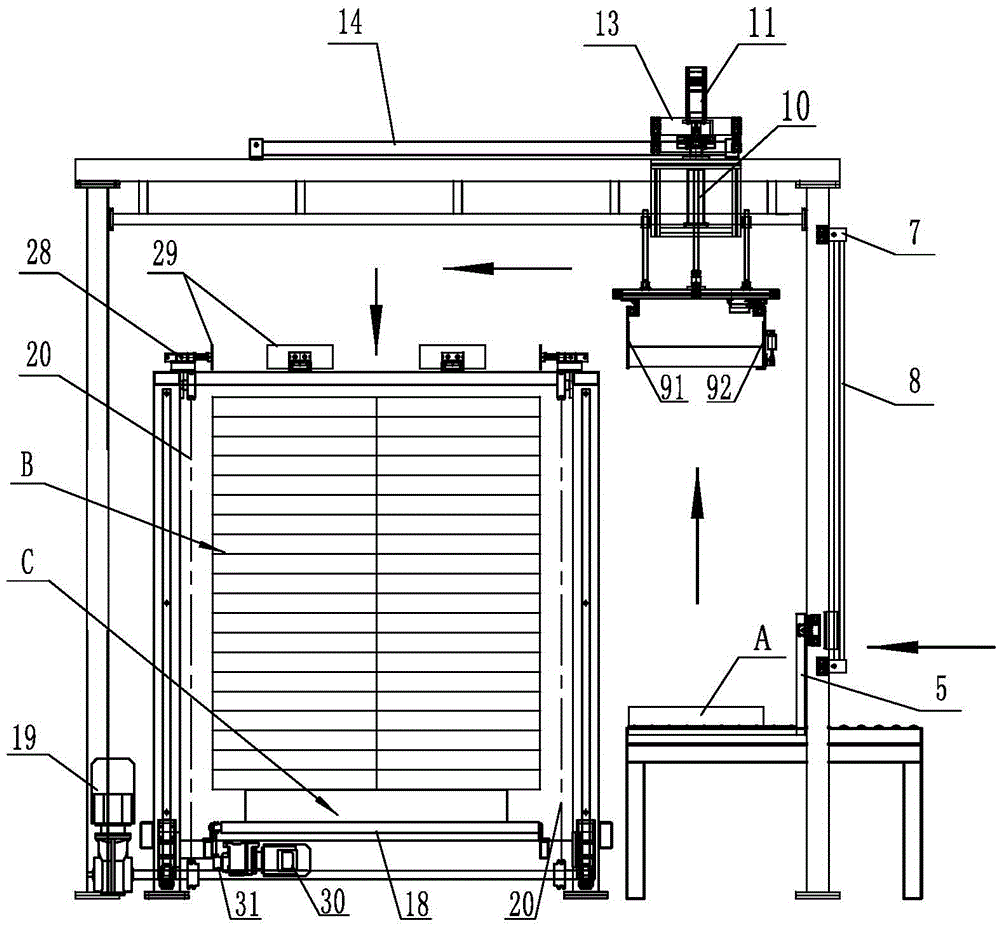

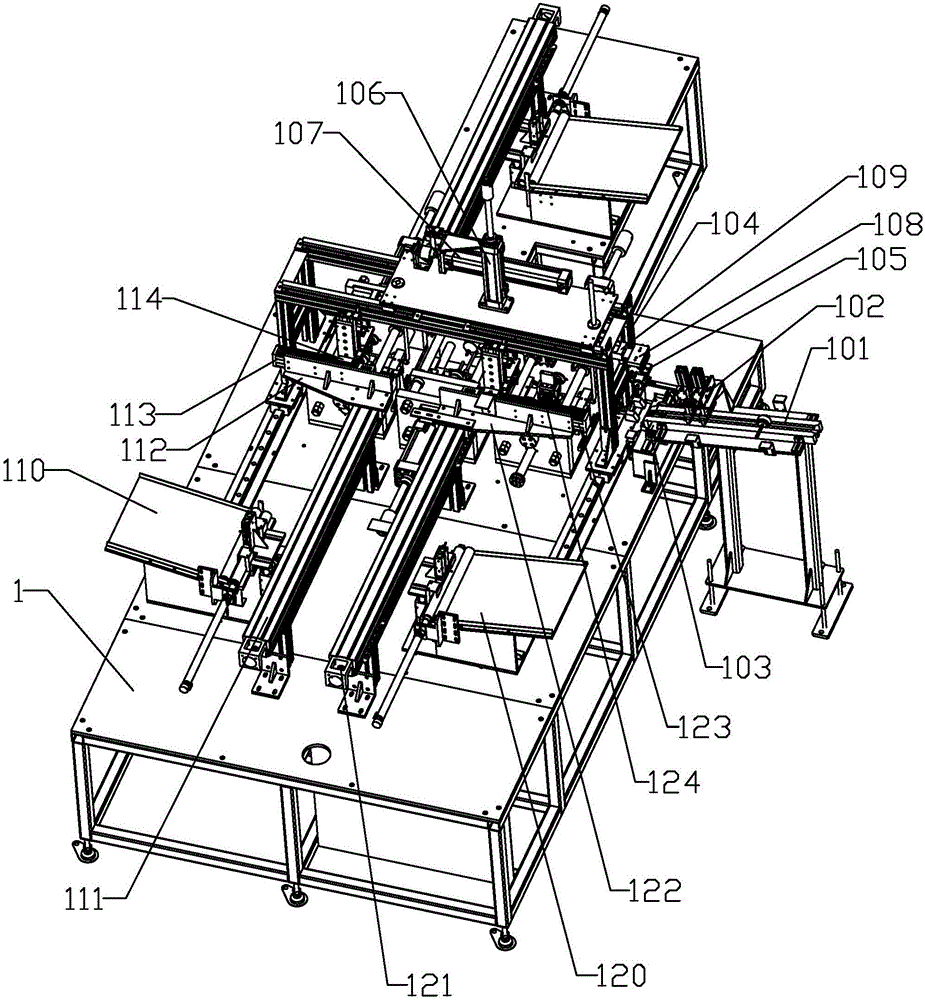

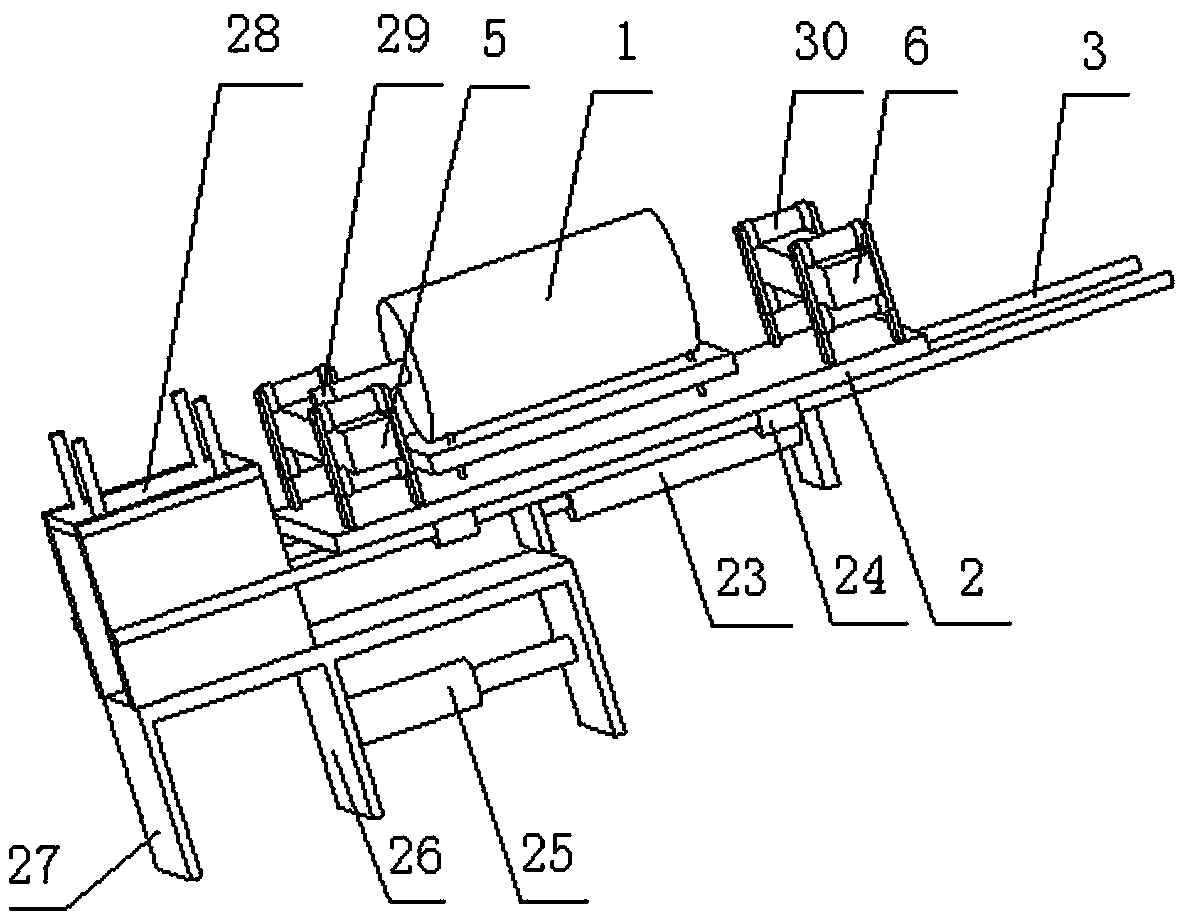

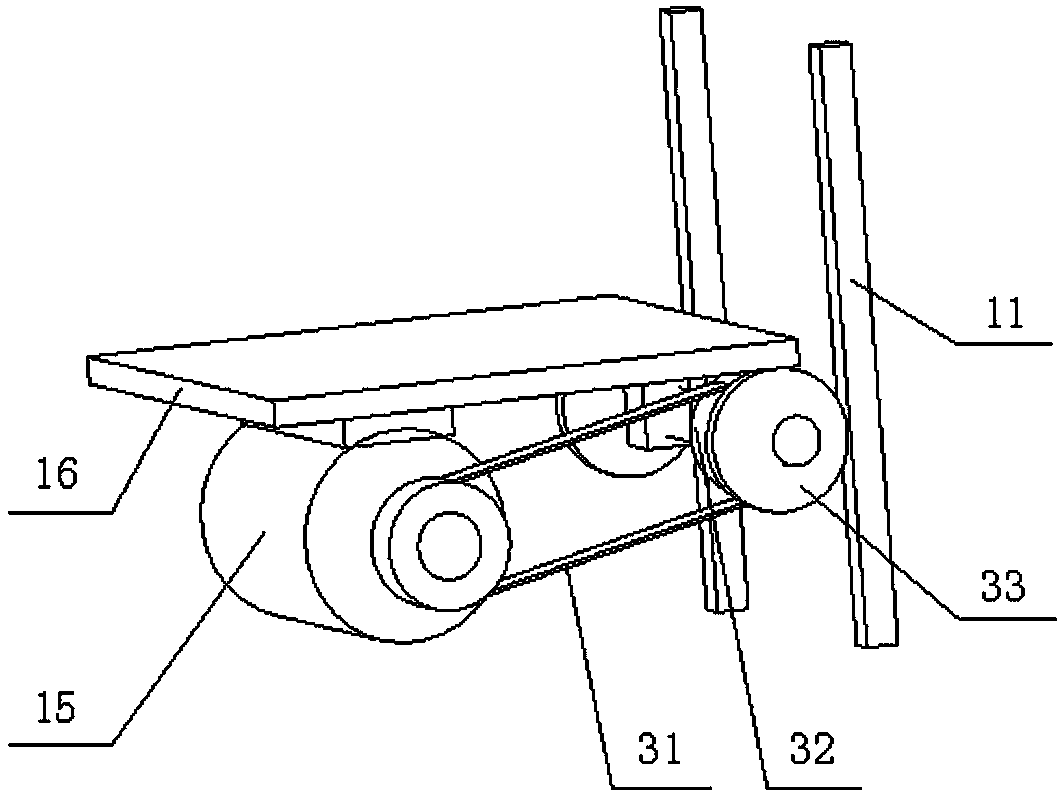

Paperboard stacking device and paperboard stacking machine

ActiveCN105565017ARealize automatic feedingAutomate operationPile receiversArticle feedersCardboardStack machine

The invention discloses a paperboard stacking machine and a paperboard stacking device. The paperboard stacking machine comprises a paperboard stacking device, a paperboard feeding mechanism, a tray feeding mechanism and a paperboard output mechanism; the paperboard stacking device comprises a main body frame; the main body frame comprises an outer frame and an inner frame; a paperboard lifting mechanism is arranged at one side of the outer frame; a gripper mechanism and a gripper translation mechanism are arranged on a top beam of the outer frame; a paper feeding normalizing mechanism is arranged on a stand column of the outer frame; a tray lifting output mechanism is arranged on the inner frame; and a stacking normalizing mechanism is arranged on a top beam of the inner frame. The paperboard stacking machine realizes automation of automatic feeding and paperboard feeding, paper feeding normalizing, lifting, grabbing, translation, rotating, releasing, stacking normalizing, paper stack descending and paper stack output of the tray, and can trimly stack packaged corrugated paperboards or cartons according to predetermined putting positions and rules, thus realizing automatic operation, being good in stacking quality and high in stacking speed, and saving manpower.

Owner:SHANDONG CENTURY MACHINERY

Automatic assembling line for motors

ActiveCN105871129AHigh degree of automationImprove assembly qualityManufacturing dynamo-electric machinesElectricityEngineering

The invention discloses an automatic assembling line for motors. The automatic assembling line for the motors comprises a frame, an automatic conveying belt, a motor rotor bearing bit synchronization oiling device, an automatic motor rotor bearing press-fitting device, an automatic spring washer distributing and detecting device, a motor end cap press-fitting device, an automatic motor bearing gap detecting device, an automatic motor ageing testing device and an automatic gluing air dryer for the motors, wherein the automatic conveying belt which is electrically connected with a circuit controller is arranged on the frame; and the motor rotor bearing bit synchronization oiling device, the automatic motor rotor bearing press-fitting device, the automatic spring washer distributing and detecting device, the motor end cap press-fitting device, the automatic motor bearing gap detecting device, the automatic motor ageing testing device and the automatic gluing air dryer for the motors are successively connected together by the automatic conveying belt and are electrically connected with the circuit controller. The automatic assembling line for the motors is high in assembling stability and good in assembling quality, and testing automation of components of the motors can be realized.

Owner:GUANGDONG LXD ROBOTICS CO LTD

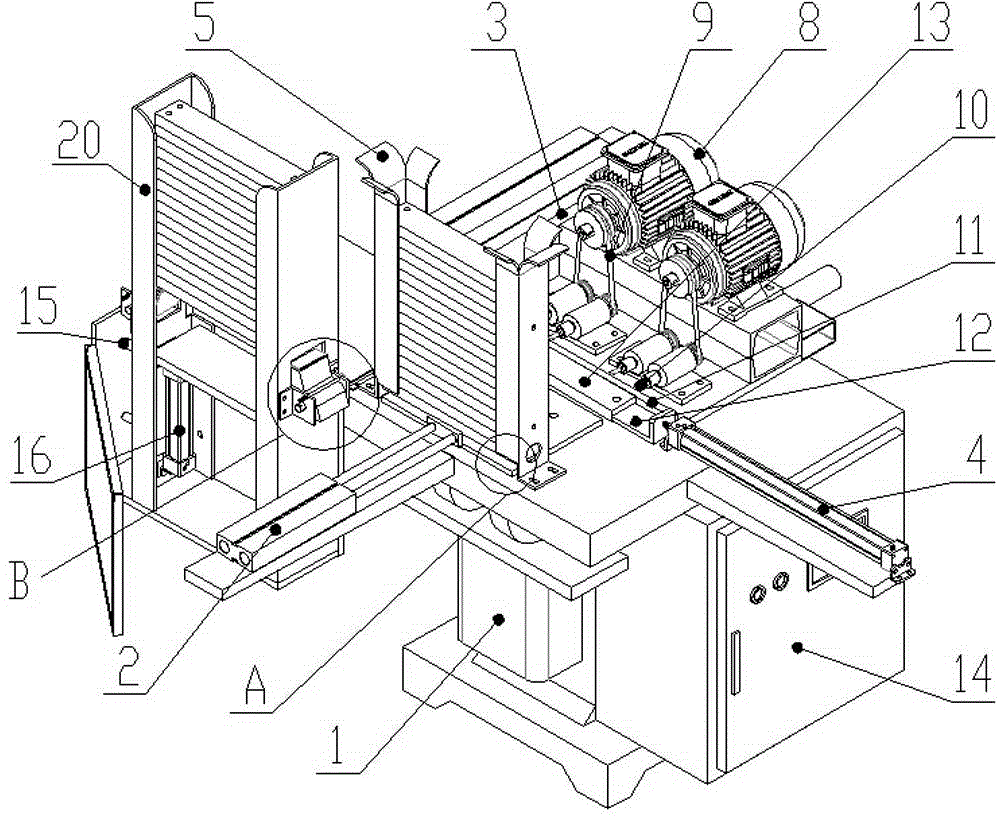

Full-automatic effective drilling machine for furniture panel

ActiveCN104875243AReduce labor intensityShorten the timeStationary drilling machinesEngineeringUltimate tensile strength

The invention belongs to the technical field of panel processing and discloses a full-automatic effective drilling machine for a furniture panel. The full-automatic effective drilling machine for the furniture panel is used for solving the problems that an existing panel drilling device is large in labor intensity and low in production efficiency due to discontinuous production. The full-automatic effective drilling machine for the furniture panel comprises a main stand, the main stand is provided with a feed cabin for holding a workpiece to be processed, the main stand before the feed cabin is provided with a push cylinder for pushing the workpiece to be processed, the main stand behind the feed cabin is provided with a drilling device for drilling the lateral surface of the workpiece to be processed, and the main stand at one side of the feed cabin is provided with a transverse push cylinder for pushing out the processed workpiece; the main stand at the other side of the feed cabin is provided with a storage device for recycling the processed workpiece, and the transverse push cylinder and storage device are respectively located at two sides of the feed cabin.

Owner:QUANYOU FURNITURE

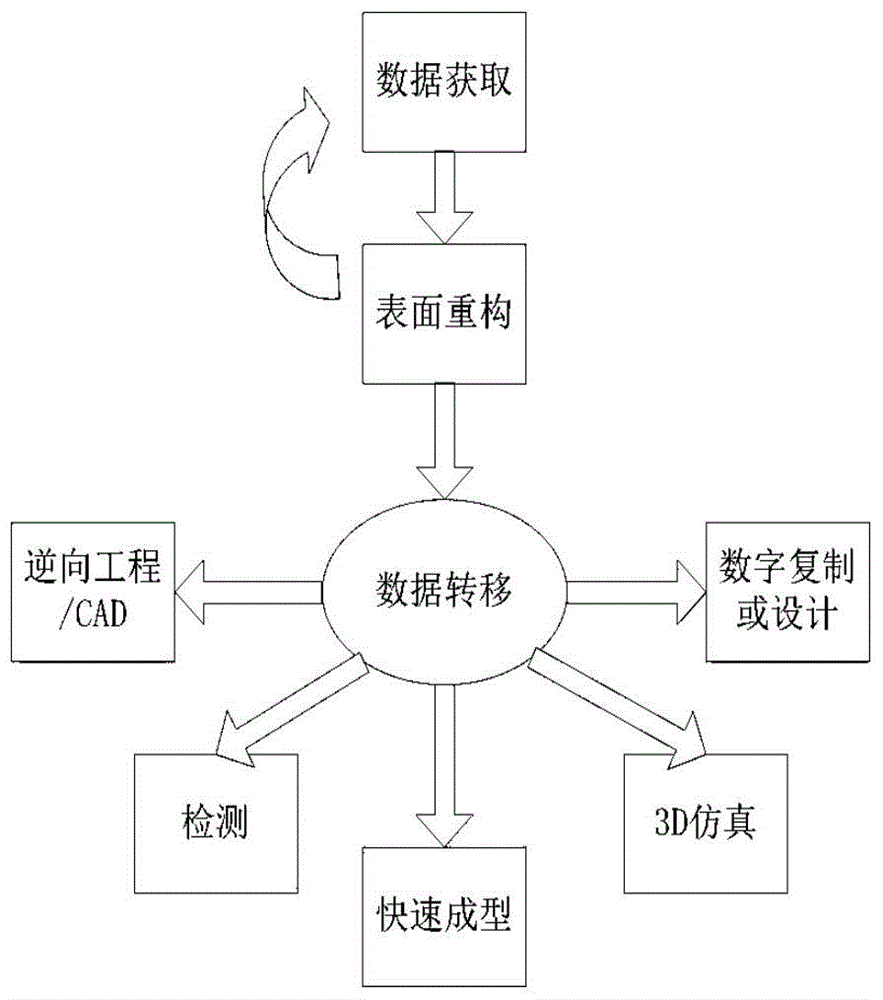

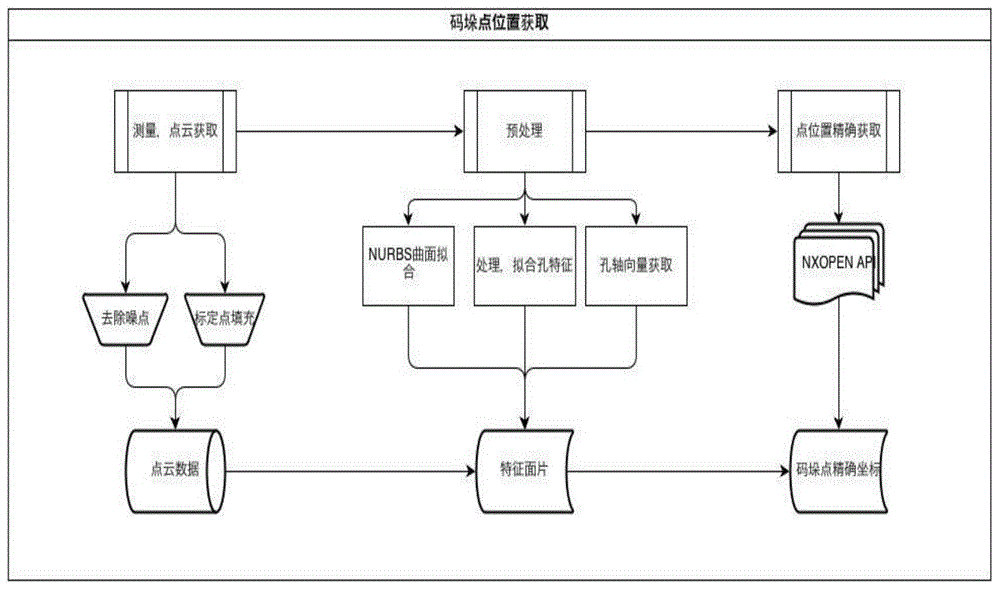

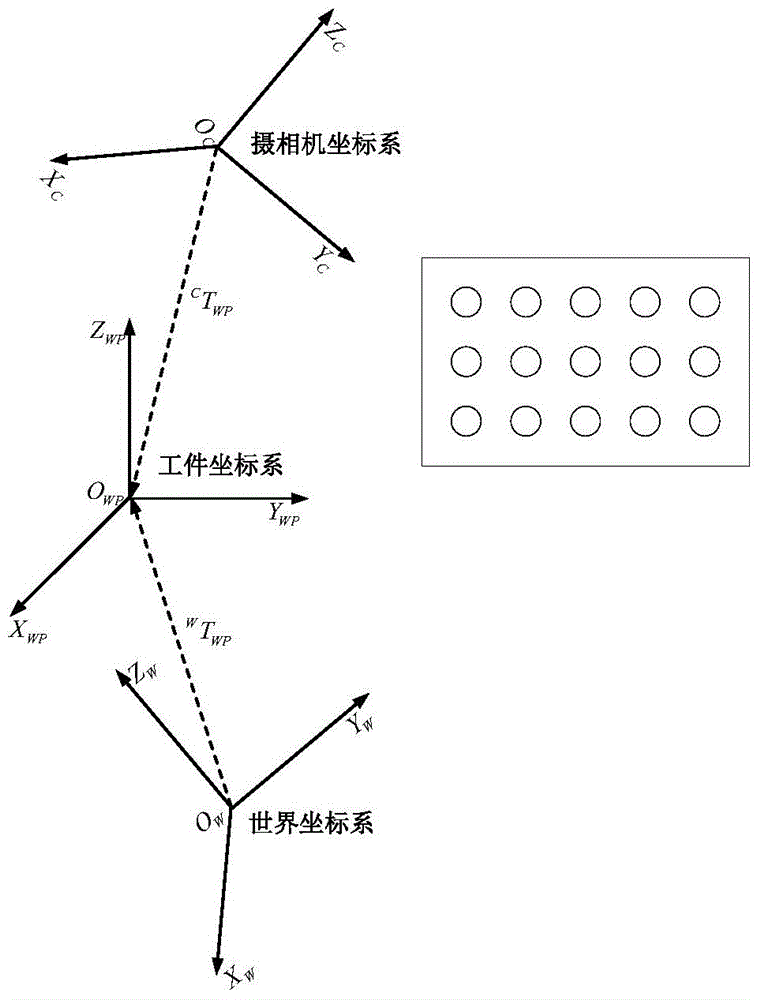

Spatial positioning method not needing teaching robot system

InactiveCN104457566AOperation automationAutomate operationProgramme controlProgramme-controlled manipulatorThree dimensional modelRobotic systems

The invention provides a spatial positioning method not needing a teaching robot system. Firstly, a high-speed accurate three-dimensional scanning instrument is used for obtaining a large batch of point cloud data of a detected object and generating a three-dimensional model of the detected object, noisy point removal, patch feature pre-processing and feature point extraction operations are carried out, and finally the coordinates of a work target point under a camera coordinate system are obtained; secondly, the coordinates of the work target point under the camera coordinate system are converted into the coordinates under a robot world coordinate system through a coordinate conversion algorithm to bring convenience to positioning for robot working; finally, the robot is controlled to work according to the coordinates of the work target point under the world coordinate system and control parameters input by a user. The spatial positioning method not needing a teaching robot system enables the whole operation to be more automatic, integrated and efficient, and has great advantages when applied to the short-time changeable occasions with multiple teaching points.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

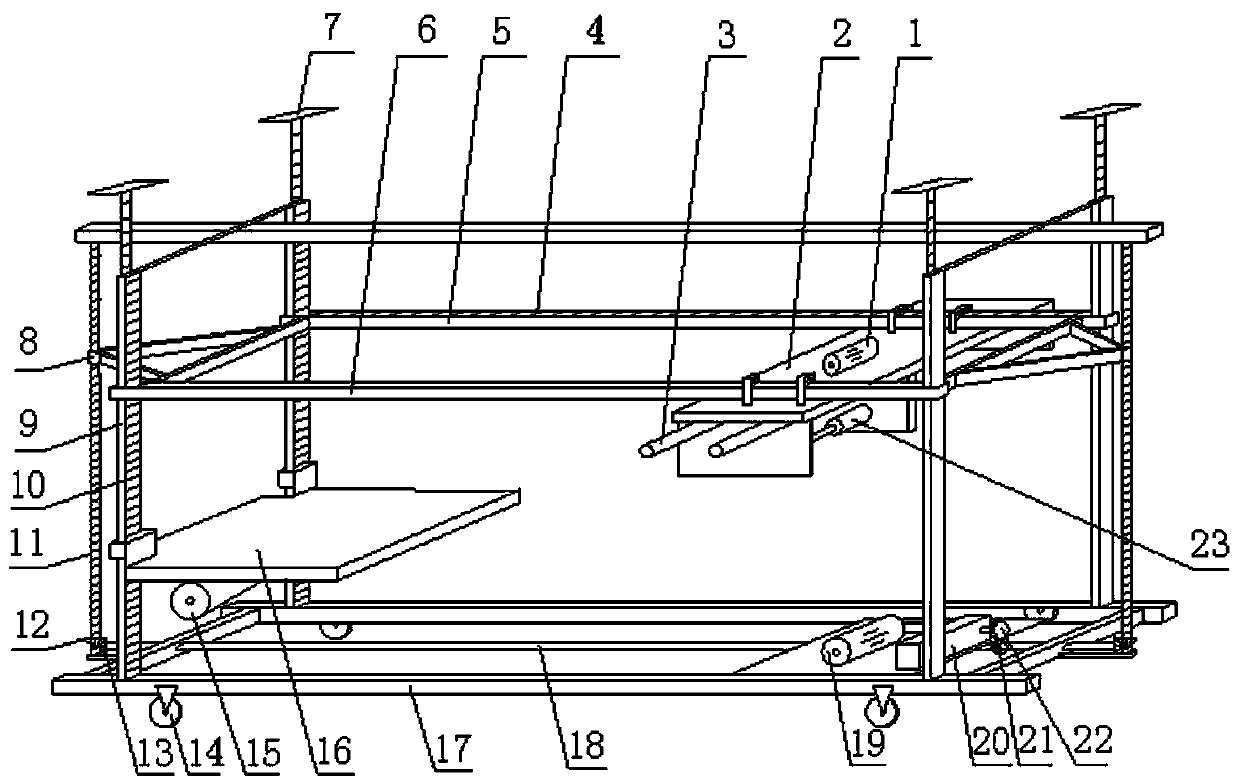

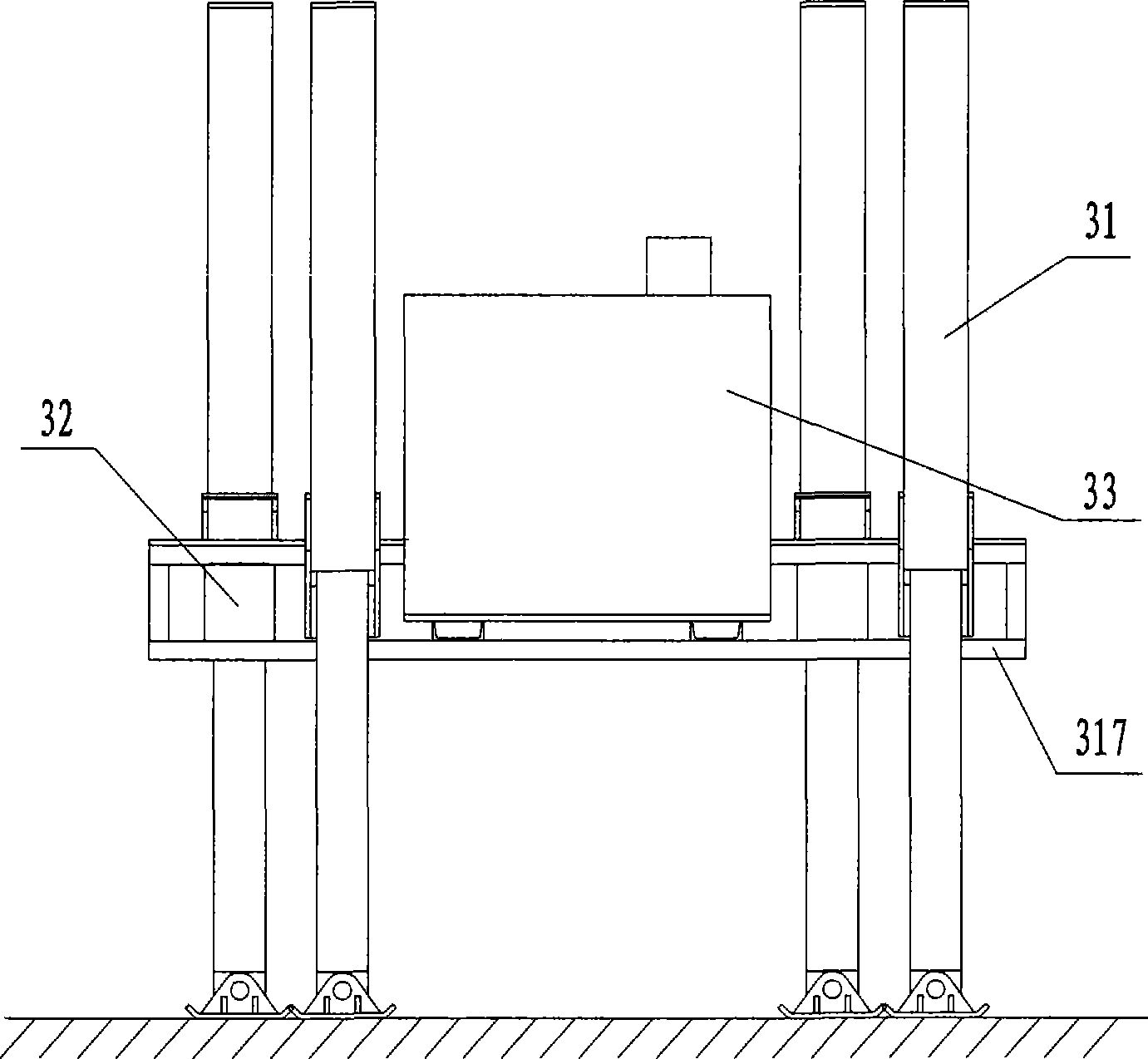

Automatic wall building machine

ActiveCN103741955AImprove work efficiencyImprove securityBuilding material handlingEngineeringMechanical engineering

The invention provides an automatic wall building machine used in building construction. The wall building machine comprises a rack with stand columns at four angles, wherein the two stand columns at one end of the frame are provided with an upper brick tray driven to move up and down through a tray motor, a cross beam driven to move along the stand columns up and down through a driving device is respectively arranged between the corresponding stand columns at the two ends of the rack, and a brick conveying support plate is arranged on the two cross beams; a brick conveying motor capable of moving the brick conveying support plate along the cross beams is arranged at the upper part of the brick conveying support plate, a brick push cylinder is arranged at the lower bottom of the brick conveying support plate, and an inverted U-shaped frame is pushed to move along the lower bottom surface of the brick conveying support plate by a brick pushing cylinder; and a brick clamping cylinder is arranged in the inverted U-shaped frame, a brick clamping plate is pushed to move in the inverted U-shaped frame by the brick clamping cylinder, and a pressing cylinder is arranged on the inverted U-shaped frame. According to the automatic wall building machine provided by the invention, the automatic operations of brick lifting, brick clamping, brick conveying, brick pushing and brick pressing can be realized, and the automatic wall building machine has the advantages of high operating efficiency, regular and standard brick-built wall, high safety factors and the like.

Owner:鄂大锐

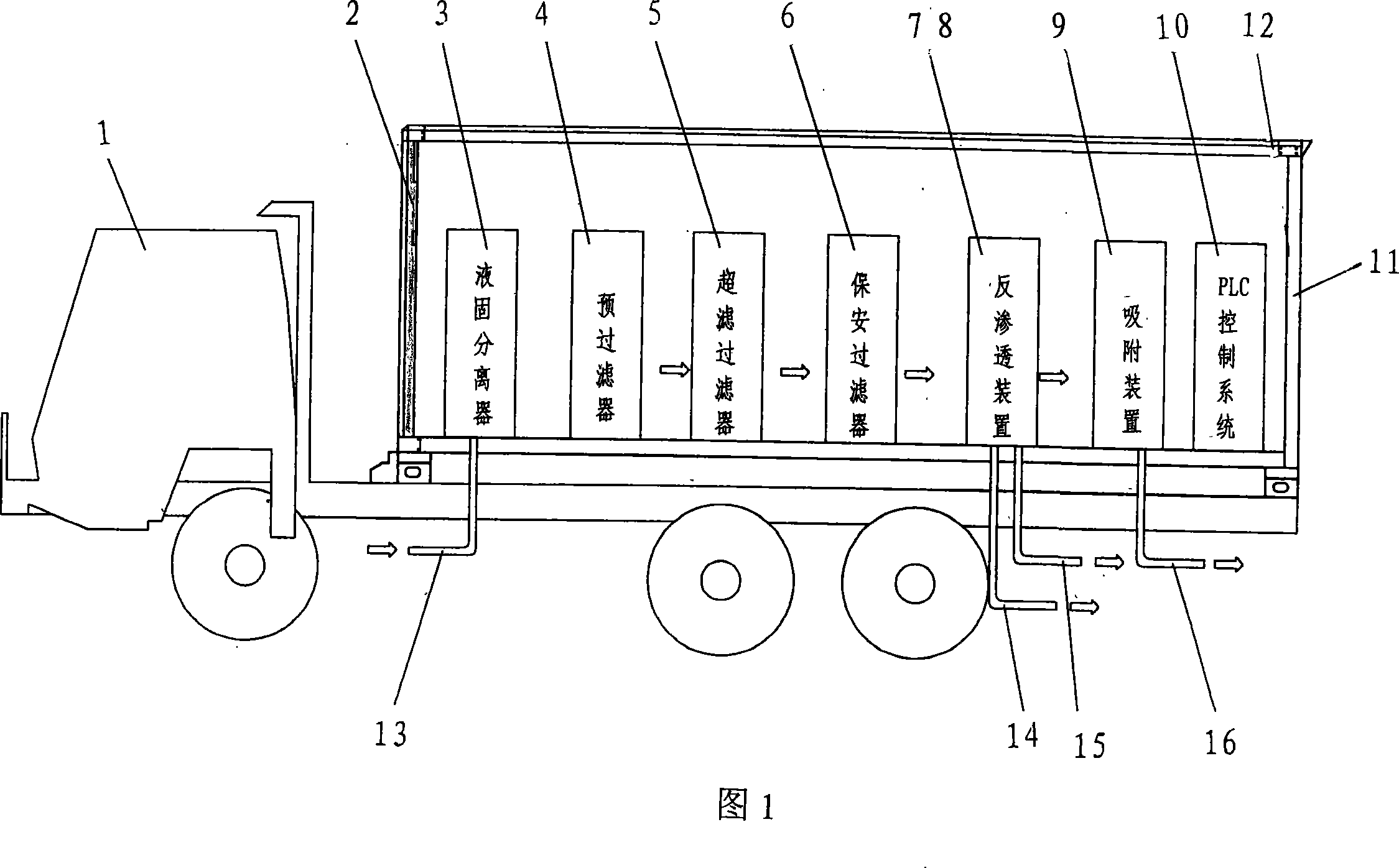

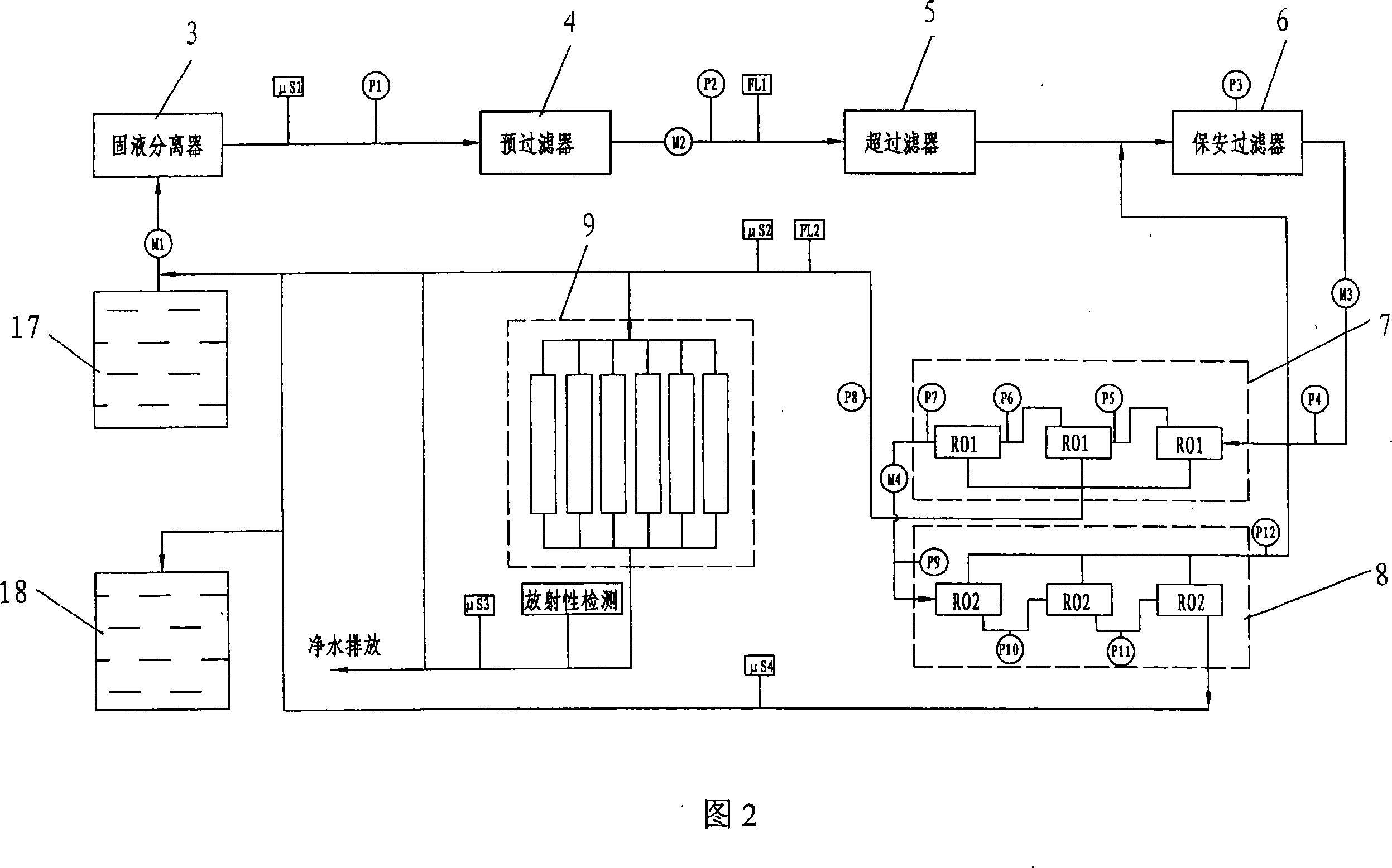

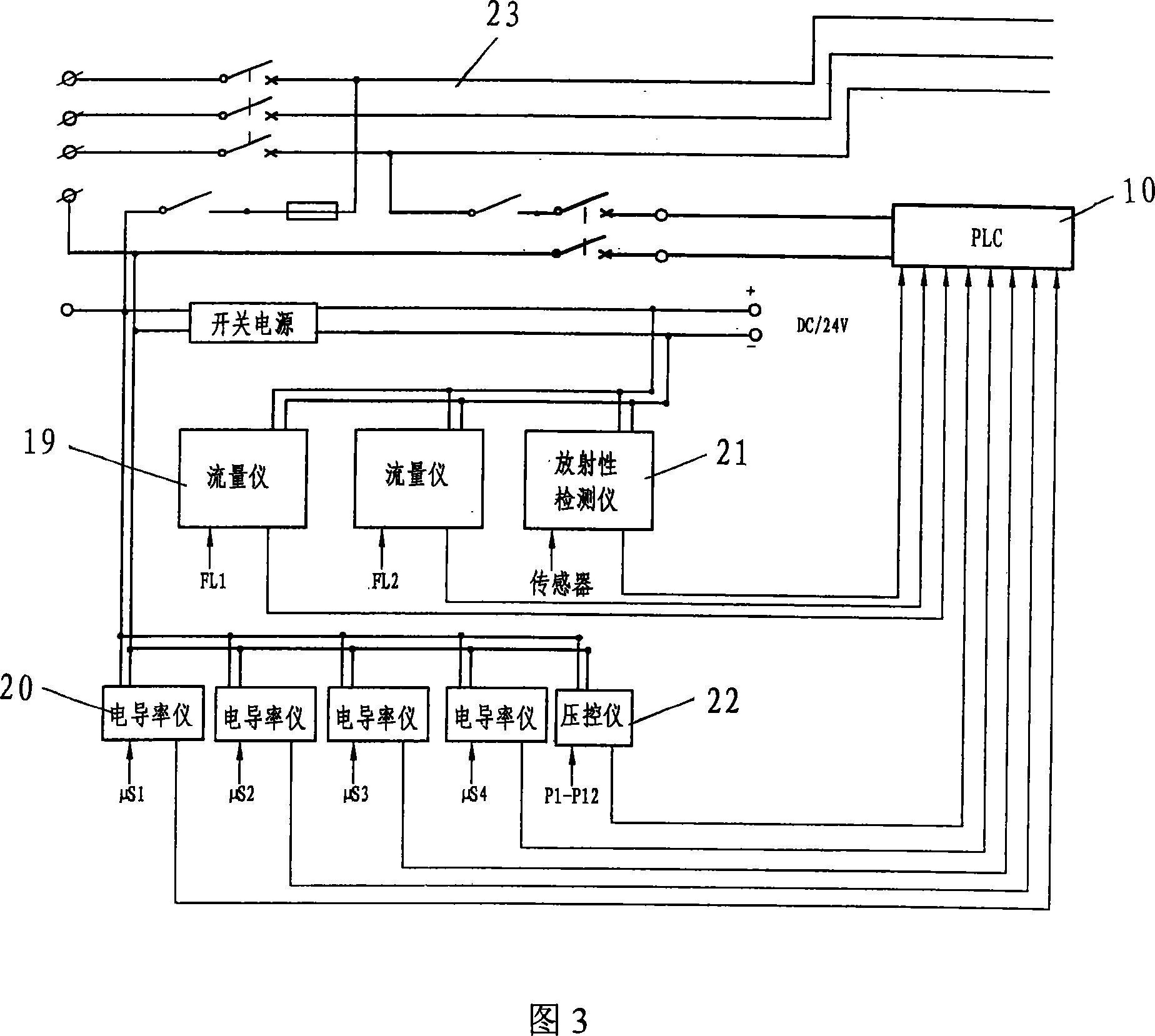

Mobile radioactive liquid waste treatment equipment

ActiveCN101229949ASolve technology integration and security issuesAutomate operationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentPre filteringExternal connection

The invention discloses a movable treatment device for radioactive waste water, which comprises a protecting vehicle, a heat preservation cabin, a treatment system of waste water, a PLC controlling system and an external connecting pipeline, wherein, the treatment system of waste waster consists of a liquid and solid separator, a pre-filter, an ultra-filter, a security filter, a reverse osmosis filter of two levels and a combined adsorption device; the PLC system consists of a PLC, a flow meter, a conductivity meter, a radioactivity detector and a pressure controlling device. The invention solves the contradiction between the low interception and adsorption efficiency of nuclide and small size under the condition of large flow, meanwhile, which solves the problems of integration of a plurality of techniques and protection of the movable treatment device of radioactive waste water and realizes automatic operation, safety and reliability in the overall process.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND +3

Oil field well workover operation machine

InactiveCN101429847AFlexible layoutEasy to install/removeDrilling rodsDrilling casingsControl systemOil field

The invention relates to an oil field operation device, in particular to an oil field workover treatment machine. The machine body is arranged on a hydraulic load-bearing traveling gear and is interlocked with the hydraulic load-bearing traveling gear. Hydraulic tongs connected with a telescopic bracket on the machine body can be extended out and retracted with the telescopic bracket. A clip seat is positioned below the hydraulic tongs and is arranged on a well head. An elevator which is suspended onto the machine body can reciprocate up and down. A faucet is positioned above the machine body and the clip seat; a pipe throwing device is arranged on the faucet and the machine body; and a clip unlocking device and a clip locking device corresponding to the elevator are arranged on the clip seat and the pipe throwing device respectively. A righting mechanism and a valve mechanism are further arranged on the faucet. A control cabinet is arranged on the machine body; and the clip seat, the hydraulic tongs, the elevator and the pipe throwing device are connected with a control system in the control cabinet respectively. The oil field workover treatment machine can be assembled and disassembled conveniently and rapidly, thereby not only facilitating transportation, but also changing the positions to meet the requirements of different work. Simultaneously the machine can be laid freely at a well field according to the practical conditions.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU +1

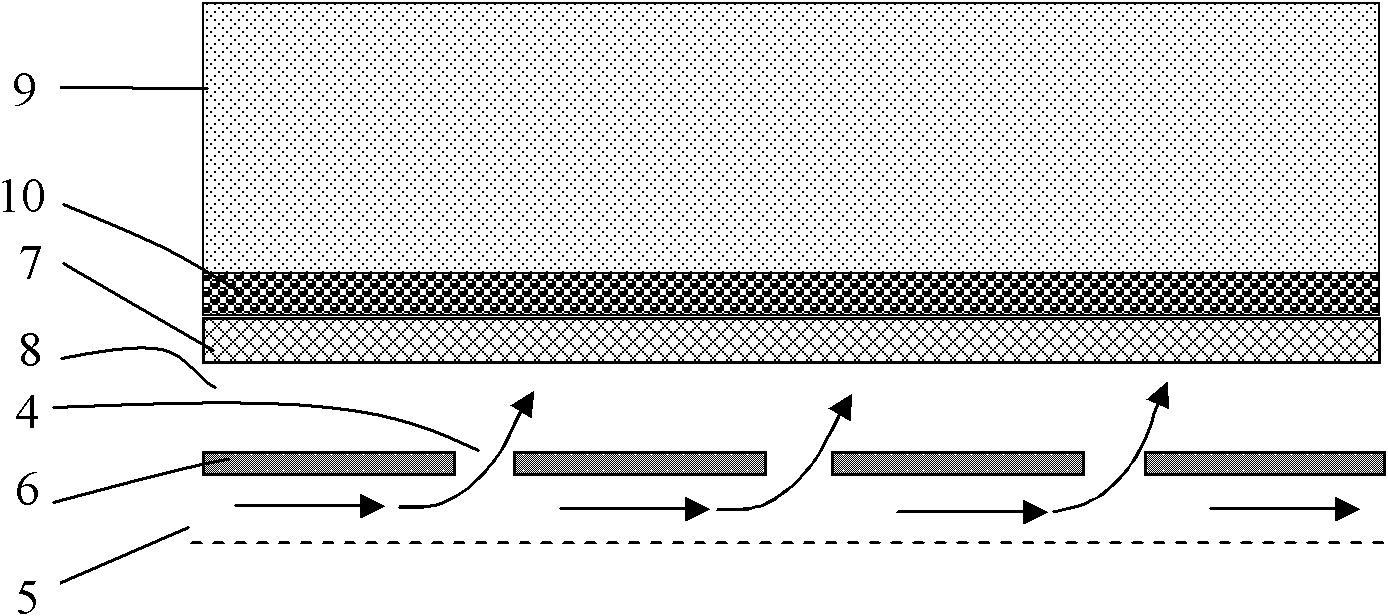

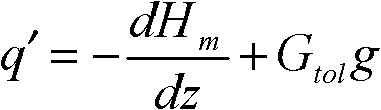

Method for uniformly injecting multi-component thermal fluid in horizontal well

The invention provides a method for uniformly injecting a multi-component thermal fluid in a horizontal well. The method comprises the following steps: (1) segmenting horizontal segments in the horizontal well; (2) initially setting the size of each discharge orifice on a tubular column in each segment of the horizontal well and the number of discharge orifices at a tail end; (3) detecting the temperature, pressure and dryness of the multi-component thermal fluid; (4) obtaining the on-way temperature, pressure, dryness and heat loss of each shaft segment of the horizontal well by iterative calculation; (5) obtaining the actual number of the discharge orifices on the tubular column in each segment of the horizontal well and the size of each discharge orifice by iterative calculation; and (6) drilling the tubular column based on the calculation result, putting the tubular column subject to drilling down into the well, and injecting the multi-component thermal fluid in the tubular column. The invention has the advantages of wide oil pool application range, relatively simple technology and low cost, and ensures that the oil pool at the horizontal well segment can be subject to uniform steam injection without changing the traditional well orifices and steam injection pipes. Besides, by using the invention, the producing degree of the oil reservoir is improved and the optimal exploitation effect can be ensured by injecting the multi-component thermal fluid in the horizontal well of the exploited oil pool.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for analysing non-centrifugal urine by image identifying system

InactiveCN1645139AAvoid breakingAccurate countCharacter and pattern recognitionBiological testingFeature extractionImage segmentation

A method for detecting urinary tangible composition includes starting up sample automatic feeding system; carrying out image-shooting for urine absorbed in counting chamber by microscopic shooting system; carrying out automatic classification, identification and count for obtained image of urinary dregs by image automatic identifying software on computer and outputting results.

Owner:DIRUI MEDICAL TECH CO LTD

O-shaped ring assembling device

InactiveCN103722353AEasy and fast assemblyEfficient assembly workMetal working apparatusEngineeringElectrical and Electronics engineering

The invention discloses an O-shaped ring assembling device which comprises a turntable device, a first feeding device, a first detection sensor, a second feeding device, a second detection sensor and a discharging device. When the O-shaped ring assembling device is in operation, only one operator is needed to perform related assisting, and the operator firstly puts an O-shaped ring workpiece to be assembled on an assembly station of a turntable working table. After the device is started, the first feeding device, the first detection sensor, the second feeding device, the second detection sensor, an intelligent camera detection device and the discharging device which are arranged around the turntable device perform automatic matched operation, a first O-shaped ring and a second O-shaped ring are quickly and accurately assembled on the workpiece, and accepted product and defective product classification and output are performed, so that the O-shaped ring assembling device is simple in operation, high in production efficiency and capable of achieving automatic operation to the most extent and greatly saving labor.

Owner:周俊雄

Automatic feeding assembling and transmitting device for electronic elements

InactiveCN102612311AAutomate operationSave manpower and material resourcesElectrical componentsWaste management

Owner:深圳市中科创安科技有限公司

Method for determining anti-nucleosome antibody IgG (intravenous gamma globulin) and reagent device

The invention provides a method for realizing immunization detection for an anti-nucleosome antibody IgG (intravenous gamma globulin) based on the enzyme-linked immunoassay principle and a reagent device therefor; and an analytic method, the reagent device and an assorted reagent are independently, individually and disposably used for detecting the anti-nucleosome antibody IgG based on enzyme-linked immunoassay. Various reagents needed by enzyme-linked immunoassay for the anti-nucleosome antibody IgG are contained in one analytic device; and by using the method, the related immunology detection can be conveniently carried out according to the using requirements of detection items so as to provide better basis for clinical application.

Owner:SHENZHEN YHLO BIOTECH

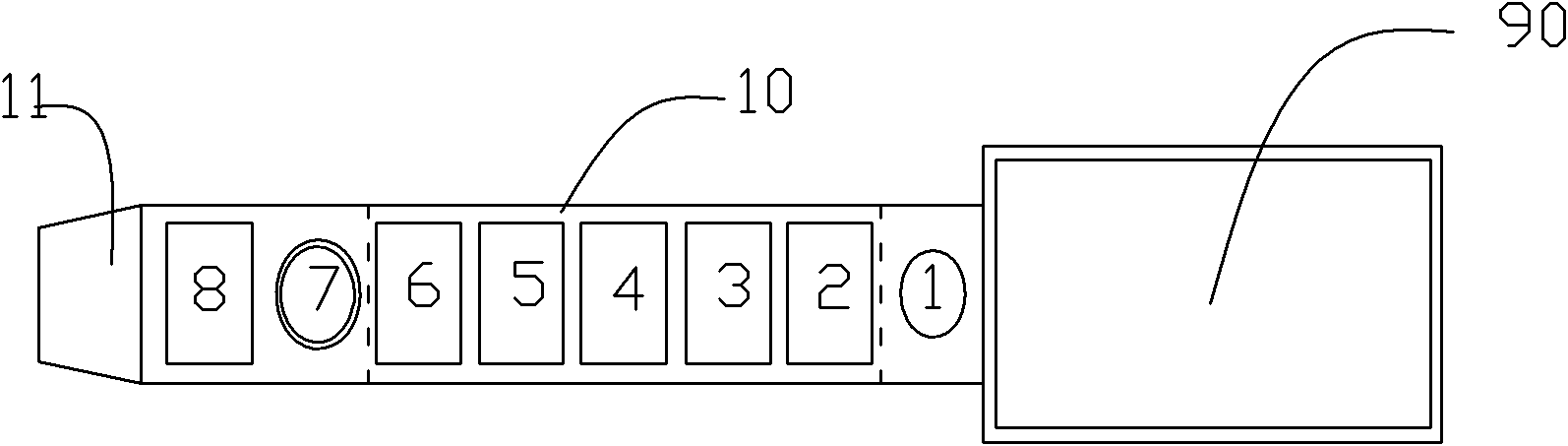

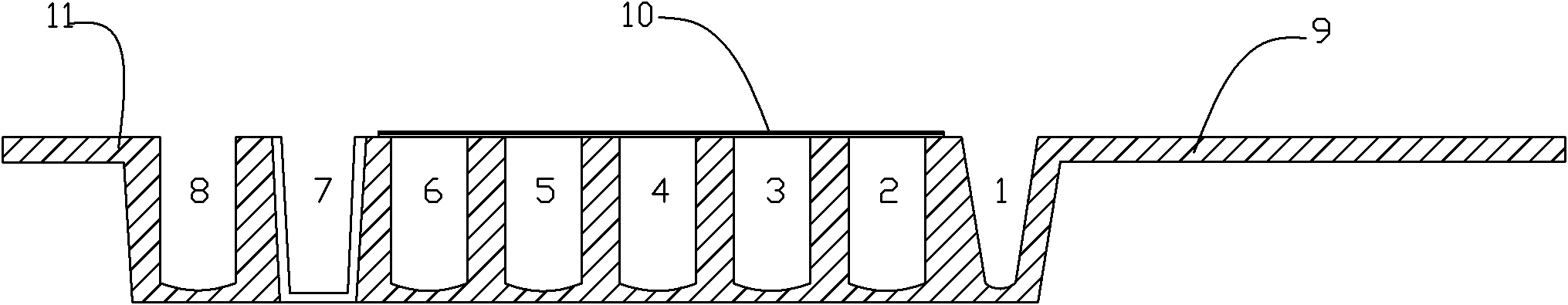

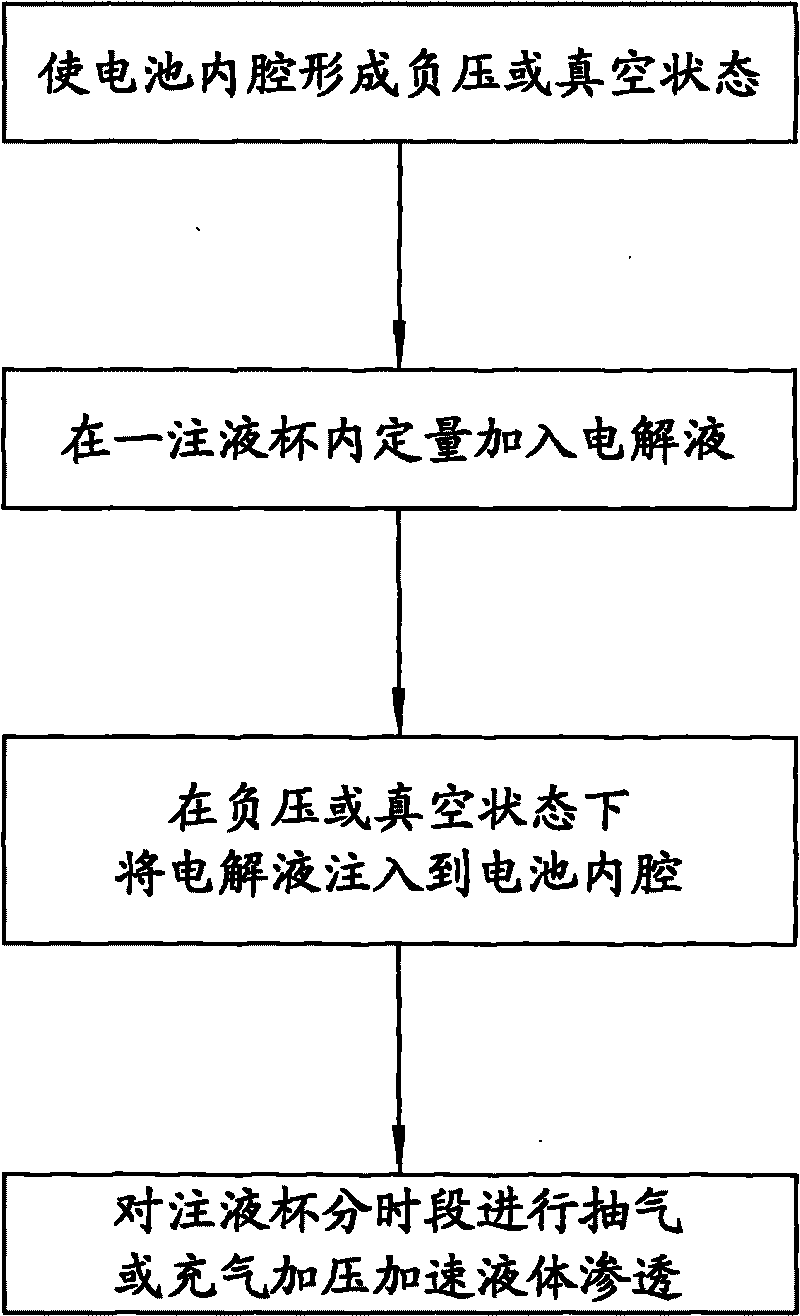

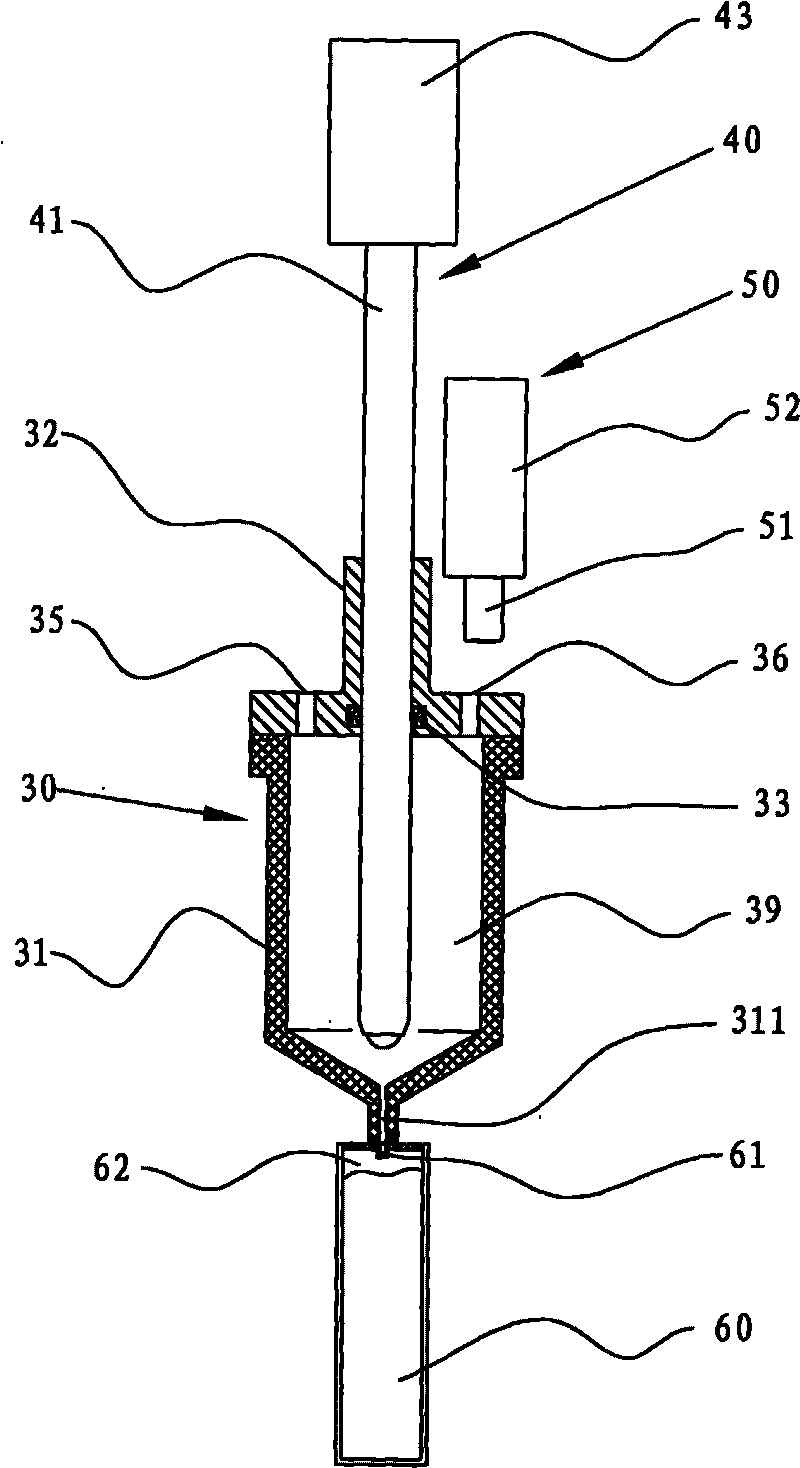

Method and device for injecting electrolyte into lithium battery

InactiveCN101697371AImprove permeabilityAutomate operationCell component detailsPermeationBattery cell

The invention discloses a method for injecting electrolyte into a lithium battery, including the flowing steps: (1) forming a negative pressure state or a vacuum state in an inner chamber of a battery; (2) quantificationally adding electrolyte into a liquid injection cup; and (3) injecting the electrolyte into the inner chamber of the battery at negative pressure state or in a vacuum state. The invention also discloses a device for injecting electrolyte into a lithium battery. The device comprises the liquid injection cup, a first sealing mechanism and a second sealing mechanism, wherein a sealing chamber is formed in the liquid injection cup, the bottom of which is provided with a liquid injection mouth installed on a liquid injection hole in the battery during liquid injection; an extract opening and a liquid feeding opening are arranged on the side wall of the sealing chamber; the first sealing mechanism comprises a slide bar penetrating through the sealing chamber, and the end part of the slide bar can control the liquid injection mouth to open and close; and the second sealing mechanism comprises a sealer which can control the liquid feeding opening to open and close. By adopting the method and the device, the purpose for injecting the electrolyte into the battery in the vacuum state can be realized, air inflation or air extraction can be carried out to accelerate permeation, the injection speed is high, quantificational injection can be carried out, the uniformity is good, and automatic operation can be realized.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

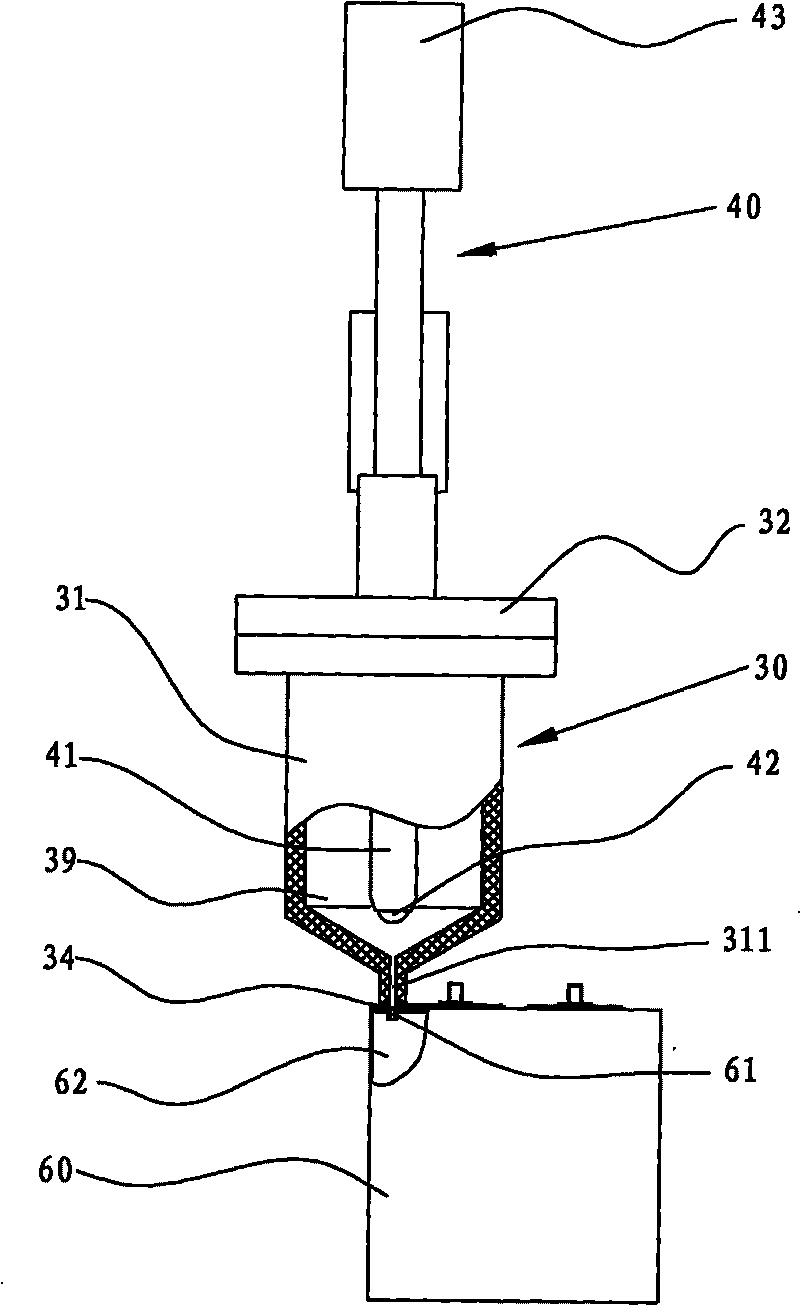

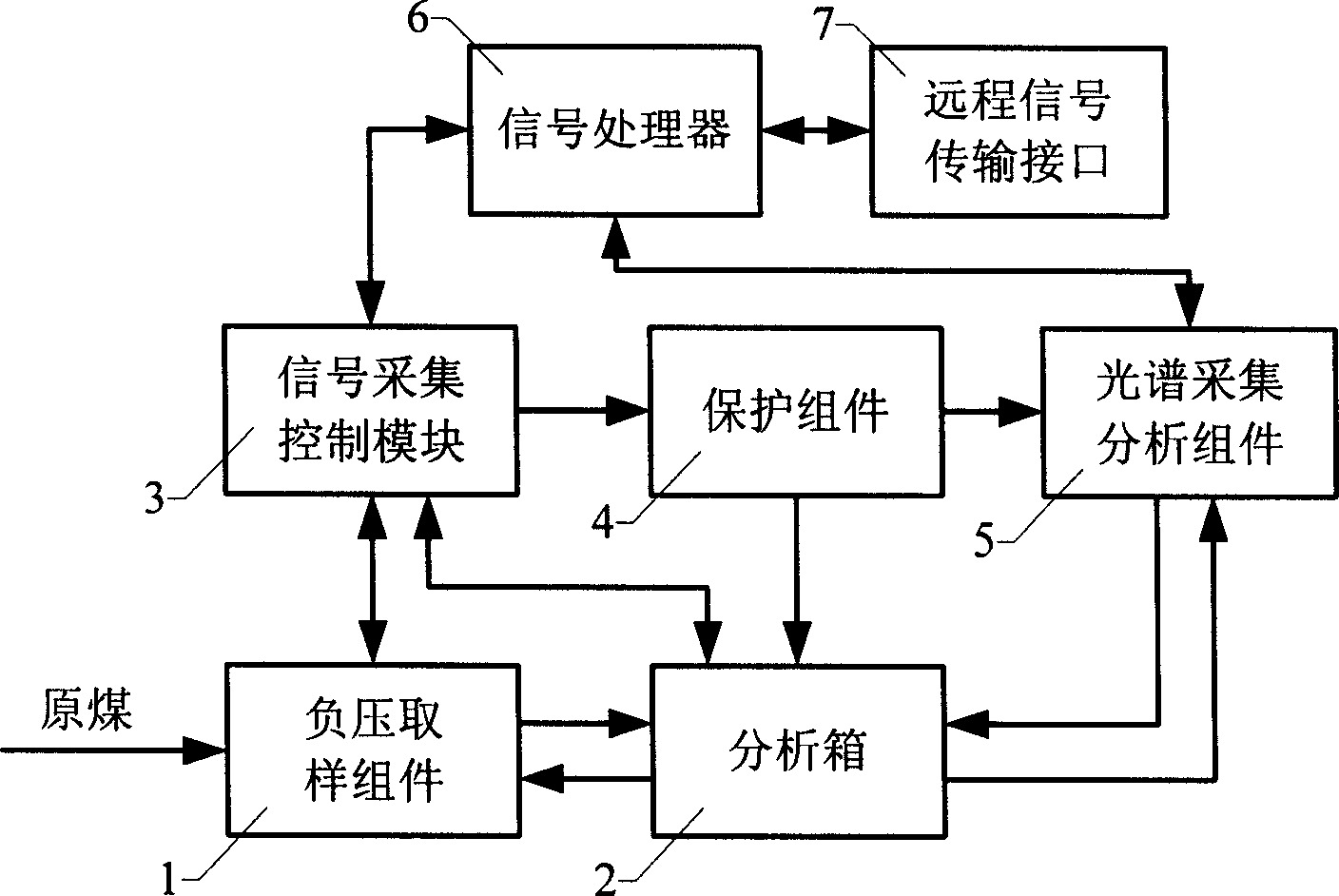

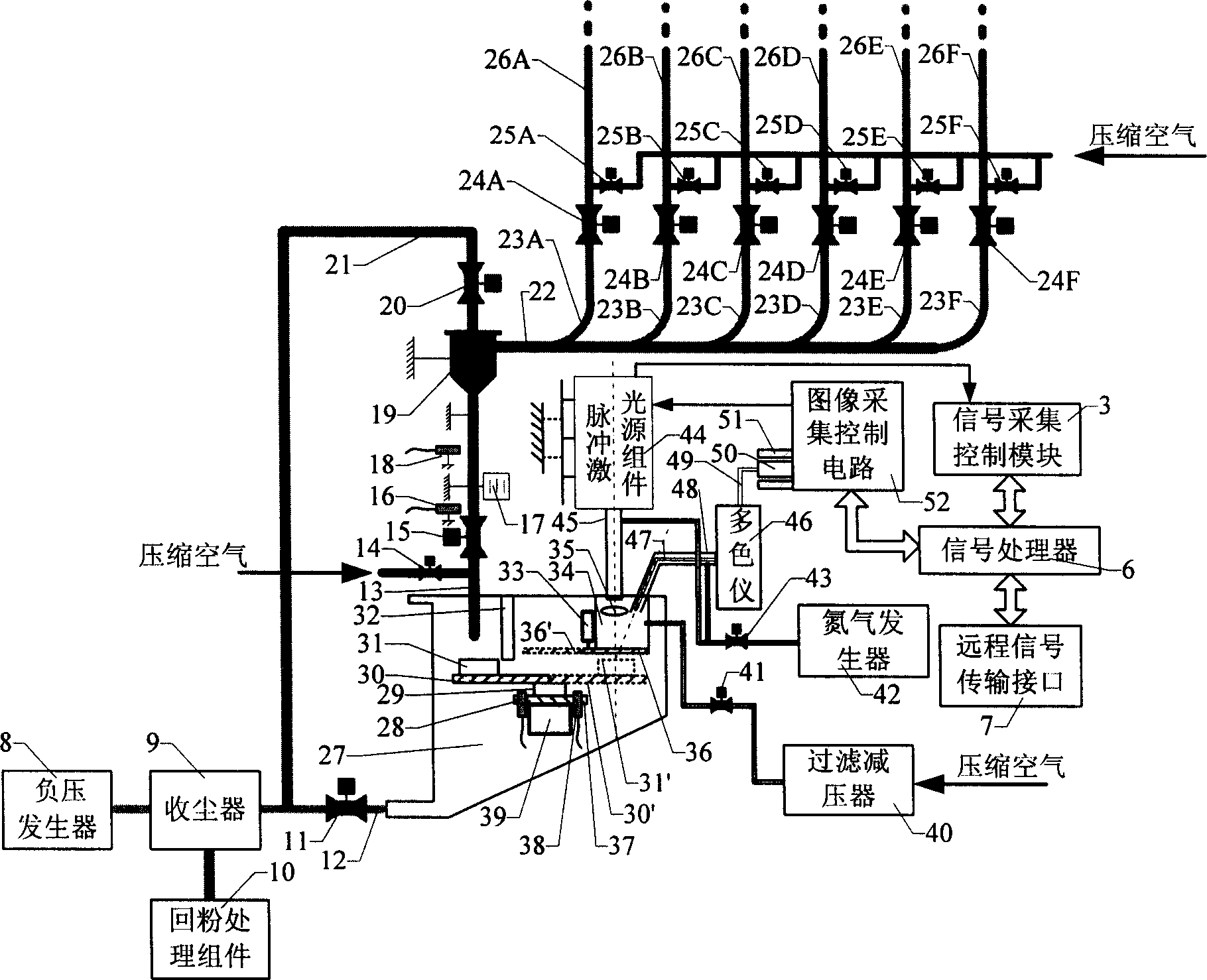

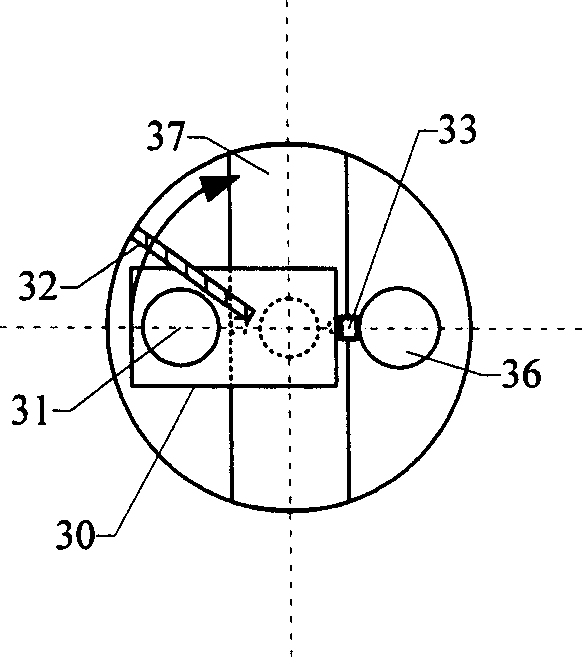

Coal on-line analyse equipment based on laser induced spectral and nerve network technology

InactiveCN1912588AImprove conversion accuracyAvoid thermal efficiency lossFluorescence/phosphorescenceSpecial data processing applicationsPhysicsWater content

An on-line analyzing and detecting device of coal quality is prepared as shining sample to be analyzed by laser to generate induced light spectrum; collecting said spectrum by CCD image transducer and image collection control circuit and calculating to obtain vector E of character element content in raw coal by signal processor; sending vector E into BP neural network for carrying out conversion to obtain heating value, water content, ash content, volatile composition and fixed carbon of raw coal; utilizing neural network to predict slagging index and temperature of ash melted point of raw coal.

Owner:太原市海通自动化技术有限公司

Full automatic bead threader

InactiveCN101947005AAutomate operationPlay a role in cooperative controlJewelleryEngineeringNylon thread

The invention discloses a full automatic bead threader, which comprises a frame, and an array mechanism used for performing row arrangement on beads, a threading mechanism used for guiding a nylon thread and introducing the nylon thread into through holes of the beads arranged in rows, and a control mechanism used for controlling the mechanisms to cooperatively work which are arranged on the frame, wherein the threading mechanism is arranged parallel to the array mechanism. The full automatic bead threader can automatically thread the beads so as to greatly reduce the cost of threading the beads.

Owner:涂善扬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com