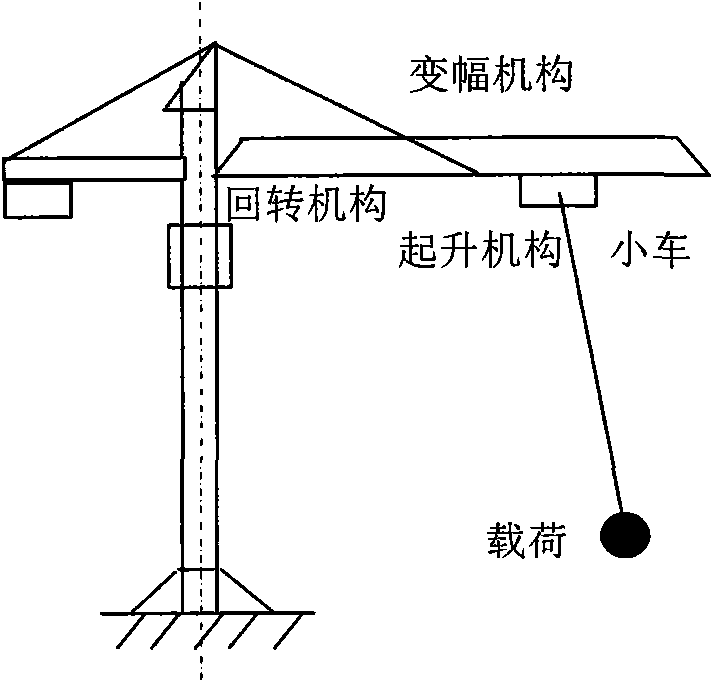

PLC frequency-converting speed-governing control system for eliminating tower-type crane load

A tower crane and control system technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of prolonging auxiliary operation time, difficulty in automatic loading/unloading of tower cranes, and increased power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

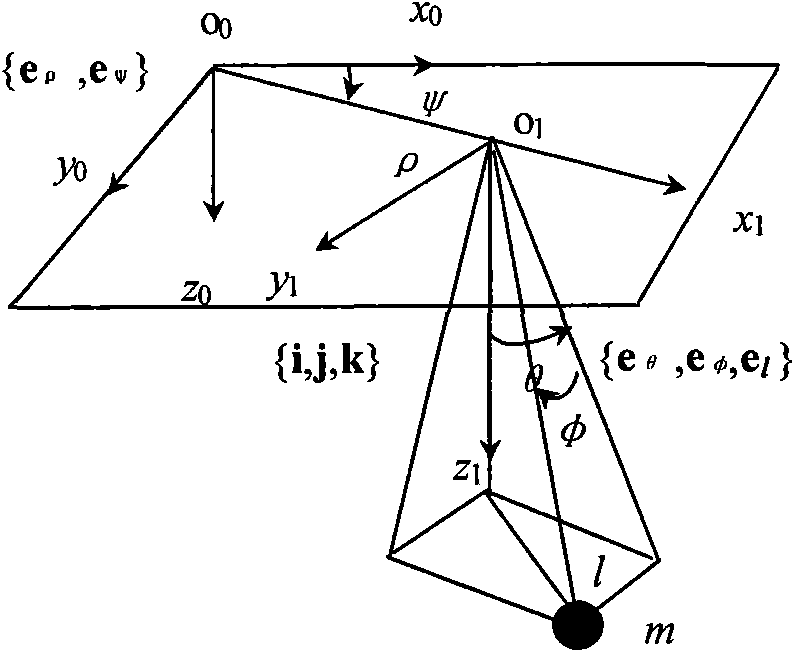

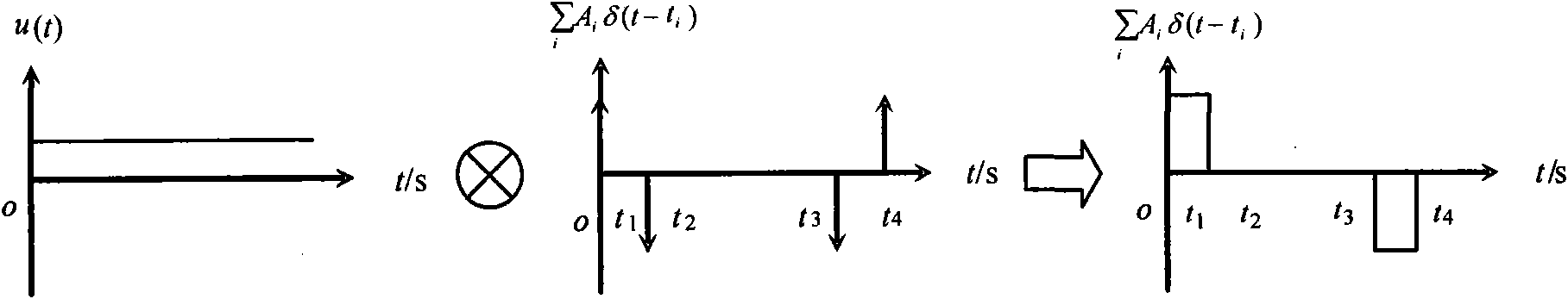

Method used

Image

Examples

Embodiment Construction

[0083] The operation mode of the hoisting mechanism. The operator presses the operation console 1 to send a speed reference signal 19 to the hoisting mechanism for lifting the load, and sends a control signal to the hoisting mechanism inverter 9 through PLC 8 calculation, so that the hoisting mechanism motor 14 drives the hoisting mechanism 13 to lift load. When the target position is reached, the operator presses the operation console 1 to send a given speed signal 19 for reducing the load to the hoisting mechanism, and sends a control signal to the frequency converter 9 of the hoisting mechanism through PLC 8 calculation, so that the motor 14 of the hoisting mechanism Reverse rotation drives the hoisting mechanism 13 to lower the load, at the same time, the hoisting mechanism brake 15 is started to brake, and finally the load is placed on the target position.

[0084]The operating mode of the luffing mechanism. The operator presses the operation console 1 to send a speed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com