Fracturing transmission and high-pressure discharging system

A high-pressure, fracturing technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of unfavorable vehicle weight, limited flexibility, large vehicle layout space, etc., and improve the stability of the vehicle performance, expand the range of selection, and reduce the size of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

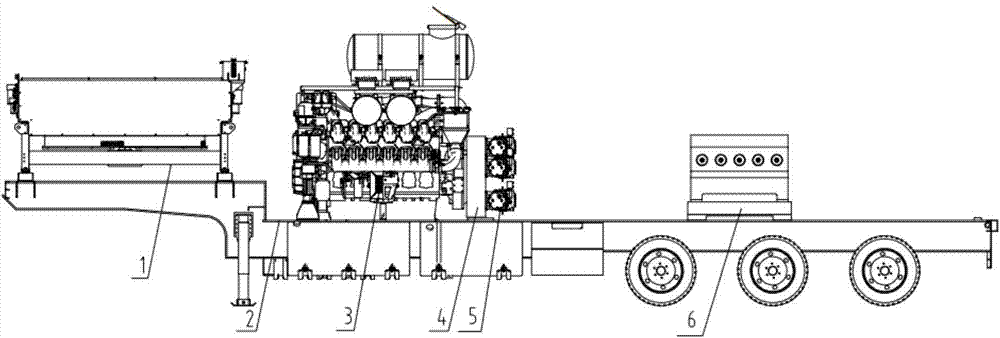

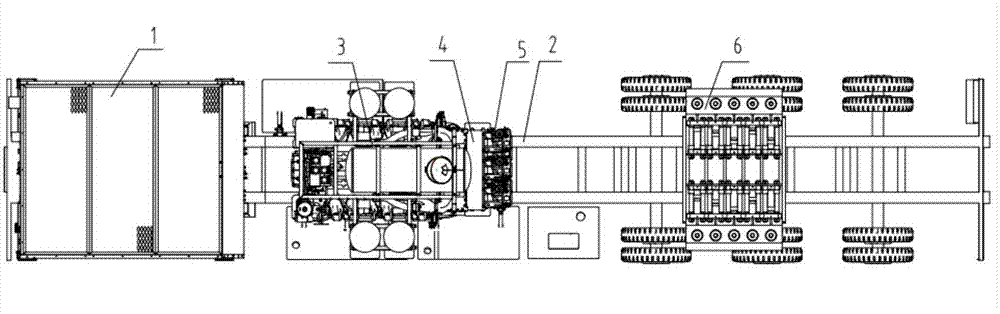

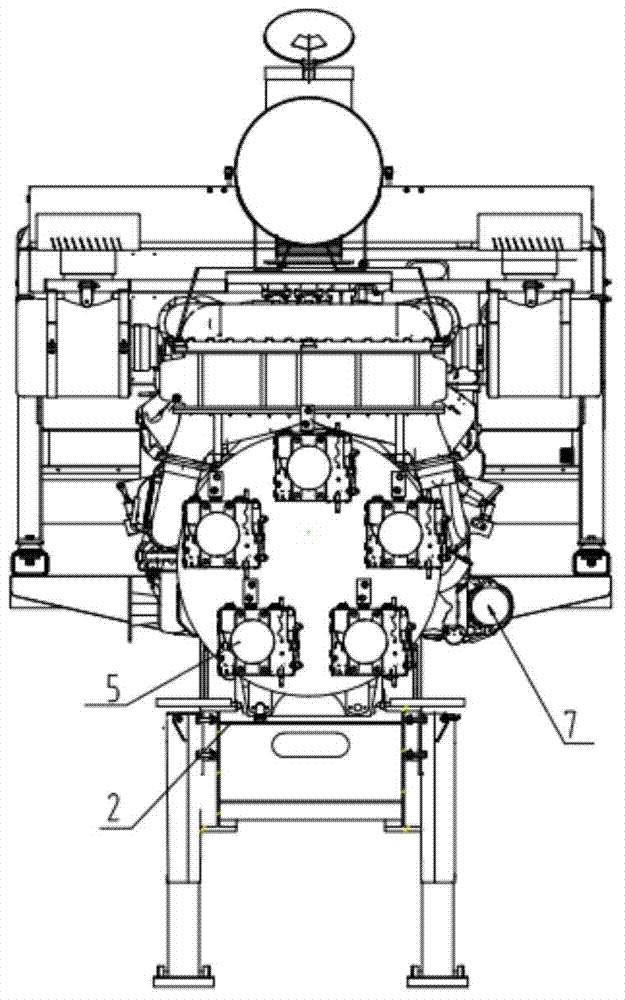

[0027] Such as Figure 1 to Figure 3 As shown, a fracturing transmission and high-pressure discharge system includes a chassis 2 on which a high-power engine 3, a transfer case 4, multiple variable-variable plunger pumps 5 and double-acting fracturing pumps 6 are arranged. , the output end of the high-power engine is connected to the input end of the transfer case, and the output end of the transfer case includes a plurality of power take-off ports, and each of the power take-off ports is respectively connected to one of the variable plunger The pump 5 is connected; the variable displacement plunger pump drives the double-acting fracturing pump 6 through a hydraulic system. The chassis here can be a semi-trailer ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com