Patents

Literature

467 results about "Gas industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degradable ball sealers and methods for use in well treatment

Described is an oil-degradable ball sealer for use in the oil and gas industry. The ball seal comprises a particular composition including ethylene and one or more alpha-olefins, prepared by an injection molding technique to provide a ball sealer which will dissolve in stimulation or wellbore fluids after stimulation operations are complete. The composition, when dissolved into wellbore fluids, does not pose a hazard or problem to aqueous wellbore fluids or further wellbore stimulations.

Owner:FAIRMOUNT SANTROL

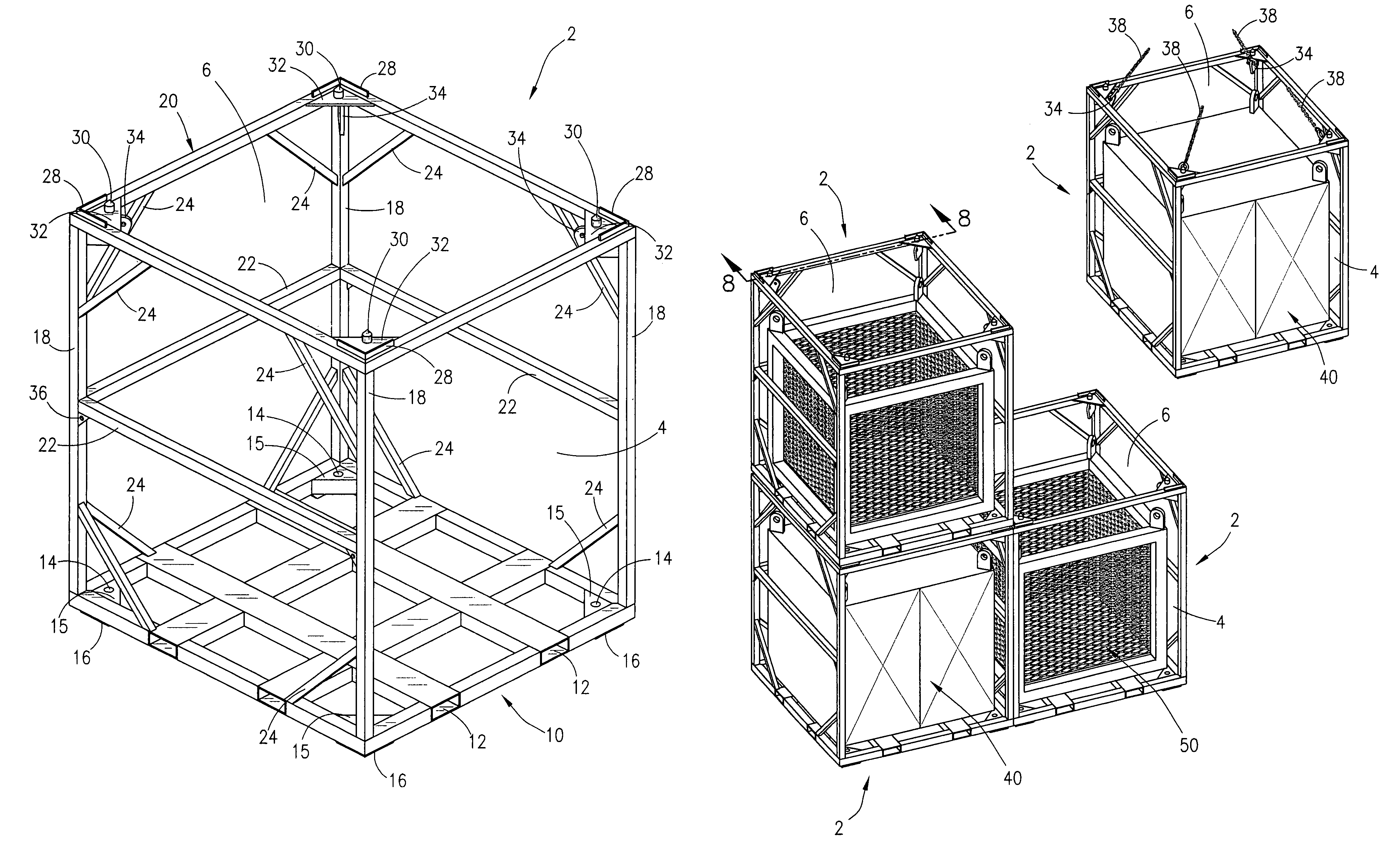

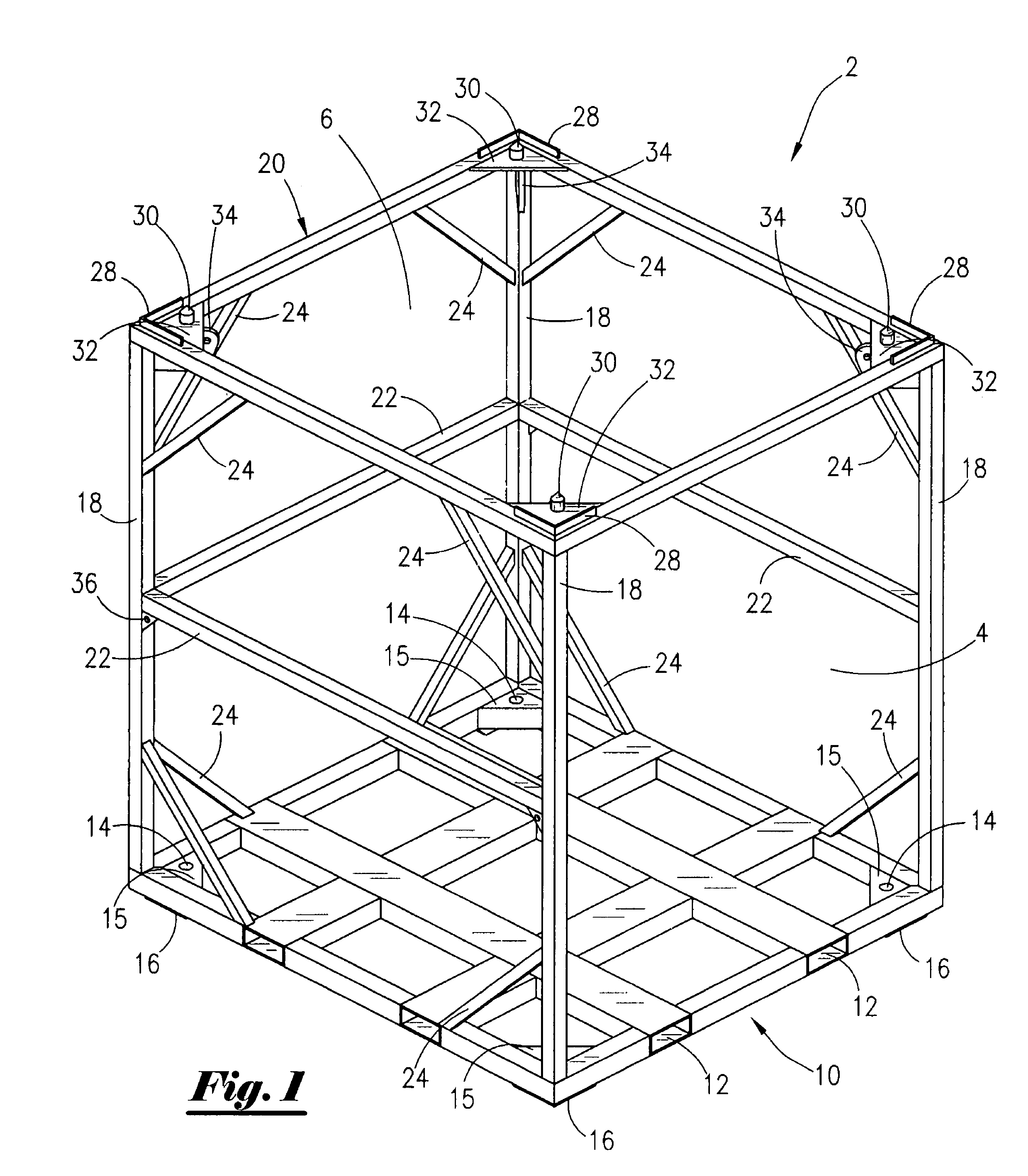

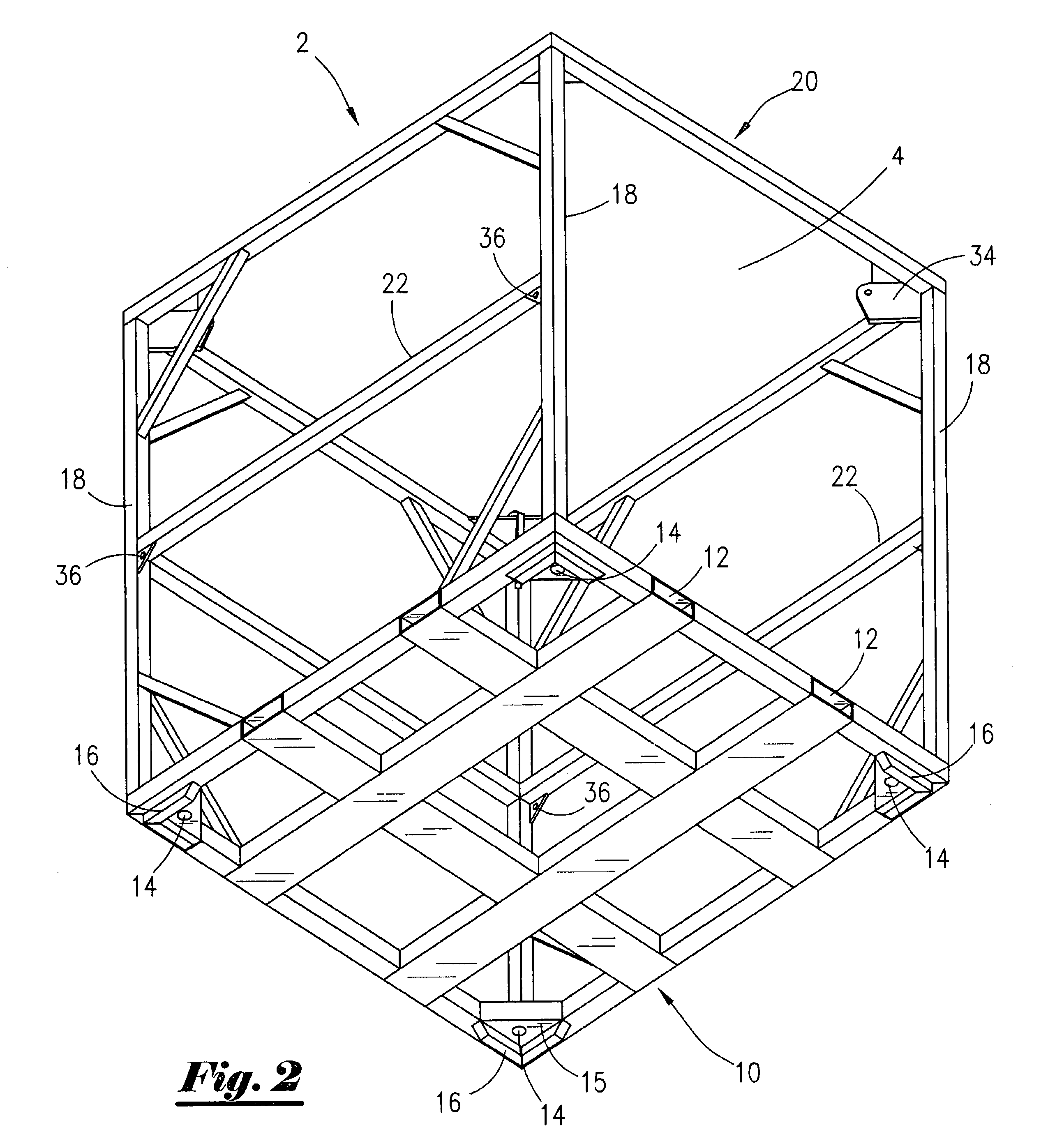

Cargo container cradle

A modular cradle for reinforcing, transporting, and stacking cargo containers used in the transportation and storage of bulk cargo in the oil and gas industry so as to allow compliance with construction and shipping standards adopted by the oil and gas industry is disclosed. The cargo cradle is comprised of a rectangular frame for holding and supporting a cargo container. The cradle has attached lifting lugs positioned within the interior of the cargo cradle for attachment of lifting cables. The lifting lugs are positioned so as to allow cradles to be stacked one upon the other. The container cradles interlock when stacked.

Owner:R3G

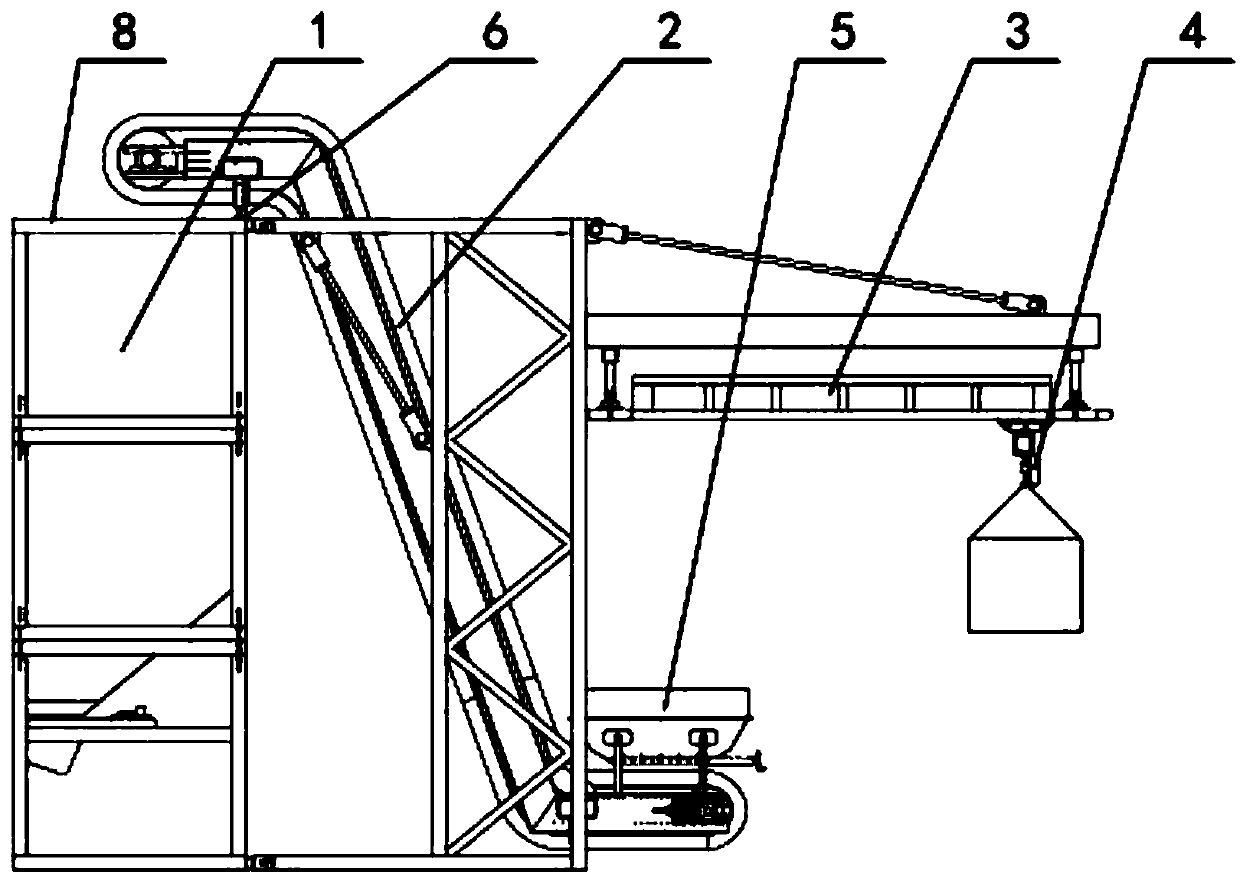

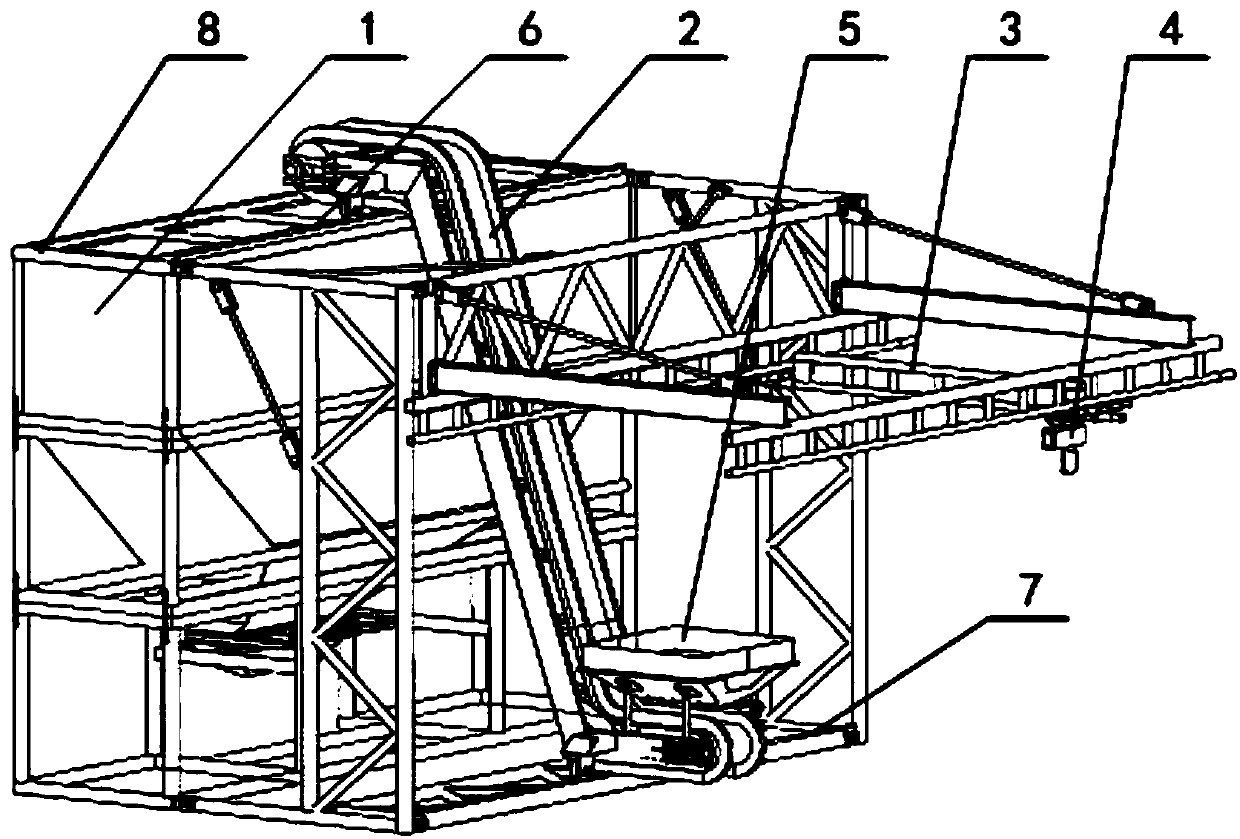

Material hoisting and transportation device

PendingCN107902427ASave on high costsEliminate potential safety hazardsStorage devicesEngineeringOrbit

The invention relates to the oil gas industry, particularly to a material hoisting and transportation device utilized in oil and gas field fracturing operation. The material hoisting and transportation device is characterized in that a material storage tank is mounted on the left of a frame body; an upper orbit is mounted at the upper part of the frame body; a lower orbit is mounted at the right end of the lower part of the frame body; a belt conveying device is mounted on the upper orbit and the lower orbit; a feeding hopper is mounted at the bottom of the belt conveying device; a hoisting device is mounted at the right end of the upper part of the frame body; the hoisting device is mounted in an operation orbit; a hook is mounted on the hoisting device; during operation, the belt conveying device can longitudinally move on the upper orbit and the lower orbit; and during operation, the hoisting device can longitudinally and transversely move in a horizontal plane. The material hoisting and transportation device has a one-key locating function, and automatic operation and locating of the belt conveying device and the hoisting device can be achieved through the function.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Degradable ball sealers and methods for use in well treatment

Described is an oil-degradable ball sealer for use in the oil and gas industry. The ball seal comprises a particular composition including ethylene and one or more alpha-olefins, prepared by an injection molding technique to provide a ball sealer which will dissolve in stimulation or wellbore fluids after stimulation operations are complete. The composition, when dissolved into wellbore fluids, does not pose a hazard or problem to aqueous wellbore fluids or further wellbore stimulations.

Owner:FAIRMOUNT SANTROL

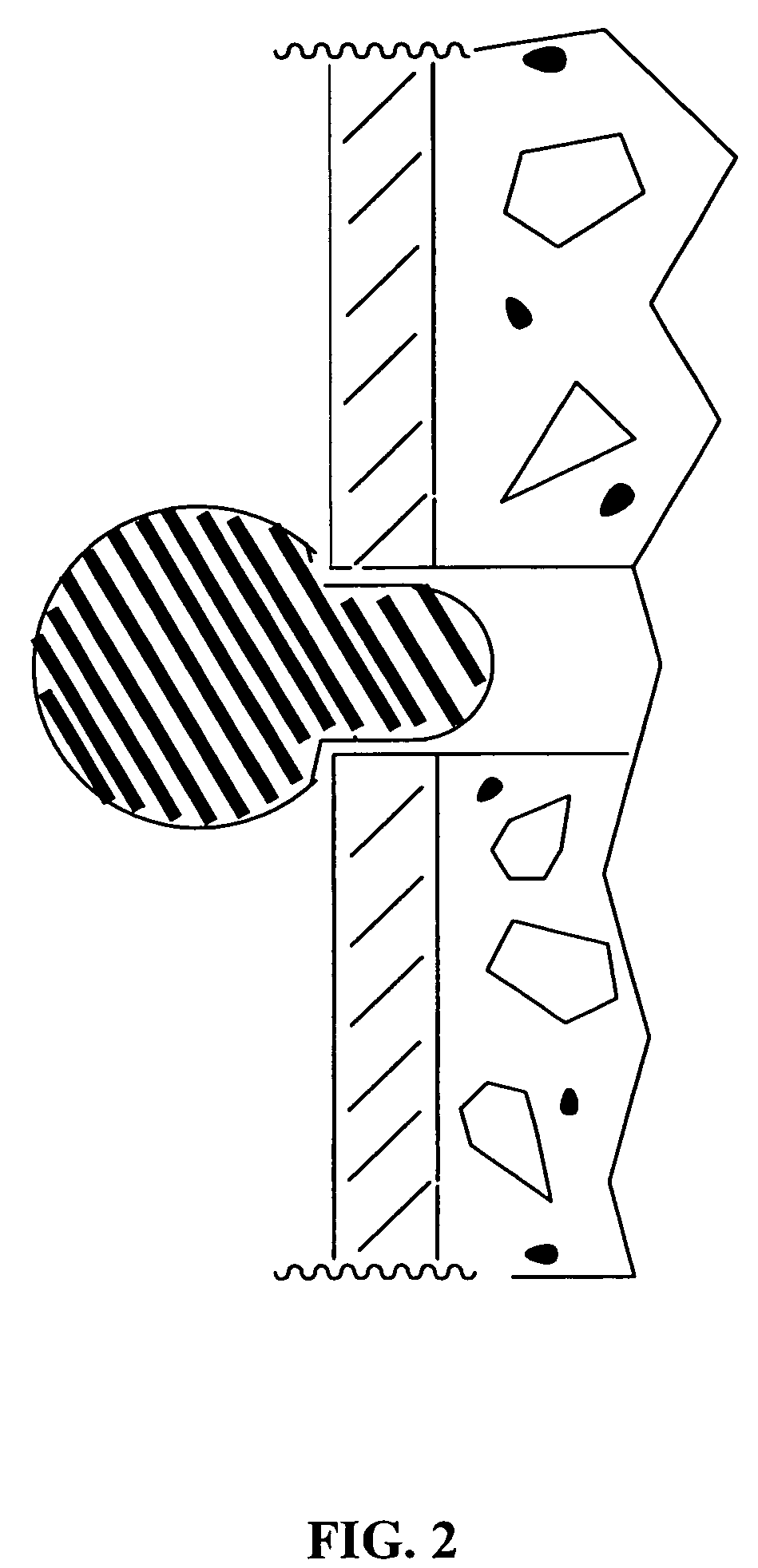

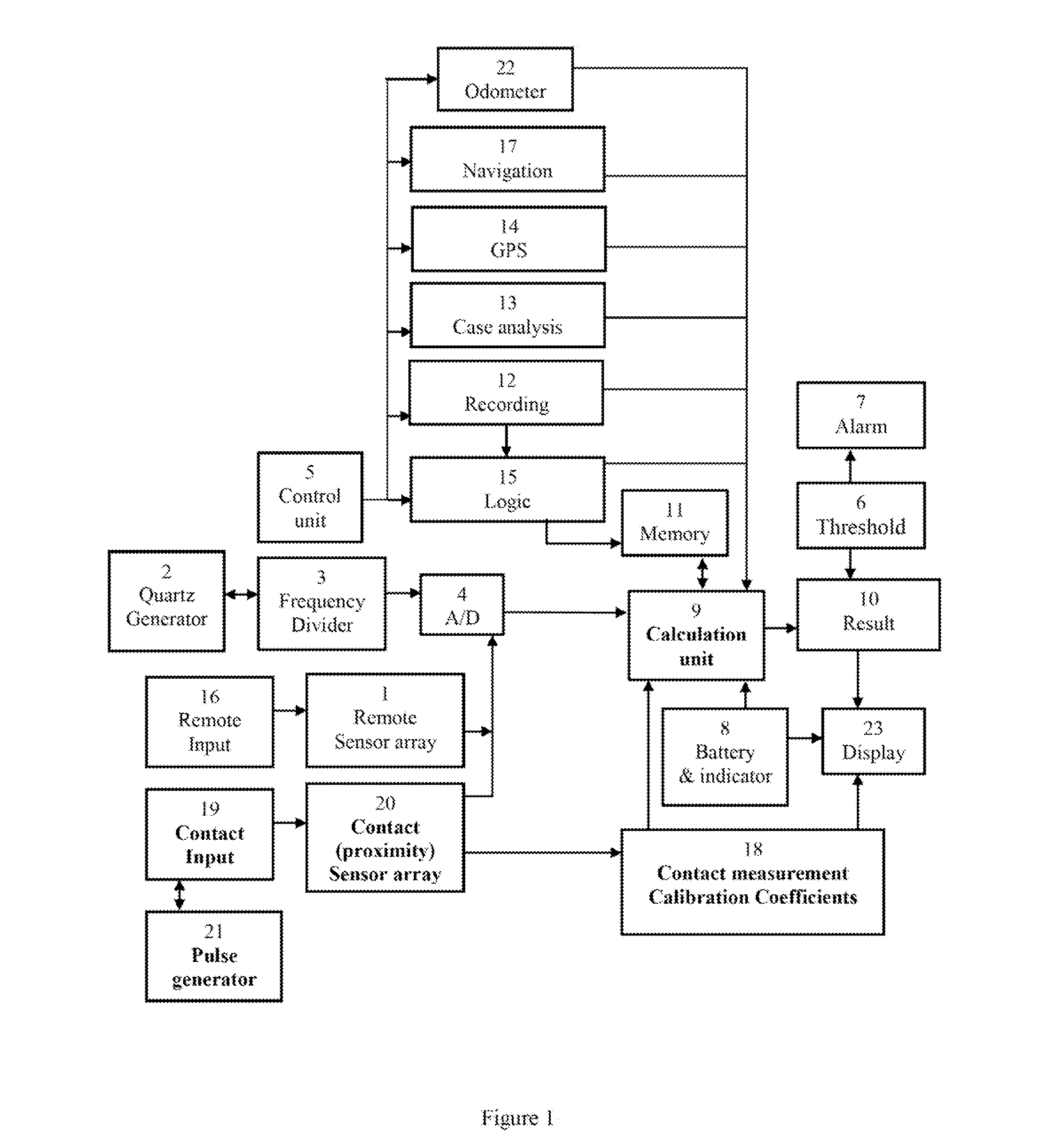

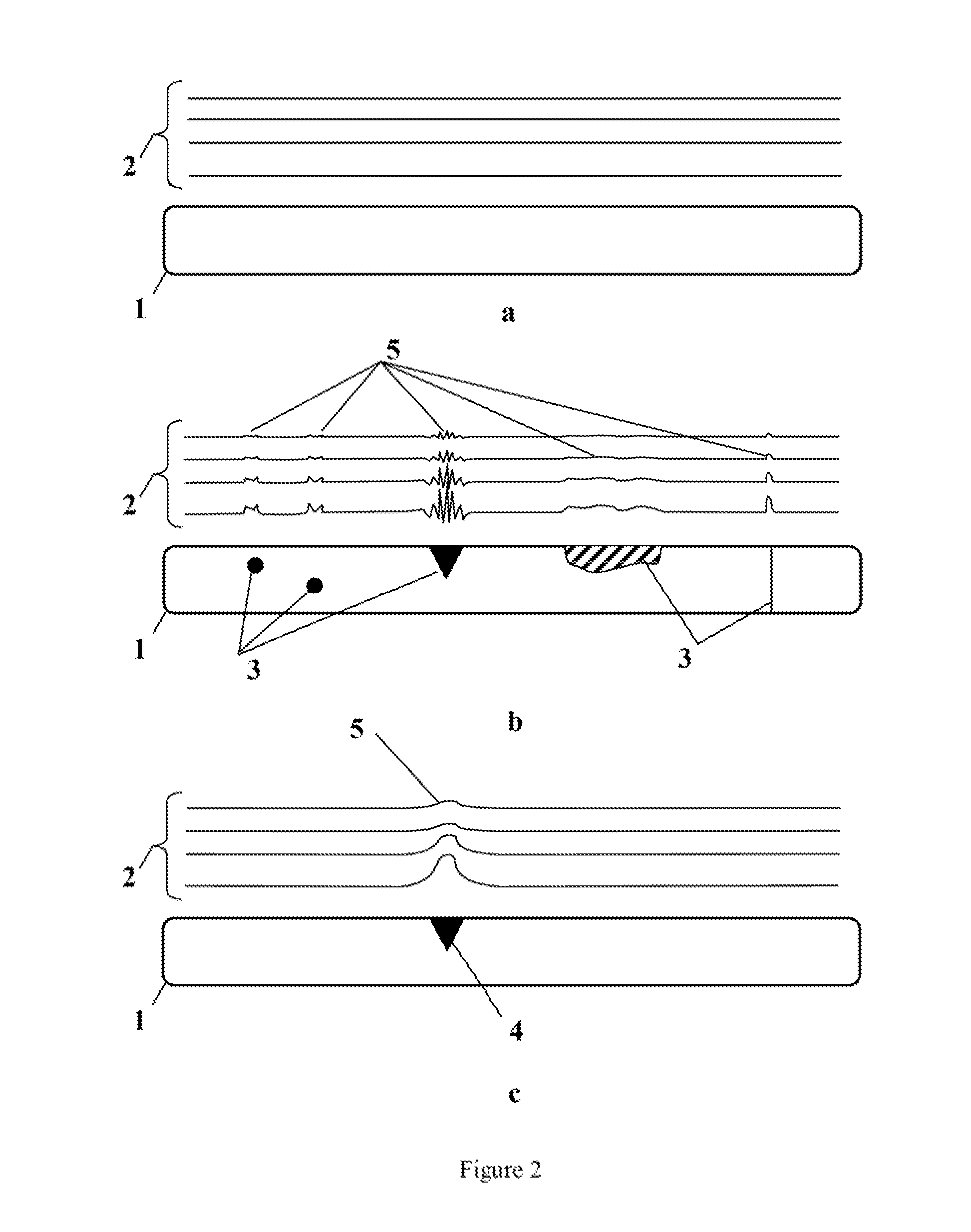

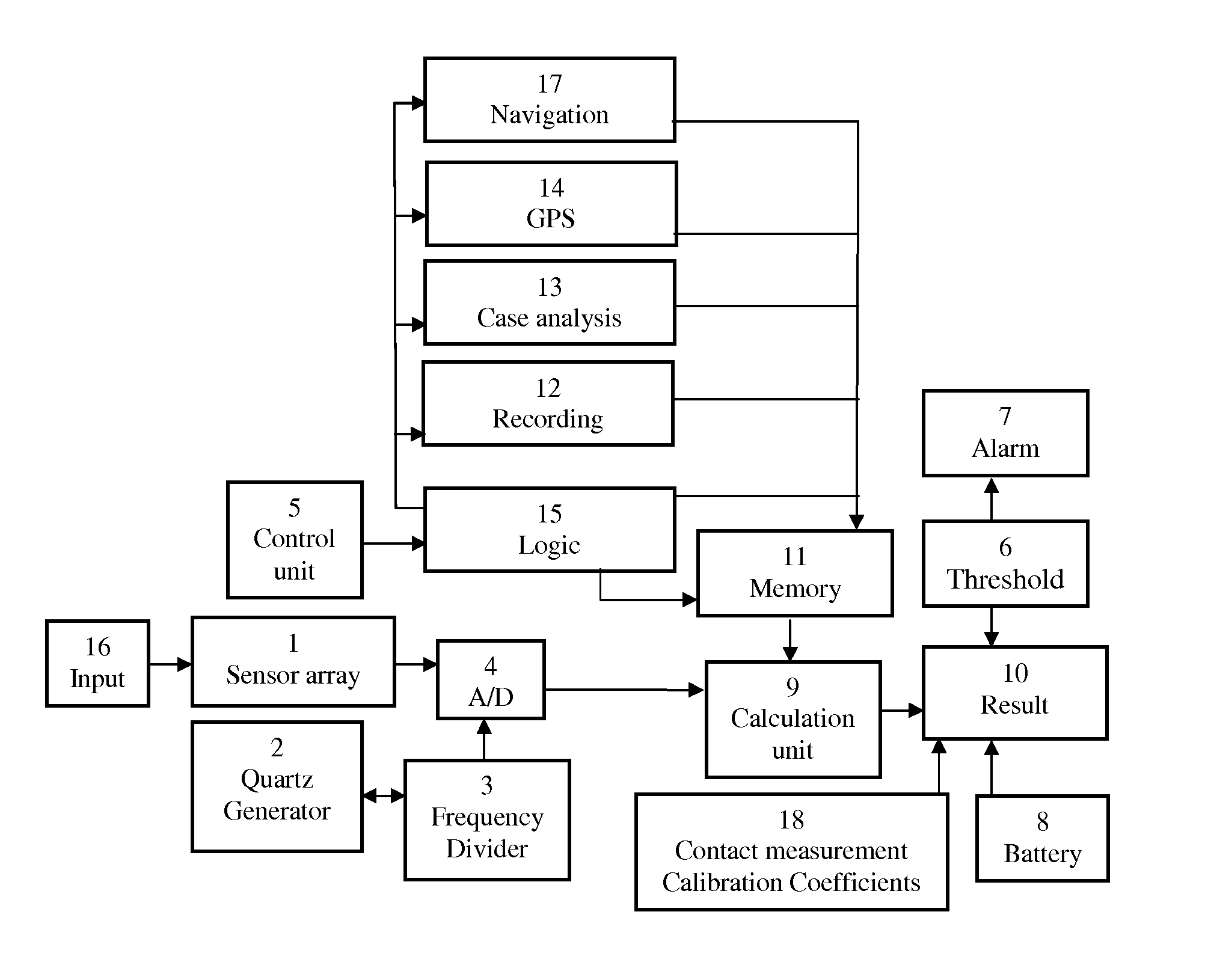

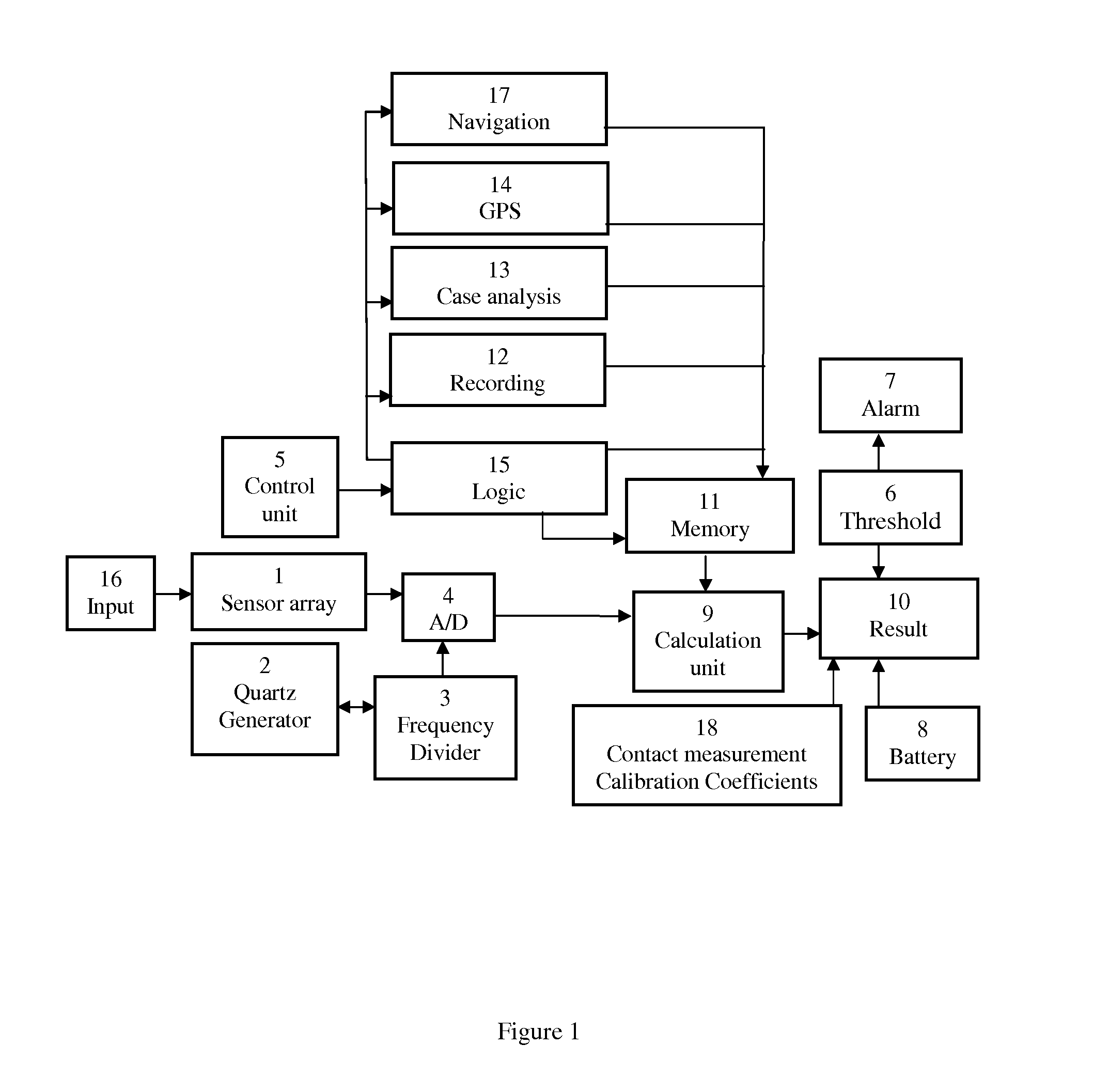

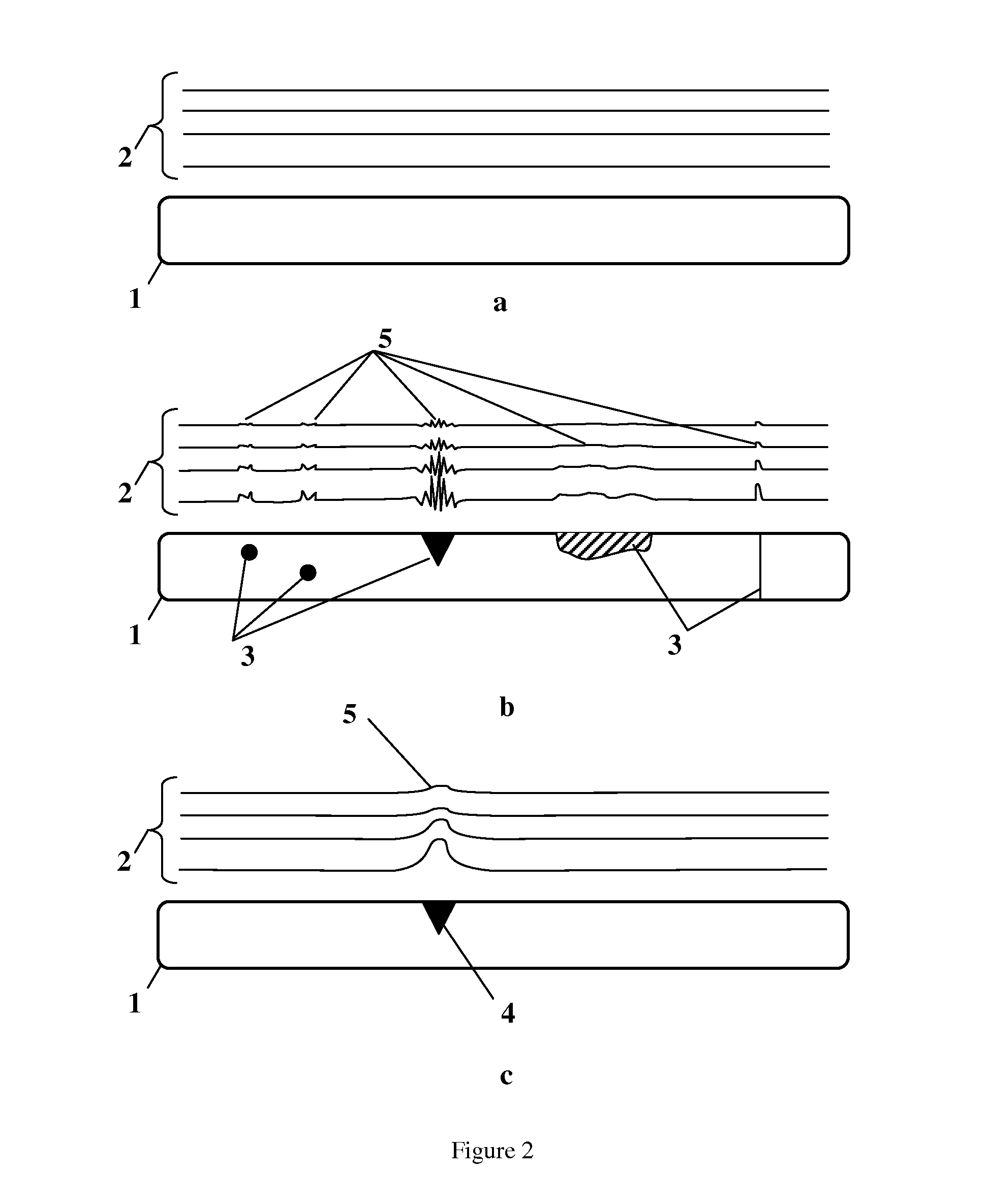

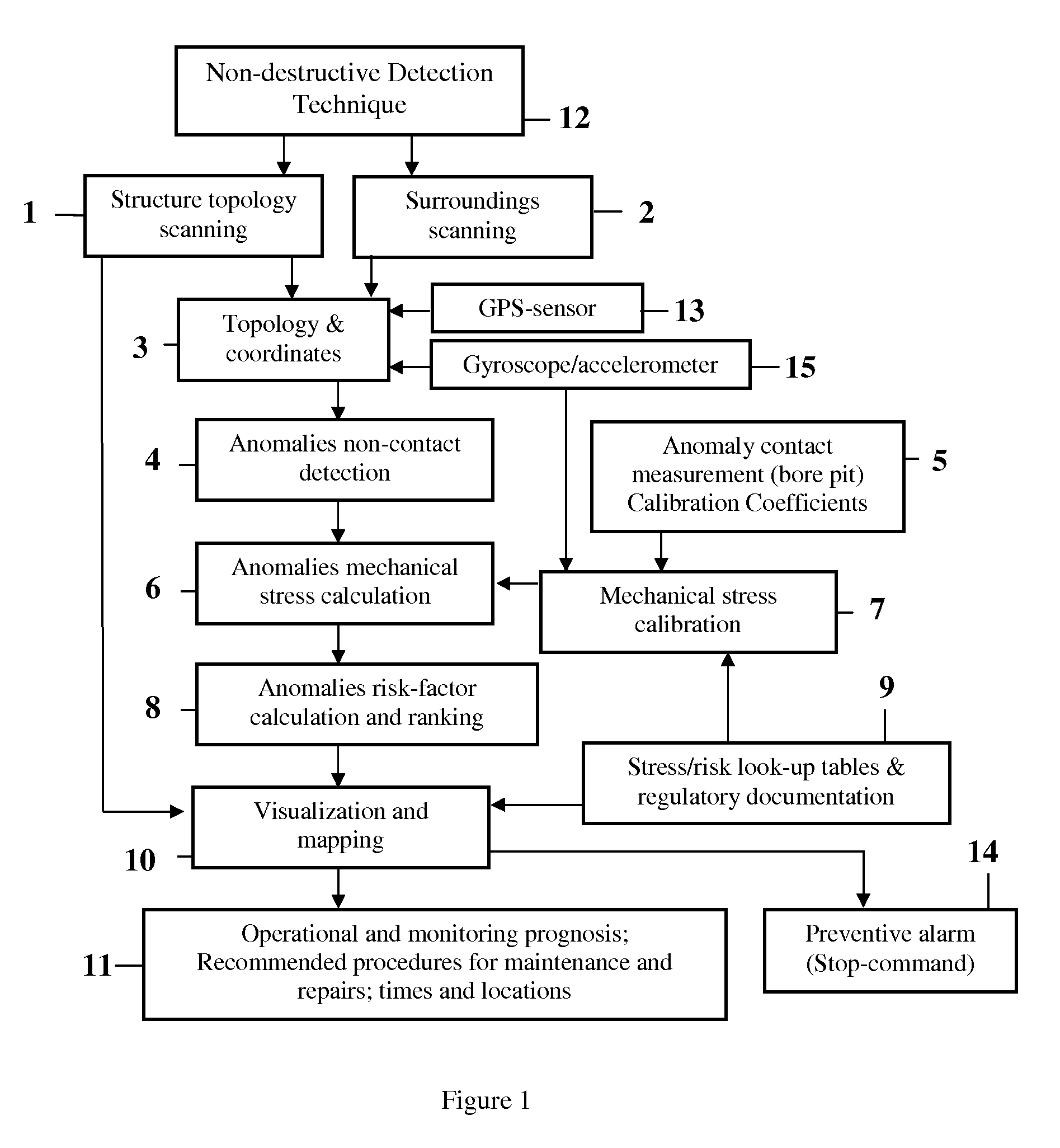

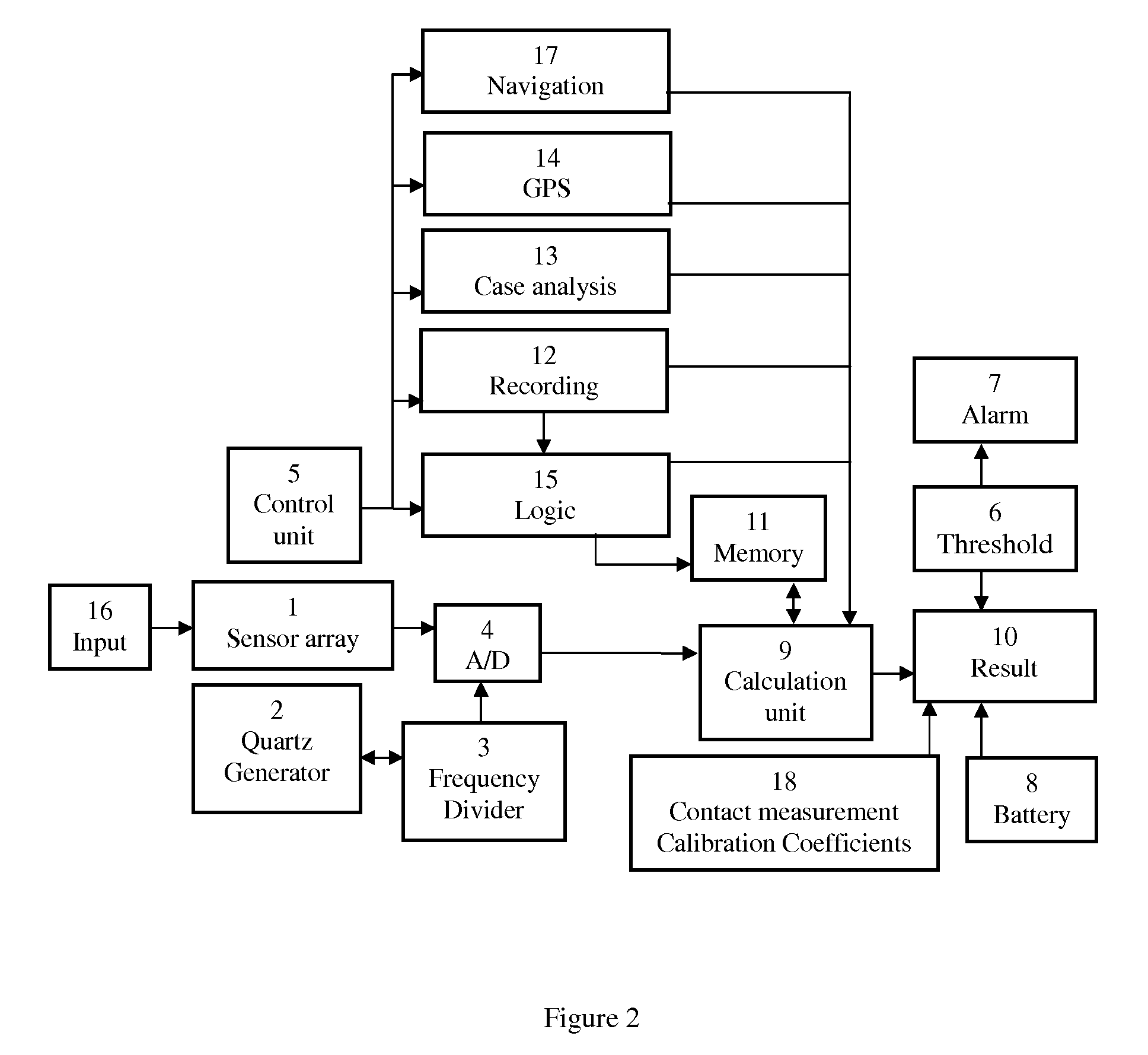

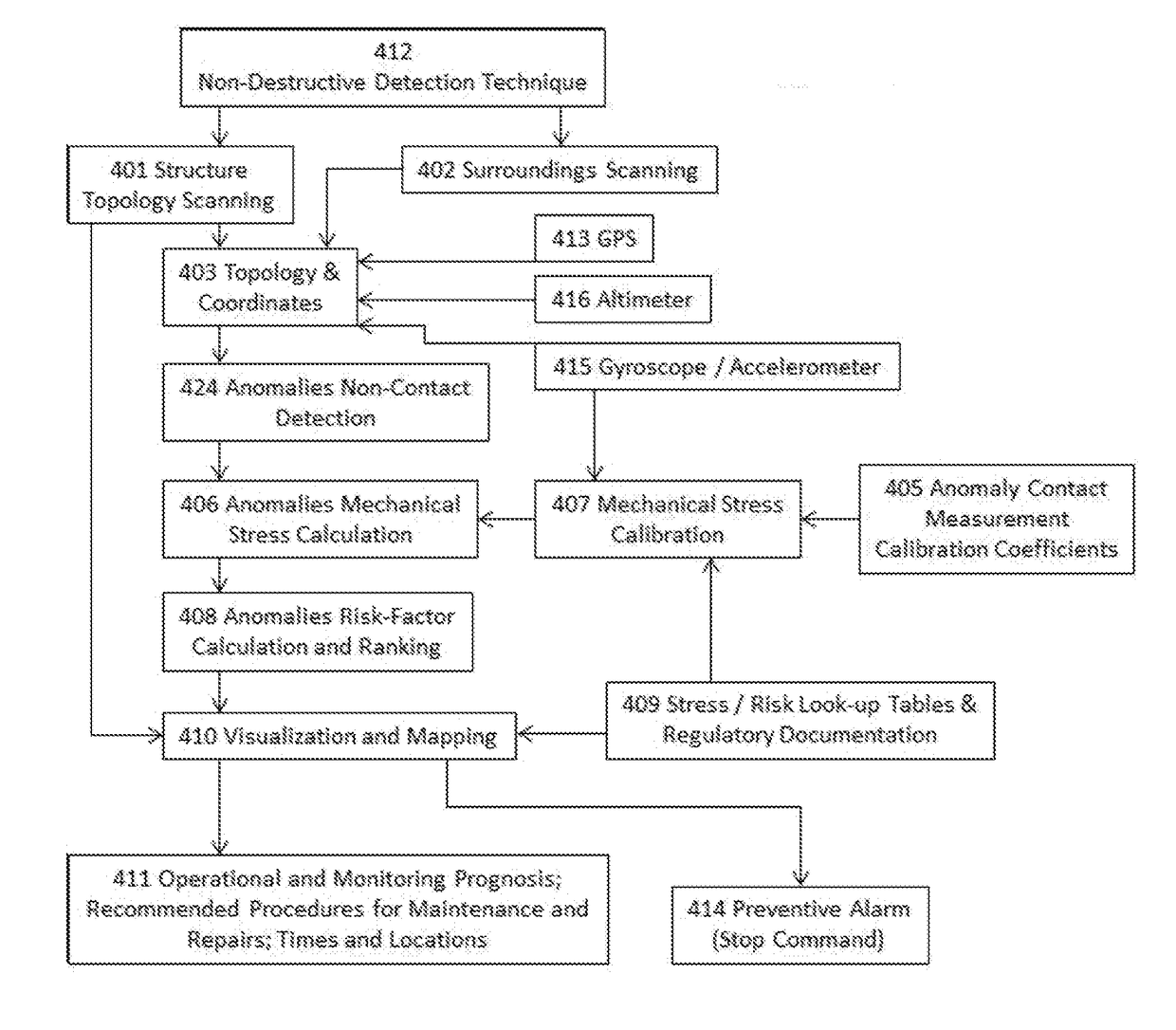

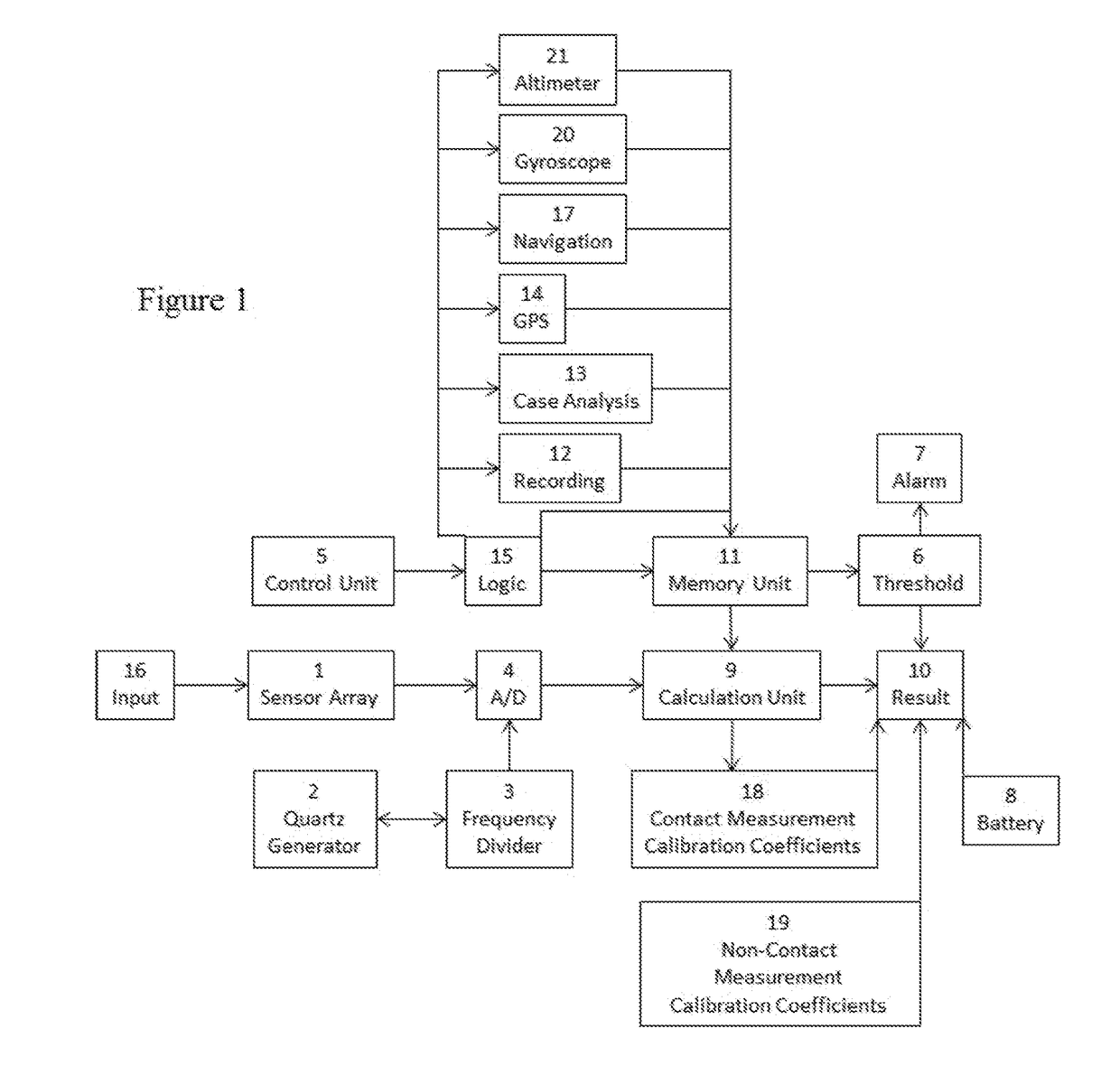

Apparatus and method for metallic constructions assessment

ActiveUS20140368191A1Improve accuracyEnsure qualitySusceptibility measurementsMaterial magnetic variablesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device includes registration means that optimized for use with metallic structures of various types, shapes and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs. etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

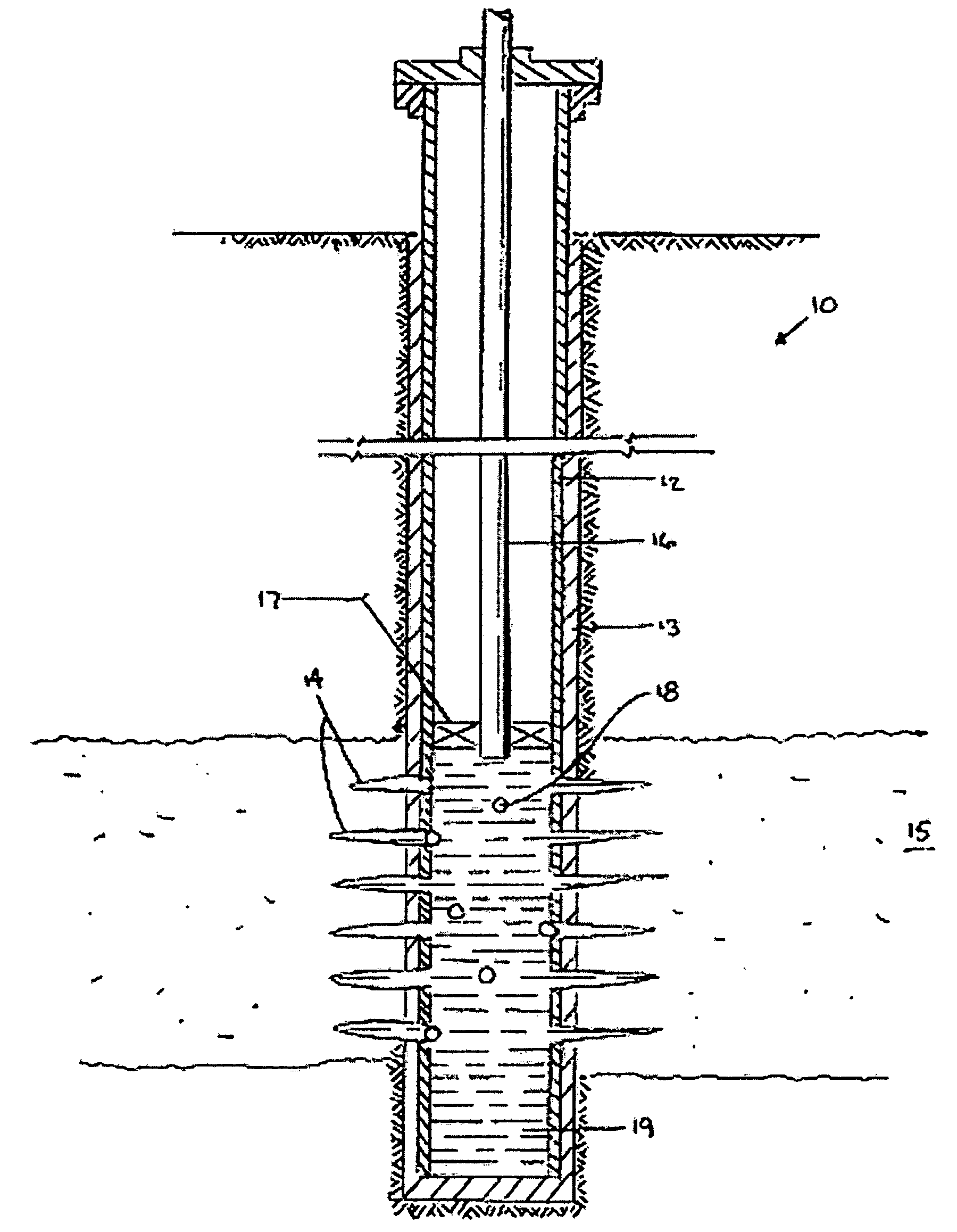

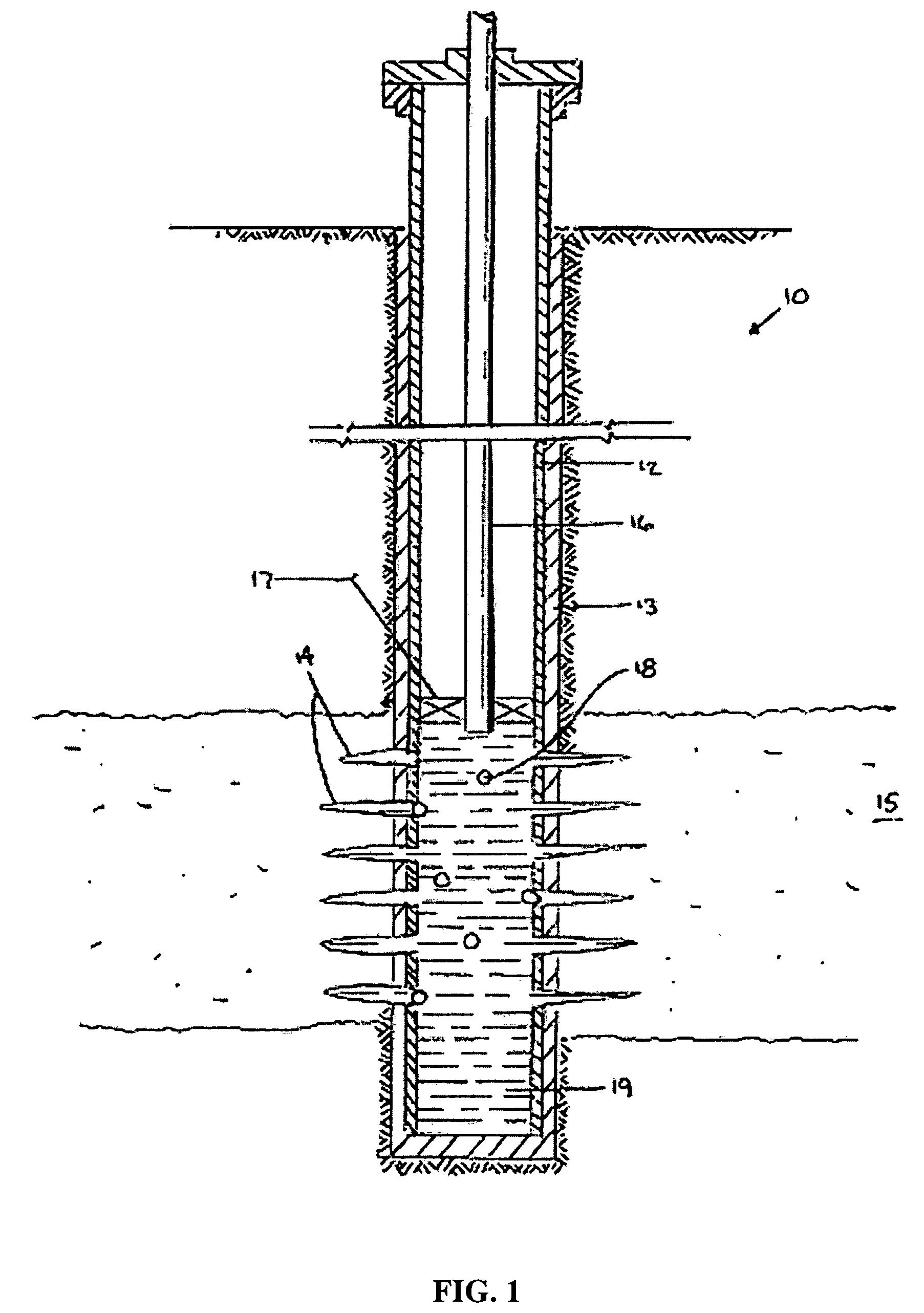

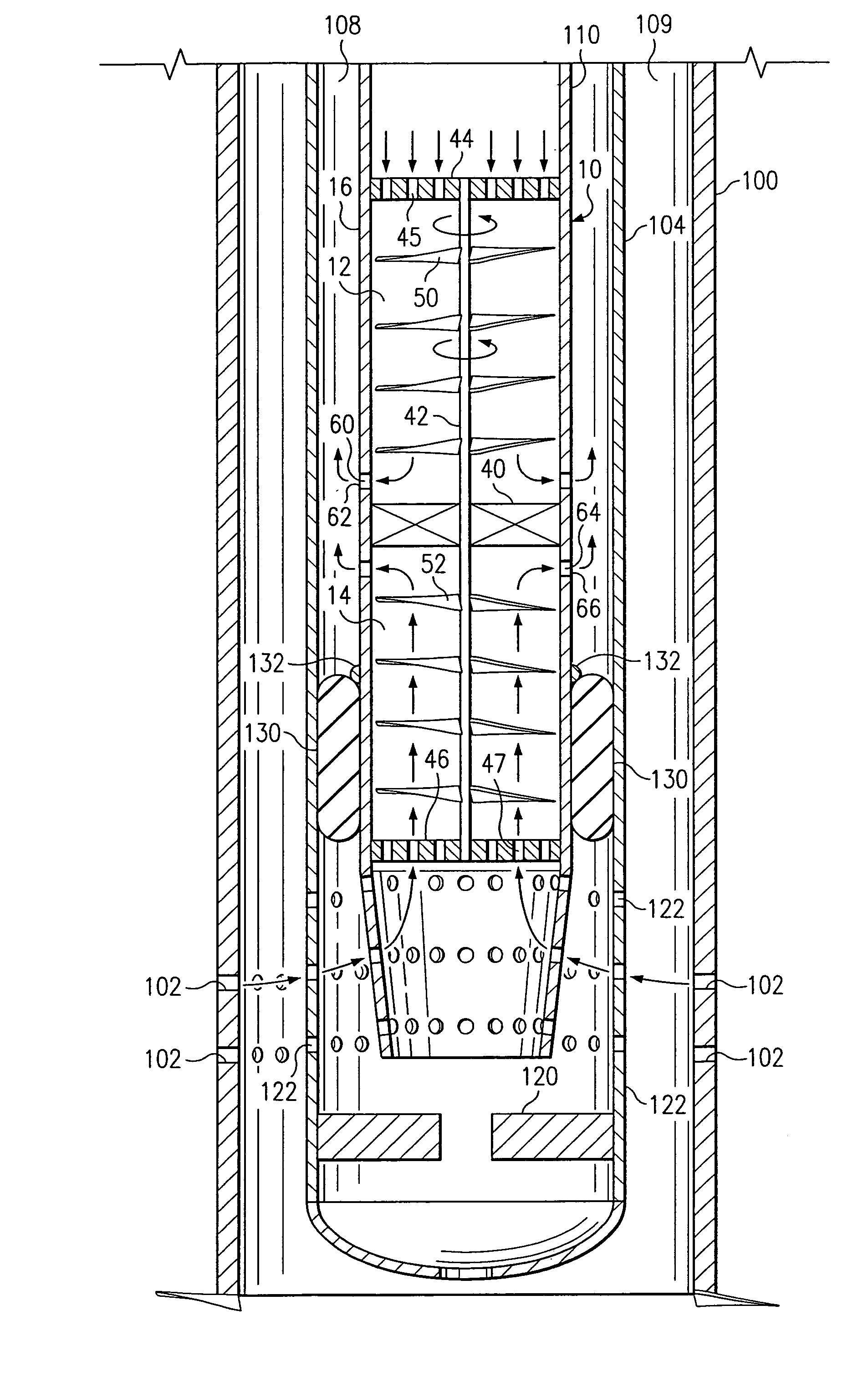

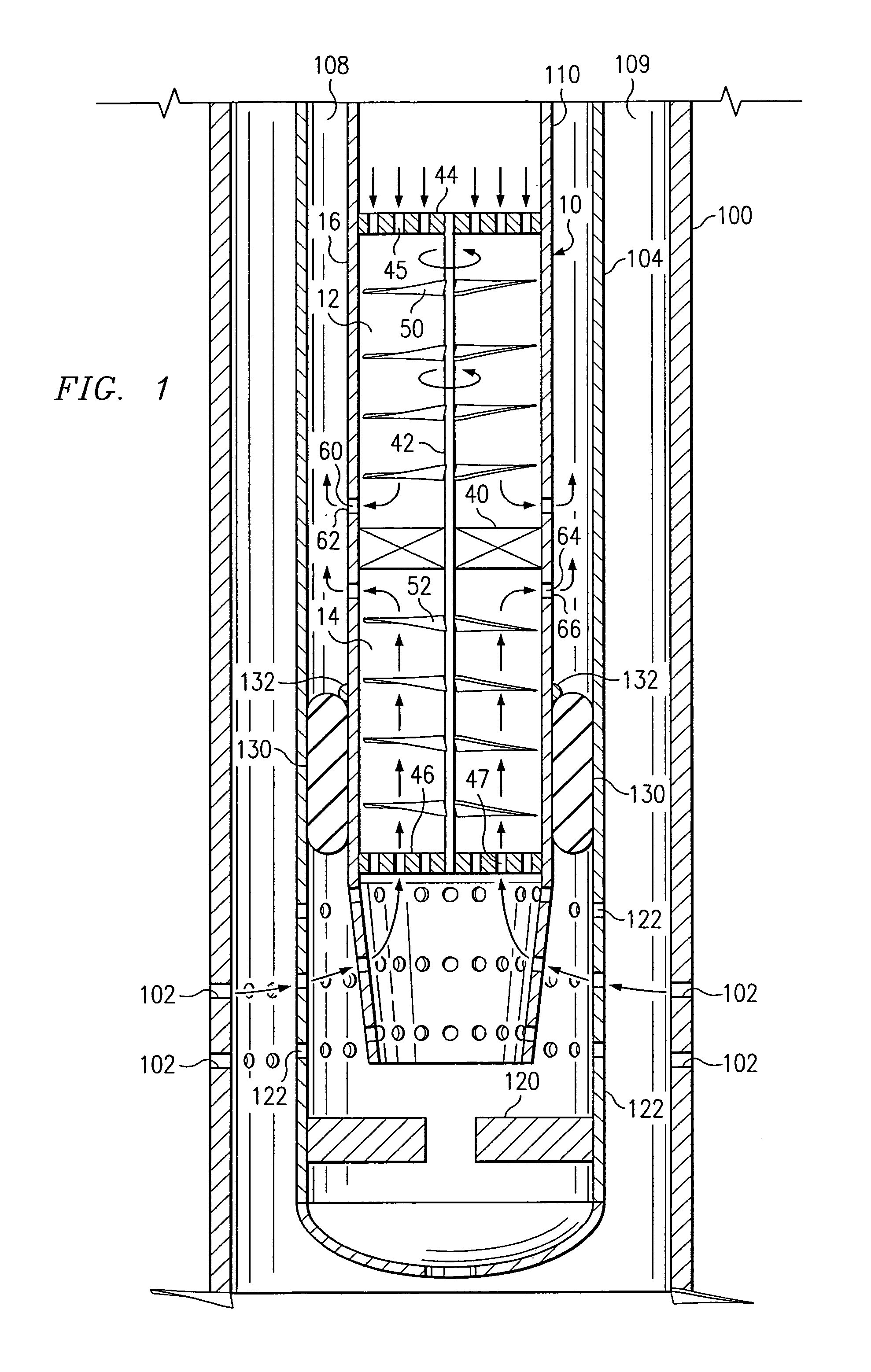

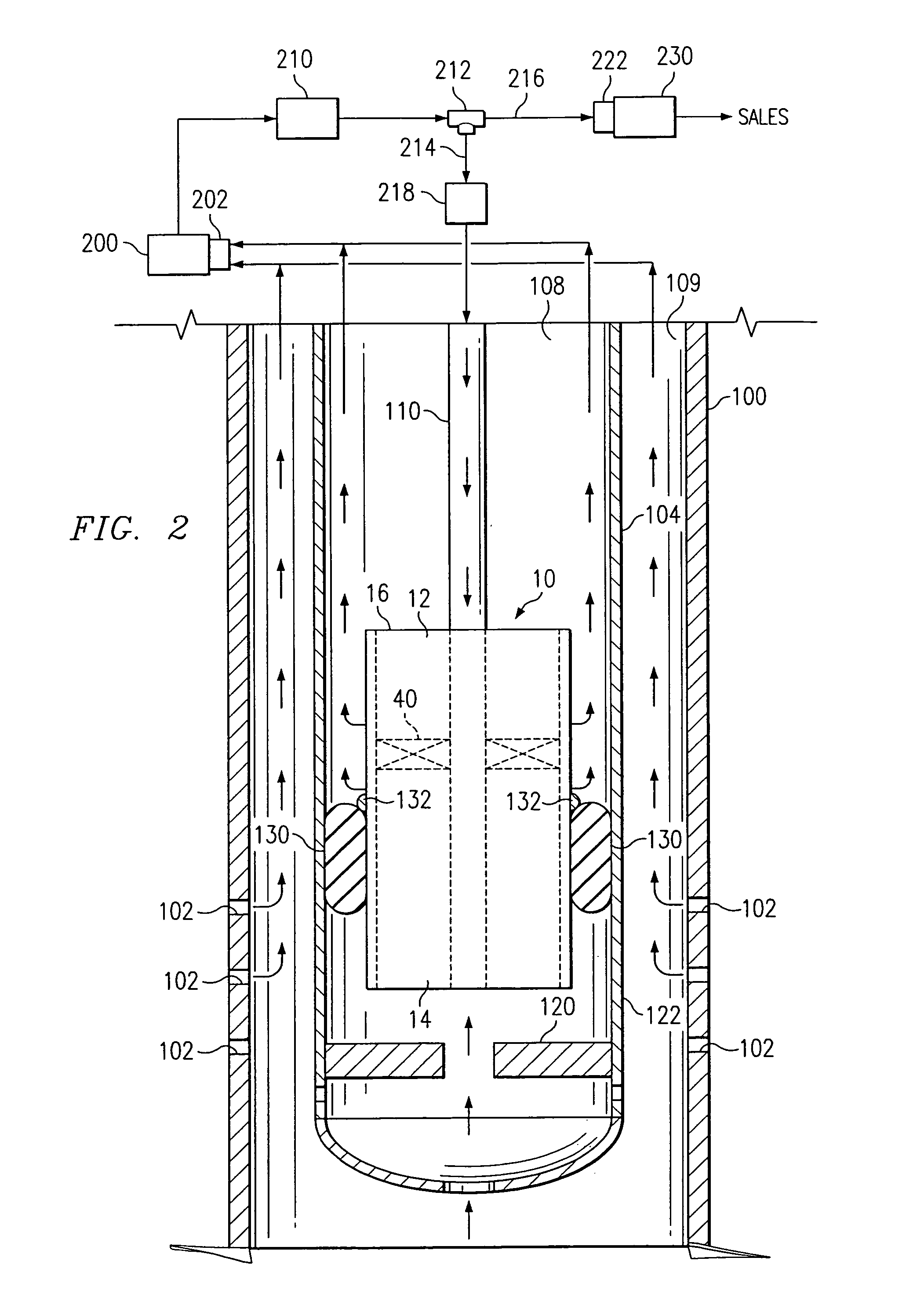

Downhole well pump

The pump and pump system of the present invention is designed to remove liquids, gas, sand and coal fines from gas and / or oil well bores. There is a need in the oil and gas industry to develop a more efficient operating pump that is capable of operating in wells that do not have enough bottom hole pressure to lift liquids to the surface causing the well to log off with fluids and if not economic, potentially be plugged prematurely. Additionally, this design will allow the producer the ability to conduct well bore maintenance such as acid flushes for perforation cleaning and scale batch treating for continued scale treatment.

Owner:BURLINGTON RESOURCES OIL & GAS LP

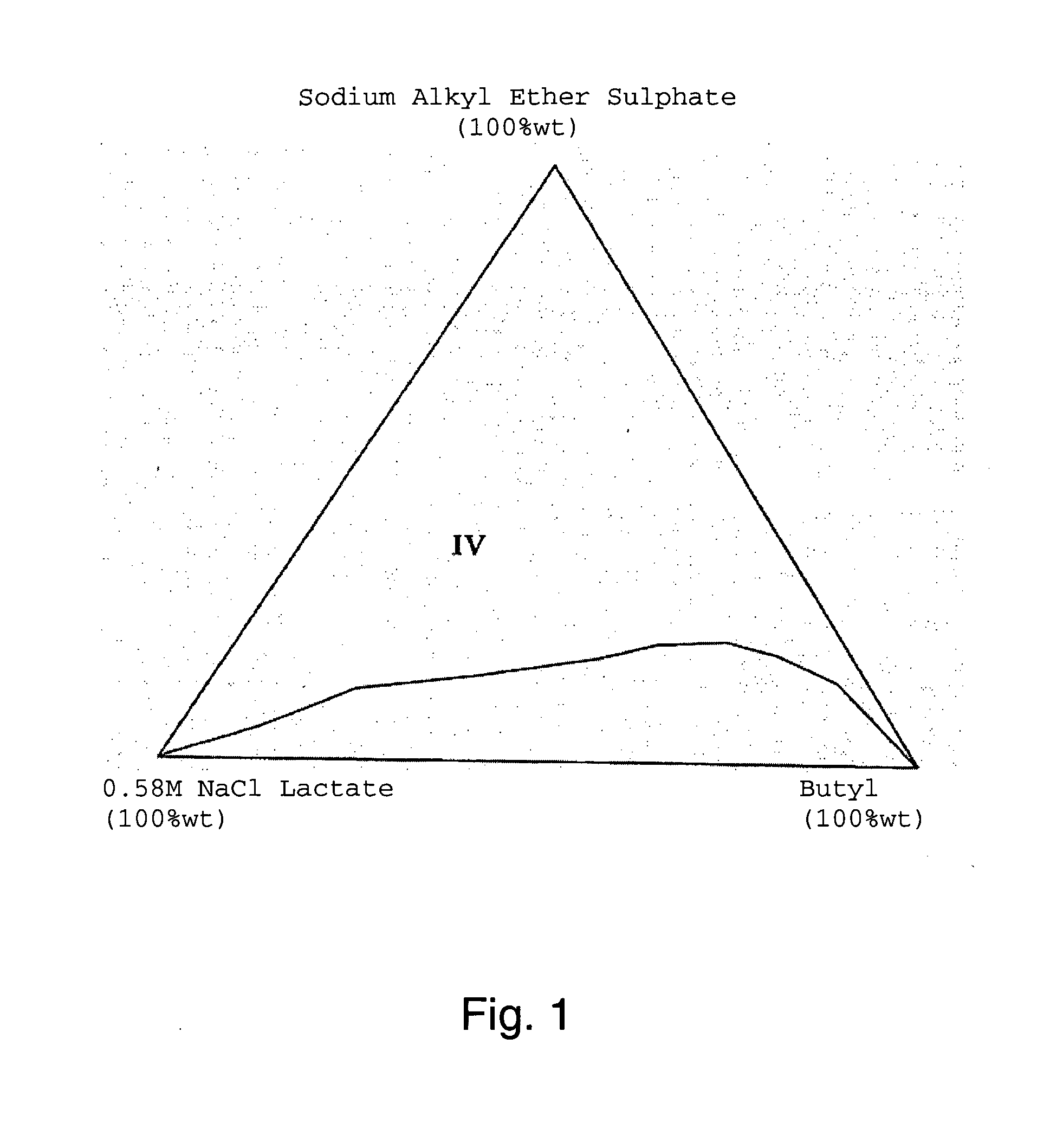

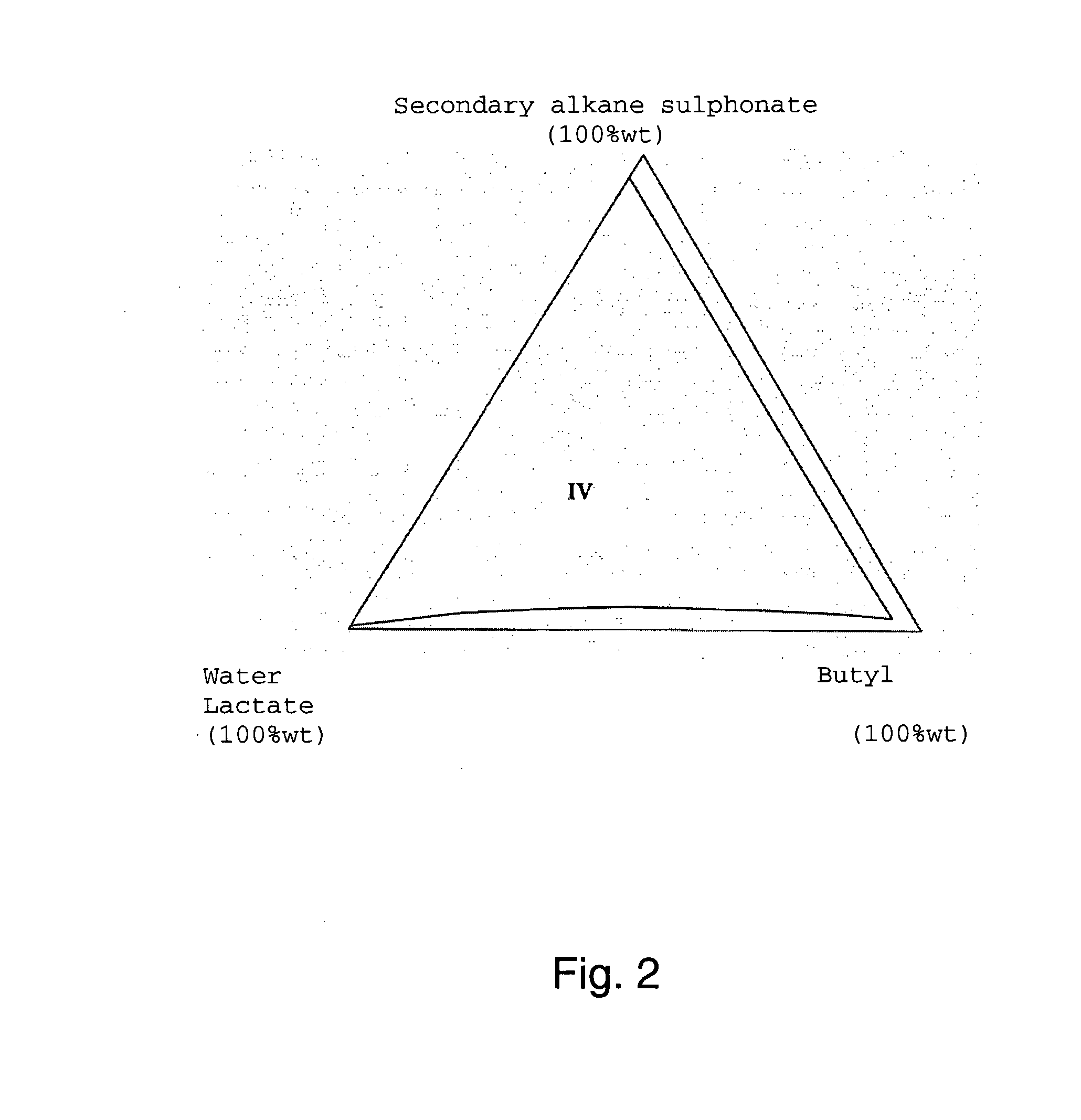

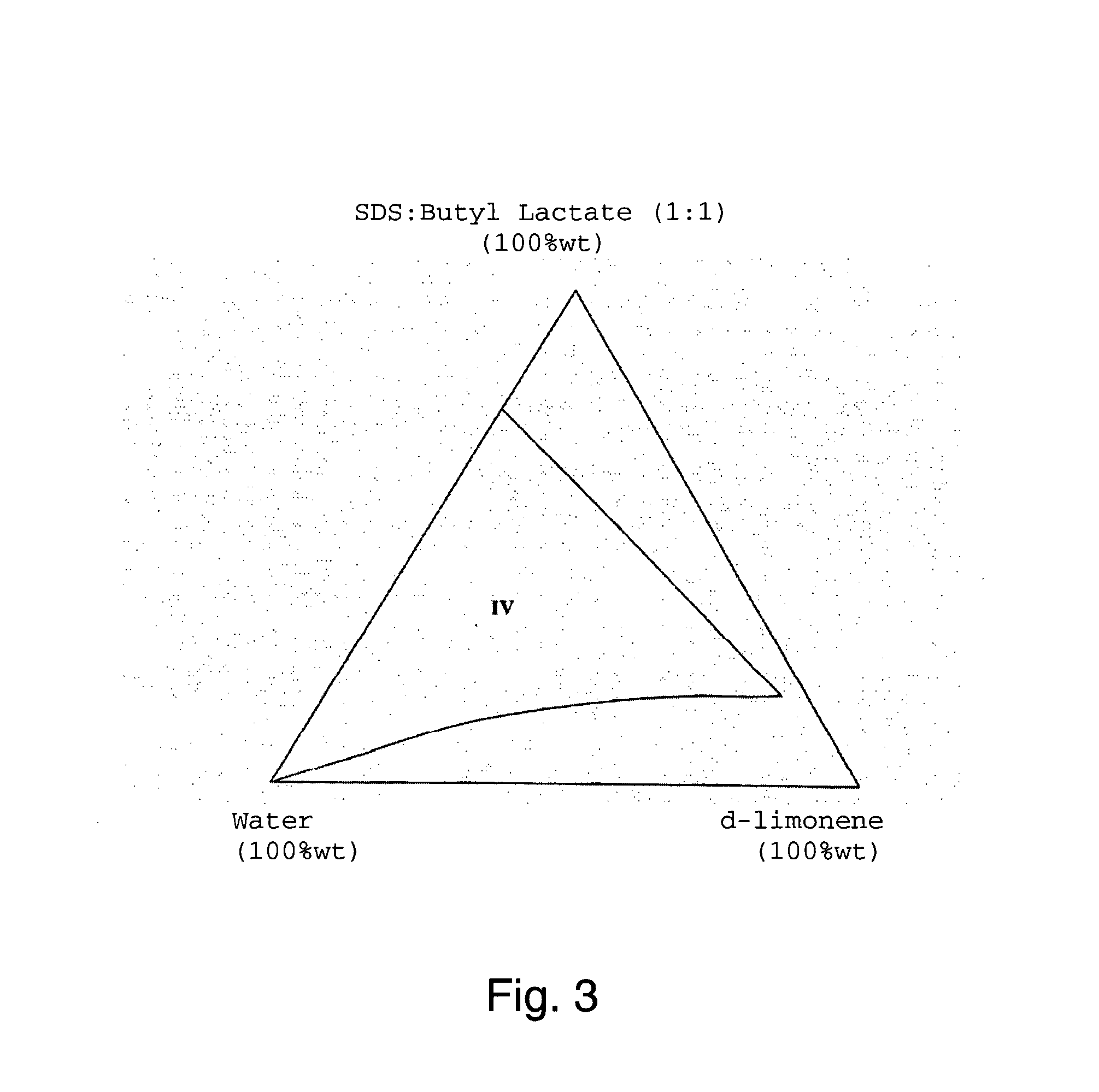

Surfactant System Method

InactiveUS20070295368A1Improve cleaning efficiencyAvoid damageInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSurface cleaning

The invention relates to the formulation and application of water based predominantly pH neutral microemulsions and microemulsion forming surfactant systems essentially comprising a surfactant or surfactant˜end, lactates)—esters) of lactic acid—and water / brine and optionally solvent. Uniquely the formulations are acid and caustic free and also do not make use of alcohol, glycol and glycol ether components in the systems as co surfactant, co-solvent or mutual solvent. In particular the invention relates to the methods and the application of this microemulsion technology for use in industrial hard surface cleaning applications especially the inks and printing industries and the oil and gas industry. In addition the formulations can be used in the production of microemulsion based drilling muds (which may or may not be Oil Based Muds—OBMs) and they may be used to enhance the drill cuttings slurrification processes for re-injection purposes or for facilitated cuttings transport.

Owner:SURFACTANT TECH +1

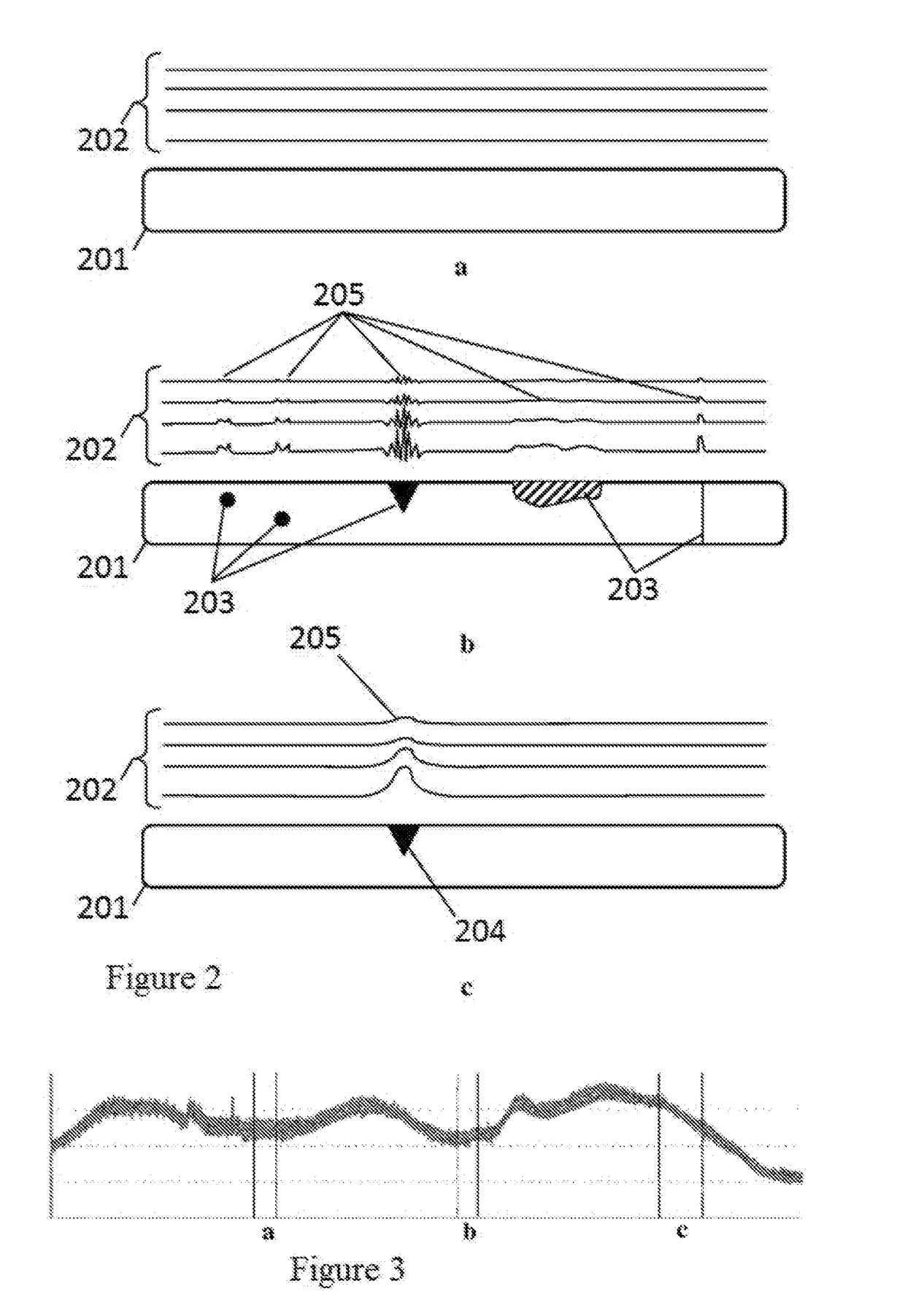

Apparatus for the non-contact metallic constructions assessment

ActiveUS8542127B1The result is accurate and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical measurementsHeavy equipmentHeavy duty

A device and method for discovering, identification and monitoring of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The technique is specifically optimized for extended, not-accessible underground and underwater metallic structures quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the technique implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

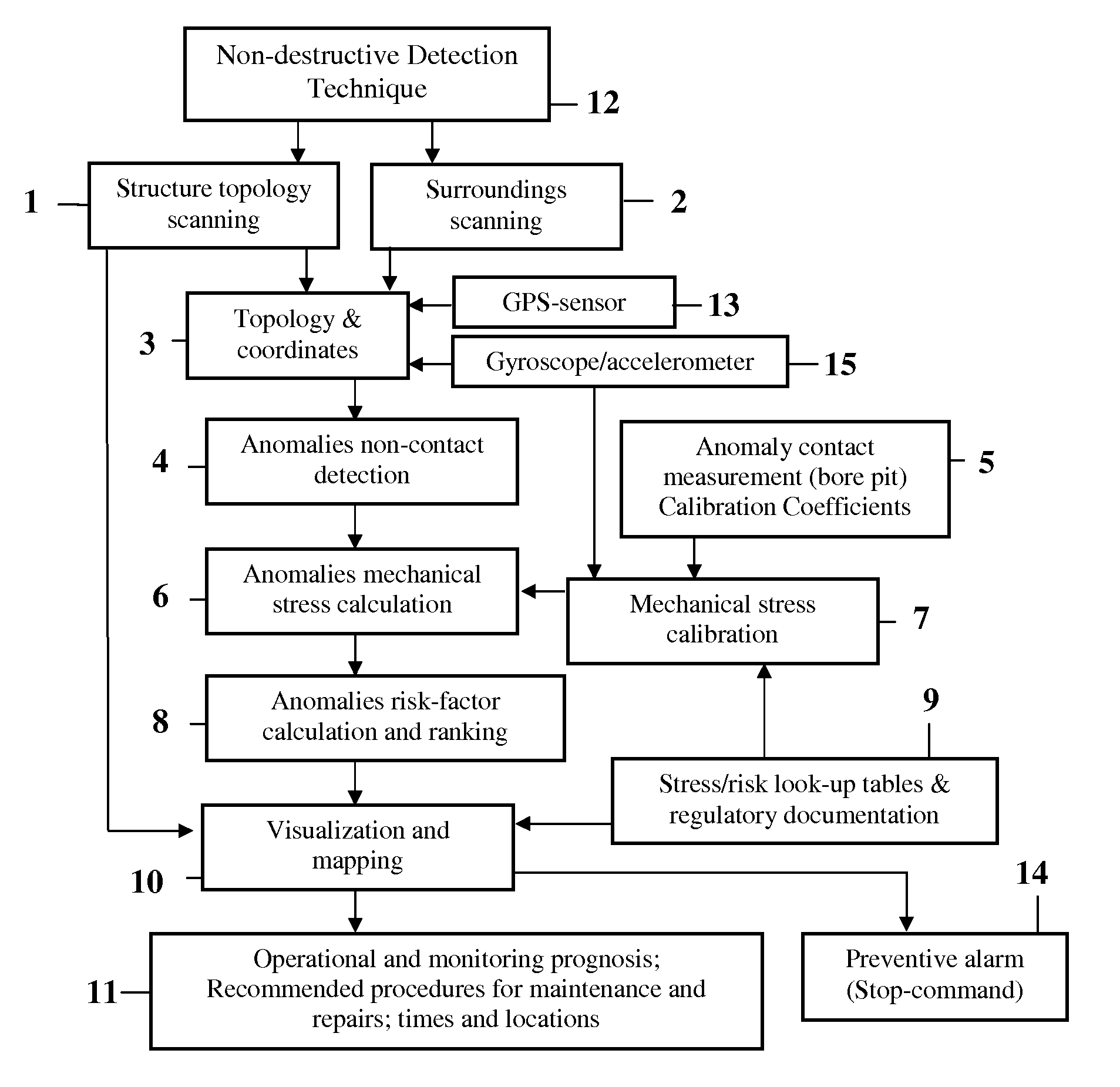

Metallic constructions integrity assessment and maintenance planning method

ActiveUS8447532B1Easy maintenancePromote repairPlug gaugesForce measurement by measuring magnetic property varationMaintenance planningHeavy duty

A method for metallic structure maintenance is disclosed. The method includes a magneto-graphic / Magnetic Tomography technique to identify stress-related defects. The method is specifically optimized for extended, non-accessible underground and underwater metallic structures in providing quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the method implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

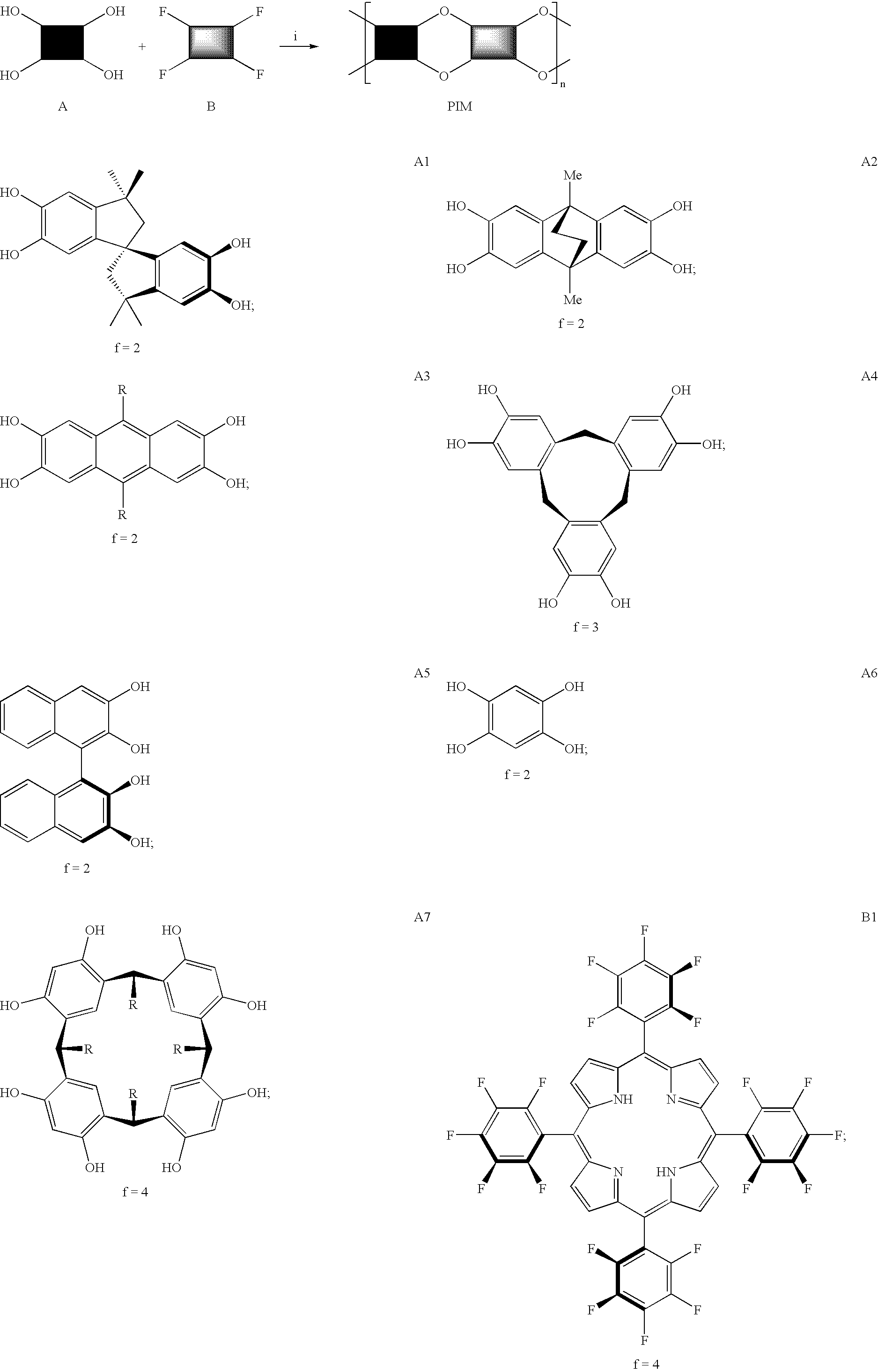

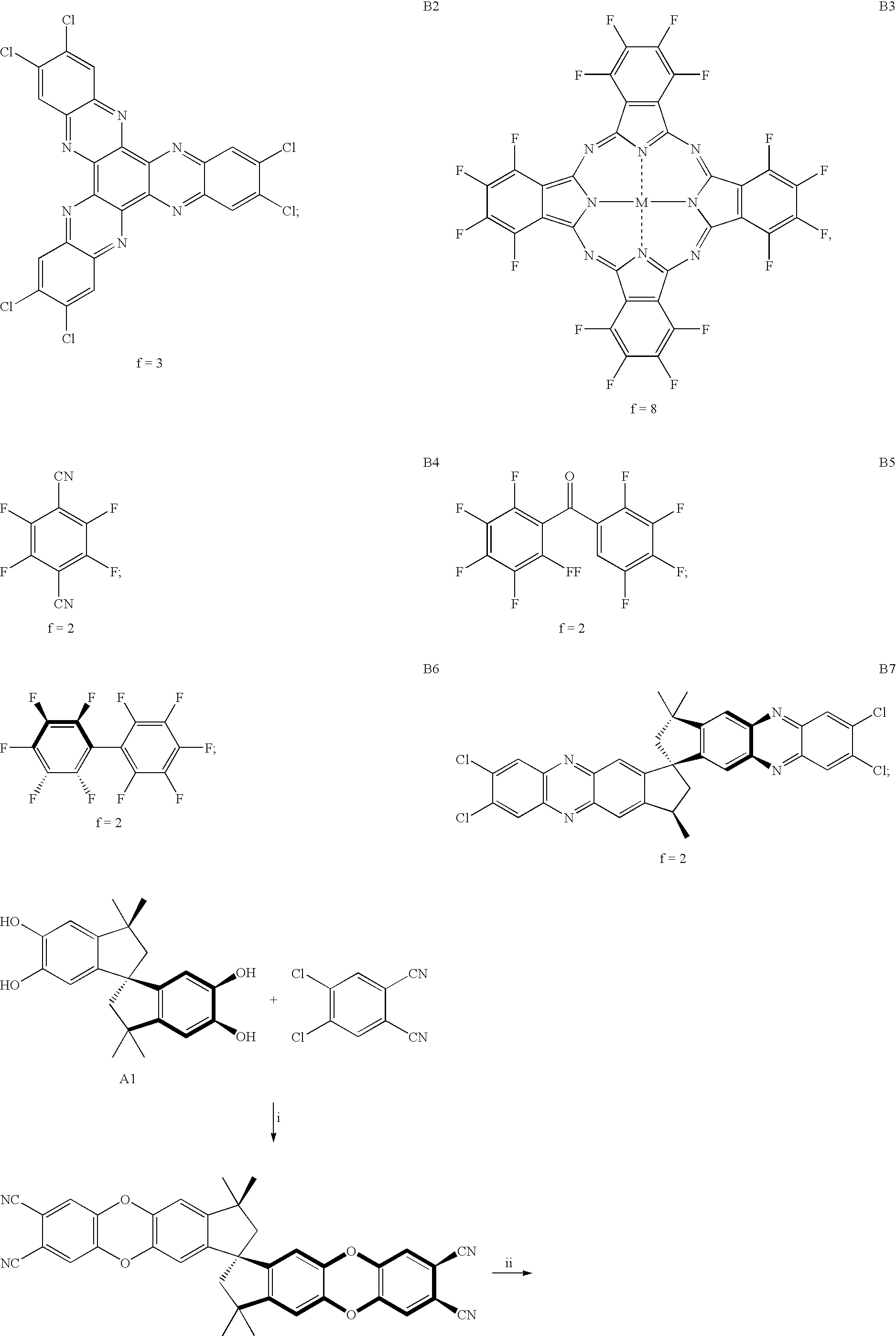

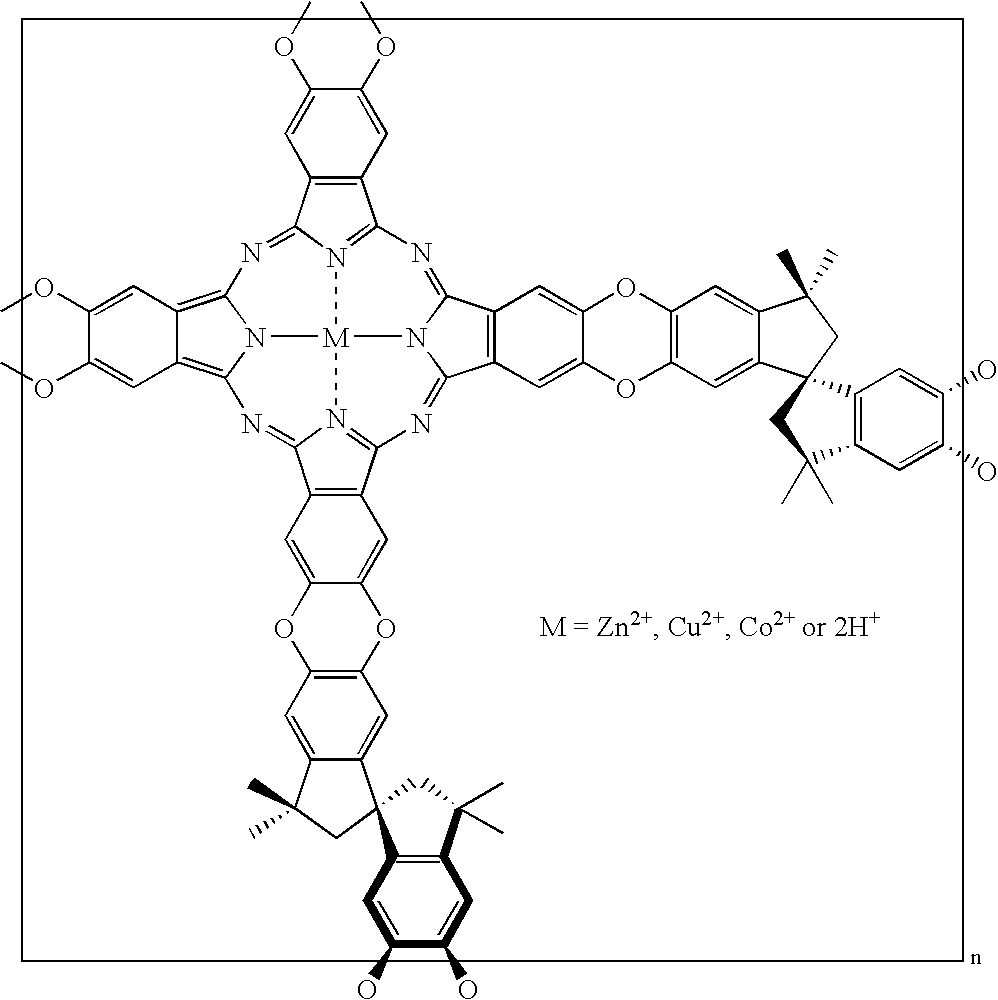

High Flux Mixed Matrix Membranes for Separations

InactiveUS20070209505A1High selectivityIncrease fluxSemi-permeable membranesIsotope separationParaffin waxPetrochemical

The present invention discloses a new class of high flux mixed matrix membranes that are made by incorporating porous inorganic fillers (e.g. microporous and mesoporous molecular sieves, carbon molecular sieves, porous metal-organic frameworks) into a high flux high surface area microporous organic polymer matrix. These microporous organic polymers are referred to as “polymers of intrinsic microporosity” or PIMs. The high flux membranes are promising for a wide range of separations including liquid separations such as pervaporation of phenol / water and also gas separations in the petrochemical, refinery, and natural gas industries such as methane / carbon dioxide, olefin / paraffin and iso / normal paraffins separations.

Owner:UOP LLC

Steel used for straight seam electric resistance welding petroleum casing and casing manufacturing method

ActiveCN101798654AHigh strengthImprove toughnessFurnace typesProcess efficiency improvementWeld seamElectric resistance welding

The invention relates to a steel used for straight seam electric resistance welding petroleum casing and a casing manufacturing method, which is applied to a straight seam electric resistance welding petroleum casing used for an oil and gas well in petroleum and gas industry. The steel used for the straight seam electric resistance welding petroleum casing comprises the following components in percentage by mass: 0.15-0.28% of C, 1.0-1.6% of Mn, 0.2-0.4% of Si, 0. 02-0.06% of Al, less than or equal to 0.01% of P, less than or equal to 0.005% of S, less than or equal to 0.008% of N, 0.001-0.005% of Ca and the balance of Fe. The preparation method comprises the steps of: preparing hot-rolled plate coils, producing straight seam electric resistance welding steel pipes by the hot-rolled plate coils, carrying out welding seam normalization or overall normalization on the welded steel pipes, straightening and cutting the normalized or tempered welded steel pipes into pipe segments with the length of 10-12m, and processing API standard screw threads. The invention has the advantages that the steel has good strength and toughness, the welding seam has no defect, and the properties of the steel are uniform with those of mother material. The yield strength is greater than or equal to 380-760MPa, the tensile strength is greater than or equal to 520-865MPa, the elongation is greater than or equal to 20%, and the impact energy of a room-temperature transverse full-size V-shaped notch is greater than or equal to 40J.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Non-destructive system and method for detecting structural defects

ActiveUS20170122909A1Stable positionImprove accuracyForce measurement by measuring magnetic property varationUnmanned aerial vehiclesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device can determine the position of the defect or stress including depth information. The device includes registration means that optimized for use with metallic structures of various types, shapes, and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in roiled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, bridges, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

Polymeric pipes and liners suitable for transporting oil and gas materials and made from blends of polyolefins and polyamides

InactiveUS20060185750A1Improve the immunityImprove barrier propertiesLayered productsPipe elementsPolyolefinPolyamide

A pipe or liner for use in the oil and gas industry that comprises a melt-mixed bend of polyamide and incompatible polyolefin and a compatibilizing agent where the polyamide exists as a discontinuous phase that is dispersed in a polyolefin matrix. The pipe or liner has enhanced resistance to the permeation of hydrocarbons relative to polyethylene.

Owner:MESTEMACHER STEVEN A

Novel enhanced systems, processes and methodologies for producing clean water and products thereby

InactiveUS20080073200A1Low costFacilitates time and cost and efficient disposalAuxillariesGeneral water supply conservationIndustrial waste waterDistillation

Improved methods for carrier-gas humidification / dehumidification [HDH] or dewvaporization enable production of clean water, derived in part from models generated and tested with produced water from the oil and gas industries, which likewise address industrial waste water remediation and generally facilitate the time and cost efficient disposal of waste waters from a plurality of industries ranging from food, wine, and beverage production to novel enhanced efficiencies within the oil and gas industries themselves. High efficiency carrier gas HDH thermal distillation functions without membranes, at ambient or near ambient pressures with no required pre- or post-treatment, and economies of scale to leverage a plastics-based processing platform. Industrial waste water including that generated by the food, wine, and beverage industries, among others, is likewise ameliorated according to the instant teachings.

Owner:ALTELA

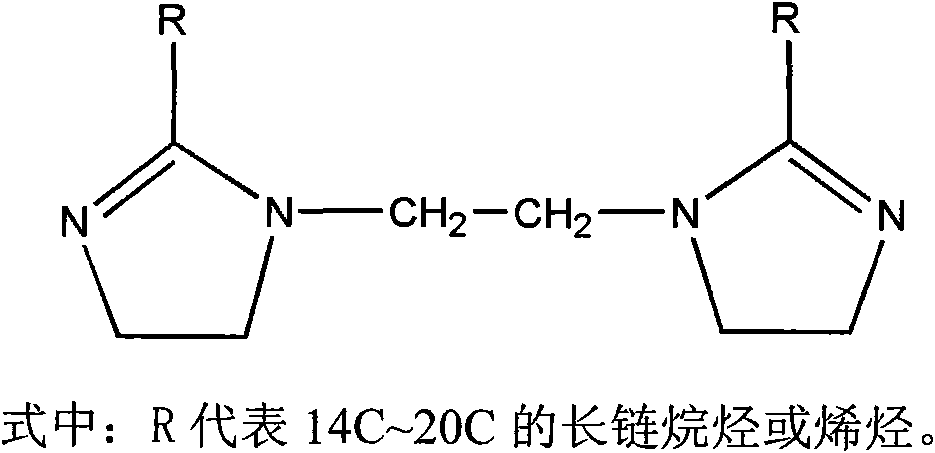

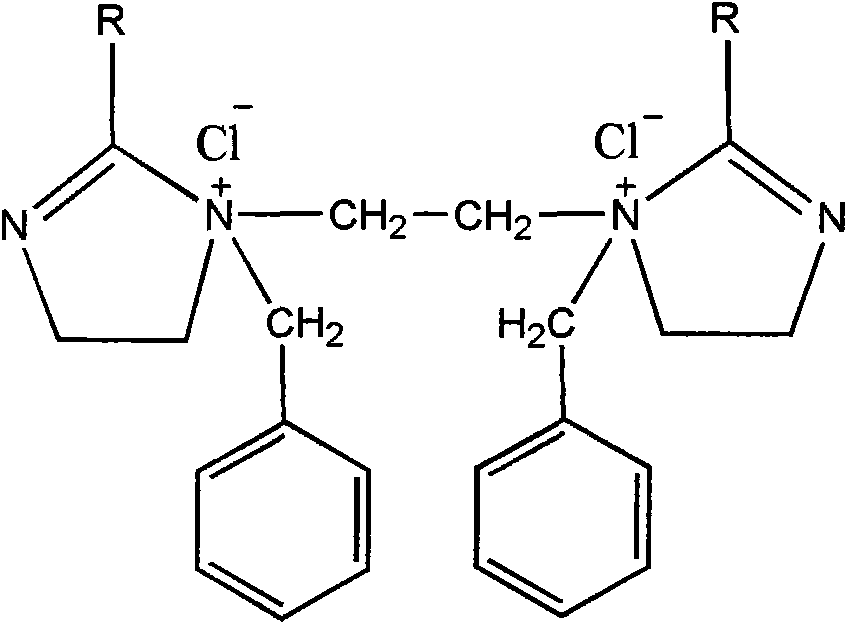

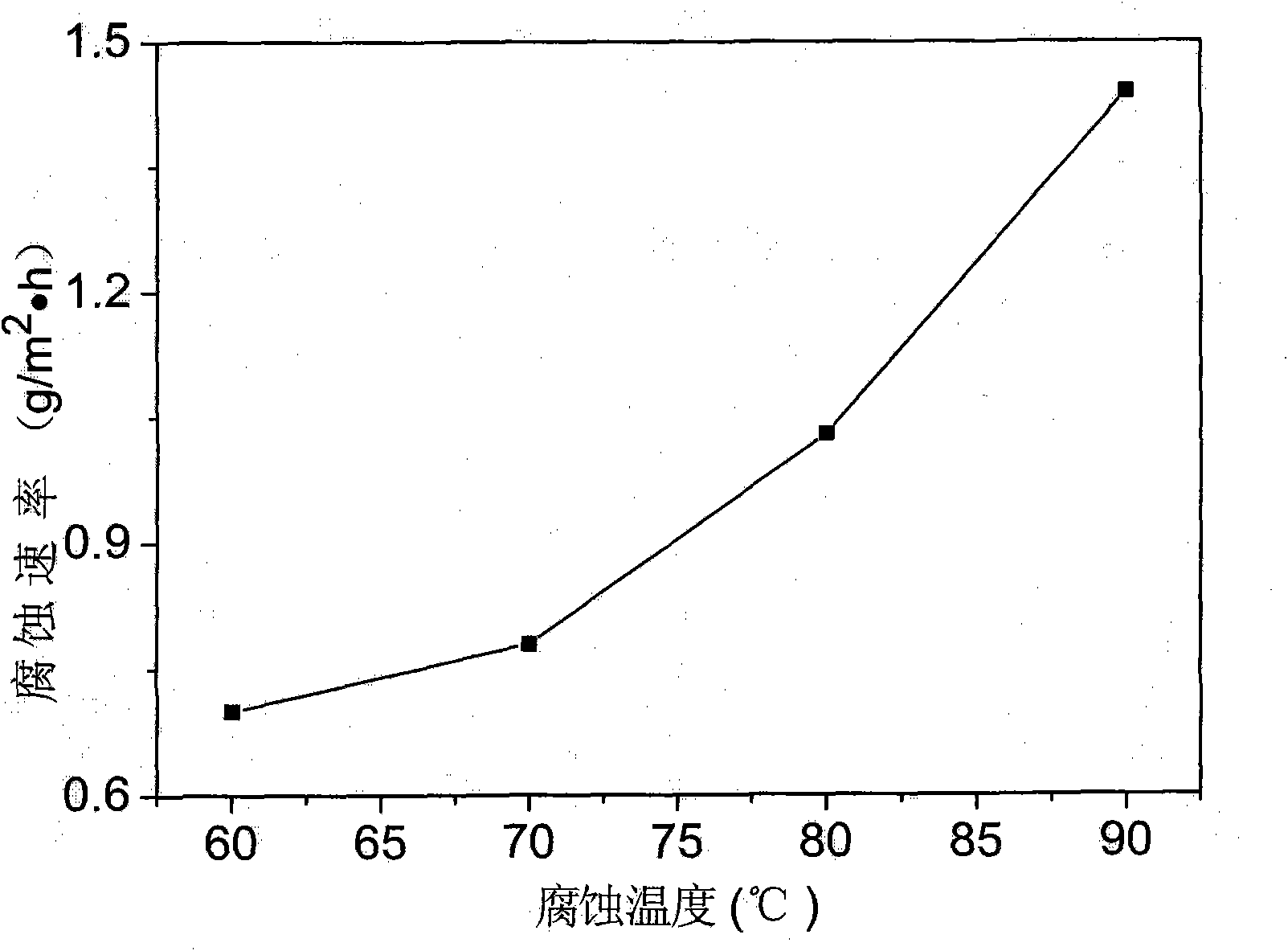

Preparation method of novel acidified corrosion inhibitor and use thereof

InactiveCN101565608AReduce dosageHigh corrosion inhibition efficiencyOrganic chemistryBorehole/well accessoriesAlcoholMass ratio

The invention relates to a acidified corrosion inhibitor for oil well and preparation method thereof. The preparation has the steps of: firstly synthesizing imidazoline intermediate body, carrying out quaternization reaction with benzyl chloride, and then compounding generated quaternary ammonium salt and propiolic alcohol according to mass ratio 3:1 for obtaining the product. 0.4% (mass percentage content) of present corrosion inhibitor in 15% HCl medium has obvious inhibition for corrosion of N80 carbon steel. The corrosion rate is 0.70 g / mh after 4h of corrosion at 60 DEG C, the corrosion inhibition efficiency thereof can reach to 99.39%; the corrosion rate is 1.44 g / mh after 4h of corrosion at 90 DEG C, which is superior to oil and gas industry standard of the People's Republic of China SY / T5405-1996 corrosion evaluating indicator first grade product standard (at 60 DEG C, first grade product standard is 2-3g / mh; at 90 DEG C, first grade product standard is 3-4g / mh).

Owner:XINJIANG UNIVERSITY

Steel for expandable casing for oil well and manufacturing method thereof

ActiveCN101812631APerformanceAvoid easy crackingTemperature control deviceFurnace typesNumerical controlAlloy

The invention discloses steel for an expandable casing for an oil well and a manufacturing method thereof, and the manufacturing method is applied to preparing the expandable casing for the oil well for petroleum and gas industrial oil. The steel alloy material of the expandable casing for the oil well comprises the following components in percentage by weight: 0.08 to 0.2 percent of C, 1 to 2 percent of Mn, 0.15 to 0.35 percent of Si, 0.02 to 0.06 percent of Al, less than or equal to 0.01 percent of P, less than or equal to 0.05 percent of S, less than or equal to 0.08 percent of N, 0.001 to 0.005 percent of Ca, and the balance of Fe. The method for preparing the expandable casing for the oil well comprises the following steps of: preparing hot rolled steel coils; producing straight seam resistance welded steel pipes by using the hot rolled steel coils; normalizing welding lines after welding; and finally, cutting into welded steel pipes, and machining API standard threads or special threads at two ends of each welded steel pipe by using a numerical control machine. The steel for the expandable casing for the oil well has the advantages of excellent comprehensive performance such as expansion deformation capacity, intensity, toughness, and the like, no defect of the welding lines and uniform and consistent performance with base metals.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Steel used for solid expandable casing of oil and gas well and manufacturing method of expandable casing

ActiveCN101805871APerformanceHigh elongationTemperature control deviceMetal rolling arrangementsAlloyUltimate tensile strength

The invention relates to a steel used for a solid expandable casing of an oil and gas well and a manufacturing method of the expandable casing, which are applied to prepare the expandable casing of the oil and gas well in oil and gas industry. The steel alloy material used for the solid expandable casing of the oil and gas well comprises the following components in percentage by mass: 0.1-0.3% of C, 1.5-3.5% of Mn, 1-2.5% of Si, 0.1-3% of Al, less than or equal to 0.010% of P, less than or equal to 0.005 % of S, 0.003-0.010% of Ca, less than or equal to 0.0007% of N and the balance of Fe. The preparation method comprises the steps of vacuum melting, continuous casting and homogenizing annealing; hot rolled plate coils are prepared via controlling rolling and cooling, and the hot rolled plate coils are used for producing straight seam resistance welded steel pipes; and expandable pipe materials can be obtained via two stages of isothermal heat treatment. Threads are processed at both ends of each steel pipe. The invention has the effects that the expandable casing has the characteristics of high uniform elongation, high plasticity, low yield strength, low yield ratio and the like before expansion, and has high strength, enough plasticity, good welding seam quality and performance after expansive deformation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Novel steel for non-magnetic drill collar and preparation method thereof

InactiveCN101660109AStrong resistance to intergranular corrosionHigh tensile strengthDrilling rodsDrilling casingsKeelHigh carbon

The invention discloses a novel steel for a non-magnetic drill collar and a preparation method thereof. The steel for non-magnetic drill collar is made from the following chemical compositions by weight: not higher than 0.03% of C, not higher than 1.0% of Si, 18-22% of Mn, not higher than 0.045% of P, not higher than 0.03% of P, 13.0-18.5% of Cr, 0.4-0.8% of Mo, 0.4-3.0% of Ni, 0.25-0.6% of N andnot higher than 0.10% of Nb. The preparation method comprises the following steps: taking scrap steel, high carbon ferrochrome, low phosphor scrap steel, ferrosilicon and the like as raw materials; primarily melting the raw materials into molten steel by an electric furnace and refining by a nitrogen and oxygen decarburization refinery furnace and an electroslag remelting furnace in three stages,pouring to form keel blocks; and cogging and stretching, cutting ends and rough turning, forging and strengthening, and the like. The steel has stronger resistance to inter-granular corrosion and completely meet Standard method for detecting sensitivity of resistance to inter-granular corrosion of austenitic stainless steel GB / T 4334-2008 and ASTM A262-08; the steel has tensile strength 10-20% greater than API standard, high impact energy up to 100J and twice more than the standard of petroleum and natural gas industries, good magnetic property, relative magnetic permeability mur controllablebelow 1.005 (standard 1.01), excellent forging and machining performances and the like, and is also applicable to machining products such as nonmagnetic stabilizer, nonmagnetic extra-heavy drill rod,nonmagnetic bearing drill rod and nonmagnetic hanging pup joint.

Owner:HENAN SHENLONG GASOLINEEUM DRILLING TOOLS

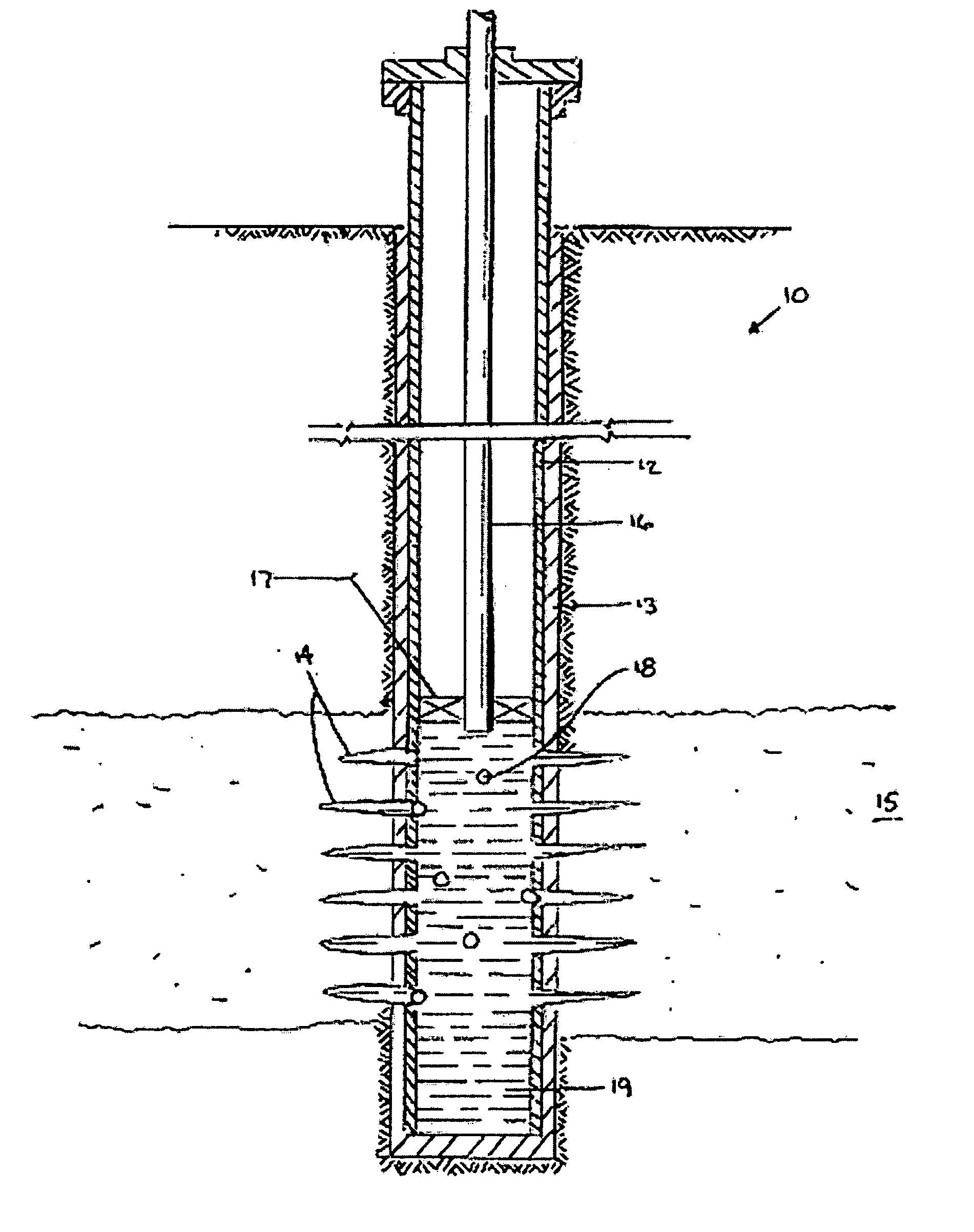

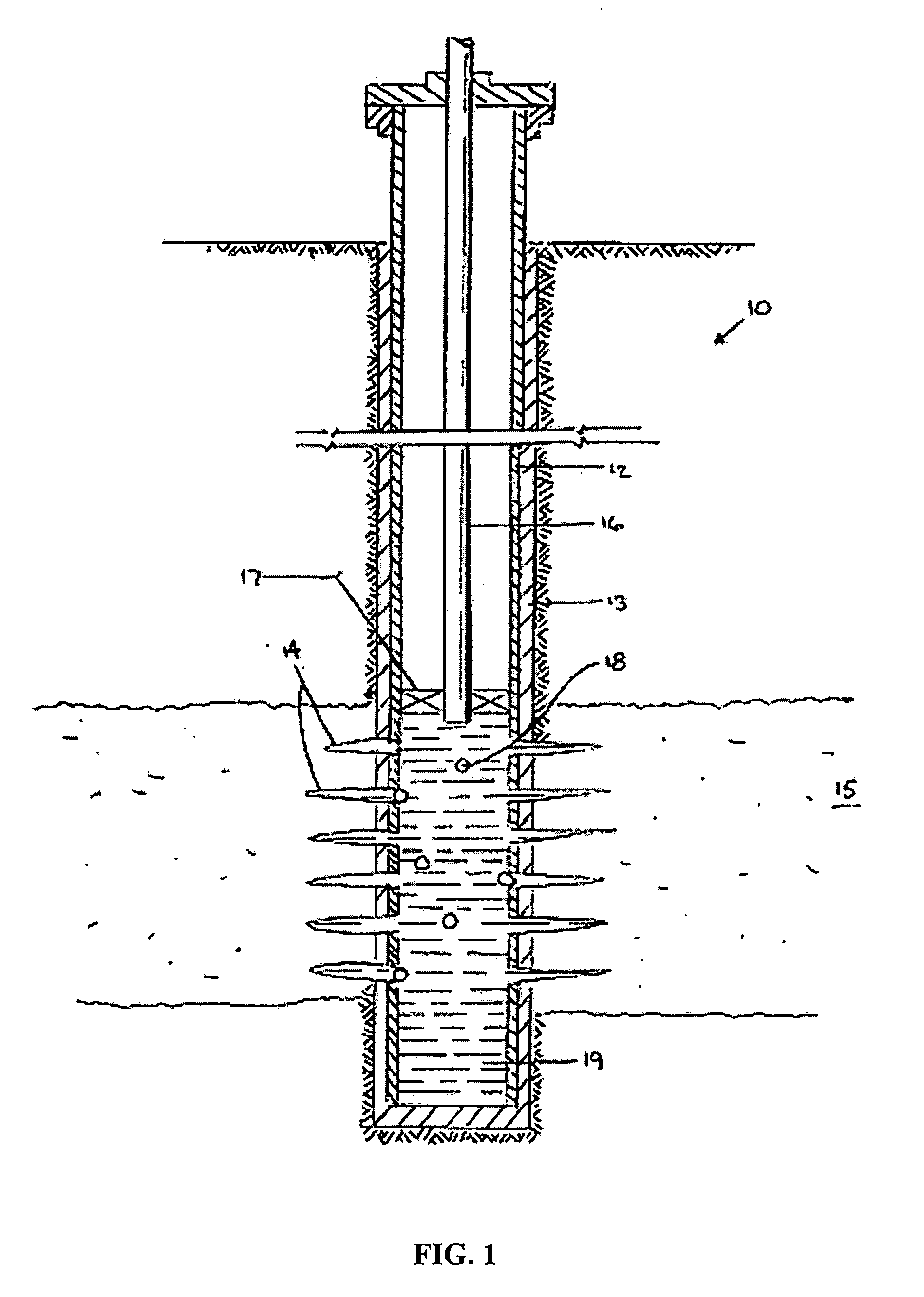

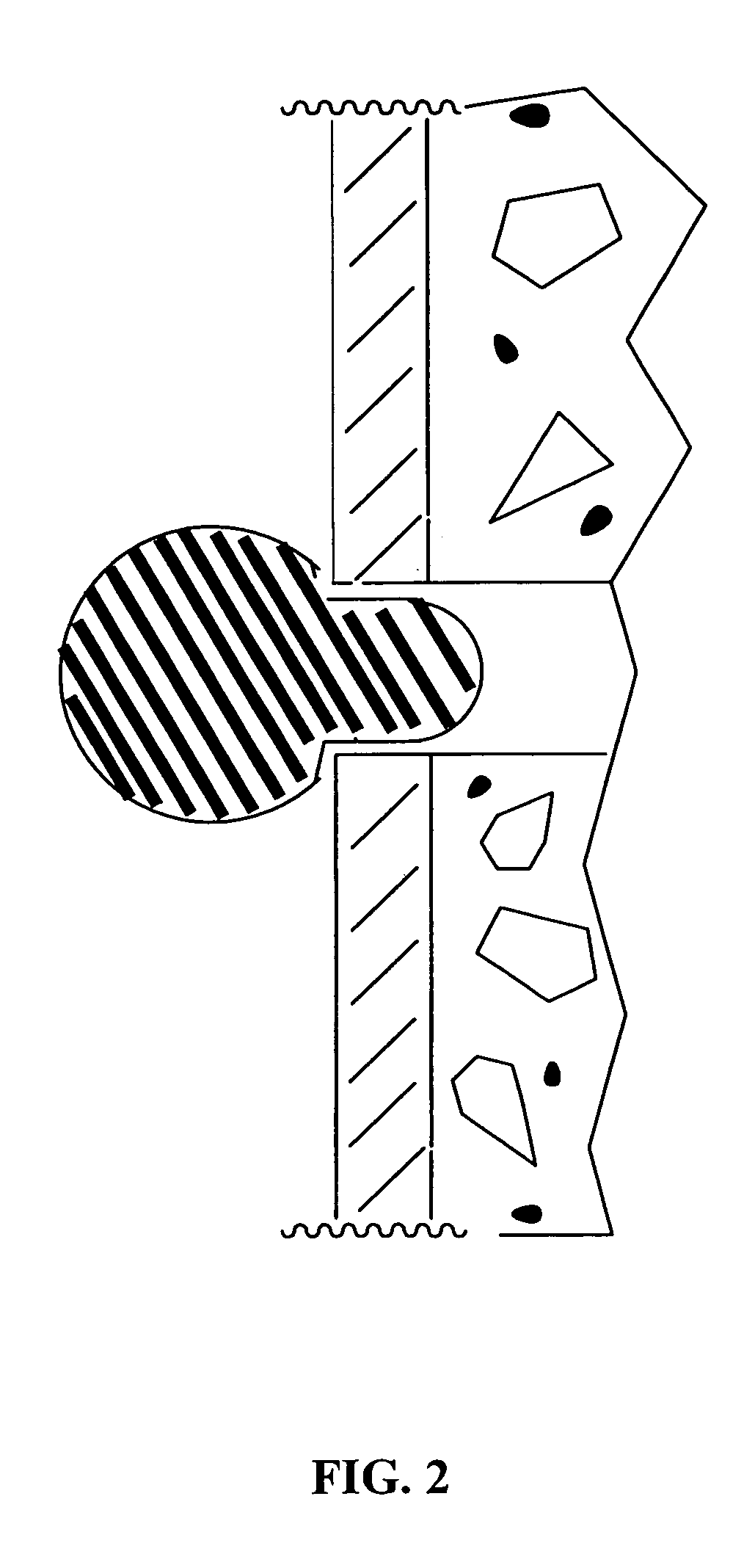

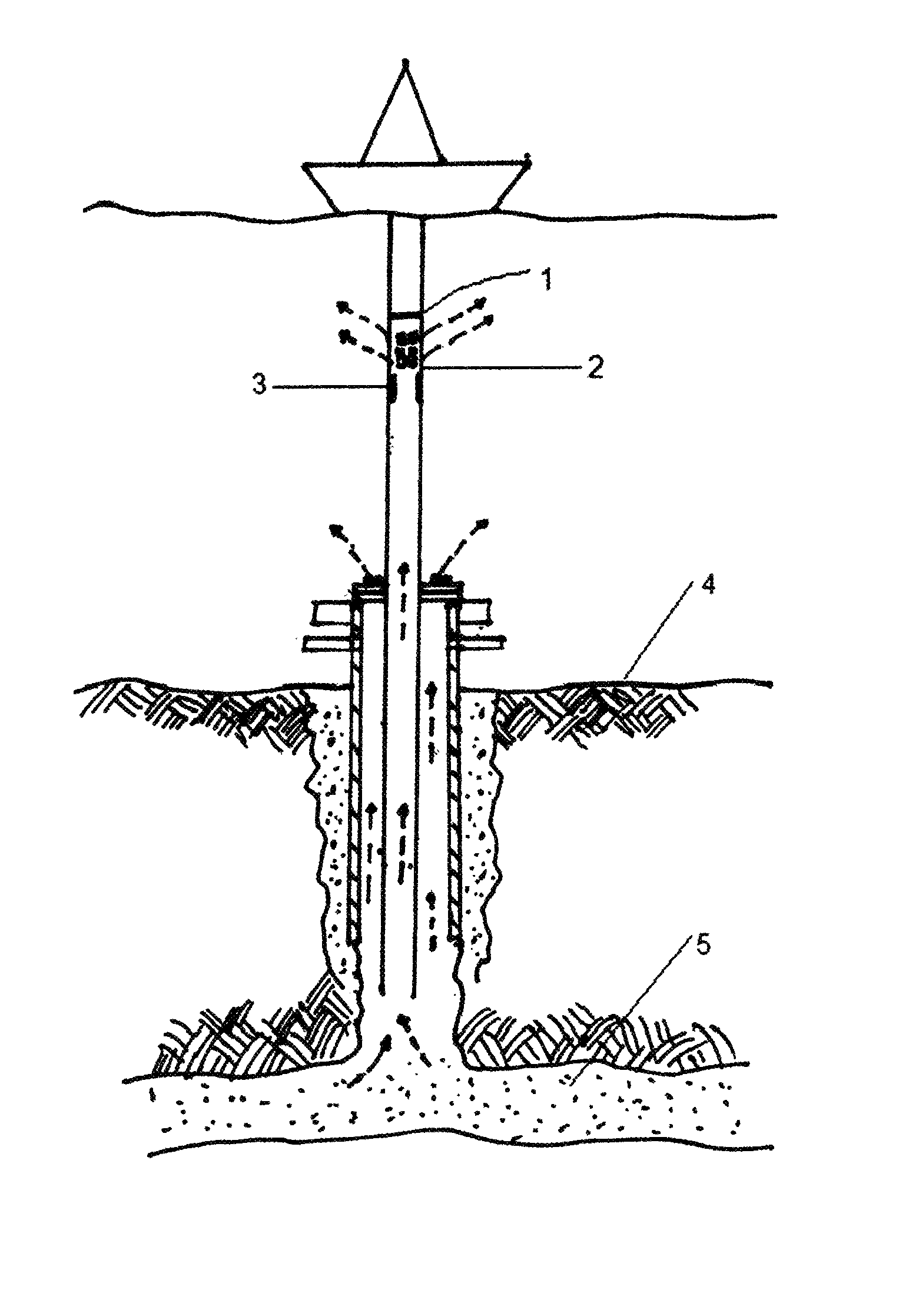

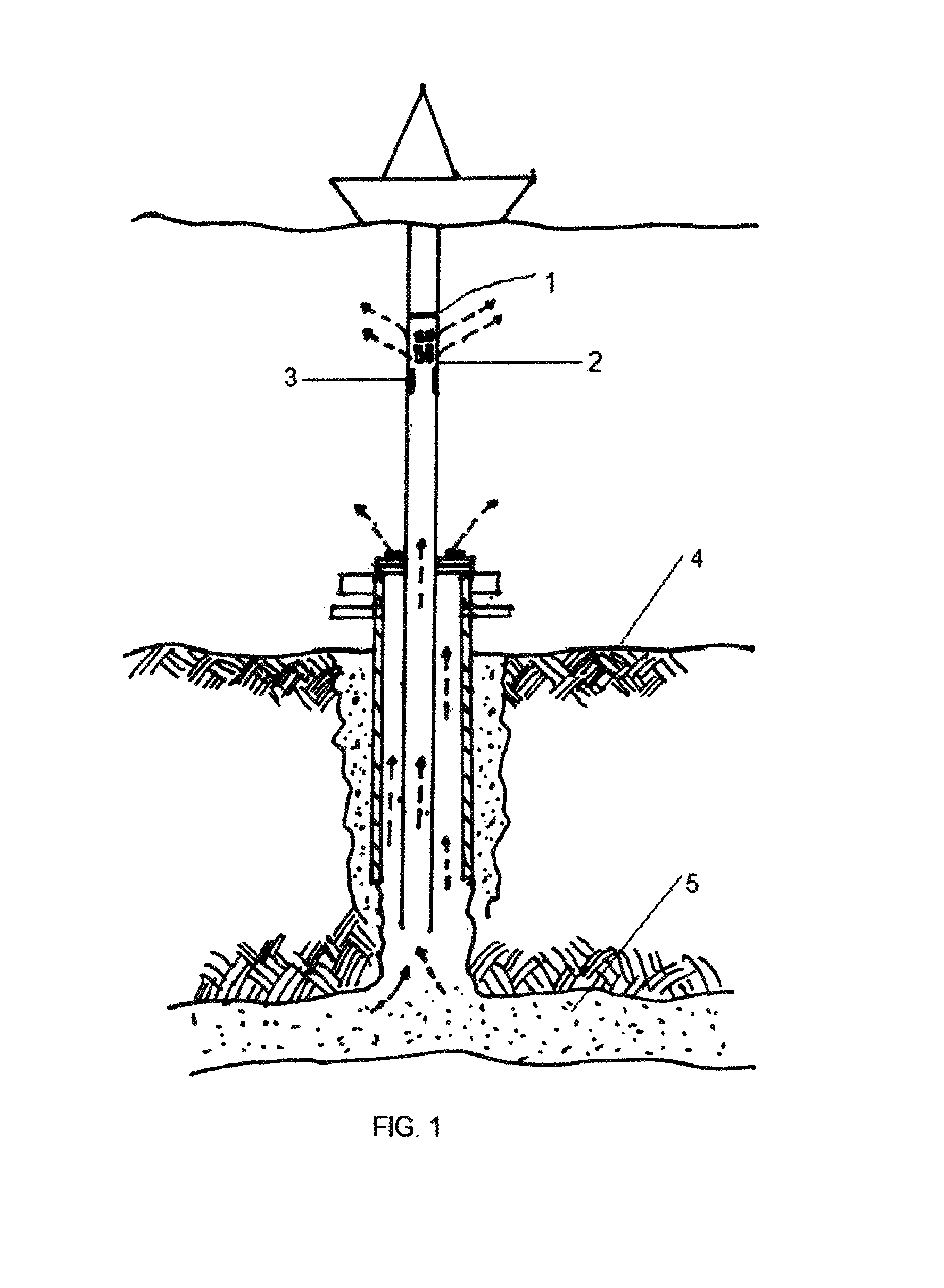

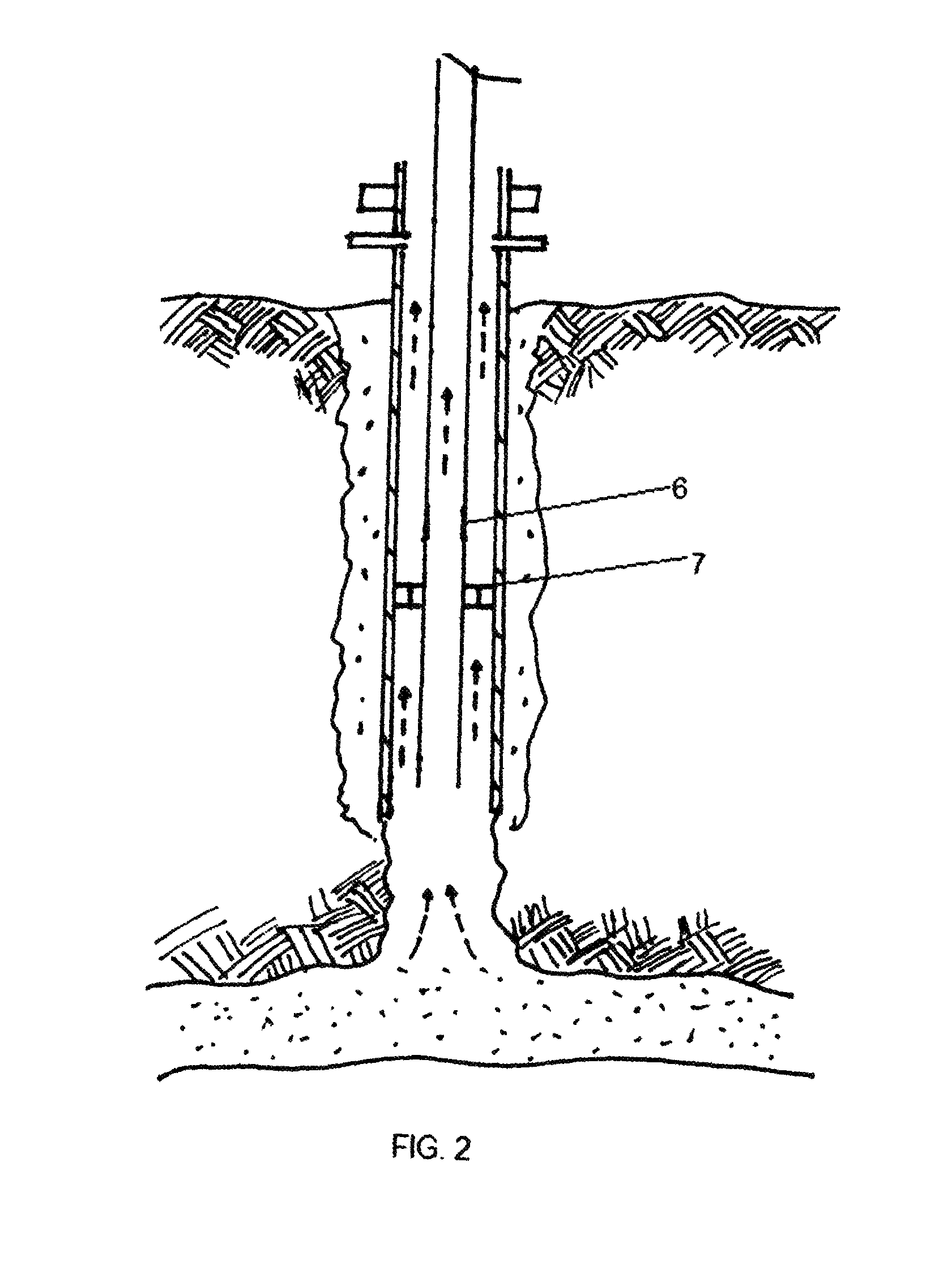

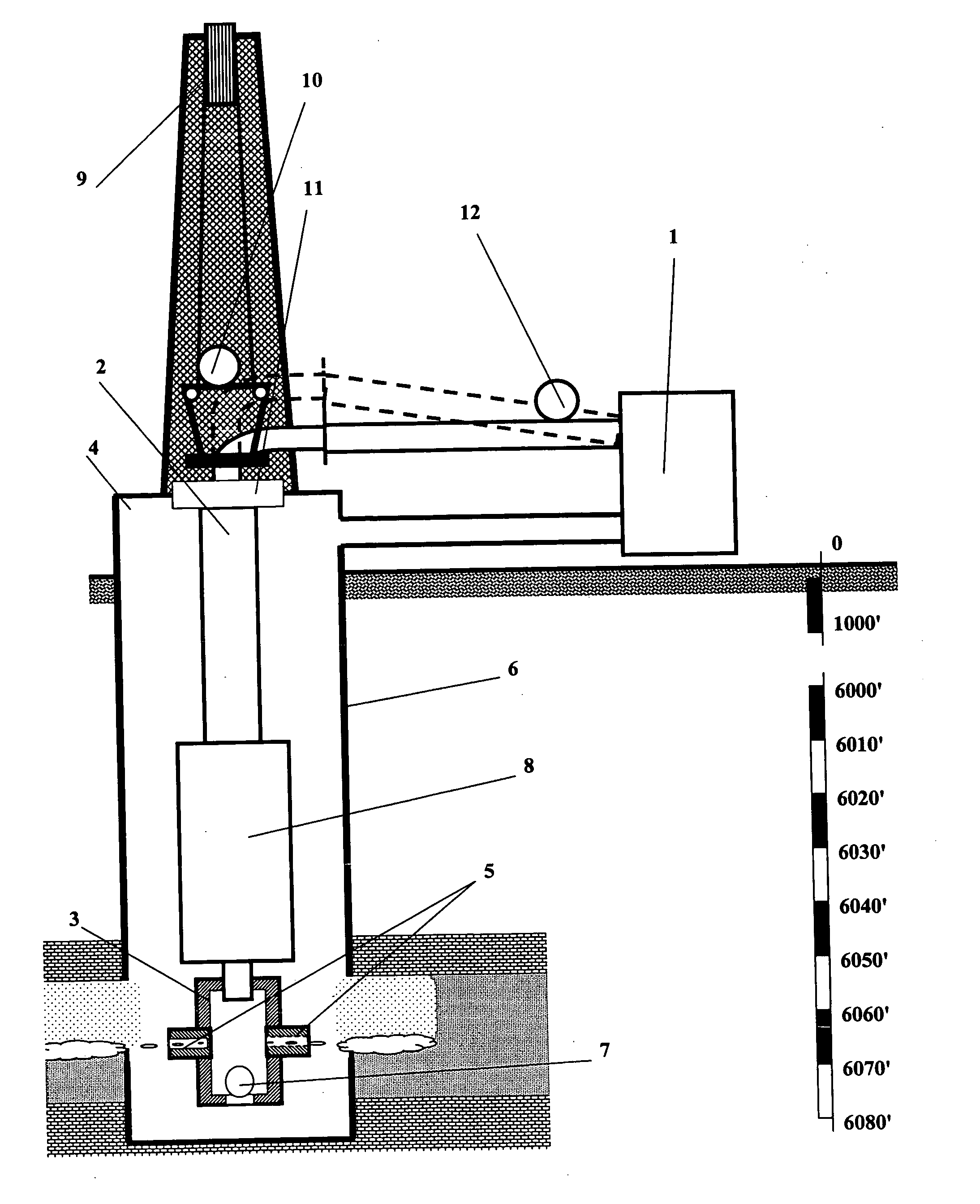

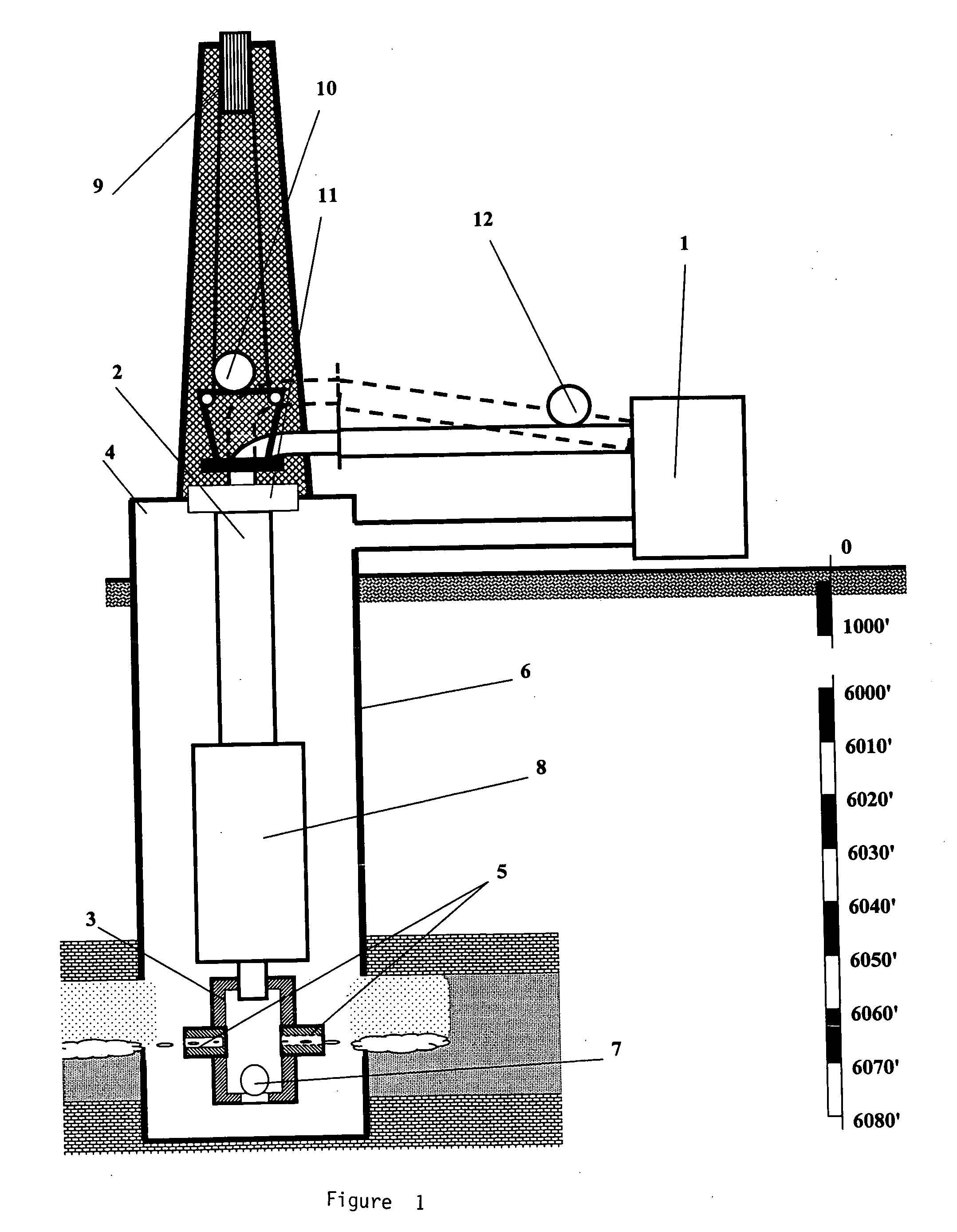

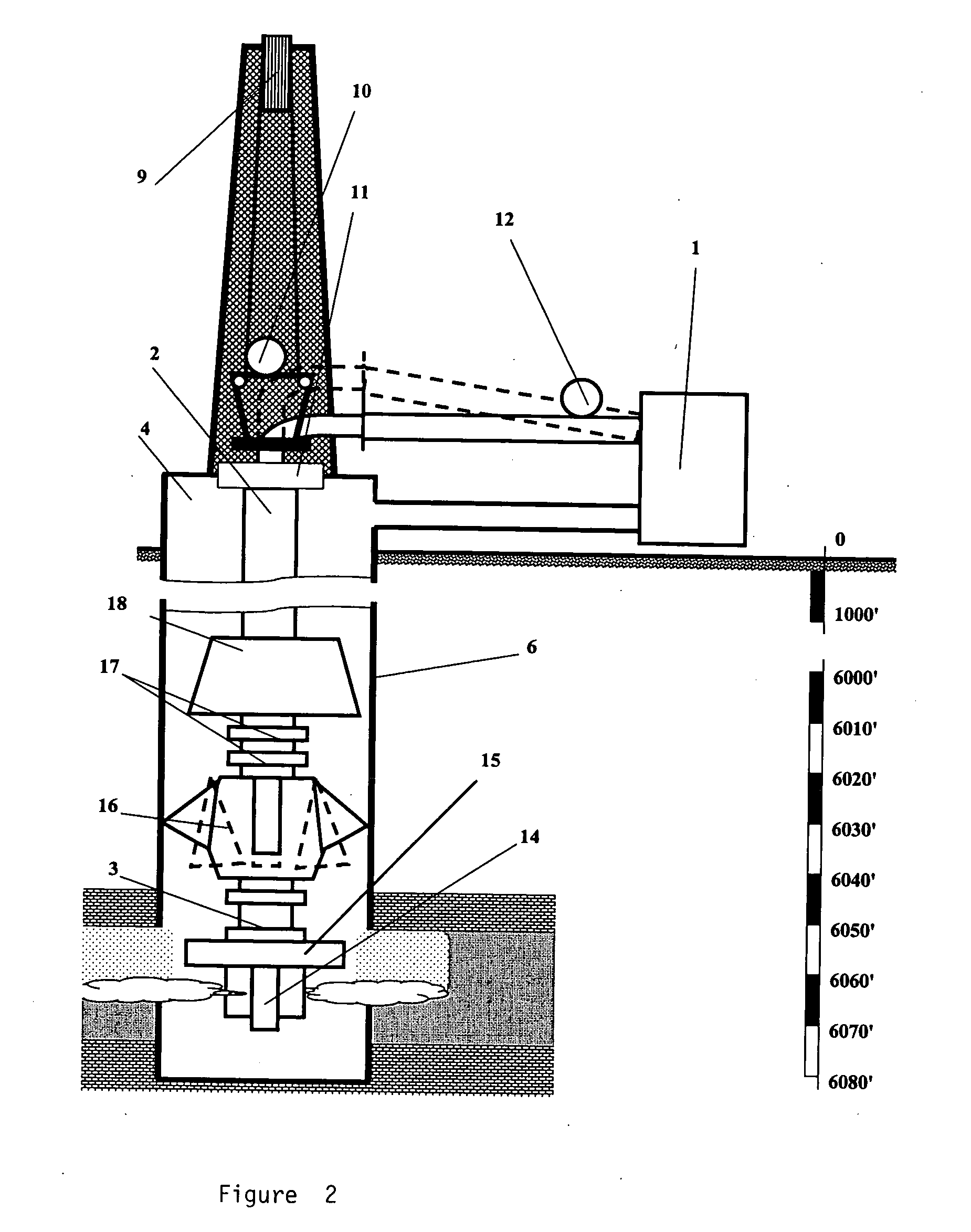

Method to shut down a high pressure oil/gas well that is leaking under blowout conditions

InactiveUS8215405B1Keep well integrityImprove integrityDrilling rodsFluid removalHigh pressurePetroleum

Year 2010 showed us that the oil / gas industry was not prepared to shut down in few days a high pressure oil / gas well. The Gulf of Mexico was polluted by thousands of barrels of oil that were leaking from a high pressure well. The environment damage was humongous as well as the economical loses. Here, I am presenting a method to shut down a high pressure oil / gas well in matter of days rather than in months. This method keeps the well integrity. This method is effective even if the well integrity was compromised.

Owner:CARRASCAL JORGE FERNANDO

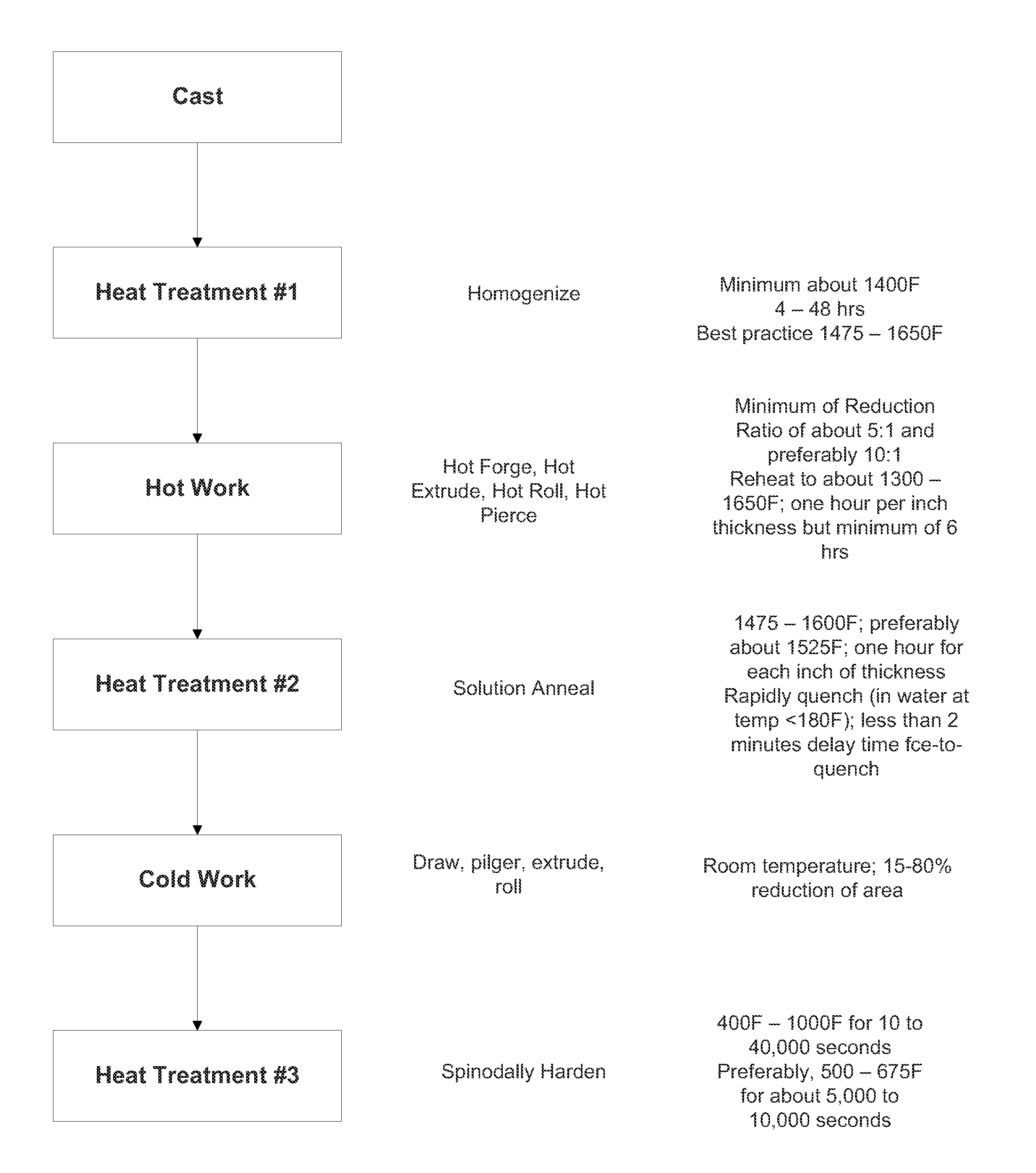

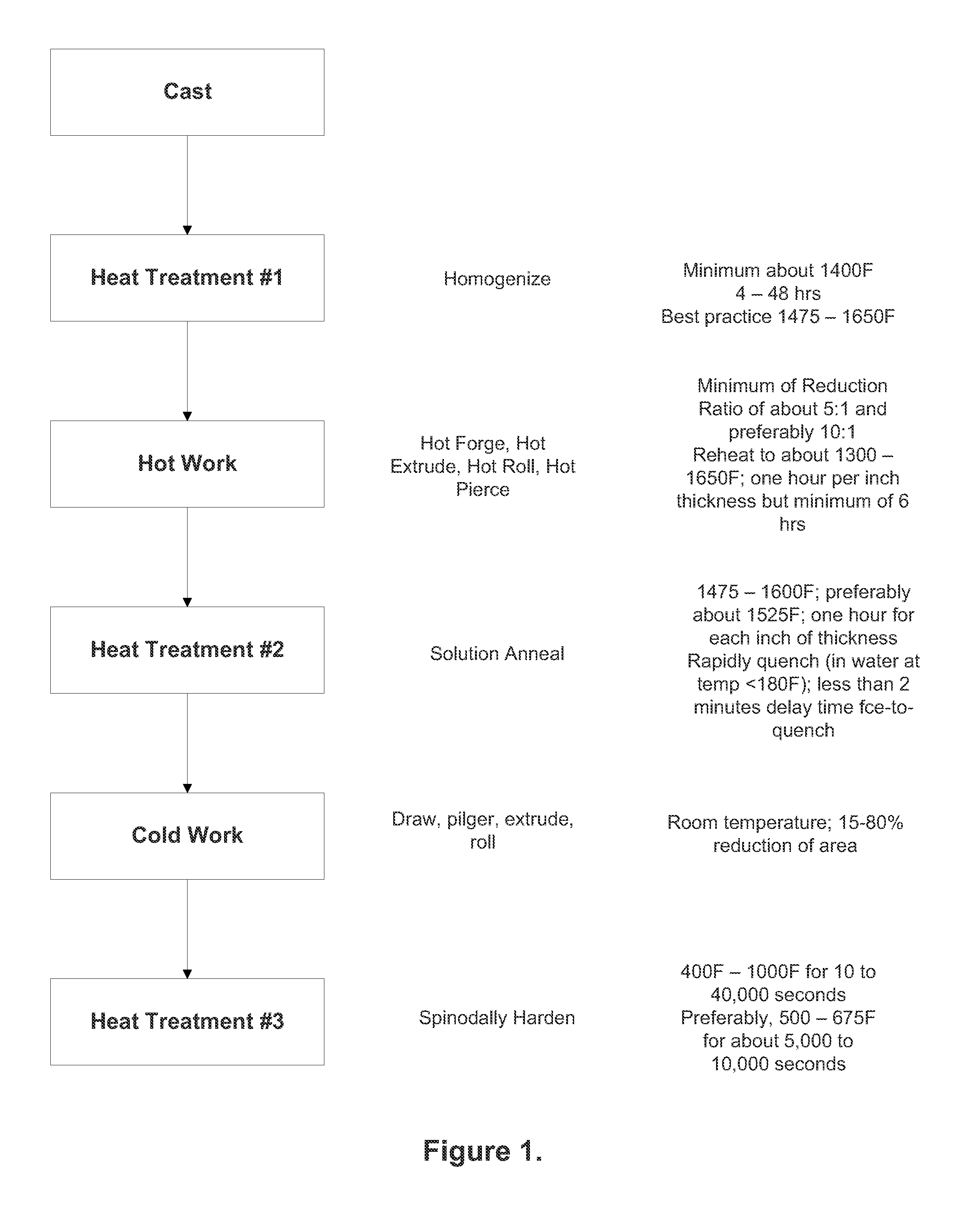

Copper-nickel-tin alloy with high toughness

A spinodal copper-nickel-tin alloy with a combination of improved impact strength, yield strength, and ductility is disclosed. The alloy is formed by process treatment steps including solution annealing, cold working and spinodal hardening. These include such processes as a first heat treatment / homogenization step followed by hot working, solution annealing, cold working, and a second heat treatment / spinodally hardening step. The spinodal alloys so produced are useful for applications demanding enhanced strength and ductility such as for pipes and tubes used in the oil and gas industry.

Owner:MATERION

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

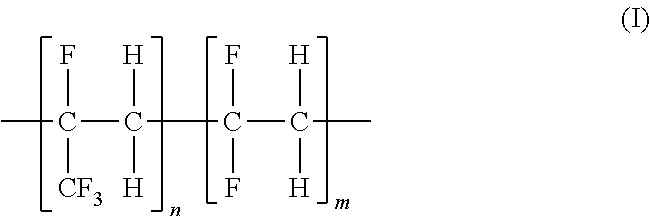

Fluorinated ethylene-propylene polymeric membranes for gas separations

A fluorinated ethylene-propylene polymeric membrane comprising a copolymer comprising 2,3,3,3-tetrafluoropropene and vinylidene fluoride is disclosed. The fluorinated ethylene-propylene polymeric membranes of the invention are especially useful in gas separation processes in air purification, petrochemical, refinery, and natural gas industries.

Owner:UOP LLC

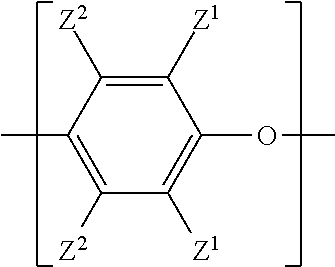

Methods utilizing polyamide-poly(phenylene ether) compositions

A polyamide-poly(phenylene ether) composition includes, based on the total weight of the composition, 35 to 80 weight percent of polyamide, and 20 to 65 weight percent of a poly(phenylene ether). The polyamide-poly(phenylene ether) composition is utilized in a variety of methods, including methods applicable to the oil and gas industry.

Owner:SABIC GLOBAL TECH BV

Analysis method for porosity degree and permeability rate of high smectite sandstone

ActiveCN101430270AAvoid the illusion of high porosity and permeabilityPreparing sample for investigationPermeability/surface area analysisPorosityPenetrance

The invention relates to a method for analyzing the porosity and the penetrance of high smectite sandstone. Sandstone without oil is selected. A sample is drilled by saturated brine. The oil is washed from the sample by toluene. The sample is cooled and is dried and vacuumized for 48 hours under normal temperature in the vacuum of minus 0.08MPa. The porosity and the penetrance are mensurated by a method for mensurating the rock porosity and the gas penetrance in PRC petroleum and natural gas industry standard SY / T 5336-1996 rock core analyzing method, and the used sample is warmed and cleaned the oil for measuring the porosity and the penetrance by the conventional PRC petroleum and natural gas industry standard SY / T 5336-1996 rock core analyzing method. Correction coefficients of the porosity and the penetrance are obtained respectively. The correction coefficients are used for correcting a same well or a same block for measuring the porosity and the penetrance data by a conventional warming and oil-washing method, so as to reflect the porosity and the penetrance data in the stratum factually.

Owner:PETROCHINA CO LTD

Methods For Preventing Proppant Carryover From Fractures, And Gravel-Packed Filters

InactiveUS20080156489A1Increasing propping filler pack strengthImprove protectionFluid removalDrilling compositionProduction rateParticulates

This invention relates to the oil and gas industry, in particular, to methods affecting the formation productivity at the oil and gas production stage.A method for fracture propping in a subsurface layer, which ensures a reliable protection of wells from the proppant carryover from the fracture, has been proposed. According to the proposed method, a fracturing fluid is mixed with a propping agent and particulate binding material wherein the particles have an average length-to-width ratio of less than or equal to about 10; thereafter, a formation fracturing process is implemented. Then, the particulate binding material hardens and forms a homogenous firm mass with the propping agent, which impedes the closing of the fracture and precludes proppant carryover from the fracture. Or, a fracturing fluid composition obtained by mixing a propping agent with a binding compound in the form of a powder whose size varies from about 1 to about 500 μm. A gravel-packed filter is then constructed; the said filter is based on the application of the working fluid comprising a propping filler and particulate binder with a length-to-width ratio of less than or equal to 10, or comprising a propping filler and a binding compound in the form of a powder with a size varying from about 1 to about 500 micrometers.

Owner:SCHLUMBERGER TECH CORP

Using non-regulated synthetic acid compositions as alternatives to conventional acids in the oil and gas industry

ActiveUS20160347994A1Improve breathabilityLower potentialCleaning apparatusFluid removalAlcoholOil and natural gas

Owner:DORF KETAL CHEM FZE

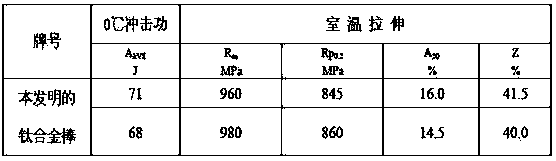

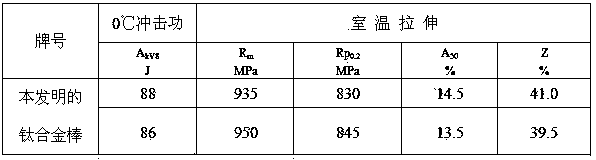

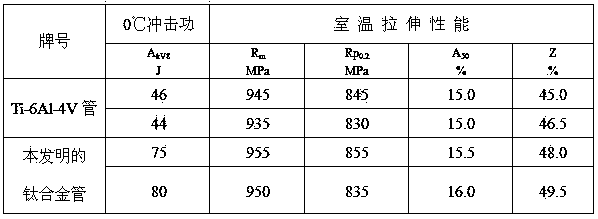

Titanium alloy and processing method thereof

ActiveCN103898359AImprove impact performanceMeet the needs of mining equipment materialsRoom temperaturePerformance index

The invention provides a titanium alloy and a preparation method thereof, relates to a titanium alloy with high impact performance, and in particular relates to a titanium alloy with high impact performance for mining equipment of petroleum, natural gas and the like and a processing method thereof. The titanium alloy is characterized by consisting of the following components in percentage by weight: 5.5-6.8% of Al, 3.5-4.5% of V, 0.3-3.0% of Zr, 0.3-2.0% of Mo, 0-1.0% of Nb, and the balance of Ti and inevitable impurities. The performances of the titanium alloy, such as 0 DEG C impact performance and room-temperature tensile property, can meet the performance index requirements of P110 grade steel, and the titanium alloy can substitute the P110 grade steel and be applied in the industries of petroleum, natural gas and the like. Compared with various existing titanium alloys, the titanium alloy has the advantages that the impact performance is improved, and room-temperature tensile property and H2S, SO2, CO2 and seawater corrosion resistance of the alloy are also improved. The titanium alloy can effectively meet the requirement of the mining equipment in the petroleum and natural gas industries for materials.

Owner:BAOJI TITANIUM IND CO LTD

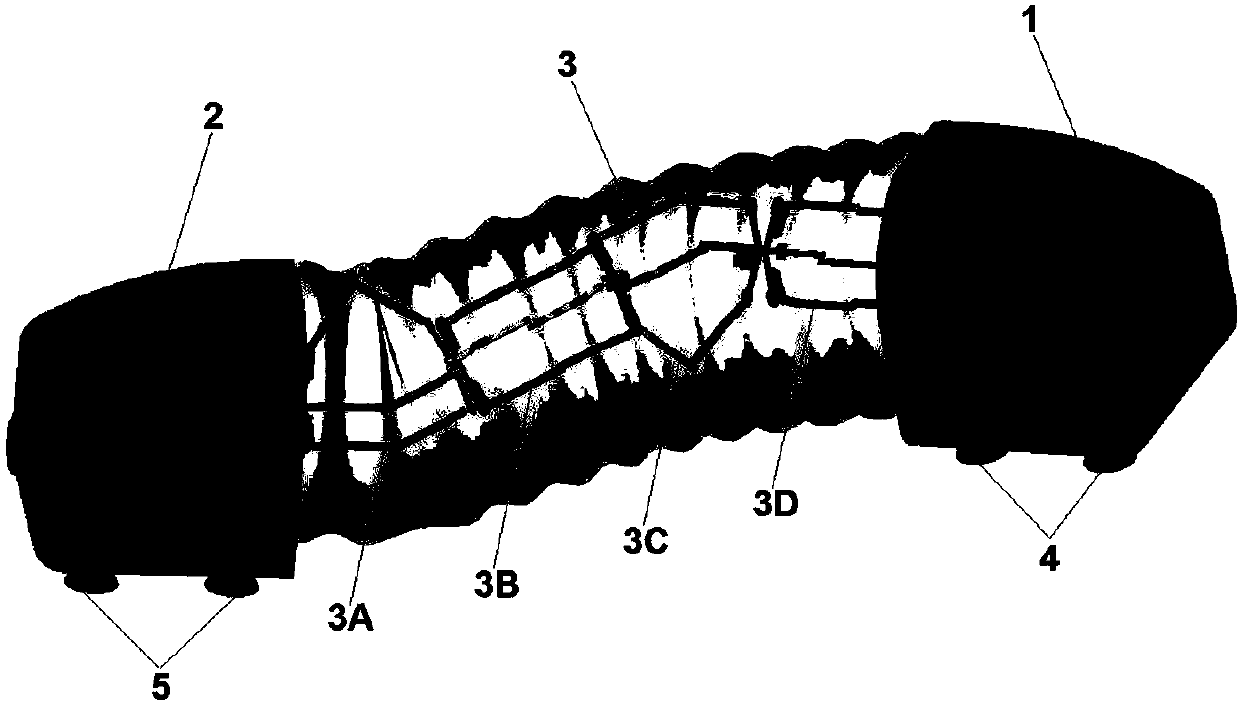

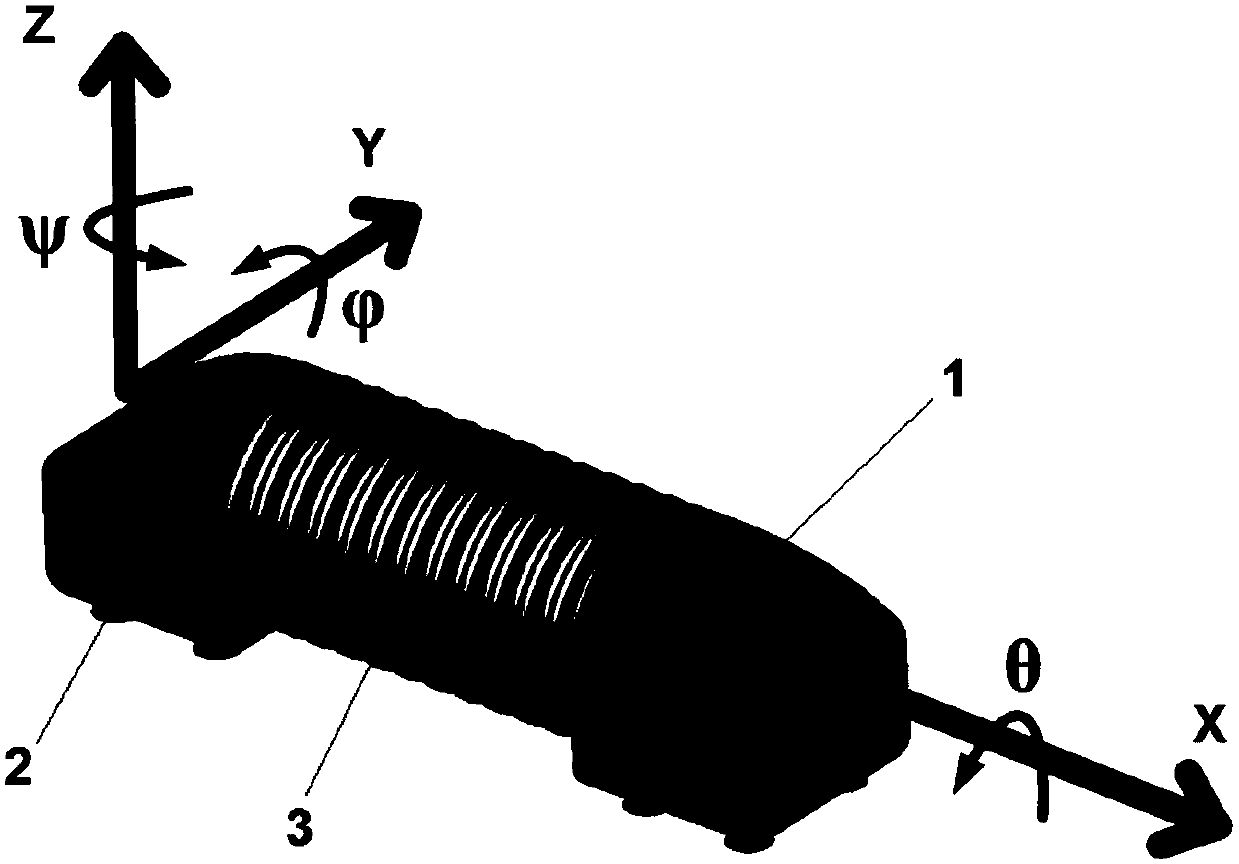

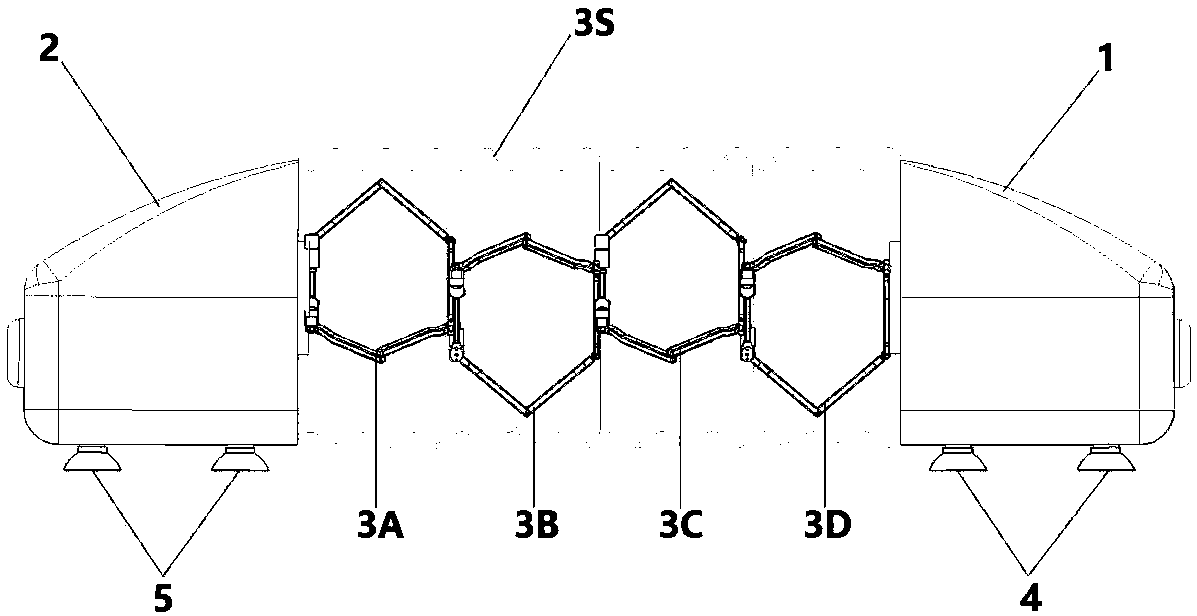

High-maneuverability looper type creeping robot

ActiveCN107830307AImprove mobilityHigh ability to turn sharplyPigs/molesEngineeringOil and natural gas

The invention provides a high-maneuverability looper type creeping robot capable of doing the creeping movement and the looper type movement at the same time. The creeping robot comprises a head and atail located at the two ends. The interior comprises a power source, a controller and a sensor module. A drive part, covered with flexible skin, between the head section and the tail section is composed of at least four same driving mechanisms. Each driving mechanism is a specially-designed three-freedom-degree mechanism, the driving mechanisms can rapidly move forwards, and due to the full hemisphere rotation capability of the driving mechanisms, the robot can sharply steer and elevate a trunk with the smaller radius. Thus, the creeping robot can penetrate a small gap beneficially and can avoid obstacles through sharp turning or crawling. Through the motion manner, the creeping robot can be applied to multiple fields such as operation endoscopy, petroleum and natural gas industry pipeline checking and search and rescue actions of flood, earthquake or nuclear accidents or other disasters.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

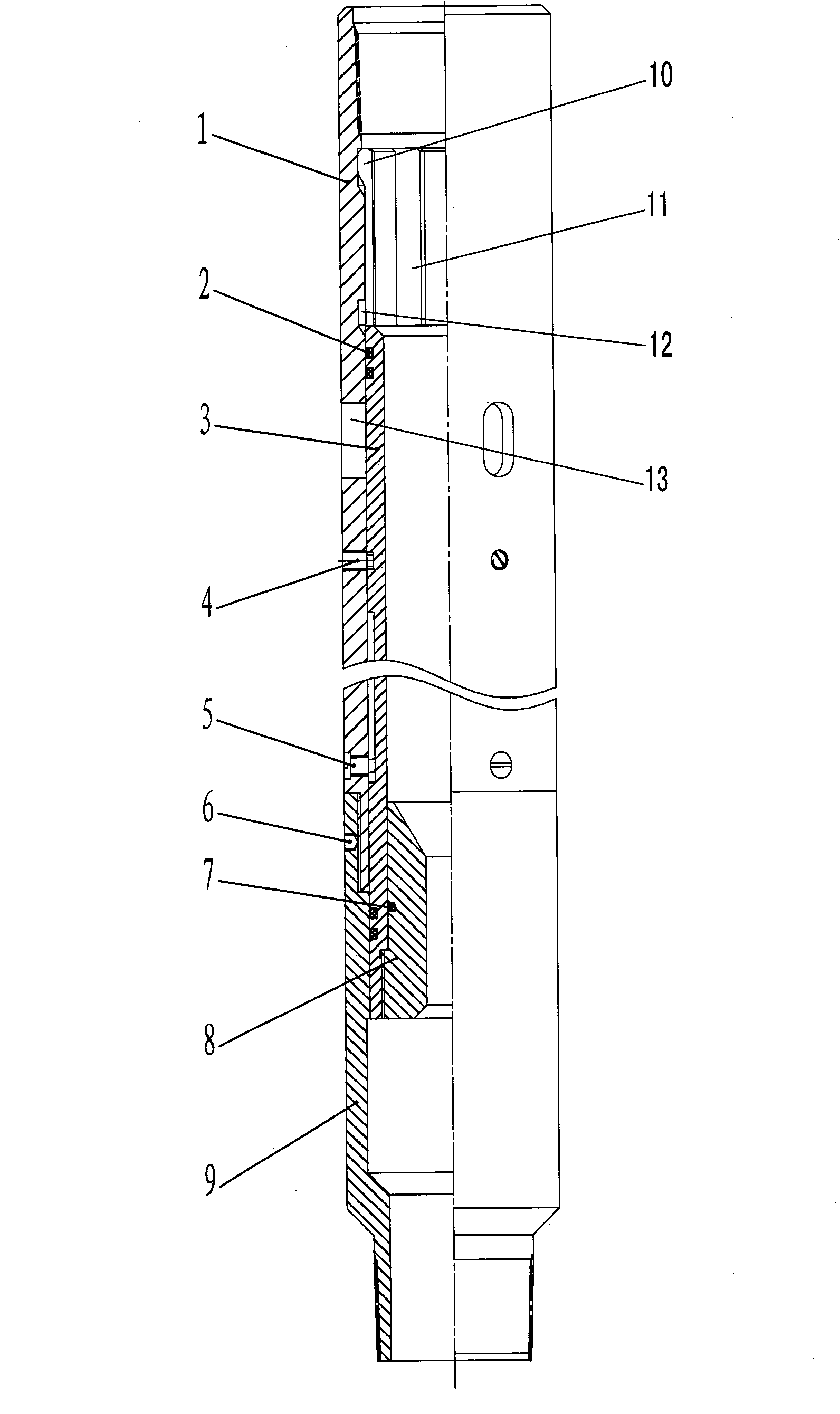

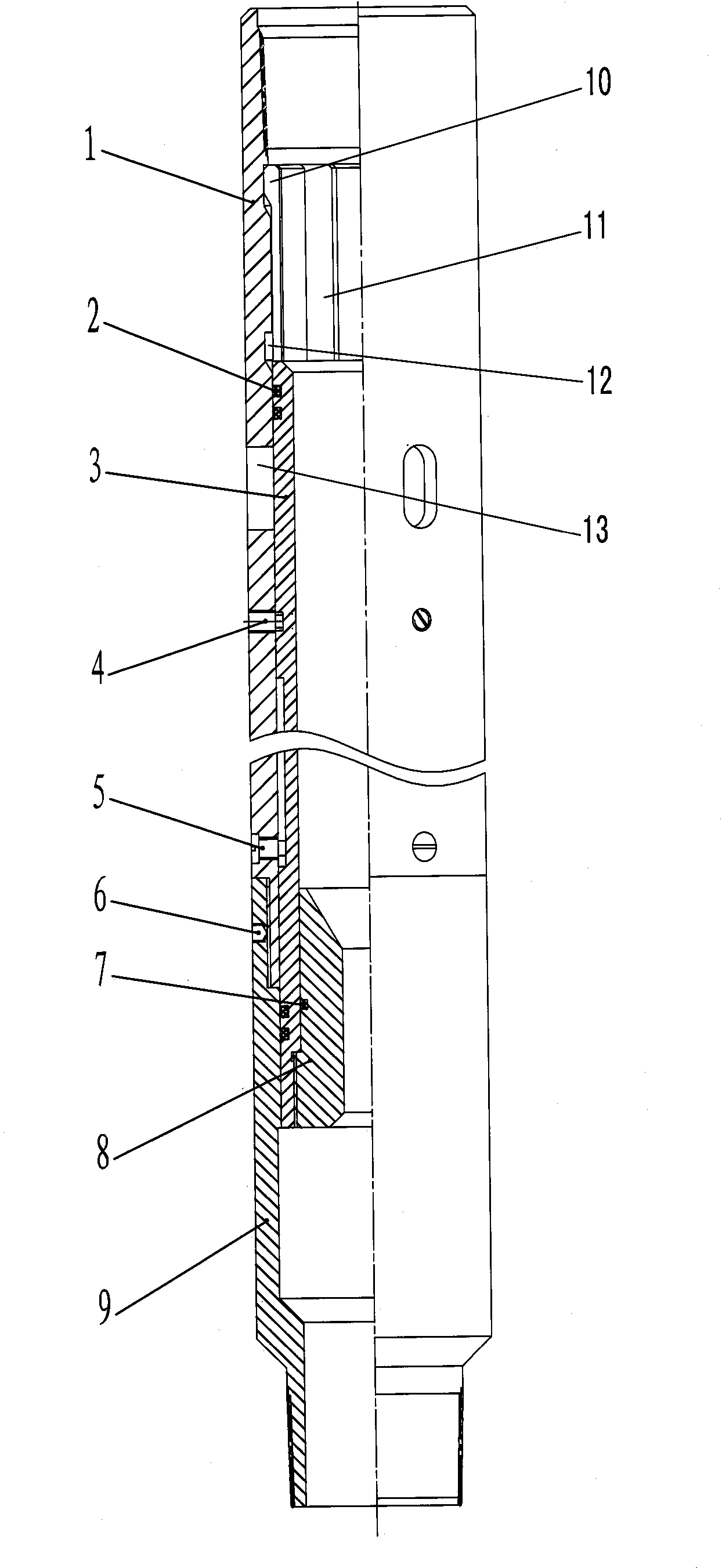

Drillable ball injection sliding sleeve suitable for horizontal well

ActiveCN101881143ASmall differential designEnhanced overall recoverySealing/packingState of artManufacturing technology

The invention provides a drillable ball injection sliding sleeve suitable for a horizontal well, belonging to the technical field of manufacturing downhole tools in oil and gas industry. The invention adopts a design way of opening before locking, and provides a drillable ball injection sliding sleeve suitable for a horizontal well which comprises a joint device and an elastic claw tube structure, wherein the upper joint and the lower joint of the joint device is connected by a thread; and the elastic claw tube structure is composed of elastic claw tubes. The invention overcomes the problems that the ball injection sliding sleeve in the prior art can not be self-locked after being opened, the ball seat can not be drilled, circumferential fixation does not exist and drilling and grinding can not be realized. The invention has the advantages of large designed outer diameter and relatively small level difference of seatbores and has operation tubular columns which can finish eight layer sections after combination.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Device for cutting slot-shaped seats in wells by hydro-sandblasting method

This device relates to the fields of mining, specifically oil and gas industry, hydro-geological, geological engineering and water supply industries and is intended for cutting slot-shaped seats in well side zones of producing formation by hydro-abrasive blast. The determined task is solved by introducing essential changes into the known device for construction of cutting slot-shaped seats from the well wall inside the rock consisting of the hydro-abrasive jet generator connected with the perforator through the pump-and-compressor tubing string; the perforator is put into the casing pipe and has two diametrical nozzles which are directed at the well wall; there is a ball valve at the perforator end, as well as devices for adjustable partial unloading of PCS, PCS weight measuring device, abrasive jet pressure measuring device and the sealer for sealing of wellhead. The changes are as follows:—The perforator is directly connected with PCS;—A pin mounted under the perforator with possible axial movements is introduced;—A cylindrical retainer washer is put on the upper part of the perforator above nozzles; the washer is fixed so as to permit axial movement;—PCS indexing mechanism, step rings and a tripping muff are mounted bottom up and in alignment on the lower tube of PCS which is in series connected with the perforator;—At the same time the pin is connected with the cylindrical washer situated on the upper part of the perforator by control-rods with possible axial movement;—The indexing mechanism is put on PCS with the possibility of fixed coupling of its body with the casing pipe wall and split engagement of its body by step rings. Step rings are to be rigidly fixed on the lower PCS tube, and the tripping muff-on the PPS with its skirt down. At least a couple of rotary fluke-claws, with one end of each hingedly connected with the body of indexing mechanism, and the other end clasped to the casing pipe wall by spacer springs mounted between the indexing mechanism body and the fluke-flaw end, can be a variant of engagement of the indexing mechanism body with the casing pipe wall. At least a couple of spring-mounted pins installed on the interior surface of the indexing device body can be a variant of split engagement of the indexing mechanism by step rings. At that the pin heads are of round shape at the contacting end set against PCS. A muff with conical inside surface and the exterior of streamlined form can be a variant of tripping muff for forced tripping of the indexing mechanism from the casing pipe wall. The optimum distance between the step rings equals to one drain port diameter D±5%, and the number of rings has to amount to prescribed length of the slot-shaped seat divided by the drain port diameter D. At the same time adjacent drainage canals will unite and form a single slot-shaped seat. The recommended force for coupling of the split pin heads with PCS lies within the limits of 10-20% of PCS weight. The recommended force for coupling of the indexing device body with the casing pipe wall is in the range from 30% of PCS weight up to breaking strength point of the casing pipe.

Owner:DAVIDSON DRILLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com