Patents

Literature

11787results about "Borehole/well accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

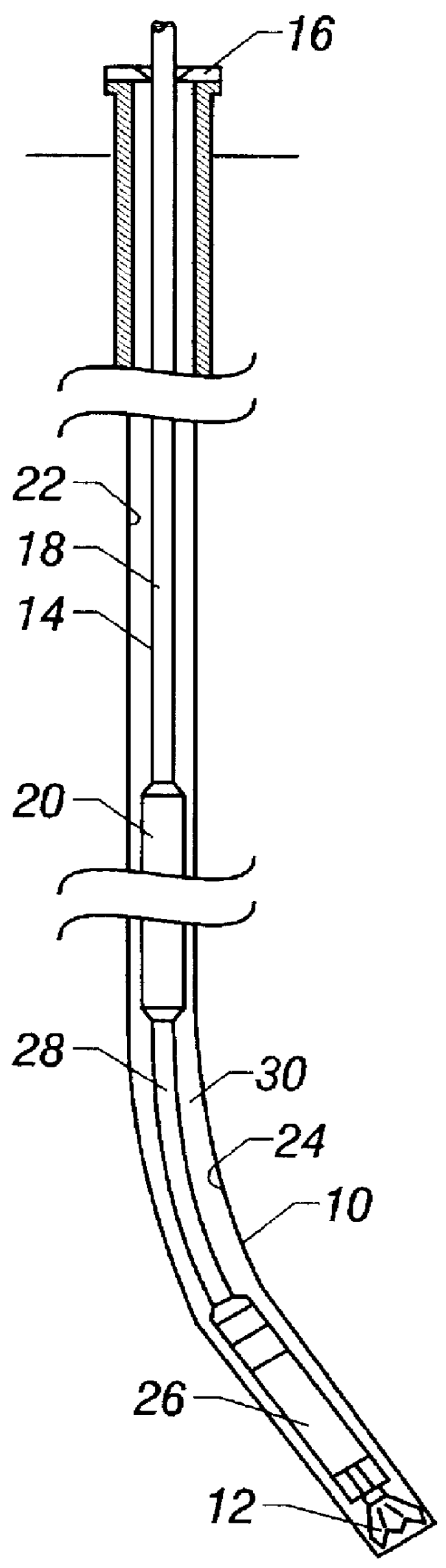

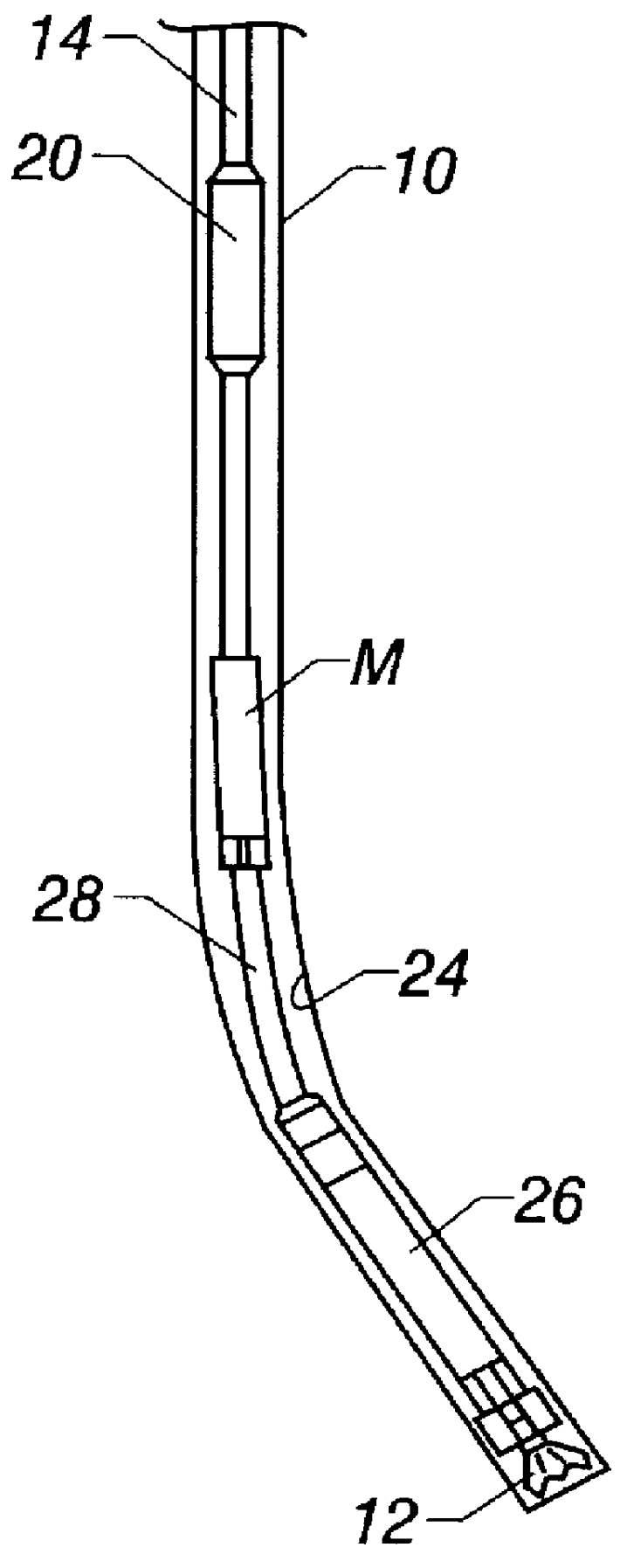

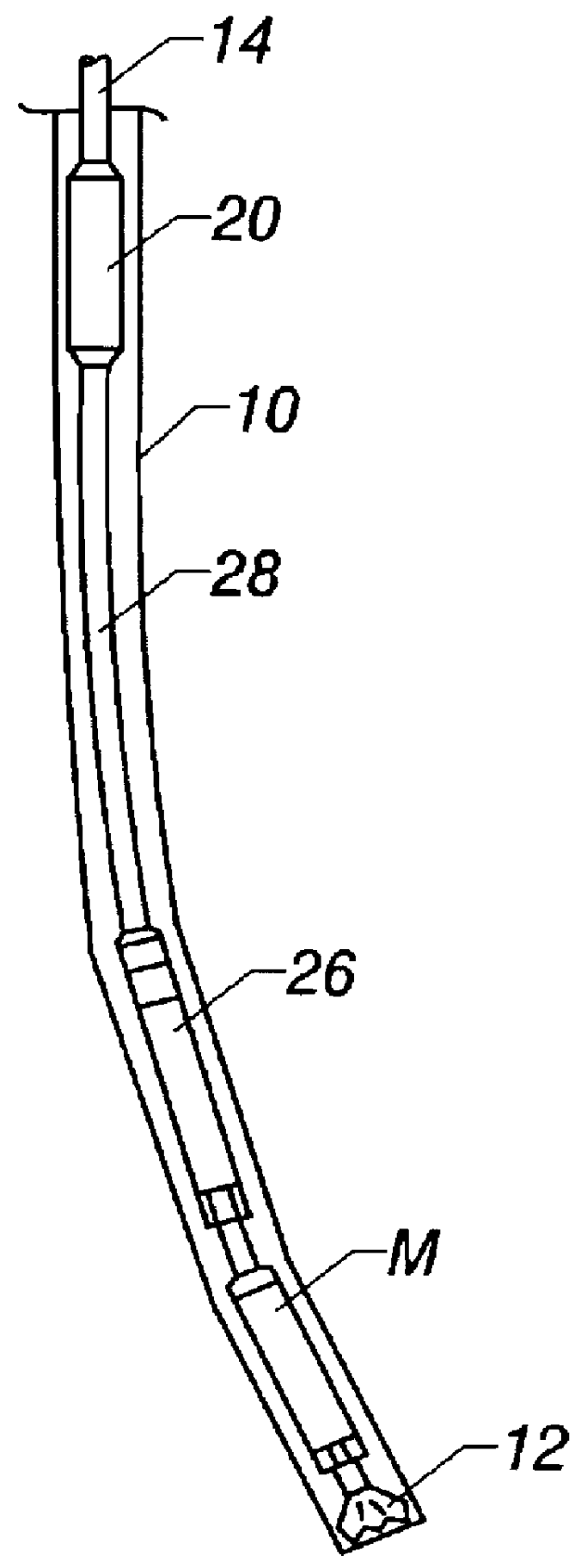

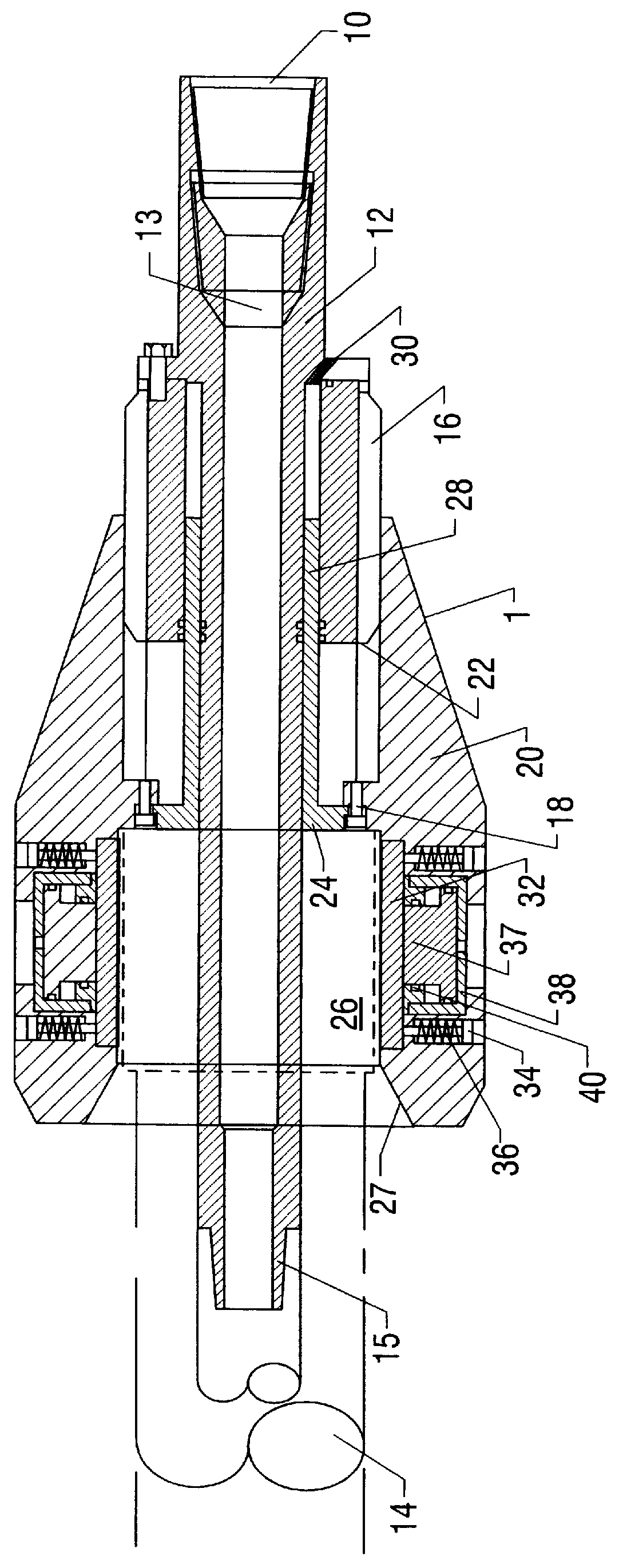

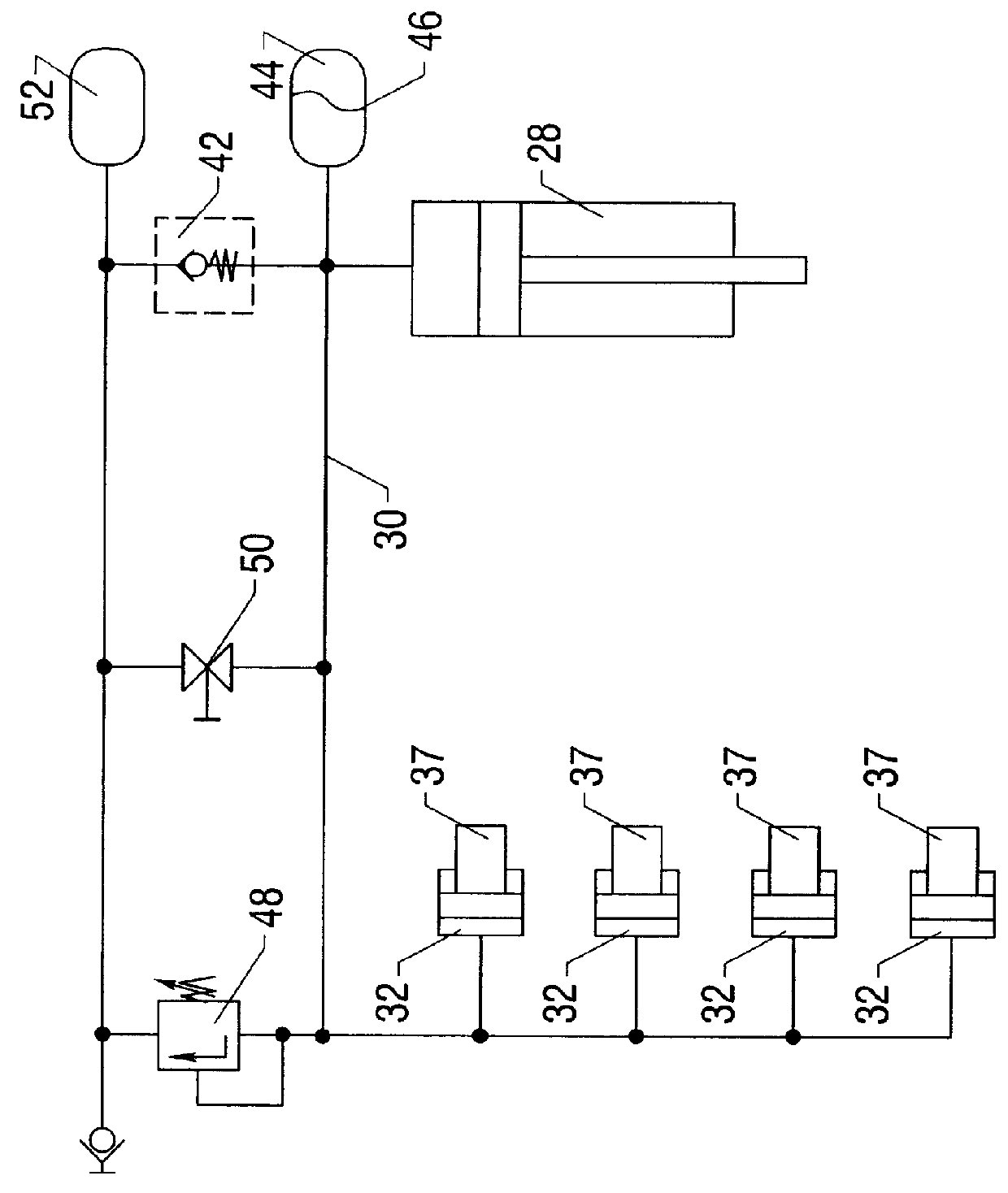

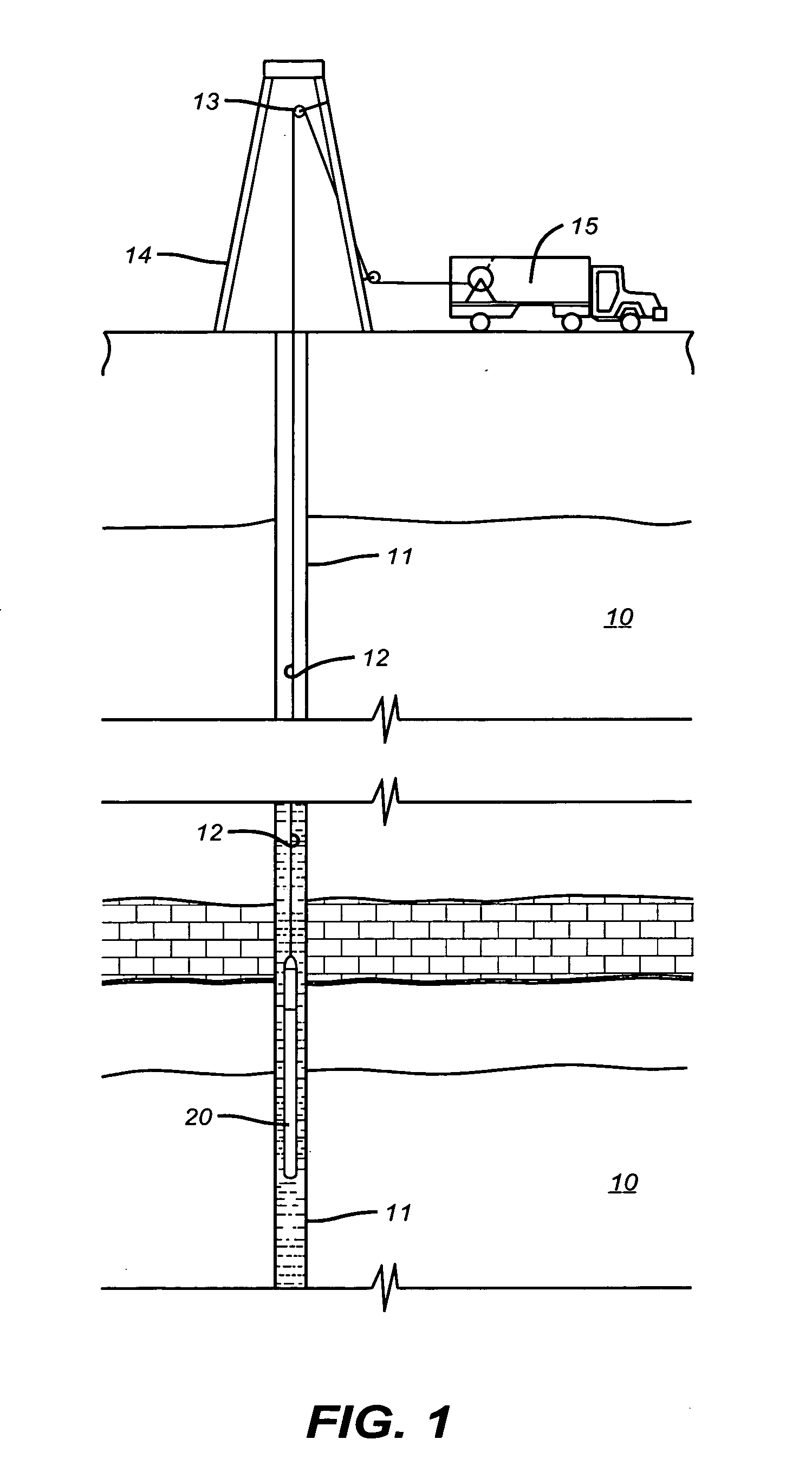

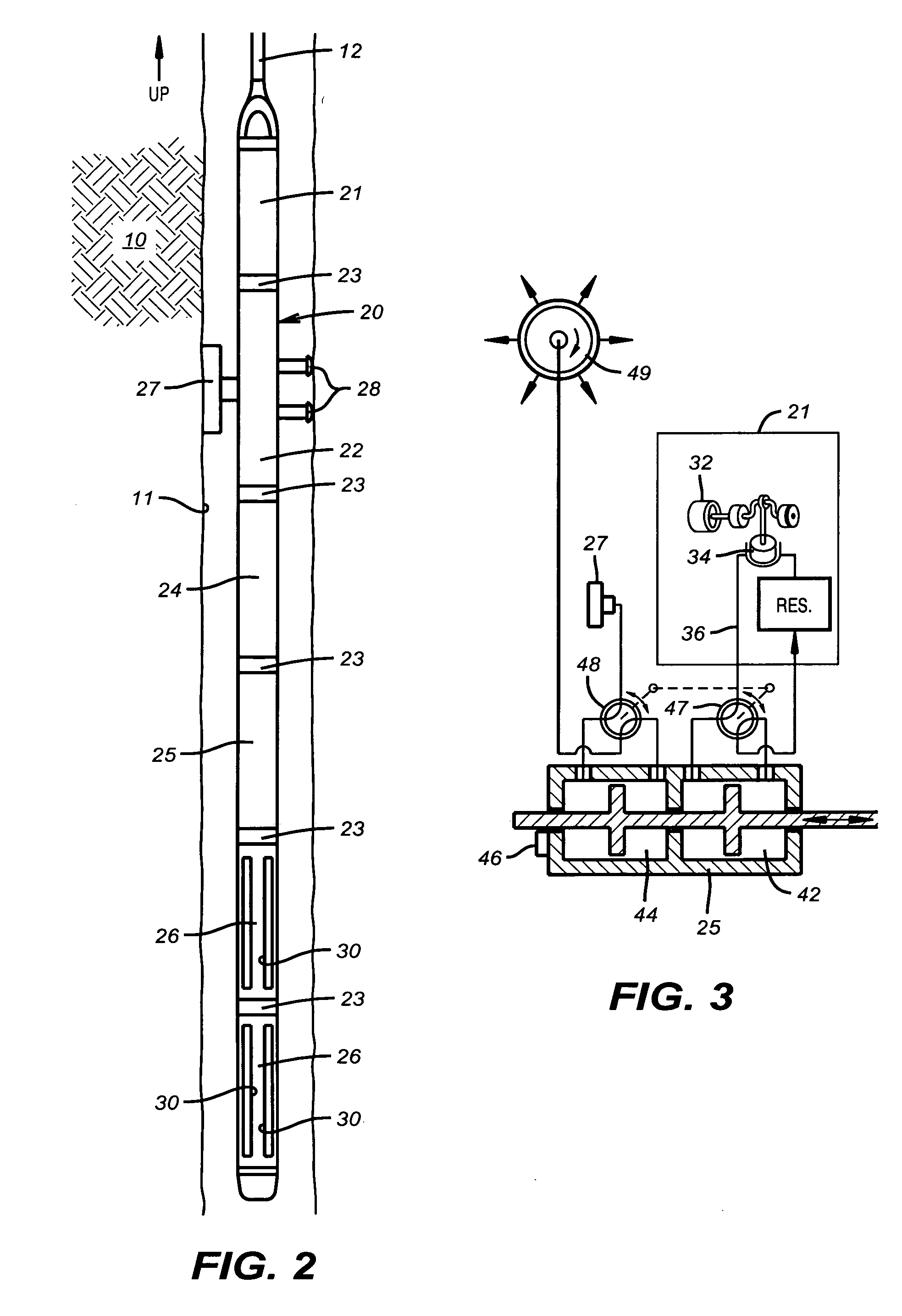

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

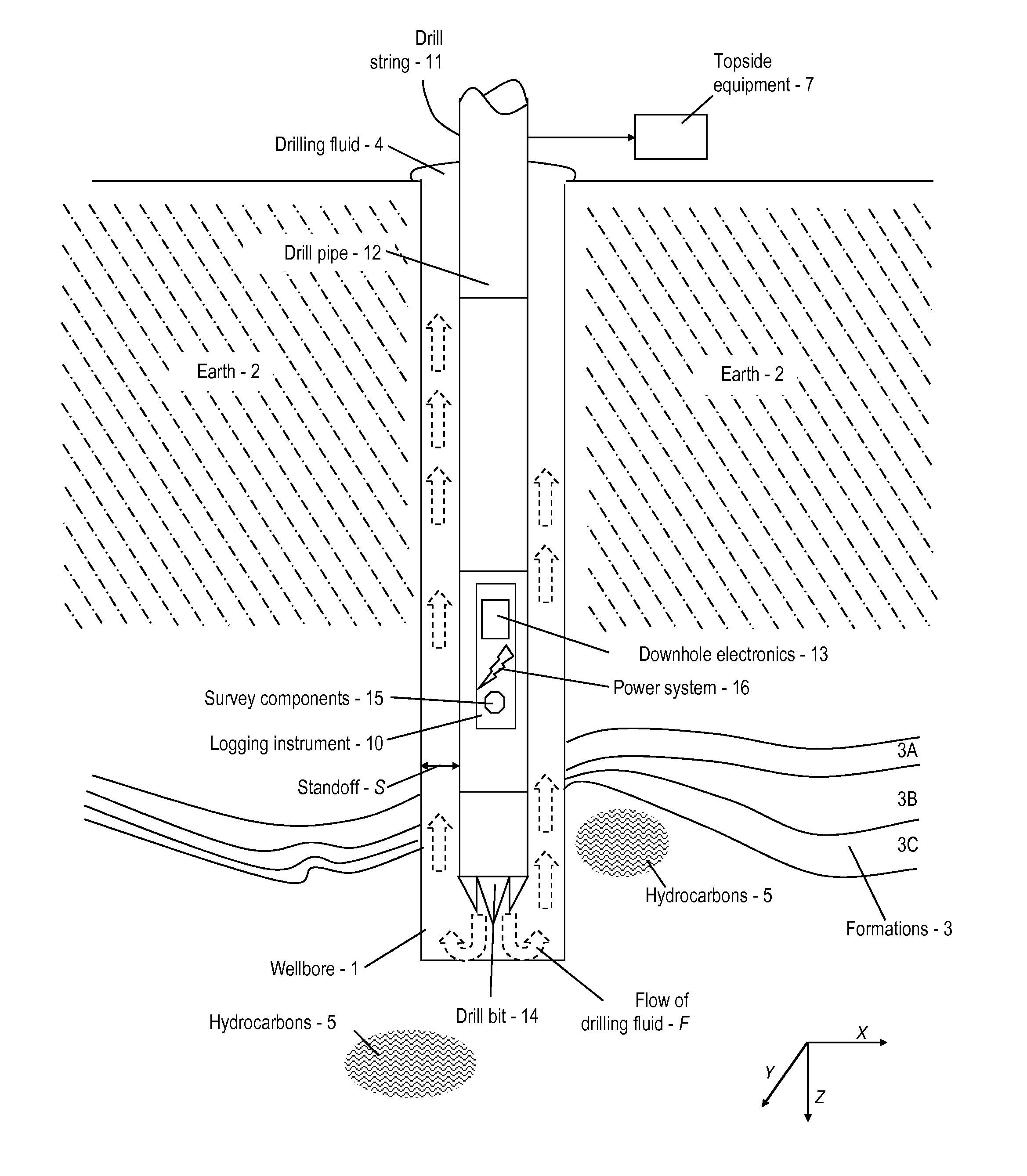

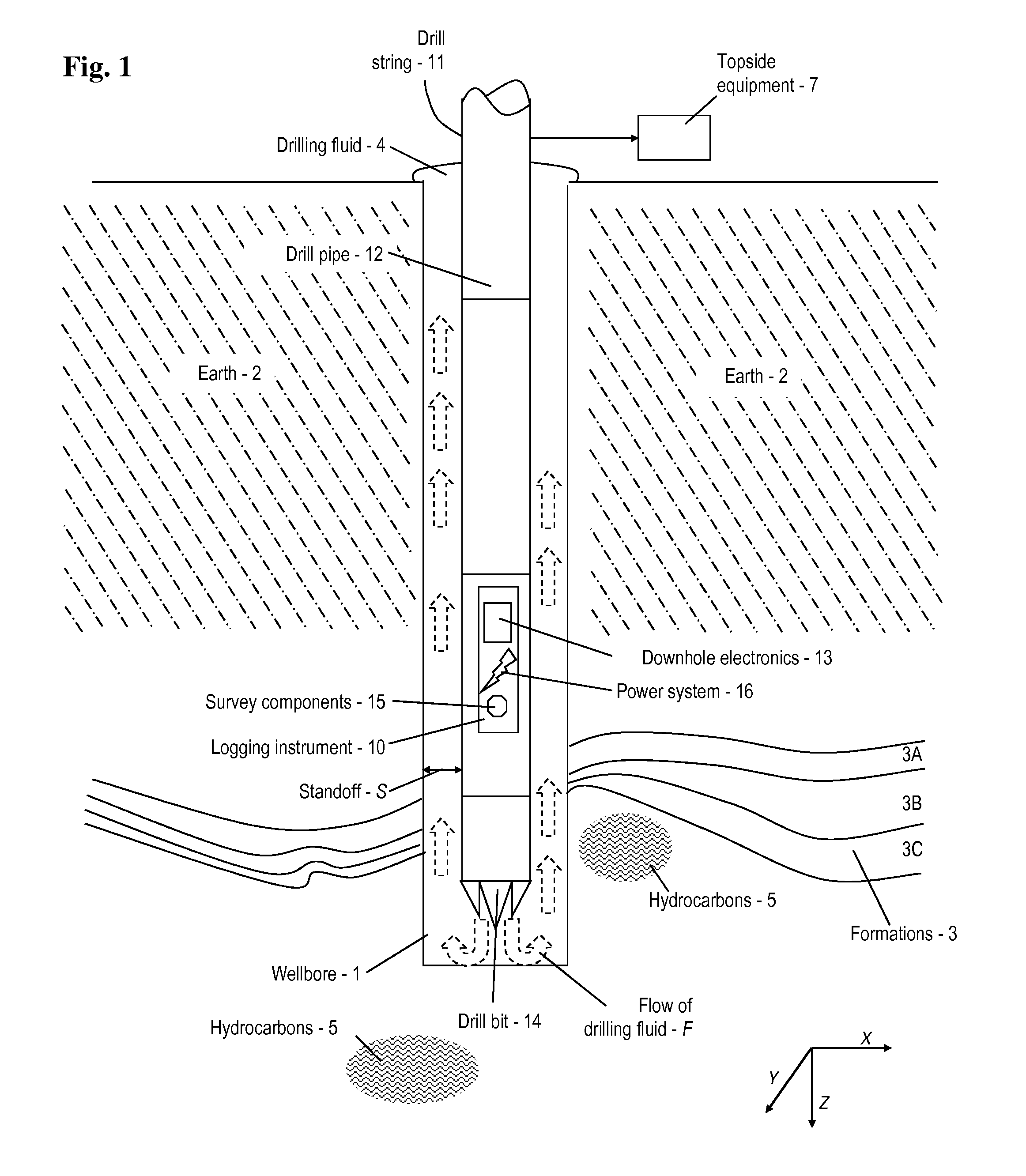

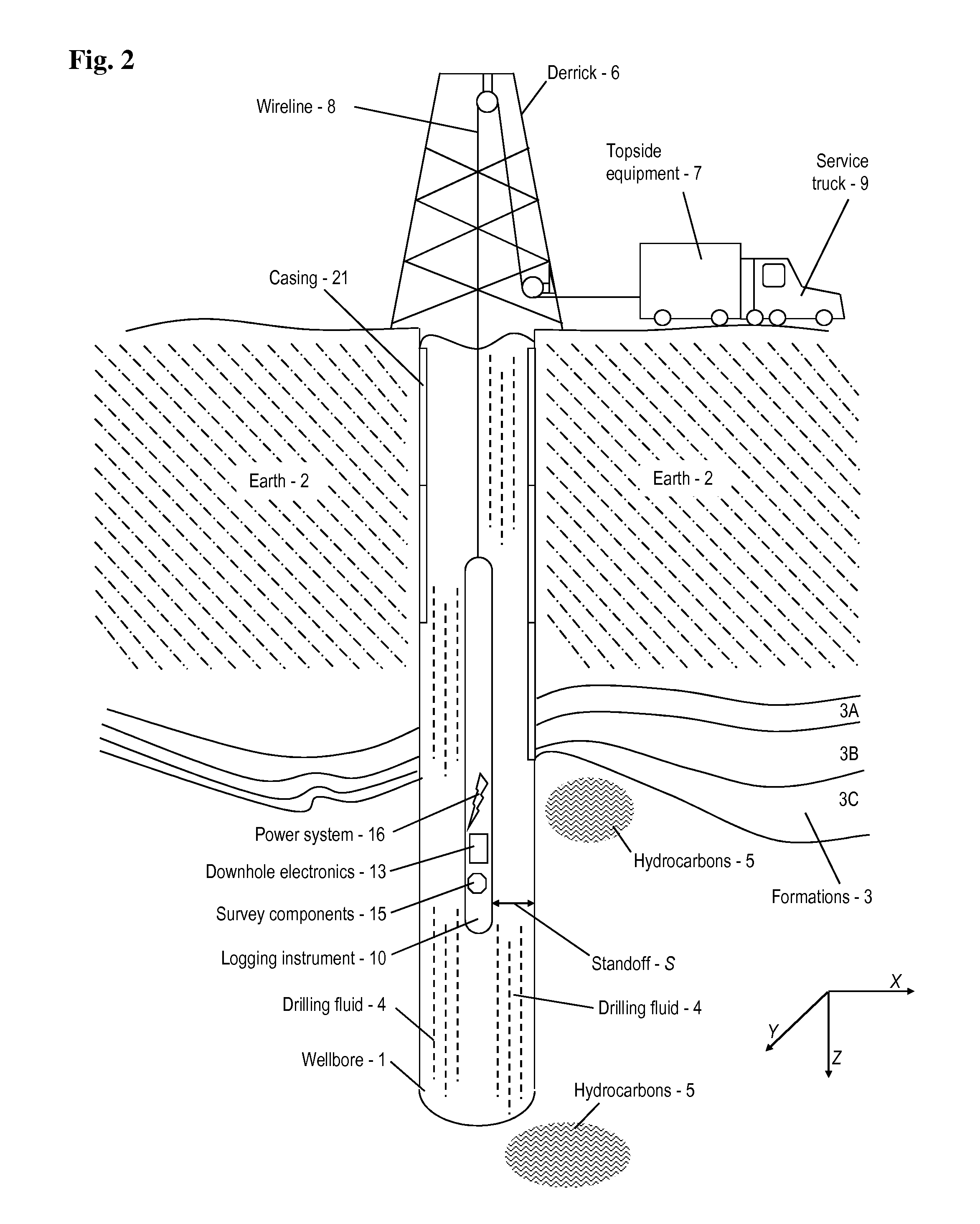

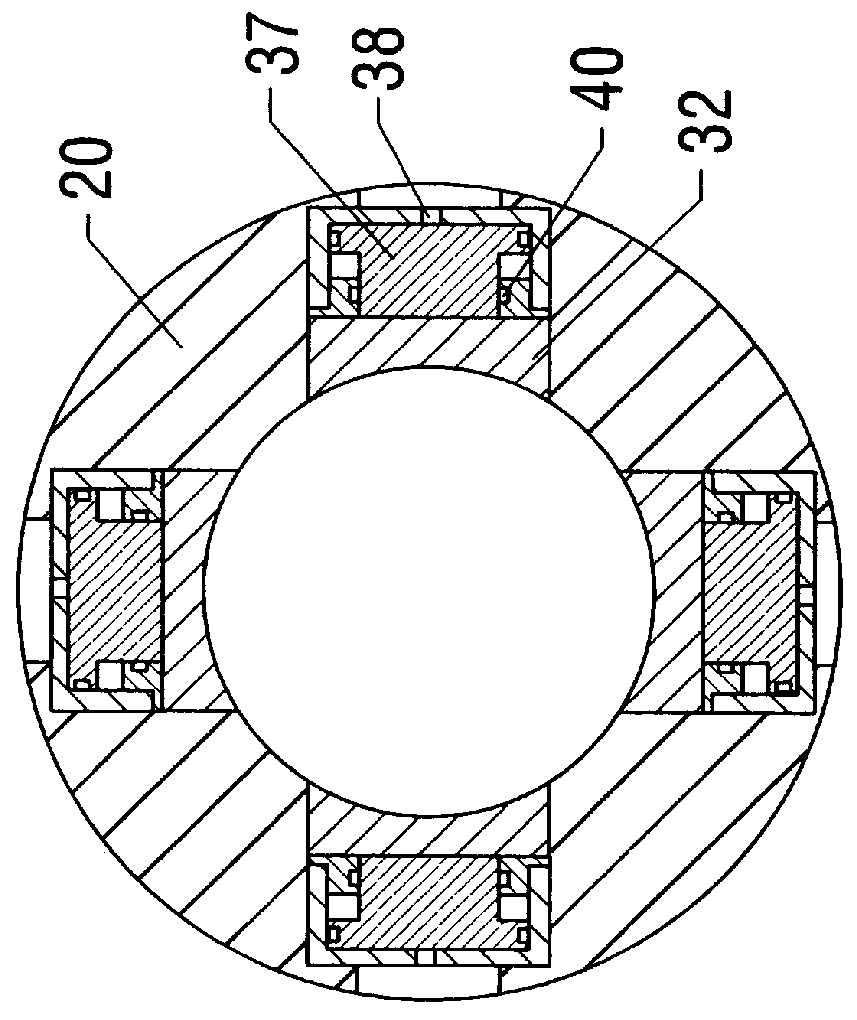

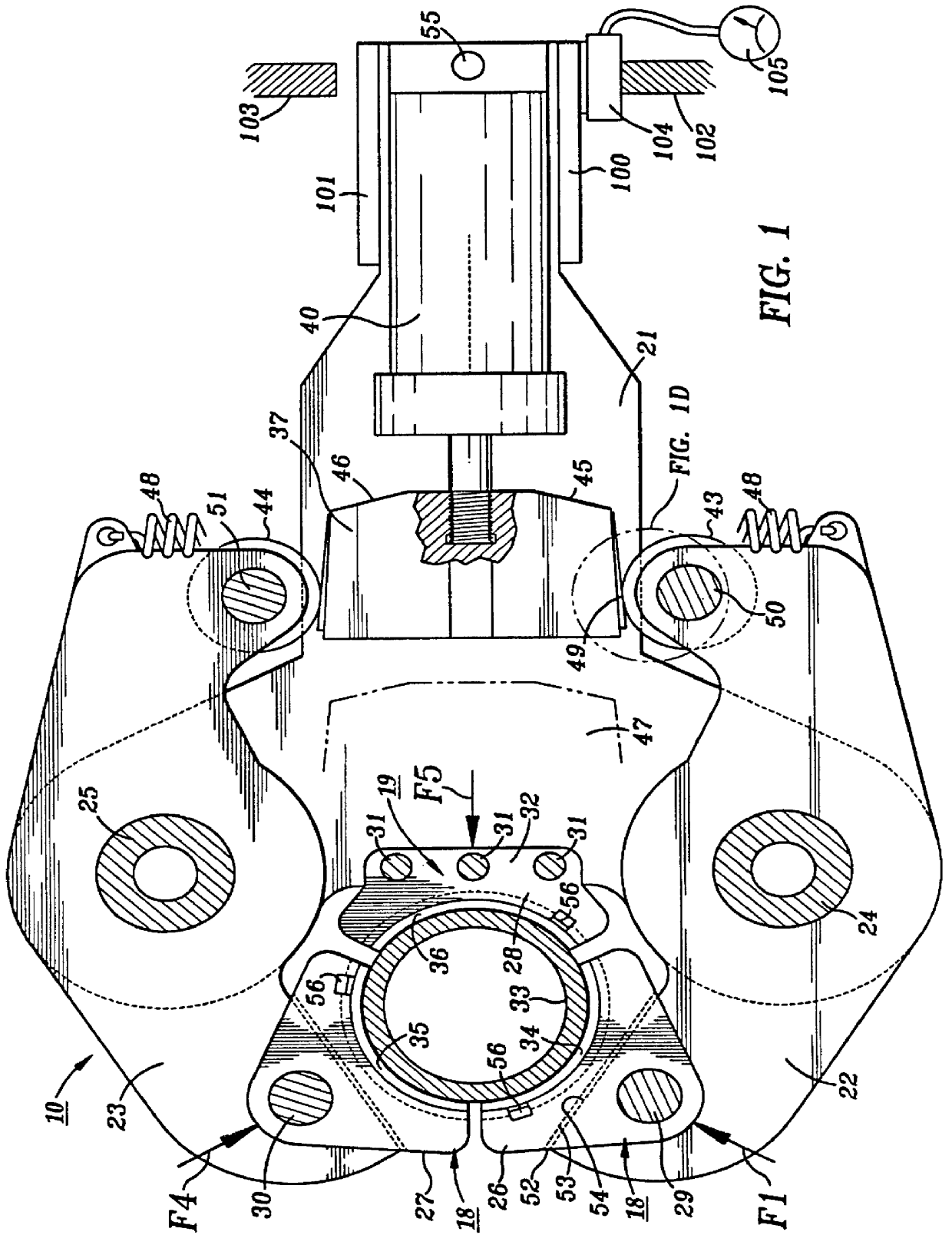

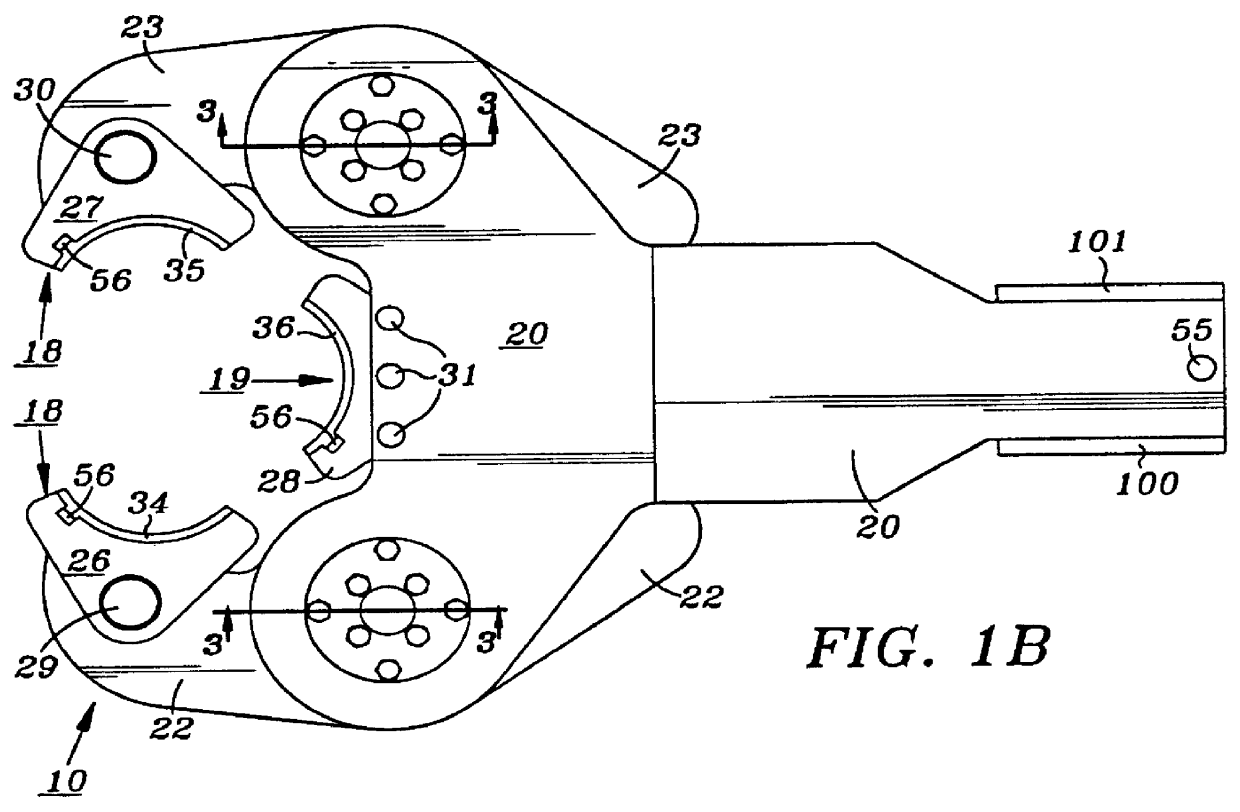

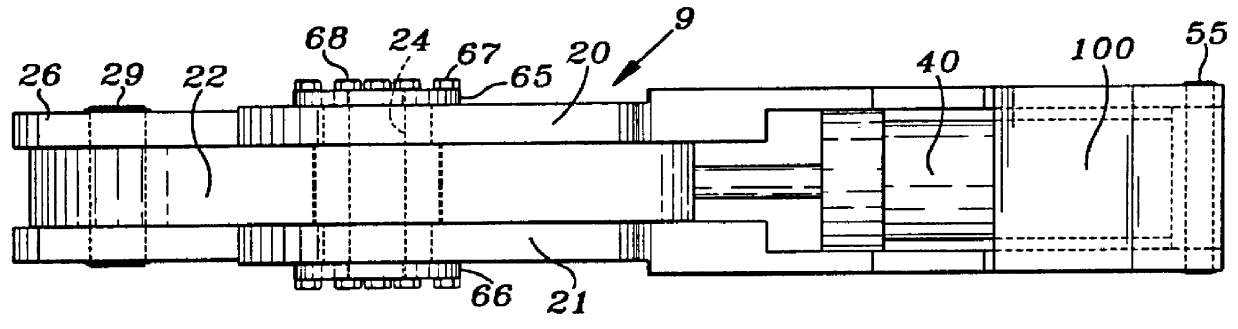

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

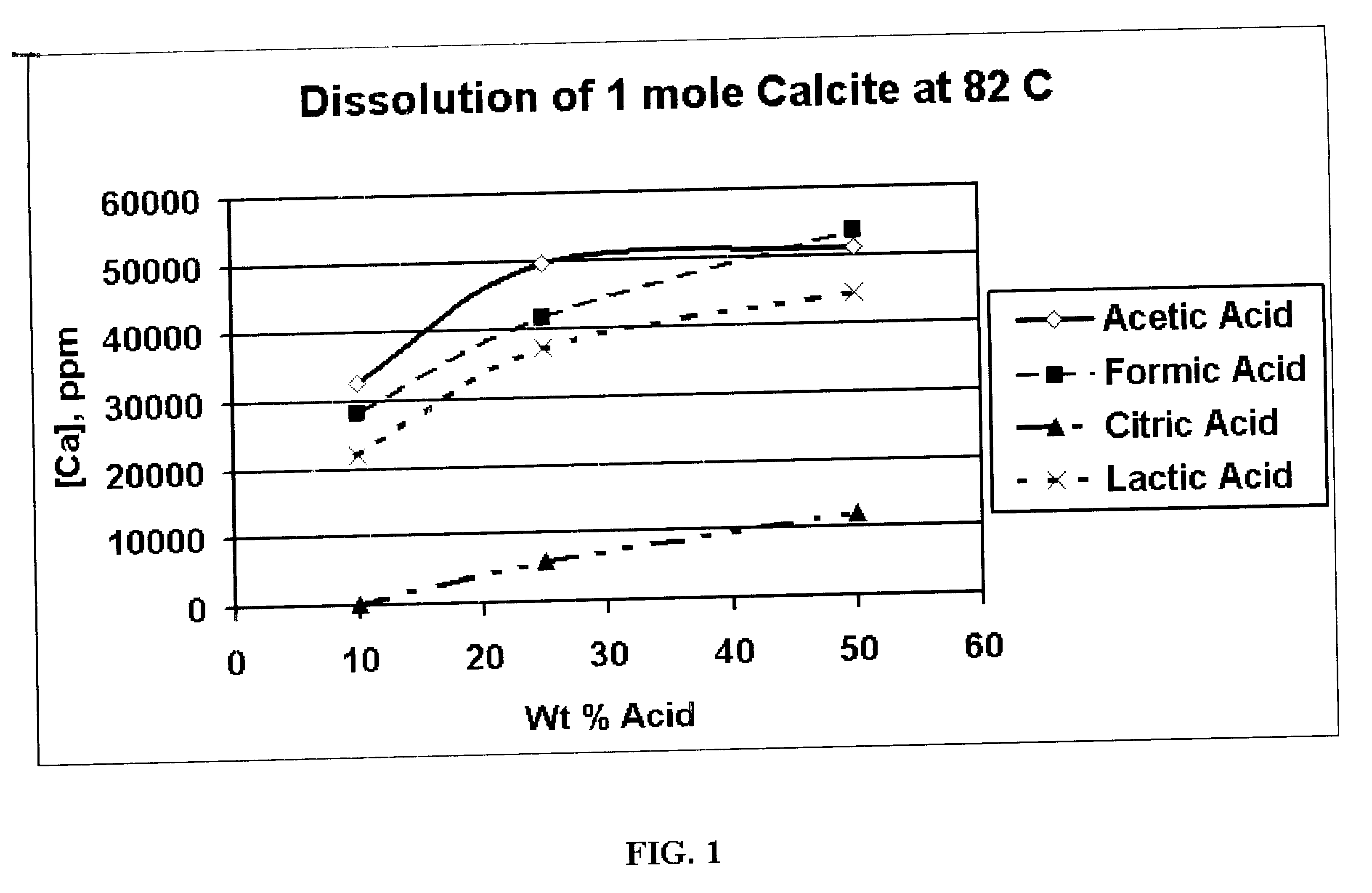

Generating Acid Downhole in Acid Fracturing

An acid fracturing method is provided in which the acid is generated in the fracture by hydrolysis of a solid acid-precursor selected from one or more than one of lactide, glycolide, polylactic acid, polyglycolic acid, a copolymer of polylactic acid and polyglycolic acid, a copolymer of glycolic acid with other hydroxy-, carboxylic acid-, or hydroxycarboxylic acid-containing moieties, and a copolymer of lactic acid with other hydroxy-, carboxylic acid or hydroxycarboxylic acid-containing moieties. The solid acid-precursor may be mixed with a solid acid-reactive material to accelerate the hydrolysis and / or coated to slow the hydrolysis. Water-soluble liquid compounds are also given that accelerate the hydrolysis. The method ensures that the acid contacts fracture faces far from the wellbore.

Owner:SCHLUMBERGER TECH CORP

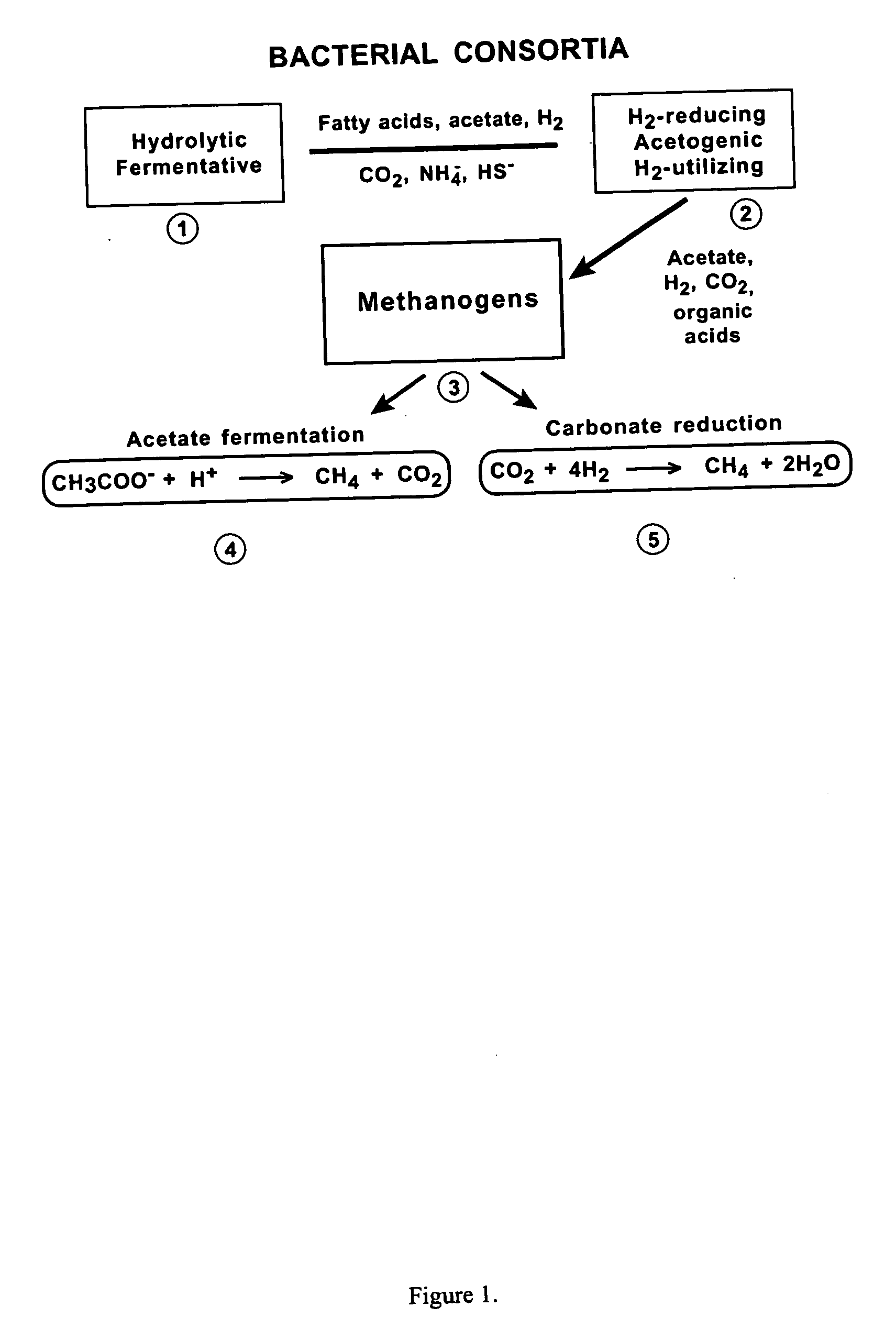

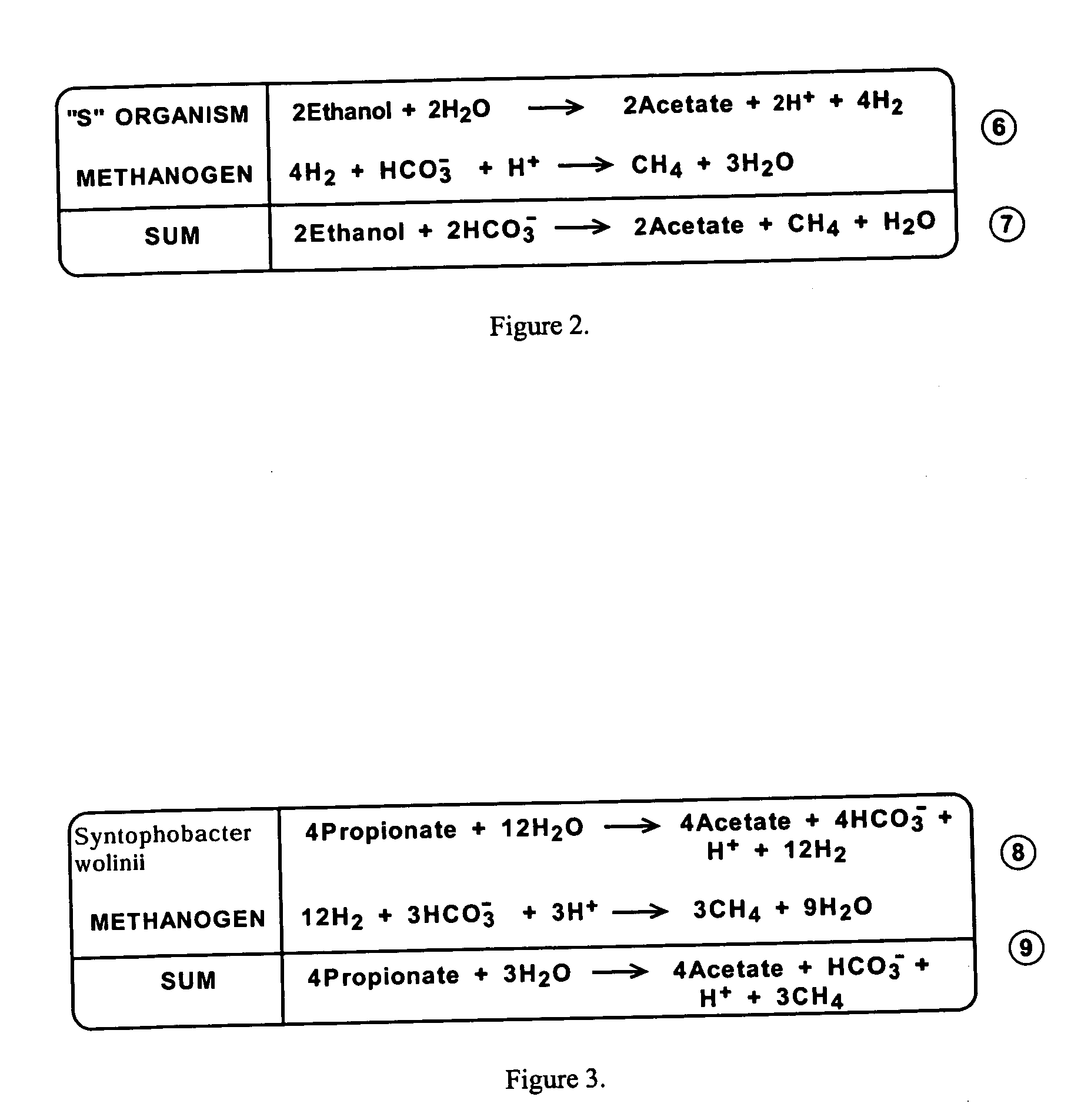

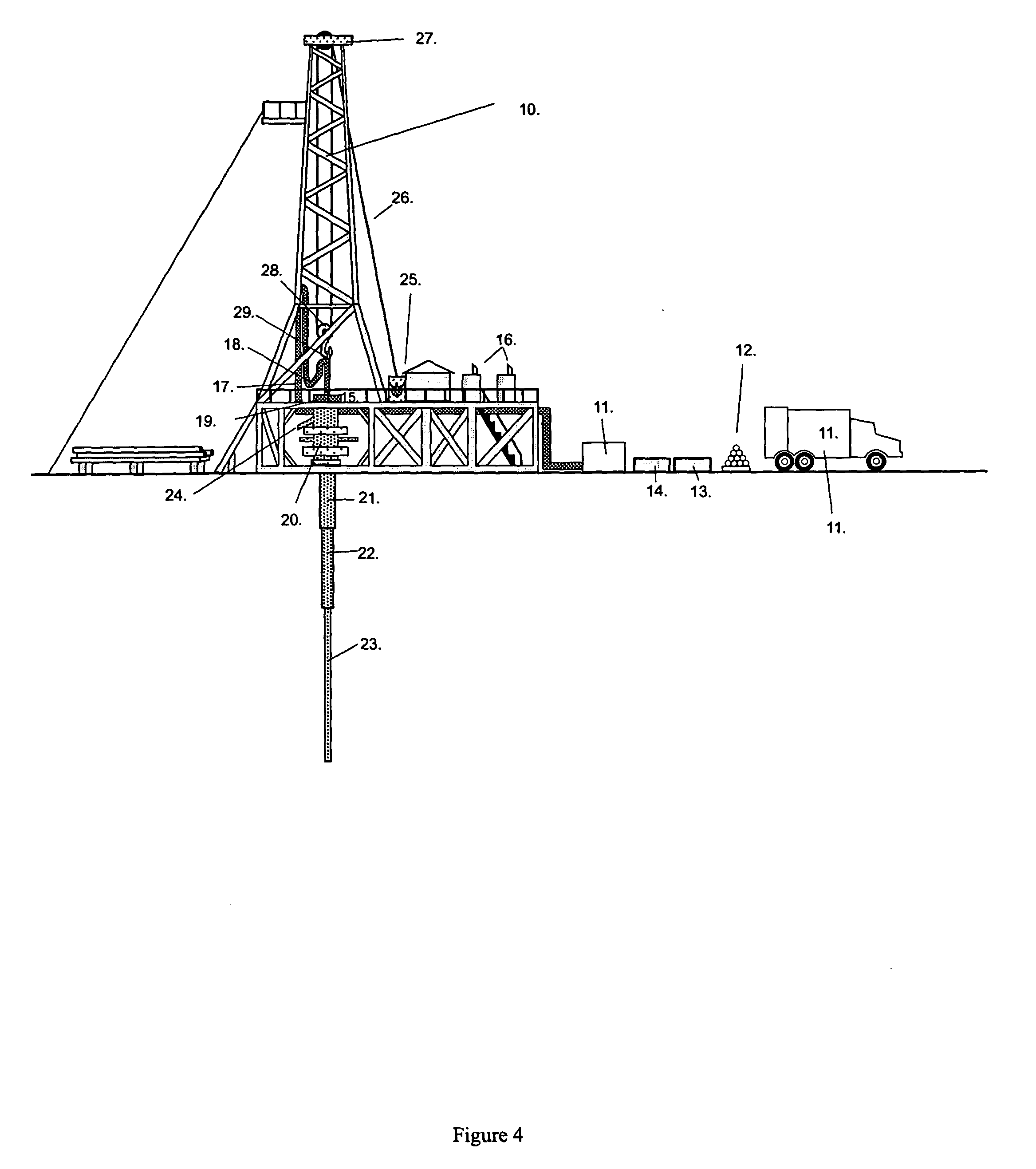

Method of generating and recovering gas from subsurface formations of coal, carbonaceous shale and organic-rich shales

InactiveUS20040033557A1Maximizes bacterial degradationStable and economically favorable and environmentally cleanMicrobiological testing/measurementGas production bioreactorsOrganic compoundCoal

A method of generating and recovering gas from naturally existing subsurface formations Of coal, carbonaceous shale or organic-rich shales comprising the steps Of: injecting into fracture of the subsurface formation, under substantially anaerobic conditions, a consortia of selected anaerobic, biological microorganisms for in situ conversion of organic compounds in said formation into methane and other compounds; and producing methane through at least one well extending from said subsurface formation to the surfaces.

Owner:SCOTT ANDREW R +1

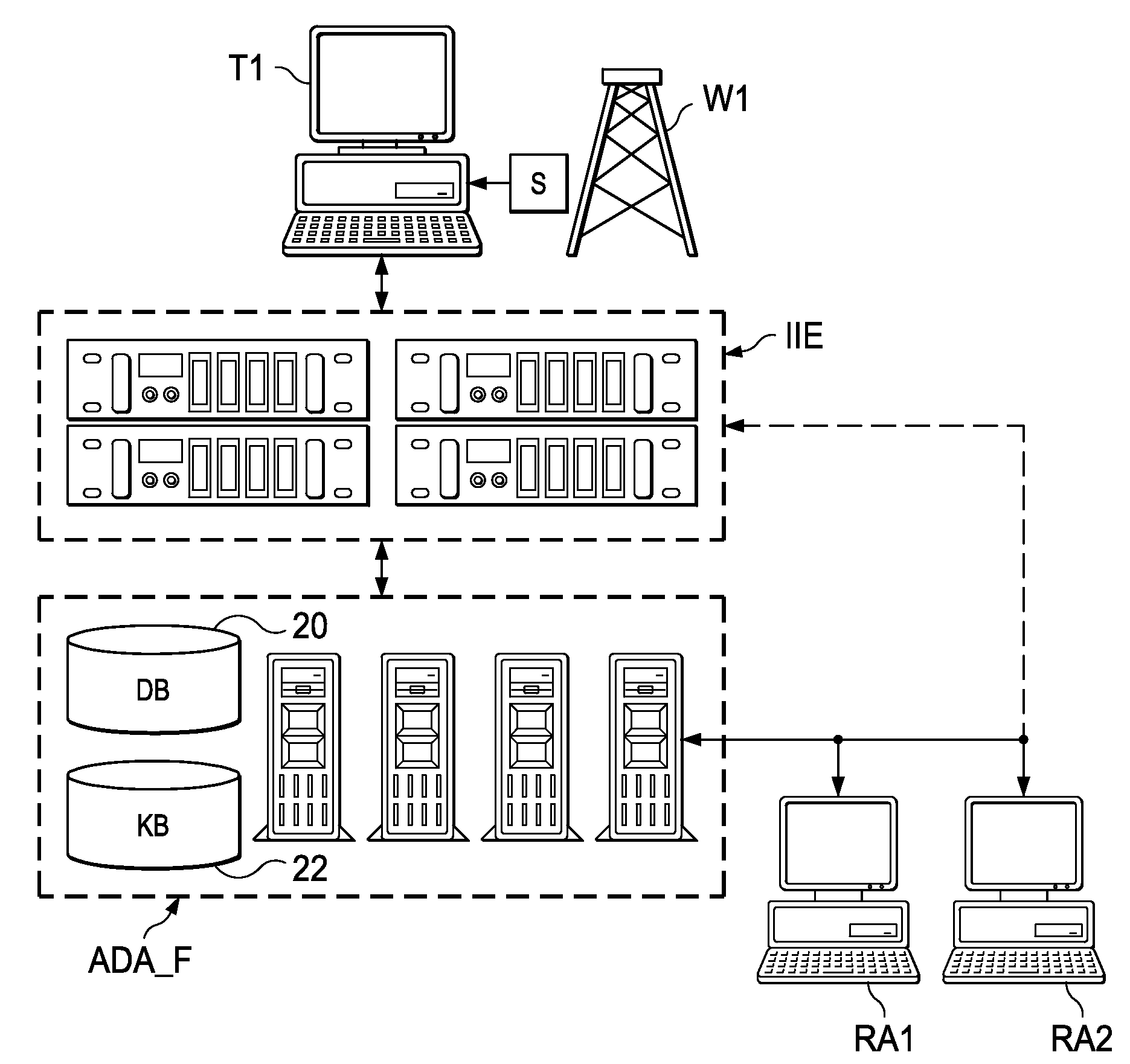

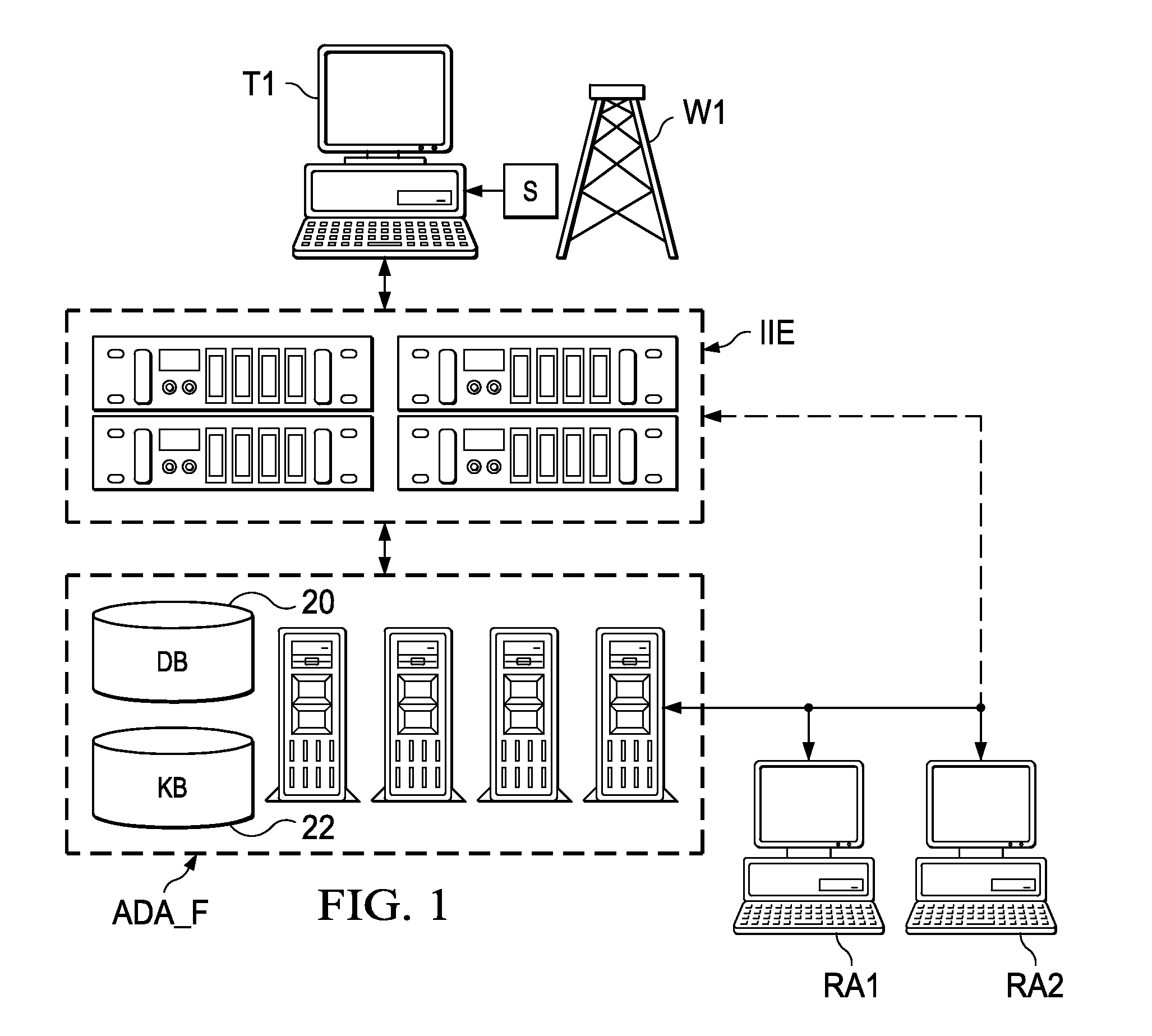

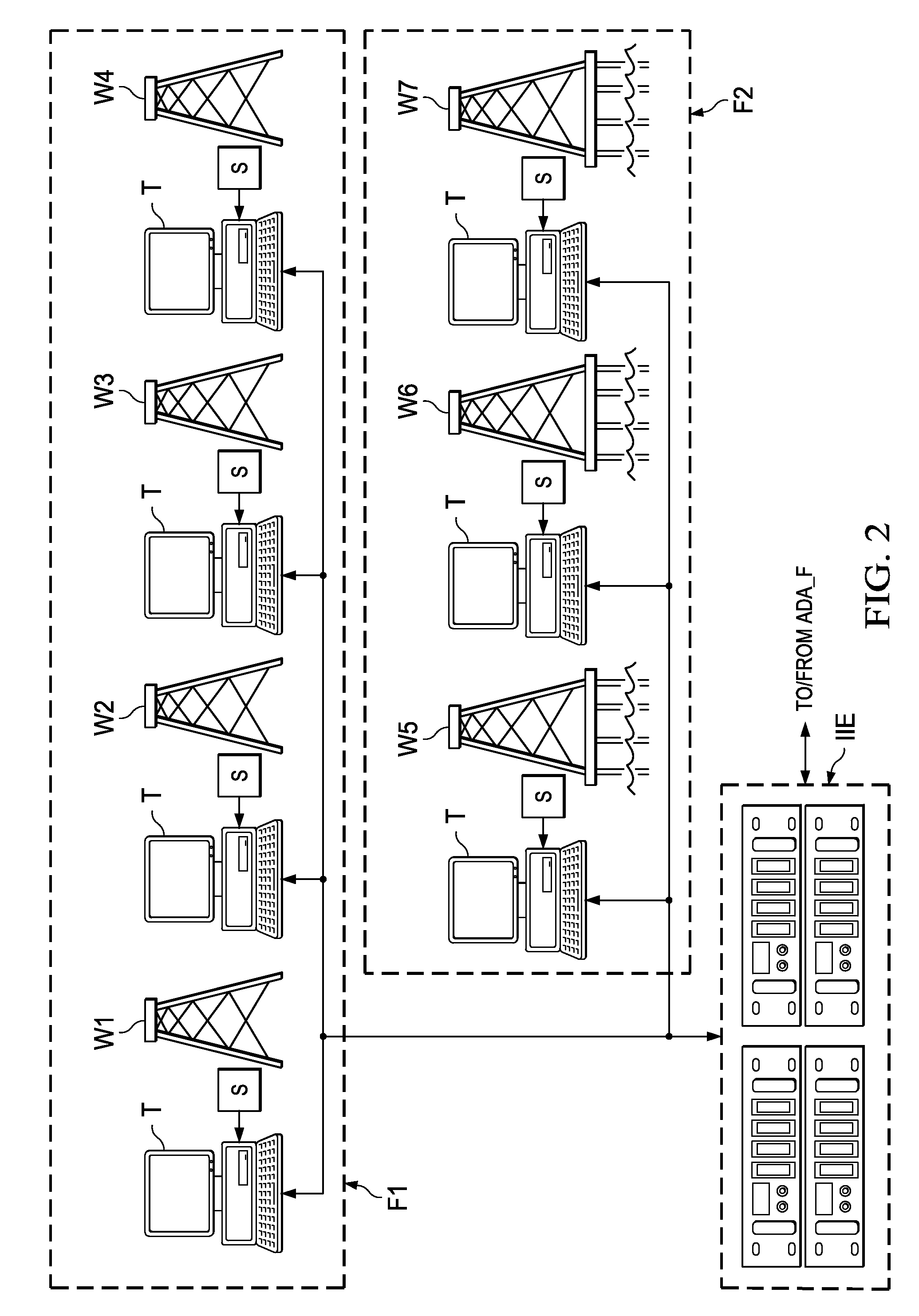

Intelligent Drilling Advisor

ActiveUS20090132458A1Loss of circulationEasy to operateElectric/magnetic detection for well-loggingKnowledge representationComputer sciencePerformance rate

A method, apparatus, and program storage device for integrating and implementing rule-based, heuristic, wellbore key performance rate of penetration indicators advising drilling operations personnel based on the situational awareness of trended earth properties and real time wellbore sensor data, is disclosed.

Owner:BP CORP NORTH AMERICA INC

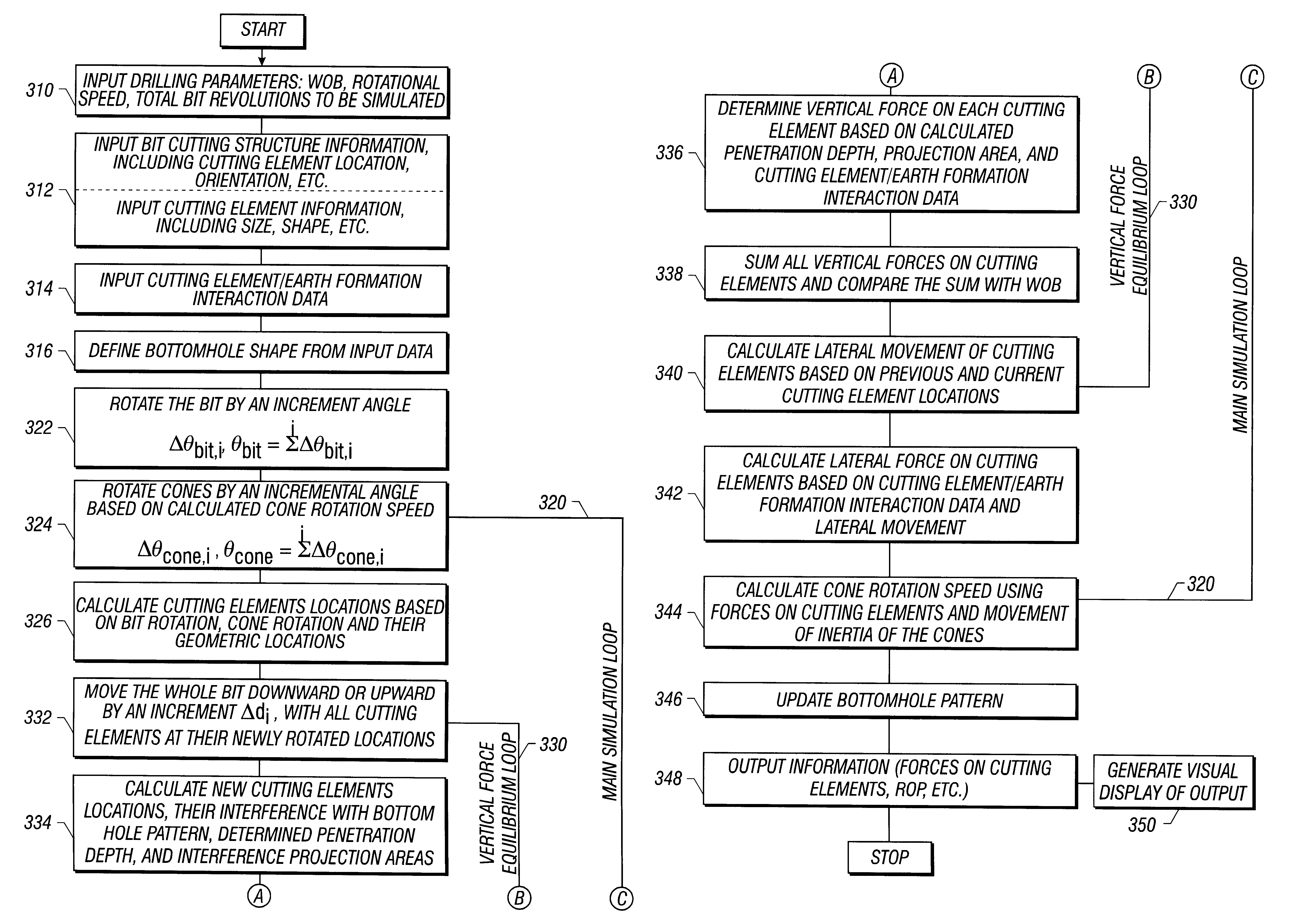

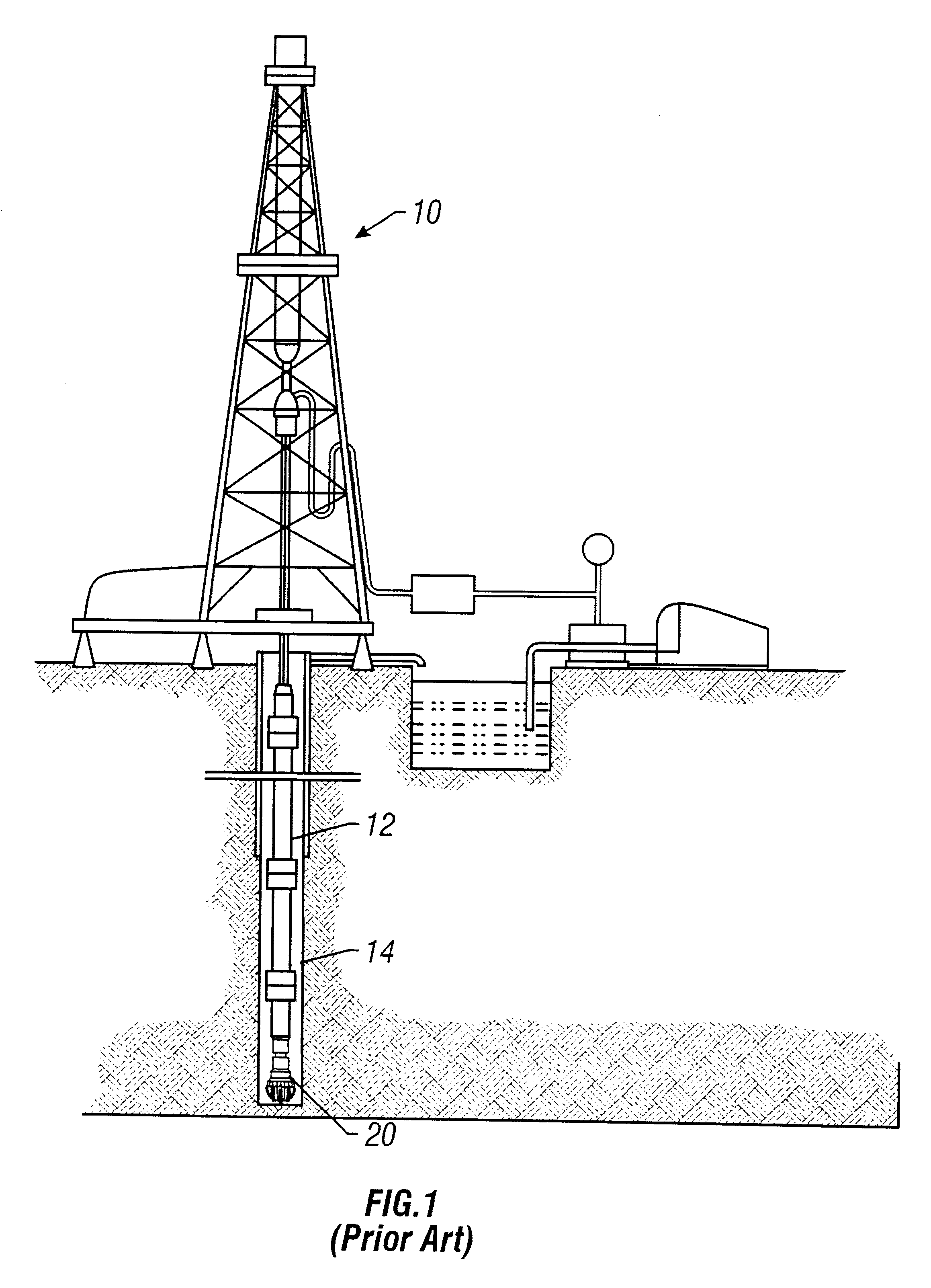

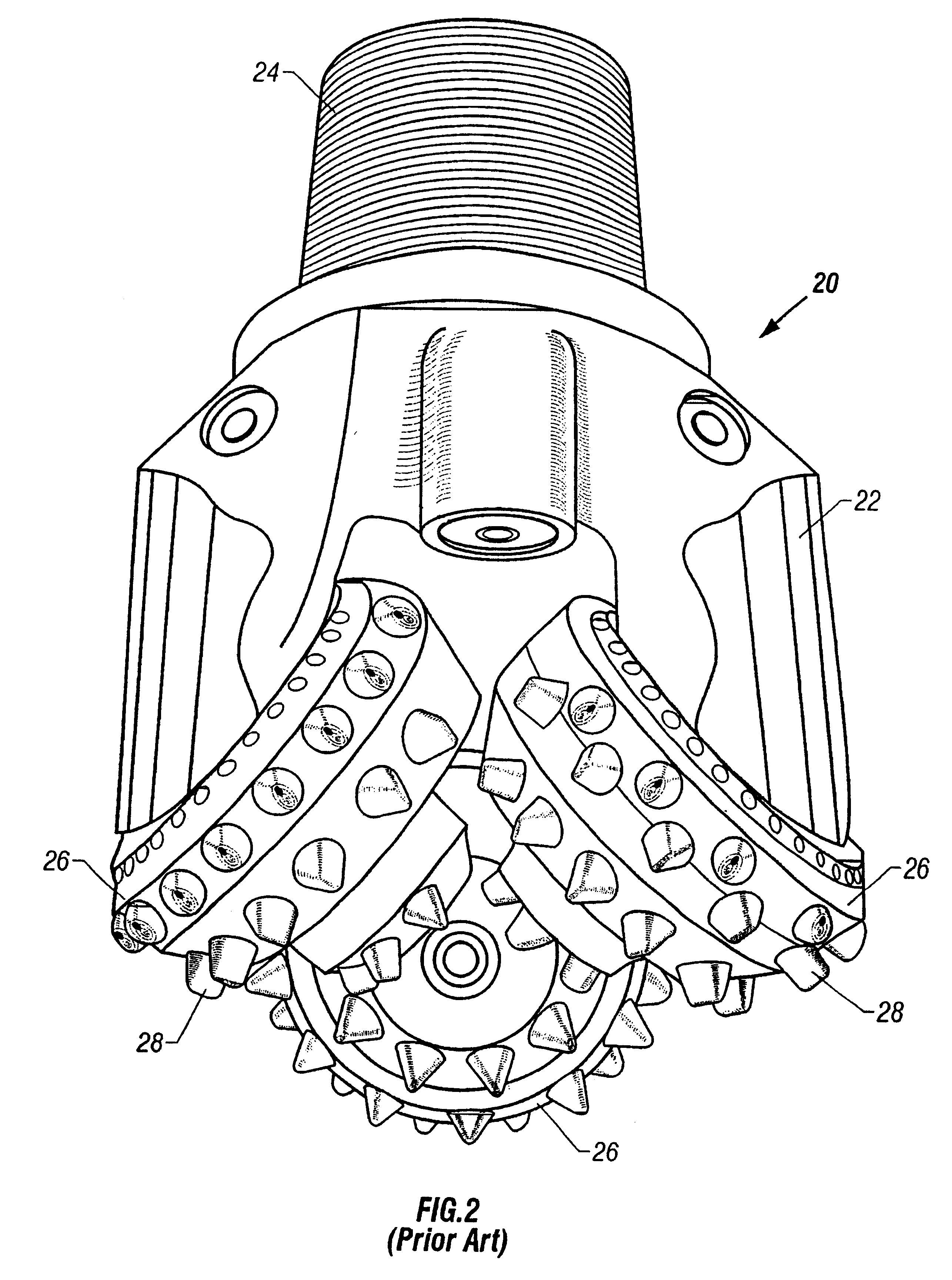

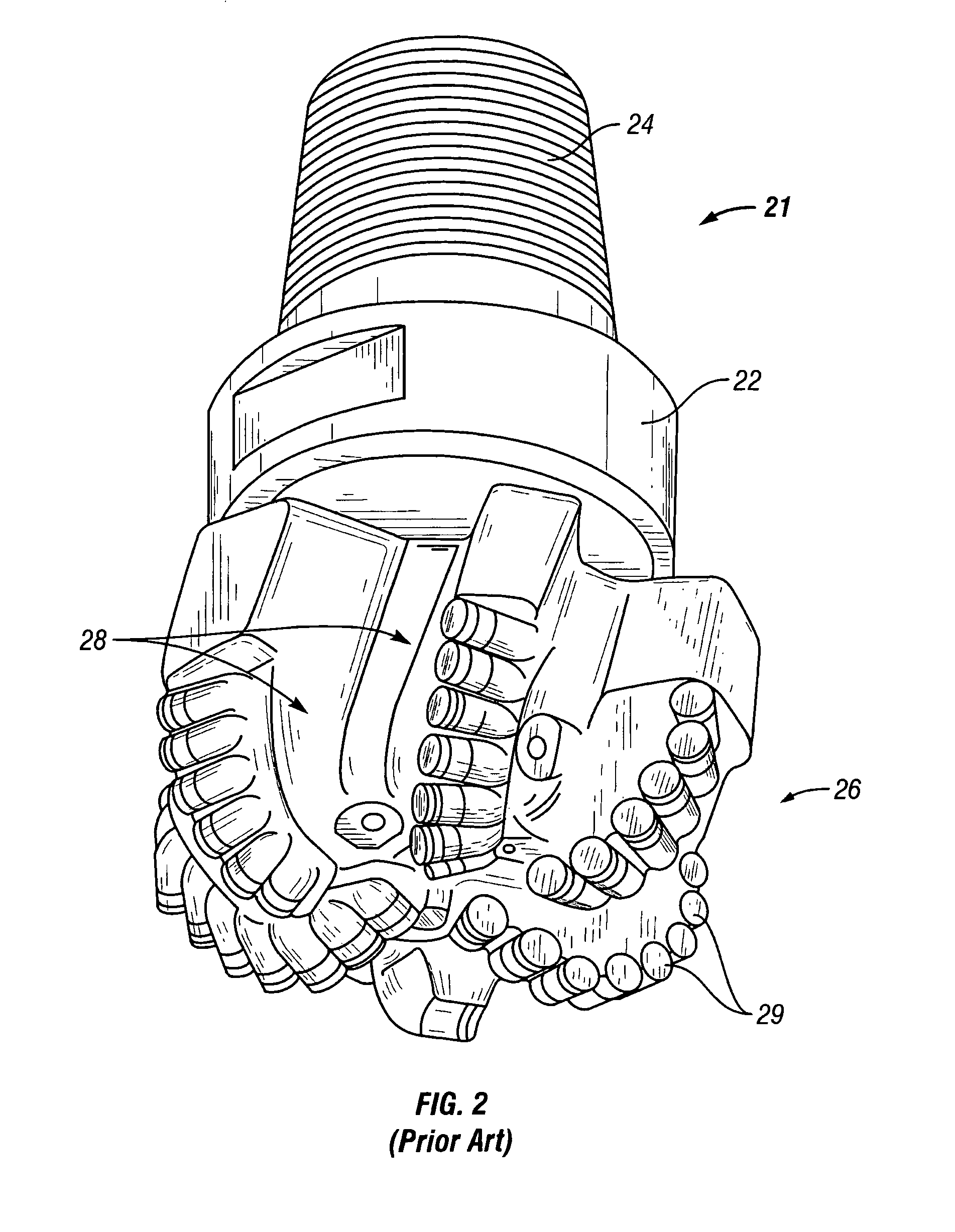

Method for simulating drilling of roller cone bits and its application to roller cone bit design and performance

InactiveUS6516293B1Electric/magnetic detection for well-loggingDrill bitsEngineeringVisual perception

A method for simulating the drilling performance of a roller cone bit drilling an earth formation may be used to generate a visual representation of drilling, to design roller cone drill bits, and to optimize the drilling performance of a roller cone bit. The method for generating a visual representation of a roller cone bit drilling earth formations includes selecting bit design parameters, selecting drilling parameters, and selecting an earth formation to be drilled. The method further includes calculating, from the bit design parameters, drilling parameters and earth formation, parameters of a crater formed when one of a plurality of cutting elements contacts the earth formation. The method further includes calculating a bottomhole geometry, wherein the crater is removed from a bottomhole surface. The method also includes incrementally rotating the bit and repeating the calculating of crater parameters and bottomhole geometry based on calculated roller cone rotation speed and geometrical location with respect to rotation of said roller cone drill bit about its axis. The method also includes converting the crater and bottomhole geometry parameters into a visual representation.

Owner:SMITH INT INC

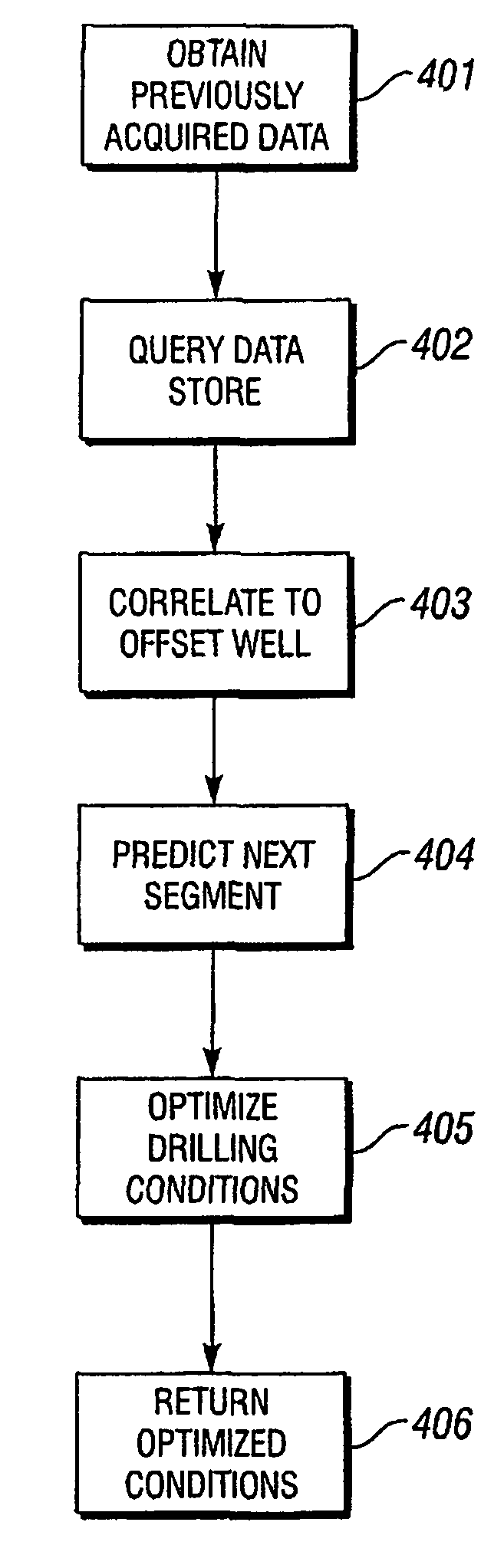

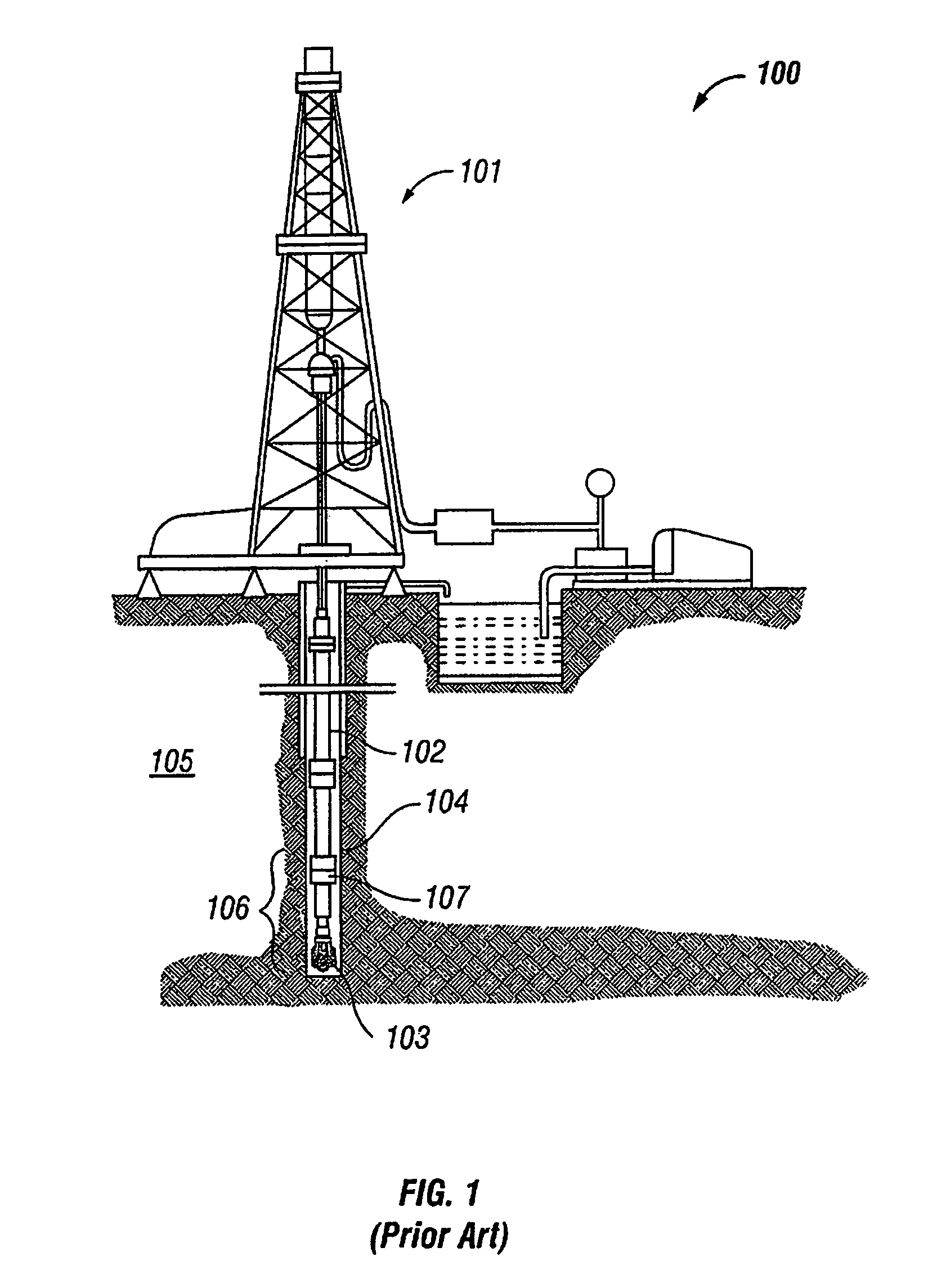

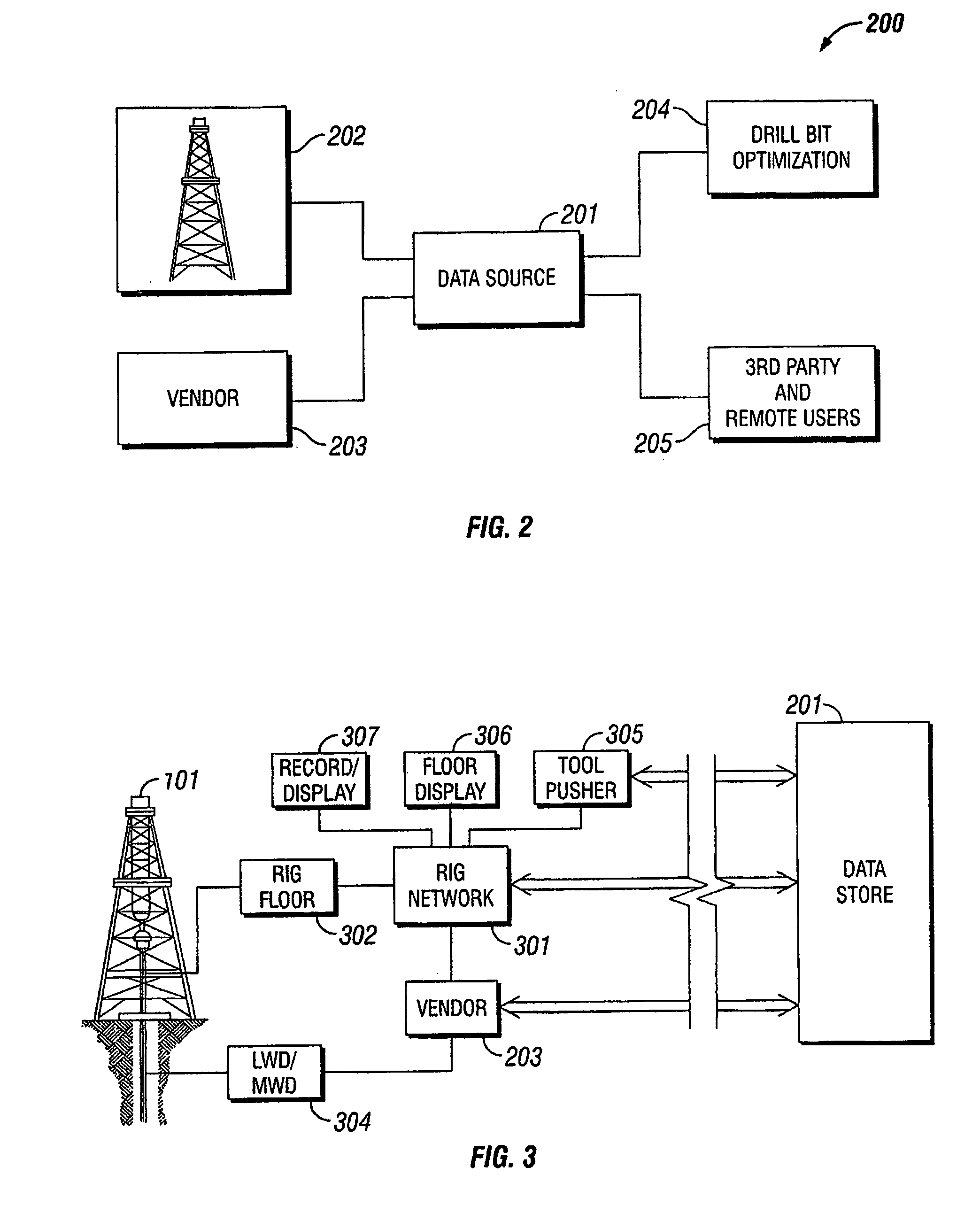

System for optimizing drilling in real time

A method for optimizing drilling parameters includes obtaining previously acquired data, querying a remote data store for current well data, determining optimized drilling parameters, and returning optimized parameters for a next segment to the remote data store. Determining optimized drilling parameters may include correlating the current well data to the previously acquired data, predicting drilling conditions for the next segment, and optimizing drilling parameters for the next segment.

Owner:SMITH INT INC

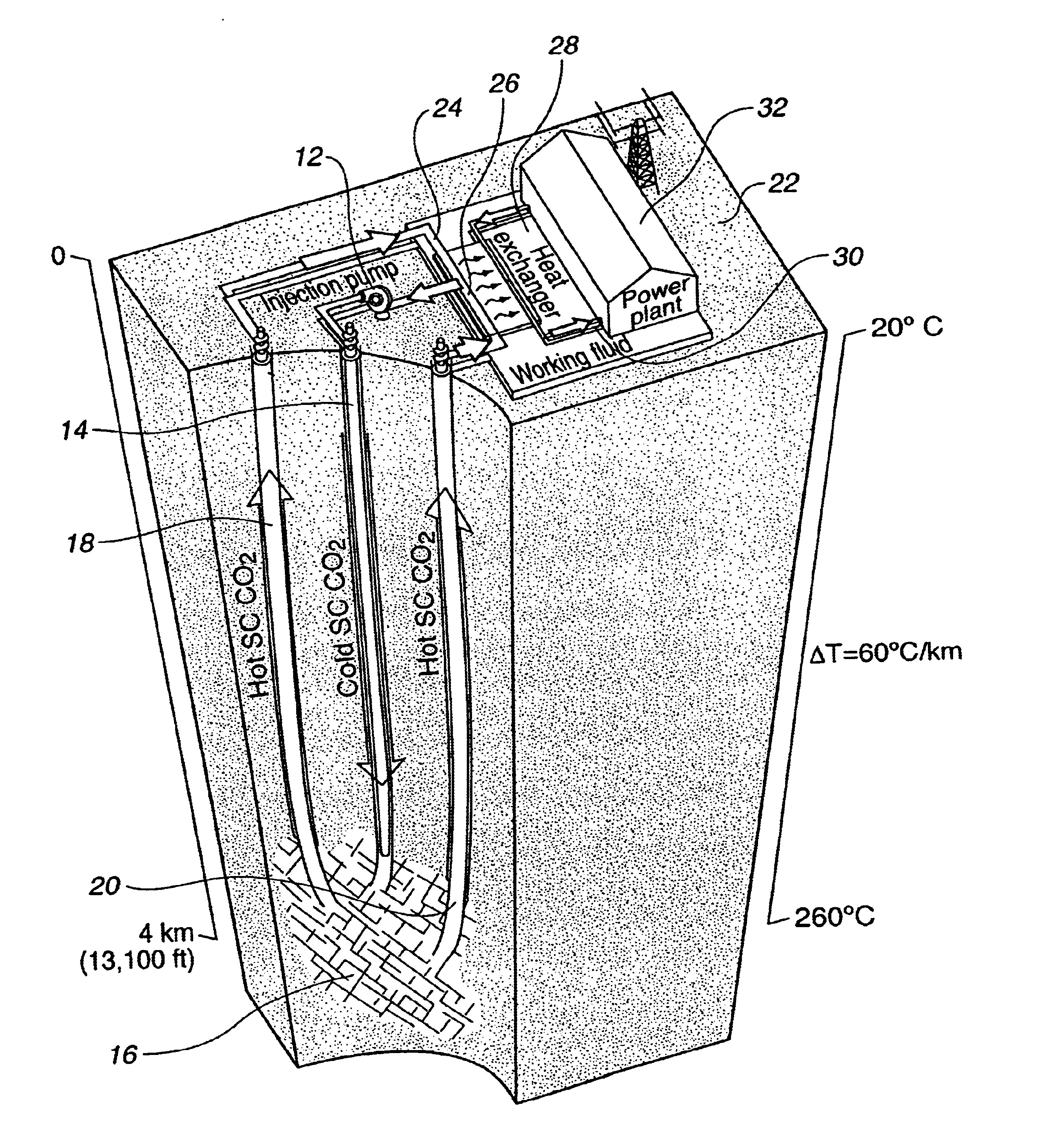

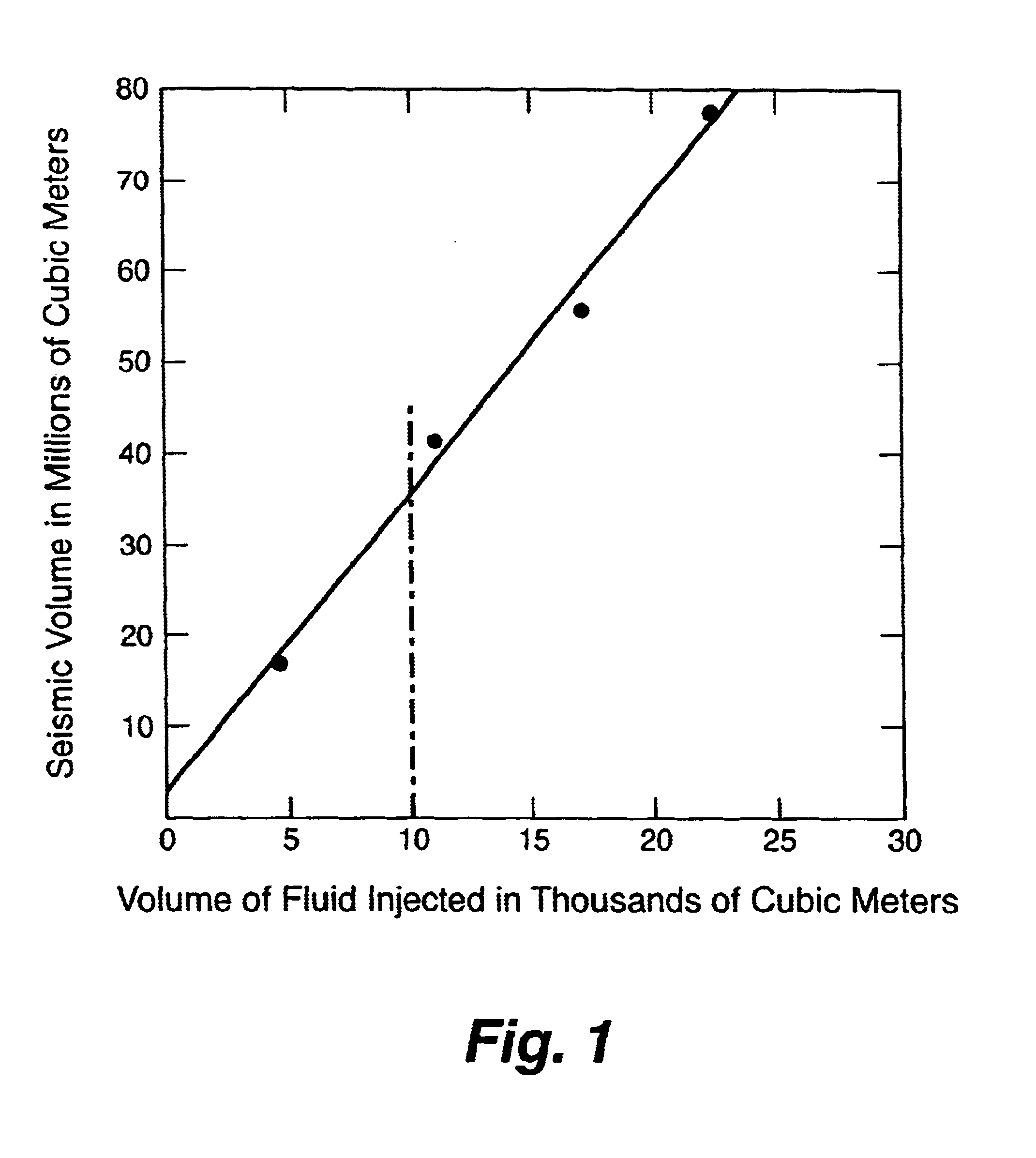

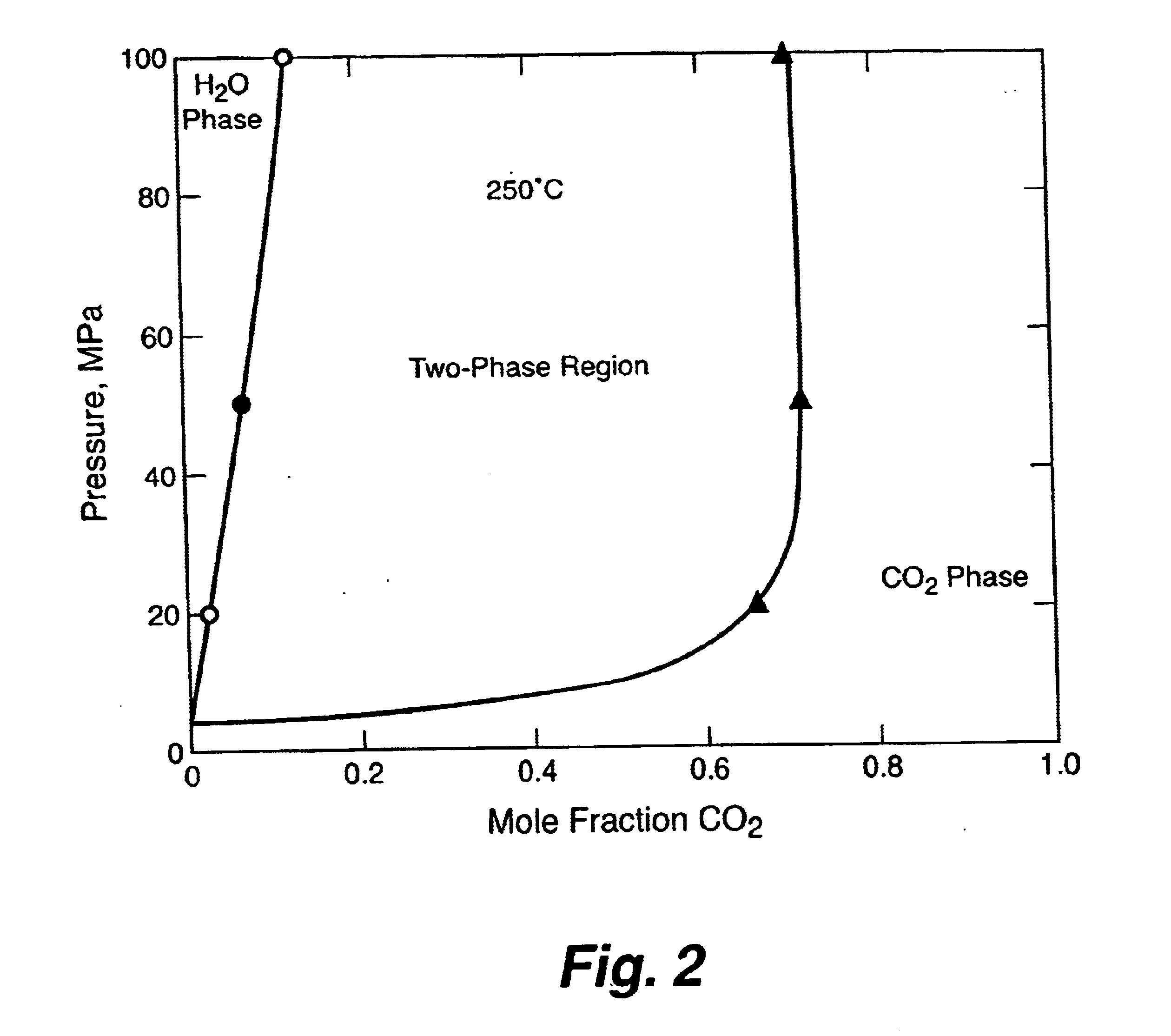

Geothermal energy production with supercritical fluids

InactiveUS6668554B1Other heat production devicesGeothermal energy generationProcess engineeringCarbon dioxide

There has been invented a method for producing geothermal energy using supercritical fluids for creation of the underground reservoir, production of the geothermal energy, and for heat transport. Underground reservoirs are created by pumping a supercritical fluid such as carbon dioxide into a formation to fracture the rock. Once the reservoir is formed, the same supercritical fluid is allowed to heat up and expand, then is pumped out of the reservoir to transfer the heat to a surface power generating plant or other application.

Owner:RGT UNIV OF CALIFORNIA LOS ALAMOS NAT LAB +1

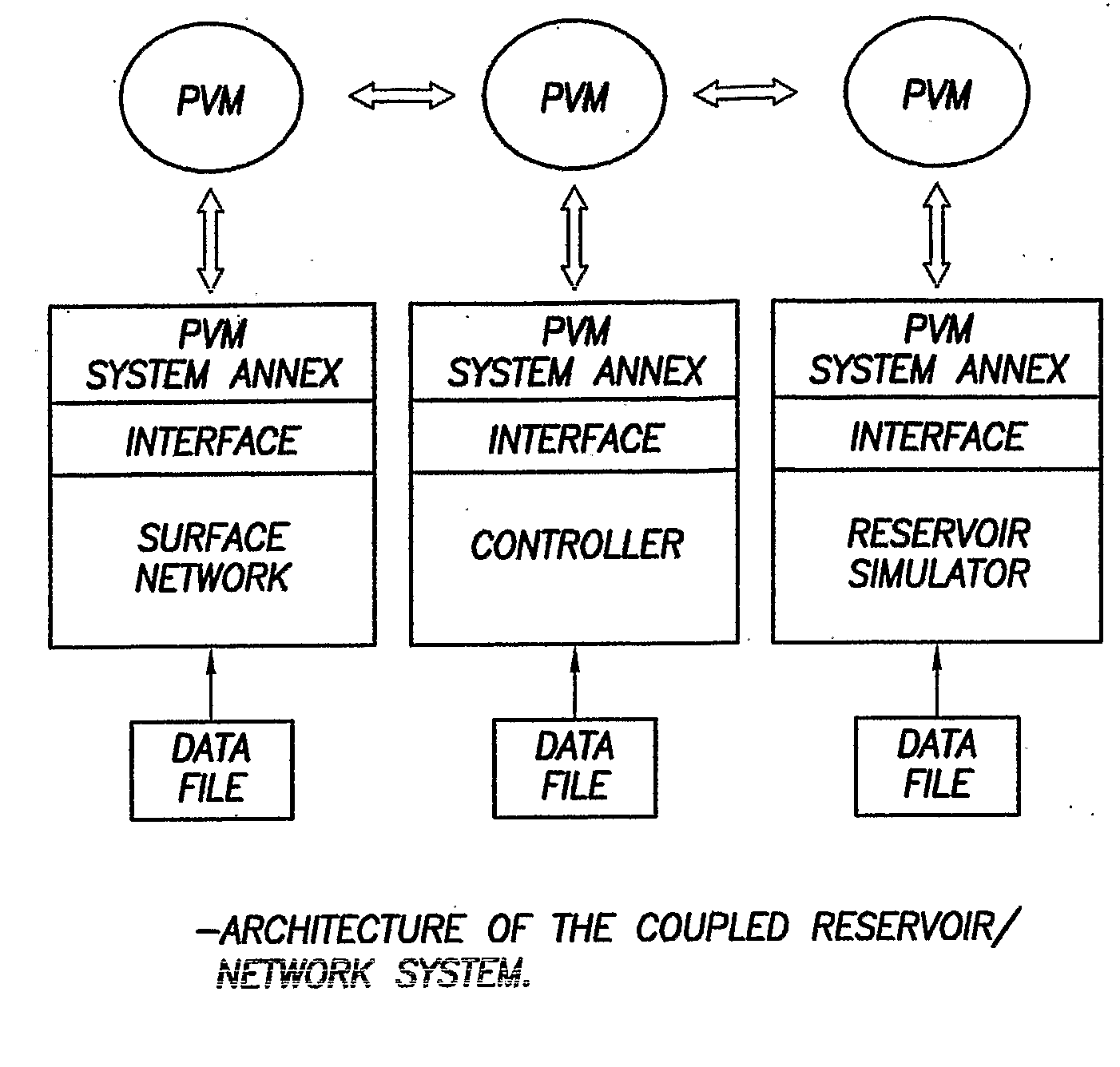

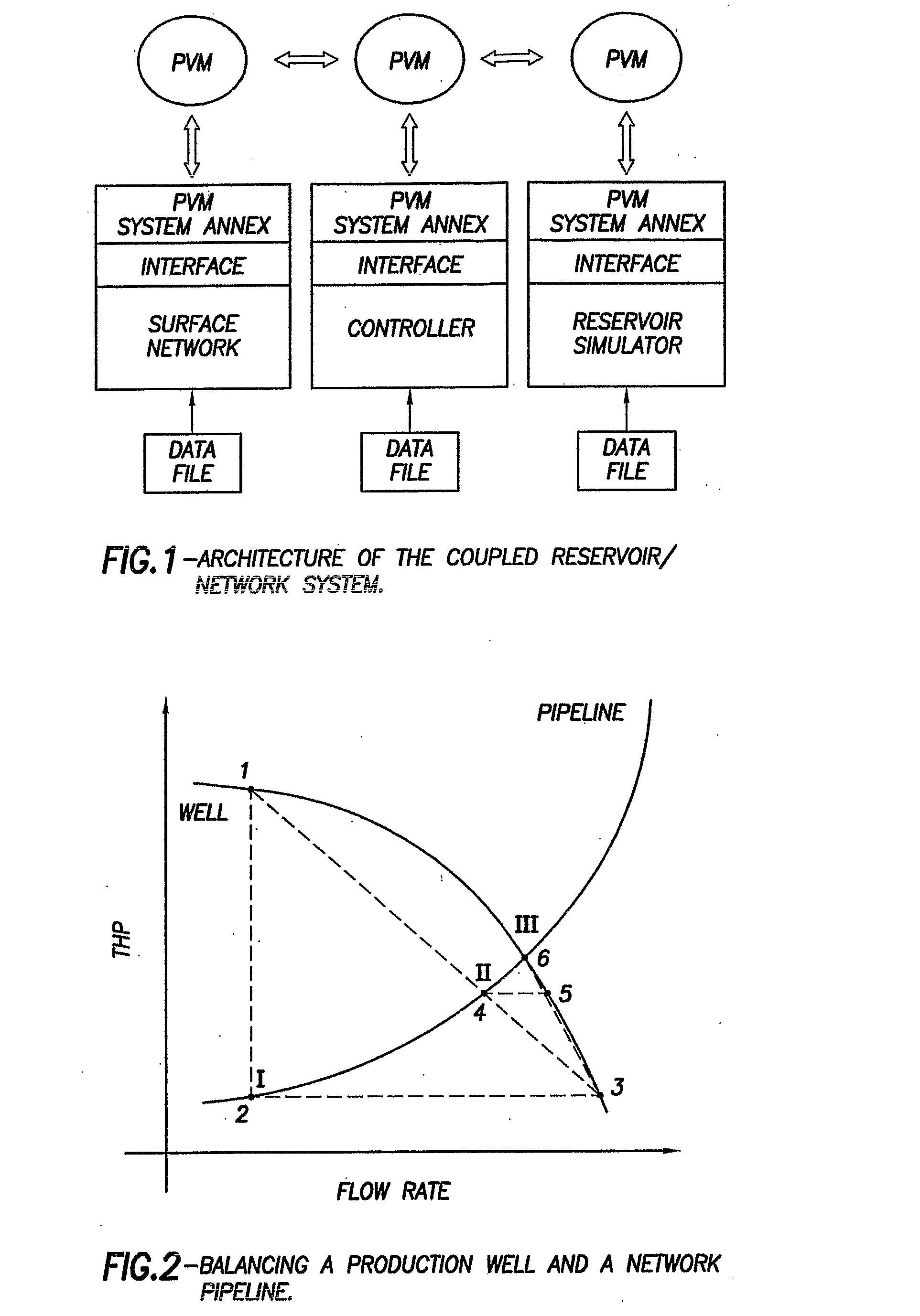

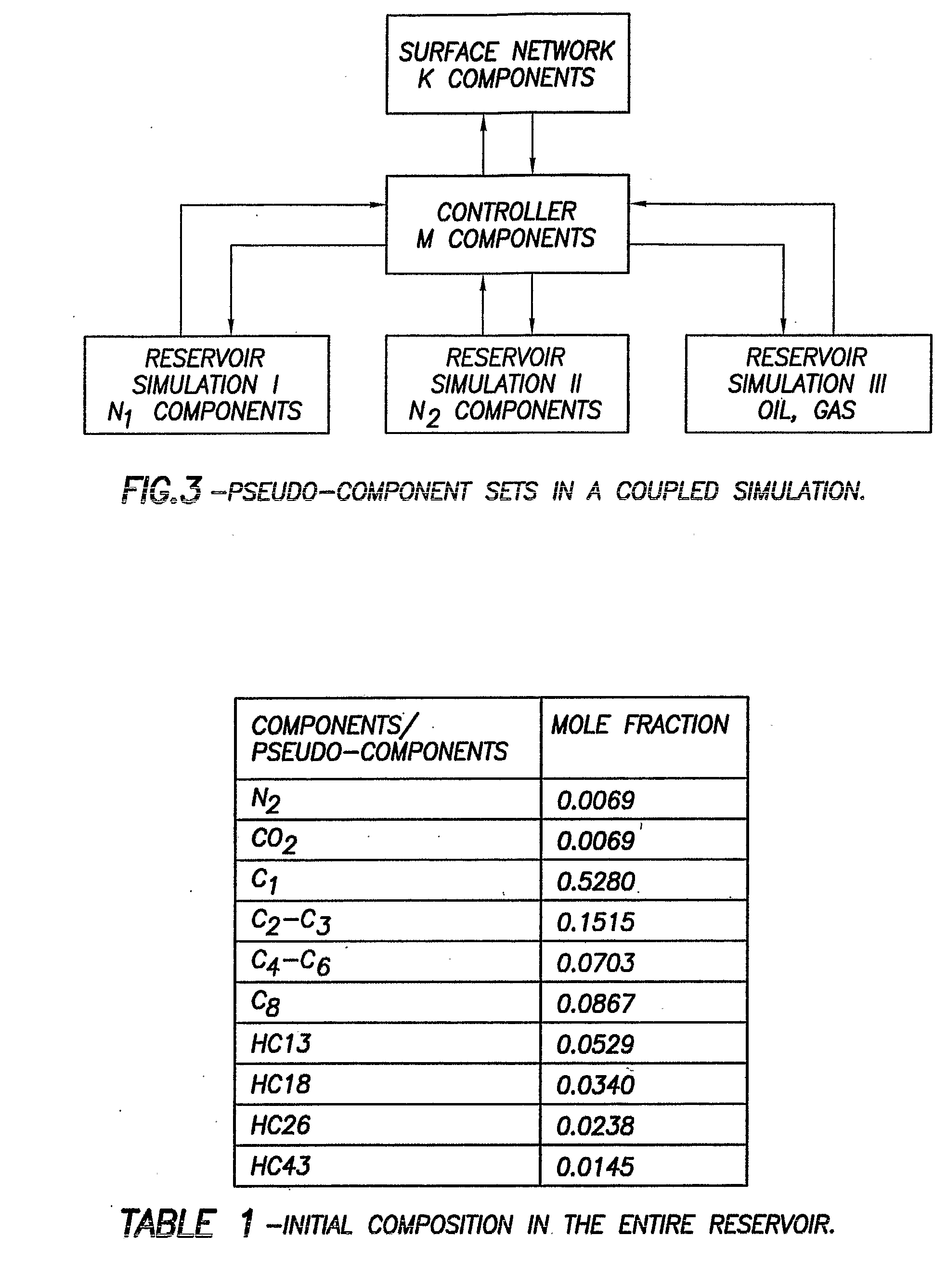

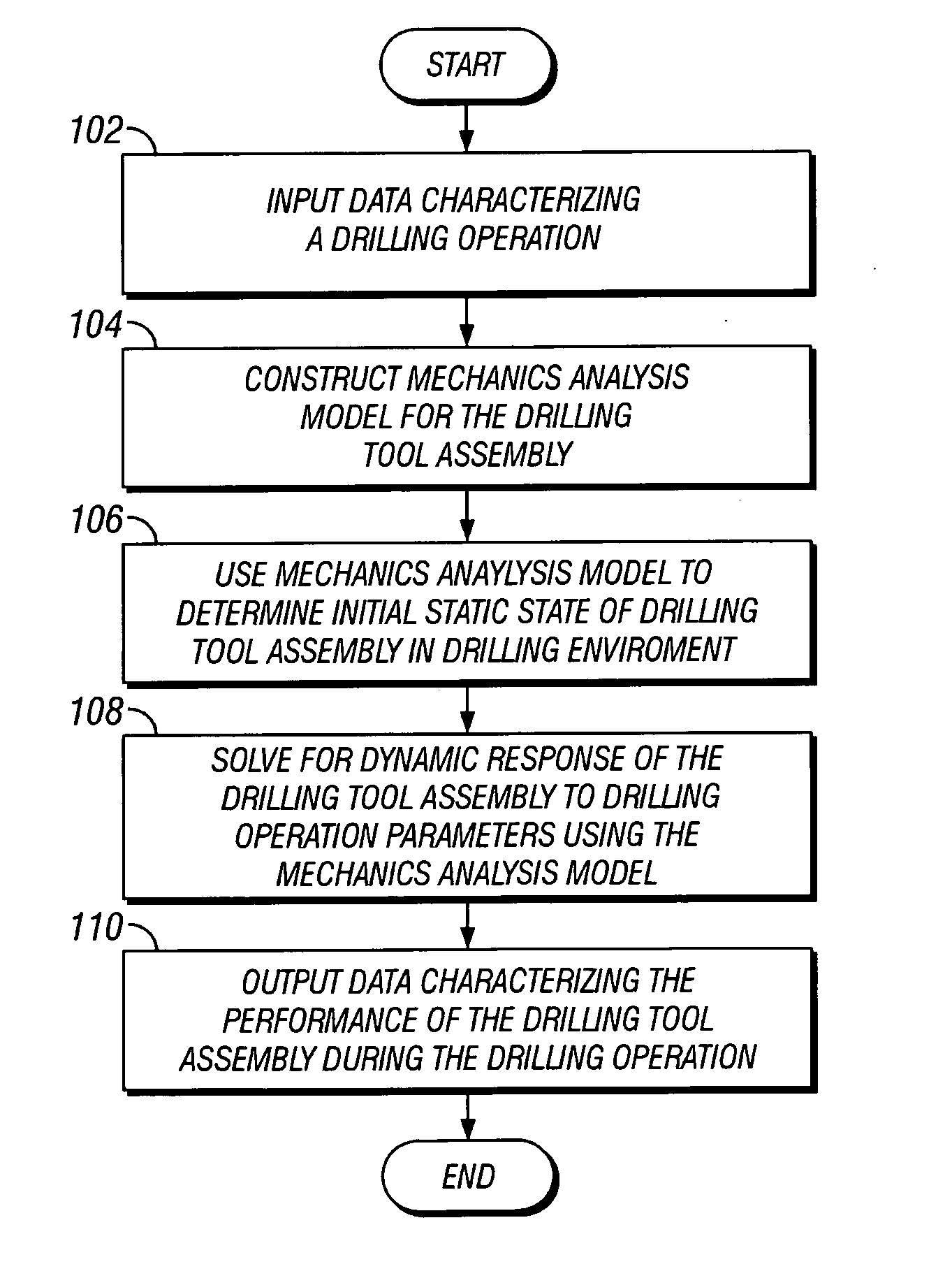

Method and system for integrated reservoir and surface facility networks simulations

InactiveUS20070112547A1Design optimisation/simulationConstraint-based CADMulti platformNetwork model

Integrated surface-subsurface modeling has been shown to have a critical impact on field development and optimization. Integrated models are often necessary to analyze properly the pressure interaction between a reservoir and a constrained surface facility network, or to predict the behavior of several fields, which may have different fluid compositions, sharing a common surface facility. The latter is gaining a tremendous significance in recent deepwater field development. These applications require an integrated solution with the following capabilities: * to balance a surface network model with a reservoir simulation model in a robust and efficient manner. * To couple multiple reservoir models, production and injection networks, synchronising their advancement through time. * To allow the reservoir and surface network models to use their own independent fluid descriptions (black oil or compositional descriptions with differing sets of pseudo-components). * To apply global production and injection constraints to the coupled system (including the transfer of re-injection fluids between reservoirs). In this paper we describe a general-purpose multi-platform reservoir and network coupling controller having all the above features. The controller communicates with a selection of reservoir simulators and surface network simulators via an open message-passing interface. It manages the balancing of the reservoirs and surface networks, and synchronizes their advancement through time. The controller also applies the global production and injection constraints, and converts the hydrocarbon fluid streams between the different sets of pseudo-components used in the simulation models. The controller's coupling and synchronization algorithms are described, and example applications are provided. The flexibility of the controller's open interface makes it possible to plug in further modules (to perform optimization, for example) and additional simulators.

Owner:SCHLUMBERGER TECH CORP

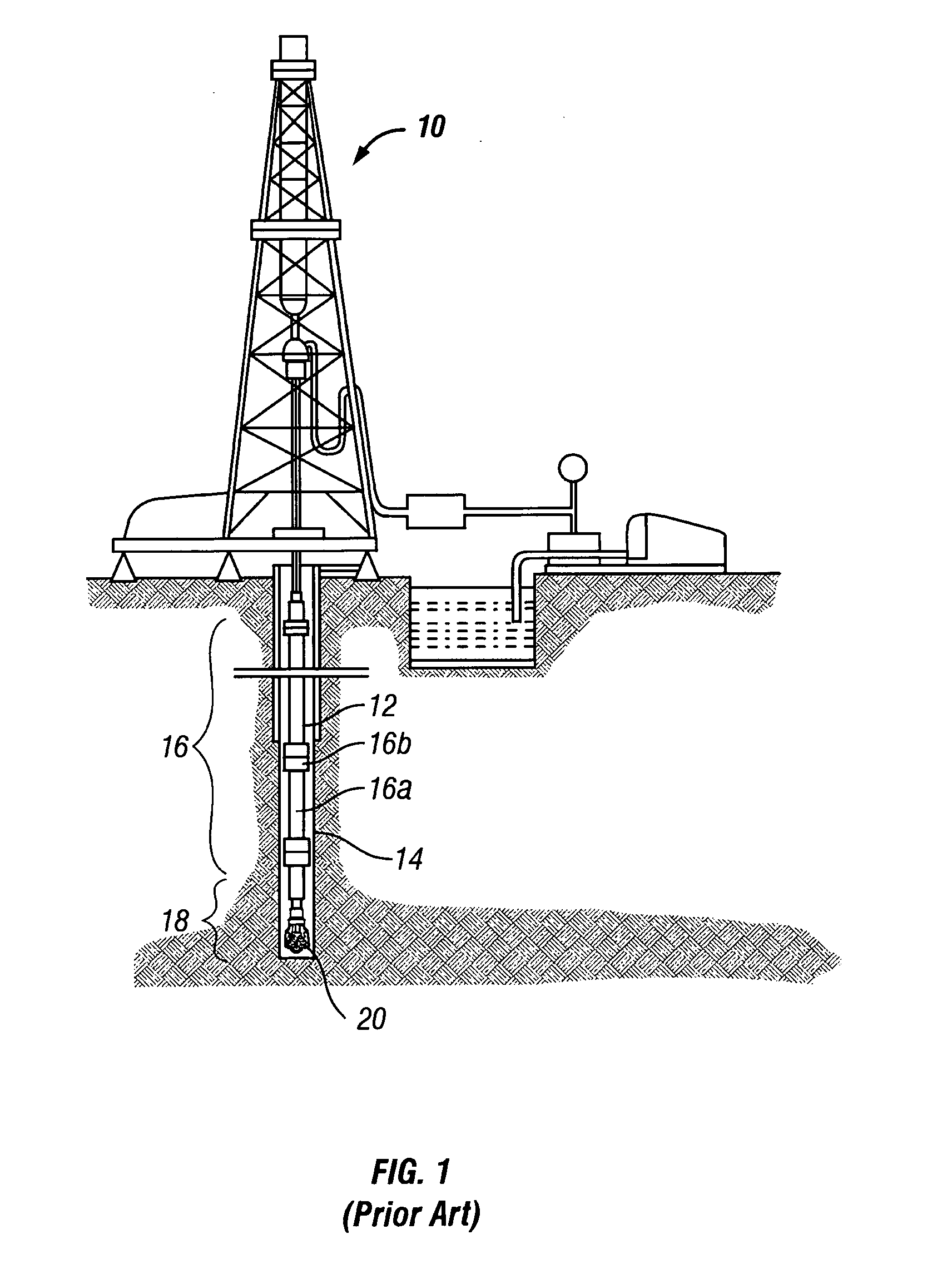

Methods for modeling, designing, and optimizing the performance of drilling tool assemblies

ActiveUS20050096847A1Electric/magnetic detection for well-loggingDrill bitsPetroleum engineeringDrill bit

A method for designing a drilling tool assembly, having a drill bit disposed at one end includes defining initial drilling tool assembly design parameters; calculating a dynamic response of the drilling tool assembly; adjusting a value of a drilling tool assembly design parameter; and repeating the calculating and the adjusting until a drilling tool assembly performance parameter is optimized.

Owner:SMITH INT INC

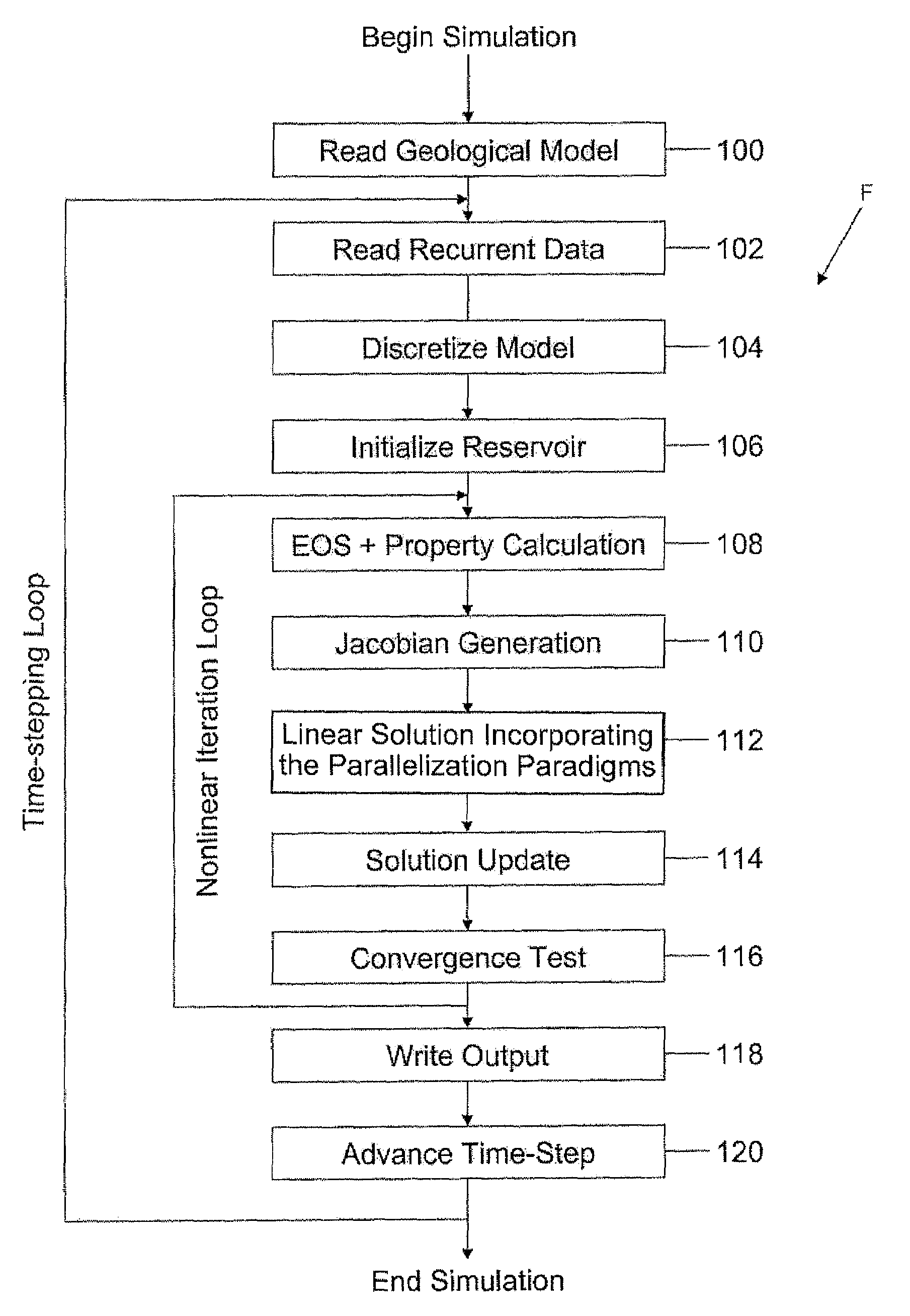

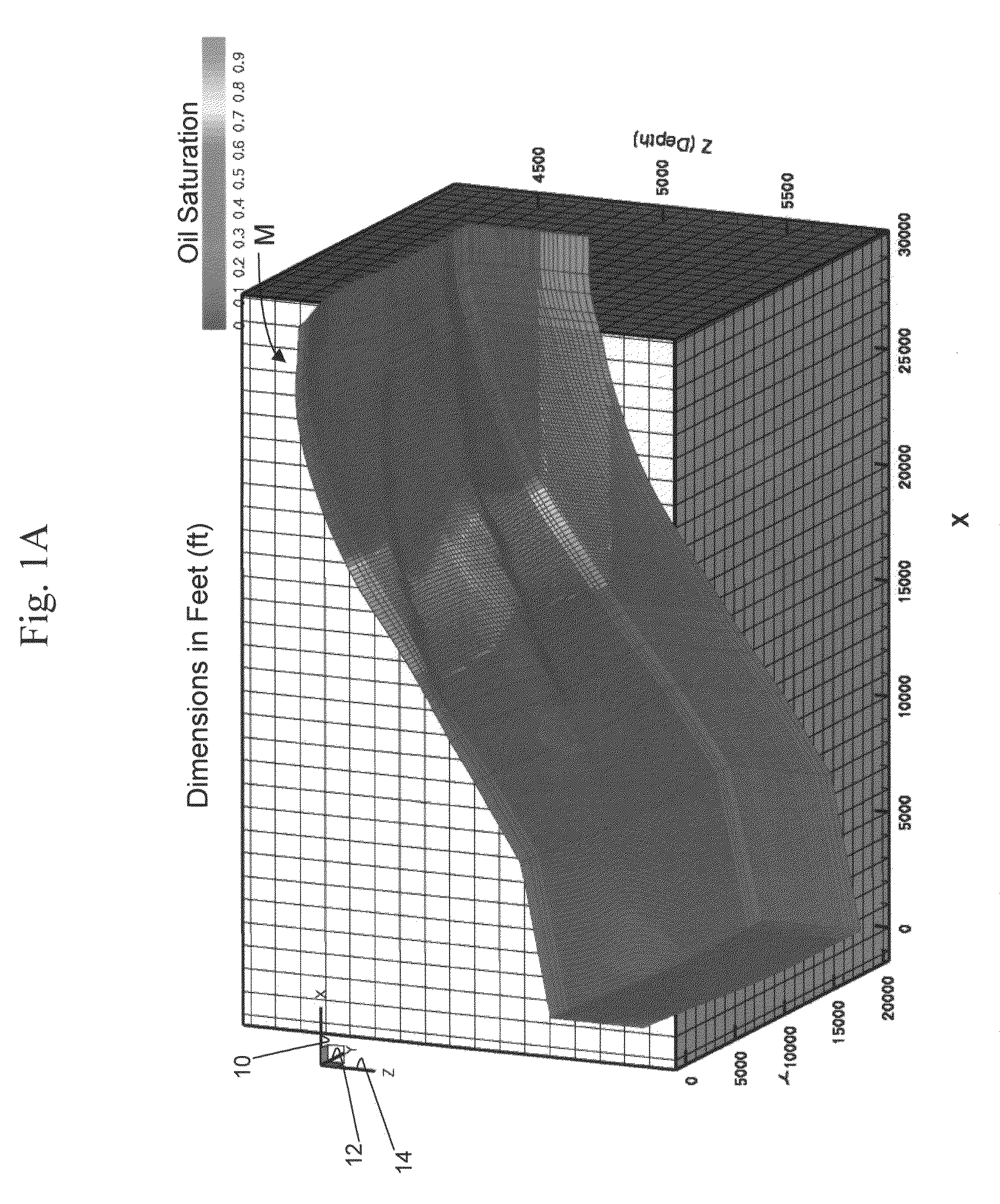

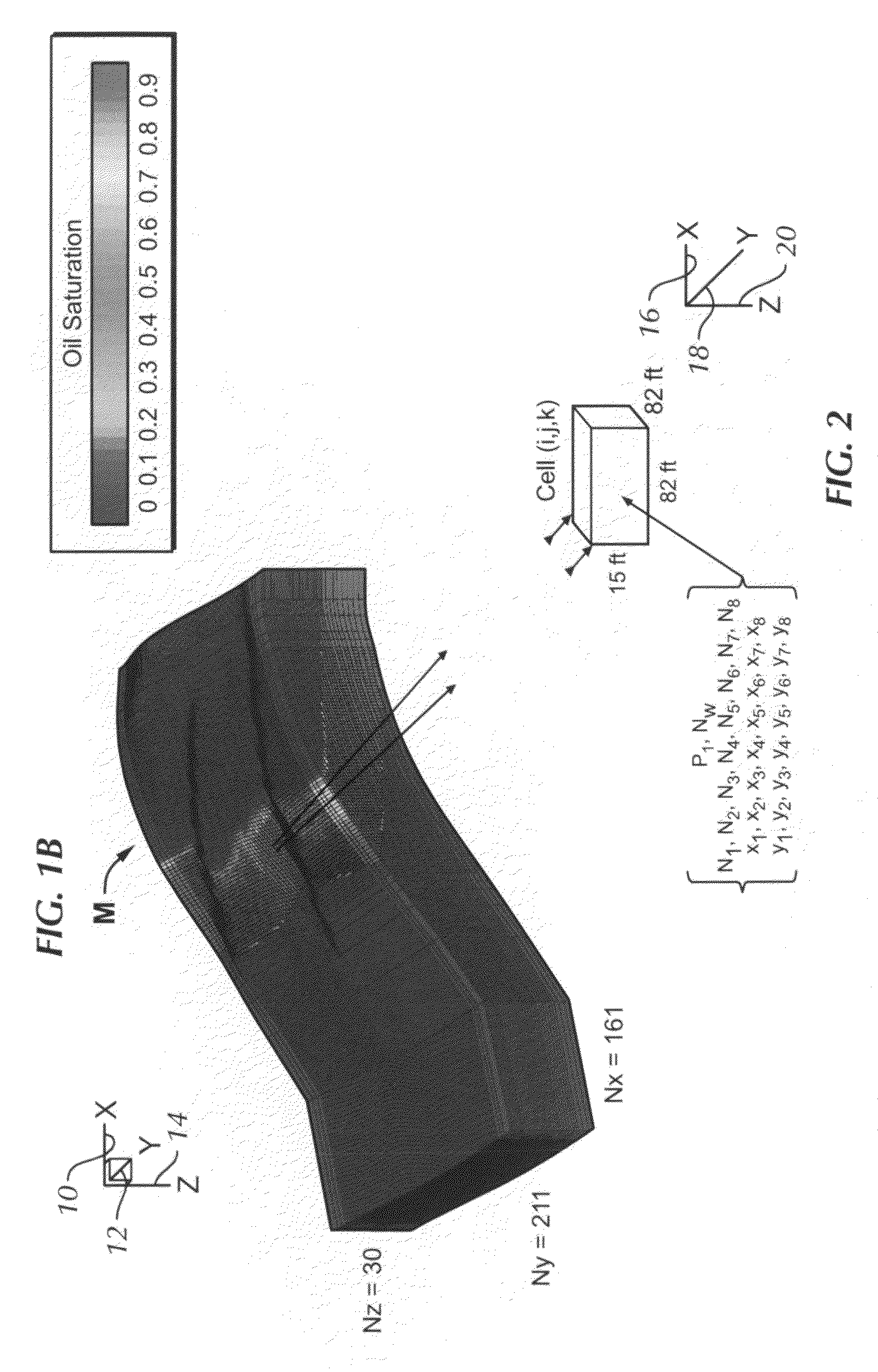

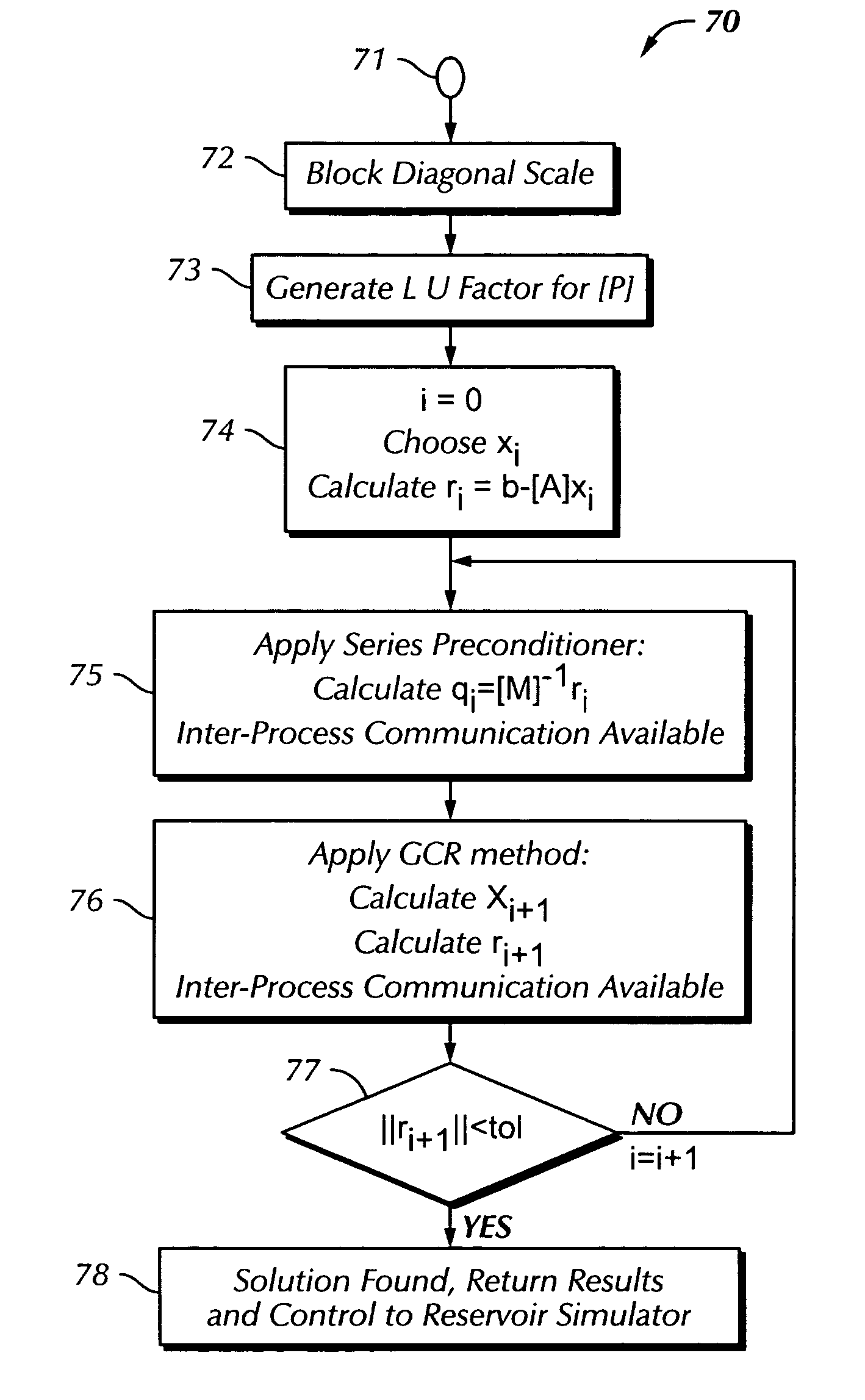

Highly-parallel, implicit compositional reservoir simulator for multi-million-cell models

ActiveUS7526418B2Reduce processing timeElectric/magnetic detection for well-loggingPermeability/surface area analysisSupercomputerDistributed memory

A fully-parallelized, highly-efficient compositional implicit hydrocarbon reservoir simulator is provided. The simulator is capable of solving giant reservoir models, of the type frequently encountered in the Middle East and elsewhere in the world, with fast turnaround time. The simulator may be implemented in a variety of computer platforms ranging from shared-memory and distributed-memory supercomputers to commercial and self-made clusters of personal computers. The performance capabilities enable analysis of reservoir models in full detail, using both fine geological characterization and detailed individual definition of the hydrocarbon components present in the reservoir fluids.

Owner:SAUDI ARABIAN OIL CO

Power system for high temperature applications with rechargeable energy storage

ActiveUS20120268074A1Material nanotechnologyElectrolytic capacitorsCelsius DegreeElectric power system

A power system adapted for supplying power in a high temperature environment is disclosed. The power system includes a rechargeable energy storage that is operable in a temperature range of between about seventy degrees Celsius and about two hundred and fifty degrees Celsius coupled to a circuit for at least one of supplying power from the energy storage and charging the energy storage; wherein the energy storage is configured to store between about one one hundredth (0.01) of a joule and about one hundred megajoules of energy, and to provide peak power of between about one one hundredth (0.01) of a watt and about one hundred megawatts, for at least two charge-discharge cycles. Methods of use and fabrication are provided. Embodiments of additional features of the power supply are included.

Owner:FASTCAP SYST

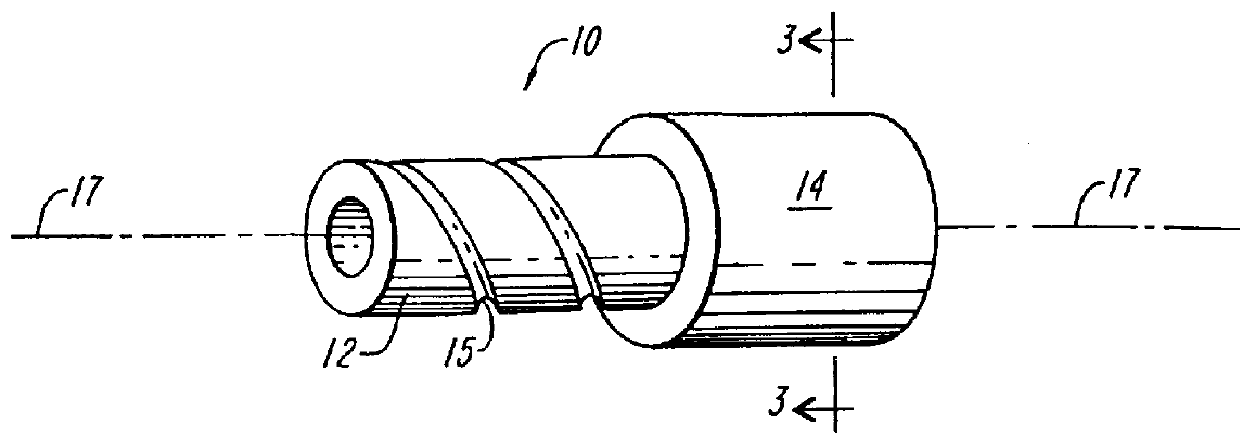

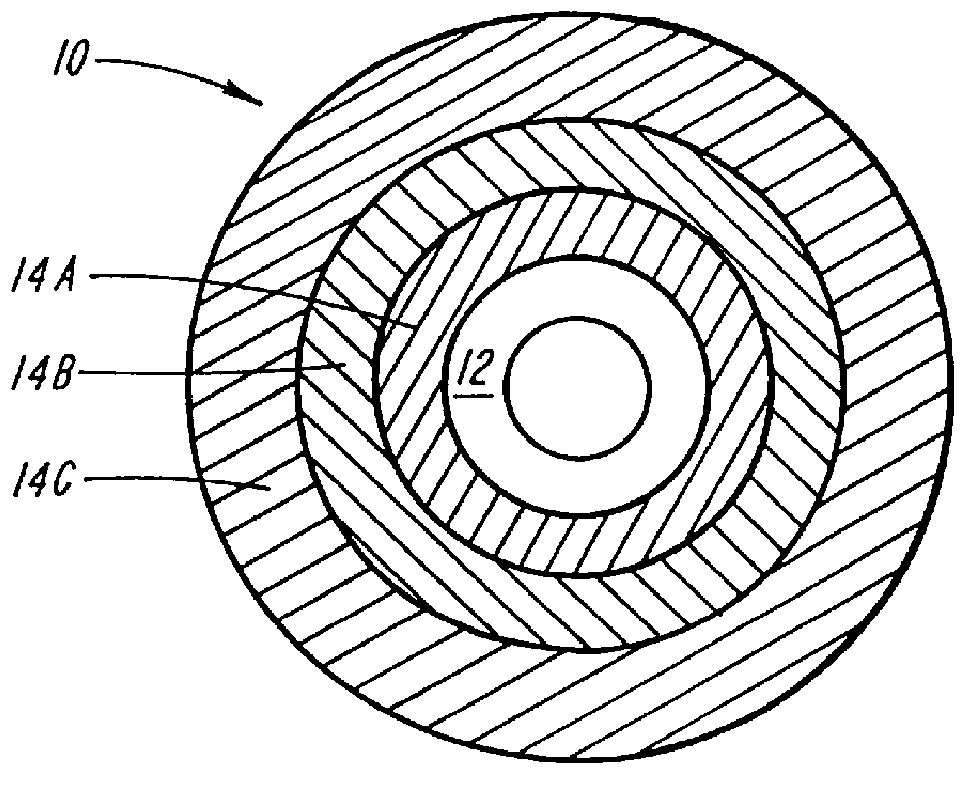

Composite spoolable tube

InactiveUS6016845AExtended service lifeExtending operational parameterDrilling rodsLayered productsInterface layerEngineering

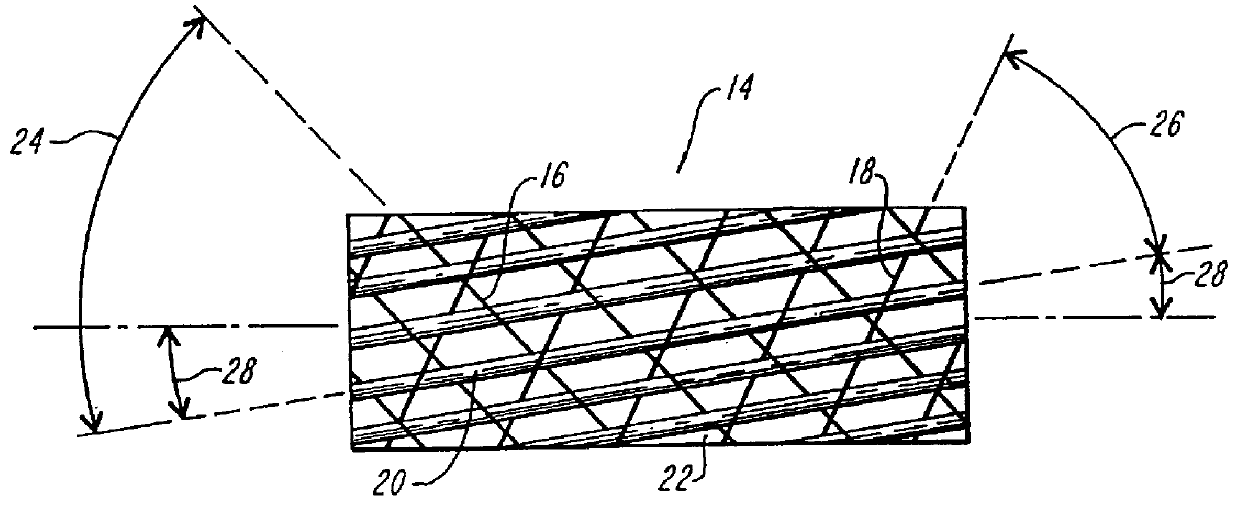

A spoolable composite tube capable of being spooled onto a reel for storage and for use in oil field applications. The spoolable tube exhibits unique anistropic characteristics that provide improved burst and collapse pressures, increased tensile strength, compression strength, and load carrying capacity, while still remaining sufficiently bendable to be spooled onto a reel in an open bore configuration. The spoolable composite tube can include an inner liner, an interface layer, fiber composite layers, a pressure barrier layer, and an outer protective layer. The fiber composite layers can have a unique triaxial braid structure.

Owner:FIBERSPAR

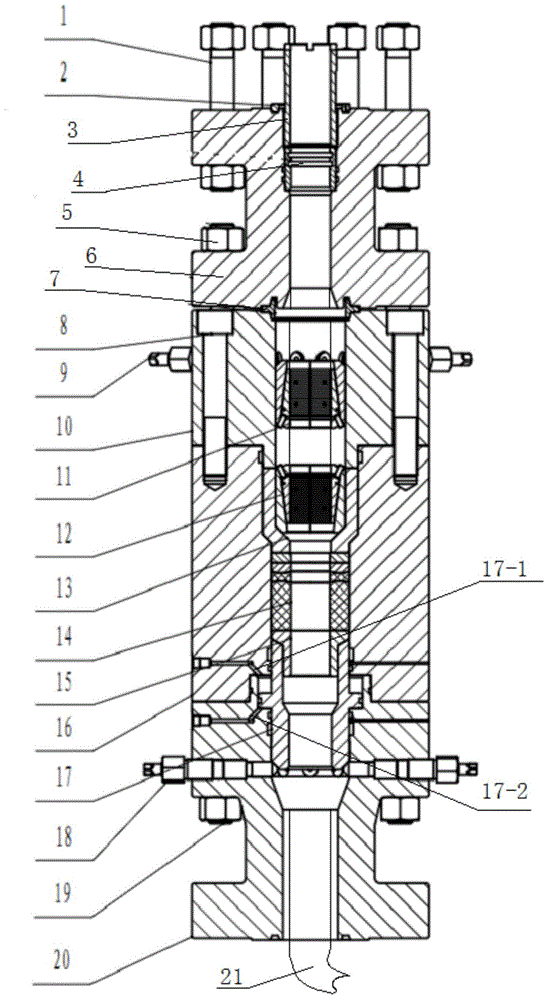

Casing pushdown and rotating tool

A pushdown and rotating tool for holding, pushing, and rotating a floated casing string into a wellbore is provided. The tool includes a mandrel, a housing attached about the external diameter of the mandrel and shaped to receive a collared casing, a jaws assembly within the housing, and an automatic hydraulics system for actuating the jaws. The mandrel and housing are connected such that they can move telescopically relative to one another, and such motion actuates the jaws. The tool has a threaded coupling for a top drive connection, the top drive providing the pushdown and rotational forces which are transmitted to the casing by way of the tool. The mandrel also has an internal passage-way through its length and a male connection at the bottom. The tool facilitates floating a casing into a substantially horizontal wellbore when the casing becomes buoyant and tries to "kick back" out of the well, or when the floated casing becomes stuck and requires rotation to extend beyond the obstacle.

Owner:BJ SERVICES CO

Gripping apparatus for power tongs and backup tools

Apparatus for gripping tubular members including self aligning gripping jaws with high coefficient of friction for resisting force applied to the elongated member to prevent rotation either clockwise or counterclockwise. Linear cams and cam rollers actuated by a fluid cylinder bring the gripping jaws to an elongated member, applying predetermined gripping force and retract the jaws for removal of the elongated member.

Owner:WESCH JR WILLIAM E

Method and apparatus for a tunable diode laser spectrometer for analysis of hydrocarbon samples

The present invention provides an down hole apparatus and method for ultrahigh resolution spectroscopy using a tunable diode laser (TDL) for analyzing a formation fluid sample downhole or at the surface to determine formation fluid parameters. In addition to absorption spectroscopy, the present invention can perform Raman spectroscopy on the fluid, by sweeping the wavelength of the TDL and detecting the Raman-scattered light using a narrow-band detector at a fixed wavelength. The spectrometer analyzes a pressurized well bore fluid sample that is collected downhole. The analysis is performed either downhole or at the surface onsite. Near infrared, mid-infrared and visible light analysis is also performed on the sample to provide an onsite surface or downhole analysis of sample properties and contamination level. The onsite and downhole analysis comprises determination of aromatics, olefins, saturates, gas oil ratio, API gravity and various other parameters which can be estimated by correlation, a trained neural network or a chemometric equation.

Owner:BAKER HUGHES INC

Solution method and apparatus for large-scale simulation of layered formations

ActiveUS20060235667A1Design optimisation/simulationSpecial data processing applicationsSupercomputerAngular point

A targeted heterogeneous medium in the form of an underground layered formation is gridded into a layered structured grid or a layered semi-unstructured grid. The structured grid can be of the irregular corner-point-geometry grid type or the simple Cartesian grid type. The semi-unstructured grid is areally unstructured, formed by arbitrarily connected control-volumes derived from the dual grid of a suitable triangulation; but the connectivity pattern does not change from layer to layer. Problems with determining fluid movement and other state changes in the formation are solved by exploiting the layered structure of the medium. The techniques are particularly suited for large-scale simulation by parallel processing on a supercomputer with multiple central processing units (CPU's).

Owner:SAUDI ARABIAN OIL CO

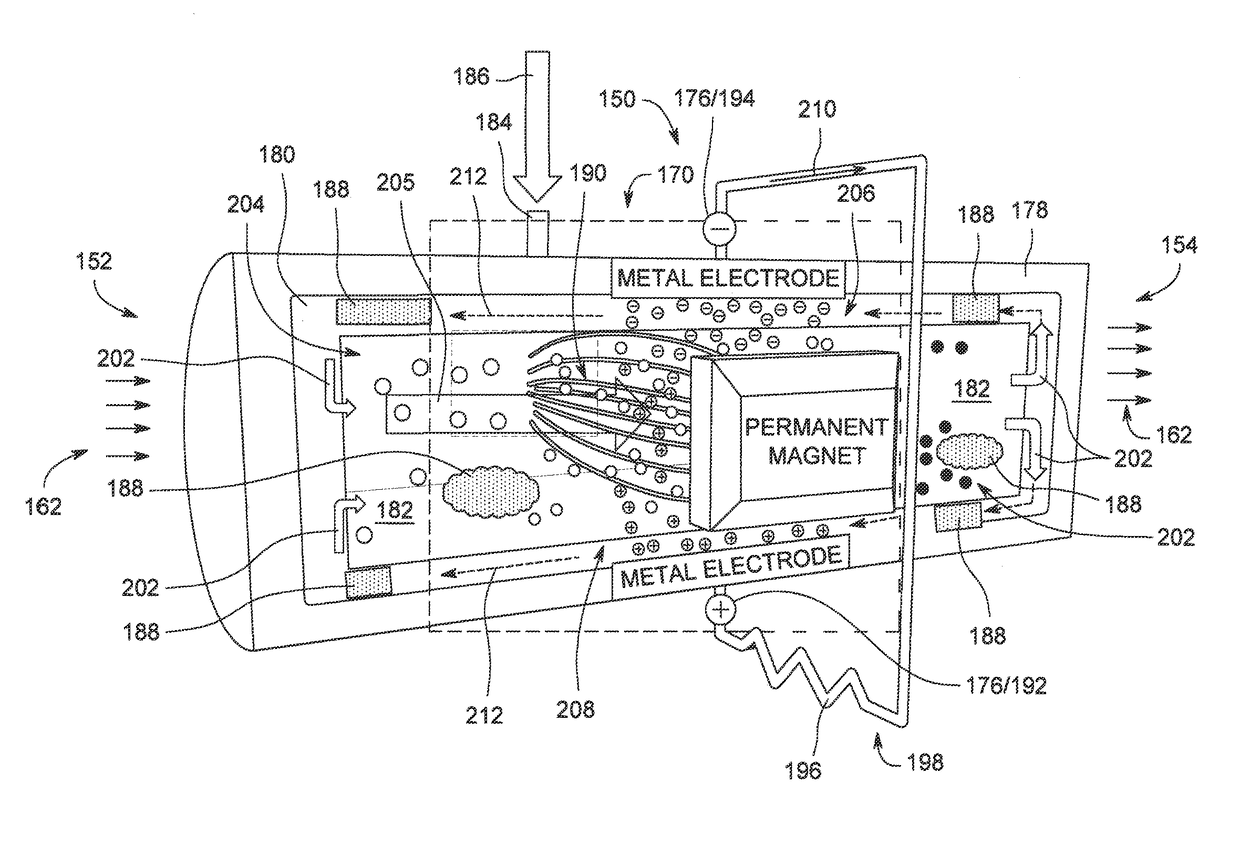

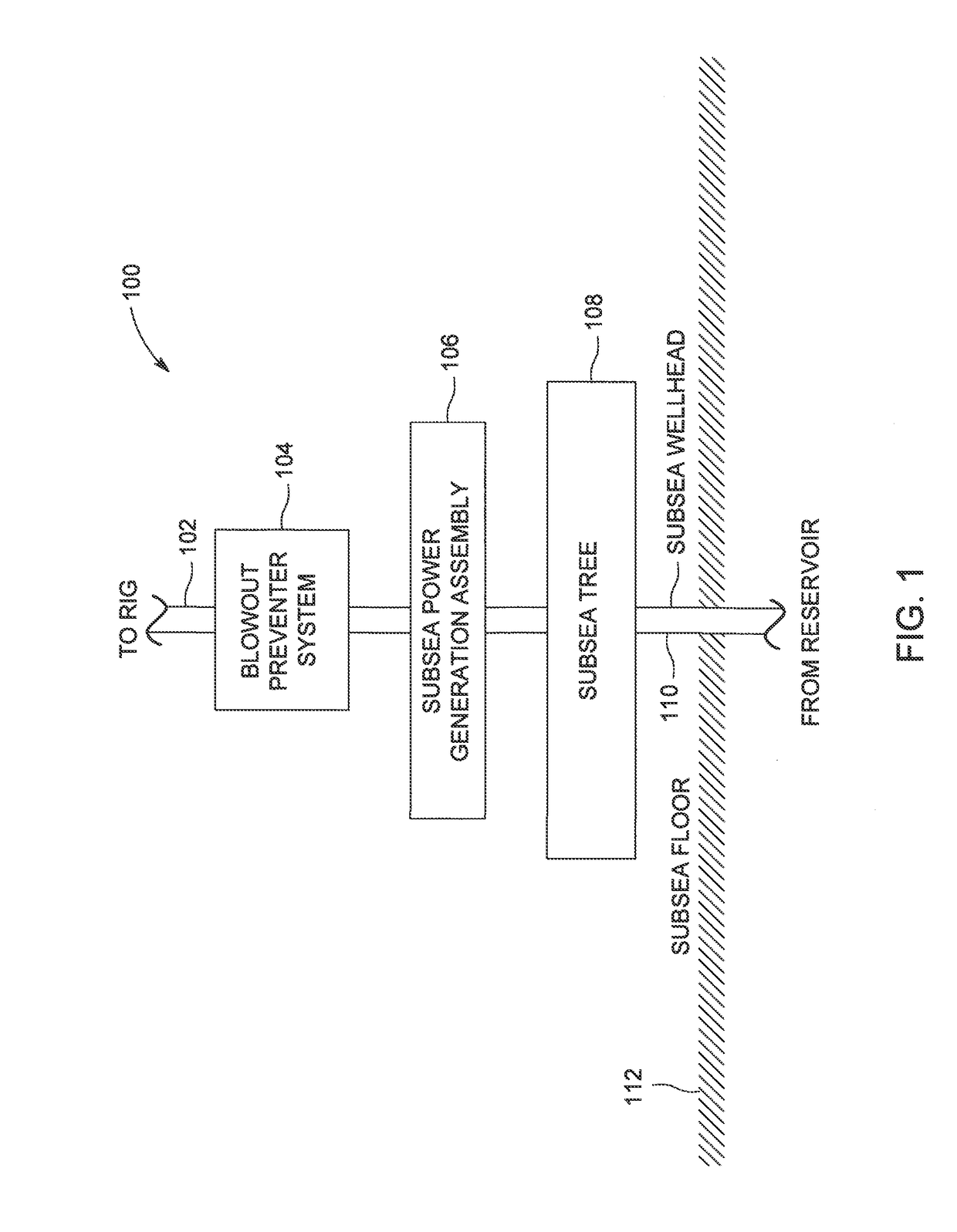

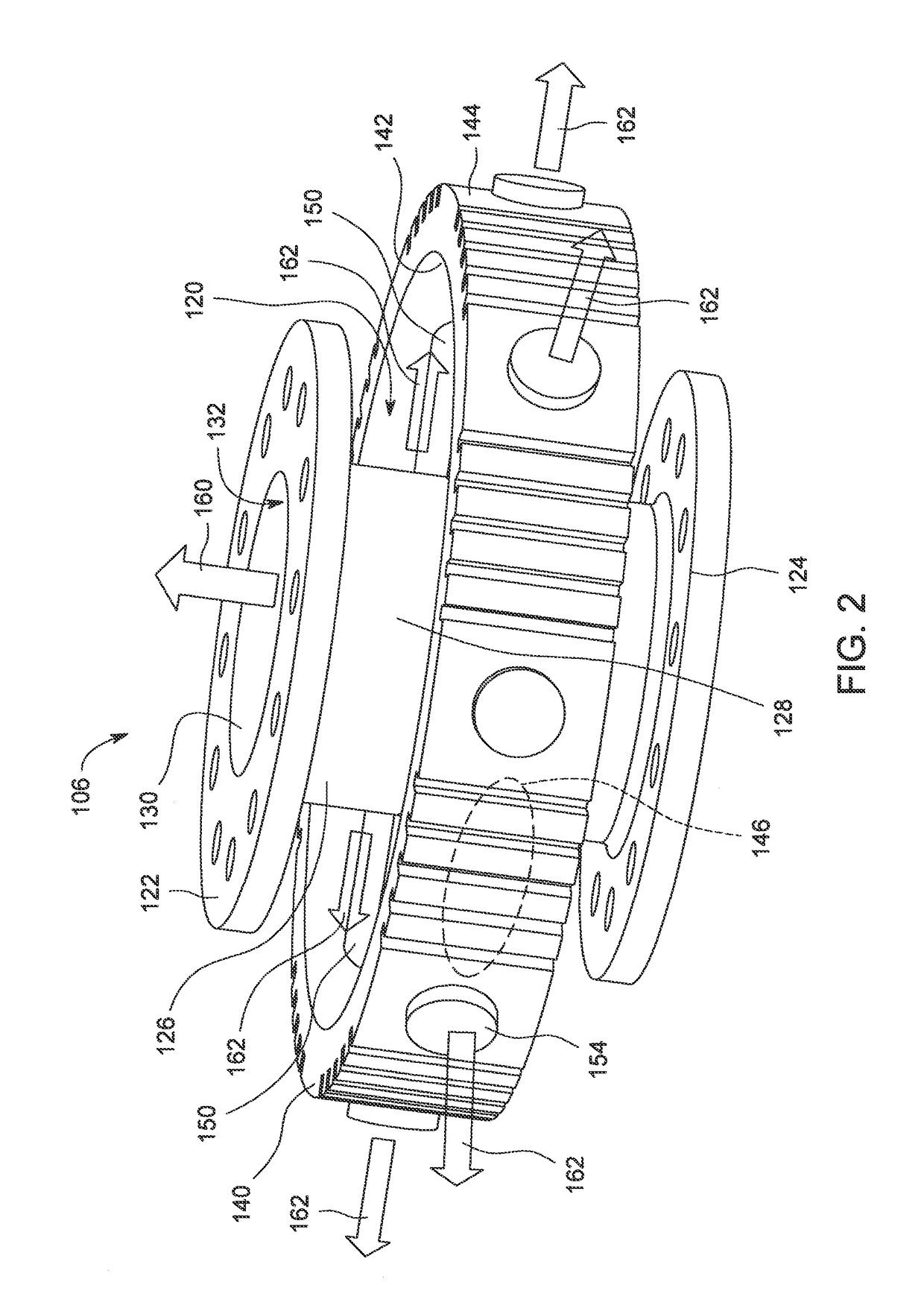

Submersible power generators and method of operating thereof

A submersible liquid-vapor generator (LVG) includes an evaporator portion in heat transfer communication with a heat energy source. The LVG also includes a magnetic field apparatus coupled in flow communication with the evaporator portion. The LVG further includes a condenser portion coupled in flow communication with the magnetic field apparatus. The LVG also includes a hybrid working fluid including nanoparticles. The evaporator portion, the magnetic field portion, and the condenser portion at least partially define a hybrid working vapor flow path. The LVG further includes an electrically non-conductive wick structure coupled in flow communication with the evaporator portion and the condenser portion. The wick structure at least partially defines a hybrid working liquid flow path extending between the condenser portion and the evaporator portion.

Owner:GENERAL ELECTRIC CO

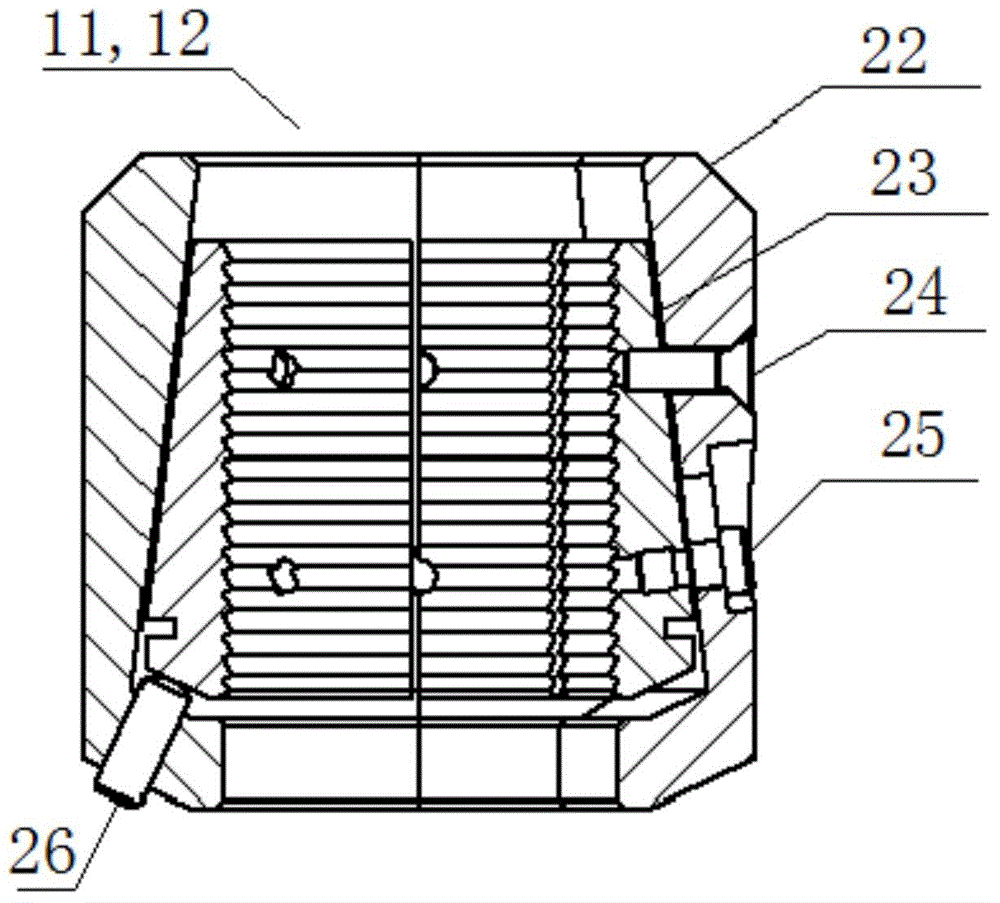

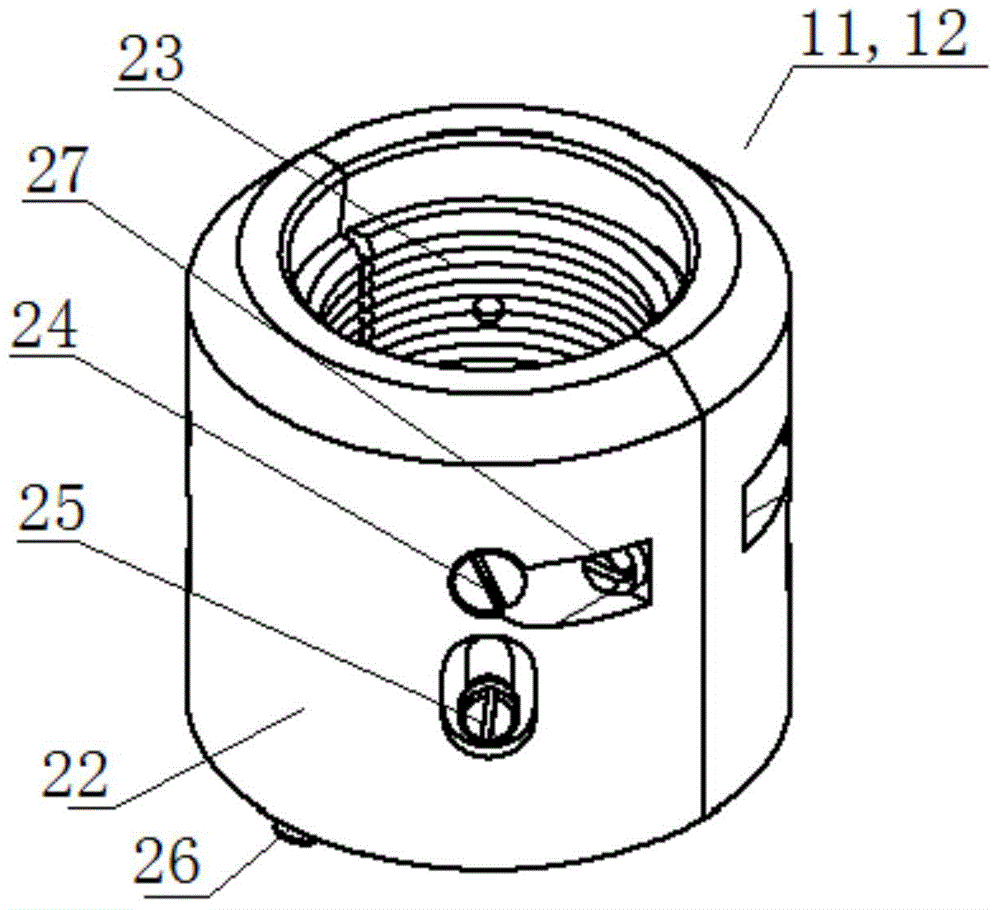

Continuous oil pipe hanger for velocity tubular column

ActiveCN104358536AGuaranteed sealing performanceFix the leakBorehole/well accessoriesCoiled tubingEngineering

The invention relates to a continuous oil pipe hanger for a velocity tubular column. The continuous oil pipe hanger comprises a continuous oil pipe, an I-shaped flange, an upper slip assembly, a lower slip assembly, an upper shell, a middle shell and a lower shell, wherein vertically penetrating central holes are formed in the upper shell, the middle shell and the lower shell; the I-shaped flange is fixedly arranged at the top of the upper shell; the continuous oil pipe passes through the I-shaped flange and the central holes of the upper shell, the middle shell and the lower shell in turn; the upper slip assembly is clamped on an inner wall of the central hole of the upper shell; the lower slip assembly is located in the central hole of the middle shell; a connecting pipe sealing set is fixedly arranged on an inner wall of the central hole of the middle shell and the lower side of a hanging supporting sleeve; at least one pair of driving pistons is arranged on the inner walls of the central holes of the middle shell and the lower shell and under the connecting pipe sealing set; an upper oil port and a lower oil port respectively communicated with the driving pistons are arranged on the side walls of the middle shell and the lower shell. The continuous oil pipe hanger has the beneficial effect of capability of hanging the continuous oil pipe.

Owner:JEREH ENERGY SERVICES

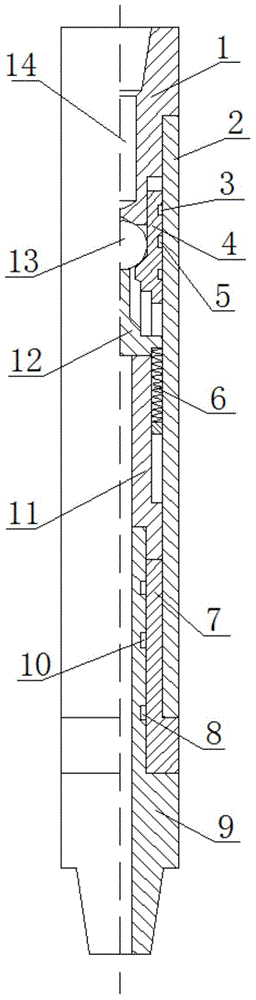

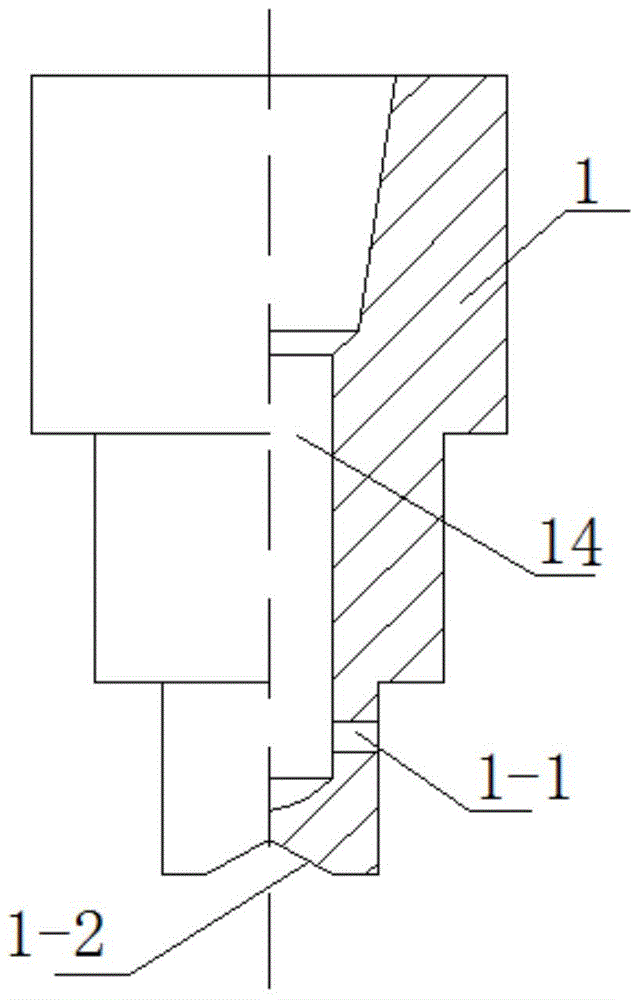

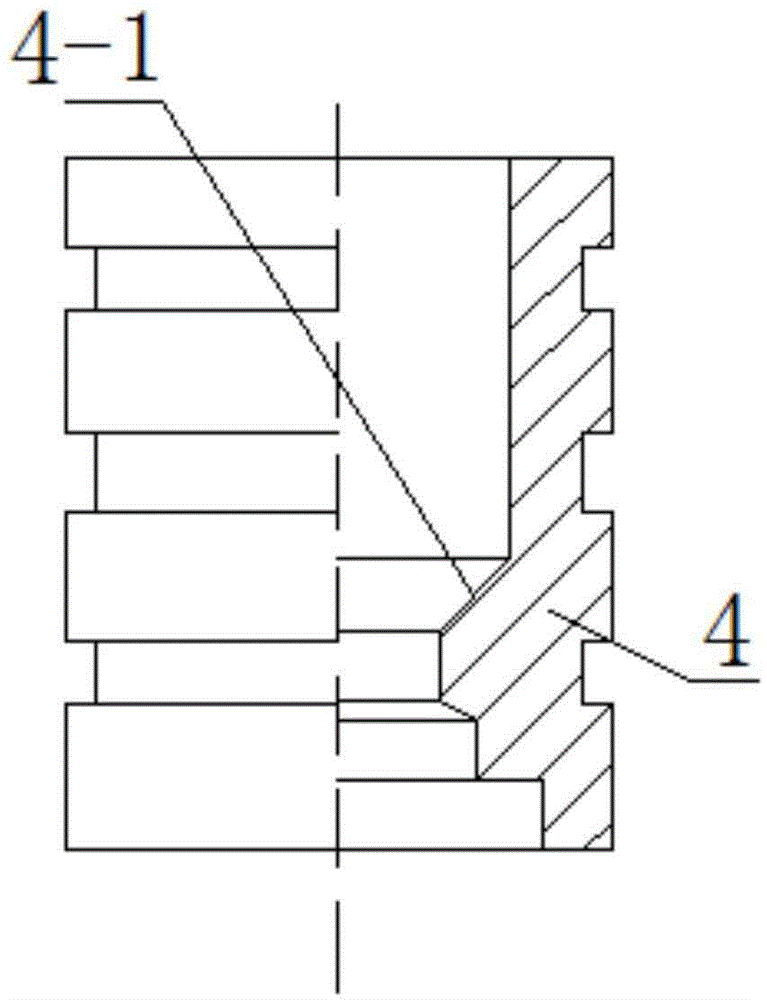

Continuous shocking tool

ActiveCN104563938AAvoid repeated lifting and loweringAvoid damageBorehole/well accessoriesUpper jointEngineering

The invention relates to a shocking tool, and specifically relates to a continuous shocking tool. The continuous shocking tool comprises an upper joint, an outer sleeve equipped with a medium hole, a piston, a shuttle key, an inserting rod, a sliding sleeve equipped with another medium hole, and a lower joint; the upper joint is inserted from the middle part of the sleeve into the central hole of the outer sleeve; a flowing groove is vertically formed in the top part of the upper joint; a guide hole which communicates with the central hole in the outer sleeve is formed in the sidewall of the flowing groove; a tapered groove is formed in the bottom part of the upper joint; the piston is vertically sealed and arranged in the central hole of the outer sleeve; the bottom part of the upper joint is inserted into an inner cavity of the piston; a sealing ball is arranged in the inner cavity of the piston; the shuttle key is positioned in the central hole of the outer sleeve; the inserting rod is positioned in the central hole of the outer sleeve; a bulge is fixedly arranged on the inner wall of the outer sleeve and below the shuttle key; a compression spring is arranged between the bulge and the base; the sliding sleeve is inserted from the bottom part of the outer sleeve into the outer sleeve; the lower joint passes through the central hole of the sliding sleeve from the bottom part of the sliding sleeve; one end of the lower joint, passing through the sliding sleeve is fixedly connected with the bottom part of the inserting rod. The continuous shocking tool has the beneficial effects of being good in shocking effect and high in shocking efficiency.

Owner:JEREH ENERGY SERVICES

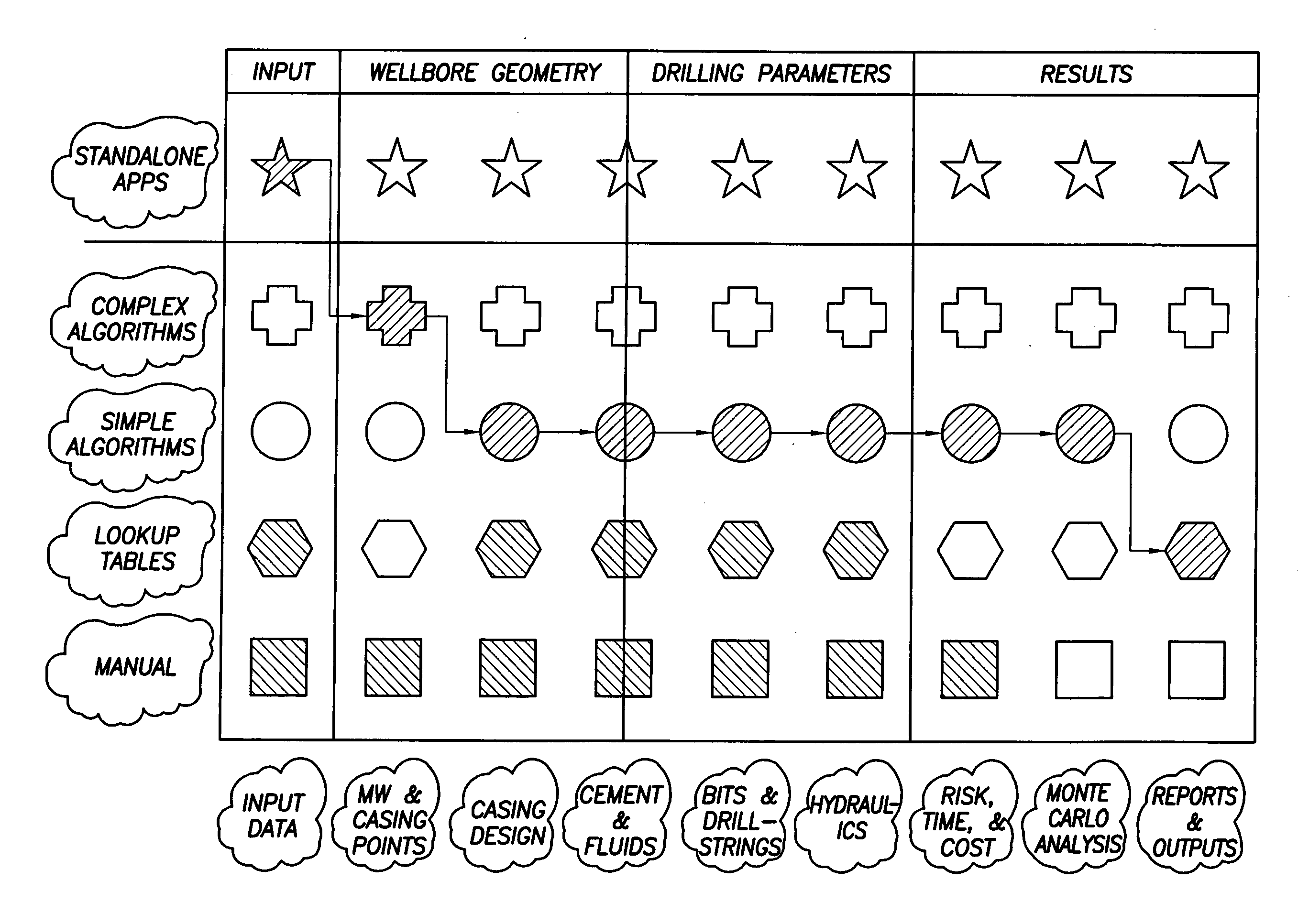

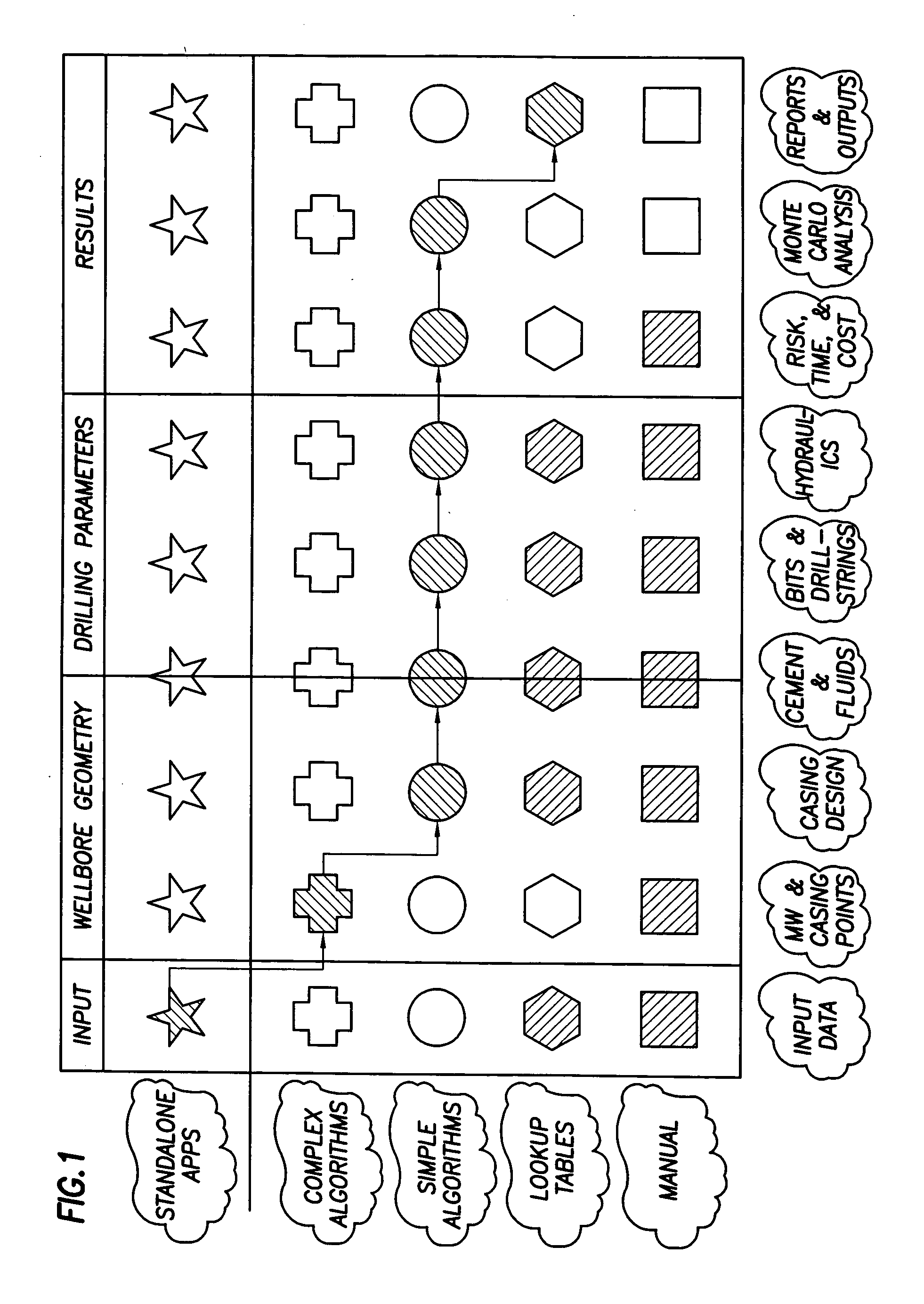

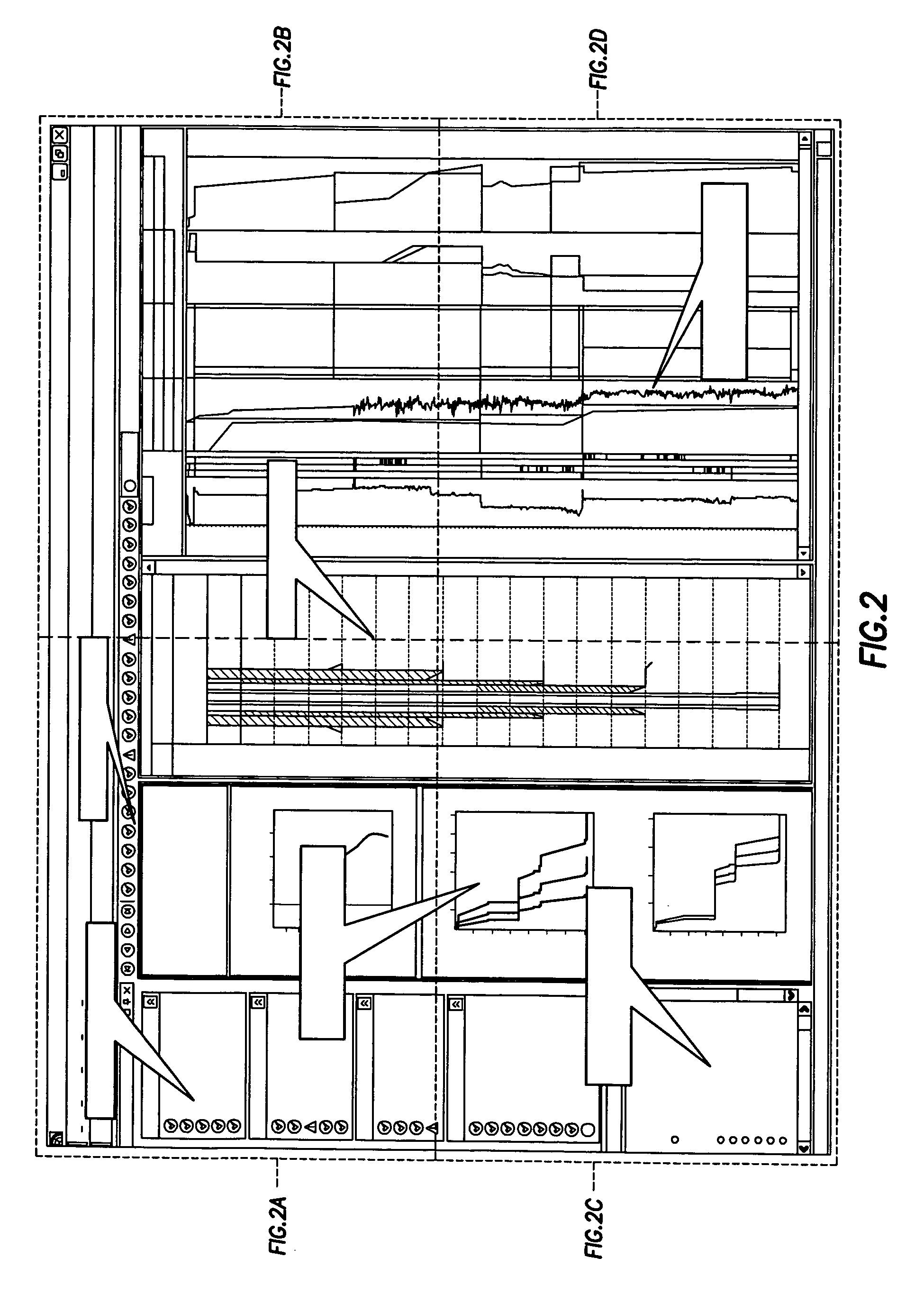

Method and apparatus and program storage device including an integrated well planning workflow control system with process dependencies

A method of well planning in an automatic well planning system comprises the steps of: selecting one or more tasks in a task manager; verifying by a task dependency a proper order of the one or more tasks; retrieving by the task manager from a task base one or more sets of instructions associated with the one or more tasks selected in the task manager and verified by the task dependency; retrieving by the task manager from an access manager one or more sets of input data associated with the one or more sets of instructions retrieved by the task manager from the task base; verifying that each set of input data of the one or more sets of input data retrieved by the task manager from the access manager is received by a corresponding one of the one or more sets of instructions retrieved by the task manager from the task base; executing, by the task manager, the one or more sets of instructions and using, by the task manager, the one or more sets of input data during the executing step thereby generating a set of results; and recording or displaying, by a task view base, the set of results on a recorder or display device.

Owner:SCHLUMBERGER TECH CORP

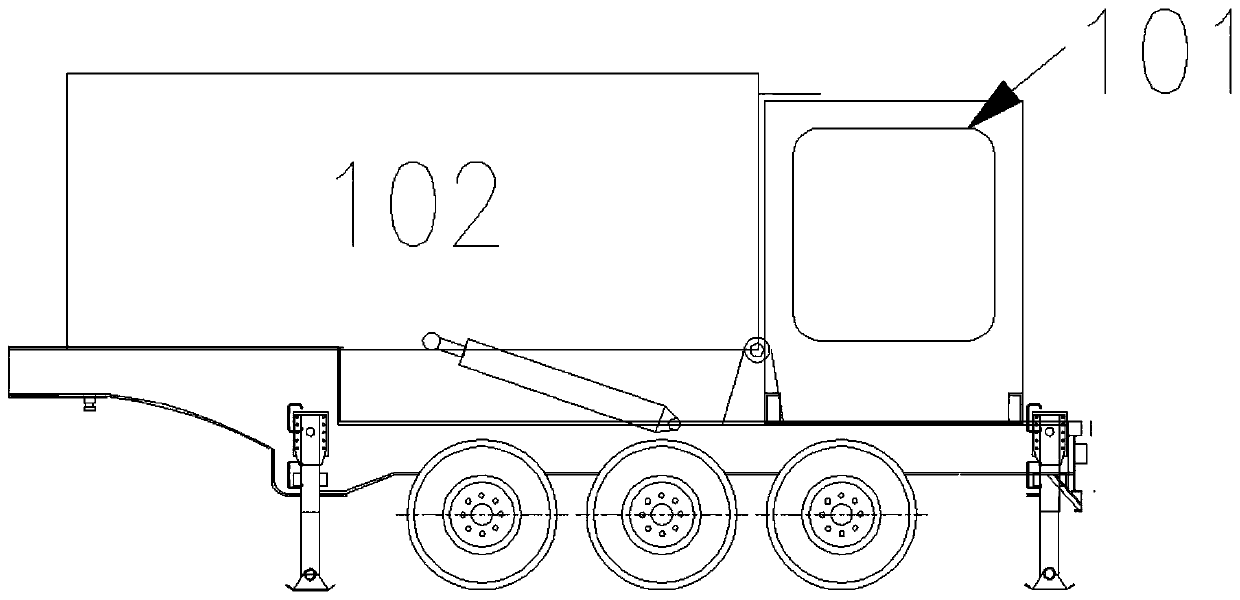

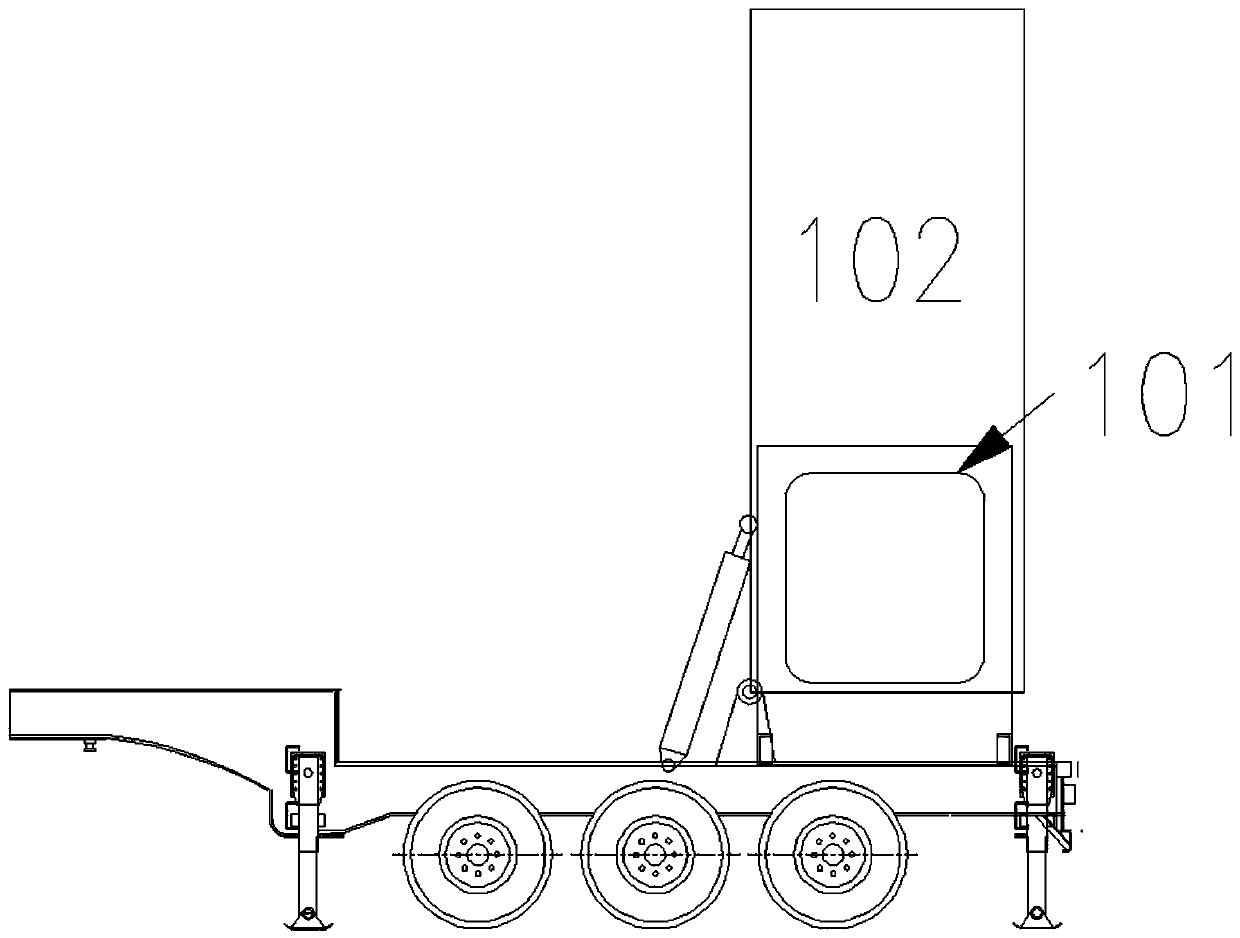

Mobile power generation system

PendingCN110159433AQuick dock installationEasy to adjustGas turbine plantsEngine componentsButt jointWind power generation

The invention discloses a mobile power generation system. A power generation device is in rapid butt joint with an air inlet assembly and an exhaust pipeline which are independently transported through telescopic joints, so that rapid installation and butt joint of the power generation system in a fracturing operation field are realized. The air inlet assembly and the exhaust pipeline are separately provided with transportation tools, and the adjustability is more flexible when the air inlet assembly and the exhaust pipeline are in butt joint. The position of the power generation device is fixed, the position of the air inlet assembly is moved, so that the air inlet assembly is in butt joint with an air inlet chamber of the power generation device; and the position of the exhaust pipelineis moved, so that the exhaust pipeline is in butt joint with an exhaust collector of the power generation device.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

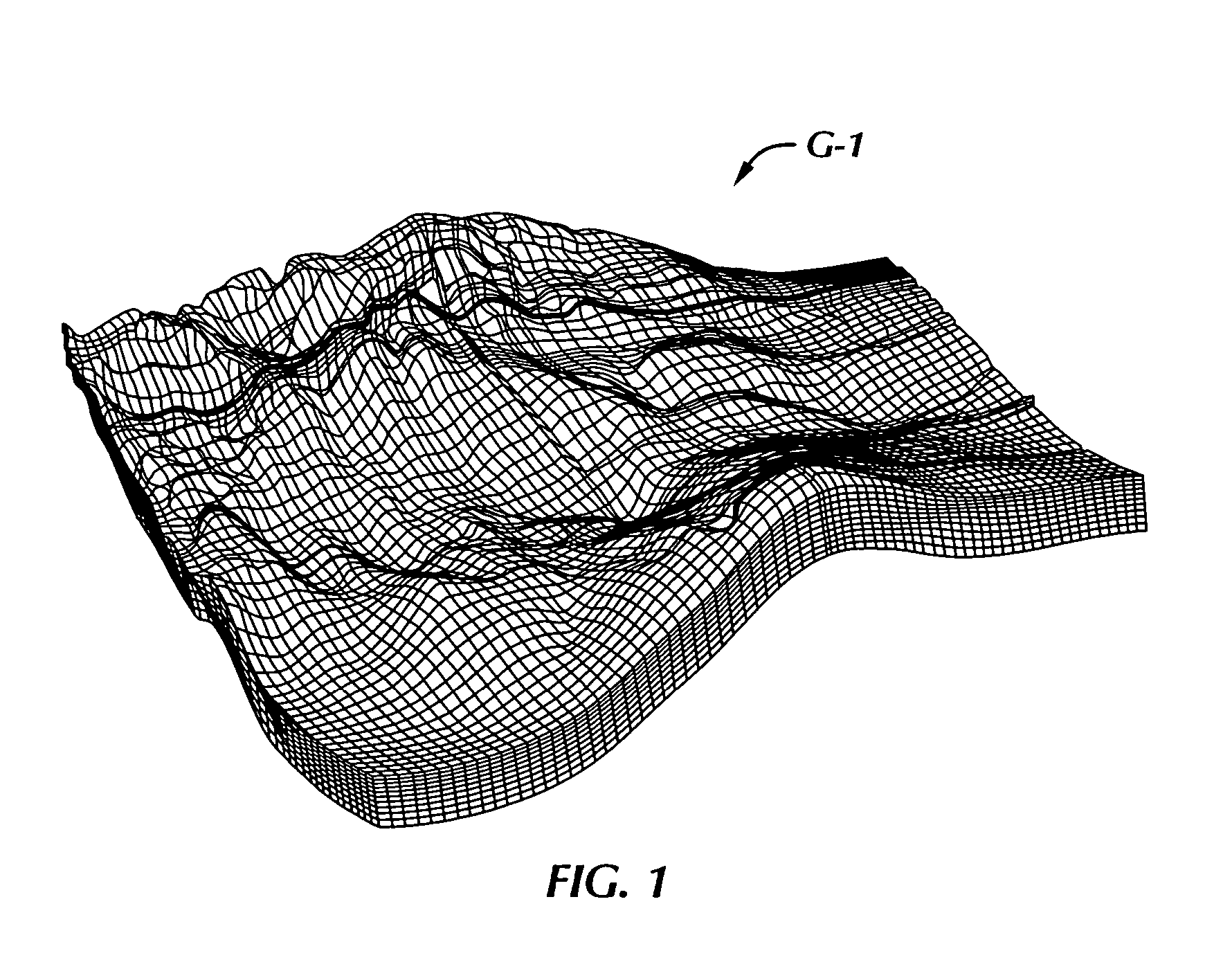

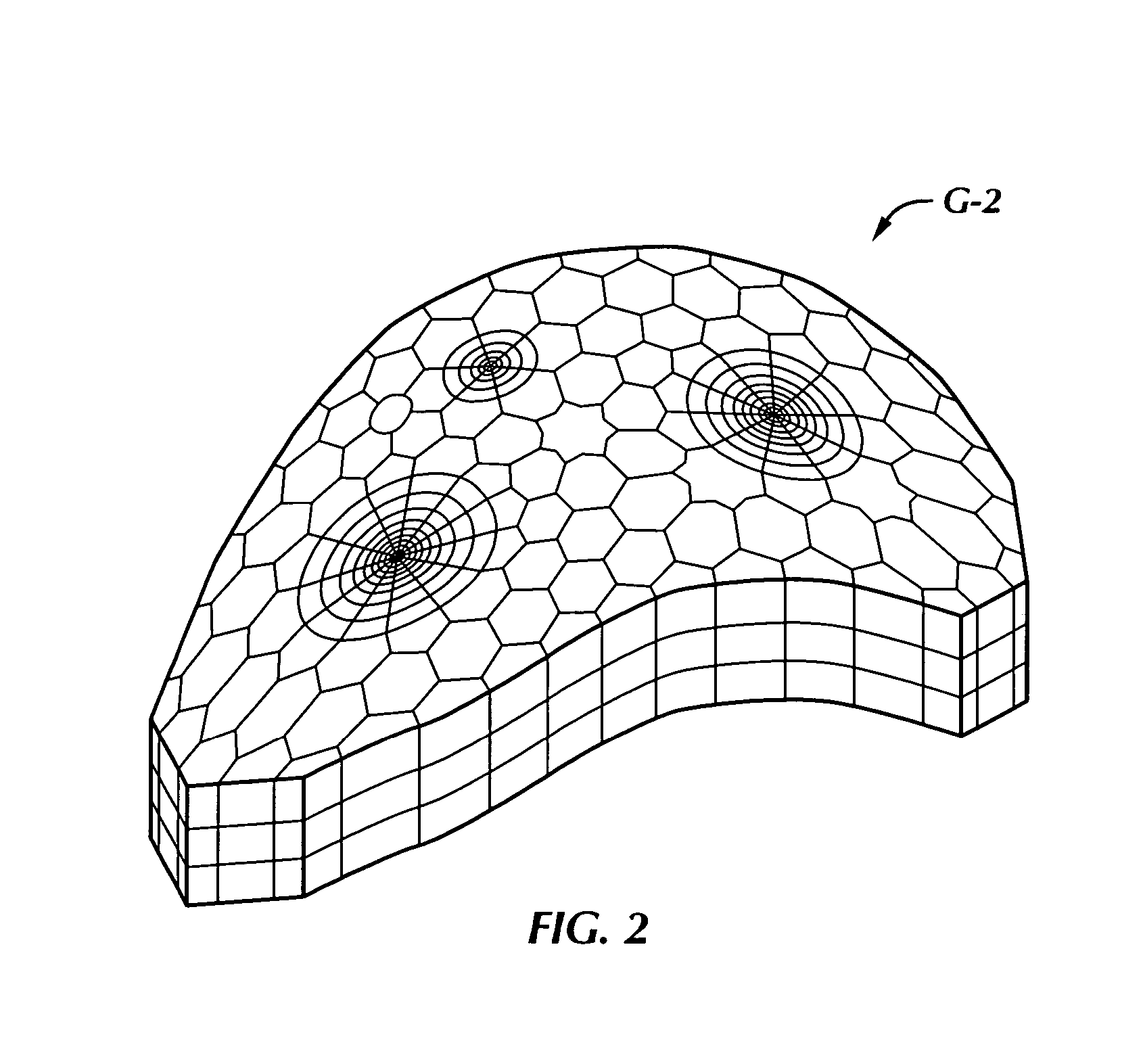

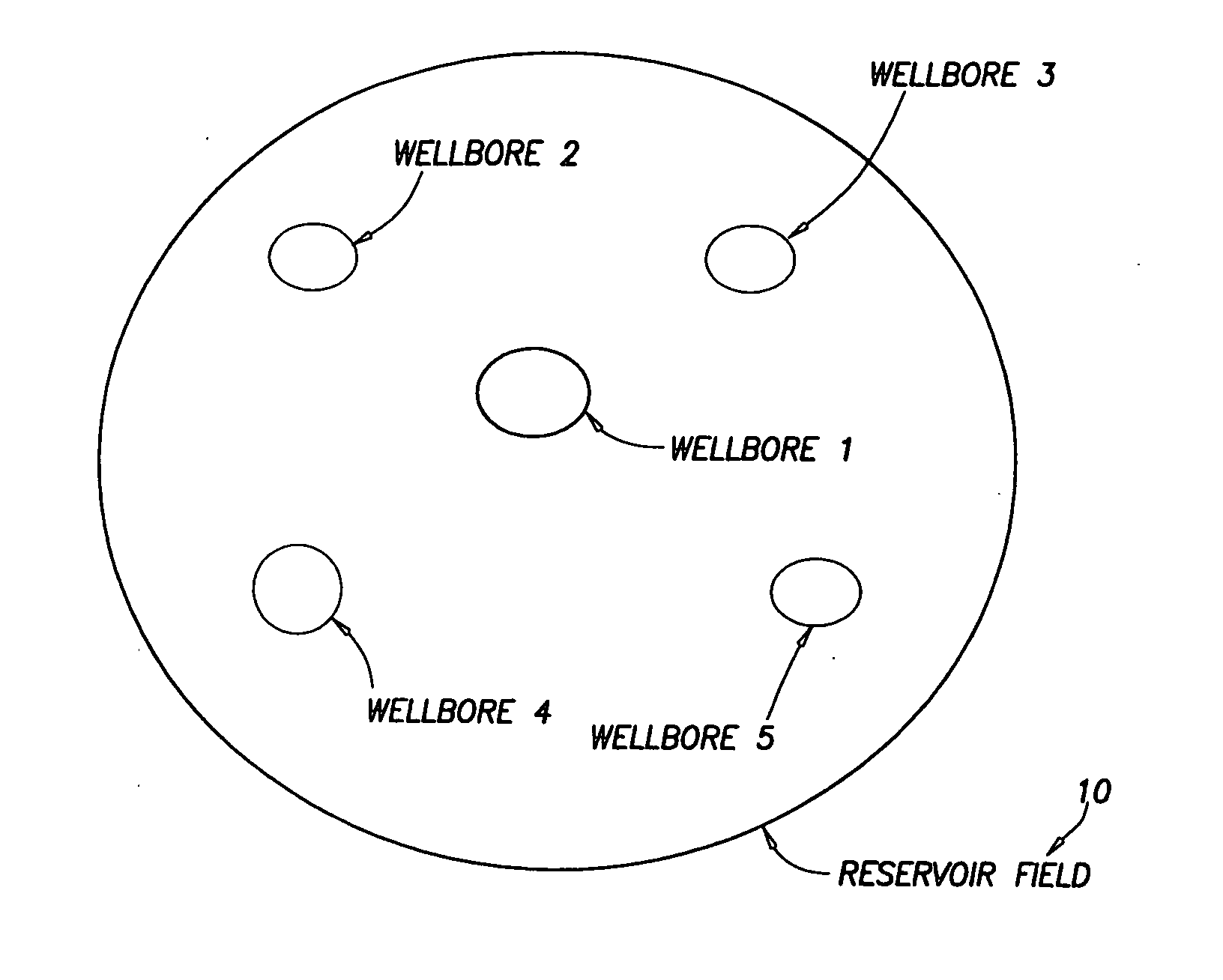

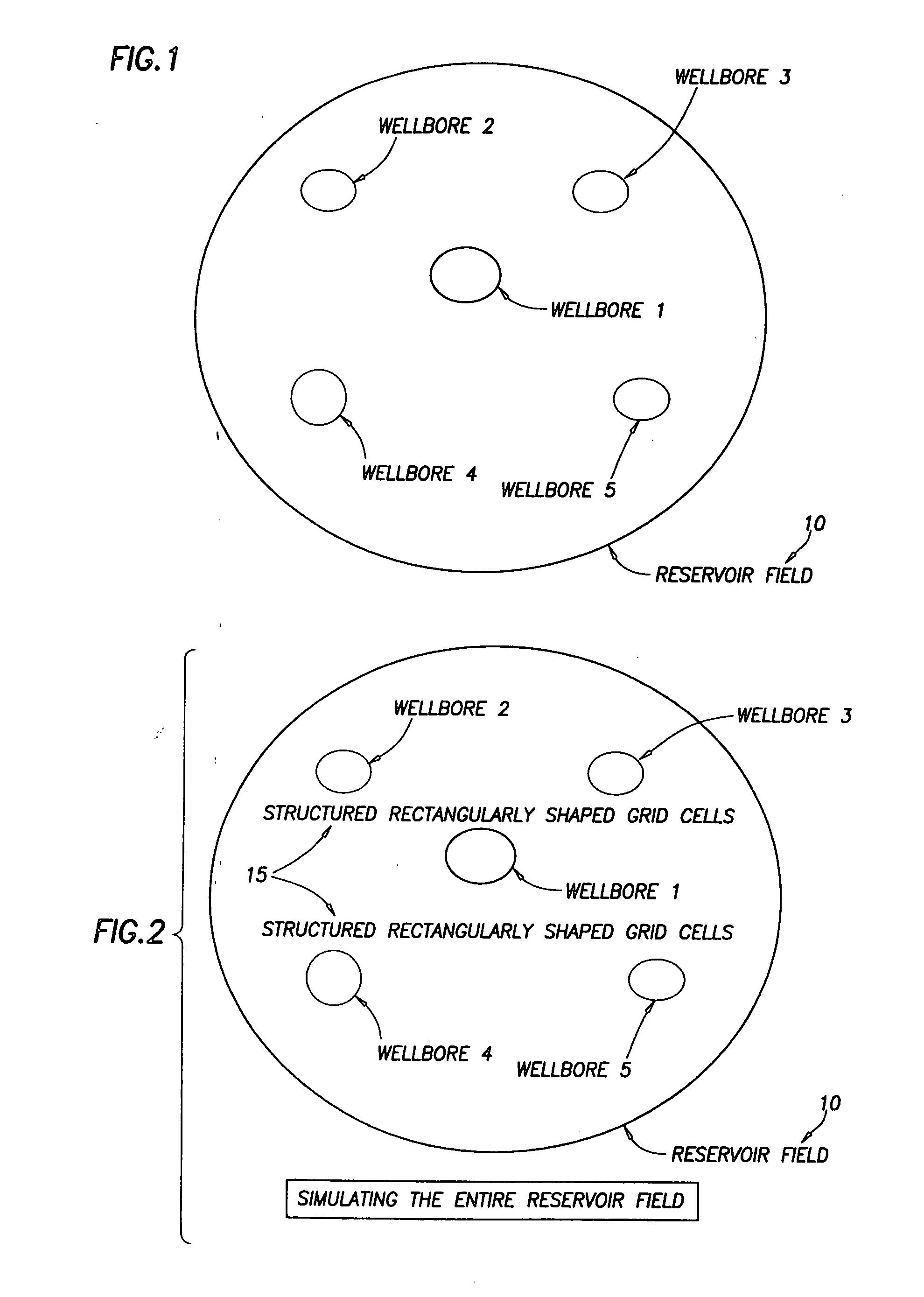

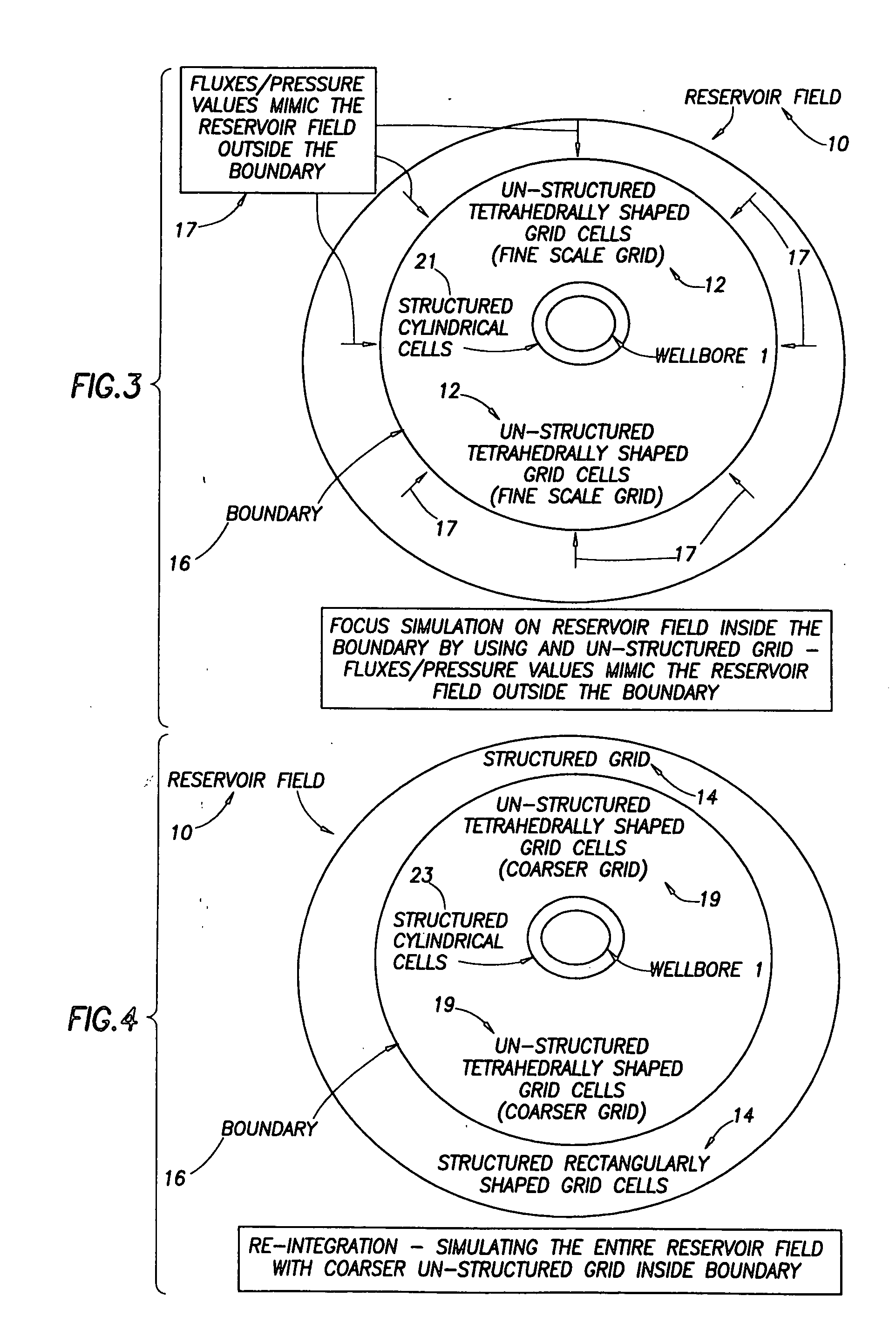

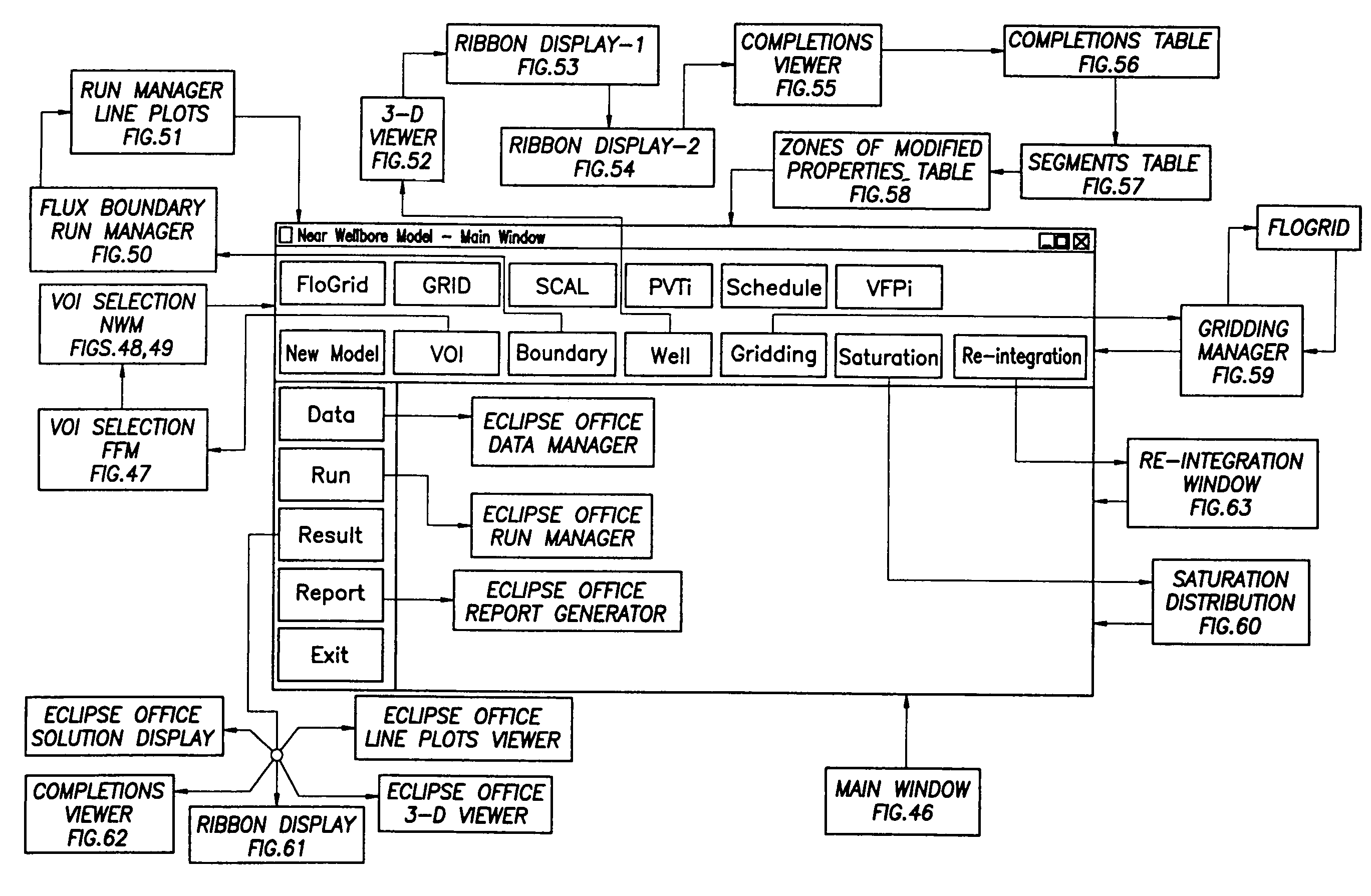

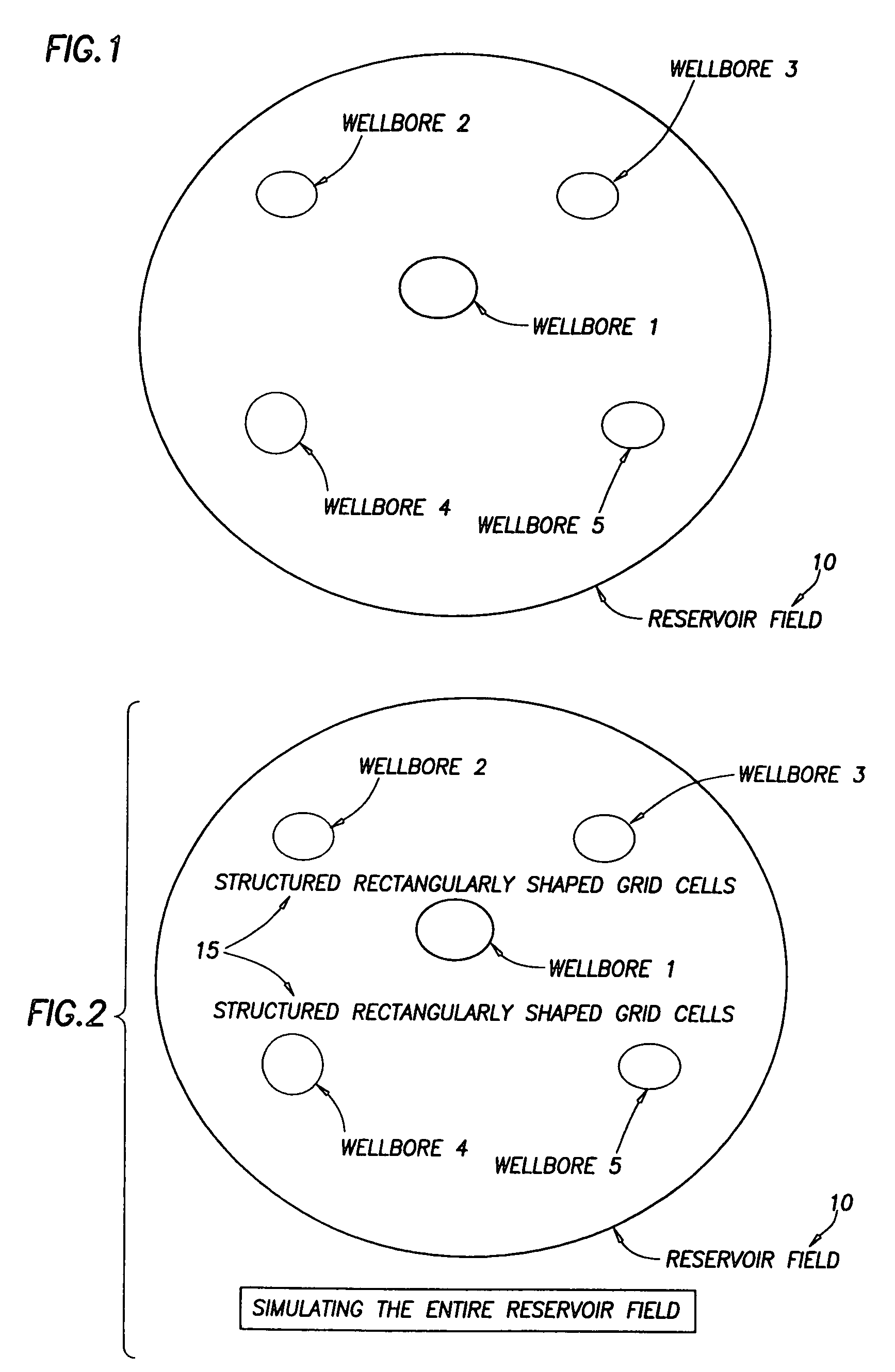

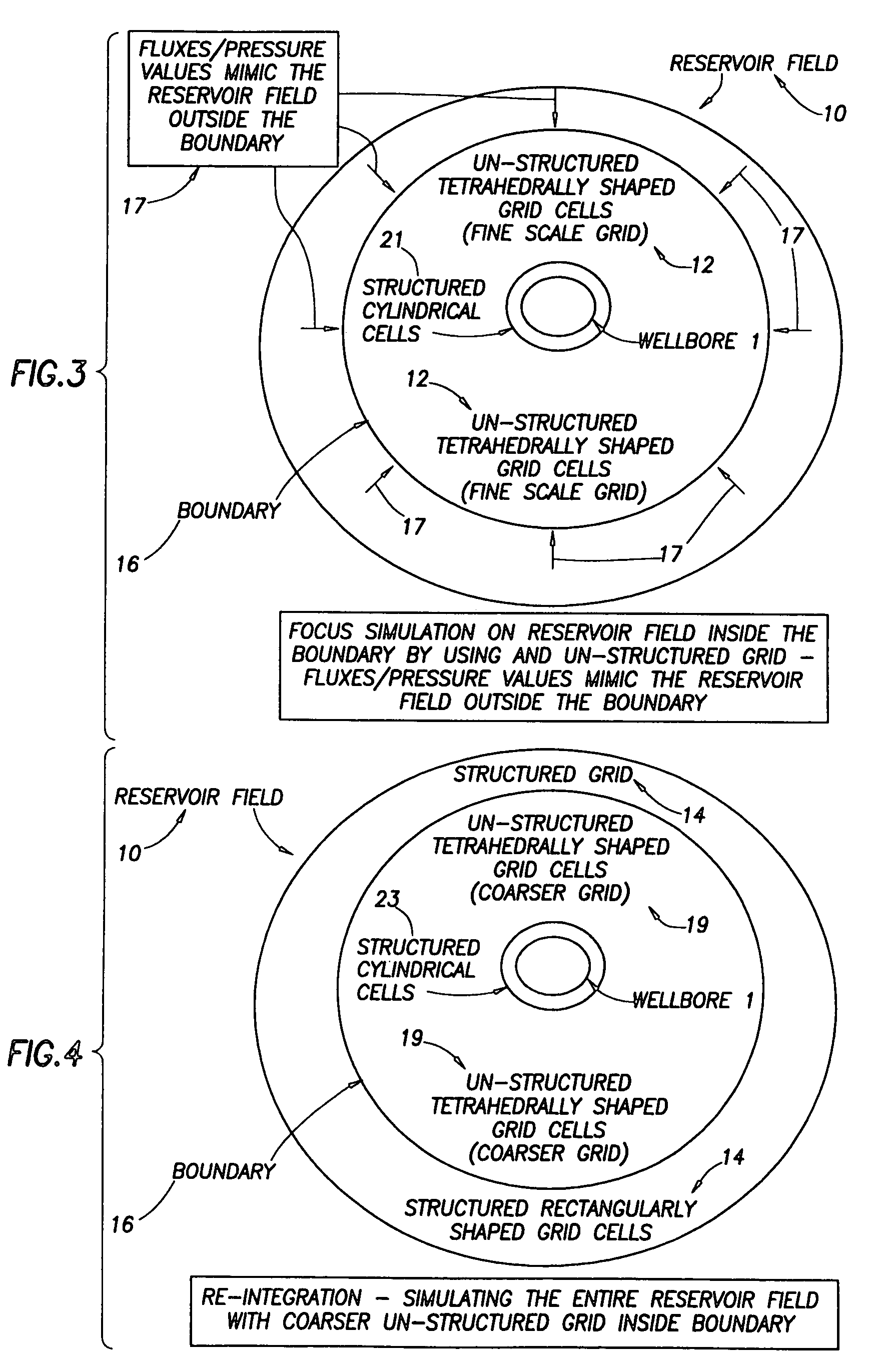

Near wellbore modeling method and apparatus

ActiveUS20050015231A1Electric/magnetic detection for well-loggingComputation using non-denominational number representationModel methodScale structure

A “near wellbore modeling” software will, when executed by a processor of a computer, model a localized area of a reservoir field which surrounds and is located near a specific wellbore in the reservoir field by performing the following functions: (1) receive input data representative of a reservoir field containing a plurality of wellbores, (2) establish a boundary around one specific wellbore in the reservoir field which will be individually modeled and simulated, (3) impose an “fine scale” unstructured grid inside the boundary consisting of a plurality of tetrahedrally shaped grid cells and further impose a fine scale structured grid about the perforated sections of the specific wellbore, (4) determine a plurality of fluxes / pressure values at the boundary, the fluxes / pressure values representing characteristics of the reservoir field located outside the boundary, (5) establish one or more properties for each tetrahedral cell of the unstructured grid and each cylindrical grid cell of the structured grid, (6) run a simulation, using the fluxes / pressure values at the boundary to mimic the reservoir field outside the boundary and using the fine scale grid inside the boundary, to thereby determine a plurality of simulation results corresponding, respectively, to the plurality of grid cells located inside the boundary, the plurality of simulation results being representative of a set of characteristics of the reservoir field located inside the boundary, (7) display the plurality of simulation results which characterize the reservoir field located inside the boundary, and (8) reintegrate by coarsening the grid inside the boundary, imposing a structured grid outside the boundary, and re-running a simulation of the entire reservoir field.

Owner:SCHLUMBERGER TECH CORP

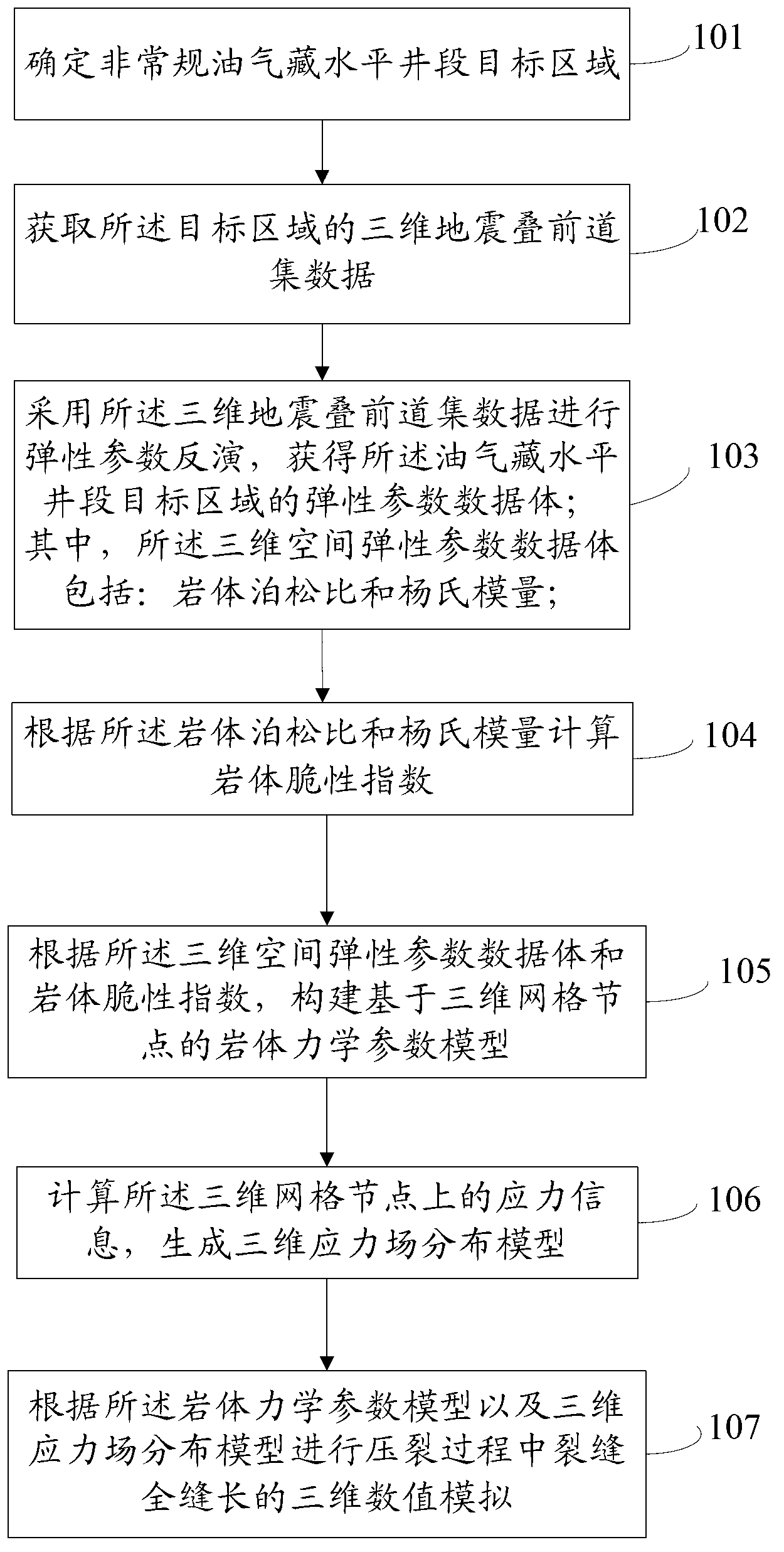

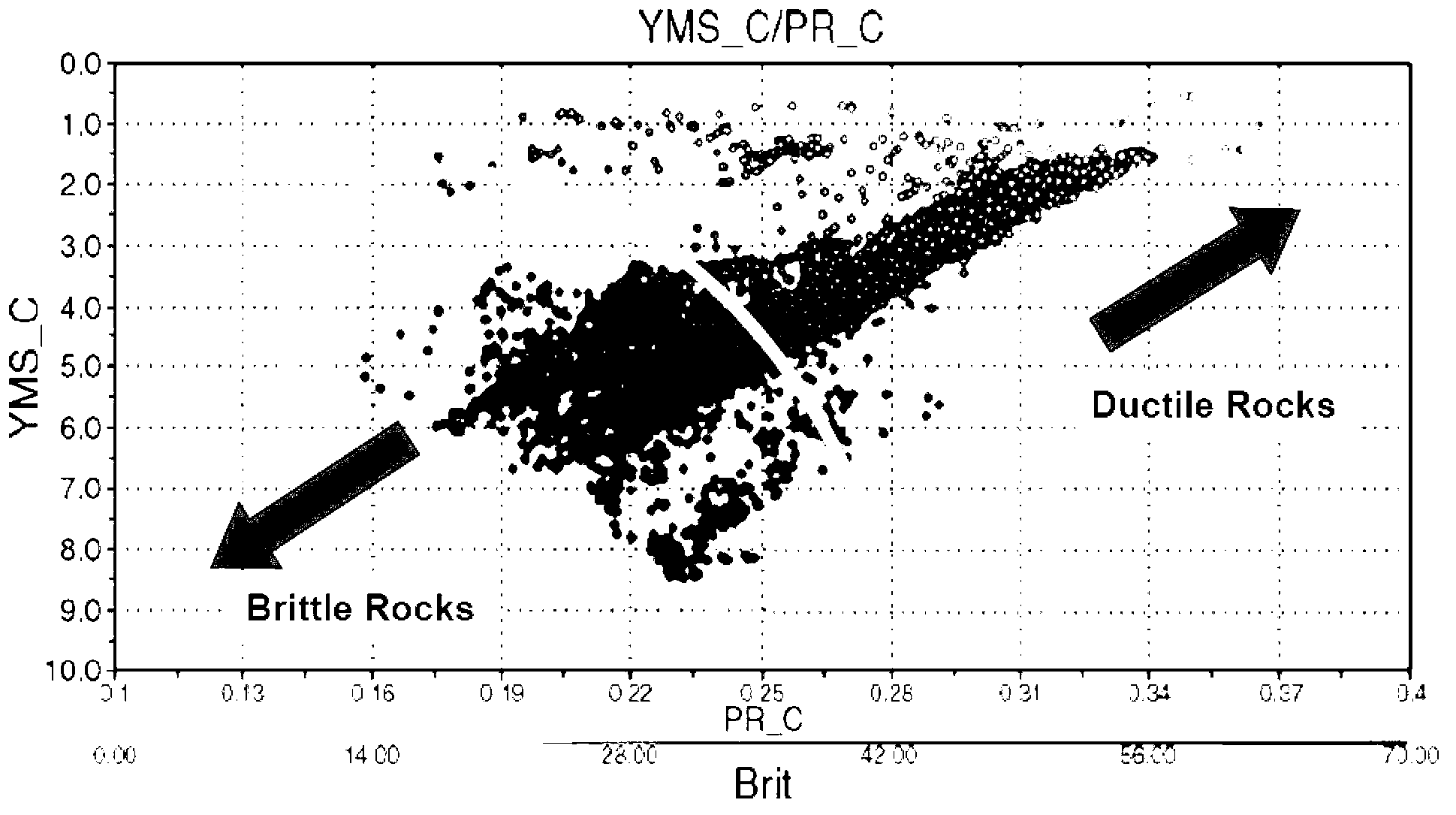

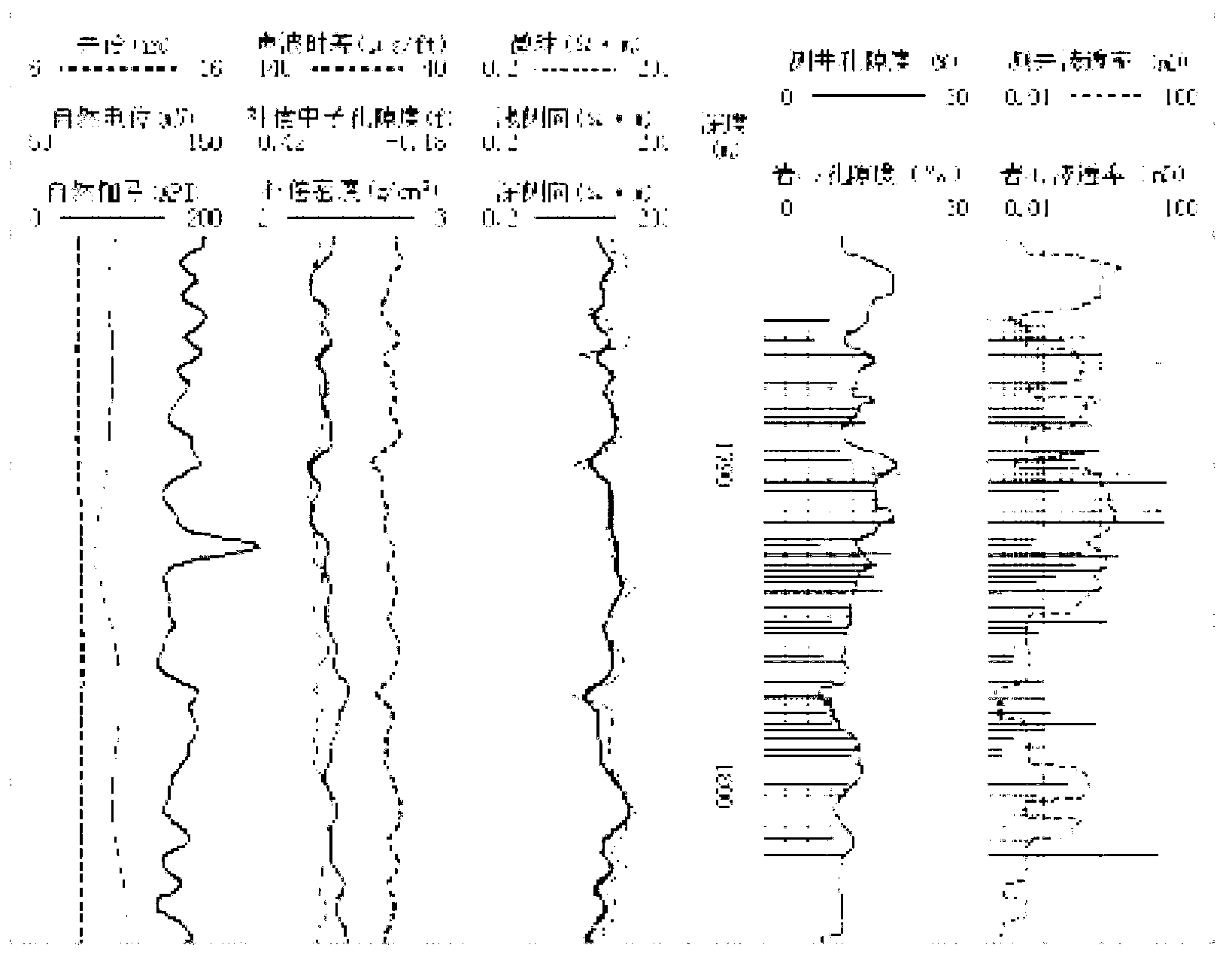

Unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog method and device

InactiveCN103256046ASolve the problem that interwell information cannot be obtainedEasy accessBorehole/well accessoriesThree-dimensional spaceYoung's modulus

The invention provides an unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog method and device. The method includes the steps of determining an unconventional oil and gas reservoir horizontal well section object region; obtaining three-dimensional earthquake prestack gathered data in the object region, conducting elastic parametric inversion and obtaining a three-dimensional space elastic parameter data body, wherein the three-dimensional space elastic parameter data body comprises a rock mass poisson ratio and Young modulus; calculating a rock mass brittleness index according to the rock mass poisson ratio and the Young modulus; establishing a rock mass mechanical parameter model based on three-dimensional grid nodes according to the three-dimensional space elastic parameter data body and the rock mass brittleness index; calculating stress information on the three-dimensional grid nodes, and generating a three-dimensional stress field distribution model; conducting full- fracture-length three-dimensional numerical simulation of fractures in the fracturing process according to the rock mass mechanical parameter model and the three-dimensional stress field distribution model. The unconventional oil and gas reservoir horizontal well section full-length-fracture fracturing parameter analog method and device can improve effectiveness and accuracy of unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog, and improve the reserve utilization degree of a reservoir stratum.

Owner:PEKING UNIV

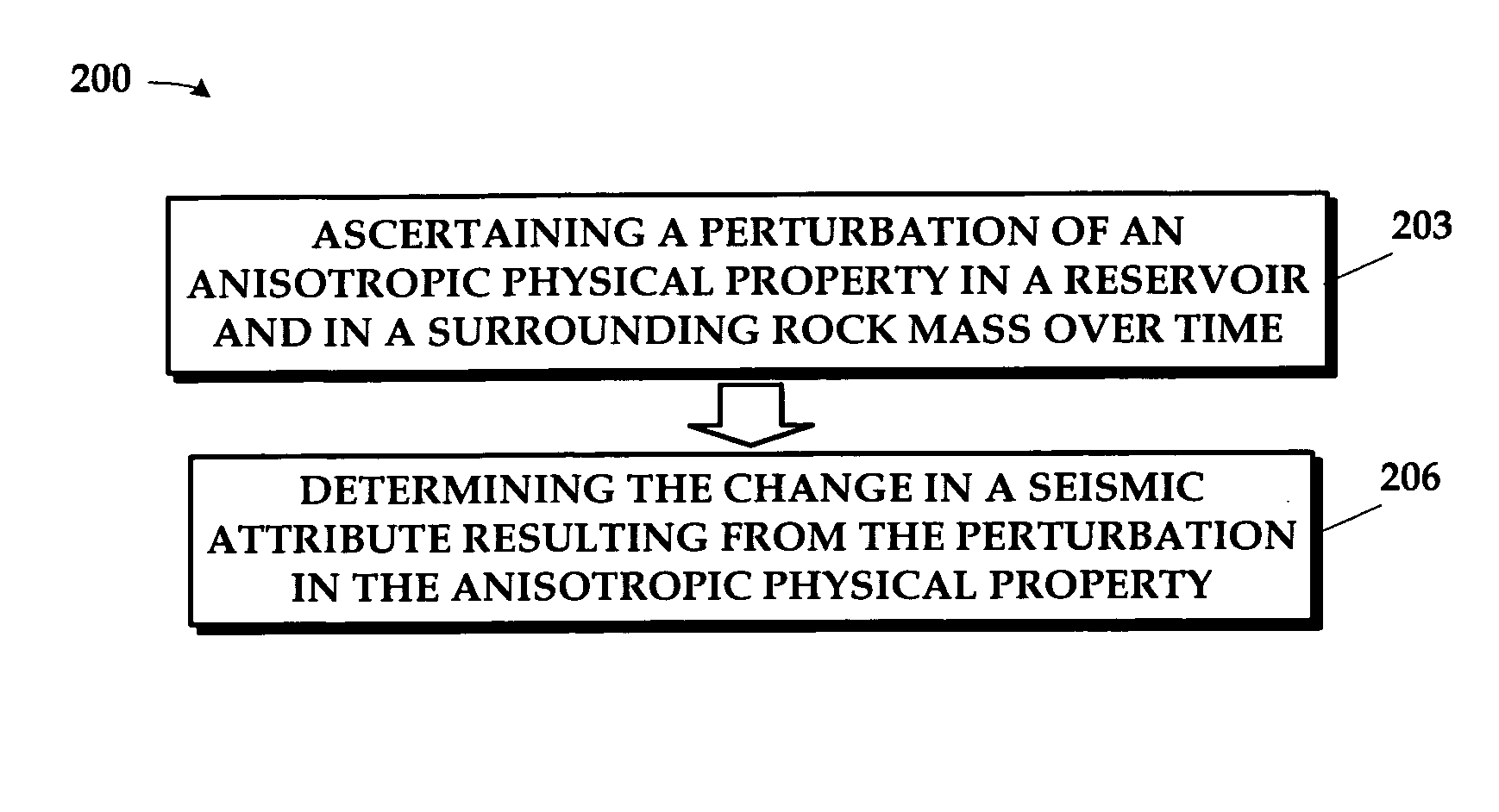

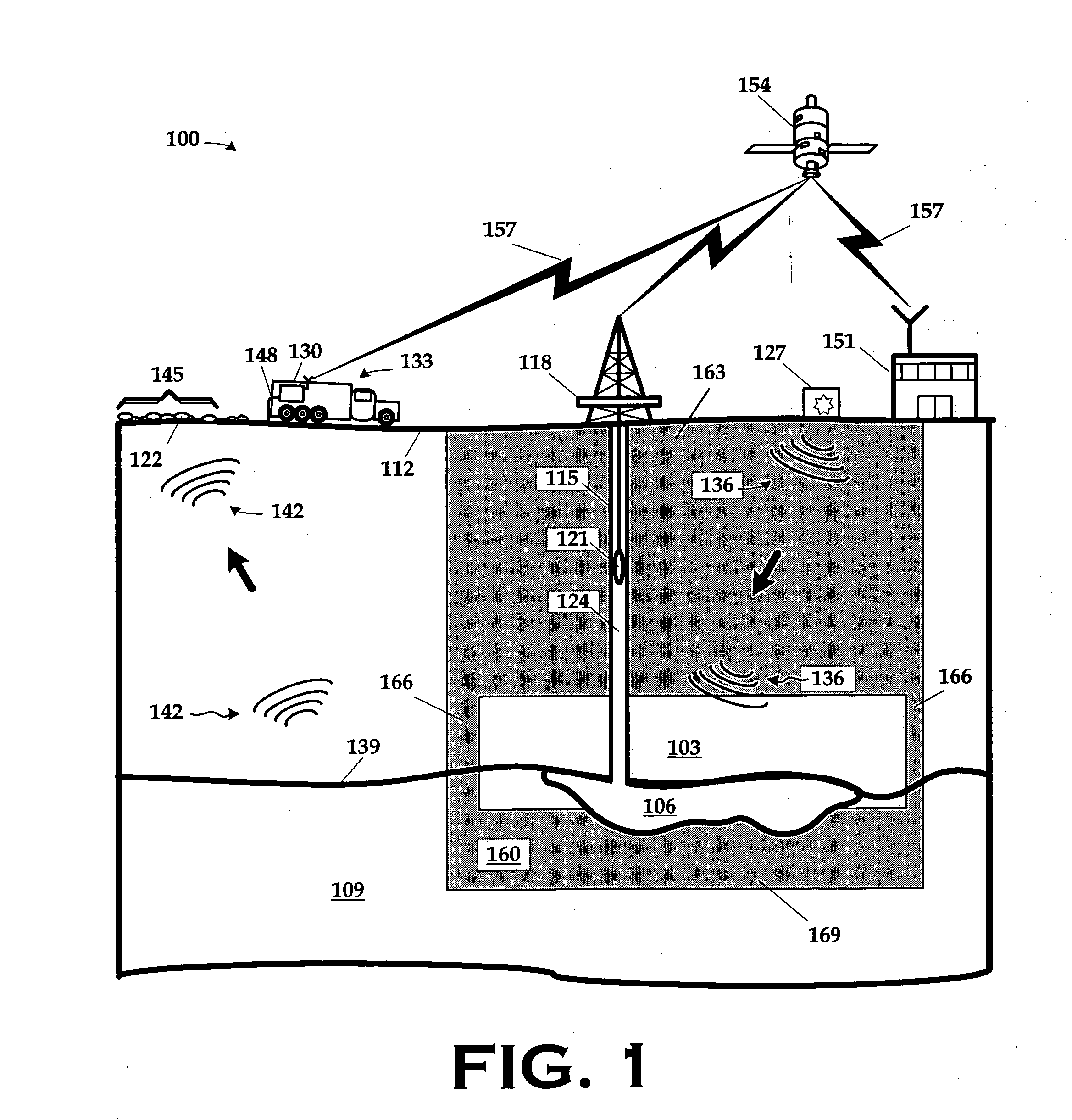

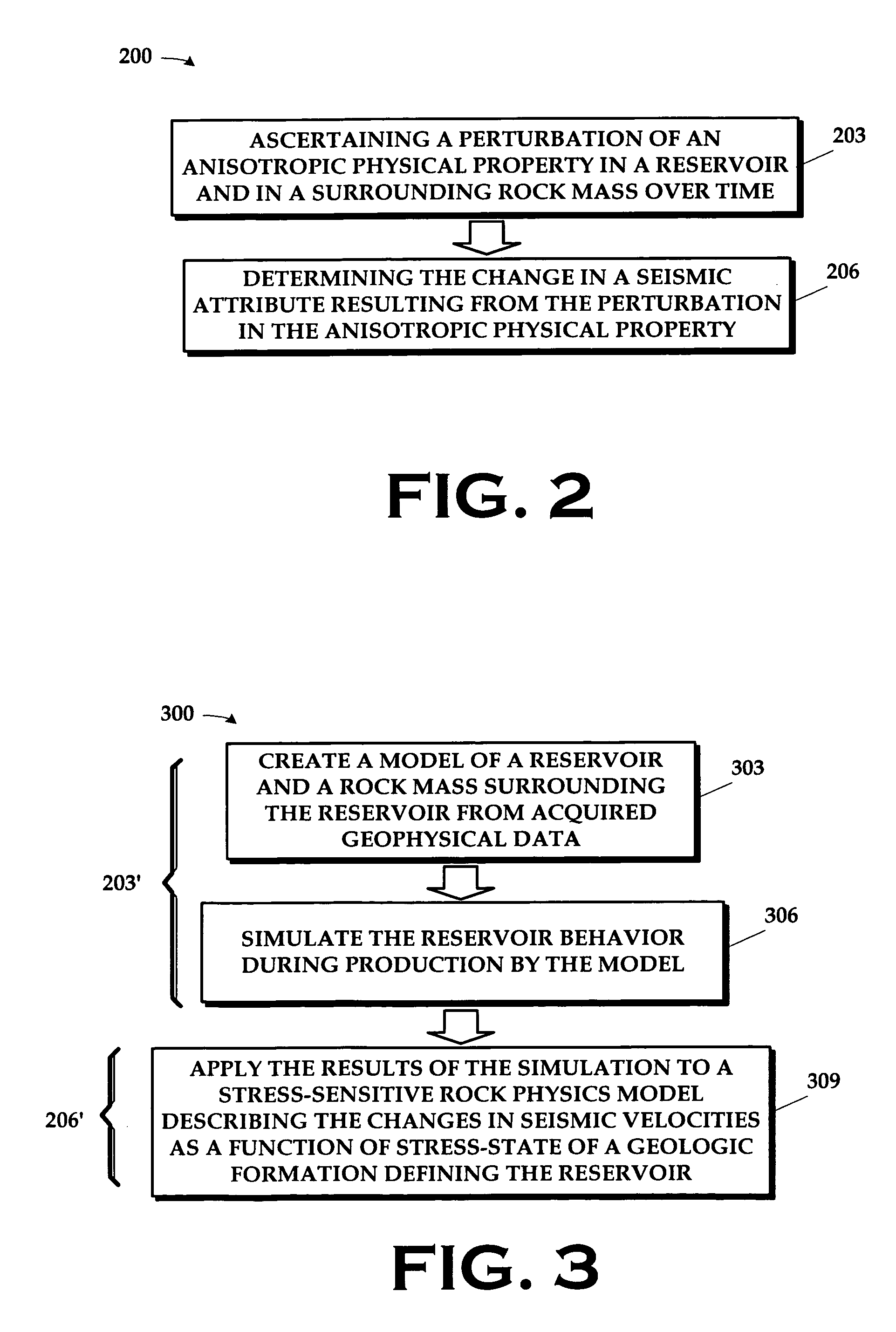

Determination of anisotropic physical characteristics in and around reservoirs

InactiveUS20060153005A1Carbon-dioxide storageSeismic signal processingSeismic attributeStressed state

A method and apparatus for use in estimating stress fields in a geological formation are disclosed. The method includes ascertaining a perturbation of stress in the triaxial stress state in a reservoir and in a surrounding rock mass over time; and determining the change in a seismic attribute resulting from the perturbation in the stress. The apparatus includes a program storage medium encoded with instructions that, when executed by a computing device, perform such a method or a computing system programmed to perform such a method.

Owner:WESTERNGECO LLC

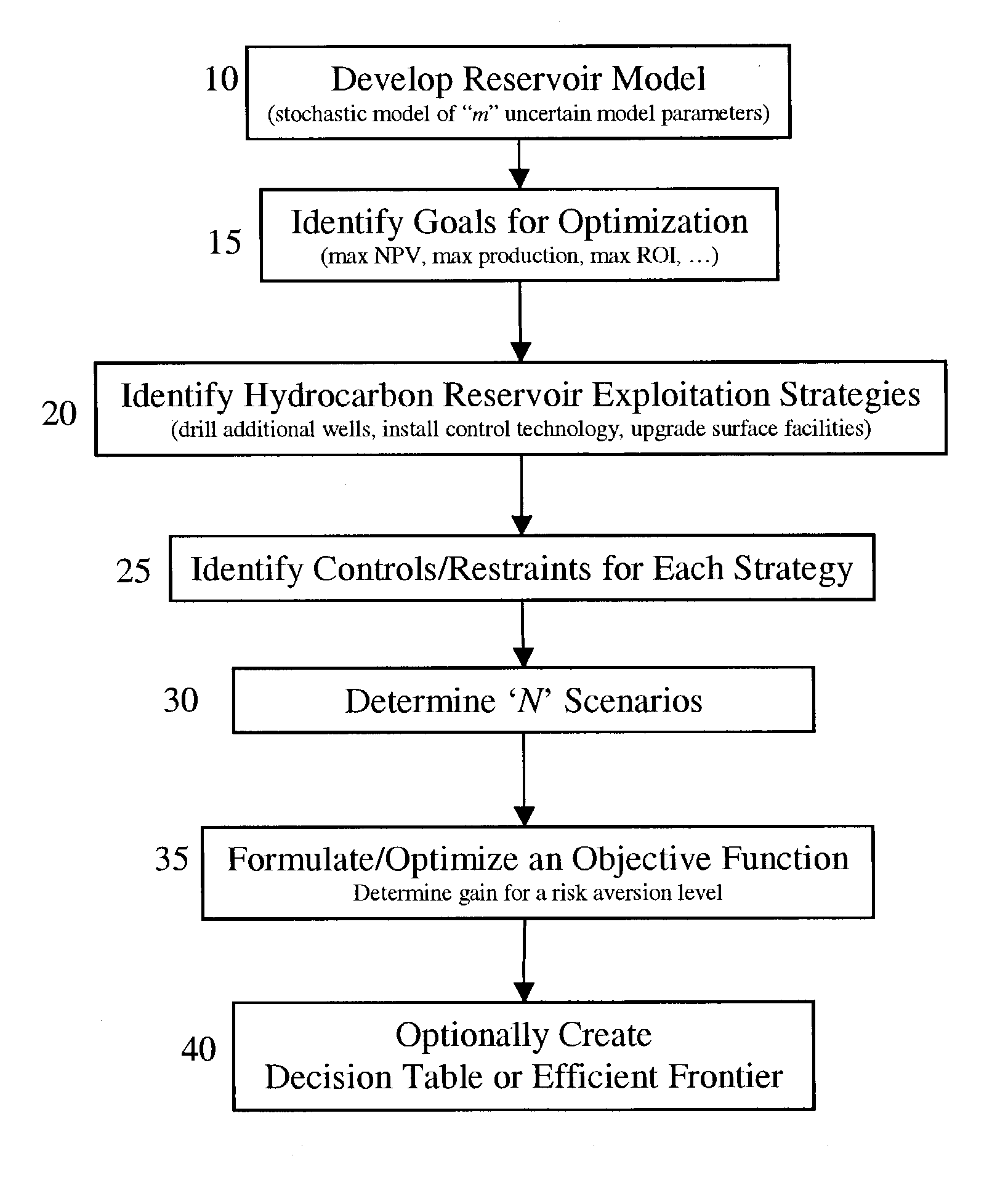

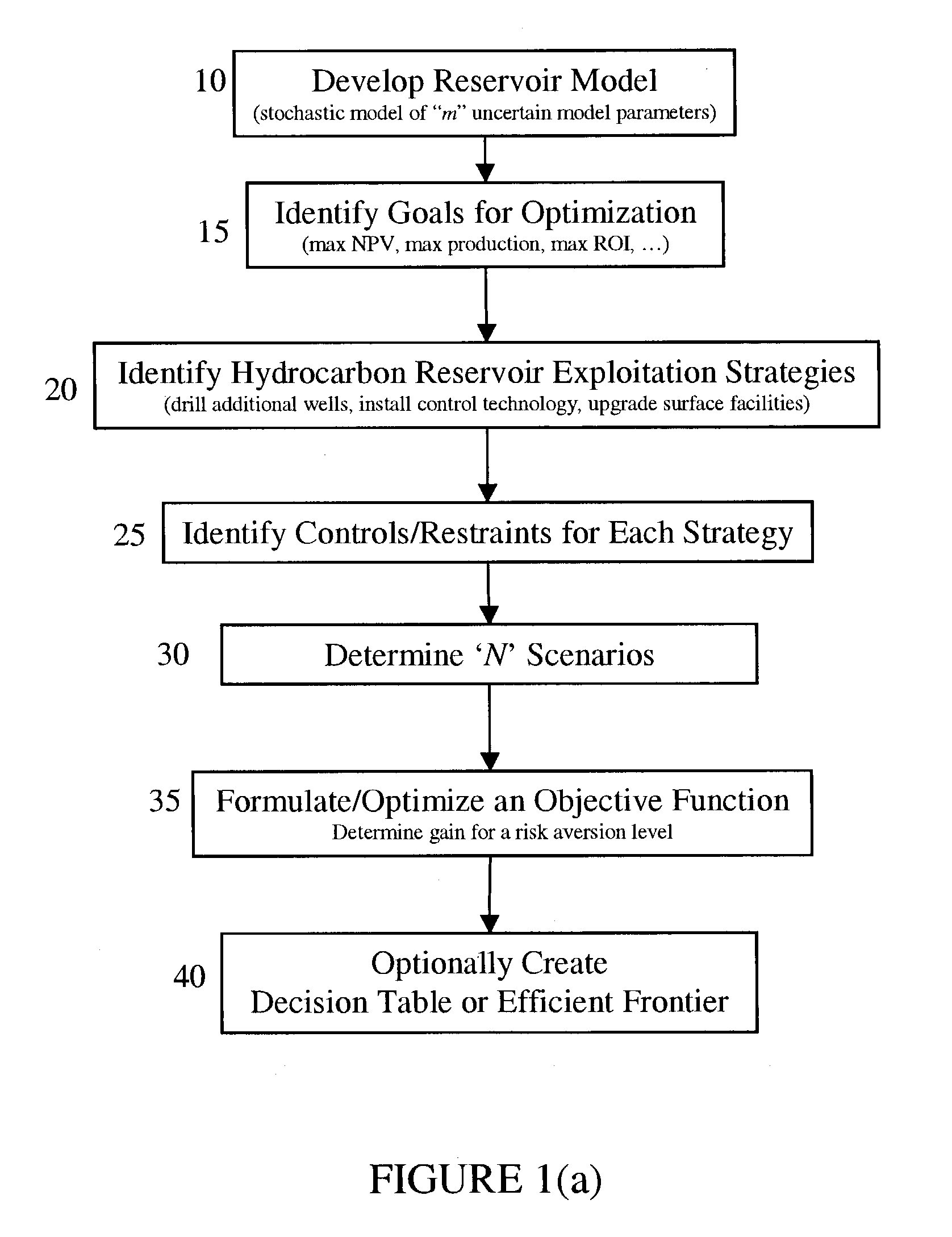

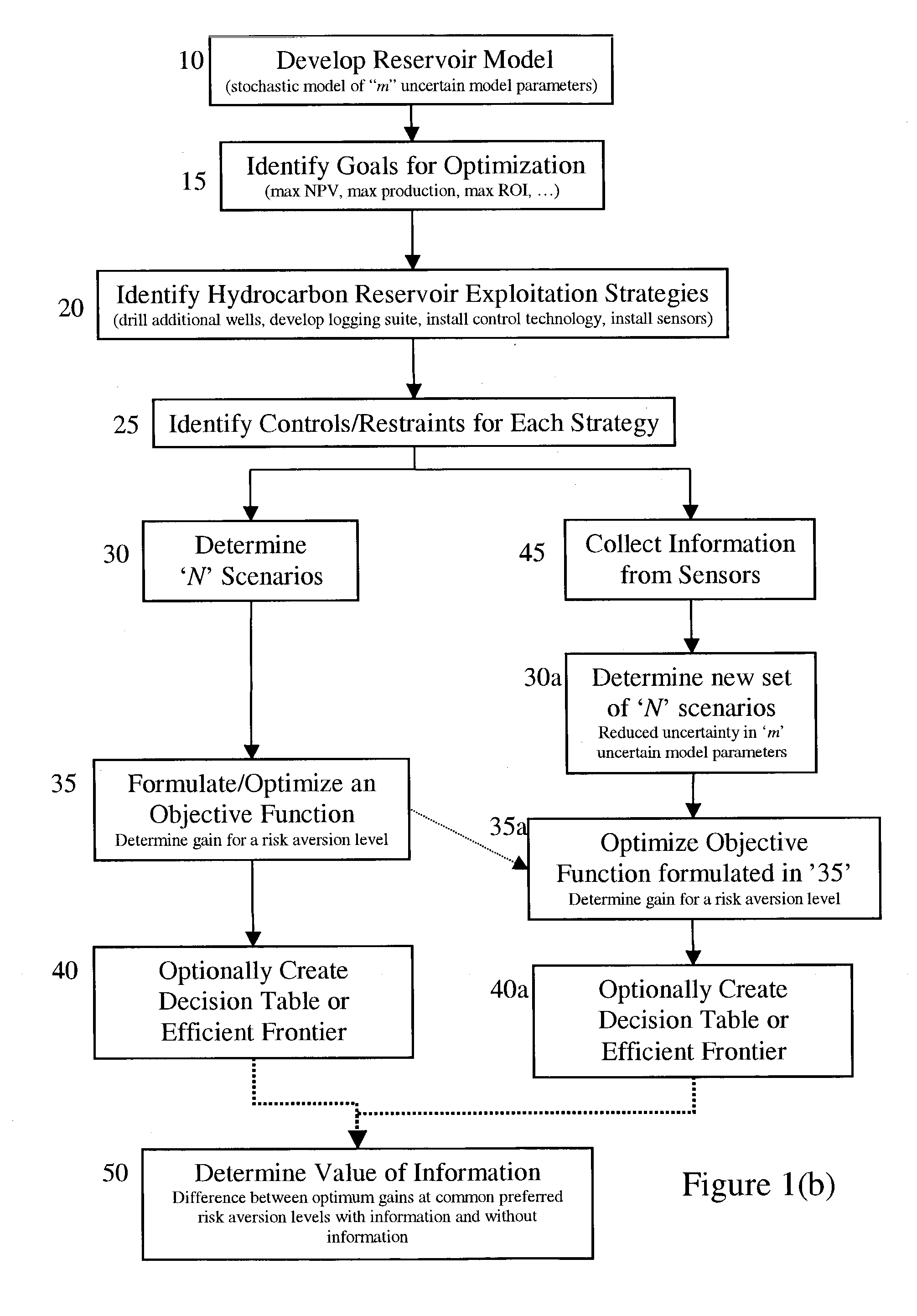

Tools for decision-making in reservoir risk management

ActiveUS20030225606A1FinanceComputation using non-denominational number representationEngineeringStochastic calculus

The present invention discloses a method for performing a stochastic analysis of one or more hydrocarbon reservoir exploitation strategies taking into consideration one or more uncertain parameters. The method optimizes an objective function that considers the gain in value of a reservoir management goal attributable to these exploitation strategies. The methodology may be used to decide whether or not to implement a strategy. Alternatively, it may be used to decide which competing strategy will yield the maximum benefit. In another embodiment of the present invention, the value of information obtained from the installation of additional sensors or new measurements is also considered.

Owner:SCHLUMBERGER TECH CORP

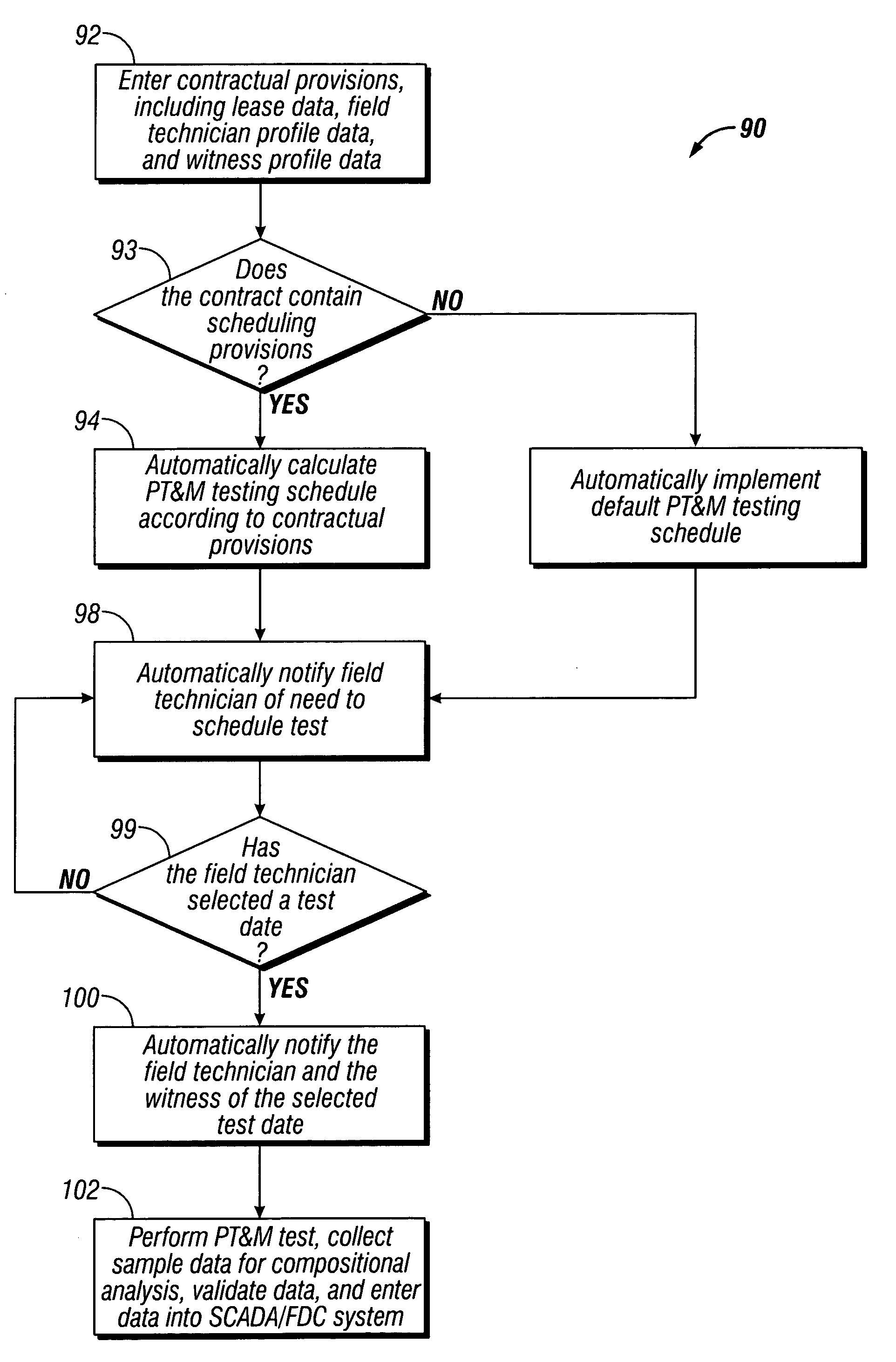

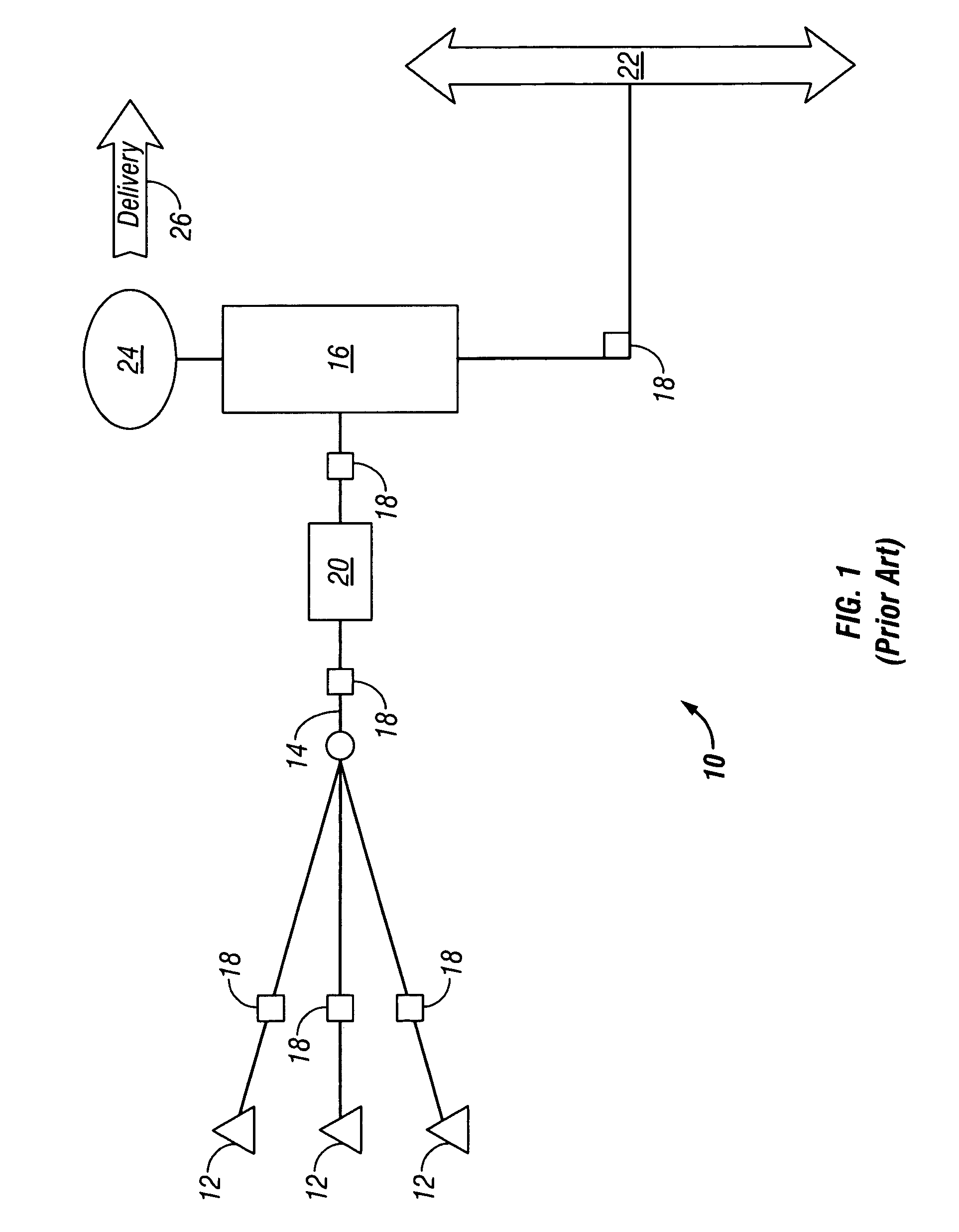

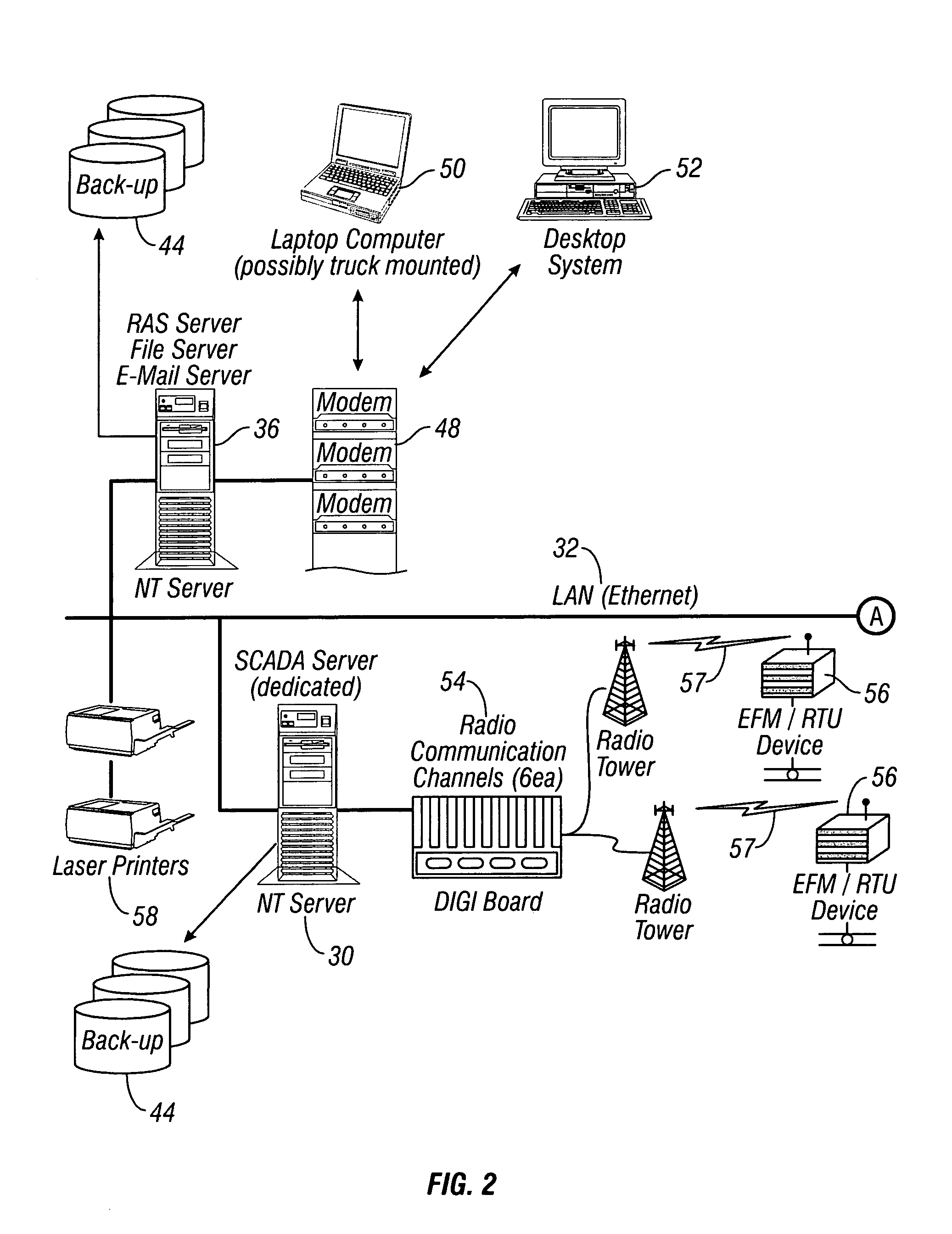

Method for automated management of hydrocarbon gathering systems

InactiveUS6978210B1Electric/magnetic detection for well-loggingPermeability/surface area analysisData storingData store

The invention is a method for automated management of hydrocarbon gathering systems. Measurement data is automatically collected from automated measurement and control devices that are located in a hydrocarbon production system The data that is collected is compared with data stored in a database. The comparison of data is used to automatically schedule tests of the plurality of automated measurement and control devices. The invention also automatically collects well test data, system balance data, and hydrocarbon composition data and uses the collected data to manage the hydrocarbon production and delivery process. The invention also automatically generates periodic grid reports concerning the status of the gathering system.

Owner:CONOCOPHILLIPS CO

Near wellbore modeling method and apparatus

ActiveUS7451066B2Electric/magnetic detection for well-loggingSeismic signal receiversModel methodScale structure

Owner:SCHLUMBERGER TECH CORP

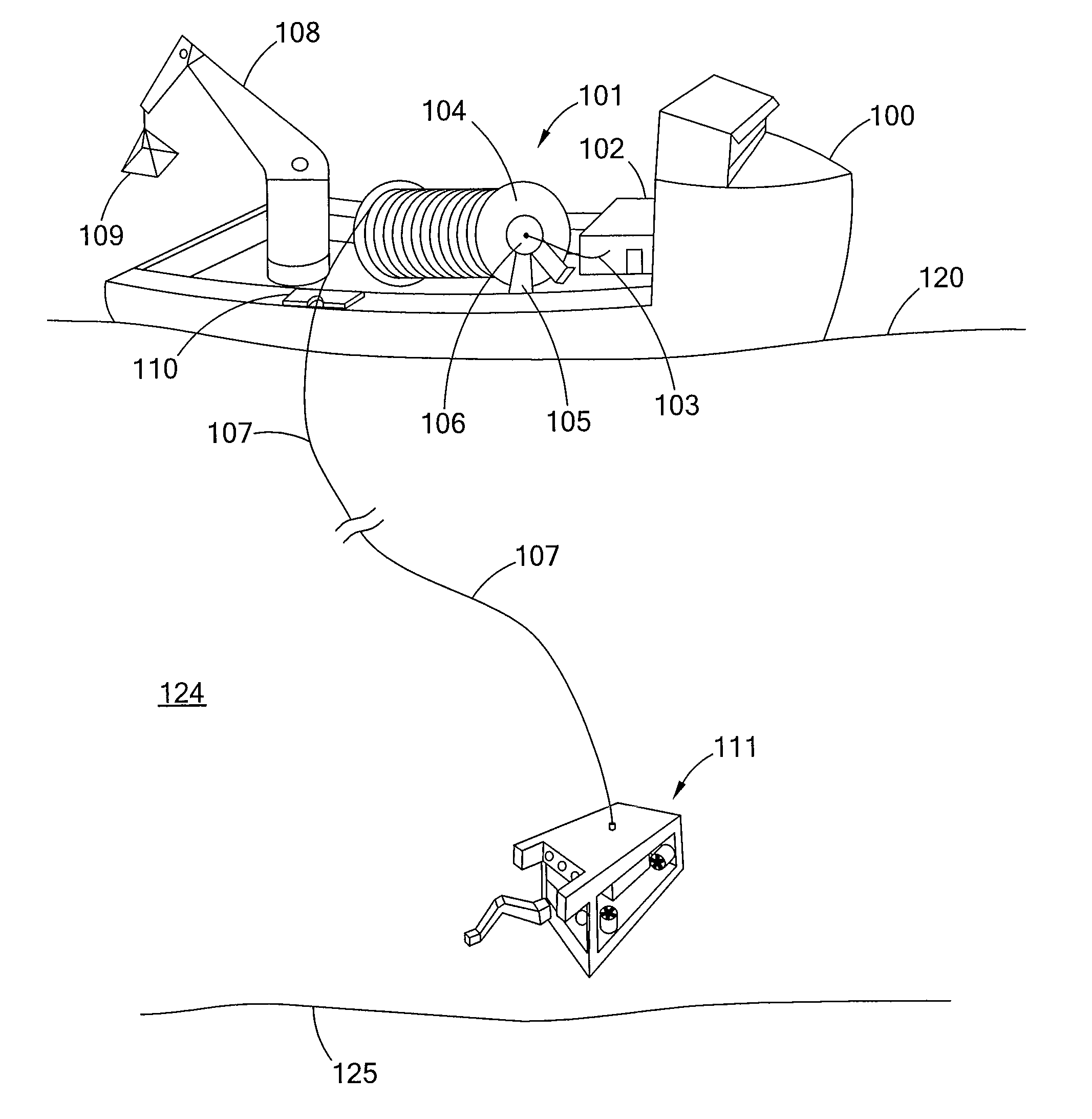

High power laser photo-conversion assemblies, apparatuses and methods of use

ActiveUS20120266803A1Without substantial loss of powerRadiation pyrometryHollow article cleaningFiberHigh power lasers

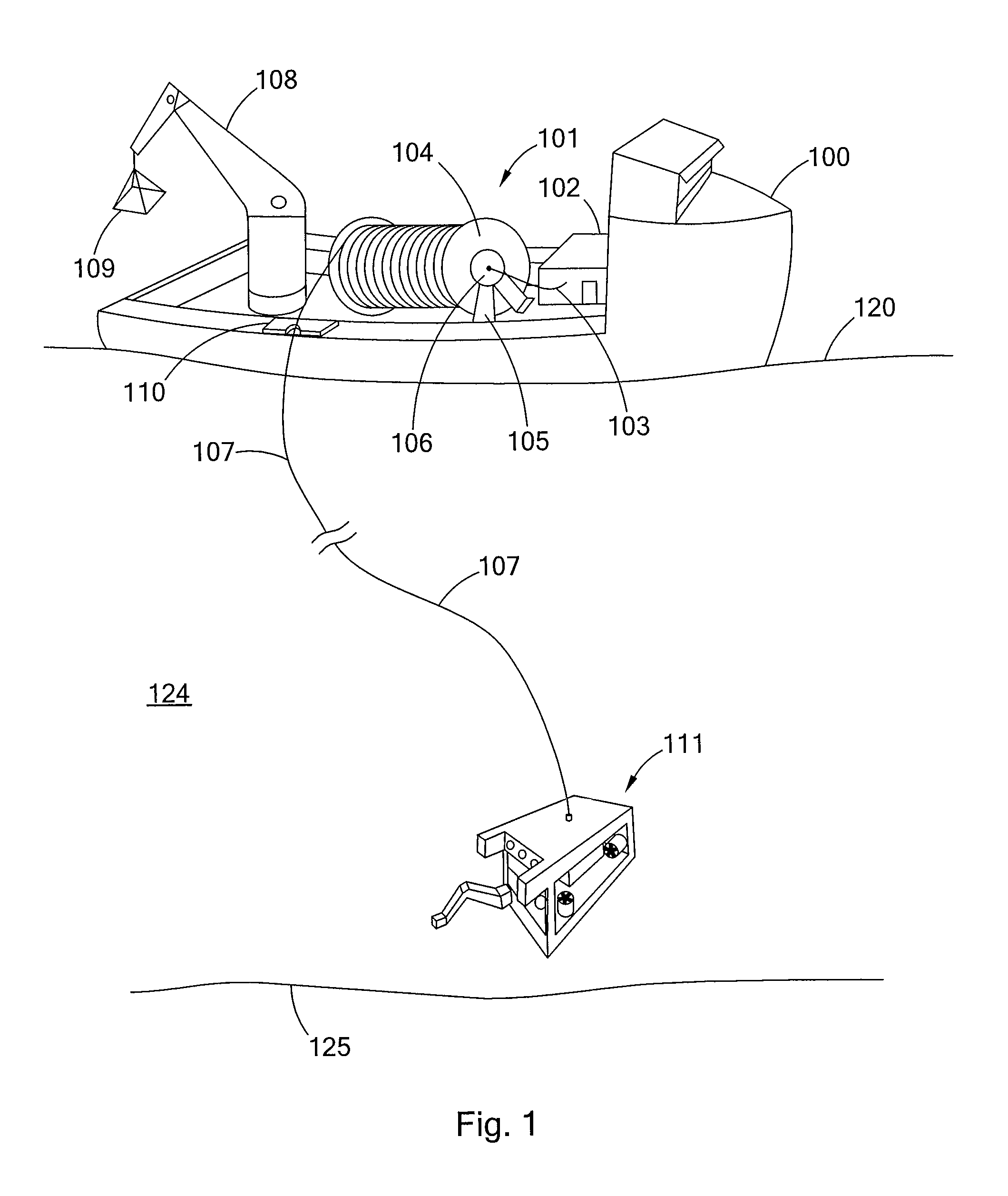

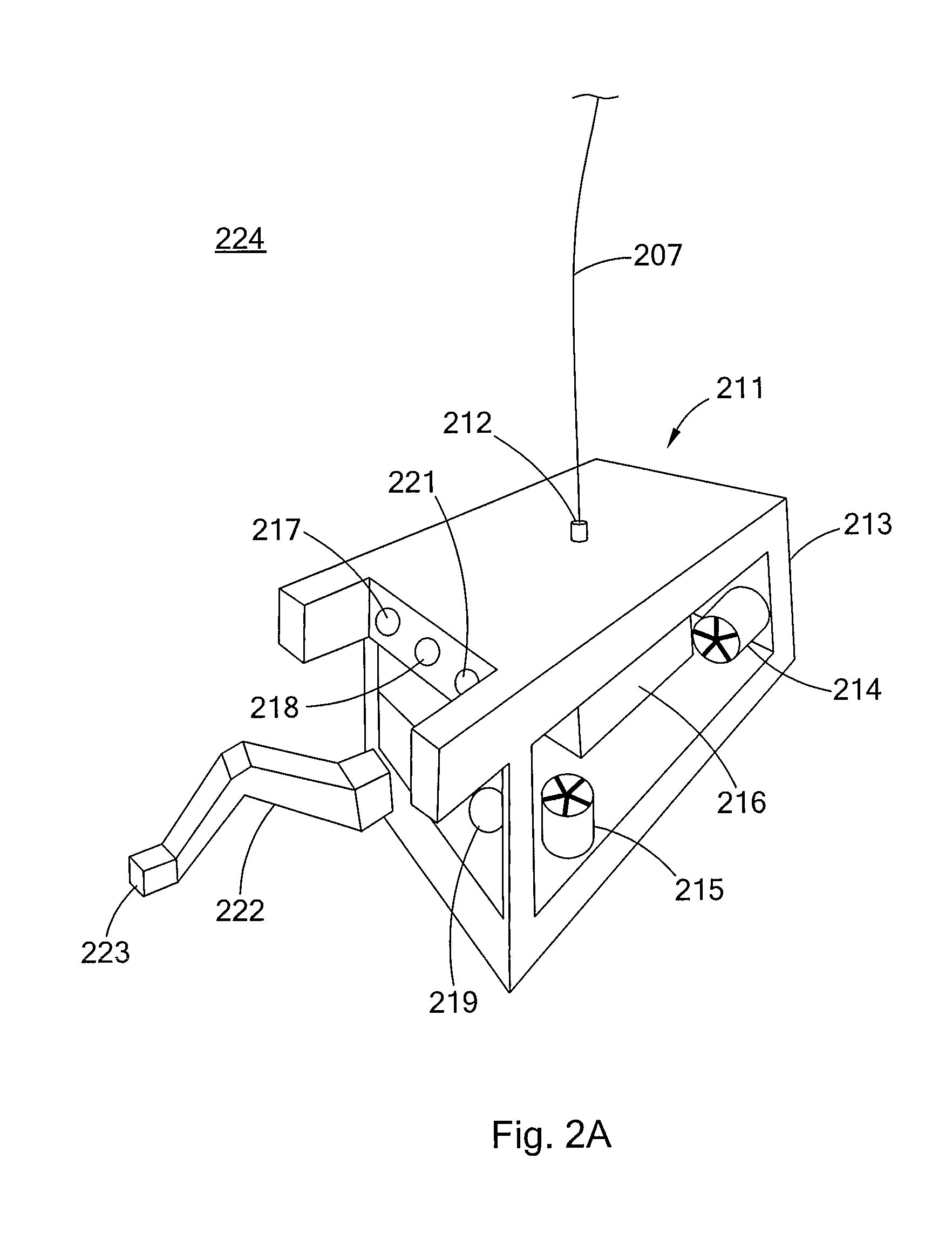

There is provided a high power laser system for powering a remotely located laser device, such as an ROV, using a high power laser fiber optic tether and a photo-conversion device, such as a laser photovoltaic assembly. Laser device systems, such as ROV systems that utilizes a high power laser cutting and / or cleaning tools are also provided.

Owner:FORO ENERGY

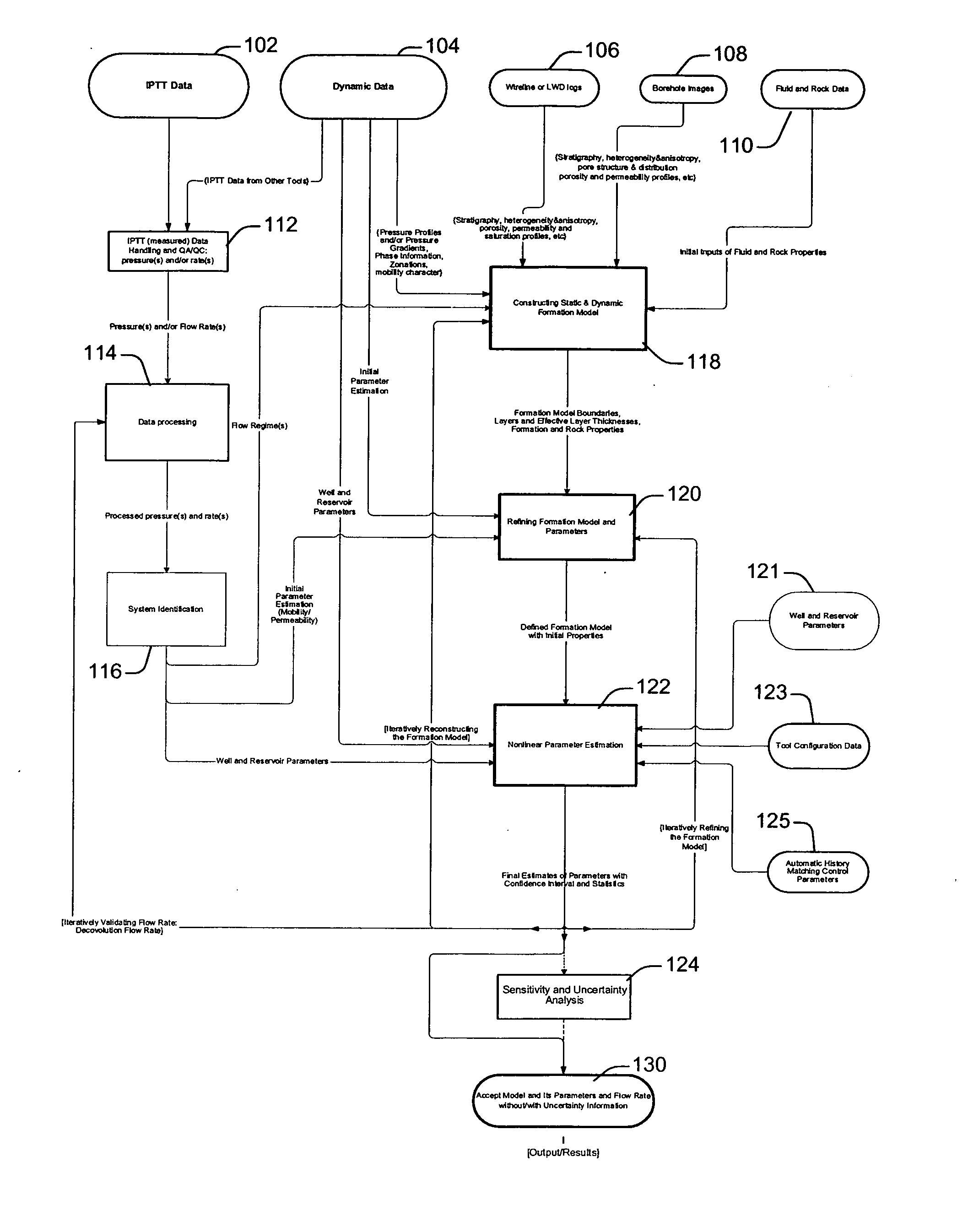

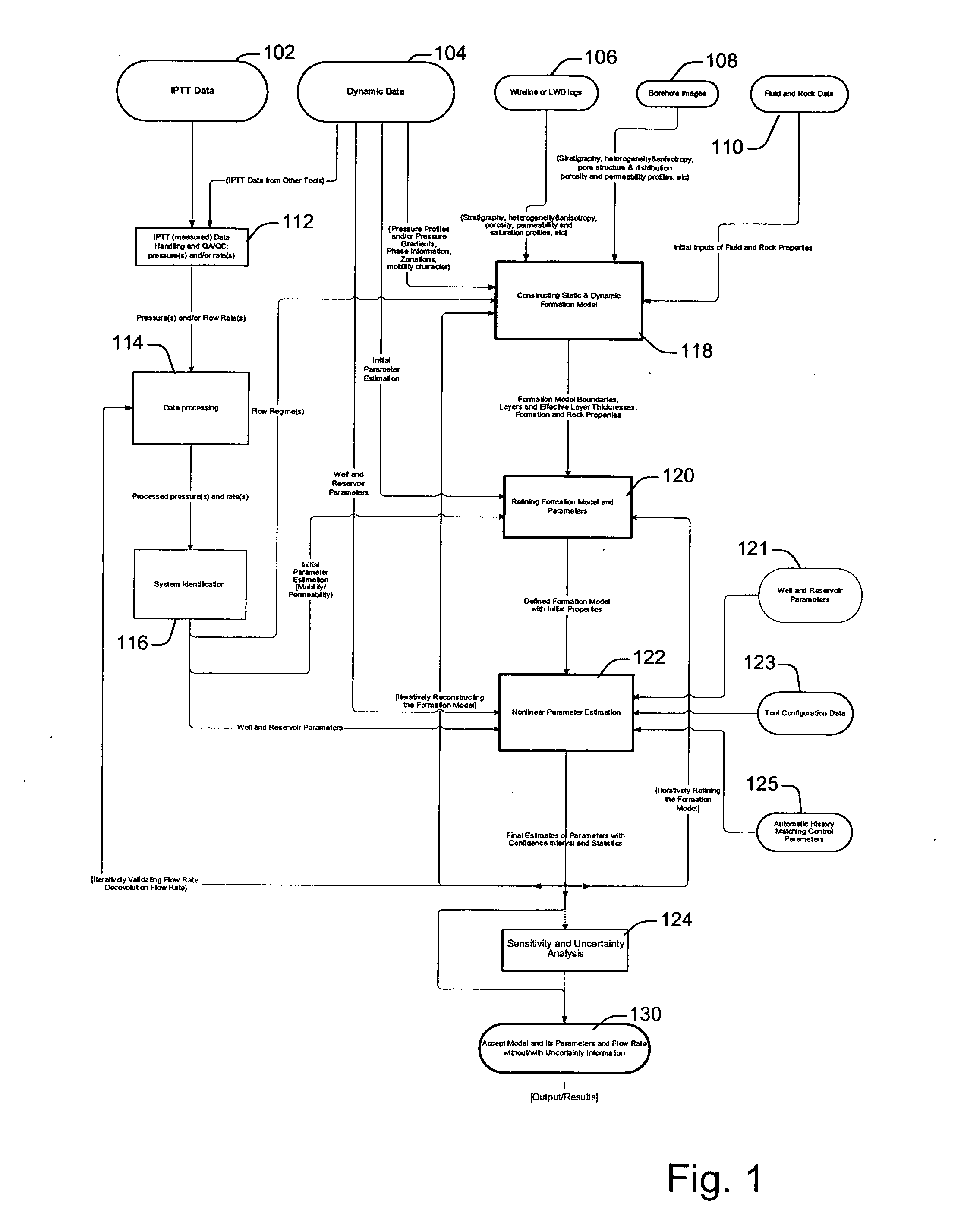

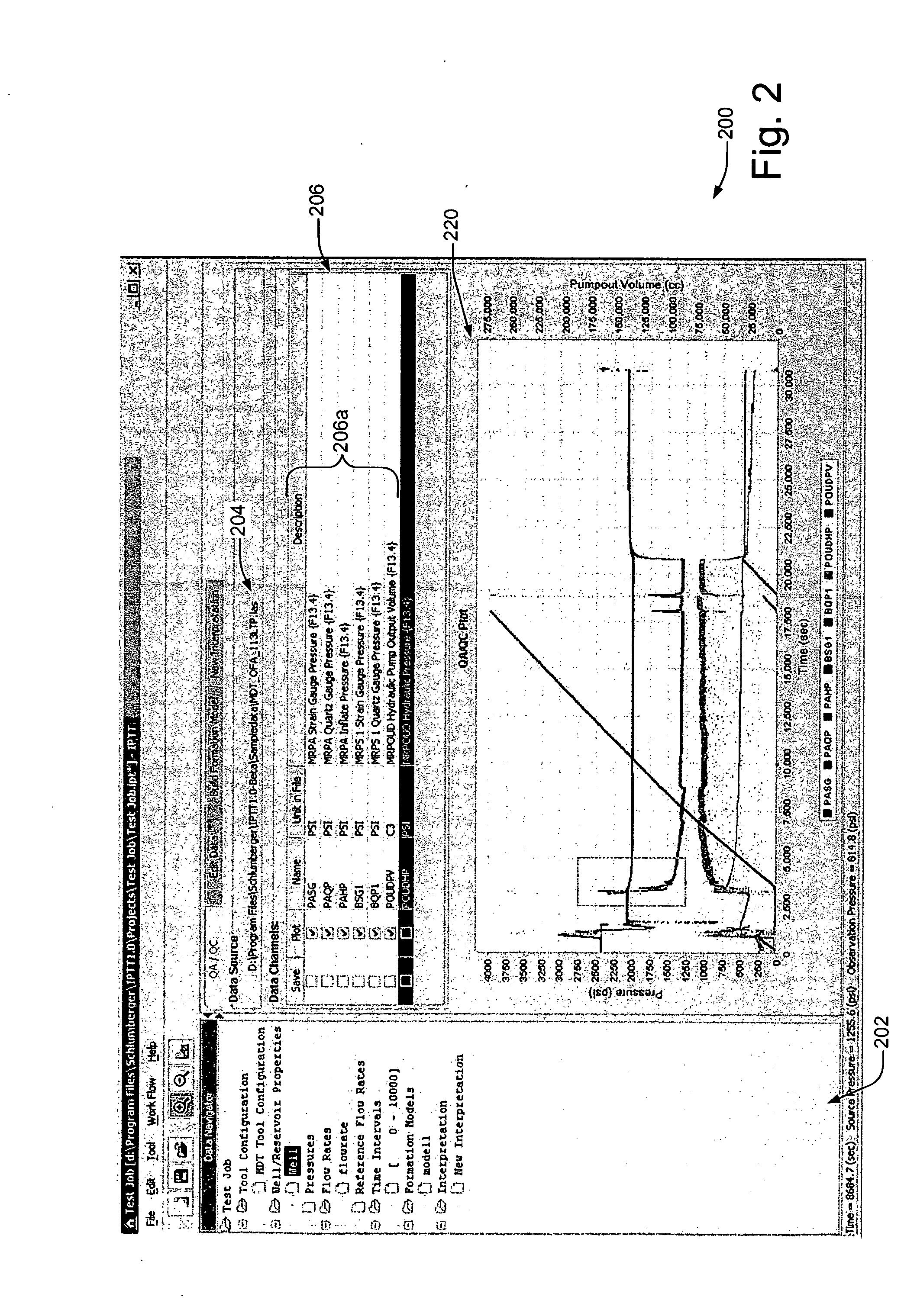

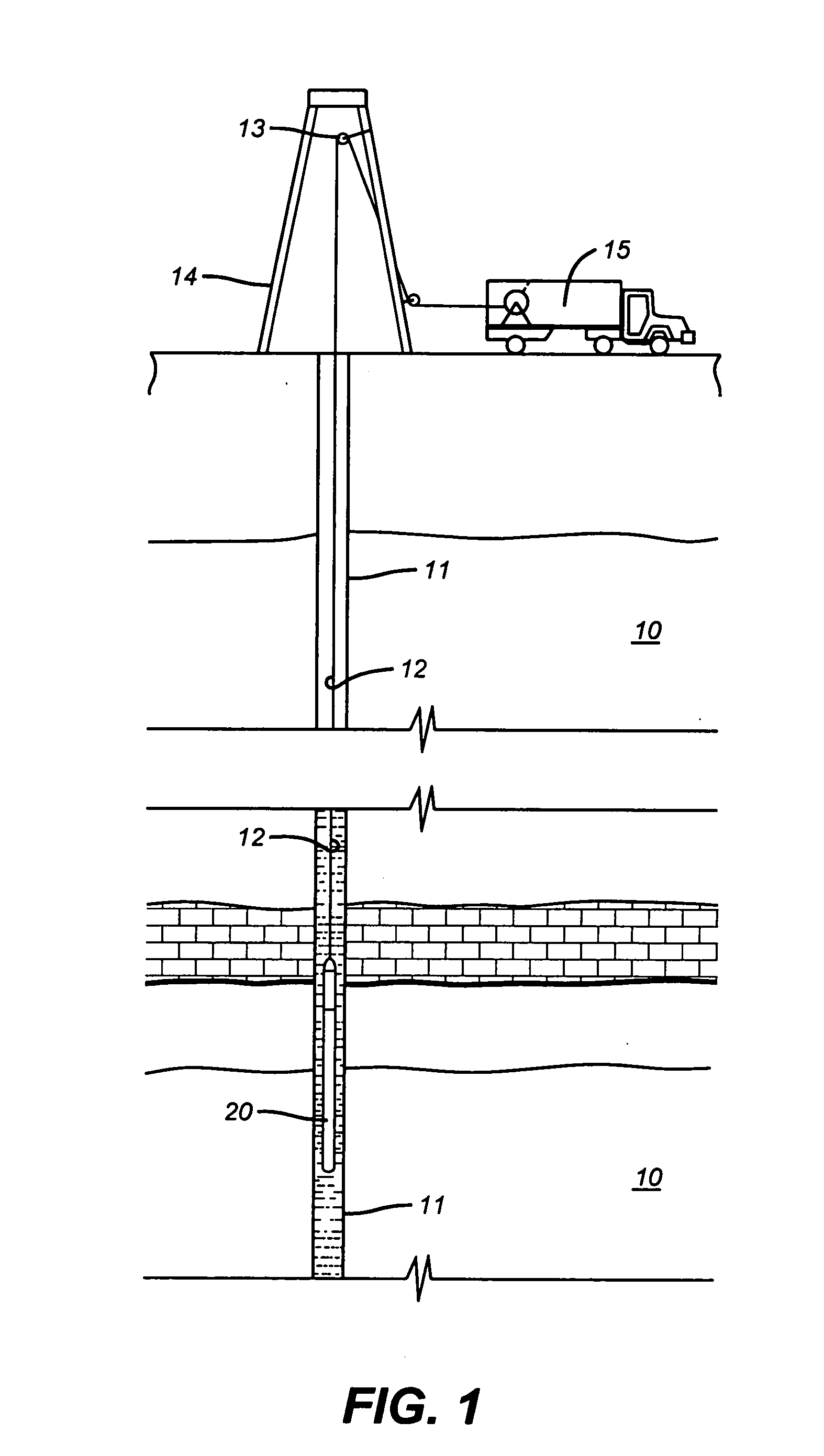

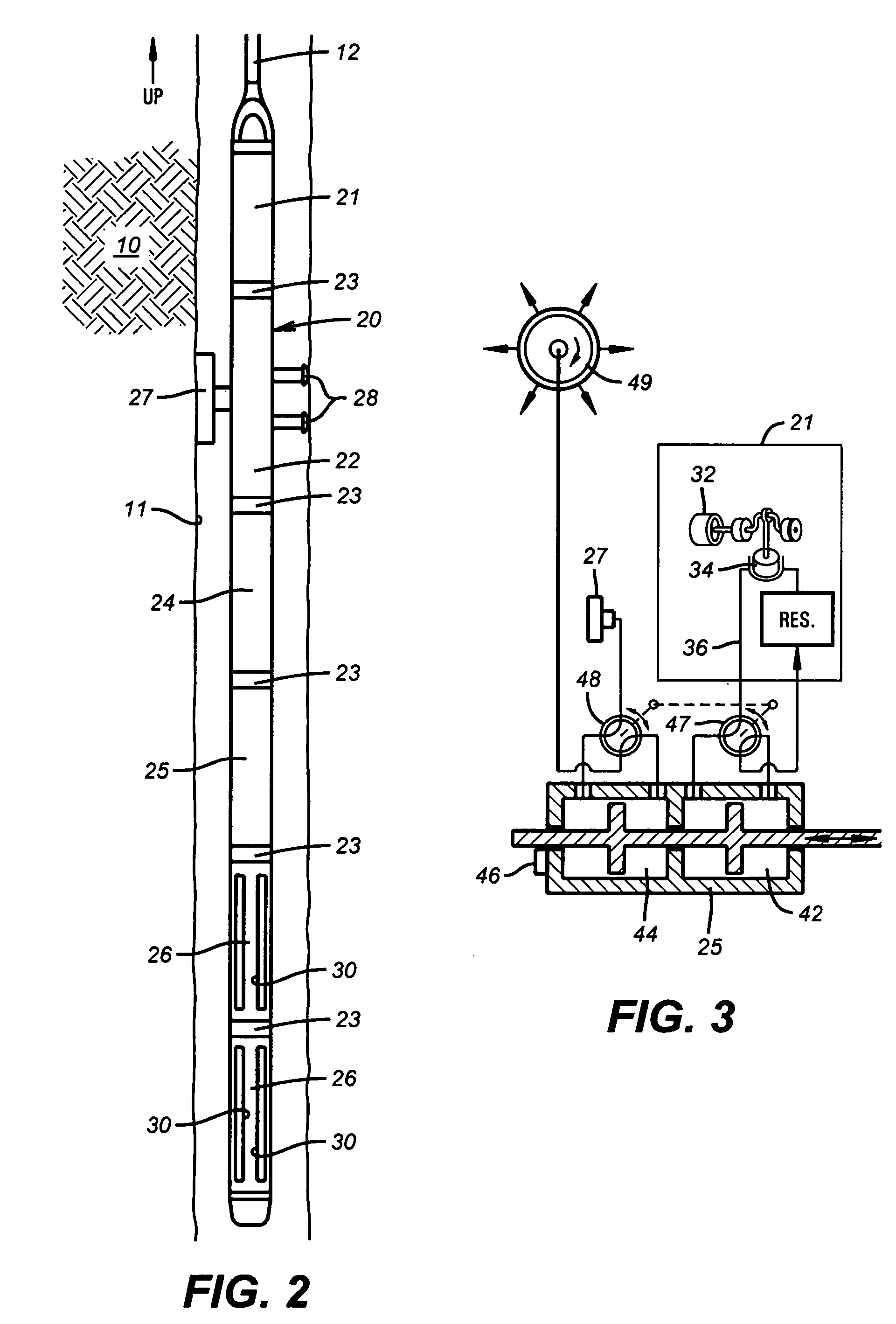

System and methods of characterizing a hydrocarbon reservoir

ActiveUS20060241867A1Facilitating in performing data processing operationEasy to operateElectric/magnetic detection for well-loggingPermeability/surface area analysisCompressibilityWork flow

A technique is described for interpretation of IPTT tests. In one implementation, the technique may be configured or designed to standardize the complete interpretation procedure of IPTT in a heterogeneous reservoir, using if available, modern wireline logs (such as, for example, nuclear magnetic resonance and imaging), dynamic data from wireline formation testers and / or any other relevant information (such as, for example, geological description, core data and local knowledge) as constraints on the interpretation. Additionally, an iterative method may be used to define formation layering. An advanced regression technology may also be used to obtain optimized horizontal and vertical permeabilities of reservoir layers. Further a graphical user interface (GUI) based IPTT workflow technique of the present invention provides an integrated user-friendly interpretation platform for analyzing formation testing pressures and flow rate measurements in order to estimate the values and associated uncertainties of local characteristics of a hydrocarbon reservoir such as, for example, local permeability, local reservoir pressure, local compressibility, etc.

Owner:SCHLUMBERGER TECH CORP

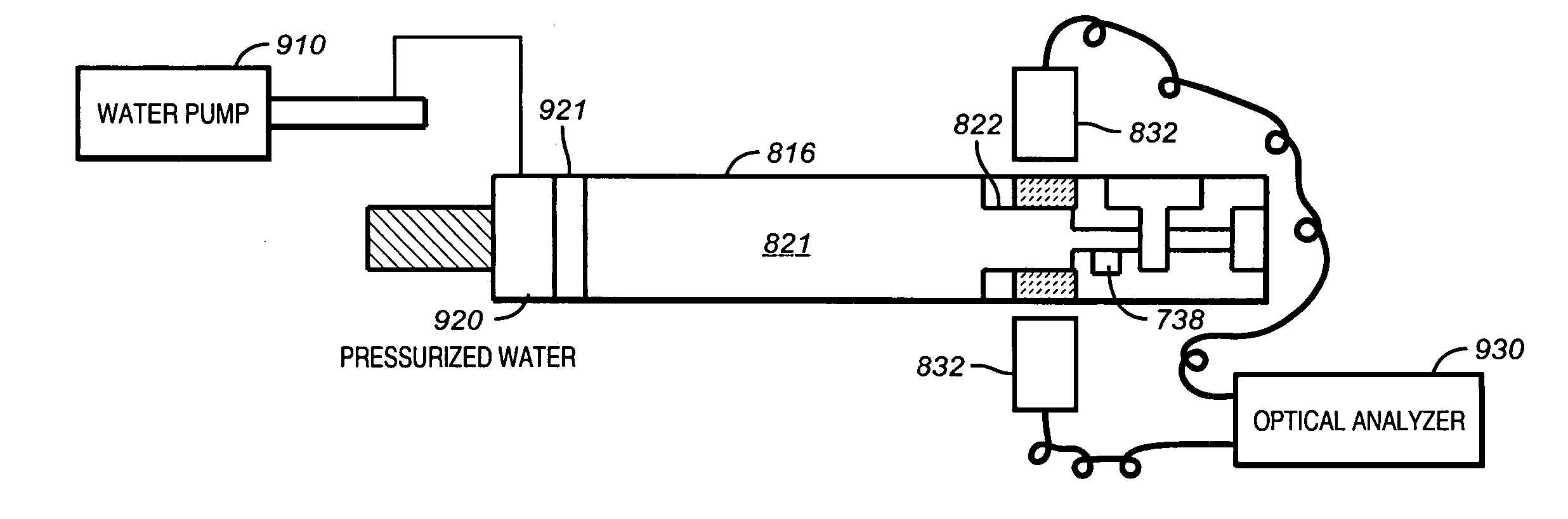

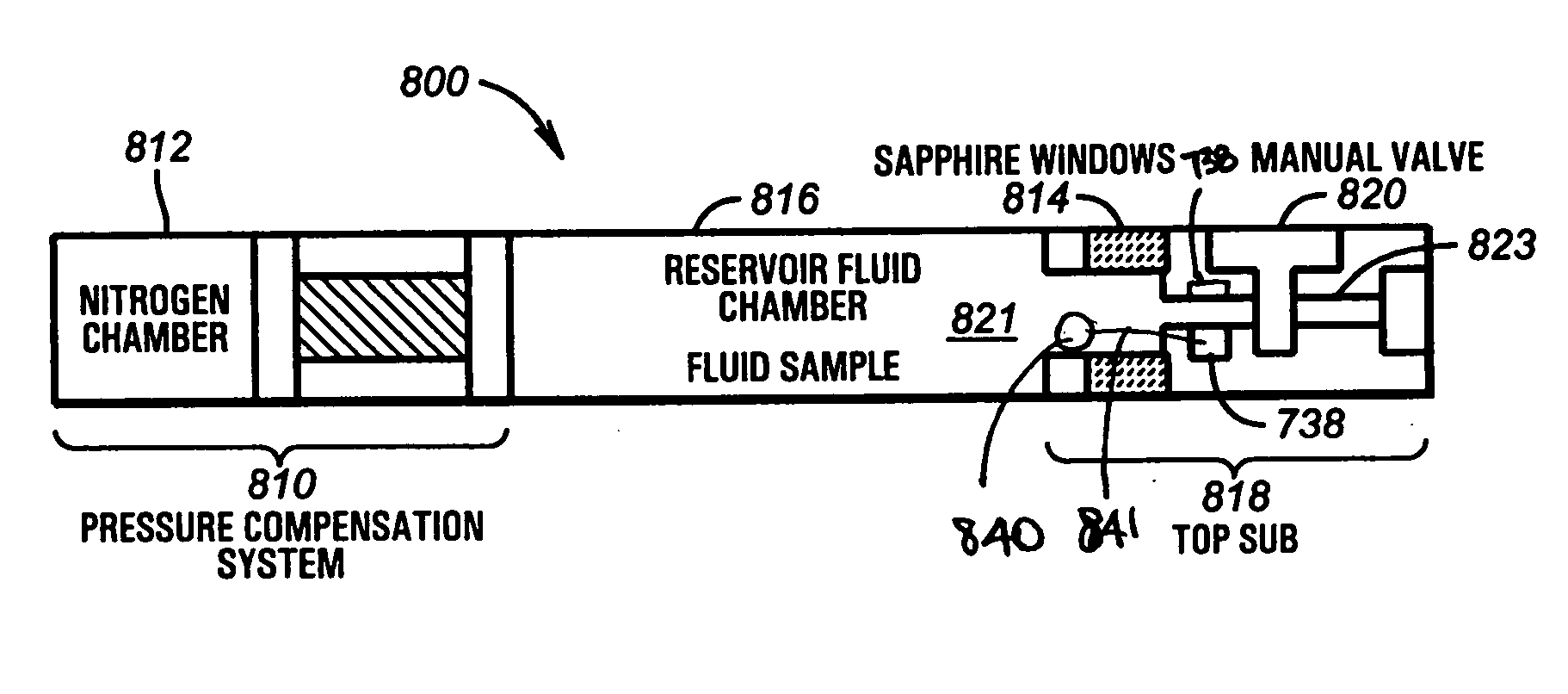

Method and apparatus for an advanced optical analyzer

ActiveUS20040218176A1Eliminate riskThe result is accurateRadiation pyrometrySpectrum investigationSmall sampleAPI gravity

The present invention provides a sample tank having a window for introduction of electromagnetic energy into the sample tank for analyzing a formation fluid sample down hole or at the surface without disturbing the sample. Near infrared, mid infrared and visible light analysis is performed on the sample to provide a downhole in situ or surface on site analysis of sample properties and contamination level. The onsite analysis comprises determination of gas oil ratio, API gravity and various other parameters which can be estimated by a trained neural network or chemometric equation. A flexural mechanical resonator is also provided to measure fluid density and viscosity from which additional parameters can be estimated by a trained neural network or chemometric equation. The sample tank is pressurized to obviate adverse pressure drop or other effects of diverting a small sample.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com