Patents

Literature

1552 results about "High power lasers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

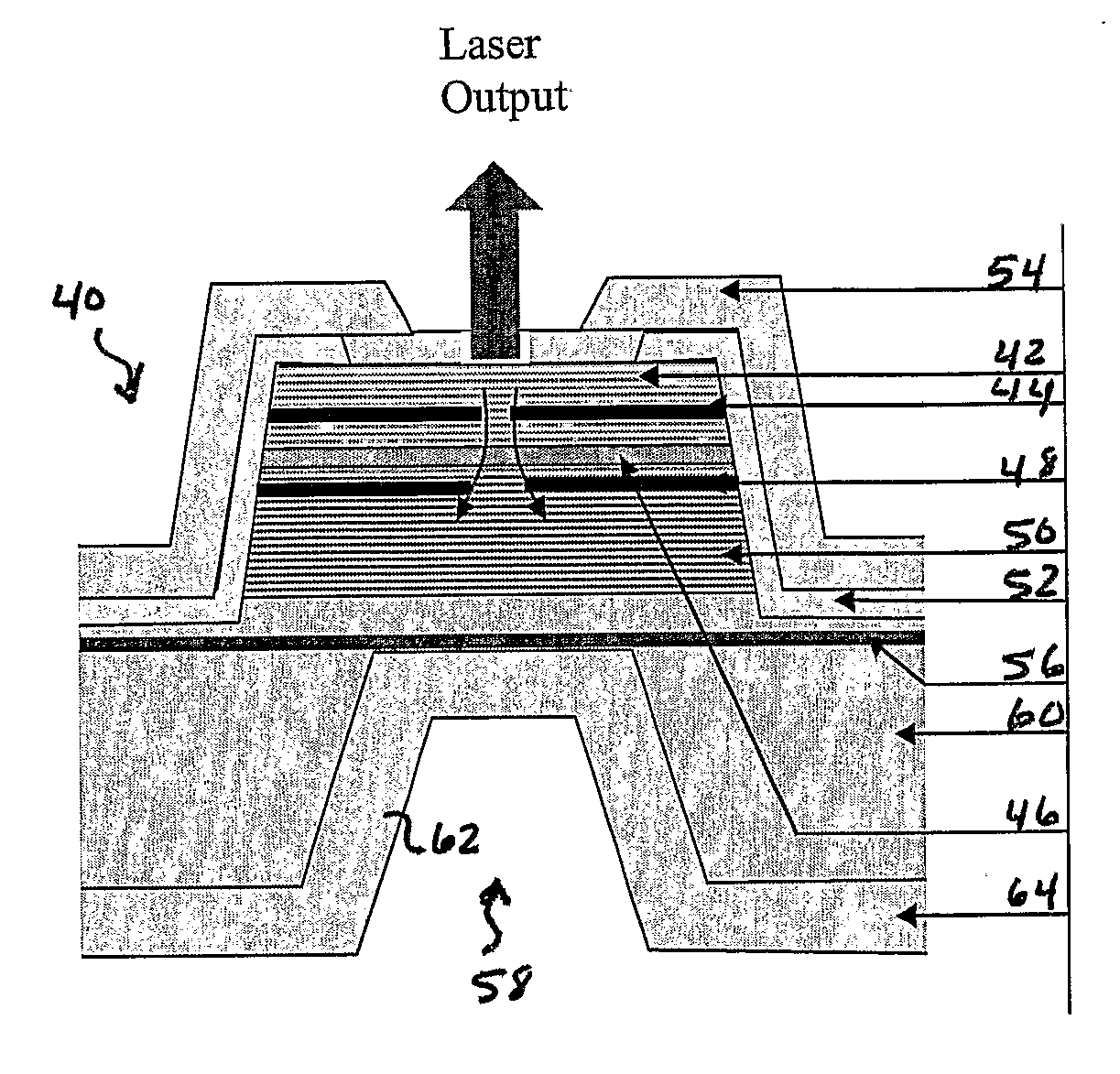

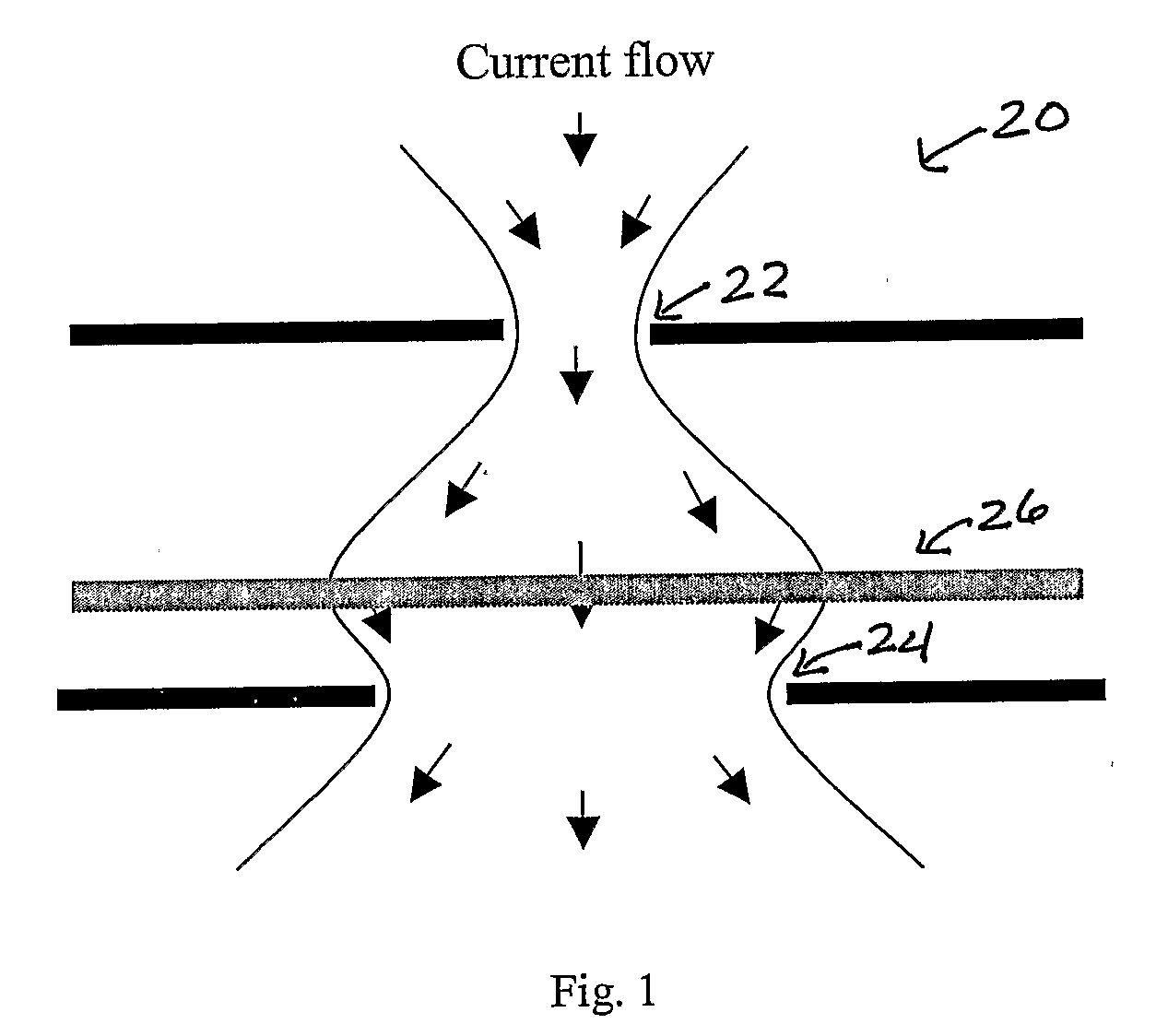

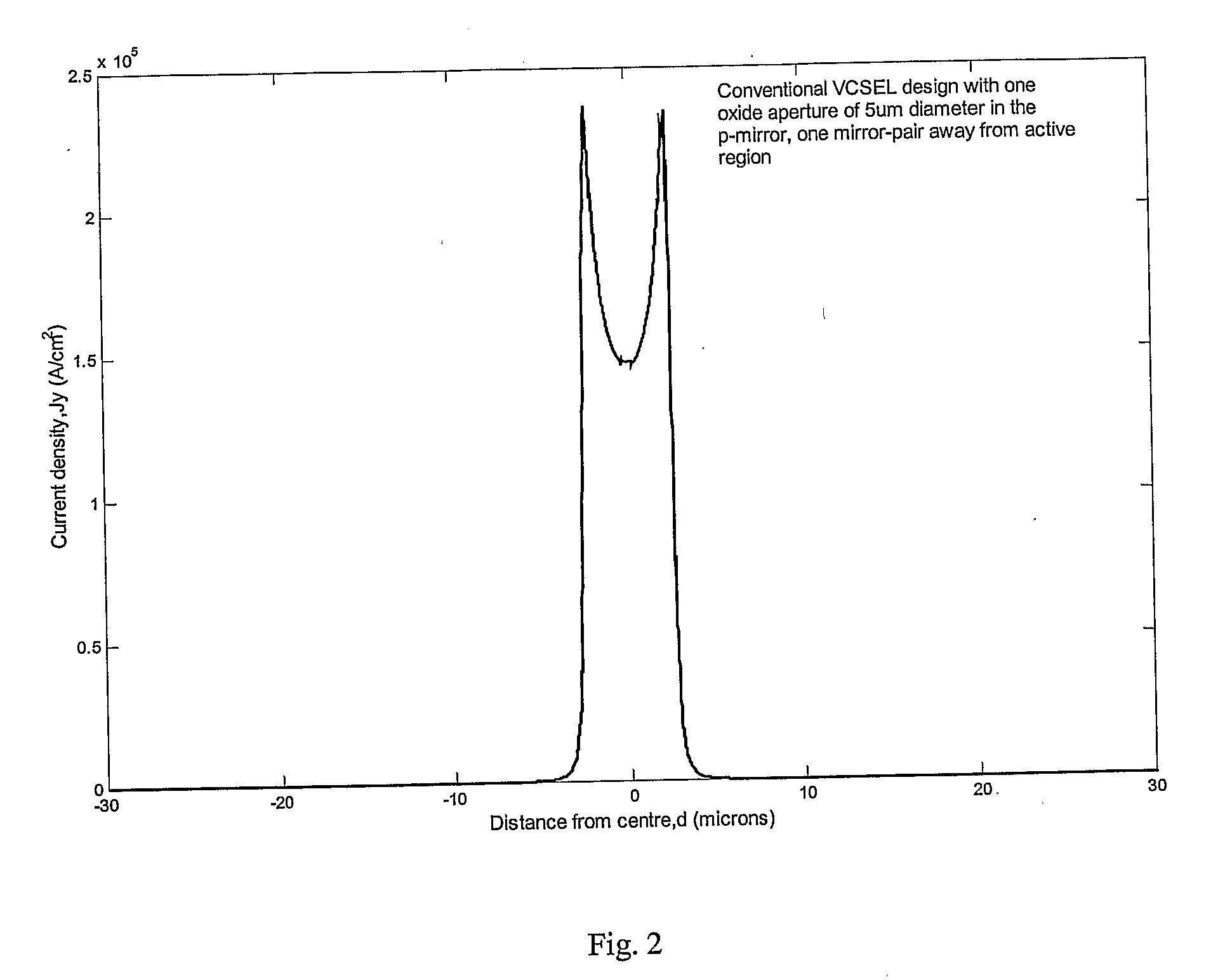

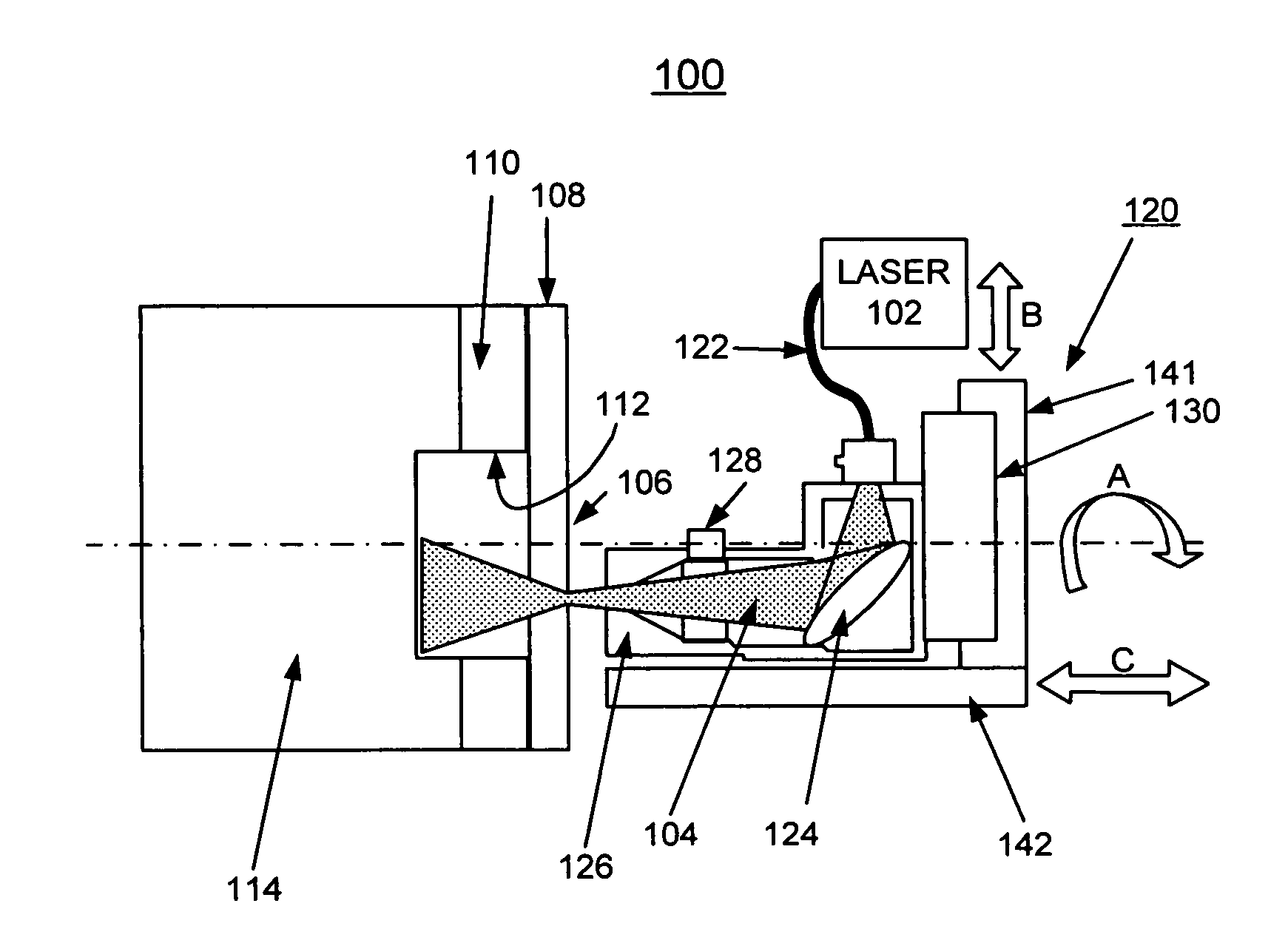

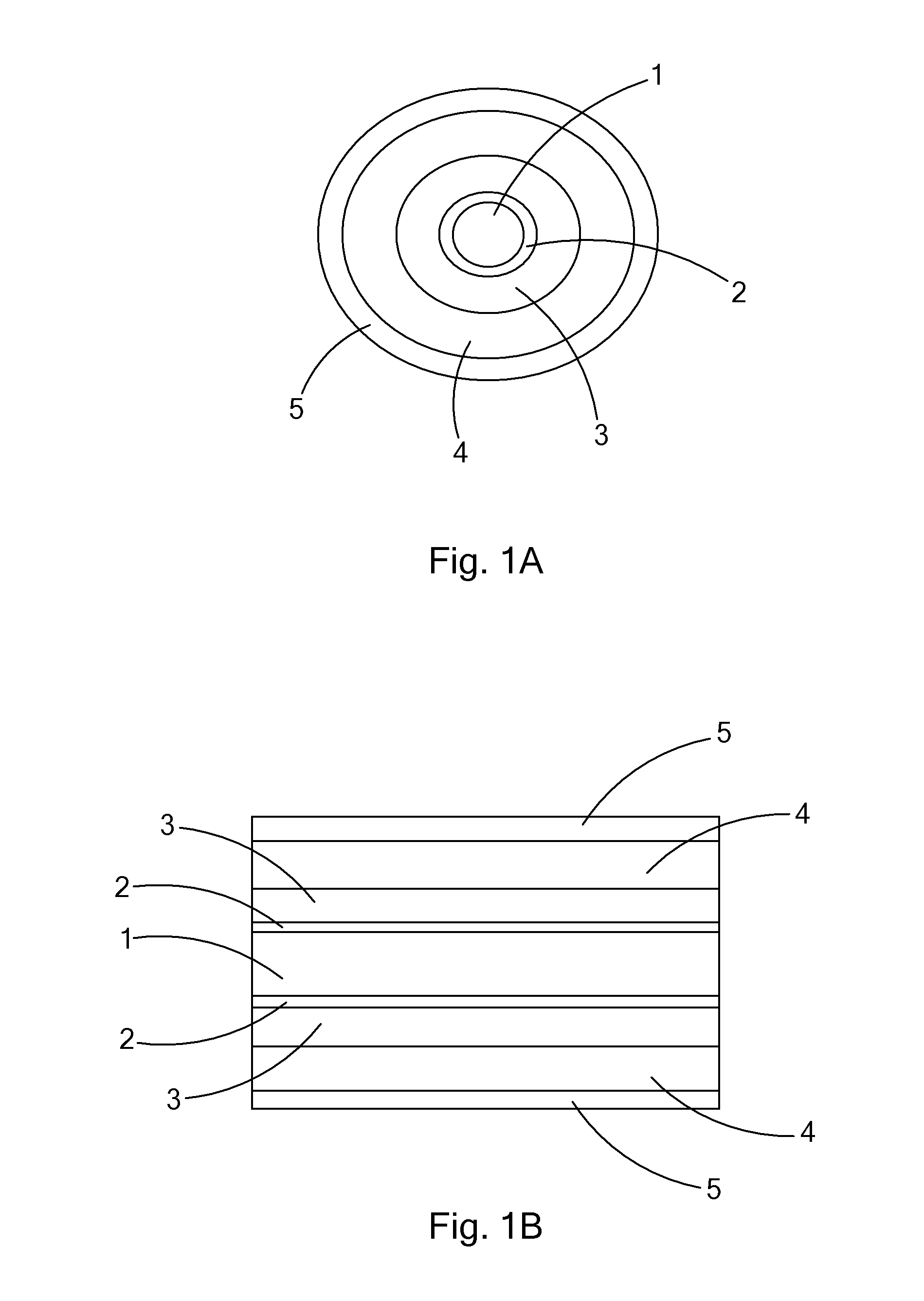

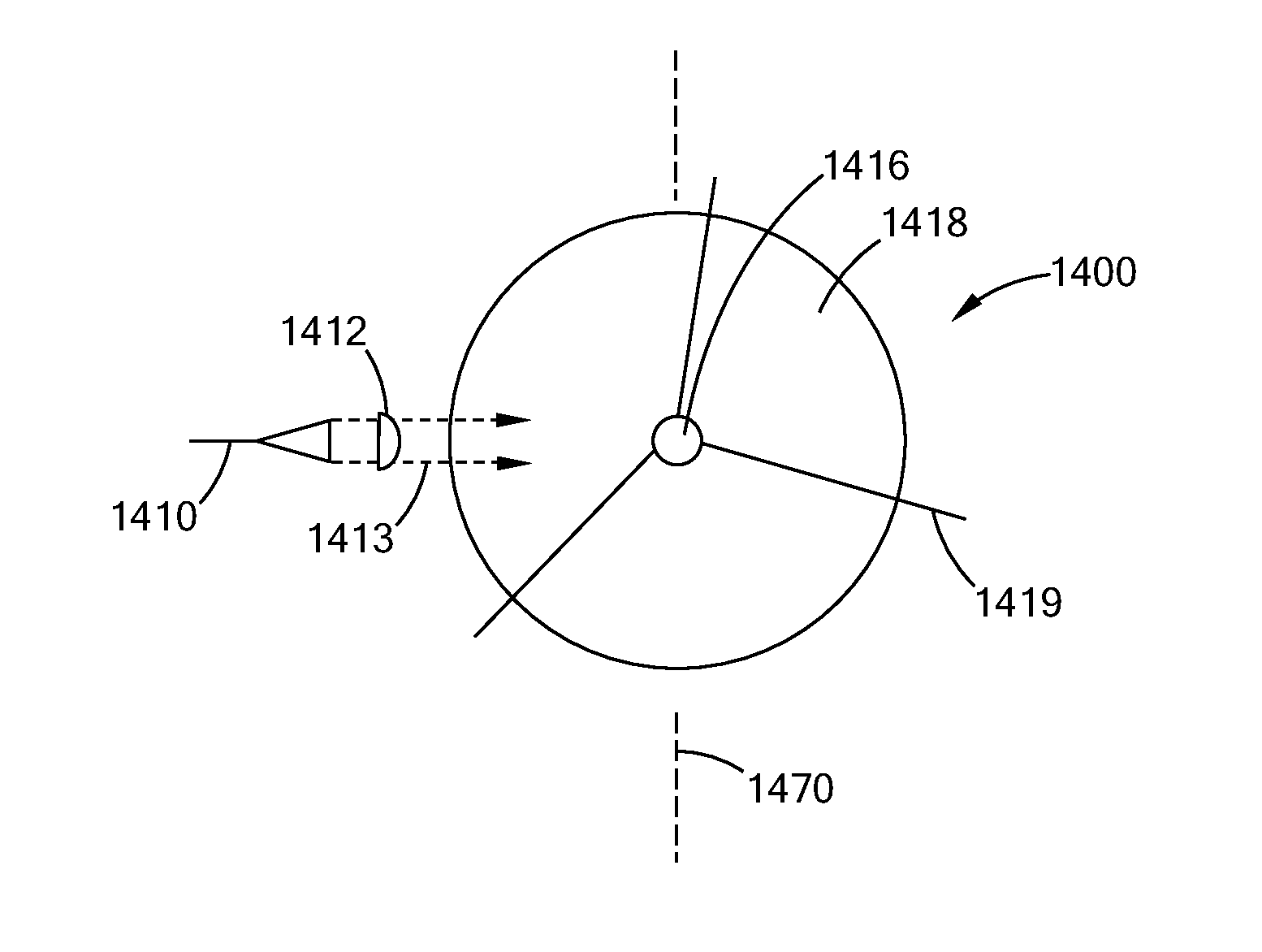

High Power Vcsels With Transverse Mode Control

InactiveUS20070242716A1High yieldSimple designLaser detailsSemiconductor lasersHigh power lasersMode control

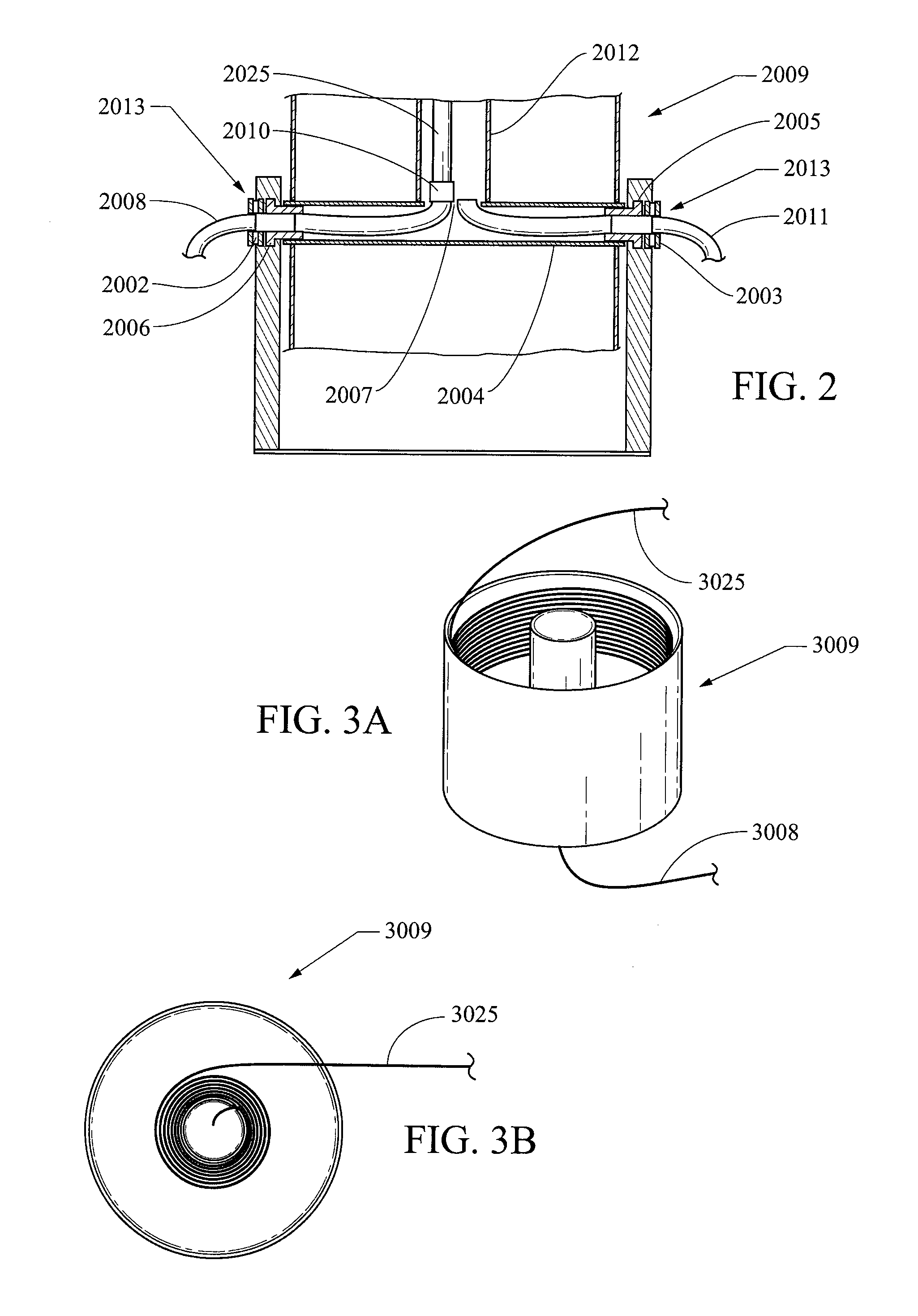

A single mode high power laser device such as a VCSEL is formed with two oxide apertures, one on each side of the active region or cavity. The sizes of the apertures and the distances from the apertures to the cavity center are chosen or optimum, near-Gaussian current density distribution. The high power of a VCSEL thus formed is improved still more by good heat removal by either formation of a via through the substrate and gold plating on top and bottom of the VCSEL (including the via) or by lifting the VCSEL structure from the substrate and locating it on a heat sink.

Owner:ARIZONA STATE UNIVERSITY

System and method for active protection of a resource

Owner:HUMATICS CORP

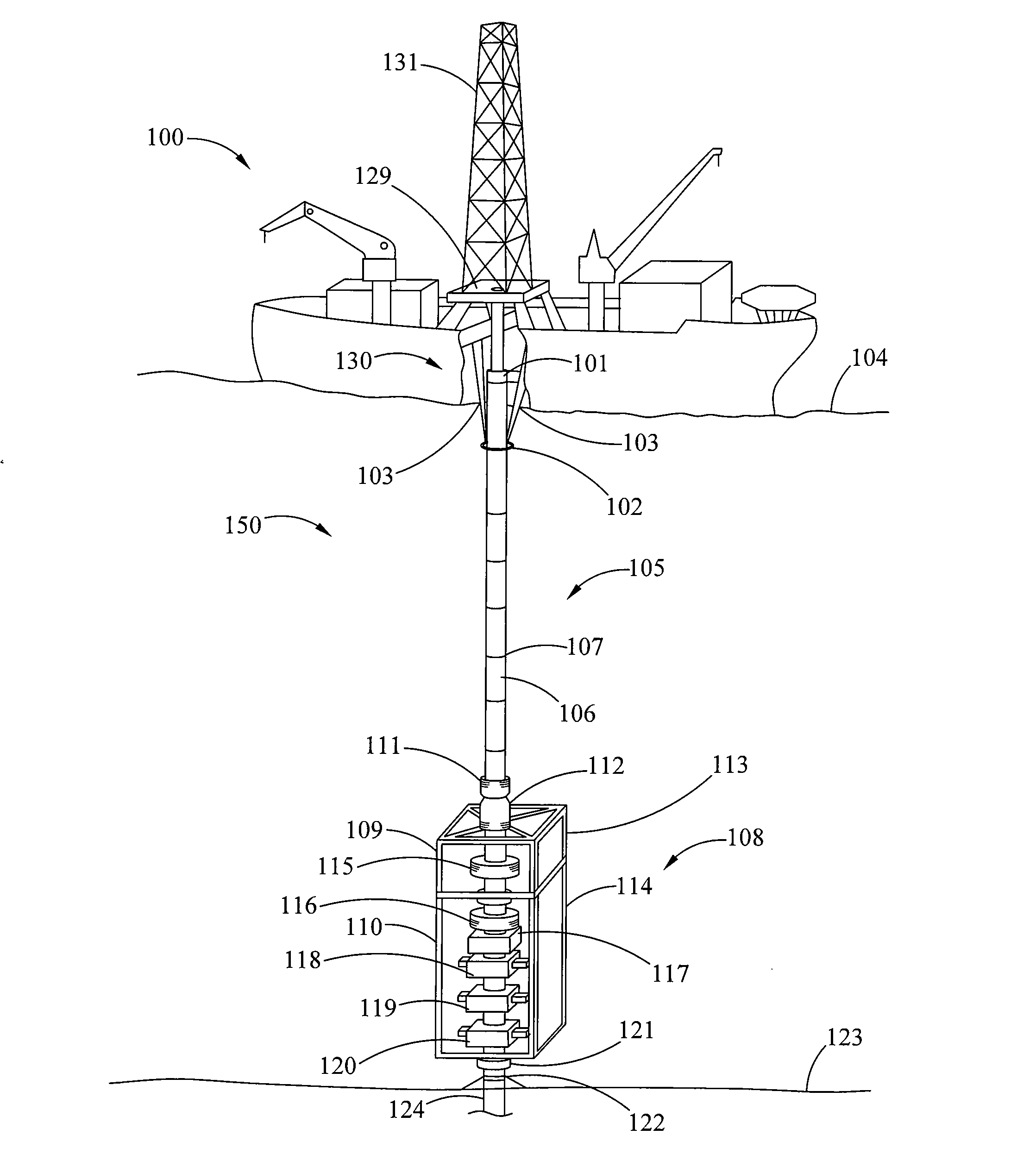

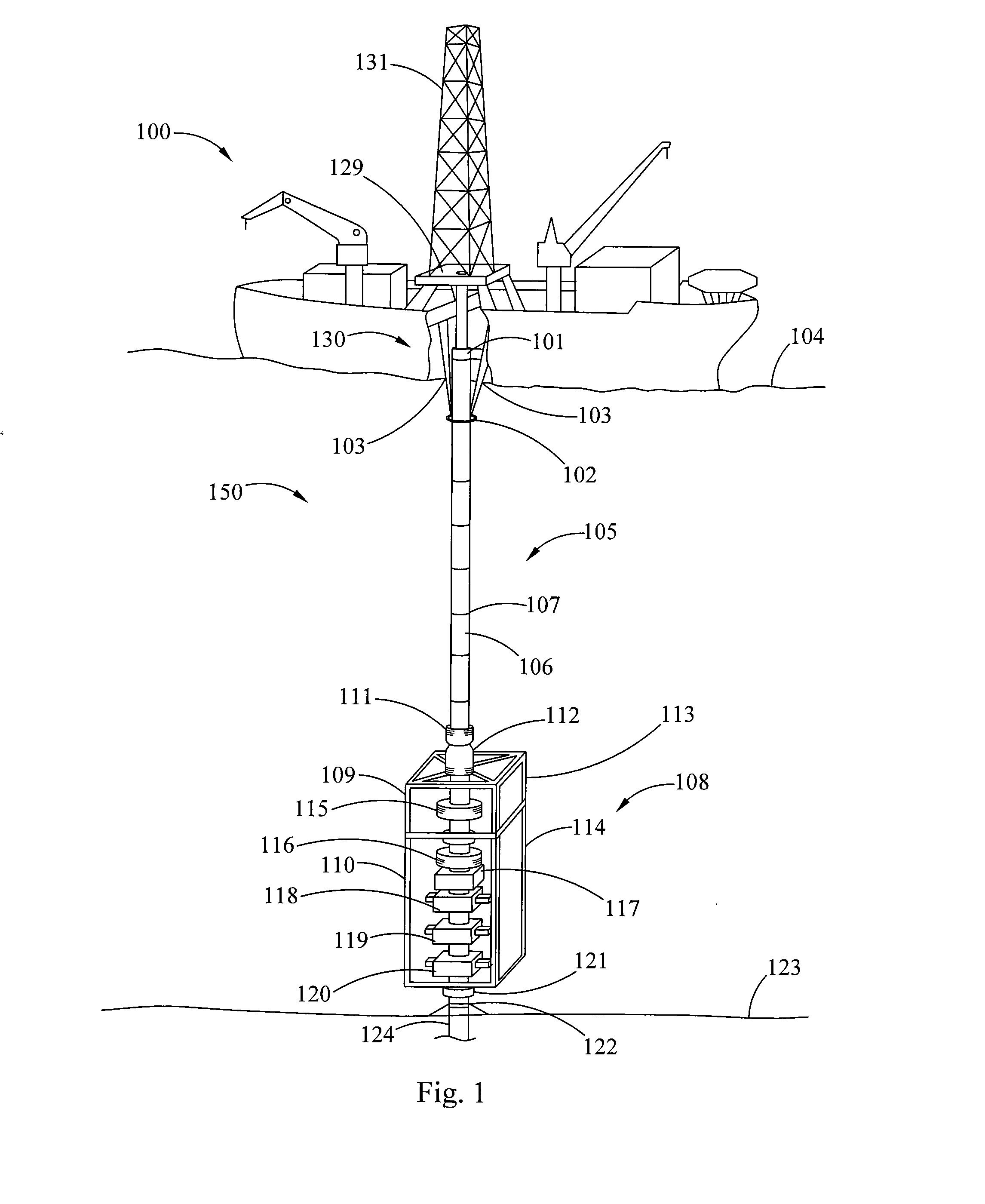

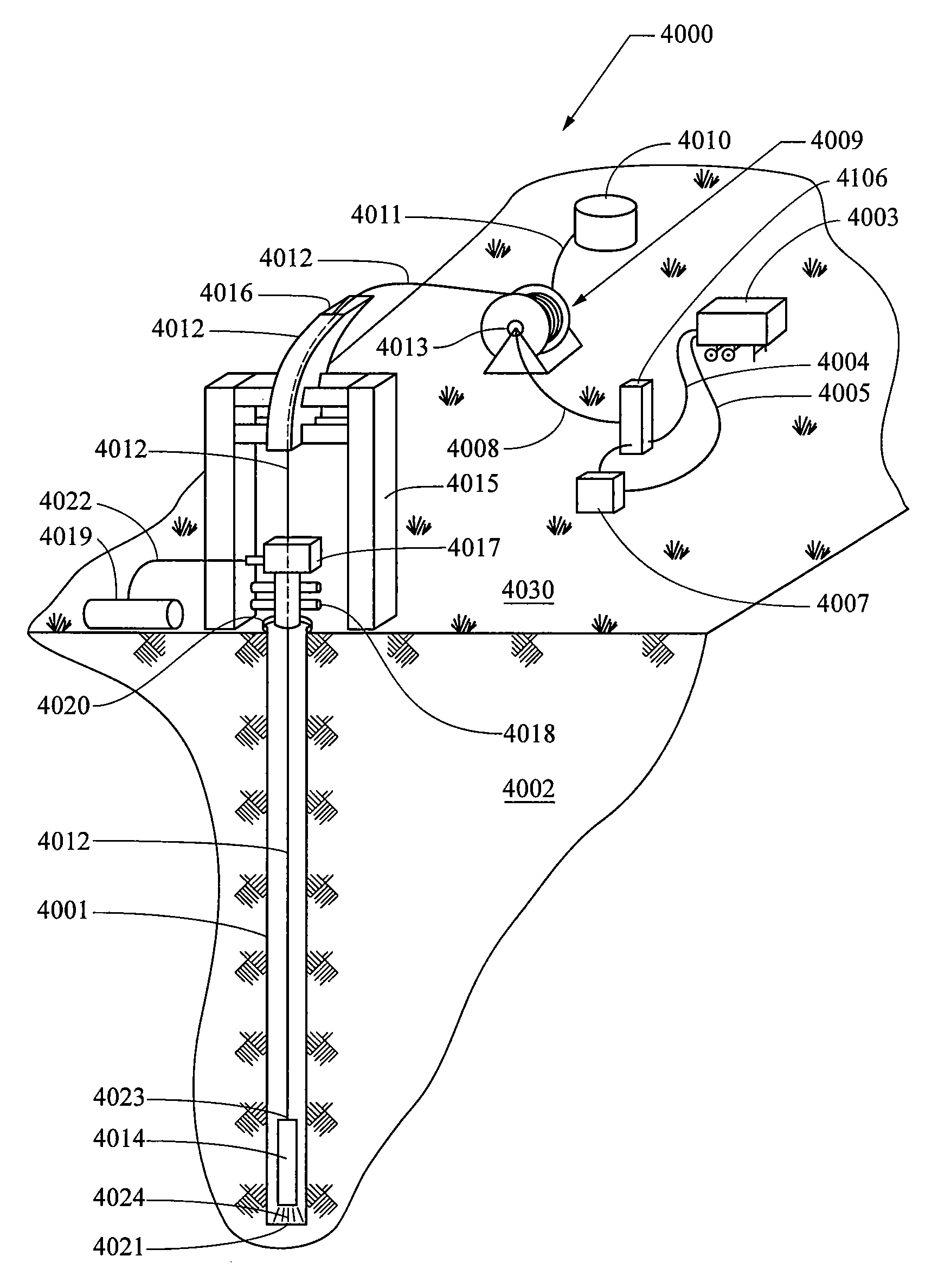

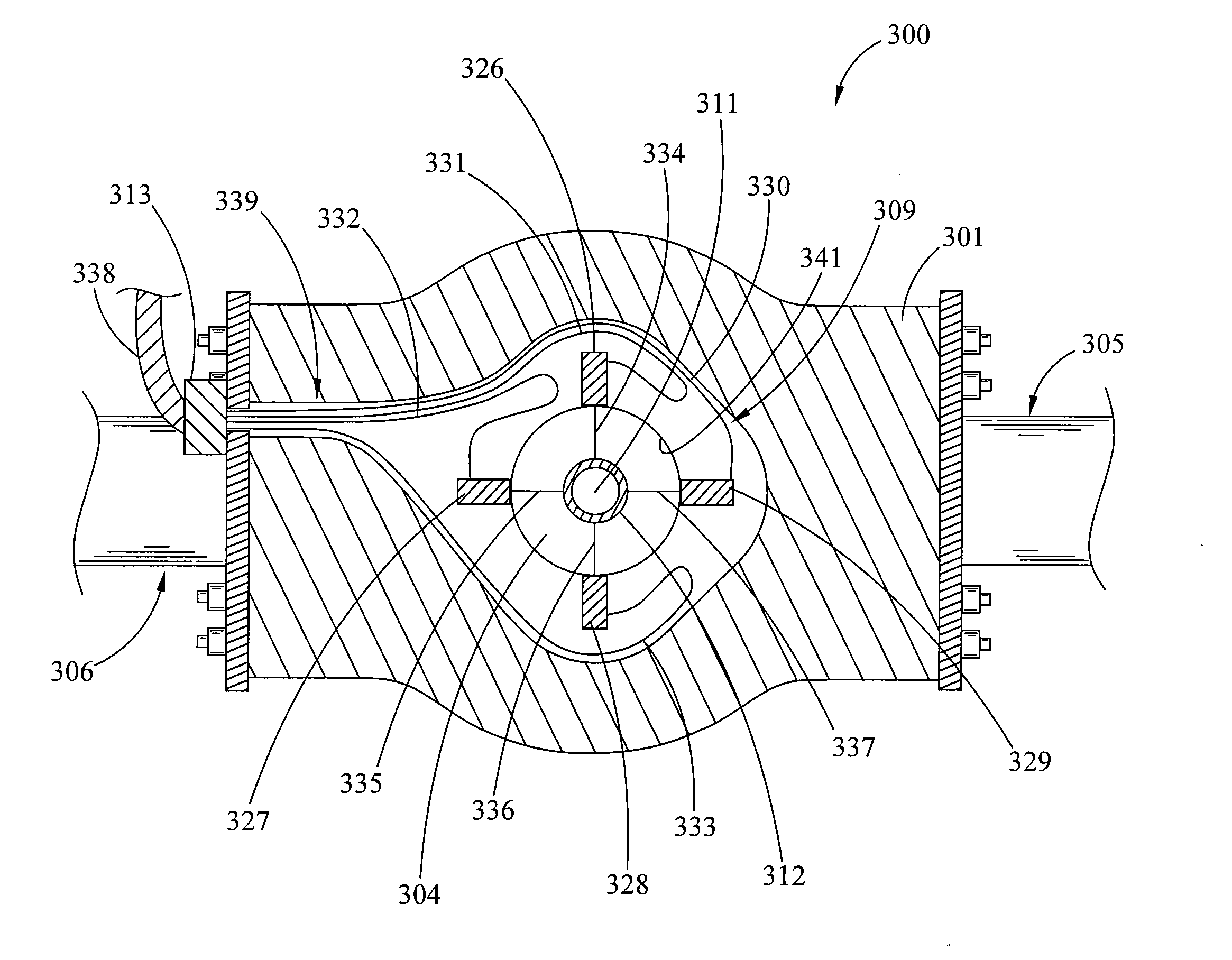

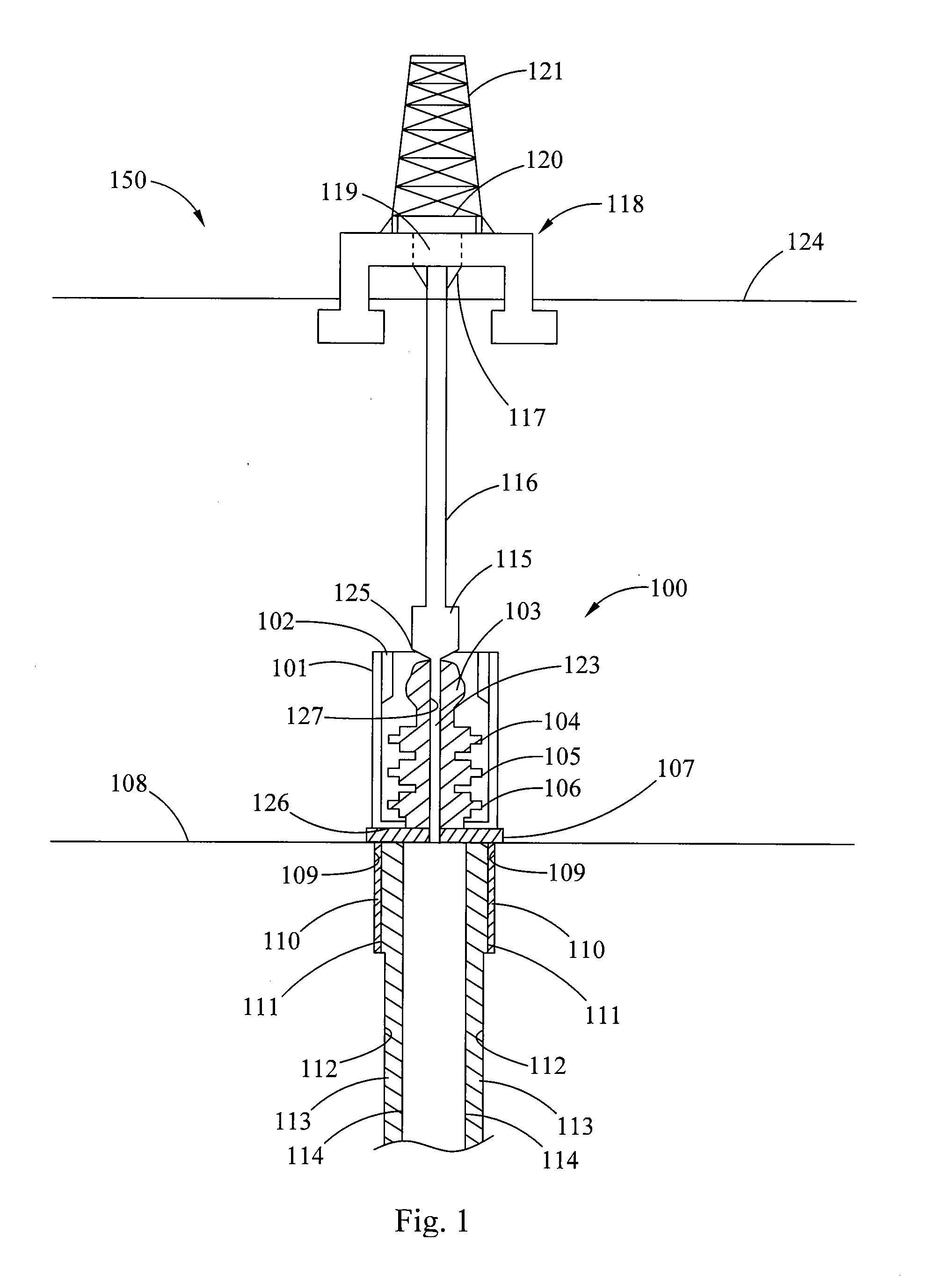

Method and apparatus for delivering high power laser energy over long distances

ActiveUS20100044106A1Suppressing nonlinear scattering phenomenonIncrease the lengthDrill bitsLaser using scattering effectsHigh power lasersOptoelectronics

There is provided a system, apparatus and methods for the laser drilling of a borehole in the earth. There is further provided with in the systems a means for delivering high power laser energy down a deep borehole, while maintaining the high power to advance such boreholes deep into the earth and at highly efficient advancement rates.

Owner:FORO ENERGY

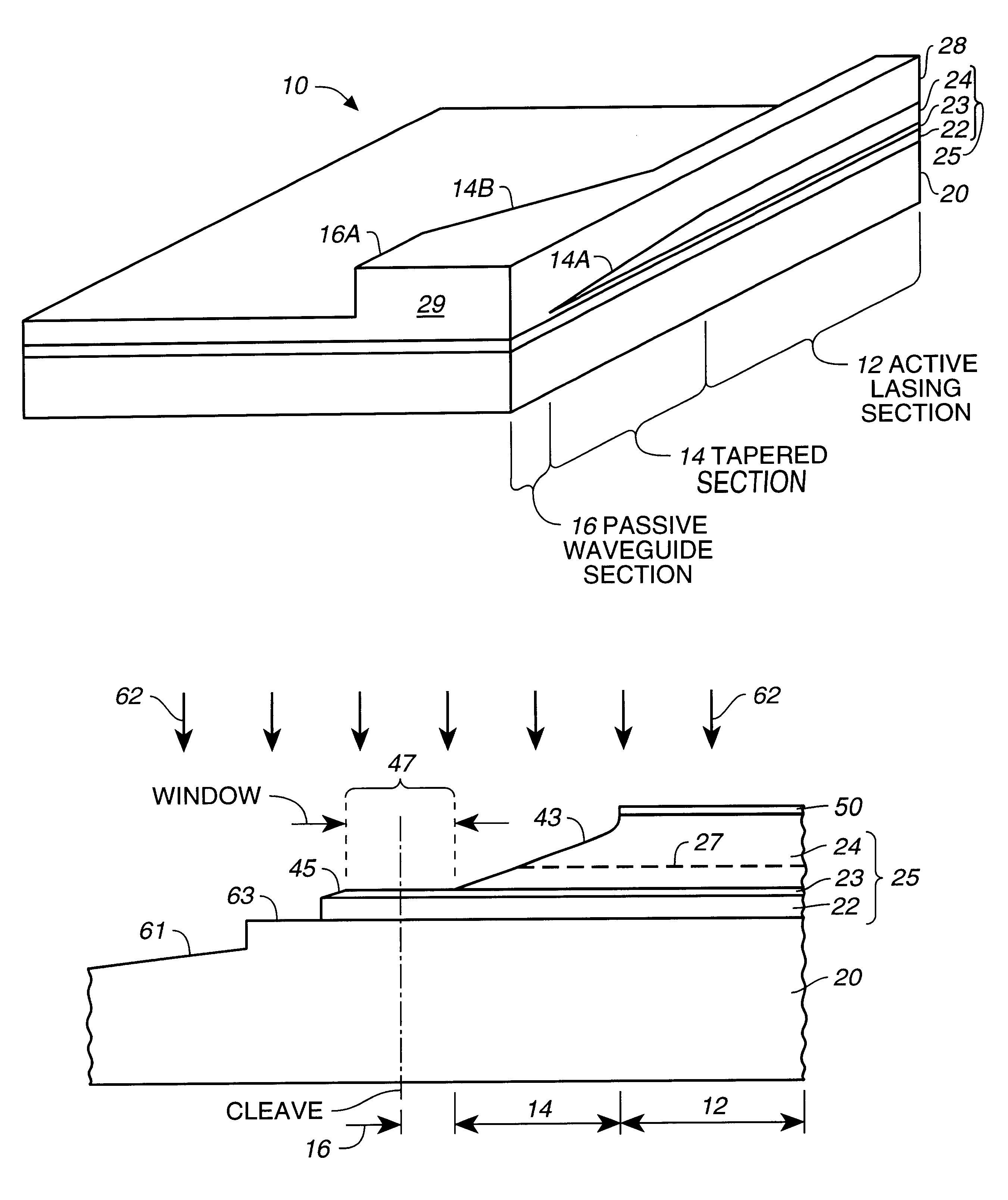

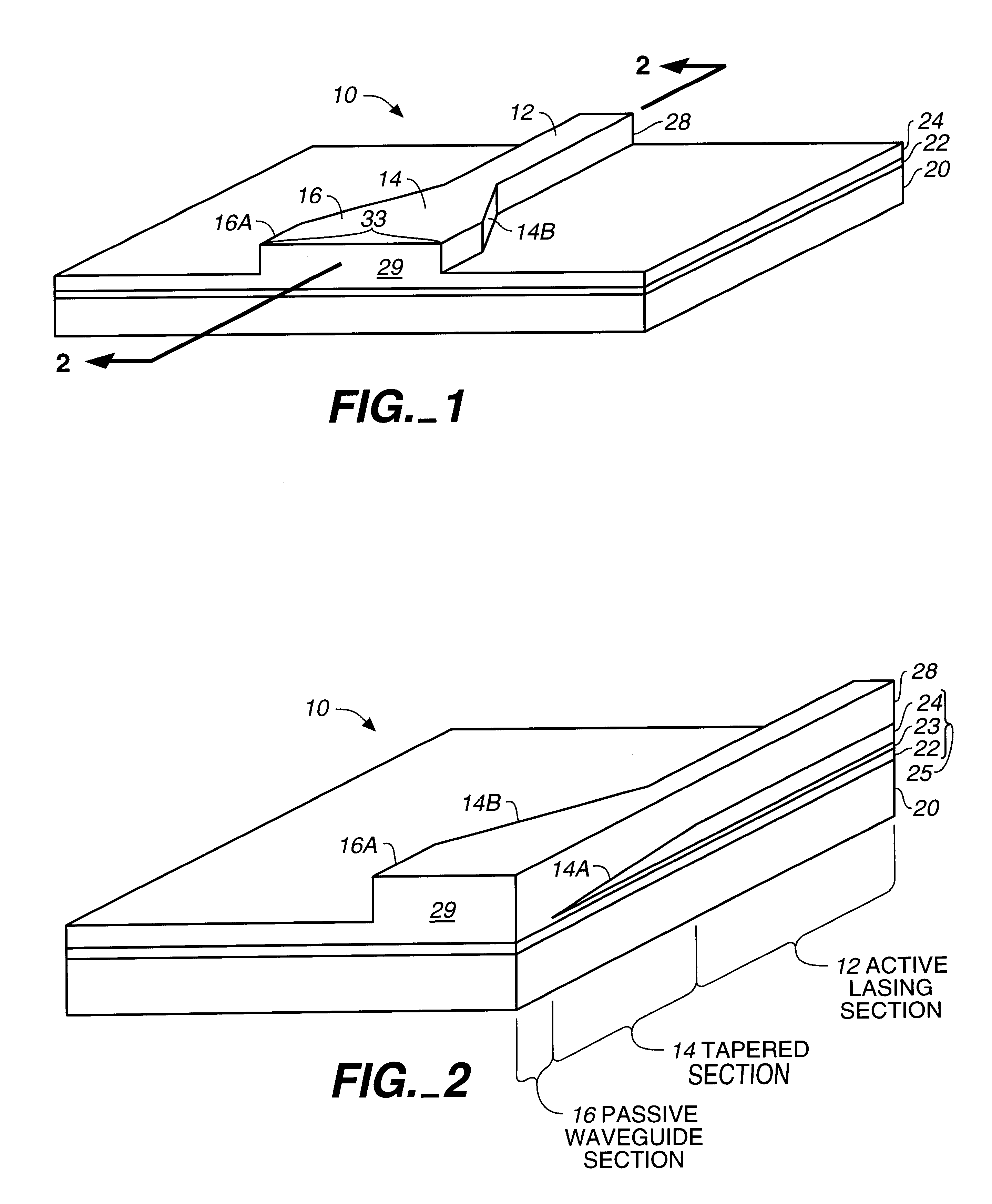

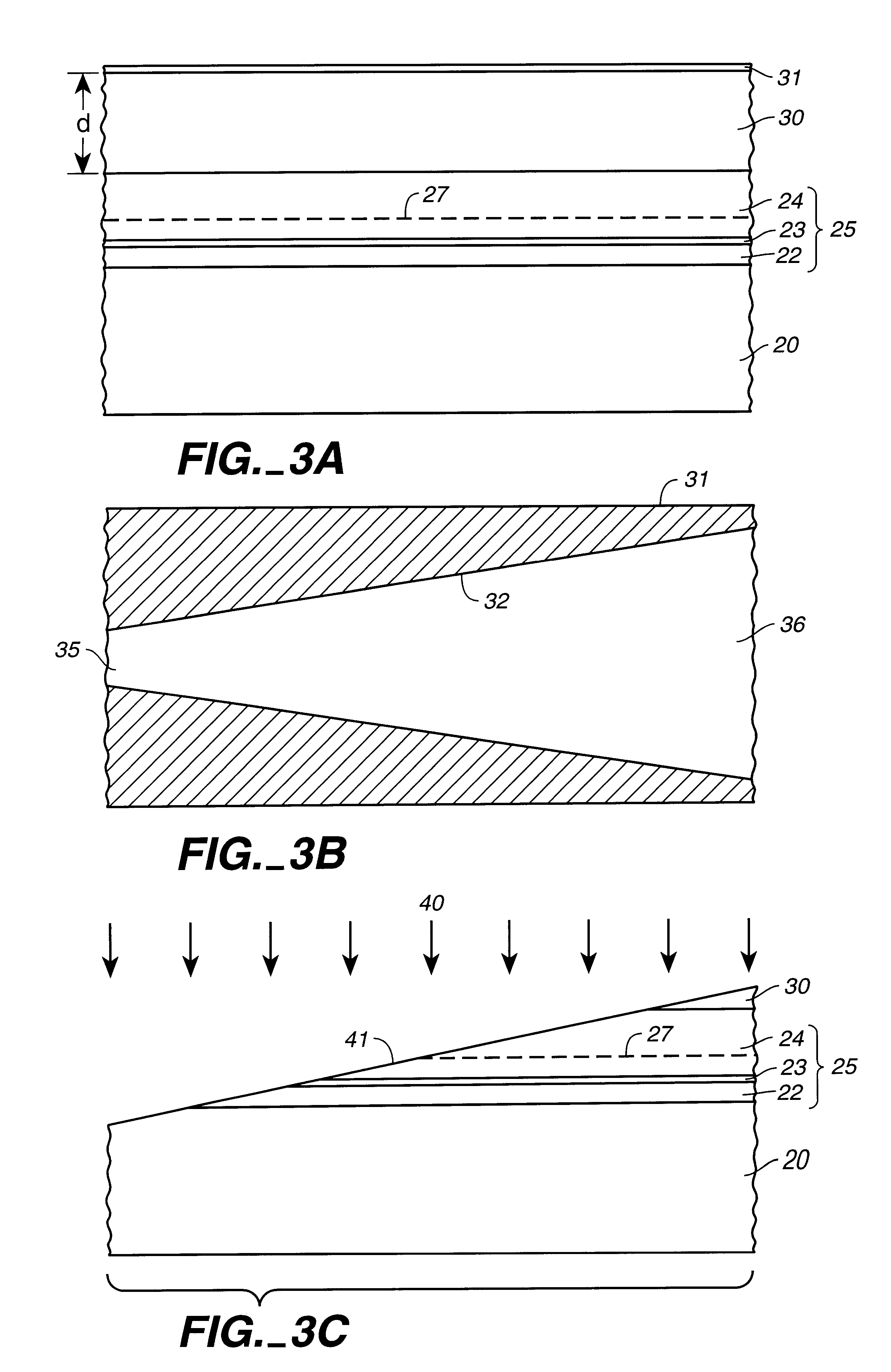

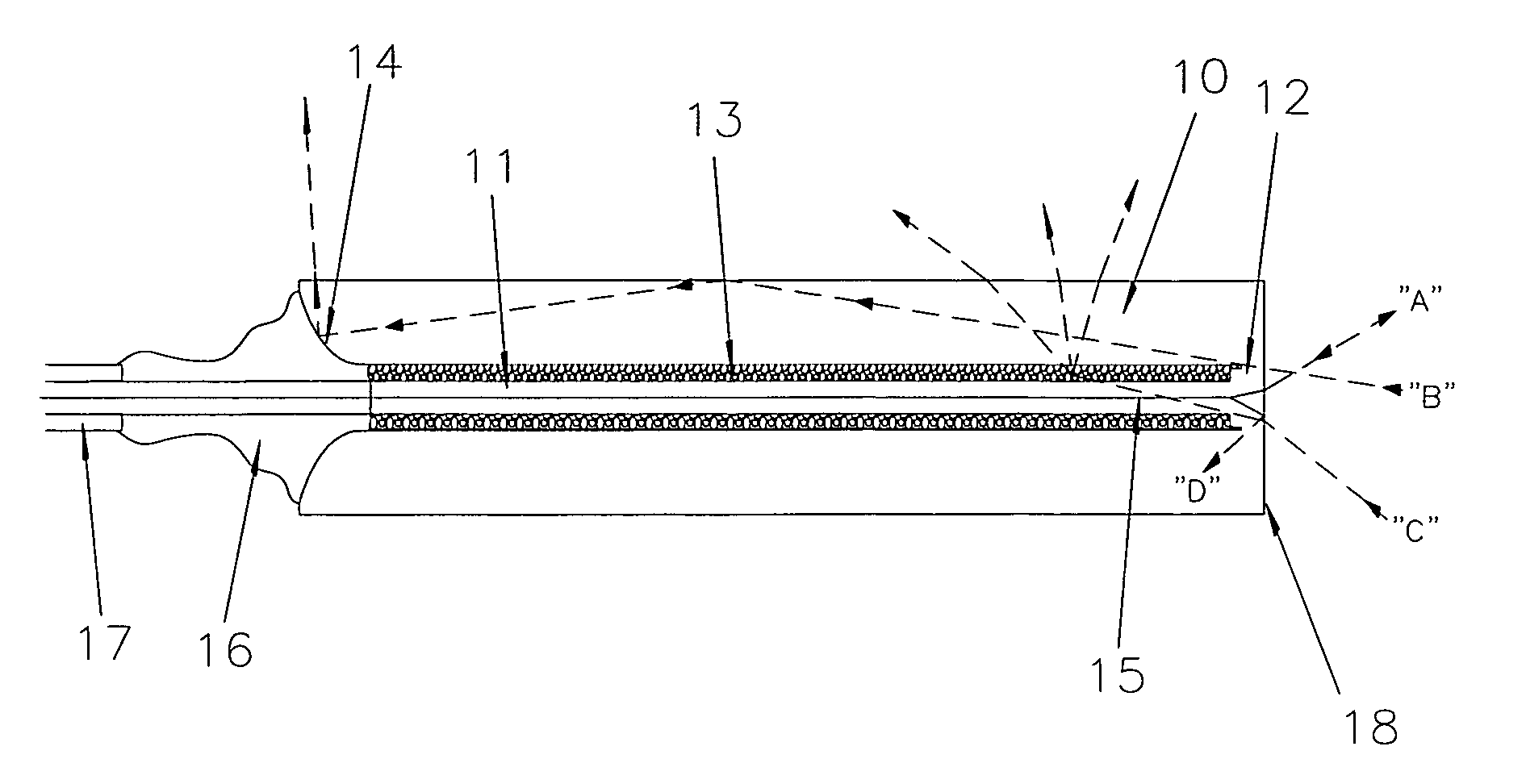

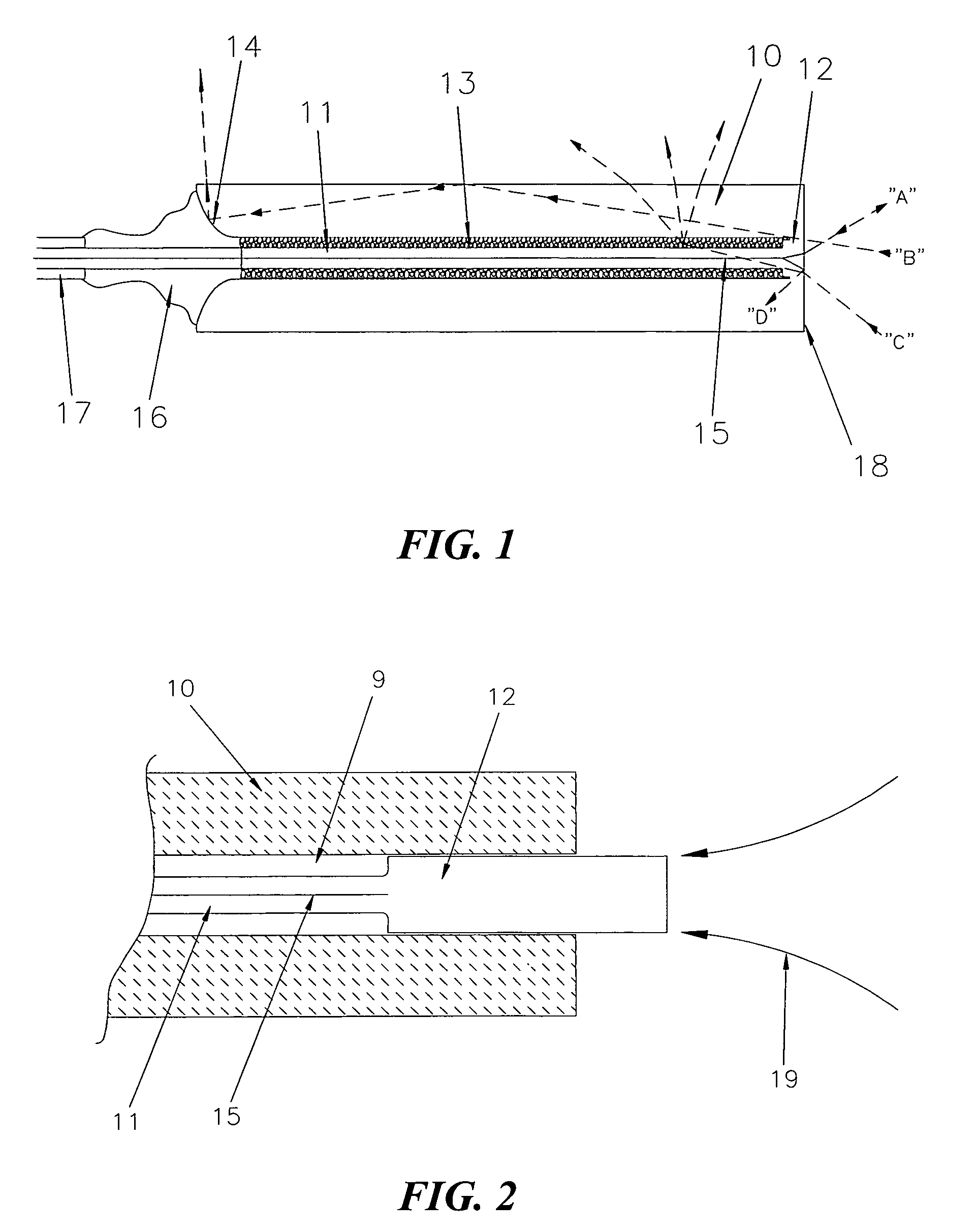

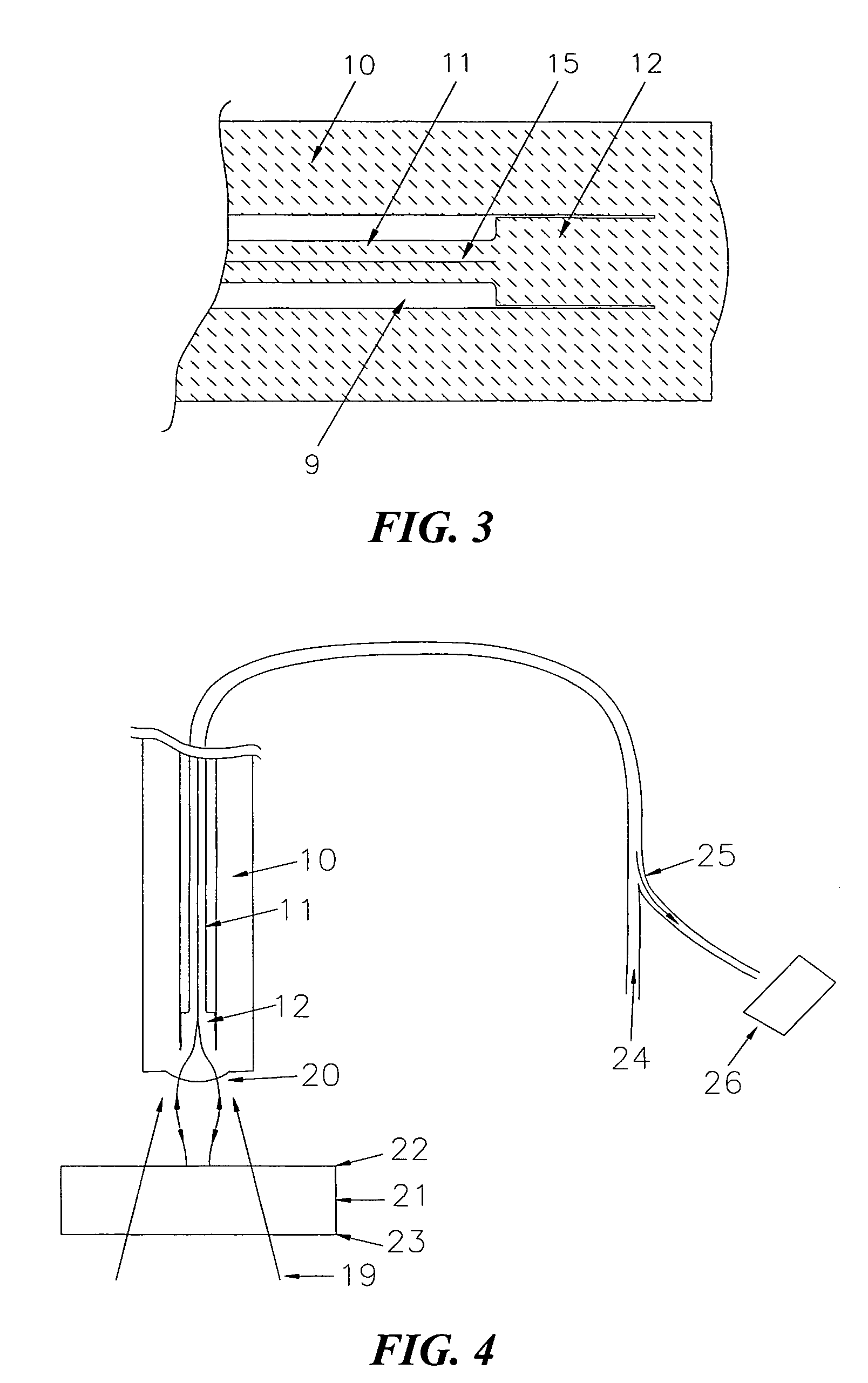

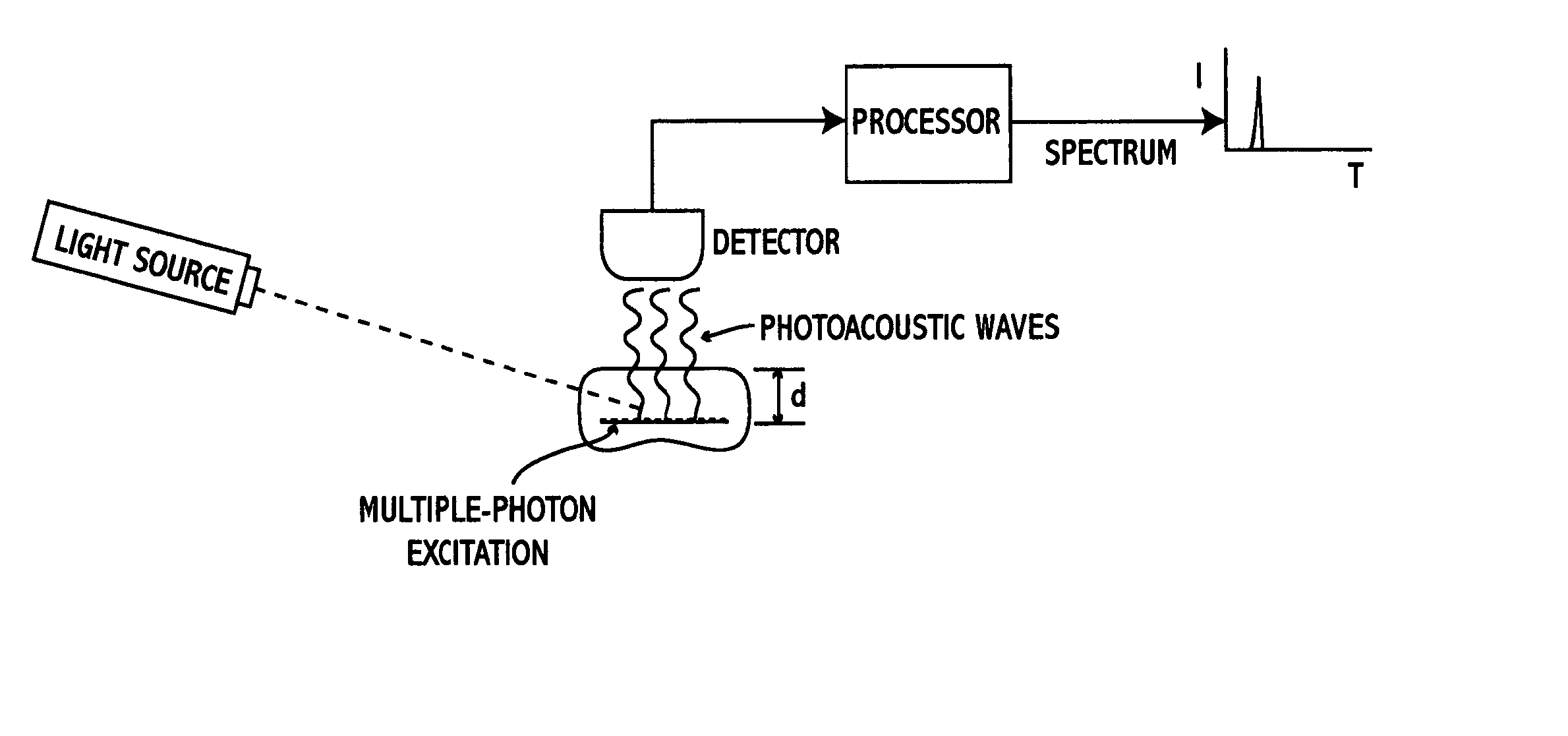

Laser diode device having a substantially circular light output beam and a method of forming a tapered section in a semiconductor device to provide for a reproducible mode profile of the output beam

InactiveUS6052397AEasy to makeGood reproducibilityLaser optical resonator constructionOptical resonator shape and constructionHigh power lasersCoupling

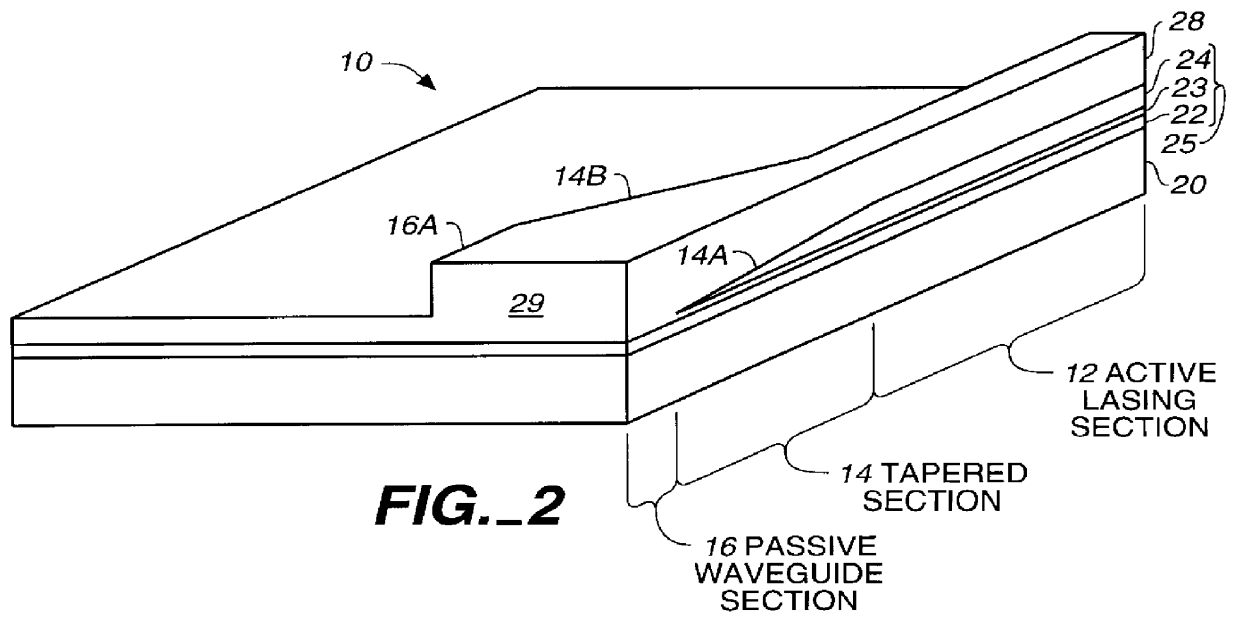

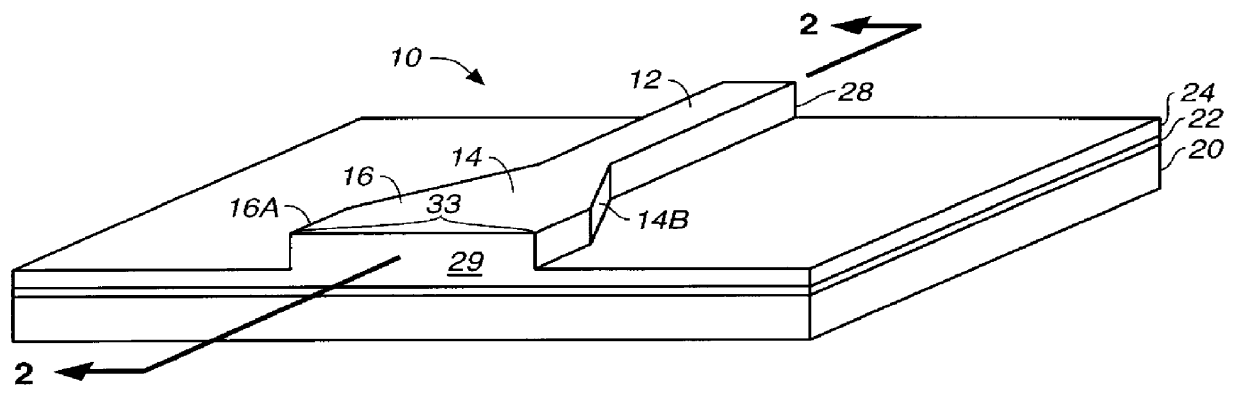

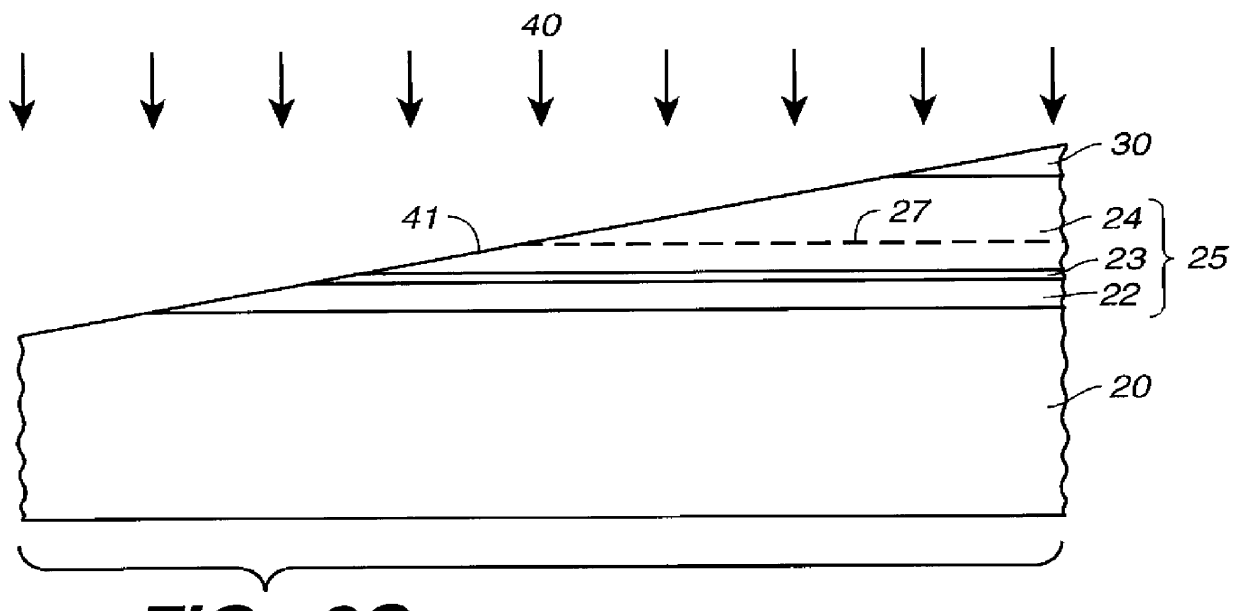

A device and method for fabricating a high power laser diode device with an output emission with a nearly circular mode profile for efficient coupling into an optical fiber. A vertical taper waveguide and a window tolerance region are formed in a base structure of the device employing successive etching steps. Further regowth completes the device structure. The resultant laser device has a vertical and lateral tapered waveguide that adiabatically transforms the highly elliptical mode profile in an active gain section of the device into a substantially circular mode profile in a passive waveguide section of the device.

Owner:JDS UNIPHASE CORP

Method of forming a tapered section in a semiconductor device to provide for reproducible mode profile of the output beam

InactiveUS6174748B1Easy to makeGood reproducibilityLaser detailsLaser optical resonator constructionHigh power lasersCoupling

A method for fabricating a high power laser diode device with an output emission with a nearly circular mode profile for efficient coupling into an optical fiber. A vertical taper waveguide and a window tolerance region are formed in a base structure of the device employing successive etching steps. Further regrowth completes the device structure. The resultant laser device has a vertical and lateral tapered waveguide that adiabatically transforms the highly elliptical mode profile in an active gain section of the device into a substantially circular mode profile in a passive waveguide section of the device.

Owner:JDS UNIPHASE CORP

Monolithic mode stripping fiber ferrule/collimator and method of making same

A monolithic ferrule / endcap / optical fiber structure is provided wherein an optical fiber is terminated in a ferrule and bonded by fusion to form a monolithic unit which minimizes optical loss and is typically capable of transmitting high power laser radiation, preferably on the order of 500 W and higher, without damage to the optical fiber and ferrule. Ferrule, endcap, optical fiber and fusible powder are composed of material of substantially the same physical characteristics such that, when all are fused together, the structure so formed is monolithic and the optical path is transparent.

Owner:ELECTRO OPTICS TEVCHNOLOGY

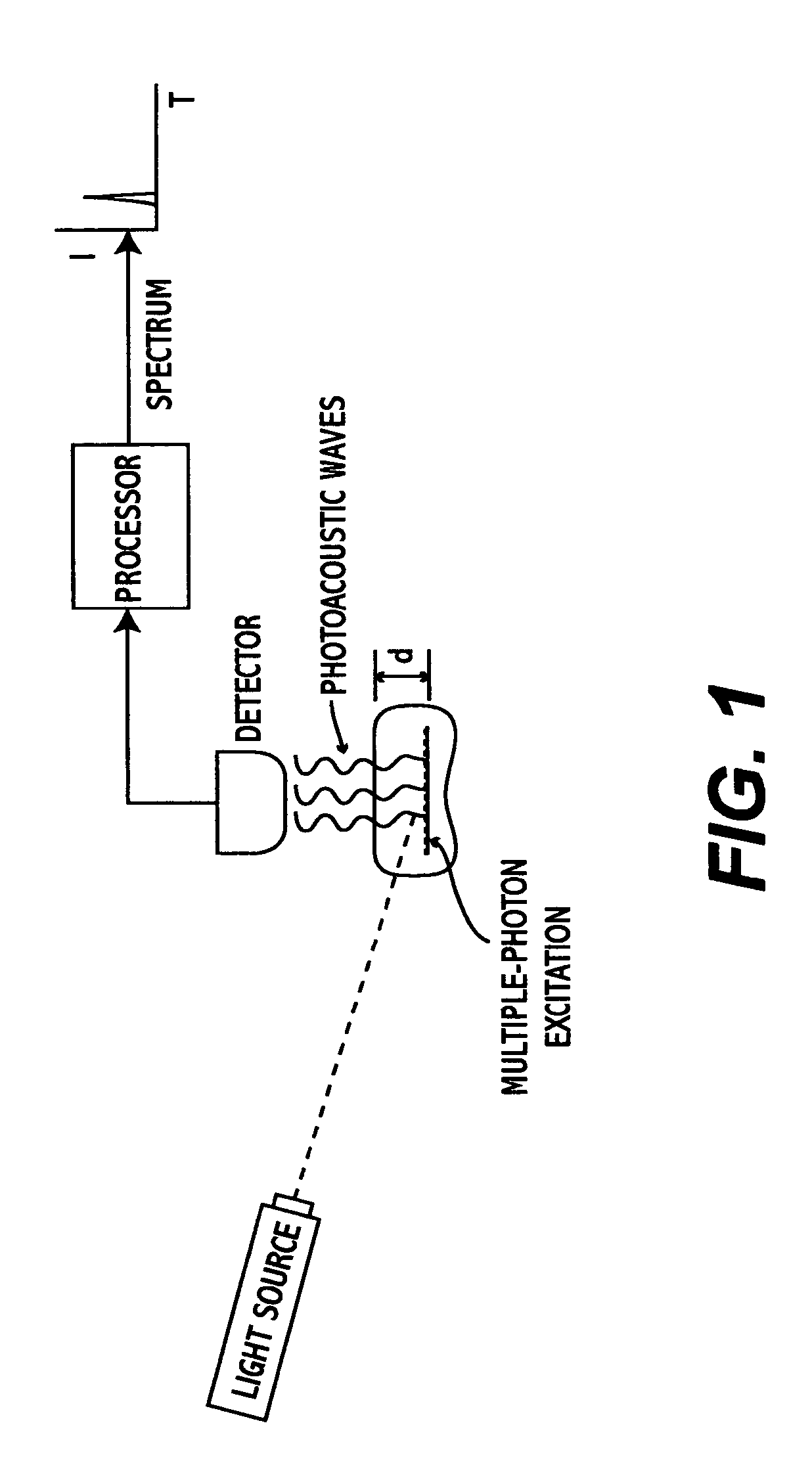

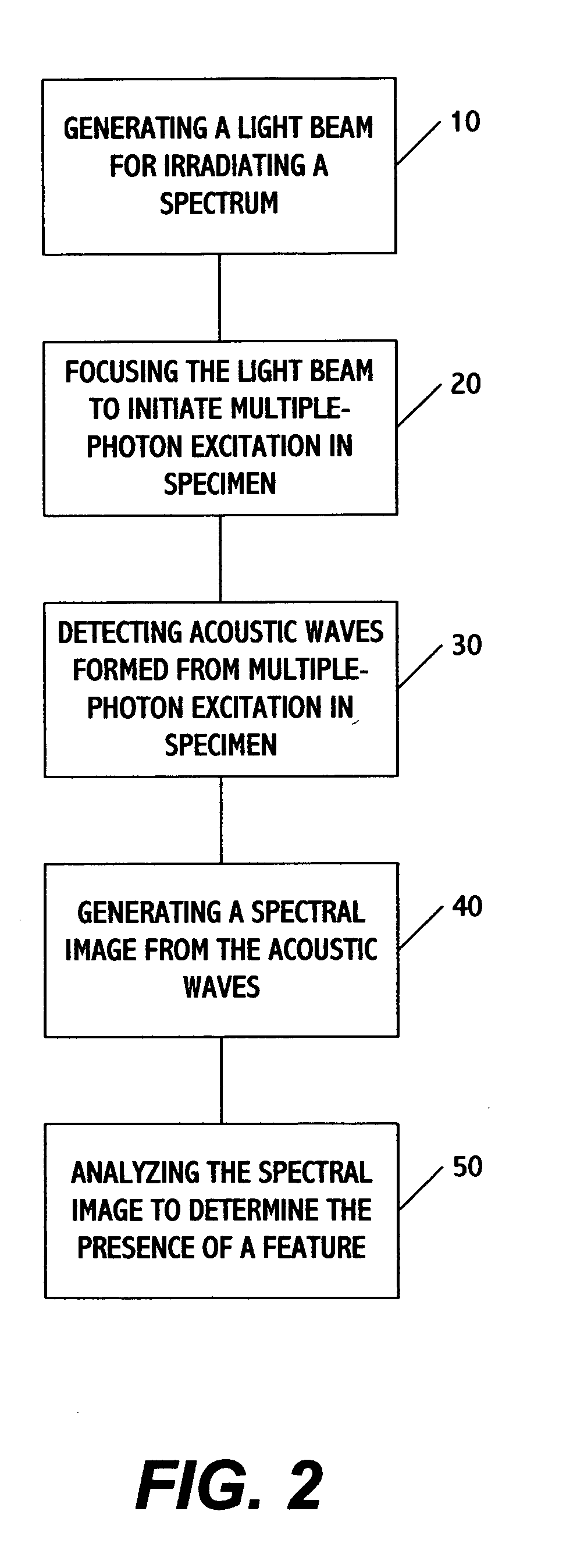

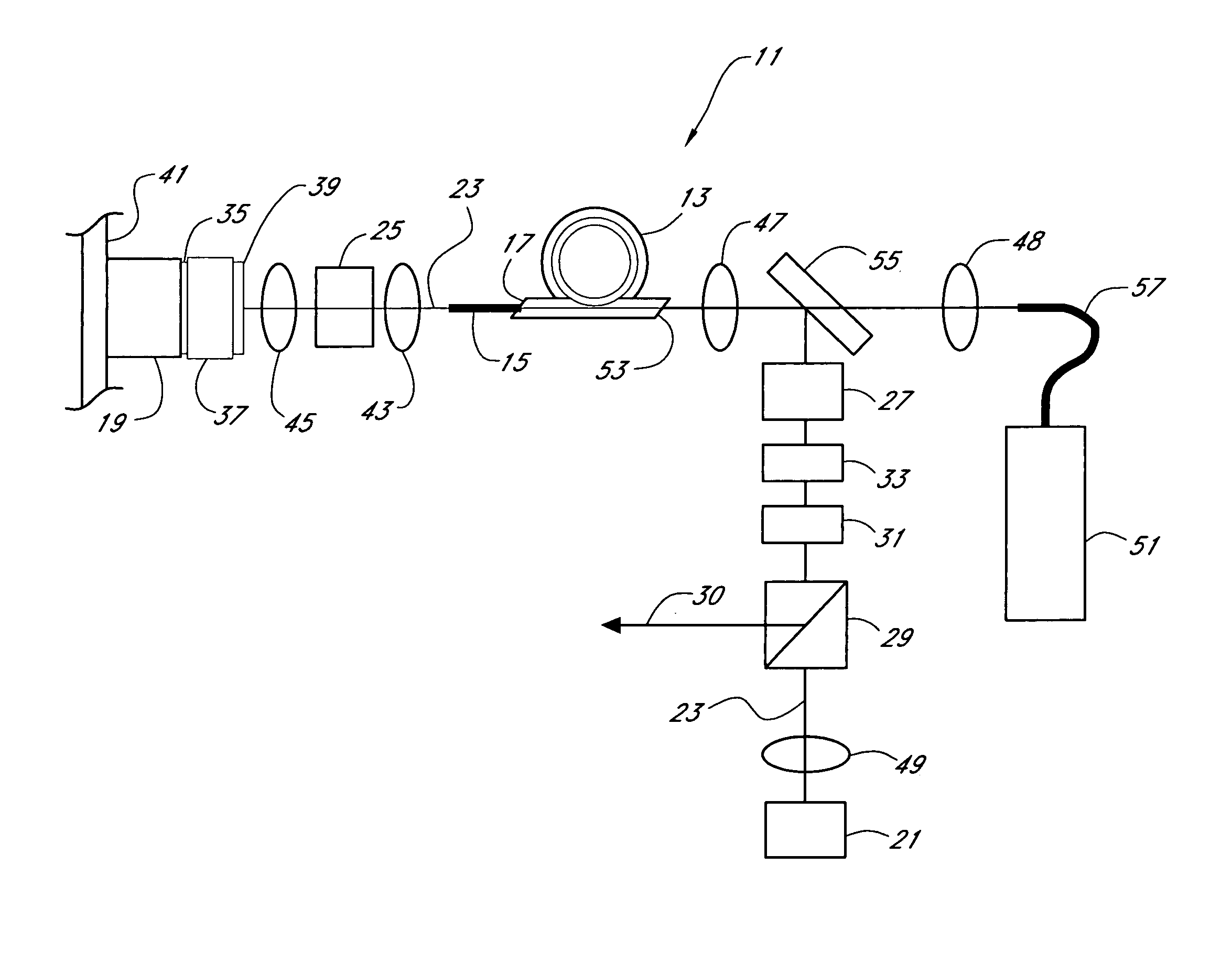

Multiphoton photoacoustic spectroscopy system and method

InactiveUS20050070803A1Non-invasively diagnosingRadiation pyrometryDiagnostics using lightHigh power lasersPhoton

A system and method for performing multispectral imaging locates features of interest in a specimen using a technique known as multiphoton photoacoustic spectroscopy. In this technique, a tunable high-power laser is used to initiate multiphoton excitation events which are then detected as an acoustic signal using a sensor such as an ultrasonic piezoelectric transducer. The transducer signal is processed to form a normalized MPPAS signal intensity which may then be used as a basis for forming a spectral image. Unlike other spectroscopies, MPPAS is able to monitor non-fluorescent species based on non-radiative relaxation of the light-absorbing species in the specimen. In addition, since the majority of energy imparted to the light-absorbing molecules is released through non-radiative pathways, sensitive measurements of even fluorescent molecules can be performed. The system and method may be applied to detect malignant cells in tissue samples although other uses are contemplated.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

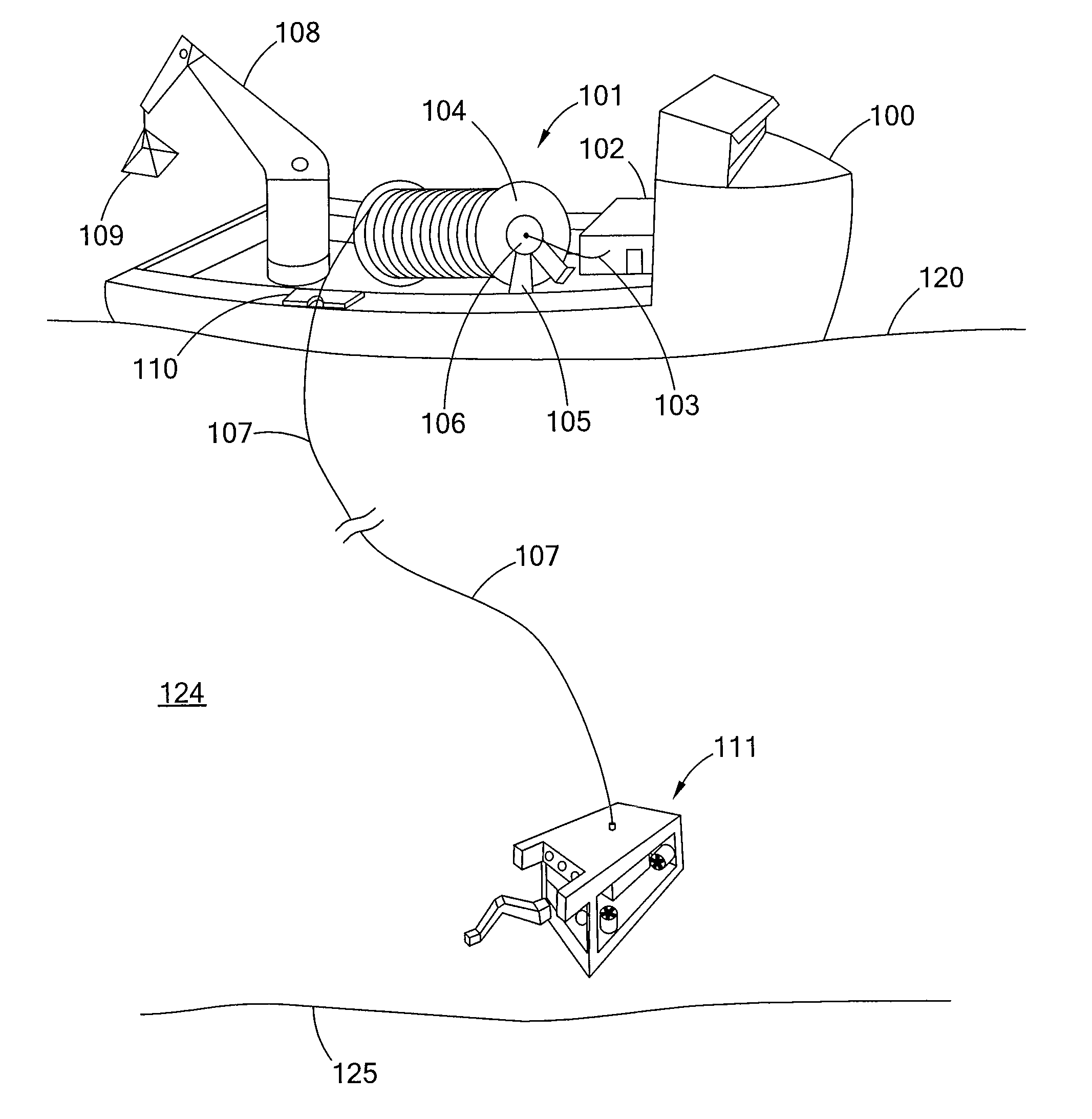

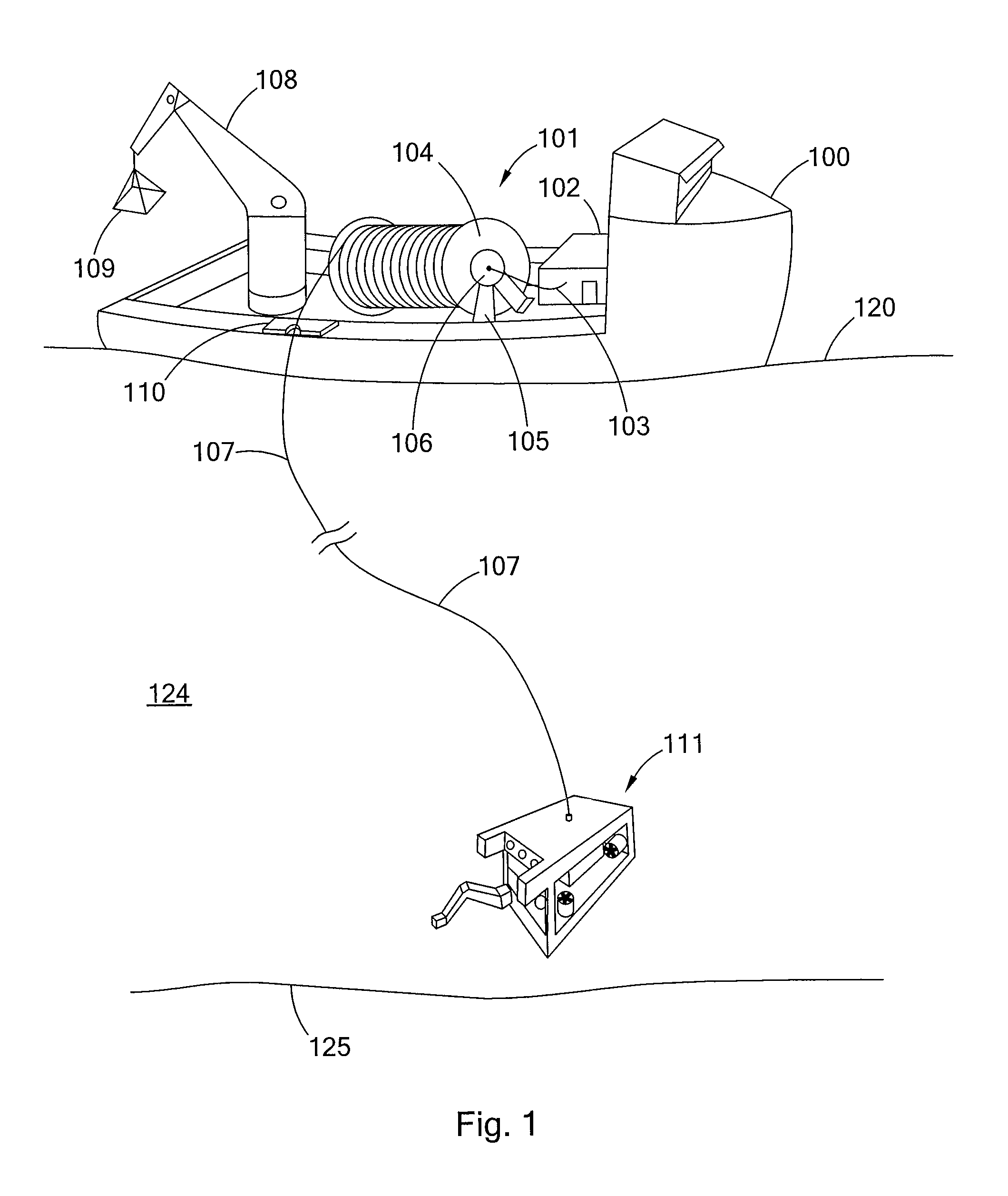

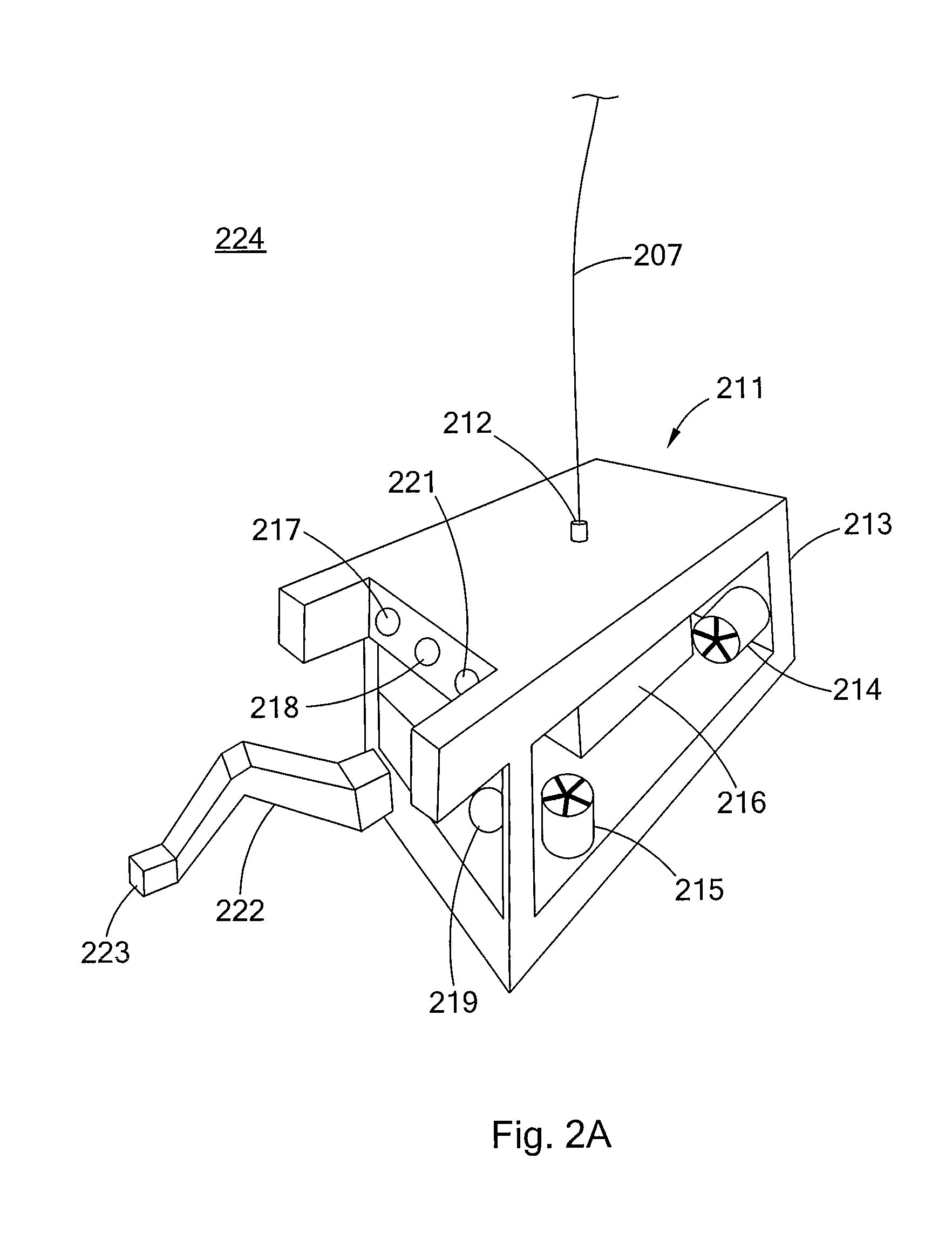

High power laser photo-conversion assemblies, apparatuses and methods of use

ActiveUS20120266803A1Without substantial loss of powerRadiation pyrometryHollow article cleaningFiberHigh power lasers

There is provided a high power laser system for powering a remotely located laser device, such as an ROV, using a high power laser fiber optic tether and a photo-conversion device, such as a laser photovoltaic assembly. Laser device systems, such as ROV systems that utilizes a high power laser cutting and / or cleaning tools are also provided.

Owner:FORO ENERGY

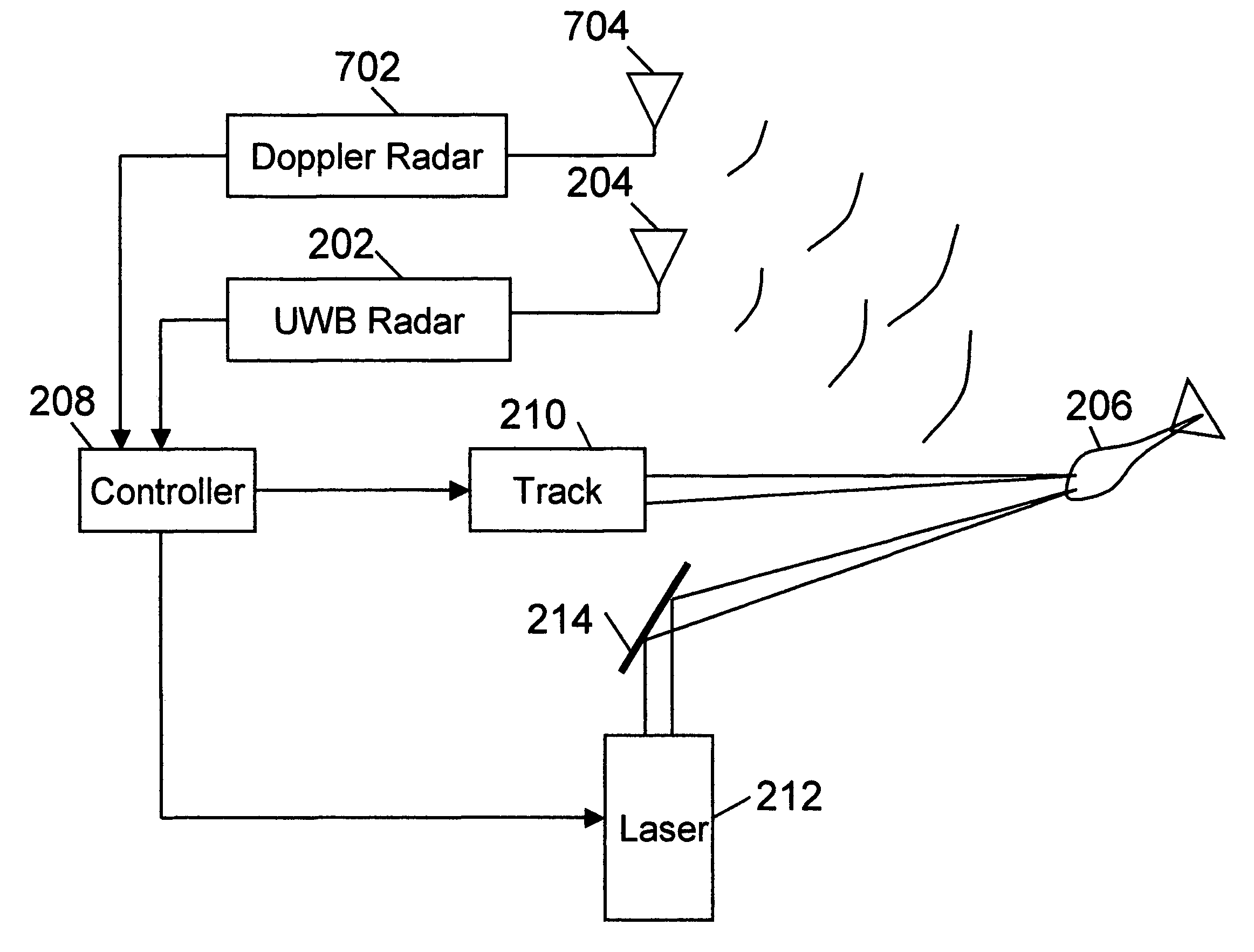

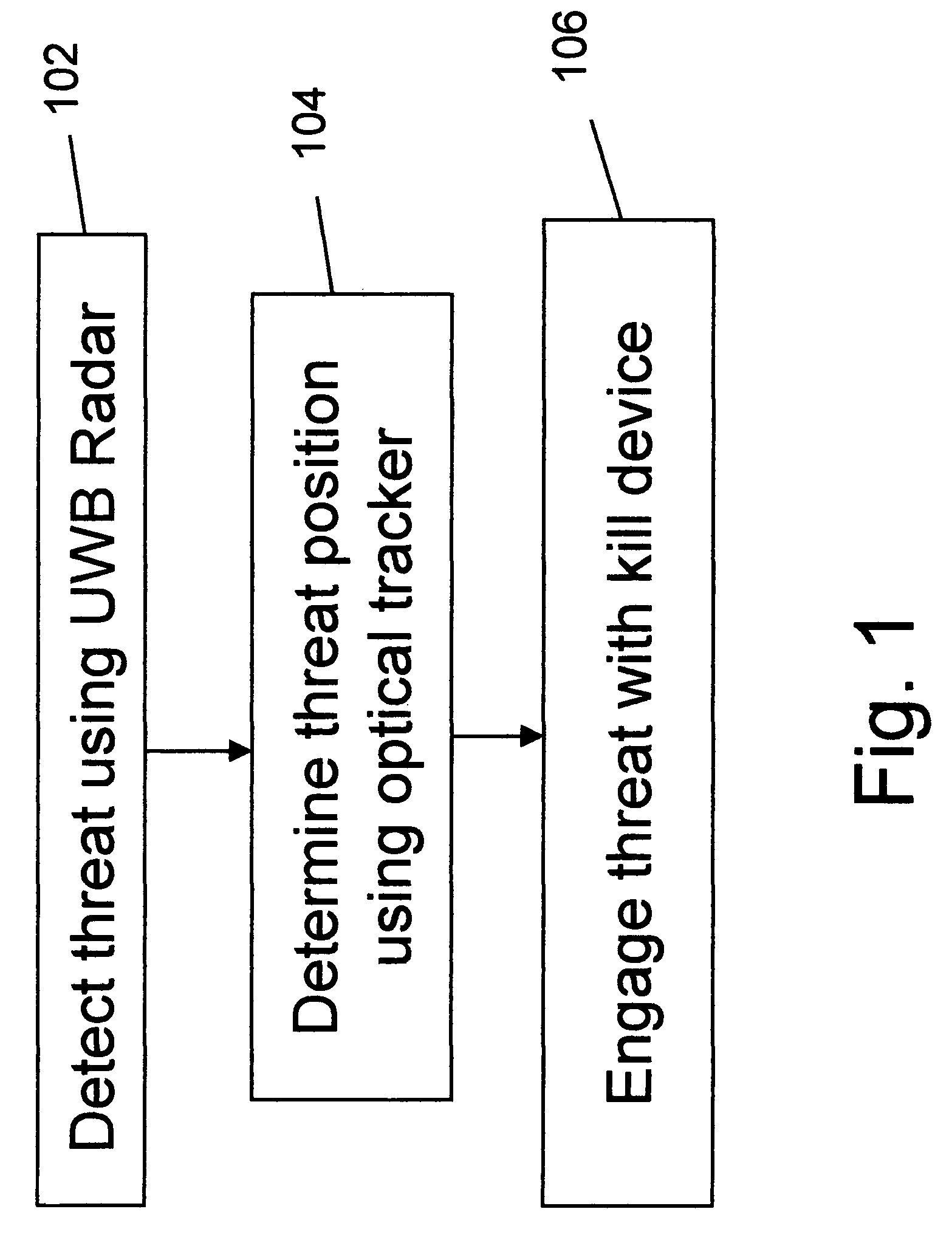

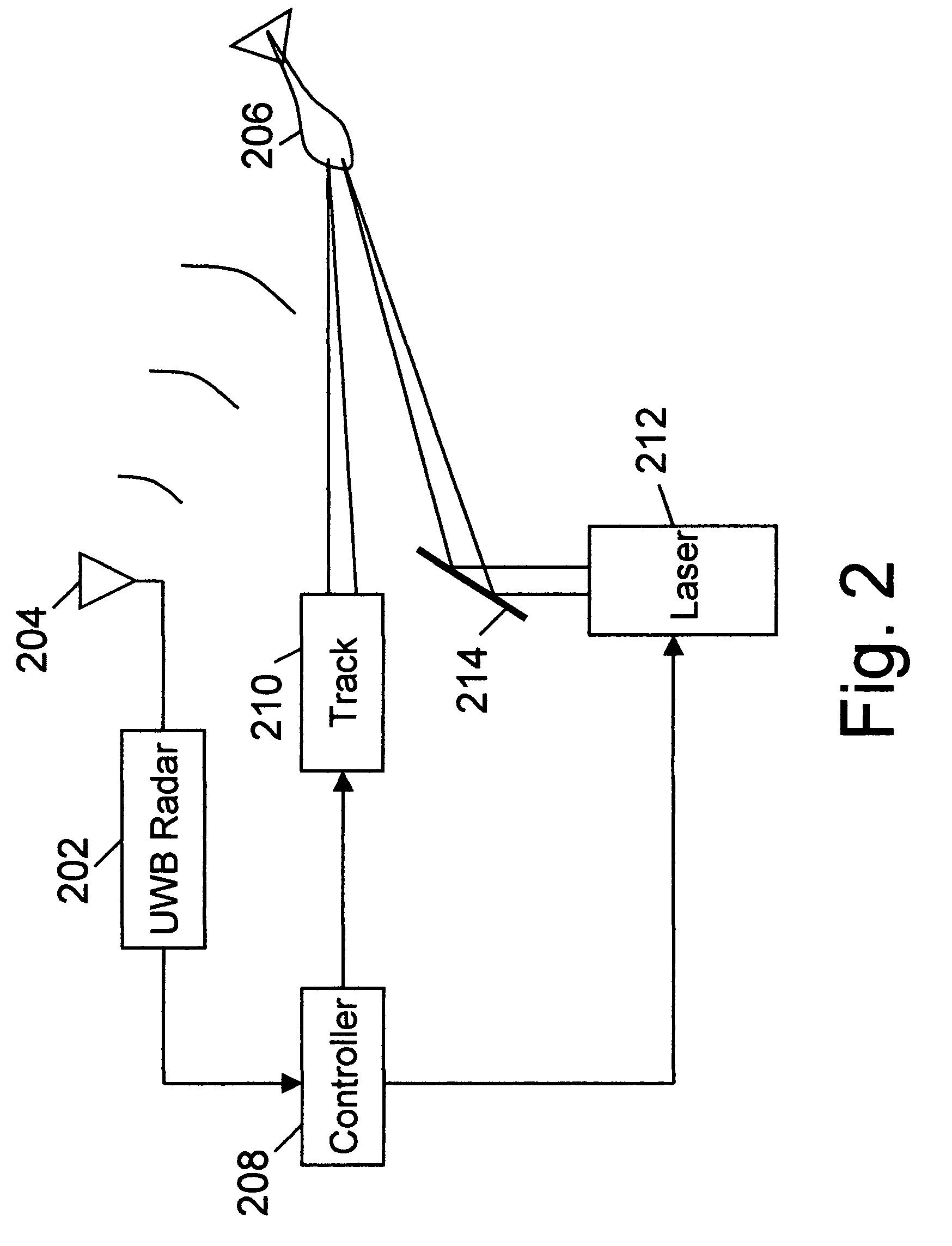

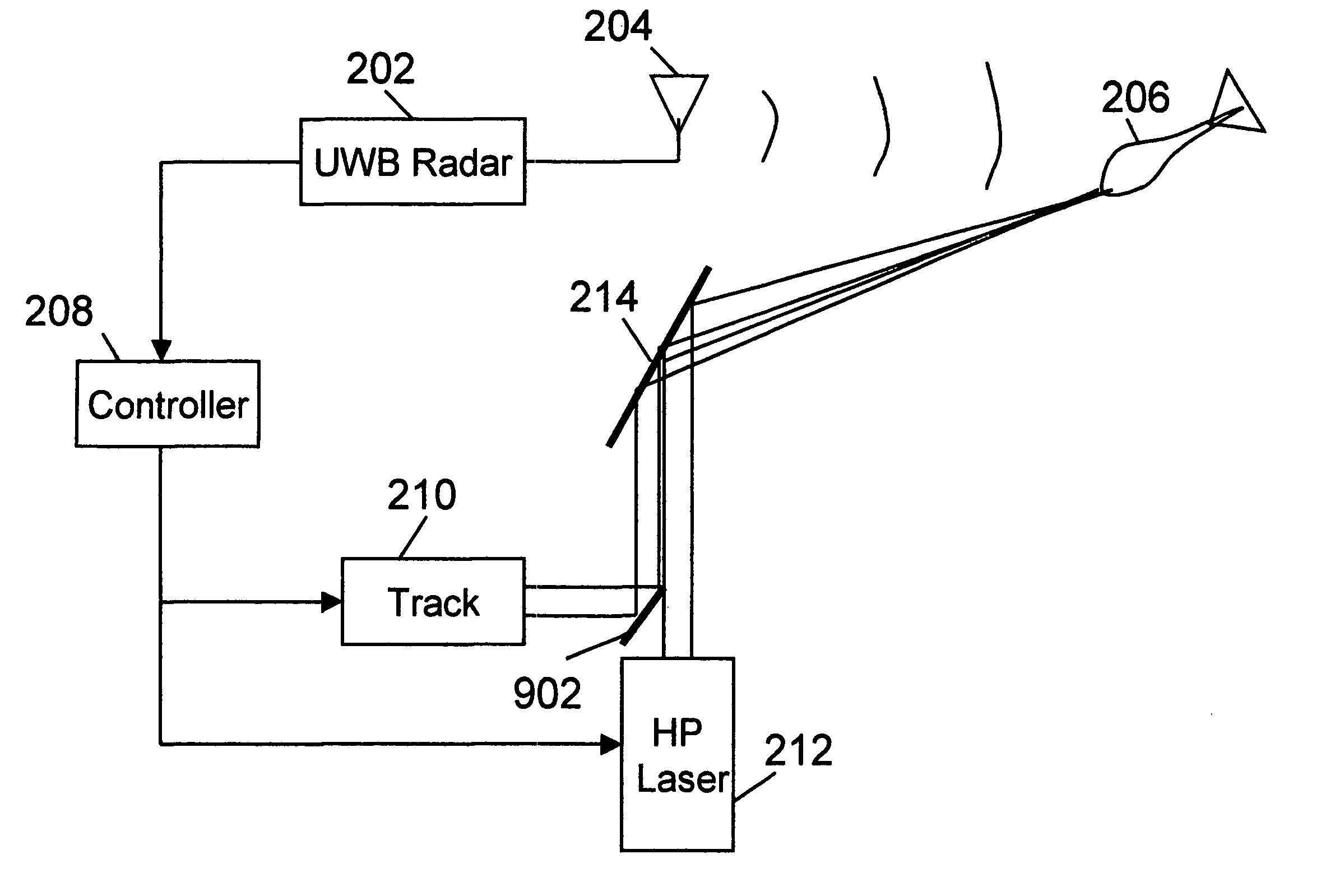

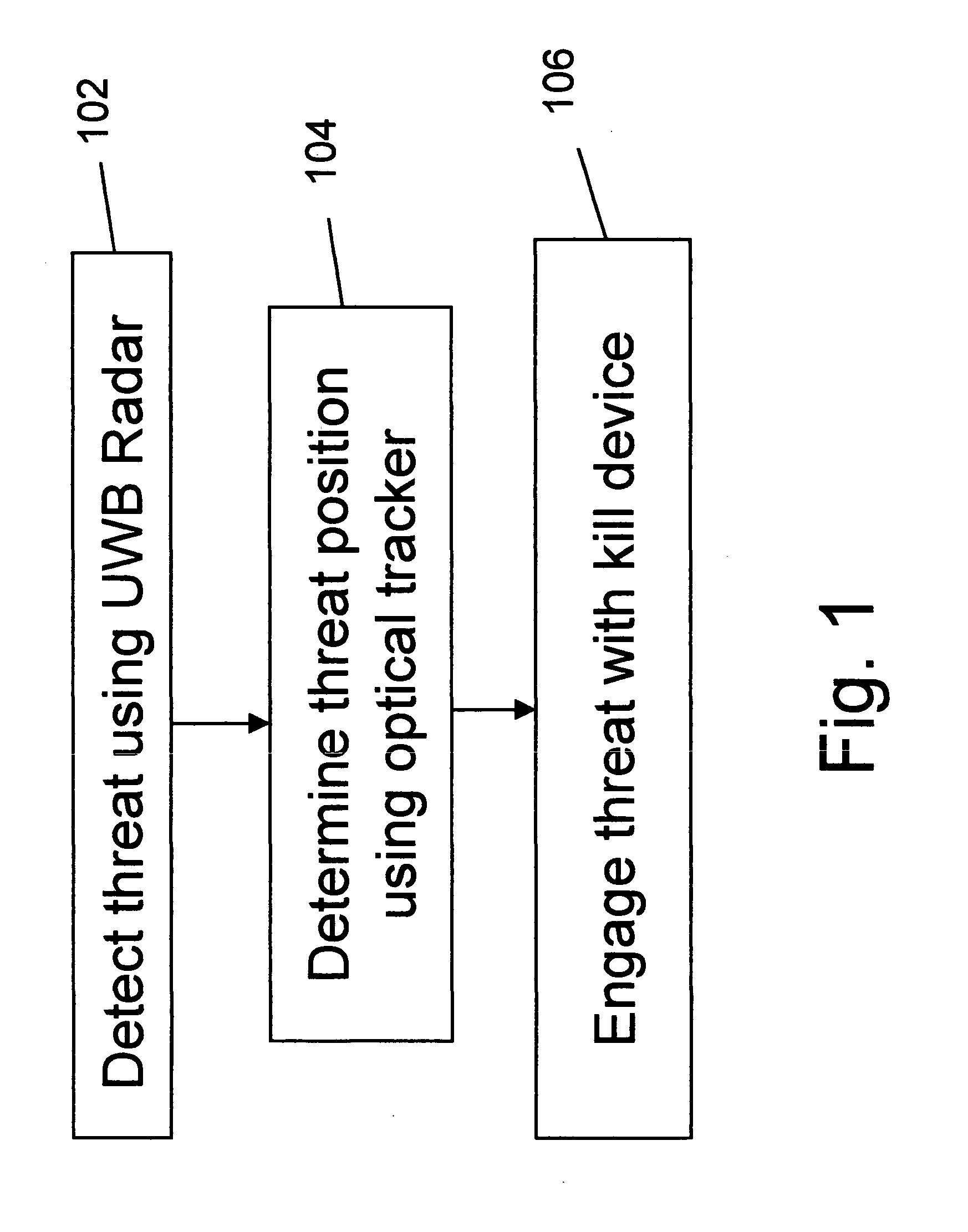

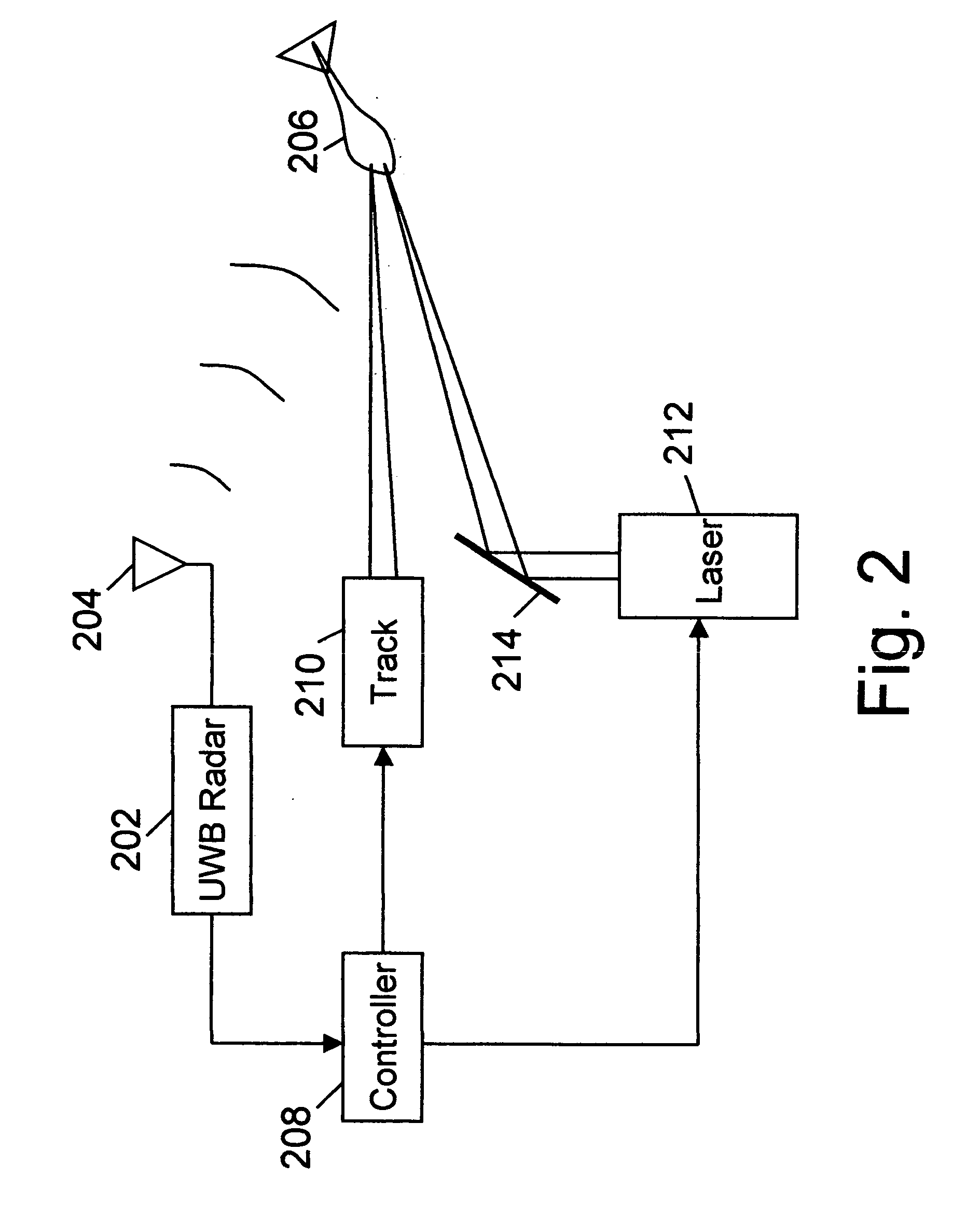

System and method for ultra wideband subarray beam steering

An active protection system comprising an ultra wideband (UWB) radar for threat detection, an optical tracker for precision threat position measurement, and a high powered laser for threat kill or mitigation. The UWB radar may use a sparse array antenna and may also utilize Doppler radar information. The high powered laser may be of the optically pumped solid state type and in one embodiment may share optics with the optical tracker. In one embodiment, the UWB radar is used to focus the high power laser. Alternative interceptor type kill mechanisms are disclosed. In a further embodiment, the kill mechanism may be directed to the source of the threat. In a further embodiment, an antenna array is steered by using subarray groups having fixed timing within the group and variable timing from group to group.

Owner:TIME DOMAIN

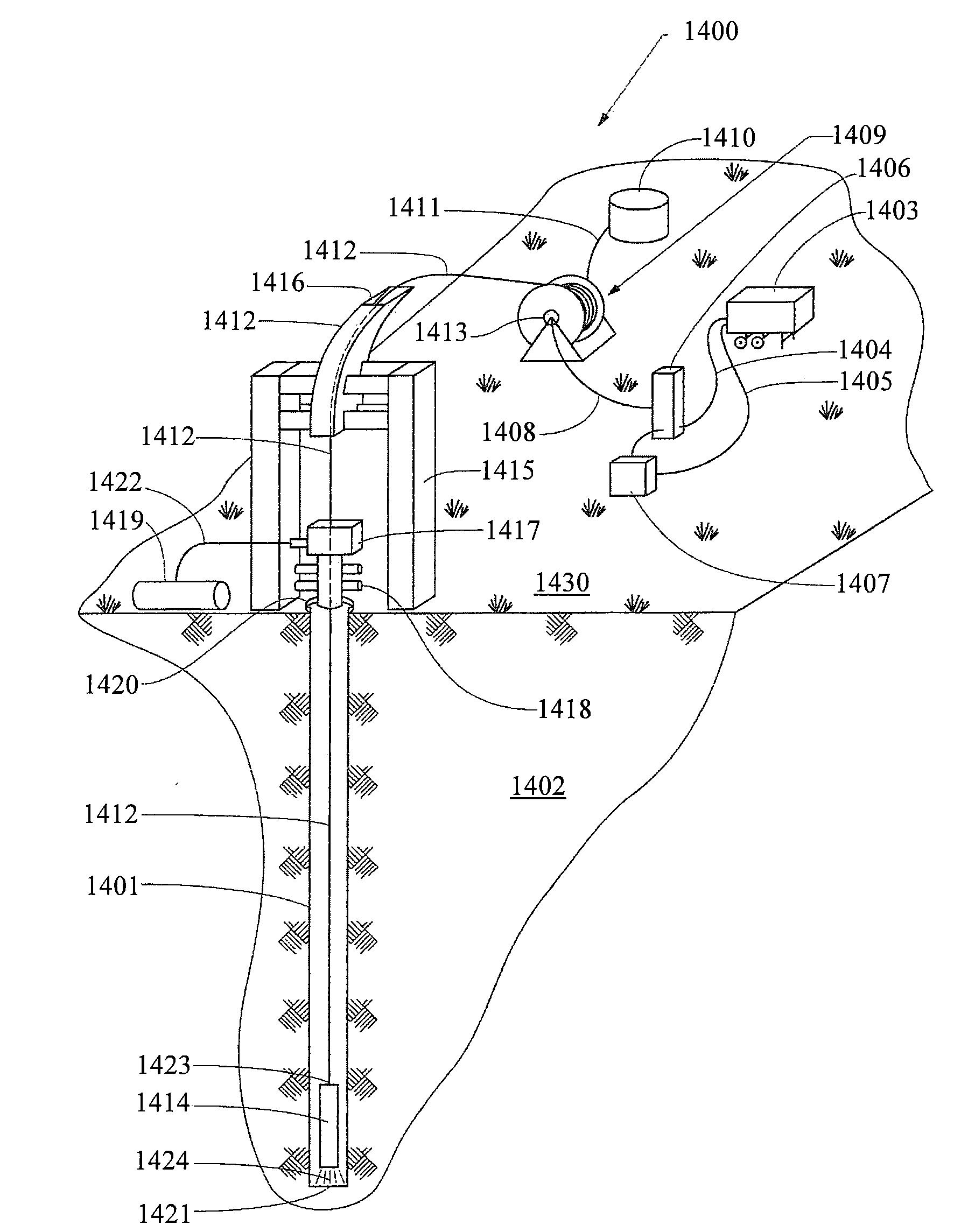

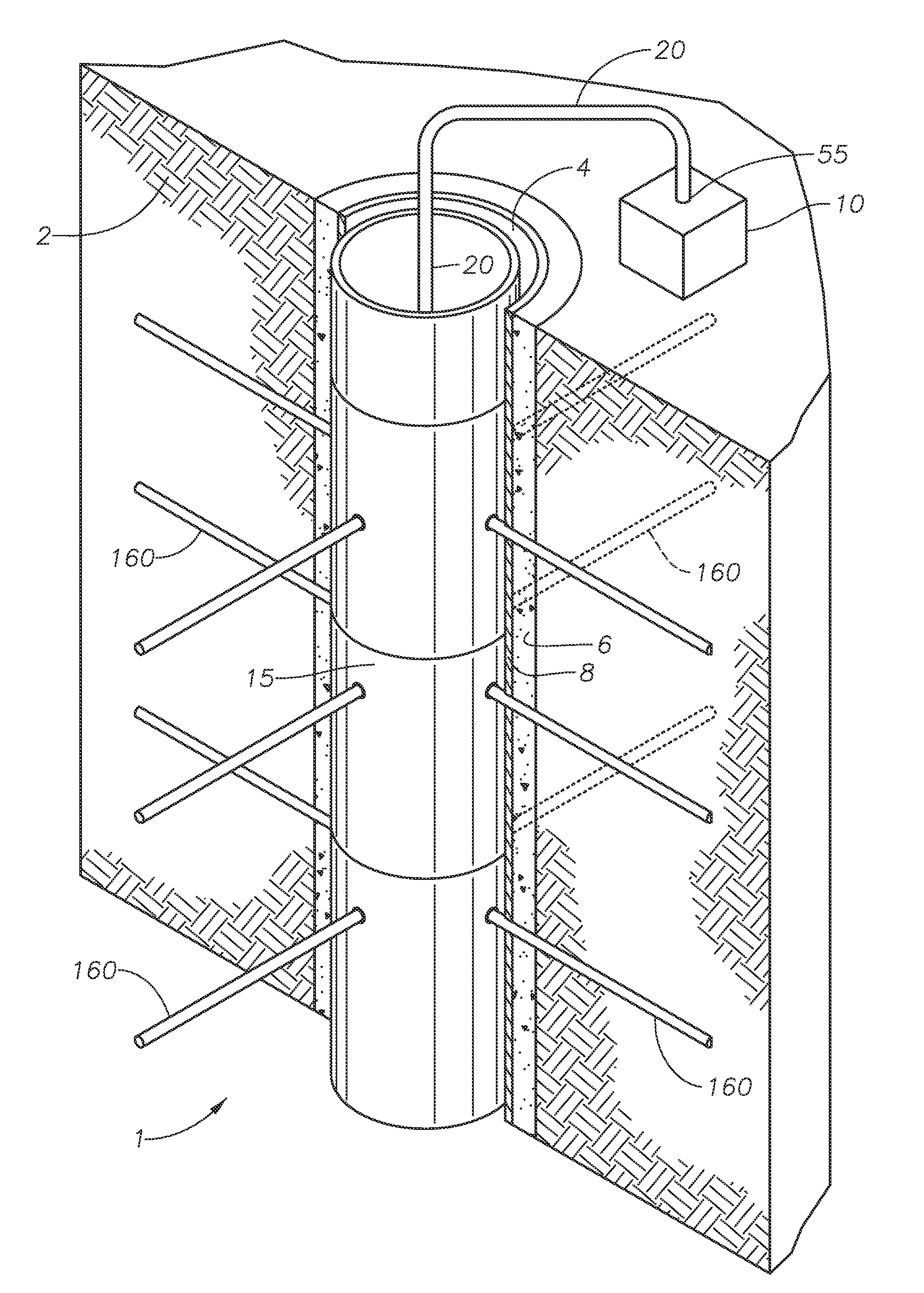

Methods of using a laser to perforate composite structures of steel casing, cement and rocks

ActiveUS20060231257A1Improve breathabilityReduce hole taperingDisloding machinesThermal drillingHigh power lasersSmall fragment

Apparatus and methods of using lasers are provided for the perforation of oil and gas well casings and rock formations. A rock removal process called laser spallation is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall or fracture the rock into small fragments that can then be easily removed from the rock formation. The use of high power laser beams of kilowatt level is provided to rapidly cut the steel casings and perforate into the formation. Techniques of the invention increase permeability and reduce hole tapering while perforating a deep hole in reservoir rock formations.

Owner:UCHICAGO ARGONNE LLC +1

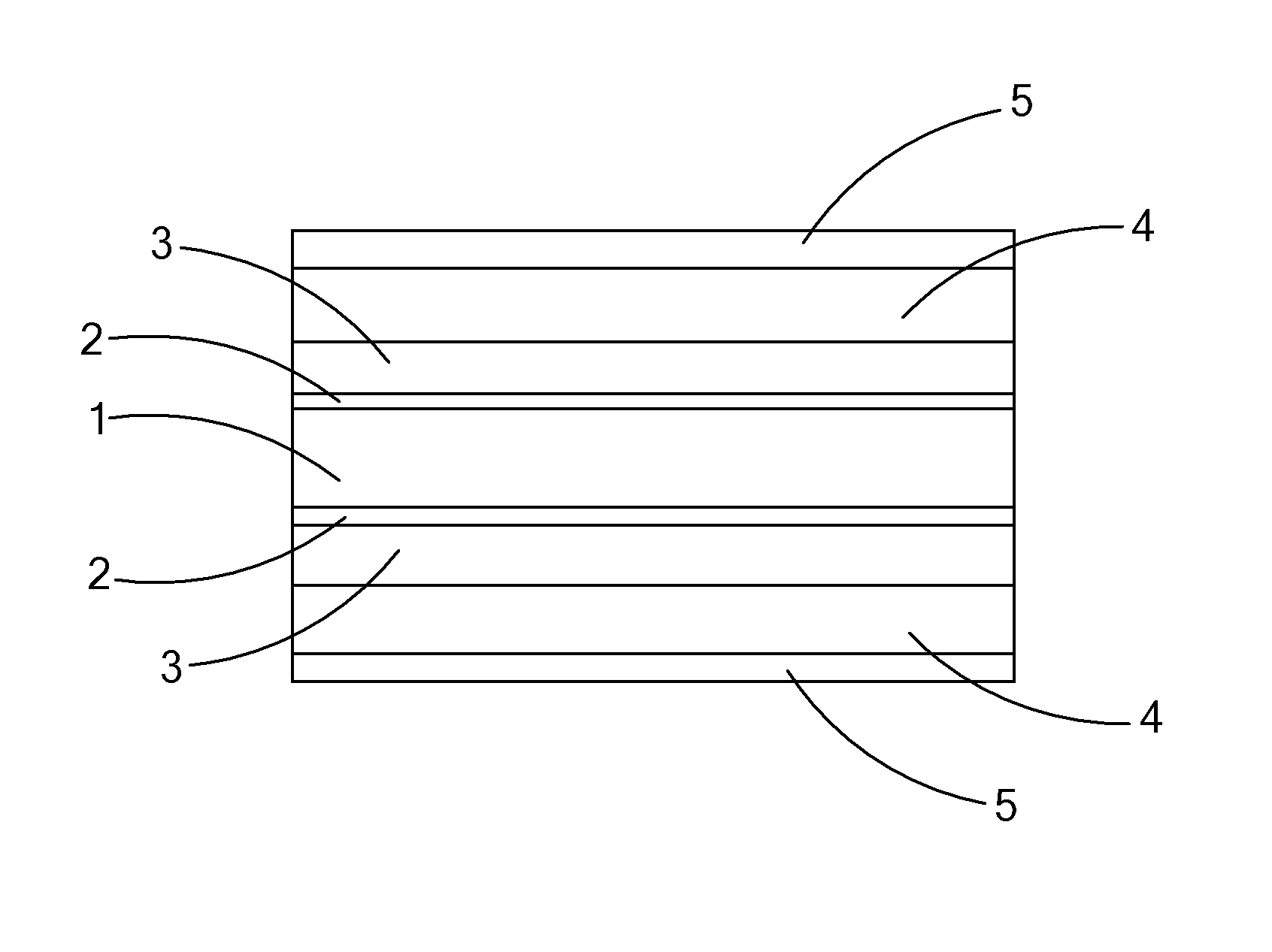

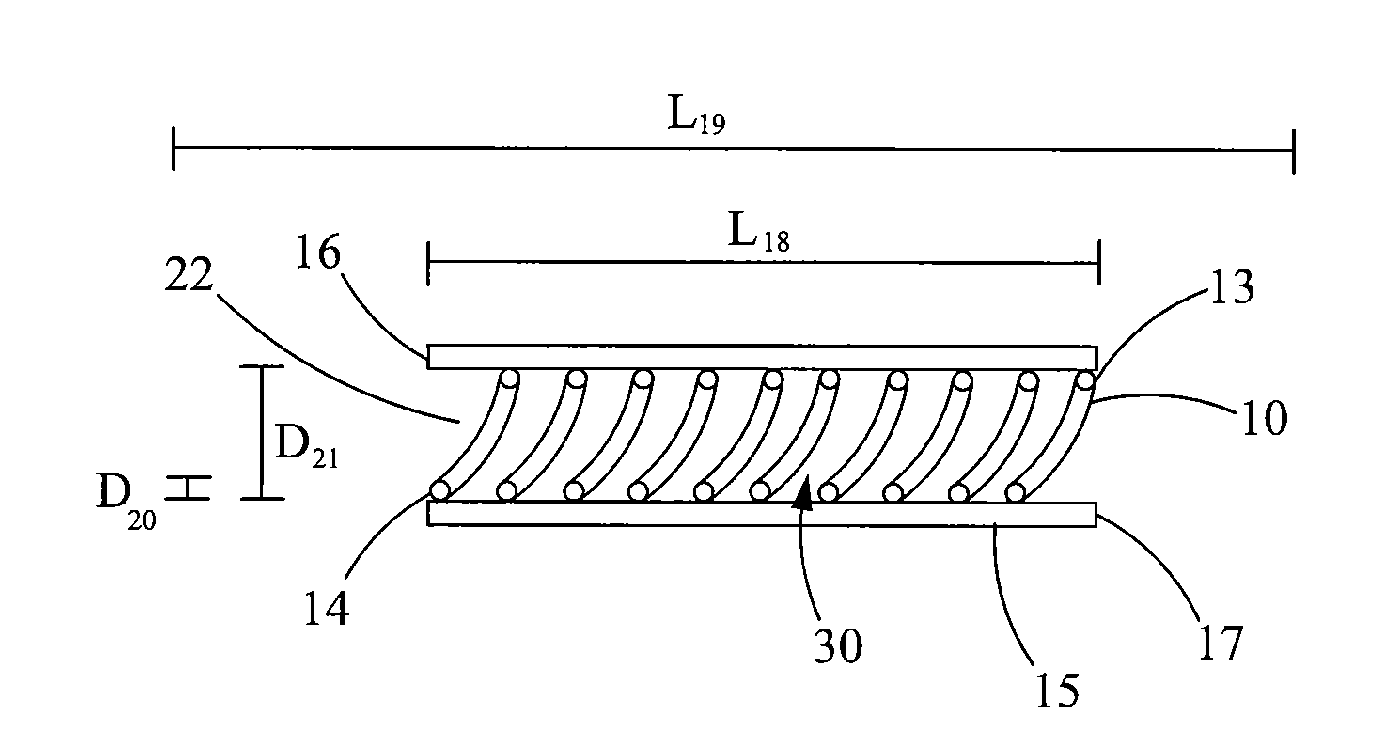

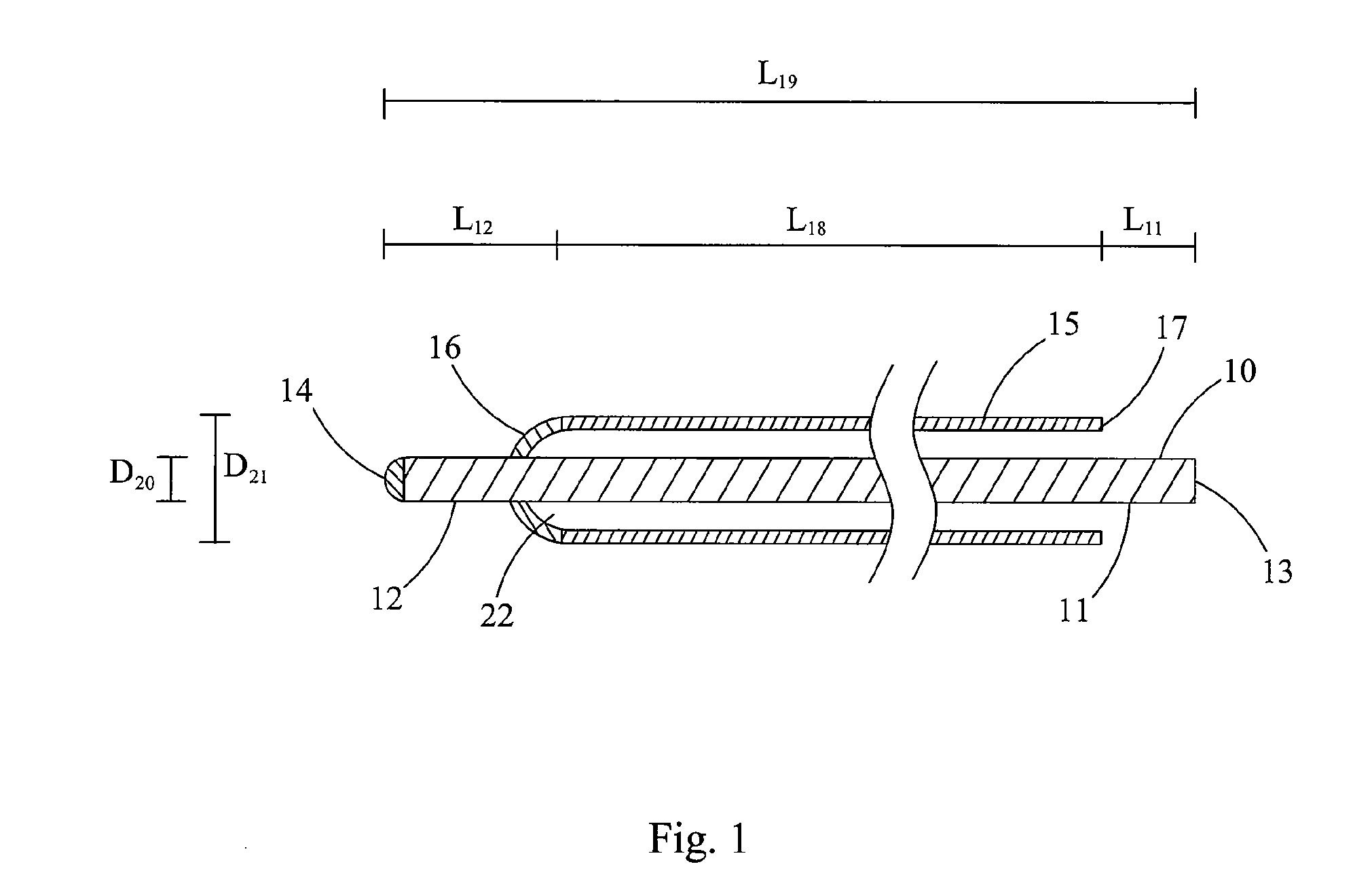

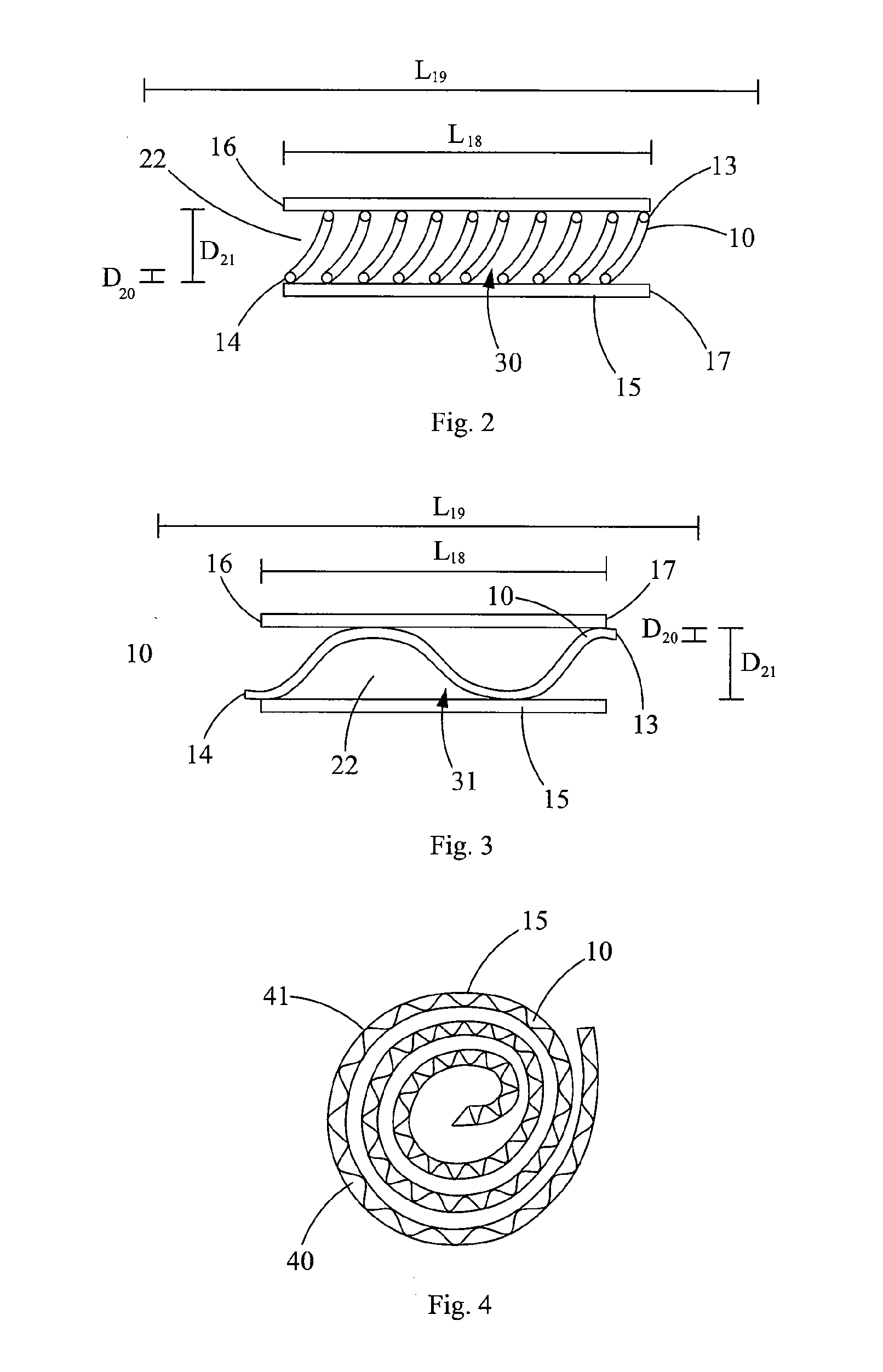

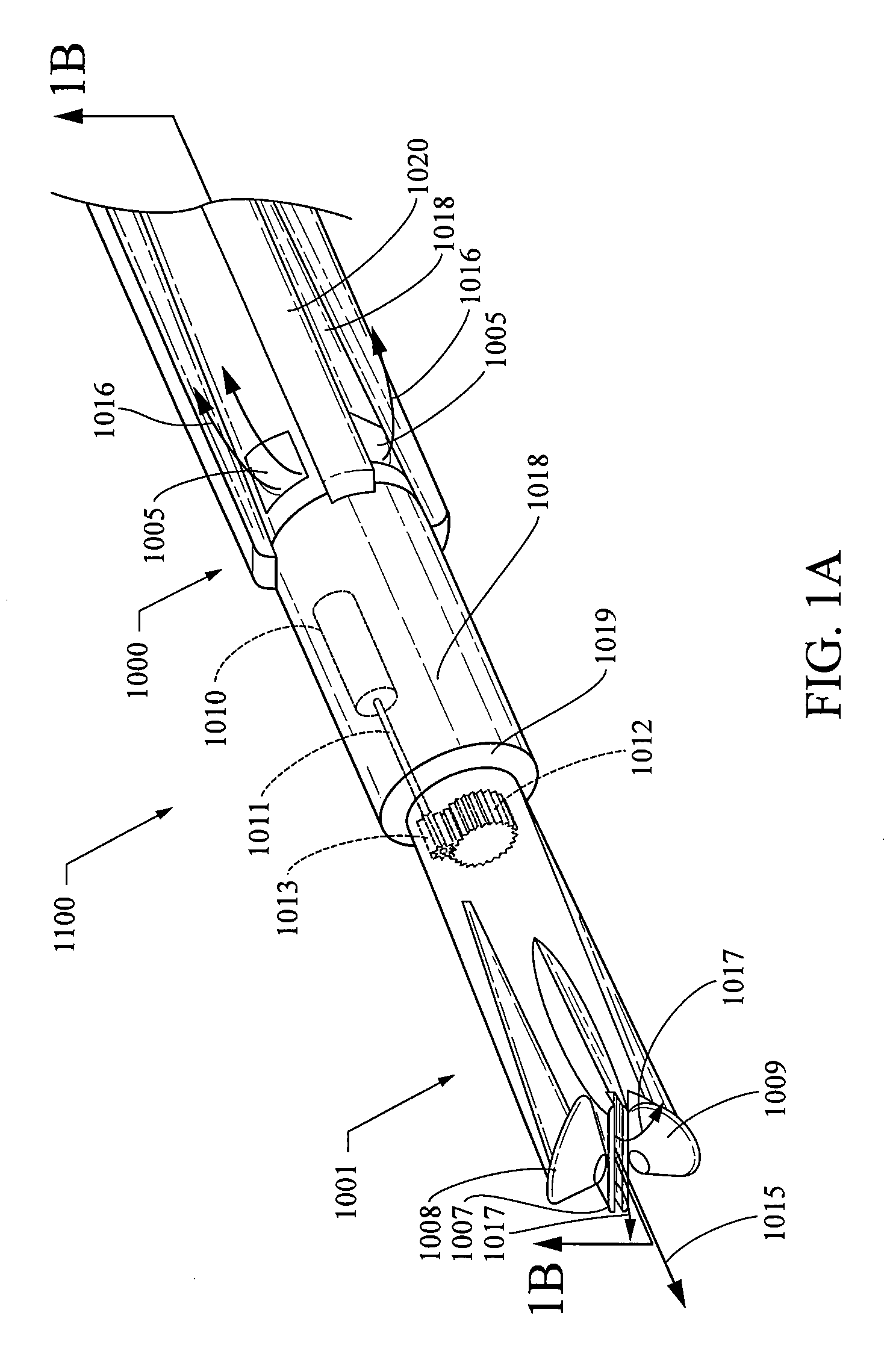

Optical Fiber Cable for Transmission of High Power Laser Energy Over Great Distances

ActiveUS20100215326A1Easy to transportIncrease powerGlass optical fibreDrill bitsHigh power lasersEngineering

There is provided a system and apparatus for the transmission of high power laser energy over great distances without substantial power loss and without the presence of stimulated Raman scattering. There is further provided systems and optical fiber cable configurations and optical fiber structures for the delivering high power laser energy over great distances to a tool or surface to perform an operation or work with the tool or upon the surface.

Owner:FORO ENERGY

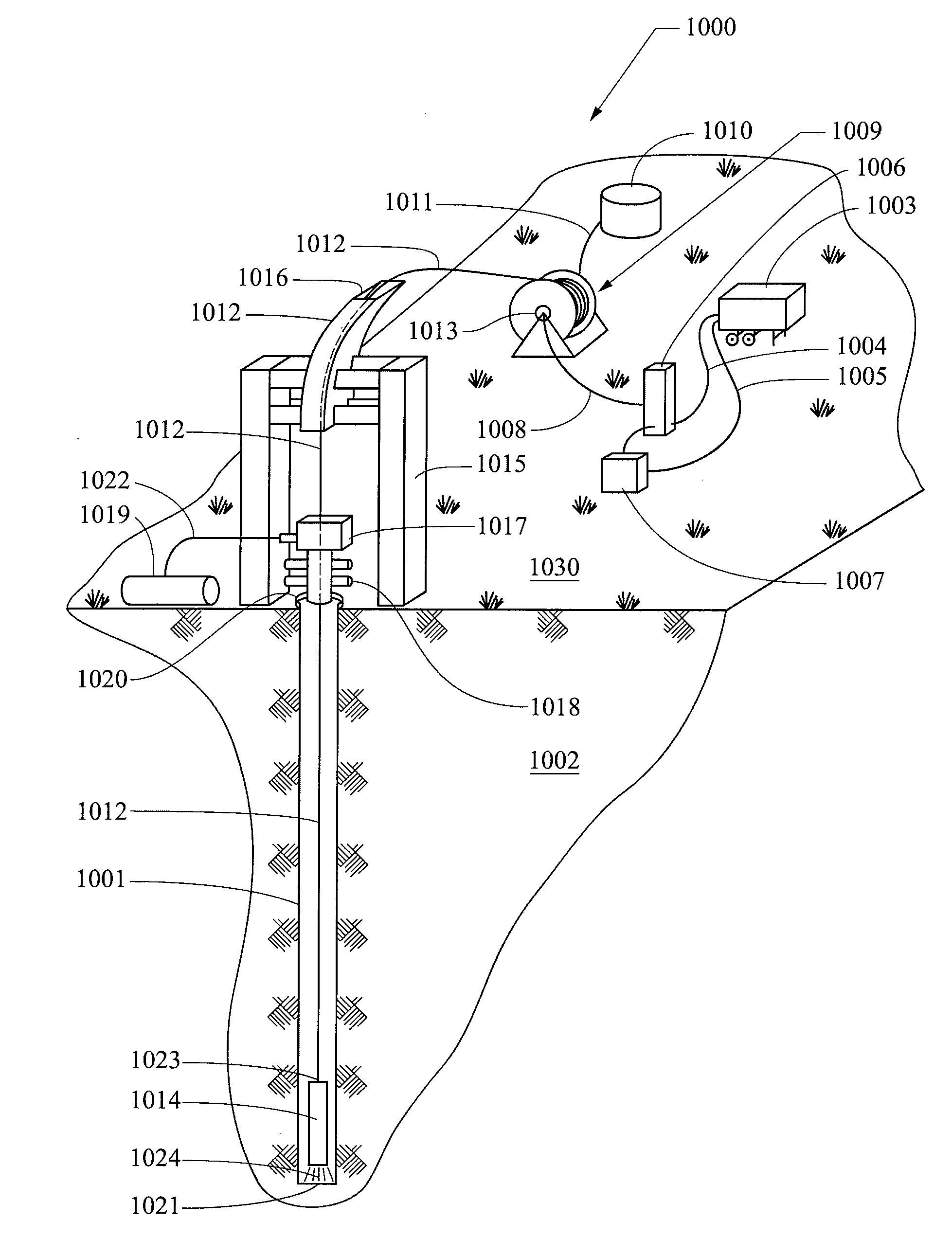

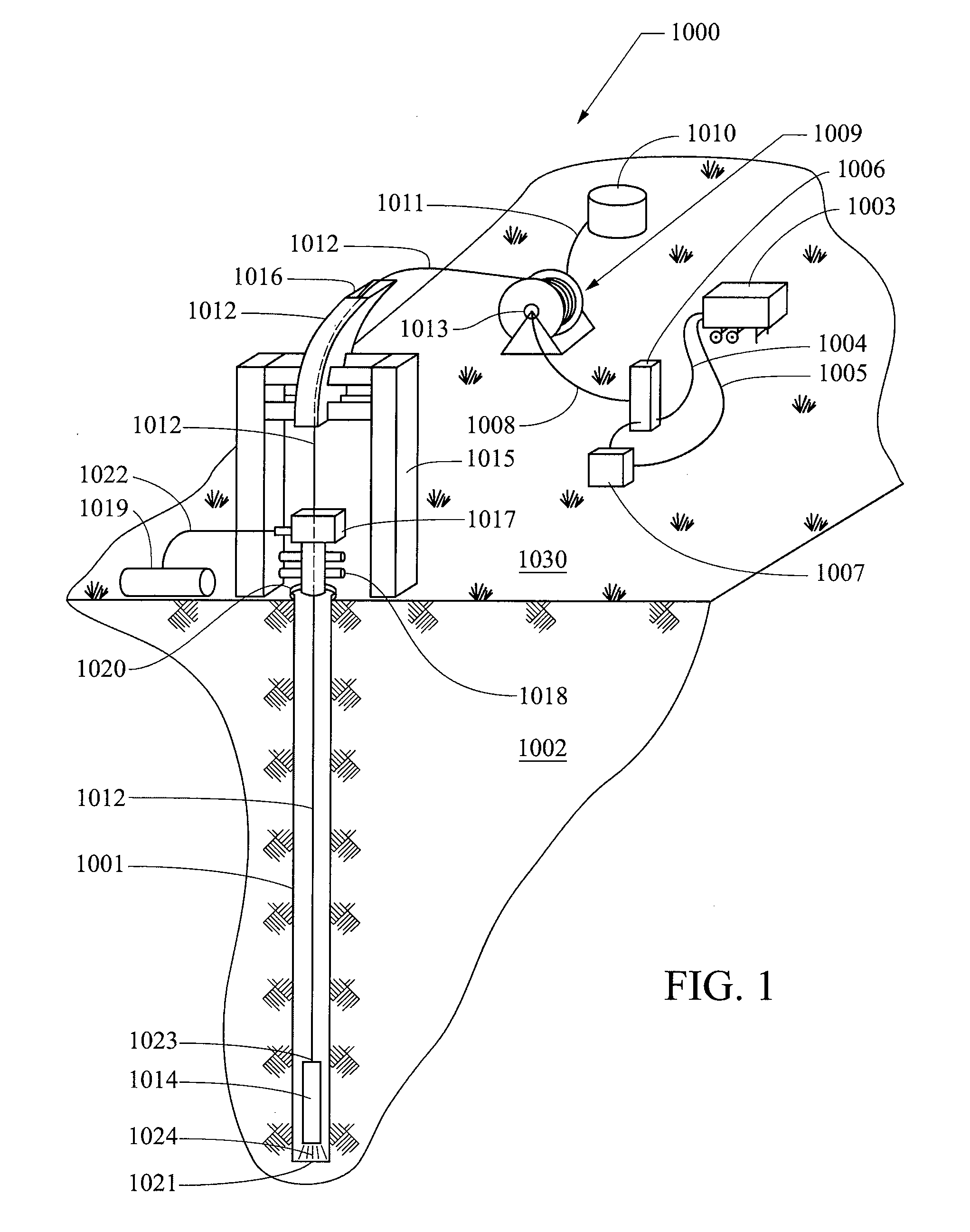

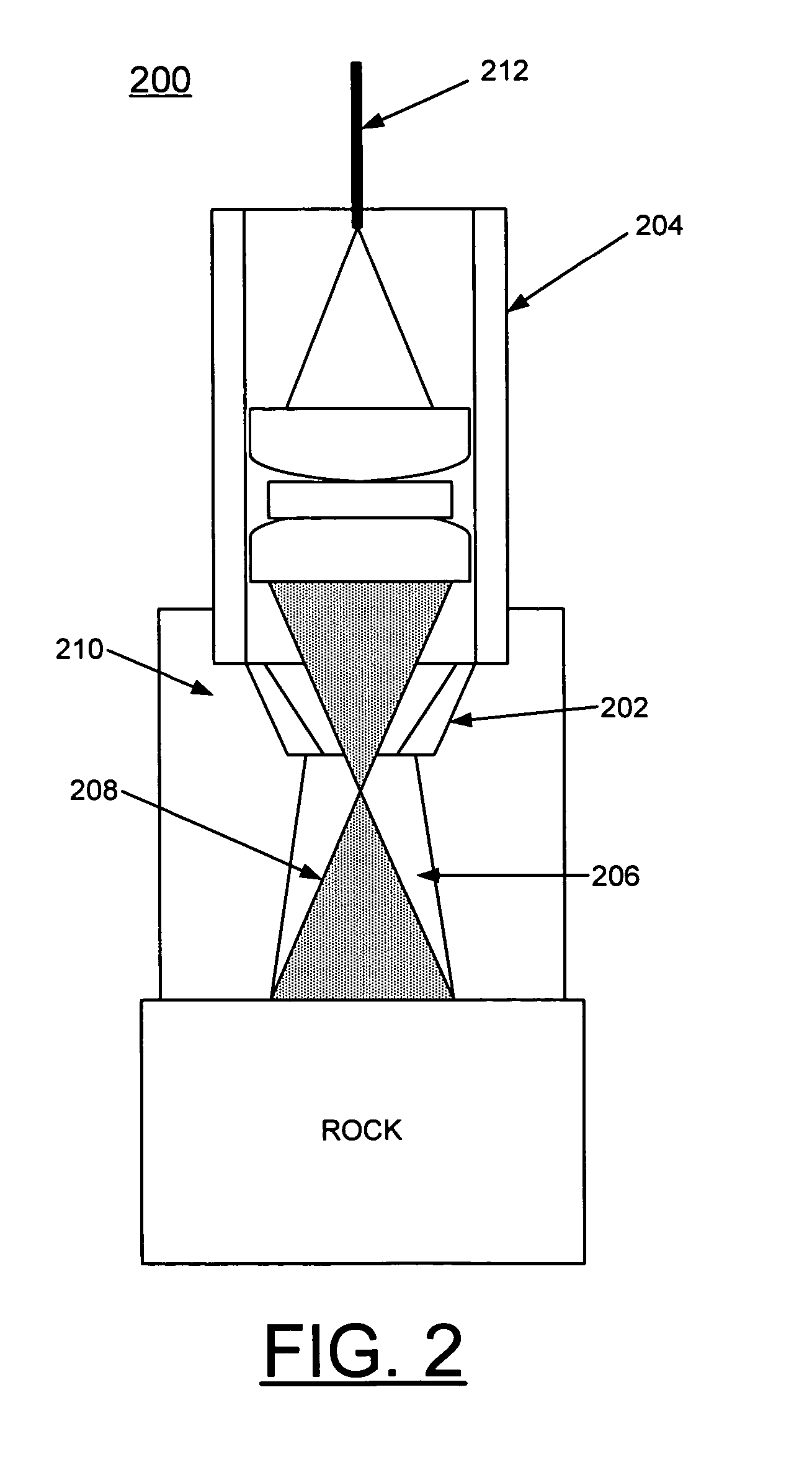

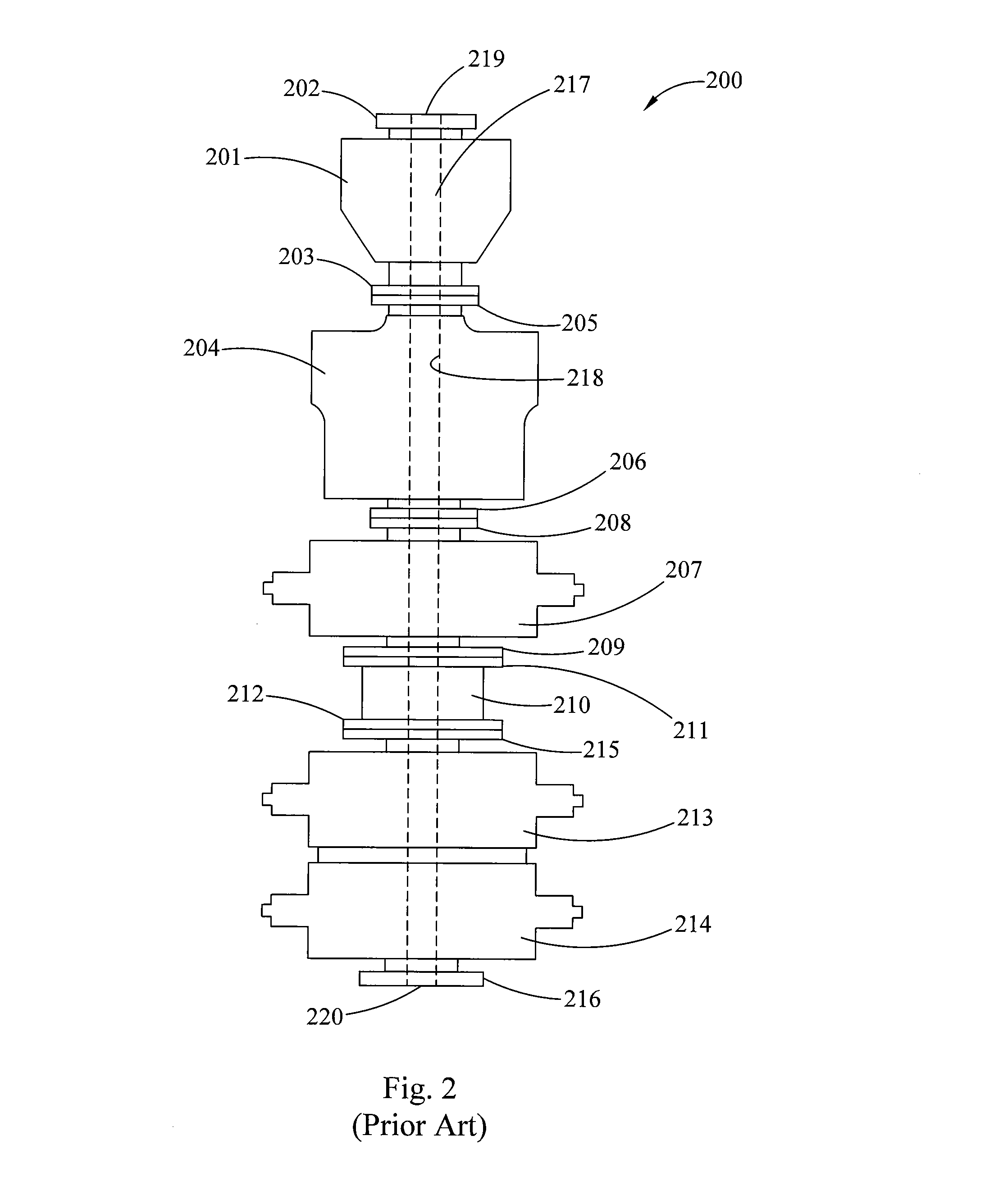

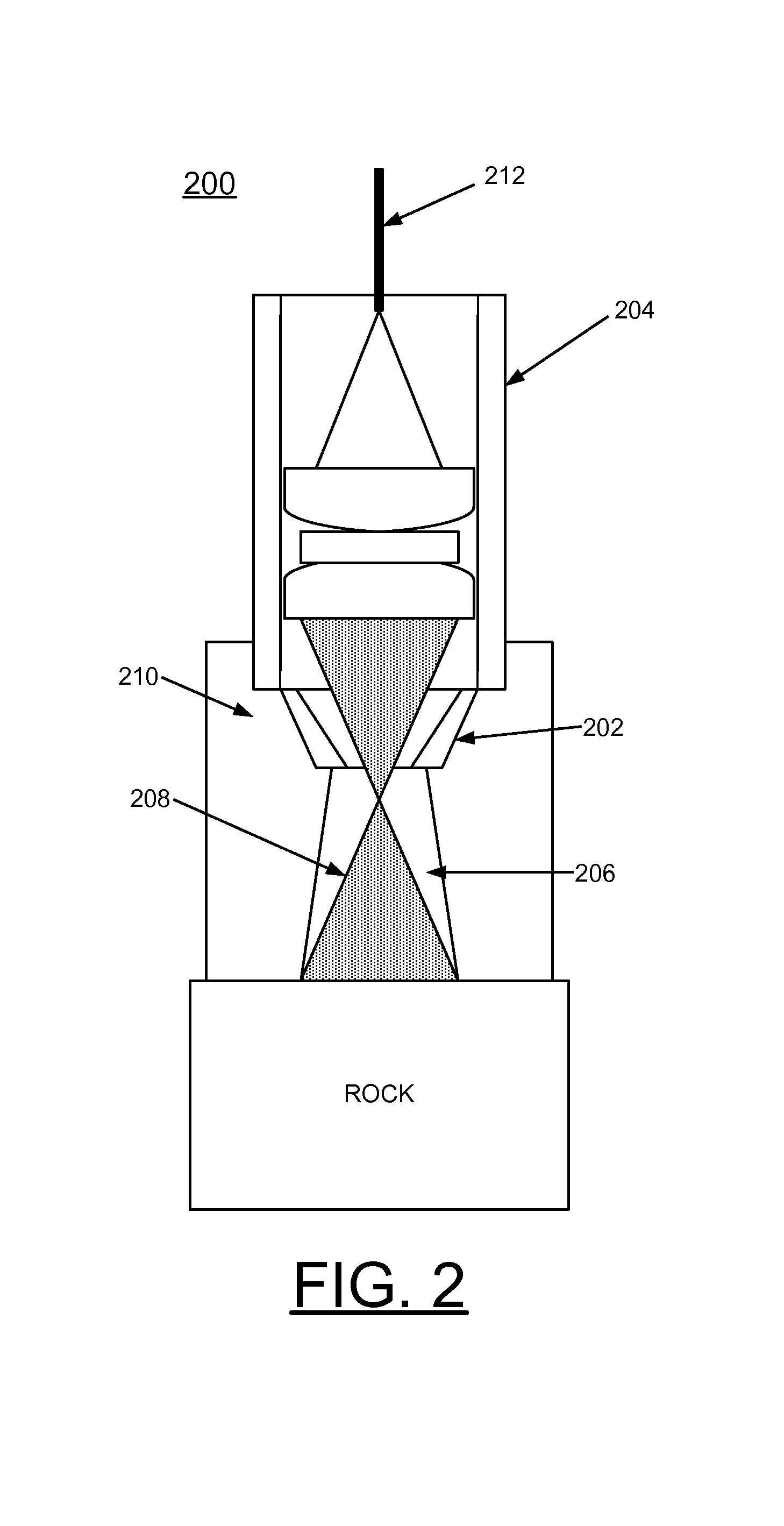

Downhole lens assembly for use with high power lasers for earth boring

InactiveUS6755262B2Difficult to controlRelative position is not easyEarth drilling toolsDisloding machinesFiberHigh power lasers

An earth boring apparatus at least partially locatable within a borehole. The apparatus includes a plurality of optical fibers, each of which has a proximal fiber light energy input end and a distal fiber light energy output end. At least one focal lens is disposed at the distal fiber light energy output end. The focal lens is made up of a plurality of focal elements, each of which corresponds to the distal fiber light energy output end of at least one optical fiber. The focal lens is arranged to receive light energy from the corresponding distal fiber light energy output end of the at least one optical fiber and focus it outwardly from the distal fiber light energy output end.

Owner:GAS TECH INST

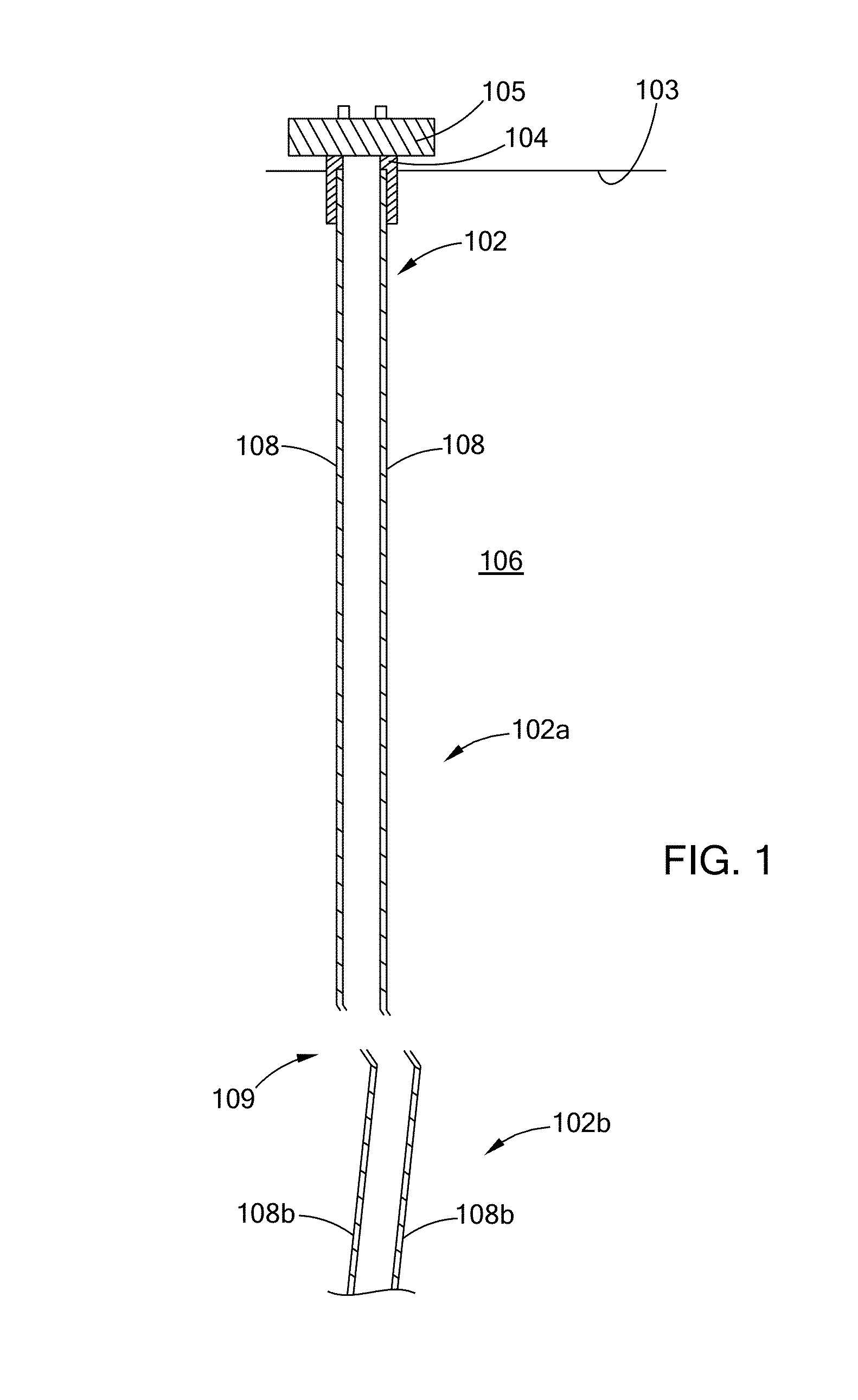

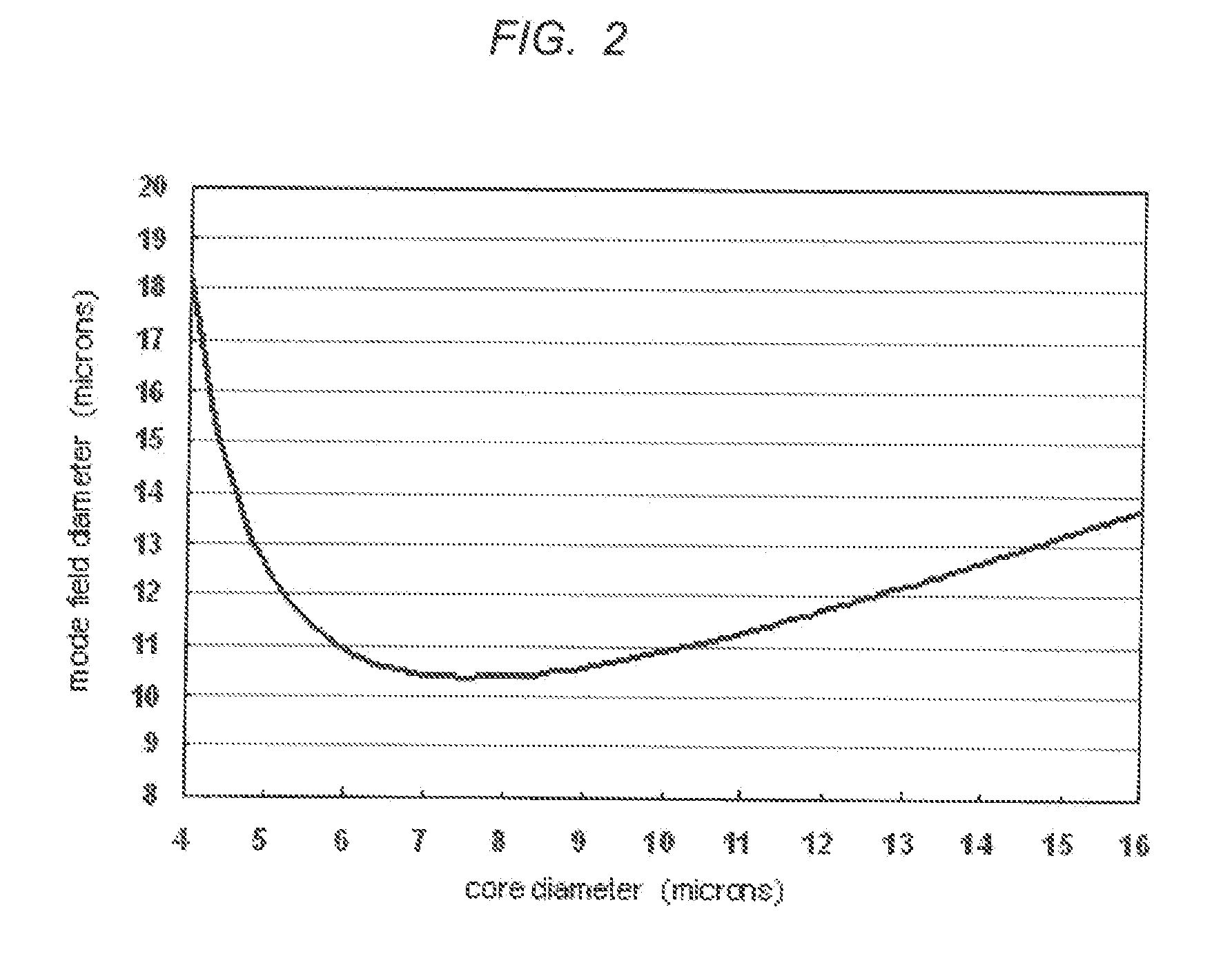

Optical fiber configurations for transmission of laser energy over great distances

ActiveUS20120020631A1Solve needsSubstantial bending lossFibre mechanical structuresMetal working apparatusFiberHigh power lasers

There are provided optical fiber configurations that provide for the delivery of laser energy, and in particular, the transmission and delivery of high power laser energy over great distances. These configurations further are hardened to protect the optical fibers from the stresses and conditions of an intended application. The configurations provide means for determining the additional fiber length (AFL) need to obtain the benefits of such additional fiber, while avoiding bending losses.

Owner:FORO ENERGY

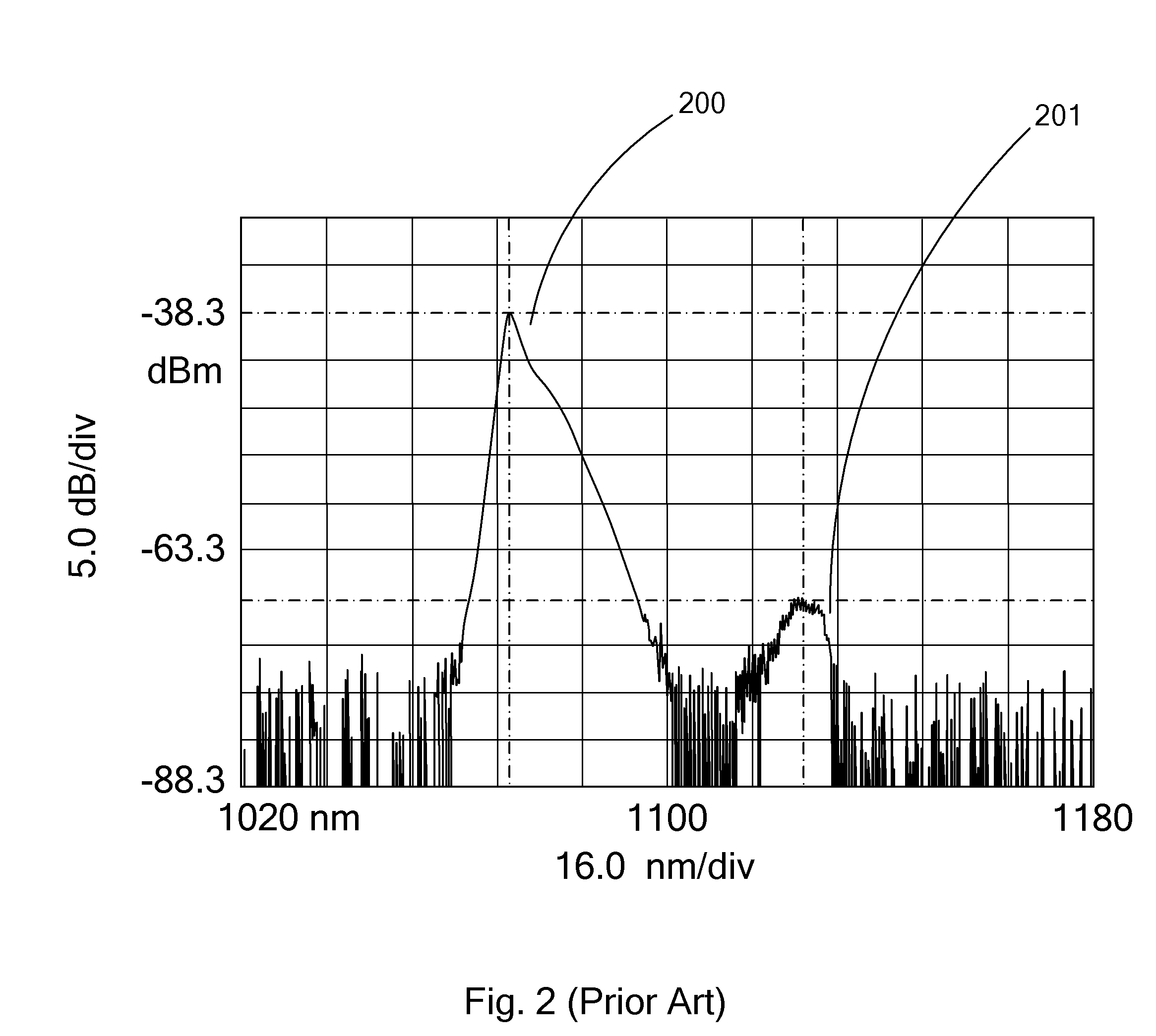

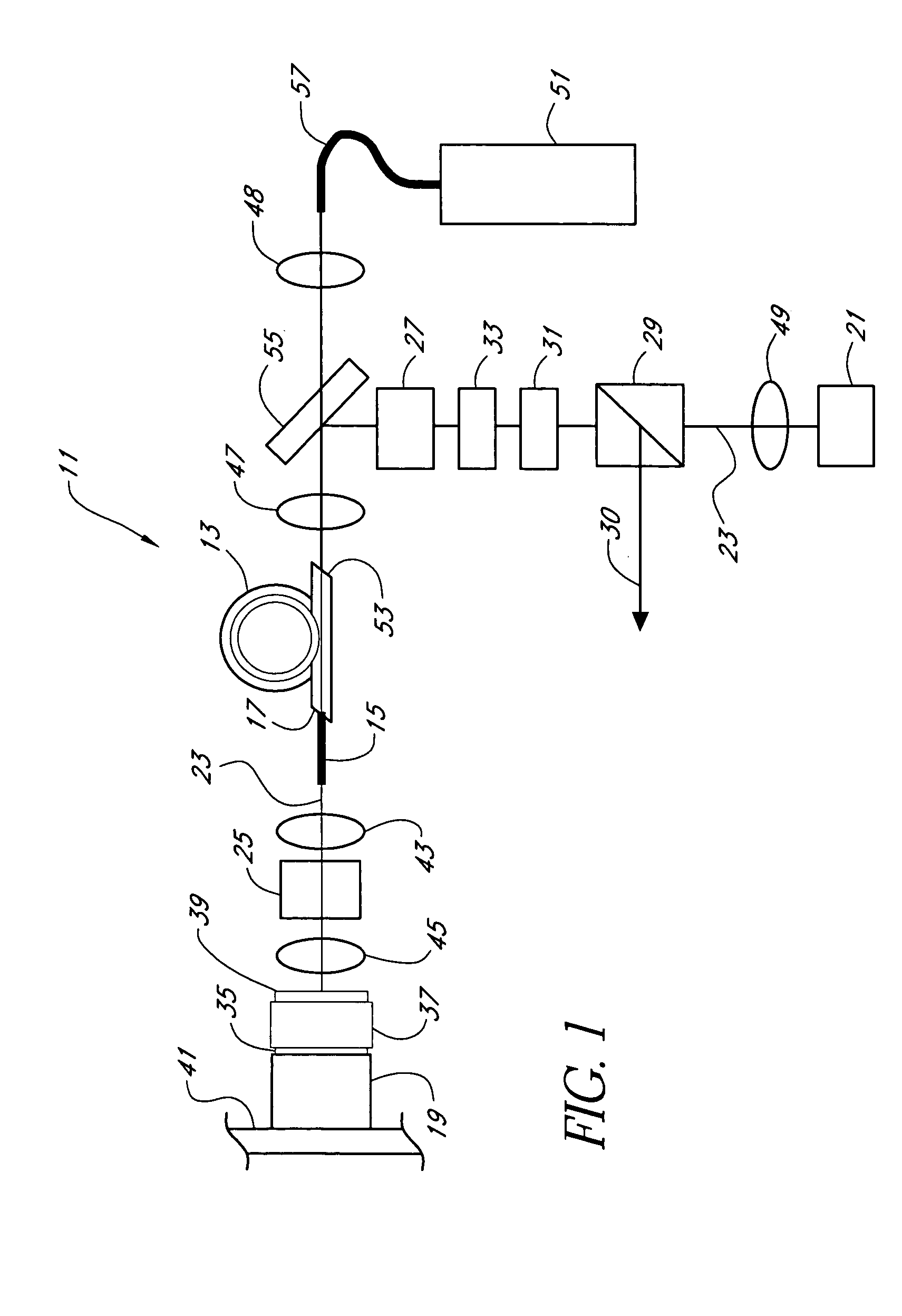

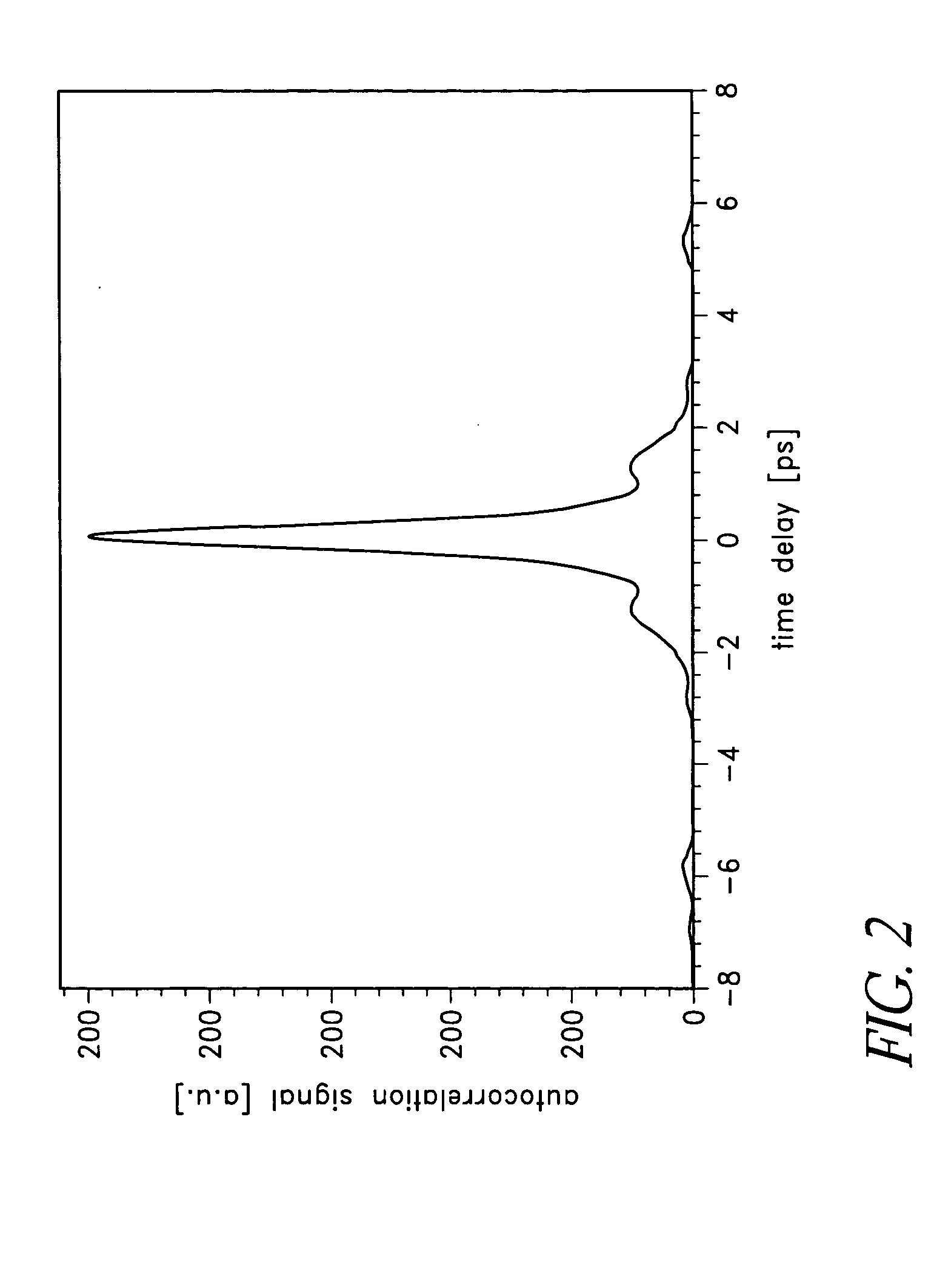

Mode-locked multi-mode fiber laser pulse source

InactiveUS20050008044A1High energy storageIncrease the sectionCoupling light guidesActive medium shape and constructionHigh power lasersPeak value

A laser utilizes a cavity design which allows the stable generation of high peak power pulses from mode-locked multi-mode fiber lasers, greatly extending the peak power limits of conventional mode-locked single-mode fiber lasers. Mode-locking may be induced by insertion of a saturable absorber into the cavity and by inserting one or more mode-filters to ensure the oscillation of the fundamental mode in the multi-mode fiber. The probability of damage of the absorber may be minimized by the insertion of an additional semiconductor optical power limiter into the cavity. To amplify and compress optical pulses in a multi-mode (MM) optical fiber, a single-mode is launched into the MM fiber by matching the modal profile of the fundamental mode of the MM fiber with a diffraction-limited optical mode at the launch end, The fundamental mode is preserved in the MM fiber by minimizing mode-coupling by using relatively short lengths of step-index MM fibers with a few hundred modes and by minimizing fiber perturbations. Doping is confined to the center of the fiber core to preferentially amplify the fundamental mode, to reduce amplified spontaneous emission and to allow gain-guiding of the fundamental mode. Gain-guiding allows for the design of systems with length-dependent and power-dependent diameters of the fundamental mode. To allow pumping with high-power laser diodes, a double-clad amplifier structure is employed. For applications in nonlinear pulse-compression, self phase modulation and dispersion in the optical fibers can be exploited. High-power optical pulses may be linearly compressed using bulk optics dispersive delay lines or by chirped fiber Bragg gratings written directly into the SM or MM optical fiber. High-power cw lasers operating in a single near-diffraction-limited mode may be constructed from MM fibers by incorporating effective mode-filters into the laser cavity. Regenerative fiber amplifiers may be constructed from MM fibers by careful control of the recirculating mode. Higher-power Q-switched fiber lasers may be constructed by exploiting the large energy stored in MM fiber amplifiers.

Owner:FERMANN MARTIN E +1

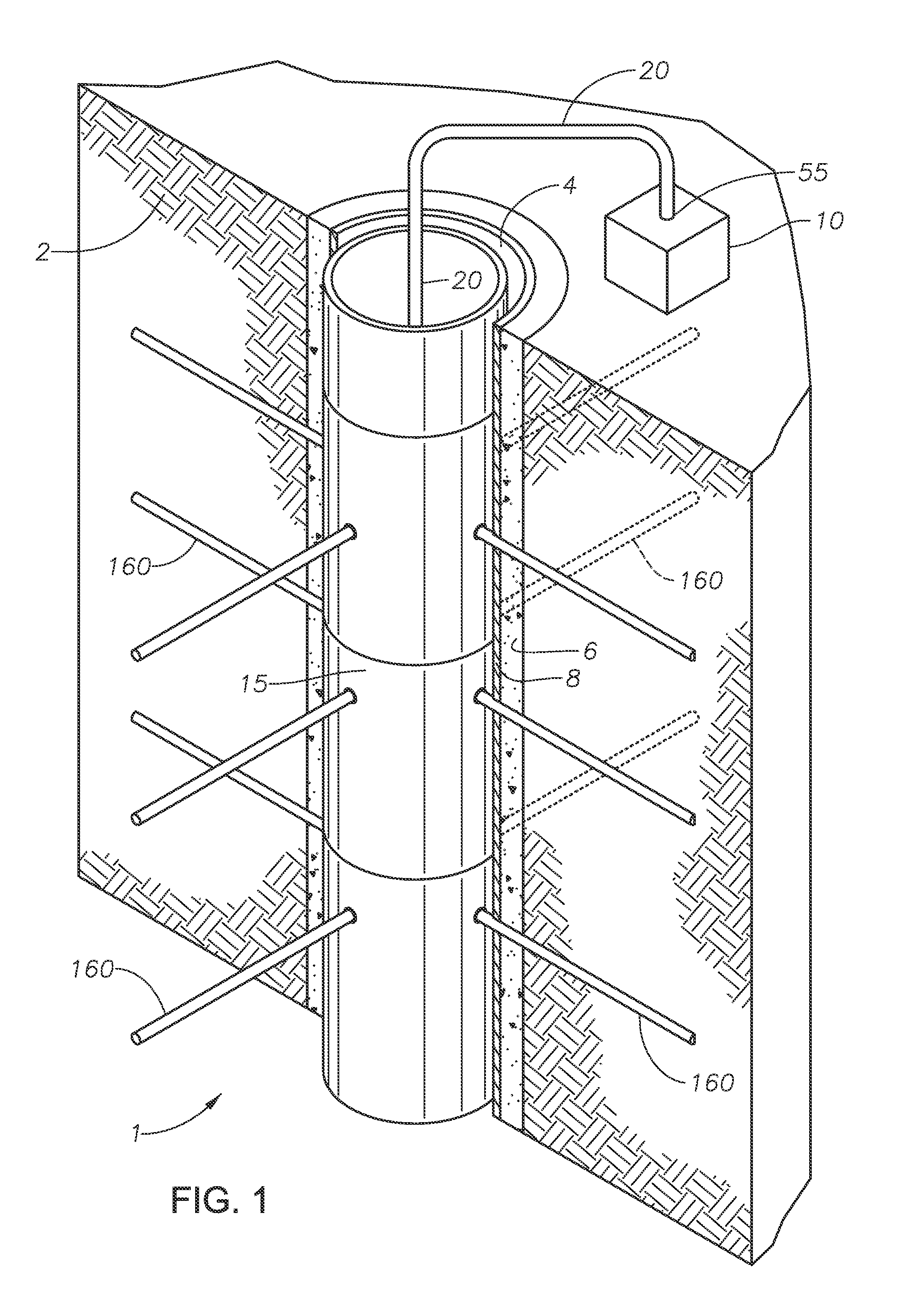

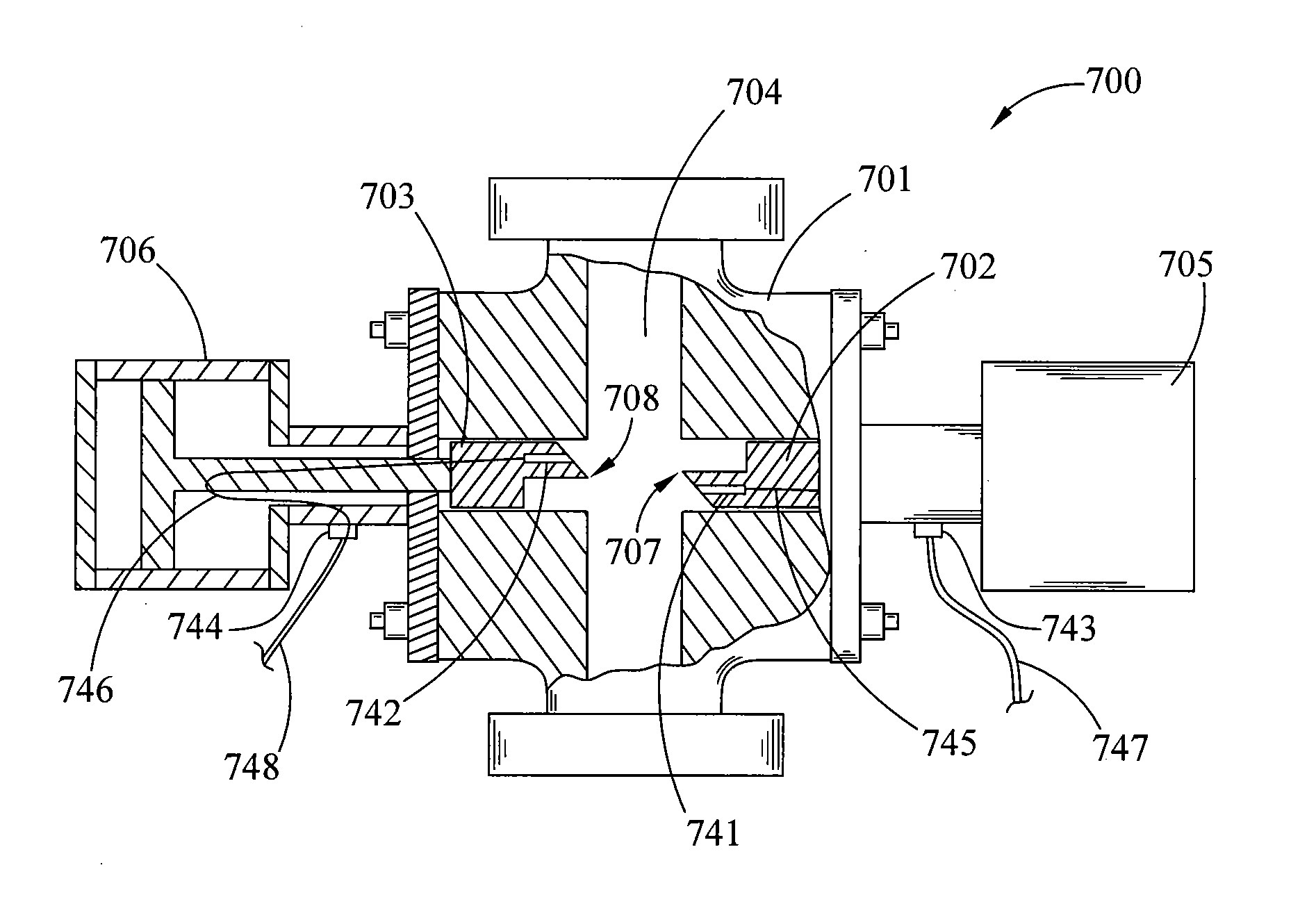

High power laser decommissioning of multistring and damaged wells

High power laser systems, high power laser tools, and methods of using these tools and systems for opening up damaged wells and for cutting, sectioning and removing structures objects, and materials, and in particular, for doing so in difficult to access locations and environments, such as offshore, underwater, or in hazardous environments, such as nuclear and chemical facilities. And, high power laser systems, high power laser tools, and methods of using these systems and tools for providing rock-to-rock plugs for decommissioning of wells.

Owner:FORO ENERGY

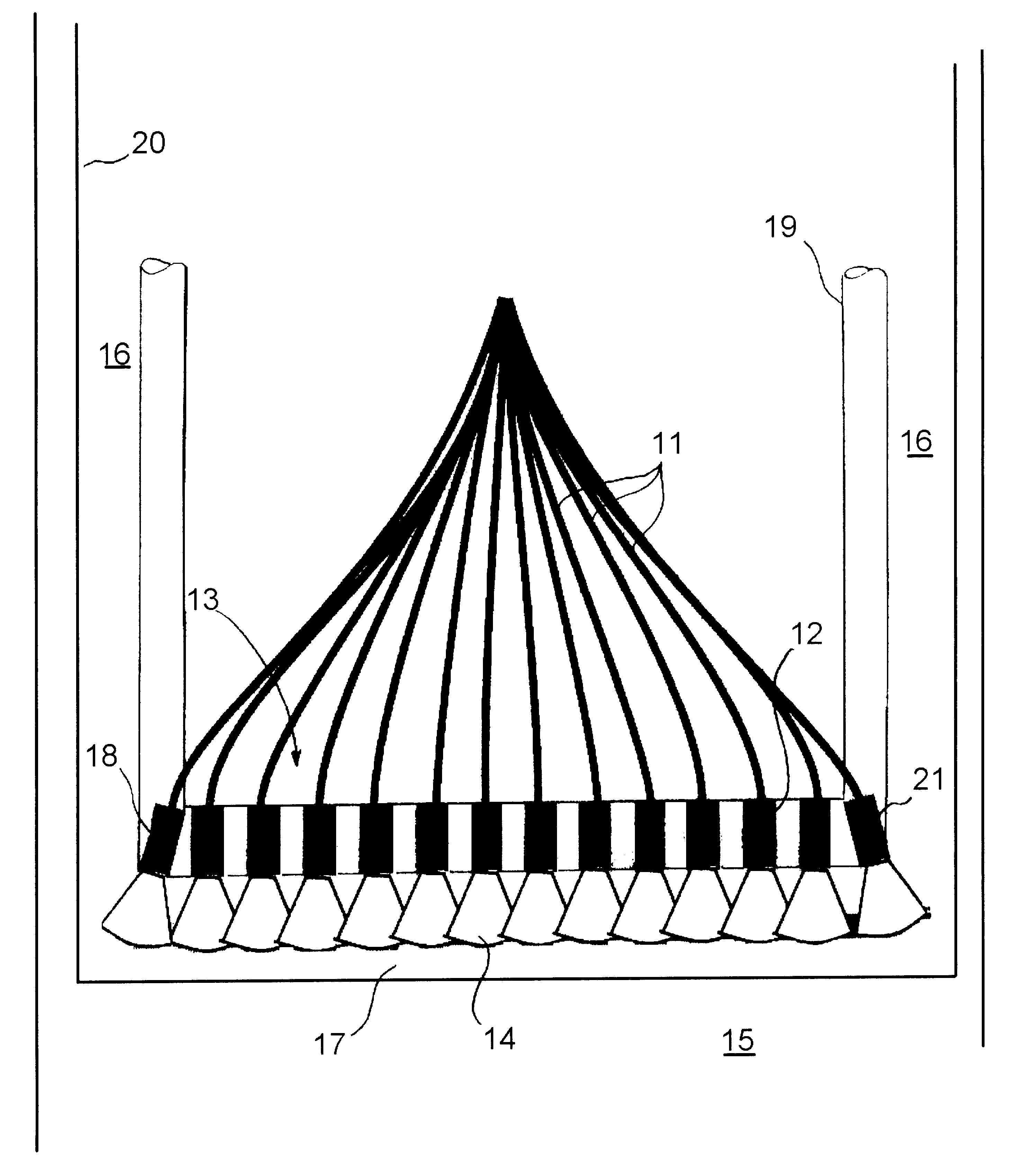

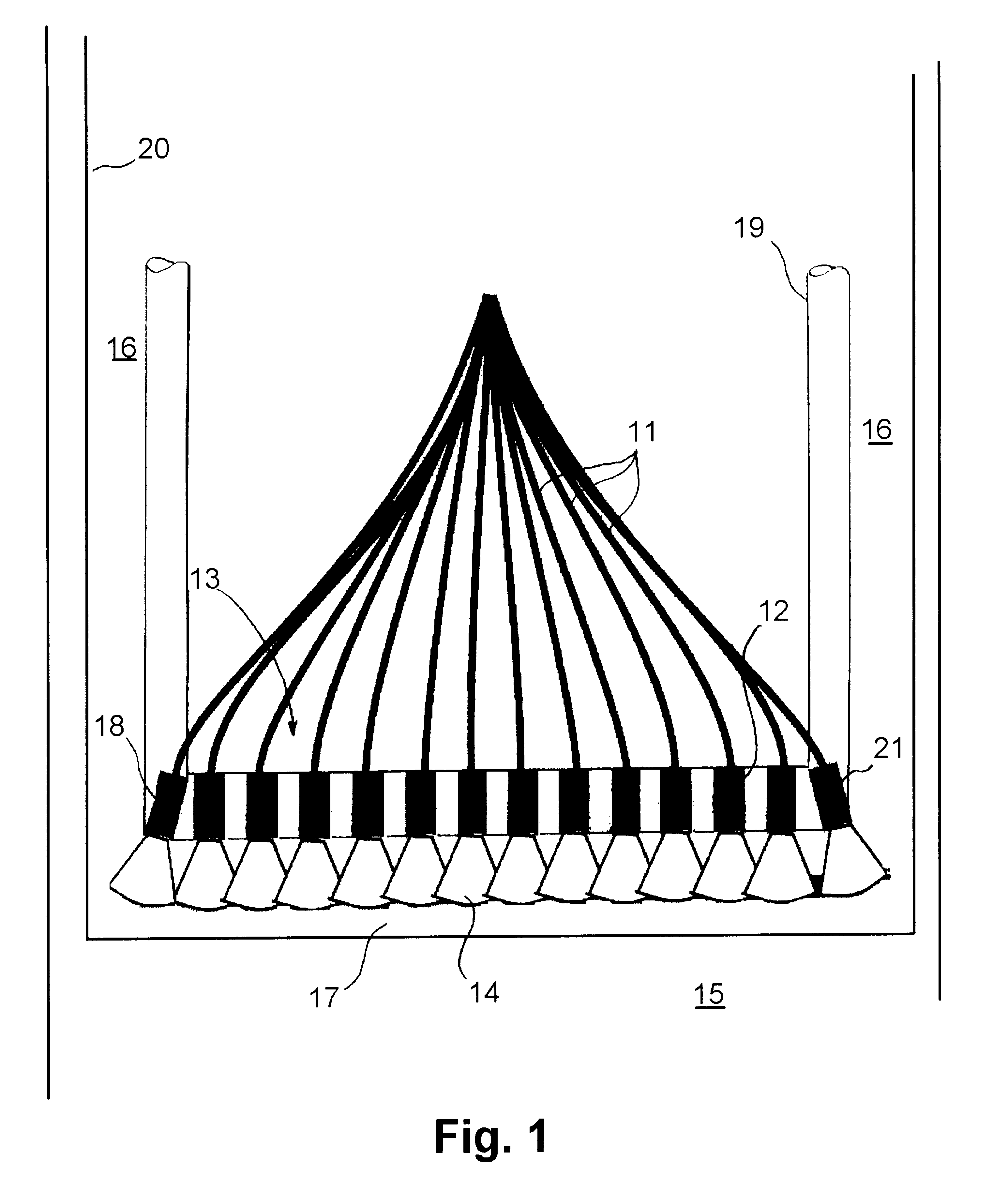

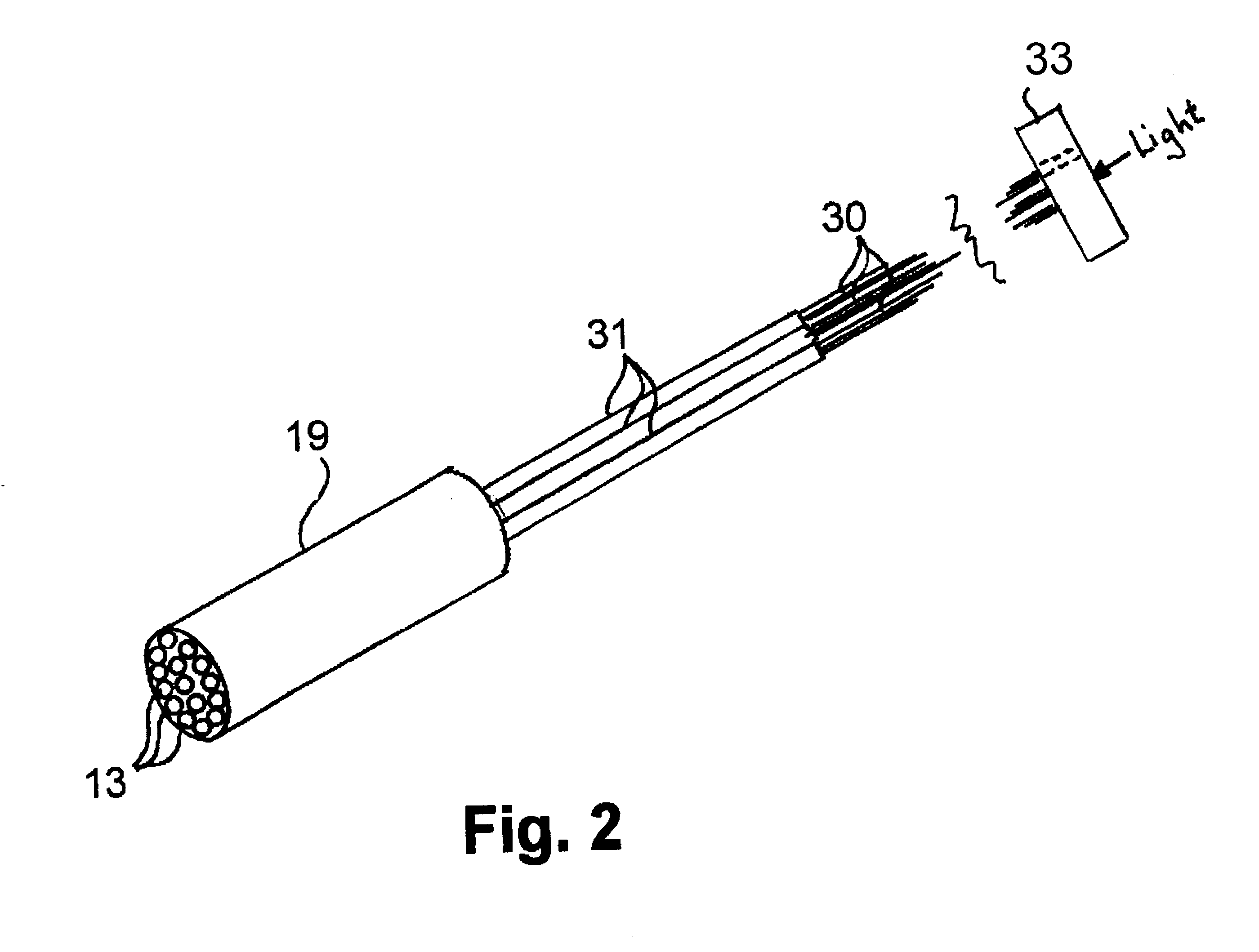

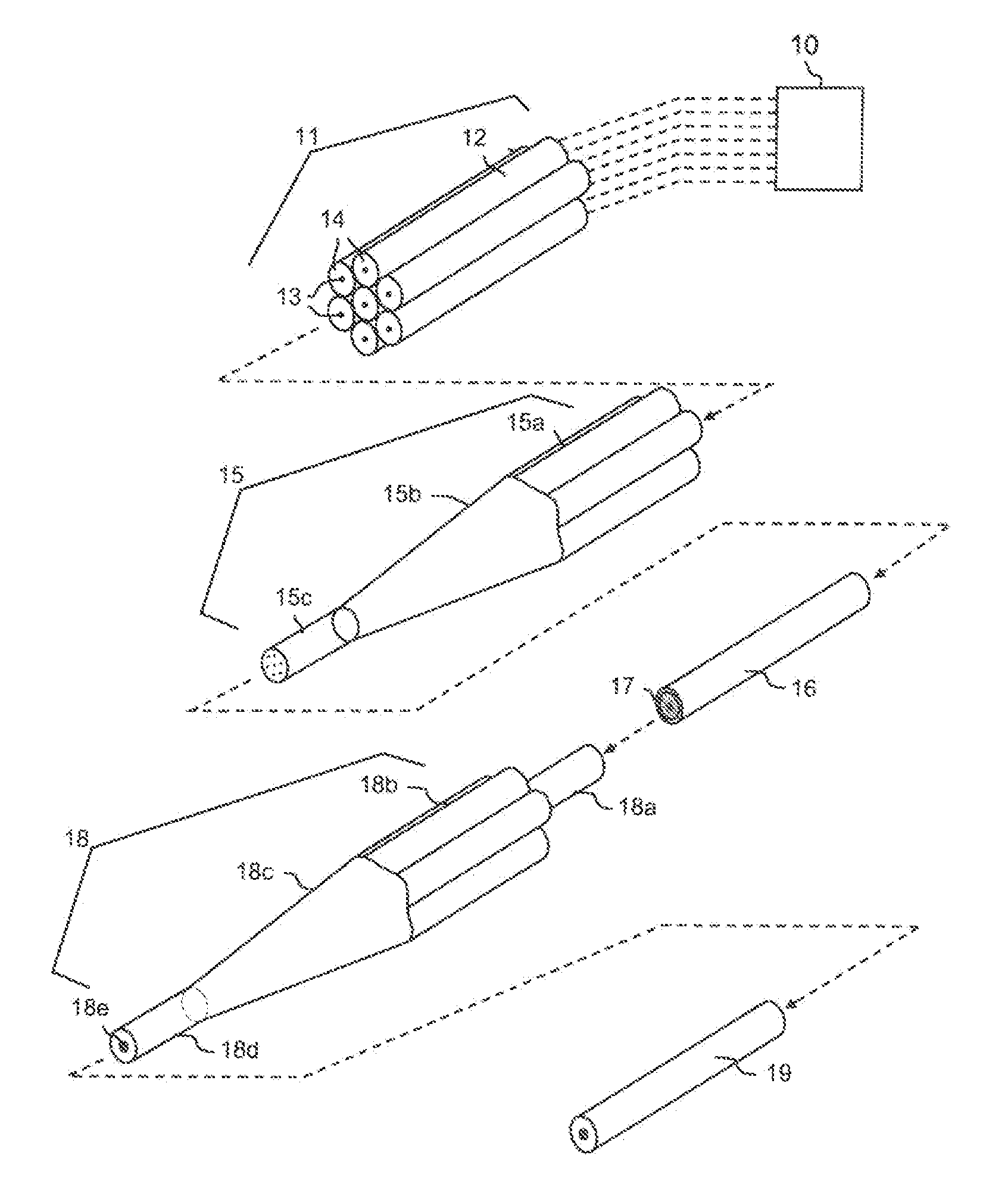

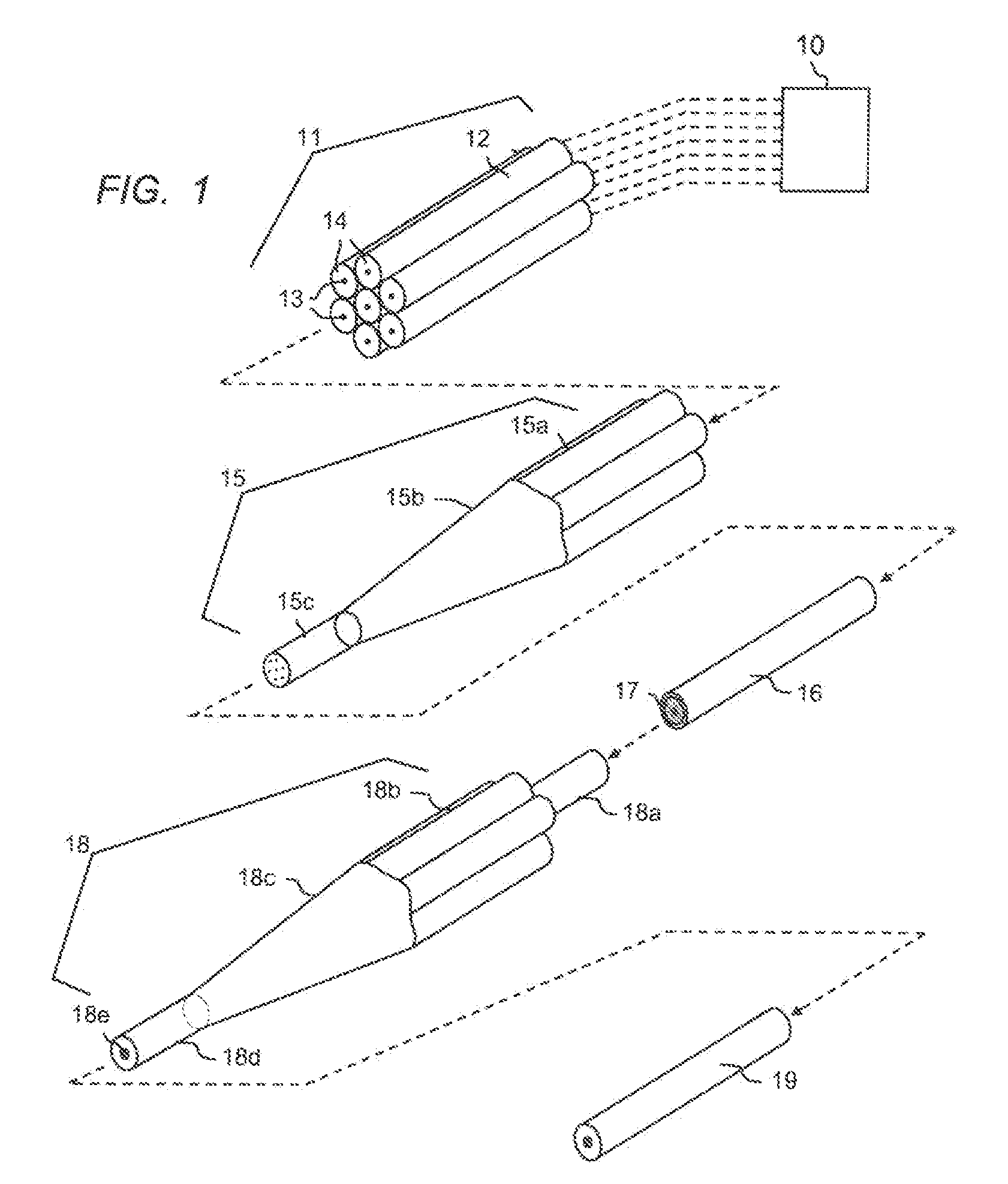

Fiber Based Laser Combiners

ActiveUS20100278486A1High optical densityOvercomes drawbackLaser detailsCoupling light guidesFiberHigh power lasers

An all-fiber combiner device is described for combining multiple high power inputs, such as high power laser inputs. The device includes a first tapered fiber section made from fibers that allow for efficient size reduction of the optical signals. The output of the first tapered fiber section may then be coupled to a multimode output fiber for delivery of the combined power beam. Alternately, the first tapered section can be coupled to a second, multimode, tapered section, which provides further size reduction of the core for splicing into a final output fiber, while adding cladding to the main fiber.

Owner:OFS FITEL LLC

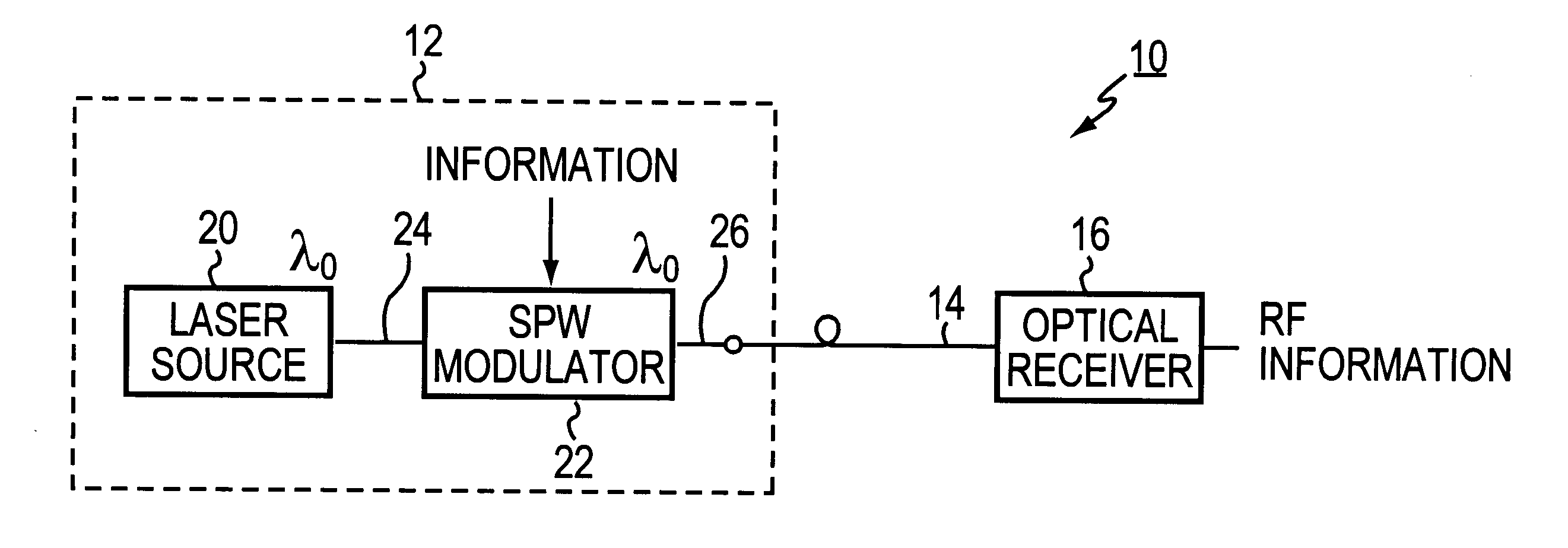

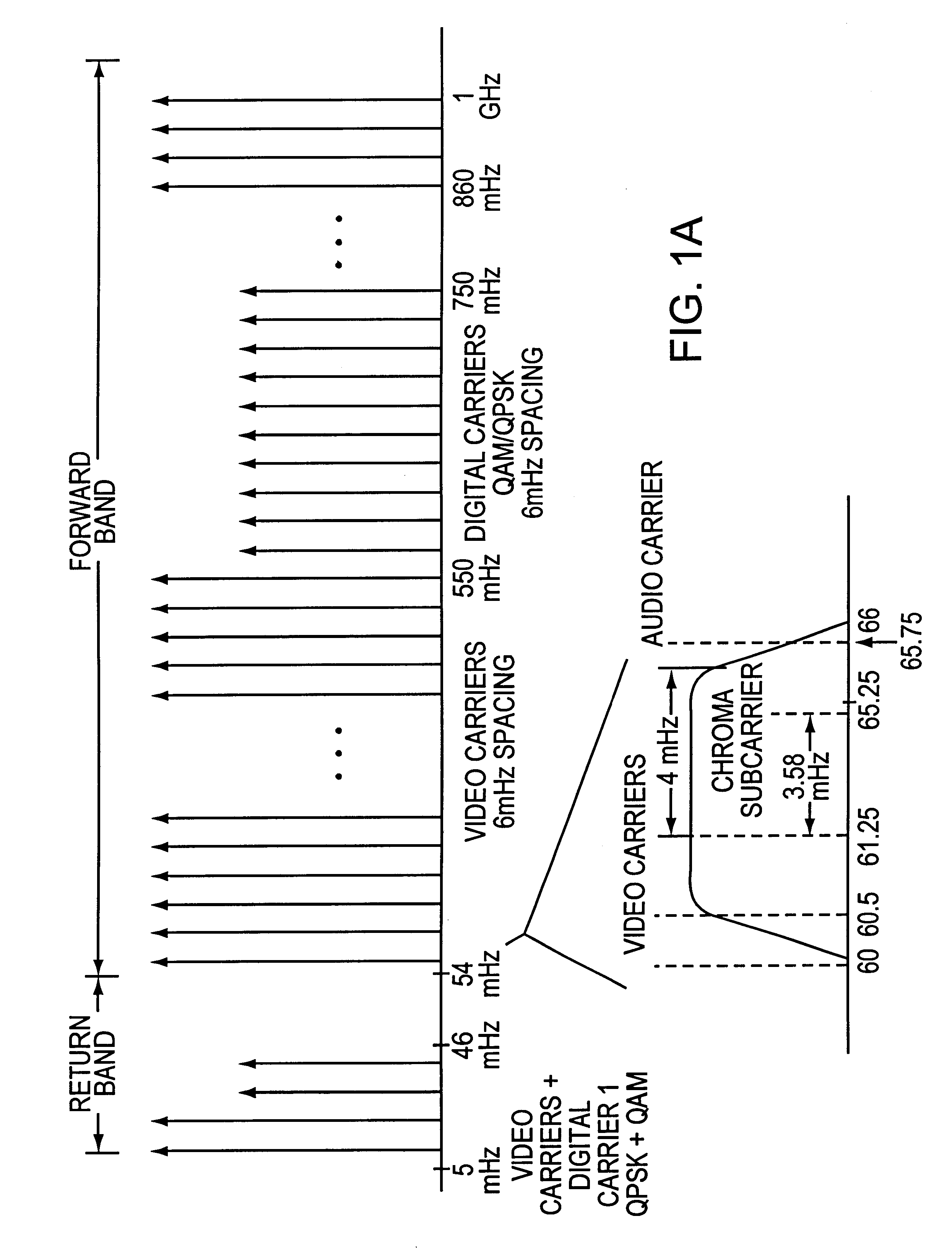

Optical surface plasmon-wave communications systems

InactiveUS6282005B1Less complexReduce necessityWavelength-division multiplex systemsTransmission monitoringLaser transmitterHigh power lasers

A plurality of optical communications systems including a SPW modulator are described. The communications systems include an optical transmitter coupled to an optical fiber communications link which carries a optically modulated information signal to an optical receiver. The laser transmitter includes a laser light source which is optically coupled to a SPW modulator which has been particularly adapted for broadband communications by selecting its transfer characteristic and modulation structure. A broadband signal containing a plurality of information channels, for example CATV channels, is applied to it modulator electrodes. The modulation signal varies the power coupling between the guided laser light source signal and a SPW in the modulator. The result is an intensity modulated optical signal that is output to the optical fiber for transmission to the optical receiver of the system. Alternatively, the communications system includes a high power laser coupled to an optical splitter to divide its output power in two or more optical source outputs. Each optical source output is then used to drive an associated SPW modulator. Each of the modulators receives a broadband signal with which to modulate its optical source. After modulation, the modulated lightwave from a modulator is coupled to a corresponding optical fiber for carriage to an optical receiver. In this manner, several broadband information signals can be communicated over the system using only one laser source. A net benefit from using one higher power laser, rather than several lower power ones, is one of cost, purity and similarity of the several signals. This configuration is enhanced by the lower loss and higher linearity of the SPW modulators. Further, several WDM embodiments including those having serially cascaded SPW modulators are provided. The transfer characteristic of the SPW modulators are tailored to either be more efficient for an analog or a digital modulation signal by adding or subtracting grating effects.

Owner:VERIFIBER TECH

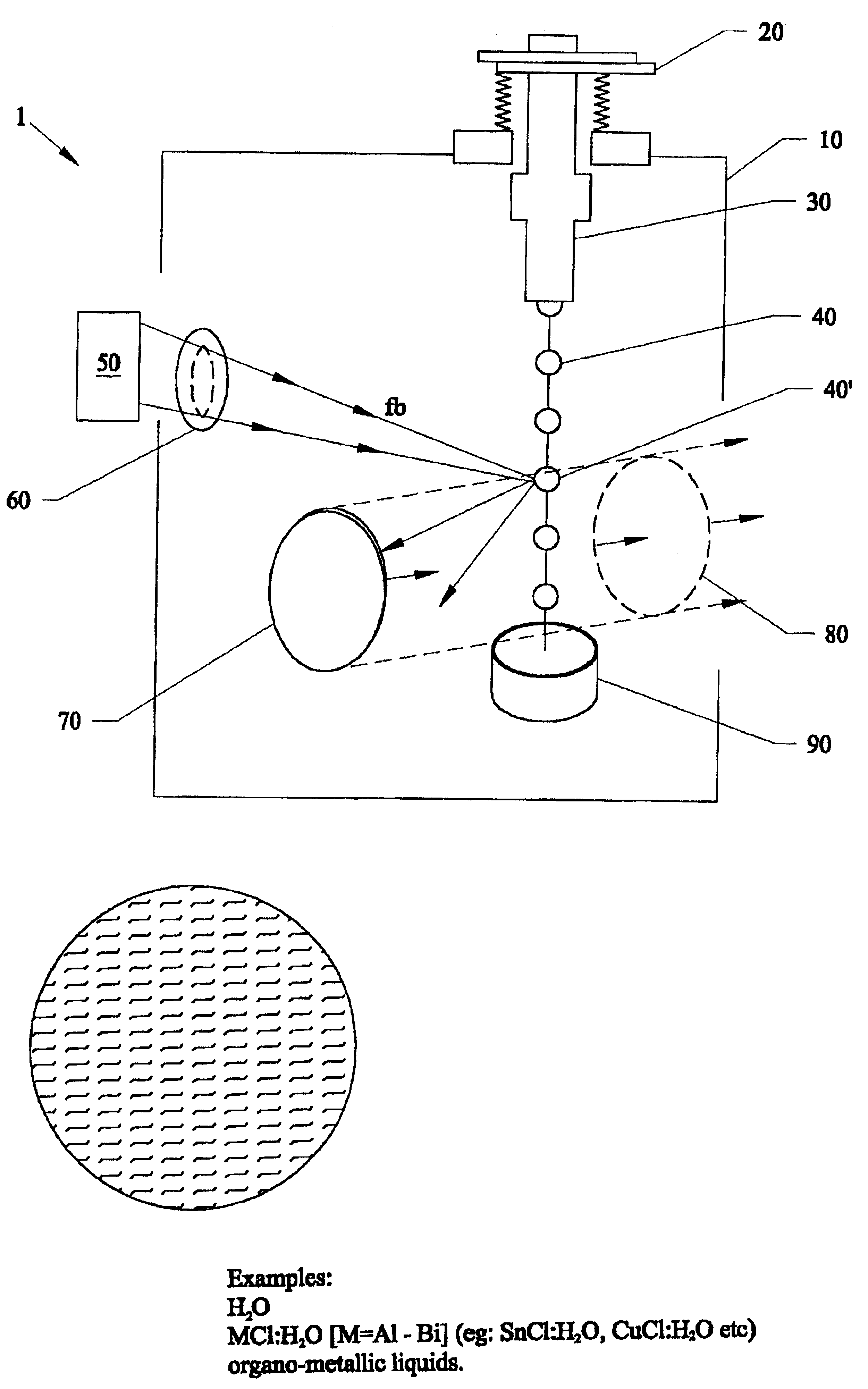

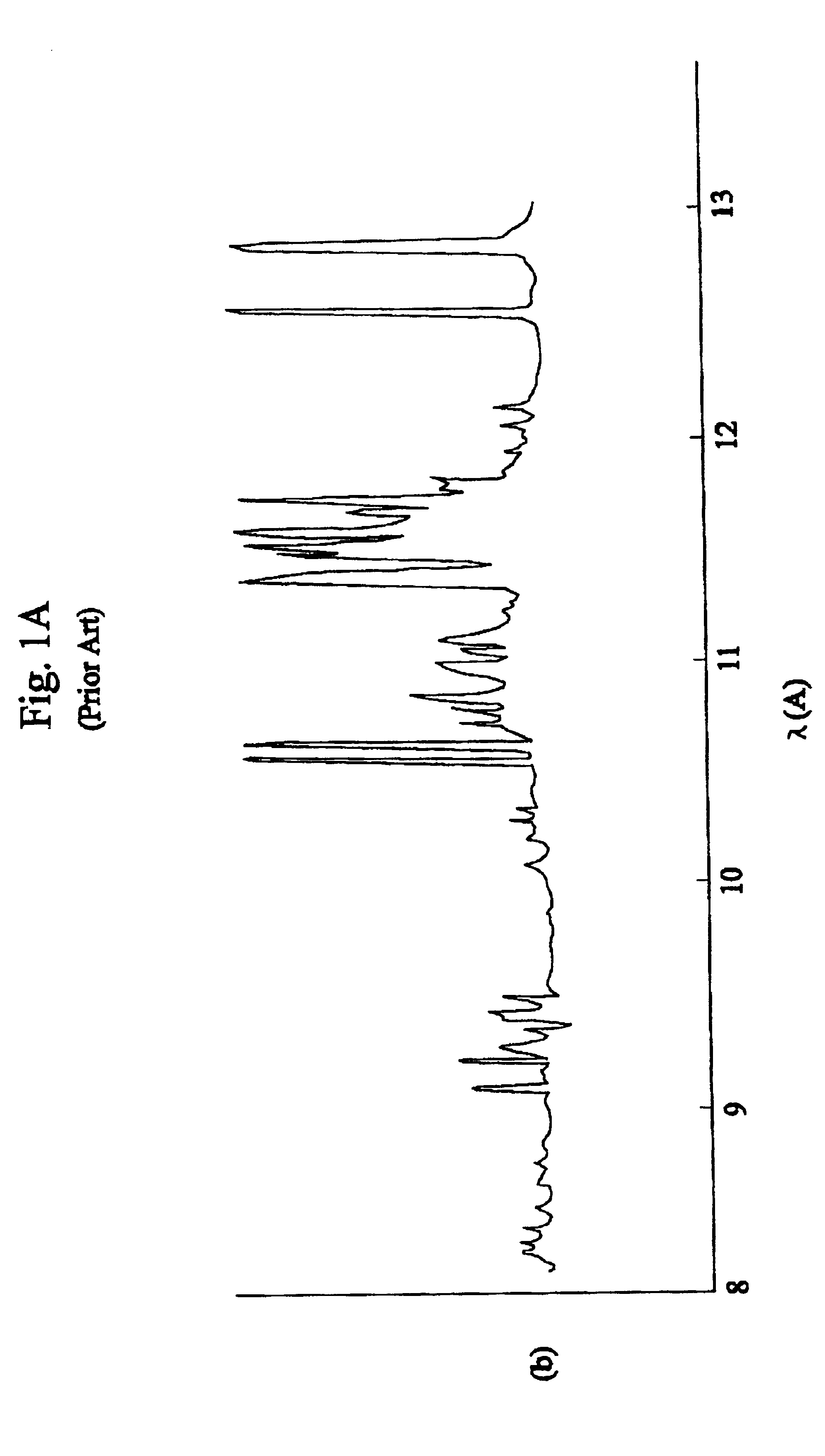

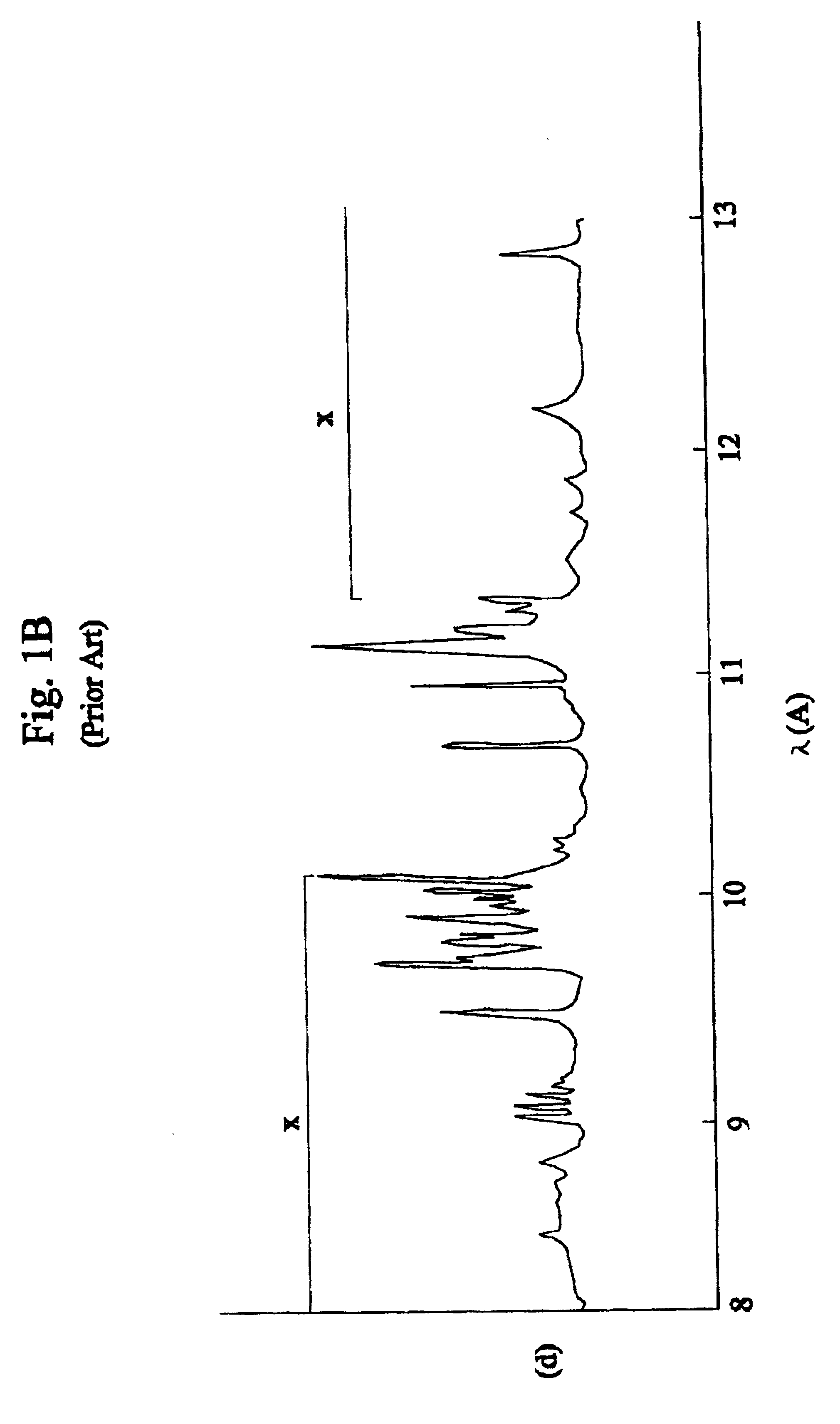

EUV, XUV, and X-ray wavelength sources created from laser plasma produced from liquid metal solutions, and nano-size particles in solutions

InactiveUS6865255B2Efficient and inexpensiveEliminate damageX-ray tube electrodesSemiconductor/solid-state device manufacturingHigh power lasersUltraviolet

Special liquid droplet targets that are irradiated by a high power laser and are plasmarized to form a point source EUV, XUV and x-ray source. Various types of liquid droplet targets include metallic solutions, and nano-sized particles in solutions having a melting temperature lower than the melting temperature of some or all of the constituent metals, used a laser point source target droplets. The solutions have no damaging debris and can produce plasma emissions in the X-rays, XUV, and EUV(extreme ultra violet) spectral ranges of approximately 0.1 nm to approximately 100 nm, approximately 11.7 nm and 13 nm, approximately 0.5 nm to approximately 1.5 nm, and approximately 2.3 nm to approximately 4.5 nm. The second type of target consists of various types of liquids which contain as a miscible fluid various nano-size particles of different types of metals and non-metal materials.

Owner:CENT FLORIDA UNIV OF

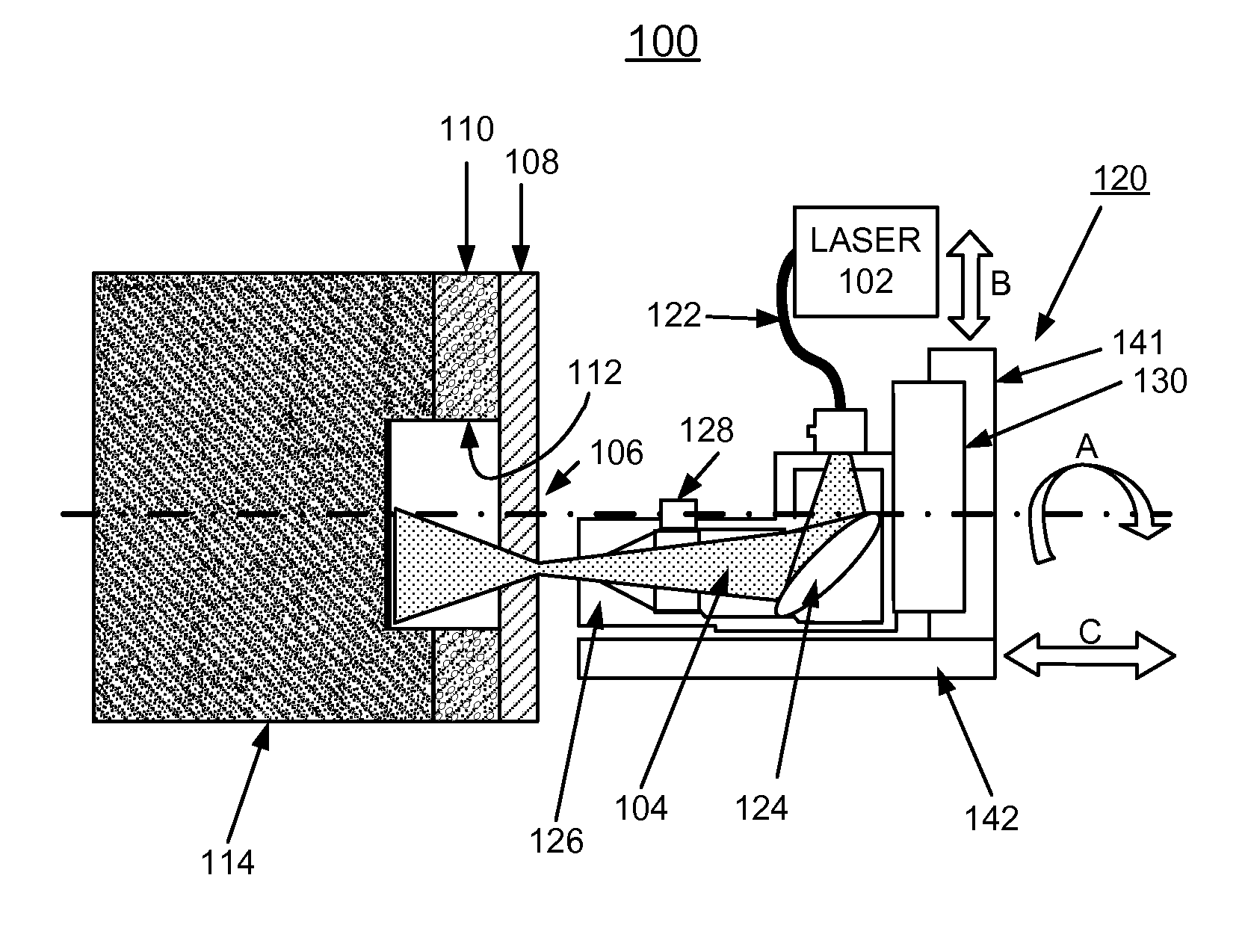

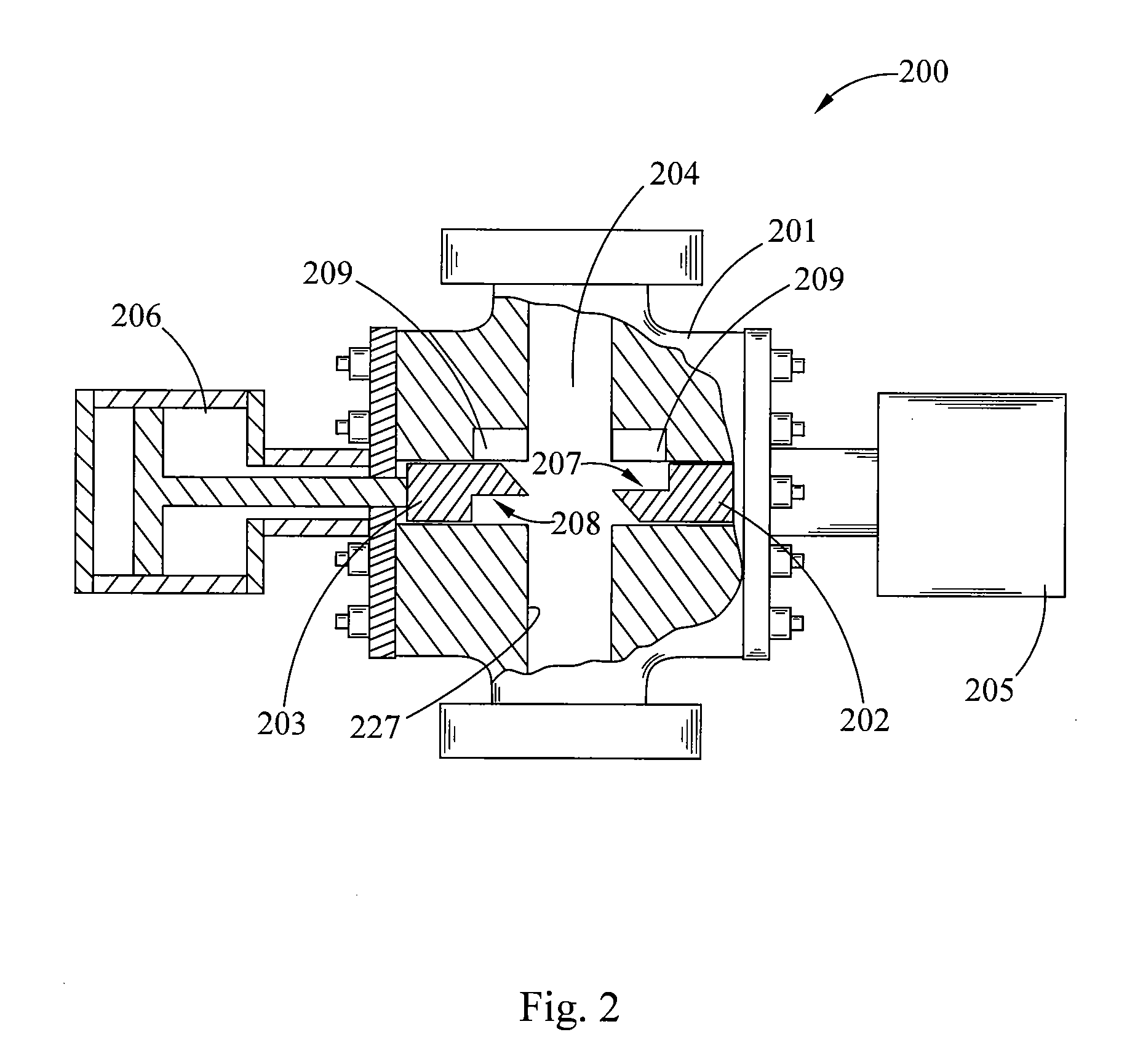

Shear laser module and method of retrofitting and use

There is provided a high power shear laser module, which can be readily included in a blowout preventer stack. The shear laser module as the capability of delivering high power laser energy to a tubular within a blowout preventer cavity, cutting the tubular and thus reducing the likelihood that the tubular will inhibit the ability of the blowout preventer to seal off a well.

Owner:FORO ENERGY

Methods of using a laser to perforate composite structures of steel casing, cement and rocks

ActiveUS7487834B2Improve breathabilityReduce hole taperingDisloding machinesThermal drillingHigh power lasersSmall fragment

Owner:UCHICAGO ARGONNE LLC +1

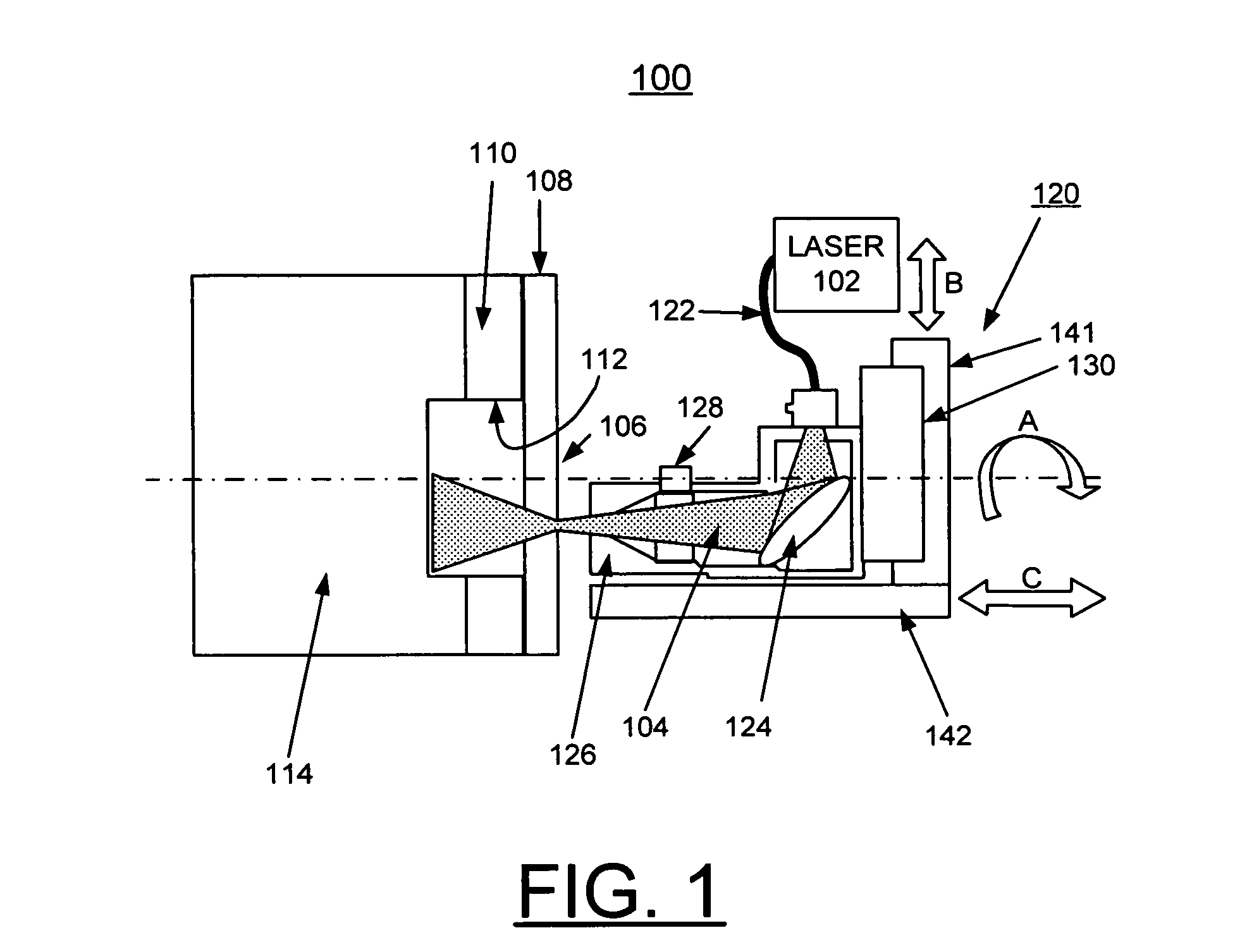

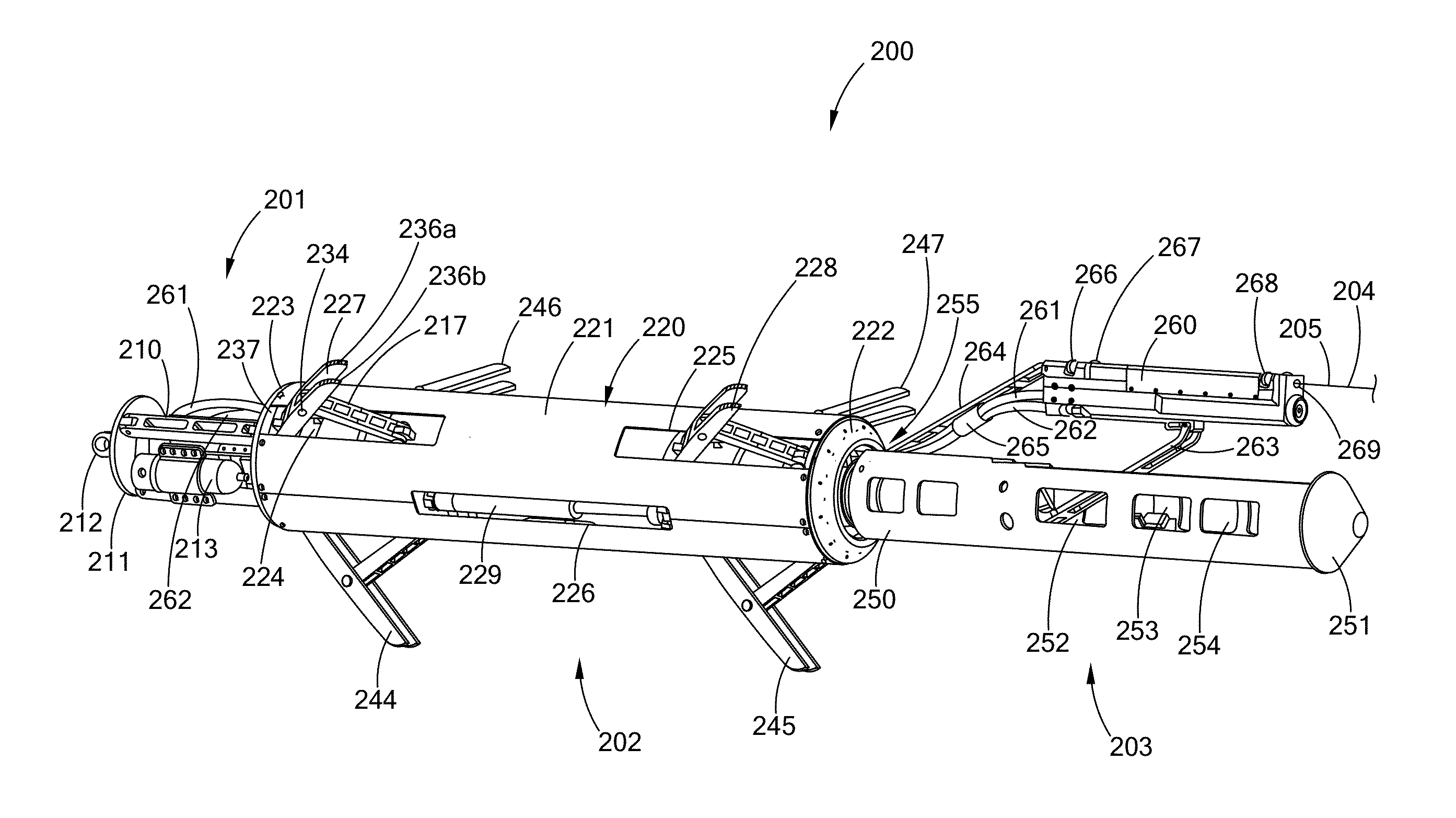

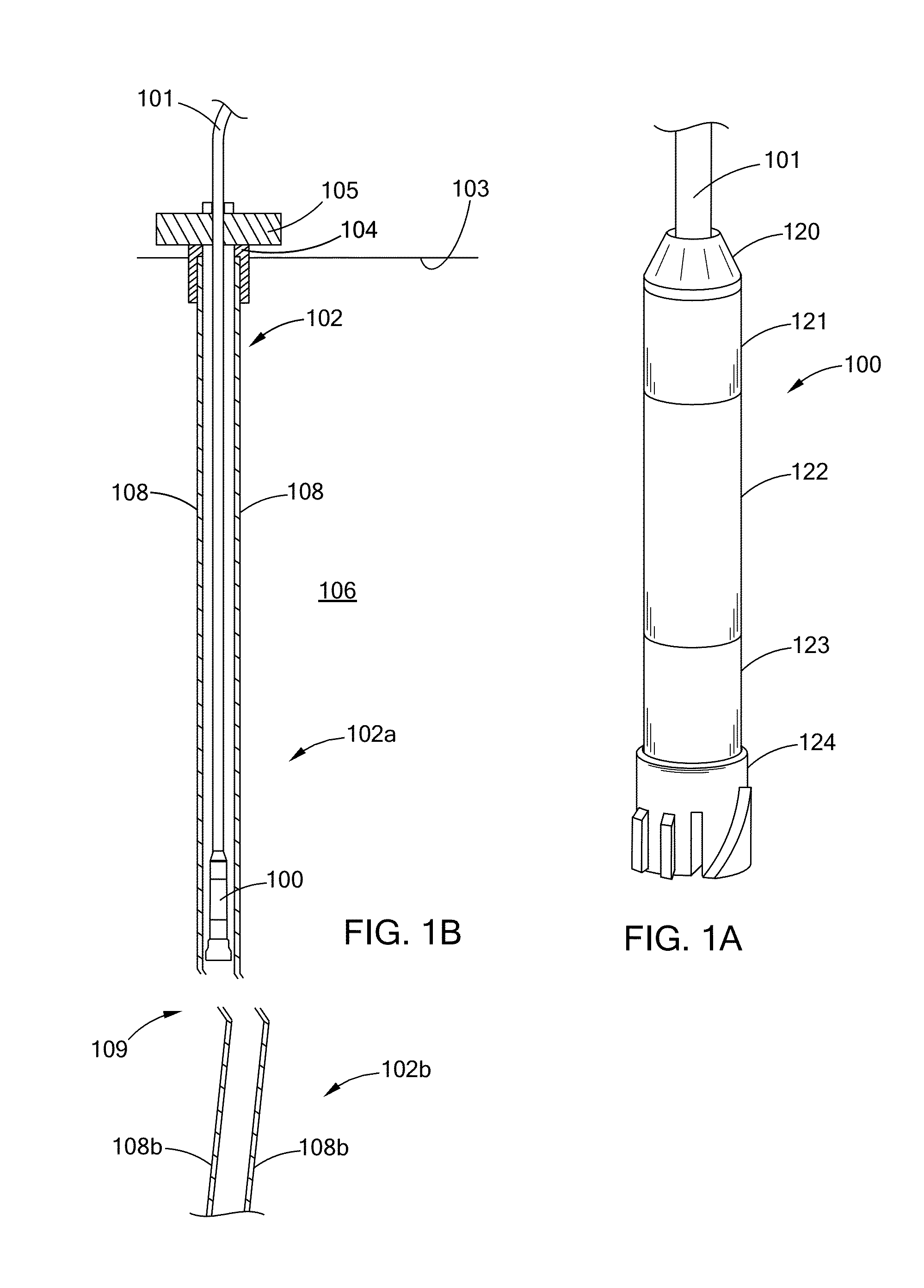

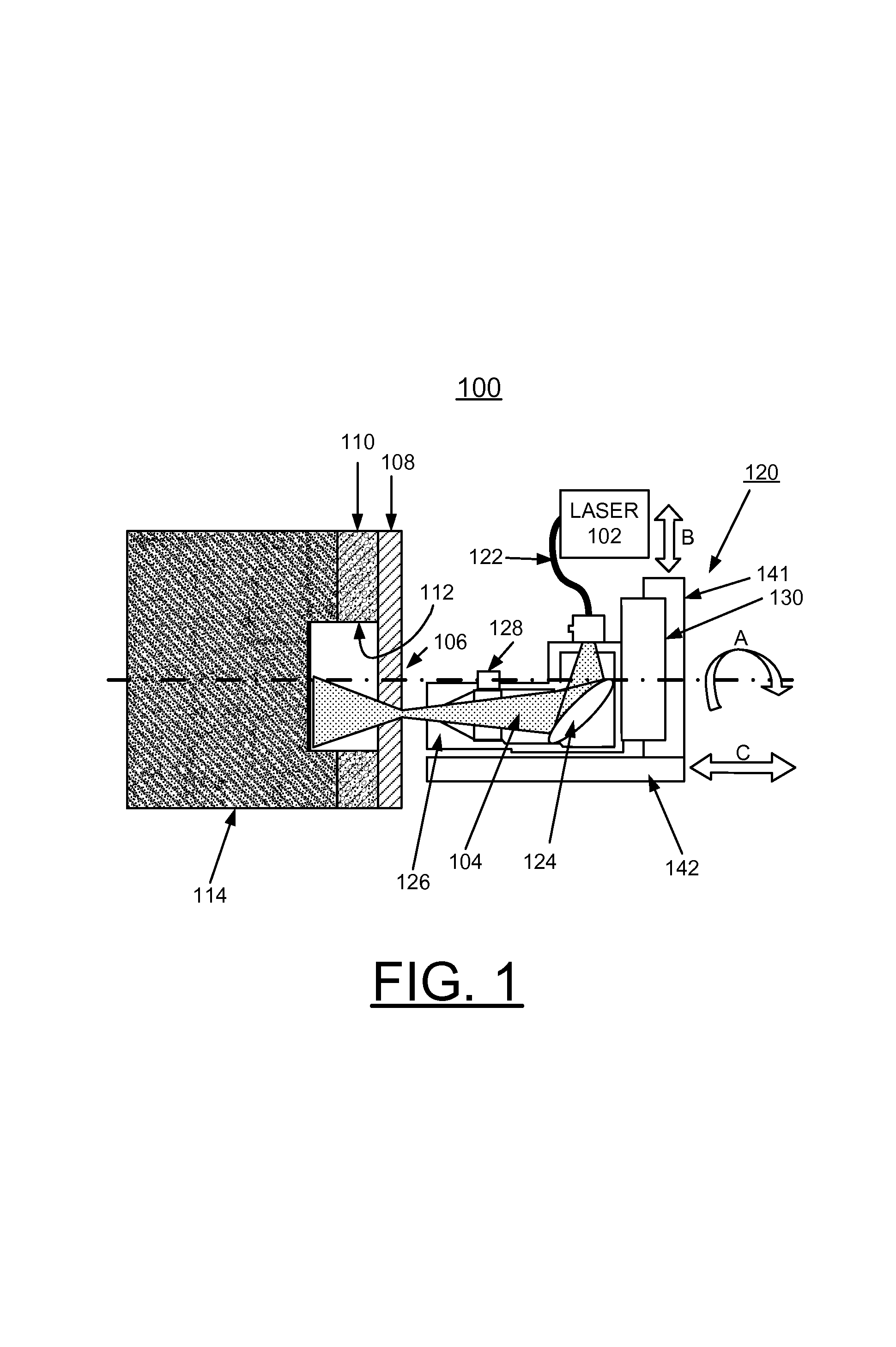

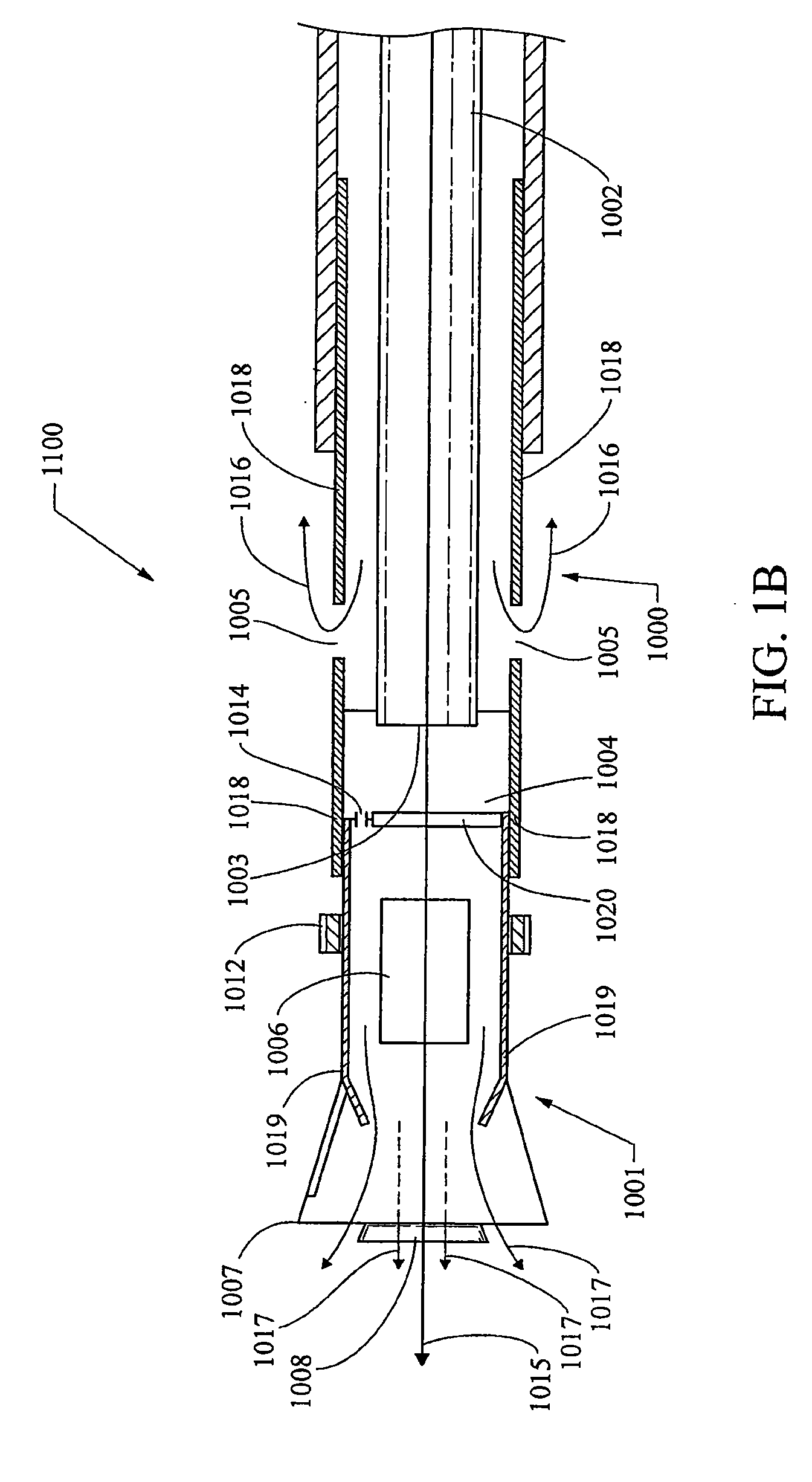

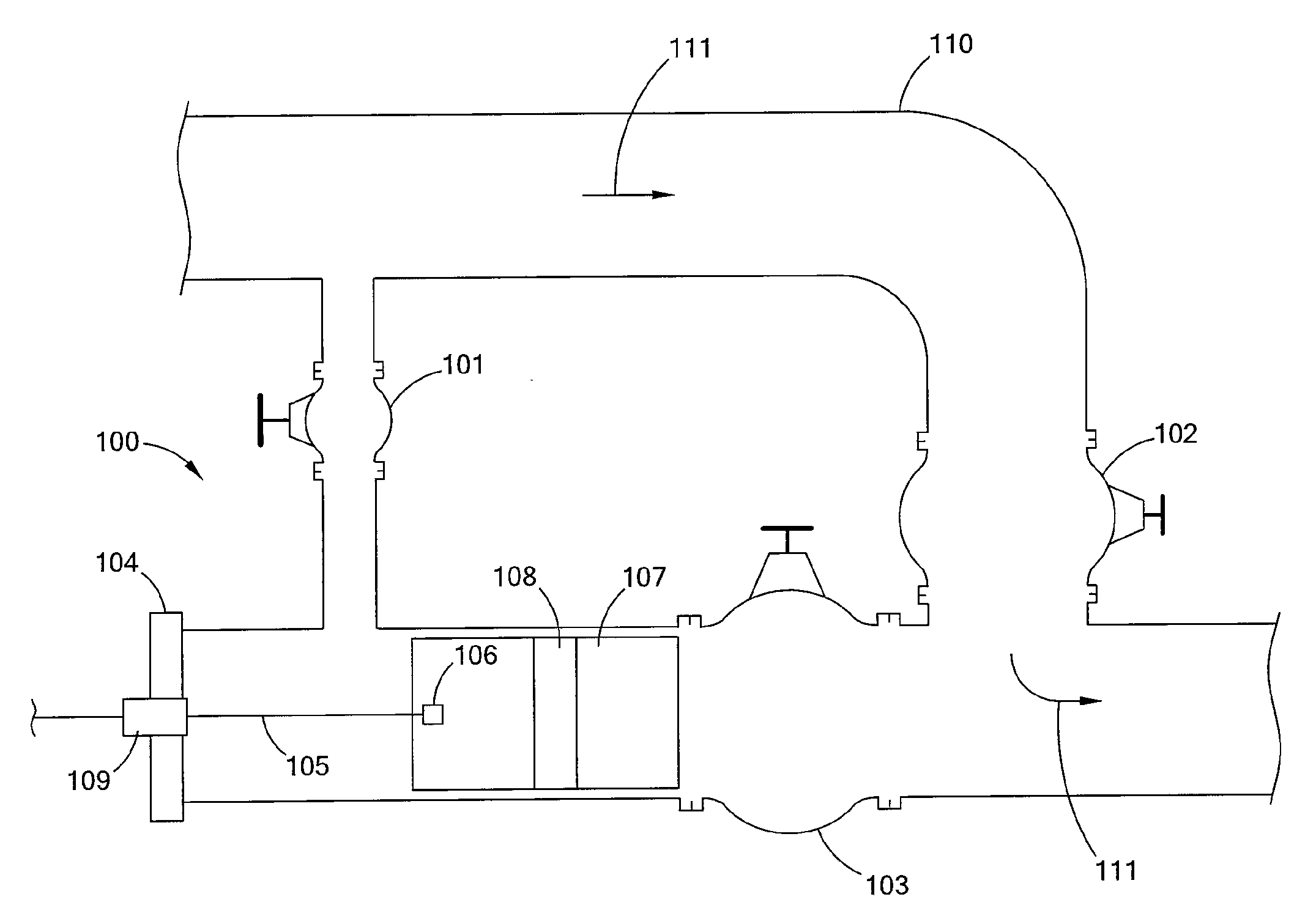

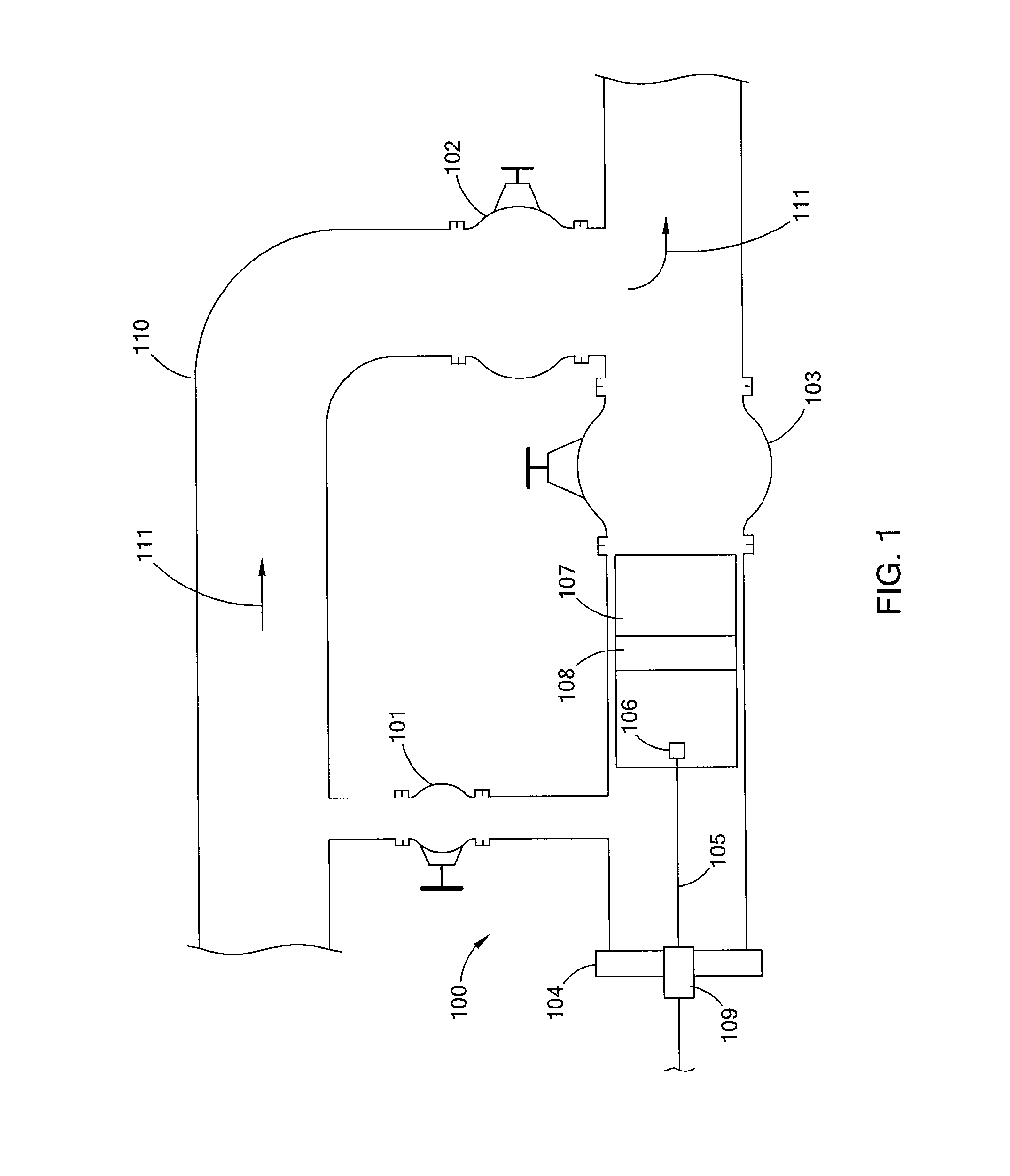

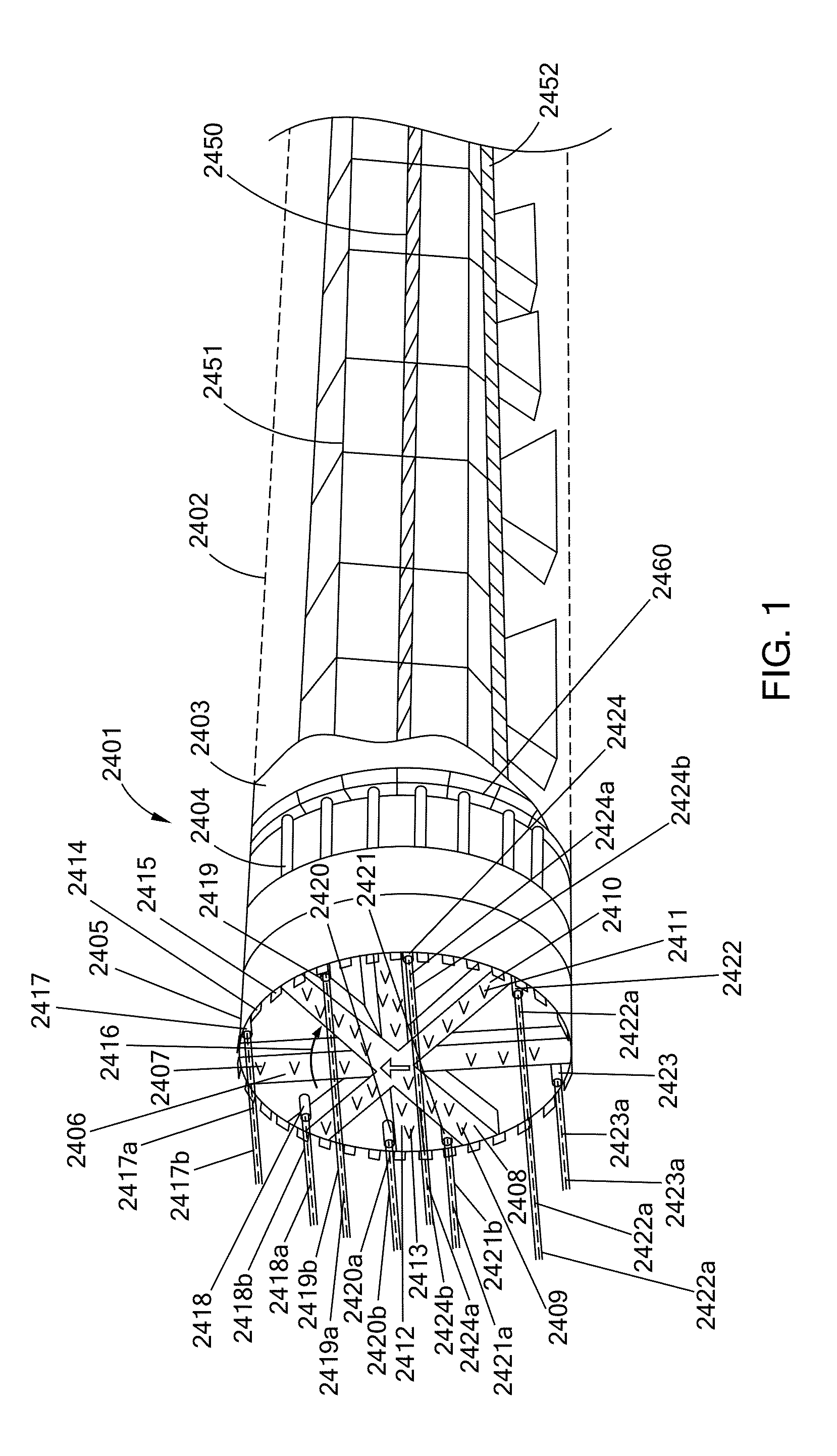

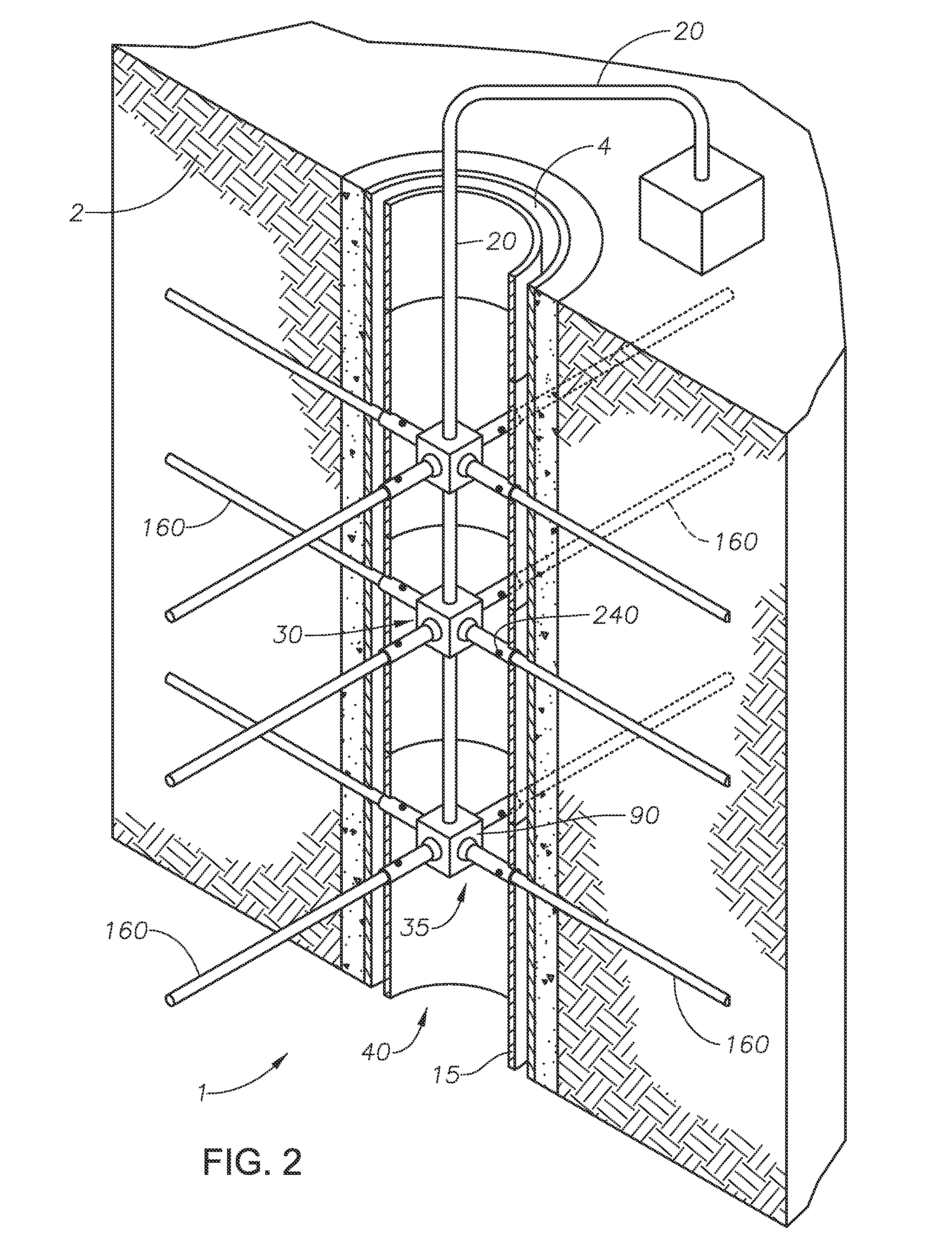

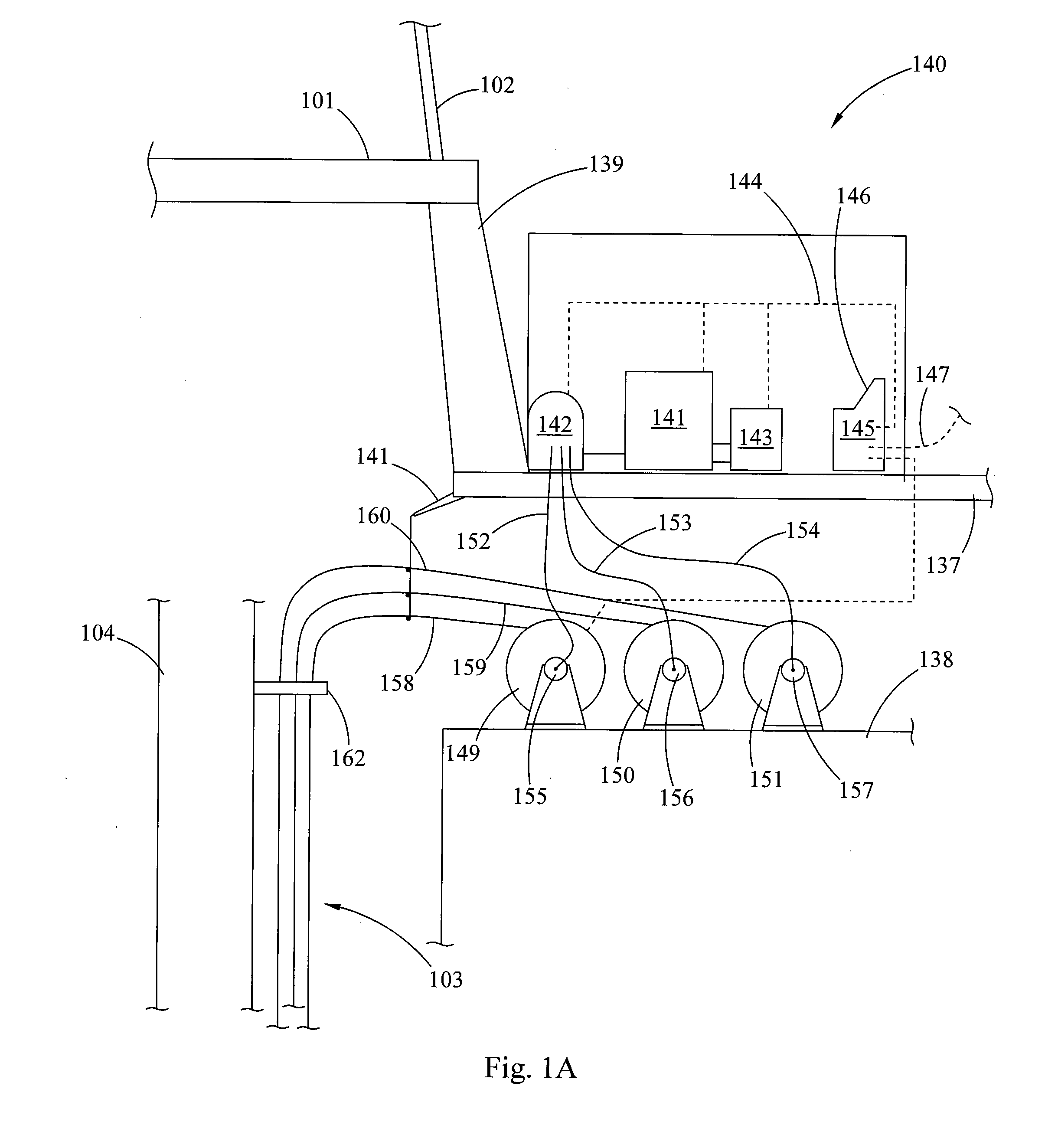

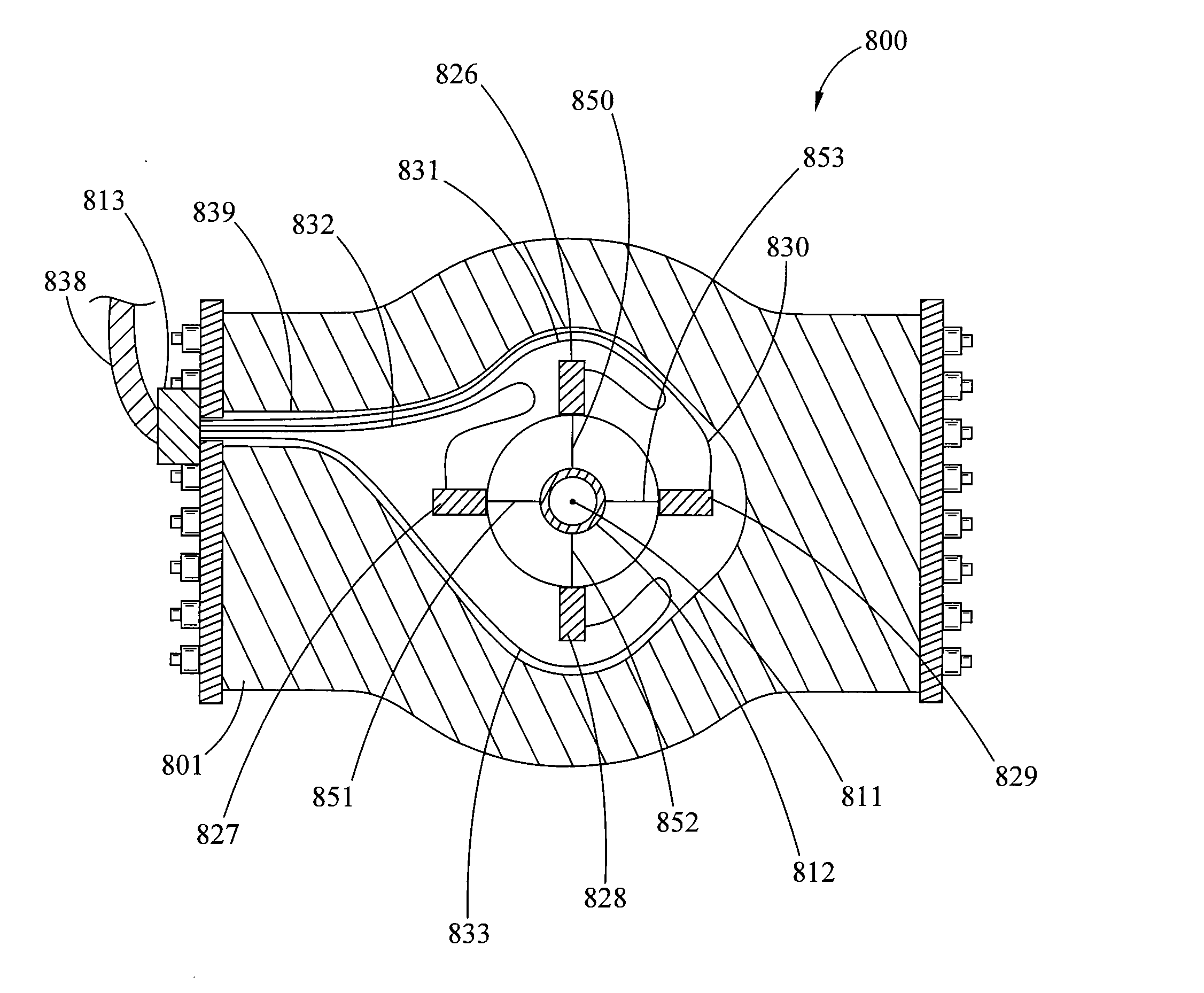

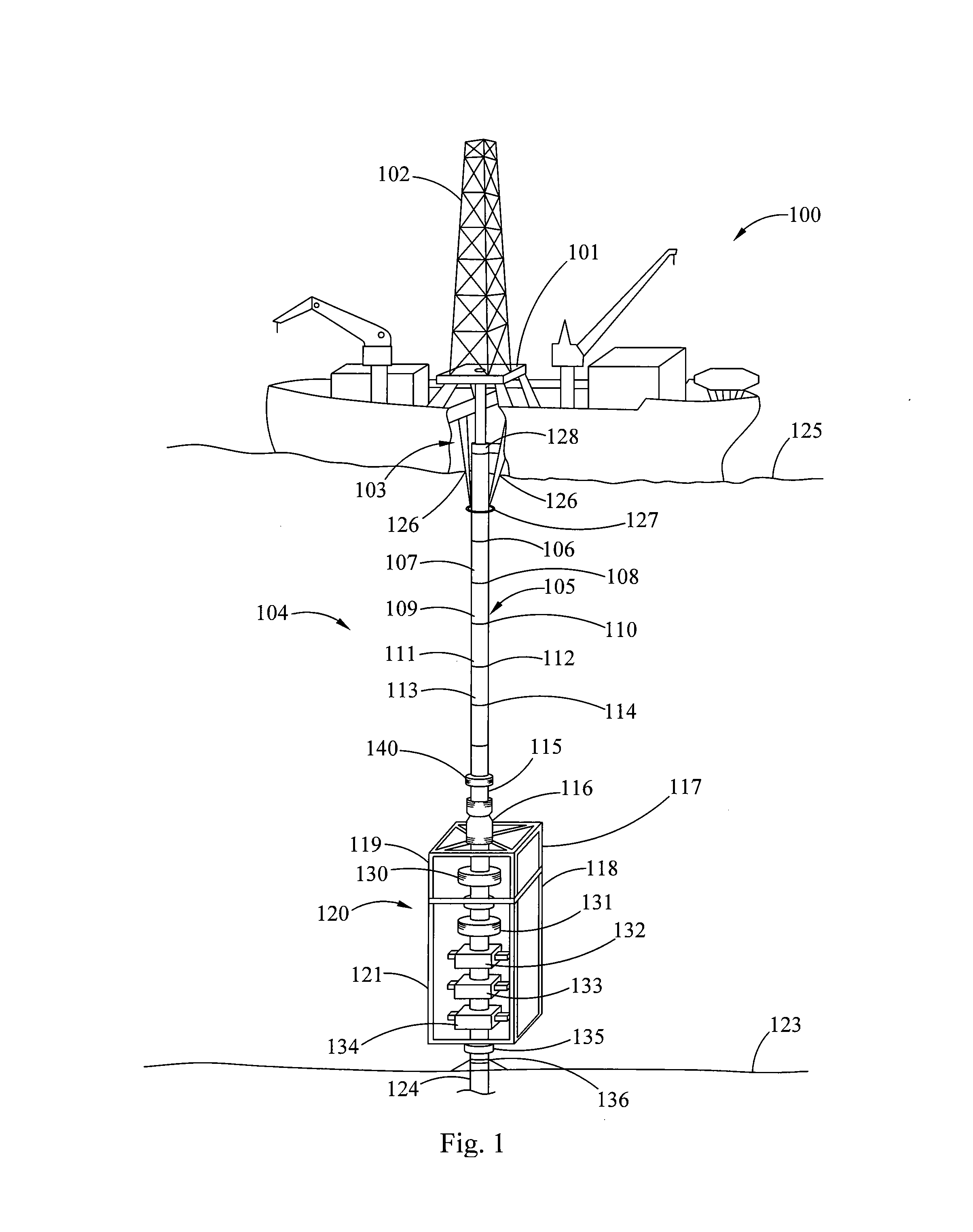

Apparatus for Advancing a Wellbore Using High Power Laser Energy

ActiveUS20100044104A1High energy laserReduce distractionsDrill bitsDisloding machinesLaser opticsHigh power lasers

There is provided a system, apparatus and methods for delivering high power laser energy to advance a borehole deep into the earth using laser energy. In particular, there is provided a laser bottom hole assembly (LBHA) for the delivery of such laser energy to the surfaces of a borehole, which assembly may have laser optics, a fluid path for debris removal and a mechanical means to remove earth.

Owner:FORO ENERGY

Fast laser depositing process of preparing antinwear heat resistant composite coating on surface of crystallizer

InactiveCN1932082ANo pollution in the processRadiation-freeMolten spray coatingArc welding apparatusAutomatic controlHigh power lasers

The fast laser depositing process of preparing antiwear heat resistant composite coating on the surface of crystallizer features that high power laser is first utilized in fast scanning to form transition layer in excellent metallurgical binding with the substrate of crystallizer copper plate on the surface of the plate and then utilized in wide band deposition to form Co base alloy with excellent heat resistance and high wear resistance on the surface of the transition layer. Compared with convenient technological process, the present invention has the advantages of precise control in laser power, position, shape and other parameters, easy automatic control of the whole process, no environmental pollution, high production efficiency, low power consumption, etc. and may be used widely.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

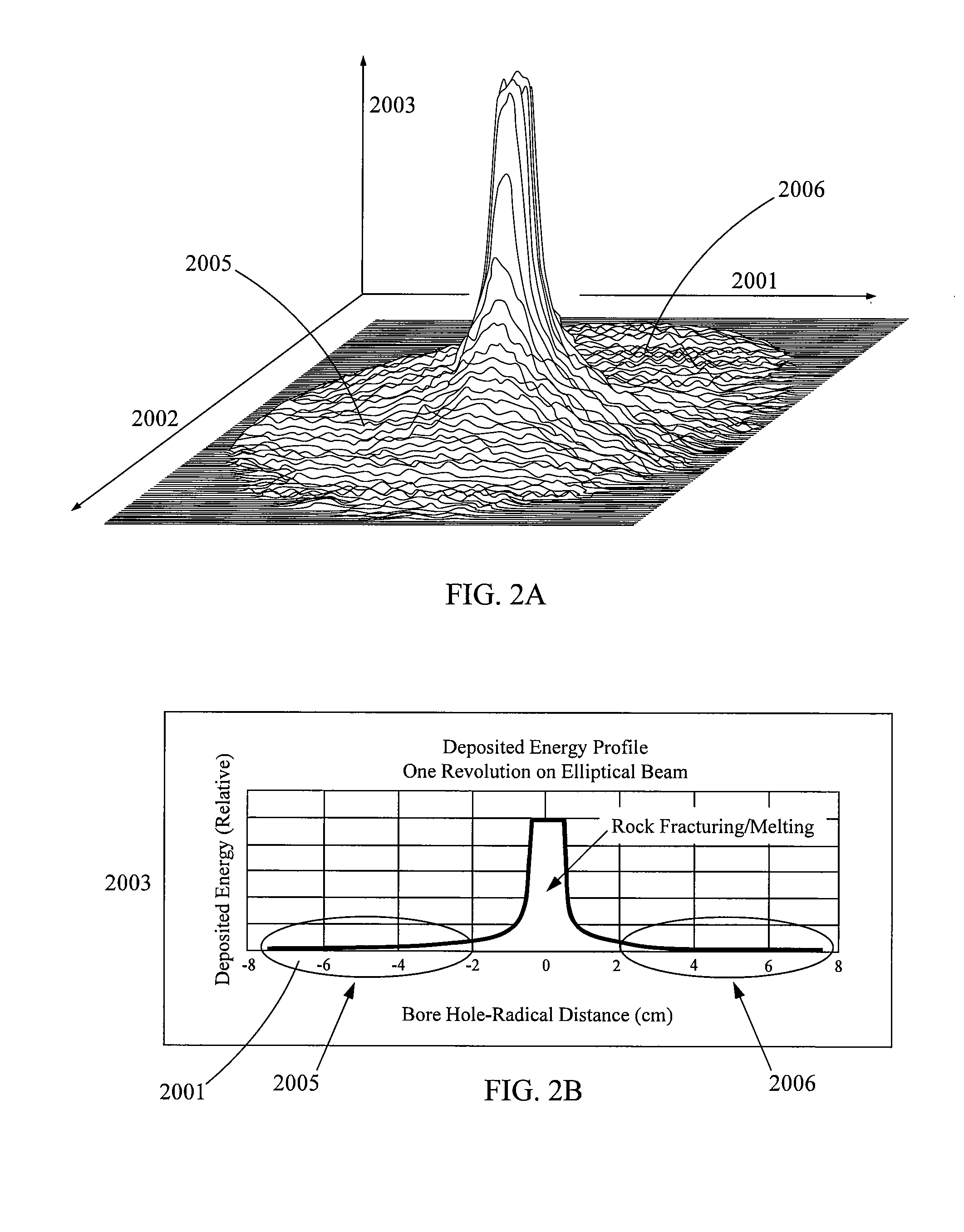

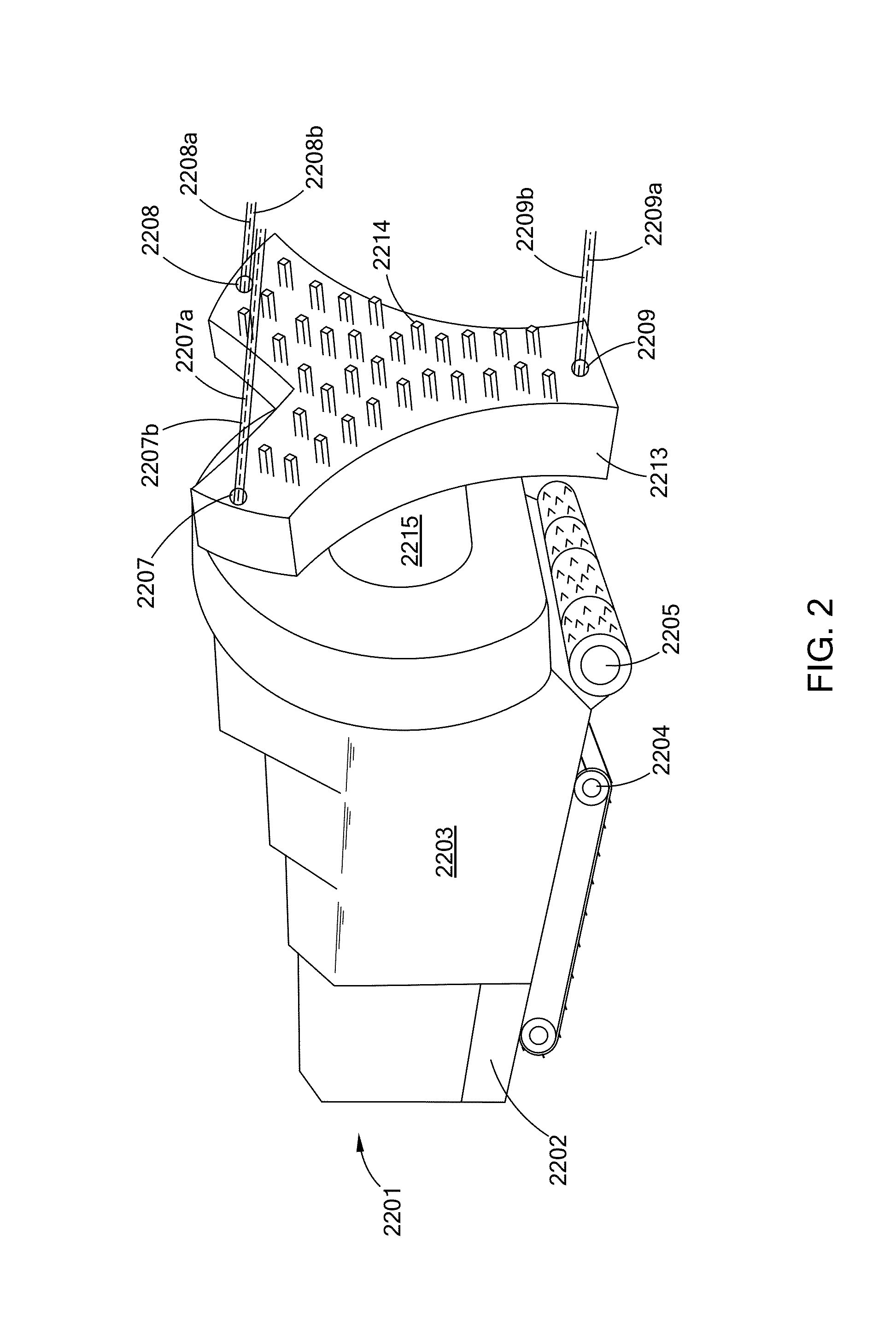

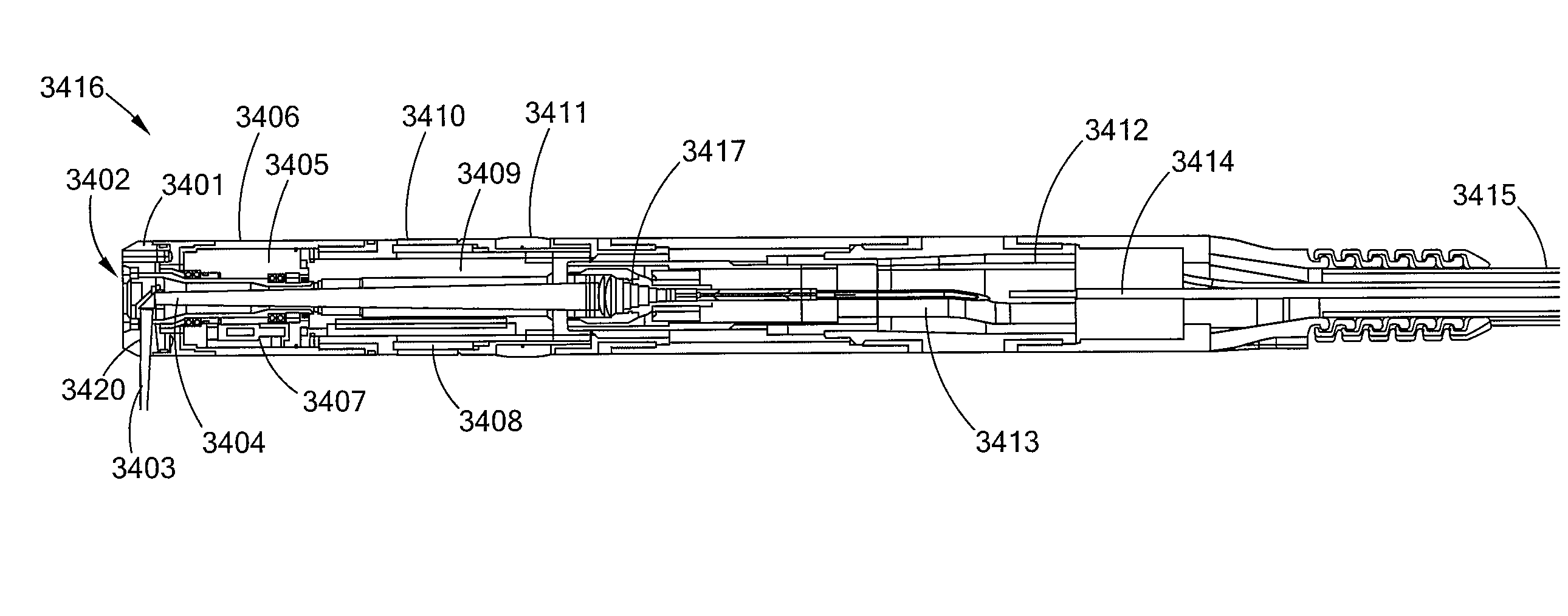

Methods and apparatus for delivering high power laser energy to a surface

ActiveUS20100044105A1High energy laserHarsh and demanding upon optical fibersDrill bitsDisloding machinesHigh power lasersEngineering

There is provided a system, apparatus and methods for providing a laser beam to borehole surface in a predetermined and energy deposition profile. The predetermined energy deposition profiles may be uniform or tailored to specific downhole applications. Optic assemblies for obtaining these predetermined energy deposition profiles are further provided.

Owner:FORO ENERGY

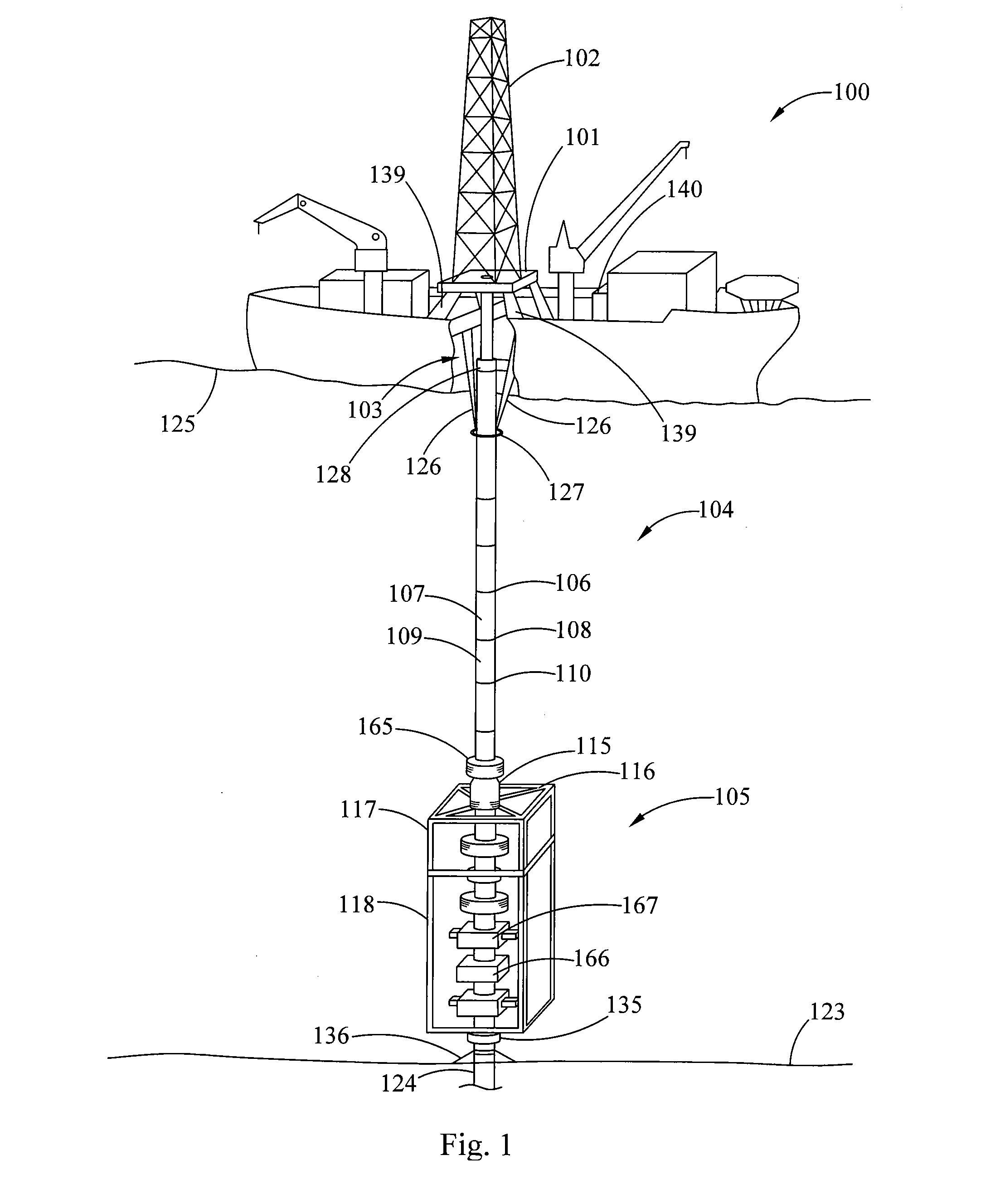

High power laser pipeline tool and methods of use

ActiveUS20120255933A1High energy laserIncrease powerHollow article cleaningArc welding apparatusHigh power lasersPigging

There is provided a high power laser tool system for transmitting and delivering high power laser energy within the interior of pipes, which includes a high power laser-pig and long distance high power optical tether. The high power laser system performs high power laser pigging operations and other operations, such as, cleaning, assembling, maintaining and monitoring of pipelines.

Owner:FORO ENERGY

High power laser tunneling mining and construction equipment and methods of use

ActiveUS20140231398A1Underground miningWelding/cutting auxillary devicesHigh power lasersEngineering

There are provided high power laser and laser mechanical earth removing equipment, and operations using laser cutting tools having stand off distances. These equipment provide high power laser beams, greater than 1 kW to cut and volumetrically remove targeted materials and to remove laser affected material with gravity assistance, mechanical cutters, fluid jets, scrapers and wheels. There is also provided a method of using this equipment in mining, road resurfacing and other earth removing or working activities.

Owner:FORO ENERGY

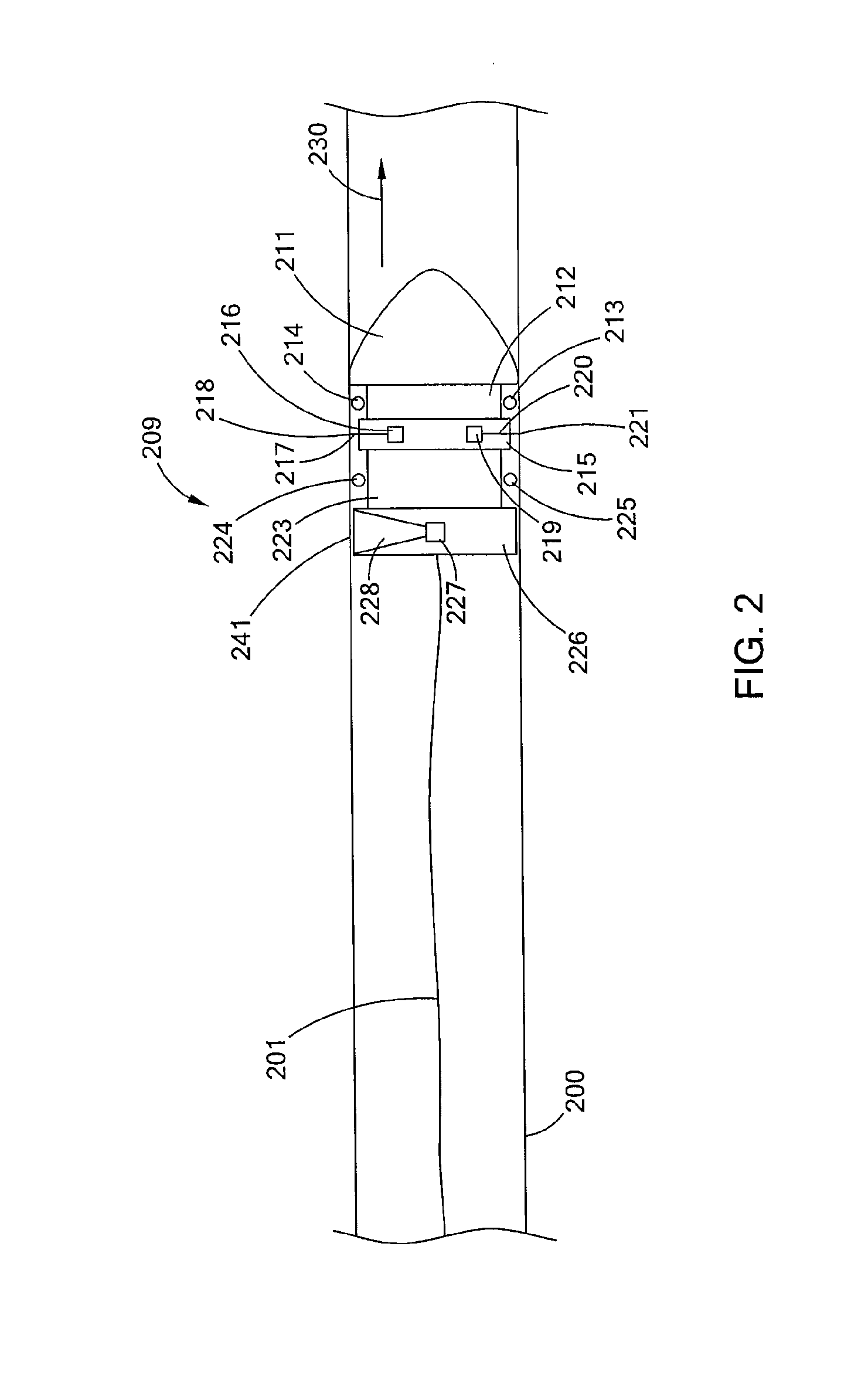

Downhole deep tunneling tool and method using high power laser beam

A downhole laser tool for penetrating a hydrocarbon bearing formation includes a laser surface unit to generate a high power laser beam, a fiber optic cable to conduct the high power laser beam from the laser surface unit to a rotational system that has a rotational head which includes a focusing system and a downhole laser tool head, the focusing system includes a beam manipulator, a focused lens, and a collimator, the downhole laser tool head includes a first cover lens to protect the focusing system, a laser muzzle to discharge the collimated laser beam from the downhole laser tool head into the hydrocarbon bearing formation, a fluid knife to sweep the first cover lens, a purging nozzle to remove dust from the path of the collimated laser beam, a vacuum nozzle to collect dust and vapor from the path of the collimated laser beam.

Owner:SAUDI ARABIAN OIL CO

Laser assisted system for controlling deep water drilling emergency situations

There is provided a high power laser riser blowout preventer system and controller for operation thereof. The system utilizes high power laser cutters that are associated with the riser and the blowout preventer to provided an integrated operation to quickly weaken or cut tubulars to address potential emergency and emergency situations that can arise during deep sea drilling.

Owner:FORO ENERGY

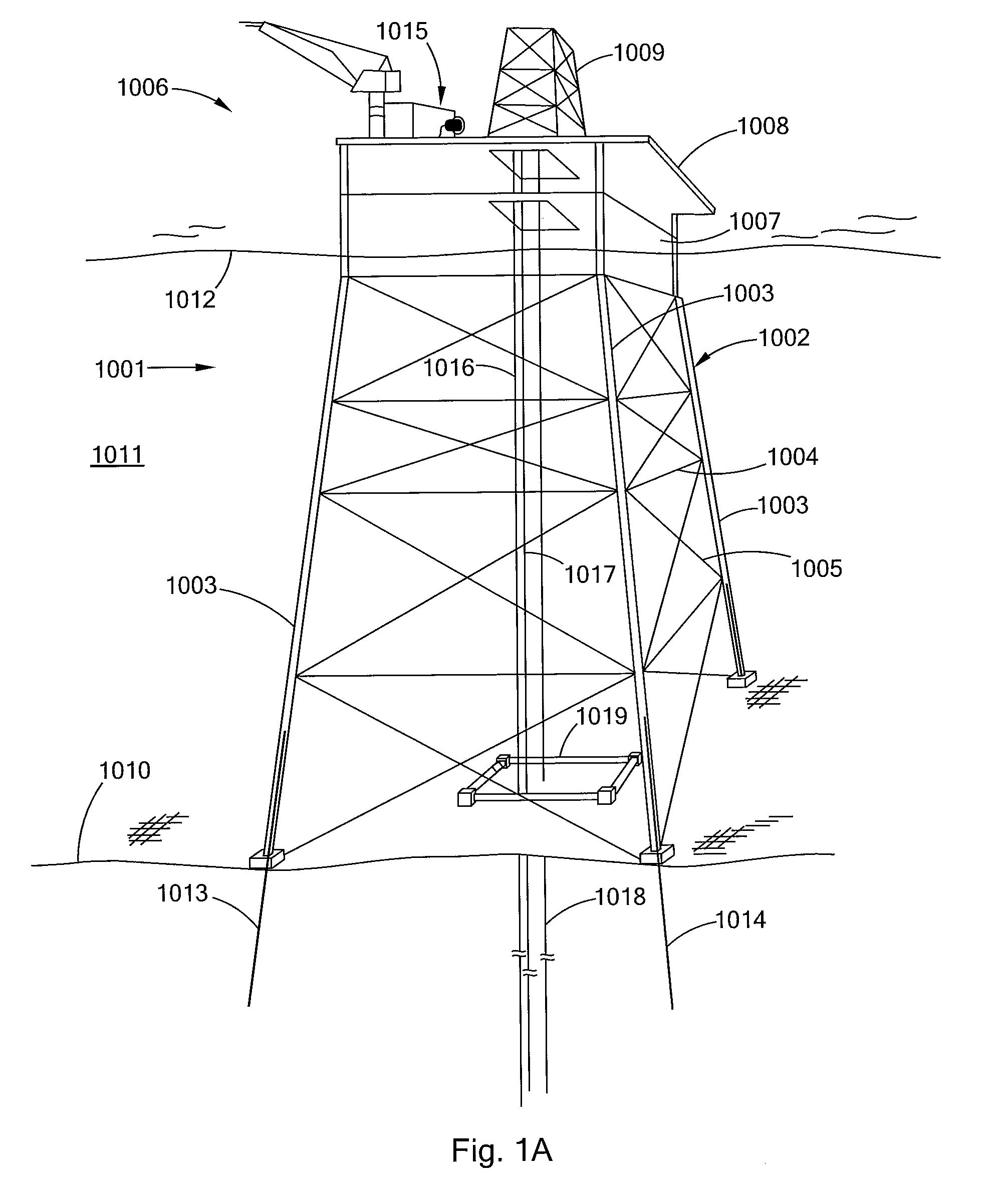

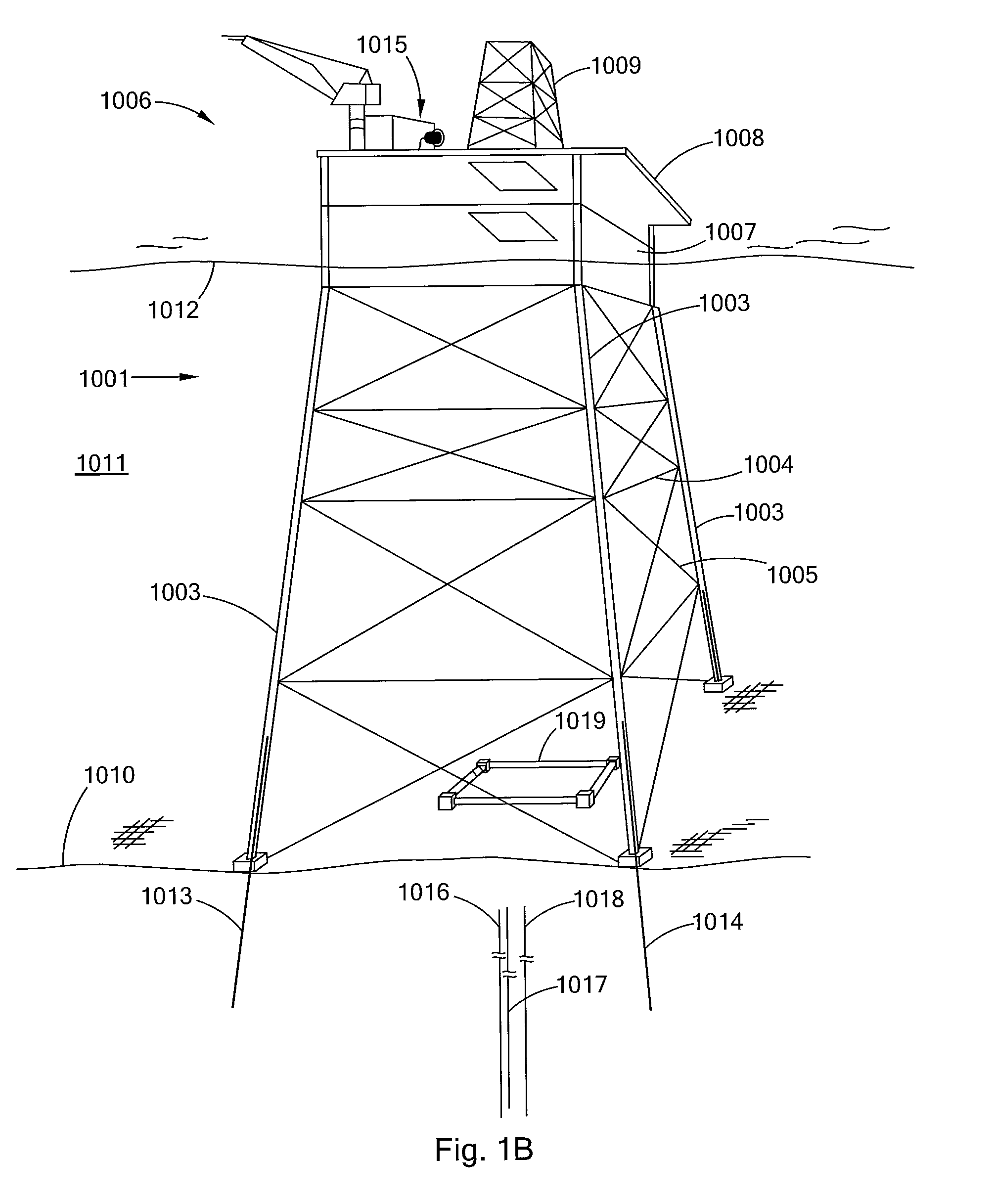

Laser systems and methods for the removal of structures

There is provided high power laser systems, high power laser tools, and methods of using these tools and systems for cutting, sectioning and removing structures objects, and materials, and in particular, for doing so in difficult to access locations and environments, such as offshore, underwater, or in hazardous environments, such as nuclear and chemical facilities. Thus, there is also provided high power laser systems, high power laser tools, and methods of using these systems and tools for removing structures, objects, and materials located offshore, under bodies of water and under the seafloor.

Owner:FORO ENERGY

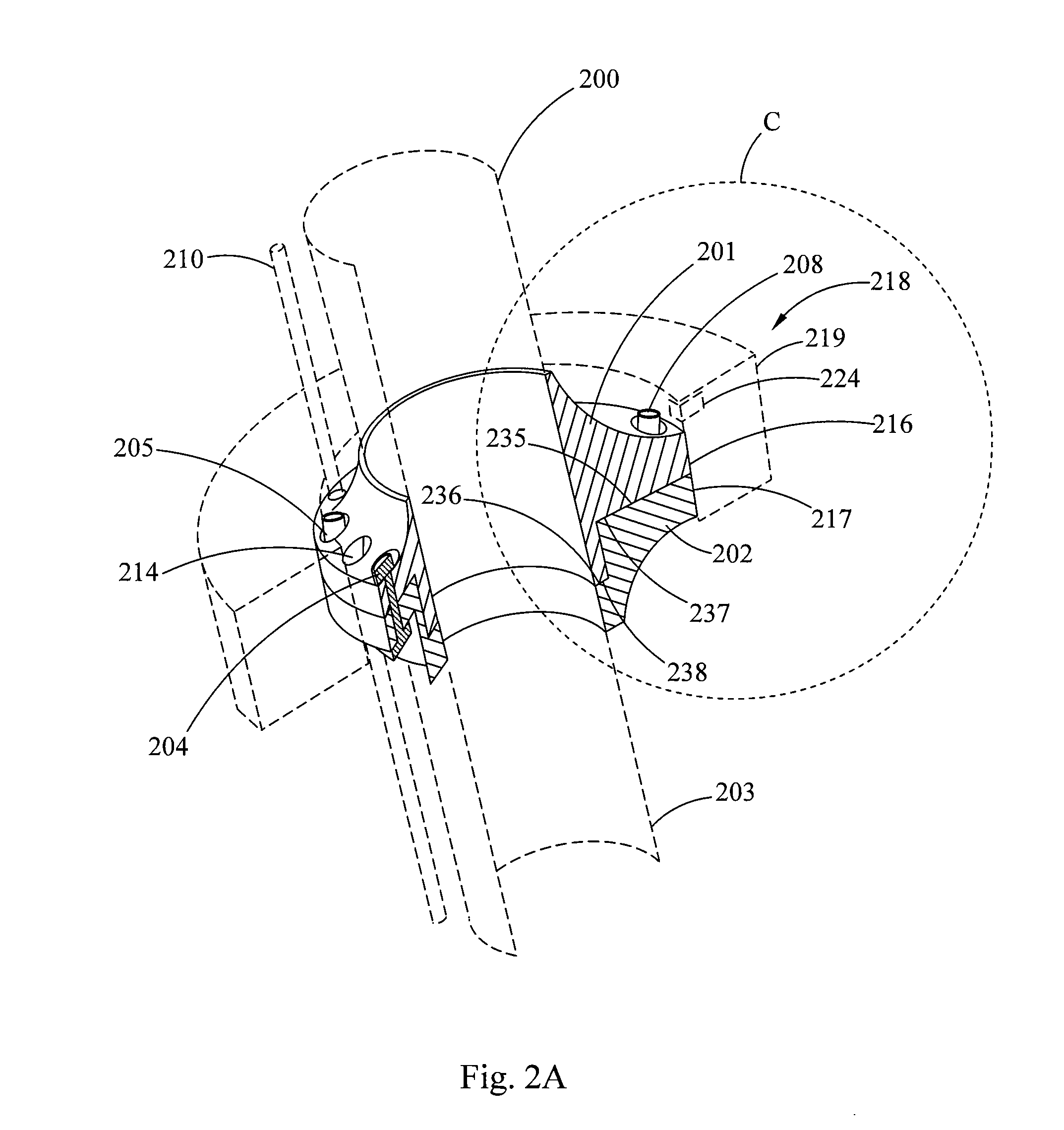

Laser assisted blowout preventer and methods of use

ActiveUS20120217018A1Quick cutProtection from damageDrilling rodsDerricks/mastsHigh power lasersLaser assisted

There is provided a high power laser assisted blowout preventer and methods of use. In particular, there are provided systems and assemblies for utilizing high power laser energy within a blowout preventer to cut tubulars that are present within the bore of the blowout prevent, reducing the risk that such tubulars will inhibit the ability of the blowout preventer to seal a well.

Owner:FORO ENERGY

Laser assisted riser disconnect and method of use

There is provided a high power laser-riser blowout preventer package and laser module for use with a subsea riser. The laser module and laser-riser package use high power laser energy to quickly cut the riser permitting an offshore drilling rig to quickly, and in a controlled manner disconnect from a blowout preventer.

Owner:FORO ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com