Patents

Literature

9364 results about "Laser cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

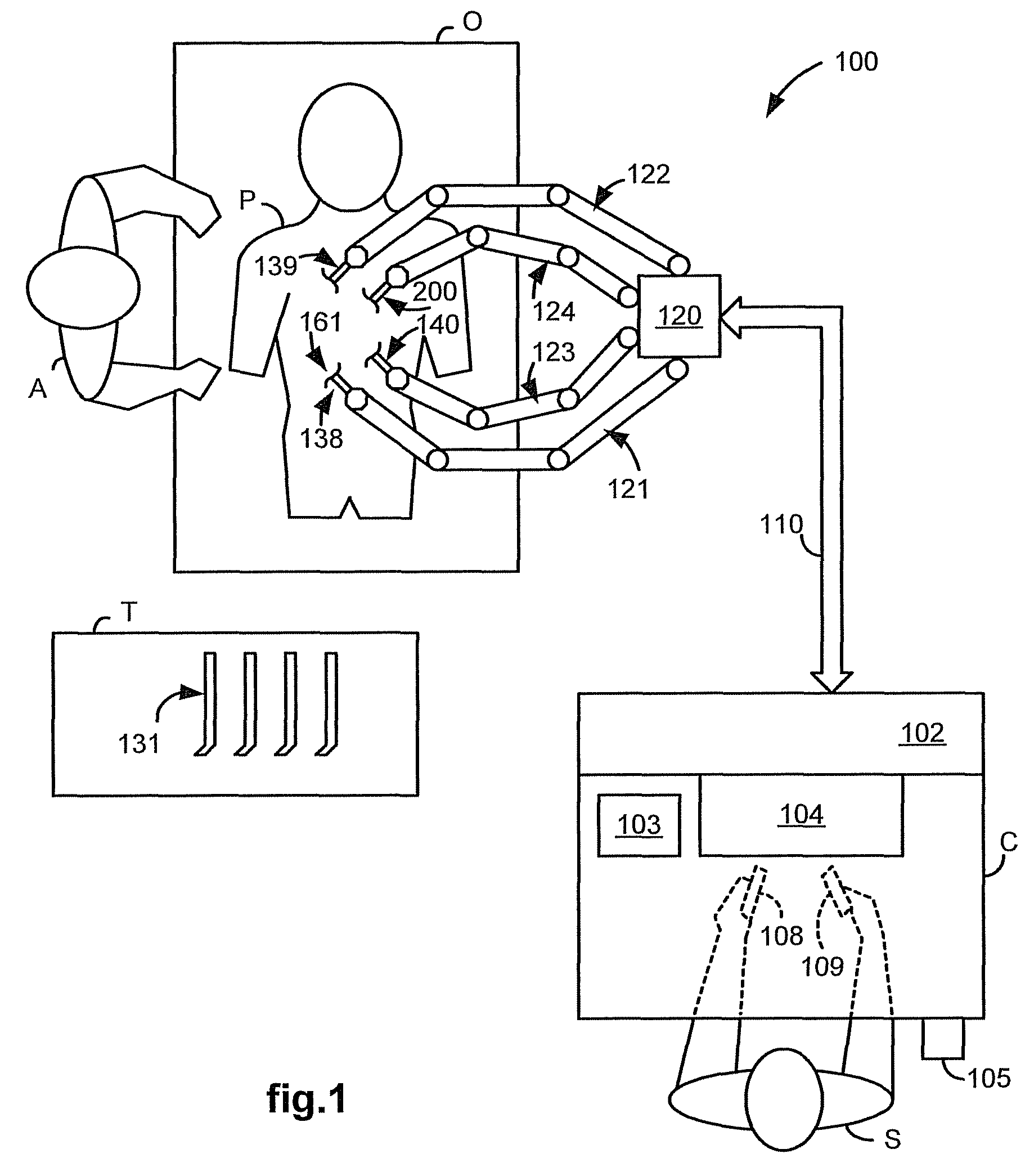

Surgical tools for laser marking and laser cutting

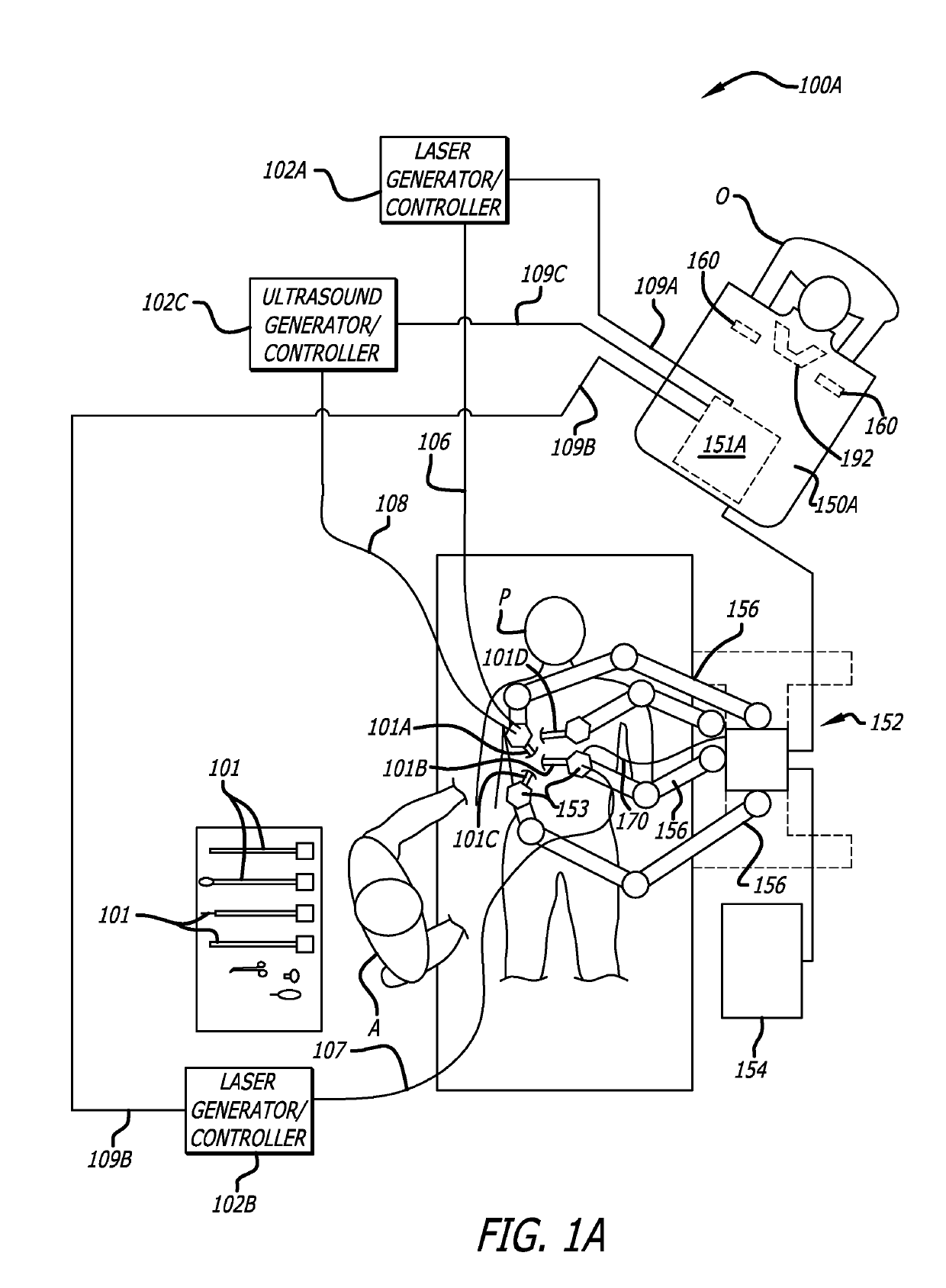

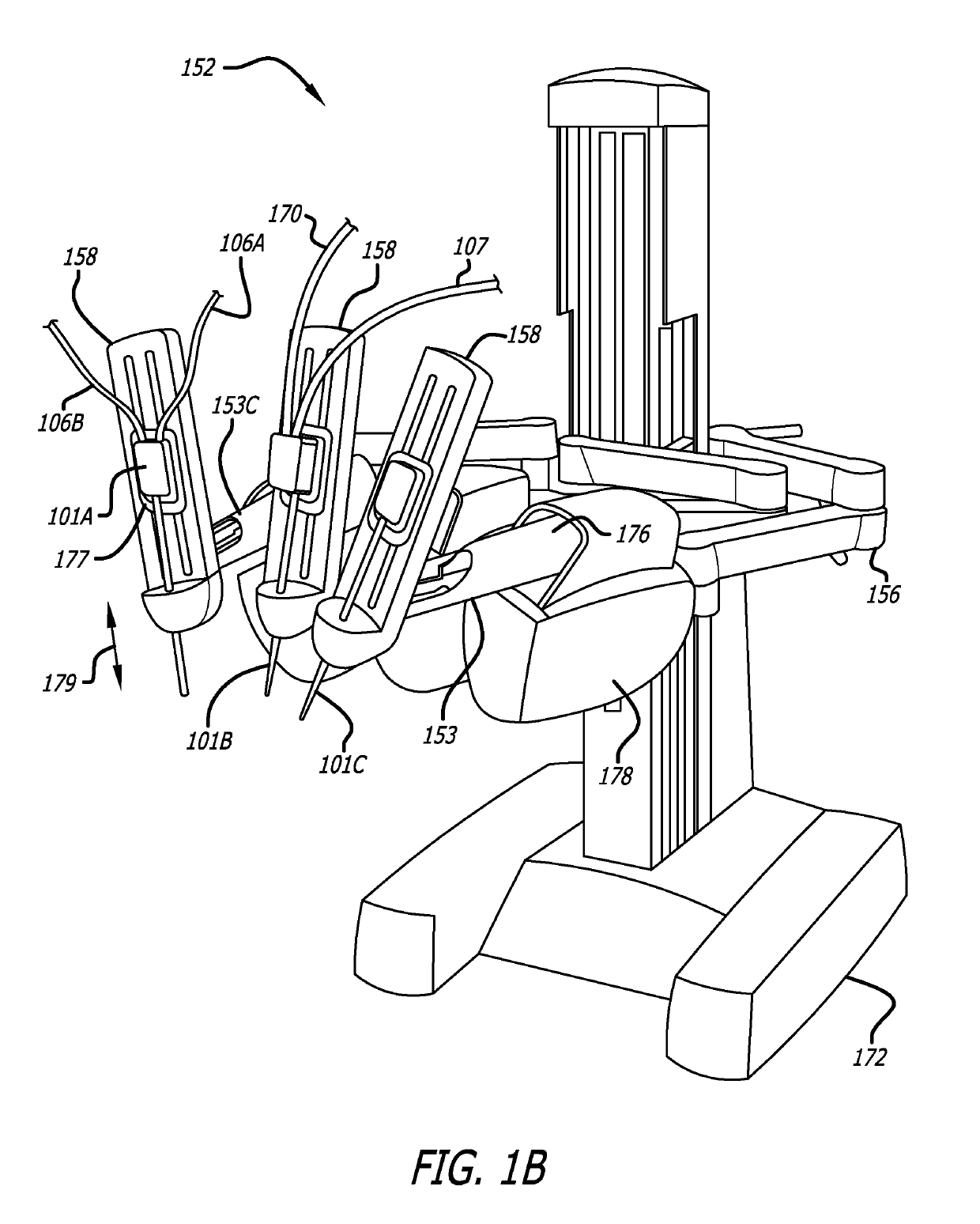

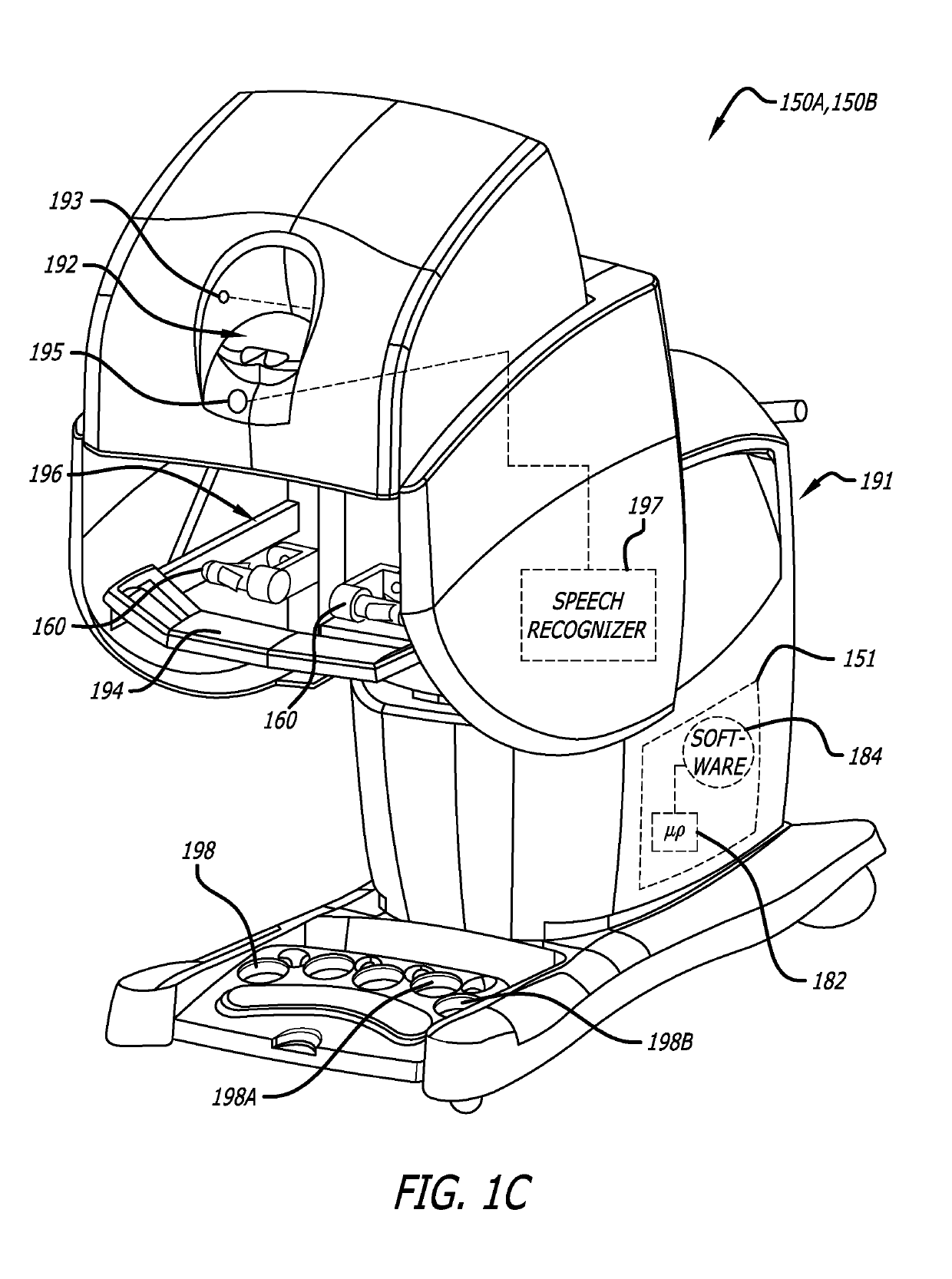

ActiveUS10368838B2Ultrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsRobotic armDisplay device

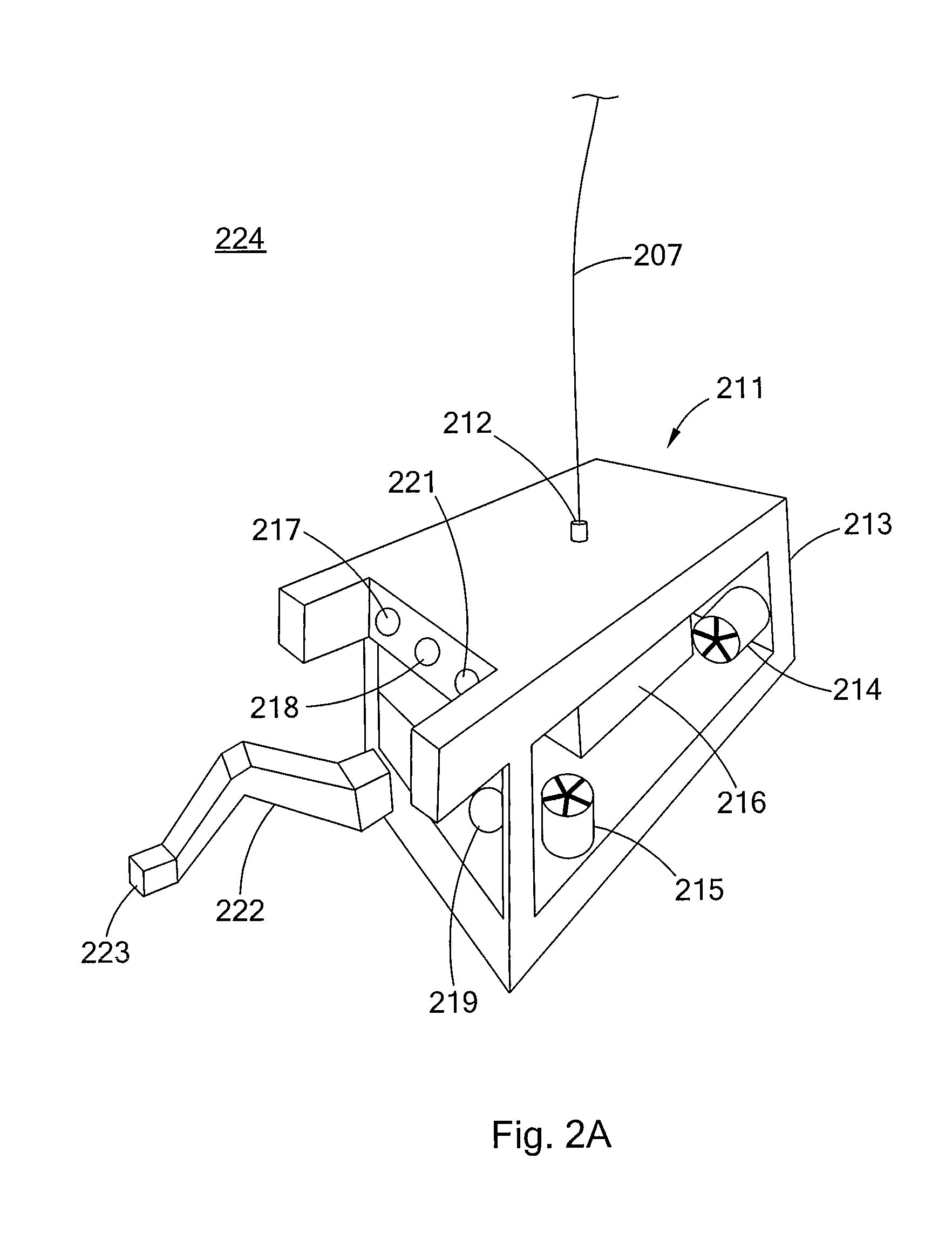

In one embodiment of the invention, a robotic surgical system includes a combined laser imaging robotic surgical tool, a control console, and a laser generator / controller. The tool is mounted to a first robotic arm of a patient side cart. The tool has a wristed joint and an end effector coupled together. The end effector has a laser-emitting device to direct a laser beam onto tissue in a surgical site and an image-capturing device to capture images of the tissue in the surgical site. The control console, in communication with the tool, receives the captured images of tissue in the surgical site and displays the captured images on a display device to a user. The laser generator / controller is coupled to the tool and the control console to control the emission of the laser beam onto tissue of the surgical site.

Owner:INTUITIVE SURGICAL OPERATIONS INC

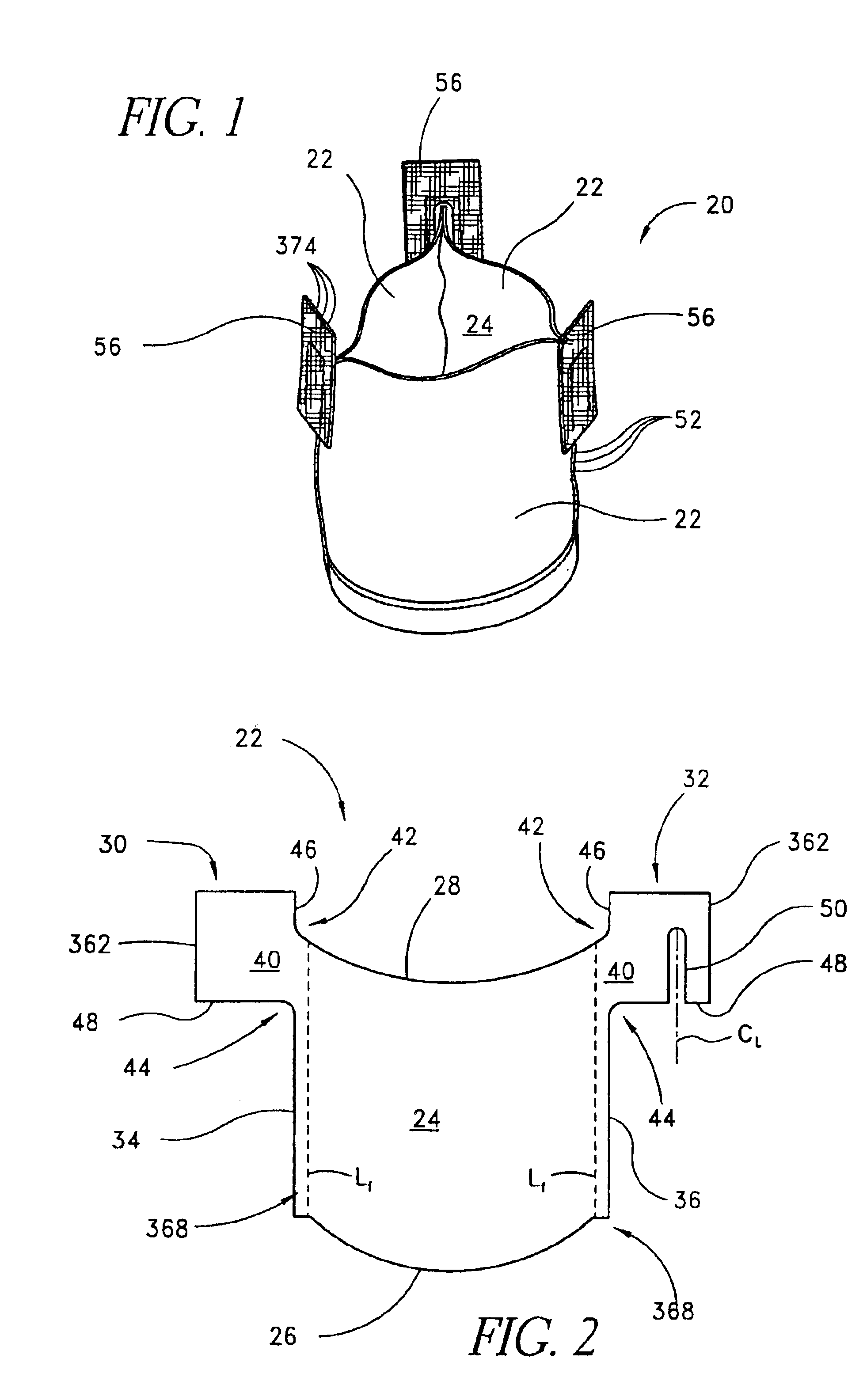

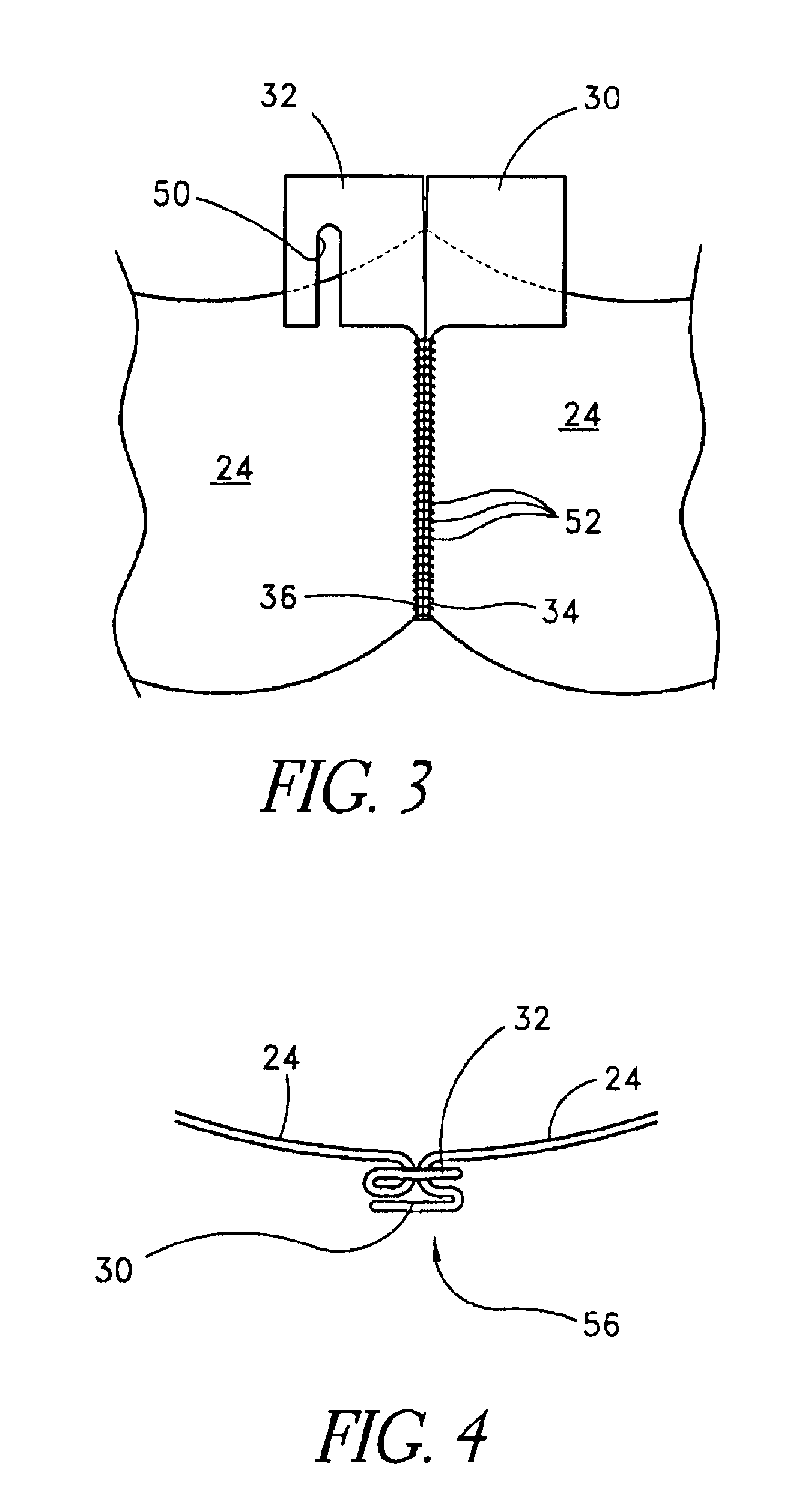

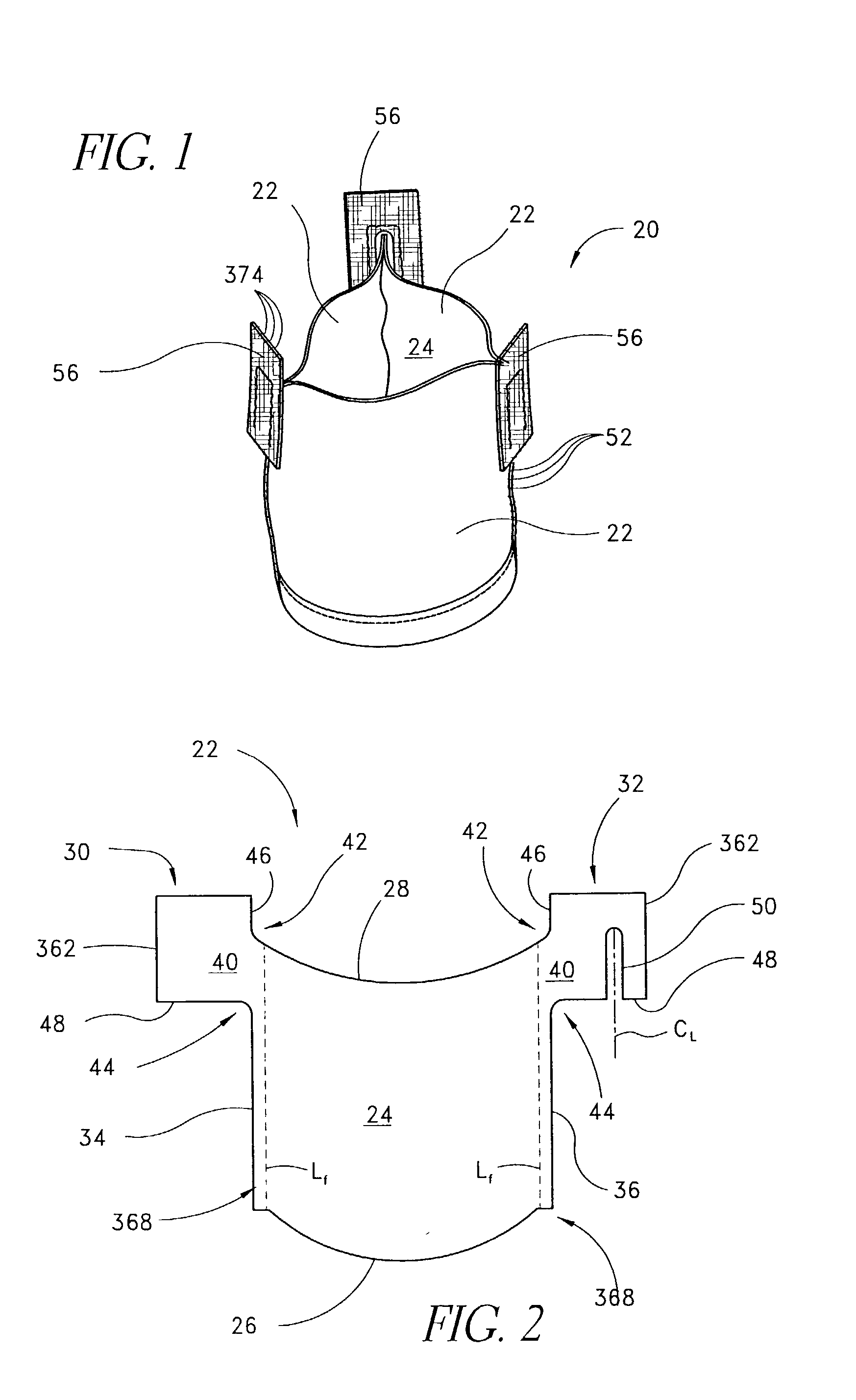

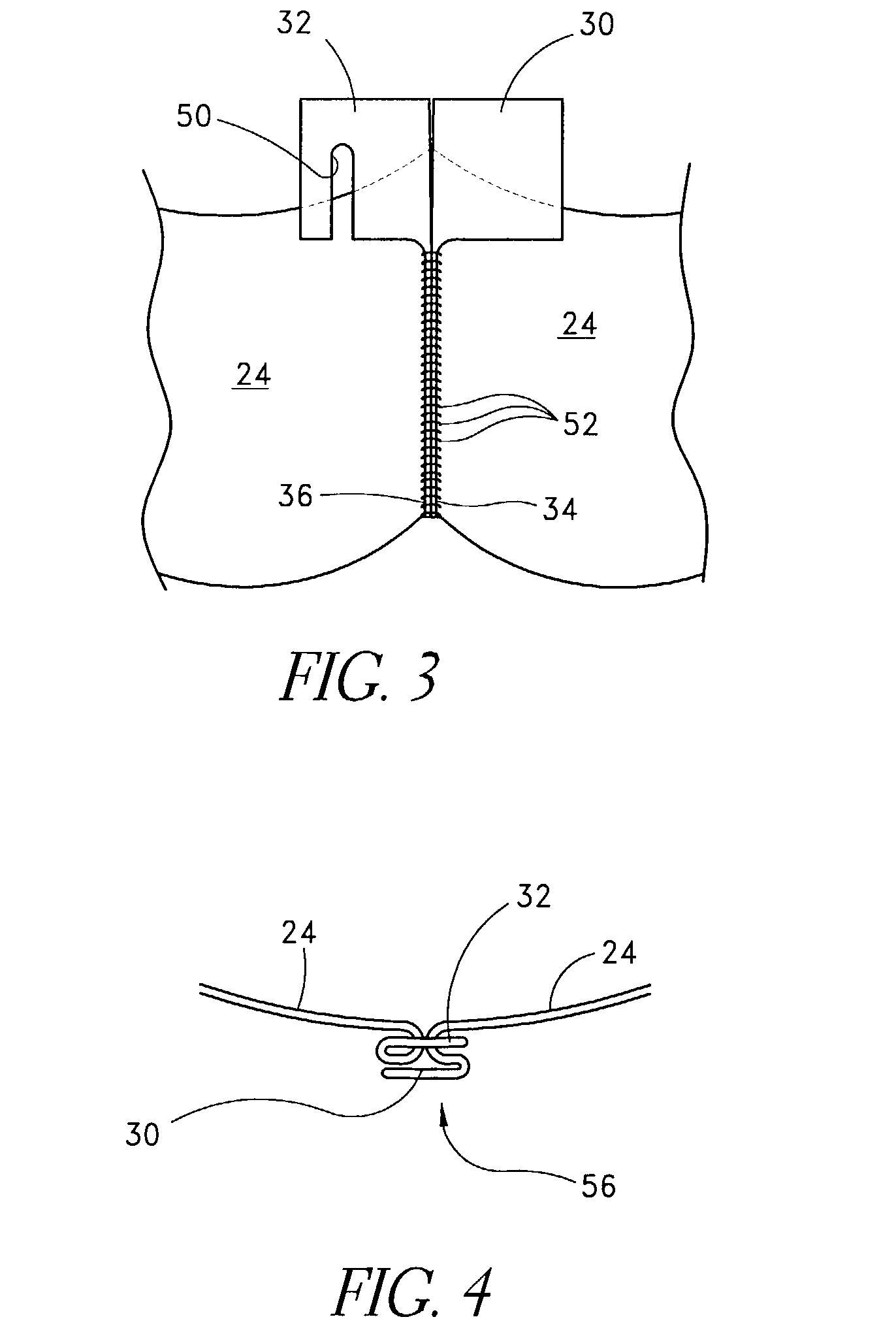

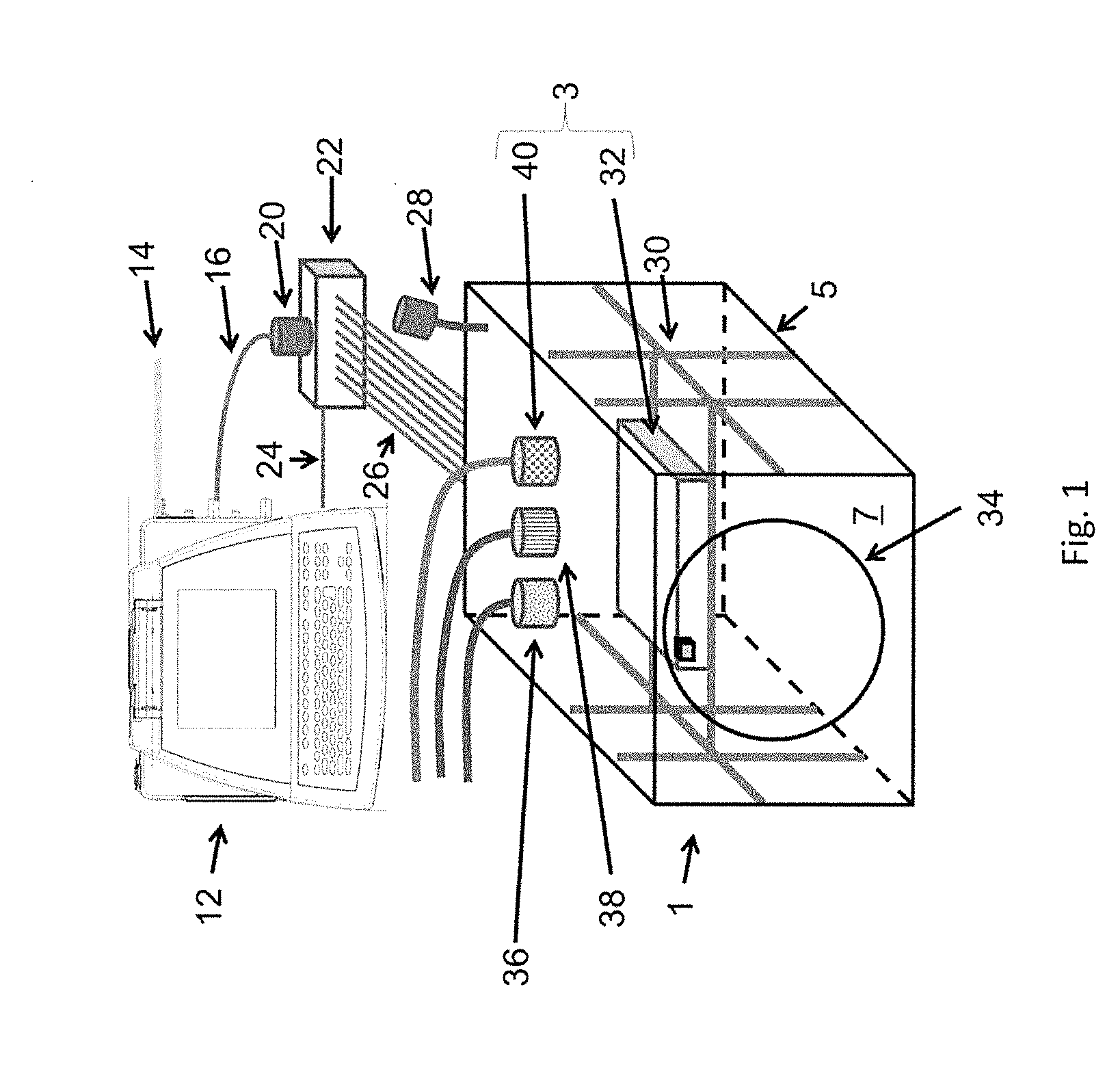

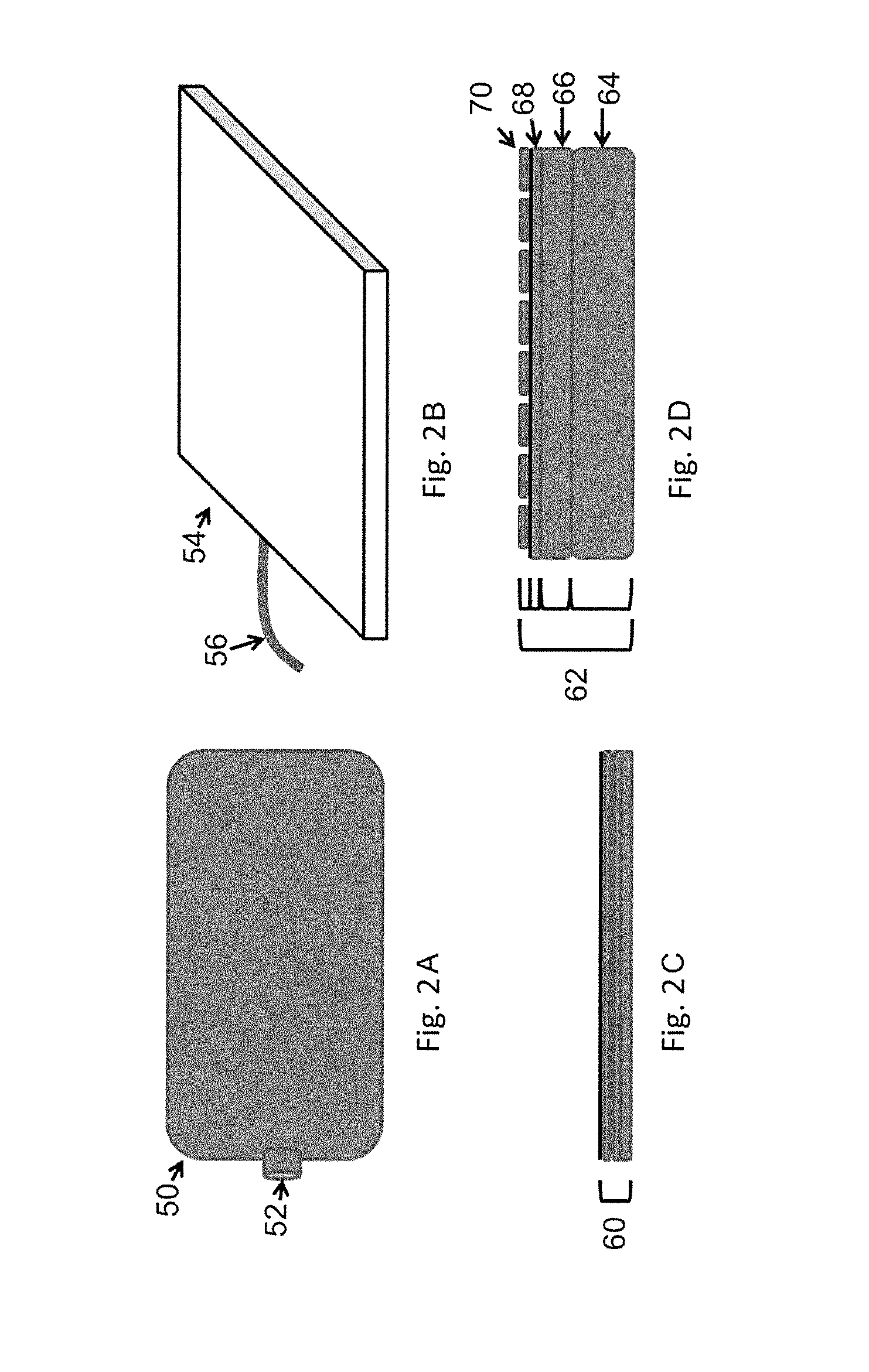

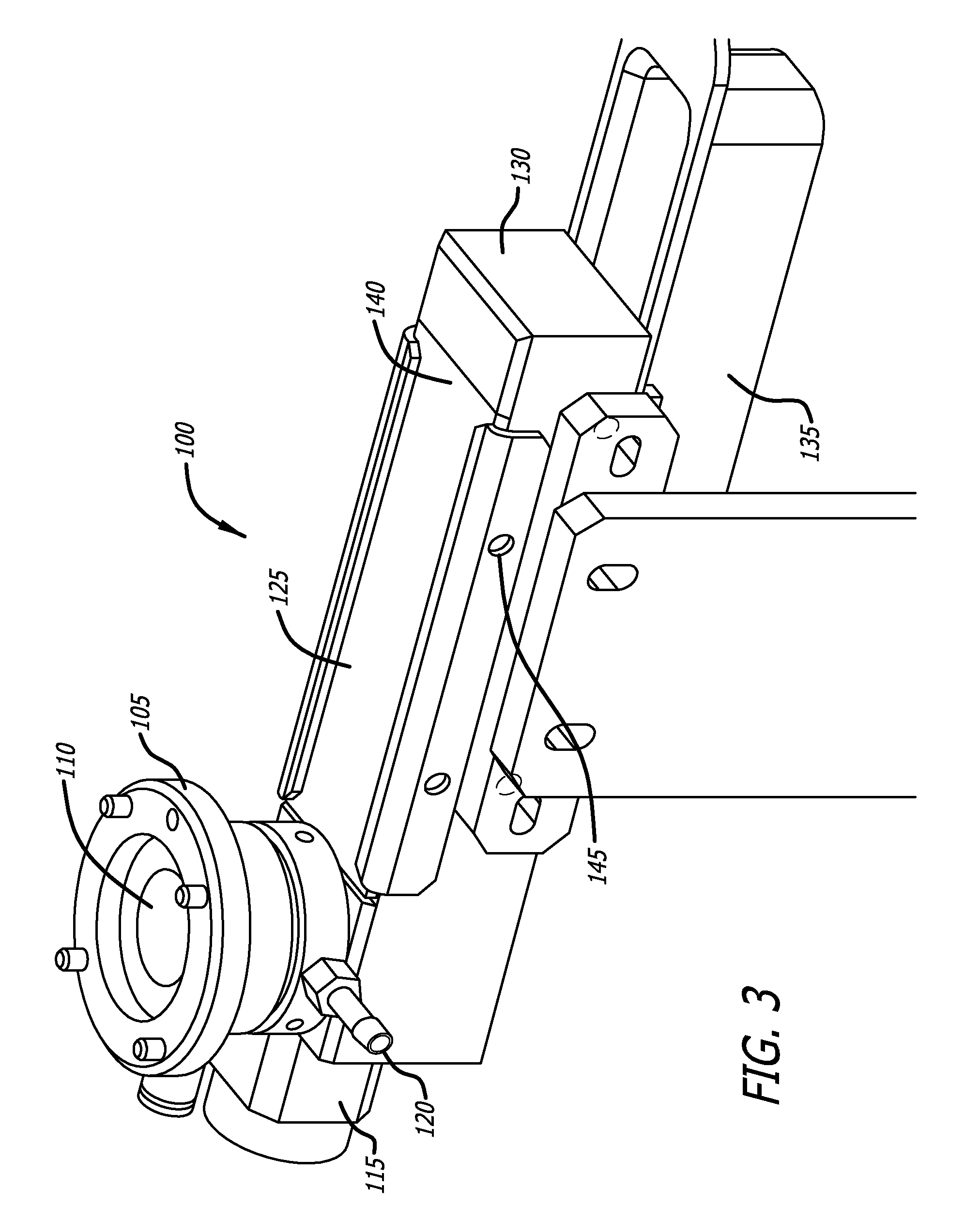

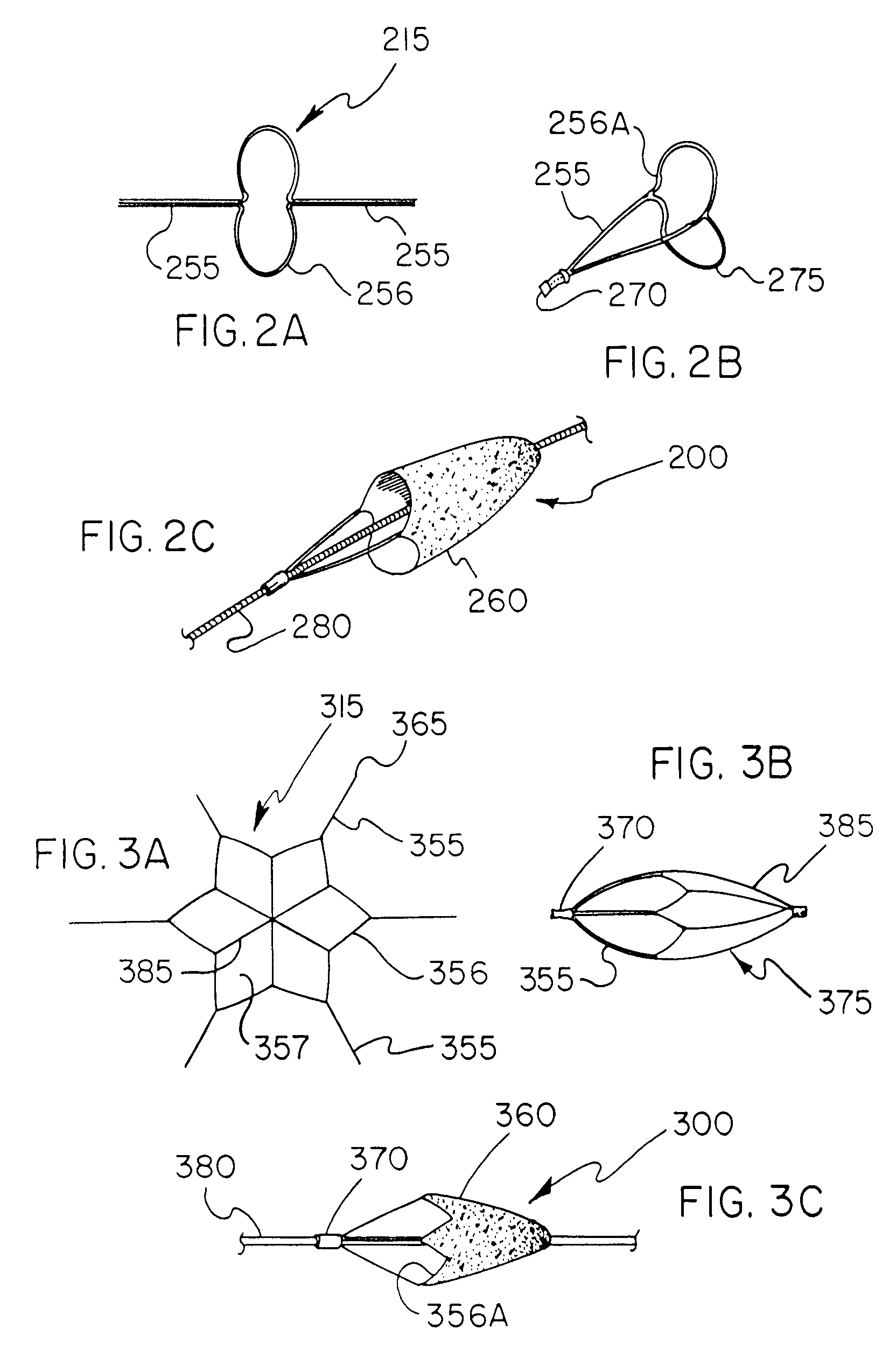

Method of cutting material for use in implantable medical device

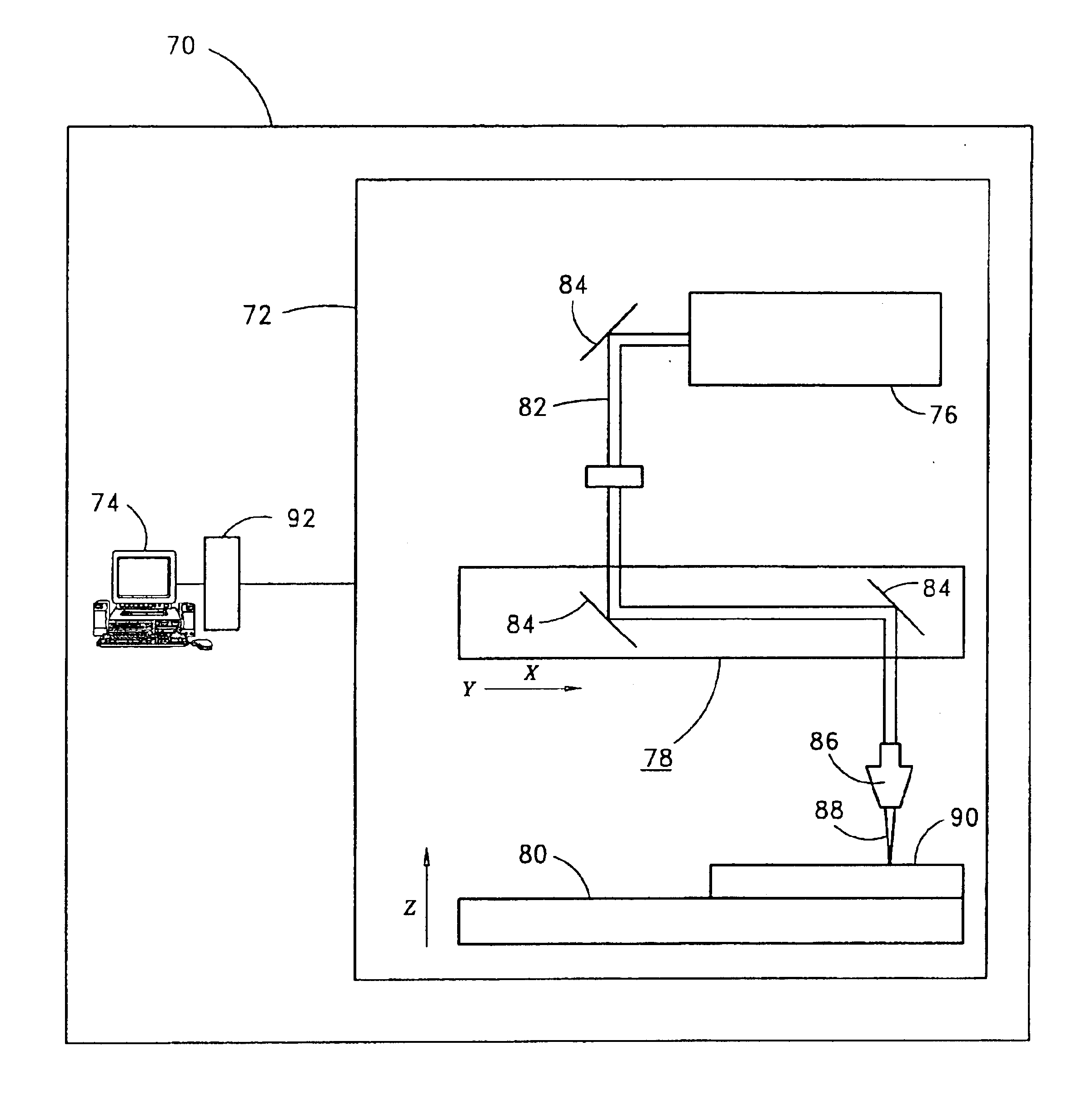

A method of cutting material for use in an implantable medical device employs a plotted laser cutting system. The laser cutting system is computer controlled and includes a laser combined with a motion system. The laser precisely cuts segments out of source material according to a predetermined pattern as designated by the computer. The segments are used in constructing implantable medical devices. The cutting energy of the laser is selected so that the cut edges of the segments are melted to discourage delamination or fraying, but communication of thermal energy into the segment beyond the edge is minimized to avoid damaging the segment adjacent the edge.

Owner:3F THERAPEUTICS

Method of cutting material for use in implantable medical device

A method of cutting material for use in an implantable medical device employs a plotted laser cutting system. The laser cutting system is computer controlled and includes a laser combined with a motion system. The laser precisely cuts segments out of source material according to a predetermined pattern as designated by the computer. The segments are used in constructing implantable medical devices. The cutting energy of the laser is selected so that the cut edges of the segments are melted to discourage delamination or fraying, but communication of thermal energy into the segment beyond the edge is minimized to avoid damaging the segment adjacent the edge.

Owner:3F THERAPEUTICS

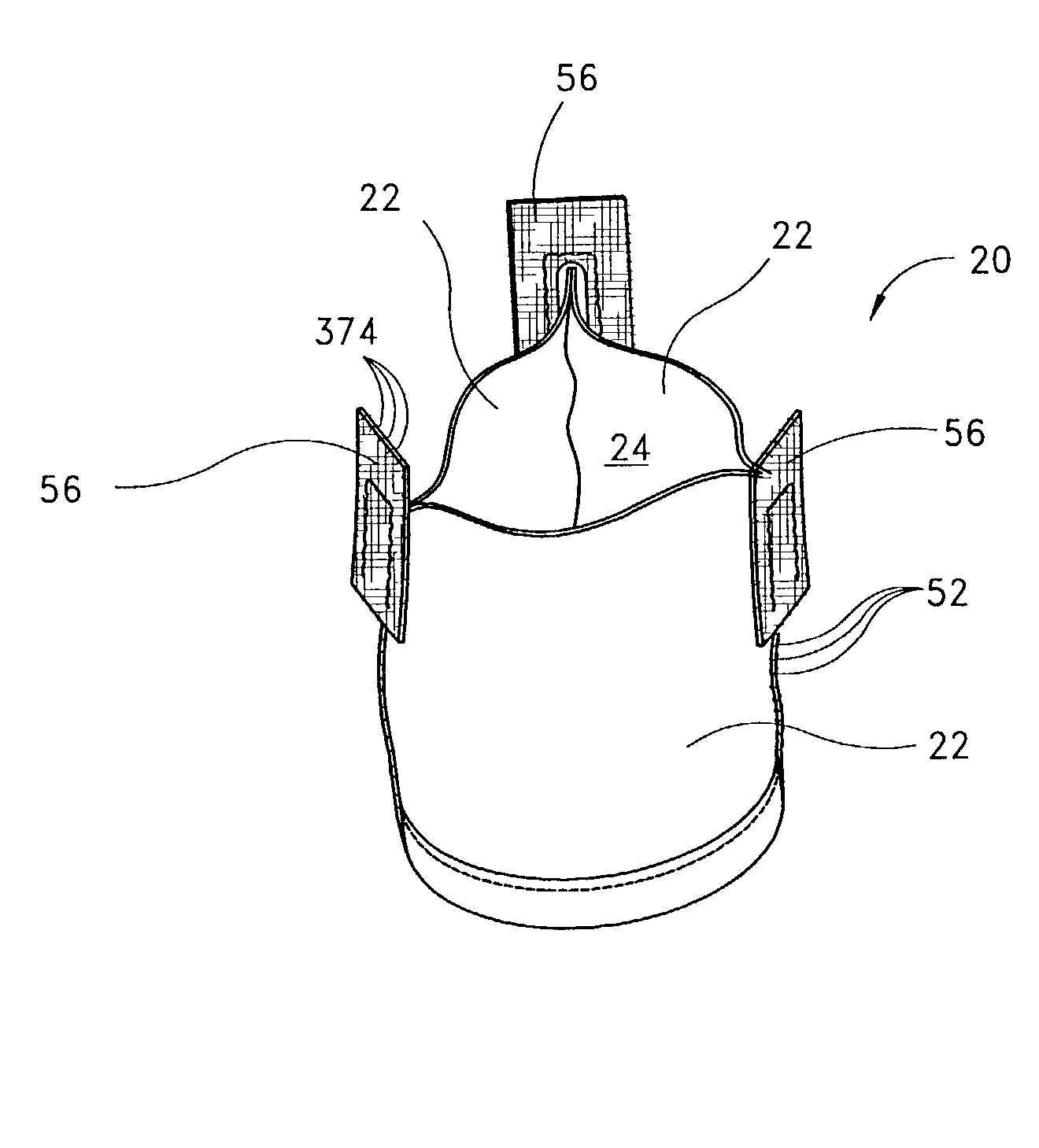

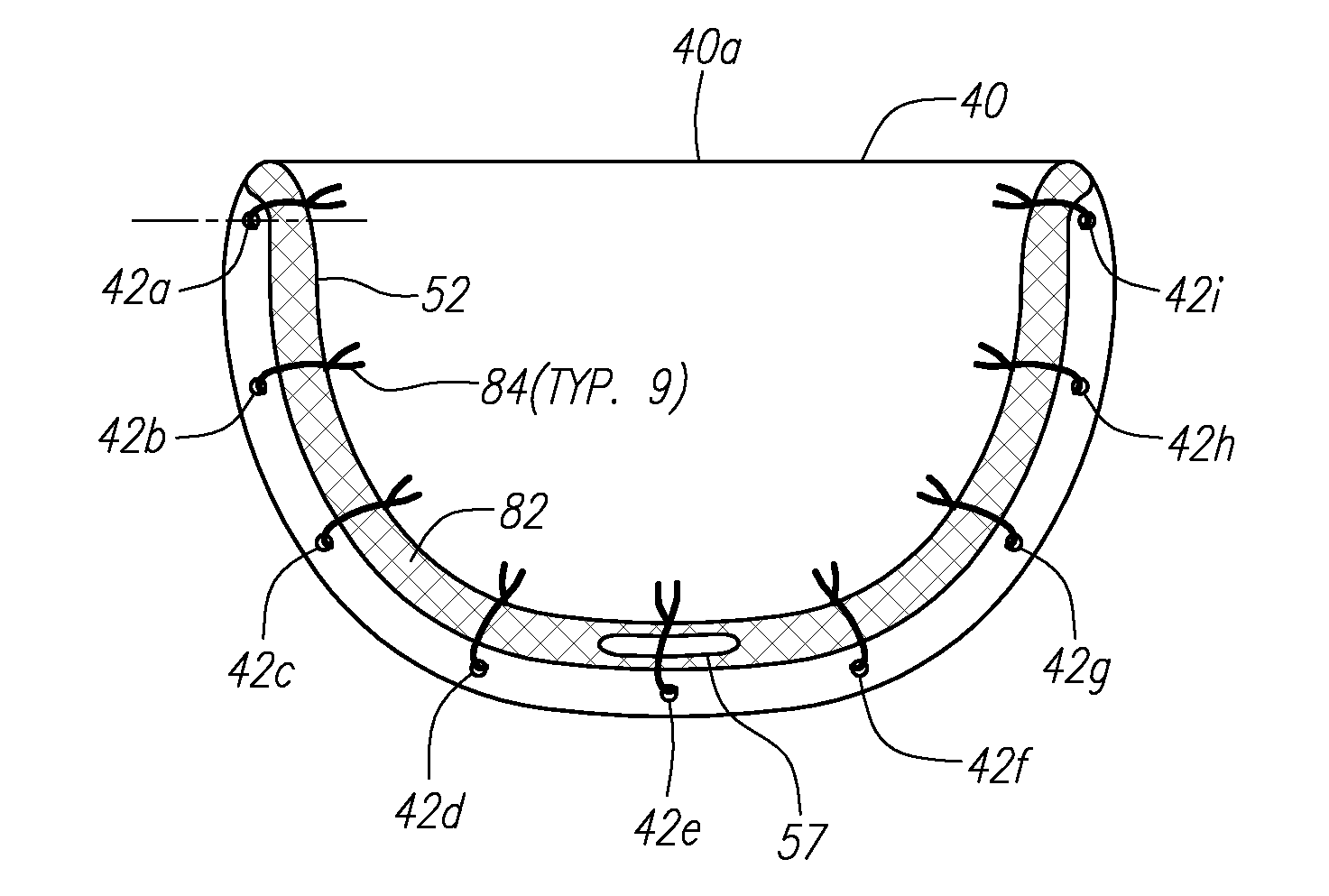

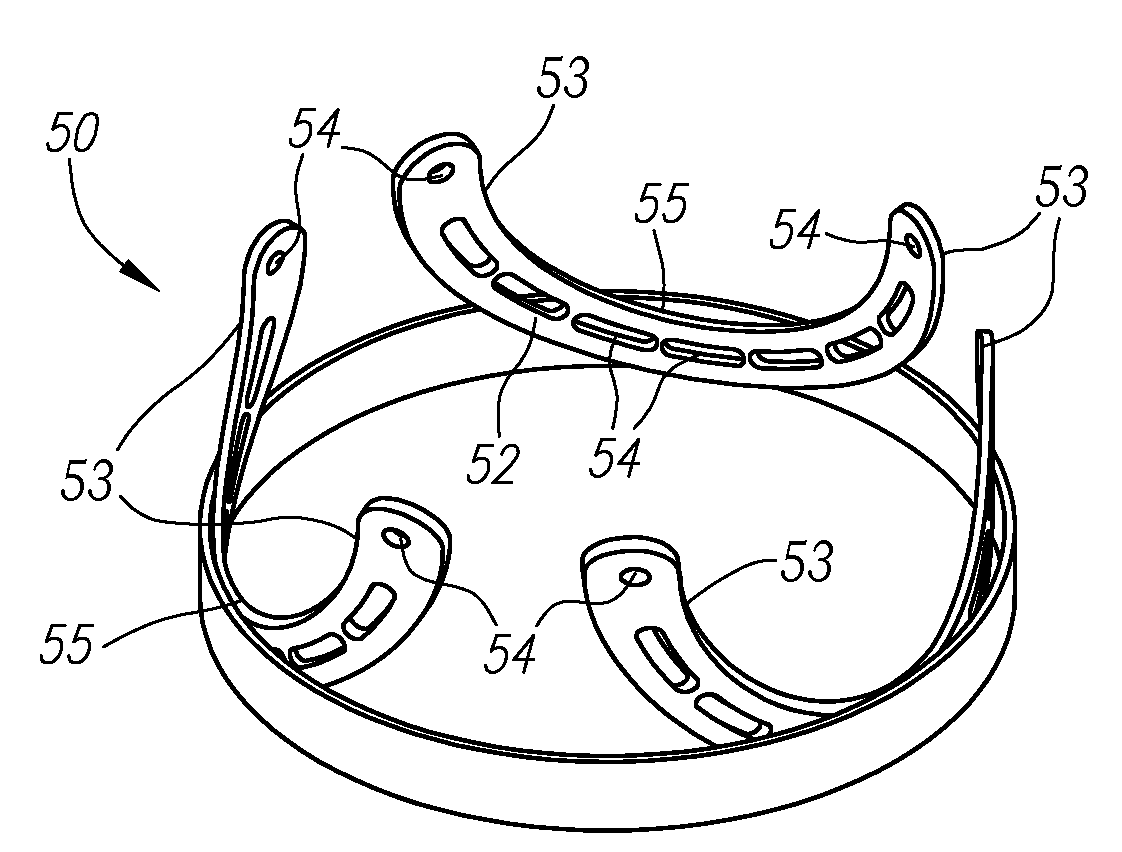

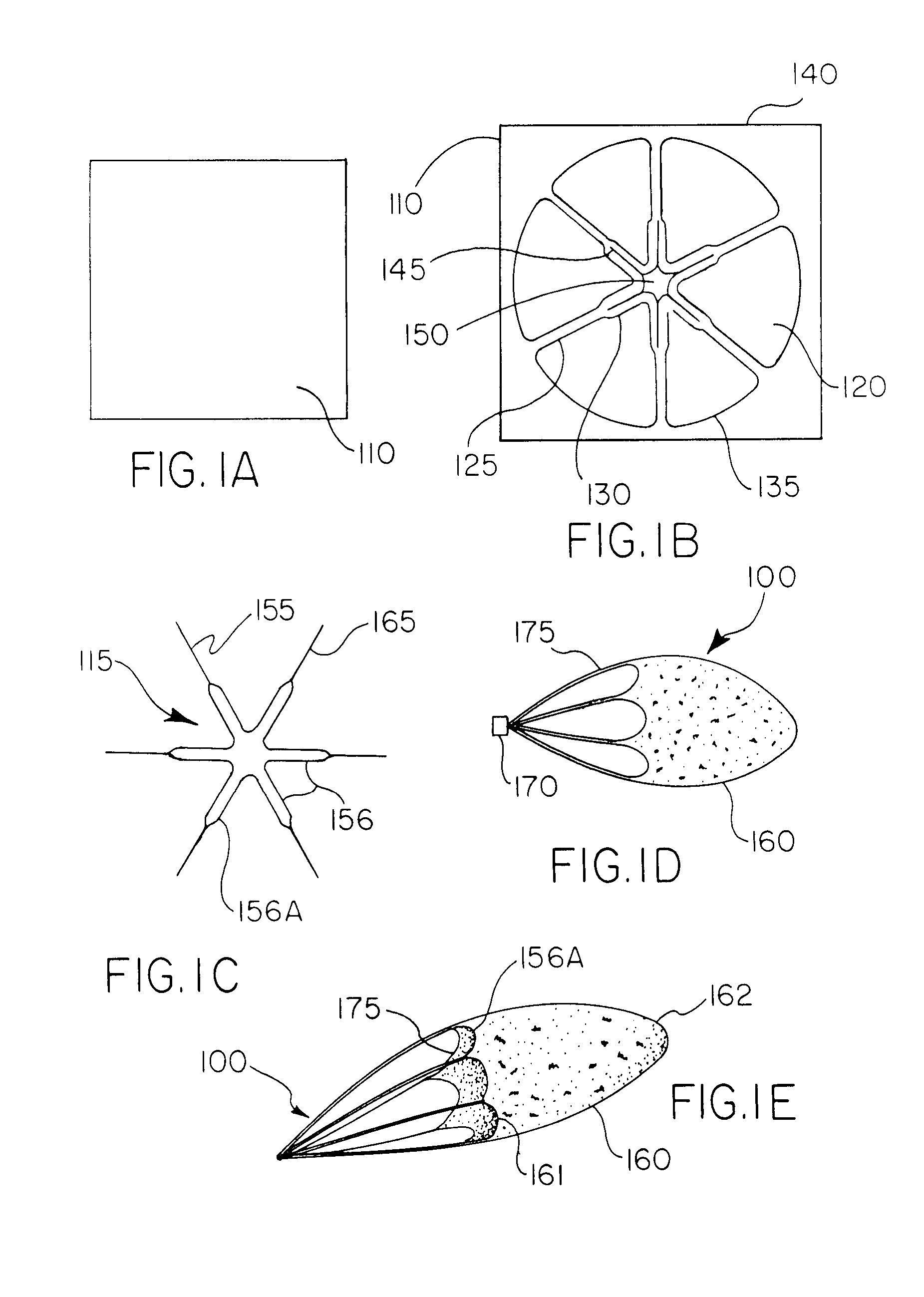

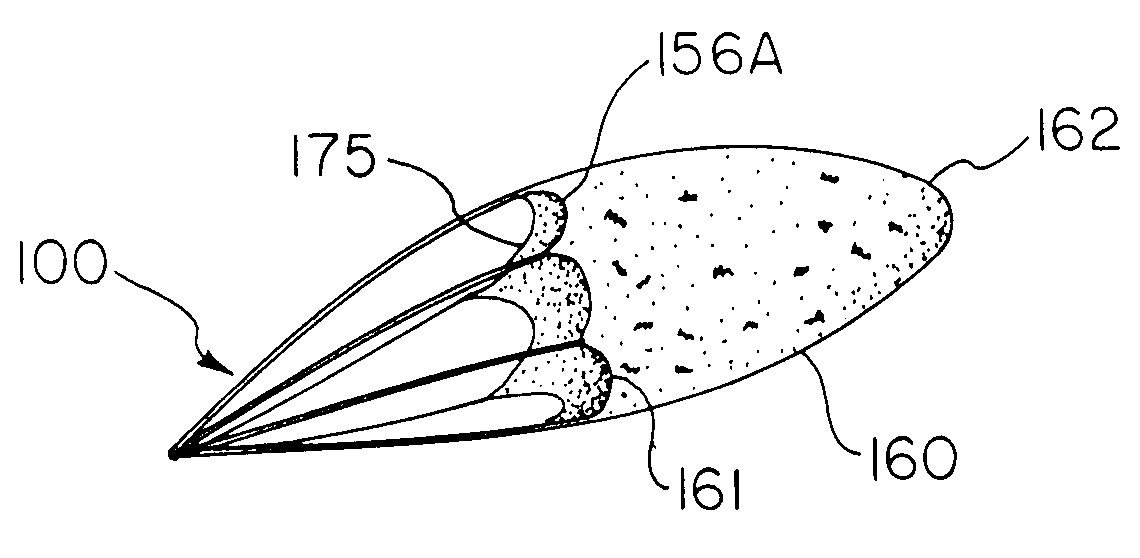

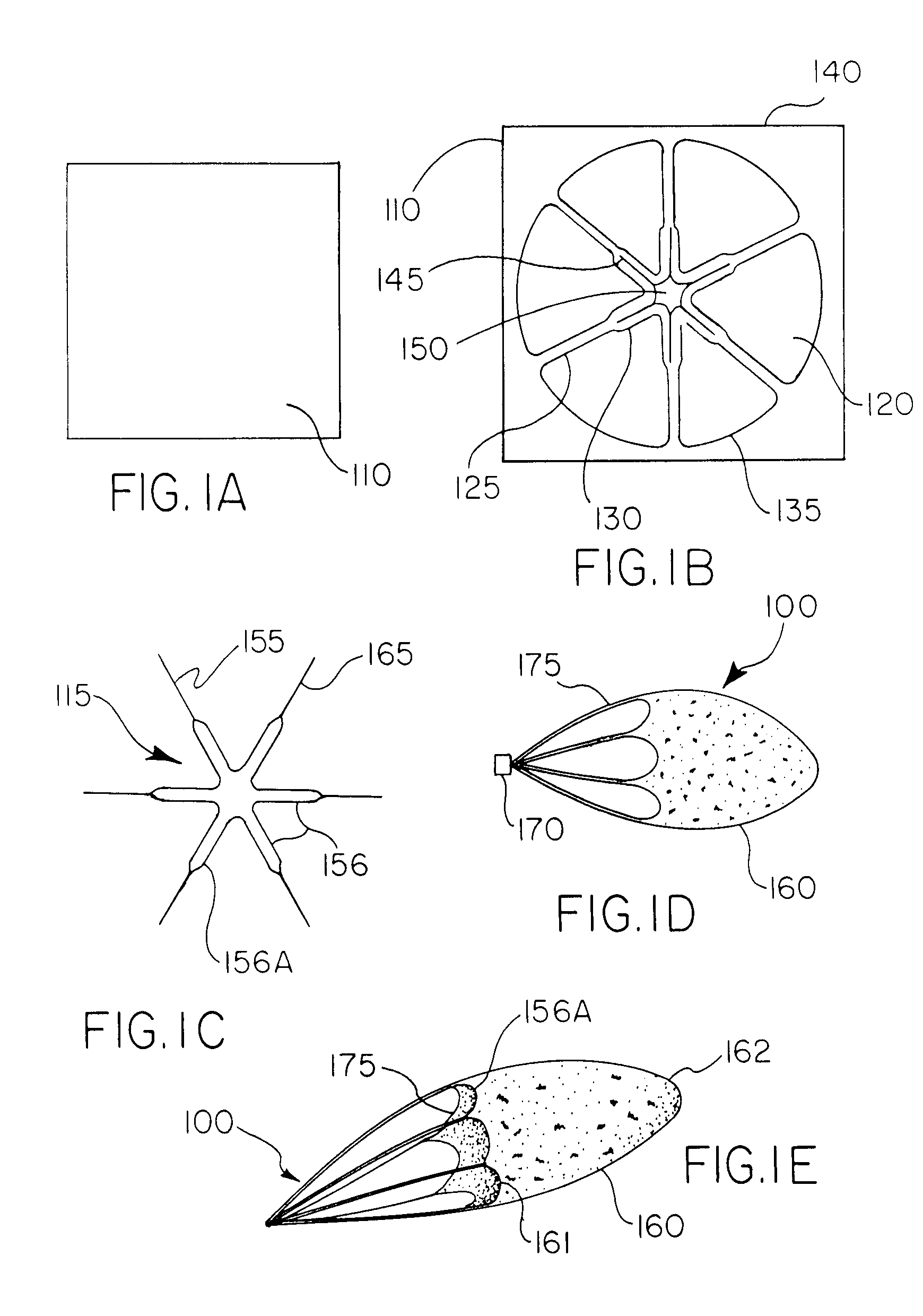

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

Apparatus and methods for making leaflets and valve prostheses including such leaflets

A method for making a bioprosthetic heart valve includes providing a non-contact cutting apparatus and a layer of tissue. The non-contact cutting apparatus may include a laser cutting system or high pressure water jet system. A leaflet is cut from the layer of tissue using a predefined template, and a plurality of alignment holes in the leaflet are created in the leaflet, e.g., along a peripheral edge. A support structure is provided having a plurality of alignment holes corresponding to alignment holes in the leaflet. The leaflet is secured to the support structure by securing one or more sutures through corresponding alignment holes in the leaflet and the support structure to provide a leaflet subassembly. A bioprosthetic heart valve is made by securing a set of leaflet subassemblies to a frame.

Owner:MEDTRONIC INC

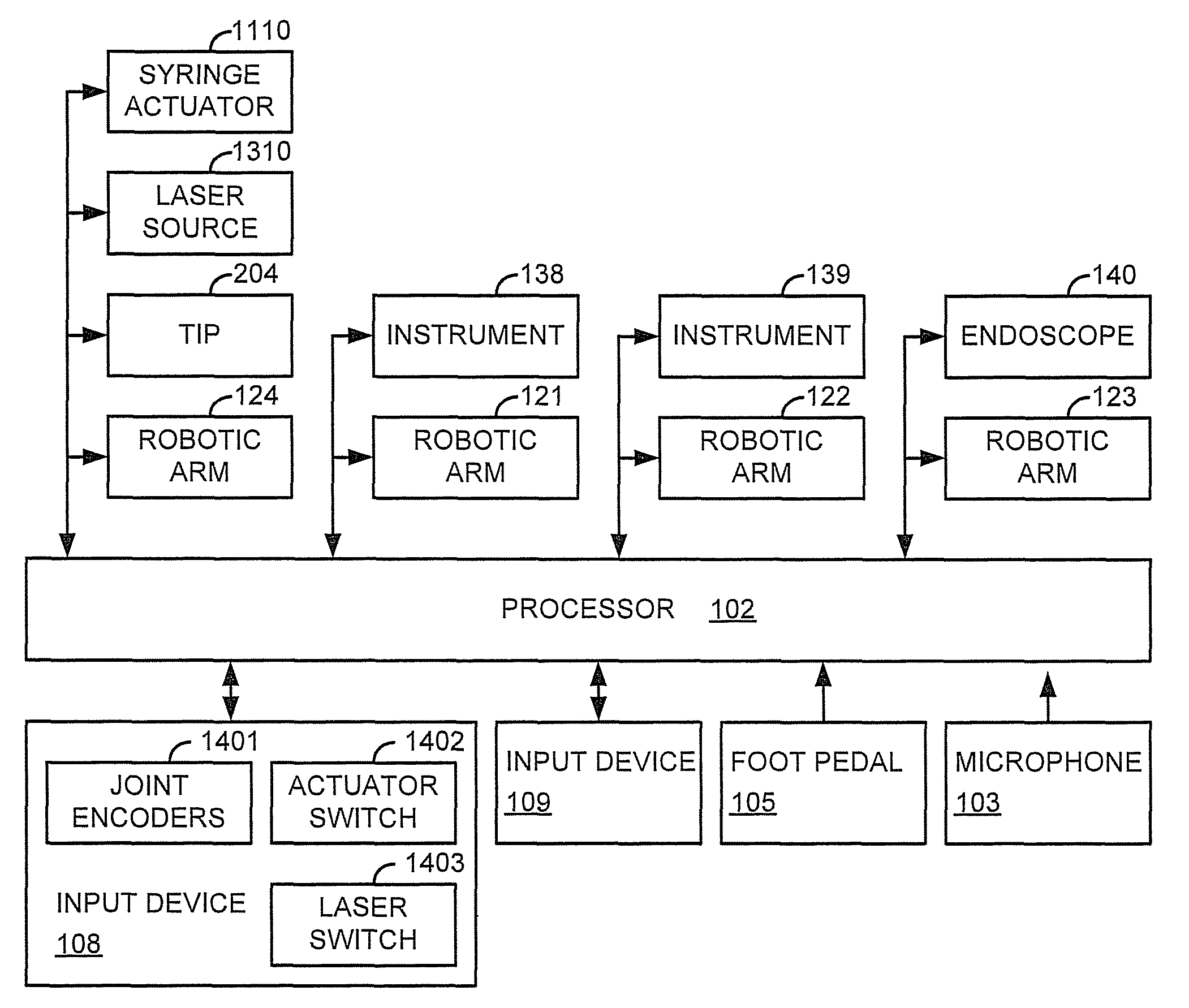

Circuit board for direct flip chip attachment

InactiveUS20090212317A1Semiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor packageLaser cutting

A packaging method comprises: forming a circuit board by forming a substantially continuous conductive layer on an insulating board and removing selected portions of the continuous conductive layer to define an electrically conductive trace; laser cutting the electrically conductive trace to define sub-traces electrically isolated from each other by a laser-cut gap formed by the laser cutting; and bonding a light emitting diode (LED) chip to the circuit board across or adjacent to the laser-cut gap, the bonding including operatively electrically connecting an electrode of the LED chip to one of the sub-traces without using an interposed submount. A semiconductor package comprises an LED chip flip-chip bonded to sub-traces of an electrically conductive trace of a circuit board, the sub-traces being electrically isolated from each other by a narrow gap of less than or about 100 microns.

Owner:LUMINATION

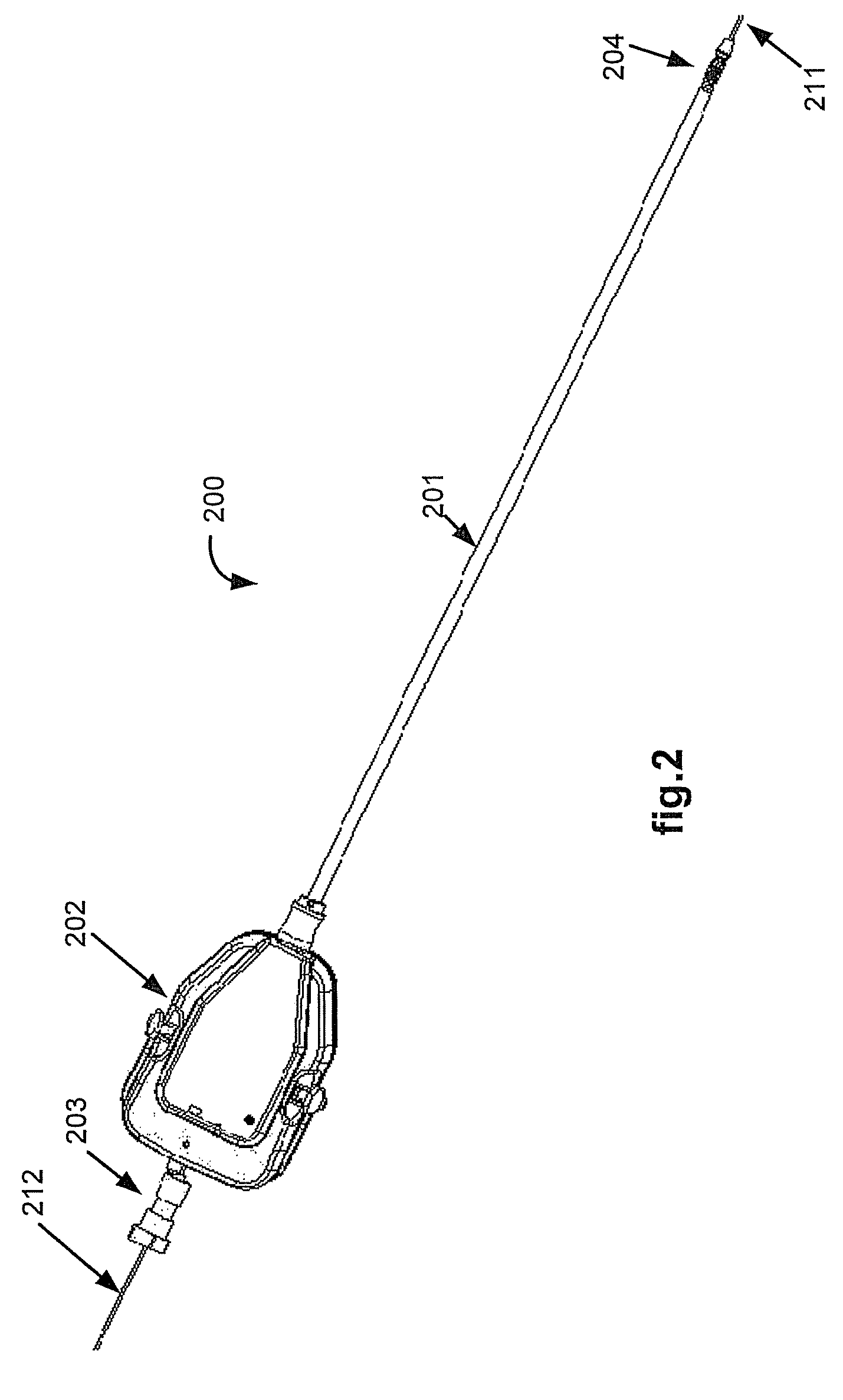

Medical device with orientable tip for robotically directed laser cutting and biomaterial application

A medical device used in a medical robotic system has a conduit and an orientable tip. An optical fiber coupled to a laser source and / or a catheter coupled to one or more biomaterial sources extends through the conduit and tip so that the tip of the medical device may be robotically directed towards a target tissue for laser and / or biomaterial application as part of a medical procedure performed at a surgical site within a patient. A protective sheath covers the fiber as it extends through the conduit and tip. A first coupler adjustably secures at least the sheath to the medical device and a second coupler adjustably secures the fiber to at least the sheath. A similar dual coupler mechanism may be used to secure the sheathed catheter to the medical device.

Owner:INTUITIVE SURGICAL OPERATIONS INC

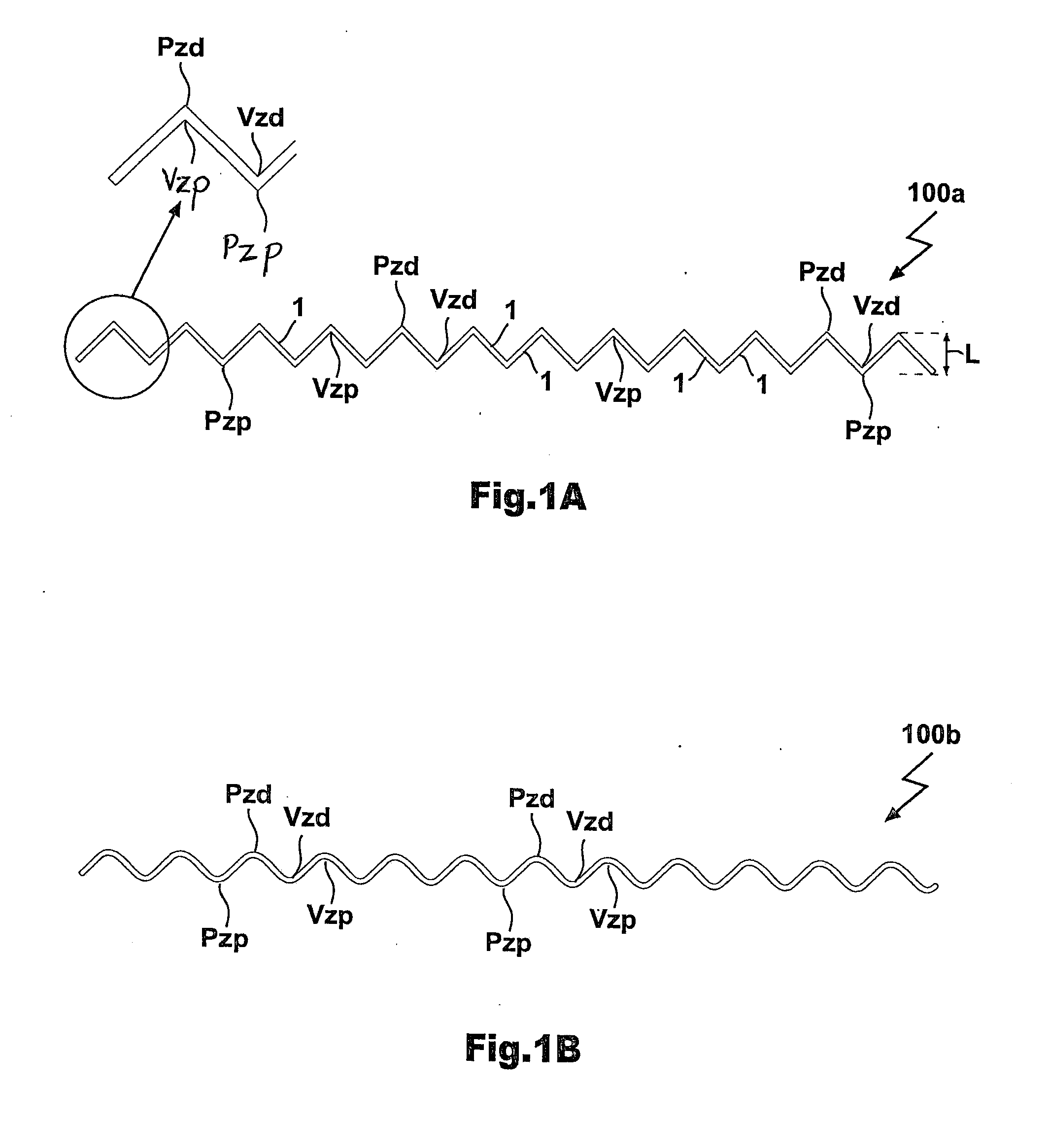

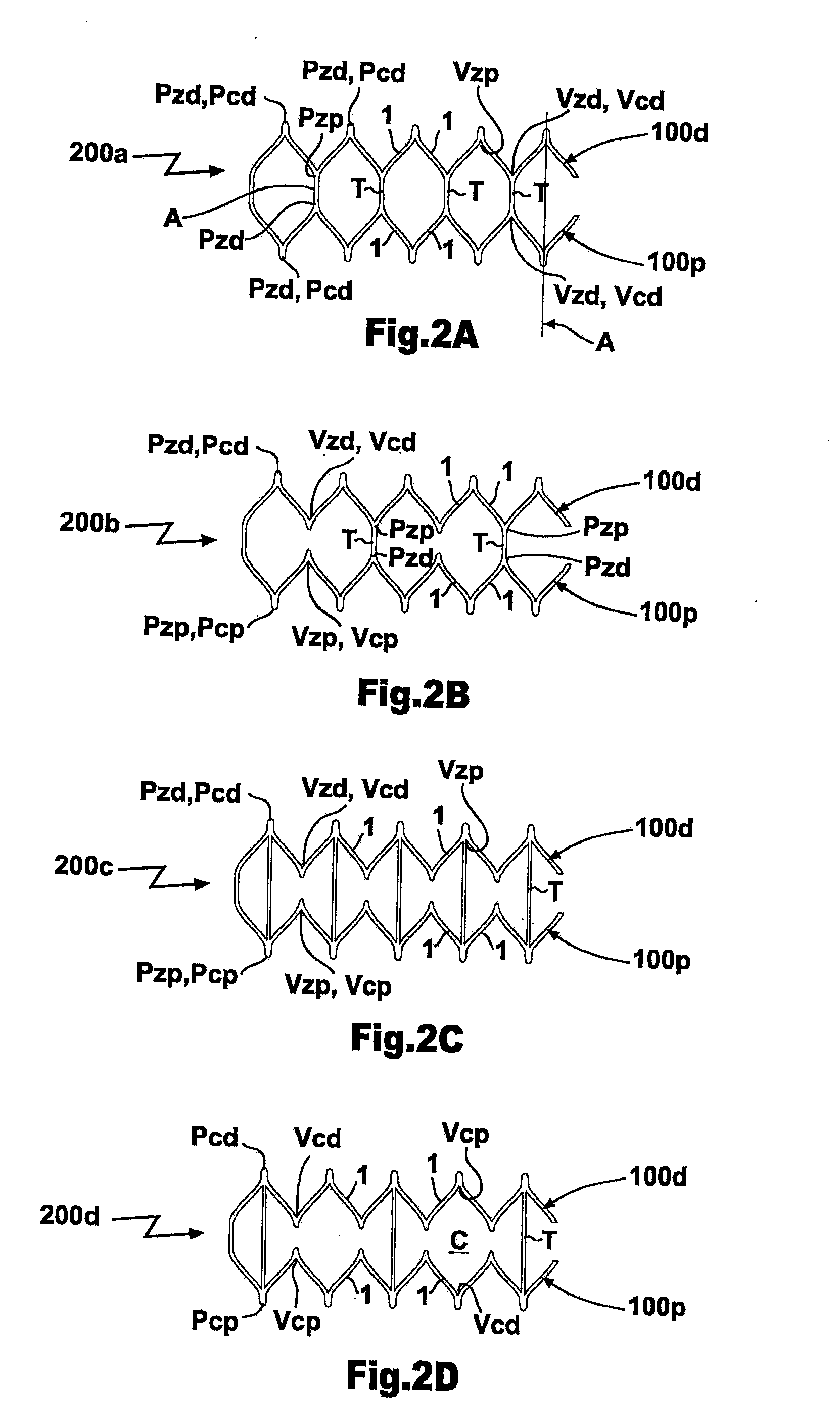

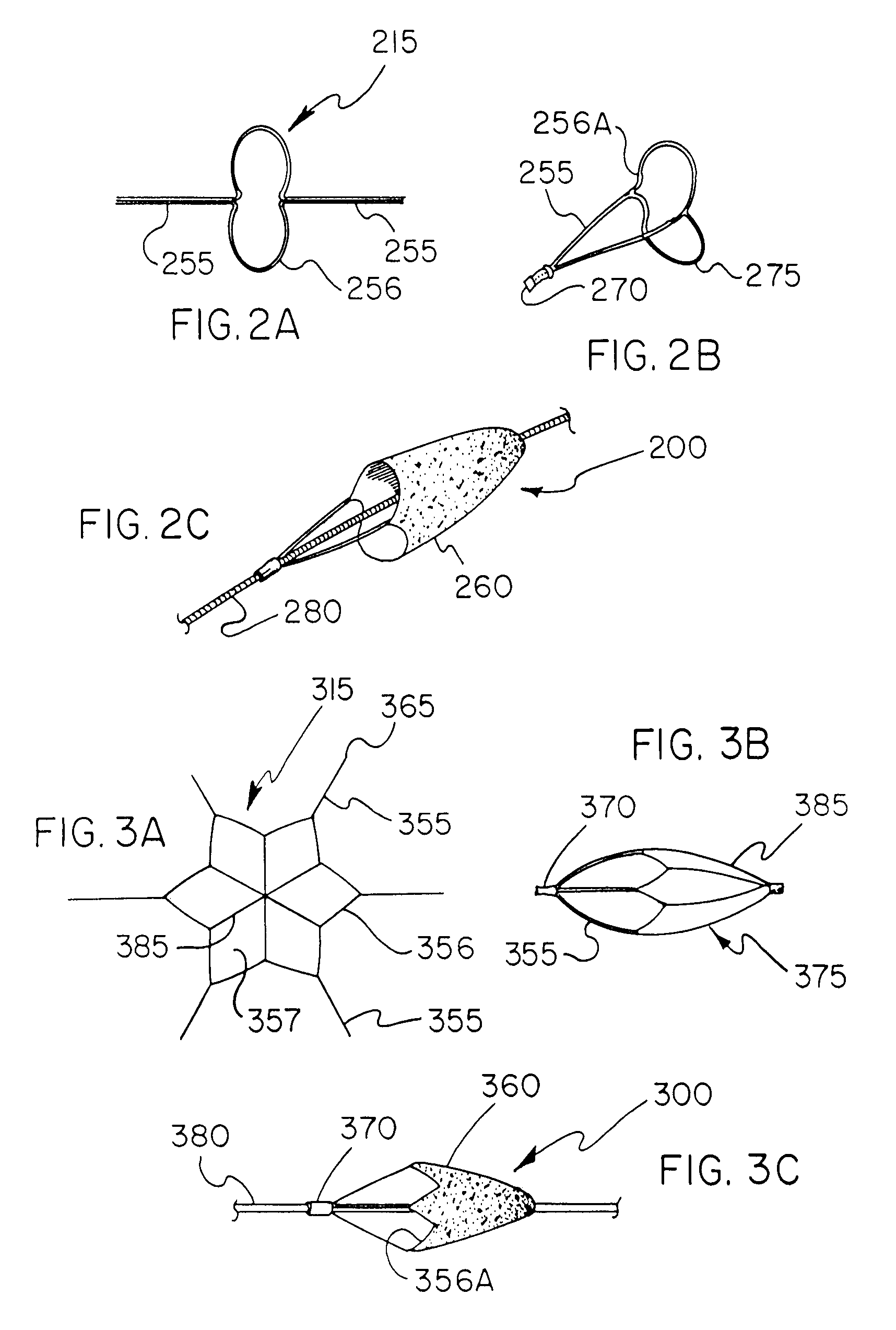

Multi-Segment Modular Stent And Methods For Manufacturing Stents

InactiveUS20100174358A1Increase flexibilityImprove the forceStentsBlood vesselsInterconnectorModularity

A modular stent comprises at least one stent module including an intermediate segment consisting of one of either a closed-cell segment or a Z-segment and a pair of end segments connected to respective longitudinal ends of said intermediate segment, each end segment consisting of the other of said closed-cell segment or Z-segment, each closed-cell segment consisting solely of at least one annular closed-cell ring and each Z-segment consisting solely of at least one annular Z-ring. A method of manufacturing a stent form a small diameter tube includes laser-cutting the small diameter tube to define a plurality of longitudinally adjacent Z-rings, providing interconnector portions of said tube integrally joining facing aligned or offset Z-rings, expanding the small diameter tube, and removing predetermined interconnector portions from the expanded tube to provide the predetermined desired arrangement of interconnected closed-cell rings and Z-rings.

Owner:RABKIN DMITRY J +2

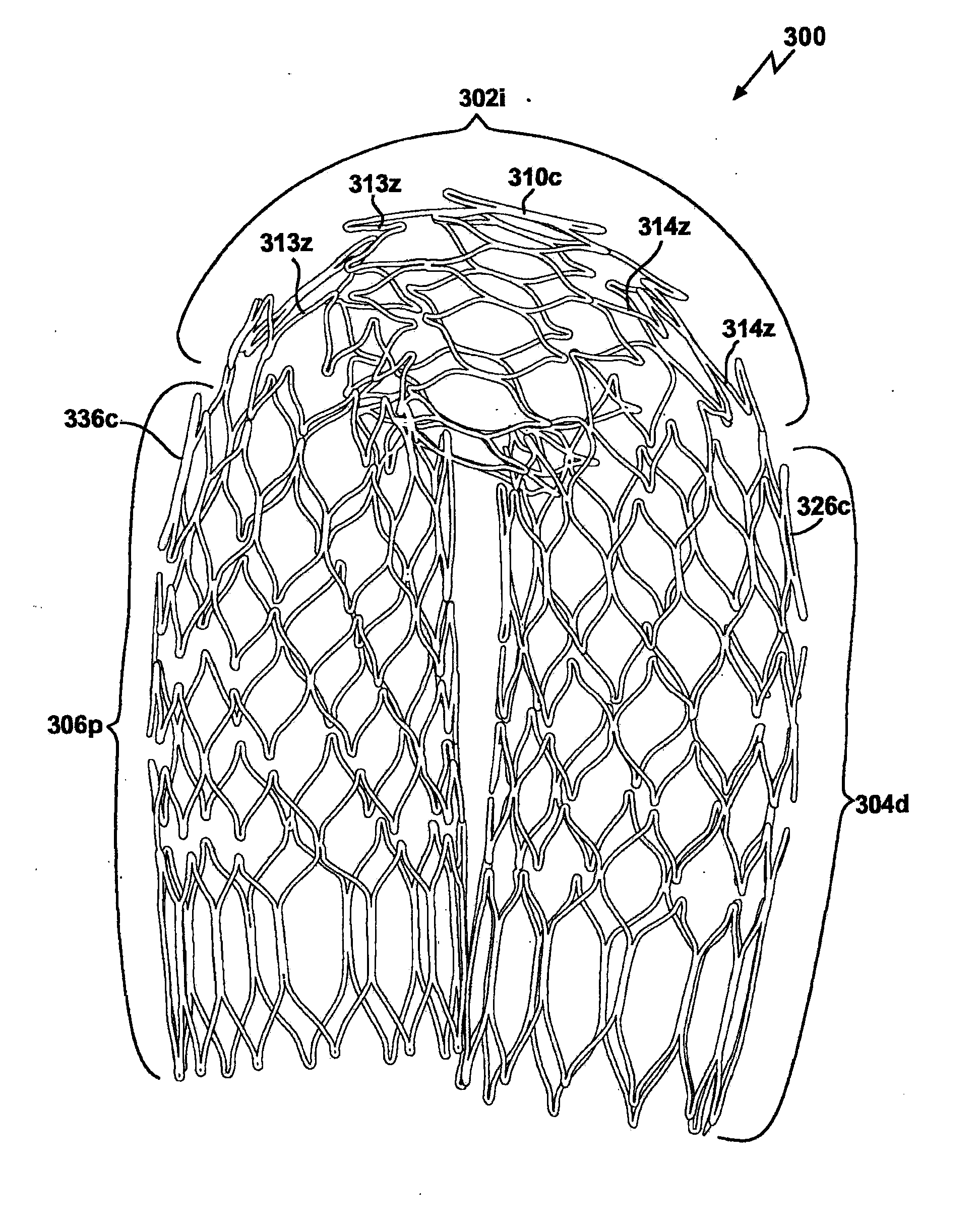

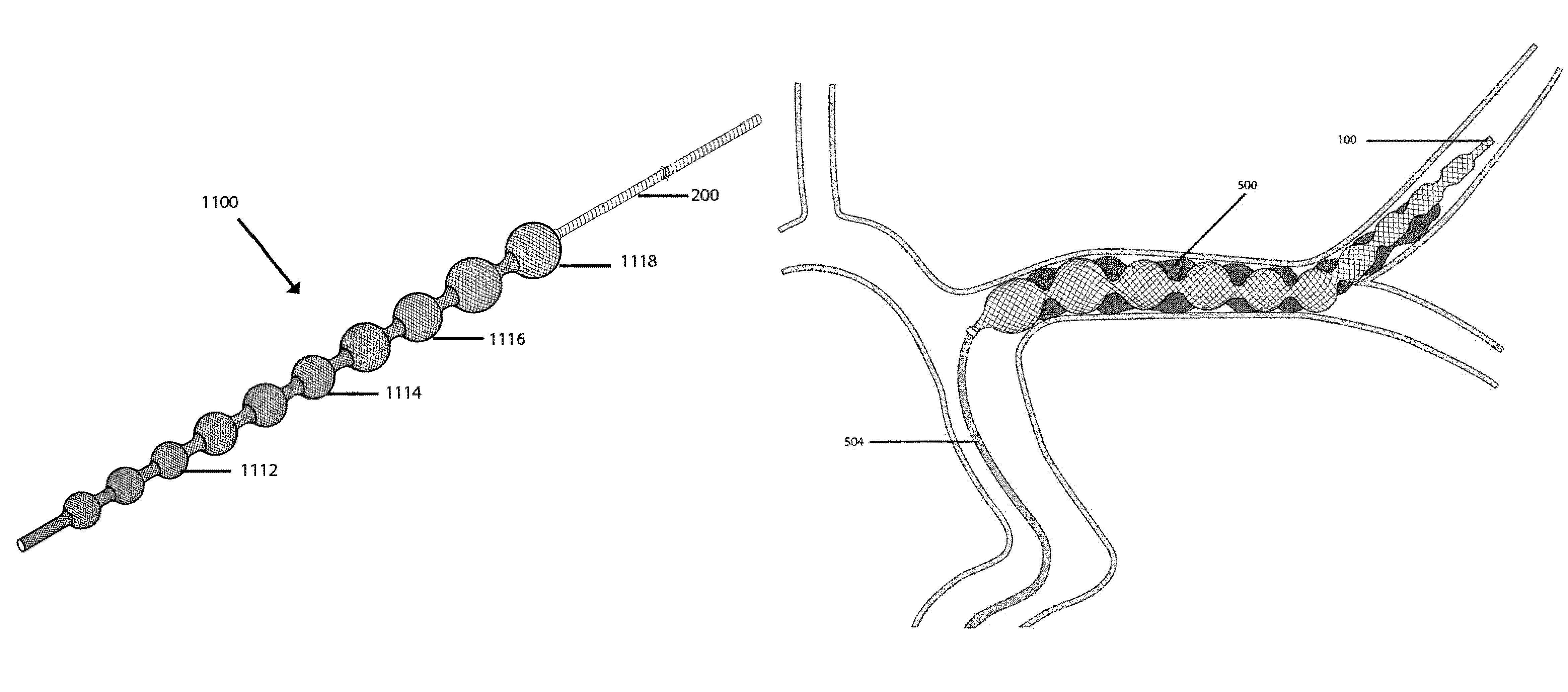

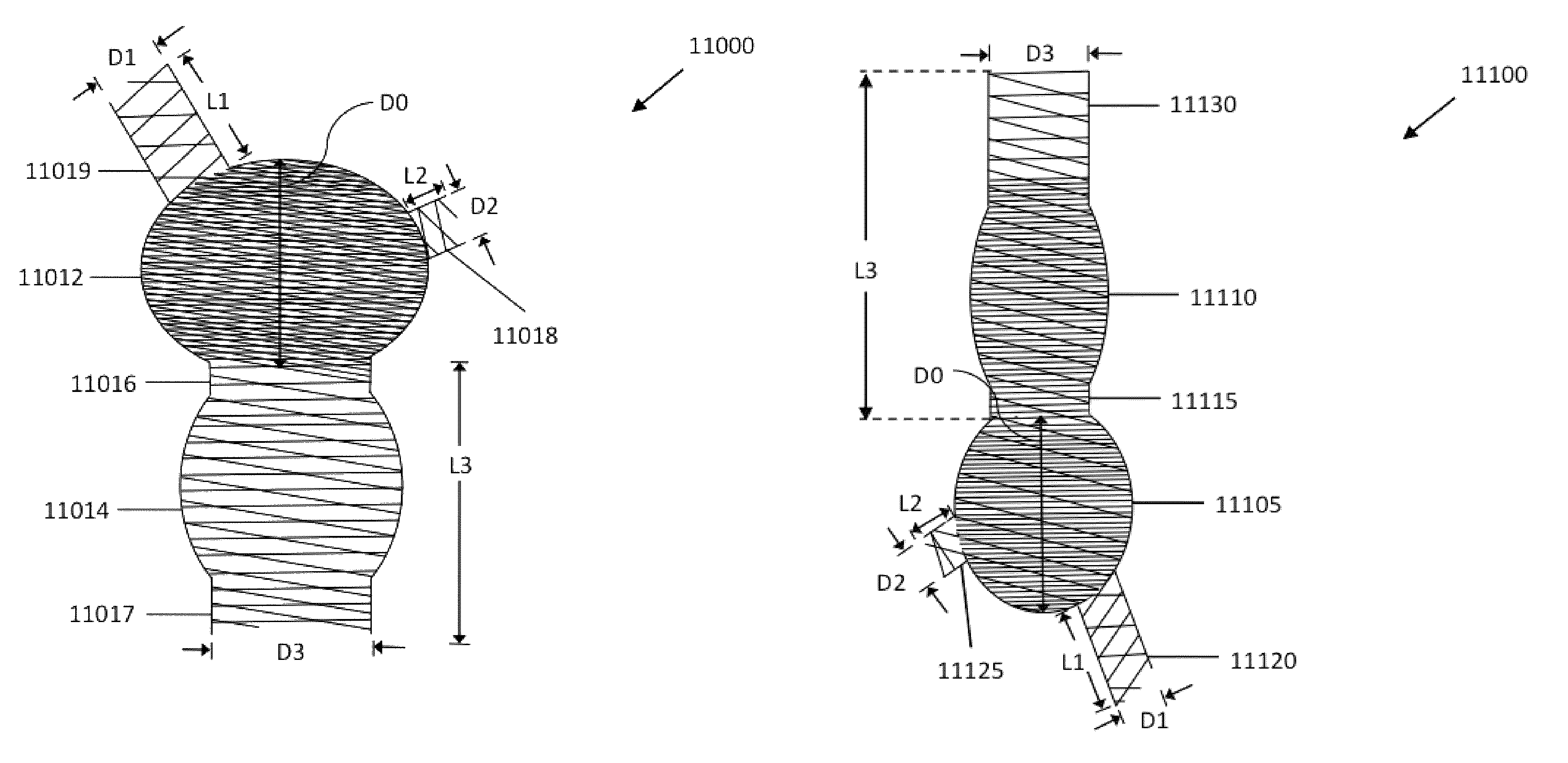

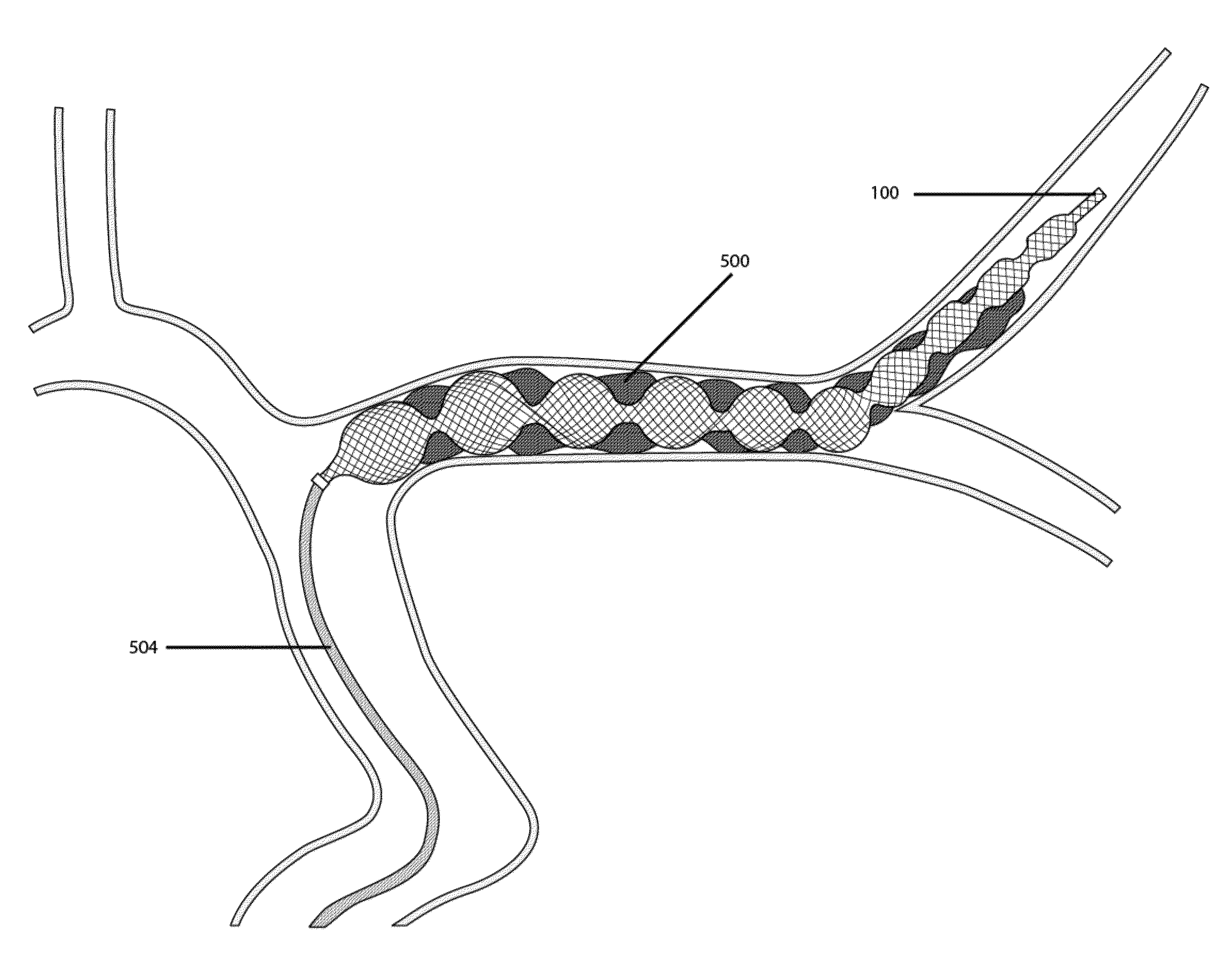

Vascular treatment methods

ActiveUS8690907B1Effectively and efficiently capturingIncrease awarenessStentsDiagnosticsX-rayCatheter

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measurable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

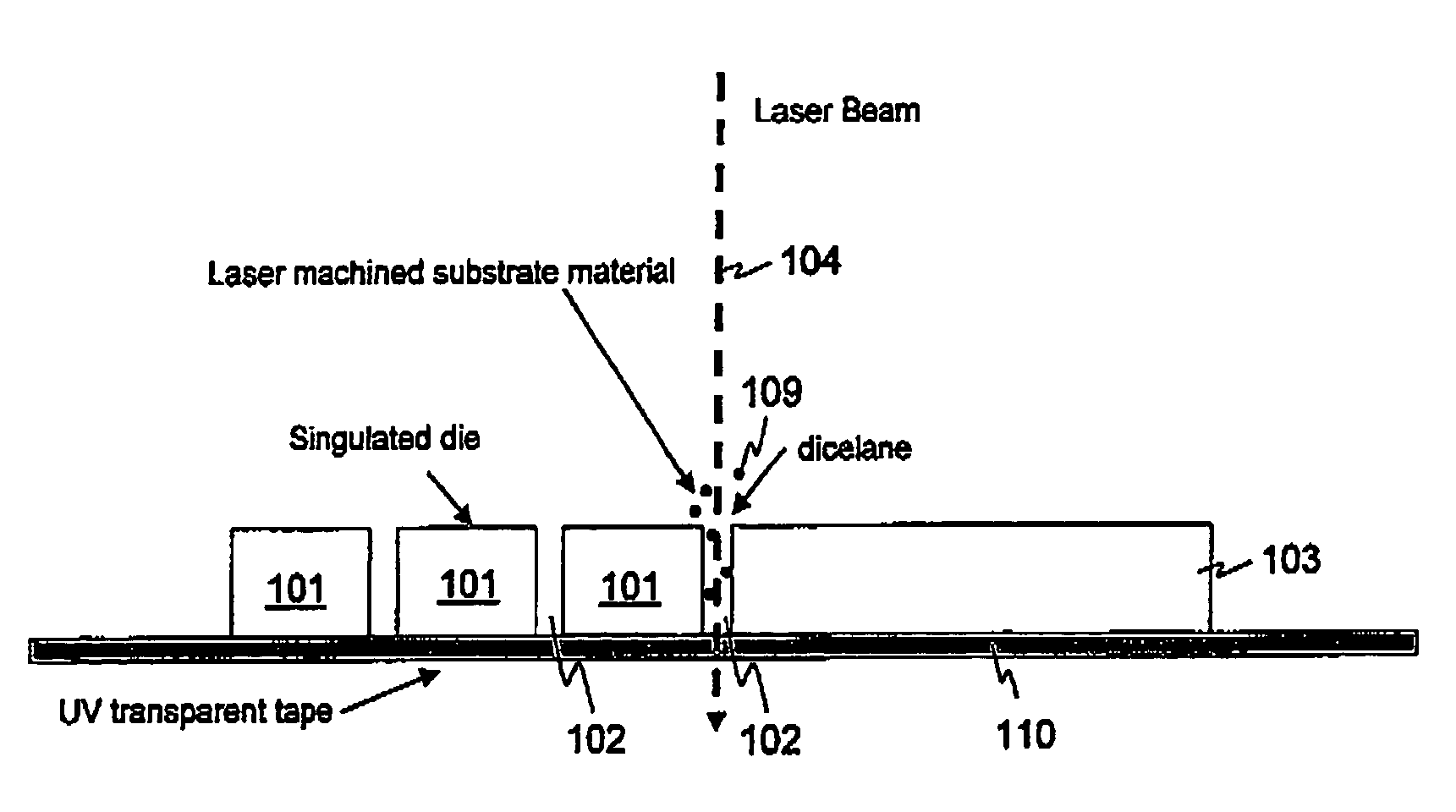

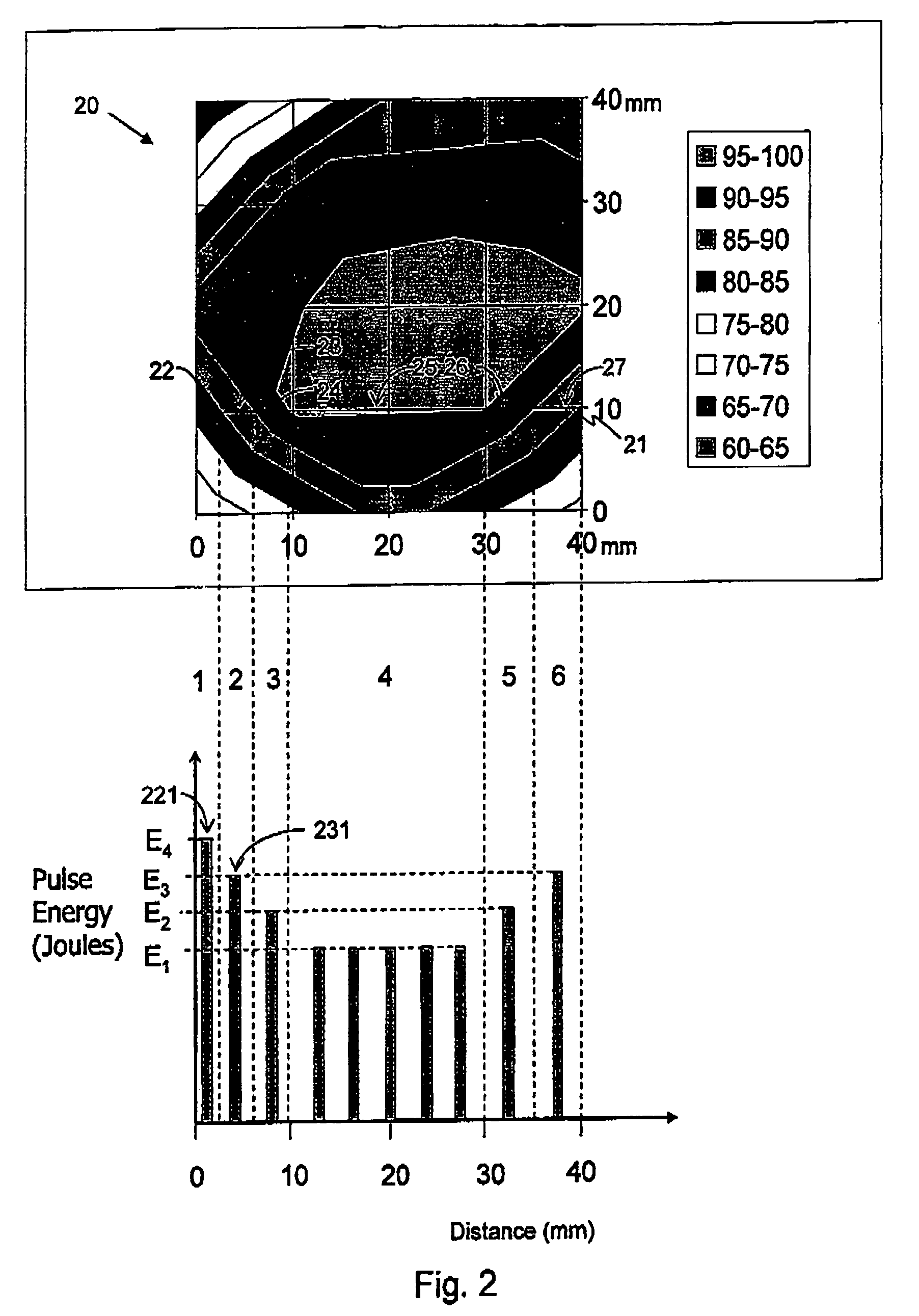

Program-controlled dicing of a substrate using a pulsed laser

InactiveUS7776720B2Facilitate dicing of the substrateControl damageSemiconductor/solid-state device manufacturingPrinted circuit manufactureChemical reactionPulse rate

A substrate is diced using a program-controlled pulsed laser beam apparatus having an associated memory for storing a laser cutting strategy file. The file contains selected combinations of pulse rate Deltat, pulse energy density E and pulse spatial overlap to machine a single layer or different types of material in different layers of the substrate while restricting damage to the layers and maximising machining rate to produce die having predetermined die strength and yield. The file also contains data relating to the number of scans necessary using a selected combination to cut through a corresponding layer. The substrate is diced using the selected combinations. Gas handling equipment for inert or active gas may be provided for preventing or inducing chemical reactions at the substrate prior to, during or after dicing.

Owner:XSIL TECH

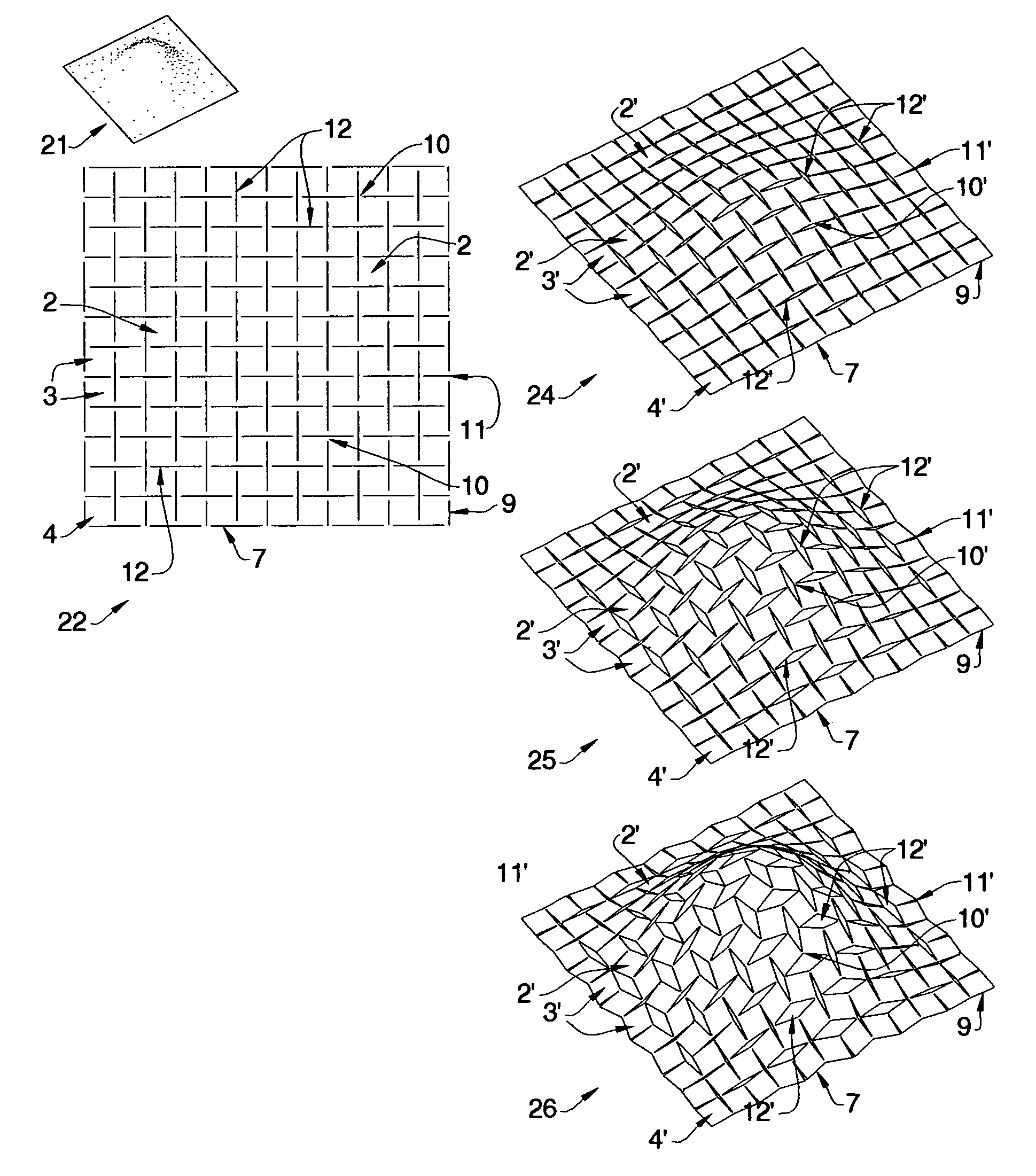

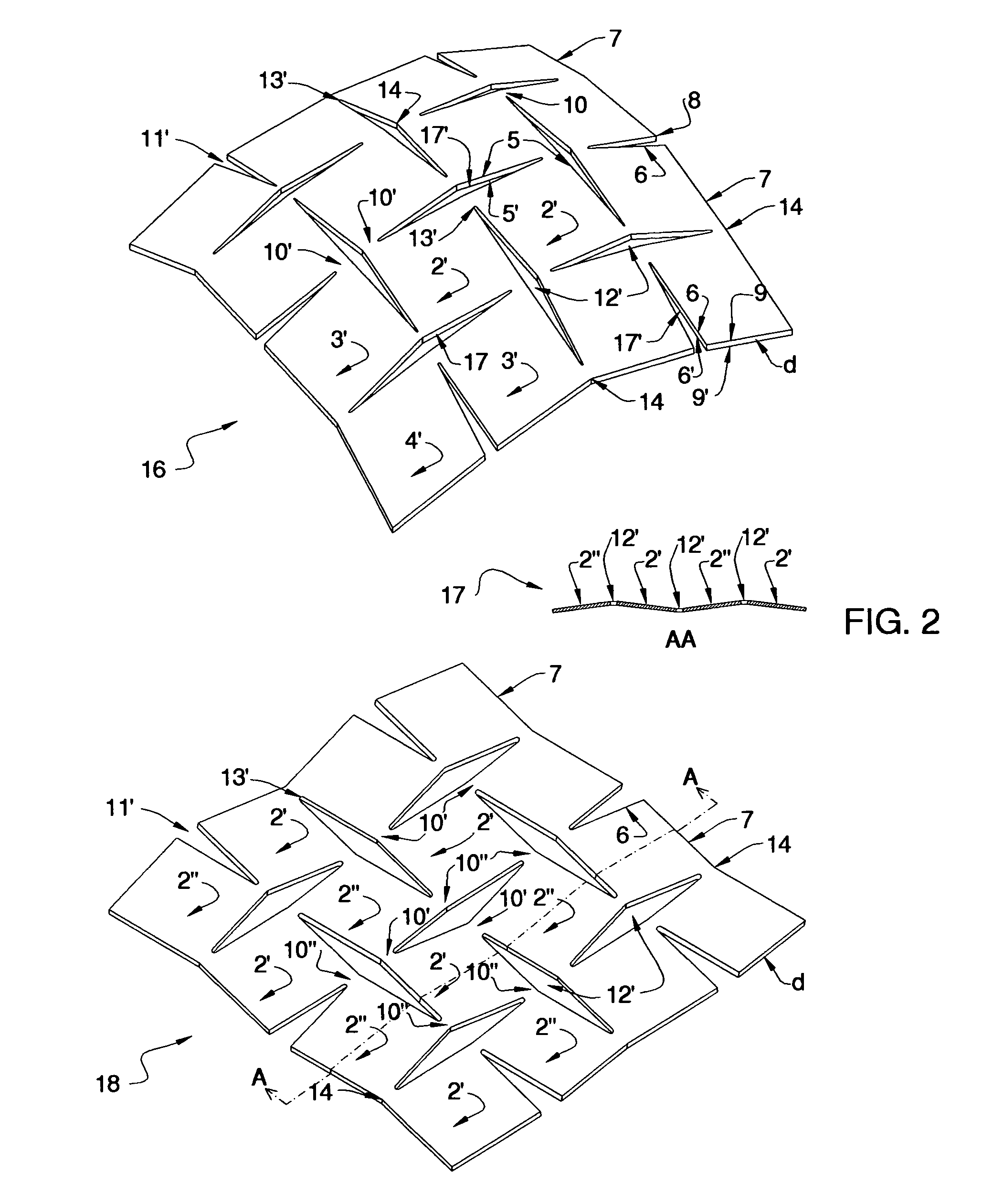

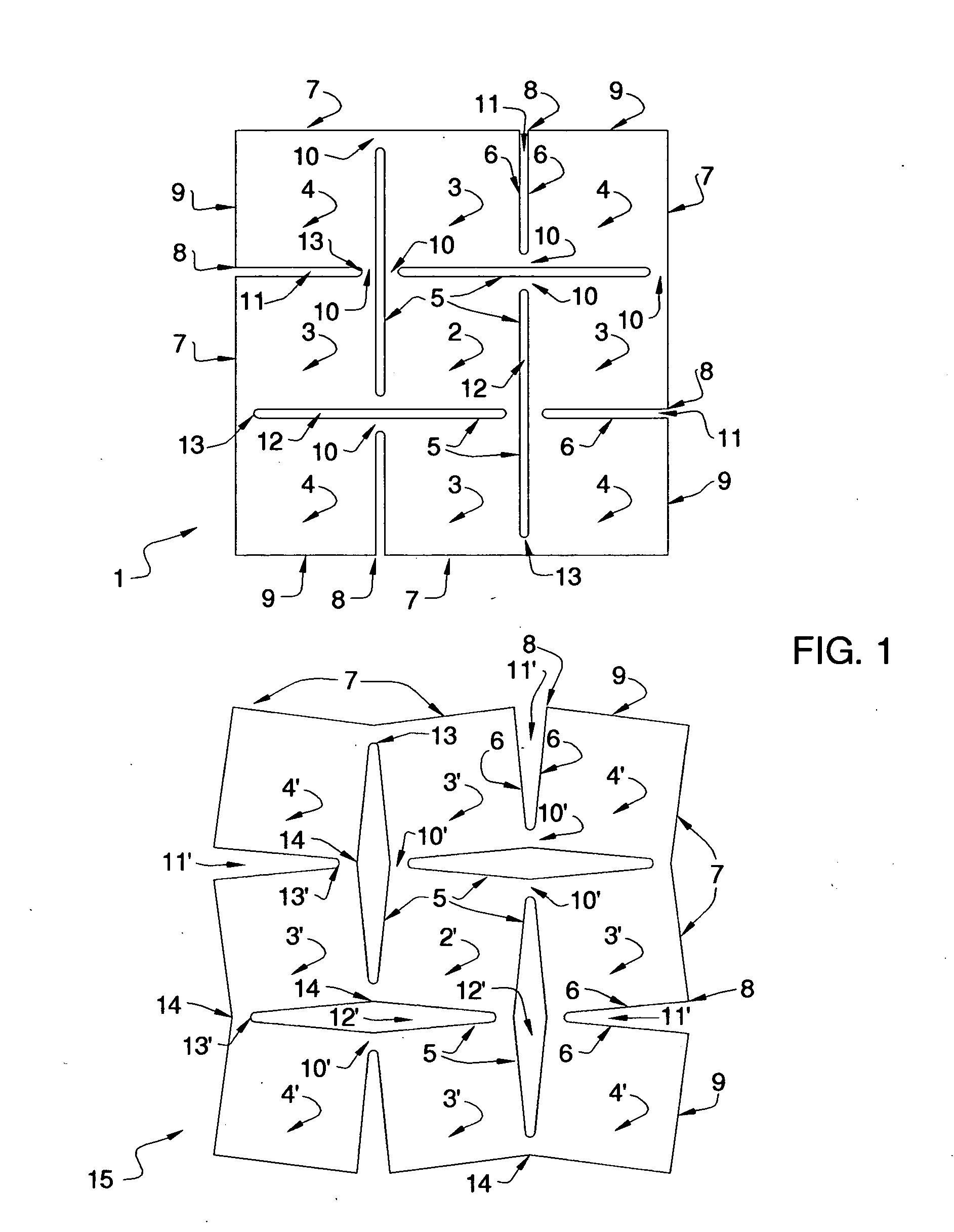

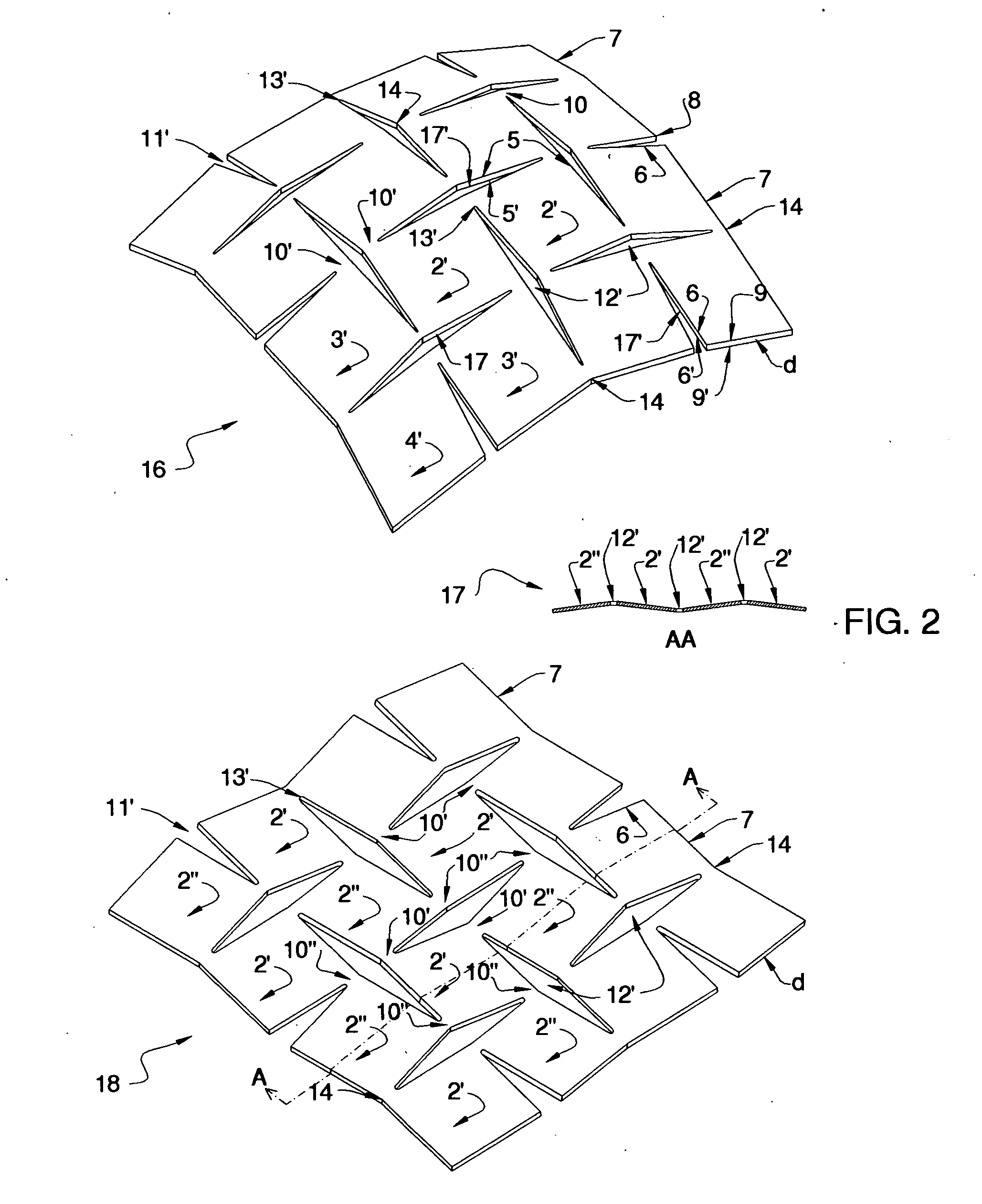

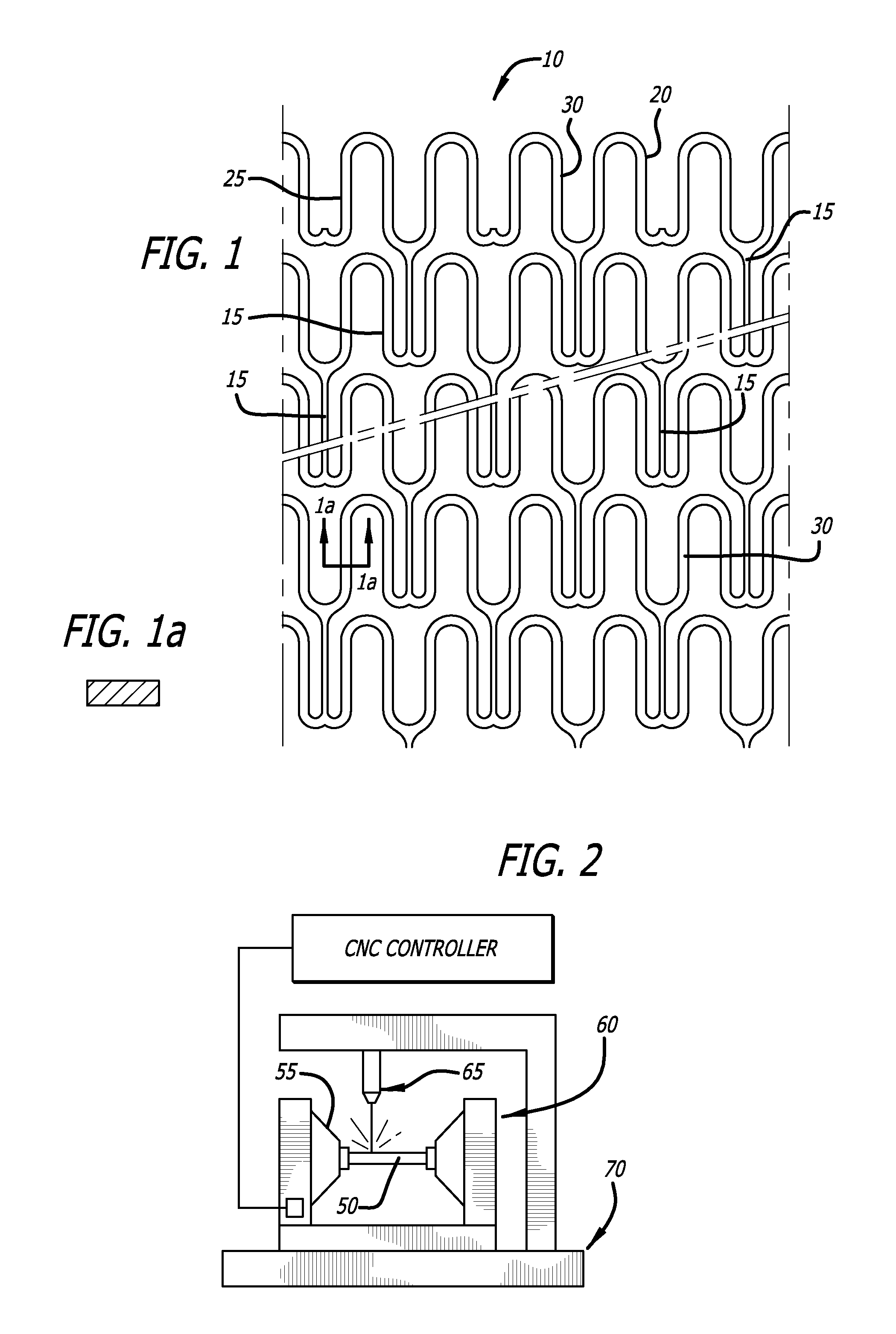

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

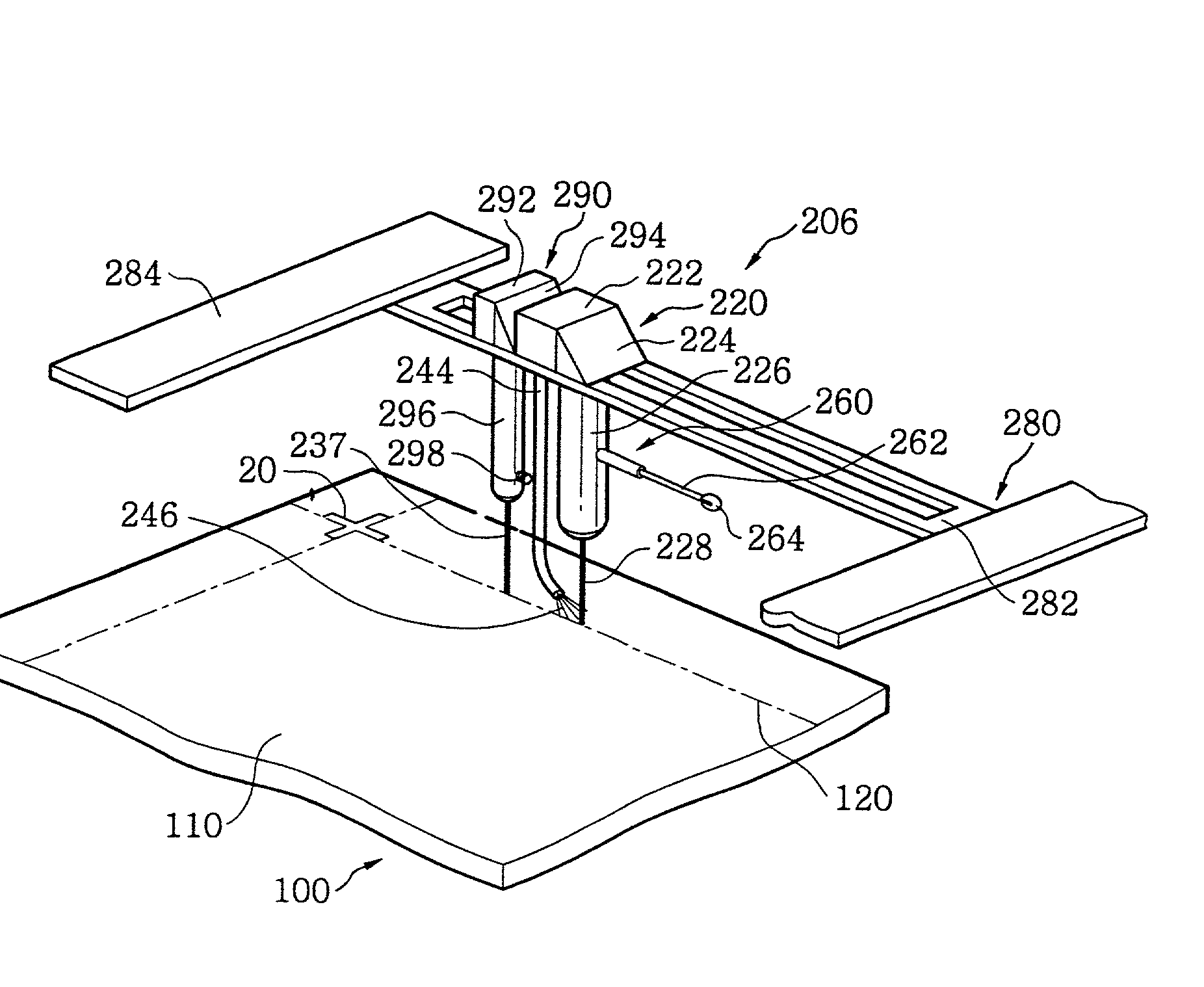

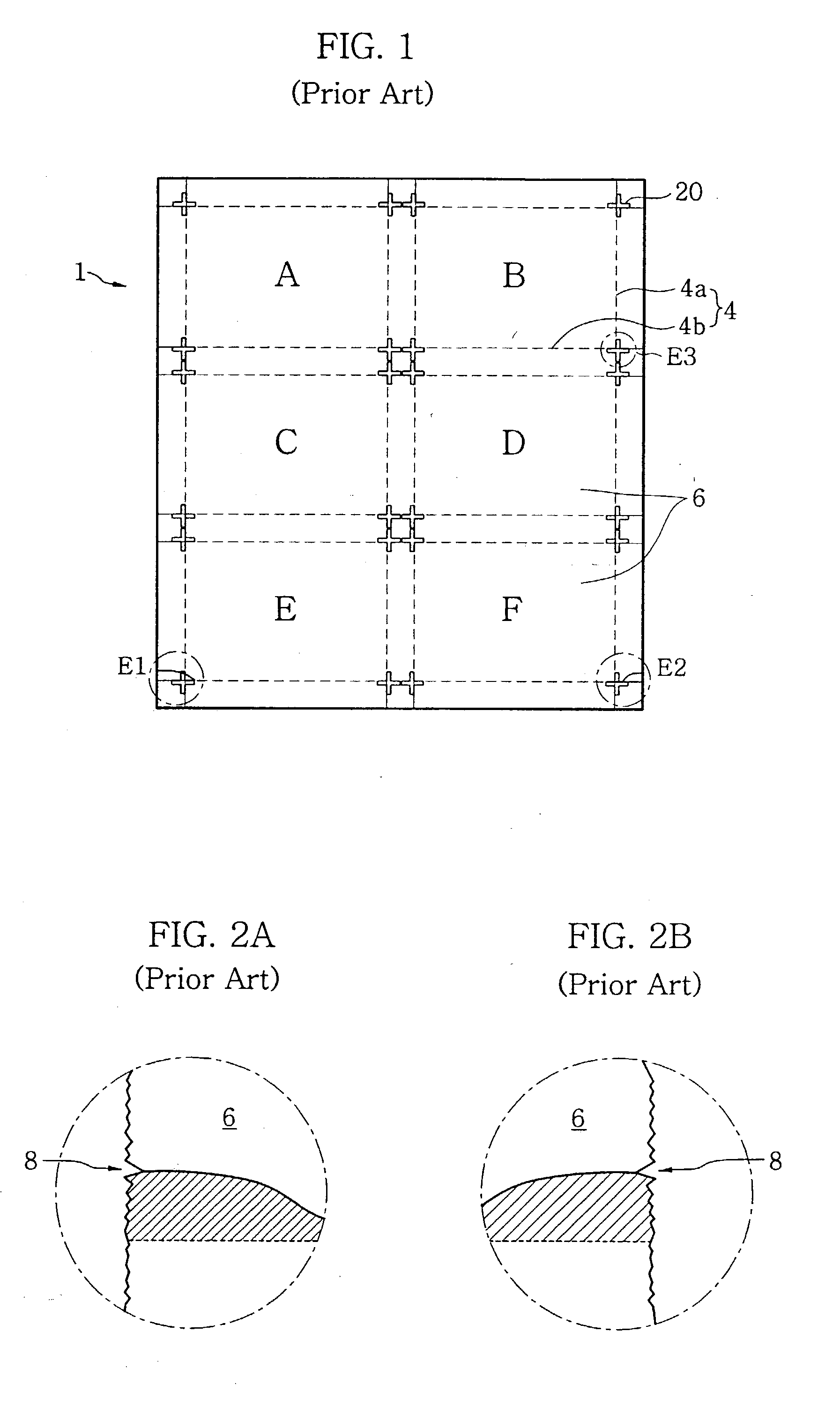

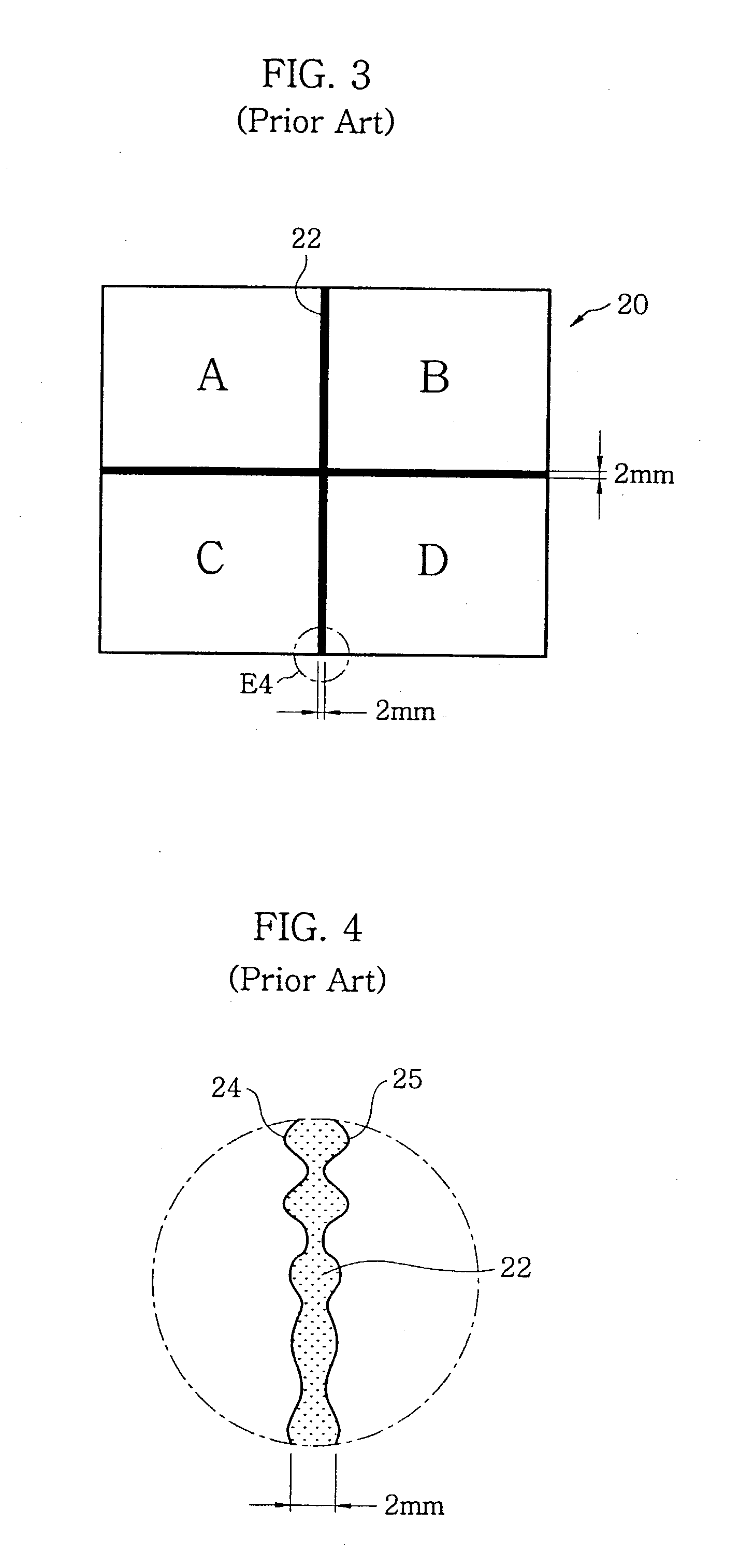

Laser cutting apparatus and method

The present invention disclose a laser cutter for cutting an object being cut such as a two glasses-attached panel for LCD using a laser beam. The laser cutter includes a laser unit for irradiating a laser beam with a specific wavelength along a marked cutting line of the object, a pre-scriber for forming a pre-cut groove at starting edge of the marked cutting line, and a cooling unit for cooling the cutting line which said laser beam has been irradiated.

Owner:SAMSUNG DISPLAY CO LTD

Methods of manufacture and use of endoluminal devices

Owner:WL GORE & ASSOC INC

Method and apparatus for dicing of thin and ultra thin semiconductor wafer using ultrafast pulse laser

InactiveUS7804043B2Minimize heating effectImprove machine qualityWelding/soldering/cutting articlesMetal working apparatusPicosecond laserBeam polarization

The present invention relates to the apparatus, system and method for dicing of semiconductor wafers using an ultrafast laser pulse of femtosecond and picosecond pulse widths directly from the ultrafast laser oscillator without an amplifier. Thin and ultrathin semiconductor wafers below 250 micrometer thickness, are diced using diode pumped, solid state mode locked ultrafast laser pulses from oscillator without amplification. The invention disclosed has means to avoid / reduce the cumulative heating effect and to avoid machine quality degrading in multi shot ablation. Also the disclosed invention provides means to change the polarization state of the laser beam to reduce the focused spot size, and improve the machining efficiency and quality. The disclosed invention provides a cost effective and stable system for high volume manufacturing applications. An ultrafast laser oscillator can be a called as femtosecond laser oscillator or a picosecond laser oscillator depending on the pulse width of the laser beam generated.

Owner:LASERFACTURING

Methods for Laser Cutting Glass Substrates

InactiveUS20110049765A1Glass severing apparatusWelding/soldering/cutting articlesCutting glassLaser cutting

A method for cutting a glass article from a strengthened glass substrate having a surface compression layer and a tensile layer includes forming an edge defect in the surface compression layer on a first edge of the strengthened glass substrate. The method further includes propagating a through vent through the surface compression and tensile layers at the edge defect. The through vent precedes a region of separation along a cut line between the glass article and the strengthened glass substrate.

Owner:CORNING INC

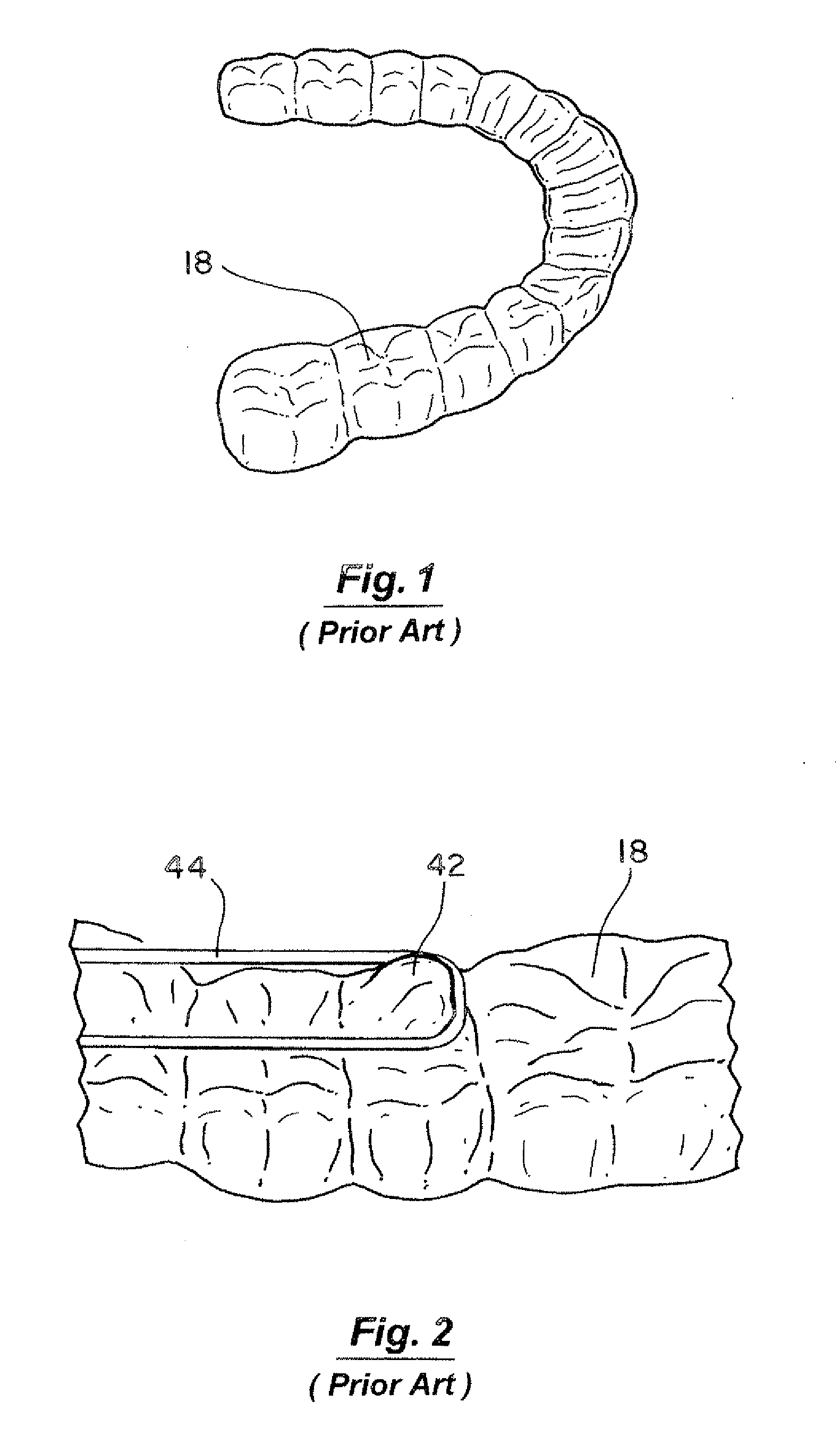

Robotic system for forming features in orthodontic aligners

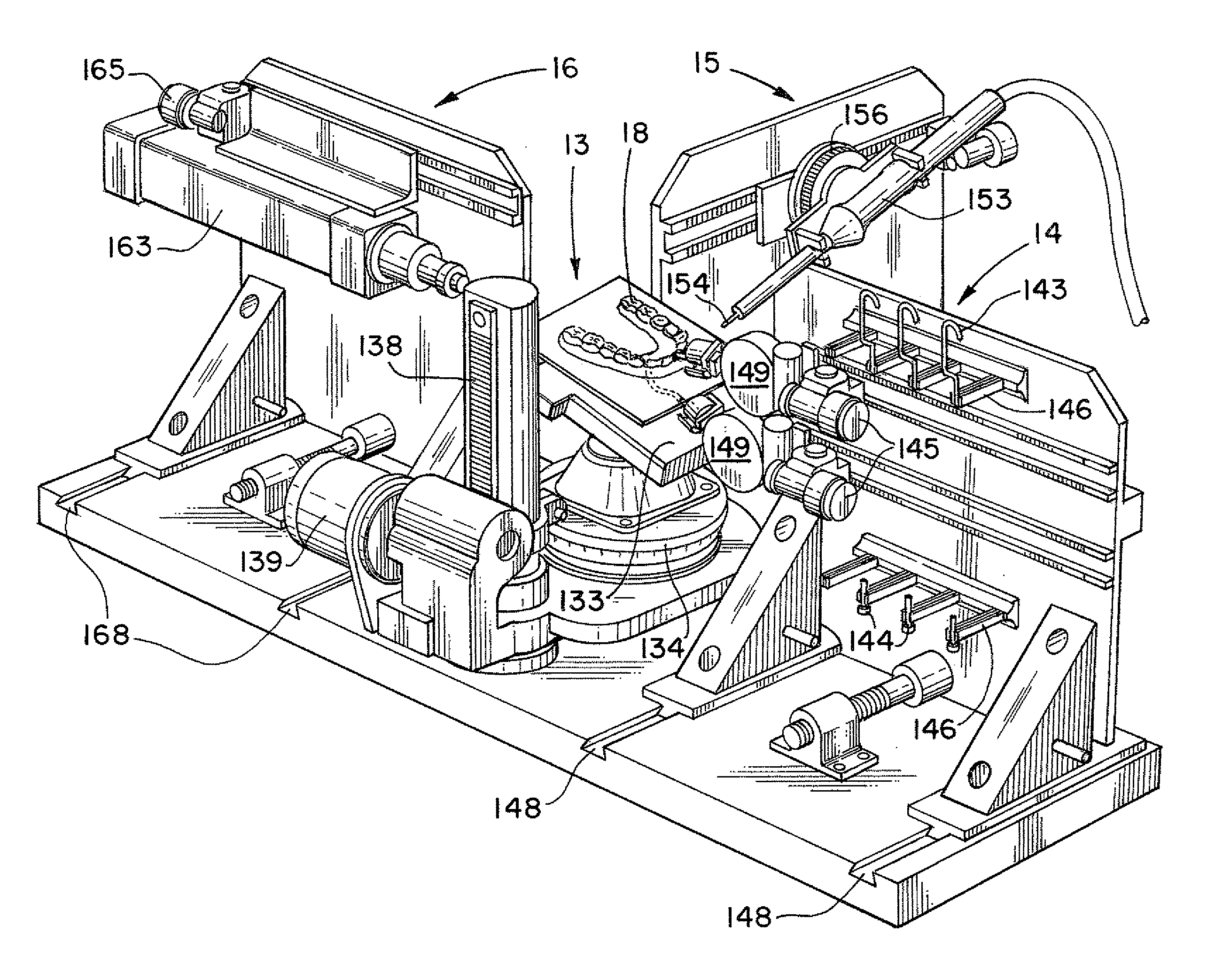

A robotic system for forming features in orthodontic aligners includes a control system, a platen for three-dimensional positioning of the aligner, a heating station for selectively heating a small region of the aligner, and a thermoforming station for manipulating the heated region to form a desired feature in the aligner. Optionally, a laser cutting and trimming station can also be included to trim excess material from the aligner or to cut features into the aligner. The control system can include a processor with CAD software to enable a user to design features for aligners.

Owner:HILLIARD JACK KEITH

Flow diverting devices

ActiveUS8715317B1Effectively and efficiently capturingIncrease awarenessLathesOrnamental textile articlesLaser cuttingBlood vessel

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measureable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

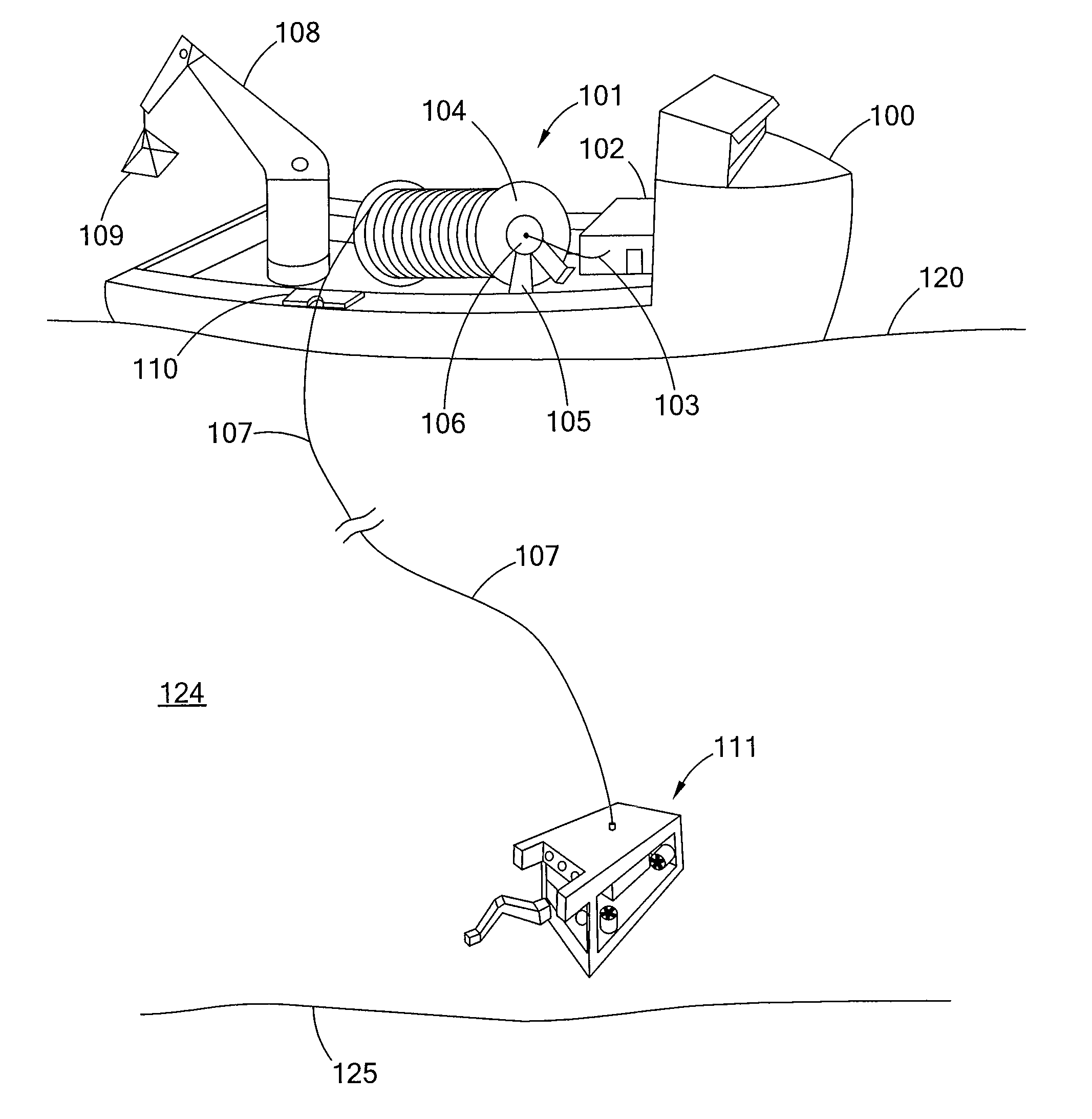

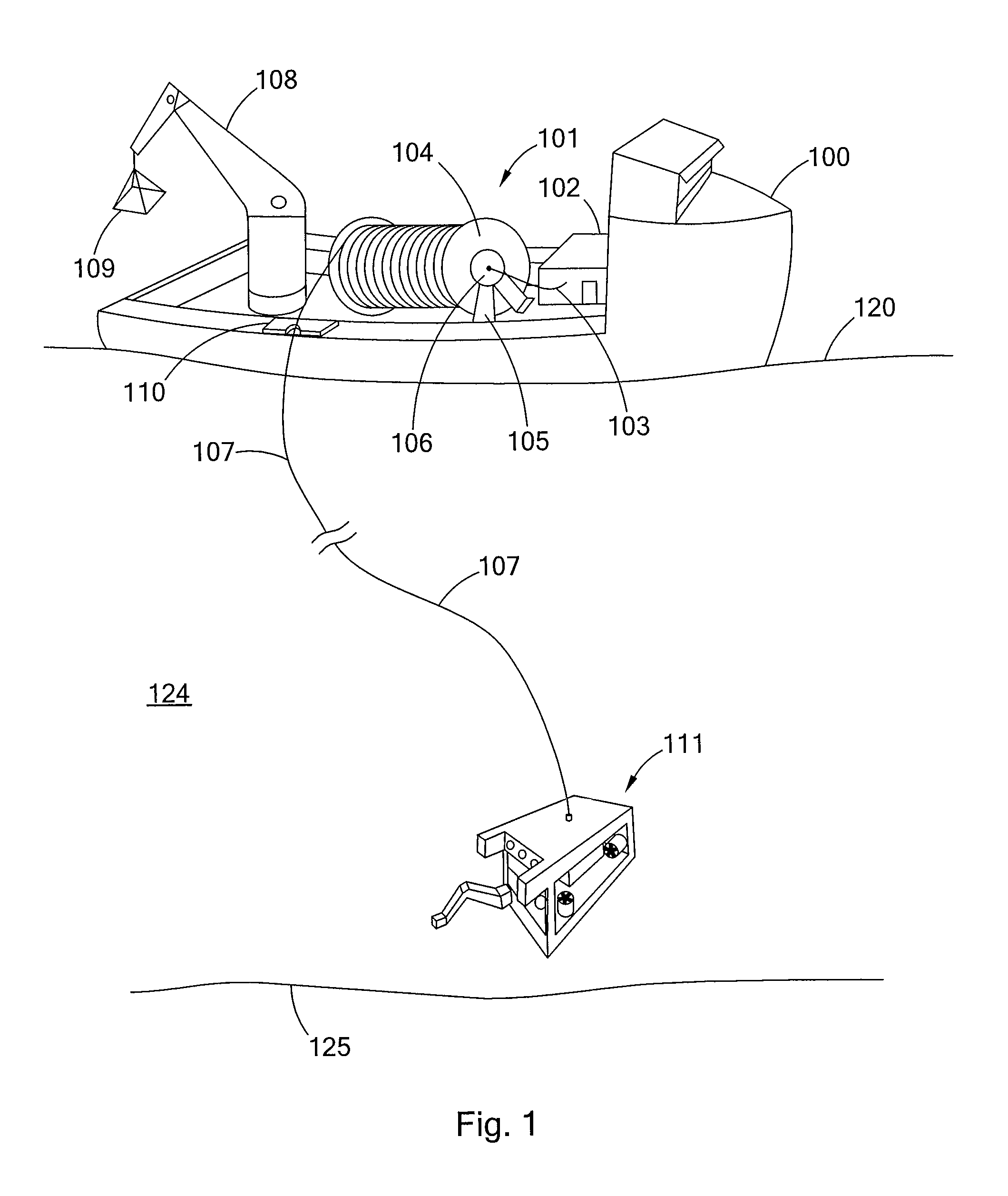

High power laser photo-conversion assemblies, apparatuses and methods of use

ActiveUS20120266803A1Without substantial loss of powerRadiation pyrometryHollow article cleaningFiberHigh power lasers

There is provided a high power laser system for powering a remotely located laser device, such as an ROV, using a high power laser fiber optic tether and a photo-conversion device, such as a laser photovoltaic assembly. Laser device systems, such as ROV systems that utilizes a high power laser cutting and / or cleaning tools are also provided.

Owner:FORO ENERGY

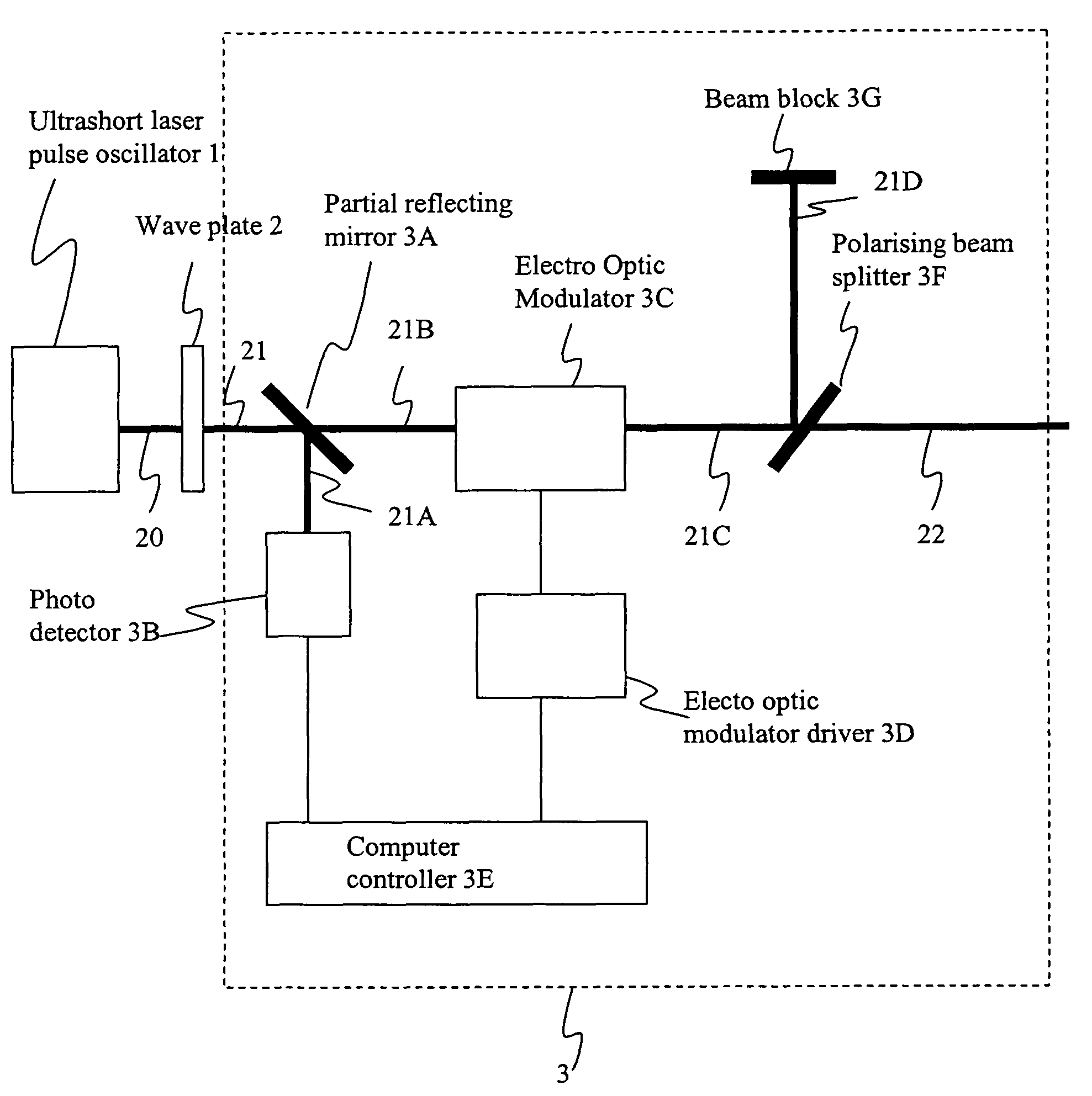

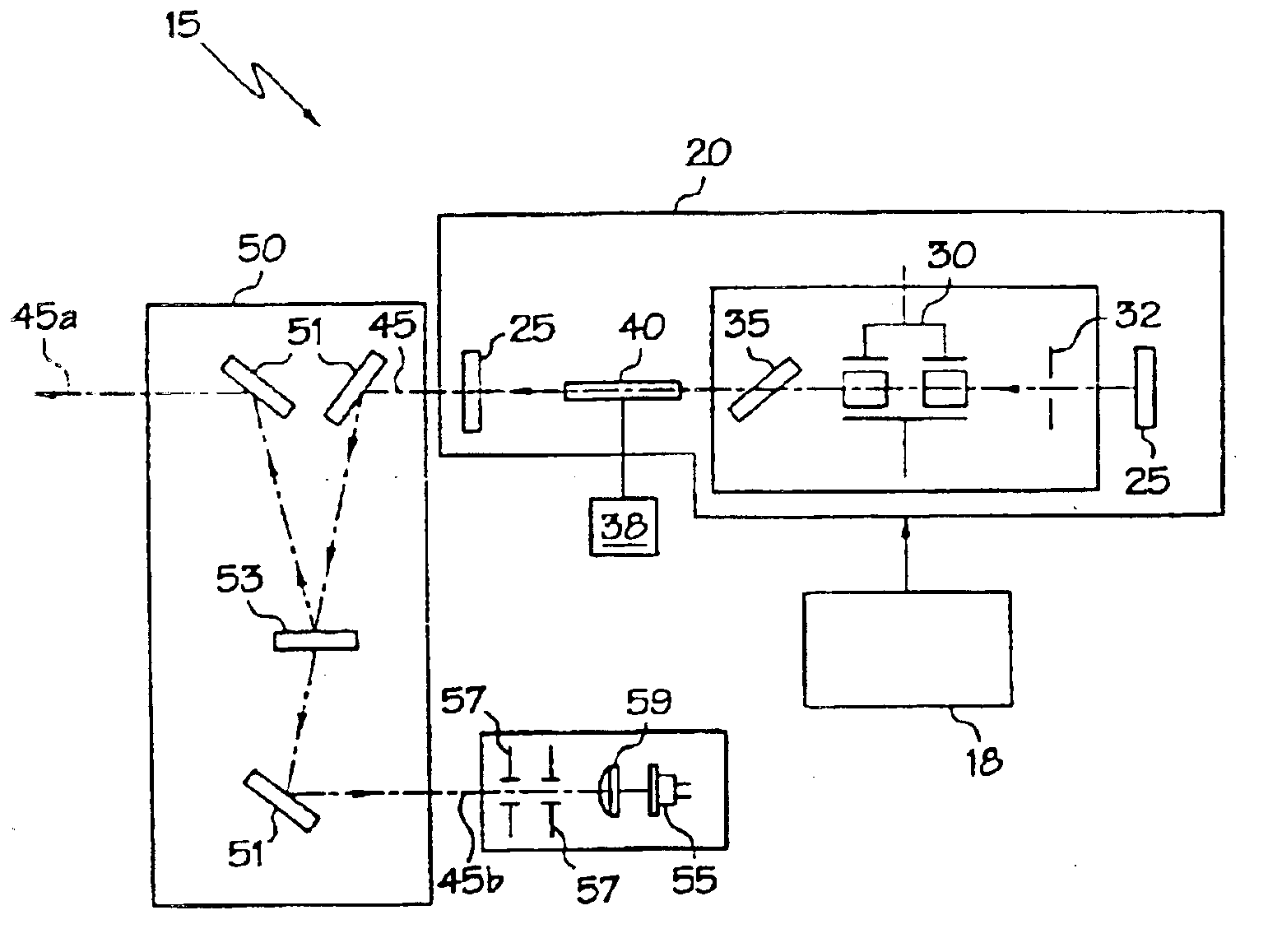

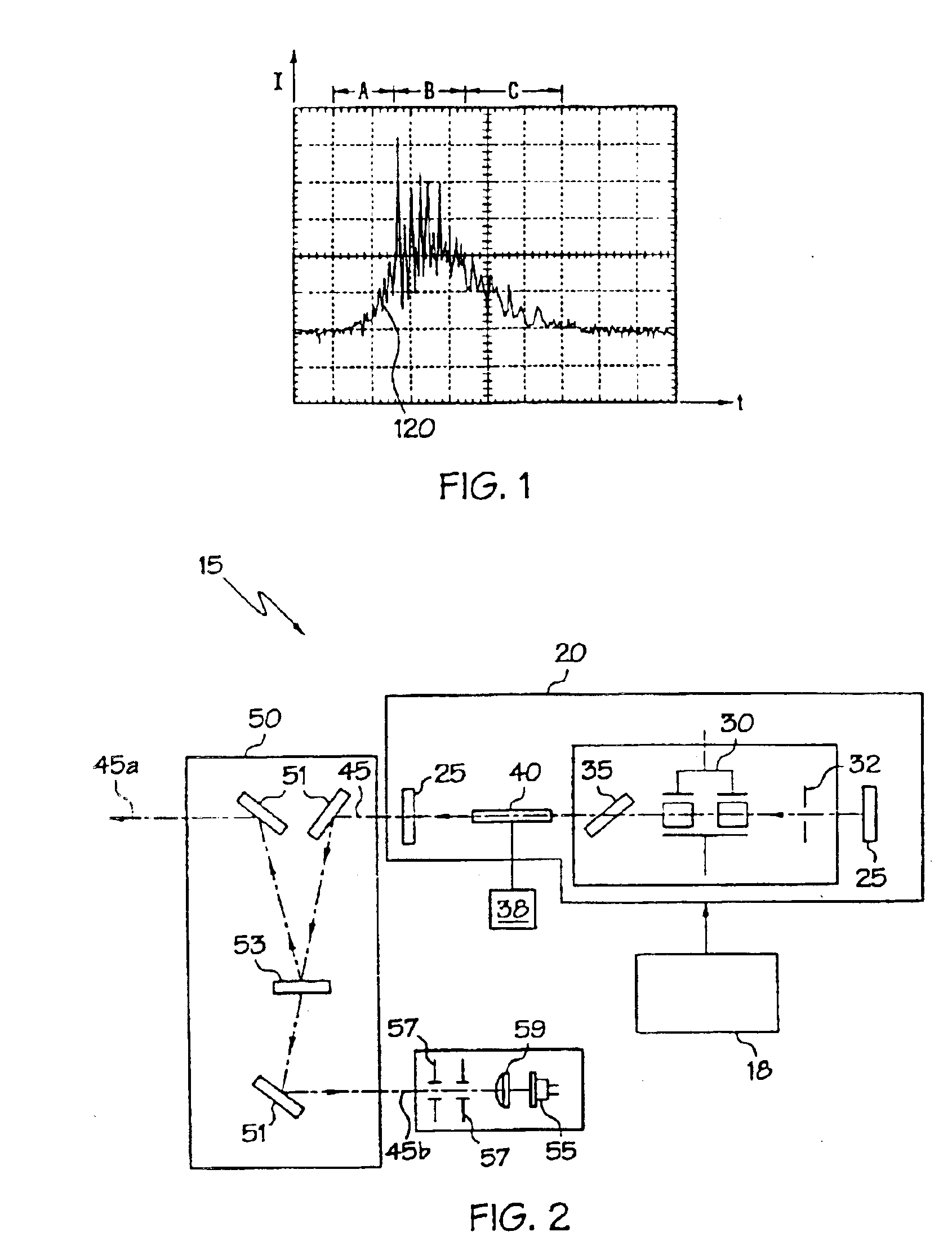

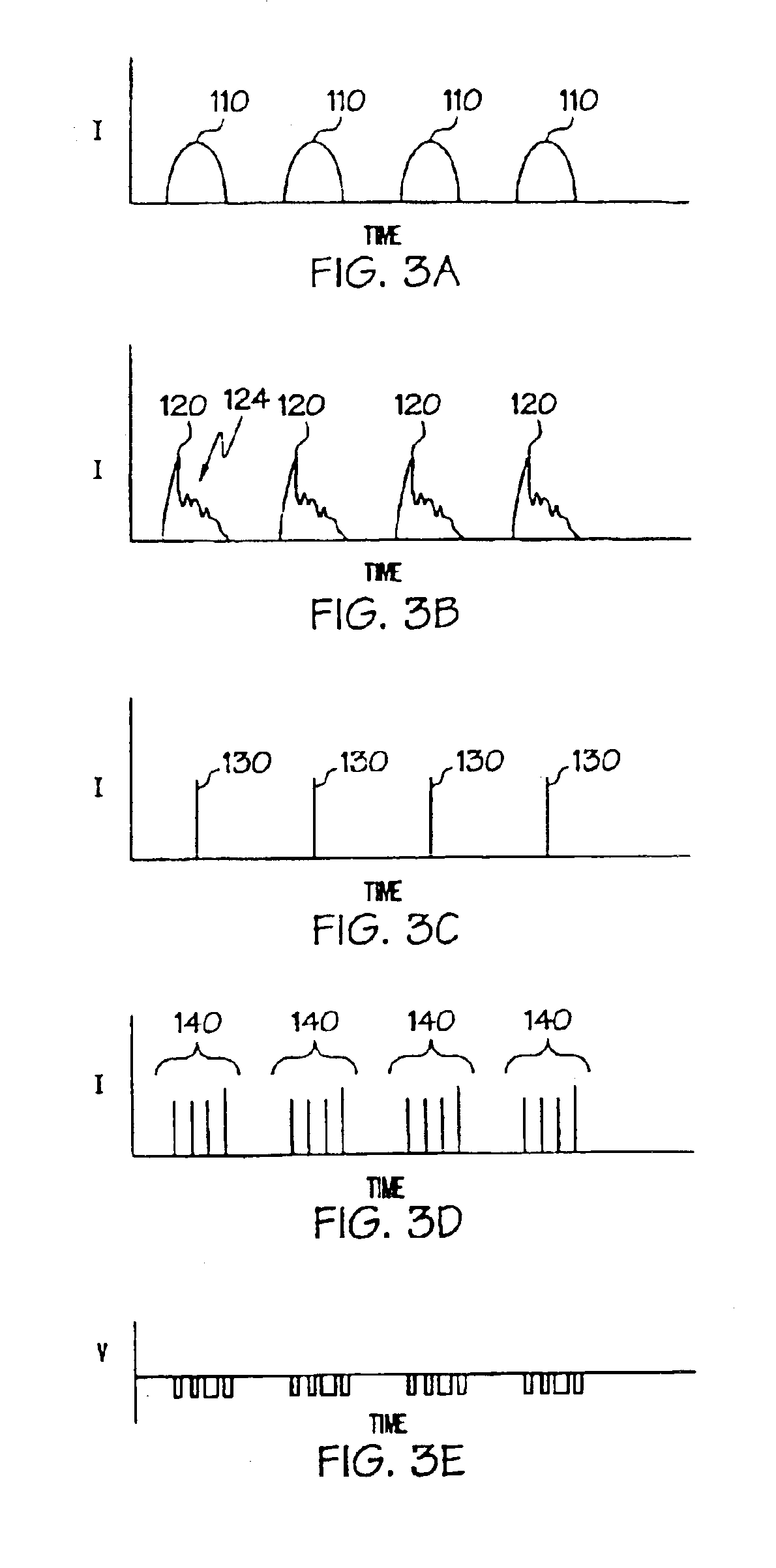

Laser cutting of stents and other medical devices

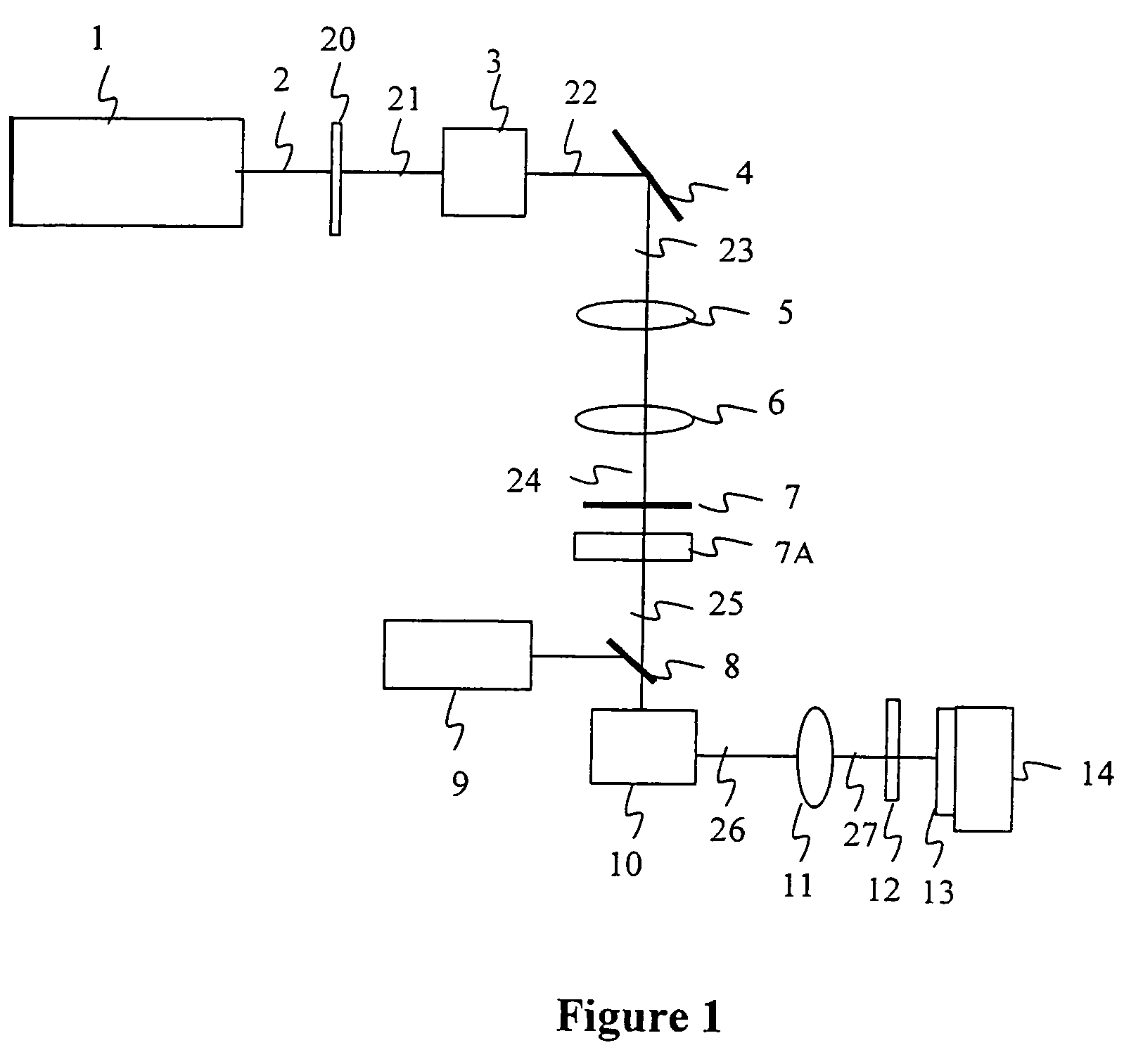

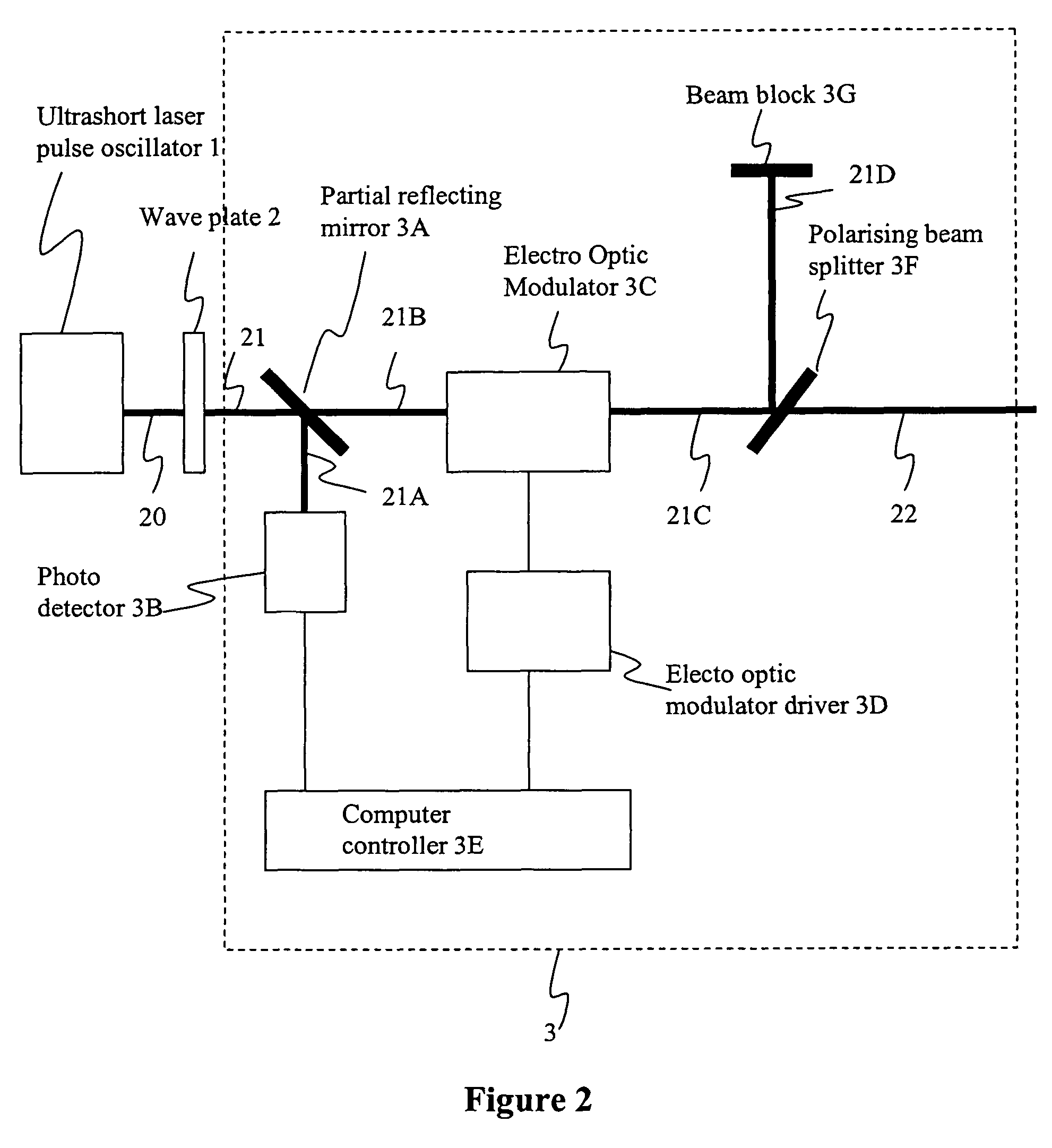

A desired pattern may be cut into a stent preform by impinging a laser beam onto the stent preform. The laser beam is formed using a laser system comprising a resonator cavity for resonating laser radiation, a gain medium contained in the resonator cavity, a pump for periodically pumping the gain medium and an electro-optical modulator in communication with the resonator cavity. The laser system produces a radiation pulse for each pump period. Each radiation pulse is conditioned by suppressing at least a portion of the pulse. The pulse may also be modulated with an electro-optical modulator to produce a pulse train of ordered pulses of radiation. Each pulse train is output from the optical cavity as an output laser beam which is directed at the stent preform to cut a desired pattern in the stent preform.

Owner:SCI MED LIFE SYST

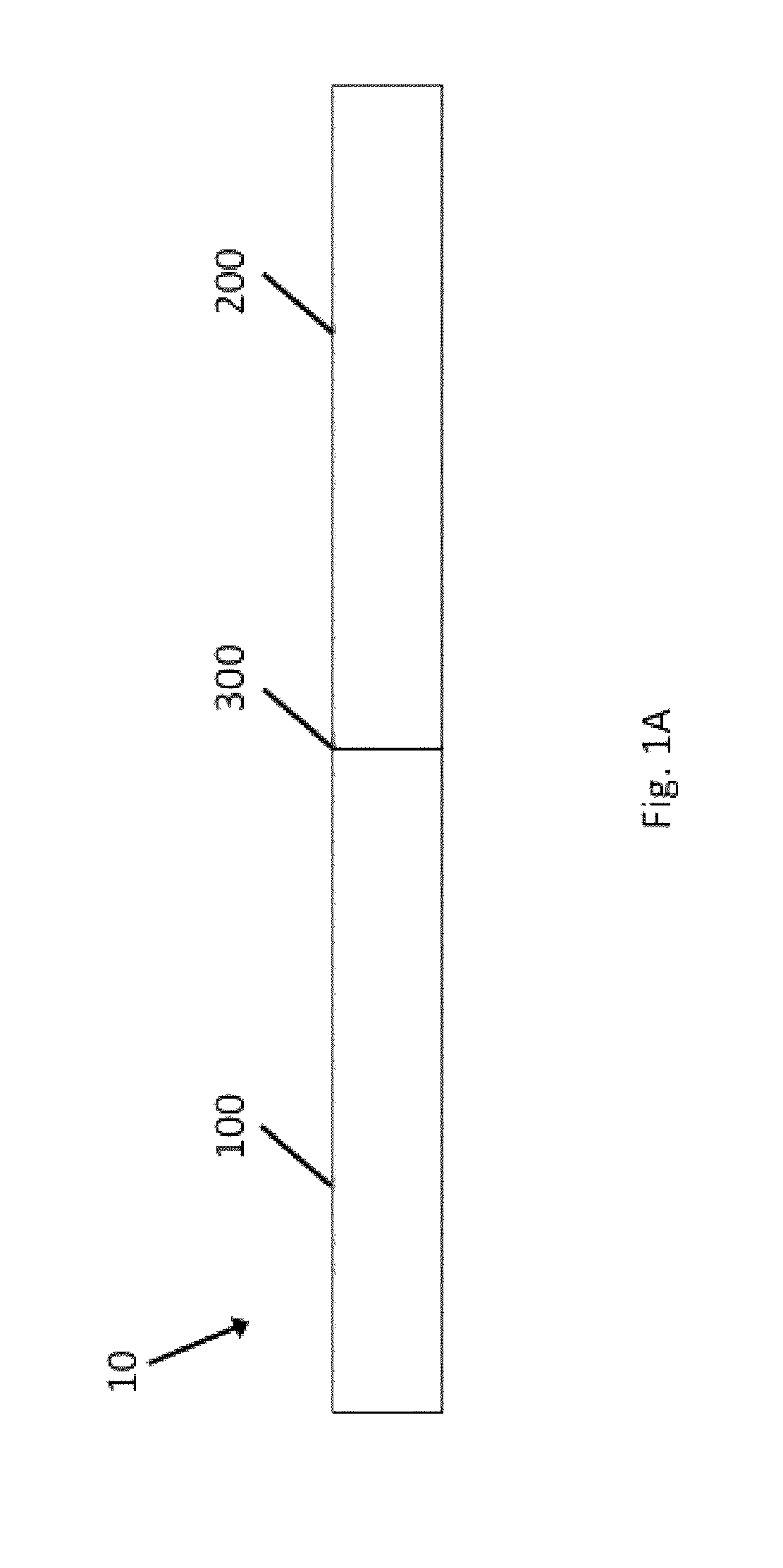

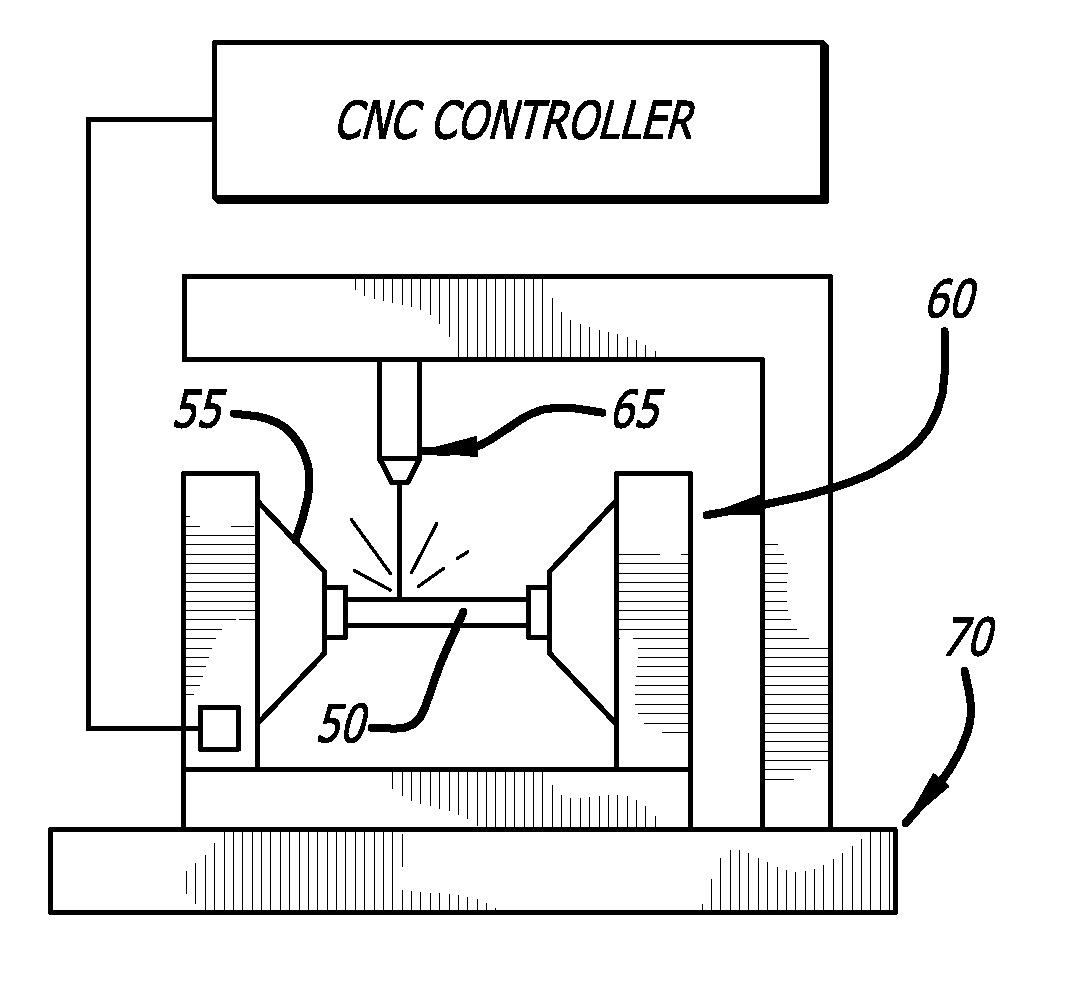

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

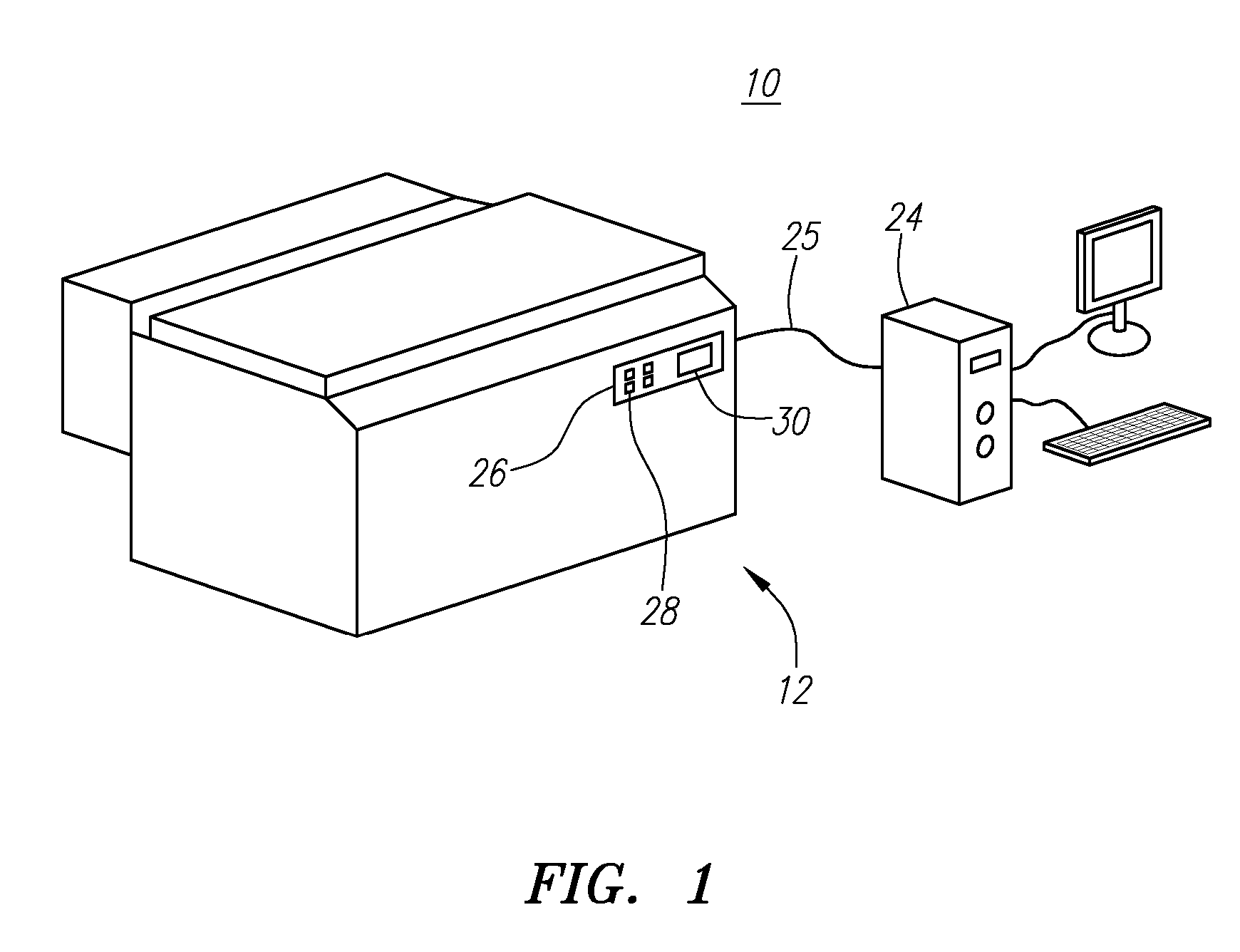

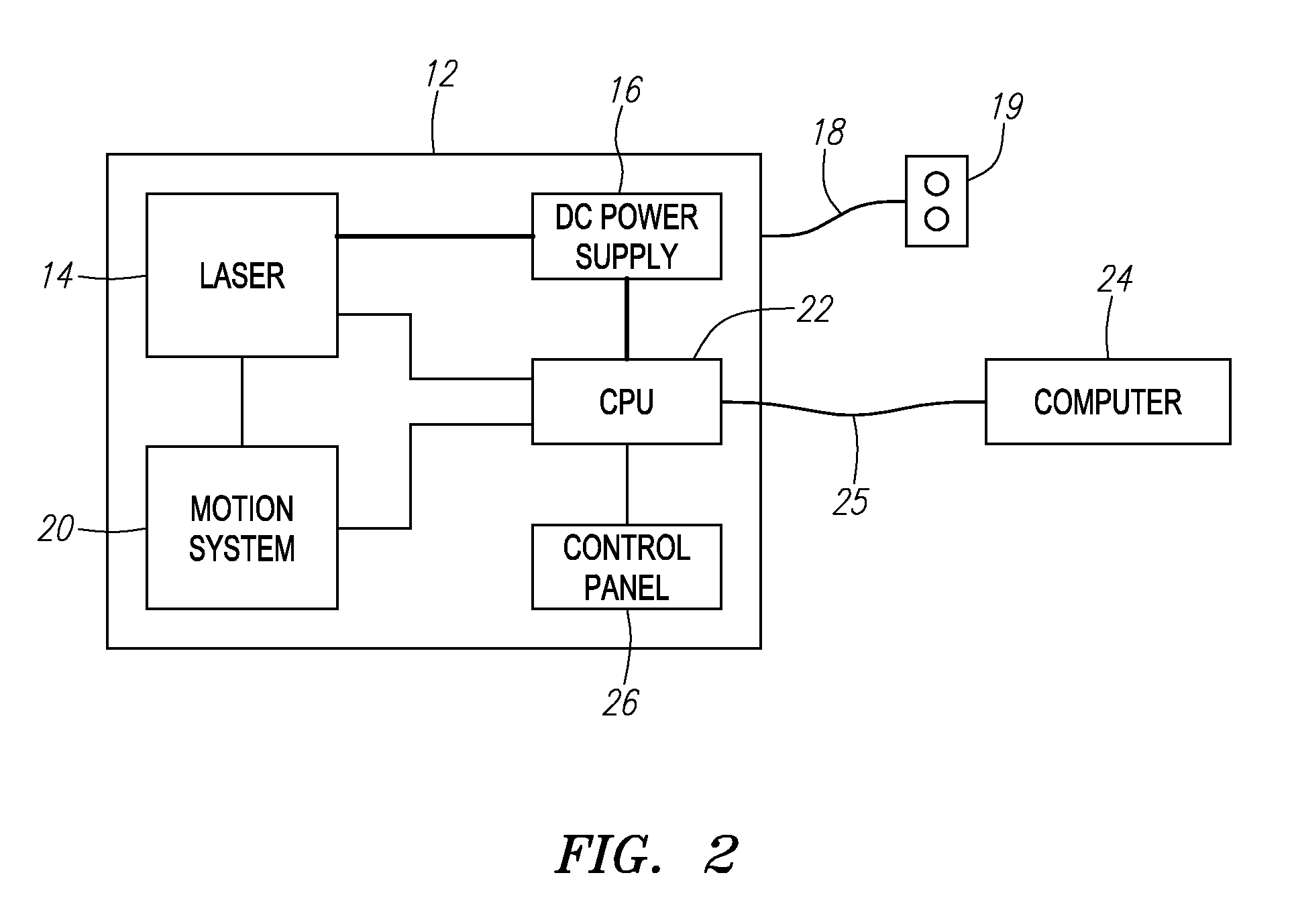

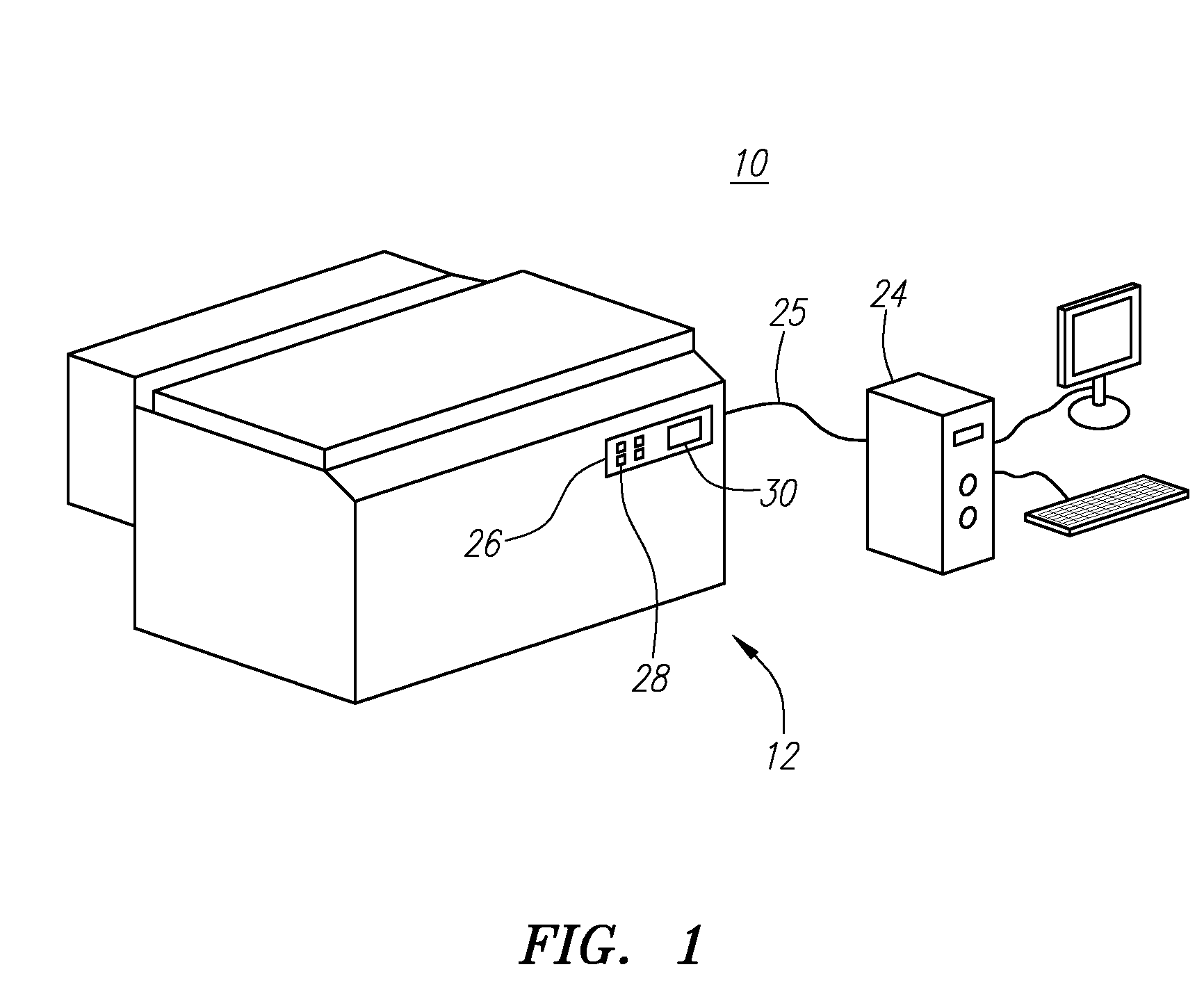

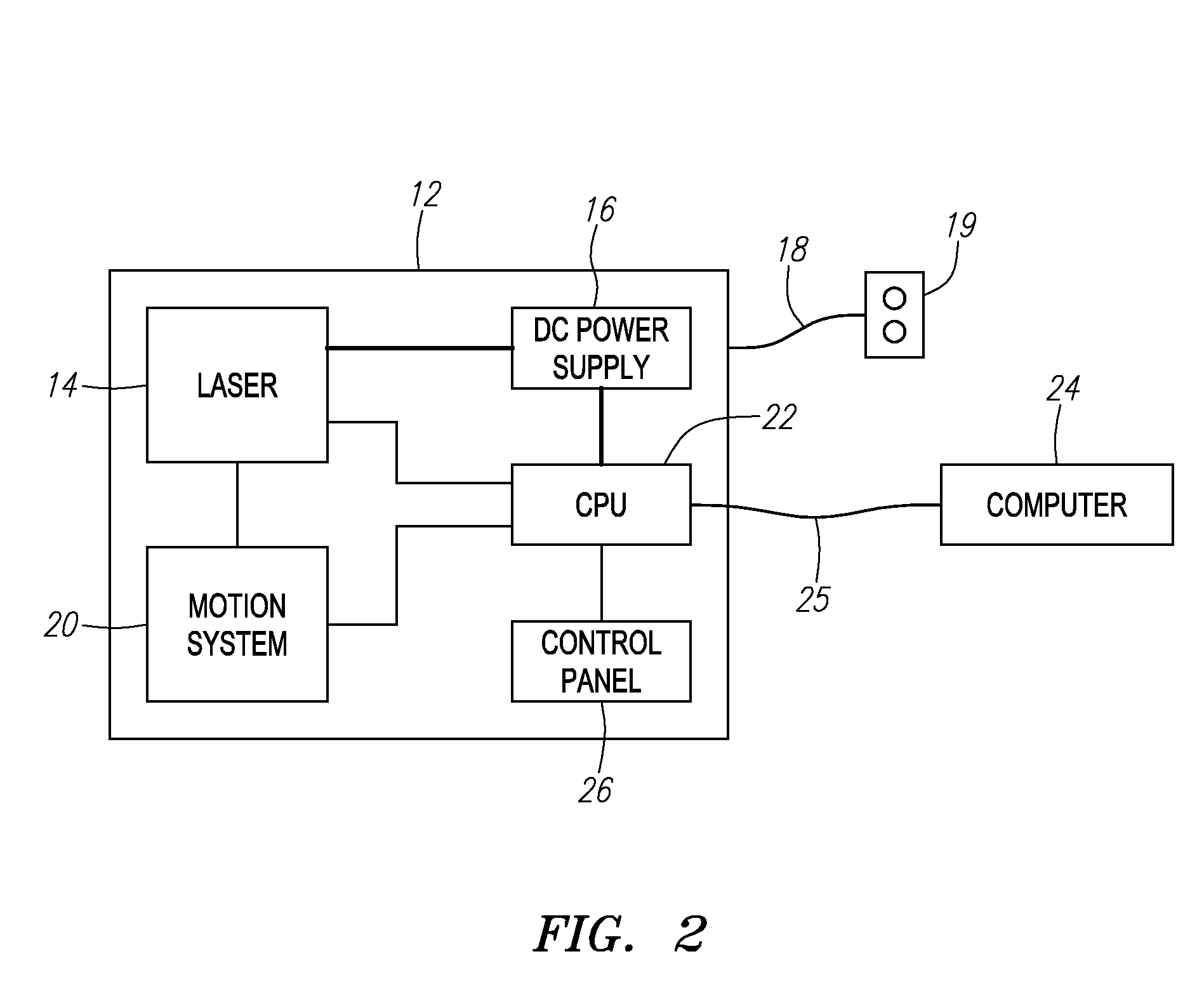

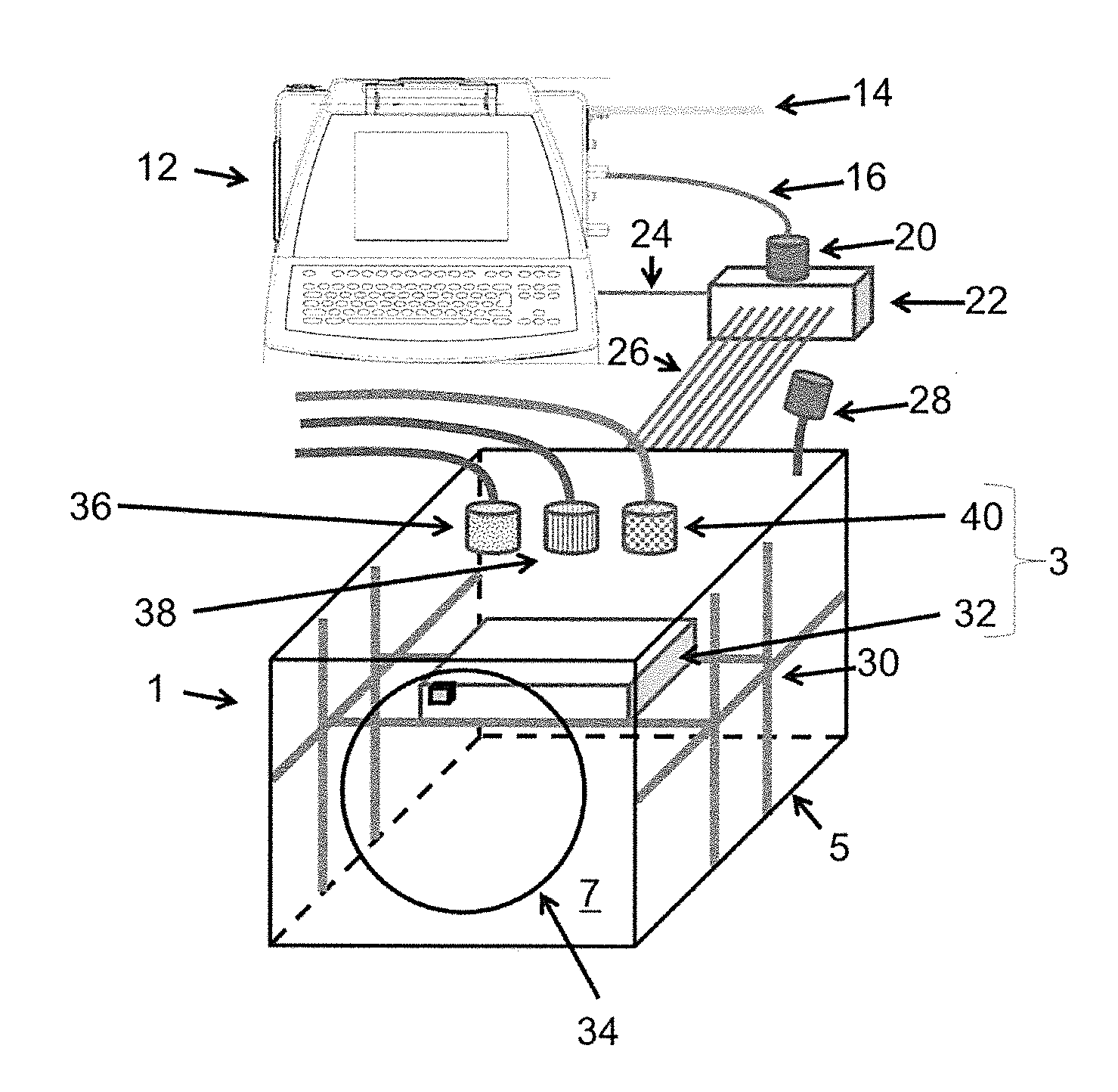

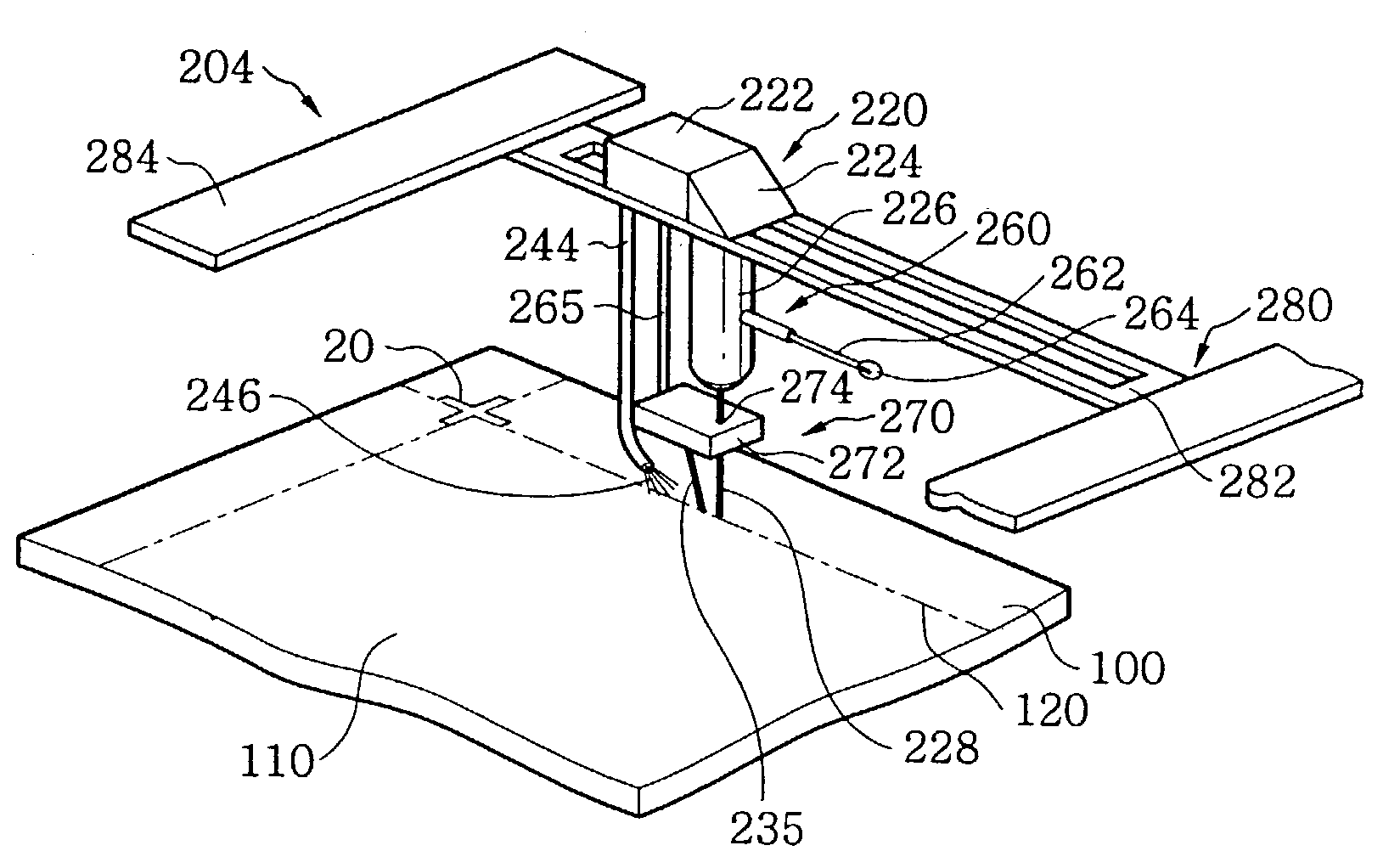

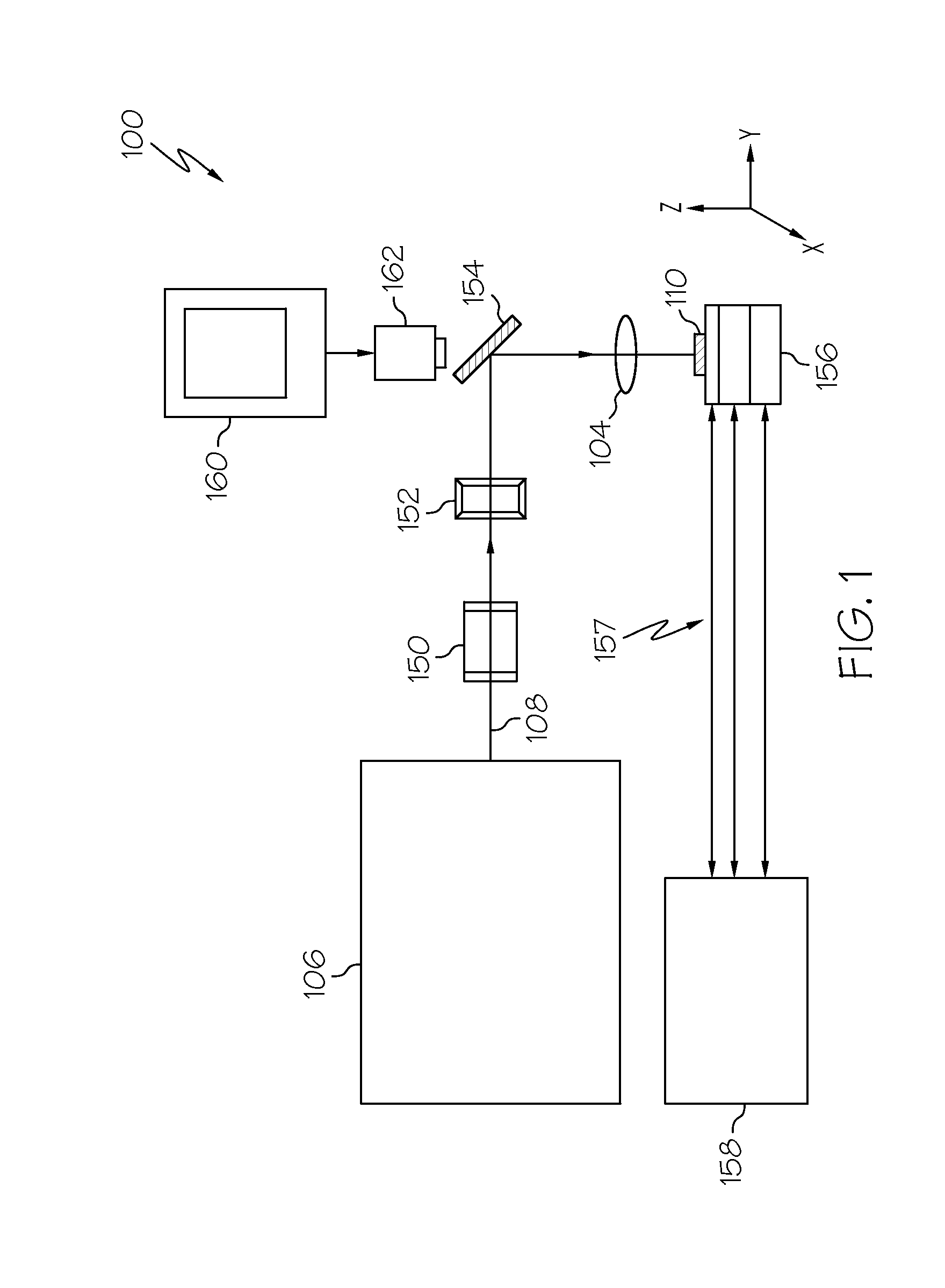

Laser cutting system

InactiveUS20100193482A1Reduce and eliminate heat and oxygen related changeAvoid damageLaser beam welding apparatusCarbon Dioxide / HeliumShielding gas

A laser cutting system including a chamber configured to provide a controlled environment while the laser is being used to cut a pattern into a material to reduce or eliminate heat and oxygen related changes to the mechanical characteristics of the material. A system for providing a gas to the controlled environment within the chamber, as well as a means for exhausting gas and cutting debris from the chamber is also described. A cutting mandrel that provides for flow of a shielding gas and also provides a means for dispersing a laser beam before it can produce unwanted damage to a section of tubing is also described.

Owner:ABBOTT CARDIOVASCULAR

Endoluminal devices

InactiveUS20050177186A1Sufficiently radiopaqueImprove capture efficiencyStentsDilatorsEtchingImplanted device

A seamless, self-expanding implantable device having a low profile is disclosed along with methods of making and using the same. The implantable device includes a frame cut out of a single piece of material that is formed into a three-dimensional shape. The implantable device may comprise an embolic filter, stent, or other implantable structure. The present invention also allows complicated frame structures to be easily formed from planar sheets of starting material, such as through laser cutting, stamping, photo-etching, or other cutting techniques.

Owner:WL GORE & ASSOC INC

Laser cutting apparatus and method

The present invention disclose a laser cutter for cutting an object being cut such as a two glasses-attached panel for LCD using a laser beam. The laser cutter includes a laser unit for irradiating a laser beam with a specific wavelength along a marked cutting line of the object, a pre-scriber for forming a pre-cut groove at starting edge of the marked cutting line, and a cooling unit for cooling the cutting line which said laser beam has been irradiated.

Owner:SAMSUNG DISPLAY CO LTD

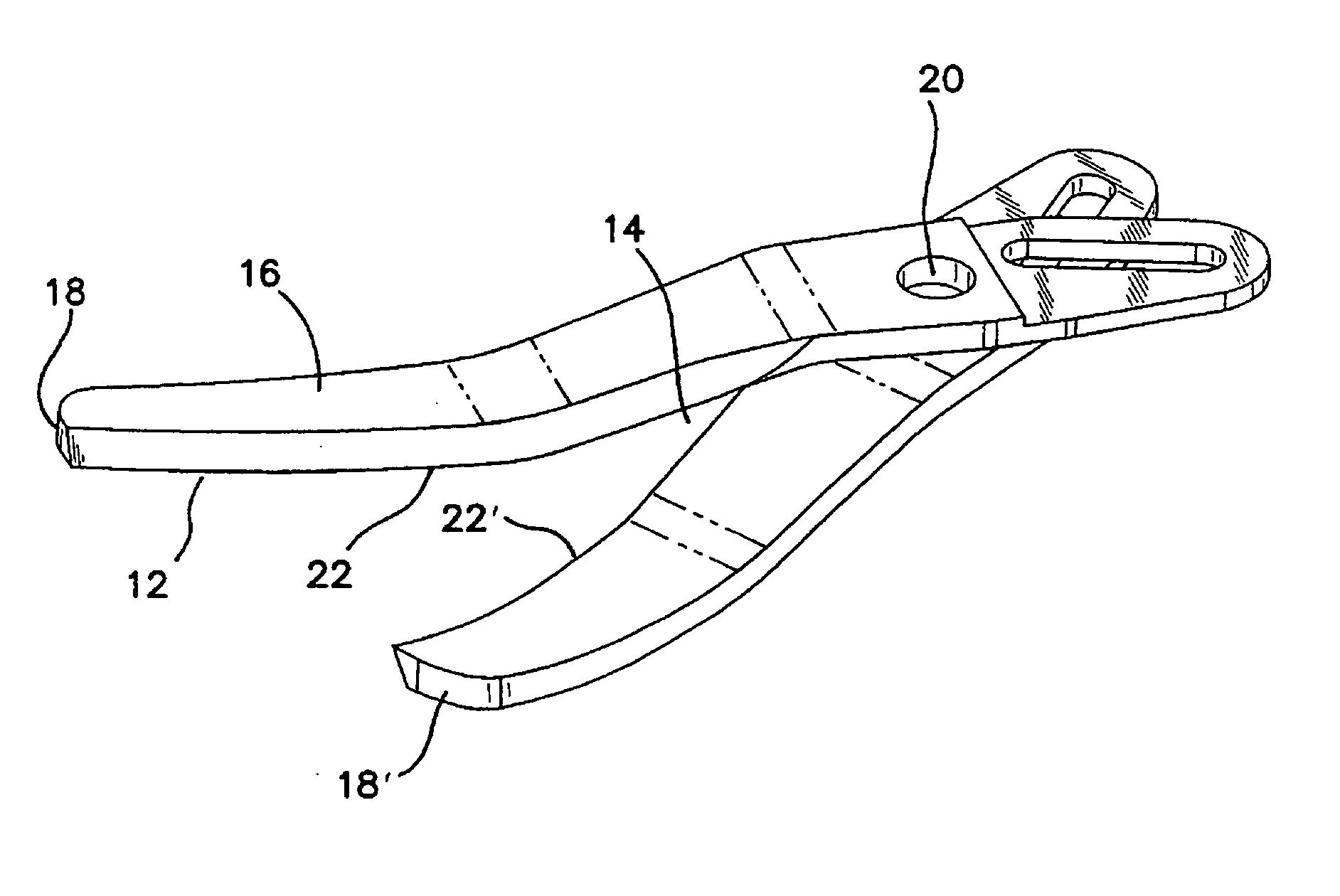

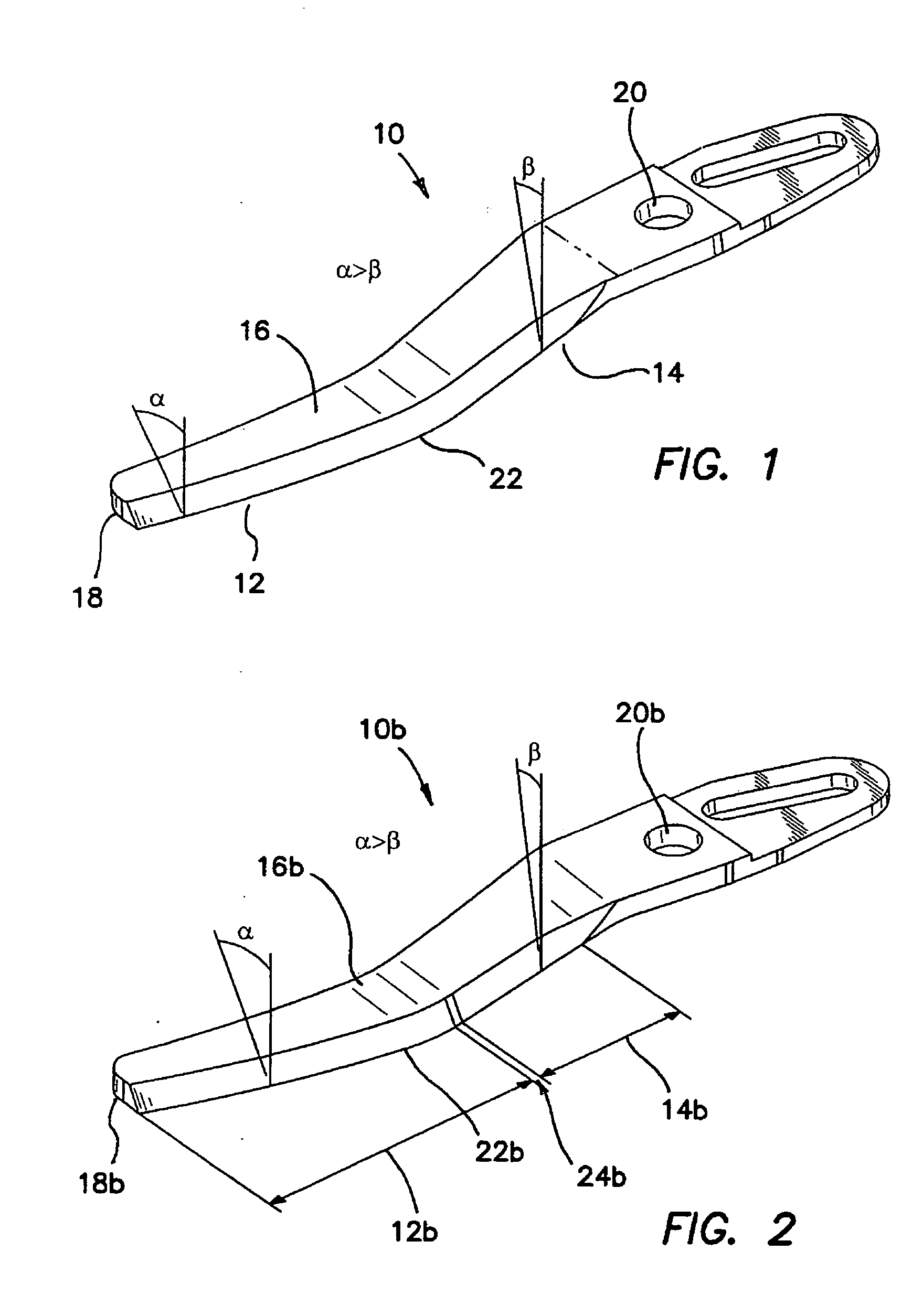

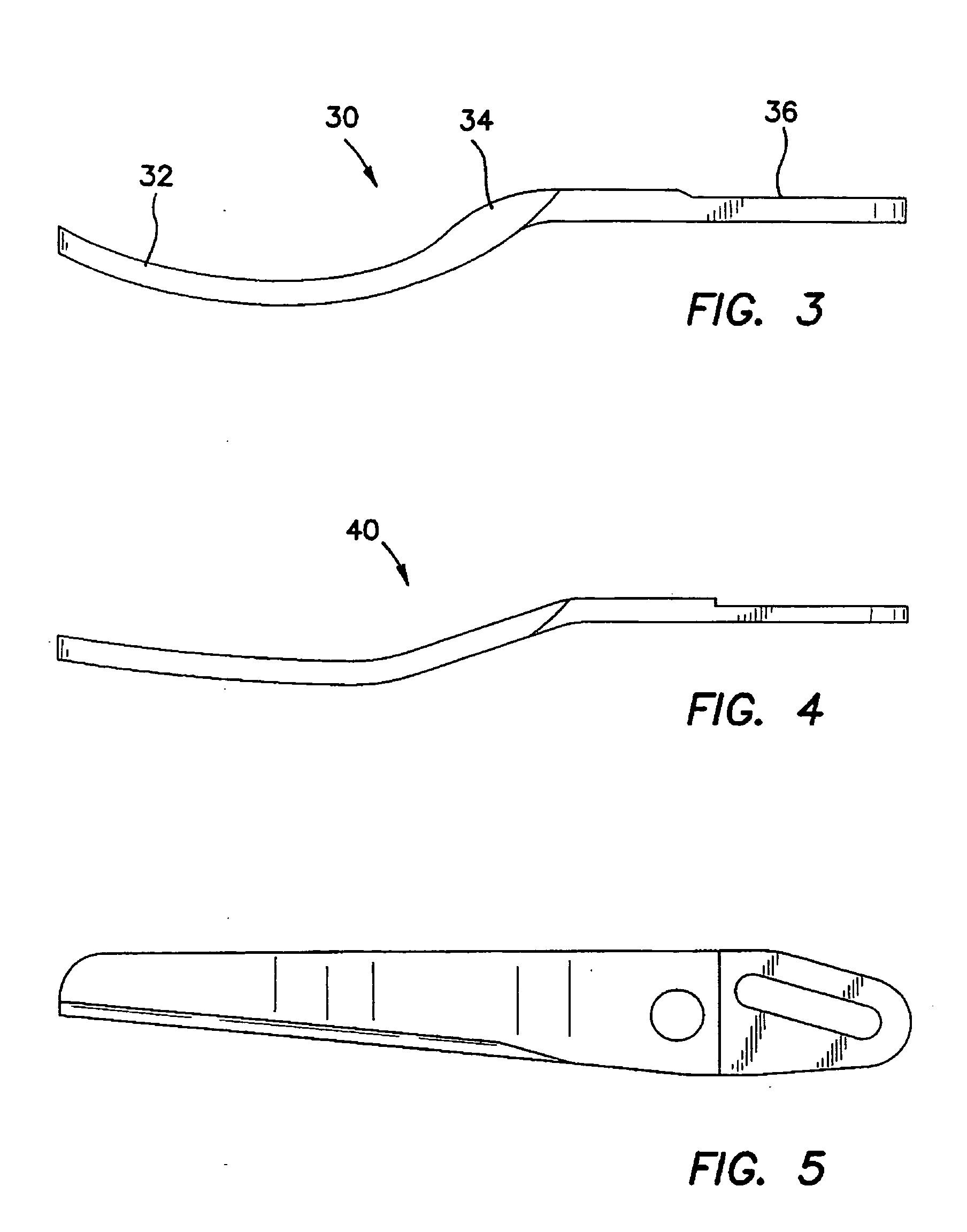

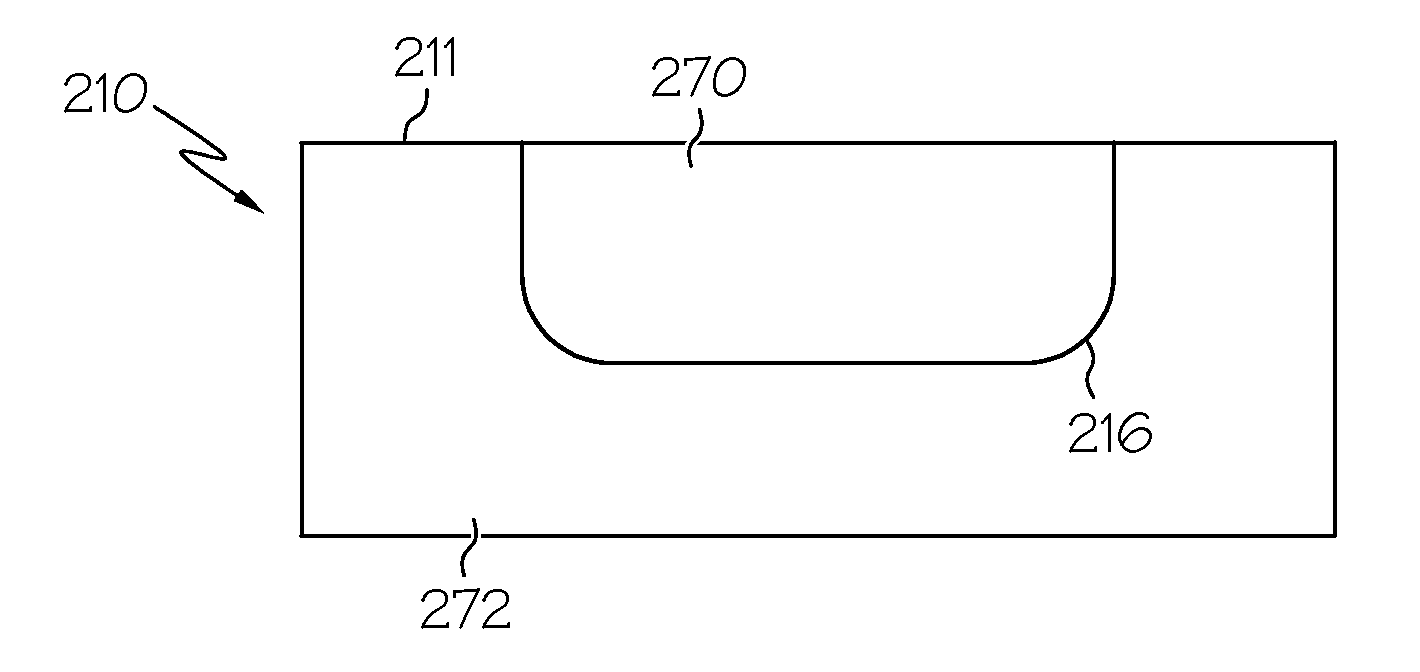

Multiple-angle scissor blade

InactiveUS20050149087A1More strengthReduce tensionSurgical scissorsOther manufacturing equipments/toolsManufacturing technologyLaser cutting

The invention is directed to a pair of laparoscopic scissors, comprising a pair of blades connected at a pivot, each of the blades having a length, a tip portion, a body portion, an outer surface, an inner surface and a cutting edge, the cutting edge forming an angle with the outer surface along the length of the blade such that tension during a cutting operation at the tip portion is about the same as tension at the body portion during the cutting operation. The angle formed may be greater at the tip portion which continuously decreases over the length of the blade. The tip portion may have a first body thickness and the body portion may have a second body thickness different from the first body thickness. During the cutting operation, the blades progressively move over each other to provide a point contact along the cutting edges. The blades may be thickened in a number of locations and combinations including: (1) one blade could be thicker than the other to force the opposing blade to flex; (2) both blades could be thicker at the body portions to give more strength when cutting staples; (3) each blade could be thickened on one side or the other to stiffen certain locations; and (4) the tips of each blade could be thicker than the body portions to provide increased tension at the tips. In another aspect of the invention, a process of manufacturing the pair of scissors of the invention is disclosed, comprising the steps of form grinding the blades into a desired shape from a pre-hardened block of material, and sharpening the cutting edges of the blades. The blades may also be formed through other processes including wire EDM, laser cutting, waterjet cutting, machining, cast or metal injection molding, and other independent profile manufacturing processes. The manufacturing process of the invention is beneficial in that each profile can be accurately controlled, and the parts will be exact every time.

Owner:APPL MEDICAL RESOURCES CORP

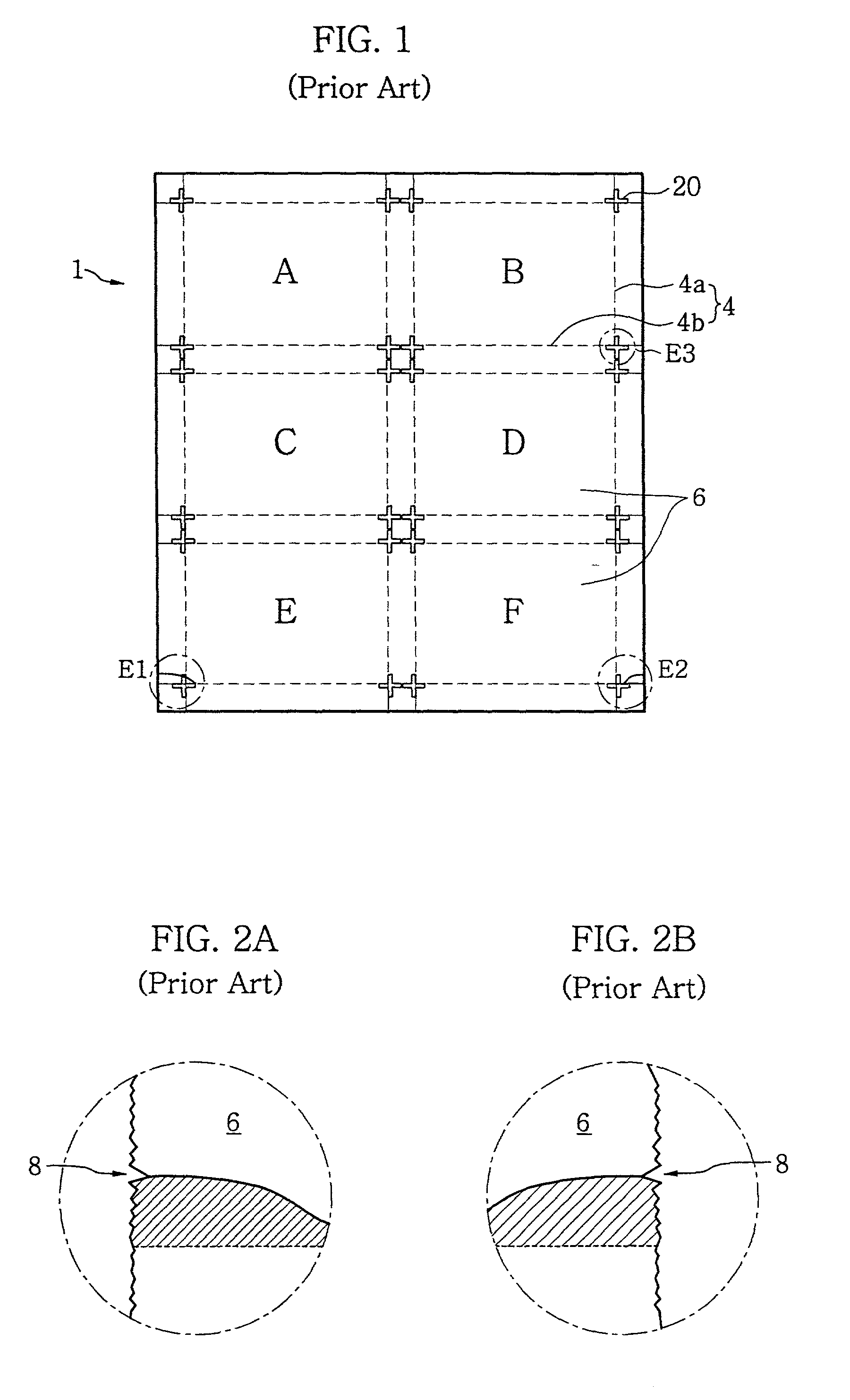

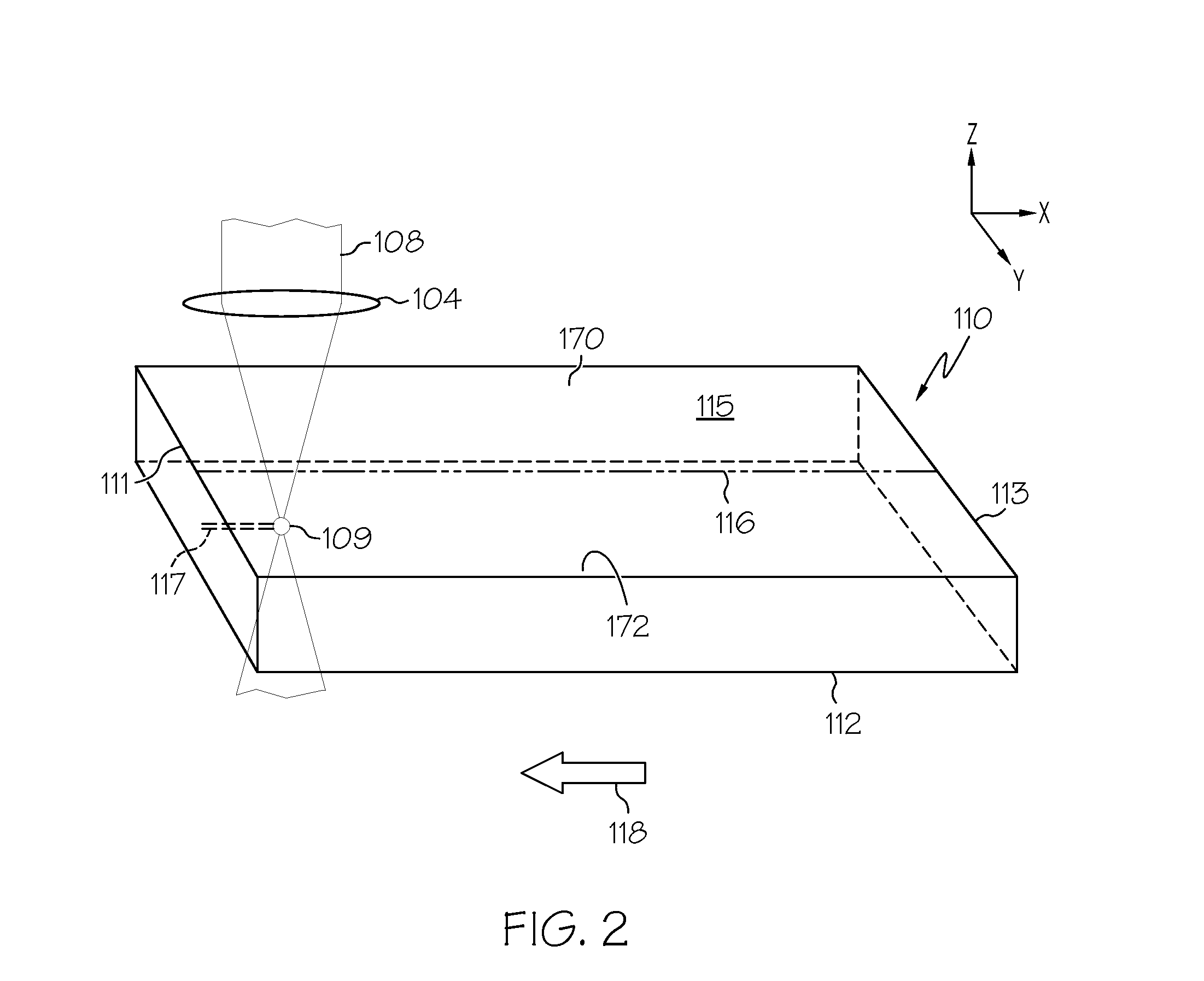

Methods for laser cutting articles from ion exchanged glass substrates

ActiveUS20120145331A1Increase the tensile stressGlass reforming apparatusGlass severing apparatusIon exchangeLaser cutting

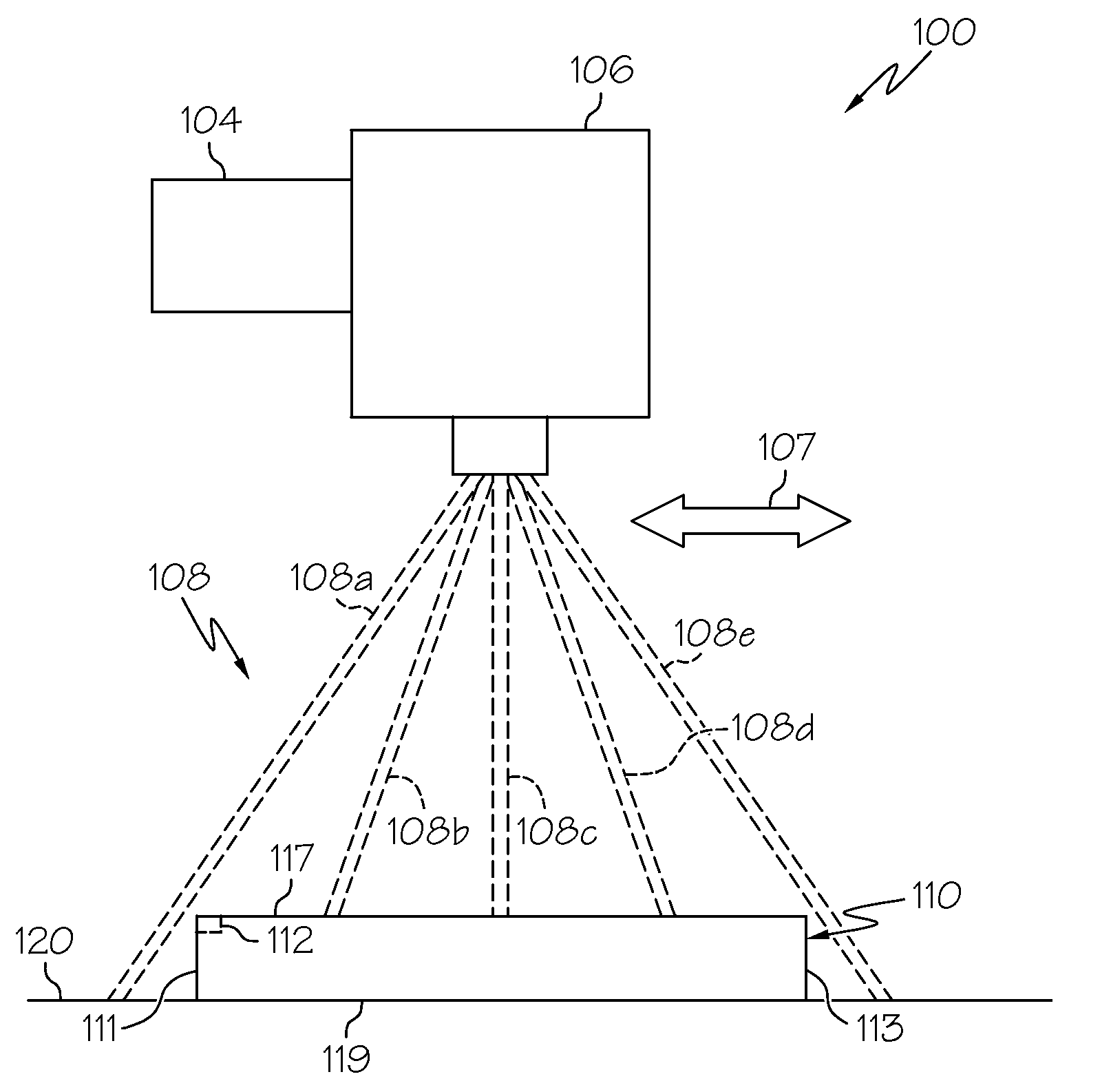

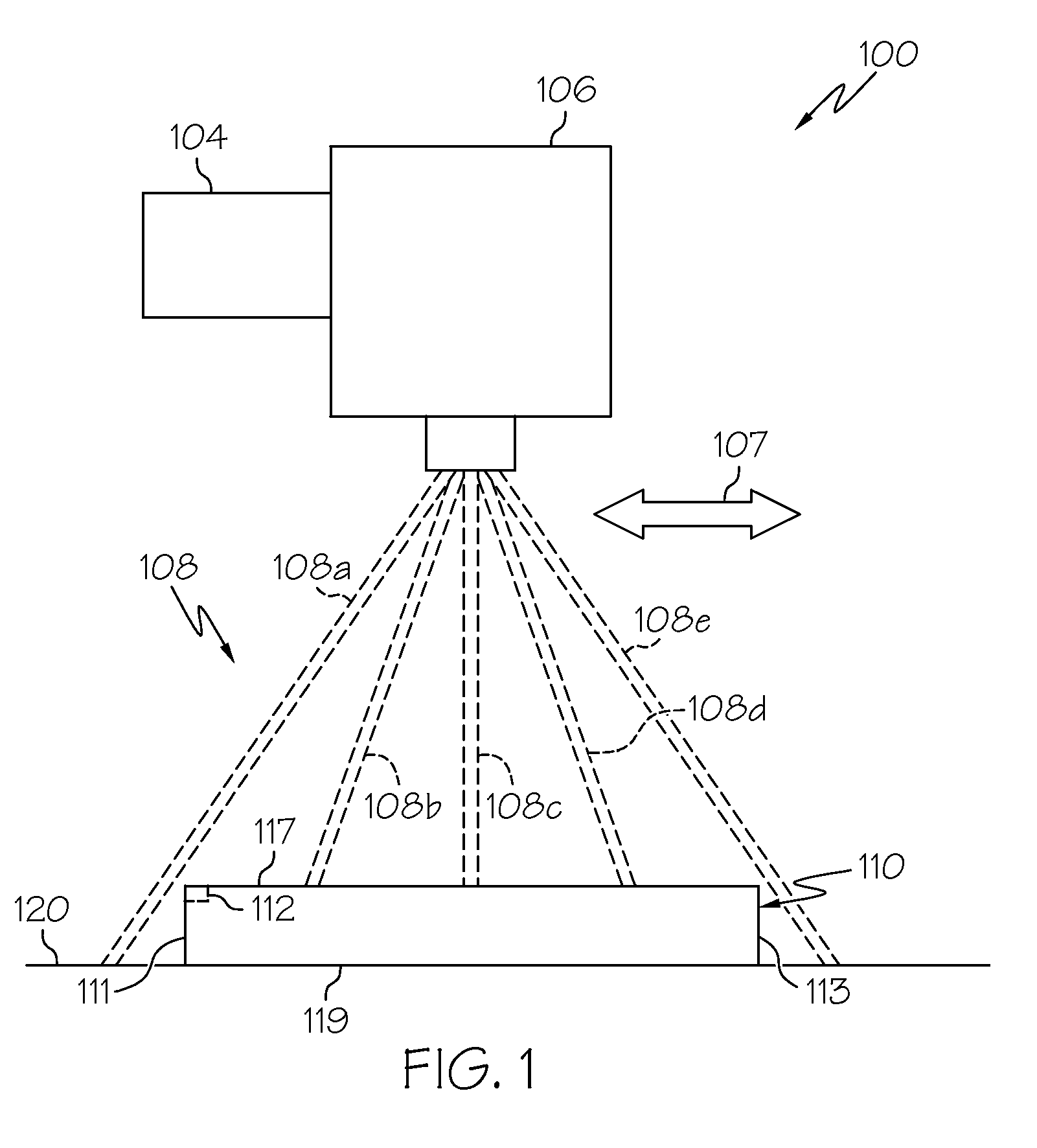

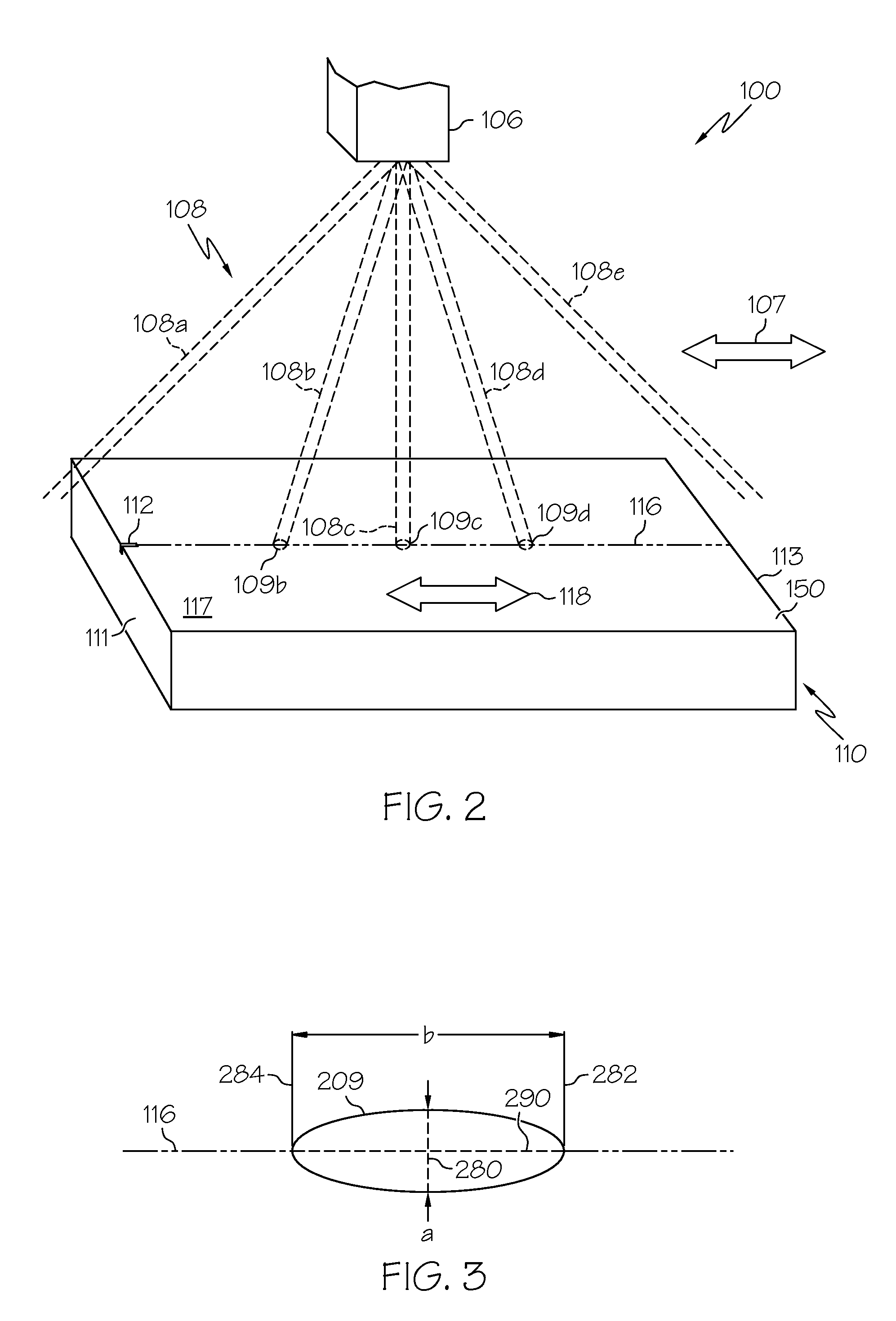

A method of cutting an article (172) from a chemically strengthened glass substrate (110) includes generating a pulsed laser beam (108) from a laser source (106). The pulsed laser beam (108) may have a pulse duration of less than about 1000 fs and an output wavelength such that the chemically strengthened glass substrate (110) is substantially transparent to the pulsed laser beam (108). The pulsed laser beam (108) may be focused to form a beam waist (109) that is positioned in the same horizontal plane as an inner tensile region (124) of the chemically strengthened glass substrate (110). The beam waist (109) may be translated in a first pass along a cut line (116), wherein the beam waist (109) traverses an edge (111) of the chemically strengthened glass substrate. The beam waist (113) may then be translated in a second pass along the cut line (116) such that a crack (119) propagates from the edge (113) along the cut line (116) ahead of the translated beam waist (109) during the second pass.

Owner:CORNING INC

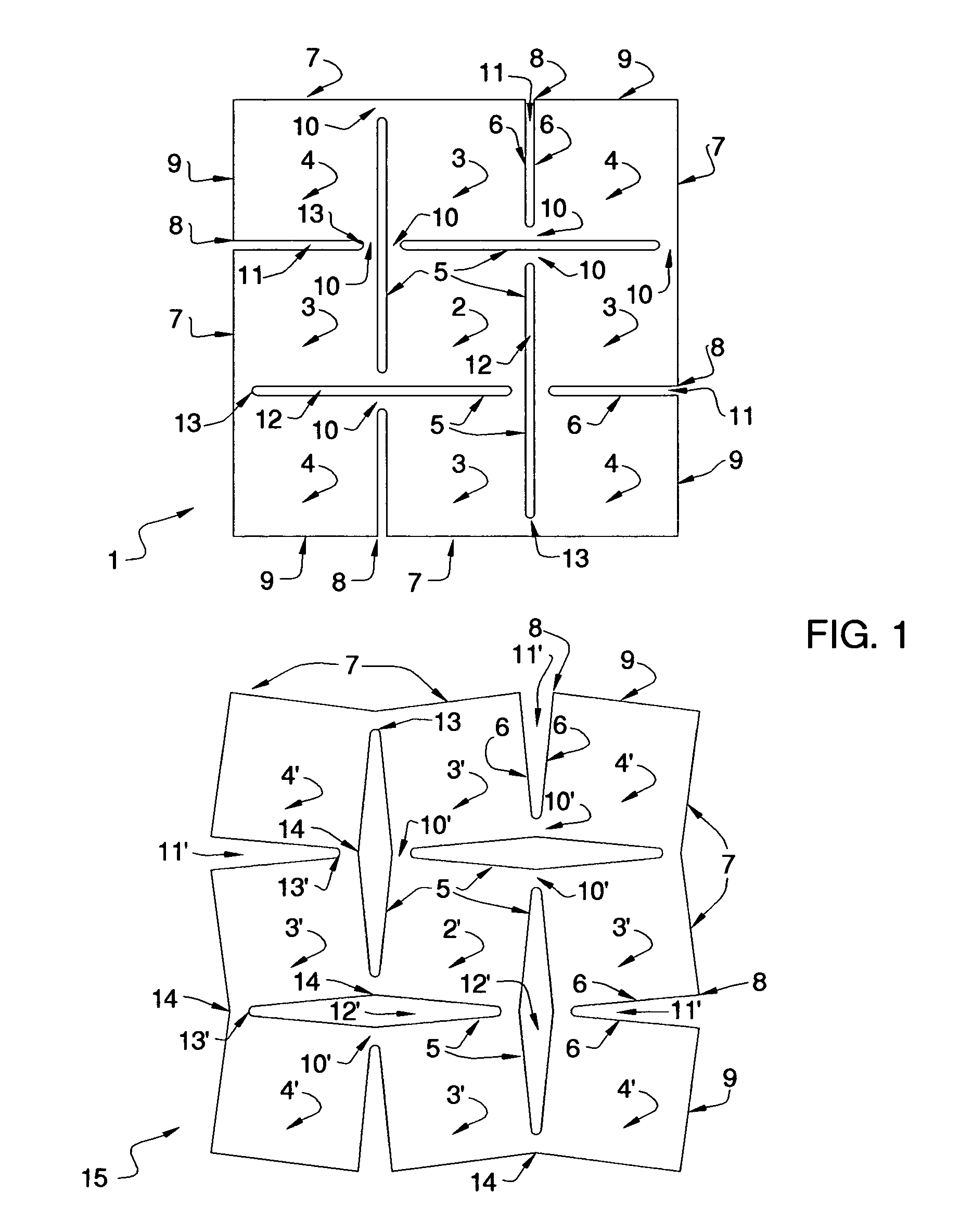

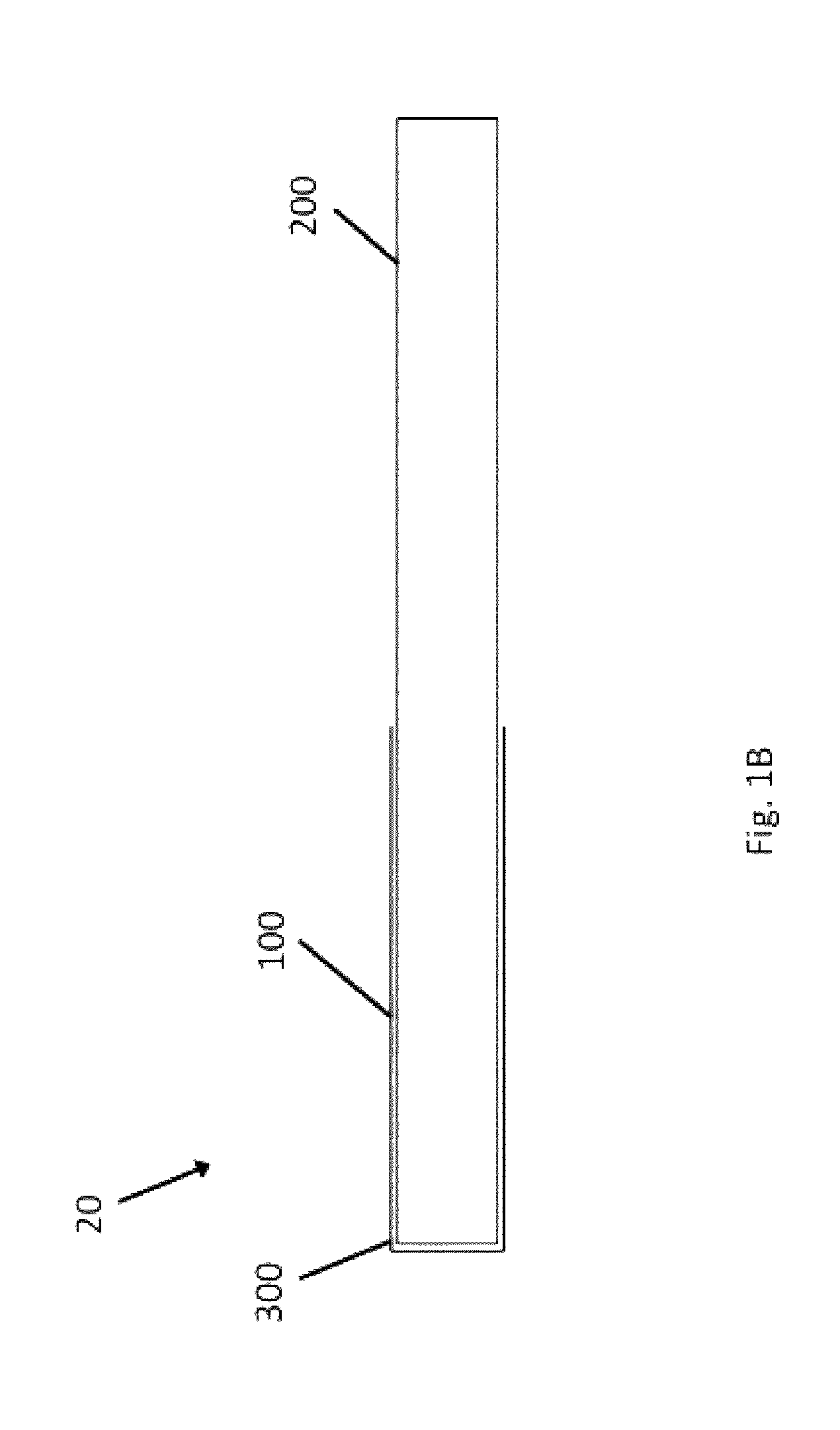

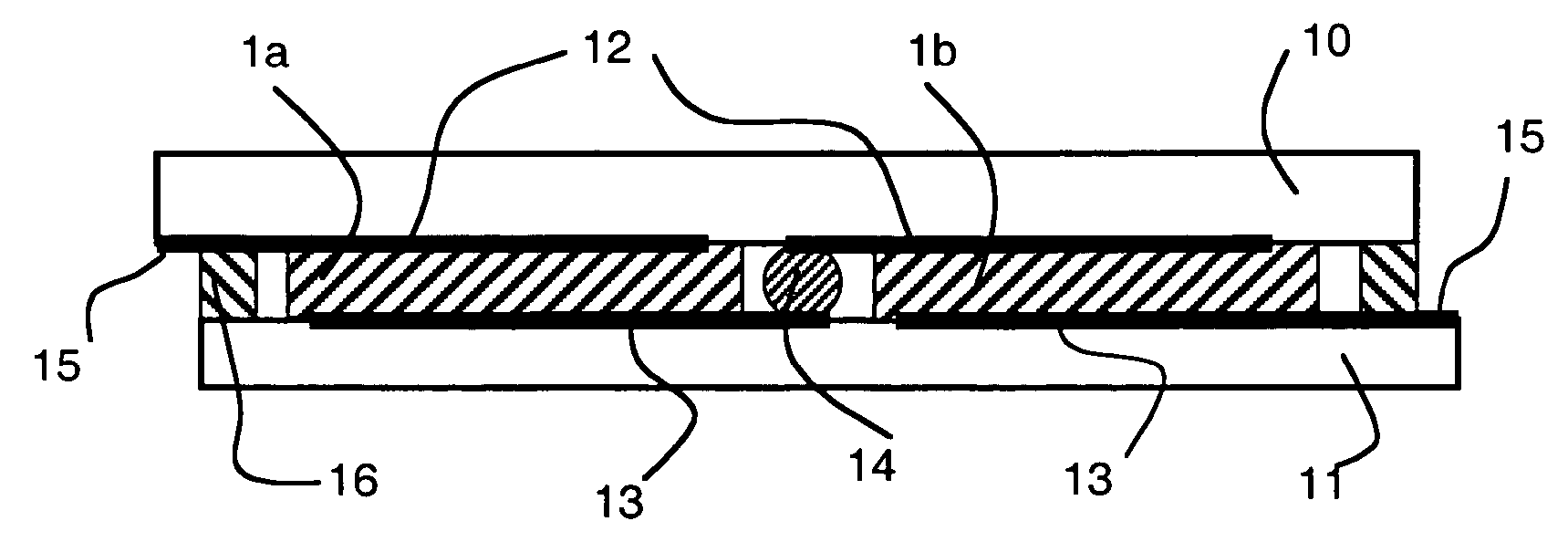

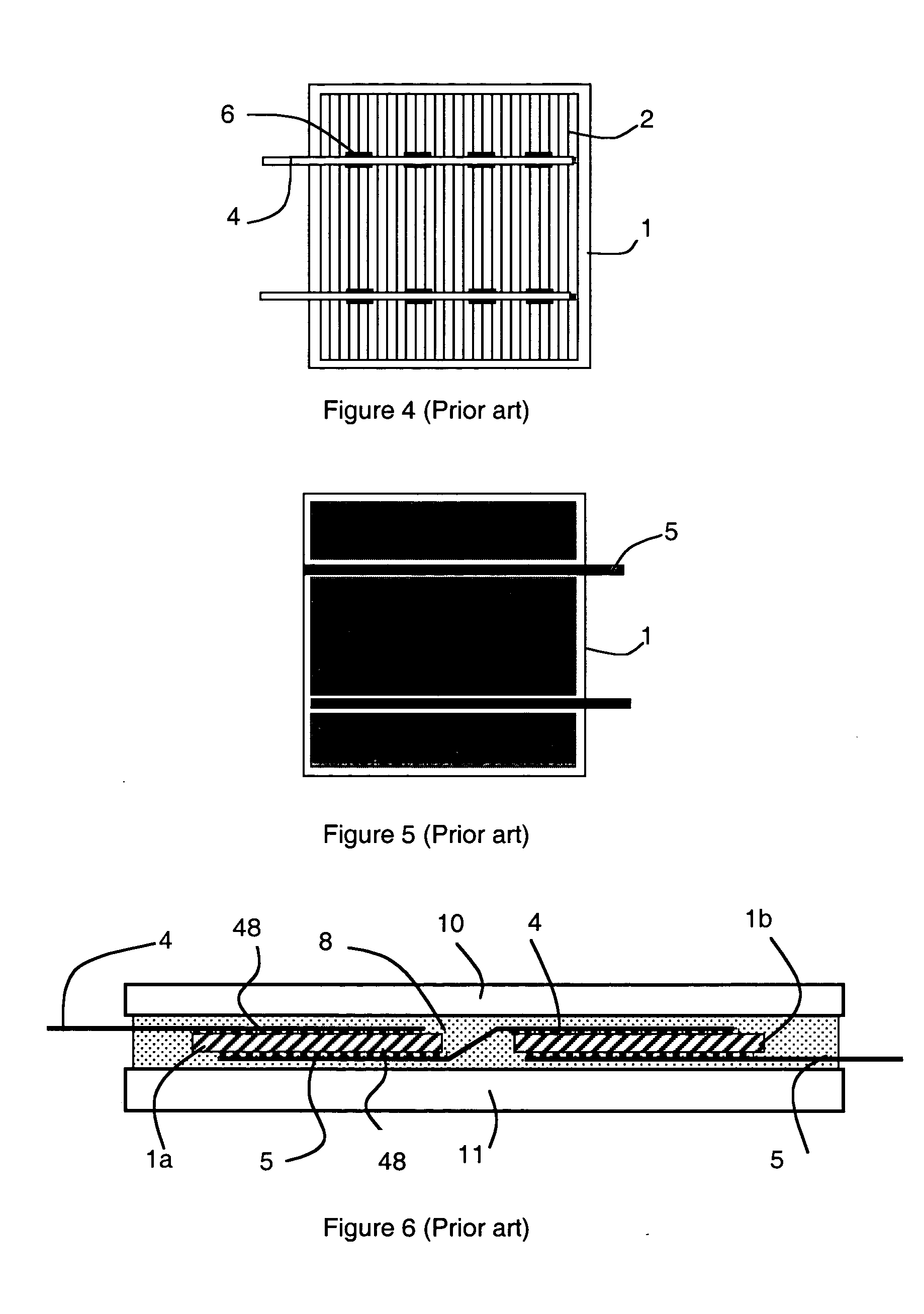

Photovoltaic cell assembly and the method of producing one such assembly

InactiveUS20050000561A1Reduce manufacturing costAccounting/billing servicesPV power plantsElectrical conductorEngineering

The photovoltaic cells (1a, 1b) of the assembly are disposed side by side between a front (10) and rear (11) glass substrates and are connected in series by means of front (12) and (13) rear connecting conductors and of interconnection elements (14). The connecting conductors can be formed on the internal face of each glass substrate facing the location of each of the cells or obtained by laser cutting, through the glass substrates, of conducting strips tightened beforehand between the cells and the glass substrates. The electrical interconnection elements (14) are disposed between two adjacent cells (1) to connect the opposite connecting conductors associated to two adjacent cells. A sealing joint (16), made of inorganic material, arranged between the two glass substrates (10, 11), defines a sealed internal volume which contains all the cells (1). Sealing is performed between 380° C. and 480° C. for a period of less than 30 minutes.

Owner:APOLLON SOLAR SAS

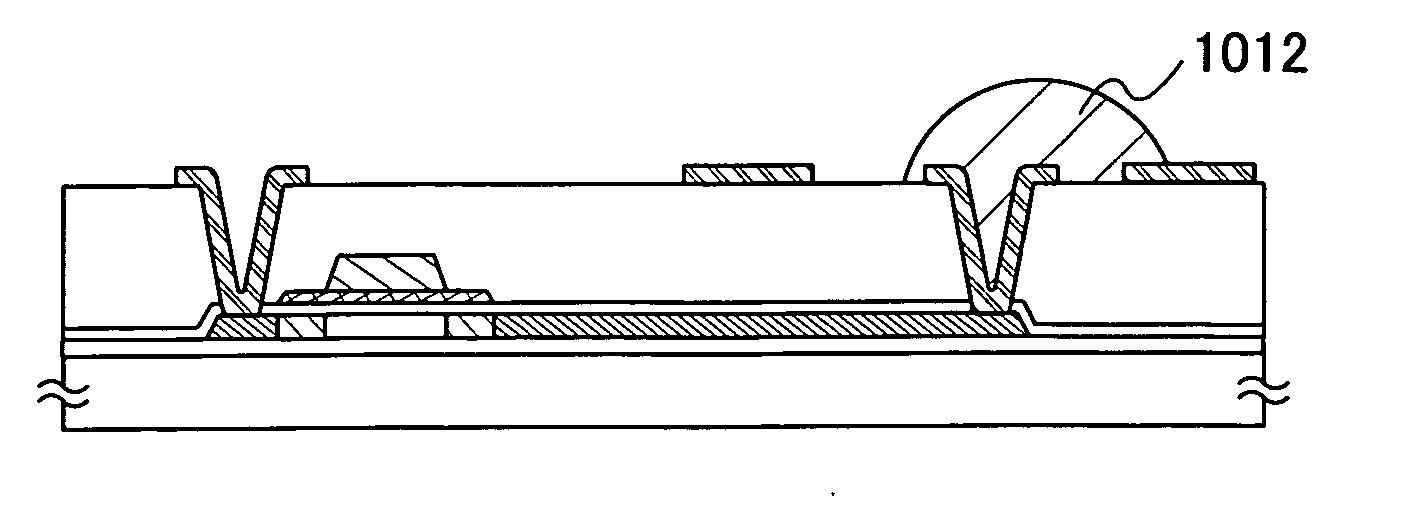

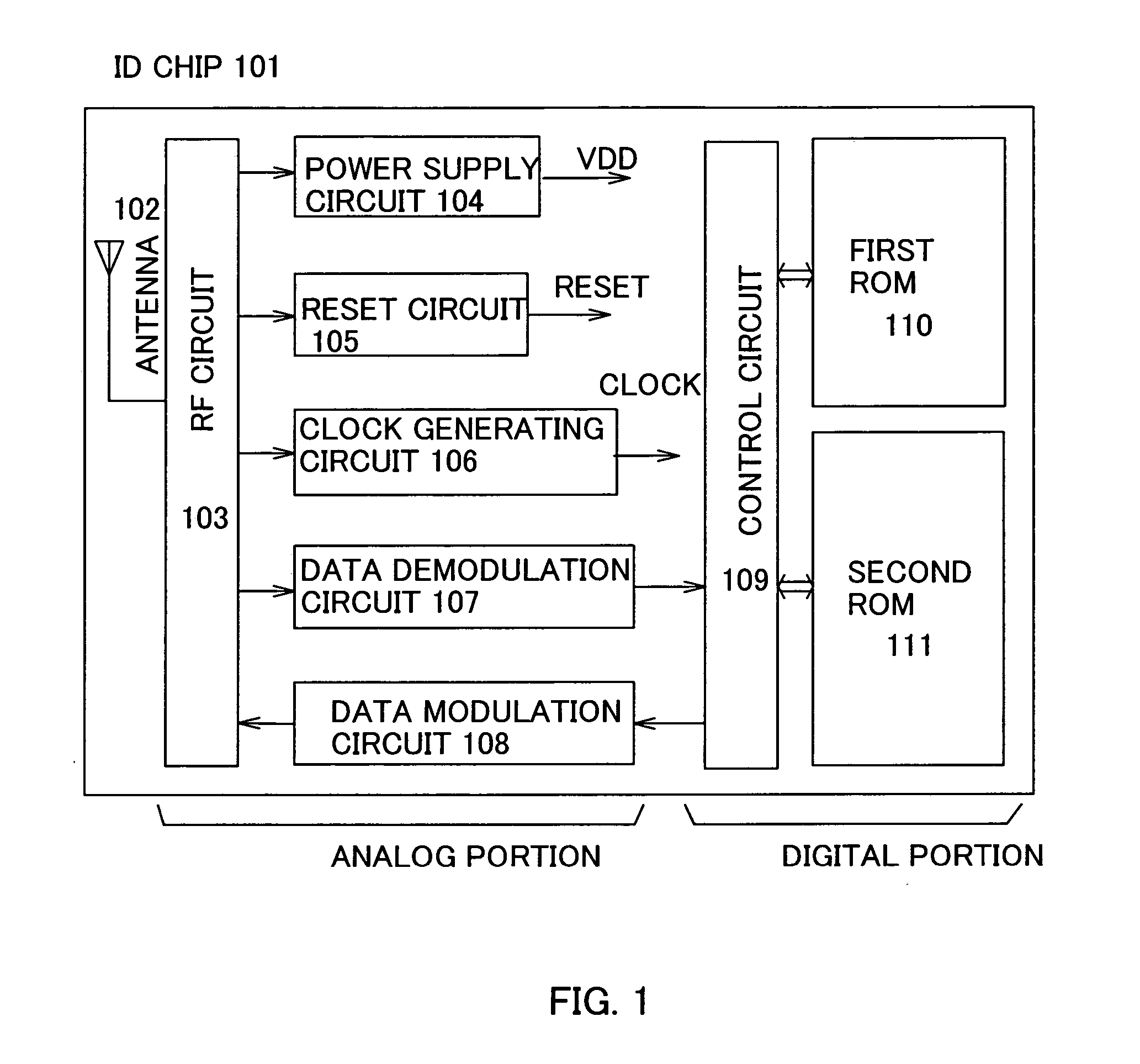

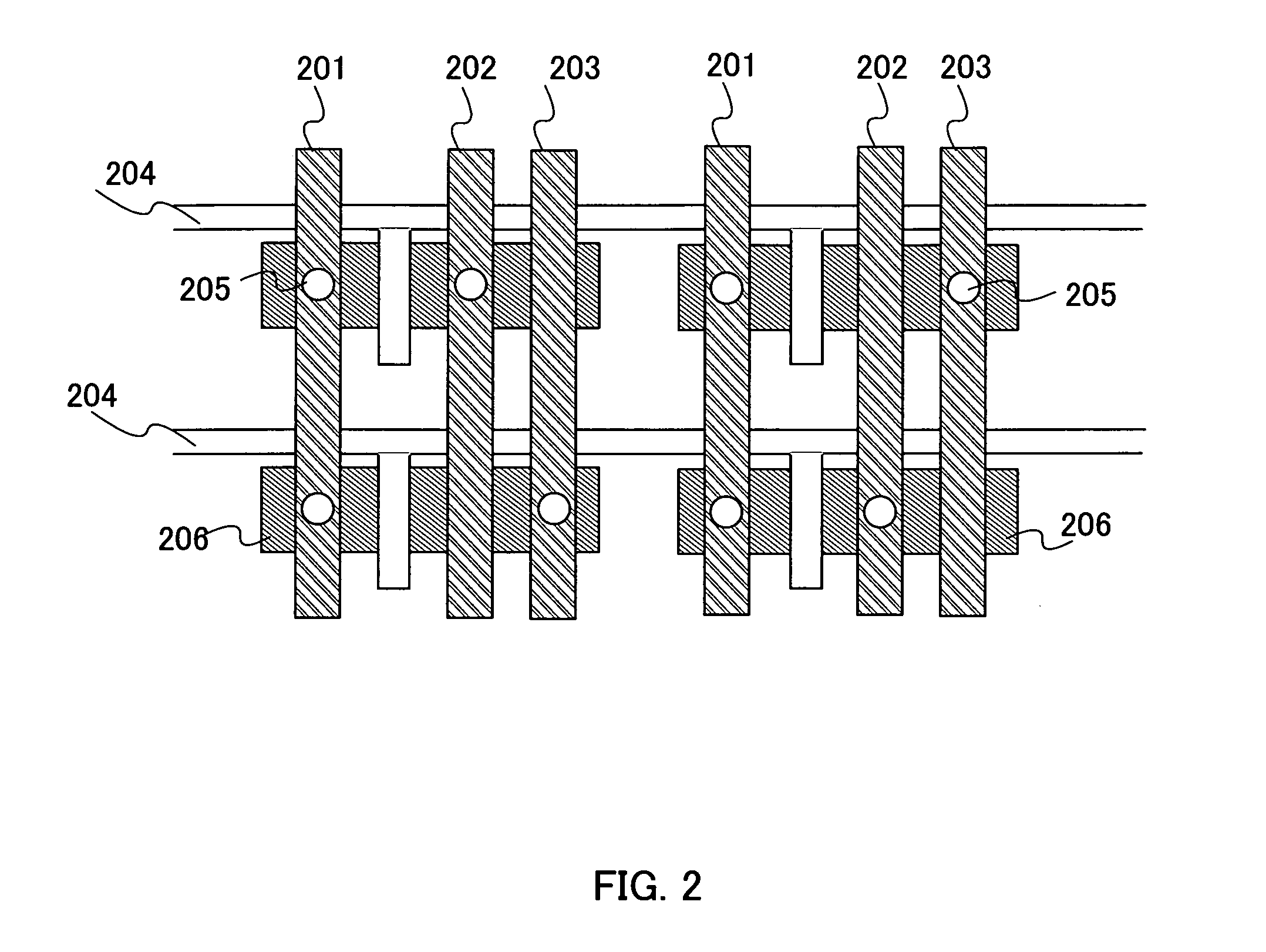

Semiconductor integrated circuit, semiconductor device, and manufacturing method of the semiconductor integrated circuit

InactiveUS20050133790A1Improve efficiencySmall amount of wasteTransistorSolid-state devicesDevice materialLaser cutting

A chip with increased impact resistance, attractive design and reduced cost, and a manufacturing method thereof are provided. A semiconductor integrated circuit is formed on a large glass substrate, and a part of data of a ROM included therein is determined by an ink jet method or a laser cutting method. Accordingly, the cost can be reduced without requiring a photomask, resulting in an inexpensive ID chip. Further, depending on the application, the semiconductor integrated circuit is transposed to a flexible substrate, thereby an ID chip with improved impact resistance and more attractive design can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

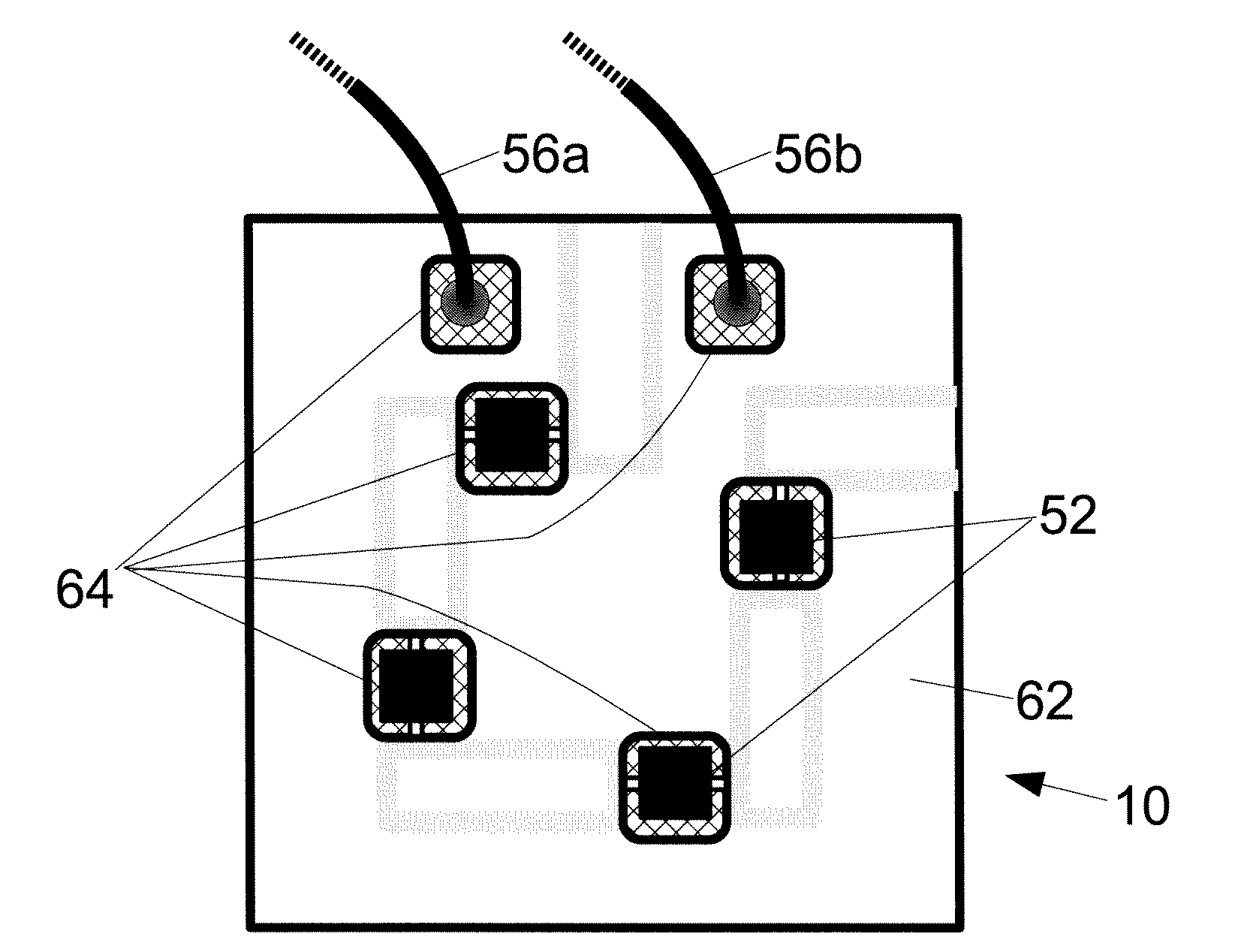

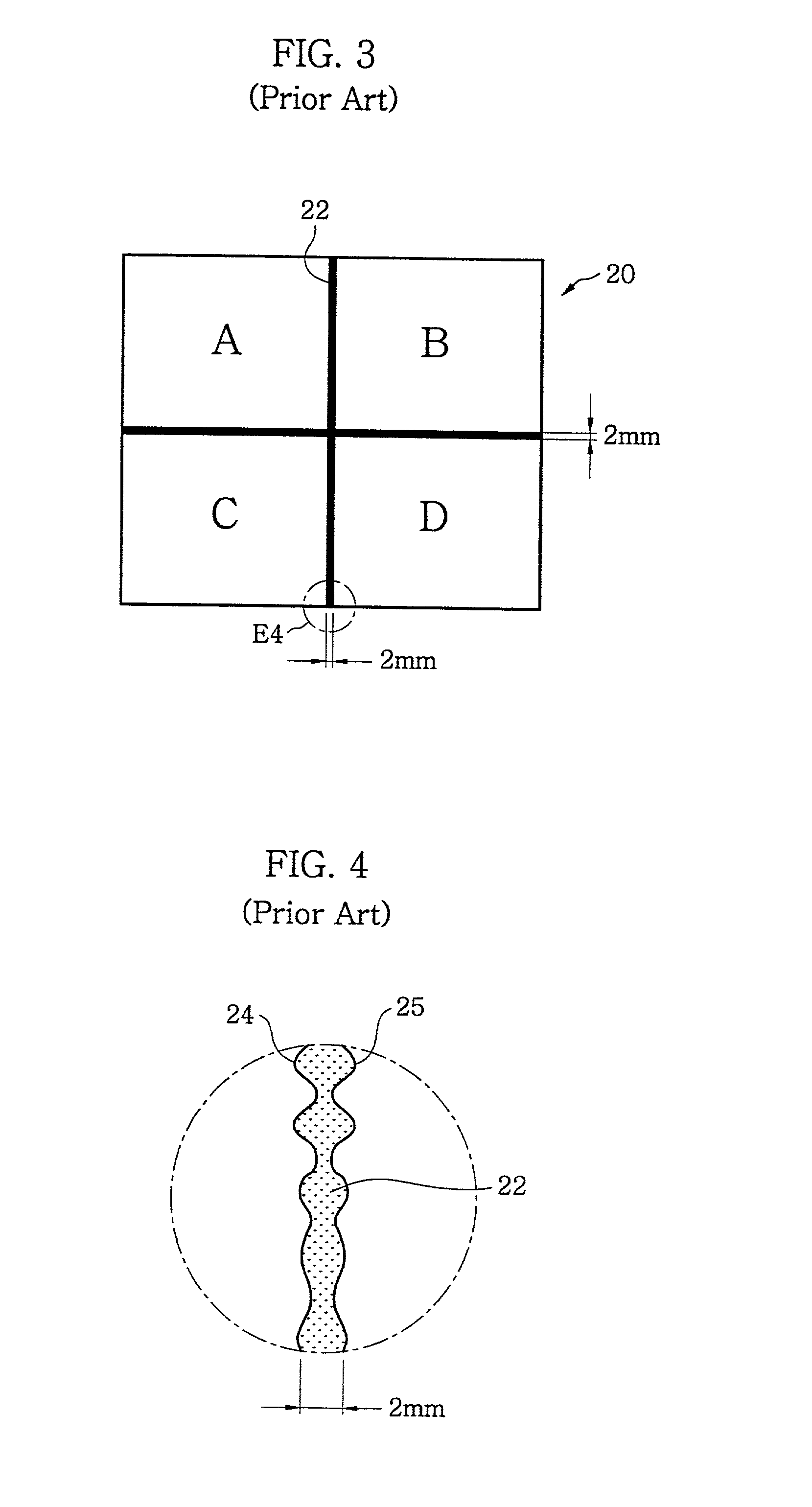

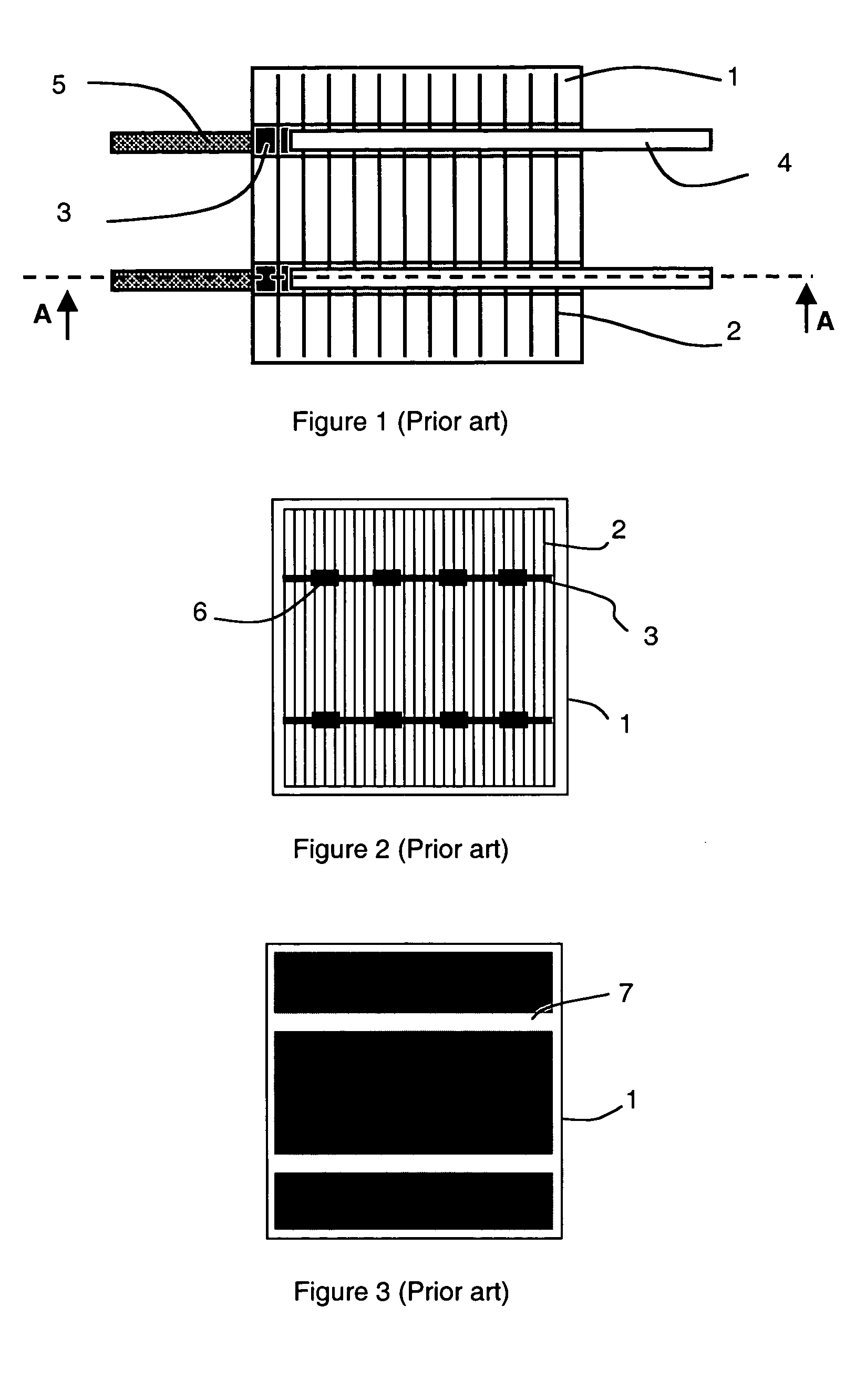

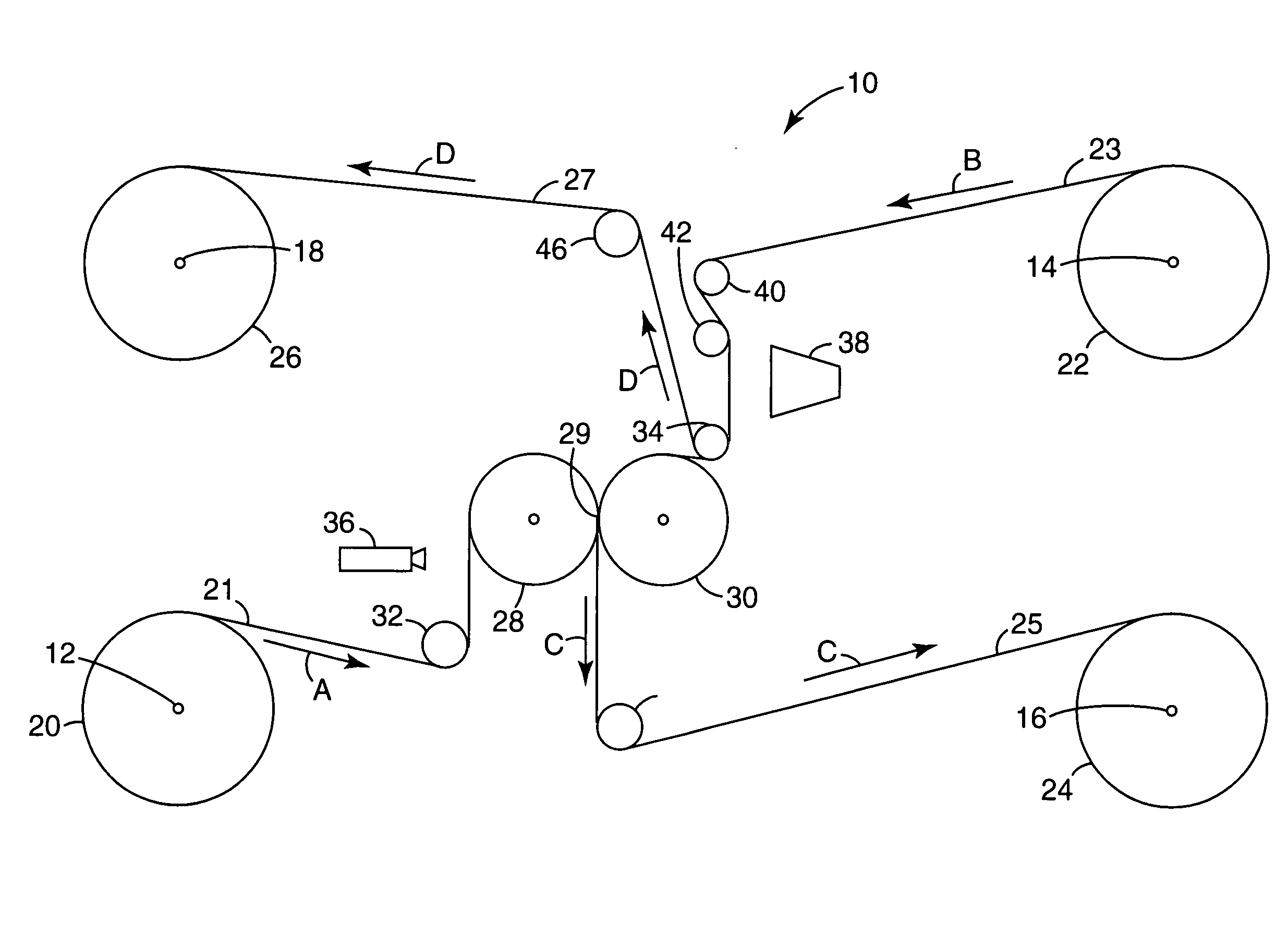

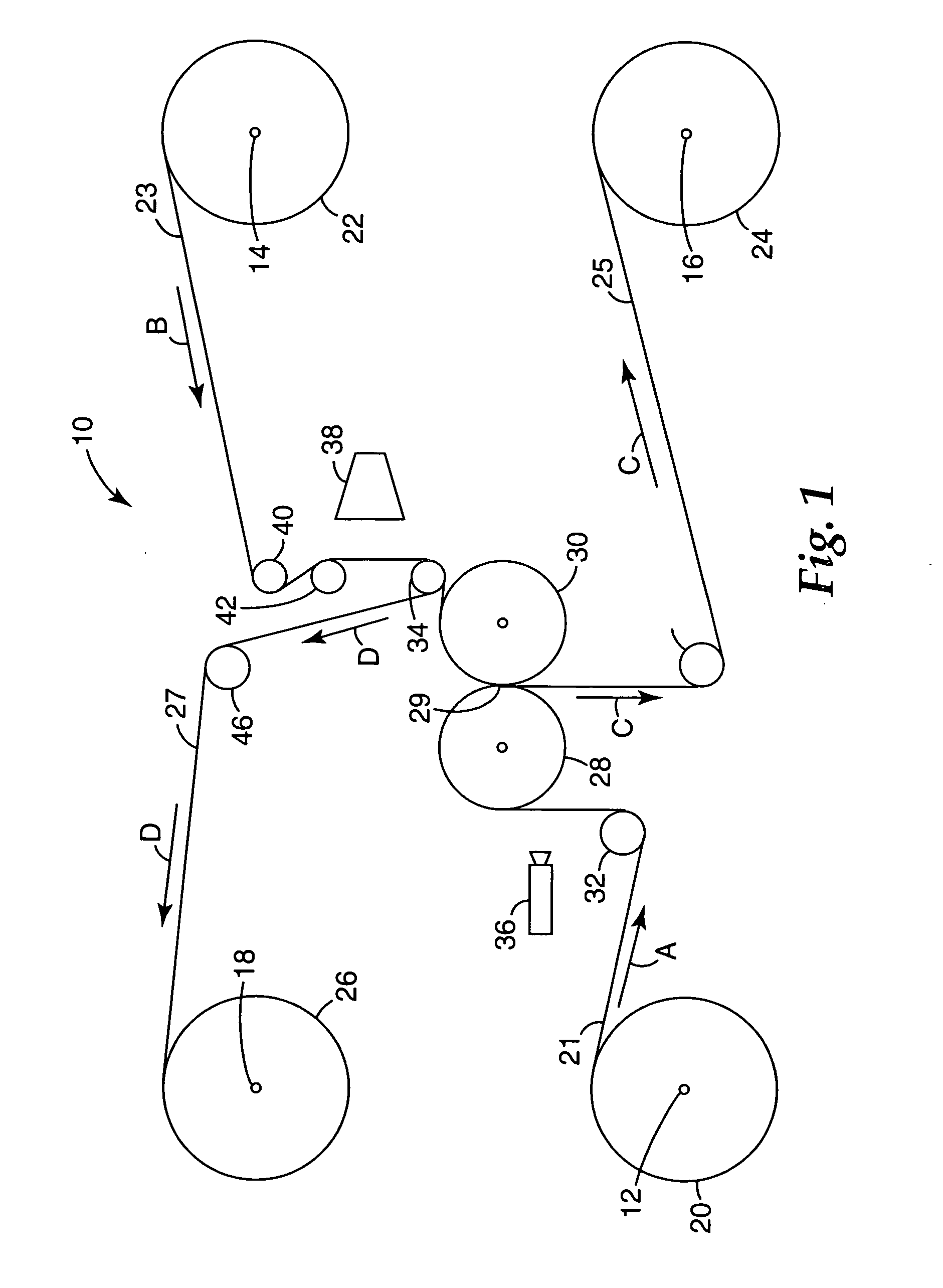

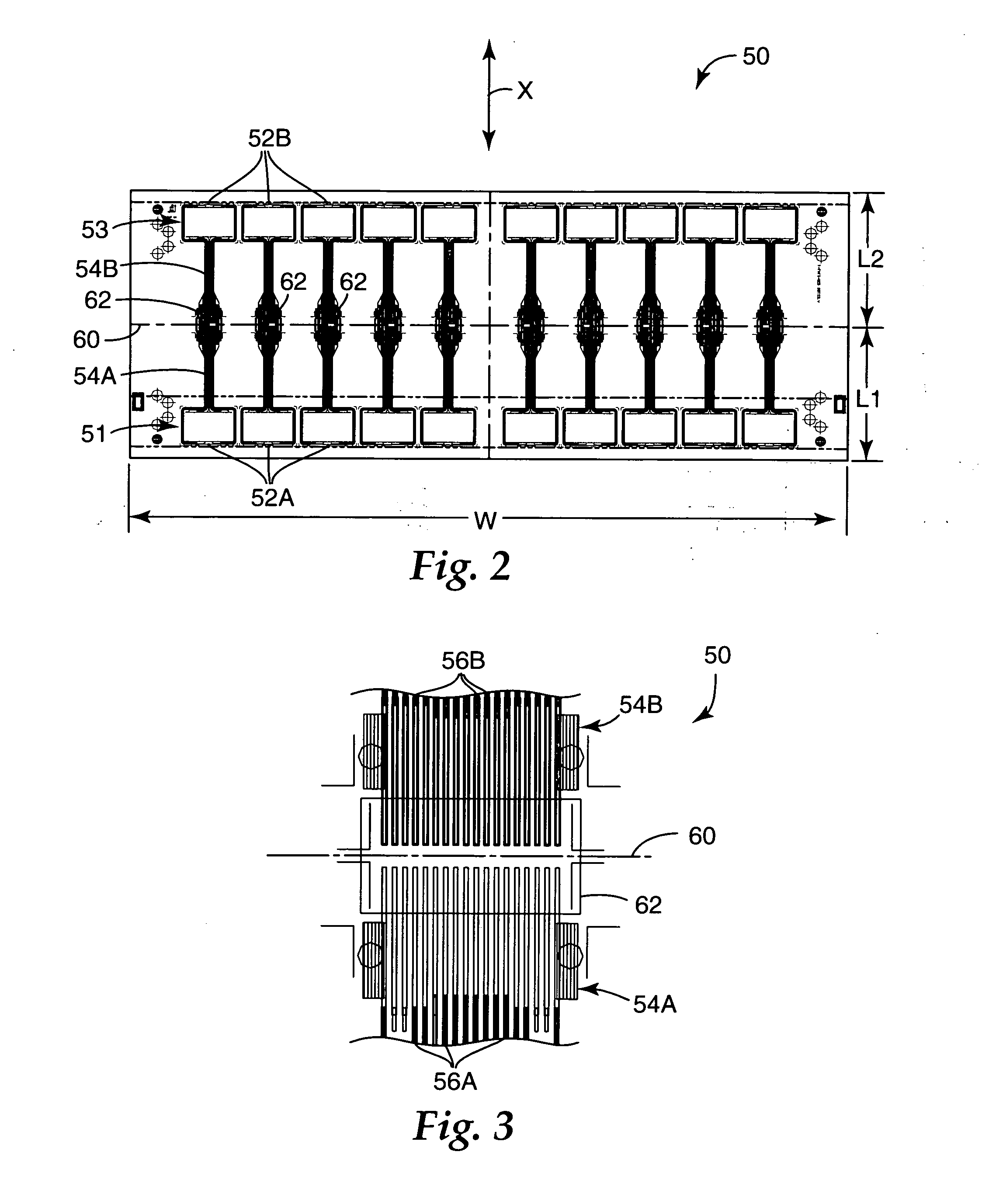

Registered lamination of webs using laser cutting

InactiveUS20060137813A1Eliminate manual processingEliminate needLamination ancillary operationsLaminationLaser cuttingWebbing

A system and method for manufacturing a multi-layered circuit assembly. The assembly includes a webbing member, a component, and a laminate layer. The method includes providing a roll of the webbing member with the component positioned thereon and a separate roll of the laminate layer, and monitoring a position of the component on the webbing member with an imaging device. The method also includes modifying a portion of the laminate layer at a location that is based on the monitored position of the component on the webbing member, and coupling the laminate layer to the webbing member to provide a continuous sheet of multi-layered circuit. The multi-layered circuit is formed with the component positioned between the webbing member and the laminate layer and aligned with the modification in the laminate layer.

Owner:3M INNOVATIVE PROPERTIES CO

Vascular treatment measurement methods

ActiveUS8715314B1Increase awarenessLathesOrnamental textile articlesLaser cuttingBiomedical engineering

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measureable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com