Patents

Literature

1182 results about "Narrow gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The symptoms of narrow gap include a noticeable (continuous) cylinder miss, hard starting if all the plugs have narrow gaps, rough idle and engine hesitation. A spark plug that does not fire, resulting from a narrow gap, will appear black or wet when inspected.

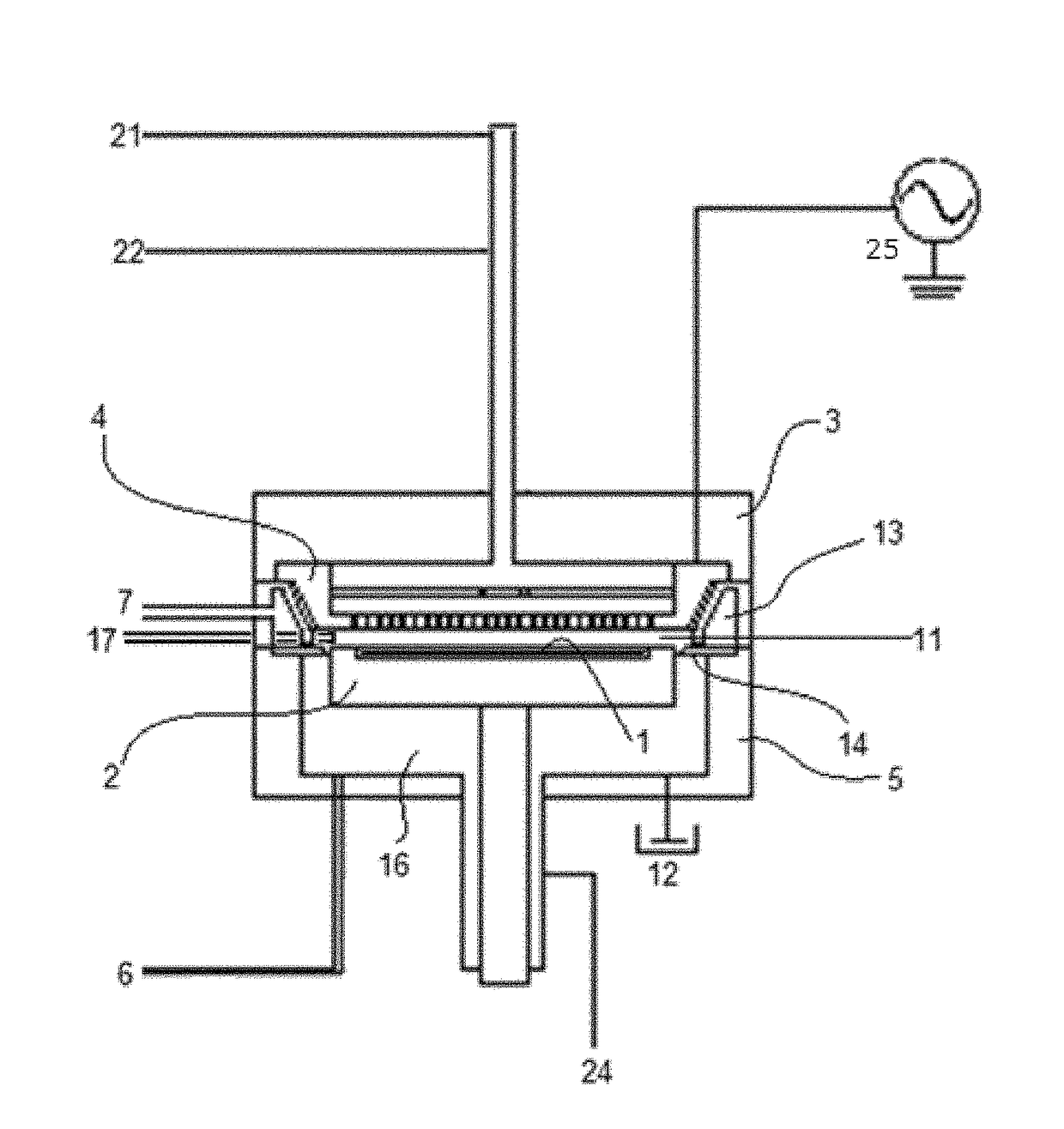

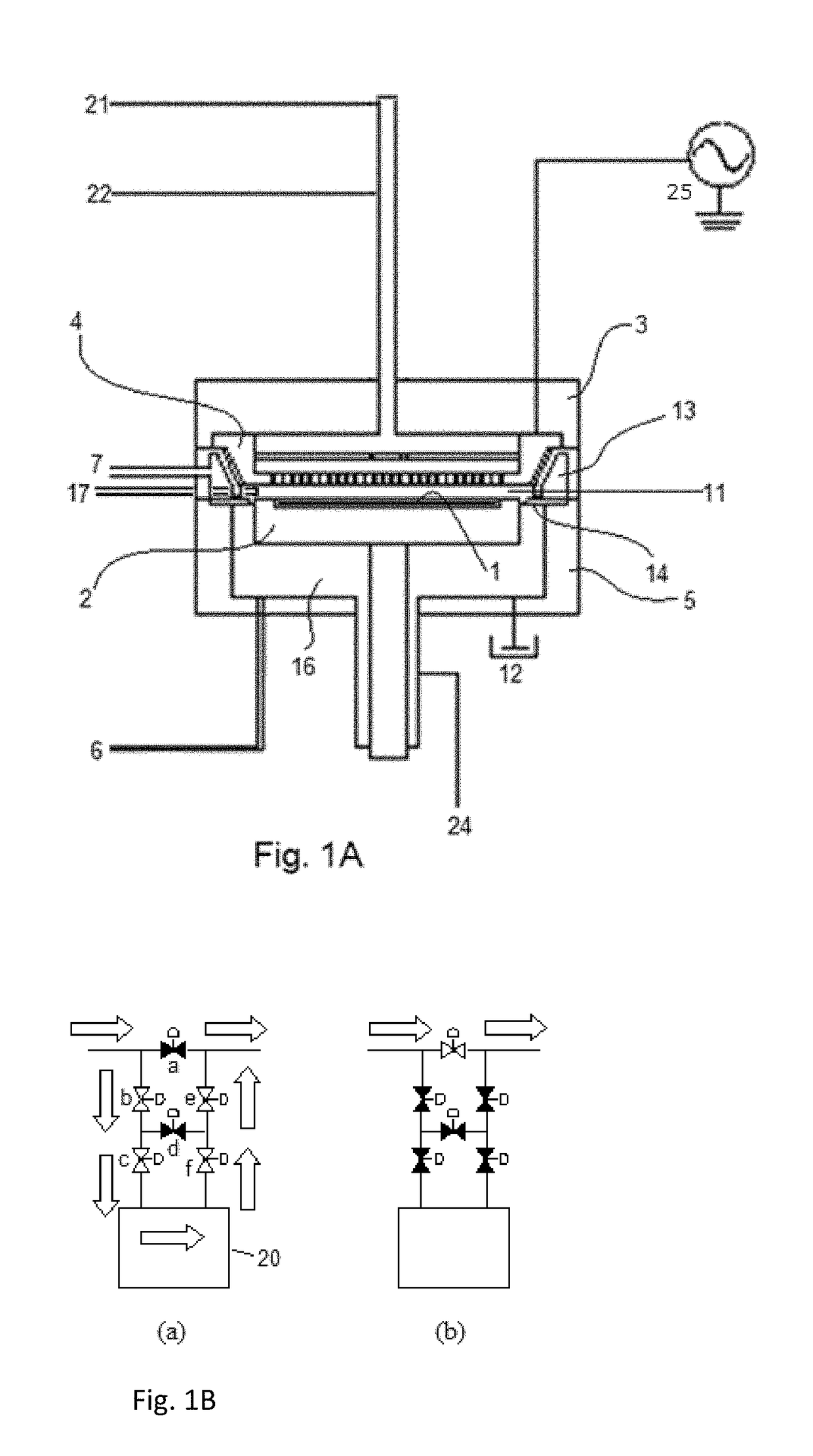

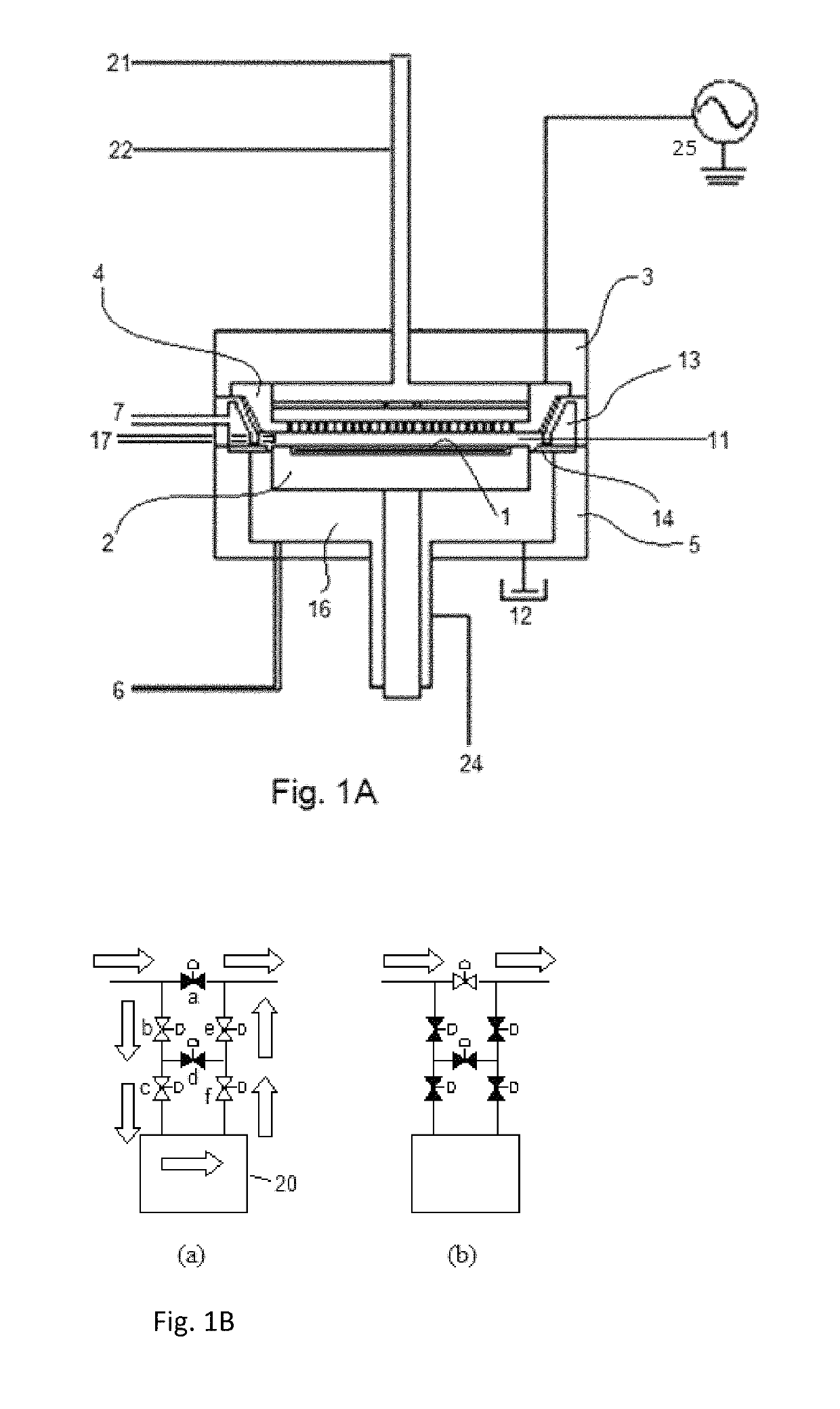

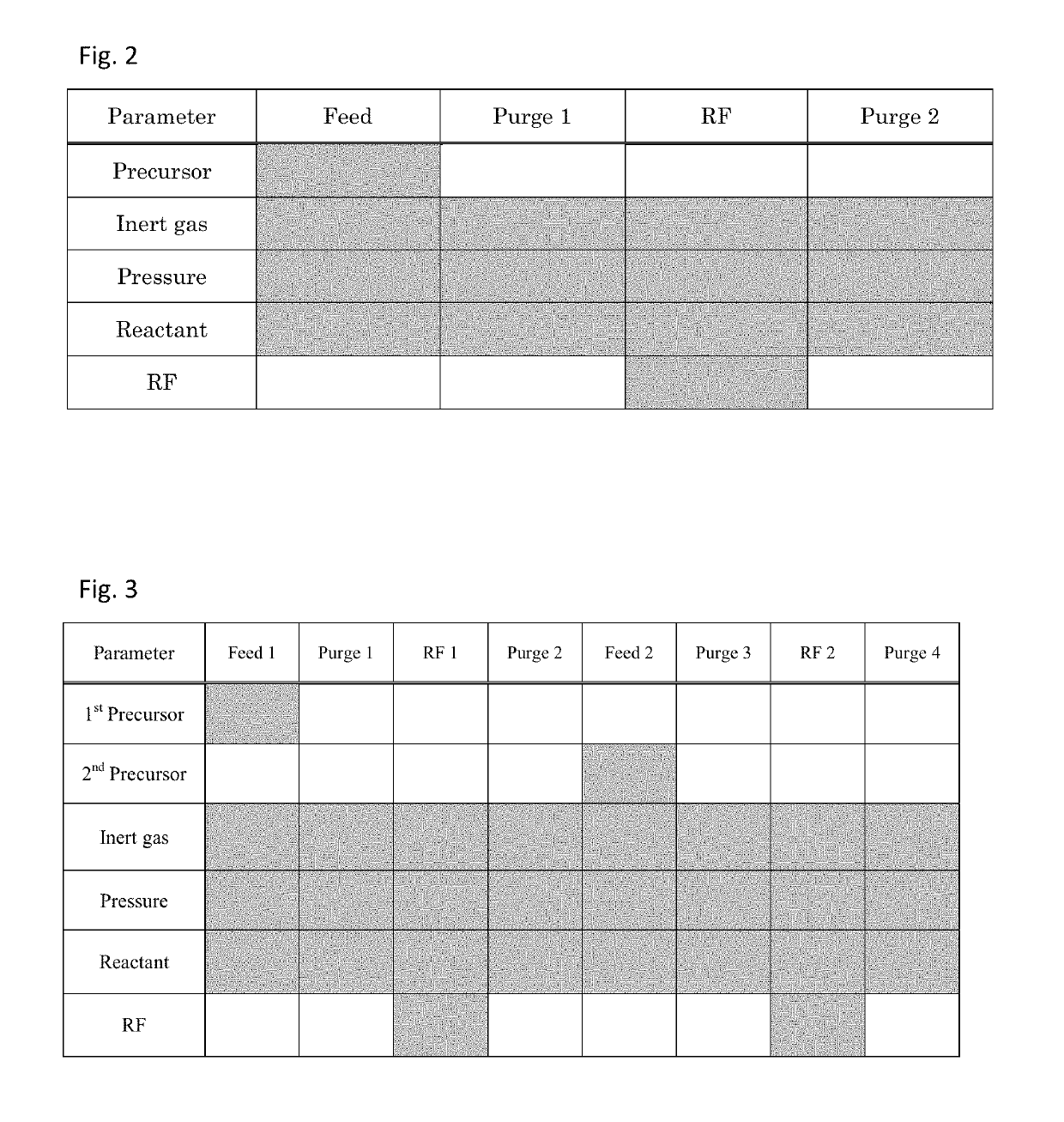

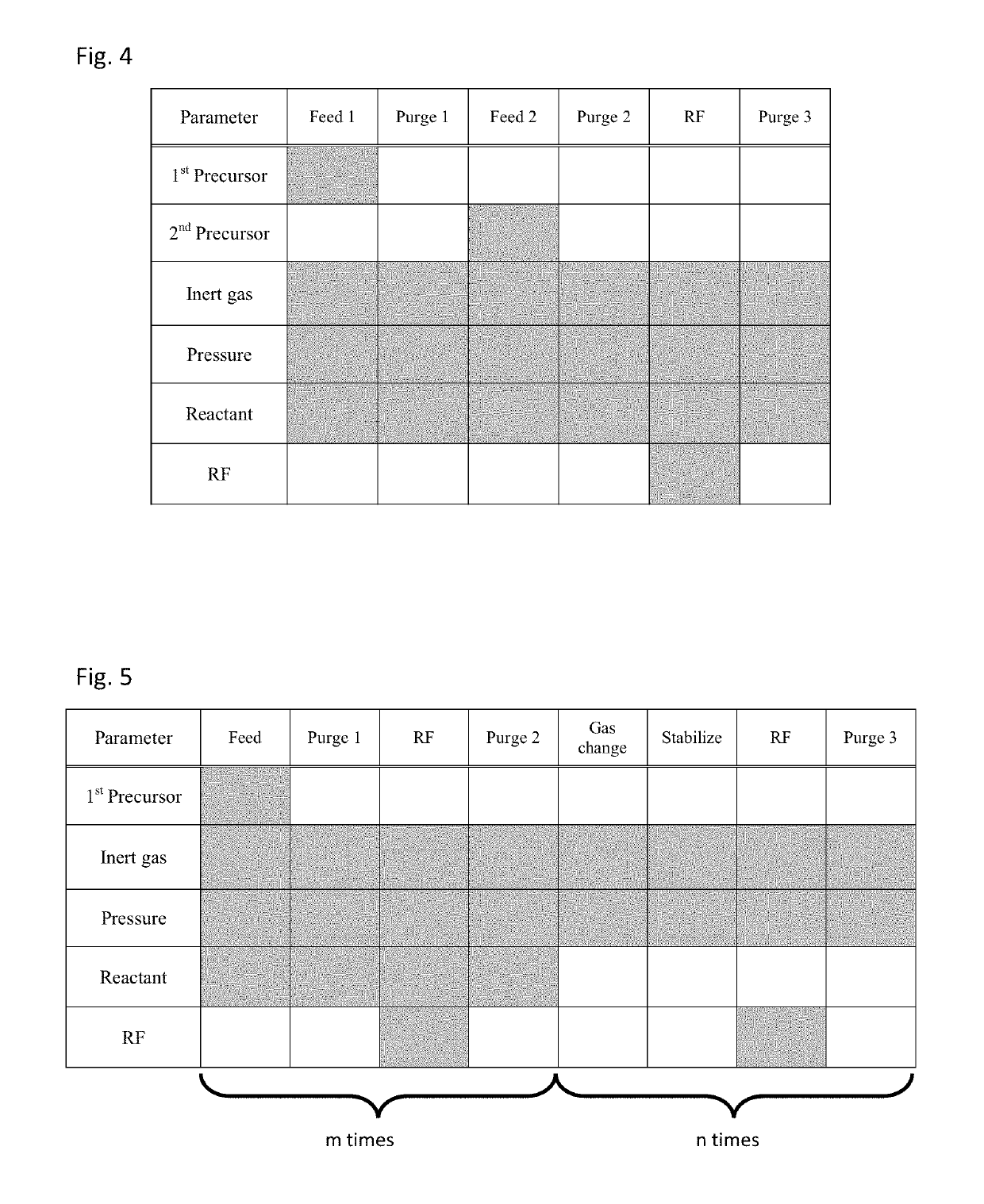

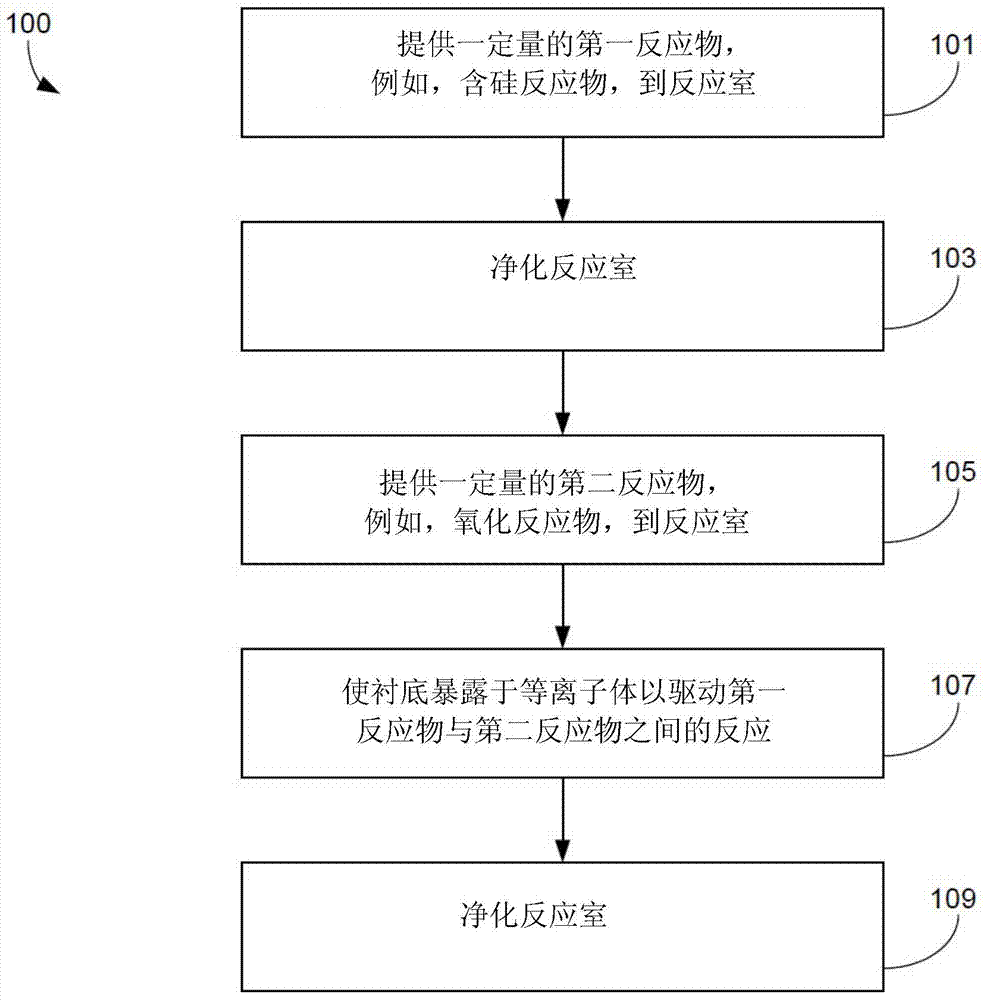

Method of subatmospheric plasma-enhanced ald using capacitively coupled electrodes with narrow gap

ActiveUS20180119283A1Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

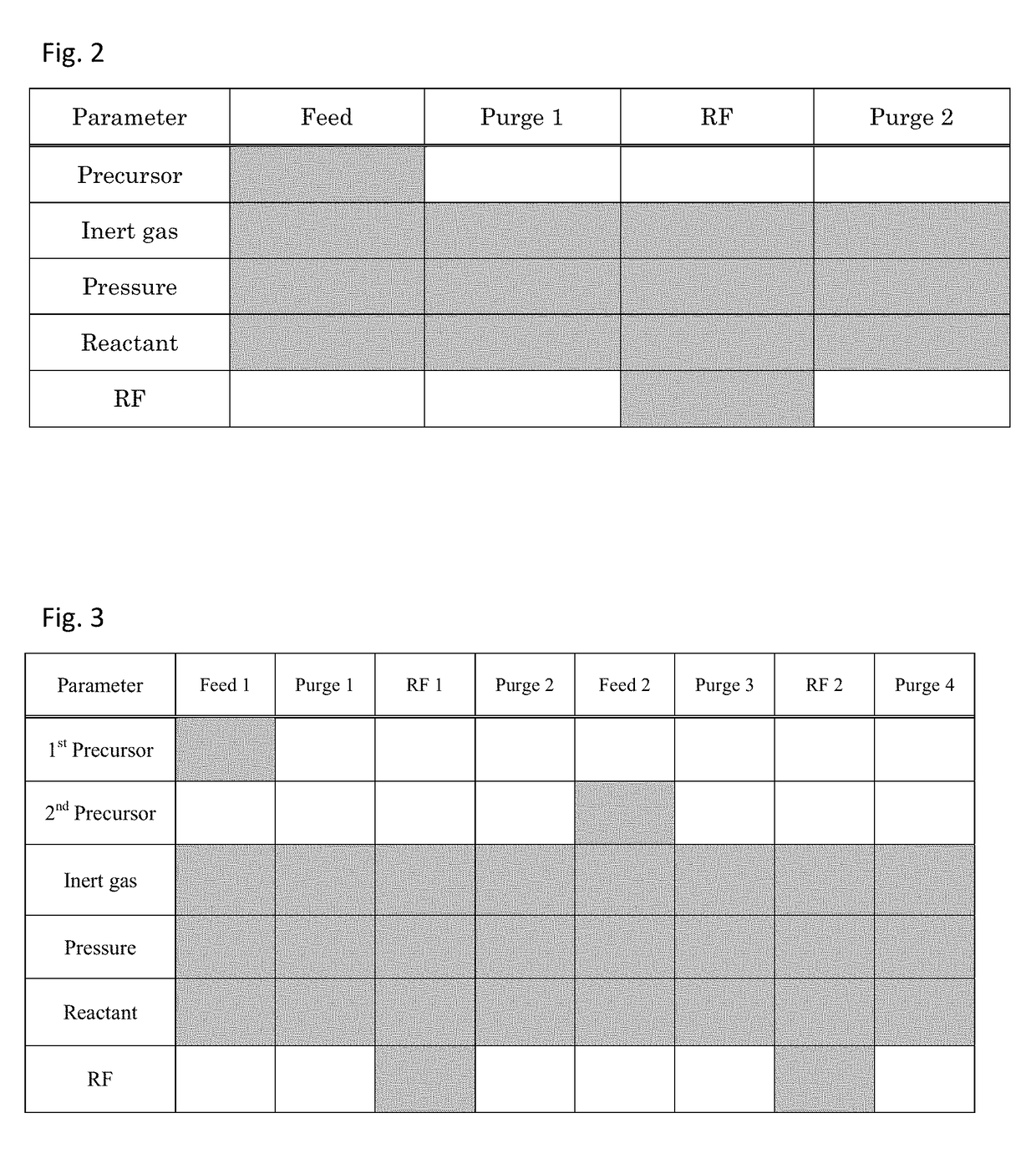

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

Method of subatmospheric plasma-enhanced ALD using capacitively coupled electrodes with narrow gap

ActiveUS10435790B2Poor conformalityGood shape retentionElectric discharge tubesChemical vapor deposition coatingCapacitanceParallel plate

A method for depositing a film by plasma-enhanced subatmospheric-pressure atomic layer deposition (subatmospheric PEALD) is conducted using capacitively coupled parallel plate electrodes with a gap of 1 mm to 5 mm, wherein one cycle of subatmospheric PEALD includes: supplying a precursor in a pulse to the reaction chamber; continuously supplying a reactant to the reaction chamber; continuously supplying an inert gas to the reaction chamber; continuously controlling a pressure of the reaction chamber in a range of 15 kPa to 80 kPa; and applying RF power for glow discharge in a pulse to one of the parallel plate electrodes.

Owner:ASM IP HLDG BV

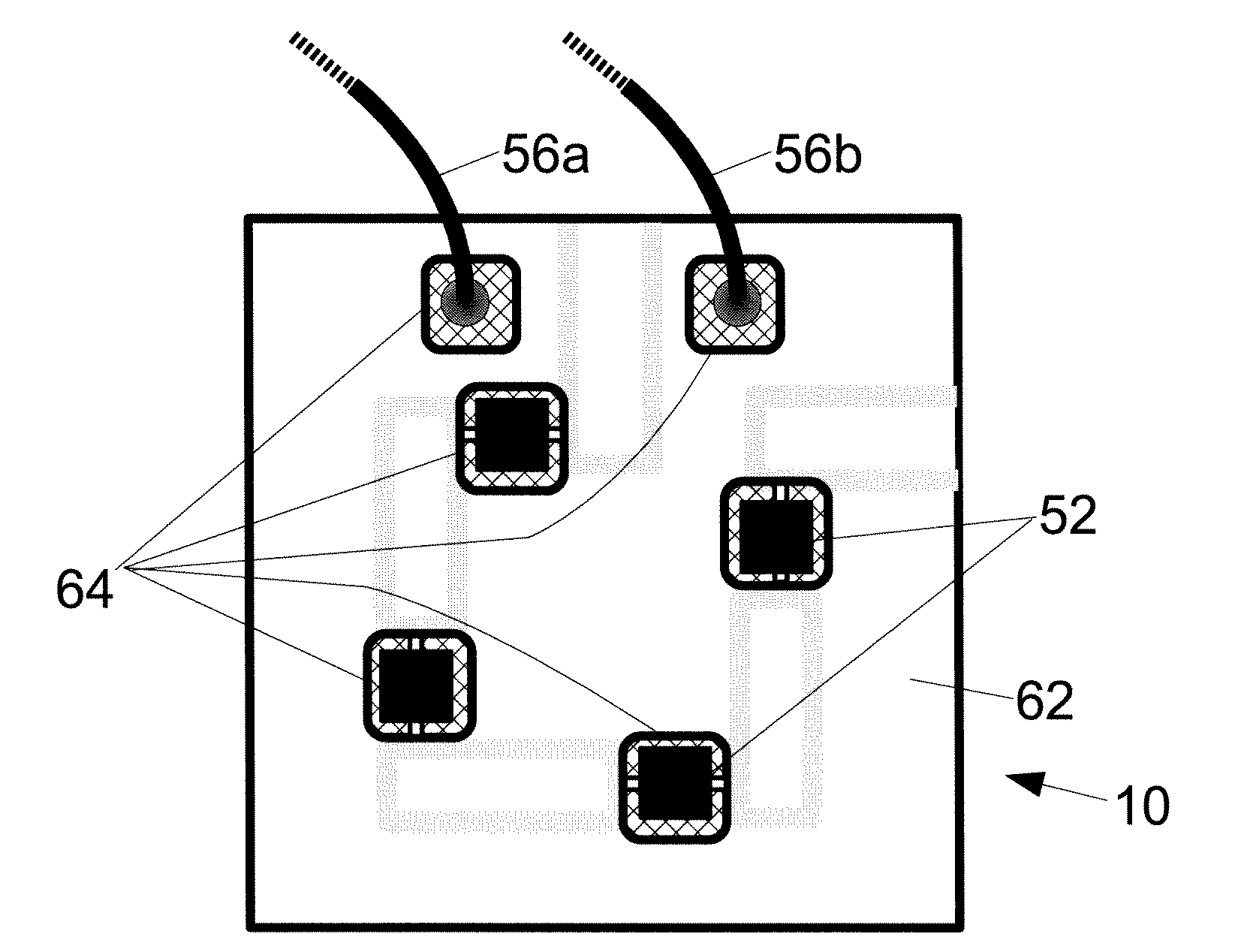

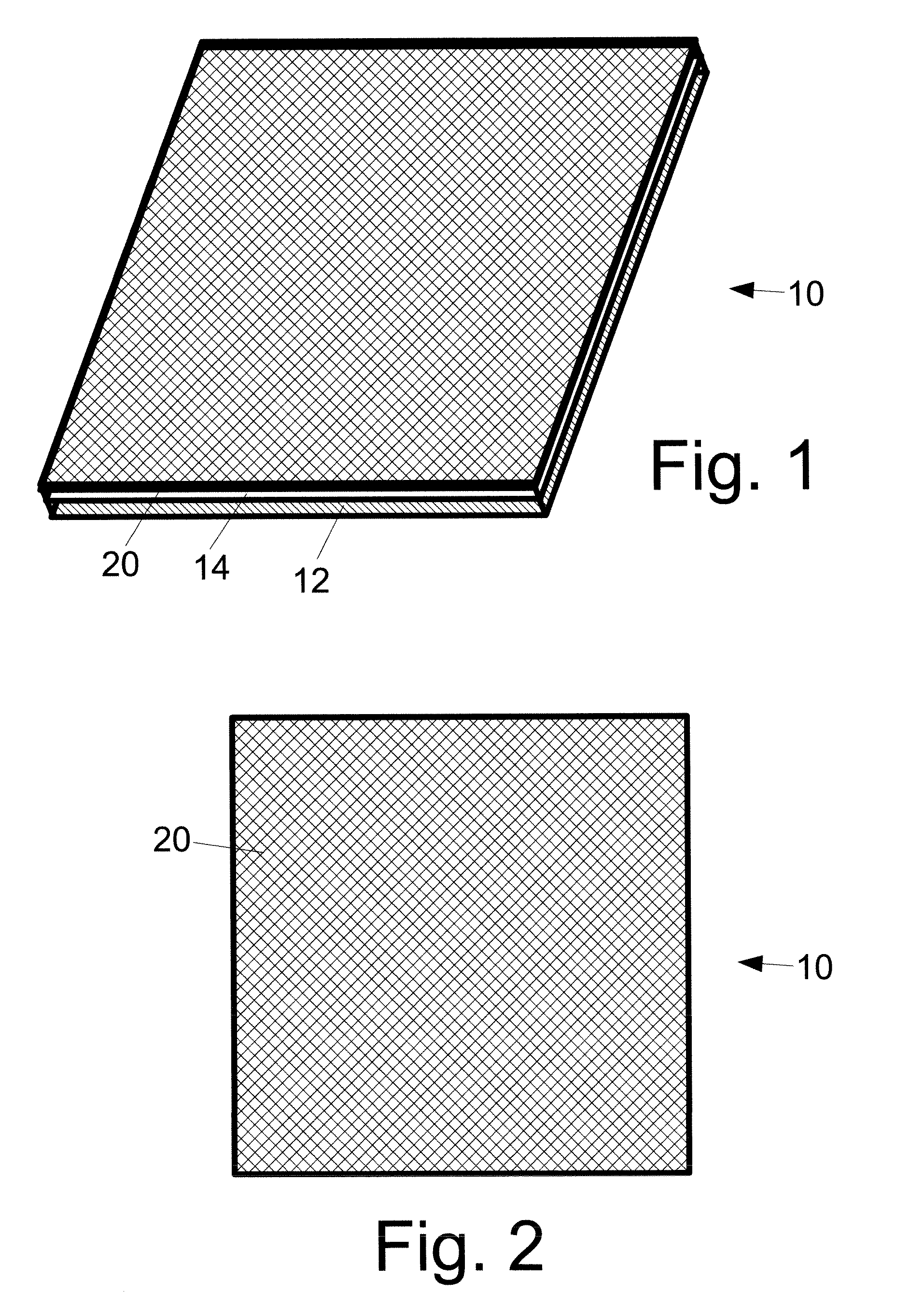

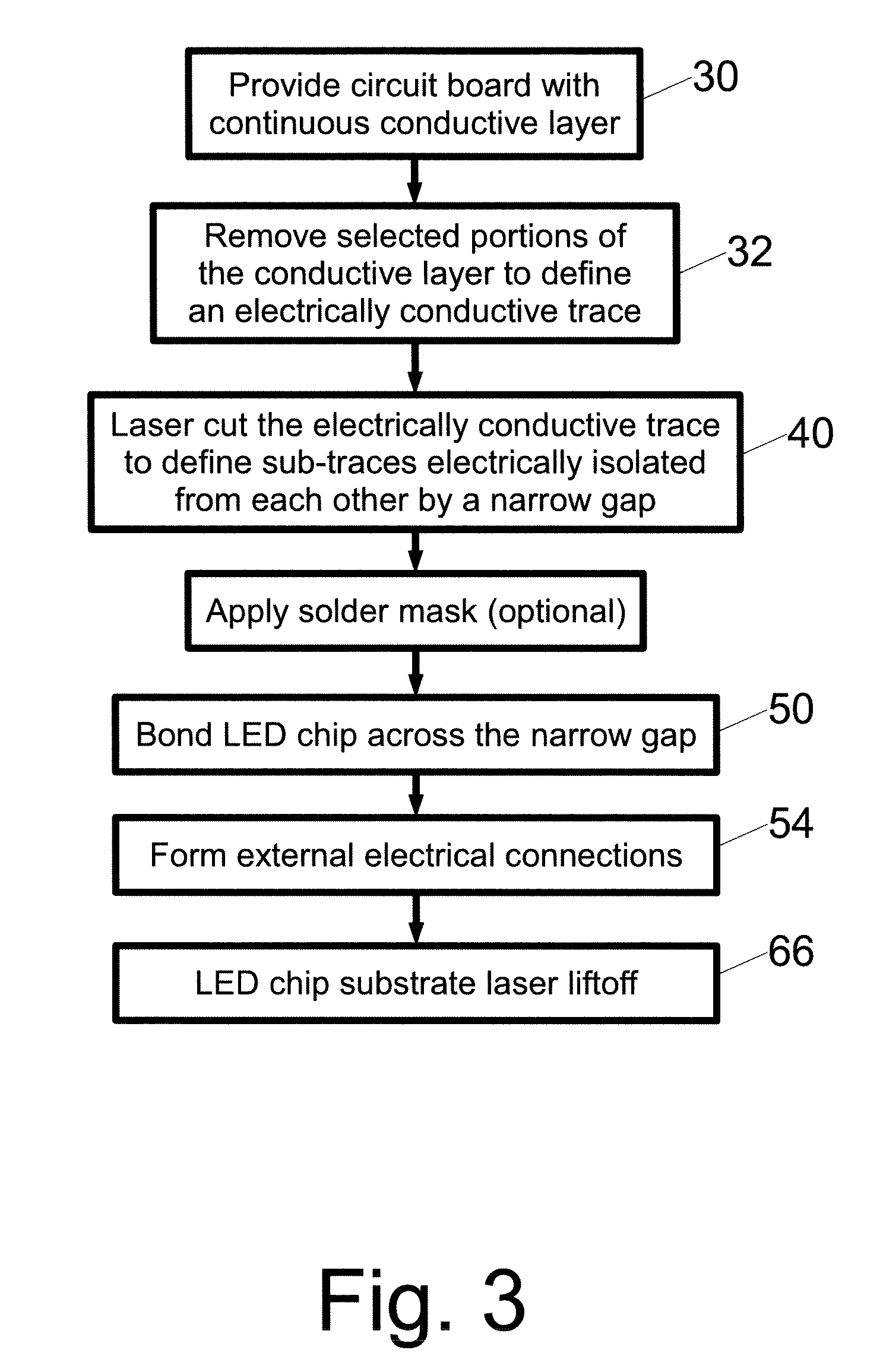

Circuit board for direct flip chip attachment

InactiveUS20090212317A1Semiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor packageLaser cutting

A packaging method comprises: forming a circuit board by forming a substantially continuous conductive layer on an insulating board and removing selected portions of the continuous conductive layer to define an electrically conductive trace; laser cutting the electrically conductive trace to define sub-traces electrically isolated from each other by a laser-cut gap formed by the laser cutting; and bonding a light emitting diode (LED) chip to the circuit board across or adjacent to the laser-cut gap, the bonding including operatively electrically connecting an electrode of the LED chip to one of the sub-traces without using an interposed submount. A semiconductor package comprises an LED chip flip-chip bonded to sub-traces of an electrically conductive trace of a circuit board, the sub-traces being electrically isolated from each other by a narrow gap of less than or about 100 microns.

Owner:LUMINATION

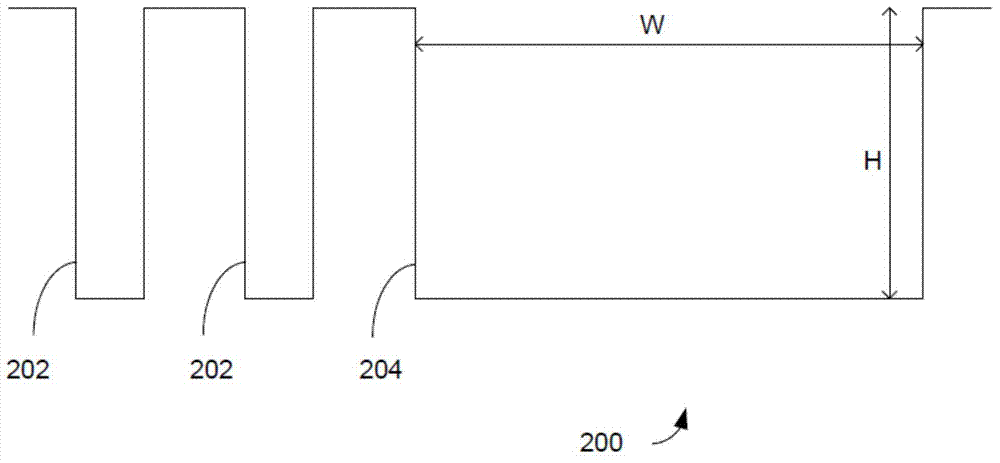

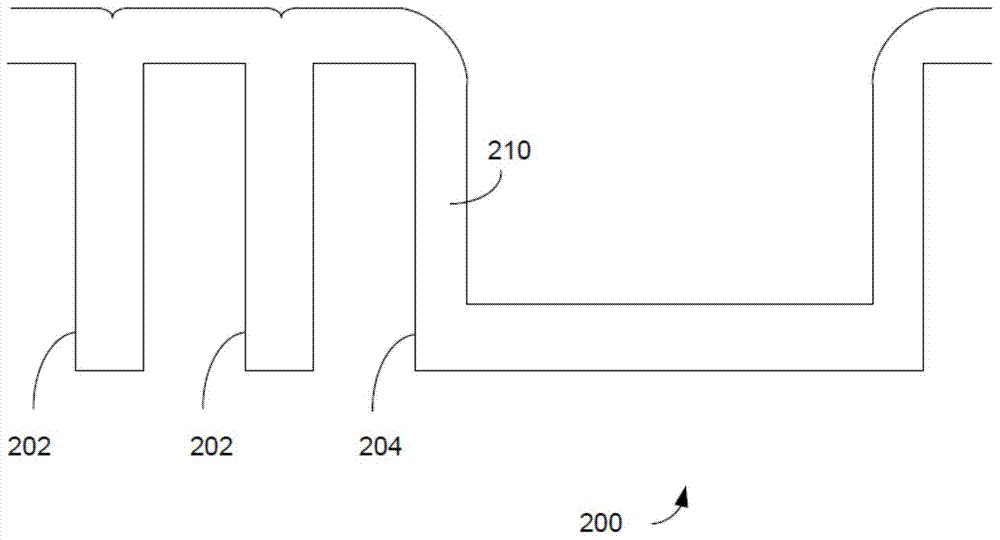

Gapfill of variable aspect ratio features with a composite PEALD and PECVD method

ActiveCN104517892ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringWide gap

The invention relates to gapfill of variable aspect ratio features with a composite PEALD and PECVD method, and specifically provides methods and apparatus for filling one or more gaps on a semiconductor substrate. The disclosed embodiments are especially useful for forming seam-free, void-free fill in both narrow and wide features. The methods may be performed without any intervening etching operations to achieve a single step deposition. In various implementations, a first operation is performed using a novel PEALD fill mechanism to fill narrow gaps and line wide gaps. A second operation may be performed using PECVD methods to continue filling the wide gaps.

Owner:LAM RES CORP

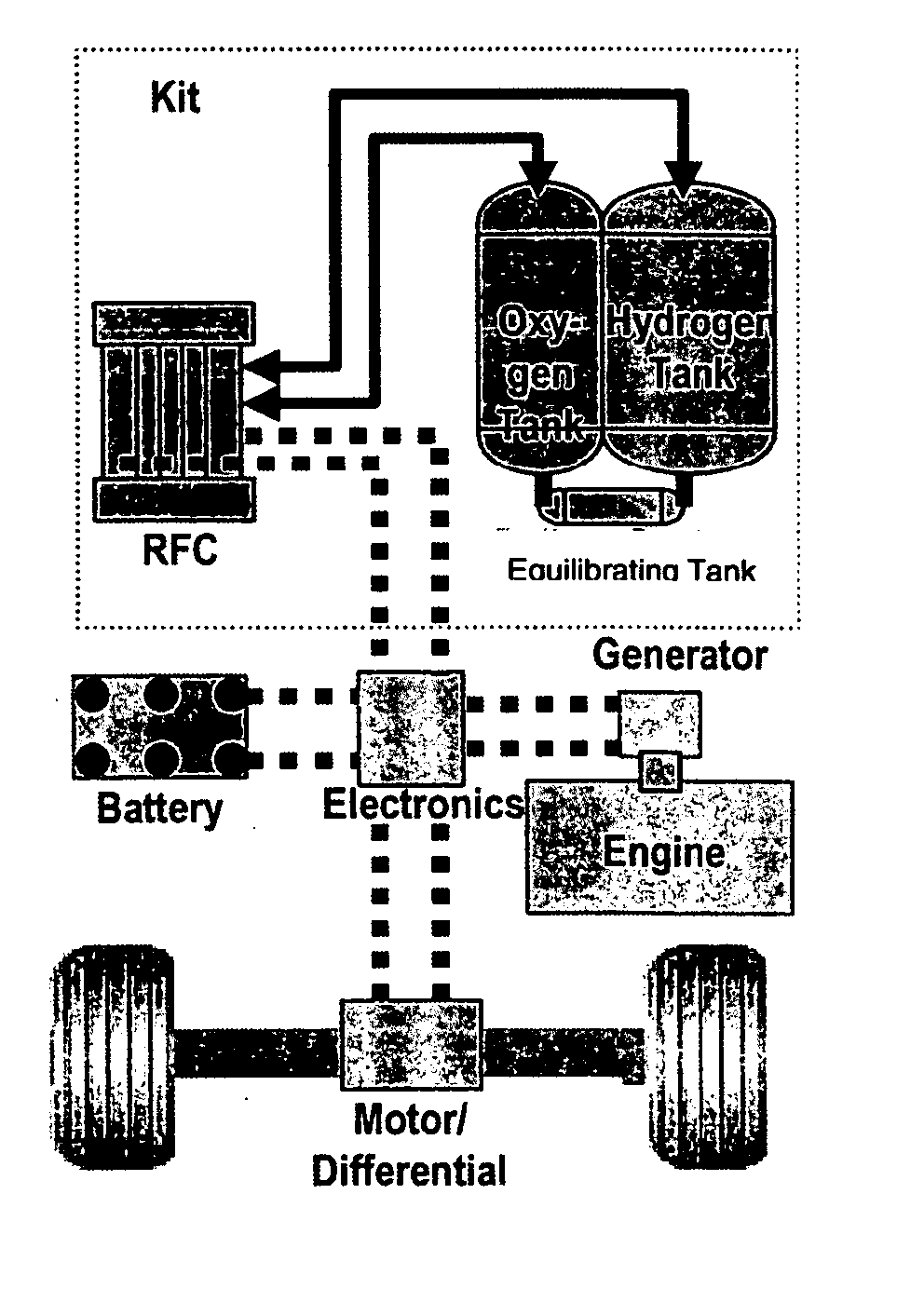

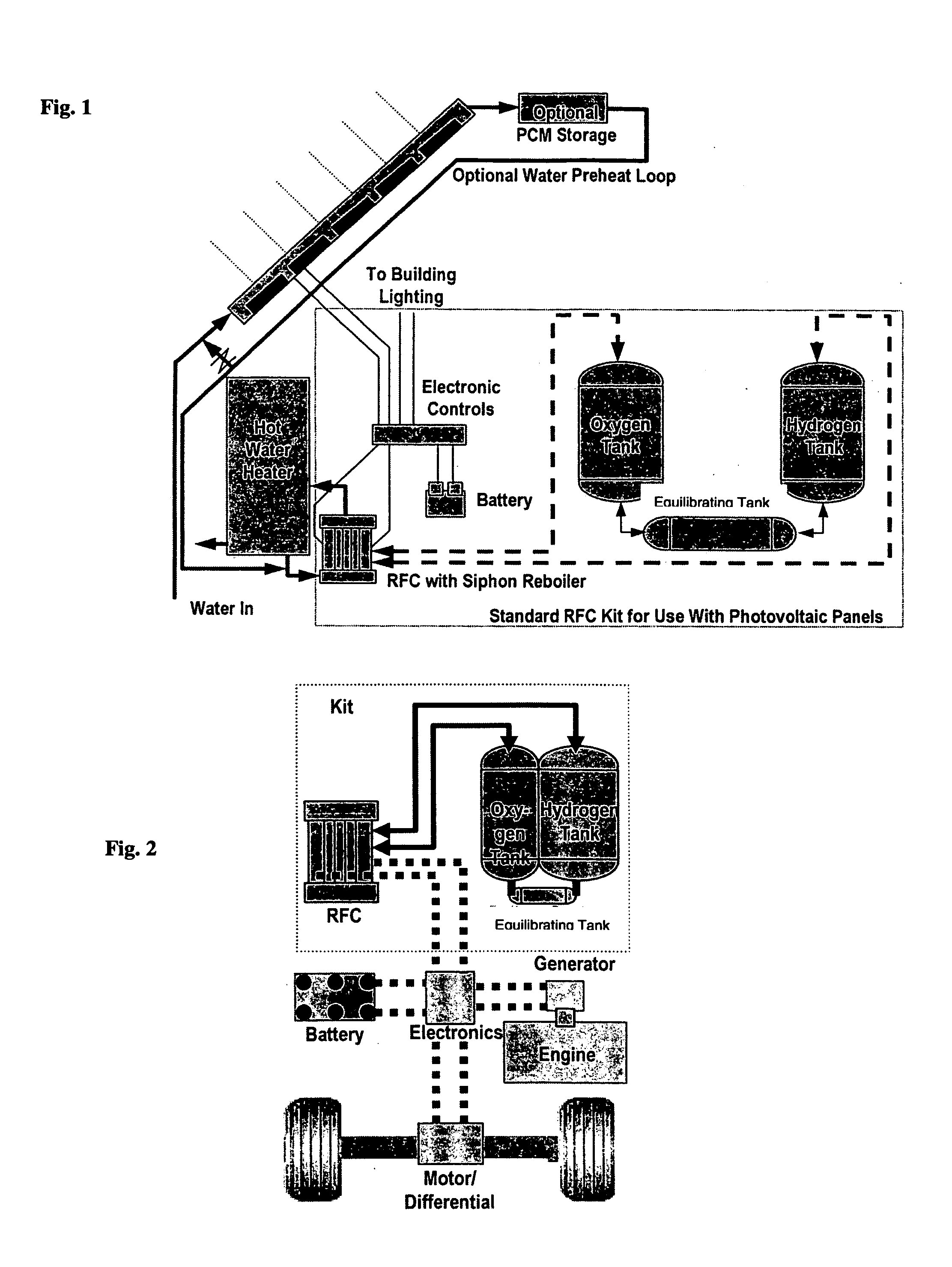

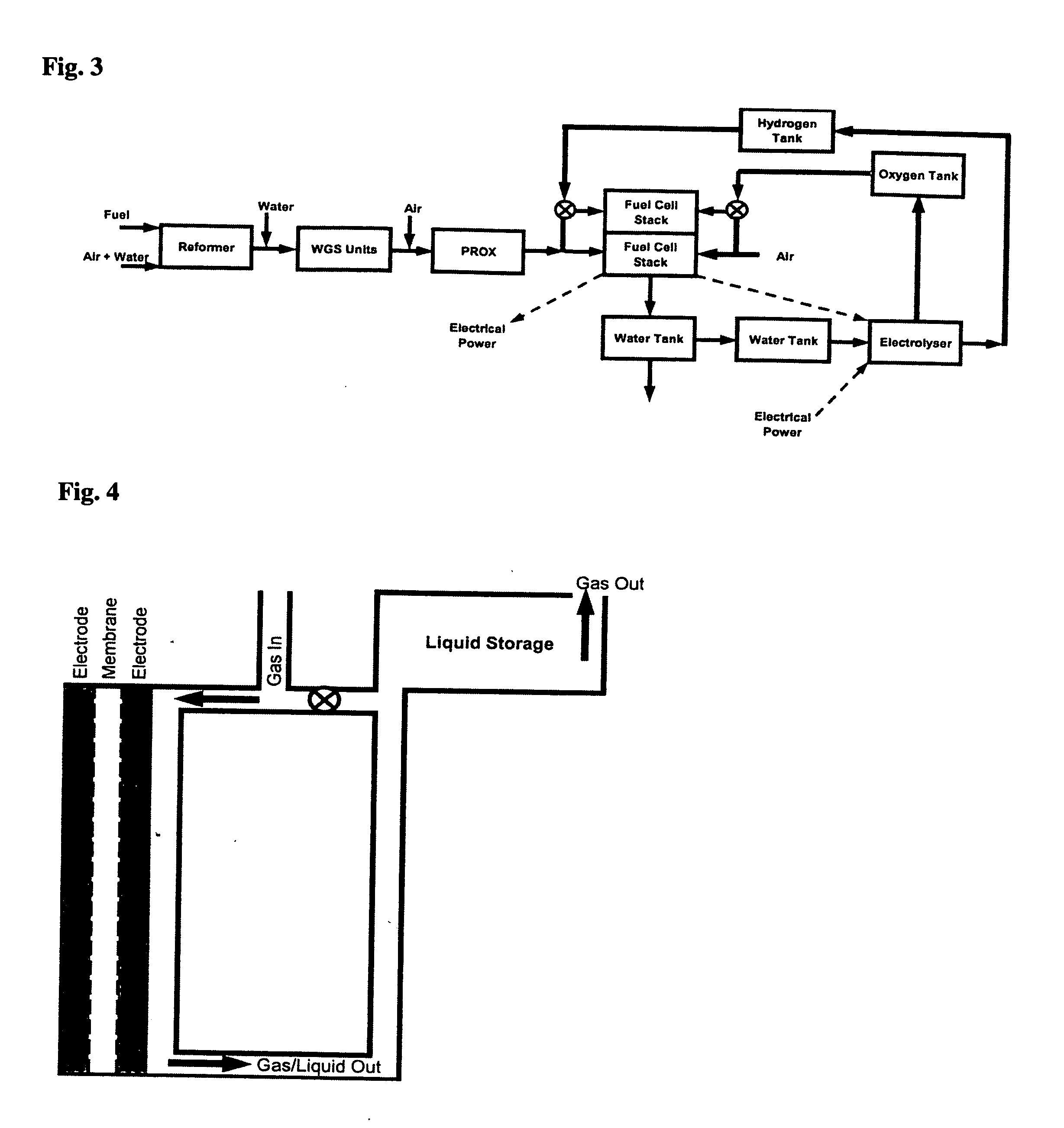

Regenerative fuel cell technology

InactiveUS20050008904A1Constant gainSmall fuel cellBatteries circuit arrangementsRegenerative fuel cellsElectrolysisOxygen

For a mobile fuel cell system a narrow-gap modular approach allows reforming to be performed in the same architecture as the fuel cell. A regenerative fuel cell operates much like a battery using electrical power to produce hydrogen and oxygen. The preferred mode of using the regenerative fuel cell is as a battery charger since this application is able to use a much smaller fuel cell than is required to power the vehicle. A novel equilibrating tank between the electrolysis oxygen and hydrogen tanks allows pressurized oxygen and hydrogen to be used without mechanical compression equipment.

Owner:SUPPES GALEN J

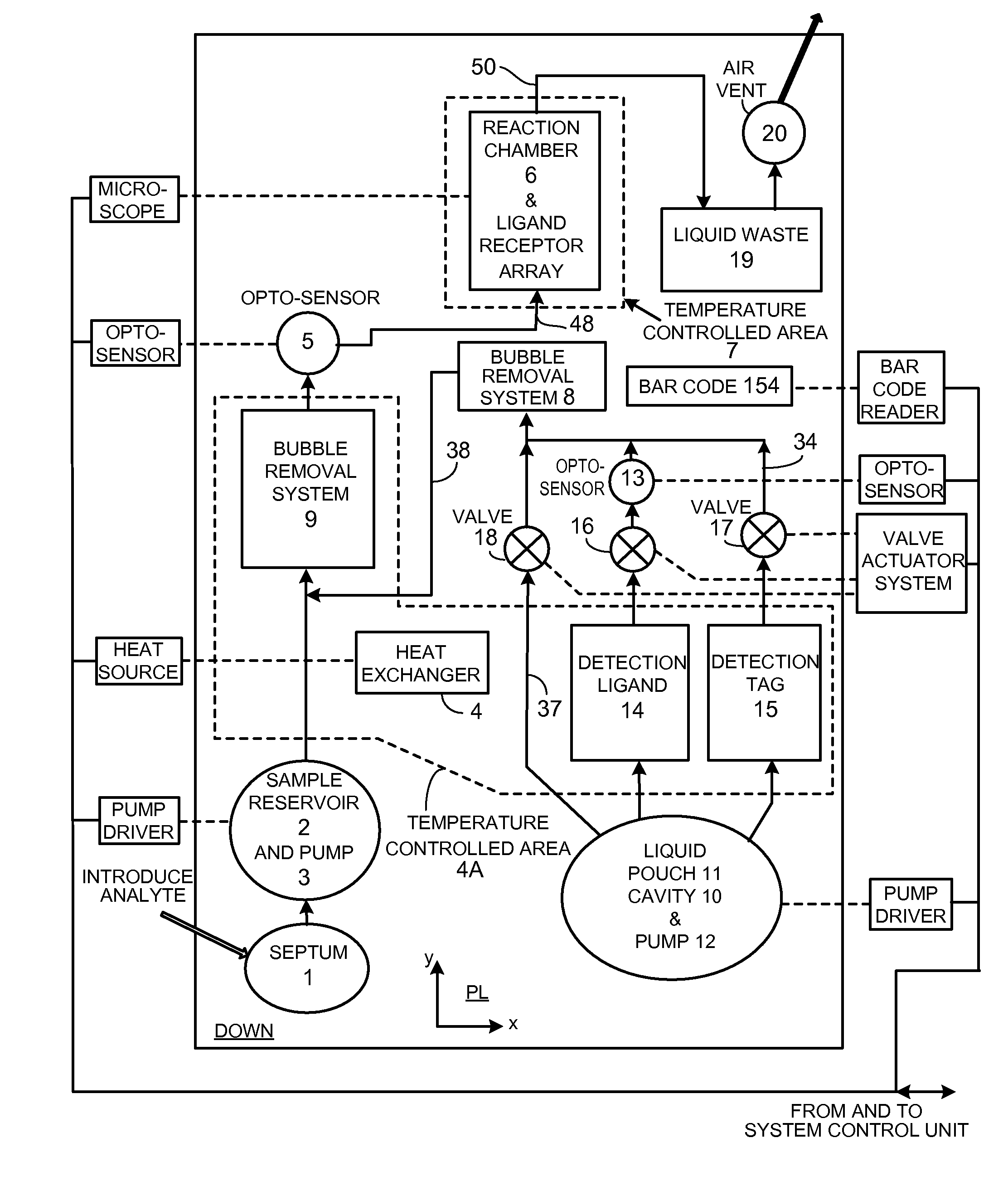

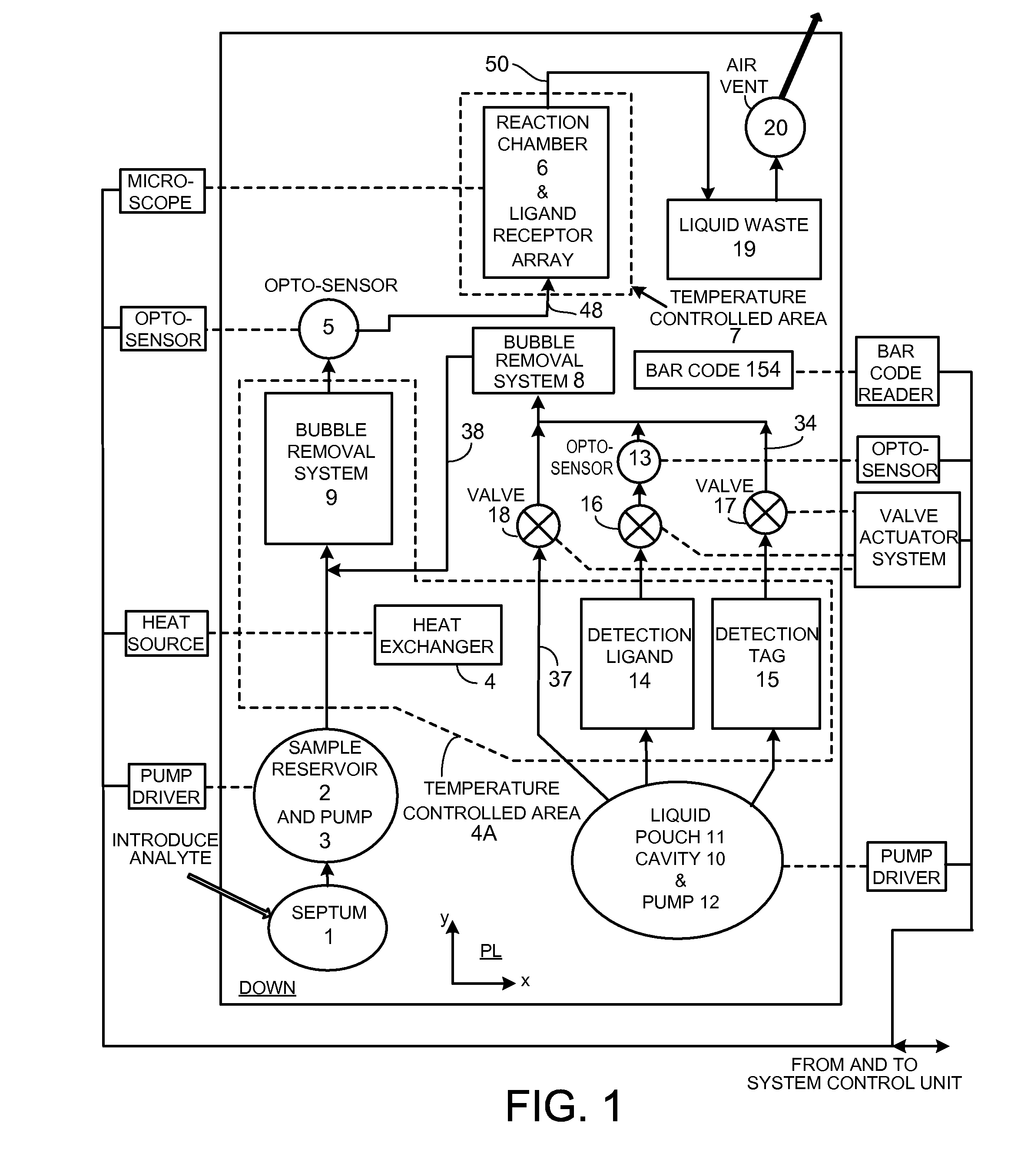

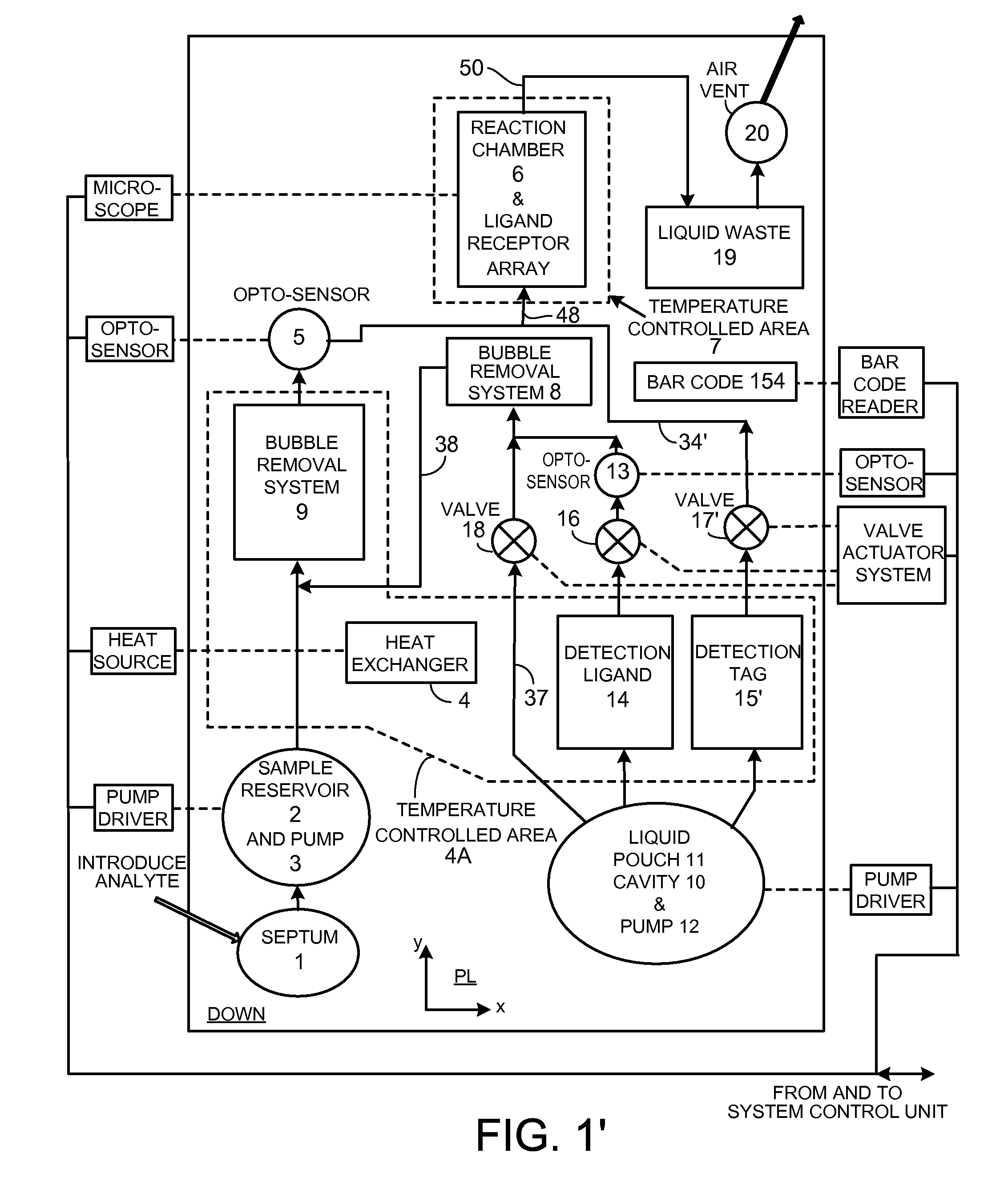

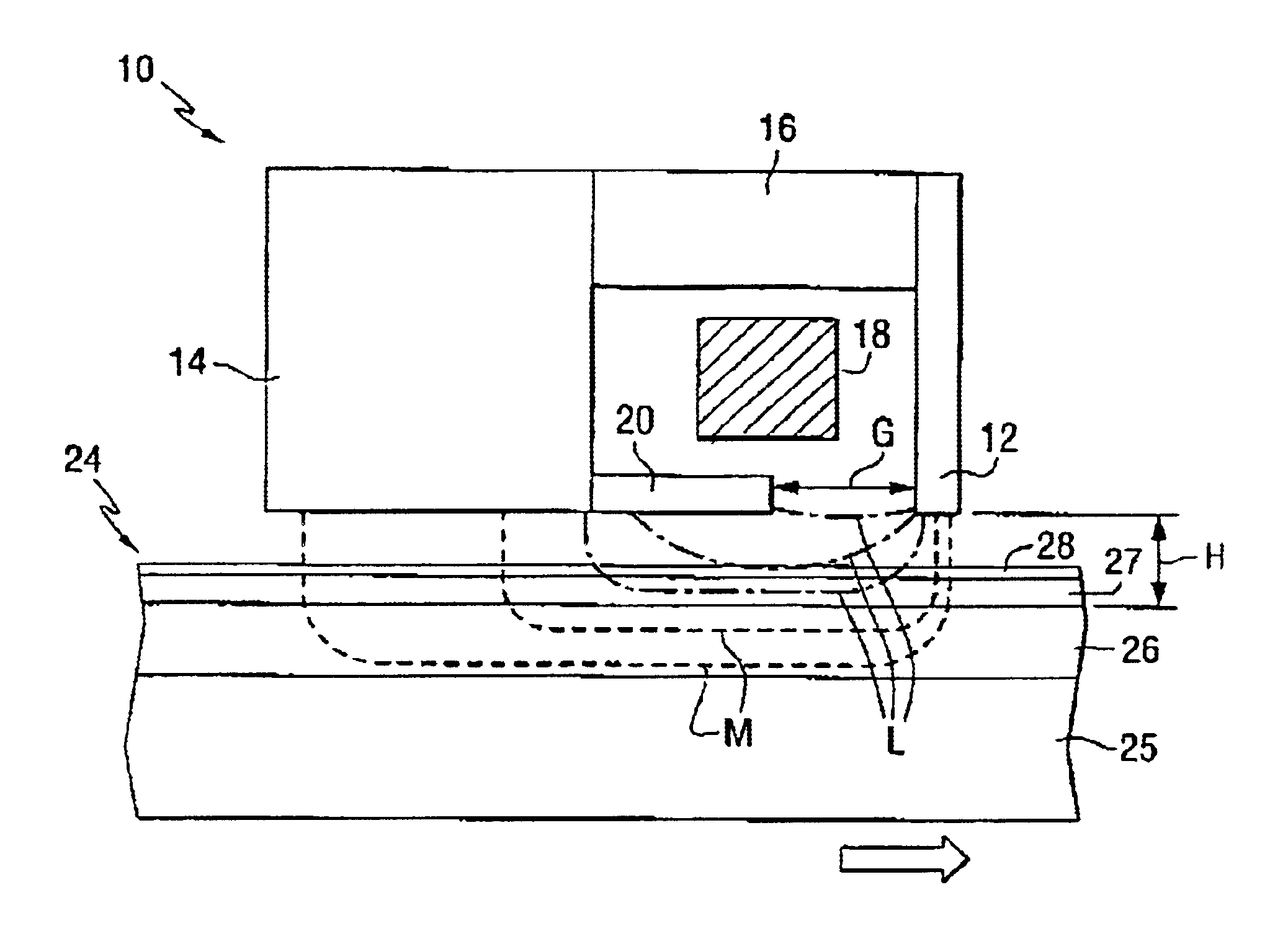

Assays Based on Liquid Flow over Arrays

InactiveUS20110207621A1Highly consistent quantitative multiplex assaysLow costLibrary screeningFlexible member pumpsFritBlister pack

Flow-through assay reaction chamber (6) of cassette has back and forth liquid mixing in narrow gap (G) over array of capture agent (S), with net flow advance to waste confinement (19), produced by reversible pumps (3 or 12), operable with rolling diaphragm action with at least limited elastic recovery that advance sample or buffer liquids through conditioning paths (4A, 8, 8′, 9, 14, 15, 15′) before reaching the reaction chamber (6). A single pump produces accurate flow control, liquid conditioning, e.g., liquefying dry reagent from internal surfaces of flow-dividing material (14a, 15A, 15A′, e.g. open cell foam or frit), heating (4A), and air bubble removal (8, 8′, 9), as well as replenishment of reagent while accomplishing mixing within the flow-through reaction chamber (6). Lower viscosity buffer liquid is arranged to propel higher viscosity reagent, the flow-dividing storage material preserving reagent concentration. A blister pack (11) acts as a reversible pump (12) in producing accurate forward and backward flows with the net flow advance. Cascaded bubble traps (8, 9) on the cassette render the system tolerant of minor pumping error during cassette priming.

Owner:AVANTRA BIOSCI CORP

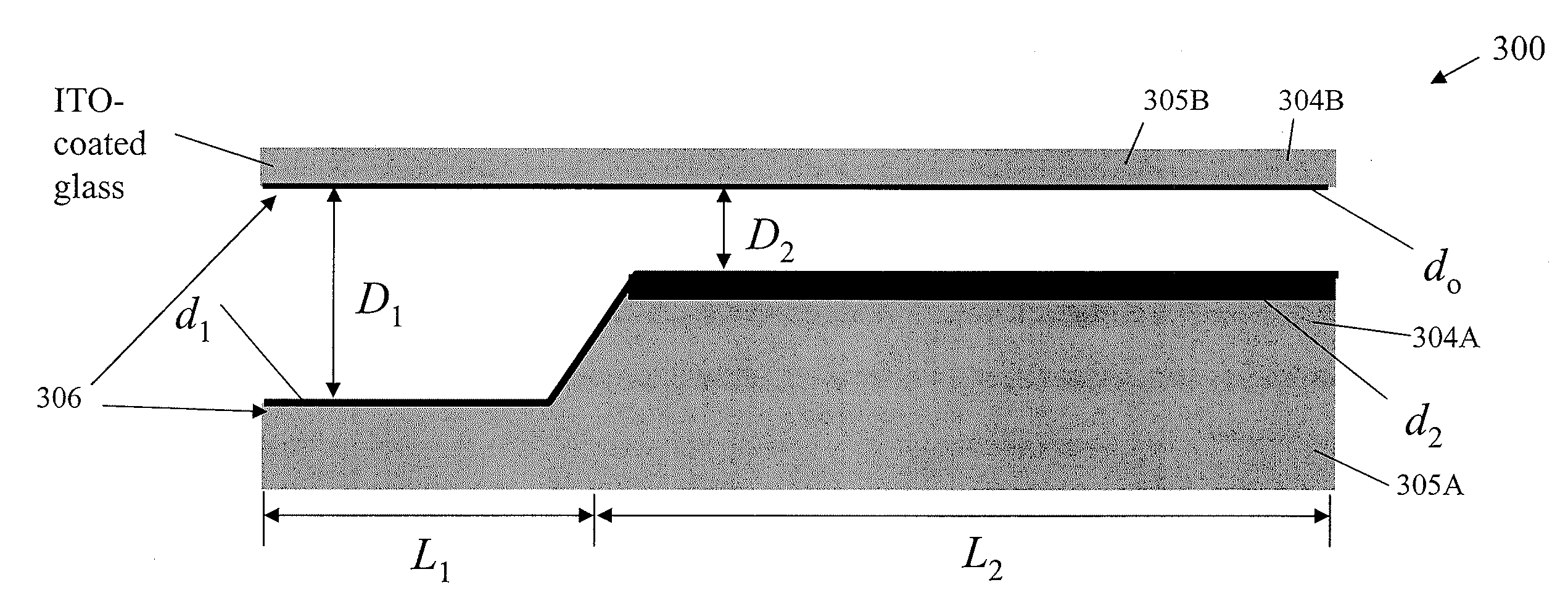

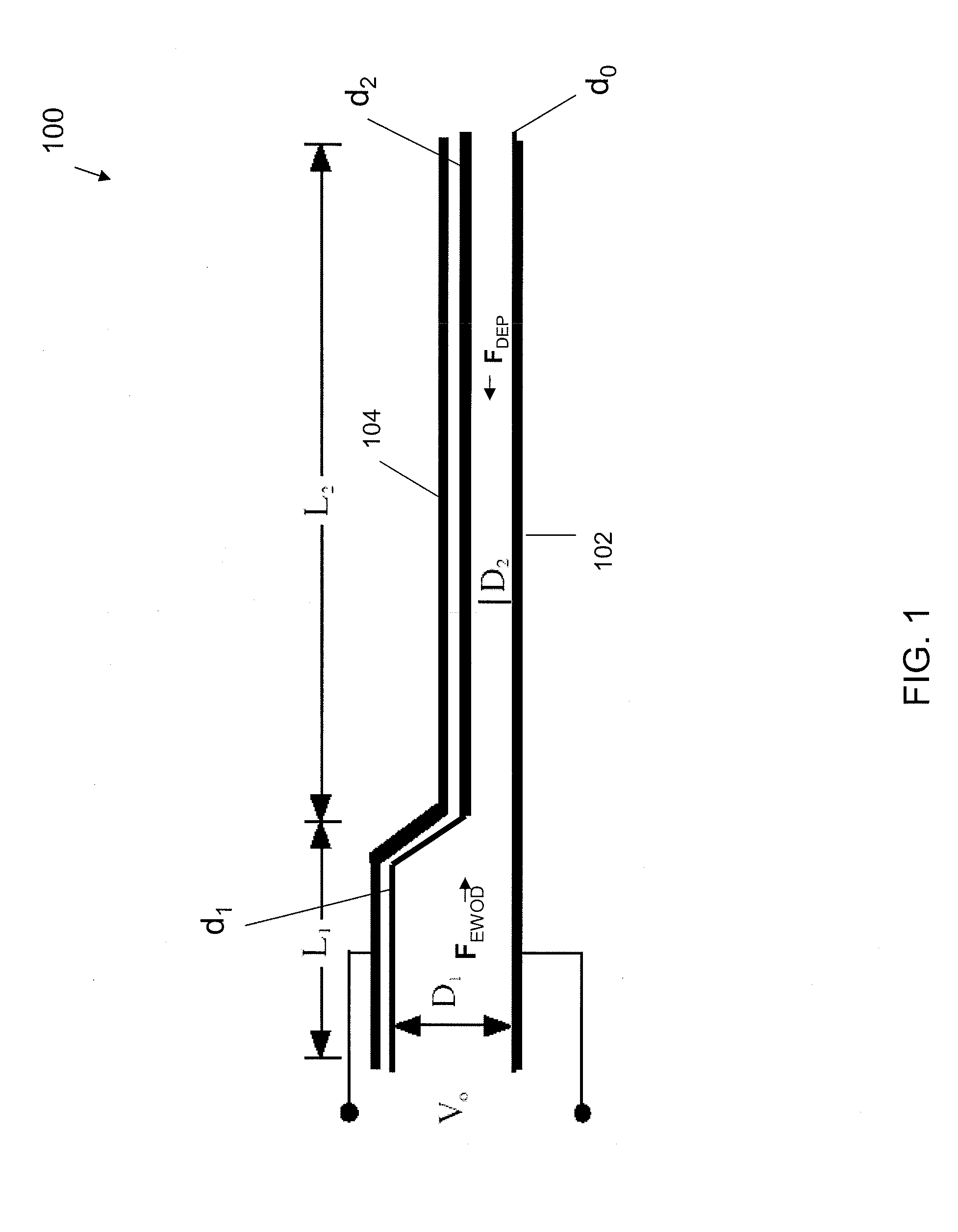

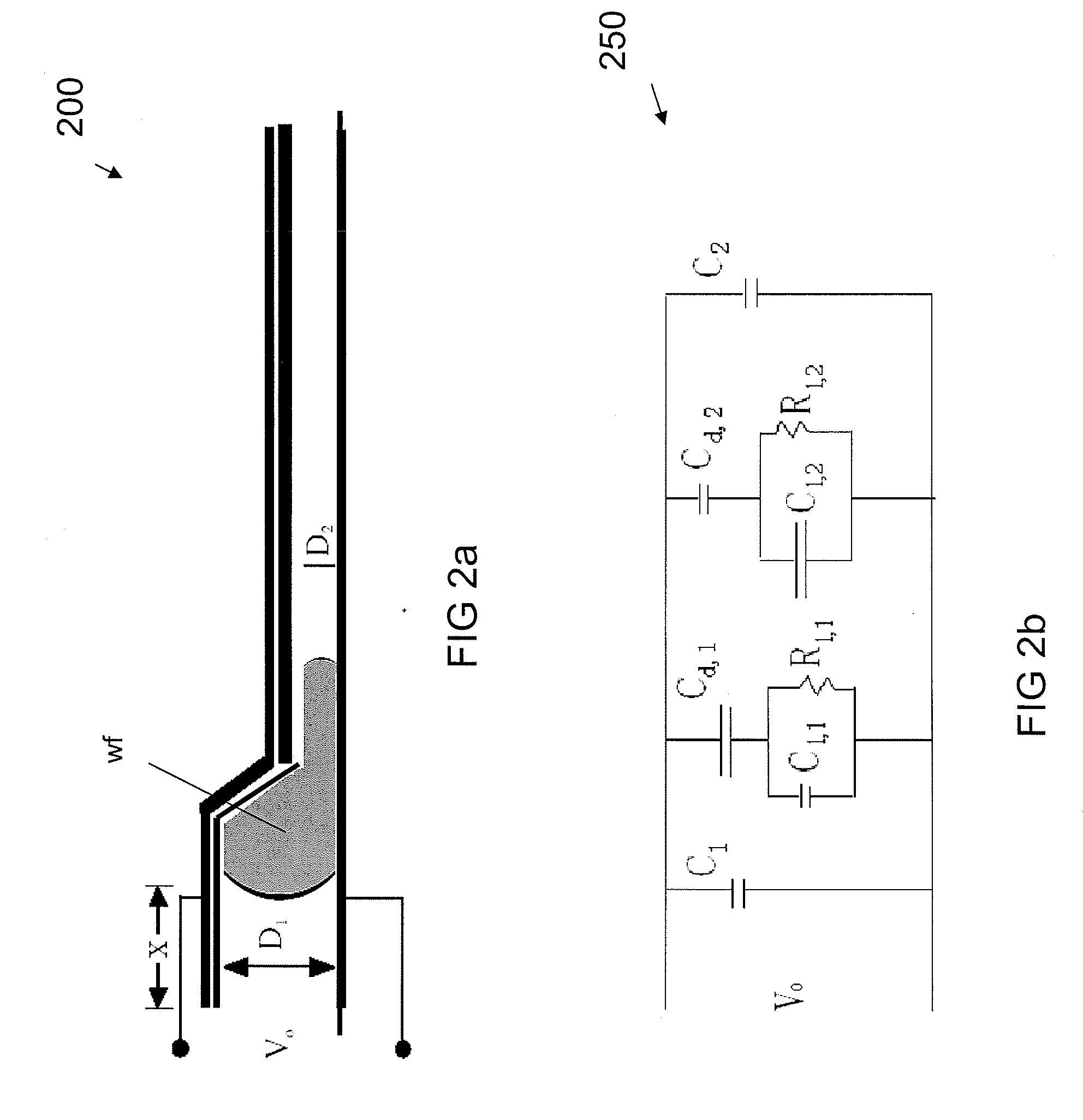

Frequency-addressable Apparatus and Methods for Actuation of Liquids

InactiveUS20080169195A1Uniform thicknessSludge treatmentElectrostatic separatorsDielectricWorking fluid

Embodiments of the invention are directed to apparatus, methods, and applications involving the actuation of a semi-insulative working fluid by electromechanical forces based on electrowetting-on-dielectric (EWOD) and liquid dielectrophoresis (liquid DEP) mechanisms that are controlled by the frequency, but not the magnitude, of an AC voltage (i.e., ‘frequency-addressable). In the various apparatus embodiments of the invention, a single, frequency-addressable electrode pair includes at least one electrode that has a spatially-varying dielectric coating thickness and thus a spatially-varying electrode gap wherein at least a portion of which a volume of a working fluid can stably reside under no influence of an applied voltage. In an exemplary aspect, a frequency-addressable, bistable apparatus includes at least one wider gap and one narrower gap associated, respectively, with a thicker and a thinner dielectric coating thickness of the electrode(s). The working fluid resides in only one of the at least two gap regions only under the influence of capillary force. A brief burst of AC voltage at a selected high frequency or low frequency will move the liquid from one gap region to another (and back) by one of an EWOD-based and a DEP-based force. In an alternative aspect, an analog apparatus has a continuous, spatially-varying electrode gap in which the dielectric coating thickness on the electrodes varies smoothly in an inverse manner. Various applications to a display device, fiber optic coupler and attenuator, controlled liquid volume dispensers, spotting arrays, well plate apparatus, and others are presented, along with control methods.

Owner:UNIVERSITY OF ROCHESTER

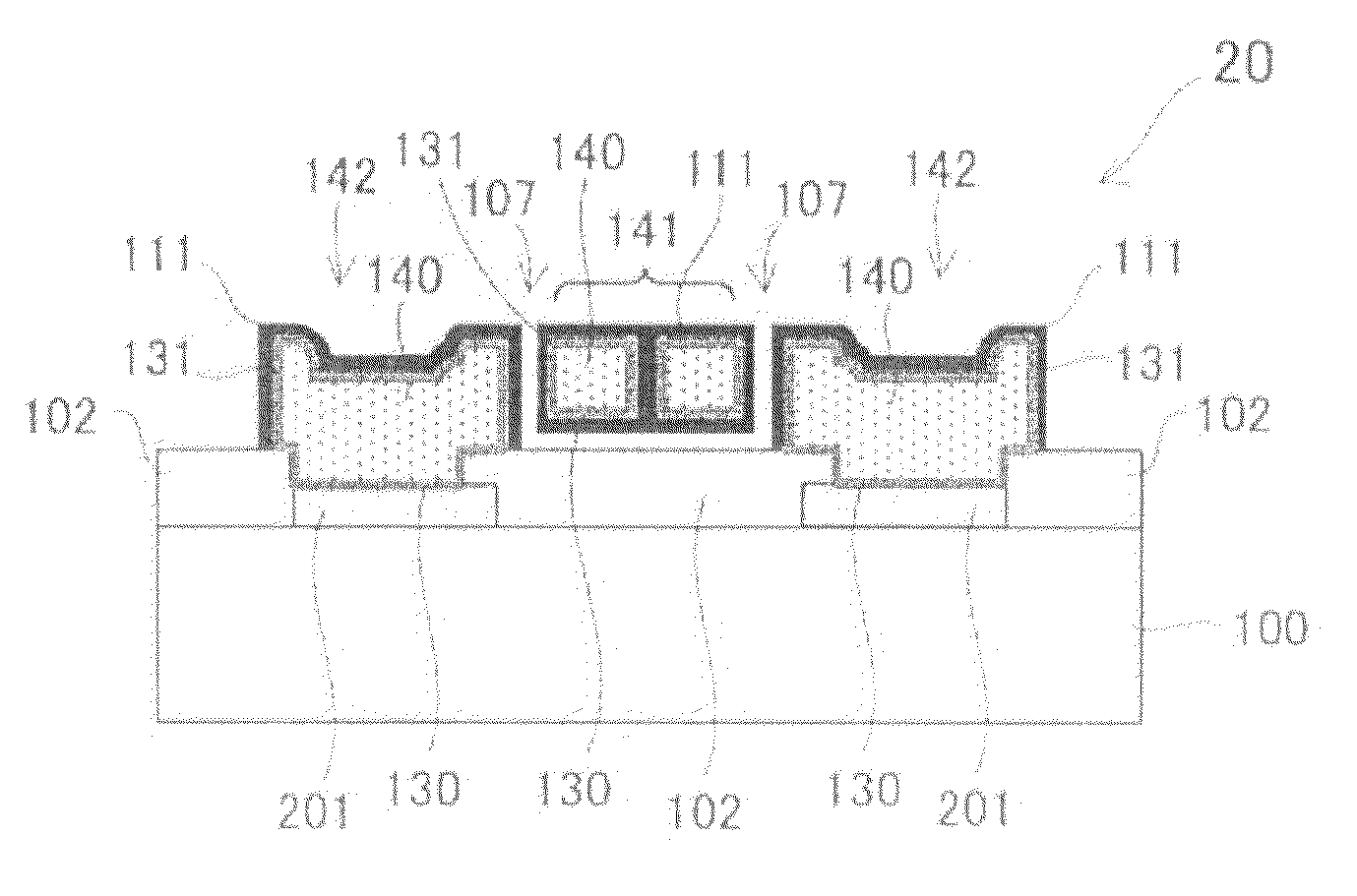

Micro electro-mechanical system and method of manufacturing the same

ActiveUS20080224319A1Avoid stickingReduce gapImpedence networksSemiconductor/solid-state device detailsMicroelectromechanical systemsEngineering

A micro electro-mechanical system, which can be stably formed so as to prevent sticking of a movable part and which has a narrow gap, and a method of manufacturing the same are provided. The micro electro-mechanical system includes at least one fixed electrode formed above a principal surface of a semiconductor substrate and at least one movable electrode formed on the principal surface. The at least one movable electrode includes the movable part separated from the principal surface and the at least one fixed electrode. The movable part is movable with respect to the principal surface and the at least one fixed electrode. The method of manufacturing the micro electromechanical system includes a sacrifical film formation step for forming a sacrifical film above the principal surface, an electrode layer formation step for forming an electrode layer above the principal surface so as to cover over the sacrifical film, an etching step for partially etching the electrode layer via a pattern so as to form the at least one electrode and the at least one fixed electrode, a sacrifical film removal step for removing the sacrifical film, and a conducting film formation step for forming a conducting film on surfaces of the at least one electrode and the at least one fixed electrode.

Owner:LAPIS SEMICON CO LTD

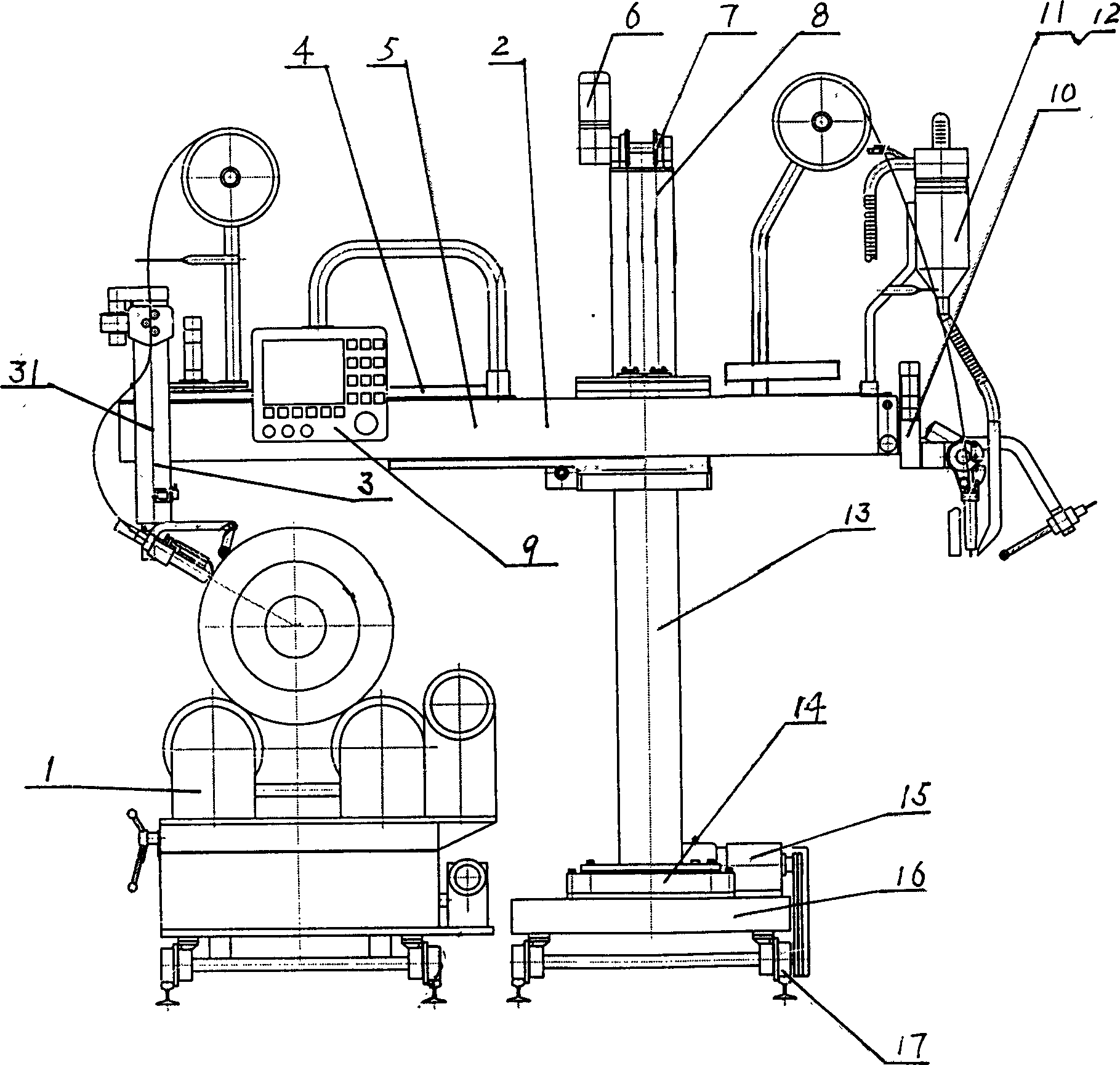

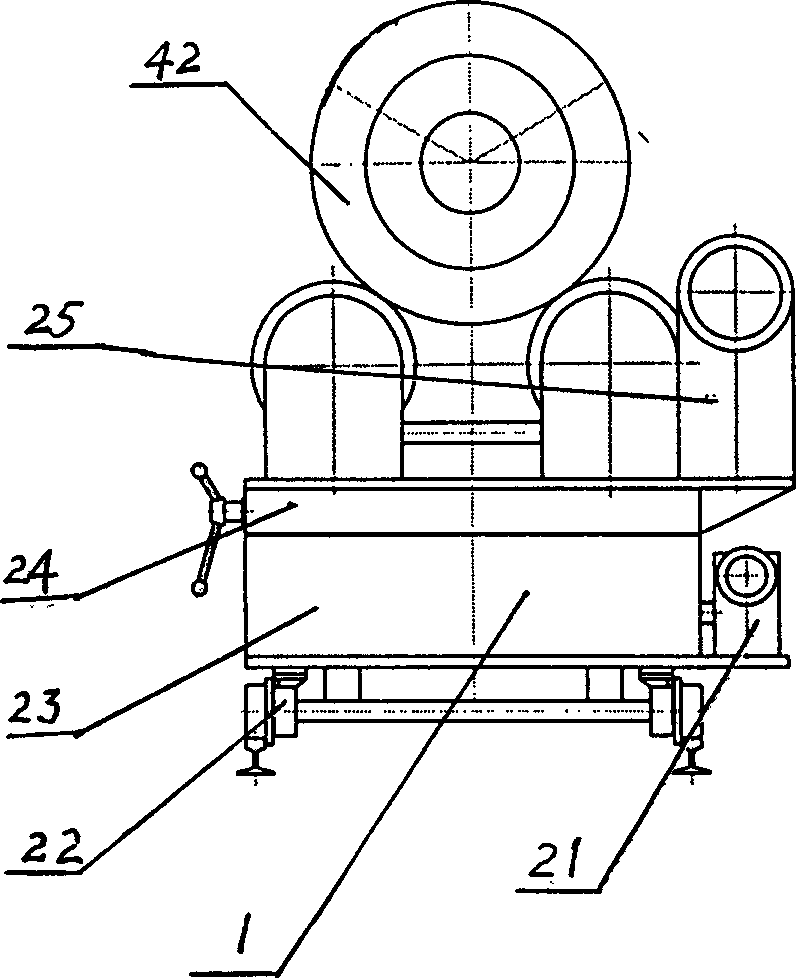

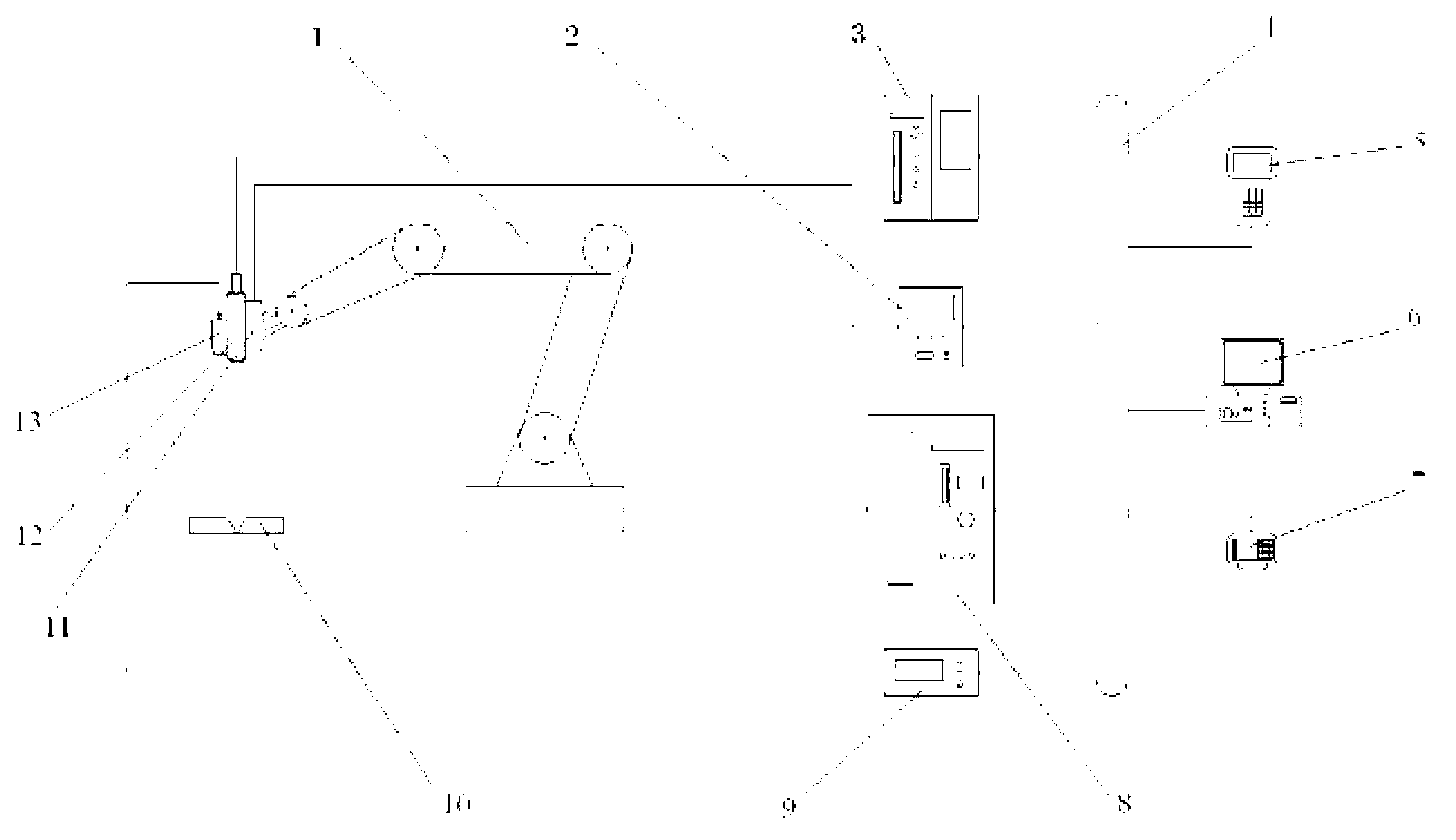

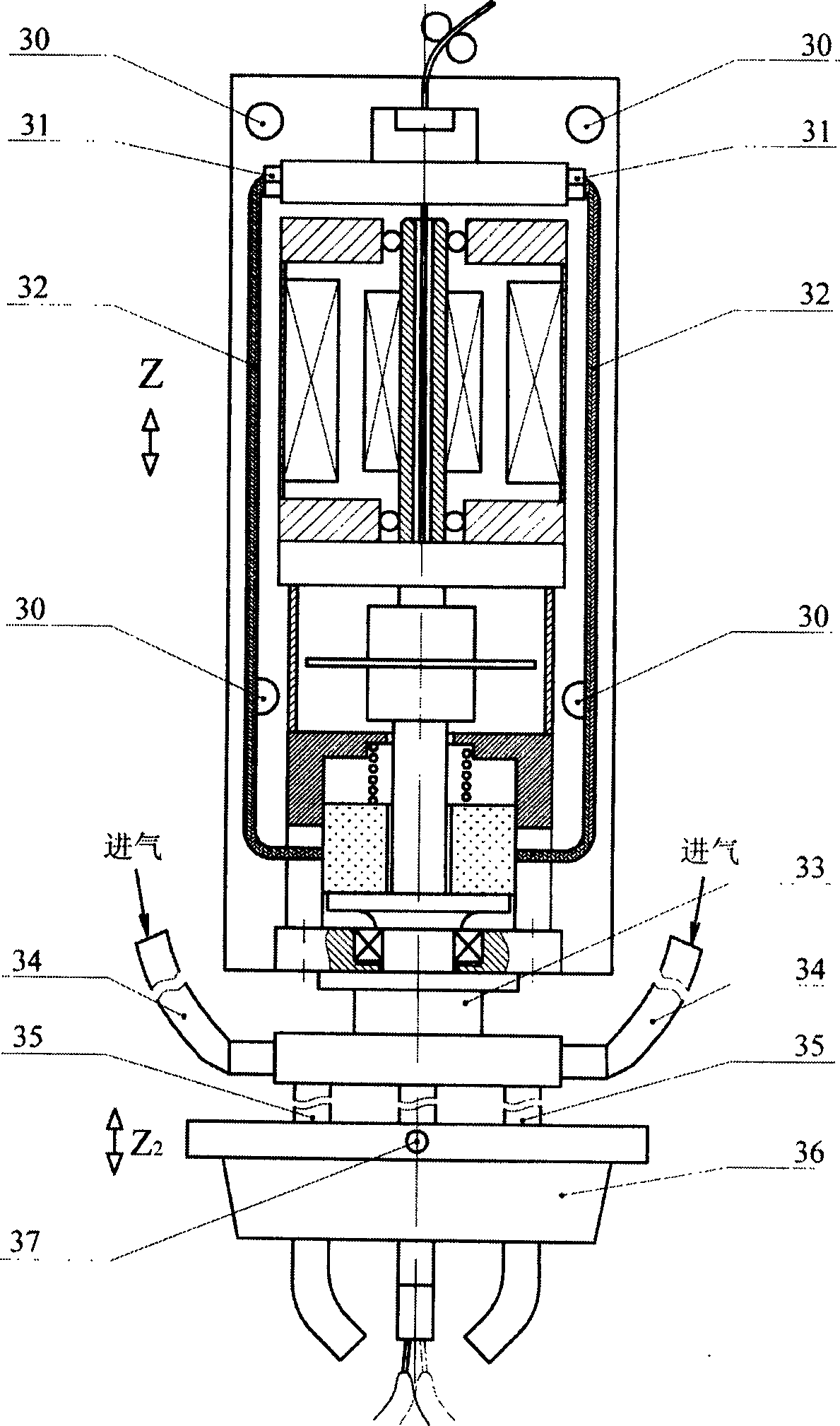

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN1714978AAutomatically calculate relative coordinate origin positionEnsure shapeArc welding apparatusBogieEngineering

The automatic argon arc welding and narrow gas submerged arc welding process for circular pipe header seam features the first horizontal and vertical welding with immobile workpiece and using automatic cold welding TIG wire until completing over one third of circle; the subsequent welding in the other two thirds of circle with automatically rotating welding roller frame; and the performing in the identical site of the annular seam assembling and the welding. The welding apparatus for the said technological process consists of roller device and welding frame bogie, and the welding frame bogie on some tracks parallel to roller frame tracks is movable. The present invention has the advantages of automatic operation, raised welding quality, etc.

Owner:SHANGHAI BOILER WORKS

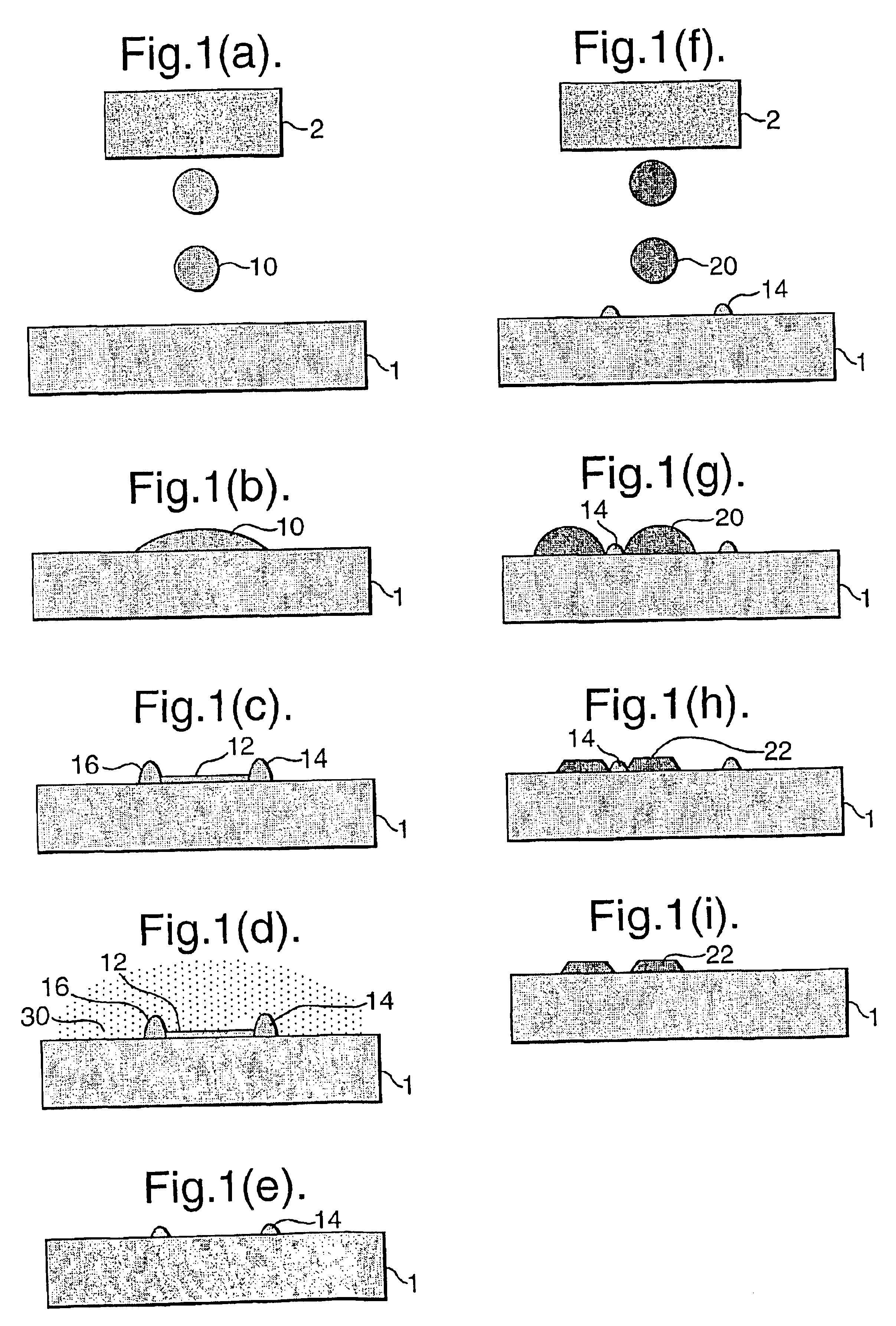

Method of patterning a substrate

InactiveUS6838361B2Increase processing costFew stepsTransistorElectroluminescent light sourcesAqueous solutionPolymer chemistry

The invention provides a method of pattering a substrate, in which a first material in solution is deposited on the substrate. The composition of the solution of the first material is selected so it dries to leave a residue of the first material on the substrate, the residue comprising a thin film in the centre and a ridge around the perimeter. The residue is etched to remove the thin film, leaving the ridge on the substrate. After etching the ridge is hydrophobic and the substrate is hydrophilic. An aqueous solution of a second material is then deposited on both sides of the ridge. After the aqueous solution has dried, the ridge is removed, leaving a layer of the second material on the substrate, the layer having a narrow gap therethrough. The layer may be used for the source and drain electrodes of an organic thin film transistor.

Owner:SEIKO EPSON CORP

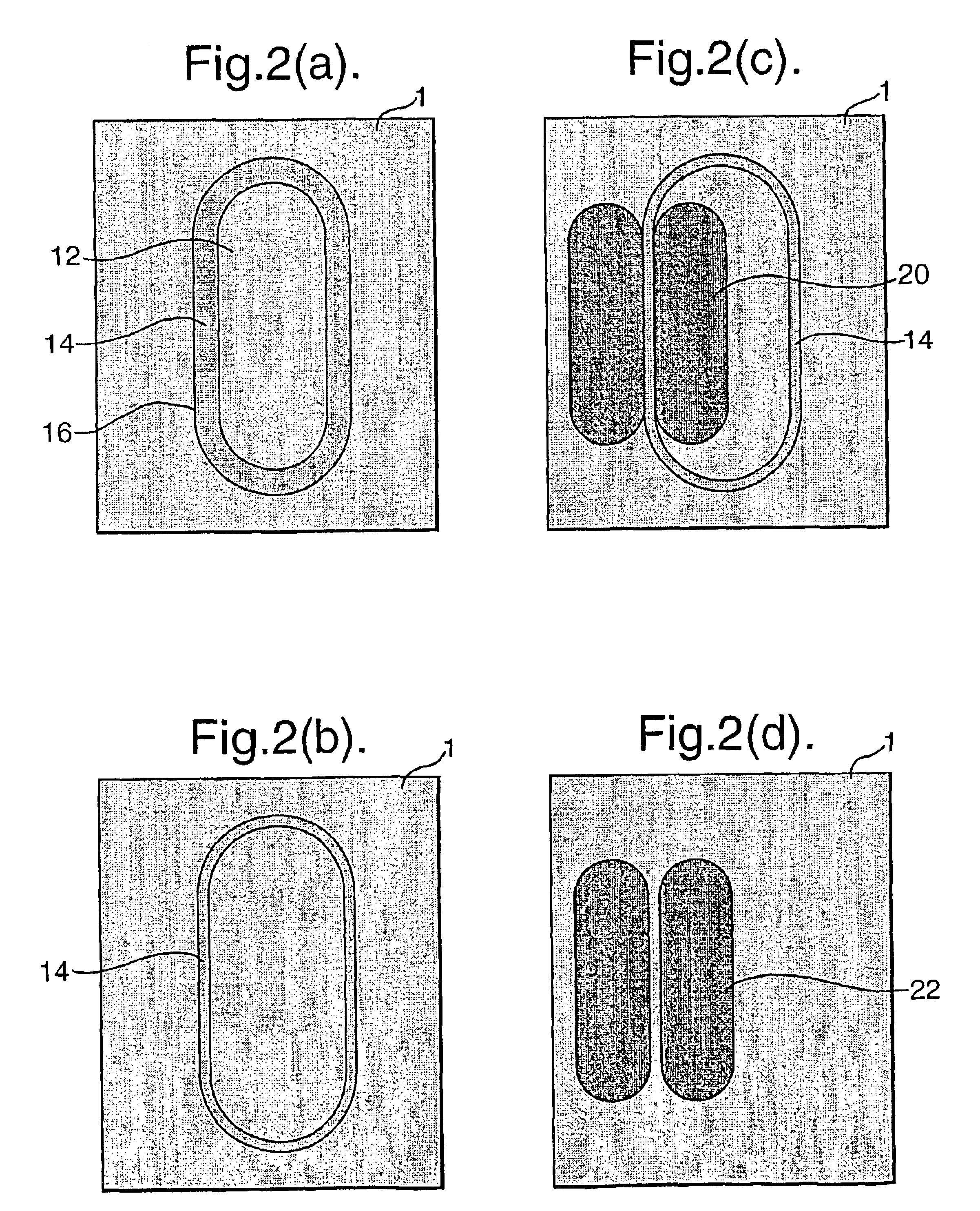

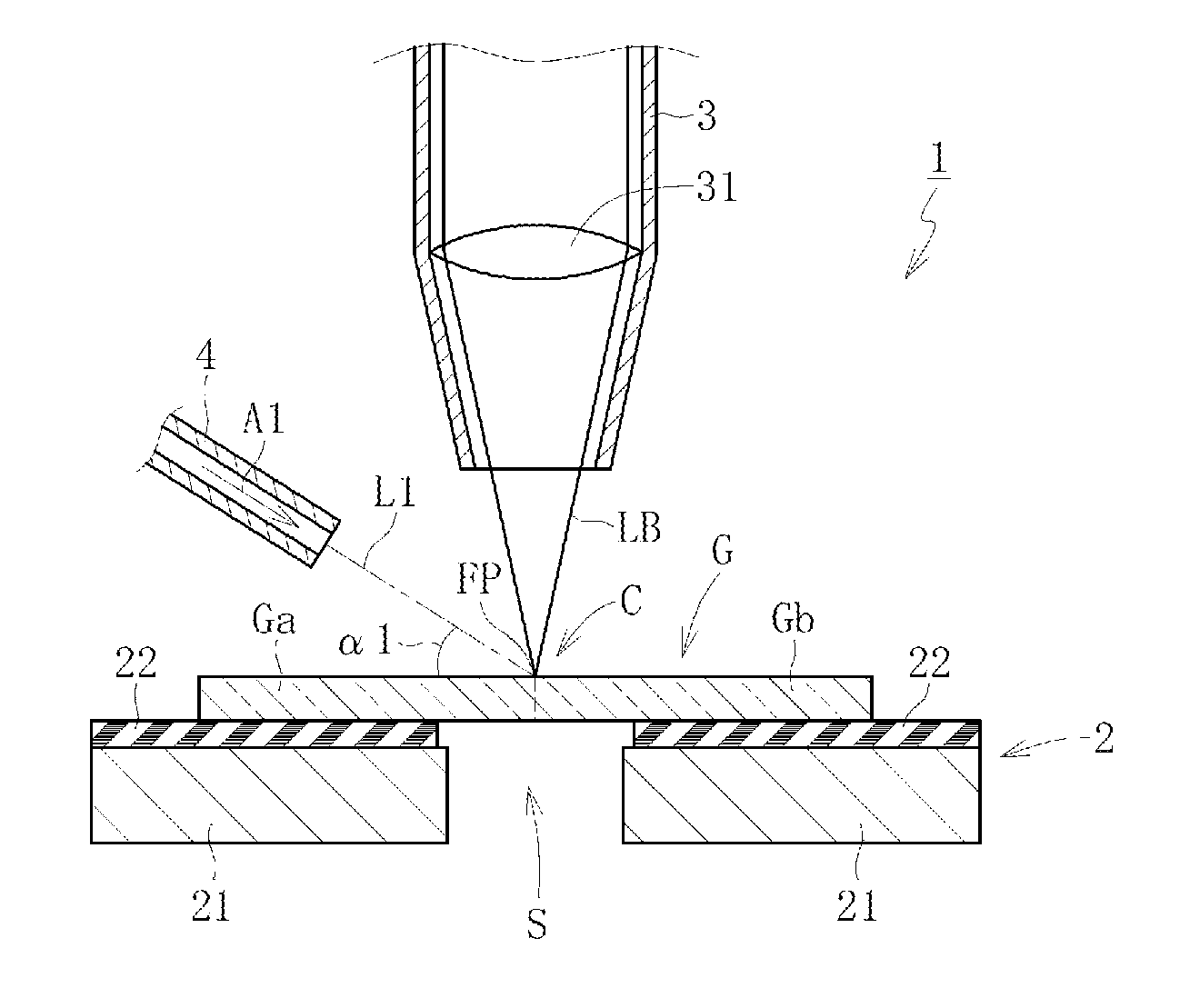

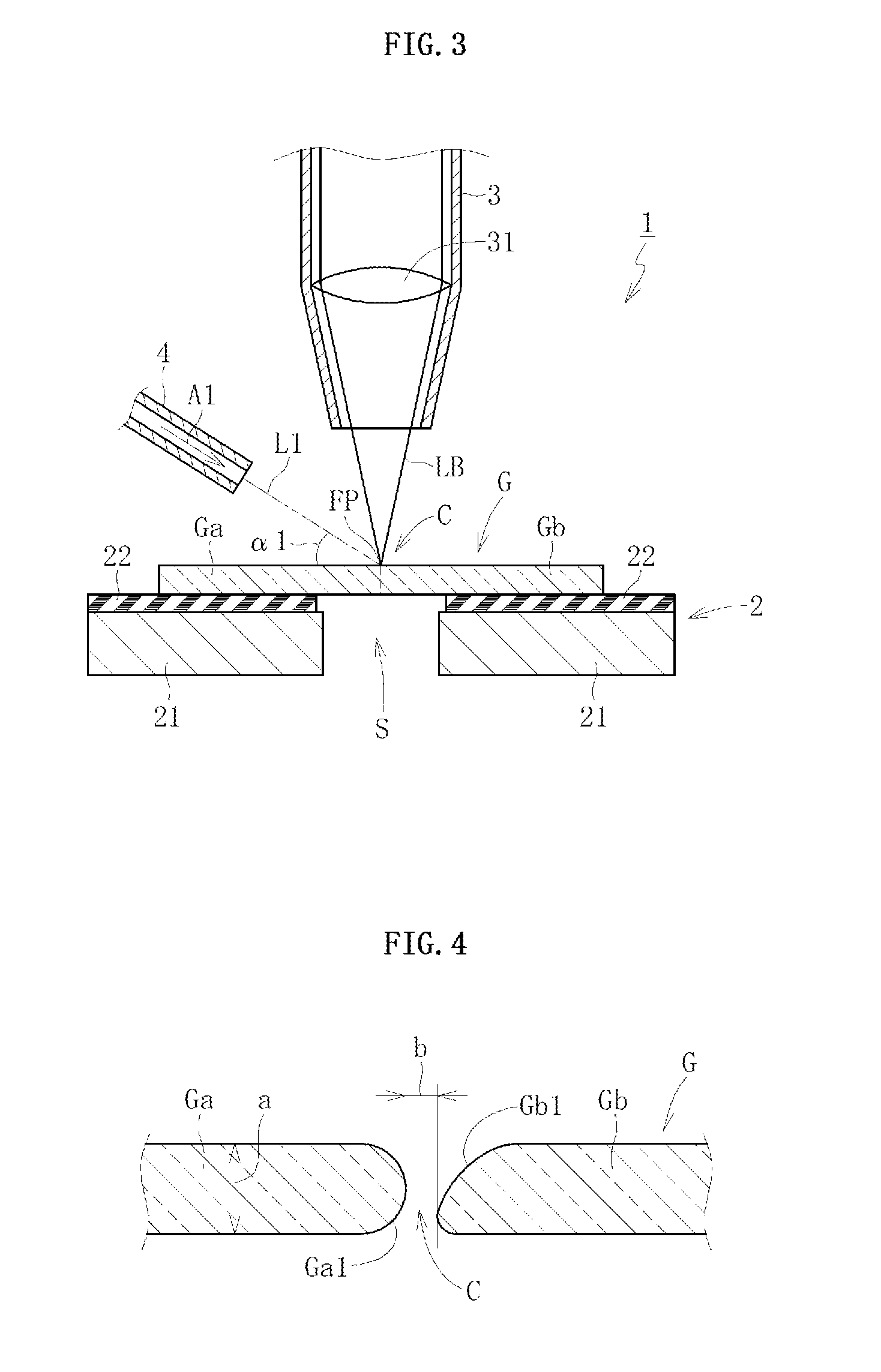

Cutting method for glass sheet and glass sheet cutting apparatus

ActiveUS20130122264A1Safe separationStrict managementGlass furnace apparatusCellulosic plastic layered productsLaser beamsGlass sheet

Provided is a cutting method for a glass sheet, comprising radiating a laser beam to a cutting portion (C) of a glass sheet (G) having a thickness of 500 μm or less to fuse the glass sheet (G), wherein a narrowest gap between fused end surfaces (Ga1 and Gb1) of the glass sheet (G), which face each other in the cutting portion (C), is managed to satisfy a relationship of 0.1≦b / a≦2, where “a” is a thickness of the glass sheet (G) and “b” is the narrowest gap.

Owner:NIPPON ELECTRIC GLASS CO LTD

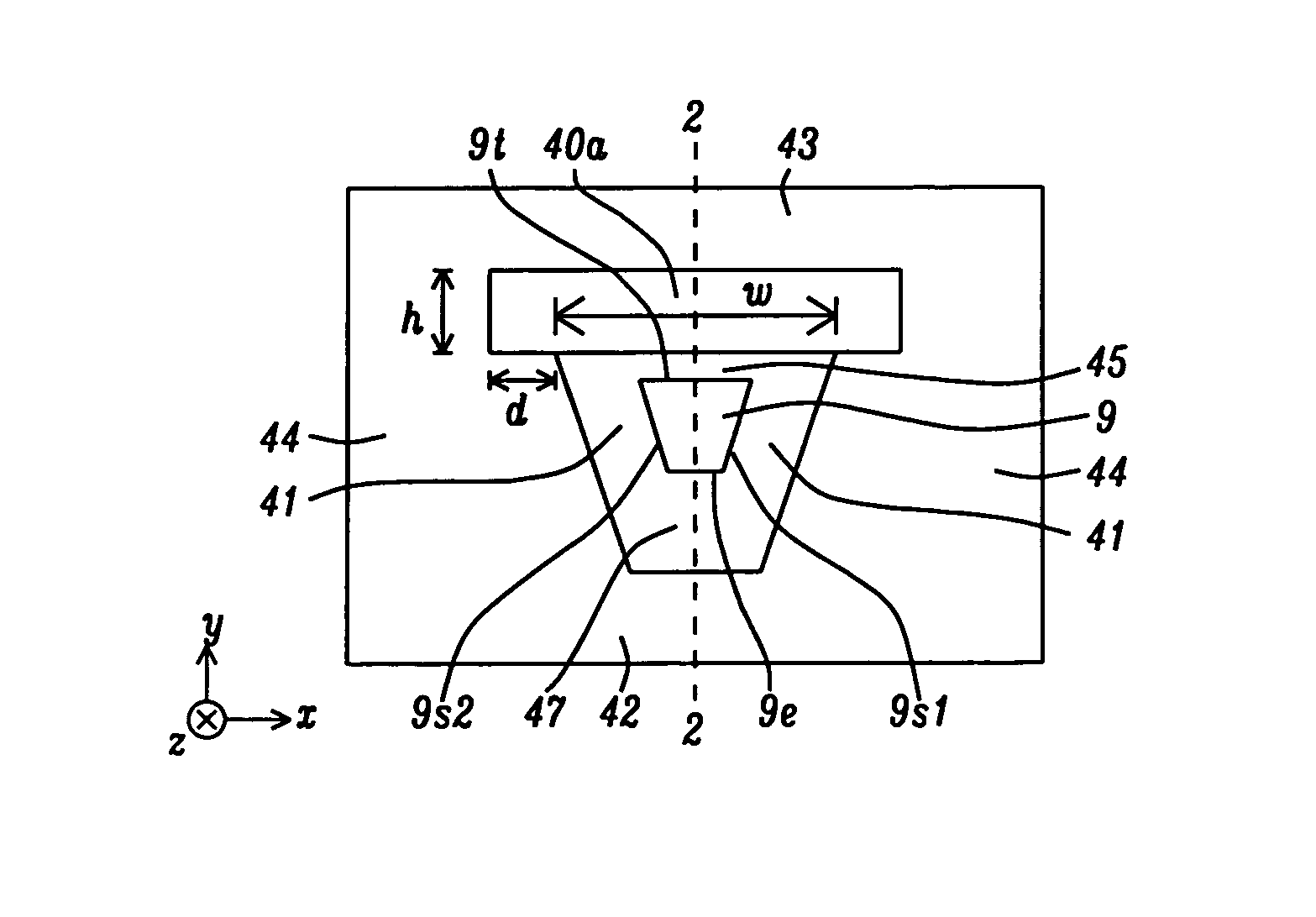

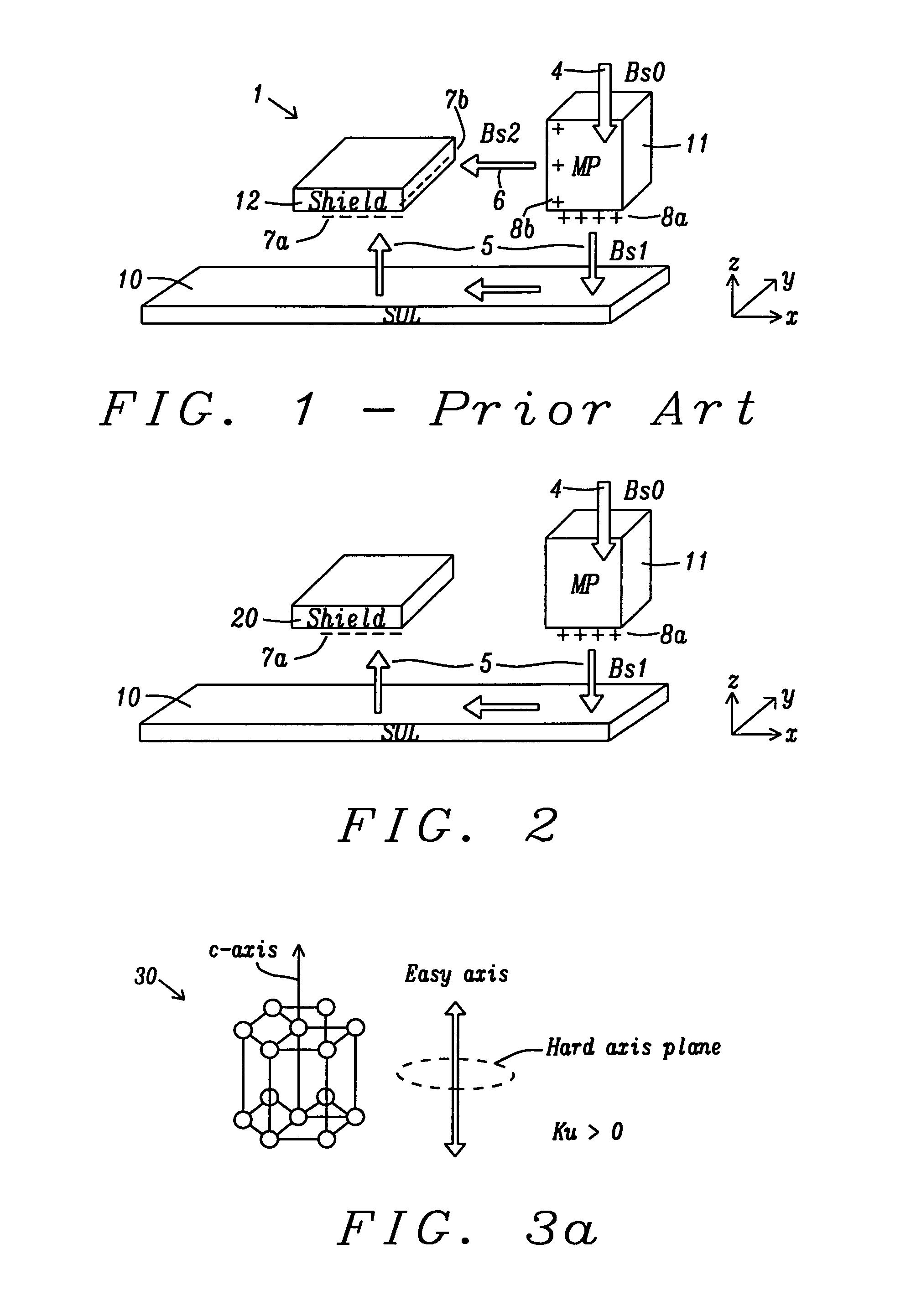

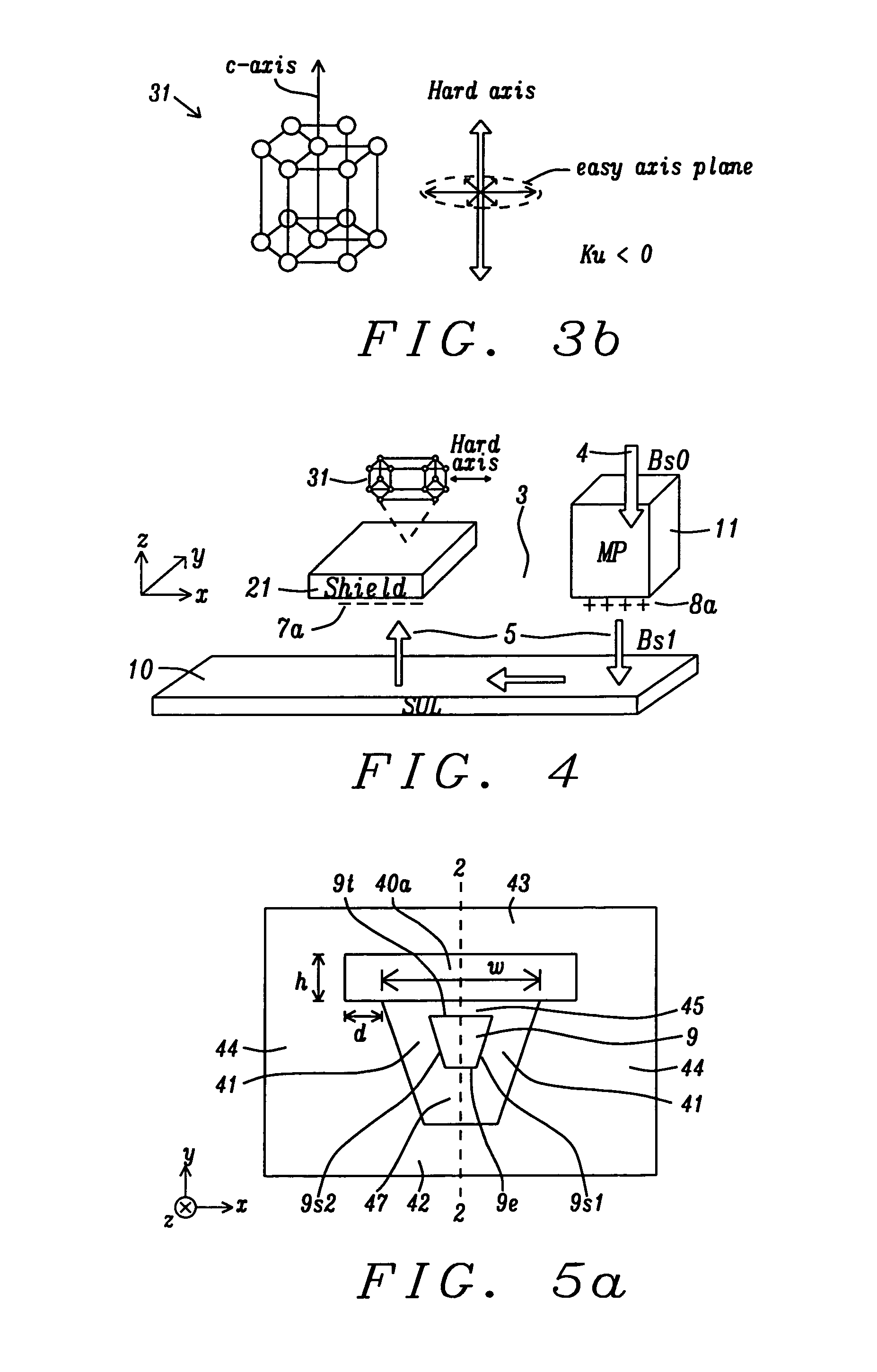

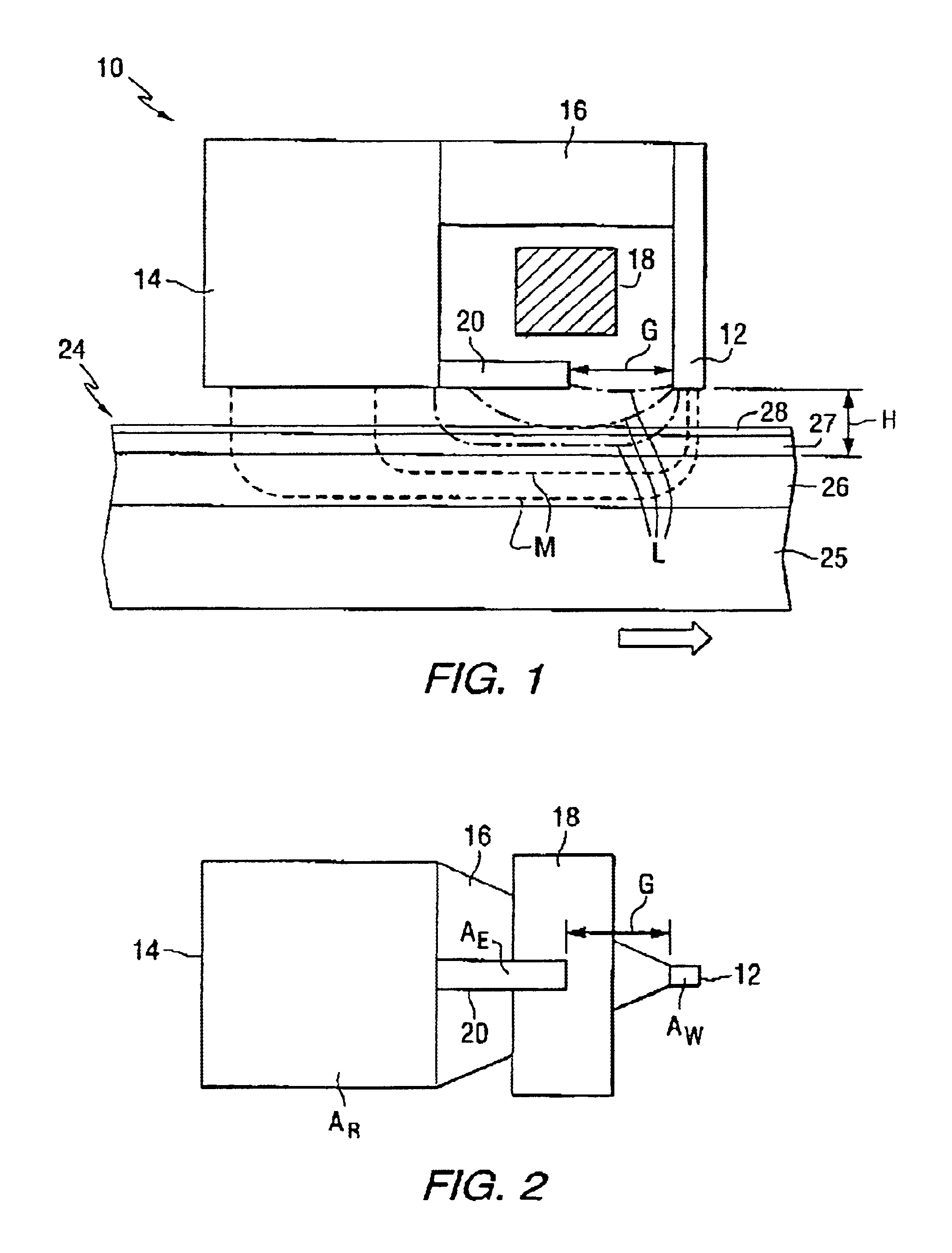

PMR write head with narrow gap for minimal internal flux loss

ActiveUS8238059B1High gradientMinimum amount of internal flux lossManufacture head surfaceRecord information storageEngineeringArea density

A PMR writer is disclosed wherein one or more of a trailing shield, leading shield, and side shields are composites with a first section made of an anisotropic (-Ku) magnetic layer adjoining a gap layer and a second section comprised of an isotropic soft magnetic layer formed on a side of the first section that faces away from the main pole. There may be a non-magnetic Ru layer between each first and second section to prevent interlayer coupling. Each first section has a hard axis in a direction toward the main pole and is comprised of hcp-CoIr, dhcp-CoFe, a′-Fe—C, or NiAs-type Mn50Sb50 with a thickness from 50 to 500 nm. As a result, flux leakage from the main pole to a shield structure is reduced and area density is increased. A method for fabricating a composite shield structure is also provided.

Owner:HEADWAY TECH INC

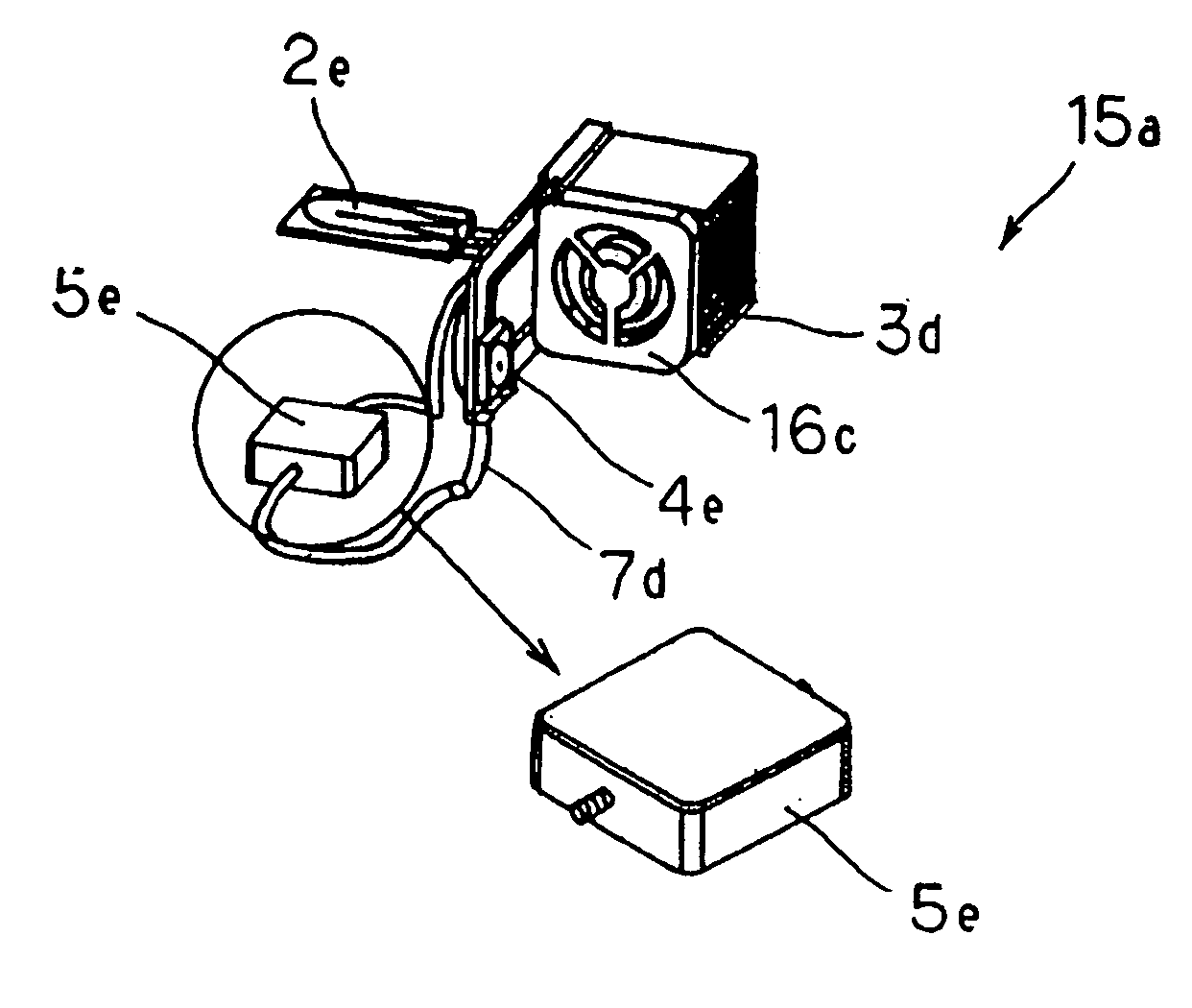

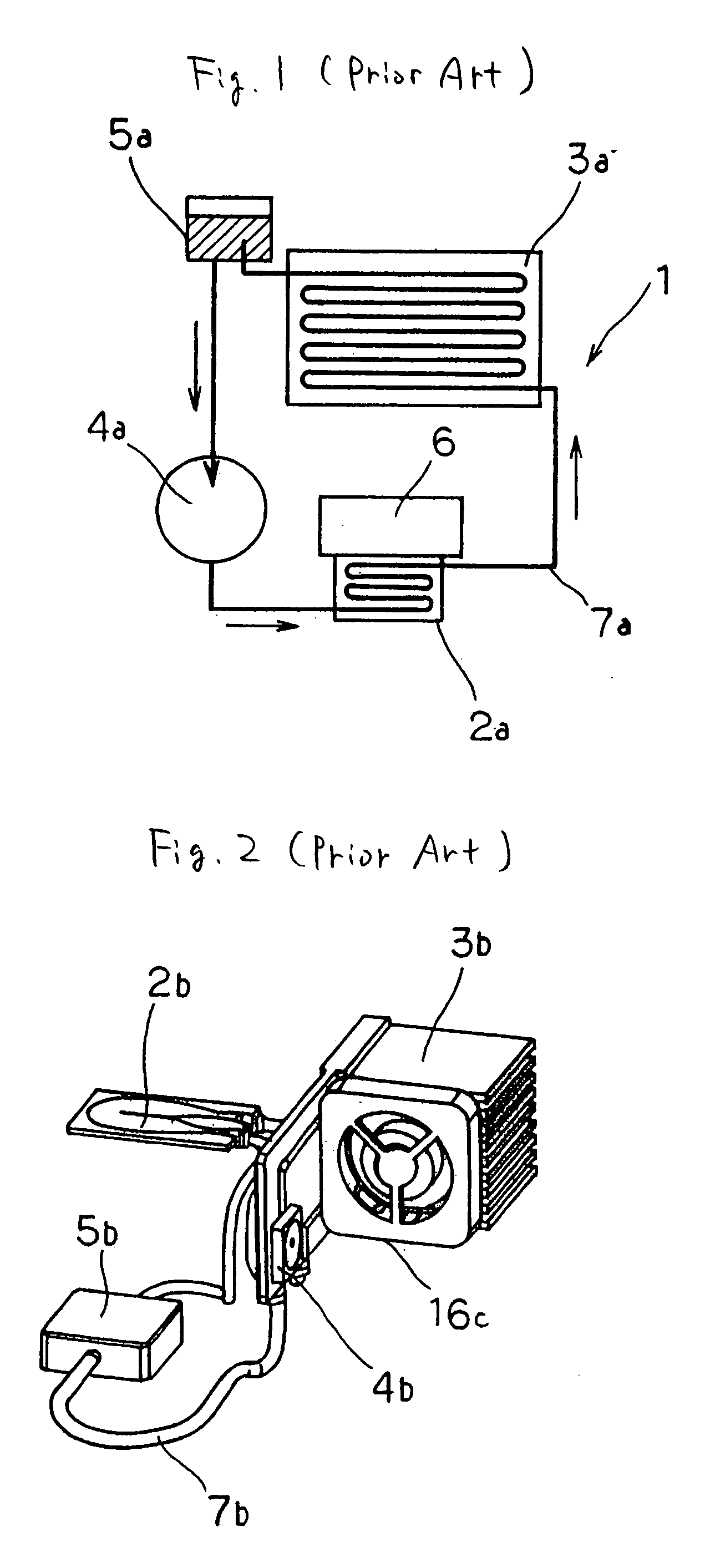

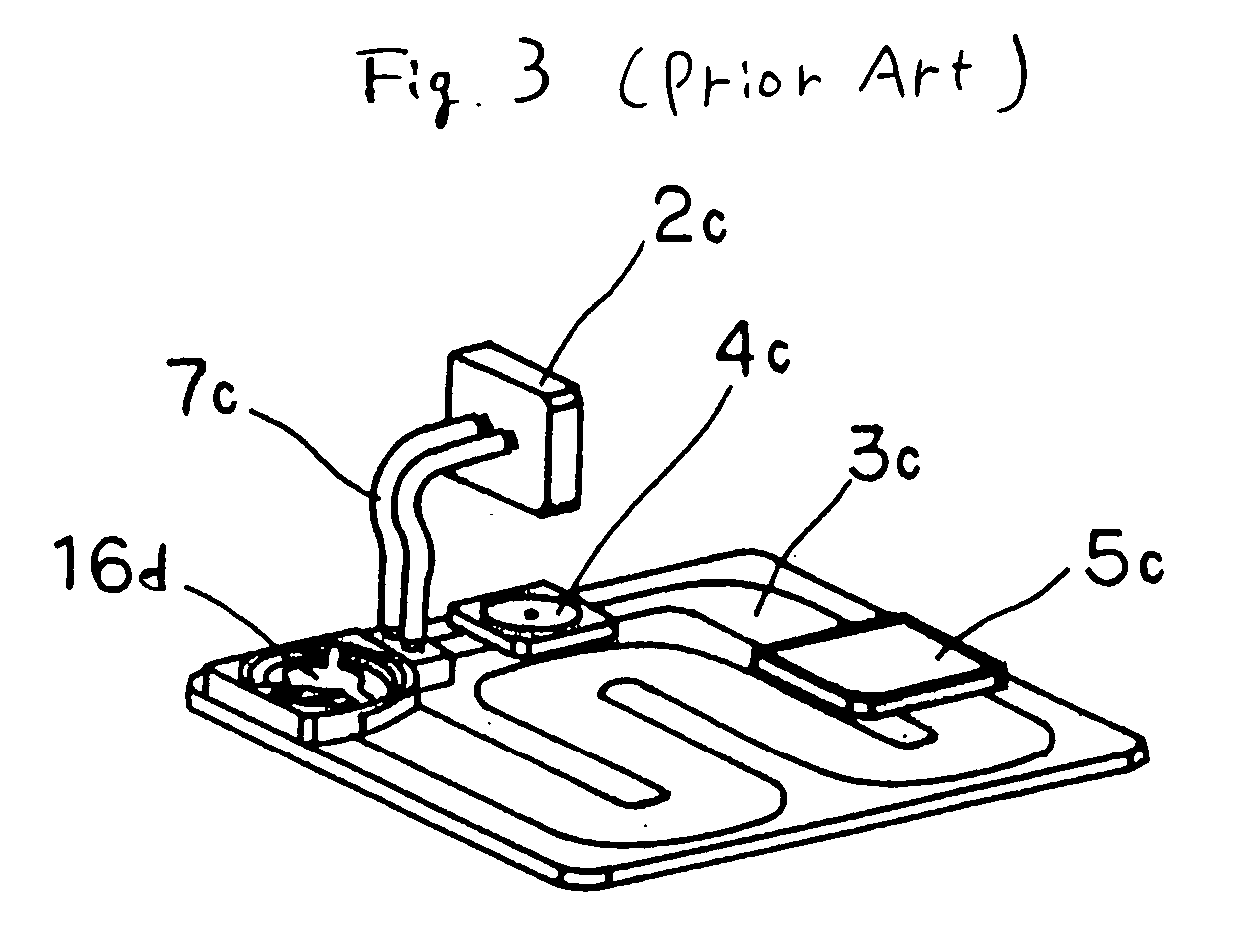

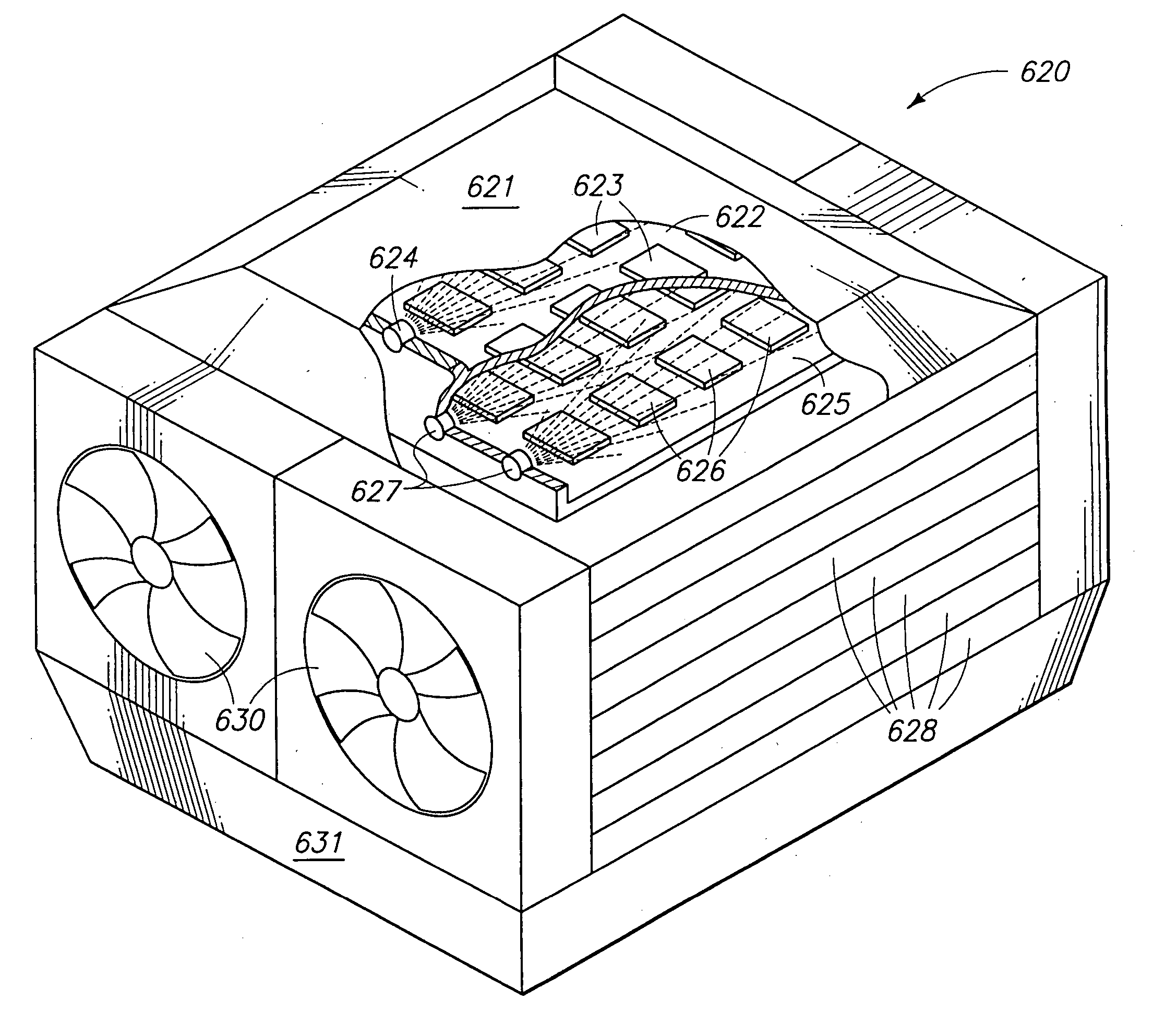

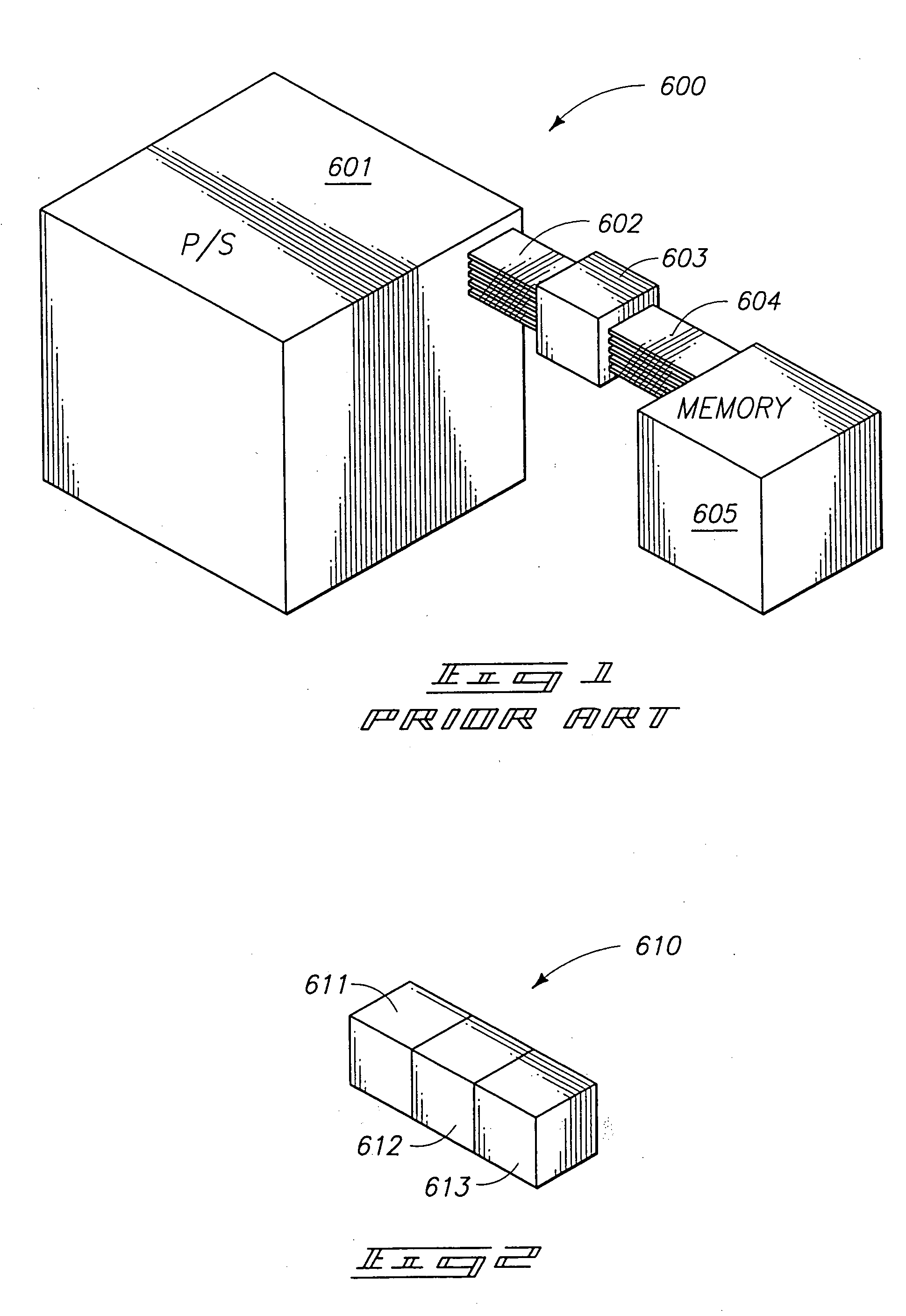

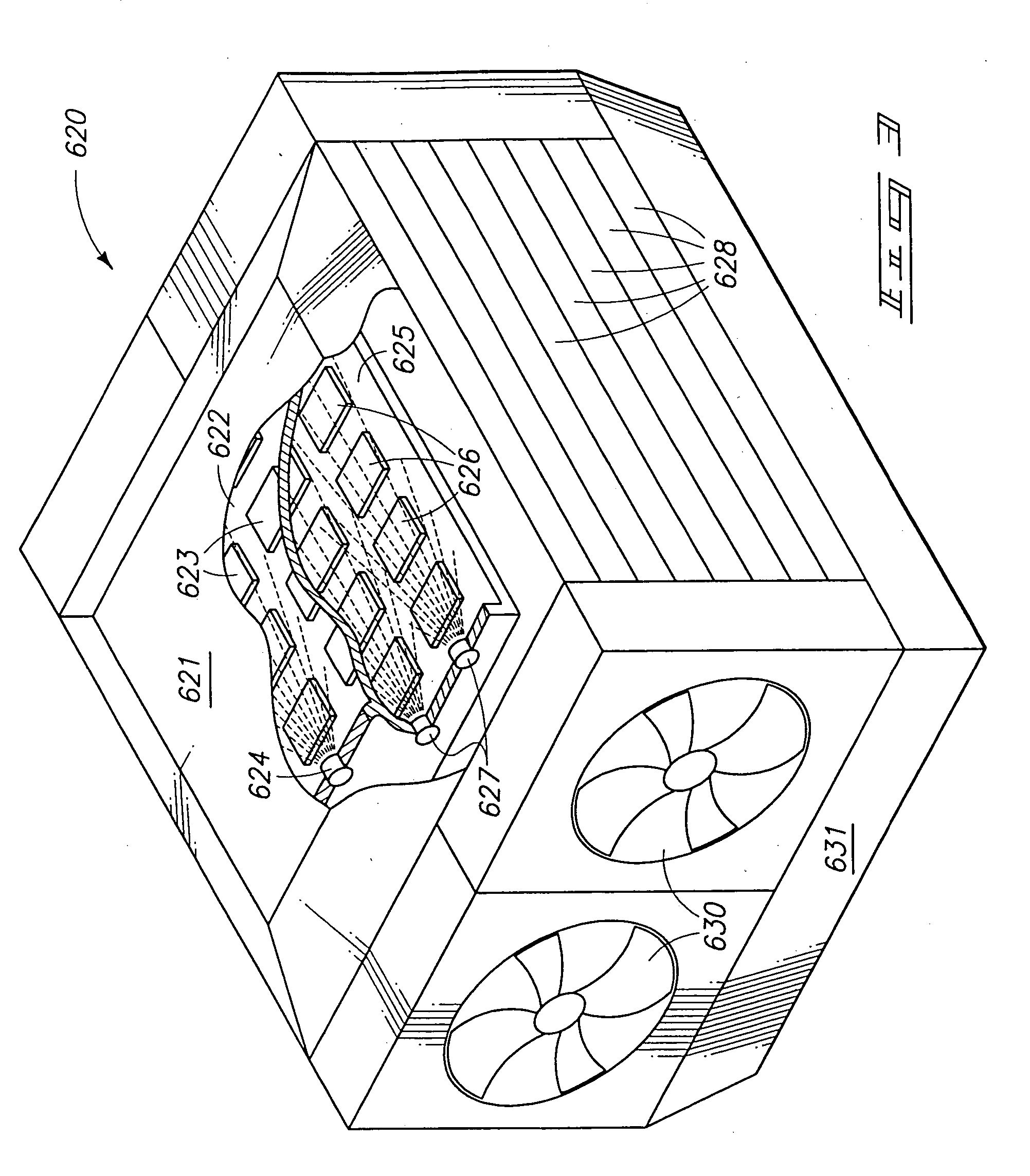

Circulation-type liquid cooling apparatus and electronic device containing same

InactiveUS20060037739A1Avoid flowEfficient removalDigital data processing detailsSemiconductor/solid-state device detailsEngineeringCooling fluid

A cooling apparatus comprises a tank for keeping a coolant liquid therein and having an air layer, a heat receiving element in contact with a heat generating part to receive heat therefrom, a radiator for radiating heat absorbed by a coolant liquid, and a circulating mechanism for circulating the coolant liquid from the heat receiving element through the tank and through the radiator again to the heat receiving element. The tank has a conduit forming area for forming a coolant liquid circulating conduit to pass through a middle position of the tank, and a narrow gap which divides the conduit forming area at the middle position of the tank.

Owner:NEC DISPLAY SOLUTIONS LTD

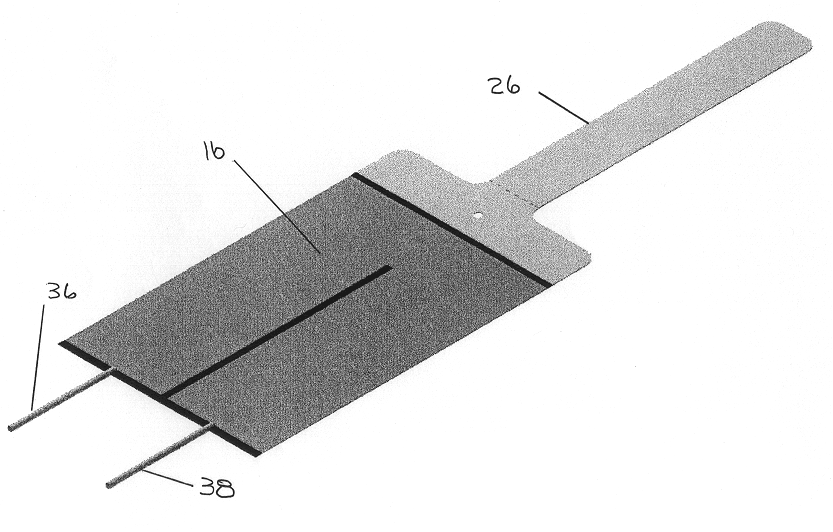

Convection blood warming system with disposable flattened tube envelope incorporating paperboard "needle" for inserting envelope between heating plates and employing active and passive insulation of outlet flow path to provide normothermic fluid at zero to 600 milliliters per minute

InactiveUS6608968B2Closer spacingEconomical and simpleWater heating stoves/rangesMedical devicesBlood warmersDistal portion

A thin, flat paperboard inserter or "needle" which is longer than the blood warmer heating plates is attached to the edge of the flattened tube envelope to enter the very narrow gap between the heating plates. The inserter is fed between the heating plates and advanced to emerge from the other end of the blood warmer where it is grasped and used to pull the envelope into operational position. A high air flow hydrophobic vent with check valve to prevent reverse flow is incorporated into the drip chamber to allow automatic priming and venting of air bubbles. A conductively heated and externally insulated drip chamber holder and a patient intravenous line that is passively insulated by a small annular air space extruded as part of the tube preserve heat in the warmed fluid, improving low flow rate performance. A reusable external heater may optionally be applied to the distal portion of the patient line to provide normothermic fluid to the patient down to essentially zero flow rate.

Owner:BAKKE ALLAN P

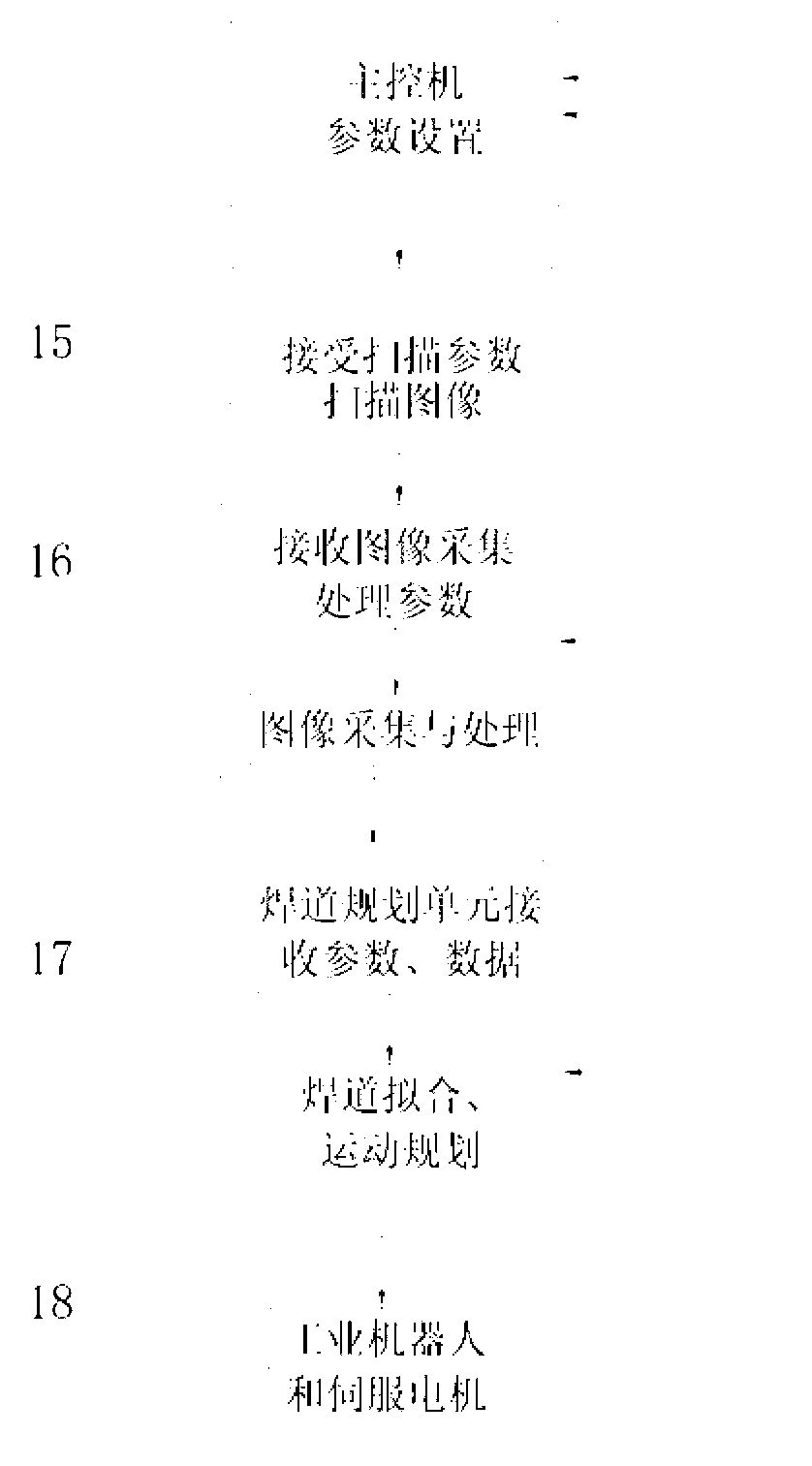

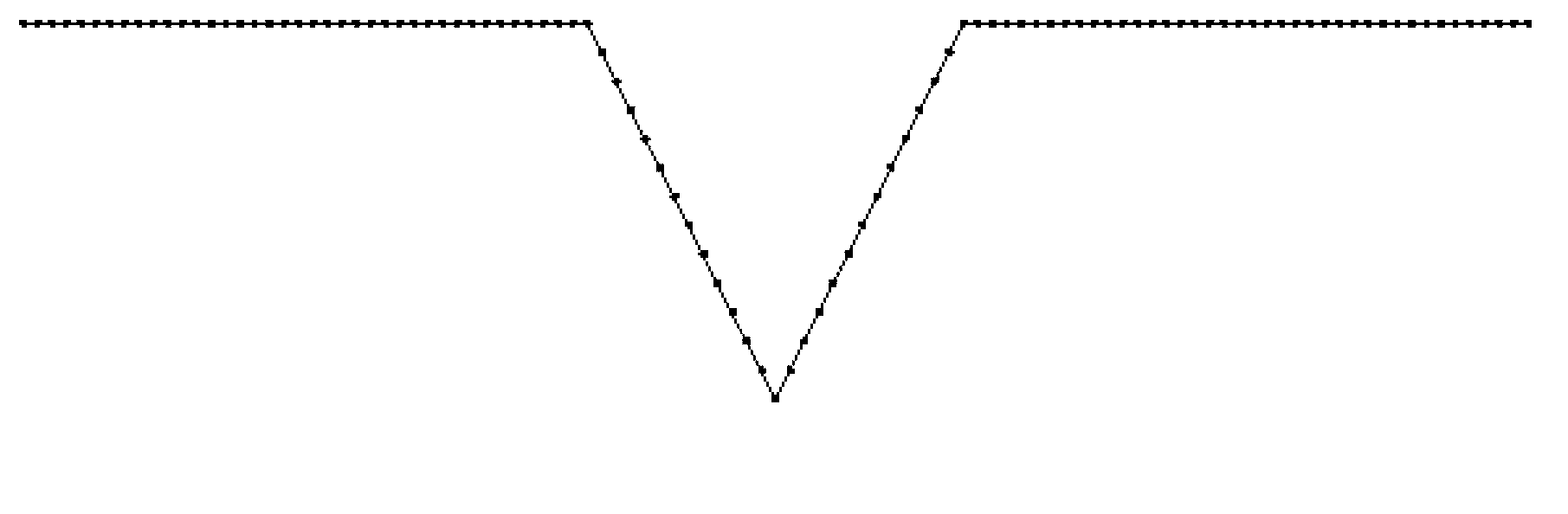

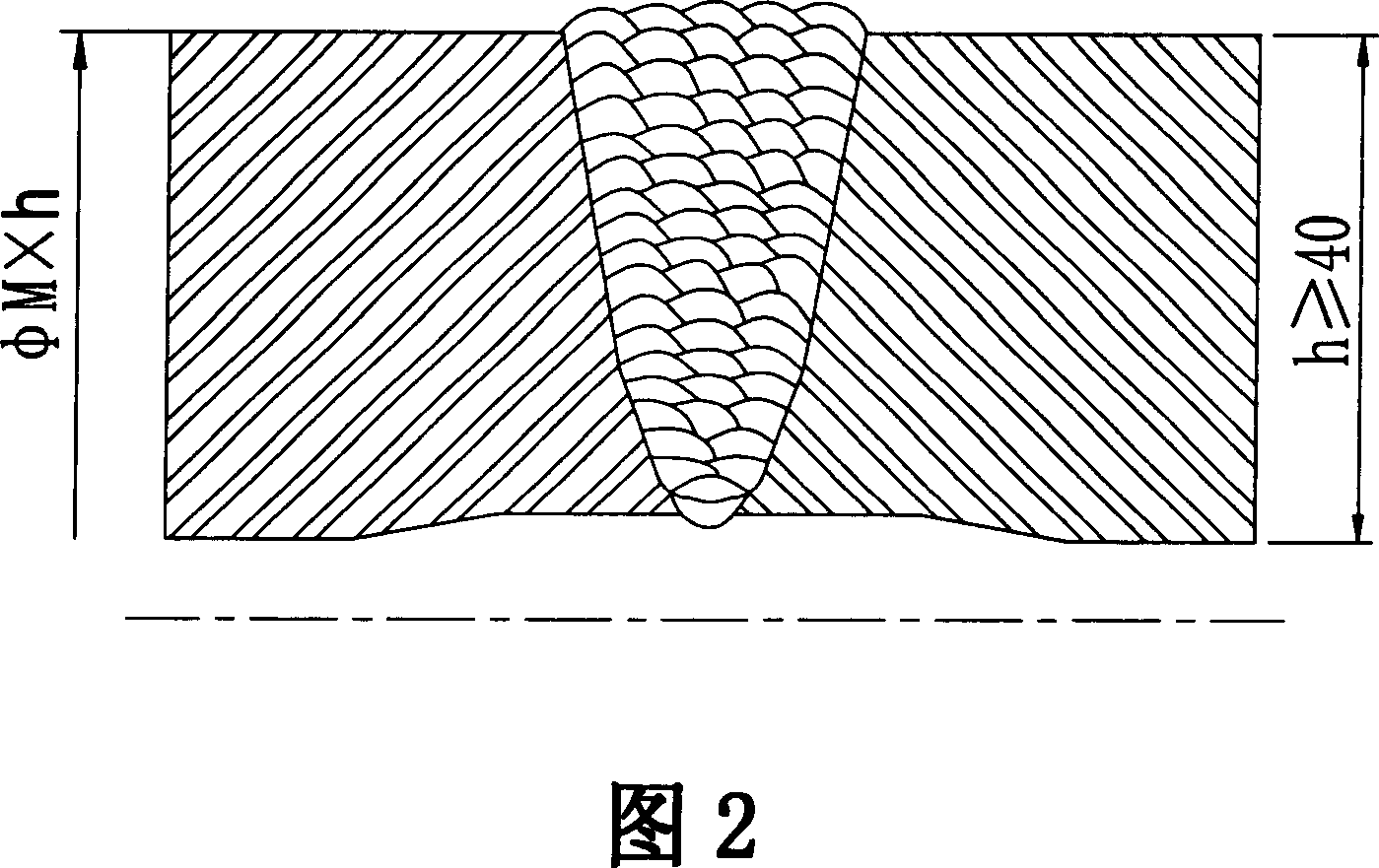

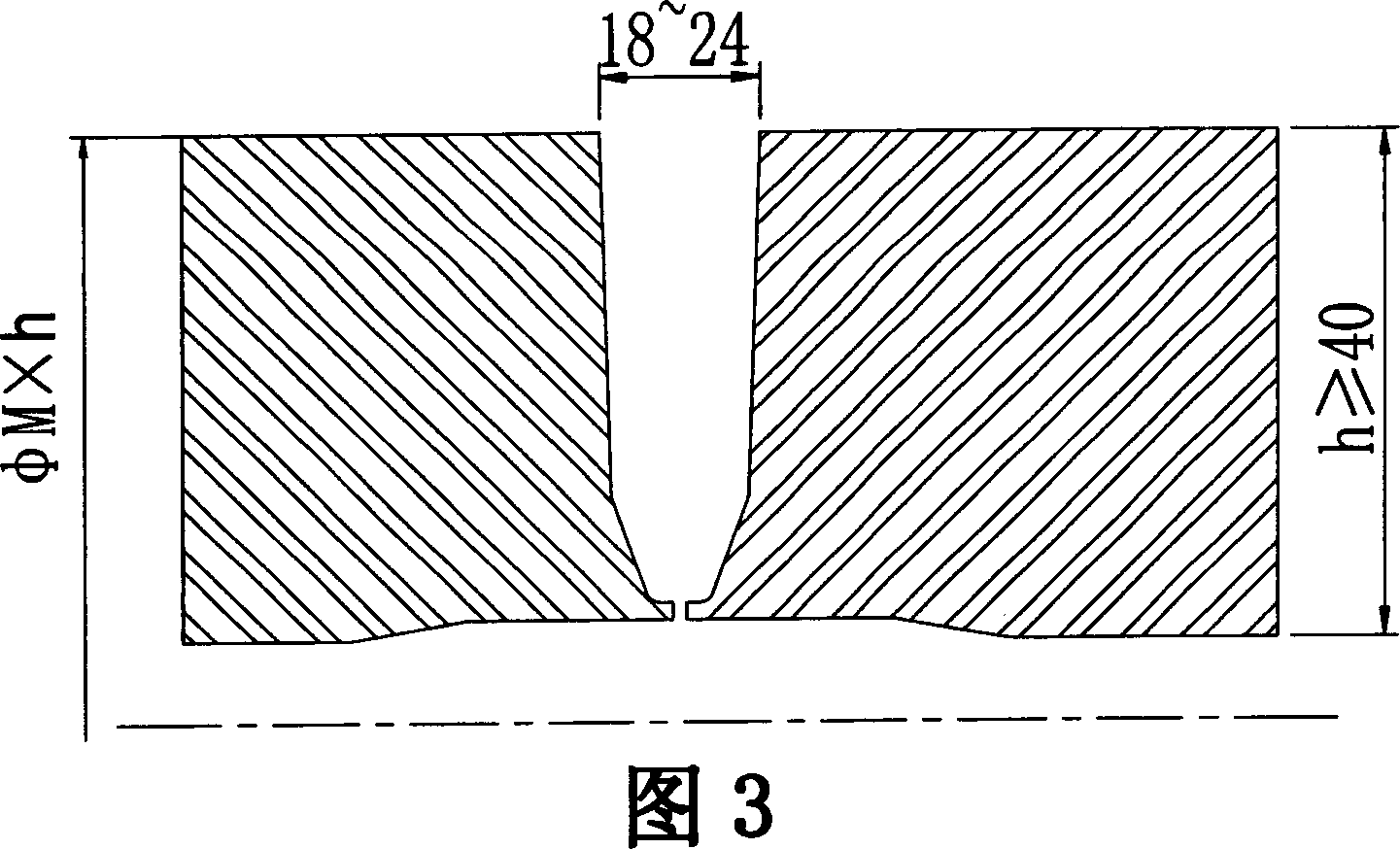

Scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for thick plate

InactiveCN102699534AImprove portabilityIncrease flexibilityLaser beam welding apparatusThick plateImaging algorithm

The invention discloses a scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for a thick plate, relates to a welding method, and aims to solve the problems that the conventional structured light vision sensing-based welding method can only be used for a simple shallow-groove laser weld seam tracking task and that when the conventional structured light vision sensing-based welding method is used for the narrow-gap deep-groove weld seam welding of the thick plate, a covering phenomenon is easily produced, the groove identification accuracy is lower, only real-time weld seam alignment calibration can be realized and narrow-gap deep-groove laser multilayer welding bead planning and welding cannot be realized. The method specifically comprises the following steps of: 1, selecting a groove form; 2, scanning a groove section image of a thick plate workpiece to be welded by using an image scanning unit; 3, processing the acquired groove section image by using an image algorithm to obtain weld seam image data; 4, performing fitting calculation; and 5, finishing the welding of welding beads layer by layer. The method is used for the deep-groove weld seam welding of the thick plate.

Owner:HARBIN INST OF TECH

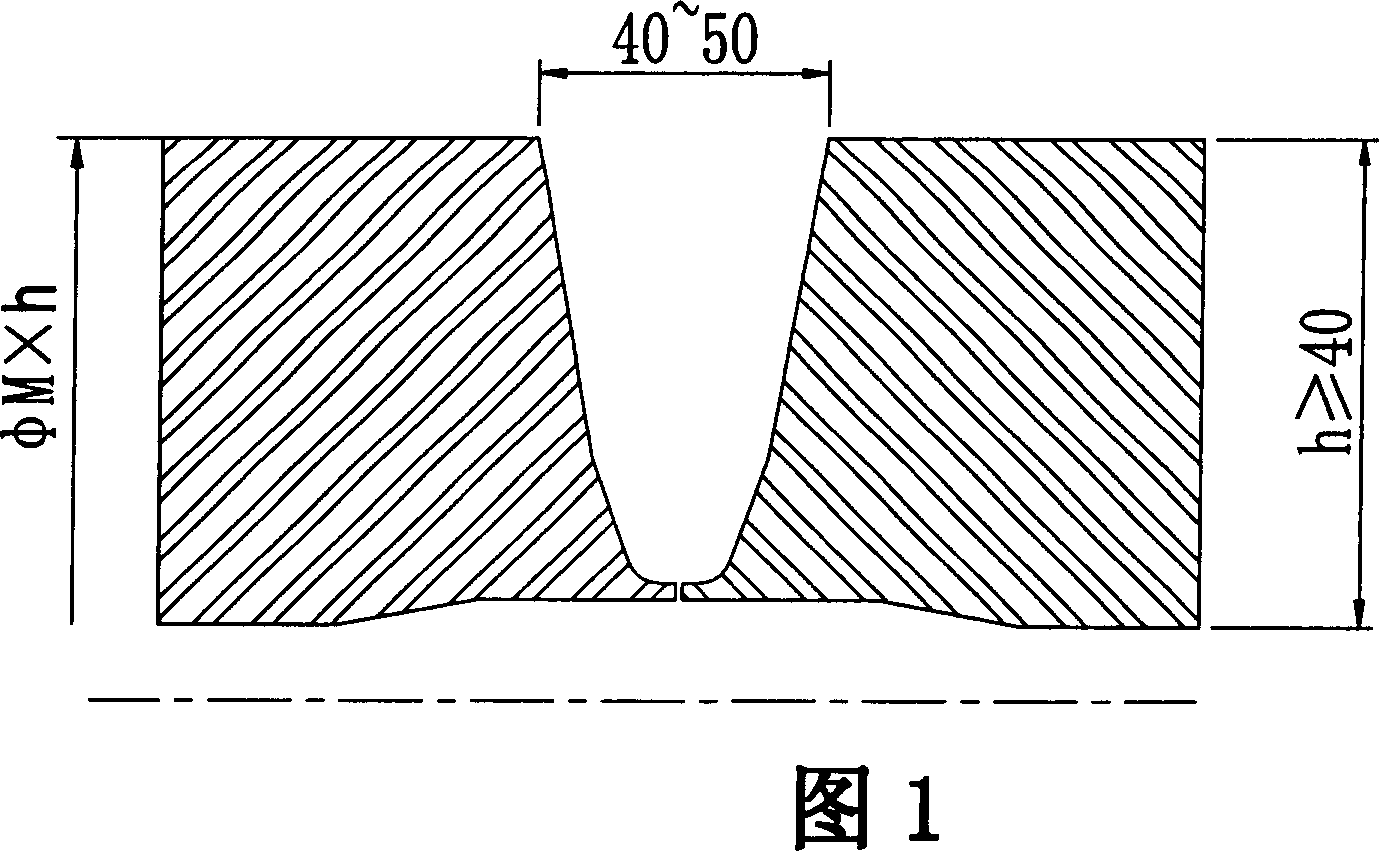

Large posted sides pipeline narrow gap tungsten electrode noble gas protecting all-position automatic soldering method

ActiveCN101077547AReduce fillingReduce welding costsArc welding apparatusWelding/cutting media/materialsNoble gasEngineering

The present invention relates to inert gas protected automatic narrow gap tungsten electrode welding process for large thick pipe with diameter over 325 mm and thickness over 40 mm. The automatic welding process includes forming combining chamfer in the opposite ends to be welded before welding, bottoming welding, single layer filling welding, and covering welding in linear or swinging weld pass. The process has less filled deposited metal, low welding cost, high welding efficiency and other advantages.

Owner:CHINA NUCLEAR IND 23 CONSTR

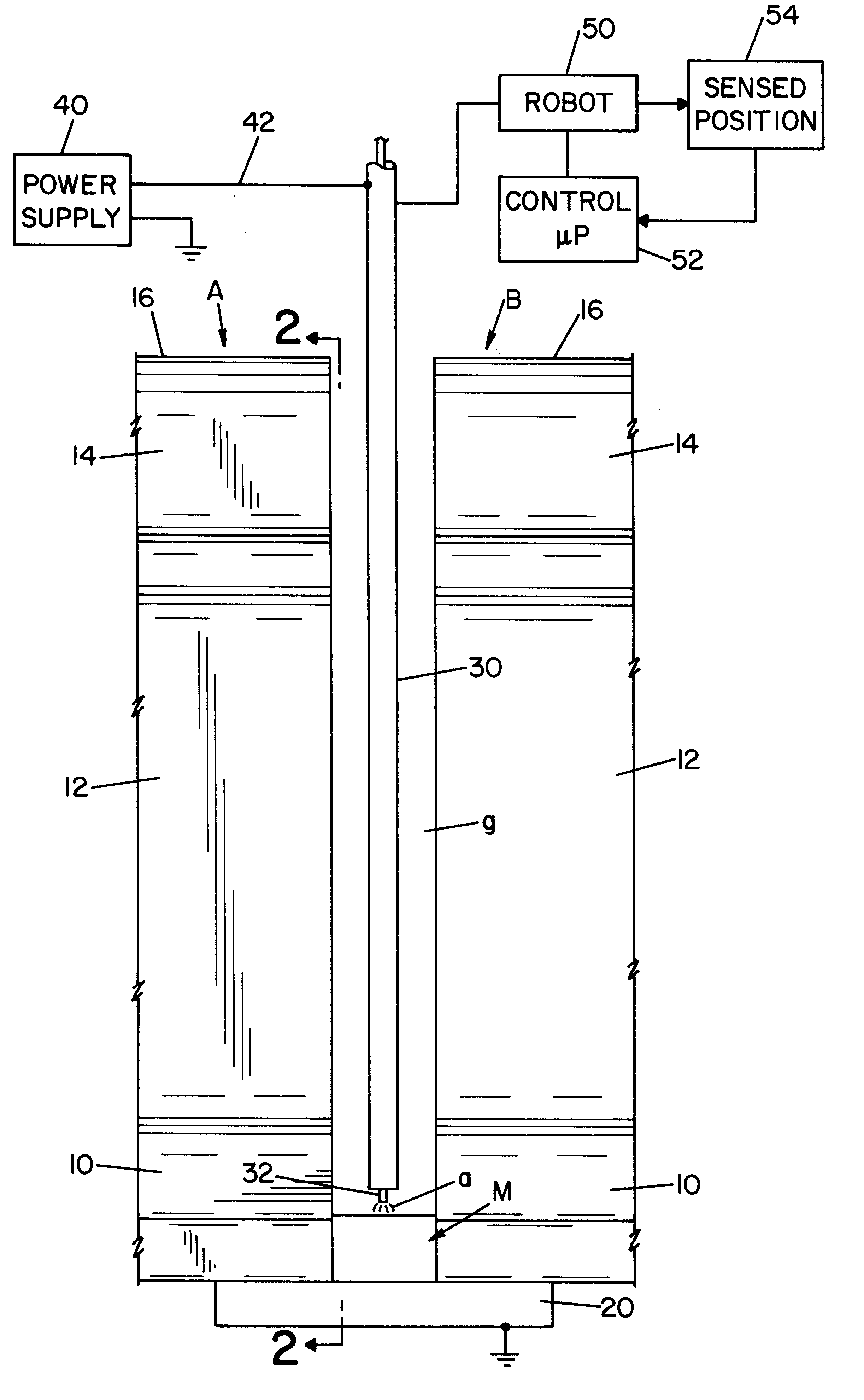

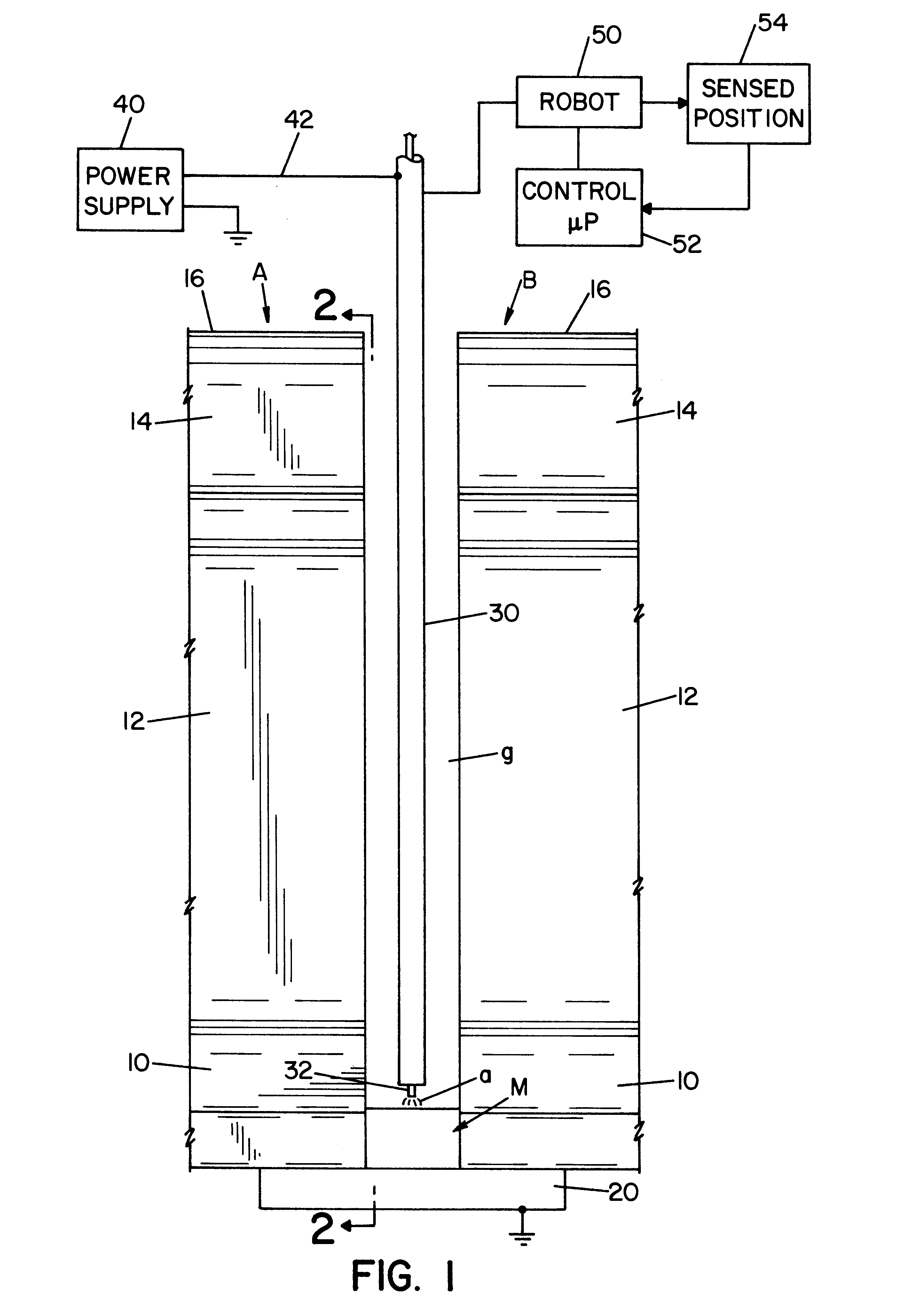

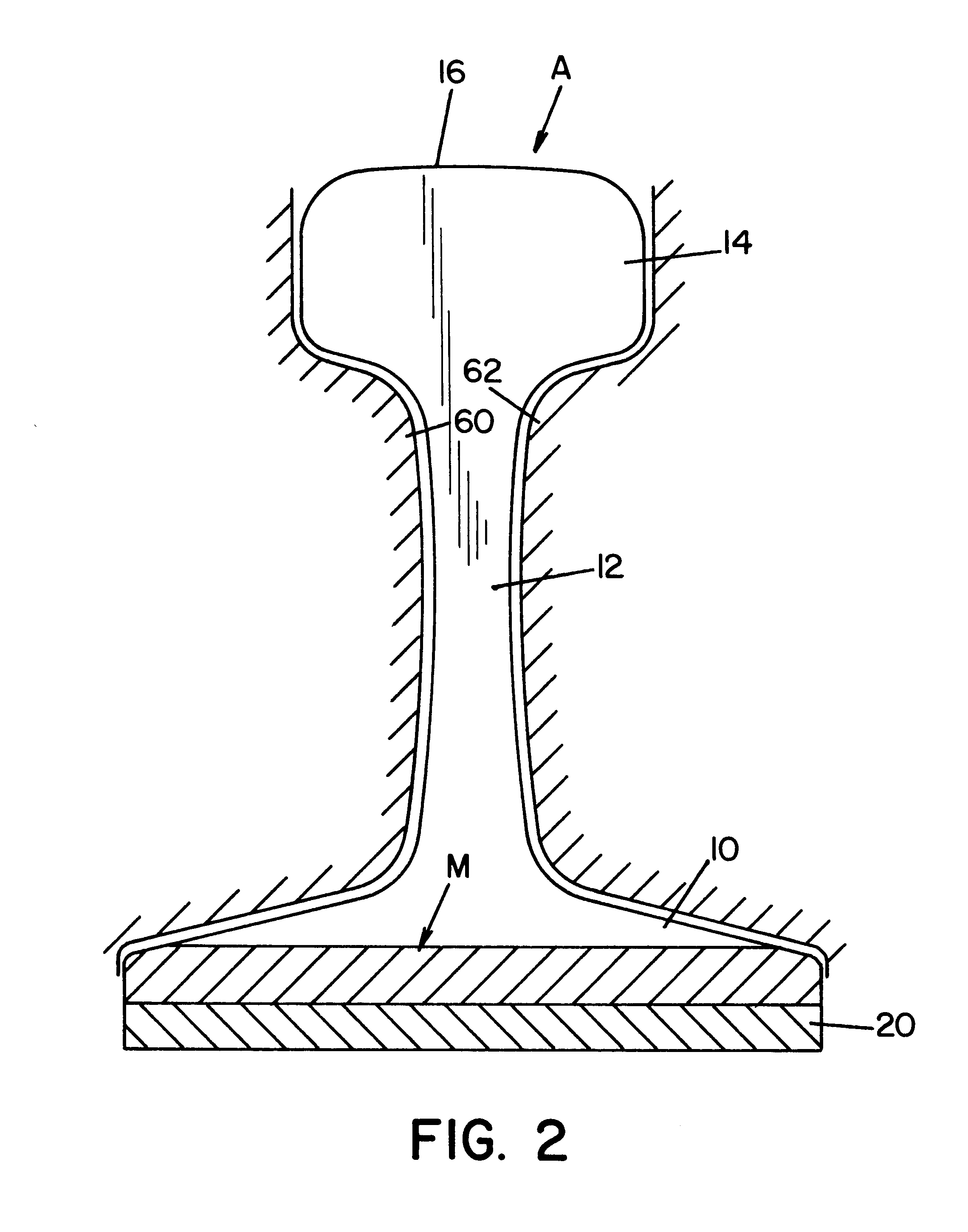

Method and system for welding railroad rails

A method and system for automatically filing the narrow gap between facing end walls of adjacent first and second railway rails by depositing vertically spaced layers of molten metal in the gap with an electric arc welding torch using a robotic mechanism that moves the torch in a pattern controlled by a low level robotic execute program from a spatial position to a next spatial position, said method and system comprising: constructing a data array for a specific gap, said array constituting a series of positions making up an idealized progression of said torch to fill said gaps in vertically spaced layers made up of multiple positions, each of said fixed positions identified by at least four coordinates, including (1) at least x, y and z, (2) the layer in which said position is a part and (3) the welding parameters to be executed while said torch moves toward the next position; outputting data relating to a specific position from said data array; processing said welding parameters associated with said outputted data using said robotic execute program; then, outputting the new fixed data relating to the next position in said series of points; processing said welding parameters associated with said new data using said robotic execute program; and, repeating said outputting and processing acts until said positions in said data array relating to a specific layer have been processed. Thereafter the method or system repeats the layer or processes the next layer comprising multiple stored positions.

Owner:LINCOLN GLOBAL INC

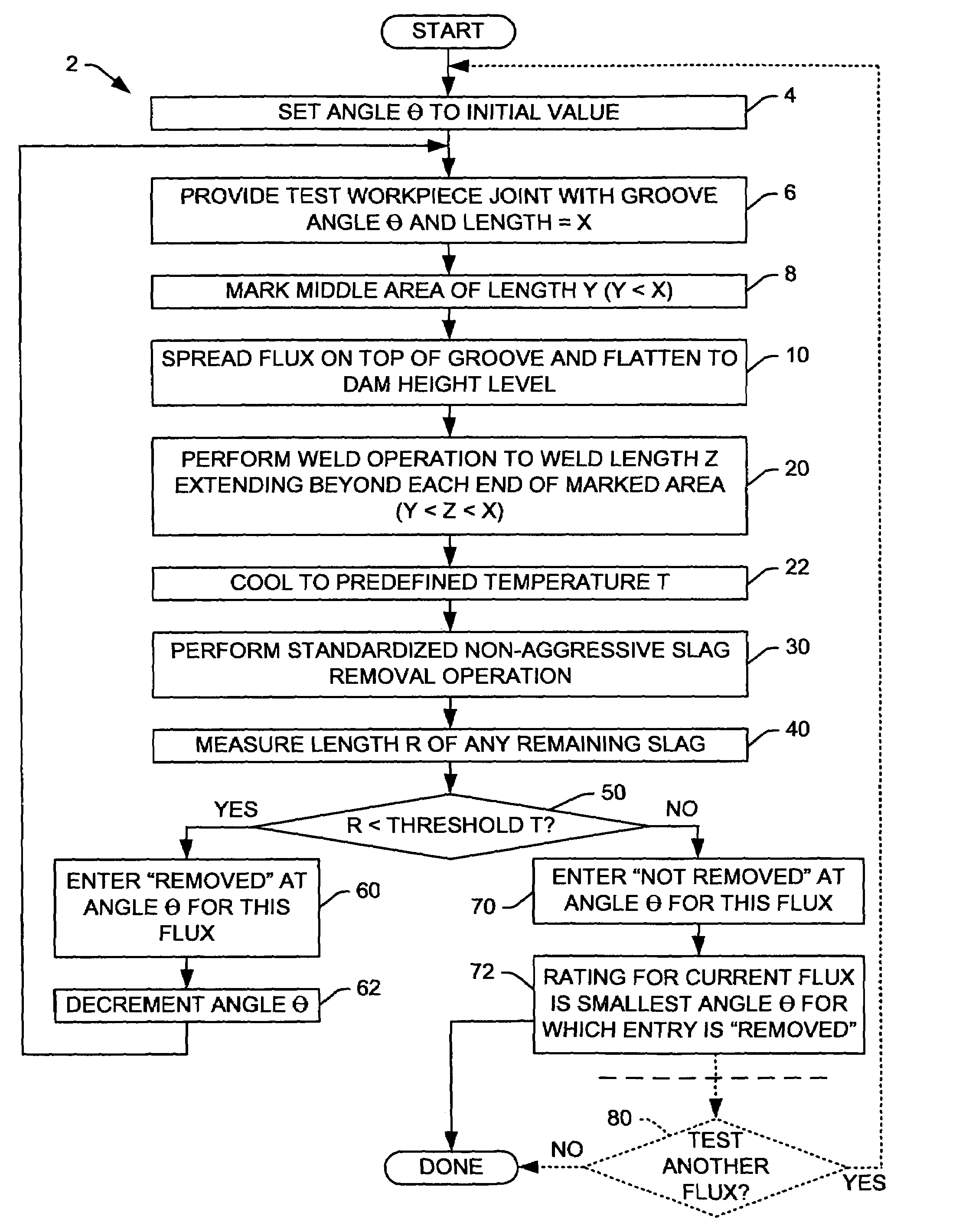

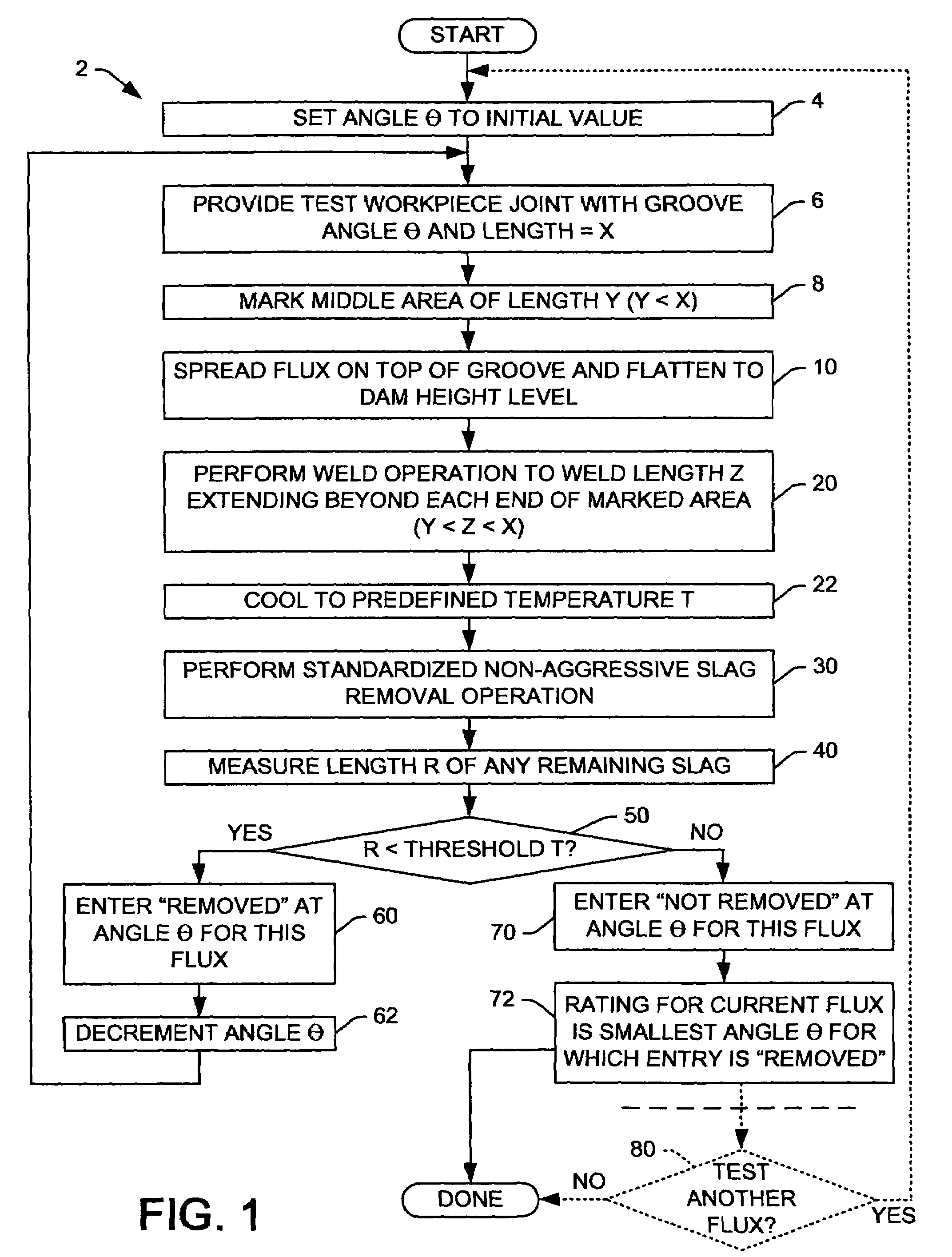

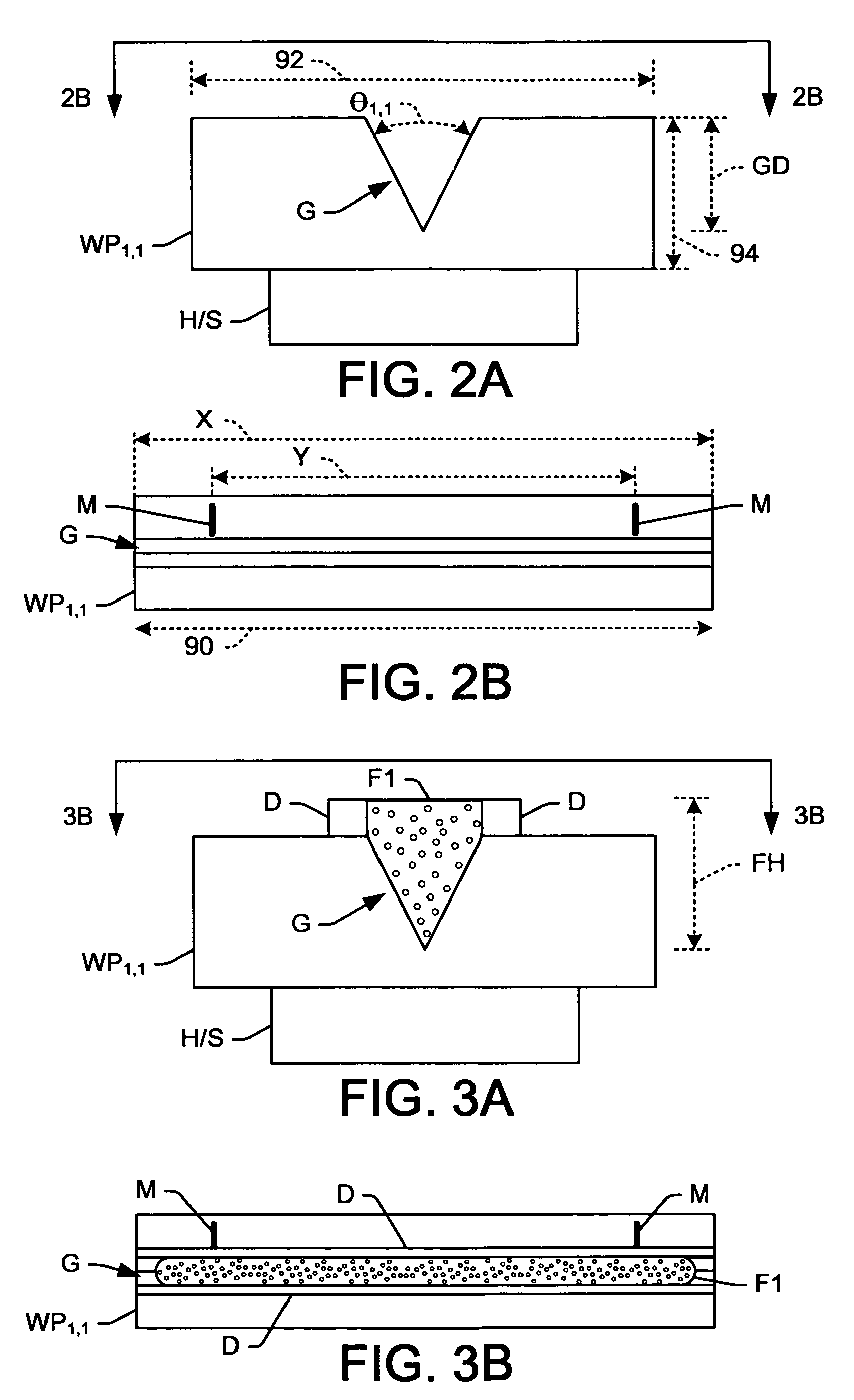

Method for evaluating and/or comparing welding consumables

Methods and systems are disclosed for characterizing a welding consumable, such as flux or an electrode, and / or for comparing two or more welding consumables for use in narrow gap deep groove welding operations, including creating test welds on fixtures having joint grooves of various angles for a given groove depth, followed by controlled standardized non-aggressive slag removal operations, and quantification of the amount of slag remaining in the groove, wherein the welding consumables are each characterized using the same fixtures, welding conditions, workpiece groove depths, groove angles, and removal operations, to construct a set of results, such as a table or rating, by which the individual welding consumables can be rated and / or a determination can be made as to which of two consumables provides superior performance with respect to ease of removal in deep groove welding operations.

Owner:LINCOLN GLOBAL INC

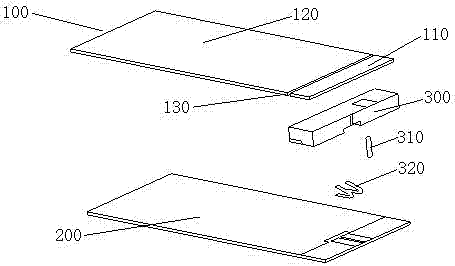

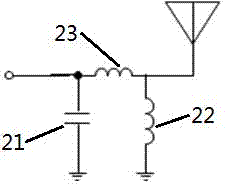

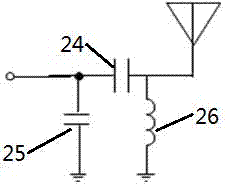

Multi-frequency-band rear metal cover mobile phone antenna

InactiveCN103178344AEffective radiationEfficient receptionSimultaneous aerial operationsAntenna supports/mountingsRadio frequencyPrinted circuit board

The invention aims at disclosing a multi-frequency-band rear metal cover mobile phone antenna which comprises a mobile phone rear metal cover, a printed circuit board and an antenna bracket, wherein the antenna bracket is positioned between the mobile phone rear metal cover and the printed circuit board; the mobile phone rear metal cover comprises a first rear metal cover and a second rear metal cover which are positioned on a same plane; a narrow gap is formed between the first rear metal cover and the second rear metal cover; the first rear metal cover is connected with an antenna part of the antenna bracket; the second rear metal cover is connected with a ground phase of the printed circuit board; a radio-frequency line of the printed circuit board is connected with the first rear metal cover; and the first rear metal cover and the ground phase of the printed circuit board are mutually connected. Compared with the prior art, the multi-frequency-band rear metal cover mobile phone antenna disclosed by the invention has the advantages that the antenna can effectively radiate or receive an electromagnetic signal in a way that the first rear metal cover of the rear metal cover is taken as a high-frequency or low-frequency radiating body of the antenna and other parts are arranged on the antenna bracket, thereby overcoming the defects of the prior art and realizing the purpose.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO +1

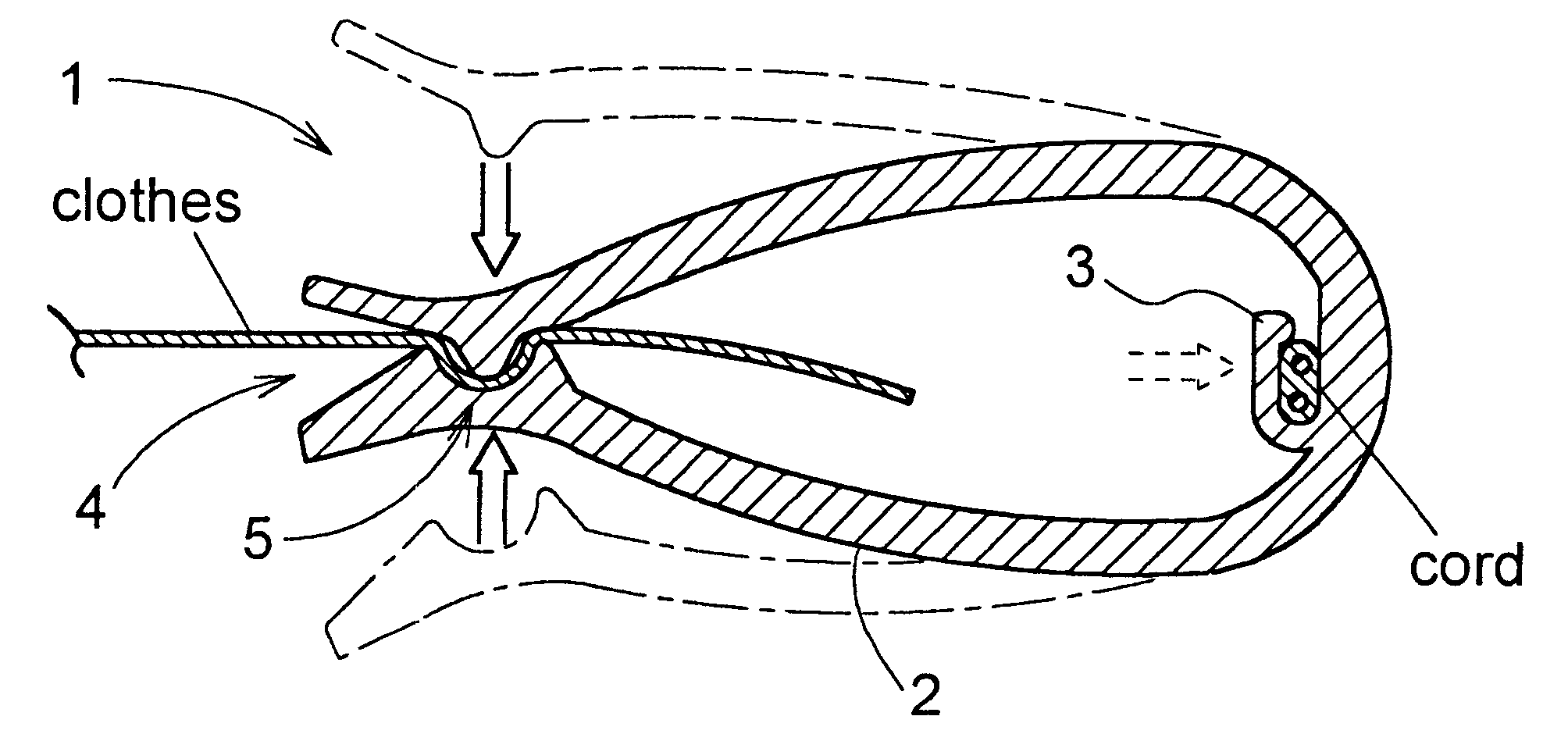

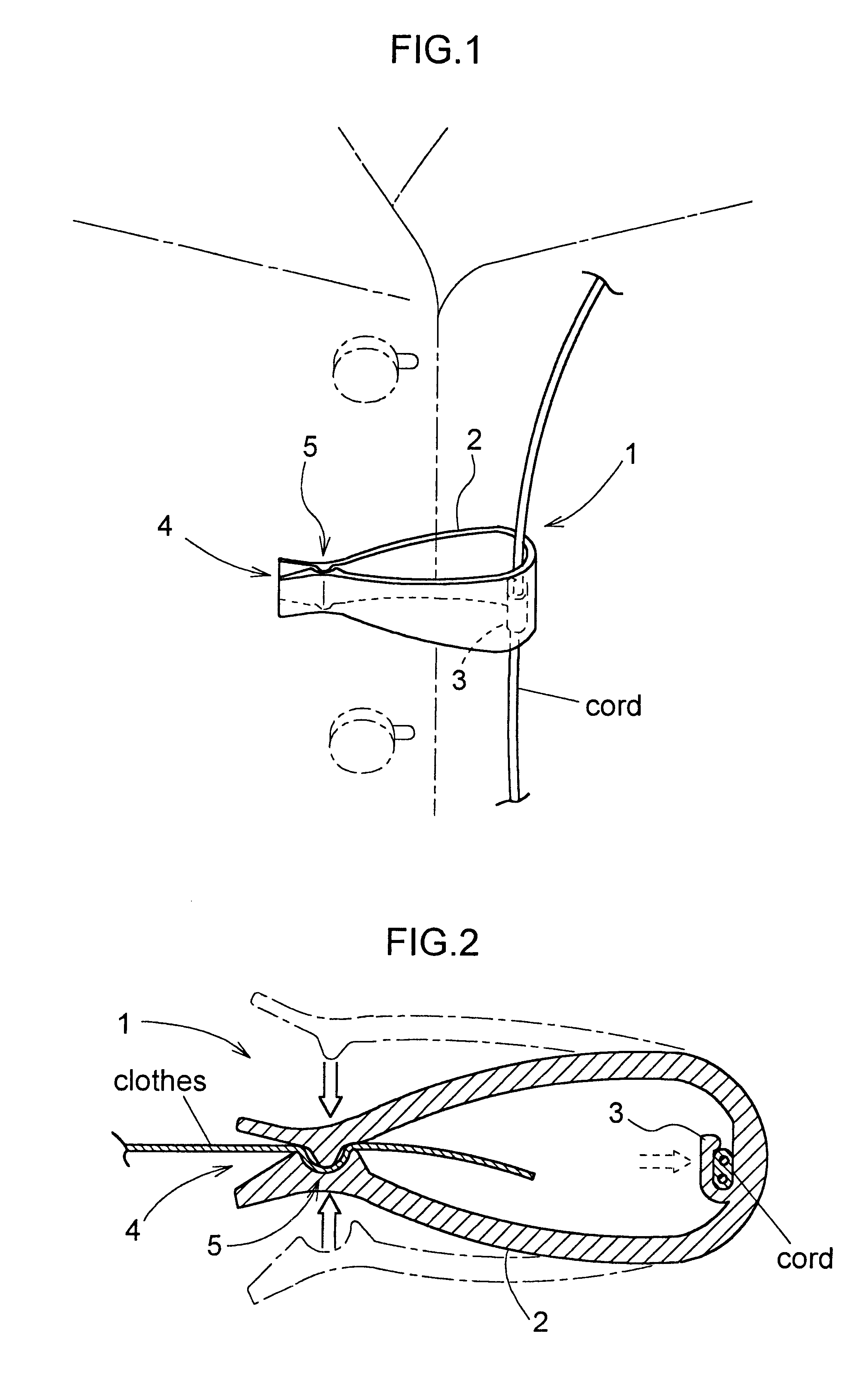

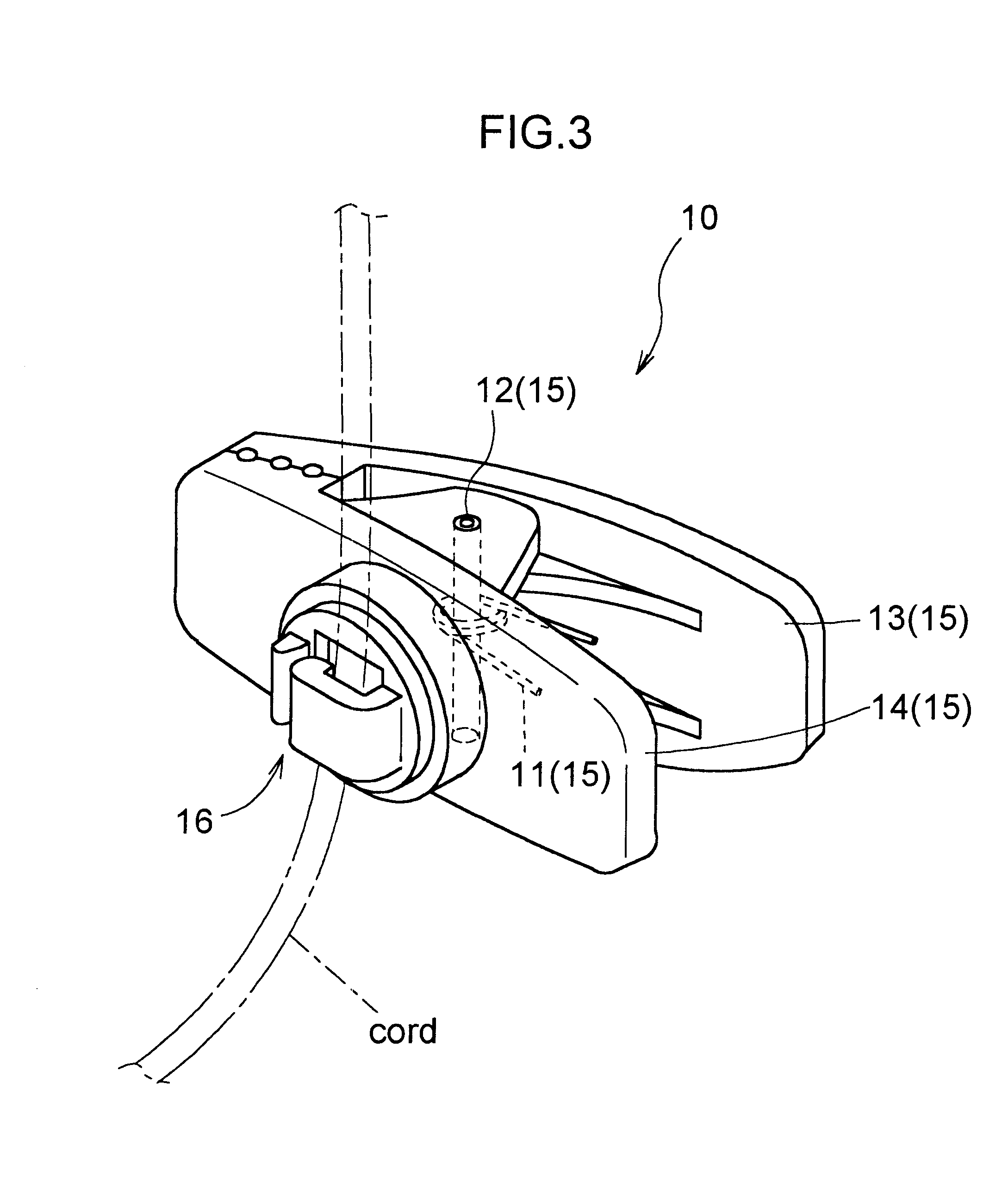

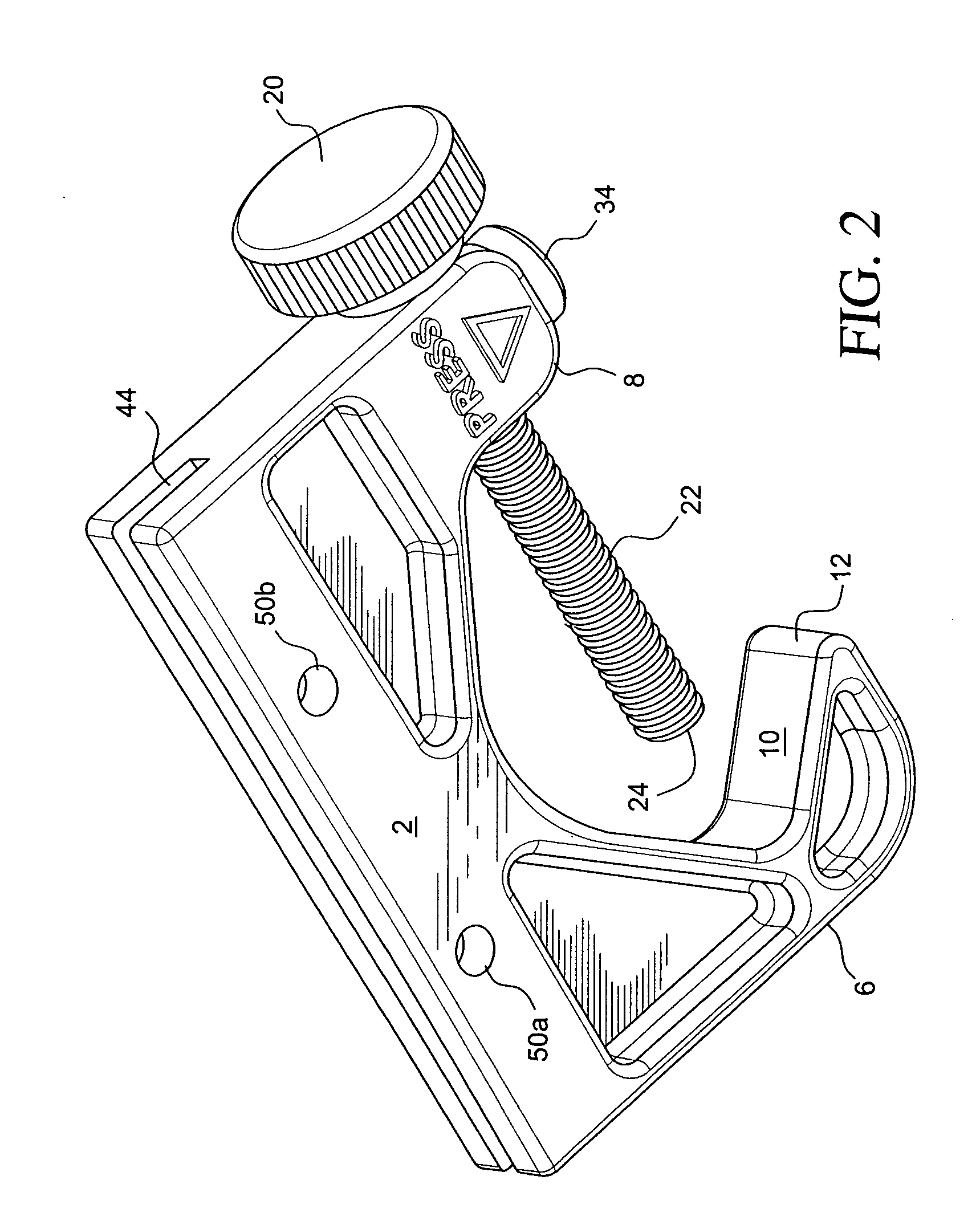

Cord clip

InactiveUS6526635B2Avoid mutual interferenceReduce part costSnap fastenersTravelling carriersEngineeringMechanical engineering

A cord clip for fastening a cord attached to e.g. an earphone to an object such as a clothes is disclosed. The cord clip includes a clipping portion for clamping the object and a cord holding portion for holding the cord. The clipping portion is formed by a first annular portion having a discontinuity at a part thereof. The clipping portion is capable of clamping the object at a clamping portion thereof provided by a narrow gap formed by the discontinuity of the first annular portion by means of an elastic resilient force of the first annular portion. The cord holding portion is formed by a second annular portion having a discontinuity at a part thereof. The cord holding portion is capable of holding the cord therein by means of an elastic resilient force of the second annular portion. This elastic resilient force of the second annular portion is independent of that of the first annular portion. The first annular portion and the second annular portion are formed integrally in a single member.

Owner:HOSIDEN CORP

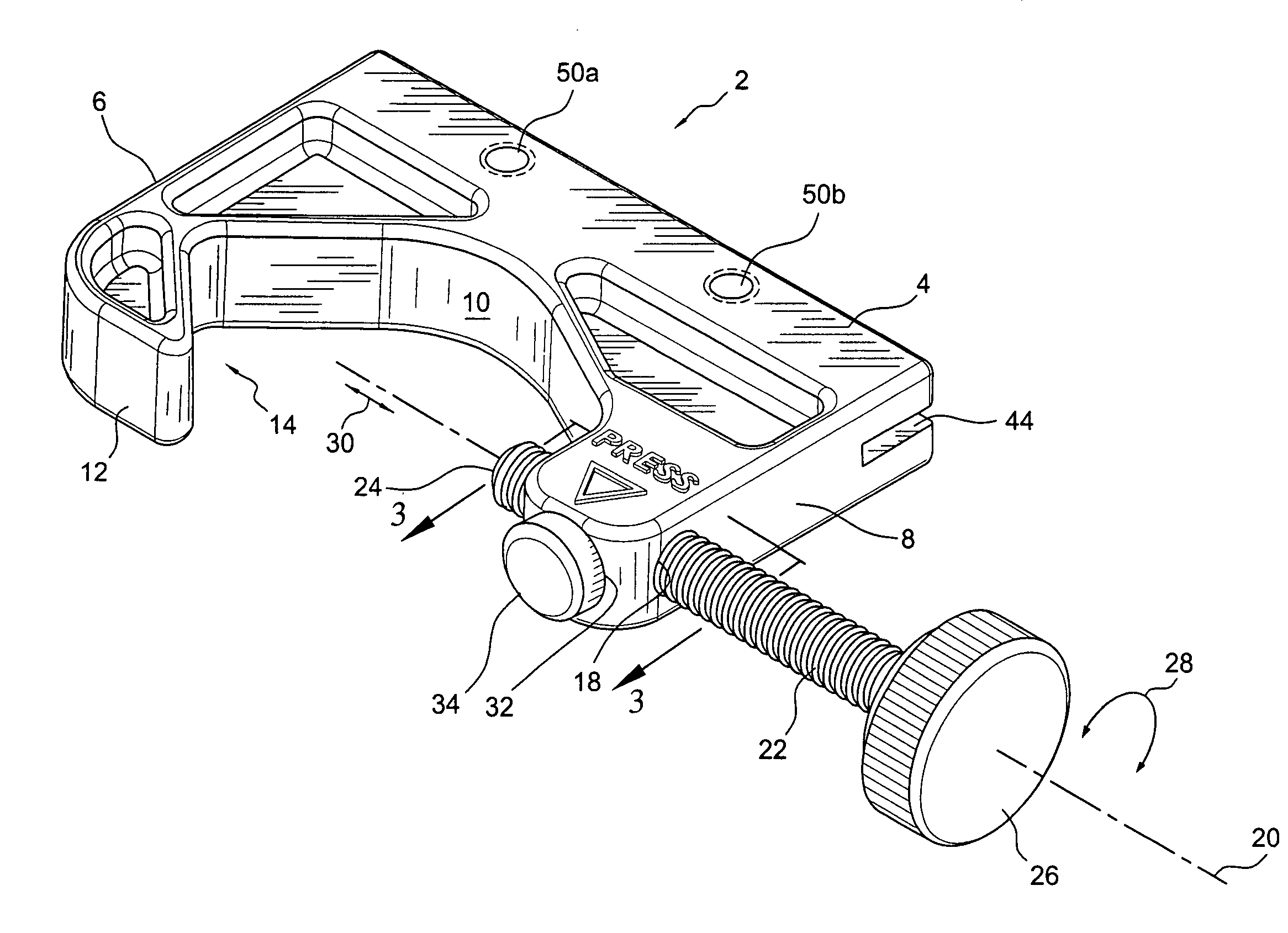

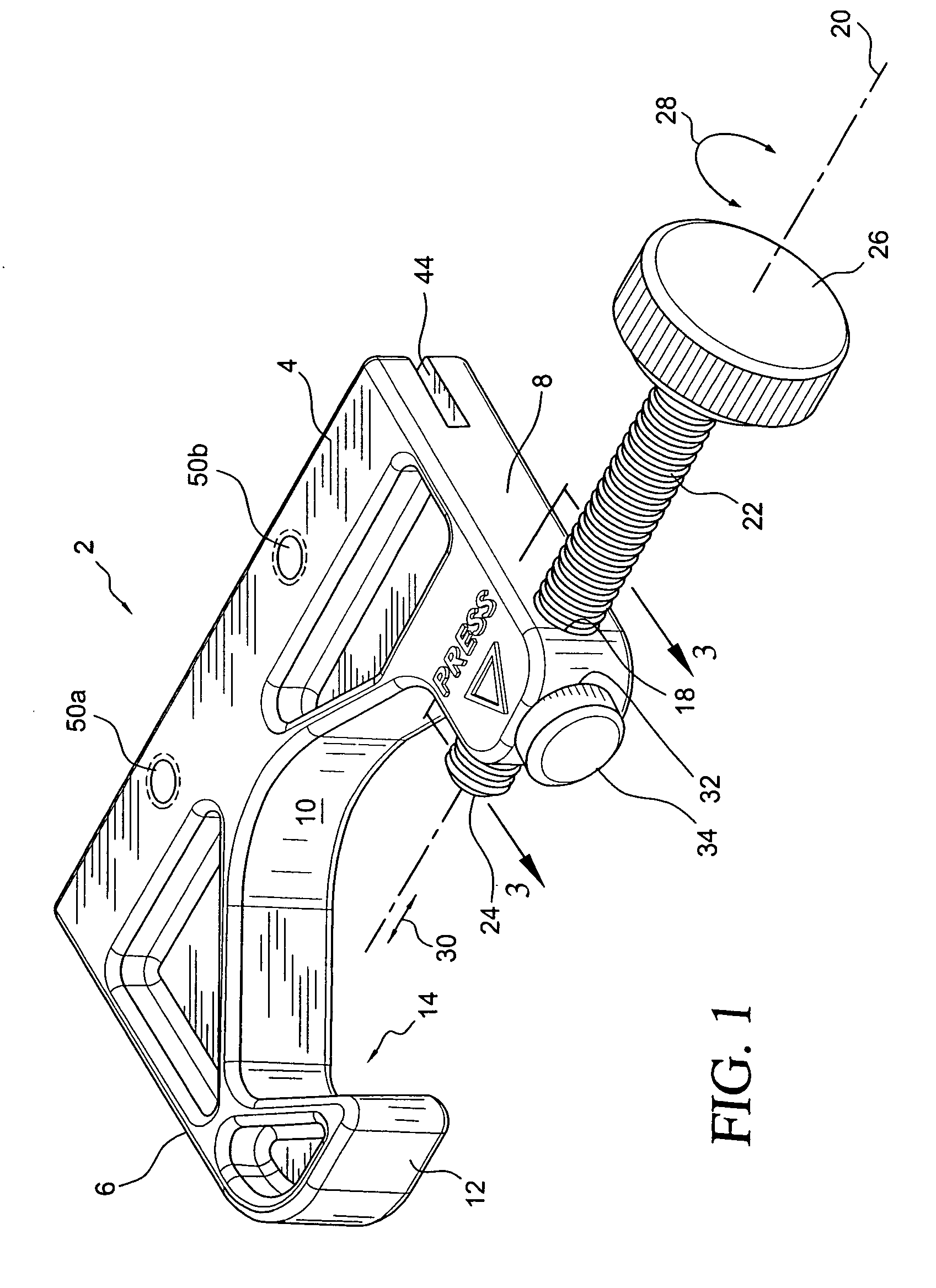

Pole Clamp

InactiveUS20100314517A1Easy for to turn shaftEasy to processOperating tablesNutsPush and pullWide gap

A pole clamp has two legs wherebetween poles of different diameters may be positioned. One of the legs is configured to grip one side surface of the pole. The other leg of the clamp member has a channel through which a threaded shaft is movable along a longitudinal axis toward the one leg. Also formed in the other leg is a bore orthogonally to the channel. A guide that may be in the form of a half nut is movable within the bore, with the threaded surface of the half nut being in a threaded relationship with the threads of the shaft, when the guide is in a first position, so that the shaft is movable along the axis when it is turned. The guide is movable to a second position to disengage its threaded surface from the shaft. When thus disengaged, the shaft is movable bidirectionally along the axis by simple push and pull movements. A second embodiment of the pole clamp utilizes a yoke slider guide having two arms with a narrow gap and a wider gap between the two arms.

Owner:SMITHS MEDICAL ASD INC

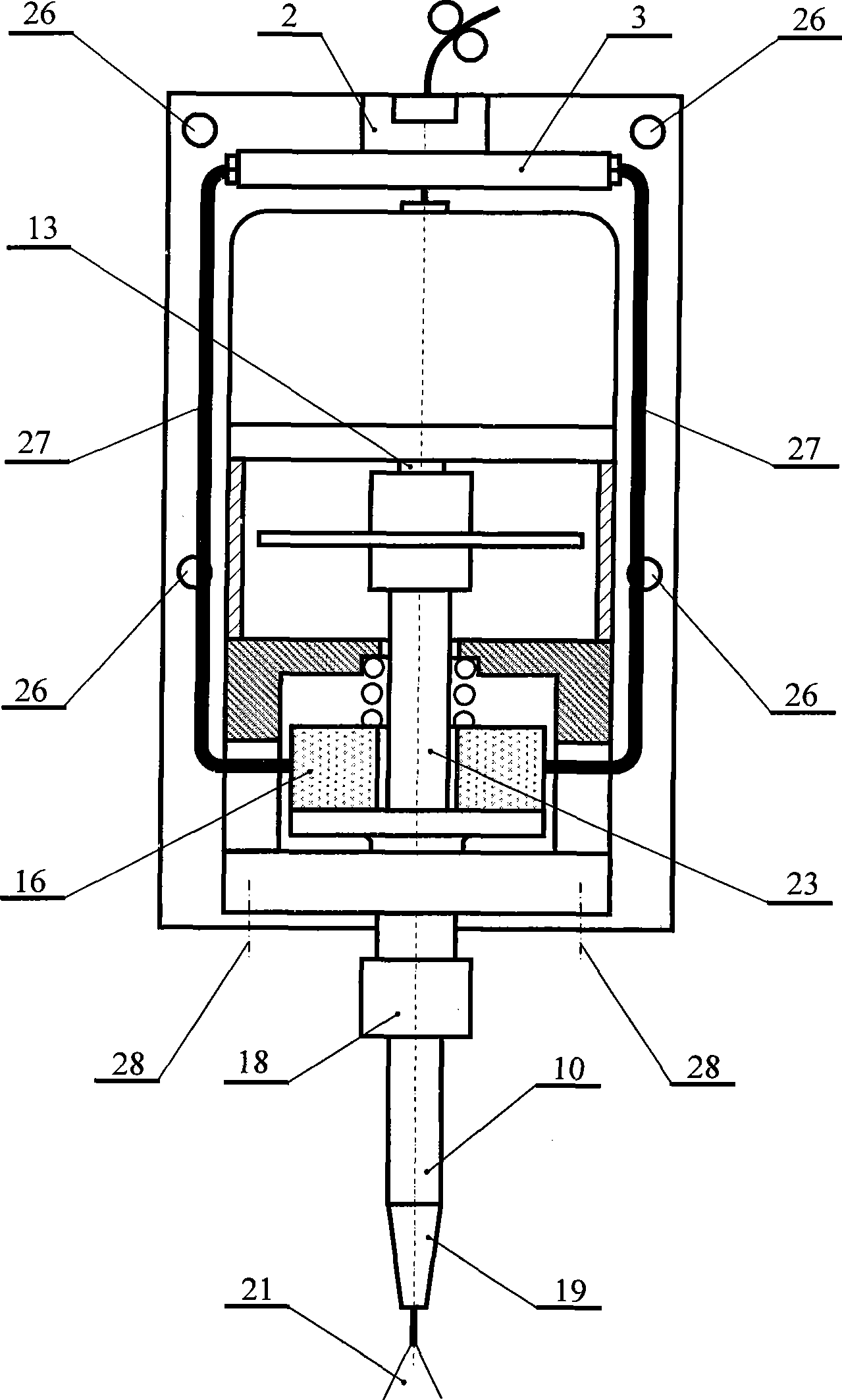

Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

InactiveCN101412143AMeet the needs of different welding processes for weldsReduce drive powerElectrode supporting devicesCouplingEngineering

The invention discloses a rocking arc narrow gap consumable electrode gas shielded welding method and a welding torch. The method comprises the following steps: a connecting cable is fixed on an electric brush mechanism and a coupling head; a hollow shaft motor is connected with a straight conducting rod through a shaft joint; a welding wire passes through a center hole of a cable coupling head, and penetrates out a center hole of a current contact nozzle; the lower end of the straight conducting rod is fixed with a connecting piece; and one end of a minor bend conducting rod is connected with the straight conducting rod through the connecting piece, while the other end of the minor bend conducting rod is connected with the current contact nozzle. The hollow shaft motor directly drives the straight conducting rod and the minor bend conducting rod capable of extending into a divided edge of a workpiece to make reciprocating rotation around the central axial line of the welding torch, thereby driving electric arc of the end of the welding wire send from the center hole of the current contact nozzle to make arc rocking in the divided edge of the workpiece so as to realize rocking arc narrow gap welding. The welding torch has the advantages of simple and compact structure, low implementation cost, high reliability of operation, strong practicality, and can adapt requirement of welding process for mean position and spatial position with different welding seams. The welding wire has strong rocking regulation, good directivity of the electric arc, and high welding quality.

Owner:JIANGSU UNIV OF SCI & TECH

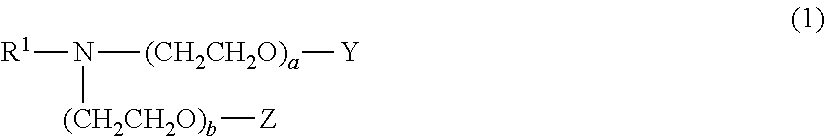

Cleaning agent for removal of, removal method for, and cleaning method for water-soluble, lead-free solder flux

InactiveUS20120090646A1Maintain good propertiesImprove securityNon-surface-active detergent compositionsDetergent mixture composition preparationGlycol ethersWater soluble

An object of this invention is to provide a cleaner for the removal of water-soluble, lead-free soldering flux, the cleaner capable of cleaning off, in a short period of time, water-soluble flux residues generated during soldering with lead-free solder using water-soluble flux, the cleaner further having excellent dissolution property as well as excellent narrow gap cleaning property. The cleaner for removing water-soluble, lead-free soldering flux of the present invention comprises 5 to 100 parts by weight of a glycol ether compound (A) per 100 parts by weight of water.

Owner:ARAKAWA CHEM IND LTD

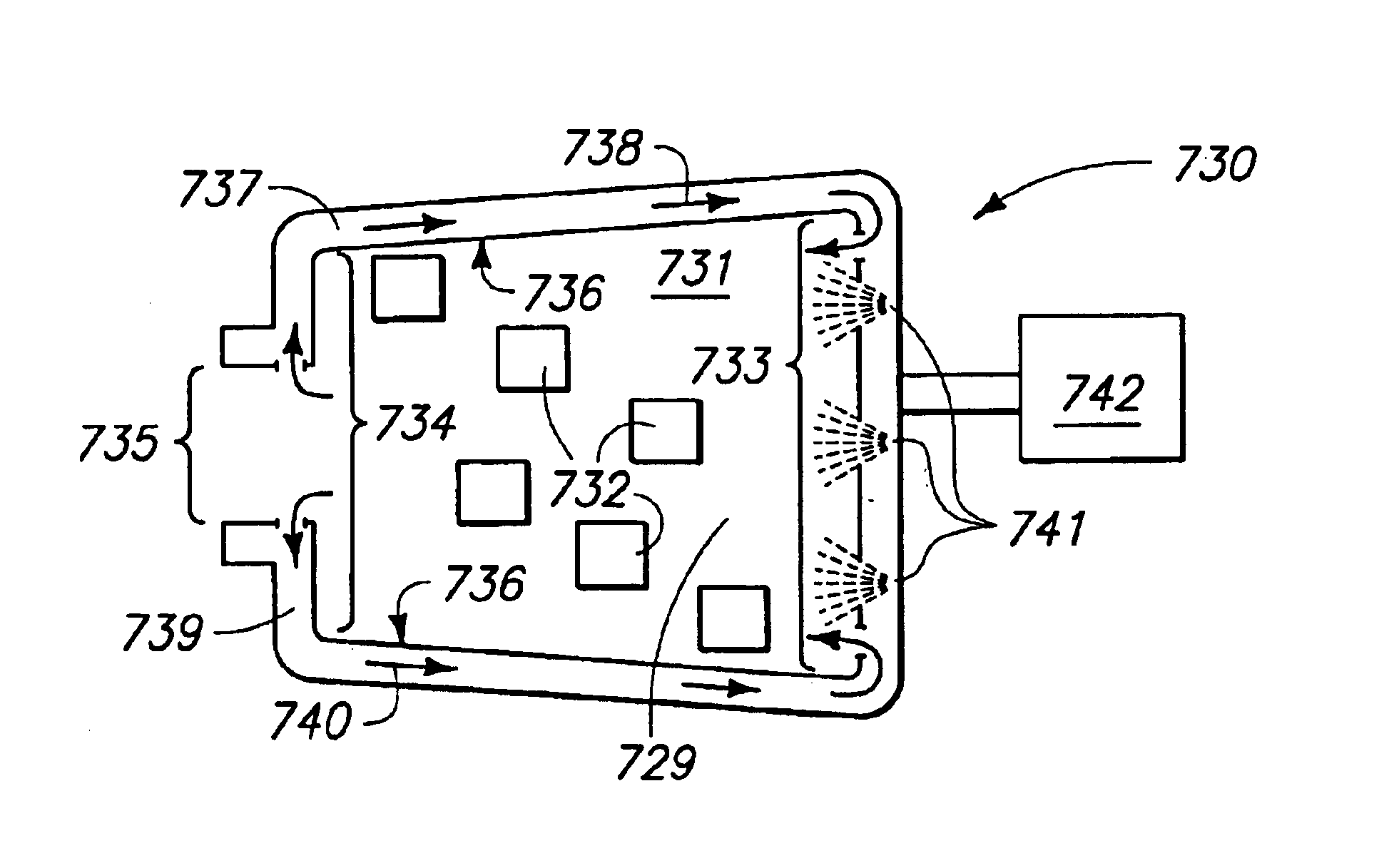

Spray cooling system for transverse thin-film evaporative spray cooling

InactiveUS6955062B2Domestic cooling apparatusSemiconductor/solid-state device detailsEngineeringElectronic component

A spray cooling system for transverse thin-film evaporative spray cooling in a narrow gap which generally includes a framework, a cooling cavity, a plurality of atomizers oriented to transversely spray coolant across the electronic components to be cooled, and preferably a vapor recirculation system and a reduction in cross section from the inlet or spray side to the exit side.

Owner:PARKER INTANGIBLES LLC

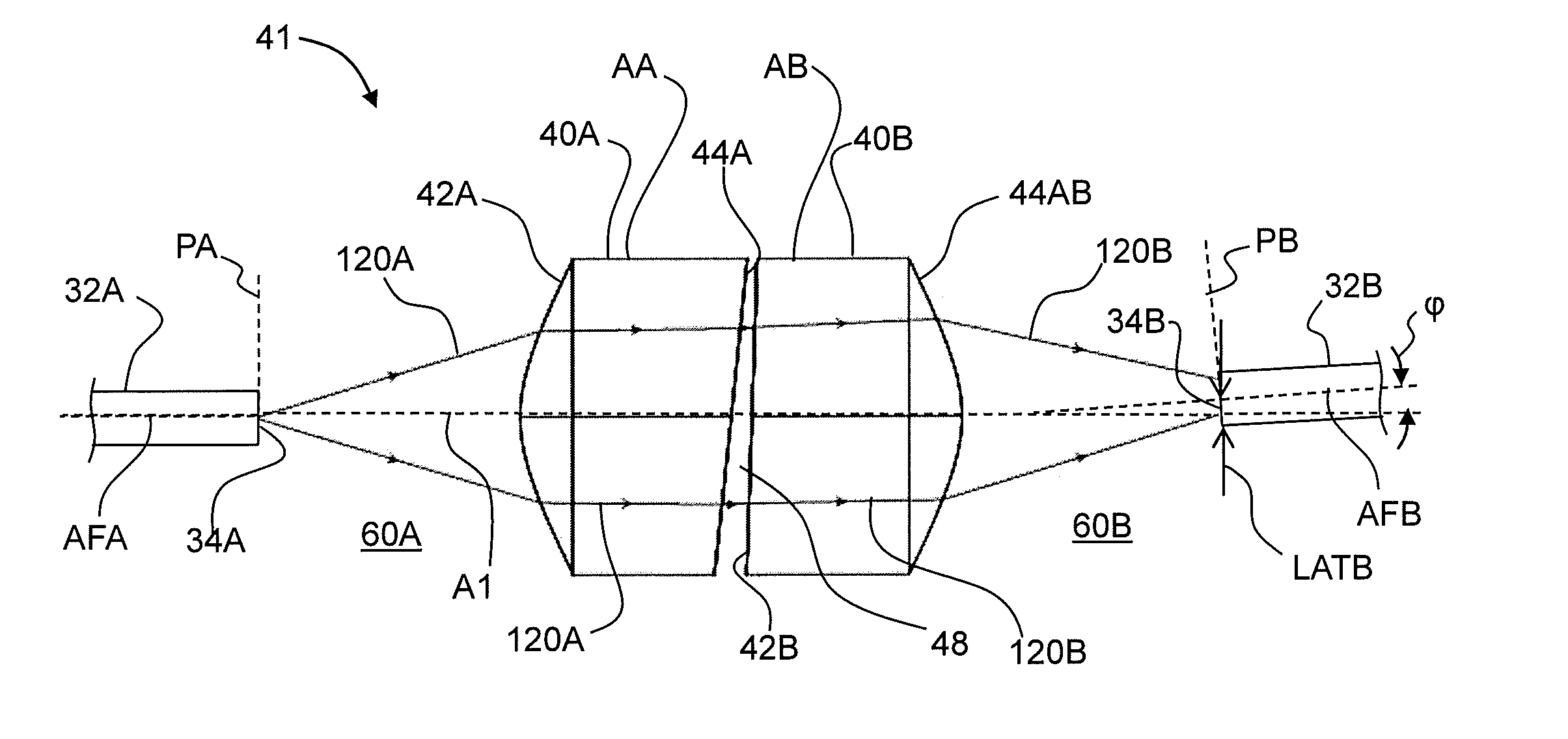

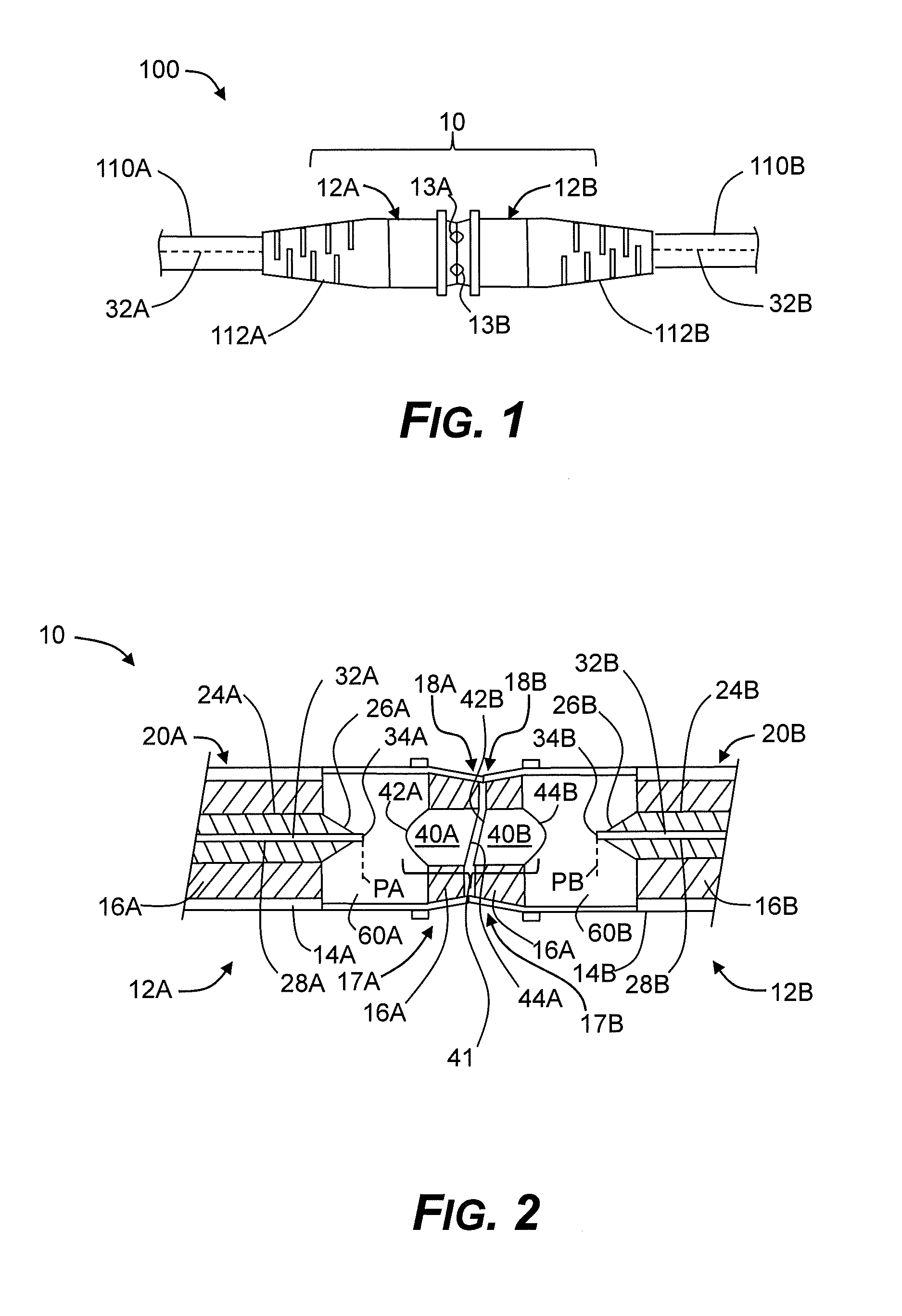

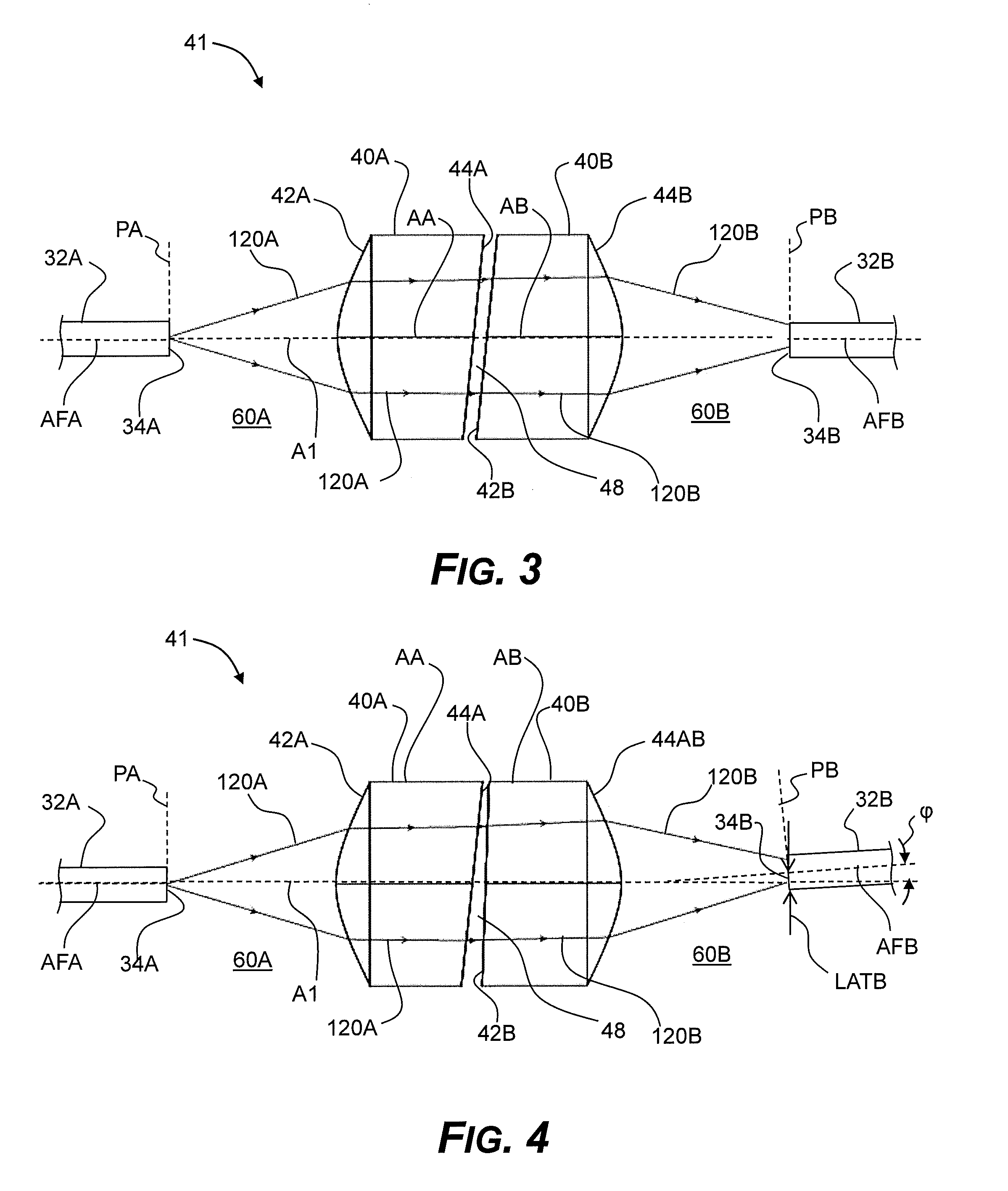

Optical connector with lenses having opposing angled planar surfaces

An optical connector for optically connecting at least one light source to at least one light receiver is disclosed. The optical connector includes first and second connector members respectively having first and second positive-power lens elements with respective first and second planar lens surfaces. The lens elements are arranged in their respective connector members such that when the two connector members are operably mated, the first and second lenses form an optical system where the first and second planar lens surfaces are spaced apart in opposition with a narrow gap in between, and are non-perpendicular to the optical system axis. The lenses may be conventional uniform-refractive-index lenses having a convex surface or may be gradient-index lenses having two planar surfaces. The optical connector is tolerant to contamination that can find its way into the narrow gap.

Owner:CORNING INC

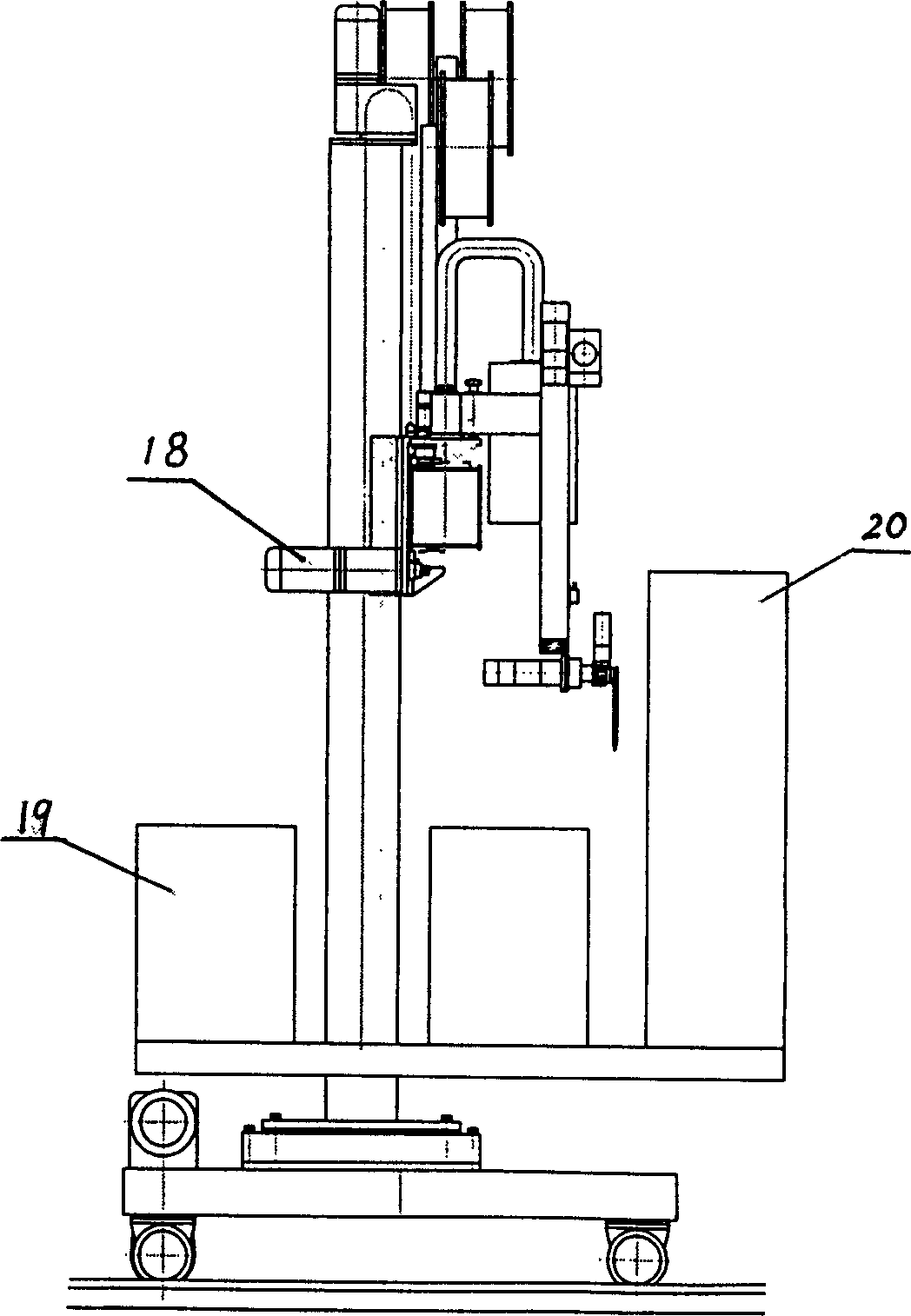

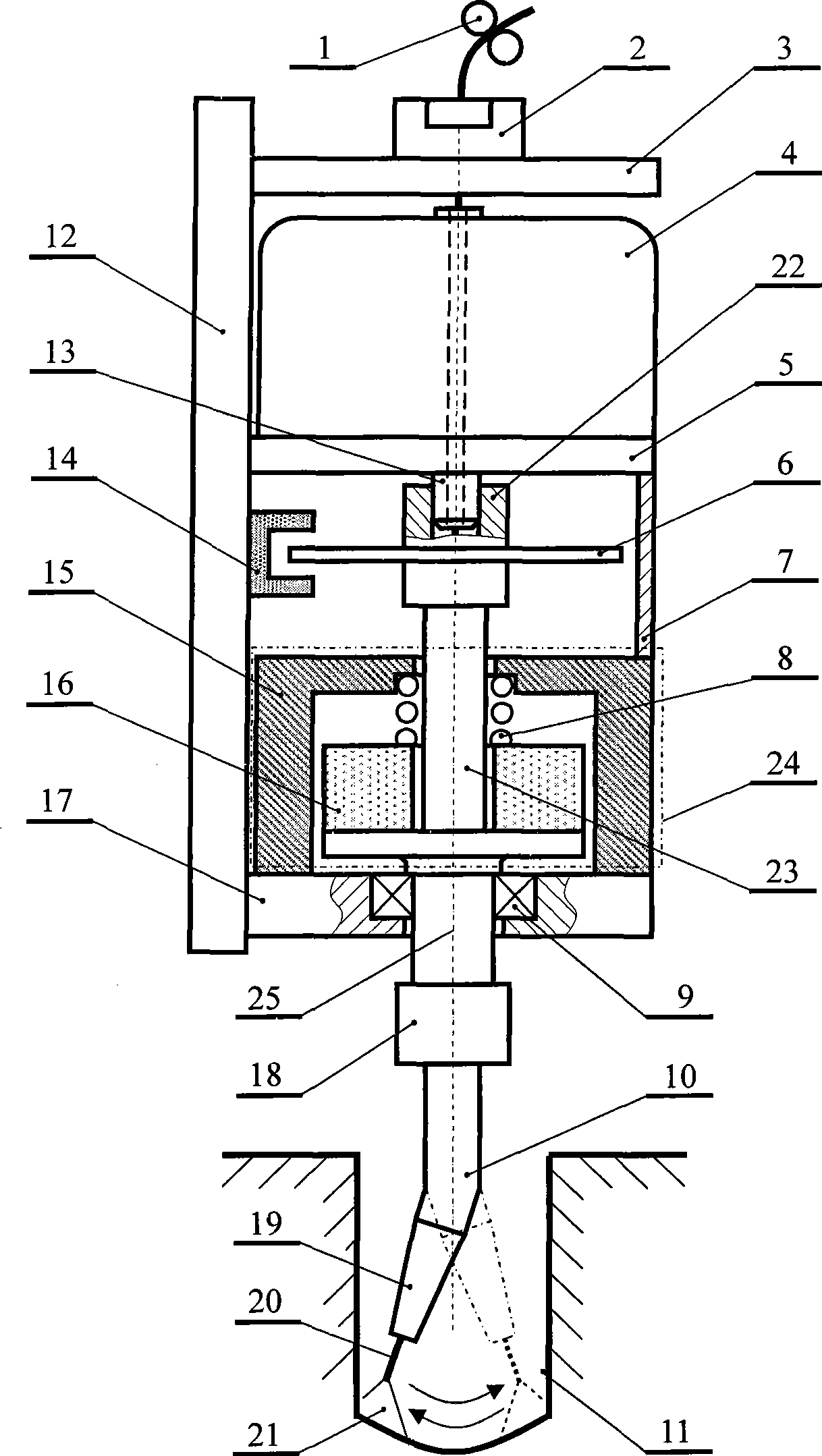

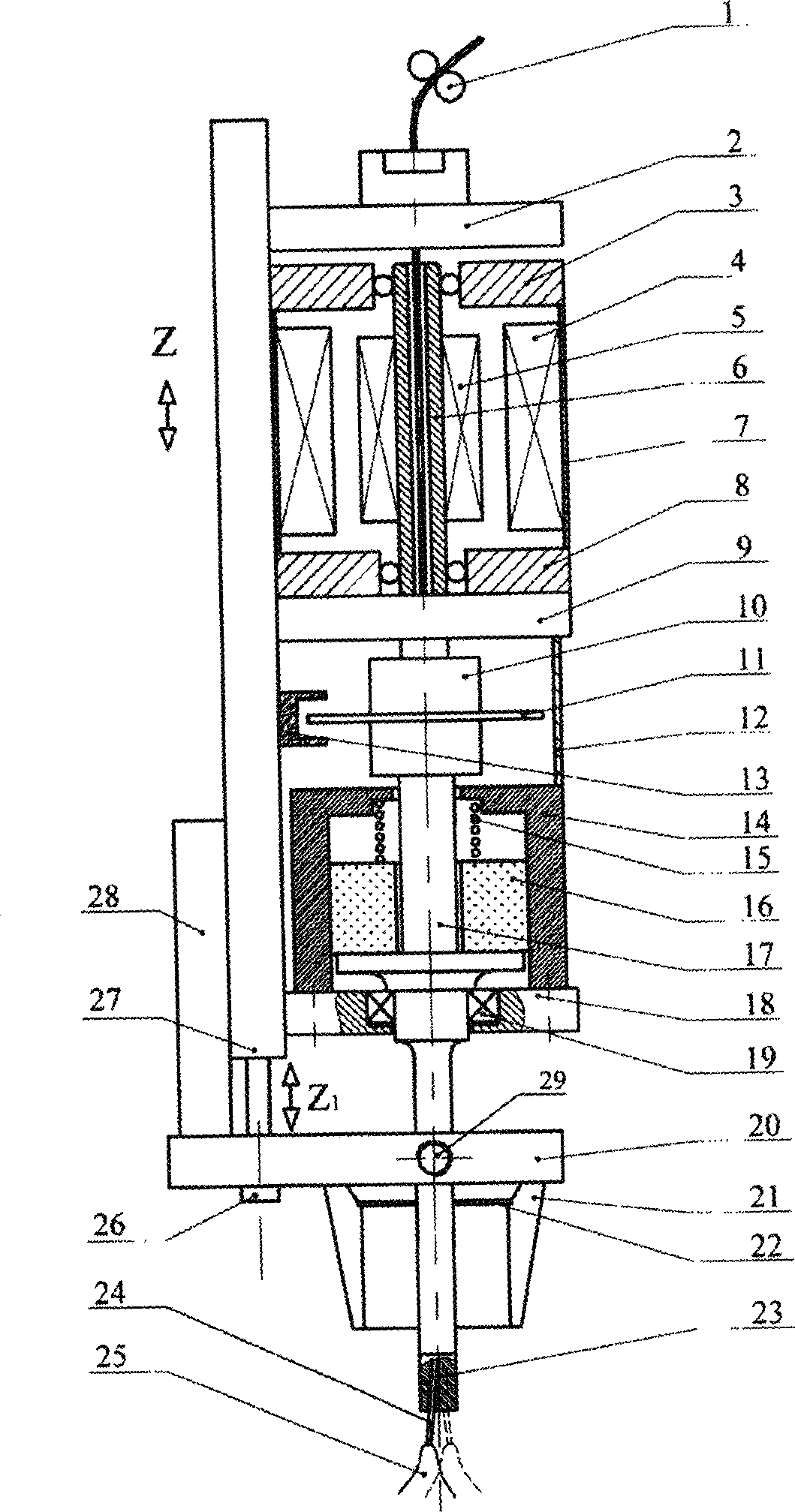

Rotary electric arc narrow gap welding method and device driven by hollow shaft motor

ActiveCN1657211AImprove welding qualityHigh working reliabilityArc welding apparatusGratingEngineering

A welding machine for welding in narrow gap by rotary arc is composed of a connector of welding electric cable, an electric motor unit with hollow shaft for feeding welding wire through it, an electric feeding unit of brush with close slide matching with the flange of electric conducting rod, a spray unit with eccentrical hole for generating the rotary arc at the front end of welding wire, and speed measuring unit consisting of raster and light coupler. Its straight nozzle can be inserted in the narrow gap to be welded.

Owner:JIANGSU UNIV OF SCI & TECH

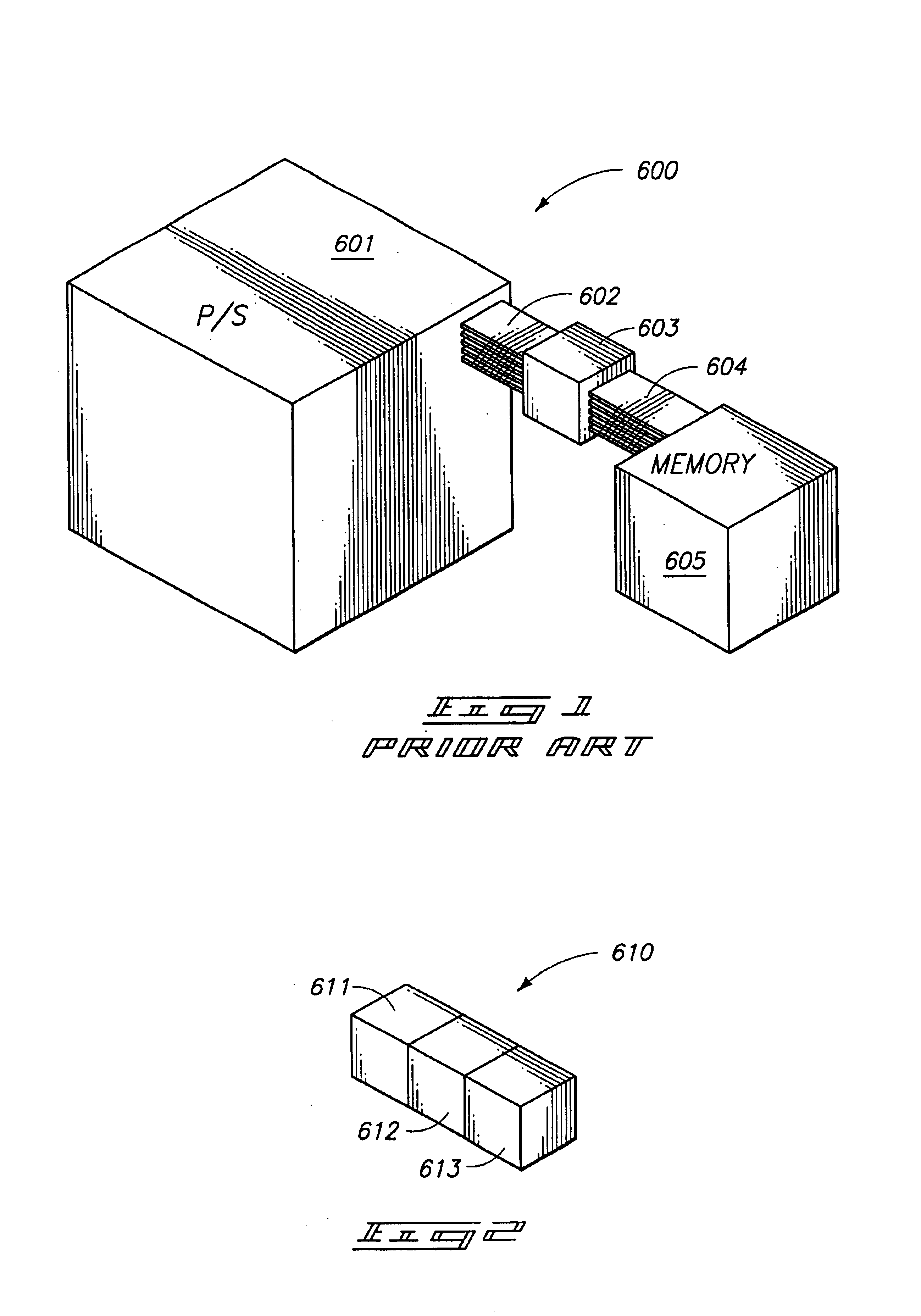

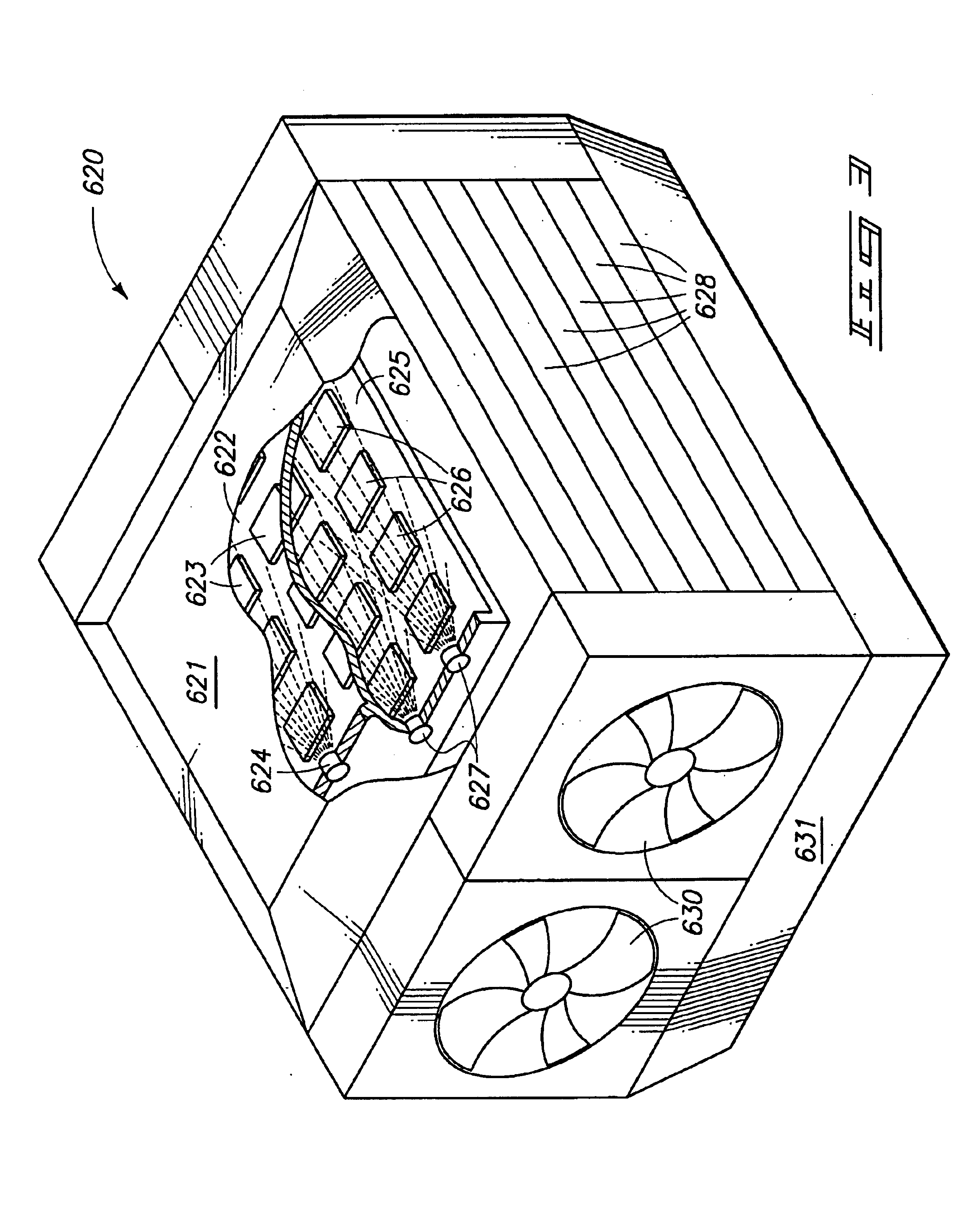

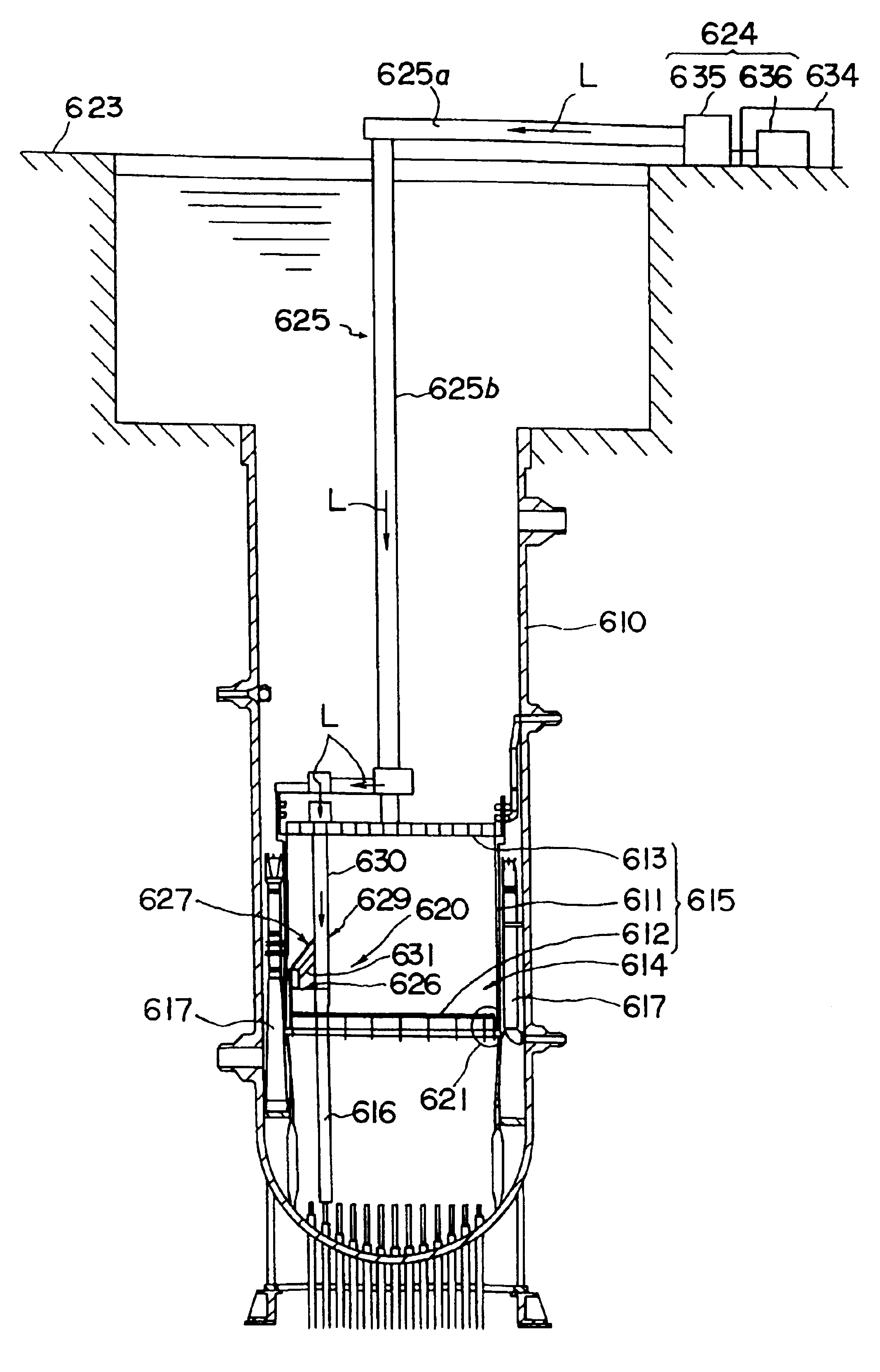

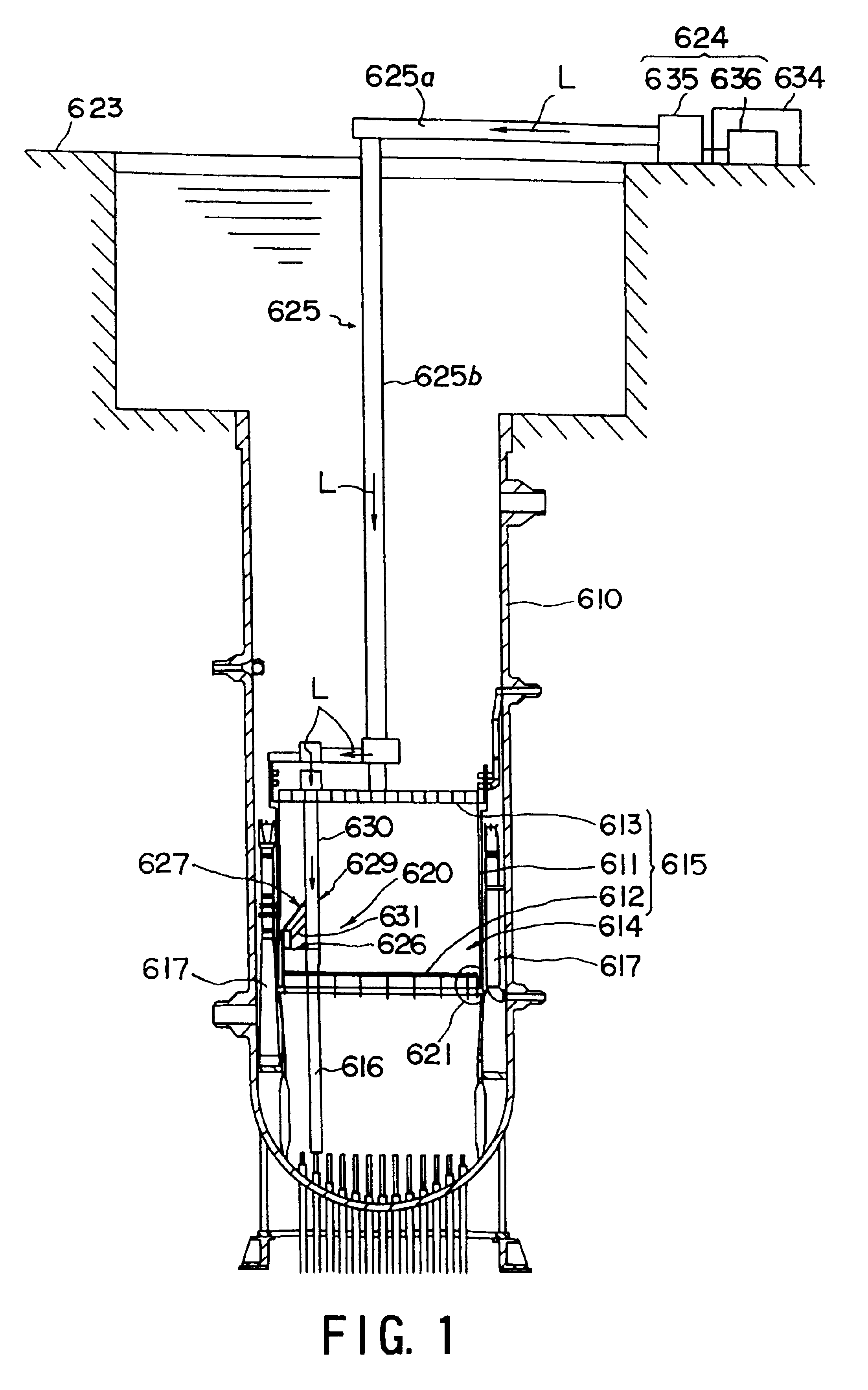

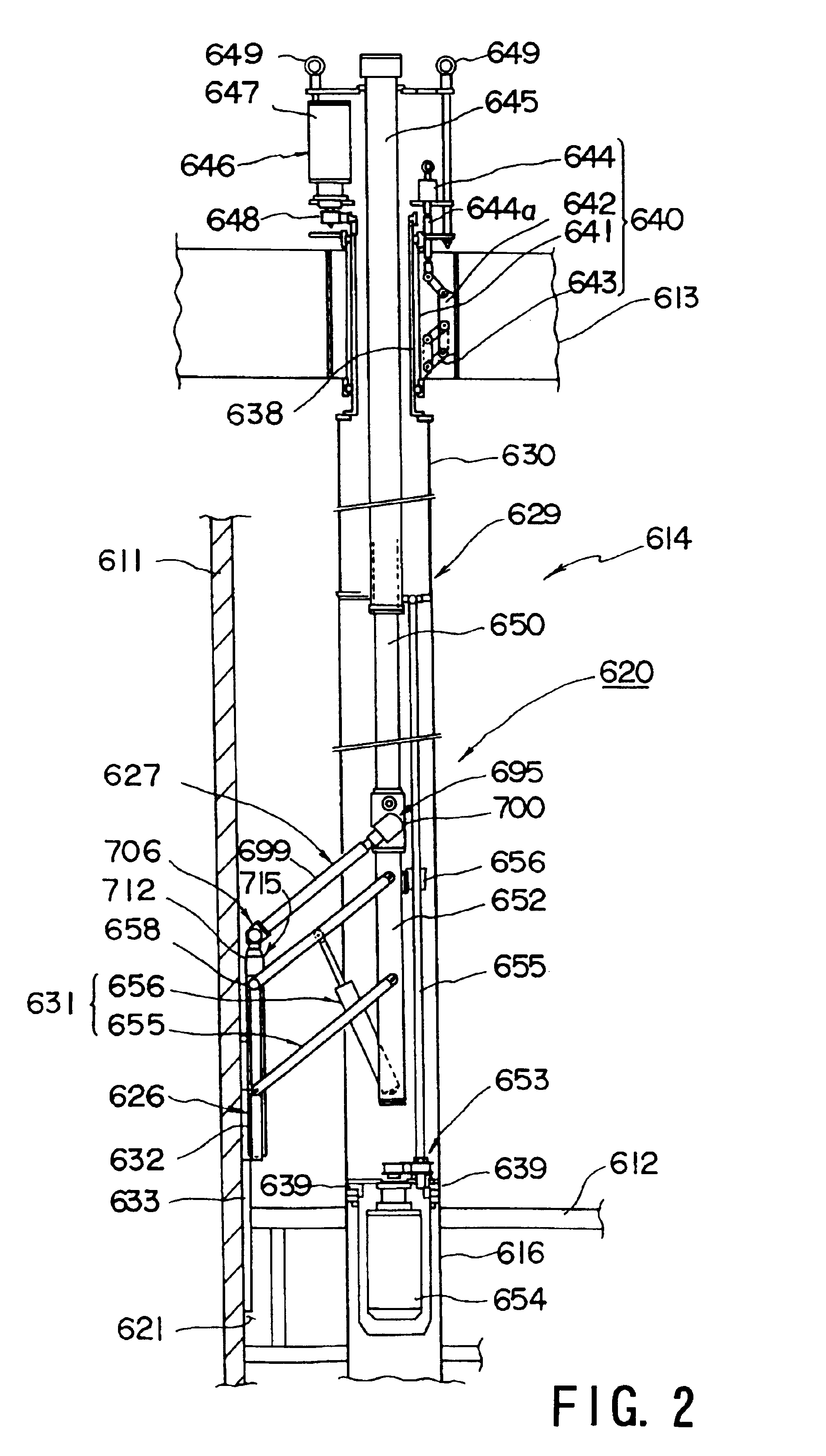

Laser emission head, laser beam transmission device, laser beam transmission device adjustment method and preventive maintenance/repair device of structure in nuclear reactor

InactiveUS6881925B1Deterioration in working can be preventedInhibit deteriorationLaser beam welding apparatusNuclear reactor coreNuclear reactor

A laser emitting head for irradiating a portion to be machined with laser beams outputted from a laser unit (624) incorporates an emitting head body having a light guide member (625) in the head for guiding the laser beams; a light converging lens (677) for converging the laser beams transmitted from the light guide member in the head; a reflecting mirror (678) for irradiating the portion to be machined with the converged laser beams; mirror rotating means (684) for holding the reflecting mirror to be rotative around the optical axis of the laser beam; distance-adjustment means (674) for adjusting the relative distance between the reflecting mirror and the converging lens; and moving means (665) for moving the reflecting mirror and the converging lens such that the relative distance is maintained so that the light guide member in the head. The converging lens and the reflecting mirror can be introduced / discharged with respect to a portion to be machined and formed in a narrow gap in an incore structure. As a result, a preventive-maintenance / repair operation using laser beams and arranged to be performed in a narrow gap in the incore structure can safely and efficiently be performed.

Owner:KK TOSHIBA

Spray cooling system for transverse thin-film evaporative spray cooling

InactiveUS20060026983A1Domestic cooling apparatusSemiconductor/solid-state device detailsEngineeringElectronic component

A spray cooling system for transverse thin-film evaporative spray cooling in a narrow gap which generally includes a framework, a cooling cavity, a plurality of atomizers oriented to transversely spray coolant across the electronic components to be cooled, and preferably a vapor recirculation system and a reduction in cross section from the inlet or spray side to the exit side.

Owner:PARKER INTANGIBLES LLC

Perpendicular magnetic recording head with longitudinal magnetic field generator to facilitate magnetization switching

InactiveUS6816339B1Increase motivationConstruction of head windingsRecord information storageMagnetizationMagnetic poles

A perpendicular magnetic recording head includes a perpendicular writing pole and a longitudinal field generator which rotates the magnetization of the perpendicular recording media prior to writing, thereby facilitating magnetization switching. The longitudinal magnetic field may be provided by a narrowed gap between the trailing write pole and the leading return pole of the head. The gap structure is designed to provide a fringing magnetic field between the poles which generates the longitudinal magnetic field in perpendicular recording media as the media travels under the perpendicular writing pole.

Owner:SEAGATE TECH LLC

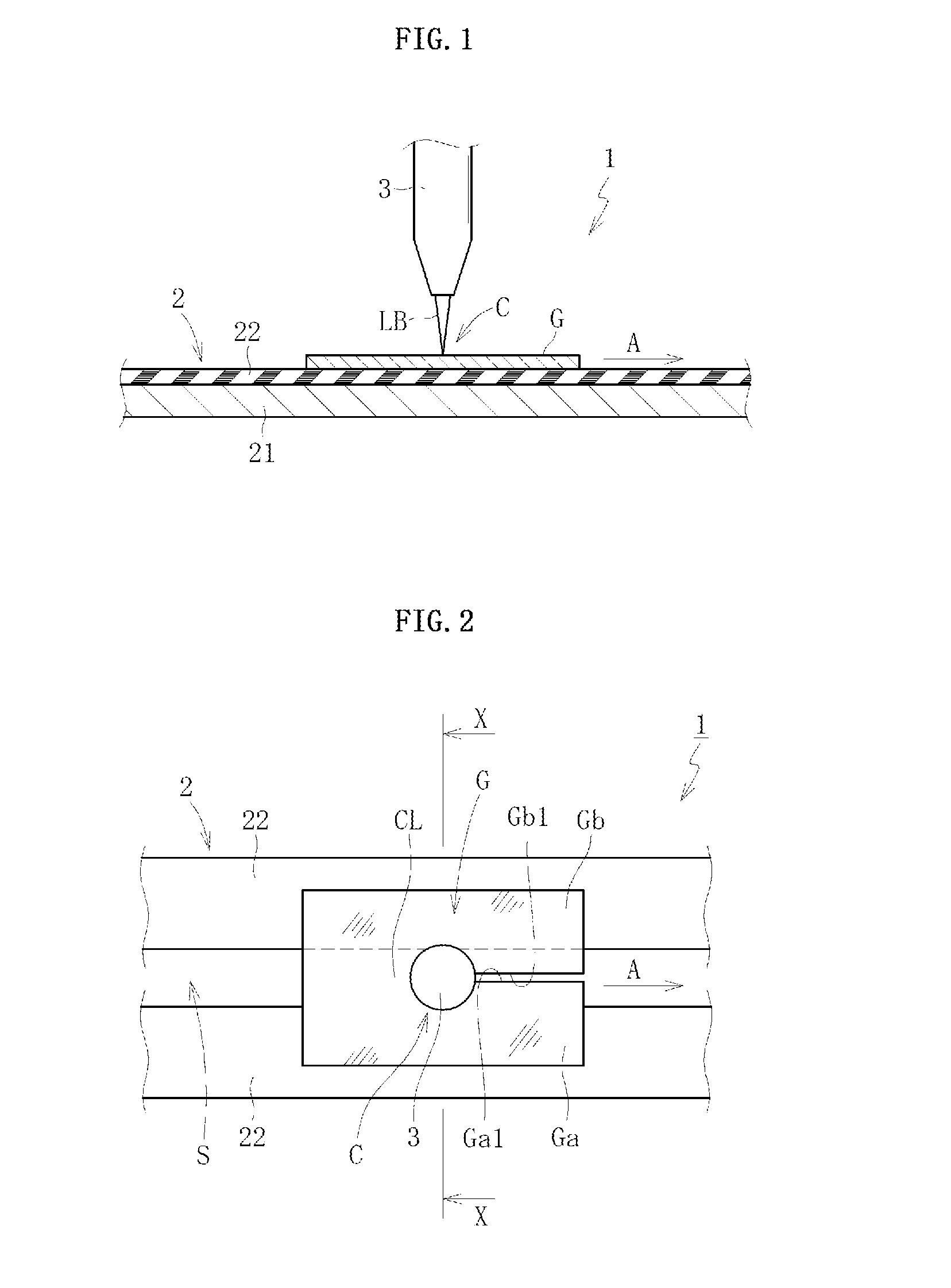

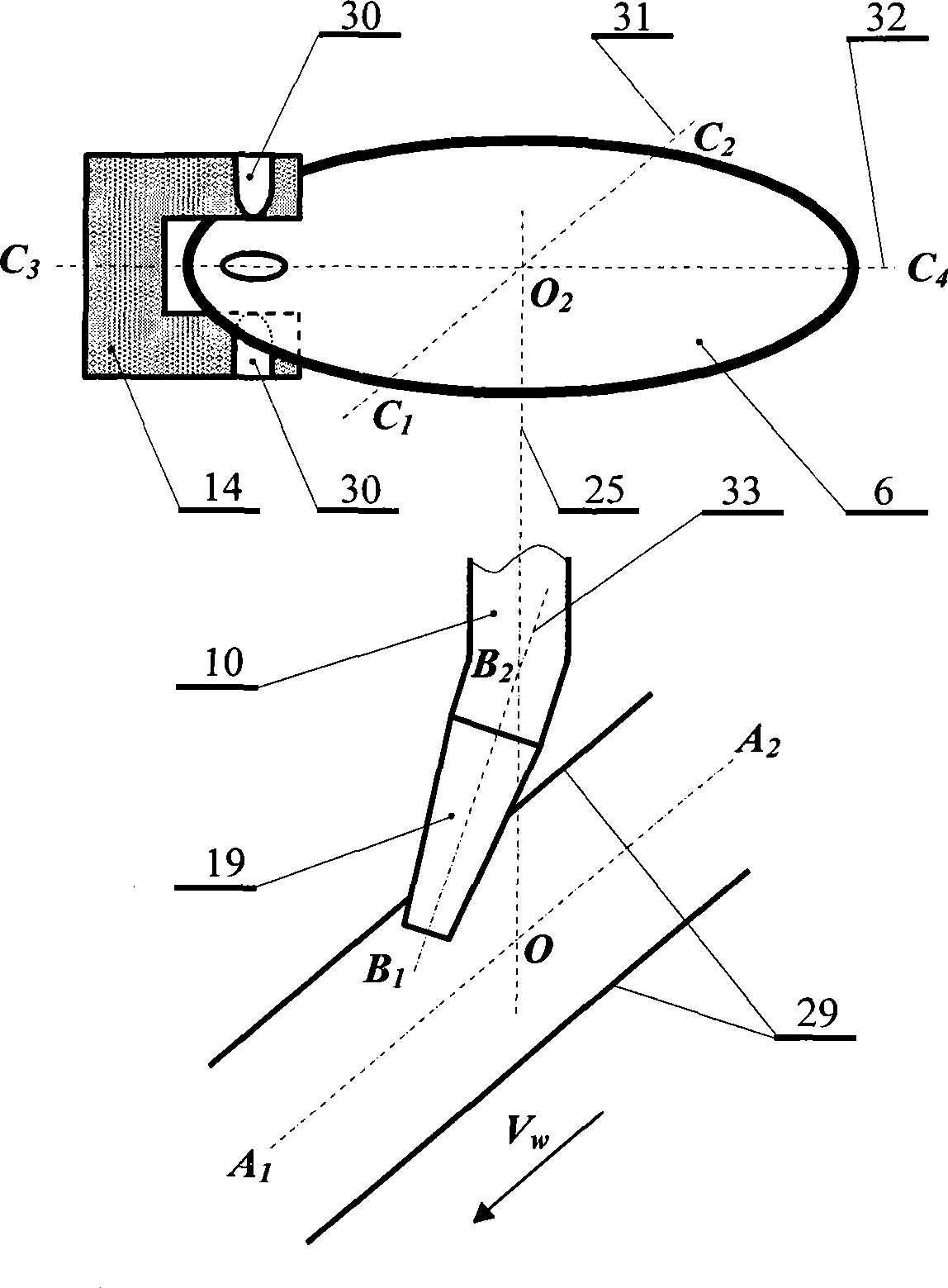

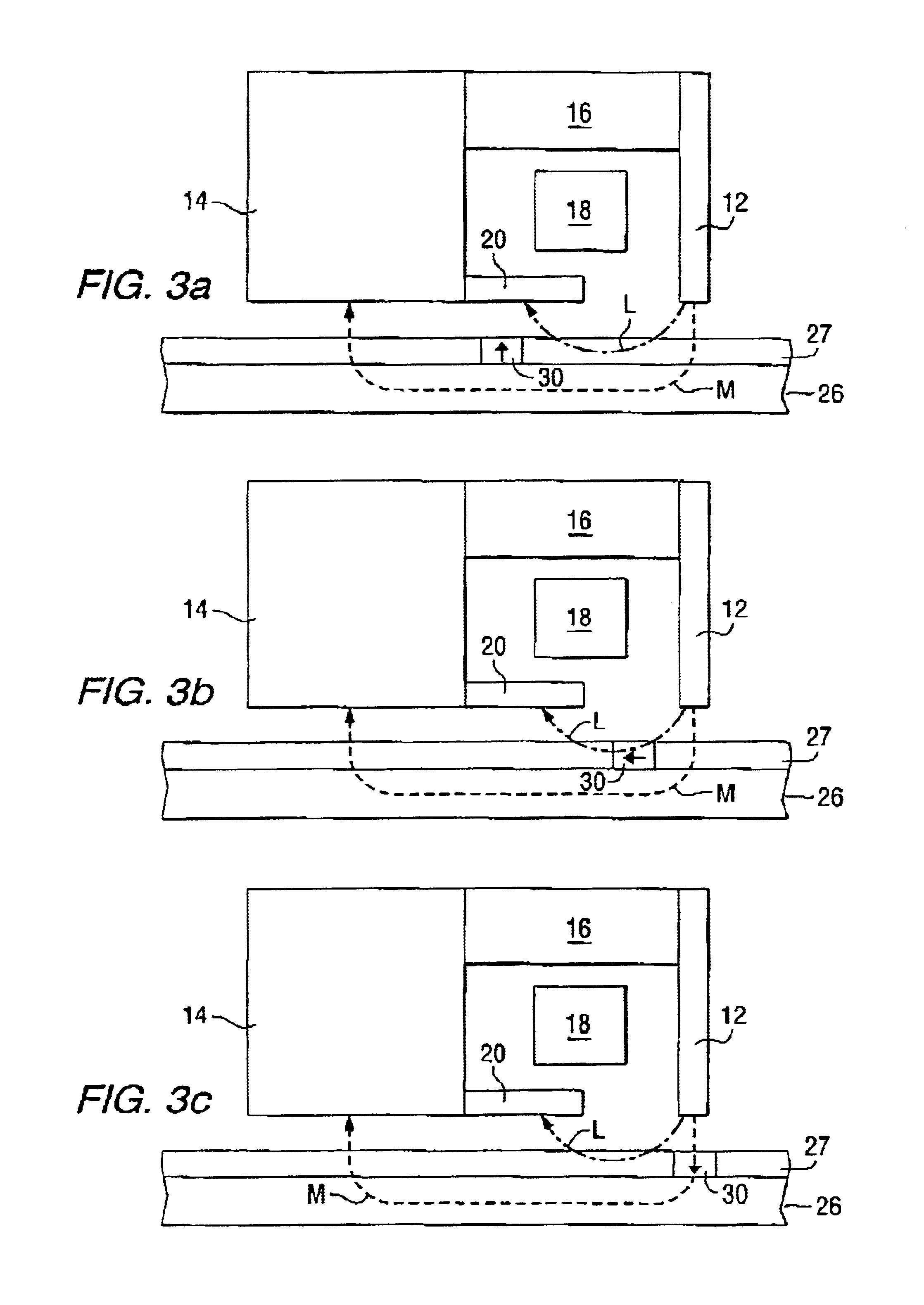

Laser-arc composite heat-source narrow-gap precision welding method

InactiveCN101362256AStable combustionHigh speedLaser beam welding apparatusWorkpiece edge portionsMetallic materialsLight beam

The invention provides a method for laser-electric arc composite heat source precision welding with a narrow gap, which belongs to the technical field of precision welding, and solves the problem of high-quality narrow-gap precision welding technology for difficultly welded material which can not be directly welded through laser. The method mainly comprises the following steps: the composite heat source can adopt the form of a laser beam (3) in the front and electric arc (7) in the back, or the electric arc (7) in the front and the laser beam (3) in the back, and the laser filament spacing h is 0-3 mm; low power electric arc (7) with 200-1000W power and 10-50A current is adopted, the power of the matched laser beam is larger than or equal to 200W, the electric arc (7) enters a narrow-gap groove (1) of a work piece under the guidance and the compression of the laser beam (3), and is stably burnt in the groove, the width of the narrow-gap groove (1) is 0.2d-1.2d, and d is the diameter of the welding wire. The composite heat source welding method is mainly used for the precision welding with narrow-gap groove.

Owner:HARBIN WELDING INST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com