Patents

Literature

470 results about "Cold welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold welding or contact welding is a solid-state welding process in which joining takes place without fusion/heating at the interface of the two parts to be welded. Unlike in the fusion-welding processes, no liquid or molten phase is present in the joint.

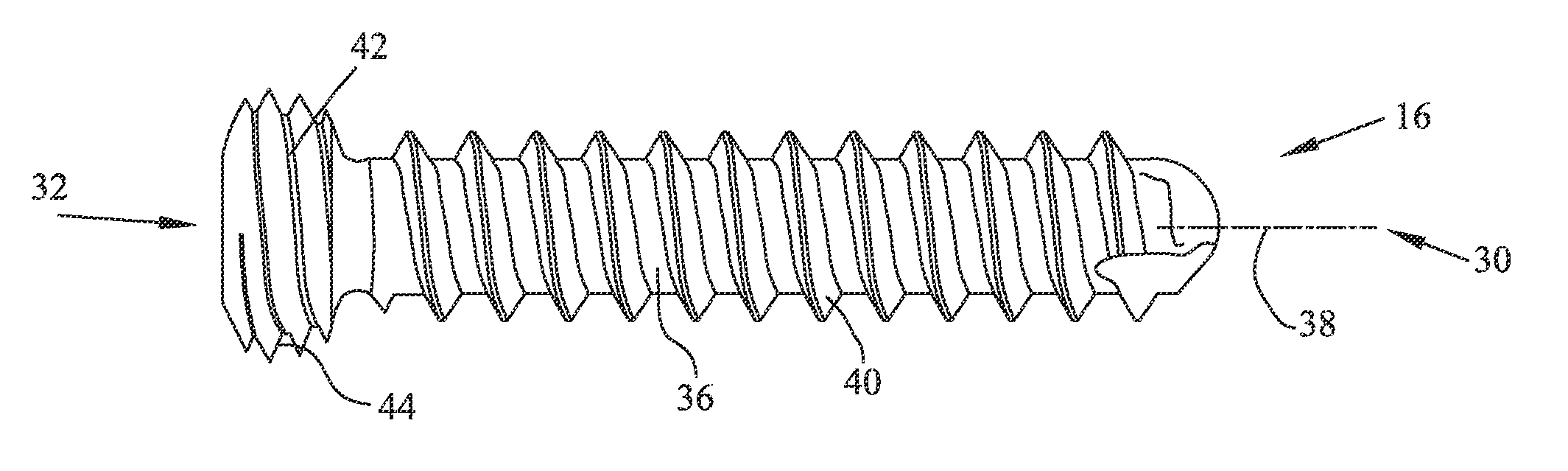

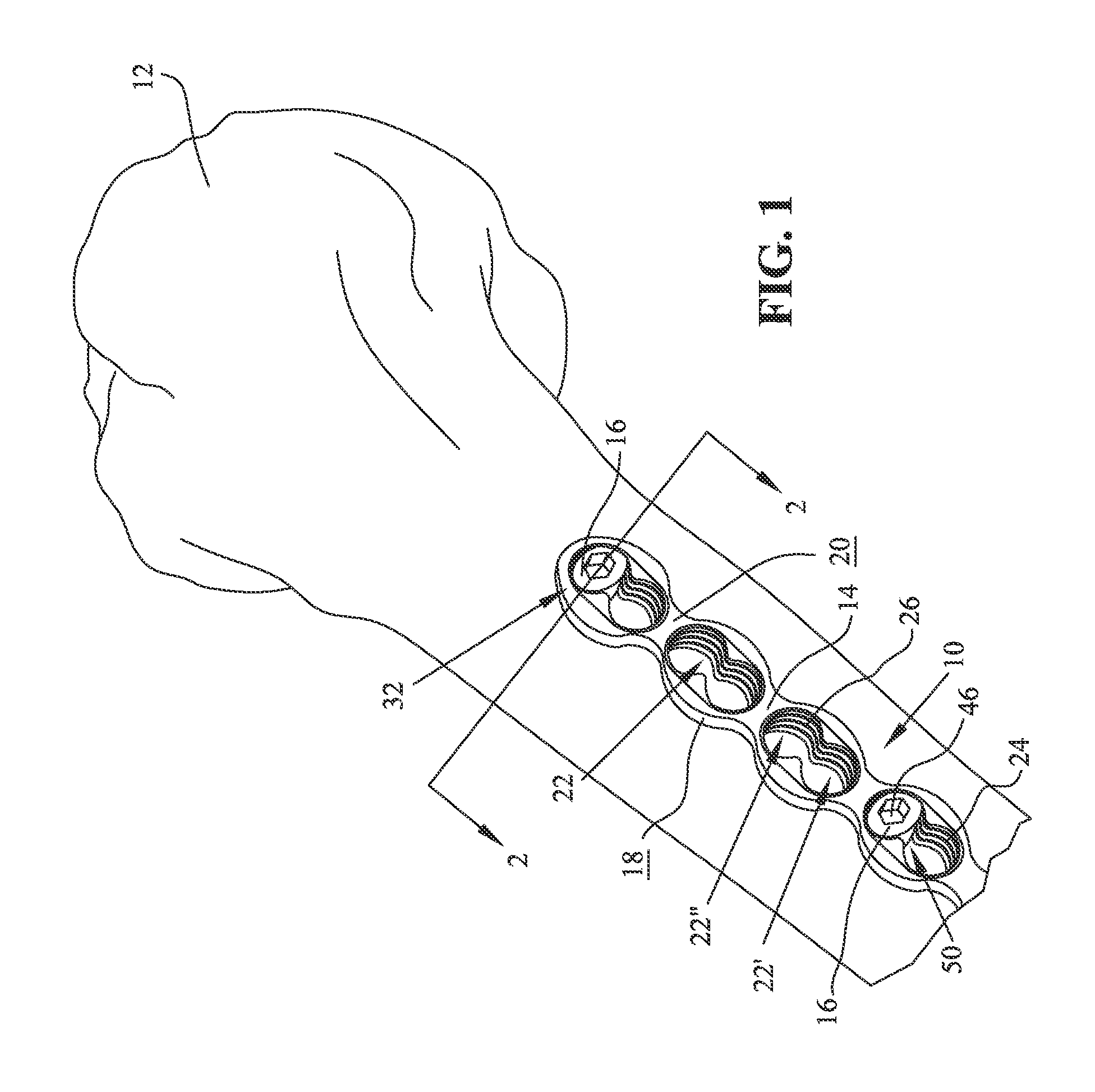

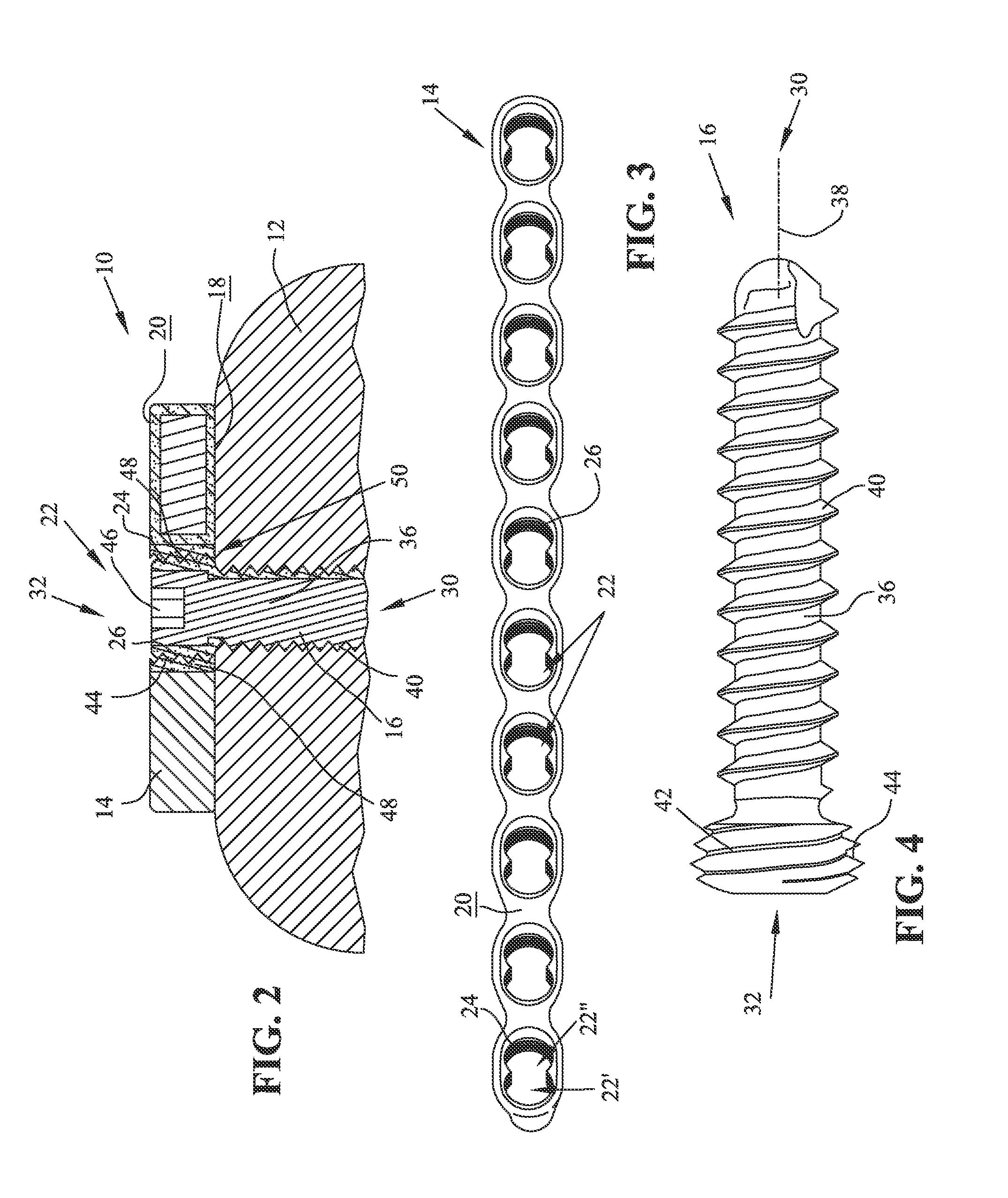

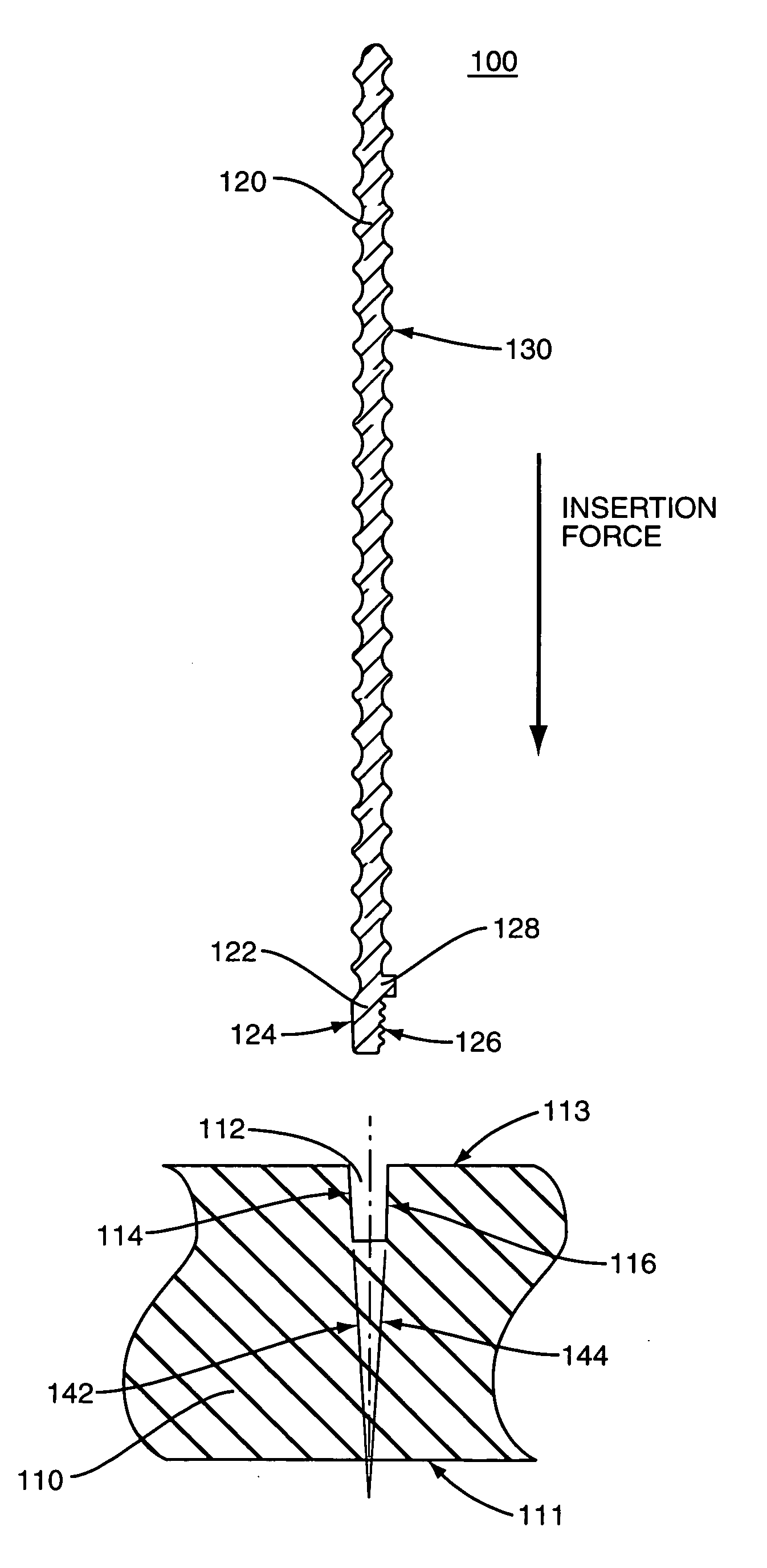

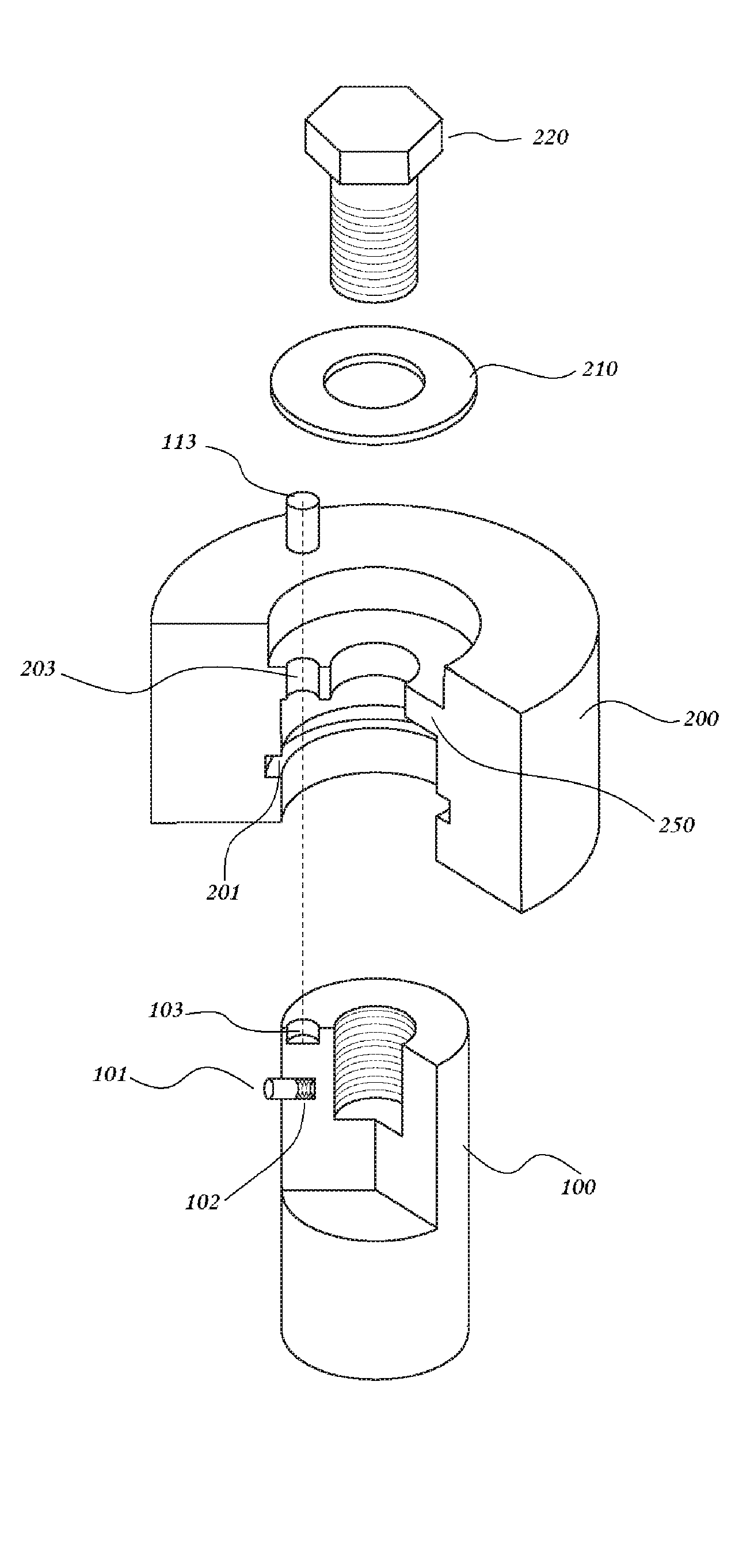

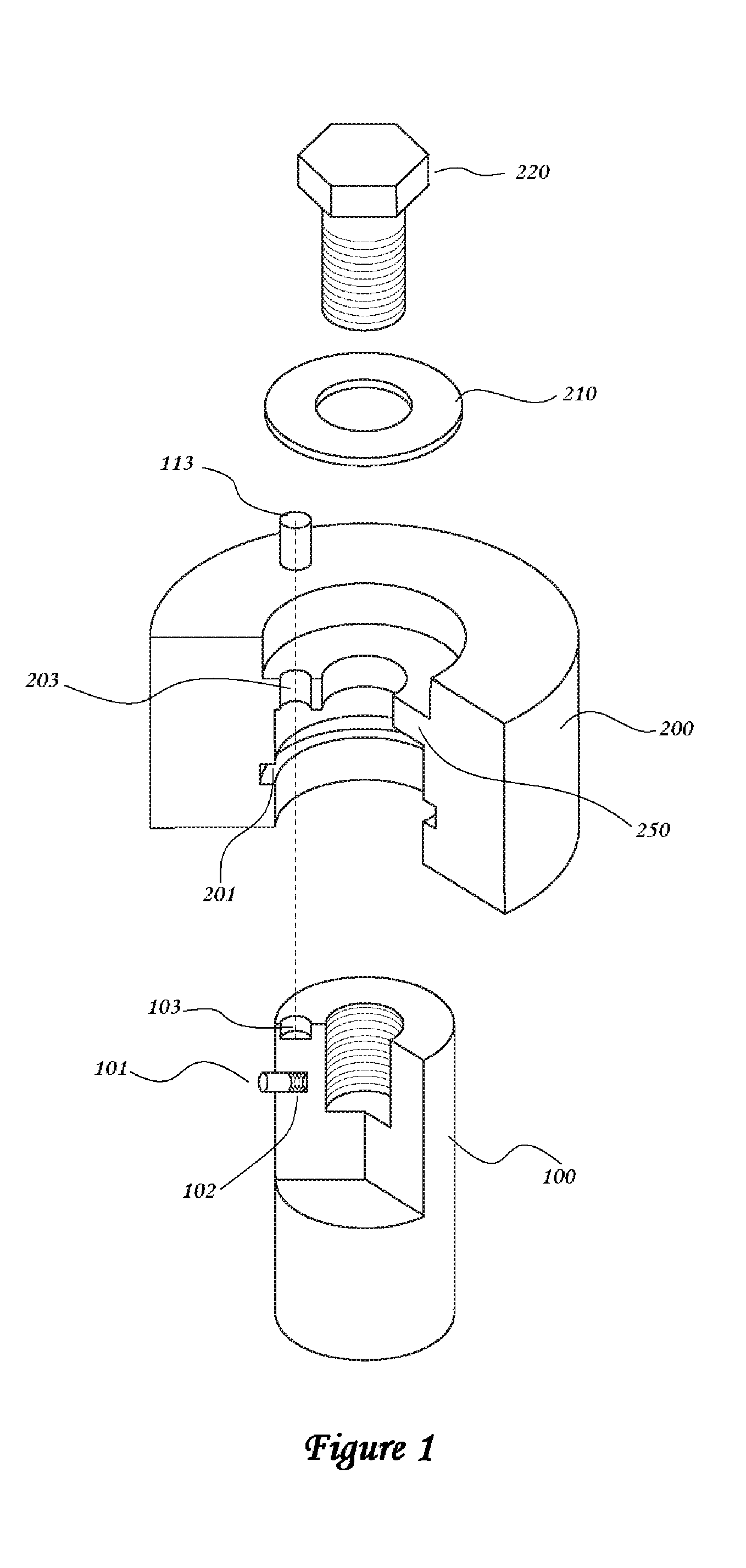

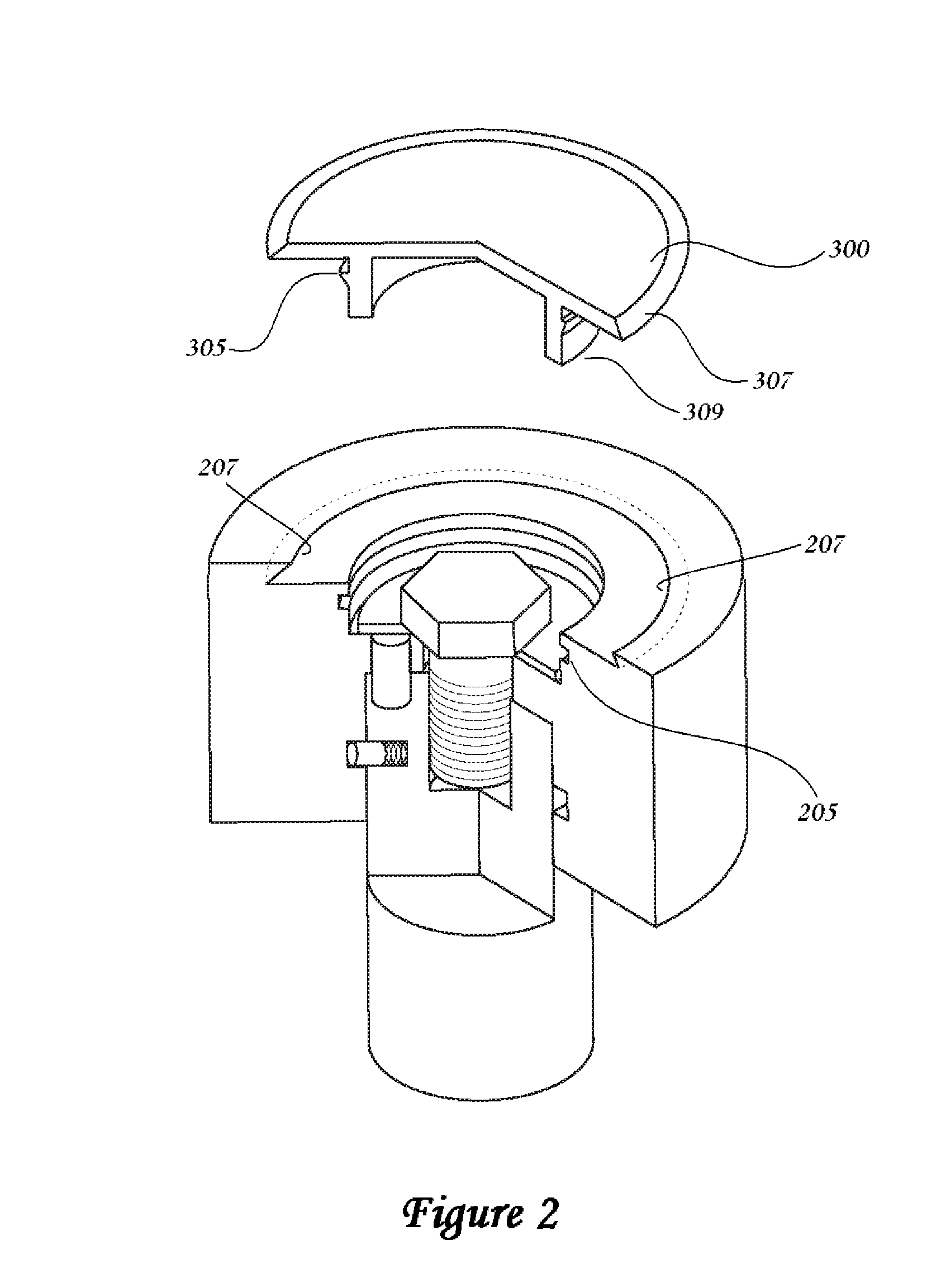

Anodized locking plate components

InactiveUS20100057086A1Minimize gallingMinimize cold weldingSuture equipmentsLigamentsGallingPlastic surgery

An orthopedic assembly including a plate and a locking screw that interlocks with the plate to secure the plate to a bone while the bone heals. To minimize galling or cold welding within an engagement region of the orthopedic assembly, an anodized coating, such as a Type II anodized coating, may be applied to both engaging surfaces of the engagement region. To avoid having to mask portions of the plate and the locking screw outside of the engagement region during the coating process, the anodized coating may be applied to the entire plate and the entire locking screw.

Owner:ZIMMER INC

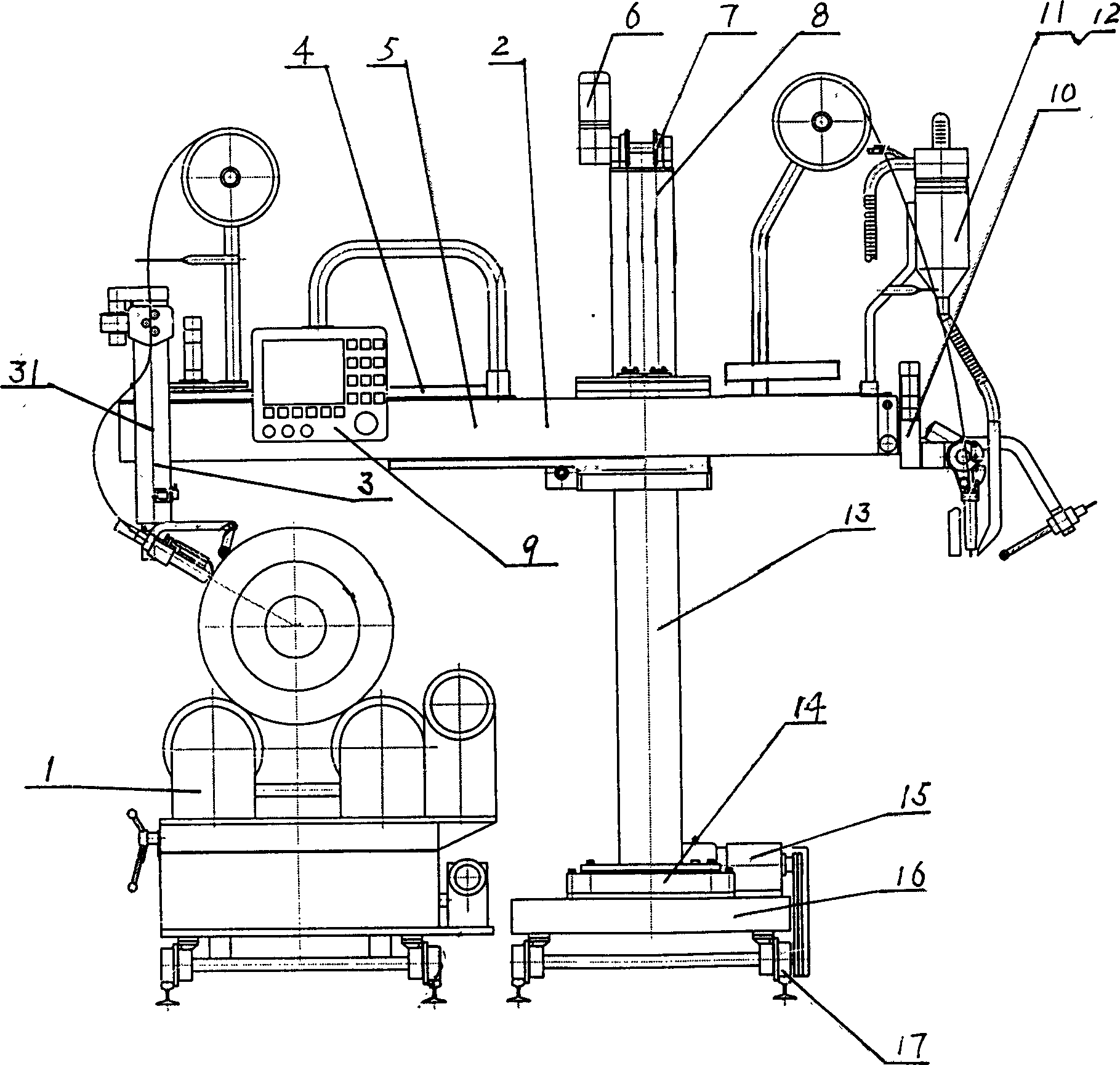

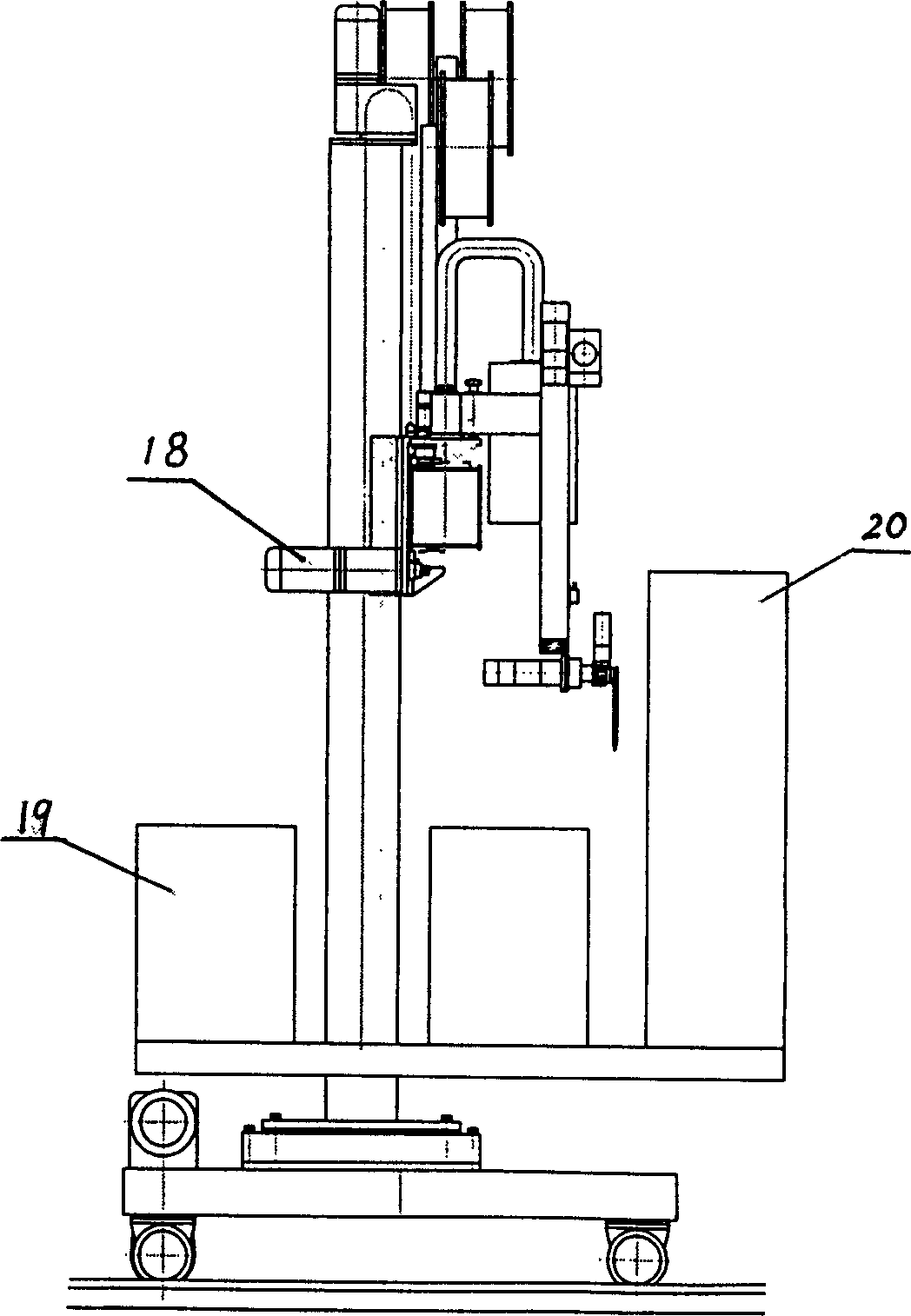

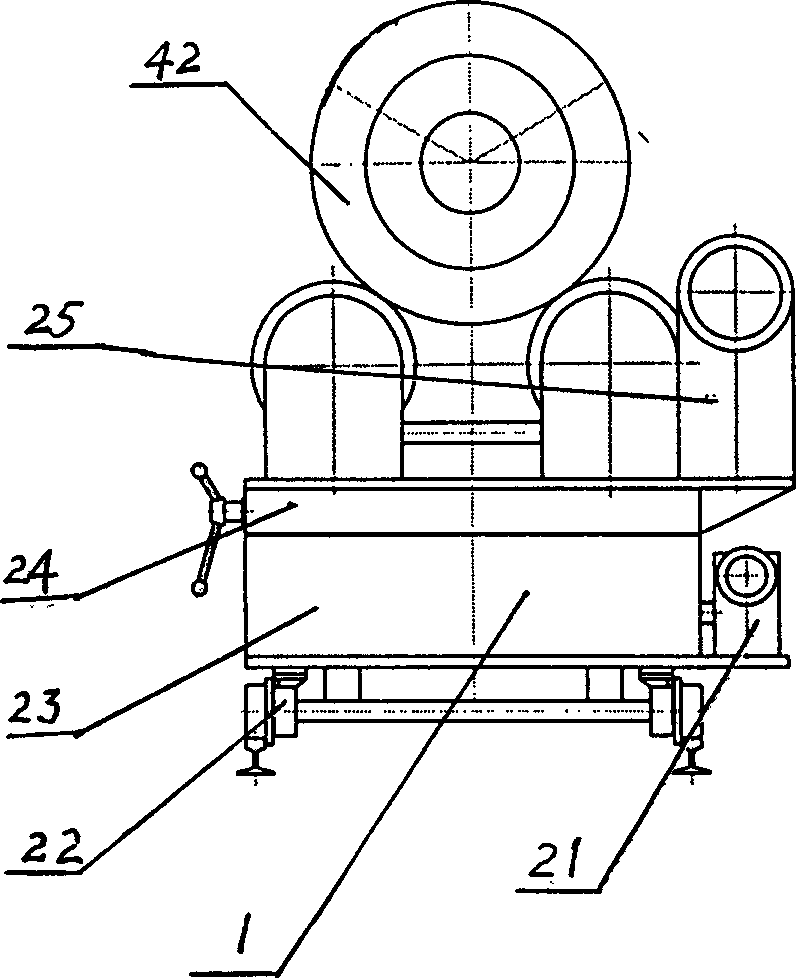

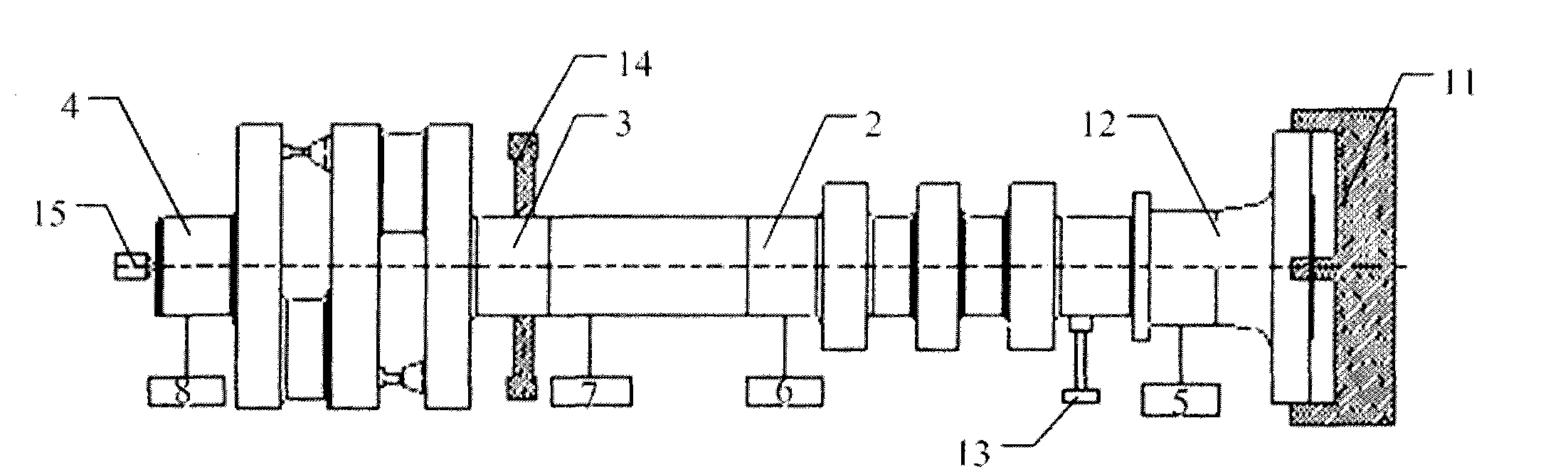

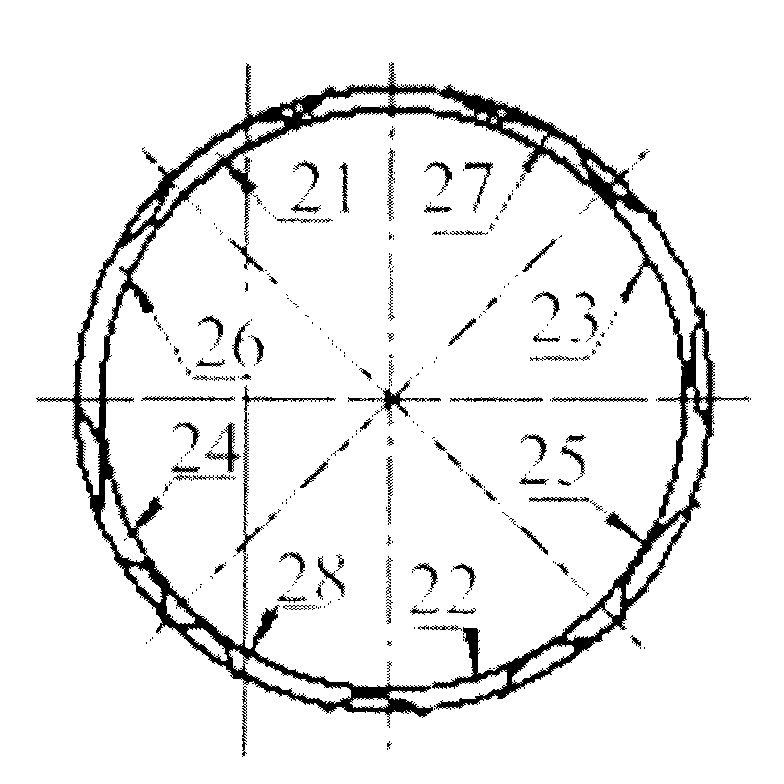

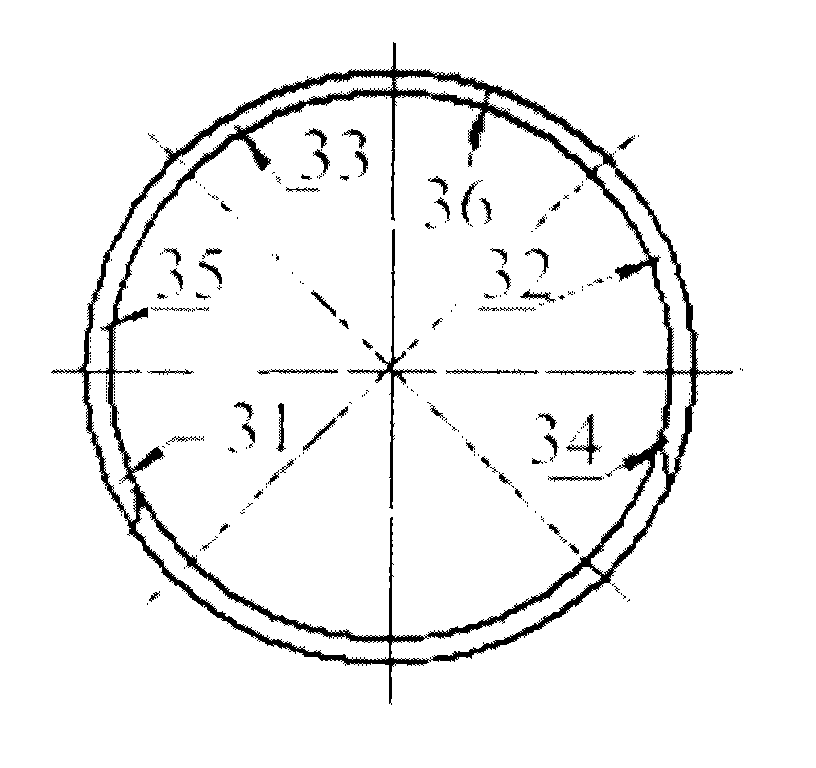

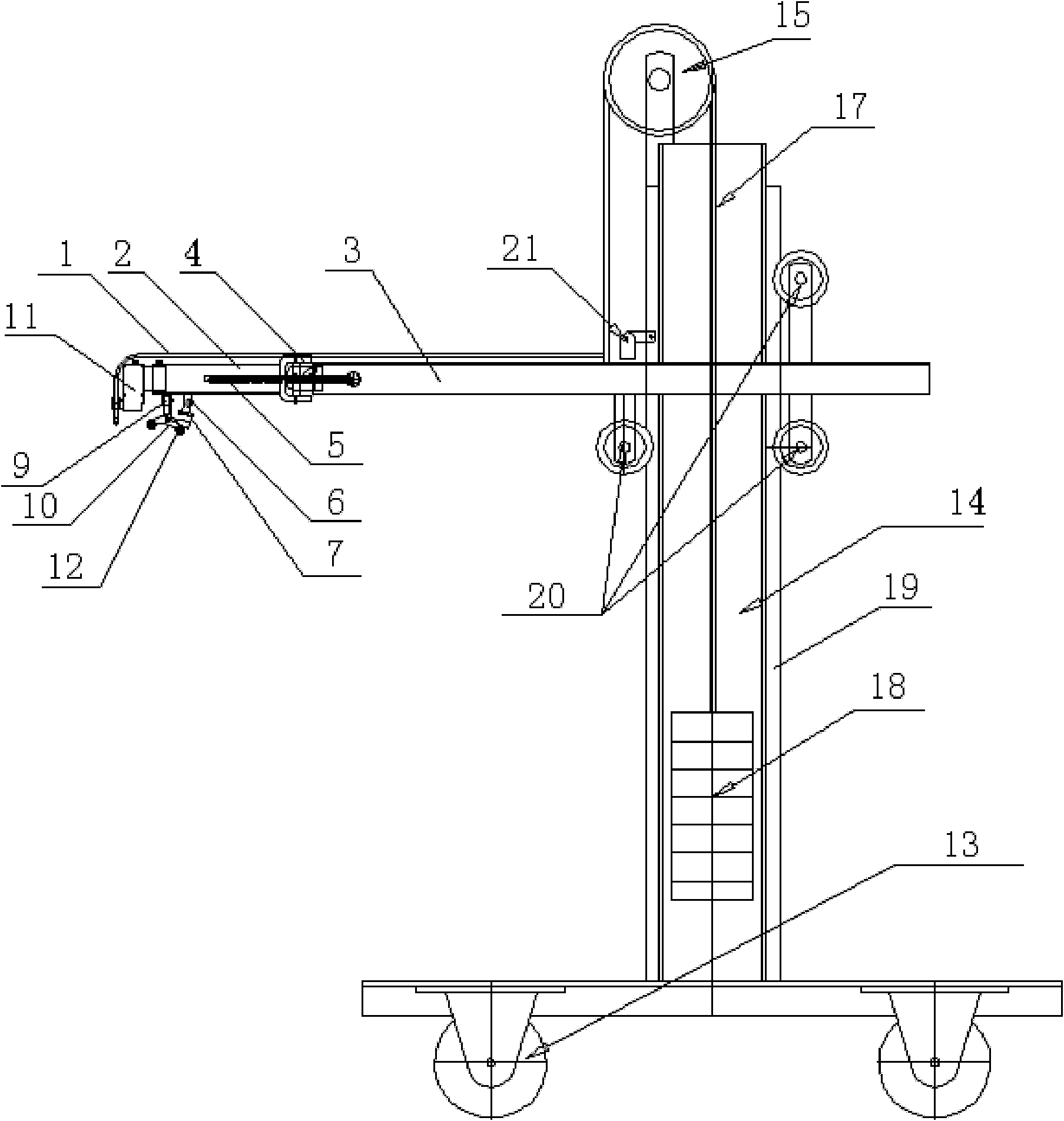

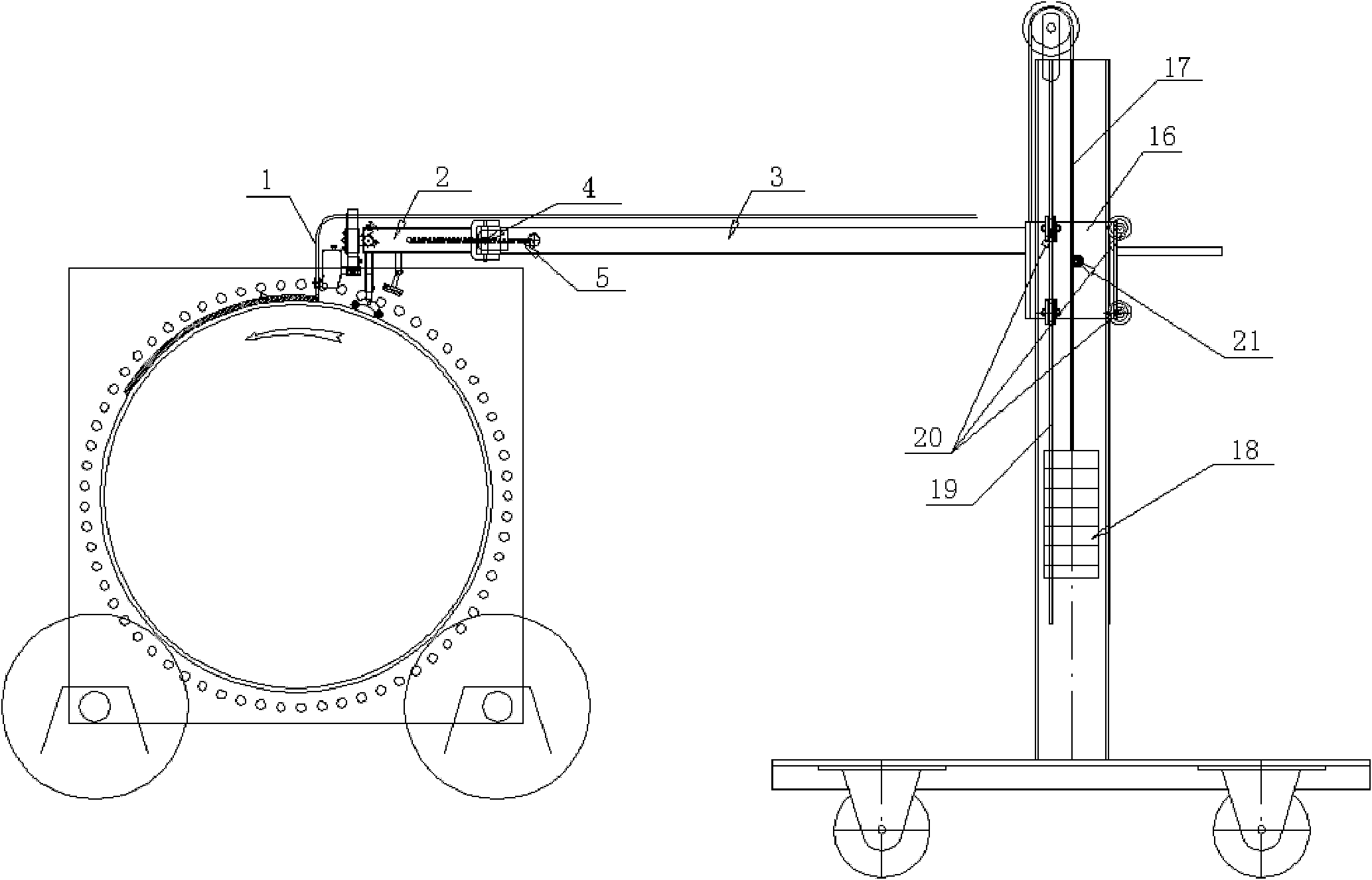

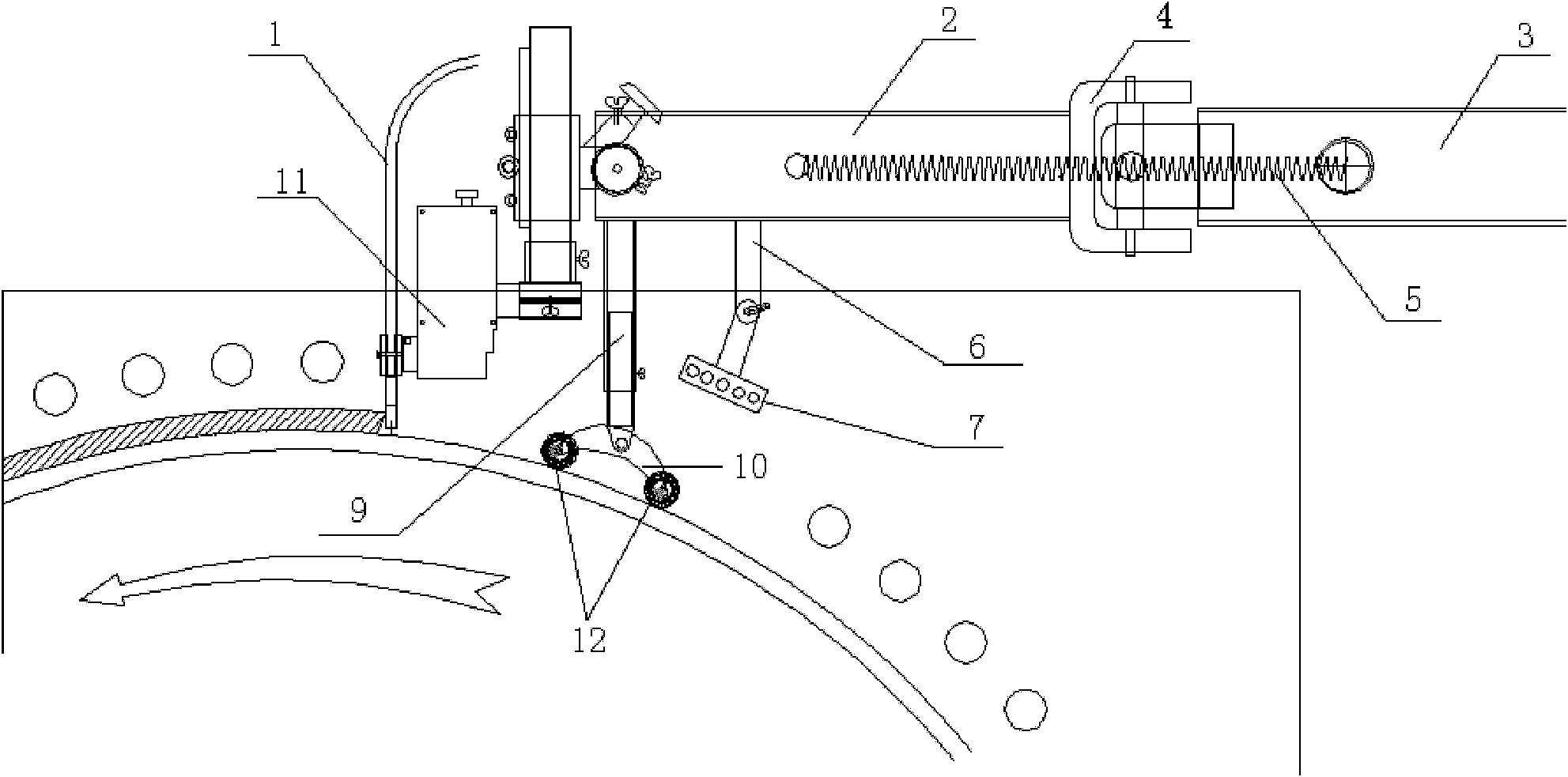

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN1714978AAutomatically calculate relative coordinate origin positionEnsure shapeArc welding apparatusBogieEngineering

The automatic argon arc welding and narrow gas submerged arc welding process for circular pipe header seam features the first horizontal and vertical welding with immobile workpiece and using automatic cold welding TIG wire until completing over one third of circle; the subsequent welding in the other two thirds of circle with automatically rotating welding roller frame; and the performing in the identical site of the annular seam assembling and the welding. The welding apparatus for the said technological process consists of roller device and welding frame bogie, and the welding frame bogie on some tracks parallel to roller frame tracks is movable. The present invention has the advantages of automatic operation, raised welding quality, etc.

Owner:SHANGHAI BOILER WORKS

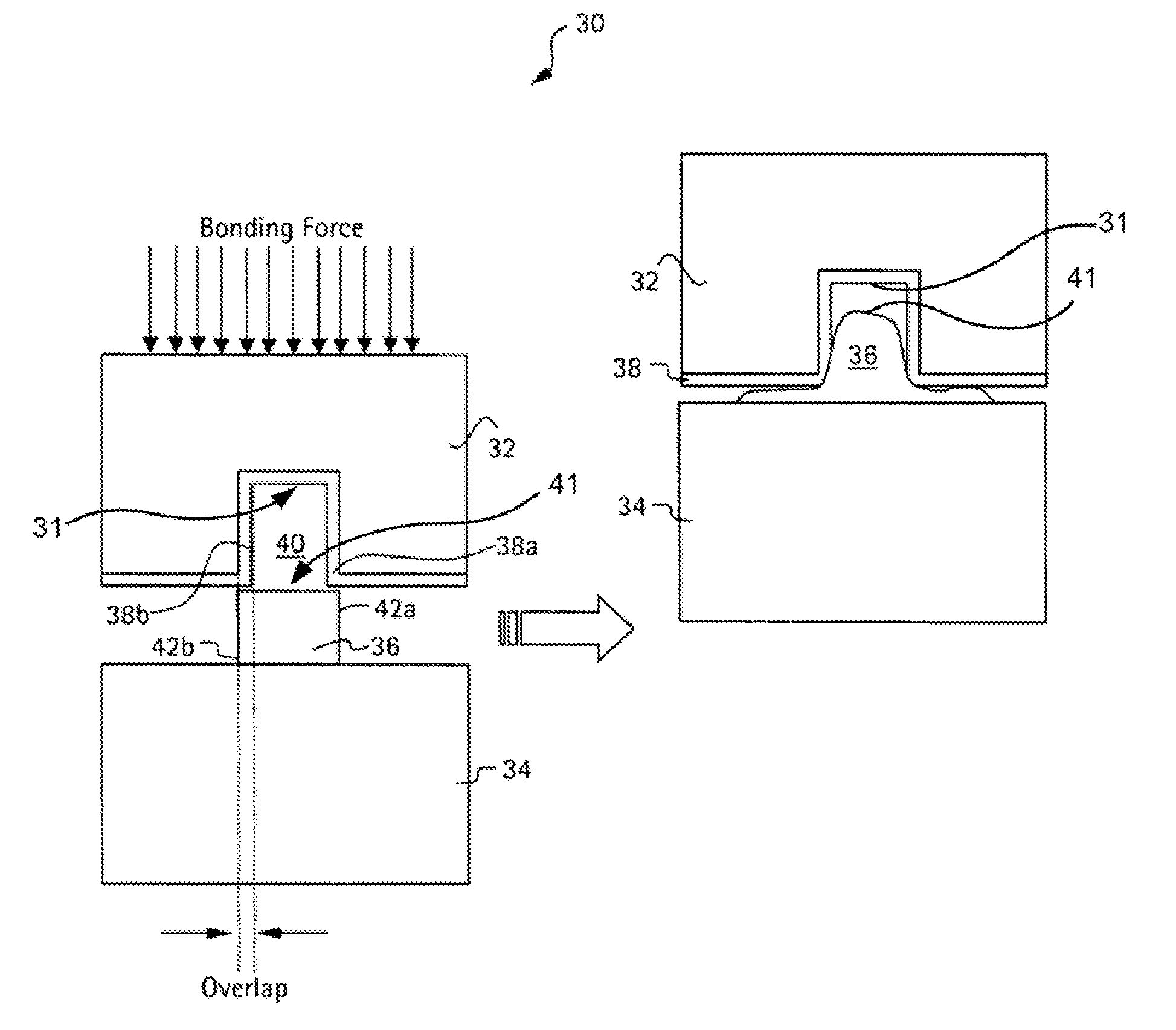

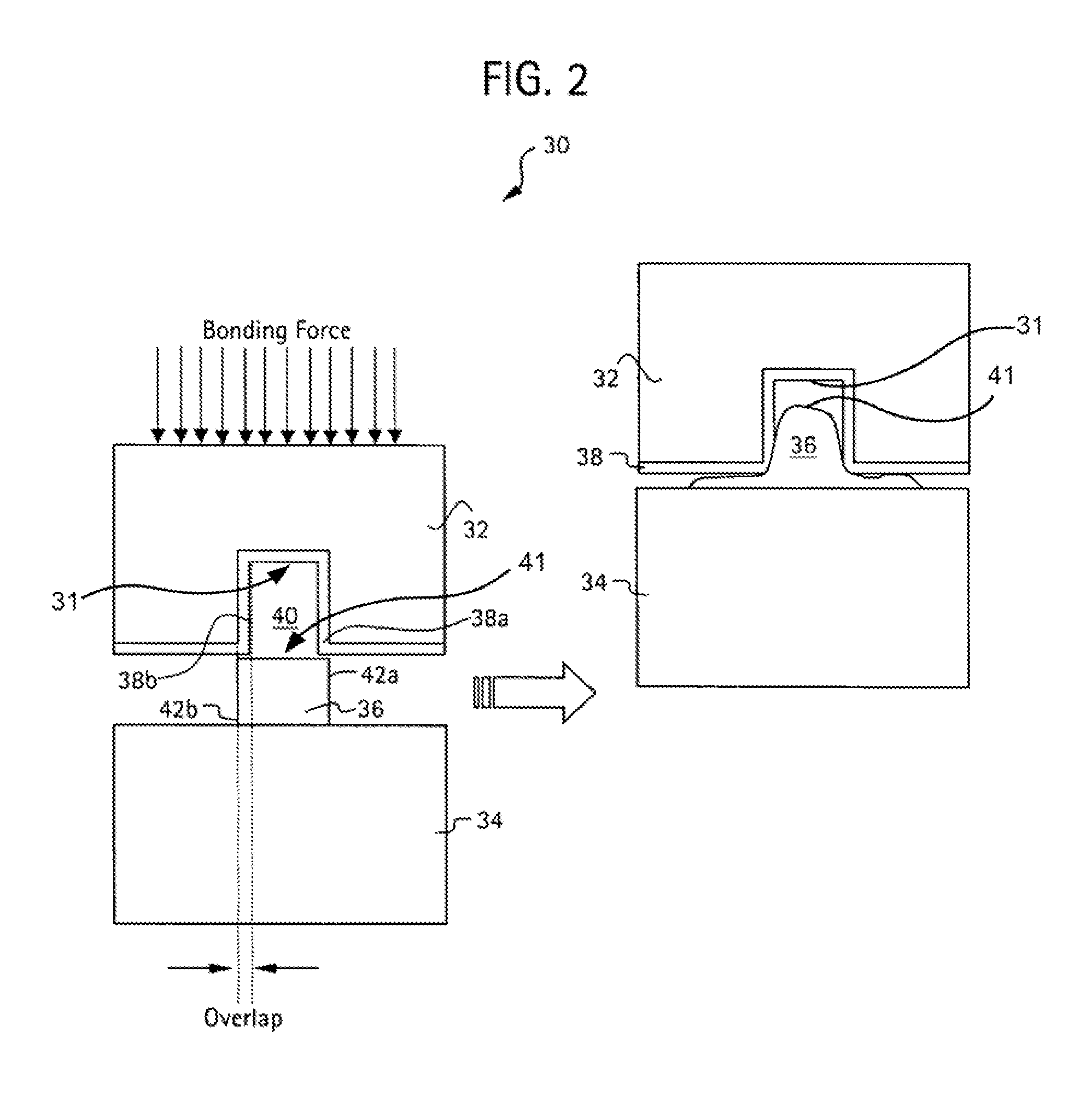

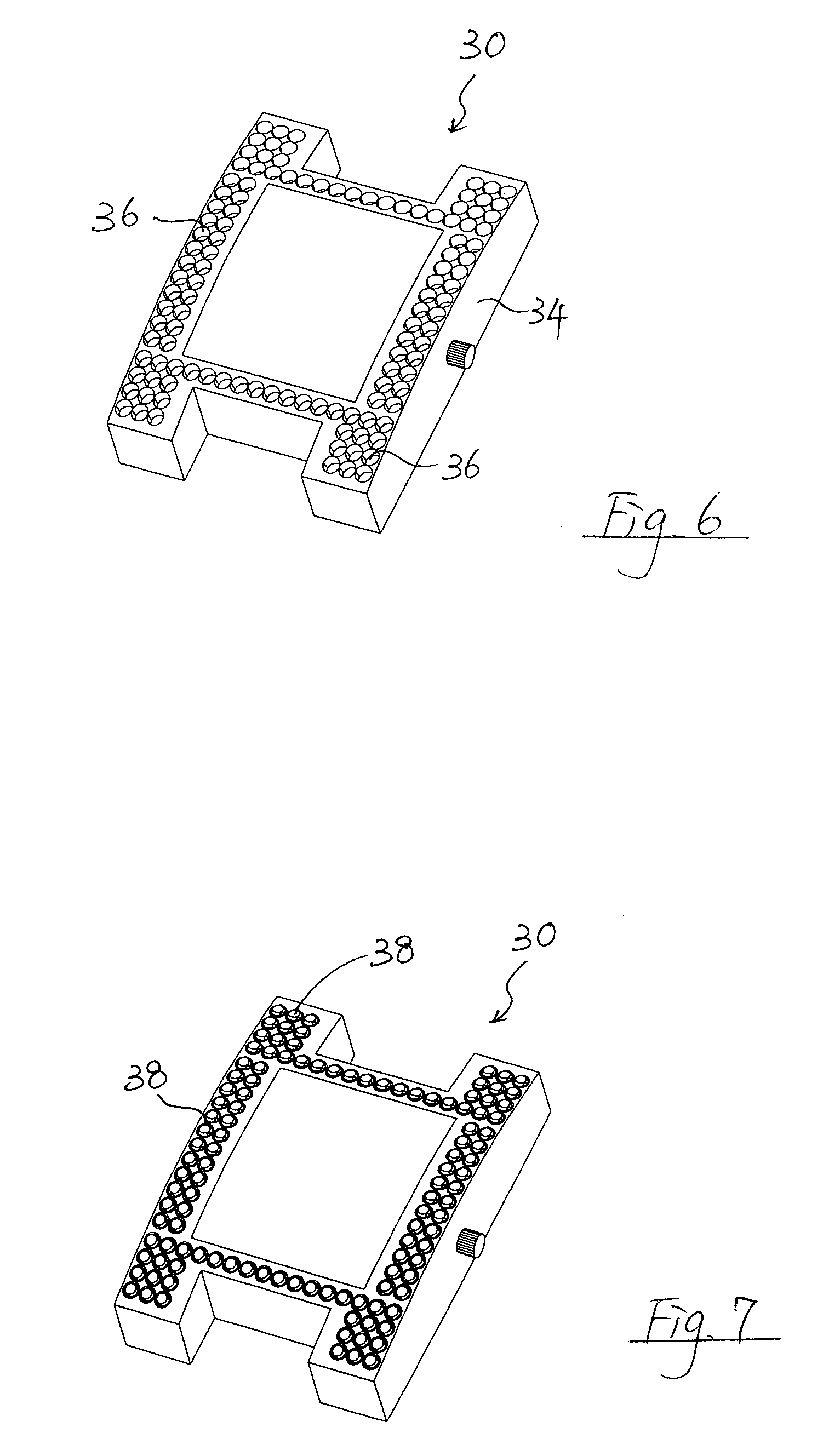

Hermetically sealing using a cold welded tongue and groove structure

ActiveUS8191756B2Provide goodReduce oxidationSemiconductor/solid-state device detailsSolid-state devicesHermetic sealEngineering

Compression cold welding methods, joint structures, and hermetically sealed containment devices are provided. The method includes providing a first substrate having at least one first joint structure which comprises a first joining surface, which surface comprises a first metal; providing a second substrate having at least one second joint structure which comprises a second joining surface, which surface comprises a second metal; and compressing together the at least one first joint structure and the at least one second joint structure to locally deform and shear the joining surfaces at one or more interfaces in an amount effective to form a metal-to-metal bond between the first metal and second metal of the joining surfaces. Overlaps at the joining surfaces are effective to displace surface contaminants and facilitate intimate contact between the joining surfaces without heat input. Hermetically sealed devices can contain drug formulations, biosensors, or MEMS devices.

Owner:DARE MB INC

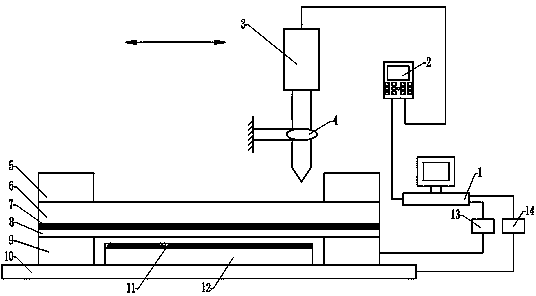

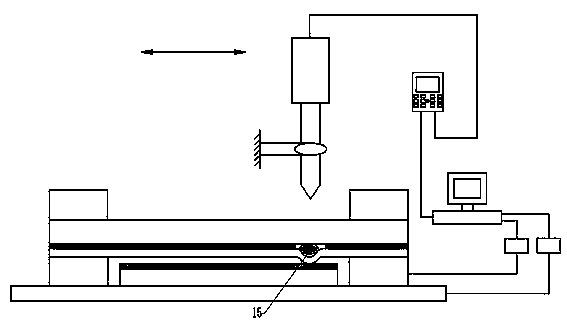

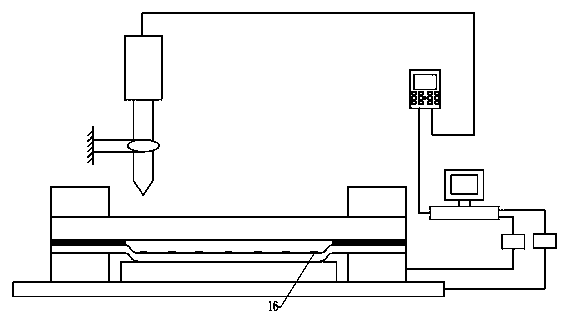

Nano coating preparation method and device based on ultrafast ultrahigh pressure photodynamics effect

InactiveCN101787528AChange compositionChange organizationMetallic material coating processesLaser beamsMechanical property

The invention discloses nano coating method and device based on ultrafast ultrahigh pressure photodynamics effect, belonging to the technical field of material surface. The invention is characterized by embedding or cold welding nanometer metal powder, nanometer nonmetal powder or compound nanometer powder which are precoated on the surface of a metal matrix in the surface layer of the metal matrix by means of laser induction mechanics effect, forming a thick nanometer particle strengthening layer or a coating layer which is called as a nano coating on the surface of the metal matrix, wherein the metal matrix is impacted and strengthened by laser. The device comprises a three-dimensional hexad working platform, a water tank, a clamp, a thermocouple, a coaxial synchronous water sender, a laser beam focusing system, a 45-degree fully-reflecting mirror, a laser beam optimizing system and a nanosecond laser. By the invention, the obtained surface nano coating has firm interface joint with the matrix and the mechanical property on the surface of the metal matrix is remarkably improved. The invention has simple technical process and lower cost, and is easy to realize automation and suitable for large-scale batch production.

Owner:JIANGSU UNIV

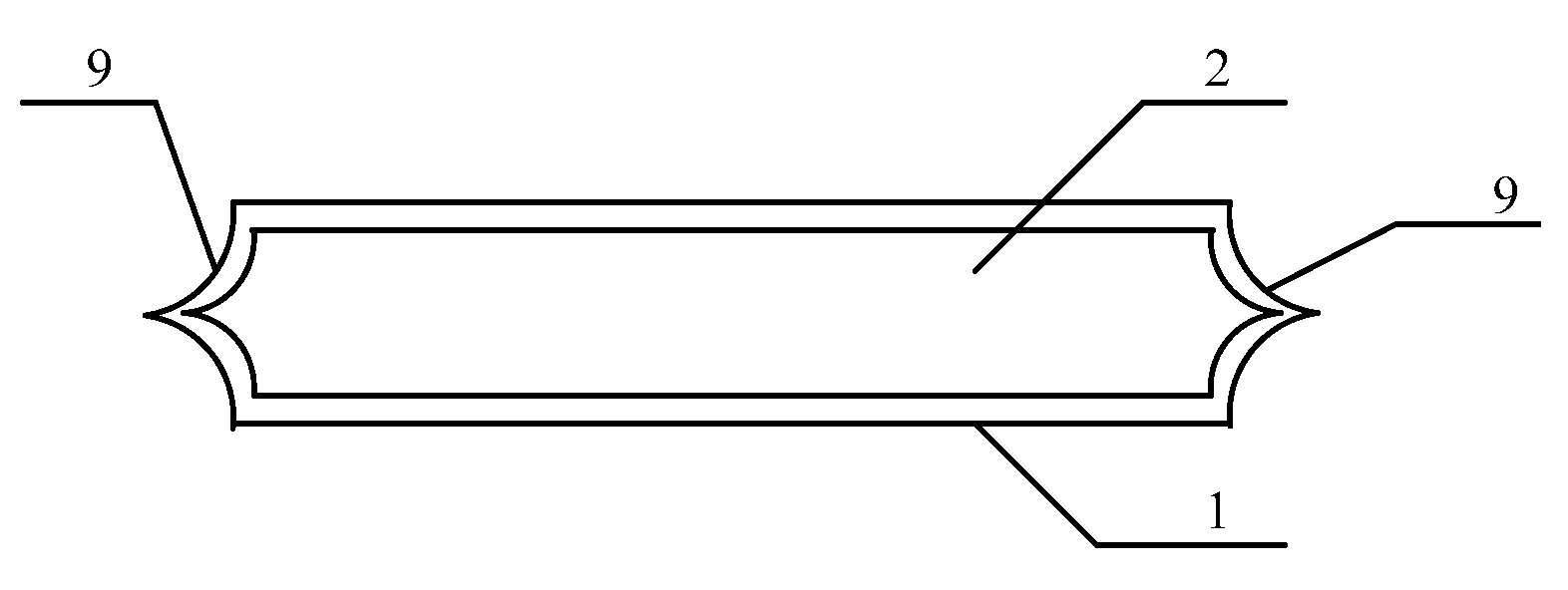

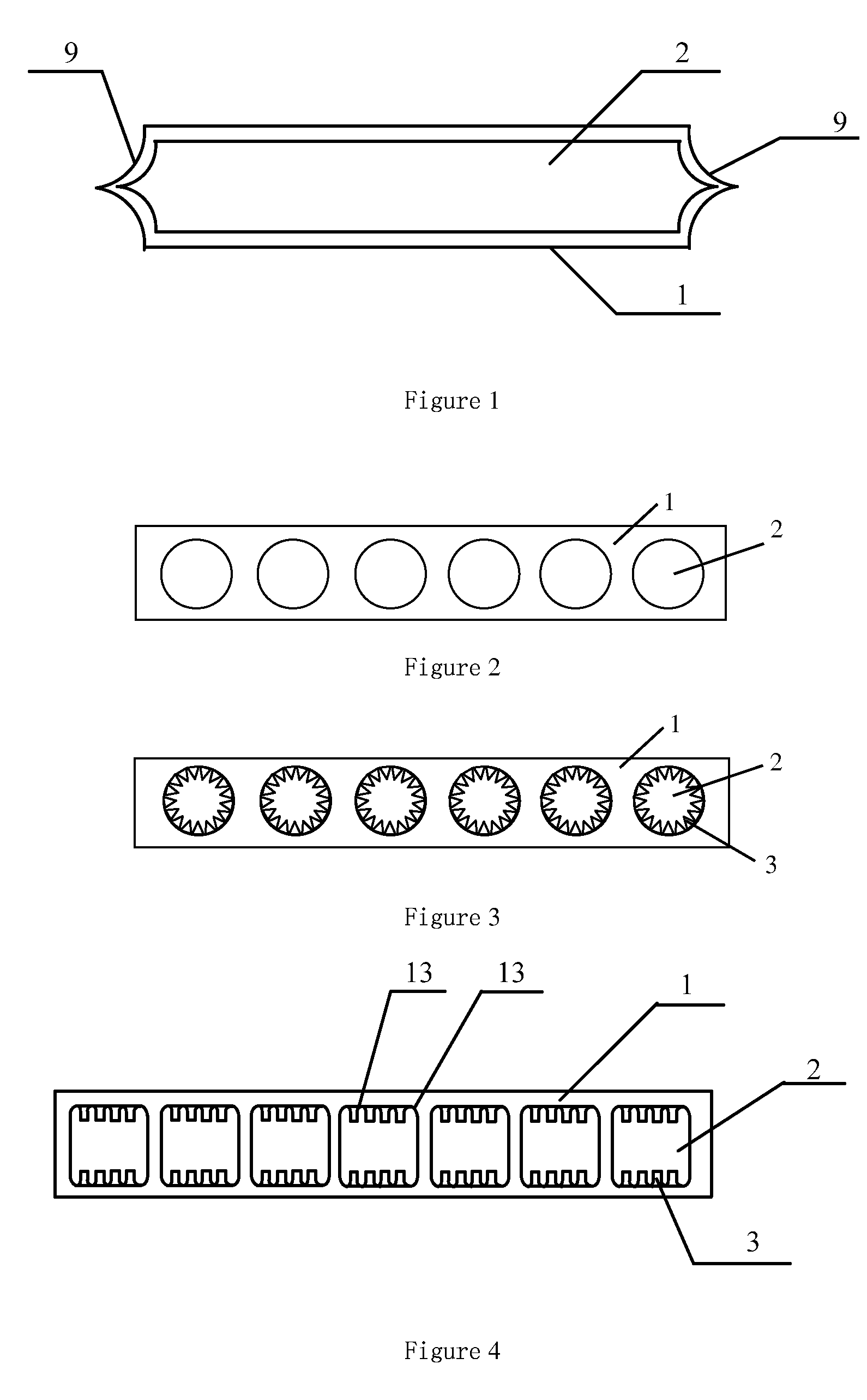

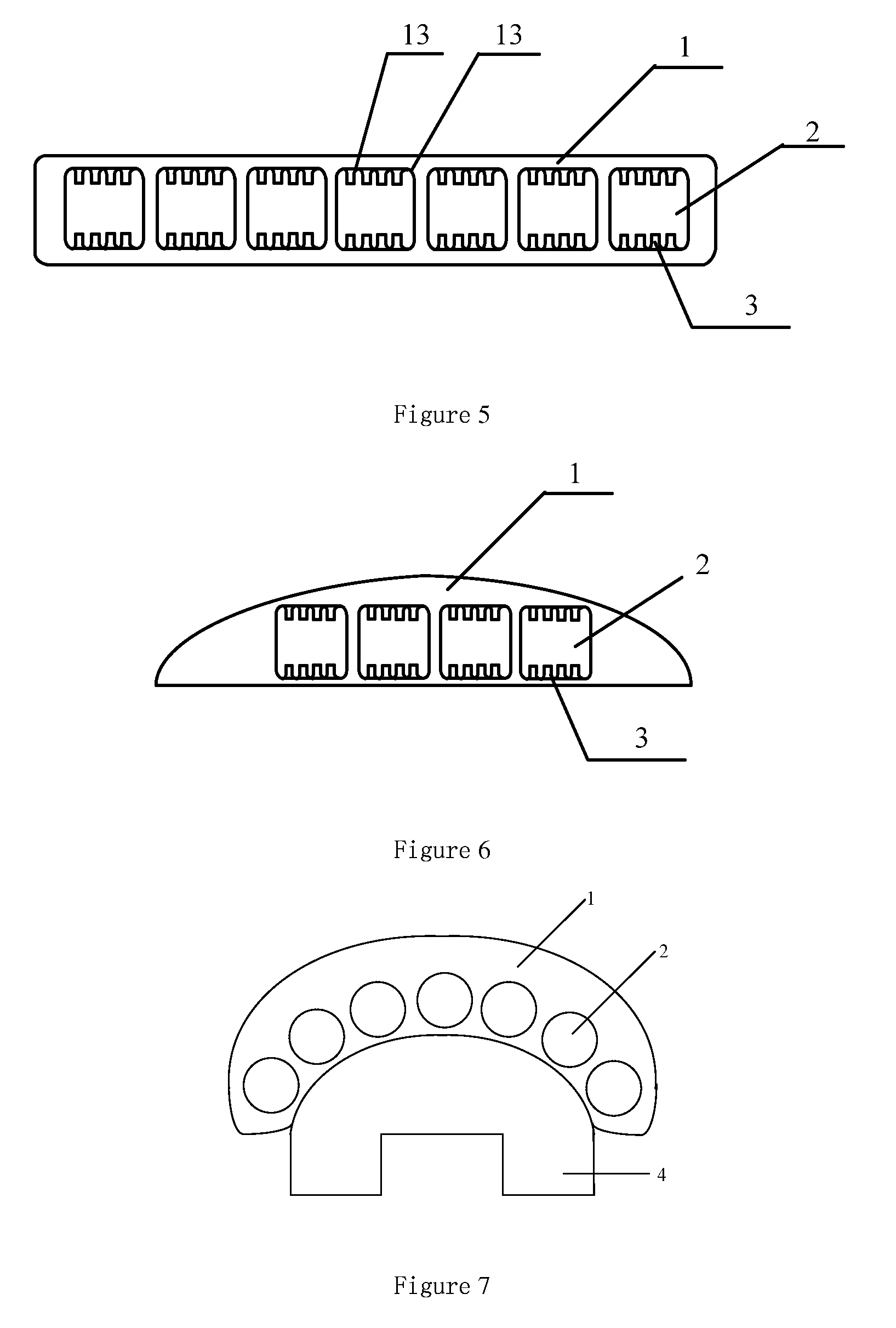

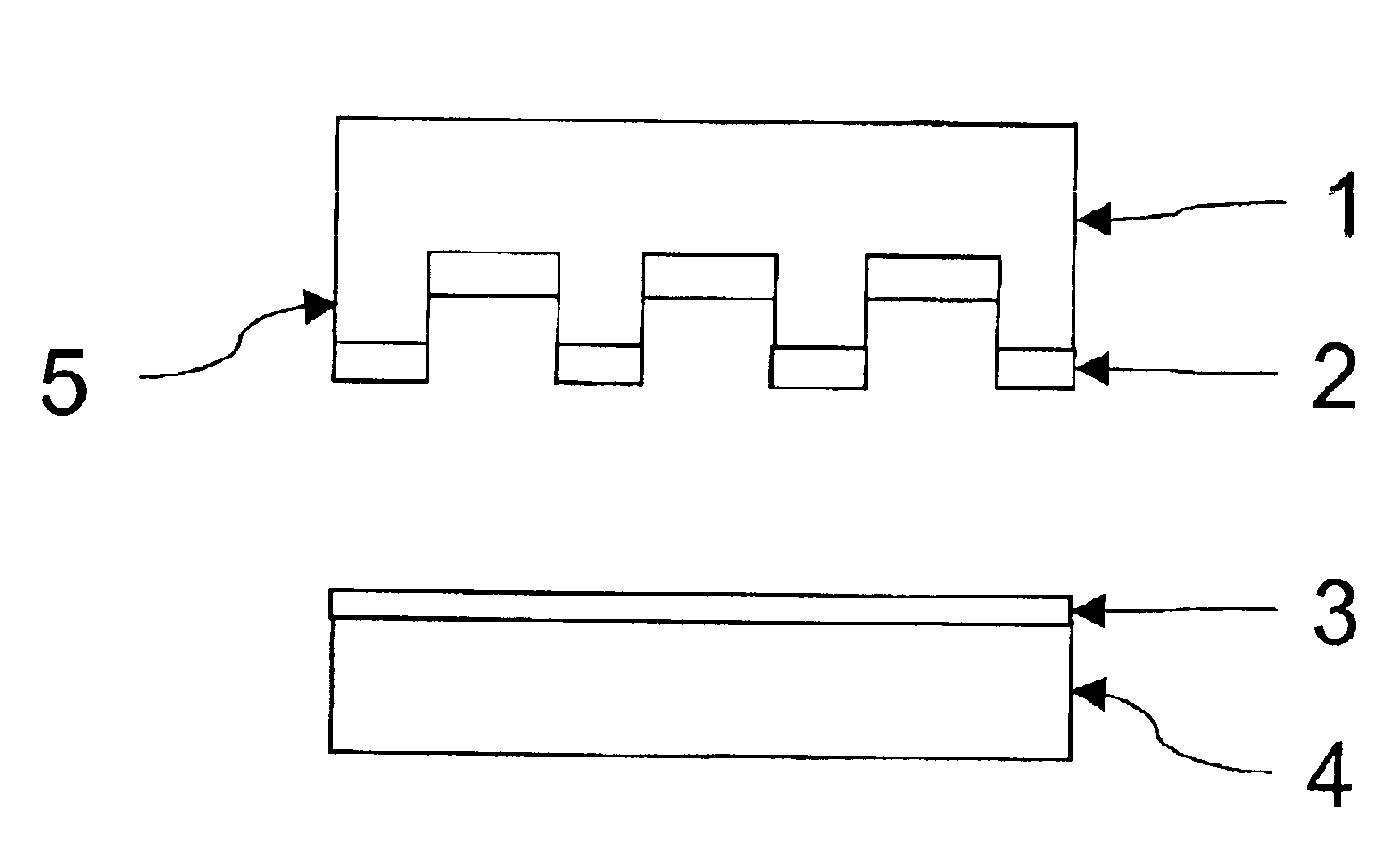

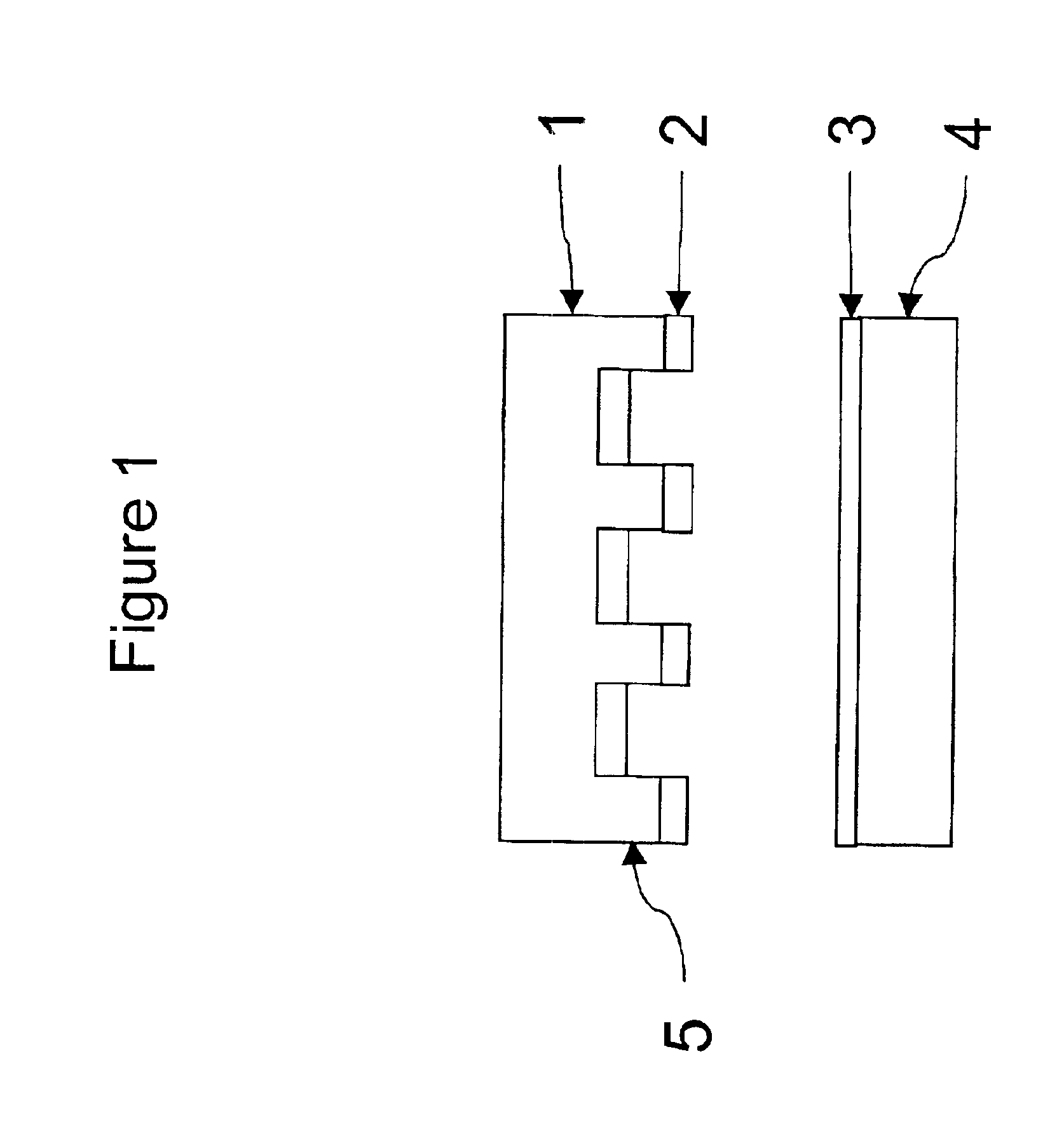

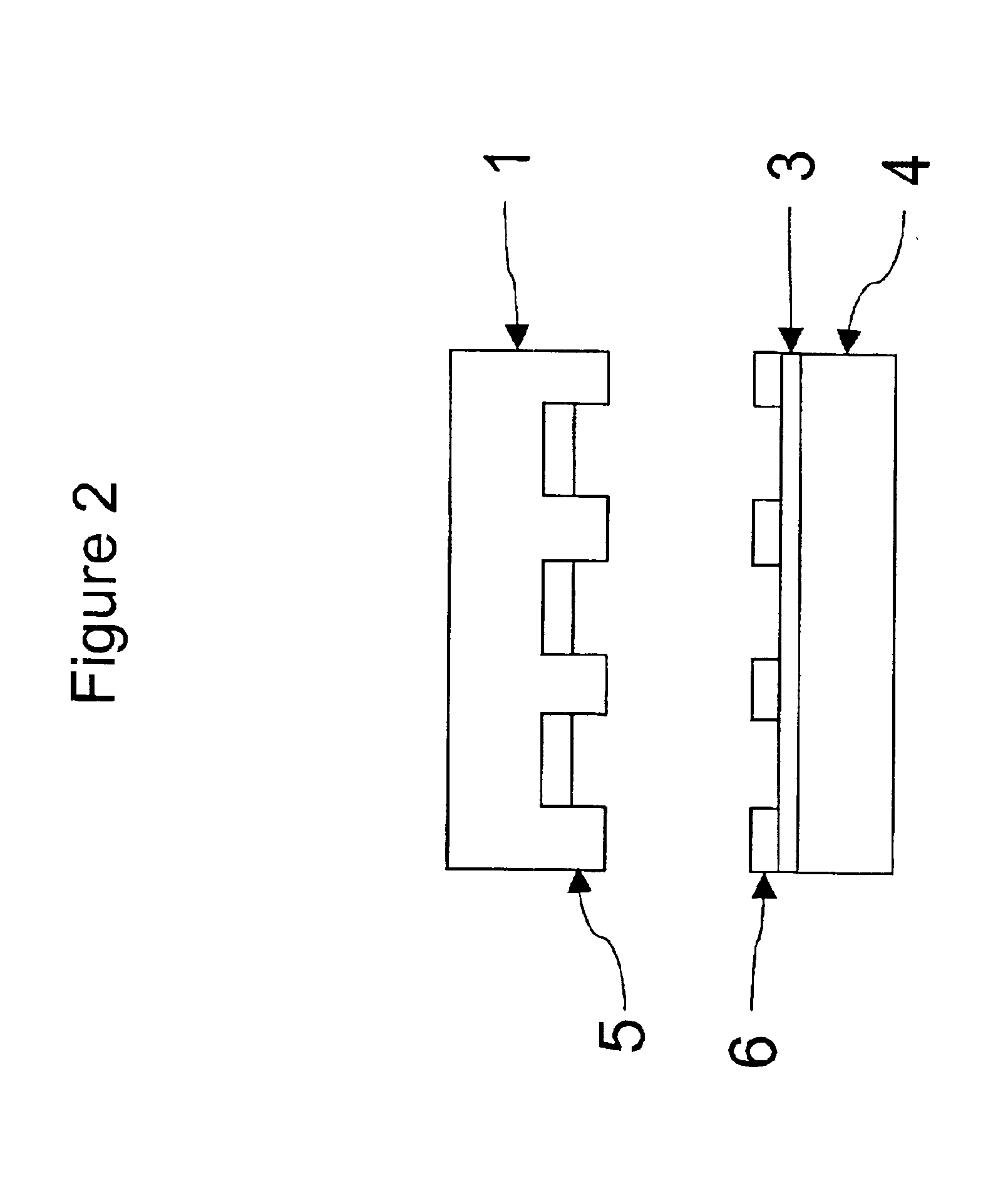

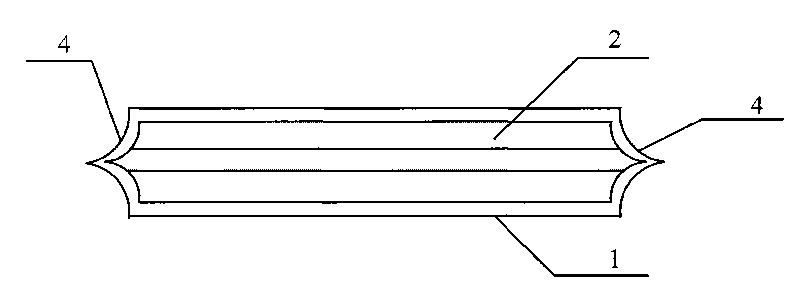

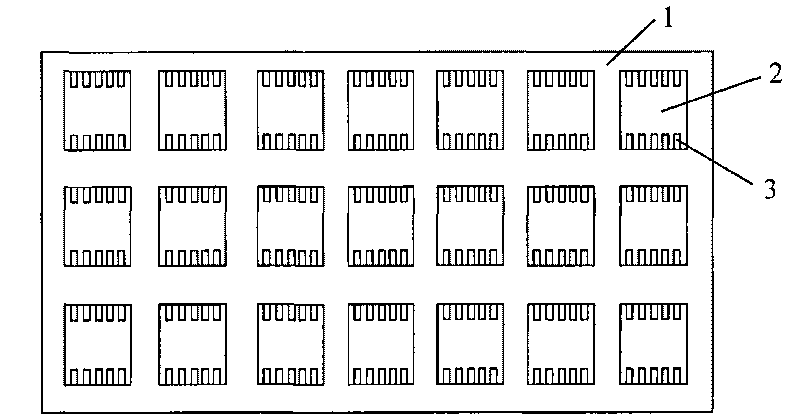

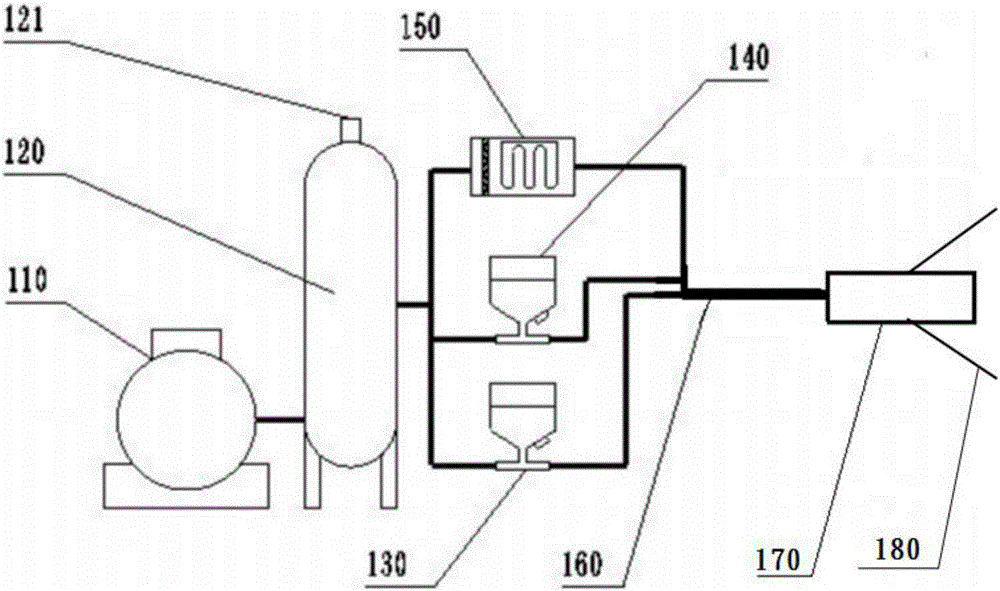

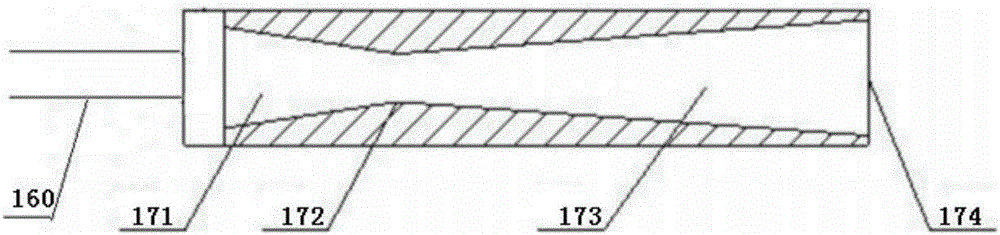

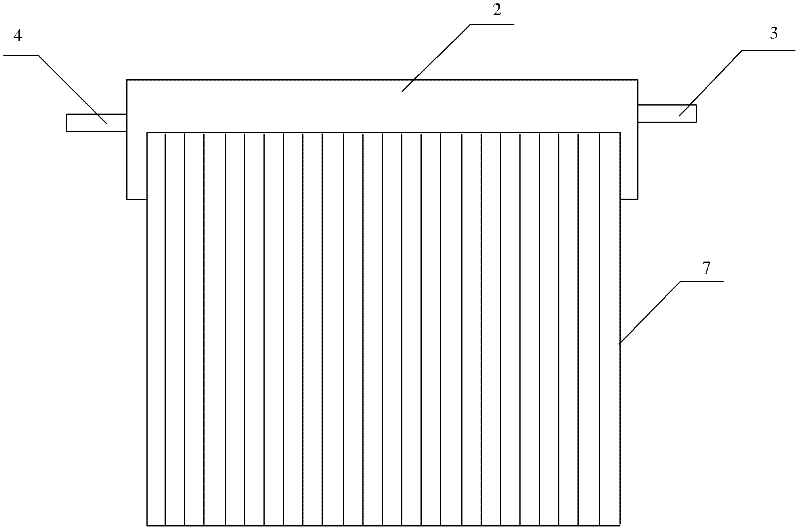

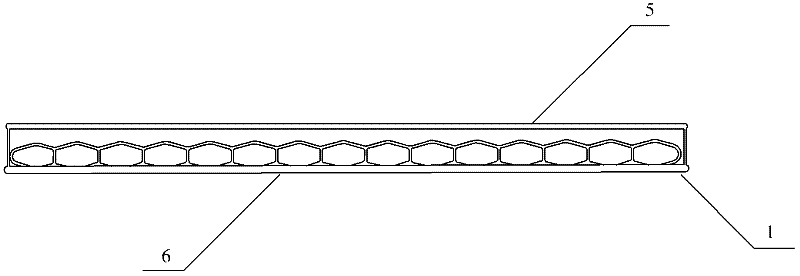

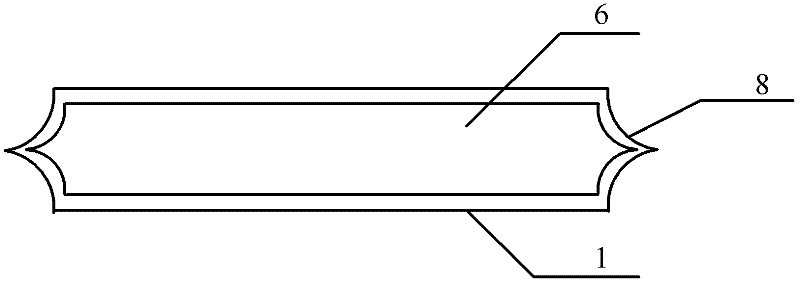

Heat pipe with micro-pore tubes array and making method thereof and heat exchanging system

ActiveUS20110203777A1Reduce welding efficiencyReduce heat resistance requirementsSolar heating energySolar heat devicesElectrical conductorEngineering

A heat pipe with micro tubes (2), comprised of a solid heat conductor (1) provided therein with two or more parallel micro tubes (2), the micro tubes being filled therein with working medium which exchanges heat through phrase change; and the two ends of the heat conductor (1) are sealed and at least one of them is provided with a sealing strip of gradually shrinking shape that is formed from cold welding. A manufacturing process for the heat pipe and a heat-exchange system comprised of the heat pipe.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

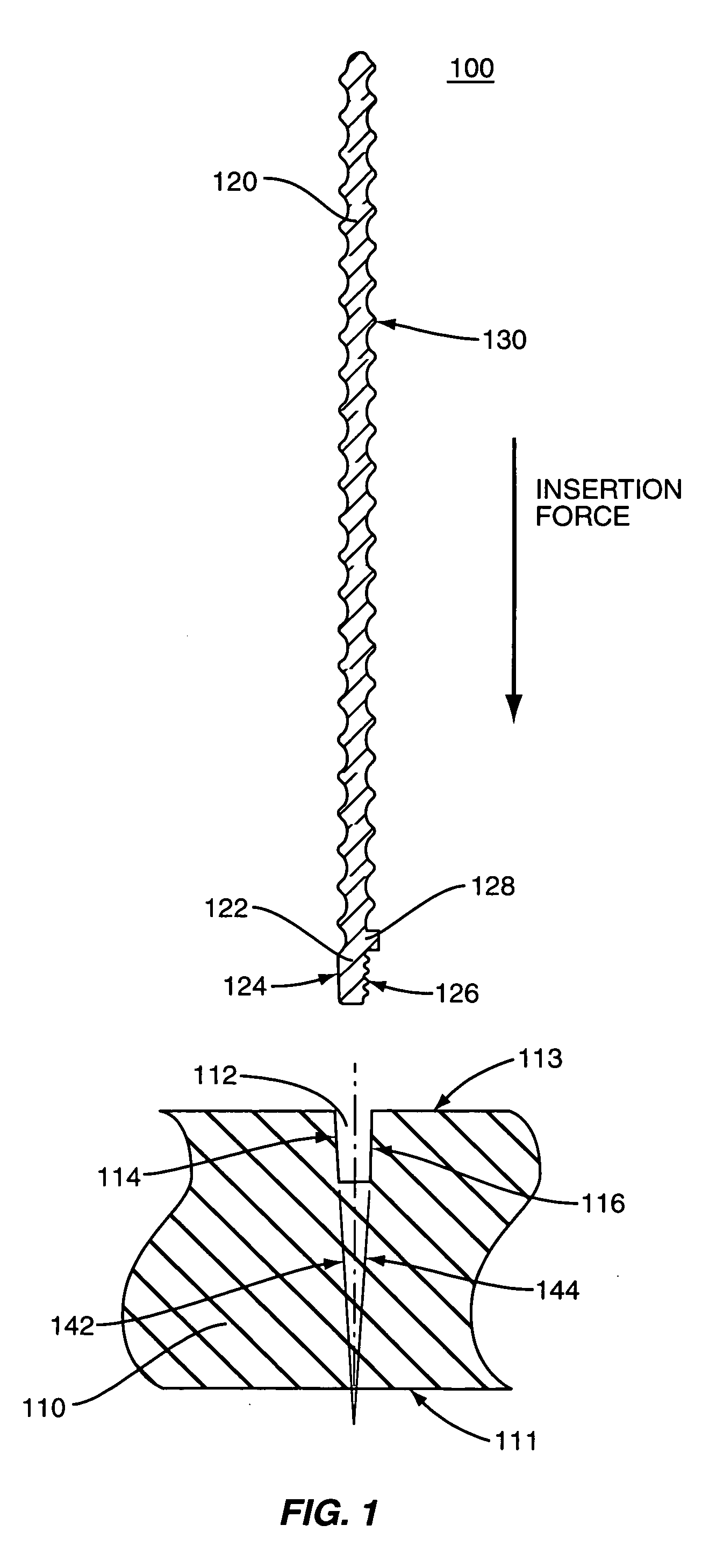

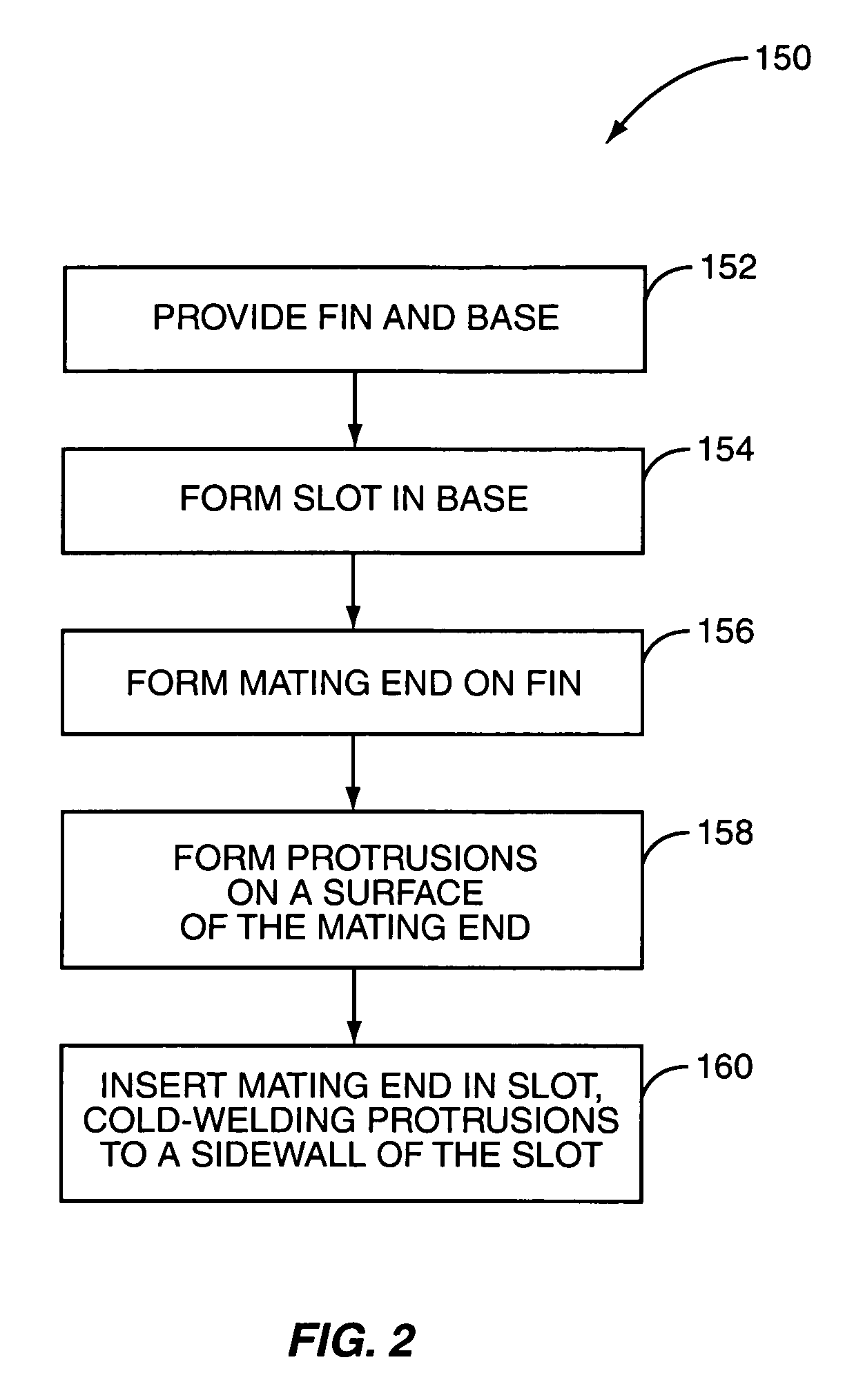

Heat sink

InactiveUS20070074850A1Reduce manufacturing costImprove mechanical performanceSemiconductor/solid-state device detailsSolid-state devicesLeading edgeEngineering

A heat sink assembly comprises a base having one or more slots, and further comprises one or more fins, each having an end configured for insertion into a respective one of the slots. Each fin end has a first surface that is configured for conformally engaging a first slot sidewall for good thermal conduction from the base into the fin, and has a second surface configured for cold welding to a second slot sidewall for good mechanical fastening of the fin to the base. The combined thermal bonding and cold-welding engagement are produced by pressing the fin ends of the fins into the base slots at a controlled pressing rate. Further, leading and / or trailing edges of the fins may be beveled to improve airflow directed edgewise across the fins.

Owner:DAU GMBH & CO KG

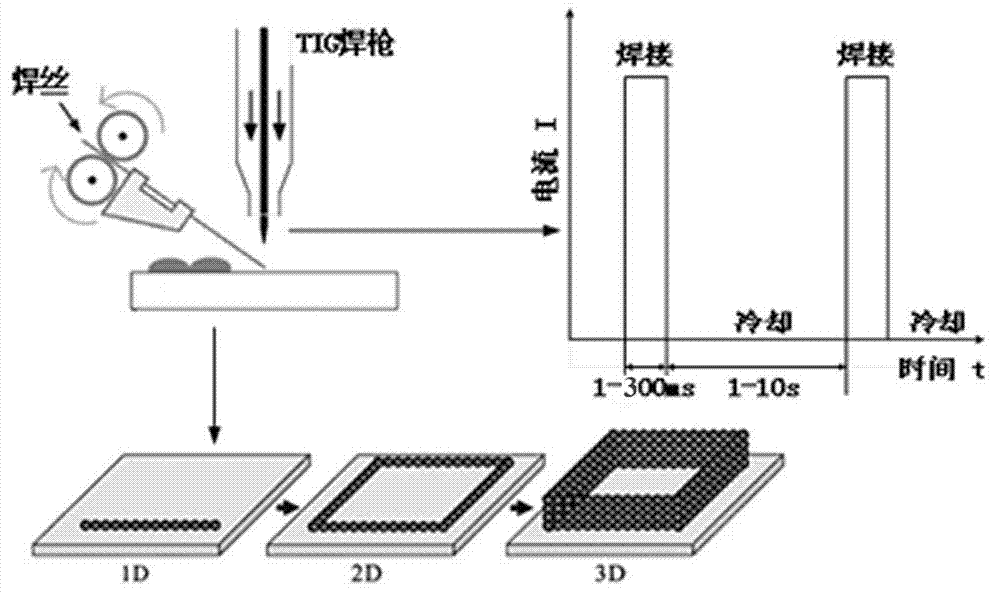

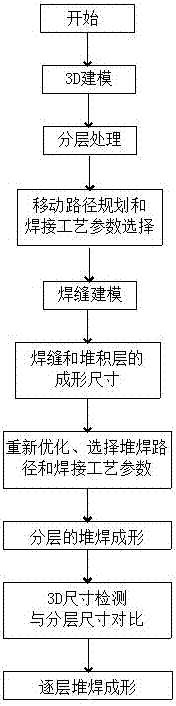

Metal cold-welding additive manufacturing method

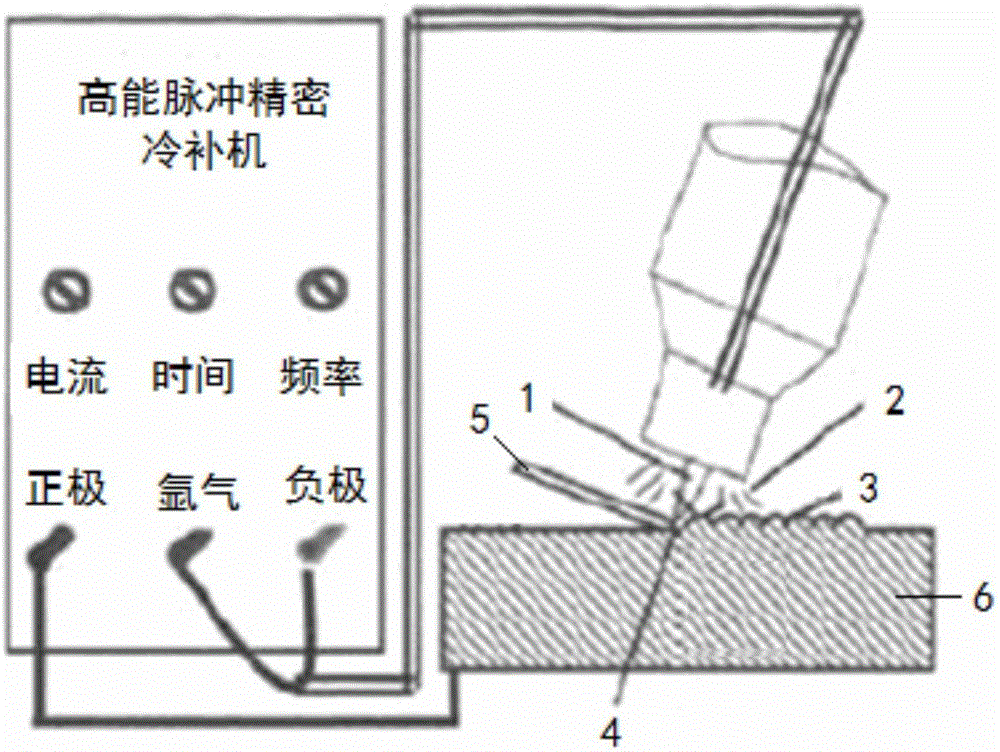

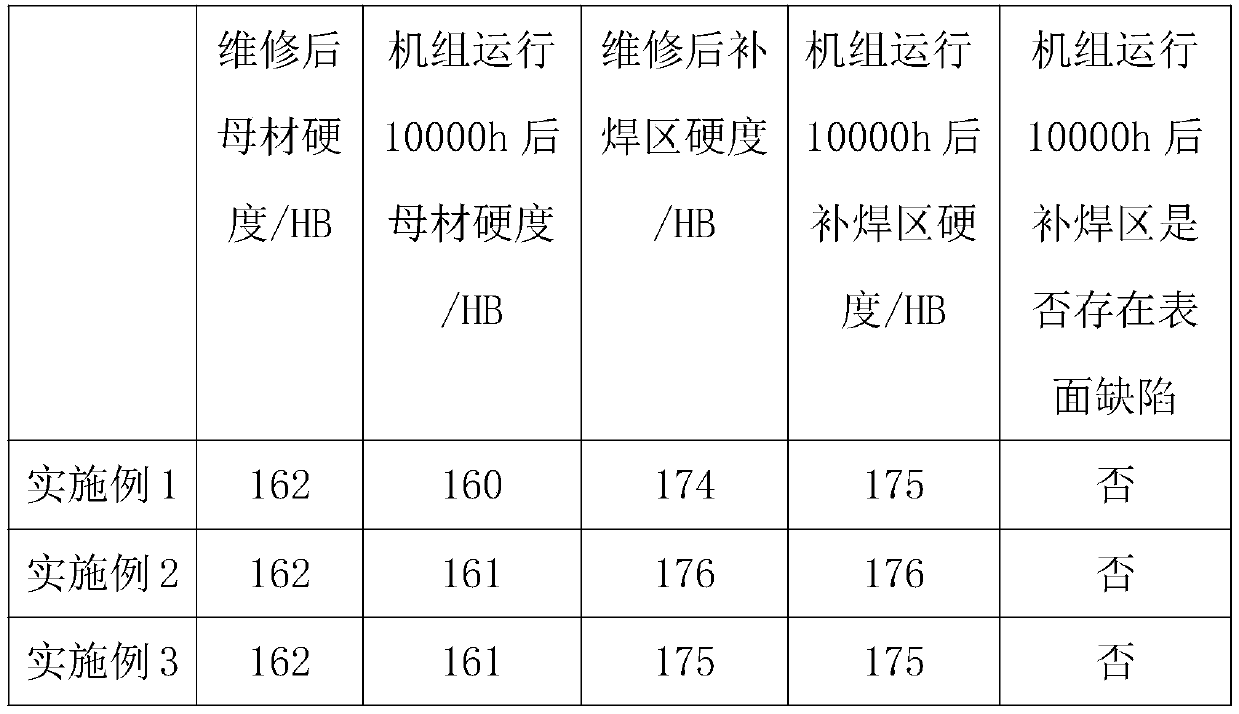

ActiveCN107008996ALittle thermal impactSmall thermal deformationArc welding apparatusHigh energyWeld seam

The invention provides a metal cold-welding additive manufacturing method. The method includes the steps that firstly, a part is subjected to 3D modeling on a main control computer, then the part is subjected to layered processing, the size and shape characteristics of each layer are obtained, a movement route is planed, welding technological parameters are selected, then a corresponding welding seam model of the part and a three-dimensional model of stacked layers are established, and the welding seam size and the stacked-layer forming size are obtained; the stacked-layer forming size is compared with the size of each layer, and then the bead weld route and the welding technological parameters are optimized and selected again; the main control computer inputs the bead weld route and the welding technological parameters into a welding machine, a wire feeder, a mechanical arm and positioning equipment; then a high-energy pulse precise cold-welding technology is adopted to perform interrupted spot welding, a spot weld is added to each pulse period, cooling for heat dissipation is performed during each pulse interval, and it is guaranteed that a base body is at a normal temperature state; and the part is formed by stacking interrupted spot welds point by point, line by line and layer by layer, and the problems that the heat input quantity, heat deformation and a grain structure are large, and it is difficult to plan the route in the manufacturing process are avoided.

Owner:HENAN UNIV OF SCI & TECH

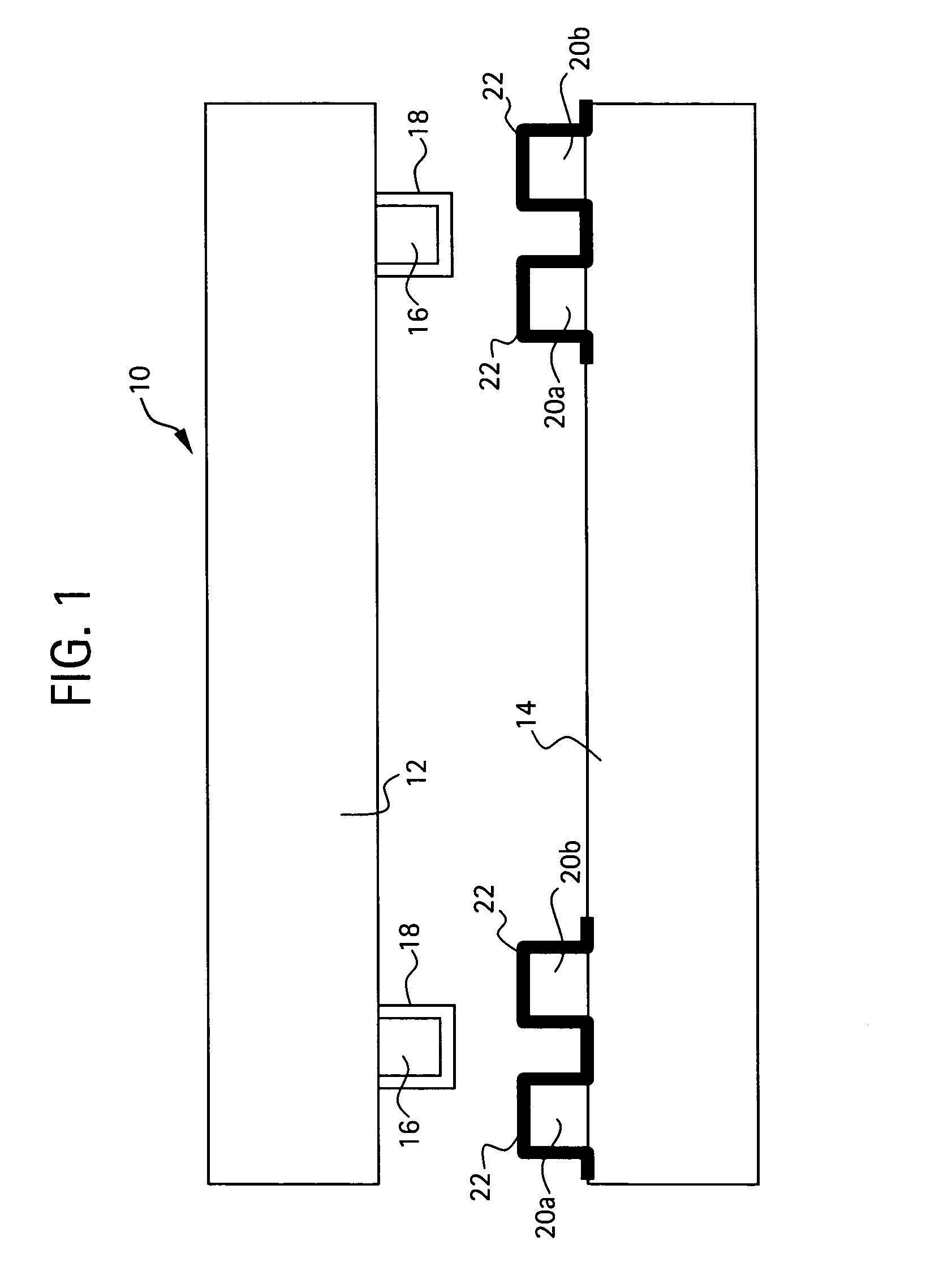

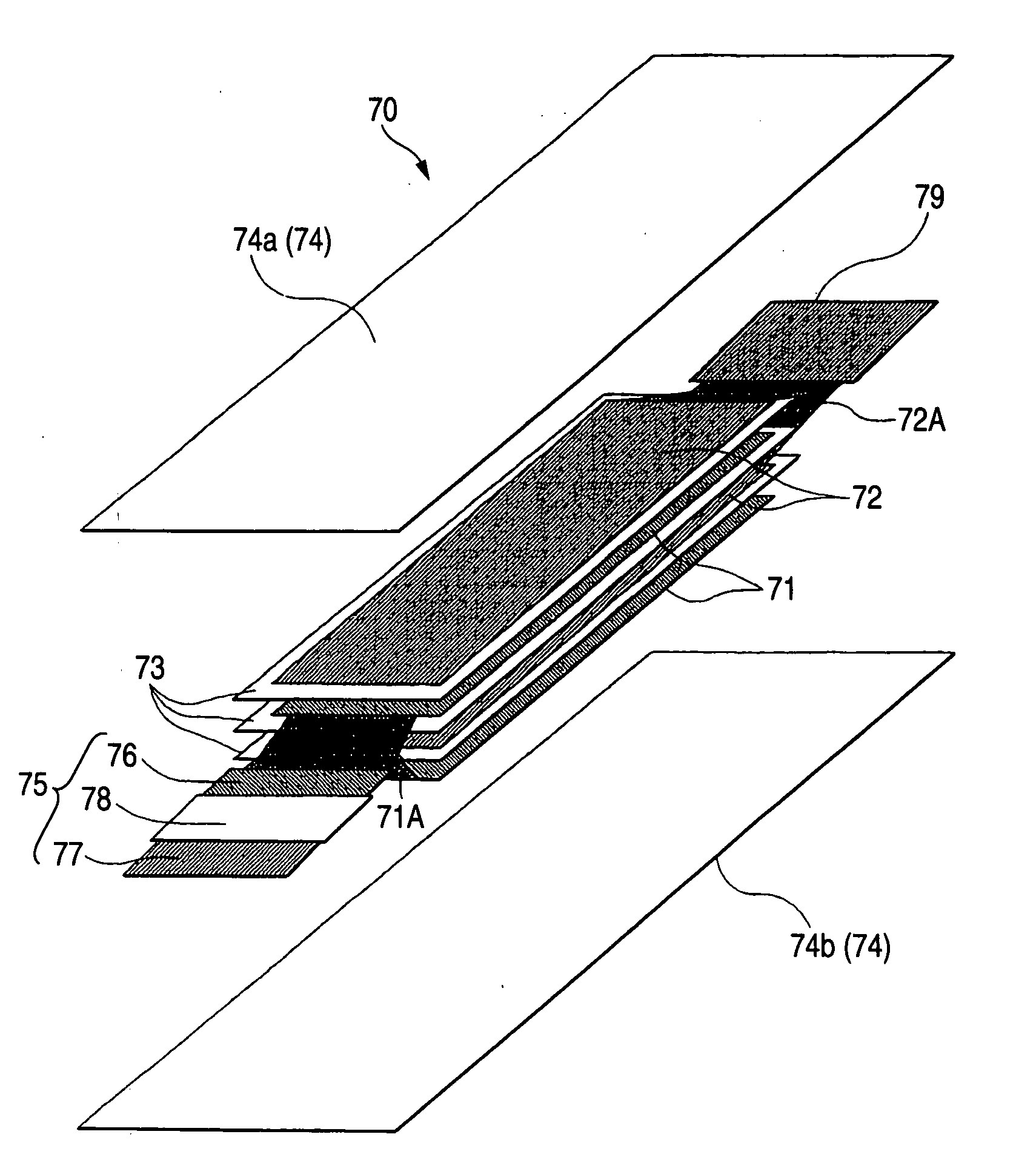

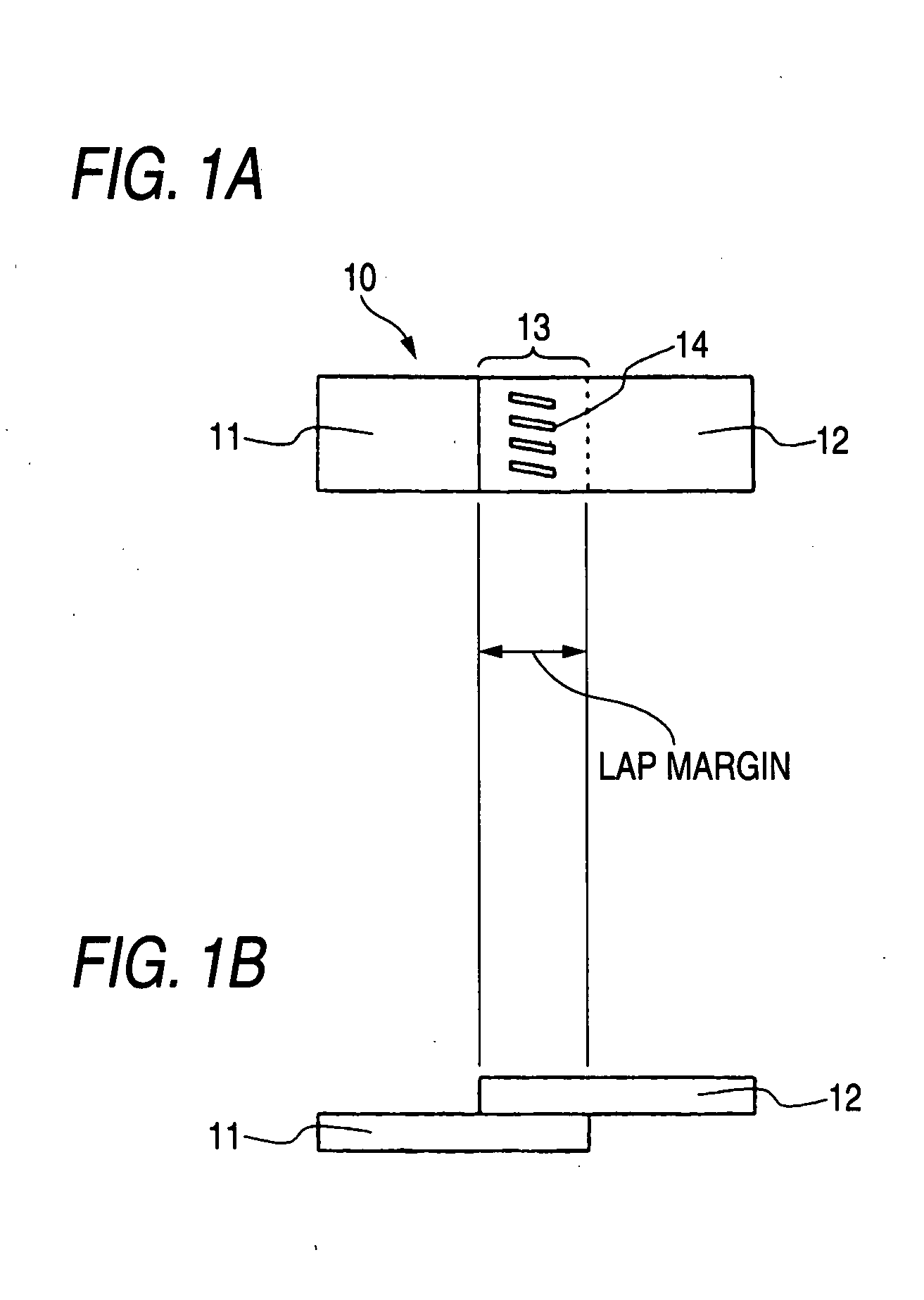

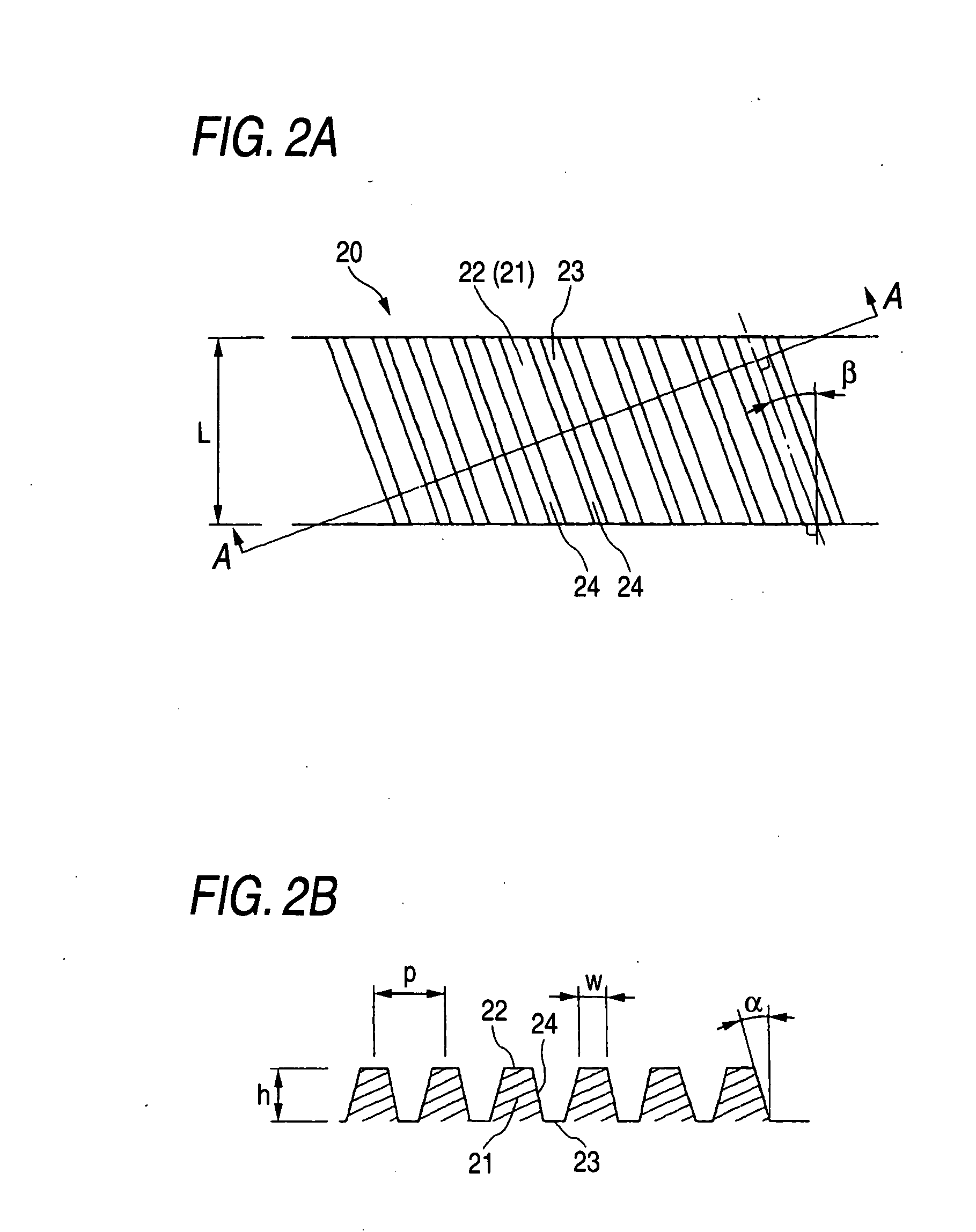

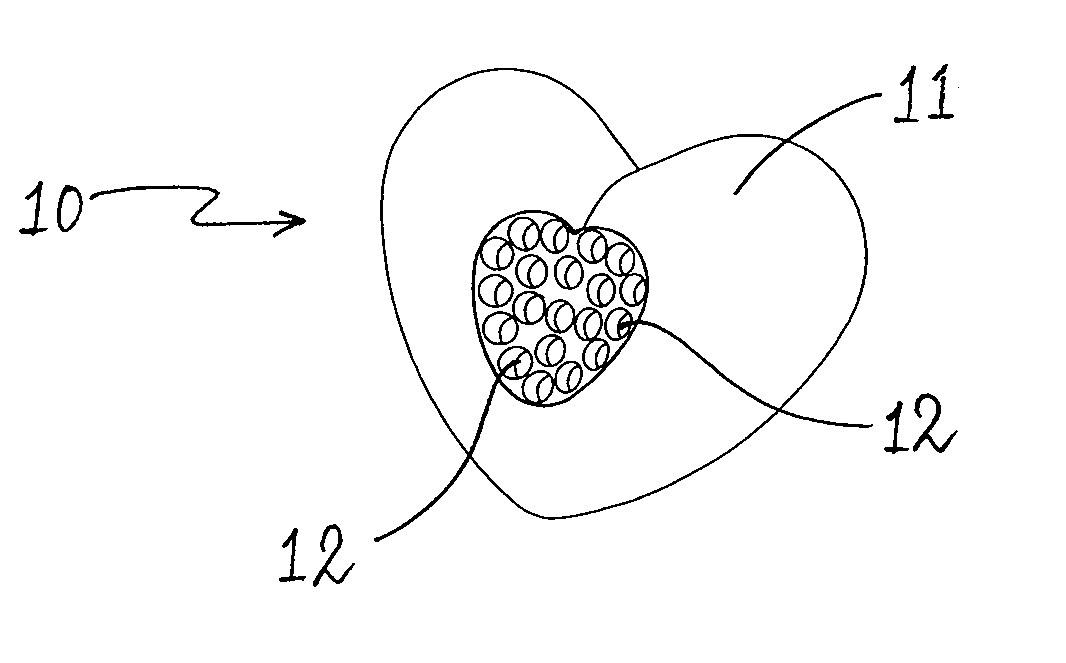

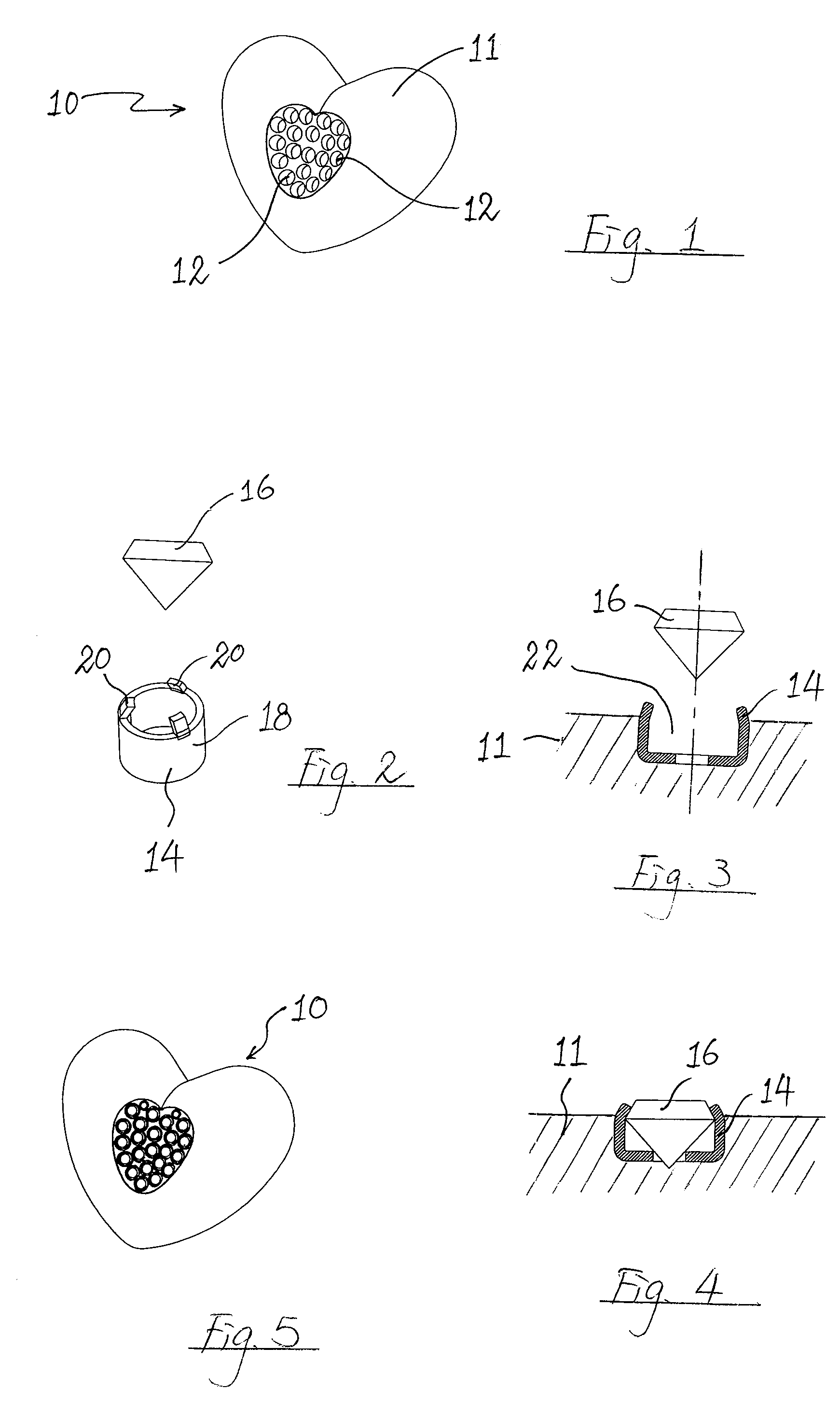

Lead member and boding method thereof and nonaqueous electrolyte electricity storing device

InactiveUS20080102362A1Easy to carryPrevent leakageHybrid capacitor electrolytesHybrid capacitor electrodesElectricityMechanical engineering

A first member 11 and a second member 12 connected to each other are provided. The first member 11 is electrically connected to an electrode. The second member 12 is bonded to a position of the first member 11 remote from the electrode and is constituted by a material of a kind different from that of the first member 11. An overlapped portion 13 is formed at the first member 11 and the second member 12 and the overlapped portion 13 is bonded by cold welding. By the cold welding, the overlapped portion 13 is formed with a plurality of pressure marks 14 in a recess shape. Each cold pressure welded mark 14 is formed with a deformation mark reducing a depth of the cold pressure welded mark of the recess shape before plastic working by plastically working the overlapped portion 13 in a thickness direction thereof.

Owner:SUMIDEN ASAHI IND LTD +1

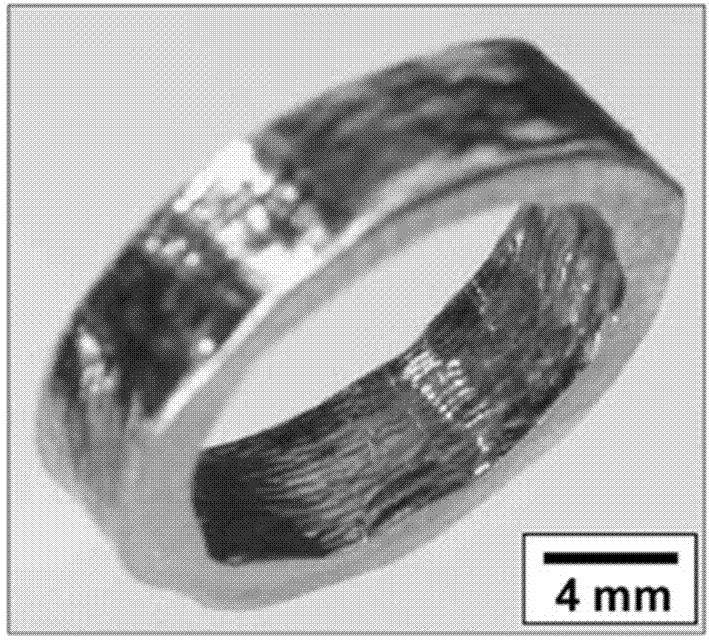

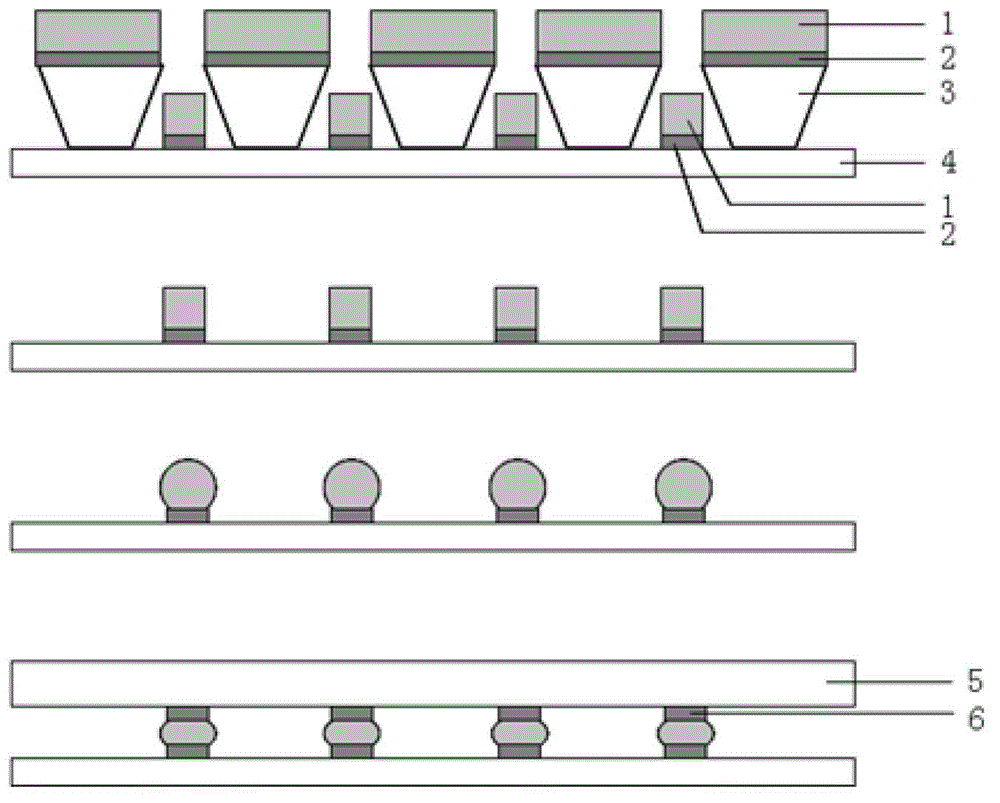

Transfer of patterned metal by cold-welding

InactiveUS6895667B2Improve adhesionReduce adhesionInsulating substrate metal adhesion improvementNanoinformaticsThin metalDevice form

Methods for patterning a metal over a substrate and devices formed using the methods are disclosed. A patterned die having at least one raised portion and having a metal layer over the die is pressed onto a thin metal film over a substrate, such that the metal layer over the raised portion of the patterned die contacts portions of the thin metal film. Pressure is then applied such that the metal layer and the thin metal film cold-weld to one another. The patterned die is removed, such that the portions of the metal layer cold-welded to the thin metal film break away from the die and remain cold-welded to the thin metal film over the substrate, in substantially the same pattern as the patterned die.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Processing method for manufacturing silver tungsten composite contact material

The invention discloses a processing method for manufacturing a silver tungsten composite contact material, which comprises the following steps: putting tungsten powder in a reaction vessel, adding water and a proper amount of reducing agents, slowly injecting a silver-ammonia complexing solution under stirring, cleaning silver tungsten coating powder to become neutral, drying the powder, performing uniform ball milling treatment by a high-energy bowl mill, performing distressing treatment of the silver tungsten powder, performing primary pressing and molding, performing presintering, infiltration sintering, and secondary pressing with the protection of reducing atmosphere to obtain the silver tungsten composite contact material. The invention has an advanced and simple process; the distribution of tungsten particles in a silver substrate is improved by a coating process based on a chemical plating principle; a high-energy bowl milling process is selected to allow the powder particlesto repeatedly generate cold welding and fractures, which causes atomic diffusion in the powder particles and improves the mechanical properties, physical properties, electrical properties, and the like of the material; a high temperature presintering process is adopted, which increases the material compactness, greatly optimizes the conductivity, reduces resistivity, and improves arc erosion resistance.

Owner:YANGZHOU LEYIN ALLOY TECH

Three-dimensional slab heat pipe with multi-layer microporous pipe arrays and processing technique thereof

ActiveCN101738118ANo need to reduce the distanceHigh efficiency of condensation heat releaseIndirect heat exchangersMetallic materialsEngineering

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

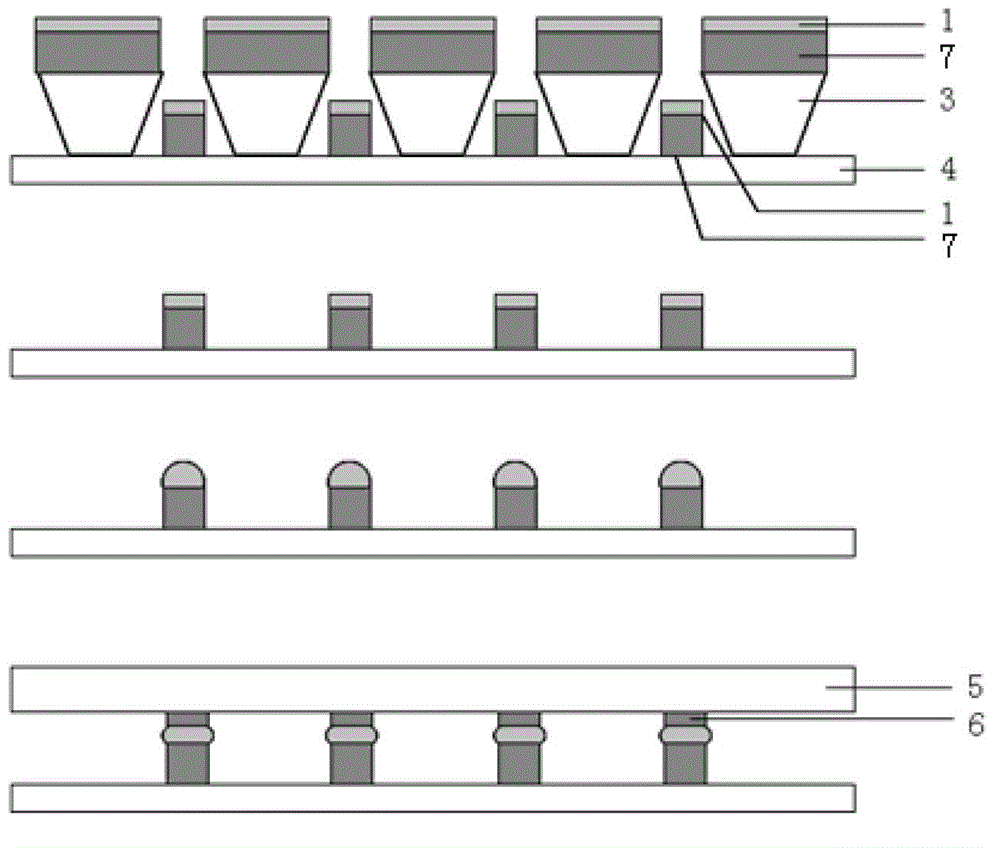

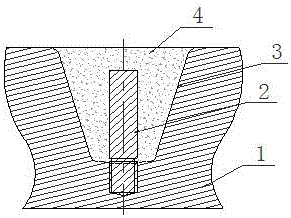

Novel focal plane array electrical interconnection process

InactiveCN102881607AImprove performanceAvoid the problem of increased thermal conductivitySolid-state devicesSemiconductor/solid-state device manufacturingMetal membranePhotoresist

The invention belongs to the technical field of photoelectronic imaging and relates to a novel focal plane array electrical interconnection process which solves the problem of increase of thermal conductance caused by deformation of indium columns during cold welding of a focal plane detector. The focal plane array electrical interconnection process includes the steps: firstly, a photoetching process on a read-out circuit of the focal plane detector; secondly, a metal membrane deposition process, namely depositing a nickel or copper metal membrane and then depositing an indium metal membrane, wherein the nickel or copper metal membrane is thicker than the indium metal membrane; thirdly, a photoresist stripping process on the read-out circuit; fourthly, an indium column reflux balling process on the read-out circuit; fifthly, an electrode manufacturing process on a focal plane chip; and sixthly, a cold welding interconnection process of the focal plane chip and the read-out circuit. Since nickel or copper is used as indium column support and electrical communication metal, the problem of increase of thermal conductance caused by deformation of indium columns during cold welding interconnection is avoided, and performances of the focal plane array detector are improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Fixed Weight Dumbbell Assembly

An easy dumbbell assembly is presented herein, so that the weight heads are attached to handle bar in a very secured manner, without the process of welding, or the concern of cold weld. After a lock nut to tighten the assembly and eliminate the spin / rotate of the handle bar, a cap piece is pressed into the specially designed grooves on the weight heads, further securing the lock nut in place, for long period of extended use, reducing safety concern as a result of loose connection between weight heads and handle bar.

Owner:CAO GUOFANG

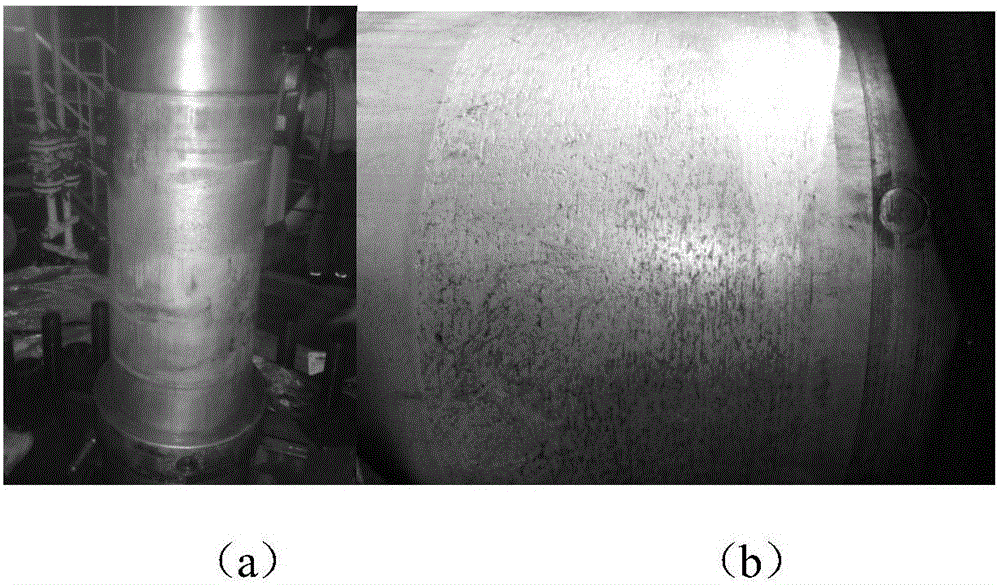

Cold welding and repairing technology of crankshaft cracks of large reciprocating compressor by manual argon arc welding

ActiveCN101898292ASimple processRepair technology is reliableArc welding apparatusThermal deformationEngineering

The invention discloses a cold welding and repairing technology of crankshaft cracks of a large reciprocating compressor by manual argon arc welding and relates to the technical field of welding, aiming to solve the technical problems that the technical risk is high, the success rate is low, major mechanical accidents are easy to cause by thermal stress and thermal deformation of the traditional welding process, and the like when non-destroyed defects of cracks, abrasions, bending, deformation, and the like which are generated for a crankshaft of a large reciprocating compressor. The technology comprises the following steps of: clearing away crankshaft neck cracks to be repaired; adjusting the coaxiality and the parallel misalignment; evaluating the welding process; hoisting and positioning; marking lines to divide areas and welding for three times; detecting and controlling the deformation in the welding process; and grinding. The invention is suitable for the cold welding and repairing of crankshaft cracks of the large reciprocating compressor by manual argon arc welding.

Owner:SICHUAN LUTIANHUA

Automatic butt welder

ActiveCN101987404ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesCouplingEngineering

The invention relates to a welder, in particular to an automatic butt welder, which is applicable to welding between cylinders with different diameters and tube plates. The automatic butt welder comprises a straight shank empty cold welding torch, an elevating gear and a transversal arm fixed on the elevating gear, wherein the straight shank empty cold welding torch is fixed on the transversal arm. The automatic butt welder is characterized in that the transversal arm is formed from a front arm and a rear arm connected by a coupling, springs are fixed on the front arm and the rear arm, a sleeve with adjustable height is arranged on the front arm, a transversal sliding shaft is arranged on the lower part of the sleeve, a roller is arranged on the top end of the transversal sliding shaft, a longitudinal telescopic rod is arranged on the front arm, a curved rod is arranged on the top end of the telescopic rod, and rollers are arranged on both ends of the curved rod. The automatic butt welder has a unique mechanical limit structure of the front arm and the rear arm, solves the problem that the head of a welder is regulated continuously during welding because a cylinder rotating on a rotator deviates longitudinally, and ensures no deviation from welds during welding.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

Method of decorating an article

A method of decorating an article of manufacture, e.g. a jewelry item, watch casing or a mobile phone, including the steps of (a) providing the article with a substrate made of a metal or metal alloy and having a number of recesses; (b) providing a number of engagement members made of the same metal or metal alloy; (c) positioning at least part of the engagement member within the recess; (d) fixedly engaging the engagement members with the substrate by laser beam welding or cold welding; and (e) fixedly engaging a decorative element with the engagement member in a snap-fit manner.

Owner:CN PRECISION CASING

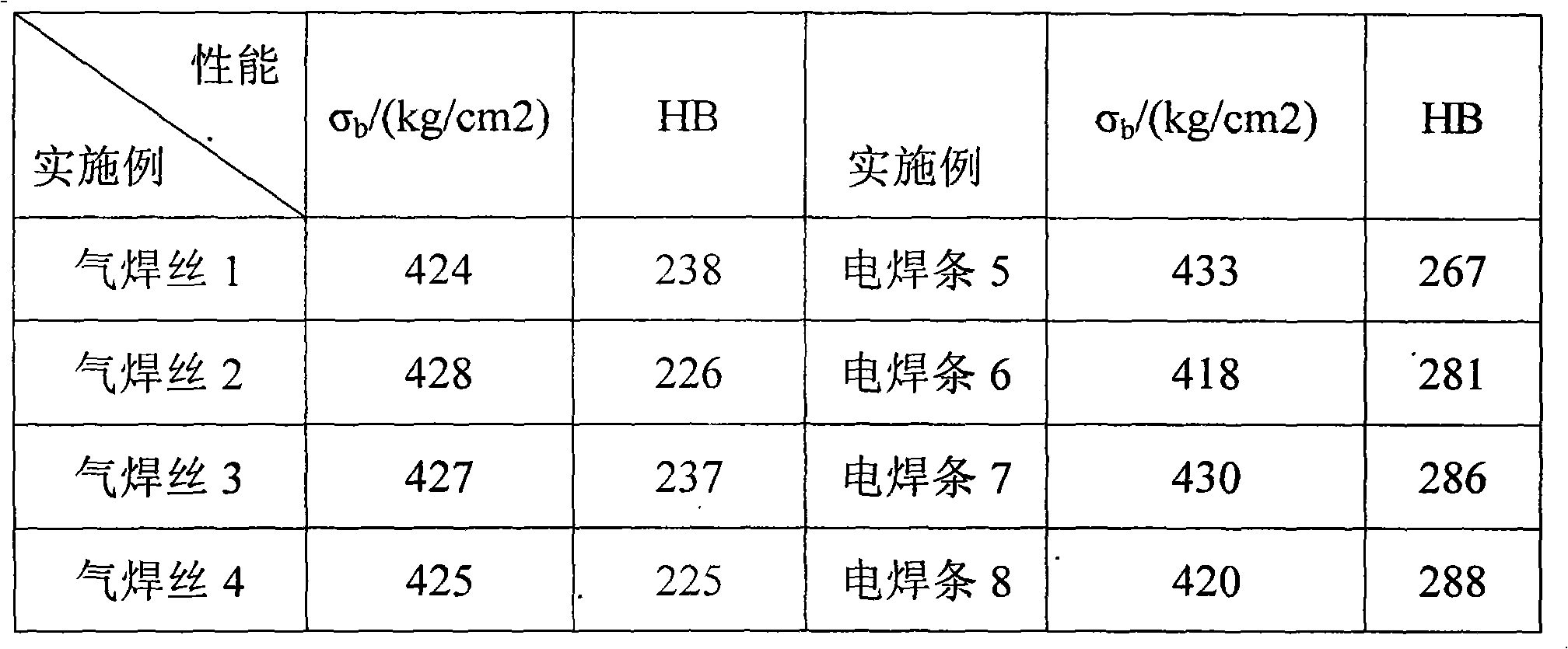

Flux-cored alloyed ductile cast iron homogeneous gas-welding wire and electric welding rod

InactiveCN101554688AConsistent weld colorConsistent weld strengthWelding/cutting media/materialsSoldering mediaSilicon alloyAluminium powder

The invention discloses a flux-cored alloyed ductile cast iron homogeneous gas-welding wire which consists of H08A steel strip and alloyed flux-cored powder cladded in the H08A steel strip, and the flux-cored powder comprises the components based on the weight percentage: 10-20% of graphite, 50-60% of 75 Si-Fe, 5-8% of Ni, 2-5% of Ti, 3.8-6% of Mg, 0.8-2.5% of Bi, 1-2.5% of Zr, 2.0-4.5% of Ba, 1.5-2.8% of Ce and 4-6% of RE, and the total weight percentage is 100%. The invention also discloses an electric welding rod, a flux-cored welding core of which consists of the H08A steel strip and the alloyed flux-cored powder cladded in the H08A steel strip, and the coating applied on the welding rod comprises the components based on the weight percentage: 5-11% of marble, 10-20% of dolomite, 5-15% of potassium feldspar, 5-15% of fluorite, 8-16% of graphite, 15-25% of 75 silicoferrite, 6-10% of 30 calcium silicon alloy, 4-6% of aluminium powder, 3-7% of ferrous powder, 5-15% of white slime, 0.5-1.5% of NaCO3, 1-3% of RE-Y, and the total weight percentage is 100%. The gas-welding wire or the electric welding rod can realize normal temperature gas welding, cold welding or low temperature preheating welding.

Owner:XIAN UNIV OF TECH

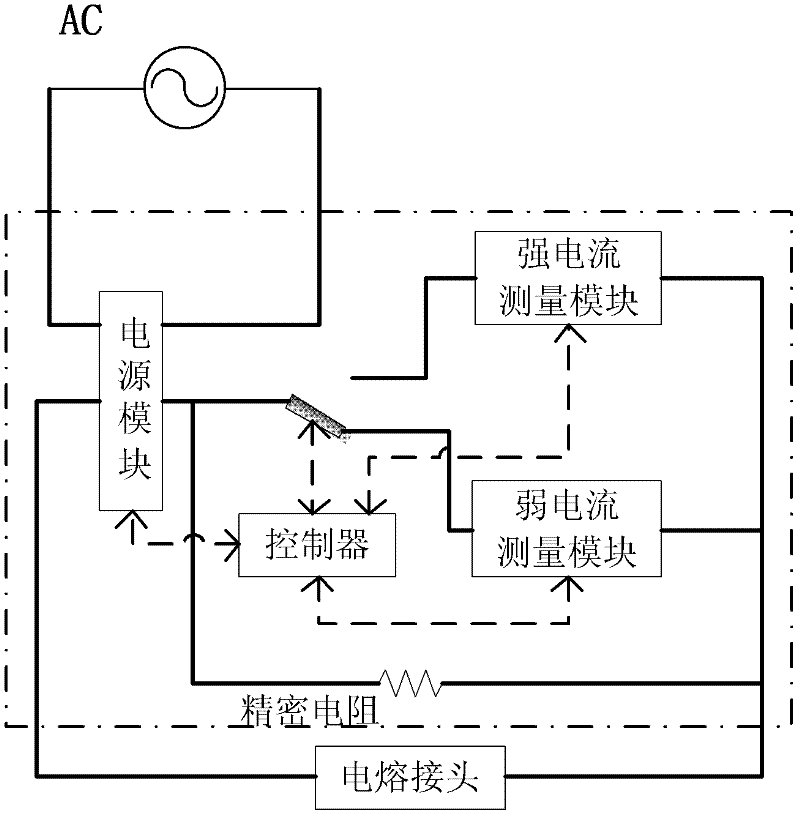

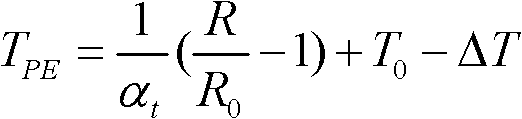

Electrofusion welding process for preventing generation of cold welding and over welding defects and electrofusion welder

The invention which relates to an electrofusion welder technology aims to provide an electrofusion welding process for preventing the generation of cold welding and over welding defects and an electrofusion welder. The process comprises the following steps: 1, measuring the current and the voltage of a welding circuit in real time in the welding process to obtain the resistance value change case of a resistance wire, controlling the voltage of the welding circuit to realize the control on the resistance value of the resistance wire and the welding power, and simultaneously controlling the temperature of a polyethylene material around the resistance wire in the welding process; and 2, recording the real-time welding power of the resistance wire in the welding process, carrying out accumulating calculation to obtain welding input heat, and ending the welding when the welding input heat reaches the value of total heat Q needed by the welding completion through an electrofusion sleeve. According to the invention, the electrofusion welder can automatically determine a reasonable welding technology only through giving the needed welding input heat. A present digital welder which can be conveniently added with the control forms the novel electrofusion welder with the cold welding and over welding prevention functions.

Owner:ZHEJIANG UNIV

Field repair and remanufacturing process of pressure container

InactiveCN105817832AExtended service lifeEasy cold welding repairHeat inorganic powder coatingSand blastingShielding gas

The invention discloses a field repair and remanufacturing process of a pressure container. The process comprises the following steps: (1) one part, to be repaired, of the container is polished and cleaned; (2) the cold welding repair is performed for the part to be repaired; the specification of a welding material is phi1.6-2.0 mm, the current is 0-300 A, and the flow of shielding gas is 3-6 L / min; (3) the excess weld metal and the edge of the welded surface are finished until the surface is qualified through nondestructive inspection; and (4) the sand blasting treatment is performed for the surface to be repaired, so that the surface is roughened; a reinforcing layer is sprayed on the surface of the container by a supersonic spraying technology; the spraying pressure is 1.5-3.5 MPa; the surface temperature of the container is not higher than 150 DEG C; and the spraying distance is 60-120 mm. The process has the following advantages: such defects as mechanical damage, corrosion and wear on the surface of the container are repaired; and the reinforcing layer with a thickness of higher than 0.1 mm is formed on the surface of the container, so that the container is protected from resisting bad corrosion and wear environments for a long time, and the service life is prolonged.

Owner:苗西魁

Cold pressure welding process for copper and aluminum

ActiveCN102489866AImprove efficiencyGood cold welding effectNon-electric welding apparatusEngineeringCopper

The invention discloses a cold pressure welding process for copper and aluminum. The process comprises the following steps of: matching clean plates which are stacked and clean foils which are needed to be welded on the plates, wherein the foils are arranged on the upper side, and positions to be welded are positioned on a smooth foundation; and pressing pits at the welding positions to form welding points by a pressure head which moves along the normal direction of the foundation, so that connecting resistance of the foils and the plates is less than or equal to that for fusion welding under the same condition. The cold pressure welding process for the copper and the aluminum is high in efficiency and good in cold welding effect.

Owner:SHANDONG YINGBO ELECTRIC POWER EQUIP

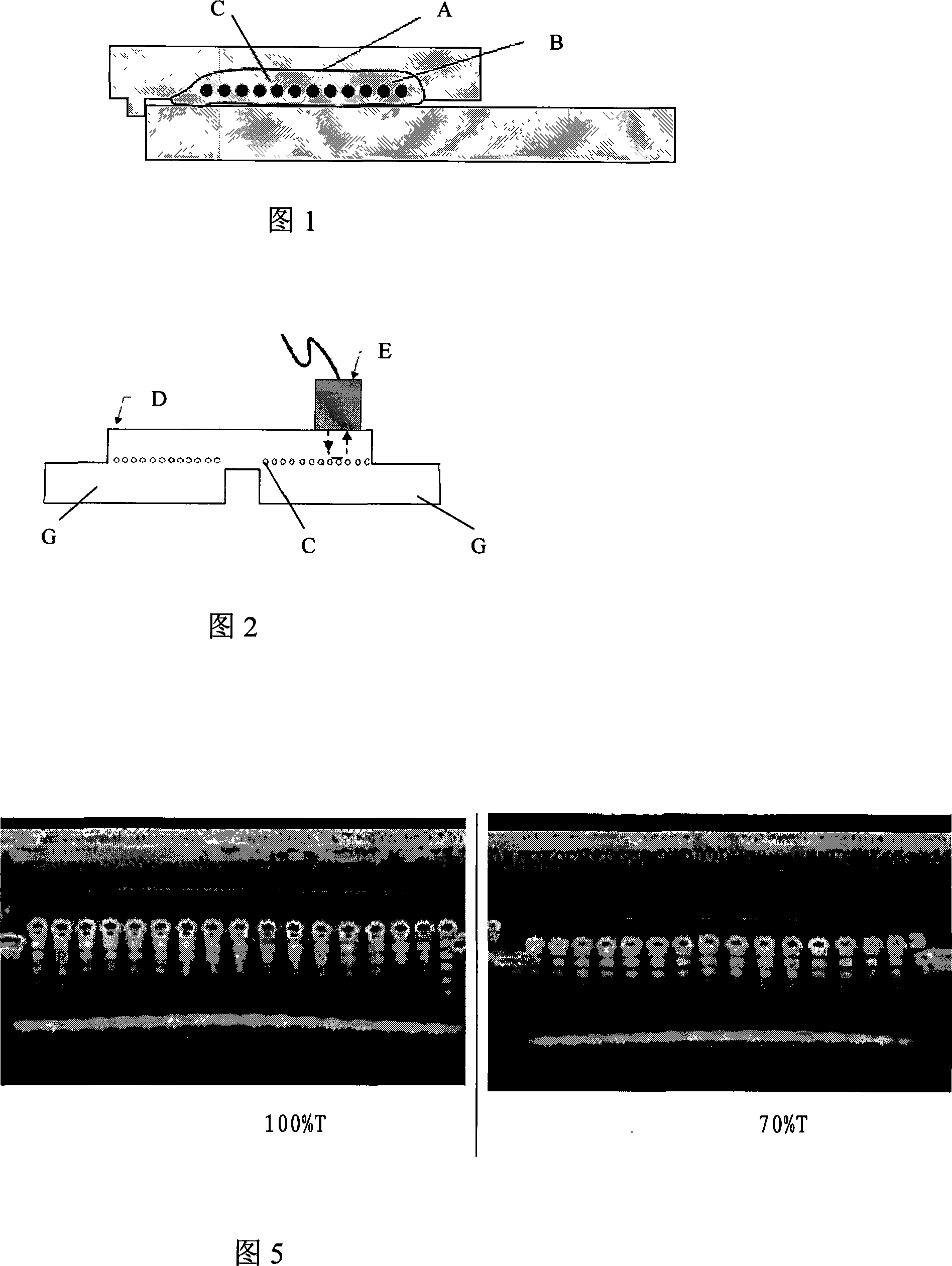

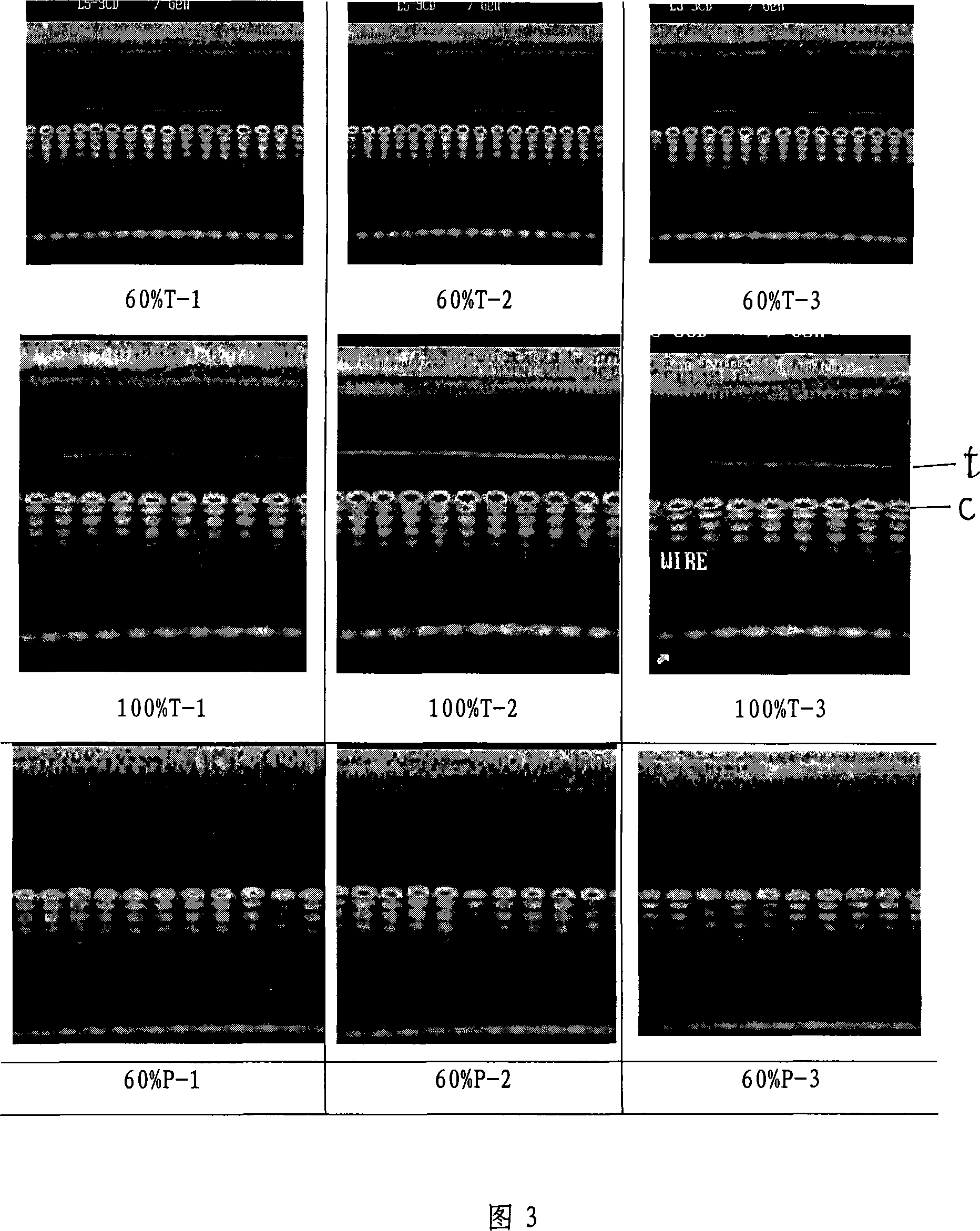

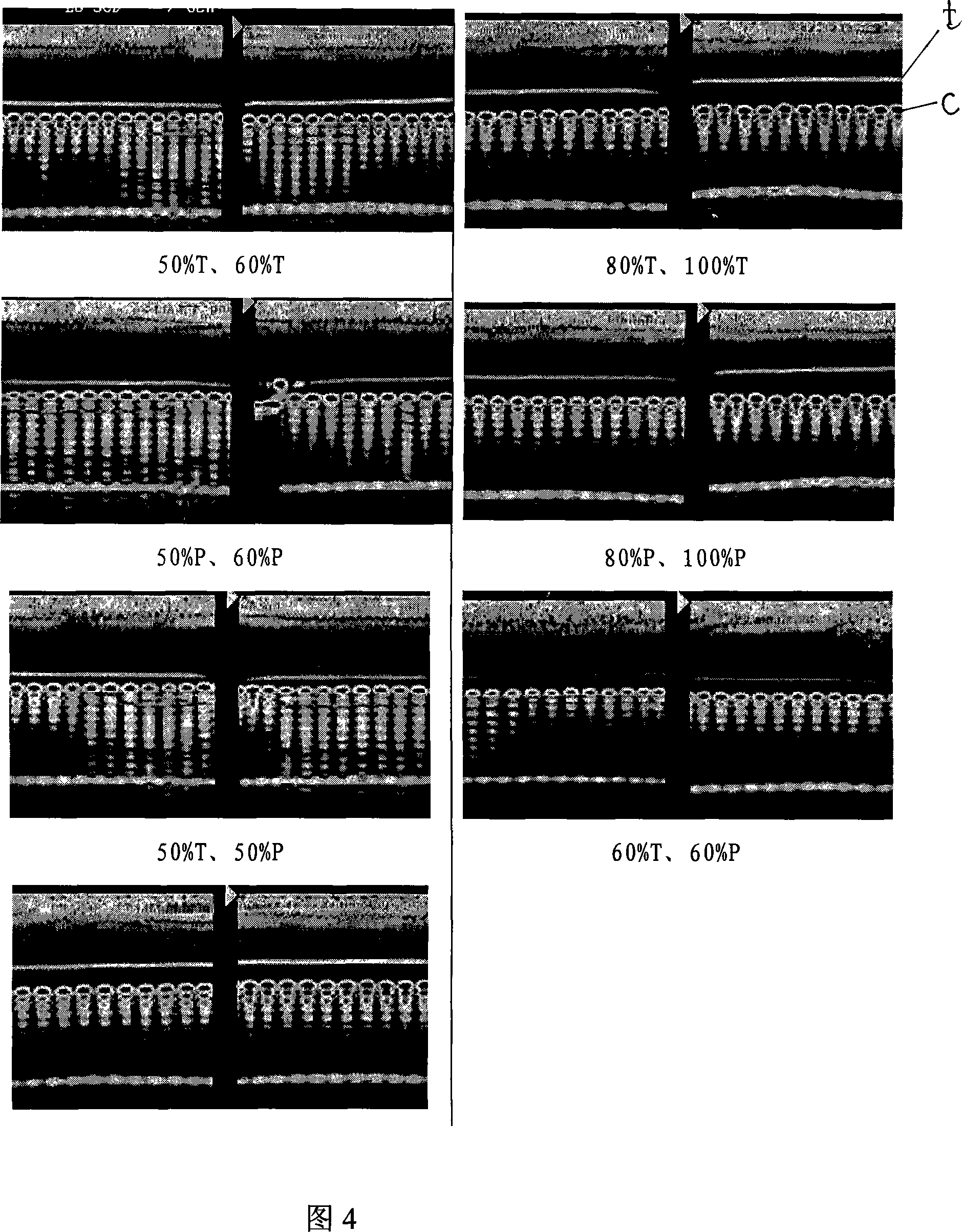

Polyolefin pipe electrofusion welding joint cold welding defect supersonic detection method

InactiveCN101101276AIntuitive imageImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityPolyolefin

The invention relates to a detection method of welded quality of polyolefin piping electric-fusion welded joint. The intention is that the detection method should have the characteristics of high detected precision, visualize and visible, easy and convenience. The plan of technology is that: the ultrasonic detection method of the cold welding bug of the polyolefin piping electric-fusion welded joint, it realizes according to the following methods: the detection of normal weld tubular product and the one section of junction seal part by ultrasonic testing method, getting the distance L of typical line and wire in the ultrasonic reflected signal image; doing ultrasonic detection for the needed electrocast joint also, getting the distance L'of typical line and wire in the ultrasonic reflected signal image; judging the needed electrocast joint if exist the cool welding bugs according to the L and L' in the above two images. Taking the L and L'to the formula: H=L' / L, and judging the needed electrocast joint if exist the cool welding bugs. The L and L' of typical line and wire in the ultrasonic reflected signal image can get by software.

Owner:浙江省特种设备检验中心 +1

Method for preparing TiAl-based alloy sheet

The invention relates to a method for preparing a TiAl-based alloy sheet, and solves the problems that: the conventional method for preparing the TiAl-based alloy from elemental powder has high cost and impurities are easy to introduce; and the conventional TiAl-based alloy is difficult to mold and process due to poor deformability during cold processing. The method comprises the following steps of: mechanically mixing TiH2 powder and pure Al powder; filling the mixed powder into a graphite die; then carrying out hot pressing sintering to obtain a Ti-Al duplex metal compound; rolling and molding the Ti-Al duplex metal compound to obtain a Ti-Al duplex metal composite sheet; and carrying out hot pressing reactive sintering on the Ti-Al duplex metal composite sheet to synthesize the TiAl-based alloy sheet. The preparation method has low cost and is simple; and cheap TiH2 powder is taken as the raw material. The TiH2 powder is fragile powder, the cold welding is difficult to generate in the powder mixing process and the required powder mixing time is short so as to reduce the introduction of the impurities. The method adopts the elemental powder process of molding first and then producing the alloy, overcomes the defect of poor deformability of the fragile TiAl alloy during the cold processing and can sufficiently meet various molding requirements.

Owner:HARBIN INST OF TECH

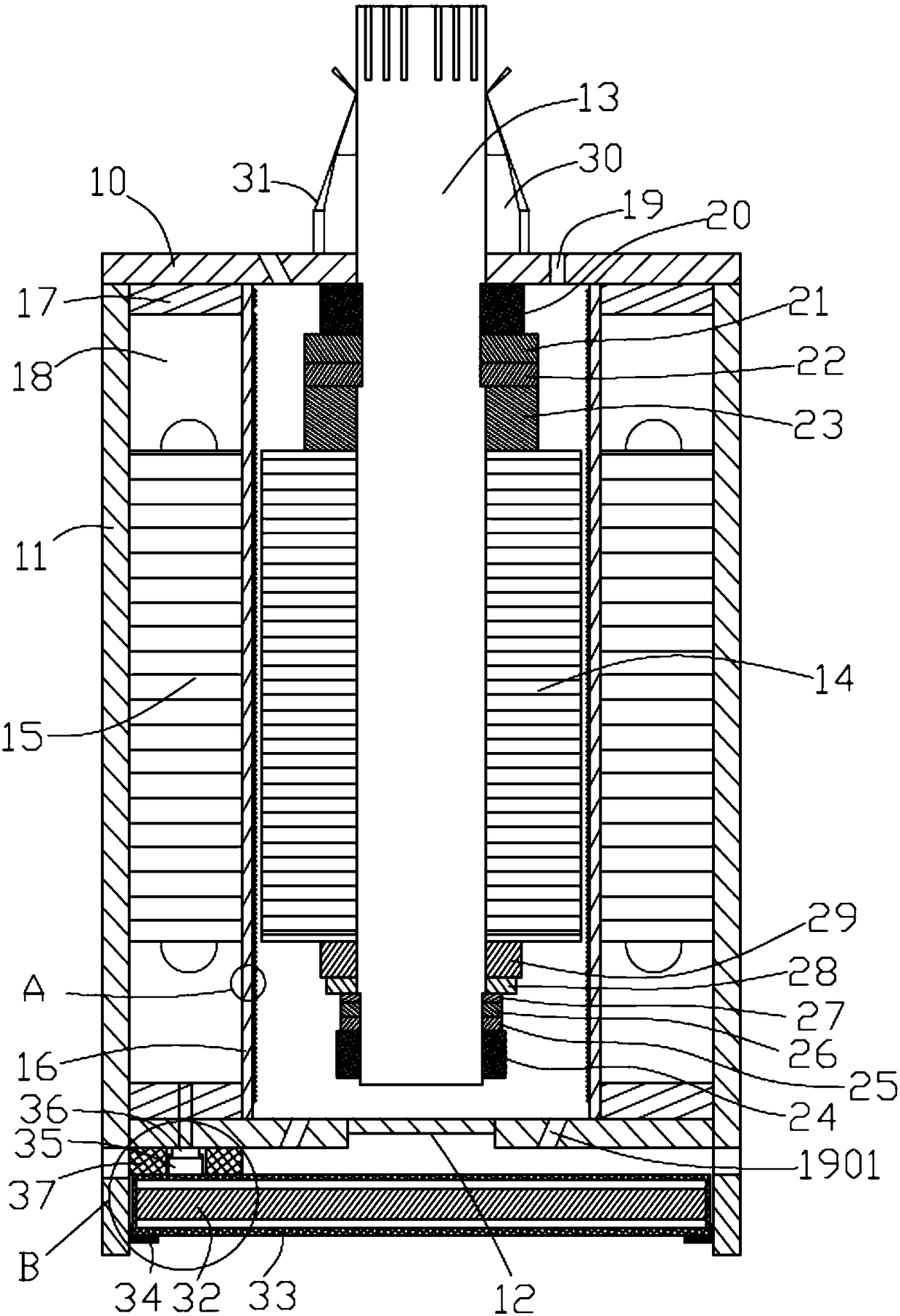

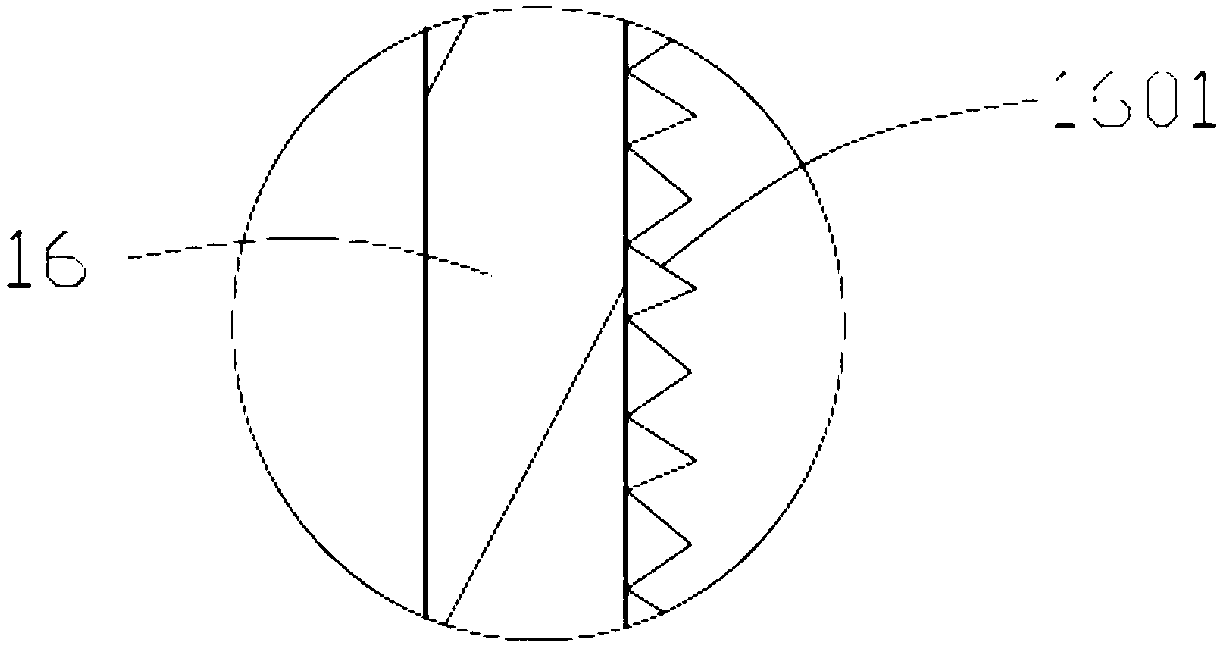

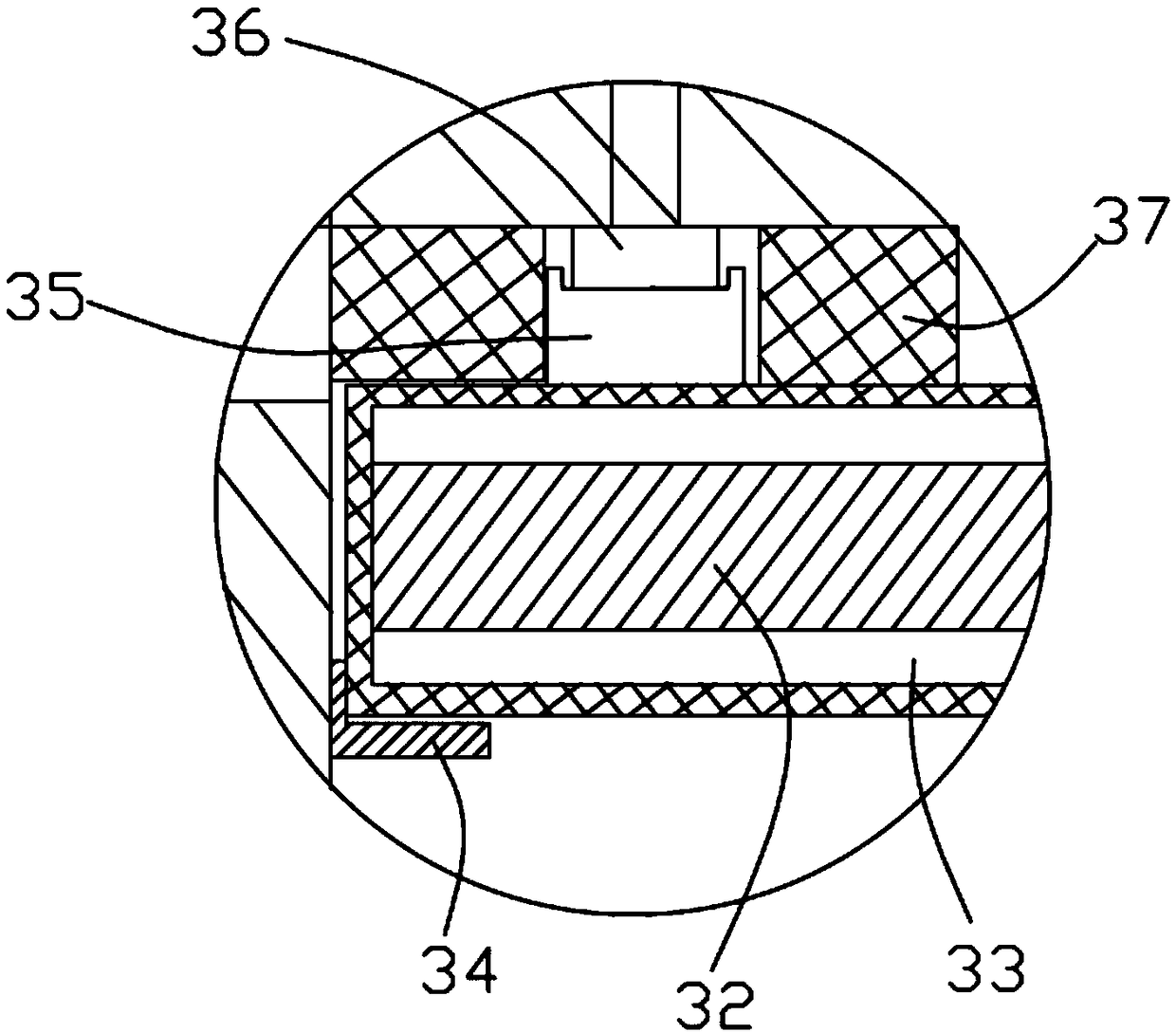

Shielding type permanent-magnetism high-speed motor of submersible pump

PendingCN108808950AAvoid feverAvoid overall overheatingSupports/enclosures/casingsWater flowControl theory

The invention relates to a shielding type permanent-magnetism high-speed motor of a submersible pump, and belongs to the technical field of submersible pumps. The motor comprises a motor casing, upperand lower end caps, a rotor shaft, a rotor and a stator, the stator is fixed to the inner wall of the motor casing, a shielding sleeve is arranged between the stator and rotor, shielding seats are arranged on and under the stator respectively, the shielding sleeve is fixedly connected to the shielding seats by cold welding, the shielding sleeve and seats are combined with the inner wall of the motor casing to form a shielding cavity, and the stator is positioned in the shielding cavity. The stator is enclosed in the independent space, threads of the shielding sleeve serve as radiating ribs, the rotor drives water current to rotate during work, the threads guide rotation of the water current to certain extent, the water current passes through the shielding sleeve at a higher speed, the heat exchange efficiency is improved, the stator is prevented from generating heat or being overheating effectively, the working efficiency of the motor is improved, loss of electric energy is reduced, and the service life is prolonged.

Owner:浙江浙水工贸有限公司

Packaging machine and packaging method for dual-interface card

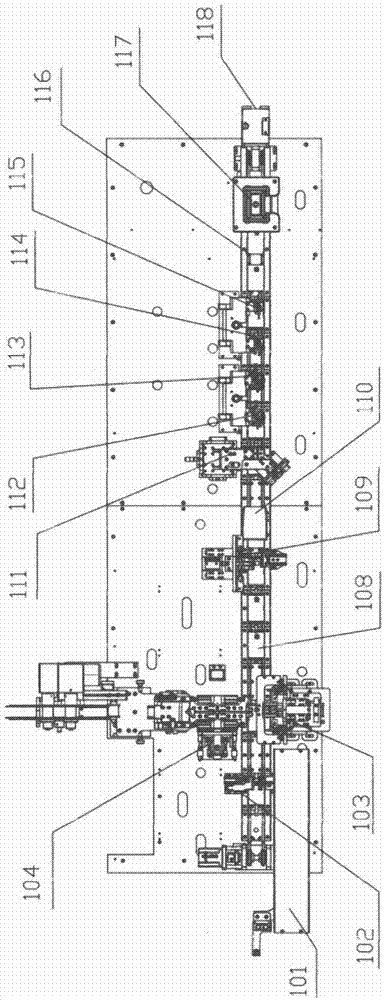

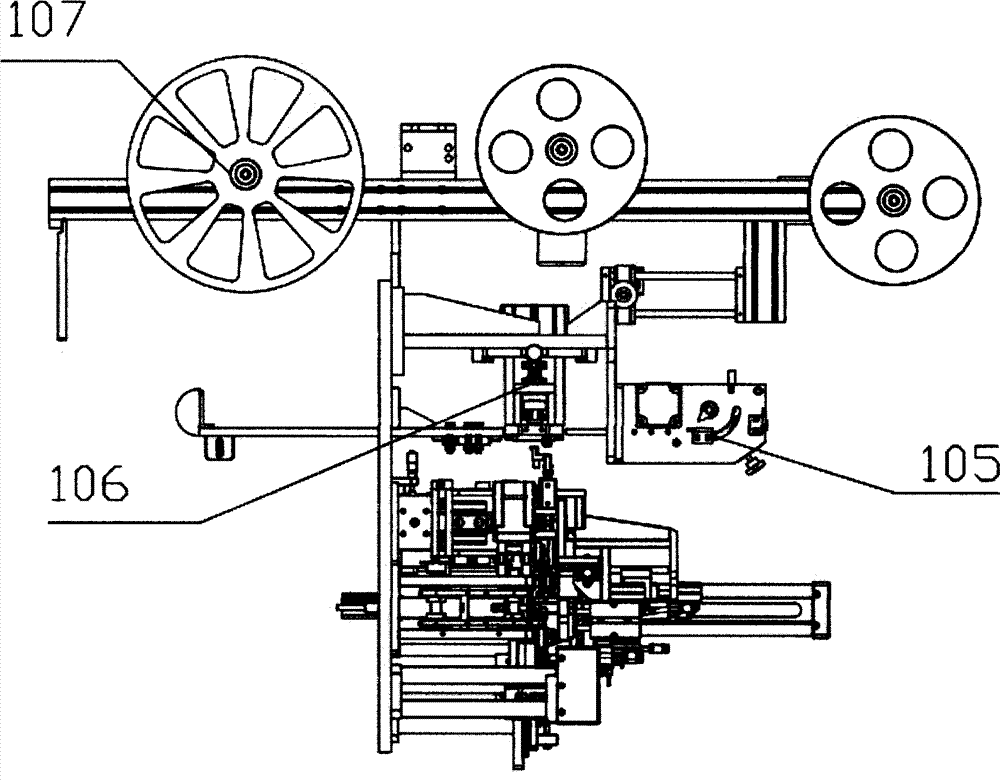

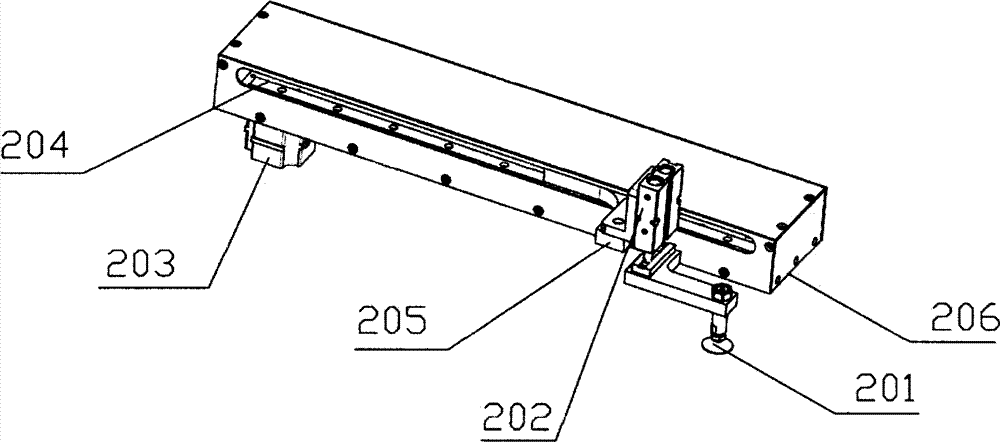

InactiveCN103192188ARealize automatic packagingRealize automatic card issuance operationWelding/cutting auxillary devicesAuxillary welding devicesButt weldingEngineering

The invention discloses a packaging machine and a packaging method for a dual-interface card. The packaging machine comprises a card-in carrying arm, a Y-direction antenna correction group, a chip turning group, an antenna correction butt-welding group, a charge coupled device (CCD) detection group, a chip push-over group, a first non-contact detection group, a correction spot-welding group, a first hot-welding group, a second hot-welding group, a cold-welding group, a contact detection group, a second non-contact detection group and a cartridge group. By adoption of the scheme, the packaging machine packages a chip of the dual-interface card on the dual-interface card with an antenna selected mechanically or manually, achieves the technical effect of automatic packaging, and can be operated singly or operated by connecting with other equipment. During single operation, automatic card distribution operation and automatic packaging can be realized only by placing the card base with the selected antenna on a material-discharging conveying belt without manual operation, and the operation is flexible and convenient.

Owner:SHENZHEN FINESUN PRECISION MACHINERY & TECH CO LTD

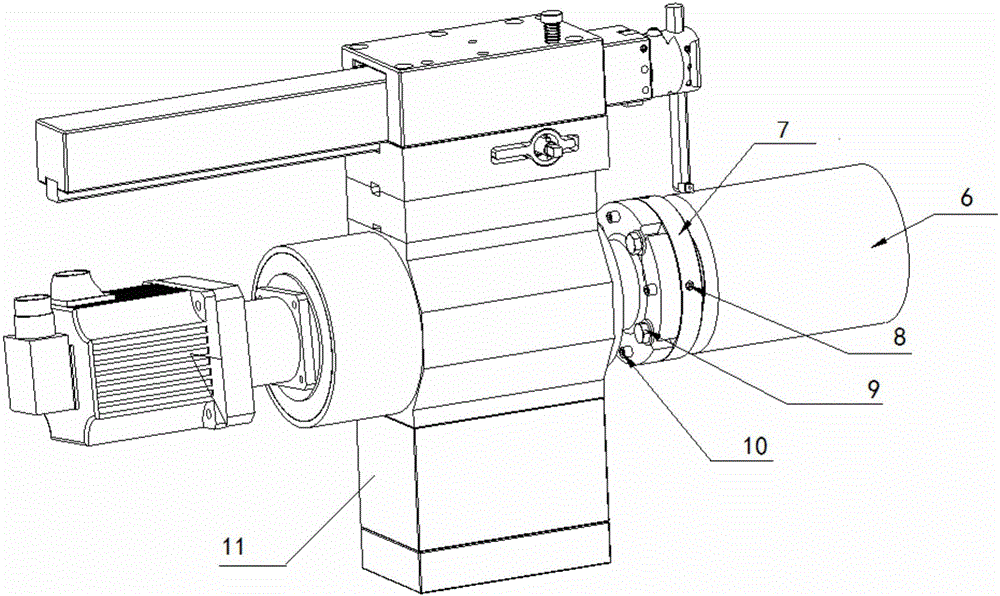

On-line repair technology for smooth shaft abrasion

The present invention relates to the field of blenders, and specifically relates to an on-line repair technology for smooth shaft abrasion of a blender. The repair technology comprises the following steps of (1) determining a repair scheme according to an abrasion degree of a smooth journal working surface of the blender during an operation process with an outer sealing ring, and inspection and confirmation of surface cleaning, abrasion loss, surface defects, shaft size precision and runout; (2) maintaining an abrasion part, determining materials for smoothing and repairing, and ensuring matching of corrosion resistance and mechanical properties of a repair region and a substrate; (3) machining the abrasion part after welding is performed, namely performing machining by using an axle end lathe after the welding is performed; and (4) performing a color nondestructive test on the repair part. By utilization of a high-precision pulse cold welding technology, the repaired binding part is more abrasion-resistant than the original substrate.

Owner:浙江翰德圣智能再制造技术有限公司

Heterogeneous cold repair welding process for online repairing crack of plug valve of main steam pipeline

The invention discloses a heterogeneous cold repair welding process for online repairing a crack of a plug valve of a main steam pipeline, and particularly relates to the technical field of pipeline repair welding. The process includes the six steps of crack trend and depth judgment, crack pre-treatment, local preheating, welding, postweld treatment and welding detection. An angular grinder is used for grinding a welding repair U-type groove towards the deep position of the inner wall along the crack, the surface of a valve body around the crack is ground to serve as a repair welding region, apriming coat is subjected to welding deposition, and the repair welding region is evenly welded in a welding manner of priming coat and weld bead filling repair welding. The depth of the crack is judged, the trend and the length of the crack are comprehensively considered, the proper repair welding process is selected, a high-chromium high-nickel nickel-based welding material is selected by a cold welding method for repair, the course of the welding process is simple, the repair speed is high, the comprehensive cost is low, the crack is pre-treated, welding flux adhesion is convenient, the priming coat and the weld bead filling repair welding process is adopted, the welding quality is improved, and it is guaranteed that the pipeline is used under high-temperature high-strength working conditions.

Owner:史海燕

Platy heat pipe and processing technology thereof

InactiveCN102506597AImprove structural strengthWith ultra-thinSolar heating energyIndirect heat exchangersTrunk structureEngineering

The invention provides a platy heat pipe, comprising a platy heat pipe frame, wherein the platy heat pipe frame is internally provided with a microporous pipe trunk structure which is formed by a group of microporous pipes, side walls of the microporous pipes are connected to mutually enhance the strength of each microporous pipe, each microporous pipe is filled with a working medium with a phase inversion heat exchange effect, two ends of the platy heat pipe are sealed, and at least one end is provided with a gradually contractive sealing belt formed by cold welding. The platy heat pipe provided by the invention has the characteristics of high strength, super thinness, high efficiency and high heat transportation volume and can substitute an oscillation heat pipe and a common heat pipe.

Owner:赵耀华

Welding process for repairing crack of ball milling iron casting

A welding process for repairing cracks in ball-milled iron castings of the present invention includes: (1) cutting a beveled U-shaped welding bevel along the cracks, then carburizing and polishing the inner surface of the beveled bevel and vulcanized layer, and cleaning the bevel The bottom is then ground and ground into a reverse arch; (2) Bolts are pre-embedded at the bottom of the U-shaped welding groove on the bevel; The manual electrode arc cold welding method of high-quality weld metal; (4) The surface of the weld meat is polished and smooth. This welding process is not easy to crack after repairing the spare parts made of ductile iron, which can effectively improve the service life of the original spare parts.

Owner:JINCHUAN GROUP LIMITED

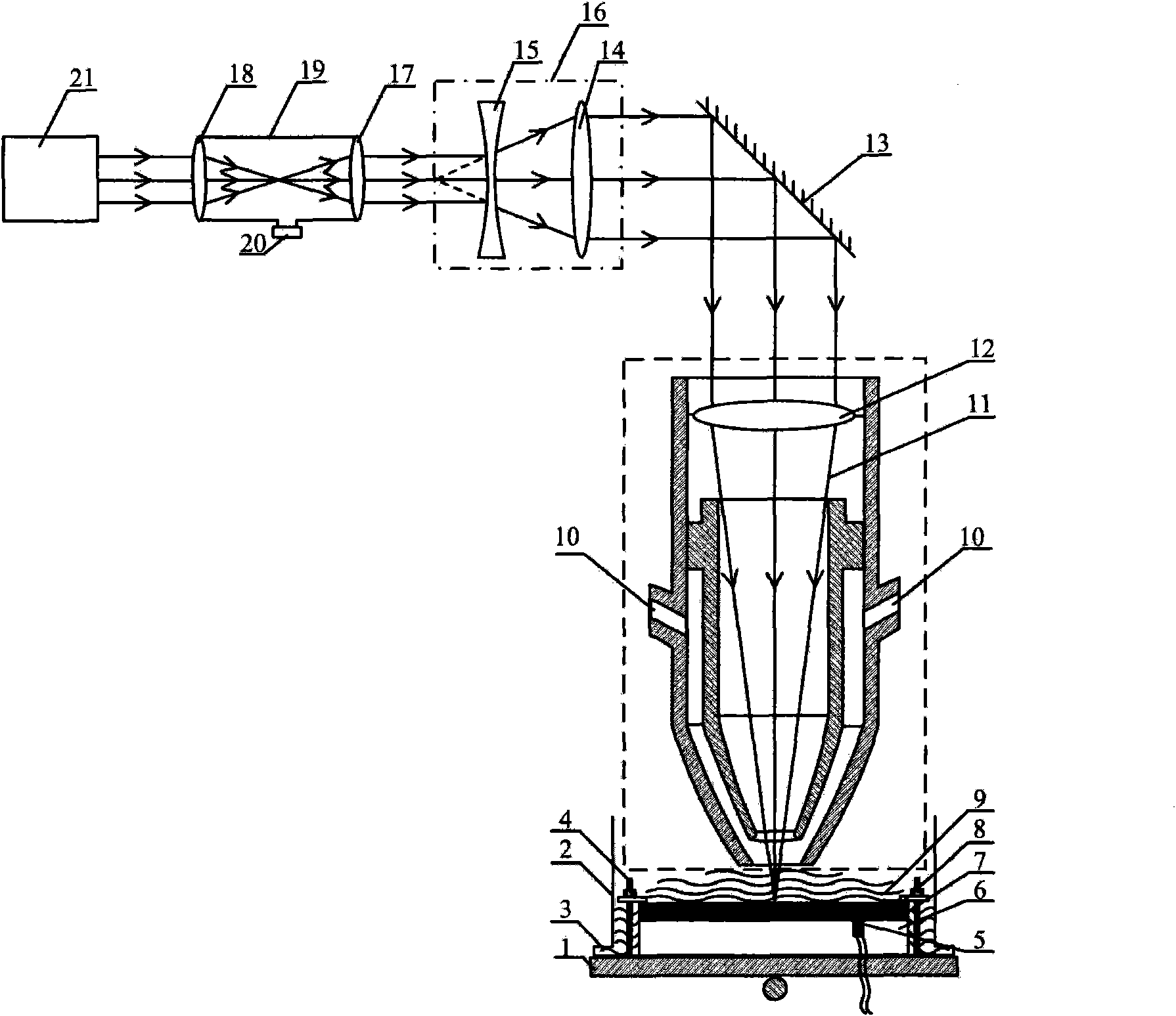

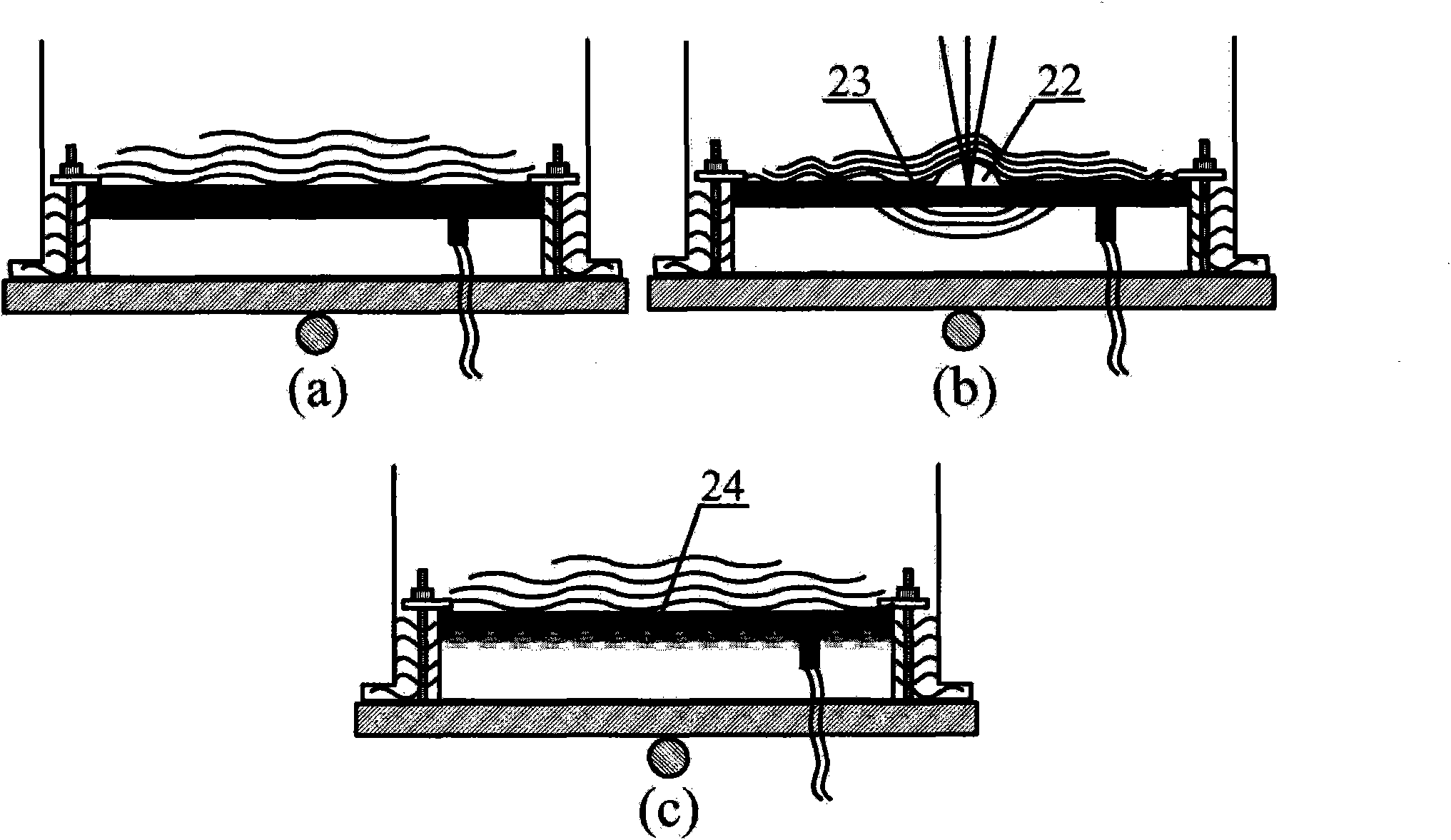

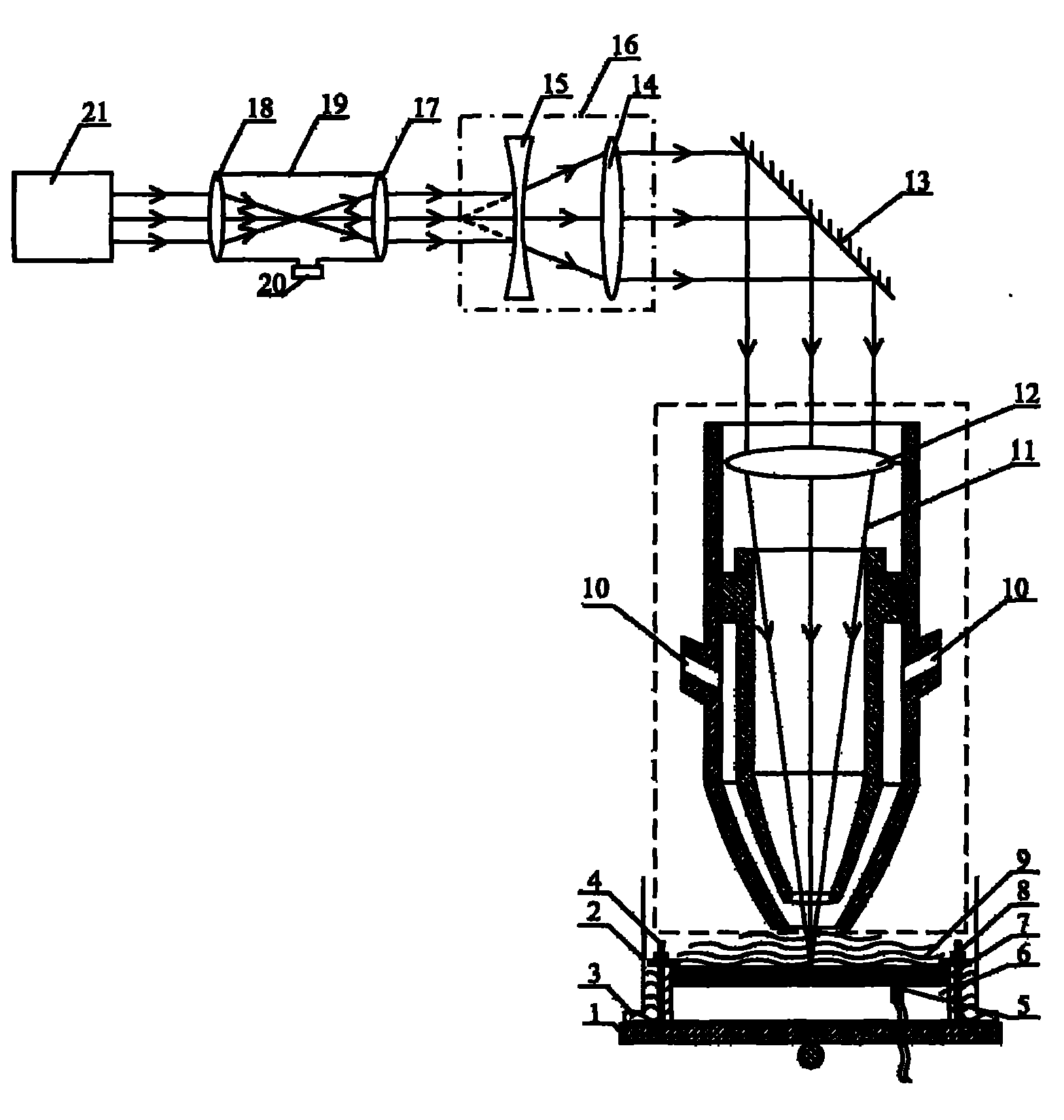

Large-area laser impact spot welding method and device based on nano-particle reinforcement

InactiveCN104227220AImprove mechanical propertiesHigh modulus of elasticityLaser beam welding apparatusNon-electric welding apparatusMicro nanoHeat-affected zone

The invention provides a large-area laser impact spot welding method and device based on nano-particle reinforcement and relates to the field of high-speed impact welding. The large-area laser impact spot welding method based on nano-particle reinforcement is characterized in that a high-energy short-pulse laser emits pulse laser light, a laser light beam forms a light spot through lens focusing to penetrate through a transparent PC board and irradiate a black paint layer, high-temperature and high-pressure plasmas are produced to inductively produce impact waves to drive a flyer to be locally bent and deformed and collide with a workpiece at high speed, micro-nano particles on the surface layer of the workpiece are directly implanted into a welding interface and thus spot cold welding of the flyer and the workpiece is realized. By implanting the micro-nano particles into the welding interface of the flyer and the workpiece during laser impact spot welding, heat affected zones and intermetallic compounds can be effectively prevented from being produced, the mechanical property of welding interface materials is obviously improved and the connecting strength of welded pieces is improved. In addition, the welding spot dimension can be accurately controlled, the device is simple and the method and the device are applicable to large-area spot welding of plates of different specifications.

Owner:JIANGSU UNIV

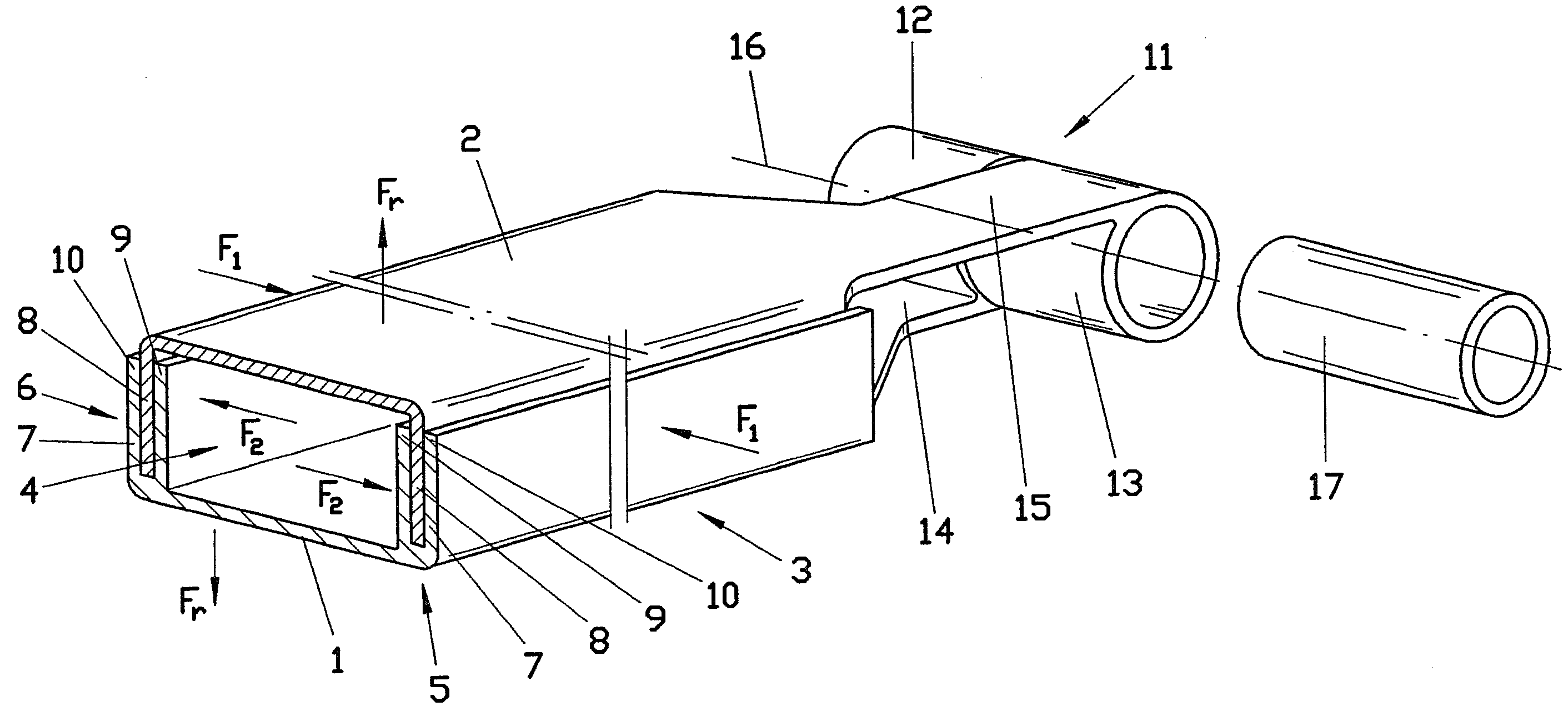

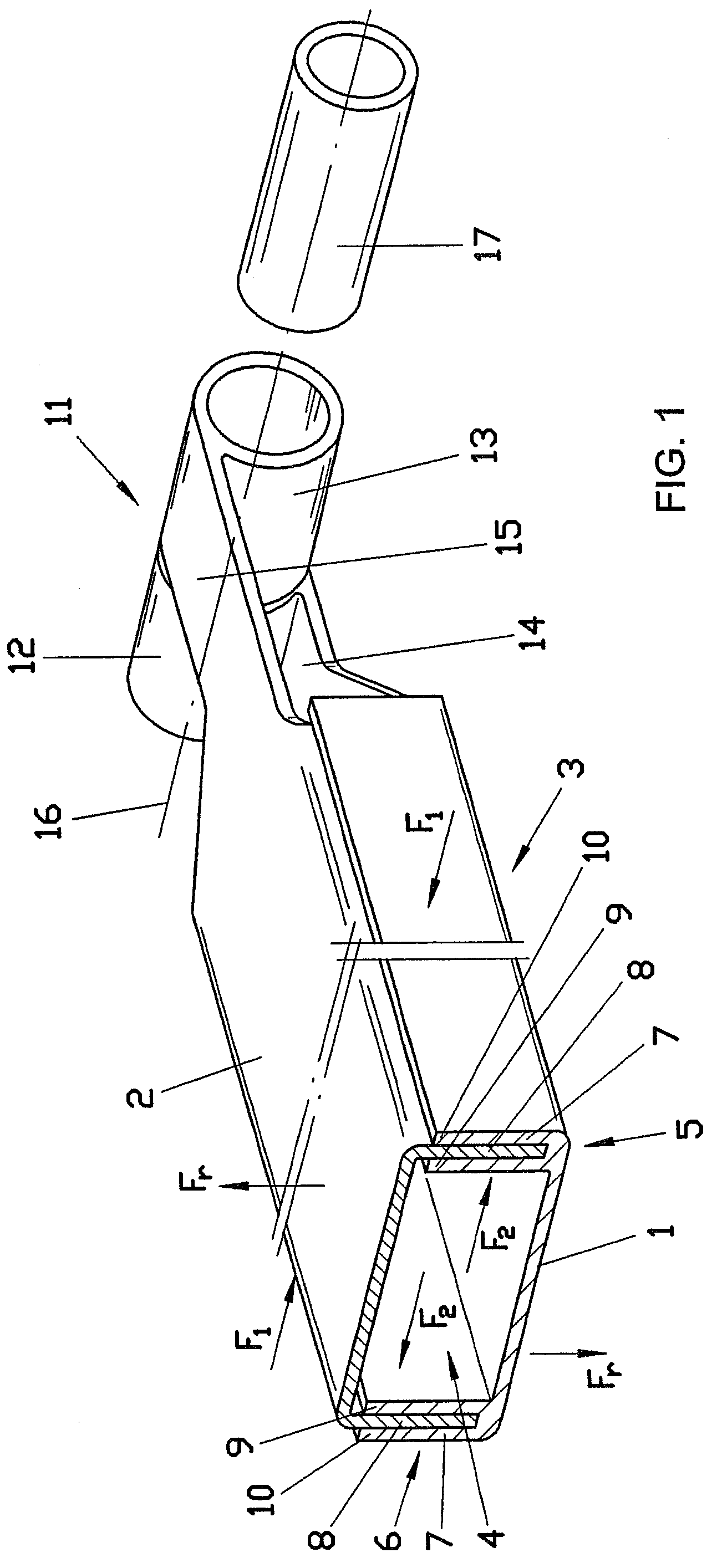

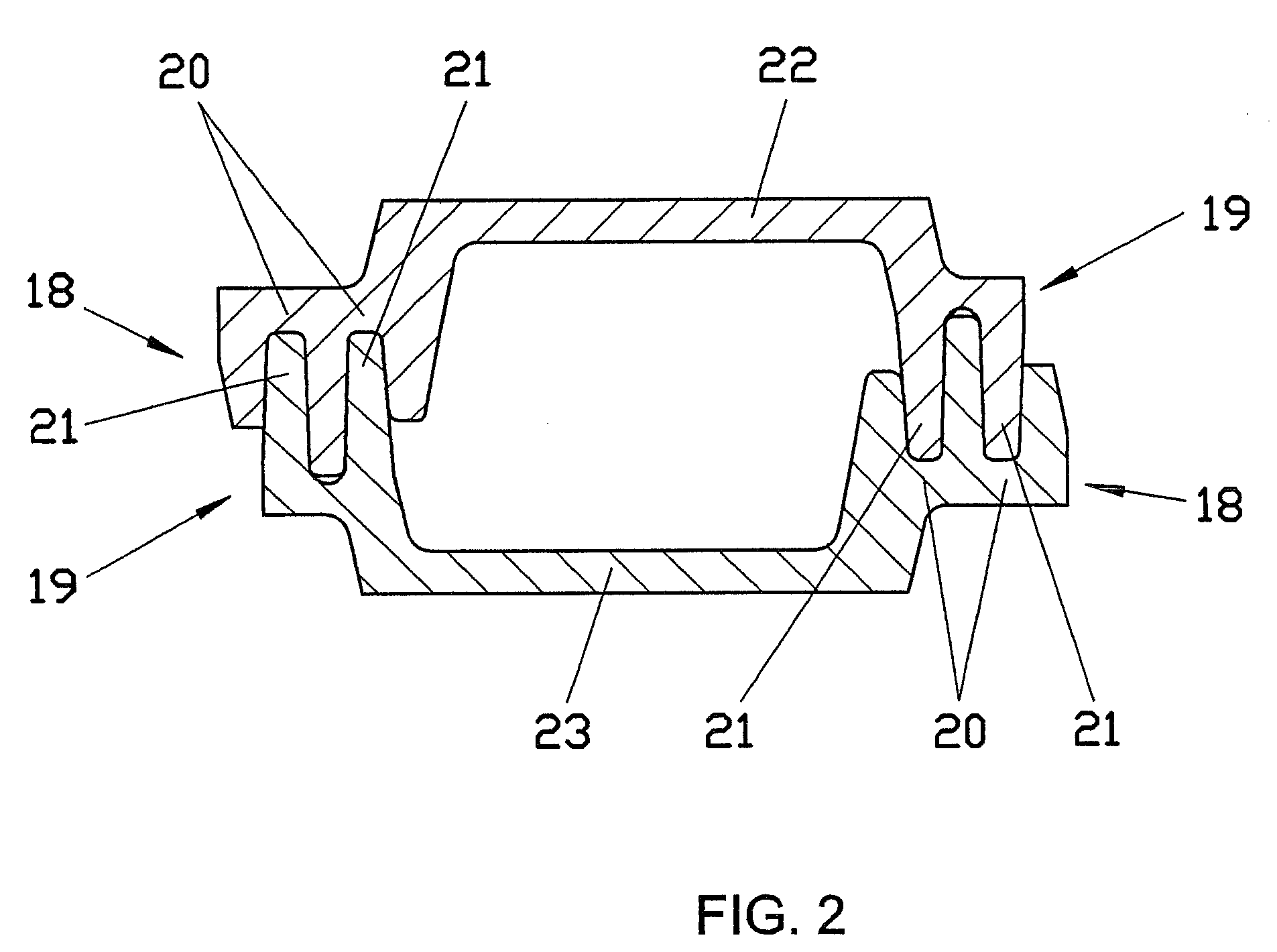

Hollow body component

InactiveUS7722280B2Low costMeet the requirementsVehicle seatsUnderstructuresContact pressureDie casting

A hollow-bodied component, which includes at least two die-cast shell elements (1, 2), is suitable in particular for use as a steering component in motor vehicle running-gear assemblies. The hollow-bodied component has a connection zone (5, 6, 18, 19) configured on the shell elements (1, 2) to be interconnected. One connection zone (5) has one first contact area (7) with an essentially U-shaped cross-section that is located on the respective shell element (1) and the other connection zone has at least one strut-type second contact area (8) that engages in the space in the U-shaped first contact area (7) and that is located on the respective other shell element (2). The connection zones (5, 6, 18, 19) are joined in a force fit in a cold welding process that uses a contact pressure (F1, F2), whose value is a multiple of the separating force components (Fr) that act on the connection zones (5, 6, 18, 19) during operation. A method is provided for producing the component.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com