Patents

Literature

4215 results about "Resistance wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistance wire is wire intended for making electrical resistors (which are used to control the amount of current in a circuit). It is better if the alloy used has a high resistivity, since a shorter wire can then be used. In many situations, the stability of the resistor is of primary importance, and thus the alloy's temperature coefficient of resistivity and corrosion resistance play a large part in material selection.

Electric heating tube made of hexagonal boron nitride and mixed heat conducting material thereof

ActiveCN101854750ALong life and high qualityImprove insulation performanceChemical industryHeat-exchange elementsHexagonal boron nitrideHeat conducting

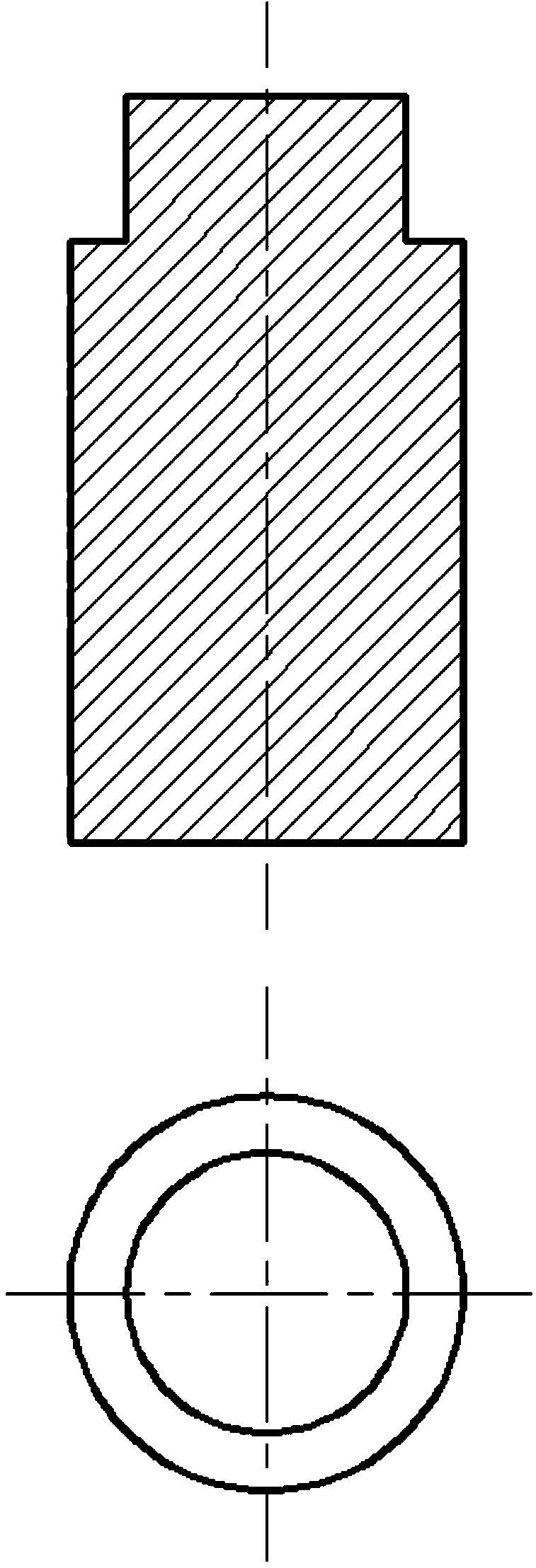

The invention belongs to the technical field of electric heating tube manufacture, and relates to an electric heating tube using hexagonal boron nitride or mixture of hexagonal boron nitride and magnesium oxide as a heat conducting material, in particular to a mixed heat conducting material for a novel electric heating tube. A main body structure comprises a metal tube body, a mixed filler, a resistance wire and accessories comprising a fixed plate, porcelain beads, sealant, a plastic plug, a leading-out bar, a terminal electrodes and screws; a cavity structure of the metal tube body is invariantly bent into a circular, elliptical or spiral geometric structure; parallel structures at two end sections of the metal tube body are fixed on the fixed plate in an interval penetration mode, and fixed screws are arranged at two ends of the fixed plate; and the resistance wire is fixed and electrically connected on the central axis of the cavity of the metal tube body and parallel to two end points on two sides of the tube wall, and the mixed filler is filled between the resistance wire and the side wall of the metal tube body. The electric heating tube has the advantages of high stability and heat conducting efficiency, high-temperature softening prevention in inert gas, long service life, high quality, good insulating property, low dielectric constant and dielectric loss, and safe use.

Owner:QINGDAO EASYTOUSE ELECTRONICS

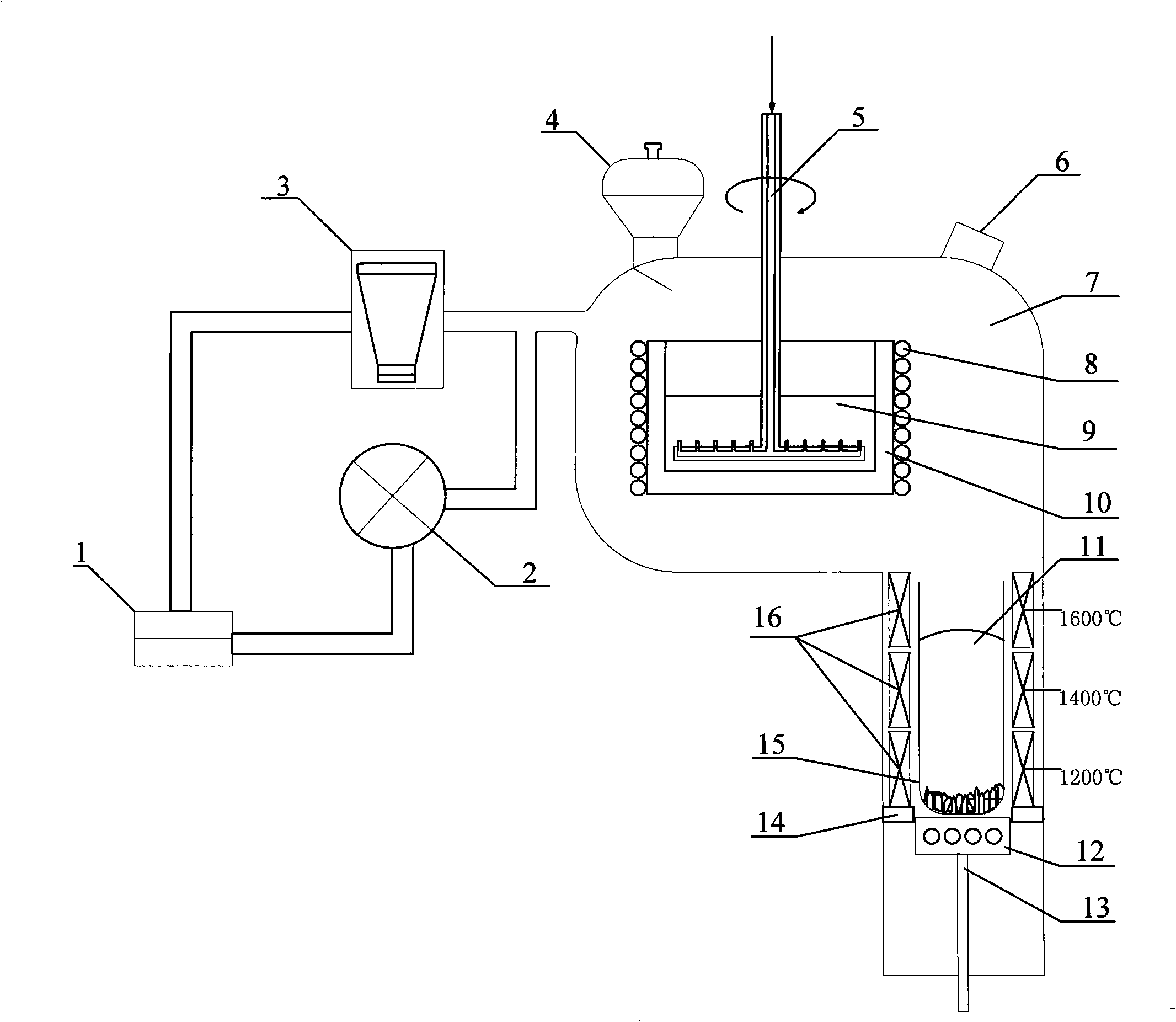

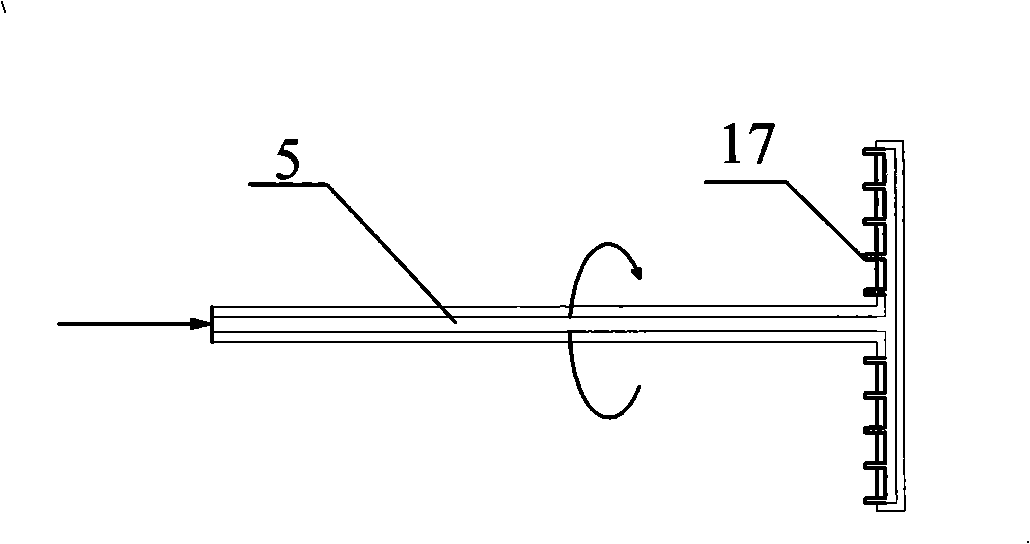

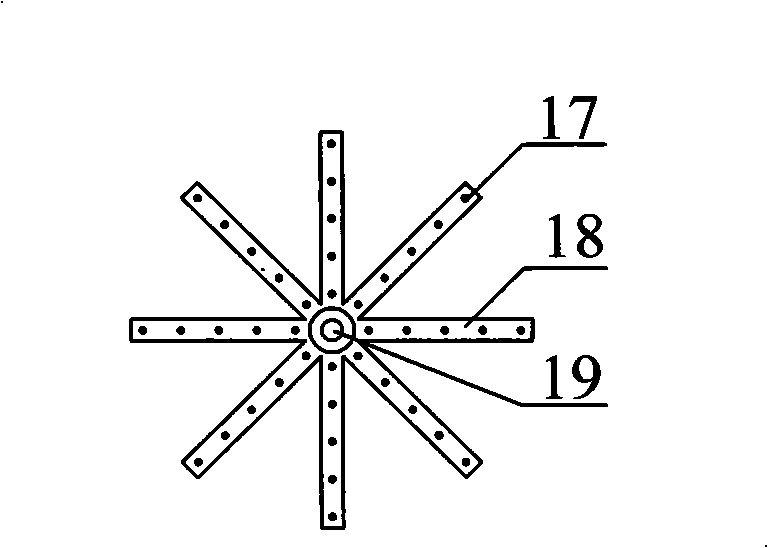

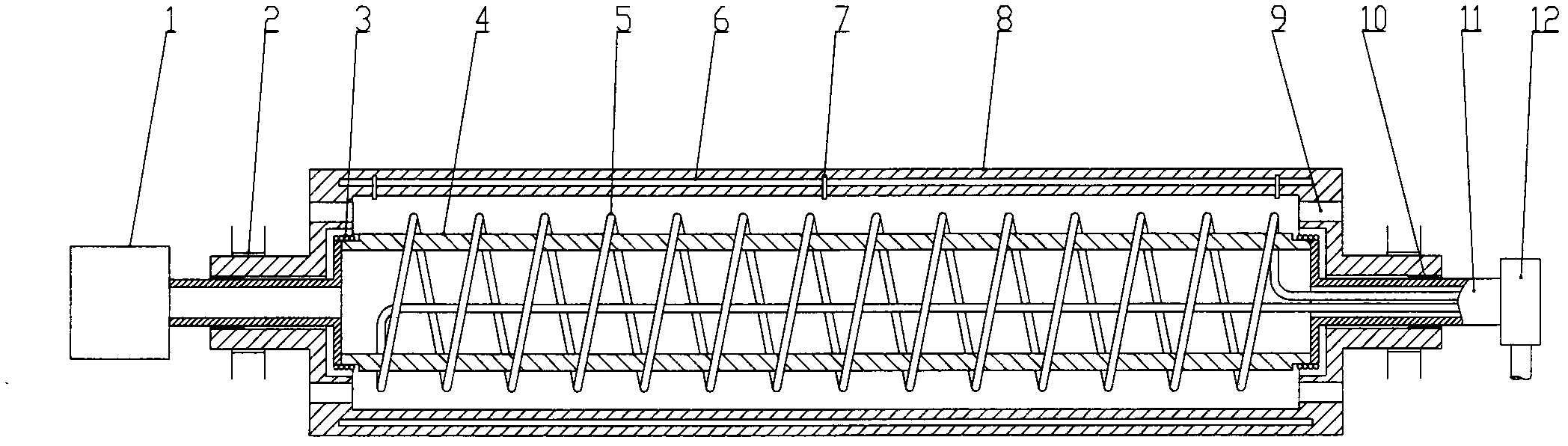

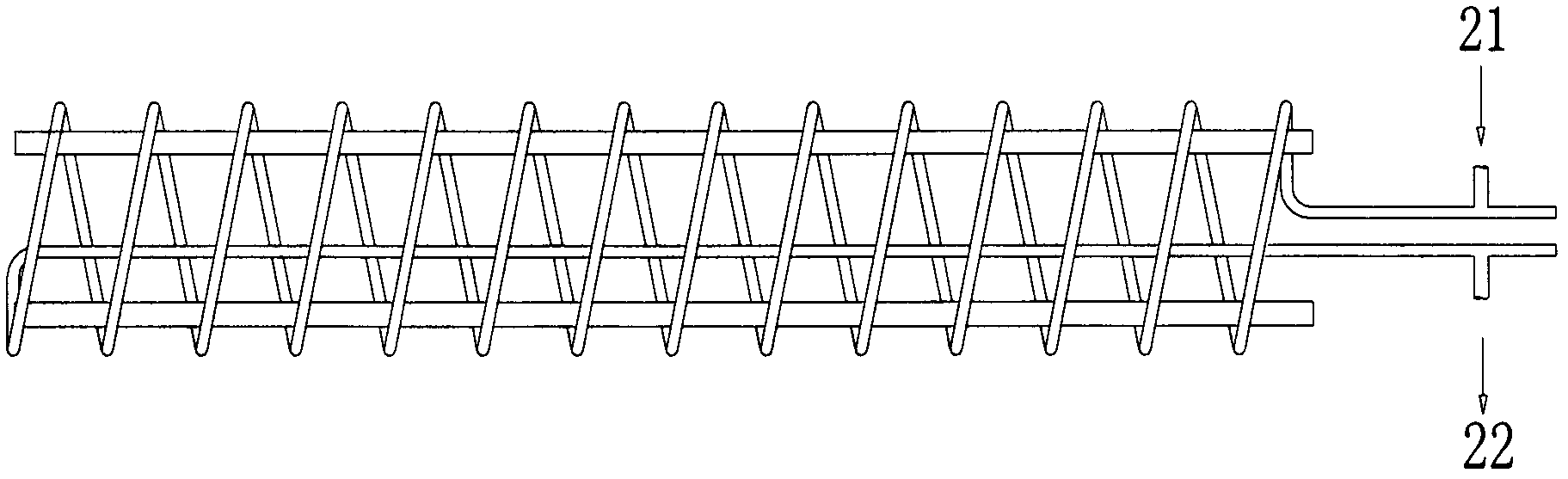

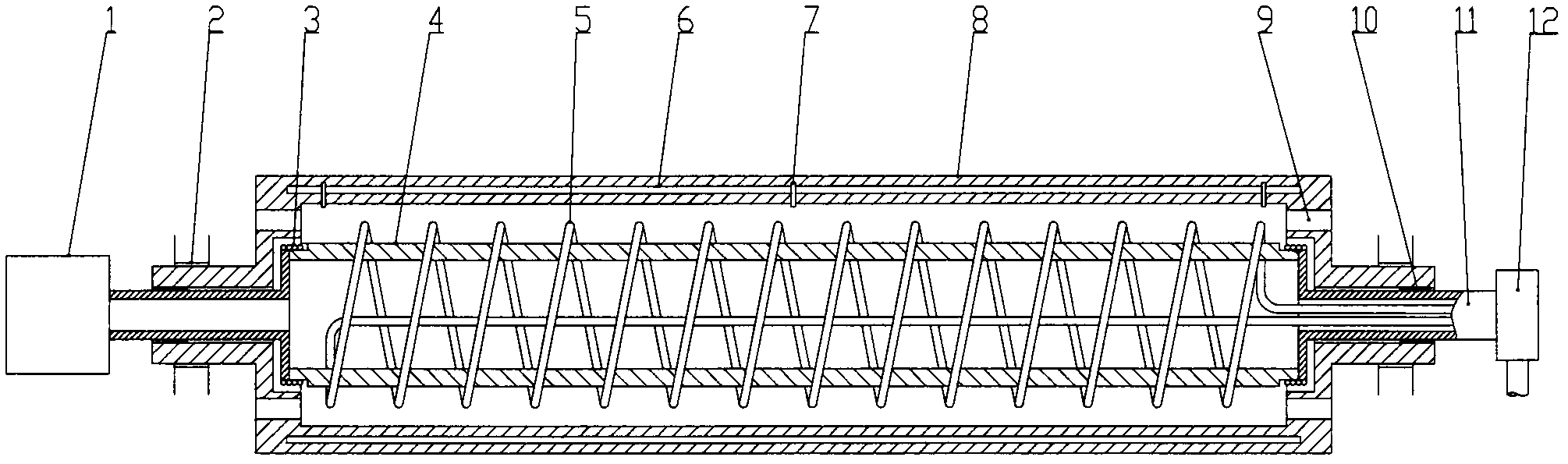

Purification apparatus and method for solar energy level polysilicon

Disclosed are a purification device as well as a purification method of solar-grade polysilicon, relating to a polysilicon, which provides a purification device and a purification method of solar-grade polysilicon characterized by low cost, high purity, simple process, easy operation and suitability for large-scale production. The purification device is equipped with a vacuum system, a melting system and a directional solidification system; wherein the vacuum system is provided with a mechanical rotary vane pump, a lobed element pump and an oil diffusion pump, and the melting system is provided with a vacuum chamber, a secondary feeder, an observation window, a rotary ventilation device which can be raised and lowered, an induction coil and a graphite crucible; and the directional solidification system is disposed at the lower part of the vacuum chamber and is equipped with an electric resistance-wire heating and holding furnace, a graphite mold, a holding furnace frame, a water-cooled copper tray and an elevating lever which can control speed. The metal silicon is treated by induction heating to be molten, the oxidizing gas is fed under conditions of low vacuum and high temperature to remove boron, and then under conditions of high temperature and high vacuum to remove phosphorus, and finally the molten silicon solution is poured into a directional mold to strictly conduct directional solidification to remove metal impurities.

Owner:XIAMEN UNIV

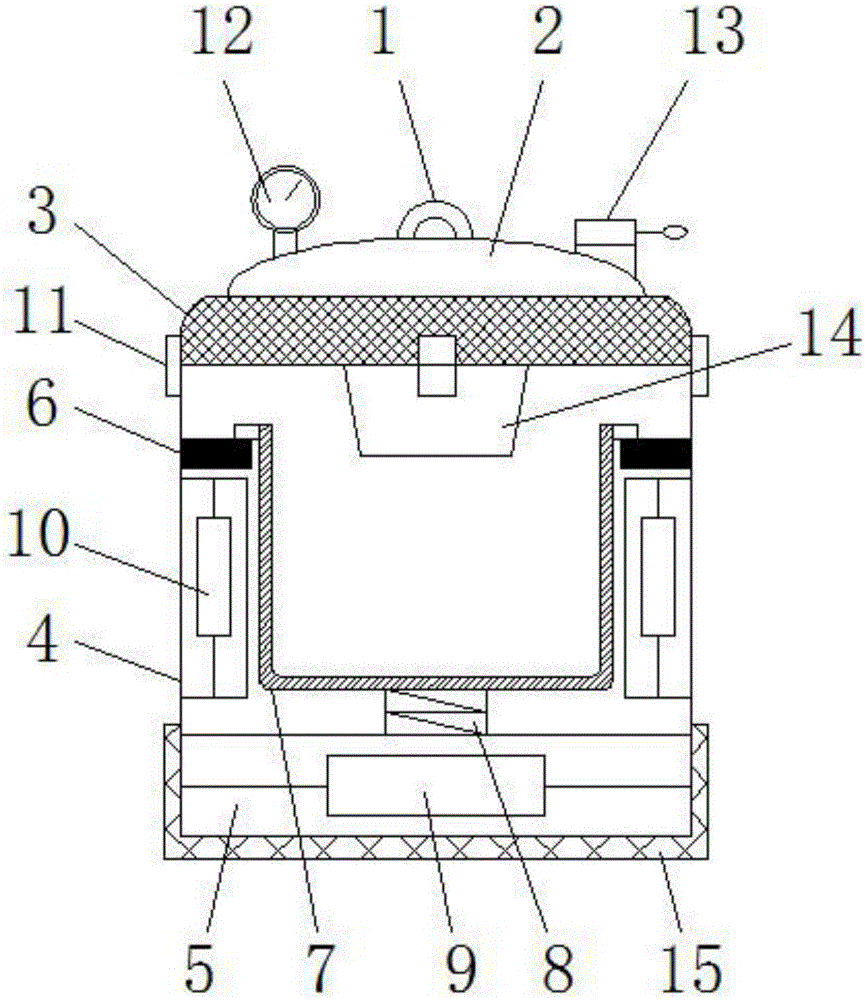

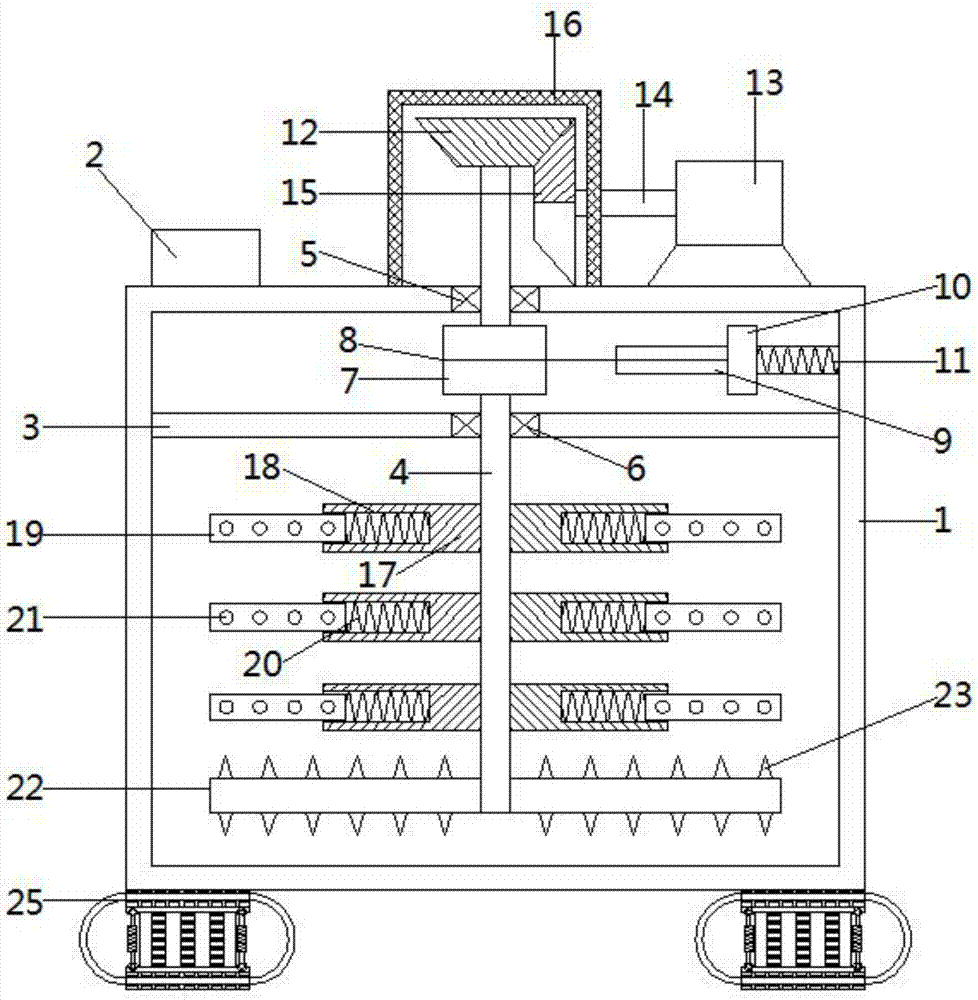

Multifunctional electric cooker with high heating efficiency

InactiveCN106264095AHigh thermal efficiencyReduce operating powerPressure-cookersResistance wireCooker

The invention discloses a multifunctional electric cooker with high heating efficiency. The multifunctional electric cooker with high heating efficiency comprises a handle, an upper top cover, a lower top cover, a pot body, a heating tank, a baffle, a liner, a spring pipe, a bottom heating resistance wire, side heating resistance wires, a safety buckle, a gas pressure meter, a gas pressure valve, a filtering bowl and a heat isolation shell, wherein the handle is connected with the lower top cover through the upper top cover, the lower top cover is connected with the heating tank through the pot body, the baffle is welded to the inner side of the pot body, the liner is arranged on the inner side of the baffle and connected with the heating tank through the spring pipe, the bottom heating resistance wire is arranged on the inner side of the heating tank, and the side heating resistance wires are arranged on the left side and the right side of the liner. The multifunctional electric cooker adopts symmetrical design, and the structure design is simple; by adoption of a three-face heating mode, heating efficiency is higher, the heating speed is higher, the electric cooker function and the pressure cooker function are integrated, the airtightness effect is good, the pneumatic control capacity is high, operating power is low, and the multifunctional electric cooker is excellent in performance and has high heating efficiency.

Owner:吕文统

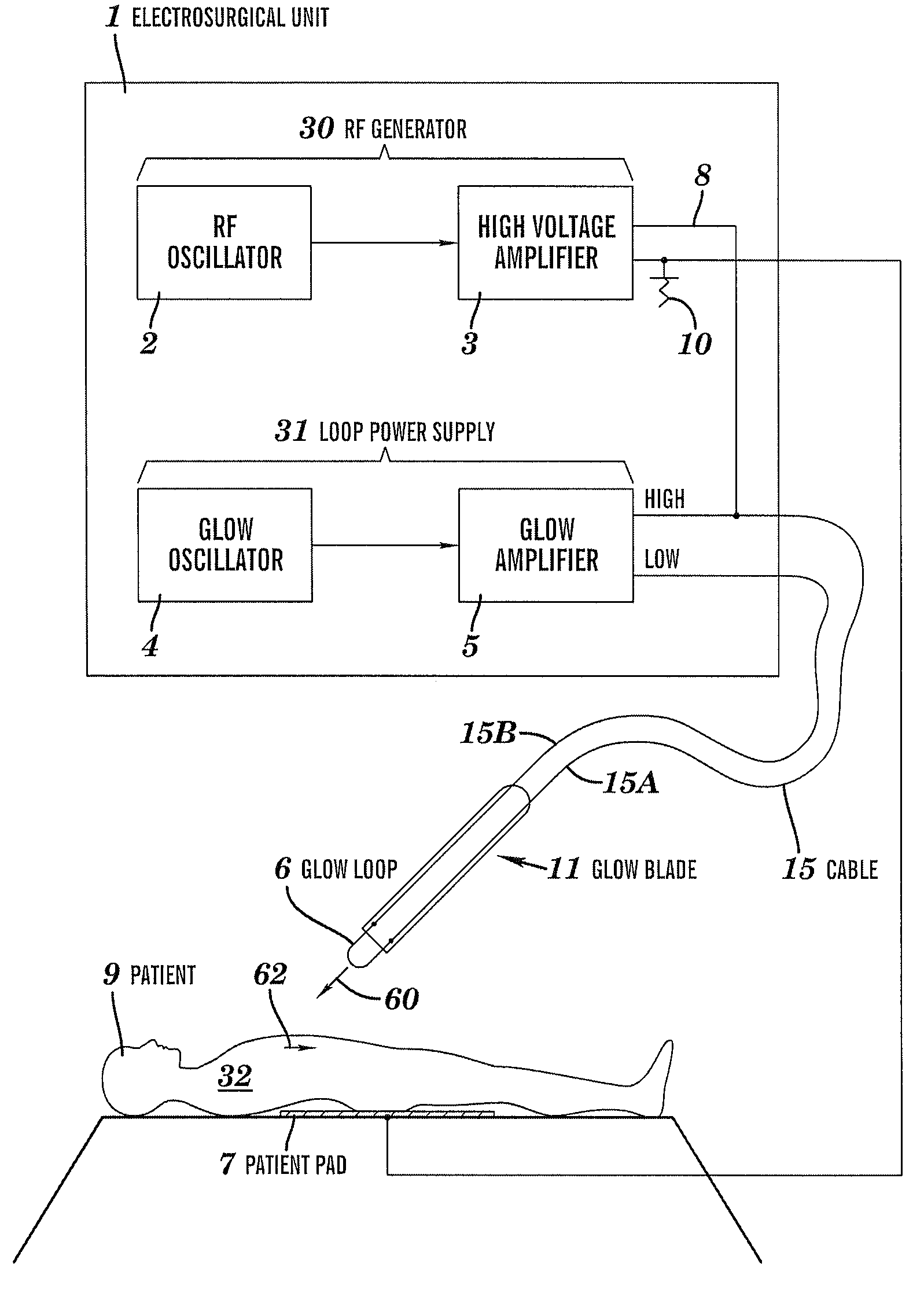

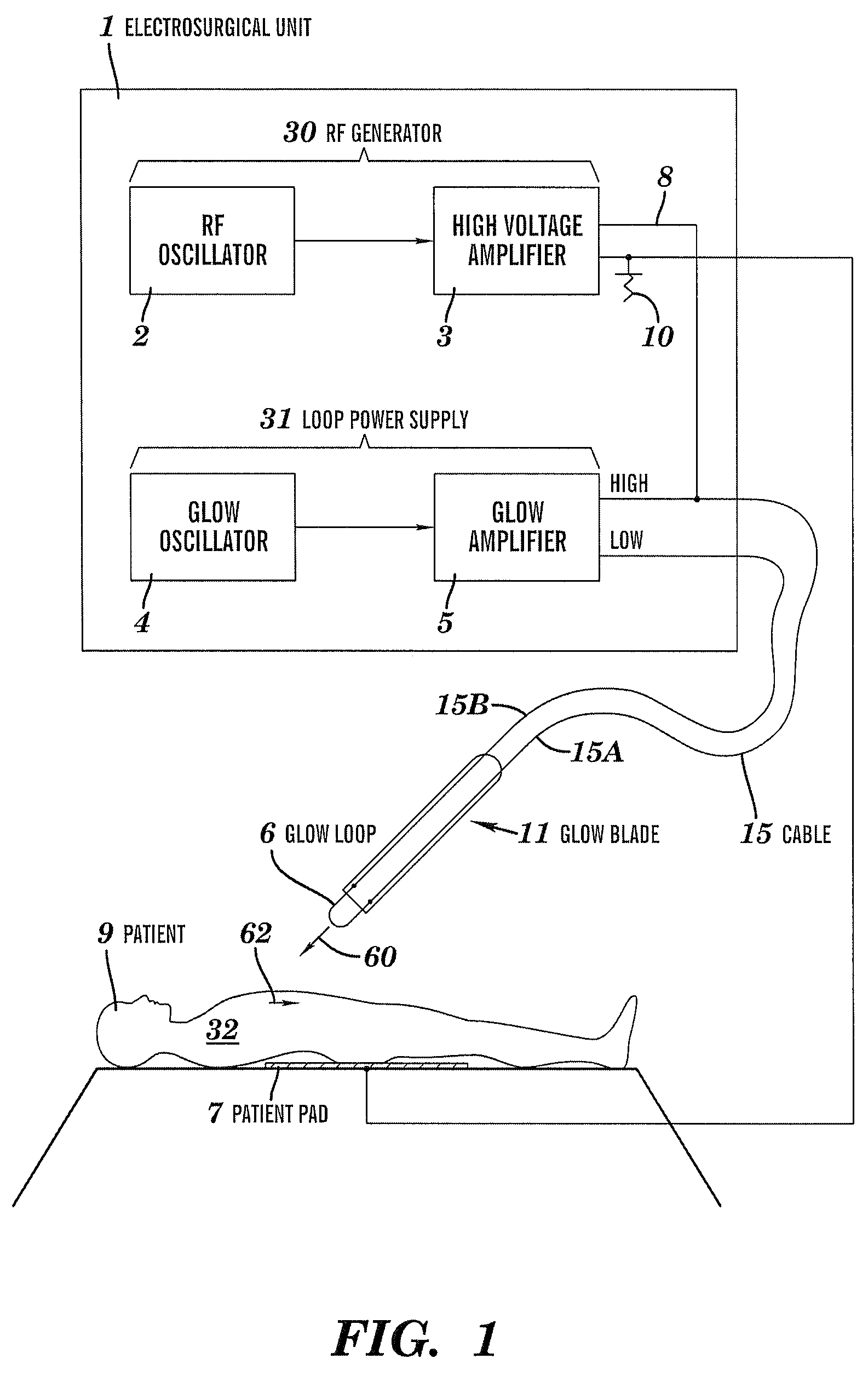

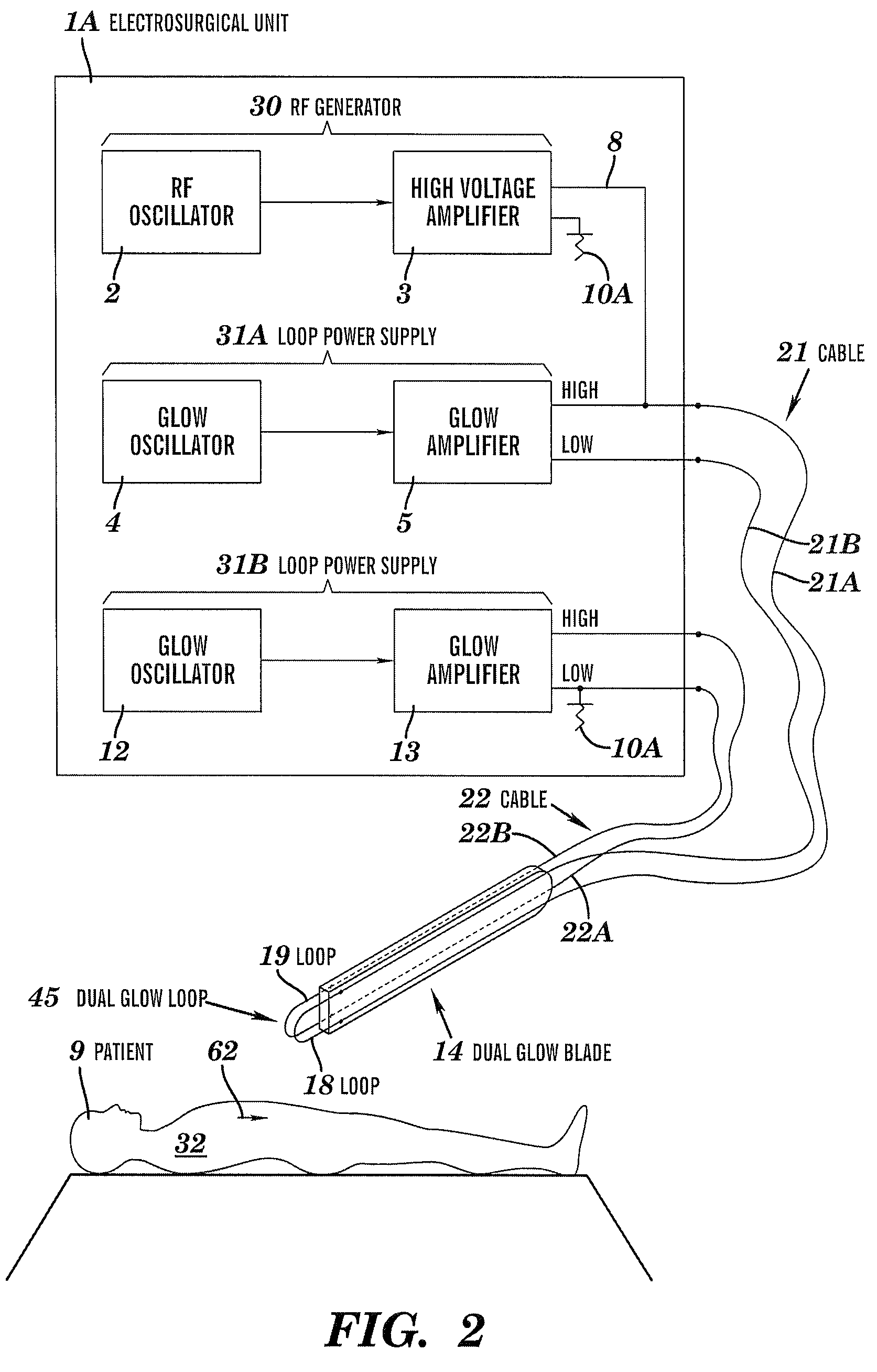

High efficiency, precision electrosurgical apparatus and method

An electrosurgical apparatus for cutting and / or coagulating living tissue, a method of forming the electrosurgical apparatus, and a method of using the electrosurgical apparatus. The cutting and / or coagulating living tissue is performed with one or two heated loops of resistance wire accompanied by sufficient electrical current across the living tissue to enable said cutting and / or coagulating to be performed. The electrosurgical apparatus may include: a glow blade having one or two glow loops of resistance wire; a radio frequency (RF) generator; and one or two voltage supplies configured to operate concurrently, while the one or two glow loops are heated to said glow, to supply both sufficient RF power and associated electrical current across the living tissue for cutting and / or coagulating the living tissue by the one or two glow loops. A first output of the RF generator is electrically coupled to the one or two glow loops.

Owner:OLYMPUS CORP

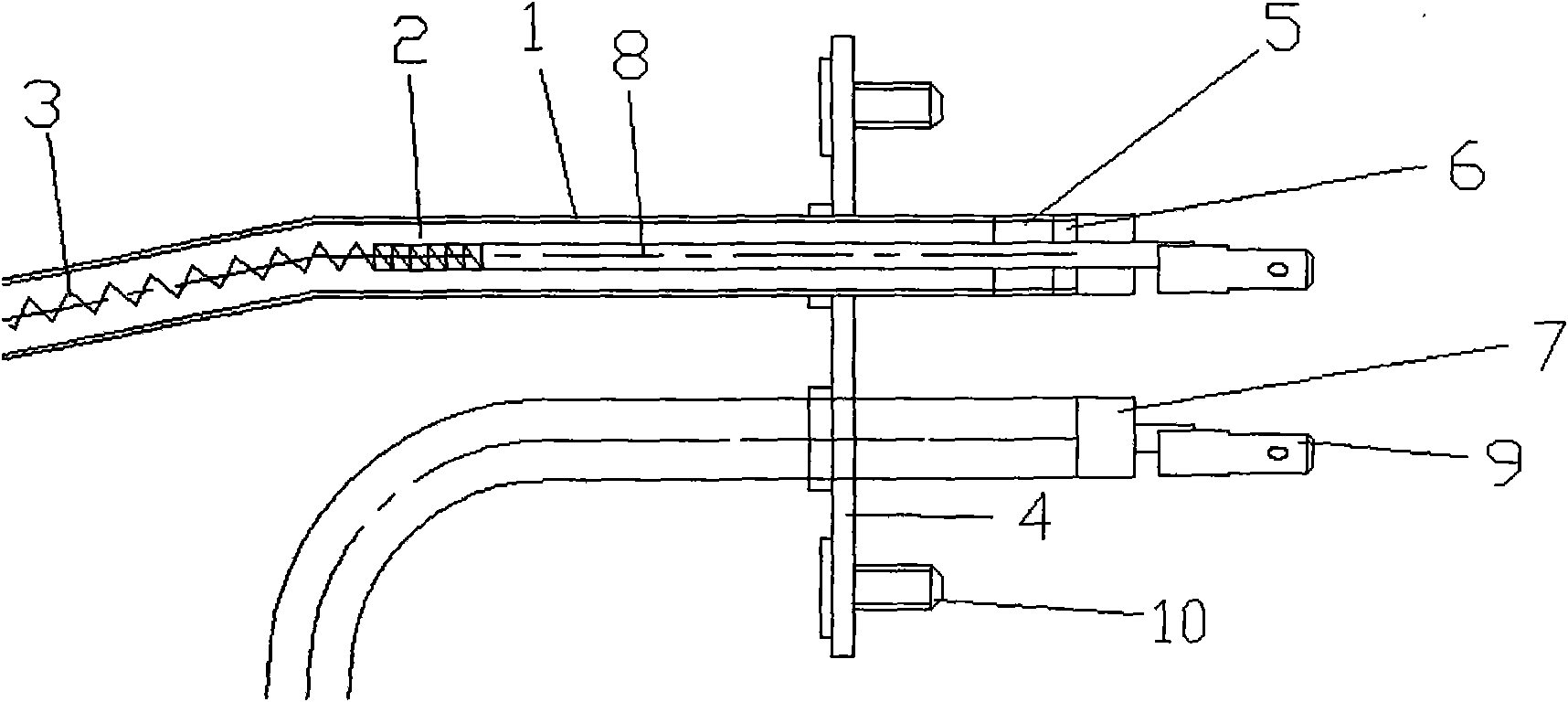

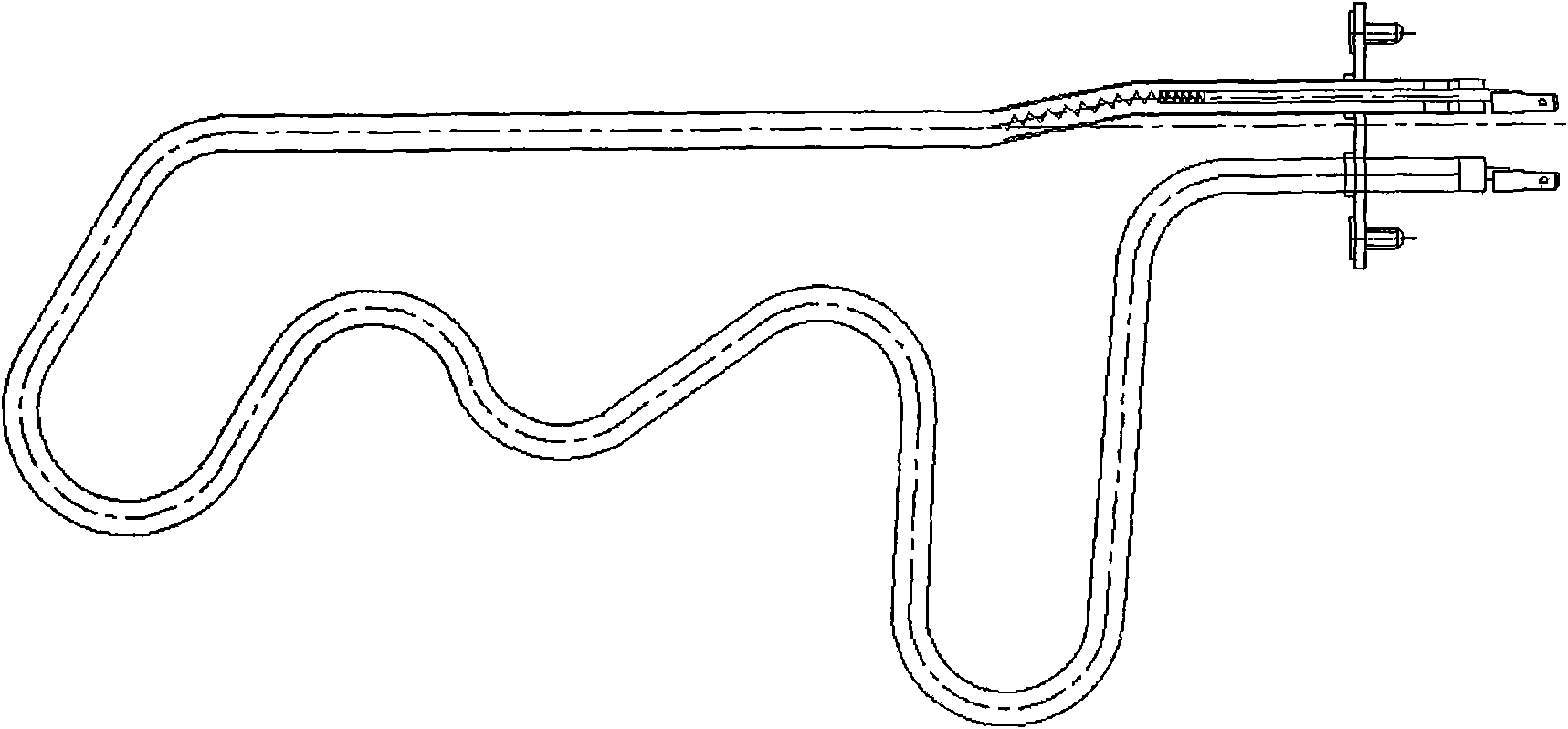

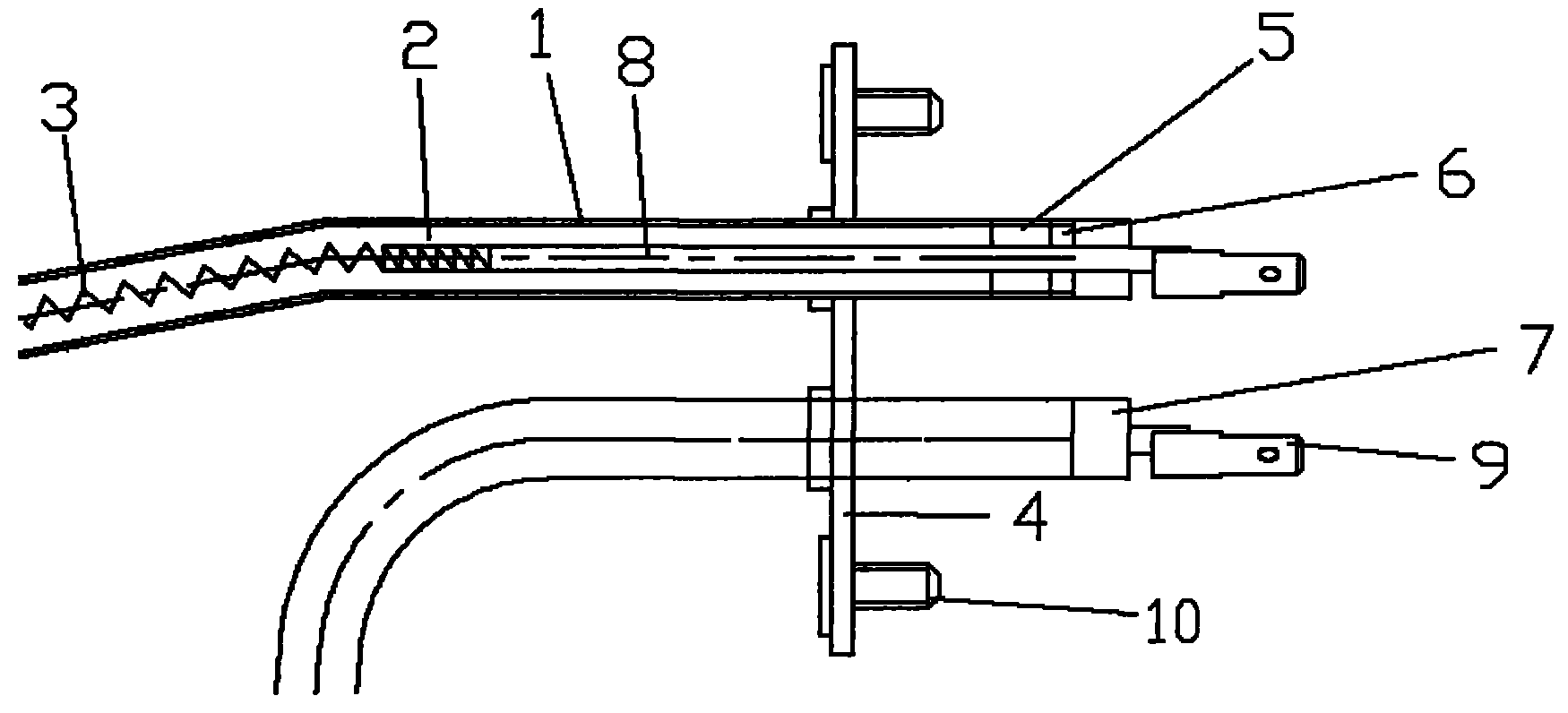

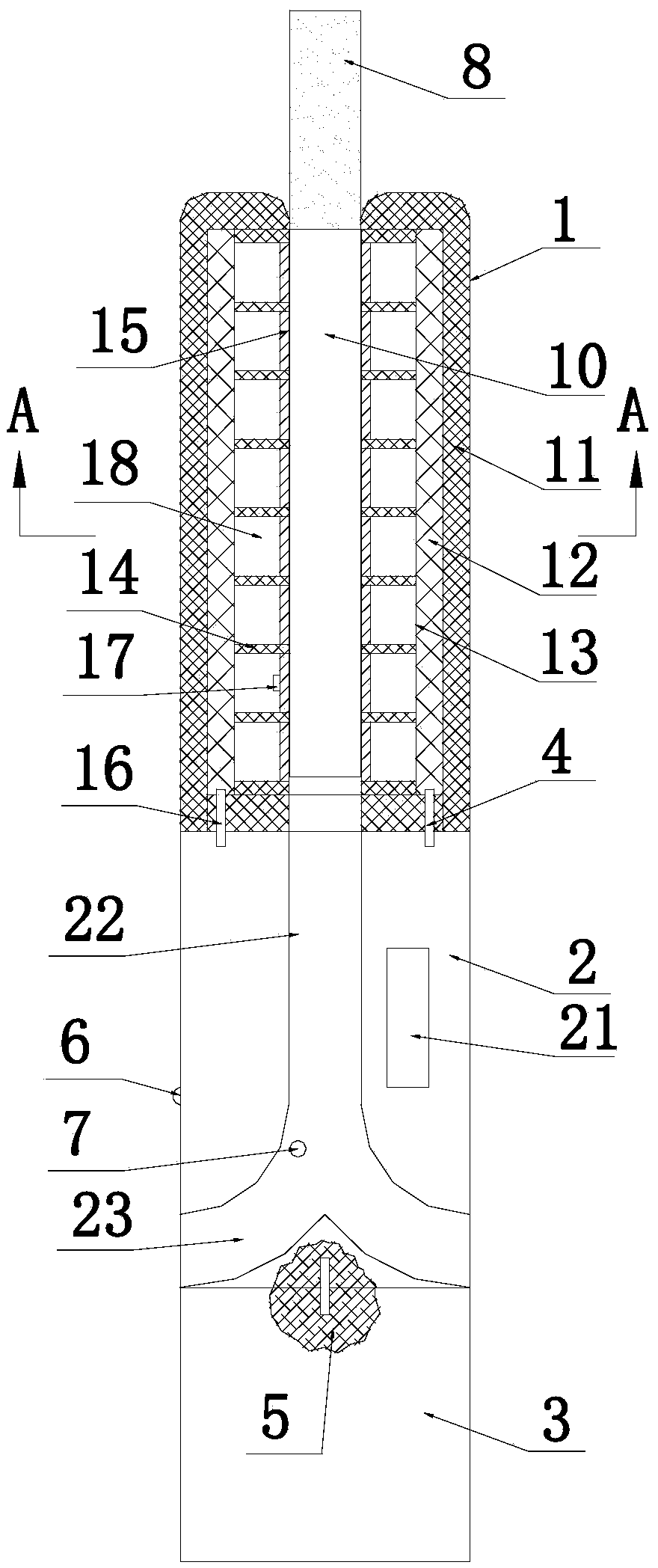

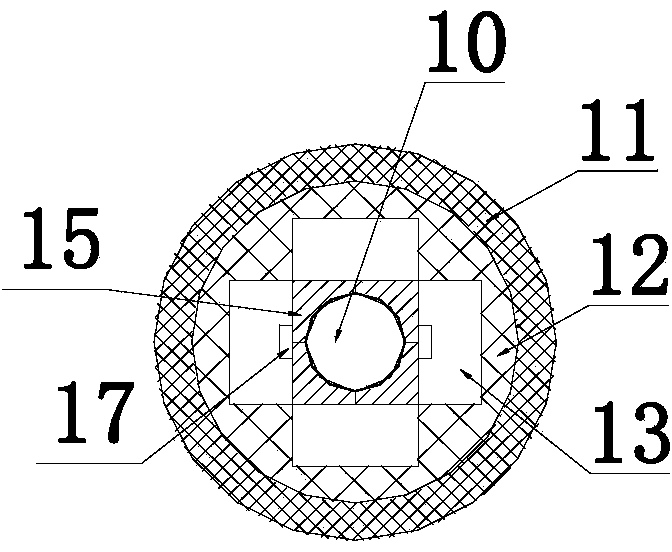

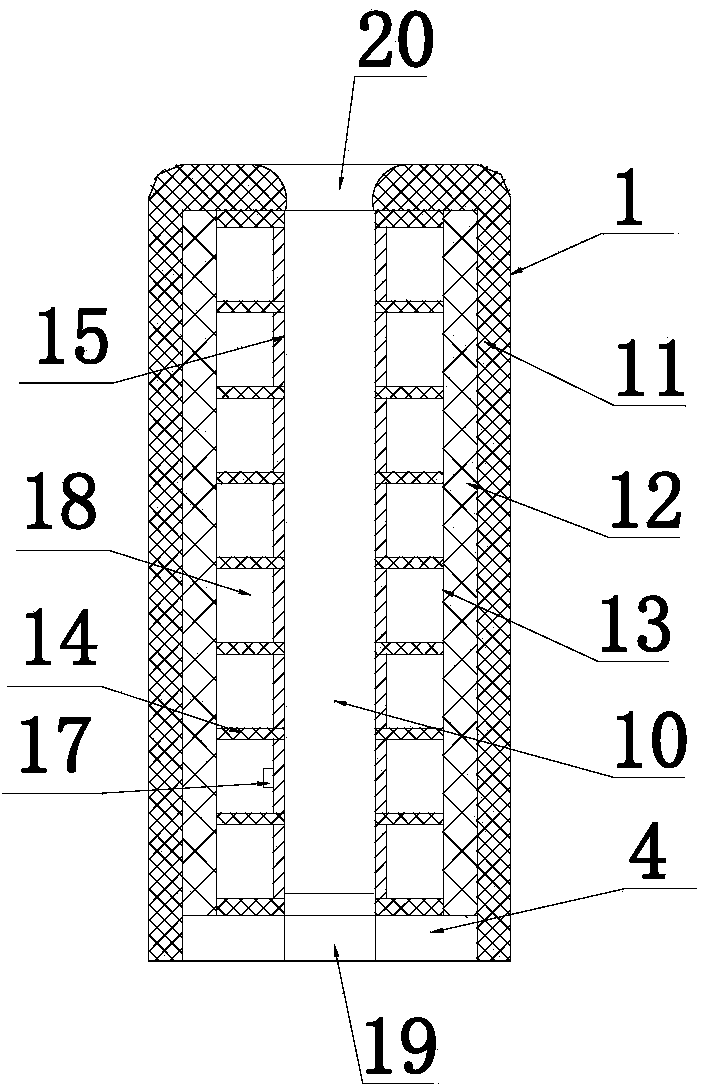

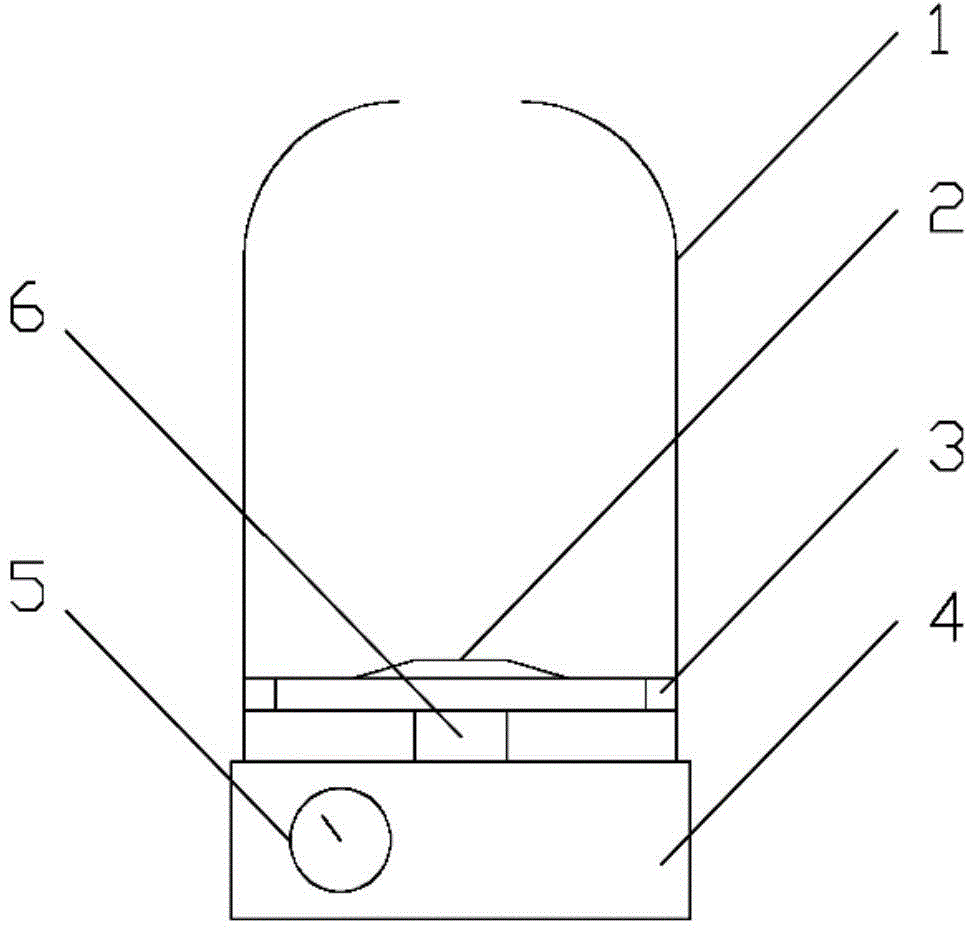

Resistance wire heating device for non-burning cigarettes

The invention relates to a resistance wire heating device for non-burning cigarettes. The device comprises an outer shell, an insulation jacket and a heater, a cigarette inlet allowing tobacco products to be inserted in is formed at the front end of the outer shell, the rear end of the outer shell is connected with an air inlet, the heater is arranged in the outer shell, and the insulation jacket is arranged between the heater and the outer shell. A resistance wire heating element is adopted as the heater and comprises a resistance wire and a ceramic heat-conducting sleeve, the resistance wire is arranged on the outer surface of the ceramic heat-conducting sleeve, a heating chamber for accommodating the tobacco products is arranged in the middle of the ceramic heat-conducting sleeve, the front end of the heating chamber is communicated with the cigarette inlet, and the rear end of the same is communicated with the air inlet. The resistance wire heating device has the advantages of high heat efficiency, constant-temperature heating, high temperature control precision, good stability and long service life.

Owner:CHINA TOBACCO ZHEJIANG IND

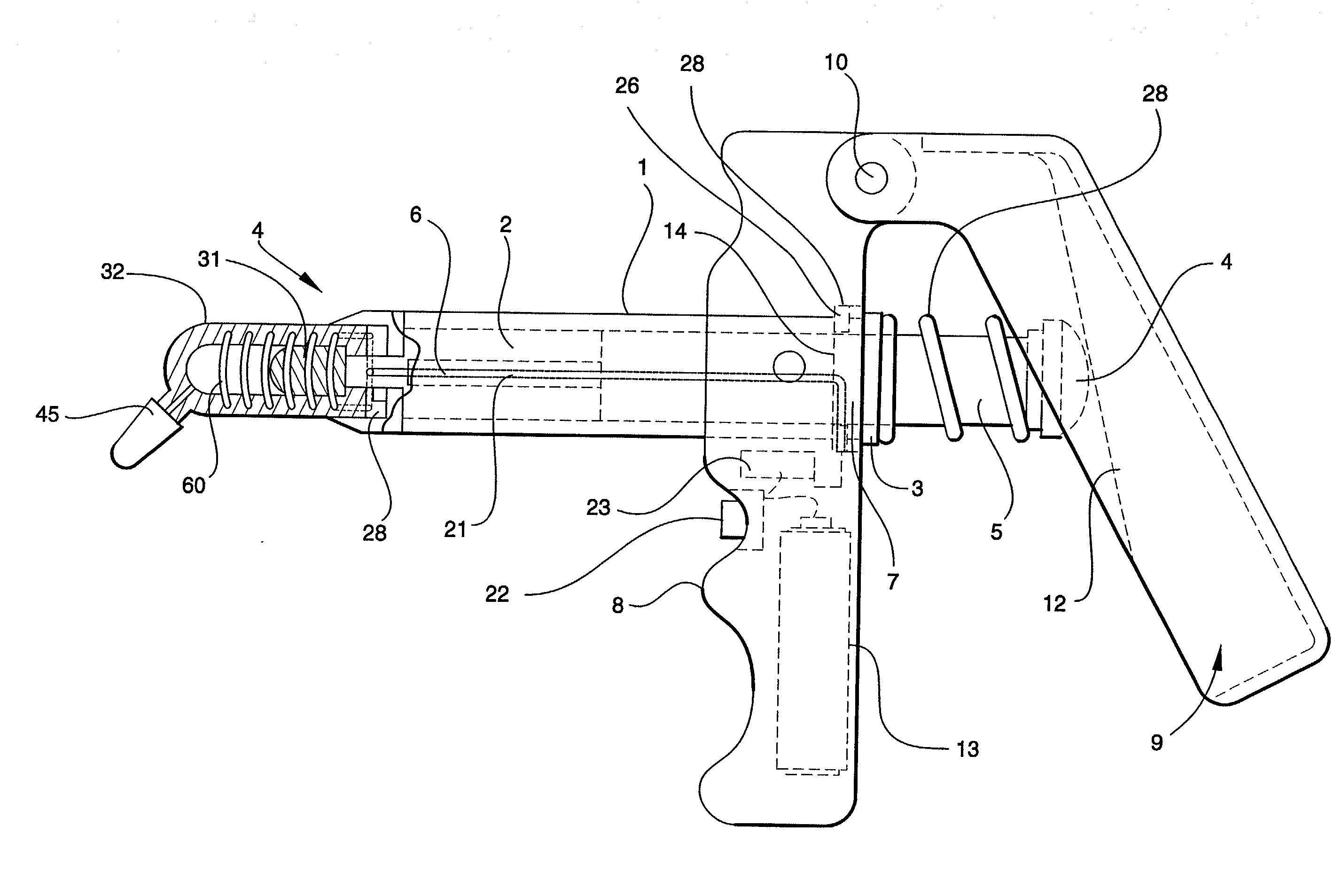

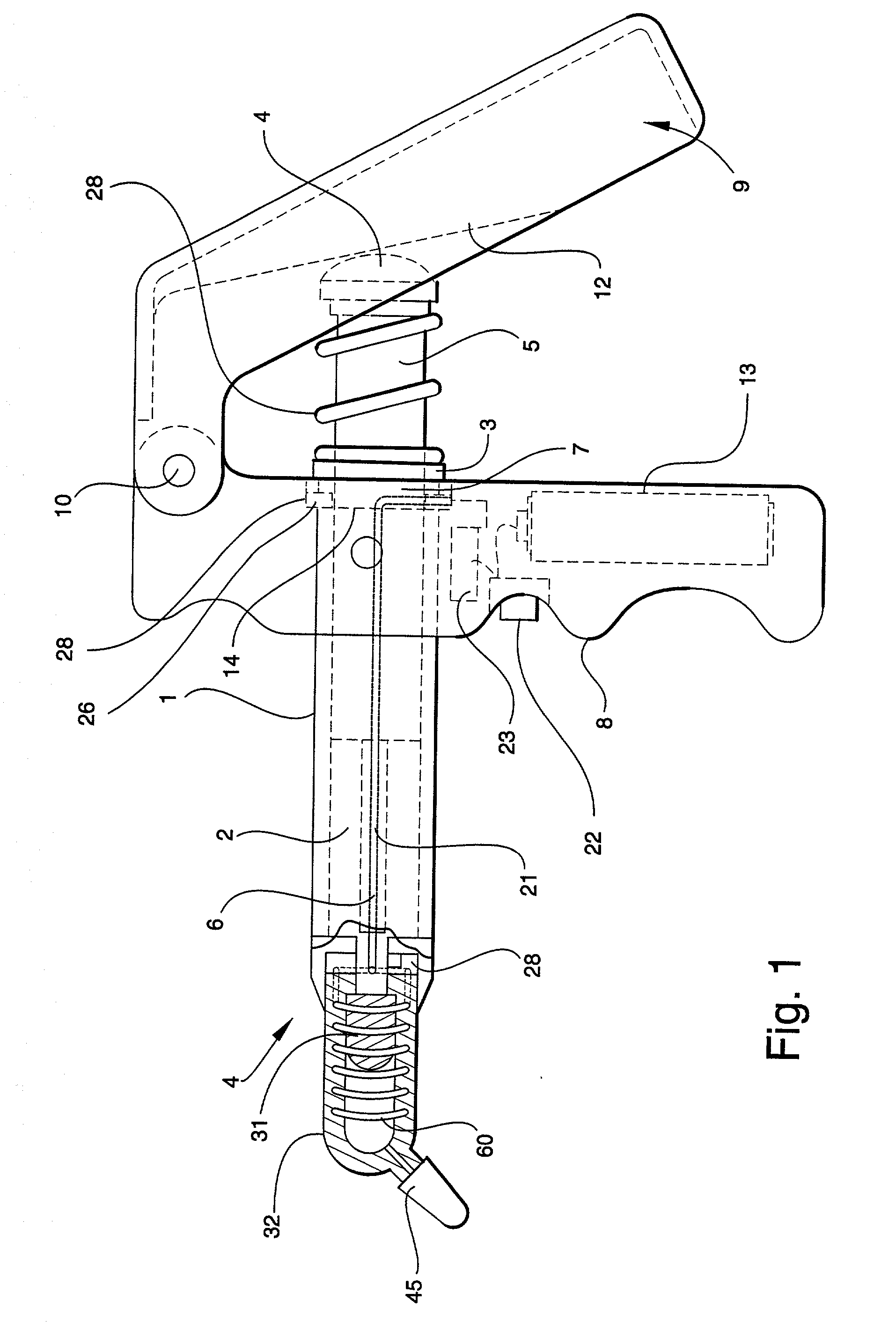

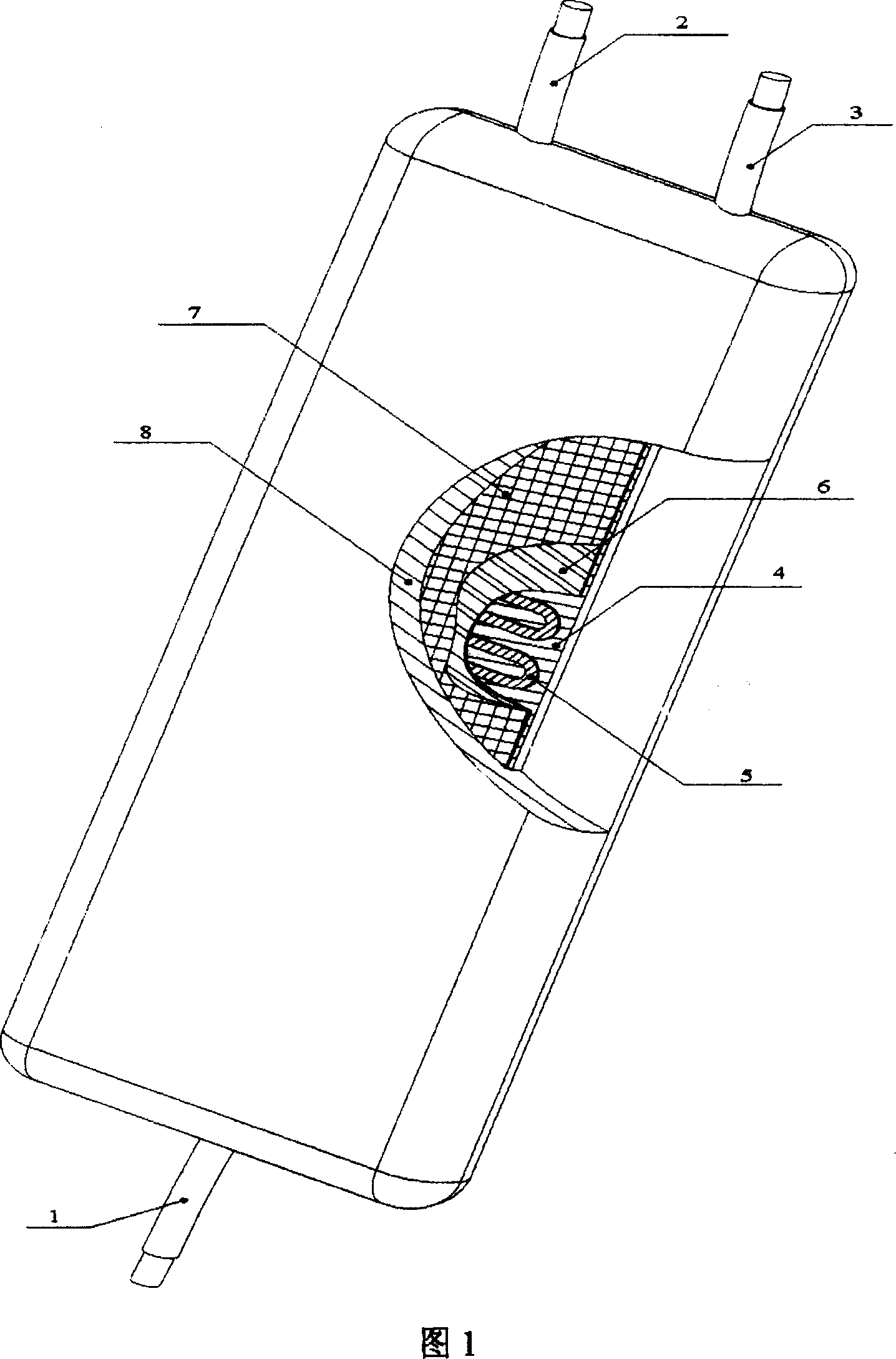

System for dispensing viscous materials

The invention provides for a delivery system where a viscous material such as dental composite is heated by an induction field or by resistance to an electric current. The system comprises at the proximal end a capsule-like cartridge that is self heating. The capsule may be fabricated of any number of heat conducting polymers or doped polymers that are susceptible to induction fields or any material that will heat when an induction current is applied. In the second instance the capsules may have a resistance wire of the appropriate metal or any other material to allow heating of the capsule when a current is applied. In the third instance the capsule may have an induction coil embedded in it's wall combined with any type of metal or other material where this becomes the heating device when current of the appropriate nature is applied. In the fourth instance a thin film or foil may be applied to either the outer surface or the inner surface of the capsule such that when a current is applied the foil or film heats and in so doing heats the capsule and the contents. Coupled with the above described capsule is a delivery device. This hand held device, whether powered manually or electrically forces a shaft to engage a piston embedded within the cartridge to move forward, dispensing the material within the cartridge at it's proximal end. In the manually powered mode, an electrical power source, whether a battery, capacitor discharge or AC / DC current, is used exclusively to activate the various heating methods described above. In the electrically powered mode, a linear stepper motor or other such motor with a proper configuration allows the shaft to engage the piston embedded in the cartridge and allow the material contained within the cartridge to be dispensed at it's proximal end. In the electrically powered configuration the power source described above is used to power the motor as well as the energy to activate the various heating elements described above. In addition where the force needed to extrude the material contained in the capsule, embedded in the device, whether manually or electrically applied to the device, such device may have the induction coil embedded in the barrel extension of the device in such placement as to provide adequate heating of the capsule.

Owner:YOBEL DAN +1

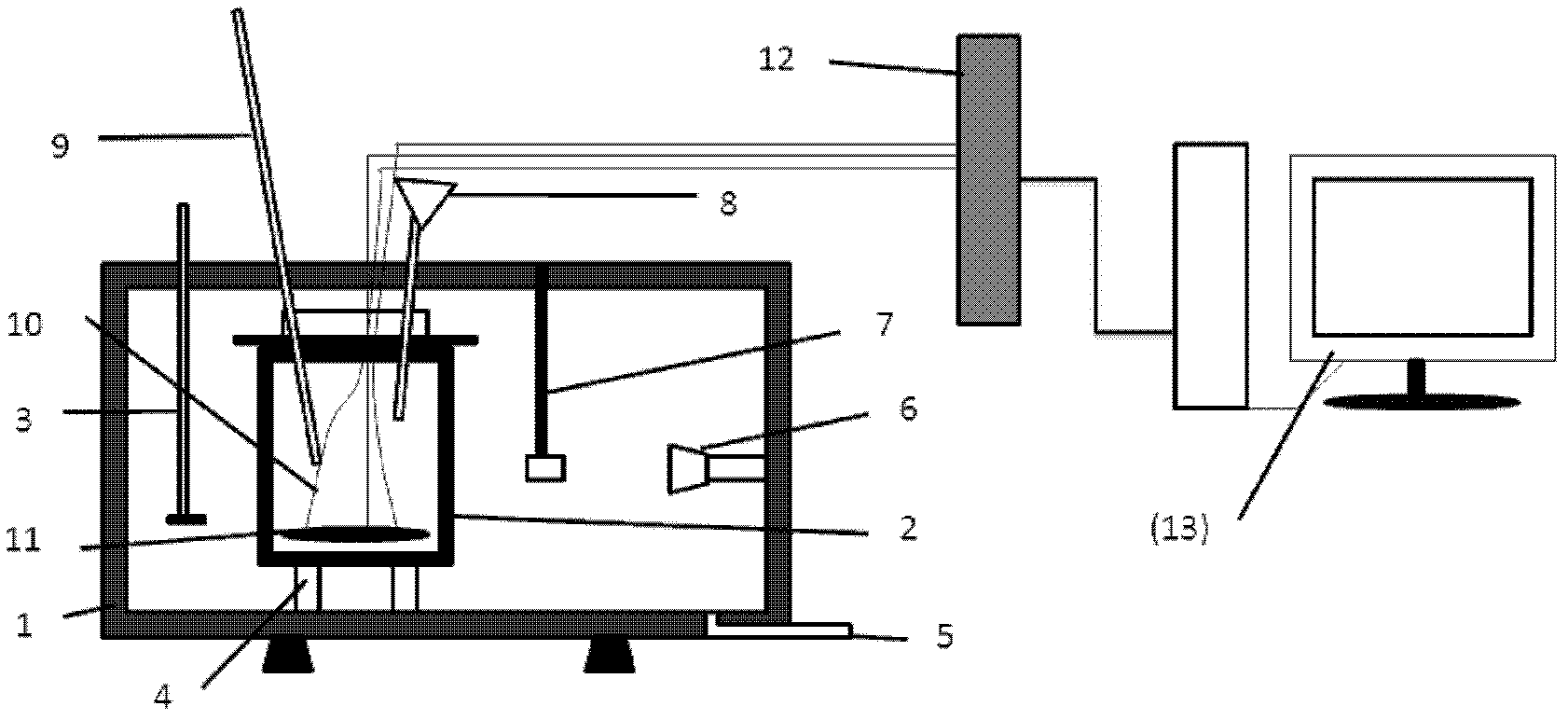

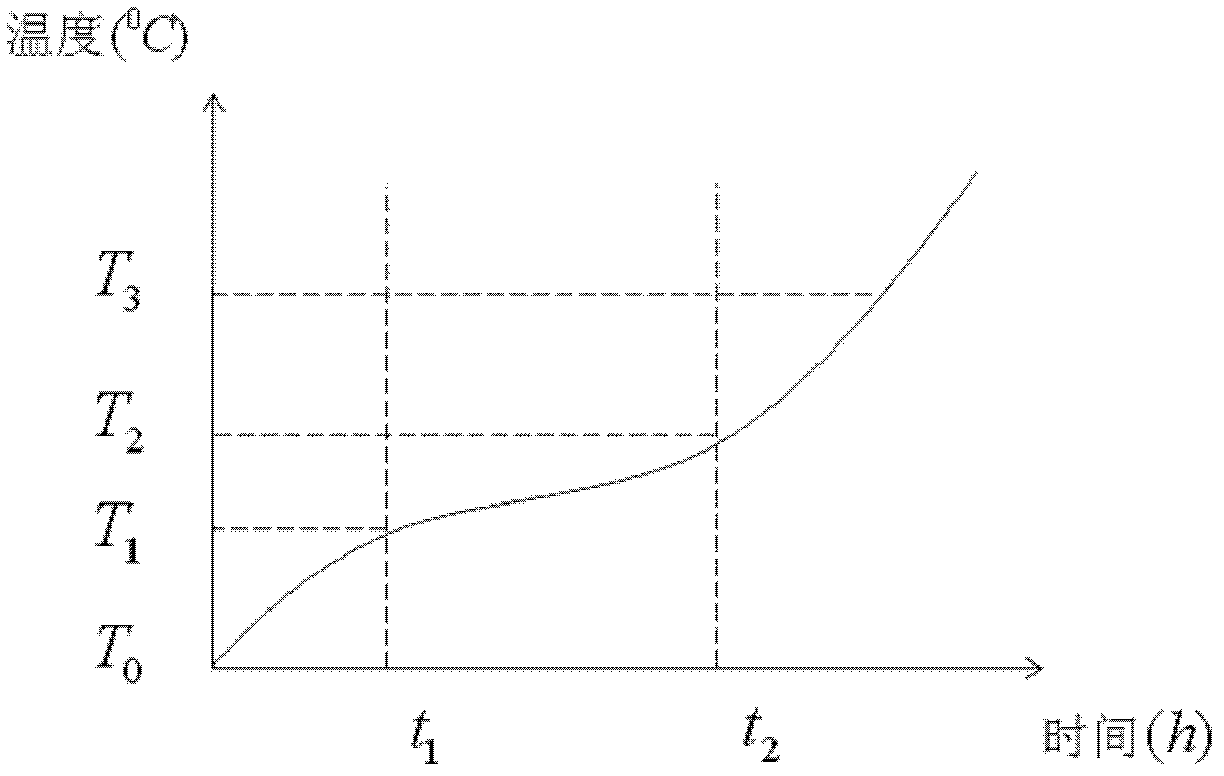

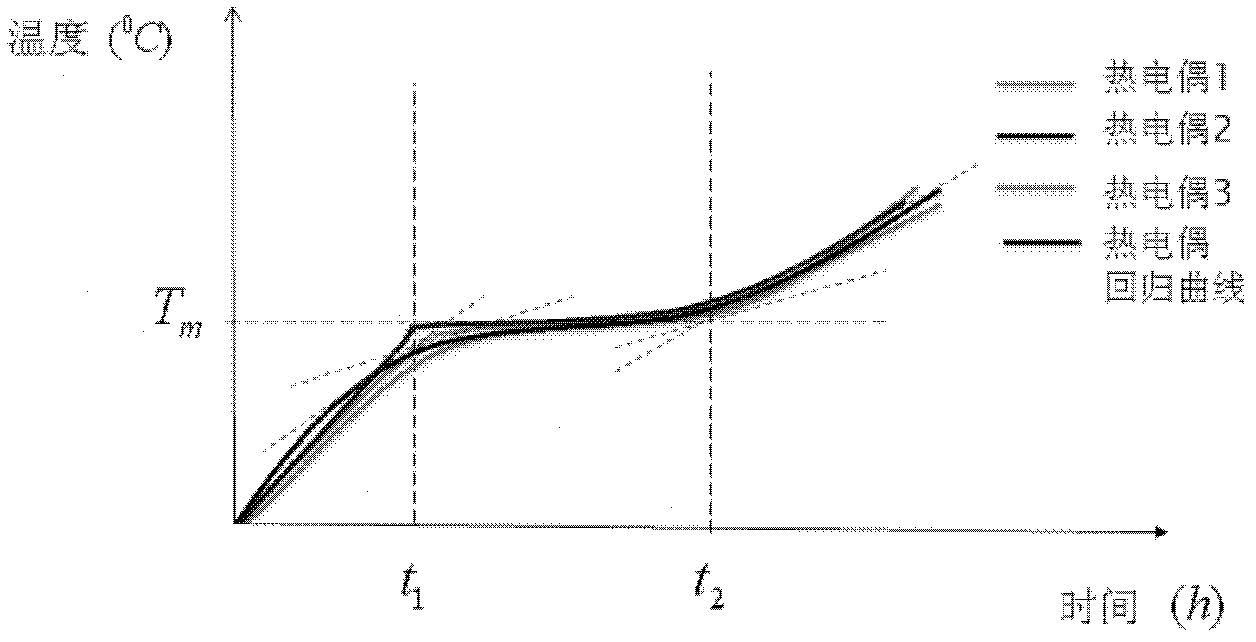

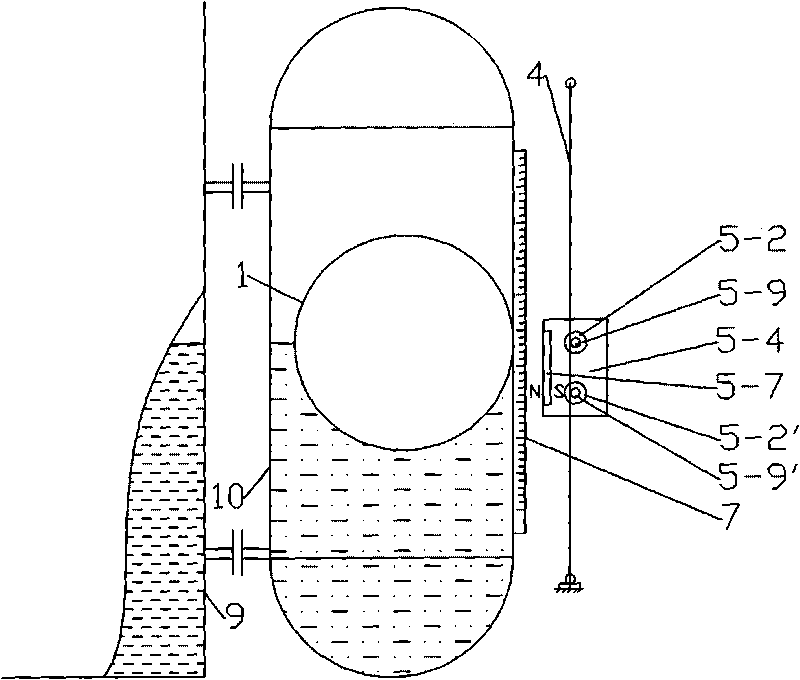

Device and method for measuring phase change latent heat of composite phase change energy storage material

ActiveCN102590263AIncrease reflectionReduce mistakesInvestigating phase/state changeWater bathsElectrical resistance and conductance

The invention discloses a device and a method for measuring phase change latent heat of a composite phase change energy storage material, and belongs to the technical field of test of building materials. Obvious shortcomings of small using amount of samples, large error, low representativeness and the like exist in the conventional method for measuring the thermal performance of a composite phase change material. The invention discloses a device for measuring the phase change latent heat of the composite phase change energy storage material and provides a corresponding measurement method. The invention is characterized in that a large quantity of phase change materials are heated by disk-type resistance wires under the condition that the heat of a constant-temperature water bath is preserved; and a curve of the temperature changed along with the time is measured by a plurality of groups of thermocouples and subjected to regression analysis, so that the thermal performance of the composite phase change material can be reflected really. The device and the method have great significance for popularization and application of the composite phase change material, particularly for building energy conservation.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP XIAMEN HONGYE

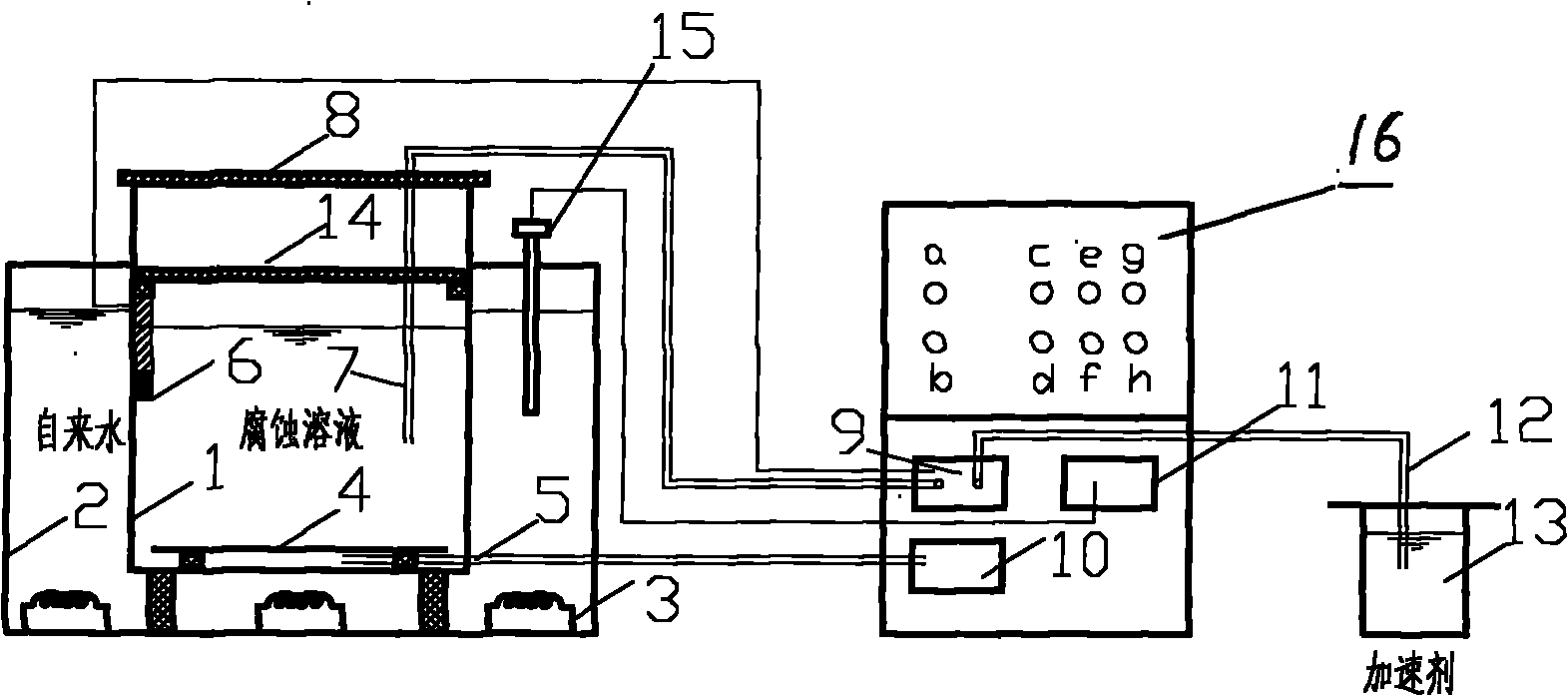

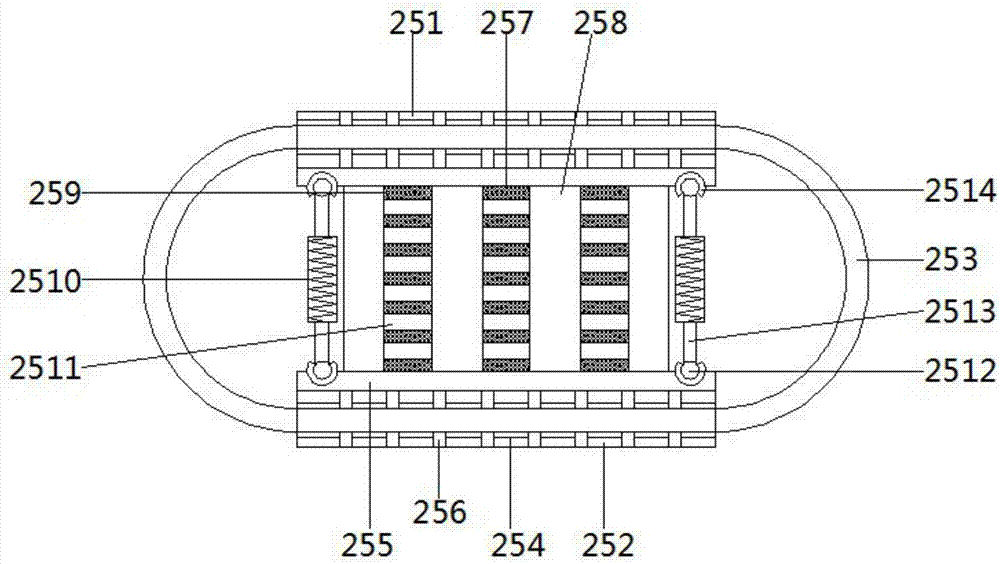

Analog accelerated corrosion test device

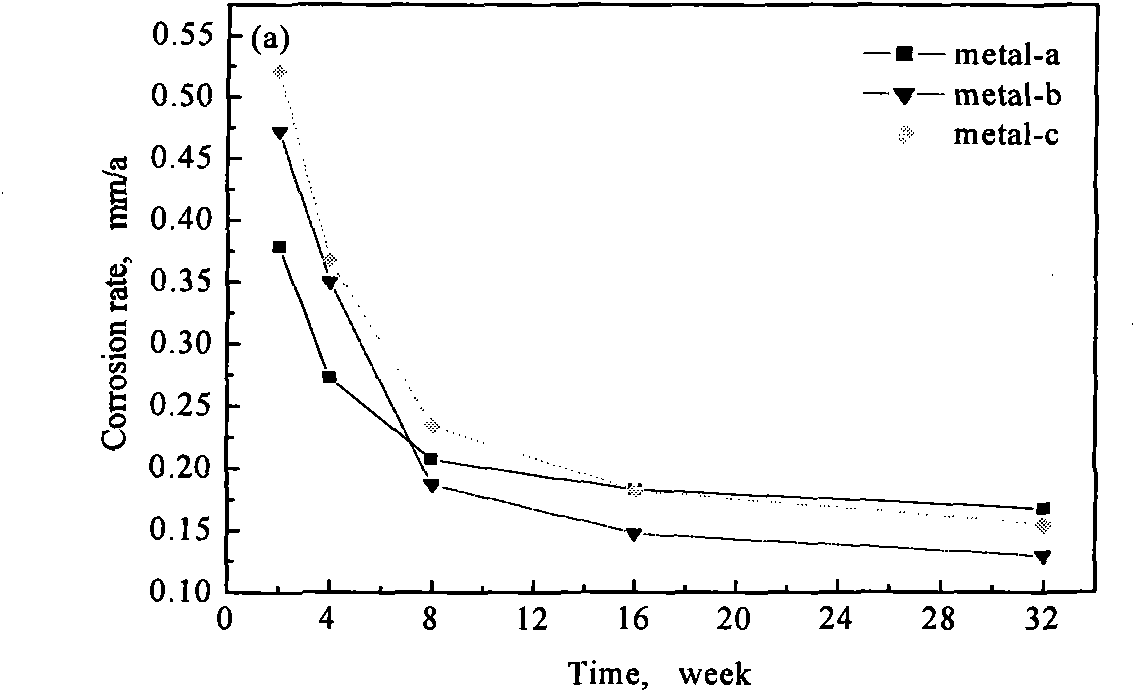

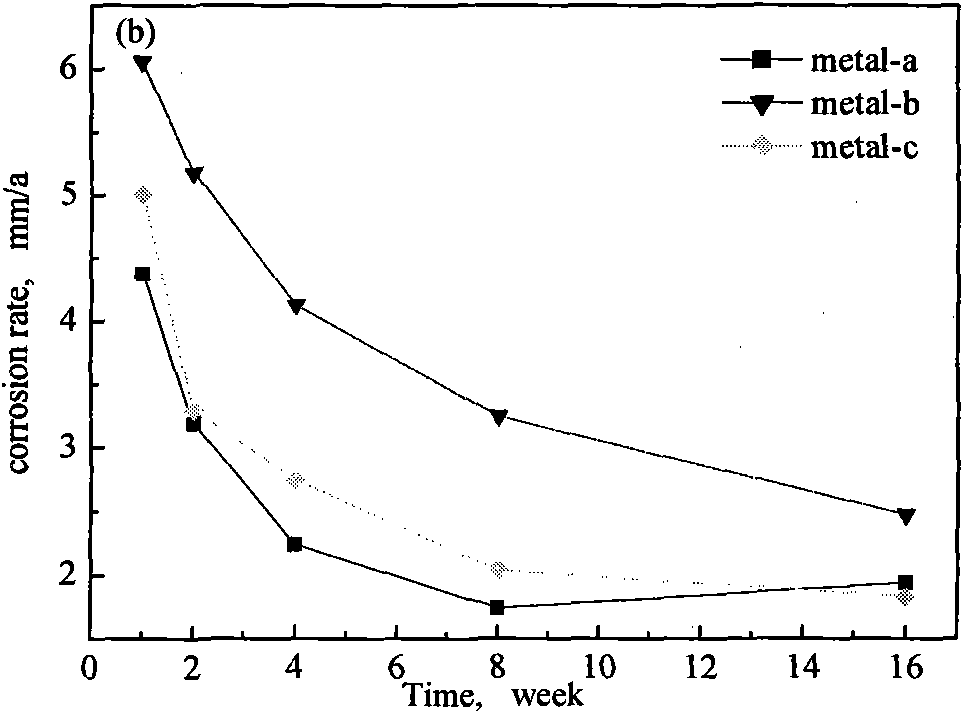

ActiveCN102081034AAccelerated seawater corrosionFast evaluation of corrosion resistanceWeather/light/corrosion resistanceElectricityWater baths

The invention belongs to the technical field of corrosion test, and relates to an analog accelerated corrosion test device. A ventilated baffle plate is arranged at the bottom of a cavity of a test box body of a square box-type structure; a corrosion solvent is filled in the cavity of the test box body; an accelerant concentration probe is arranged on the side wall of the upper middle part of thetest box body; a sample holder is transversely placed on the upper part of the cavity of the test box body; a test box cover plate is arranged at the top of the test box body; the test box body is placed at the middle position of a water bath body of an oblong box-type structure in a supported mode; tap water is filled in the outside space of the test box body in the cavity of the water bath body; a resistance wire serving as heating equipment is arranged in the side wall of the bottom of the water bath body; an accelerant concentration controller, an aeration quantity controller and an electronic temperature controller are combined into an integrated structure in an electric communication mode; and an accelerant is filled in an accelerant accommodating tank. The device has short test period, high material corrosion resistance evaluation speed and good effect, is favorable for popularization and application of new materials, saves the materials, and has low test cost.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

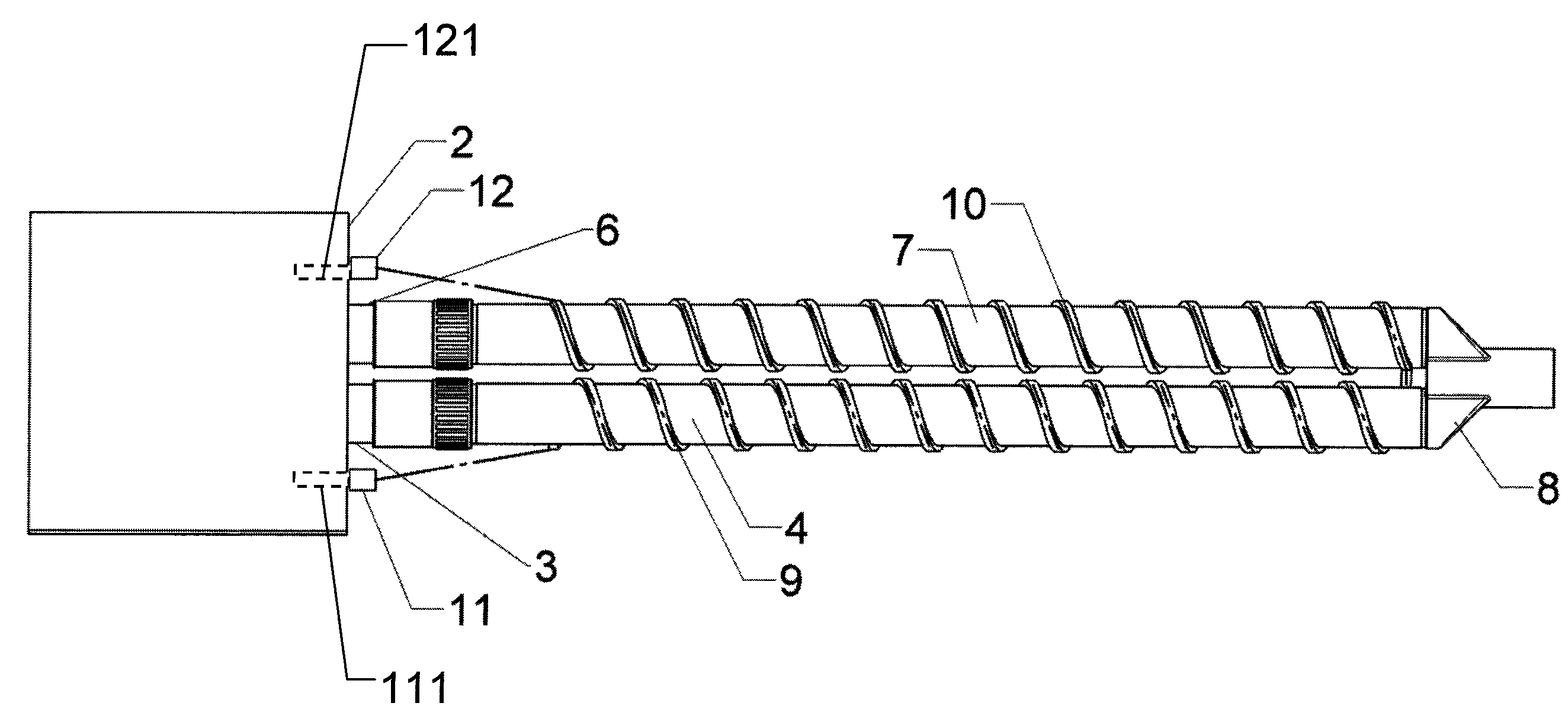

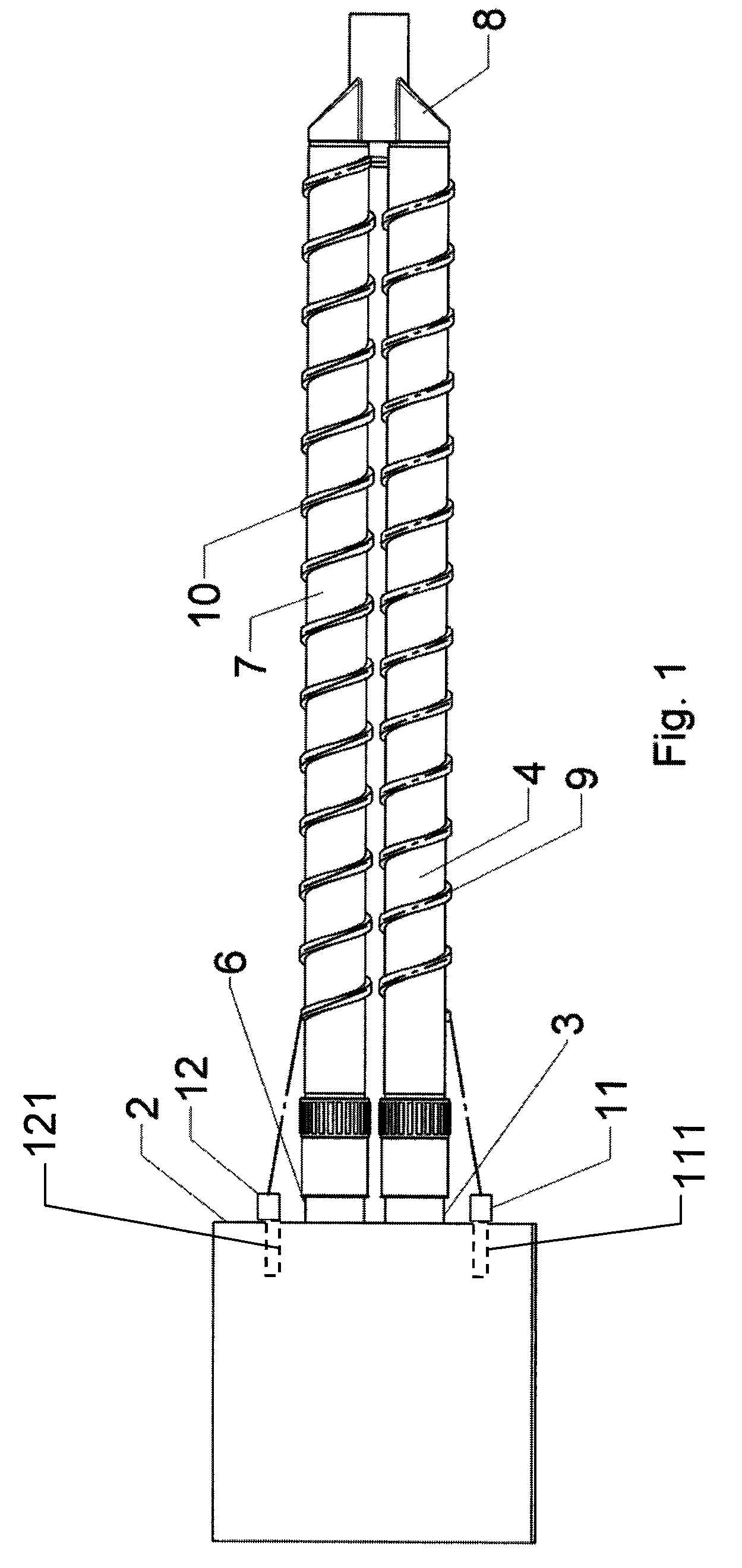

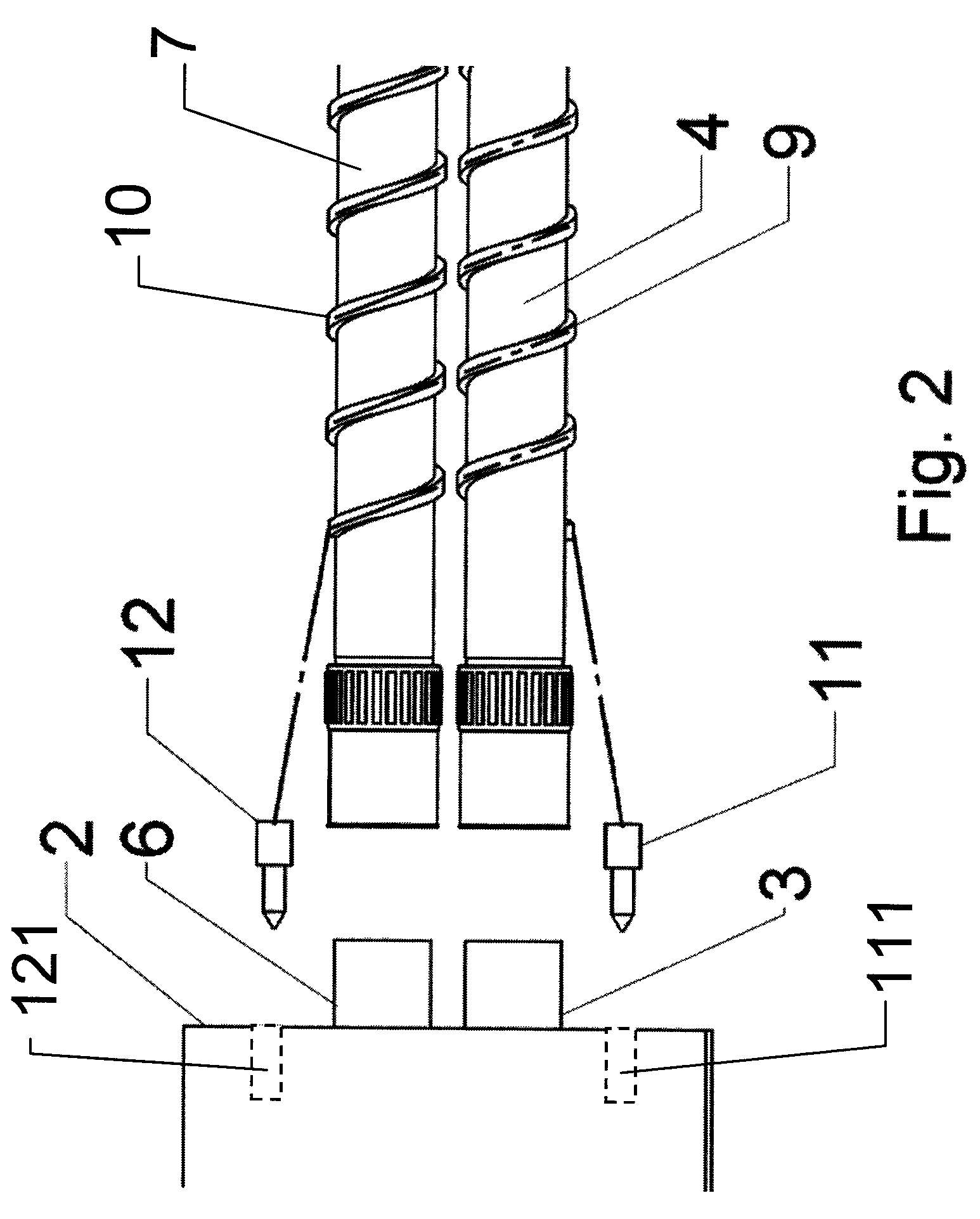

Respirator with a breathing tube system

InactiveUS8360059B2Avoid temperature riseRespiratorsOther heat production devicesRespiratorEngineering

A breathing tube system for connection to a respirator (2), which is provided with a tube heater, avoids a local increase in temperature during the heating of the tube (4, 7). Resistance wires (9, 10) are connected to one another on the breathing tubes (4, 7) in the form of a series connection and are contacted at the respirator (2) in the area of an inspiration port (3) and of an expiration port (6).

Owner:DRAGERWERK AG

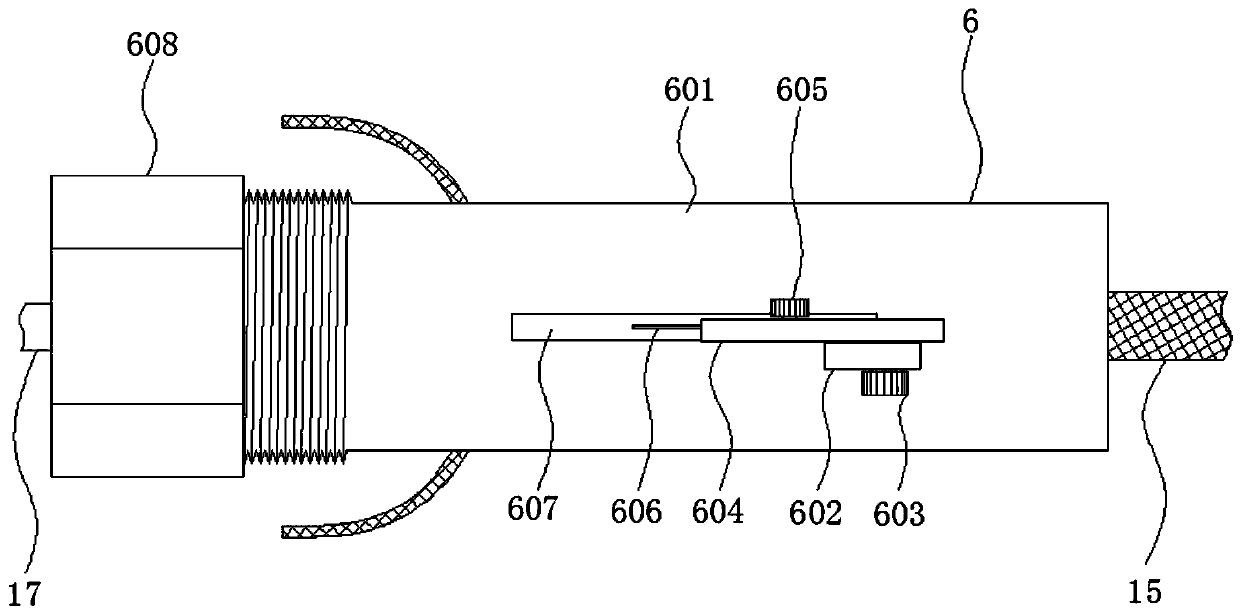

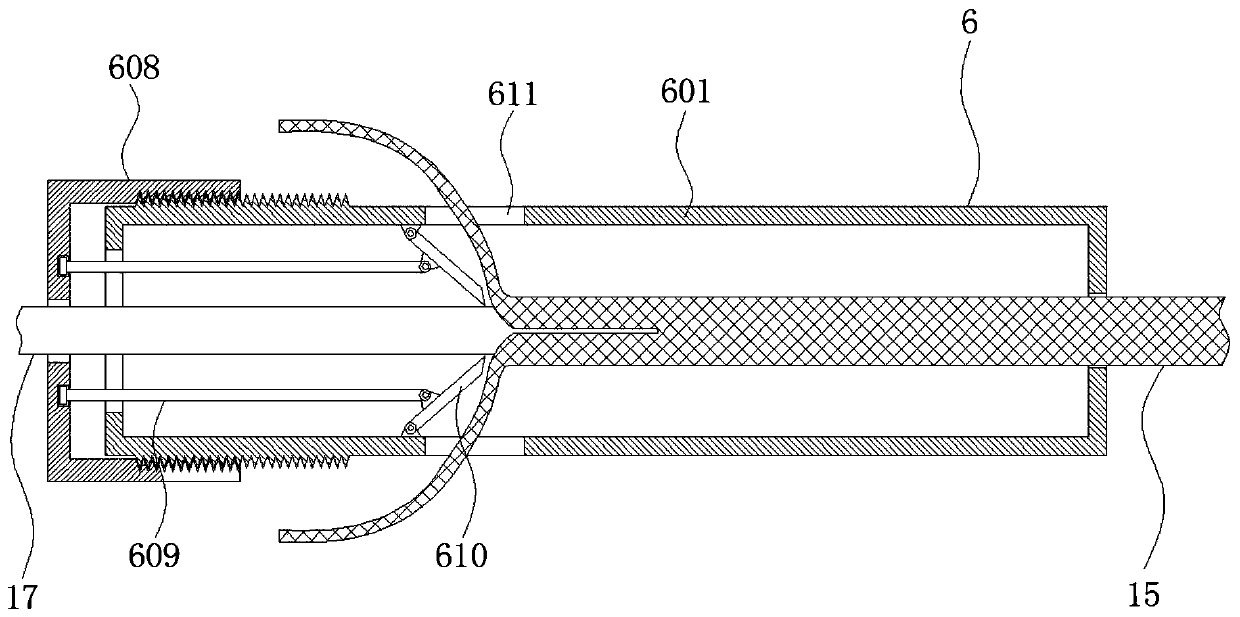

Slide-bar type 3D printer capable allowing output materials to be changed

InactiveCN103419370AImprove work efficiencySave feeding auxiliary timeCeramic shaping apparatusFood shapingElectrical resistance and conductanceBarrel Shaped

The invention discloses a slide-bar type 3D printer allowing output materials to be changed. The 3D printer comprises a base, a door-shaped support, a beam, a jet head and a printing platform, wherein the jet head comprises a barrel-shaped feeding barrel and a tapered heater; the feeding barrel is arranged at the upper part of the jet head; the tapered heater is arranged at the lower part of the jet head; a resistance wire is wound around the inner chamber wall of the heater; a nozzle is arranged at the bottom of the heater; an opening allowing a raw material tank to go in and out is formed in the body of the feeding barrel; a slide-bar type press-feeding mechanism for pressing materials in the raw material tank into the heater is arranged on the beam at the top of the feeding barrel and comprises an extruding head, a slide bar and a gear; the slide rod is vertically arranged; the extruding head is arranged at the bottom of the slide bar; the gear is arranged on the side of the slide bar and meshed with the gear rack on the slide bar. According to the 3D printer, raw material change can be performed on the jet head directly, conveniently and quickly. Therefore, the non-cutting feeding time is shortened, and the working efficiency of the 3D printer is improved.

Owner:GUANGXI QINZHOU YUJIA INVESTMENT

Device for realizing 3D metal printing by virtue of supporting structure

ActiveCN105618756AReasonable structureSimple structureAdditive manufacturing apparatusAutomatic controlShielding gas

The invention relates to a device for realizing 3D metal printing by virtue of a supporting structure. The device comprises a translation stage capable of moving along the X-axis, the Y-axis and the Z-axis. Heating resistance wires and a thermocouple are arranged on a base plate of the translation stage. The heating resistance wires are used for preheating the base plate, so as to enable metal droplet layers to be tightly overlapped. The thermocouple is used for realizing the measurement and the feedback control of a temperature. An electromagnetic induction heating copper pipe and a cooling water pipe are arranged outside a graphite crucible, metallic raw materials are enabled to be molten to form molten metal, the bottom of the graphite crucible is connected with a metal printing spray nozzle, a protective gas is inputted from a gas inlet pipe at the top of the graphite crucible, and under the pulse pressure, molten metal forms regular metal droplets to drip to the base plate of the translation stage. The 3D metal droplet printing is realized through the cooperation with the movement of the translation stage. A supporting material spray nozzle is adjacent to the metal printing spray nozzle. A uniform mixture of gypsum and photosensitive resin is extruded stably under the constant pressure inputted by the gas inlet pipe so as to print the supporting part of a part. The switching between metal and the supporting material is automatically recognized and controlled by a control system. The 3D metal printing device is reasonable, high in operability, high in degree of automation, high in production efficiency, and suitable for being widely popularized, and ensures the molding quality.

Owner:STATE GRID CORP OF CHINA +5

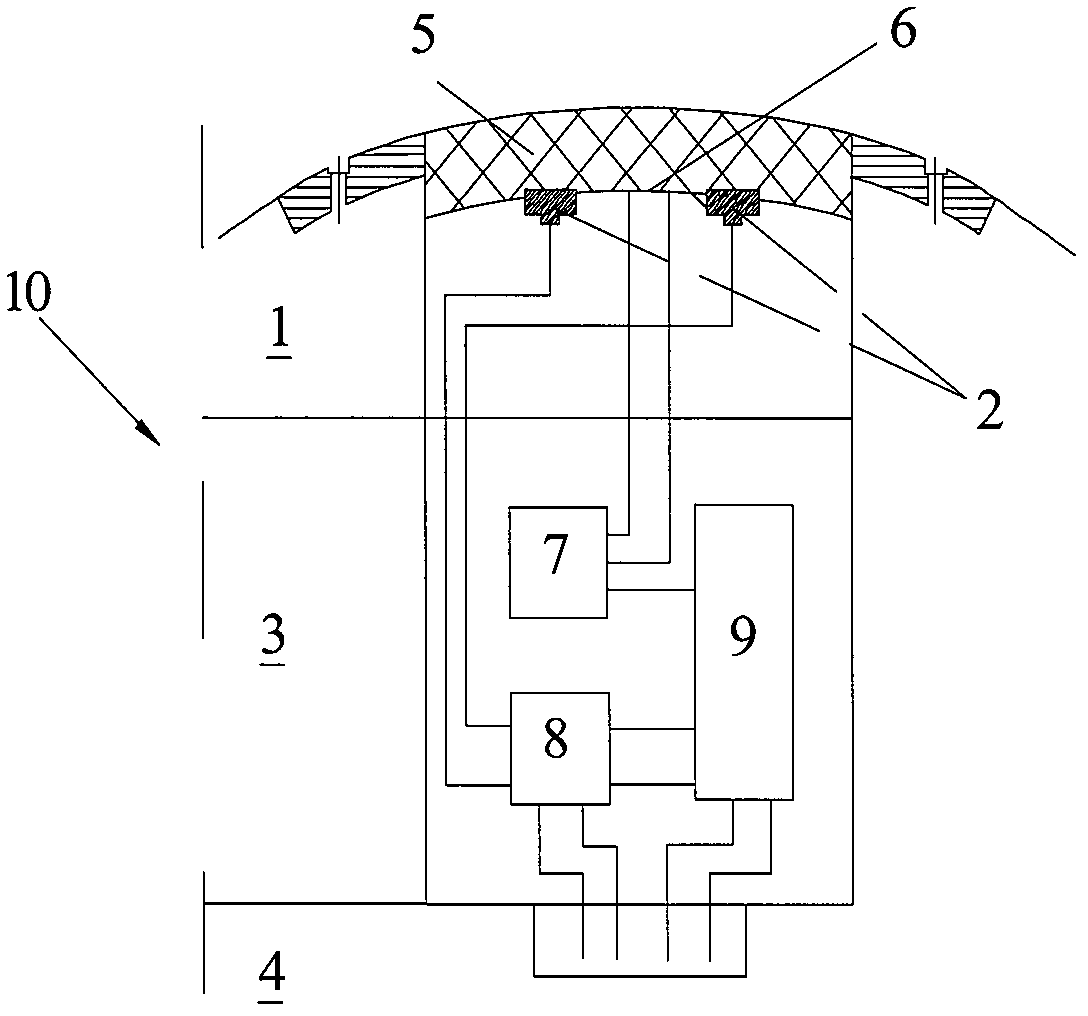

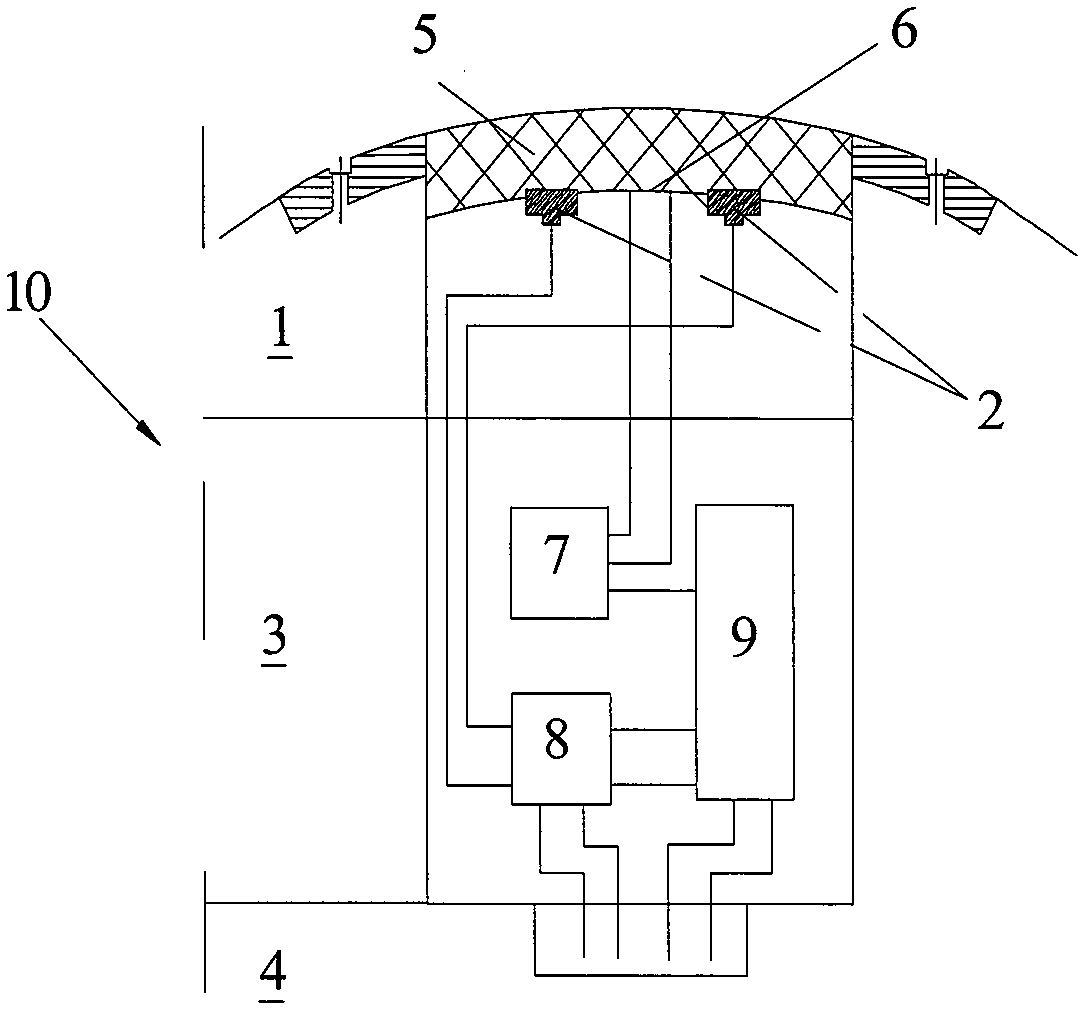

Ice formation condition detector

ActiveCN102407942ADoes not affect aerodynamic shapeThere is no critical temperature differenceDe-icing equipmentsElectrical resistance and conductanceThermal insulation

The invention provides an ice formation condition detector, which comprises a sensing element, a temperature sensor and a controller, wherein the sensing element comprises a temperature sensing layer and a thermal insulation layer; a resistance wire is embedded into the temperature sensing layer; the thermal insulation layer is fixed on the inner surface of the temperature sensing layer; the temperature sensor is used for measuring real-time temperatures of the sensing element; the controller comprises a heating control module, a data storage module and a processor; the heating control module is used for heating the resistance wire by using constant electric power to ensure that the temperature of the sensing element is kept to be more than 0 DEG C; the data storage module is used for storing temperature target values of the sensing element under different flight conditions and acquiring real-time temperature values, which are measured by the temperature sensor, of the sensing element; and the processor is used for retrieving the temperature target values of the sensing element from the data storage module under a certain flight condition, comparing the temperature target values with the real-time temperature values and determining that an airplane runs into an ice formation condition if the real-time temperature values are less than the temperature target values.

Owner:COMAC +1

12kv fixed-sealed resistant voltage divider

ActiveCN101075490AReduce volumeReduce power consumptionResistor housing/enclosing/embeddingNon-adjustable resistorsElectromagnetic interferenceEngineering

A 12kv resistance divider includes wire terminal, signal terminal, earthing terminal, ceramic wafer, resistance wire, and a green color protection layer covered by a black protection layer then rubber.

Owner:BEIHAI GALAXY SWITCH DEVICES

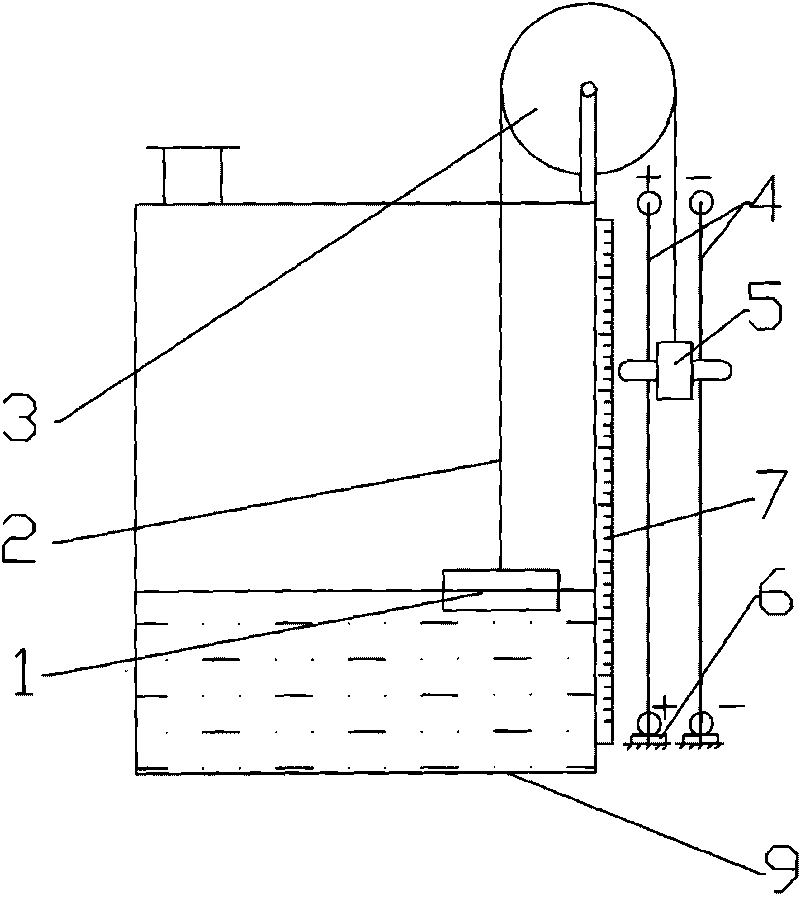

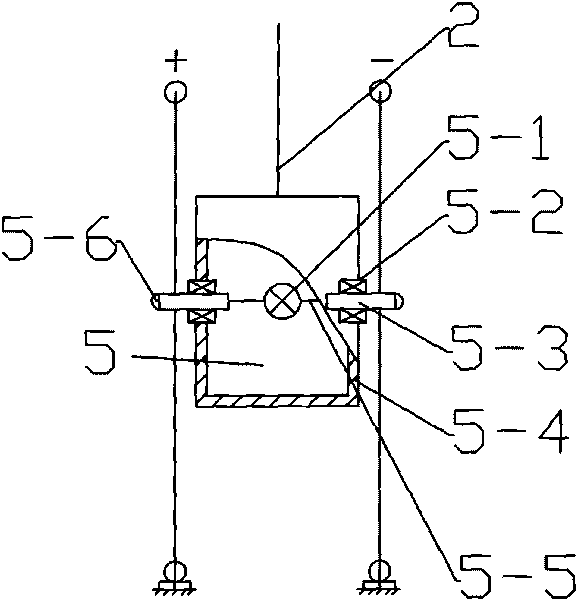

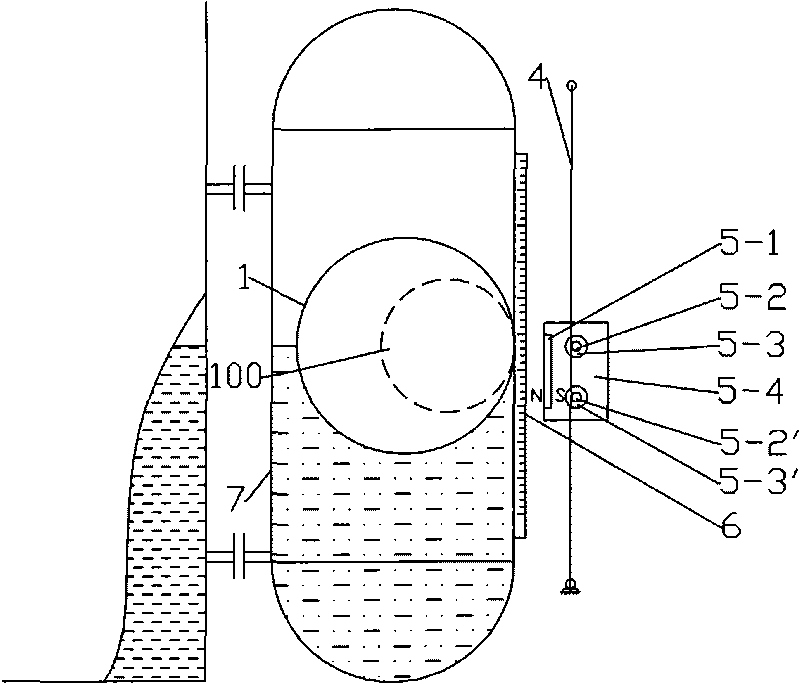

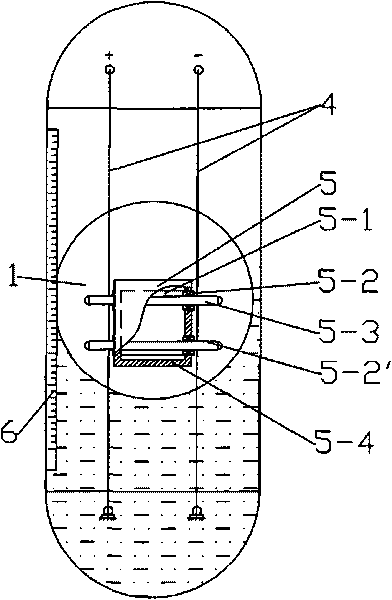

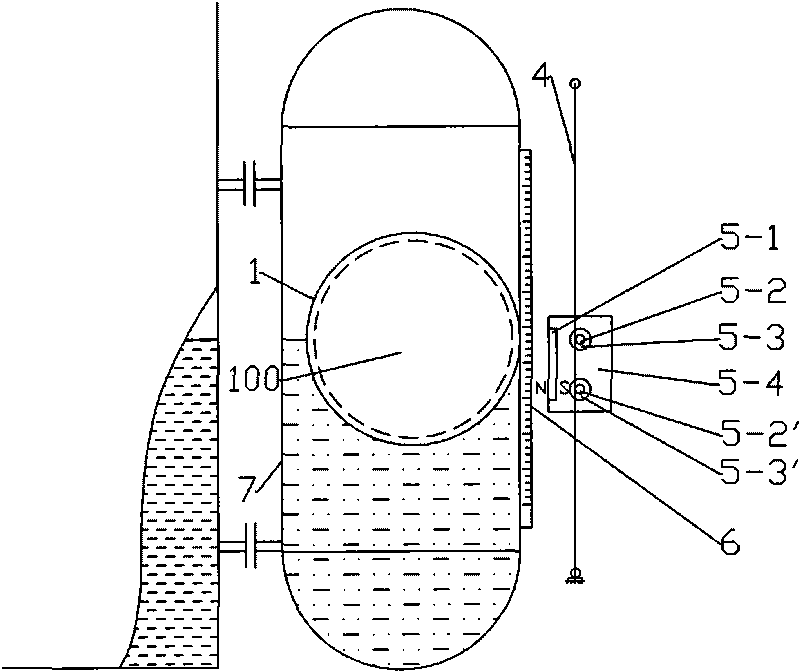

Float type level gauge for on-site indication

InactiveCN101706308AReduce procurement costsReduce In-Place DirectionsLevel indicators by floatsMagnetic tension forceElectrical resistance and conductance

The invention relates to a float type level gauge for on-site indication, which comprises a float, a graduated scale and a noctilucence wheel, and is characterized by further comprising a conducting or magnetic conducting guide rail, wherein the noctilucence wheel comprises an insulating box, a light source, two longitudinally arranged magnetic shafts or metal shafts, and two conducting wires for supplying power to the light source; for a magnetic float type level gauge, the noctilucence wheel also comprises a steel magnet; under the magnetic action, the magnetic shafts or the metal shafts, along with upward and downward movements of the float, move upwards and downwards along the guide rail so as to indicate the liquid level on-site accurately in time; or a resistance wire is enwound on the guide rail, and the resistance value of a conducting loop comprising the guide rail, the magnetic shafts or the metal shafts, the conducting wire, the light source and the like is measured to acquire a corresponding liquid level value so as to achieve the continuous long-distance transmission of liquid level data. The float type level gauge can also comprise a pulley wheel, a counterbalance, a connecting rope or a connecting belt to balance the noctilucence wheel. The float type level gauge has the significant characteristics of simple structure, clear and obvious on-site indication, flexible and accurate measurement and continuous long-distance signals.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

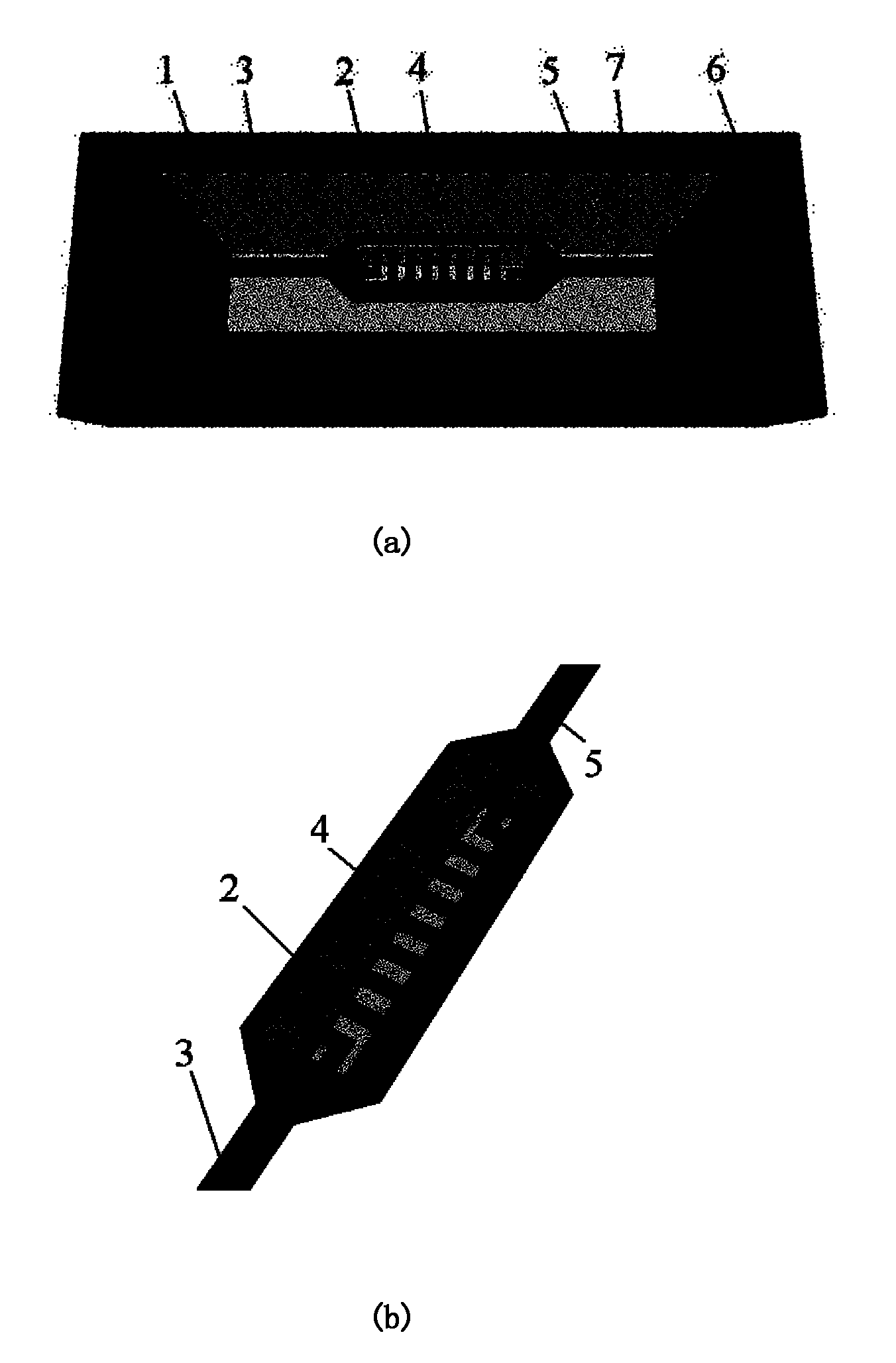

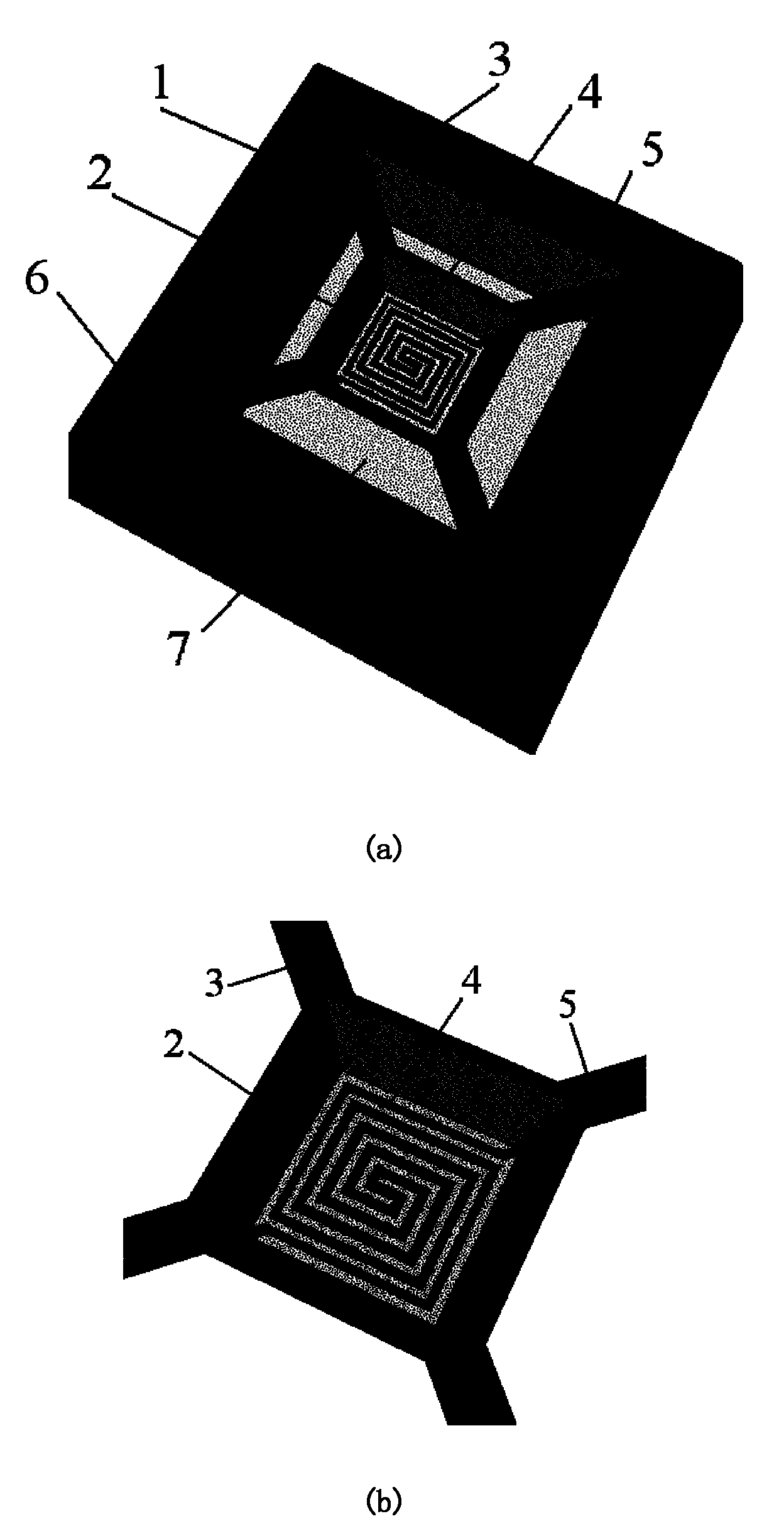

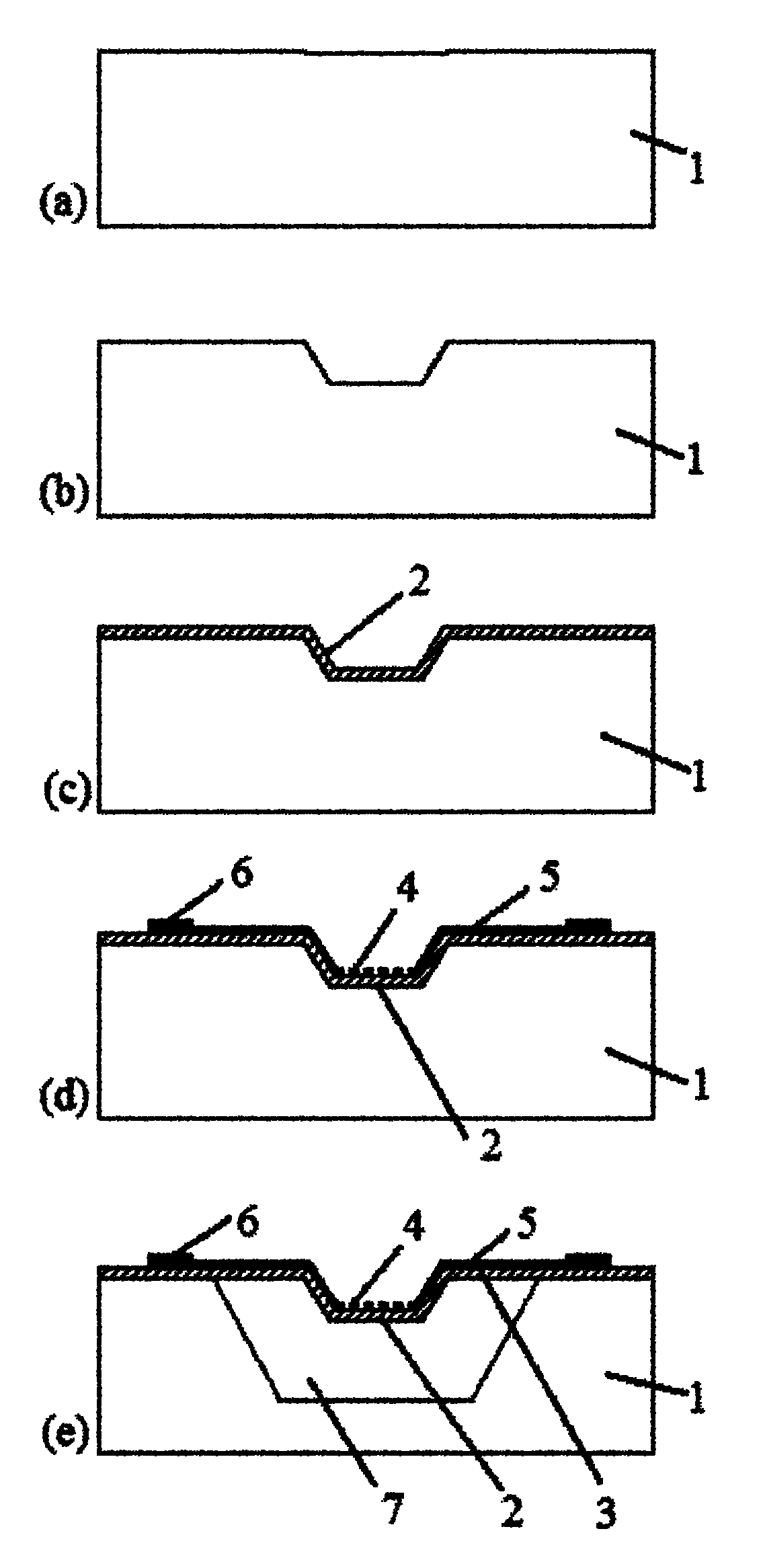

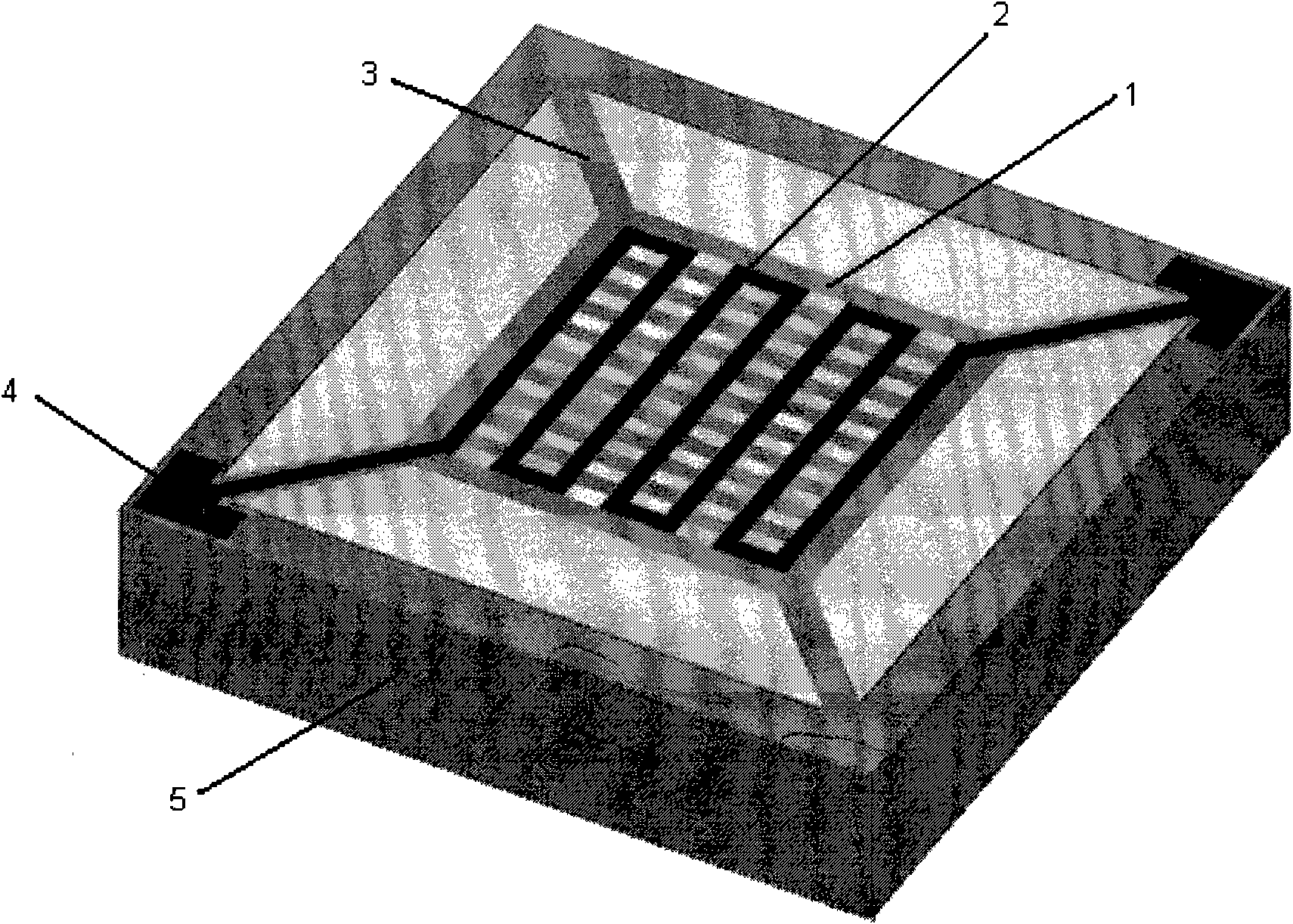

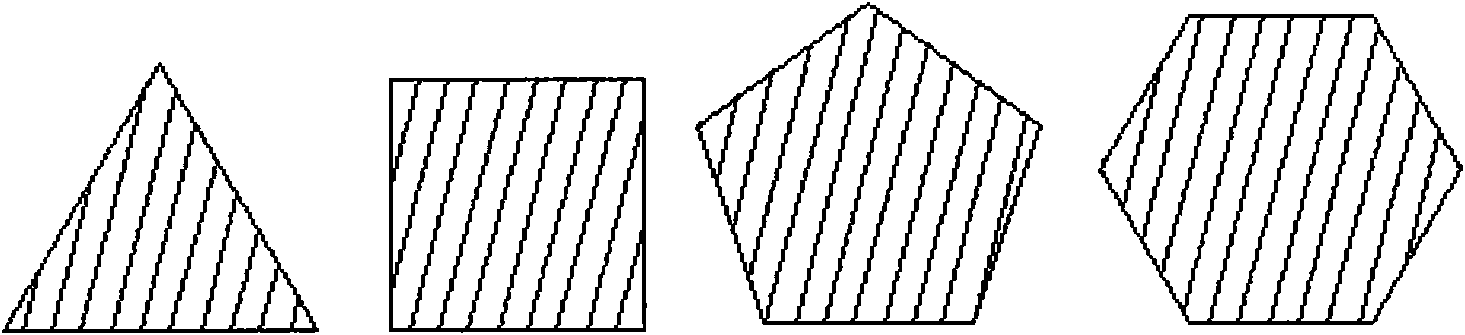

Three-dimensional micro heater with groove-shaped heating film region and manufacturing method thereof

ActiveCN101917784AGood surface smoothnessEasy to controlDecorative surface effectsHeating element materialsElectrical resistance and conductancePolygonal line

The invention relates to a three-dimensional micro heater with a groove-shaped heating film region and a manufacturing method thereof. The three-dimensional micro heater is characterized in that: the groove-shaped heating film region of which the cross section is in a V-shaped or an inverse trapezoid-shaped structure is connected with a substrate framework through a supporting suspended beam; a heat resistance wire is distributed inside a groove of the heating film region in the form of fold line and is connected with the electrode on the substrate framework through a lead wire on the supporting suspended beam; and a heat insulation cavities formed by a silicon anisotropic wet etching method is arranged below the heating film region and the supporting suspended beam. The heat resistance wire of the three-dimensional micro heater is distributed inside the groove of the heating film region with a three-dimensional structure, has low heat loss caused by heat convection and is favorable for reducing power consumption of the heater. The groove structure concentrates heat, improves the heating efficiency and is favorable for application of the heater in the fields of infrared light sources and sensing.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

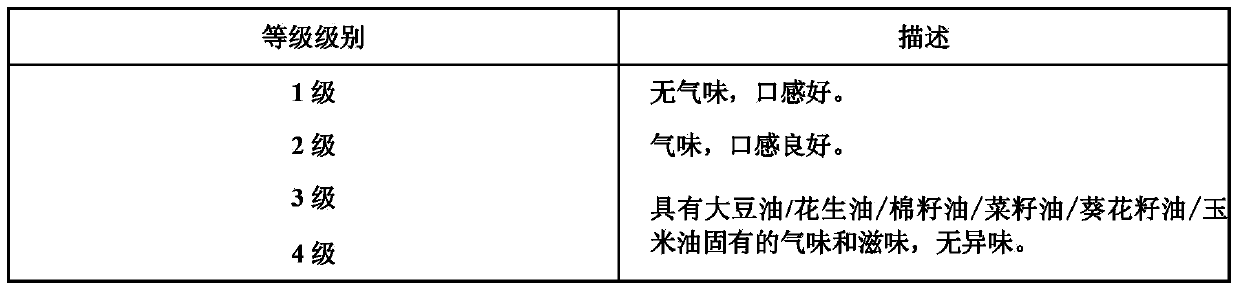

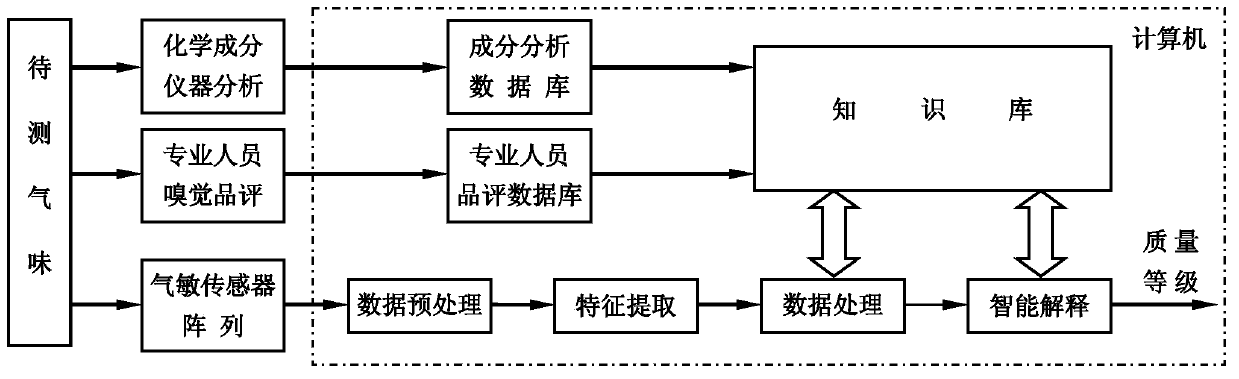

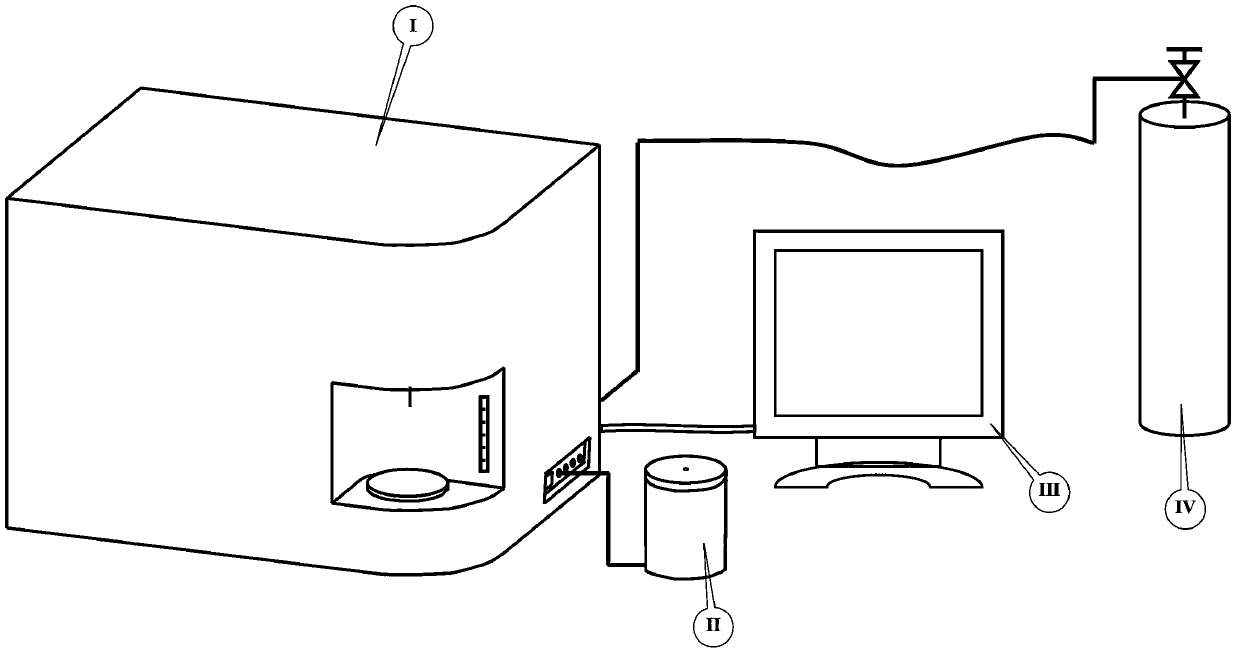

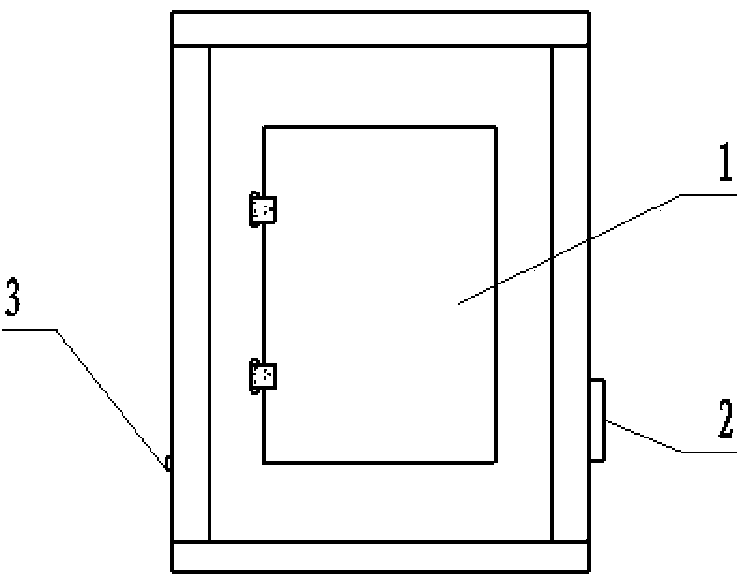

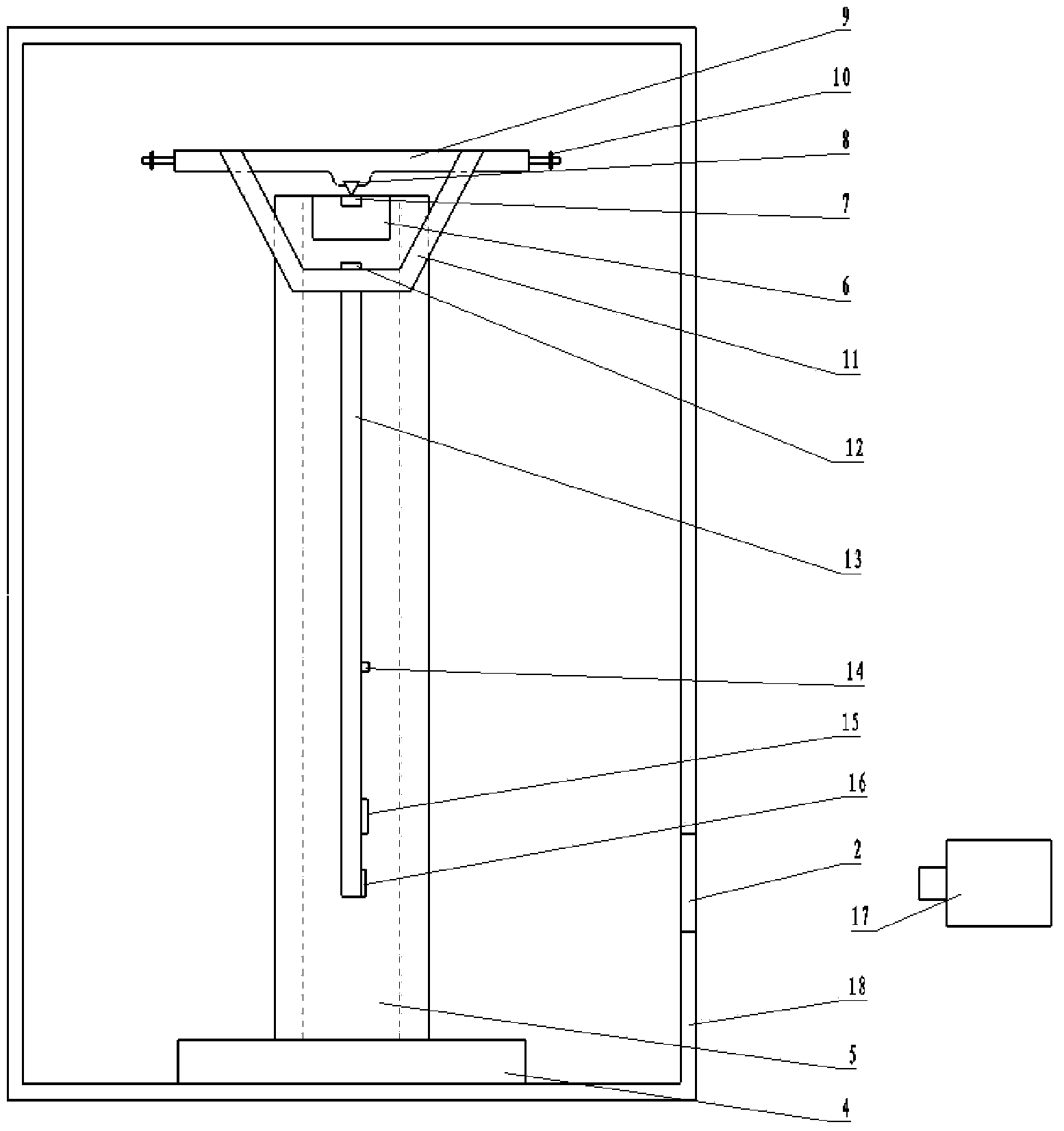

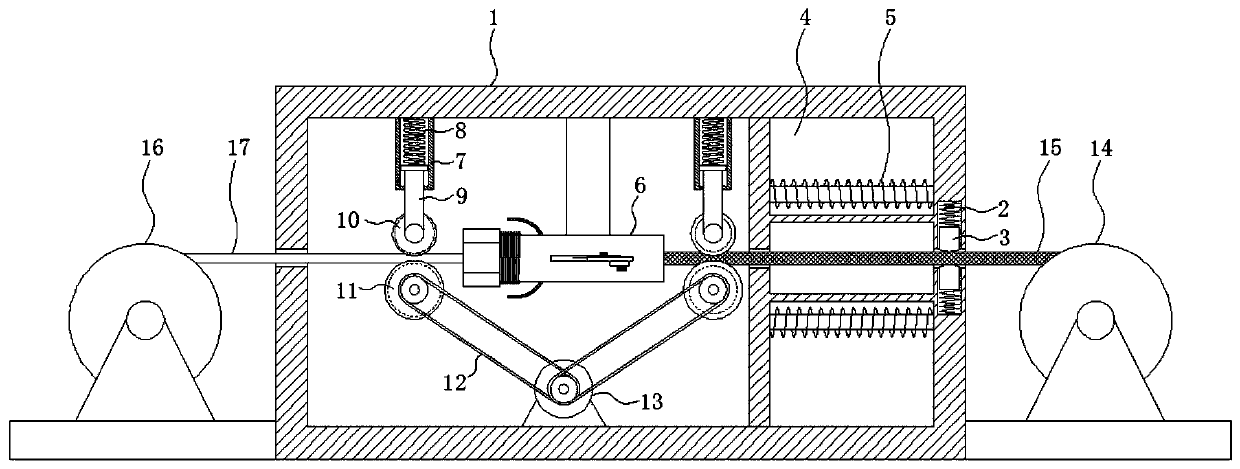

Olfactory analog instrument and on-site analysis method for odor grade of specific substance

ActiveCN103472094AHigh degree of integrationHigh constant temperatureMaterial analysis by electric/magnetic meansSensor arrayVegetable oil

The invention provides an olfactory analog instrument and an on-site analysis method for the odor grade of a specific substance. The invention has the following characteristics: 1, a gas sensor array constant temperature operation room, a computer and an autoinjection system are integrated in a test box; 2, utilization of a sample bottle with a volume of 250 ml and 25 ml of a to-be-tested sample enables a gas-liquid ratio to be 9: 1; 3, parallel resistance wires respectively wind in a semi-circle manner to generate 45-W power, so the sample and headspace volatilized gas are heated to a temperature of 80 DEG C in only 8 min and maintained at the temperature for 30 min; 4, 25 ml of an aqueous ethanol solution with a concentration of 100 ppm is used to generate standard reference gas in the sample bottle with a volume of 250 ml, and correction on gas sensors are carried out based on the generated standard reference gas; 5, headspace sampling flow is 500 ml / min, sampling time is 30 s, and gas sensor response signals undergo lowpass filtering and dimensionality reduction pretreatment; and 6, a database is established, and the olfactory analog instrument carries out on-site detection and grade prediction and identification on the odor of specific substances consisting of an adhesive, petroleum wax, leather, glycerin and edible vegetable oil.

Owner:EAST CHINA UNIV OF SCI & TECH

Dangling type micro-impulse testing device and method

InactiveCN104374506AEliminate the effects ofEliminate deviationApparatus for force/torque/work measurementElectrical resistance and conductanceAerodynamic drag

The invention discloses a dangling type micro-impulse testing device and method. A dangling system is fixed in a vacuum box, a thruster ignition power source, a circuit switch, a wire and a miniature thruster are integrated to the dangling system in a modularization mode, a dangling type micro-impulse testing system works in a vacuum environment, a remote control switch serves as a circuit switch to conduct remote control ignition, and influences of a miniature thruster ignition resistance wire power source and the wire on testing results are eliminated. A laser Doppler measurer is installed outside the vacuum box, a light path of a single beam laser head in the laser Doppler measurer is adjusted to be centered with a target reflector, the deviation of outgoing beams and incident beams is eliminated, displacement changes of the thruster are accurately measured, and influences of air friction during dangling are avoided. By means of the dangling type micro-impulse testing device and method, the working force of a miniature rocket motor in a short time can be tested, the micro impulses can be tested, and the impulse testing accuracy is high.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Automatic stripping device for power communication cable recycling

InactiveCN110265932AImprove practicalityEasy to cutBasic electric elementsApparatus for removing/armouring cablesResistance wireEngineering

The invention provides an automatic stripping device for power communication cable recycling, which relates to the technical field of communication cable recycling. The automatic stripping device for power communication cable recovery includes a frame. An extruding block is fixedly connected inside the right inner wall of the frame through a first spring. A heating box is arranged on the right side inside the frame. A heating resistance wire is fixedly connected inside the heating box. A stripping device is fixedly installed inside the frame. A cylinder is fixedly installed at the top end of the inside of the frame. A pressure bar is fixedly connected inside the cylinder through a second spring. The bottom end of the pressure bar is rotationally connected with a driven wheel. The automatic peeling device for power communication cable recycling facilitates the cutting and removing of the sheath. The blade can be easily adjusted and replaced, which makes the device highly practical. Because a push plate is added, there is no need for the blade to cut off the sheath completely, the scratch of the surface of the copper core is avoided, and the wear of the blade is reduced.

Owner:朱兴兴

Low-power consumption micro-heater with mesh-structured heating film and fabrication method thereof

ActiveCN101795505AReduce power consumptionReduce conductionDecorative surface effectsOhmic-resistance heatingElectrical resistance and conductanceMicroheater

The invention relates to a low-power consumption micro-heater with a mesh-structured heating film and a fabrication method thereof, and the micro-heater is characterized in that the micro-heater comprises the heating film with a mesh structure formed by regular arrangement of special-shaped meshes according to certain rules, the heating film is connected with a substrate frame through a support cantilever beam, and heating resistance wires are arranged on the heating film in the fold line way and connected with an electrode for a lead wire on the substrate frame through the support cantileverbeam. The structure can not only effectively reduce the heat conduction from the area of the heating film of the heater to the support cantilever beam, further reduce the power consumption of the device and expand the fabrication methods of the heater. The heater is particularly applicable to applications in the field of gas detection.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

Electromagnetic induction heating roller

InactiveCN102325395AReduce pollutionReduce fireCoil arrangementsInduction heating apparatusElectricityKerosene

The invention discloses an electromagnetic induction heating roller in which high-frequency electromagnetic induction coils are arranged. The main body is a hollow roller body; a magnetism conductive iron core is arranged in the roller body; one end of the magnetism conductive iron core is connected with a cable connector through a half shaft; a heating coil wound on the magnetism conductive iron core is led into the roller body via the cable connector; a compensative heating coil wound on both ends of the magnetism conductive iron core is led into the roller body via the cable connector; a layer of water-filled isolating cavity is arranged in the wall of the roller body; and the surfaces of both ends of the roller body are respectively provided with a plurality of air holes for exhausting heat. The heating roller which is produced by utilizing the electromagnetic induction heating principle can replace various other heating rollers which are still used in a large quantity at present. Compared with the currently used steam heating, resistance wires, electric heating tubes or method for heating the surface of the heating roller with hot kerosene, the electromagnetic induction heating roller can save more electricity consumption and increase the temperature stability and precision of the roller surface.

Owner:张家港市弘扬机械设备有限公司

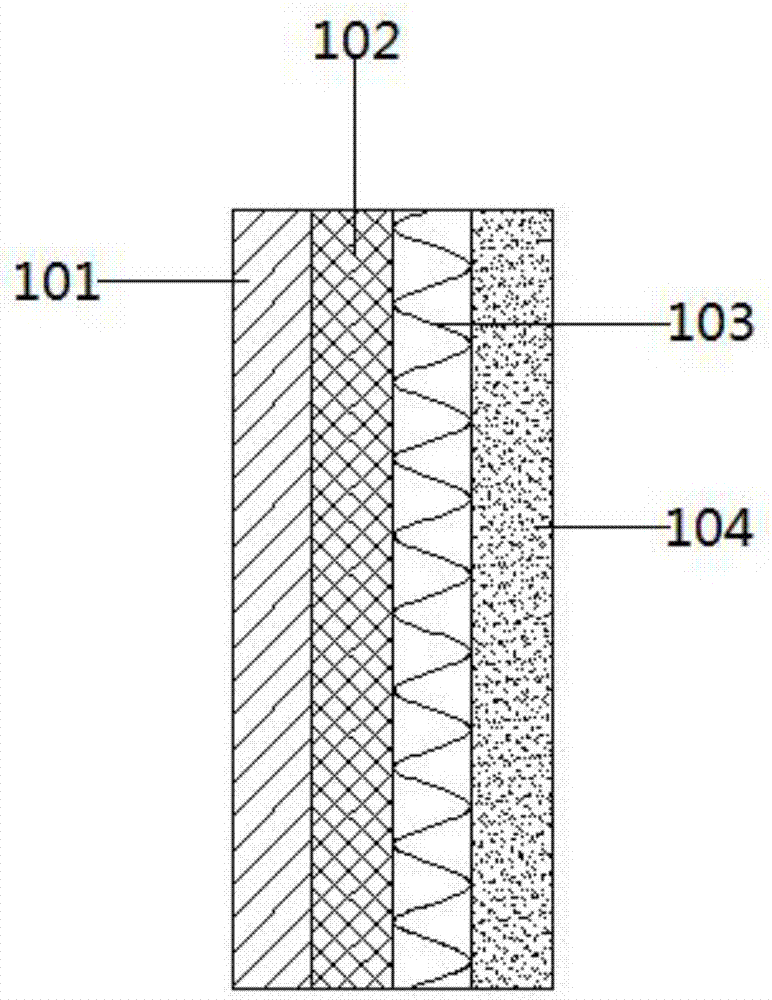

Material mixing device for chemical production

InactiveCN107321224AExtended service lifeStir wellRotary stirring mixersTransportation and packagingElectrical resistance and conductanceEnergy absorption

The invention discloses a material mixing device for chemical production. The material mixing device comprises a device body; the device body comprises a main body, the inner side of the main body is provided with a heat preservation layer, the inner side of the heat preservation layer is provided with a resistance wire heating layer, and the inner side of the resistance wire heating layer is provided with a ceramic layer; a feeding opening is formed in the left end of the upper side of the device body; a clapboard is horizontally arranged on the upper side of the interior of the device body and fixed on the inner wall of the device body; a bearing base is connected to the center of the top of the device body. The material mixing device for the chemical production is reasonable in structural design and long in service life; a stirring rotating shaft rotates clockwise and counterclockwise alternately, so that the material mixing effect and the working efficiency are effectively improved; the length of a stirring rod can be increased or decreased according to the rotation speed, and therefore the mixing radius is changed; through the arrangement of a stirring disc, materials at the bottom can be mixed, and the material mixing effect is further improved; in addition, under the cooperation function of a damping and energy-absorption part, a connecting rod, an annular spring part and an auxiliary damping part, the vibration caused when the device runs can be greatly reduced, and the stability is improved.

Owner:林红英

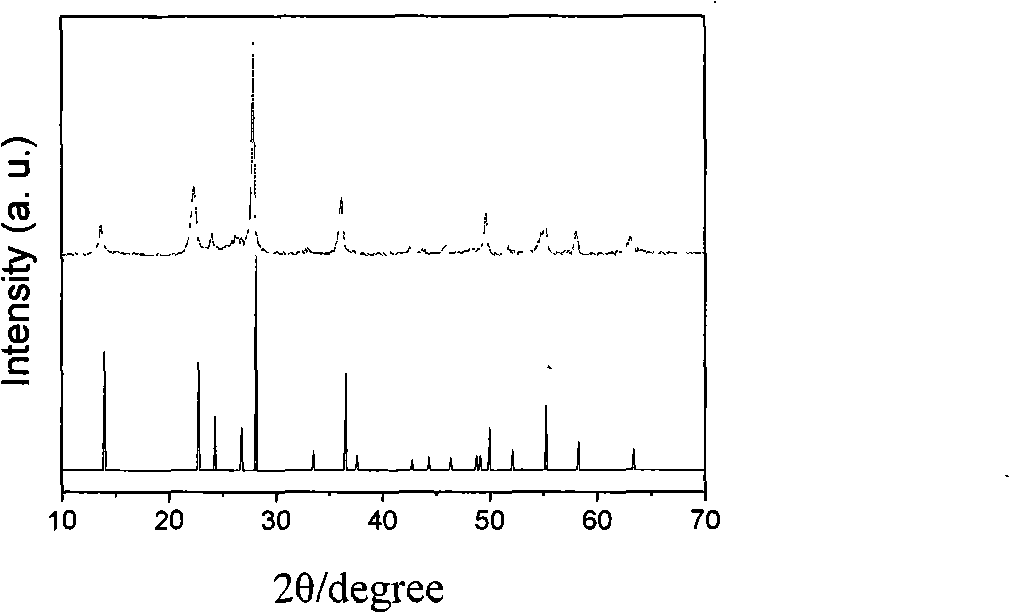

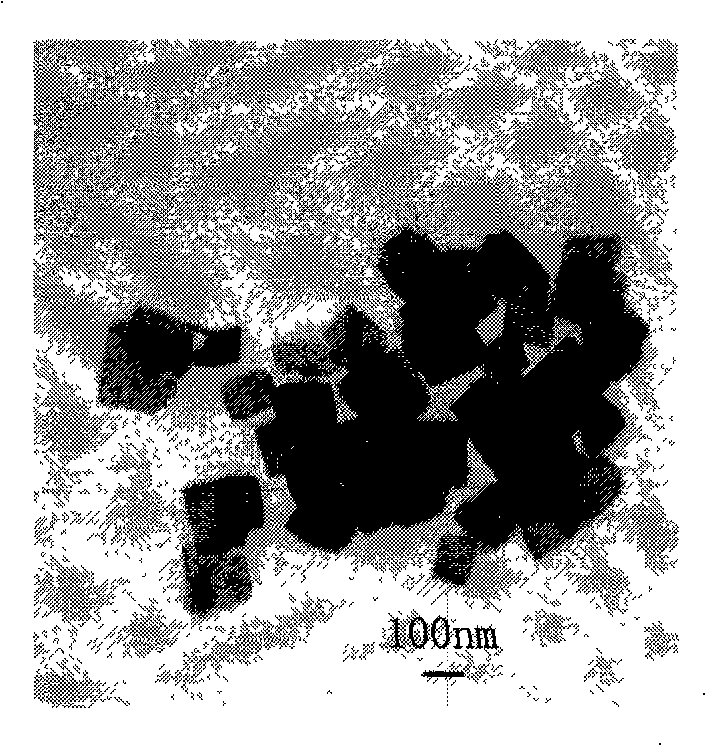

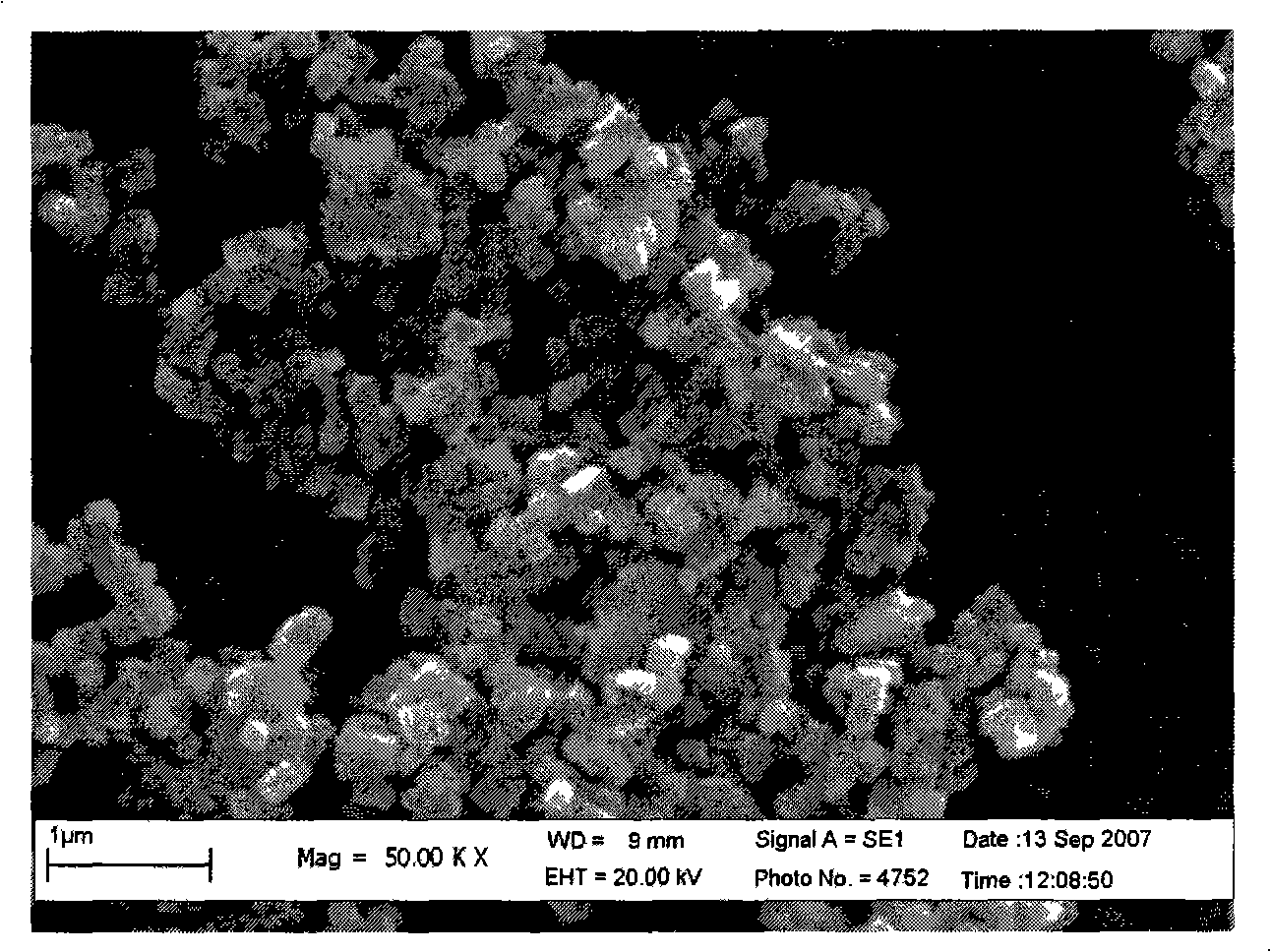

Method for synthesizing quadrangle tungsten oxide nano-powder

InactiveCN101407339AUniform sizeNo reunionNanostructure manufactureTungsten oxides/hydroxidesMetallic materialsHigh pressure

The invention relates to a preparation method of square tungsten oxide nano powder, belonging to the field of inorganic non-metallic materials. The content thereof is as follows: tungstenic acid deposition obtained by the reaction of sodium tungstate and hydrochloric acid is used as a precursor, citric acid is used as an auxiliary reagent, hydrochloric acid is used to adjust pH value and nano tungsten oxide is grown in a high-pressure autoclave by heating. Heating mode can be microwave heating and resistance wire heating, and the nanocrystalline grown is square. The characteristic of the square tungsten oxide powder material is that: the size of the square tungsten oxide is between 80 and 150nm. The advantages of the method are that: the process is simple, the cost is low and the shape and size of the tungsten oxide crystal are hydrothermally controlled by the citric acid auxiliary.

Owner:XINJIANG UNIVERSITY

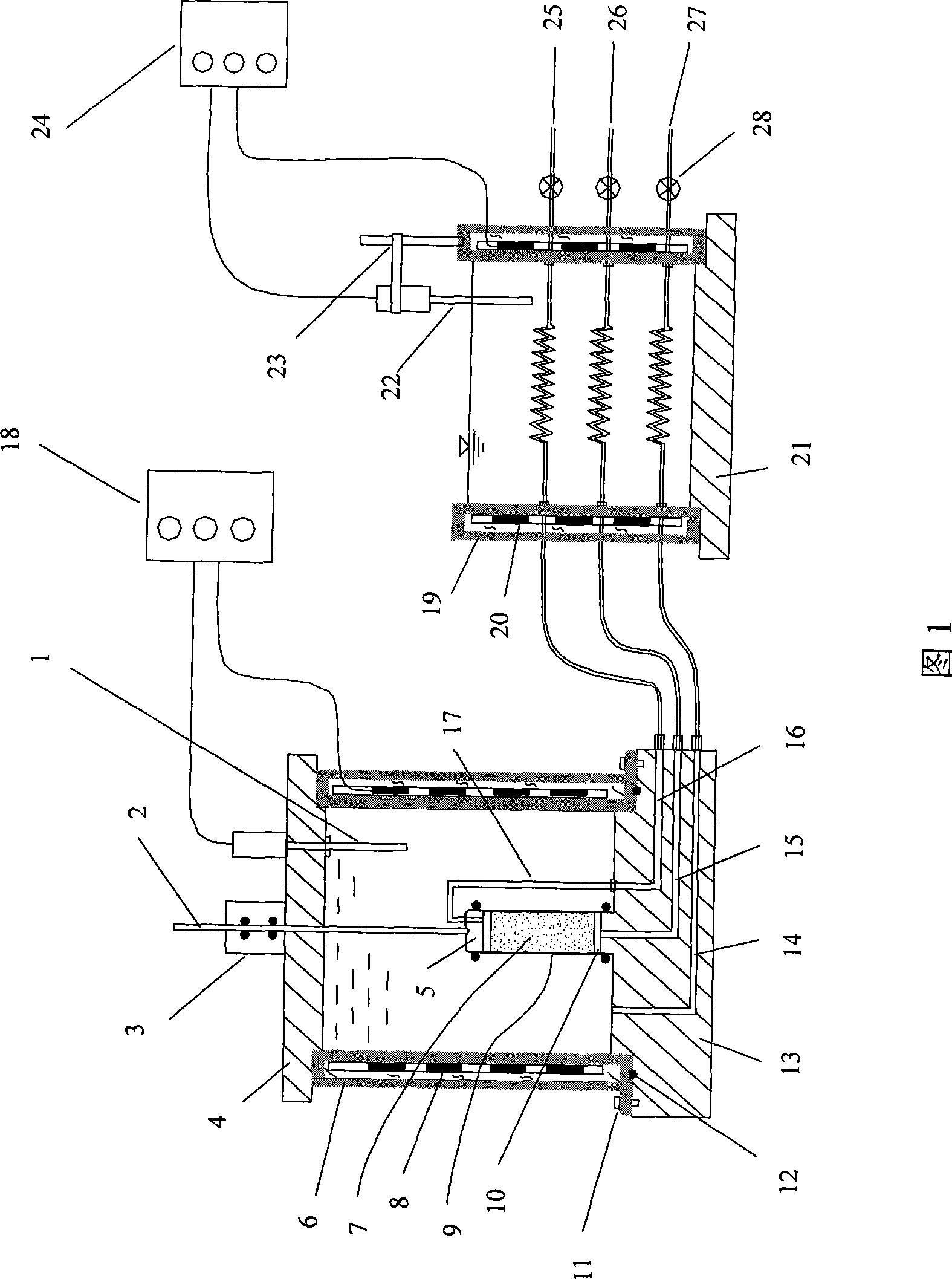

Temperature-control consolidation pressure chamber system

InactiveCN101430318AAccurate determination of thermal consolidation deformationAccurate determination of discharge volumeEarth material testingStrength propertiesElectrical resistance and conductanceTemperature control

The invention relates to a temperature-controlled consolidation pressure chamber system used in thermal consolidation test of a saturated soil cylinder sample. Side walls (6) of the temperature-controlled consolidation pressure chamber are of empty-cavity structures made of stainless steel; cylinder thermal plates (8) are embedded in the side walls; the two ends of resistance wires of the cylinder thermal plates (8) of the pressure chamber are connected with a temperature controller (18); an electric couple (1) is arranged at the top cap of the pressure chamber, one end of the electric couple is arranged in the pressure chamber which is full of water and the output end is connected with the temperature controller. Sample water drain pipes, pipes for measuring pore water pressure and ambient pressure connection pipes are made of stainless steel and the middle sections take a shape of a spiral arranged in a water receptacle with a constant temperature; the sample drain pipe coming out of the water receptacle is connected with a pipe for detecting leakage of sample; the pipes for measuring pore water pressure are connected with a pore water pressure measuring system; the ambient pressure connection pipes are connected with a pressure regulating system. The system can satisfy the requirements of the saturated soil sample consolidation test under the action of loading at the changing temperature, thus the system can test the thermal consolidation deformation of the saturated soil sample accurately.

Owner:BEIJING JIAOTONG UNIV +1

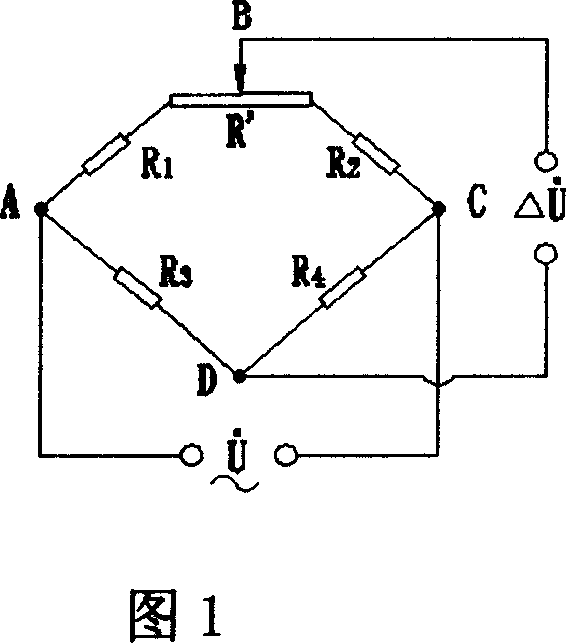

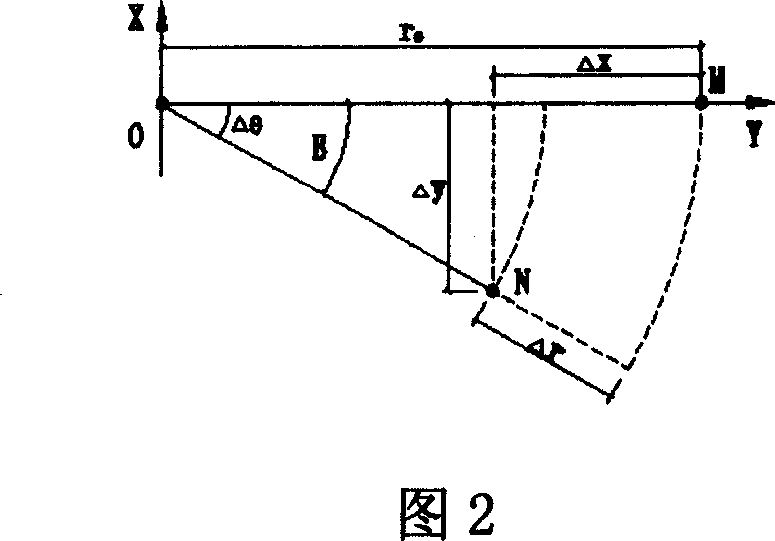

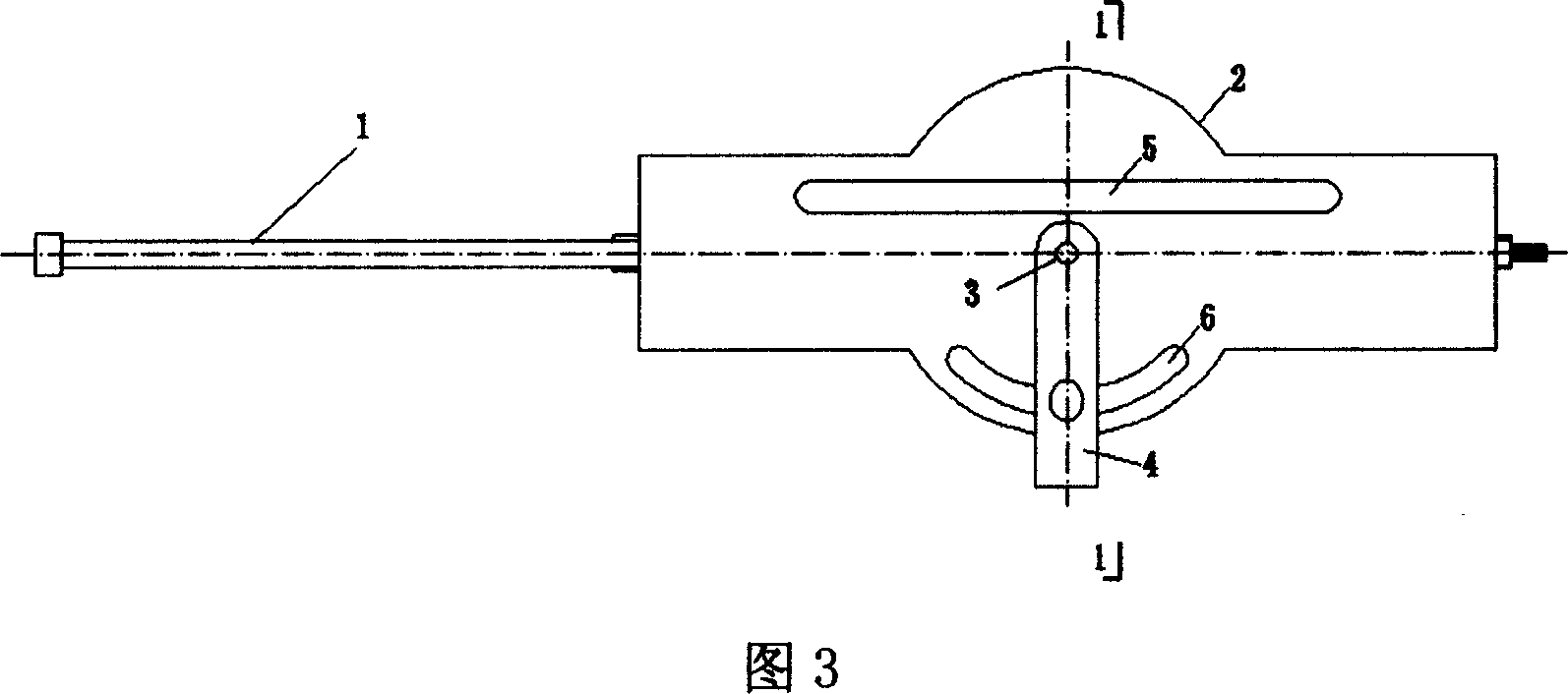

Method for measuring two-dimension displacement and two-dimension displacement sensor

ActiveCN101063621ASimple structureHigh measurement accuracyUsing electrical meansConverting sensor output electrically/magneticallyEngineeringRotation around a fixed axis

This invention relates to one 2D displacement measurement method, which comprises the following steps: according to Wheatstone bridge circuit test principle to distribute the bridge resistance wire into direct or arc shape and the direct resistance wire is to test line displacement; the arc resistance wire is to test arc length change volume and then according to the relationship between arc length and radium to get test point rotary angle; through testing points in electrode coordinate displacement change to realize 2D displacement. The 2D displacement sensor comprises the test bridge line resistance wire and arc resistance wire fixed onto one structure around axis and it also comprises data transmission line.

Owner:上海筑邦测控科技有限公司

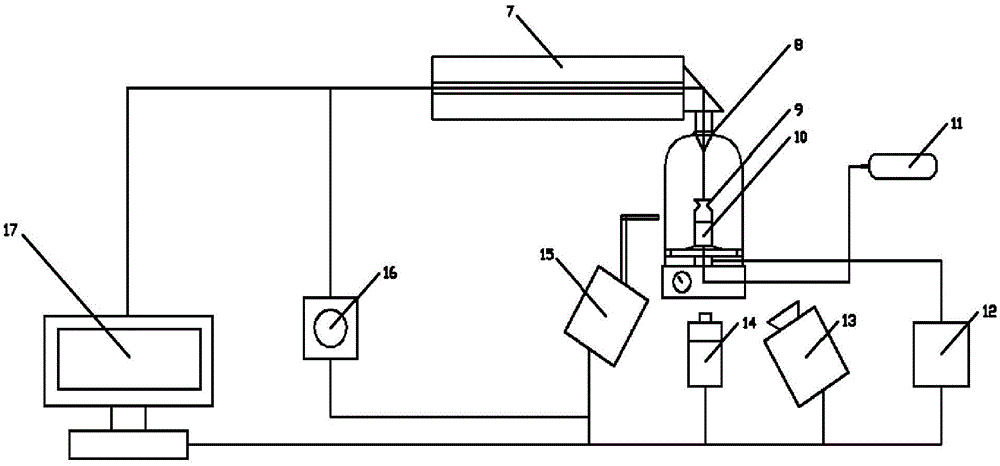

Device for testing ignition combustion characteristics and propulsive performance of solid fuel micro-thruster

The invention relates to a testing device for testing ignition combustion characteristics and propulsive performance and is to disclose a device for testing ignition combustion characteristics and propulsive performance of a solid fuel micro-thruster. The device comprises a laser, a reactor, a vacuum pump, a high-speed camera, a high-speed temperature detector, a fiber optic spectrometer, a data acquisition card, a synchronous trigger switch and a computer, wherein the reactor comprises a pressure-resistant glass cover, a micro-thruster fixing rack, a sealing ring, a pedestal, a pressure gauge and a high-sensitivity pressure sensor. The device is characterized in that a propulsive agent in the thruster is ignited by a laser ignition method; the ignition energy, the ignition temperature and the heating rate are basically the same as these of the actual resistance wire, but the cost is greatly reduced, the process is greatly simplified, and the working stability is better; thus the testing device is very suitable for test and research in a laboratory.

Owner:ZHEJIANG UNIV

Float type level gauge for high-temperature high-pressure or high-temperature low-density medium

InactiveCN101726344ASolve high temperature and high pressureSolve densityLevel indicators by floatsMagnetic tension forceSpherical shaped

The invention relates to a float type level gauge for high-temperature high-pressure or high-temperature low-density medium, comprising a float chamber, a float and a graduated scale; the float type level gauge is characterized in that: the float is a hollow spherical shape; the float type level gauge further comprises a guide rail and a magnetic connector, a magnetic steel or a disc-shaped magnetic steel is arranged in the magnetic connector and forms magnetic attraction with a magnetic ball body in the float made of the nonferrous magnetic material or the disc-shaped magnetic steel the float made of the nonferrous magnetic material, a metal shaft laterally spanned at two side walls of the magnetic connector is exposed to two side walls and is attached to the guide rail by magnetic force, and the metal shaft can move up and down along the guide rail under the driving of the magnetic force; in addition, resistance wires are wound on the guide rail to measure the change of the resistance value of a return circuit, so as to realize continuous remote transmission of a signal. The float type level gauge for high-temperature high-pressure or high-temperature low-density medium solves the difficult problem of liquid level measurement in the high-temperature high-pressure or high-temperature low-density medium and has high measuring precision; in addition, the structure is simple, the usage is convenient, the manufacturing and maintaining cost is low and the application is wide.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

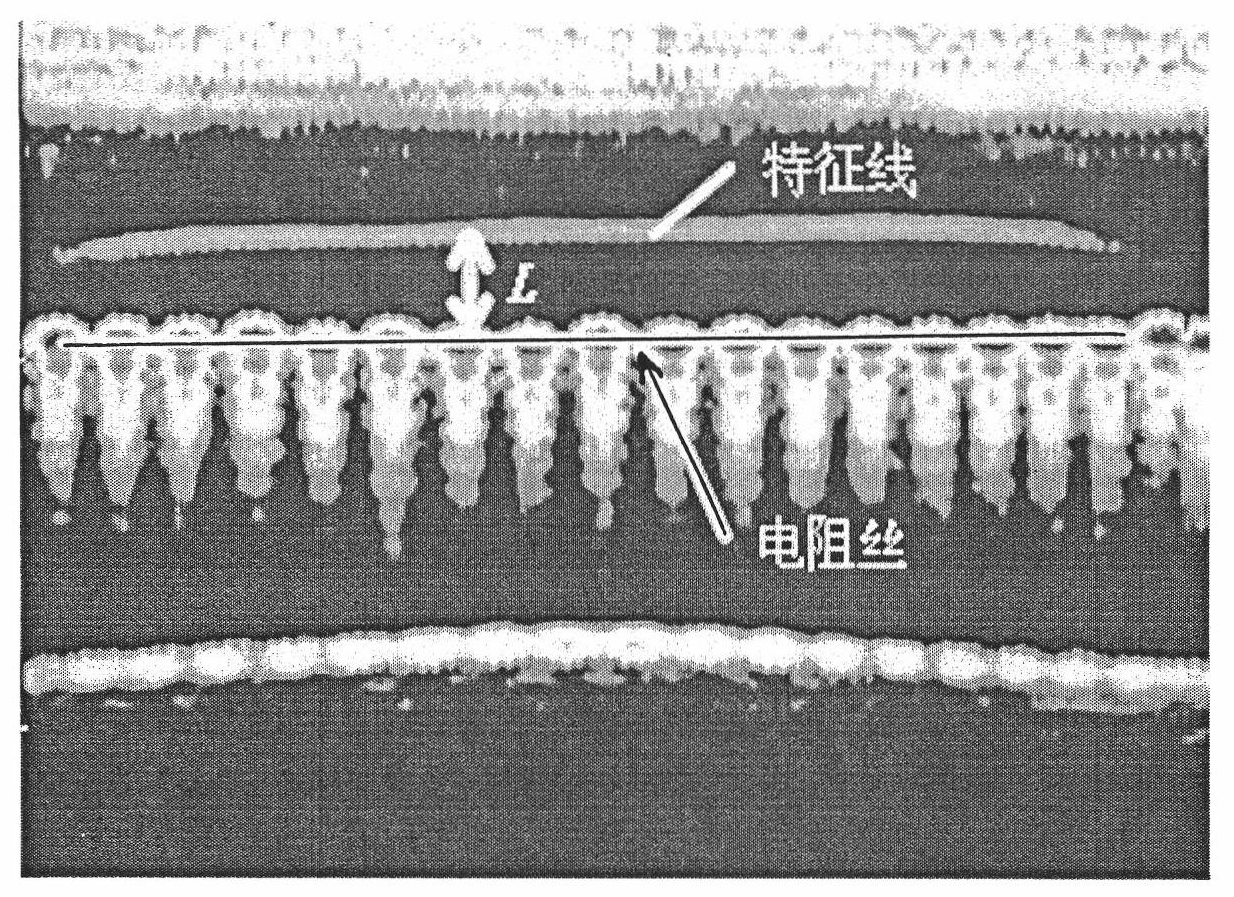

Method for testing welding quality of electro-fusion joint and realizing automatic evaluation

ActiveCN102009474AQuality improvementAvoid putting into useTubular articlesElectrical resistance and conductanceEvaluation result

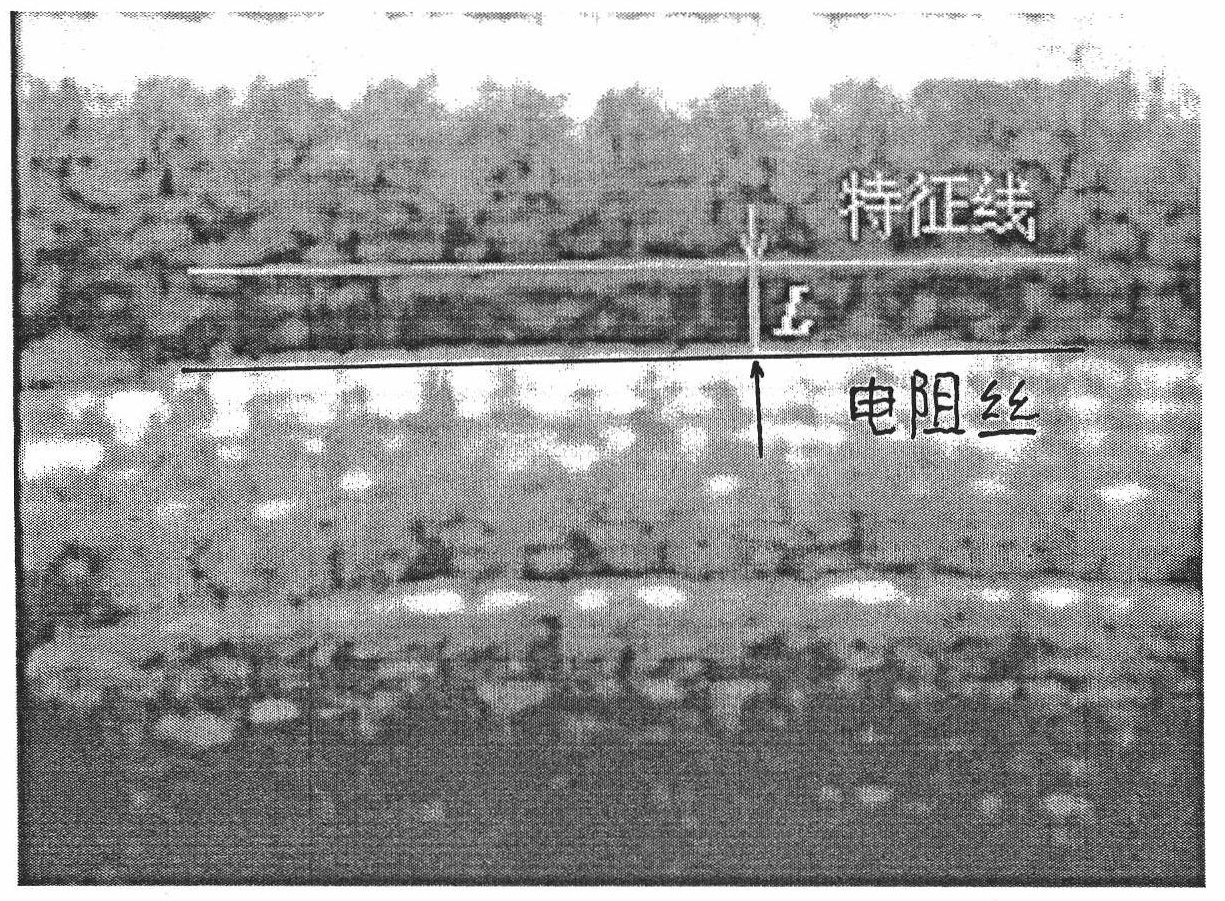

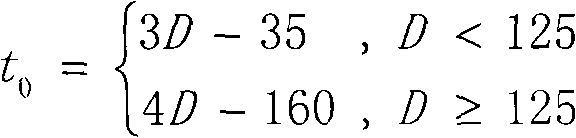

The invention relates to electro-fusion welding technology for plastic pipelines or plastic composite pipelines, and aims to provide a method for testing the welding quality of an electro-fusion joint and realizing automatic evaluation. The method comprises the following steps of: measuring peeling energies E of the electro-fusion joint and the distance L between a characteristic line and a resistance wire under different welding conditions, and acquiring a fitted curve, serving as a calibration basis, of the peeling energy per unit area Ep and the distance L; and testing the welding quality of the electro-fusion joint and realizing the automatic evaluation. The method can prevent unqualified electro-fusion joints from being put into use, so that the safety of plastic pipes and composite pipe systems is ensured. A software module for realizing the method is integrated on an electro-fusion welded or electro-fusion jointed ultrasonic testing instrument, so that a welder automatically controls the welding quality or the testing instrument automatically evaluates an electro-fusion welded joint to be tested, the influence of human factors is avoided, and the quality of a welded joint is more reliable and the evaluation result is more objective.

Owner:ZHEJIANG UNIV

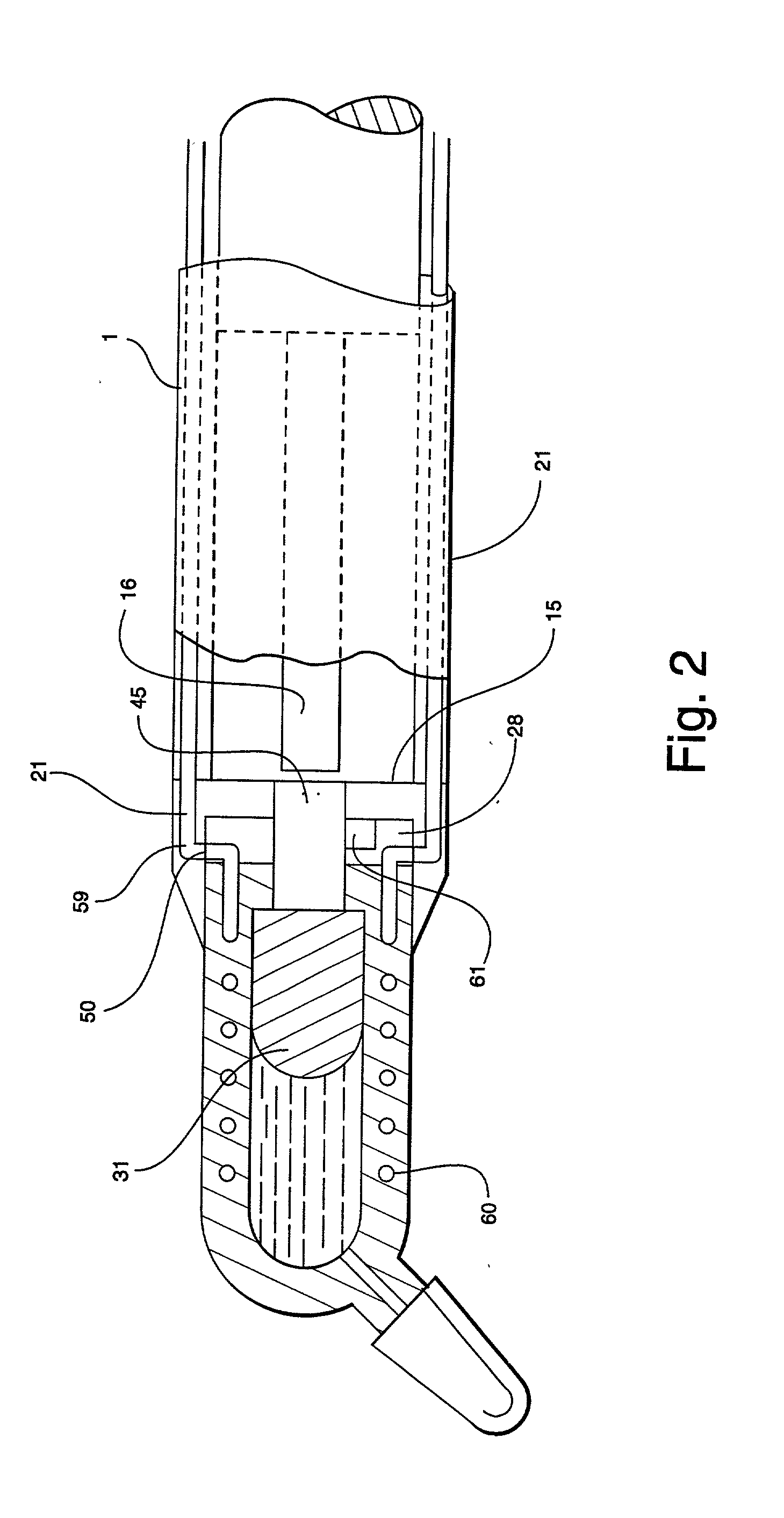

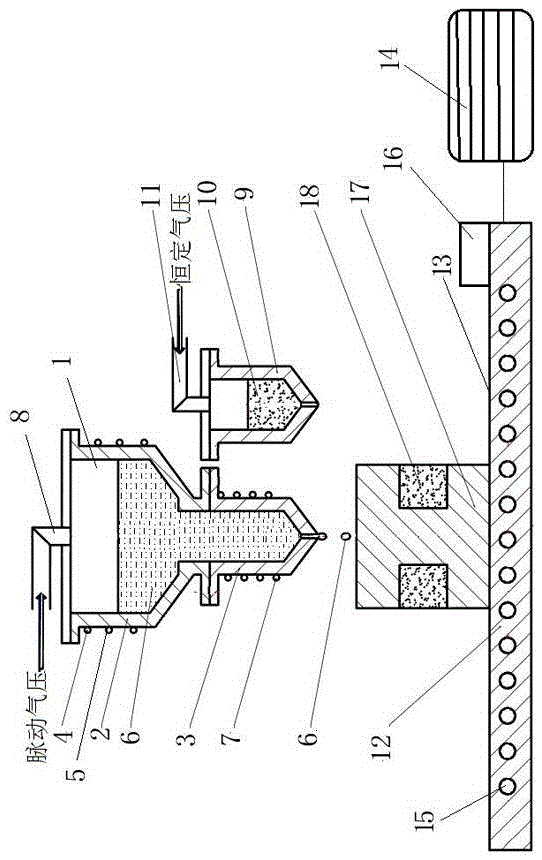

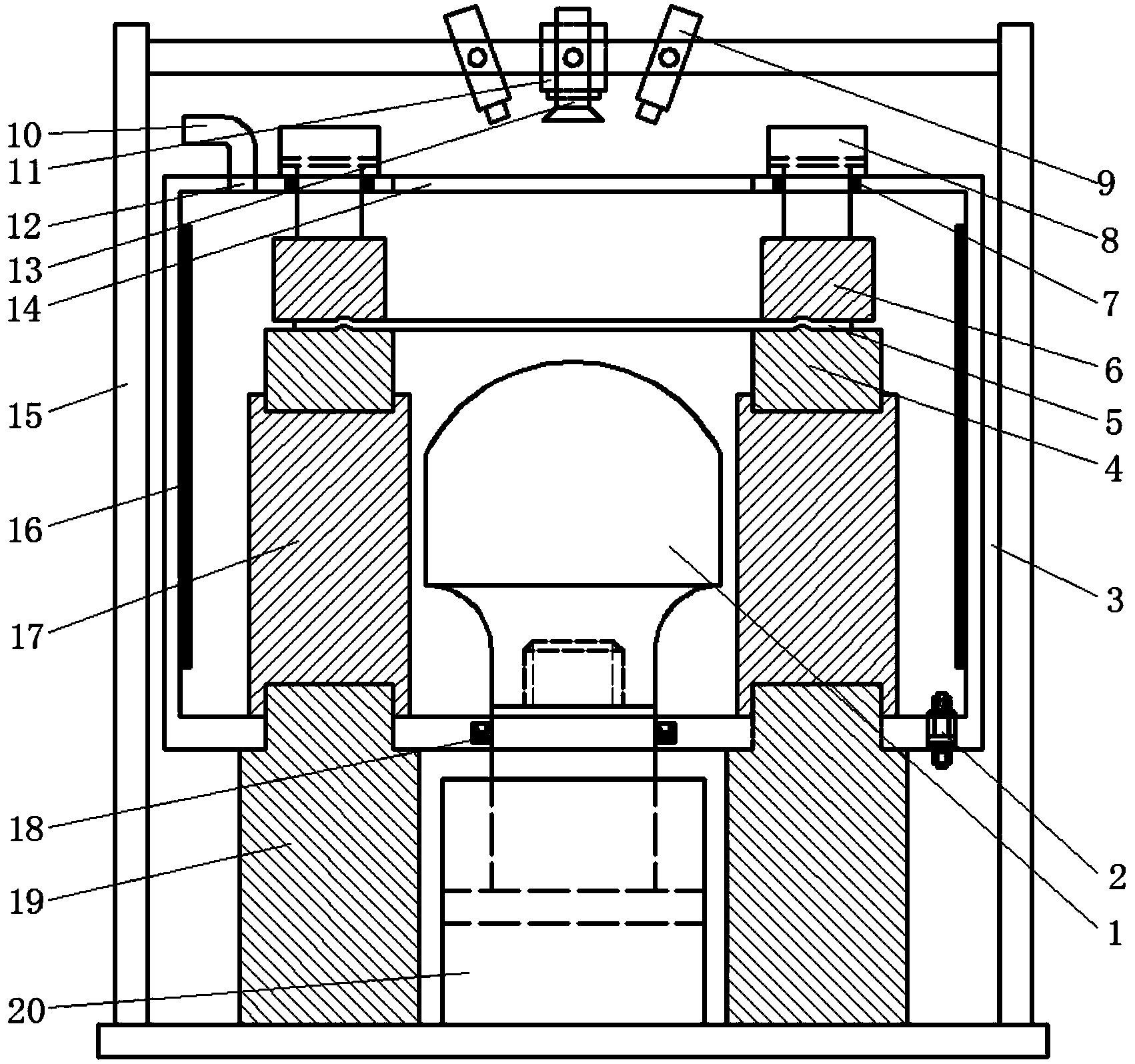

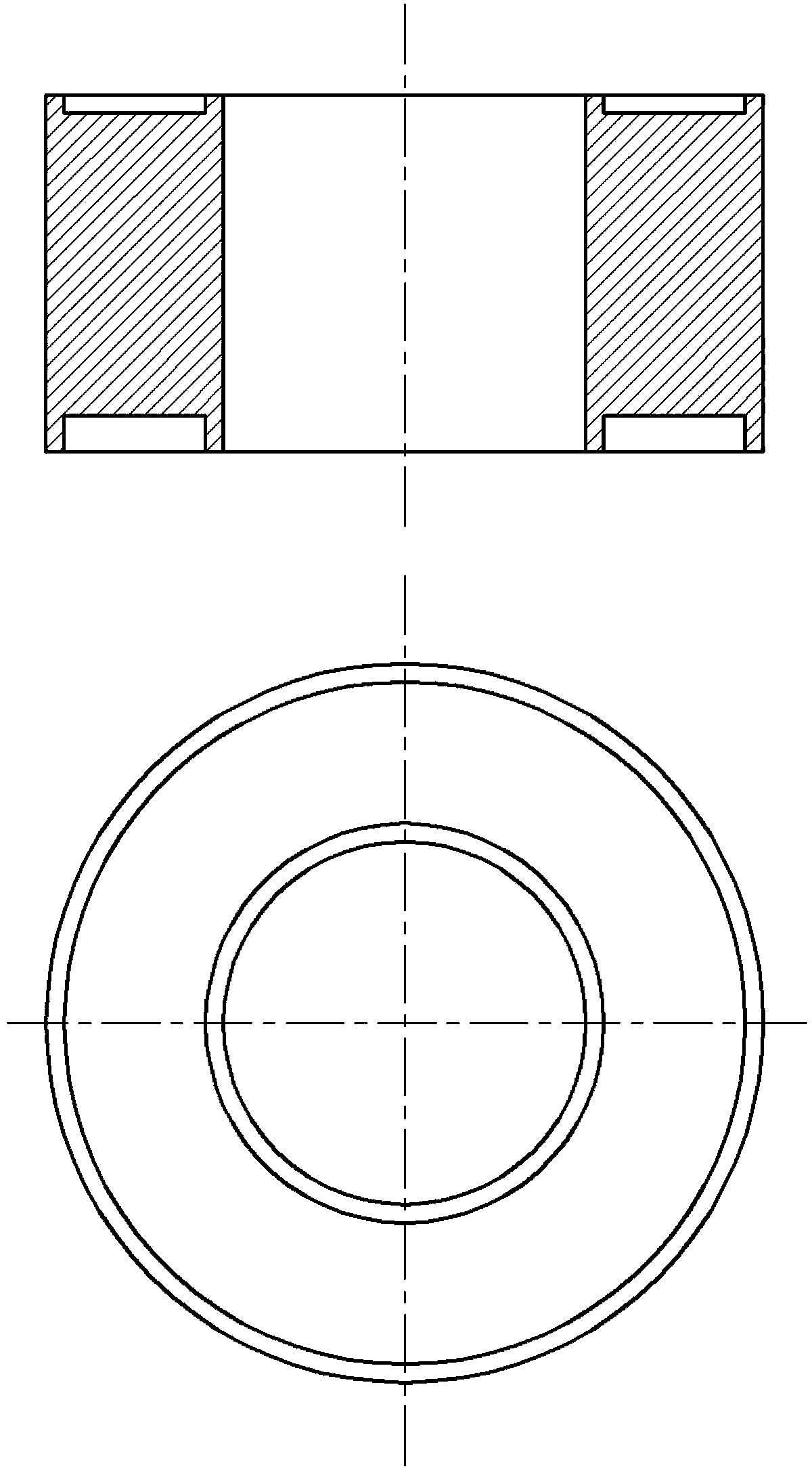

Thermal forming limit experimental device for metal sheet and testing method

InactiveCN103852388AAvoid errorsIntuitive and accurate judgmentInvestigating material ductilityElectrical resistance and conductanceHydraulic pump

The invention relates to a thermal forming limit experimental device for a metal sheet and a testing method. The device comprises a punch (1), a gas one-way valve (2), a seal box (3), a blank holder (4), a die (6), a die pressure lever sealing ring (7), a die hydraulic pump (8), a high-speed camera (9), an air inlet pipe (10), an infrared temperature sensing device (11), a vent hole (12), an illuminating lamp (13), toughened glass (14), a bracket (15), a resistance wire (16), a blank holder support (17), a punch hydraulic pump connecting rod sealing ring (18), a seal box support (19) and a punch hydraulic pump (20). Test pieces can be heated by the thermal forming limit experimental device during experiments, and errors caused by heating a sample outside and transferring the heated sample to a mould are prevented.

Owner:HUNAN UNIV

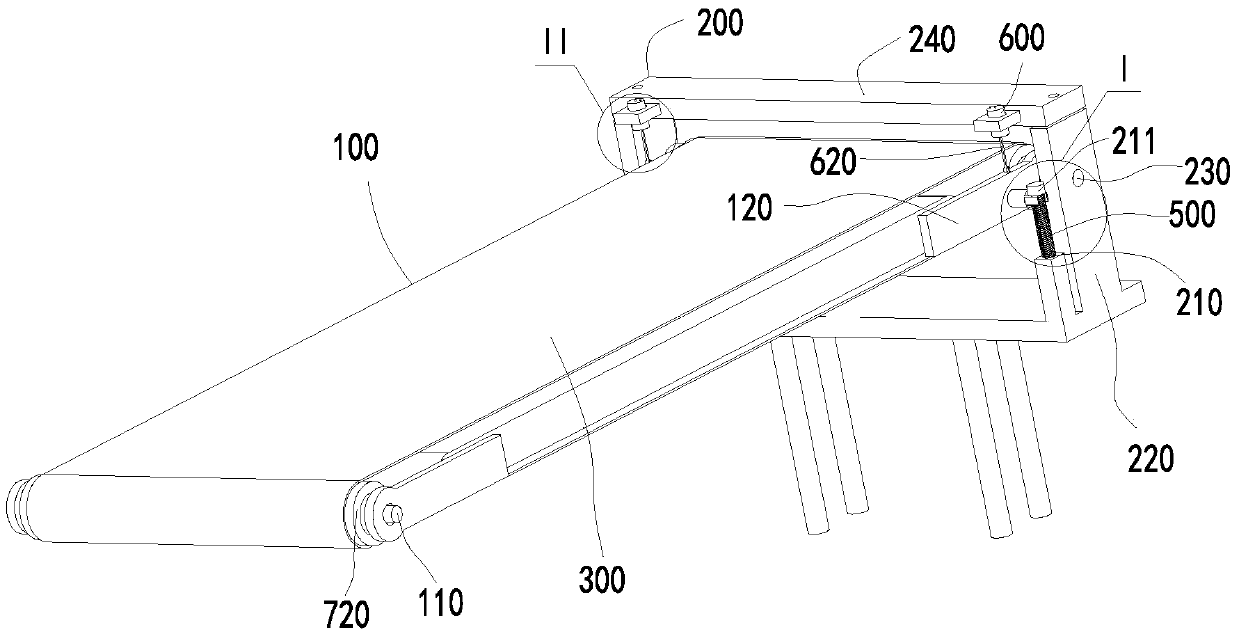

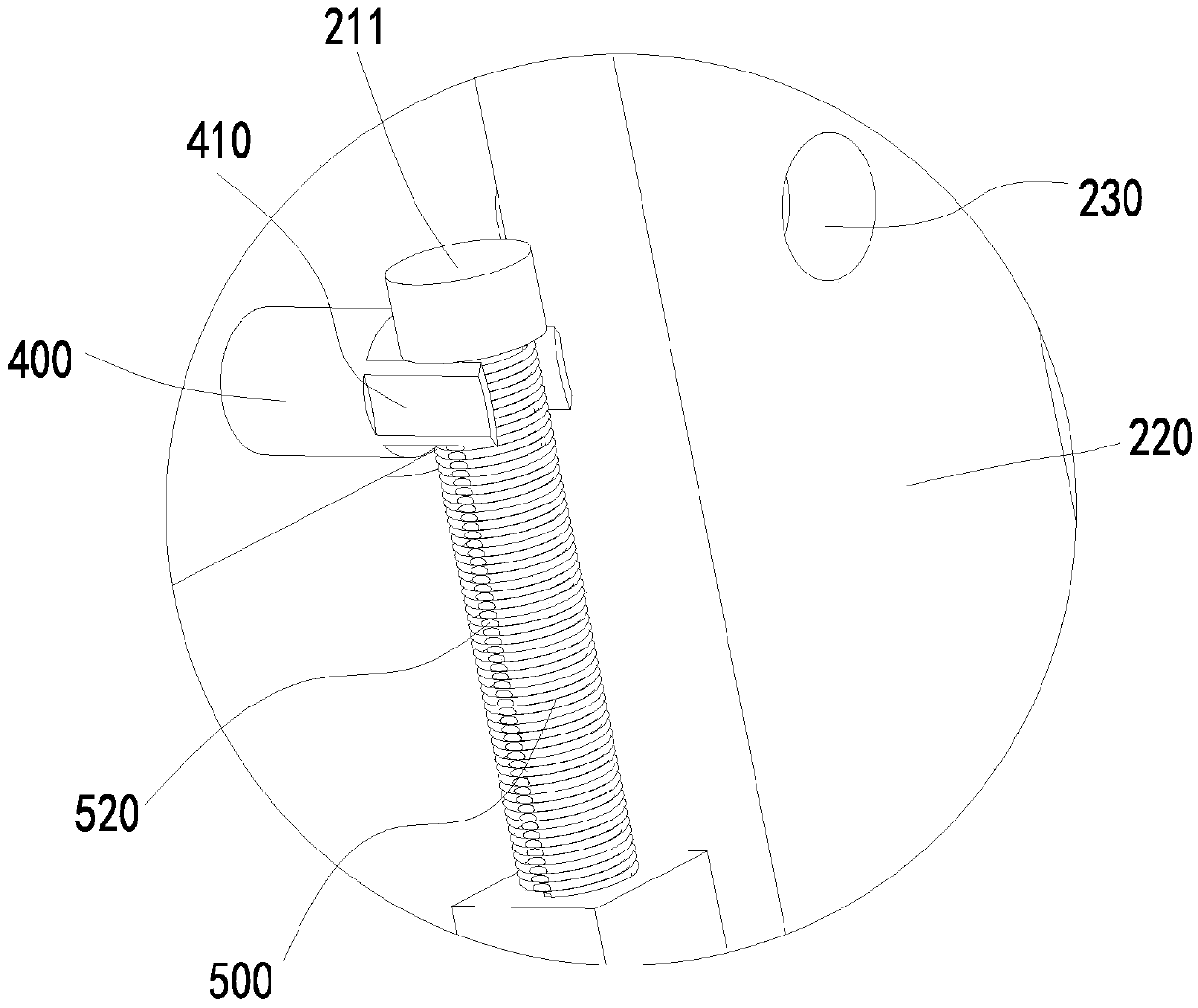

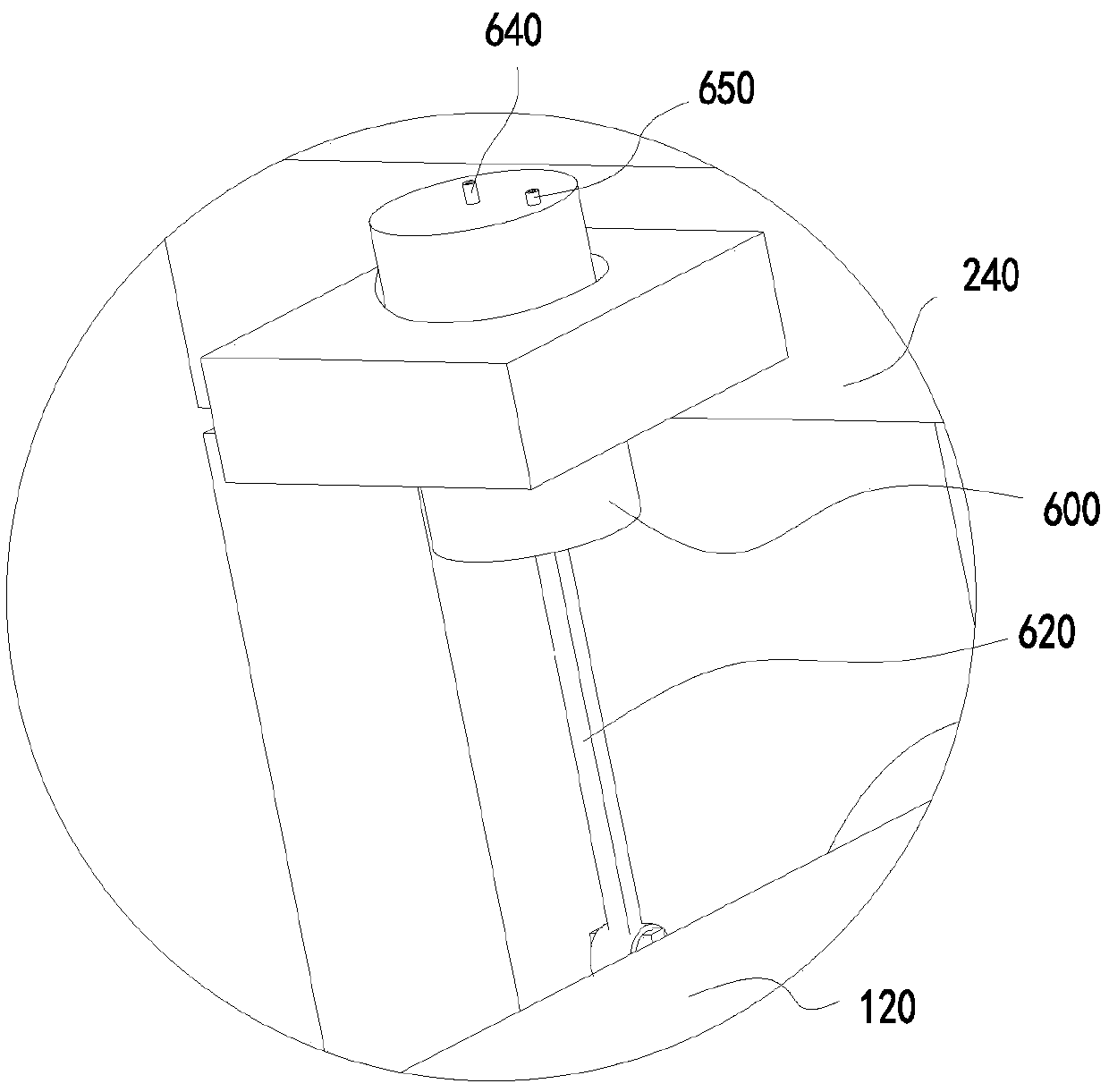

Automatic balancing device for cleaning equipment

InactiveCN105496333AHigh degree of intelligenceReduce energy consumptionTableware washing/rinsing machine detailsCleaning equipmentElectrical resistance and conductanceDrive wheel

The invention provides an automatic balancing device for cleaning equipment. The device comprises a conveying belt, a rotation mechanism, a supporting mechanism, an elastic contact chip, a resistance wire, a cylinder, a piston, a piston rod, a driving device and a driving wheel, wherein two ends of the piston rod are respectively connected on the piston and the rotation mechanism; a supporting part is arranged on the supporting mechanism; the resistance wire is wound outside the supporting part, and an insulation layer covers the resistance wire; each circle of the resistance wire forms a resistance ring, and adjacent resistance rings are attached with each other; a notch is formed in each resistance ring, and adjacent notches are communicated with each other; and a contact is formed in the front end of the elastic contact chip, is contacted with the resistance wire at the notches, and can slide to and fro in the channel formed by each notch. After load disappears, the cylinder returns to the initial balanced state, so that the detected resistance value is recovered to the initial value, and the driving device can run at an adaptive rotating speed according to the size of the load under an unmanned situation and can halt in time after the load disappears.

Owner:CHANGSHA GAOHUI ENVIRONMENTAL PROTECTION SCI & TECH

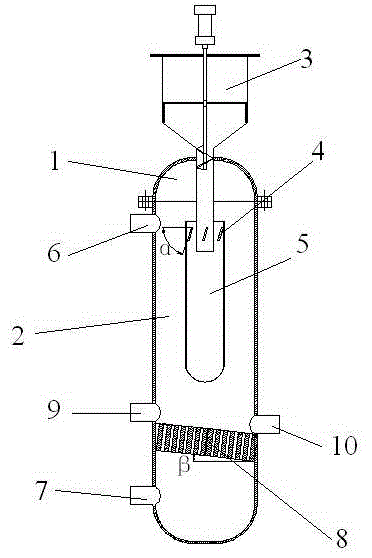

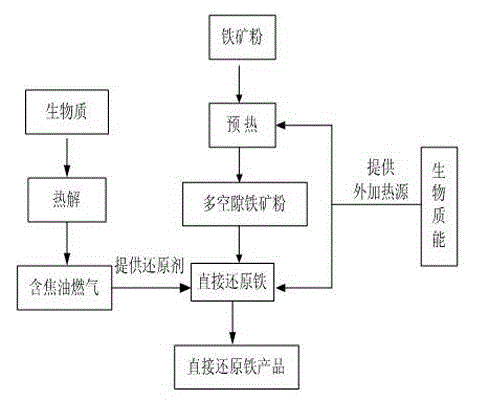

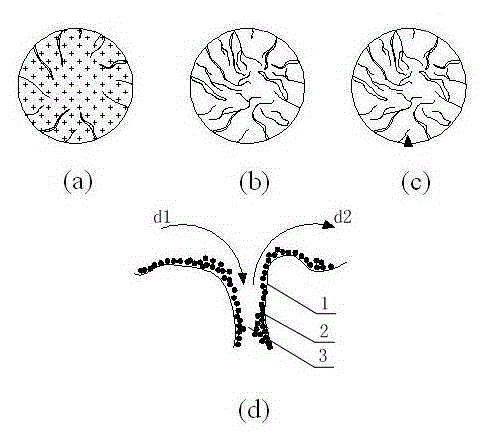

Device and method for direct reduction and iron making of pyrolyzing tar based on biomass

InactiveCN103146865AGet rid of dependenceLess investmentGas emission reductionElectrical resistance and conductanceIron powder

The invention provides a device and method for direct reduction and iron making of pyrolyzing tar based on biomass. The device is composed of a biomass pyrolysis area and an iron ore reduction area, wherein a biomass feeder is arranged on the top of the biomass pyrolysis area; the baiting pipe of the biomass feeder is connected with a pyrolysis basket through a baffle board; the iron ore area is provided with a gas inlet, a gas outlet, a ceramic screen, an iron powder feed port and an iron powder discharging port; and a resistance wire is arranged on outer side surface of the iron ore reduction area. The method comprises the following steps: pre-heating, dehydrating and pore-forming of the iron ore powder, deposition of gaseous biomass tar on the surface of porous iron ore powder surface, tar cracking and iron ore reduction. The direct reduction and iron marking is performed by pyrolyzing tar based on biomass in replacement of the coal and natural gas, so the investment is less, the cost is low, the production efficiency is high, and the obtained product is high in quality, the dependence of the iron-making industry to the fossil energy is cast off, the harm to the environment is reduced while directly improving the quality of the directly reduced iron product, and the technical and equipment problem in the environment-friendly iron-making industry is fundamentally solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com