Patents

Literature

1656 results about "Hexagonal boron nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

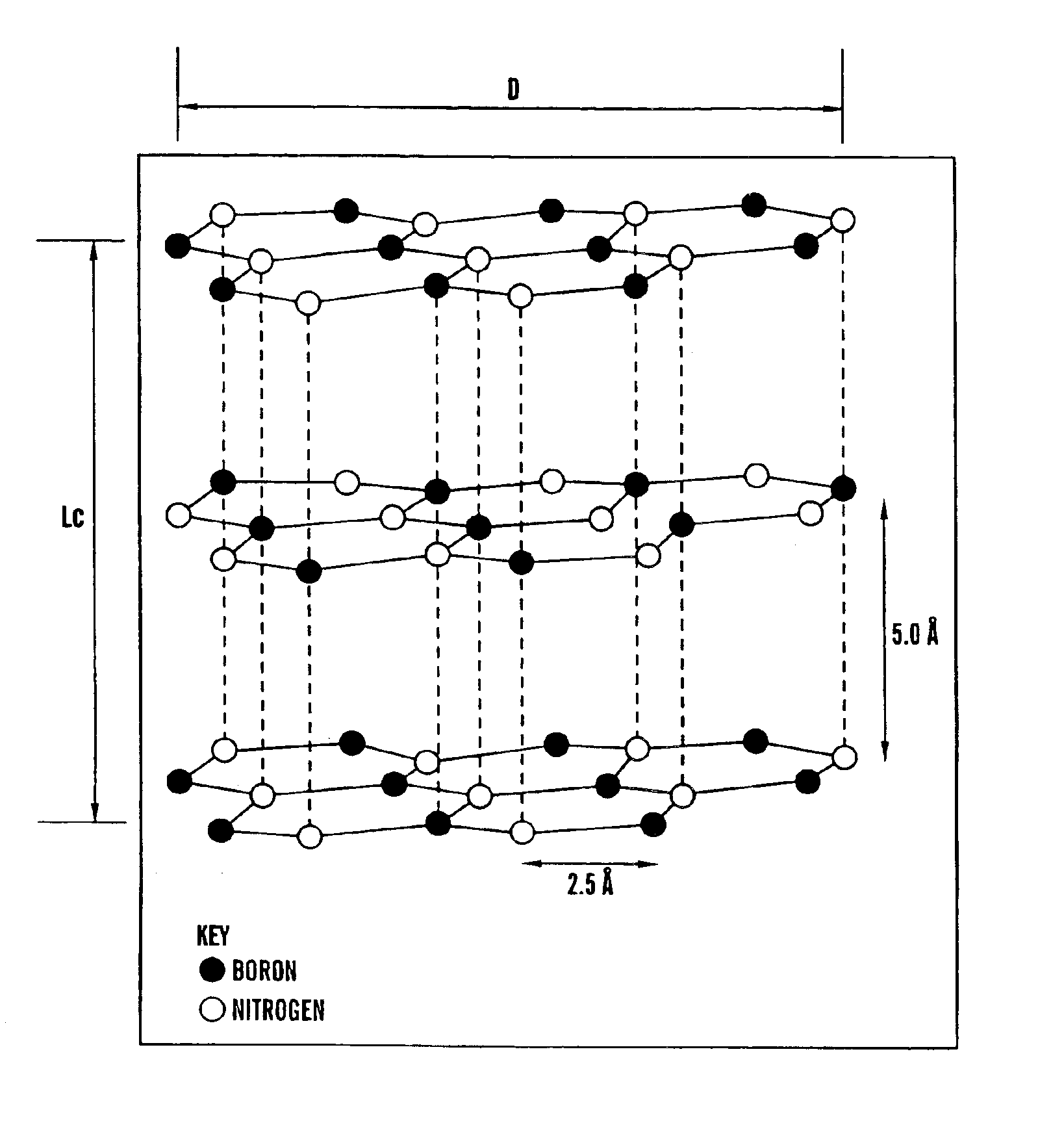

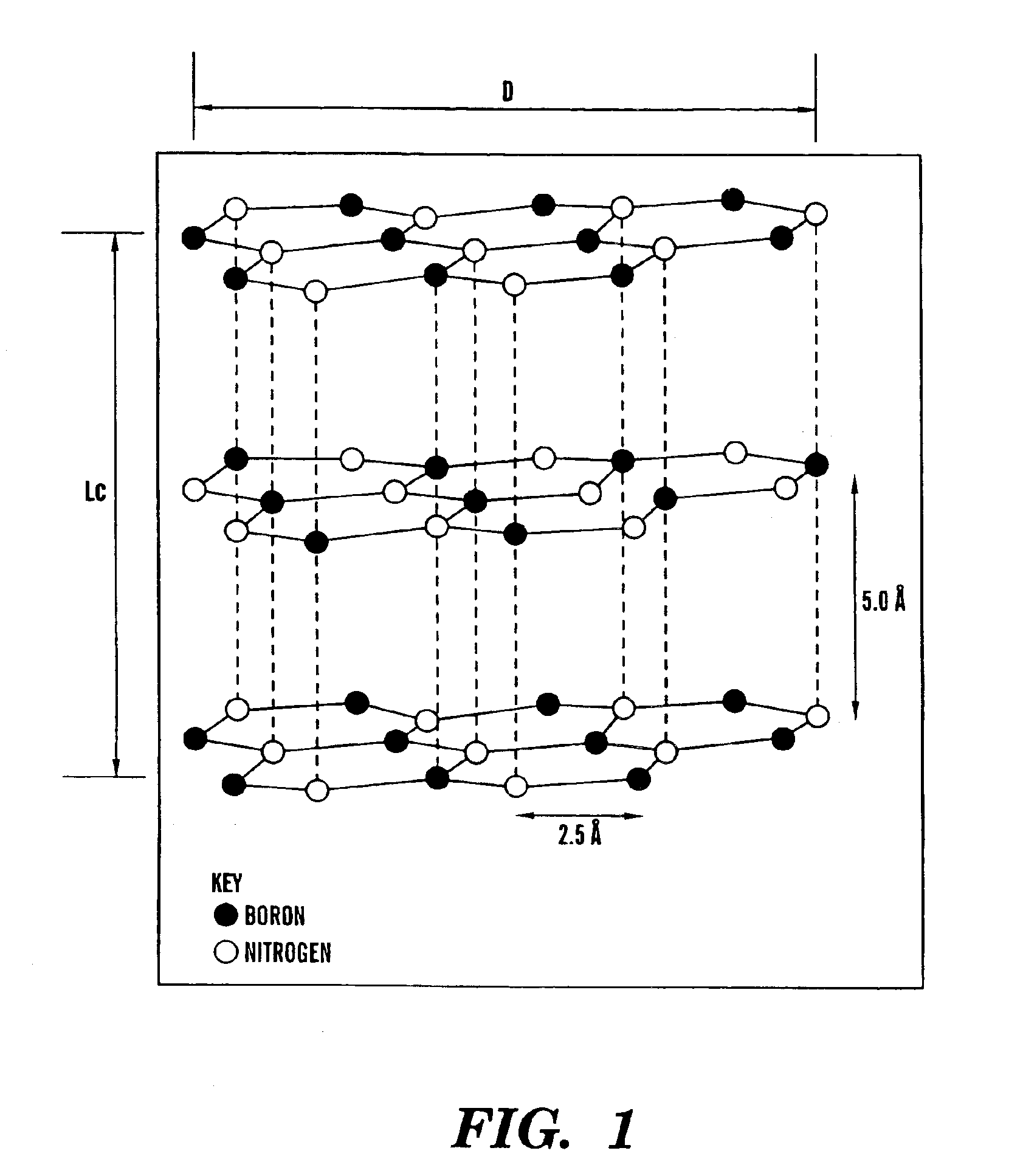

Hexagonal Boron Nitride (HBN) is an advanced bullet-coating material. HBN, also known as ‘White Graphite’, has similar (hexagonal) crystal structure as graphite, though it is a much better lubricant. For those who prefer shooting coated bullets, HBN appears to have many advantages over molybdenum disulfide (moly).

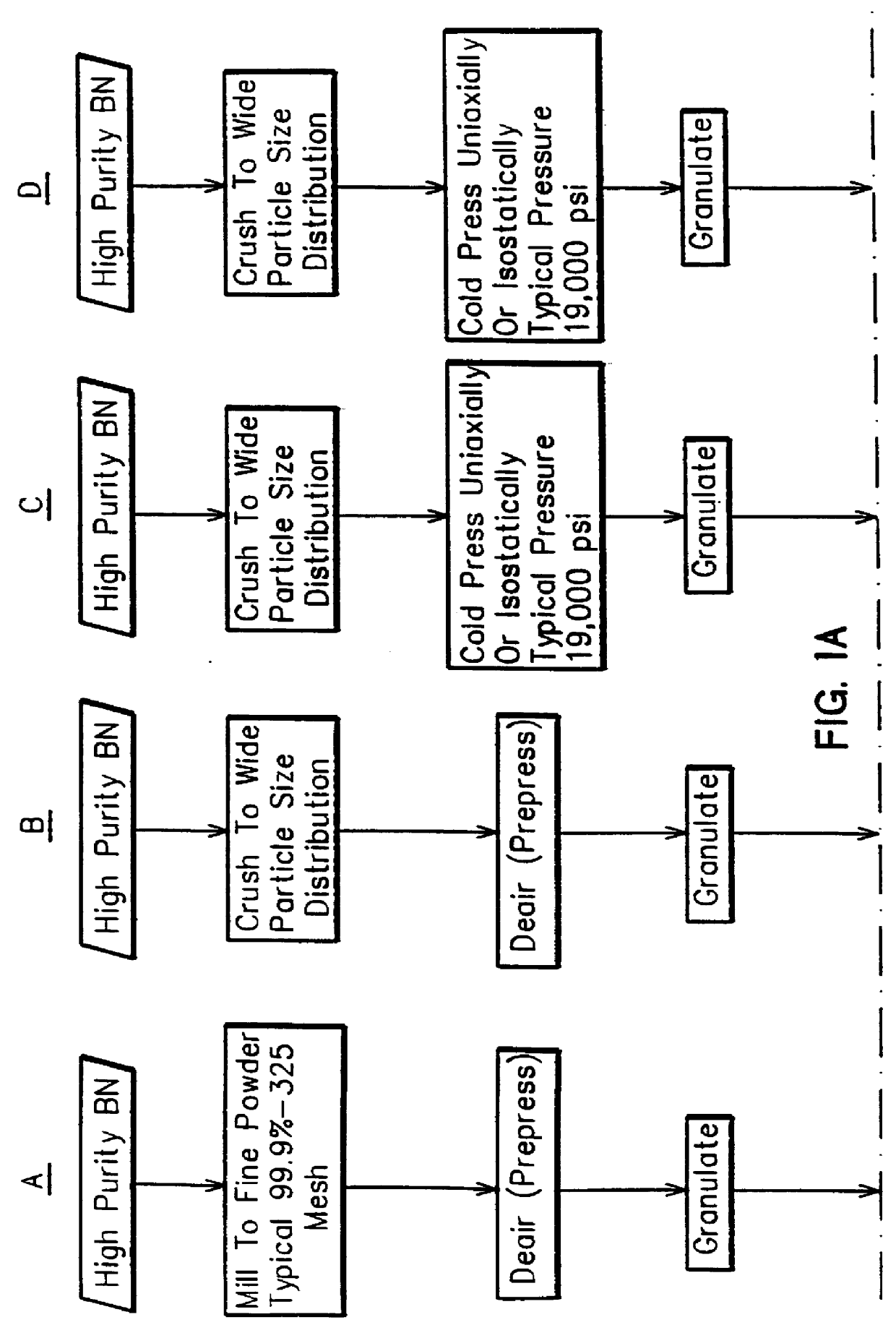

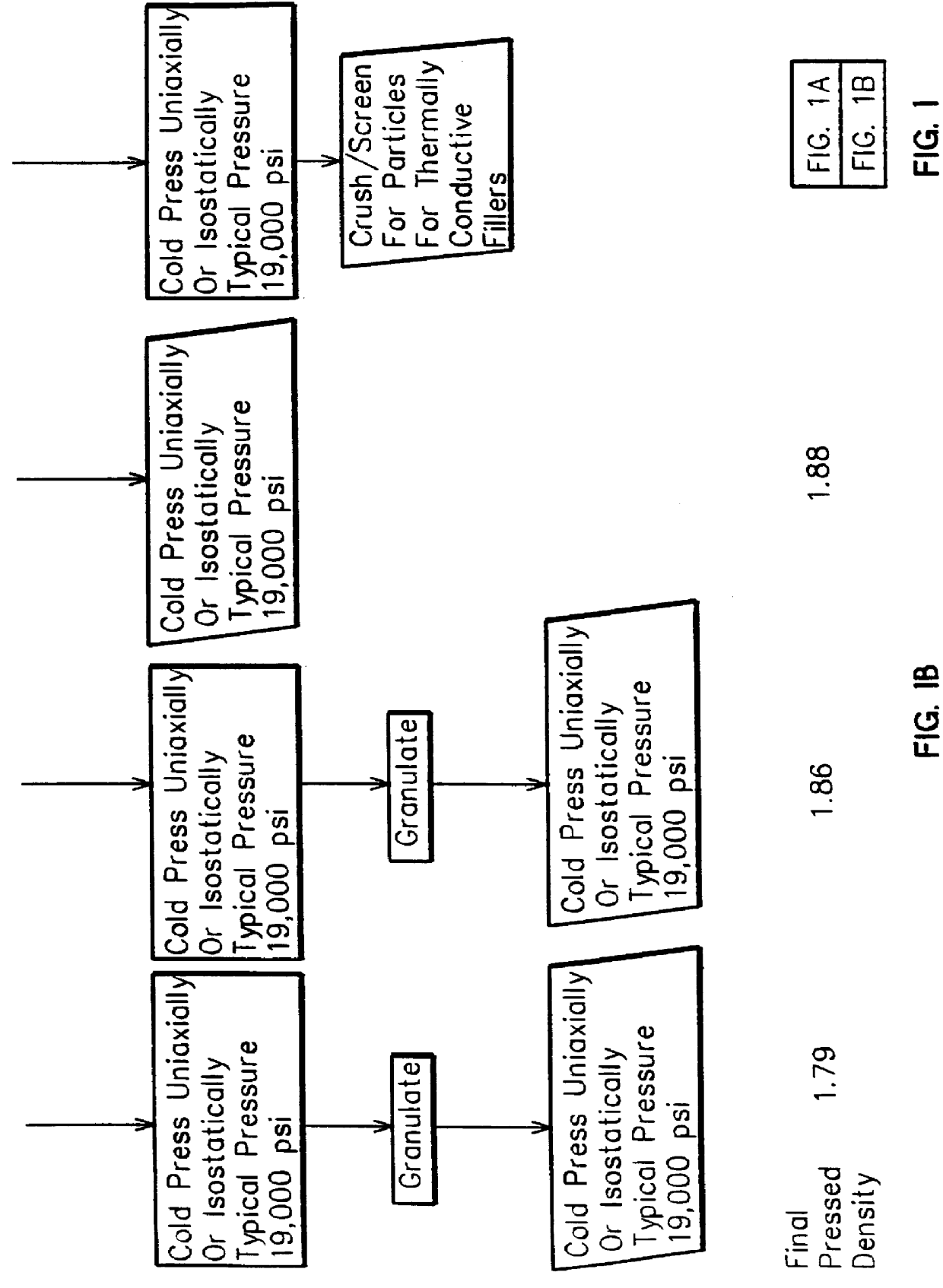

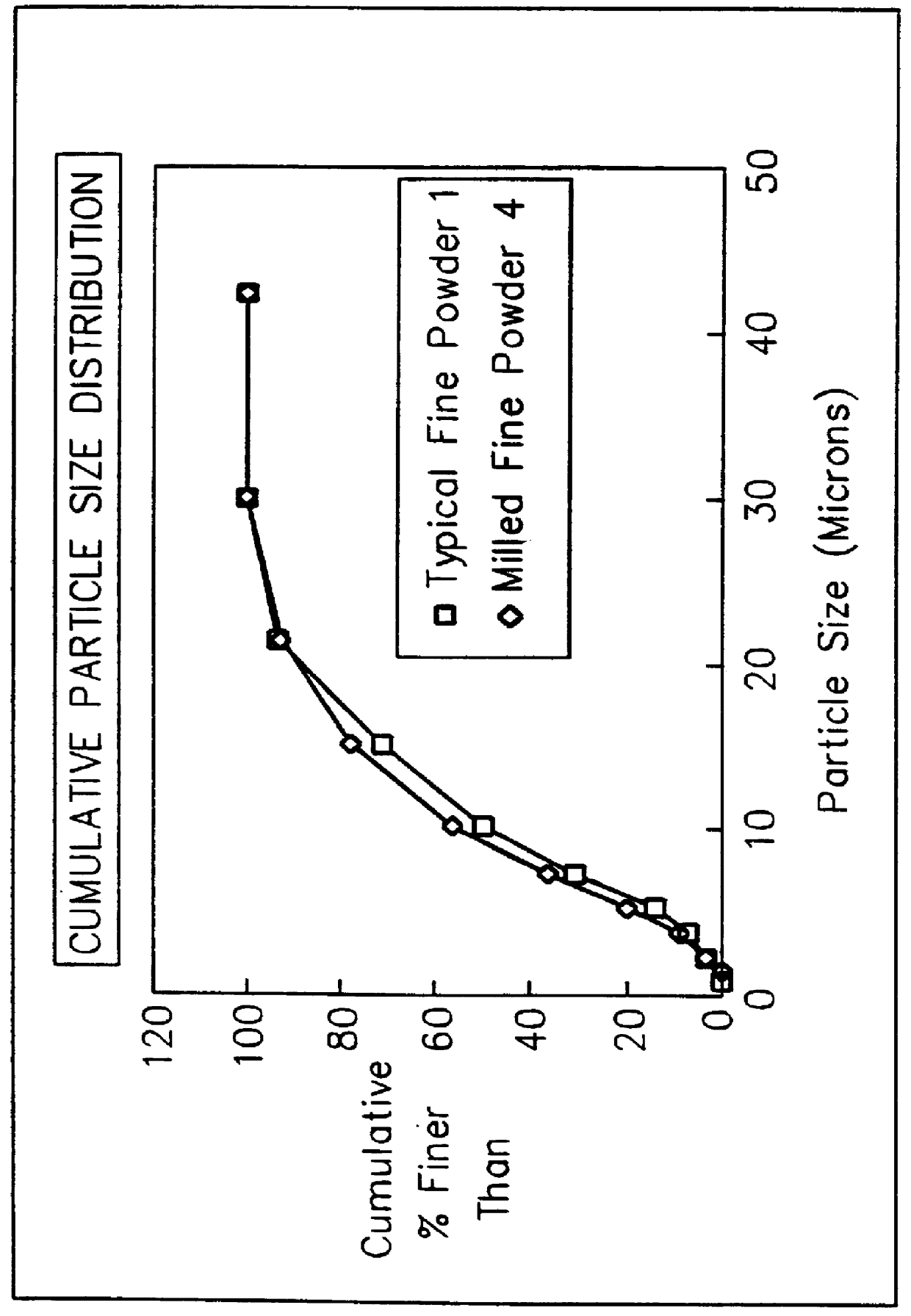

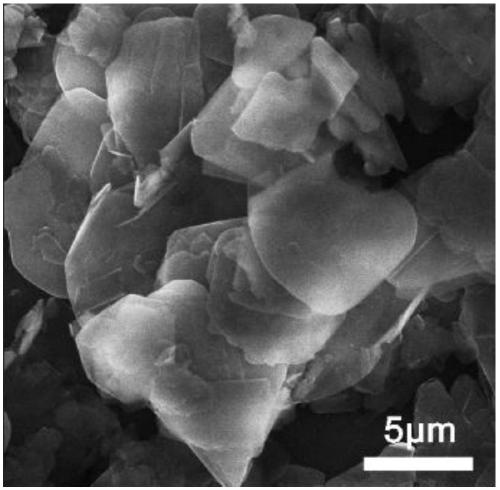

Method for forming high density boron nitride and high density agglomerated boron nitride particles

A method of forming pellets or agglomerates of high density boron nitride from high purity hexagonal boron nitride by crushing the high purity hexagonal boron nitride into boron nitride particles extending over a size range of at least 100 microns with the majority of the particles having a particle size above 50 microns and cold pressing the crushed particles into a compacted form. The compacted form is then granulated into a granulated powder and again cold pressed to form pellets or agglomerates of boron nitride particles with the operations of cold pressing and granulation occurring in one or more stages.

Owner:GENERAL ELECTRIC CO

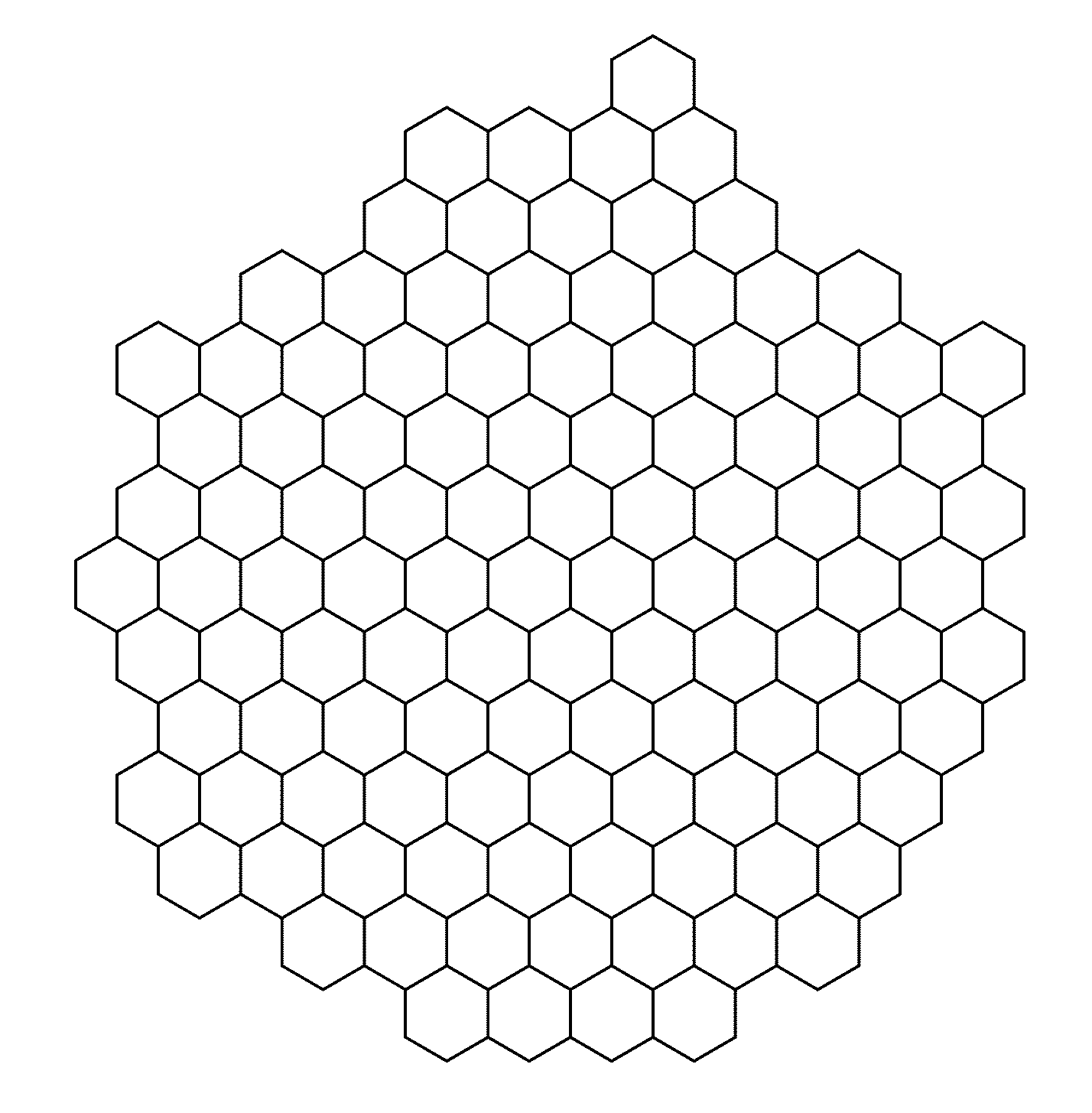

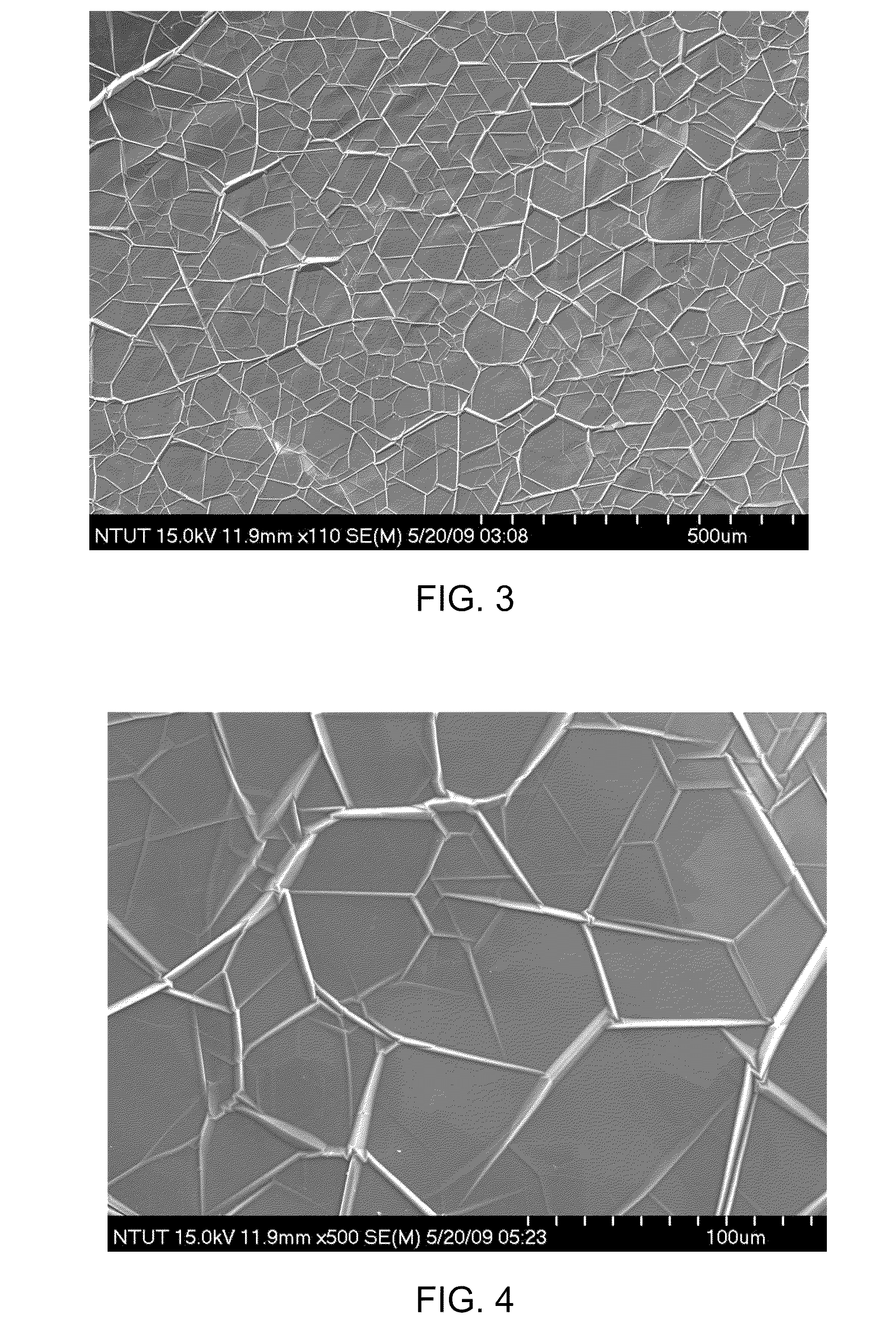

Graphene and Hexagonal Boron Nitride Planes and Associated Methods

InactiveUS20100055464A1Material nanotechnologyNitrogen compoundsHexagonal boron nitrideBoron nitride

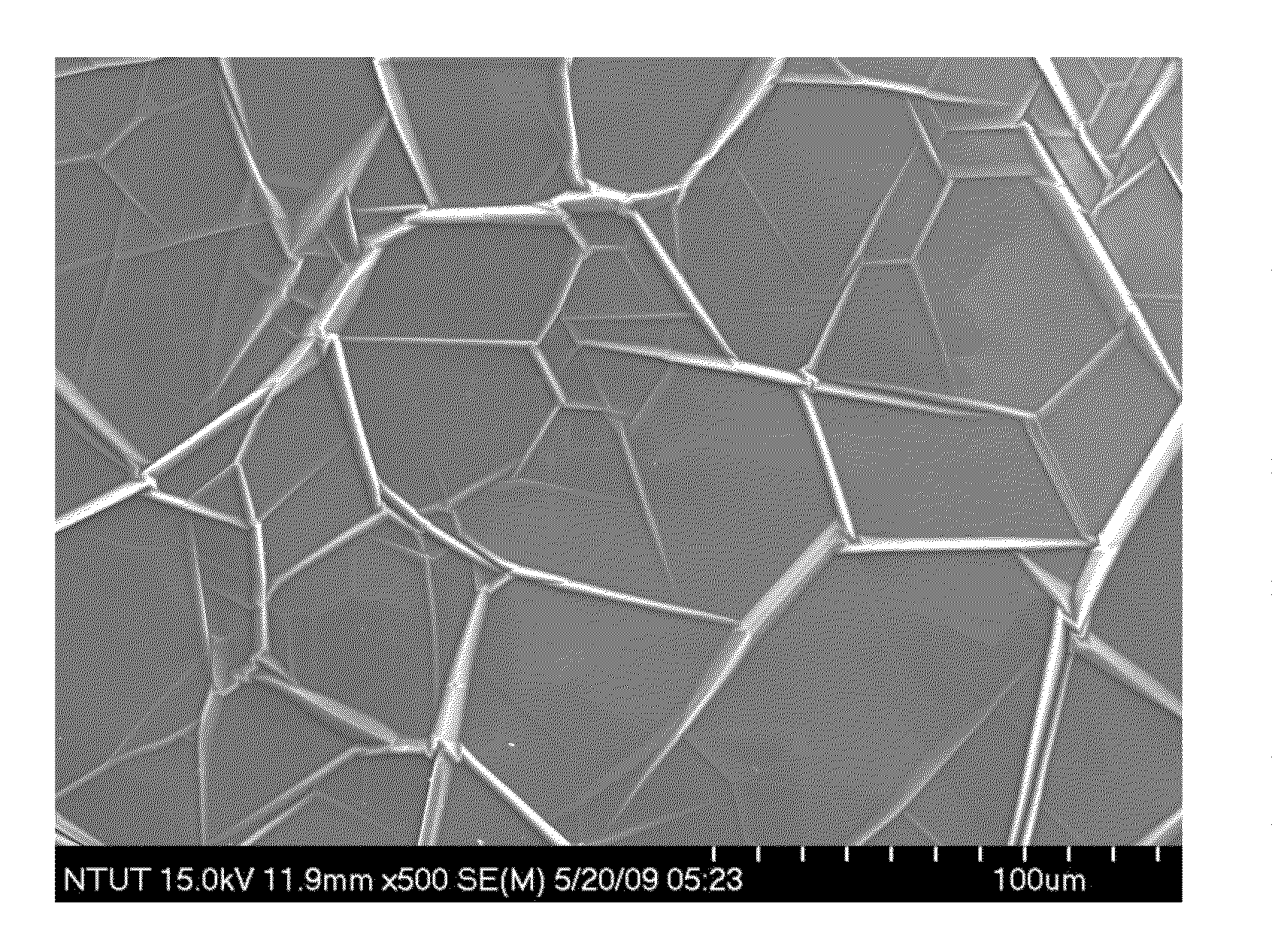

Graphene layers, hexagonal boron nitride layers, as well as other materials made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, for example, a method of forming a graphene layer is provided. Such a method may include mixing a carbon source with a horizontally oriented molten solvent, precipitating the carbon source from the molten solvent to form a graphite layer across the molten solvent, and separating the graphite layer into a plurality of graphene layers.

Owner:SUNG CHIEN MIN

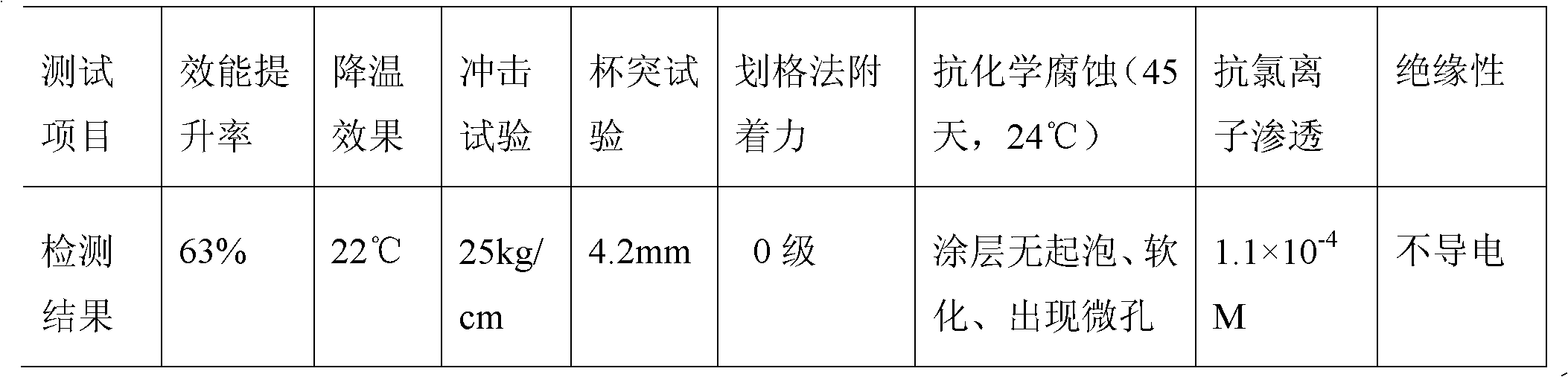

Environmental-protection anti-corrosive heat-dissipation powder paint, and preparation method and application thereof

ActiveCN102061121AFacilitate cross-linkingImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsHexagonal boron nitrideCooling effect

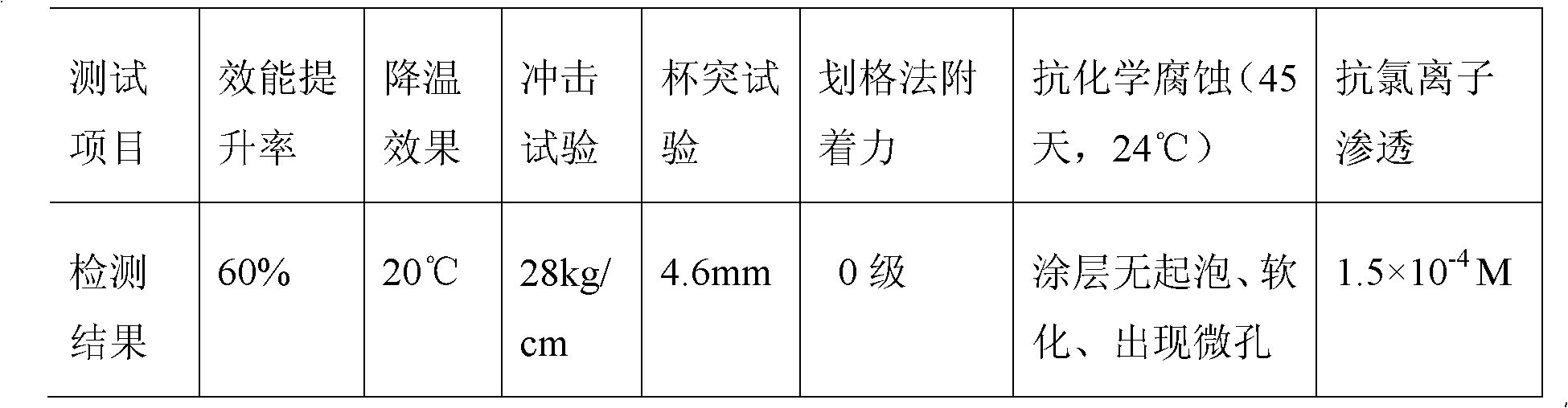

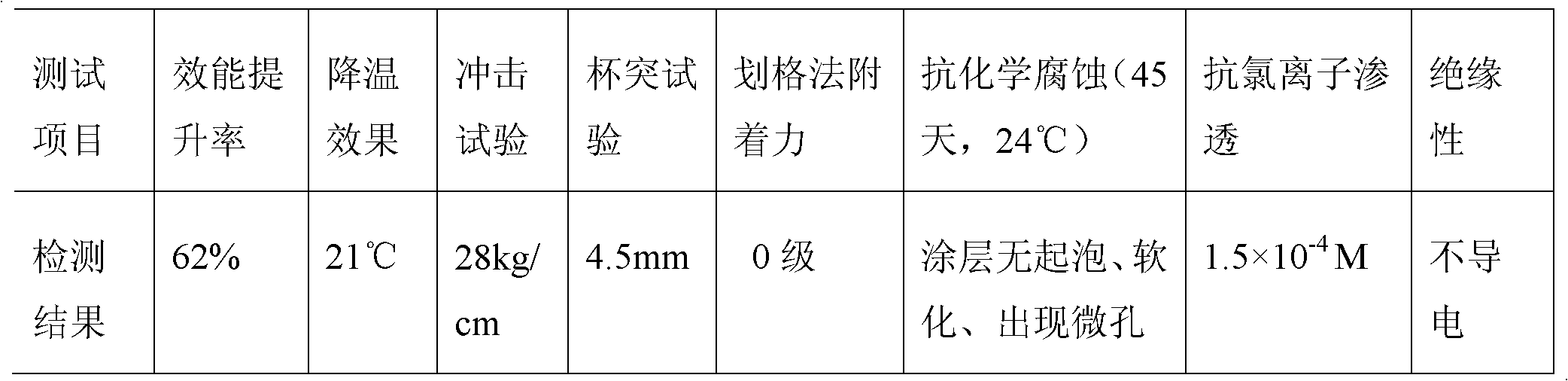

The invention discloses an environmental-protection anti-corrosive heat-dissipation powder paint, and a preparation method and application thereof. The environmental-protection anti-corrosive heat-dissipation powder paint comprises the following raw materials in parts by weight: 40-90 parts of matrix resin, 2-40 parts of curing agent, 0.5-10 parts of carbon nanotube, 0.5-2 parts of additive, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The composition and proportioning of the raw materials of the powder paint disclosed by the invention are scientific and reasonable. The experimental result indicates that the powder paint has the advantages of favorable heat-dissipation effect, high efficacy enhancement rate (higher than 60%) and favorable cooling effect (more than 20 DEG C), and can effectively solve the problem of poor heat-dissipation effect in the high-power electronic product, thereby prolonging the service life of the electronic product. The powder paint disclosed by the invention is free of organic solvent, and is environment-friendly and safe; the powder paint disclosed by the invention also has favorable comprehensive properties, such as flexibility, hardness, adhesive force and the like, and stable chemical properties; and the coating formed by the powder paint has the advantages of high corrosion resistance and shock resistance, favorable insulation property and wide application range.

Owner:TIGER DRYLAC TAICANG

Graphene and Hexagonal Boron Nitride Planes and Associated Methods

Graphene layers made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, for example, a method of forming a graphite film can include heating a solid substrate under vacuum to a solubilizing temperature that is less than a melting point of the solid substrate, solubilizing carbon atoms from a graphite source into the heated solid substrate, and cooling the heated solid substrate at a rate sufficient to form a graphite film from the solubilized carbon atoms on at least one surface of the solid substrate. The graphite film is formed to be substantially free of lattice defects.

Owner:SUNG CHIEN MIN

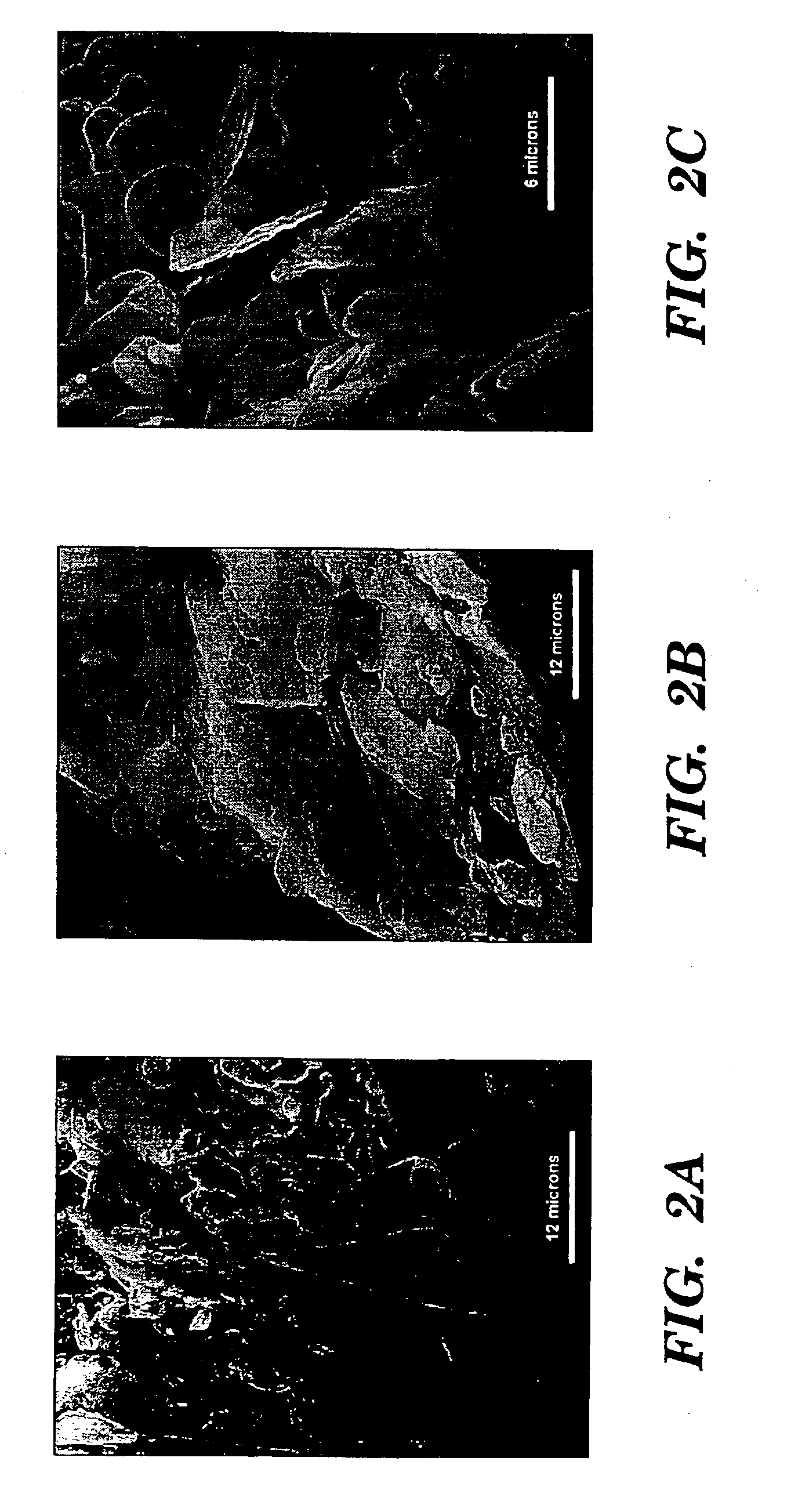

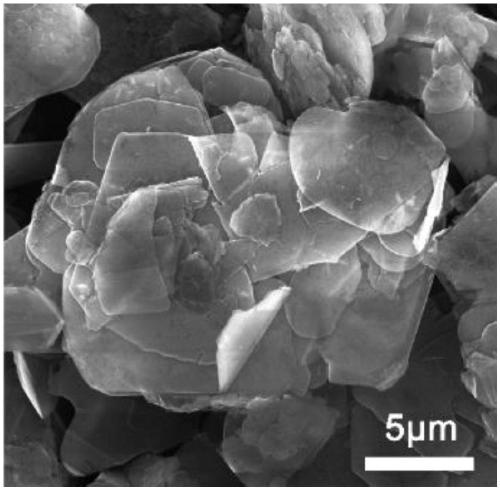

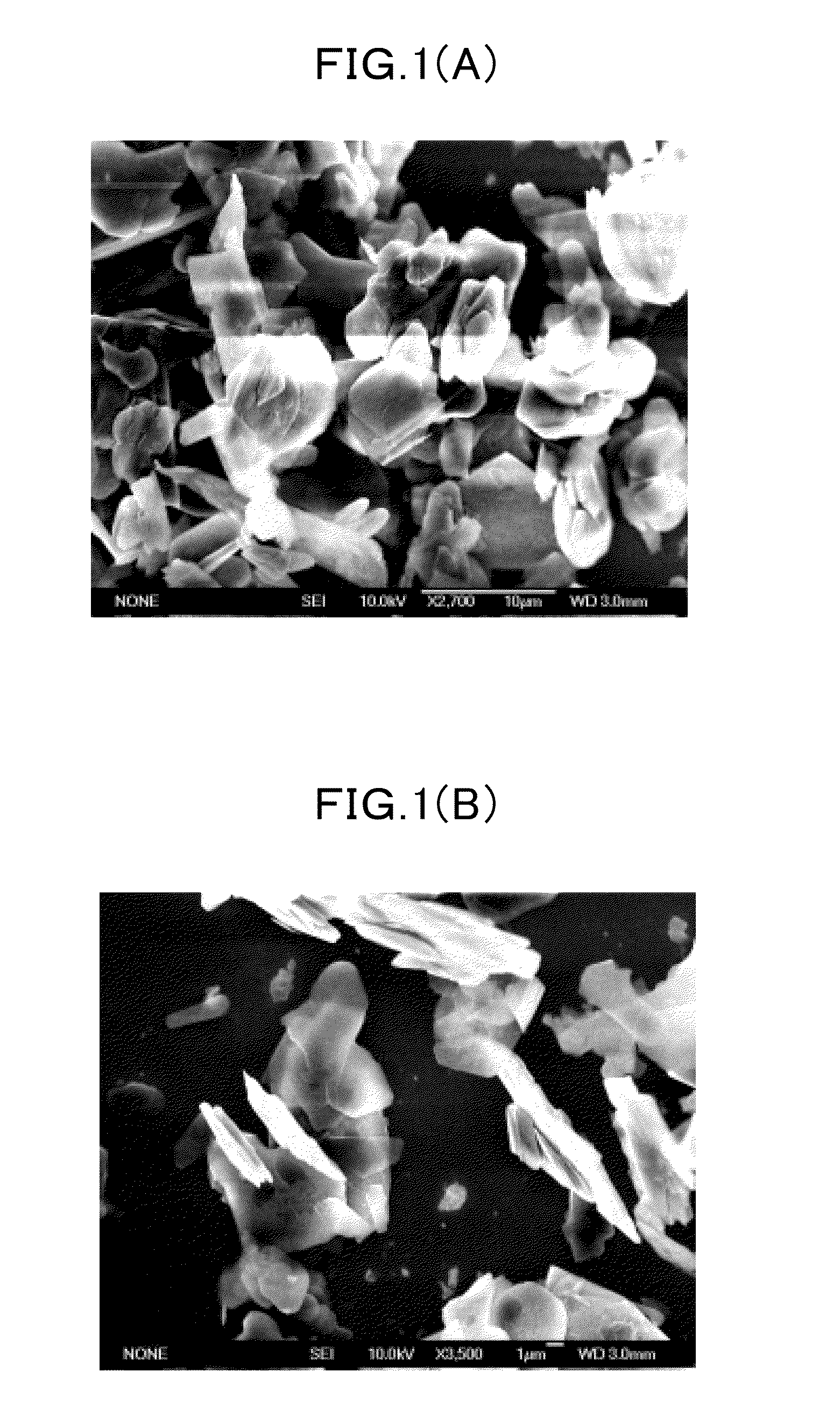

Highly delaminated hexagonal boron nitride powders, process for making, and uses thereof

InactiveUS6951583B2Increase surface areaHighly delaminatedNitrogen compoundsSynthetic resin layered productsHexagonal boron nitrideMetallurgy

The present invention relates to a powder comprising boron nitride particles having an aspect ratio of from about 50 to about 300. The present invention also relates to a method of making delaminated boron nitride powder. This method involves providing boron nitride powder and milling the boron nitride powder in a mixture including a milling media and a milling liquid under conditions effective to produce delaminated boron nitride powder.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Method of producing an abrasive product containing cubic boron nitride

A method of producing an abrasive product consists of providing a mixture of a mass of discrete carbide particles and a mass of cubic boron nitride particles, the cubic boron nitride particles being present in the mixture in an amount such that the cubic boron nitride content of the abrasive product is 25% or less by weight, and subjecting the mixture to elevated temperature and pressure conditions at which the cubic boron nitride is crystallographically stable and at which substantially no hexagonal boron nitride is formed, in the presence of a bonding metal or alloy capable of bonding the mixture into a coherent, sintered product, to form the abrasive product. The bonding metal or alloy comprises a combination of a transition metal or a transition alloy and up to 40% by volume of the bonding metal or alloy of a second metal which is a stronger nitride or boride former than the transition metal or the transition metal alloy.

Owner:FRIES ROBERT +1

Graphene and Hexagonal Boron Nitride Devices

InactiveUS20110163298A1Vibration measurement in solidsOptical rangefindersHexagonal boron nitrideBoron nitride

Graphene layers, hexagonal boron nitride (hBN) layers, as well as other materials made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, the present invention provides graphene and hBN devices. In one aspect, for example, an electronic device is provided including a graphene layer and a planar hBN layer operably associated with the graphene layer and forming a functional interface therebetween. Numerous functional interfaces are contemplated, depending on the desired functionality of the device.

Owner:SUNG CHIEN MIN

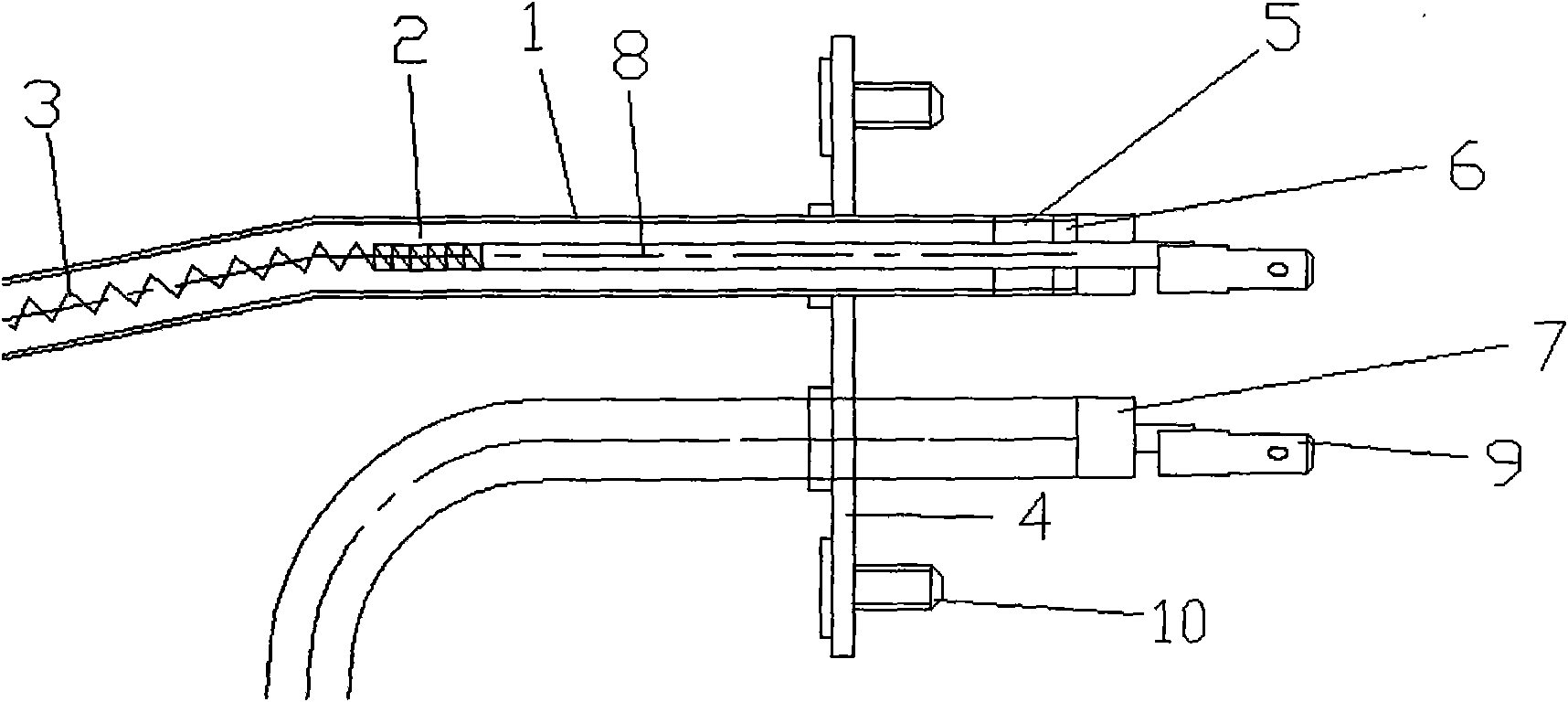

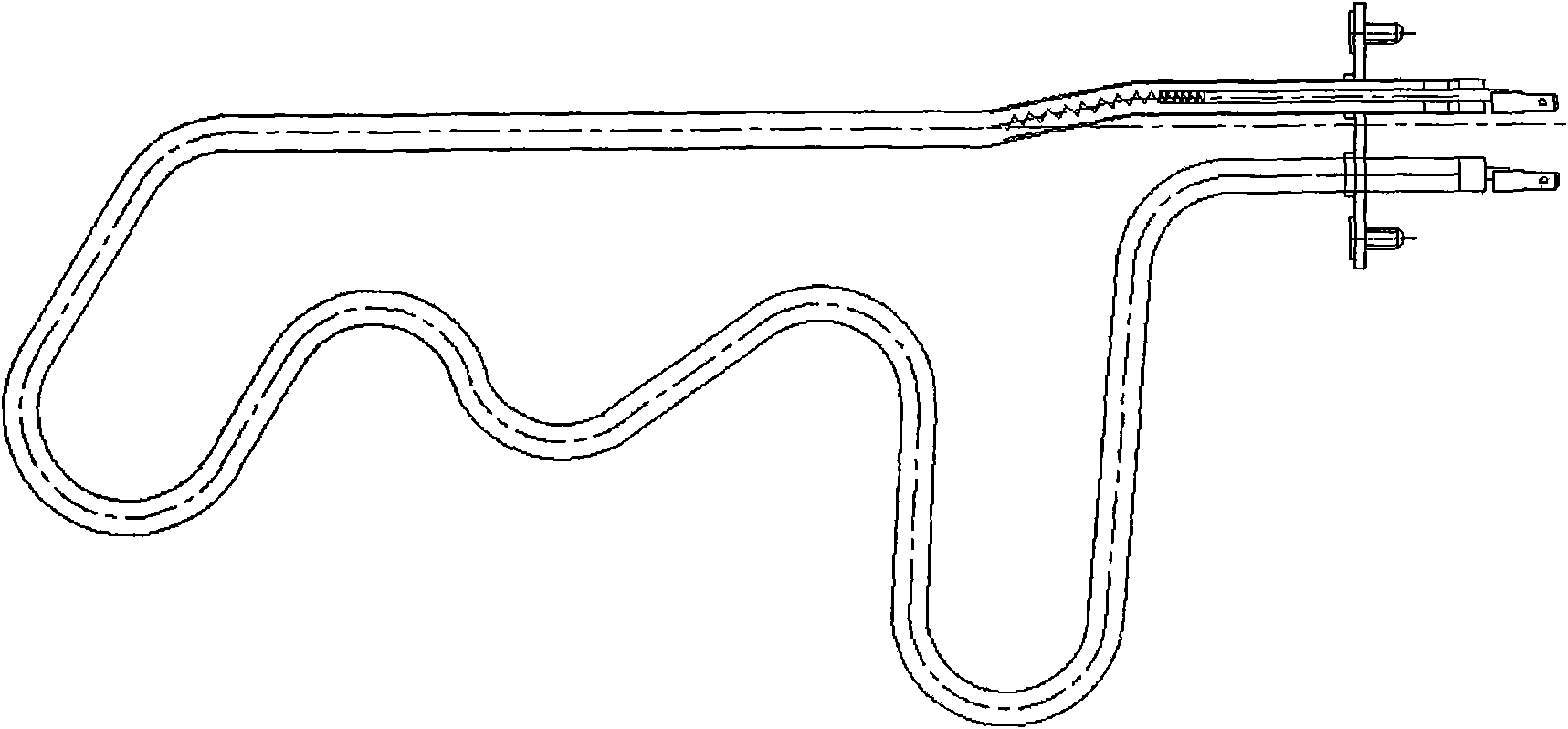

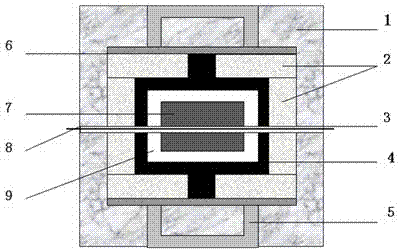

Electric heating tube made of hexagonal boron nitride and mixed heat conducting material thereof

ActiveCN101854750ALong life and high qualityImprove insulation performanceChemical industryHeat-exchange elementsHexagonal boron nitrideHeat conducting

The invention belongs to the technical field of electric heating tube manufacture, and relates to an electric heating tube using hexagonal boron nitride or mixture of hexagonal boron nitride and magnesium oxide as a heat conducting material, in particular to a mixed heat conducting material for a novel electric heating tube. A main body structure comprises a metal tube body, a mixed filler, a resistance wire and accessories comprising a fixed plate, porcelain beads, sealant, a plastic plug, a leading-out bar, a terminal electrodes and screws; a cavity structure of the metal tube body is invariantly bent into a circular, elliptical or spiral geometric structure; parallel structures at two end sections of the metal tube body are fixed on the fixed plate in an interval penetration mode, and fixed screws are arranged at two ends of the fixed plate; and the resistance wire is fixed and electrically connected on the central axis of the cavity of the metal tube body and parallel to two end points on two sides of the tube wall, and the mixed filler is filled between the resistance wire and the side wall of the metal tube body. The electric heating tube has the advantages of high stability and heat conducting efficiency, high-temperature softening prevention in inert gas, long service life, high quality, good insulating property, low dielectric constant and dielectric loss, and safe use.

Owner:QINGDAO EASYTOUSE ELECTRONICS

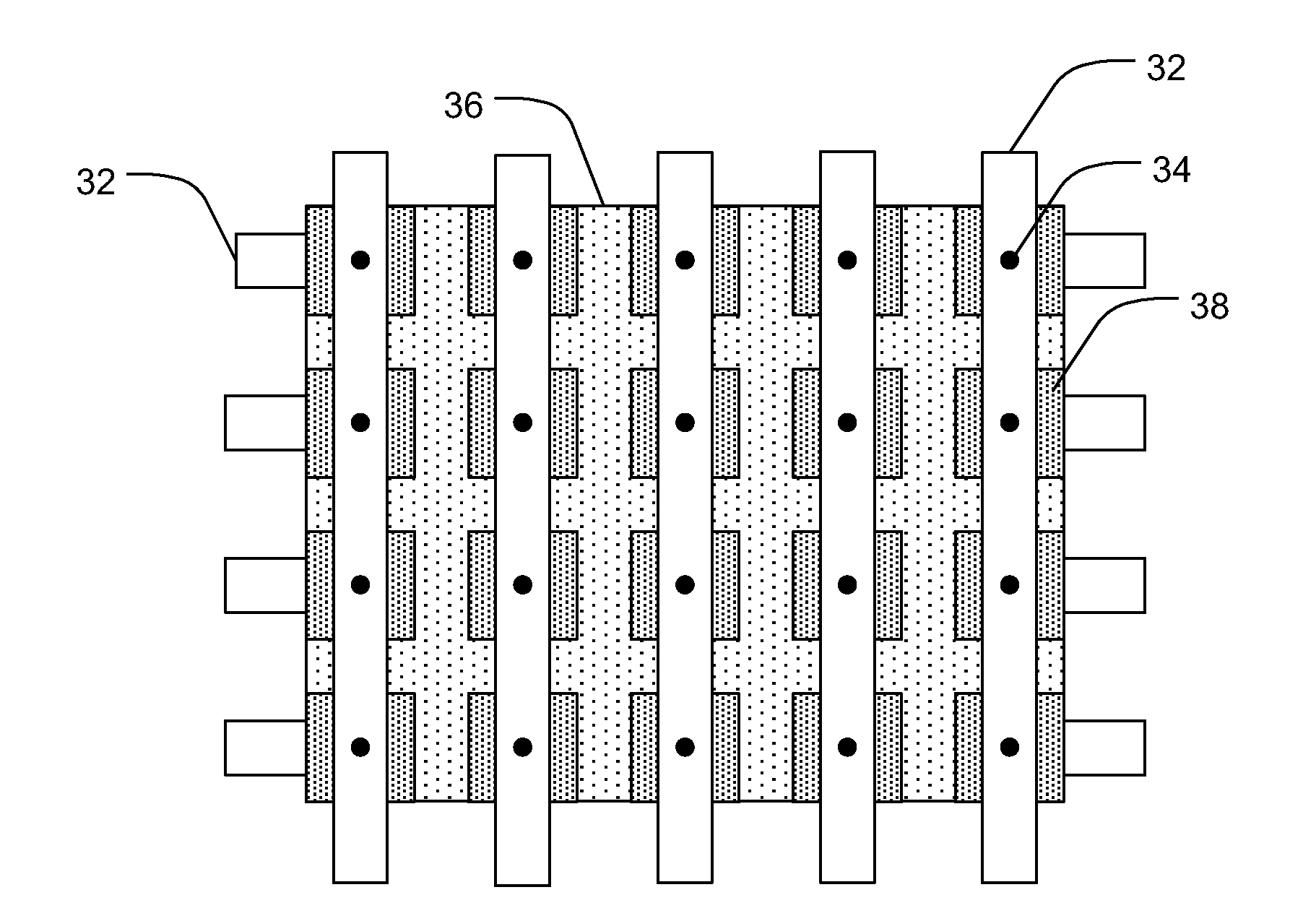

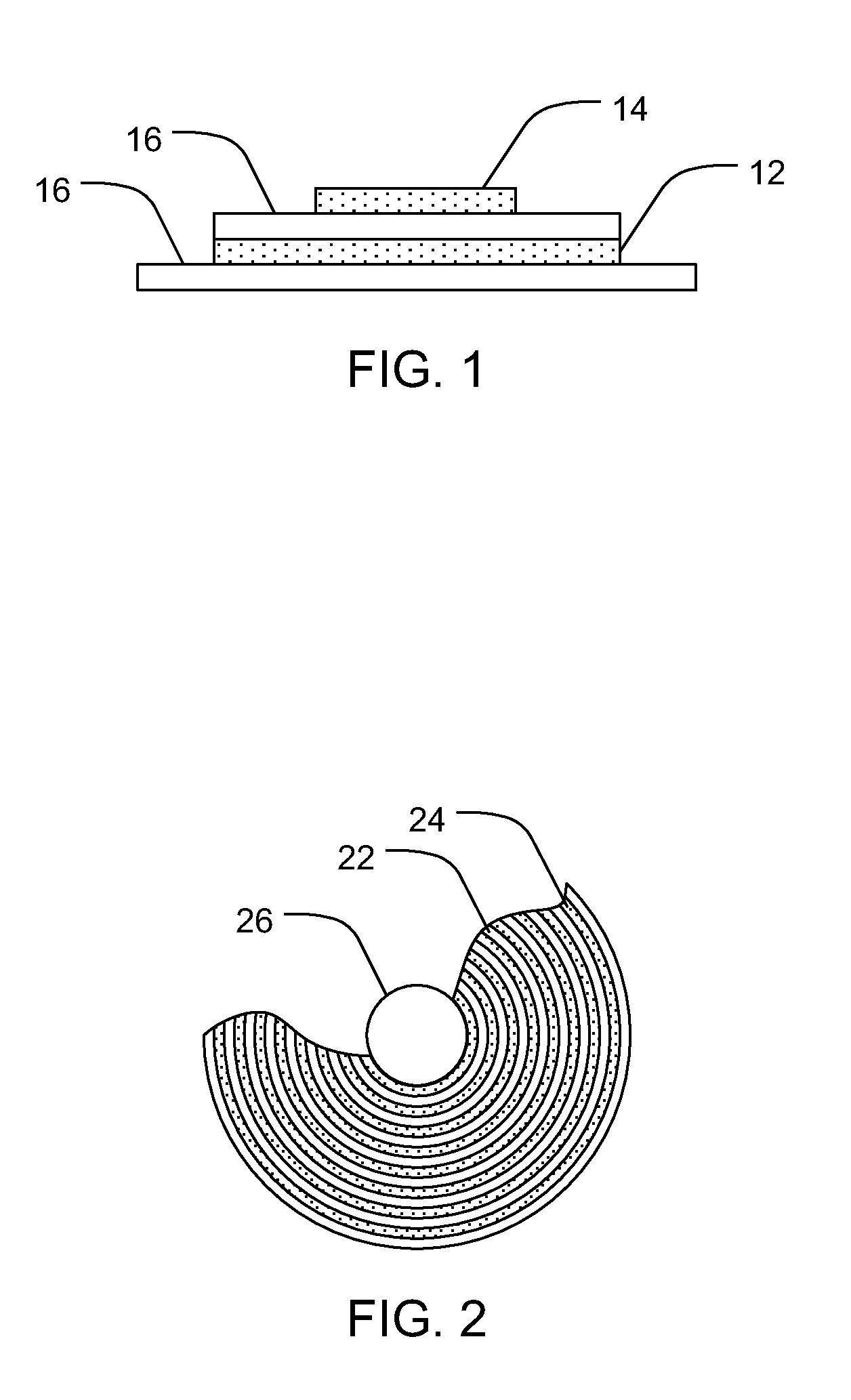

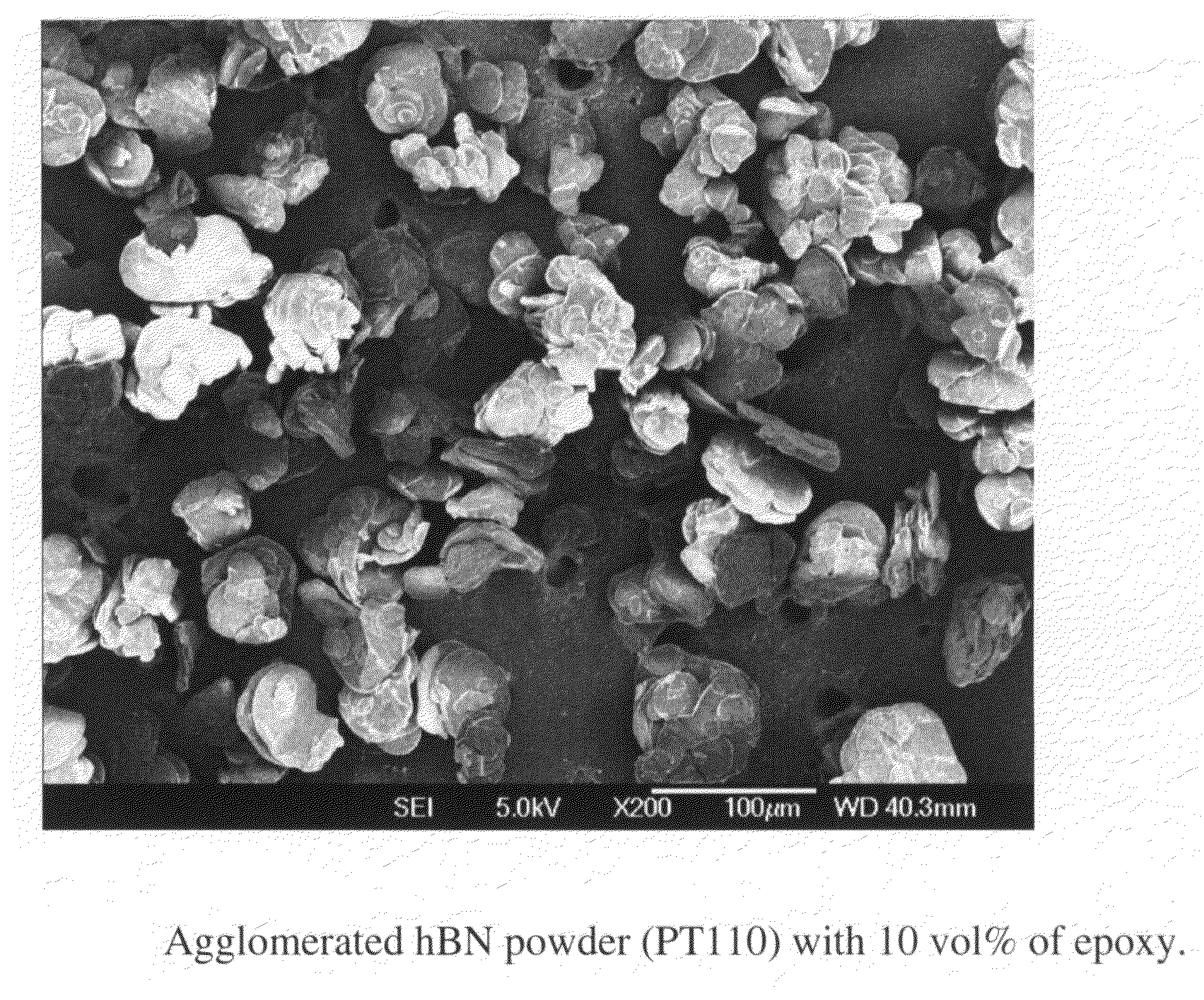

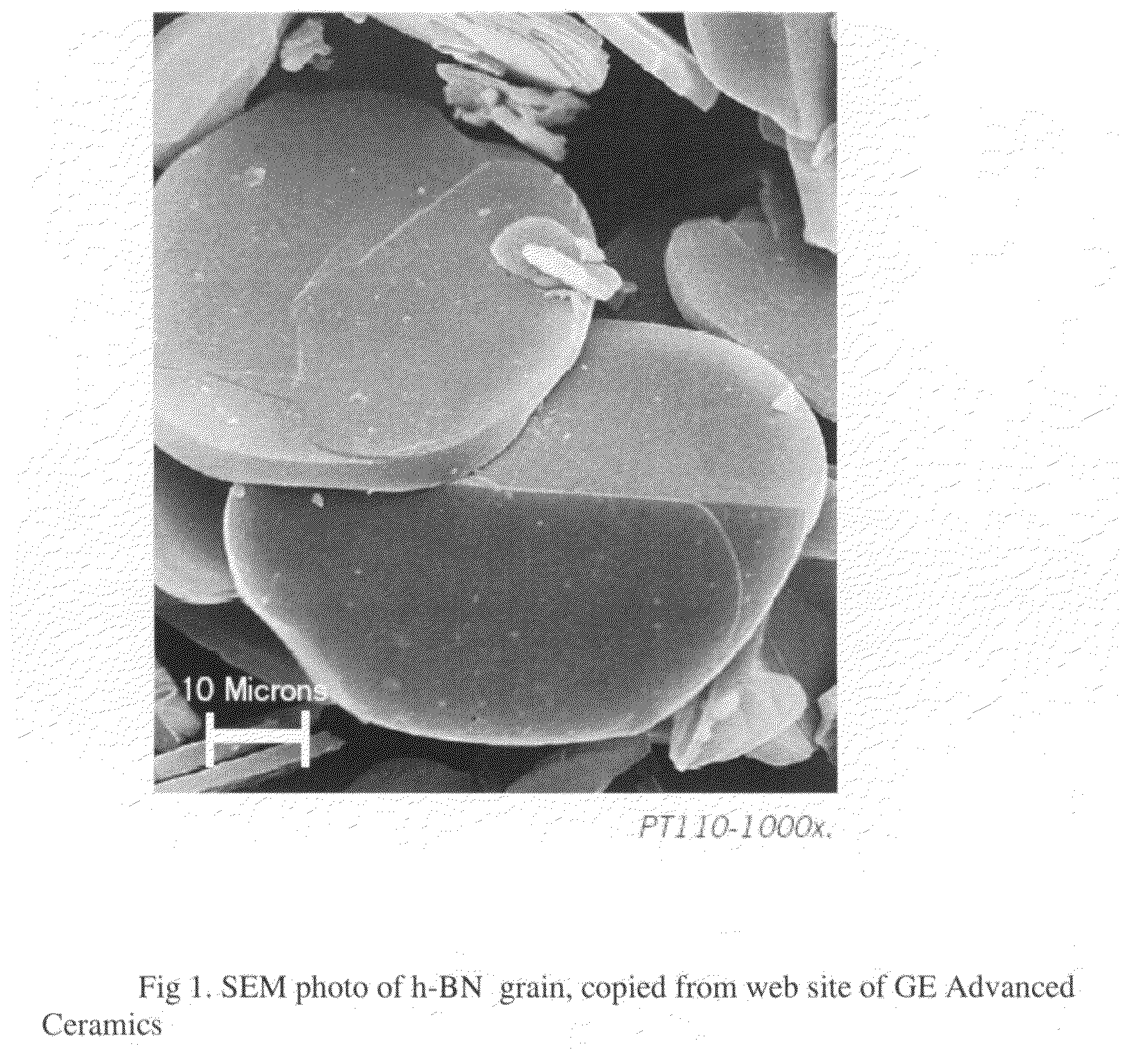

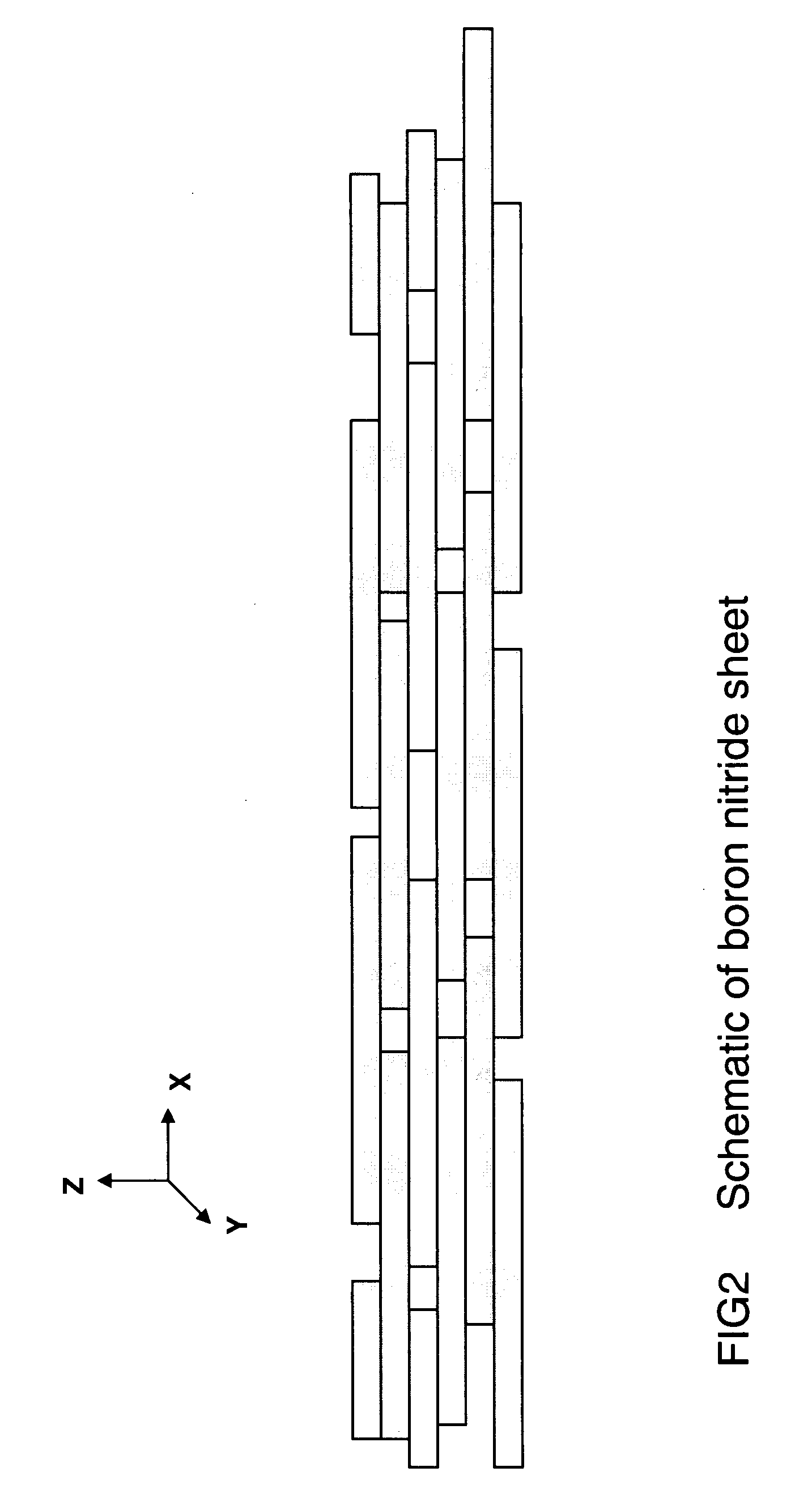

Heat spread sheet with anisotropic thermal conductivity

InactiveUS20070259211A1Increase compaction densityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesEpoxySpread sheet

This invention relates to a heat spread sheet material comprised of hexagonal boron nitride with adhesives. Extraction process for adhesive coating greatly decreases the adhesive fraction and provides an evenly distributed thin adhesive film on the surface of hexagonal boron nitride powders. This sheet material shows a layer structure and anisotropic properties. With 10 vol % (5.5 wt %) of phenolic epoxy, thermal conductivity along the base plane of the sheet reaches 48 W / m·K, and CTE reaches 3.5 ppm / K.

Owner:WANG NING

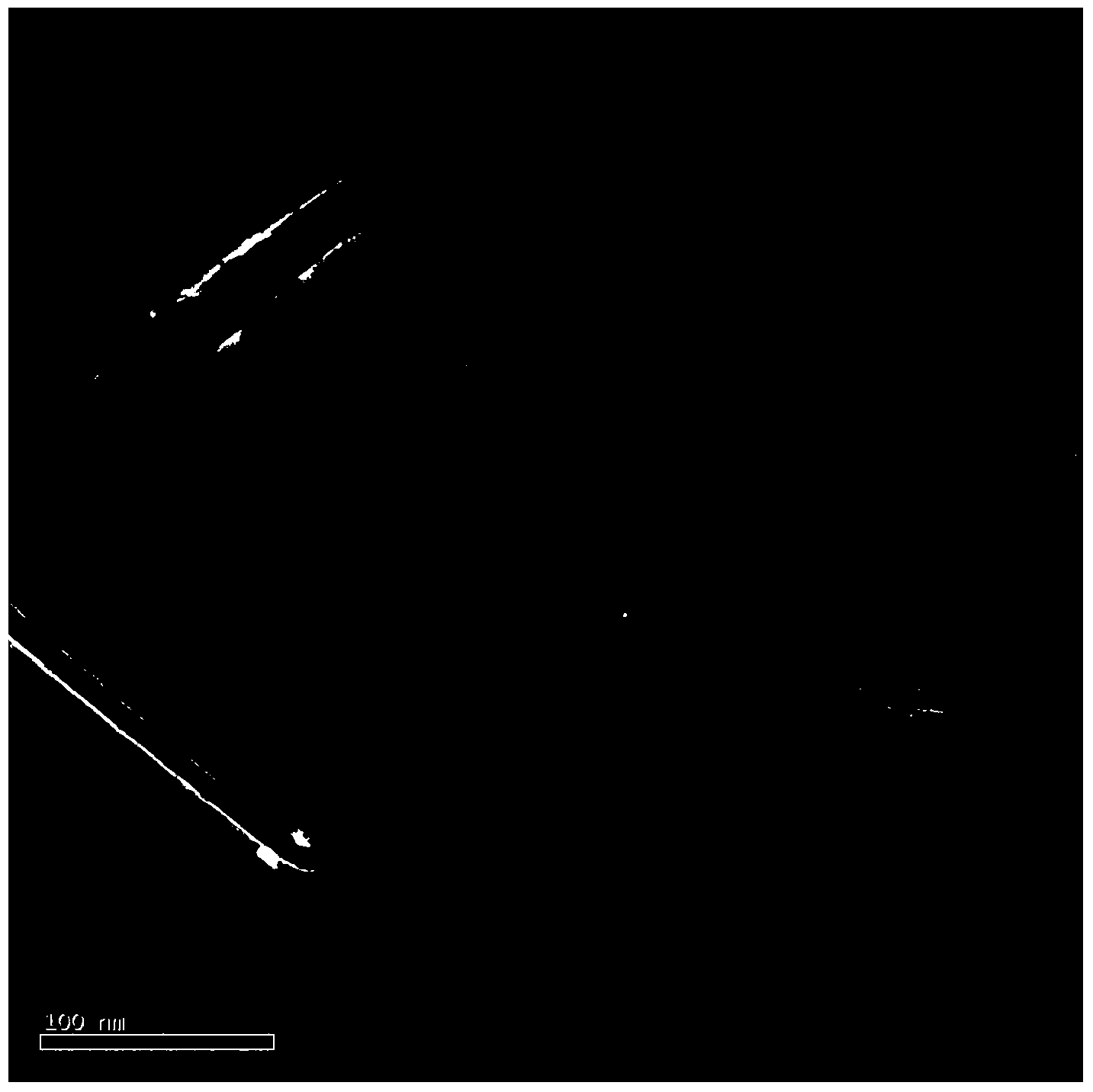

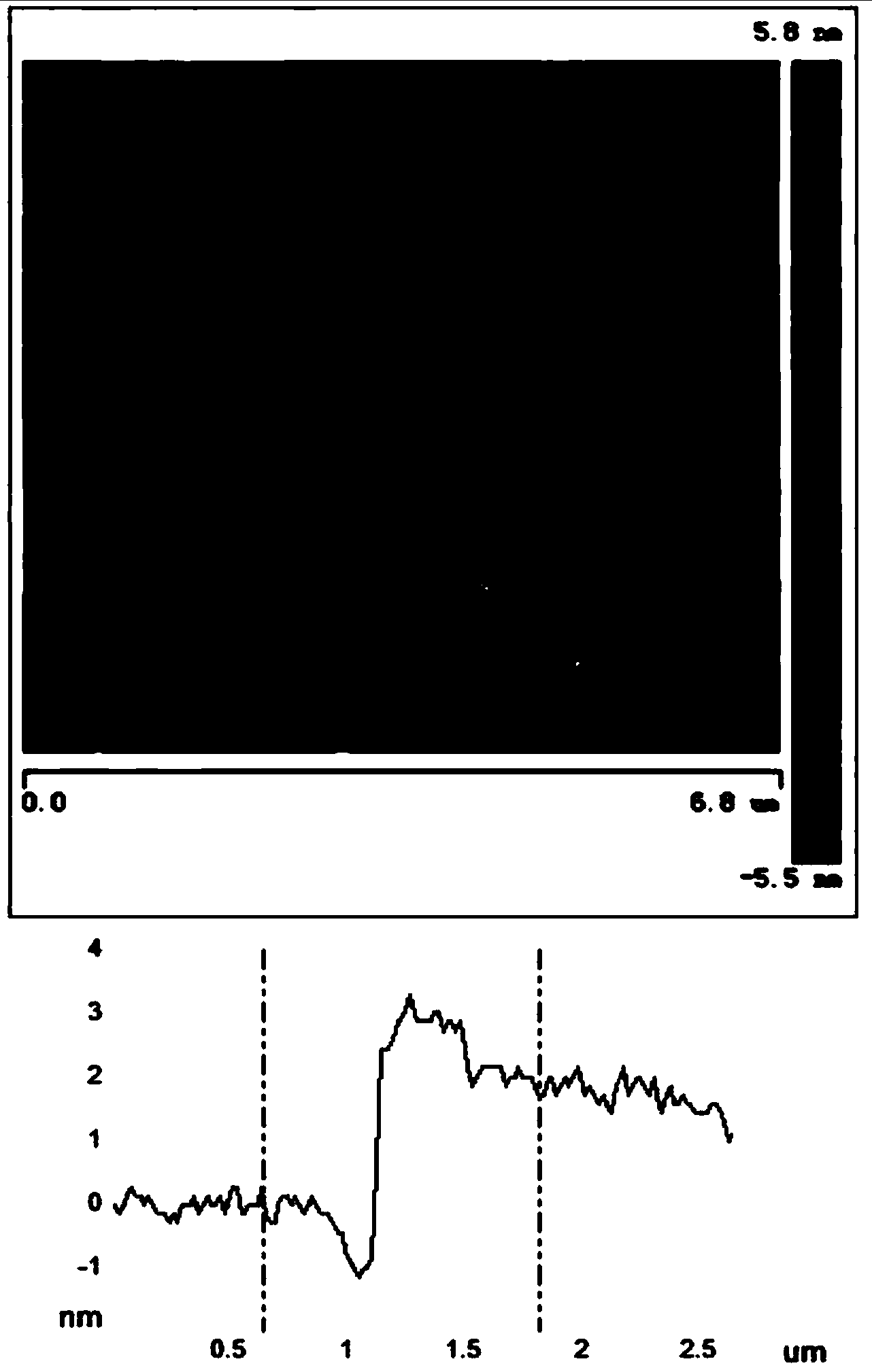

Method for Exfoliation of Hexagonal Boron Nitride

ActiveUS20110045223A1Simplify the chemical processEasy post-processingNitrogen compoundsLayered productsBulk crystalOrganic solvent

A new method is disclosed for the exfoliation of hexagonal boron nitride into mono- and few-layered nanosheets (or nanoplatelets, nanomesh, nanoribbons). The method does not necessarily require high temperature or vacuum, but uses commercially available h-BN powders (or those derived from these materials, bulk crystals) and only requires wet chemical processing. The method is facile, cost efficient, and scalable. The resultant exfoliated h-BN is dispersible in an organic solvent or water thus amenable for solution processing for unique microelectronic or composite applications.

Owner:NASA

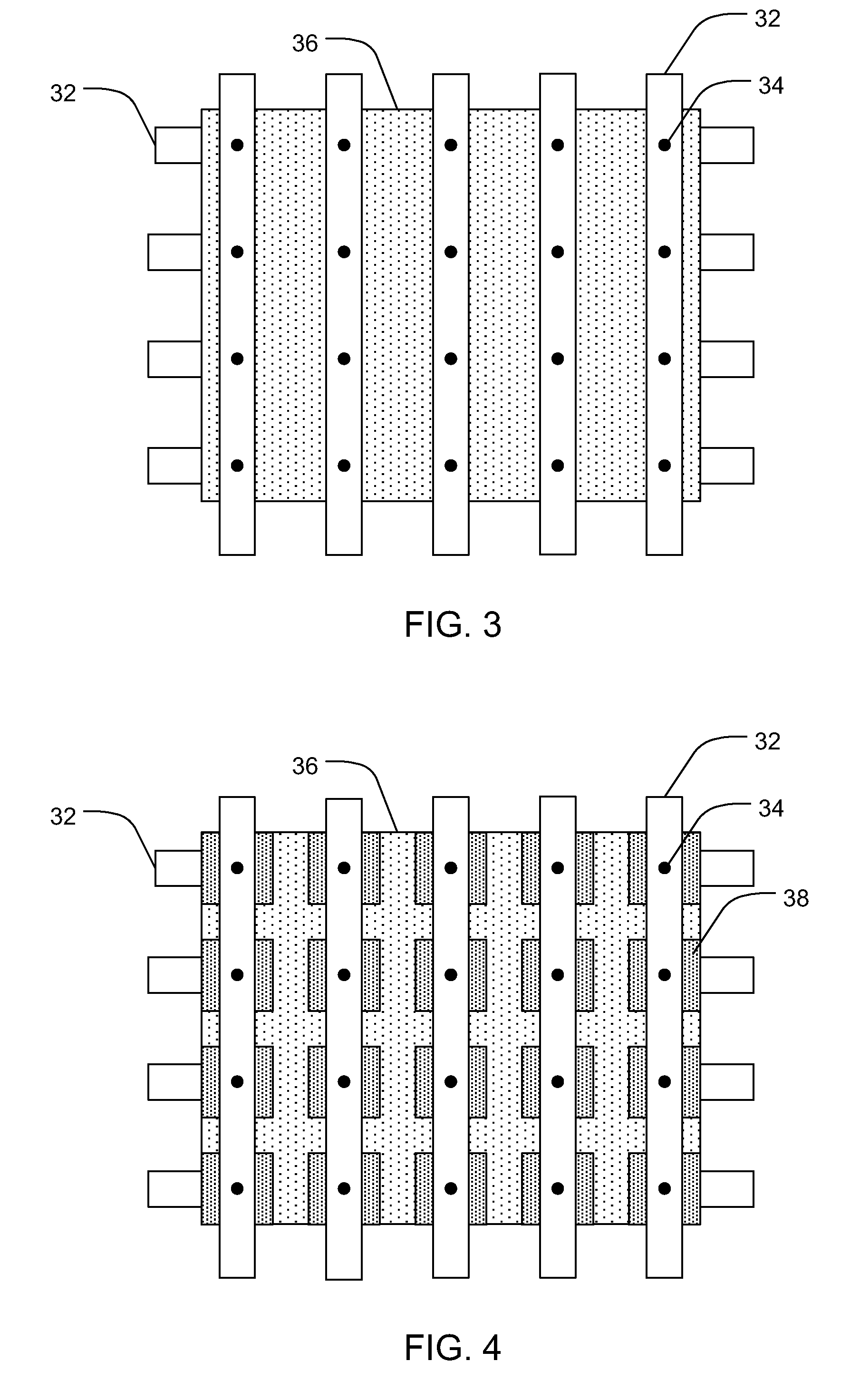

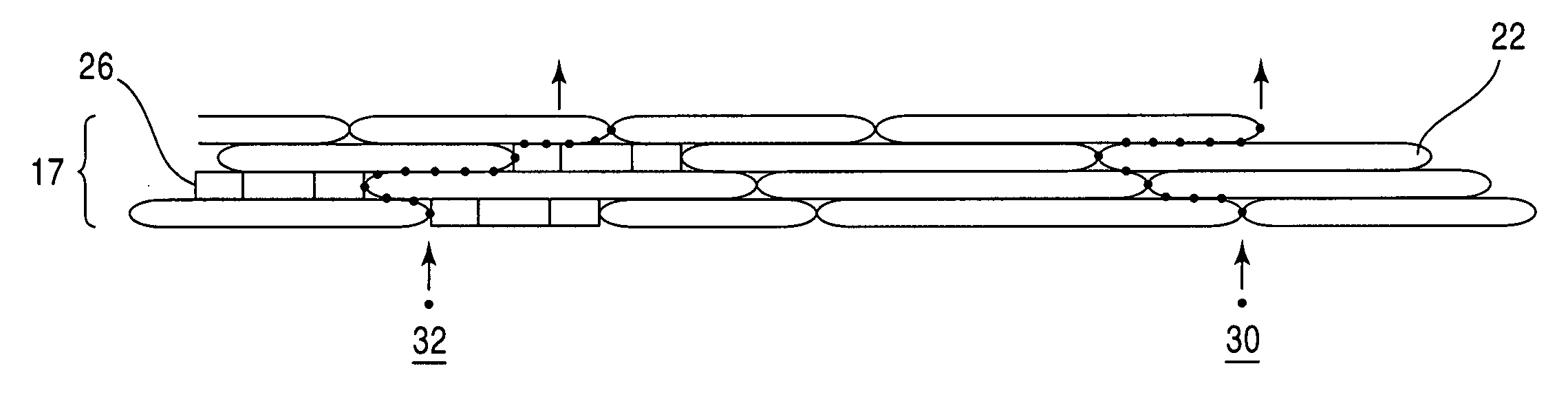

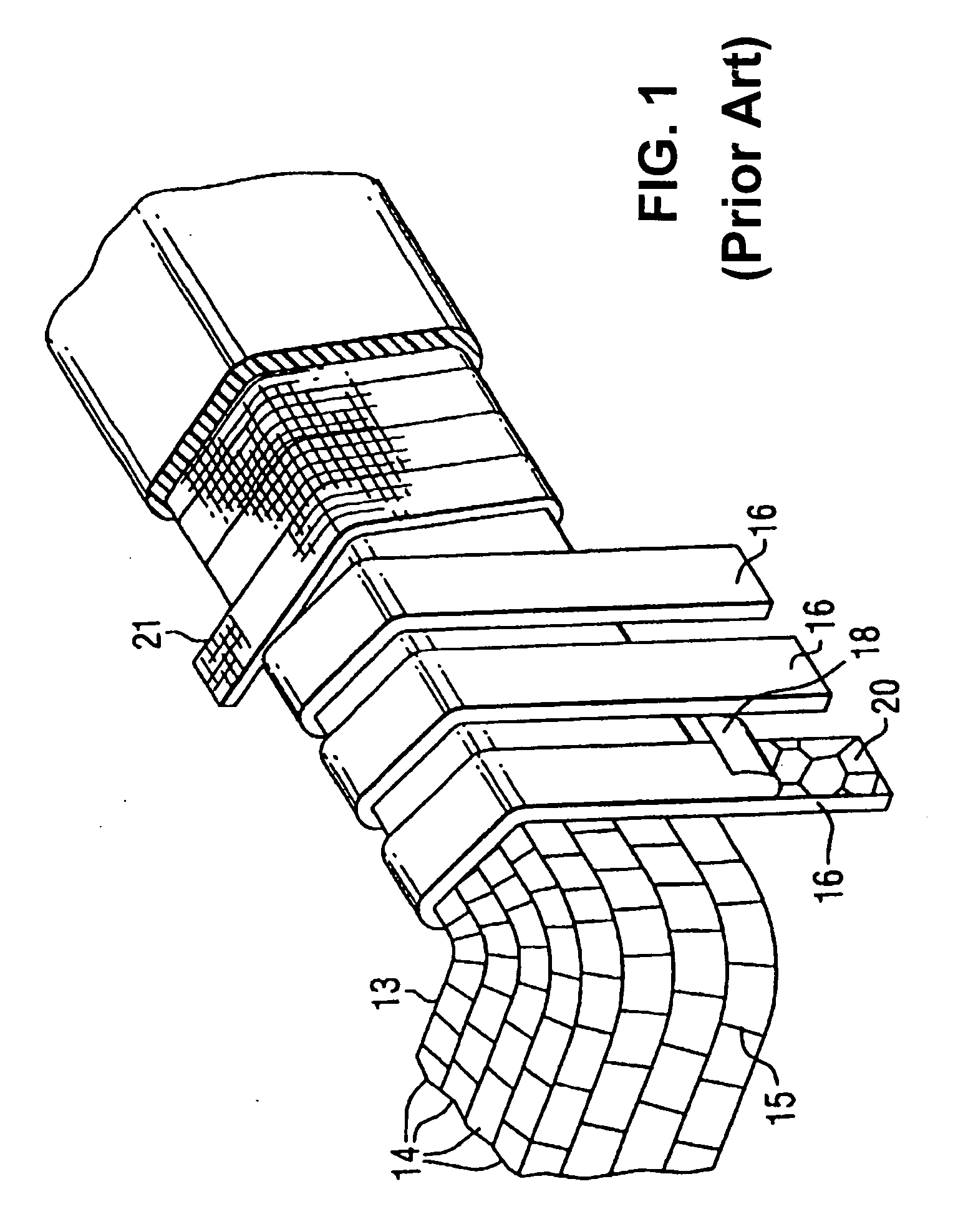

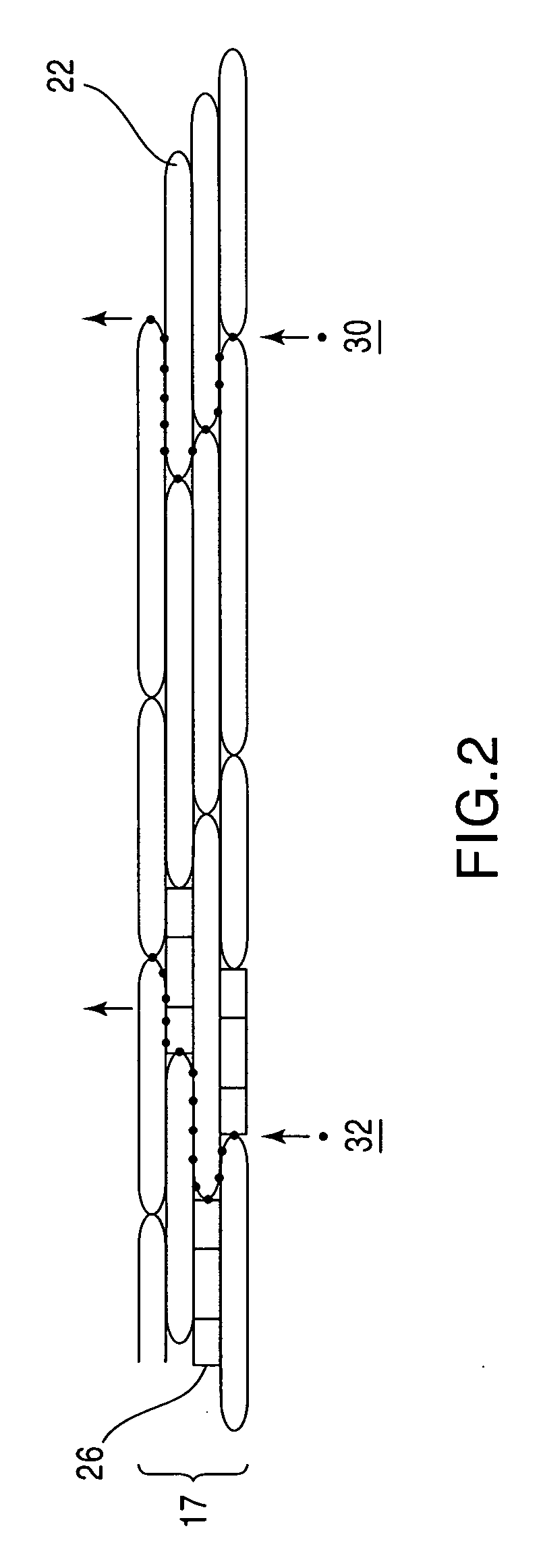

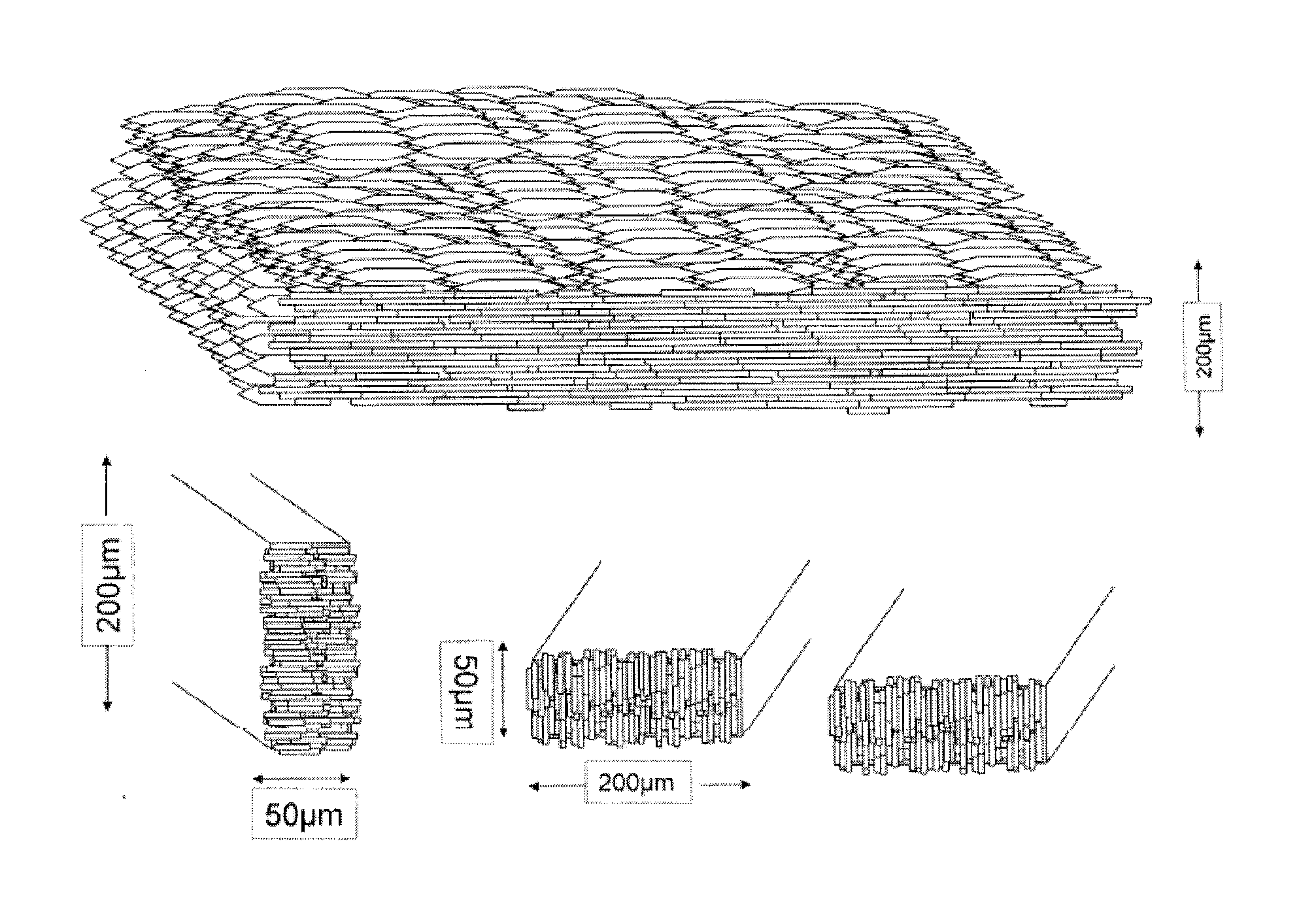

Multi-layered platelet structure

ActiveUS20070141324A1Improve thermal conductivityHigh viscositySynthetic resin layered productsMicaHexagonal boron nitrideElectrical insulation paper

An electrical insulation paper that is made of mica flakelets (22), having an average size range of 0.01 to 0.05 mm in their thinnest dimension, hexagonal boron nitride (26), which has an average size range of 10 to 1,000 nm in their longest dimension, and a resin matrix. The mica flakelets and the hexagonal boron nitride are mixed and formed into a paper (17), and the resin is added to the paper after formation, the ratio by weight of the hexagonal boron nitride to the mica flakelets is directly proportional to the average size of the hexagonal boron nitride compared to the average size of the mica flakelets, within an adjustment factor.

Owner:SIEMENS ENERGY INC

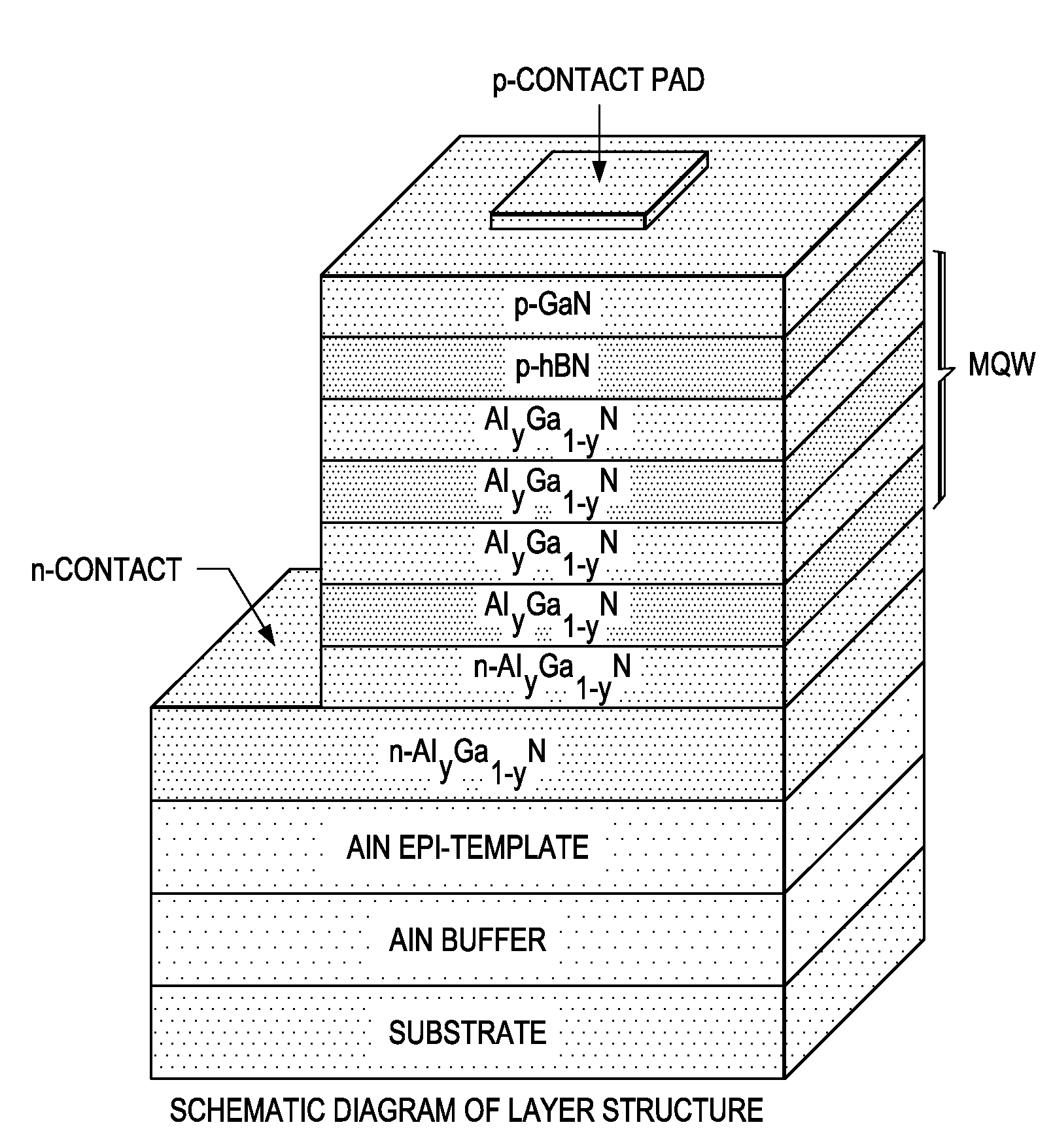

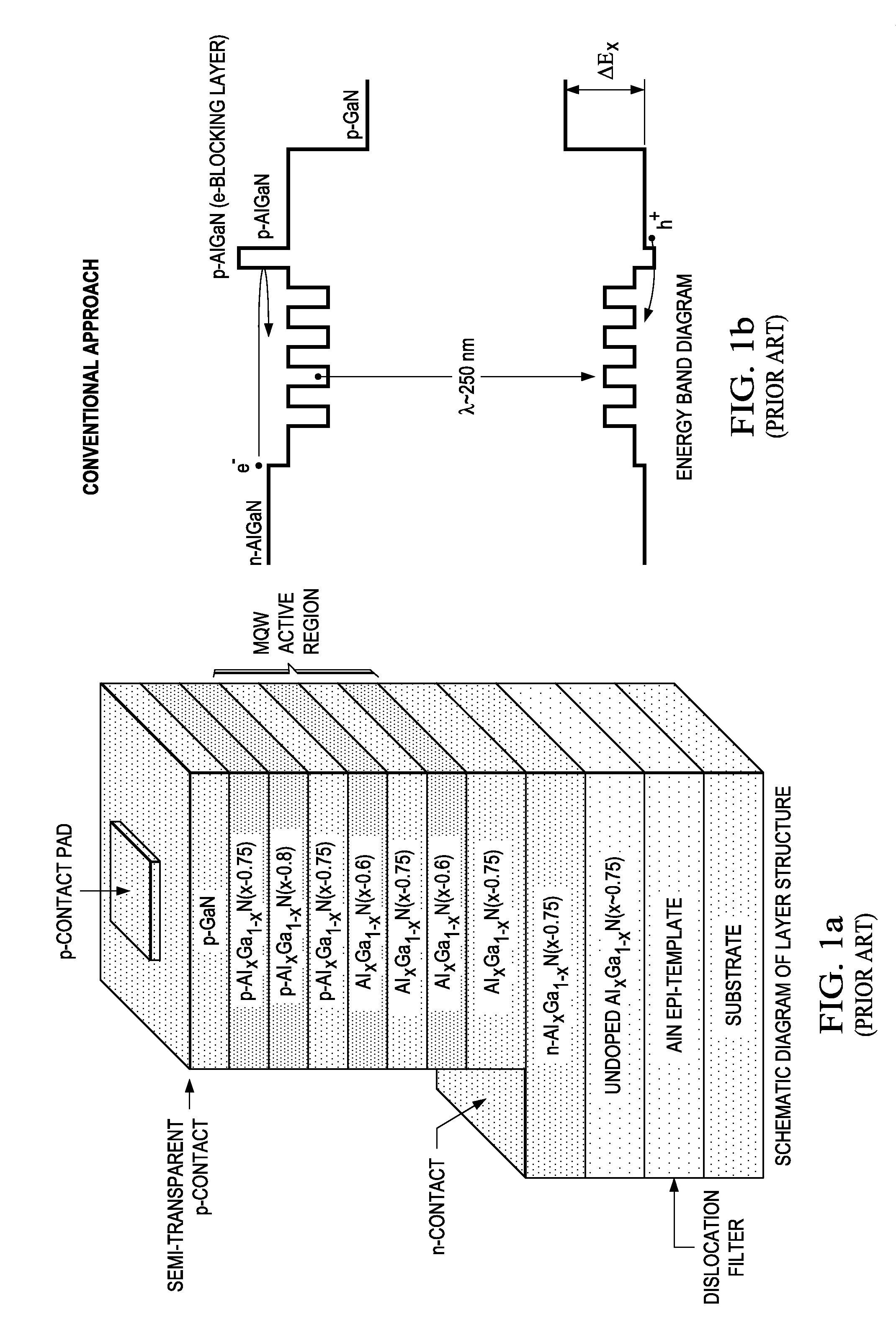

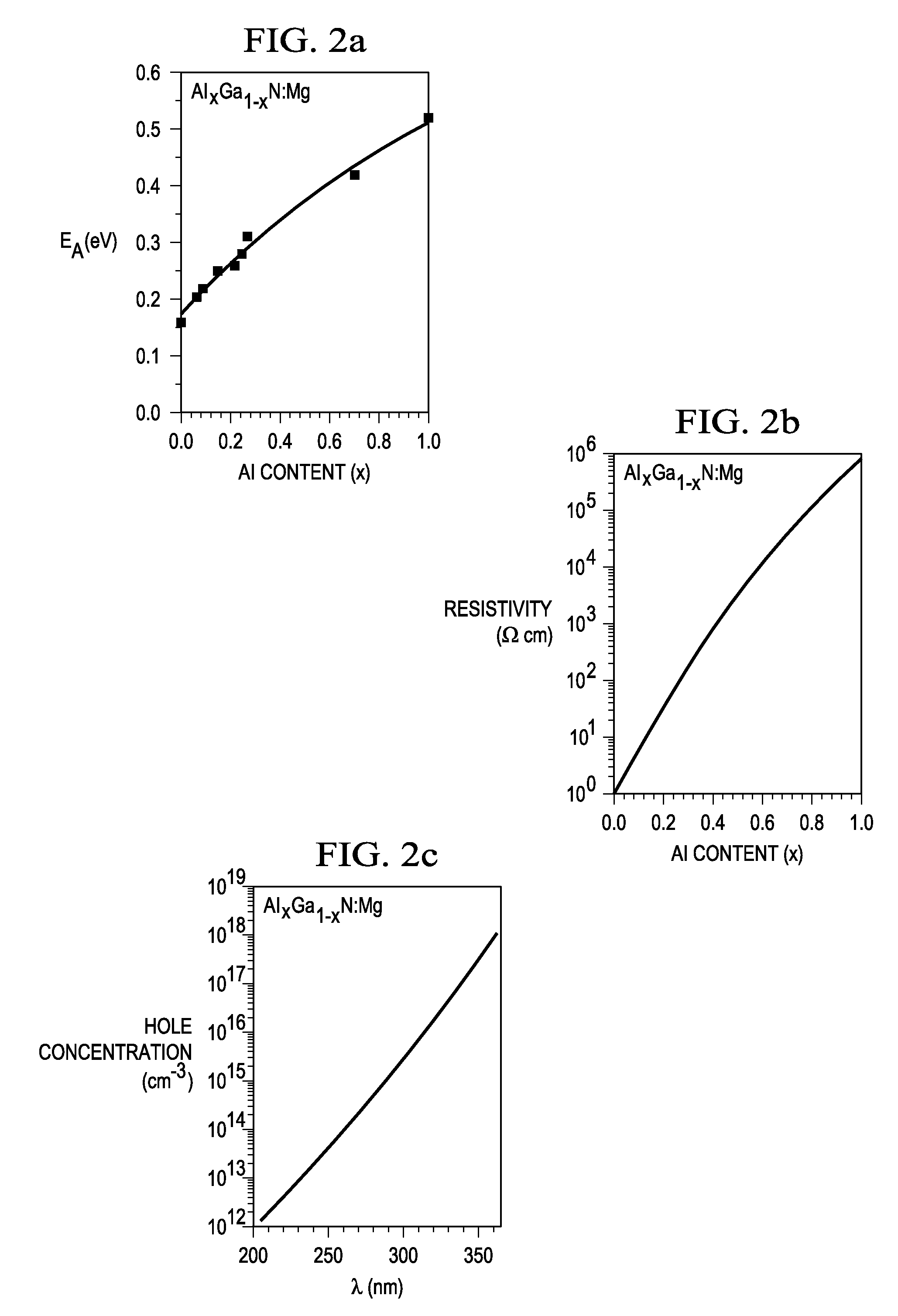

Structures and Devices Based on Boron Nitride and Boron Nitride-III-Nitride Heterostructures

InactiveUS20130292685A1Revolutionize neutron detectionImprove abilitiesFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionHexagonal boron nitride

The present invention relates to optoelectronic device layer structures, light emitting devices, and detectors based upon heterostructures formed between hexagonal boron nitride (hNB) and III-nitrides, and more particularly, to heterojunction devices capable of emitting and detecting photons in the ultraviolet (UV) and extremely ultraviolet (RUV) spectral range. The present invention also relates to neutron detectors based on epitaxially grown hBN thin films (or epitaxial layers) and hBN stacked thin films (or epitaxial layers) to satisfy the thickness required for capturing all incoming neutrons.

Owner:TEXAS TECH UNIV SYST

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

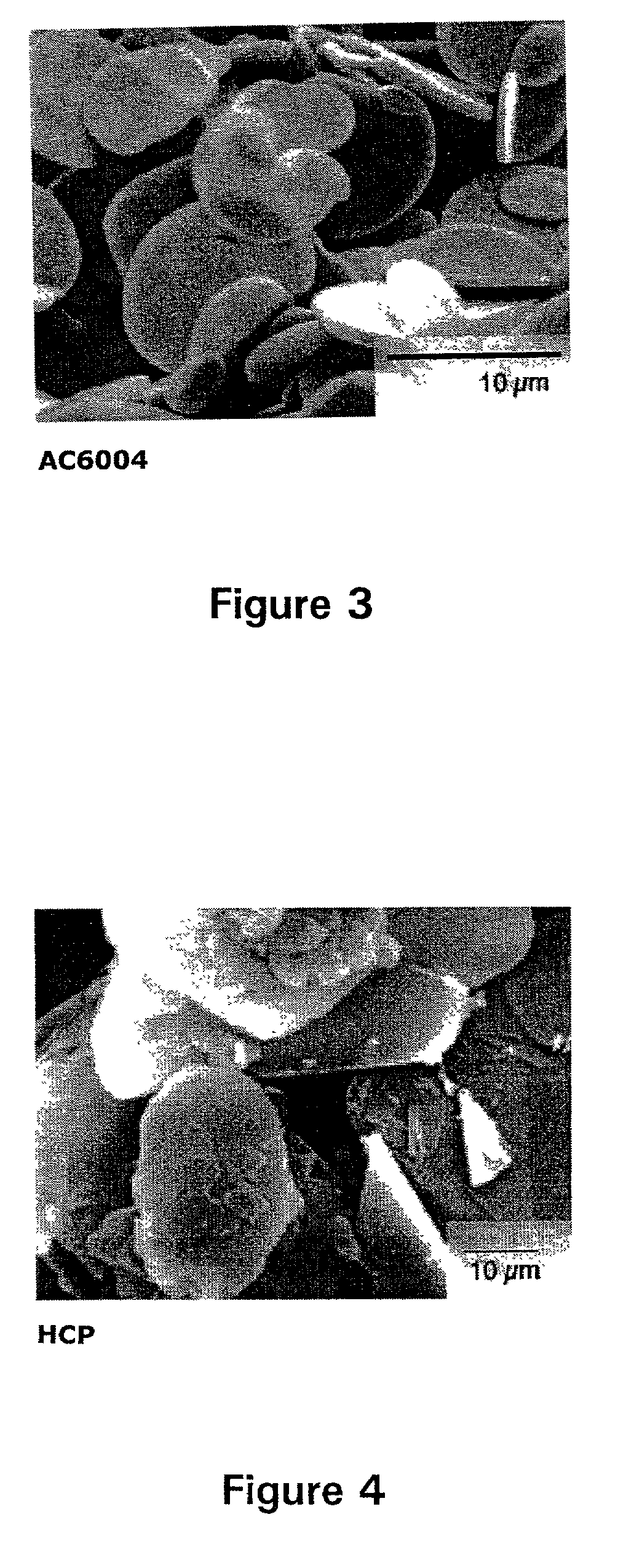

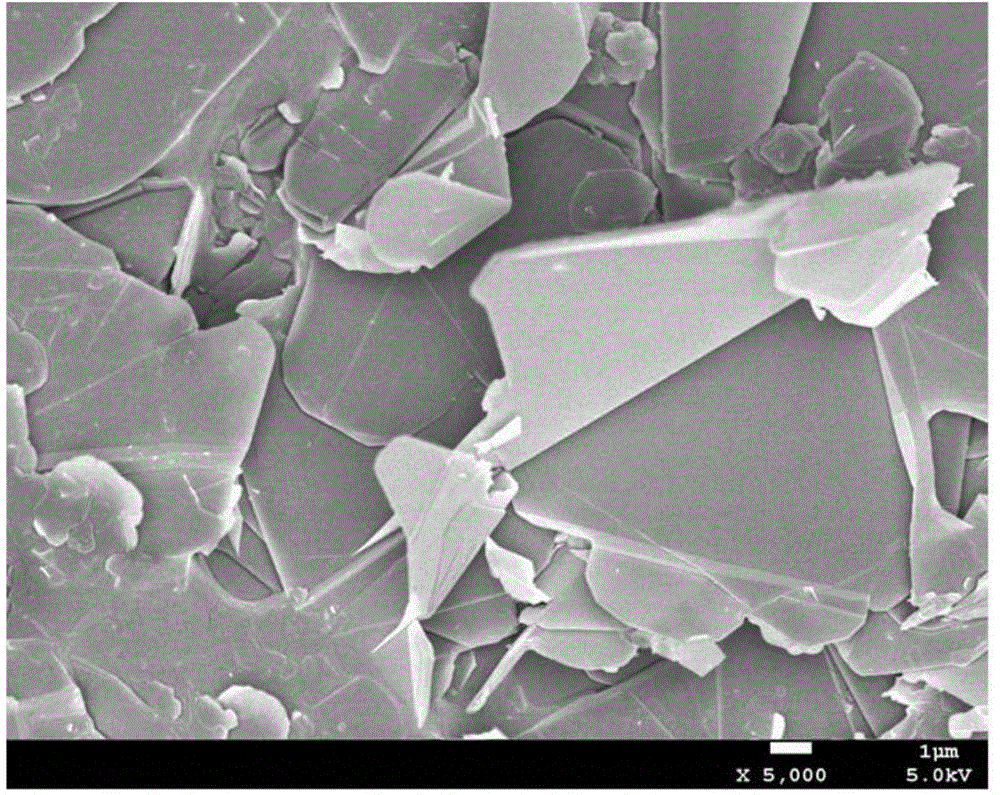

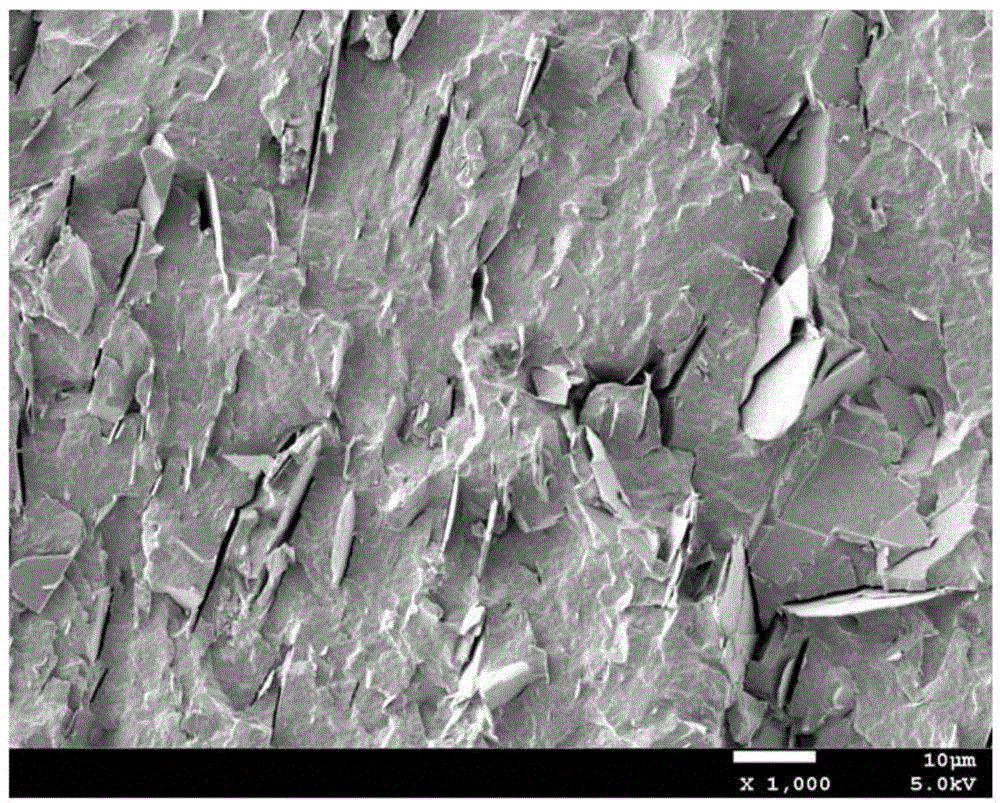

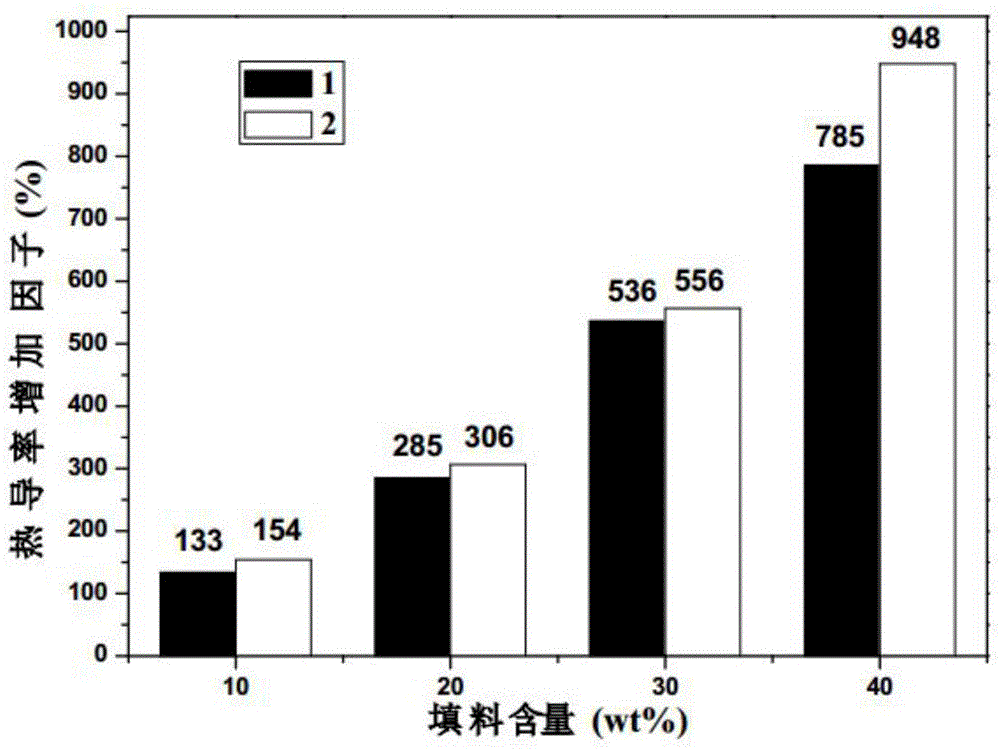

Preparation method of BN/epoxy resin heat conductive insulation composite material

The invention provides a preparation method of a BN / epoxy resin heat conductive insulation composite material and belongs to the field of preparation of heat conductive insulation composite materials.The method includes: firstly, performing annealing pretreatment to BN powder and then surface modification with a silane coupling agent; then according to certain ratio, filling an epoxy resin matrixwith the modified hexagonal BN micropowder and the modified cubic BN micropowder. The method is simple process, wherein by adding the BN in different appearances, dimensions and phase structures, effective heat conduction channels are formed to finally improve the heat conductivity of the epoxy resin. After modification, the interface combination between the HBN and the resin is strong, wherein the sheet-like HBN and bulk CBN are overlapped in the epoxy resin to form excellent heat conductive network, thus effectively reducing interfacial thermo-resistance. The composite material is beneficial to quick transmission of heat, improves heat conductivity of the epoxy resin, has excellent insulation performance, and is improved in mechanical property.

Owner:JILIN UNIV

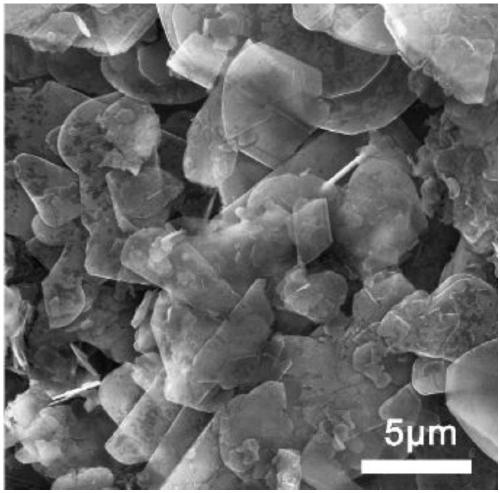

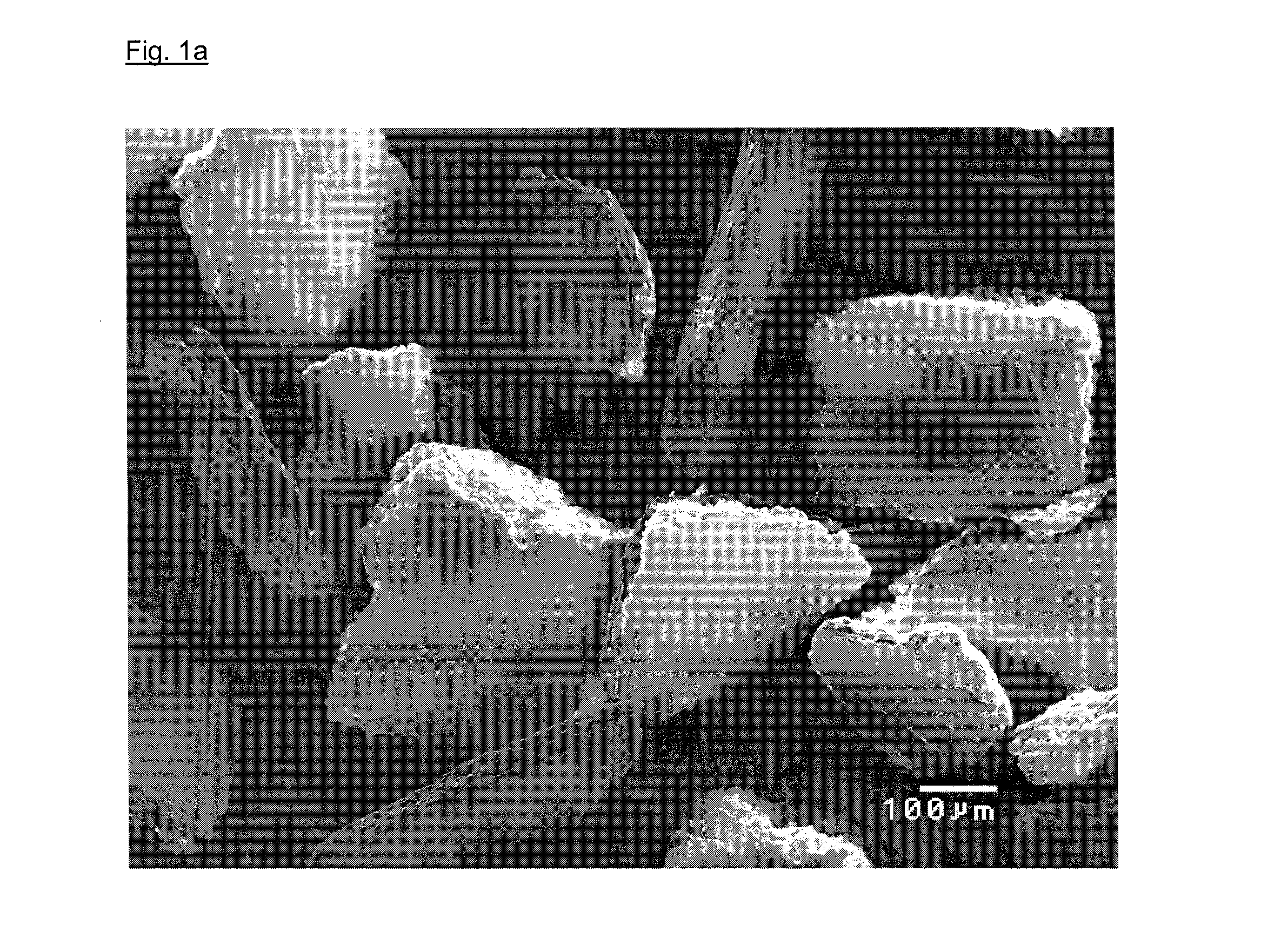

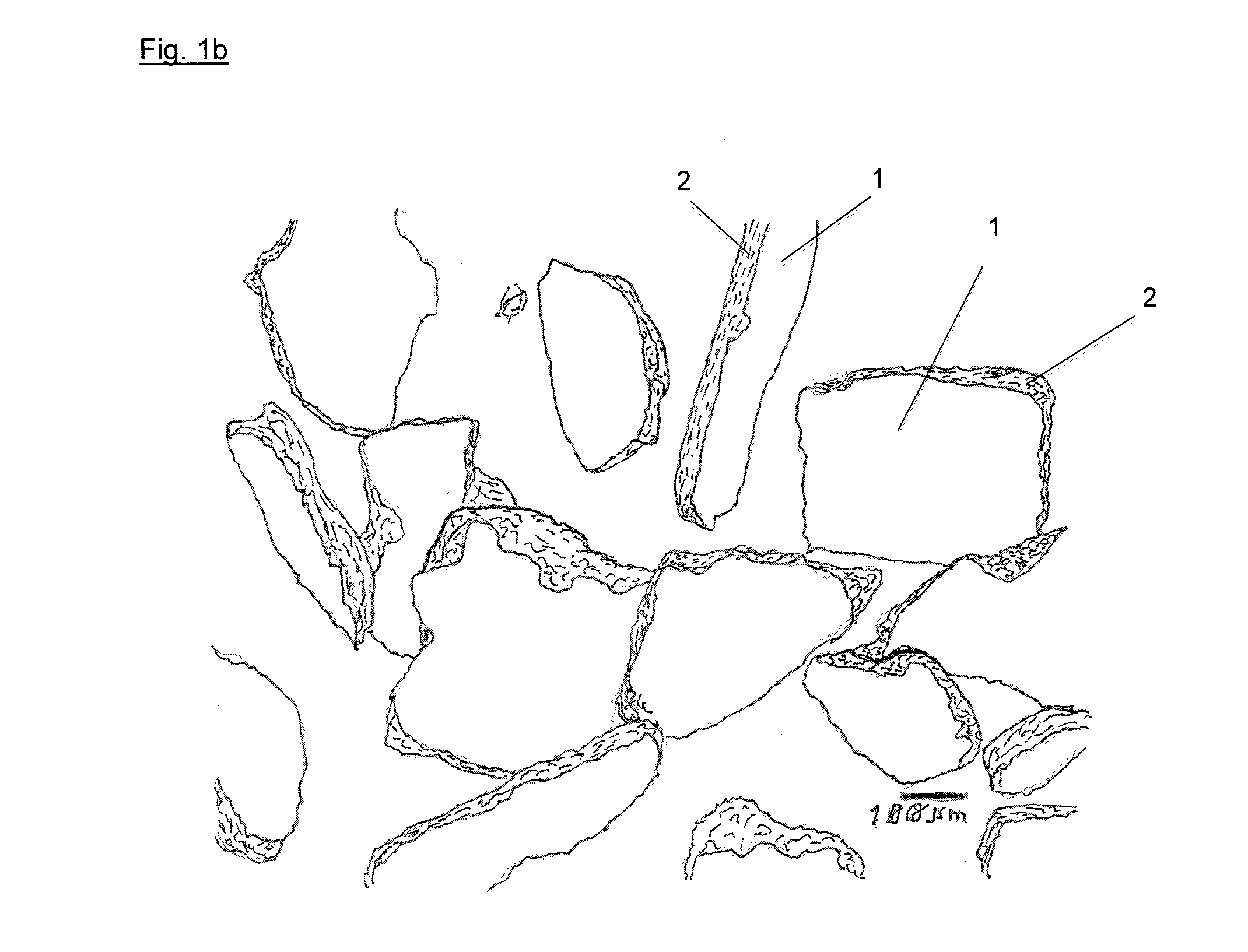

Boron nitride agglomerates, method of production thereof and use thereof

InactiveUS20120114905A1Increased through-plane thermal conductivityEasy to measureNitrogen compoundsSynthetic resin layered productsHexagonal boron nitrideBoron nitride

The invention relates to boron nitride agglomerates, comprising lamellar, hexagonal boron nitride primary particles, which are agglomerated with one another with a preferred orientation, the agglomerates formed being flake-shaped.The invention also relates to a method for producing said boron nitride agglomerates, characterized in that lamellar, hexagonal boron nitride primary particles are agglomerated in such a way that they line up with one another with a preferred orientation.The flake-shaped agglomerates according to the invention are suitable as filler for polymers for making polymer-boron nitride composites and for hot pressing of boron nitride sintered compacts.

Owner:3M INNOVATIVE PROPERTIES CO

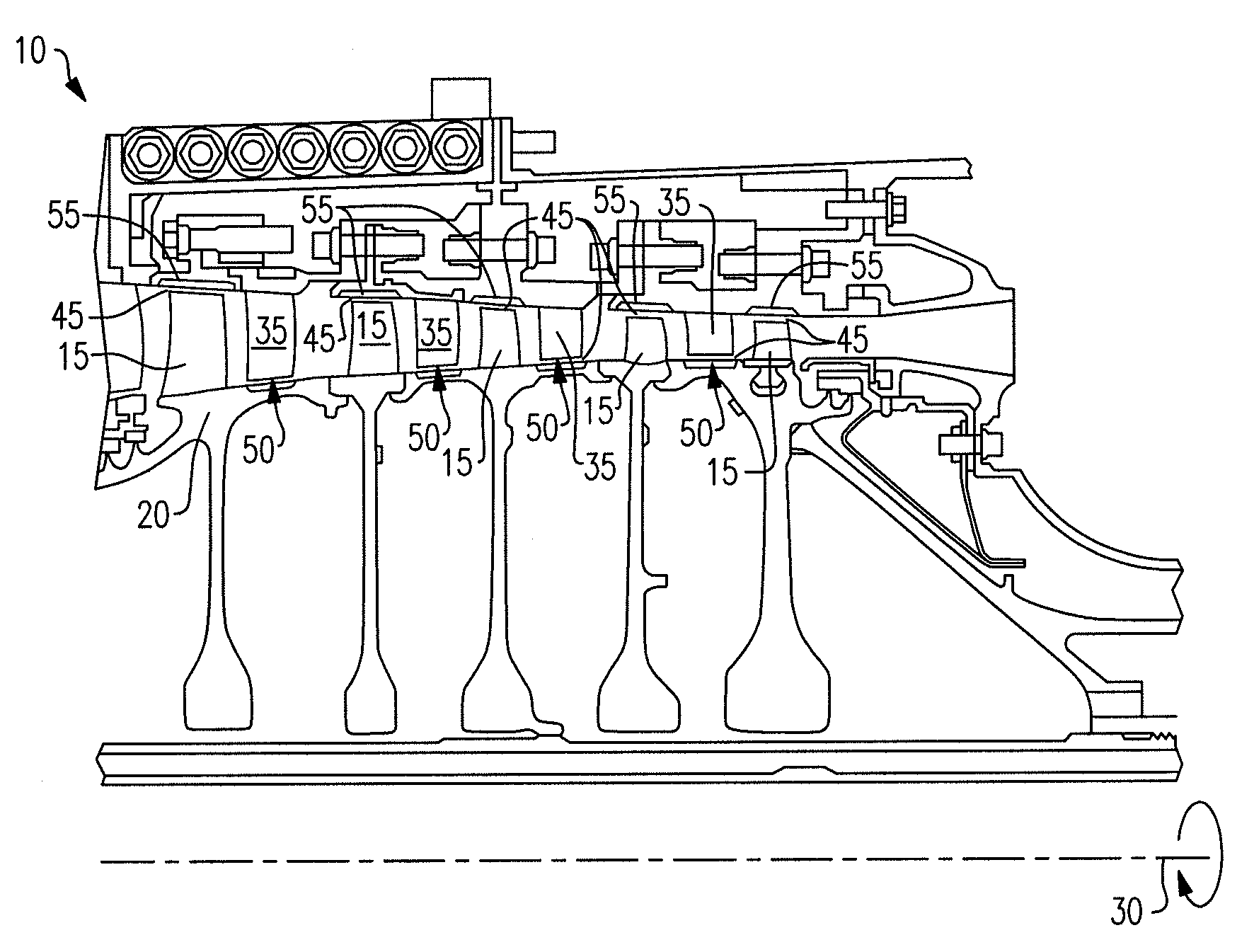

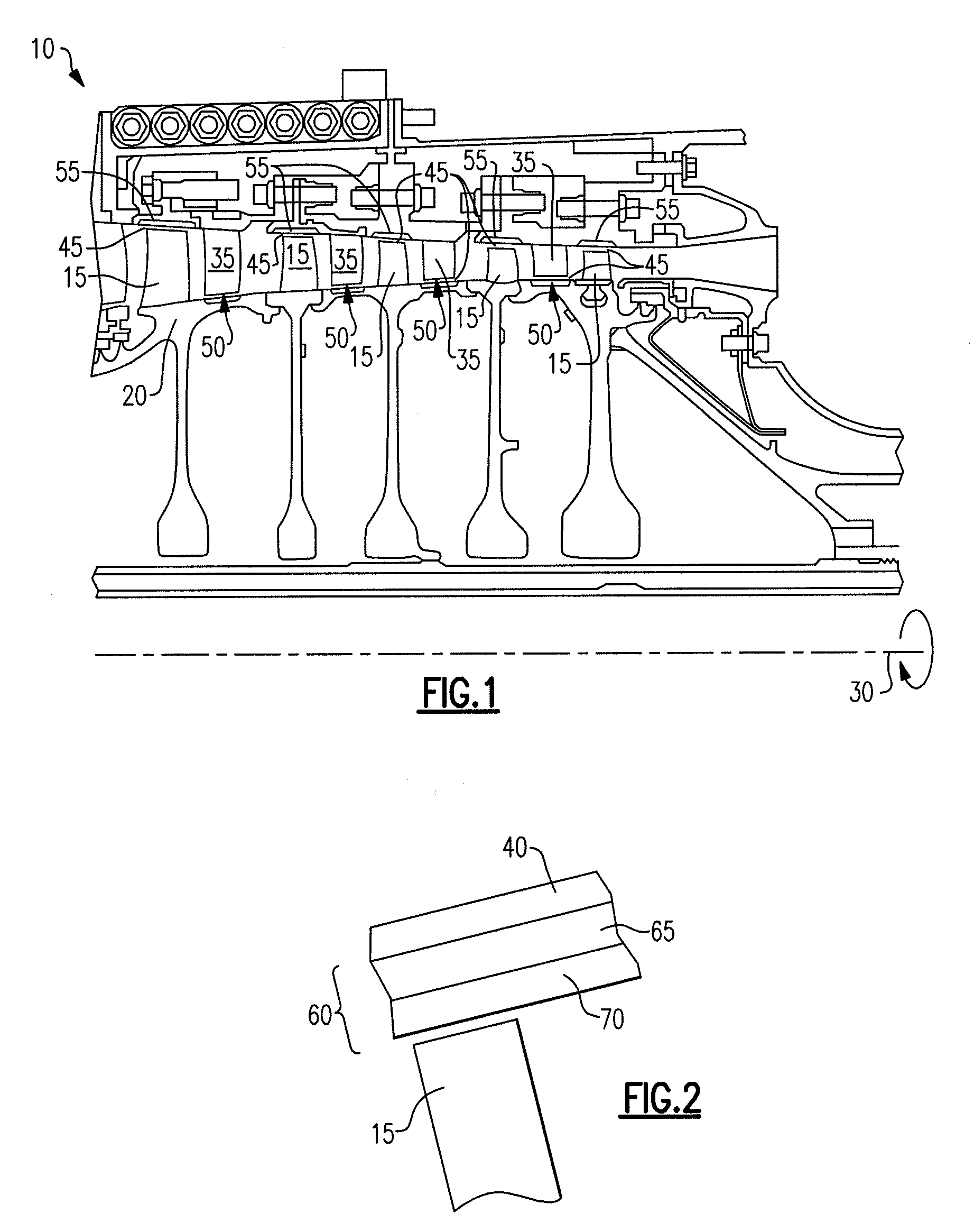

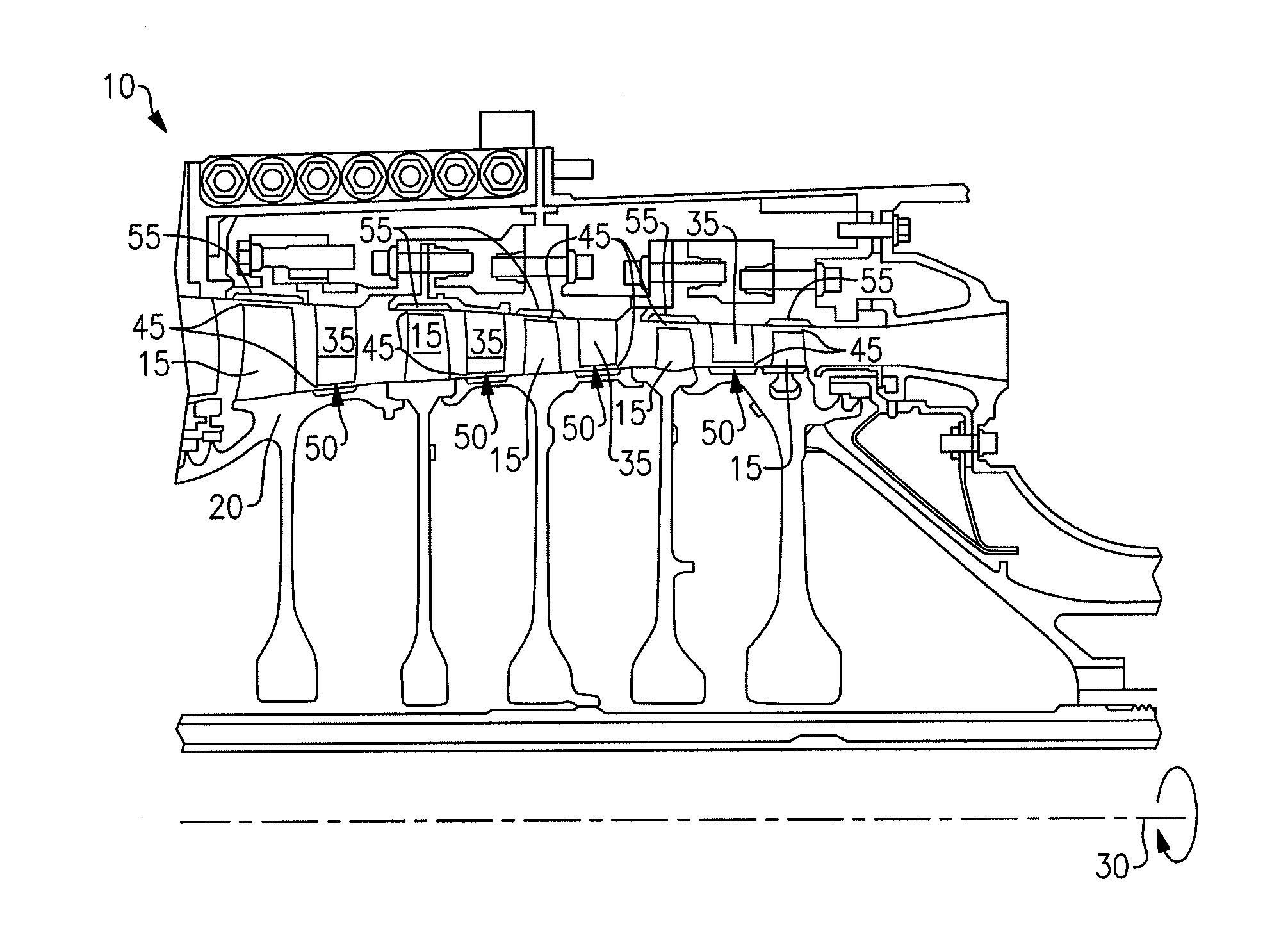

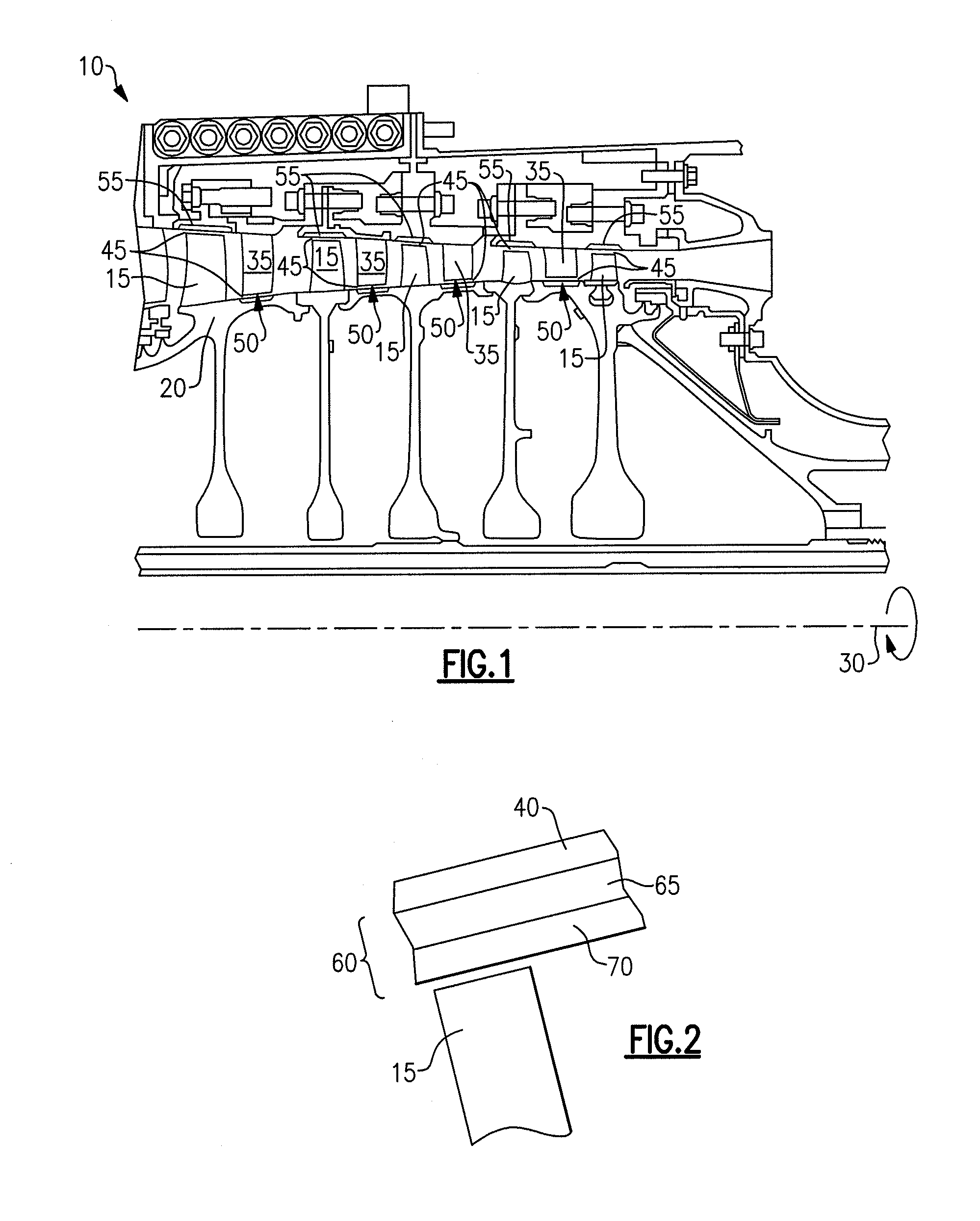

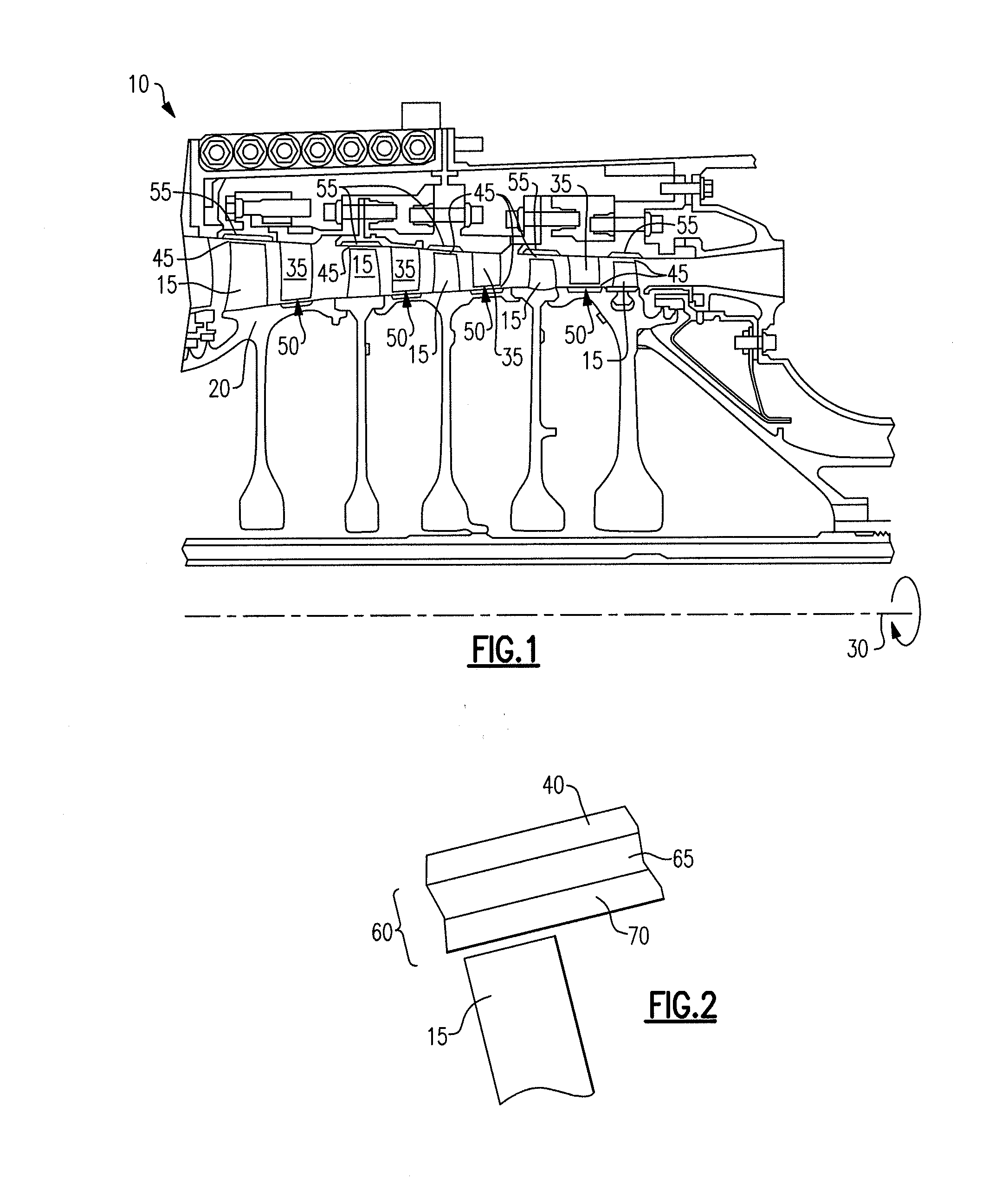

Blade air seal with integral barrier

ActiveUS8777562B2Liquid surface applicatorsPump componentsHexagonal boron nitrideThermal barrier coating

An air seal for use with rotating parts includes a thermal barrier coating layer adhered to a substrate. An abradable layer is adhered to the thermal barrier coating layer. The abradable layer comprises a matrix of agglomerated hexagonal boron nitride and a metallic alloy. Another hexagonal boron nitride is interspersed with the matrix.

Owner:RTX CORP

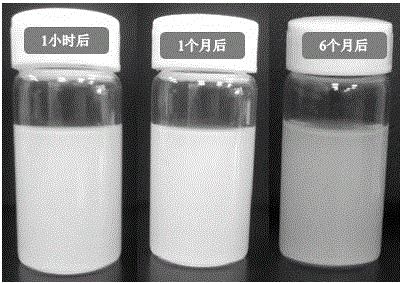

Method for modifying boron nitride nanosheet surface with polydopamine

The invention relates to a method for modifying a boron nitride nanosheet with polydopamine. The invention aims to provide a method of using a mixed solvent of a polar organic solvent and water to conduct ultrasonic stripping of hexagonal boron nitride and modifying a boron nitride nanosheet surface with polydopamine. The boron nitride nanosheet obtained by the method provided by the invention has the characteristics of good dispersibility in the mixed solvent of the polar organic solvent and water, high yield and long storage time. The polydopamine surface modified boron nitride nanosheet prepared by the method has easy storage properties and good dispersibility in a solvent. The method for modifying a boron nitride nanosheet with polydopamine provided by the invention has the advantages of simple operation, safety and low cost, etc.

Owner:SHANGHAI UNIV

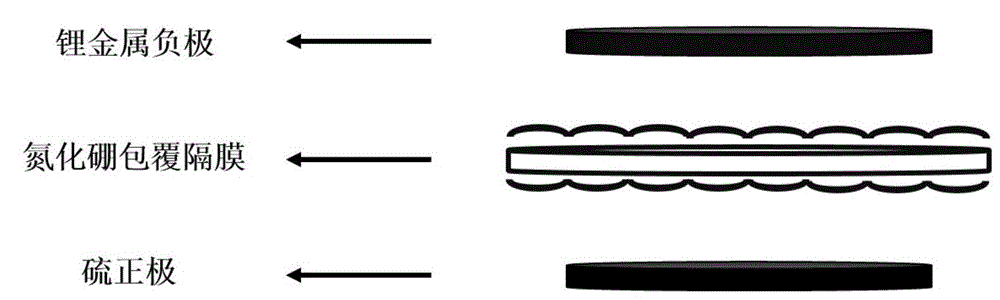

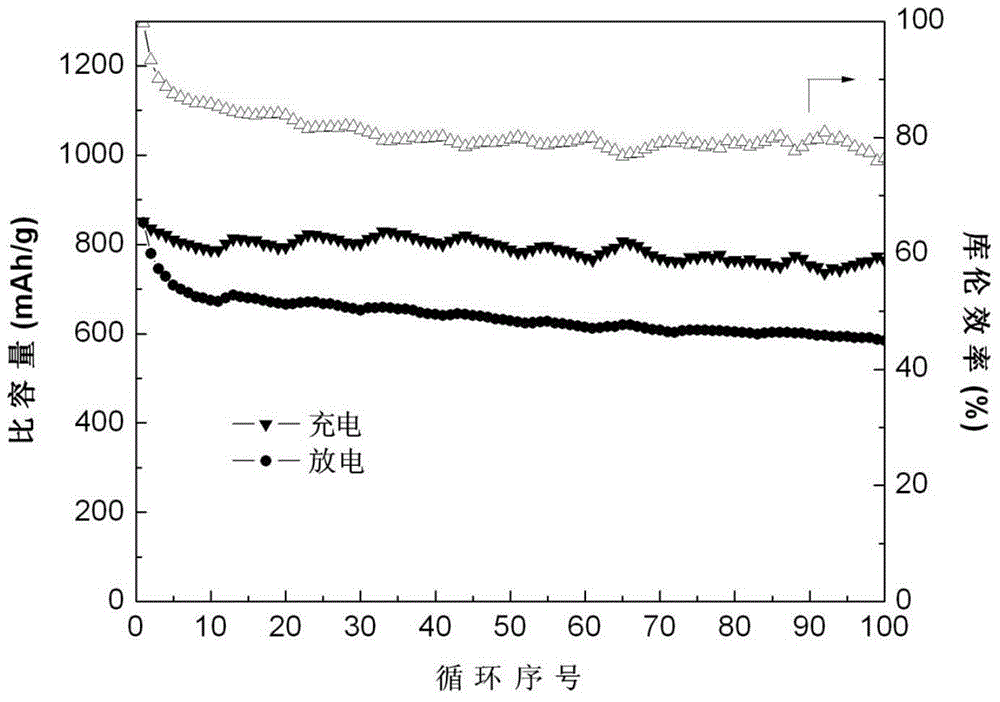

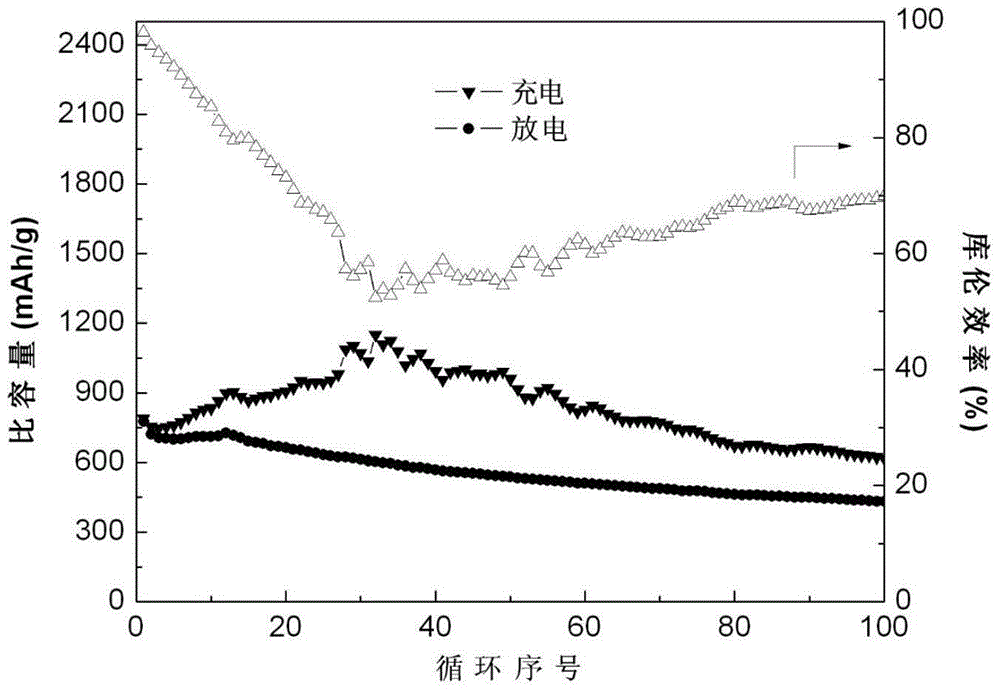

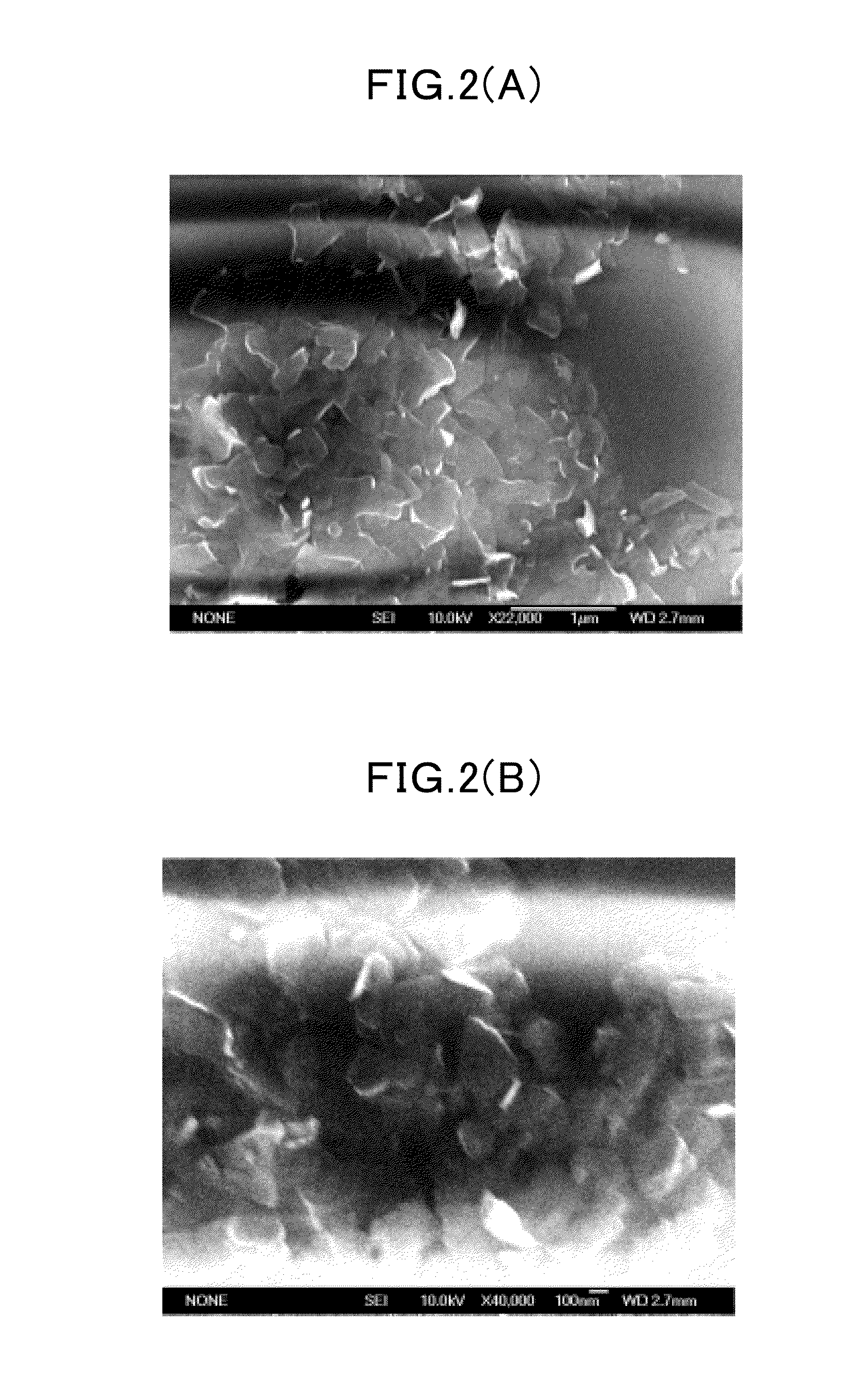

Production method of boron nitride coated diaphragm of lithium-sulfur battery

ActiveCN104993083AIncrease capacityImprove Coulombic efficiencyLi-accumulatorsCell component detailsHexagonal boron nitrideBoron nitride

The invention relates to a production method of a boron nitride coated diaphragm of a lithium-sulfur battery. The diaphragm is produced from a commercial polypropylene diaphragm, two sides of the diaphragm are uniformly covered with hexagonal boron nitride, and the characteristics of hexagonal boron nitride 'white graphite' are used, so lithium ions are allowed to pass, shuttle of polysulfide anions is obstructed, a reaction of a lithium negative electrode with the polysulfide anions is inhibited, formation of lithium dendrites, lithium sulfide precipitate and fixed lithium is prevented, the capacity, the coulombic efficiency and the cycle stability of the lithium-sulfur battery are improved, the growth of the negative electrode metal dendrite in the cycle process is effectively inhibited, and the safety of the battery is improved. The method has the advantages of simple process route and clear purpose, and the produced diaphragm has multiple functions, and can greatly overcome disadvantages of present technologies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

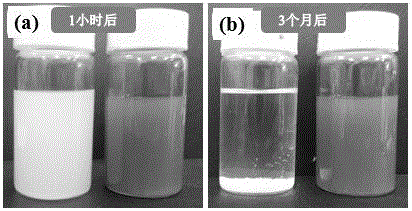

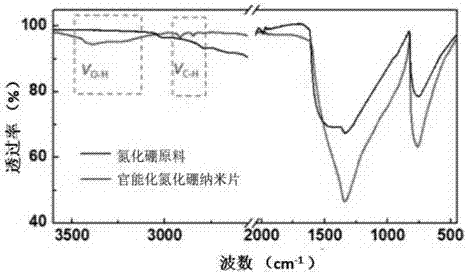

Functionalized boron nitride nanosheet and preparation method and application thereof

ActiveCN107163290ASimple and fast operationImprove stripping efficiencyNitrogen compoundsNanotechnologyOrganic solventHexagonal boron nitride

The invention discloses a functionalized boron nitride nanosheet and a preparation method and application thereof. The preparation method of the functionalized boron nitride nanosheet mainly comprises the following steps: (1) uniformly mixing boron nitride powder with a hydroxyl-containing organic solid; (2) continuously or discontinuously applying a mechanical acting force to the mixture; (3) removing residual organic solid in the mixture by means of water or an organic solvent to obtain wet functionalized boron nitride, and further drying and grinding the wet functionalized boron nitride to obtain dry functionalized boron nitride; (4) dispersing the wet or dry functionalized boron nitride in a solvent, leaving the mixture to stand or centrifugalizing the mixture, and taking supernate; and (5) filtering or centrifugalizing the supernate at a high speed and collecting the solid matter to dry to obtain the functionalized boron nitride nanosheet. The preparation method disclosed by the invention has the advantages of being simple to operate, high in yield, low in cost and the like, and the obtained functionalized boron nitride nanosheet is good in dispersibility in water, organic solvents and resin matrixes, and convenient for scaled production and application.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

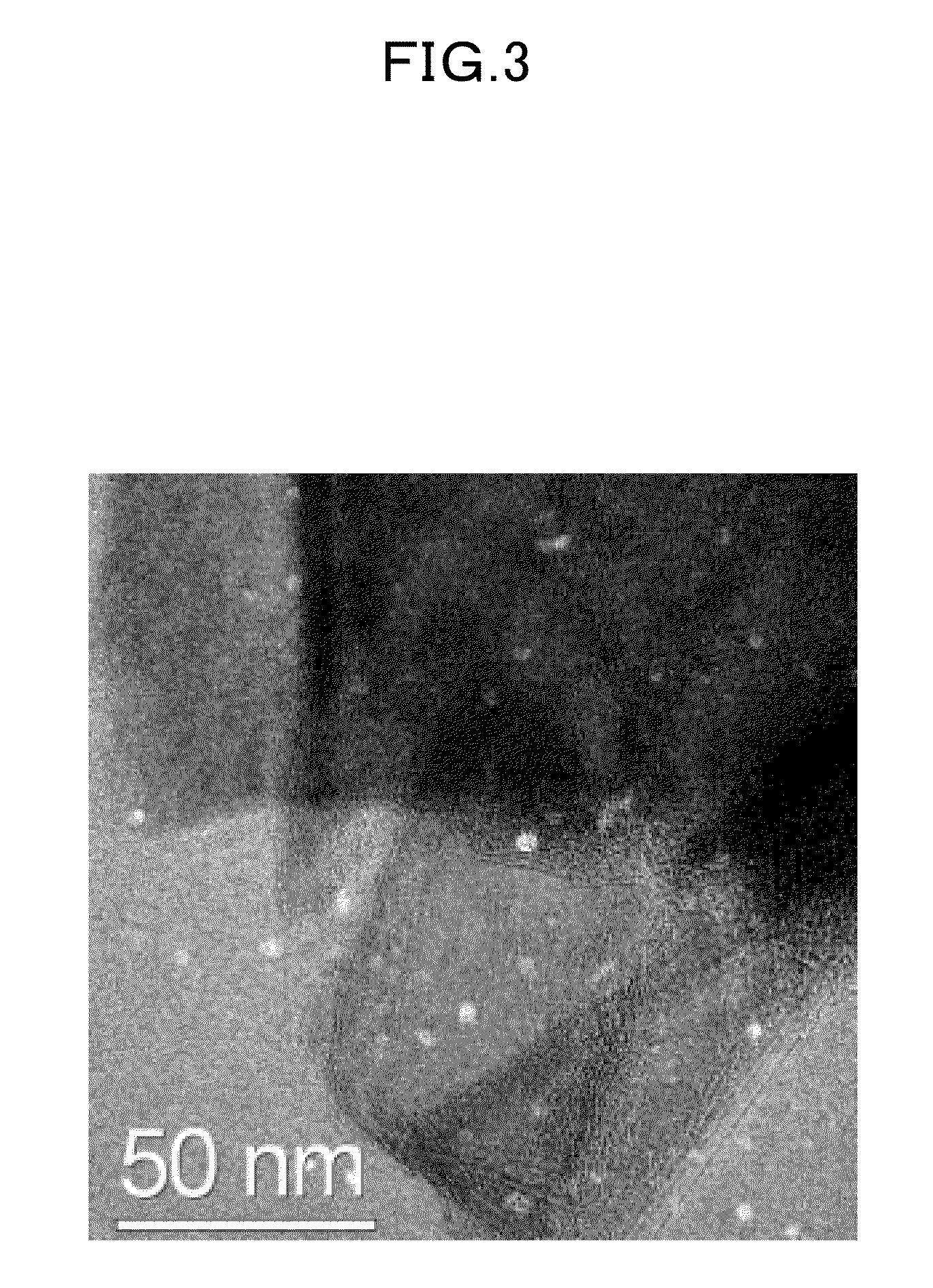

Doped hexagonal boron nitride nano sheet, preparation method thereof, catalyst using same as carrier, and applications thereof

ActiveCN105293453AReduce catalytic activityImprove conversion rateMaterial nanotechnologyPhysical/chemical process catalystsPtru catalystHexagonal boron nitride

The invention relates to a doped hexagonal boron nitride nano sheet, a preparation method thereof, a catalyst using the same as the carrier, and applications thereof. The preparation method comprises the following steps: adding a single substance or compound of hetero atoms, a single substance or compound of boron, and a nitrogen compound into water, evenly mixing, drying to remove water; then grinding the solid, placing the powder in a tubular furnace, introducing inert gas into the tubular furnace, heating the tubular furnace to a temperature of 800 to 1200 DEG C by program to carry out reactions, after reactions, cooling to the room temperature; grinding the reaction products, then boiling the grinded products in hot water, filtering when the water is still hot, washing the filter residue by hot water and ethanol, and drying. The doped hexagonal boron nitride nano sheet is taken as the carrier to prepare a catalyst, the active components loaded on the carrier can be one or more of transition metals, and the catalyst is used to catalyze organic reactions. A high temperature pyrolysis method is adopted, and the controllable preparation of nano material is achieved through controlling the ratio of each element in raw materials. The method is simple, the operation is easy, and the yield is high. The doped hexagonal boron nitride nano sheet can be used as the catalyst carrier, and is capable of improving the dispersity and catalytic activity of metal nano particles.

Owner:SHANTOU UNIV

Boron nitride nanosheet, method for producing boron nitride nanosheet thereof and composition containing boron nitride nanosheet thereof

InactiveUS20110086965A1Large specific surface areaImprove polymer propertiesNitrogen compoundsSynthetic resin layered productsOrganic solventHexagonal boron nitride

A boron nitride nanosheet containing three-layered hexagonal boron nitride, which is in a form of multi-layered hexagonal boron nitride with some its layers peeled, can be produced by dispersing pristine hexagonal boron nitride powder in an organic solvent and by subjecting the fluid dispersion to ultrasonication.

Owner:NAT INST FOR MATERIALS SCI +1

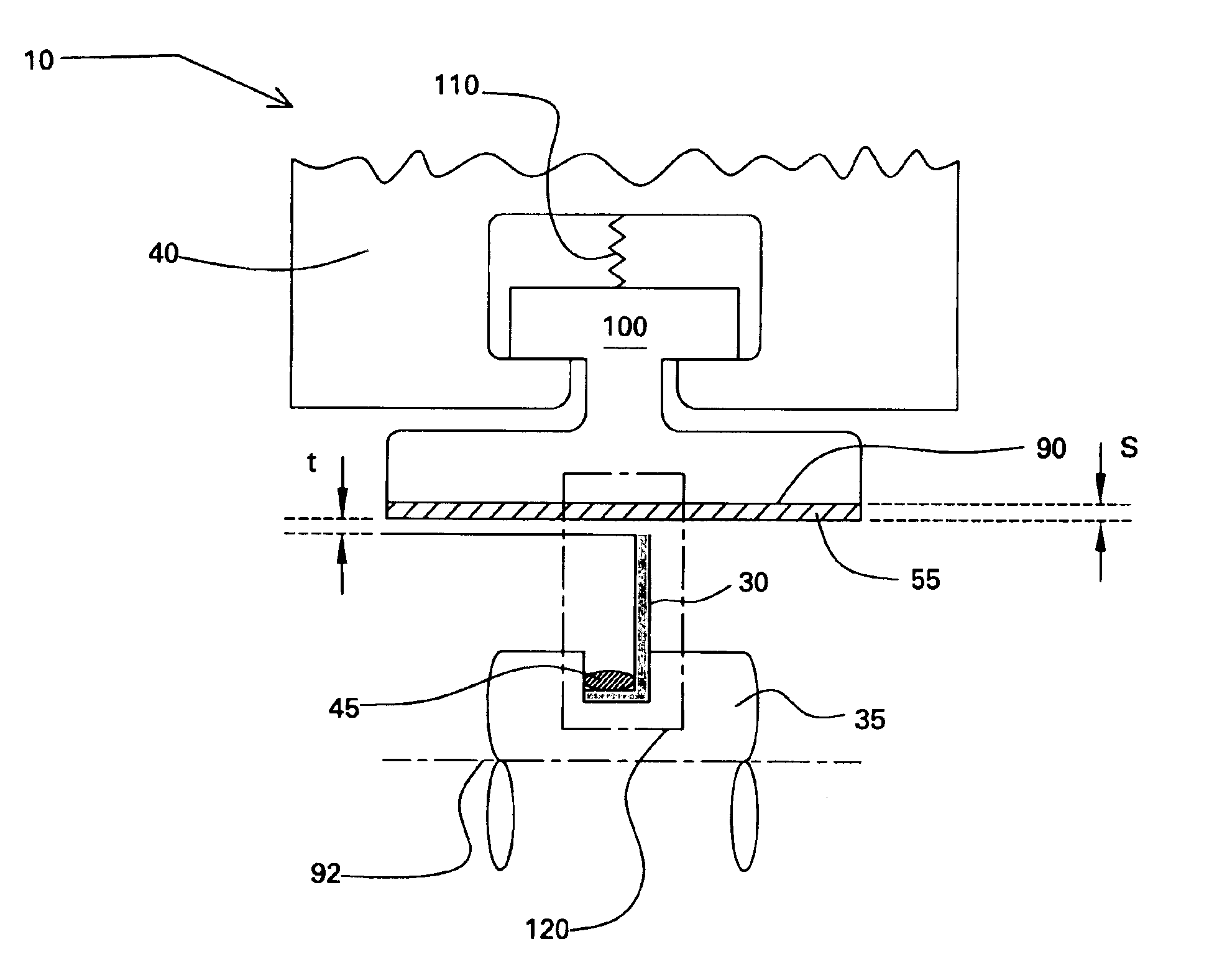

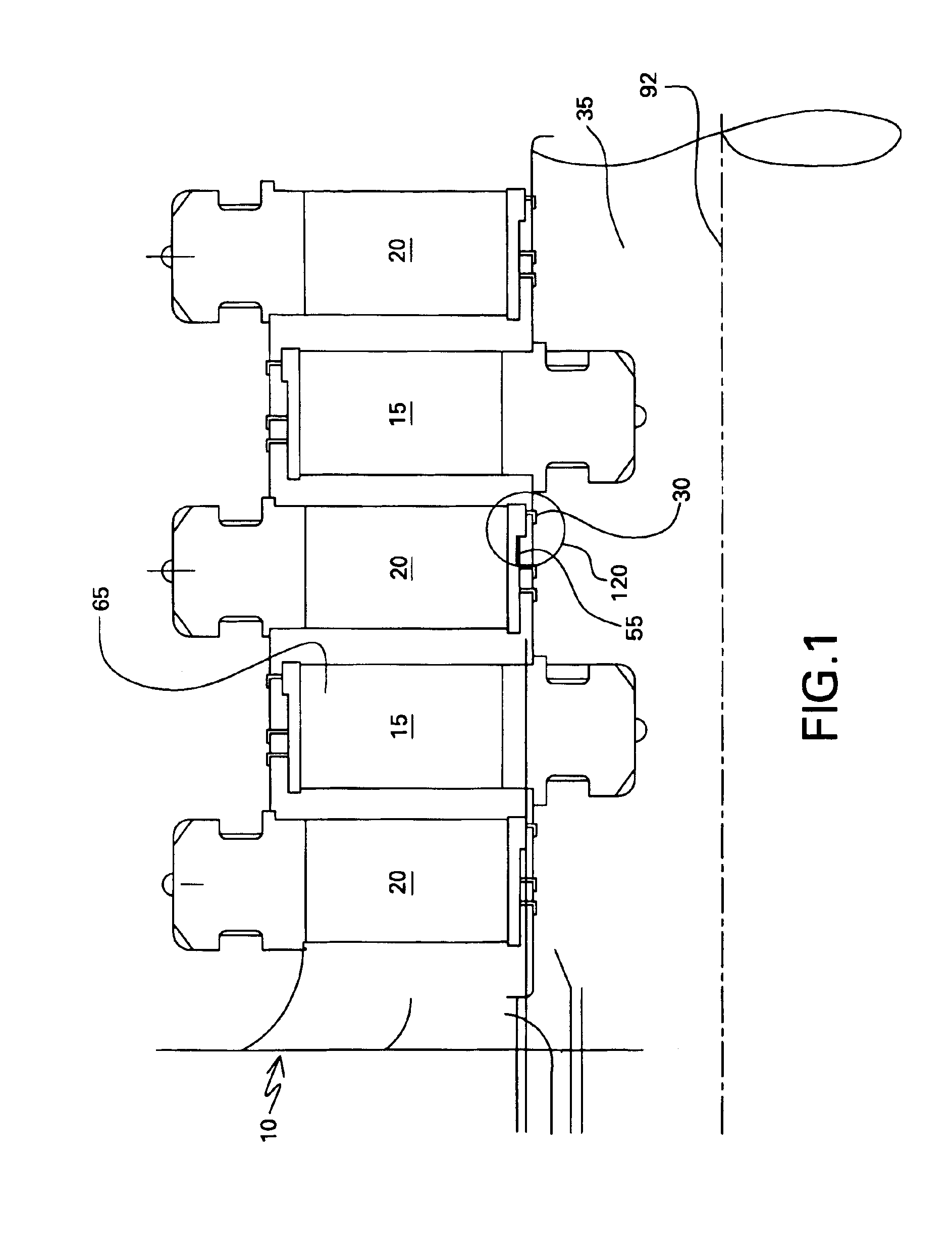

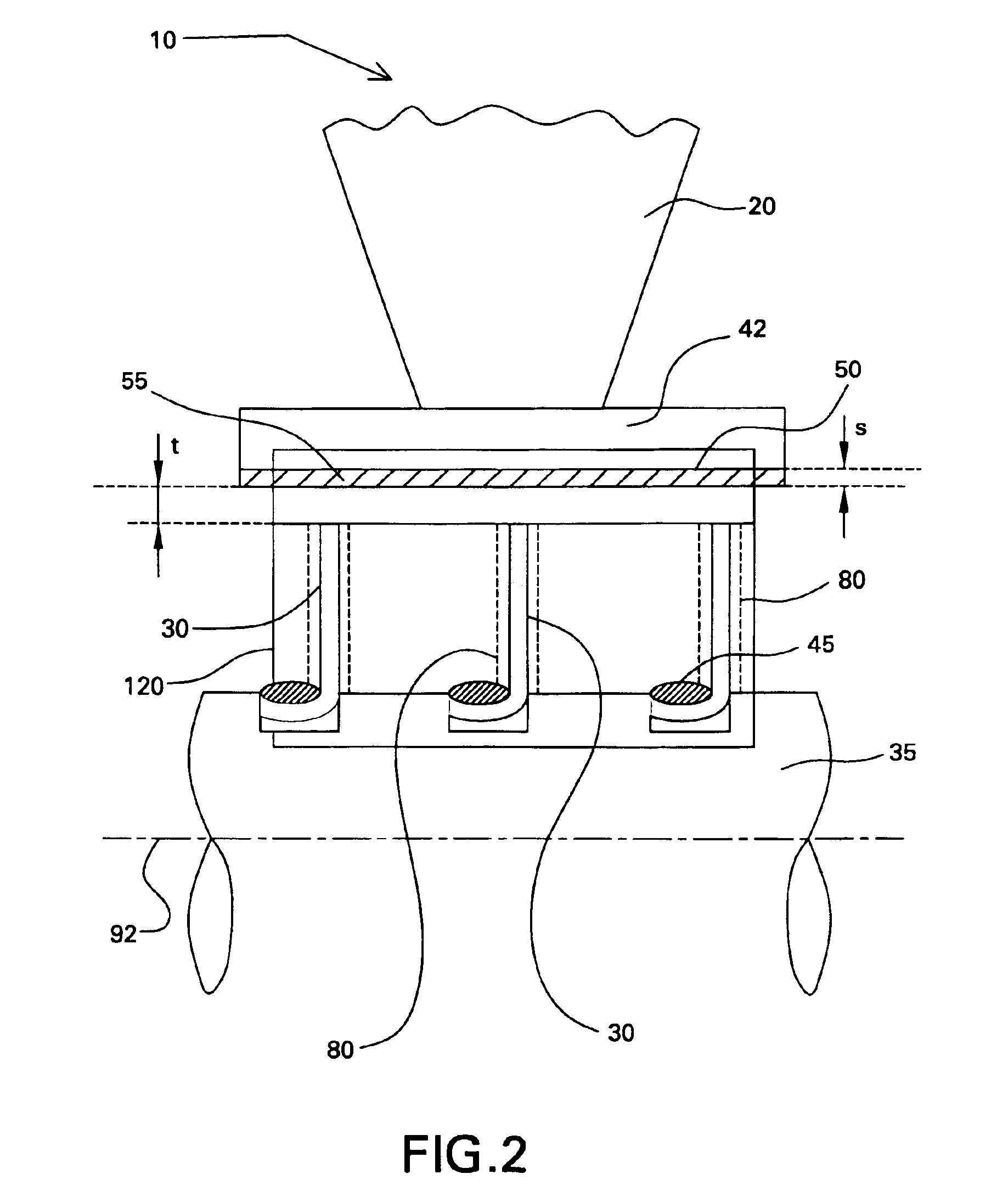

Rotary machine sealing assembly

A sealing assembly for disposition in a rotary machine is disposed between a rotary component and a stationary component of the rotary machine. The sealing assembly includes at least one sealing strip affixed by caulking to one of the rotary and stationary components. An abradable portion is disposed on another of the rotary and stationary components and is positioned radially opposite to the at least one sealing strip. The abradable portion includes a thermal spray coated material, and the thermal spray coated material includes Cobalt, Nickel, Chromium, Aluminum, Yttrium (CoNiCrAlY) and further includes a material selected from the group consisting of hexagonal boron nitride, a thermoset polymer, and combinations thereof.

Owner:GENERAL ELECTRIC CO

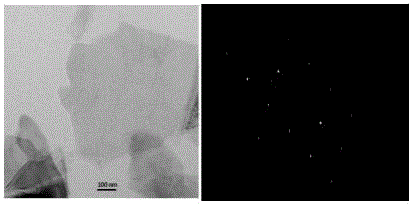

Method for preparing hexagonal boron nitride nanosheets by chemical stripping

InactiveCN103626141AEasy to operateLow costMaterial nanotechnologyNitrogen compoundsAnhydrous ethanolHexagonal boron nitride

The invention provides a method for preparing hexagonal boron nitride nanosheets by chemical stripping, which comprises the following steps: (1) uniformly mixing and stirring every 0.5-5g of hexagonal boron nitride powder with 100ml of acid, adding potassium permanganate according to the potassium permanganate / hexagonal boron nitride powder mass ratio of 1:10:10:1, and continuing stirring to prepare a mixture; (2) stirring the mixture in an ice bath to react for 1-24 hours; dropwisely adding oxydol to remove the residual potassium permanganate; and (3) finally, washing the reaction product with water until the pH value is 6-8, dissolving in anhydrous ethanol for separation, and removing unstripped boron nitride powder to obtain the boron nitride nanosheets. The acid, potassium permanganate, oxydol and hexagonal boron nitride react together to prepare the boron nitride nanosheets; and thus, the method is simple to operate and low in cost, does not need complex or expensive equipment, and is beneficial to large-scale production.

Owner:SHANDONG UNIV

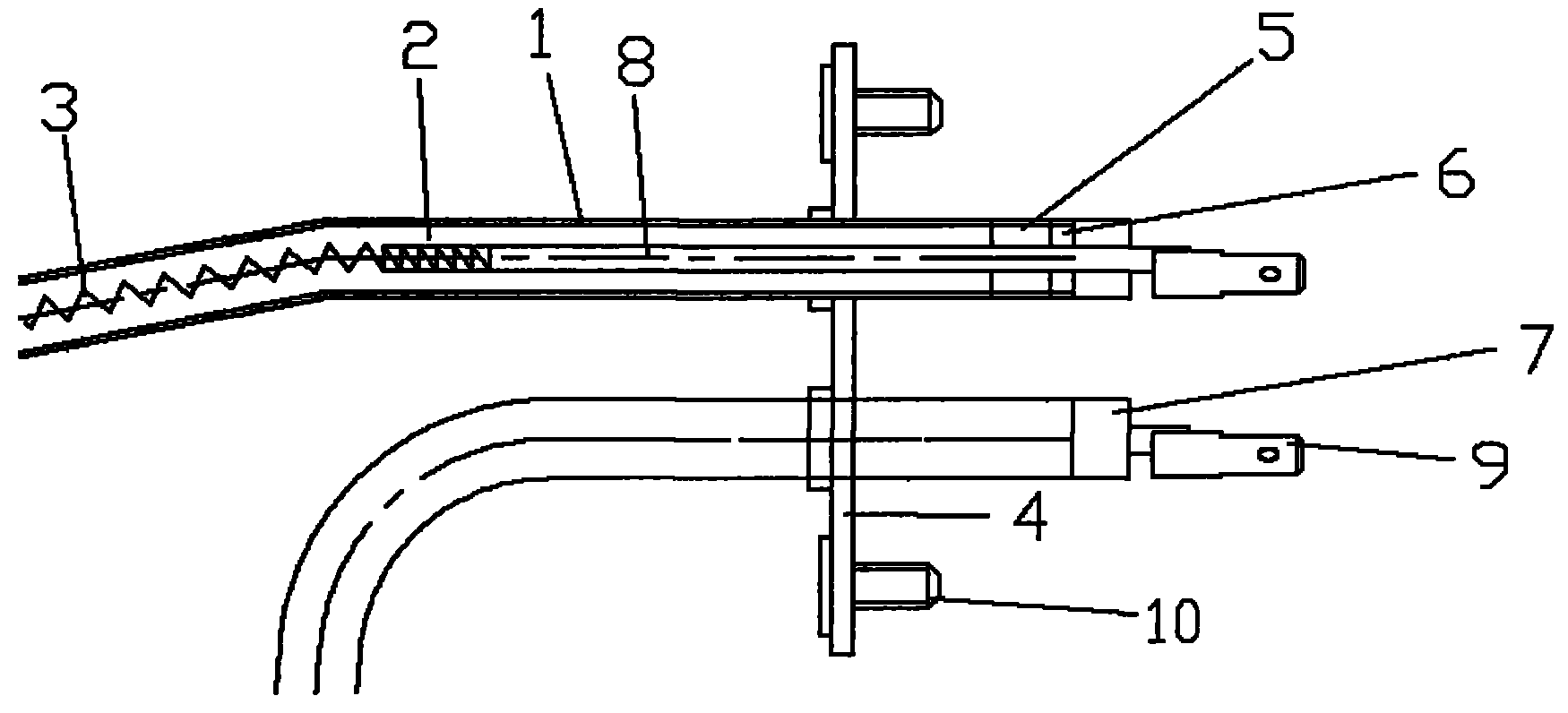

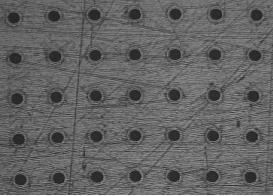

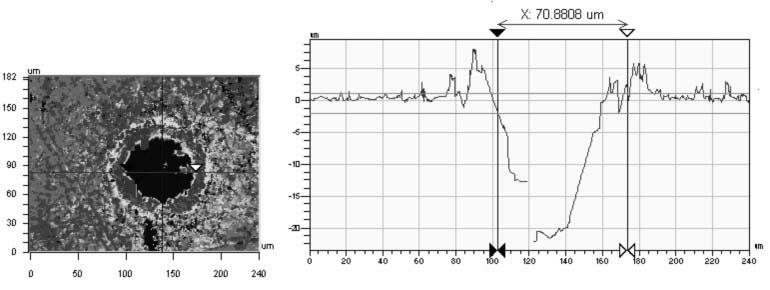

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

Blade air seal with integral barrier

ActiveUS20130078085A1Liquid surface applicatorsPump componentsHexagonal boron nitrideThermal barrier coating

An air seal for use with rotating parts includes a thermal barrier coating layer adhered to a substrate. An abradable layer is adhered to the thermal barrier coating layer. The abradable layer comprises a matrix of agglomerated hexagonal boron nitride and a metallic alloy. Another hexagonal boron nitride is interspersed with the matrix.

Owner:RTX CORP

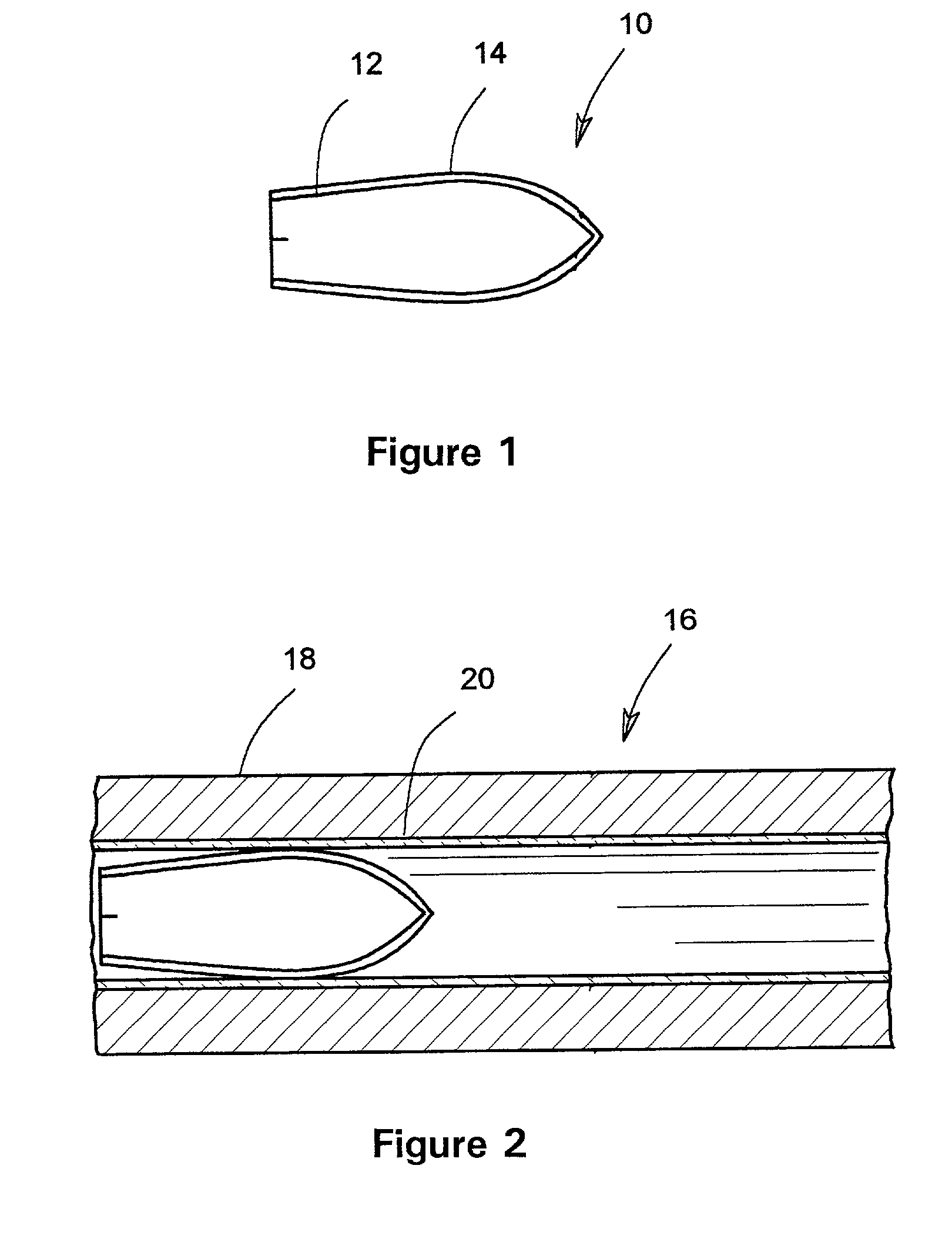

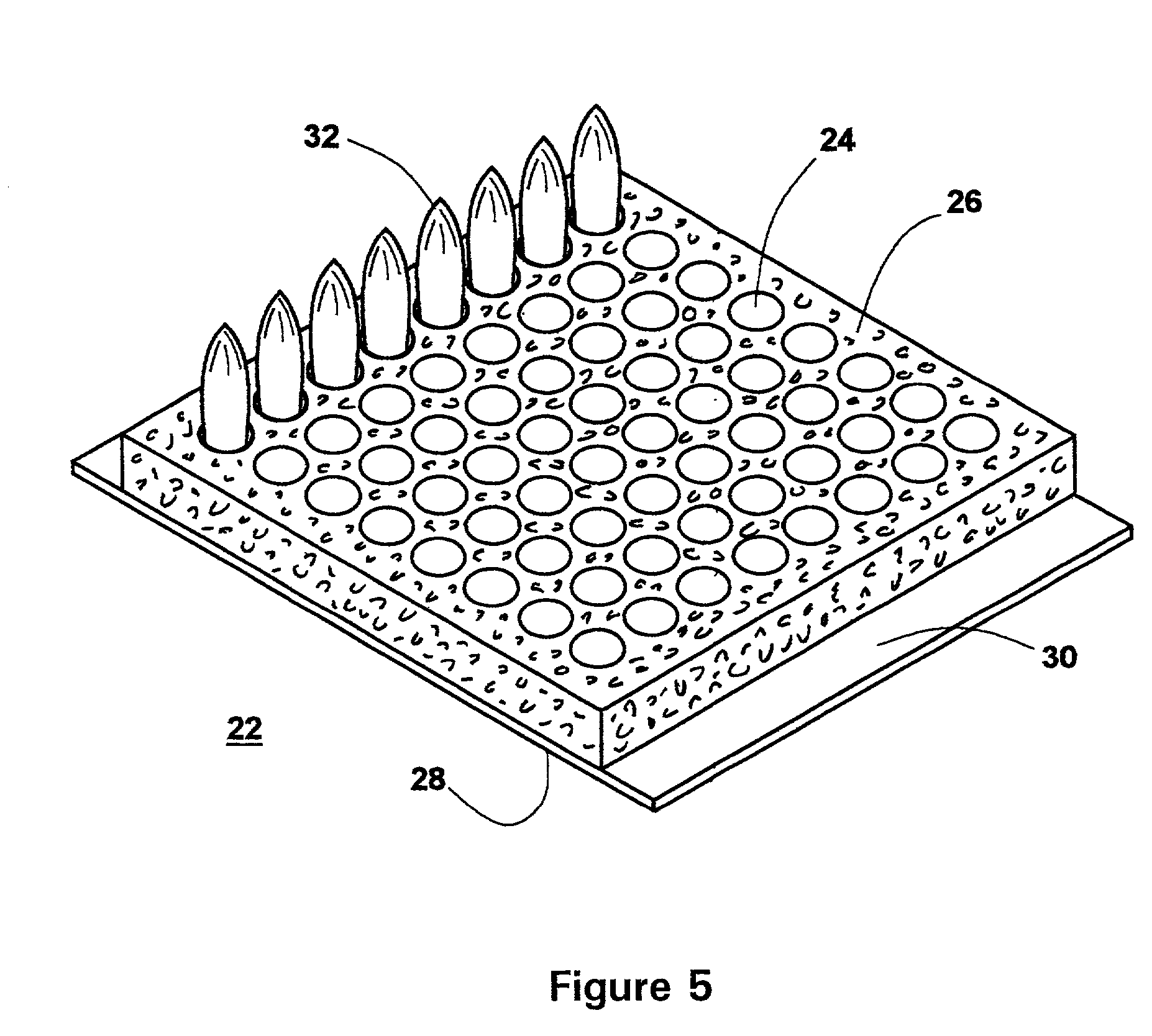

Ballistics conditioning

InactiveUS20030078170A1Quick and easy spray-coatingHigh hardnessAmmunition projectilesMoulding toolsHexagonal boron nitrideAcrylic resin

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

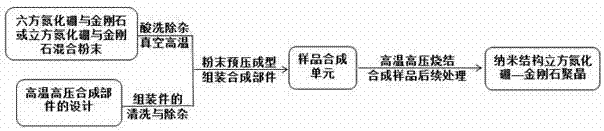

Preparation method of cubic boron nitride and diamond polycrystal with nanometer structure

The invention relates to a preparation method of a cubic boron nitride and diamond polycrystal with a nanometer structure. The preparation method comprises the steps: with hexagonal boron nitride and diamond mixed powder or cubic boron nitride and diamond mixed powder as the raw material, purifying for removing impurities in the raw material, then, assembling a sintering unit without adding any binder, and directly sintering at high temperature and superhigh pressure to prepare the cubic boron nitride and diamond polycrystal with the nanometer structure, wherein diamond accounts for 10-90% of the mass percentage of the raw material. The cubic boron nitride and diamond polycrystal with the nanometer structure is uniform in phase distribution, cubic boron nitride crystal grains have nanometer sizes, and diamond crystal grains are uniformly distributed in the nano cubic boron nitride crystal grains, thus a nanometer cubic boron nitride and diamond interface which is compact in combination and high in strength is formed at a large area. Therefore, the hardness of the high-performance cubic boron nitride and diamond polycrystal with the nanometer structure is equal to that of a diamond monocrystal, and the thermal stability, hardness and wear resistance of the high-performance cubic boron nitride and diamond polycrystal with the nanometer structure are also remarkably higher than those of a diamond polycrystal containing a metal binder.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

High thermal conductive and insulating polymer composite and preparing method and application thereof

The invention discloses a high thermal conductive and insulating polymer composite and a preparing method and application thereof. The preparing method is characterized in that 0.1-1.0 part of hexagonal boron nitride is evenly stirred and mixed with 50-1000 parts of organic solvent, and is added into an ultrasonic cleaner with the power ranging from 100 w to 1000 w or an ultrasonic cell disruptor, ultrasonic treatment is carried out for 4 hours to 72 hours, and mixed liquor is obtained; standing is carried out on the mixed liquor for 24 hours to 72 hours, after filtering or rotary evaporating is carried out, a product is cleaned for twice to five times by using acetone, and a boron nitride nano-sheet with the higher yield is obtained; 60-90 parts of a polymer matrix and 40-10 parts of the boron nitride nano-sheet are added into a high-speed blender mixer, the temperature ranges from 200 DEG C to 300 DEG C, the rotary speed ranges from 30 rpm to 60 rpm, mixing is carried out for 5 minutes to 10 minutes, and granulates are extruded by a screw extruder; the high thermal conductive and insulating polymer composite can be obtained through smelting and forming. According to the high thermal conductive and insulating polymer composite, the mechanical property can be maintained, and meanwhile the thermal conductivity is improved maximally.

Owner:SICHUAN UNIV

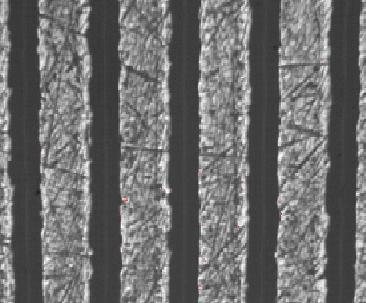

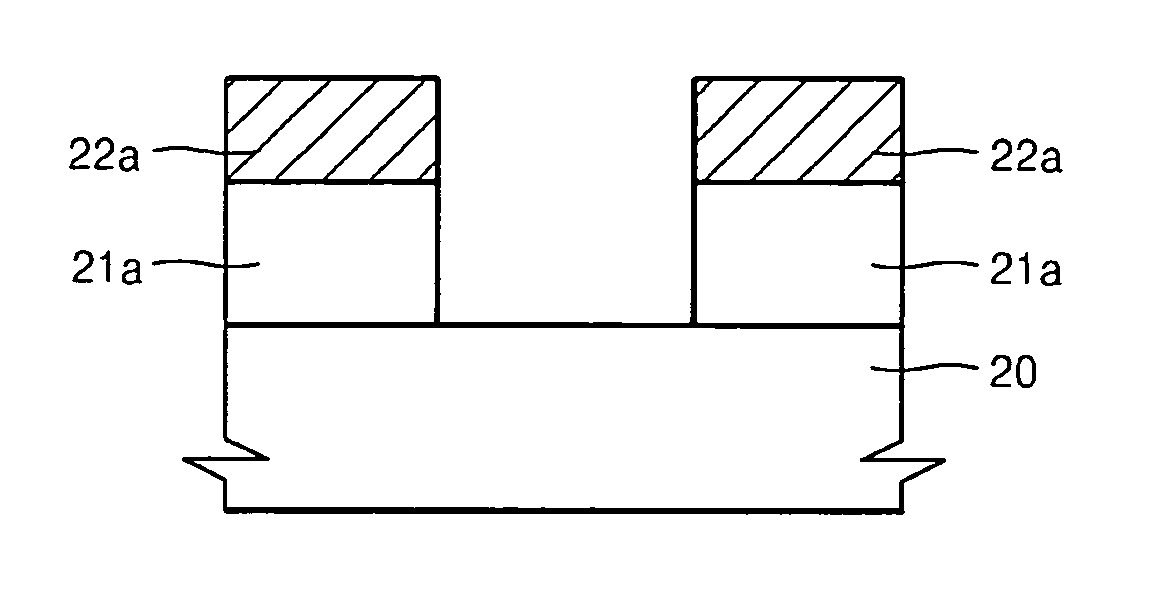

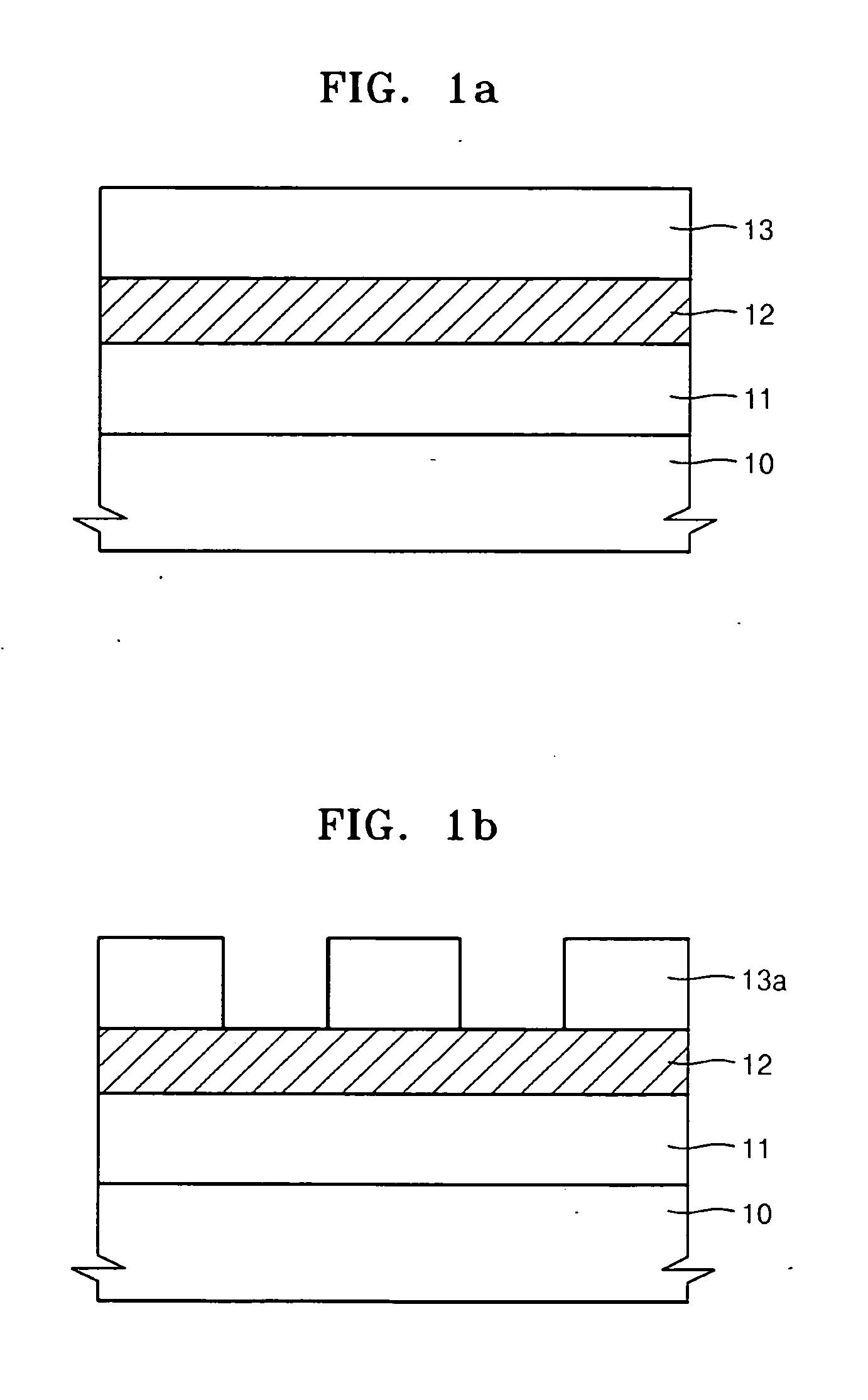

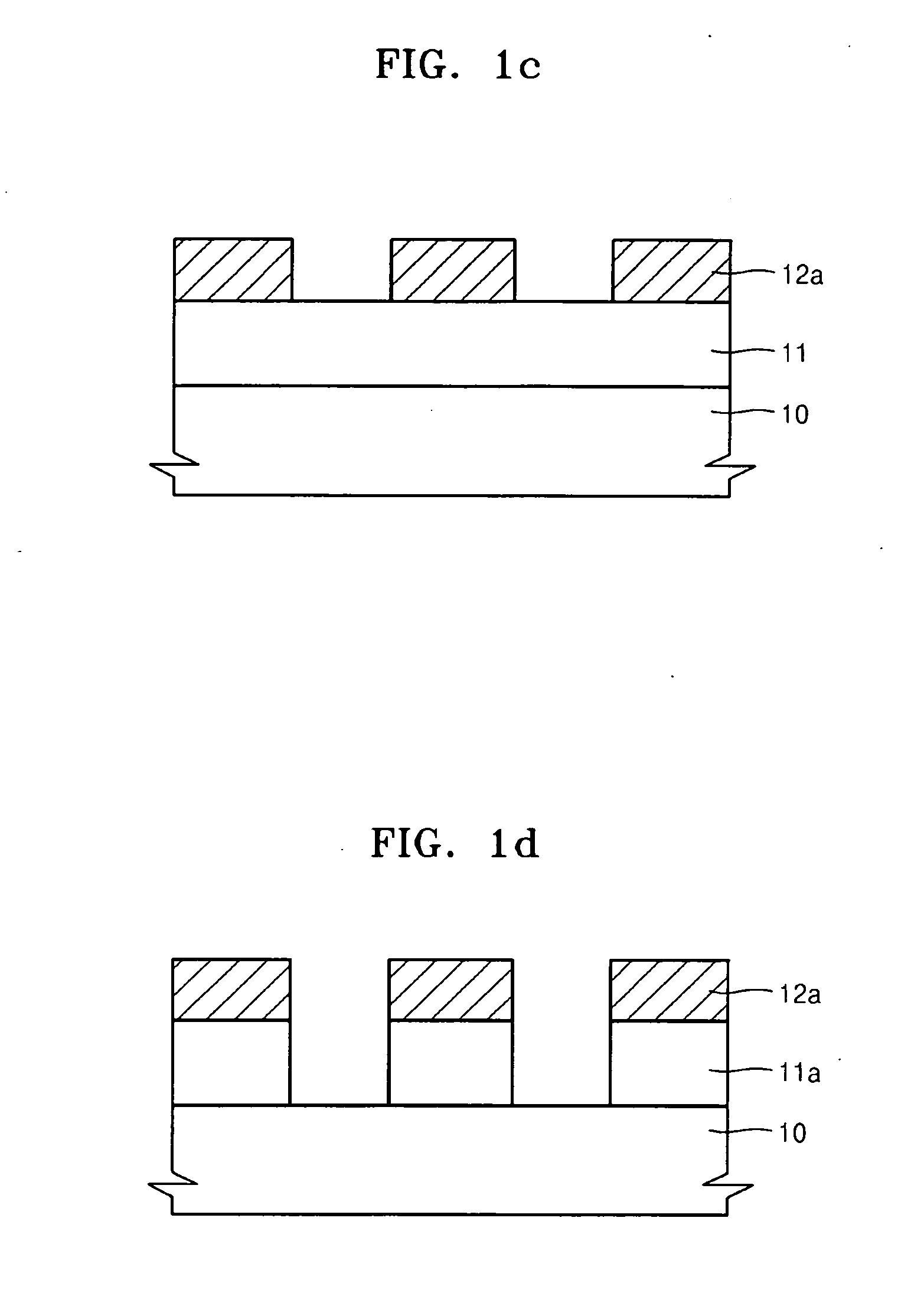

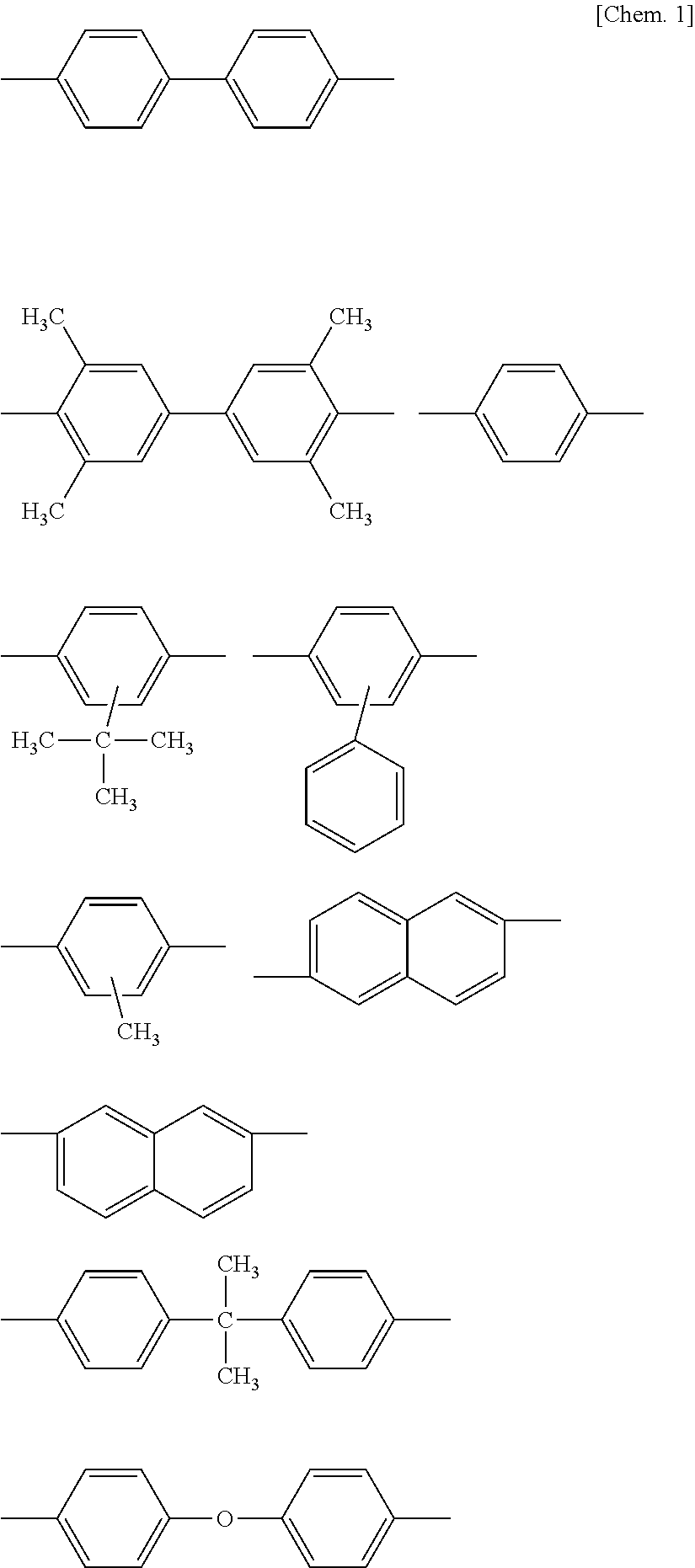

Hardmask composition and method of forming pattern using the hardmask composition

InactiveUS20160005625A1Excellent etch resistanceSemiconductor/solid-state device manufacturingAnti-corrosive paintsPolymer scienceHexagonal boron nitride

A hardmask composition includes a first material including one of an aromatic ring-containing monomer and a polymer containing a repeating unit including an aromatic ring-containing monomer, a second material including at least one of a hexagonal boron nitride and a precursor thereof, a chalcogenide-based material and a precursor thereof, and a two-dimensional carbon nanostructure and a precursor thereof, the two-dimensional carbon nanostructure containing about 0.01 atom % to about 40 atom % of oxygen, and a solvent.

Owner:SAMSUNG ELECTRONICS CO LTD

Highly thermally conductive resin molded article

ActiveUS20110027565A1Efficiently and easily disperseImprove thermal conductivitySemiconductor/solid-state device detailsSynthetic resin layered productsDiffusion AnisotropyHexagonal boron nitride

An object of the present invention is to industrially easily mold a molded article which is excellent in thermal conductivity, electric insulation property, low density, and an injection moldability and has a thermal conduction anisotropy. The present invention relates to a highly thermally conductive resin molded article having a thermal diffusion anisotropy, the highly thermally conductive resin molded article comprising a resin composition, the resin composition containing at least resin (A) and plate-like hexagonal boron nitride powder (B) in a (A) / (B) volume ratio falling within a range of 90 / 10 to 30 / 70, the resin (A) including a thermoplastic polyester resin and / or a thermoplastic polyamide resin, the highly thermally conductive resin molded article having a thickness of not more than 1.3 mm in a part of or all over a three-dimensional shape of the highly thermally conductive resin molded article, a thermal diffusivity measured in a plane direction of the highly thermally conductive resin molded article, being (i) two or more times higher than a thermal diffusivity measured in a thickness direction of the highly thermally conductive resin molded article and (ii) not less than 0.5 mm2 / sec.

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com