Patents

Literature

3447 results about "Alkyd" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

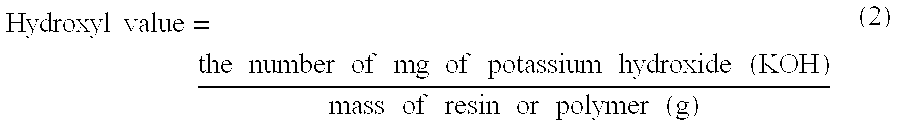

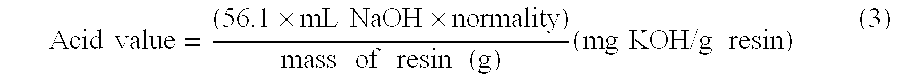

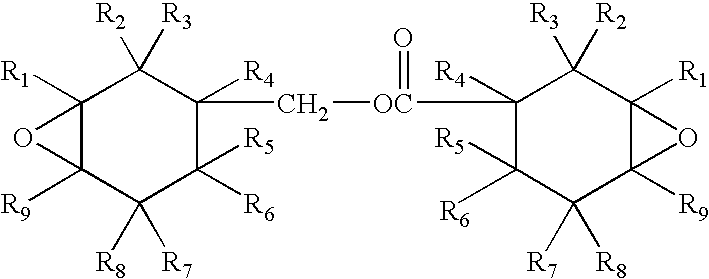

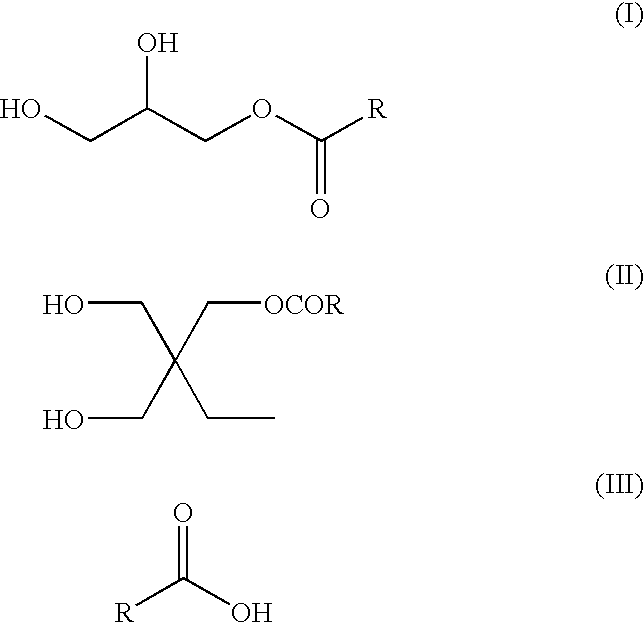

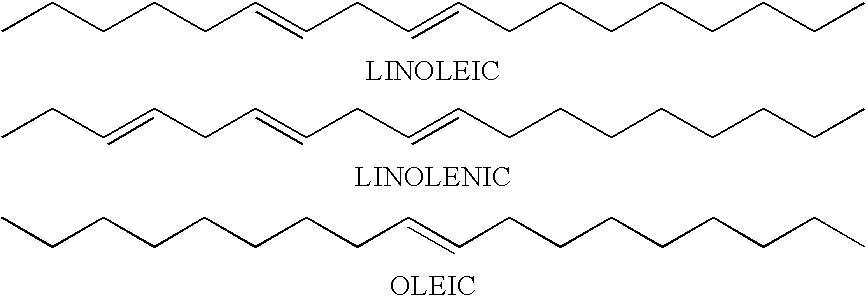

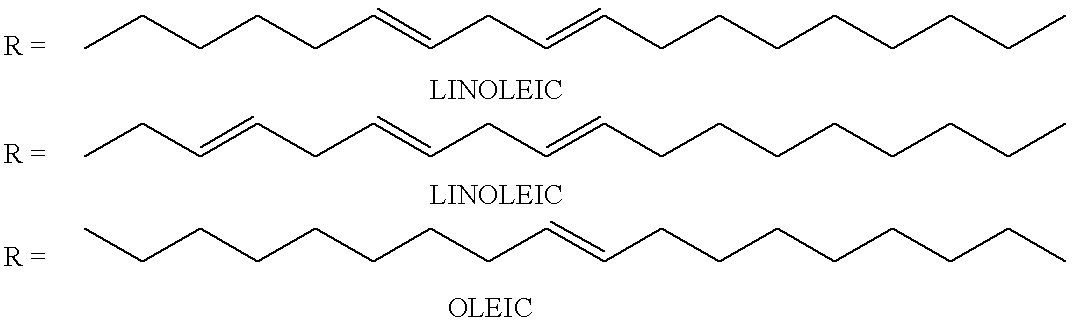

An alkyd is a polyester modified by the addition of fatty acids and other components. They are derived from polyols and a dicarboxylic acid or carboxylic acid anhydride. The term alkyd is a modification of the original name "alcid", reflecting the fact that they are derived from alcohol and organic acids. The inclusion of the fatty acid confers a tendency to form flexible coating. Alkyds are used in paints and in moulds for casting. They are the dominant resin or "binder" in most commercial "oil-based" coatings. Approximately 200,000 tons of alkyd resins are produced each year. The original alkyds were compounds of glycerol and phthalic acid sold under the name Glyptal. These were sold as substitutes for the darker-colored Copal resins, thus creating alkyd varnishes which were much paler in colour. From these, the alkyds we know today were developed.

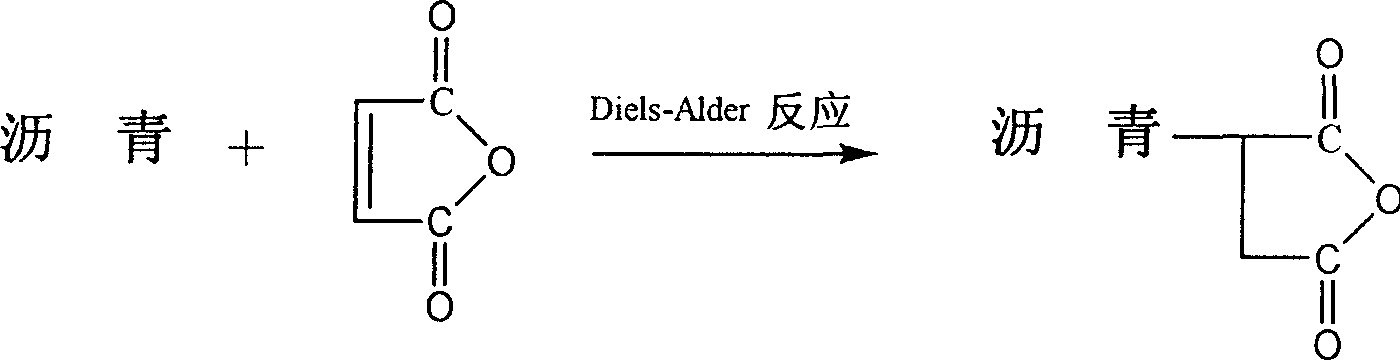

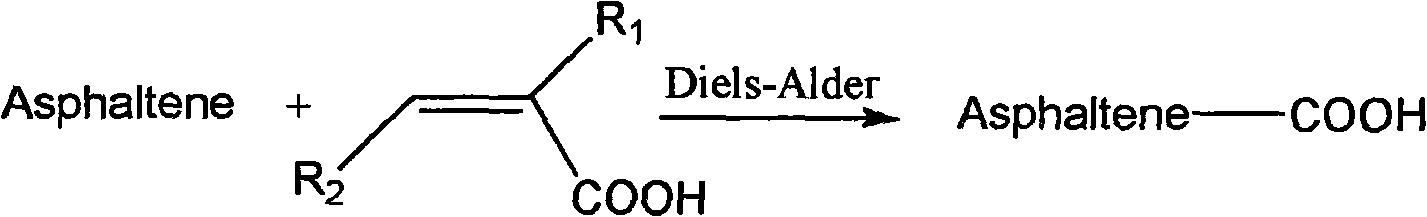

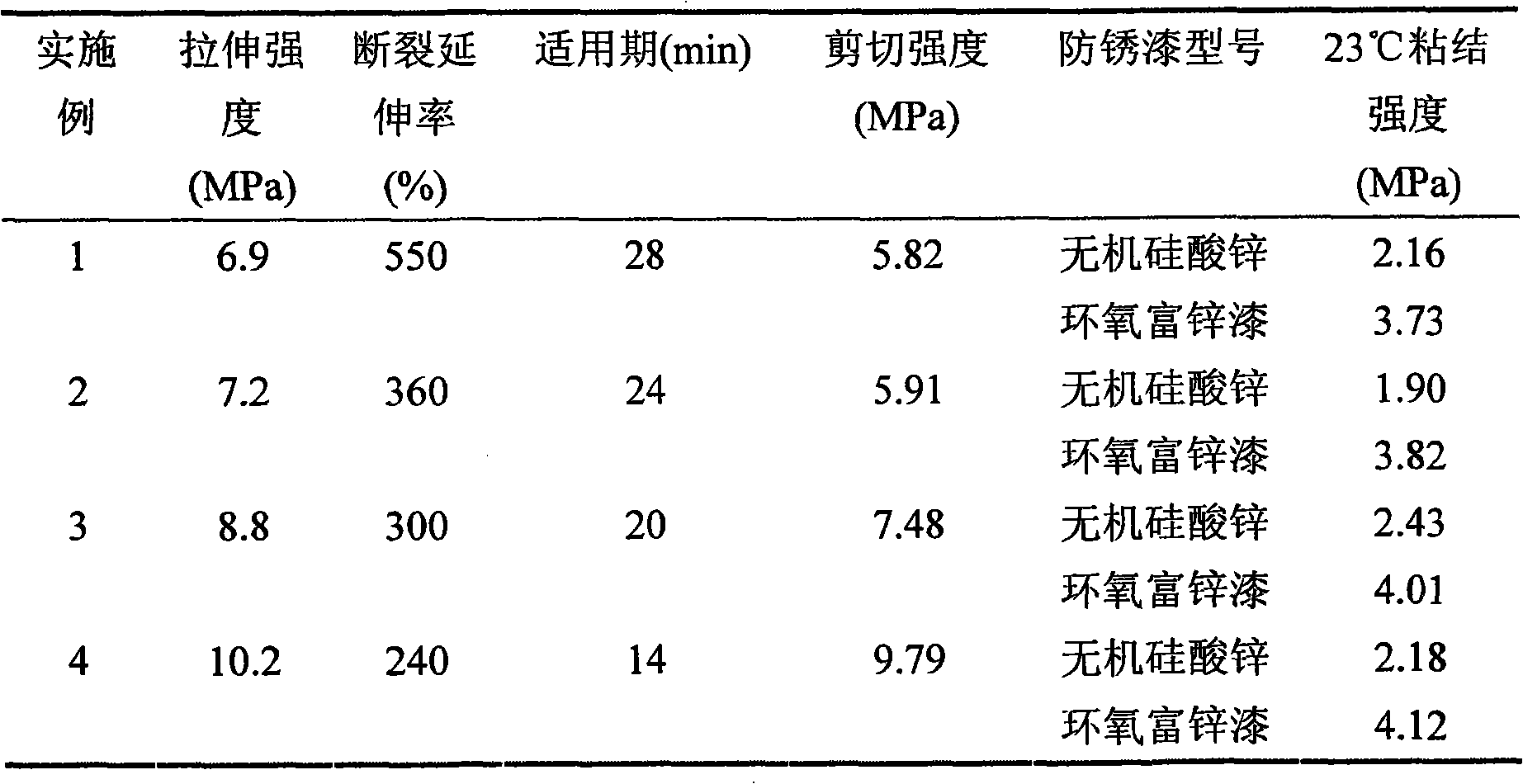

Thermosetting epoxy asphalt materials for pavement and bridge and process for preparing same

ActiveCN1837290AImprove performanceHigh strengthIn situ pavingsBuilding insulationsBituminous materialsTar

The invention discloses a bridge heat fixed epoxy tar material and preparing method, which consists of A and B, wherein A part quality component is 60-76 modified tar with carboxy group or acid anhydride, grease group diacid, 11-25 dimer acid or alkyd resin, 10-25 fatty acid and 0.05-0.65 solidifying celeratist; B is epoxy resin; the quality rate of A and B is 2:1-8:1. The invention possesses high strength and good flexibility, which is fit for higher occasion.

Owner:JURONG NINGWU SCI & TECH DEV

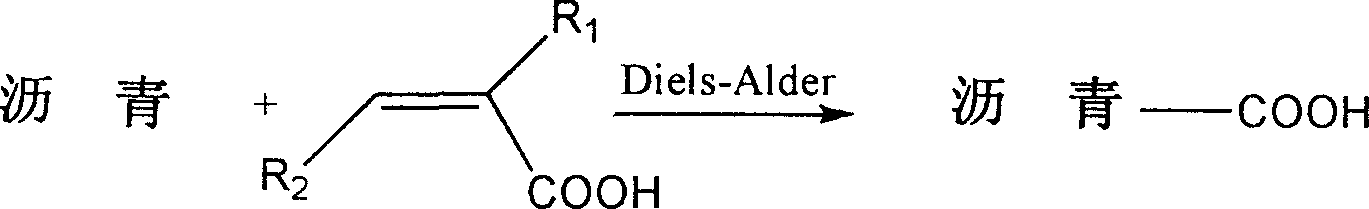

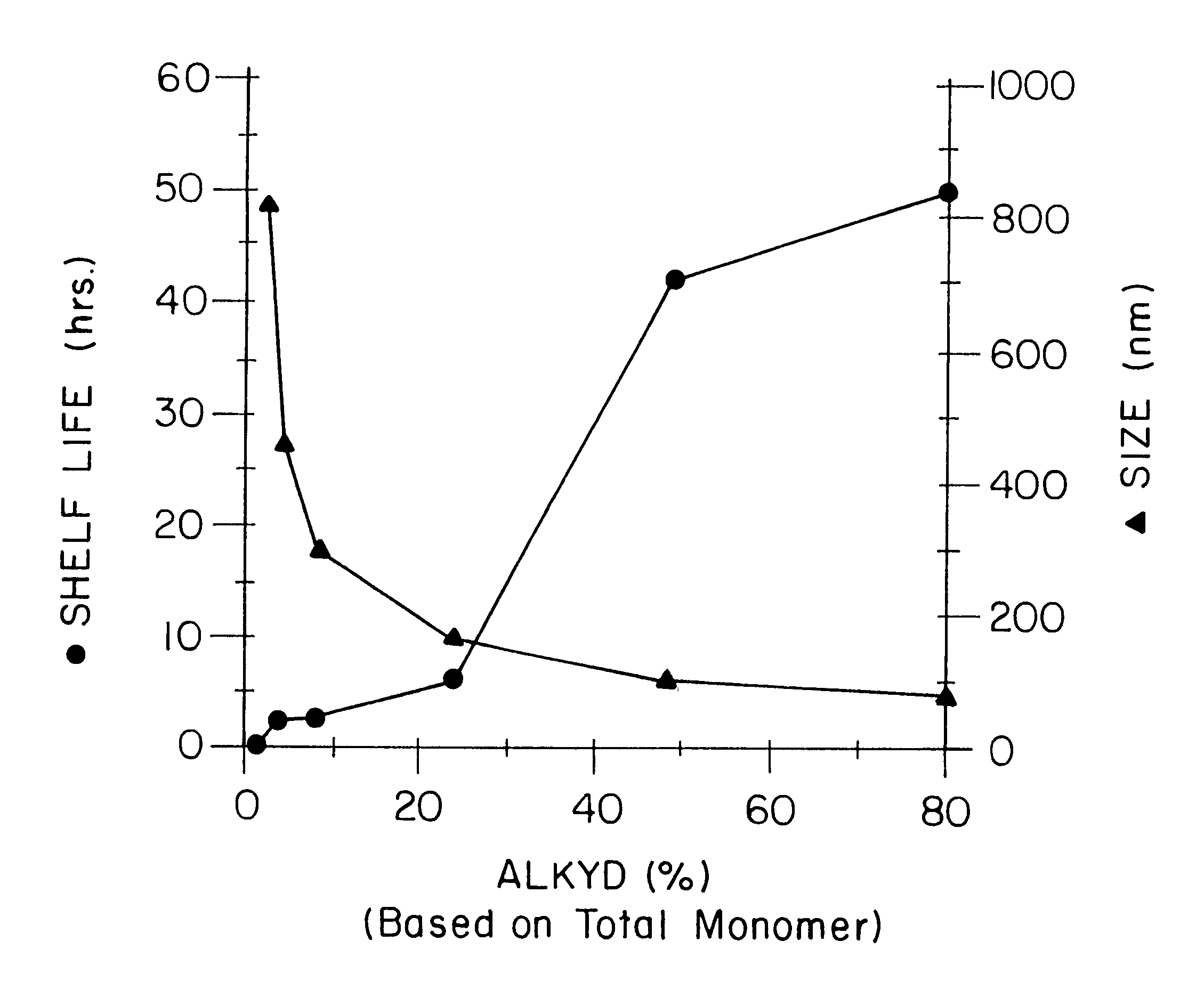

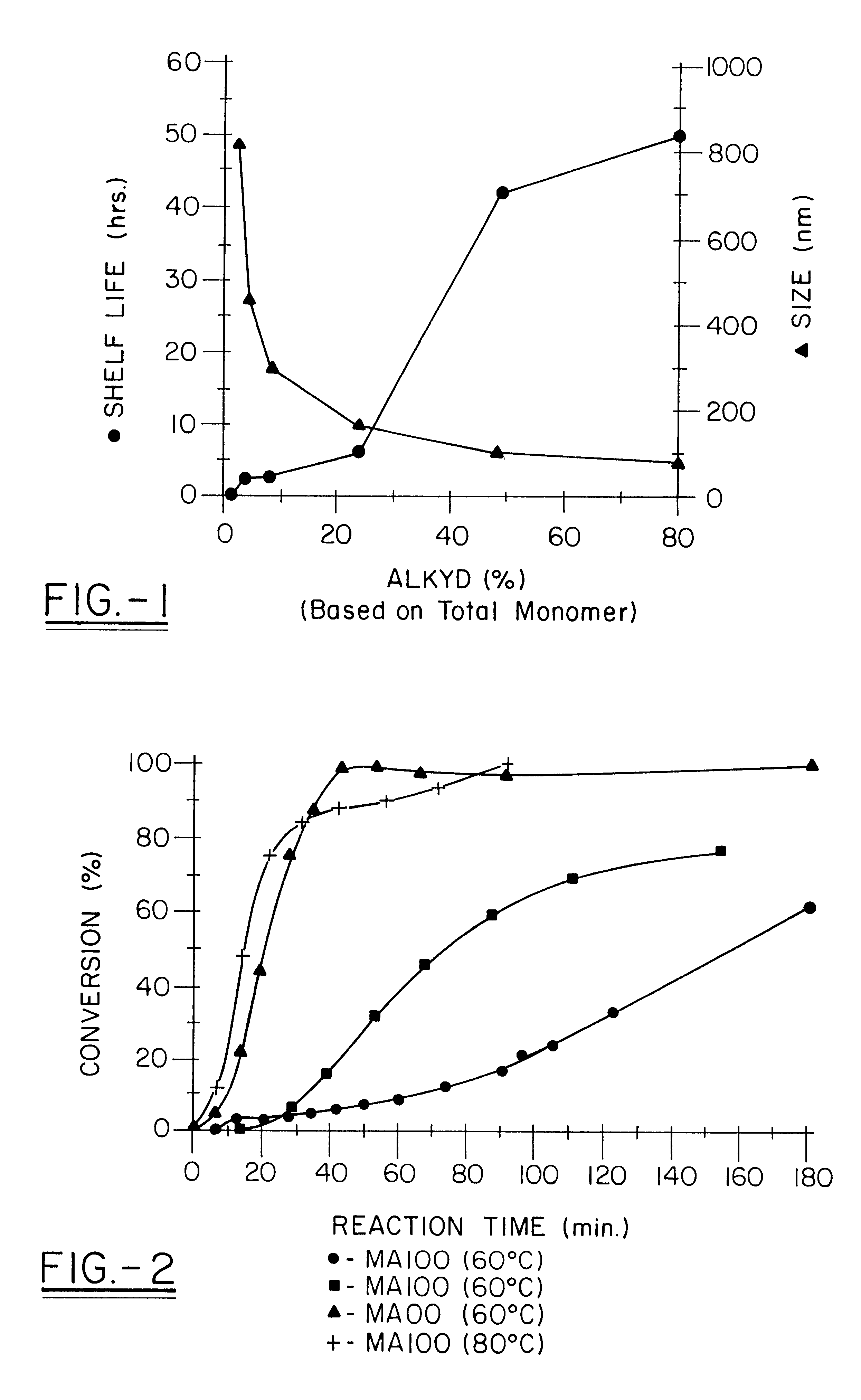

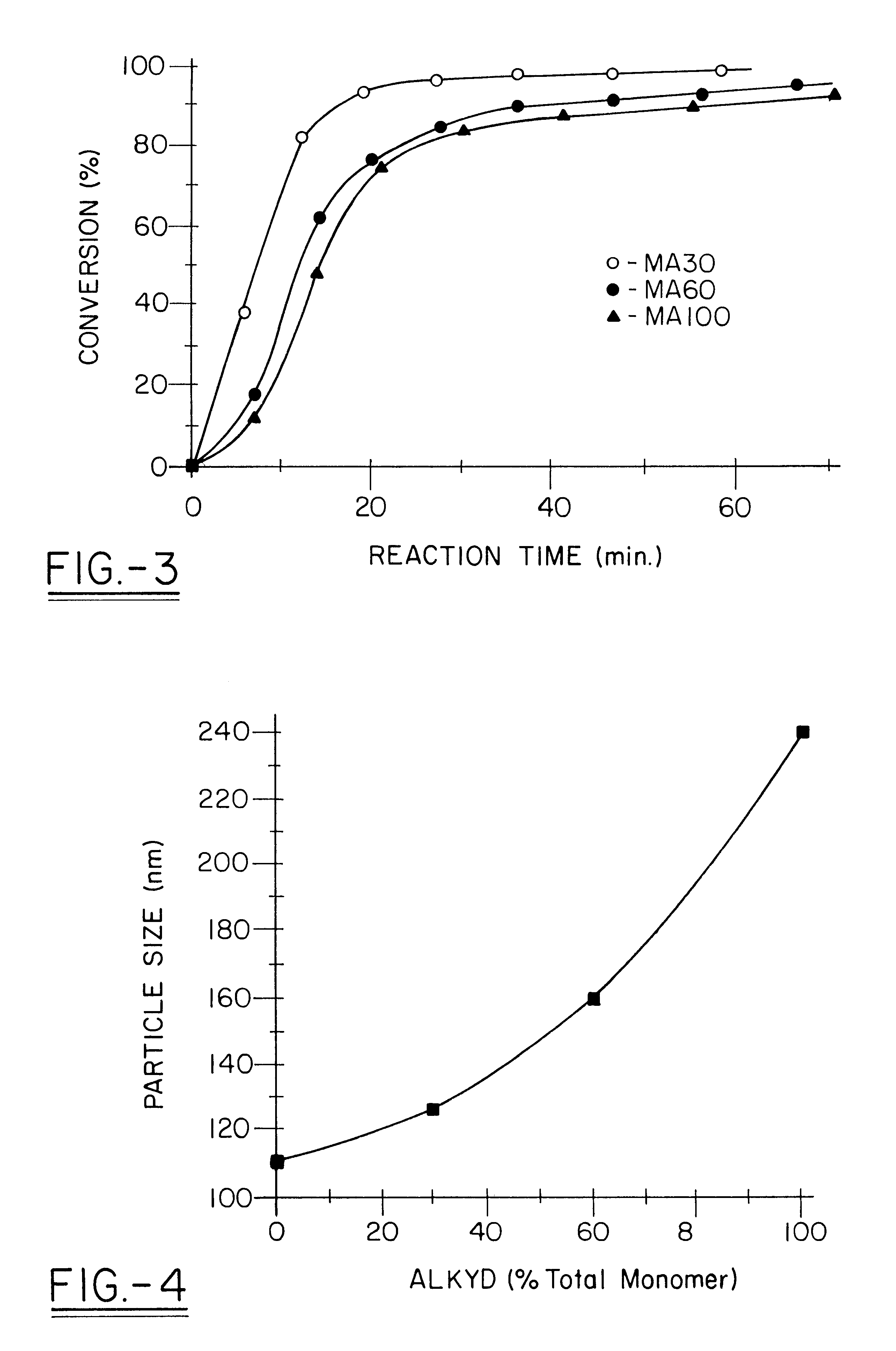

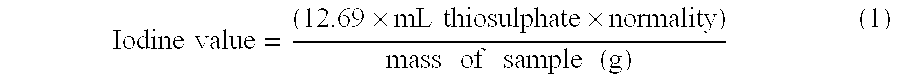

Water-borne alkyd coatings by miniemulsion polymerization

A distinctive graft copolymer is made by dissolving an alkyd resin in various vinyl monomers (methyl methacrylate, styrene, etc.). The monomer / alkyd solution is then miniemulsion polymerized to form a latex consisting of submicron particles of polymer with the alkyd grafted onto the polymer backbone. The latex can be applied to a substrate, which on drying forms a polymeric film with good film properties. The latex can be used in a latex paint formulation in place of an acrylate, acetate or styrene-divinyl benzene latex. In this way it is possible to produce water-borne alkyd coatings which combine the film hardness properties of an oil-based alkyd coating with easy application and cleanup. The coating will beneficially lack organic solvent exposure of typical standard latex coatings.

Owner:GEORGIA TECH RES CORP

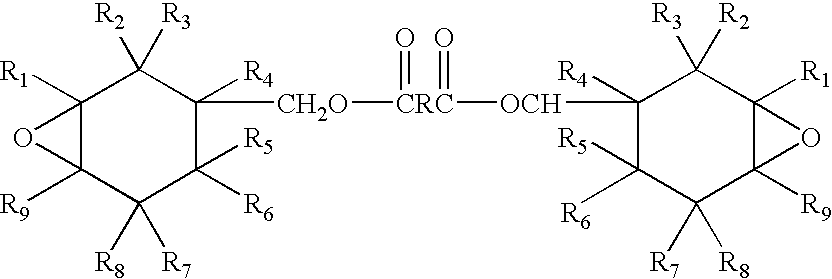

Radiation-curable coating composition

The present invention relates to a radiation-curable solvent-free coating composition for optical fiber having a radiation-curable urethane (meth)acrylate oligomer comprising an alkyd backbone,a reactive diluent, and a photoinitiator, and optionally an additive.

Owner:DSM IP ASSETS BV

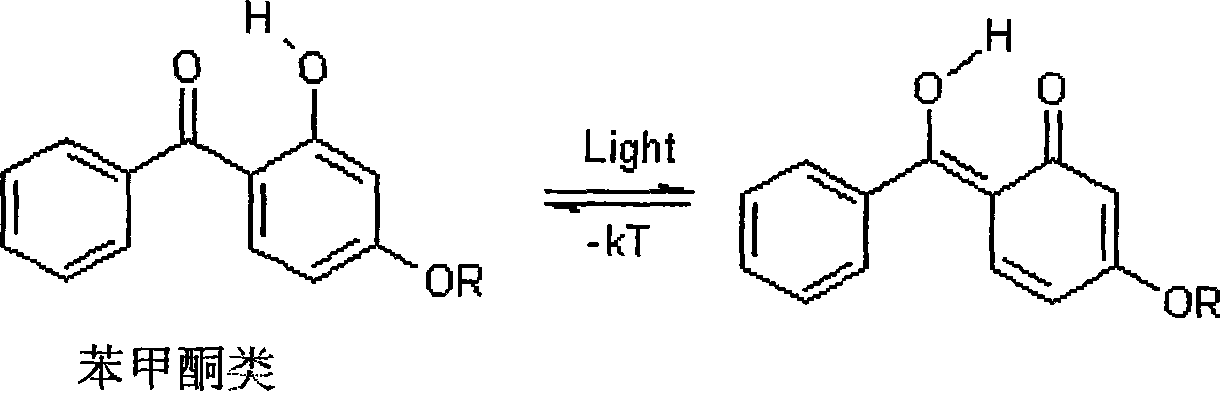

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

Drier for air-drying coatings

The invention pertains to a drier composition for air-drying alkyd-based coatings, inks, or floor coverings, comprising a combination of the following components: a) a transition metal salt with the formula: (Men+)(Xk−)m in which Me is the transition metal; X− represents a coordinating ligand; and k− is the valence state of the transition metal and m is the number of ligands X. b) a reducing biomolecule. The reducing biomolecule is in particular ascorbic acid or a derivative thereof, including ascorbyl palmitate.

Owner:ATO

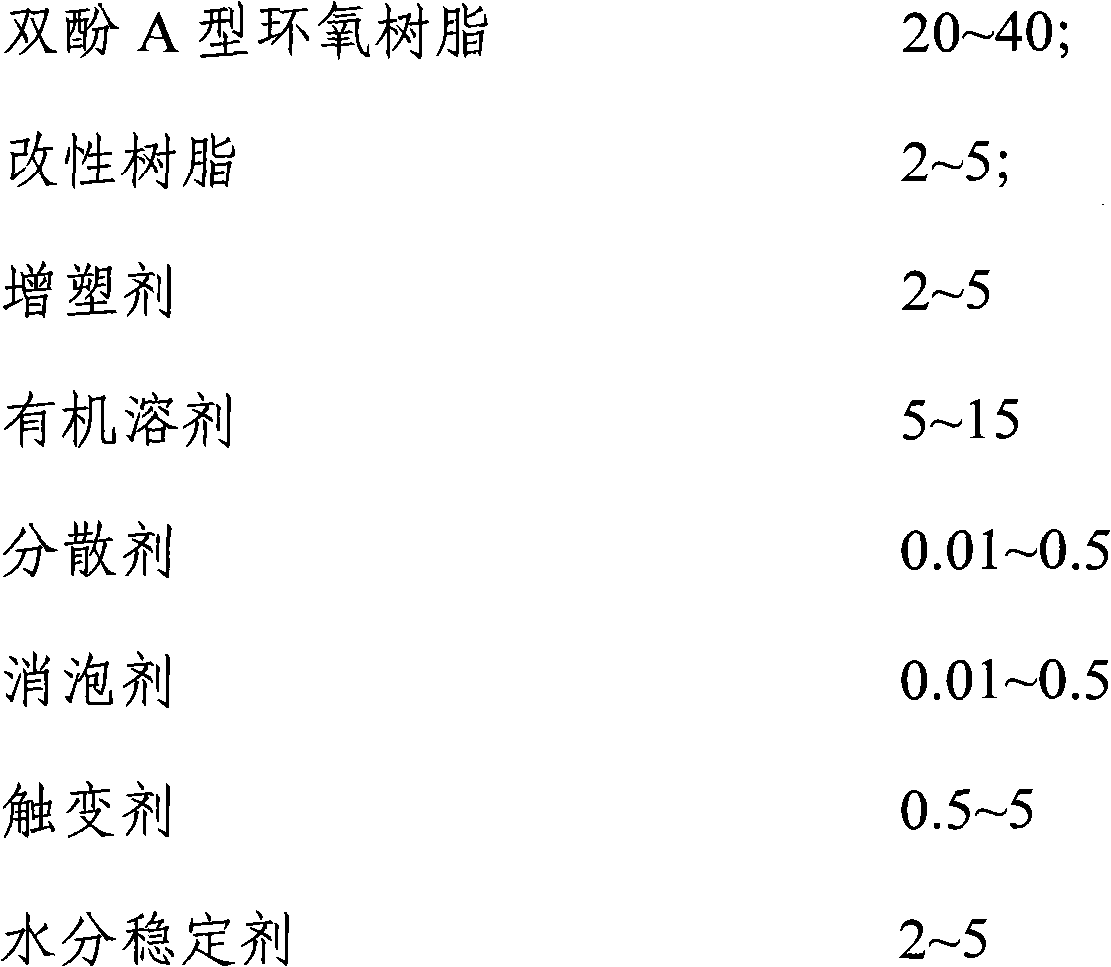

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

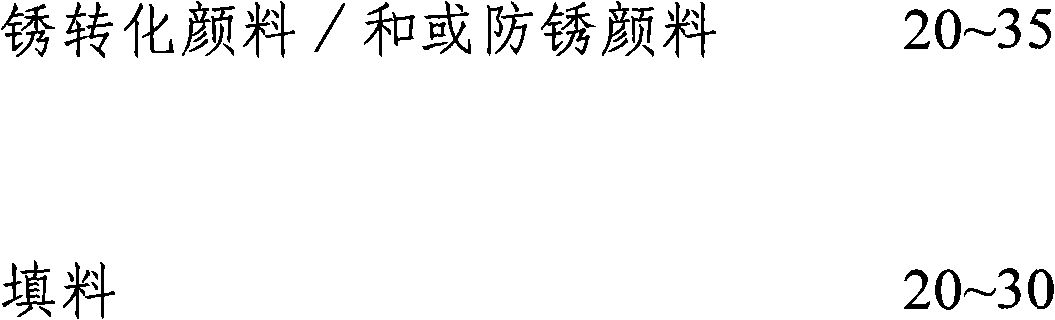

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

Priming coating composition and preparation method thereof

InactiveCN101153155AImprove adhesionHigh hardnessAnti-corrosive paintsPolyether coatingsEpoxyPolymer resin

The present invention discloses a priming dope compound; the compound comprises hot plastic acryl resin, palette and solvent. Wherein, the compound also comprises an assistant film component; the assistant film component can be divided into hydroxyl polymer resin, and or chloroacetic resin. The hydroxyl polymer resin can select one or more than one among hydroxyl acrylic acid resin, hydroxyl polyester resin, hydroxyl polyether resin, hydroxyl alkyd or epoxide resin. The priming dope compound has the advantages of much better coating performance, much better adhesion performance between different lacquer levels when making multi-painting; in addition, the rigidity of the lacquer level after being solidified is much higher.

Owner:BYD CO LTD

Composition of insulating mold coating in use for glass, and preparation method

InactiveCN101050065ACurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyFatty alcohol

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

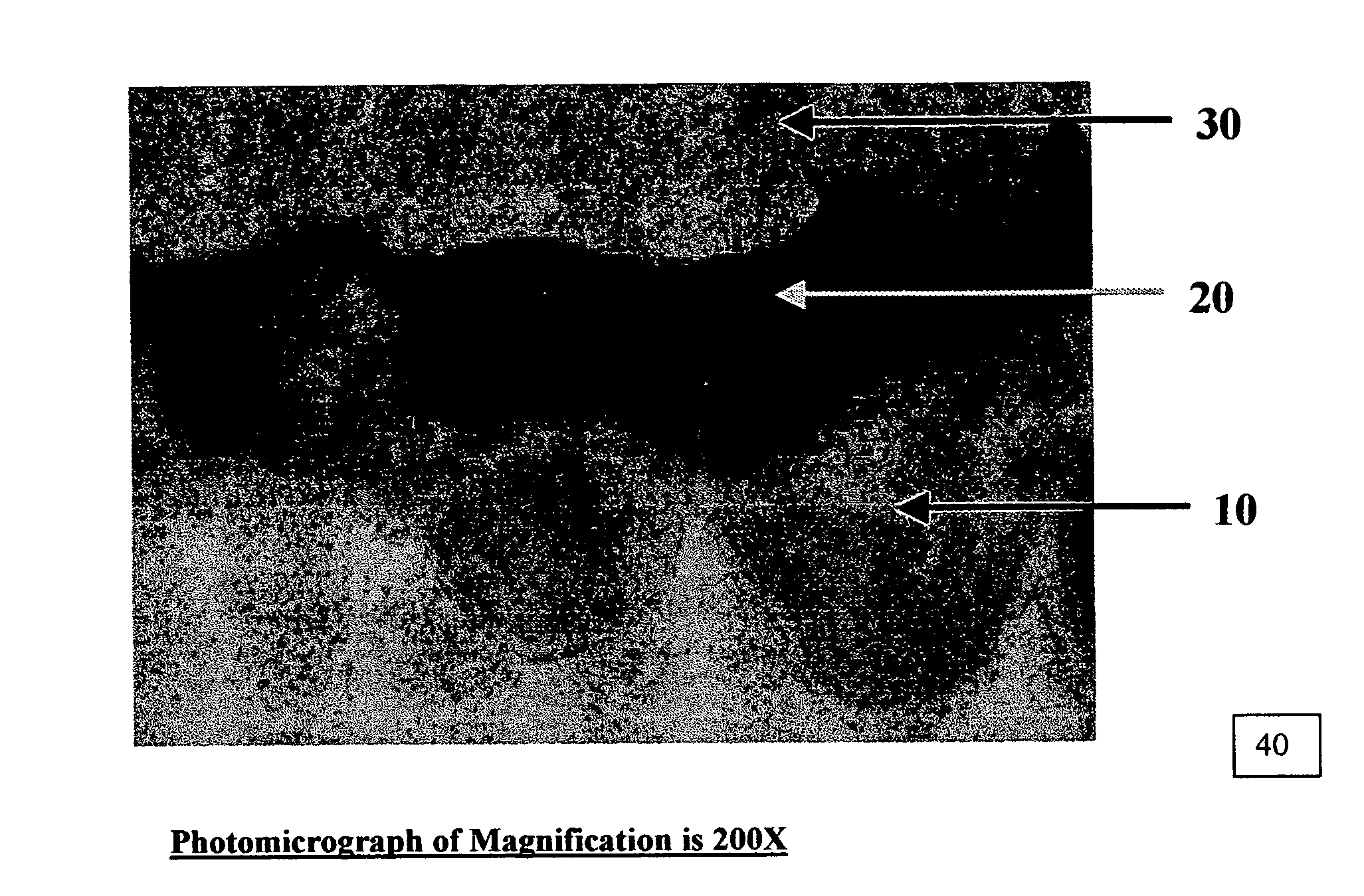

System, method, and composition for adhering performed thermoplastic traffic control signage to pavement

InactiveUS20070059441A1Easy to handleEasy to installCovering/liningsWallsThermoplasticHydrocotyle bowlesioides

The present invention relates to a method for adhering detectable warning devices, pavement markings and preformed traffic control devices (turn arrows, stop bars) that are hydrocarbon or alkyd thermoplastic in nature to an uncured or “green” concrete substrate providing permanent adhesion for detectable warning devices, pedestrian and traffic control markings.

Owner:ENNIS FLINT INC

Rubber composition for tire and pneumatic tire using the same

A rubber composition for a tire, in which a specific tackifier is compounded, and tackiness and various physical properties are improved, compared with compounding a petroleum resin or a terpene resin, is provided. The rubber composition for a tire comprising an alkyd resin and a pneumatic tire using the same. It is preferable that a material derived from a resource other than petroleum, particularly, a material derived from animal and / or vegetable, and more particularly, a material derived from an animal oil and / or a vegetable oil is contained in the alkyd resin, and it is preferable that unsaturated polybasic acid is contained in the alkyd resin.

Owner:SUMITOMO RUBBER IND LTD

Acrylate-functional alkyd resins having improved dry time

InactiveUS6946509B2Extended drying timeHigh in calciumEngine sealsSynthetic resin layered productsDesiccantCalcium content

An acrylate-functionalized alkyd coating composition is disclosed having improved dry time. The compositon includes an acrylate-functionalized alkyd resin, a solvent, and a drier package that provides the composition with a cobalt content of at least 0.01 wt %, based on binder solids content, and a calcium content of from 0.15 wt % to 5 wt %, based on the binder solids content. The drier mixture disclosed results in the coating composition having improved dry time when compared with similar coating compositions using conventional drier packages.

Owner:PCCR USA

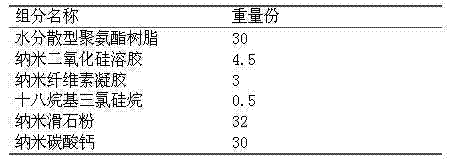

Transparent super-hydrophobicity wood coating and preparation method thereof

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

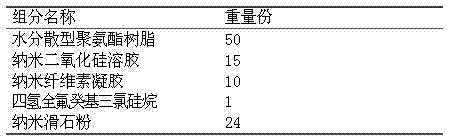

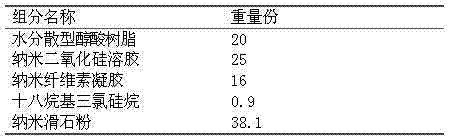

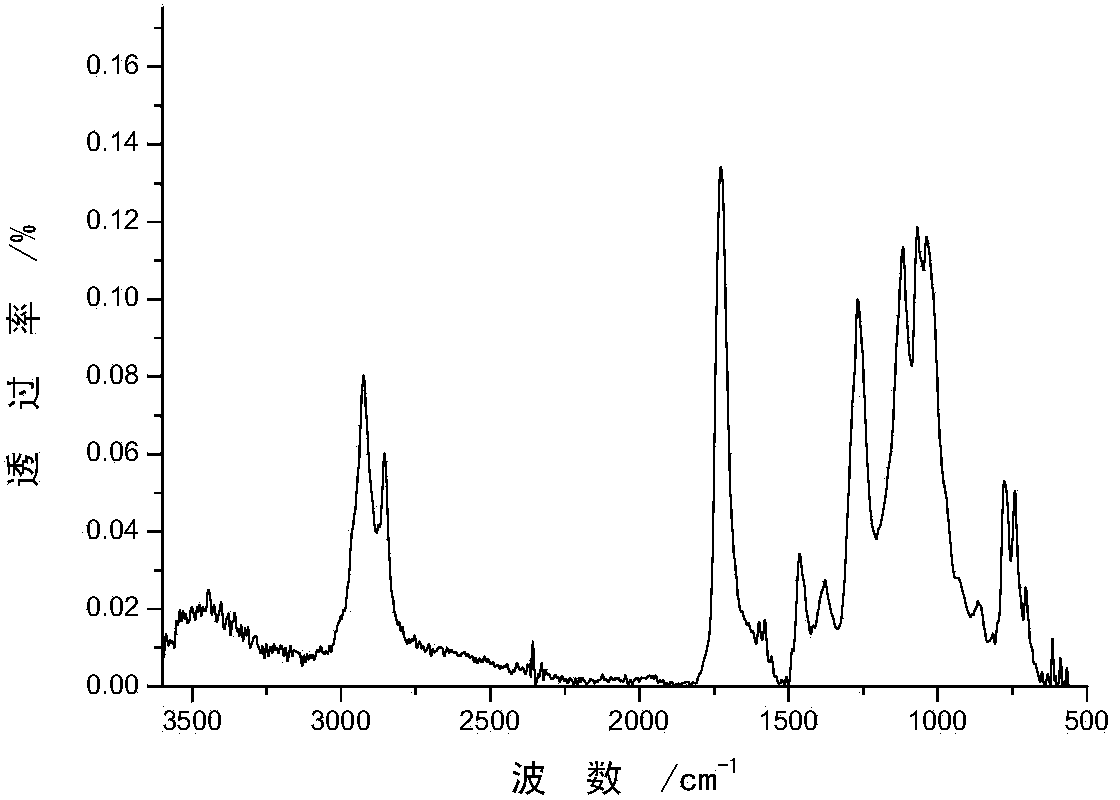

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

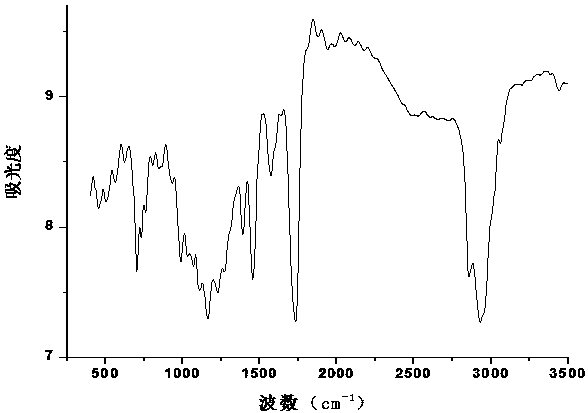

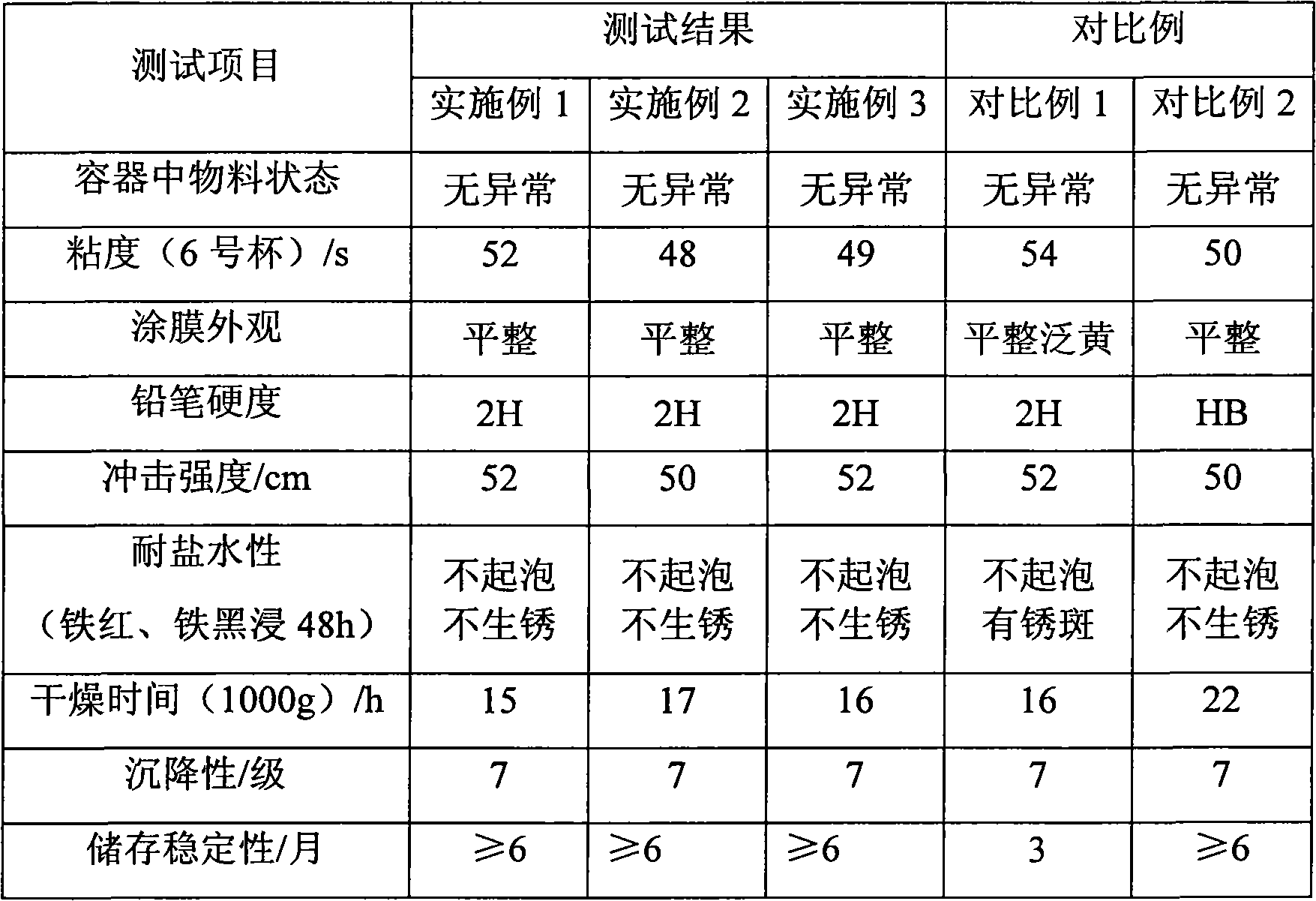

Aqueous organosilicone-modified alkyd resin and preparing method thereof

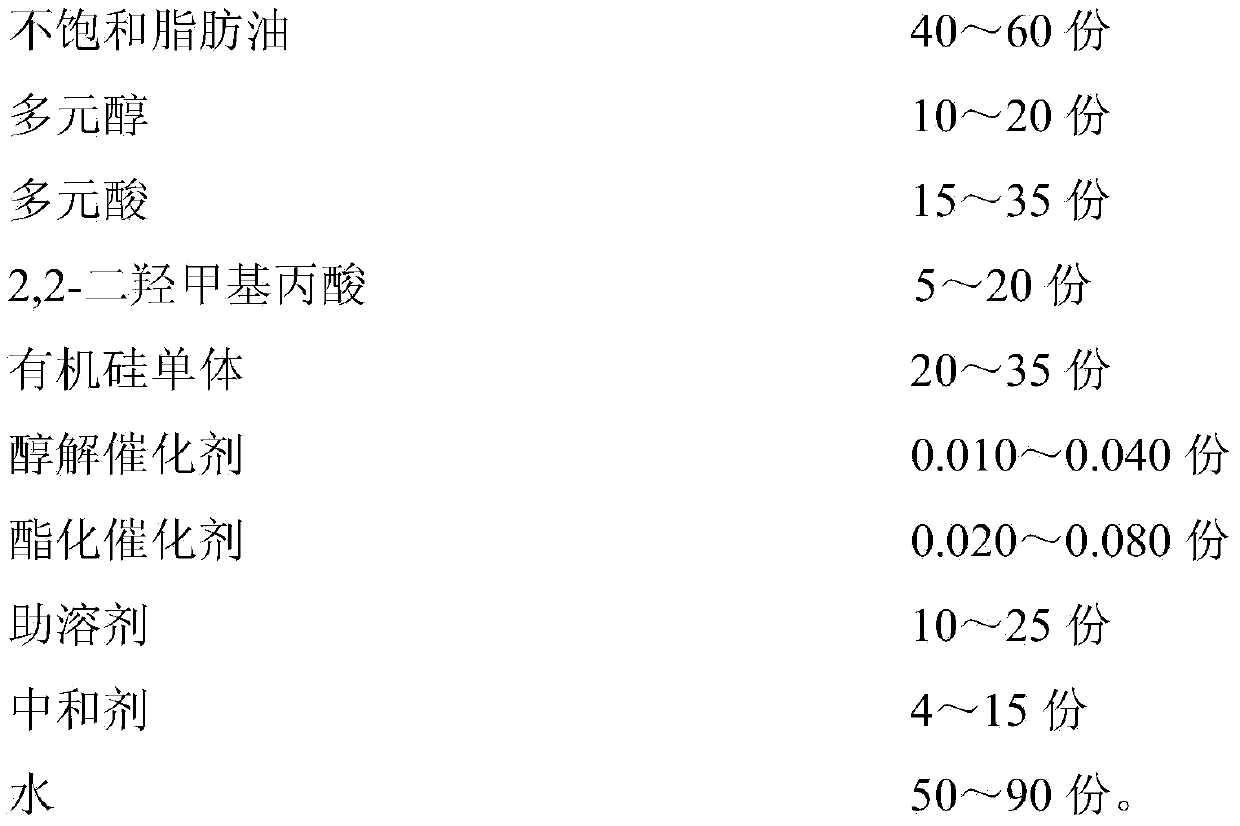

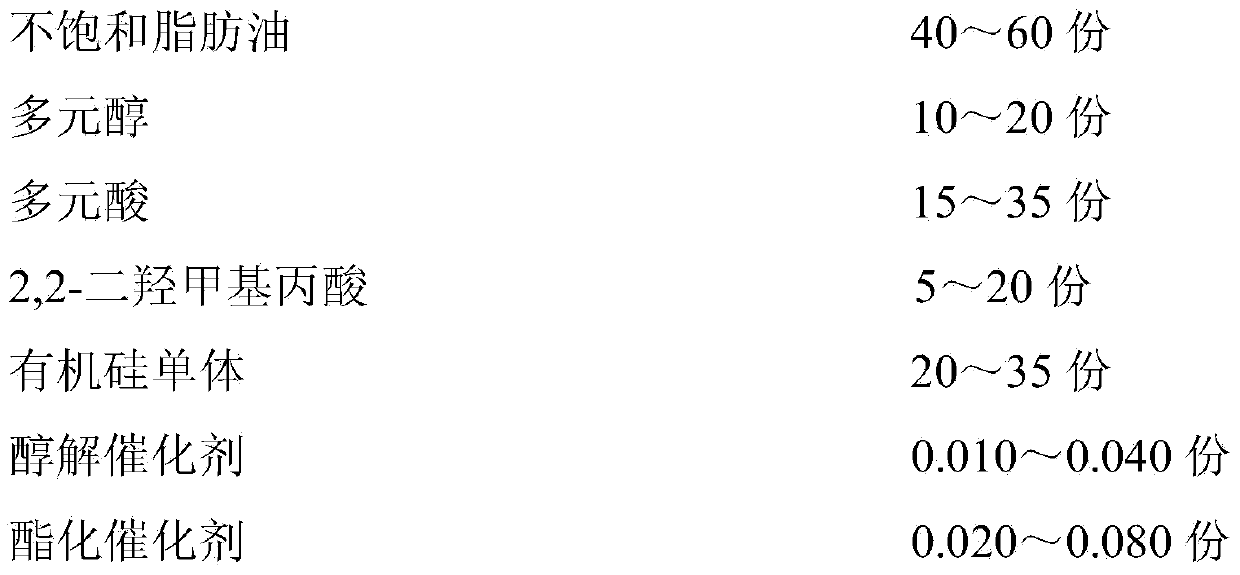

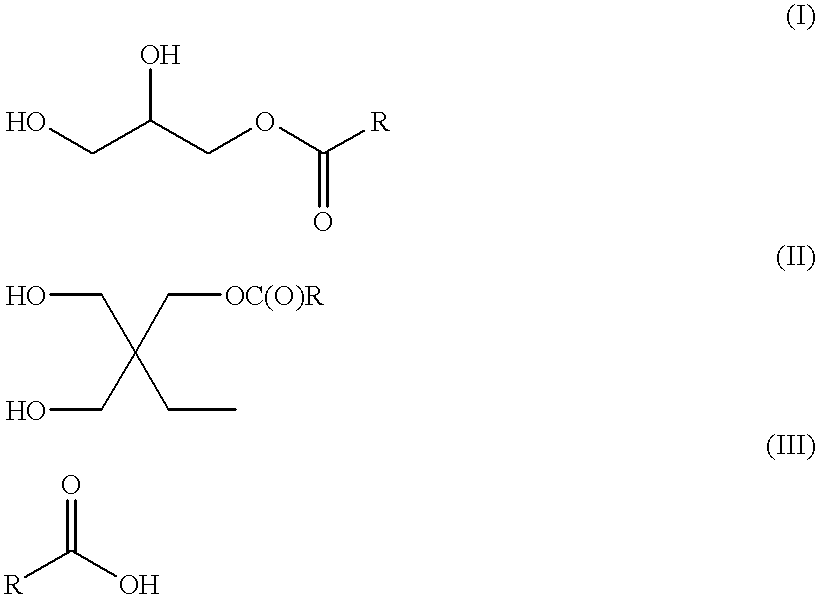

The invention belongs to the technical field of chemical engineering, and discloses aqueous organosilicone-modified alkyd resin and a preparing method thereof. The aqueous organosilicone-modified alkyd resin comprises following components by weight: 40-60 parts of nonsaturated fatty oil, 10-20 parts of polyol, 15-35 parts of polyatomic acid, 5-20 parts of 2,2-dimethylolpropionic acid, 20-35 parts of an organosilicon monomer, 0.010-0.040 part of an alcoholysis catalyst, 0.020-0.080 part of an esterification catalyst, 10-25 parts of a cosolvent, 4-15 parts of a neutralizer and 50-90 parts of water. The prepared alkyd resin has characteristics of clear appearance, good water solubility, good properties, no toxicity, no harm, and capability of meeting the environmental requirements.

Owner:SOUTH CHINA UNIV OF TECH

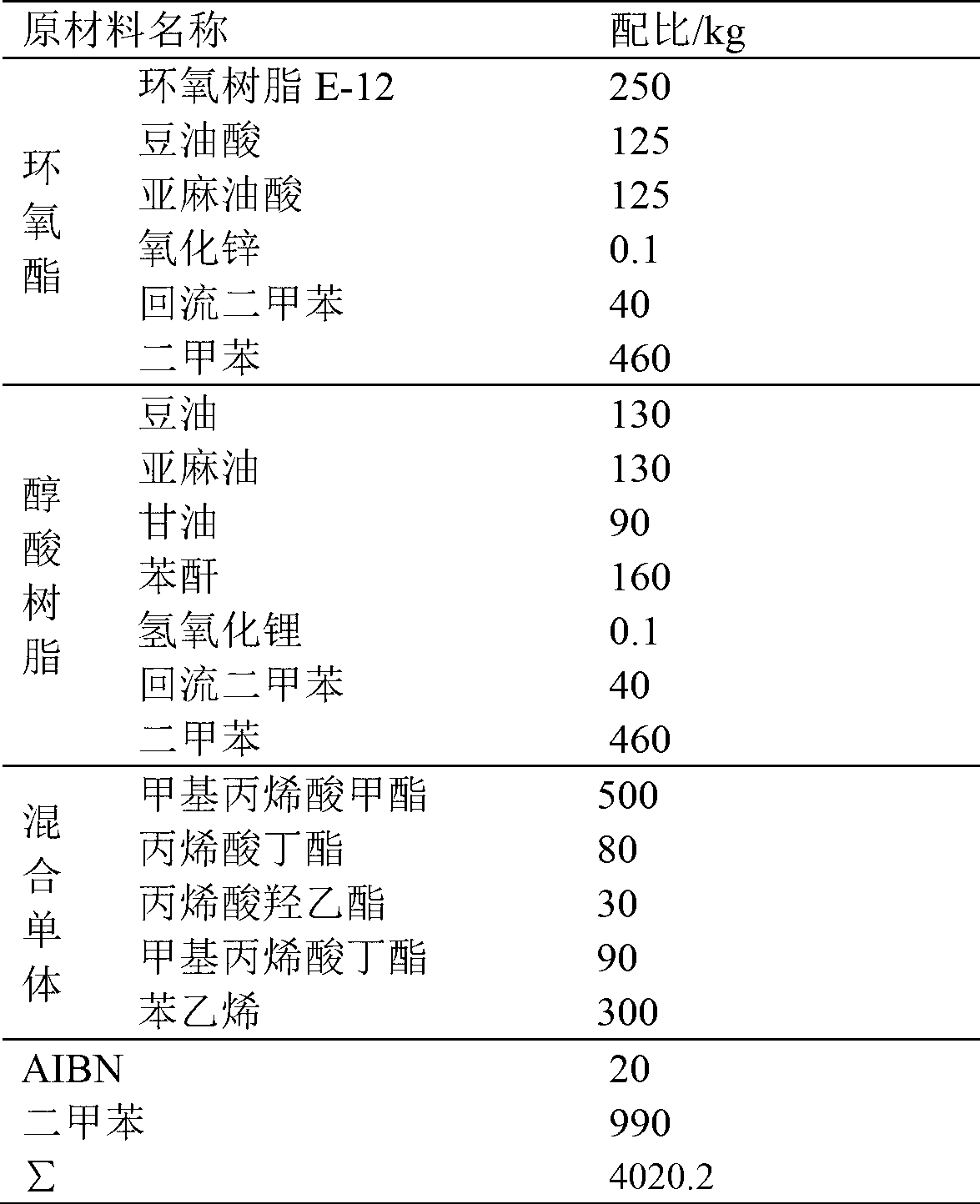

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

InactiveCN101942063AStrong adhesionImprove performanceDyeing processCoatingsEnvironmental resistanceEpoxy

The invention provides water-borne epoxy ester modified alkyd resin emulsion and a preparation method thereof. The method comprises the following steps: allowing unsaturated fatty oil, polyalcohol, epoxy resin and the like to carry out alcoholysis reaction by using triphenylphosphine and an alcoholysis catalyst; adding polyacid for esterification; dropwise adding crylic acid monomers such as methacrylic acid, phenylethylene, butyl acrylate and the like and a silane coupling agent for copolymerization under initiation of benzoyl peroxide; adding amine to the obtained copolymer for neutralizing to form salt; and dispersing with water to obtain the high-performance water-borne epoxy ester modified alkyd resin emulsion. The emulsion maintains self-drying property, flexibility and other excellent properties of alkyd resin, has excellent adhesive property of the epoxy resin as well as excellent adhesion force, excellent physical and mechanical properties and strong water resistance, strong salt fog resistance, strong acid and alkali resistance and other properties; and the emulsion has the advantages of possessing good stability and being nontoxic and harmless, thus meeting the environmental friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

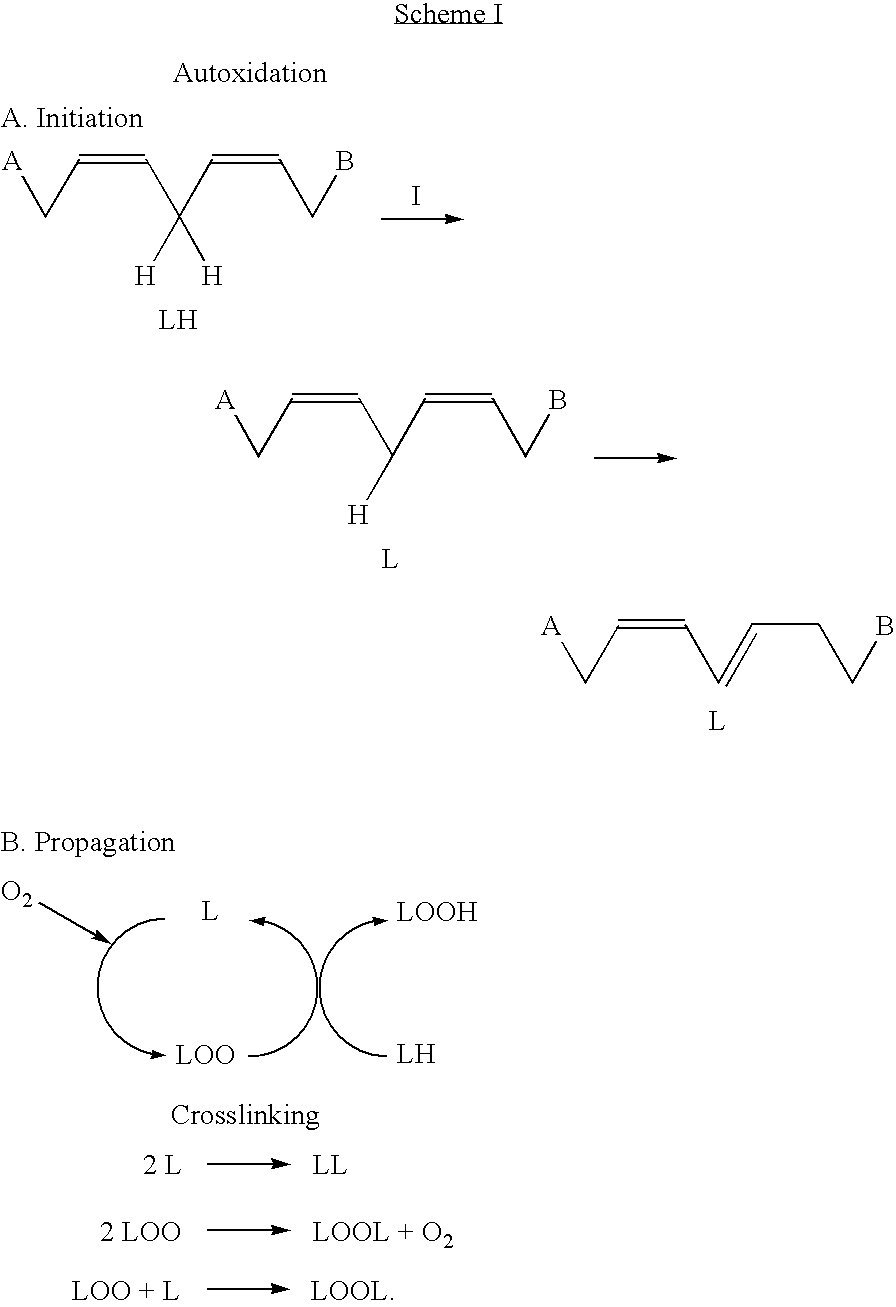

Acrylic modified waterborne alkyd or uralkyd dispersions

A water-based latex of an acrylic-modified waterborne alkyd or uralkyd dispersion in water is described. The acrylic-modified waterborne alkyd or uralkyd is a hybrid resin prepared by the polymerization of at least one latent oxidatively-functional (LOF) acrylic monomer in the presence of a waterborne alkyd or uralkyd. Alternatively, the acrylic-modified waterborne alkyd or uralkyd is a hybrid resin prepared by shearing a mini-emulsion based on a solvent-borne alkyd or uralkyd dissolved in at least one LOF acrylic monomer. Preparation of the latexes may be achieved by emulsion polymerization of at least one latent oxidatively-functional acrylic monomer in the presence of a waterborne alkyd or uralkyd whereby the latent oxidative functionality of the acrylic polymer survives polymerization. Water-based latexes may also be prepared by polymerizing a sheared mini-emulsion based on a solvent-borne alkyd or uralkyd dissolved in at least one LOF acrylic monomer such that the latent oxidative functionality of the acrylic polymer survives polymerization. Such acrylic-modified waterborne alkyd or uralkyds are useful in a variety of coating compositions.

Owner:SYNTHOMER USA LLC

Water dispersion of self-drying acrylic modified alkyd resin industrial topcoat using the water dispersion as base

InactiveCN101307137AGood self-dryingImprove adhesionPolyester coatingsSurface-active agentsHydrolysis

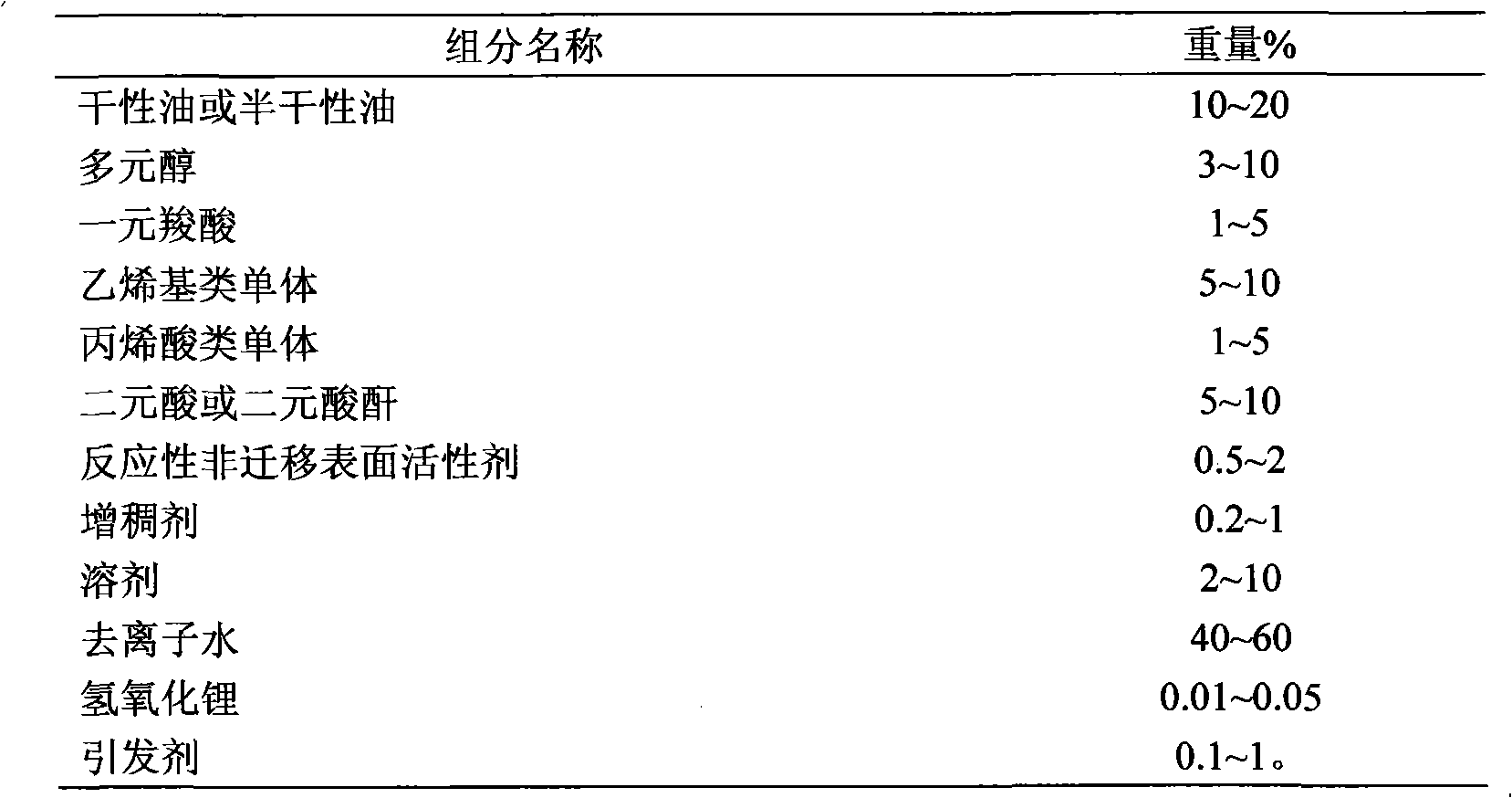

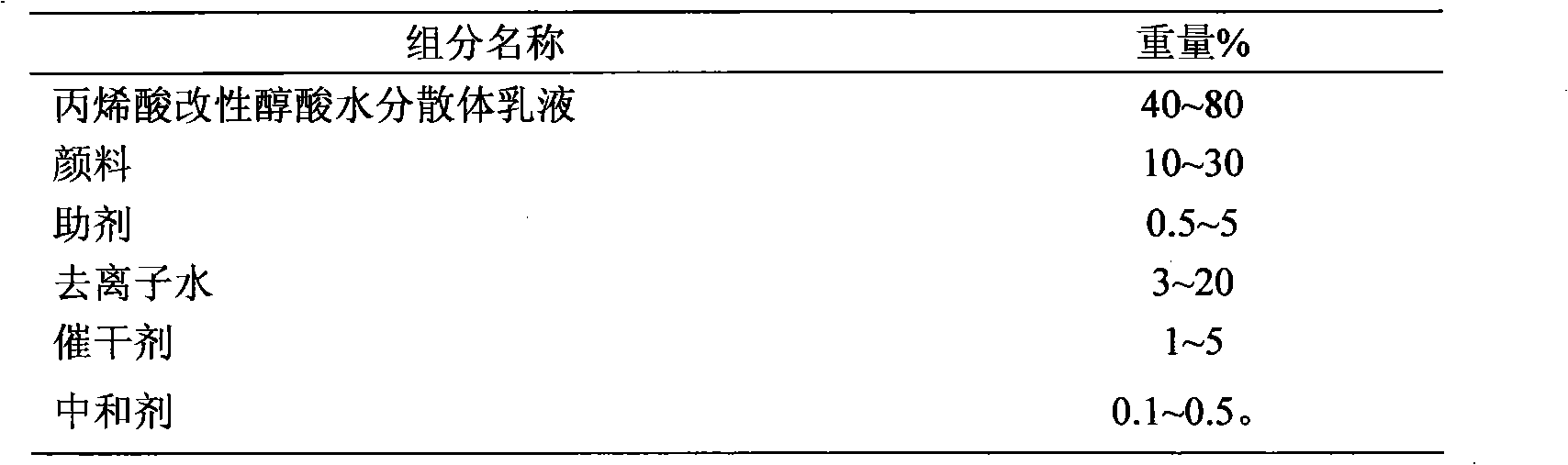

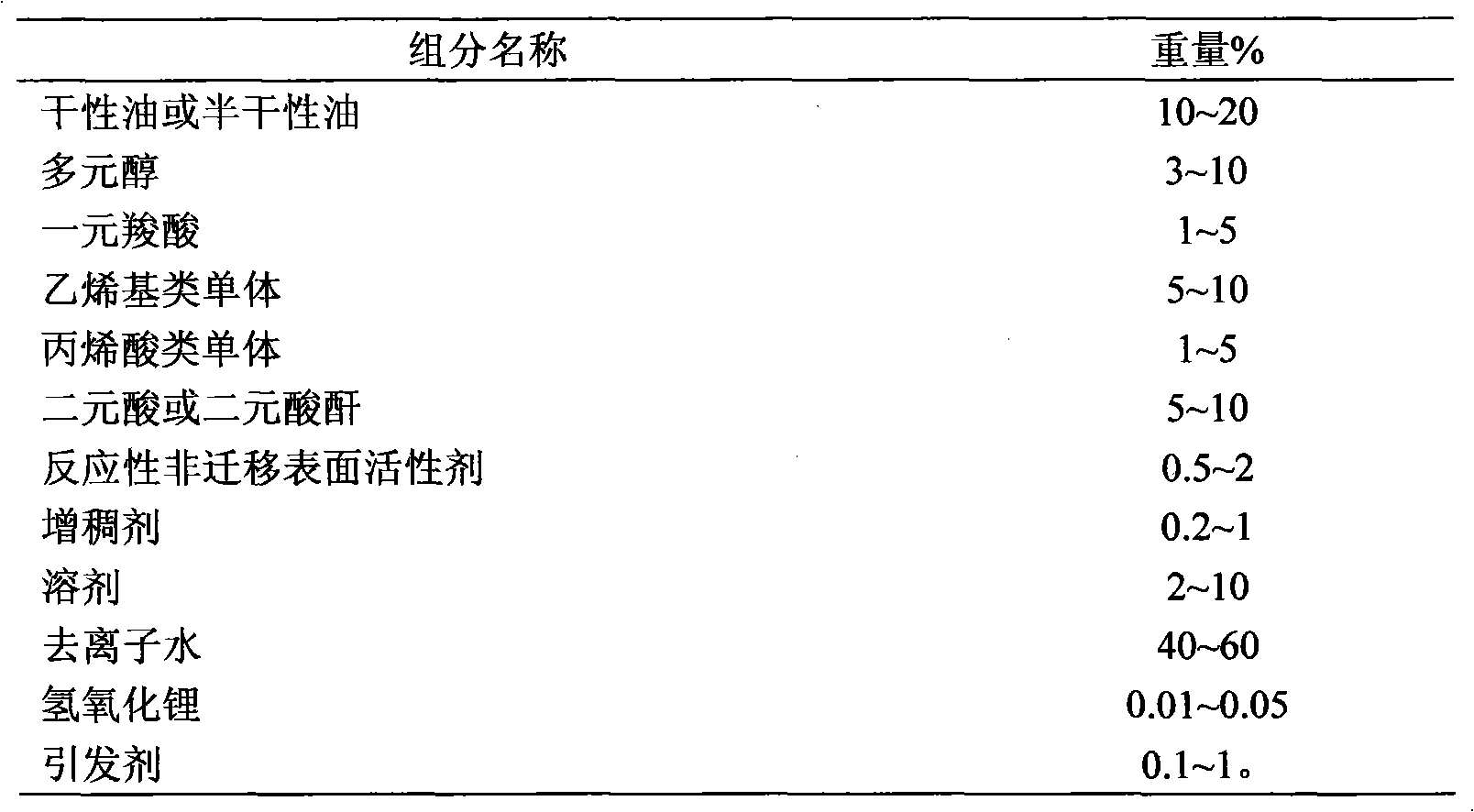

The invention relates to 'core-shell' structure self-drying acrylic modified alkyd water dispersoid emulsion with acrylic modified alkyd as the 'core' and reactive nonmigratory surface active agent as the 'shell' and with a acid value between 5 and 20 mgKOH / g, a solid content between 40 and 60 weight percent and an emulsion grain diameter between 0.2 and 2 micrometers, and water dispersoid industrial finish paint with the acrylic modified alkyd water dispersoid emulsion as base material. The acrylic modified alkyd water dispersoid emulsion has good storage stability and hydrolysis resistance (the acid value of the acrylic modified alkyd water dispersoid emulsion is almost unchanged during the storage process). The acrylic modified alkyd water dispersoid finish paint with high glossiness and decorativeness can be made by taking the emulsion as the base material and matching with pigment and auxiliary agent. The construction performance, the self-drying property, the mechanical strength and the decorativeness of the acrylic modified alkyd water dispersoid finish paint can be compared with those of solvent alkyd finish paint.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Environmental protection type laser transfer composite aluminium foil paper and its preparation technology

InactiveCN1724811AGood printabilityMeet environmental protection requirementsNon-fibrous pulp additionPaper coatingSolventMaterials science

The invention relates an environmental protection laser transferred composite aluminum foil paper and the preparing technique, mainly solving the problems of the environment pollution and complicated technique caused by separant coating and laser layer protection coating of the existing commonly used solvent laser transferred composite aluminum foil paper. Its mixing proportion (by weight) of the raw materials is: water soluble amino resin 1-20 (or water soluble polyurethane resin 1-30, or water soluble alcohol acid resin 1-30, or water soluble acrylate resin 1-40, or cellulose resin 1-20), assistant 1-10, pigment 0-10, auxiliary solvent 1-30, and water 30-80, or their arbitrary combination, through synthesizing and wet-dispersing to mix into a water laser transfer coating, coating the transfer coating on a carrier thin film, drying, cross-linking curing, laser-mould pressing, and aluminizing to obtain the laser composite aluminum foil paper. It has the characters of improving environmental protection performance, simplifying producing process, saving energy sources, reducing production cost, stable production quality, etc.

Owner:张学毅

Isocyanate modified alkyd resin and preparation method thereof

The invention relates to isocyanate modified alkyd resin and a preparation method thereof. Isocyanate is utilized to modify alkyd resin, and the alkyd resin containing an ammonia ester structure is synthesized. The basic formula comprises, by weight: 20-33% of plant oil, 5-8% of polyatomic alcohol, 2-8% of organic acid anhydride, 5-10% of the isocyanate, 0.02-0.5% of catalyst, 35-50% of solvent and 3-8% of terminator. Varnish and enamel paint prepared by the isocyanate modified alkyd resin are better than ordinary middle-long-oil-degree alkyd resin paint in aspects of dryness, hardness, water resistance and the like, and are better than double-component polyurethane paint in aspects of toxicity, application property, odor and the like. The isocyanate modified alkyd resin is widely applied to the surfaces of products made of wood, metal, plastic and the like to have functions of protection and decoration. Due to the fact that the isocyanate modified alkyd resin is both hard and soft, the isocyanate modified alkyd resin has certain resistance to stone strike, can serve as primer and repair paint of agricultural vehicles and trucks, and has good market prospects accordingly.

Owner:UNION FOSHAN CHEM

Aqueous primer coating composition and article coated therewith

InactiveUS6344500B1Improve adhesionExcellent in gasohol resistanceEpoxy resin coatingsPolyester coatingsEmulsionPigment dispersion

The present invention provides: an aqueous primer coating composition of which the deterioration of the water resistance is prevented with the high adhesion maintained, and which is excellent in the gasohol resistance and the pigment dispersion stability; and a thing coated with this aqueous primer coating composition. The aqueous primer coating composition according to the present invention, comprises acid anhydride-modified poly(olefin chloride) emulsion resin (A), aqueous alkyd resin (B) and aqueous novolac-type epoxy resin (C), wherein the contents of the (A), (B), and (C) are (A) 20 to 60 weight %, (B) 10 to 60 weight %, and (C) 10 to 60 weight % in terms of solid content weight % to the total resin solid content in the composition. The coated thing, according to the present invention, is coated with the present invention aqueous primer coating composition.

Owner:HONDA MOTOR CO LTD +1

Special-purpose protection dope for petroleum pipe/drill pipe and its preparation method and construction method

The invention relates to a protecting paint special for petroleum pipe / drill pipe, and a construction method and a preparation method thereof. The paint is composed of modified acrylic resin and modified alkyd resin as main film-forming substances, formaldehyde resin, chlorinated polyether resin and epoxy resin, etc. as modifiers, nontoxic tinting pigment, nanometer micro powder, environment-friendly solvent, nontoxic excluder pigment, additive, accessory ingredient, etc.; the paint is provided with the following advantages: low cost, good storage stability, not prone to deposit, good application property, strong anti-sagging property, coat flame retarding, good drying and fullness, strong adhesion, weathering resistance, rust prevention, non-toxicity and environment-friendly. The protecting paint special for petroleum pipe / drill pipe is specially designed for short-term antiseptic coat, such as sleeve of petroleum casing pipe, oil well pipe, oil well drill pipe, etc.

Owner:江阴市天邦涂料股份有限公司

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

Alkyd resin for wood lacquer and preparation method thereof

The invention discloses alkyd resin for wood lacquer and a preparation method thereof. According to the raw material formula, the alkyd resin for the wood lacquer comprises the following components in percentage by mass: 18.3 to 28.3 percent of soybean oleic acid, 10.2 to 20.2 percent of glycerin, 3.8 to 7.8 percent of pentaerythritol, 17.6 to 21.6 percent of recycled terephthalic acid, 0.05 to 0.2 percent of color substration agent, 0.05 to 0.2 percent of antioxidant, 2.5 to 5.5 percent of phthalic anhydride, 3.2 to 7.2 percent of benzoic acid, 2 to 5 percent of dimethylbenzene, 18 to 30 percent of thinning agent and 0.05 to 0.2 percent of wetting dispersant. Terephthalic acid is adopted, and the unique chemical performance of the terephthalic acid endows the resin with high dryness and weather resistance; waste and inferior terephthalic acid produced by a petrochemical enterprise is utilized, so that the production cost of the resin is lower than that of alkyd resin produced by the conventional method; simultaneously, waste of the petrochemical enterprise is reduced, the environment is prevented from being polluted, and wastes are utilized to save energy and reduce emission.

Owner:HUIZHOU CHANGRUNFA PAINT

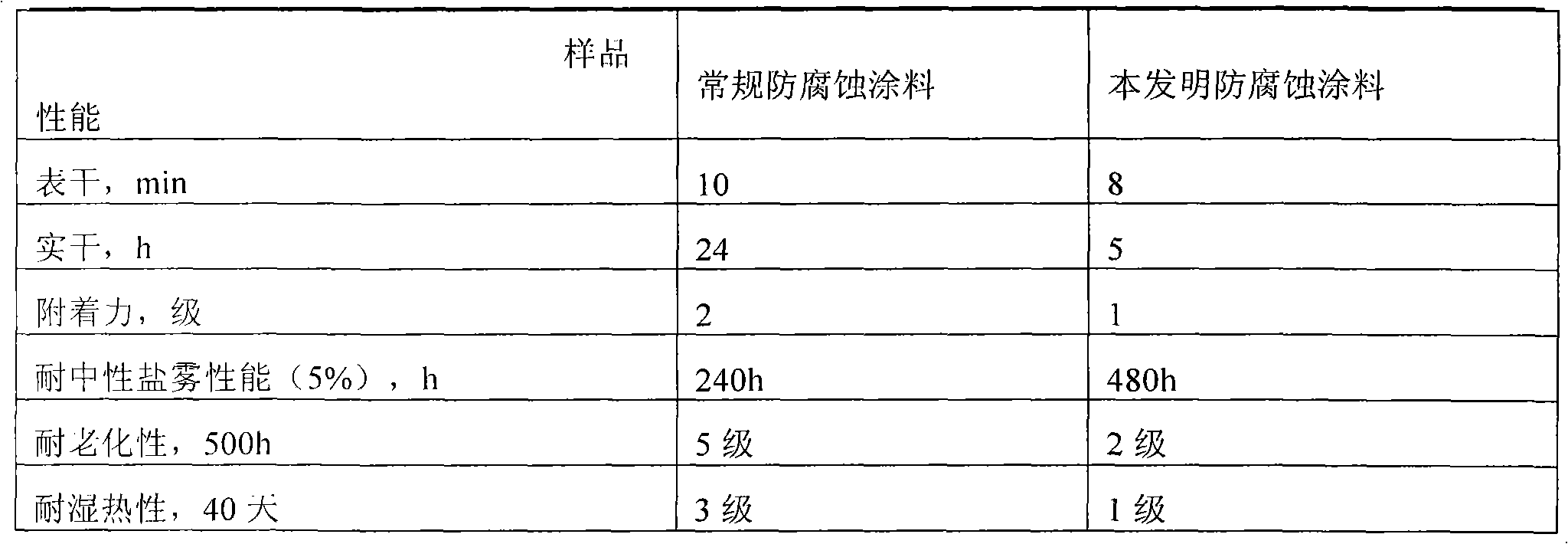

Anticorrosive paint for weather-resistant corrosion-resistant steel pipe outer wall

ActiveCN102120909AFast dryingDry fastGeneral water supply conservationAnti-corrosive paintsEpoxyWeather resistance

The invention relates to an anticorrosive paint for a weather-resistant corrosion-resistant steel pipe outer wall, which is prepared from 30-50 parts of alkyd resin, 2-5 parts of epoxy resin, 10-15 parts of terpene resin, 30-50 parts of hydrocarbon solvent, 3-8 parts of anticorrosive agent and 1-3 parts of drying agent. The paint provided by the invention can be applied by brushing, spraying, dipcoating, curtain coating or the like, and is naturally dried at normal temperature. The terpene resin adopted in the invention has high stability for oxygen, heat and light, and has excellent ageing resistance, so that the paint has excellent weather resistance. The rust inhibitor adopted in the invention can form a compact protective layer with high adhesive force on the surface of a steel pipe,and thus, prevents or slows the permeation of oxygen and water in the environment under the isolation action, thereby inhibiting the generation of corrosion microcells and performing a favorable anticorrosive protection function.

Owner:TIANJIN COLOROAD COATING & CHEM

Environment-friendly flexographic ink

The invention relates to an environment-friendly flexographic ink, which comprises a coloring agent, a bonding material, a viscosity regulator and a dispersant; the coloring agent is natural plant dye; the weight contents of the compositions are 10 to 30 weight portions of the plant dye, 45 to 70 weight portions of the liquid bonding material, 1 to 5 percent of the viscosity regulator and 1 to 6 weight portions of the dispersant; the bonding material comprises natural plant oil, mineral oil and natural or synthetic resin; and the viscosity regulator is plant oil or viscosity reductant, the plant oil is selected from Chinese wood oil, flax oil or soybean oil, and the viscosity reductant is aluminium salt, low-viscosity alkyd or paraffin oil. The vegetable dye takes pure natural plants as raw materials, has reproducing property and good ecological environmental protection property, and has no harm to human bodies and environment so as to reduce the pollution of the ink to the environment.

Owner:苏州科德教育科技股份有限公司

Porous films with chemical resistance

InactiveUS20070036959A1Good chemical resistanceMaintain good propertiesSemi-permeable membranesMembranesEpoxyCellulose acetate

A porous film with chemical resistance of this invention includes a porous film base covered with a chemical-resistant polymeric compound and has a multiplicity of communicating micropores having an average pore size of 0.01 to 10 μm. The chemical-resistant polymeric compound can be, for example, any of phenolic resins, urea resins, melamine resins, benzoguanamine resins, polyimide resins, epoxy resins, benzoxazine resins, polypropylene resins, polyurethane resins, fluororesins, alkyd resins, cellulose acetate resins, phthalic resins, maleic resins, and silicone resins.

Owner:DAICEL CHEM IND LTD

Modified dry oil alkyd resin for protective paint for metal coating on the back of the mirror and the curtain coating paint

InactiveCN1621430AImprove drynessImprove water resistancePolyester coatingsOptical elementsEpoxySolvent

The modified drying alkyd resin for curtain coated paint protecting metal coating in the back of mirror includes medium oil content drying alkyd resin in 55-70 wt%, acrylate monomer in 20-30 wt% and epoxy resin as modifier in 10-15 wt%. The medium oil content drying alkyd resin and the acrylate monomer form copolymer resin, and the copolymer resin is reacted with epoxy resin to form the modified drying alkyd resin with final viscosity of 150-300 s, acid value lower than 5 mg KOH / g and solid powder content over 50 wt%. The modified drying alkyd resin, selected cross-linking resin, pigment and solvent constitute curtain coated paint capable of well attaching to the surface of smooth metal coating.

Owner:徐金龙

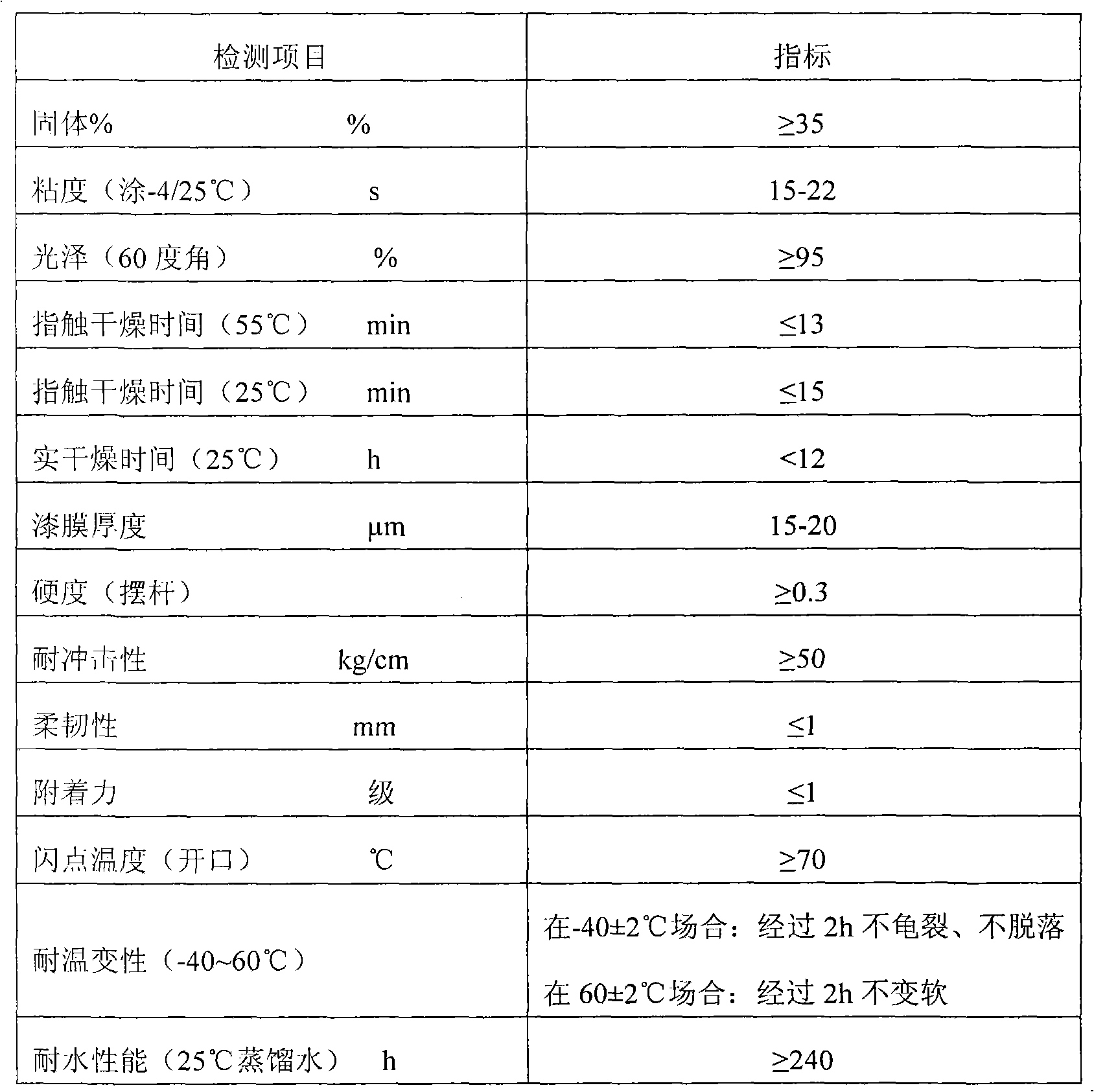

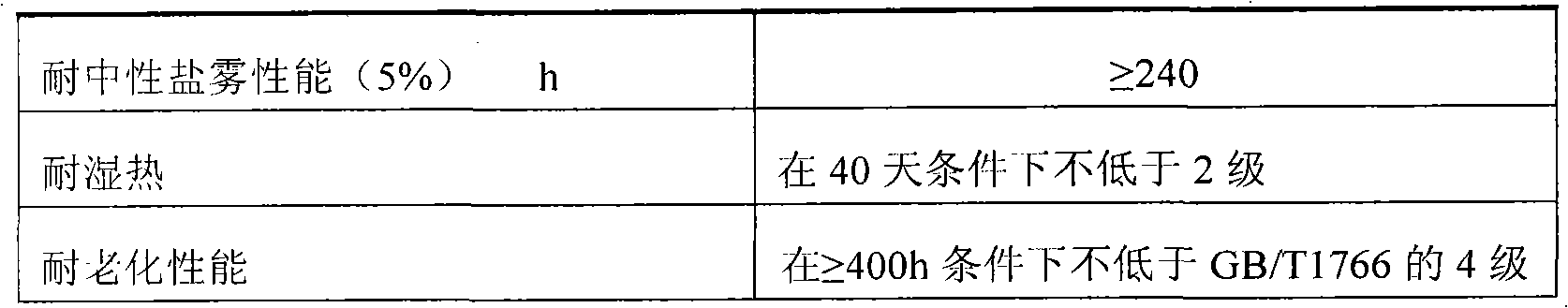

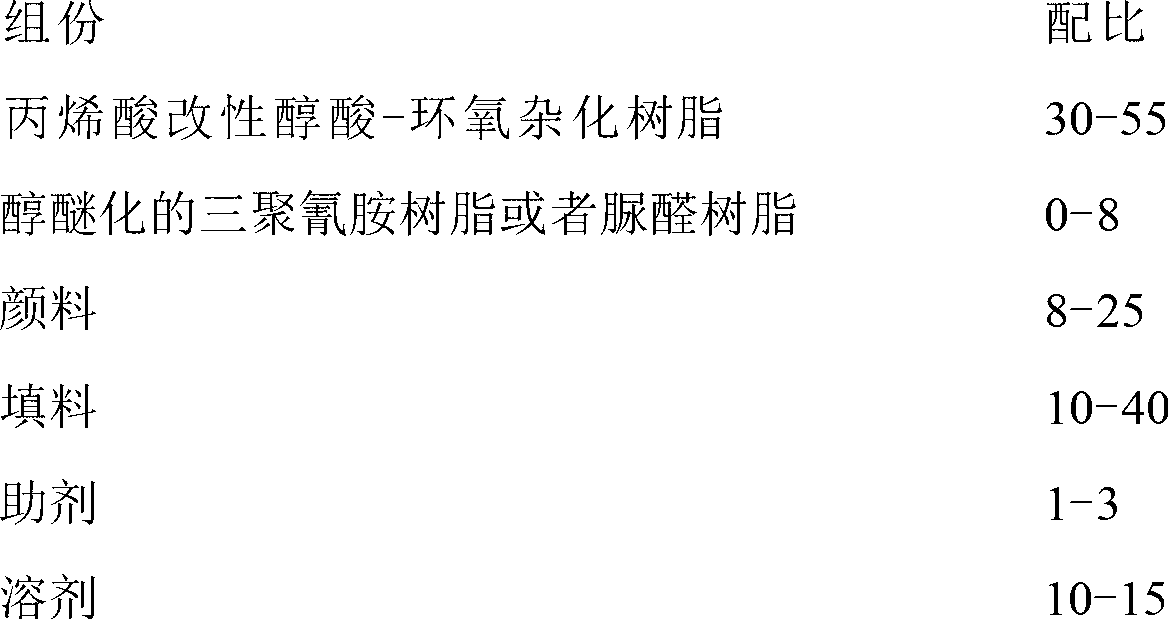

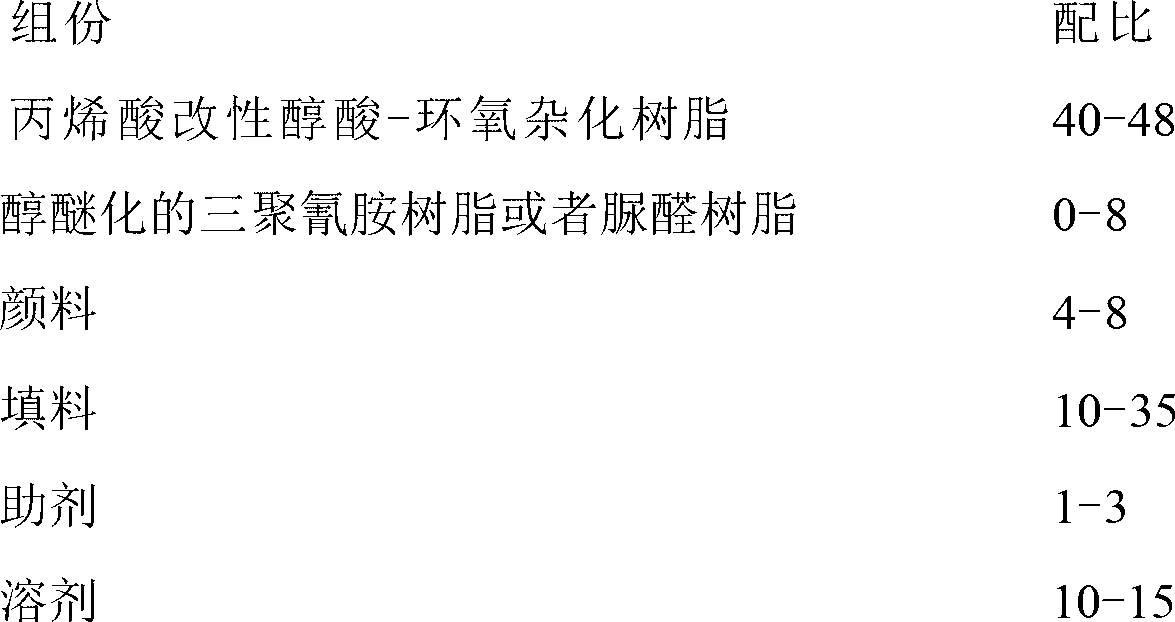

Acrylic-modified alcohol acid-epoxy ester hybrid resin and paint thereof

The invention relates to an acrylic-modified alcohol acid-epoxy ester hybrid resin which is prepared by the following steps: carrying out high-temperature esterification reaction on an epoxy resin and fatty acid under the action of an esterification catalyst to obtain epoxy ester; carrying out alcoholysis on vegetable oil and polyalcohol at high temperature, cooling, and adding polybasic acid for esterification, thereby obtaining an alkyd resin; and adding acrylic monomers into the epoxy ester-alkyd resin mixed solution, and carrying out graft polymerization under the action of an initiator to obtain the hybrid resin. The hybrid resin can be used as a main film forming material to prepare a high-temperature baking varnish together with a crosslinking agent. The high-temperature baking varnish can be used as various curtain-coating mirror back paints, including silver mirror back paints, aluminum mirror back paints, glass paints and the like, can satisfy the technological requirements for application of curtain coating production lines of which the width exceeds 3m, has a stable curtain coating, and can become completely dry after being baked at 150-130 DEG C for 3-5 minutes. The product has the advantages of low-temperature quick drying, high hardness, excellent adhesive force, dampness-heat resistance, chemical resistance, salt-fog resistance and the like.

Owner:常州市弘可利办公用品有限公司 +1

Quick-dry type acrylic modified alkyd paint and preparation method thereof

The invention relates to quick-dry type acrylic modified alkyd paint which is characterized by comprising the following components in parts by weight: 35-65 parts of acrylic modified alkyd resin, 15-25 parts of pigment, 10-25 parts of filling, 0.5-2.0 parts of anti-settling agent, 0.3-1.0 part of dispersant, 0.3-0.6 part of flatting agent, 0.3-0.6 part of antifoaming agent, 2-5 parts of drier, 0.1-0.3 part of anti skinning agent, 10-20 parts of heavy aromatic, 10-20 parts of xylene and 5-15 parts of prime city naphtha. The preparation method comprises the following steps of: adding the front four raw materials of the acrylic modified alkyd resin, and the like into a burdening pot; evenly stirring a mixture, dispersing the mixture for 20 minutes at high speed; grinding the mixture in a sand grinder into fineness of 30micron; filling pigment paste into a paint mixing tank; adding the last seven raw materials; evenly stirring; and filtering. The invention has the beneficial effects that various colors of acrylic modified alkyd paint is prepared by using the acrylic modified alkyd resin as a base material; and a paint film is quickly dried, and has the characteristics of good light retention property, weather resistance and recoatability, high decoration performance, and greatly improved comprehensive physical and chemical properties.

Owner:天津灯塔涂料工业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com