Patents

Literature

30results about How to "Good self-drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy ester resin water dispersion and method for manufacturing rust-inhibiting primer using the same as foundation

InactiveCN101177518ALow acid valueReduce dosageAnti-corrosive paintsEpoxy resin coatingsEpoxyResin coating

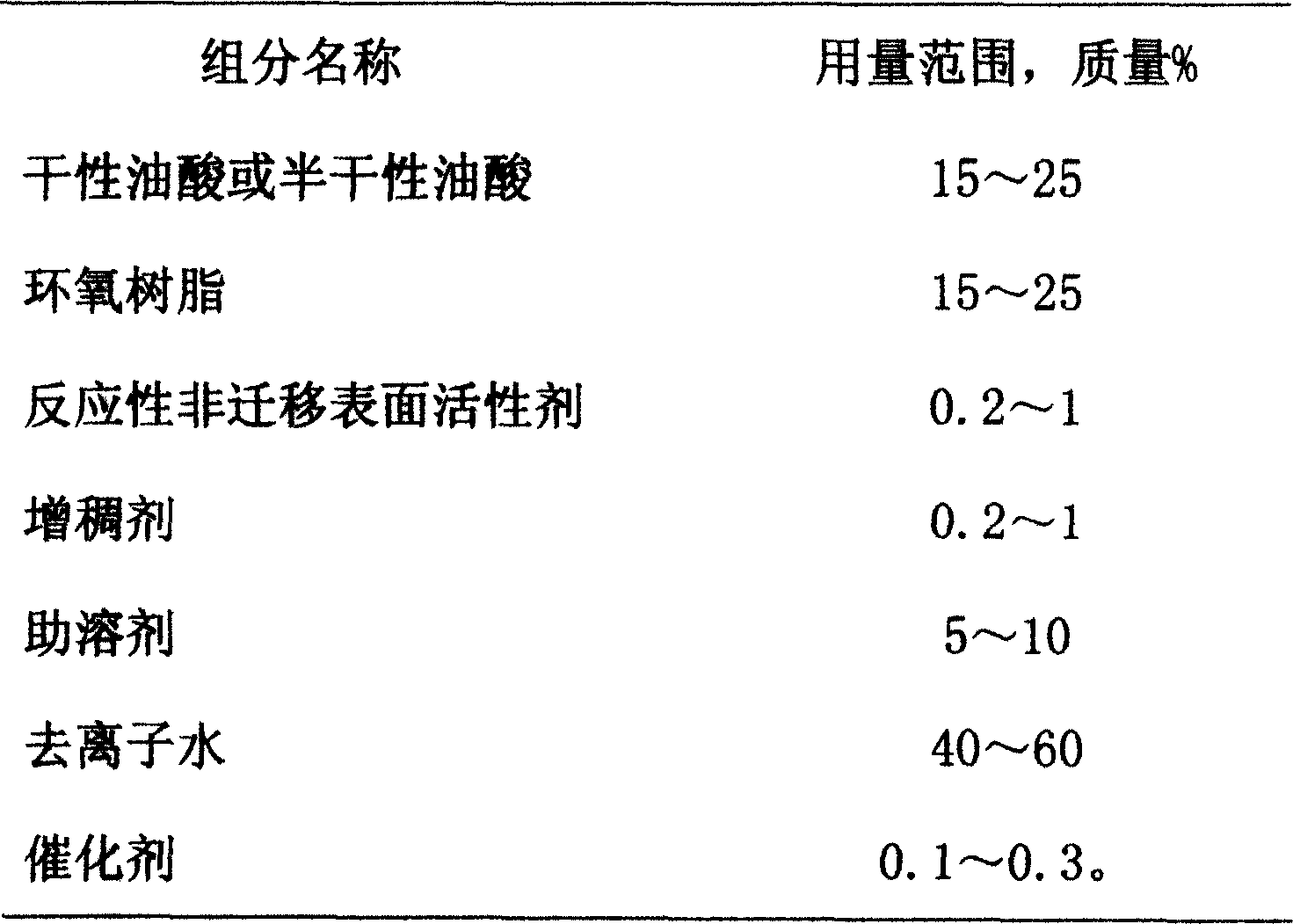

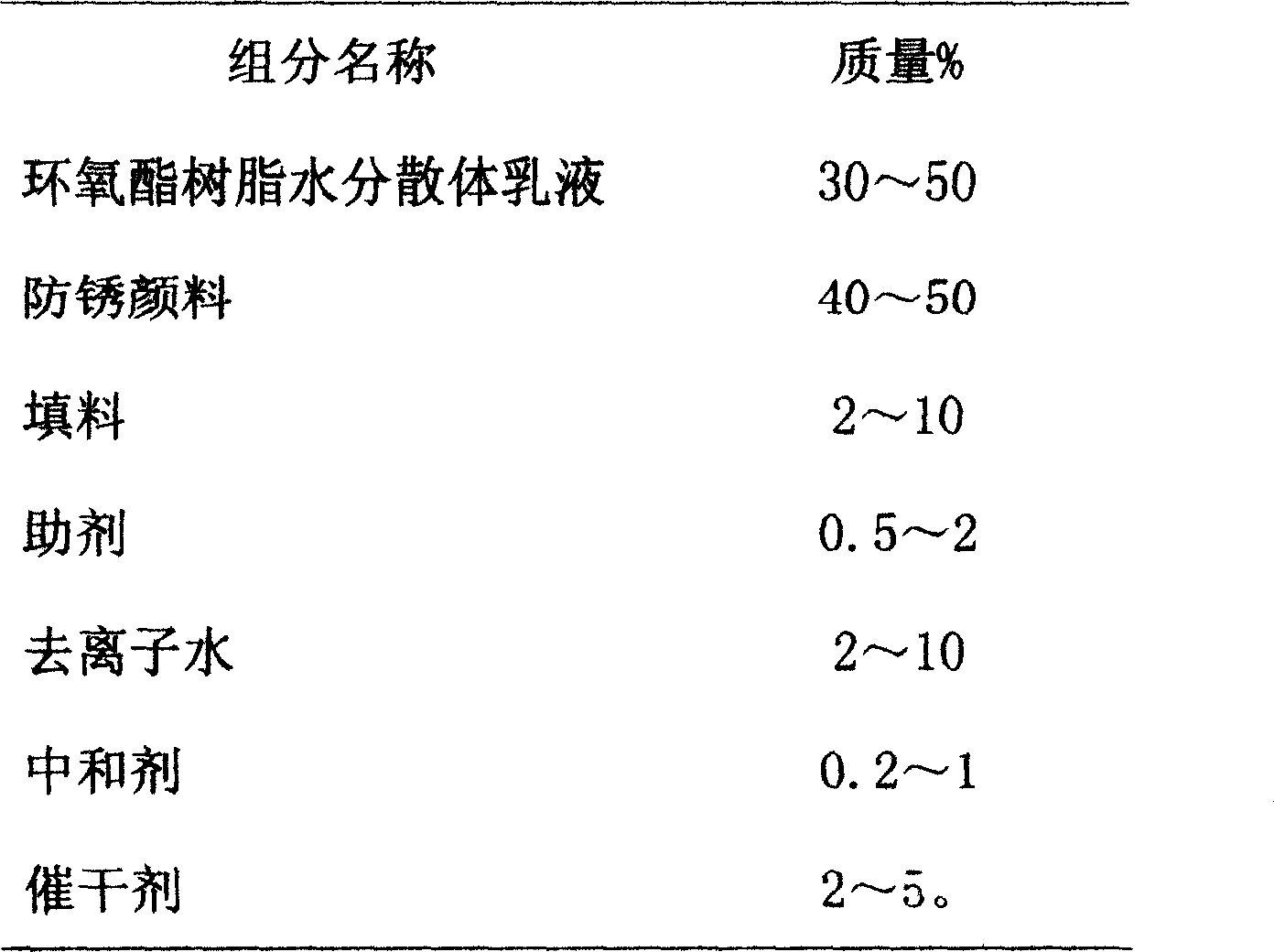

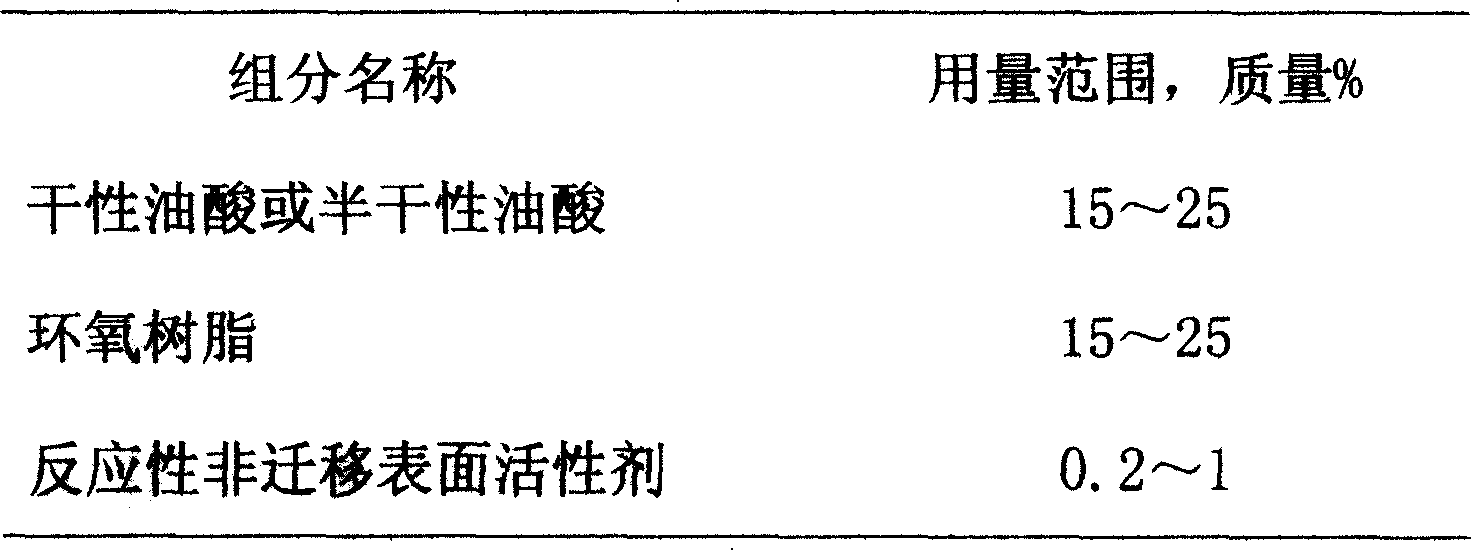

The invention discloses a manufacturing method of an epoxy-ester resin aqueous dispersion and the anti-corrosion primer on the basis of the epoxy-ester resin aqueous dispersion, characterized in that the aqueous dispersion is a self-drying core-shell structured aqueous dispersion emulsion with the epoxy resin as the core and the reactive non-transfer surfactant as the shell; the anti-corrosion primer has the epoxy-ester resin aqueous dispersion emulsion with acid value of 2 to 10 mg KOH / g, solid content ranging from 40 percent to 60 percent as the basic component. The construction performance, self-drying property and the paint film mechanical strength of the produced waterborne anti-corrosion primer are all comparable to the solvent type epoxy resin coating.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

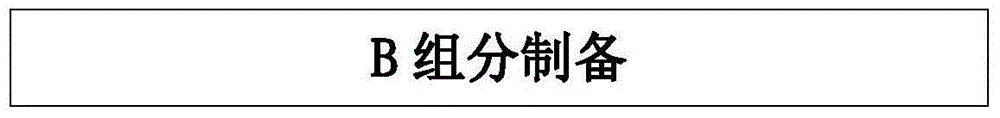

Ultra-low VOC air-drying poly-aspartic paint for engineering machinery

InactiveCN104893523AImprove mechanical propertiesImprove corrosion resistancePolyurea/polyurethane coatingsEquivalence ratioPolyaspartic

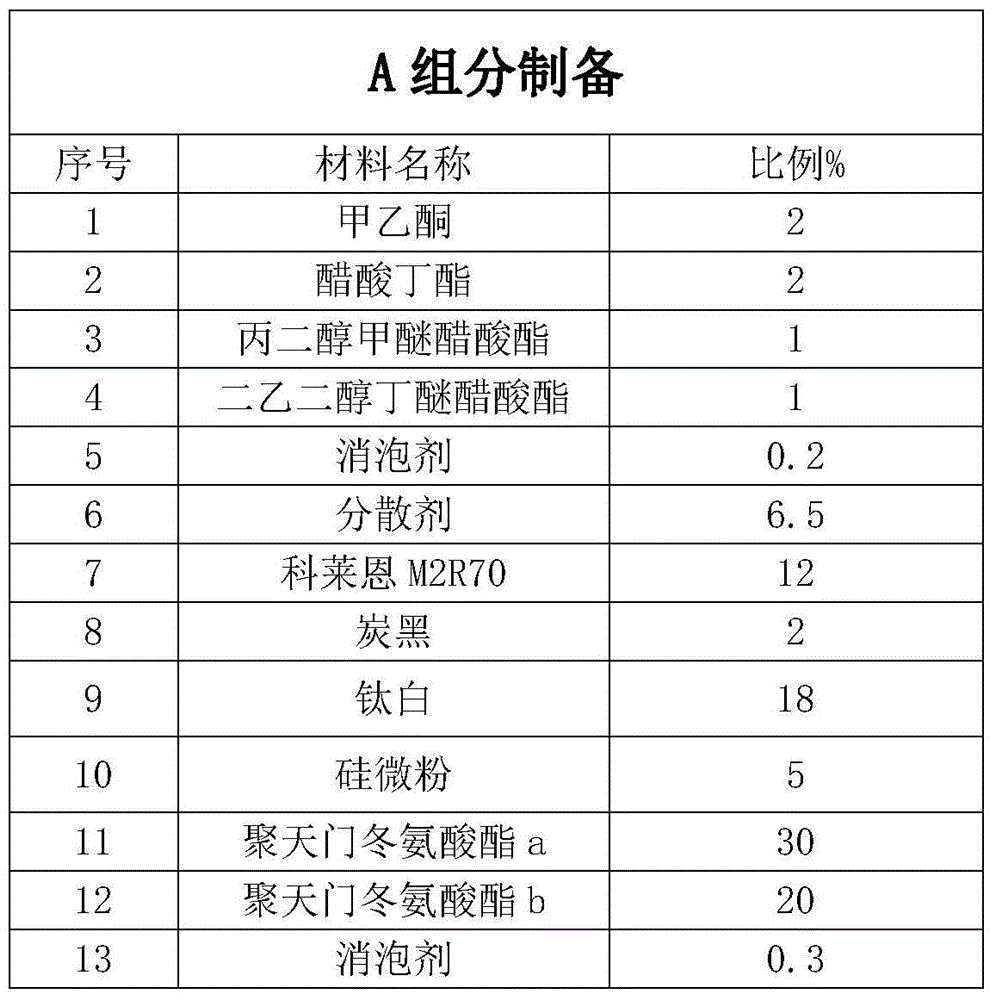

The invention relates to an ultra-low VOC air-drying poly-aspartic paint for engineering machinery. The poly-aspartic paint comprises a component A and a component B, wherein the component A comprises the following raw materials: 25 to 37 parts of polyaspartic ester a, 15 to 23 parts of polyaspartic ester b, 30 to 40 parts of pigments and fillers, 3 to 10 parts of one or more additives, and 0 to 15 parts of one or more solvents; the polyaspartic ester a and the polyaspartic ester b are Bayer NH1420 / NH1520, or Zhuhaifeiyang F420 / F520; the mass ratio of the polyaspartic ester a to the polyaspartic ester b is (1 to 2):1; the component B comprises the following raw materials: 50 to 70 parts of HDI uretdione isocyanate, 30 to 40 parts of HDI tripolymer isocyanate, 0 to 3 parts of one or more additives, and 0 to 5 parts of one or more solvents; the mass ratio of HDI uretdione isocyanate and HDI tripolymer isocyanate is (1.5 to 2):1; the equivalence ratio of the component B to the component A, that is, -NCO of the component B to -OH of the component A, is 1.05:1. The poly-aspartic paint provided by the invention is ultra-low in VOC, fast in air drying and film formation, and excellent in coating appearance and performance, and suitable for being applied to environment-friendly one coat paint or finishing coat paint.

Owner:HAOLISEN COATING SHANGHAI

Quenching oil capable of enabling automobile plate spring to blacken automatically after quenched and quenching method thereof

ActiveCN105925768AWarranty Strength RequirementsGuaranteed stiffness requirementsFurnace typesMetallic material coating processesAntioxidantBase oil

The invention discloses quenching oil capable of enabling an automobile plate spring to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.4-0.7 parts of blackening composite agent, 0.3-0.5 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.03 parts of antioxidant. The effect is best when the maximum cooling speed of the quenching oil for the plate spring is about 110-120 DEG C / s and the using temperature is 65-70 DEG C. Under the above conditions, the strength and the stiffness of the quenched plate spring are greatly improved, at the same time the effect of the automatic surface blackening can be realized and a protective film formed on the surface is strong in adhesion and good in wear-resisting property. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

Quenching oil dedicated to small module gears and preparation method of quenching oil

The invention discloses quenching oil dedicated to small module gears and a preparation method of quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises the following components in parts by mass: 35 to 40 parts of refined base oil, 2 to 3 parts of a cooling compound agent, 0.5 to 0.8 part of a blackening compound agent, 0.3 to 0.7 part of a brightening agent, 0.6 to 0.8 part of a surfactant and 0.04 to 0.06 part of an antioxidant. The quenching oil is specially developed for the small module gears of which the module is 1 mm or below, the optimal utilization temperature is 100 to 110 DEG C, the fluidity of the quenching oil is good in the temperature range, the cooling velocity for the small module gears is moderate, protective films are formed on the surfaces of the gears through automatic blackening during quenching, the secondary coating antirust treatment on the surfaces after heat treatment is reduced, the resources are saved, the procedure is reduced, and the efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

Quenching oil capable of making fastener become black by itself after quenching and application method of quenching oil

ActiveCN105969957ASmall surface hardnessSmall deformation rateFurnace typesMetallic material coating processesAntioxidantSurface-active agents

The invention discloses quenching oil capable of making a fastener become black by itself after quenching and an application method of the quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises, by mass, 35-40 parts of refined base oil, 7-10 parts of composite cooling accelerant, 0.5-0.7 part of a composite blacking agent, 0.4-0.8 part of a brightening agent, 0.5-0.8 part of a surface active agent and 0.02-0.04 part of antioxidant. The composite cooling accelerant is the mixture of polyisobutene, dimethyl naphthalene and mahogany petroleum sulfonate. The composite blacking agent is the mixture of short oil alkyd resin, a coloring agent and a wetting agent. The brightening agent is the mixture of imidazoline oleate and methyl terpene resin. The coloring agent is disperse black 9. The wetting agent is fatty alcohol-polyoxyethylene ether. The surface active agent is span-80. The optimal using temperature of the quenching oil ranges from 70 DEG C to 75 DEG C, the speed for cooling the fastener is moderate, a protection film is formed on the surface in a self-blacking manner during quenching, and efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

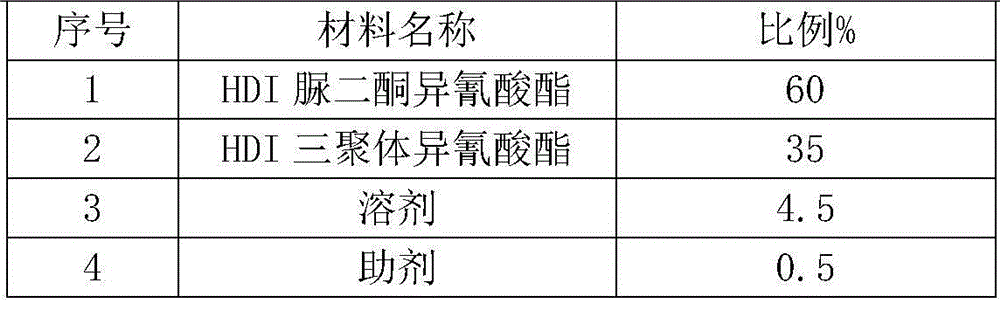

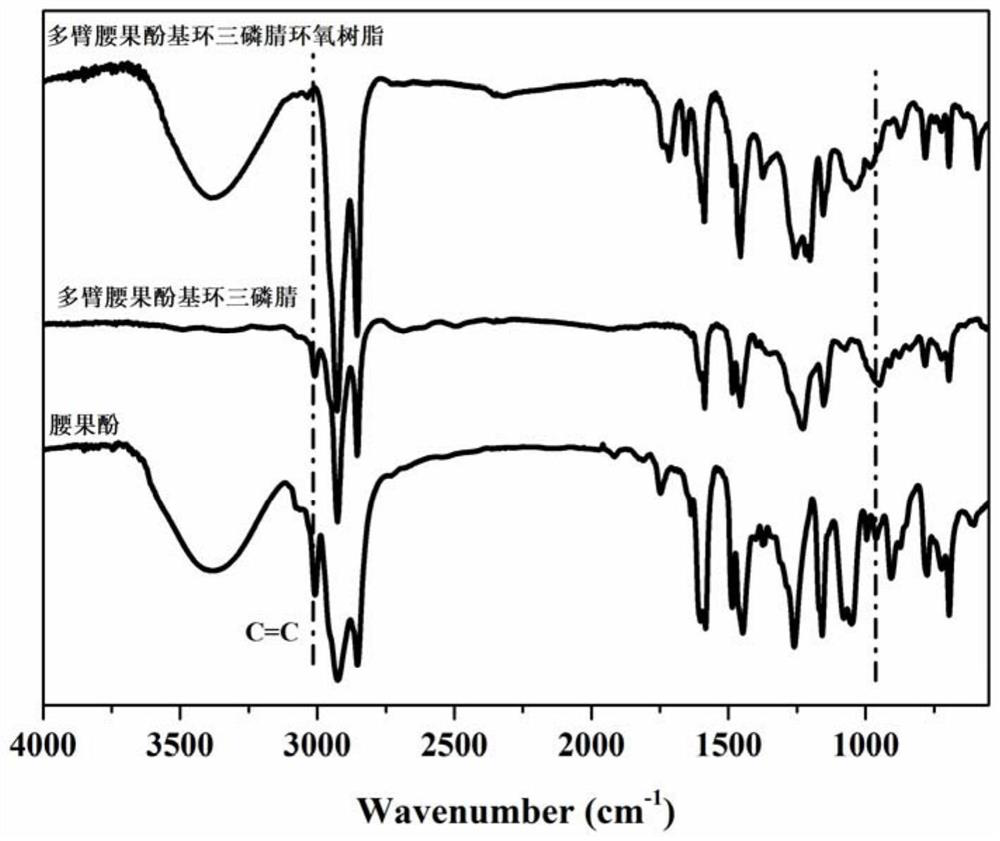

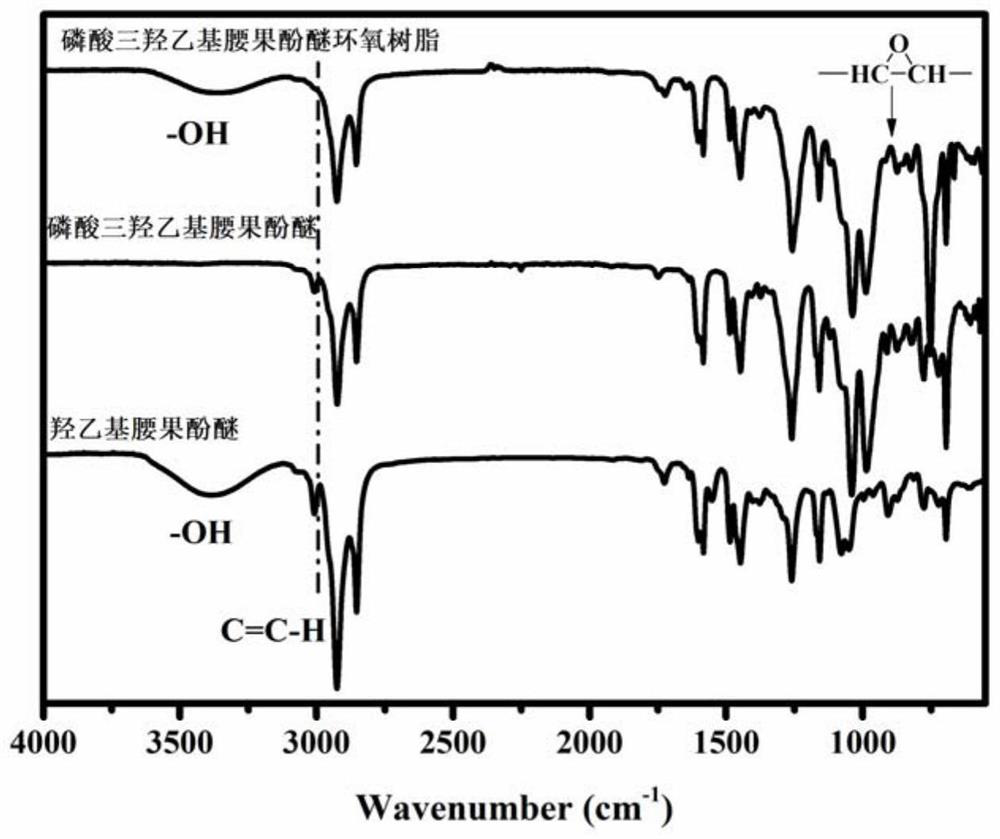

Bio-based epoxy resin pouring sealant and preparation method thereof

ActiveCN113881376AAddressing the Excessive Use of Petrochemical ResourcesImprove flame retardant performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceBis epoxide

The invention discloses a bio-based epoxy resin pouring sealant. The bio-based epoxy resin pouring sealant contains multi-arm cardanol-based cyclotriphosphazene epoxy resin, and the multi-arm cardanol-based cyclotriphosphazene epoxy resin is prepared by reacting phosphonitrilic chloride trimer with cardanol and then performing epoxidation. According to the invention, cardanol and cyclotriphosphazene are organically combined through molecular design, the functionalized cardanol epoxy resin with excellent thermal stability and flame retardance is prepared, the bio-based epoxy pouring sealant with excellent comprehensive performance is prepared, and the bio-based epoxy pouring sealant has important application value.

Owner:JIANGNAN UNIV +1

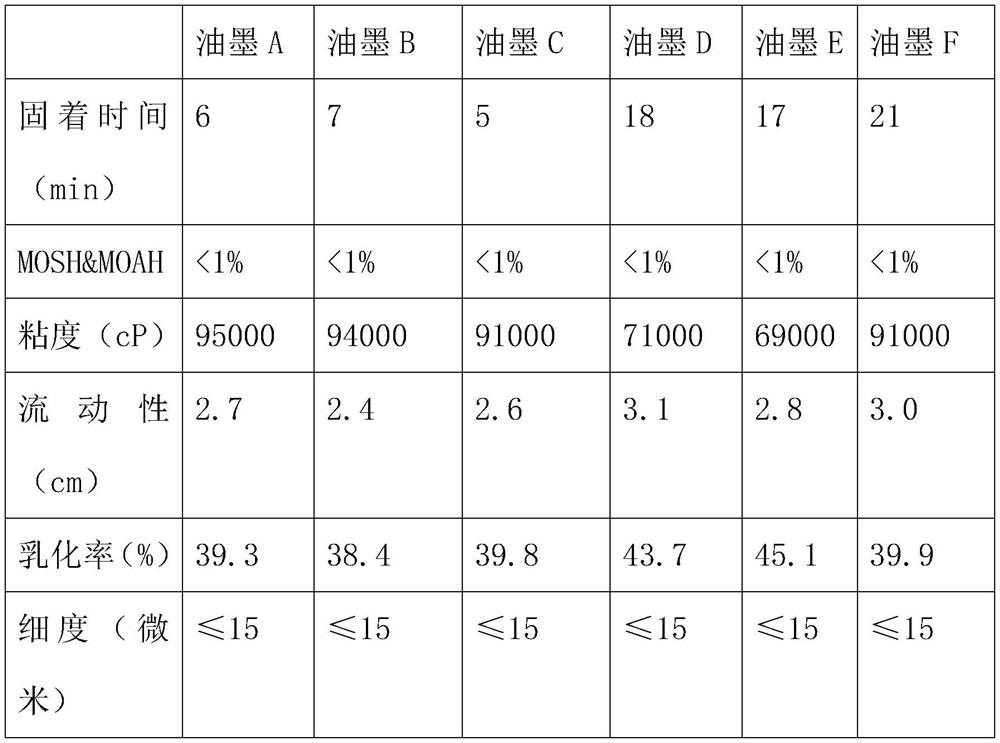

Vegetable oil-based low-halogen environment-friendly printing ink and preparation method thereof

The invention discloses plant oil-based low-halogen environment-friendly ink and a preparation method thereof. The plant oil-based low-halogen environment-friendly ink is prepared from the following raw materials: pigment particles, polyethylene wax, a binder, soybean methyl oleate, a cobalt drying agent and a dispersing agent. The printing ink disclosed by the invention is refined from pure vegetable oil, is green and environment-friendly, is suitable for various offset printing machines, is quick to fix, quick to dry, high in gloss, stable in on-machine printing and good in wear resistance, and is a product which is excellent in printing performance and wide in application and is very in line with the environment-friendly requirements of packaging and green printing in various industries; the preparation method comprises the steps of dispersing and matching, rolling and grinding and filtering and packaging. The modified short-oil alkyd resin is prepared by a double-bond copolymerization method, and the modified alkyd resin has excellent self-drying property; the self-made modified short oil alkyd resin is put into the preparation process of the connecting material through a two-step method, and the prepared connecting material endows the ink with excellent flowing and printing capabilities, so that an ink film is high in gloss and resistant to friction.

Owner:中山市富日印刷材料有限公司

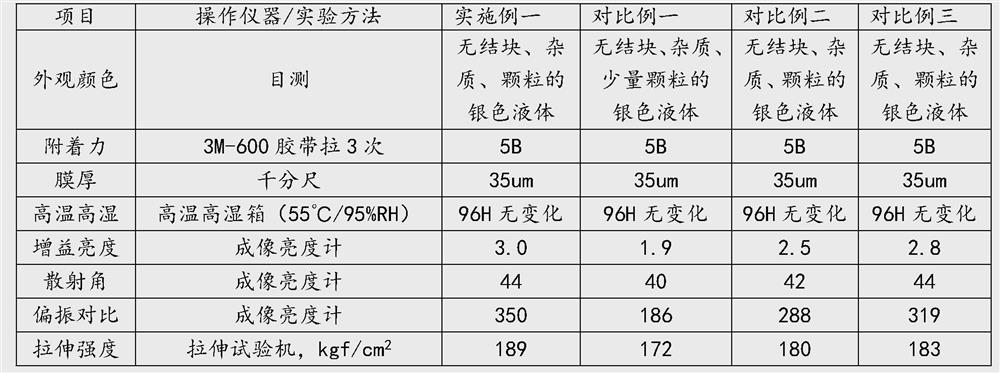

Self-drying water-based aluminum powder coating for PVC screen, and preparation method and application thereof

ActiveCN112029357AGood film formingReduce usagePolyurea/polyurethane coatingsPaints with free metalsAluminium powderSlurry

The invention discloses a self-drying water-based aluminum powder coating for a PVC screen, and a preparation method and application thereof. The self-drying water-based aluminum powder coating comprises, by mass, 50-60% of water-based resin, 20-25% of water-based aluminum powder and 5-15% of an water-based additive. Furthermore, the water-based additive comprises a water-based dispersing agent, awater-based leveling agent, a water-based defoamer, a water-based anti-settling agent and water-based wax slurry. The water-based coating is used for replacing an oil-based coating, water is used asa solvent, the cost is reduced, safety and environmental protection are achieved, and pollution to the environment and physical health of constructors are greatly reduced; and the performance indexesof the screen used for a long time are slow in attenuation, and the emission of VOC is reduced as the resin with lower film-forming temperature is selected and used without additionally adding a high-boiling-point cosolvent.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Thermal-insulation coating and preparation method thereof

InactiveCN106752643AGood heat insulationImprove moisture resistancePolyester coatingsThermal insulationEthyl acetate

The invention discloses thermal-insulation coating and a preparation method thereof. The coating is prepared from the following components: light calcium carbonate, modified graphene, polyvinyl acetate, phenolic resin, alkyd resin, sodium tripolyphosphate, fatty alcohol polyoxyethylene ether sodium sulphate, hydroxypropyl methyl cellulose, absolute ethyl alcohol, silicon dioxide, ethyl acetate and water. The preparation method comprises the following steps: adding light calcium carbonate, polyvinyl acetate, phenolic resin and alkyd resin into absolute ethyl alcohol, and uniformly stirring and mixing to obtain mixed liquid I; then, adding sodium tripolyphosphate, fatty alcohol polyoxyethylene ether sodium sulphate and hydroxypropyl methyl cellulose into water, heating and stirring to obtain mixed liquid II; adding the modified graphene into the mixed liquid I, adding ethyl acetate, heating and refluxing under a stirring state to obtain mixed liquid III; and finally adding the mixed liquid II and silicon dioxide into the mixed liquid III, uniformly mixing, and grinding to obtain the thermal-insulation coating. The coating has excellent thermal insulation and wet resistance.

Owner:吴德炳

Chain piece specific quenching oil and quenching method thereof

ActiveCN105925769ABeautify the appearanceSave resourcesFurnace typesMetallic material coating processesQuenchingAntioxidant

The invention discloses chain piece specific quenching oil and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.5-0.7 parts of blackening composite agent, 0.4-0.8 parts of brightening agent, 0.5-0.8 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The effect of is best when the maximum cooling speed of the quenching oil for the chain piece is about 93-102 DEG C / s and the using temperature is 70-80 DEG C. Under the above conditions, the ideal quenching hardness can be obtained, the deformation rate is low, the effect of the automatic surface blackening can be realized, a protective film formed on the surface is strong in adhesion and not easy to fall off, and the effect of the appearance beautification and short-term rust prevention can be realized. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

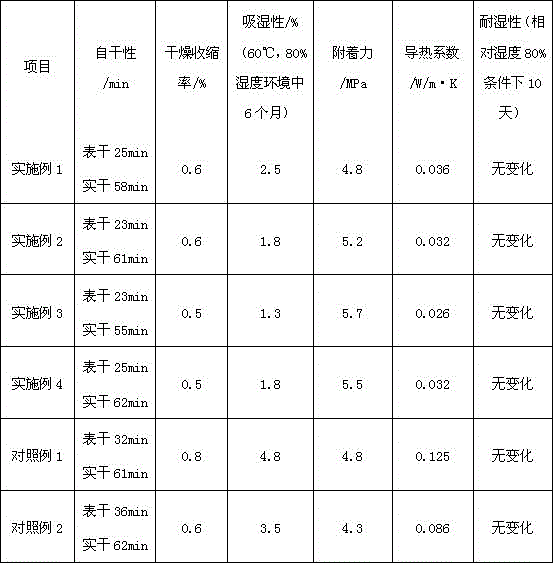

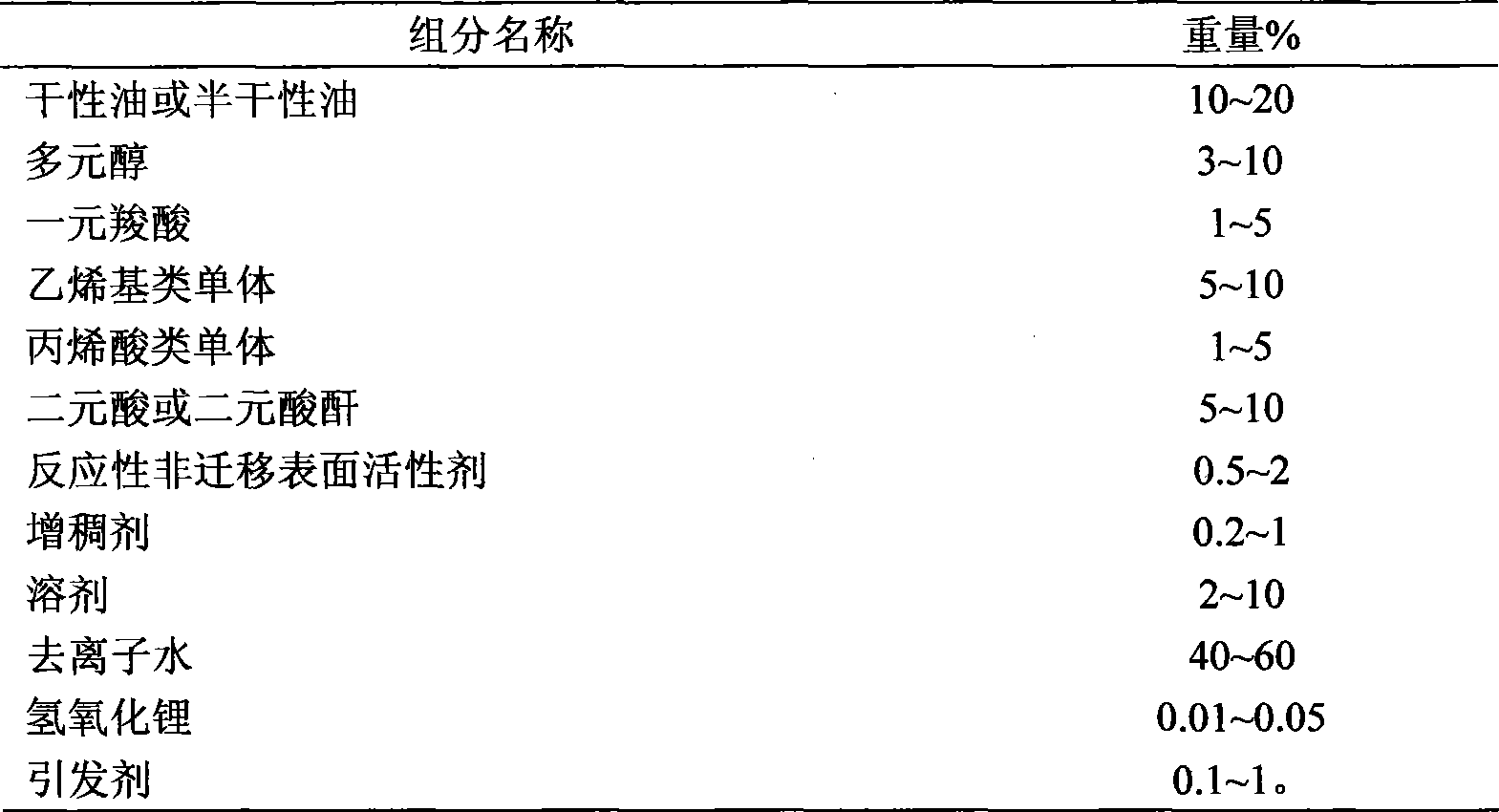

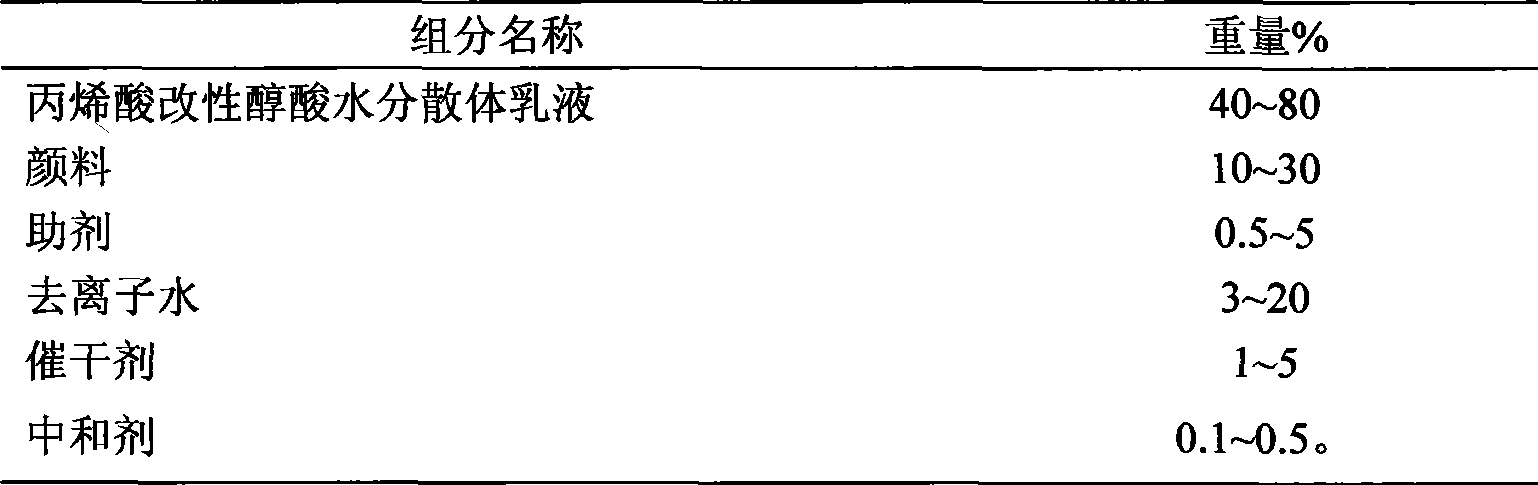

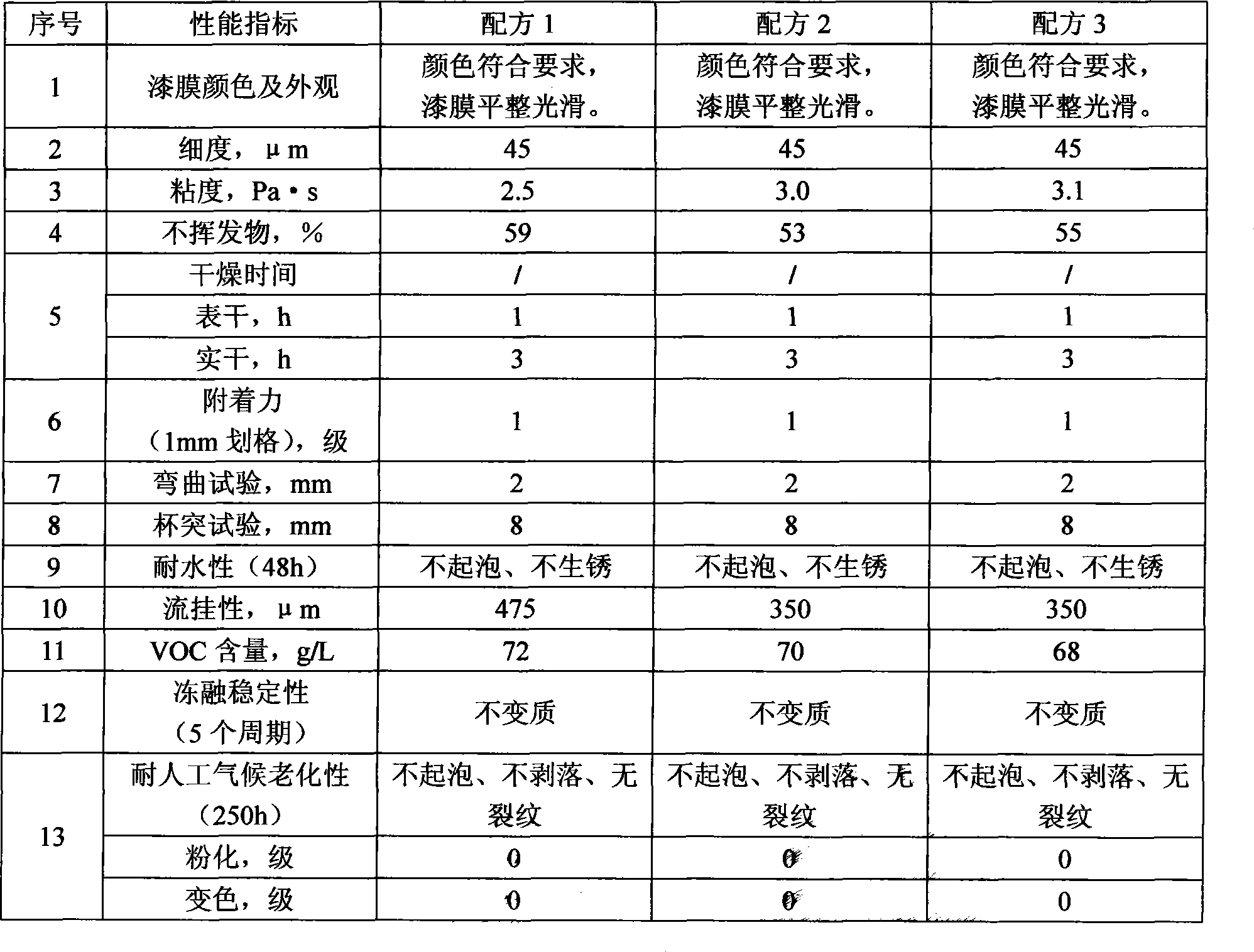

Water dispersion of self-drying acrylic modified alkyd resin and industrial topcoat using the water dispersion as base

The invention relates to 'core-shell' structure self-drying acrylic modified alkyd water dispersoid emulsion with acrylic modified alkyd as the 'core' and reactive nonmigratory surface active agent as the 'shell' and with a acid value between 5 and 20 mgKOH / g, a solid content between 40 and 60 weight percent and an emulsion grain diameter between 0.2 and 2 micrometers, and water dispersoid industrial finish paint with the acrylic modified alkyd water dispersoid emulsion as base material. The acrylic modified alkyd water dispersoid emulsion has good storage stability and hydrolysis resistance (the acid value of the acrylic modified alkyd water dispersoid emulsion is almost unchanged during the storage process). The acrylic modified alkyd water dispersoid finish paint with high glossiness and decorativeness can be made by taking the emulsion as the base material and matching with pigment and auxiliary agent. The construction performance, the self-drying property, the mechanical strengthand the decorativeness of the acrylic modified alkyd water dispersoid finish paint can be compared with those of solvent alkyd finish paint.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Quenching oil capable of enabling screw to blacken automatically after quenched and quenching method thereof

ActiveCN105925770AGuaranteed surface hardnessGuaranteed internal metallographic structureFurnace typesMetallic material coating processesAntioxidantFatty alcohol

The invention discloses quenching oil capable of enabling an screw to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 6-10 parts of cooling catalyzed composite agent, 0.4-0.6 parts of blackening composite agent, 0.3-0.7 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The cooling catalyzed composite agent is a mixture of dialkyl naphthalene and petroleum sulfonate; the blackening composite agent the mixture of short oil alkyd resin, colouring agent and wetting agent; the brightening agent is the mixture of imidazoline oleate and methyl terpene resin; the surface activating agent is span-80. The colouring agent is disperse black 9; the wetting agent is fatty alcohol-polyoxyethylene ether. The best using temperature of the quenching oil is between 75 DEG C and 80 DEG C. Between 75 DEG C and 80 DEG C, the cooling speed of the quenching oil for the screw is moderate, the surface can be blackened automatically and a protective film can be formed while the quenching, so that the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

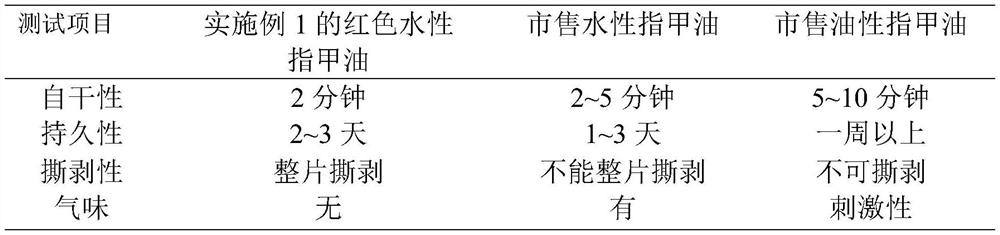

Water-based environment-friendly nail polish

InactiveCN112641673AHas fastnessIt has the effect of fastness; polyurethane-2 has the function of solubilizationCosmetic preparationsToilet preparationsPolyurethane dispersionPolymer science

The invention provides water-based environment-friendly nail polish. The water-based environment-friendly nail polish is characterized by comprising the following raw material components in parts by weight of 60-90 parts of water-based polyurethane dispersoid, wherein the water-based polyurethane dispersoid comprises polyurethane-35, polyurethane-10, polyurethane-11 and polyurethane-2. The nail polish is an environment-friendly healthy nail polish which is good in self-drying performance, durable in appearance, capable of being integrally torn off for makeup removal and odorless. The invention also provides a preparation method of the nail polish, which is characterized by comprising the following steps of 1, mixing various water-based polyurethane dispersoid according to the formula to obtain a basic dispersion solution; 2, stirring the basic dispersion liquid, measuring and adjusting the solid content, and keeping the solid content at 40-45%; and 3, adding other raw material components into the basic dispersion solution, uniformly mixing, and testing the brushing performance and the raw material stability of the nail polish.

Owner:上海泽霈化妆品科技有限公司

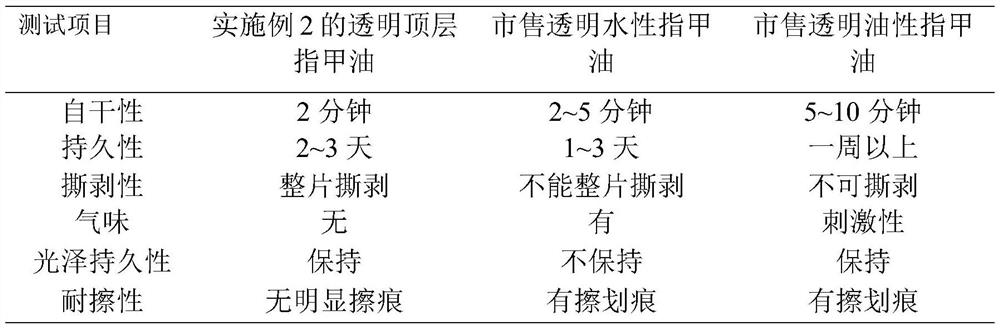

High-toughness epoxy resin adhesive and preparation method thereof

PendingCN114591709AWide variety of sourcesSoft structureEpoxy resin adhesivesPolymer scienceFirming agent

The invention discloses a high-toughness epoxy resin adhesive and a preparation method thereof, relates to the field of epoxy resin adhesives, and solves the problem that the toughness requirement of special parts cannot be met at the present stage. Comprising an adhesive A and an adhesive B. The adhesive B comprises the following raw materials: methyl tetrahydrophthalic anhydride, cardanol and a catalyst, and a part of methyl tetrahydrophthalic anhydride, cardanol and the catalyst are mixed and subjected to a polymerization reaction to obtain a cardanol modified methyl tetrahydrophthalic anhydride compound. Cardanol modified methyl tetrahydrophthalic anhydride serves as a reaction product of methyl tetrahydrophthalic anhydride and cardanol and can serve as a curing agent of epoxy resin glue, and a benzene ring structure of cardanol has the characteristics of aromatic compounds, improves high temperature resistance and has the characteristics of a long straight chain alkyl structure, namely good flexibility, self-drying performance and the like. The adhesive B has a soft structure, cracking caused by curing shrinkage and temperature rise change is overcome, and the toughening effect is achieved.

Owner:温州神祐新材料有限公司

Novel anti-flaming coating

The invention discloses a novel flame-retardant coating, which relates to the technical field of coatings. The flame retardant coating includes the following components by weight: 15 parts of calcium carbonate, 12 parts of hydroxyethyl cellulose, 7 parts of sodium hexametaphosphate, 6 parts of anhydrous sodium sulfite, 7 parts of dehydrated sodium silicate, 12 parts of crystalline silicon 10 parts of magnesium dioxide, 12 parts of quicklime, 6 parts of quasi-spherical silica powder, 13 parts of carbon black, 4 parts of plant fragrance, 4 parts of natural antibacterial agent, 3 parts of vinyl acetate, 10 parts of sodium sulfate, 5 parts of zinc oxide 10 parts, 10 parts of zinc dihydrogen phosphate, 5 parts of additives, 12 parts of aluminum hydroxide flame retardant. The preparation method is simple, has good self-drying property, strong adhesion, convenient construction, good fire resistance and fire prevention performance, and many raw materials in it are environmentally friendly raw materials, which are relatively safe and environmentally friendly, and the raw materials are easy to obtain, and the production cost is low. It also includes natural fragrances, so that the coated furniture has a natural fragrance.

Owner:冯志容

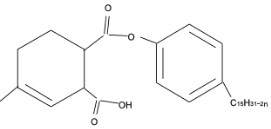

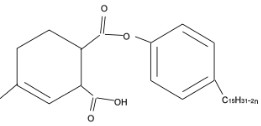

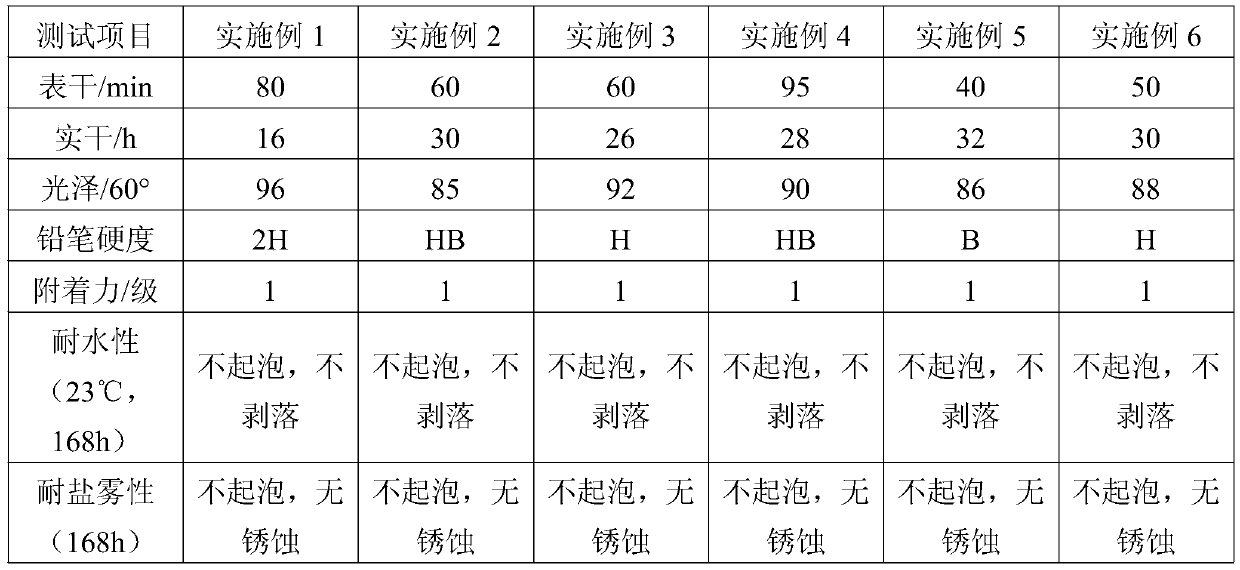

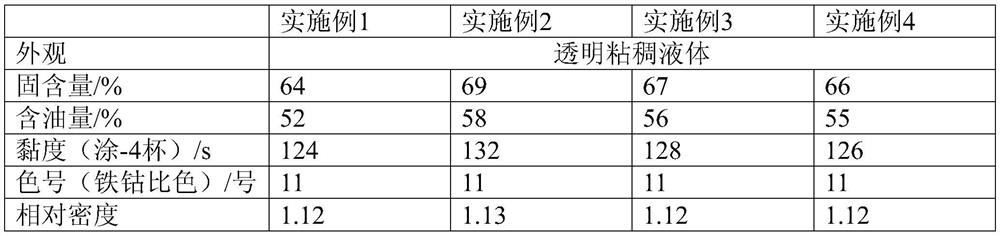

A kind of water-based self-drying acrylic acid modified epoxy ester resin emulsion and preparation method thereof

The invention relates to water-based self-drying acrylic modified epoxy ester resin emulsion and a method for preparing the same. The water-based self-drying acrylic modified epoxy ester resin emulsion is prepared from raw materials including, by weight, 5-9 parts of reactive emulsifiers I, 6-14 parts of reactive emulsifiers II, 0.3-0.9 part of sodium bicarbonate, 3-9 parts of acrylic monomers, 30-50 parts of epoxy ester, 0.1-1.7 parts of initiators and 30-50 parts of deionized water. The water-based self-drying acrylic modified epoxy ester resin emulsion and the method have the advantages that the method for preparing the water-based self-drying acrylic modified epoxy ester resin emulsion is extremely low in solvent dosage, the reaction temperatures are easy to control, the water-based self-drying acrylic modified epoxy ester resin emulsion prepared by the aid of the method contains the reactive emulsifiers, single components in the water-based self-drying acrylic modified epoxy esterresin emulsion can be voluntarily cured at the room temperature, and paint films are excellent in self-drying, adhesion, water resistance and salt fog resistance.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP XIAMEN HONGYE

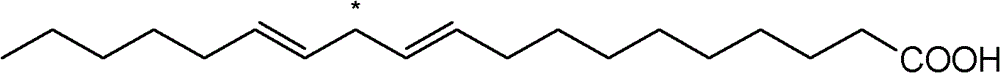

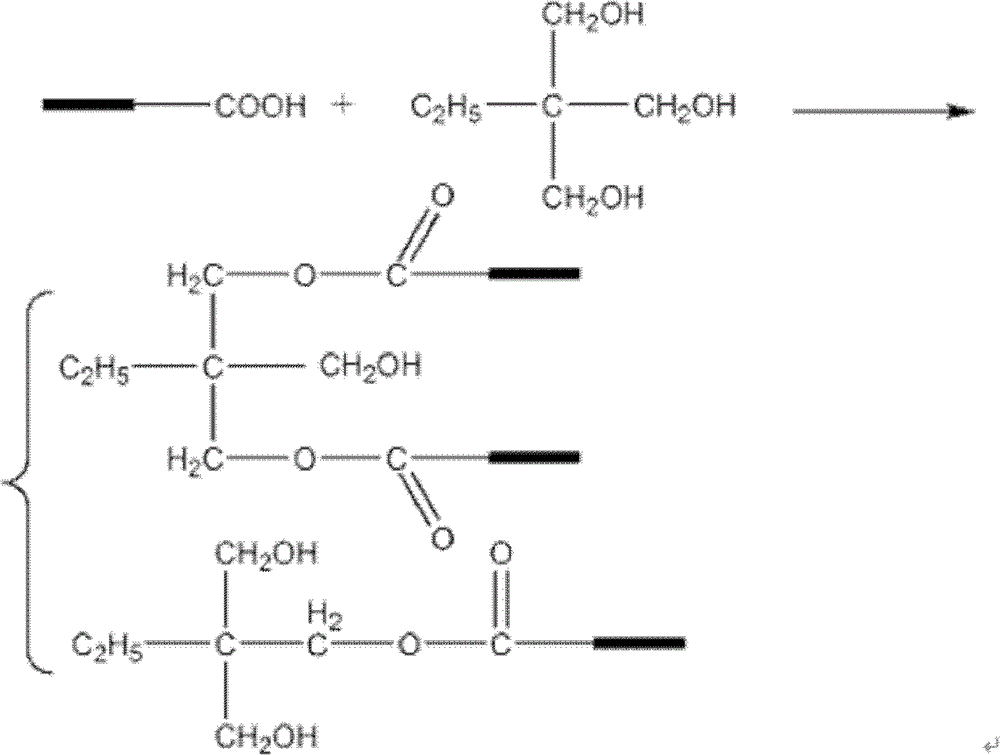

Emulsifiable oily medium oil solvent type alkyd resin and preparation method thereof

The invention discloses an emulsifiable oily medium oil solvent type alkyd resin and a preparation method thereof, and belongs to the field of alkyd resins. The product is prepared from the following components in parts by weight: acrylate modified alkyd resin, polyethylene glycol modified epoxy resin, ethylene glycol butyl ether and deionized water. According to the invention, the medium oil alkyd resin is prepared from castor oil or / and linseed oil. The yield of castor oil and linseed oil is very abundant in China, and the castor oil and linseed oil have certain affinity with the epoxy resin, so that the epoxy resin has a better emulsification effect; in addition, the acrylic acid modified alkyd resin is adopted, the defect of slow drying of the alkyd resin can be overcome by adding the acrylic acid, the alkyd resin is endowed with excellent quick-drying and self-drying performance; besides, the hydroxyl in the acrylic acid and polyethylene glycol have certain affinity, so that the resin has better emulsifying performance.

Owner:山东齐鲁漆业有限公司

A kind of special quenching oil capable of making large modulus gears self-blackening after quenching and its preparation method

ActiveCN105950845BAchieve mechanical strengthImprove quenching effectFurnace typesQuenching agentsAntioxidantHardness

Owner:马鞍山金泉工业介质科技有限公司

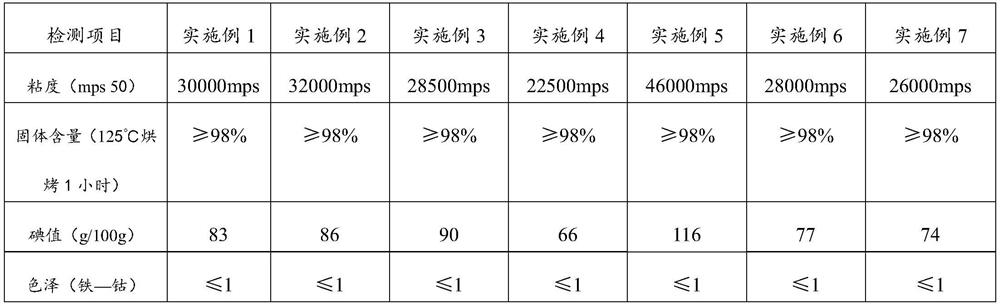

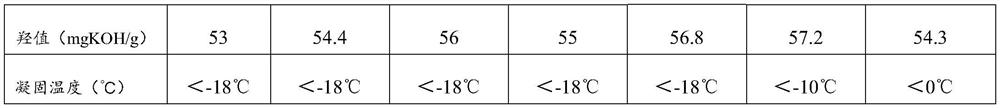

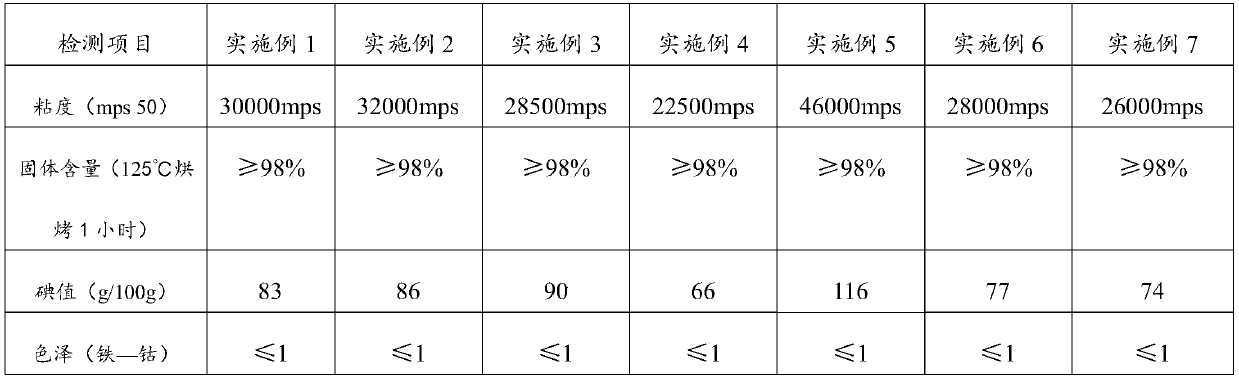

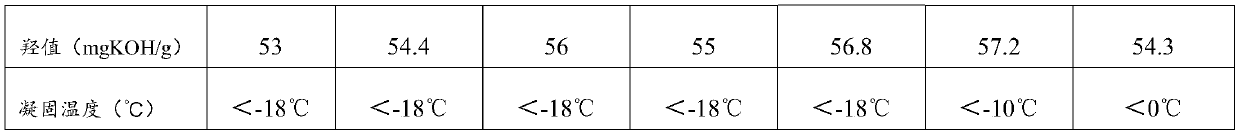

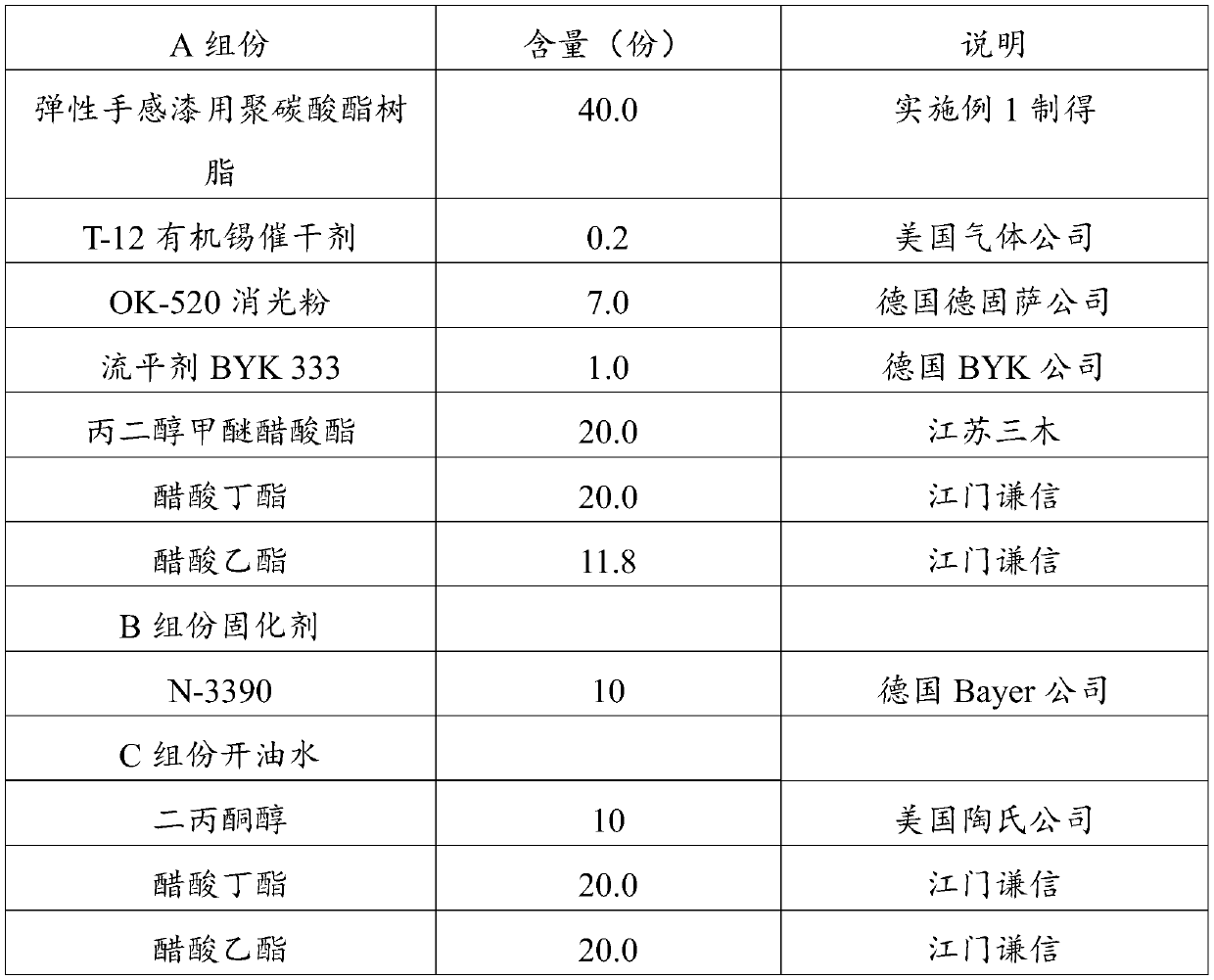

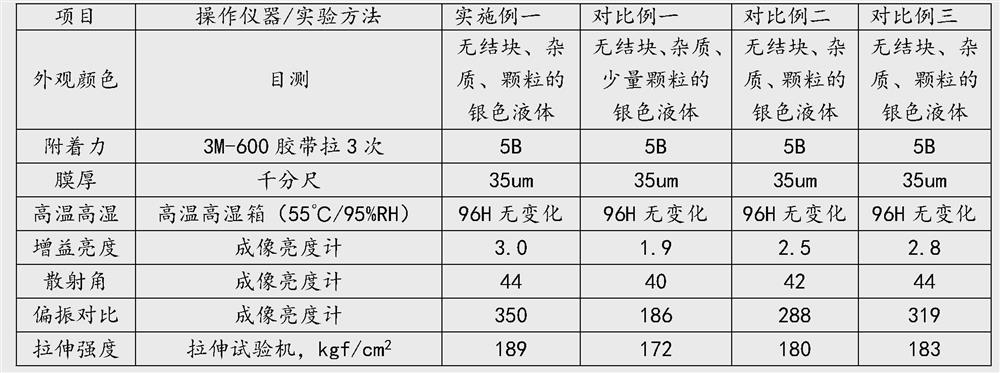

Polycarbonate resin for elastic hand paint and preparation method thereof, and elastic hand paint

The present invention provides a polycarbonate resin for elastic hand-feel paint, the polycarbonate resin for elastic hand-feel paint comprising an unsaturated double bond and a hydroxyl group. The polycarbonate resin for elastic hand-feel paint provided by the present invention contains both unsaturated double bonds and hydroxyl groups, which can be cured by oxidation and self-crosslinking of the double bonds, and can also be cured by crosslinking with an isocyanate curing agent into macromolecules. Therefore, The polycarbonate resin for elastic hand paint of the present invention has dual curing properties, so that the polycarbonate resin for elastic hand paint has good self-drying property, softness, hydrolysis resistance, weather resistance and low temperature non-coagulation. The present invention also provides a preparation method of the polycarbonate resin for elastic hand paint and an elastic hand paint prepared from the polycarbonate resin for elastic hand paint as a raw material.

Owner:东莞市左镕工实业有限公司

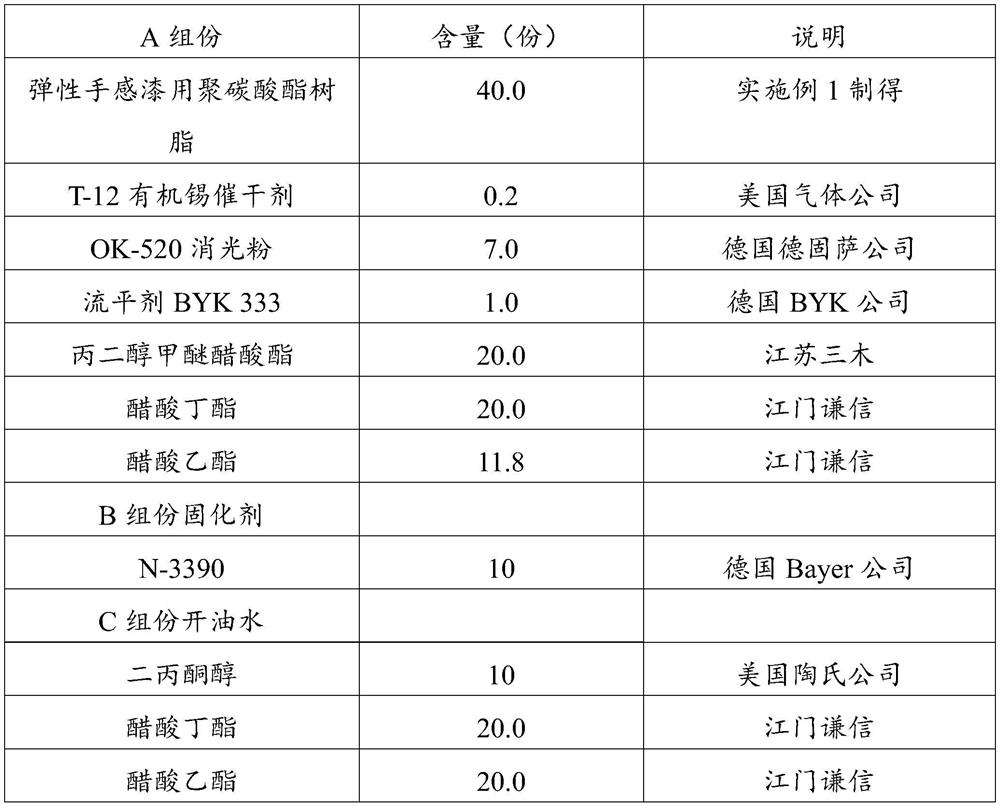

Water-based scratch-resistant matt varnish and preparation method thereof

The invention discloses water-based scratch-resistant matt varnish, which comprises a main agent and a curing agent, wherein the main agent comprises water-based polyurethane, a leveling agent, an antifoaming agent, polysiloxane, a rheological agent and water, and the curing agent comprises isocyanate and methyl methacrylate. The method comprises: stirring waterborne polyurethane, a leveling agent, an antifoaming agent and polysiloxane, and then adding a rheological agent and water to obtain a main agent; and adding a diluted curing agent into the main agent to obtain the water-based scratch-resistant matt varnish. According to the invention, the water-based scratch-resistant matt varnish is prepared from water-based polyurethane, mixed ultra-high molecular weight polysiloxane, water as amain solvent and a water-dispersible isocyanate curing agent; and compared with the existing water-based scratch-resistant matt varnish, the scratch-resistant matt varnish disclosed by the invention is excellent in scratch resistance, good in adhesive force on the surfaces of most base materials and gloss oil and extremely low in the matte degree.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

A kind of quenching oil capable of making automobile leaf springs blacken after quenching and quenching method thereof

ActiveCN105925768BImprove bindingNot easy to fall offFurnace typesMetallic material coating processesAntioxidantBase oil

The invention discloses quenching oil capable of enabling an automobile plate spring to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.4-0.7 parts of blackening composite agent, 0.3-0.5 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.03 parts of antioxidant. The effect is best when the maximum cooling speed of the quenching oil for the plate spring is about 110-120 DEG C / s and the using temperature is 65-70 DEG C. Under the above conditions, the strength and the stiffness of the quenched plate spring are greatly improved, at the same time the effect of the automatic surface blackening can be realized and a protective film formed on the surface is strong in adhesion and good in wear-resisting property. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

Synthesis process for air-drying waterborne polyurethane and dispersion thereof

InactiveCN102633979BAccelerate evaporationWide variety of sourcesPolyurea/polyurethane coatingsCross-linkPolyurethane dispersion

The invention discloses a synthesis process for air-drying waterborne polyurethane and dispersion thereof. The process comprises the following steps: (1) mixing diisocyanate and polymer polyol to react to obtain a polyurethane prepolymer; (2) controlling the temperature to 60-80DEG C, dripping hydrophilic chain extender A and chain extender B into the polyurethane prepolymer; carrying out reflux reaction for 1-5 hours; then adding alkali to form salt; and adding water to disperse and emulsify; and adding catalyst to obtain the air-drying waterborne polyurethane dispersion. The synthesis process is characterized in that dry oil grease structure containing active methylene is introduced in the polyurethane structure to synthesize air-drying waterborne polyurethane dispersion with good self-drying performance and water tolerance. The air-drying waterborne polyurethane dispersion can carry out self cross linking in the air after drying catalyst is added so as to quicken moisture to volatilize, and the drying rate is obviously improved. The air-drying waterborne polyurethane dispersion has the advantages of abundant raw material resource, simple synthesis technology and wide application prospect in the building coating field, is cheap and easy to obtain and is easy for industrial production.

Owner:ANHUI UNIVERSITY

A kind of quenching oil capable of making fasteners self-blackening after quenching and its application method

ActiveCN105969957BImprove quenching effectGood effectFurnace typesMetallic material coating processesAntioxidantSurface-active agents

The invention discloses quenching oil capable of making a fastener become black by itself after quenching and an application method of the quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises, by mass, 35-40 parts of refined base oil, 7-10 parts of composite cooling accelerant, 0.5-0.7 part of a composite blacking agent, 0.4-0.8 part of a brightening agent, 0.5-0.8 part of a surface active agent and 0.02-0.04 part of antioxidant. The composite cooling accelerant is the mixture of polyisobutene, dimethyl naphthalene and mahogany petroleum sulfonate. The composite blacking agent is the mixture of short oil alkyd resin, a coloring agent and a wetting agent. The brightening agent is the mixture of imidazoline oleate and methyl terpene resin. The coloring agent is disperse black 9. The wetting agent is fatty alcohol-polyoxyethylene ether. The surface active agent is span-80. The optimal using temperature of the quenching oil ranges from 70 DEG C to 75 DEG C, the speed for cooling the fastener is moderate, a protection film is formed on the surface in a self-blacking manner during quenching, and efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

Epoxy ester resin water dispersion and method for manufacturing rust-inhibiting primer using the same as foundation

InactiveCN101177518BLow acid valueReduce dosageAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a manufacturing method of an epoxy-ester resin aqueous dispersion and the anti-corrosion primer on the basis of the epoxy-ester resin aqueous dispersion, characterized in that the aqueous dispersion is a self-drying core-shell structured aqueous dispersion emulsion with the epoxy resin as the core and the reactive non-transfer surfactant as the shell; the anti-corrosion primer has the epoxy-ester resin aqueous dispersion emulsion with acid value of 2 to 10 mg KOH / g, solid content ranging from 40 percent to 60 percent as the basic component. The construction performance, self-drying property and the paint film mechanical strength of the produced waterborne anti-corrosion primer are all comparable to the solvent type epoxy resin coating.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Polycarbonate resin for elastic hand feeling paint, preparation method thereof, and elastic hand feeling paint

The invention provides polycarbonate resin for elastic hand feeling paint, which comprises unsaturated double bonds and hydroxyl. The polycarbonate resin for the elastic hand feeling paint contains unsaturated double bonds and hydroxyl groups; compared with the prior art, the polycarbonate resin for the paint with the elastic hand feeling can be subjected to double-bond oxidation self-crosslinkingcuring, and can also be subjected to crosslinking curing with an isocyanate curing agent to form macromolecules, so that the polycarbonate resin for the paint with the elastic hand feeling has dual-curing performance, so that the polycarbonate resin for the paint with the elastic hand feeling has good air-drying performance, softness, hydrolysis resistance, weather resistance and low-temperaturenon-solidification. The invention further provides a preparation method of the polycarbonate resin for the elastic hand feeling paint and the elastic hand feeling paint prepared by taking the polycarbonate resin for the elastic hand feeling paint as a raw material.

Owner:东莞市左镕工实业有限公司

A kind of quenching oil and quenching method capable of making screws self-blackening after quenching

ActiveCN105925770BAchieve mechanical strengthAchieve hardnessFurnace typesMetallic material coating processesAntioxidantFatty alcohol

The invention discloses quenching oil capable of enabling an screw to blacken automatically after quenched and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 6-10 parts of cooling catalyzed composite agent, 0.4-0.6 parts of blackening composite agent, 0.3-0.7 parts of brightening agent, 0.4-0.7 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The cooling catalyzed composite agent is a mixture of dialkyl naphthalene and petroleum sulfonate; the blackening composite agent the mixture of short oil alkyd resin, colouring agent and wetting agent; the brightening agent is the mixture of imidazoline oleate and methyl terpene resin; the surface activating agent is span-80. The colouring agent is disperse black 9; the wetting agent is fatty alcohol-polyoxyethylene ether. The best using temperature of the quenching oil is between 75 DEG C and 80 DEG C. Between 75 DEG C and 80 DEG C, the cooling speed of the quenching oil for the screw is moderate, the surface can be blackened automatically and a protective film can be formed while the quenching, so that the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

A special quenching oil for small modulus gears and its preparation method

ActiveCN105950844BAchieve mechanical strengthImprove quenching effectFurnace typesQuenching agentsAntioxidantBase oil

The invention discloses quenching oil dedicated to small module gears and a preparation method of quenching oil, and belongs to the technical field of metal heat treatment. The quenching oil comprises the following components in parts by mass: 35 to 40 parts of refined base oil, 2 to 3 parts of a cooling compound agent, 0.5 to 0.8 part of a blackening compound agent, 0.3 to 0.7 part of a brightening agent, 0.6 to 0.8 part of a surfactant and 0.04 to 0.06 part of an antioxidant. The quenching oil is specially developed for the small module gears of which the module is 1 mm or below, the optimal utilization temperature is 100 to 110 DEG C, the fluidity of the quenching oil is good in the temperature range, the cooling velocity for the small module gears is moderate, protective films are formed on the surfaces of the gears through automatic blackening during quenching, the secondary coating antirust treatment on the surfaces after heat treatment is reduced, the resources are saved, the procedure is reduced, and the efficiency is improved.

Owner:马鞍山金泉工业介质科技有限公司

Self-drying water-based aluminum powder coating for pvc screen and its preparation method and application

ActiveCN112029357BGood film formingReduce usagePolyurea/polyurethane coatingsPaints with free metalsWaxAluminium powder

The invention discloses a self-drying water-based aluminum powder coating for PVC screens and its preparation method and application, comprising water-based resin, water-based aluminum powder, water-based additives and water, wherein the mass percentage of the water-based resin is 50-60%, and the water-based aluminum powder The mass percentage is 20-25%, and the water-based additive is 5-15%. Further, the water-based additives include water-based dispersants, water-based leveling agents, water-based defoamers, water-based anti-settling agents, and water-based wax pastes. The present invention uses water-based paint instead of oil-based paint, uses water as a solvent, reduces costs, is safe and environmentally friendly, and greatly reduces environmental pollution and the health of construction workers; Resins with a lower film-forming temperature do not need to add additional high-boiling co-solvents, which reduces VOC emissions.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

A kind of special quenching oil for chain chain piece and quenching method thereof

ActiveCN105925769BImprove bindingNot easy to fall offFurnace typesMetallic material coating processesAntioxidantHardness

The invention discloses chain piece specific quenching oil and a quenching method thereof. The invention belongs to the field of metal heat treatment technology. The quenching oil comprises the following components, by weight, 35-40 parts of refined base oil, 7-10 parts of cooling catalyzed composite agent, 0.5-0.7 parts of blackening composite agent, 0.4-0.8 parts of brightening agent, 0.5-0.8 parts of surface activating agent and 0.02-0.04 parts of antioxidant. The effect of is best when the maximum cooling speed of the quenching oil for the chain piece is about 93-102 DEG C / s and the using temperature is 70-80 DEG C. Under the above conditions, the ideal quenching hardness can be obtained, the deformation rate is low, the effect of the automatic surface blackening can be realized, a protective film formed on the surface is strong in adhesion and not easy to fall off, and the effect of the appearance beautification and short-term rust prevention can be realized. Once more surface coating and rust preventing treatment after the heat treatment can be reduced, so that the resources can be saved, the processes can be reduced and the efficiency can be improved.

Owner:马鞍山金泉工业介质科技有限公司

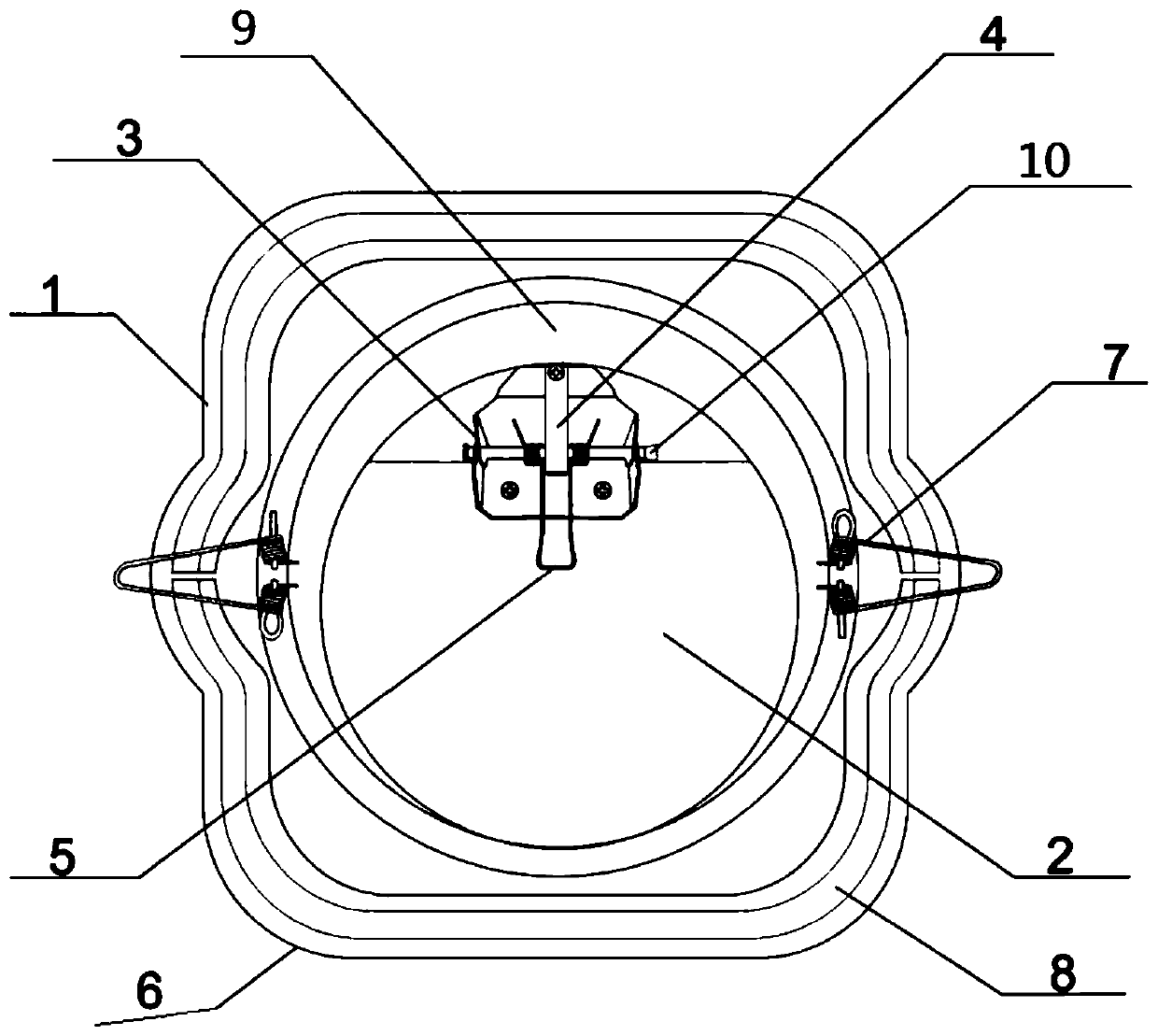

Flue gas discharge subsystem of residential flue gas emission system

The invention provides a glue gas discharge subsystem of a residential flue gas emission system. The flue gas discharge subsystem of the residential flue gas emission system comprises a combined cast-in-place roof preformed hole, a combined connection sleeve and an inertia wind-proof cap. The wind-proof cap is provided with a supporting cylinder with one end located on the roof of a building, a wind-proof cylinder located on the radial outer side of the other end of the supporting cylinder and a wind-proof shield assembly arranged in the wind-proof cylinder. An air duct installation assembly is arranged at the connection position between an exhaust pipeline of the subsystem and the floor slab of the building. The installation assembly comprises a connection sleeve pipe and a connection sleeve plate, wherein the diameters of the two ends of the connection sleeve pipe are identical with the inner diameter of the floor slab preformed hole, the middle portion of the connection sleeve pipeis provided with a square outside and a circular inside, and the connection sleeve plate is provided with a square outside and an circular inside. The inner diameter of the circle of the sleeve platewhich is provided with the square outside and the circular inside is equal to the outer diameter of the connection sleeve pipe.

Owner:徐仁春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com