Patents

Literature

1032results about How to "Low acid value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

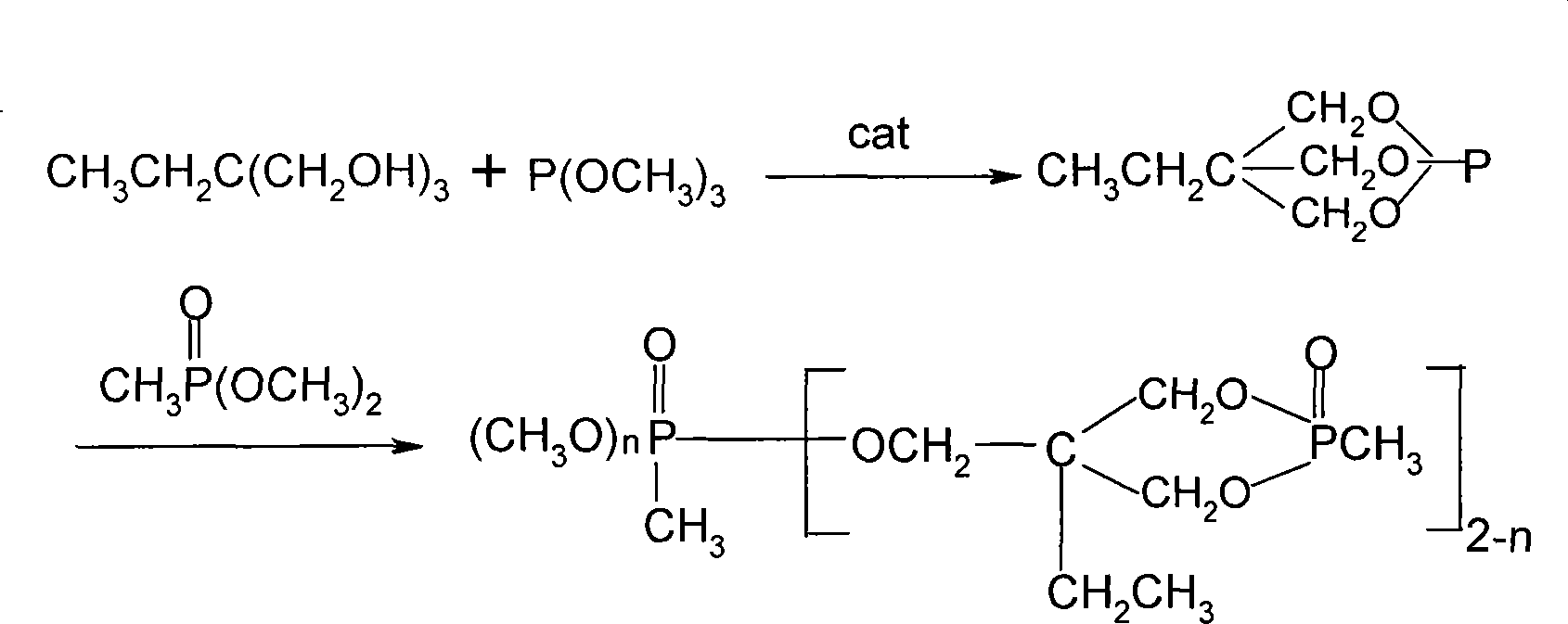

Method for preparing annular phosphonate or annular phosphate flame retardant

InactiveCN101230274AThe preparation method is simple and environmentally friendlyEasy to operateFlame-proof filament manufactureGroup 5/15 element organic compoundsDimethyl methylphosphonateTriethylphosphite

The invention provides a preparation method of annular phosphonate or annular organic phosphate flame retardant. The steps are that (1) trimethylolpropane and trimethyl phosphate or triethyl phosphate are taken as the material, and react to synthesize into midbody under the condition of catalyzer; (2) phosphonate or organic phosphate is added into the midbody and is heated, and then the product of annular phosphonate or annular organic phosphate flame retardant can be obtained. The phosphite ester is selected from trimethyl phosphate and triethyl phosphate. The phosphonate is selected from dimethyl-phosphine and diethyl ethyl phosphine. The organic phosphate is selected from trimethyl phosphate, triethyl phosphate, phosphate propyl, tributyl phosphate and tricresyl aromatic ester. The invention overcomes the shortcomings of the prior art, the new preparation method of annular phosphonate or annular organic phosphate flame retardant is environment-friendly, solution is not needed, and the operation is simple. The termination product has excellent color and luster, low acid value and excellent viscosity; and does not need additional decoloration.

Owner:NANJING NORMAL UNIVERSITY +1

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

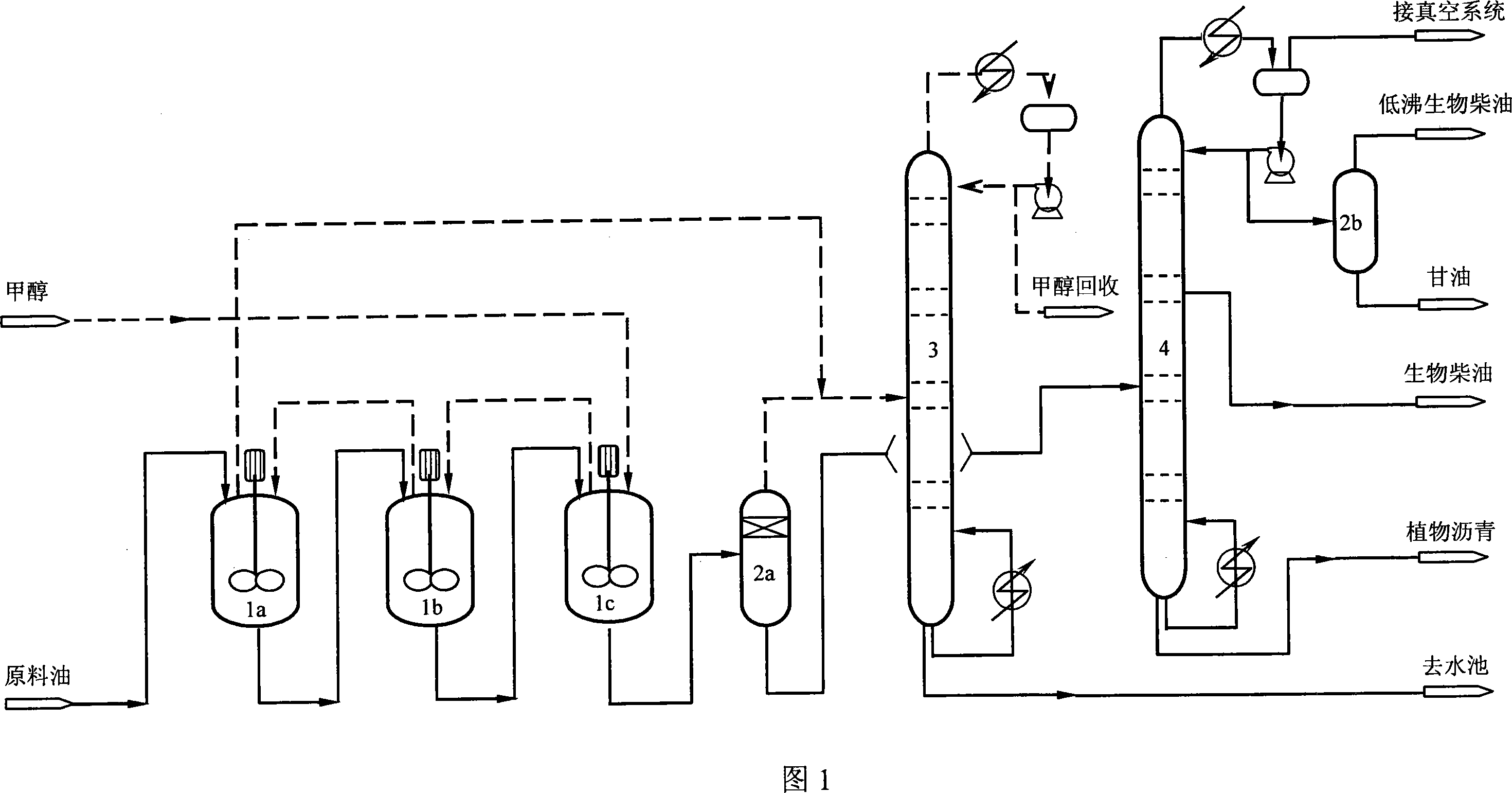

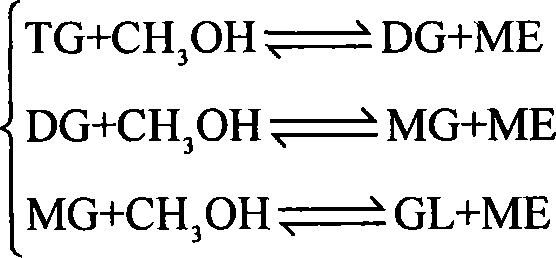

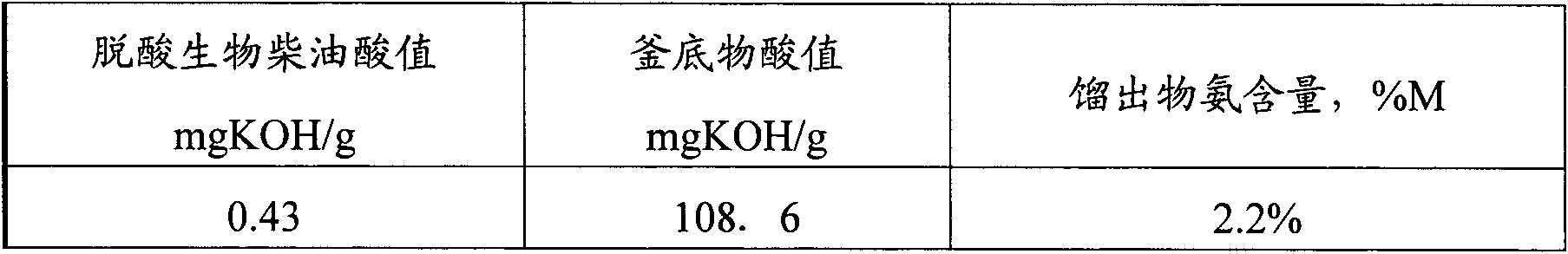

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

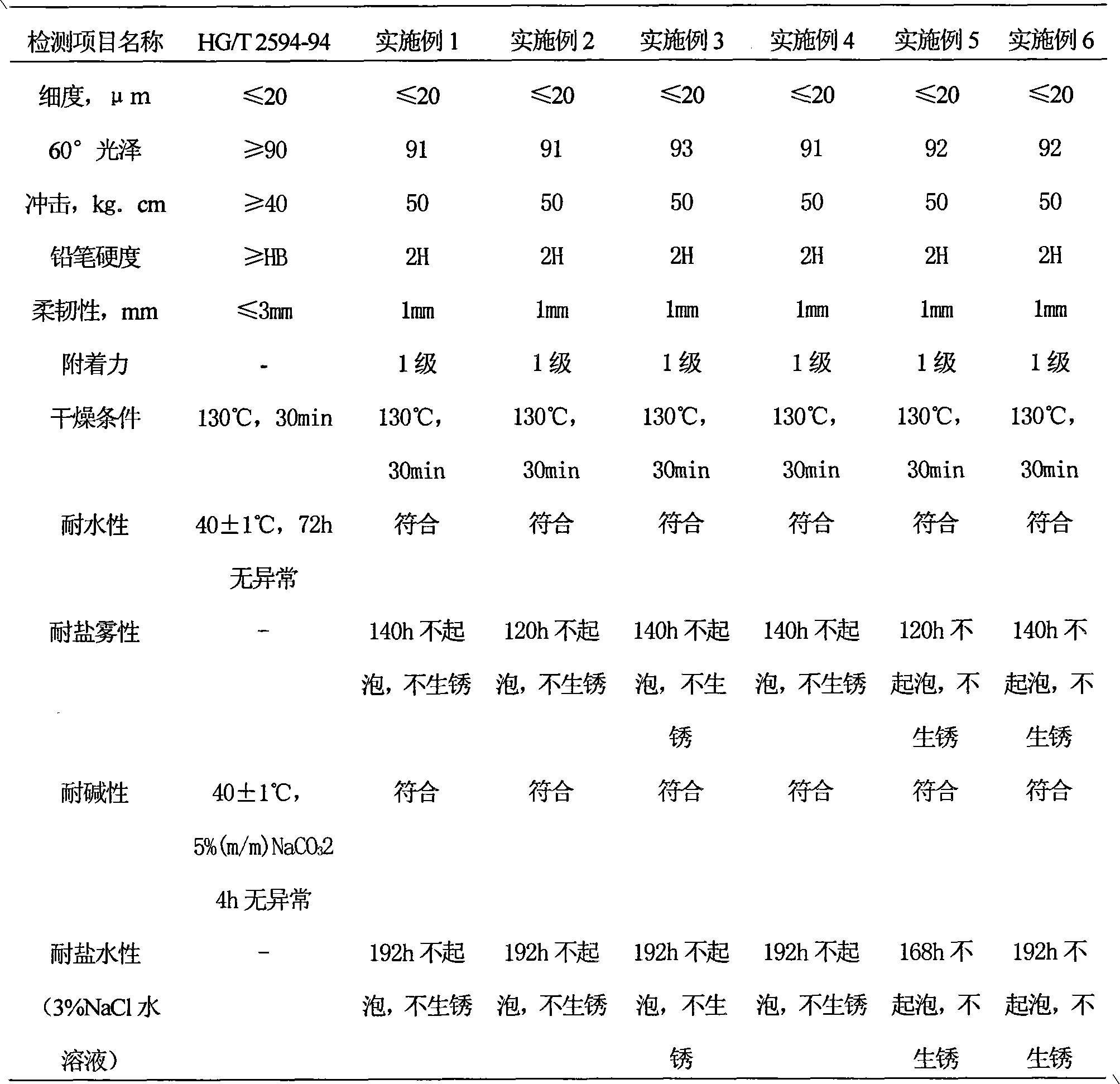

Mono-component aqueous metal baking paint and preparation method thereof

The invention discloses a mono-component aqueous metal baking paint and a preparation method thereof. The mono-component aqueous metal baking paint consists of the following components by weight: 40 to 57 percent of tap water, 28 to 34 percent of aqueous acrylic modified polyester resin, 7 to 8.5 percent of amino resin, 1.12 to 1.36 percent of amine modifier, 0.1 to 0.3 percent of wetting dispersing agent A, 0.1 to 0.3 percent of wetting dispersing agent B, 0.01 to 0.1 percent of defoaming agent, 0.5 to 1.2 percent of thickening agent, and 0.2 to 0.6 percent of levelling agent. The mono-component aqueous metal baking paint uses water as a solvent without adding an alcohol / ether cosolvent so that environmental protection is excellent; because of mono-component, the construction is simple and convenient, and the performance is stable; and a paint film is plumpy, the luster is high, the mechanical property is excellent, and the adhesive force is good. The mono-component aqueous metal baking paint is applicable to metal surface corrosion protection and decoration, and can be used as a finishing paint, a priming paint or a coating varnish; and when used for bottom surface integral coating, the mono-component aqueous metal baking paint still has excellent surface effect and protective action.

Owner:GUANGZHOU JOINTAS CHEM

Method for preparing biodiesel by lowering value of high acid palm oil

InactiveCN101230309AReduce energy consumptionLow acid valueFatty acid esterificationBiofuelsChemistryAcid value

The invention provides a method which uses palm oil to prepare biologic diesel oil and can lower the high acid value. The method uses solid super acids of SO>4<2- > / ZrO2, SO4< 2- > / TiO2, and SO4< 2- > / xZrO<2- yTiO2 as catalyst, and uses low-carbon alcohol as esterifying agent to pre-treat the high acid value palm oil, can effectively lower the acid value of the oil, and can ensure the acid vale of the obtained biologic diesel oil to easily meet the standard (less than 0.8mgKOH / g, ASTM). The catalyst used by the invention has high catalytic activity, and is reusable. The process flow is simple, the production cost is decreased, and the environmental pollution is reduced greatly.

Owner:SICHUAN UNIV

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Method for preparing acrylic aqueous dispersion with hydroxyl through two-step polymerization

The invention provides a method for preparing acrylic aqueous dispersions with hydroxyl through two-step polymerization and the method comprises the synthesis of hydroxy acrylic resin, the removal ofsolvent, the neutralization and salt-formation and the deionized water dispersion, wherein the synthesis of hydroxy acrylic resin adopts two-step feeding synthesis method instead of one-step feeding method in prior art, the composition of the first added monomer mixture is different from that of the second added monomer mixture and preferentially, the weight percent of the second added hydrophilicmonomer is higher than that of the first added monomer when feeding tends to end up. The aqueous dispersions obtained by the technical solution of the invention reduces the dosage of monomer with hydroxyl so as to increase the water resistance of coating which is formed by combining aqueous dispersions and curing agent, reduce the grain size of dispersions, lower the viscosity and increase the stability obviously.

Owner:ZHEJIANG HUANDA PAINT IND GROUP +1

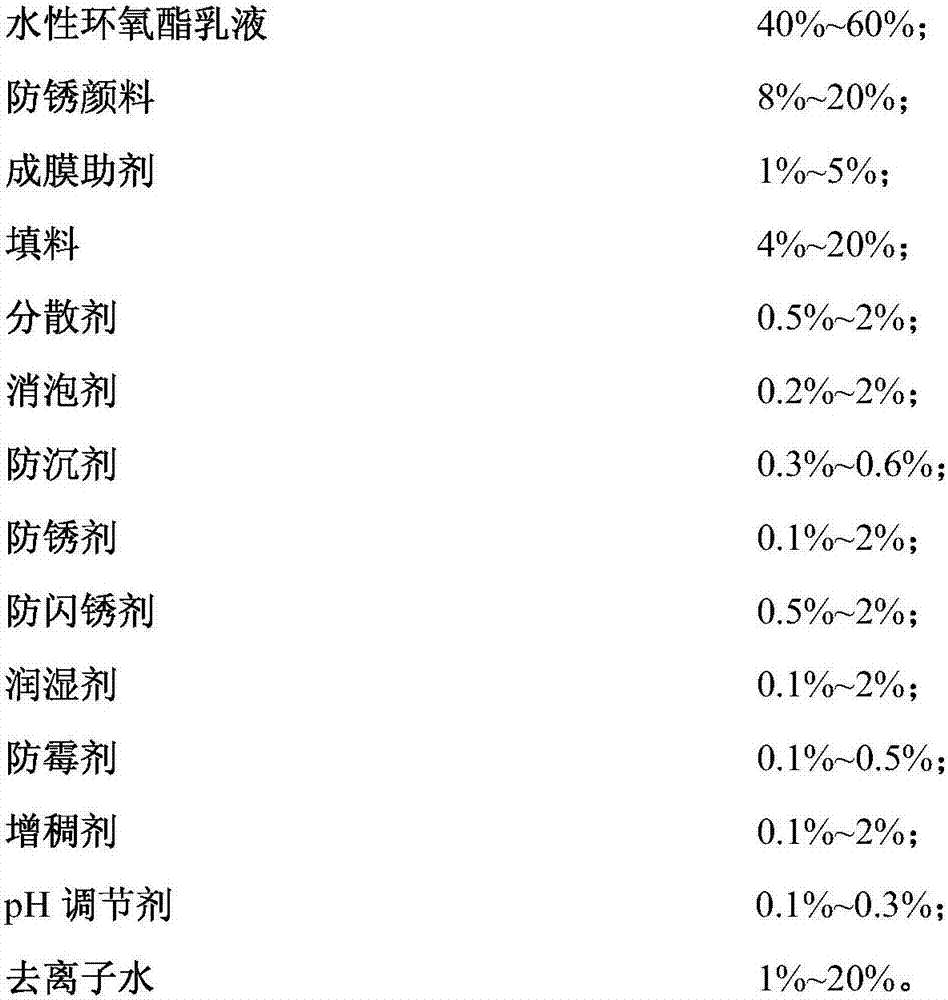

Salt-spray-resistant and anti-aging water-based paint and preparation method thereof

ActiveCN107286798AGood storage stabilityImprove water resistanceAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses salt-spray-resistant and anti-aging water-based paint and a preparation method thereof. The salt-spray-resistant and anti-aging water-based paint is prepared from components in percentage by weight as follows: 40%-60% of a water-based epoxy ester emulsion, 8%-20% of an anti-rust pigment, 1%-5% of a coalescing agent, 4%-20% of filler, 0.5%-2% of a dispersant, 0.5%-2% of a defoaming agent, 0.3%-0.6% of an anti-settling agent, 0.1%-2% of an anti-rust agent, 0.5%-2% of a flash-rust inhibitor, 0.1%-2% of a wetting agent, 0.1%-0.5% of a mildew preventive, 0.1%-2% of a thickening agent, 0.1%-0.3% of a pH conditioning agent and 1%-20% of deionized water. The water-based paint can resist neutral salt spray for 550 H and resist QUV aging for 600 H, has the advantages of high water resistance, good storage stability, contamination resistance, fast drying, safety, environment-friendliness, simple preparation process and the like, is environment-friendly, accords with the environmental protection development trend and is suitable for industrial production.

Owner:HUNAN BANFERT NEW MATERIALS TECH

A kind of preparation method of rice bran oil with low acid value

InactiveCN102295986ALow acid valueSimple processFatty-oils/fats refiningFatty-oils/fats productionAcid valueRice Bran Extract

The invention provides a preparation method of rice bran oil with the low acid value, which comprises the following steps: fresh-keeping the rice bran, extracting the rice bran oil, degumming, de-waxing, decolouring, deacidifying and deodorizing. The invention has the advantages of simple technology and low production cost; since the extracted crude rice bran oil is performed a fresh-keeping treatment, the acid value is relative low. The final finished product rice bran oil treated by the above steps is detected by a method prescribed by GB / T5530-2005, the acid value is between 1.0-3.0 (KOH) (mg / g).

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

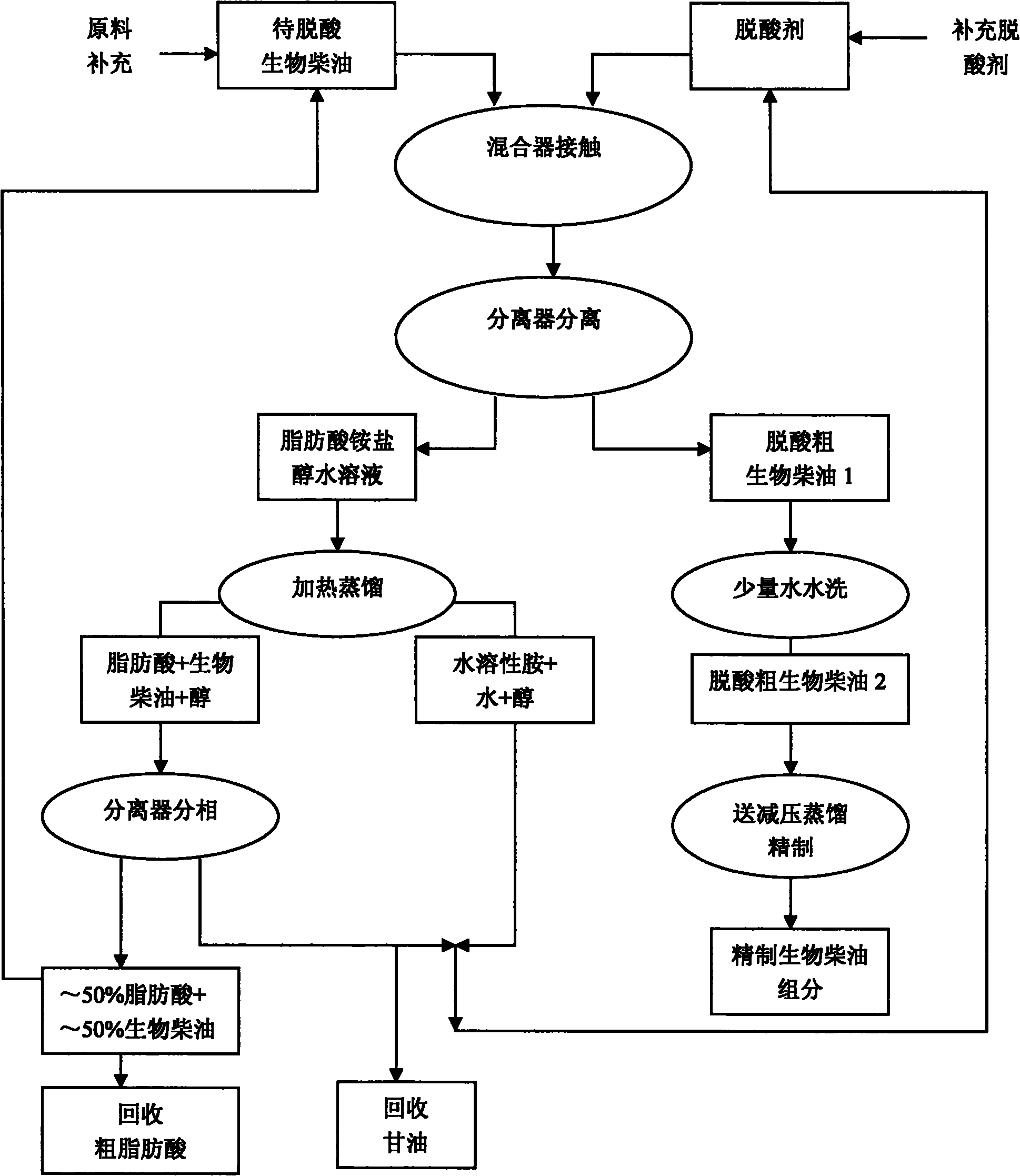

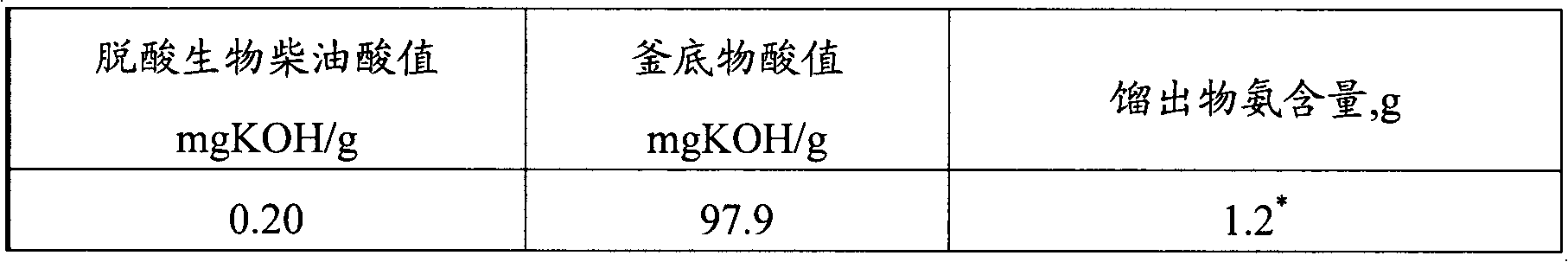

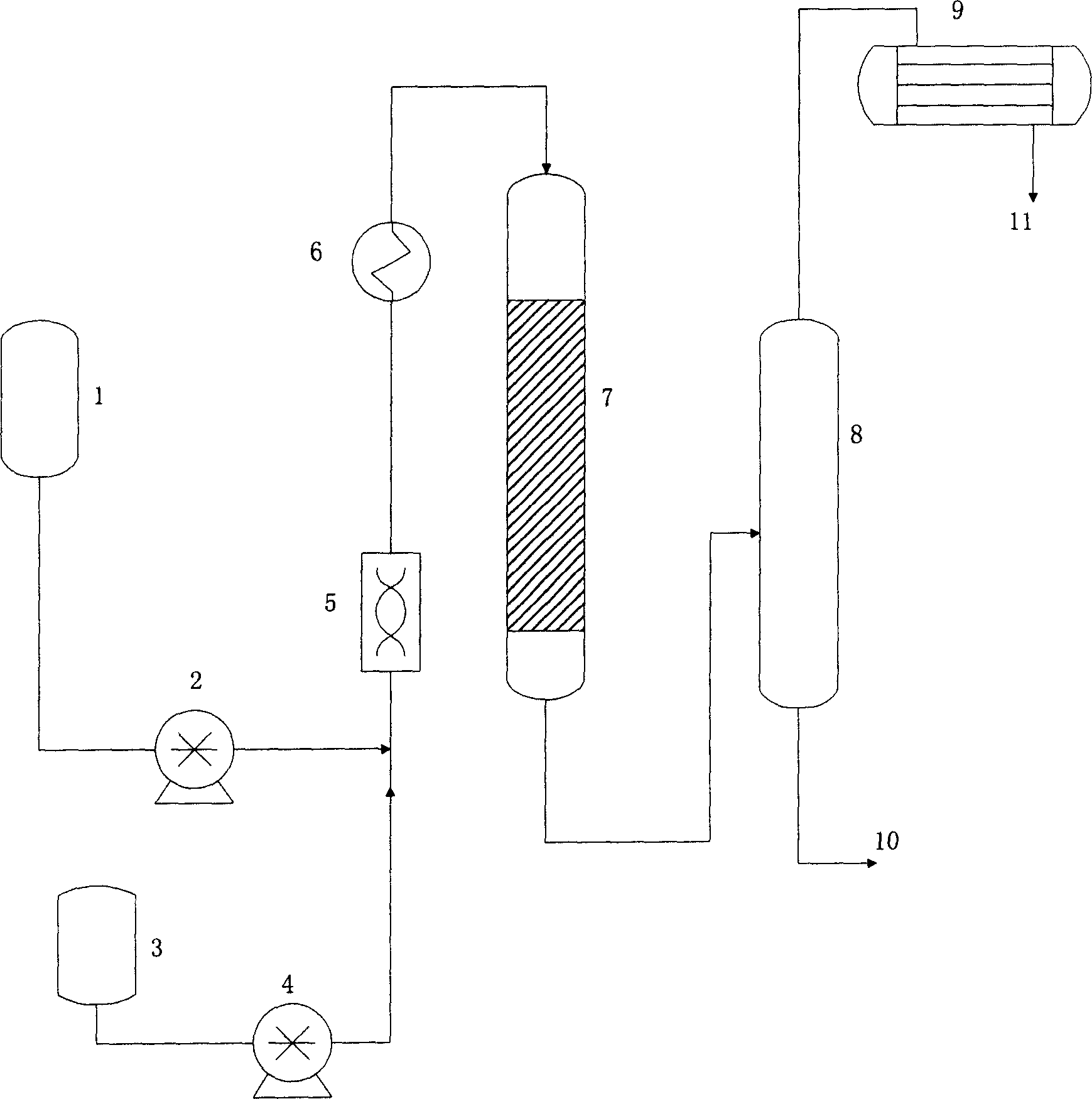

Method for deacidifying biodiesel

ActiveCN101993776AEasy to removeEfficient reuseBiofuelsFatty-oils/fats refiningOrganic acidBiodiesel

The invention provides a method for deacidifying biodiesel, comprising the following steps of: mixing the biodiesel to be deacidified with a deacidification agent containing water-soluble alcohol, water-soluble amine and water, separating out an oil phase and an aqueous phase after layering, and refining the oil phase to obtain the biodiesel with a qualified acid value. The biodiesel to be deacidified can be a biodiesel intermediate with unseparated glycerol after the ester exchange between oil and alcohol, and can also be crude biodiesel which is removed with the glycerol or / and has a product acid value still out of limits after distillation for colloid removal. The method in the invention not only can be used for conveniently removing organic acid in the biodiesel and obviously reducing the acid value of the biodiesel, but also can be used for effectively reusing or recovering the organic acid and glycerol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for esterification deacidification of crude oil and distillate oil and process thereof

The invention discloses a process for lowering acid value of crude oil and distillate oil, which comprises proceeding esterification reaction by menthol with crude oil or naphthenic acid in distillate oil, producing naphthenic acid ester in fixed bed reactor equipped with catalyst, then recovering the non-reacted methanol through distillation. The catalyst comprises carrying agent, which includes aluminium oxide, silica gel, molecular sieve, diatomite and carclazyte, amounting to 20-98 wt% of the catalyst, and active component including Sn or Zn, amounting to 2-40 wt% of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Combination circulation steam turbine lubricating oil composition

ActiveCN101240212AExcellent high temperature oxidation resistanceMeet lubrication needsAdditivesAntioxidantRust

The invention relates to a combined-cycle gas turbine lubricant combination which is suitable to be used in a large-scale gas steam combined-cycle gas turbine, and the composition and content of the combined-cycle gas turbine lubricant combination by weight percentage of antioxidant of 0.1 to 2 percent, anti-wear agent of 0.01 to 1 percent, no gray rust-proof agent of 0.01 to 1 percent, metal deactivating agent of 0.01 to 1 percent, anti-foam agent of 0.001 to 1 percent, the allowance is based oil, which is Class II or Class III paraffin-based oil, and the sulfur content is less than 0.03 percent, the lubricant combination of the invention has an extremely long induction period of oxidation and excellent performance of high temperature oxidation, excellent extreme pressure antifriction property and corrosion, good water separation, air separation and filterability, and can well meet the lubricating demand of large-scale combined cycle gas turbine.

Owner:PETROCHINA CO LTD

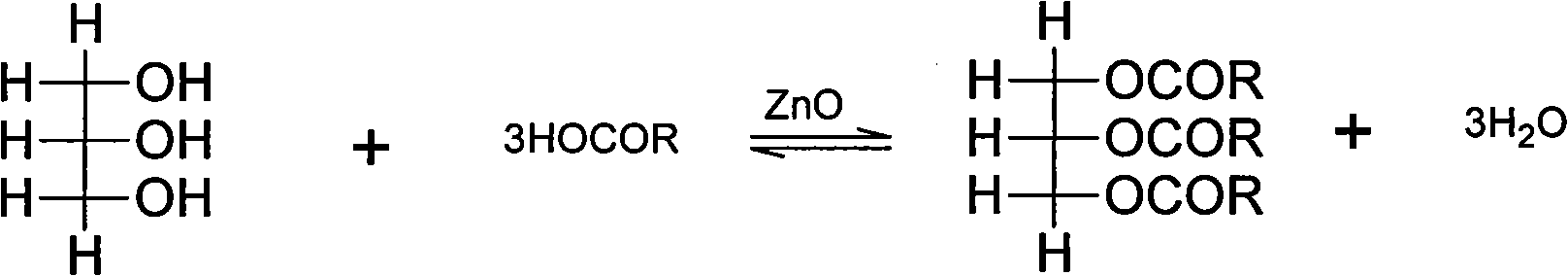

High-acid value rice bran oil esterification depickling process

InactiveCN101319167APromote esterification reactionLow acid valueFatty acid esterificationFatty-oils/fats refiningPre treatmentRice Bran Extract

The invention relates to an esterification deacidification process for high acid number rice bran oil, and the process can well solve the problem of a low refining rate. The esterification deacidification process for high acid number rice bran oil comprises grease pretreatment, namely two steps of degumming and decolorizing. A decolorized substance is obtained after the decolorizing, and then esterification deacidification is carried out. The concrete operating method comprises the following steps of: adding glycerin after the decolorized substance is stirred and heated at a vacuum degree of 0.09 MPa; adding a catalyst of zinc oxide or zinc to carry out a catalytic reaction to generate low acid number rice bran oil with an acid number of 5-7mgKOH / g. The zinc oxide or zinc which is taken as the catalyst of the esterification deacidification of the high acid number bran oil can effectively boost the esterification reaction and rapidly reduce the acid number; simultaneously the process overcomes the problems of the low refining rate lying in a traditional refining method and a great deal of sewage produced by a chemical alkali refining method; the zinc oxide or zinc has a low price, thereby reducing production cost; compared with other chemical esterification catalysts, the zinc oxide or zinc has a very low toxity, thereby being very suitable for the production of edible grease.

Owner:HEFEI UNIV OF TECH

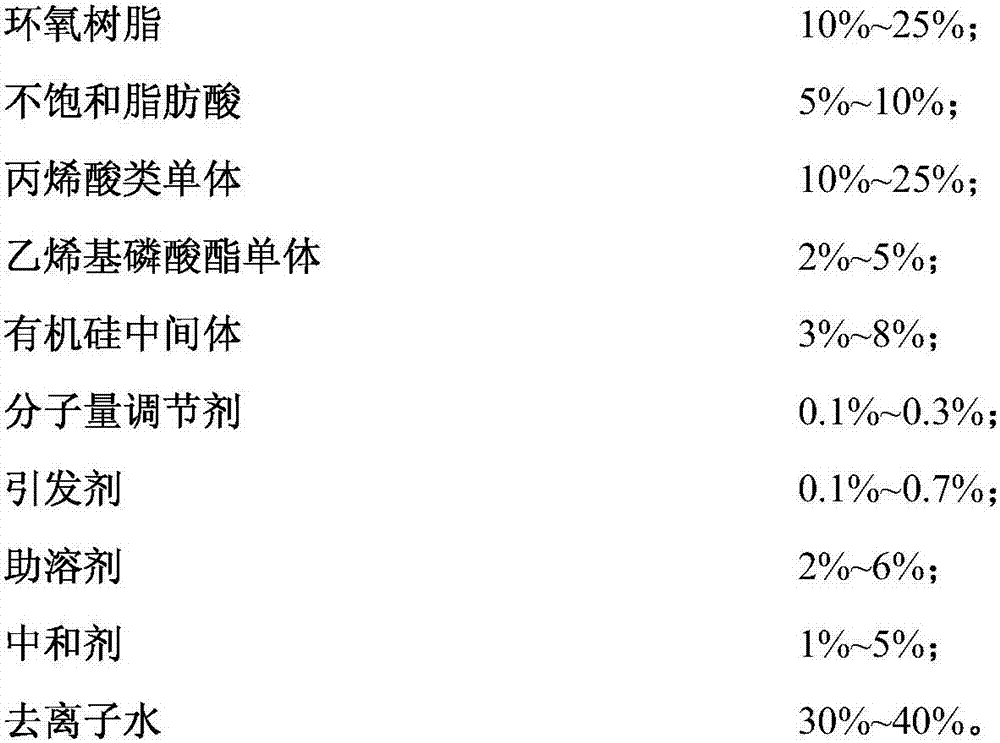

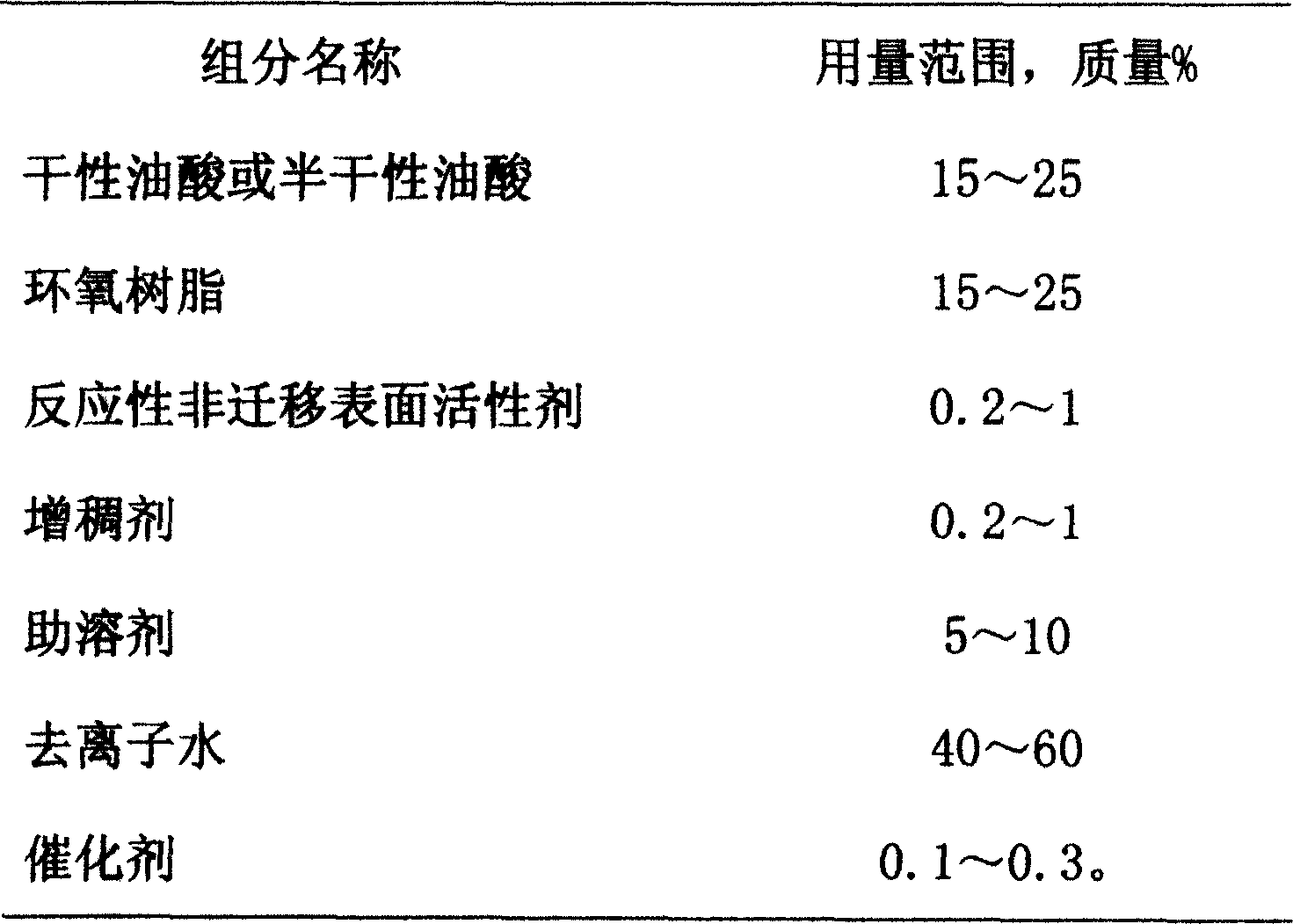

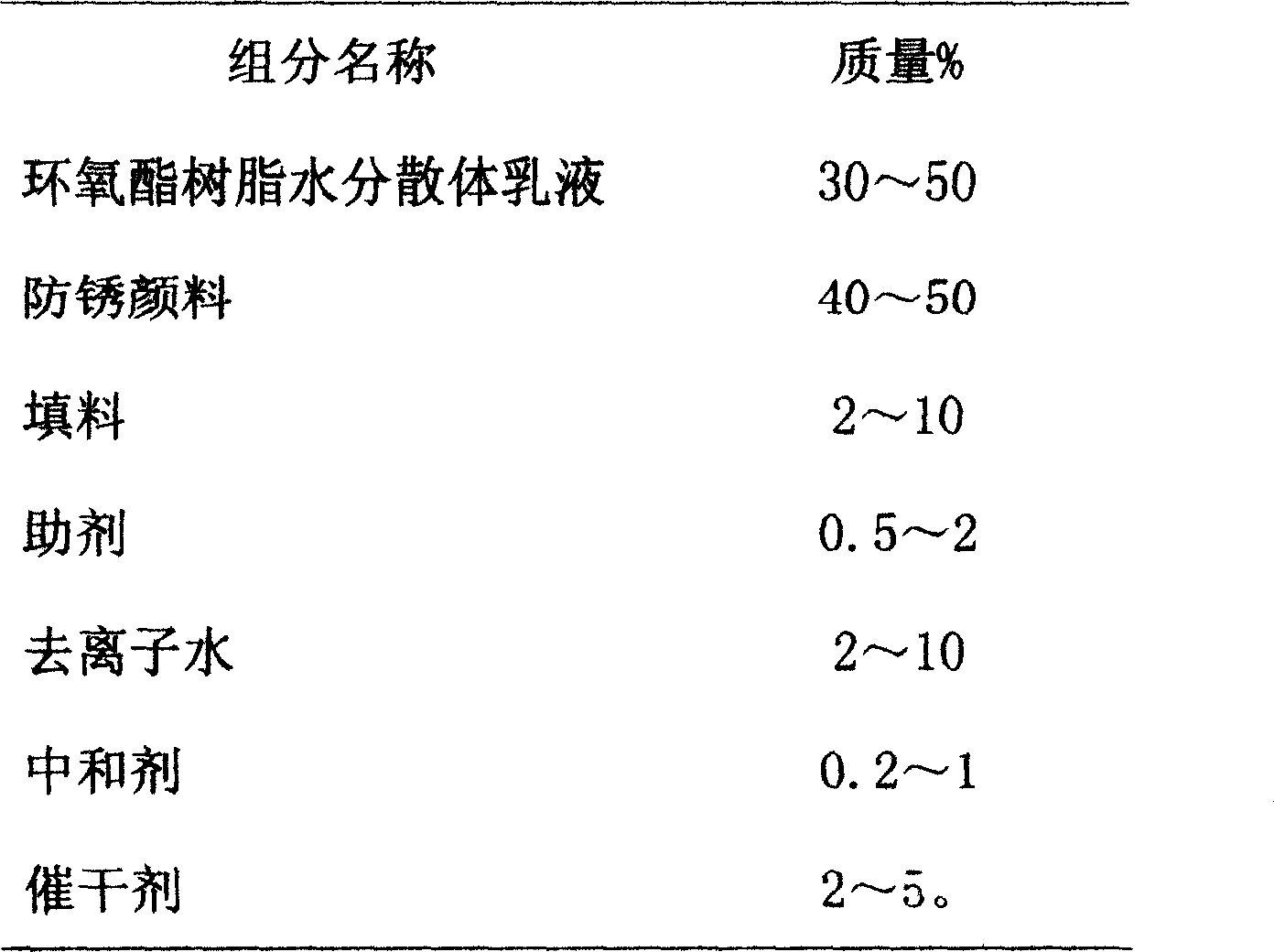

Epoxy ester resin water dispersion and method for manufacturing rust-inhibiting primer using the same as foundation

InactiveCN101177518ALow acid valueReduce dosageAnti-corrosive paintsEpoxy resin coatingsEpoxyResin coating

The invention discloses a manufacturing method of an epoxy-ester resin aqueous dispersion and the anti-corrosion primer on the basis of the epoxy-ester resin aqueous dispersion, characterized in that the aqueous dispersion is a self-drying core-shell structured aqueous dispersion emulsion with the epoxy resin as the core and the reactive non-transfer surfactant as the shell; the anti-corrosion primer has the epoxy-ester resin aqueous dispersion emulsion with acid value of 2 to 10 mg KOH / g, solid content ranging from 40 percent to 60 percent as the basic component. The construction performance, self-drying property and the paint film mechanical strength of the produced waterborne anti-corrosion primer are all comparable to the solvent type epoxy resin coating.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Hydroxy acrylic resin dispersoid and waterborne coating prepared from same

InactiveCN107722186ASimple and fast operationReduce energy consumptionAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

The invention relates to a hydroxy acrylic resin dispersoid and a waterborne coating prepared from the same. Resin is obtained by two-step polymerization, amine is added to perform neutralization, andwater is added to disperse the resin to obtain the stably stored hydroxy acrylic resin dispersoid with a core-shell structure. Two steps include: first, preparing a hydrophobic portion by free radical solution polymerization; second, preparing a hydrophilic portion by free radical solution polymerization. The hydroxy acrylic resin dispersoid has the core-shell layered structure and has the advantages of high solid content, low viscosity and the like. The two-component waterborne acrylic coating prepared by the method can combine the advantages of an acrylic coating and a polyurethane coating,has excellent physical performance, chemical performance and appearance performance, has the advantages of high paint film crosslinking density and hardness, good toughness and chemical medium resistance, high drying speed, capability of drying at room temperature and the like, and is widely applied to priming paint, finishing paint and priming and finishing combined paint of various engineeringmachinery and automobiles.

Owner:CHANGZHOU HUAKE POLYMERS

Nano-size incombustible polyether polyol polymer and its preparing process and application

A nano-size (10-200 nm) incombustible polyether polyol polymer (MPP) is prepared through dispersing or locally grafting tripolycyanamine, cyanoguanidine and formaldehyde on high-activity polyether polyol at 40-160 deg.C for 5-16 hr. Said MPP has viscosity lower than 2300 MPa.s / 25 deg.C and density of 1.120-1.126g / ml, and can be used along with high-activity polyether polyol and assistant to prepare high-resilience foam polyurethane plastics.

Owner:朱吕民

Method for extracting tea seed oil by using enzymatic hydrolysis method

ActiveCN102061217AHigh purityLight colorFatty-oils/fats productionOil and greaseEnzymatic hydrolysis

The invention discloses a method for extracting tea seed oil by using an enzymatic hydrolysis method, which comprises the following steps of: airing, unshelling, husking and pulverizing tea seeds; carrying out enzymolysis on the tea seeds in the material-liquid ratios of 1:3 to 1:5 at the extraction temperature of 40-60 DEG C for 1-5h with the enzyme quantity of 40-600U under the pH natural condition; centrifugally layering; adding an organic solvent into centrifugal liquid and extracting; and rotating and evaporating to obtain an oil sample. By adopting the scheme, the method has the advantages of low temperature for equipment operation, low energy consumption, high purity of extracted oil, low content of phospholipid, low acid value and low peroxide value, shallow color, low BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) values, easiness of treatment and less pollution, and the oil yield ratio is up to 23.1 percent.

Owner:HUAQIAO UNIVERSITY

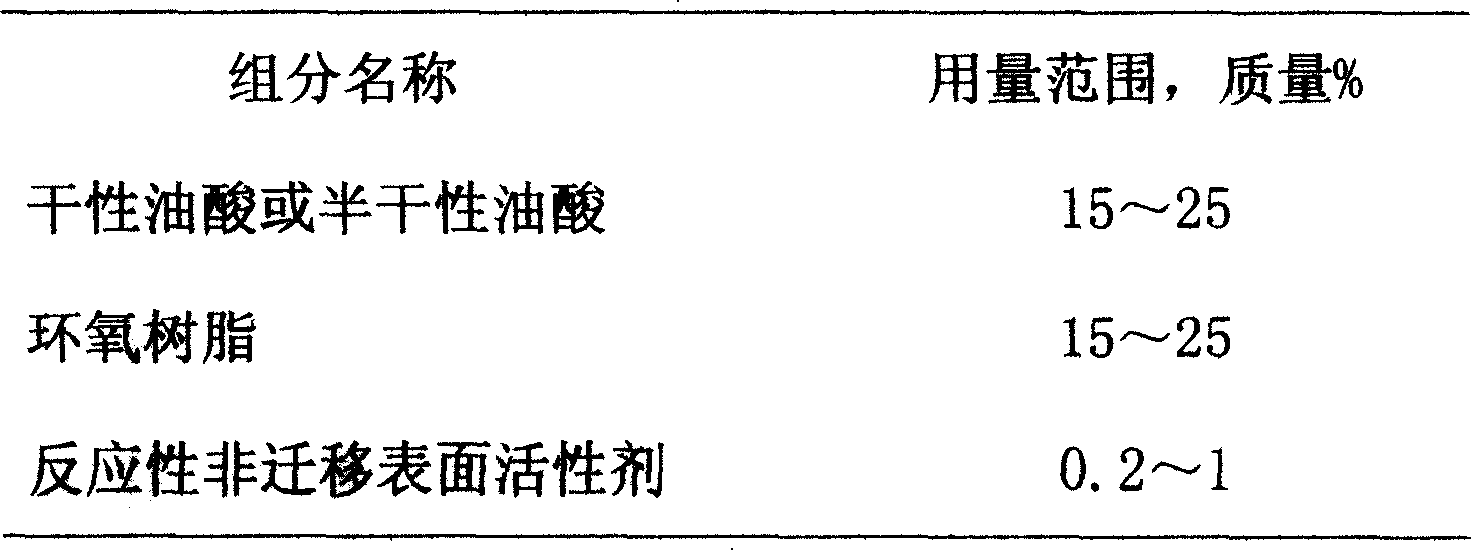

Preparation method of diethyl succinate

InactiveCN101323566AImprove protectionMild control conditionsOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

The invention discloses a preparation method of butane diacid dimethyl ester. The preparation process comprises the following steps of: (1) the rate of raw materials and a catalyst and dosage quality rate thereof is: butane diacid : industrial ethanol : absolute ethyl alcohol : the catalyst is equal to 1 : 0.8 to 1.1 : 0.1 to 0 : 0.01 to 0.02; 1) putting butane diacid, industrial ethyl alcohol of 20 percent of total amount and the catalyst into an esterification kettle and increasing temperature to 120 DEG C; 2) inputting residual industrial ethanol continuously for 8 hours to 9 hours, maintaining the temperature of the kettle at 115 DEG C to 120 DEG C and the temperature of the top of distillation device less than 105 DEG C; 4) sampling to detect acid value and inputting absolute ethyl alcohol when the acid value is 40mgKOH / g to 48mgKOH / g; 5) sampling to detect acid value after an hour and stopping heating when the acid value is 10mgKOH / g to 15mgKOH / g; 6) reducing the temperature to 80 DEG C after ethyl alcohol is withdrawn from the kettle by opening vacuum; 7) separating the catalyst from the materials cooled to 80 DEG C and putting the catalyst into an alkaline washing kettle; 8) inputting alkali solution of proper amount and mixing for 20 minutes to 40 minutes under temperature of 60 DEG C to 70 DEG C; 9) placing stilly for layering and emitting the lower water layer; 10) adding crude product after the alkaline washing into a rectification kettle, raising the temperature to 150 DEG C to 170 DEG C and dehydrating; 11) opening vacuum and collecting distillate of 160 DEG C to 190 DEG C which is the final product.

Owner:SHENZHEN FEIYANG IND CO LTD

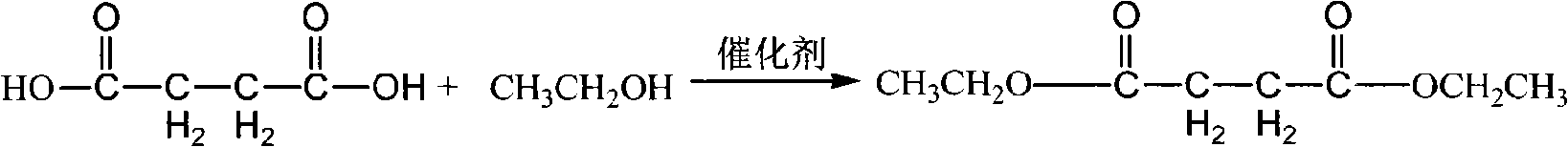

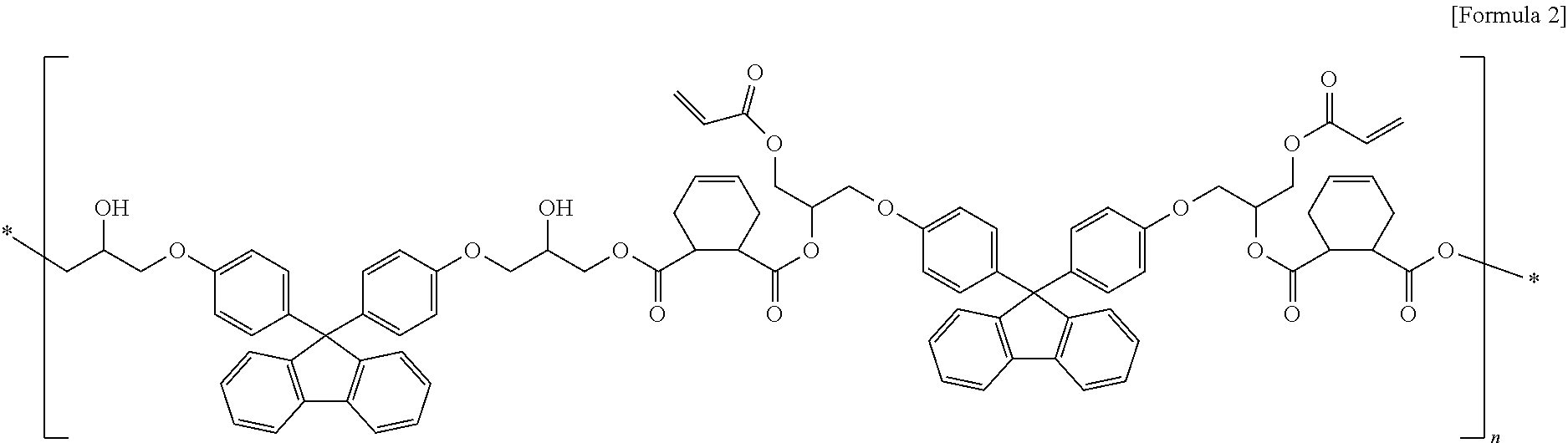

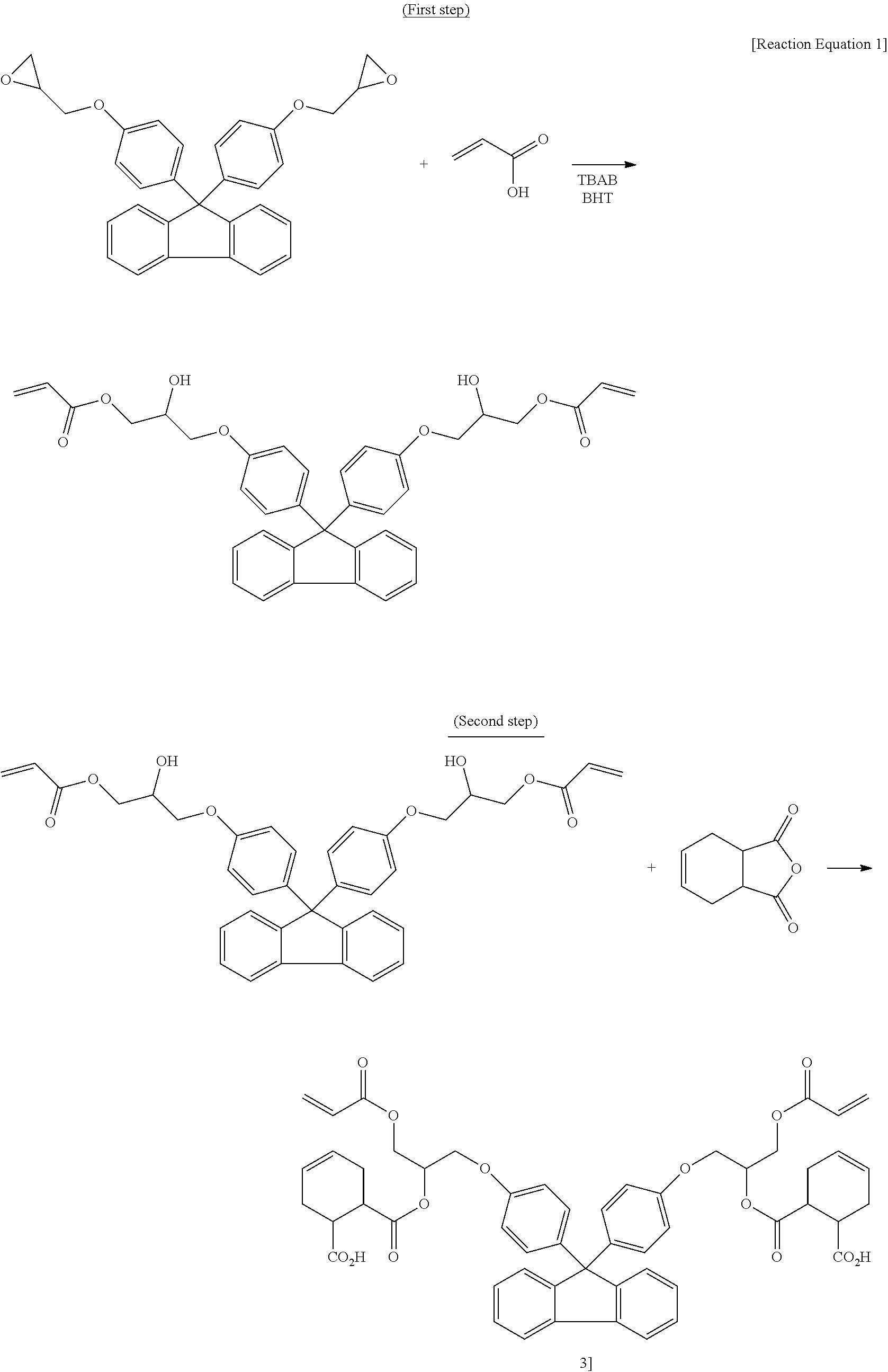

Fluorene-based resin polymer and photo-sensitive resin composition comprising the same

ActiveUS20120196949A1Excellent adhesive propertyGood develop propertyImpression capsPhotomechanical apparatusPolymer chemistryFluorene

The present invention relates to a fluorene-based resin polymer, and a photosensitive resin composition including the same, and the fluorene-based resin polymer according to the exemplary embodiment of the present invention has a high molecular weight, a low acid value, and excellent developing property, adhesive property and stability.

Owner:LG CHEM LTD

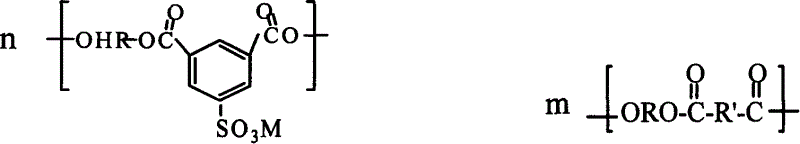

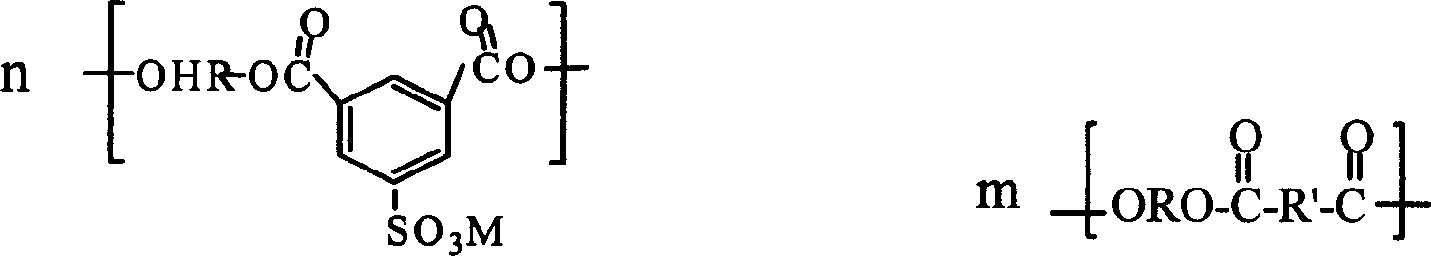

Water dispersible sulfonated polyester polyol and its preparing method

The present invention relates to a kind of water dispersible sulfonated polyester polyol and its preparation process. It is prepared through the ester exchange reaction between dimethyl isophthalate-5-sulfonate and diol to obtain sulfonated diol, and further esterifying dewatering reaction to obtain water dispersible sulfonated polyester polyol. Owing to the homogeneous block distribution of hydrophilic sulfonated groups in main polyester chain, the product has high dispersion in water, may find its wide application in water soluble environment protecting products and may be used directly in water soluble polyurethane paint, adhesive, etc.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Method of extracting DHA and EPA in type of triglyceride from deep-sea fish

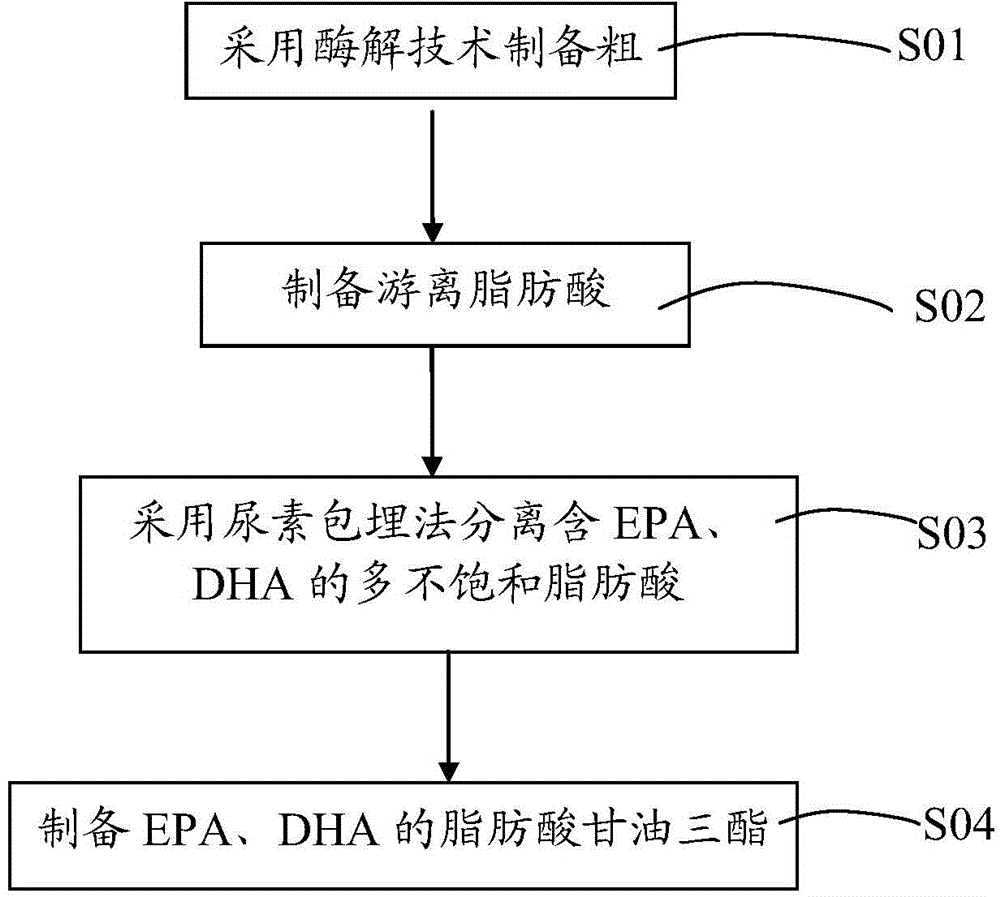

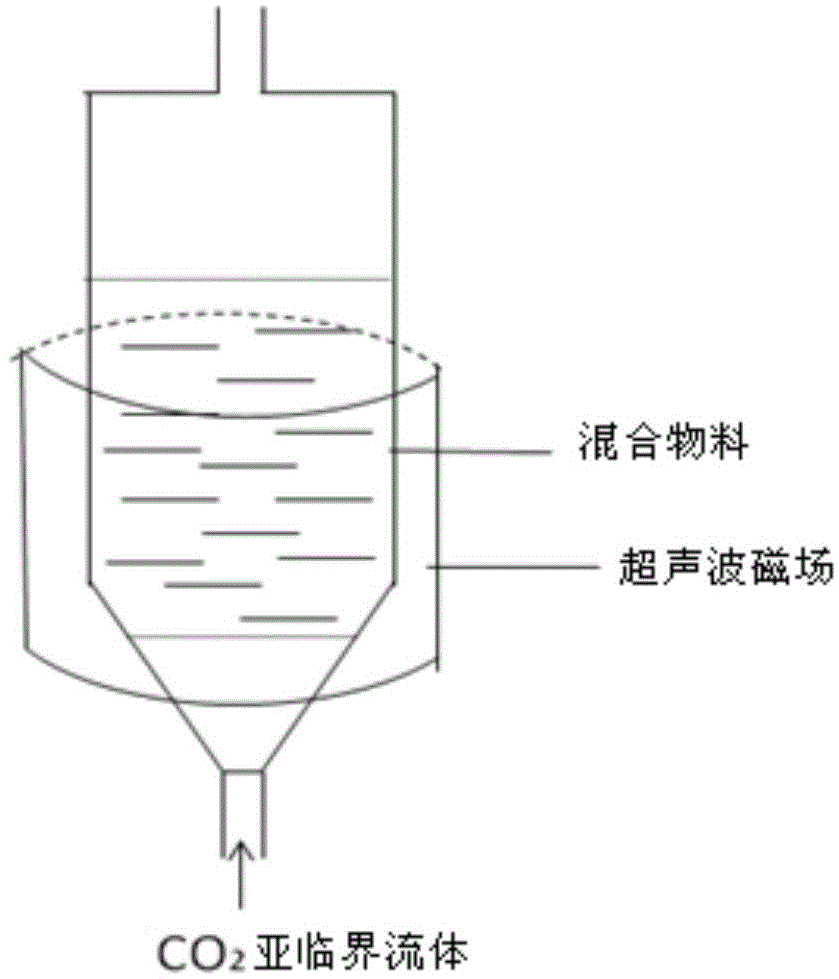

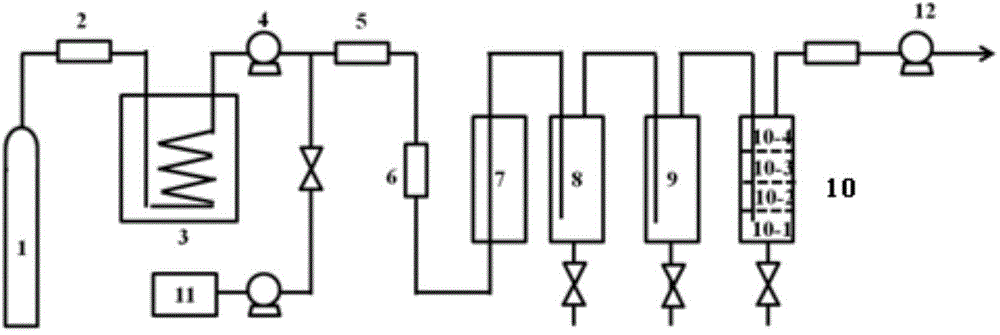

ActiveCN104651422AIncrease contentLow acid valueFermentationBulk chemical productionTriglycerideFish oil

The invention belongs to the technical field of biopharmacy and provides a method of extracting DHA and EPA in the type of triglyceride from deep-sea fish. The method includes steps of: preparing crude fish oil with enzymolysis technology, preparing free fatty acid, separating poly-unsaturated fatty acids containing the EPA and the DHA through a urea-embedding method, and preparing the fatty acid triglyceride of the DHA and the EPA. The method can effectively extract and enrich the DNA and the EPA from the deep-sea fish. The obtained crude fish oil is low in acidic value and is high in hydrolysis degree of esterified fatty acids. The finally products of the DHA and the EPA are in the type of triglyceride with the contents of the DHA and the EPA are in the type of triglyceride being high.

Owner:SHENZHEN HAIYOUKANG BIOTECH CO LTD

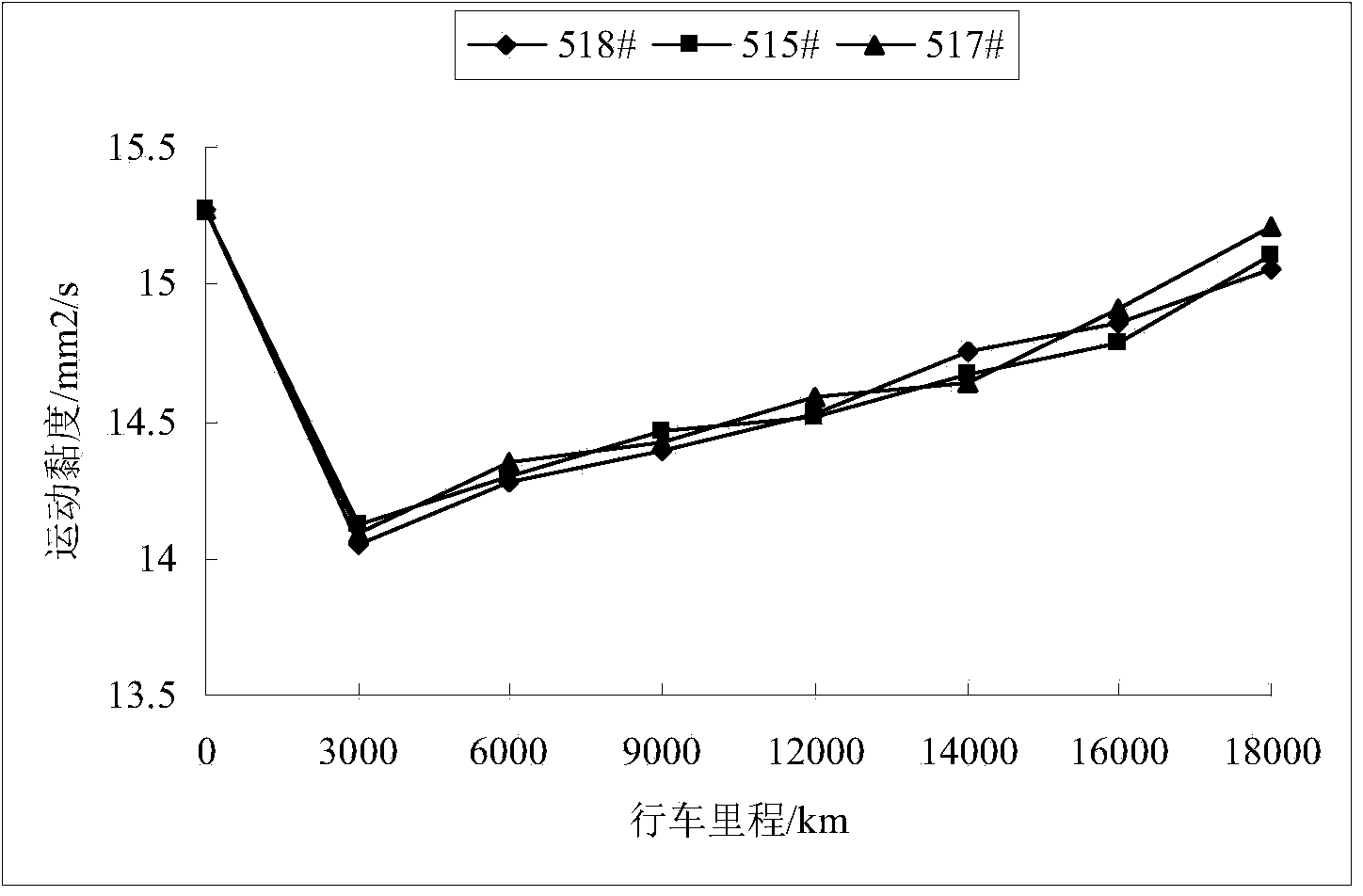

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

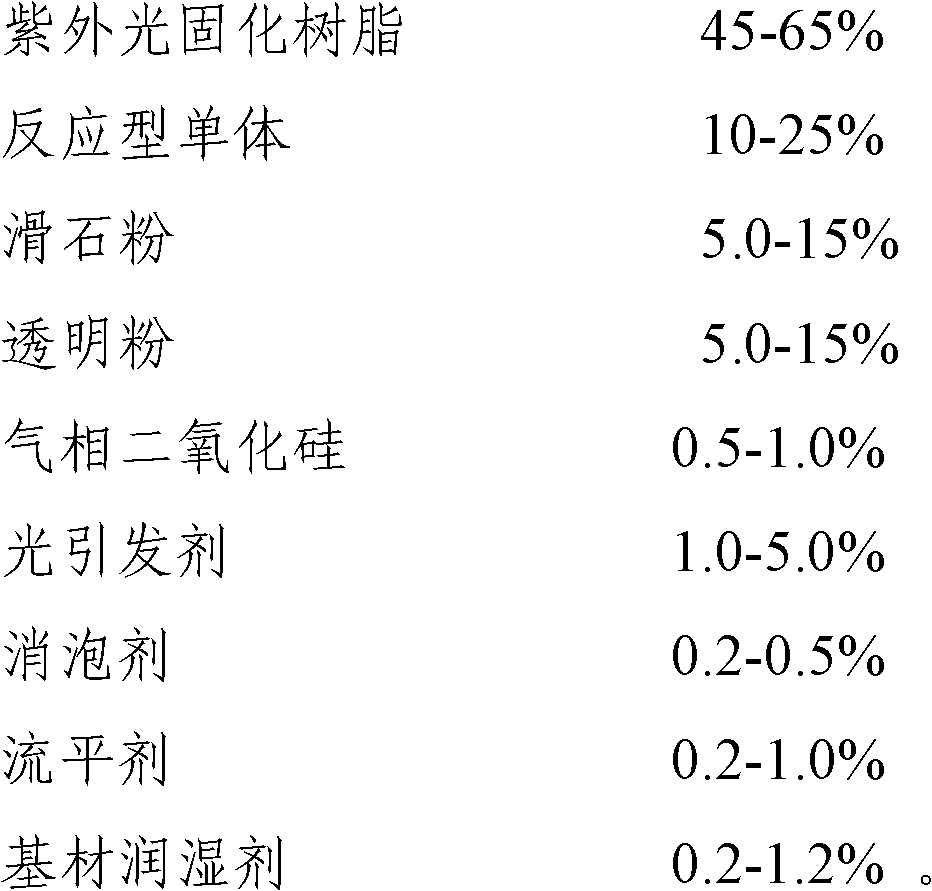

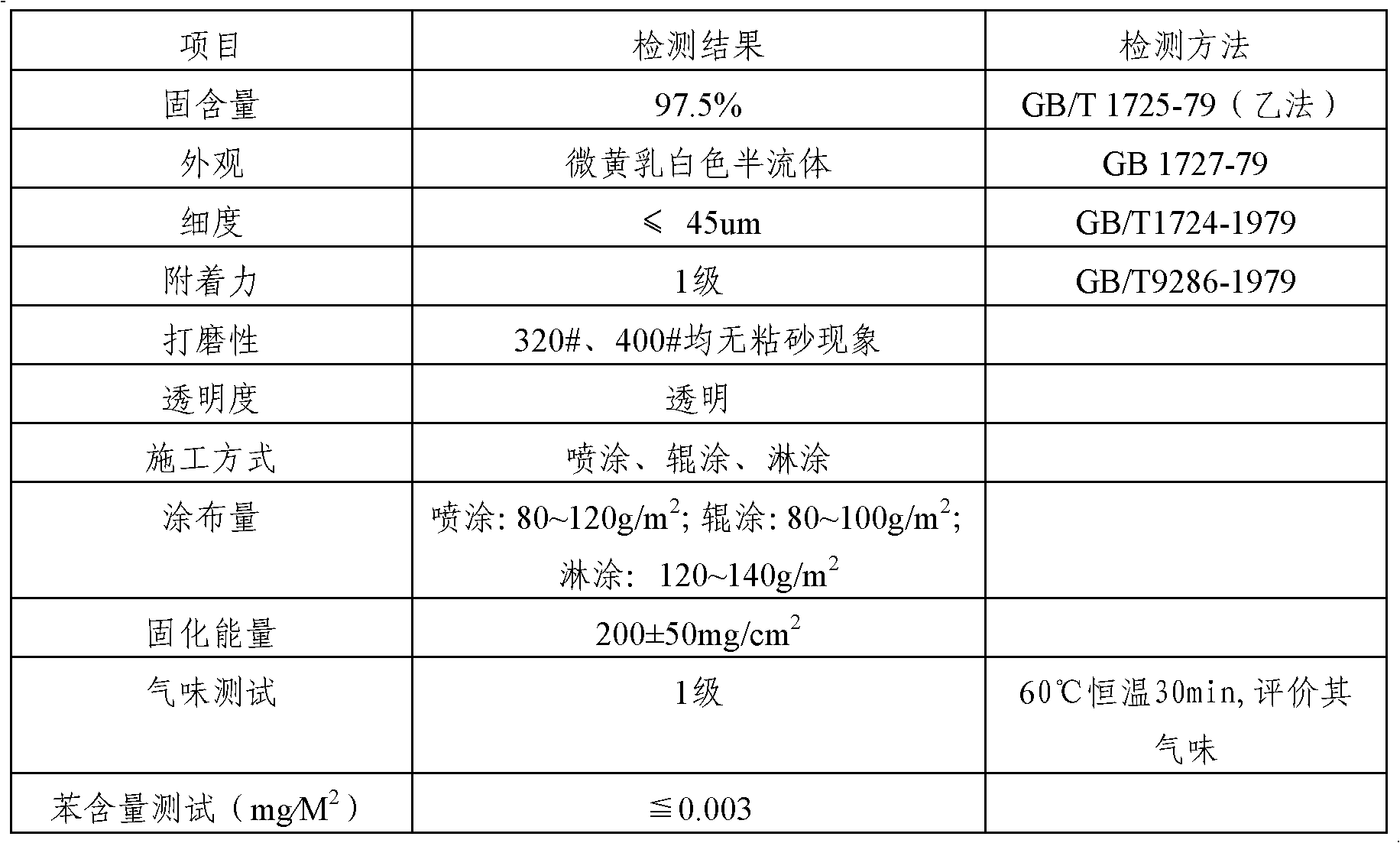

Odorless ultraviolet-curing wood lacquer and preparation method thereof

ActiveCN102352173AEnvironmental protection is goodReduce heavy metal contentEpoxy resin coatingsPolyesterBenzene

The invention relates to an odorless ultraviolet-curing wood lacquer and a preparation method thereof. The wood lacquer is prepared from the following components in percentage by weight: 45-65% of ultraviolet-curing resin, 10-25% of reactive monomer, 5.0-15% of talcum powder, 5.0-15% of transparent powder, 0.5-1.0% of gas-phase silicon dioxide, 1.0-5.0% of photoinitiator, 0.2-0.5% of defoaming agent, 0.2-1.0% of leveling agent and 0.2-1.2% of wetting agent. The odorless ultraviolet-curing wood lacquer does not have irritating odor before and after construction, does not contain benzene, and can be used immediately after construction; and meanwhile, the surface effect and fullness are not inferior to those of nitrocellulose dope, unsaturated paint or polyester paint.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

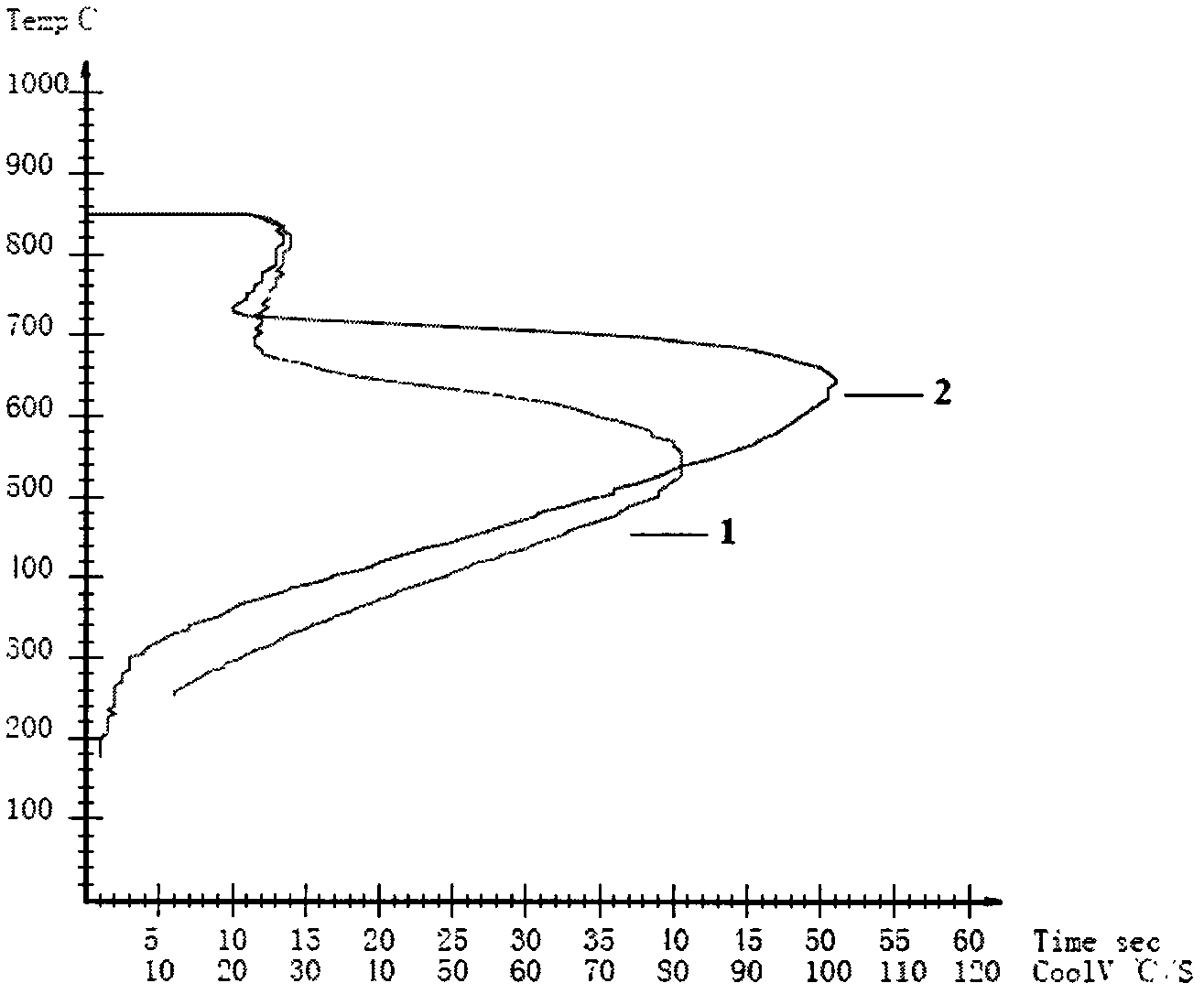

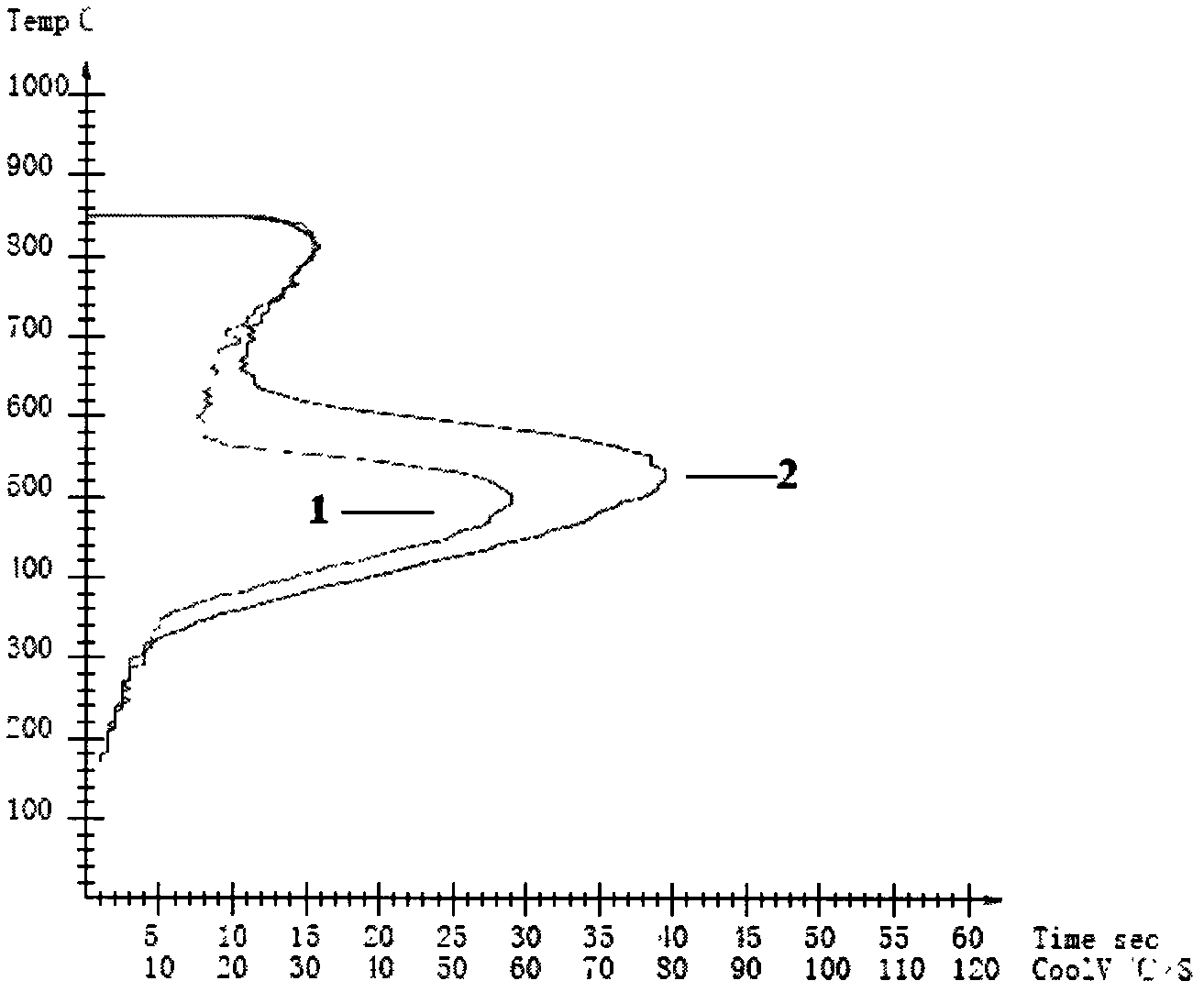

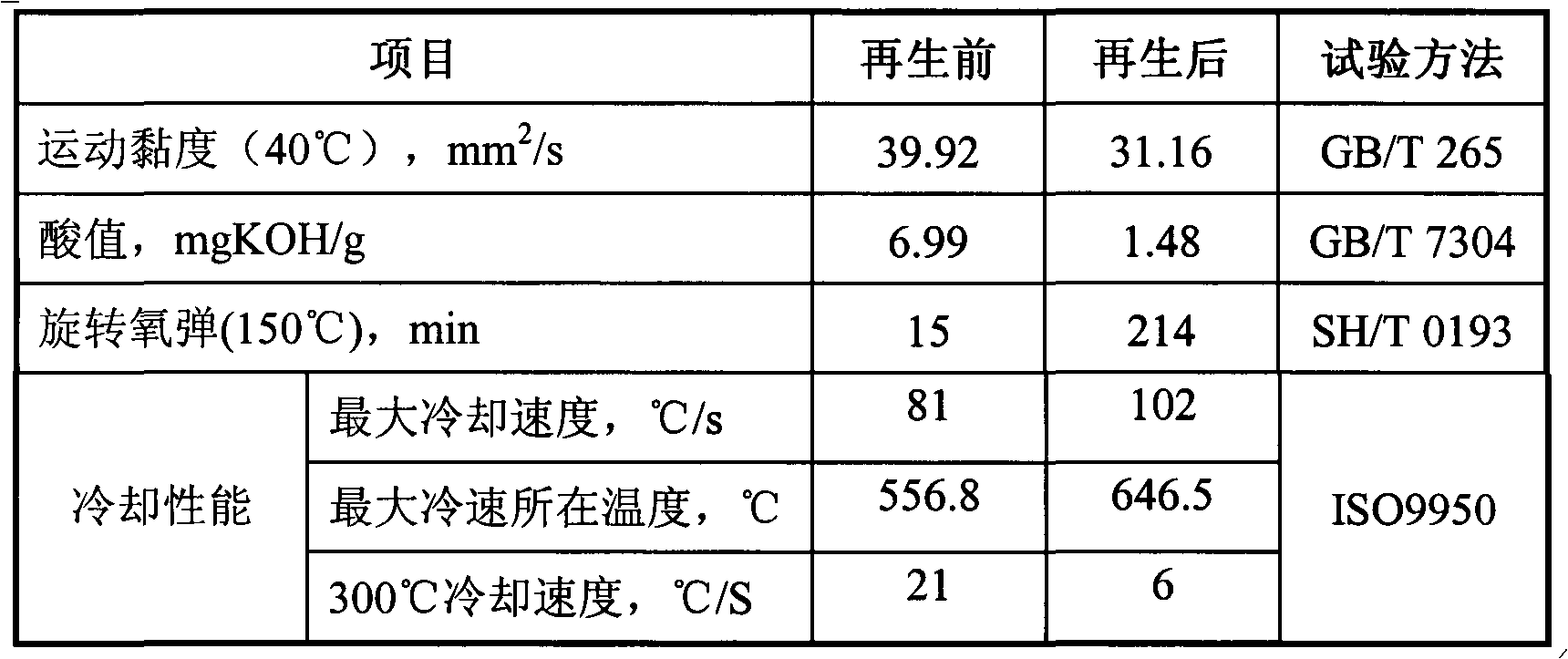

Quenching oil regeneration method

ActiveCN102978356ALow acid valueSpeed up the aging processQuenching agentsAlkaline earth metalFiltration

The invention relates to a quenching oil regeneration method. The quenching oil regeneration method mainly solves the technical problem that the existing regeneration method needs complicated additional treatment units, and has complicated processes and a high cost. The method comprises the processes of 1, sedimentation or filtration, 2, acid value reduction, 3, adsorption, 4, dehydration, and 5, function adjustment, wherein at least one used acid value-reducing agent is selected from oxides, hydroxides and carbonates of alkali metals and alkaline-earth metals and the weight of the at least one used acid value-reducing agent is 0.5-3.0wt% of the weight of quenching oil to be treated. The quenching oil regeneration method solves the existing problem and can be used for industrial production of the regeneration of quenching oil.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing SIPE from SIPA by direct esterification method

ActiveCN101265218ALow costEliminate environmental concernsSulfonic acid preparationPolyesterAcid value

The invention discloses a method of preparing m-phthalic acid diglycol ester-5-sulphonate by directly esterifying m-phthalic acid-5-sulphonate. The m-phthalic acid-5-sulphonate (SIPA) and glycol (EG) are used as raw material and are directly esterified to prepare the m-phthalic acid diglycol ester-5-sulphonate (SIPE); the esterification rate is more than 99 percent, the acid value is less than 1(mgKOH / g), and the content of diglycol (DEGA) is less than 2.0 percent. Therefore, the m-phthalic acid diglycol ester-5-sulphonate (SIPE) which is manufactured by adopting the method is almost esterified completely; the disadvantages of high equipment investment, high recovery cost of methanol, and going against environment protection are elminated when the m-phthalic acid diglycol ester-5-sulphonate (SIPE) is prepared by using dimethyl-m-phthalate-5-sulphonate (SIPM) through an interesterification method; the m-phthalic acid diglycol ester-5-sulphonate (SIPE) has the characteristics of low acid value, high purity, less byproducts, etc.; the m-phthalic acid diglycol ester-5-sulphonate (SIPE) is used as a dye modifier or a third monomer and is added in polyester, so that the mass-producing demand is achieved; the method is a preparation method with stable way and excellent quality.

Owner:厦门翔鹭化纤股份有限公司

Technological process of preparing biological diesel oil with vegetable oil niger

InactiveCN1931961AFatty acid content decreasedImprove efficiencyBiofuelsLiquid hydrocarbon mixture productionSide productGlycerol

The present invention is technological process of preparing biological diesel oil with vegetable oil niger, and features that vegetable oil niger is prepared into biological diesel oil through acidifying with 50 % concentration sulfuric acid solution to obtain acidified oil, adding methanol to react and separating out esterified resultant, adding 20 % concentration methanol solution to obtain crude methyl fatty ester product, molecular distilling the crude methyl fatty ester product to obtain light methyl fatty ester component as the biological diesel oil product with purity up to 95 %. The present invention adopts twice esterification to convert high acid value oil into methyl fatty ester and molecular distilling to refine, and has raised reaction efficiency, short reaction time, product purity over 98 %, recovery of side product glycerin and low technological cost.

Owner:HEFEI UNIV OF TECH

Method for preparing low acid-value fatty acid methyl ester

ActiveCN102153465AHigh reactivityShort reaction timeOrganic compound preparationCarboxylic acid esters preparationDistillationSolid acid

The invention relates to a method for synthesizing low acid-value fatty acid methyl ester by esterification reaction and aims at providing the method with the characteristics that a process is simple; a catalyst and a product are easy to separate and can be recycled; the reaction conversion rate is high; and the obtained fatty acid methyl ester has low acid value. The method for preparing the lowacid-value fatty acid methyl ester sequentially comprises the following steps of: 1, feeding fatty acid and a resin catalyst together or feeding the fatty acid and a solid acid catalyst together, andthen heating the mixture with stirring; 2, after a temperature of a reaction system is raised to 50 to 80 DEG C, dropwise adding methanol into the reaction system, distilling the methanol and water generated in the reaction process, sampling and monitoring the reaction conversion rate in the reaction process and finishing the reaction until the acid value reaches below 0.5mgKOH / g, wherein the pressure of the reaction system is in the range of 10 to 101Kpa and the reaction time is in the range of 4 to 6 hours; and 3, after finishing the reaction, filtering out the catalyst, carrying out reduced pressure distillation on filtrate to separate out excessive methanol and water to obtain a finished product and directly recycling the resin catalyst or the solid acid catalyst.

Owner:ZANYU TECH GRP CO LTD

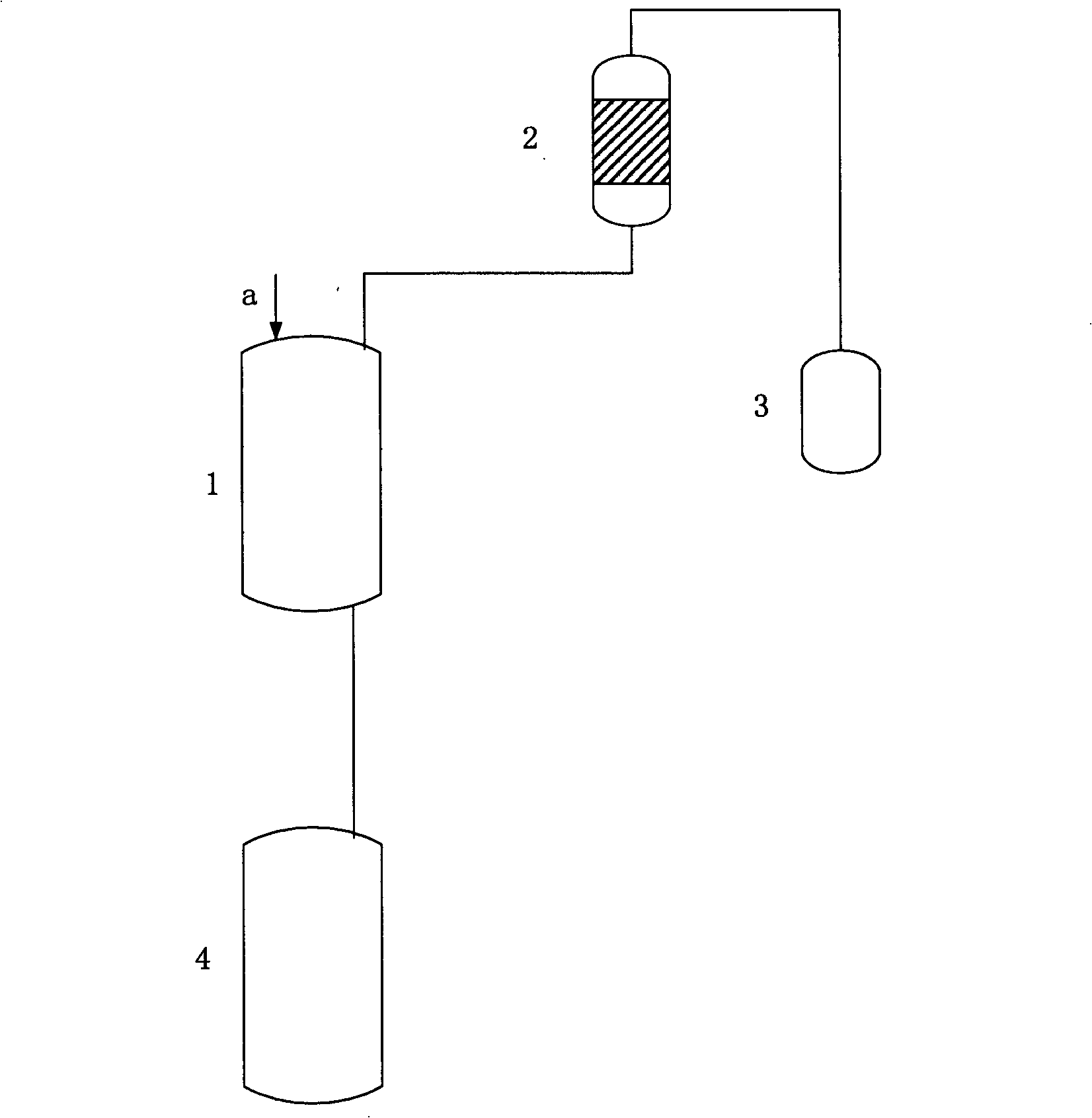

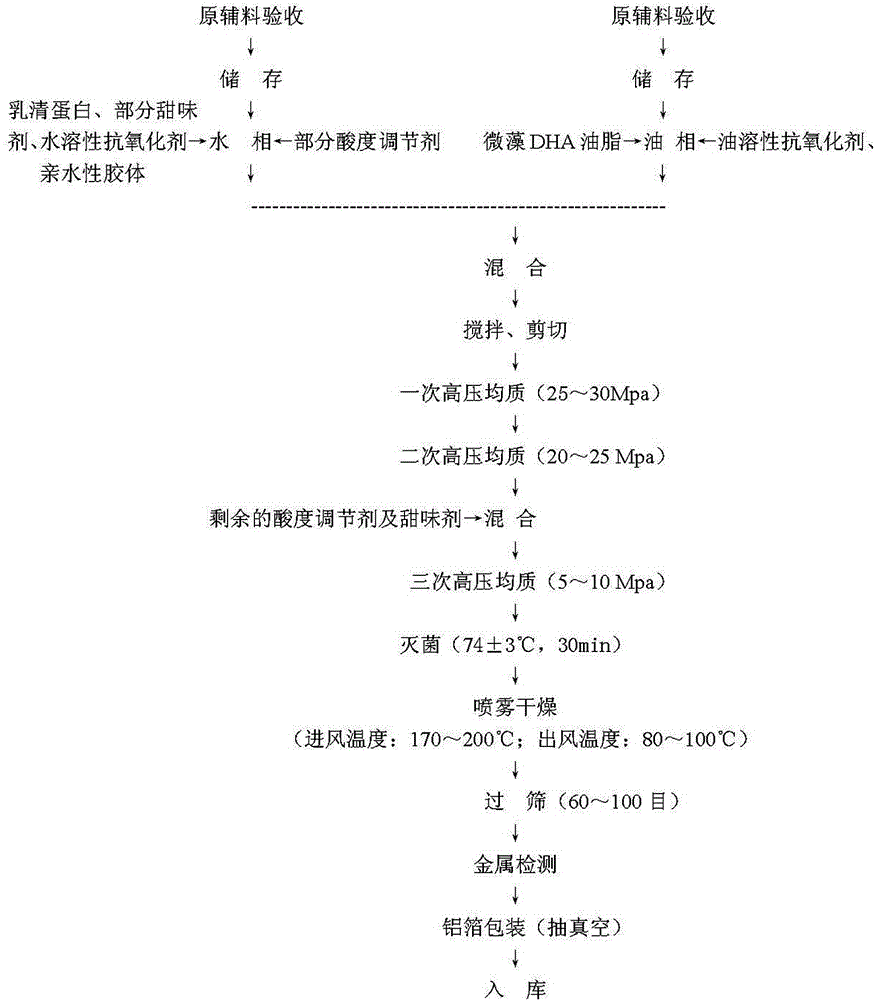

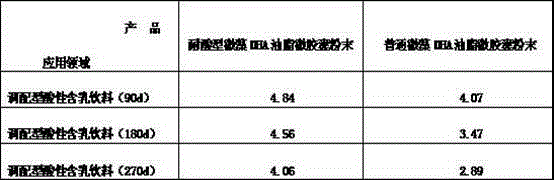

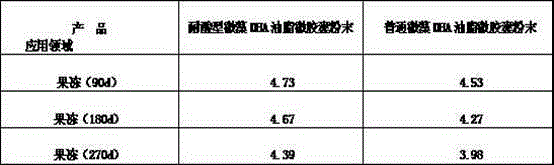

Acid-proof type microalgae DHA oil microcapsule powder and preparation method thereof

ActiveCN104432059AImprove stabilityNo flocculationSugar food ingredientsFood shapingBiotechnologyAcid water

The invention relates to an acid-proof type microalgae DHA oil microcapsule powder and a preparation method thereof. The acid-proof type microalgae DHA oil microcapsule powder is prepared from 12.6%-30.3% of core materials and 69.7%-87.4% of wall materials, concretely comprising the following active ingredients in percentage by weight: 12.5%-30.0% of microalgae DHA oil, 0.1%-0.3% of antioxidant, 25.0%-50.0% of whey protein, 3.0%-8.0% of food emulsifier, 20.0%-54.4% of sweetener, 4.40%-8.0% of hydrophilic colloid, and 0.60%-1.20% of acidity regulator. The prepared acid-proof type microalgae DHA oil microcapsule powder has good acid-proof property, and can be applied in a food system of an acid water system with pH of more than or equal to 3.5, the oxidization speed of microalgae DHA can be effectively reduced and delayed, the activity of the microalgae DHA can be maintained, the stability of microalgae DHA in acid water system food can be enhanced, and the shelf life of the acid water system food with microalgae DHA can be prolonged.

Owner:RUNKE BIOENG FUJIAN

Method of manufacturing biological diesel oil from hogwash oil

InactiveCN101012388AHigh speedReduce dosageBiofuelsLiquid hydrocarbon mixture productionBiodieselGas phase

The invention discloses a making method of biological diesel through trench oil, which comprises the following steps: A. adding 97-99.8% trench oil and 0.2-3% solid acid catalyst of porous carrier into autoclave; controlling reacting temperature between 95 and 130 deg.c; aerating gas-phase carbinol; stirring 1-4h; esterifying; separating solid acid catalyst; B. adding 70-80% liquid, 15-25% carbinol and 1-5% solid alkaline catalyst into autoclave; controlling the reacting temperature between 50 and 65 deg.c; stirring under normal pressure for 0.5-2h; proceeding ester exchange reaction; C. stewing liquid or centrifuging; adopting upper layer as product and lower layer as glycerine, solid alkaline catalyst and carbinol.

Owner:张伟明

Polyvinyl acetal film and uses thereof

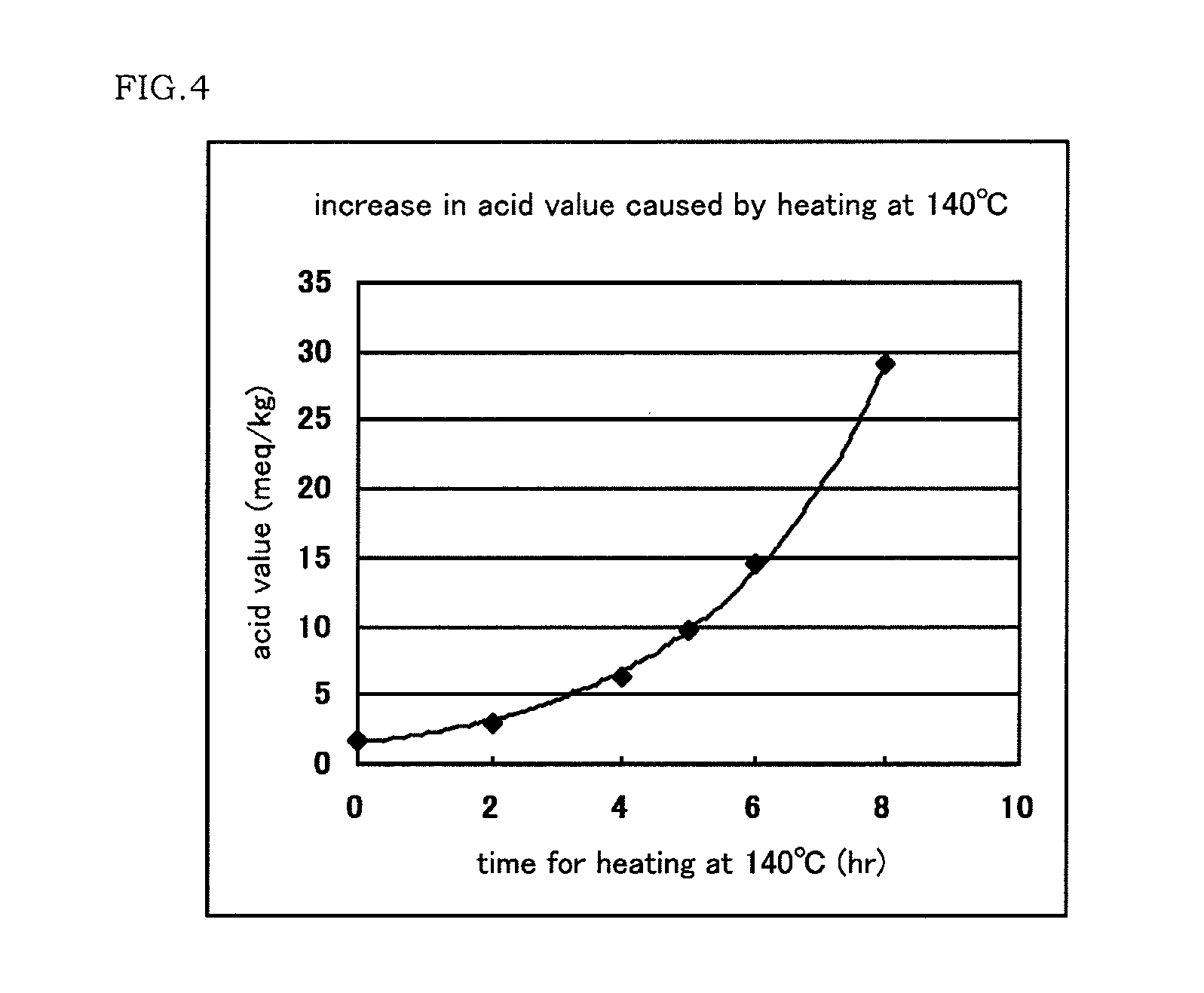

ActiveUS20130074910A1Reduce yellownessGood lookingPV power plantsGlass/slag layered productsPolyvinyl alcoholOxygen

A polyvinyl acetal film as an intermediate film for a laminated glass, can provide a laminated glass that exhibits a low degree of yellowness and excellent surface appearance, and is useful as a sealing material or intermediate film that can prolong the life of a laminated glass provided with a solar cell or functional unit. The content of corrosion-causing substance in the polyvinyl acetal film is low, so that the polyvinyl acetal film permits high-temperature lamination and ensures excellent productivity. A solar cell module and a laminated glass are prepared using the polyvinyl acetal film. A plasticized polyvinyl acetal film which comprises 15 to 60 parts by mass of a plasticizer having a total number of 28 or more of carbon atoms and oxygen atoms constituting a molecule based on 100 parts by mass of a polyvinyl acetal resin, and which has an acid value of 5.0 meq / kg or less.

Owner:KURARAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com