Patents

Literature

136results about How to "Meet lubrication needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

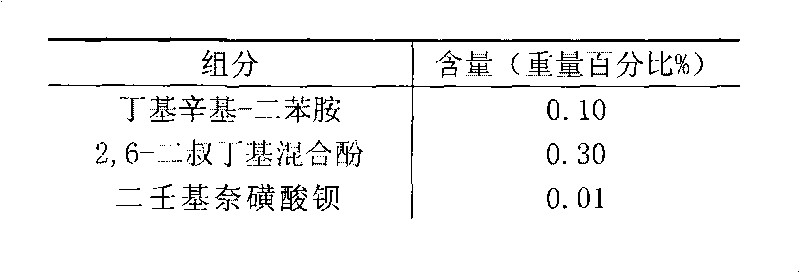

Combination circulation steam turbine lubricating oil composition

ActiveCN101240212AExcellent high temperature oxidation resistanceMeet lubrication needsAdditivesAntioxidantRust

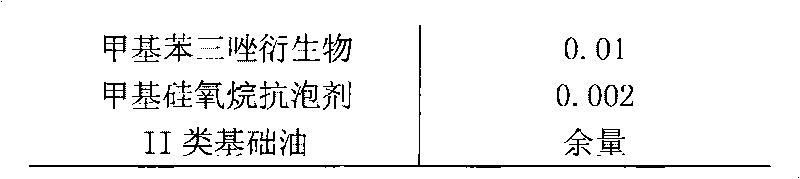

The invention relates to a combined-cycle gas turbine lubricant combination which is suitable to be used in a large-scale gas steam combined-cycle gas turbine, and the composition and content of the combined-cycle gas turbine lubricant combination by weight percentage of antioxidant of 0.1 to 2 percent, anti-wear agent of 0.01 to 1 percent, no gray rust-proof agent of 0.01 to 1 percent, metal deactivating agent of 0.01 to 1 percent, anti-foam agent of 0.001 to 1 percent, the allowance is based oil, which is Class II or Class III paraffin-based oil, and the sulfur content is less than 0.03 percent, the lubricant combination of the invention has an extremely long induction period of oxidation and excellent performance of high temperature oxidation, excellent extreme pressure antifriction property and corrosion, good water separation, air separation and filterability, and can well meet the lubricating demand of large-scale combined cycle gas turbine.

Owner:PETROCHINA CO LTD

Lubricating agent for superfine copper wire drawing

The invention discloses a lubricating agent for superfine copper wire drawing. The lubricating agent comprises the following components in parts by mass: 5-25 parts of lubrication base oil, 10-30 parts of an emulsifying agent, 1-5 parts of a surface active agent, 1-10 parts of an antirust agent, 1-5 parts of an extreme pressure antiwear additive, 1-5 parts of a thickening agent, 5-25 parts of an alkali retention agent, 1-5 parts of a bactericide, 0.1 part of a defoaming agent and 30-50 parts of water. The lubricating agent for superfine copper wire drawing has good oxidation resisting, cooling, cleaning, lubricating, rust preventing, hard water resisting and copper soap dispersing properties, and is particularly suitable for superfine copper wire drawing.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

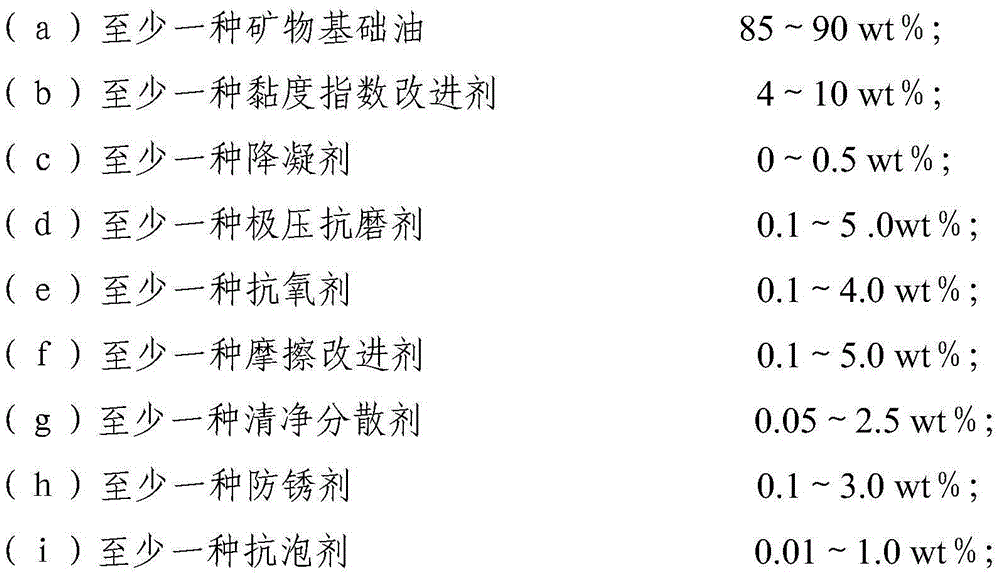

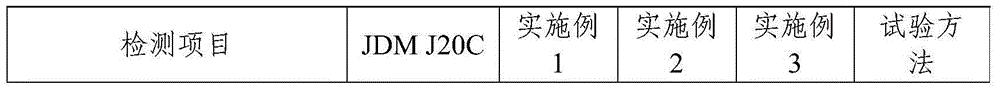

Tractor three-purpose lubricating oil composition and preparation method of tractor three-purpose lubricating oil composition

ActiveCN105176641AGood high and low temperature performanceIncrease frictionLubricant compositionAntioxidantLubrication

The invention relates to a tractor three-purpose lubricating oil composition, which comprises (a) at least one mineral base oil with higher viscosity index; (b) at least one viscosity index improving agent; (c) at least one pour inhibitor; (d) at least one EP-antiwear additive; (e) at least one antioxidant; (f) at least one friction improving agent; (g) at least one clean dispersing agent; (h) at least one antirust agent; (i) at least one anti-foaming agent. The tractor three-purpose lubricating oil composition has excellent high-low-temperature performance, thermal oxidization stability, EP-antiwear performance, anti-corrosion performance, anti-rust performance and anti-emulsification anti-foaming performance, can meet the requirements of a general hydraulic system, a transmission system and a braking system of a large-and-middle-sized tractor and engineering machinery, can realize the comprehensive lubrication protection on the hydraulic and gear transmission, power output and braking components; long service life is realized; the improvement of the operation stability of the equipment is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP

Open type gear oil composition

ActiveCN1962835AGuaranteed adhesionGuaranteed viscosity-temperature characteristicsAdditivesEngineeringBase oil

The invention discloses a new open-typed gear oil composition, which comprises the following parts: 0.2-70% thickener, 0.1-5% extreme-pressure antiwear agent, 0.005-0.5% anti-emulsifier, 0.5-8% oil-soluble friction modifier and basic oil. The invention expands the application scale of oil, which satisfies the lubricating need of different equipments.

Owner:CHINA PETROLEUM & CHEM CORP

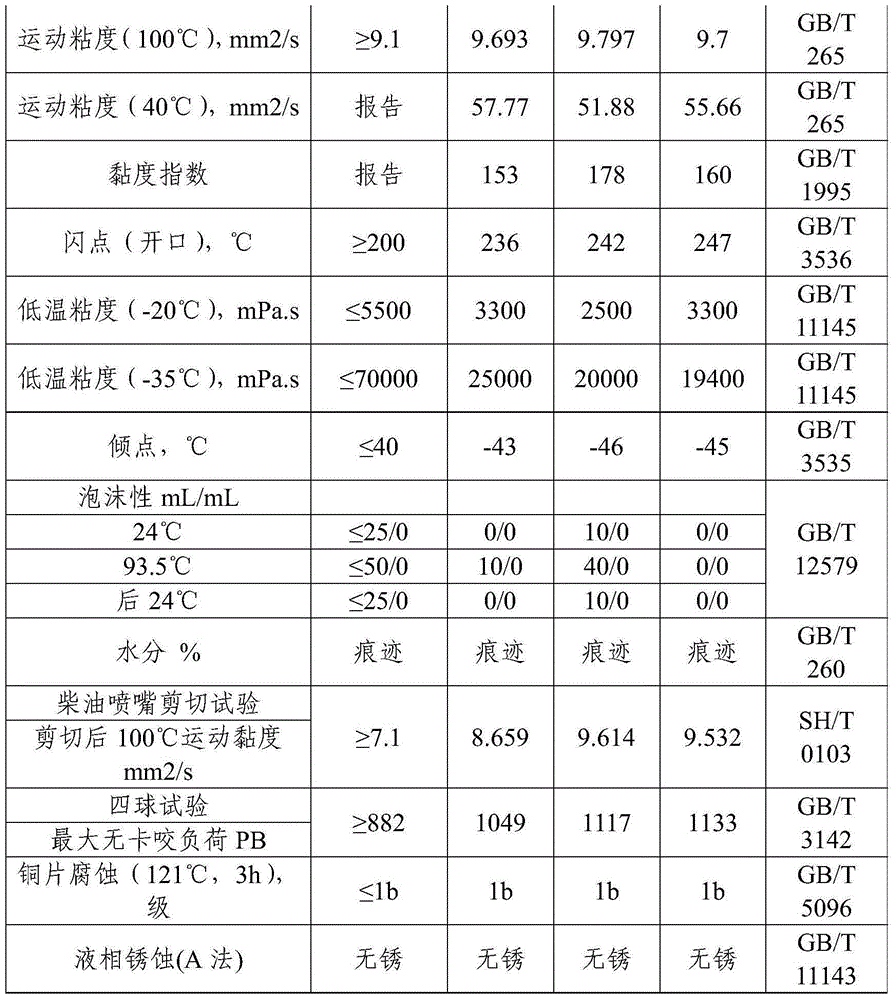

Intelligentized heat management system of propulsion plant

InactiveCN101109310ABest working condition rangeEmission reductionCoolant flow controlPositive displacement pump componentsHeat managementPollutant emissions

The invention discloses an intelligent heat management system for a power equipment, which comprises a plurality of cooling units, an electronic control unit ECU, a fan and a motorized pump, and is characterized in that the ECU can make judgment depending upon the feedback signal of the temperature of the cooling media, adjust the speed of the fan and the motorized pump, so as to control the operation temperature of the thermal media of each cooling unit to be optimal. The invention realizes the most economic oil consumption by the ECU, guarantees that the engine is always under the optimal operation state under different environments. The advantages with the invention are: 1. The invention can guarantee that the engine is always under the optimal operation condition. 2. The invention can save energy, reduce emission of pollutant, is environmental friendly. 3. Each heat exchanging unit can cool as necessary, no overhot or over cold condition will happen. 4. The intelligent heat management system for power equipments is realized completely depending upon the feedback temperature signal by the ECU.

Owner:ZHEJIANG YINLUN MACHINERY

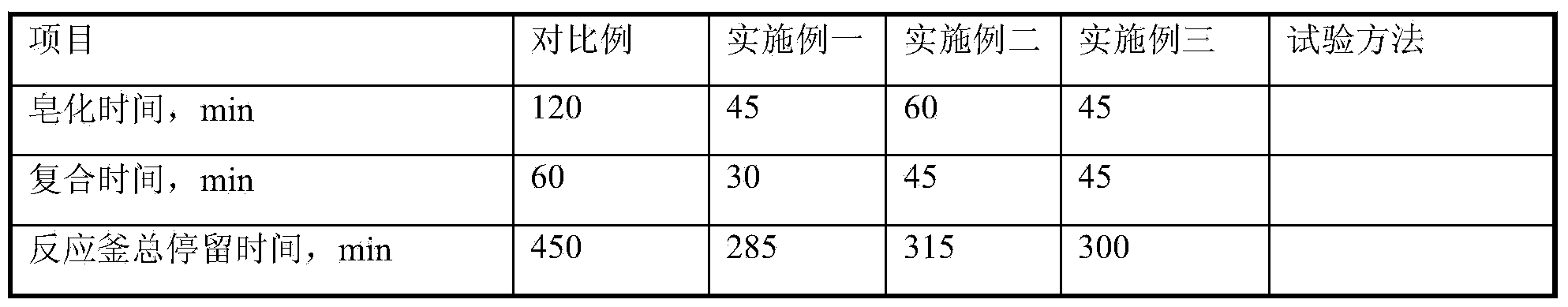

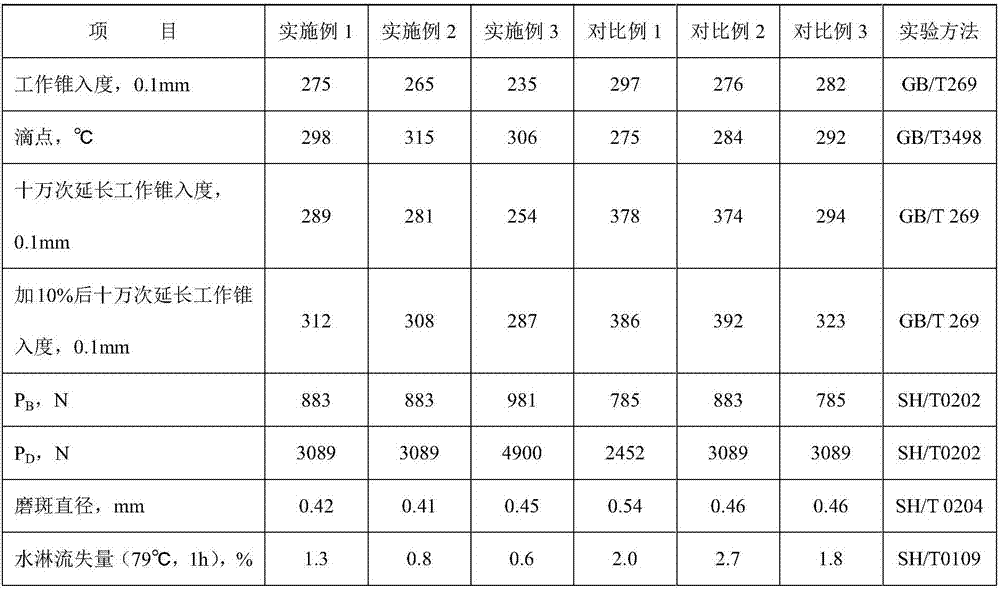

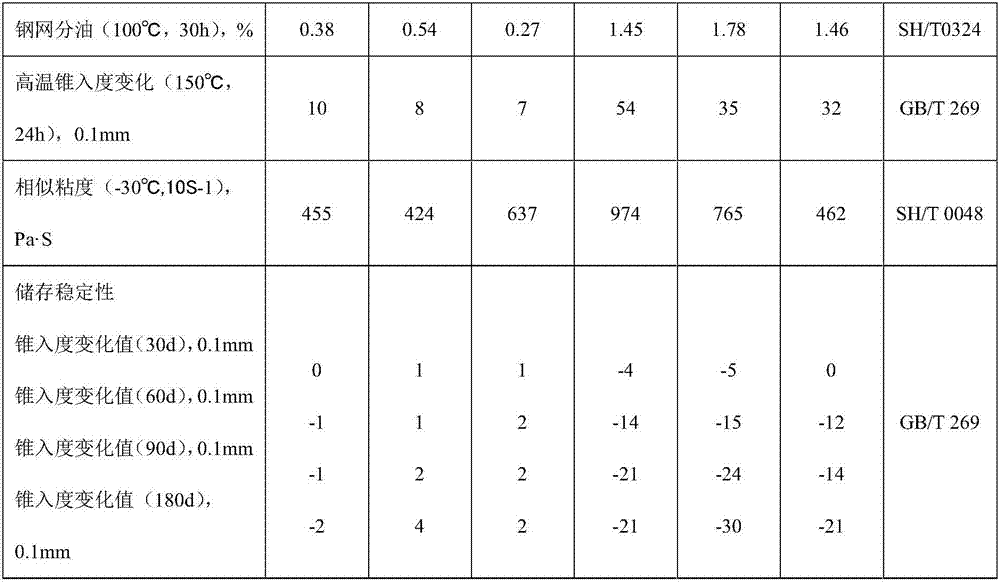

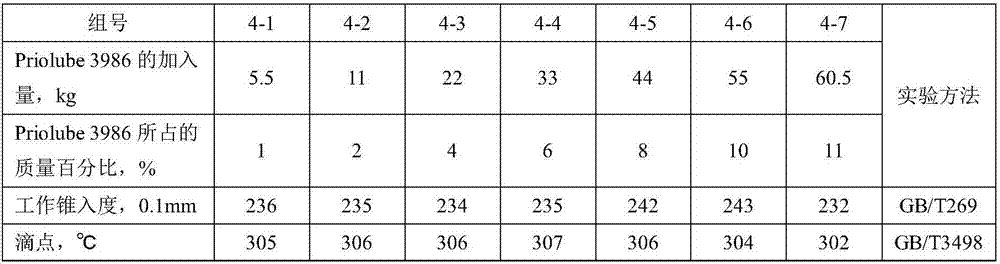

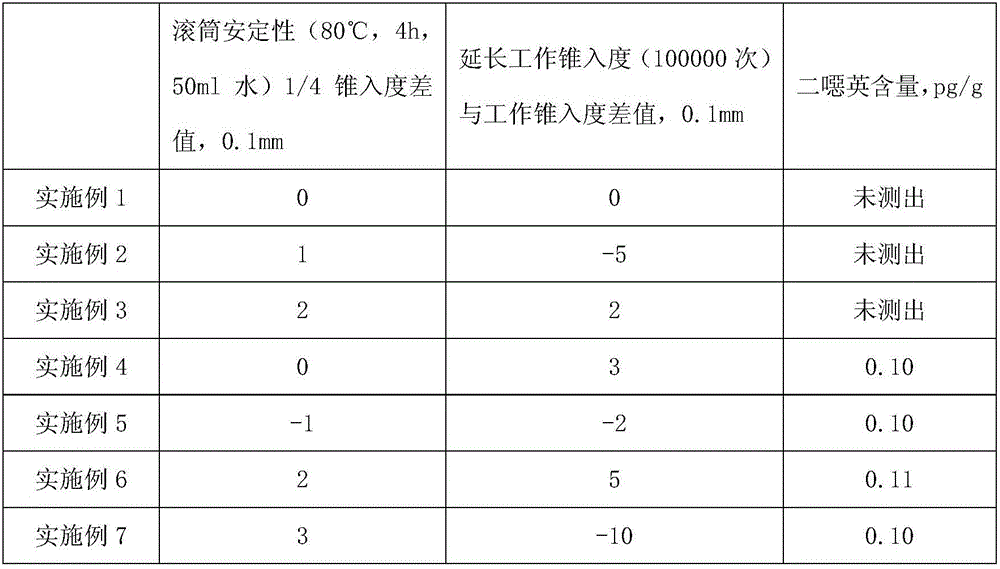

Lubricating grease for hub bearing of heavy load truck and preparation method thereof

InactiveCN103450978AEliminates tendency to overflowSlow dehydration stepThickenersThiocarbamateChemical industry

The invention relates to a lubricating grease and a preparation method thereof, particularly relates to a lubricating grease for a hub bearing of a heavy load truck and a preparation method thereof, and belongs to the technical field of a chemical industry. The lubricating grease is prepared from the following raw materials: (A) base oil which accounts for 60-85% of total weight of the lubricating grease, (B) a thickening agent, which is C12-C22 unitary organic acid which accounts for 7-12% of total weight of the lubricating grease, 0.5-3% of sebacic acid, 0.2-1% of boric acid, and 3-5% of lithium hydroxide oil solution, (C) an additive, which is thiocarbamate which accounts for 0.5-3% of total weight of the lubricating grease, 2-5% of sulfide olefin cottonseed oil, 2-4% of dialkyl dithiocarbamate salt, 0.5-2.5% of molybdenum dialkyl dithiophosphate, 0.3-2% of antirust agent and 0.3-1% of antioxidant. The lubricating grease has the beneficial effects that the production time is shortened; the lubricating grease is more controllable in process, stable in product quality, less in seepage loss of a high-temperature bearing, and prominent in extreme pressure property; lubricating protection can be better provided for hubs of the heavy load truck; the lubricating requirements of the hub bearing of the heavy load truck under various working conditions can be met; the grease exchange period of the hub bearing is prolonged.

Owner:JIANGSU LOPALTECH

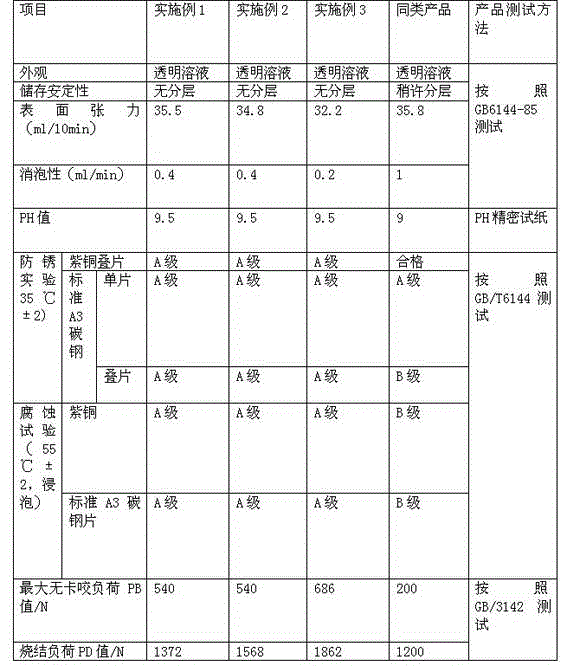

Total synthesis metal cutting solution and preparation method thereof

The invention discloses a total synthesis metal cutting solution comprising the following components by weight percent: 0.5-1% of pH regulator, 10-20% of antirust agent, 10-15% of mixed hydramine, 5-8% of lubricating agent, 0.1-0.3% of copper alloy corrosion inhibitor, 1-2% of sterilizing agent, 0.1-0.2% of defoaming agent, 0-0.5% of EDTA-4 sodium and the balance of water. The invention provides a preparation method of the total synthesis metal cutting solution. The total synthesis metal cutting solution is good in lubricating performance, and the use effect is superior to that of emulsification solution. By utilizing the total synthesis metal cutting solution, surface smoothness of a workpiece can be improved, a grinding wheel can not be sticked, and abrasion of the grinding wheel is reduced. The total synthesis metal cutting solution has a good sedimentation effect and is less in bubbles, long in service life and excellent in anti-rust property, cooling property, permeability and cleanability. By utilizing the total synthesis metal cutting solution, the service life of the grinding wheel can be effectively prolonged. The total synthesis metal cutting solution is suitable for materials, such as bearing steel, carbon steel and the like, the solution is colorless and transparent, and surface processing conditions are easy to observe. Meanwhile, the total synthesis metal cutting solution does not contain toxic and harmful substances, such as sodium nitrite, phenols and the like and is harmless to environment and operator health.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Composition for anti-ammonia turbine oil

InactiveCN101724487AAppropriate thicknessImprove the lubrication effectAdditivesBase-materialsOil sludgePhenol

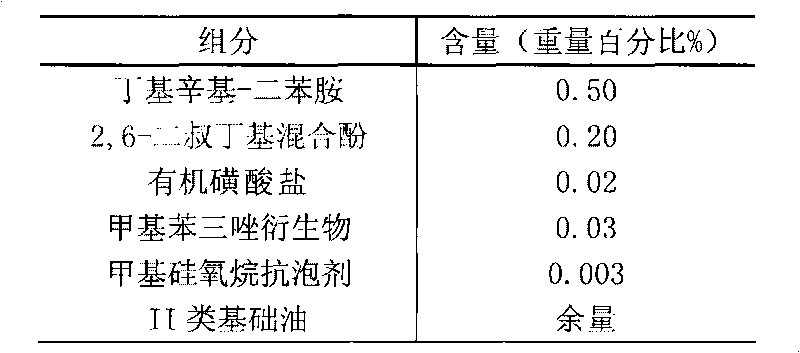

The invention relates to a composition for anti-ammonia turbine oil. The composition comprises the following components by weight percentage: 1.1-2.0% of screening phenol antioxygen, alkyl diphenylamine antioxygen or formulated mixture antioxygen thereof, 0.01-2.0% of non-acid antirusting agent, 0.01-1% of metal passivator, 0.001-0.01% of anti-foaming agent and the balance of base oil. The base oil is II type hydrogenated base oil, and in the II type hydrogenated base oil, the sulphur content of the II type hydrogenated base oil based on weight is no more than 0.03%, and the saturation is no less than 90%. The antioxygen is formulated by the screening phenol antioxygen and the alkyl diphenylamine antioxygen, and the weight proportion of the antioxygen 1:0.1-10. The invention has the advantages of excellent lubricity, oxidation stability, favorable water separation, air release property and strong anticorrosion property, maintains neutral for ammonia and synthesis gas, has little possibility of sludge generation, reduces the time of machine halt, andreduces operation and maintenance cost.

Owner:PETROCHINA CO LTD

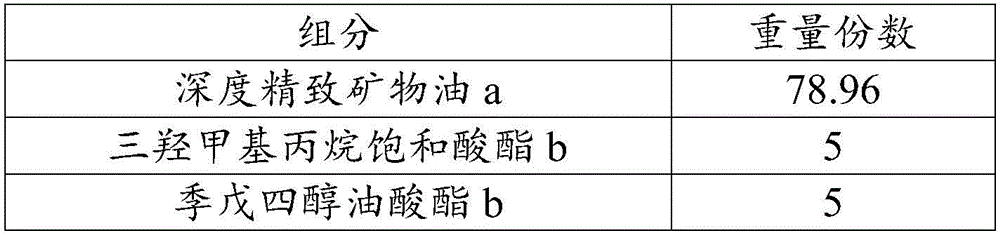

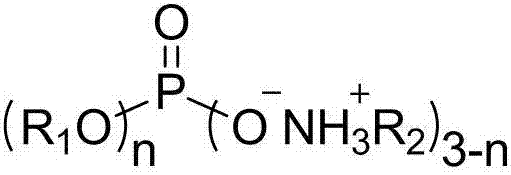

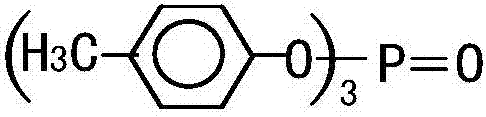

High-lubricating rolling oil composition and application thereof

ActiveCN106318568AImprove the lubrication effectMeet lubrication needsLubricant compositionPhosphateButylated hydroxytoluene

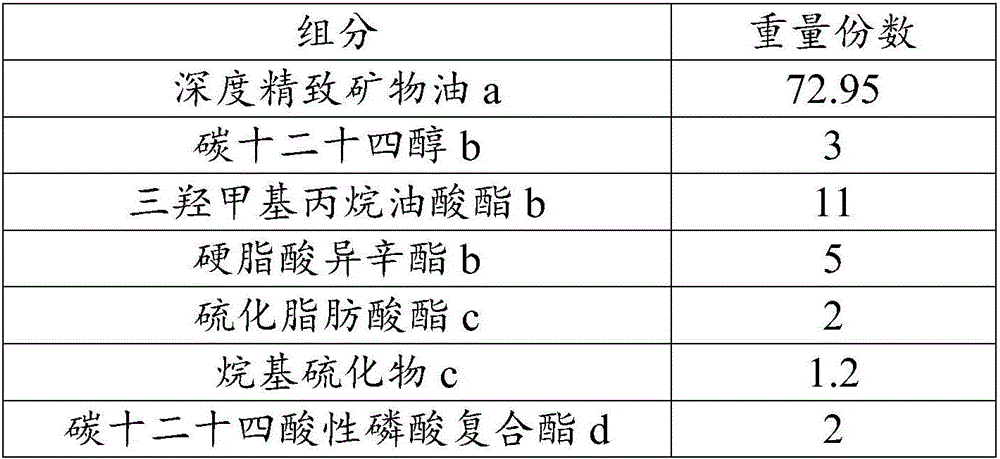

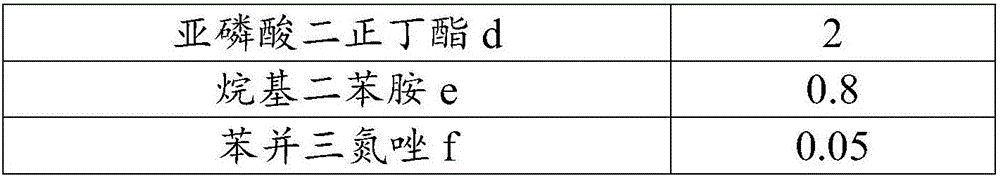

The invention relates to a high-lubricating rolling oil composition and application thereof. The composition is prepared from 40-90 parts of highly refined mineral oil, 10-30 parts of carbon dodecanol tetradecyl alcohol, isotridecyl alcohol, n-octanol, pentaerythritol oleate, trimethylolpropane trioleate, diisooctyl phthalate, 2-ethylhexyl palmitate, isooctyl stearate, methyl palmitate or butyl stearate, 1-5 parts of ZDTP, octadecyl zinc dithiophosphate, sulfurized olefin, sulfide aliphatic acid ester, sulfurized animal oil, alkyl sulfide or sulfur phosphorus molybdenum, 0.5-5 parts of amine thiophosphate, isooctyl acidic phosphate octadecylamine, tricresyl phosphate, tributyl phosphate, dibutyl phosphate and carbon-12 to carbon-14 acid phosphate compound ester, 0.1-5 parts of 2,6-butylated hydroxytoluene, N-phenyl naphthylamine, thioether phenol or alkyl diphenylamine and 0.01-2 parts of 1H-benzotriazole, thiadiazole derivative and benzotriazole.

Owner:CHINA PETROLEUM & CHEM CORP

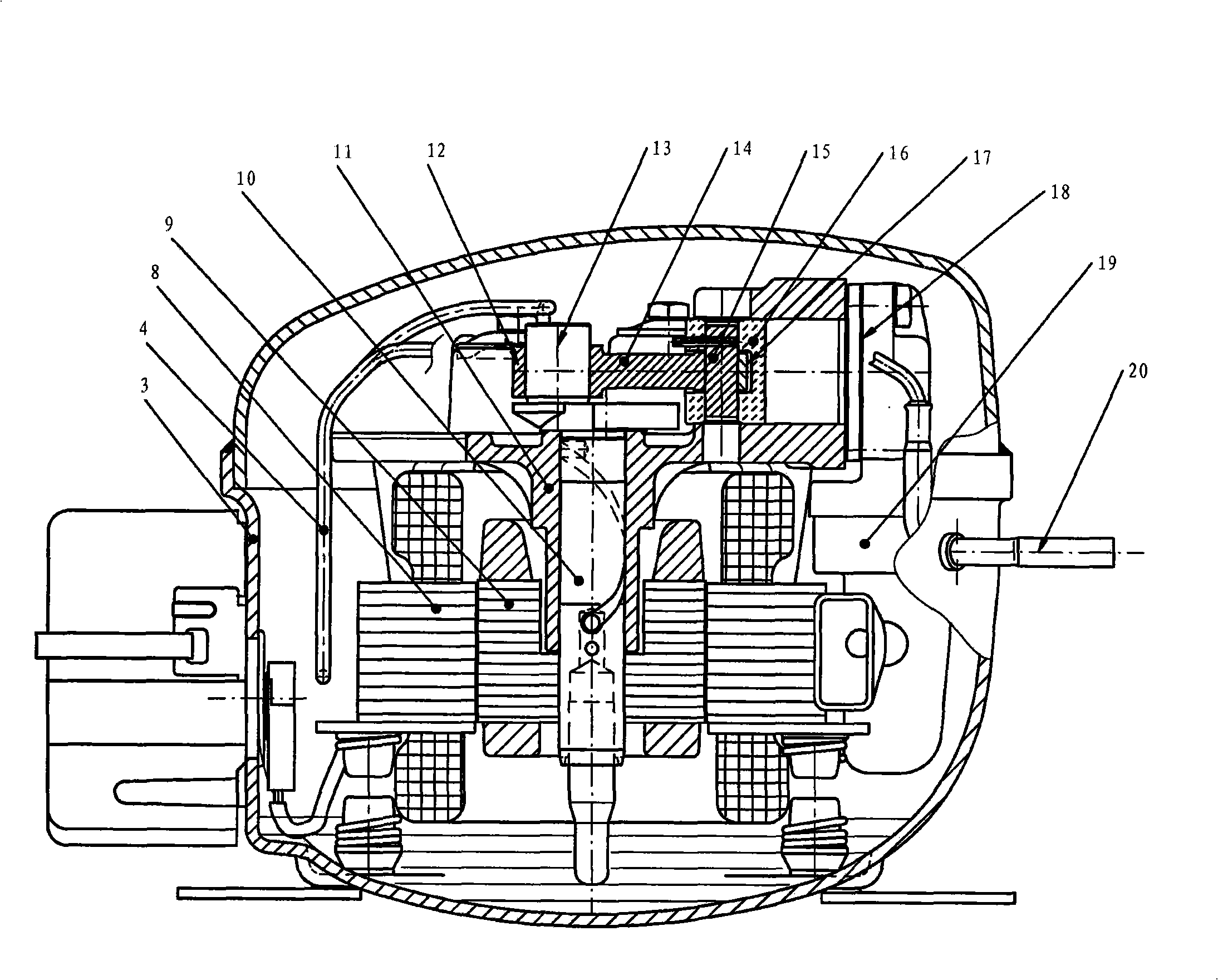

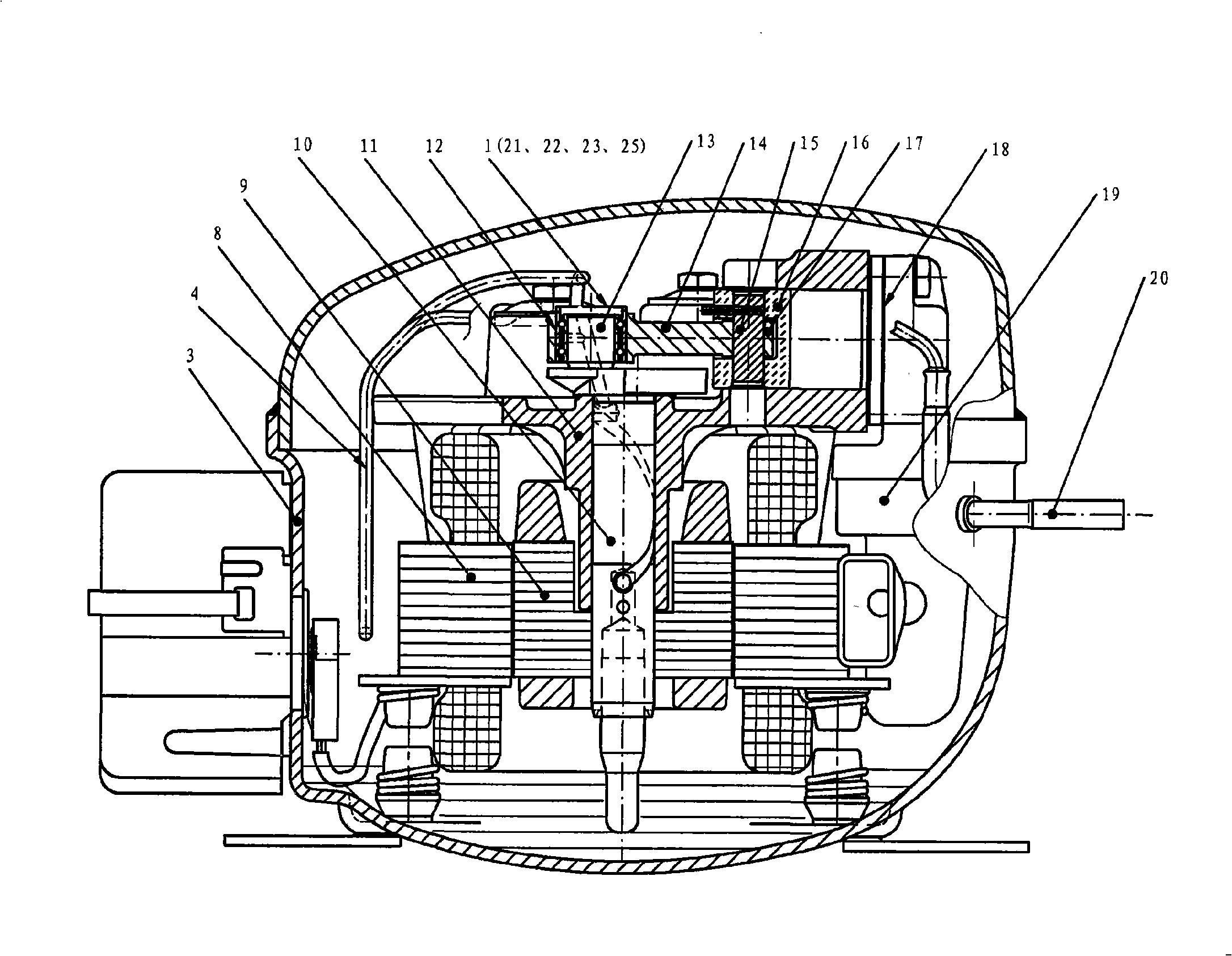

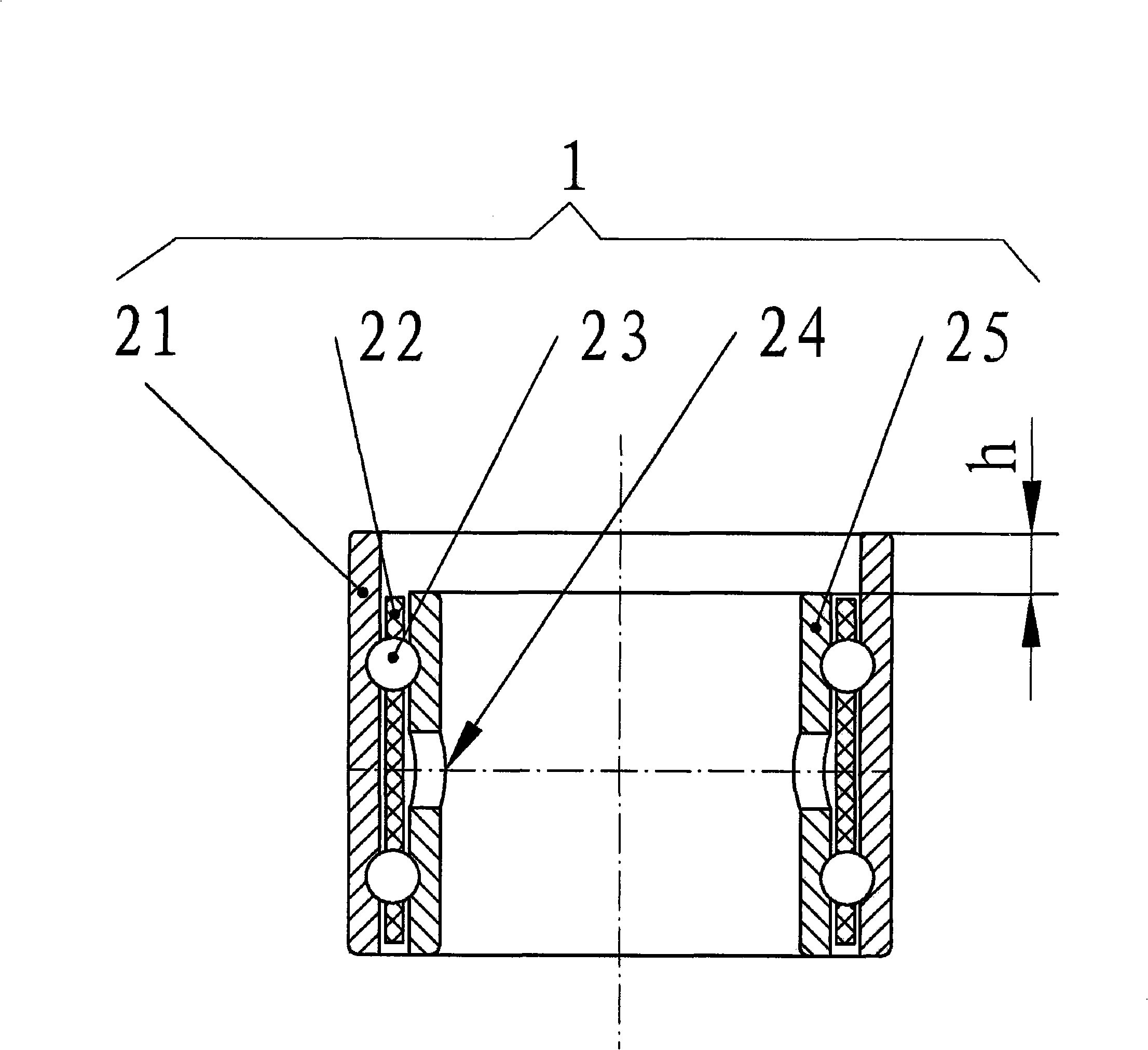

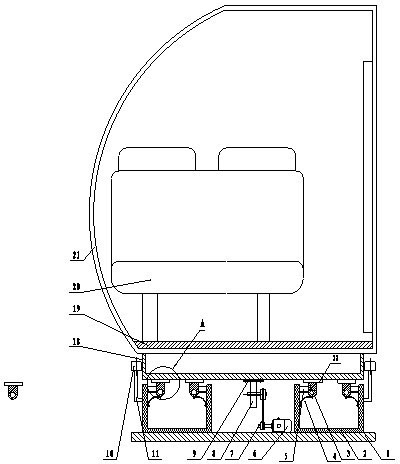

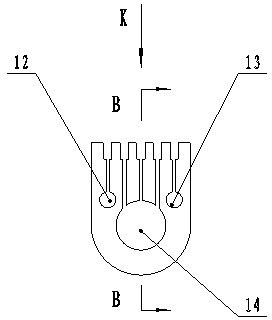

Reciprocating-piston type sealing compressor

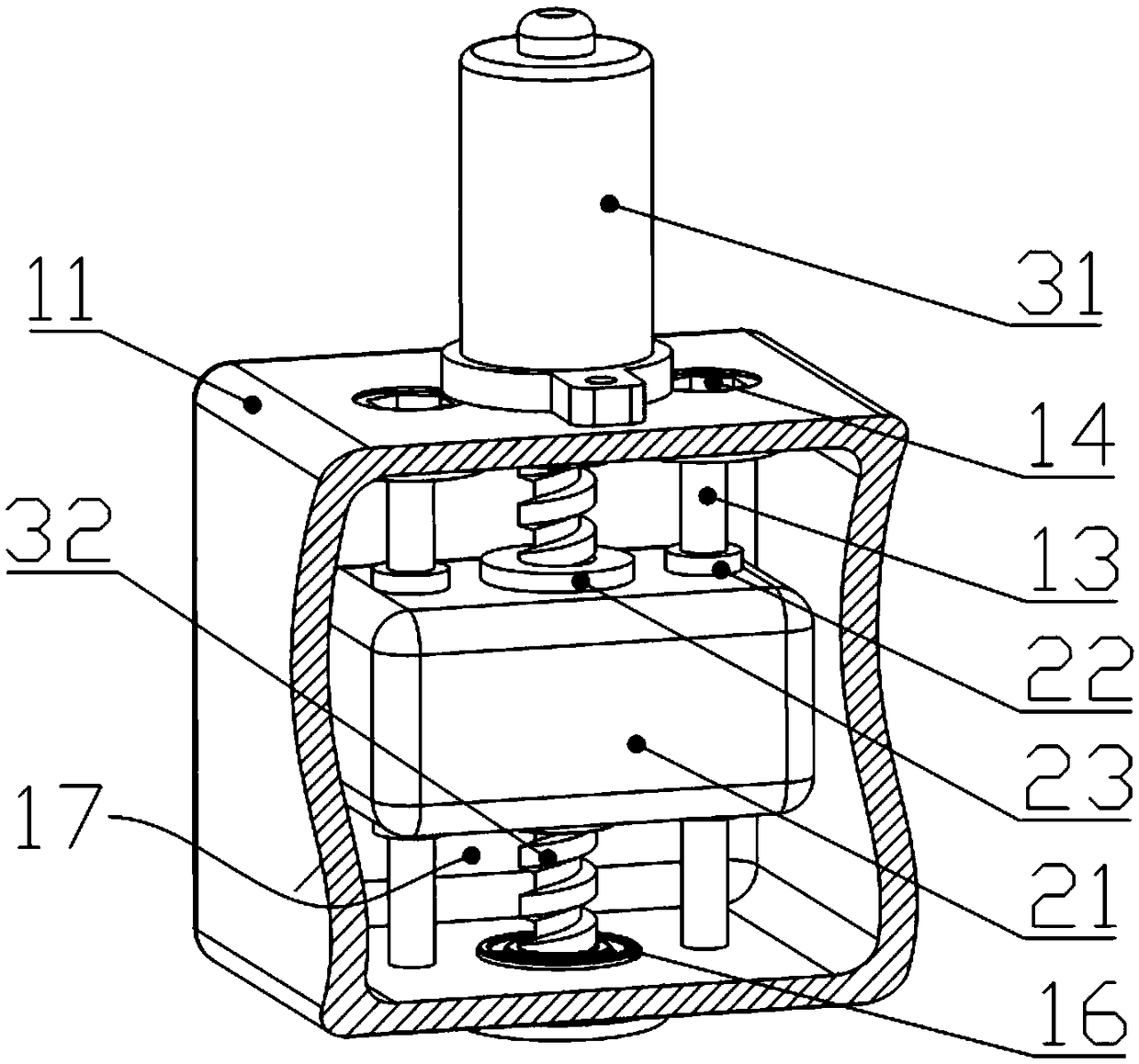

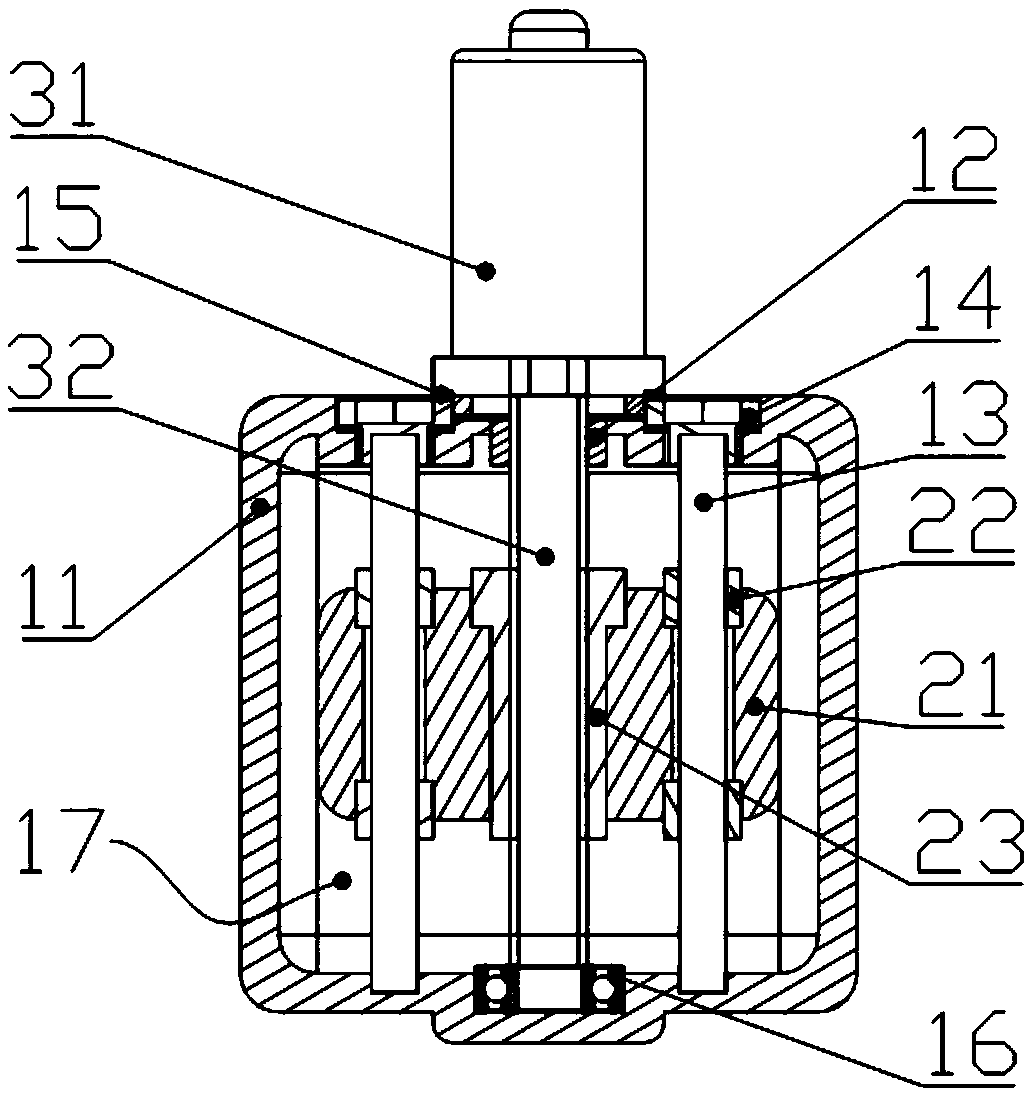

ActiveCN101265893AMeet lubrication needsImprove lubrication conditionsPositive displacement pump componentsPositive-displacement liquid enginesBall bearingRolling resistance

The invention discloses a reciprocating piston-type sealing compressor, which comprises housing, a motor, a crank shaft, a crank shaft case, a connecting bar, a piston, a valve bank, an aspiratory muffler and a ball bearing component, wherein, an eccentric shaft on the upper end of the crank shaft is connected with a big-end hole of the connecting bar via the ball bearing component, and the ball bearing component is internally provided with two rows of balls. Therefore, the friction between the eccentric shaft and the connecting bar is converted into rolling friction, thus further deducing the mechanical loss of the position and further enhancing the efficiency of the complete machine of the compressor. Meanwhile, as the design of two-row balls is adopted in the structure, smaller balls can be used and the radial dimension of smaller ball bearing component is used for meeting the needs of integrant loading strength; in addition, a lubricating oil hole is easy to be arranged between the two-row balls, thus ensuring sufficient lubrication of the balls.

Owner:JIAXIPERA COMPRESSOR

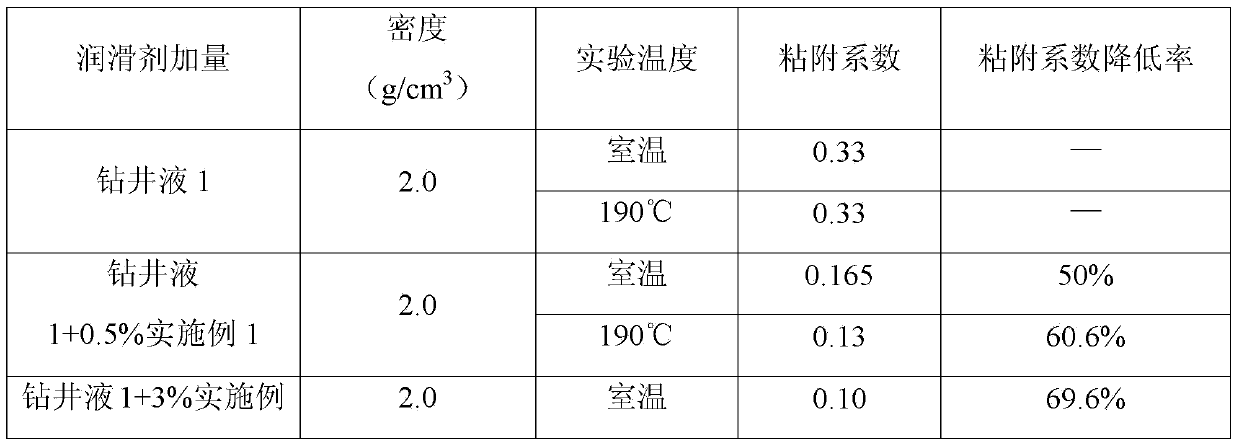

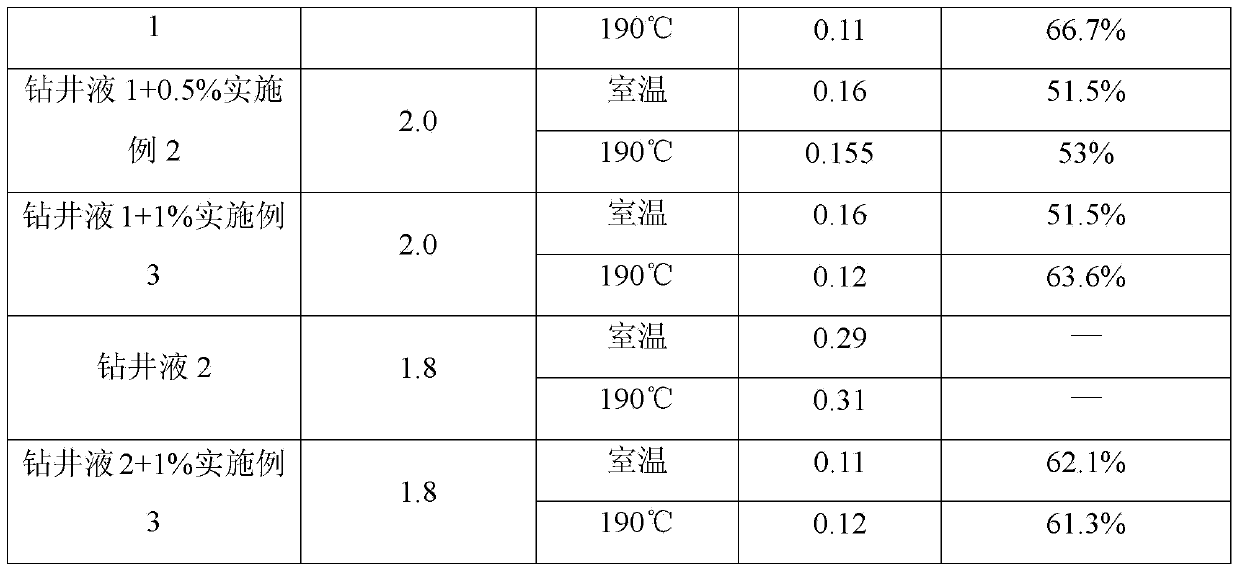

Preparation and application methods of high-temperature-resistant lubricant for drilling fluid

InactiveCN103725267AEfficient lubricationHigh temperature resistantDrilling compositionVegetable oilTemperature resistance

The invention discloses a preparation method of a high-temperature-resistant lubricant for a drilling fluid, which comprises the following steps: 1) while stirring, sequentially adding 100-120 parts by mass of waste animal and vegetable oil, 8-12 parts by mass of triethanolamine and 2-5 parts by mass of concentrated sulfuric acid into a reaction kettle, and reacting at 120-140 DEG C for 3-5 hours; 2) cooling the reaction product to 60-80 DEG C, adding 20-50 parts by mass of fatty acid methyl ester and 20-50 parts by mass of white oil into the reaction kettle in the stirring state, and stirring for 1-2 hours; 3) adding 3-10 parts by mass of molybdenum disulfide into the reaction kettle in the stirring state, and stirring for 1-3 hours; and 4) cooling to normal temperature to obtain the high-temperature-resistant lubricant for a drilling fluid. The lubricant has the characteristics of high lubricating efficiency and high temperature resistance; after rolling at 190 DEG C for 16 hours, the lubricating factor decreasing rate can still reach 50% above; and thus, the lubricant can satisfy the lubricating demands for deep wells and ultradeep wells.

Owner:CNPC BOHAI DRILLING ENG

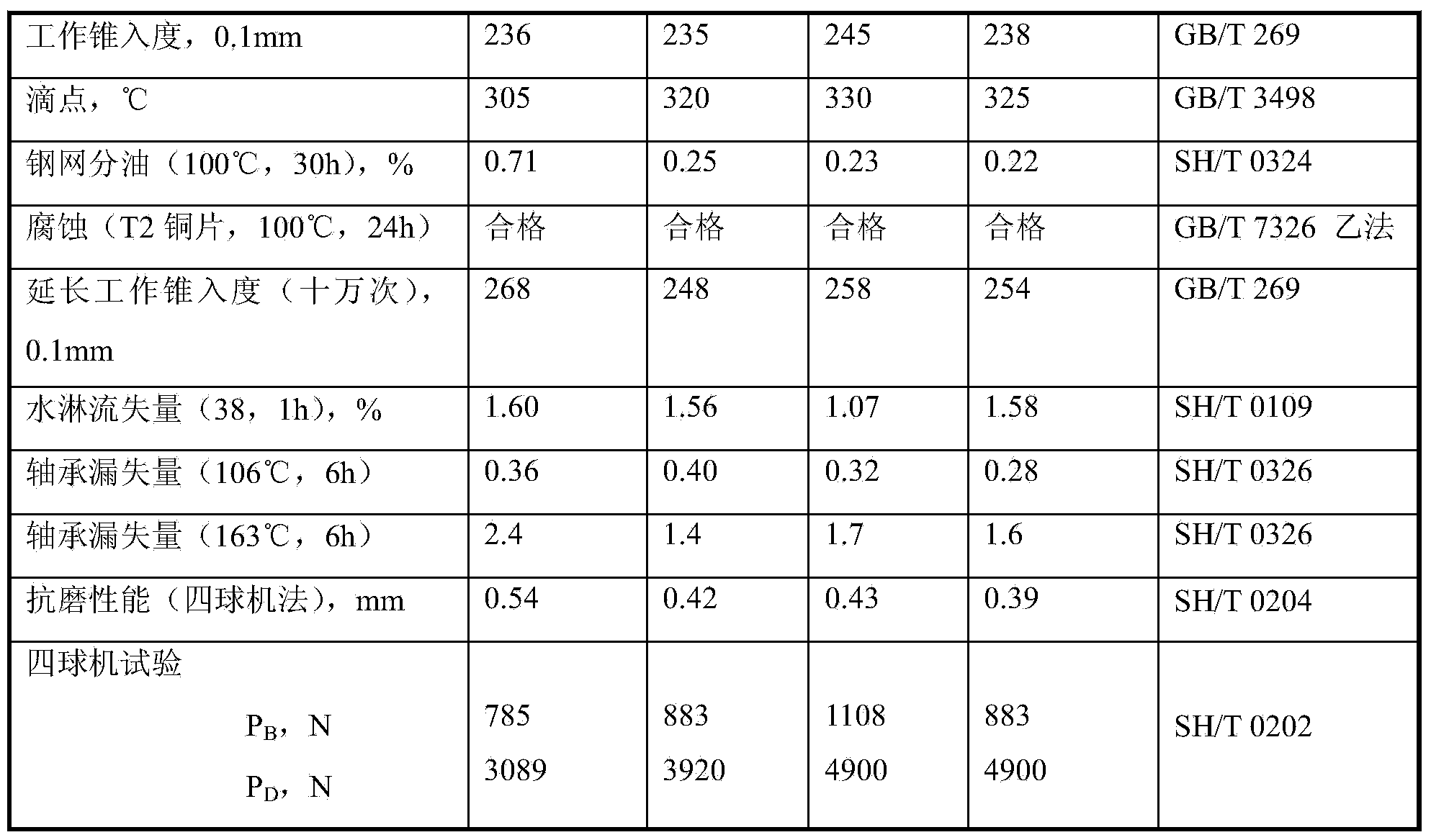

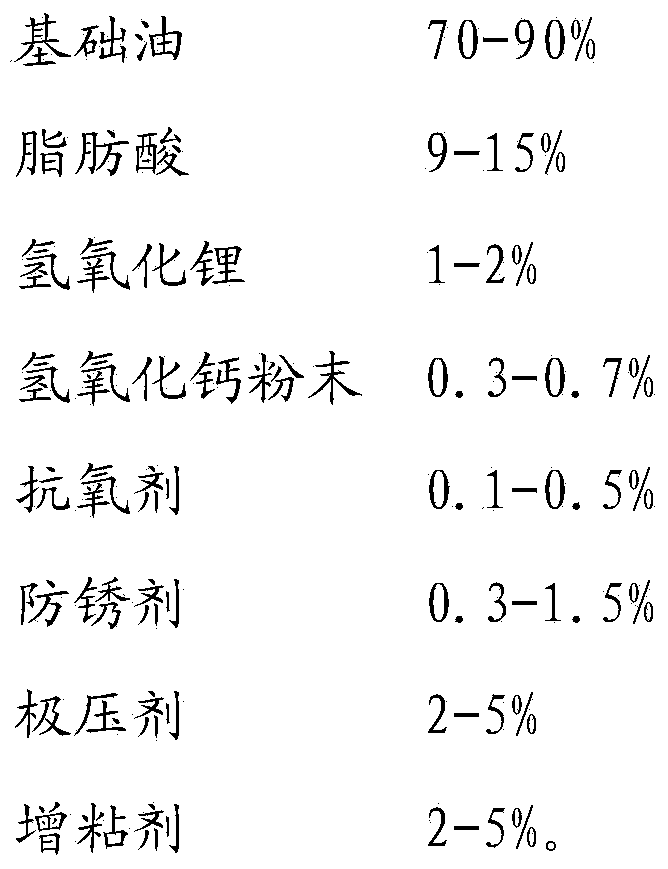

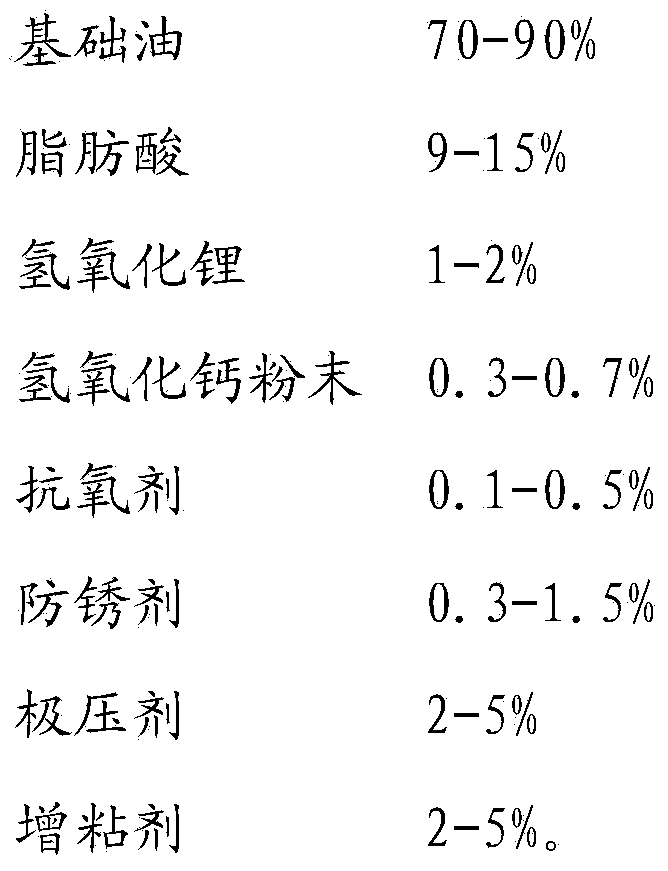

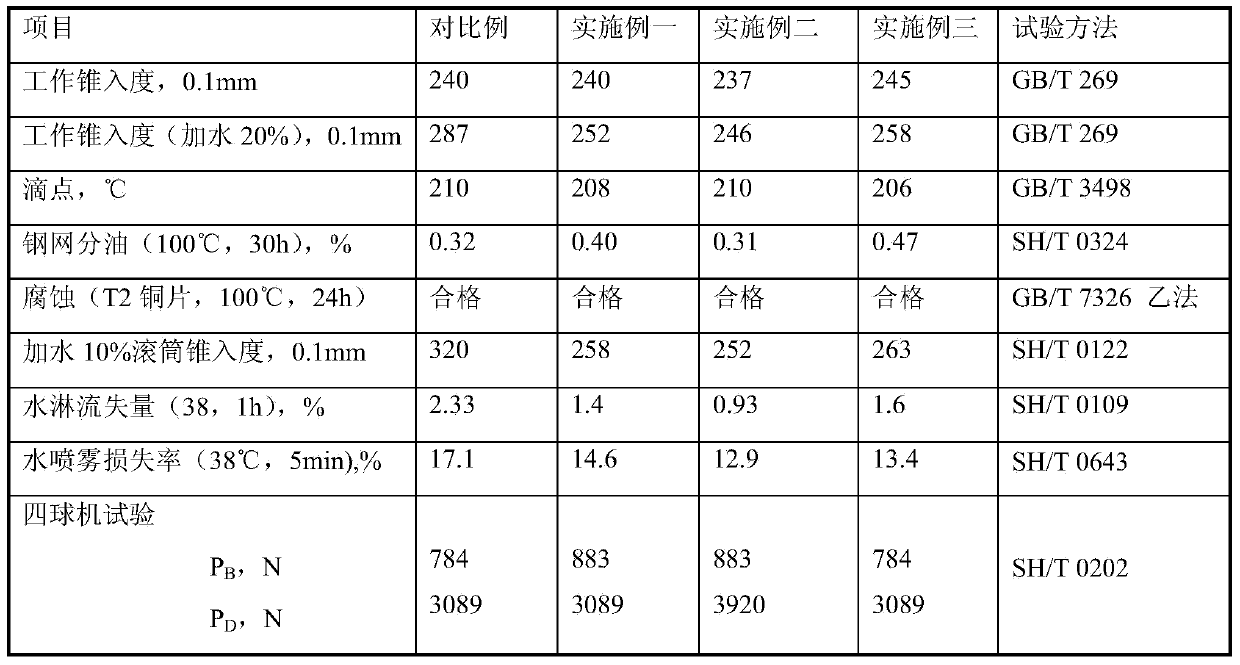

Water-resistant extreme pressure lithium lubricating grease and preparation method thereof

ActiveCN103468357AShorten saponification and dehydration timeDrop point highLubricant compositionLubricationChemistry

The invention relates to lubricating grease and a preparation method thereof, particularly relates to water-resistant extreme pressure lithium lubricating grease and a preparation method thereof, and belongs to the technical field of chemical engineering. The water-resistant extreme pressure lithium lubricating grease comprises the following components by weight percent: 70-90% of base oil, 9-15% of fatty acid, 1-2% of lithium hydrate, 0.3-0.7% of calcium hydroxide powder, 0.1-0.5% of antioxidant, 0.3-1.5% of antirust agent, 2-5% of extreme pressure agent and 2-5% of tackifier. The water-resistant extreme pressure lithium lubricating grease has the beneficial effects that the condition that the water-resistant extreme pressure lithium lubricating grease product has a high dropping point and good shear stability under a general condition is ensured; the product has excellent water-resistance, so that less loss in washing of a lot of water is ensured; the water-resistant extreme pressure lithium lubricating grease can work in the presence of water, is not easily softened to run off, and is good in mechanical stability; the product has excellent anti-rust property and extreme pressure anti-wear property; excellent lubrication of heavy duty equipment under a humid condition can be improved; the lubricating surface is prevented from being rusted.

Owner:JIANGSU LOPALTECH

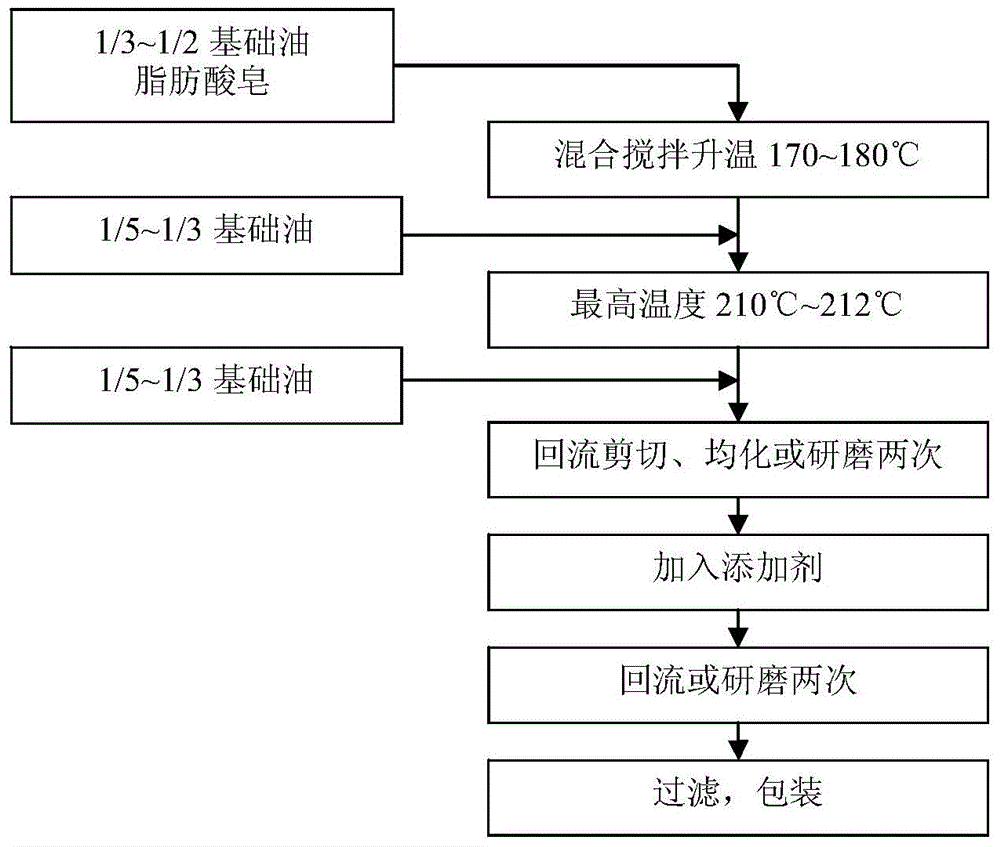

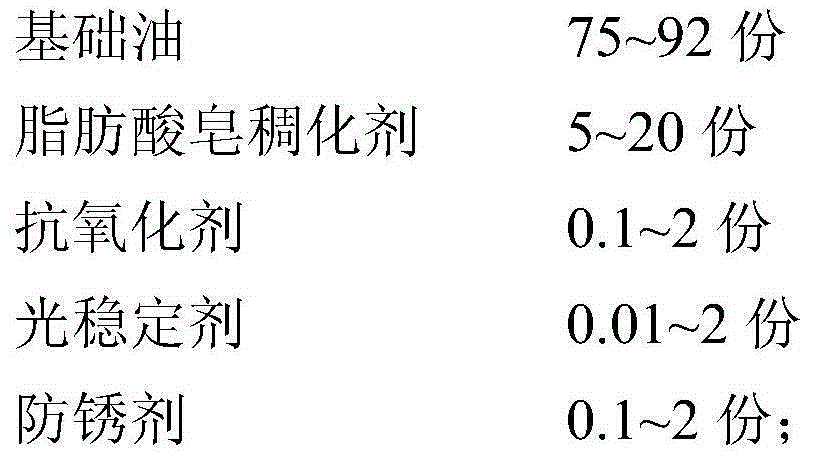

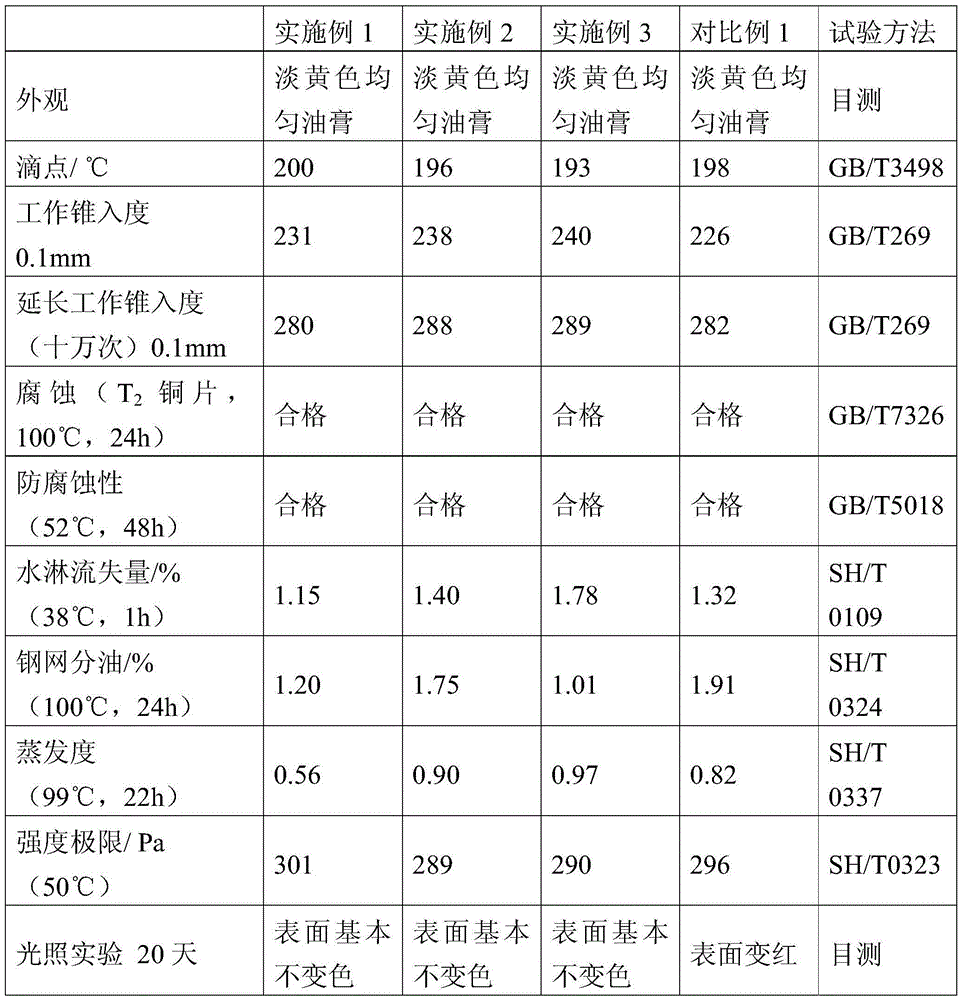

Photo-stabilization type lubricating grease and preparation method thereof

InactiveCN104403763AGuaranteed performanceGood value for moneyLubricant compositionPhoto stabilityBase oil

The present invention discloses a photo-stabilization type lubricating grease, which comprises, by weight, 75-92 parts of a base oil, 5-20 parts of a fatty acid soap thickener, 0.1-2 parts of an antioxidant, 0.01-2 parts of a light stabilizer, and 0.1-2 parts of an anti-rust agent, wherein the components are matched under a certain condition according to the ratio to obtain the photo-stabilization type lubricating grease. According to the present invention, the added functional additive does not affect the product structure, wherein the specific performance is that the consistency (cone penetration) and the strength limit of the product are not changed significantly; and with the addition of the light stabilizer, the photo-stabilization type lubricating grease of the present invention has the light stability, wherein the appearance of the lubricating grease is essentially the same before and after the illumination, and the product meets a variety of lubricating requirements.

Owner:无锡中石油润滑脂有限责任公司

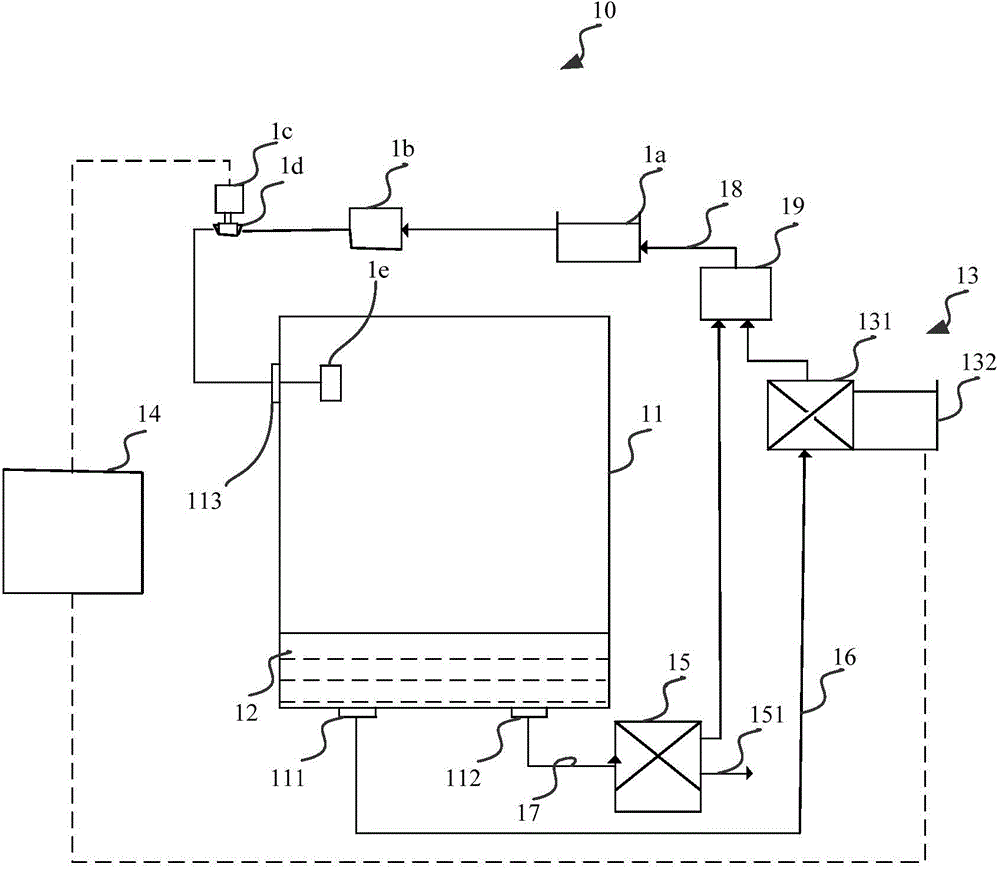

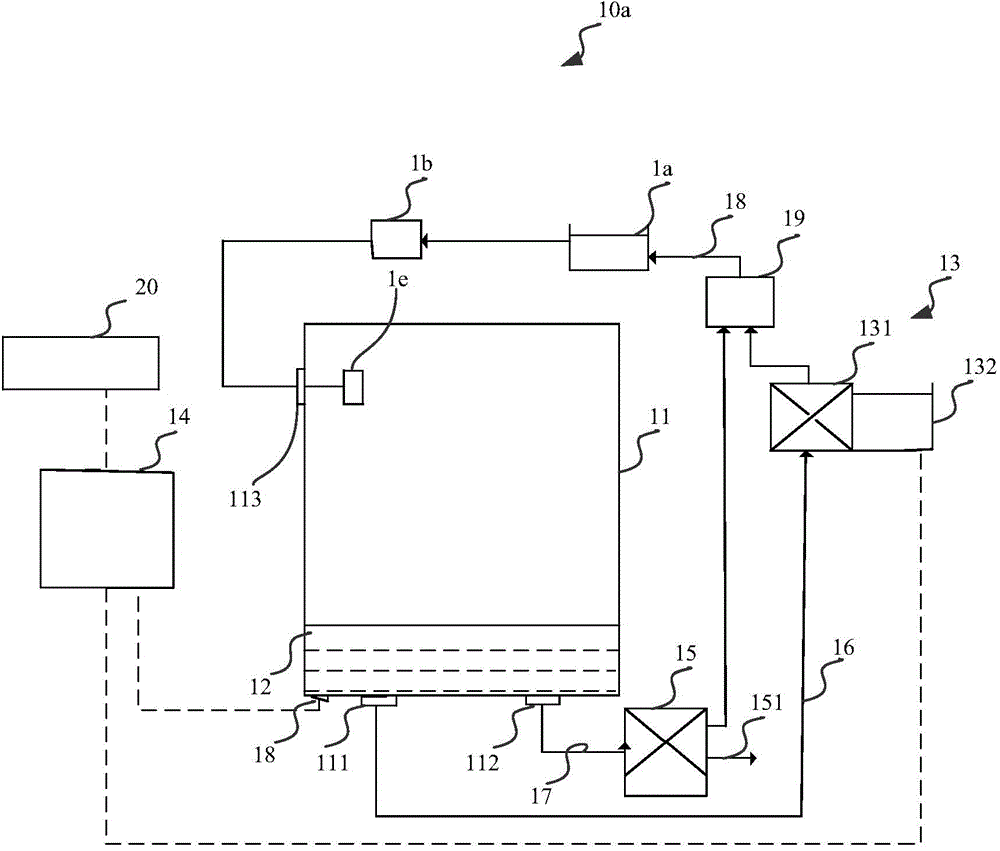

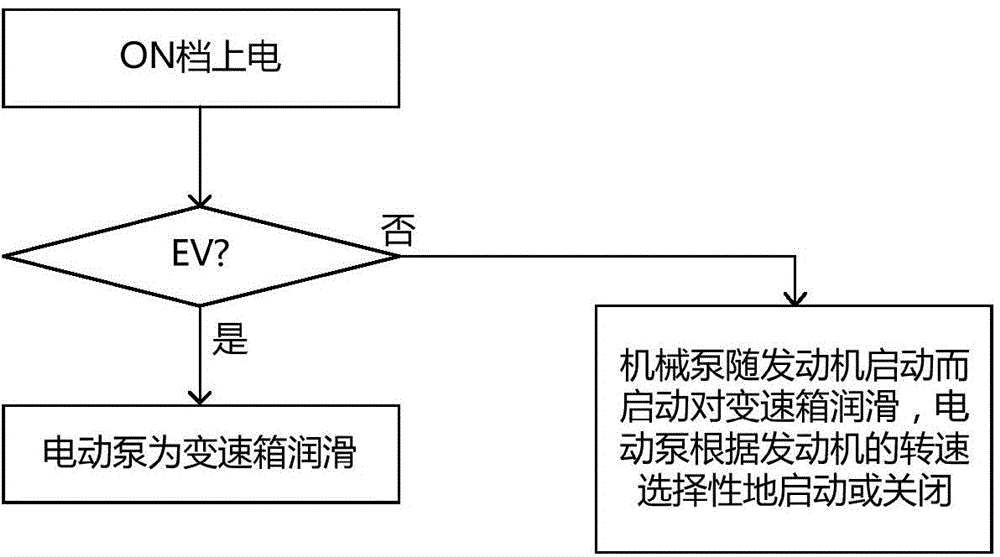

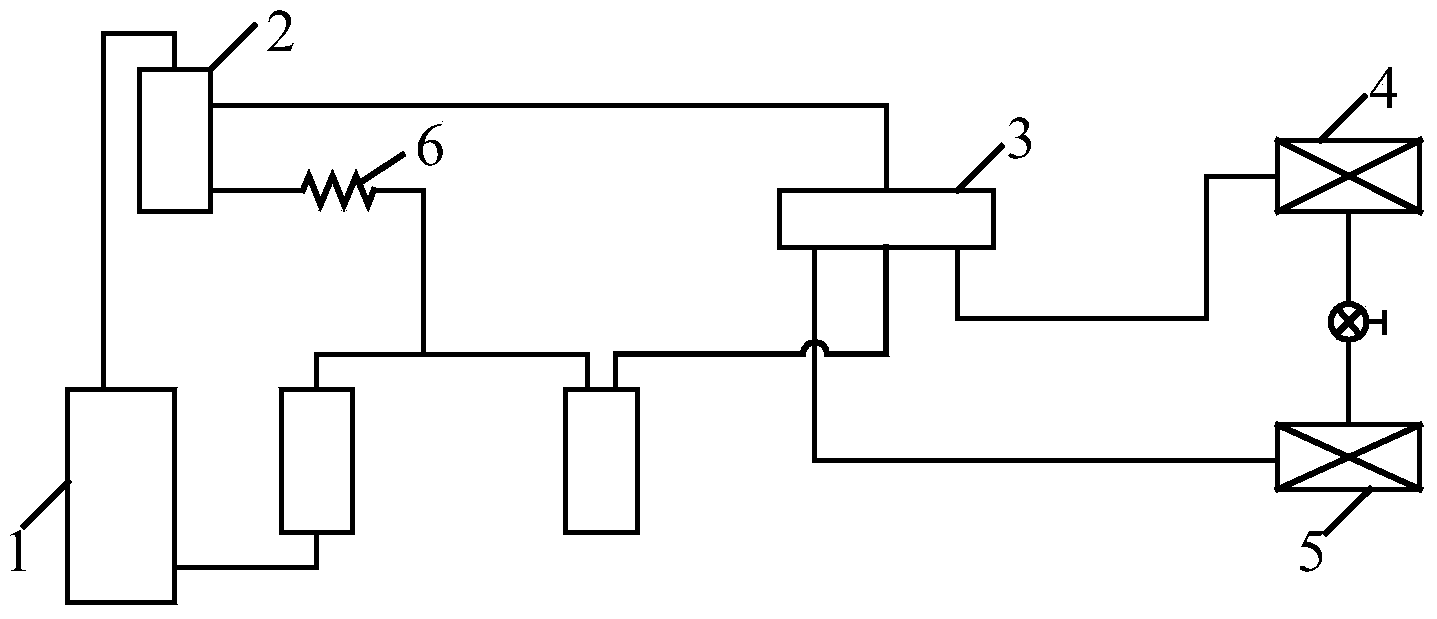

Transmission lubricating system and method suitable for hybrid electric vehicle

The invention discloses a transmission lubricating system suitable for a hybrid electric vehicle. The system comprises a transmission, lubricating oil, an electric pump, a controller and a mechanical pump. The lubricating oil is accommodated in the transmission. The electric pump is communicated with the bottom and the top of the transmission. The controller is connected with the electric pump for controlling the electric pump to suck out the lubricating oil from the bottom of the transmission for pressurizing and spraying the lubricating oil to the top of the transmission to lubricate the transmission. The mechanical pump is communicated with the bottom and the top of the transmission. The mechanical pump is connected with an engine of the vehicle for starting along with the engine to suck out the lubricating oil from the bottom of the transmission for pressurizing and spraying the lubricating oil from the top of the transmission to lubricate the transmission. Even if a driving force transfer path of a driving motor and a power transmission path of the engine both work in a high-speed area with low speed and high torque, the transmission lubricating system can satisfy the lubricating demands. The invention further discloses a transmission lubricating method suitable for the hybrid electric vehicle.

Owner:BYD CO LTD

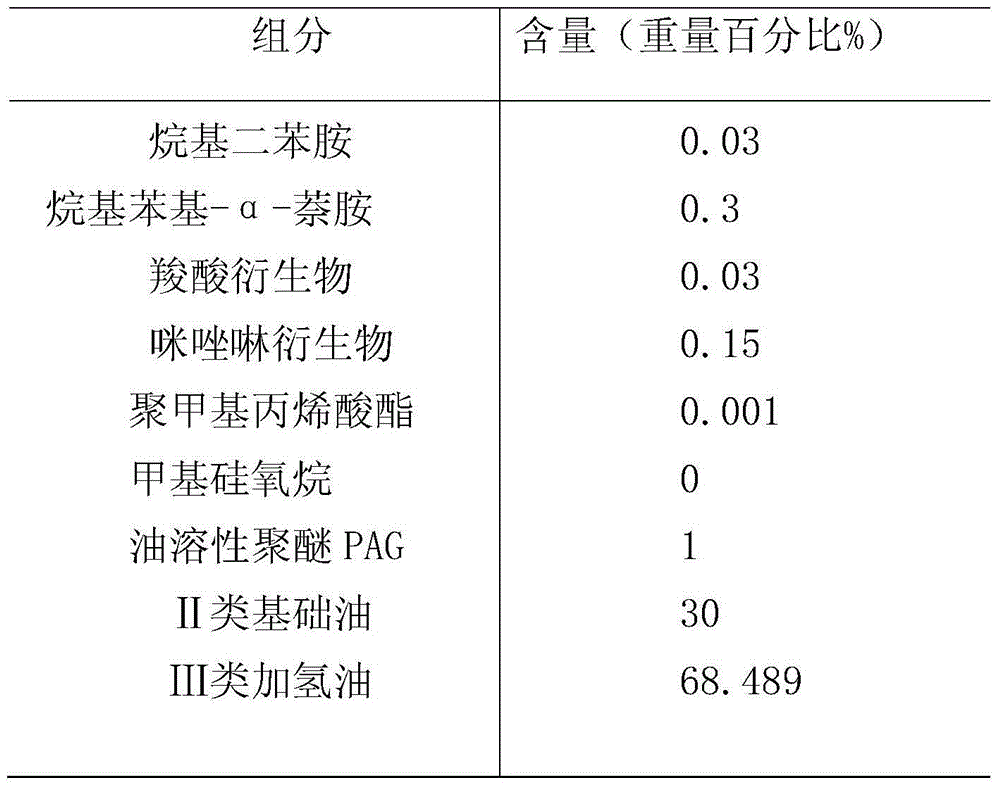

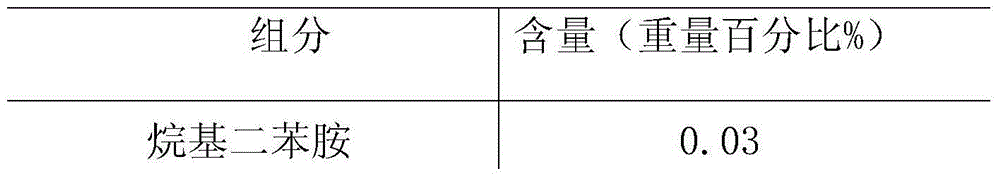

Steam turbine lubricating oil composition with low greasy filth

ActiveCN105733762AGood high temperature resistance and oxidation resistanceImprove rust resistanceLubricant compositionOil sludgeImidazoline derivatives

The invention belongs to the technical field of steam turbine lubrication, and is a low-sludge steam turbine lubricating oil composition. 0.03% to 0.2% antirust agent compounded with derivatives, 0.001% to 0.1% antifoaming agent, 1% to 20% polyether, and base oil as the balance. The advantages of the present invention: excellent high temperature resistance and oxidation resistance, in the Dry-TOST test at 120°C, the oxidation life of the remaining rotary oxygen bomb rate of 25% is at least 500 hours, the rotary oxygen bomb is more than 900 minutes, and the TOST oxidation life is more than 10000 Hours; very little sludge formation tendency, in the Dry-TOST test at 120°C, the sludge formation is less than 60mg / kg when the remaining rotary oxygen bomb rate is 25%, and the sludge formation is less than 200mg after TOST test 1000h; the composition can be very good Meet the lubrication requirements of steam turbines and gas turbines with low oil sludge requirements.

Owner:PETROCHINA CO LTD

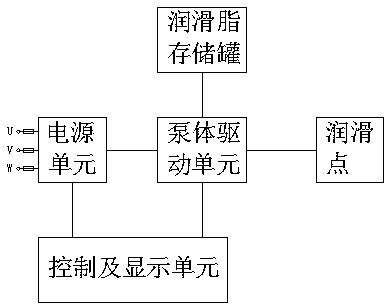

Locomotive auxiliary engine self-lubrication method and system

PendingCN107842703AExtended service lifeUnimpeded or not monitoringBearing componentsVehicle componentsElectric machineryControl theory

The invention discloses a locomotive auxiliary engine self-lubrication method and system. The method is realized through the locomotive auxiliary engine self-lubrication system and includes the stepsthat after a locomotive is started and a locomotive auxiliary engine begins to work, a power unit of the locomotive auxiliary engine self-lubrication system acquires the power from the locomotive auxiliary engine and transmits the power to all subsequent units so as to make the locomotive auxiliary engine self-lubrication system operate; and a control and display unit of the locomotive auxiliary engine self-lubrication system controls a pump body drive unit to drive a plunger to suck in lubricating grease from a lubricating grease storage tank and to convey the lubricating grease to all lubricating points needing to be lubricated of the auxiliary engine. By means of the locomotive auxiliary engine self-lubrication method and system, locomotive auxiliary fan motor bearings can be self-lubricated in timing and quantifying modes, the effect that the motor bearings are in a lubrication state all the time is guaranteed, the service life of the locomotive auxiliary fan motor bearings is prolonged, traffic safety is guaranteed, and the locomotive auxiliary engine self-lubrication method and system are suitable for self-lubrication of the auxiliary fan motor bearings of various sorts of DClocomotives and AC locomotives.

Owner:株洲中车电气科技有限公司

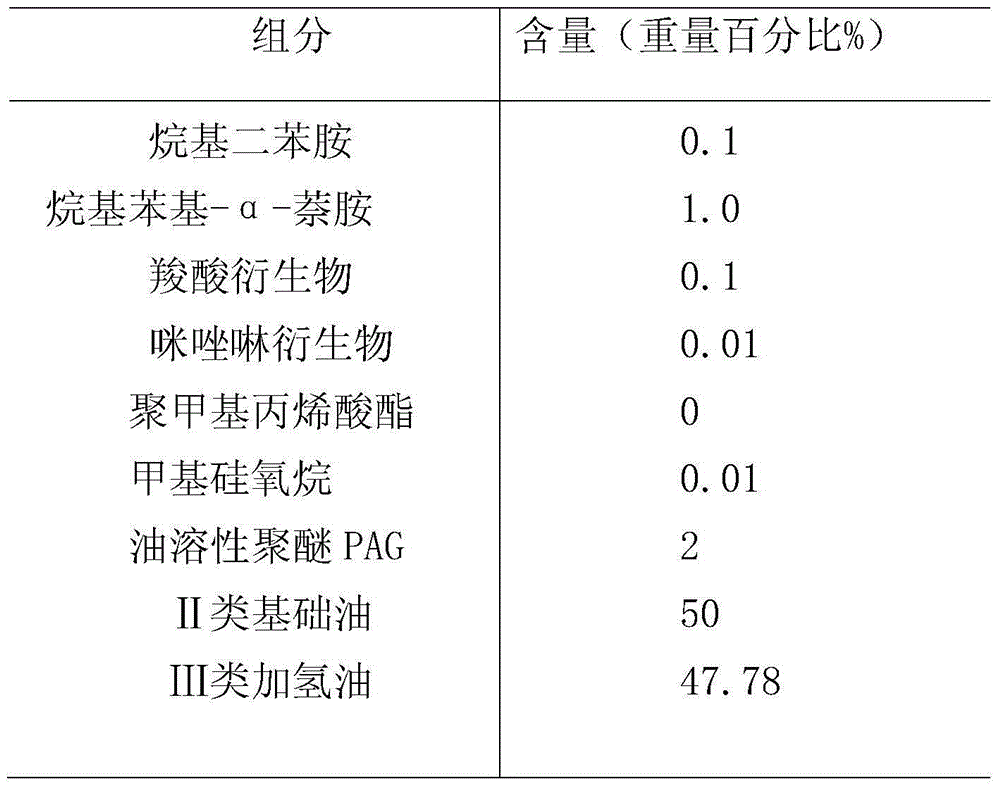

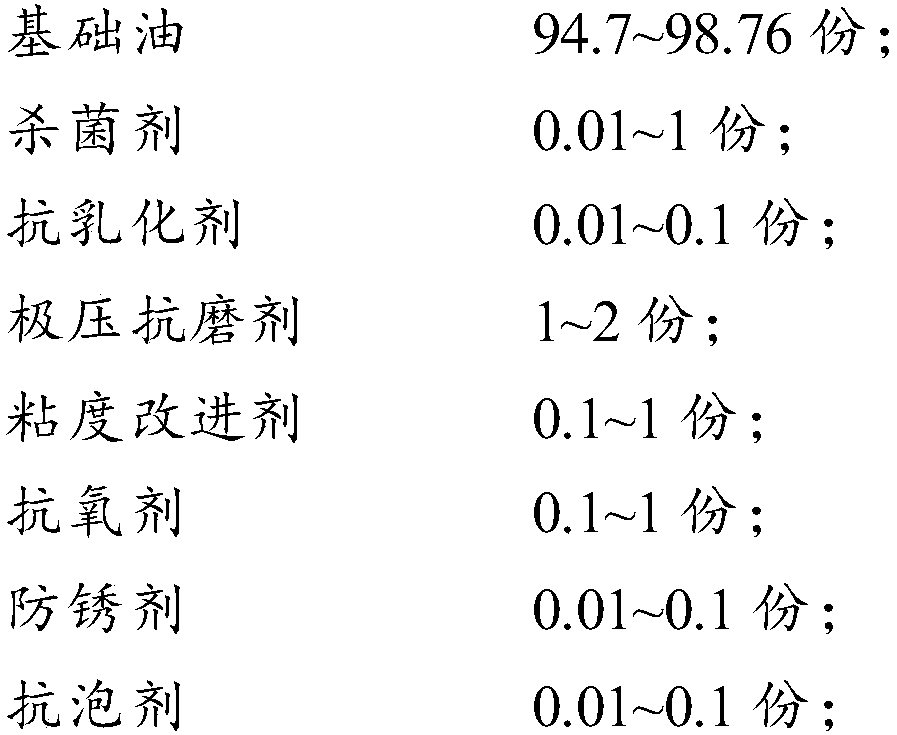

Oil membrane bearing oil composition and preparation method thereof

ActiveCN109097171AImprove performanceImprove antibacterial propertiesLubricant compositionAntioxidantSulfur containing

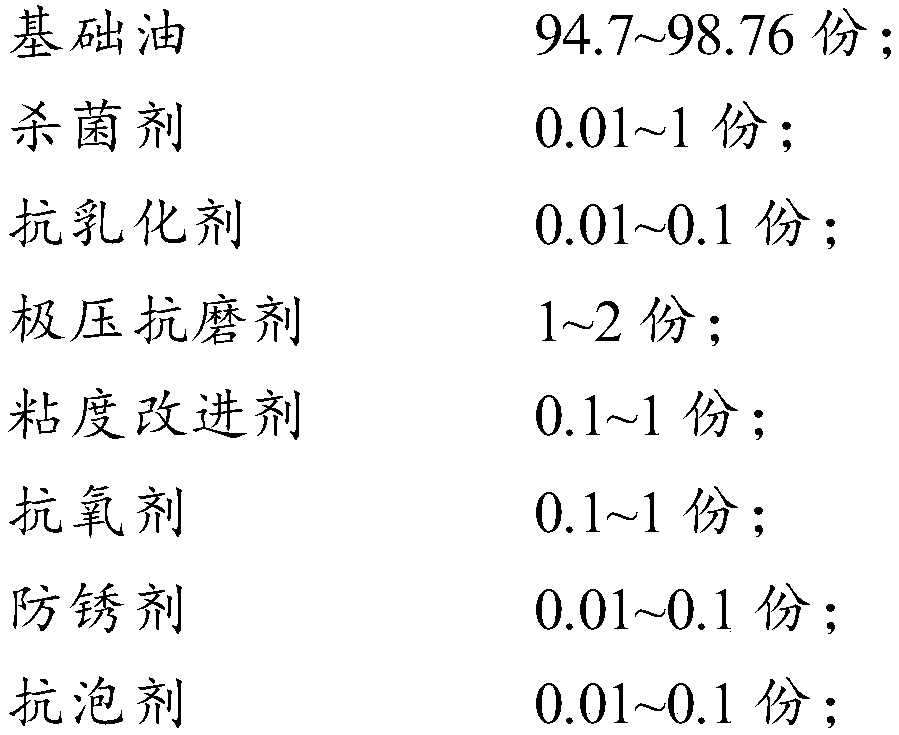

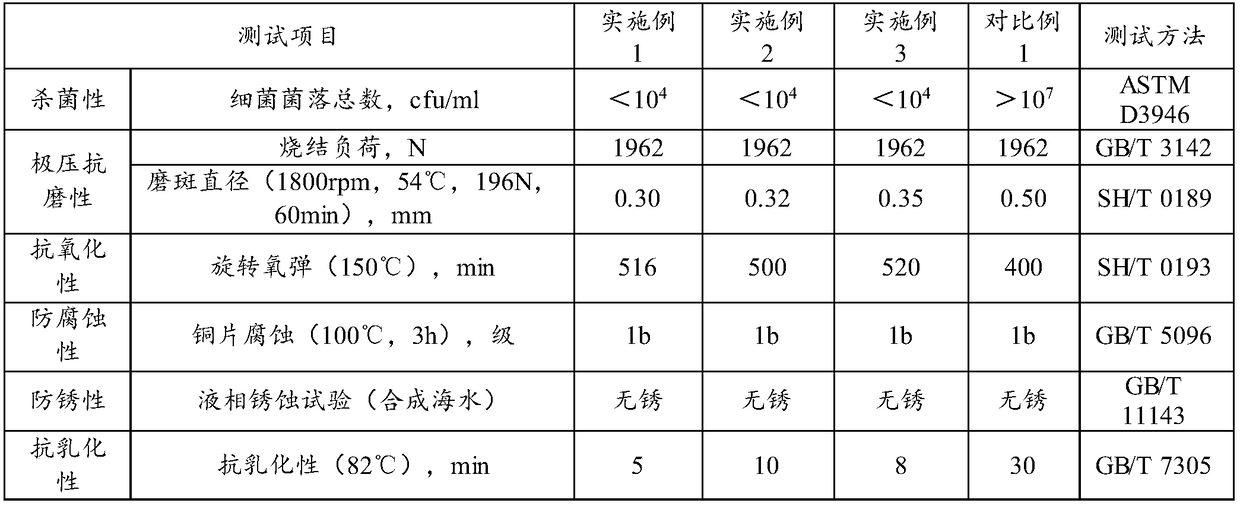

The invention provides an oil membrane bearing oil composition and a preparation method thereof. The oil membrane bearing oil composition provided by the invention comprises the following components:94.7-98.76 parts of basic oil, 0.01-1 part of a sterilization agent, 0.01-0.1 part of a demulsifying agent, 1-2 parts of an extreme pressure anti-wear reagent, 0.1-1 part of a viscosity improver, 0.1-1 part of an antioxidant, 0.01-0.1 part of an anti-rusting agent and 0.01-0.1 part of an anti-foaming agent, wherein the basic oil is selected from one or more of HVII basic oil and HVIII basic oil; the sterilization agent is selected one or more of isothiazolinone and quaternary ammonium salt; the demulsifying agent is selected from one or more of a condensation compound of amino and ethylene oxide and gylcol ester; the extreme pressure anti-wear reagent is selected from one or more of a sulfur-containing extreme pressure anti-wear reagent and a phosphorus containing extreme pressure anti-wear reagent. The bearing oil is not only excellent in antibacterial agent, but also excellent in oxidation resistance, extreme pressure wearing resistance and anti-rusting corrosion resistance, and is capable of well meeting use requirements of an oil membrane bearing.

Owner:CHINA PETROLEUM & CHEM CORP

Gearbox lubricating oil liquid level adjusting and controlling system and adjusting and controlling method thereof

PendingCN109296741AFlexible adjustment of liquid levelLower the liquid levelGear lubrication/coolingDrive motorEngineering

The invention provides a gearbox lubricating oil liquid level adjusting and controlling system and an adjusting and controlling method thereof. The side face of a bottom lubricating oil storing bin ofa gearbox shell is provided with a communicating containing cavity; the adjusting and controlling system is installed in the containing cavity; a lifting device is formed in a manner that a driving motor and a lead screw are coaxially connected; an oil discharging device is formed in a manner that a floating cavity, a guiding sleeve and a threaded long sleeve are fixedly connected; the floating cavity is in sliding connection with a supporting and guiding assembly through the guiding sleeve, and is in threaded connection with the lifting device through the threaded long sleeve; under drivingby the lifting device, the floating cavity performs lifting movement in the containing cavity along the supporting and guiding assembly, and therefore the liquid level height of lubricating oil in thecontaining cavity is controlled; a control assembly is composed of a controller and a vehicle state sensor in a signal connection manner; and the adjusting and controlling method comprises an adjusting and controlling method for increasing and decreasing the liquid level height of the lubricating oil. According to the gearbox lubricating oil liquid level adjusting and controlling system and the adjusting and controlling method thereof, the amount of the lubricating oil needed by each part is determined according to the specific work state of a gearbox, the liquid level of the lubricating oilis controlled at the position of optimal height, the oil stirring loss is reduced, and the overall transmission efficiency of the gearbox is improved.

Owner:JILIN UNIV

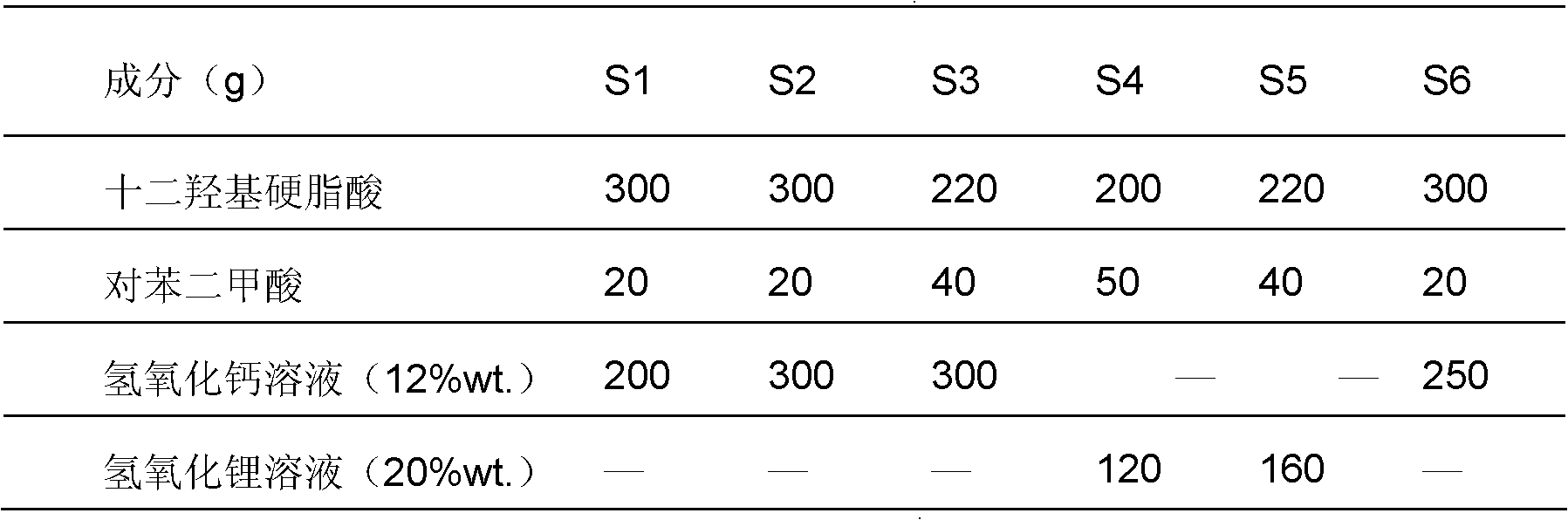

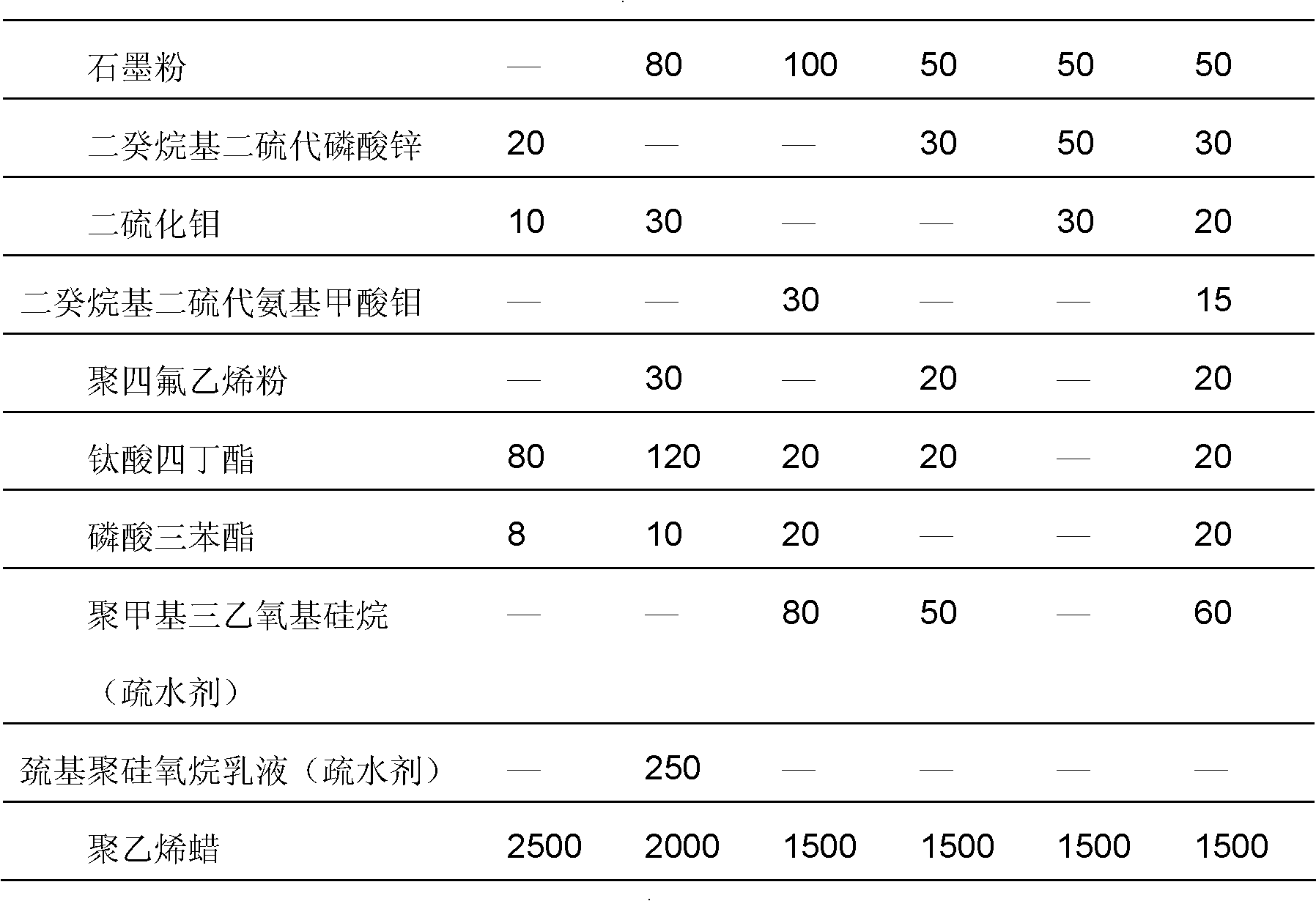

Grease for low speed and heavy duty

InactiveCN101974362AGood low temperature resistanceGood lubrication effectLubricant compositionZincLow speed

The invention relates to grease for low speed and heavy duty. The grease contains 8-20% of thickening agents, 1-4% of graphite powder, 0.3-6% of other extreme pressure additives, 0.3-6% of organic ester and the balance base oil by weight, wherein other extreme pressure additives are one or more of zinc dialkyldithiophosphate, molybdenium disulfide, molybdenum dialkyldithiocarbamate and other organic molybdenum salt containing alkyl; and the organic ester is tetrabutyl titanate, phosphate ester or combination of tetrabutyl titanate and phosphate ester.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

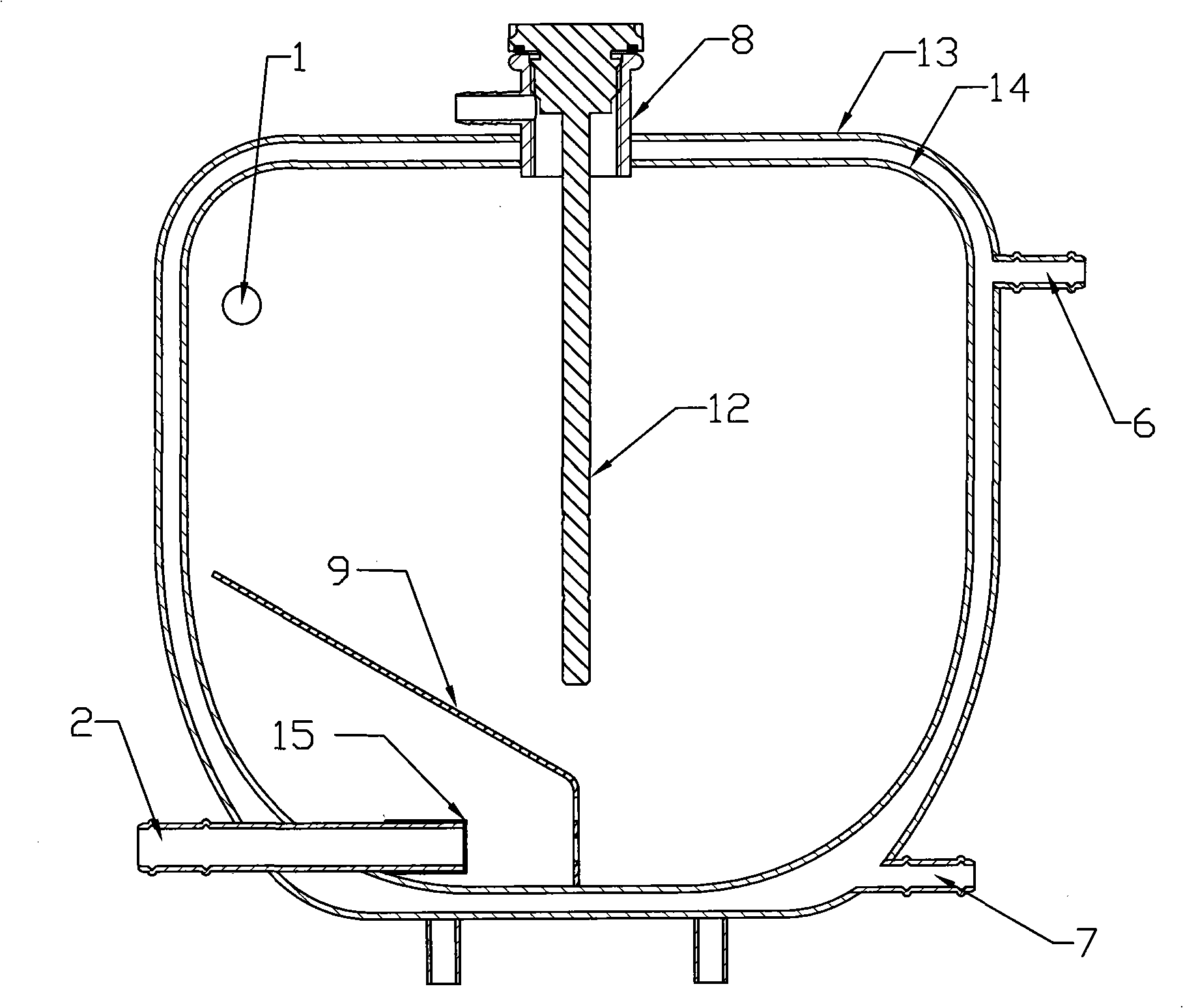

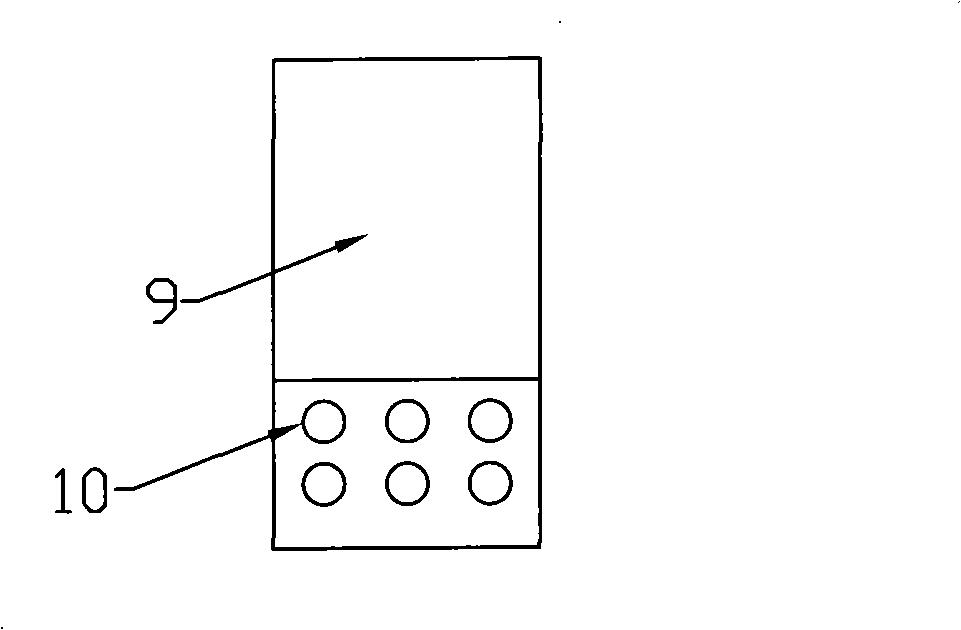

Broad sense crankcase oil tray for motorboat engine

InactiveCN101289951AReduce wearGuaranteed reliabilityMachines/enginesLubricant filling/drainingPipingEngineering

The invention discloses a generalized crankcase oil tray of a motorboat engine. The generalized crankcase oil tray is provided with an inner-layer shell body, an outer-layer shell body, an oil inlet pipe joint, an oil outlet pipe joint, a water inlet pipe joint, a water outlet pipe joint, an oil drain plug seat, an oil drain plug screw, an oil filling port seat and an oil filling port cover; engine oil is stored in the inner-layer shell body; cooling water flows in a jacket between the inner-layer shell body and the outer-layer shell body. The application of the generalized crankcase oil tray reduces both the height of the dry-type crankcase oil tray of the motorboat engine and the gravity of the motorboat engine, so that the whole motorboat has better dynamic property; the middle space of the motorboat is utilized to get the operations of the engine oil filling, the engine oil draining, the observation of the lube level height, etc. more convenient.

Owner:海宁艾斯比威机车制造有限公司

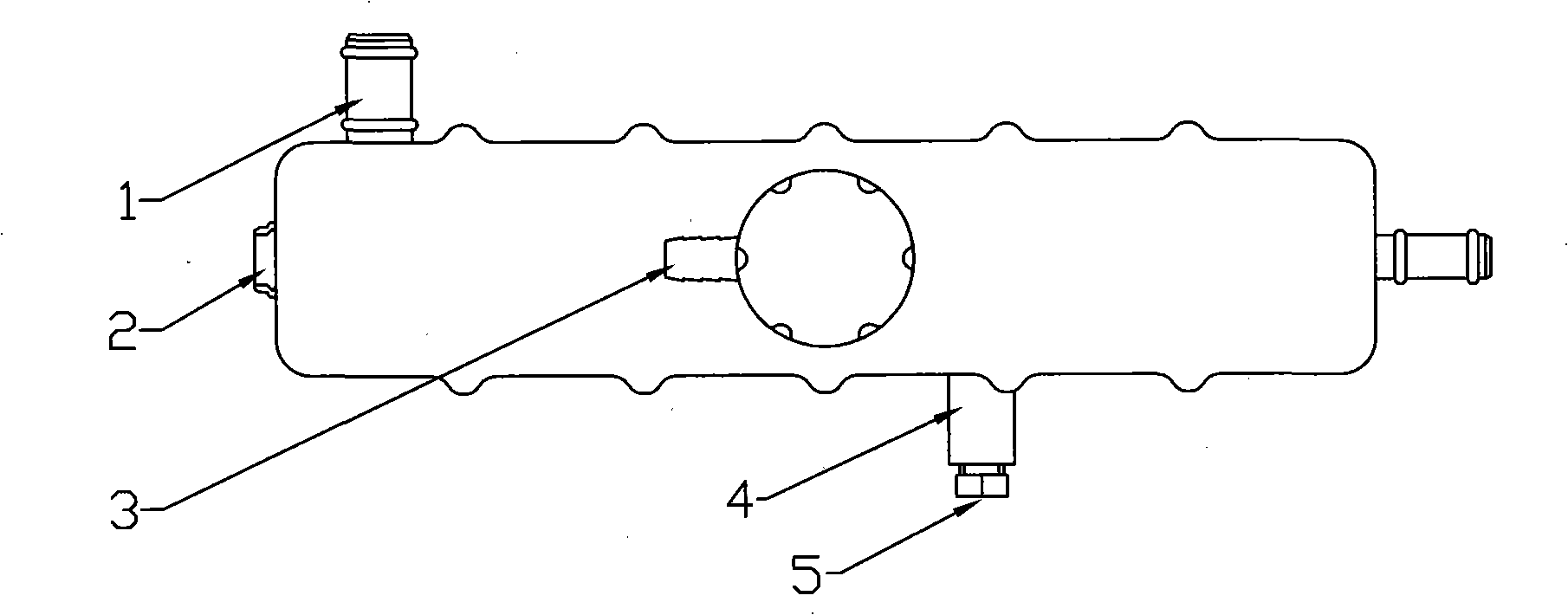

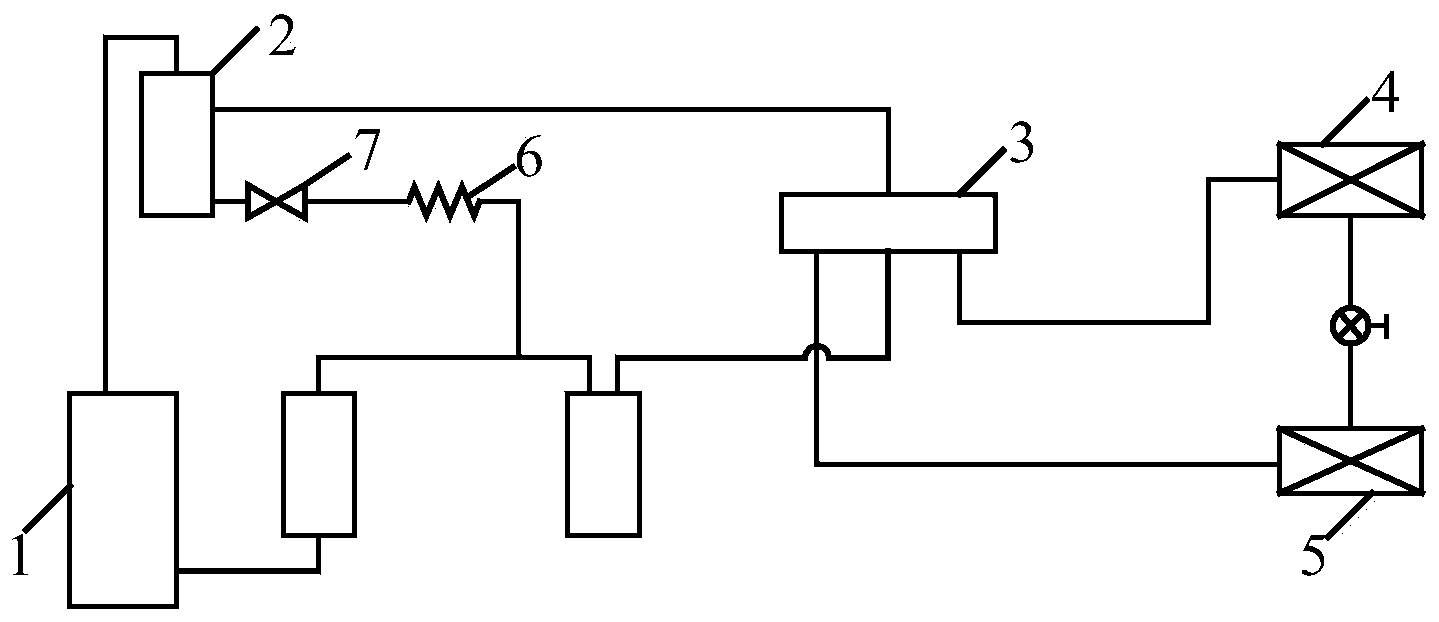

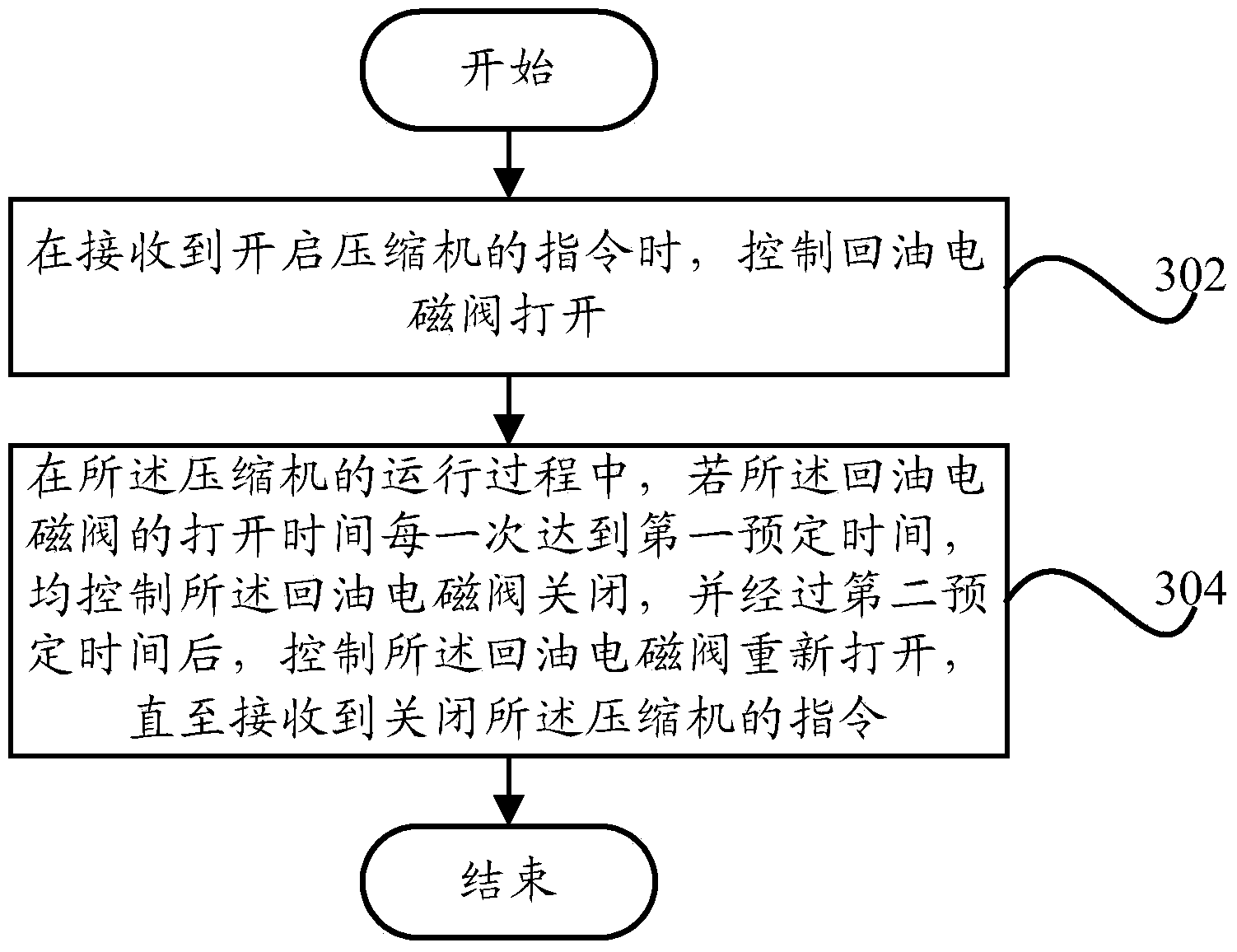

Oil return control method and oil return control system for compressor system

InactiveCN104236168AAffect the heat transfer effectMeet lubrication needsCompressorRefrigeration safety arrangementControl systemElectromagnetic valve

The invention provides an oil return control method and an oil return control system for a compressor system. The compressor system comprises a compressor, an oil separator connected with an exhaust port of the compressor and an oil return electromagnetic valve connected between an oil outlet of the oil separator and an air return port of the compressor. The oil return control method comprises the following steps: when receiving an instruction of starting the compressor, controlling the oil return electromagnetic valve to open; during an operating process of the compressor, if the opening time of the oil return electromagnetic valve reaches a first preset time every time, controlling the oil return electromagnetic valve to close, and after a second preset time, controlling the oil return electromagnetic valve to reopen until receiving an instruction of shutting down the compressor. According to the technical scheme, the system and the method are capable of ensuring that lubricating oil returned to the compressor has a relatively low temperature and furthermore ensuring that an air conditioner always keeps a favorable heat exchange effect.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD

Air suspension track running equipment

InactiveCN102275589AReduce frictionEasy to driveSliding/levitation railway systemsAxle-box lubricationElectric machineryDrive motor

Provided is an air suspension railway operating device, comprising a suspension mechanism, a driving mechanism, a sealing mechanism and a transport carrier. The suspension mechanism is composed of two high-pressure air chambers which are symmetrically arranged at left and right sides, and a railway base. Each high-pressure air chamber comprises a high-pressure gas cell, a lubricant airtight slide rail and a slide rail supporting bracket. The high-pressure air chambers are fixed on the railway base. The driving mechanism comprises a driving motor, a speed reducing mechanism, a friction wheel and a friction plate, which are installed between the railway base and a U-shaped frame of the transport carrier. The sealing mechanism comprises the lubricant airtight slide rail and a sealing strip which is mounted between the bottom of the lubricant airtight slide rail and the inner wall of the high-pressure gas cell. In the invention, the lubricant airtight slide rail is adopted to seal high-pressure air, the high-pressure air suspension technology is applied, and the friction wheel is driven by the motor to drive the friction plate for power supply, thereby creating the energy-saving environmentally-friendly public transport running rail and creating the pollution-free noise-free peaceful and harmonic public transport environment.

Owner:谢向勇

Lubricating grease with long service life, extreme pressure and high-temperature resistance and preparation method thereof

InactiveCN107955677AImprove extreme pressure performanceMeet lubrication needsLubricant compositionPolyesterAntioxidant

The invention discloses lubricating grease with long service life, extreme pressure and high-temperature resistance and a preparation method thereof. The lubricating grease comprises the following components in percentages by weight: 8.1 to 18.6% of a thickening agent, 0.3 to 0.7% of fatty alcohol, 2 to 10% of dibasic acid polyester, 0.3 to 1.5% of an antioxidant, 0.3 to 1.0% of a metal deactivator and 2 to 5% of an extreme-pressure antiwear agent, with the balance being base oil. The invention has the following advantages: the lubricating grease has excellent high-temperature resistance, shear stability and extreme-pressure wear resistance and good storage stability, adhesiveness and low-temperature fluidity; the requirement of a bearing for lubricating under various working conditions ofhigh temperature, high speed, heavy load and even impulse load can be met; a grease exchange period can be prolonged; meanwhile, the preparation process for the lubricating grease is simple, and facilitates large-scale industrial production.

Owner:JIANGSU LOPALTECH

High pressure oil pump lubricating oil passage of direct injection gasoline engine

ActiveCN103016335AAchieve lubricationMeet lubrication needsPositive displacement pump componentsLiquid fuel engine componentsGasolineCam

The invention relates to a high pressure oil pump lubricating oil passage of a direct injection gasoline engine. The high pressure oil pump lubricating oil passage comprises a cylinder cover oil path arranged on an engine cylinder cover and is characterized by further comprising an annular oil groove formed in a cam shaft, wherein the annular oil groove is formed in a working shaft neck of the cam shaft and formed on one side of a high pressure oil pump driving cam on a non-working shaft neck of the cam shaft; the high pressure oil pump lubricating oil passage further comprises a connecting oil path and a high pressure oil pump oil path, wherein the connecting oil path is arranged on an integrated cam shaft cover; the high pressure oil pump oil path is communicated with the connecting oil path; the high pressure oil pump oil path is communicated with a high pressure oil pump tappet hole; and the cylinder cover oil path on the engine cylinder cover and the connecting oil path on the integrated cam shaft cover are respectively communicated with the annular oil groove of the cam shaft. The high pressure oil pump lubricating oil passage of the direct injection gasoline engine, provided by the invention, has the advantages as follows: the structural layout is compact; spaces can be saved; and moreover, a high pressure oil pump can be lubricated without an external lubricating oil path and additional parts, so that the assembling difficulty and manufacturing cost of the engine can be prevented from being increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

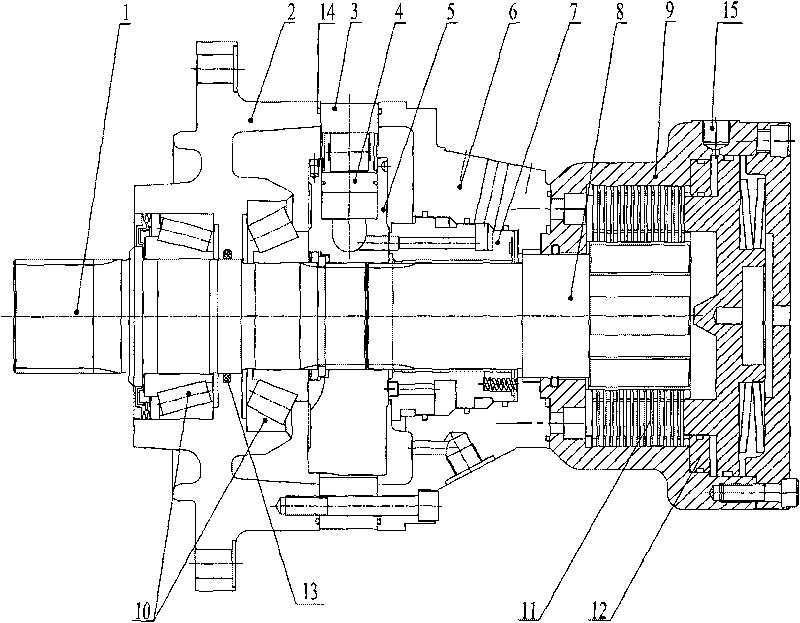

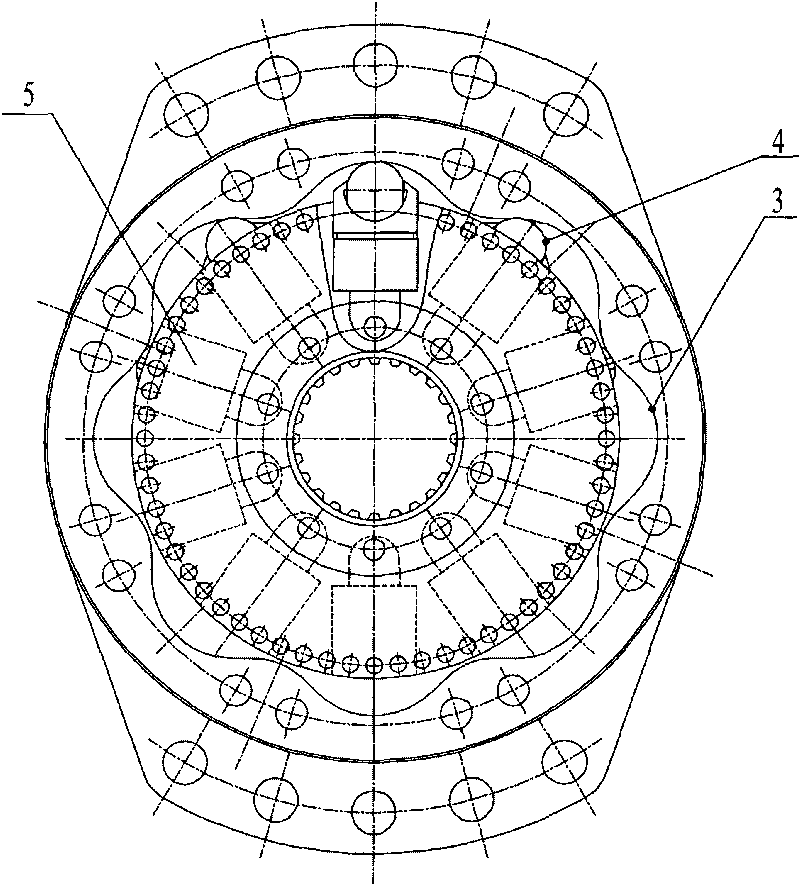

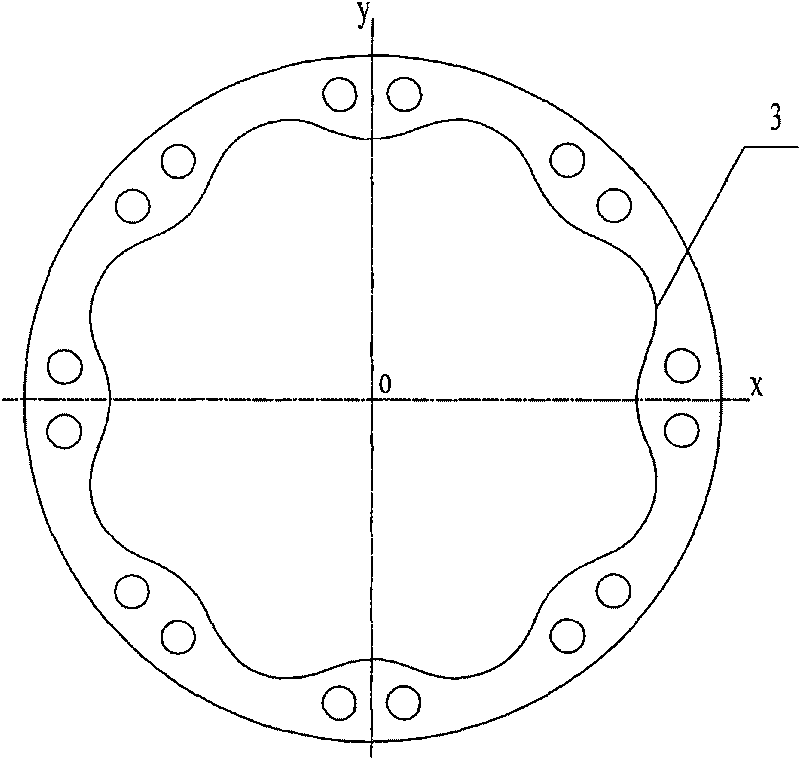

Radial plunger type multiple-action inner curved hydraulic motor

InactiveCN101709685AMeet lubrication needsGuaranteed lubrication needsReciprocating piston enginesHydraulic motorWorking environment

The invention relates to a radial plunger type multiple-action inner curved hydraulic motor, which is hydraulic equipment mainly applicable to stokeholes and other severe working environments. The hydraulic motor mainly comprises an output shaft, an installation seat, gear rings, a plunger piston, a driving disk, a rear seat, an oil pan, a brake, a brake axle, and the like. Tracks of the motor adopt the gear rings processed by a single curve track formula so as to meet plunger piston movement, the use of multiple types of sealing rings can avoid obvious leakage between a high pressure chamber and a low pressure chamber, and meanwhile, miniature leakage rate can meet the requirement of a bearing on lubrication, thereby guaranteeing that a machine can not be damaged due to overtemperature in the process of running.

Owner:YICHANG YANSHI TECH DEV

Heavy-load hydrodynamic drive lubricating oil composition

InactiveCN107474928AExtreme pressure antiwear agent goodGood fluidity at low temperatureLubricant compositionFluid couplingChemical composition

The invention relates to a heavy-load hydrodynamic drive lubricating oil composition, which especially can meet the lubrication demand of hydrodynamic drive equipment (including automatic gearbox, a hydraulic coupler, a hydraulic torque converter) used under extremely low-temperature conditions. The composition also adopts special multifunctional antioxidant and antifriction lubricant, ashless dispersant and anti-wear agent at extreme pressure except for base oil, and is compound together with special clean dispersant and antioxidant, thus giving full play to the synergistic effect among the additives. The lubricating oil composition has good low-temperature fluidity, antiwear property at extreme pressure and anti-oxidization stability, as well as certain anticorrosion and anti-rust properties and anti-emulsion property, thus meeting the lubrication demand of the automatic gearbox, the hydraulic torque converter and the hydraulic couple used under various special environment conditions.

Owner:西安石油大佳润实业有限公司

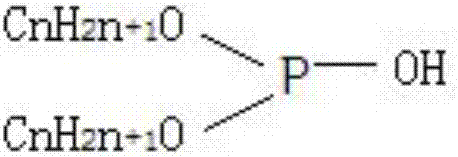

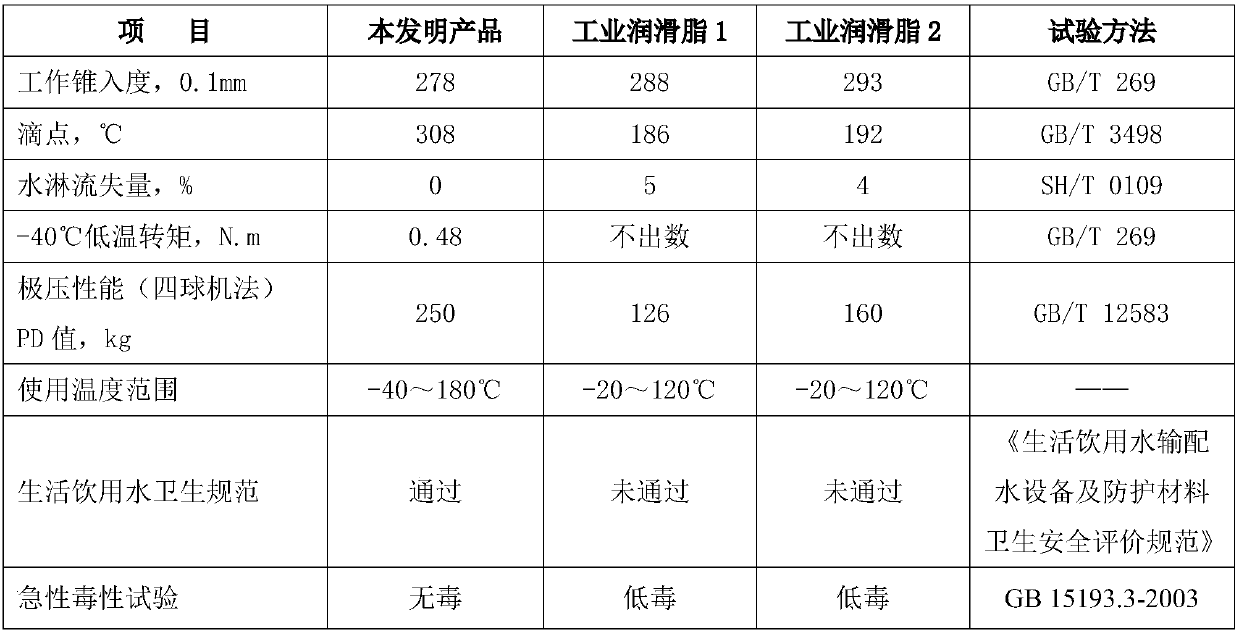

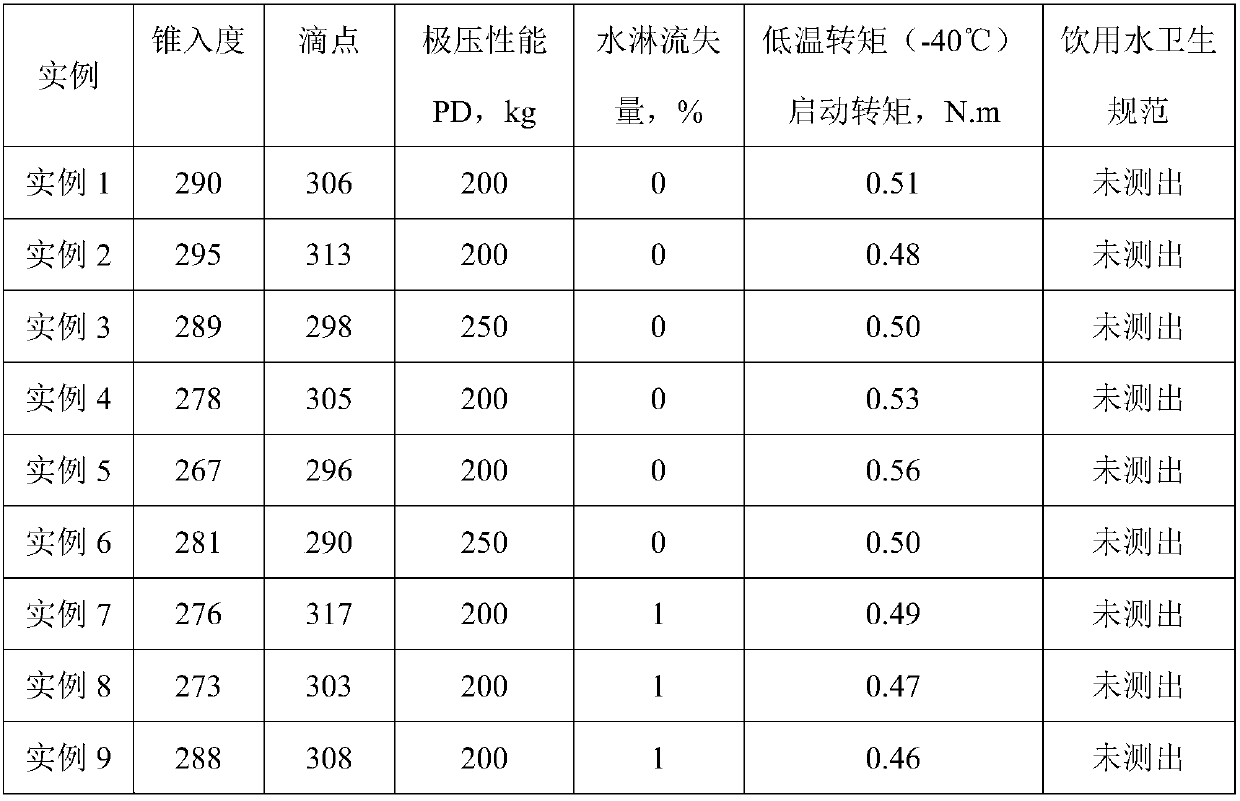

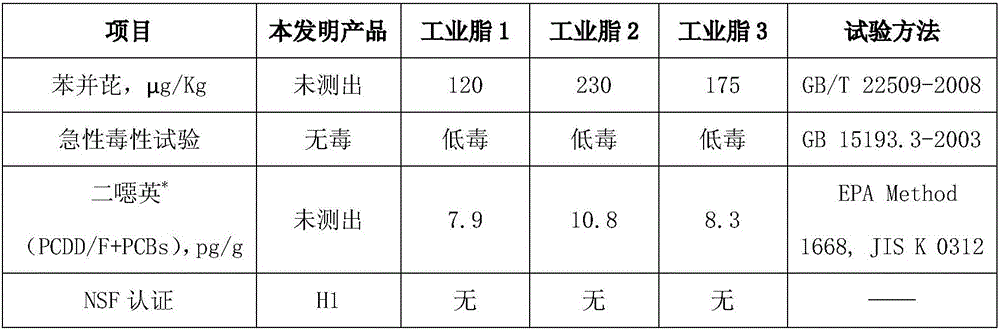

Food grade bearing grease for hydraulic engineering as well as preparation method and application thereof

InactiveCN107686763AMeet health and safety regulationsMeet lubrication needsLubricant compositionOperating temperature rangeHydraulic engineering

The invention provides food grade bearing grease for hydraulic engineering as well as a preparation method and application thereof. The grease composition comprises food grade base oil, a thickening agent and an additive composition. The grease composition comprises the following components in percentage in weight: 84-94% of base oil, 6-16% of the thickening agent, 0.5-10% of an additional antirust agent and 0.1-10% of an additional anti-wear reagent at extreme pressure. The thickening agent is composed of reactants of C16-C20 long-chain fatty acids, aromatic acid and organic aluminum and meets the food grade requirement. The molar ratio of the three raw materials is 1 to 1-1.7 to 1-1.3. The organic aluminum comprises aluminum isopropoxide or triisopropanol trioxide. The bearing grease disclosed by the invention is excellent in anti-wear and extreme pressure property, and the service life of the bearing is prolonged; the water resistance is excellent, the high / low-temperature performance is excellent, and the operating temperature ranges from 40 DEG C below zero to 80 DEG C. The bearing grease disclosed by the invention can meet the lubricating requirements of hydraulic engineeringbearings, and the safety and hygiene requirements in the drinking water industry are met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Food grade lubricating grease used for feed processing machines, and preparation method and application thereof

InactiveCN106497643AImprove protectionSatisfy safety and hygieneThickenersBenzoic acidALUMINUM STEARATES

The invention relates to a food grade lubricating grease used for feed processing machines, and a preparation method and an application thereof. The lubricating grease comprises, by mass, 85-95% of base oil, 5-15% of a composite aluminum thickener, and 6-12% of an additional extreme pressure anti-wear agent. The preparation method comprises the following steps: heating all the base oil to 50-60 DEG C, adding benzoic acid, heating benzoic acid to 70-80 DEG C, adding a preheated aluminum stearate polyoxide polymer after the benzoic acid is dissolved, stirring the dissolved benzoic acid and the preheated aluminum stearate polyoxide polymer, heating the stirred materials to 150 DEG C in 1-2 h, continuously heating the stirred materials to a highest refining temperature of 200-220 DEG C, cooling the heated materials to 80 DEG C, adding a pressurizing anti-wear agent, uniformly stirring all above materials, grinding the obtained mixture, degassing the ground mixture, and filling the degassed mixture. The preparation method of the lubricating grease has the advantages of simplicity, short cycle, and improvement of the quality of the above product and the safety and the healthiness of the production process only through three raw materials. The lubricating grease meets lubricating demands in running of the feed processing machines, such as granulator devices, and accords with the safety and health demands in the feed processing industry.

Owner:CHINA PETROLEUM & CHEM CORP

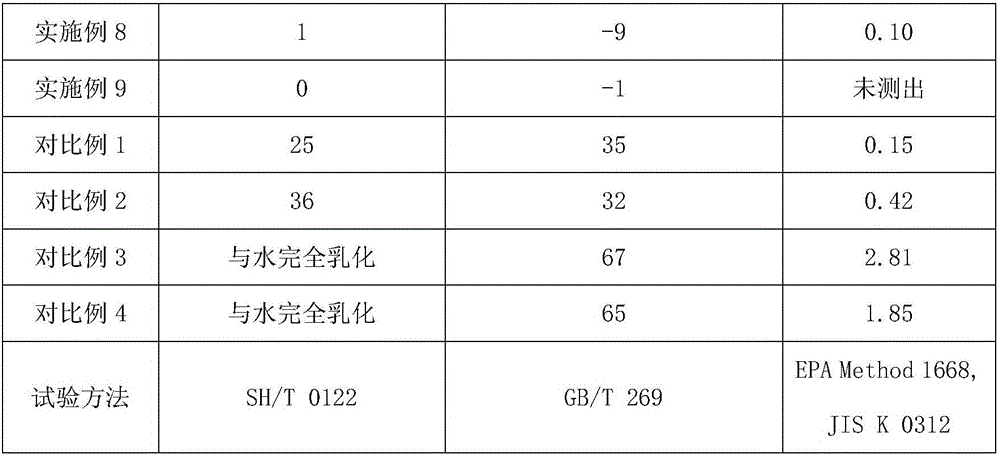

On-line cleaning method for oil injection compressor lubricating oil and system thereof

ActiveCN103334903ARealize cycle cleaningQuality improvementPositive displacement pump componentsPump controlThermodynamicsCleaning methods

The invention discloses an on-line cleaning method for oil injection compressor lubricating oil and a system thereof. Under the working state of an oil injection compressor, lubricating oil is introduced into an on-line cleaning system except the compressor; in the system, liquid impurities brought from a compressor inlet are removed from the lubricating oil by a vacuum removal device; meanwhile, the system is controlled to be automatically started and stopped according to the inlet liquid impurity content detected by an inlet liquid impurity detection device or compressor suction end pressure detected by the pressure sensor. Parts of lubricating oil are subjected to circulating cleaning outside the compressor under the working state of the oil injection compressor. On the premise that the normal work of the compressor is not affected, liquid impurities in the lubricating oil are removed, and the quality of the lubricating oil is improved to satisfy the lubrication requirement of the compressor so as to prolong the service life of the lubricating oil and improve the working efficiency of the compressor.

Owner:冰轮(武汉)能源科技有限公司

All-methanol engine lubricating oil

The invention relates to lubricating oil, in particular to all-methanol engine lubricating oil. Aiming at the defect that most of the current engine lubricating oil is not suitable for use on an all-methanol engine, the invention provides the all-methanol engine lubricating oil suitable for use on an engine which burns pure methanol. The technical scheme is as follows: the engine lubricating oil used on a methanol engine comprises the components of mineral oil, polyolefine and additive, wherein the additive is salicylate with high base number, succimide, zinc dialkyl dithiophosphate and assistant antiseptic agent.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com