Patents

Literature

4084results about How to "Improve the finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

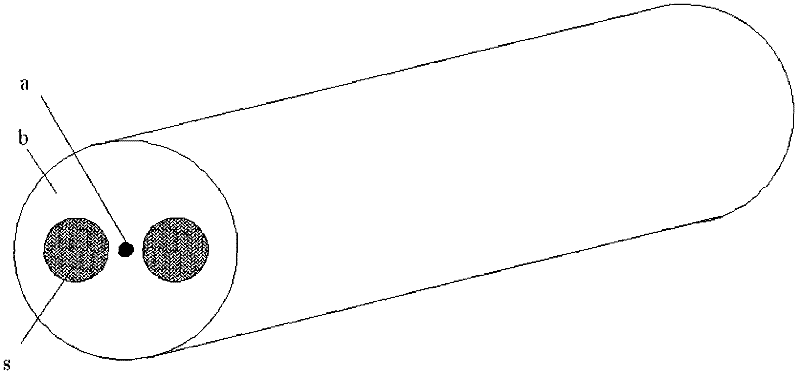

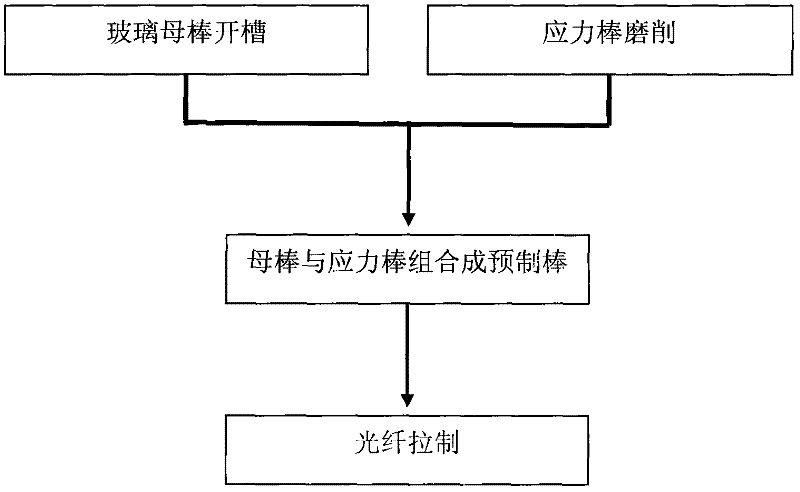

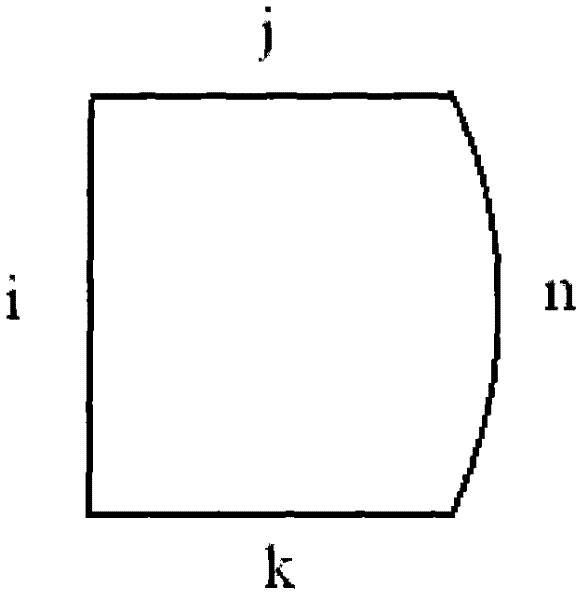

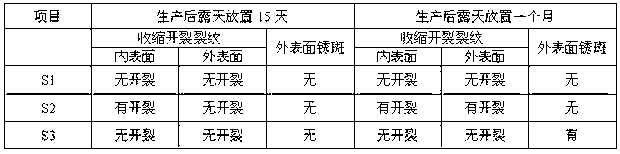

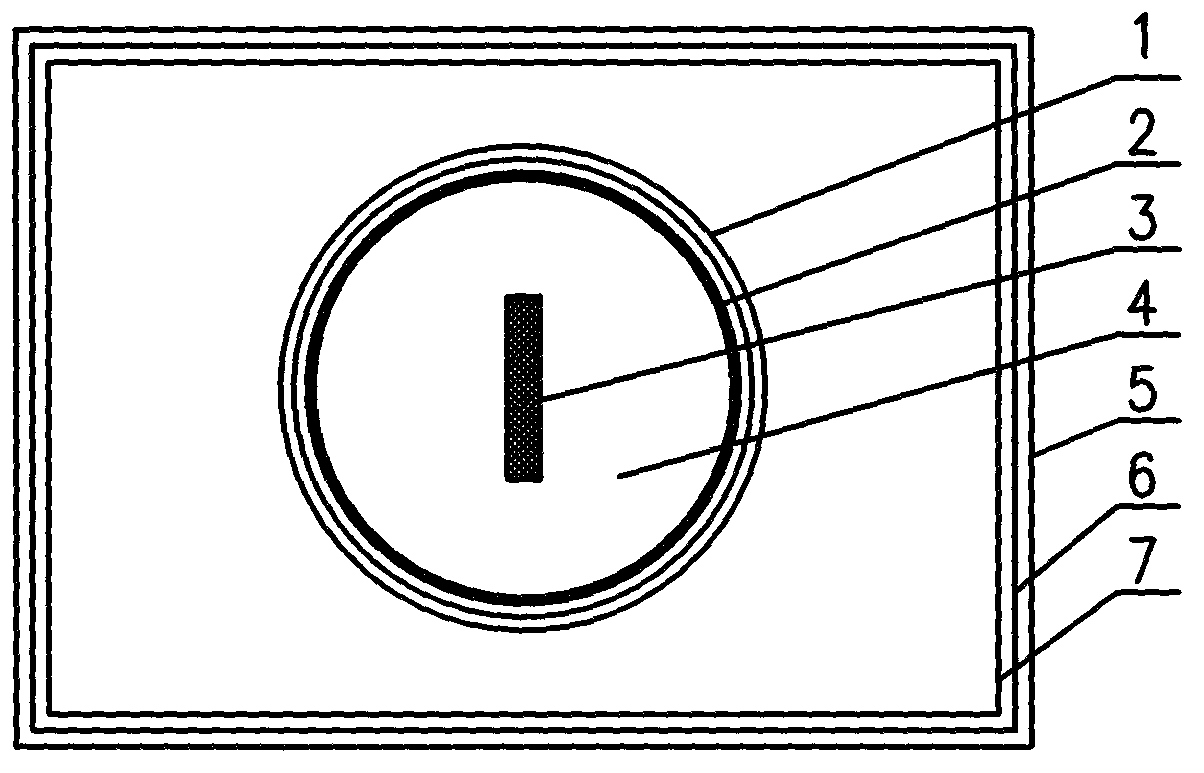

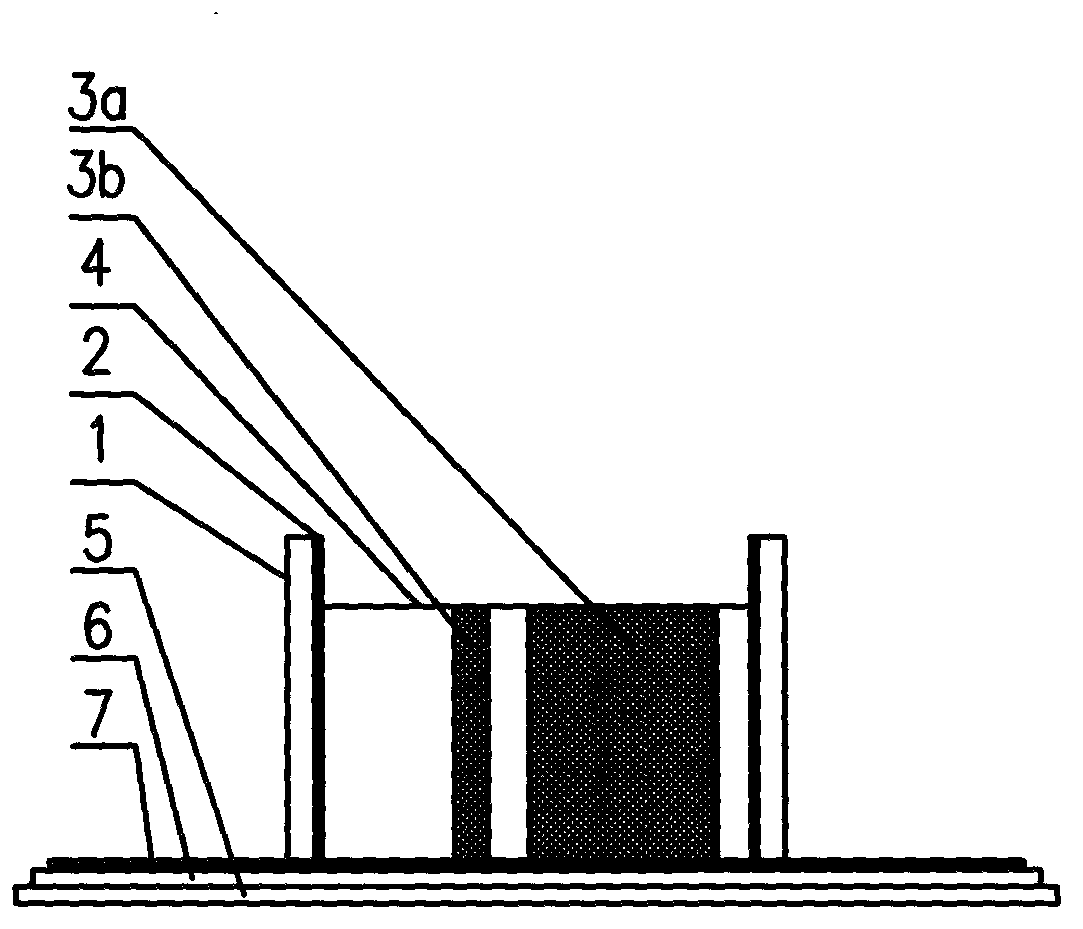

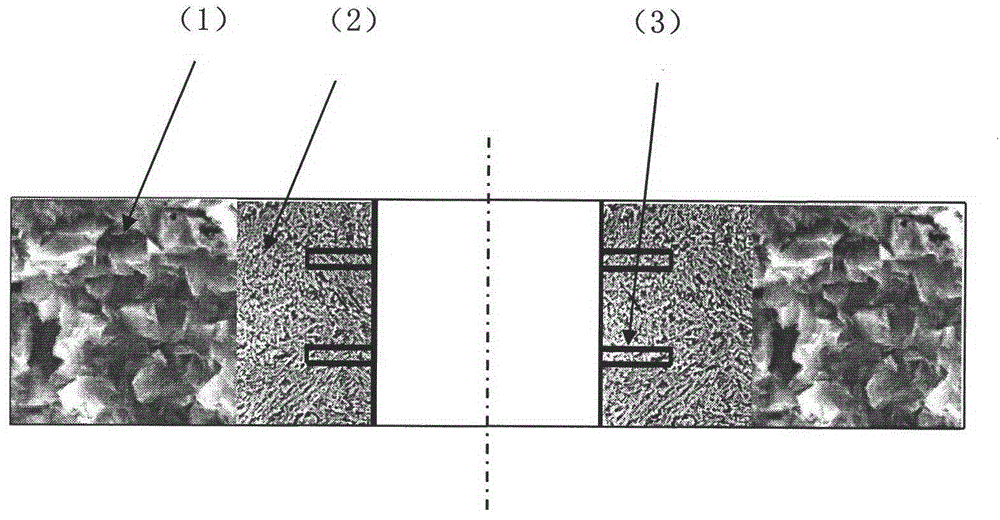

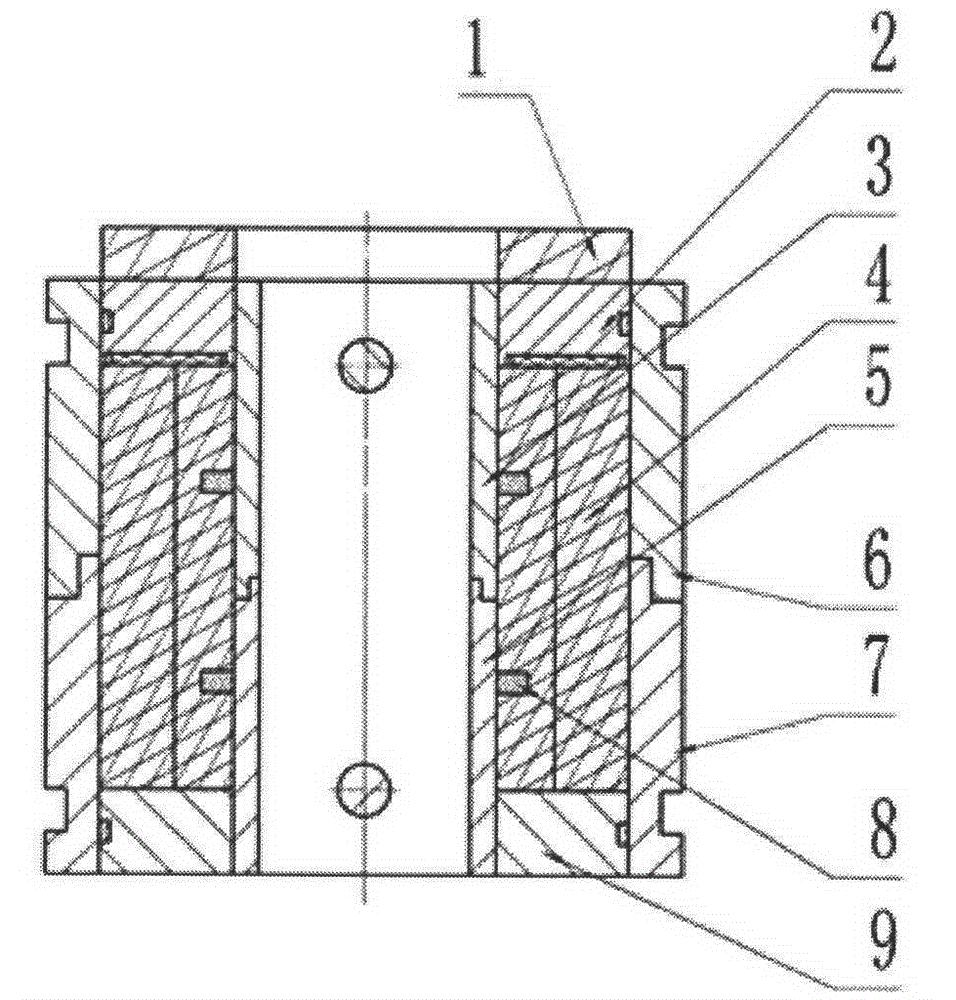

Manufacture method for polarization maintaining fiber and polarization maintaining fiber

InactiveCN102351415AImprove the finishImprove processing efficiencyGlass making apparatusOptical fibre with polarisationSurface finishPolarization-maintaining optical fiber

The invention provides a manufacture method for polarization maintaining fiber and a polarization maintaining fiber, and relates to optical waveguide fibers in the field of fiber-optical communication and fiber optical sensors. The method comprises the following steps that: (1) two oppositely arranged open slots with a same shape are inwardly provided at a side surface of a glass mother rod, stress rods are machined to obtain a shape matching the open slots, and the centers of the cross sections of the two open slots and the center of circle in the cross section of the glass mother rod are in a same line; (2) the stress rods are respectively inserted into each open slot on the glass mother rod, and the assembled glass mother rod and stress rods are put in a cannula to form a preformed rod of the polarization maintaining fiber; (3) the preformed rod of the polarization maintaining fiber is drew to form the polarization maintaining fiber. According to the invention, the glass mother rod is provided with the open slots, and the stress rods are embedded in the open slots, thereby obtaining high process repeatability; inner surfaces of the open slots have high fineness, and the open slots have good symmetry, thereby improving processing efficiency; therefore, the optical performance and reliability of the polarization maintaining fiber are substantially improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

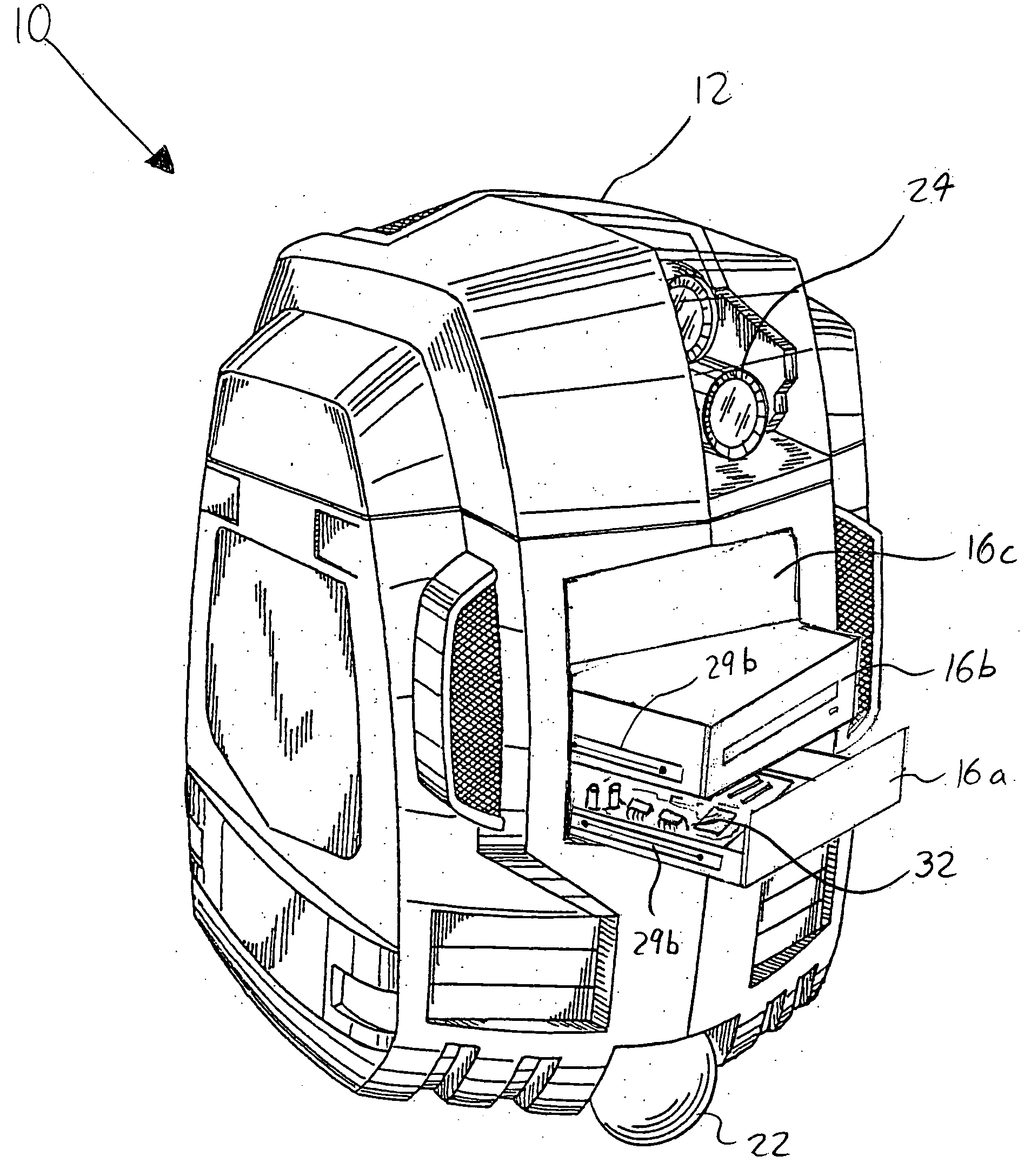

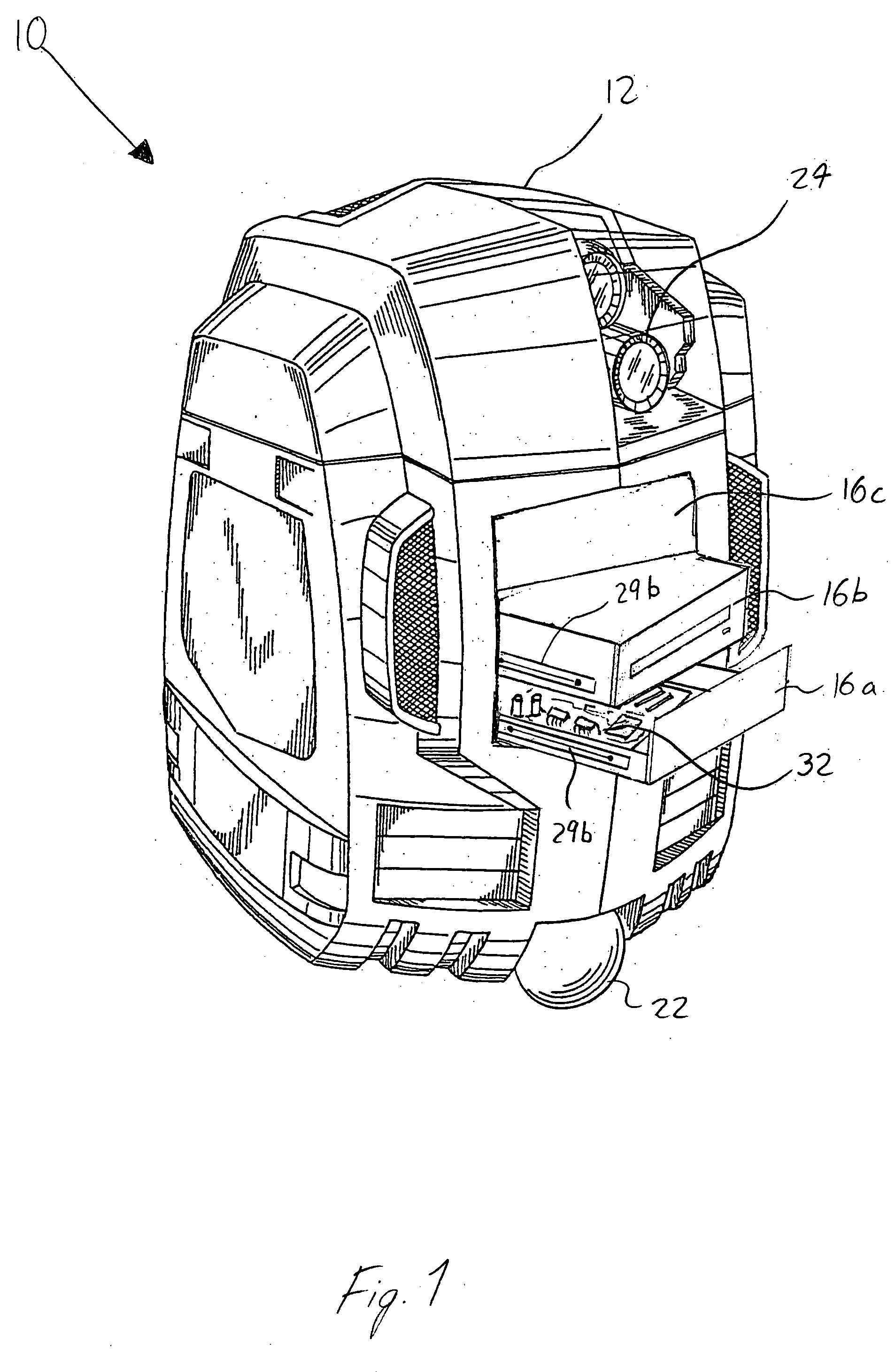

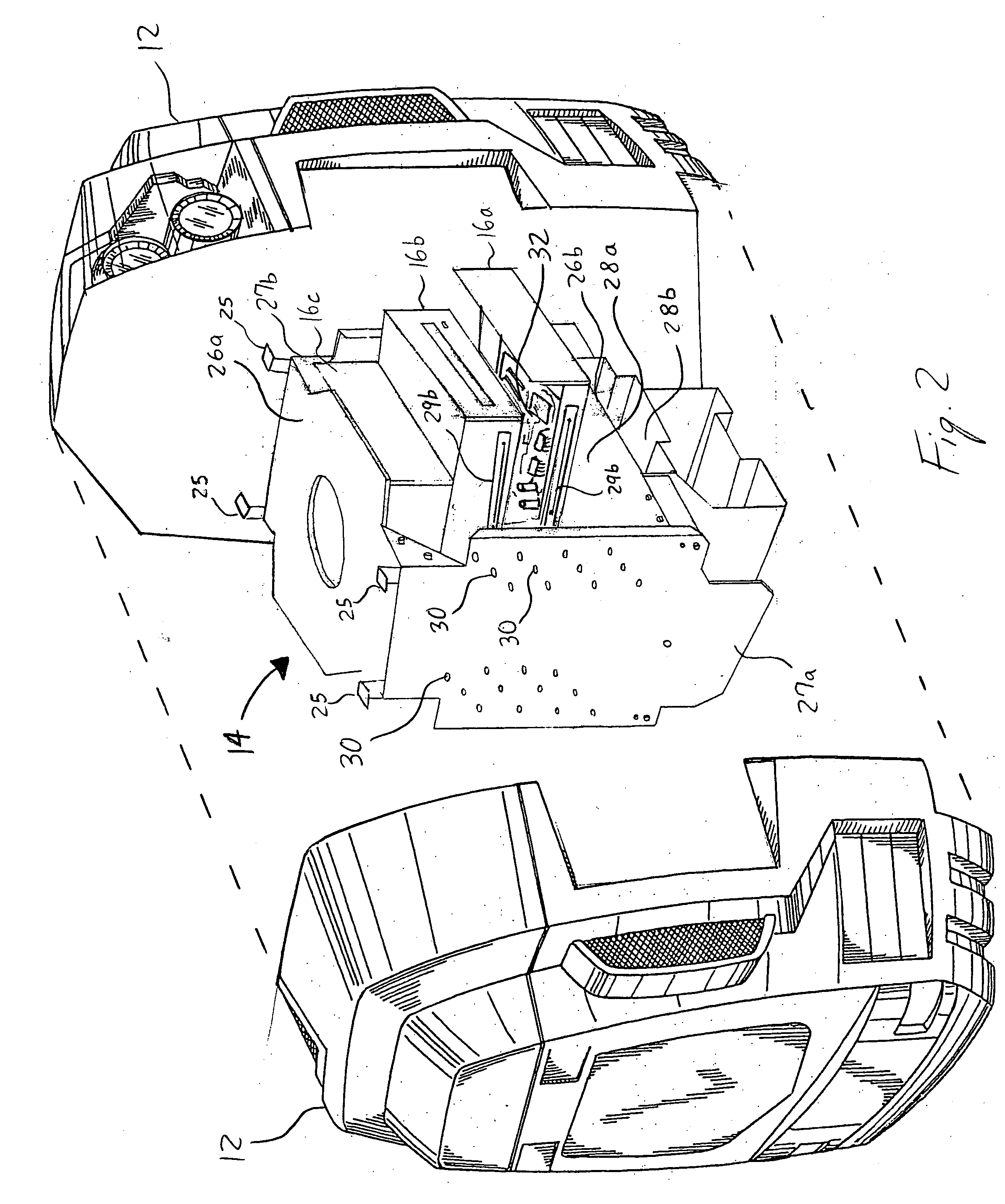

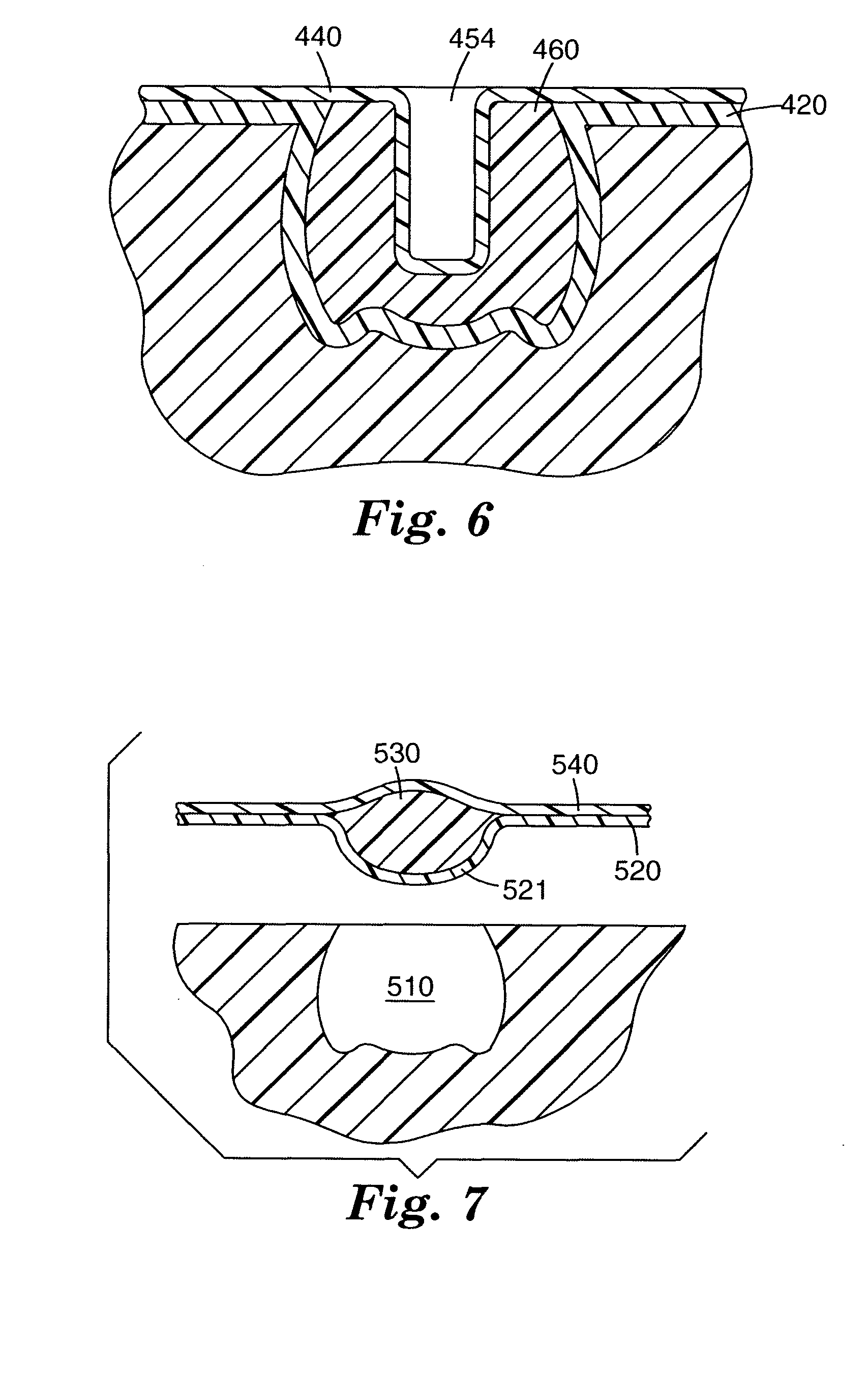

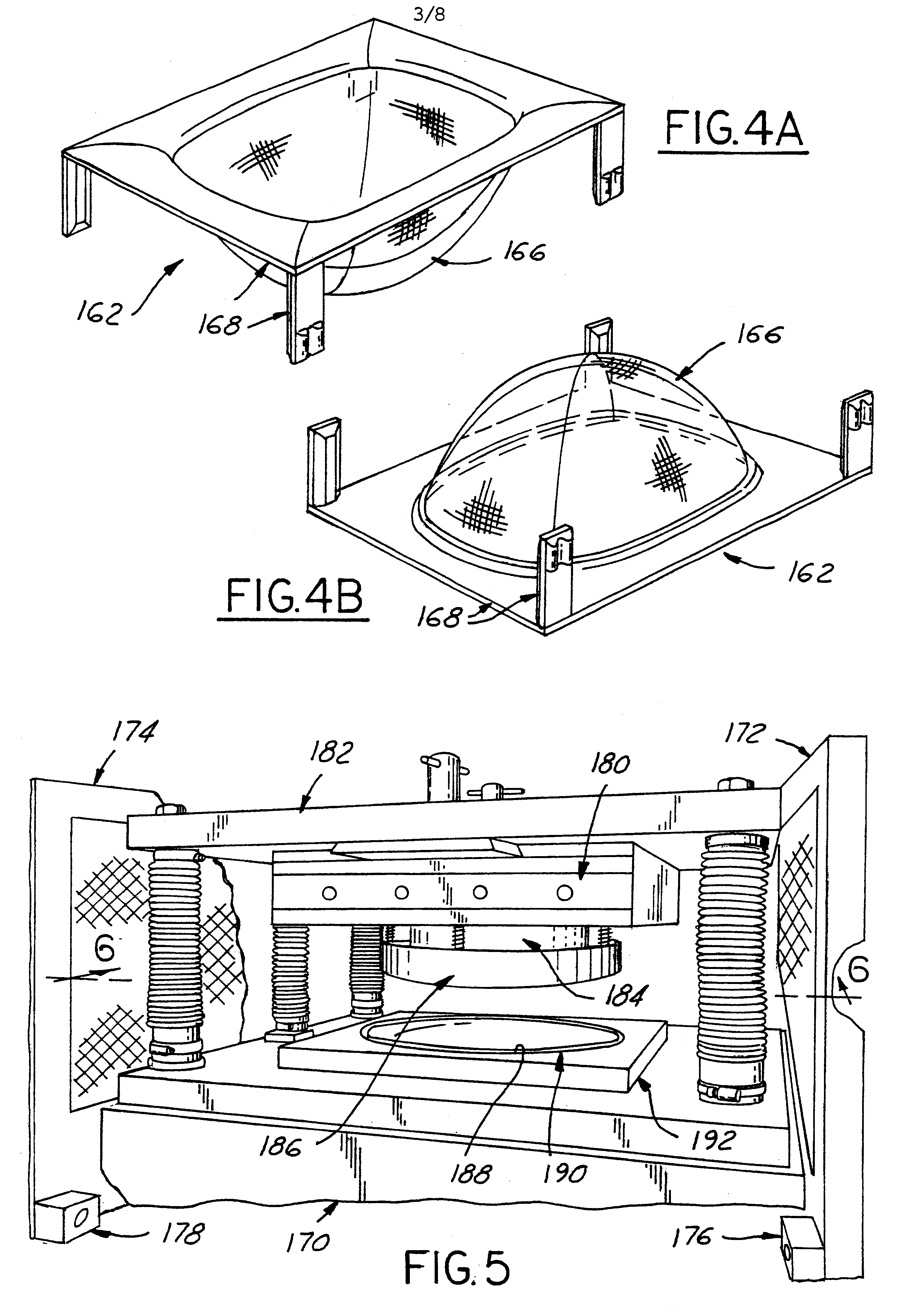

Robot with removable mounting elements

InactiveUS20050038564A1Quickly and easily associated with and securedEasy to mountProgramme-controlled manipulatorElectric propulsion mountingEngineeringMechanical engineering

A hobby robot having a support structure includes a cavity defined within the support structure, wherein the cavity includes means positioned within the cavity for removably coupling at least one mounting element to an interior portion of the cavity. The support structure also includes means for securing an encasement shell to the support structure. The mounting element may be a tray or hardware that performs a desired function in connection with the operation of the robot. The support structure is adapted to receive a self-contained power source and means for imparting motive force to the support structure.

Owner:JAMES JEREMY

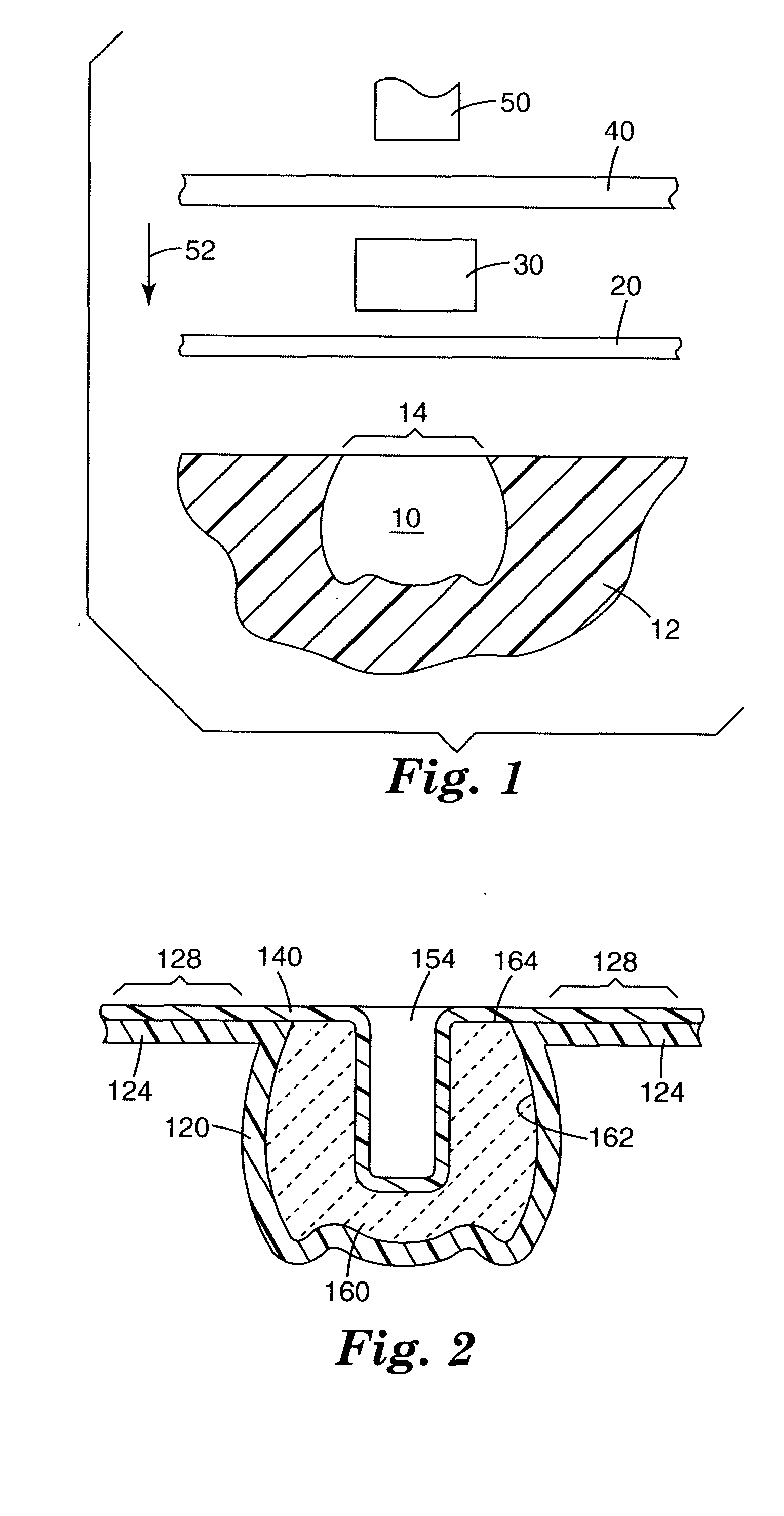

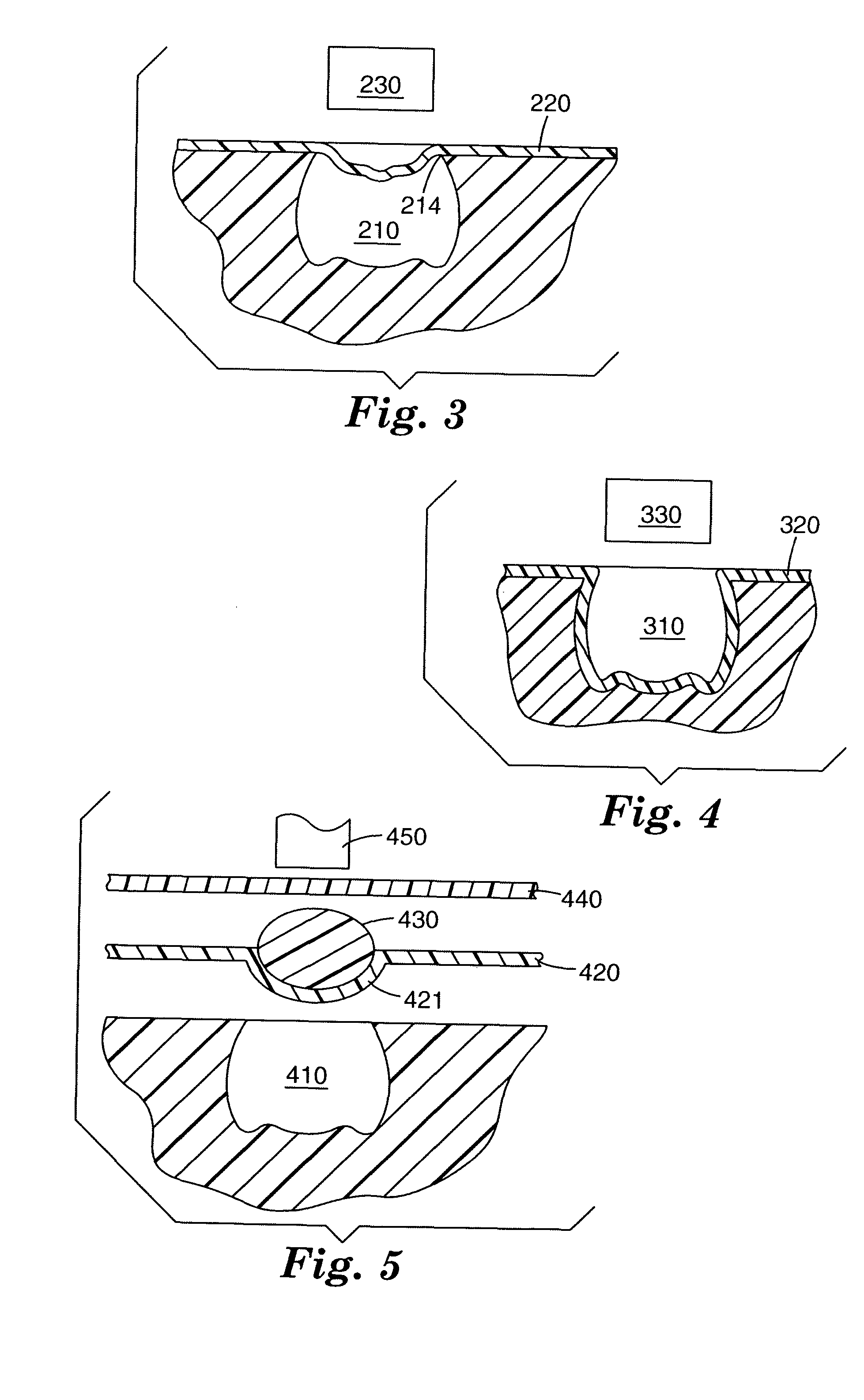

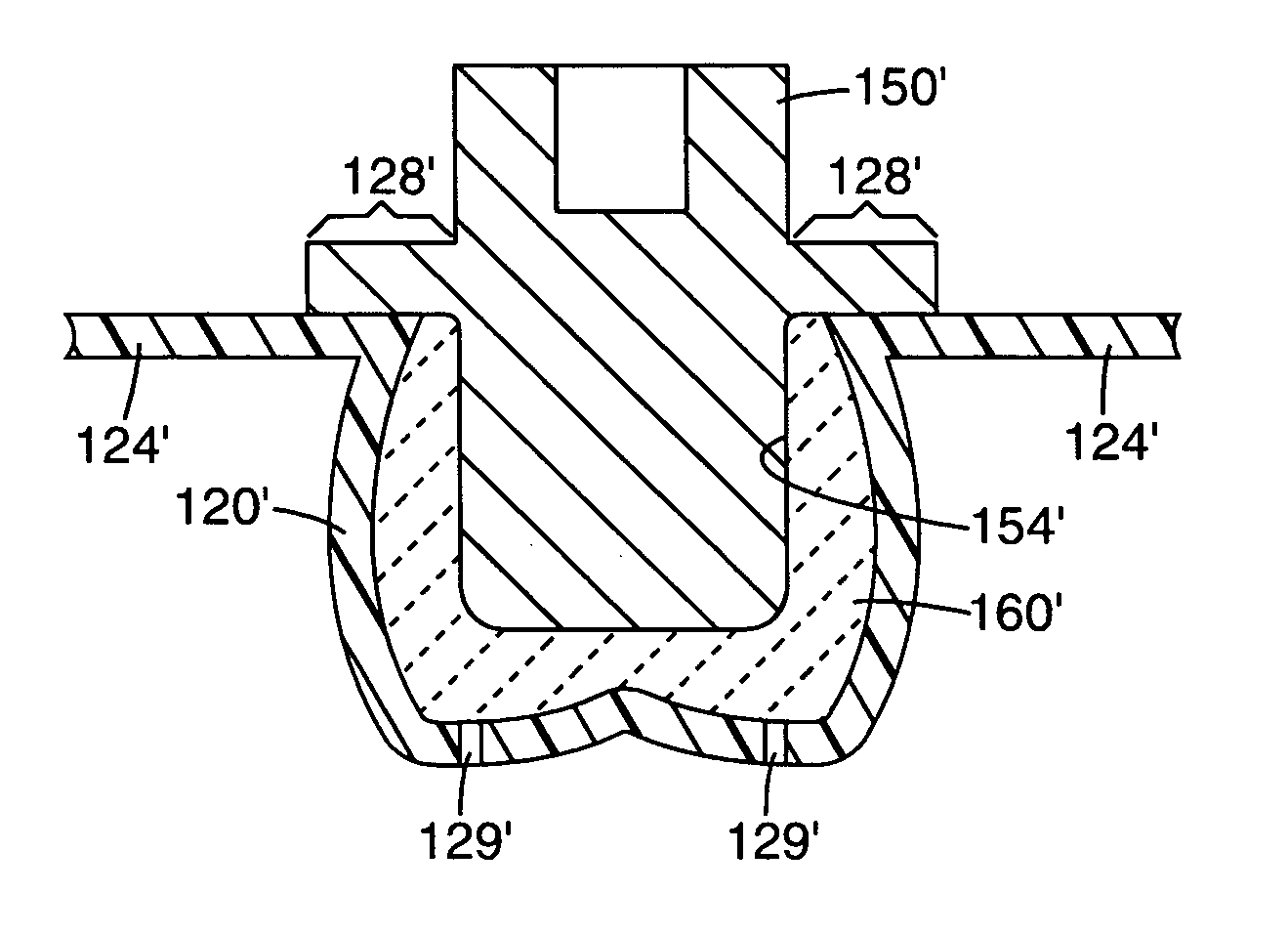

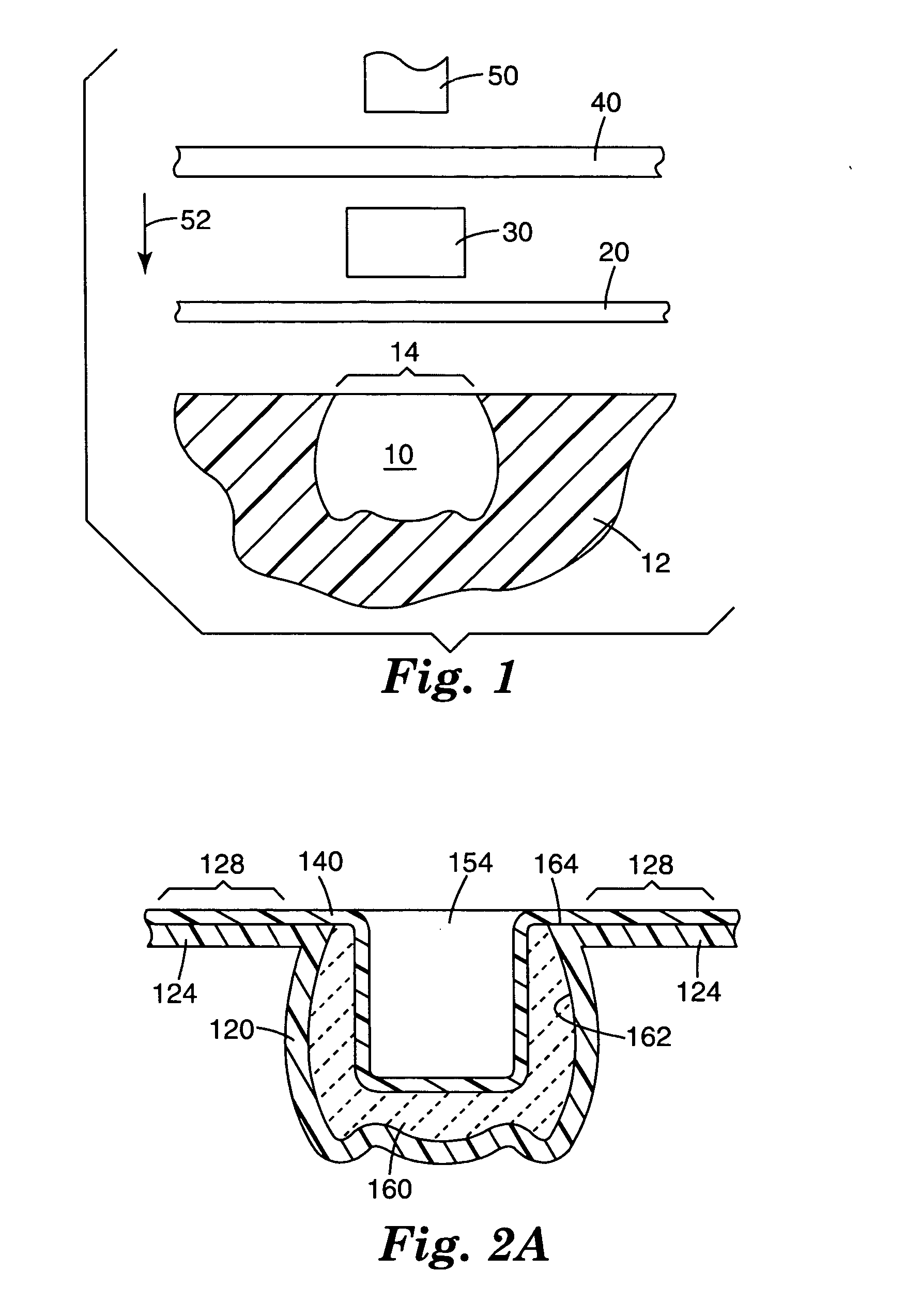

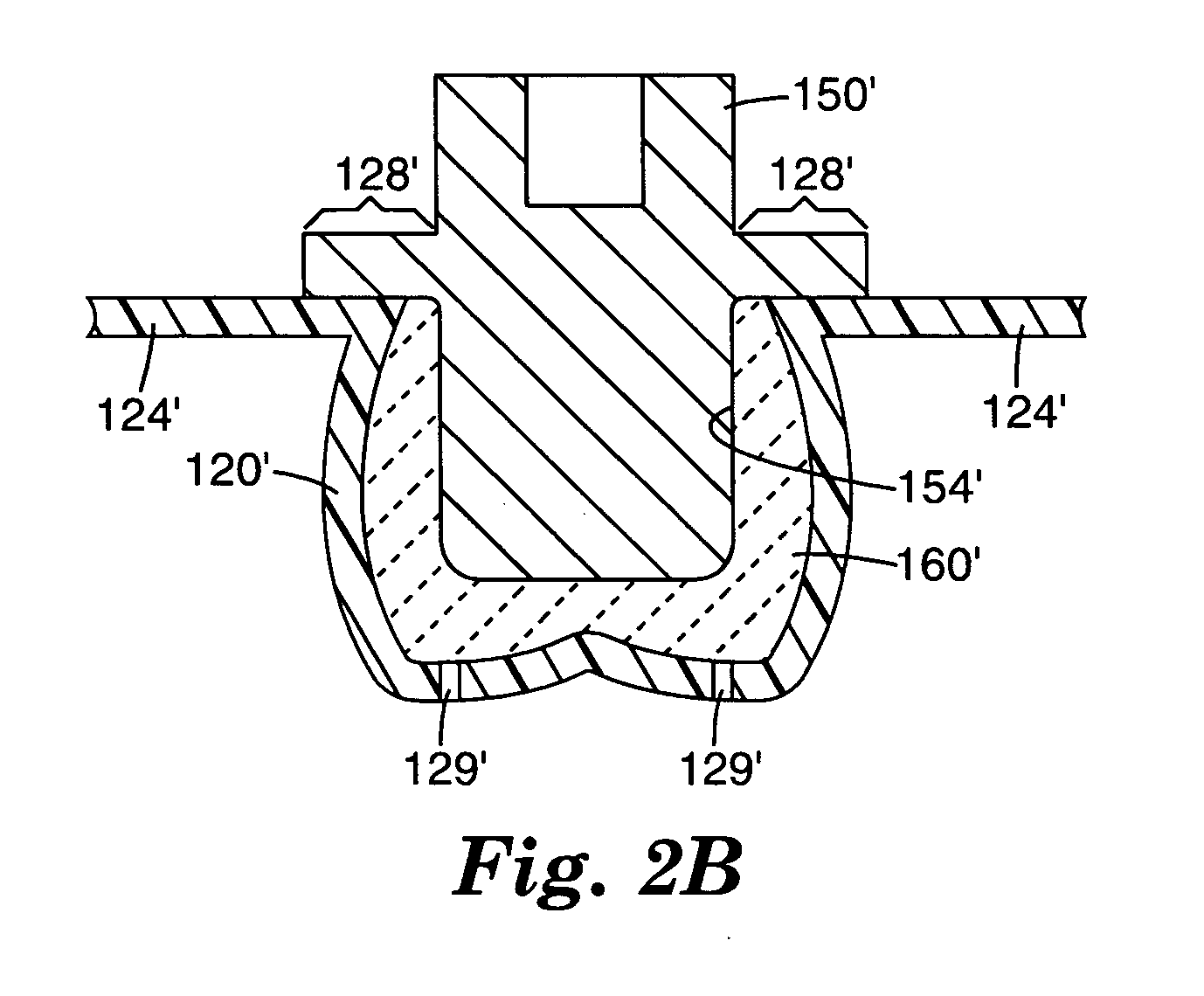

Hardenable dental article and method of manufacturing the same

InactiveUS20050040551A1Improve the finishEnhancing the finish of the dental articleTooth crownsArtificial teethMaterials science

Methods of manufacturing hardenable dental articles, packaged hardenable dental articles, and methods of packaging hardenable dental articles are disclosed. In various embodiments, the manufacturing may involve molding a hardenable dental material in a mold cavity that may be lined with a mold liner. The mold body may also form the package of the hardenable dental article formed within the mold cavity. In other embodiments, the hardenable dental articles may be provided in mold cavities located in sacrificial mold bodies that may be torn, stretched, softened, dissolved, etc. to release the hardenable dental articles in the mold cavities.

Owner:3M INNOVATIVE PROPERTIES CO

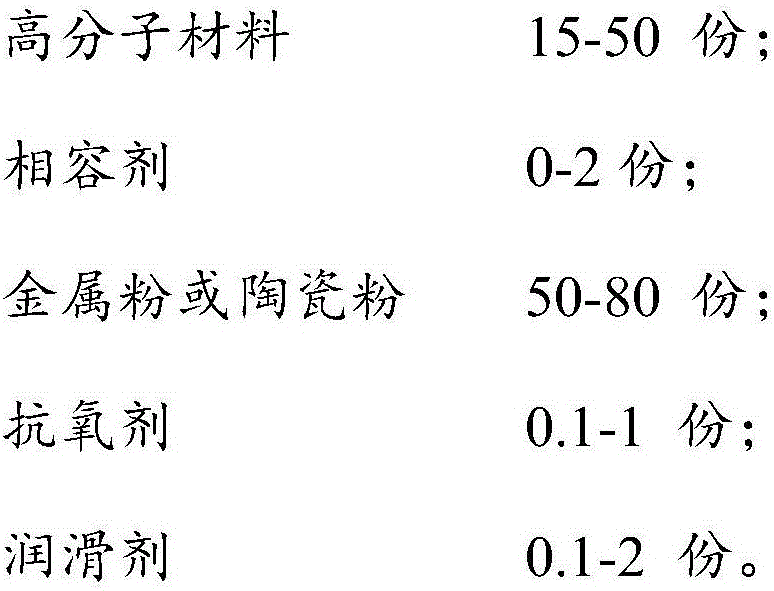

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

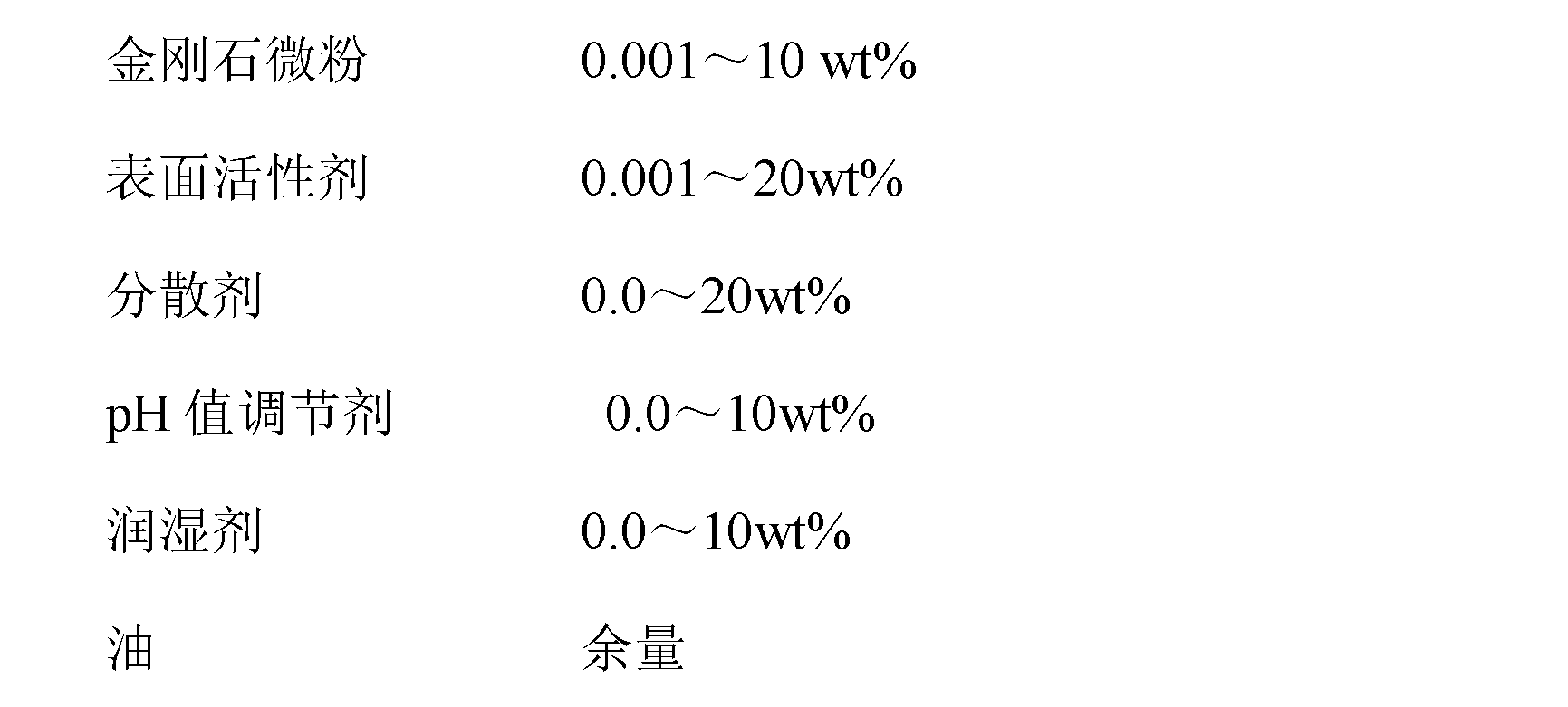

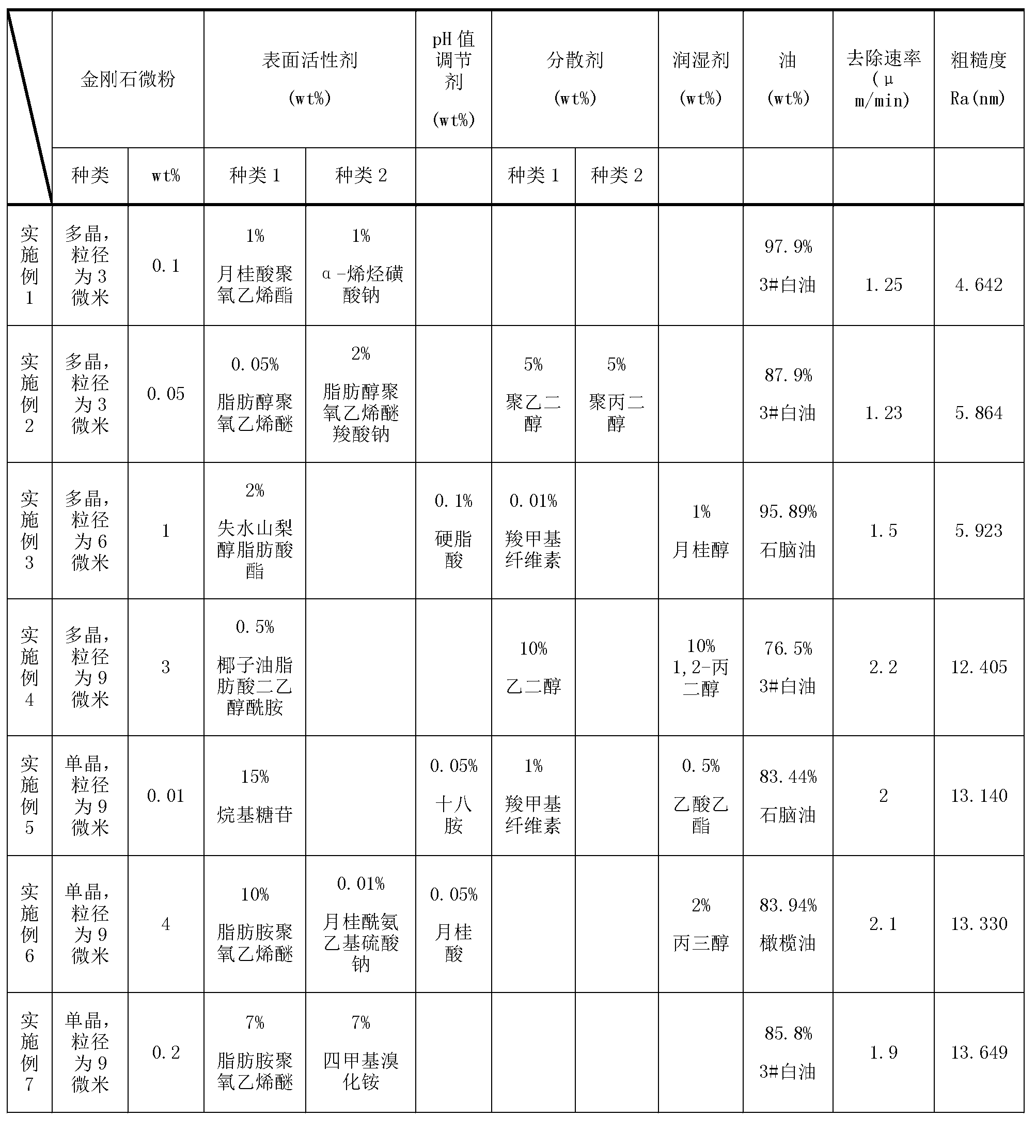

Oily diamond grinding liquid and preparation method thereof

InactiveCN103013345AImprove polishing efficiencyImprove matchPolishing compositions with abrasivesStable stateEnvironmental resistance

The invention discloses an oily diamond grinding liquid and a preparation method thereof, and belongs to the technical field of surface superfine grinding. The grinding liquid comprises the following components by weight percent: 0.001%-10% of diamond micro powder, 0.001%-20% of surface active agent, 0-20% of dispersant, 0-10% of pH value regulator, 0-10% of wetting agent and oil in balancing amount. The oily diamond grinding liquid is mainly applied to surface grinding and polishing of silicon carbide wafers, LED sapphire substrate slices, ceramic, optical fiber, dies, semi-conductor compound wafers and the like. By the use of the oily diamond grinding liquid provided by the invention, the polishing efficiency can be greatly improved; the dispersing performance is good; a uniform and stable state can be kept for a long time; the degree of finish of products polished with the oily diamond grinding liquid is high; the polishing effect is good; no ingredient harmful to human body is contained; the cleaning is easy; and the environmental protection is facilitated.

Owner:TSINGHUA UNIV +2

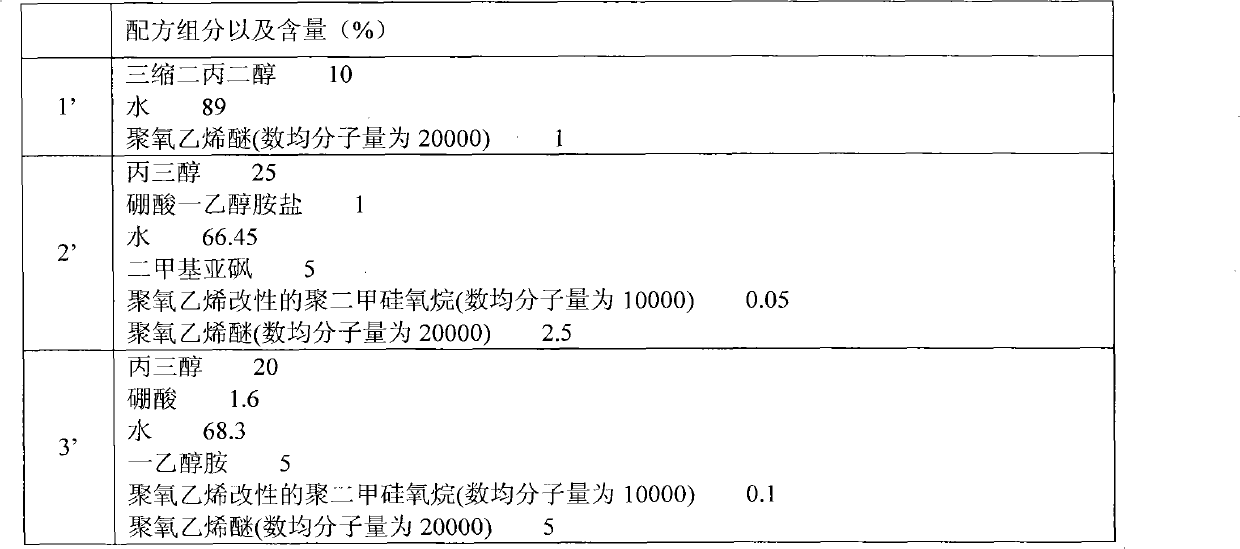

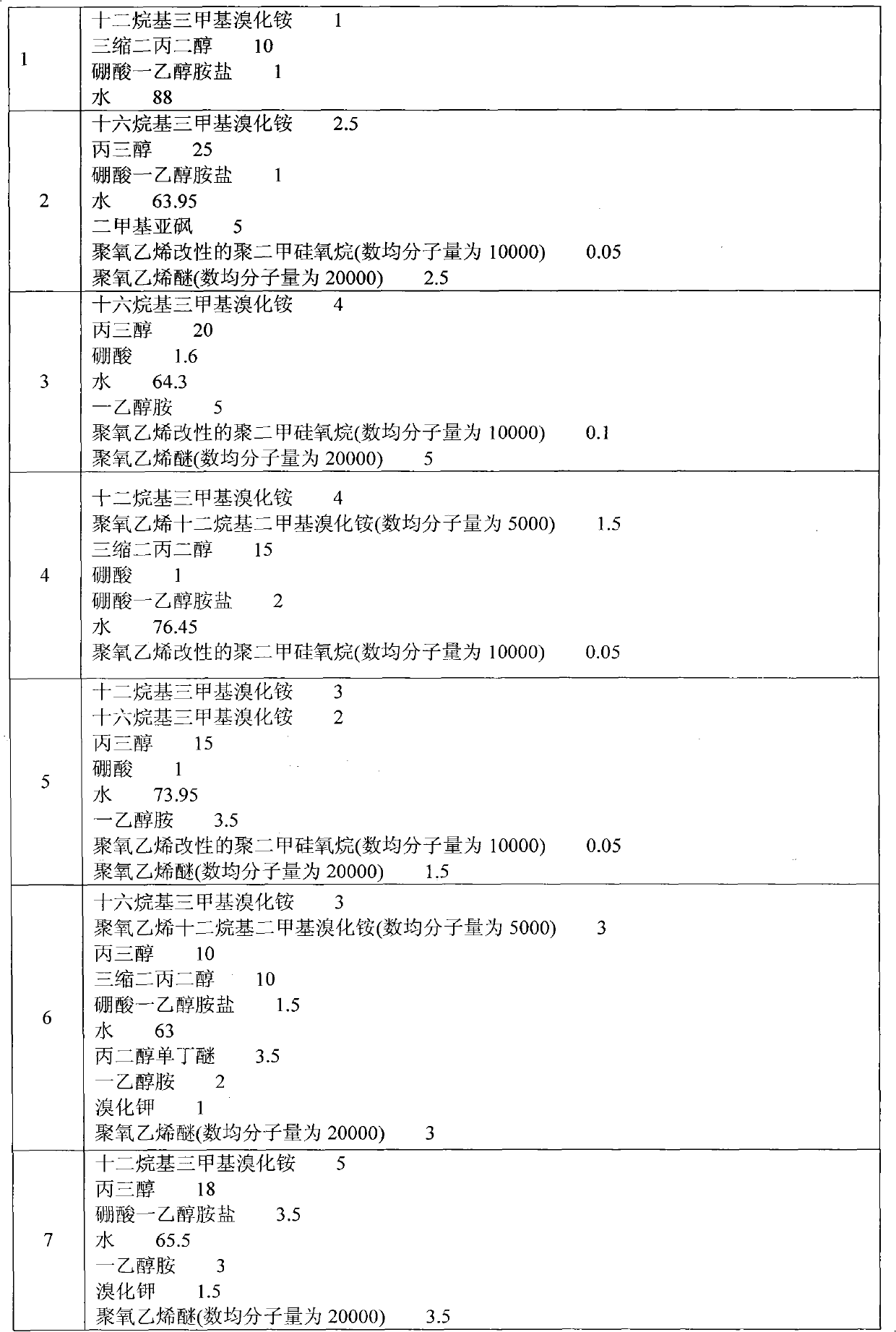

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Hardenable dental article and method of manufacturing the same

ActiveUS20050100868A1Improve the finishEnhancing the finish of the dental articleTooth crownsArtificial teethMaterials science

Owner:3M INNOVATIVE PROPERTIES CO

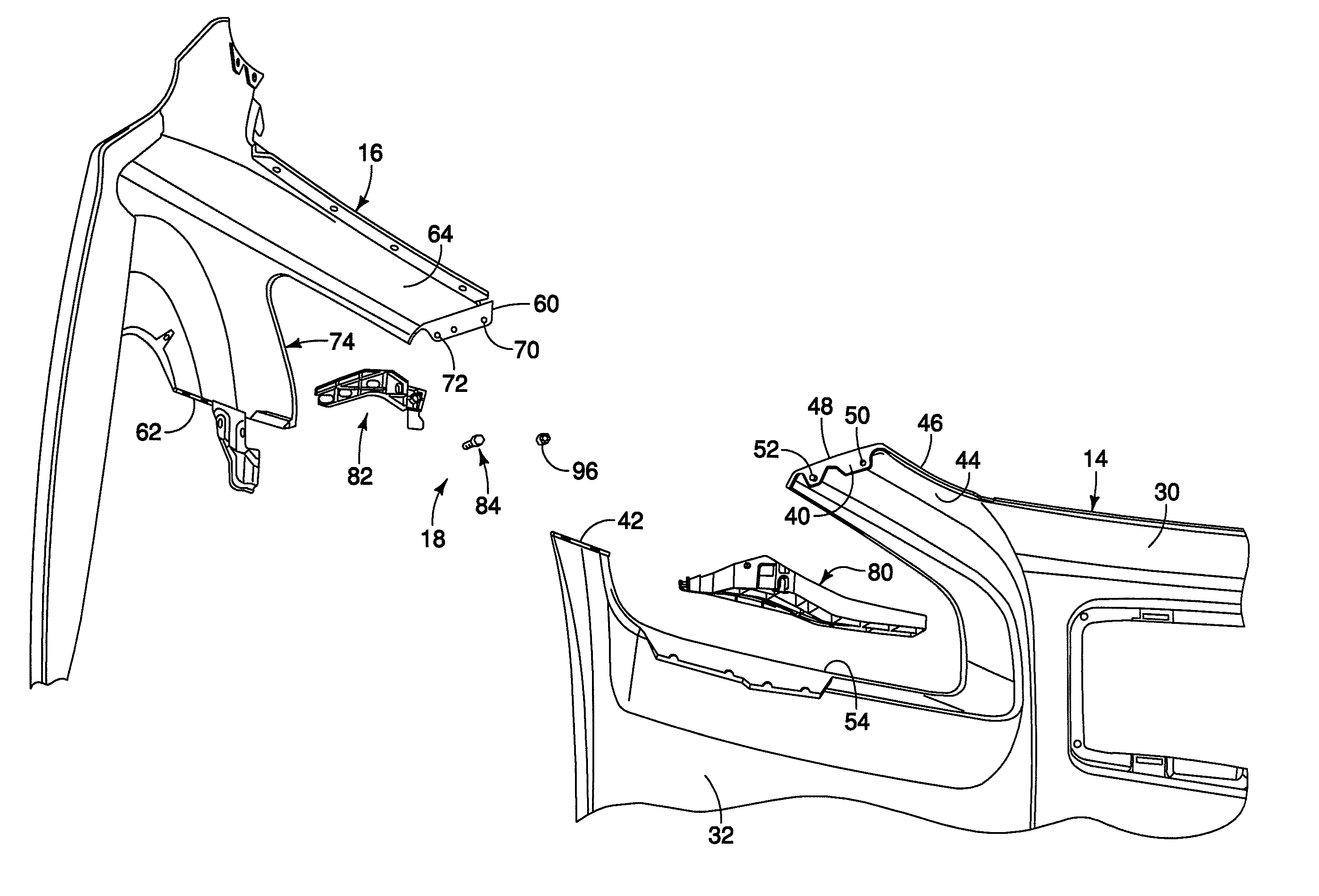

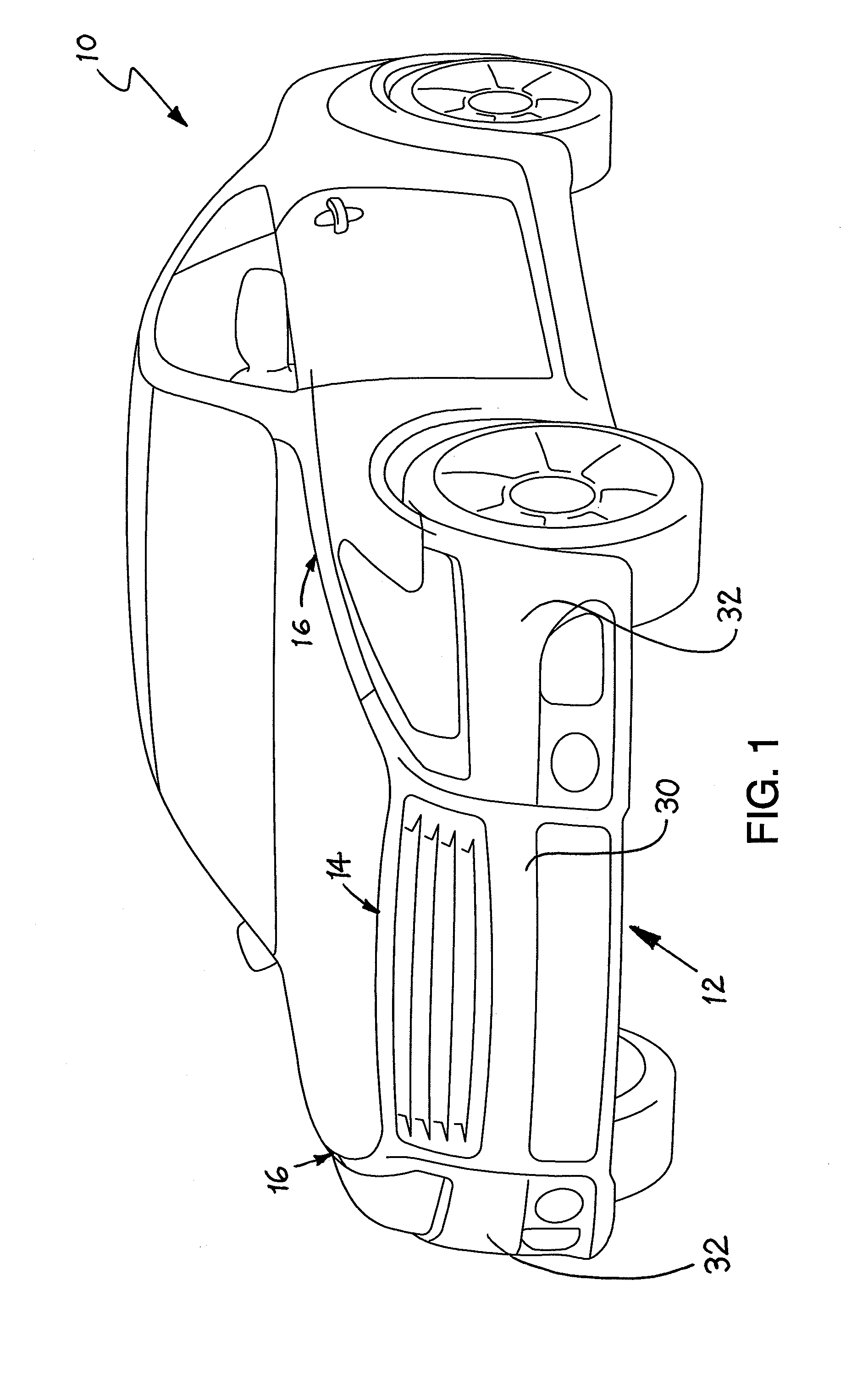

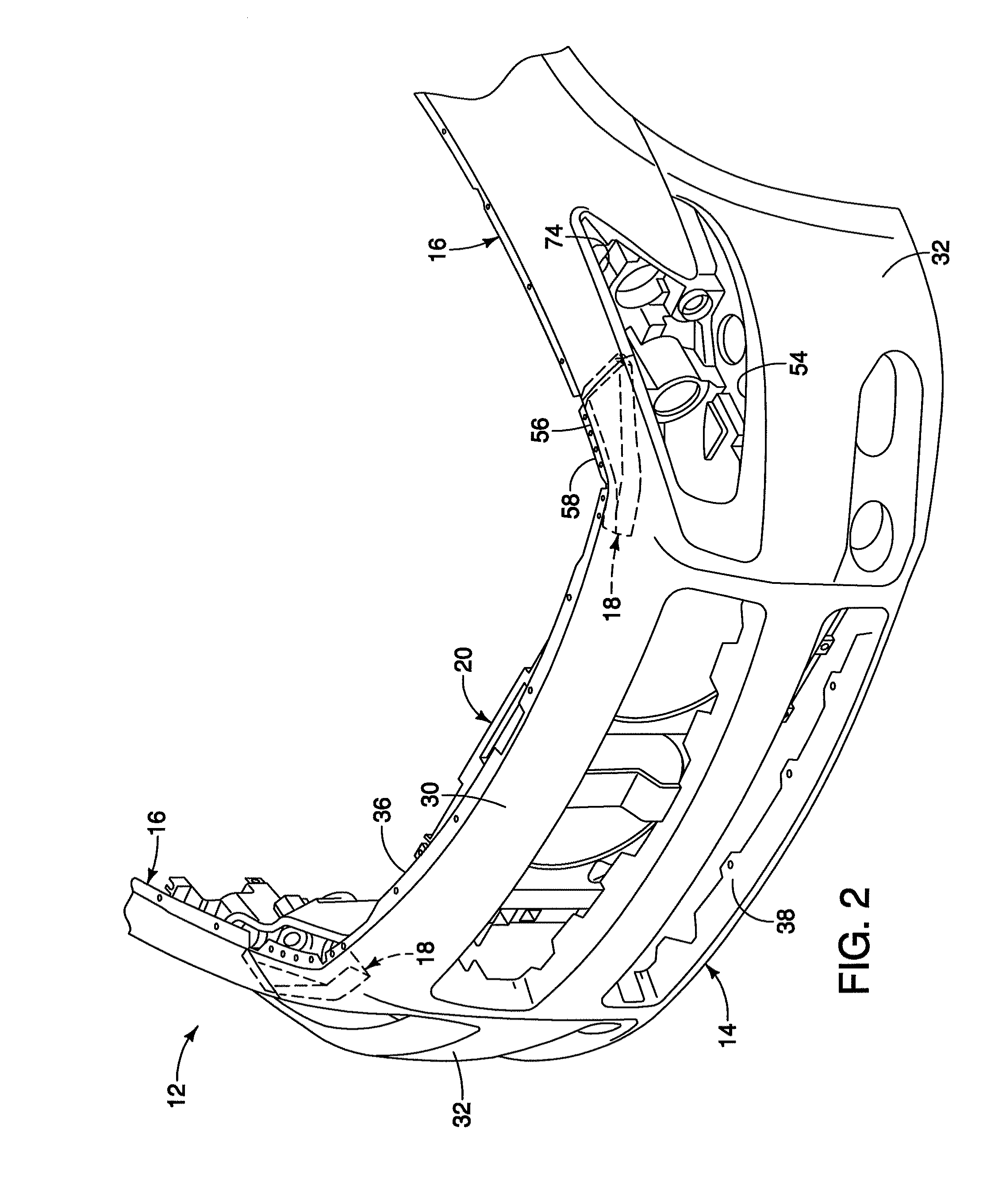

Vehicle body structure

InactiveUS7540550B1Improve fitImprove the finishVehicle seatsSuperstructure connectionsEngineeringFace sheet

A vehicle body structure is provided with a bumper fascia panel with a bumper fascia mounting flange, a fender body panel with a fender mounting flange and a mounting flange attachment that secures the mounting flanges together. The mounting flange attachment arrangement has a first fastening member overlying the bumper fascia mounting flange, a second fastening member overlying the fender mounting flange and a fastening element coupling the first and second fastening members together. The bumper fascia mounting flange and the fender mounting flange are sandwiched between the first and second fastening members. The fastening element has a tool engagement portion located on an inboard side of the mounting flange attachment and a center fastening axis angled in an inboard direction of the vehicle body structure.

Owner:NISSAN MOTOR CO LTD

Glass fibre reinforced nylon colorful heat insulation stripe for al-alloy door & window and method for preparing same

InactiveCN101307147ADifficult to disperseSolve easy discolorationDoors/windowsMasterbatchGlass fiber

The invention discloses a glass fiber reinforced nylon colored insulated strip used for an aluminum alloy door and window. The compositions by weight portion of the glass fiber reinforced nylon colored insulated strip are: 100 portions of nylon resin, 5 to 50 portions of glass fibers, 0 to 50 portions of inorganic filler, 5 to 25 portions of toughening agent, 0.3 to 5 portions of coupling agent, 0.3 to 5 portions of dispersing lubricant, 0.2 to 5 portions of antioxidant, 0.1 to 1 portion of light stabilizer, 0.1 to 1 portion of heat stabilizer and 2 to 10 portions of colored masterbatch. The invention also discloses a method for preparing the colored insulated strip. The glass fiber reinforced nylon colored insulated strip solves the problems that the masterbatch and the filler are difficult to disperse and nylon 66 is easy to change color during the processing procedure; the insulated strip products have various colors, superior performance and beautiful appearance; and the glass fiber reinforced nylon colored insulated strip realizes perfect matching with the window color, can achieve the beautility effect, meets and enlarges the demand of clients and the market, and is favorable for promotion, use and development of the glass fiber reinforced nylon 66 insulated strip.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

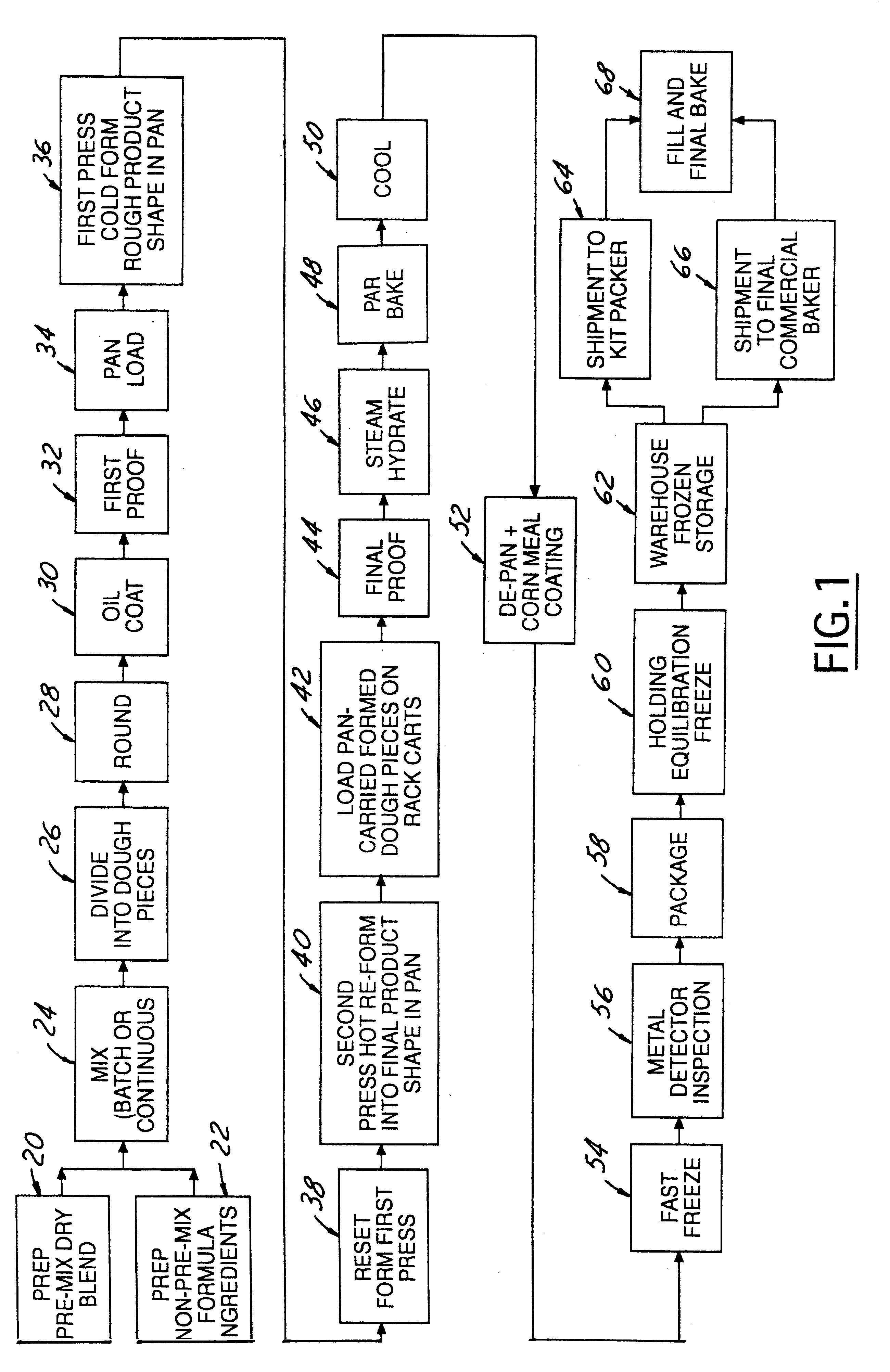

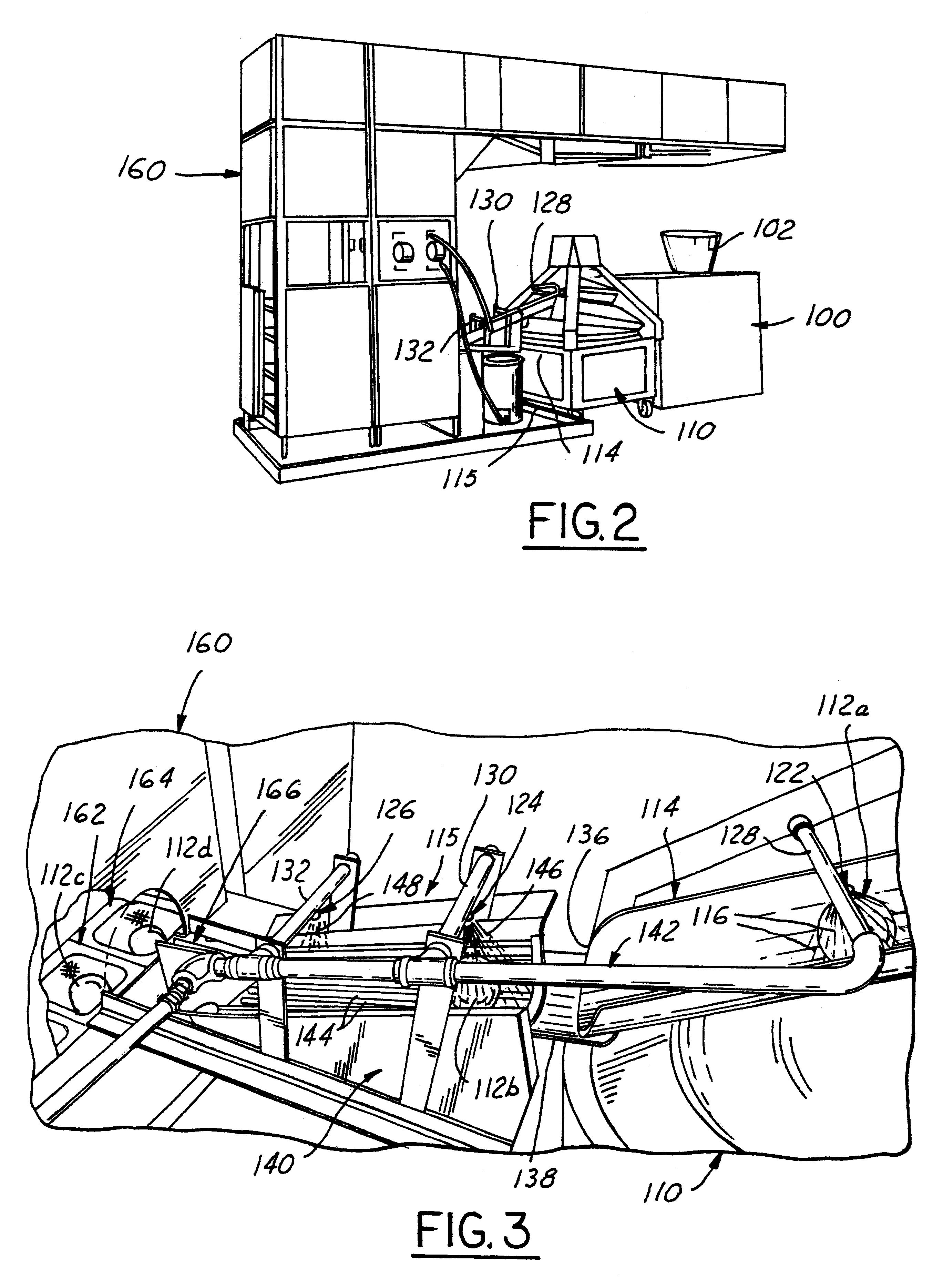

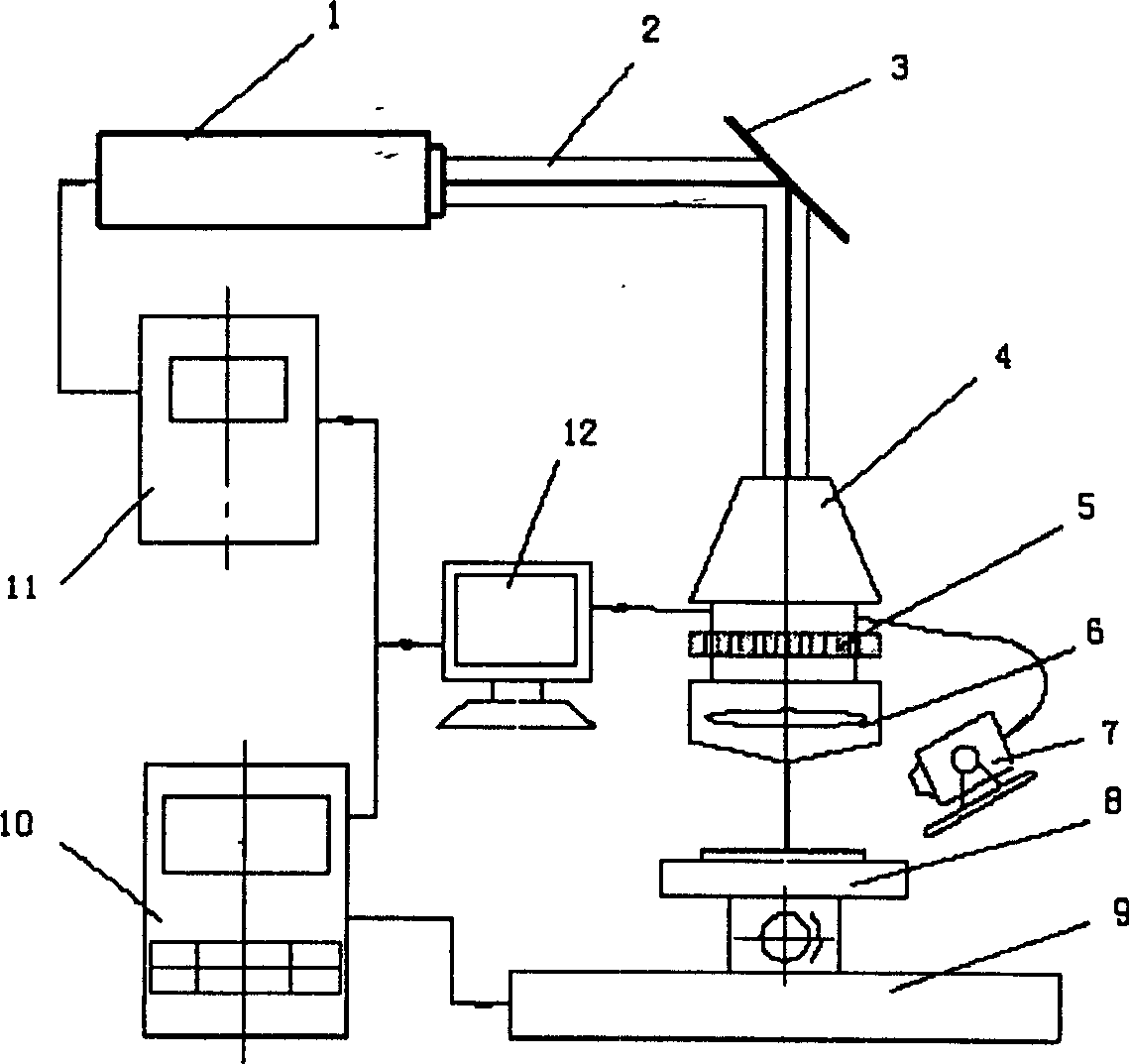

Pizza crust and process and apparatus for making same

InactiveUS6365210B1Increase moistureImprove the finishMilk preservationDough treatmentMoisture absorptionSugar

A method of preparing parbaked food products, such as pizza crust shells, apparatus and dough formulation used therein, and the product produced by the process. The process comprises the steps of providing a dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed. The prepared dough piece is then steam hydrated under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition is adjusted selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough.

Owner:M & M HLDG

Preparation method of molding sand for gray iron casting

InactiveCN102366811AThe preparation process steps are simpleEasy to operateFoundry mouldsFoundry coresDrying timePollution

The invention discloses a preparation method of molding sand for gray iron casting, comprising the following three steps: preparing raw materials, preparing the molding sand, and mixing the molding sand. The preparation method has the advantages of simple process steps, easy operation, no use of coal dust, clean workshop, little pollution, and low cost and environmental protection by using straw powder, modified starch and other renewable raw materials. The prepared molding sand has small gas content, short drying time, good permeability and high baked tensile strength in casting, and can improve the releasability of the sand mold, further improving the fineness of casts.

Owner:辛培兴

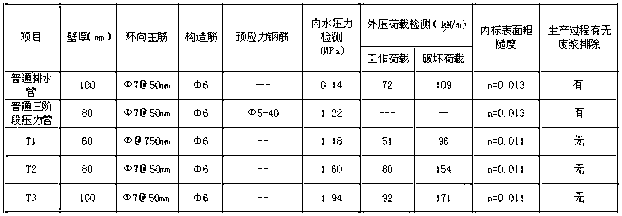

Green environmentally-friendly powder reinforced concrete water delivery pipe

ActiveCN103224356ALow costReduce pollution treatment costsCeramic shaping apparatusSlagMesh reinforcement

The invention belongs to the field of water delivery engineering and relates to a green environmentally-friendly powder reinforced concrete water delivery pipe. The green environmentally-friendly powder reinforced concrete water delivery pipe is manufactured by uniform distribution of concrete on a reinforcement mat. The concrete is prepared from 450 to 500 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 90 to 130 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 130 to 160 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 520 to 600 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 800 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 12 to 20 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 45 to 50 weight parts of a high-efficiency expanding agent, 130 to 150 weight parts of water, 0.8 to 1.2 weight parts of polypropylene fibers, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The reinforcement mat is manufactured by weaving hard-drawn wires having the diameter of 4.0 to 6.0 millimeters as reinforcements and cold-rolled ribbed bars having the diameter of 5.0 to 10.0 millimeters as hoop reinforcements.

Owner:黄贺明

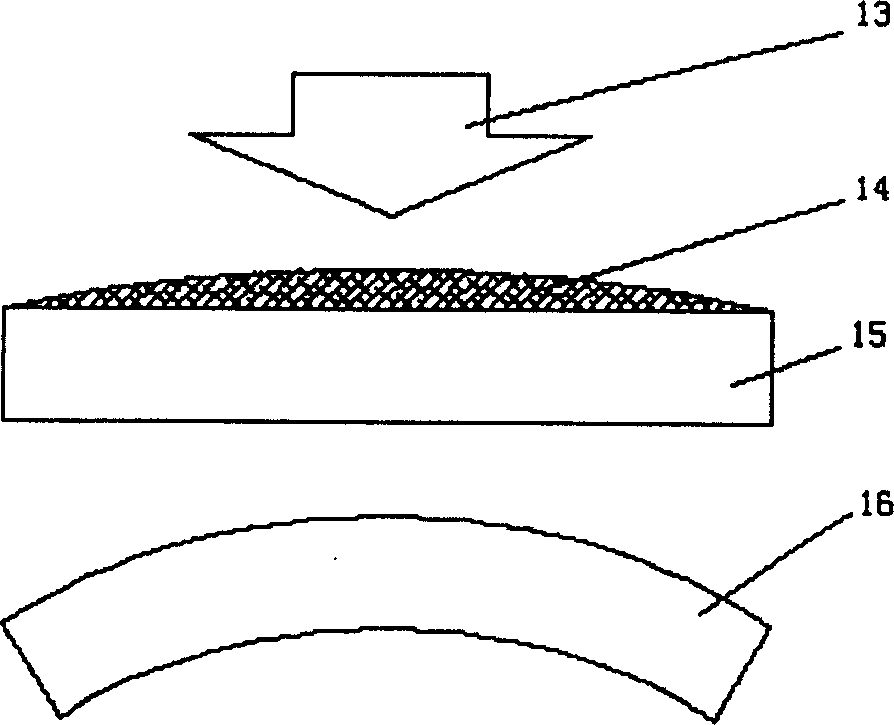

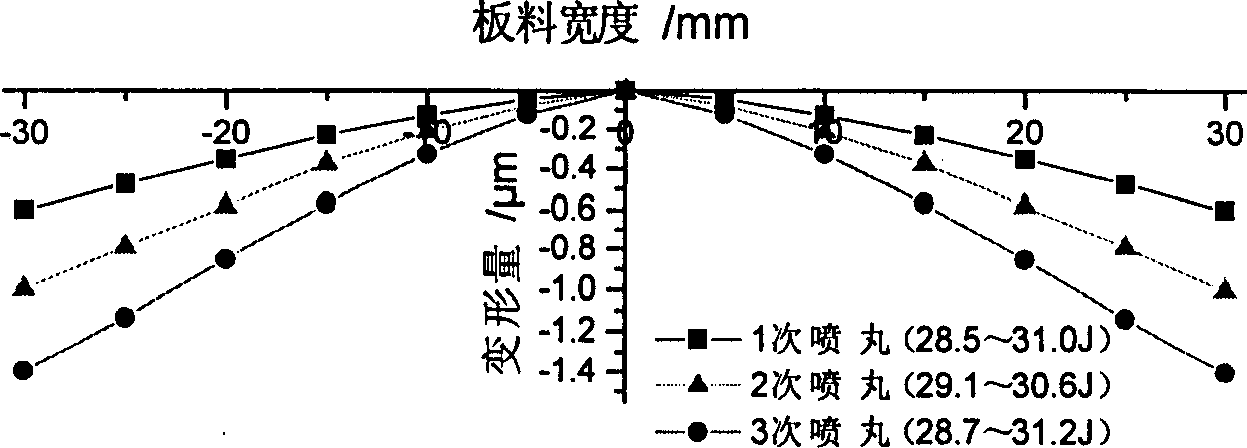

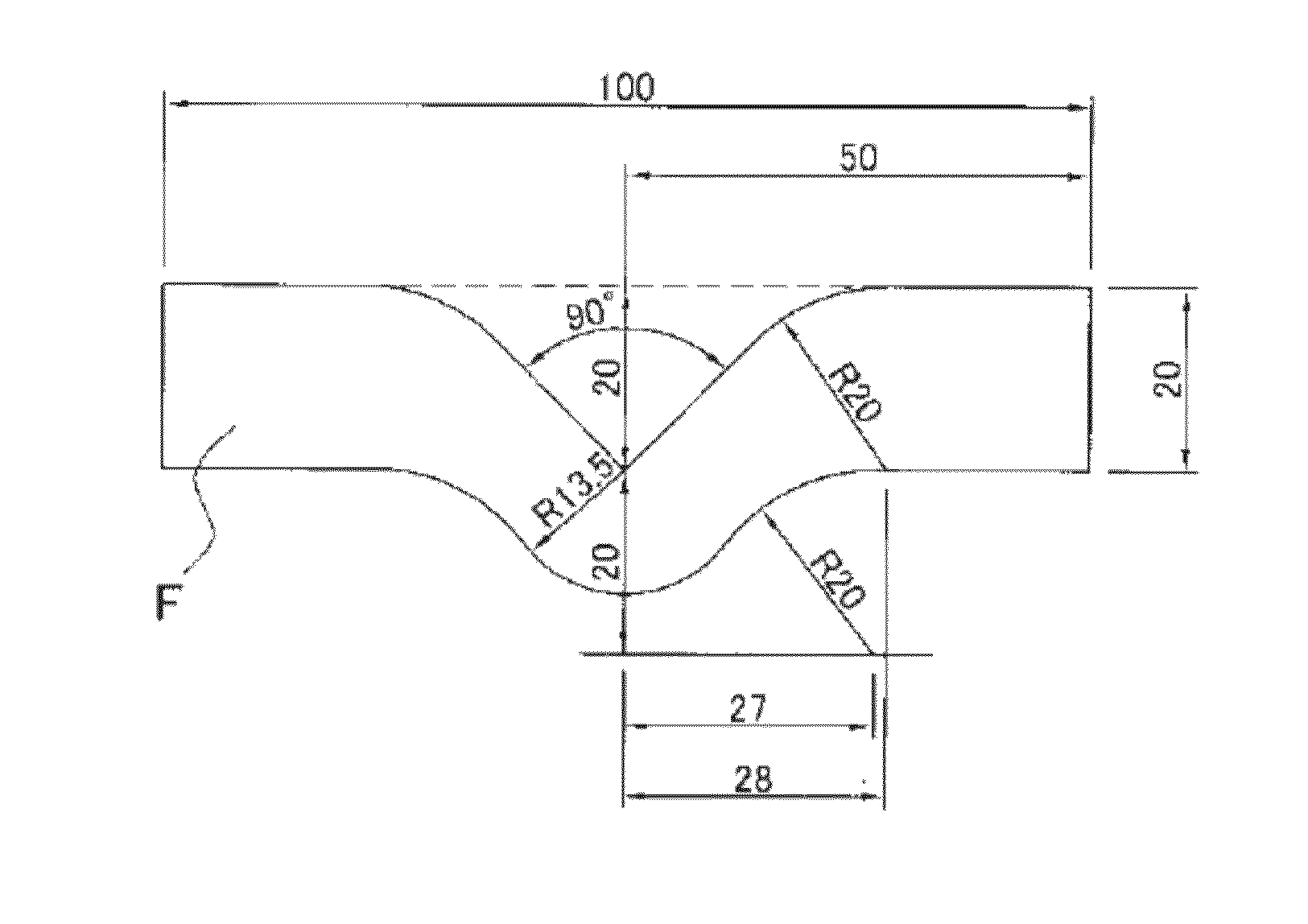

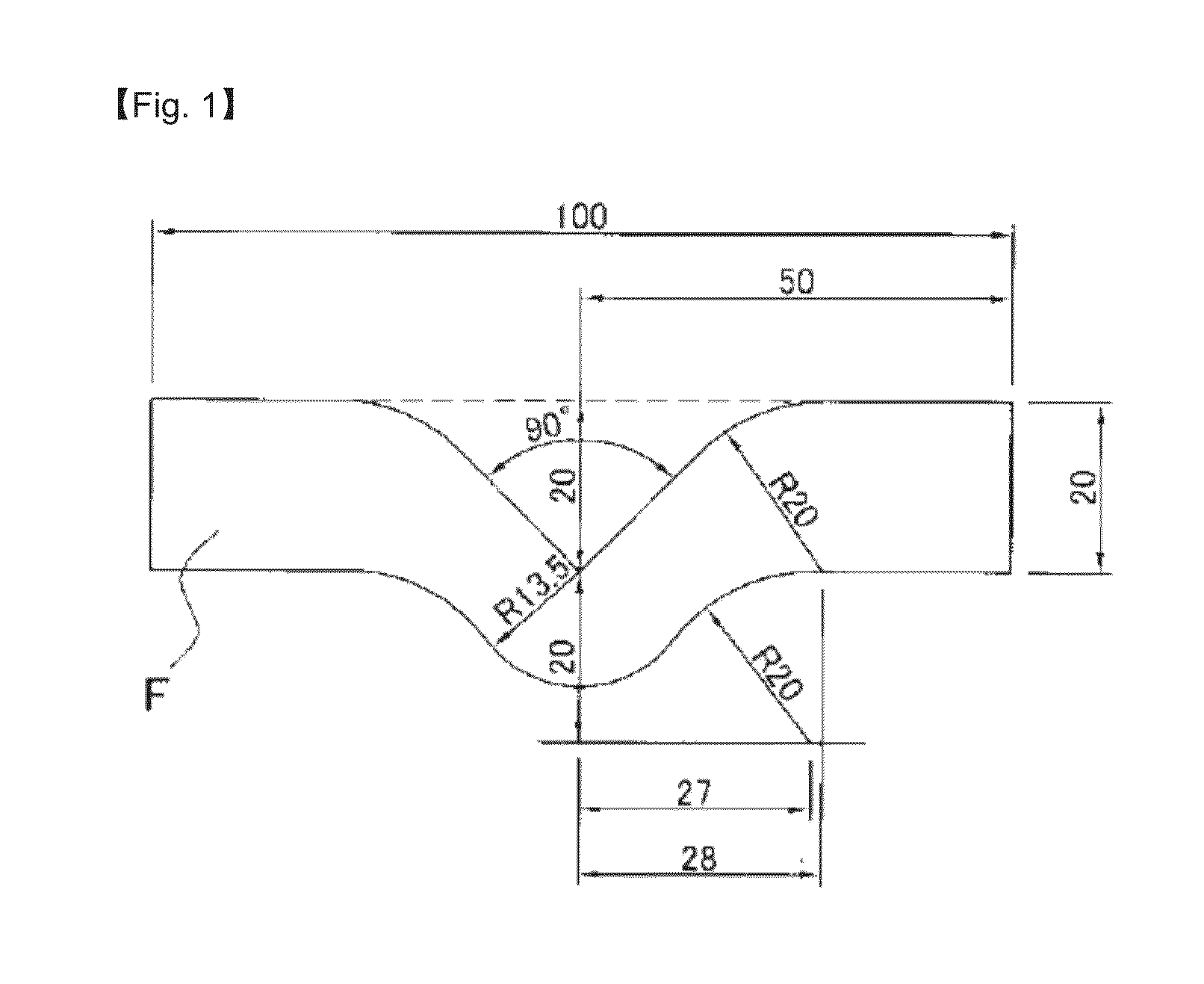

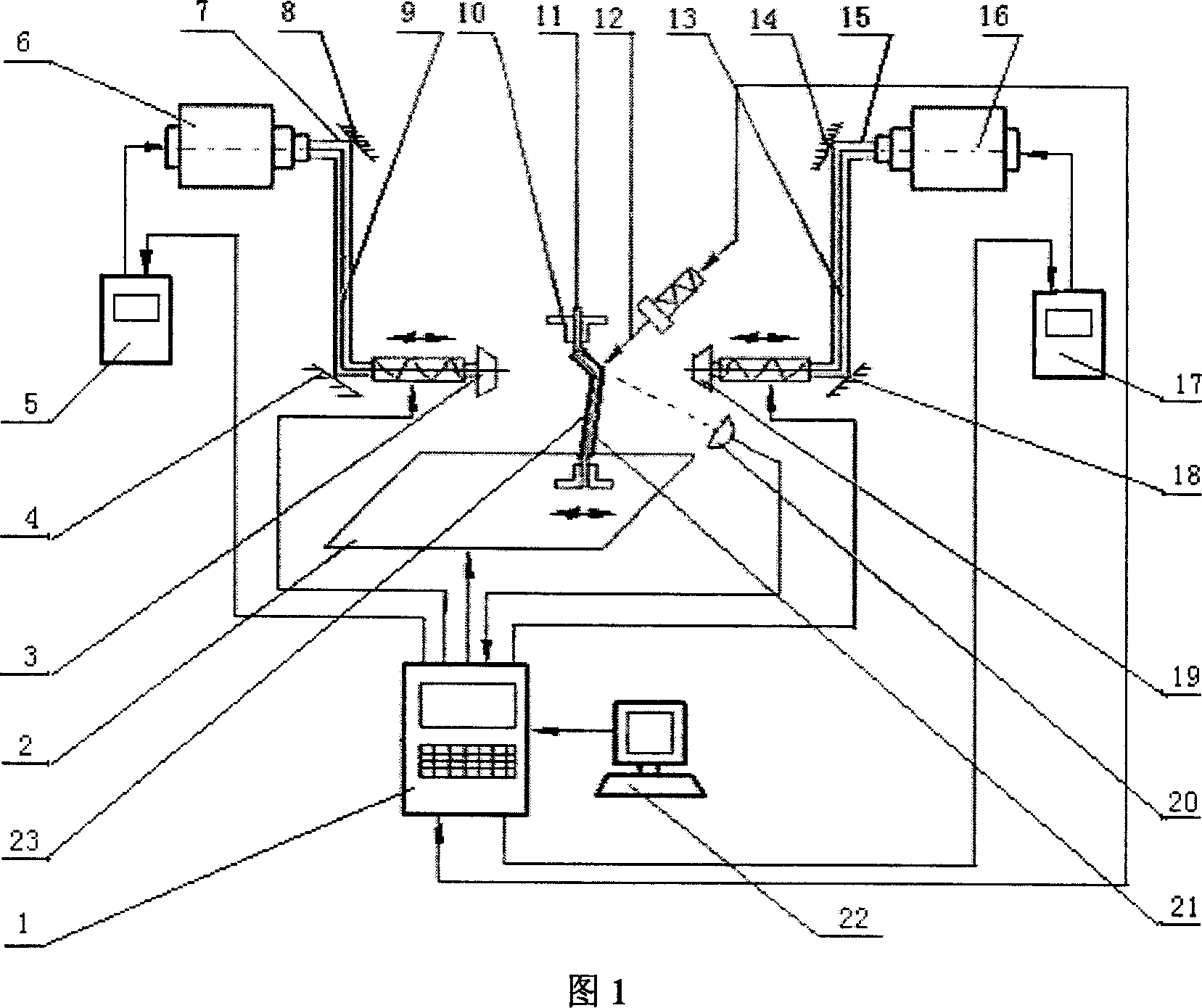

Method and equipment for forming plate of moderate thickness through laser shot blast

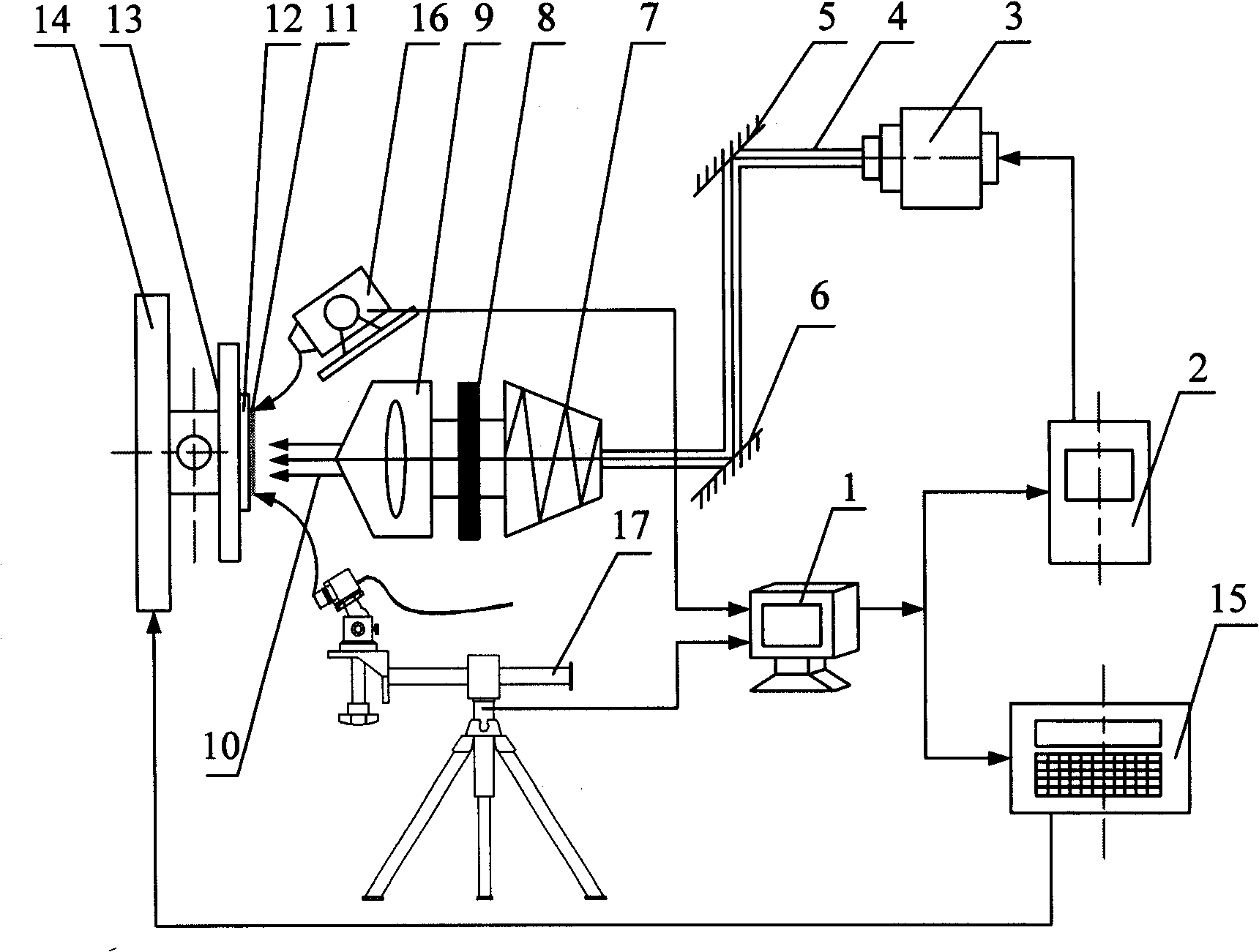

InactiveCN1695873AReduce surface roughness valueGood finishComputer controlNumerical controlShock waveEngineering

A laser blasting apparatus for shaping on the surface of medium-thick plate is composed of laser device, optical guide system, laser blasting head, fixture system for workpiece, and control system. Its shaping process includes computer simulation of the stress field distribution according to the curved surface shape to be processed, optimizing it to obtain the distribution of shock wave pressure and blasting tracing on the surface of plate, automatically choosing the parameters of laser pulse optical beam converte and optical mask, writing control program, generating strong short laser pulses, covering them to several pulse clusters, passing through optical mask, acting on energy converting body on the surface of workpiece to obtain shock waves, acting on the surface of workpiece for shaping.

Owner:JIANGSU UNIV

Production process of honey peach CZ diamond

InactiveCN102838277ANo pollution damagePlay a role in fluxingGlass furnace apparatusGlass productionMachine toolKiln

The invention relates to a production process of a honey peach CZ diamond. The honey peach CZ diamond comprises the following raw materials in parts by weight: 60-70 parts of SiO2, 0.5-1.5 parts of Al2O3, 0.5-2.5 parts of BaO, 1.5-5 parts of ZnO, 1.0-2.5 parts of B2O3, 3-8 parts of K2O3, 8-15 parts of Na2O, 0.5-1.5 parts of CaO, 0.3-1.5 parts of Se and 0.03-0.3 parts of S. The production process comprises the following steps of: smelting by a hot smelting kiln and classifying; discharging to obtain a CZ diamond bead blank; sequentially carrying out fire polishing by a fire polishing furnace, and grinding by a grinding machine; and grinding a plurality of cutting surfaces of the CZ diamond by a multi-faced grinding machine tool and chemically plating to obtain a CZ diamond finished product.

Owner:JIANGSU JINCHENG GRP TECH

Heat-shrinkable polyester film and package

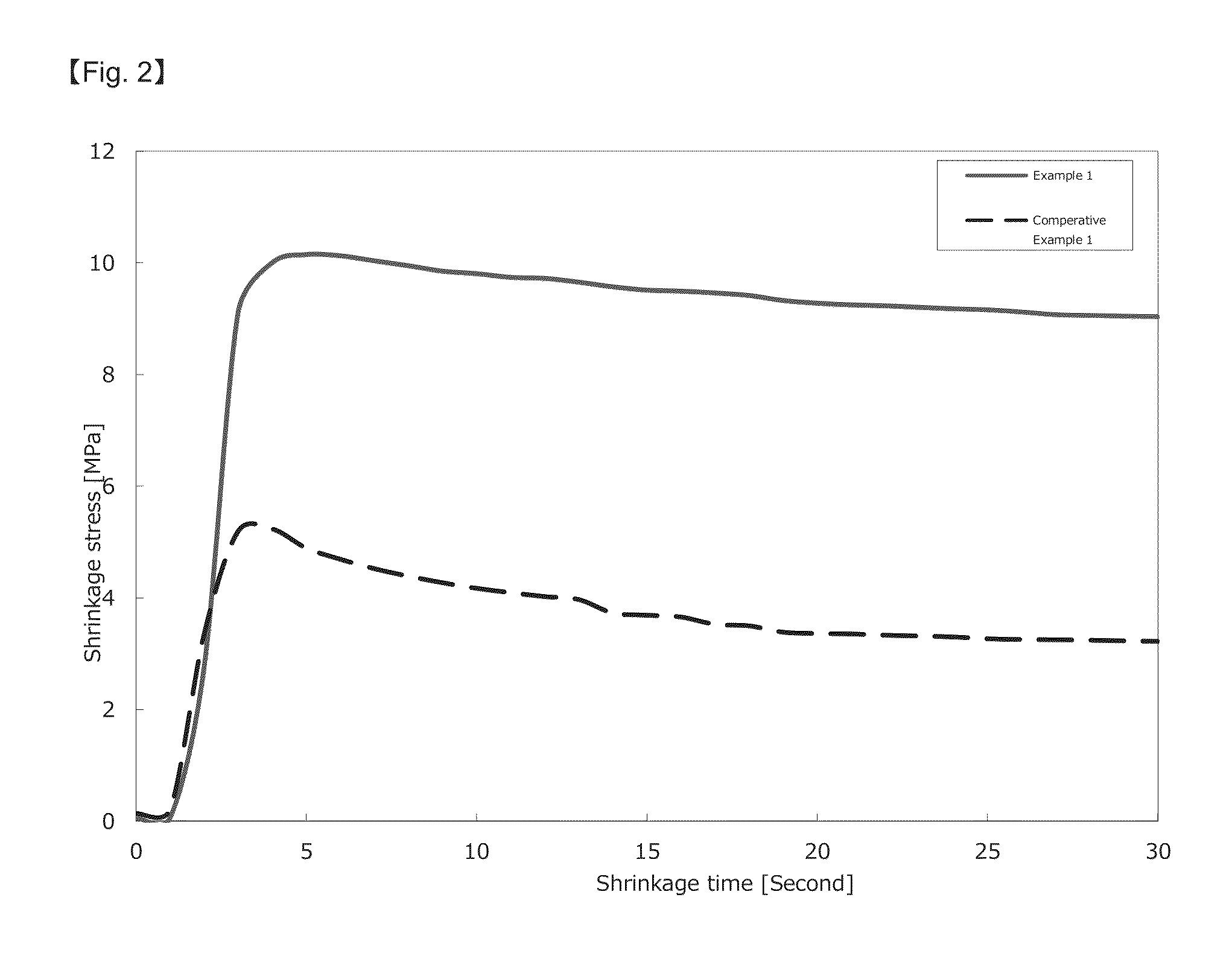

ActiveUS20160090456A1Excellent in shrinkage finish propertyLower performance requirementsLayered productsPolyesterAbsorbance

Provided is a heat-shrinkable polyester film that suppresses deterioration of the shrinkage finish property associated with a decline in performance during aging and does not loosen even after being used as a label. This heat-shrinkable polyester film comprising a polyester of a predetermined composition fulfills all of the following: (1) a ratio A1 / A2 of the absorbancy (A1) at 1340 cm−1 and the absorbancy (A2) at 1.410 cm−1 of the film measured by polarized ATR-FTIR from 0.45 to 0.75 or from 0.40 to less than 0.45 in either the width direction or longitudinal direction of the film; (2) a ratio (shrinkage stress after 30 seconds / maximum shrinkage stress) of the shrinkage stress after 30 seconds when the film is heat shrunk for 30 seconds in 90° C. hot air (shrinkage stress after 30 seconds) and the maximum shrinkage stress of from 75% to 100%; and (3) a hot-water shrinkage in the width direction of from 30% to 55% when, after aging the film for 672 hours in a 30° C., 85% RH atmosphere, the aged film is dipped in 70° C. water for 10 seconds.

Owner:TOYOBO CO LTD

Anti-fatigue controlled laser shot peening method and device therefor

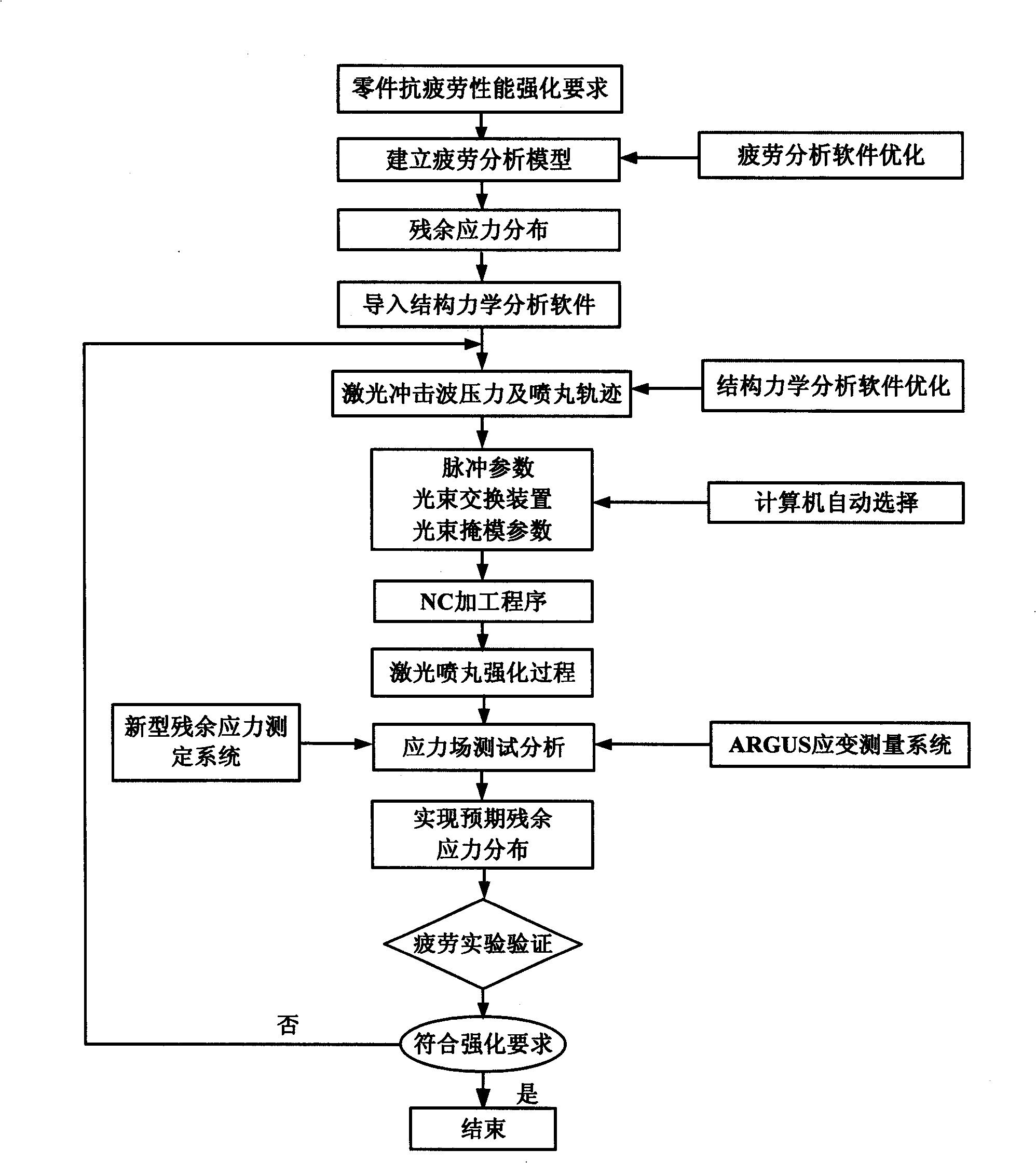

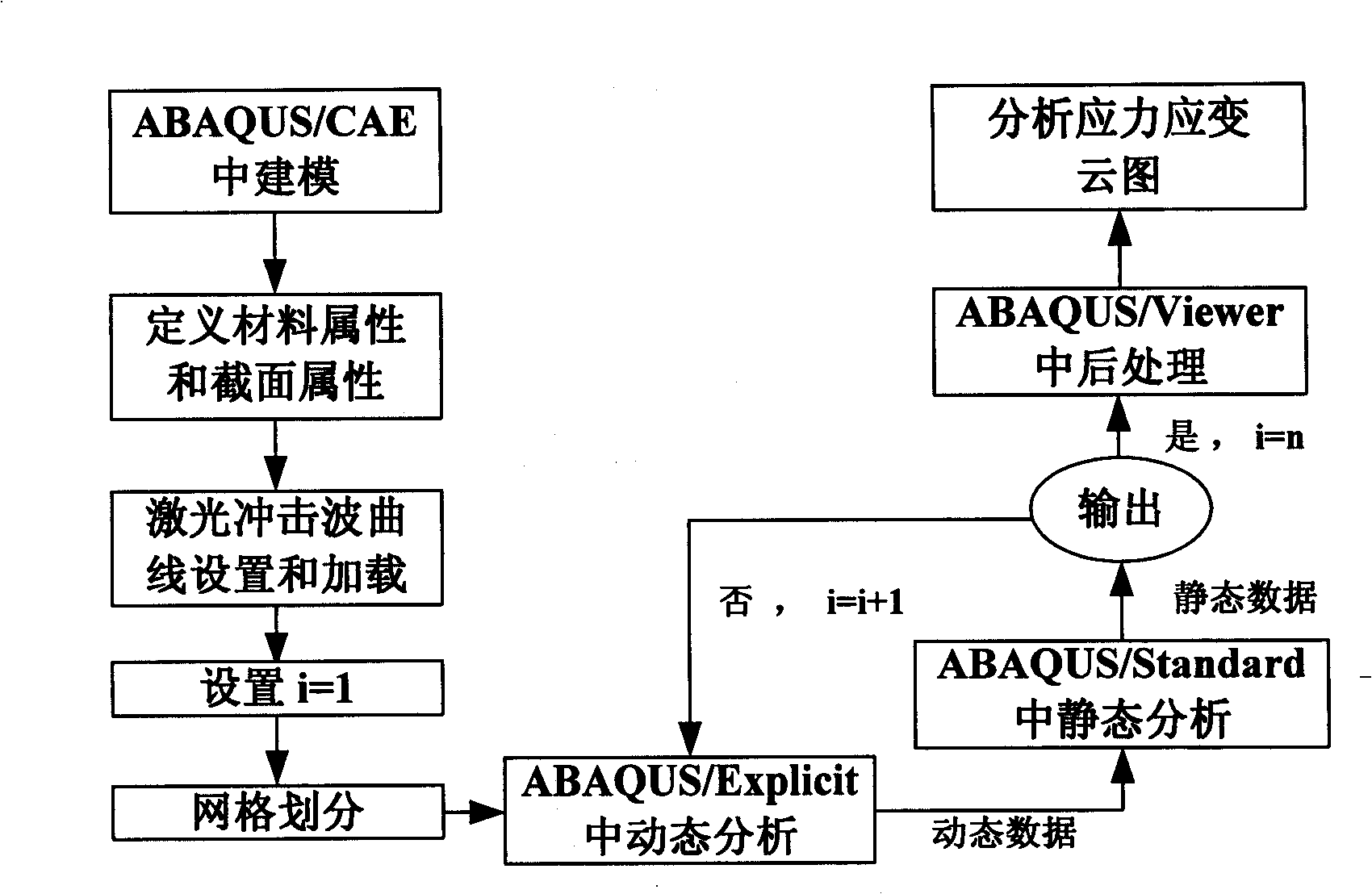

InactiveCN101275177AImprove work efficiencyMeet the reinforcement requirementsHeat treatment process controlProcess efficiency improvementLife valuePulse parameter

The invention relates to a method and a device for intensifying controlled laser shot peening, first of all, a fatigue analysis model is established in a fatigue analysis software, distribution of residual stress in the accessories is optimized in light of the expectant fatigue life value after the intensification to obtain the distribution of residual stress which meets the demand; the distribution of residual stress is imported into a structural mechanics CAE analysis software to obtain by optimization laser shock wave pressure acting on the surface of a sheet metal and the shot peening track; after than a computer control system automatically selects the pulse parameter and a light beam changing device while the laser shot peening; the laser emits a high energy short pulse laser beam to be converted into the high amplitude shock wave pressure acting on the surface of the accessories after being subjected to an optical changing device and an optical mask; a measurement feedback system is used to online check the distribution situation of the stress and strain on the surface layer of the accessories in the laser shot peening, the special computer software module is utilized to perform error analysis and parameter correction, ensuring to generate the expectant distribution of residual stress on the surface layer of the accessories to meet the intensification demand of the anti-fatigue performance.

Owner:JIANGSU UNIV

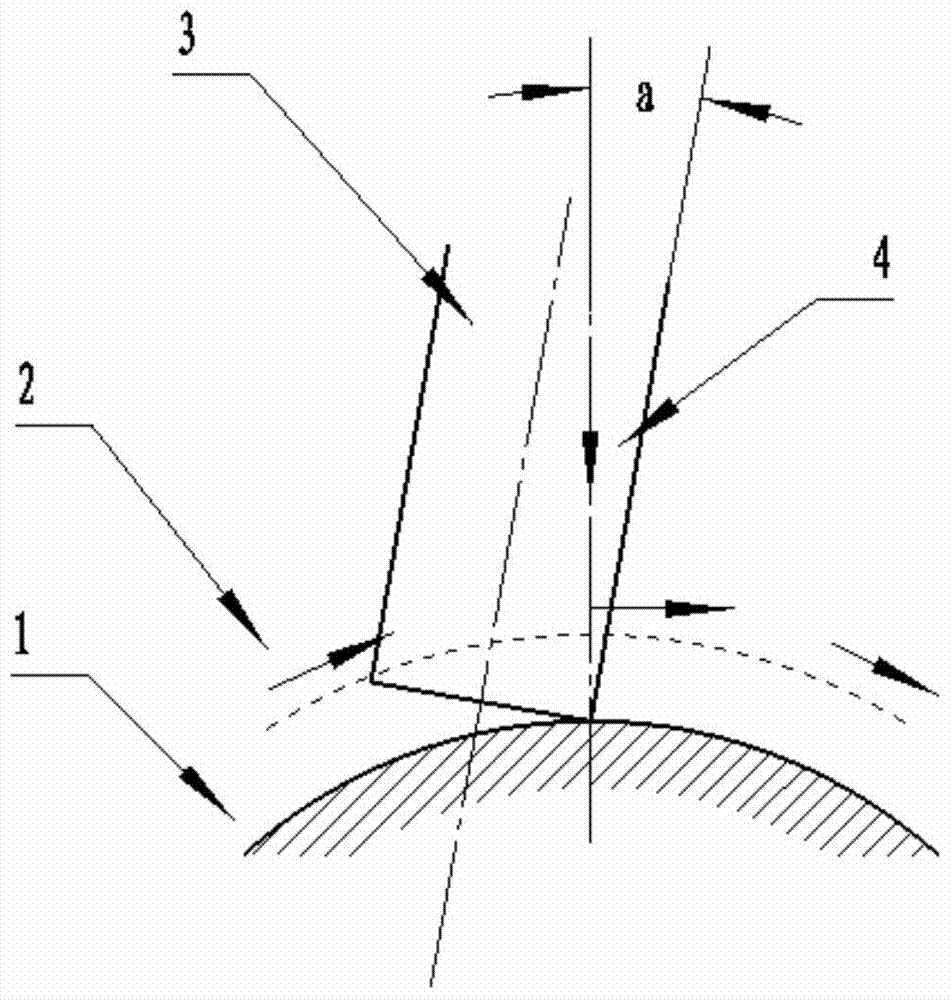

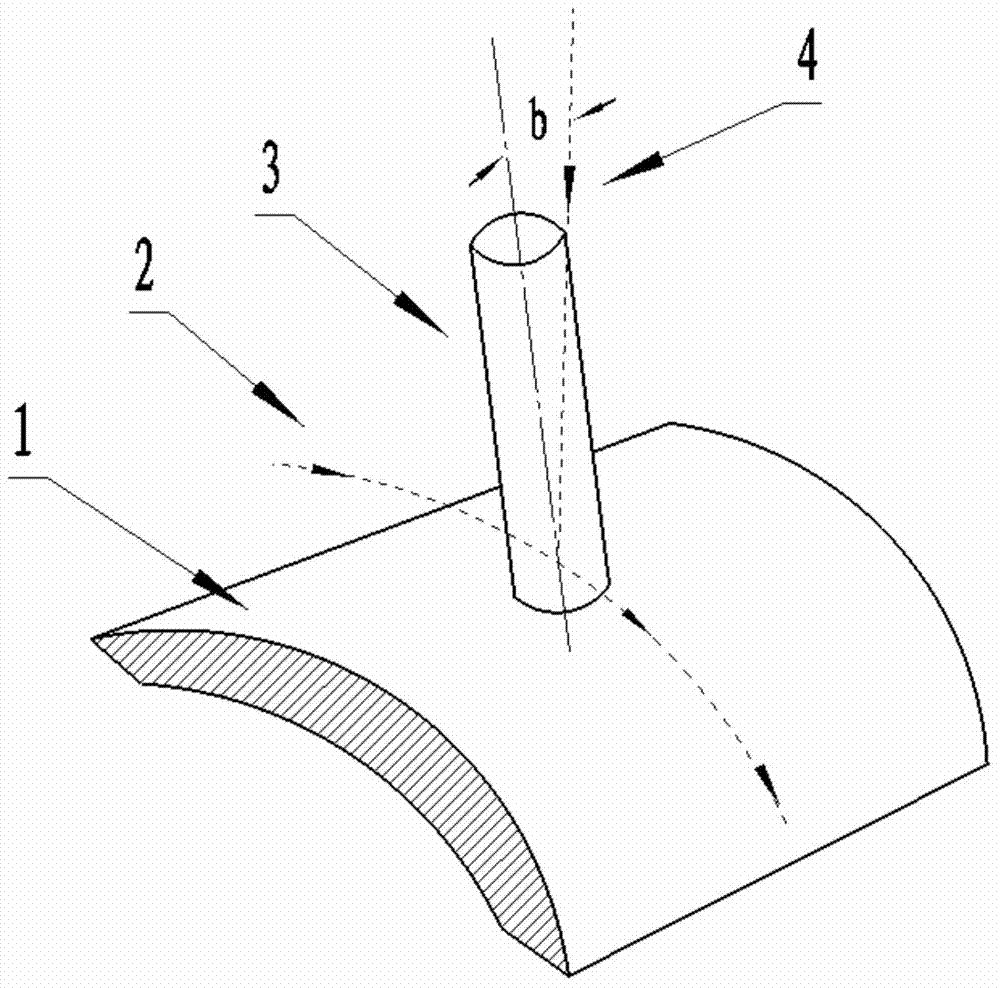

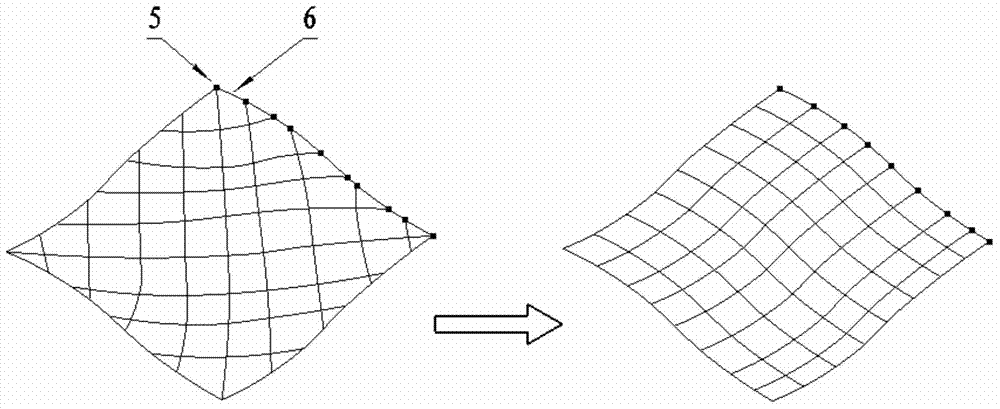

Multi-axis curved surface type numerically-controlled method for machining complicated curved surface part

ActiveCN103537743AImprove cutting efficiencySmall residualAutomatic control devicesFeeding apparatusNumerical controlMilling cutter

The invention discloses a multi-axis curved surface type numerically-controlled method for machining a complicated curved surface part. According to the method disclosed by the invention, the axis of a cutter can be arranged according to the directions of longitude and latitude normal lines for forming a curved surface, an inclined angle is adjusted to generate a cutter path, and the machining efficiency and the part surface smoothness can be improved. The numerically-controlled method can be realized by the following technical scheme: a part is fixed in a rotary center of a five-shaft machine tool; a curved surface is reconstructed according to the curvature change, the normal line direction of the curved surface and a machining path; a space change of an axis vector of the cutter is controlled by adjusting the front inclined angle and the side inclined angle of a cutter shaft of a flat-bottom end mill so that the cutter always keeps that a cutter tip participates in curved surface cutting in the five-axis continuous cutting process; a curved surface projection machining manner is adopted in the programming process so that the mill can carry out multi-axis linked milling machining according to the curvature change of the curved surface; the axis of the cutter is similar with a relatively small front inclined angle alpha overlapped to the normal line direction of the cutter path and a side inclined angle is set as 0; the axis of the cutter is kept vertical to the direction of the machining path to implement a five-axis linked machining numerical control procedure.

Owner:四川泛华航空仪表电器有限公司

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

Aluminum alloy welding wire and preparation method thereof

The invention relates to an aluminum alloy welding wire and a preparation method thereof. The aluminum alloy welding wire is characterized by comprising the following chemical components in percentage by weight: 4-6 percent of Mg, 0.1-0.3 percent of Cr, not more than 0.1 percent of Fe and Si, 0.05-0.08 percent of Cu, 0.04-0.07 percent of Zn, 0.12-0.16 percent of Mn and the balance of Al. The preparation method of the aluminum alloy welding wire comprises the steps of: melting and refining, casting, homogenizing, thermally extruding, annealing, drawing, skiving and brightening, packaging and storing. The aluminum alloy welding wire provided by the invention is few in impurities, stable in performance, and small in texture grains, and has the characteristics of fatigue resistance, crack resistance, welding property and the like.

Owner:GUANGXI DOCTOR HAIYI INFORMATION TECH

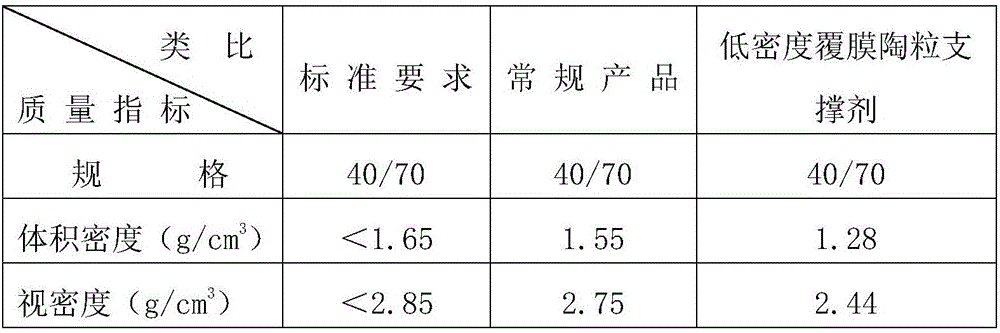

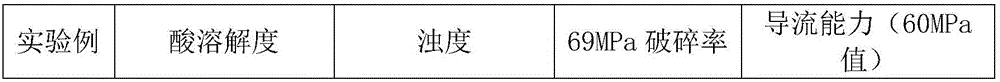

Low-density coated ceramsite proppant and preparation method thereof

ActiveCN106281299AImprove the finishImproves breakage resistanceDrilling compositionPetroleumMaterials science

The invention relates to a low-density coated ceramsite proppant and a preparation method thereof, and belongs to the field of petroleum proppants. A ceramsite base material and mixed resin coating the surface of the ceramsite base material are adopted, so that compared with the traditional proppant, the breaking-resistant capacity is greatly improved, the breaking rate is much lower under the condition of the same consumption of resin, and the low-density coated ceramsite proppant can be suitable for deeper well fracturing. Compared with the traditional proppant, the production cost is lower, the chemical inertness is better, the fracturing effective period can be prolonged, and the low-density coated ceramsite proppant is suitable for the fracturing construction under various complicated stratum environment conditions and is higher in flow conductivity.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

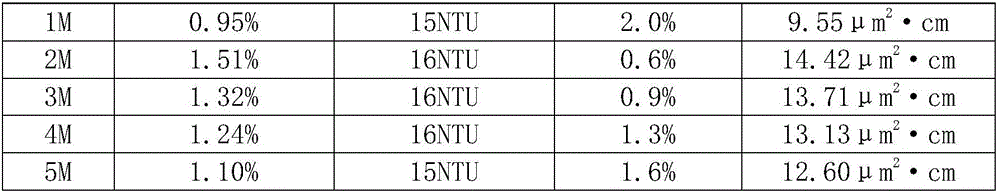

Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

The invention discloses an aluminum oxide ceramic substrate with high heat conductivity. The aluminum oxide ceramic substrate is prepared by steps of stirring a ceramic powder material, a binder, a plasticizer, a dispersant and a solvent uniformly, preparing a ceramic raw-ceramic substrate through a tape casting method, glue discharging and sintering. The aluminum oxide ceramic substrate is characterized in that the solvent is a mixture of butanol, isopropanol and butyl acetate, and the ceramic powder material comprises aluminium oxide powder and auxiliary agents. The invention also discloses a preparation method for the aluminum oxide ceramic substrate with the high heat conductivity. According to the aluminum oxide ceramic substrate and the preparation method, the solvent system which comprises the butanol, the isopropanol and the butyl acetate are used as the main solvent in place of traditional toluene, thus enhancing dissolution of PVB by the solvent, thereby guaranteeing uniformity of raw ceramic slurry, making physical properties of sintered ceramic stable, reducing environmental influences of the exhausted gas during production processes compared to traditional modes of production, contributing to energy conservation and emission reduction, and reducing the cost.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

High-gloss, low-smell, reinforced nylon composite material and preparation method thereof

The invention relates to a high-gloss and low-odor reinforced nylon composite material and the preparation method thereof. The composite material is characterized in that the composite material contains, by weight percentage, PA66 resin, PA6 resin, glass fiber, inorganic minerals, micro-beads, compatibilizer, antioxidant, lubricant, etc. The preparation method comprises the following steps: mixing the above materials in a high-speed mixer; discharging, and extruding and granulating the mixed material in a screw extruder. Compared with common fiber glass reinforced PA and mineral reinforced PA, the PA composite material prepared by the method has the advantages of high gloss, high strength, low odor, etc., and can be widely used for exterior trimming parts such as electric tool housing and motor housing and for interior parts.

Owner:SHANGHAI SUNNY

Melamine decorative veneer and preparation method thereof

ActiveCN101439524AImprove the finishHigh glossWood veneer joiningWood layered productsAdhesiveHeat resistance

The invention discloses a melamine veneer and a preparation method thereof, and belongs to the technical field of decorating materials. The melamine veneer is composed of a substrate and melamine impregnated paper. The melamine impregnated paper is obtained by impregnating paper in a melamine resign adhesive and processing the impregnated paper. The melamine resin adhesive has better activity as the formula thereof is determined by repeated tests. The melamine veneer has a simple processing technology, which causes the melamine resin adhesive to be more evenly and thoroughly immersed into decorating paper. The veneer formed by pressing has a plurality of advantages of the traditional melamine veneer such as high hardness, good abrasion resistance and good heat resistance, good chemical resistance, smooth and clean surface, easy maintenance and cleaning and the like, and further has the advantage of high luminance.

Owner:QUANYOU FURNITURE

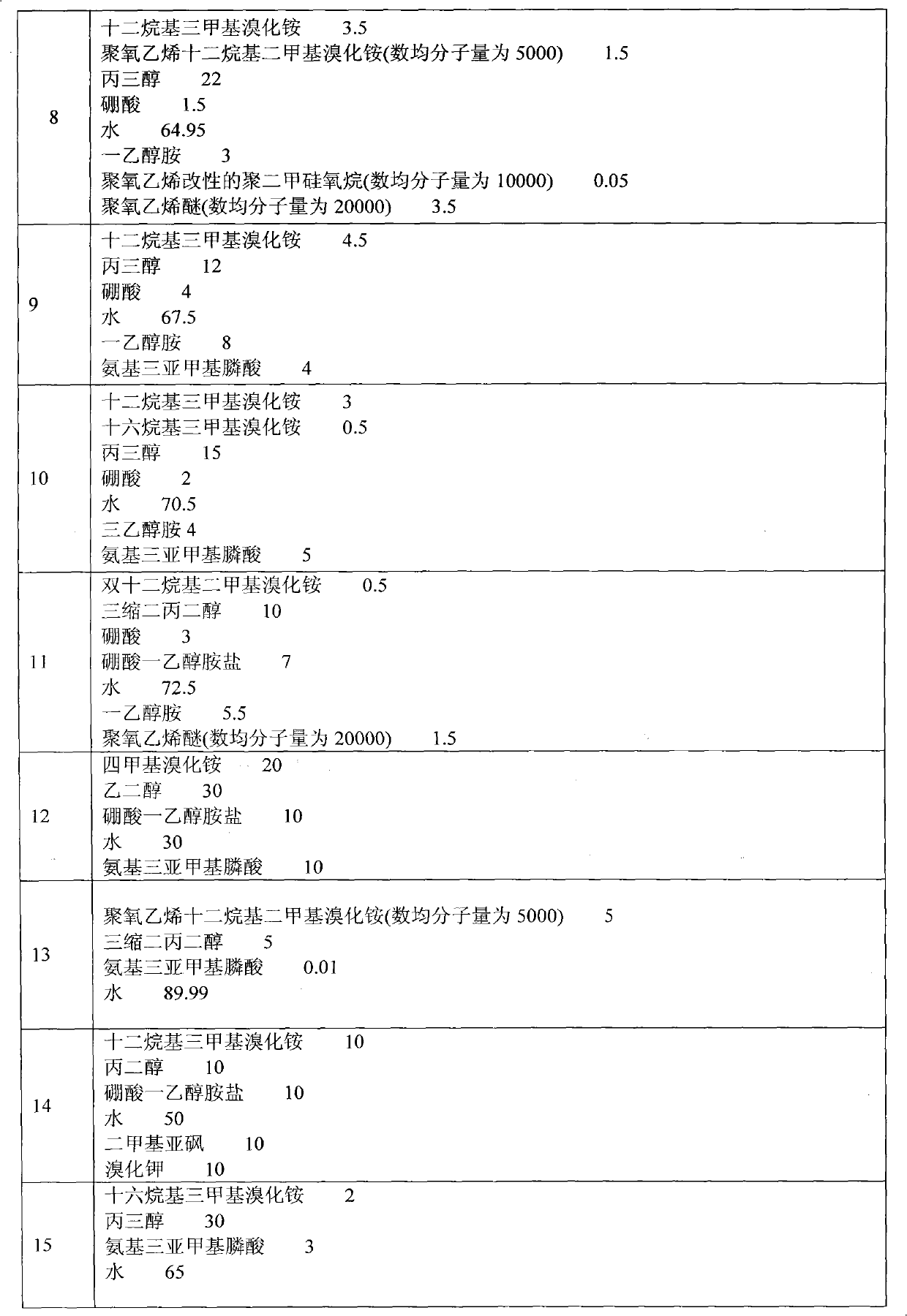

Water-based glass grinding fluid

InactiveCN102559354AImprove cooling effectImprove the lubrication effectLubricant compositionAlcoholActive agent

The invention discloses a water-based glass grinding fluid which comprises a brominated alkyl quaternary ammonium salt surfactant, organic alcohol, a corrosion inhibitor and water. The water-based glass grinding fluid has excellent properties of cooling, lubricating, washing, corrosion preventing and the like, and has a better chemical dressing function on a diamond grinding tool; and according to the water-based glass grinding fluid, the grinding precision can be remarkably improved, the service life of the grinding tool is prolonged, and the greasy blockage of the grinding tool is effectively prevented. The water-based glass grinding fluid has good glass grinding efficiency, excellent chemical stability and low cost, has no harm to the health, does not pollute the environment, is convenient for use, and can be widely applied to the grinding and cleaning processes of various kinds of glass.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Corrosion sample inlaying method

InactiveCN103543060ATightly boundSample preparation is beautiful and generousPreparing sample for investigationEpoxyRoom temperature

The invention discloses a corrosion sample inlaying method. The method comprises the following steps of: based on an epoxy resin inlay, which is composed of 60-80% of matrix resin, 10-25% of conductive powder, 2-10% of dispersing agent and 7-15% of curing agent by weight, orderly arranging the sample to be inlaid, namely the corrosion sample, completely covering the sample with a die, and then, pouring the epoxy resin inlay into the die until submerging the corrosion sample; curing 3-12h at room temperature, uncovering flat surface paper, taking out the sample from the die, respectively sanding the sample with 120#, 240#, 400#, 600#, 800# and 1000# sand paper stage by stage, and then, polishing the sample. With the method disclosed by the invention, the processed corrosion sample can be used for metallomicroscopy observation or electron microscopy scanning observation, so that organization, structure and form of the cross section of the corrosion sample are shown integrally and really.

Owner:CHINA PETROCHEMICAL CORP +1

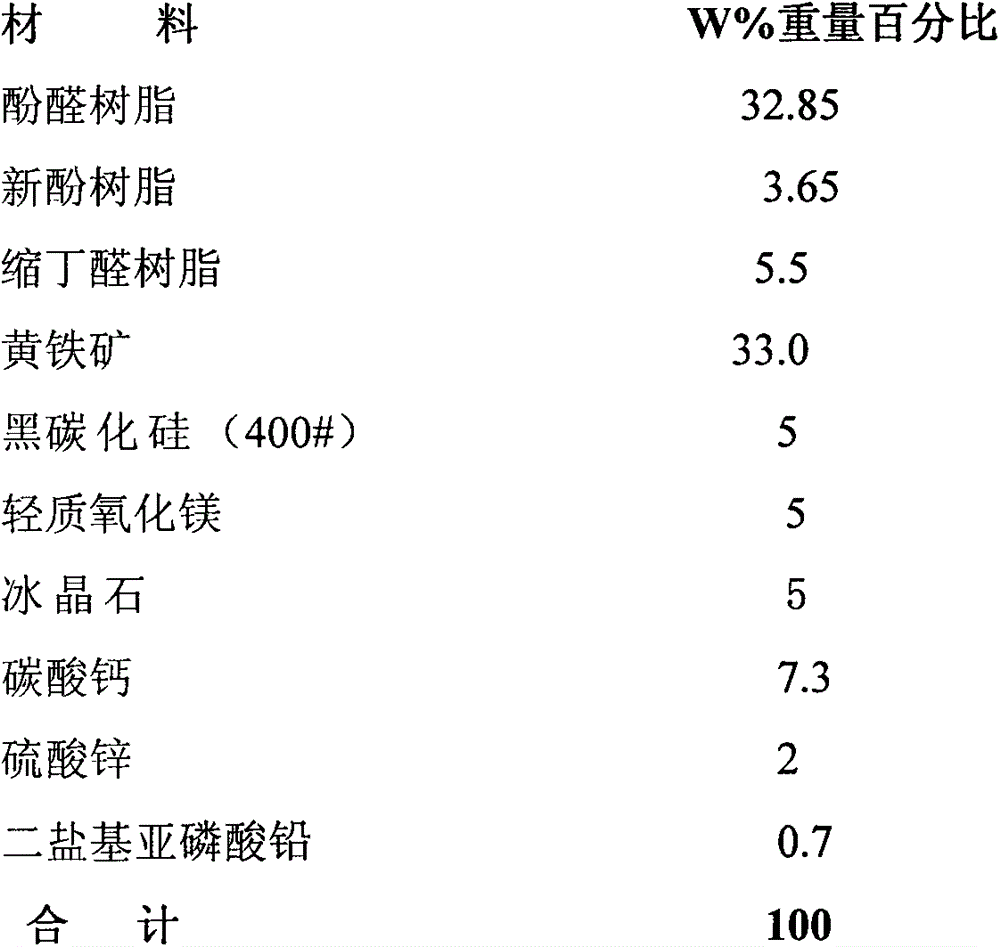

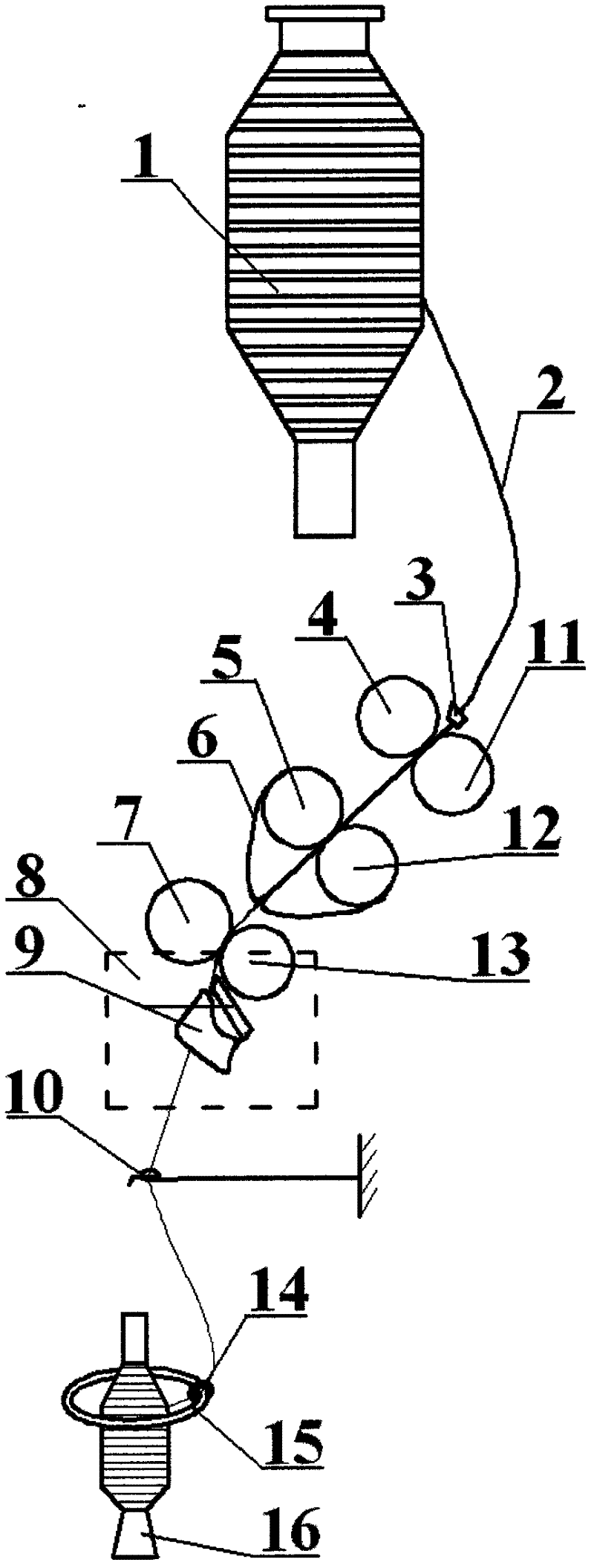

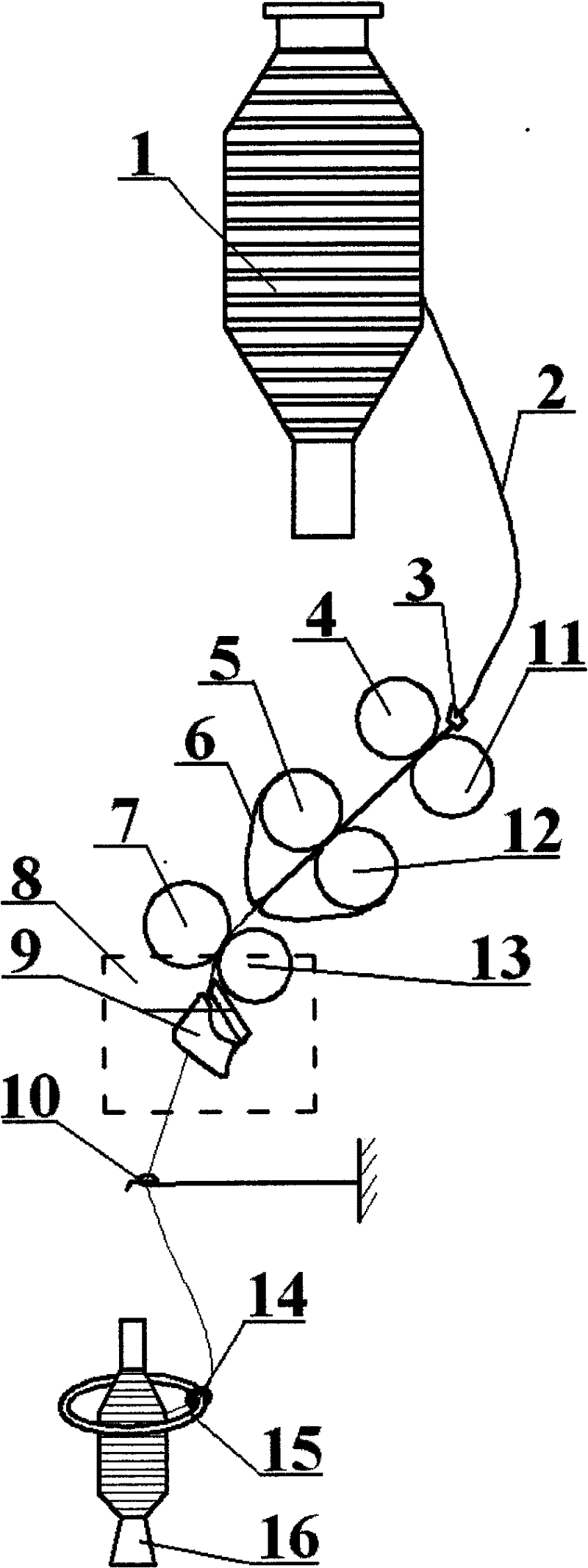

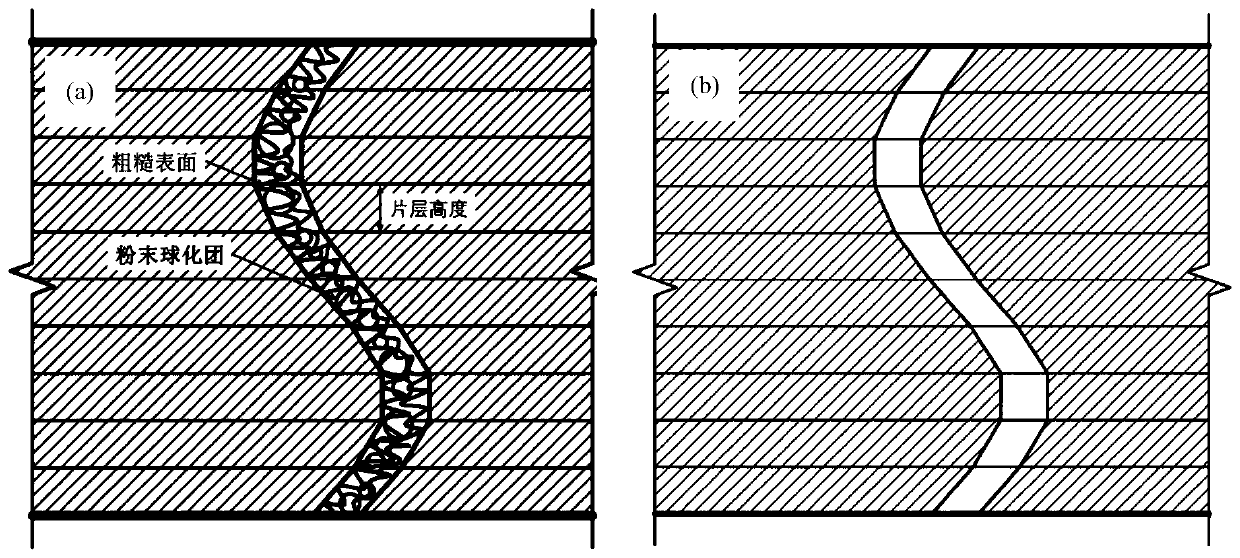

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Soft and clean spinning method

The invention relates to a soft and clean spinning method which can be used for improving the performances of yarn, especially the performances of yarn hairiness and belongs to the technical field of textile processing. On each drafting mechanism of a ring spinning frame, a roving sliver subjected to drafting is output from a front jaw, and a heat and moisture treatment device is used for performing on-line heat and moisture treatment on the on-line twisted roving slivers which are output from the front jaws and enter into a twisting triangular area. Under the combined action of heat and moisture, bending modulus and rigidity of fiber of the on-line twisted roving slivers are greatly reduced immediately, the softening speed and the degree are greatly improved, soft twisting and yarn forming can be performed on the thicker slivers when the lower modulus and the lower rigidity performance are achieved, and the ends of the fiber are easier to transfer and wind under the action of twisting torsional force and finally twisted into yarn bodies or attached on the surfaces of the slivers, thereby effectively eliminating hair feather in the formed yarn and greatly improving the degree of finish of the surface of the formed yarn. Simultaneously, the residual torque and residual stress of the ring-spun yarn can be reduced, not only can the entanglement phenomenon in the formed yarn be effectively solved, but also the softness of the formed yarn can be improved.

Owner:WUHAN TEXTILE UNIV

Molding sand for aluminum casting and preparation technology thereof

ActiveCN101574725AImprove the finishImprove breathabilityFoundry mouldsFoundry coresFoundrySodium Bentonite

The invention belongs to the field of foundry industry, in particular relates to molding sand for aluminum casting and a preparation technology thereof. The molding sand for the aluminum casting comprises the following constituents: old sand, new sand, bentonite and water. The preparation technology of the molding sand for the aluminum casting comprises a sand-mixing method: weighting the old sand, the new sand and the bentonite according to a proportion, firstly mixing the same for 10 to 20 seconds, adding water to mix for 80 to 100 seconds and standing the mixed material for 20 seconds after the mixed material is well mixed. The invention has the advantages that the particle sizes of the sand are strictly controlled, the sand with the particle size of 200 / 100 meshes is selected, and the proportion of the sand failing to pass 200 meshes is larger than 50 percent so that both the surface smoothness of aloxite parts and the air permeability of the molding sand are favorable.

Owner:SHANDONG LIANCHENG PRECISION MFG CO LTD

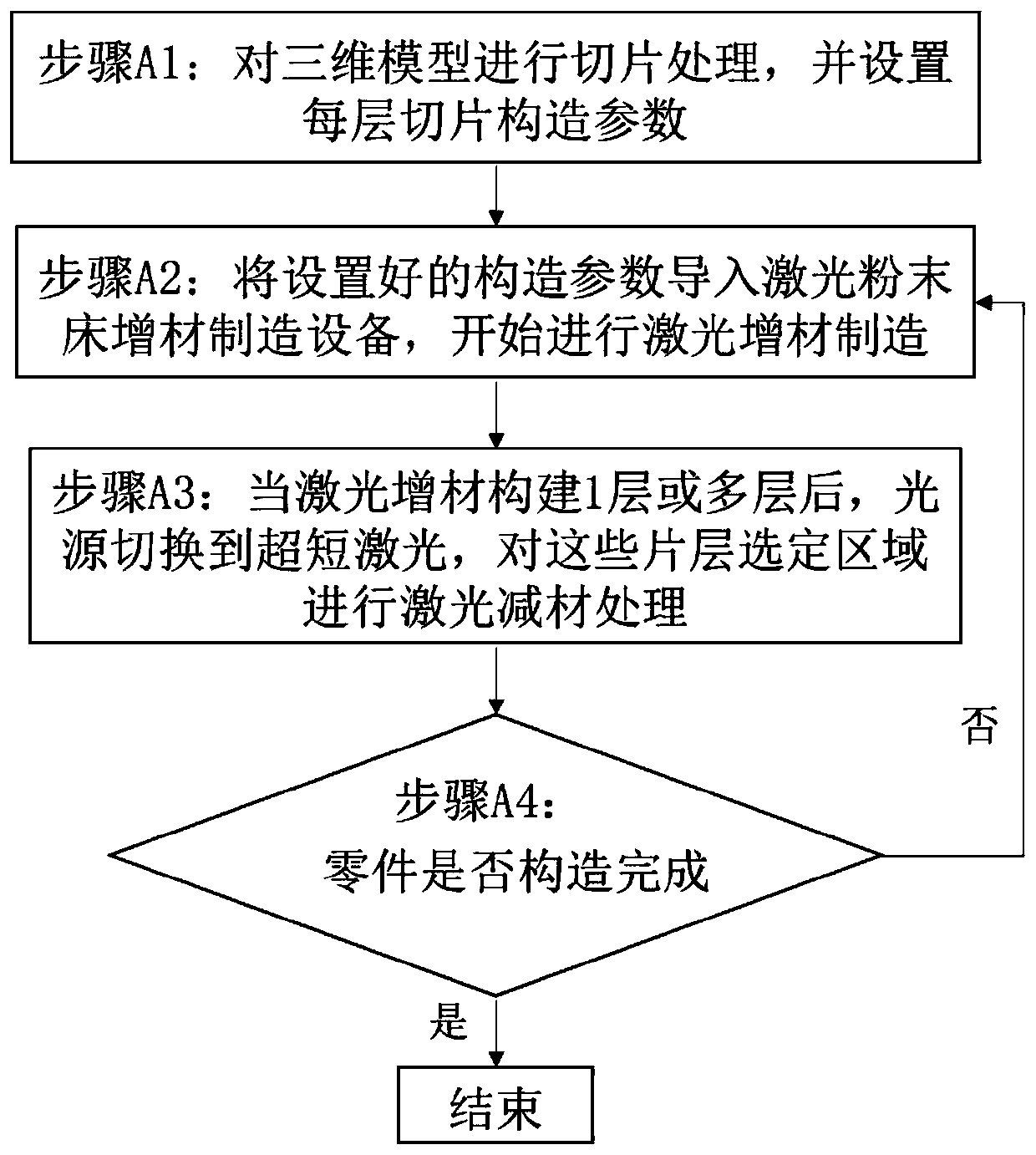

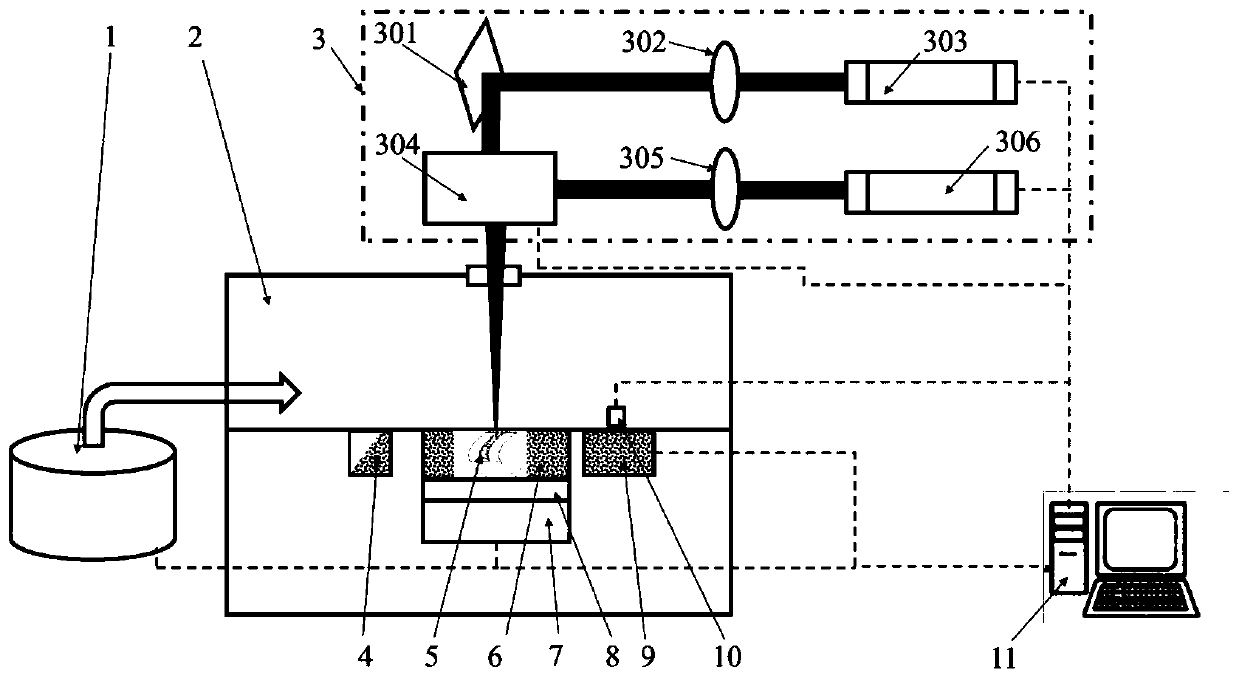

Near-net forming method and device for composite manufacturing fine workpiece based on laser additive manufacturing and subtractive manufacturing

PendingCN110369725AShort duration of actionChange the surface morphologyAdditive manufacturing apparatusIncreasing energy efficiencyFine structureLaser processing

The invention belongs to the field of laser processing, and relates to a near-net forming method and device for composite manufacturing a fine workpiece based on laser additive manufacturing and subtractive manufacturing. According to the method, the construction parameters of a three-dimensional digital-to-layer slicing layer are generated by utilizing software, laser additive manufacturing processing is carried out, and ultrafast pulse laser subtractive manufacturing processing is carried out alternately in the laser additive manufacturing processing process to form a three-dimensional entity. The device comprises a computer control device, a sealing molding chamber, a light path selecting system and an inert protection gas source; during additive manufacturing processing, the computer control device controls the light path selecting system to select the laser emitted by an additive manufacturing laser device and perform laser additive manufacturing processing; and during subtractivemanufacturing processing, the computer control device controls the light path selecting system to select ultrafast pulse lasers emitted by a subtractive manufacturing laser device and perform the ultrafast pulse laser subtractive manufacturing processing. According to the near-net forming method and device, the preparation of complex and fine-structure parts can be completed in a high-precision and integrated manner, the defects that traditional laser additive manufacturing is low in the forming precision, high in roughness and cannot be used for preparing a fine and complex inner cavity areovercome.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method for high purity fructo-oligosaccharide

ActiveCN101368195AImprove performanceSuitable for useOn/in organic carrierFermentationSucrosePeroxidase

The invention relates to a preparation method of high purified fructo-oligosaccharide, in particular to a method for preparing the high purified fructo-oligosaccharide by using immobilized enzyme. The preparation method of the invention prepares immobilized fructosyltransferase, immobilized glucose oxidase and immobilized mimic hydrogen peroxidase; then prepared enzymes are used to prepare the high purified fructo-oligosaccharide through an interrupted or continuous production method. In the preparation method, cheap metalporphyrin compounds are used as the mimic hydrogen peroxidase to replace expansive catalase; the fructosyltransferase, the glucose oxidase and the mimic hydrogen peroxidase are all immobilized and all can be recycled and reused; the stability and the operating factor of the enzymes are improved; the production cost for preparing the high purified fructo-oligosaccharide is greatly reduced. The preparation method can use one step method to directly produce the high purified fructo-oligosaccharide from cane sugar.

Owner:量子高科(广东)生物有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com