Anti-fatigue controlled laser shot peening method and device therefor

A laser peening and anti-fatigue technology, which is applied in the direction of manufacturing tools, heat treatment process control, process efficiency improvement, etc., can solve the problems that have not yet been searched for controlled laser peening strengthening, and meet the strengthening requirements and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

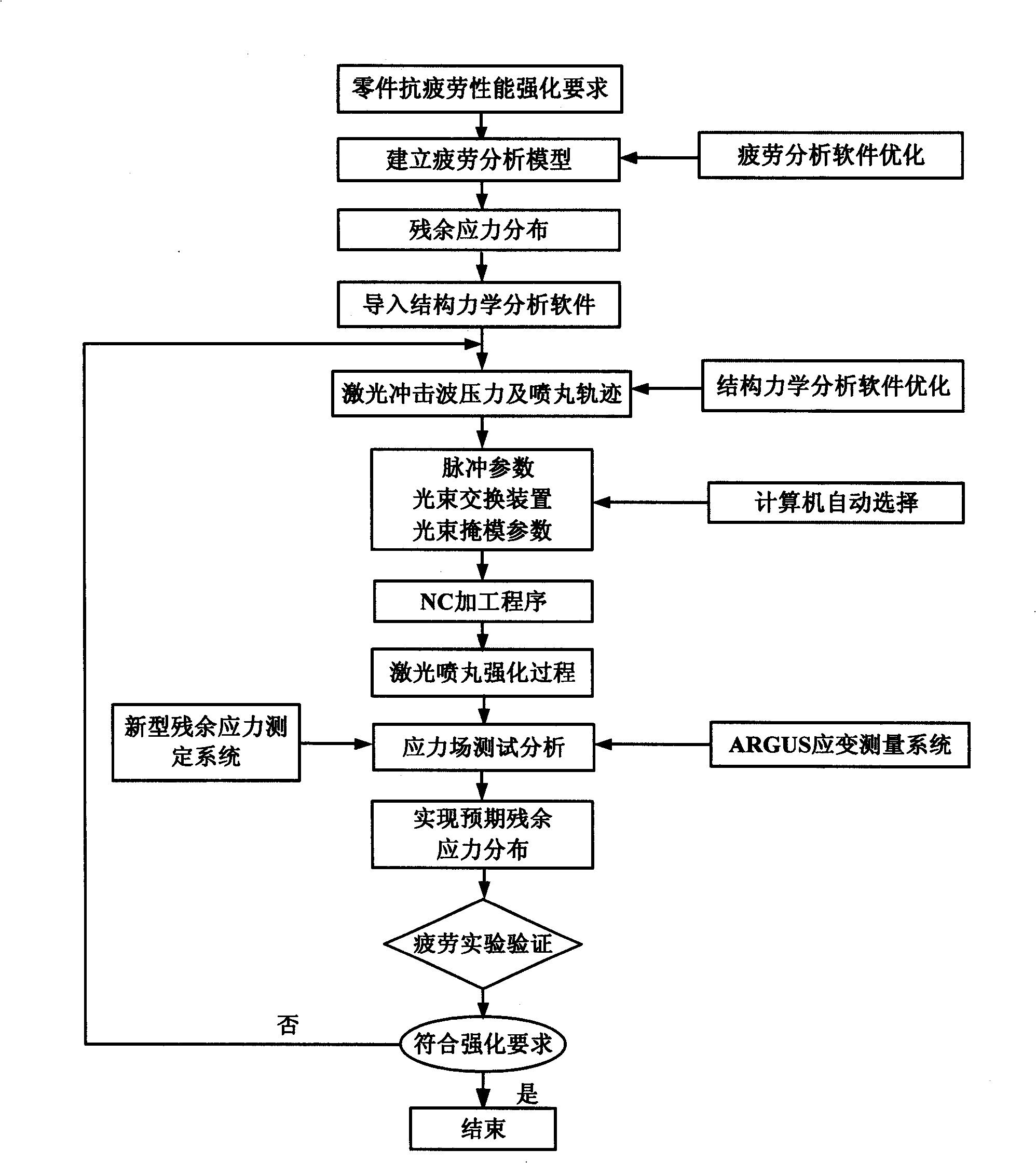

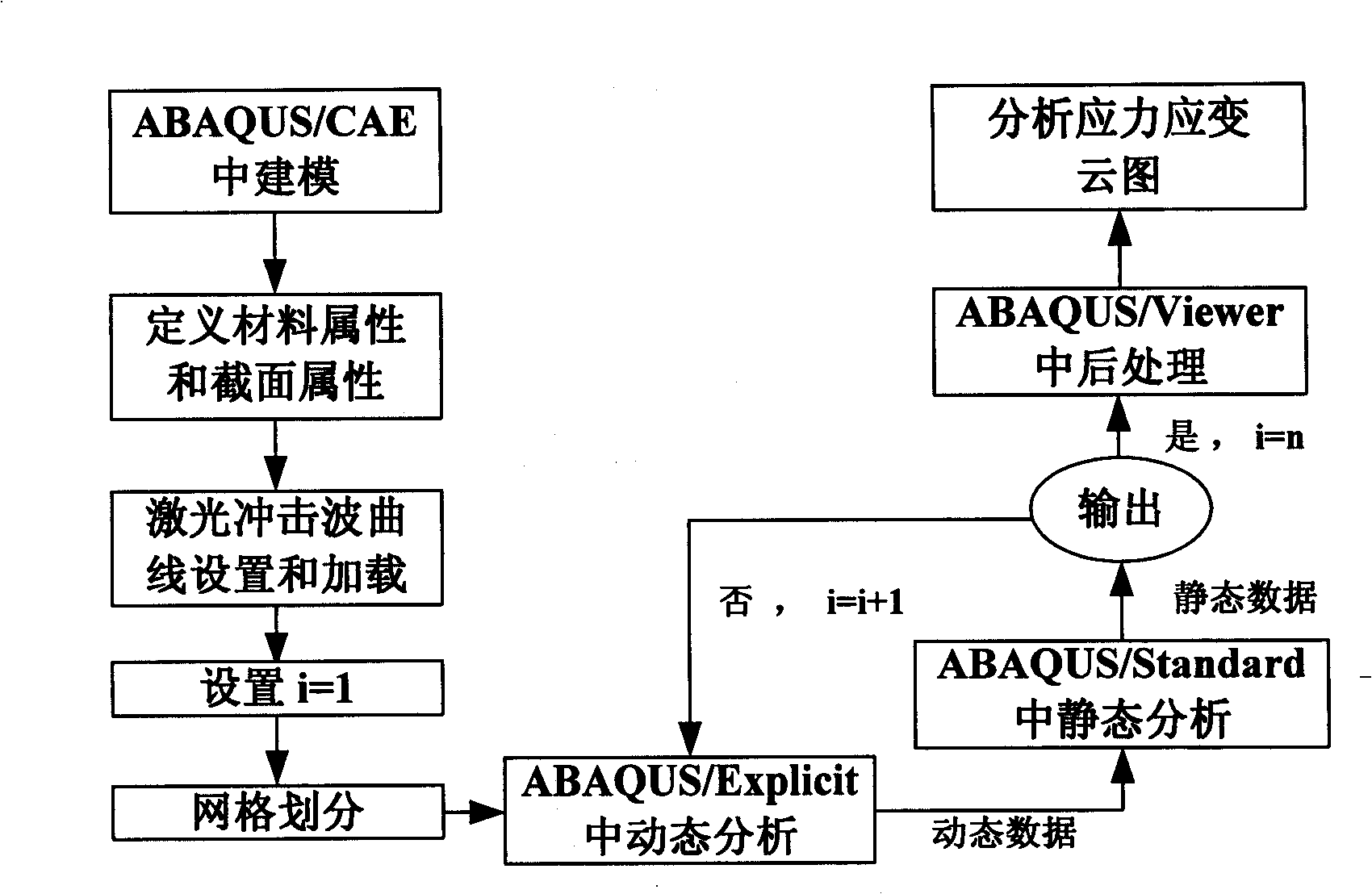

Method used

Image

Examples

example

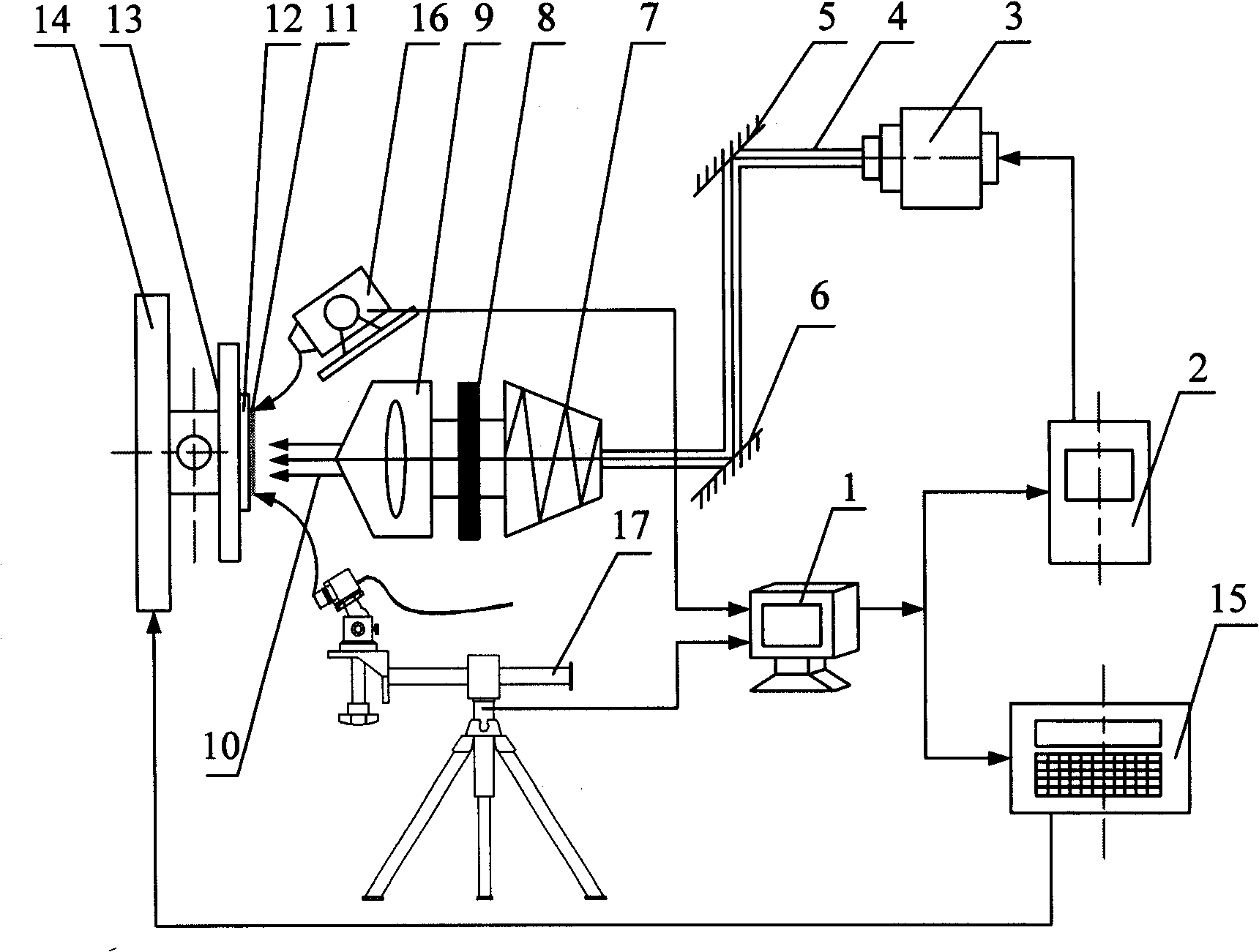

[0051] Example: Laser shot peening of 6061-T6 aviation aluminum alloy single-joint central hole fatigue test piece

[0052] Since laser shot peening is particularly suitable for dealing with fatigue parts with local stress concentration, such as machine parts with fatigue-prone notches, holes, and corners, and aluminum alloy is a commonly used aerospace material, 6061-T6 is selected in this example The aviation aluminum alloy single-joint center hole fatigue test piece is strengthened by laser shot peening, and its shape and size are as follows: Figure 4 As shown, the outer dimensions are machined first, and then the center hole is bored to a diameter of 2mm. The experiment adopts PLA30050 fatigue tensile testing machine. Before the laser shot peening of parts, when the maximum load is 7KN, the minimum load is 0.7KN, the stress ratio is 0.1, and the test frequency is 13HZ, the fatigue life is 88000. About times, it is now required to increase the fatigue life by more than 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com