Patents

Literature

266results about How to "No mechanical damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-fatigue controlled laser shot peening method and device therefor

InactiveCN101275177AImprove work efficiencyMeet the reinforcement requirementsHeat treatment process controlProcess efficiency improvementLife valuePulse parameter

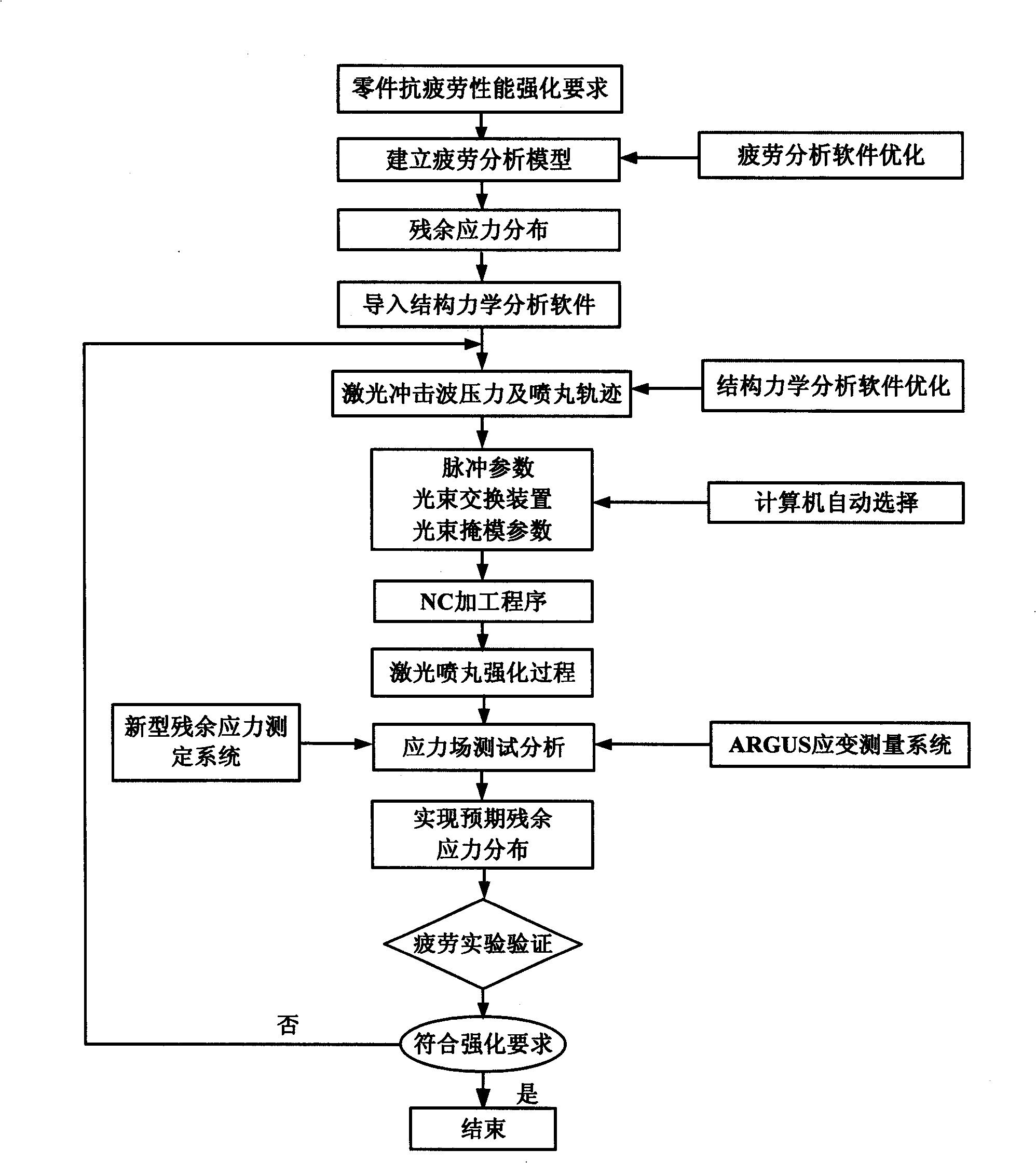

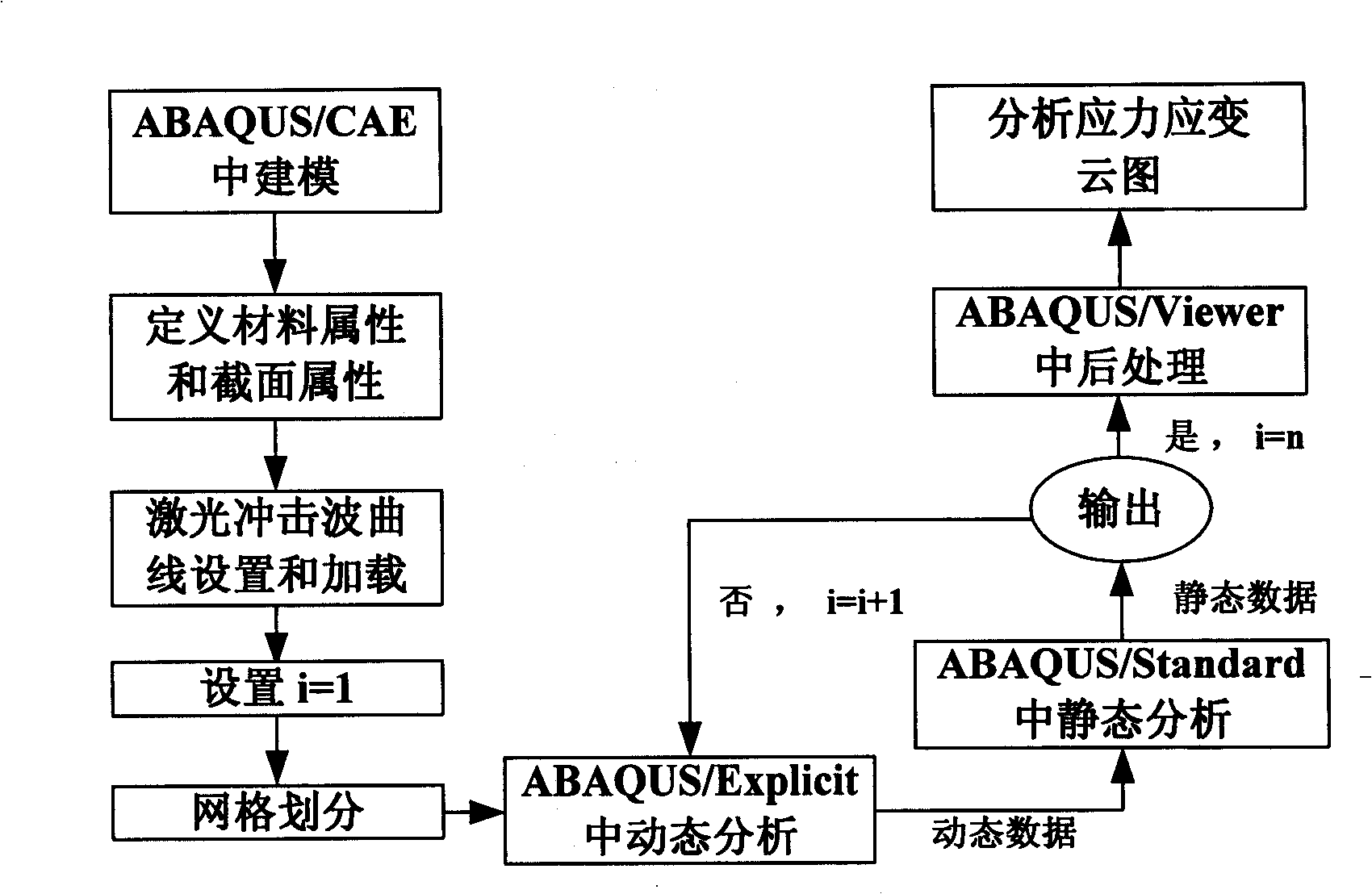

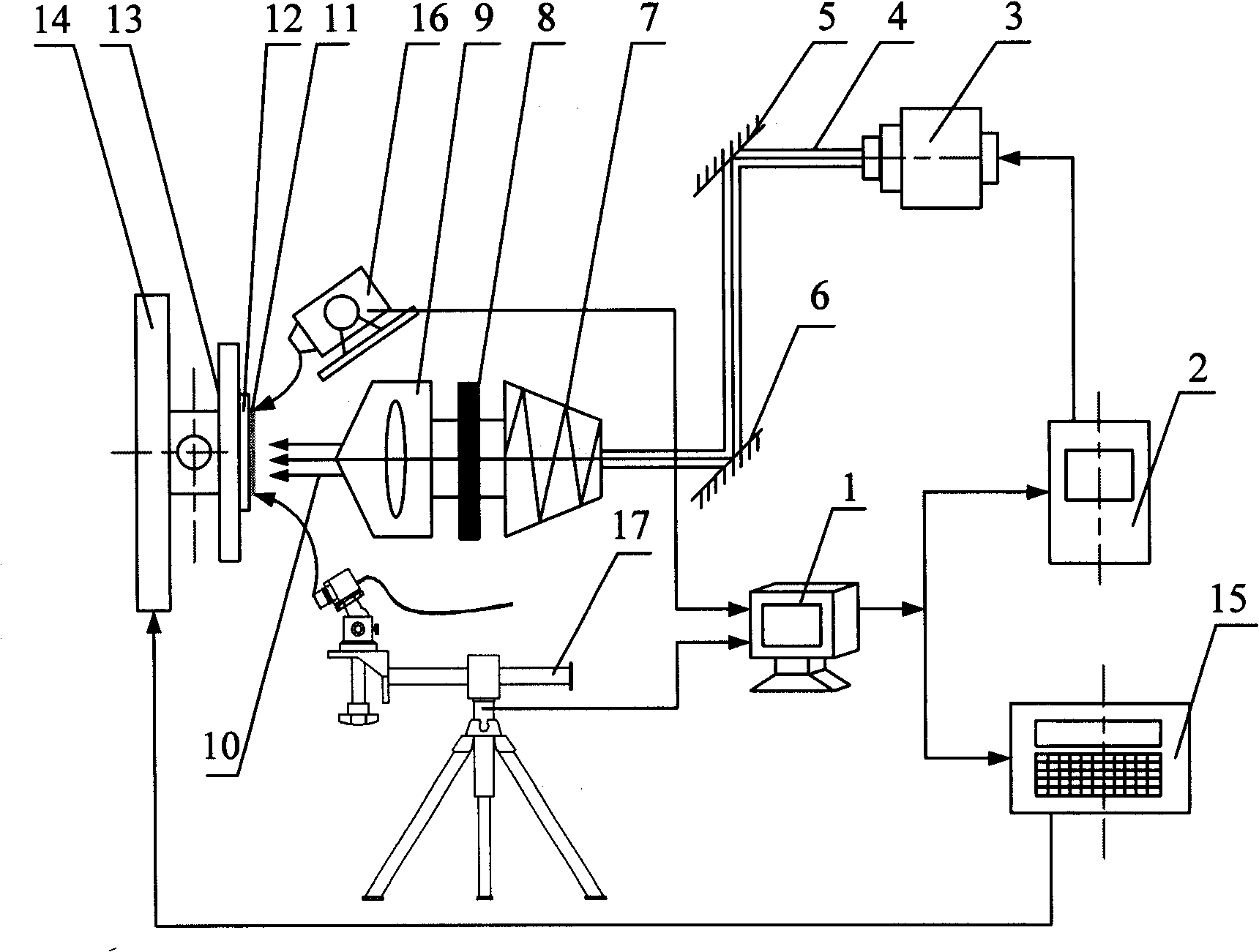

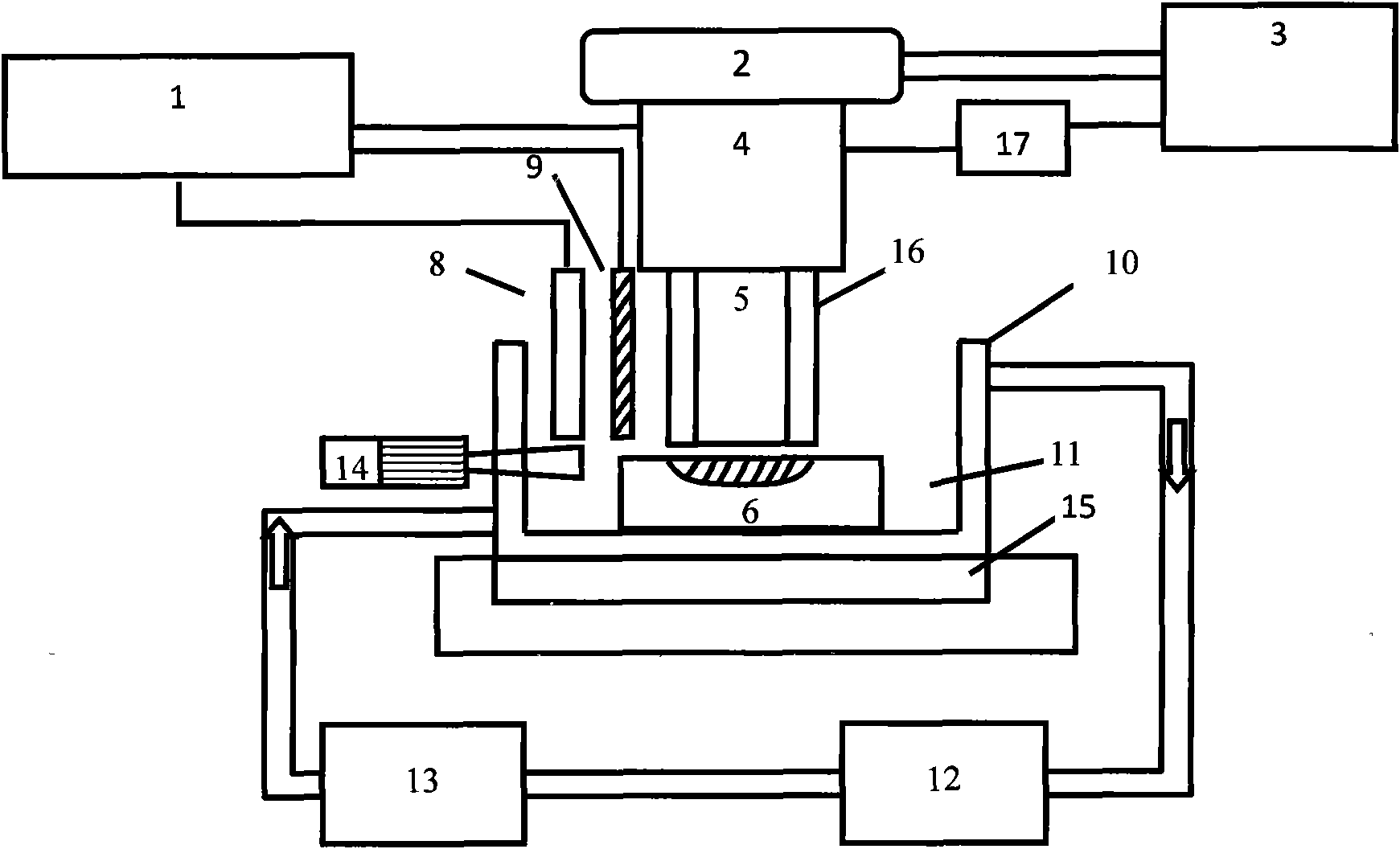

The invention relates to a method and a device for intensifying controlled laser shot peening, first of all, a fatigue analysis model is established in a fatigue analysis software, distribution of residual stress in the accessories is optimized in light of the expectant fatigue life value after the intensification to obtain the distribution of residual stress which meets the demand; the distribution of residual stress is imported into a structural mechanics CAE analysis software to obtain by optimization laser shock wave pressure acting on the surface of a sheet metal and the shot peening track; after than a computer control system automatically selects the pulse parameter and a light beam changing device while the laser shot peening; the laser emits a high energy short pulse laser beam to be converted into the high amplitude shock wave pressure acting on the surface of the accessories after being subjected to an optical changing device and an optical mask; a measurement feedback system is used to online check the distribution situation of the stress and strain on the surface layer of the accessories in the laser shot peening, the special computer software module is utilized to perform error analysis and parameter correction, ensuring to generate the expectant distribution of residual stress on the surface layer of the accessories to meet the intensification demand of the anti-fatigue performance.

Owner:JIANGSU UNIV

Electrochemical levelling and polishing processing method with nanometer precision and device thereof

ActiveCN101880907ANo mechanical damageNo pollution problemElectrolysis componentsSemiconductor/solid-state device manufacturingElectrochemical responseLiquid layer

The invention provides an electrochemical levelling and polishing processing method with nanometer precision and a device thereof, relating to an electrochemical etching levelling and polishing technology. The device is provided with a cutter with nanometer levelling precision, an electrochemical reaction control system capable of accurately controlling the thickness of an etching levelling agent liquid layer in nanoscale, a solution circulating device, a solution thermostat and an automatic control system. The method is implemented by the following steps: preparing the cutter with nanometer levelling precision to serve as an electrochemical working electrode, and placing the cutter at the bottom of a container together with a workpiece; immersing the cutter in a solution, starting an electrochemical system, generating the etching levelling agent on the surface of the cutter, compressing the etching levelling agent liquid layer on the cutter surface into a nanoscale thickness, and regulating and controlling the thickness of the etching levelling agent liquid layer; driving a tri-dimensional micro-drive device, leading the cutter to approach the workpiece gradually, and regulating and controlling the distance and parallelism between the workpiece surface and the cutter; and leading the cutter to move toward the workpiece surface, and enabling the constraint etching levelling agent liquid layer on the cuter surface to contact with the workpiece surface until the whole workpiece is etched, leveled and polished.

Owner:XIAMEN UNIV

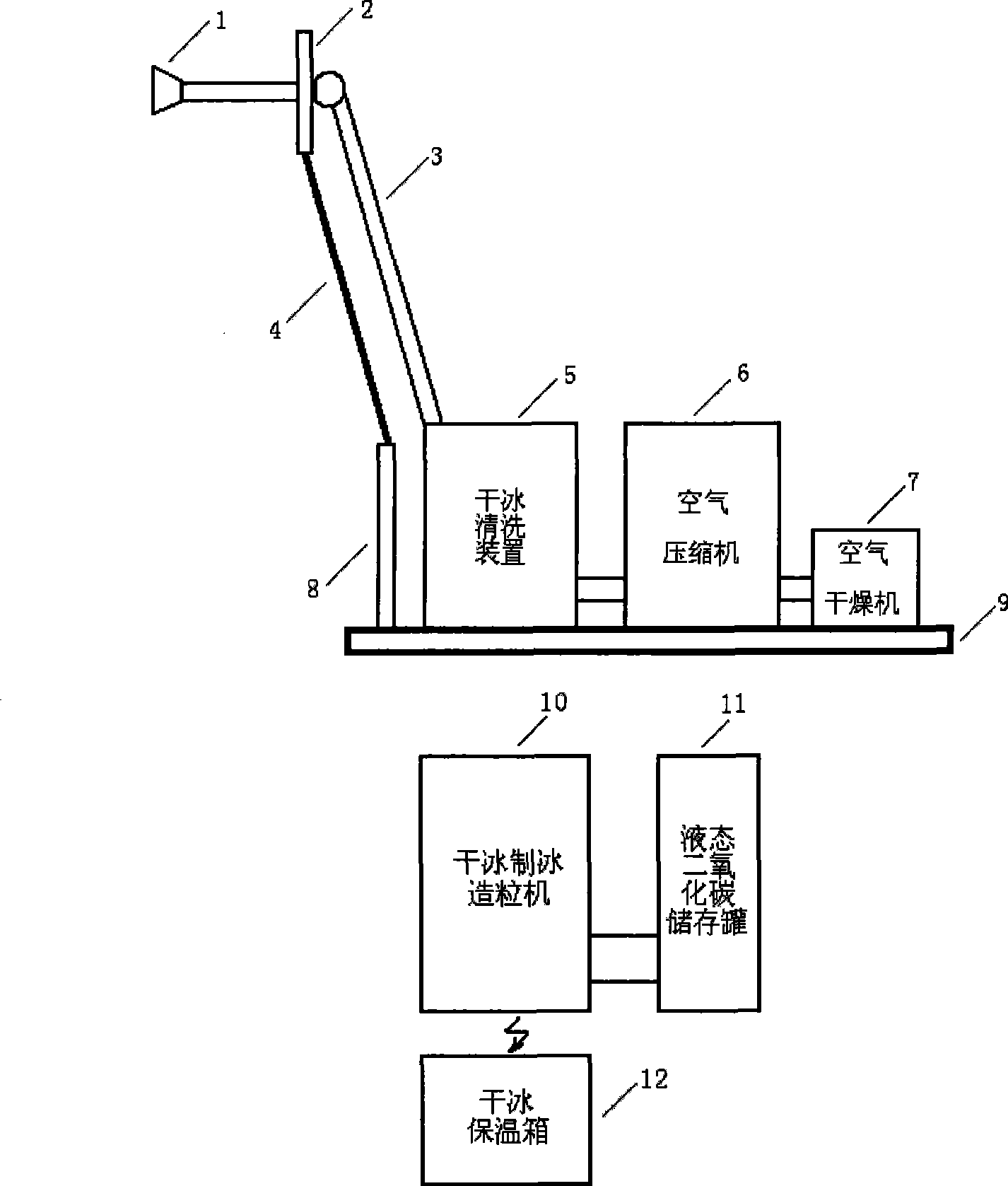

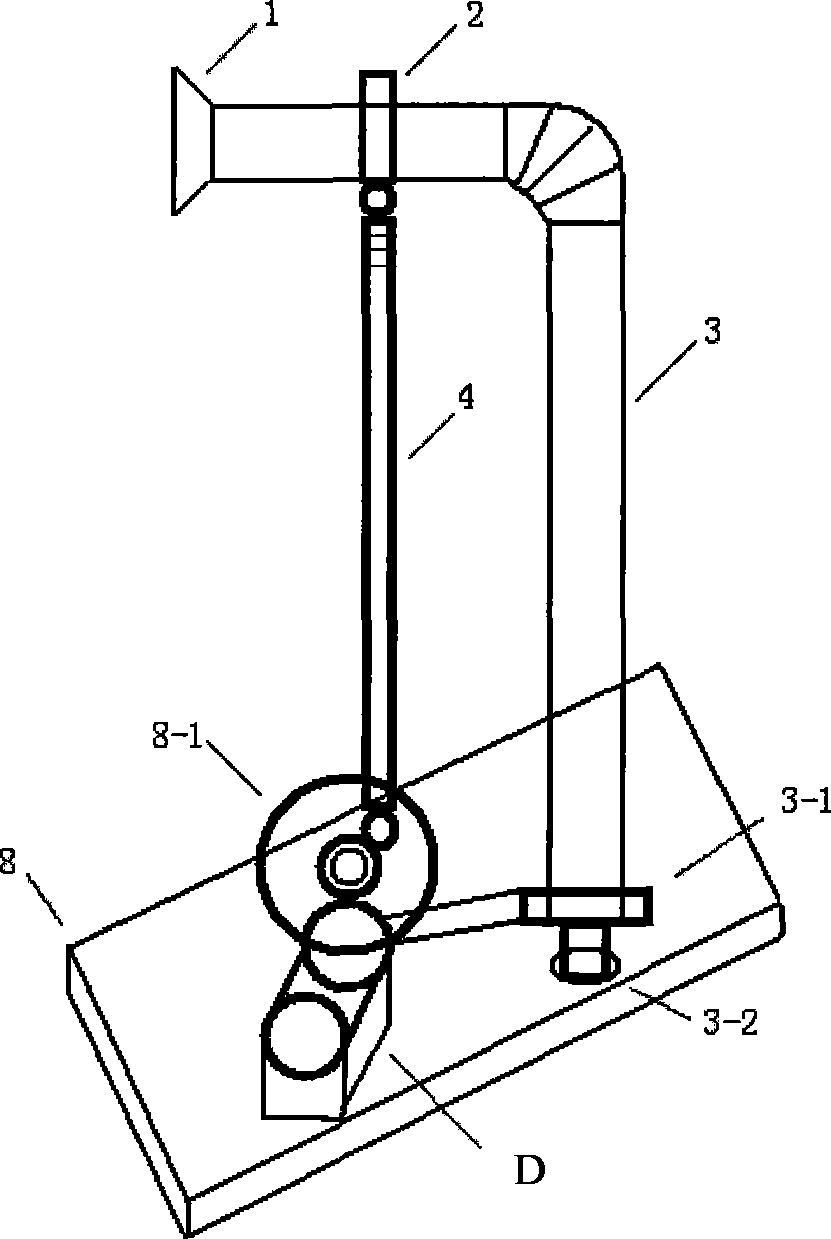

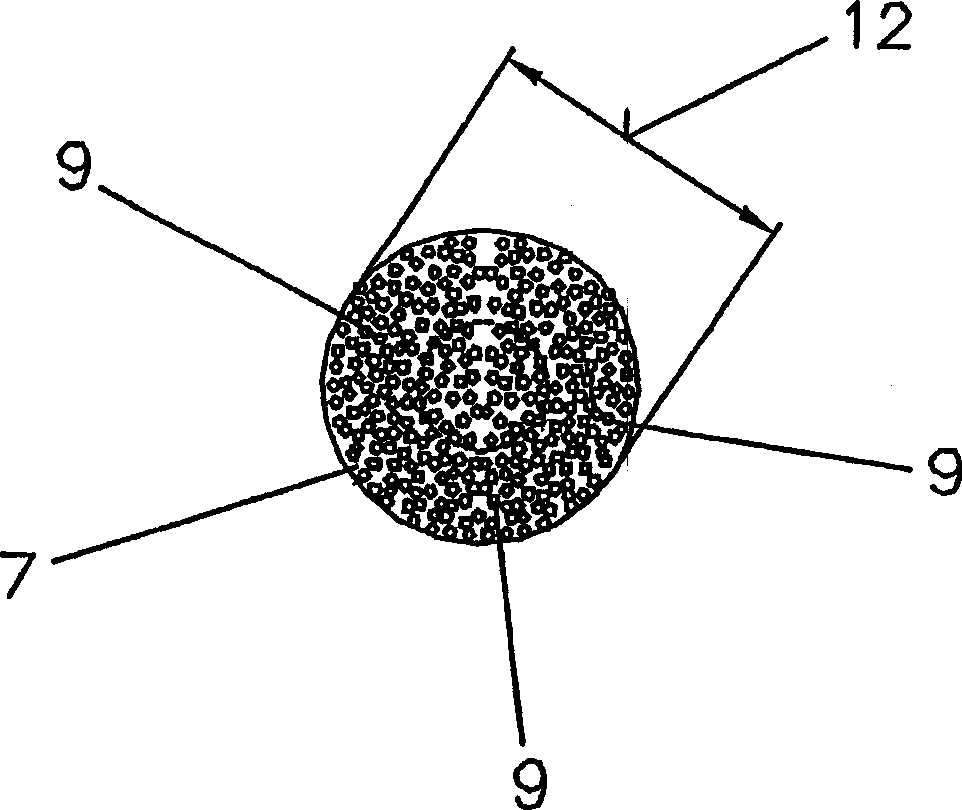

Dry ice cleaning system for electrical apparatus external insulation

InactiveCN101480651AAvoid influenceLow costCleaning processes and apparatusTransformerElectric power system

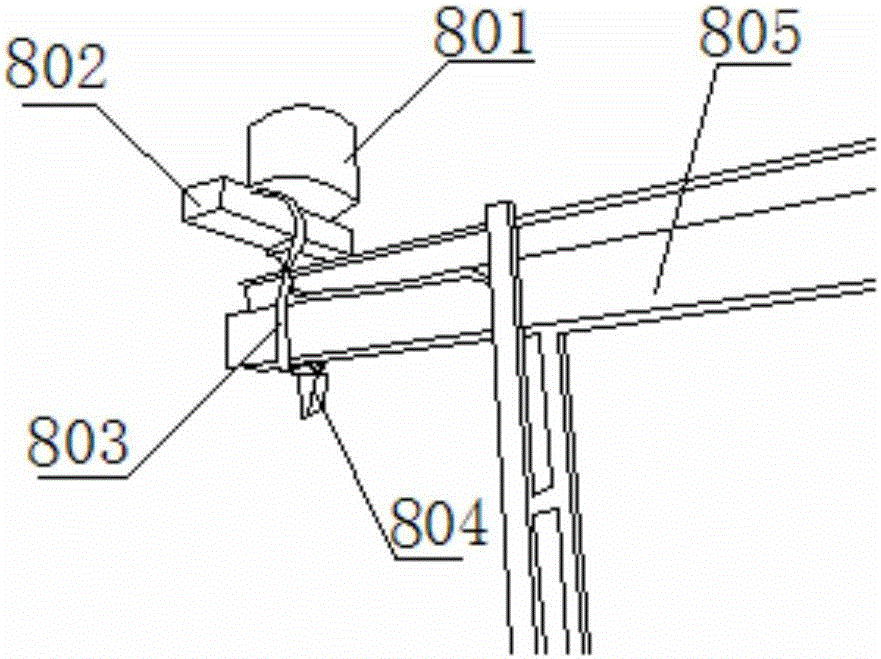

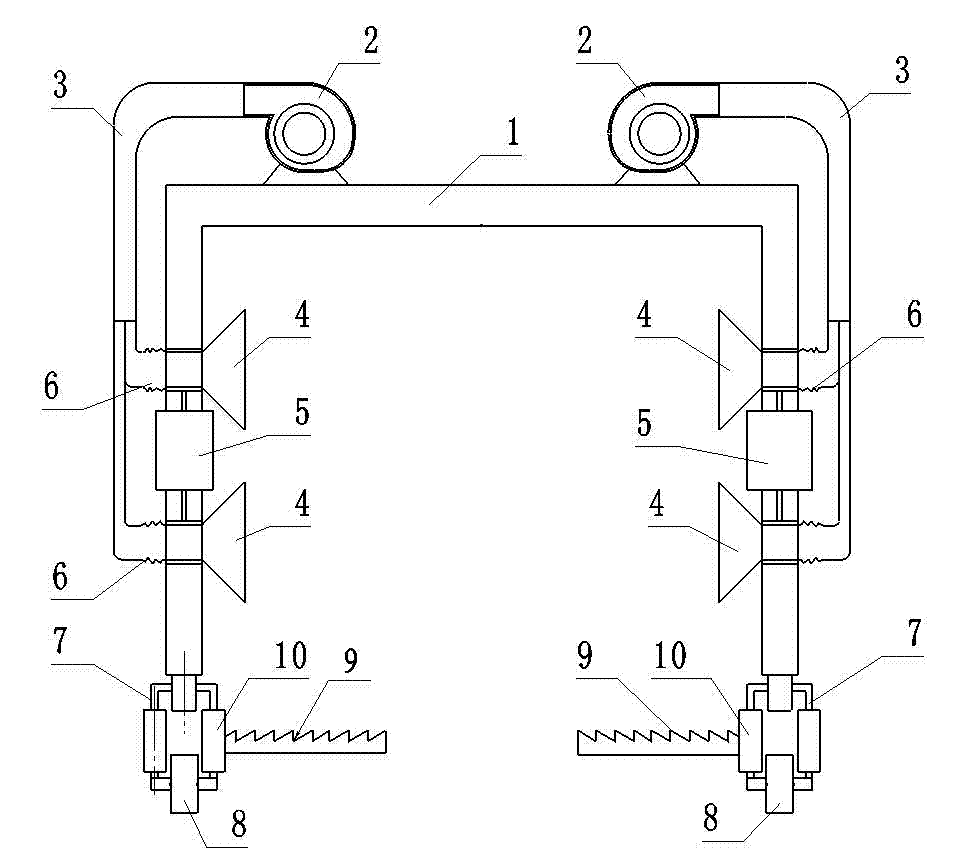

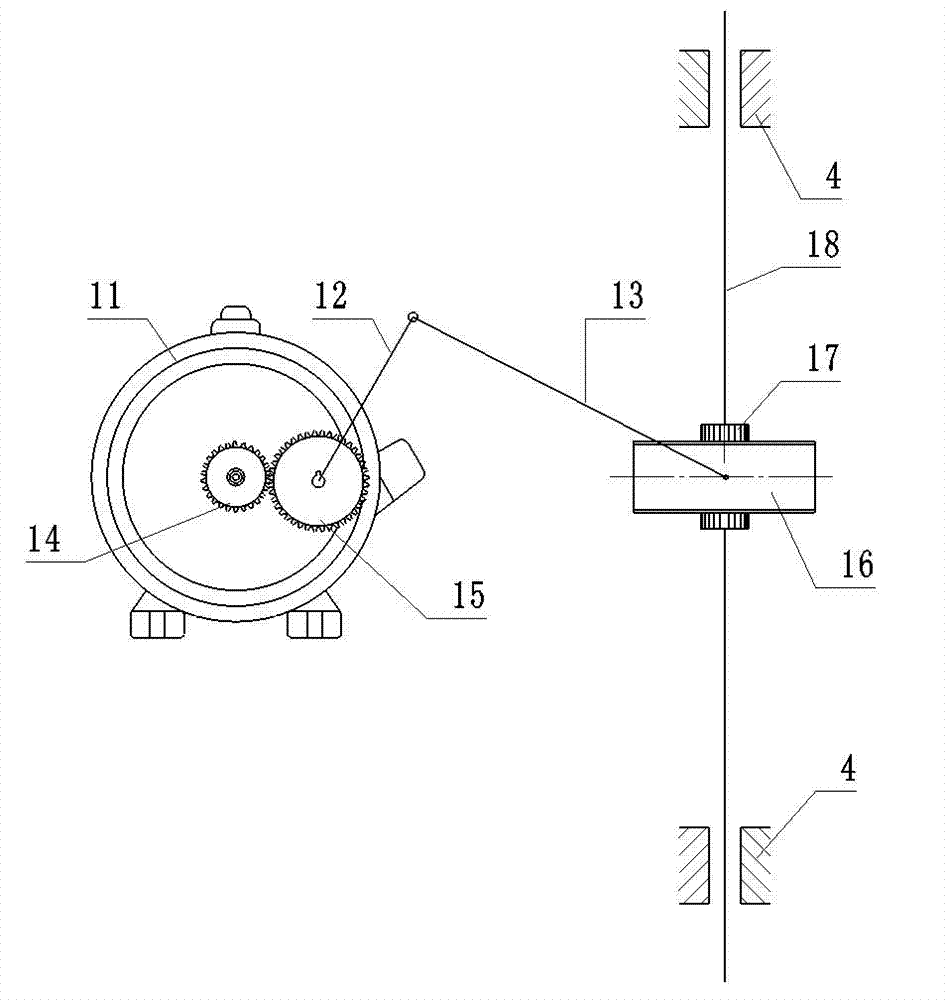

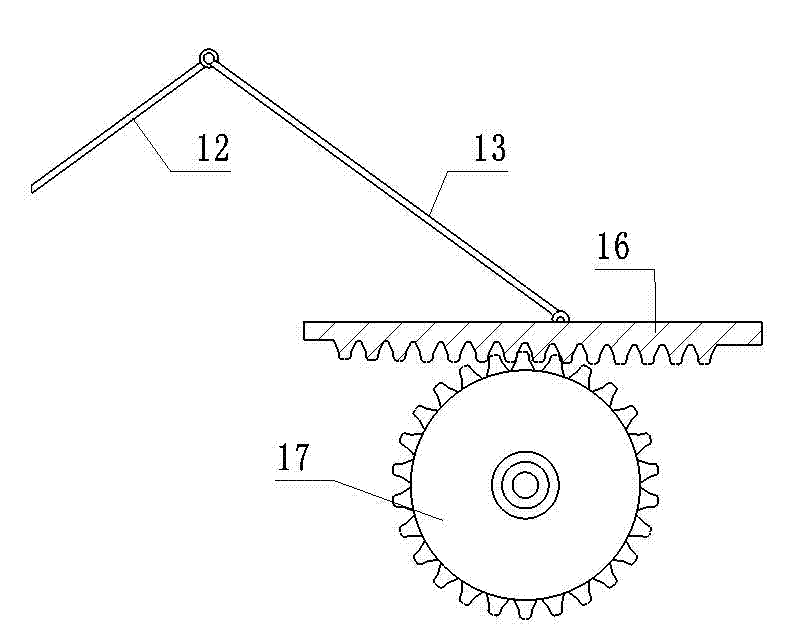

The invention discloses a external-insulation dry-ice cleaning system for electrical equipment, which belongs to the technical field of the external-insulation dirt removal of electrical equipment of an electrical system. The external-insulation dry-ice cleaning system adopts the structure that a dry-ice particle spray nozzle (1), an insulating adjustable bracket (2), a dry-ice transmission insulating pipe (3), a dry-ice cleaning device (5), an air compressor (6) and an air dryer (7) are sequentially connected with each other front and back, wherein the dry-ice particle spray nozzle (1), the insulating adjustable bracket (2), an insulating bracket regulating lever pipe (4) and a bracket regulating power device (8) are sequentially connected with each other from front and back, a dry-ice making granulating machine (10) is connected with a liquid carbon dioxide storage tank (11), a dry-ice insulation can (12) is independent equipment, and an earthing base (9) is taken as a safe earthing pedestal of the external-insulation dry-ice cleaning system. The invention has high dirt removing efficiency, is suitable for the on-line cleaning of an insulating sleeve and an insulating mainstay or an erected transmission line insulator inside a transformer station, and is an effective measure for safely generating the electricity and ensuring the electricity supply.

Owner:WUHAN UNIV

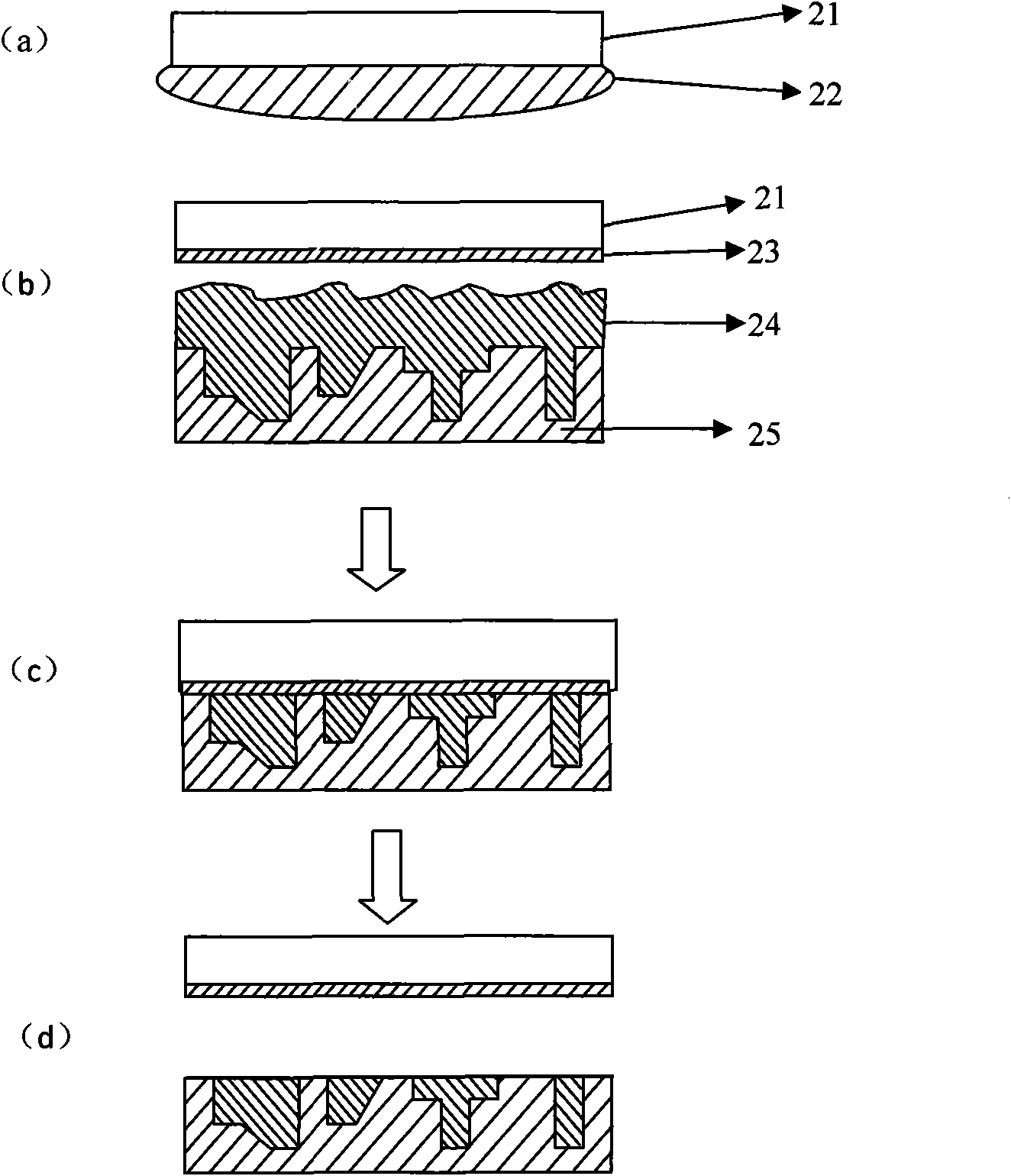

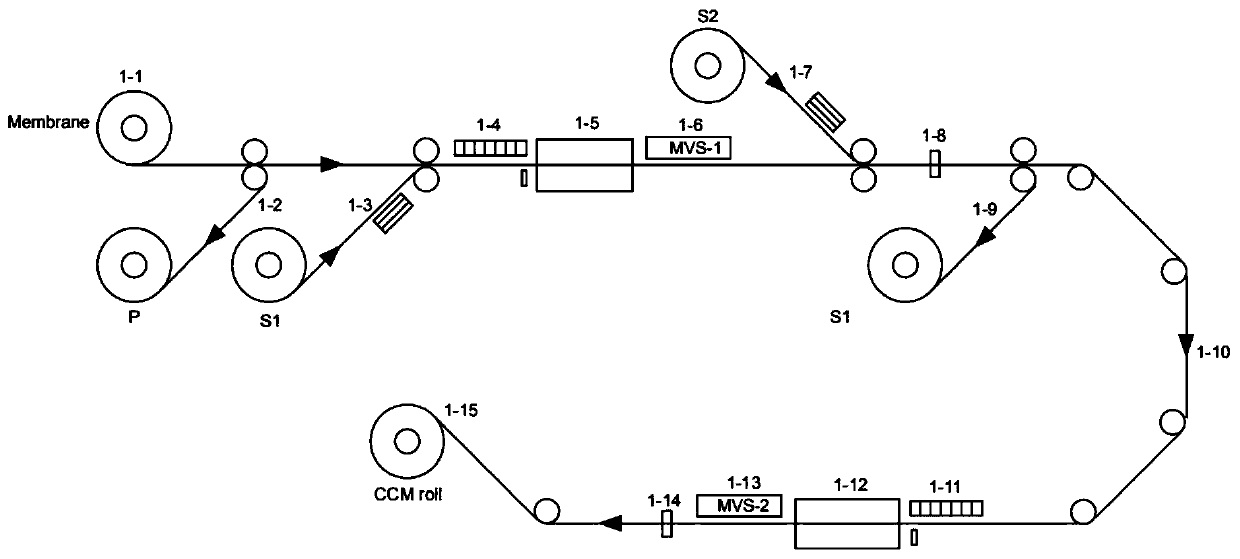

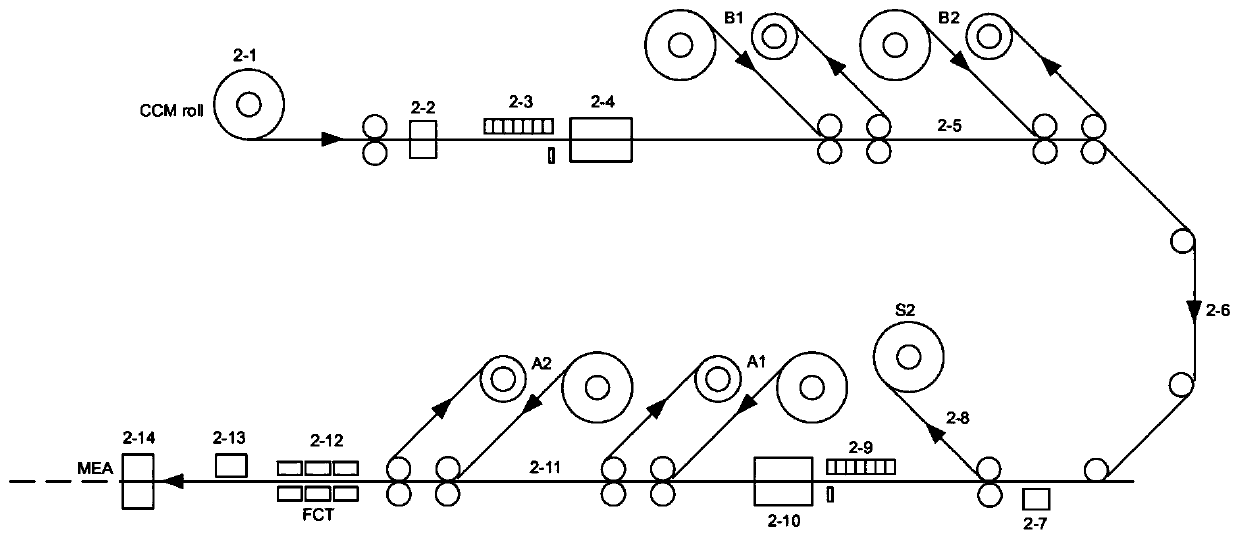

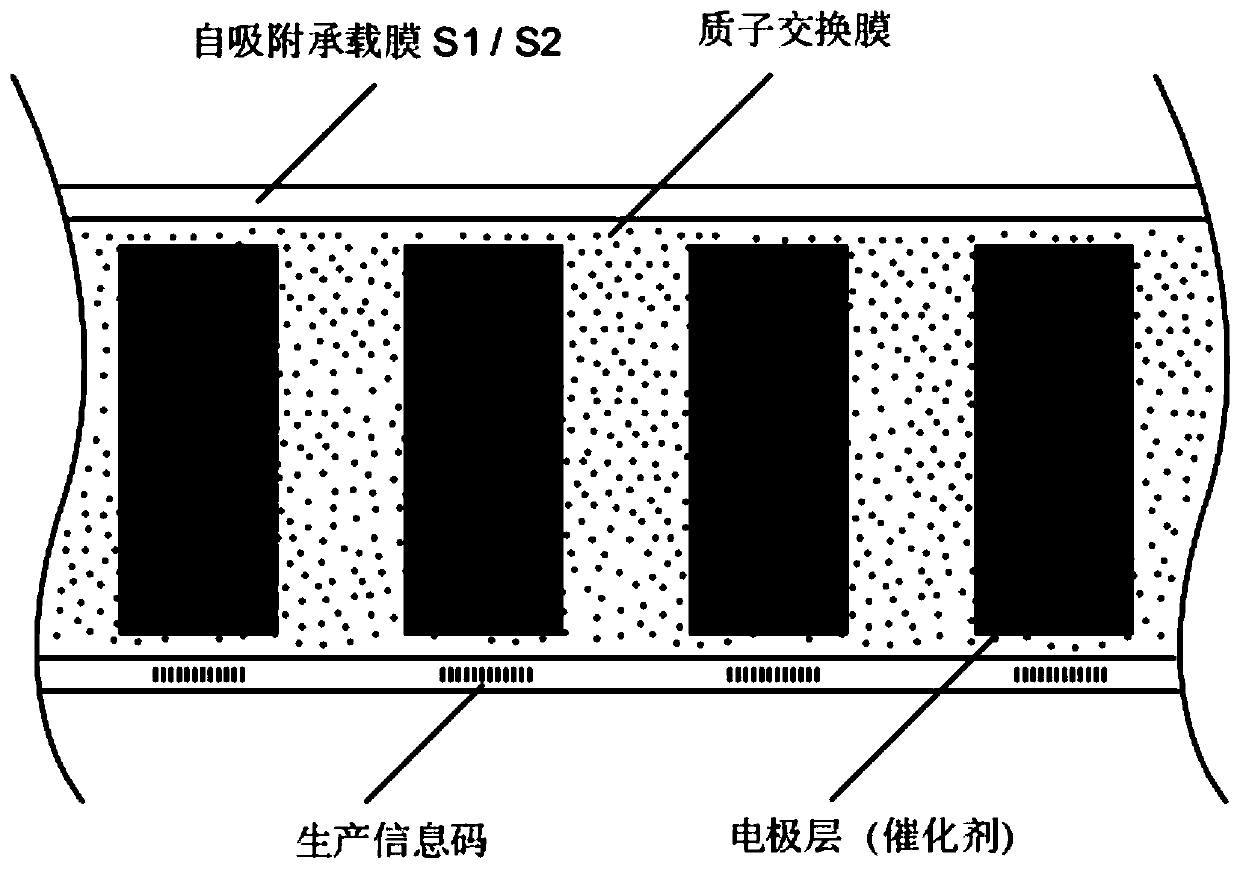

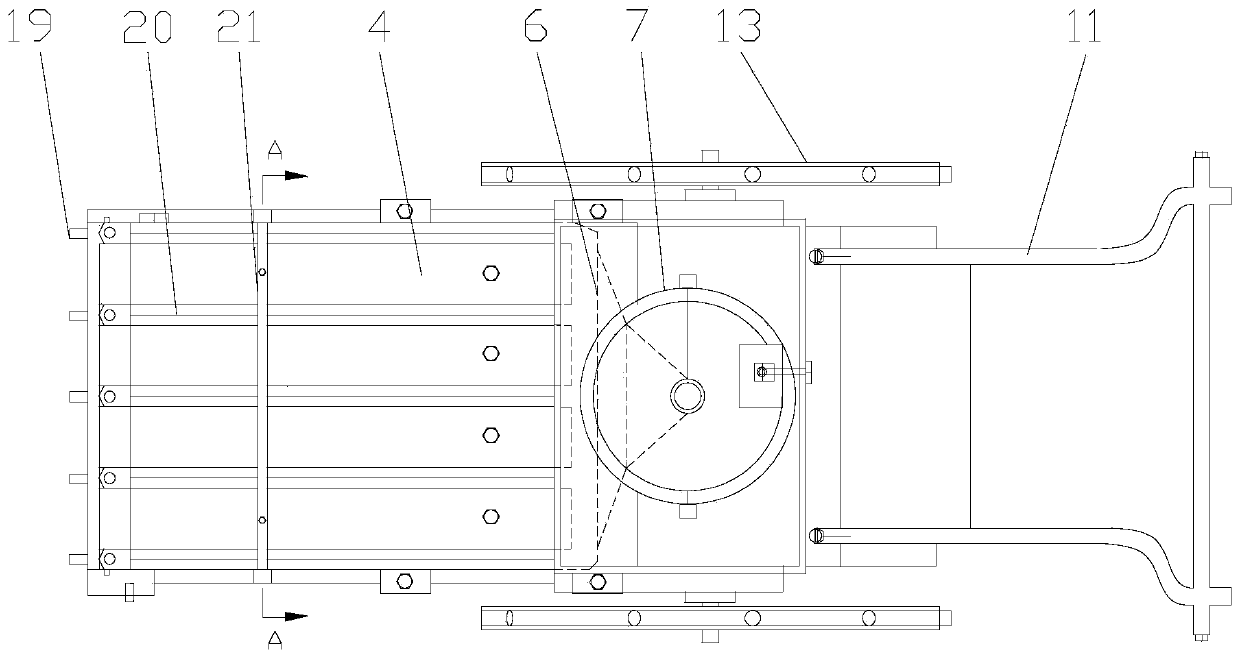

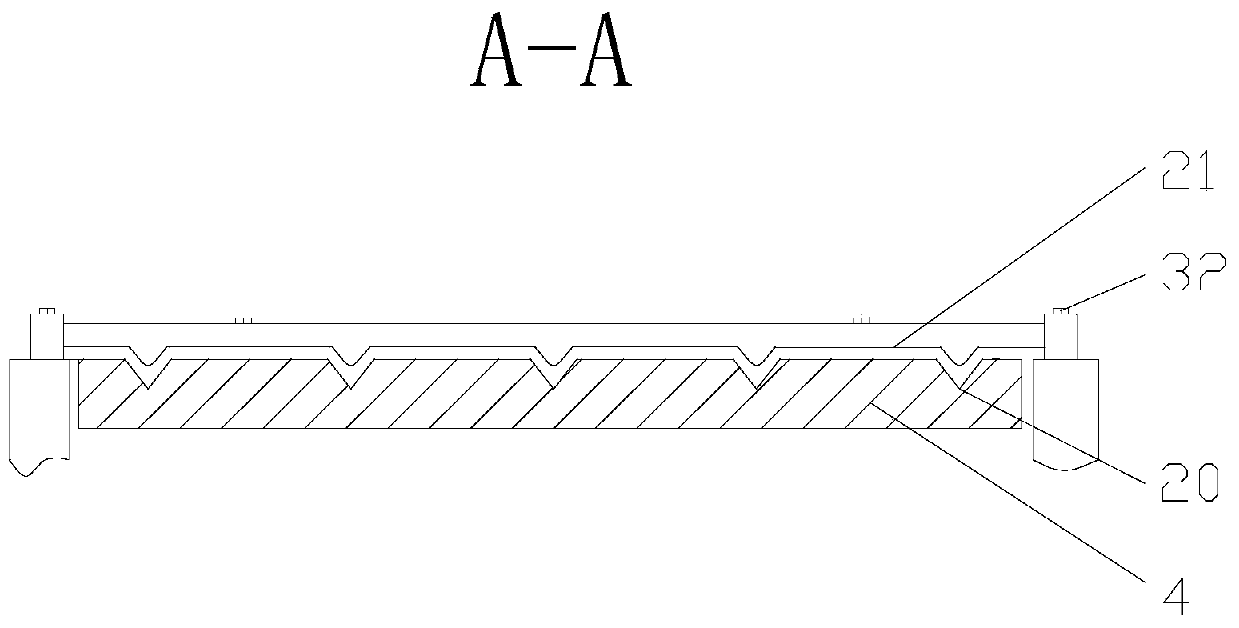

Continuous preparation device and method for fuel cell membrane electrode

ActiveCN110611113AReduce surface friction coefficientNo mechanical damageCell electrodesFinal product manufactureFuel cellsProton

The invention discloses a continuous preparation device and method for a fuel cell MEA membrane electrode. The device comprises a continuous preparation device for a roll fuel cell CCM membrane electrode and a continuous preparation device for a sheet fuel cell MEA membrane electrode. According to the device and method, which are provided by the invention, electrode layers are coated on both sidesof a proton exchange membrane; a self-adhesive carrier membrane capable of repeated simultaneous attachment and peeling is used as a carrier and a production information recorder to prepare a continuous CCM membrane electrode coil, wherein the surface of the self-adhesive carrier membrane is processed; the self-adhesive carrier membrane is further used as the carrier; relying on a precise conveying system, the processes of gas diffusion layer bonding and gas sealing layer bonding are carried out to prepare an MEA membrane electrode monomer; and synchronous cutting is carried out to acquire the MEA membrane electrode monomer meeting industrial standards. The high-efficiency, intelligent, integrated and fully-closed device disclosed by the invention can greatly improve the production capacity and greatly reduce the cost of the membrane electrode monomer.

Owner:上海好世材料科技有限公司

Preparation and its products for composite nanometer filter membrane

InactiveCN1745885AUniform cross-linkingEasy to operateSemi-permeable membranesAqueous solutionPolymethacrylic Acids

A process for preparing the composite nano-class filtering membrane includes such steps as providing the ultra-filter membrane made of polysulfone or poly vinylidene fluoride as substrate, dipping in the aqueous solution of aminoester polyacrylate polymers chosen from polymethyl acrylate-N, N-dimethylamino ethylester, polymethyl acrylate-N, N-dimethylamino methylester, polymethyl acrylate-N, N-diethylamino methylester, etc, drying, and beta-ray irradiating for cross-linking.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH

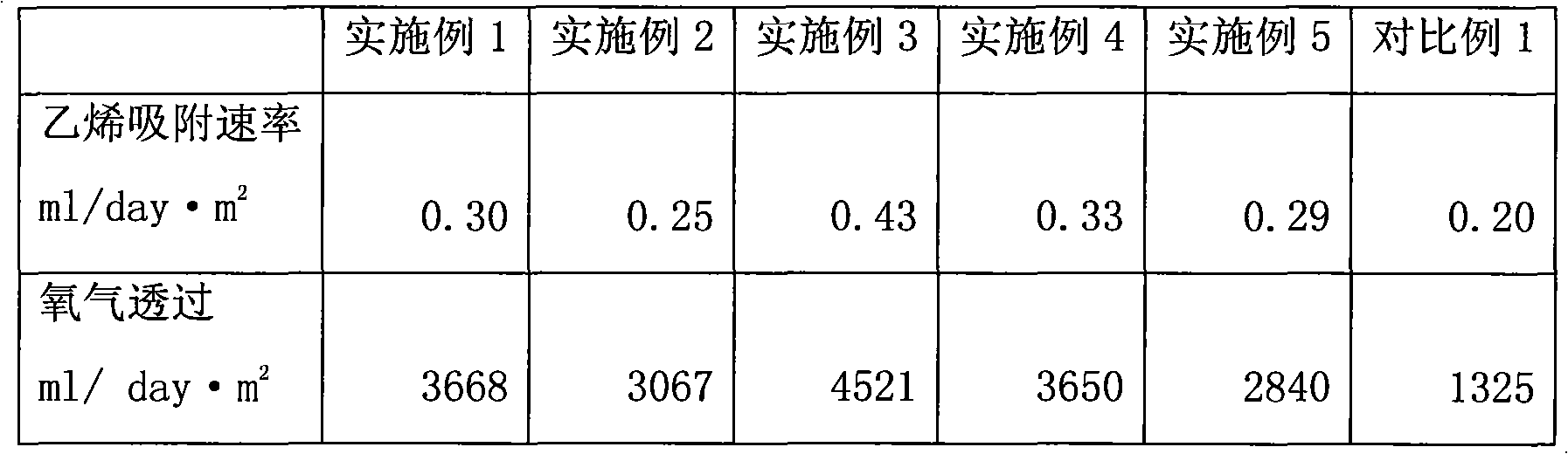

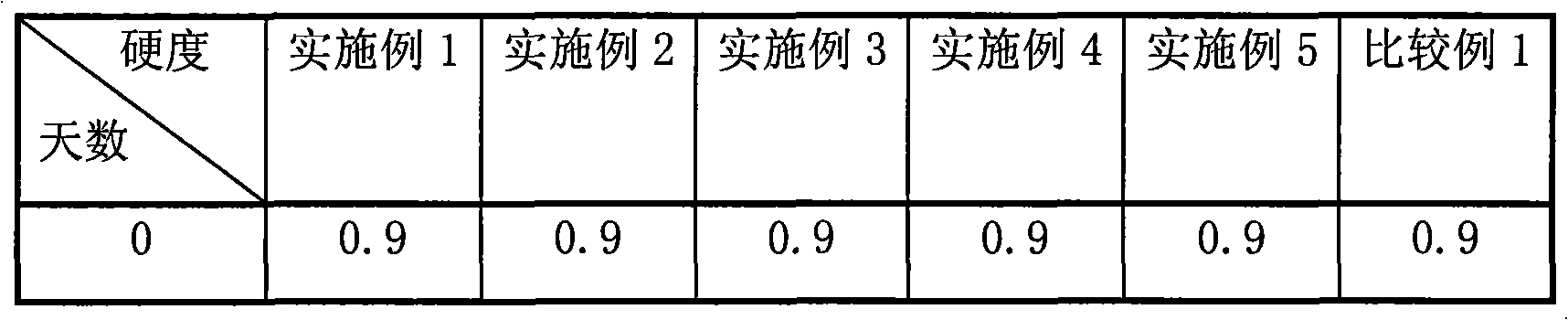

Fruit-preserving green packing material with ethylene adsorption function and preparation method thereof

ActiveCN101967245AAvoid knife woundsConsistent maturityFruit and vegetables preservationContainers preventing decayMolecular sieveGranularity

The invention discloses a fruit-preserving green packing material with an ethylene adsorption function and a preparation method thereof, belonging to the field of packing materials. The material comprises 100-90 parts of polyethylene or polypropylene resin by weight and 0.5-10 parts of aluminum silicate molecular sieve by weight, wherein the granularity of the aluminum silicate molecular sieve is 5-100 microns and the silica alumina ratio of the same is 5-100. The preparation method comprises the steps of: firstly preparing the aluminum silicate molecular sieve; then melting and blending the aluminum silicate molecular sieve and the polyethylene or polypropylene resin, and blowing to make thin films. The ethylene adsorption rate of the packing material in the invention reaches 0.25-0.43ml / day.m<2>, and the oxygen transmissivity reaches 1300-4600ml / day.m<2>, therefore, a banana shelf life is prolonged by 25-125%, and the weightlessness is reduced by more than 50%.

Owner:大家智合(北京)网络科技股份有限公司

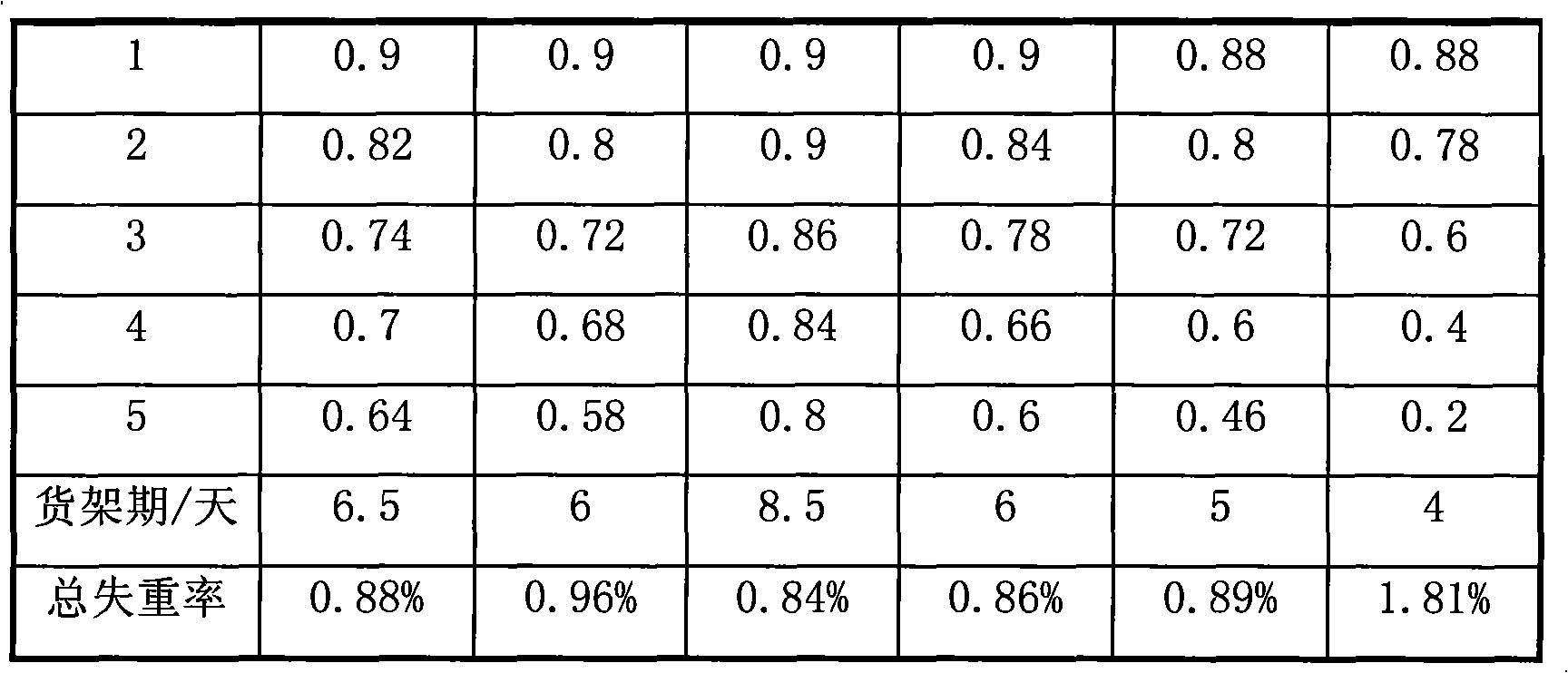

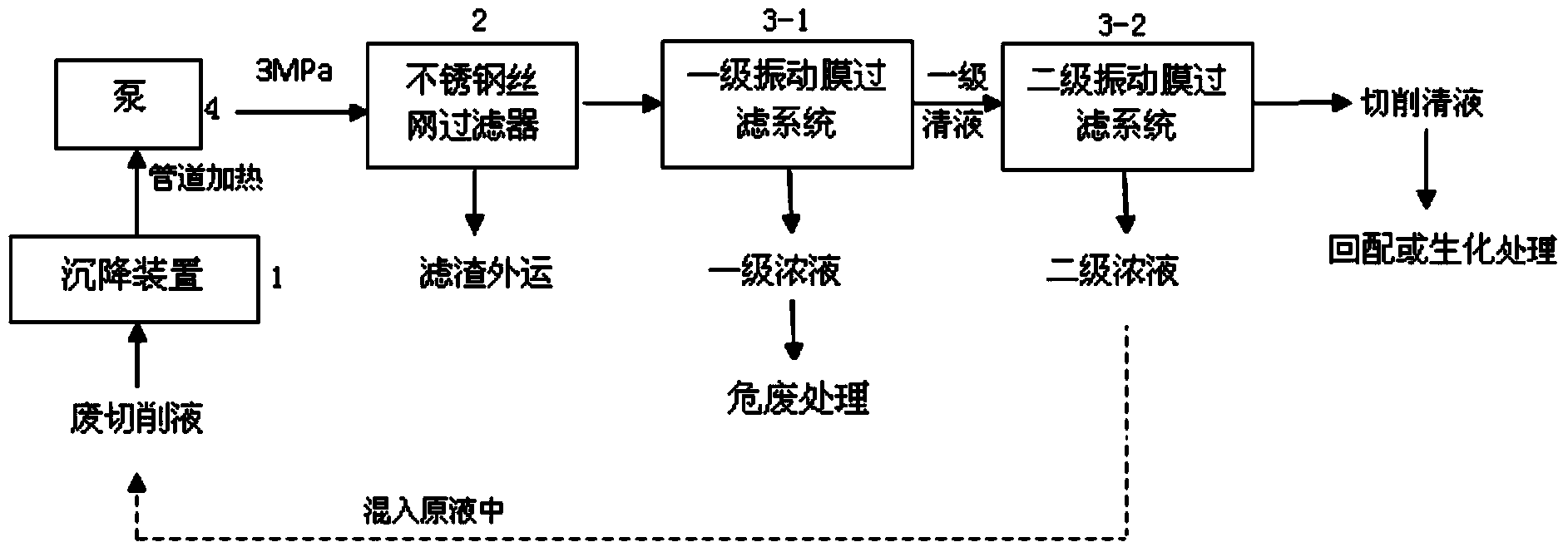

Treatment method and separation recovering system of waste cutting liquid

ActiveCN104031733ASimple processing methodShort separation timeLubricant compositionFiltrationTherapeutic effect

The invention discloses a treatment method and a separation recovering system of a waste cutting liquid, belonging to the technical field of chemical equipment. The technical scheme is as follows: the treatment method comprises the steps: heating and pressurizing a waste cutting liquid to be treated and then coarsely filtering to remove solid impurities; performing film filtration and separation on the coarsely filtered waste cutting liquid to obtain a cutting clear liquid and a cutting concentrated liquid; and treating the cutting concentrated liquid as a dangerous waste liquid, making the cutting clear liquid be used for preparing a cutting liquid again or conveying the cutting clear liquid to a sewage treatment system, and discharging after the cutting liquid reaches the standard through biochemical treatment. The treatment method disclosed by the invention is simple and reliable in operation and high in separation efficiency, and capable of effectively realizing separation of the cutting liquid from water. The separation recovering system is simple in structure, easy to operate, convenient to maintain, safe and reliable in operation, and good in treatment effect.

Owner:西安粤环节能环保工程有限公司

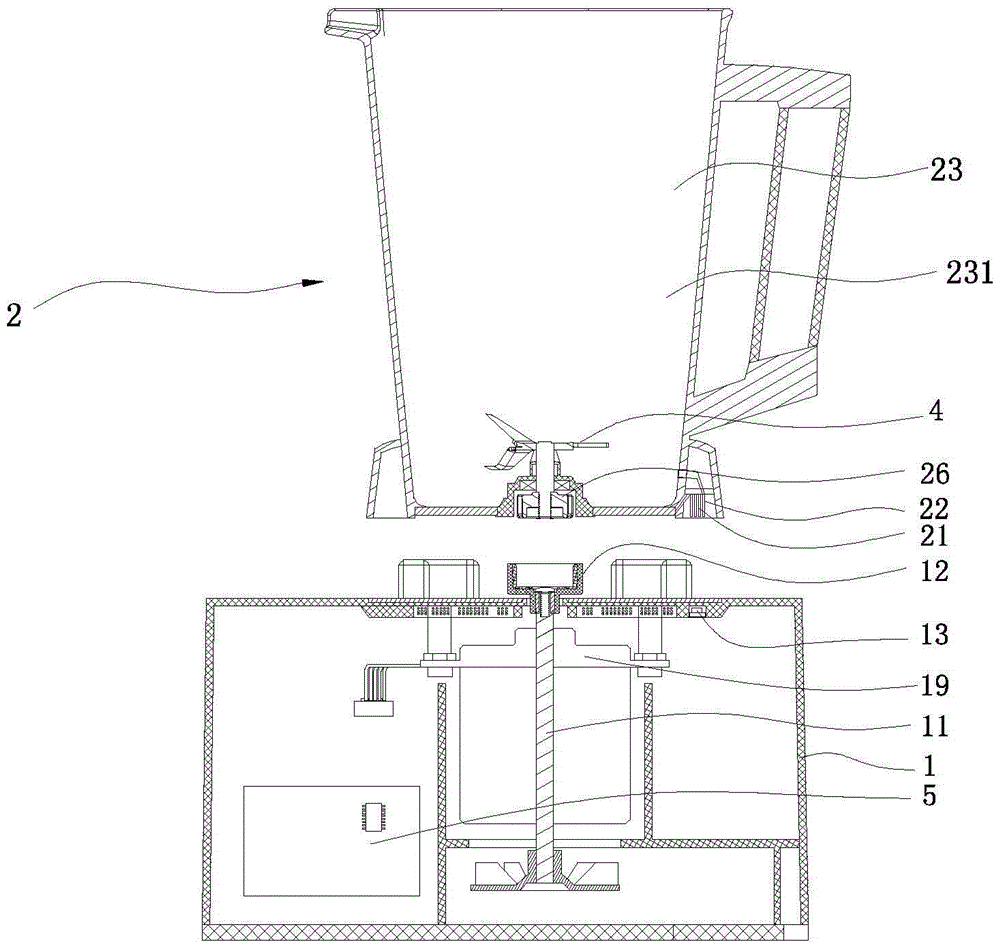

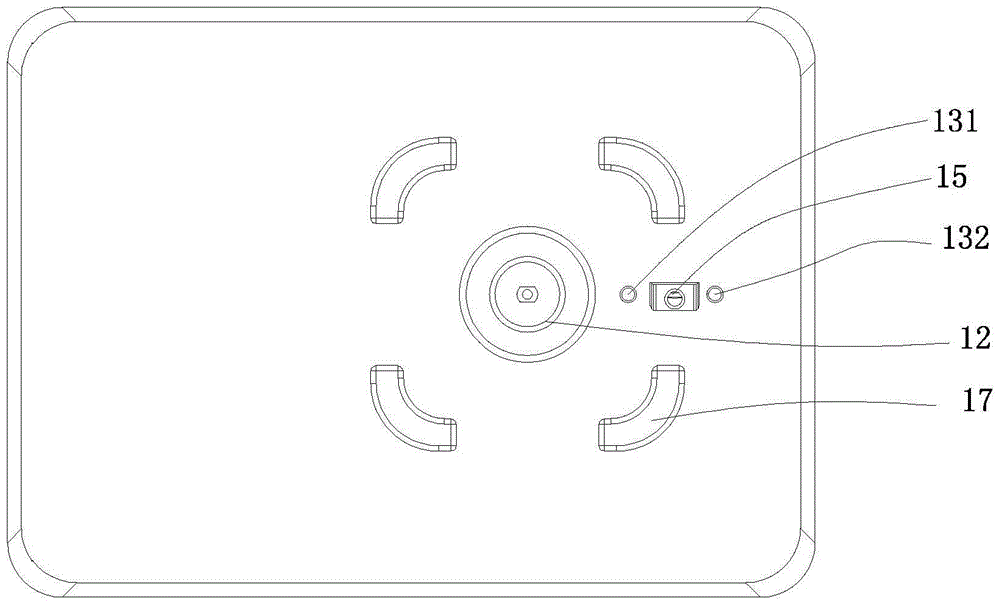

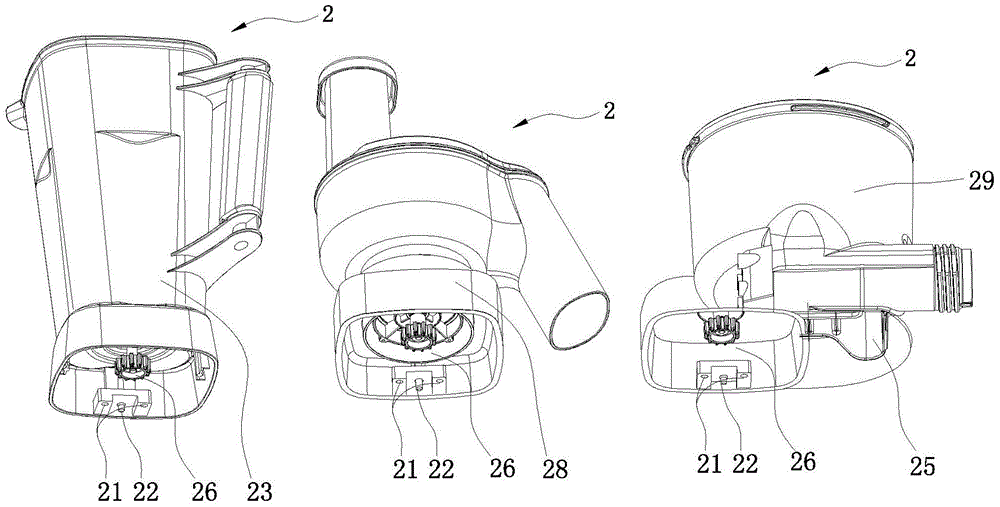

Multifunctional food processing platform

The invention relates to the technical field of domestic kitchen appliances, in particular to a multifunctional food processing platform. The multifunctional food processing platform comprises a machine base. A driving motor is arranged in the machine base. A speed feedback device is arranged on the driving motor. Matched food processing assemblies are arranged on the platform body. A plurality of sensors used for detecting whether the food processing assemblies are mounted in place or not are arranged on the machine base. A trigger mechanism is arranged at the bottoms of the food processing assemblies and corresponds to the sensors. The sensors are triggered by the trigger mechanism to identify the types of the processing assemblies. According to the types of the food processing assemblies, a control system controls the driving motor to act through the sensors, so that the food processing assemblies are driven to work correspondingly. Multiple functions of the platform are achieved, and the platform is more intelligent, automatic and humanized to use and can achieve the effect that foods manufactured through all functions are good in effect.

Owner:JOYOUNG CO LTD

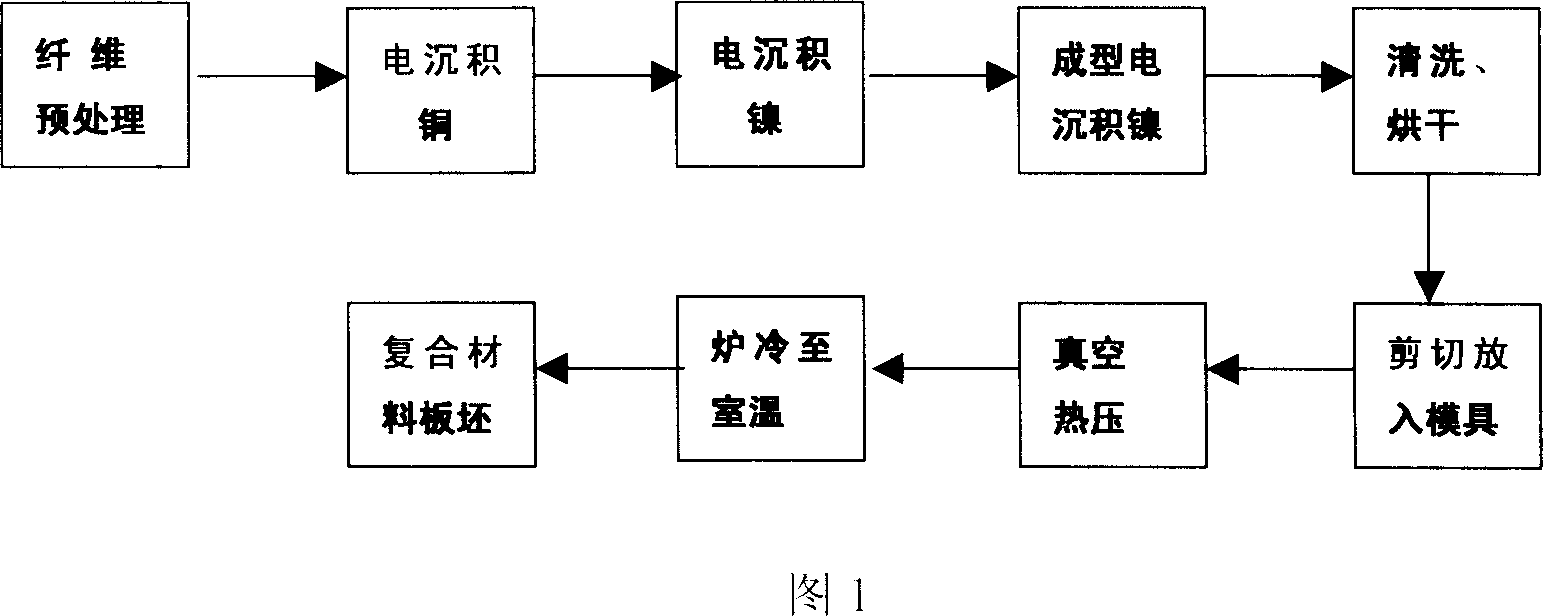

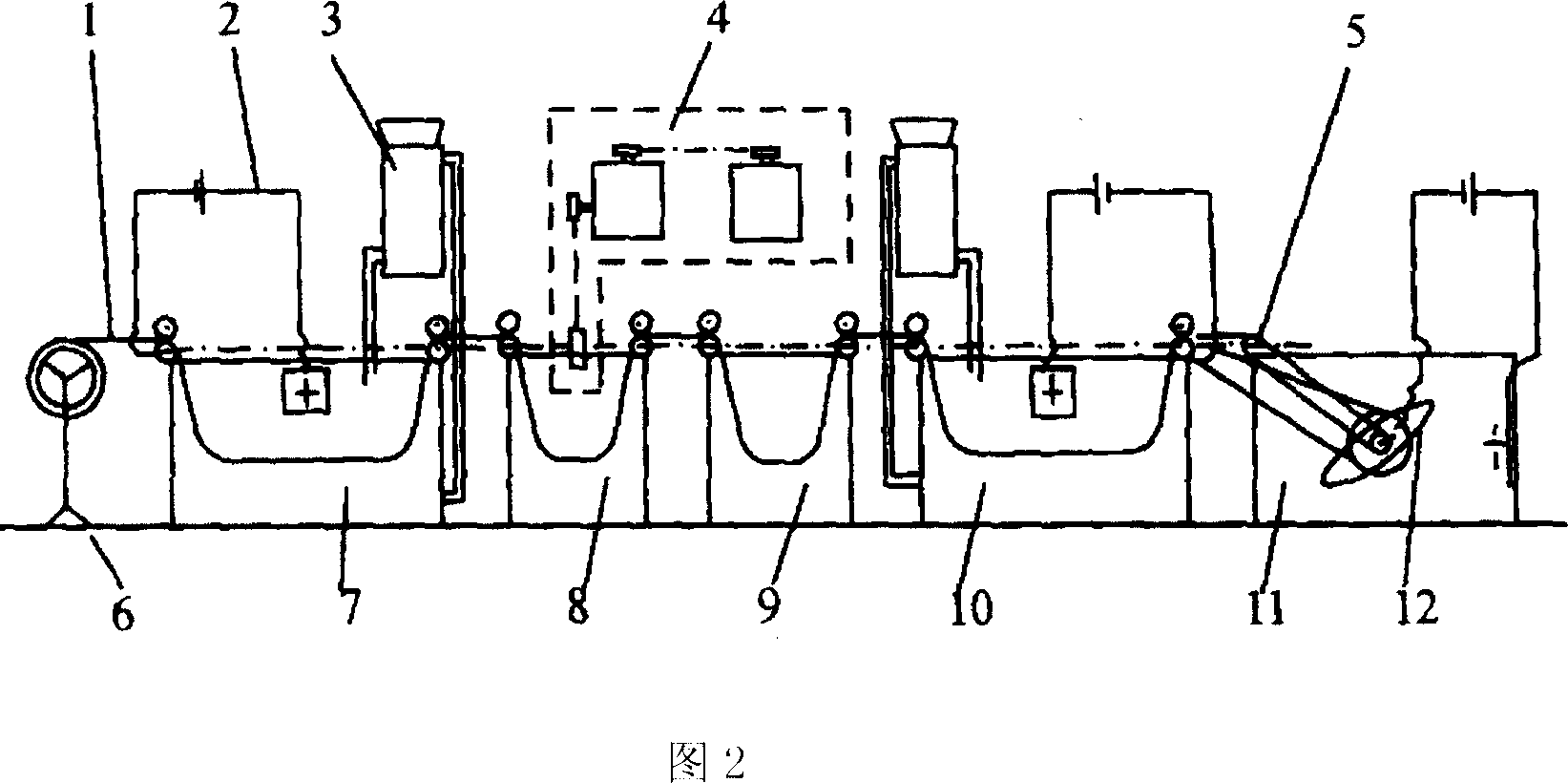

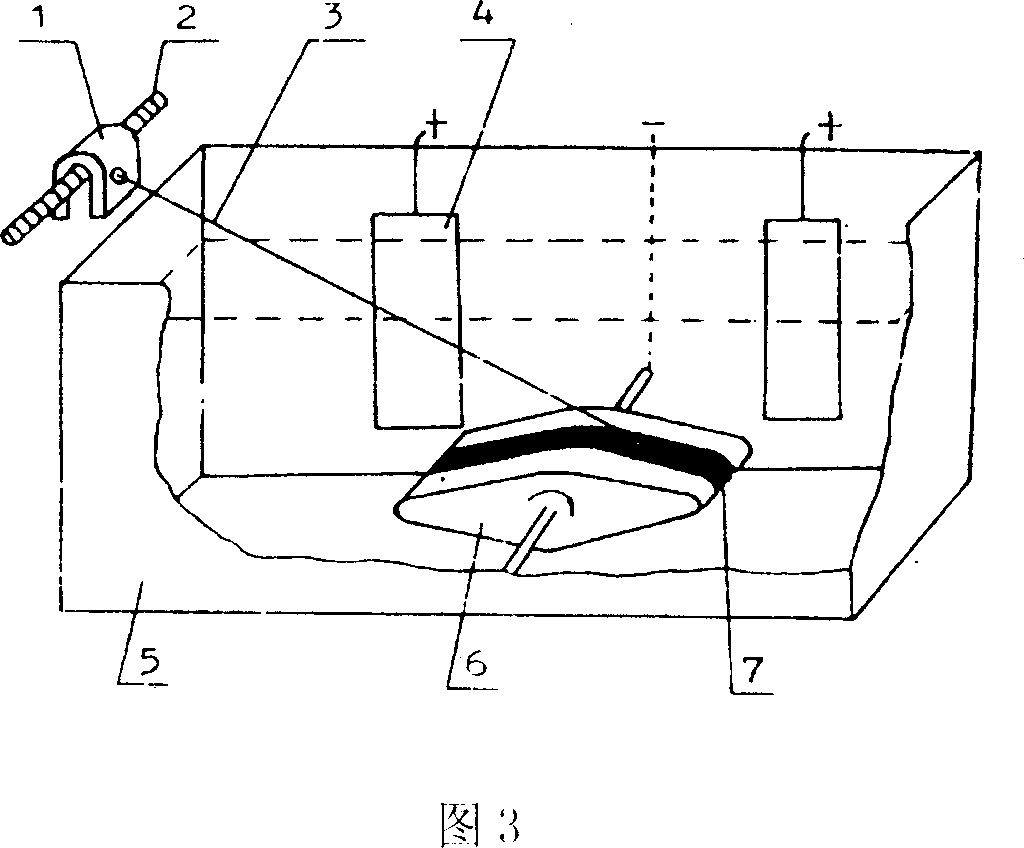

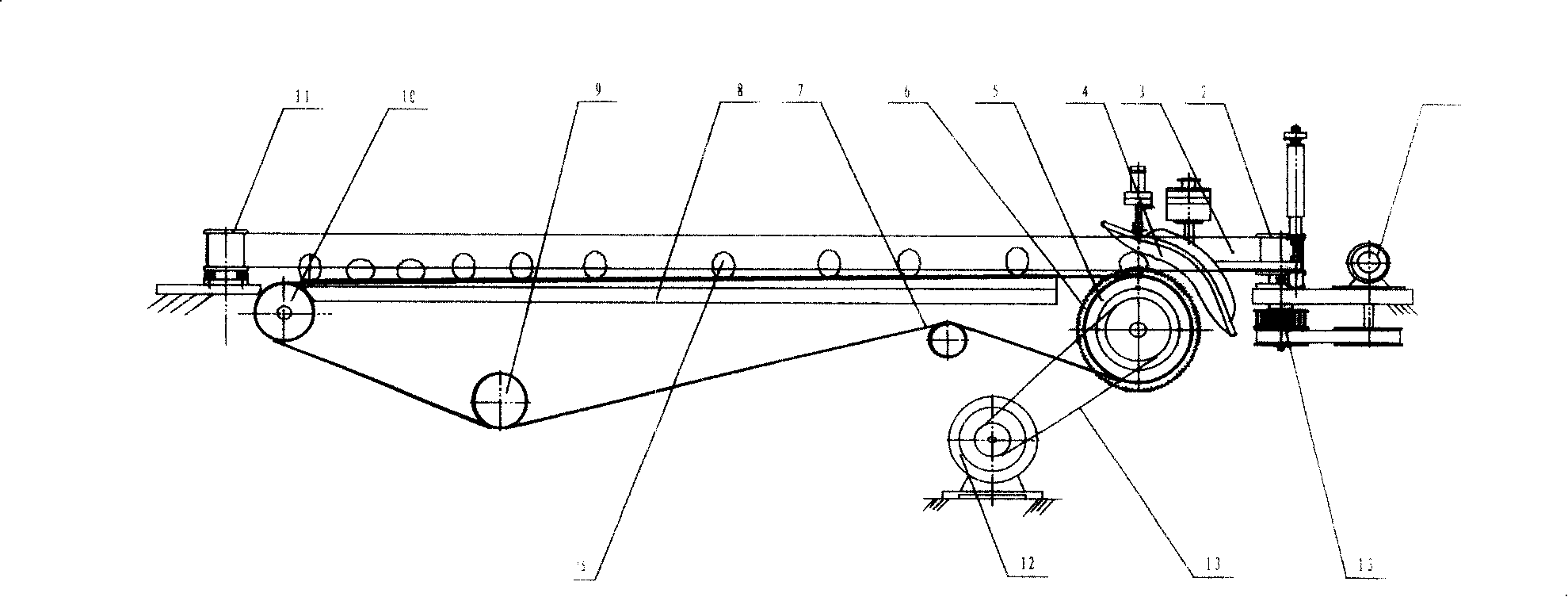

Carbon fiber reinforced nickel-based composite material and producing method thereof

The present invention discloses one kind of carbon fiber reinforced Ni-base composite material and its preparation process, and relates to metal-base composite material. The carbon fiber reinforced Ni-base composite material consists of carbon fiber 30-35 vol%, Cu 6-8 vol %, and Ni 57-64 vol %. The technological process of preparing the composite material includes the steps of: pre-treatment of carbon fiber, electrodepositing Cu, washing, neutralizing, electrodepositing Ni, electrodepositing Ni to form, washing, stoving, cutting, vacuum hot pressing in mold, and cooling in the furnace. The present invention prepares the composite material in a three-step electrodepositing process, and the composite material has high heat strength, high elastic modulus, low density, high smelting point and other advantages, and may be used in the vane of gas-burning turbine engine, etc.

Owner:ZHONGBEI UNIV

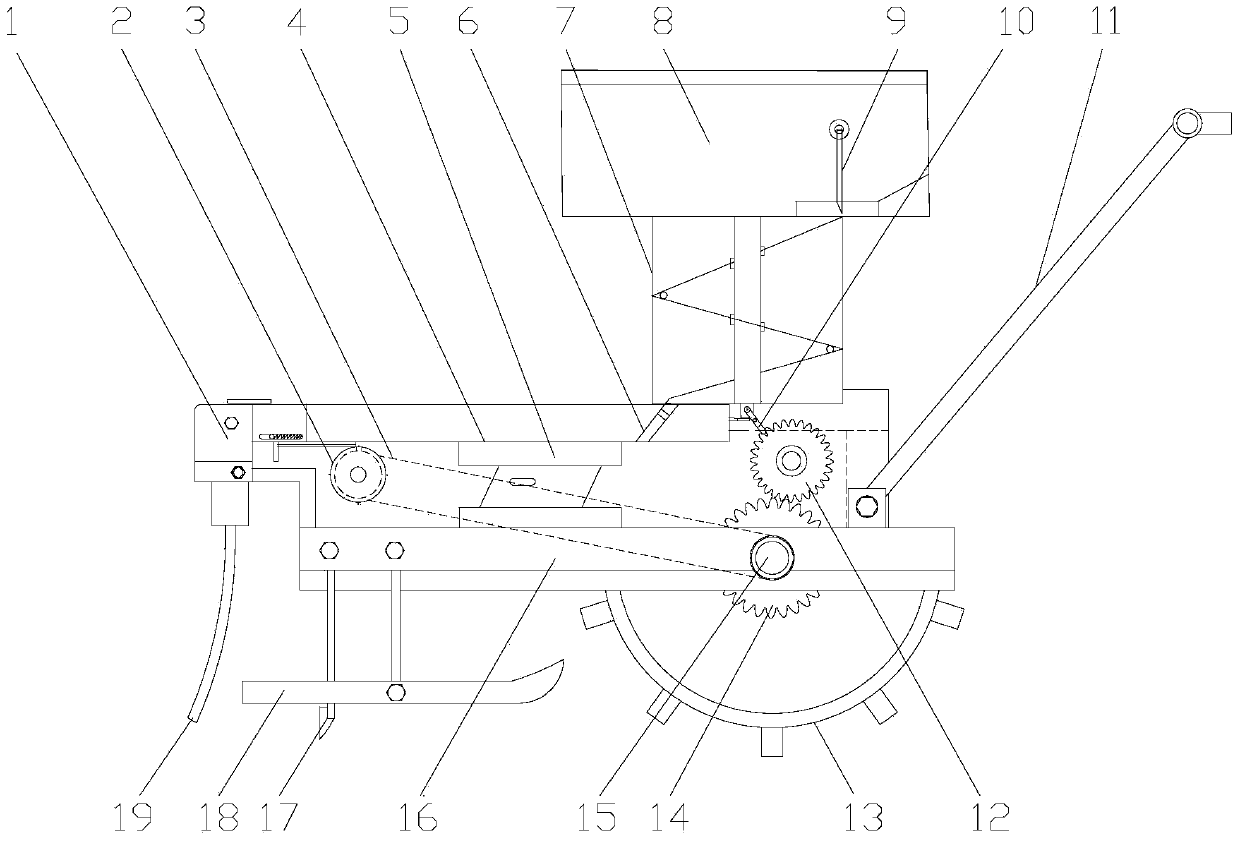

Device for automatically cutting and extracting stone for fruits

InactiveCN101214082ANo mechanical damageOrientation is accurateFruit stoningCircular discEngineering

A fruit automatic orientation slitting and coring device includes at least one independent channel. Two clamping belts are respectively wound on active belt rollers and positive belt rollers. A pair of active belt rollers rotates at the same speed and in reverse direction. The linear velocity and the direction of the tight sides of the two clamping belts are uniform. Two oriented belts are arranged under the clamping belts. The velocity difference is provided between the oriented belt and the clamping belt. The moving directions are uniform. The tight side of the oriented belt which is arranged in a V-shaped groove and moves levelly and straightly drives fruit to rotate. A milling is equipped with a disc sickle with sharp triangle teeth, the edge line of which coincides with the central line of the independent channel. A float cutting guide device is arranged above the disc sickle. When the disc sickle comes across a flinty kernel, the float cutting guide device moves upward. Therefore, the disc sickle is protected from being damaged. The disc sickle continuously applies forces on the kernel to lead to the loosening combination between the kernel and the flesh. And the kernel is separated from the flesh. The device is provided with high operation efficiency. Complete valves can be obtained. And the device is applied to the slitting and coring of fruits with kernels, such as the plums apricots, etc., with ovum shape.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

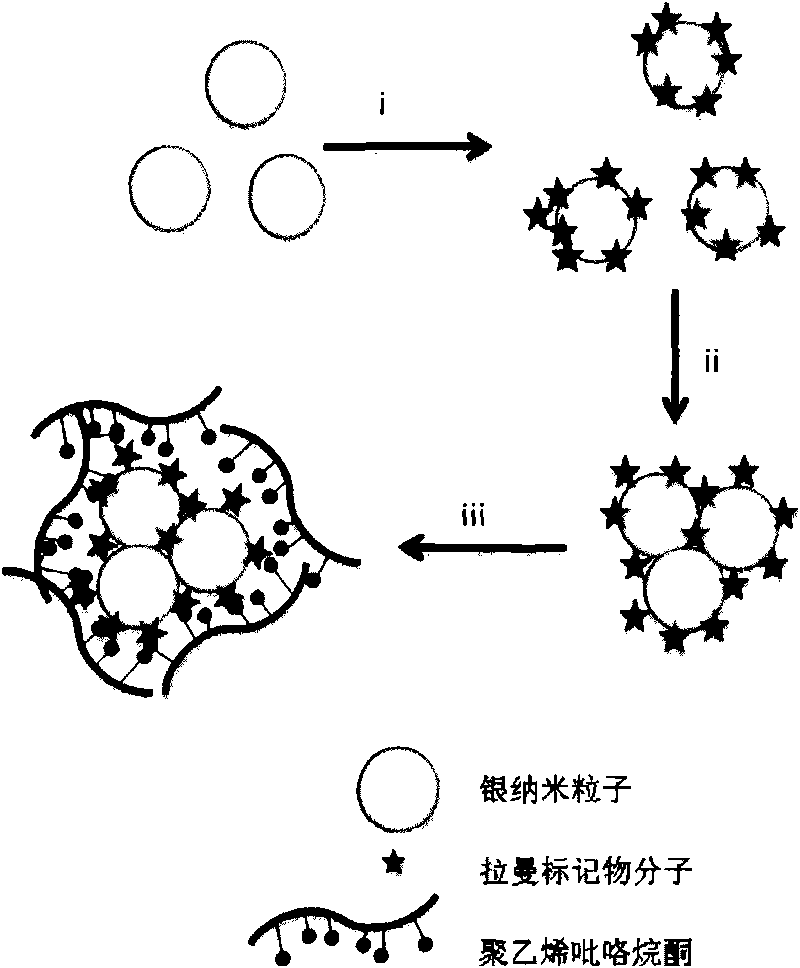

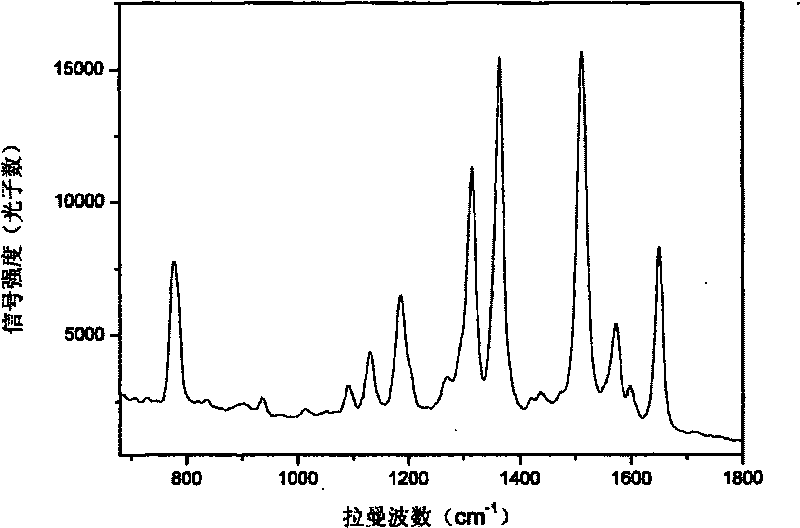

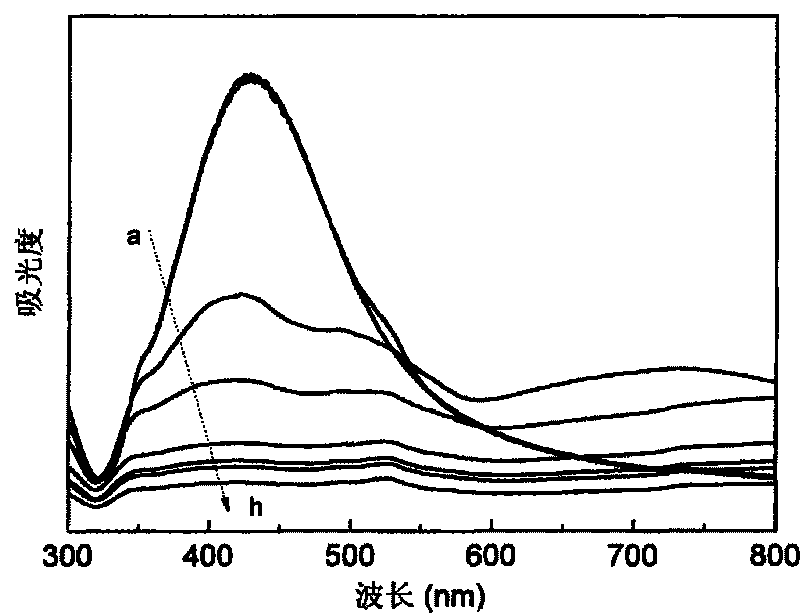

Preparation method of surface-enhanced Raman scattering probe

InactiveCN101694467AGood chemical stabilityEasy to operateRaman scatteringRaman scatteringWater soluble

The invention provides a preparation method of a surface-enhanced Raman scattering probe, relating to a preparation method of a silver nano aggregation probe which has high surface-enhanced Raman scattering activity and is coated by polyvinylpyrrolidone, as well as applications thereof in regulation of aggregation degree of silver nano particles and SERS detection in cells. The method selects silver colloid solution as a raw material, selects sodium chloride as an aggregation agent, and coats the polyvinylpyrrolidone on the surface of silver aggregates; and specifically comprises the following steps: evenly mixing Raman markers and the silver colloid solution according to volume ratio of 1: 1000 to 1:100 under the stirring condition, then adding sodium chloride solution to aggregate the silver colloid solution mixed with the Raman markers into aggregates with two to five particles, finally adding the polyvinylpyrrolidone solution, continuously stirring for 5 to 15 minutes, filtering the obtained solution with a filter with the aperture specification of 100 to 220nm and then obtaining the surface-enhanced Raman scattering probe. The probe is water-soluble colloid solution.

Owner:SOUTHEAST UNIV

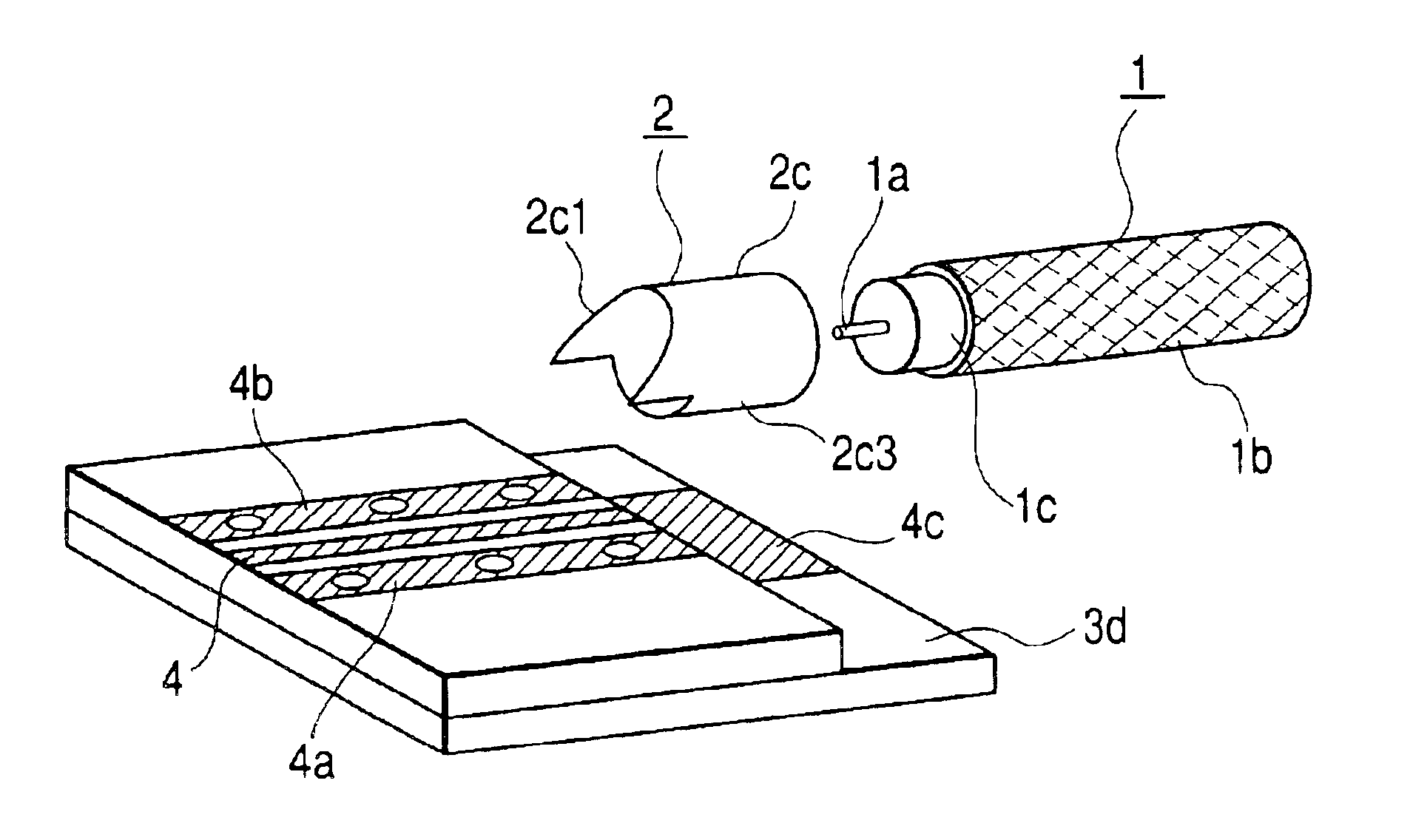

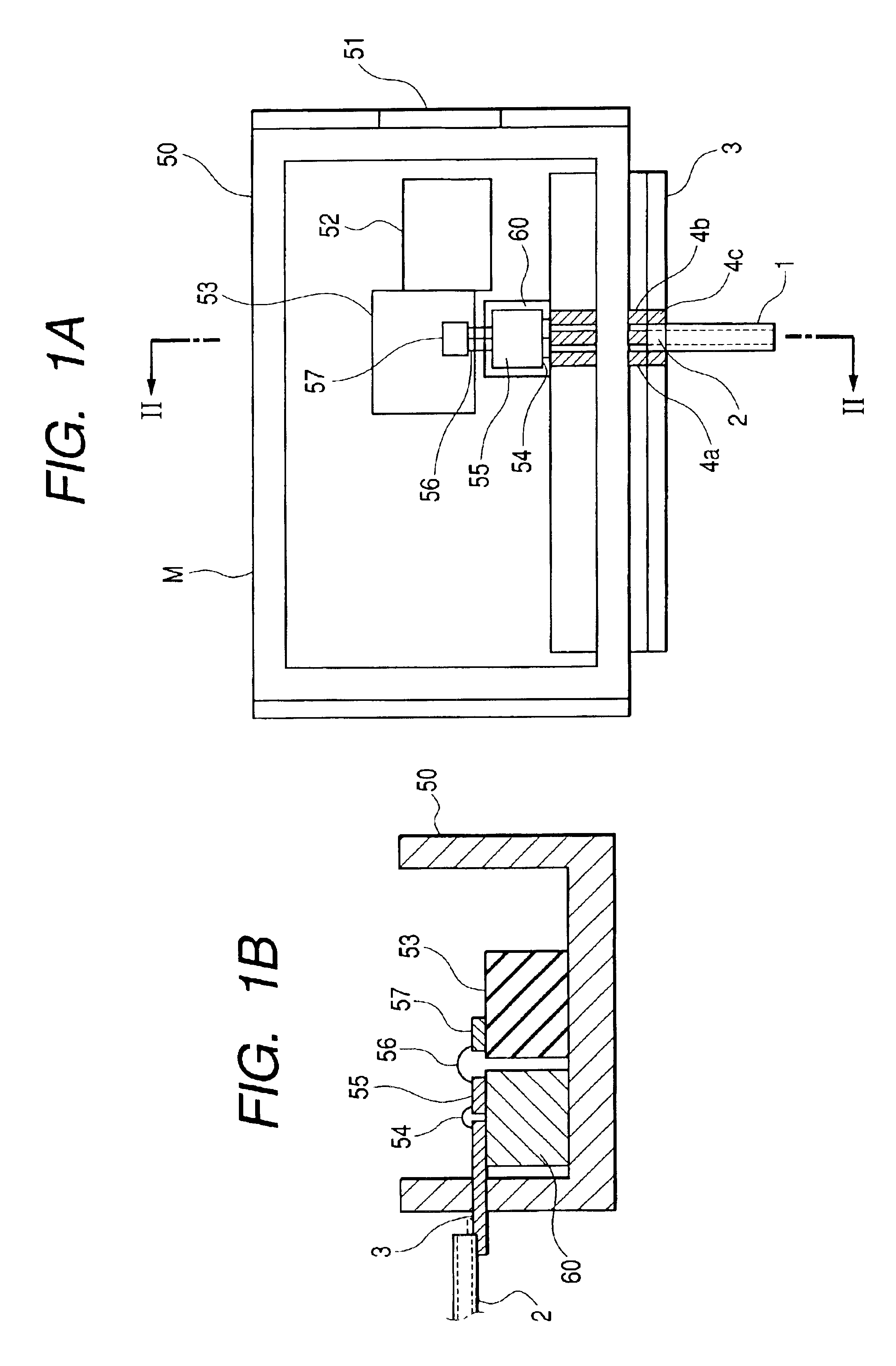

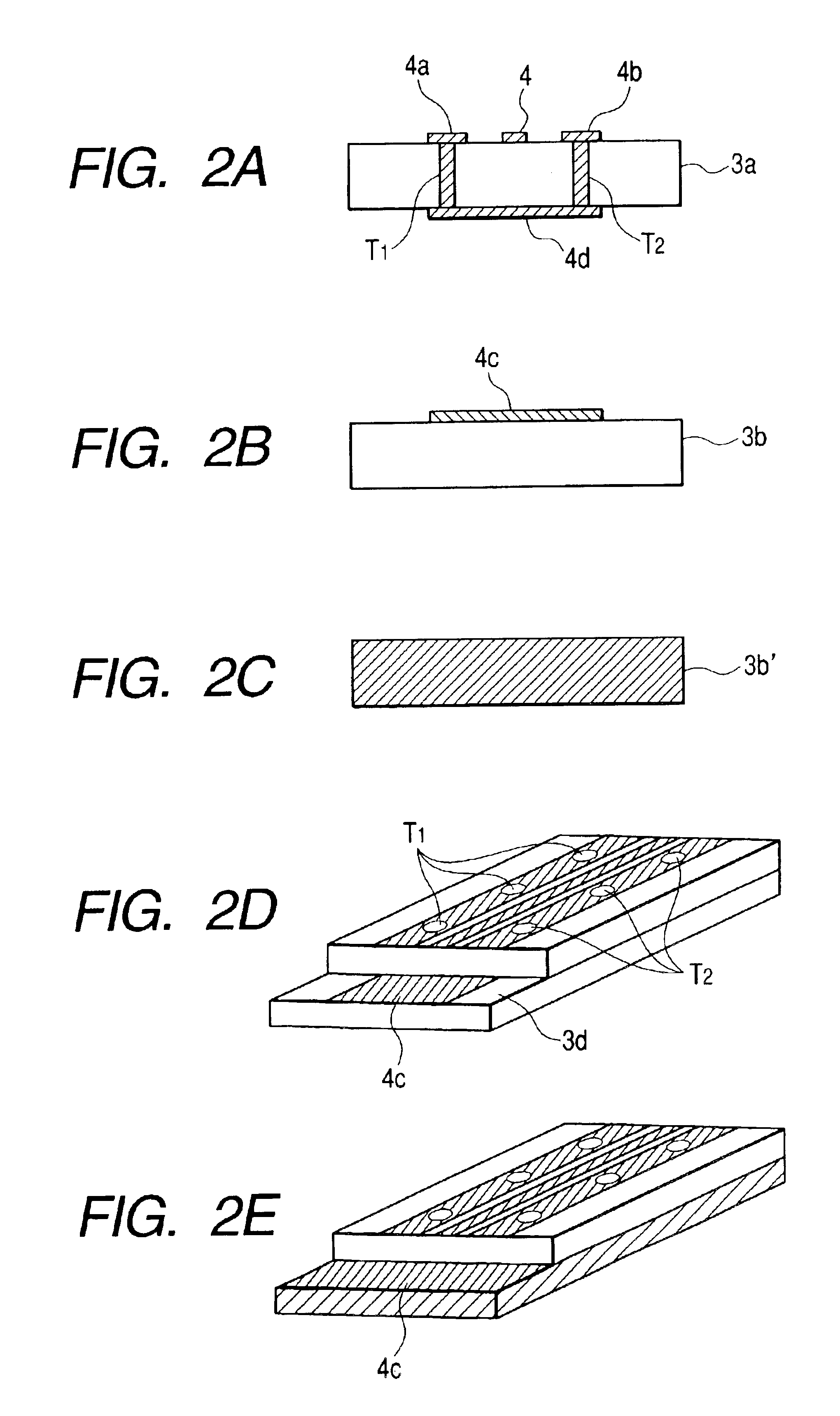

Optical transmission module

InactiveUS6927655B2Avoid excessive radiationExcellent high-frequency characteristicMultiple-port networksPrinted circuit assemblingElectrical conductorCoaxial cable

There is provided a thin and small size connector-less optical transmission module M which assures excellent high frequency characteristic. This optical transmission module comprises transmission line substrates and a coaxial cable for connecting these transmission line substrates and is connected to the transmission line substrate via a contact sleeve which is provided with projections fixed to the external conductor of the coaxial cable and projected in the extending direction of the coaxial cable. Since an electromagnetic field mode alleviating portion formed of a dielectric material is provided to the core wire of the coaxial cable, the thin and small size optical transmission module M can assure less amount of radiation of an interference electromagnetic wave, high frequency characteristic through connection with the coaxial cable.

Owner:LUMENTUM JAPAN INC

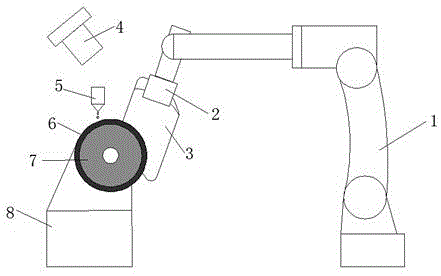

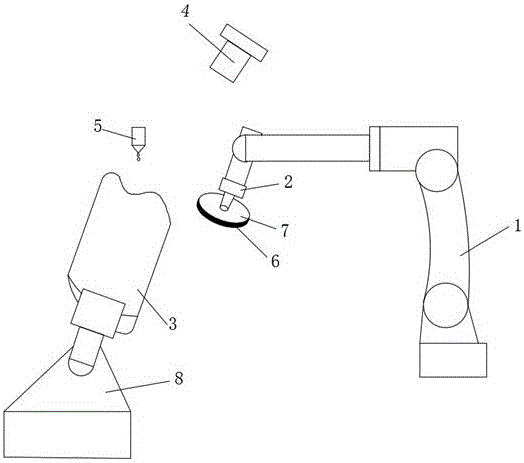

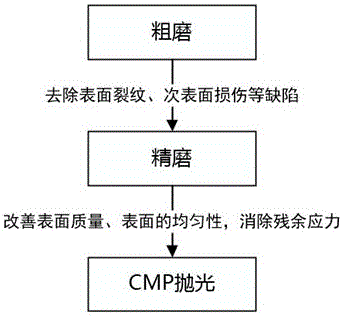

Robot grinding and polishing system based on CMP

ActiveCN105666287AImprove grinding efficiencyImprove efficiencyPolishing machinesGrinding machinesEngineeringMaster controller

The invention discloses a robot grinding and polishing system based on CMP. The robot grinding and polishing system comprises a six-axis robot, a workpiece clamp used for placing workpieces, a contour detection unit used for detecting the workpieces needing to be polished and conducting three-dimensional reconstruction, a grinding wheel with a polishing pad, a base provided with the grinding wheel and a master controller. The free end of the six-axis robot is provided with an electric spindle provided with servo motors. A polishing liquid jetting device capable of jetting CMP polishing liquid to the workpieces is arranged above the workpiece clamp. The workpiece clamp is installed on the electric spindle. The master controller controls the contour detection unit, the six-axis robot, the electric spindle and all the servo motors. The workpiece clamp and the grinding wheel with the polishing pad can also be exchanged in position so as to adapt to polishing of different sizes of workpieces. The robot grinding and polishing system is high in efficiency and good in machining consistency, harmful effects such as mechanical damage and burns which may be caused by common grinding cannot be caused on the workpieces, damage to surfaces or sub surfaces cannot occur, and perfect surfaces can be machined.

Owner:WUHAN UNIV

Container nursery method for white bark pine seeds

InactiveCN104541906APrevent loose rootsNovel structureClimate change adaptationFertilising methodsComing outDisease

The invention discloses a container nursery technology and a container nursery method for white bark pine seeds, and relates to the technical field of plant propagation. The container nursery method is characterized by comprising the following steps of (1) container selection, (2) treatment of seeds, (3) treatment of a matrix, (4) nursery, and (5) management of container-grown seedlings. The white bark pine seeds are subjected to standard nursery. The container nursery method for the white bark pine seeds has the advantages that the container nursery method is novel in design, and used appliances are unique in structure and are widely used. White bark pine seedlings can come out nursery after three years, white bark pines which come out nursery meets forestation specification requirements and have developed root systems, and a good root ball can be formed. Seedling trunks are upright, the color is normal, apical buds are full, and the white bark pines are not damaged mechanically and are not damaged by diseases and insects. The problem that white bark pine seeds are bred slowly in the northern region is solved. The container nursery method is low in investment, easy to operate, high in effect and high in practicality and generalization performance, and takes effect quickly.

Owner:JIAOCHENG COUNTY QINGMU AGRI & FORESTRY SCI & TECH

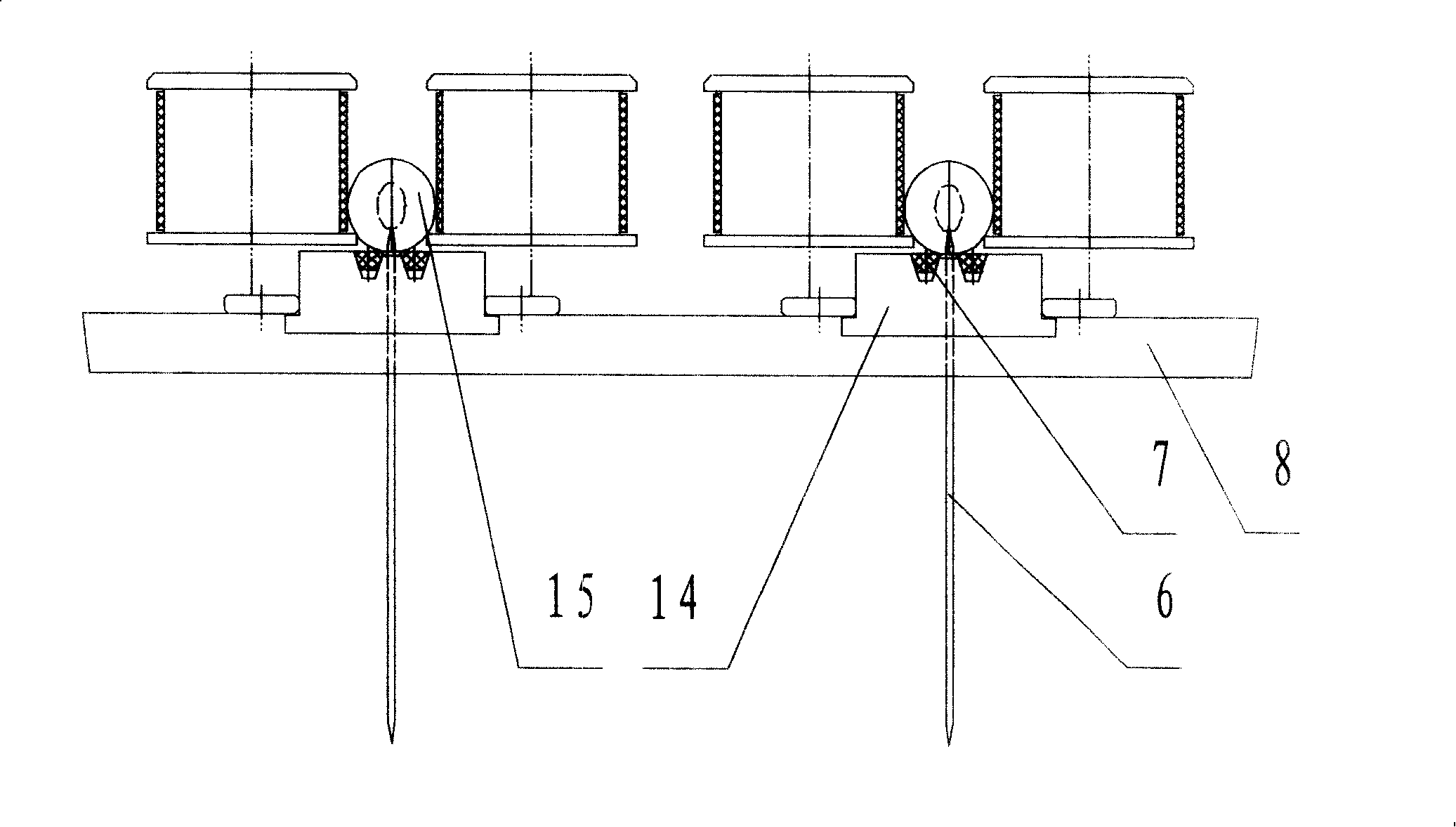

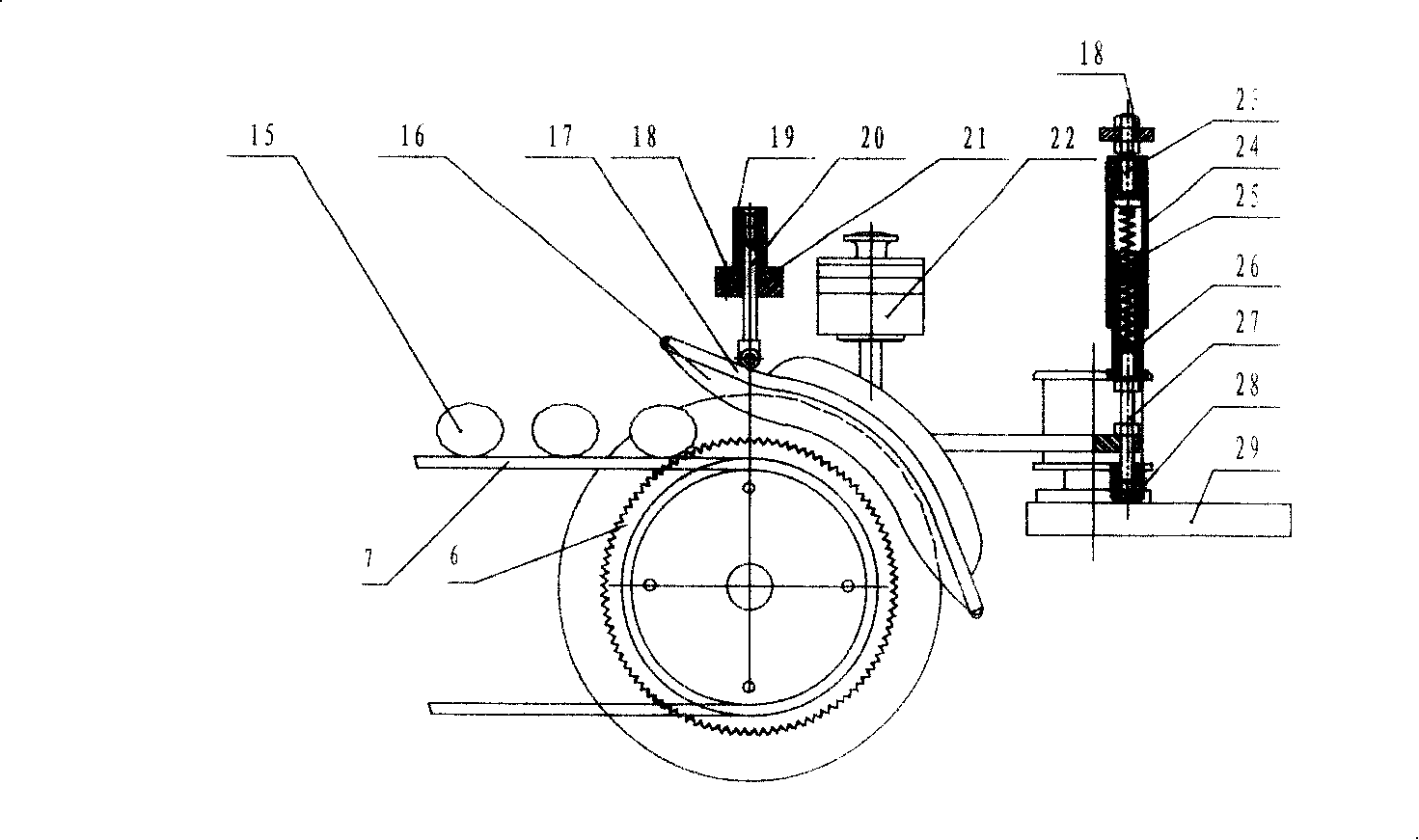

Vibrating type paddy planter

InactiveCN103733778ANo mechanical damageNo cloggingSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringBud

The invention discloses a vibrating type paddy planter which mainly comprises a rack with a walking device, wherein a seeding device is arranged on the rack; the seeding device comprises a seed box, a horizontal seed guide plate and an intermittent seeding mechanism; the horizontal seed guide plate is fixed on the rack through a vibrator; multiple seed guide slots are formed in the horizontal seed guide plate; one end of the seed guide slot is connected with the seed box through a falling hopper, and the other end is connected with the intermittent seeding mechanism; the intermittent seeding mechanism comprises a seed guide pipe and a seeding stop tongue which can be intermittently opened; the seed guide pipes and the seed guide slots are in para-position connection to realize discharge of paddy seed buds; the seeding stop tongue is arranged in each seed guide slot; the seed guide slot is started or stopped through the intermittent mechanism. The vibrating type paddy planter disclosed by the invention has the advantages of relatively small overall volume and high sowing precision, is flexible and convenient to use, avoids mechanical damage to the buds and effectively improves the sowing efficiency.

Owner:HUNAN AGRICULTURAL UNIV

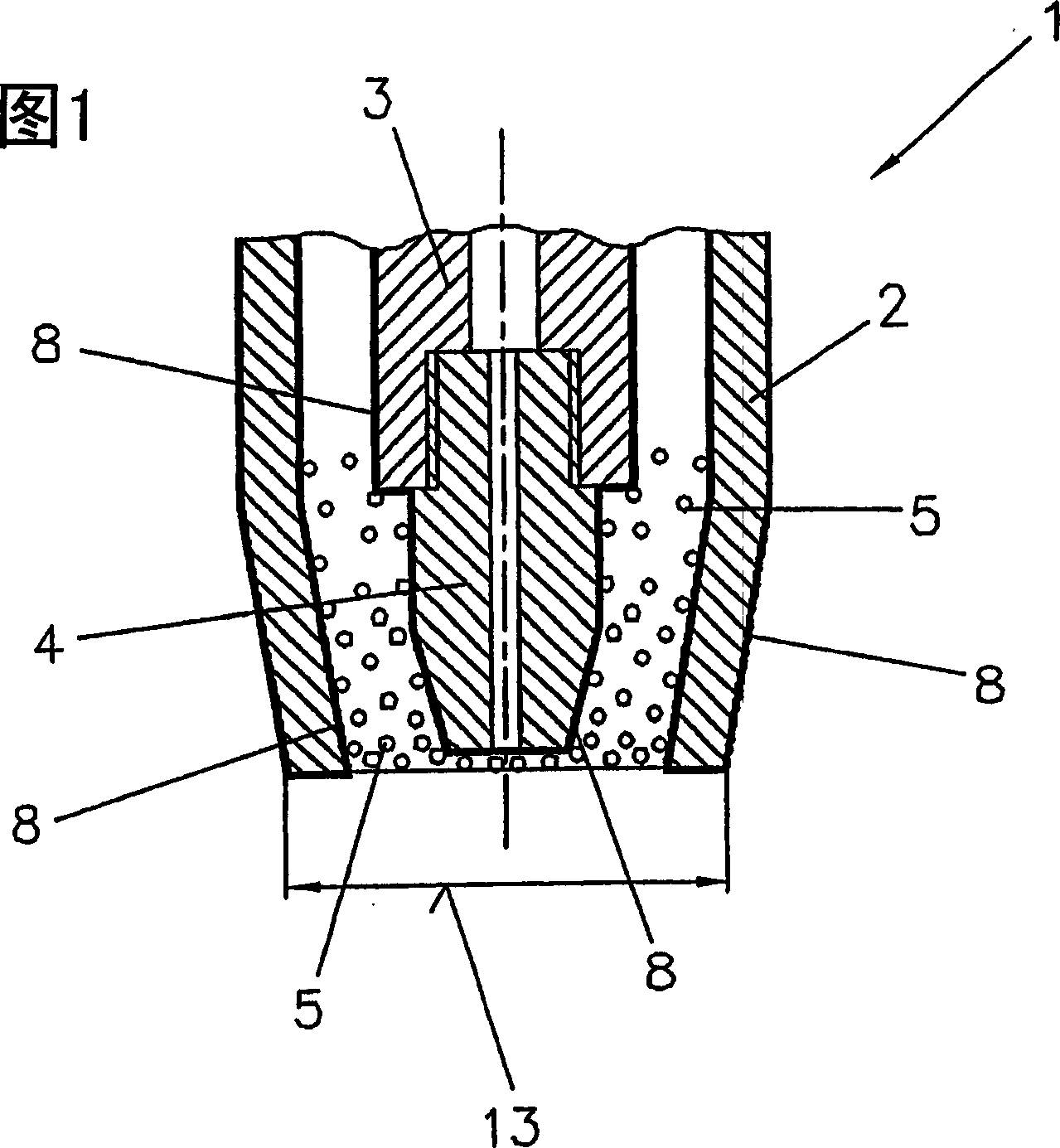

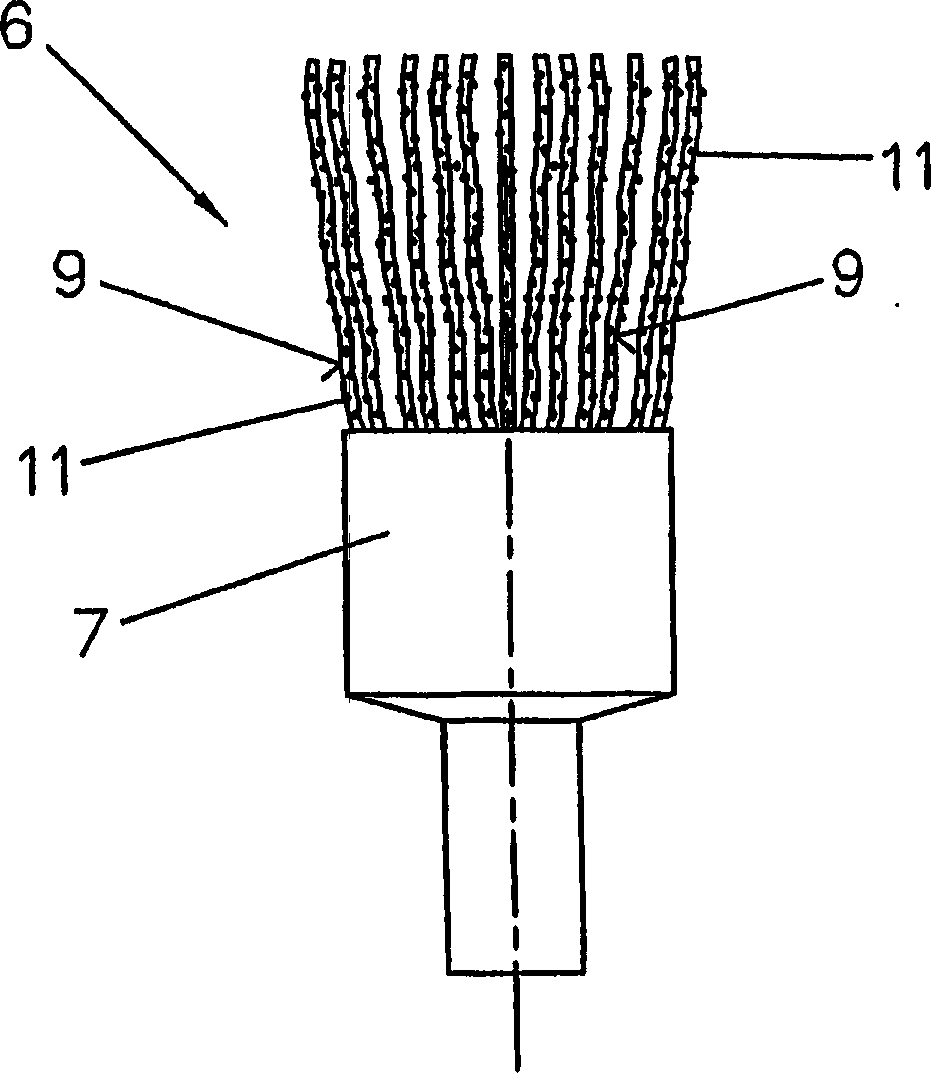

Gas nozzle for a welding torch, welding torch having a produced patina layer; cleaning device for a welding torch having bristles made of a soft elastic material and abrasive grains embedded in these

The invention relates to a gas nozzle (2) and a welding torch (1) equipped with said gas nozzle (2), a nozzle assembly (3) and a conductive tube (4), said gas nozzle (2), nozzle The component ( 3 ) and the conductive tube ( 4 ) have an artificially produced patina ( 8 ) on at least a partial area of their surface for the purpose of reducing the adhesion of welding spatter. The invention also relates to a cleaning device for a welding torch (1) having a brush with bristles. These bristles are made of a very soft elastic material, preferably plastic, and abrasive particles are embedded in said bristles.

Owner:FRONIUS INTERNATIONAL GMBH

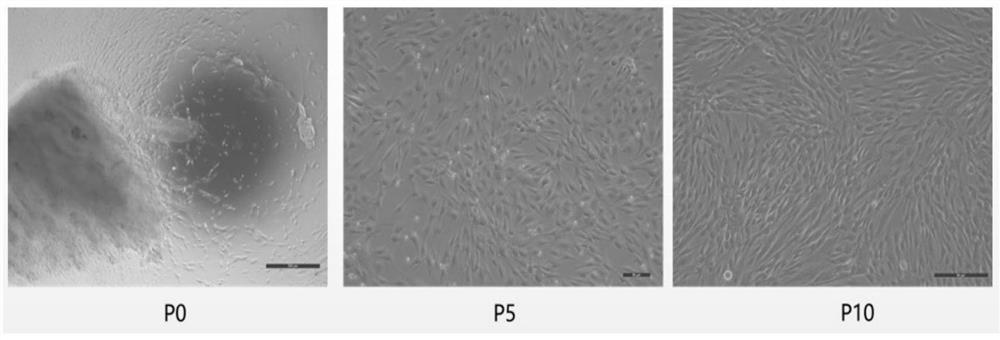

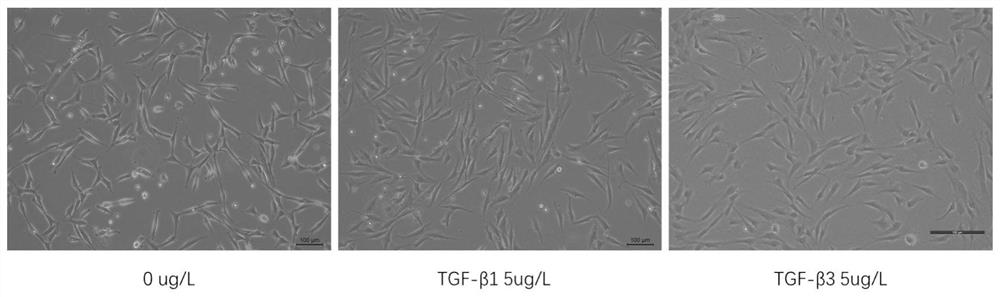

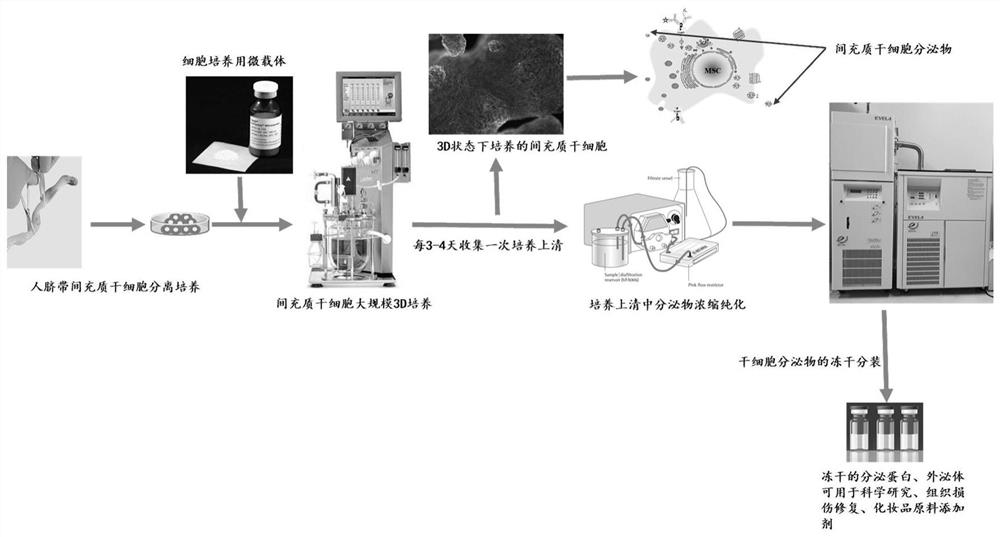

Culture method of mesenchymal stem cells

ActiveCN112522191AImprove proliferative abilityComplete formCulture processSkeletal/connective tissue cellsMesenchymal stem cellSecretion

The invention relates to the technical field of cell culture, and particularly relates to a culture method of mesenchymal stem cells. In the culture method, a serum-free culture medium optimized by the invention is used for culturing the mesenchymal stem cells. In addition, the invention further provides a better culture method for 3D culture. The cells obtained by the culture method disclosed bythe invention are strong in proliferation capacity, intact in shape and strong in secretion capacity, and are in accord with the international quality control standards of the mesenchymal stem cells.Meanwhile, according to the culture method disclosed by the invention, a large number of mesenchymal stem cells (particularly human umbilical cord mesenchymal stem cells) can be obtained by amplifyinga small number of mesenchymal stem cells under the conditions of small space occupation, less culture medium consumption, simpler and more convenient operation and greatly reduced workload; and a solid technical scheme and a theoretical basis are provided for obtaining a large number of high-quality mesenchymal stem cells (especially human umbilical cord mesenchymal stem cells) and secretions thereof in the clinical field.

Owner:YUNNAN KEY LAB OF PRIMATE BIOMEDICINE RES

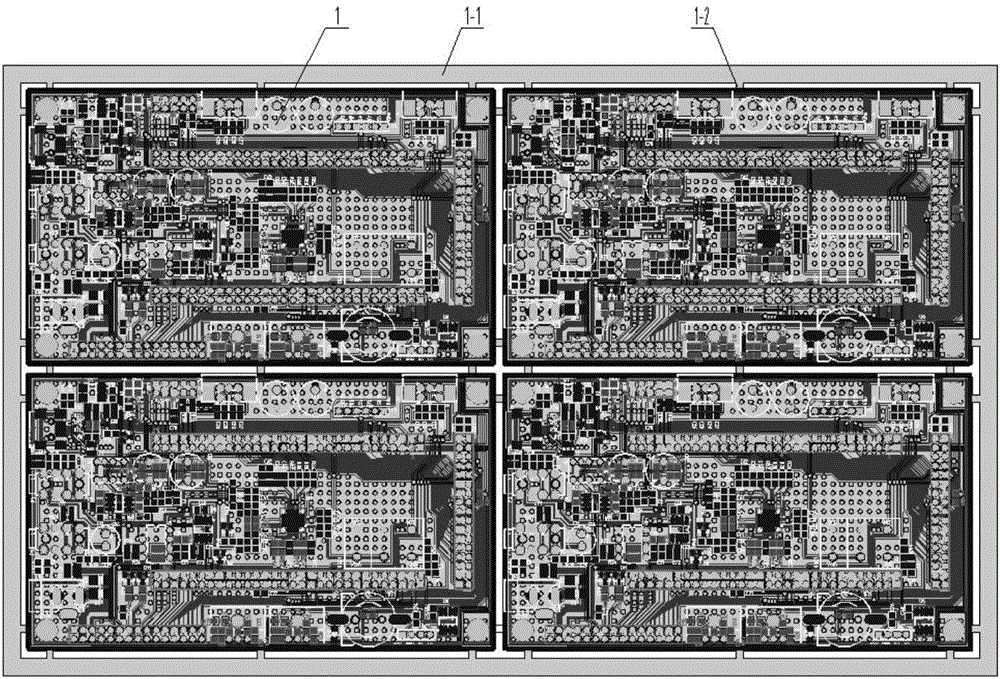

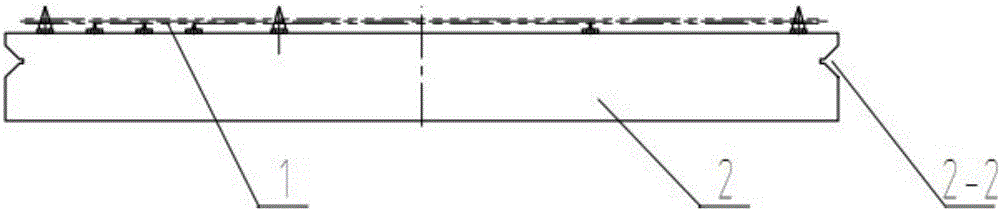

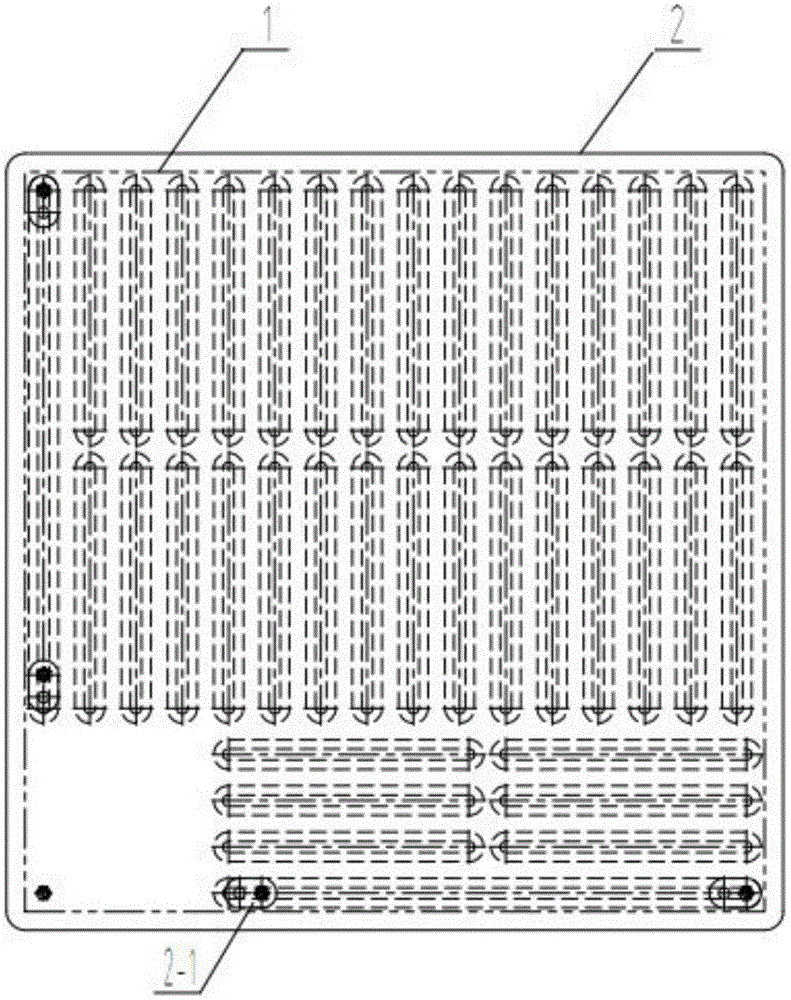

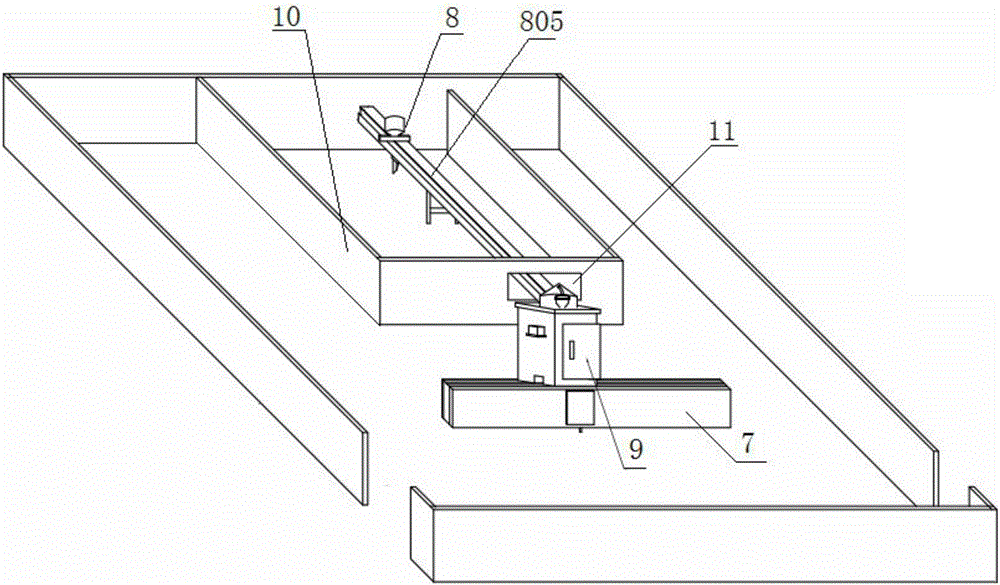

Full closed-loop automatic laser board splitting machine and method for PCBs

ActiveCN106425123AFully automatedNo mechanical damagePrinted circuitsMetal working apparatusControl systemClosed loop

The invention provides a full closed-loop automatic laser board splitting machine for PCBs. The full closed-loop automatic laser board splitting machine comprises a laser board splitting machine body, a laser cutting mechanism, a circulating automatic feeding mechanism, a grabbing and lifting mechanism, a control system and an image recognition system. The circulating automatic feeding mechanism is arranged on the laser board splitting machine body. The laser cutting mechanism, the grabbing and lifting mechanism and the image recognition system are located above the circulating automatic feeding mechanism. The circulating automatic feeding mechanism is used for conveying a jig to the position of the grabbing and lifting mechanism, and the jig is used for loading the PCBs. The grabbing and lifting mechanism is used for elevating the jig to the position of the focus of the laser cutting mechanism. The image recognition system is used for shooting the PCBs and sending a shooting result to the control system. The control system controls the laser cutting mechanism to cut PCB areas on the multiple integrated PCBs according to the shooting result, and the grabbing and lifting mechanism is also used for arranging the jig on the circulating automatic feeding mechanism for recycling. By means of the full closed-loop automatic laser board splitting machine, full-automatic laser board splitting is achieved, the labor intensity can be effectively reduced, and the production efficiency is improved.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

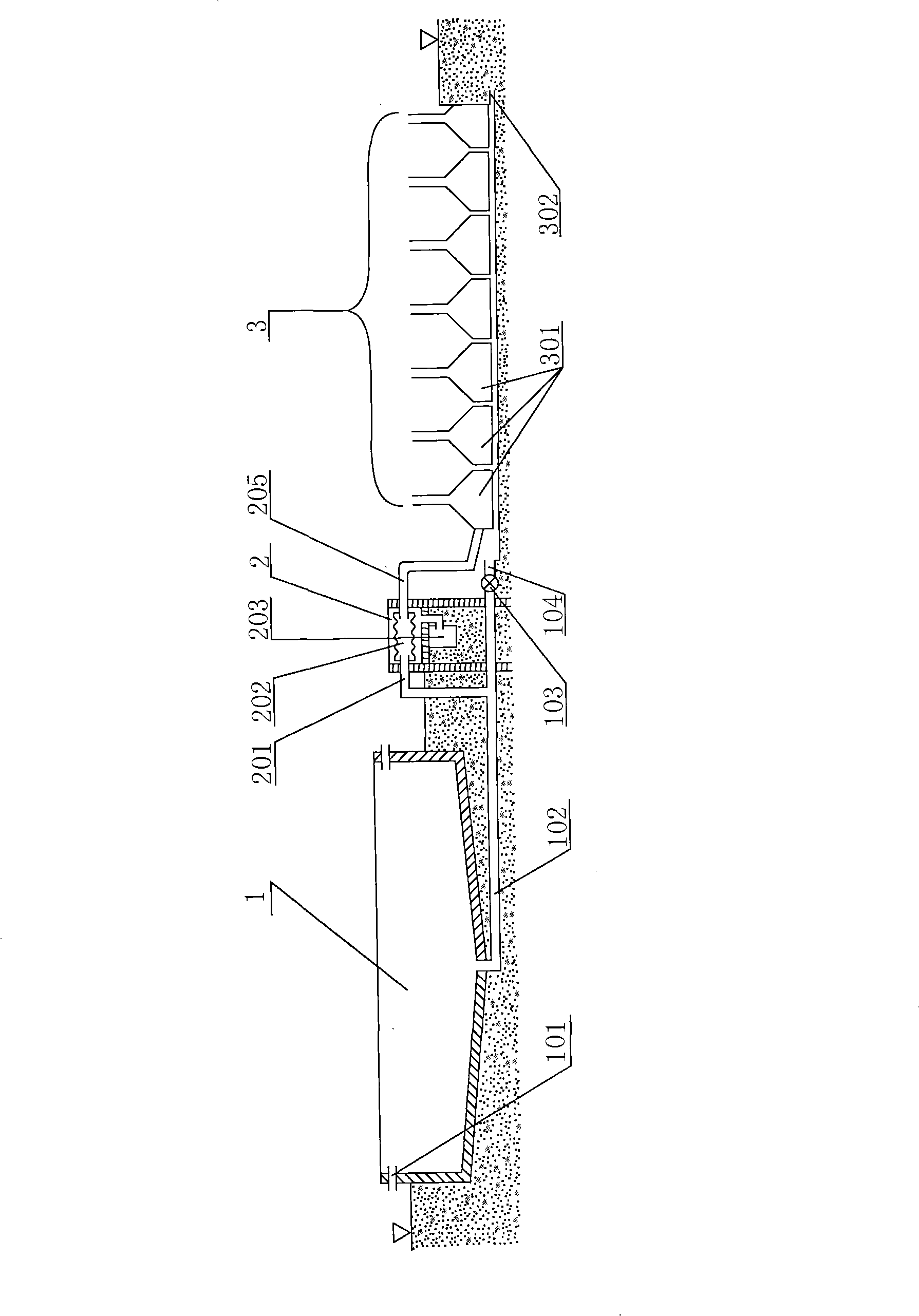

Device and method for automatically collecting fish-egg

InactiveCN101297638ALess egg damageIncreased fry hatchabilityClimate change adaptationPisciculture and aquariaEngineeringWater level

The invention relates to a device used for collecting roes automatically and a method thereof; the existing method for collecting the roes is operated by manpower with time-wasting and labor-wasting and the roes are easy to be damaged for a long time a plurality of times of collision and friction with the container wall, such as buckets, thus having influence on hatchability. The technical proposal of the invention is that the device used for collecting roes automatically, which is designed by using the principle of the process that water and the roes flow simultaneously in the production process of fry and the water head and consists of a spawning pond, a roe-collecting pond and a hatching pond, leads the roes to be collected automatically in the roe-collecting pond, is filtered by a water strainer and then flows to a hatching bucket by a roe-collecting pipe, and the whole process is completed in the process that the water and the roes flow simultaneously. The device used for collecting roes automatically and the method has the advantages of reducing the labor intensity, improving the working efficiency; reducing the damage of the roes, improving the hatchability; having simple structure, reducing the occupy area, improving the environment and obtaining more ideal positive effects that the labor is saved, the quality is improved, the cost is reduced and the effect is obvious after the practical application of the fish havens.

Owner:上海市嘉定区水产技术推广站

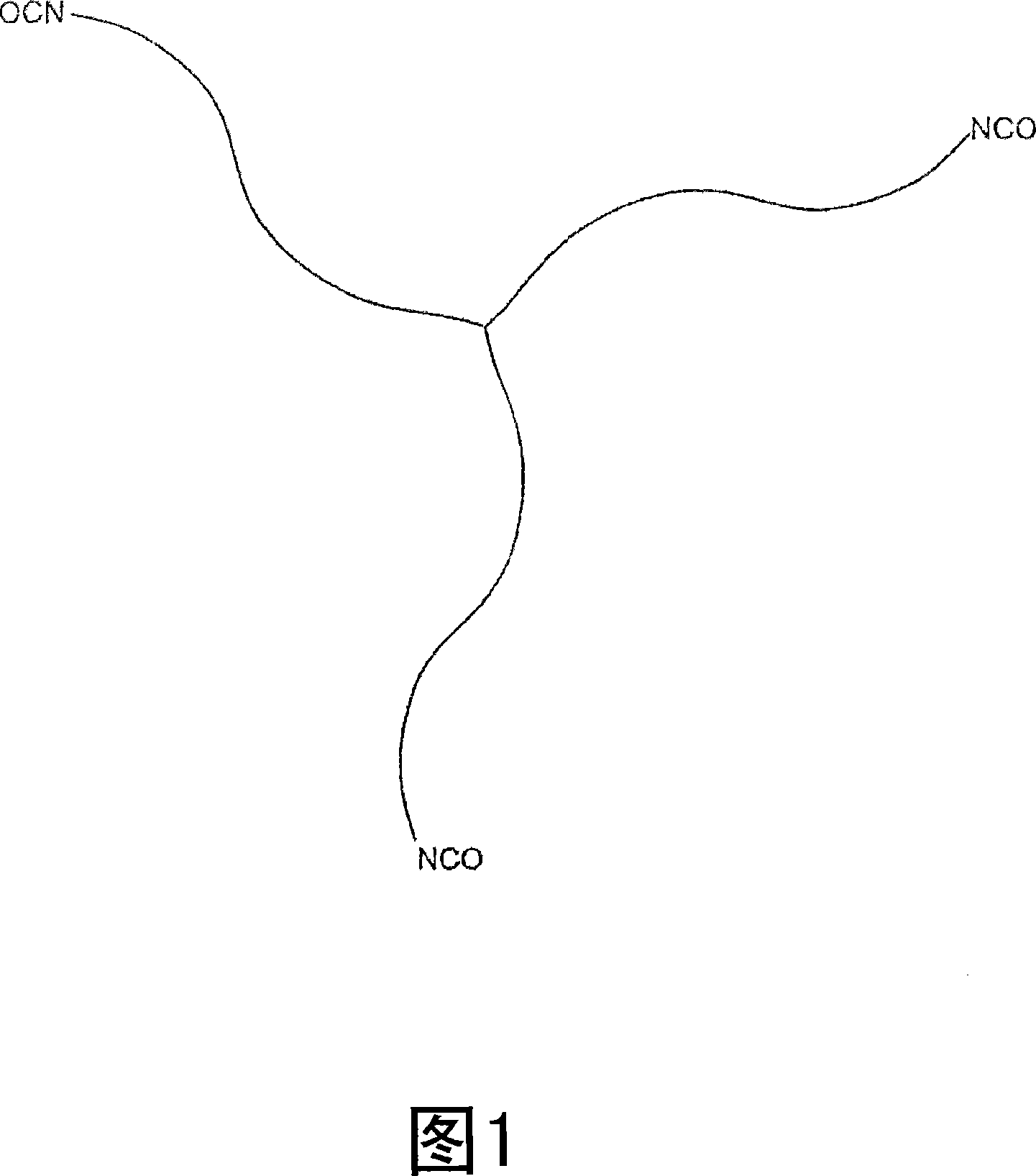

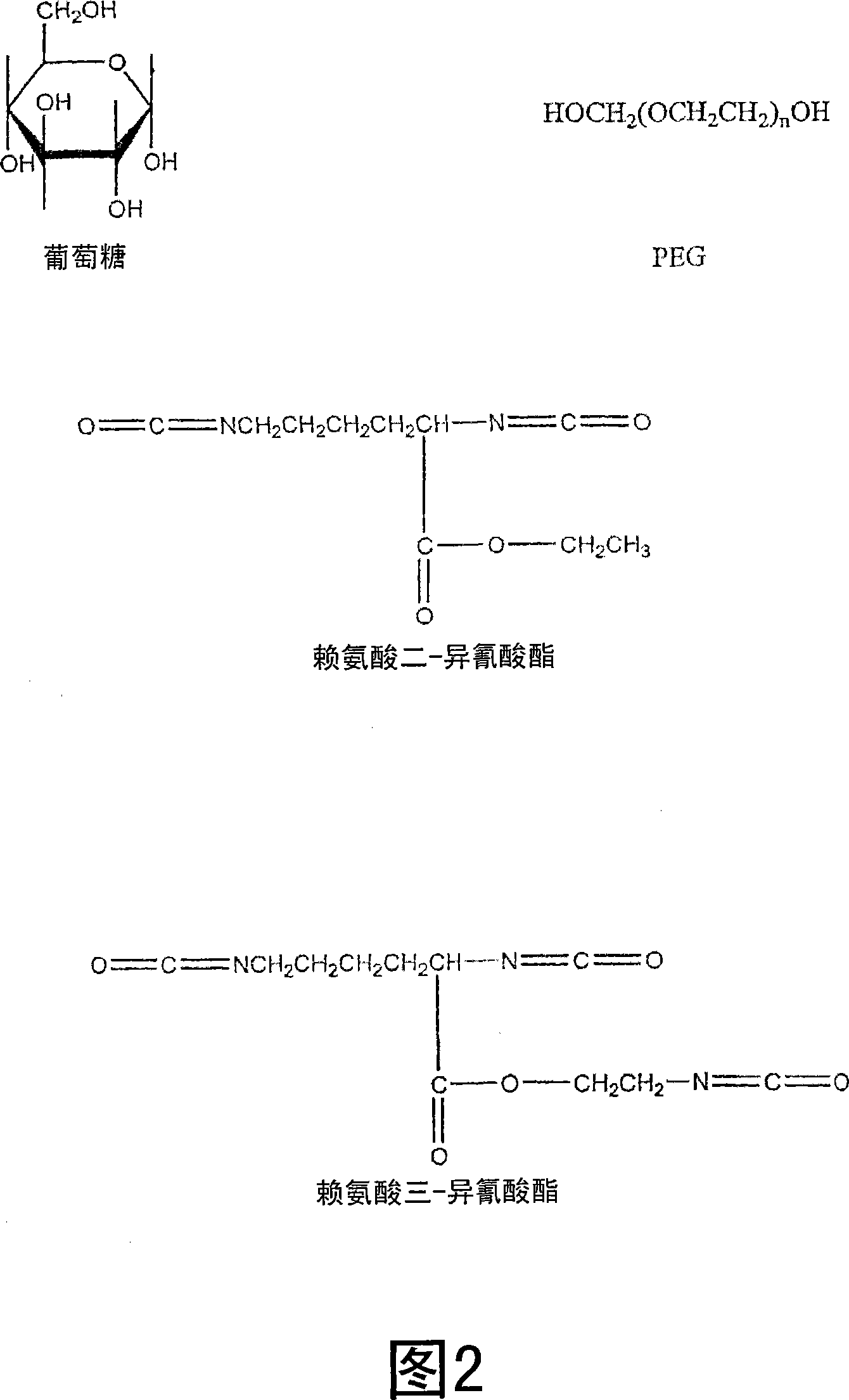

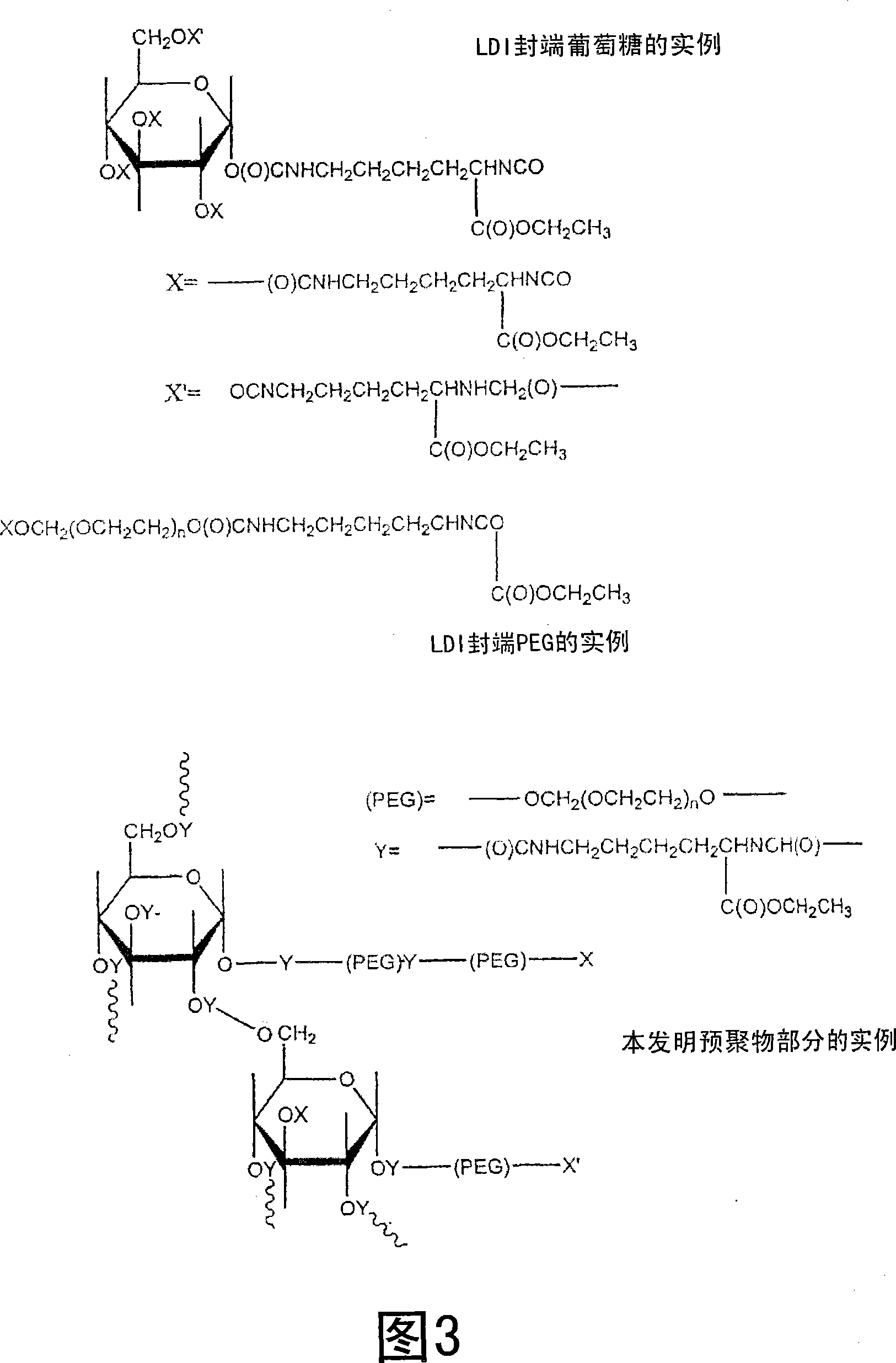

Medical adhesive and methods of tissue adhesion

InactiveCN1968718ANo mechanical damageHigh tensile strengthSurgical adhesivesAdhesivePolymer network

An adhesive including a mixture of isocyanate capped molecules formed by reacting multi-isocyanate functional molecules with multi-functional precursor molecules including terminal functional groups selected from the group consisting of a hydroxyl group, a primary amino group and a secondary amino group. Preferably, the functional groups are hydroxyl groups. The multi-functional precursor compounds are biocompatible. Multiamine functional precursors of the multi-isocyanate functional molecules are also biocompatible. As discussed, above, the mixture of molecules preferably has an average isocyanate functionality of at least 2.1 and, more preferably, has an average isocyanate functionality of at least 2.5. As also described above, the mixture of molecules preferably has a viscosity in the range of approximately 1 to approximately 100 centipoise. The mixture of molecules forms a crosslinked polymer network upon contact with the organic tissue in the presence of water. The crosslinked polymer network is biocompatible and biodegradable. The crosslinked polymer network degrades into degradation products including the precursor molecules and the multi-amine functional precursors.

Owner:UNIVERSITY OF PITTSBURGH

Solid chemical dredging agent for pipeline dredging and preparing method thereof

InactiveCN1488781AAchieve the purpose of dredgingImprove dredging effectCleaning using liquidsSodium dodecylbenzenesulfonateCleansing Agents

The present invention relates to a solid chemical pipe cleaning agent and its preparation method. It is characterized by that it is formed from 52-68% of granular sodium hydroxide, 11-19% of sodium carbonate, 15-21% of high test bleaching powder, 4-10% of sodium dodecyl benzene sulfonate and 0.02% of essence. Said invention has no need of adding metal aluminium, can obtain good cleaning effect, and can be used for killing pathogenic bacteria and insect eggs. Said invention also provides its preparation method and production steps.

Owner:汪立强

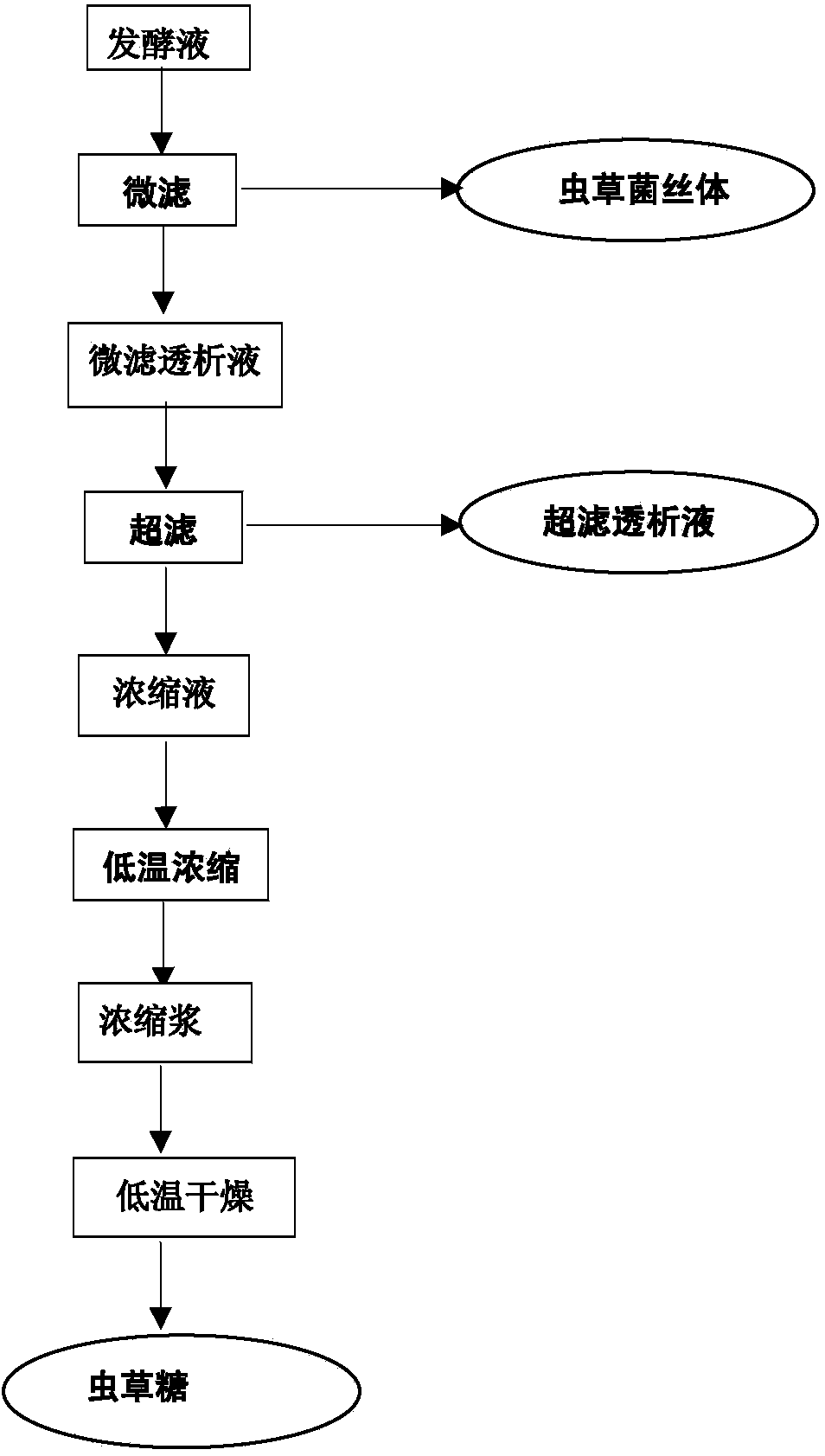

Novel green extraction technology for cordyceps polysaccharide

The invention discloses a novel green extraction technology for cordyceps polysaccharide, particularly discloses a method for extracting cordyceps polysaccharide through a two-membrane process. According to the method, the micro-filtration membrane and ultra-filtration membrane treatment and separation are performed on a cordyceps fermentation liquor under specific conditions to obtain the cordyceps polysaccharide. Through the adoption of the method, the traditional extraction mode of water extract and alcohol precipitate of cordyceps polysaccharide is changed, the purification effect of cordyceps polysaccharide is improved, the use level of ethyl alcohol during production is reduced, the economic benefit is increased, meanwhile, the amount of discharged filtrate waste water can be reduced, and the social benefit is obviously improved.

Owner:JIANGSU SHENHUA PHARMA

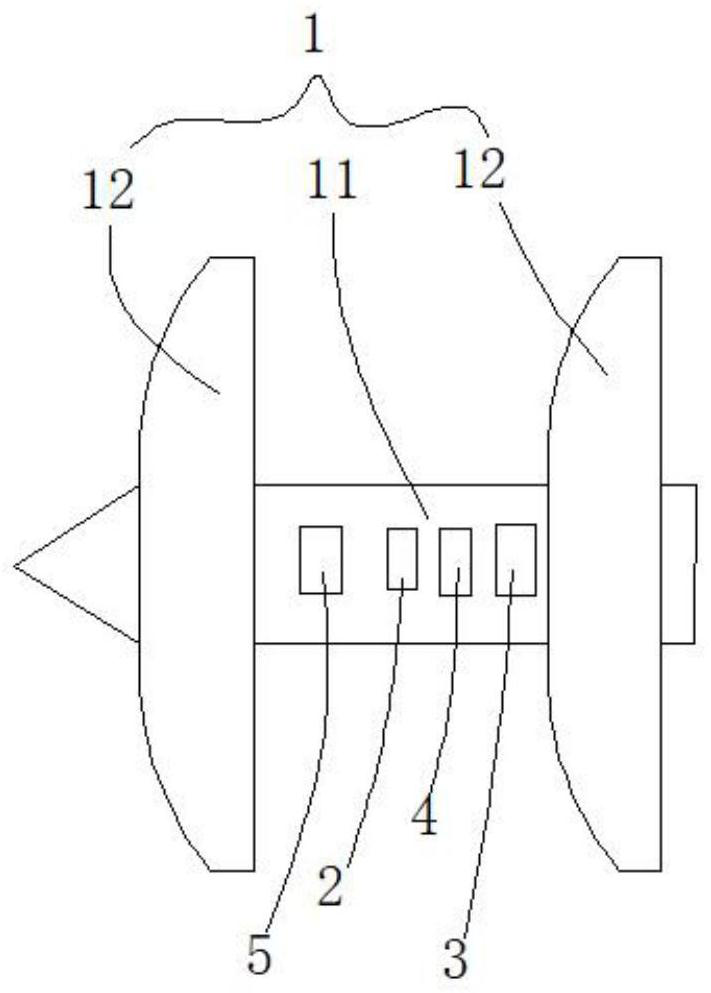

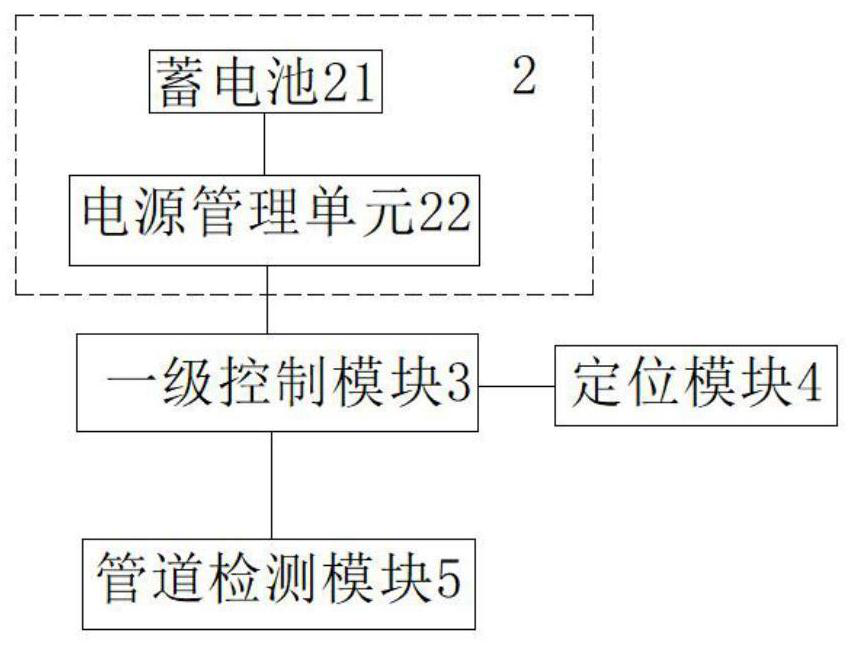

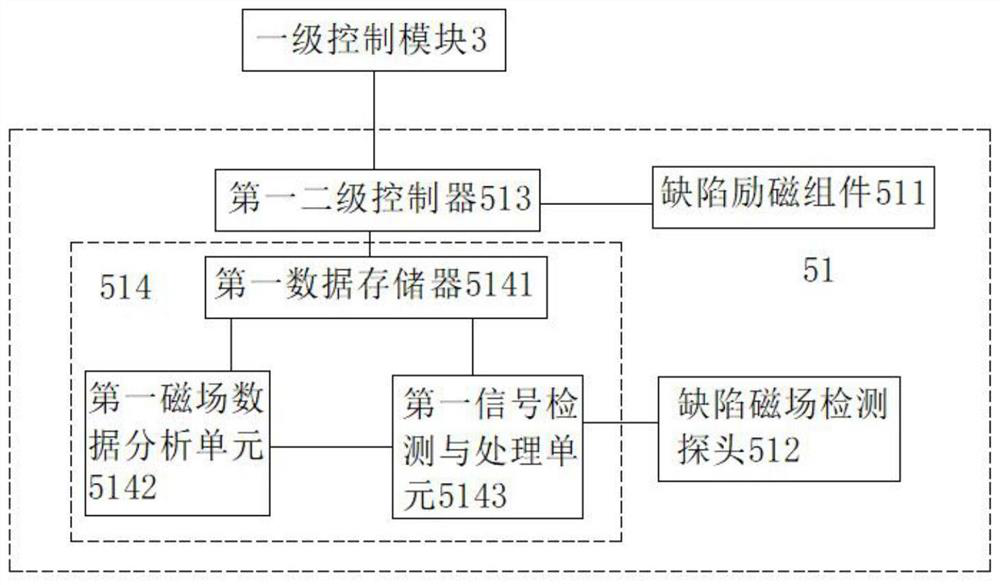

Pipeline detection robot

PendingCN111649192ASimple structureEasy to useDetection of fluid at leakage pointForce measurement by measuring magnetic property varationControl engineeringReliability engineering

The invention discloses a pipeline detection robot which is arranged in a fluid conveying pipeline and comprises a mobile carrier, and a power module, a primary control module, a positioning module and a pipeline detection module arranged on the mobile carrier. The power module, the primary control module and the positioning module are arranged on the mobile carrier; the power module, the positioning module and the pipeline detection module are electrically connected with the primary control module; the positioning module is used for positioning a geographic space position of the mobile carrier; and the pipeline detection module is connected with the mobile carrier and is used for detecting whether the state along the pipeline is abnormal or not. The pipeline detection robot is simple in structure and convenient to use; and the robot only needs to be put in the pipeline after being started, so that the robot moves in the pipeline along a material flowing direction, the pipeline state at a current position point is detected through the carried pipeline detection module, and in addition, the positioning module can jointly provide the state distribution information along the pipelineaccording to the combination of positioning information and a result detected by the pipeline detection module at the same time.

Owner:YICHANG HUATENG PIPELINE ENG CO LTD +1

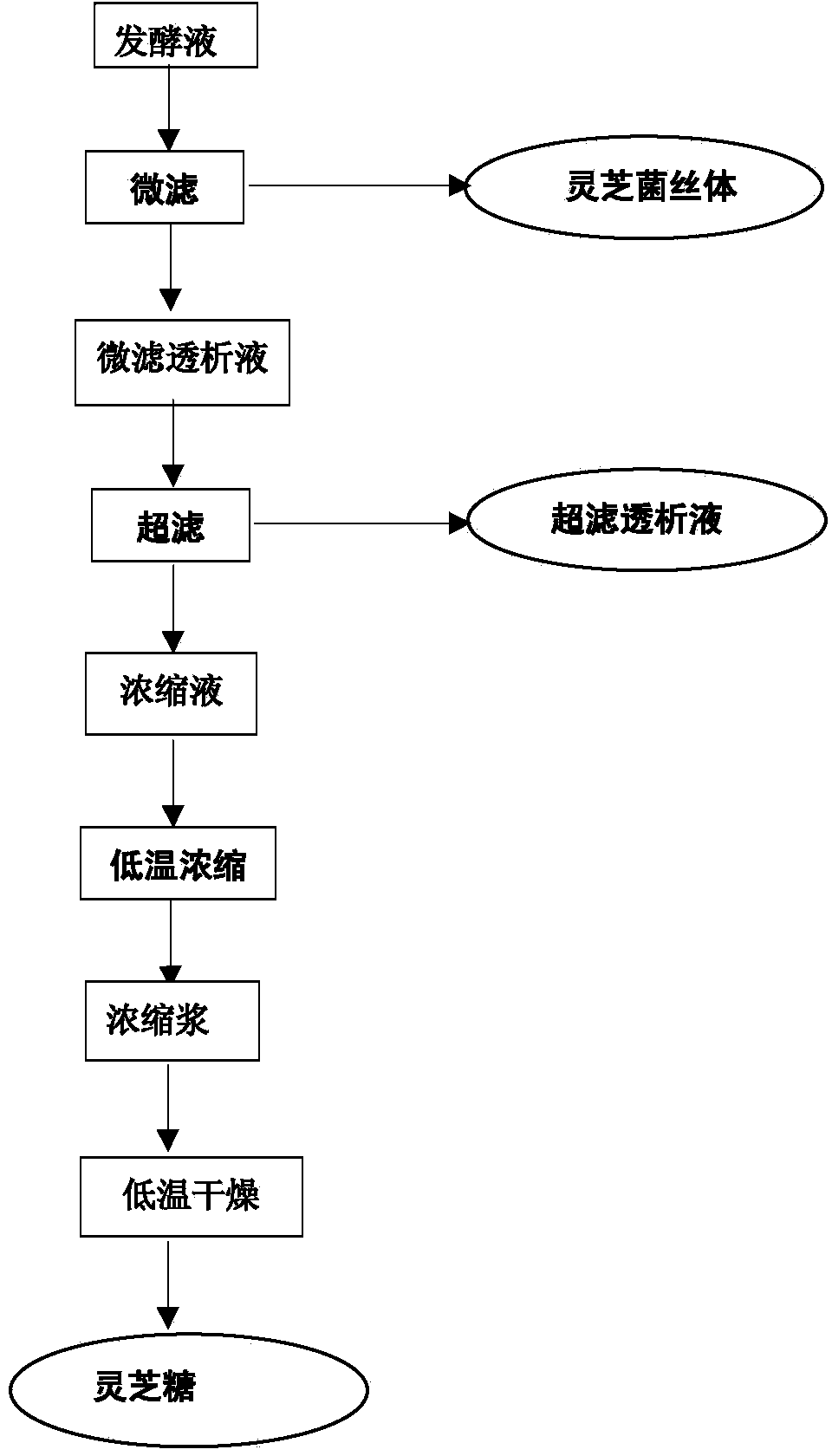

Novel green process for extracting ganoderma lucidum polysaccharides

The invention discloses a novel green process for extracting ganoderma lucidum polysaccharides and in particular relates to a method for extracting ganoderma lucidum polysaccharides by a double membrane process. According to the method, ganoderma lucidum polysaccharides are obtained by separating a lucid ganoderma fermentation liquor using a micro-filtration membrane and an ultrafiltration membrane under special conditions. According to the invention, the conventional ganoderma lucidum polysaccharide extraction mode of water extraction and ethanol precipitation is changed, the purification effect of ganoderma lucidum polysaccharides is improved, and the consumption of ethanol during production is reduced, therefore the economic benefit is increased. Besides, with adoption of the method, the emission of filtrate wastewater is reduced and the social benefit is remarkably increased.

Owner:JIANGSU SHENHUA PHARMA

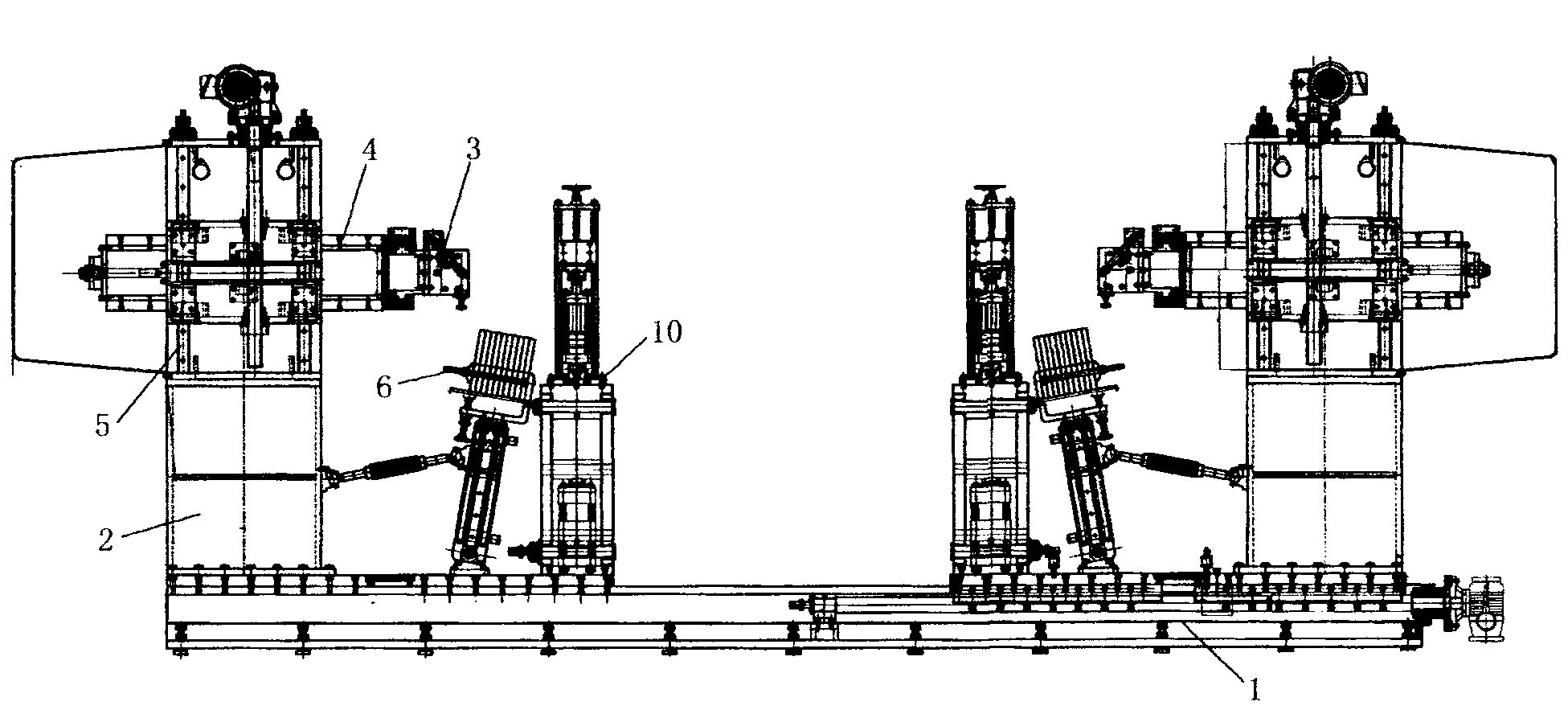

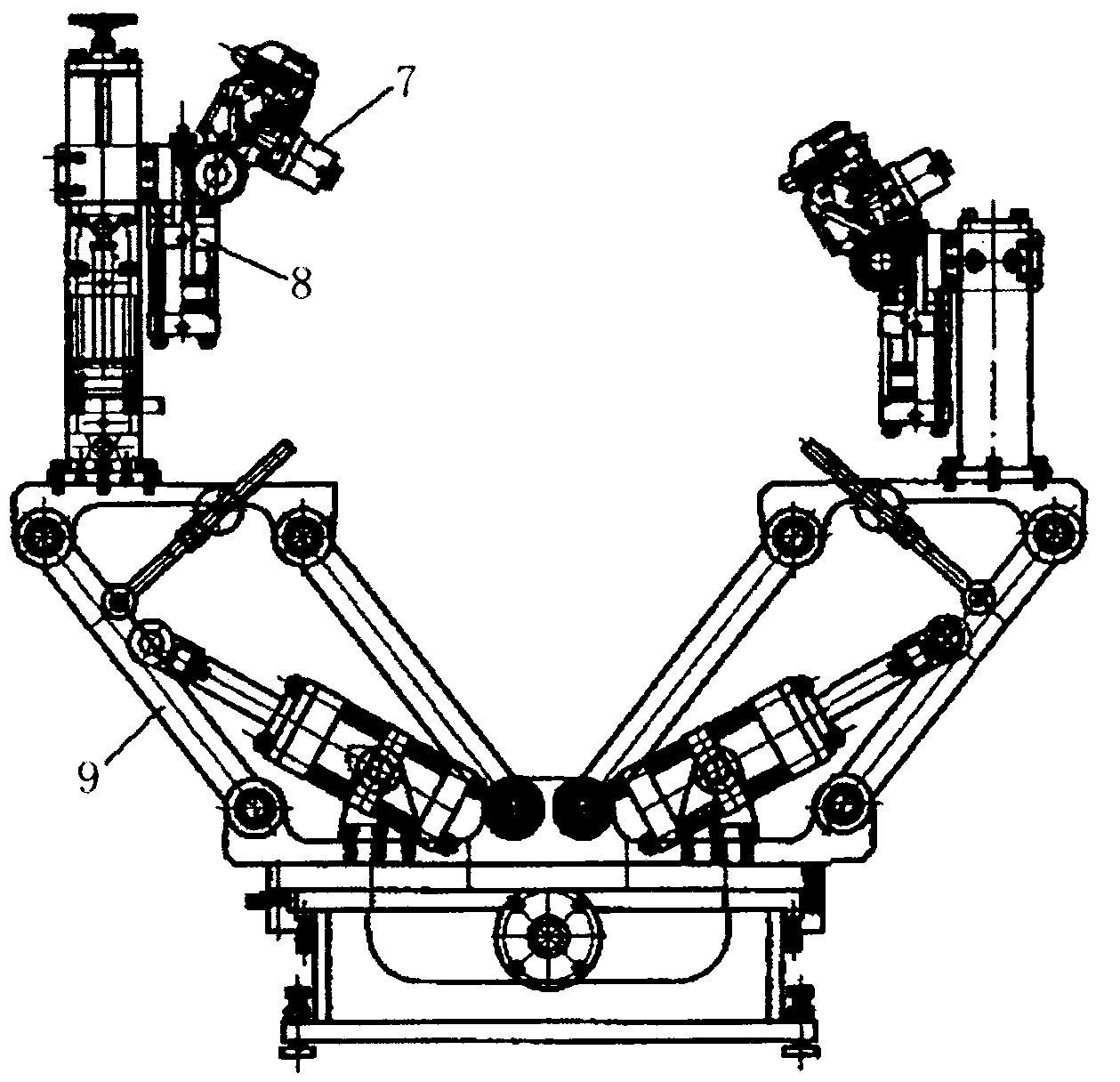

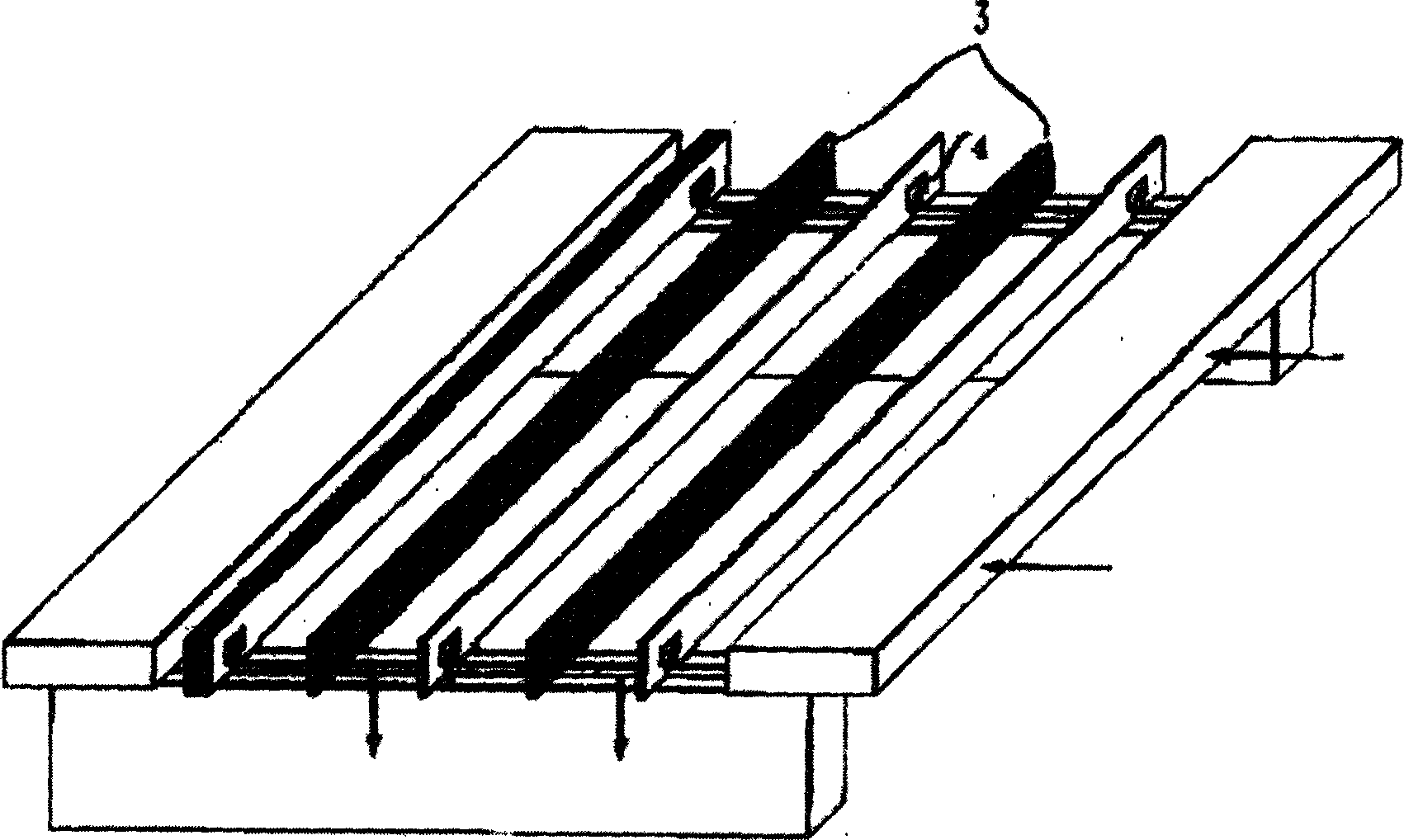

Numerical control roof-arc spreading machine

ActiveCN103208889AWith automatic distanceFunctionalManufacturing dynamo-electric machinesNumerical controlLeft half

A numerical control roof-arc spreading machine comprises a base guide rail mechanism, four bases, two coil nose clamping mechanisms, four coil bar roof radian mechanisms, four coil bar clamping spreading mechanisms, a hydraulic station and a sensor control numerical control circuit system. The two bases are respectively arranged on the left half portion and the right half portion of the upper end of the base guide rail mechanism and the two coil nose clamping mechanisms are respectively connected with the upper ends of the two bases. The other two bases are arranged in the middle of the upper end of the base guide rail mechanism. The four coil bar clamping spreading mechanisms are respectively arranged at the upper ends of the two bases with two coil bar clamping spreading mechanisms as a pair and the four coil bar roof radian mechanisms are respectively arranged on the sides of the four coil bar clamping spreading mechanisms. During working, the four coil bar clamping spreading mechanisms which are symmetrical all around are utilized to spread large coils and the two coil bar clamping spreading mechanisms which are symmetrical in a front-and-back mode are utilized to spread small coils. The numerical control roof-arc spreading machine can accurately and rapidly achieve one-step spreading forming machining of various motor coils.

Owner:上海闵行机械工程技术研究所有限公司

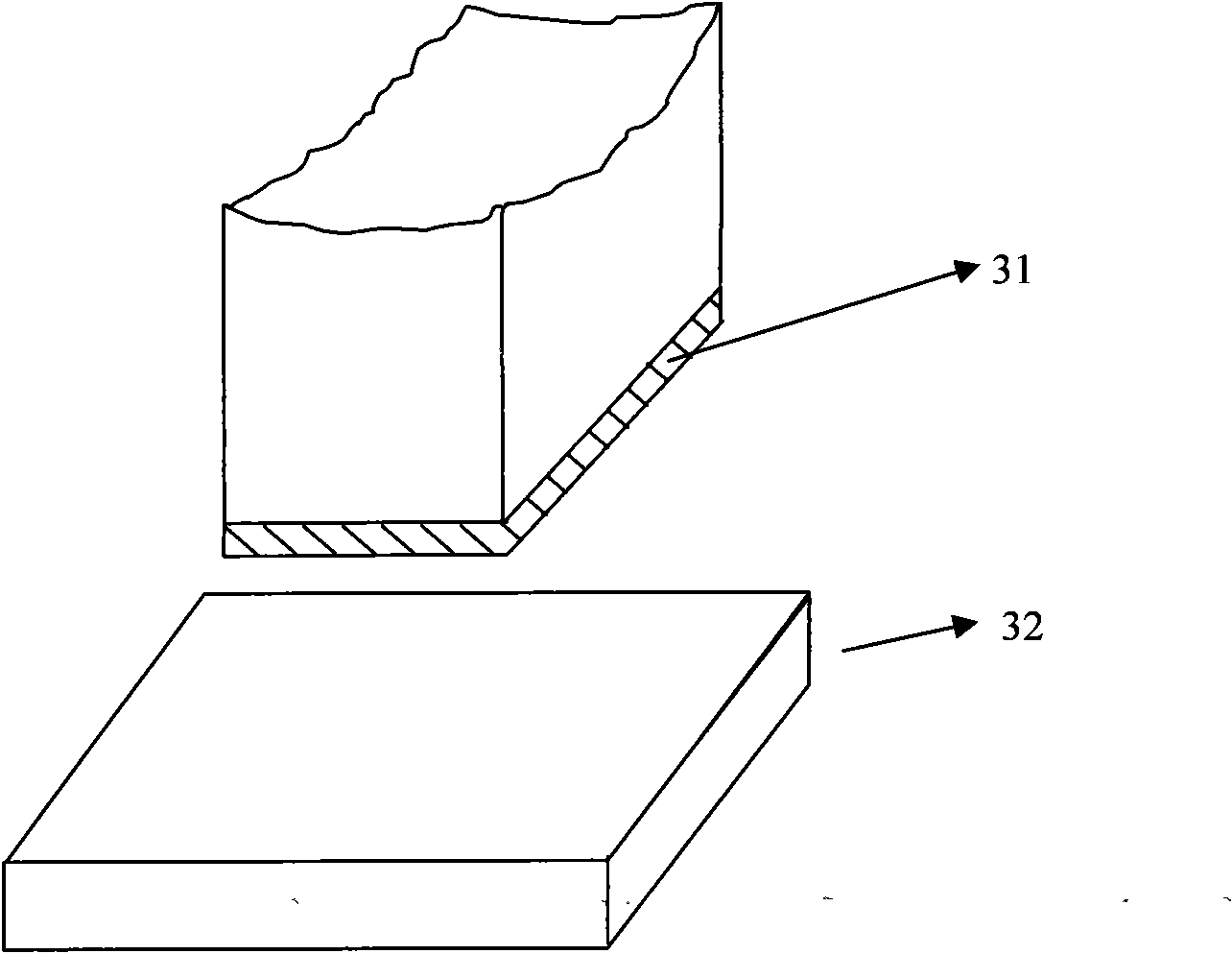

Gripper used for semiconductor laser chamber surface filming and bar loading device

InactiveCN1606204ANo mechanical damageGuaranteed uniformityLaser optical resonator constructionVicesMechanical engineeringSemiconductor

This invention provides a clamp used semiconductor laser cavity face coating composed of three parallel concave plates, a rectangular thin plate and a block for fixing and gripping. This invented strip installing device includes a vertical slide unit, a horizontal slide unit and a base, the vertical and slide units are same in structure all constituting a slide guide and a screw stem for adjusting the slide and a slide block.

Owner:BEIJING UNIV OF TECH

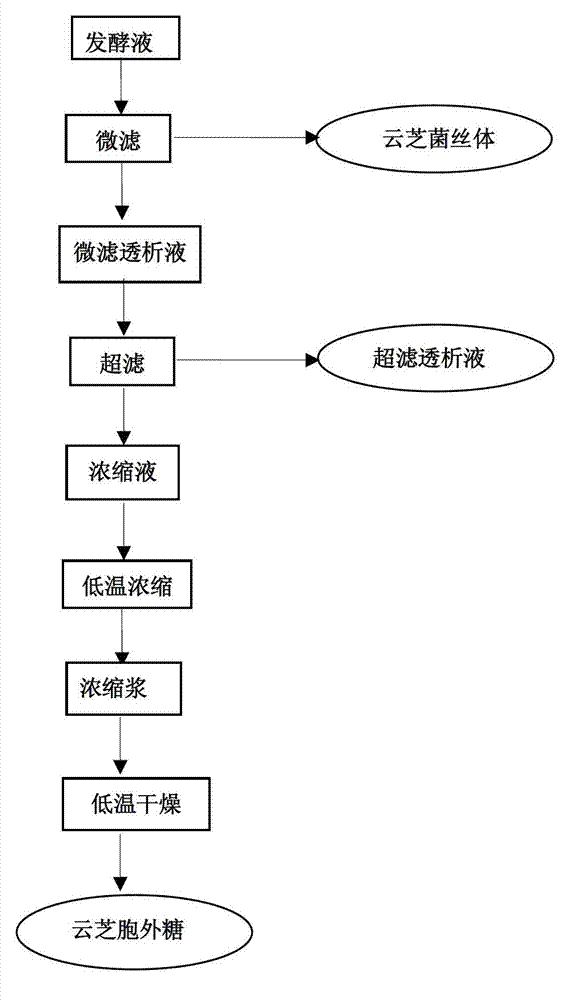

Method for extracting trametes versicolor exopolysaccharide through two-membrane process

ActiveCN102827304AHigh yieldPreserve the intracellular sugar content of Versicolor versicolorBULK ACTIVE INGREDIENTTrametes

The invention discloses a method for extracting trametes versicolor exopolysaccharide through a two-membrane process, which comprises the steps that trametes versicolor fermentation liquor is sequentially subjected to microfiltration and ultrafiltration for separation to obtain trametes versicolor exopolysaccharide. According to the method, the conventional 'water extraction and alcohol precipitation' extraction mode of trametes versicolor exopolysaccharide is changed, the extraction effect of the active ingredients of the trametes versicolor exopolysaccharide is improved, the ethanol usage during the production is lowered, the filtrate wastewater discharge is reduced, and the economic and social benefits are obviously increased.

Owner:JIANGSU SHENHUA PHARMA

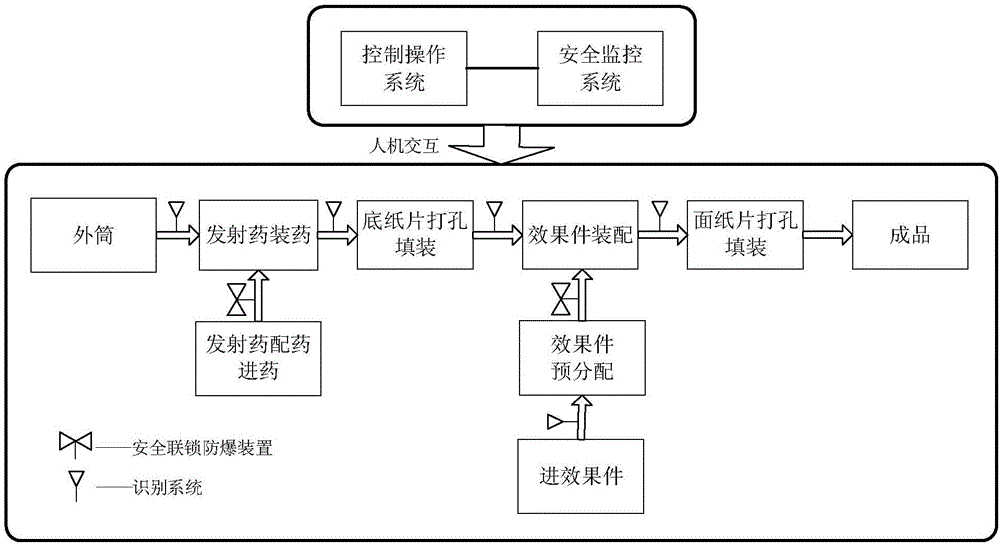

Combined firework automatic assembling system

The invention discloses a combined firework automatic assembling system. The combined firework automatic assembling system comprises a propellant powder charging subsystem, a bottom paper piece punching and filling subsystem, an effect piece filling subsystem and a surface paper piece filling subsystem which are connected by a combined firework outer cylinder transmitting mechanism sequentially, and also comprises a control and operating subsystem and a safety monitoring subsystem. Mechanical equipment is adopted during production of fireworks and crackers, and an automatic flow line production system comprising combined firework production main processes, especially dangerous processes, is established, so accidents are prevented to the greatest extent; and in case of the accident, personal casualties are avoided. As a whole, the automatic flow line production system has the advantages that the safety is improved, the enterprise production cost is greatly reduced, the product quality is obviously improved, the working efficiency is improved and the like.

Owner:DANCING FIREWORKS GROUP CO LTD

High-speed high-voltage pulse air-sweeping type red date harvesting machine

InactiveCN103797977AImprove harvesting efficiencyAvoid damagePicking devicesFruit treeHydraulic motor

The invention belongs to forest and fruit harvesting mechanical equipment, and particularly relates to a high-speed high-voltage pulse air-sweeping type red date harvesting machine which is used for harvesting red dates in a date garden. The high-speed high-voltage pulse air-sweeping type red date harvesting machine mainly comprises a machine frame and walking wheels. Two sets of harvesting devices are arranged on the machine frame in a bilateral-symmetry mode. Each set of harvesting device comprises a high-pressure fan, an air conveying pipeline, a plurality of air outlets, an air outlet swinging mechanism and a fruit conveying belt, wherein the air outlet swinging mechanism comprises a hydraulic motor, a driving gear, a driven gear, a front connecting rod, a rear connecting rod, a swinging gear, a rack and a connecting rod, the air outlets formed in the same side of the machine frame are connected through the corresponding air outlet swinging mechanism, and the air outlets can be driven to swing left and right or up and down through the air outlet swinging mechanisms. The high-speed high-voltage pulse air-sweeping type red date harvesting machine is simple in structure, low in manufacturing cost, reliable in working, high in harvesting efficiency and free of mechanical damage to fruit trees.

Owner:TARIM UNIV

Non-invasive extraction method of Haliotis discus hannai ino genome DNA

InactiveCN102747069AQuality improvementProtect organizational integrityDNA preparationCuticleNon invasive

The invention discloses a non-invasive extraction method of Haliotis discus hannai ino genome DNA, comprising the steps of using 75% of alcohol to sterilize and irritate pallium of Haliotis discus hannai ino; scraping to obtain a mixture of mucus and epidermal tissue fragments; treating the mixture, centrifugally separating the mixture to obtain precipitate; adding a cell lysate and protease K to the precipitate; after digesting and oscillating, cooling the mixture for a certain time; adding NH4Ac to the sample; centrifugally separating to collect supernate; adding isopropanol to the supernate; after oscillating and mixing uniformly, and then centrifugally separating to obtain precipitate; using ethanol to wash the precipitate; drying the precipitate at room temperature for 5 minutes to obtain the Haliotis discus hannai ino genome DNA. The non-invasive extraction method of the Haliotis discus hannai ino genome DNA is simple, efficient and convenient, does not damage the Haliotis discus hannai ino and does not influence survival ability and production performance.

Owner:DALIAN HAIBAO FISHERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com