Patents

Literature

1135 results about "Air dryer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compressed air dryers are special types of filter systems that are specifically designed to remove the water that is inherent in compressed air. The process of compressing air raises its temperature and concentrates atmospheric contaminants, primarily water vapor. Consequently, the compressed air is generally at an elevated temperature and 100% relative humidity. As the compressed air cools, water vapor condenses into the tank(s), pipes, hoses and tools that are downstream from the compressor. Water vapor is removed from compressed air to prevent condensation from occurring and to prevent moisture from interfering in sensitive industrial processes.

E-1 air dryer liquid separator with baffle

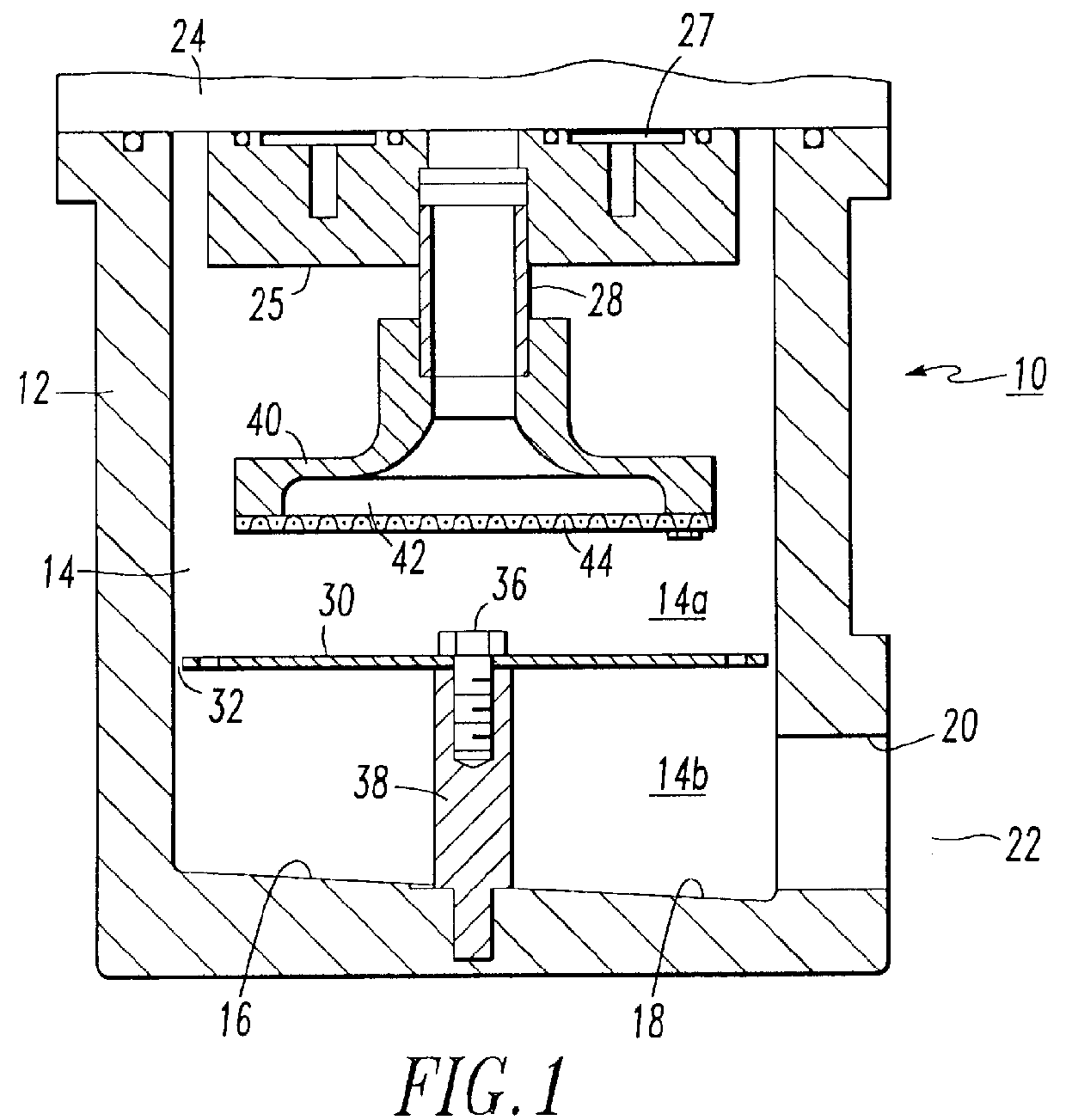

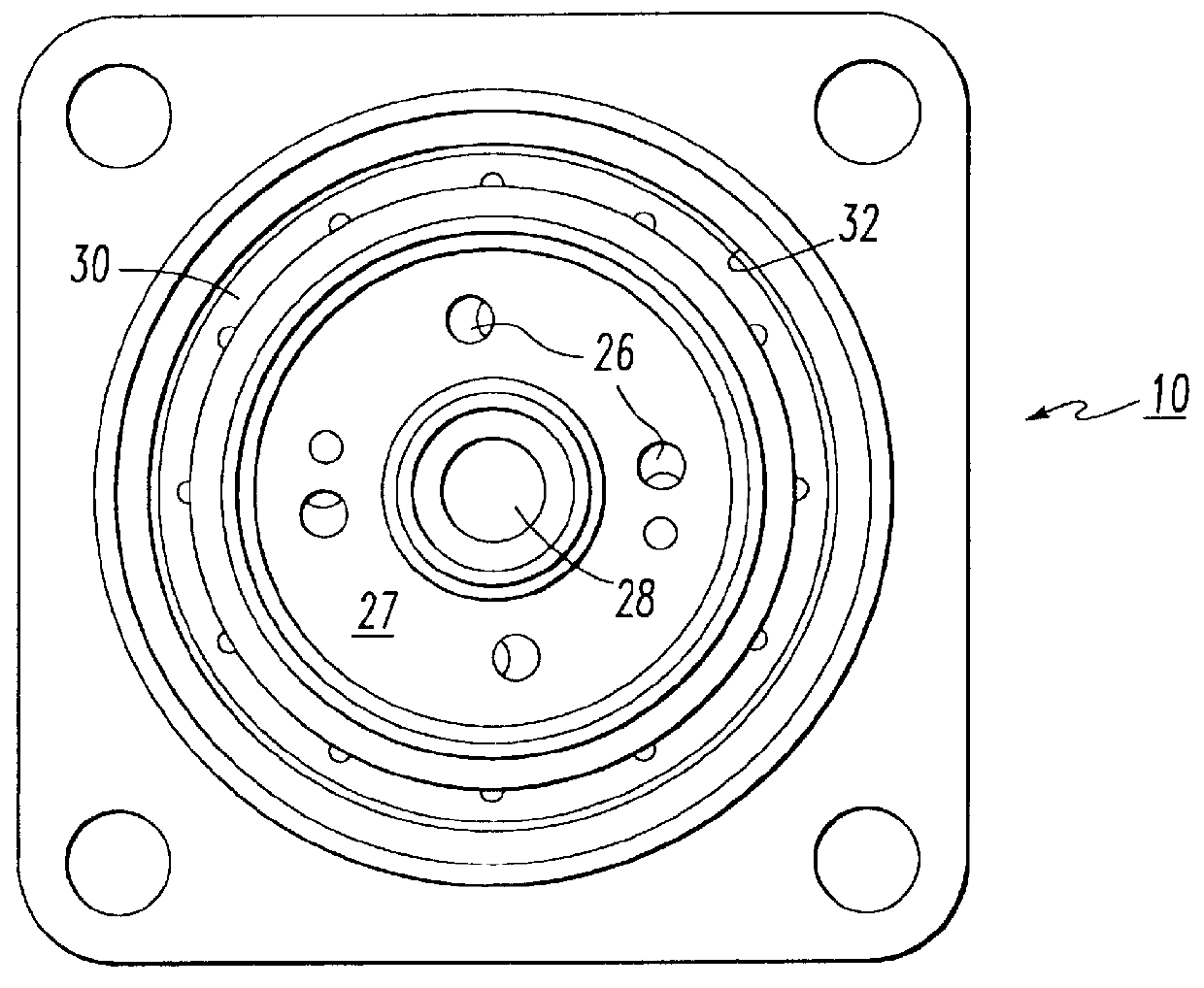

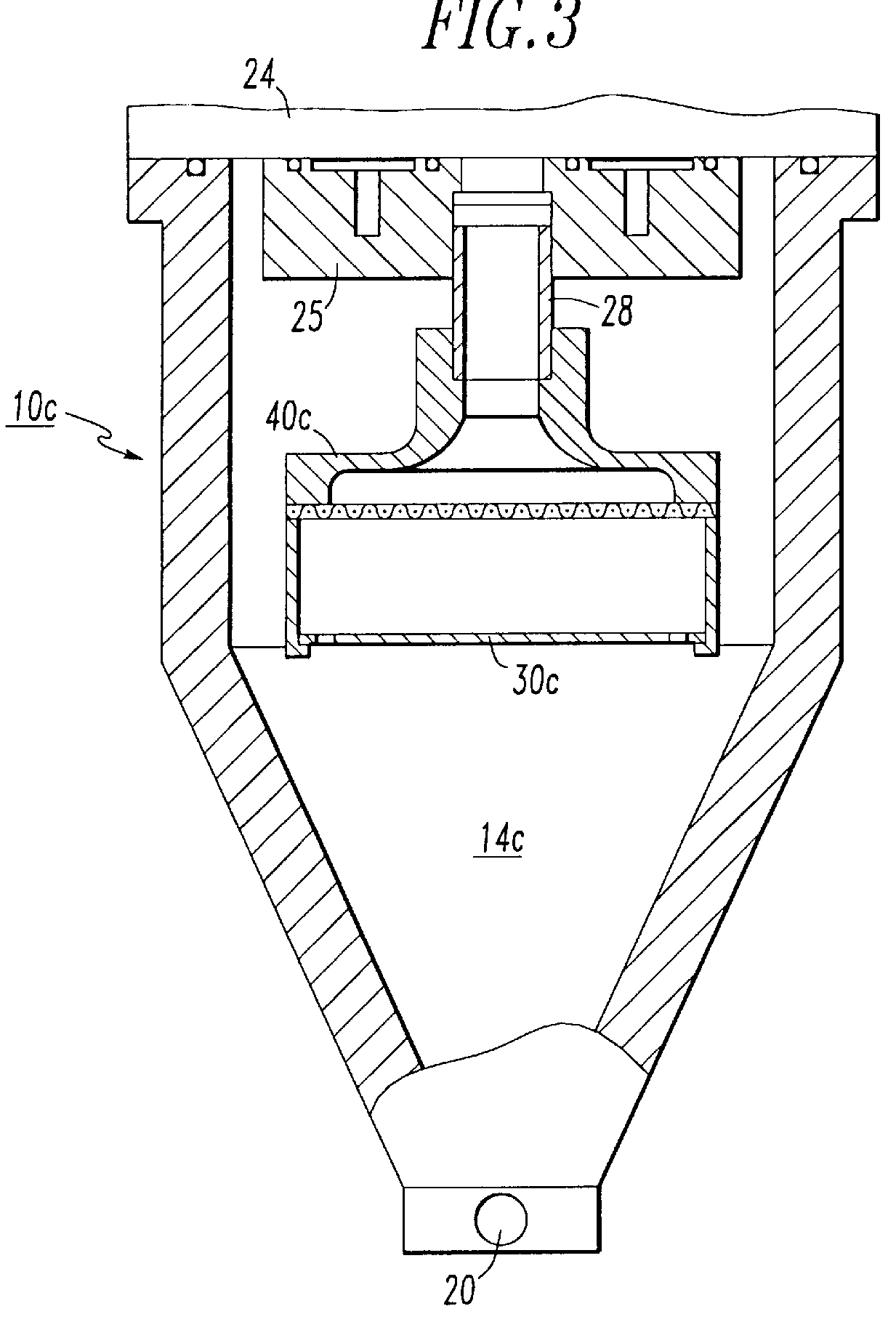

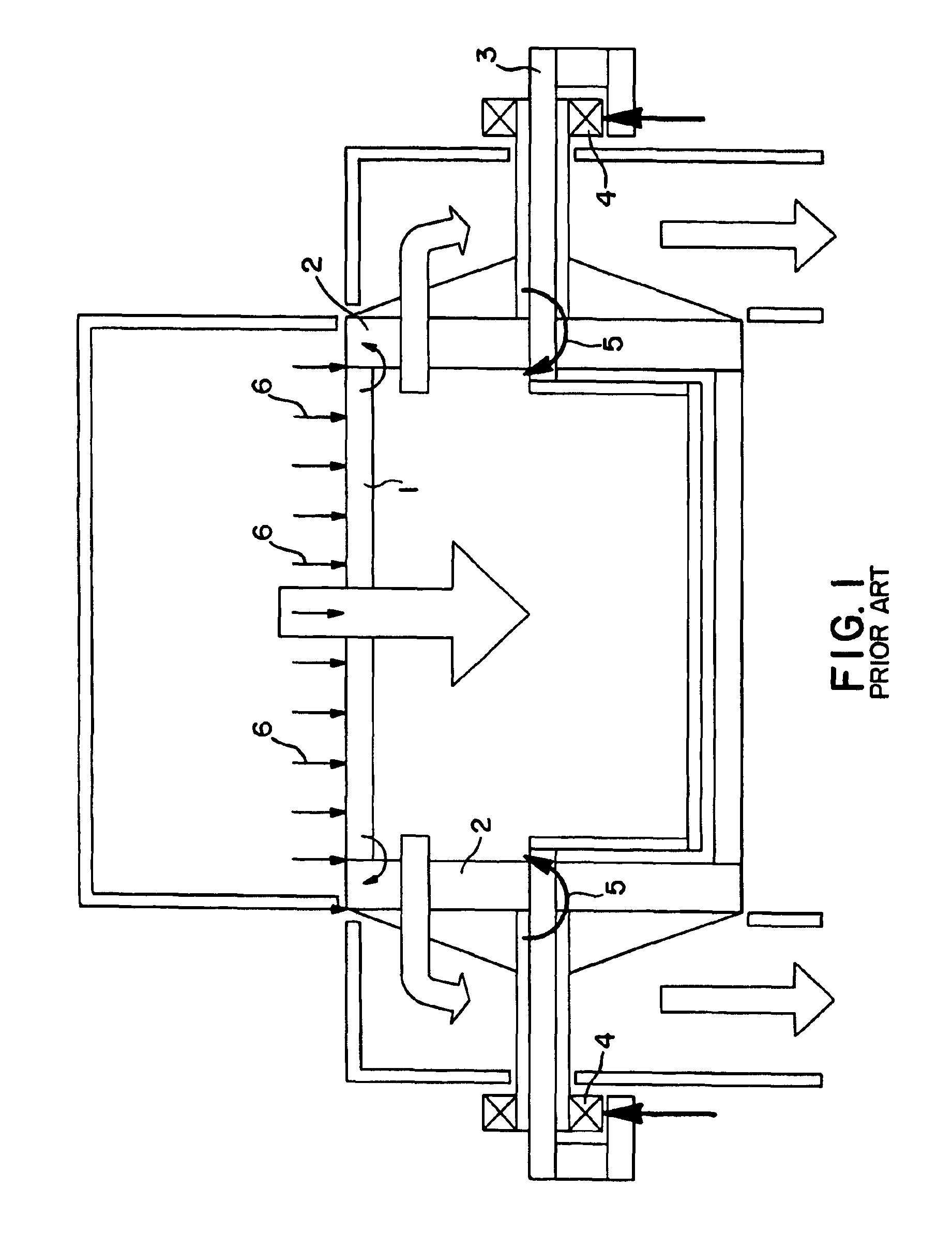

In a centrifugal separator for separating a liquid from a compressed gas, a baffle is provided to separate the centrifugal chamber into an upper sub-chamber and a lower sub-chamber but does not contact the walls of the chamber thereby being insufficient to prevent downward flow of separated liquid along the interior wall of the two sub-chambers, and insufficient to prevent flow of compressed gas from one sub-chamber to the other sub-chamber, the baffle nevertheless being sufficient to prevent turbulent gas flow in the lower sub-chamber when collected liquid is drained therefrom.

Owner:WESTINGHOUSE AIR BRAKE CO

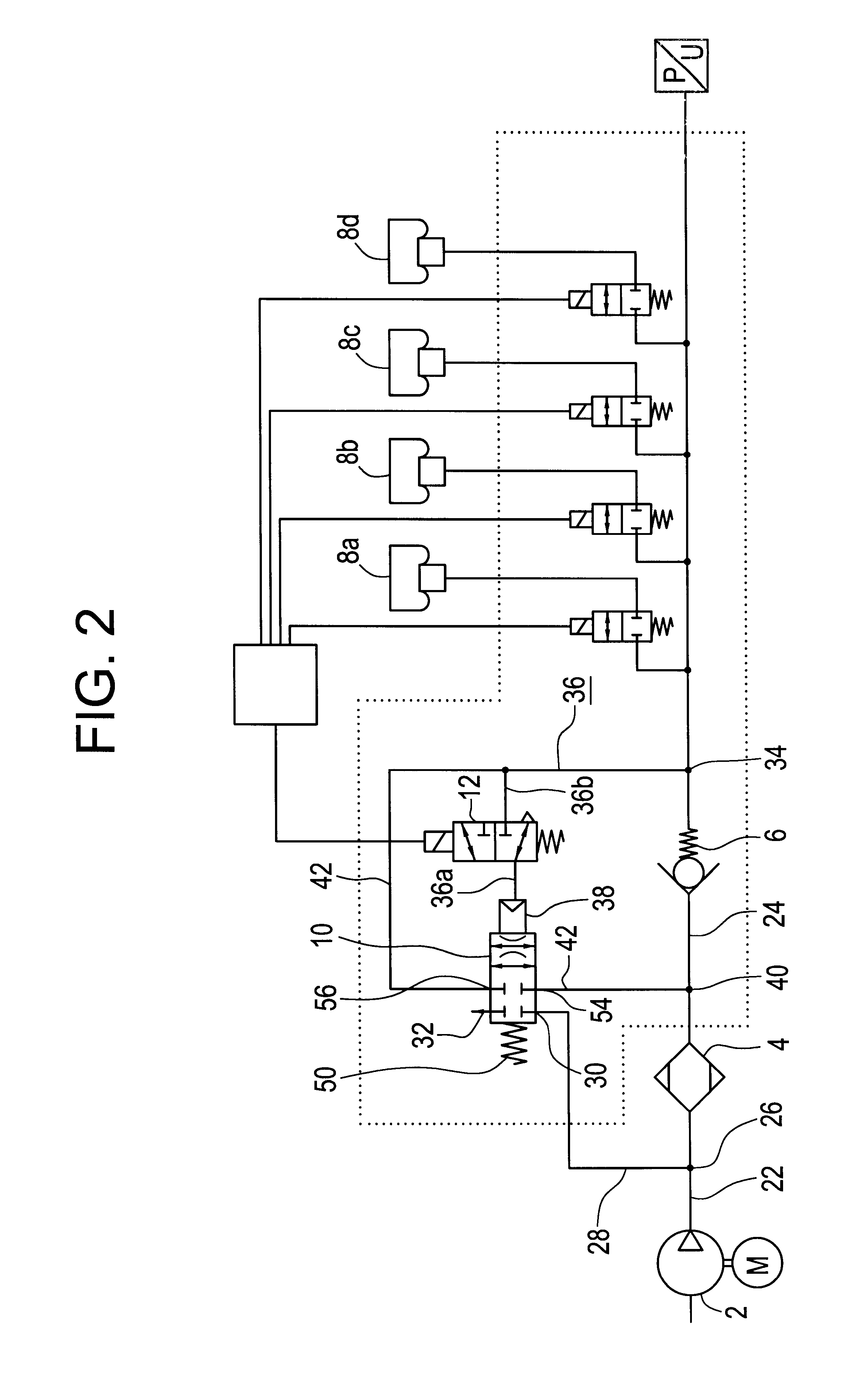

Level adjustment device for vehicles with air springs

InactiveUS6332623B1Fast emptyingLarge flowVehicle body stabilisationVehicle cleaning apparatusAir springAtmospheric air

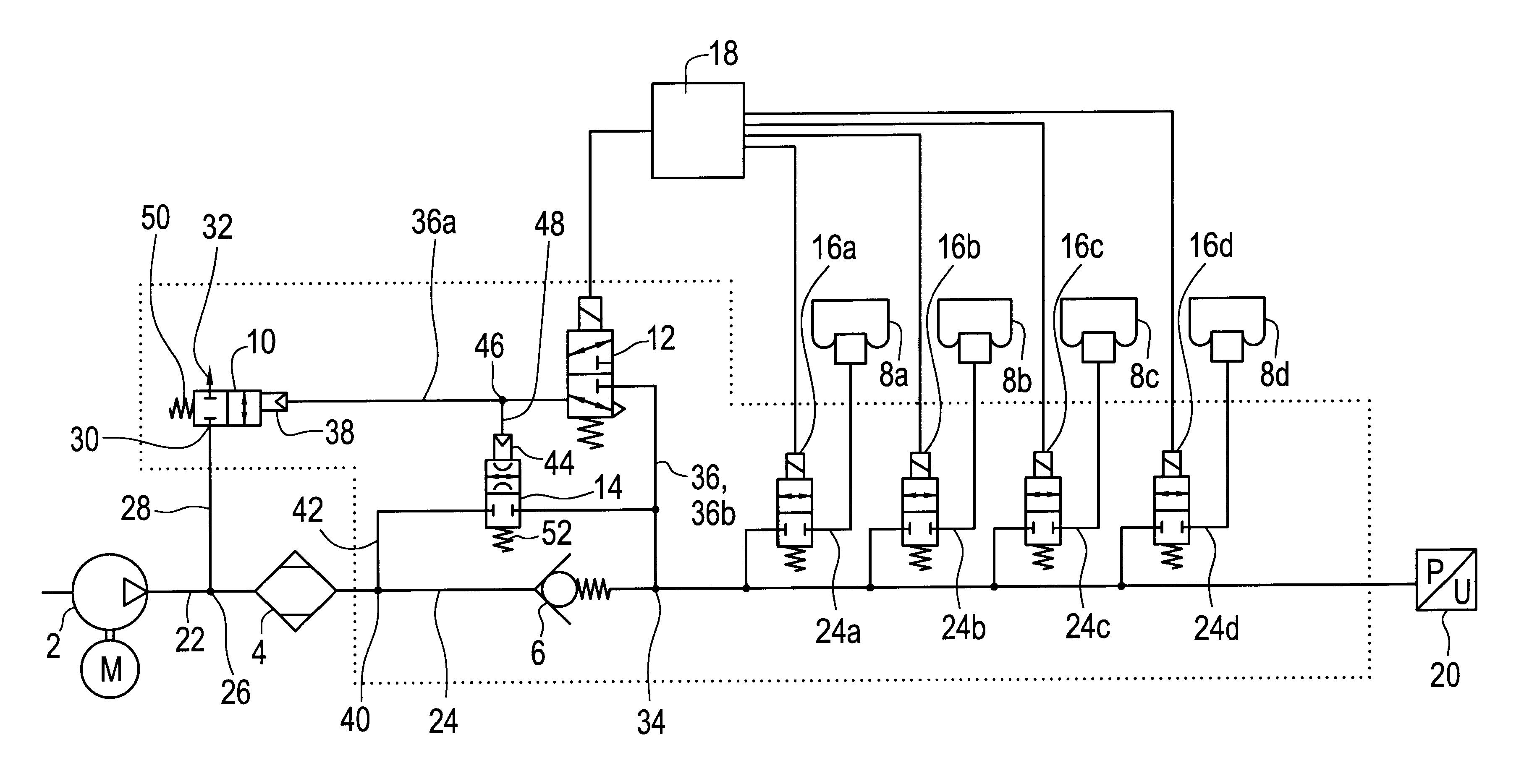

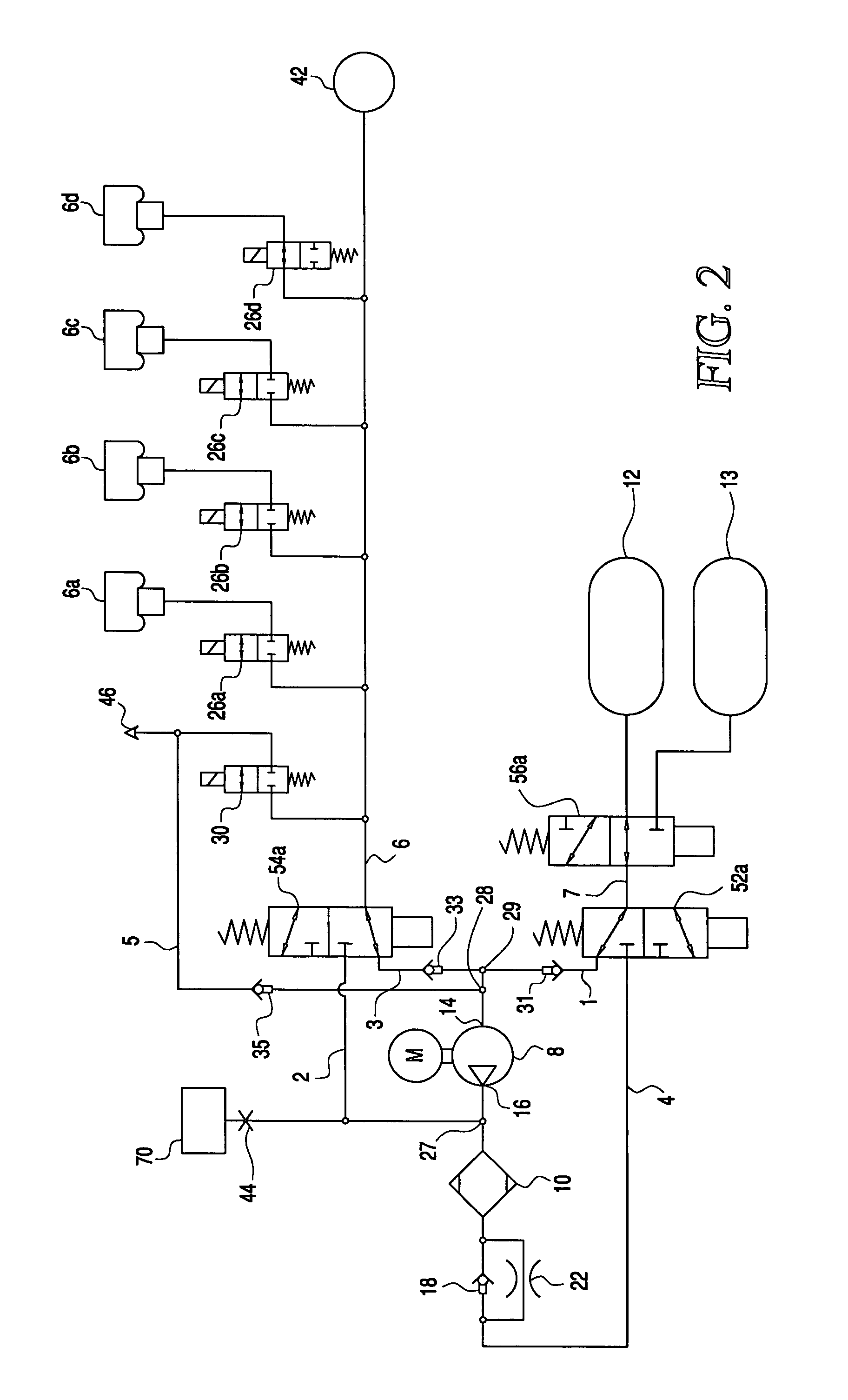

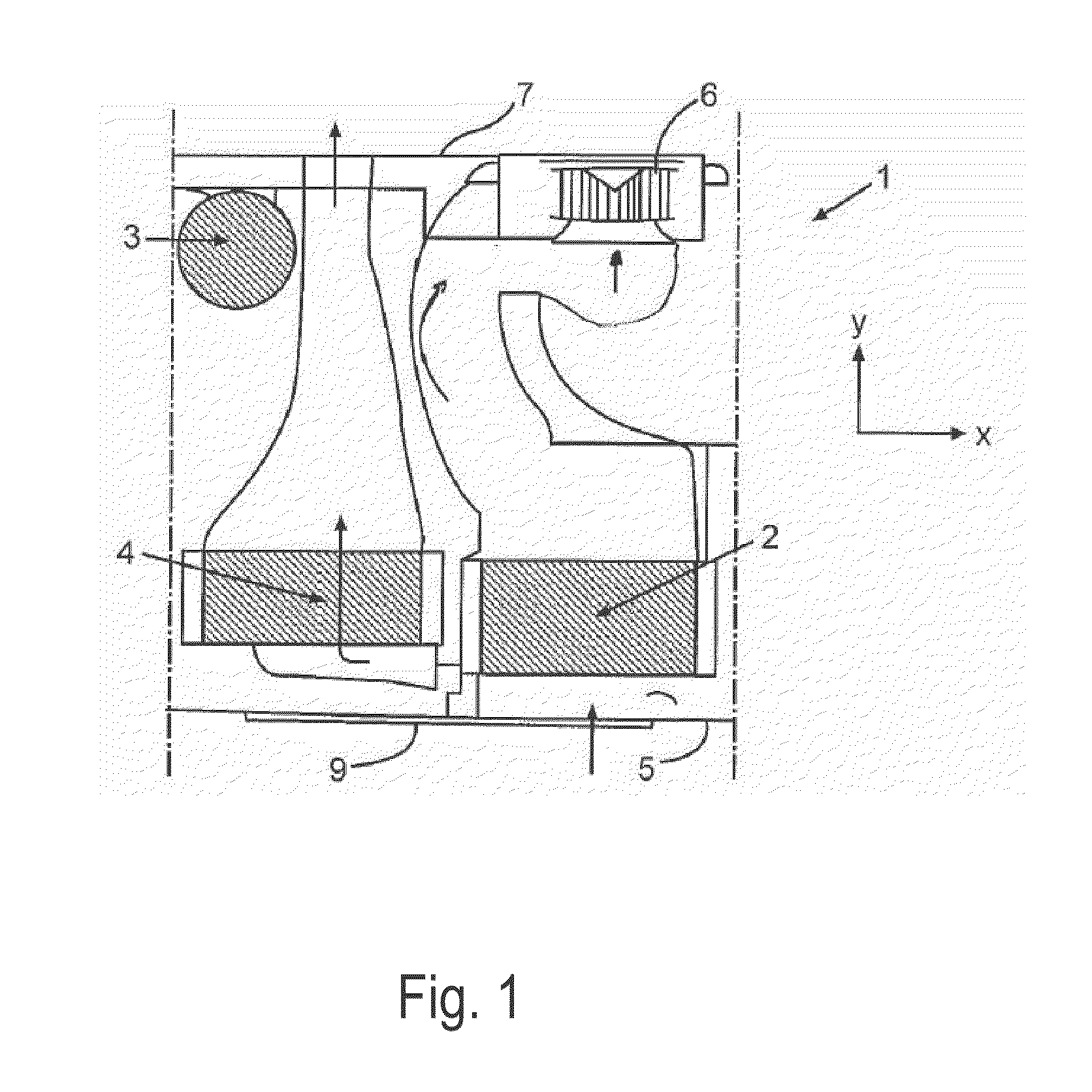

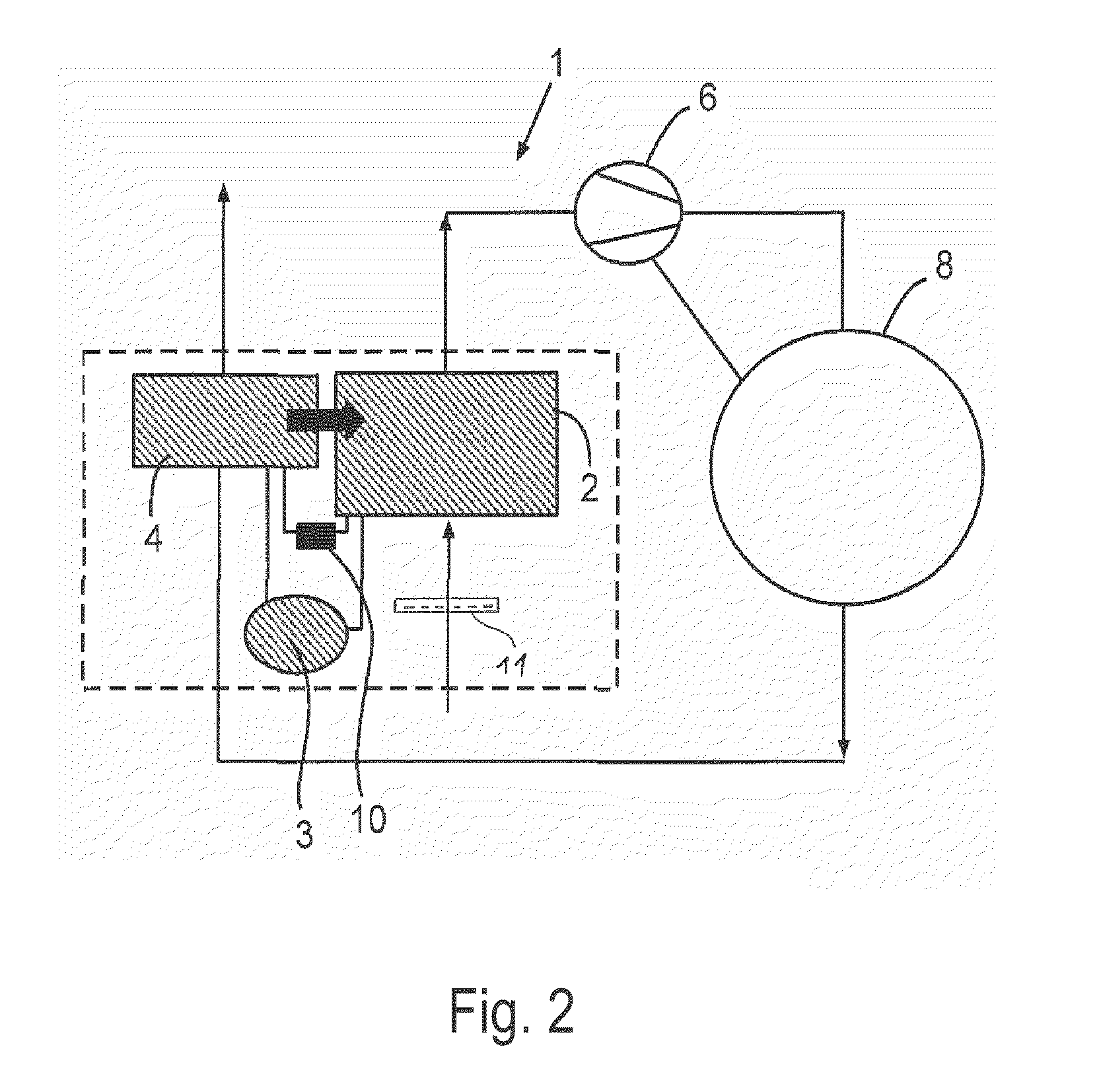

Level adjustment device for vehicles with air springs 8a through 8d, by which a vehicle body is furnished with suspension on at least one vehicle axle, which includes the following:a source of compressed air 2, which, for the purpose of filling air springs 8a through 8d, can be connected to air springs 8a through 8d via an air dryer 4, the air dryer 4, for the purpose of filling the air springs, is connected on one side to air springs 8a through 8d through a check valve 6 that is open to air springs 8a through 8d, each air spring 8a through 8d, for the purpose of emptying them, can be connected through the air dryer 4 and through a pneumatically controlled first distribution valve 10 to the atmosphere, wherein the pneumatic control input 38 of this distribution valve 10 is then impinged through a second controllable distribution valve 12 with the pressure in air springs 8a through 8d against a restoring force 50 acting on the pneumatic control input 38, the pneumatic control input 38 of the pneumatically controlled first distribution valve 10, for the purpose of ending the emptying process, can be connected to the atmosphere, wherein the air dryer 4 is connected on the other side to air springs 8a through 8d through a pneumatically controlled third distribution valve 14, wherein the pneumatic control input 44 of this distribution valve is then impinged with the pressure of air springs 8a through 8d against a restoring force 52 acting on the pneumatic control input 44.

Owner:CONTINENTAL AG

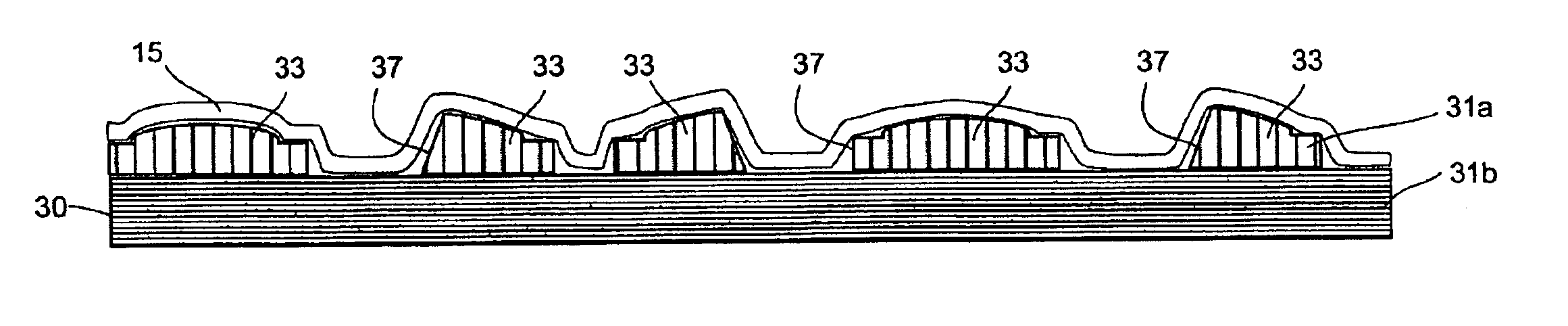

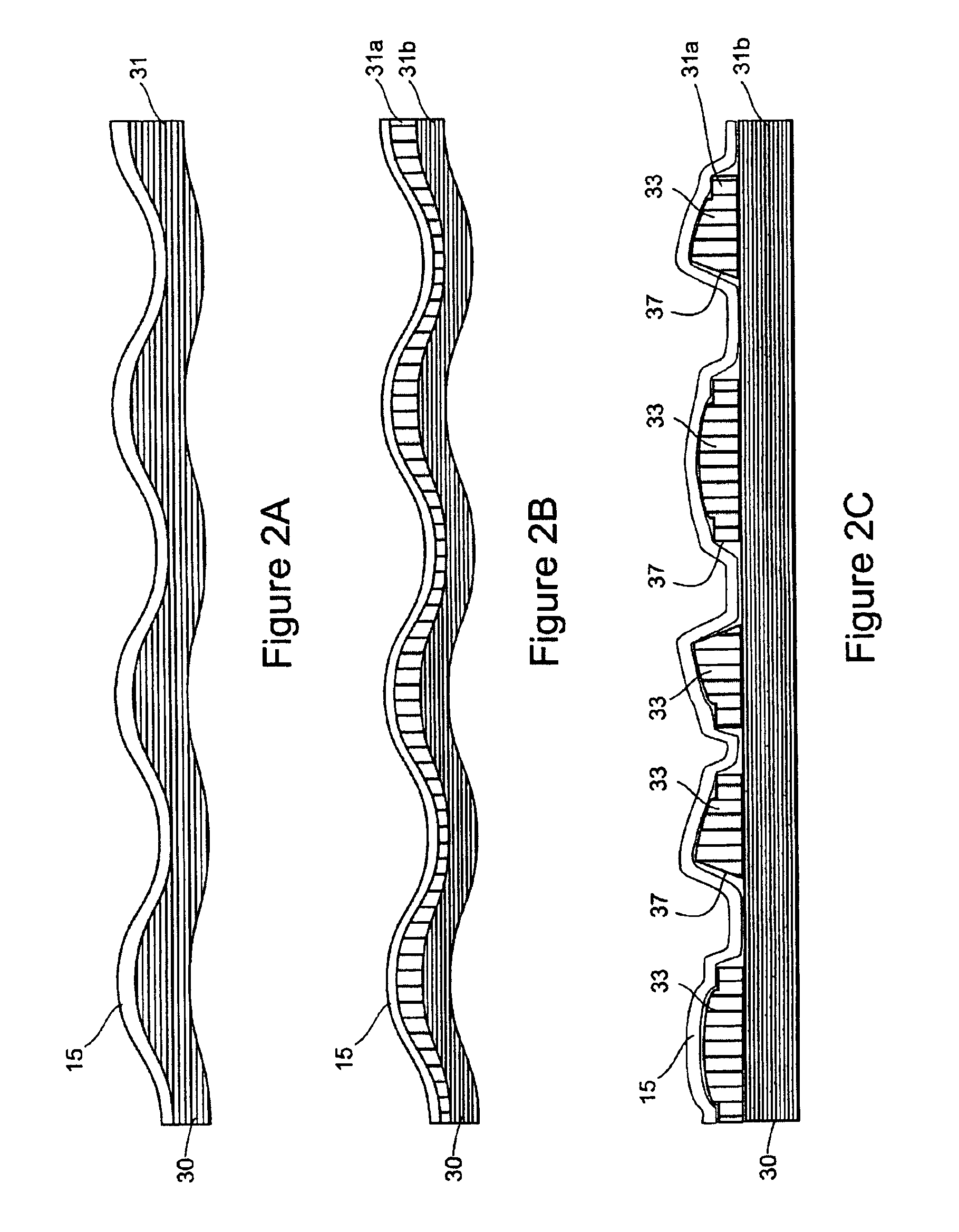

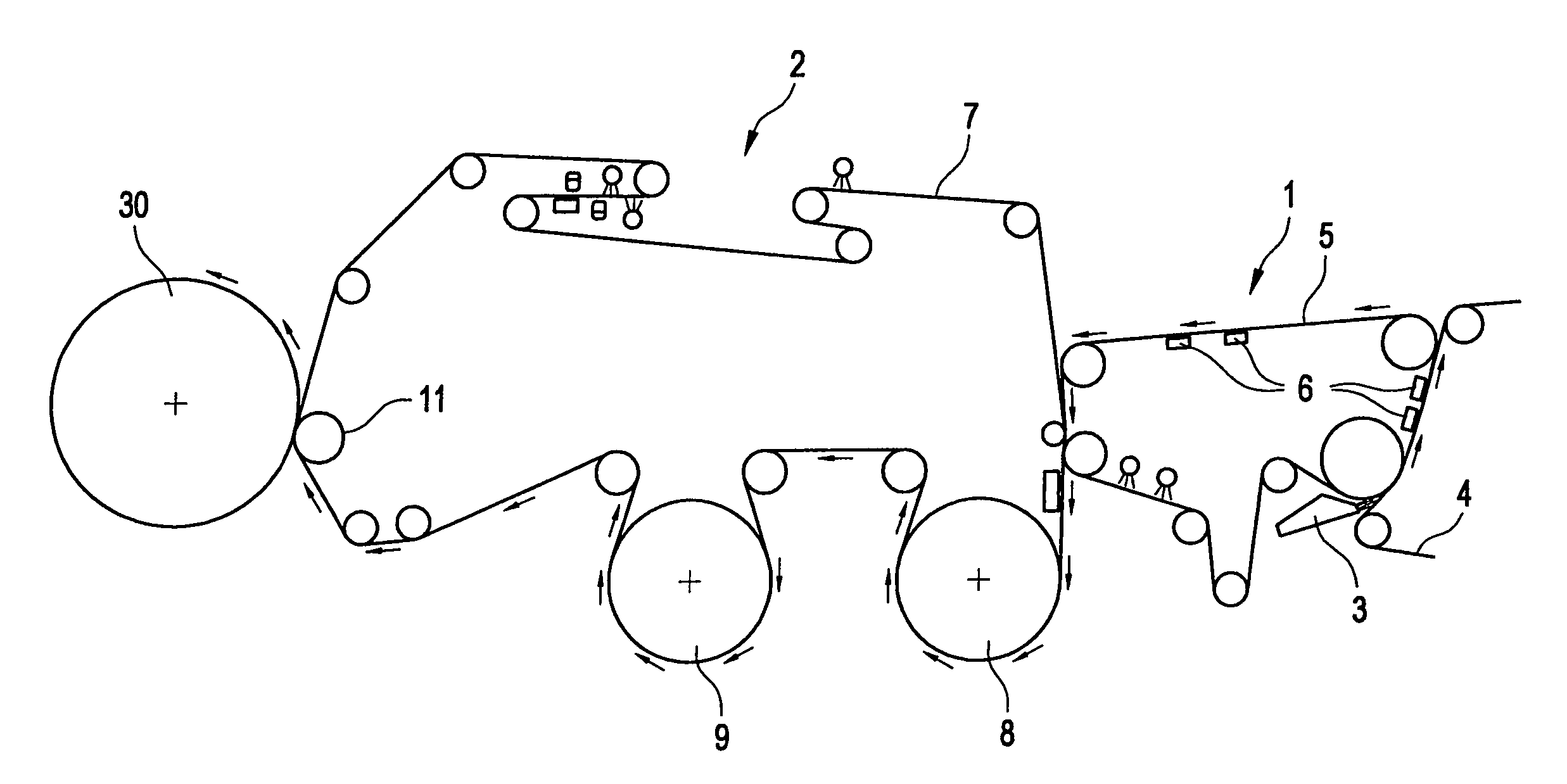

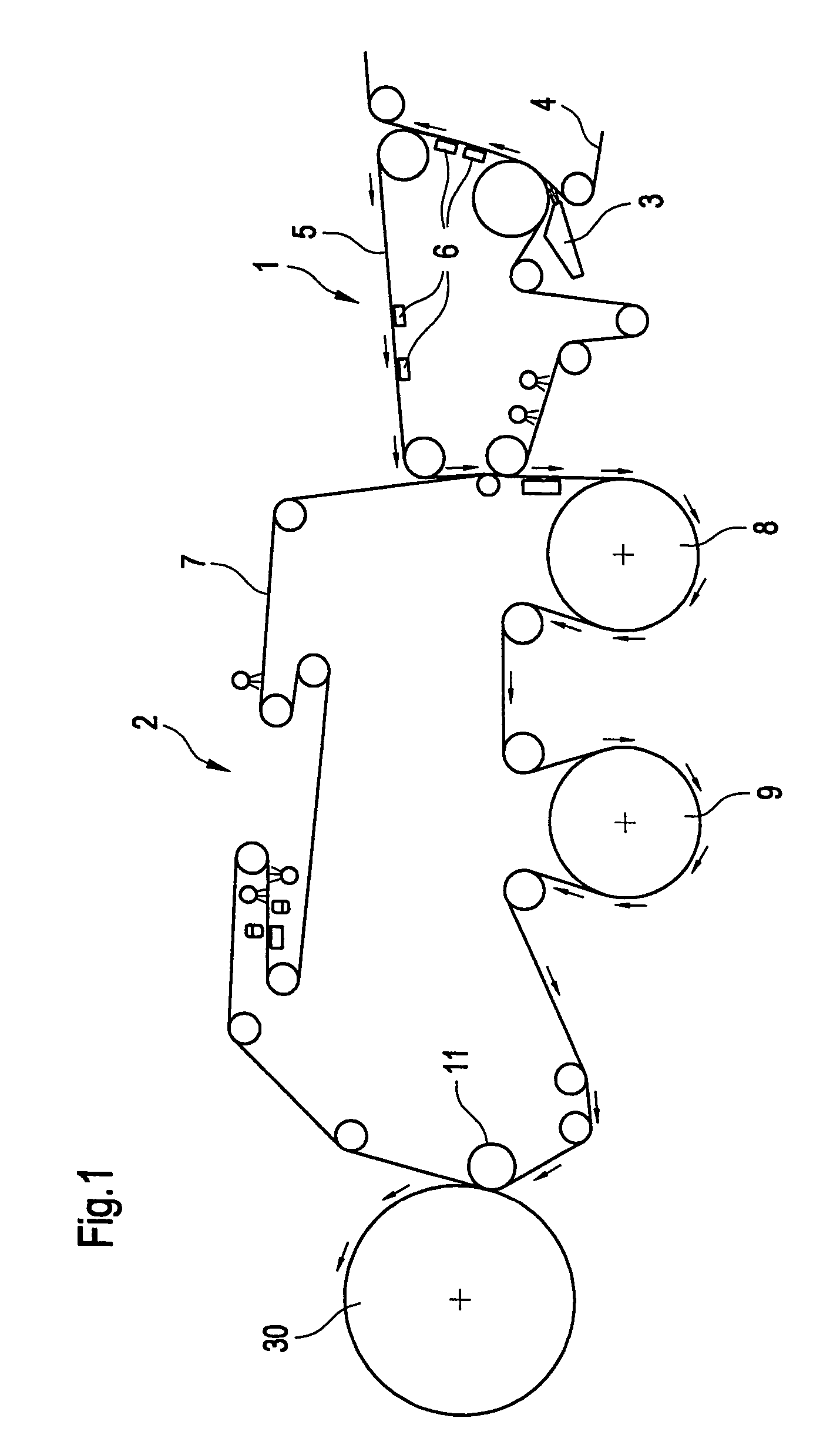

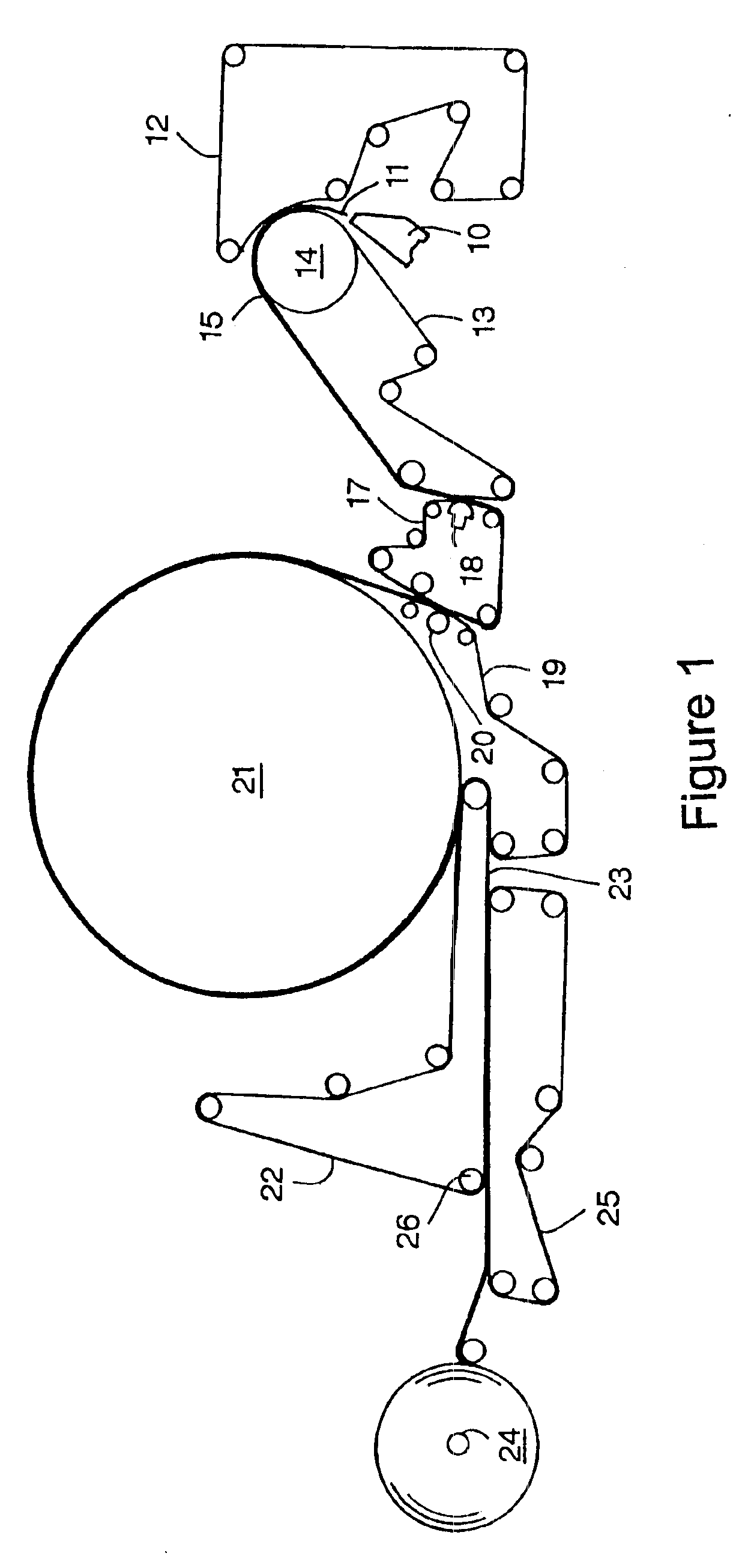

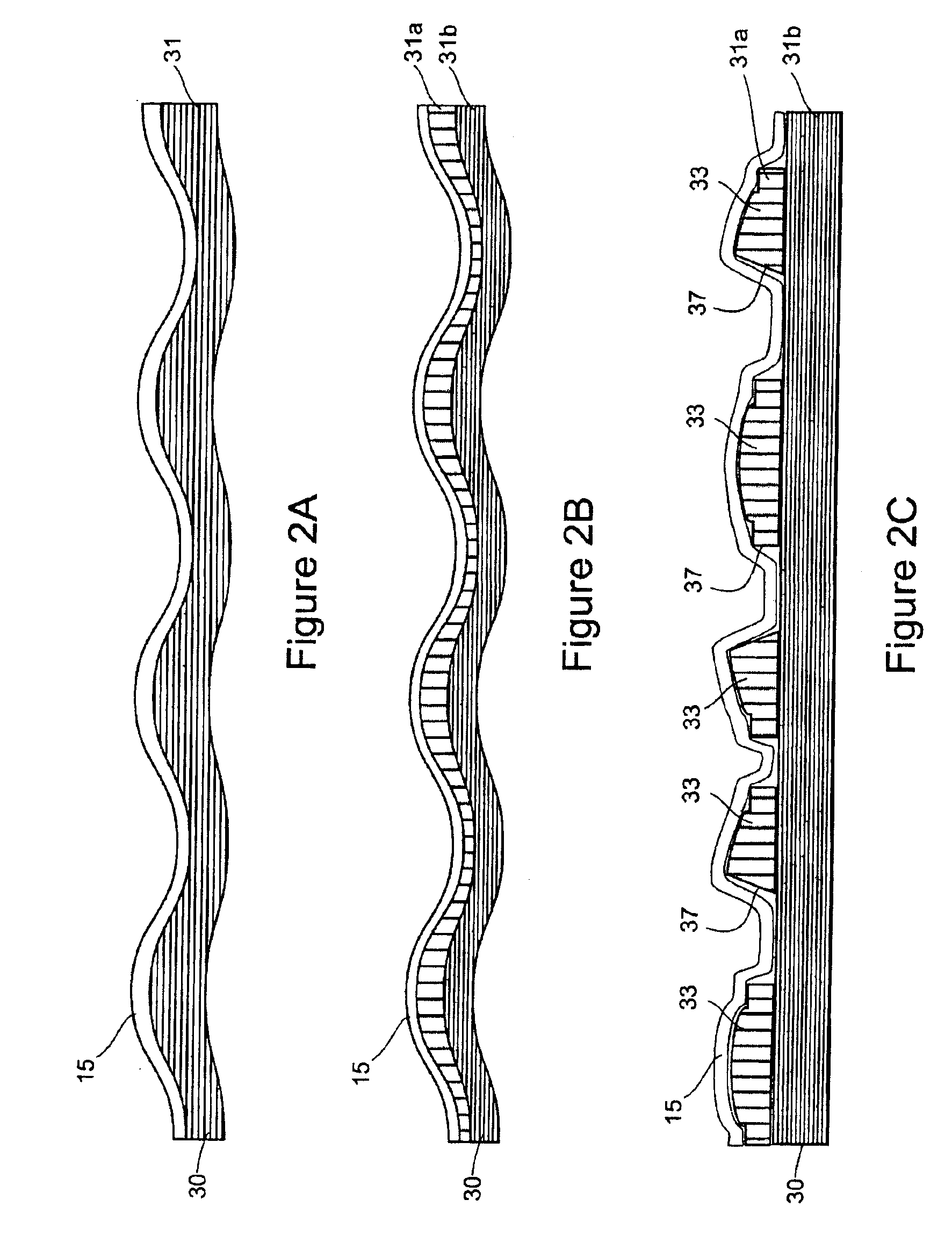

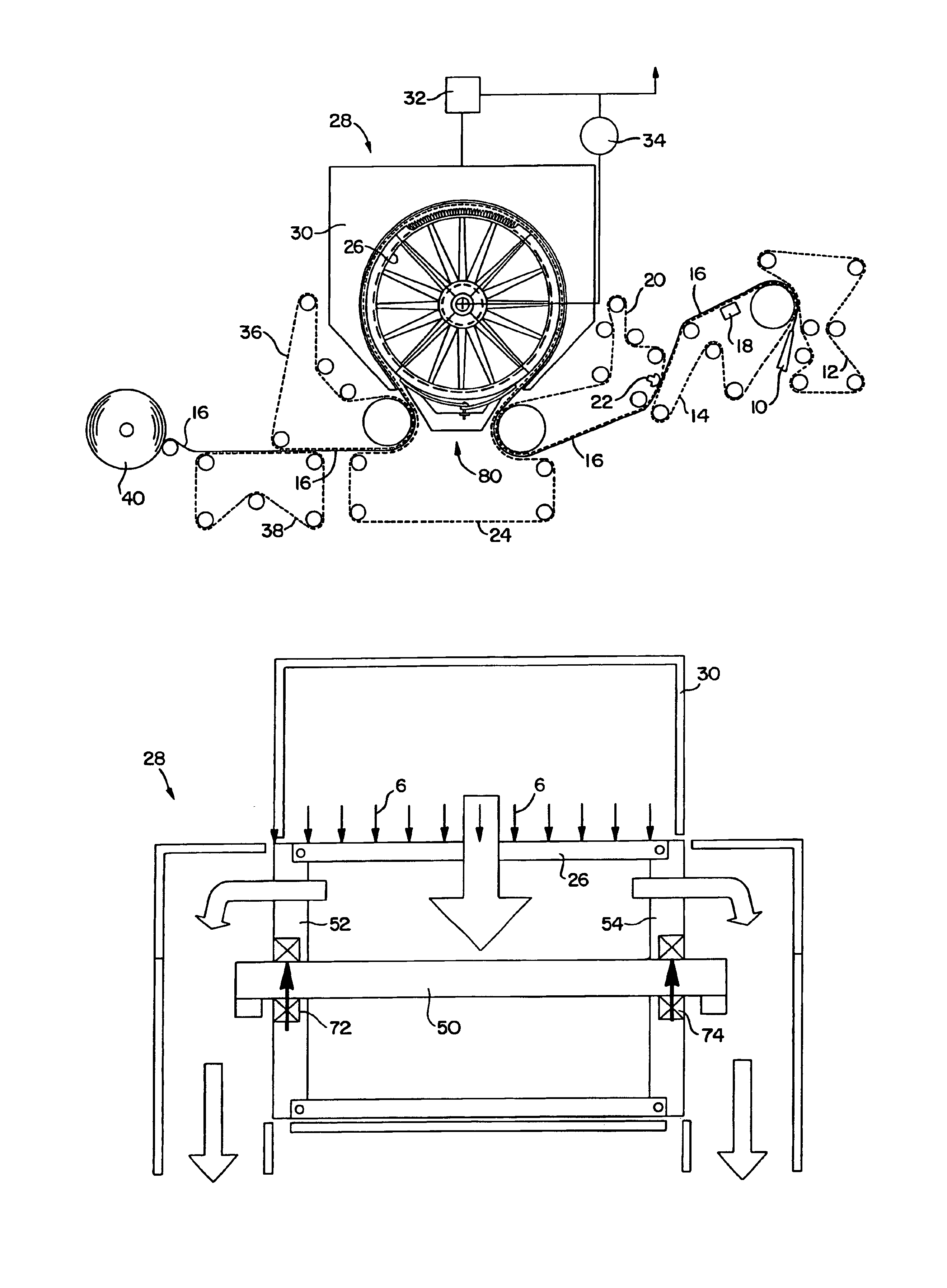

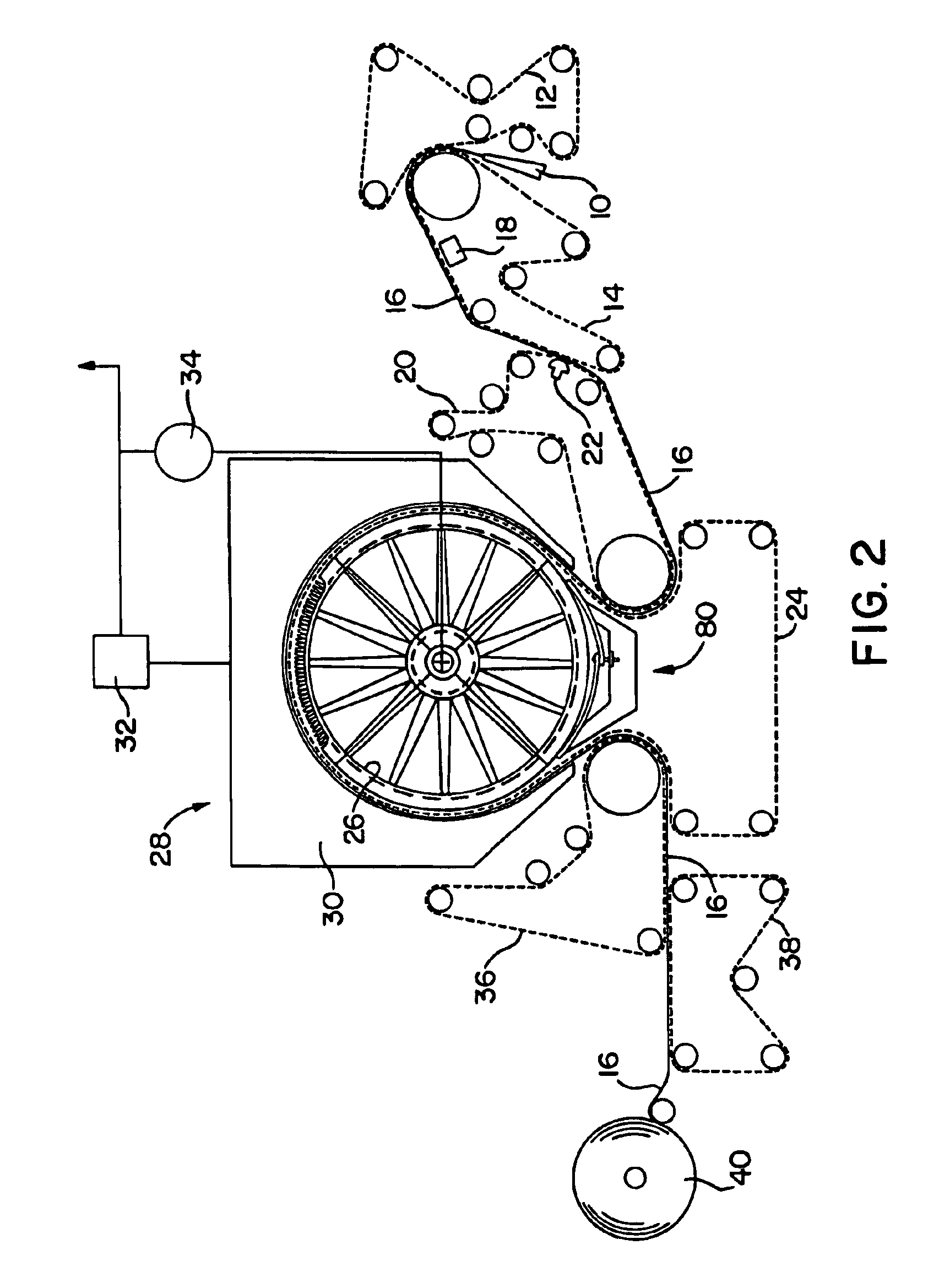

Non-woven through air dryer and transfer fabrics for tissue making

InactiveUS6878238B2High fabric strengthHigh thicknessNon-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricAir dryer

One embodiment of the present invention is an endless non-woven tissue making fabric having a three-dimensional texture suitable for use as a fabric for producing three-dimensional fibrous webs. The endless non-woven tissue making fabric comprises a plurality of substantially parallel adjoining sections of non-woven material. Each section of non-woven material has a width substantially less than the width of the non-woven tissue making fabric. Each section of non-woven material may be joined to at least one other adjoining section of non-woven material. The non-woven tissue making fabric has a machine direction, a cross-machine direction, a tissue contacting surface and a tissue machine contacting surface. The tissue contacting surface comprises solid matter at a plurality of heights such that the tissue contacting surface of the non-woven tissue making fabric has an Overall Surface Depth of at least 0.2 mm in regions of solid matter on the tissue contacting surface.

Owner:KIMBERLY-CLARK WORLDWIDE INC

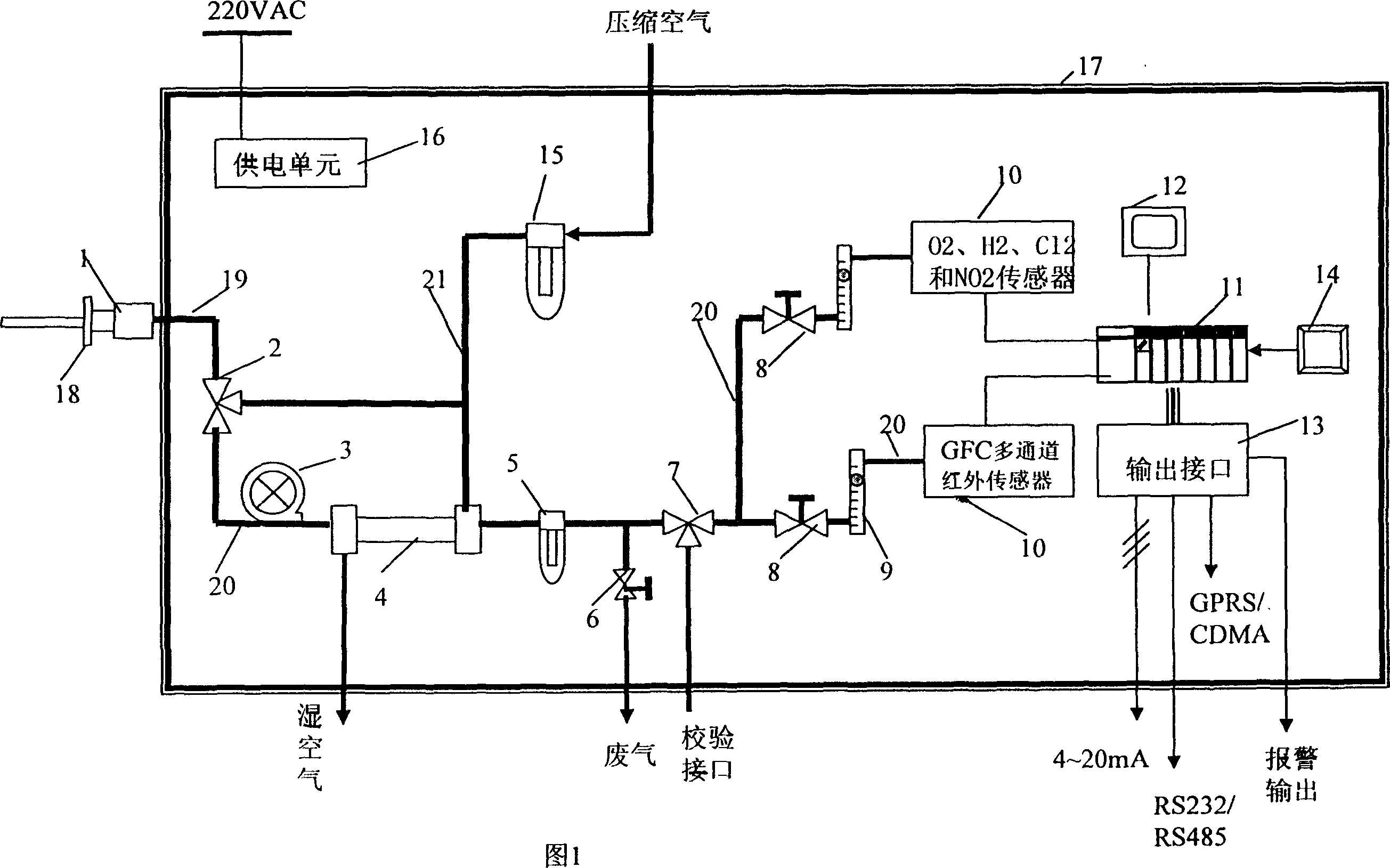

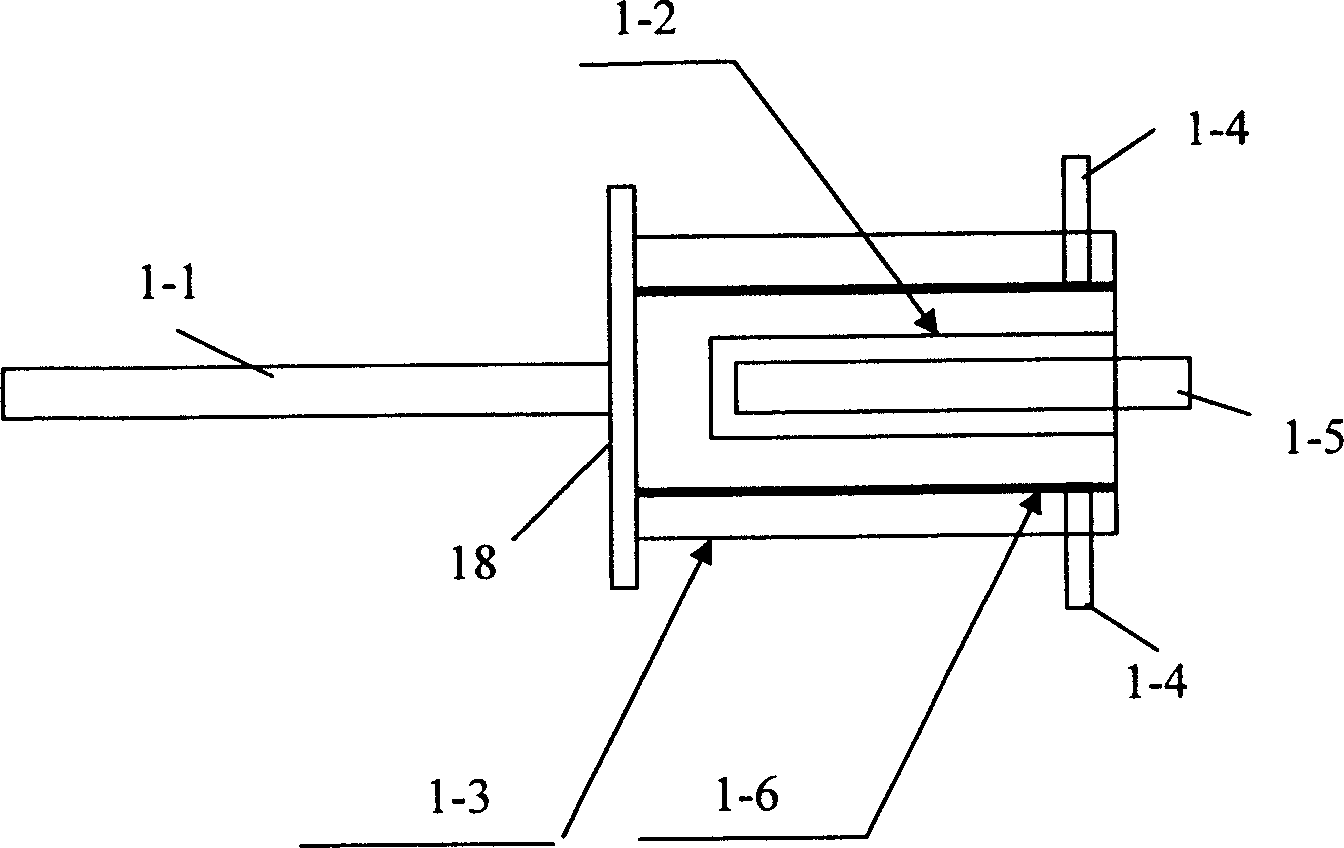

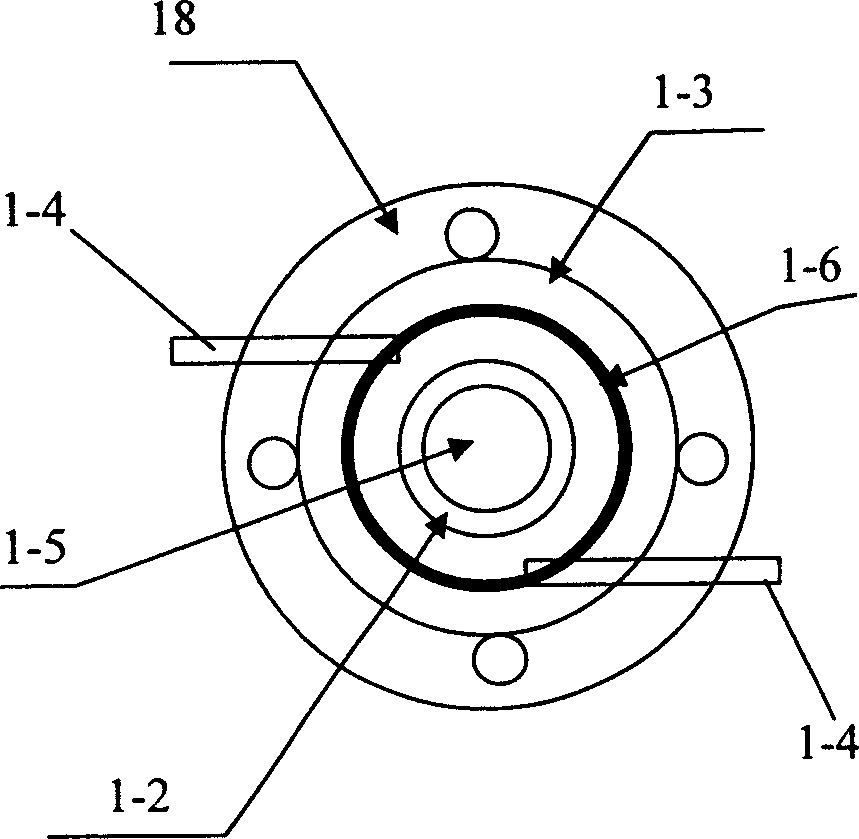

Integrated gas online detector

InactiveCN1866027ARealize simultaneous measurementAvoid long distance transportPreparing sample for investigationMaterial analysis by electric/magnetic meansGas analysisGas composition

The related integrated on-line gas detector can continual detect the content of CO, CO2, SO2, NO, NO2, N2O, CH4, HCl, H2S, HF, O2, H2 and Cl2 in smoke gas, kiln gas and furnace gas, which comprises: a sampling probe, a back-blow valve, a pump, a dehydrator, a fine filter, a bypass valve, a check valve, a stable valve, a flowmeter, a gas analysis sensor, a controller, a signal display, a signal output interface, an operation button, a drier, a power, an outdoor case, a sampling pipe, a sample-gas pipe, and a back-blow pipe. This invention has wide application.

Owner:南京卓成自动化设备有限公司

Through air dryer fabric

Owner:VOITH PATENT GMBH

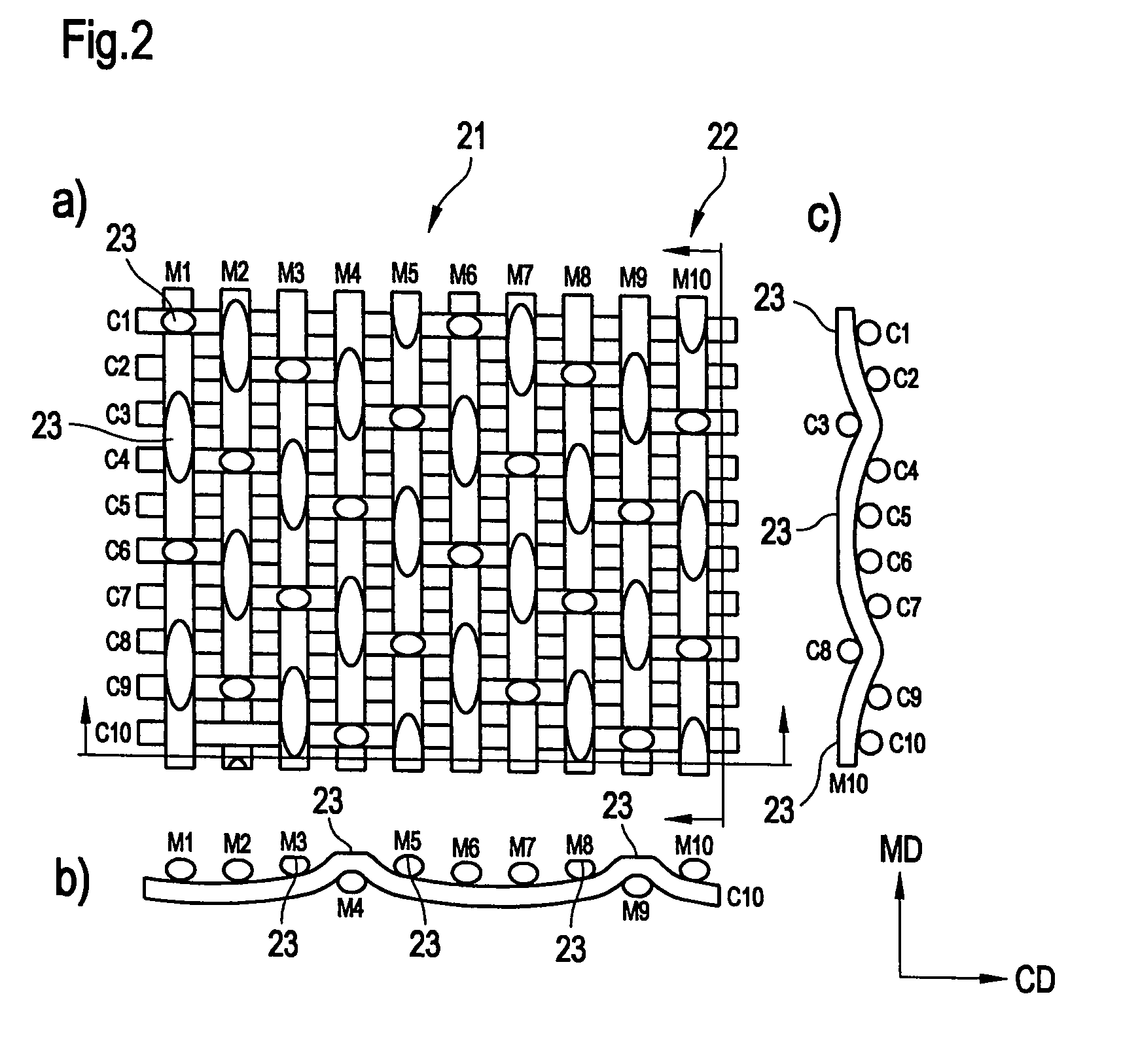

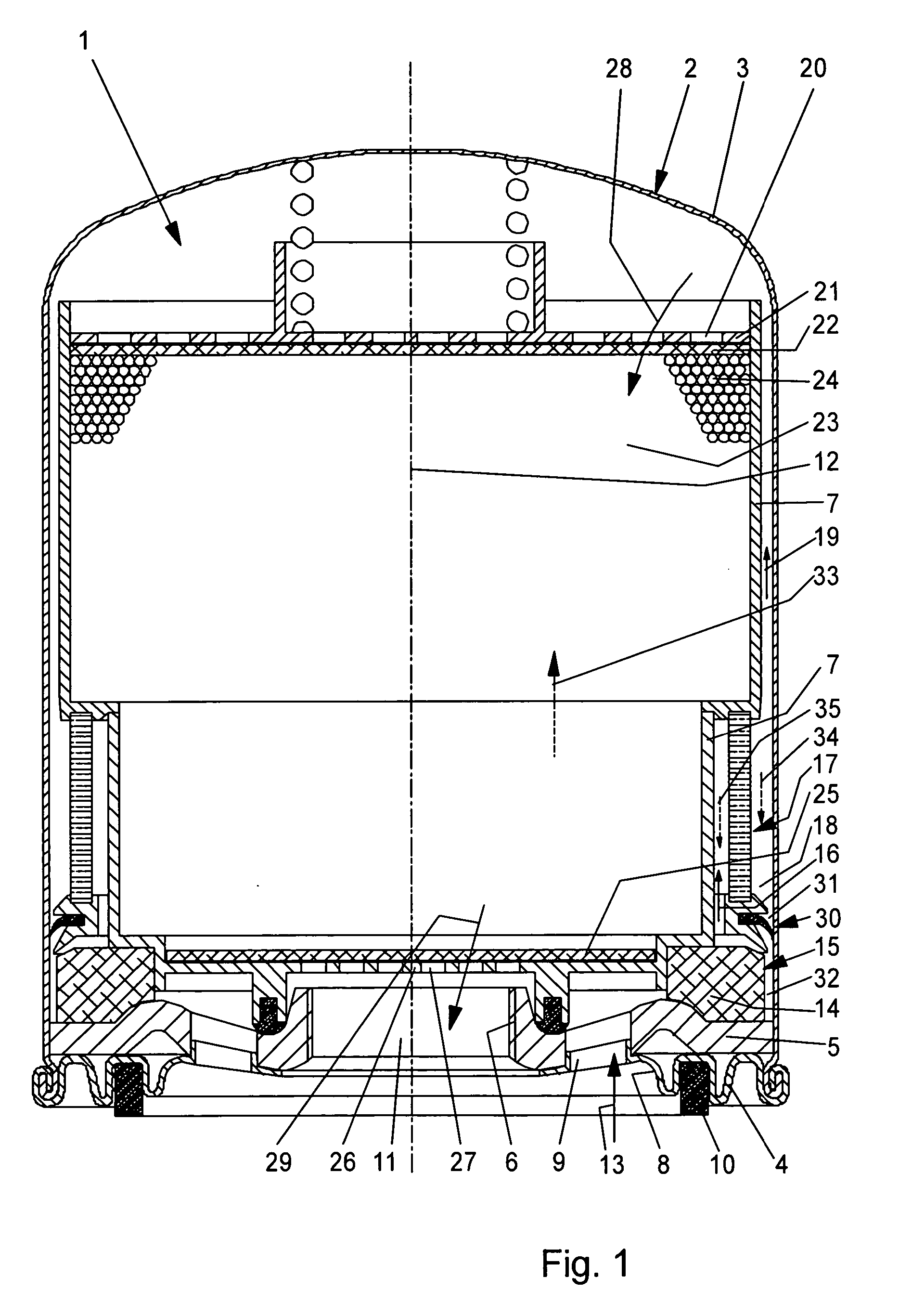

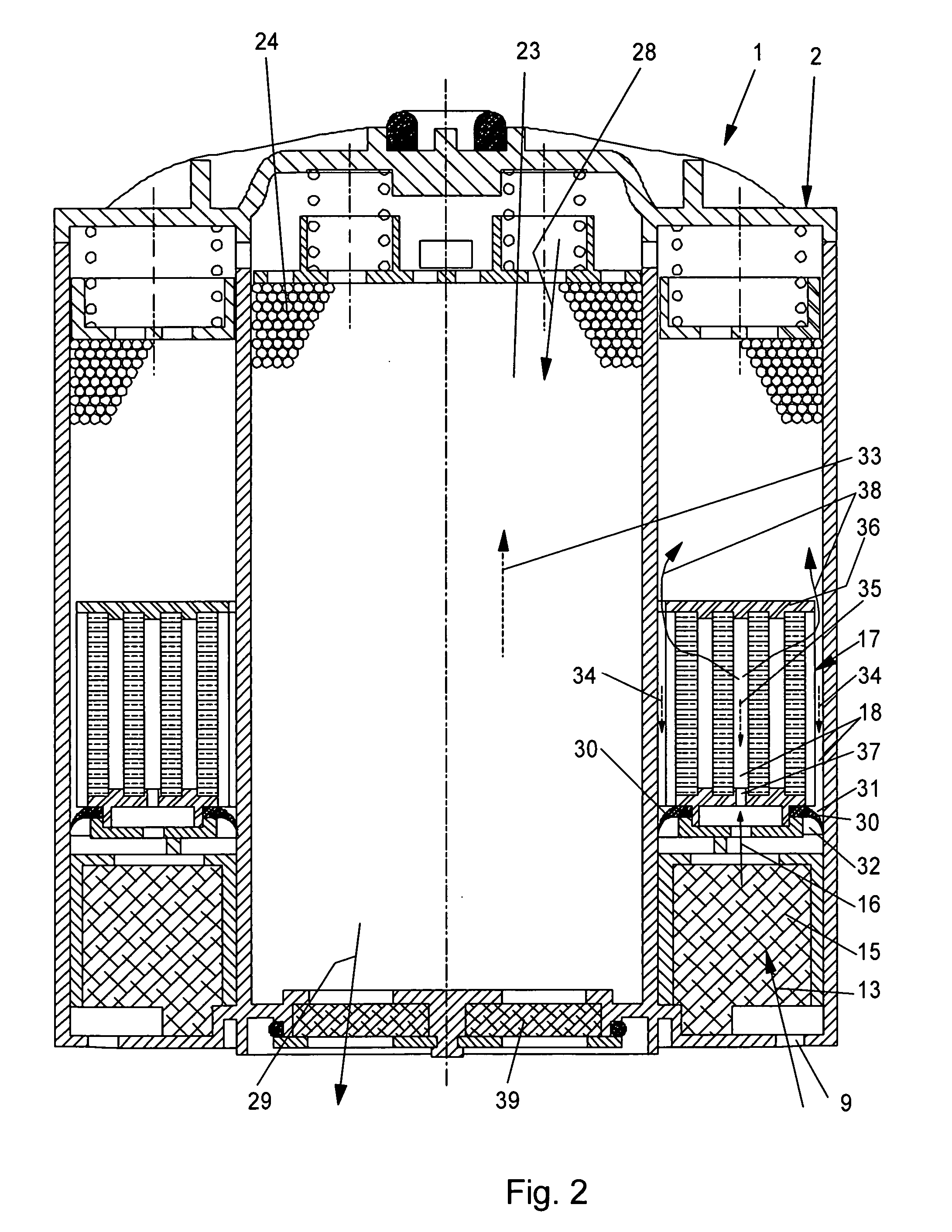

Cartridge for cleaning compressed air in compressed air supply systems of motor vehicles

ActiveUS20060123743A1Reduce continued transferExtended service lifeDispersed particle filtrationAir treatment devicesCheck valveTruck

A cartridge of an air dryer serves for cleaning compressed air to be used in compressed air supply systems of motor vehicles, especially trucks. The cartridge includes a housing, a pre-filter, a deposit chamber, a coalescing filter, a bypass conduit and a check valve. The deposit chamber is located downstream of the pre-filter. The deposit chamber is filled with a treating substance. The coalescing filter is arranged between the pre-filter and the deposit chamber. The bypass conduit is designed and arranged to bypass the coalescing filter and not to bypass the pre-filter. The check valve is arranged in the bypass conduit in a way that it opens during regeneration of the cartridge.

Owner:HALDEX BRAKE PROD AB

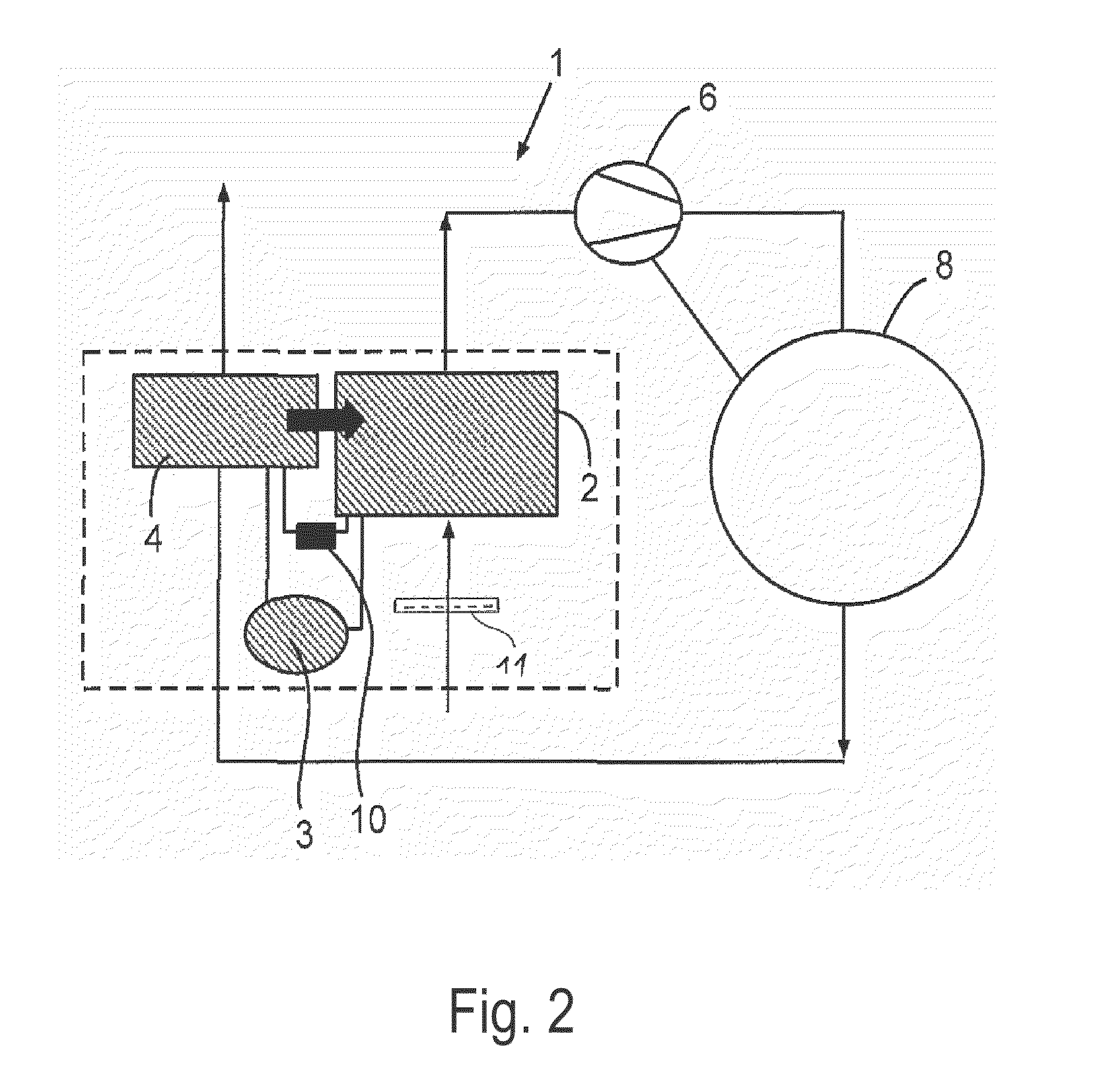

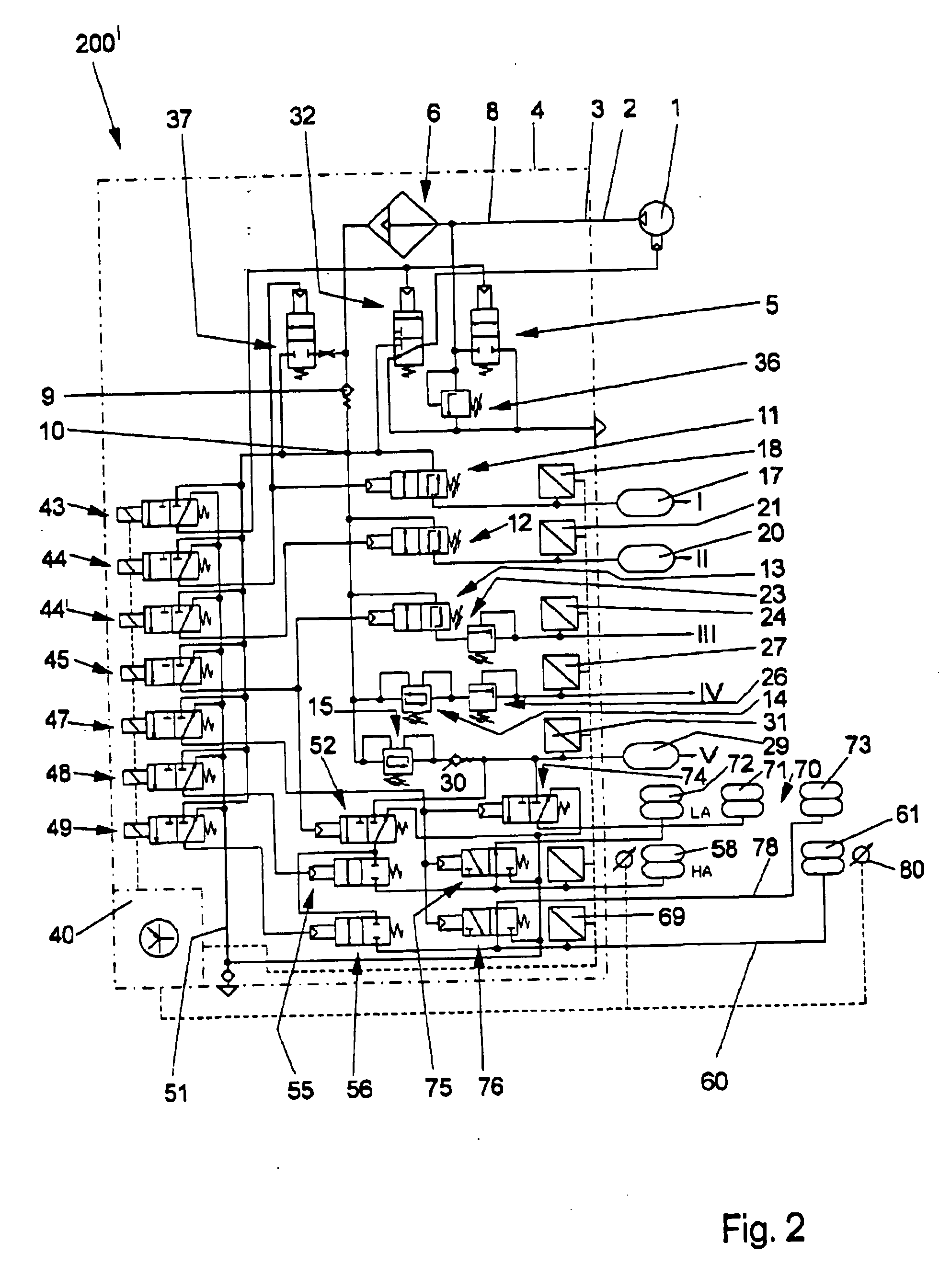

Closed level control system for a vehicle with the system having two pressure stores

InactiveUS7032895B2Fast controlIncrease pressureLiquid springsResilient suspensionsControl systemAir dryer

In a closed level control system for vehicles, a vehicle body is suspended relative to at least one vehicle axle. The level control system includes pressurized medium chambers, a compressor, an air dryer and a pressurized medium supply vessel which is partitioned into first and second pressurized medium spaces. The two pressurized medium spaces have no direct connection. Either the first pressurized medium space or the second pressurized medium space can be connected to the compressor input or the compressor output via at least one common controllable directional valve so that the pressurized medium from the pressurized medium chambers can be transferred into the first or into the second pressurized medium space or pressurized medium can be transferred from the first or the second pressurized medium space into the pressurized medium chambers.

Owner:CONTINENTAL AG

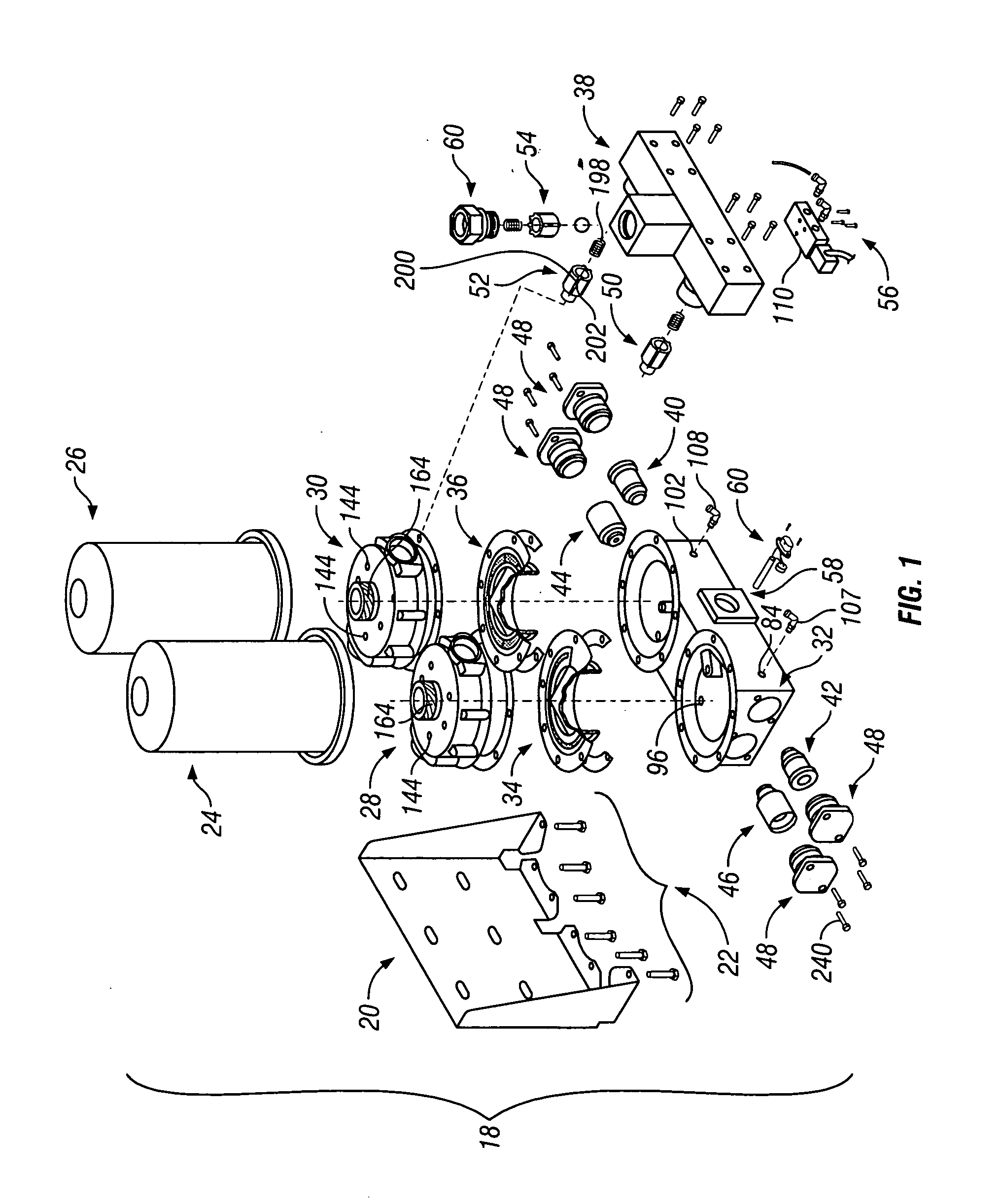

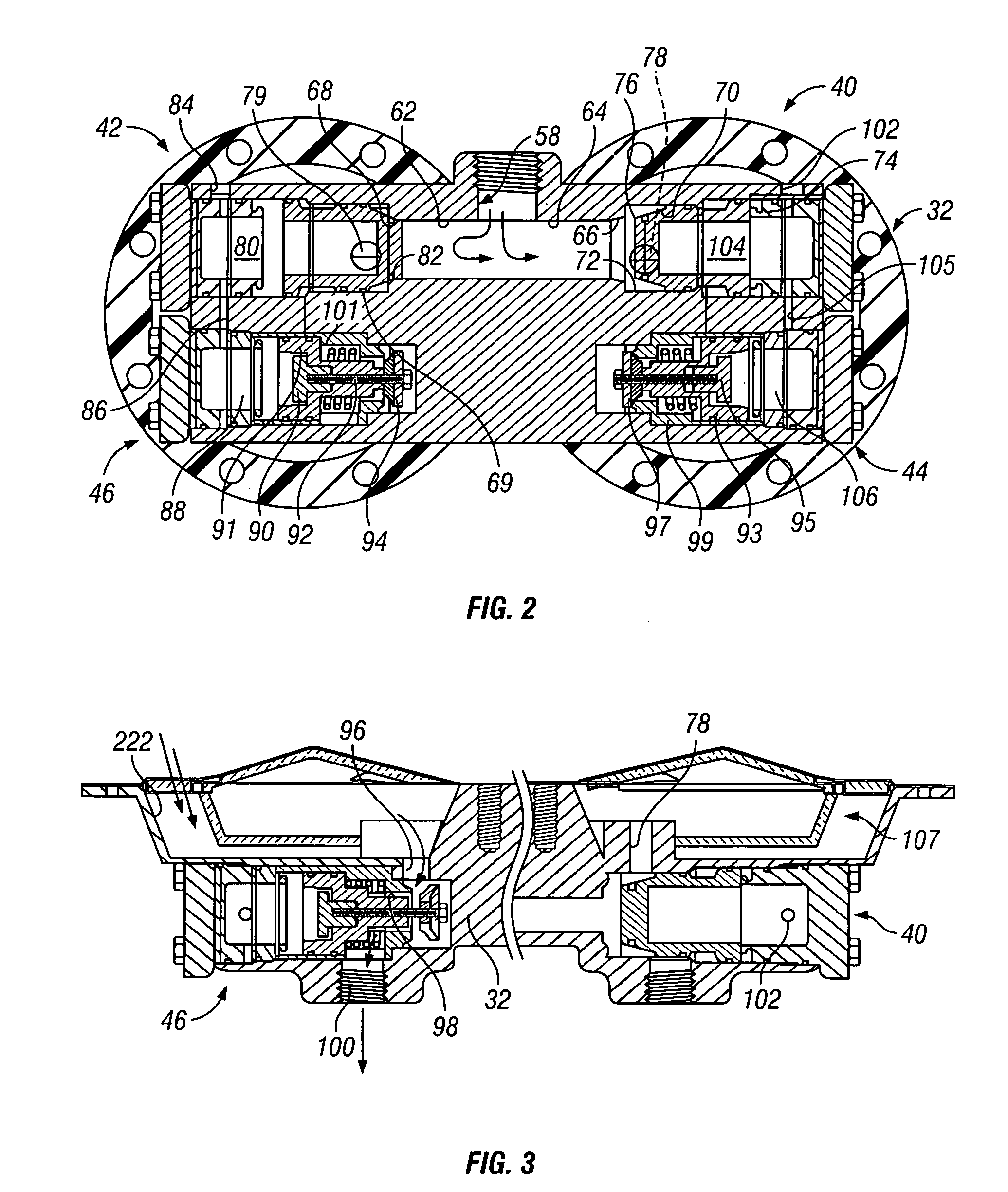

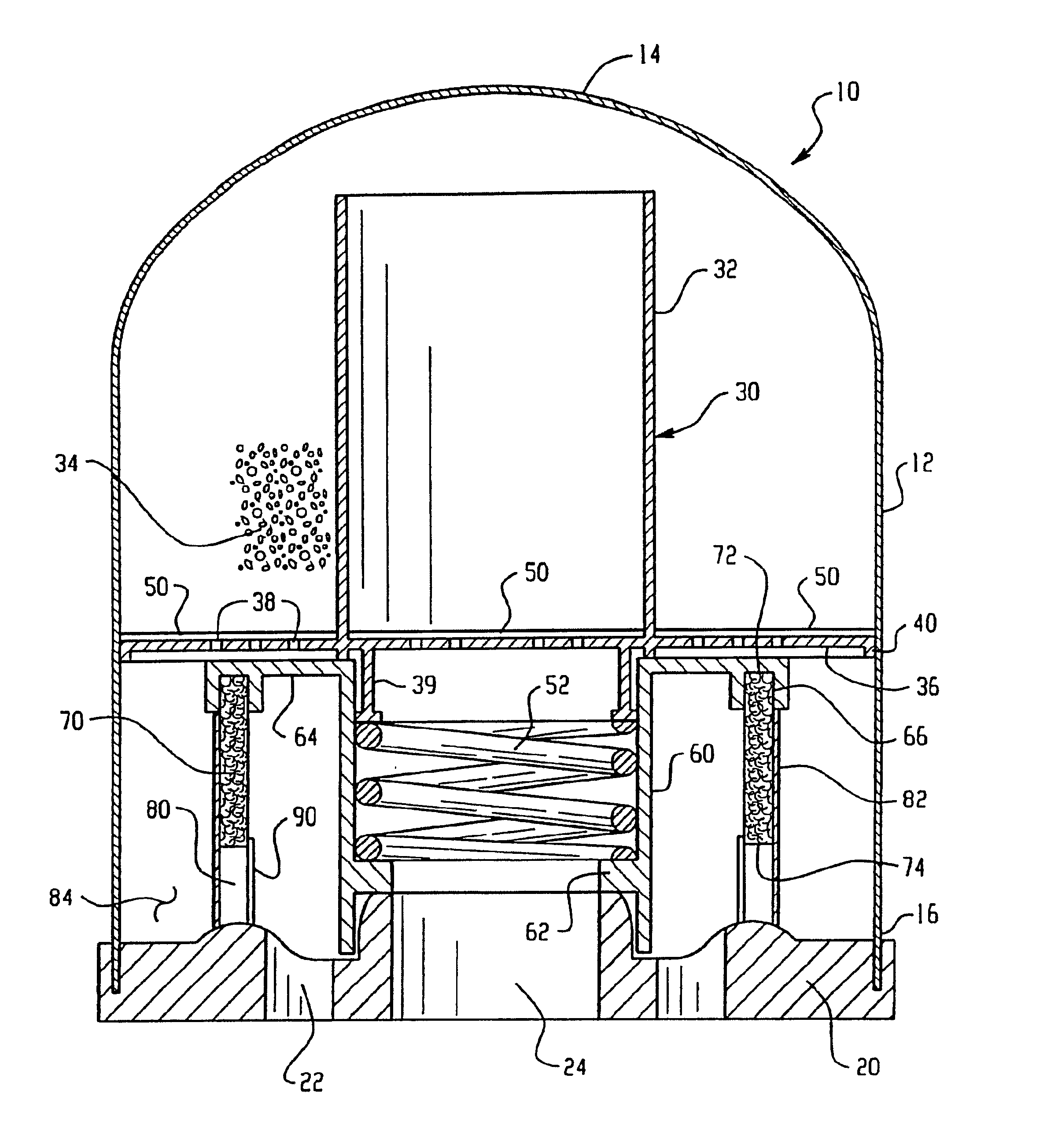

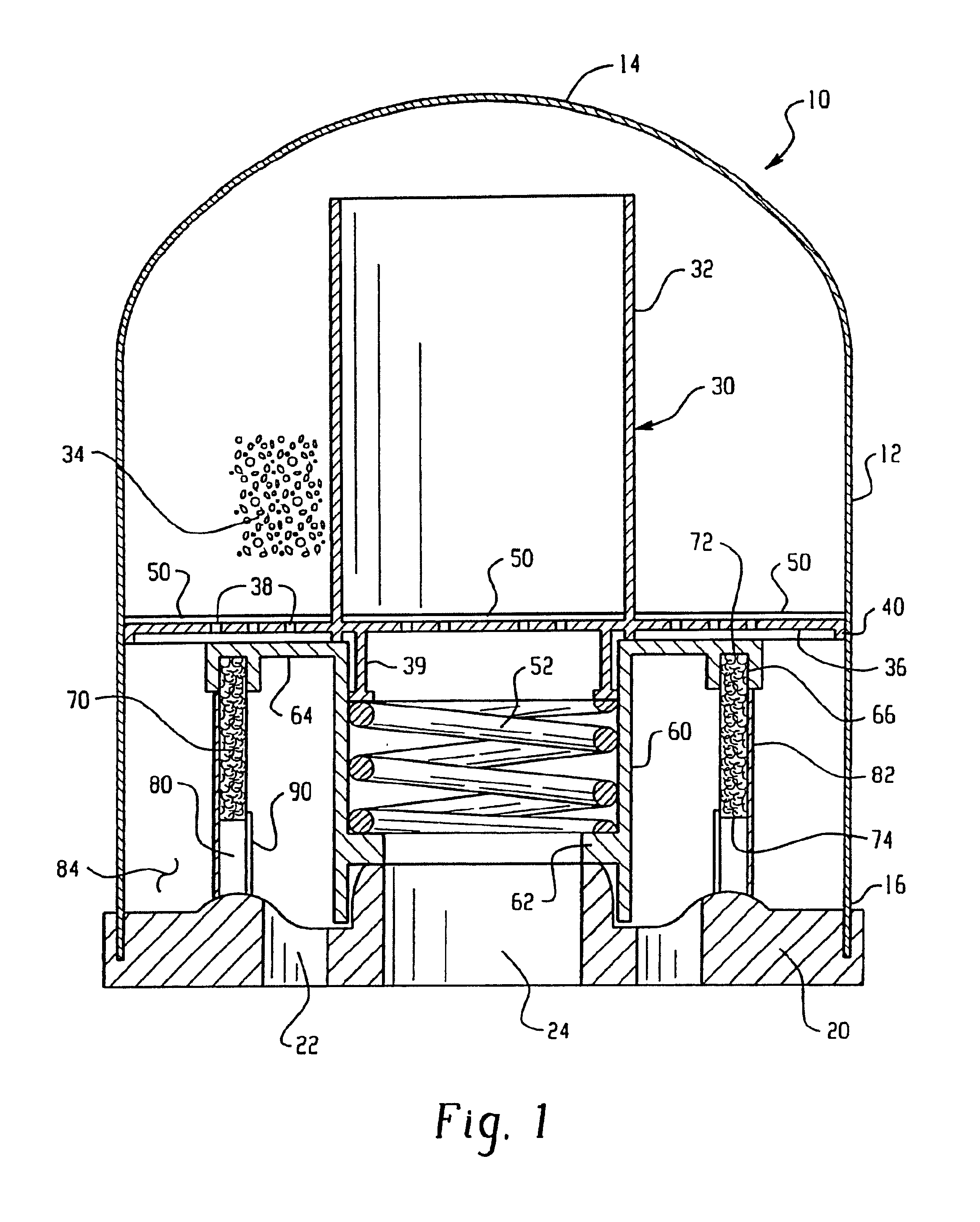

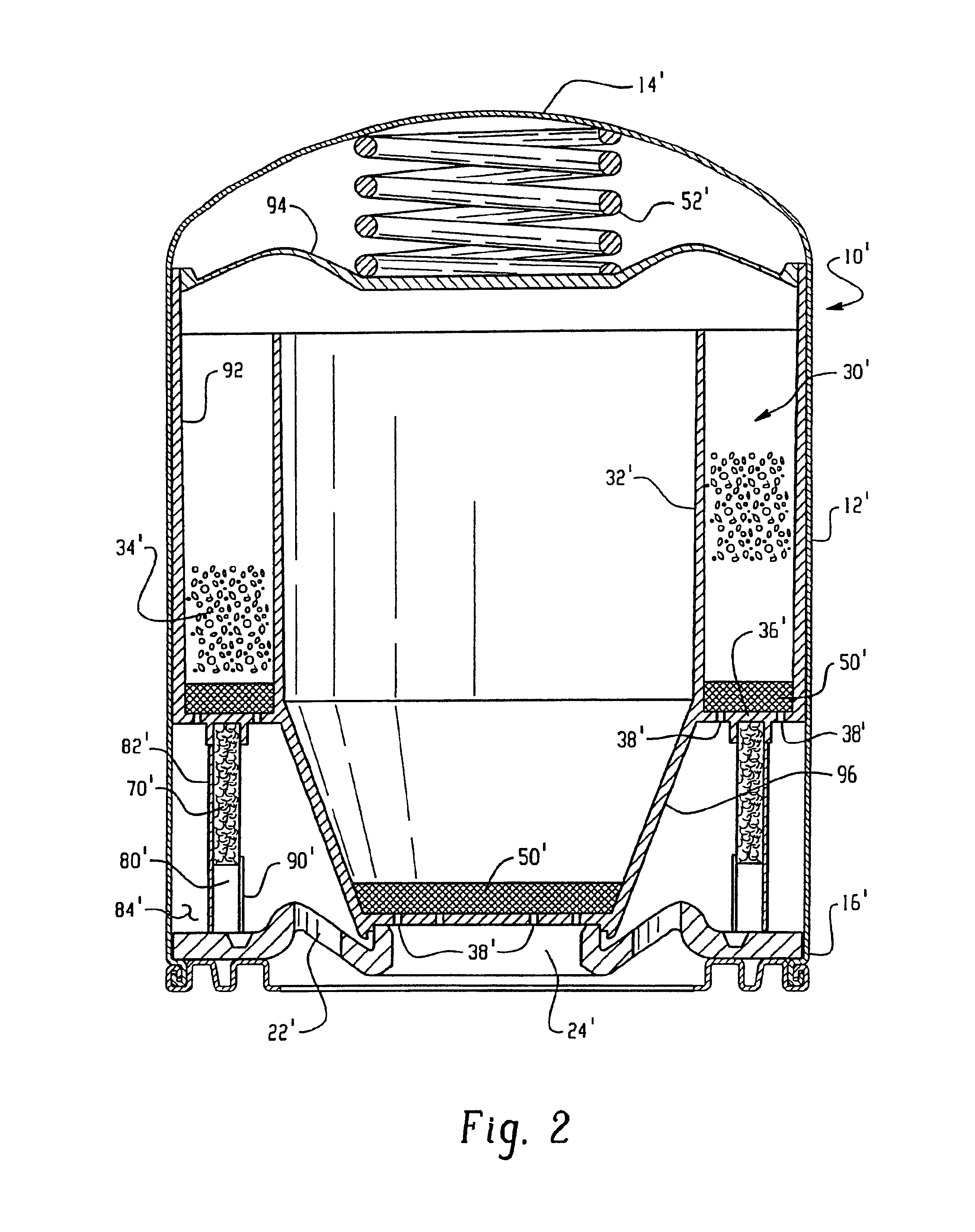

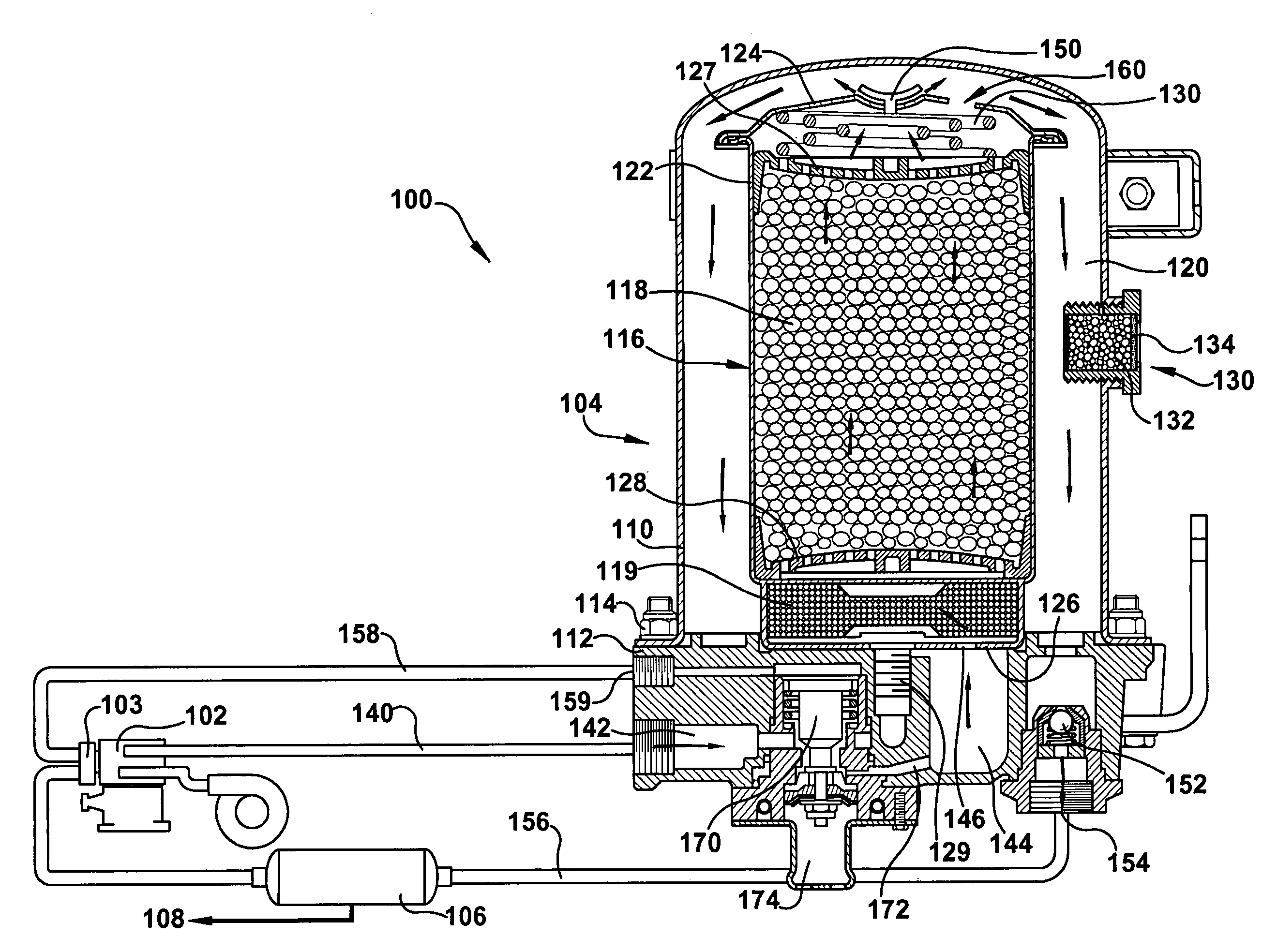

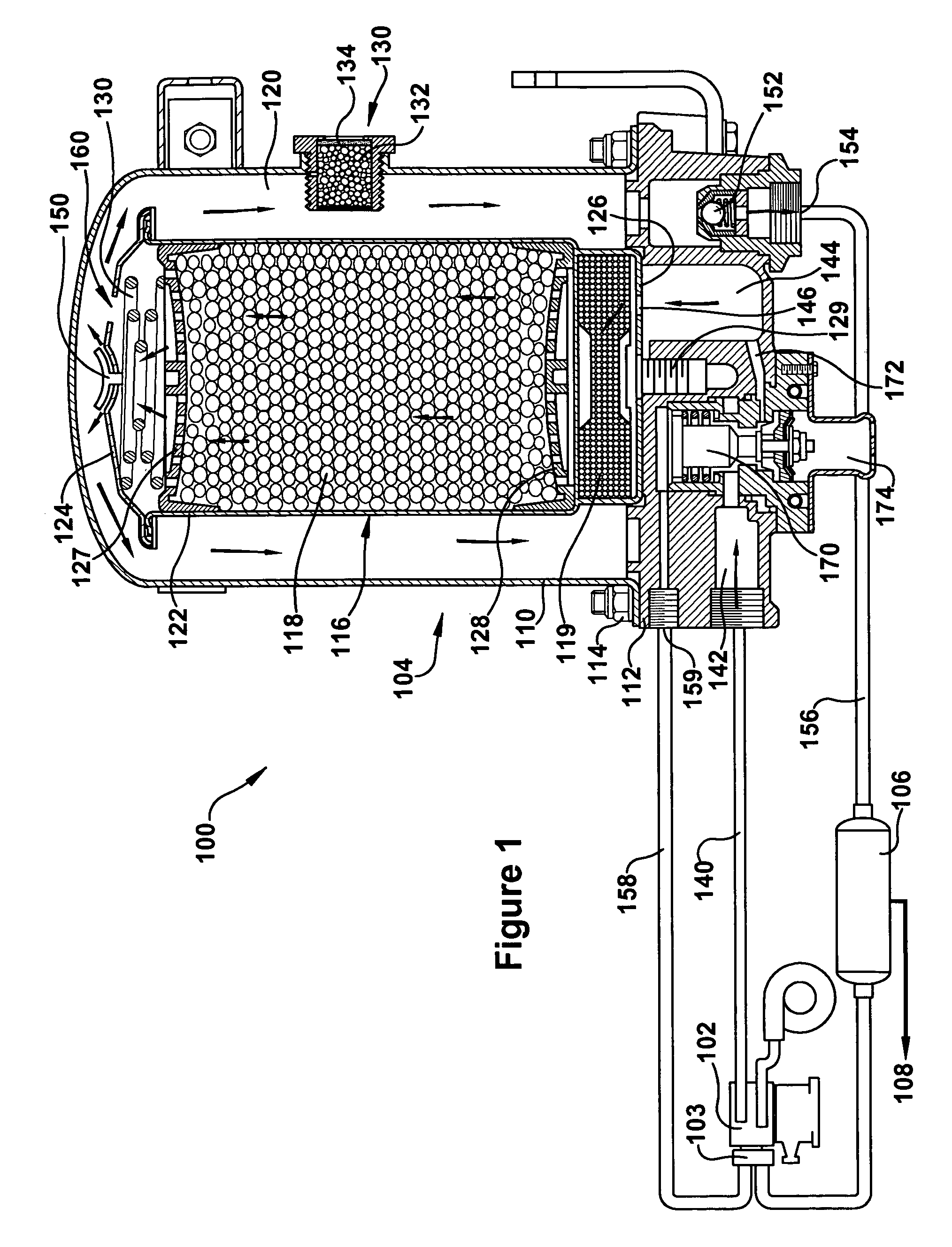

Dual cartridge air dryer with oil separator and readily changeable valves

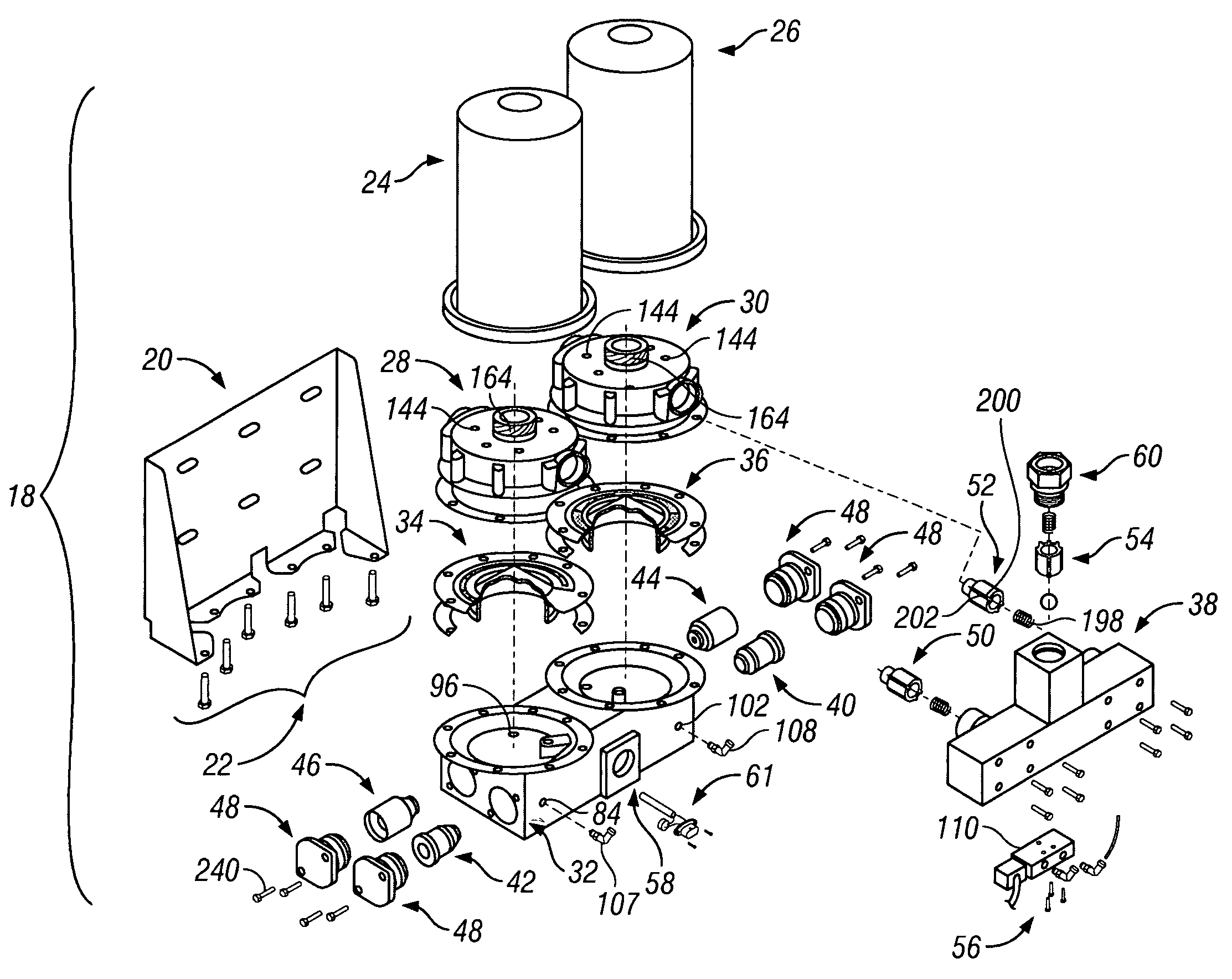

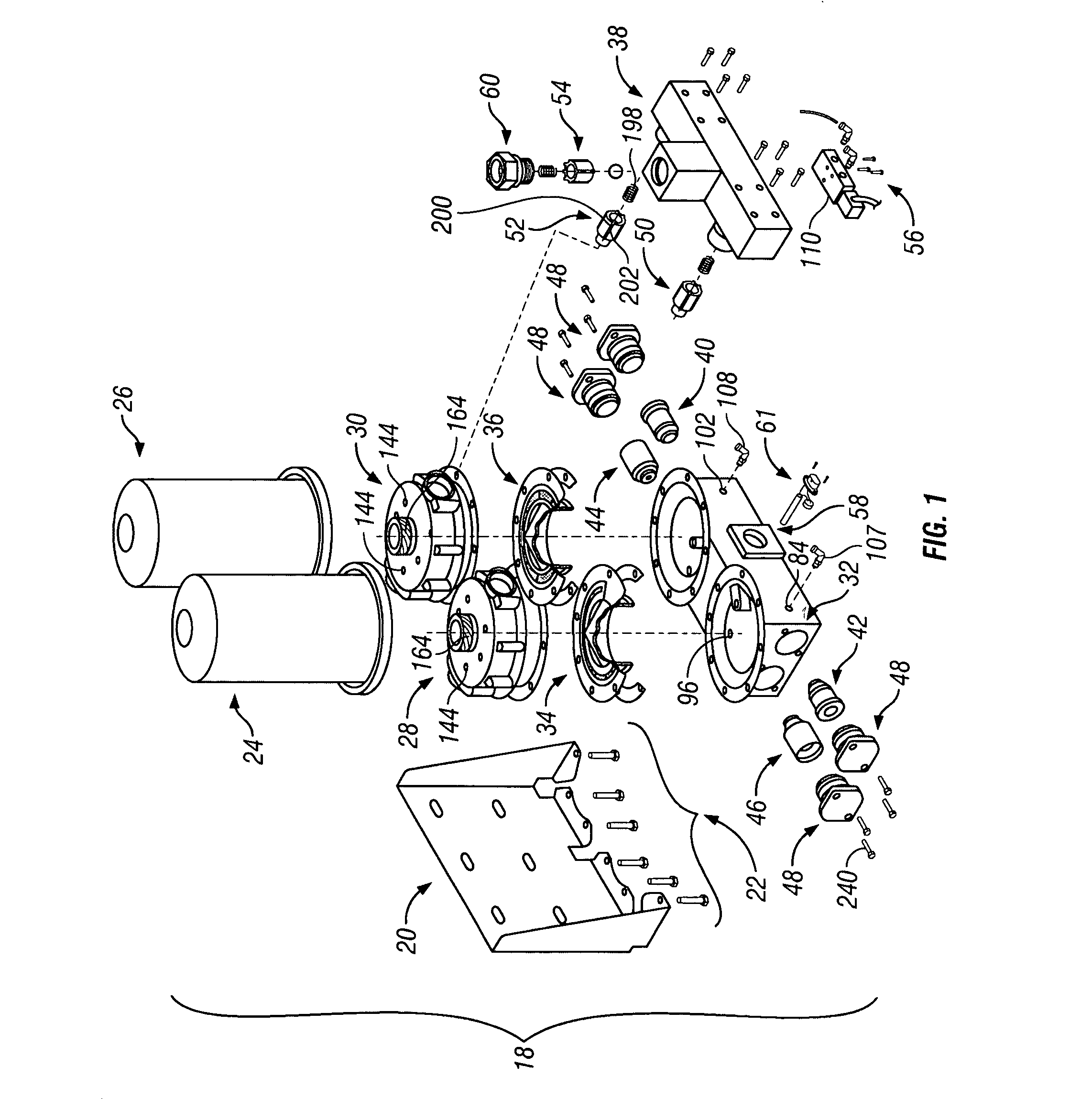

ActiveUS20050188848A1Achieve economyMaximum effectivenessGas treatmentDispersed particle filtrationDesiccantFilter media

An air dryer system including two substantially identical canister-type air dryer units. Each includes, in one mode, a first moist air inlet, a first desiccant for drying air, a first dry air outlet, and first means for supplying dry air to a storage facility. The system also including, in the same mode, a first bleed valve supplying a small portion of said dry air to regenerate a second desiccant, and a first moist air purge valve for dumping moisture collected during regeneration. The system is also operable in an opposite mode and having a second moist air inlet, a second desiccant, a second dry air outlet and a second means for supplying air to a storage facility. A second bleed valve supplies a small portion of dry air to regenerate the first desiccant, and purges air through a second moist air valve. Located between the moist air inlets and said desiccants are a pair of air-oil separators. Upwardly directed air flows through a housing, striking a deflector plate, and escapes beneath a vertically extending fence and through vents containing a filter medium.

Owner:SKF USA INC

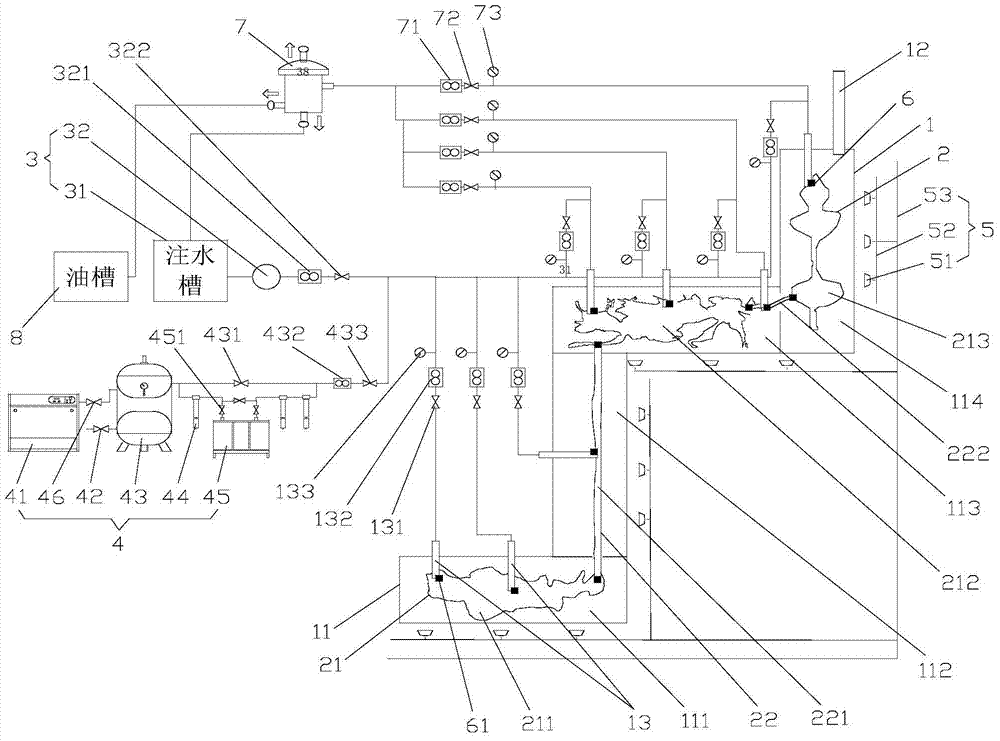

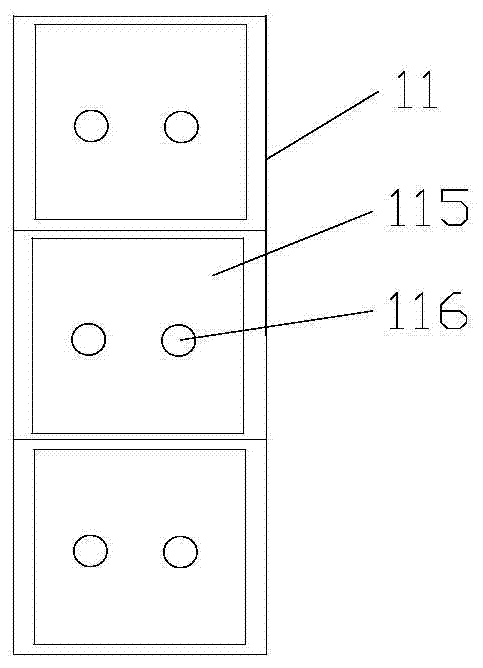

Fully-three-dimensional simulated visualized displacement simulation experiment system of fractured-vuggy oil reservoir

InactiveCN103615241ASimple structural designReasonable structural designBorehole/well accessoriesData acquisitionThree-phase

The invention relates to a fully-three-dimensional simulated visualized displacement simulation experiment system of a fractured-vuggy oil reservoir. The fully-three-dimensional simulated visualized displacement simulation experiment system comprises trough, fractured-vuggy model, water injection, air injection, image acquisition and data acquisition simulation unit, a simulation oil groove and a three-phase separator. The trough simulation unit comprises a cubic trough, a glass pipe and a shaft. The fractured-vuggy model simulation unit comprises a cavern model and a crack model. The water injection simulation unit comprises a water injection tank and a water pump. The air injection simulation unit comprises an air compressor, an air storage tank, an emptying valve, a water draining filter and an air dryer. A particle forming test module of the image acquisition simulation unit is arranged on a sliding rod and installed on a support through the sliding rod. A pressure variator of the data acquisition simulation unit is installed at the connecting position of the shaft and the fractured-vuggy model simulation unit. The output end of the three-phase separator is respectively connected with the simulation oil groove and the water injection tank, and the input end of the three-phase separator is connected with the shaft. The fully-three-dimensional simulated visualized displacement simulation experiment system of the fractured-vuggy oil reservoir is simple and reasonable in structural design and capable of timely, intuitively and accurately monitoring a flow field and pressure change in a stratum.

Owner:SOUTHWEST PETROLEUM UNIV

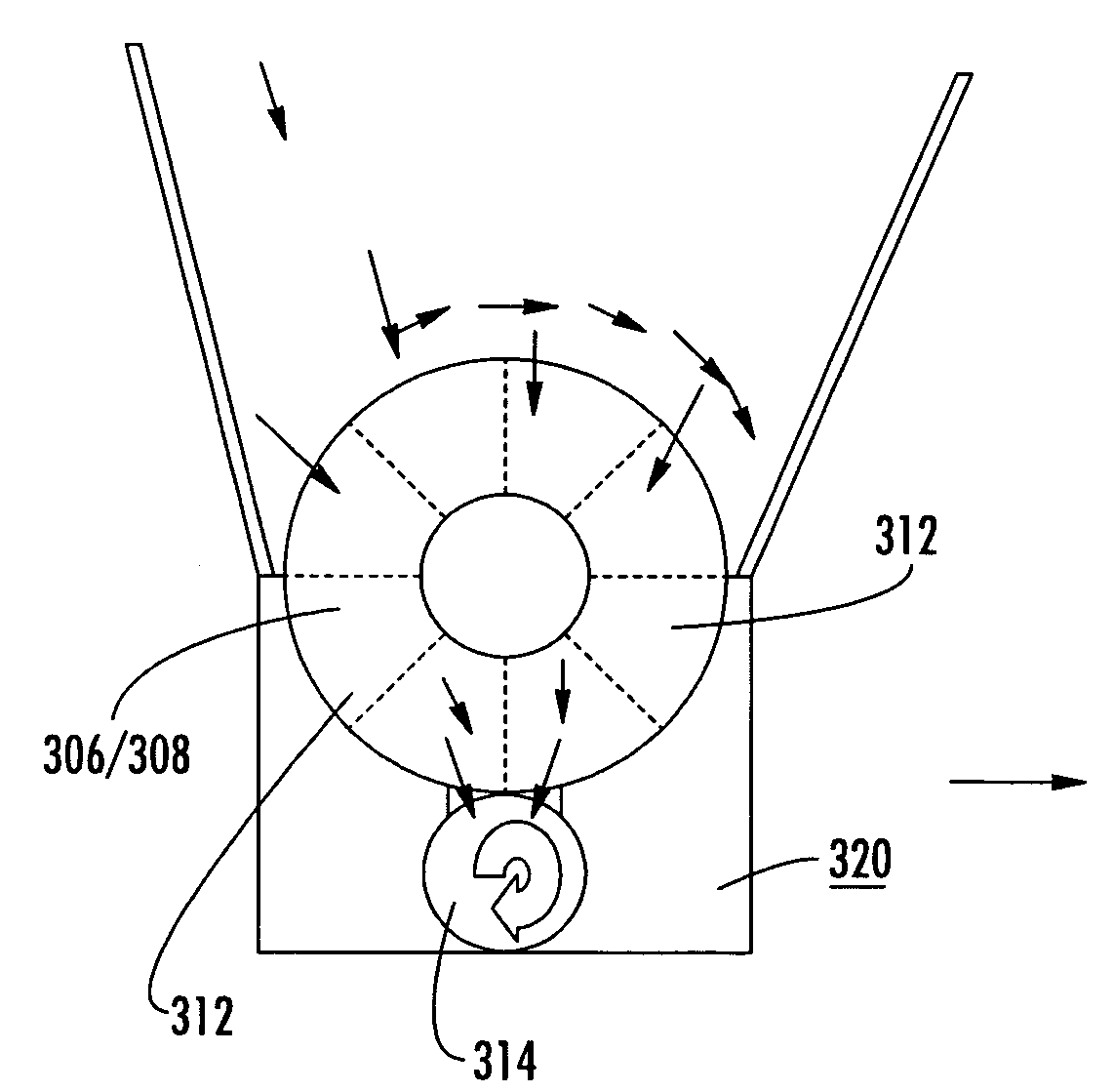

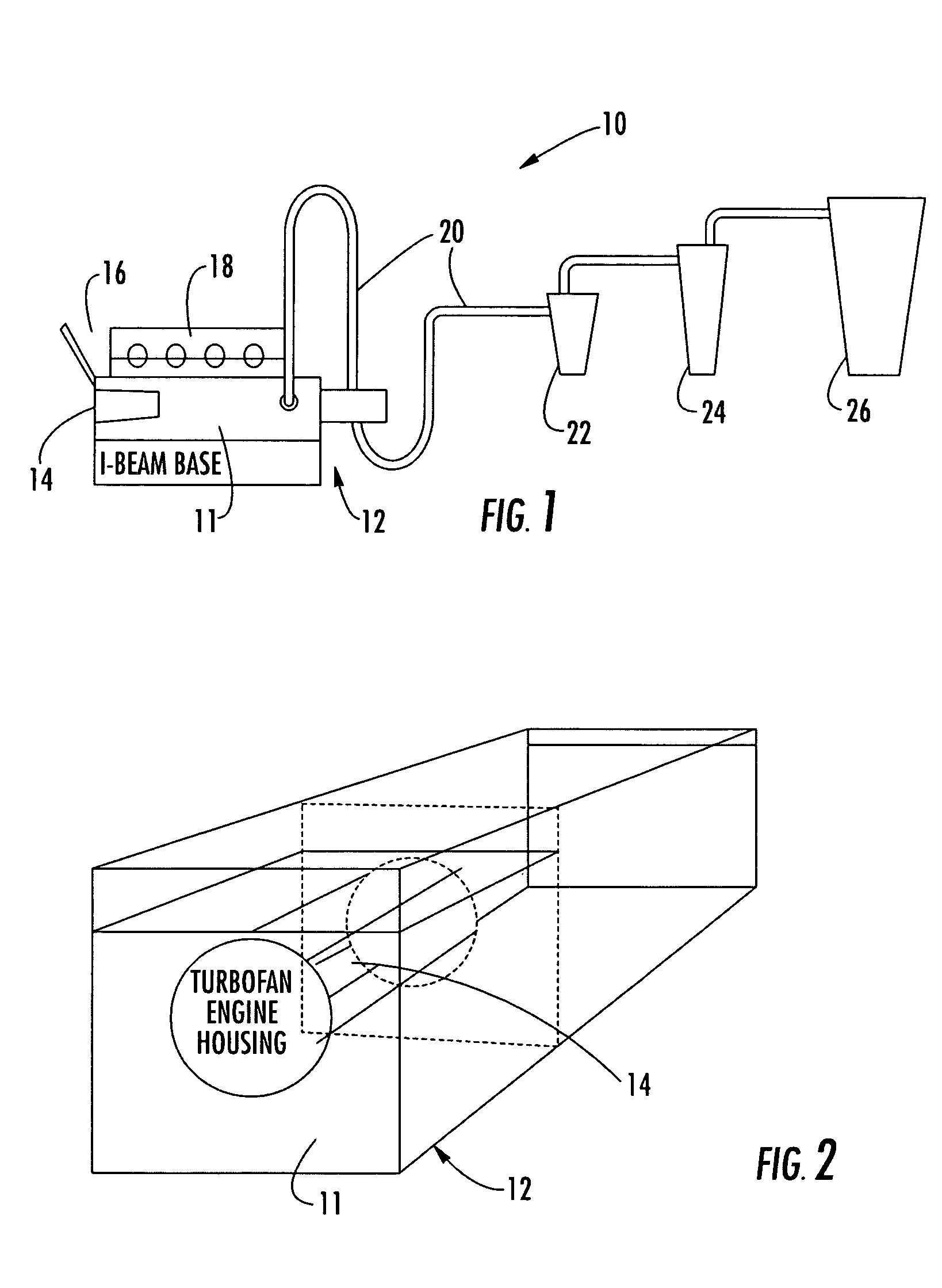

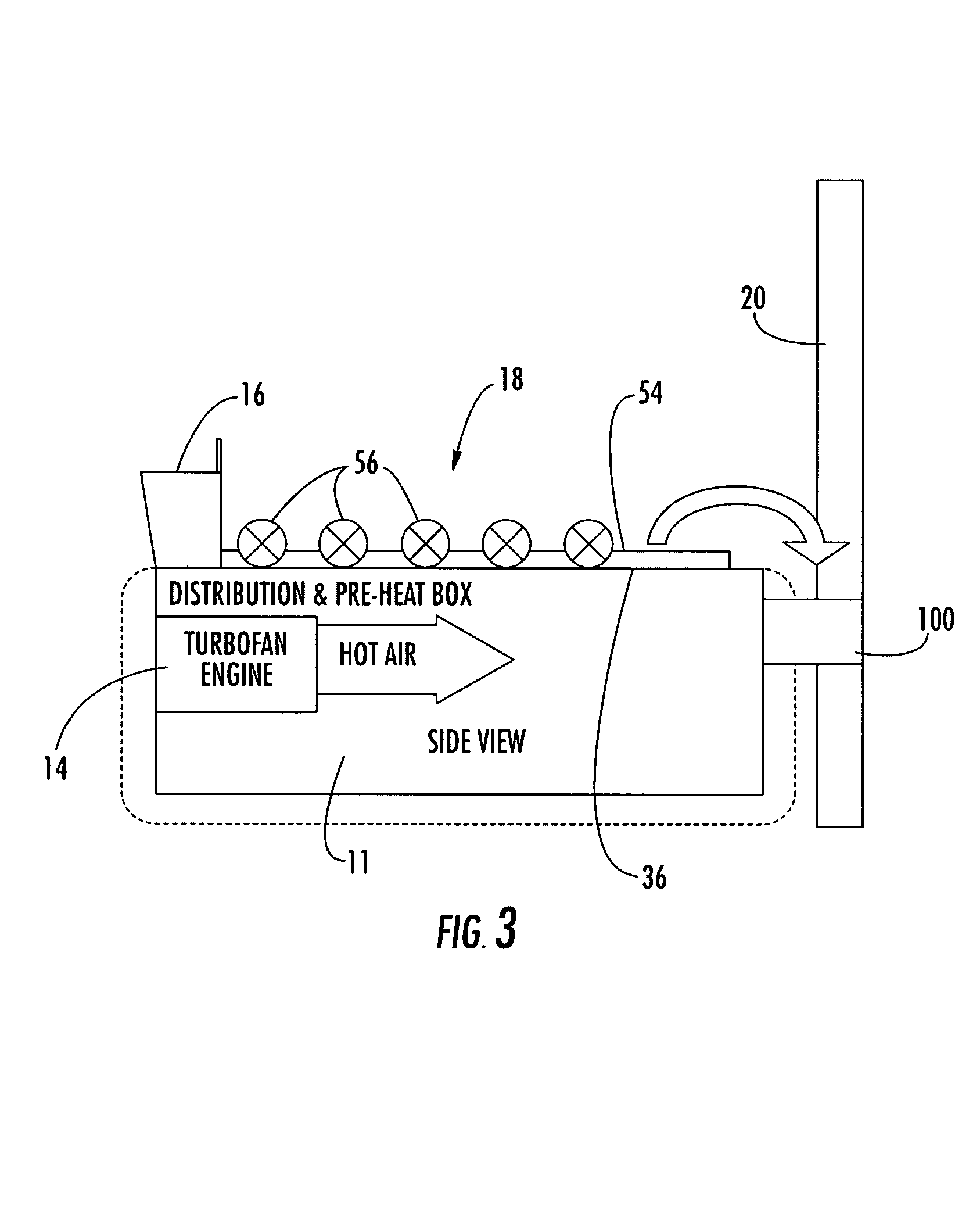

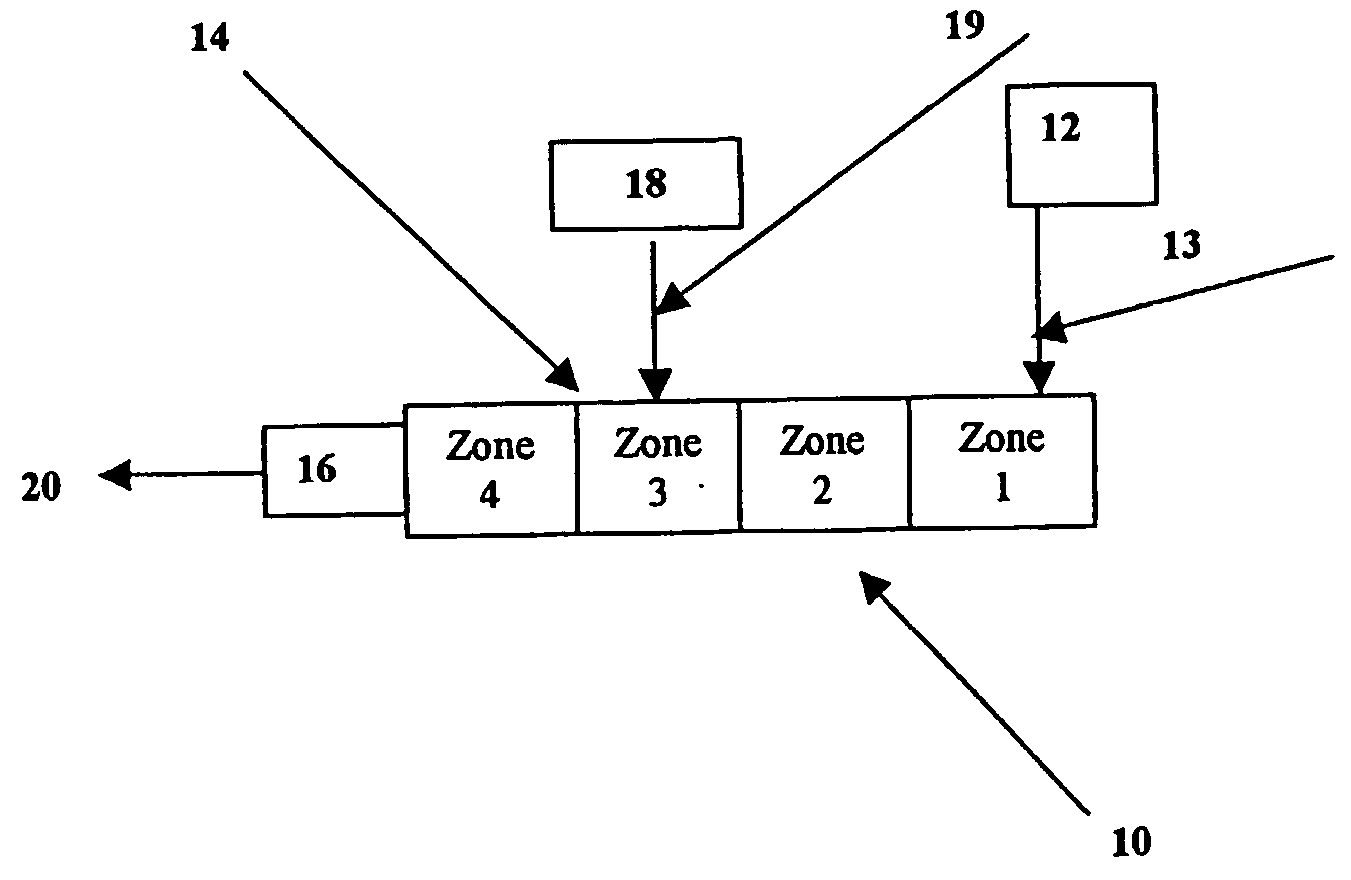

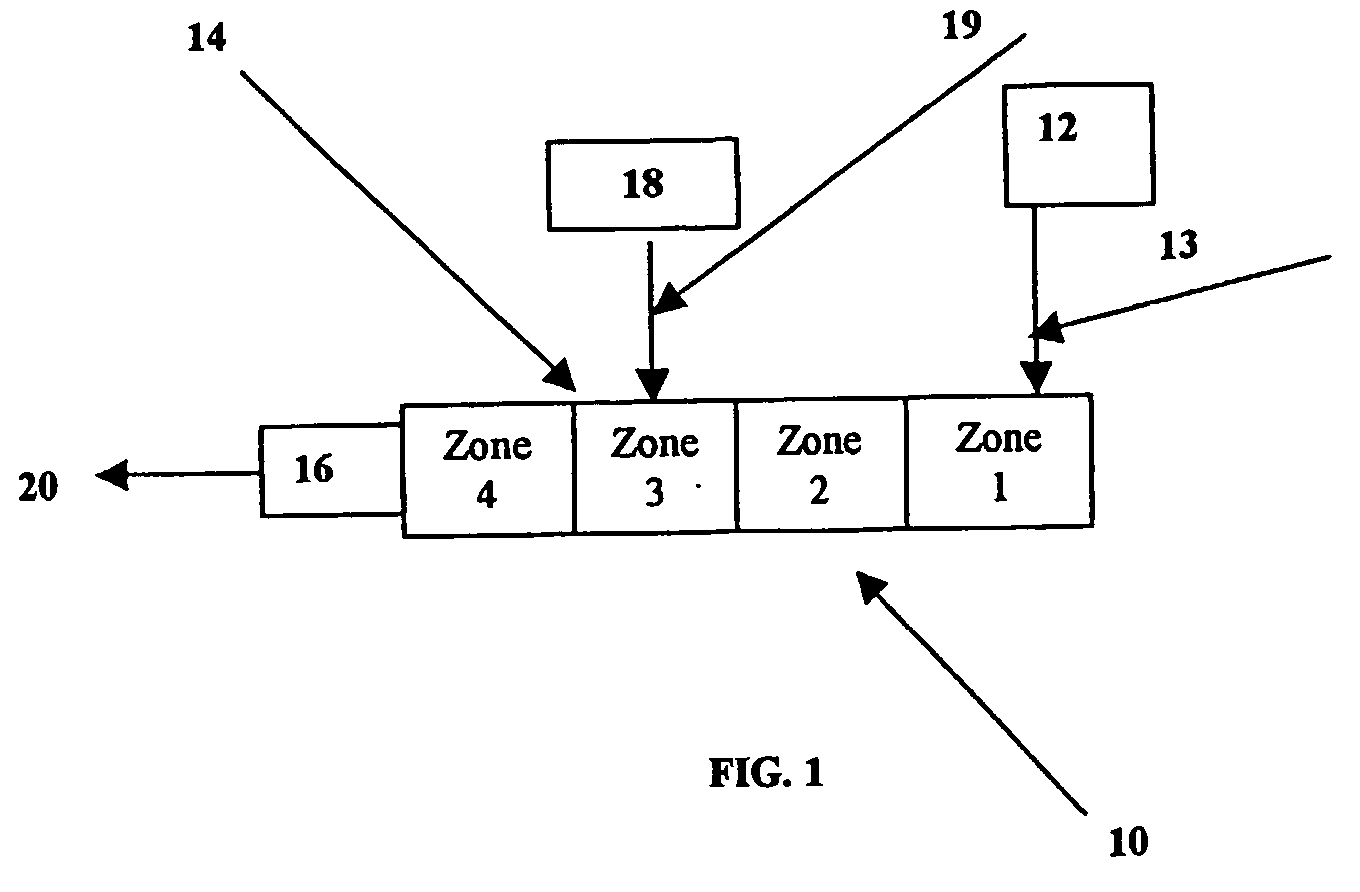

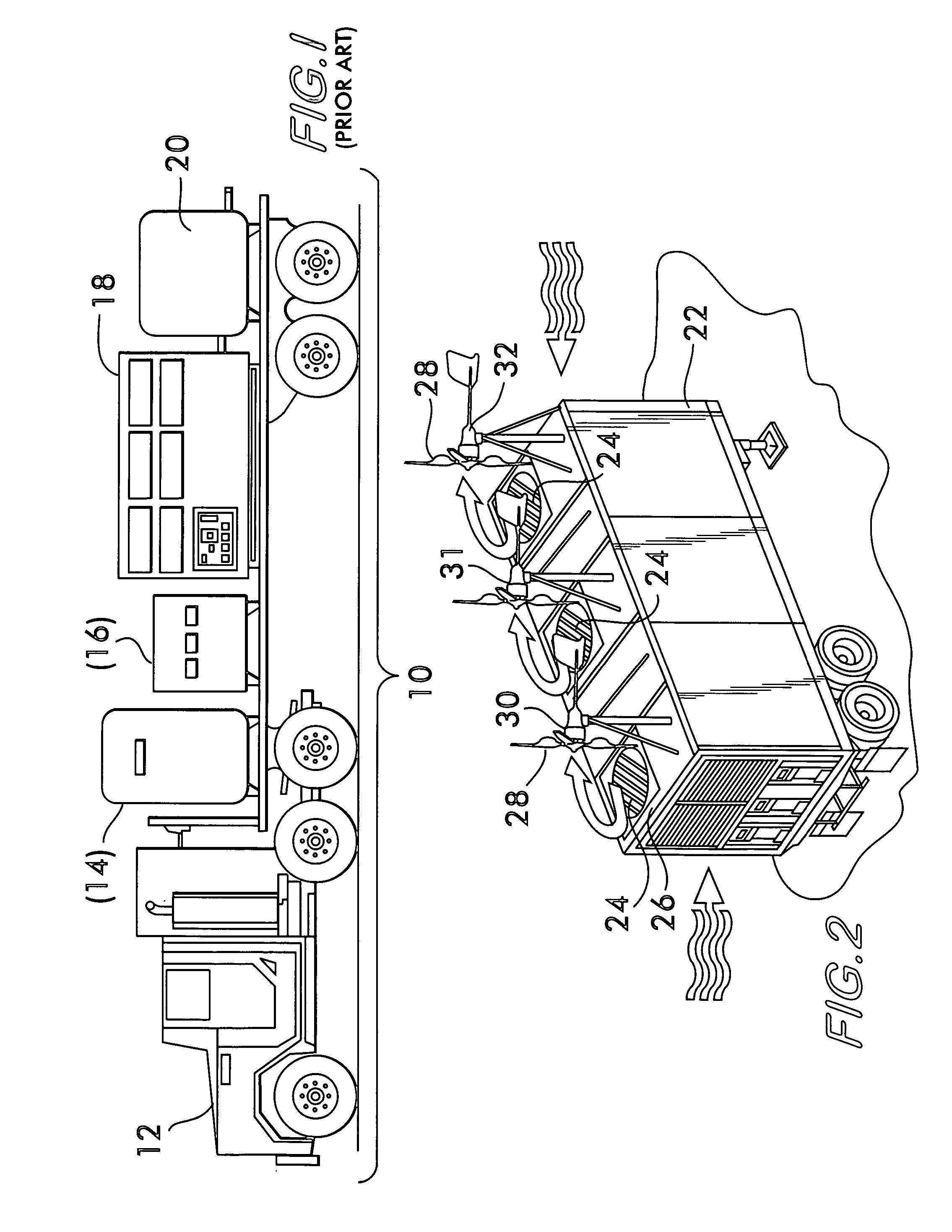

Air dryer system and method employing a jet engine

InactiveUS6944967B1Operate operating costQuality improvementDrying gas arrangementsDrying machines with non-progressive movementsJet engineTurbofan

An air dryer and process employs a jet engine for producing high quality dried products. A turbofan jet engine in an air-drying system uses both thermal and non-thermal air-drying. The turbofan jet engine is housed within an air distribution chamber for directing exhaust air and bypass air from the jet engine into a product drying tube, where it is dried through a combination of thermal drying from heat content in an engine exhaust, and by the kinetic energy of air flowing past the product traveling through the drying tube, that may include a physical impediment for retarding retard the speed of the product solids flowing in the air stream through the tube.

Owner:STAPLES WESLEY A

Low-density cellular wood plastic composite and process for formation

InactiveUS20040147625A1Low costIncrease stiffnessWood working apparatusDomestic articlesProcess engineeringEngineering

A low-pressure CO2 tank or an air compressor with a refrigerated air dryer is attached to the vent zone of a standard twin-screw extruder. During extrusion, the gas is dissolved in the wood-plastic melt. The CO2 expands which foams the wood-plastic material.

Owner:WASHINGTON STATE UNIVERSITY

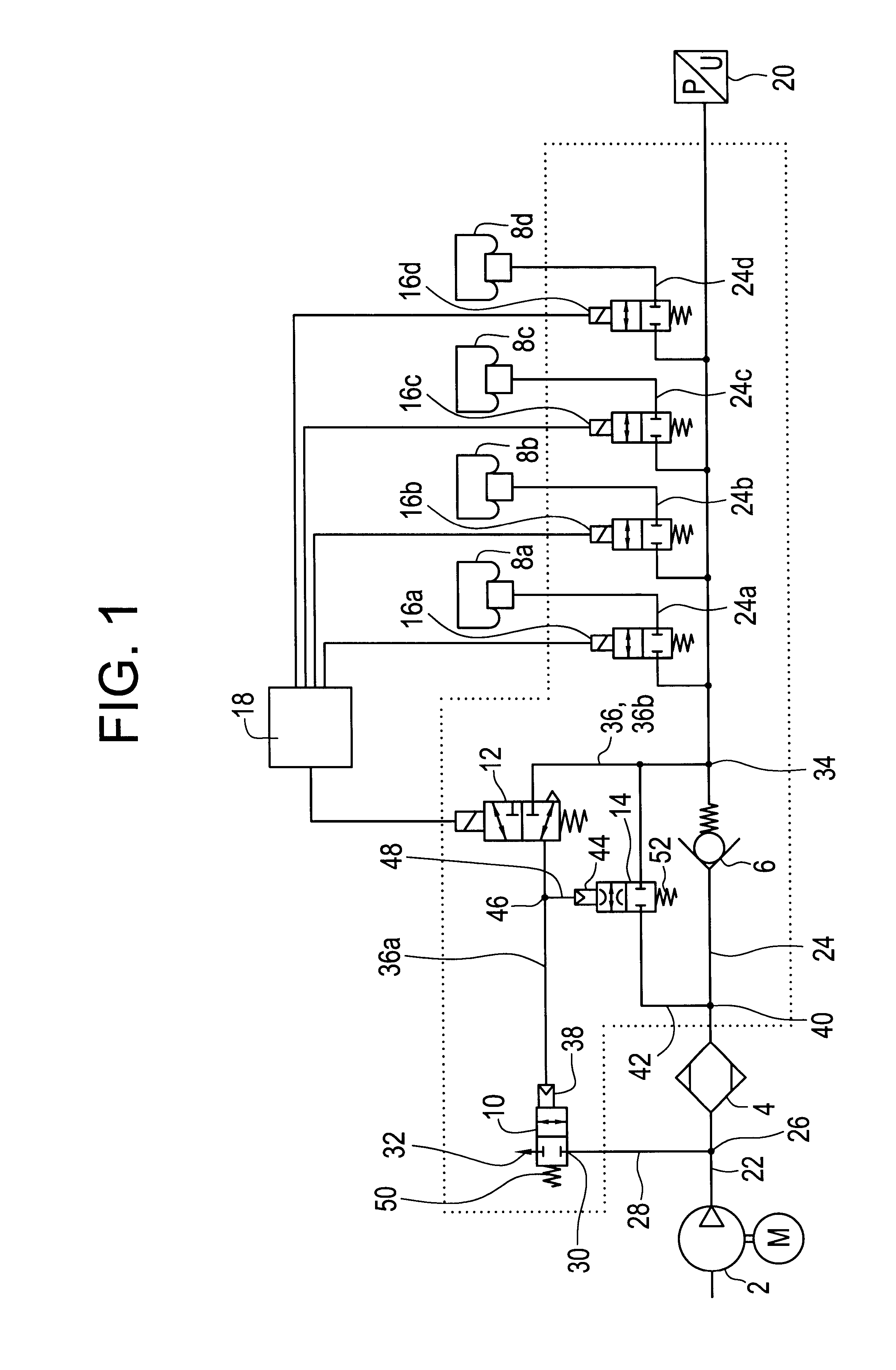

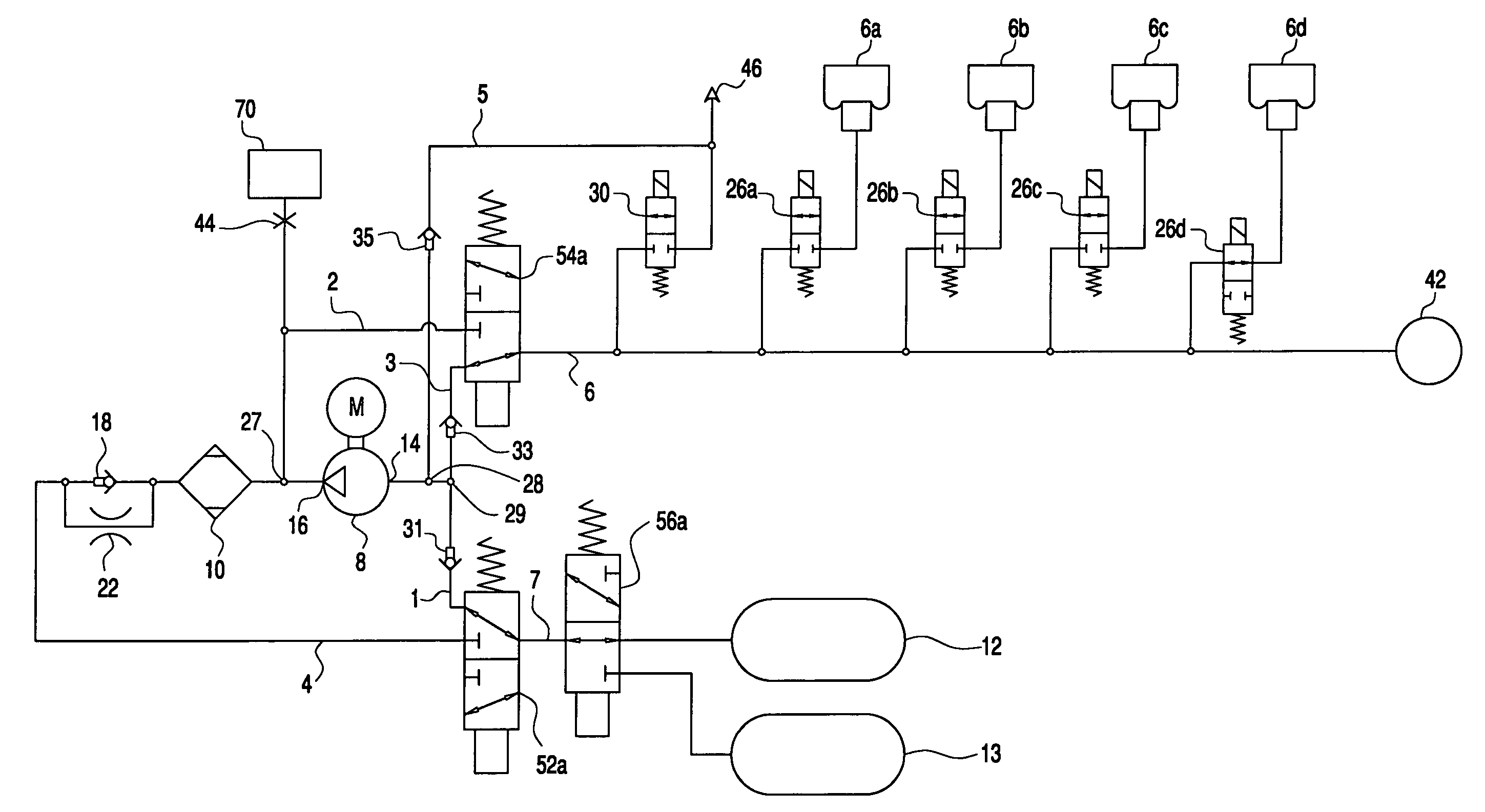

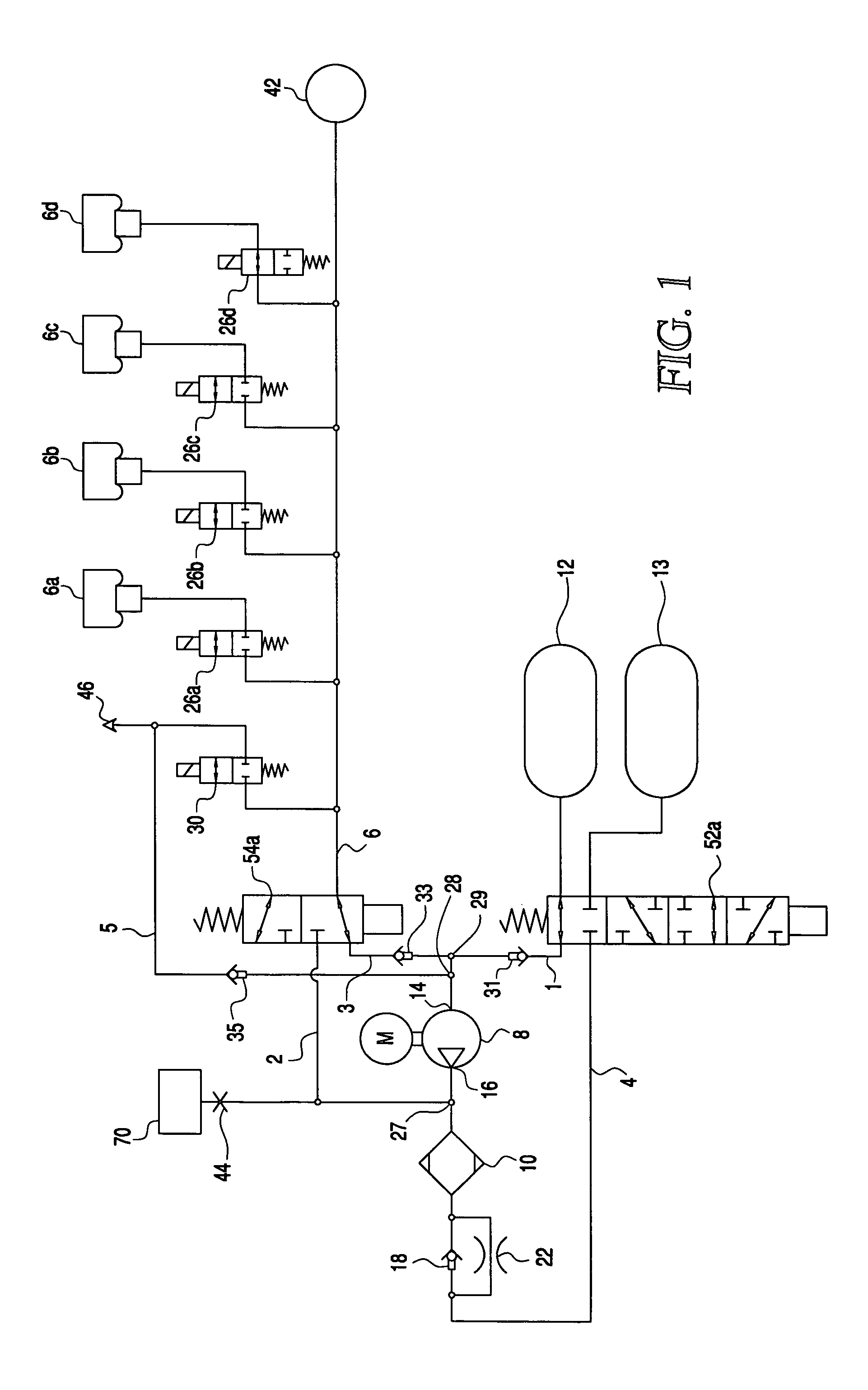

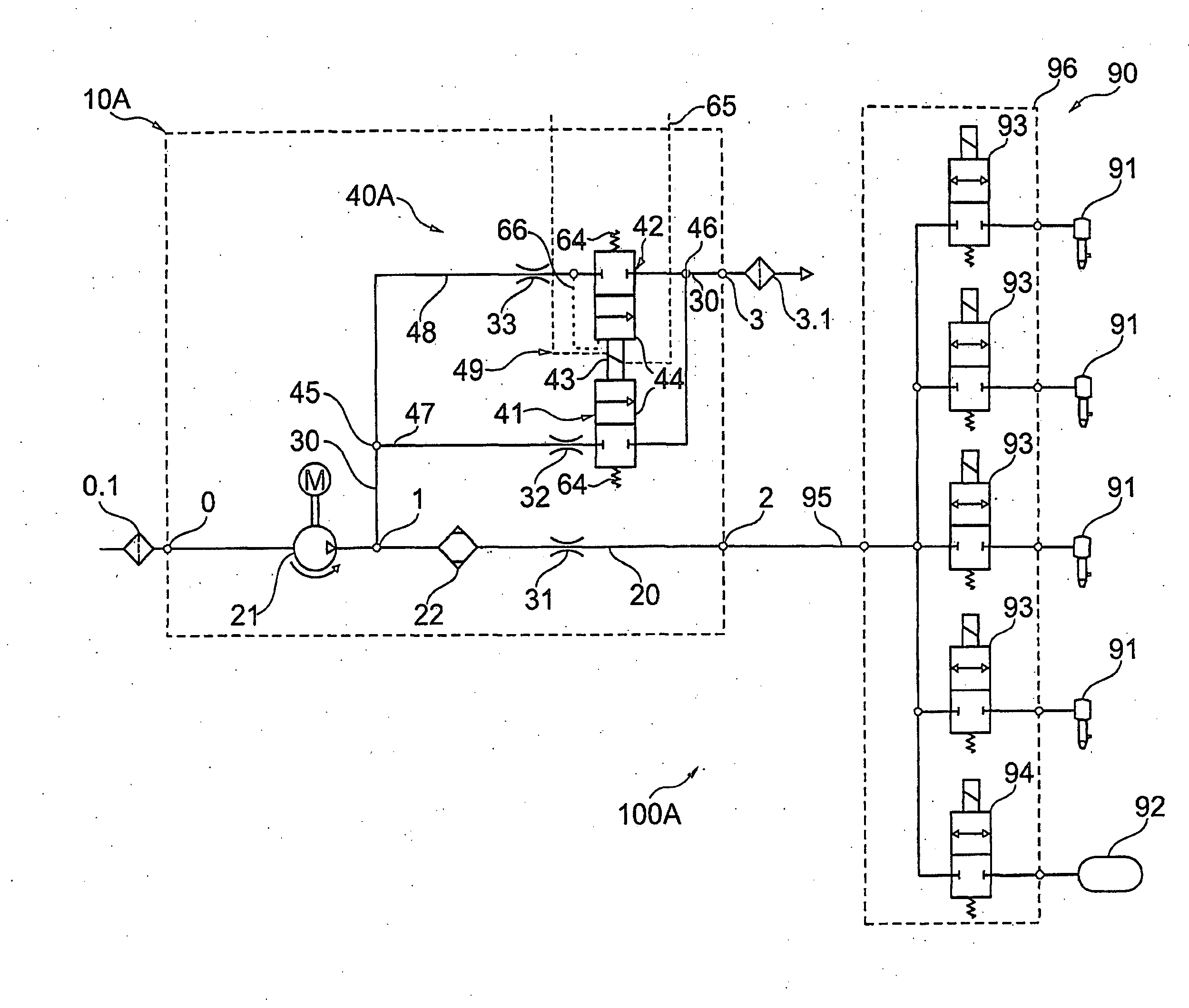

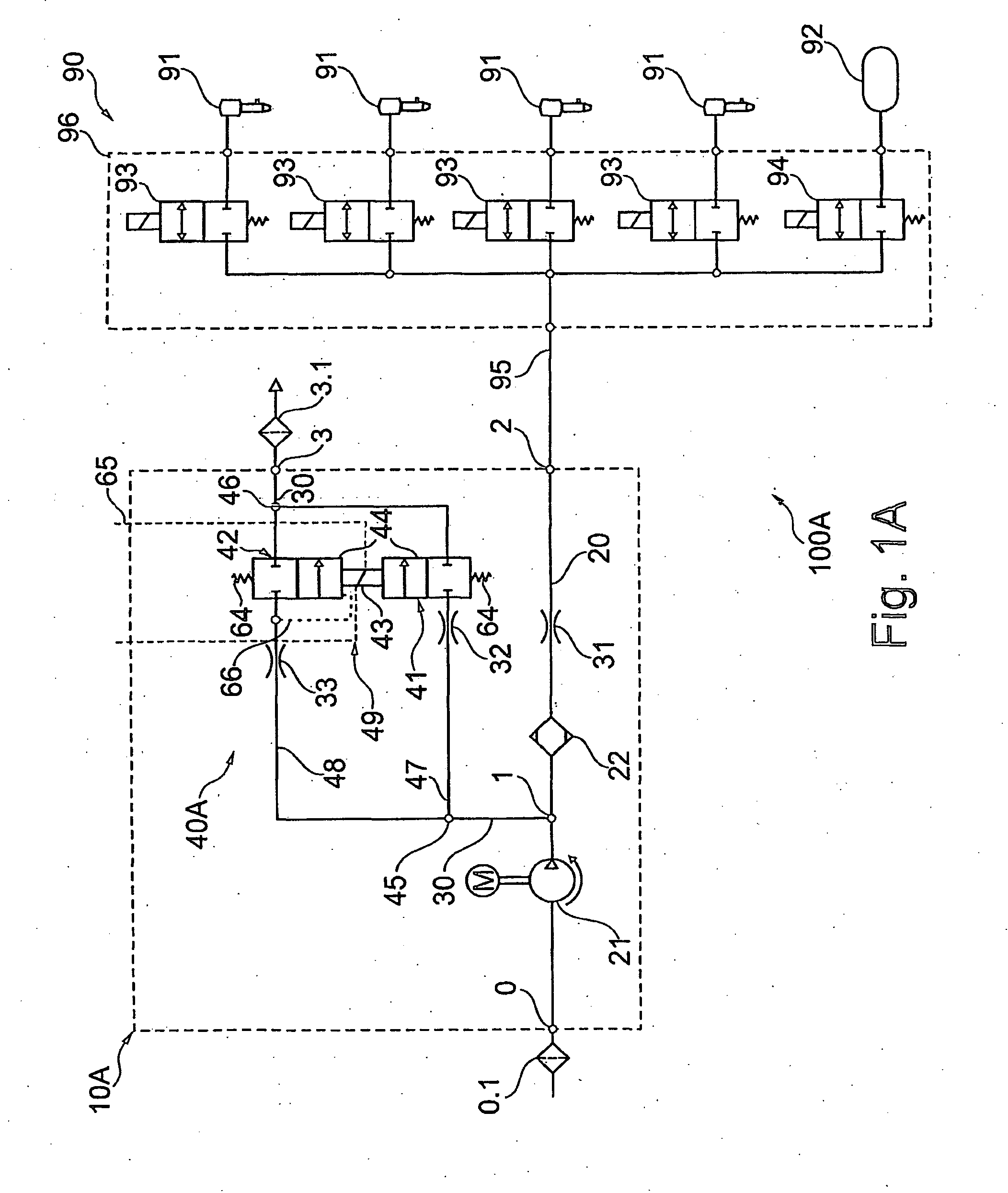

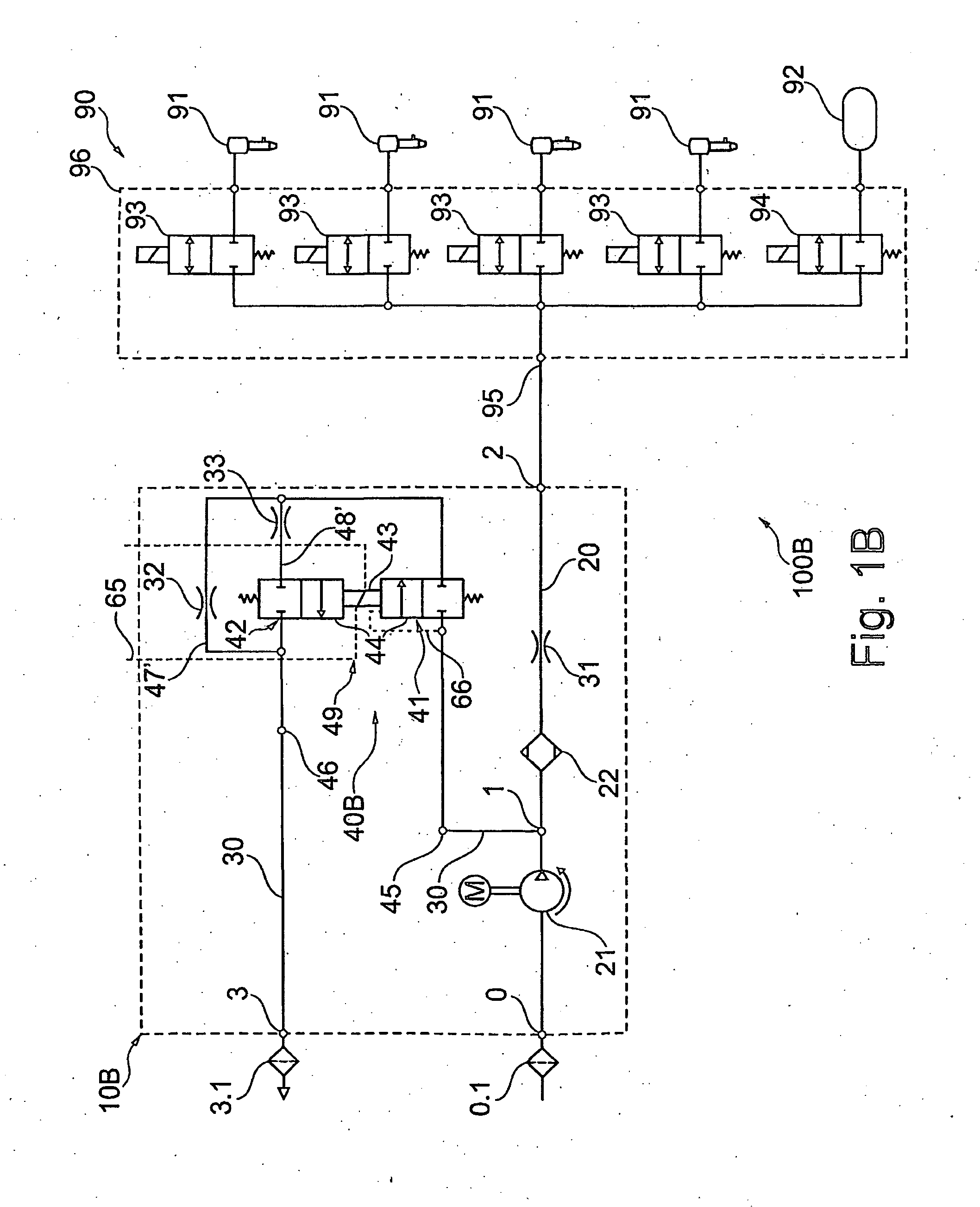

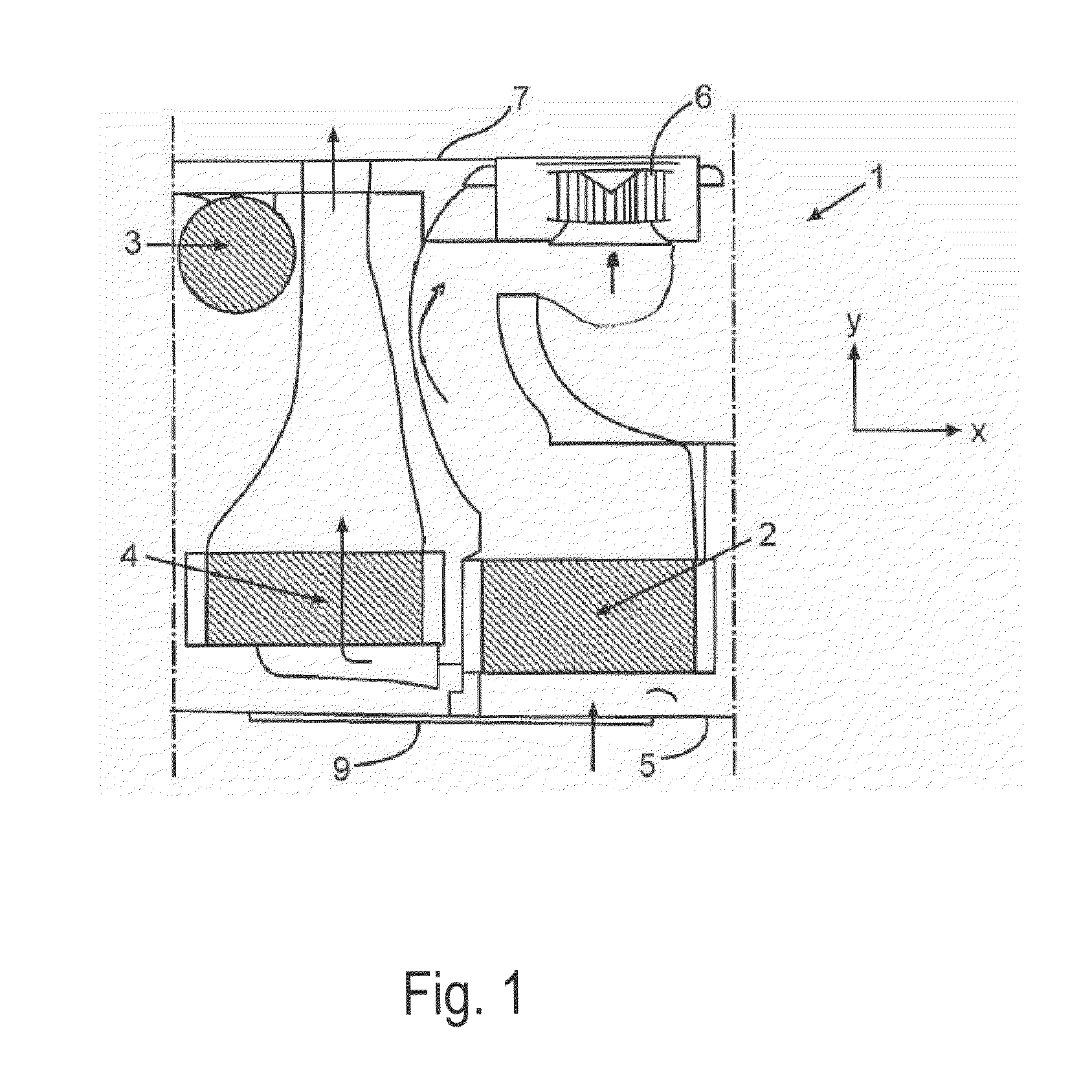

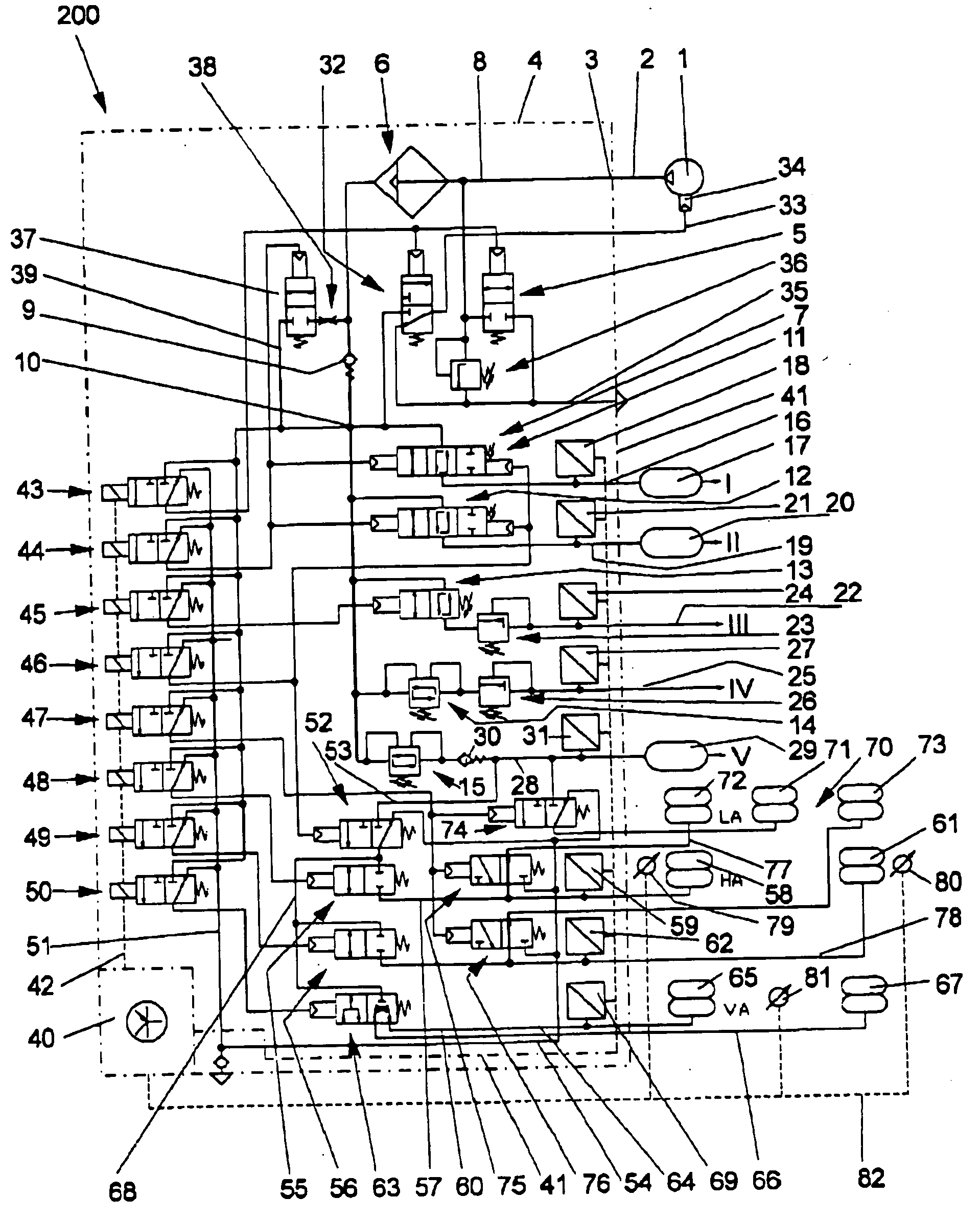

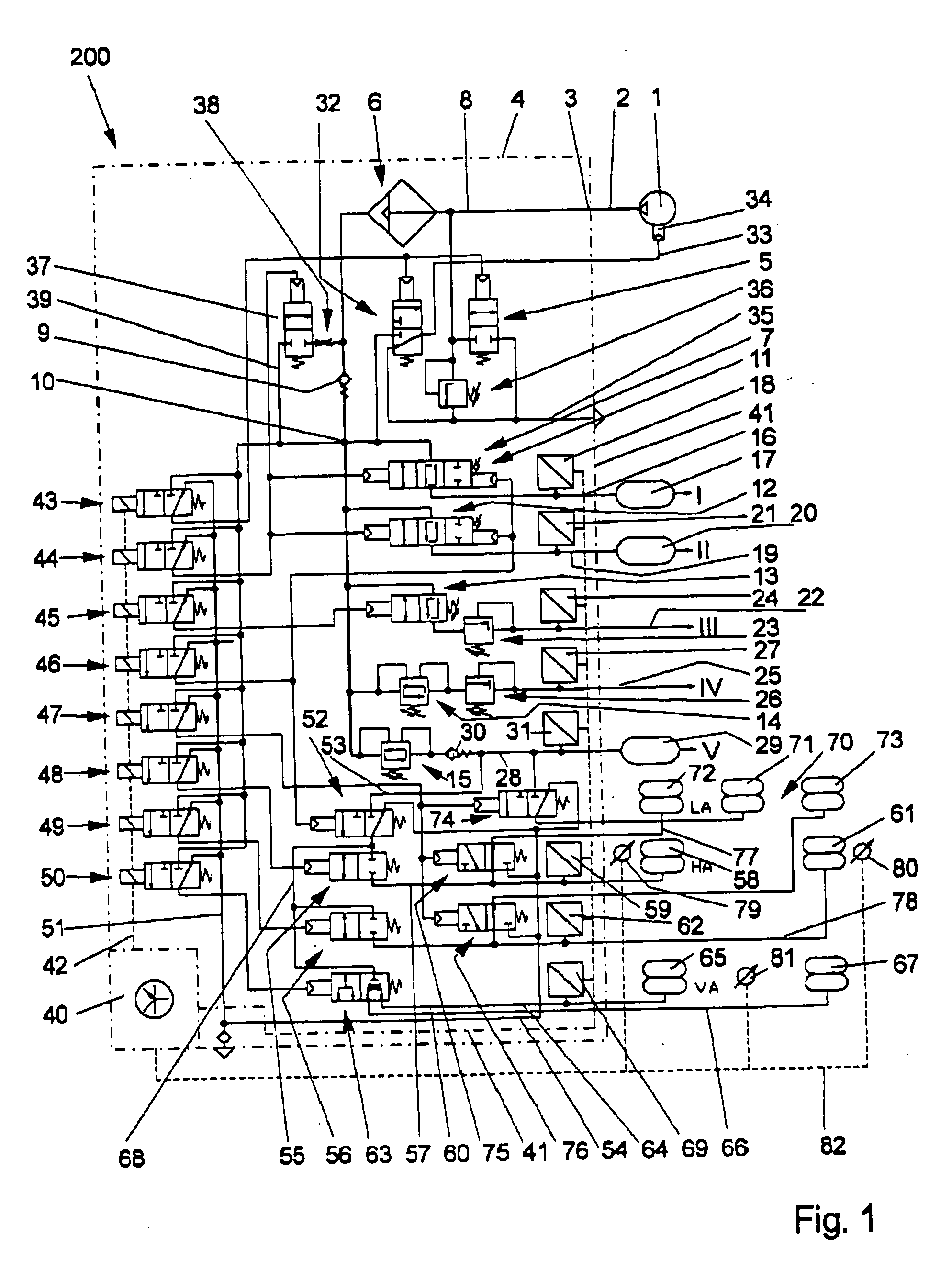

Compressed Air Supply Installation, Pneumatic System and Method

ActiveUS20130318954A1Reliable and yet flexibleFast principle of operationRotary clutchesResilient suspensionsAir compressionSolenoid valve

A compressed air supply installation for operating a pneumatic installation, especially an air suspension installation of a vehicle, includes: an air supply unit and an air compression unit for supplying a compressed air supply unit with compressed air, a pneumatic connection, especially a bleeding line, comprising a bleeding valve system in the form of a controllable solenoid valve system and a bleeding port for bleeding air, and a pneumatic connection, especially a compressed air supply line, comprising an air drier and a compressed air port for supplying the compressed air. The solenoid valve system comprises a primary valve and a secondary valve, which are actuatable by a controller of the solenoid valve system that is common to both valves and acts upon both valves.

Owner:ZF CV SYST EURO BV

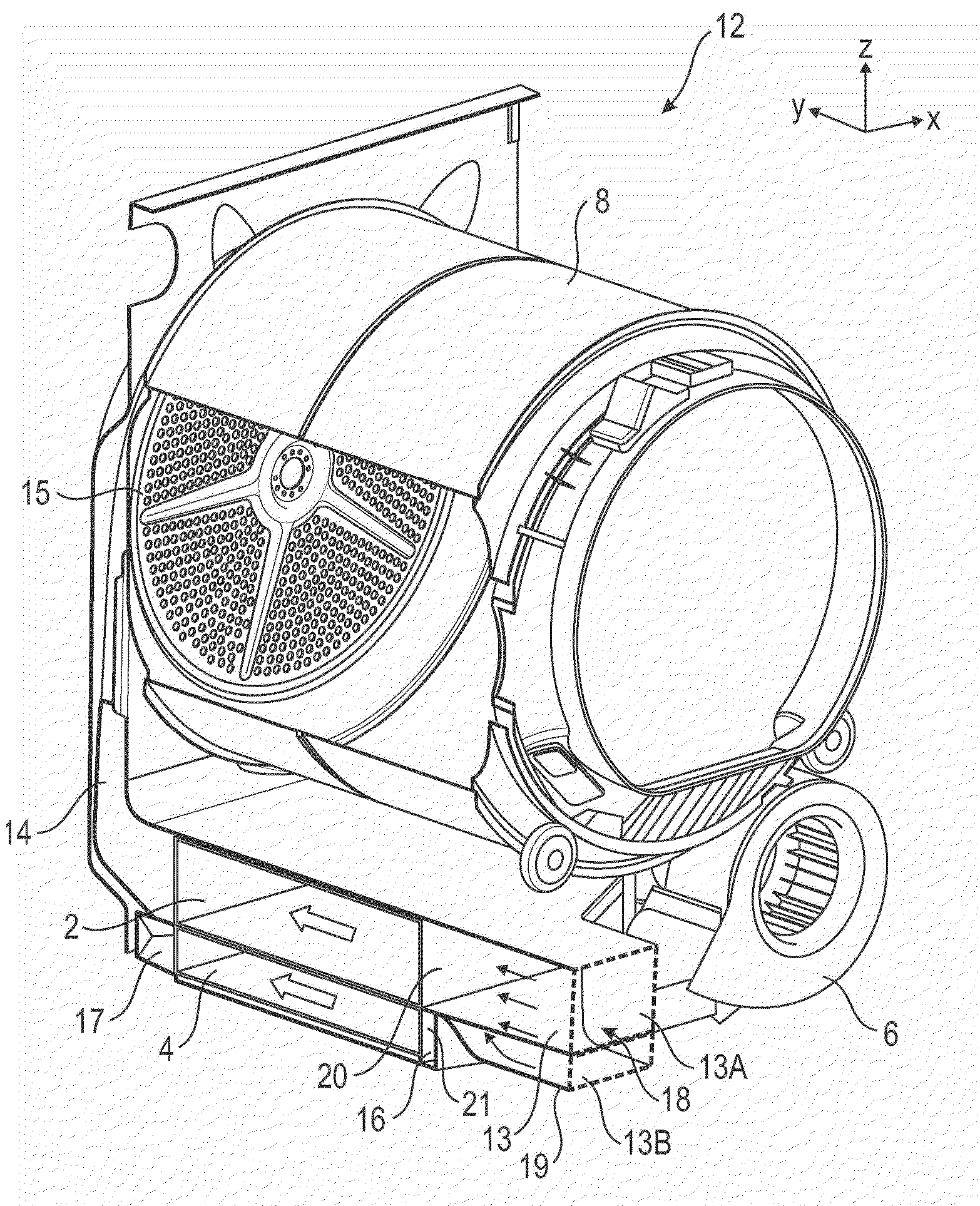

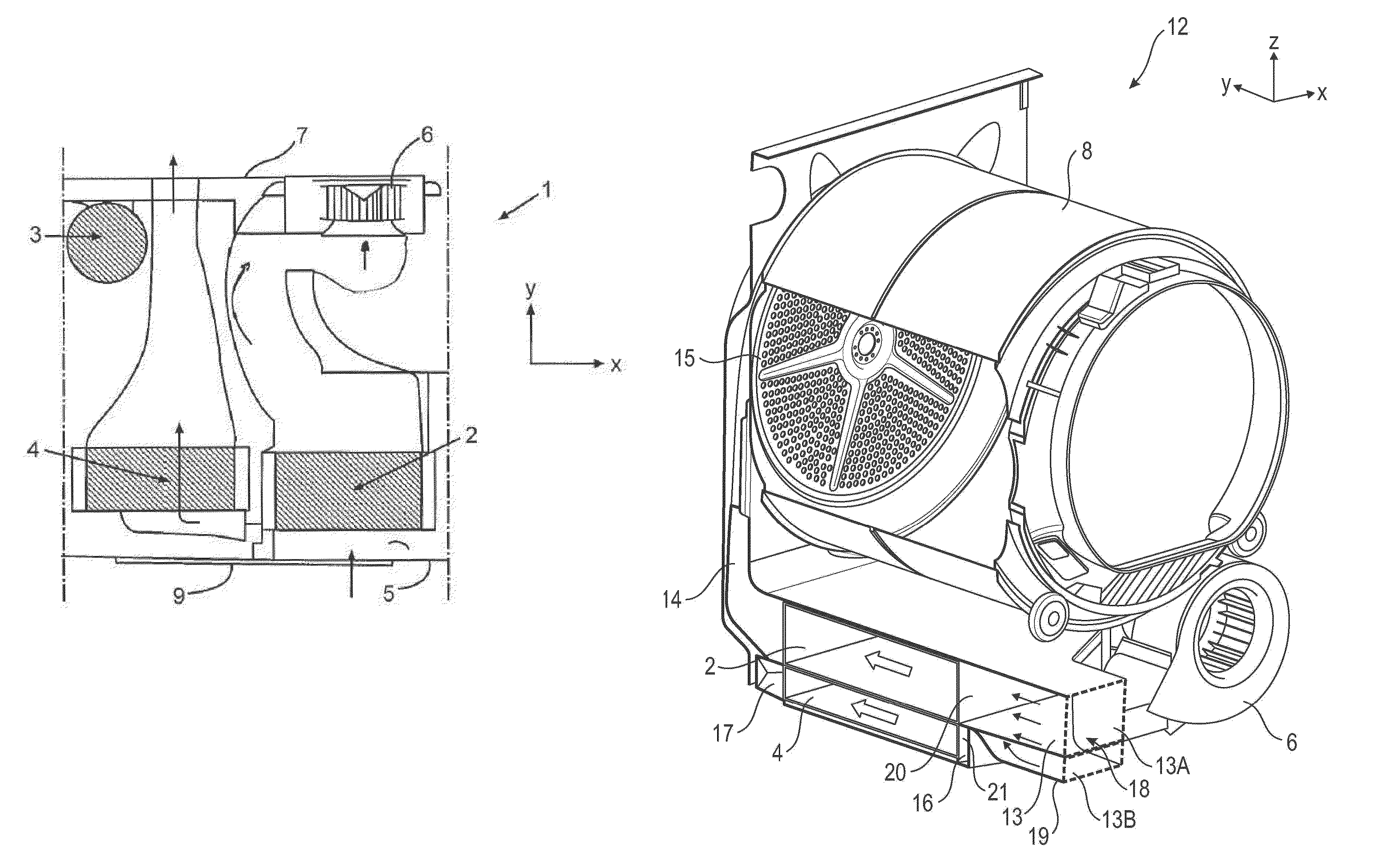

Exhaust air dryer with heat exchanger

ActiveUS20100011608A1Reduce total pressure lossRestricting or even eliminating a deterioration of efficiencyCompression machines with non-reversible cycleDrying chambers/containersPlate heat exchangerEngineering

An exhaust air dryer with a drying chamber for items to be dried. The dryer includes a process air fan, a heat exchanger which includes a heat source, a heat sink of a heat pump, and a flushing device for flushing of a first inflow surface of the heat source and a second inflow surface of the heat sink with a liquid which is assigned to the heat source and the heat sink for removing of soil; and air ducts interconnecting the drying chamber, the process air fan, and the heat exchanger for conducting process air.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

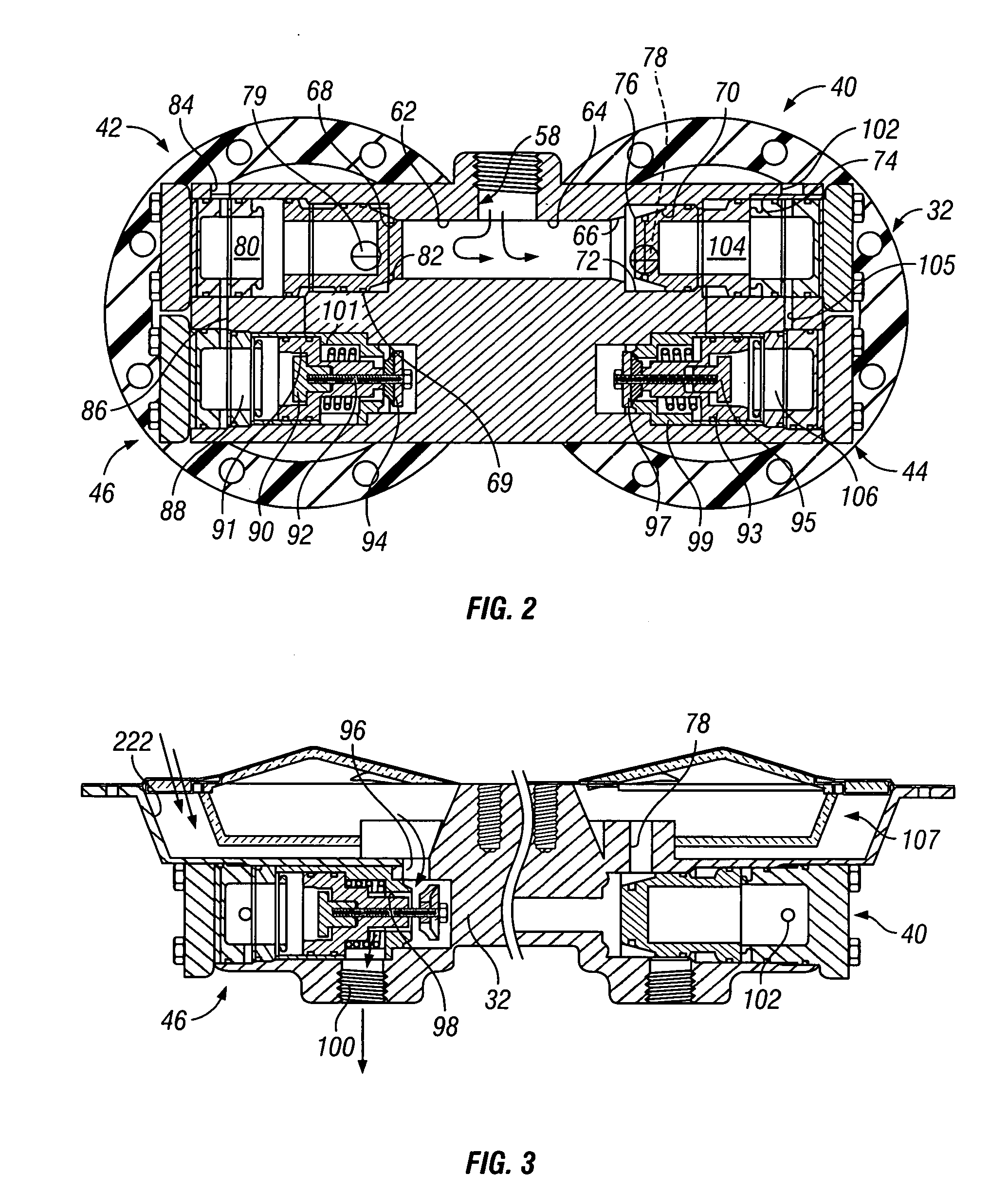

Dual cartridge air dryer with oil separator and readily changeable valves

ActiveUS7097696B2Maximum effectivenessAchieve economyGas treatmentDispersed particle filtrationDesiccantFilter media

An air dryer system including two substantially identical canister-type air dryer units. Each includes a moist air inlet, a first desiccant, a dry air outlet, and means for supplying dry air to a storage facility. The system also includes a bleed valve supplying a small portion of the dry air to regenerate a second desiccant, and a first moist air purge valve. The system operates in the opposite mode and supplies air to a storage facility. Located between the moist air inlets and the desiccants are a pair of air-oil separators. In these, upwardly directed air flows through a housing, striking a deflector plate, and escapes beneath a vertically extending fence and through vents containing a filter medium.

Owner:SKF USA INC

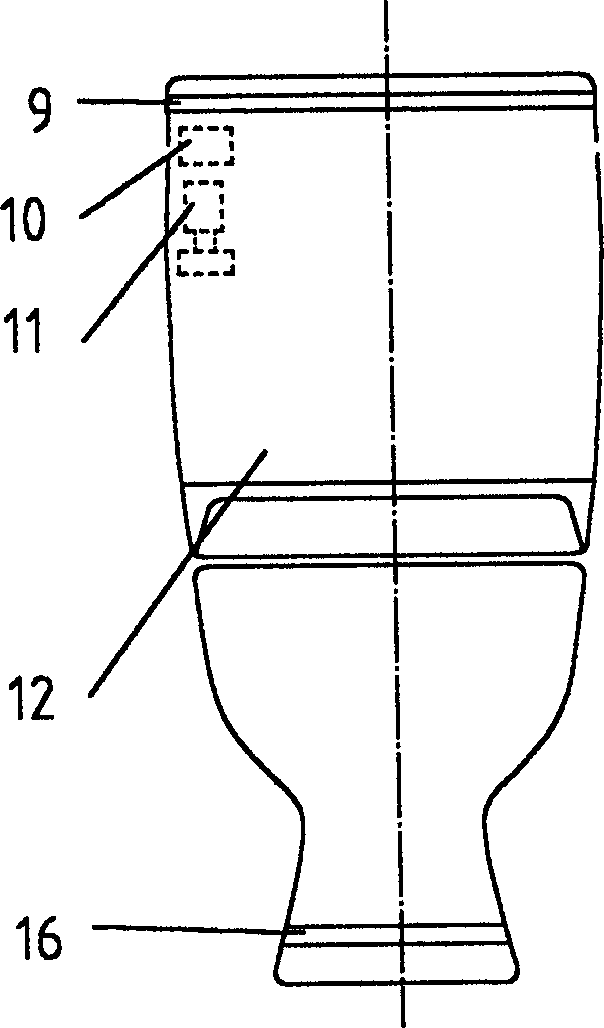

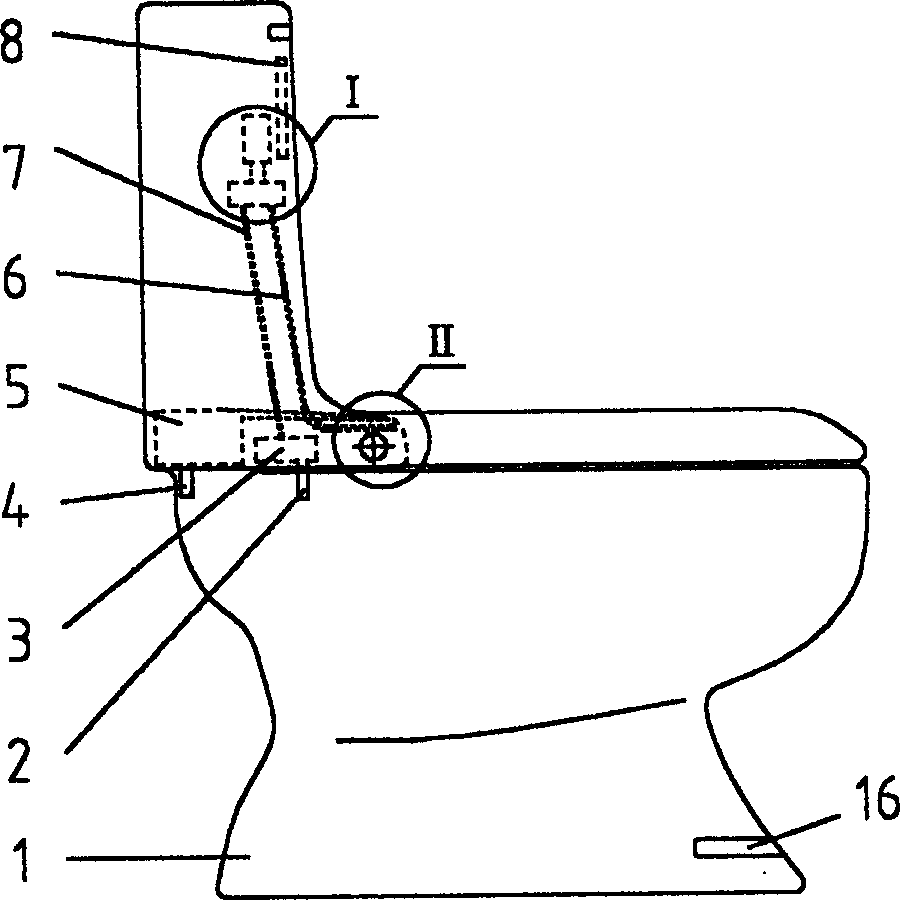

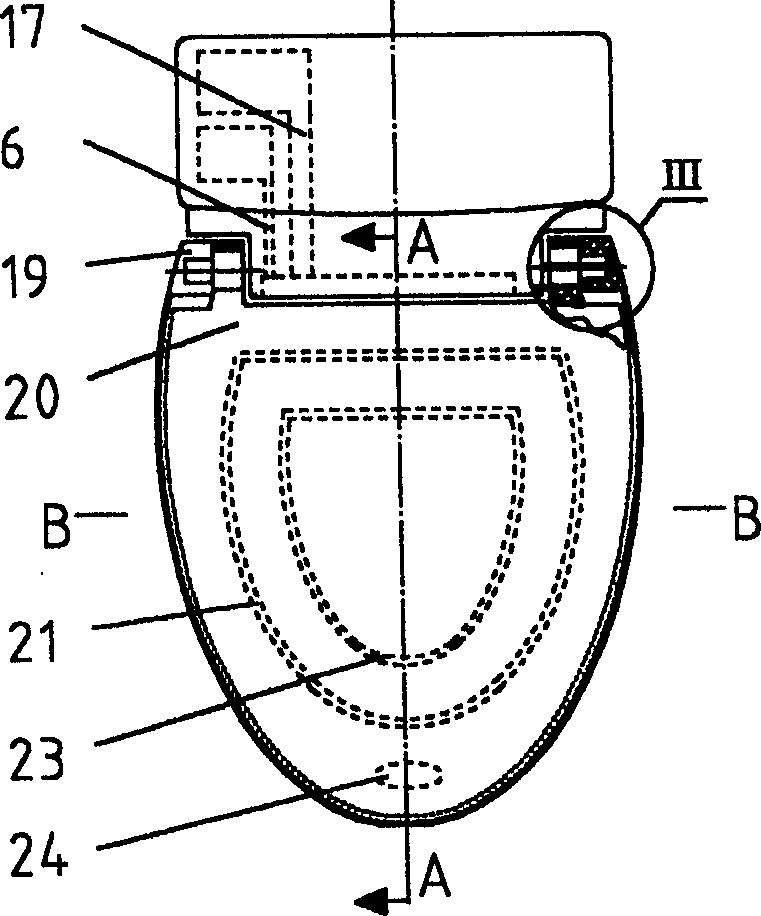

Full-automatic intelligent water-closet pan

InactiveCN1401863AAvoid cross infectionEasy to rinseFlushing devicesLavatory sanitoryOzone generatorEngineering

A full-automatic intelligent water closet is composed of the ozone generator in water line, disinfecting liquid and its box, automatic feeder of disinfecting liquid, water sterilizing and flushing unit, warm-air dryer, automatic opener of cover, automatic temp regulator, and intelligent recognition controller.

Owner:曹增全

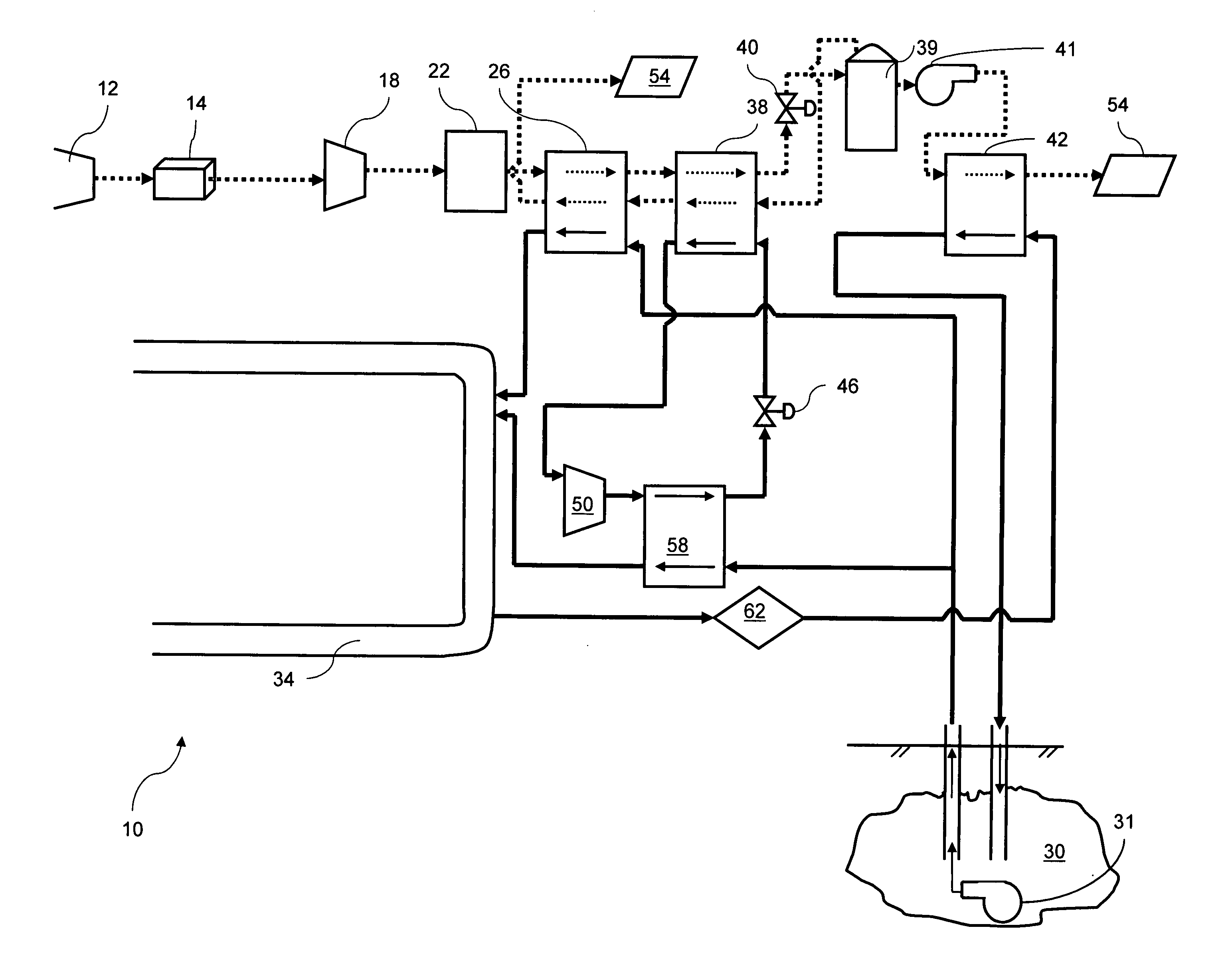

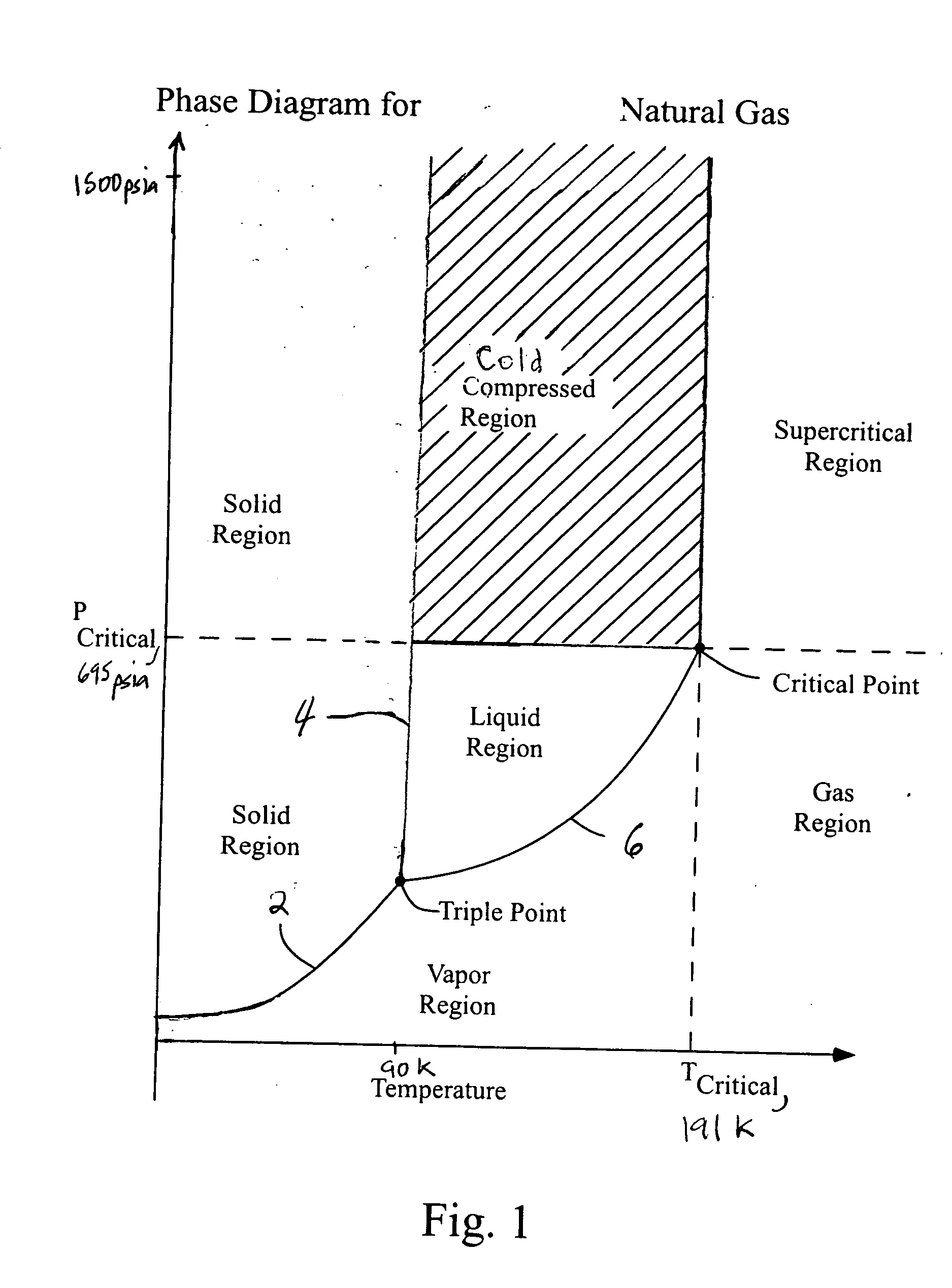

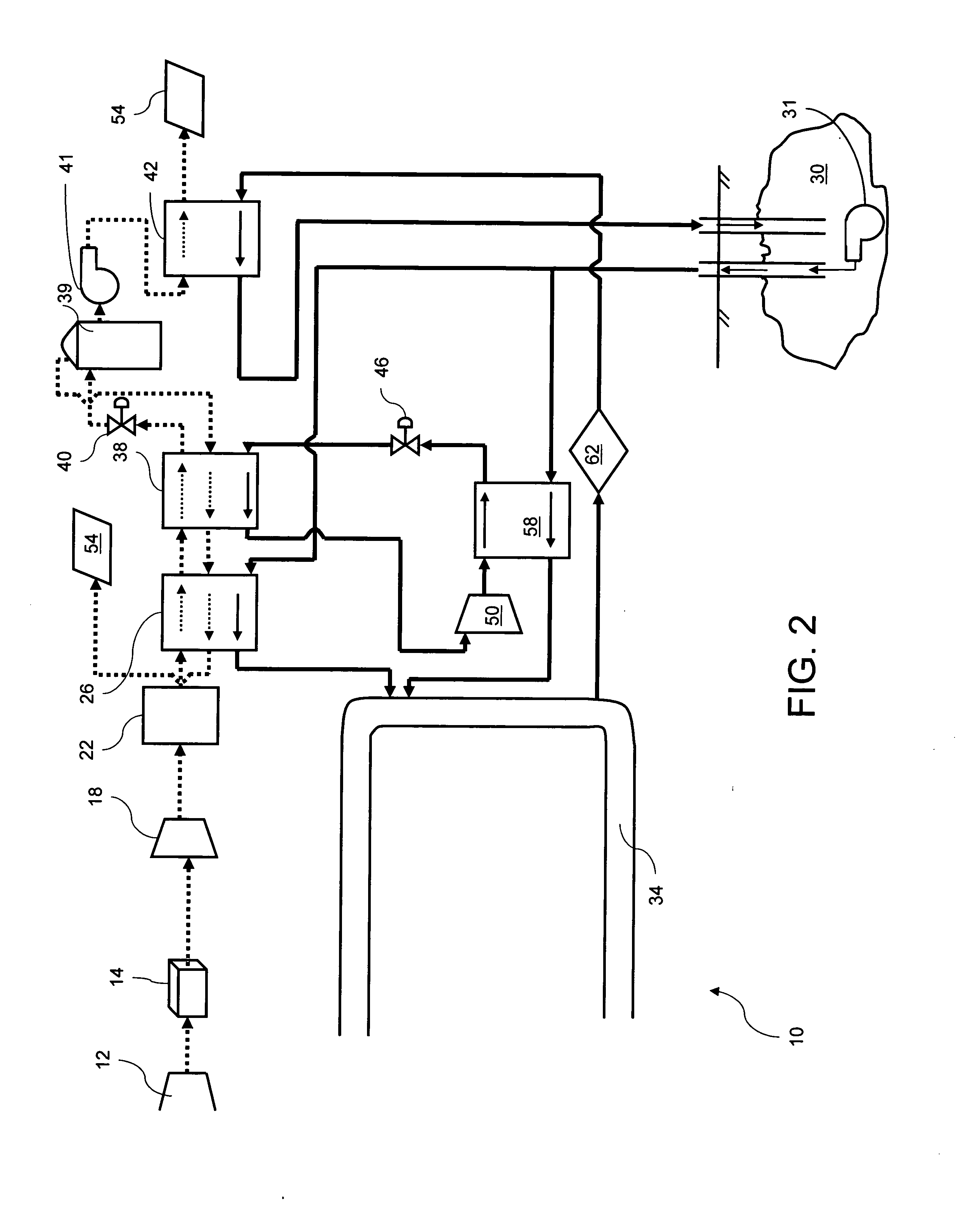

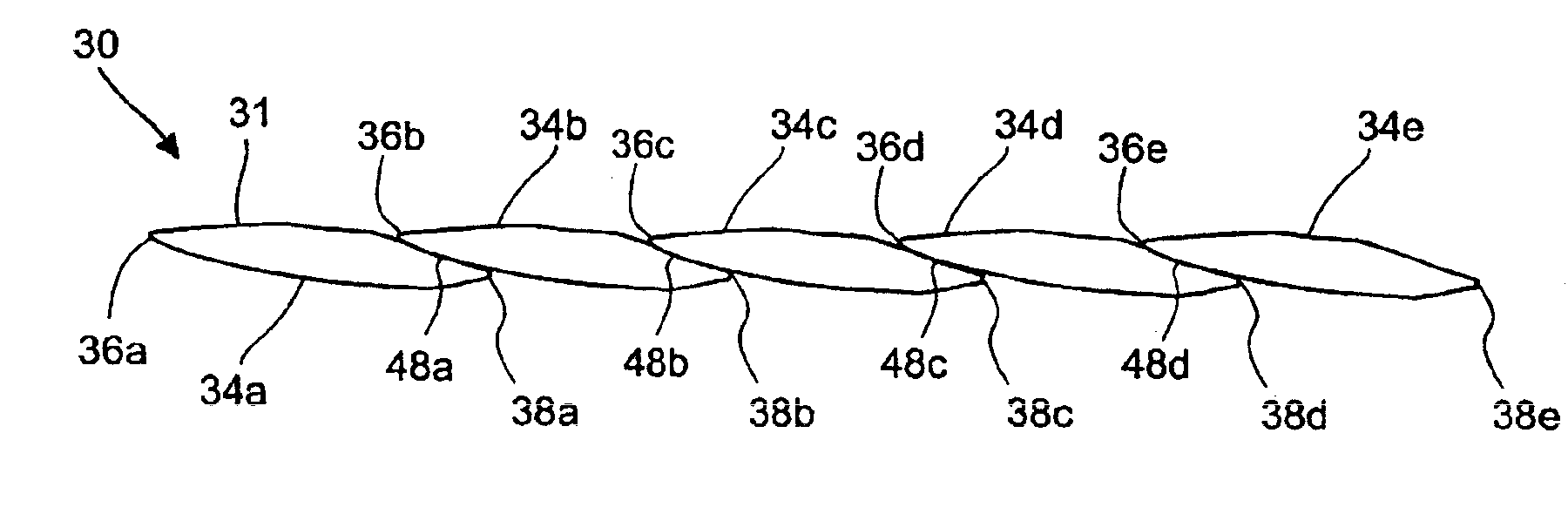

System and method for cold recovery

A method of cold recovery in a cold compressed natural gas cycle, the method comprising: compressing air; drying air; heat exchanging air with cold compressed natural gas from a storage vessel, in a first heat exchanger, thereby forming cooled air; heat exchanging the cooled air with liquid methane, in a second heat exchanger, such that the cooled air becomes liquid air and the liquid methane becomes methane; heat exchanging the liquid air with natural gas from a pipeline, in a third heat exchanger, such that the natural gas cools to a cold compressed natural gas and the liquid air becomes air in a gaseous state; discharging the air in a gaseous state. A system of cold recovery comprising: an air dryer; an air compressor in fluid communication with the air dryer; a first heat exchanger in fluid communication with the air compressor; a second heat exchanger in fluid communication with the first heat exchanger; a third heat exchanger in fluid communication with the second heat exchanger; a methane expander valve in fluid communication with the second heat exchanger; a fourth heat exchanger in fluid communication with the methane expansion valve; a methane compressor in fluid communication with the second heat exchanger and with the fourth heat exchanger; a natural gas scrubber in fluid communication with a third heat exchanger; a natural gas pipeline in fluid communication with the first heat exchanger; the fourth heat exchanger, and the natural gas scrubber; and a storage vessel in fluid communication with the first heat exchanger, the third heat exchanger, and the fourth heat exchanger.

Owner:EXPANSION ENERGY

Non-woven through air dryer and transfer fabrics for tissue making

InactiveUS6875315B2High fabric strengthHigh thicknessNon-fibrous pulp additionNatural cellulose pulp/paperNonwoven fabricAir dryer

One embodiment of the present invention is an endless non-woven tissue making fabric. The endless non-woven tissue making fabric has a machine direction, cross-machine direction, a tissue machine contacting surface, a tissue contacting surface, a first side edge, and a second side edge. The non-woven tissue making fabric comprises a fabric strip of non-woven material comprising at least one layer of non-woven material. The fabric strip has a first edge, an opposing second edge, a machine direction, and a cross-machine direction. The fabric strip may be spirally wound in a plurality of contiguous turns wherein the first edge in a turn of the fabric strip extends beyond the second edge of an adjacent turn of the fabric strip, thereby forming a spirally continuous seam with adjacent turns of the fabric strip.

Owner:KIMBERLY-CLARK WORLDWIDE INC

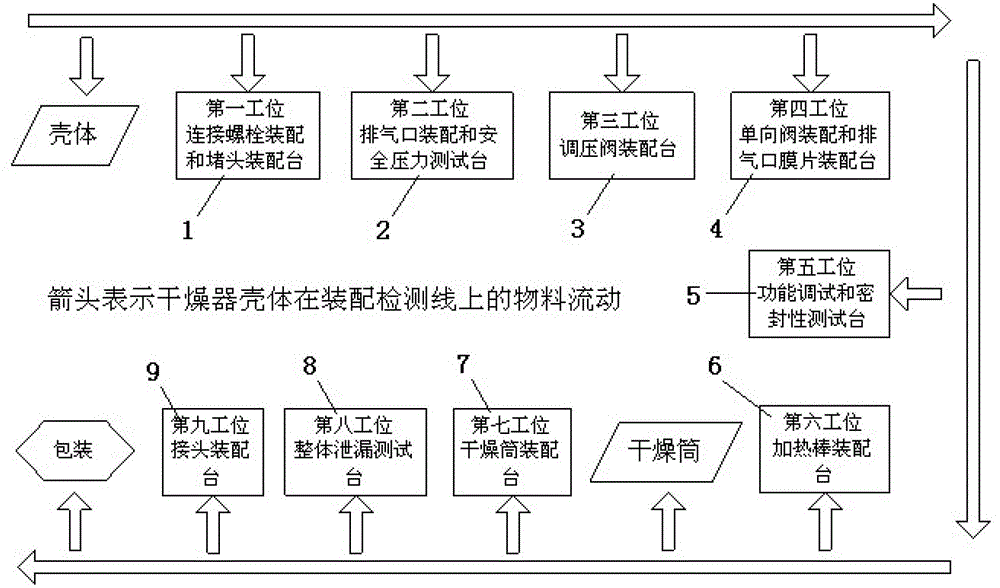

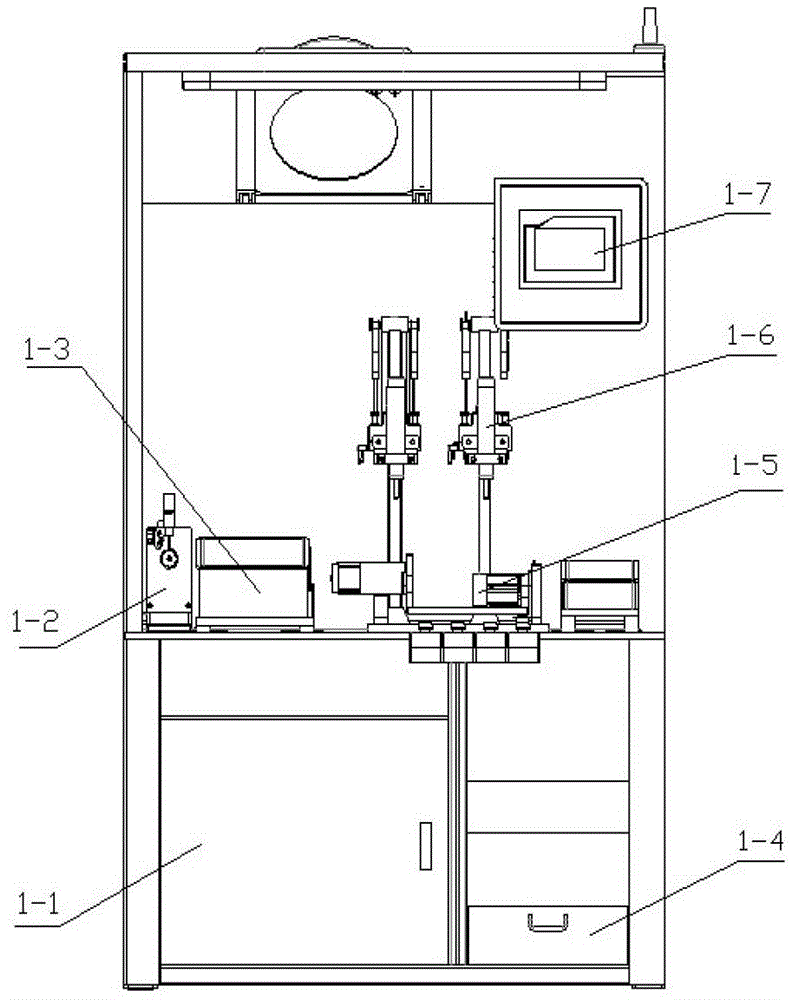

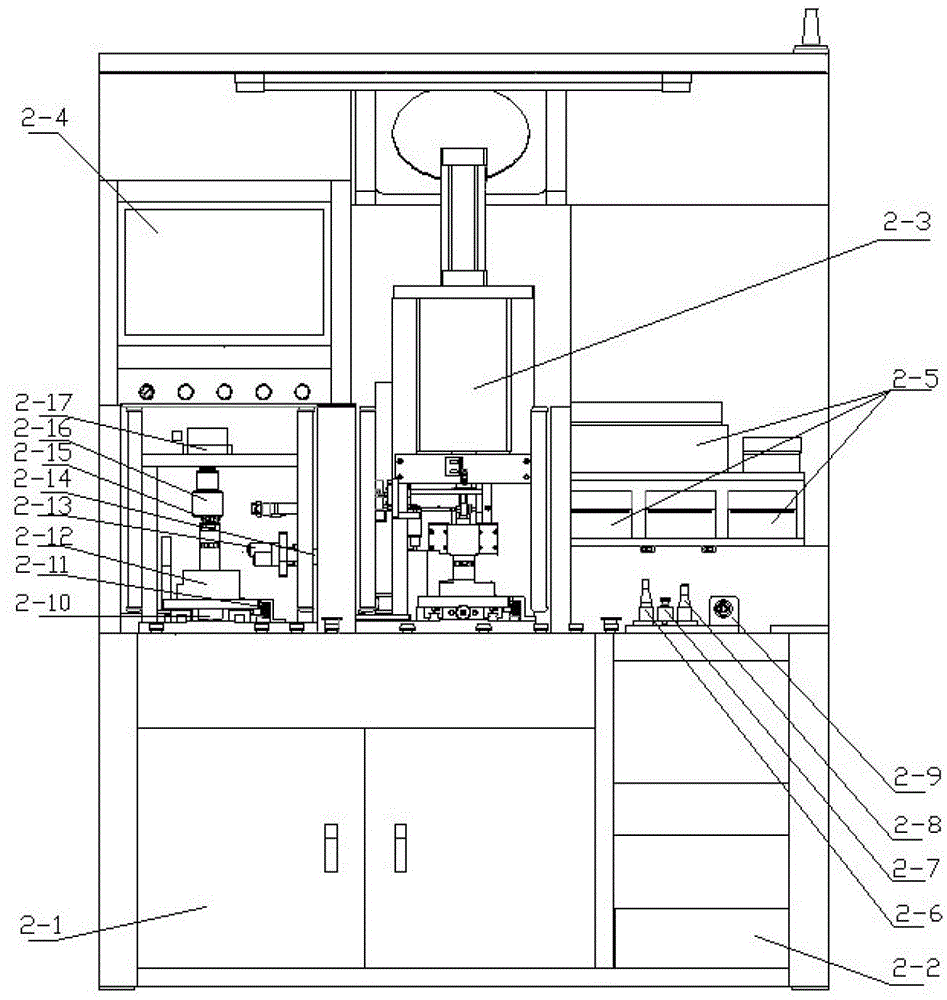

Automobile air dryer assembling and testing production line

ActiveCN103182645AReasonable structural designFlexible layout adjustmentVehicle testingMeasurement of fluid loss/gain rateTest efficiencyProduction line

The invention discloses an automobile air dryer assembling and testing production line. At present, assembly of most of automobile air dryers at home is in a scattered operation state and a testing method is a manual intermittent partial testing method; however, selection and matching of the conventional assembling and testing equipment are not reasonable enough and poor in coordination; and therefore, the assembling process of the automobile air dryer is poor in smoothness and low in assembling and testing efficiency. The automobile air dryer assembling and testing production line comprises a U-shaped workbench line body, wherein the U-shaped workbench line body comprises six assembling workstations, two testing workstations and an assembling and testing workstation, namely a first workstation, a second workstation, a third workstation, a fourth workstation, a fifth workstation, a sixth workstation, a seventh workstation, an eighth workstation and a ninth workstation sequentially; the adjacent workstations are related to each other through a material conveying belt. A shell of the assembled and tested air dryer is transferred among the workstations through the material conveying belts between the workstations, working procedures are continuous, and the workstations are related through the material conveying belts, so that the assembling pace is ensured and the manufacturing cost is reduced.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

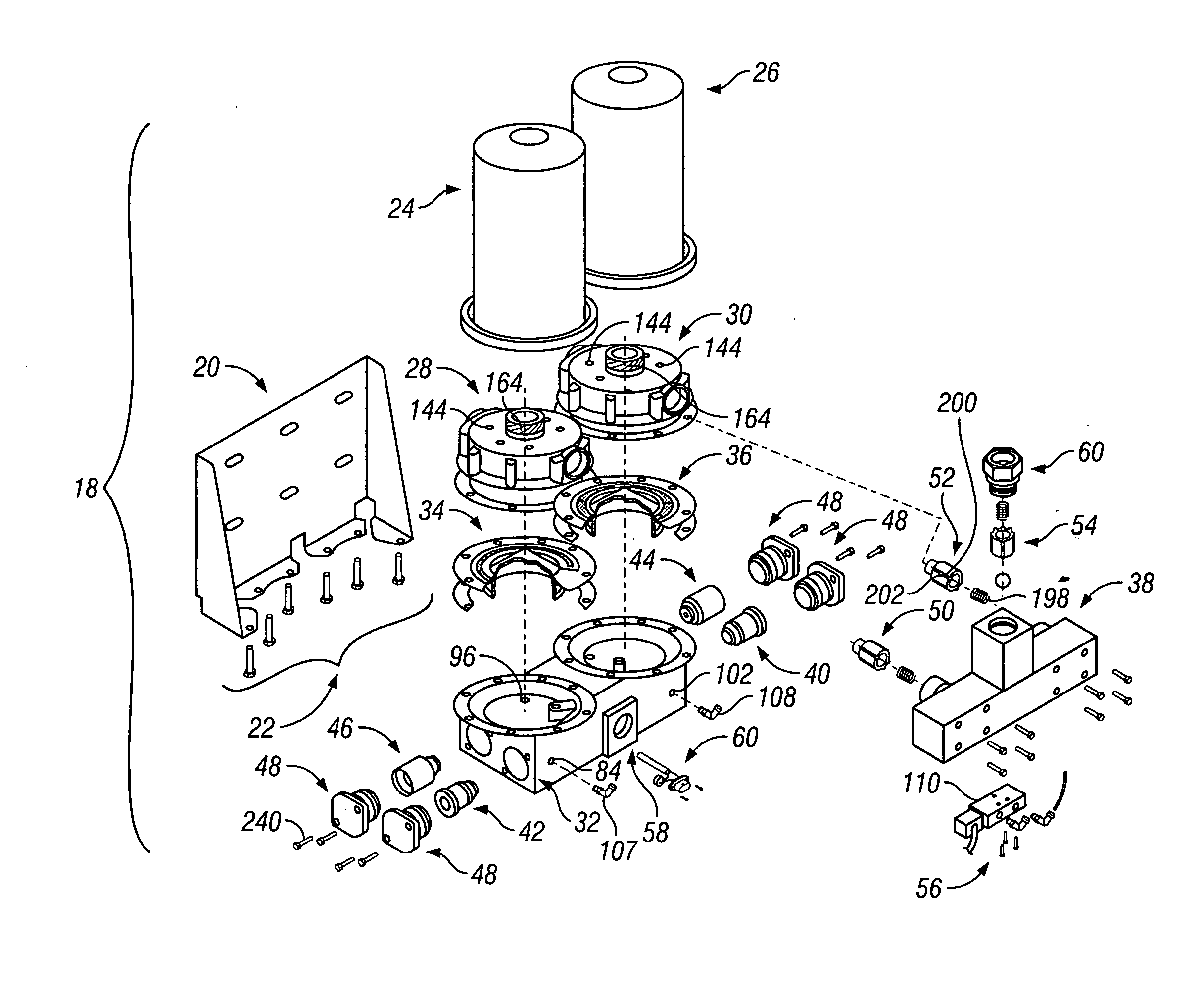

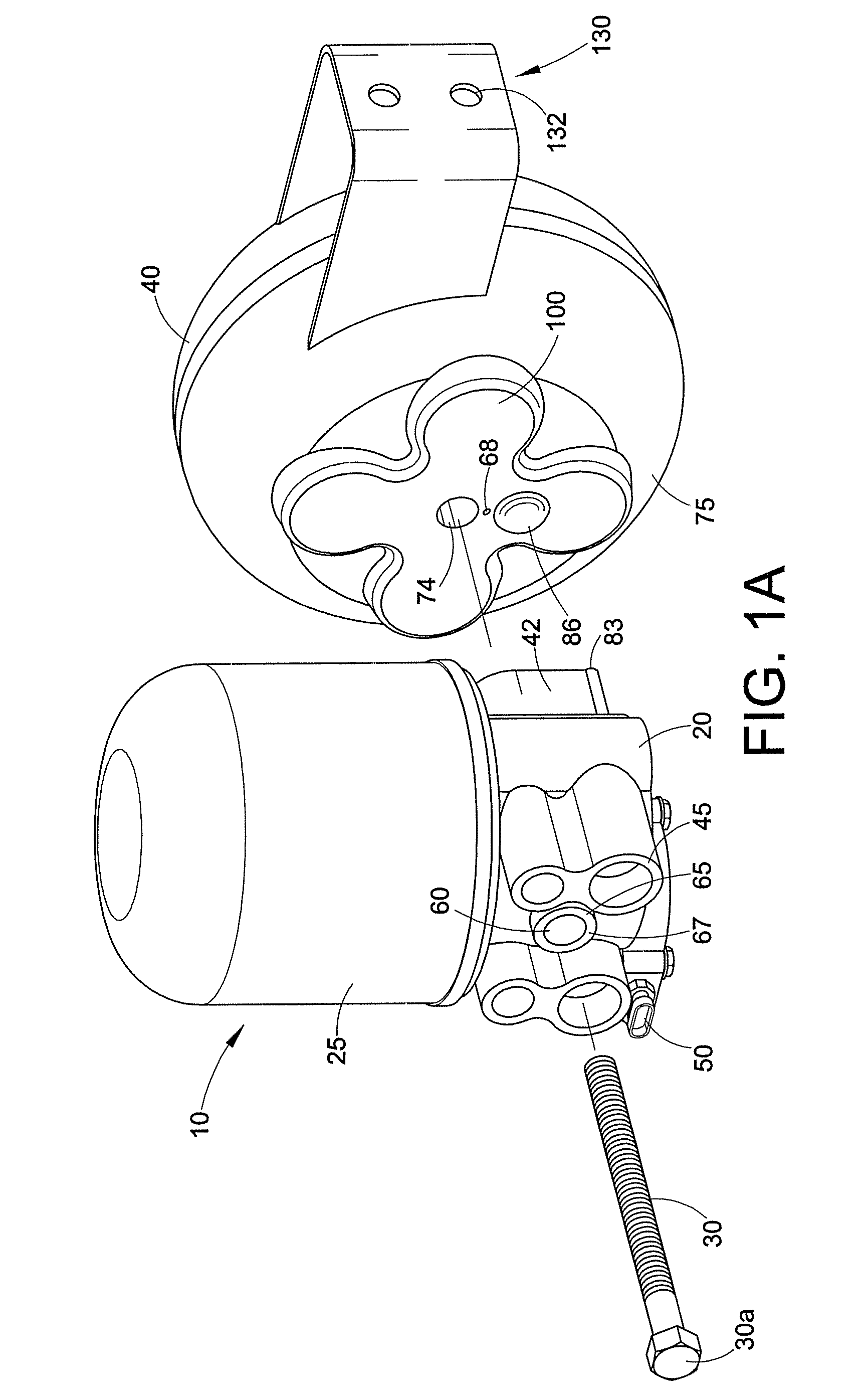

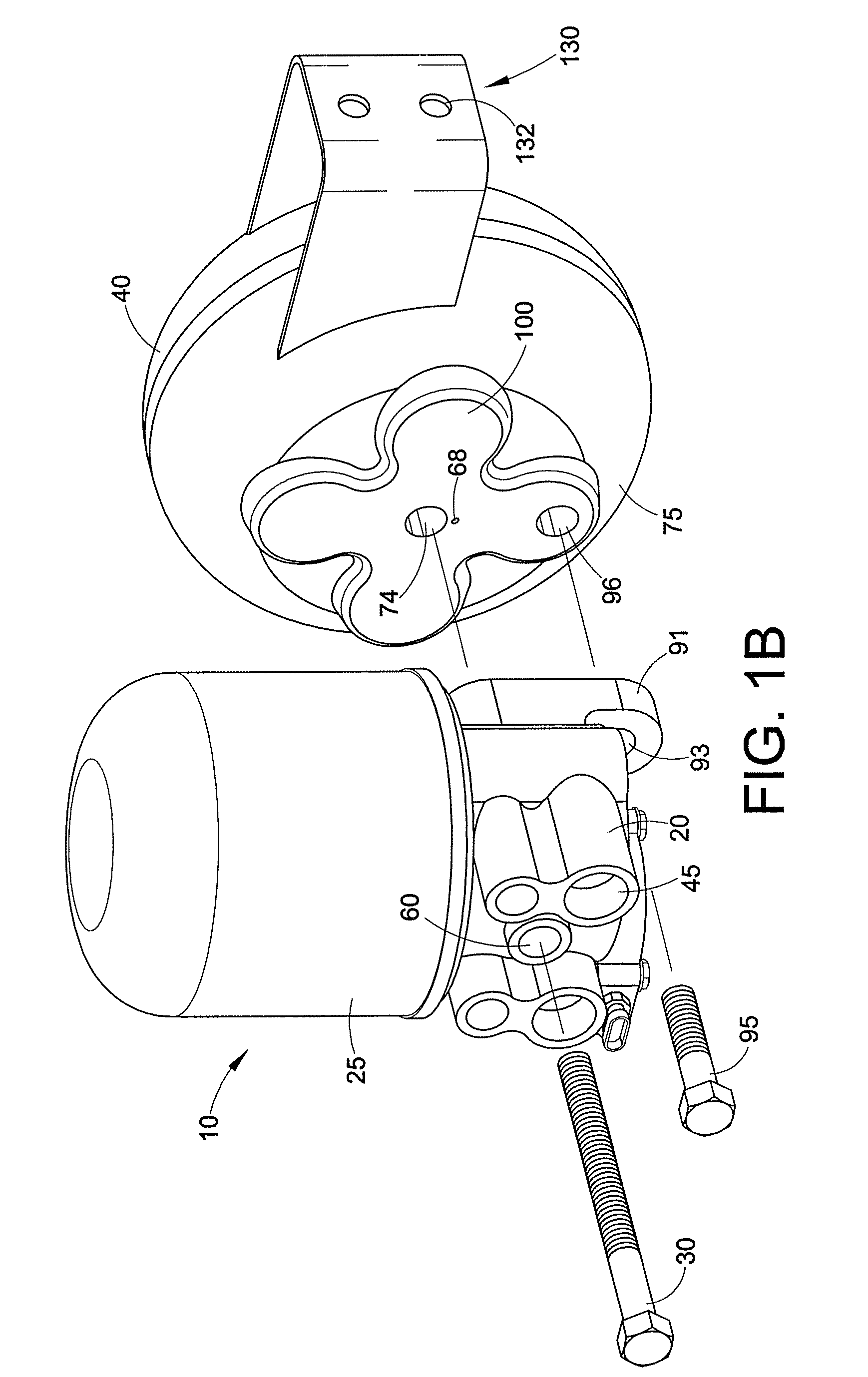

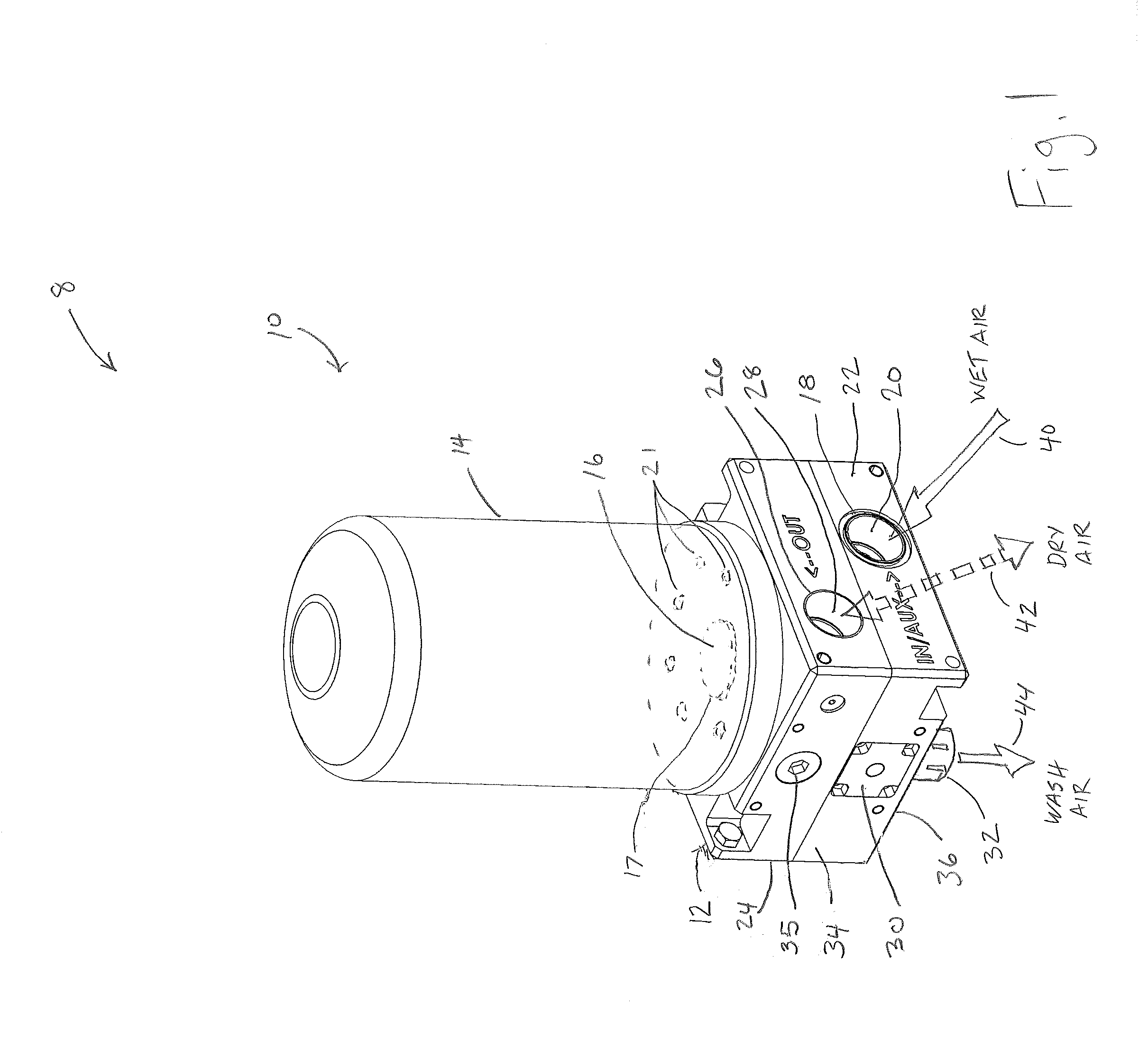

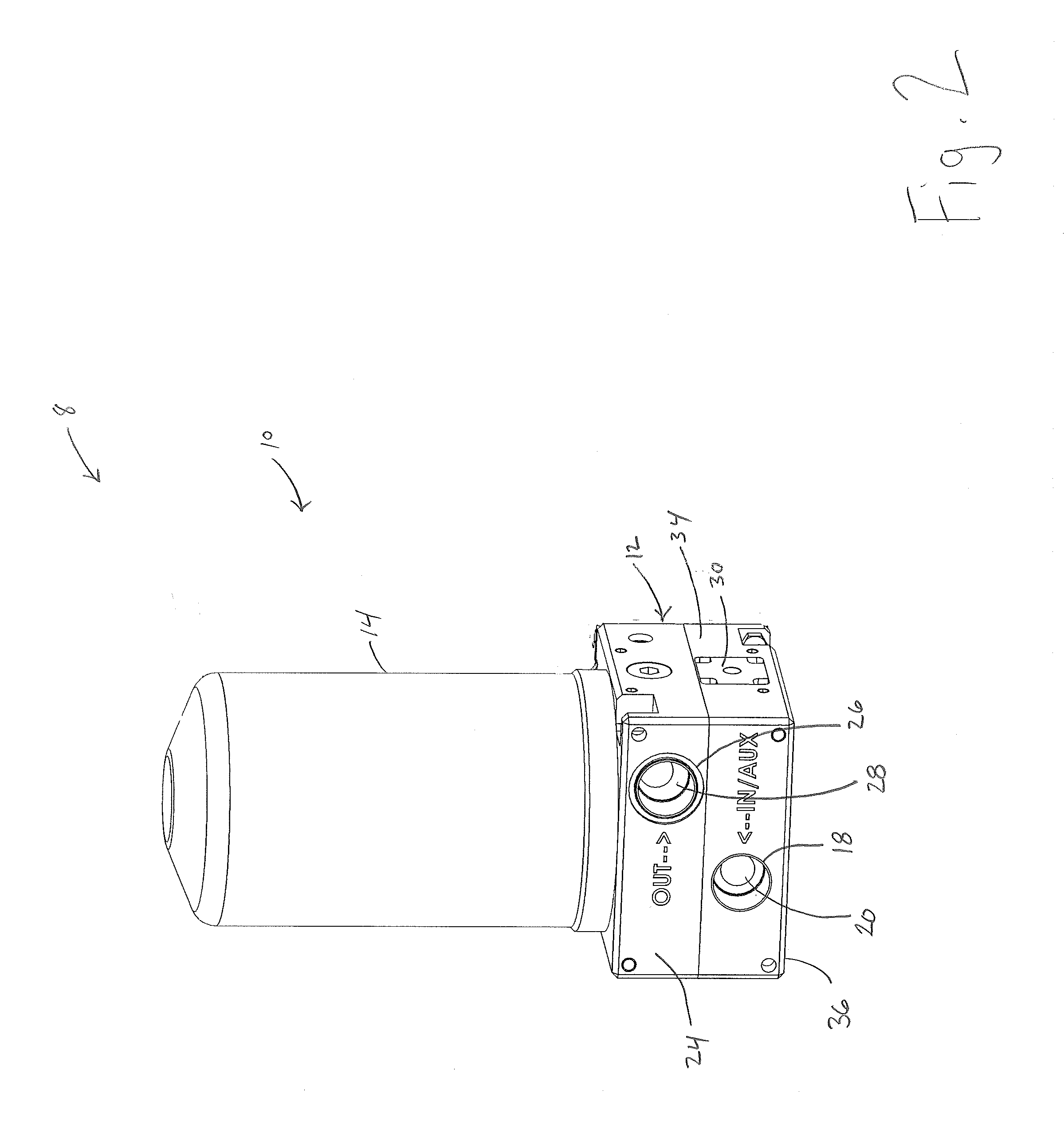

Air dryer mounting assembly

InactiveUS7100305B2Easy to assembleThe process is compact and efficientCombination devicesPipe supportsDesiccantEngineering

An improved system and method for mounting an air dryer is provided. The improved system and method employs a single centralized special fitting that secures the air dryer manifold to a reservoir. The bore in which the fitting is disposed is used to communicate air from the reservoir to the air dryer in order to purge the desiccant in the air dryer. The mounting assembly includes anti-rotational mechanisms which prevent the air dryer from rotating about its axis. The mounting assembly may also include a reservoir and a mounting bracket for the reservoir which uses less than 75 percent of a truck mounting rail height.

Owner:BENDIX COMML VEHICLE SYST LLC

Exhaust air dryer with heat exchanger

ActiveUS8266813B2Restricting or even eliminating a deterioration of efficiencyImprove user friendlinessOther washing machinesDrying machines with non-progressive movementsEngineeringAir dryer

An exhaust air dryer with a drying chamber for items to be dried. The dryer includes a process air fan, a heat exchanger which includes a heat source, a heat sink of a heat pump, and a flushing device for flushing of a first inflow surface of the heat source and a second inflow surface of the heat sink with a liquid which is assigned to the heat source and the heat sink for removing of soil; and air ducts interconnecting the drying chamber, the process air fan, and the heat exchanger for conducting process air.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

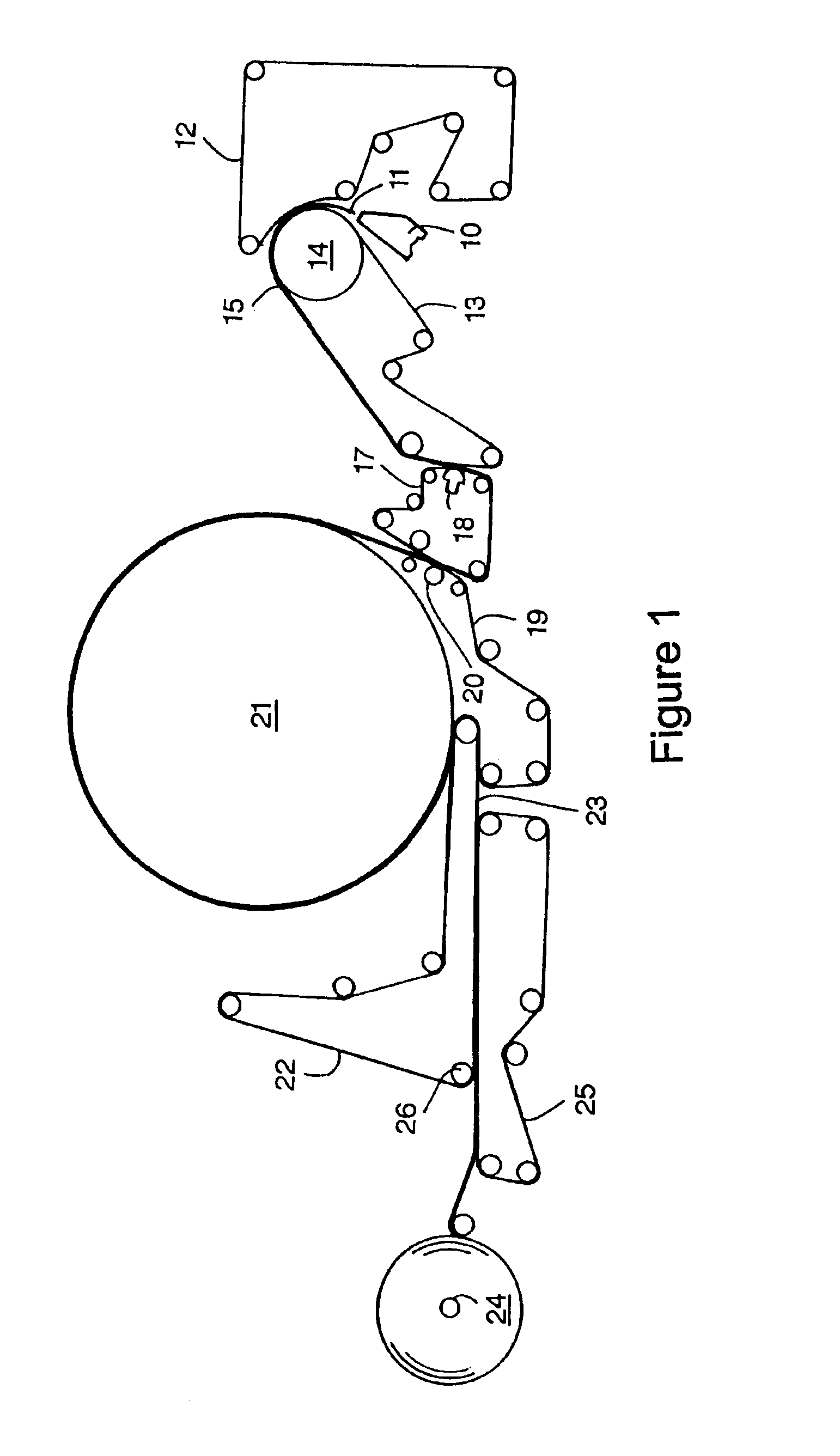

Through-air dryer assembly

ActiveUS6877246B1Easy to transportLessening structural demandDryer sectionDrying machines with progressive movementsAir dryerMechanical engineering

A through-air dryer is disclosed. The through-air dryer includes a cylindrical deck made from a plurality of deck plates that support a throughdrying fabric. The deck plates are supported by opposing hubs. Each of the hubs is in communication with the bearing that is mounted to a stationary shaft for allowing the cylindrical deck and the hubs to rotate. The bearings are positioned so as to create a through-air dryer structure that remains stable during operation and allows for easy calculation of loads on the dryer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

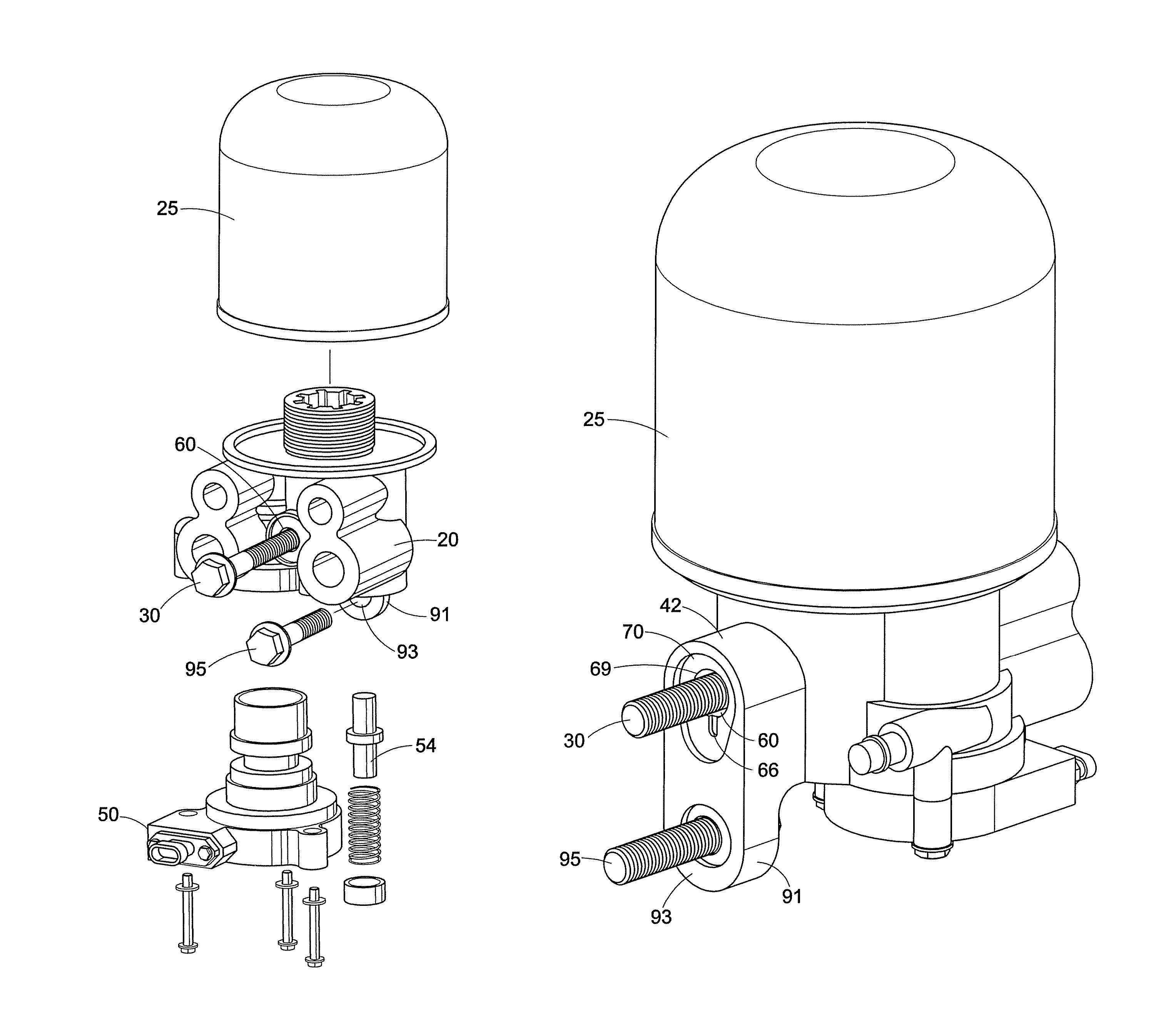

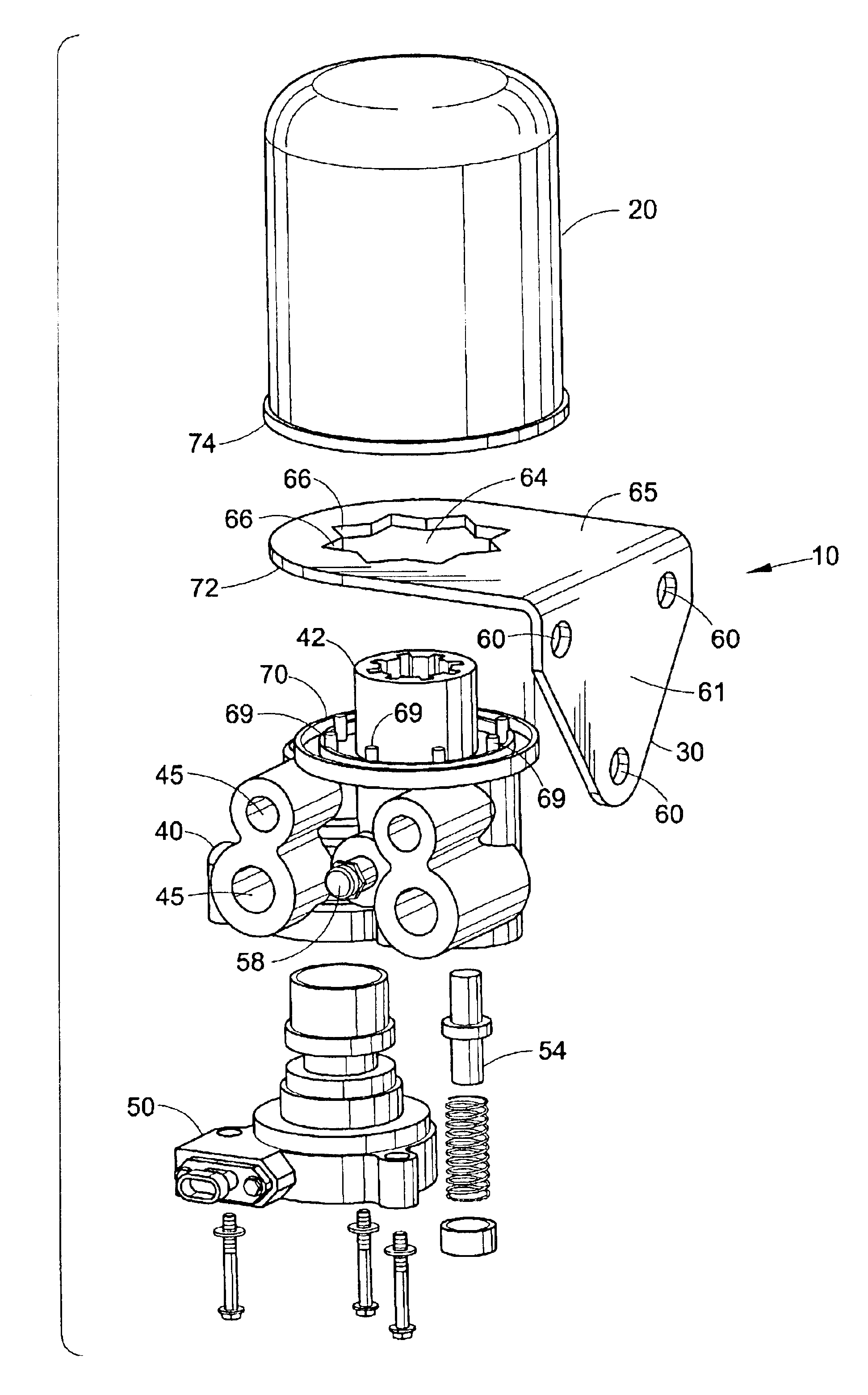

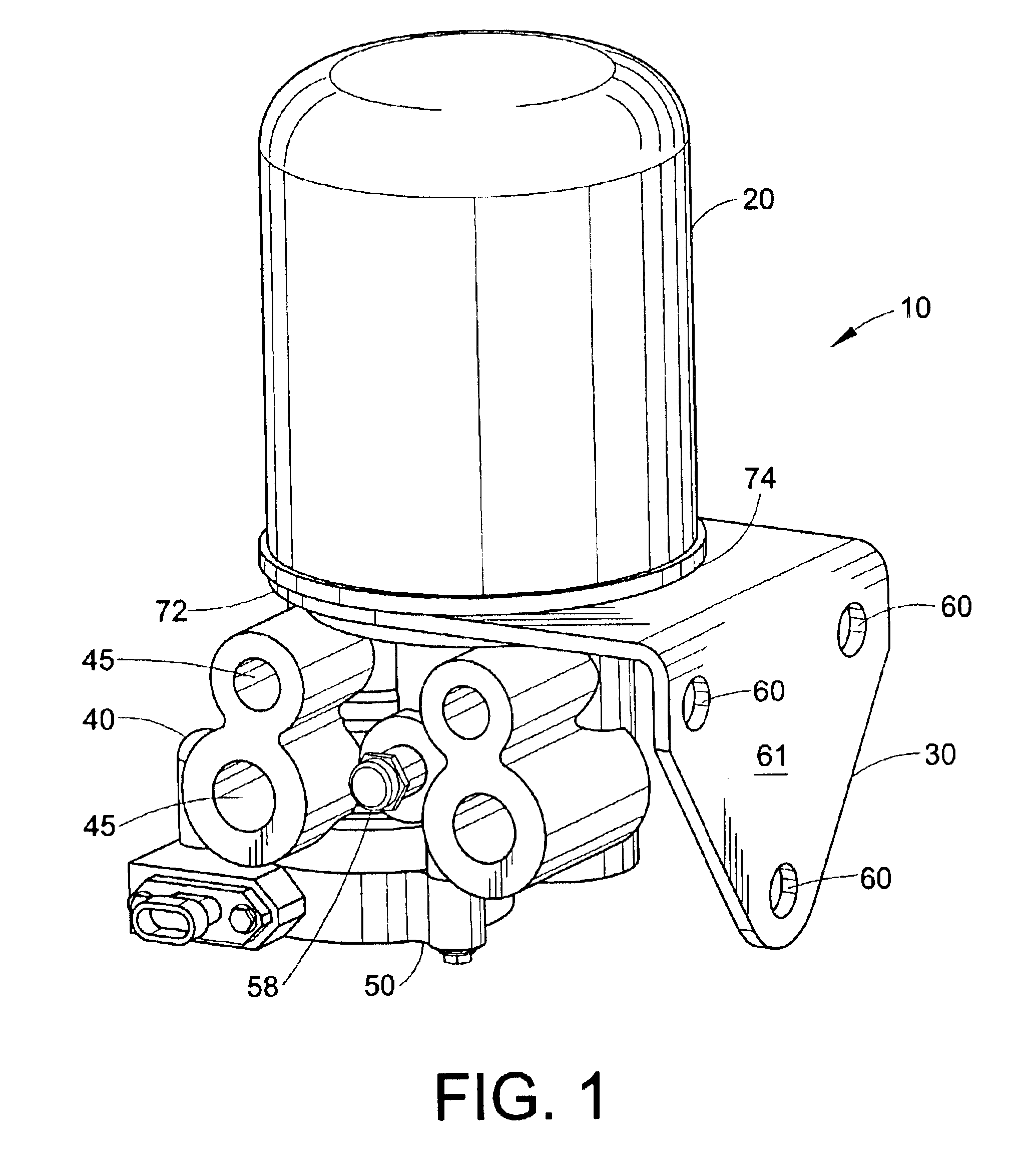

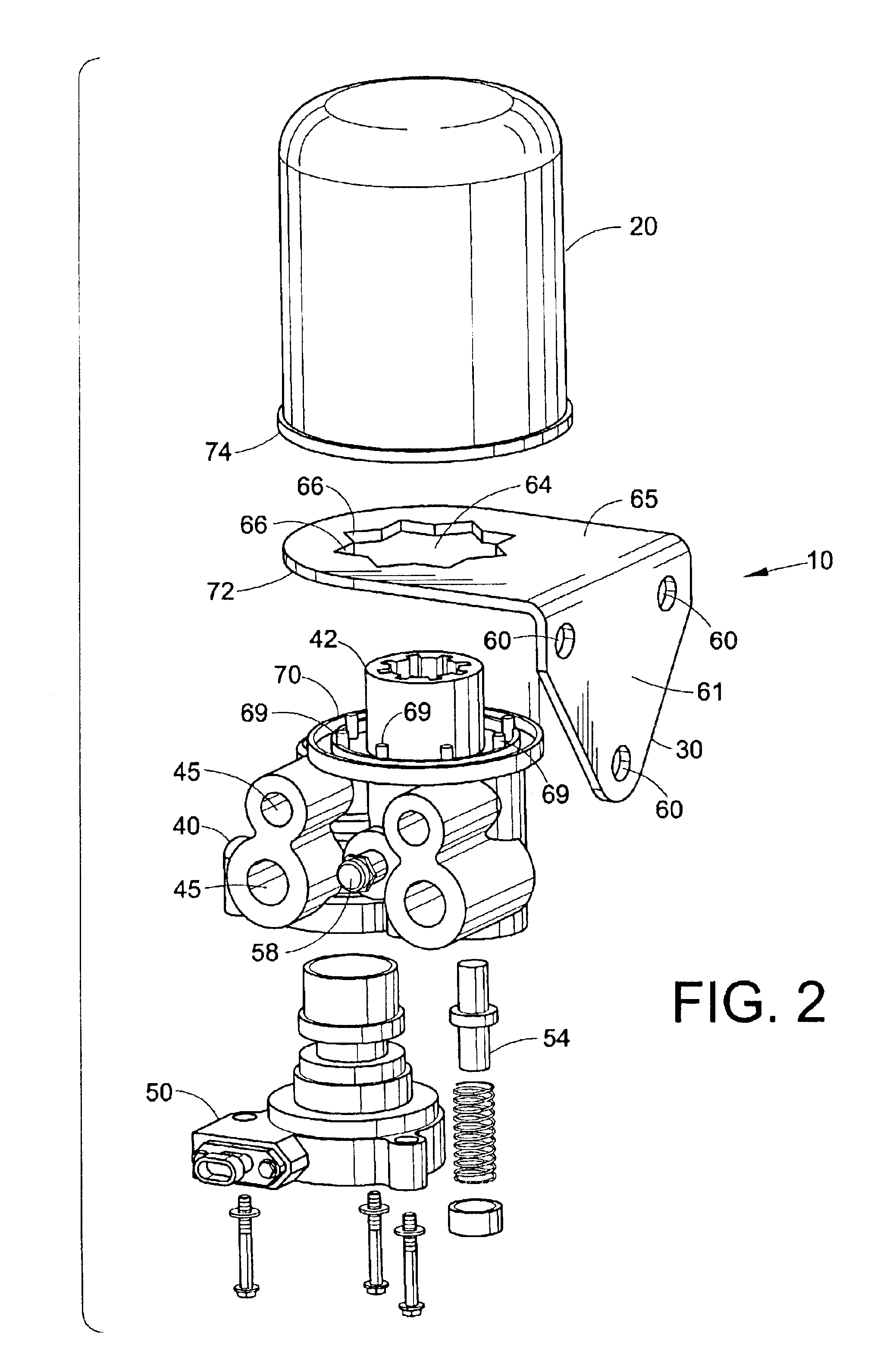

Spin-on desiccant cartridge with integral oil removal filter

InactiveUS6951581B2Simple and economical mannerCombination devicesAuxillary pretreatmentDesiccantCheck valve

An air dryer assembly for removing moisture and oil from a compressed air system includes a desiccant material received in a shell for adsorbing moisture as compressed air passes therethrough. A coalescing element is disposed between an inlet and outlet for removing oil aerosols from the compressed air. A check valve is disposed in parallel with the coalescing element and forces the compressed air to pass through the coalescing element as air flows from the inlet to the outlet. During a purge or reverse flow, compressed air bypasses the coalescing element and removes oil collected in the cartridge through the inlet.

Owner:BENDIX COMML VEHICLE SYST LLC

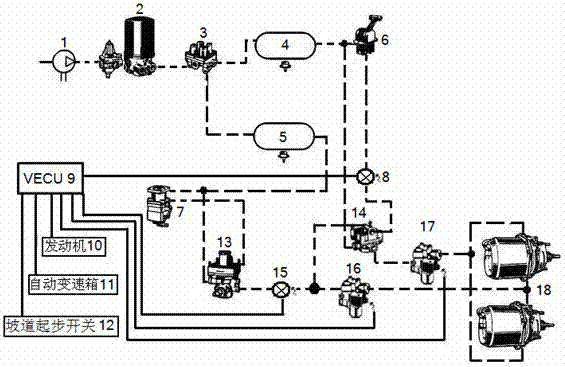

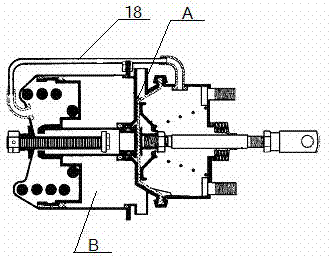

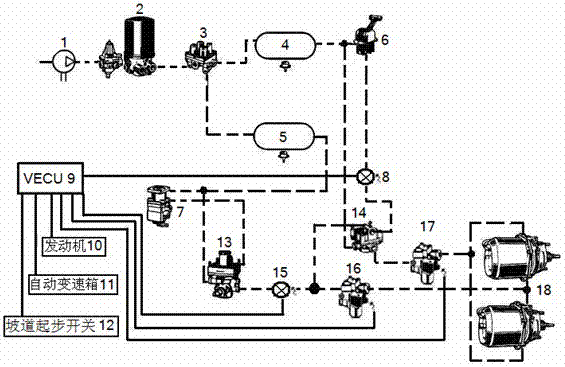

Hill-start control device under traveling and parking braking and using method thereof

The invention relates to a hill-start control device under traveling and parking braking and a using method thereof. In the invention, an air compressor is communicated with a hand braking reservoir and a feet braking reservoir through an air drier and a four-loop protective valve; the other end of the hand braking reservoir is communicated with a spring air chamber sequentially through a hand braking valve, a differential relay valve and a parking hill-start electromagnetic valve; the other end of the feet braking reservoir is communicated with the spring air chamber sequentially through a feet braking valve, an intermediate valve and a traveling hill-start electromagnetic valve; a parking air pressure sensor is arranged on an air path between the hand braking valve and the differential relay valve; a traveling air pressure sensor is arranged on an air path between the intermediate valve and the traveling hill-start electromagnetic valve; and the air pressure sensor and the hill-start electromagnetic valve are both connected with a whole electric control system circuit. The hill-start control device disclosed by the invention has the advantages of hill-start function under traveling and parking braking, stronger automaticity, higher sensitivity, strong controllability, wider application range and higher safety.

Owner:DONGFENG MOTOR CORP HUBEI

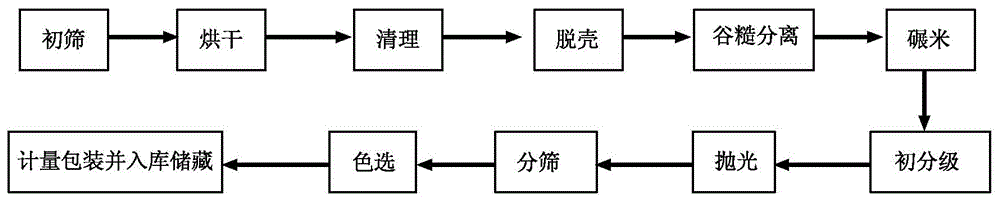

Processing technique for rice

ActiveCN105728084AReduce artificial drying landIncrease the burdenDrying solid materials with heatDrying gas arrangementsAgricultural engineeringRice grain

The invention relates to a processing technique for rice. The processing technique comprises the following steps of preliminary screening, drying, secondary screening, cleaning, unshelling, husked rice separation, rice milling, preliminary classification, polishing, screening, color sorting, metering, packaging, warehousing and storing. The drying process comprises the following specific steps of firstly, feeding preliminarily-screened rice into a hot air dryer, and performing drying treatment at the temperature of 40 to 45DEG C until the water content is 15 to 18 percent; and secondly, feeding the rice subjected to hot air drying into microwave drying equipment for performing drying treatment until the water content is smaller than 13 percent. According to the processing technique disclosed by the invention, a drying mode combines a hot air drying method with a microwave drying method, so that the cost of production equipment is reduced and the production efficiency is improved; and more importantly, the content of soluble amylopectin of the rice can be increased, and the rice is enabled to obtain good mouthfeel.

Owner:聚宝金昊农业高科有限公司

Compressed air processing apparatus for compressed air systems of motor vehicles

InactiveUS20050017474A1Reduce in quantityStructural expenditure in a motor vehicle requiredResilient suspensionsPump/compressor arrangementsAir treatmentAir dryer

A compressed air processing apparatus includes a pressure controller, an air dryer, a multi-circuit protection valve and an electronic control unit. A switching valve is designed and arranged to supply compressed air to an air suspension system and to deaerate the air suspension system. The electronic control unit is designed and arranged to control the pressure controller, the air dryer and the multi-circuit protection valve. The electronic control unit is designed and arranged to also control the switching valve of the air suspension system.

Owner:HALDEX BRAKE PROD GMBH

Vehicle air system having an indicator device and method

Various compressed air systems for commercial vehicles are disclosed. In one embodiment, a compressed air system is provided that includes a compressor, an air dryer apparatus, a purge reservoir, and an indicator device. The indicator device comprises a moisture-indicating material that is in contact with the purge air within the purge reservoir.

Owner:BENDIX COMML VEHICLE SYST LLC

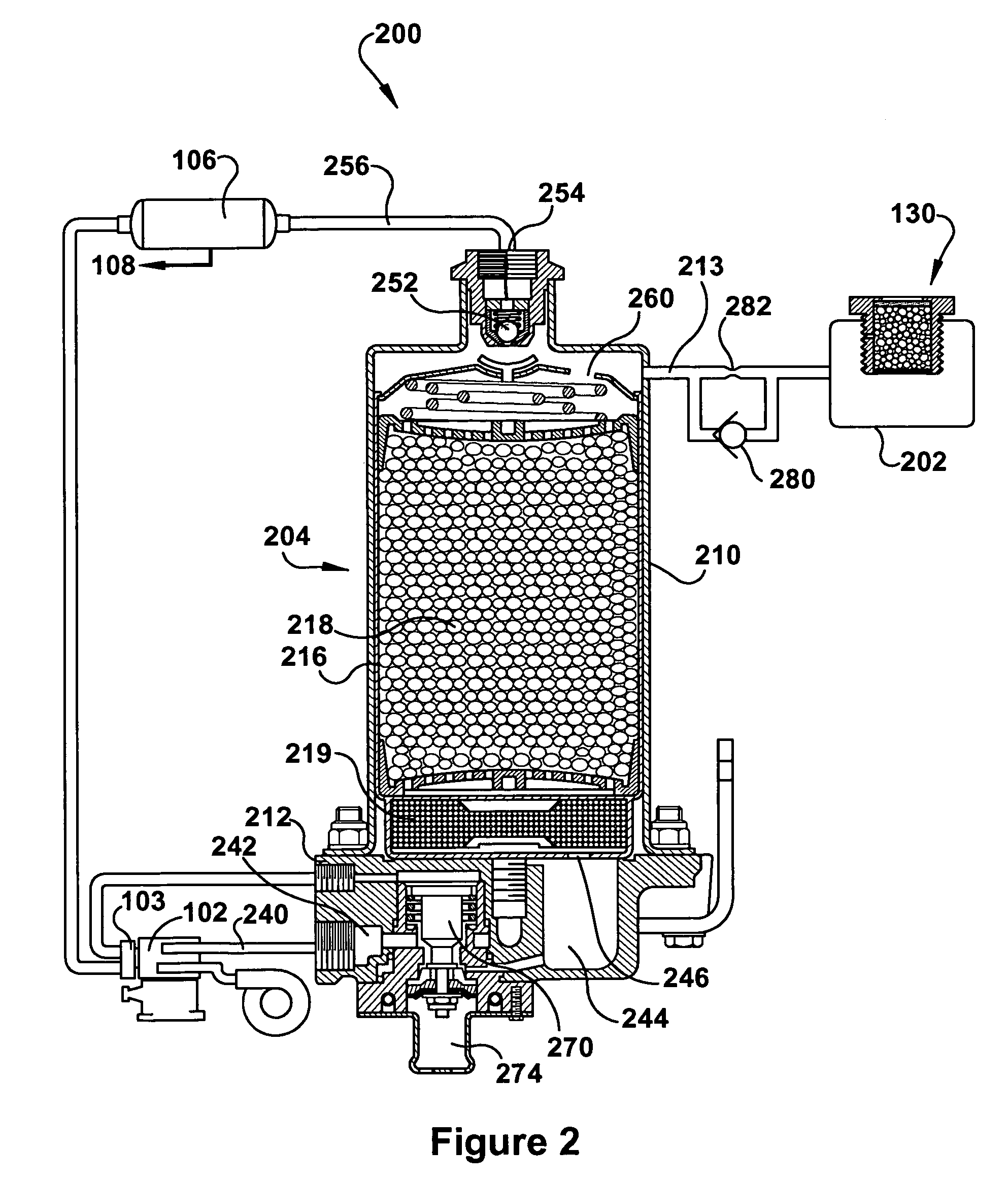

Regenerative air dryer

ActiveUS20140013956A1Simplified air pathsReduces external pipingGas treatmentIsotope separationDesiccantAir dryer

A regenerative air drying system including at least one dryer module including a housing having a inlet air passage, an outlet air passage, and a wash air passage. The air dryer system further includes a desiccant canister mounted to the housing and in communication with the inlet, outlet, and exhaust air passages, and a single controllable valve selectively moveable between a first position and a second position, wherein the single controllable valve, when in the first position, forms a supply air flow path from the inlet air passage, through the desiccant canister in a first direction, and to the outlet air passage, and when in the second position, forms a wash air path from the outlet air passage, through the desiccant canister in a direction opposite the first direction, and to the exhaust air passage.

Owner:SUBURBAN MFG

Remote purge drying unit for compressed gas

An air dryer assembly and mounting bracket for mounting an air dryer to a vehicle. The air dryer assembly has a manifold and a canister which seal against the surface of the mounting bracket. Orientation pegs are provided along the sealing surface of the air dryer manifold and receive corresponding indented regions in a cut out region in the mounting bracket. By providing a number of orientation pegs on the surface of the manifold, a number of mounting orientations for the air dryer assembly can be achieved.

Owner:BENDIX COMML VEHICLE SYST LLC

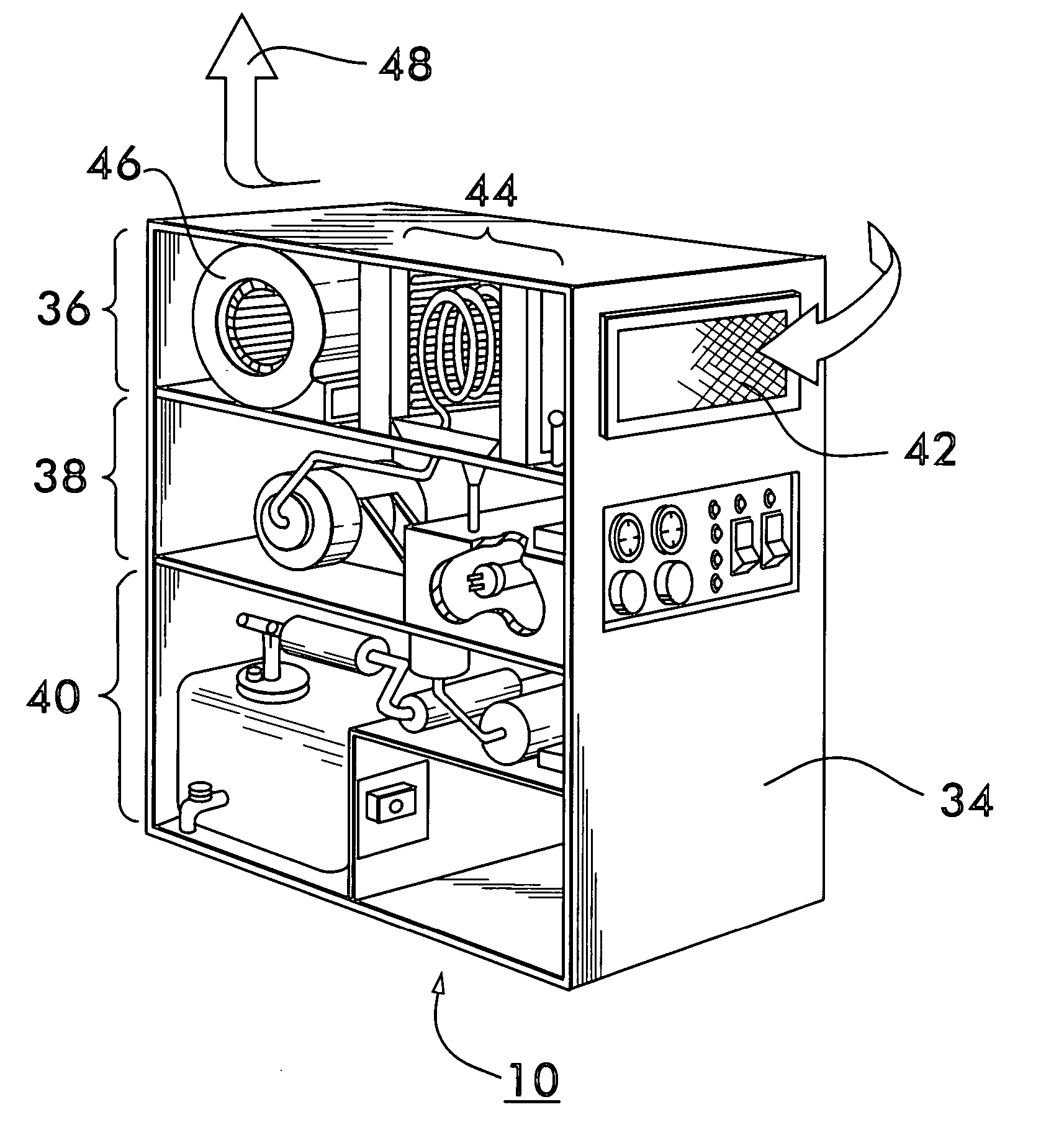

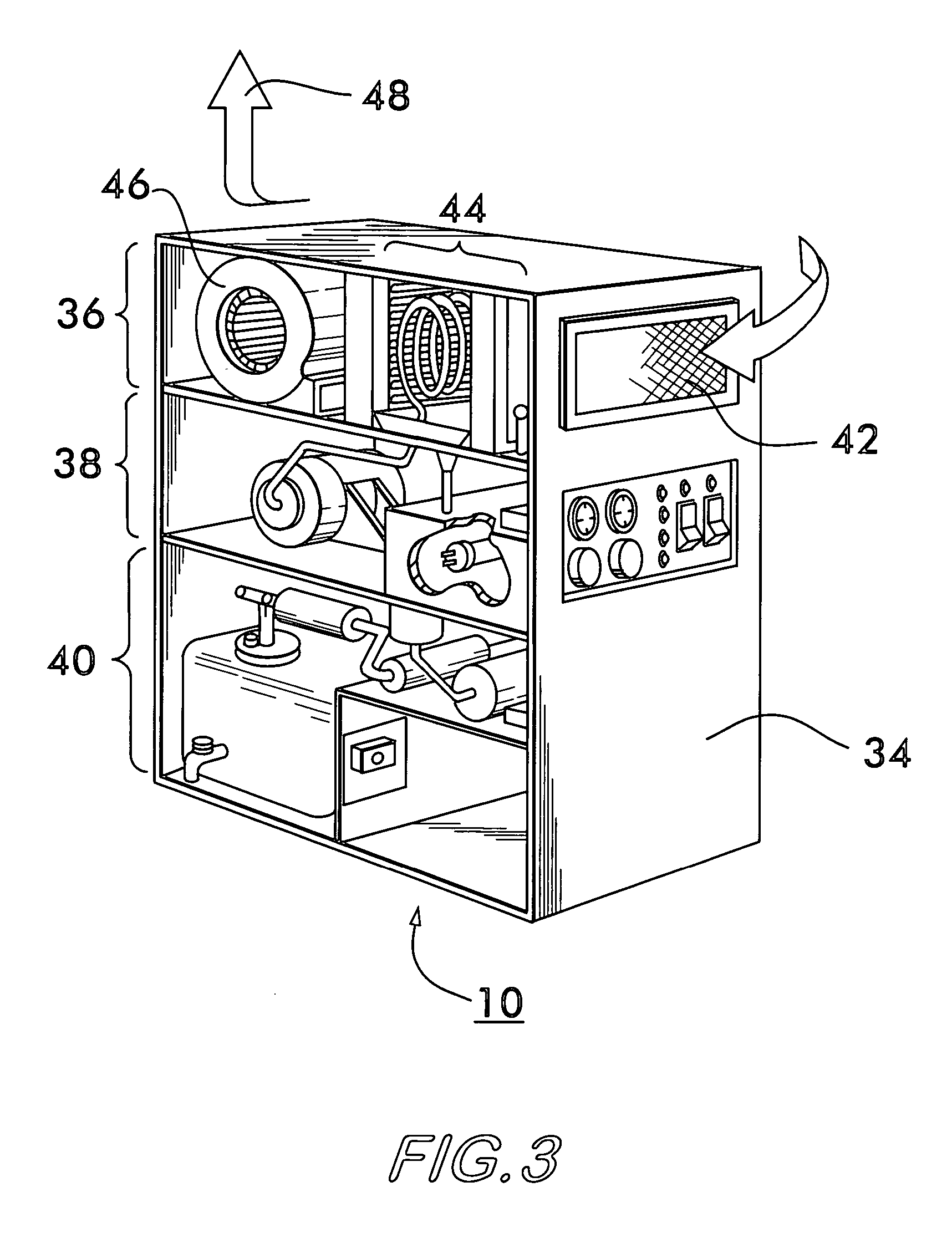

Co-generation power system for supplying electricity to an air-water recovery system

InactiveUS20060257258A1Reduce consumptionCost of operationPropellersPump componentsCogenerationForced-air

A mobile, self-propelled platform, which includes an enclosed trailer containing a portable air-water recovery system, is disclosed. This trailer includes a wind turbine mounted outside of the closed trailer environment, and adapted for recovery of energy from an exhaust air stream that is vented from within the enclosed trailer environment. The energy generated from such exhaust air stream is used to supplement traditional power sources associated with the operation of water generation process. The energy recovered from the exhaust air stream is projected to reduce the overall operating cost of the air-water recovery system by least 25%, based upon its current energy consumption needs. This system has application to other environments in which a force air stream is produce incident to operation of a primary process, as for example, where a high pressure, air dryer is used to remove moisture from a product, or to accelerate a curing operation.

Owner:ZWEBNER MICHAEL J

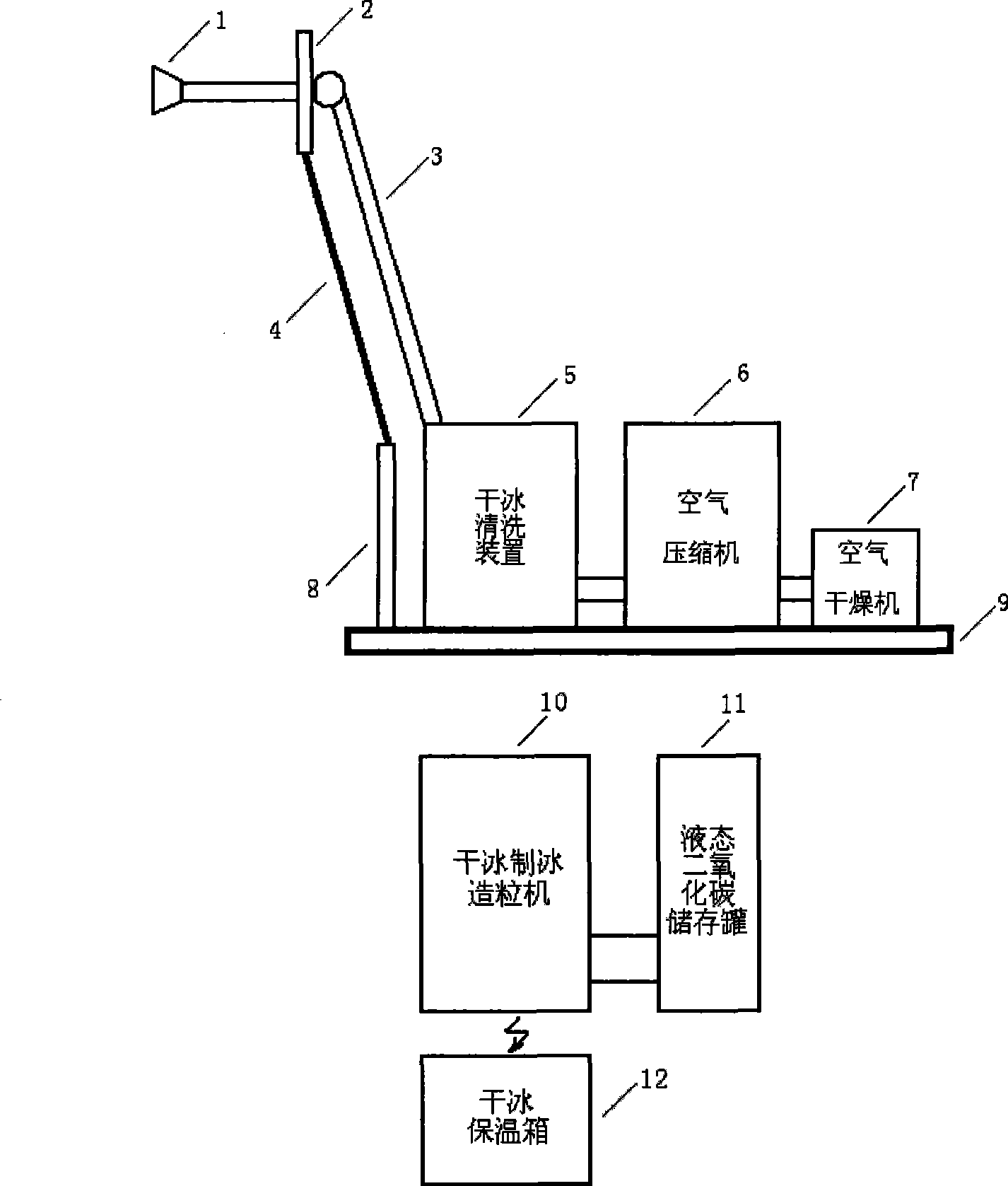

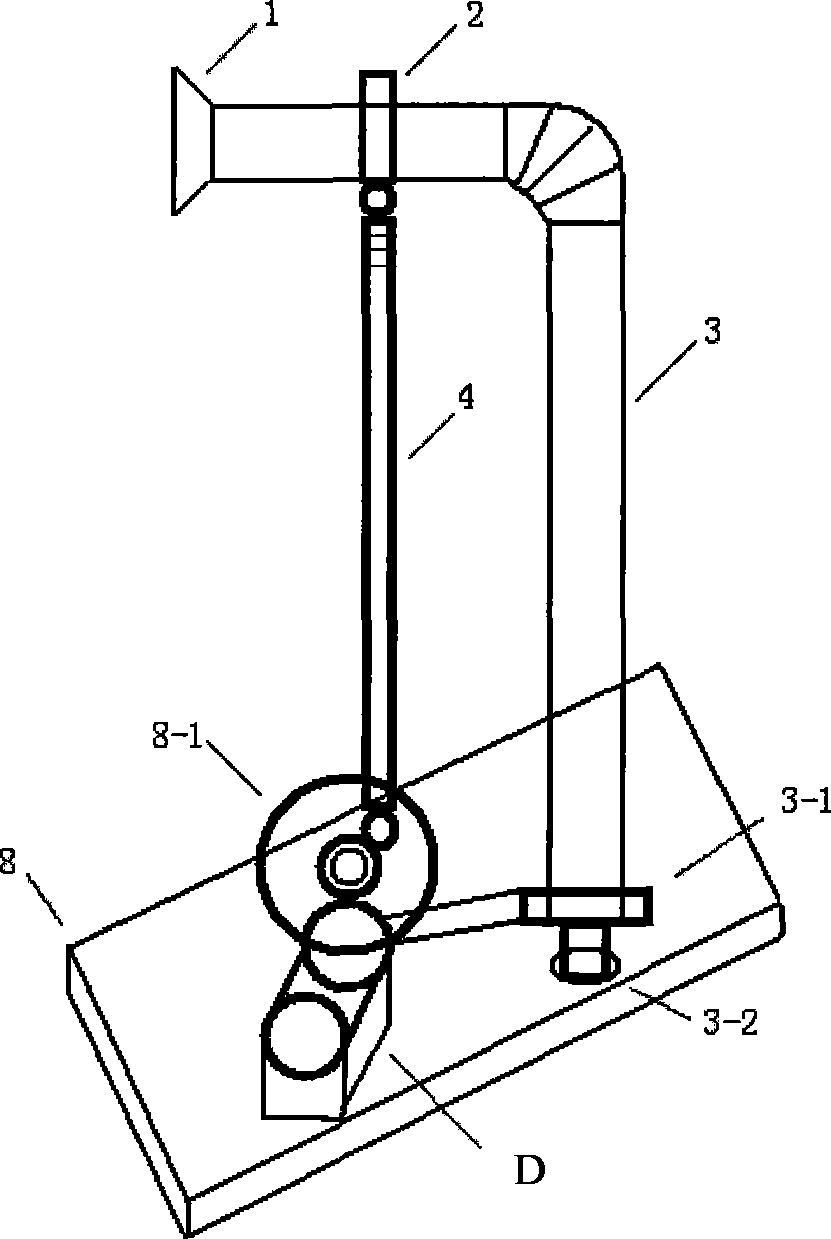

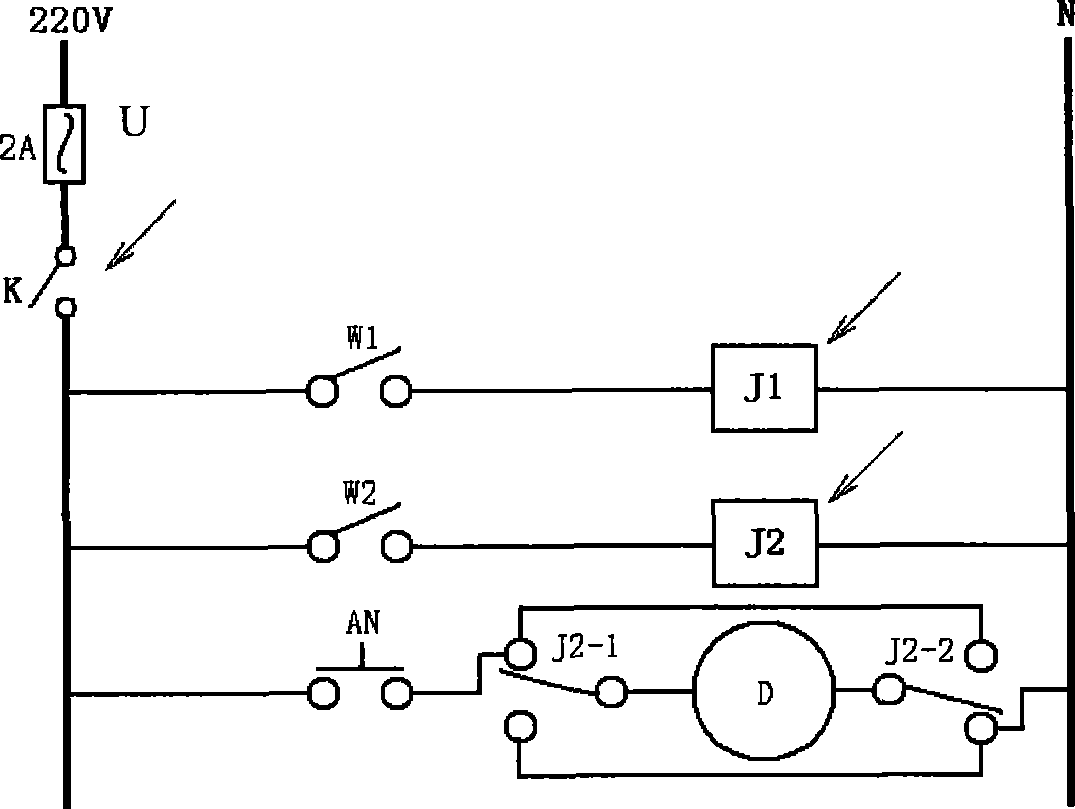

Dry ice cleaning system for electrical apparatus external insulation

InactiveCN101480651AAvoid influenceLow costCleaning processes and apparatusTransformerElectric power system

The invention discloses a external-insulation dry-ice cleaning system for electrical equipment, which belongs to the technical field of the external-insulation dirt removal of electrical equipment of an electrical system. The external-insulation dry-ice cleaning system adopts the structure that a dry-ice particle spray nozzle (1), an insulating adjustable bracket (2), a dry-ice transmission insulating pipe (3), a dry-ice cleaning device (5), an air compressor (6) and an air dryer (7) are sequentially connected with each other front and back, wherein the dry-ice particle spray nozzle (1), the insulating adjustable bracket (2), an insulating bracket regulating lever pipe (4) and a bracket regulating power device (8) are sequentially connected with each other from front and back, a dry-ice making granulating machine (10) is connected with a liquid carbon dioxide storage tank (11), a dry-ice insulation can (12) is independent equipment, and an earthing base (9) is taken as a safe earthing pedestal of the external-insulation dry-ice cleaning system. The invention has high dirt removing efficiency, is suitable for the on-line cleaning of an insulating sleeve and an insulating mainstay or an erected transmission line insulator inside a transformer station, and is an effective measure for safely generating the electricity and ensuring the electricity supply.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com