Patents

Literature

318results about How to "Fast control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

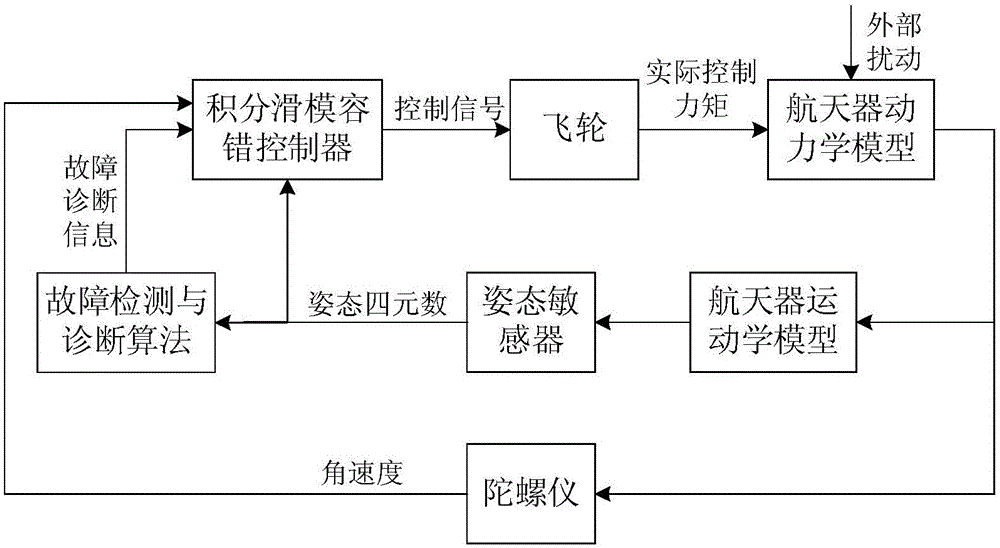

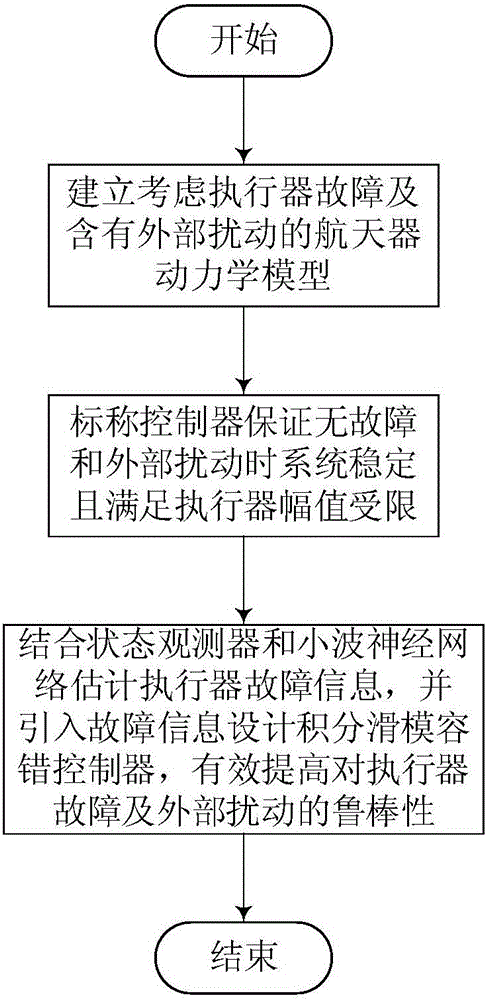

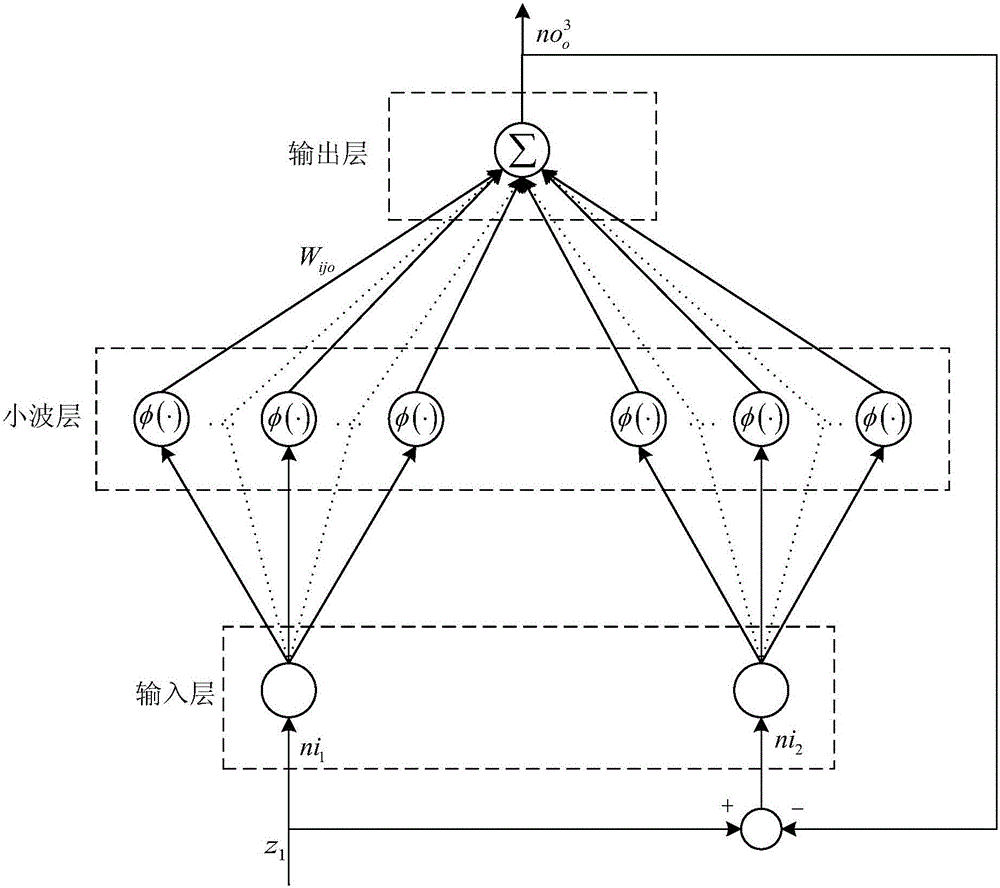

Spacecraft attitude integral sliding mode fault tolerance control method taking consideration of performer fault

ActiveCN105843240AEasy to satisfy control torque limited constraintsSatisfy the control torque limited constraintCosmonautic vehiclesCosmonautic partsActive faultDynamic models

The invention relates to a spacecraft attitude integral sliding mode fault tolerance control method taking consideration of a performer fault and provides a robustness attitude active fault tolerance control method based on an integral sliding mode surface for problems of the performer fault, external disturbance and control moment amplitude limits in a spacecraft attitude control process. The method comprises steps that firstly, a spacecraft attitude dynamics model taking consideration of the performer fault and containing external disturbance is established; secondly, on the condition that a performer is not in fault, a designed nominal controller can guarantee system stability, and input saturation amplitude limits can be easily satisfied through adjusting controller parameters; lastly, the fault information is introduced to design an integral sliding mode controller, robustness of external disturbance and the performer fault can be effectively improved, system stability is analyzed on the basis of an Lyapunov method. The method is advantaged in that stability of the attitude control system is guaranteed when a spacecraft operating on orbit generates the performer fault, and relatively strong fault tolerance capability and external disturbance robustness are realized.

Owner:BEIHANG UNIV

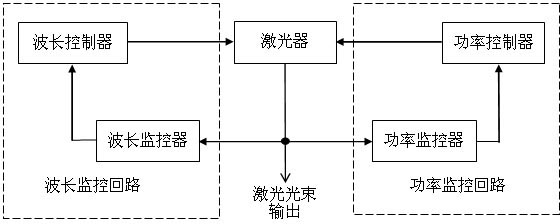

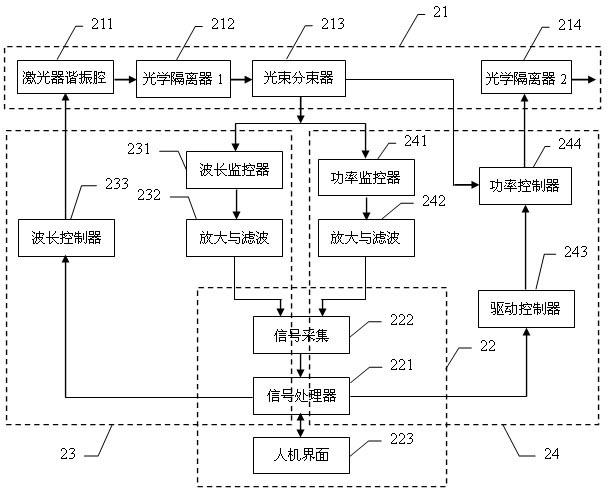

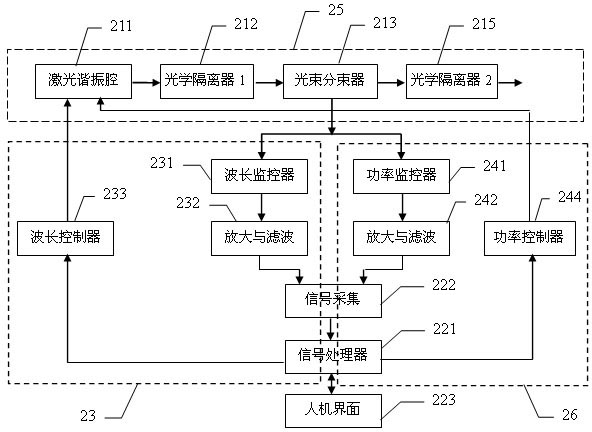

Control method for simultaneously stabilizing laser wavelength and power and control device thereof

ActiveCN102629731AWavelength stableStable powerLaser detailsSemiconductor lasersFrequency stabilizationLow noise

Owner:宁波核芯光电科技有限公司

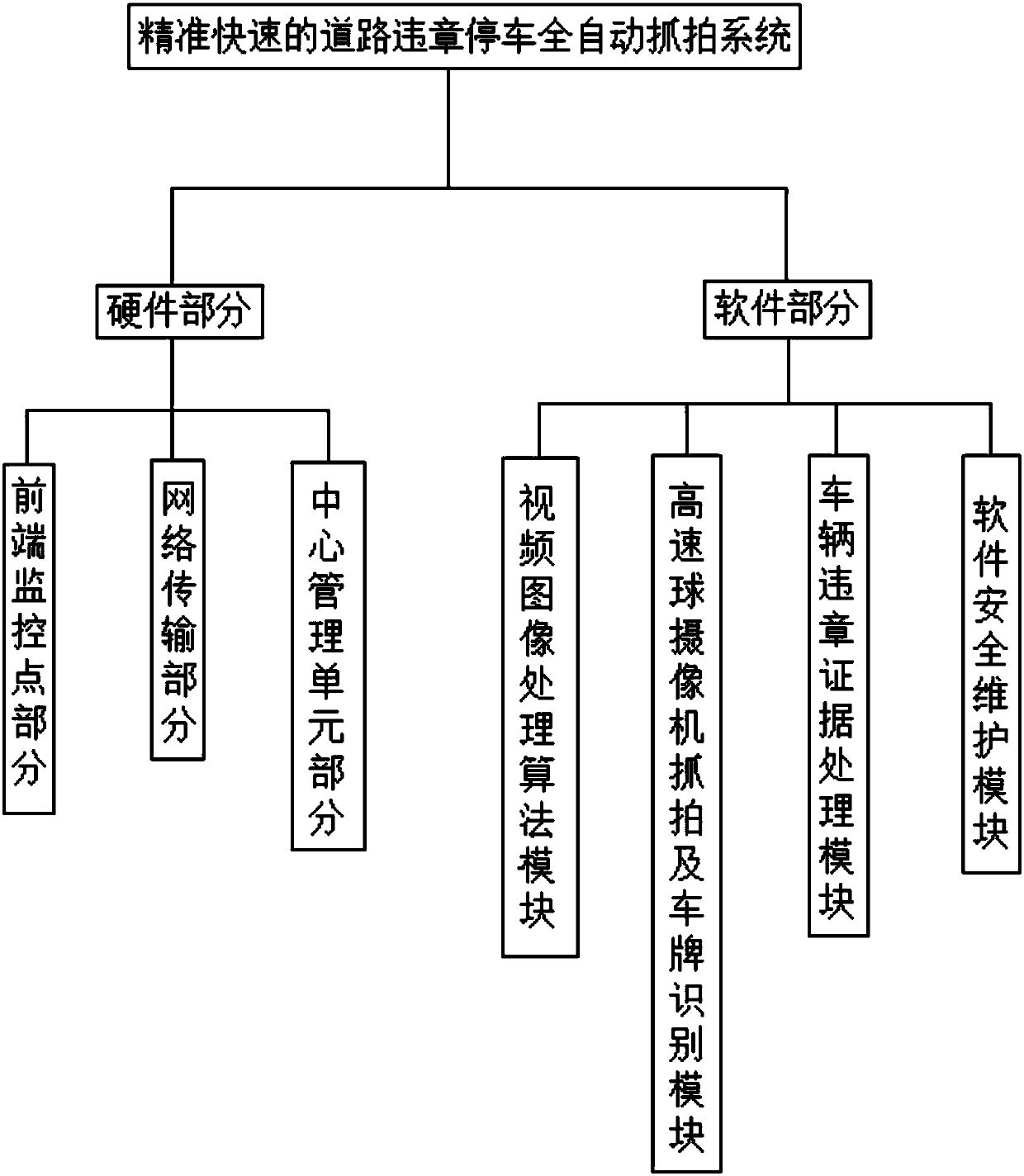

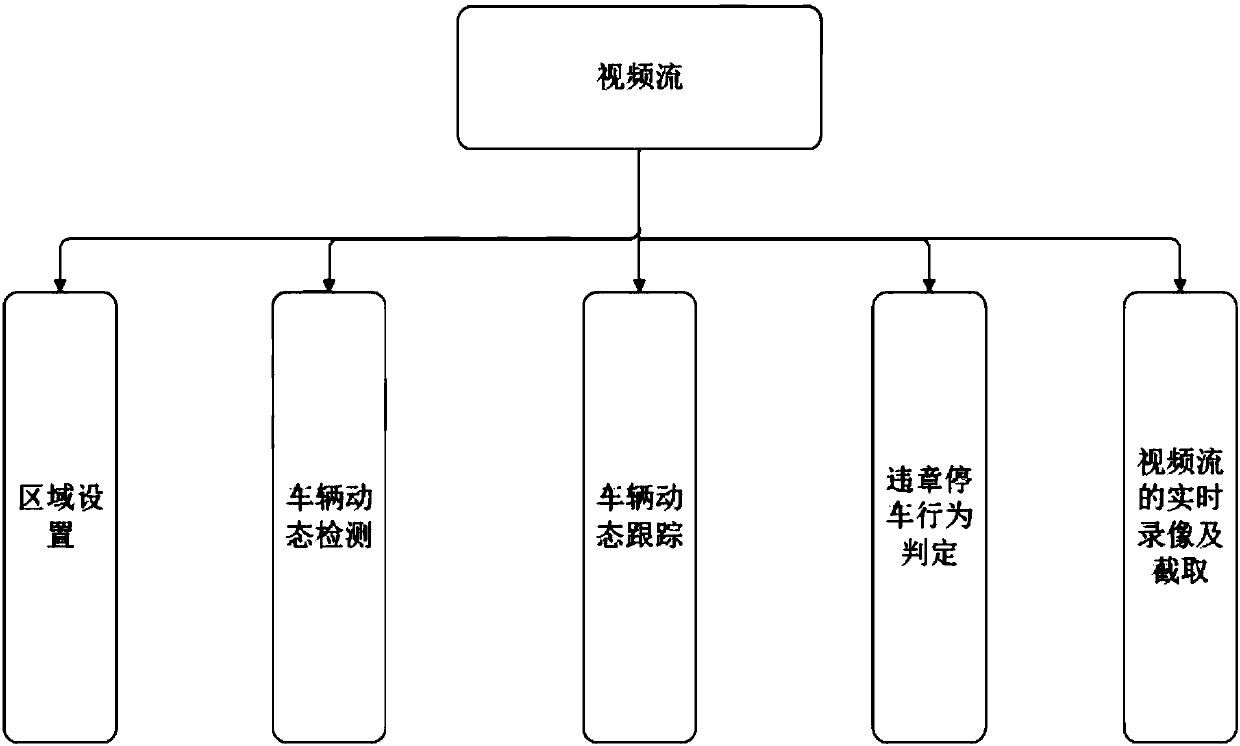

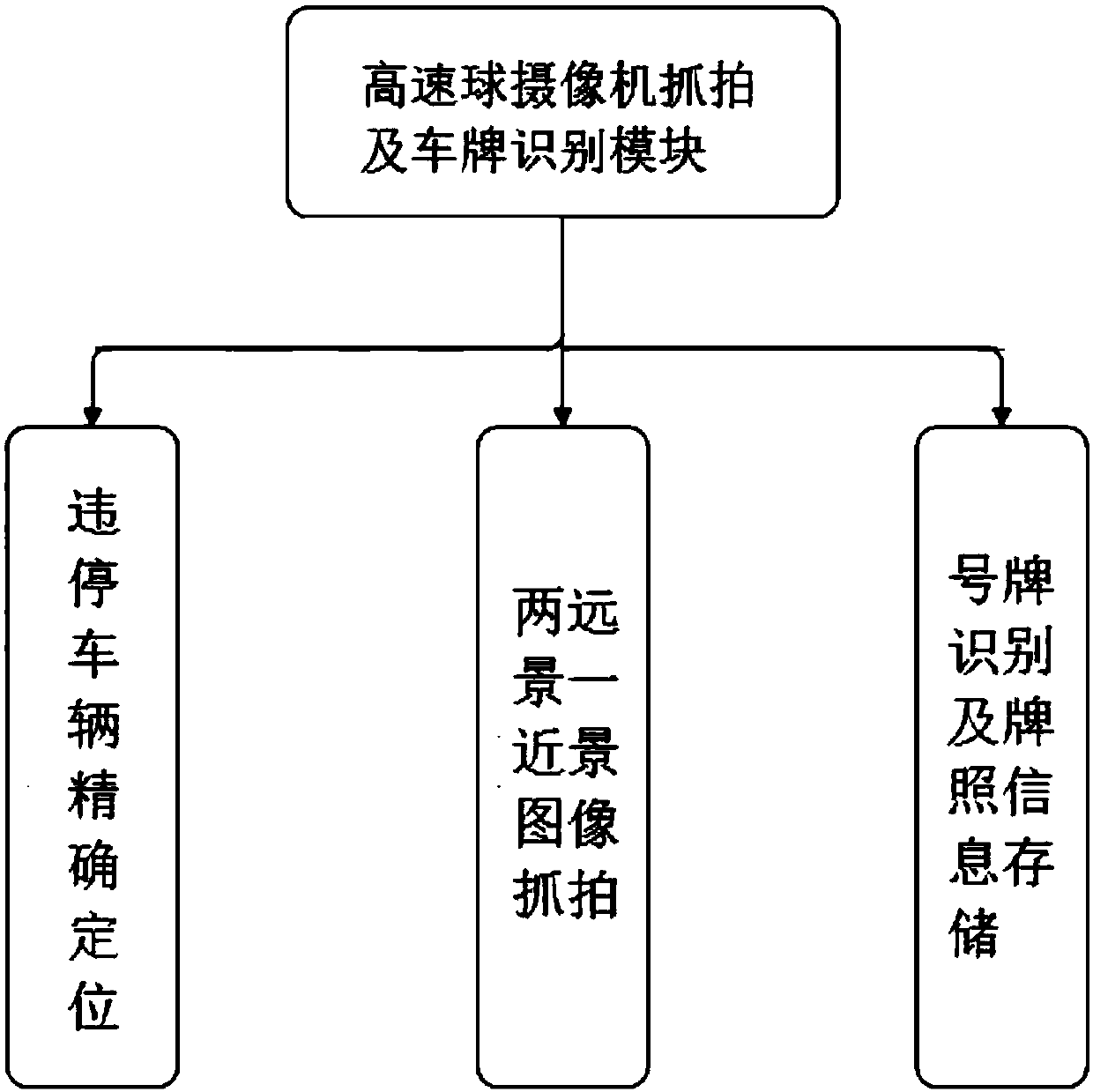

Accurate and rapid road violation and parking full-automatic snapshot system

InactiveCN107705574AAccurate and rapid detection recordsRapid detection recordRoad vehicles traffic controlVideo monitoringVehicle dynamics

The invention provides an accurate and rapid road violation and parking full-automatic snapshot system. The system comprises a front-end monitoring point part, a network transmission part and a centermanagement unit. The vehicle detection technologies mainly comprise the vehicle dynamic detection technology and the vehicle tracking technology. A matched vehicle tracking method is estimated by utilizing the motion detection method based on time-based motion historical images and feature-point optical flows. In order to achieve a better motion detection effect, a shadow removing method is usedand a moving vehicle is more accurately detected. The multi-feature point optical flow detection tracking mode is adopted, and the tracking accuracy is obviously improved in combination with a vehicleshielding solution. The system is powerful in function and is sufficient to meet the requirements of various application occasions. By adopting the system, the functions of the remote control on a ball machine at a front end monitoring point, the previewing of the video monitoring, the automatic detection of the illegal parking, the automatic identification of license plate numbers, the association of the high-definition video recording with illegal behavior videos, the storage and the browsing of the vehicle information, the system management, the remote maintenance and the like are realized.

Owner:荆门程远电子科技有限公司

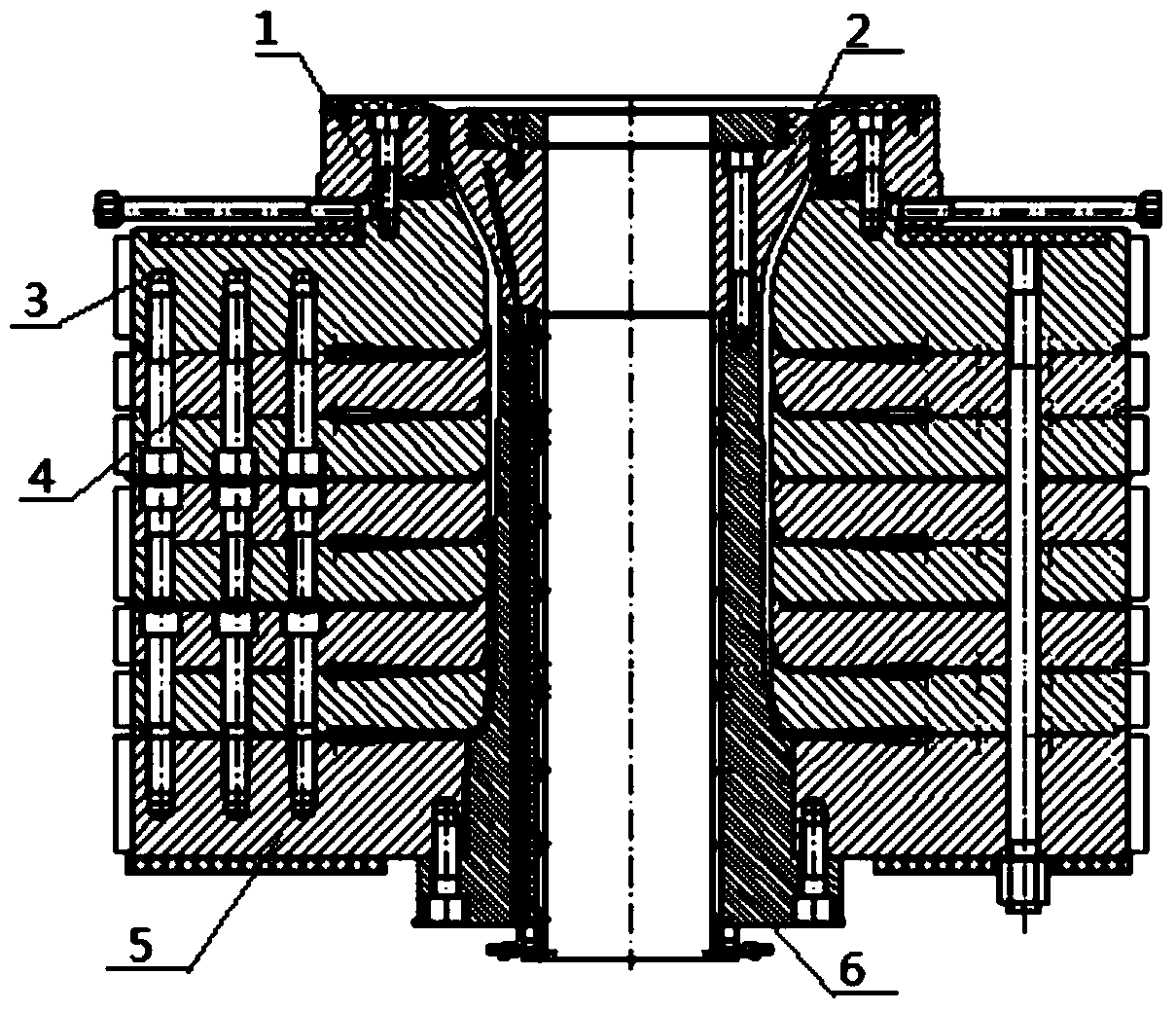

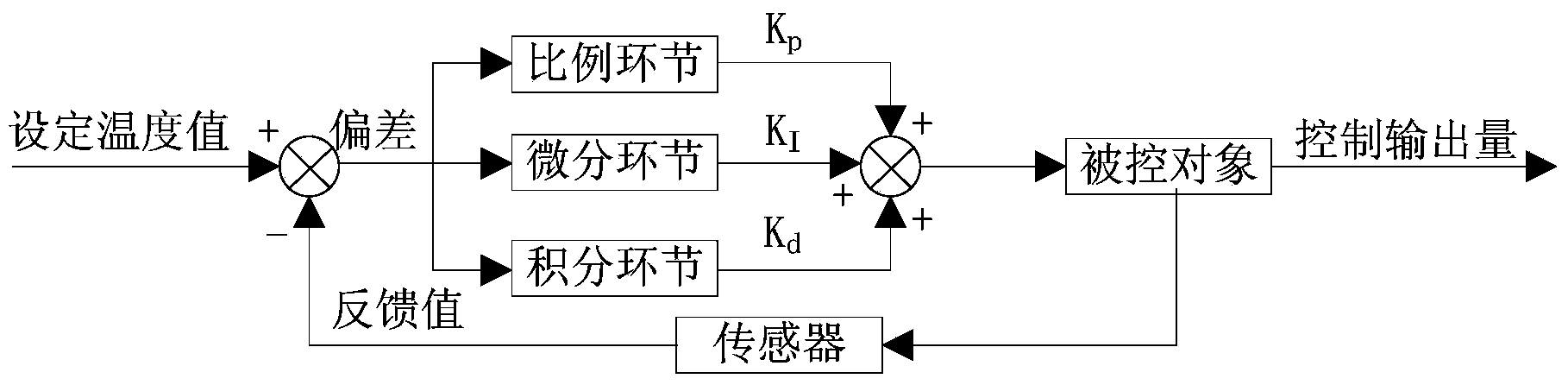

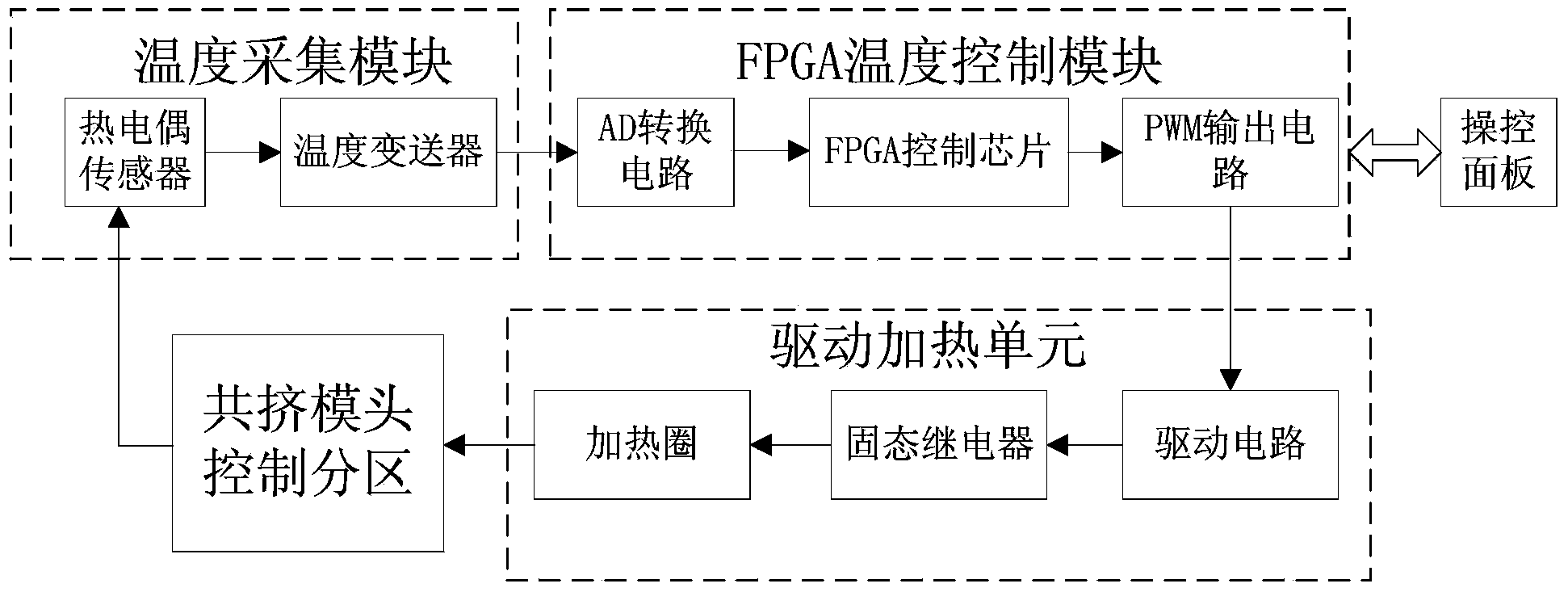

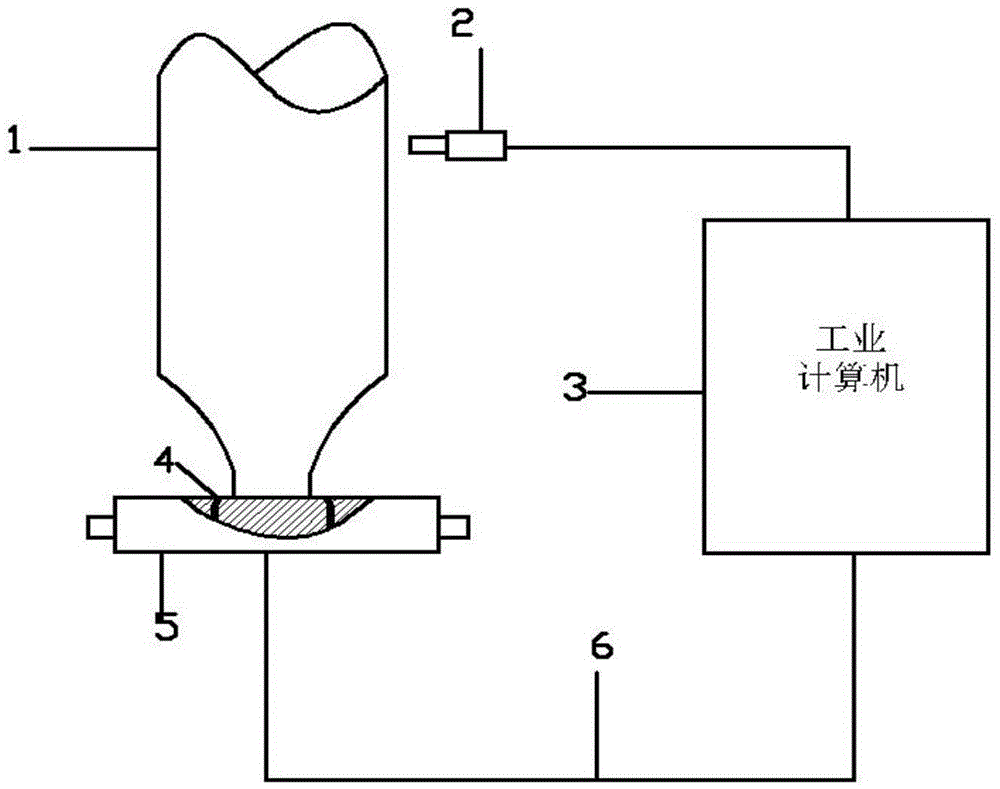

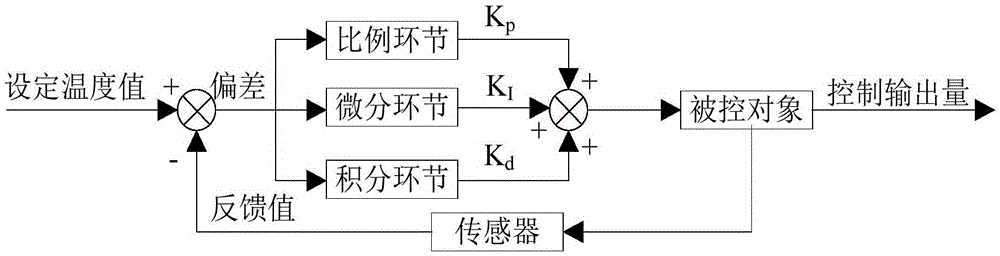

Multi-layer co-extrusion die head intelligent temperature control system and control method thereof

The invention relates to a multi-layer co-extrusion die head intelligent temperature control system including a temperature acquisition module, an FPGA temperature control module, a drive heating module and a control panel. The temperature acquisition module includes N temperature acquisition units; the FPGA temperature control module includes an AD switching circuit, an FPGA control chip for realizing a fuzzy PID control algorithm, and a PWM output circuit; the drive heating module includes N drive heating units corresponding to heaters in a control partition; temperature signals of the control partition are acquired by the temperature acquisition units and are inputted into the FPGA temperature control module, and after treatment, N paths of PWM control variables are outputted and are respectively outputted to the drive heating units by the PWM output circuit in a single path mode. According to the control method, double-parameter input of a deviation e and a deviation change rate e[c] is adopted, correction values of a PID parameter value obtained by fuzzy inference are corrected, final PID input parameter values are obtained, and thus heating coil temperature intelligent control is realized.

Owner:XI AN JIAOTONG UNIV

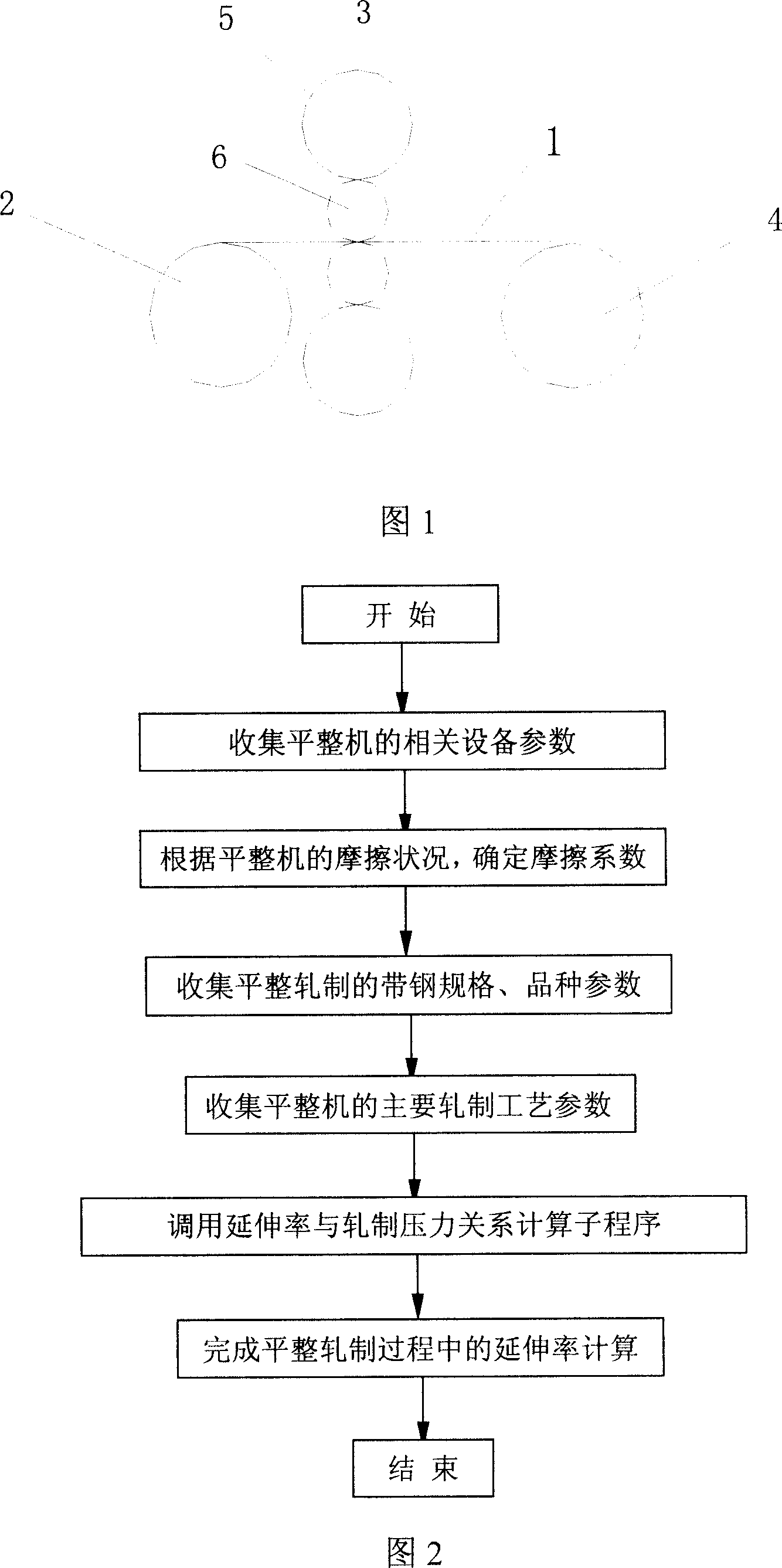

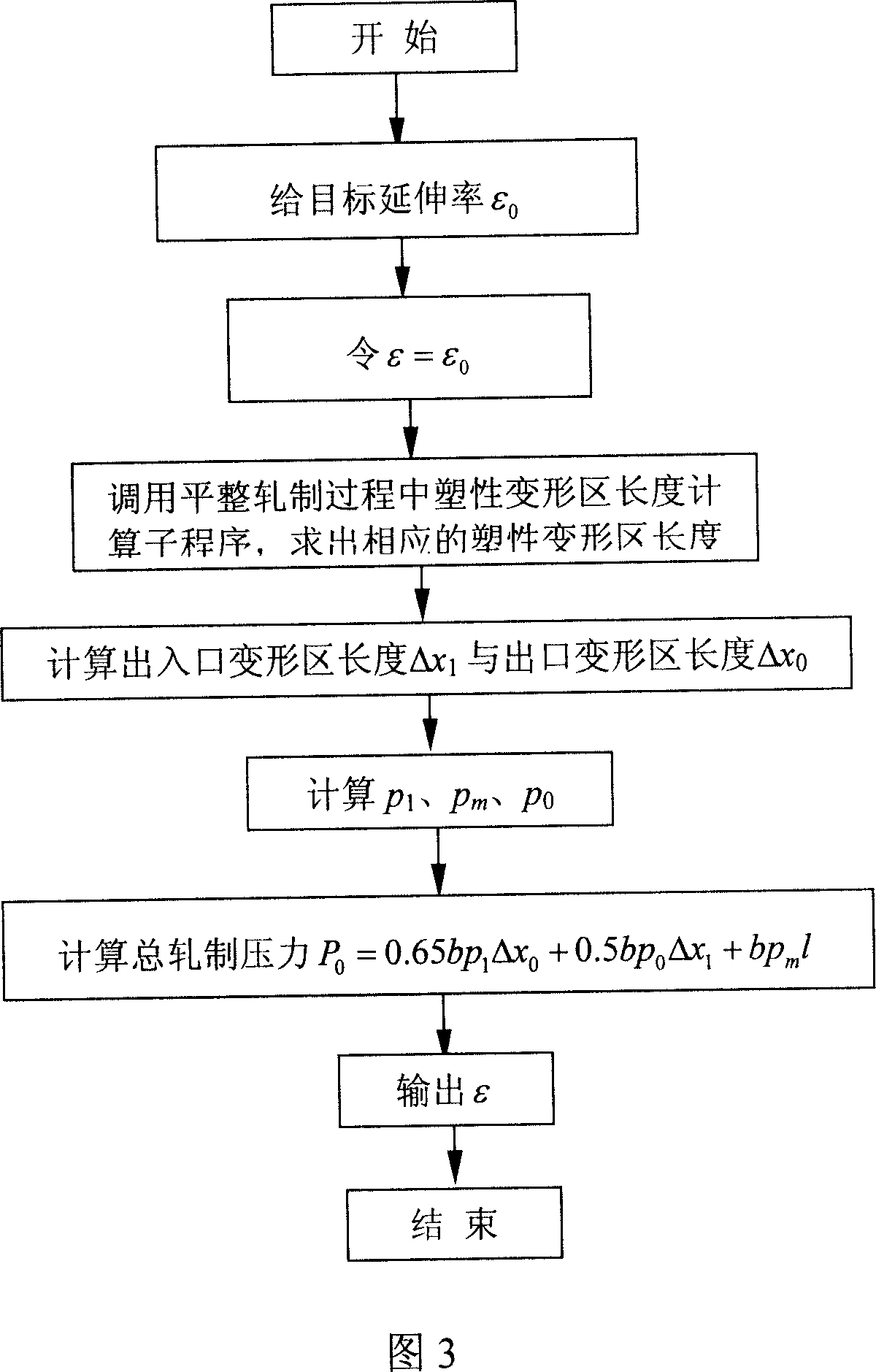

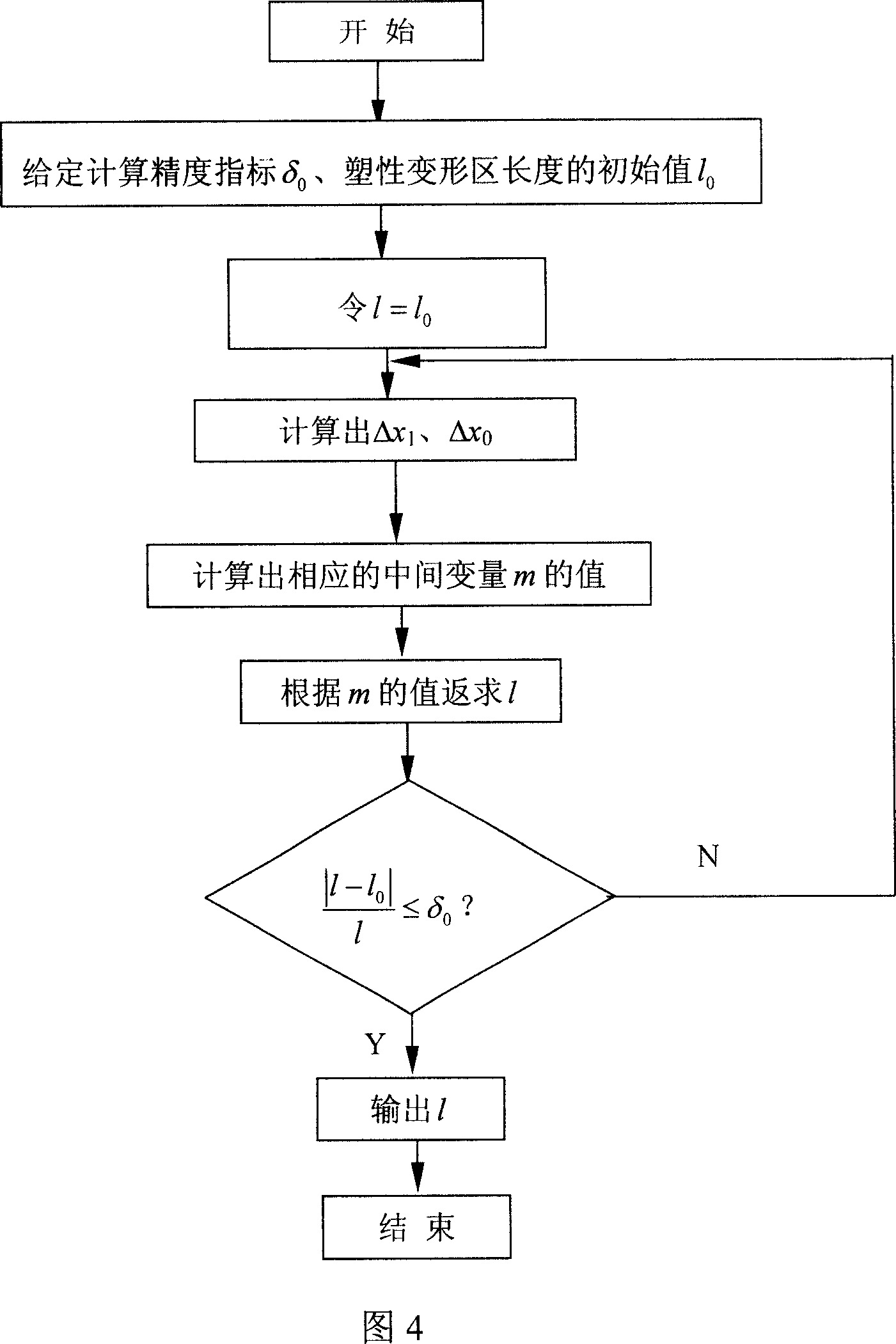

Method for comprehensive control of elongation coefficient and plate shape of steel band during even rolling process

InactiveCN101003063AImprove mechanical propertiesQuality improvementProfile control deviceMetal rolling arrangementsControl objectiveStrip steel

A method for controlling the elongation percentage, plate shape, etc in the skin rolling procedure of band steel features that an elongation percentage control unit, a plate shape control unit and an integrated control unit for both elongation percentage and plate shape are used, which use respectively three different optimizing algorithms to be used in a single iterative calculation procedure consisting of multiple optimizing calculation sub-procedures.

Owner:BAOSHAN IRON & STEEL CO LTD +1

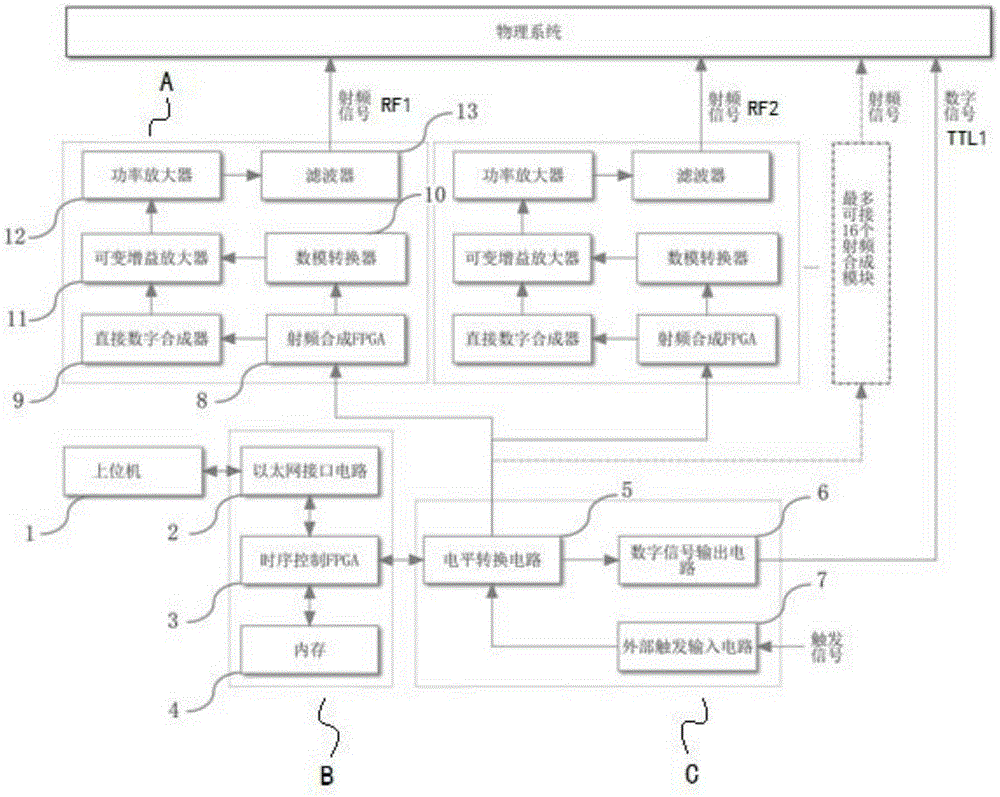

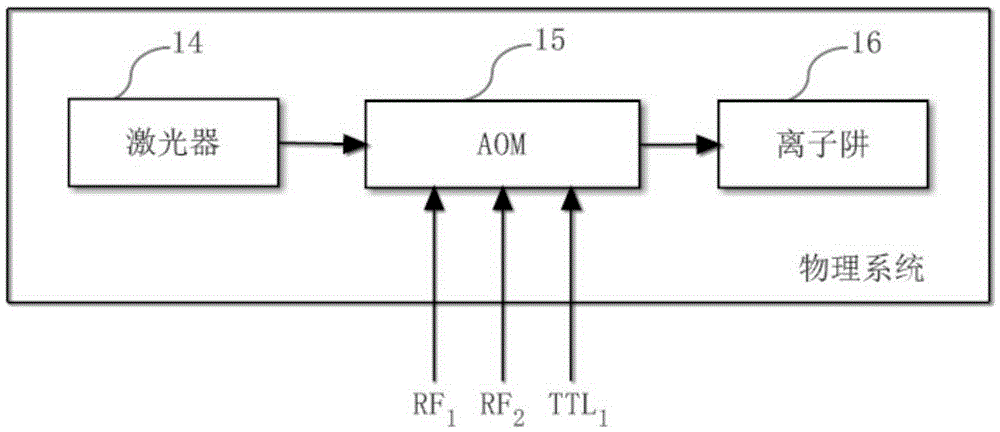

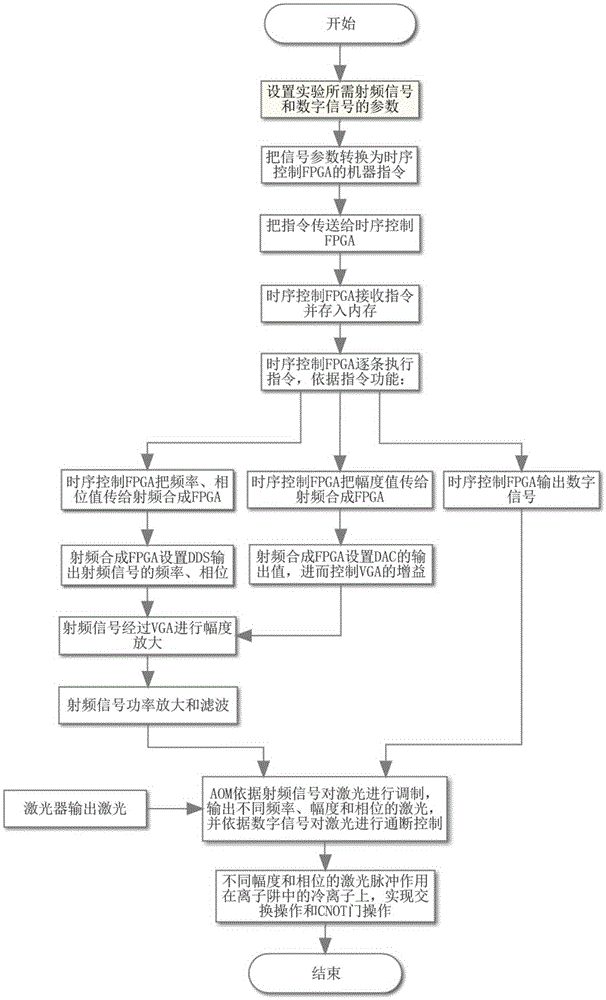

Sequential control signal generation method and device of cold ion quantum information processor

ActiveCN105281886ARealize intuitive descriptionAvoid duplication of workSynchronising arrangementControl signalRadio frequency signal

The invention provides a sequential control signal generation method of a cold ion quantum information processor. Radio frequency signal and digital signal parameters are set through a principal computer command on a principal computer; the principal computer command is converted into a machine command which is transmitted to a sequential control FPGA; the sequential control FPGA executes the machine command and digital signals and radio frequency signals are output through a conversion module and a radio frequency synthesis module. The invention also provides a sequential control signal generation device of a cold ion quantum information processor. The device comprises a principal computer, a sequential control module, a radio frequency synthesis module and a conversion module. According to the invention, sequential control signals for experiments are described intuitively; programmed principal computer commands can be used repeatedly, so that repeated work is prevented and improvement can be made according to experiment results conveniently; the parameters such as the frequency, the phase and the amplitude of radio frequency signals can be changed conveniently; multiple paths of control signals can be controlled accurately to work cooperatively; the extendibility is great.

Owner:WUHAN INST OF PHYSICS & MATHEMATICS CHINESE ACADEMY OF SCI

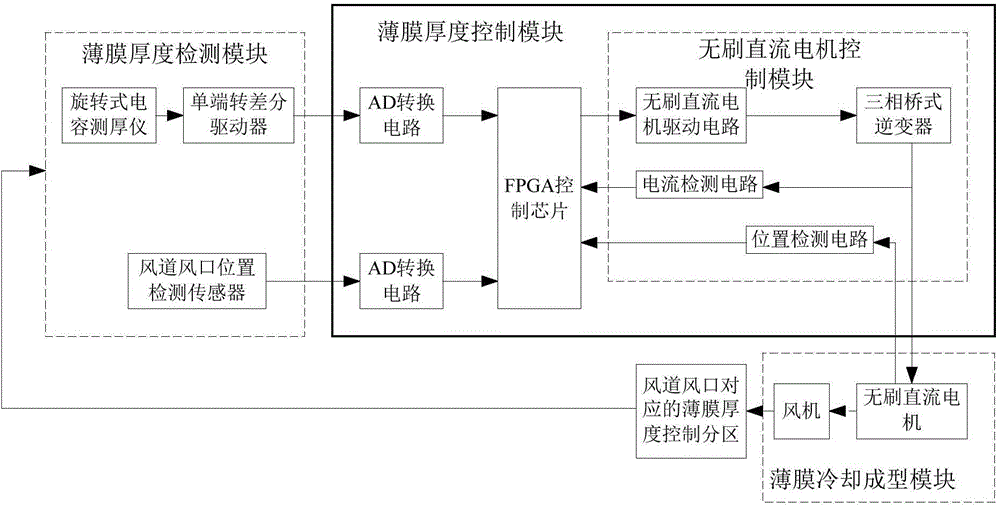

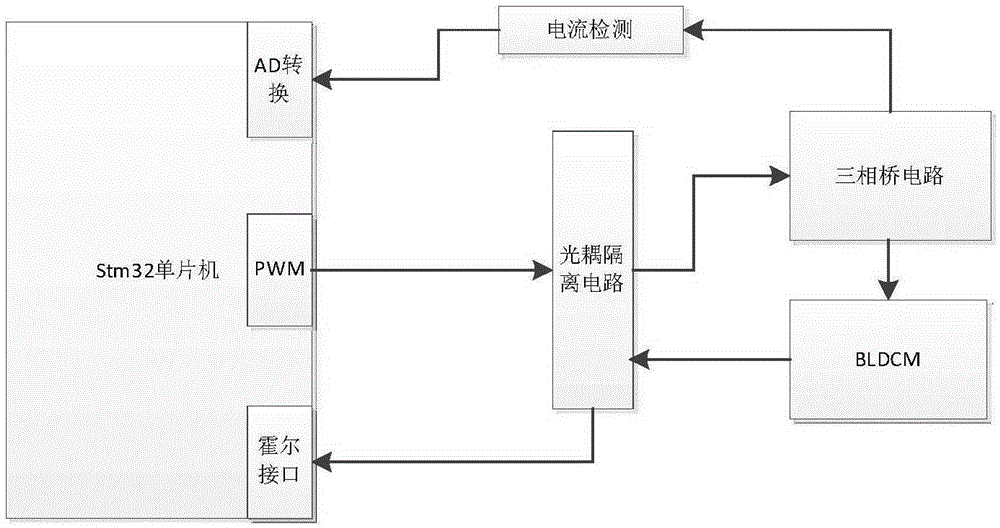

Automatic thickness control system and method of blown film

The invention discloses an automatic thickness control system and method of a blown film. The automatic thickness control system of the blown film comprises a film thickness detection module, a film thickness control module, a film cooling and forming mold with a plurality of brushless direct-current motors as well as a control panel. According to the invention, an FPGA (field programmable gate array) control chip of a programmable logic device is utilized to achieve a fuzzy control algorithm so as to obtain the speed control quantity of the brushless direct-current motors; by combining a double-closed-ring control algorithm for the brushless direct-current motors a control signal output by the FPGA control chip is changed and adjusted correspondingly when the thickness of the film is changed; the thickness uniformity of the films at different circumferential parts can be controlled by acquiring horizontal thicknesses of the films at controlled subzones and the positions of air flue openings corresponding to the films via transmission and decoupling control, so that the control requirement on horizontal thickness uniformity of the films can be met; the automatic thickness control system and method of the blown film are high in integrity, small in volume, good in robust performance, stable and reliable in operation, high in expansibility, high in control precision, low in accumulative error, and high in adaptability.

Owner:XI AN JIAOTONG UNIV

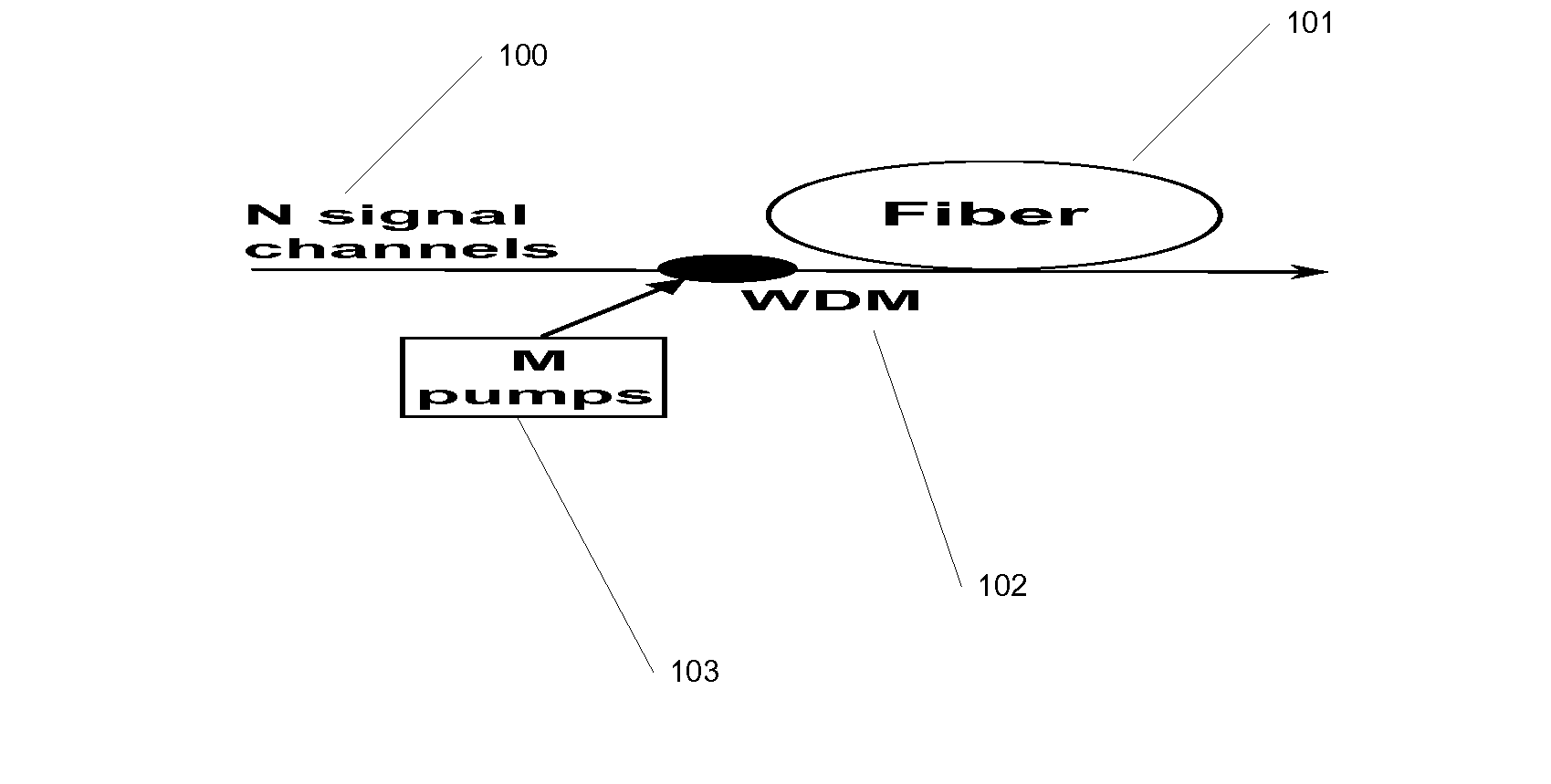

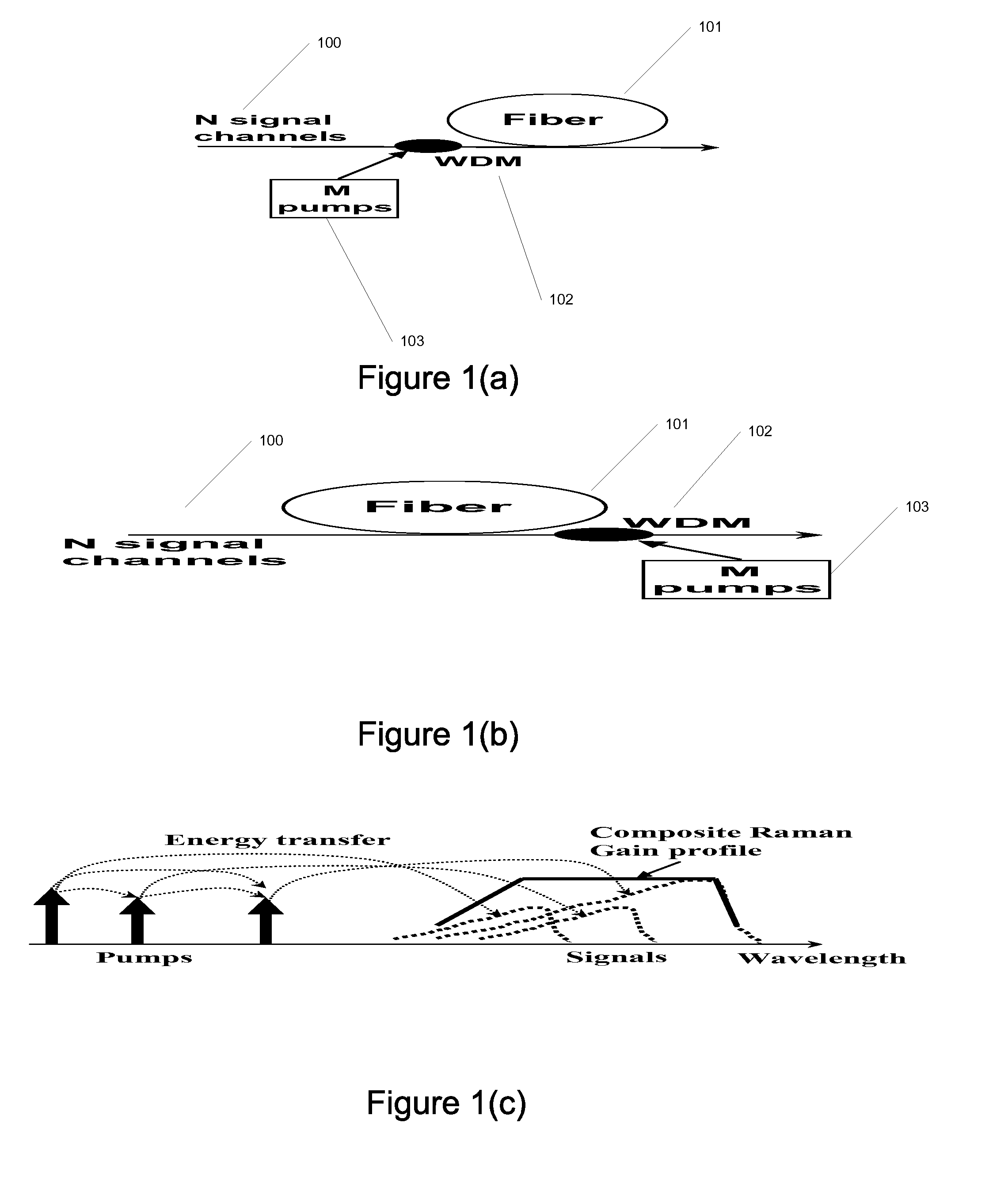

Improved feedback dynamic gain control for a WDM system employing multi wavelength pumped raman fiber amplifiers

InactiveUS20070258132A1Fast controlRobust against polarization-related issueLaser detailsElectromagnetic transmissionMulti wavelengthTelemetry Equipment

An improved feedback-based dynamic gain control technique for a WDM system employing multi-wavelength-pumped Raman fiber amplifiers (RFAs) is proposed, in which only one feedback or feed-forward signal is required for the control of multiple Raman pumps. Compared to the traditional method requiring multiple feedback signals for multiple pumps, the proposed method results in substantial simplification of the control circuit and also exhibits faster control speed. Moreover, the proposed method allows use of the total signal gain as the feedback signal, which is more robust against polarization-related issues than the traditional method using signal powers at several different channels as the feedback signals. The improved technique has advantage for dynamic gain control in a backward-pumped distributed RFA because the feedback signal may be detected right after the RFA. For feed-forward, a telemetry channel may be used to send the feed-forward signal to a feed-forward control circuit for the multiple Raman pumps. In addition, the feed-forward control technique and the feedback control technique may be used together to achieve better performance than using each of them separately to control multiple Raman pumps. Polarization-related issues may be reduced by utilizing amplified spontaneous emission (ASE) noise as the feedback signal for a feedback-based gain control circuit for the RFA.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

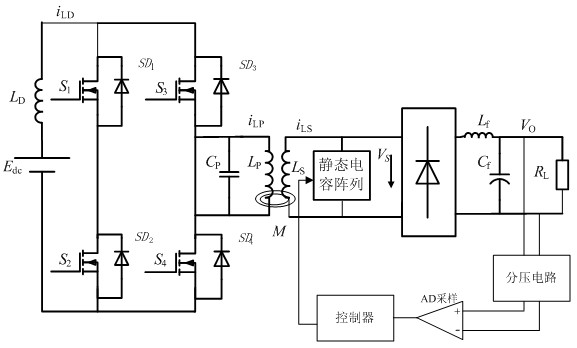

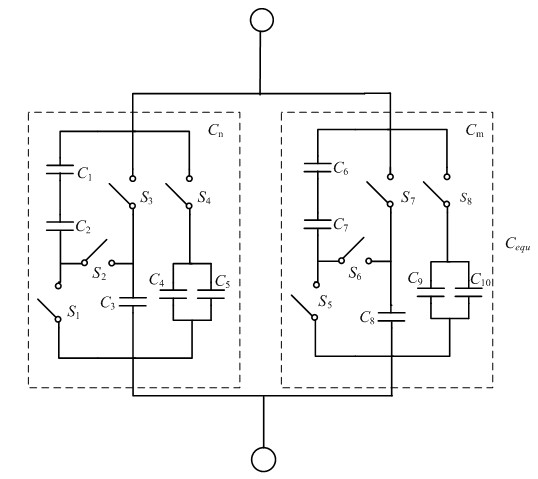

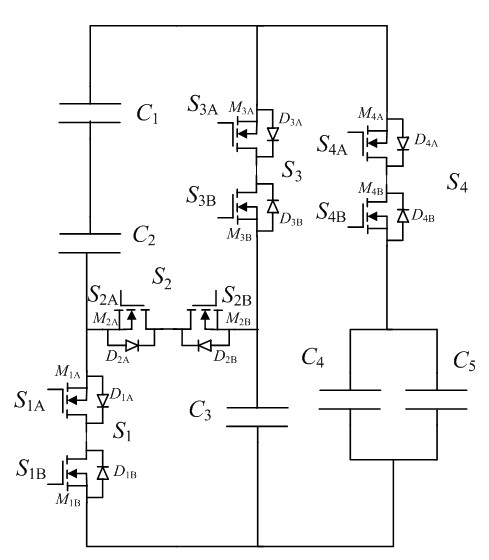

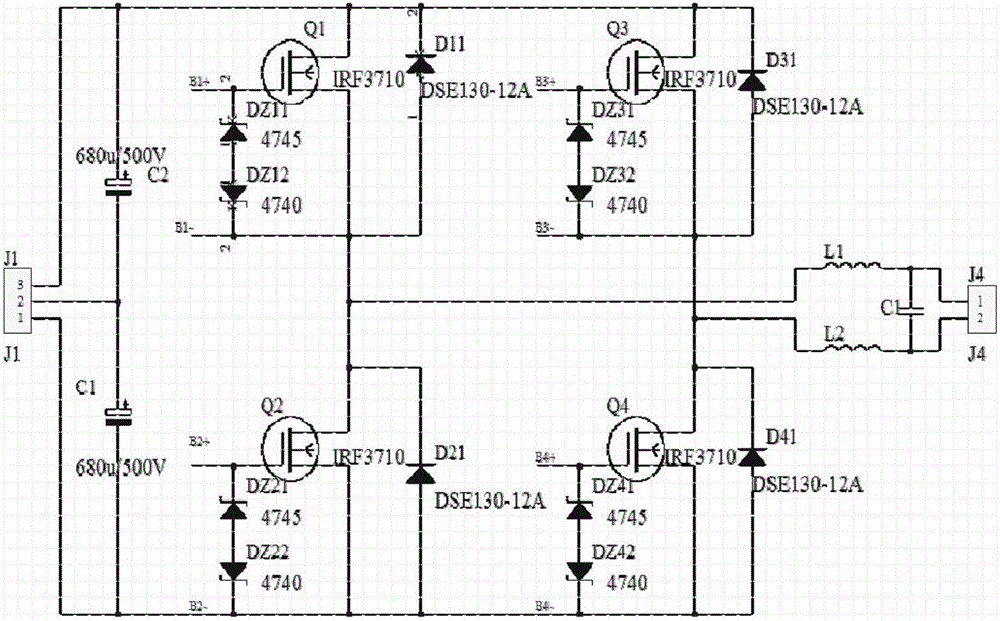

CPT (contact-less power transfer) system based on static capacitor array and control method thereof

ActiveCN102361357AAchieve indirect controlLarge adjustment rangeElectromagnetic wave systemCircuit arrangementsSoft switchingDividing circuits

The invention discloses a CPT (contact-less power transfer) system based on a static capacitor array and a control method thereof, and belongs to the field of CPT system. In the CPT system, the static capacitor array is additionally arranged on a pick-up end circuit; a resonant inductor Ls on the pick-up end circuit is connected with the static capacitor array in parallel; two ends of load RL areconnected with an input terminal of an AD (analog-to-digital) sampling module through a voltage division circuit; an output terminal of the AD sampling module is connected with an input terminal of acontroller; and an output terminal of the controller is connected with the static capacitor array so as to control the static capacitor array to output different equivalent capacitance values. In thecontrol method of the CPT system, a segmented control method based on a soft-switching technology is provided for adjusting the equivalent capacitance values output by the static capacitor array in alogical operation manner, thereby realizing control of output voltage of the CPT system. The CPT system and the control method thereof have the advantages that the adjustment range of the output voltage of the CPT system is extended, the loss of a dynamic switch is reduced and the overall stability of the system is improved.

Owner:重庆艾普特电气有限公司

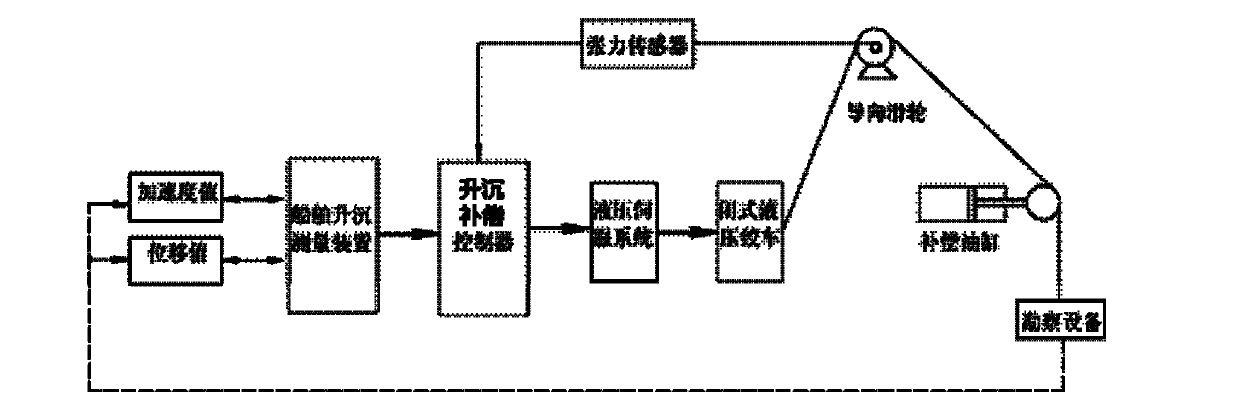

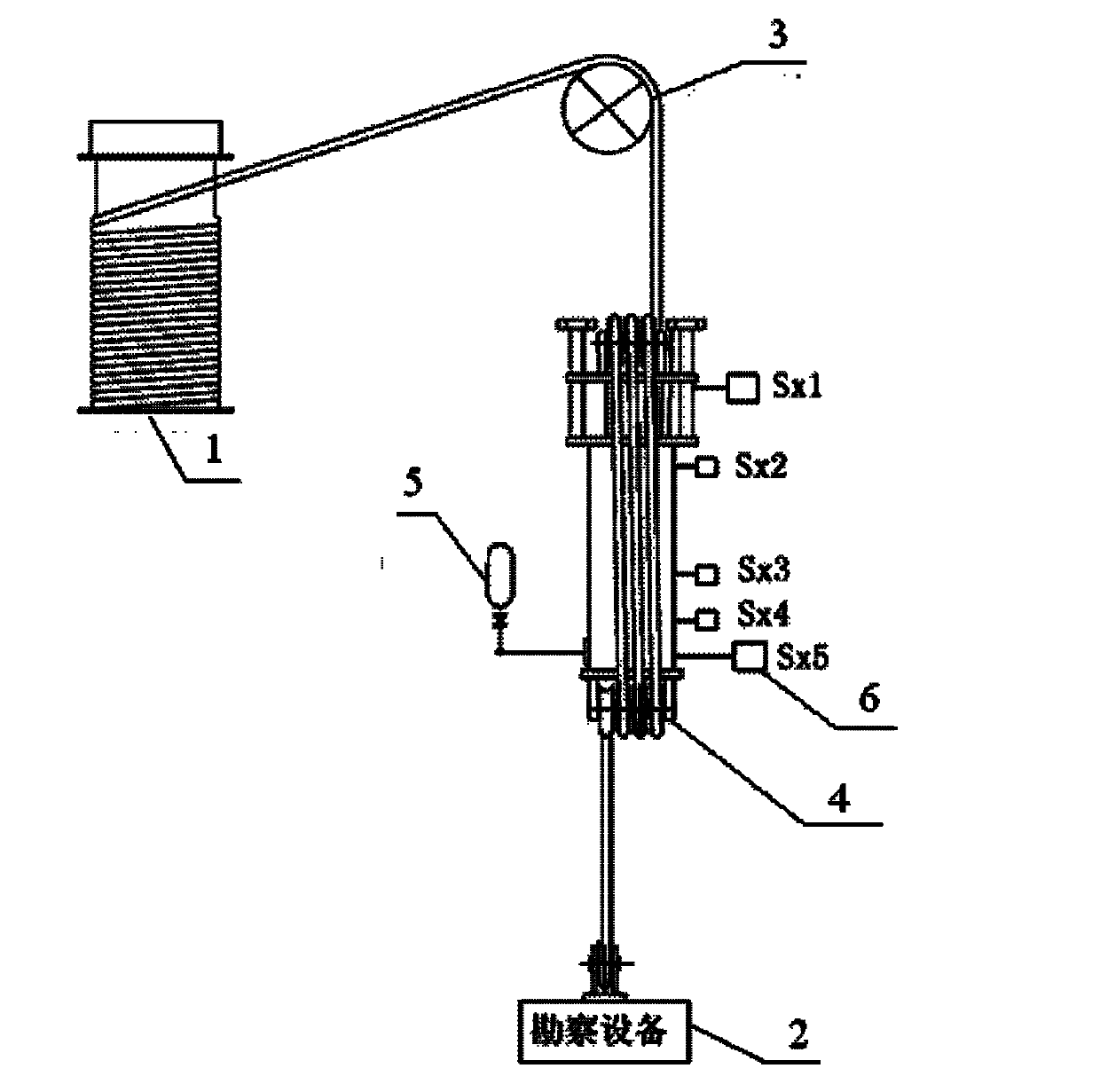

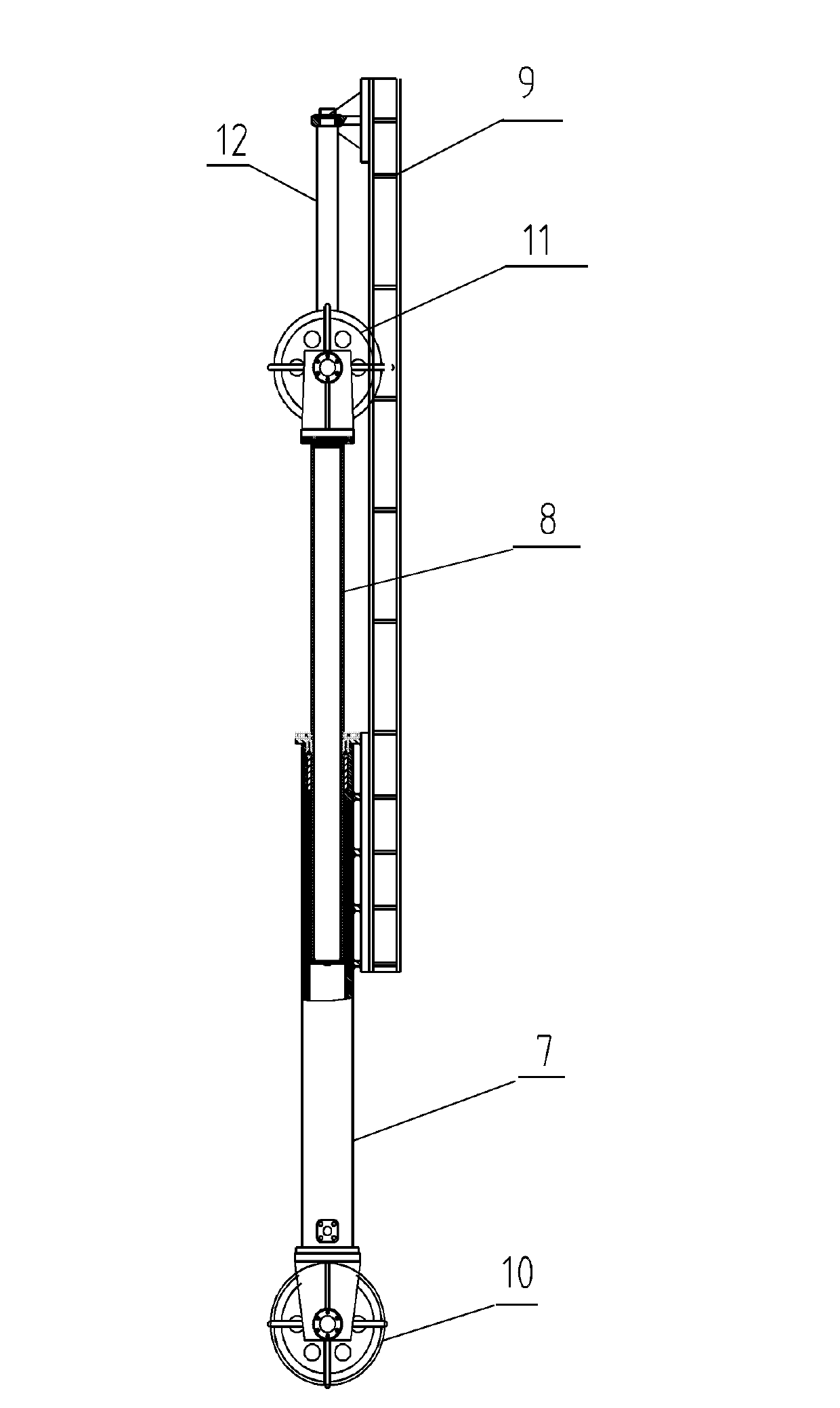

Heave compensating control system of ocean exploration equipment and control method

The invention relates to ocean exploration equipment, which belongs to the field of ocean exploration. A heave compensating control system of the ocean exploration equipment comprises exploration equipment, a lifting truck, a guide pulley and a compensating oil cylinder, wherein the lifting truck and the exploration equipment are connected by steel wires, and the guide pulley and the compensating oil cylinder are arranged between the exploration equipment and the lifting truck, the steel wires connecting the exploration equipment and the lifting truck lead out from the lifting truck and are wound on the guide pulley and connected with the exploration equipment after being wound on the compensating oil cylinder, a steel wire tension sensor is mounted on the guide pulley, the compensating oil cylinder is connected with an energy storage device, the steel wire tension sensor transmits signals to a heave compensating controller, the heave compensating controller is connected with the lifting truck and controls the lifting truck to adjust the exploration equipment. By combining the oil cylinder and tension compensation and combining active compensation and passive compensation, the heave compensating control system is applicable to various wave conditions, energy-saving and high in efficiency, can be closer to field conditions and high in control speed due to real-time feedback.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

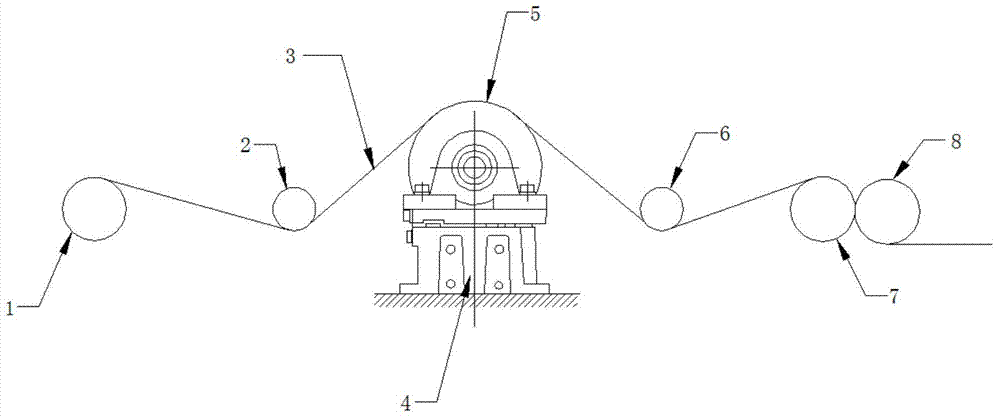

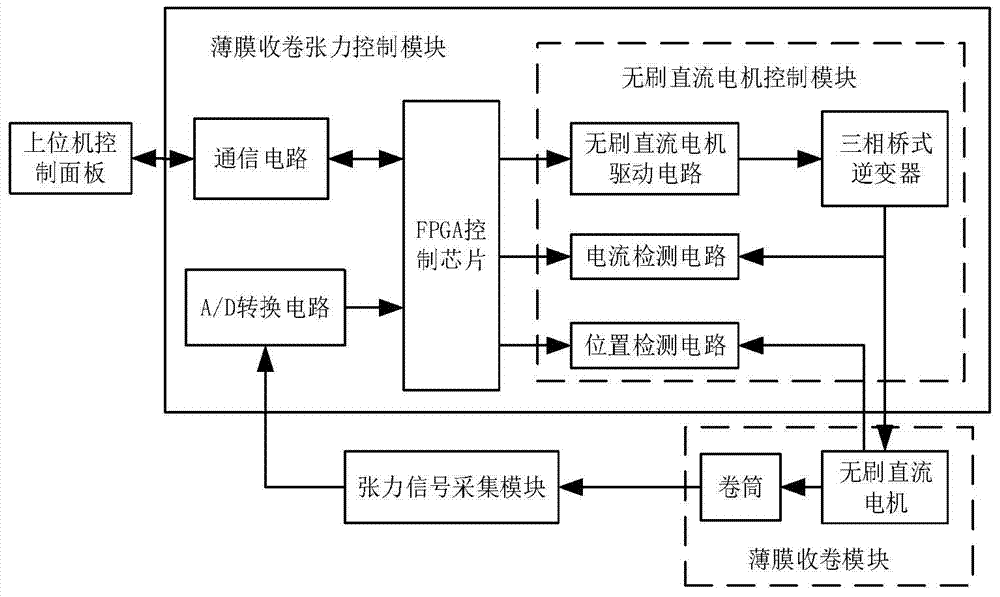

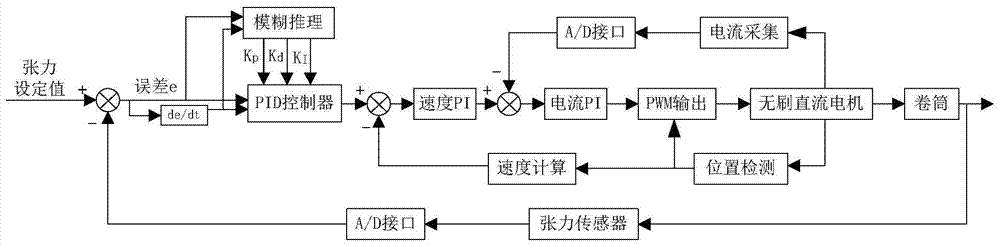

FPGA-based thin film rolling tension control system and method

InactiveCN104709748AImprove stabilityImprove parallel processing capabilitiesWebs handlingControl signalProgrammable logic device

The invention discloses an FPGA-based thin film rolling tension control system and method. The system comprises a tension signal collection module, a thin film rolling tension control module, a thin film rolling module and an upper computer operation panel. A programmable logic device FPGA controls a chip to achieve a fuzzy PID control algorithm, the speed controlled quantity of a brushless direct current motor is obtained, a double closed-loop control algorithm of the brushless direct current motor is combined, then signals are controlled to be correspondingly changed and adjusted when tension changes in the rolling process of a thin film, and constant control over the tension in the rolling process of the thin film can be achieved through real-time collection of tension of the thin film by utilization of the fuzzy PID control algorithm; the development cost is low, the integration level of the system is high, the steady state performance is good, the response speed is high, the control precision is high, and adaptability is high.

Owner:XI AN JIAOTONG UNIV

DC power control method inhibition multi-feed-in DC commutation failure

ActiveCN108695879AFast and accurate controlEasy to implementElectric power transfer ac networkAc network voltage adjustmentReduced modelPower control

The invention discloses a DC power control method inhibition multi-feed-in DC commutation failure. A simplified model of a multi-feed-in DC power transmission system is established, start of DC powercontrol is determined on the basis of sin-cos component detection method, further the DC power adjustment amount and DC power control rate are determined, and DC power control in different commutationfailure scenes is carried out according to the DC power adjustment amount and DC power control rate. The control method is high in control speed, accurate, convenient to realize, good in control effect and high in economic performance, does not need wide area measurement data or extra investment, and does not interfere operation of other equipment.

Owner:SICHUAN UNIV

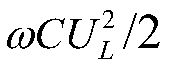

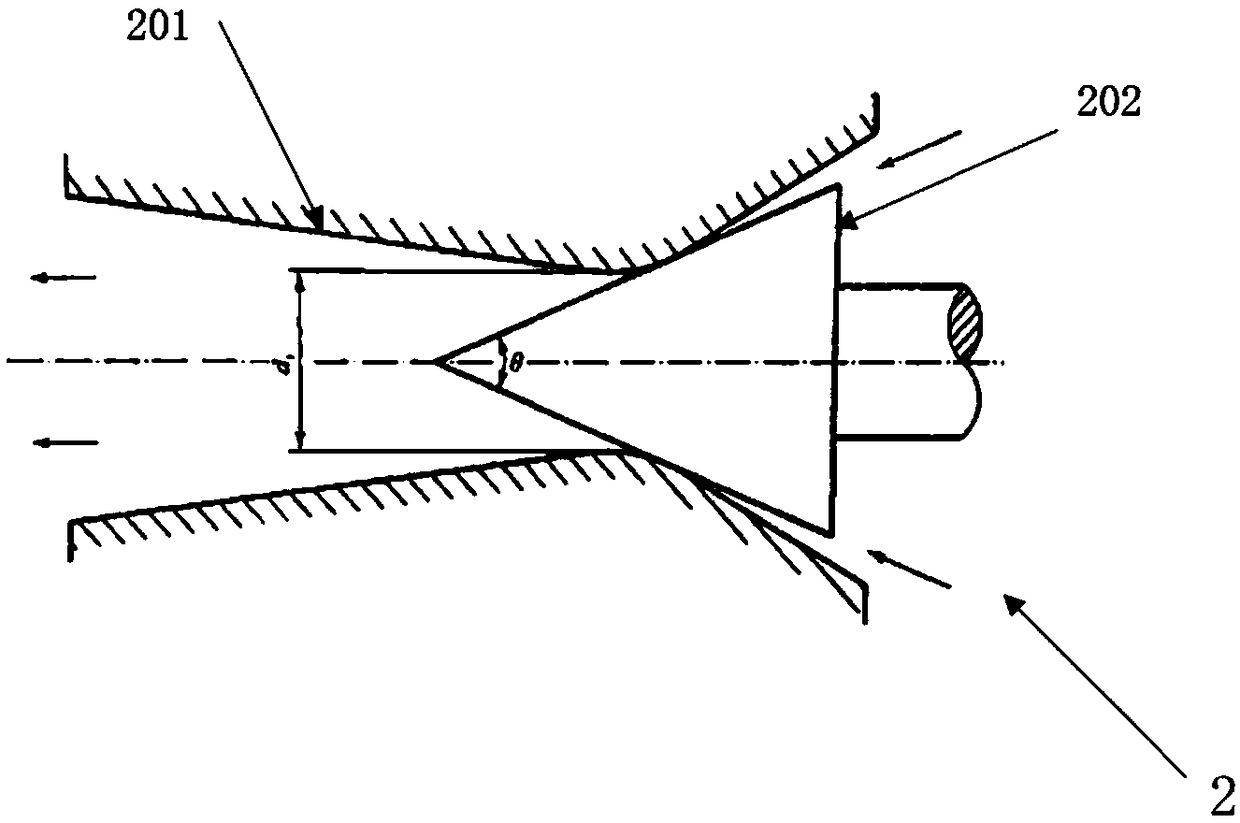

Hydrogen peroxide posture control system applied to solid-liquid hybrid power carrier rocket

InactiveCN108895921AReduce in quantityImprove transportation capacityRocket engine plantsProjectilesFailure rateControl system

The invention relates to the field of carrier rocket posture control systems, in particular to a hydrogen peroxide posture control system applied to a solid-liquid hybrid power carrier rocket. The system includes four pitching rolling posture control engines and two yawing posture control engines; the two yawing posture control engines are arranged in the positive and negative directions of a Z axis of the outer side of a rocket three-sublevel main engine separately; the first pitching rolling posture control engine is installed on the surface of the main engine, and a 40-degree included angleis formed between the first pitching rolling posture control engine and the negative direction of the Z axis; the fourth pitching rolling posture control engine is installed on the surface of the main engine, and a 40-degree included angle is formed between the fourth pitching rolling posture control engine and the positive direction of the Z axis; the other two pitching rolling posture control engines are installed symmetrically on the surface of the main engine relatively to an XZ plane. According to the scheme, six posture control engines are adopted as propelling force, the number of thrusters is small, invalid loads can be reduced to a great extent, and the conveying capability of the whole carrier rocket is improved. Meanwhile, the failure rate of the posture control system is decreased, and the stability and safety of the system are improved.

Owner:BEIHANG UNIV

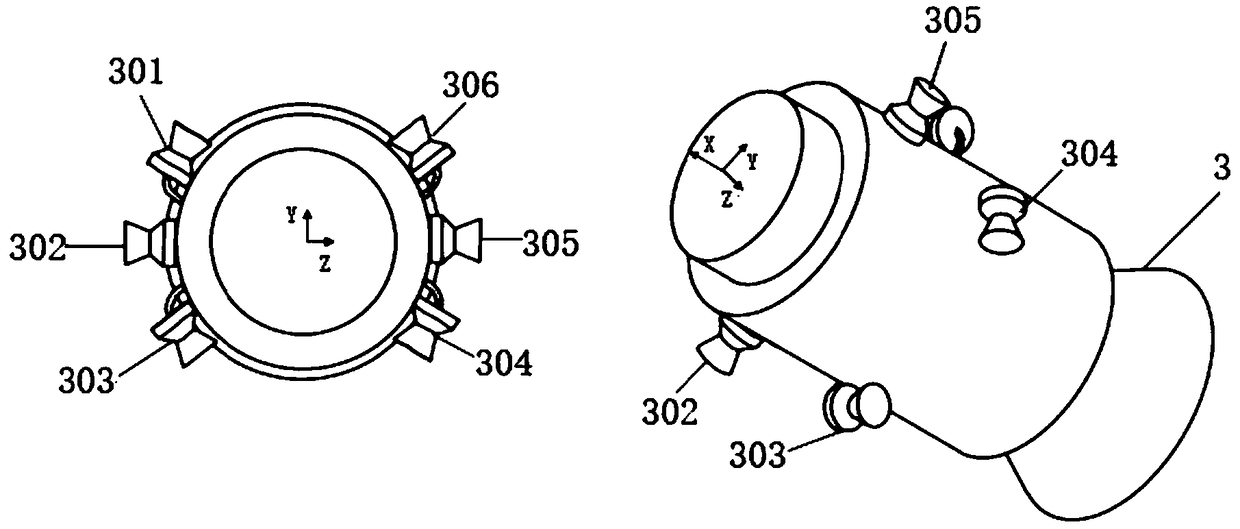

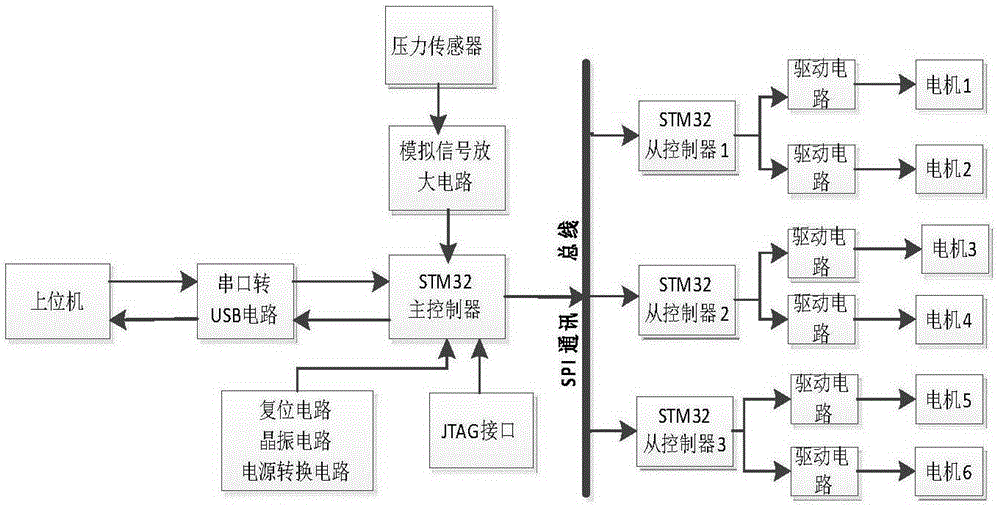

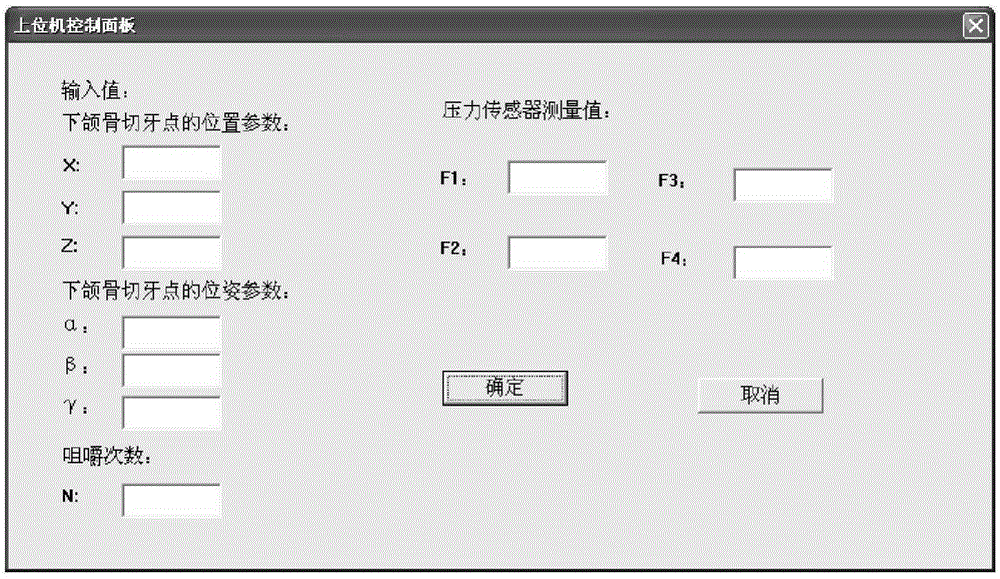

Six-degree-of-freedom chewing robot control system

InactiveCN105204394ASmall sizeIncrease in sizeProgramme controlComputer controlFuzzy pid controlControl system

The invention provides a six-degree-of-freedom chewing robot control system, and aims at solving problems that conventional point-to-point cubic polynomial interpolation is high in the required torque and relatively large in the required equipment size. Each chewing robot has problems of individual difference and symmetry of six driving rods due to the factor of machining accuracy of the robot so that consistent PID control parameters are difficult to obtain. The following scheme is adopted: step one: the movement tracks of each branch rod of the chewing robot are planned, telescoping of each driving rod is solved through the position and the posture of incisor points, and the expected position and speed of each driving rod are solved through a path passing point cubic polynomial interpolation method; and step two: the chewing process of the robot is controlled according to the movement tracks of each branch rod, and the chewing process includes three phases of opening, closing and occlusion; and fuzzy control is used in the opening and closing phases, and fuzzy PID control is used in the occlusion phase.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

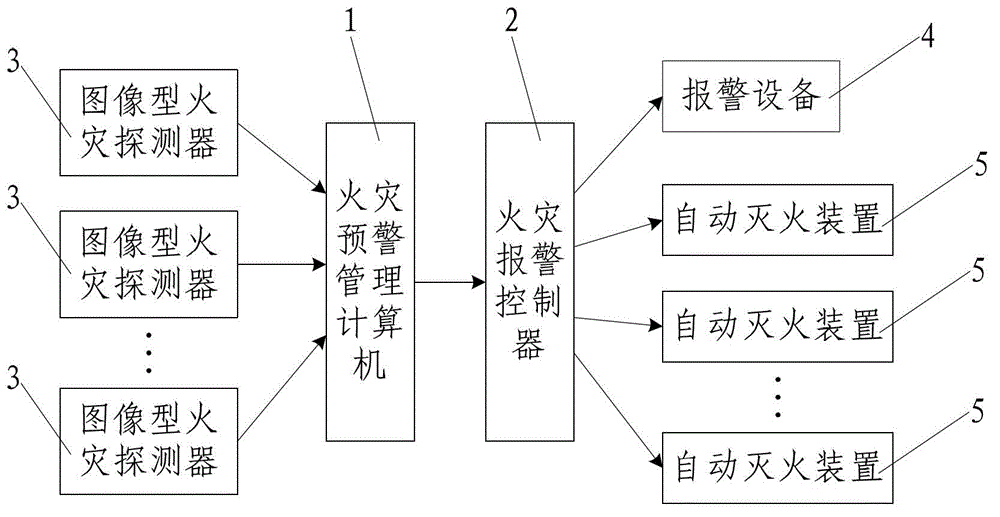

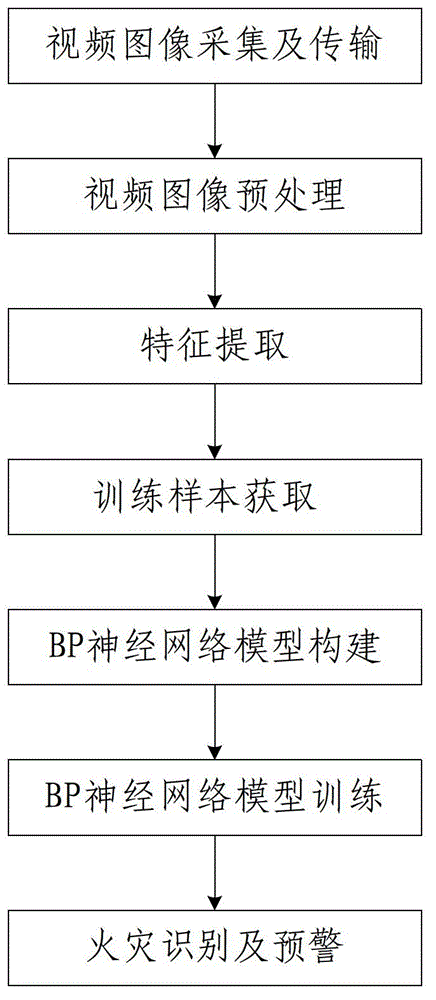

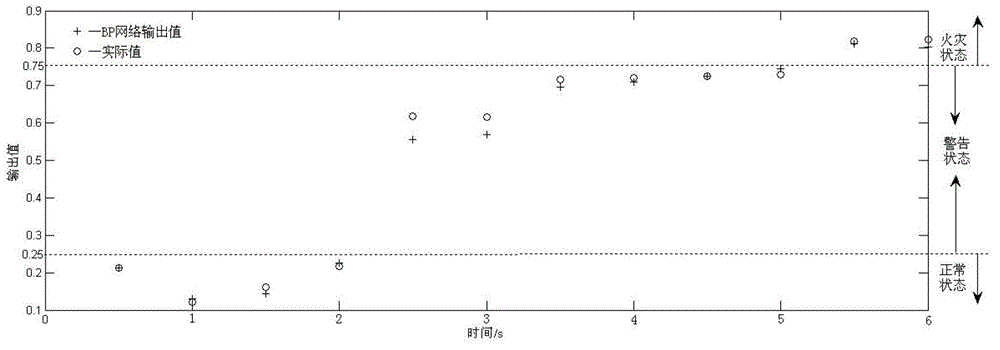

System and method for oil field united station fire disaster pre-warning system based on video images

ActiveCN103337123ASimple structureReasonable designCharacter and pattern recognitionFire alarmsAnti jammingNetwork model

The invention discloses a system and a method for oil field united station fire disaster pre-warning system based on video images. The system comprises a fire disaster pre-warning management computer and a fire disaster pre-warning controller connected with the fire disaster pre-warning management computer; the input end of the fire disaster pre-warning management computer is connected with a plurality of image type fire disaster detectors arranged in the monitored oil field united station. The method comprises the following steps: 1, acquiring and transmitting video images, 2, pre-processing the video images, 3, extracting characteristics, 4, acquiring a training sample, 5, constructing BP neural network model, 6, training BP neural network model, and 7, recognizing fire disaster and pre-warning. The system and the method have reasonable design, good real-time property, high sensitivity, high accuracy, high effectiveness and reliability, strong anti-jamming capability, strong practicability, good use effect, and high popularization and application values.

Owner:SATPRO MEASUREMENT & CONTROL TECH

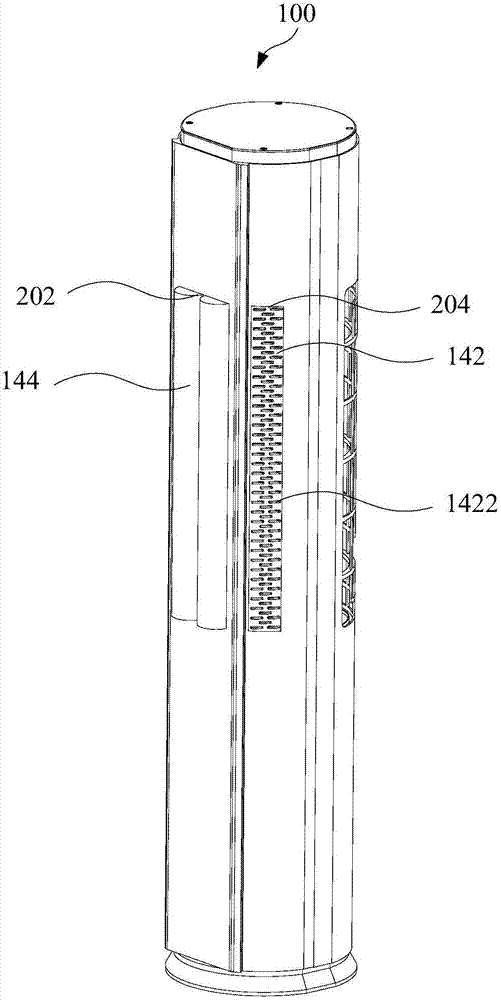

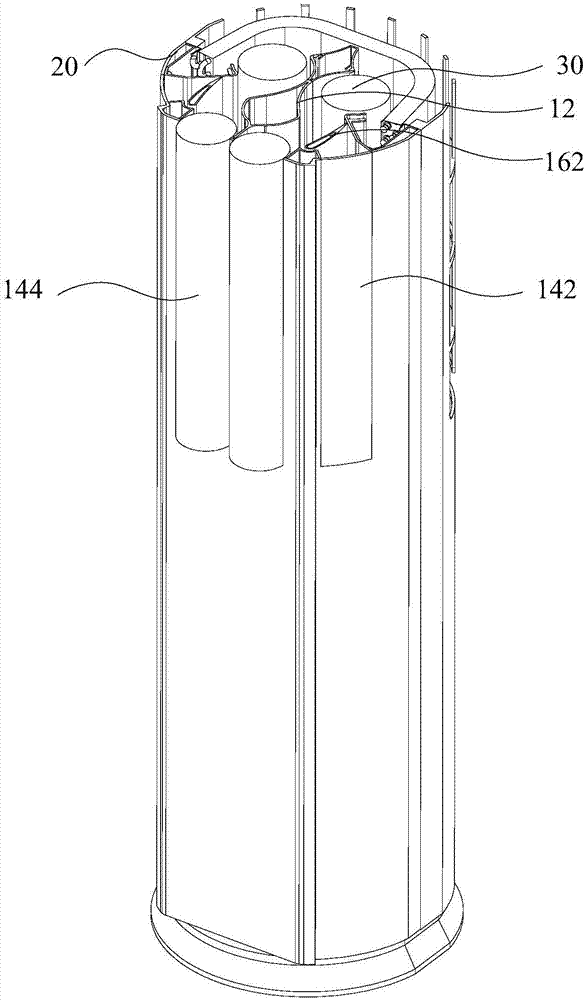

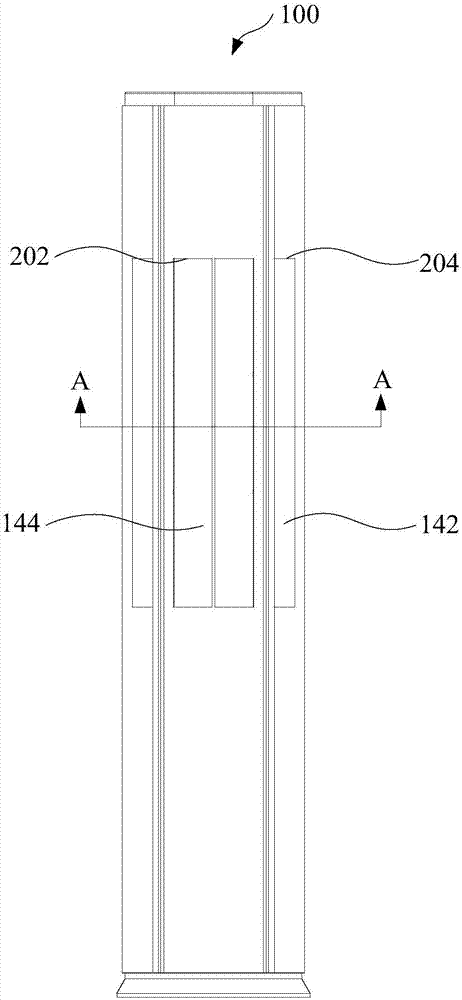

Wind guiding device, wind guiding control method and air conditioner

PendingCN106949541ASatisfy the pursuit of multi-dimensional air outletImprove user experienceDucting arrangementsMechanical apparatusEngineeringMechanical engineering

The invention provides a wind guiding device, a wind guiding control method and an air conditioner. The wind guiding device comprises a wind channel component and a wind door component, wherein the wind channel component is arranged inside a housing; the wind door component is mounted on the housing and comprises at least one wind-feeling-free wind discharging plate and at least one cylindrical rotating door which cover two middle wind outlets and two side wind outlets; a plurality of through holes are formed in the at least one wind-feeling-free wind discharging plate; a ventilation channel is formed in the at least one cylindrical rotating door. According to the wind guiding device, the wind generated by operation of wind wheels is blown to the user through the through holes of the wind-feeling-free wind discharging plate, so that the discharged wind is gentle; the wind-feeling-free wind discharging plates and the cylindrical rotating doors can open both middle wind outlets and / or both side wind outlet to be matched with each other; the wind-feeling-free wind discharging and the conventional wind discharging can be carried out at the same time, so that rapid cooling or heating can be achieved; the usage comfort level of the user can be ensured; meanwhile, the ventilation channel communicates with the inside and the outside of the housing through different positions so as to change the wind discharging directions of the wind outlets; the usage experience of the user can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

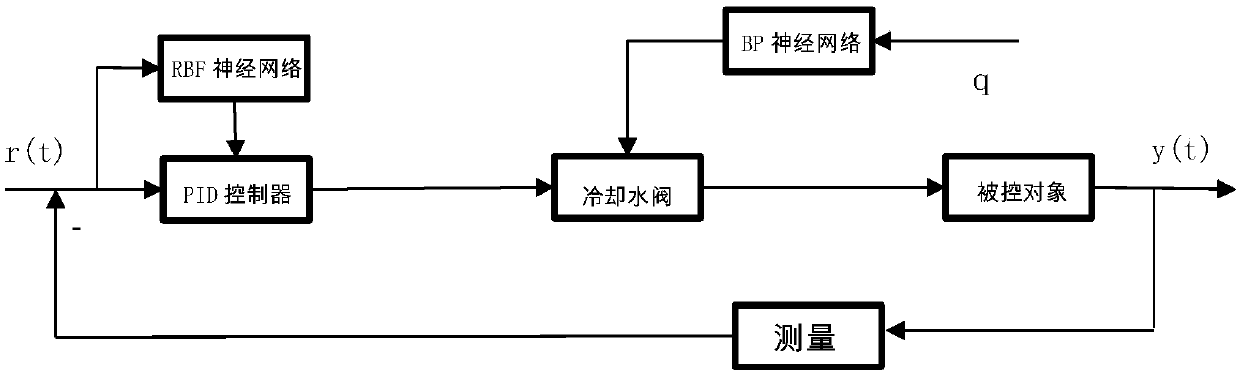

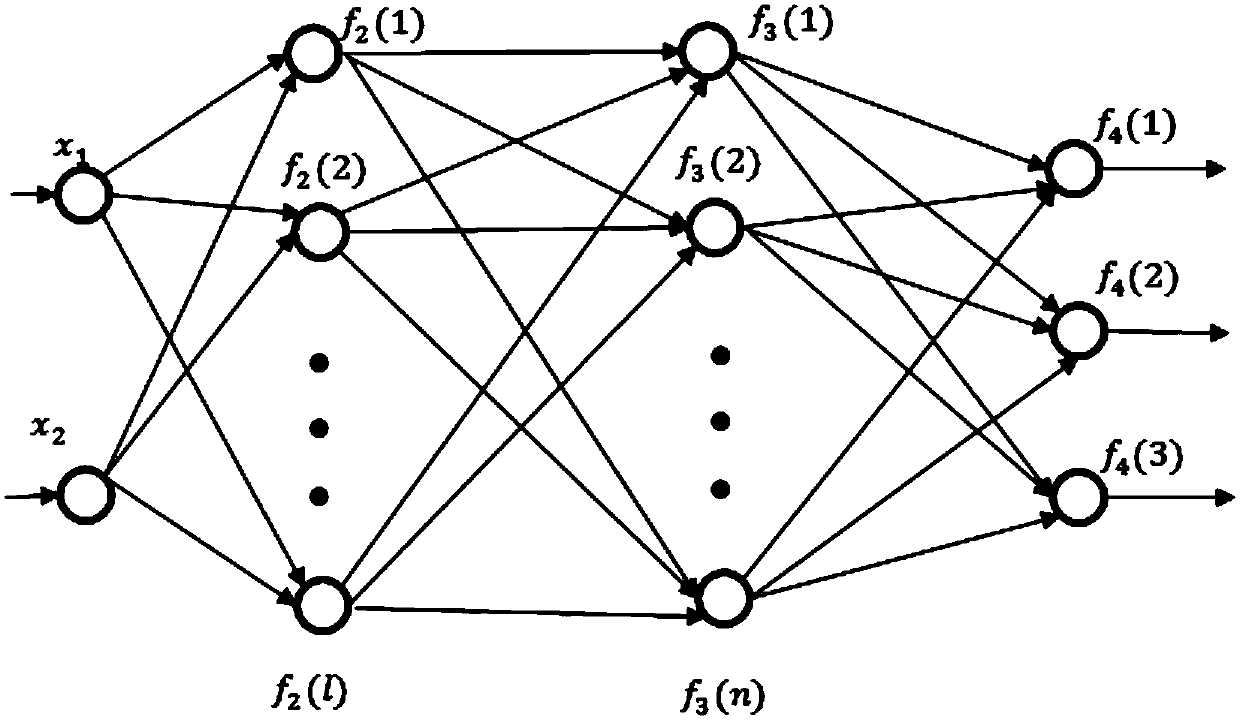

Ultrasonic dispersion instrument temperature control method based on neural network

InactiveCN109597449AOvershootFast controlAuxillary controllers with auxillary heating devicesNeural architecturesTemperature controlControl system

The invention discloses an ultrasonic dispersion instrument temperature control method based on a neural network. The method comprises the following steps: performing data collection on various indexes of a constant temperature control system through a sensor, performing training and feed-forward control on the BP neural network, and then filtering a temperature sampling signal in a reaction stillby using a filter algorithm, training the RBF neural network, and finally computing a PID parameter by using a fuzzy RBF neural network; transmitting the PID parameter to a PID controller, and controlling an opening of a cooling water valve by outputting a control signal of the cooling water valve. The control method disclosed by the invention is fast in control speed, high in robustness and hassuper adjustment.

Owner:杭州庆睿科技有限公司

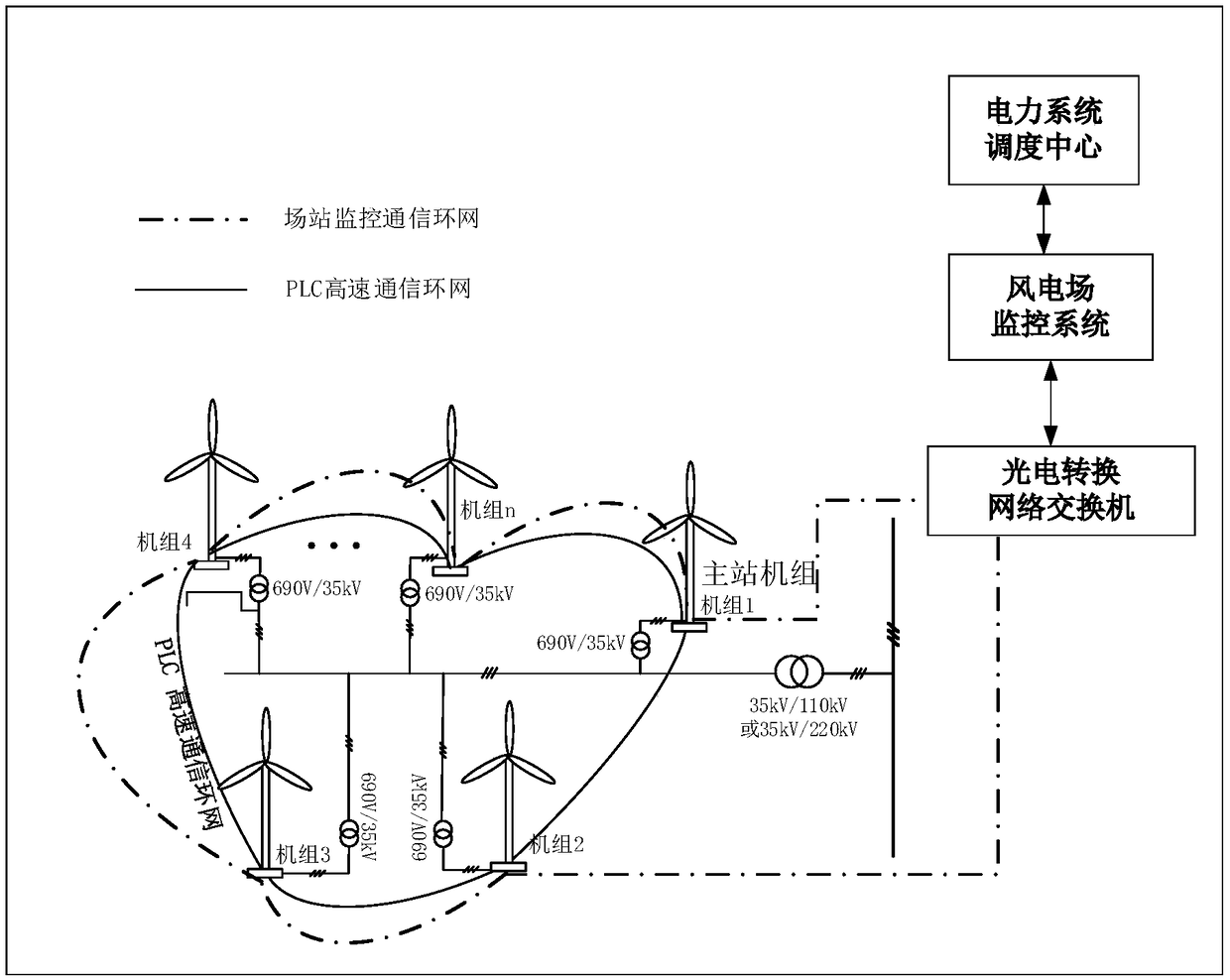

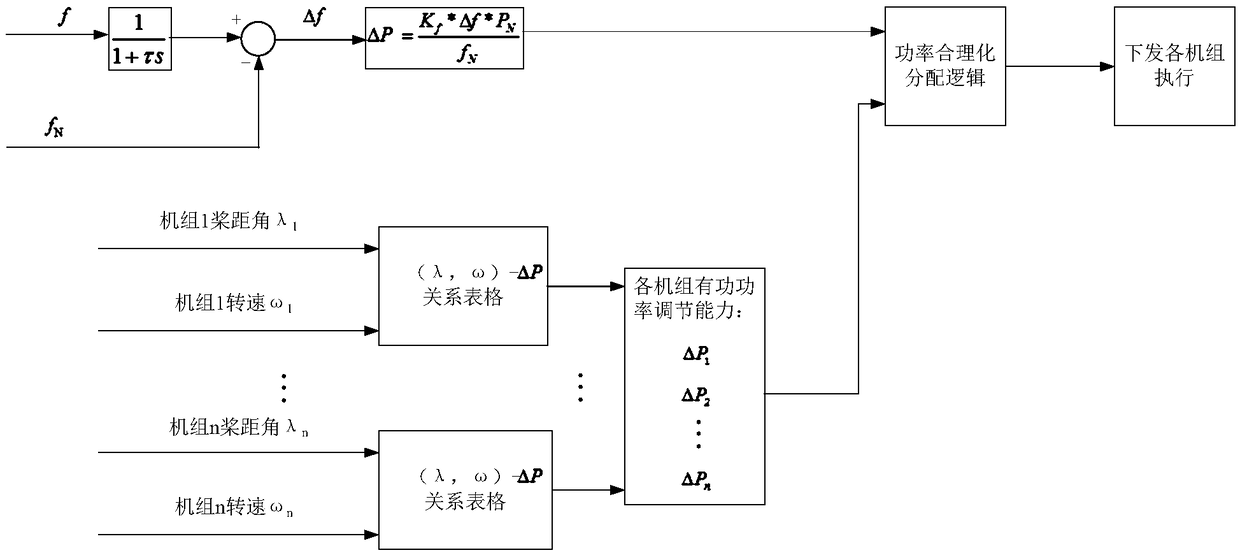

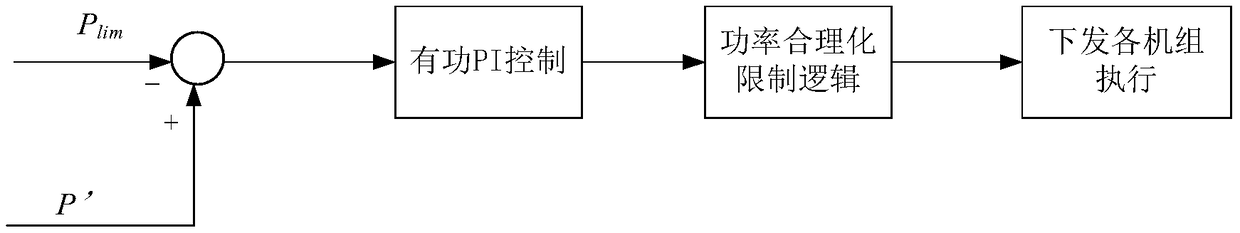

Power control method and system for wind farm unit to participate in frequency modulation and voltage regulation

ActiveCN109494811AAchieving Adaptive Regulatory ControlFast controlSingle network parallel feeding arrangementsPower oscillations reduction/preventionElectric power systemVoltage regulation

The invention relates to a power control method and a system for a wind farm unit to participate in frequency modulation and voltage regulation, which belongs to the field of circuit devices of an alternating current distribution network. The method comprises the steps that primary frequency modulation is carried out through active-frequency sag control; and when primary frequency modulation doesnot meet a frequency modulation requirement, secondary frequency modulation is carried out through AGC control. Primary frequency modulation is used as an active adjustment function under the condition of frequency fluctuation, and mainly relies on the condition of a wind farm to realize adaptive adjustment control of the system. AGC control assumes the secondary adjustment function of a power system. Complete frequency modulation capability of the wind farm is realized through primary frequency modulation and secondary frequency modulation. The method has the advantages of fast control speed,high precision and high reliability. At the same time, the invention further carries out primary voltage regulation through reactive-voltage regulation sag control. When primary voltage regulation does not meet a voltage regulation requirement, secondary voltage regulation is carried out through AVC control to realize grid-connected voltage adjustment.

Owner:ELECTRIC POWER SCI RES INST OF STATE GRID XINJIANG ELECTRIC POWER +3

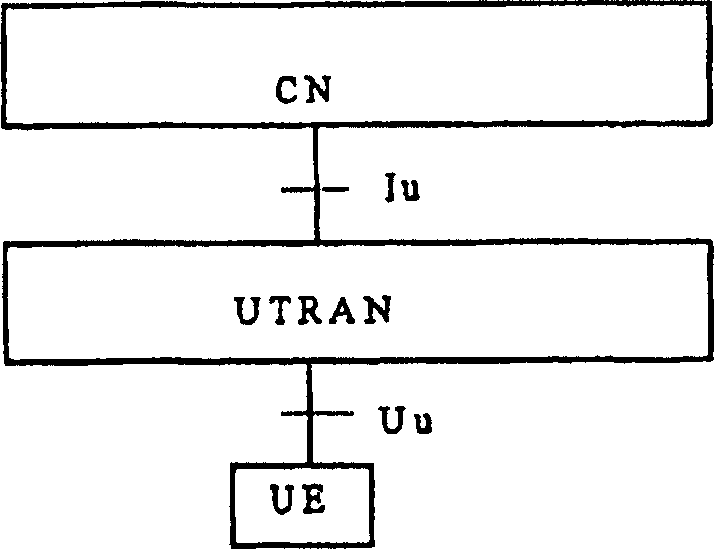

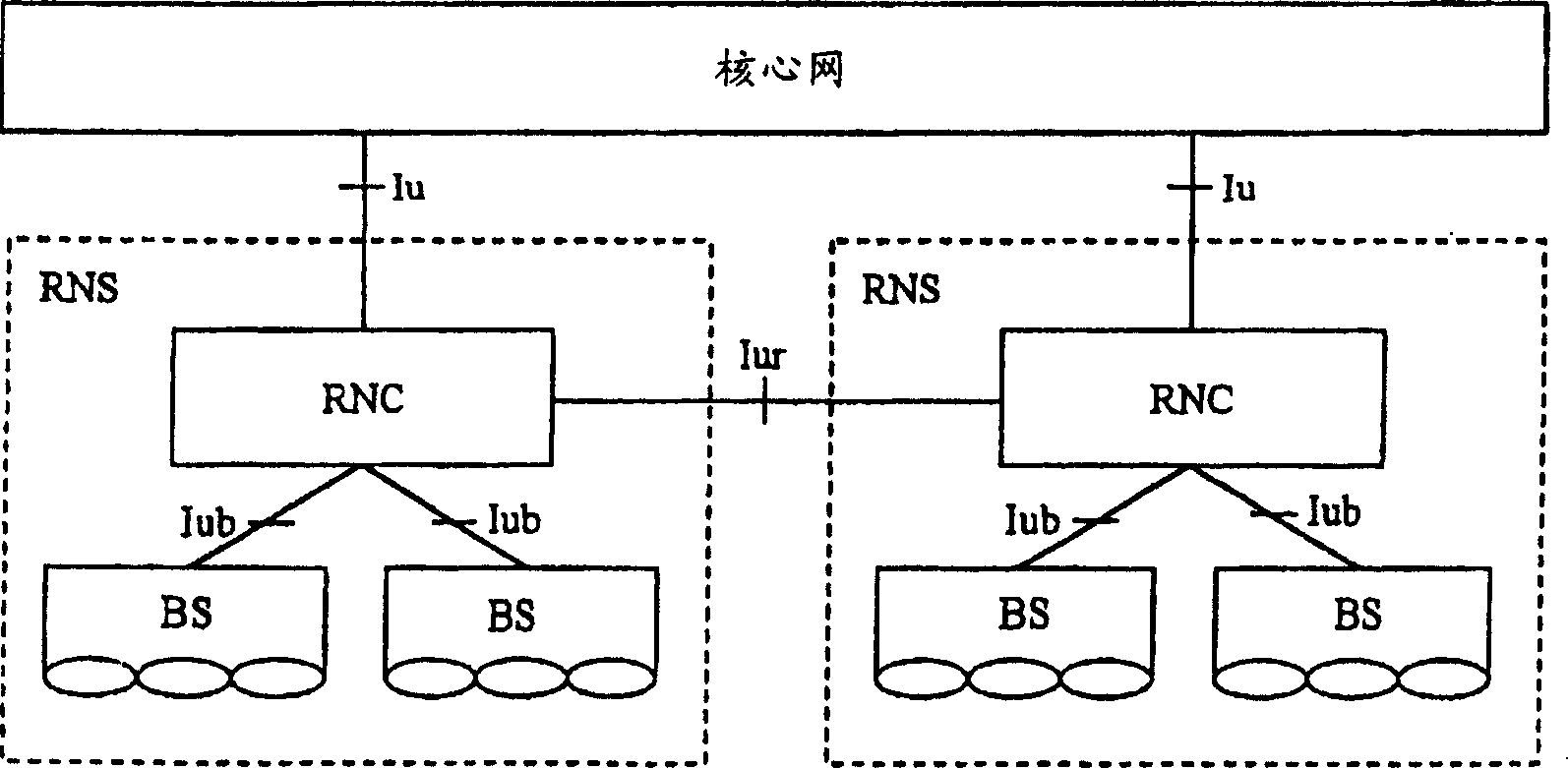

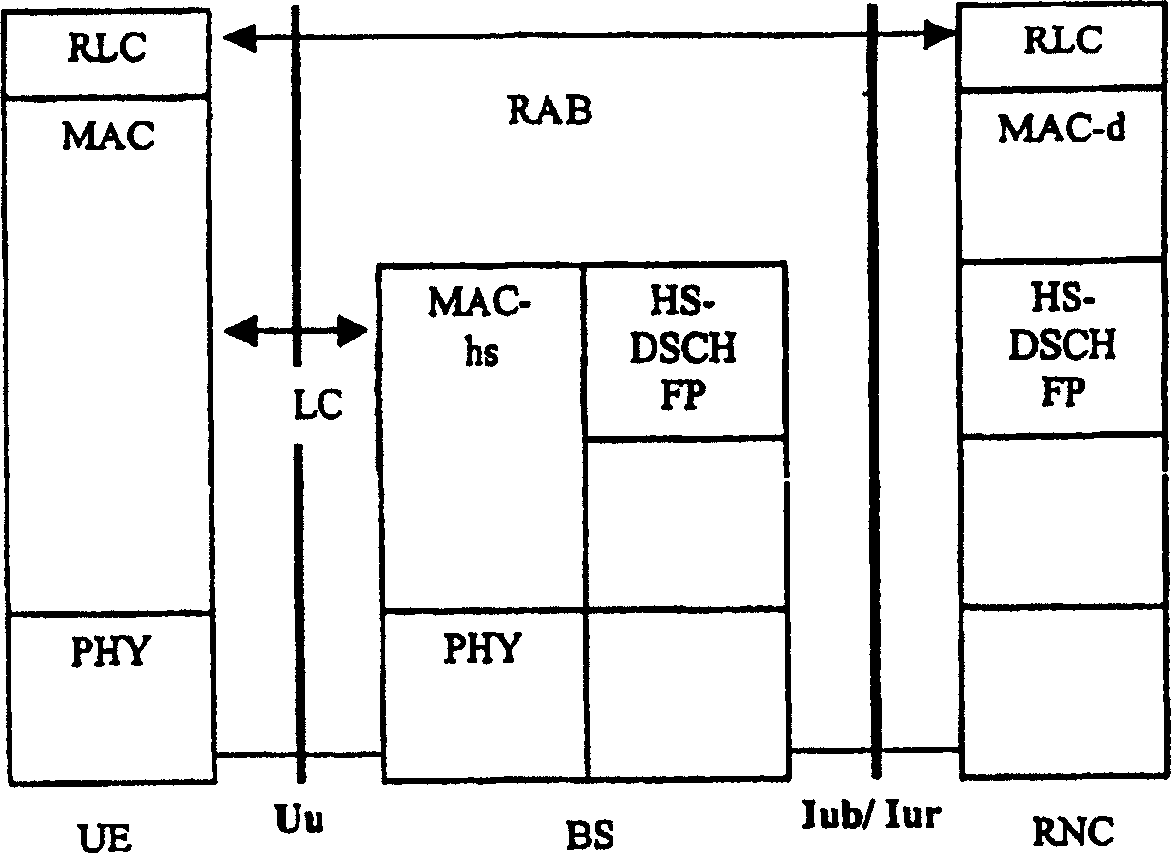

Method for controlling the data rate of transmitting data packets in a wireless communications system, receiver and transmitter therefor

InactiveCN1643837APrevent overflowFast controlError prevention/detection by using return channelNetwork traffic/resource managementAutomatic repeat requestData rate

A method of controlling the data rate of transmitting data packets in a wireless communications system comprising a transmitter communicating with at least one receiver by means of radio communication signals employing at least one automatic repeat request (ARQ) or a hybrid ARC protocol. The data packets are allocated to at least one logical channel which is mapped on at least one physical downlink communication channel for transmission from the transmitter to the receiver. The receiver transmits signaling information relating to the receipt of said data packets in an uplink feedback channel to the transmitter. According to the invention, the data rate control is based on the receiver's current capability to process the amount of received data packets comprised in the communication signals. Further, the signaling information in the uplink feedback channel comprises a request to control the data rate in at least one logical channel. In addition, the invention relates to a receiver and transmitter adapted to carry out the control method.

Owner:PANASONIC CORP

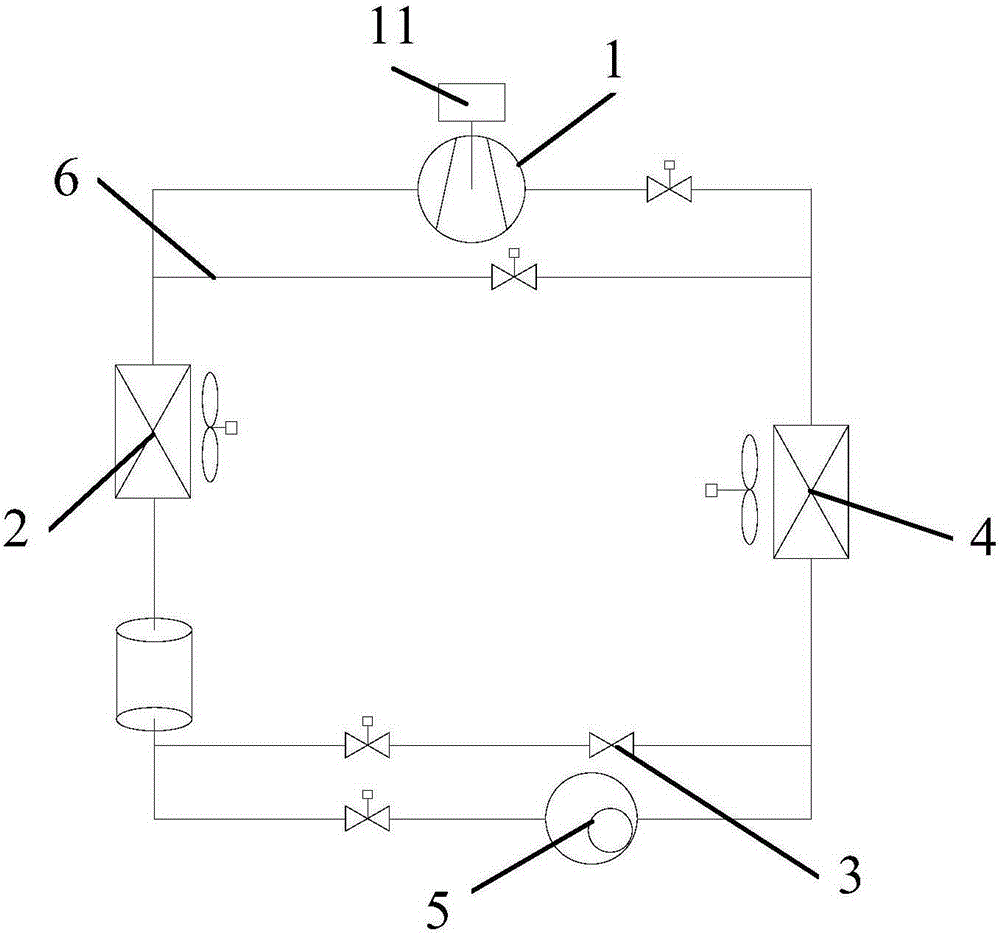

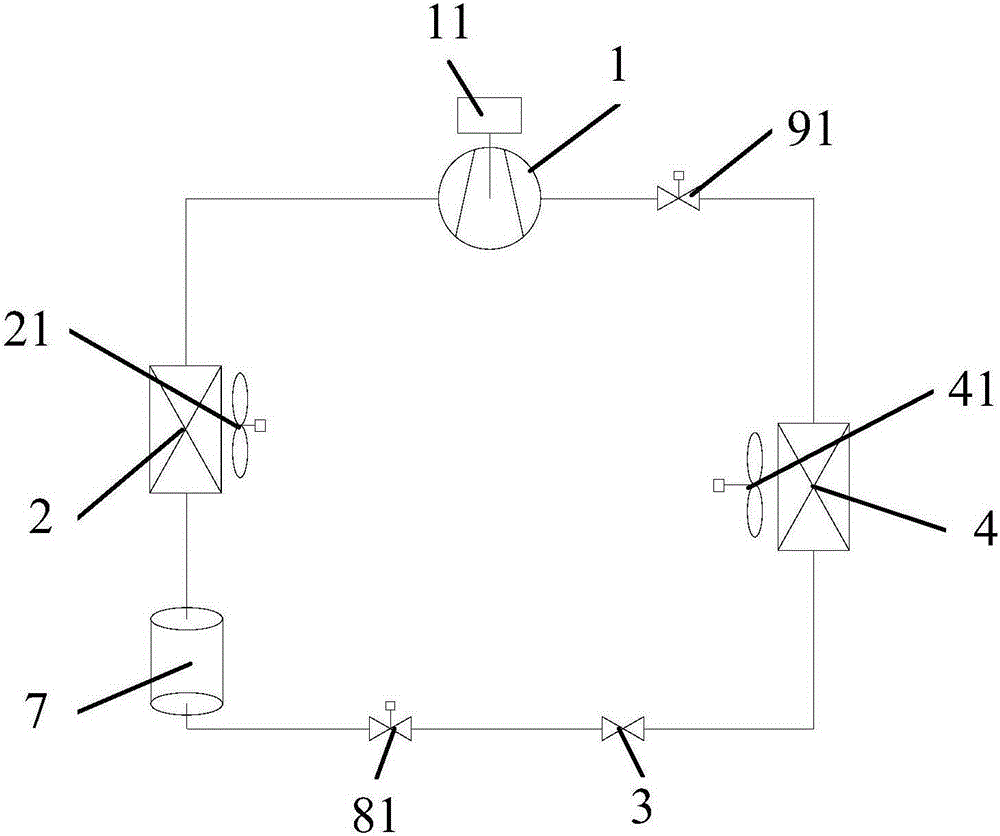

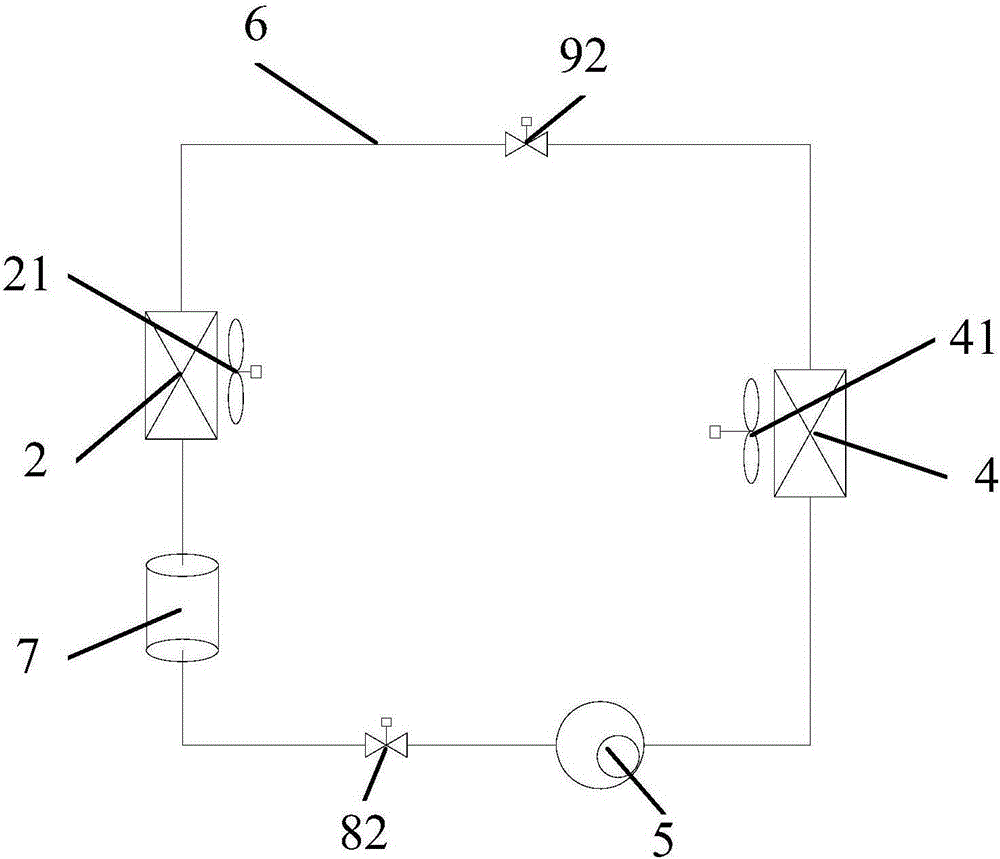

Machine room air conditioner system and control method thereof

InactiveCN105180348AReduce energy consumptionImprove cooling effectSpace heating and ventilation safety systemsLighting and heating apparatusCold seasonEngineering

The invention provides a machine room air conditioner system and a control method thereof. The machine room air conditioner system comprises a refrigeration circulating system and a heat pipe loop system. The refrigeration circulating system comprises a compressor, a condenser, a throttling device and an evaporator which are all connected with one another. A controller controlling the compression ratio of the compressor is arranged on the compressor. The controller is connected with a temperature sensor arranged outside a machine room. The heat pipe loop system comprises a fluorine pump and a heat pipe which are connected with the condenser and the evaporator; the heat pipe loop system is formed by the fluorine pump, the heat pipe, the condenser and the evaporator; and the heat pipe loop system can cool the machine room through a natural cold source outside the machine room. According to the technical scheme, on one hand, the compression ratio can be automatically adjusted by the machine room air conditioner system according to the outside temperature, and therefore the compressor can perform variable-compression-ratio work; and on the other hand, the machine room air conditioner system can cool the machine room through the outside natural cold source in winter and other cold seasons, and therefore the energy consumption of the machine room air conditioner system can be reduced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

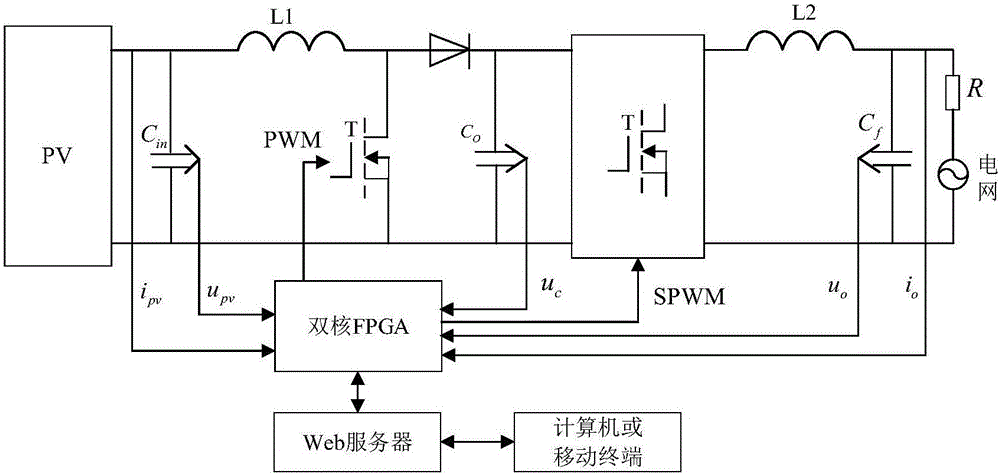

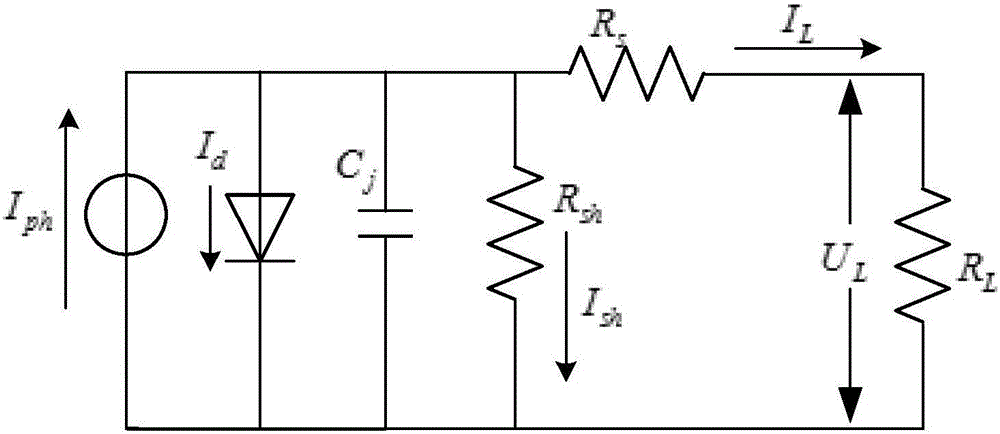

Photovoltaic grid-connected system based on FPGA and realization method thereof

ActiveCN106329567AFlexible combinationImprove operational efficiencySingle network parallel feeding arrangementsPhotovoltaic energy generationWeb serverFull bridge inverter

The invention discloses a photovoltaic grid-connected system based on an FPGA and a realization method thereof. The system comprises following apparatuses: a photovoltaic cell PV, a voltage-stabilizing capacitor, a DC / DC converting circuit, a direct current bus, a DC / AC full-bridge inverter, a core controller FPGA, an alternating current power grid and power supply device, a Web server, and a computer or a mobile terminal etc., the core controller FPGA employs a heterogeneous double-core mode, core-1 generates PWM driving signals of the pre-stage DC / DC converting circuit and the post-stage DC / AC full-bridge inverter and maximum power point tracking (MPPT) control signals, and core-0 performs functions of network service, a database, and remote monitoring etc. through a Linux system. The system and the realization method thereof are advantageous in that the heterogeneous double-core FPGA can process tasks in parallel, flexible combination of various functions is realized, and the operation efficiency of the system is improved; the expansion of the double-core system is easy, high processing performance can be combined with small size, and the system with the appearance is also advantaged by low power consumption and low heat generated by calculation of the power consumption.

Owner:SHANGHAI XINHUA CONTROL TECH (GRP) CO LTD

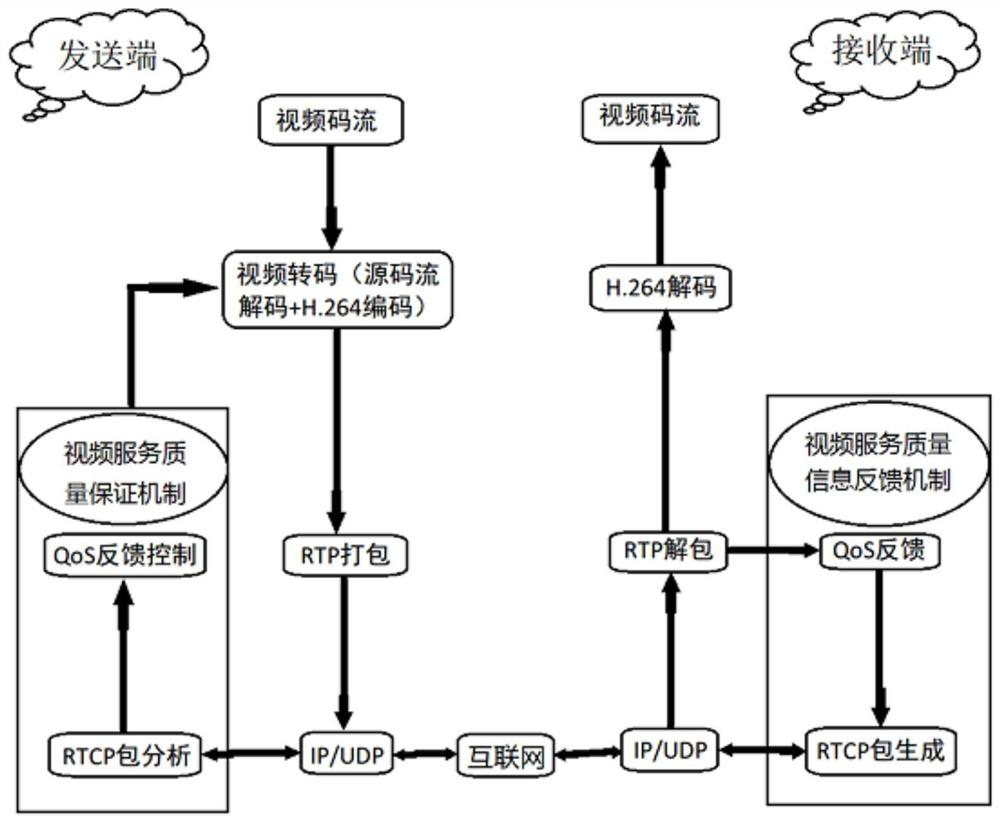

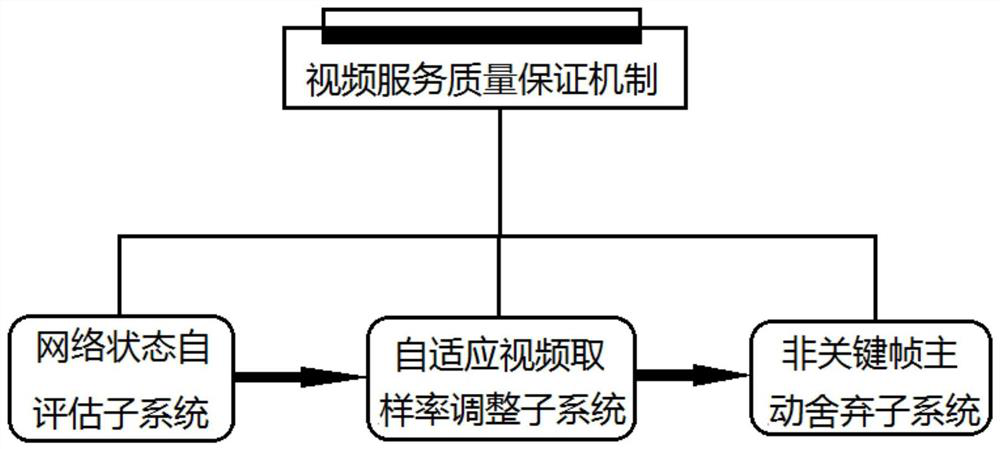

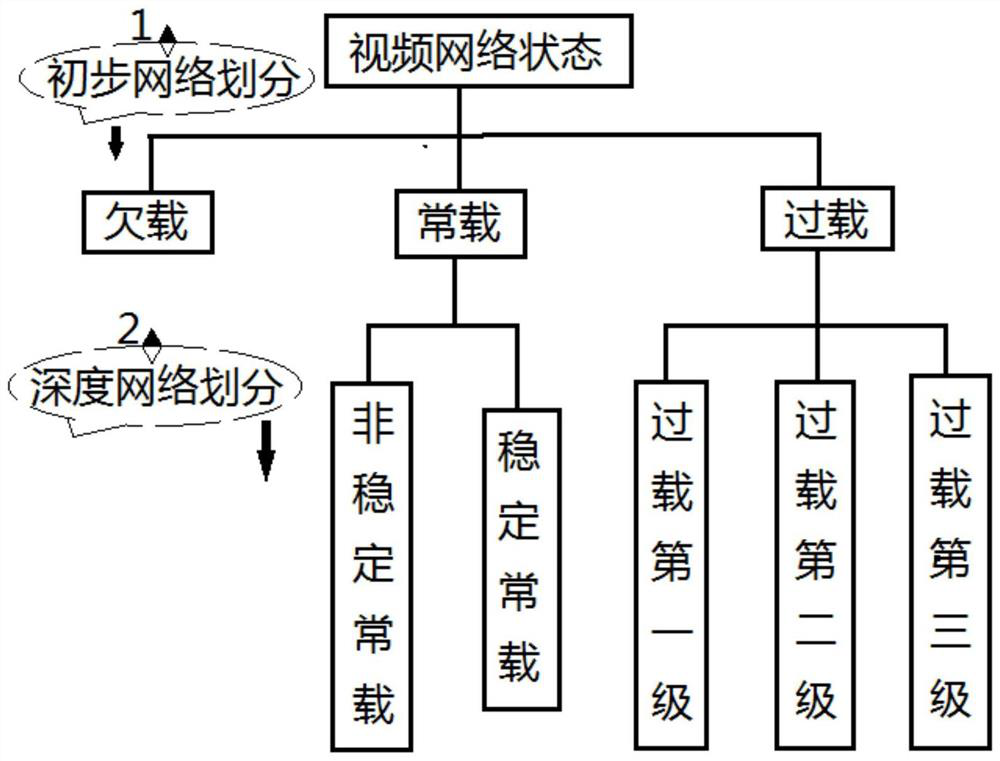

Video coding conversion transmission control system based on network state self-evaluation

ActiveCN111615006APrevent overloadAccurate judgmentSelective content distributionAlgorithmVideo transmission

The invention provides a video coding conversion transmission control system based on network state self-evaluation. Aiming at the problems that the network evaluation algorithm judges the network state only by depending on the packet loss rate, the judgment division is too rough, the limitation of serving as a video transmission rate adjustment basis is large and the like, the invention providesa method for combining the packet loss rate, the network delay and the delay jitter as network state evaluation factors, and the judgment of the network state is more scientific and accurate. Aiming at the problem that effective pre-control measures cannot be taken under the condition that a network has an overload trend but is not overloaded, a network overload pre-control method is added, and the network overload problem is skillfully processed at any time. Aiming at the problems that the network overload is too serious and overload control cannot be carried out by simply adjusting coding parameters, the invention provides a non-key frame active abandoning method, so that the video quality is ensured, the transmission quality is also ensured, a frame loss strategy is carried out before coding, the coding workload is reduced, and the robustness and the high efficiency are higher.

Owner:北京讯众通信技术股份有限公司

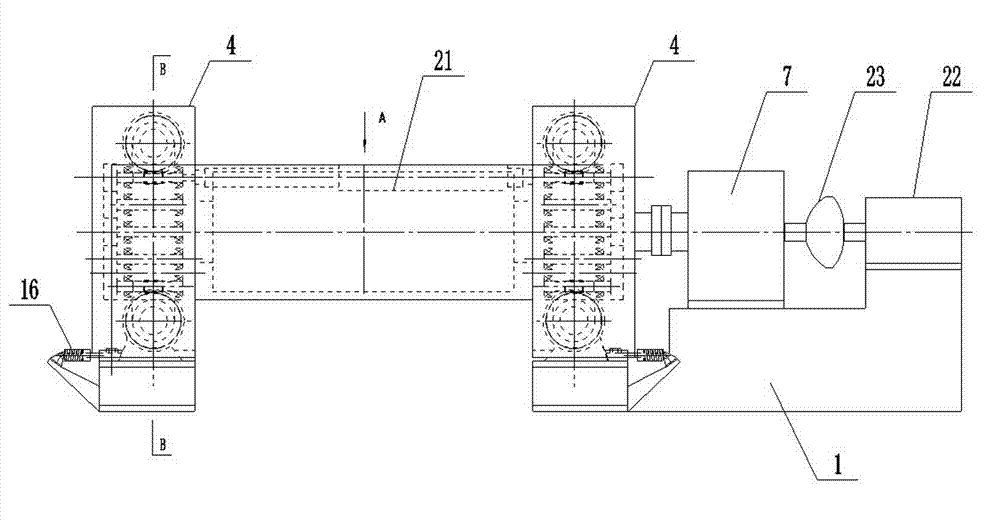

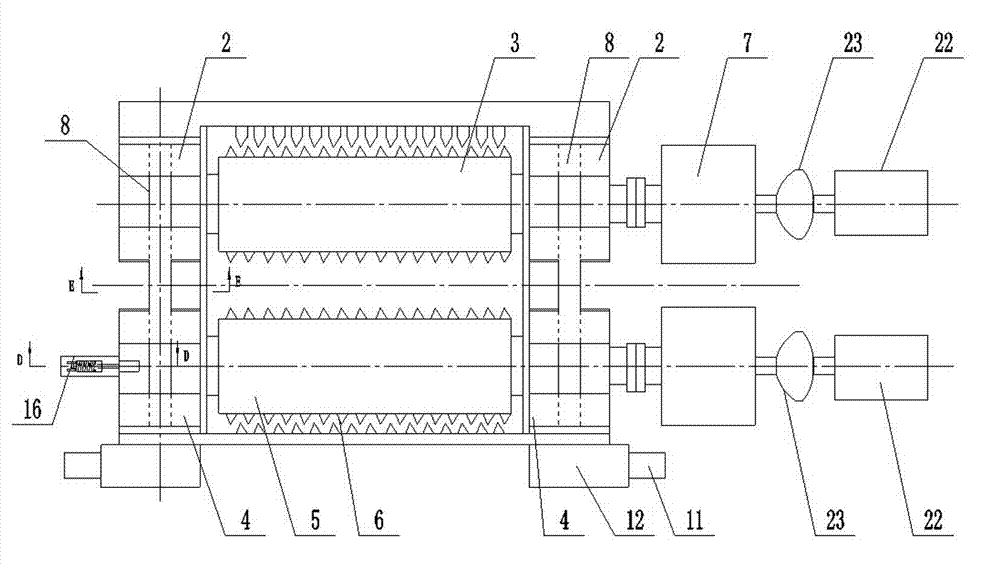

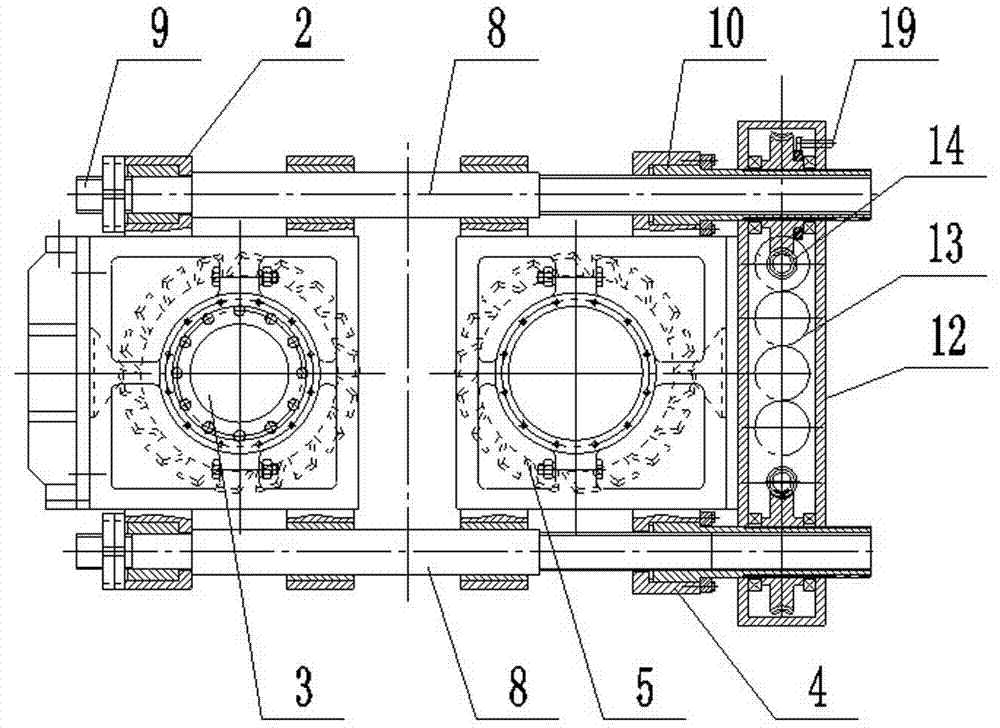

Double-geared roller strong graded crusher capable of adjusting and controlling particle size continuously

ActiveCN103028461AGranular adjustmentAdjustable spacingGrain treatmentsHydraulic motorControl system

The invention relates to industrial crushing equipment, in particular to a double-geared roller strong graded crusher capable of adjusting and controlling a particle size continuously. The crusher solves the problems of low degree of automation, high labor intensity, long construction period, high adjustment difficulty and the like of the conventional crusher during the adjustment of the particle size. The crusher comprises a base, a movable bearing block, a static bearing block, a static tooth roller and a movable tooth roller, wherein the movable bearing block is connected with the static bearing block by a pull rod; the static bearing block is locked with the pull rod; the movable bearing block can move to and fro along the pull rod by an adjusting gearbox driven by a hydraulic motor and a worm and worm wheel mechanism; a movable bearing block slide is arranged on the base; a hydraulic locking cylinder is mounted on the base; a compression sliding block which can extrude the movable bearing block is fixed at the front end of the piston rod of the hydraulic locking cylinder; an encoder is mounted in the adjusting gearbox; and a displacement sensor is mounted in the hydraulic locking cylinder and is connected with a programmable logic controller (PLC) control system. The crusher has the advantages of simple structure, simplicity and convenience in operation, short adjustment period, high production efficiency and degree of automation and the like, and can be widely applied to the field of industrial crushing.

Owner:TZ COAL MINE MACHINERY

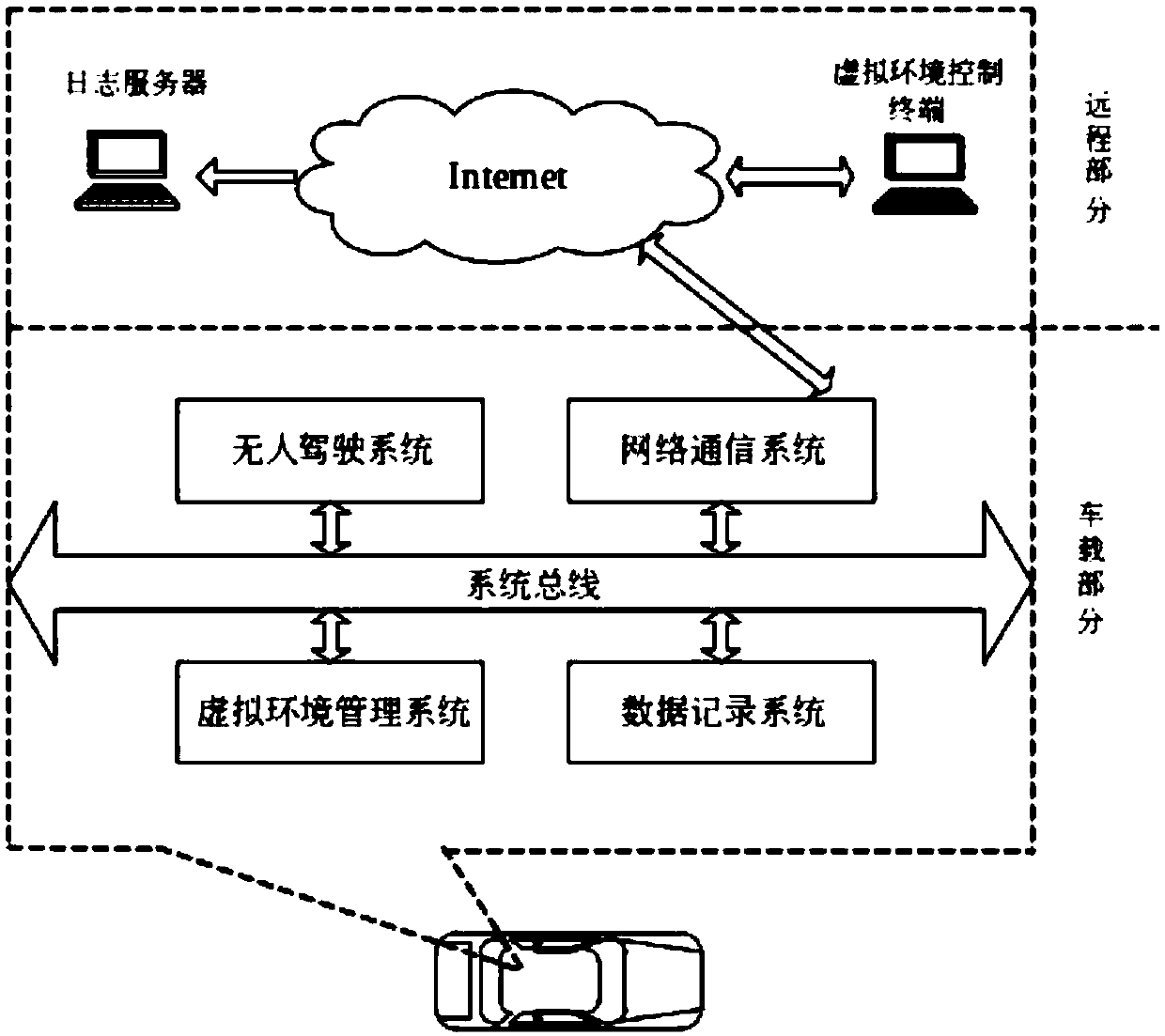

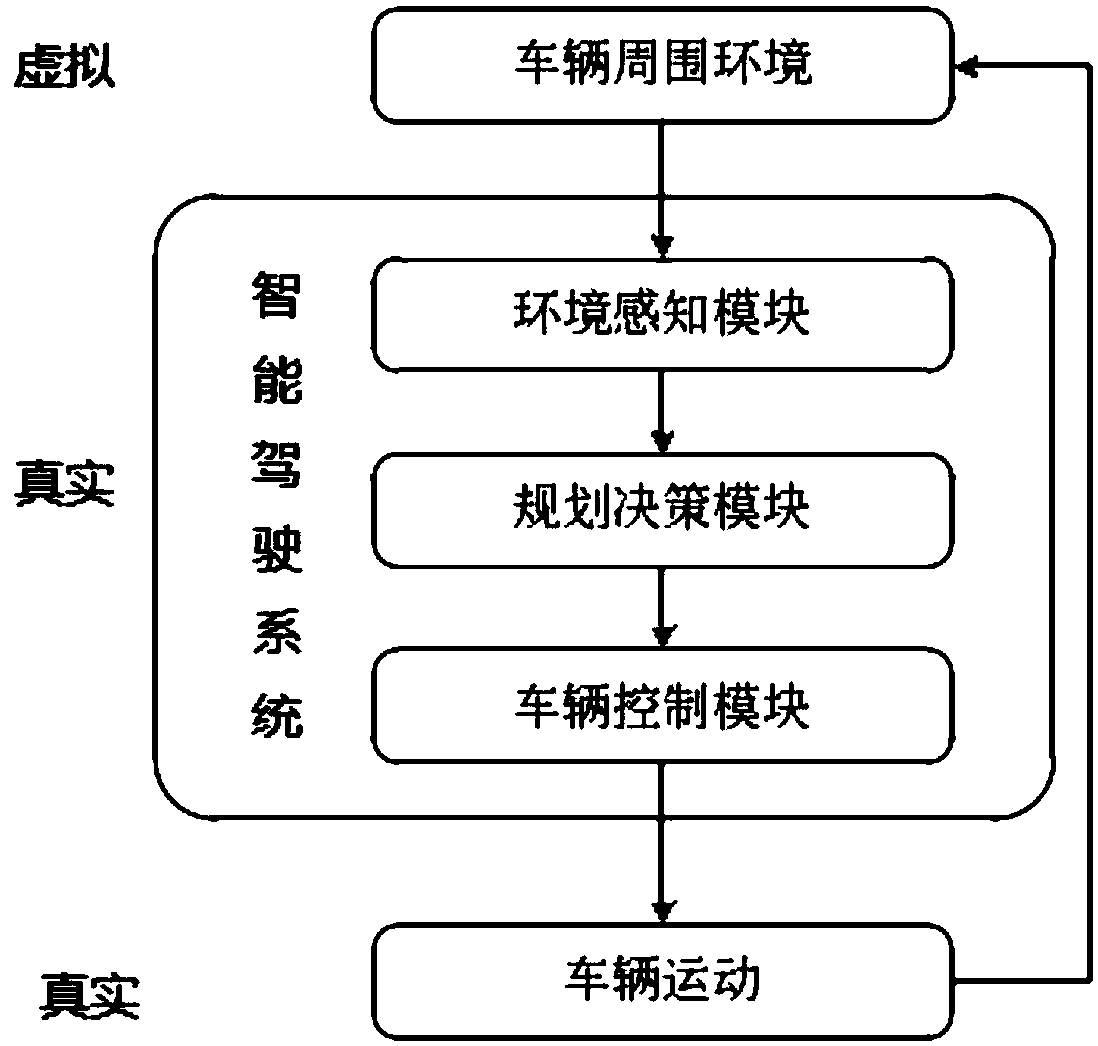

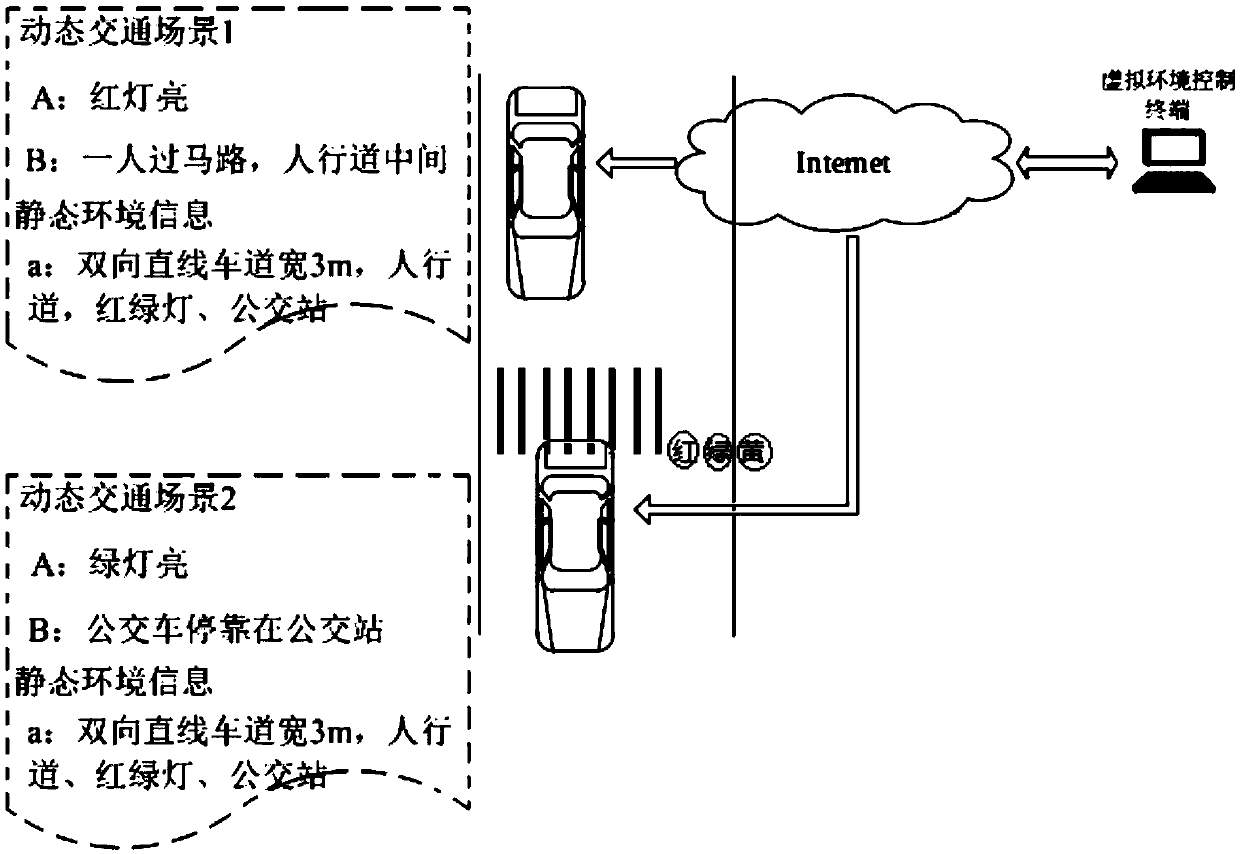

Test method, in-vehicle control device and test system of vehicle-in-loop intelligent driving vehicle

The invention discloses a test method, in-vehicle control device and test system of a vehicle-in-loop intelligent driving vehicle. The test method comprises the steps that the in-vehicle control device of the intelligent driving vehicle loads virtual environment information, and the virtual environment information includes static environment information of a test site and dynamic environmental information simulating a real dynamic traffic scene in the test site; and the in-vehicle control device performs a planning decision based on the loaded virtual environment information to control the motion of the intelligent driving vehicle. Based on the method, the intelligent driving system can be tested safely, efficiently, and at low cost by quickly creating a virtual scene.

Owner:UISEE TECH BEIJING LTD

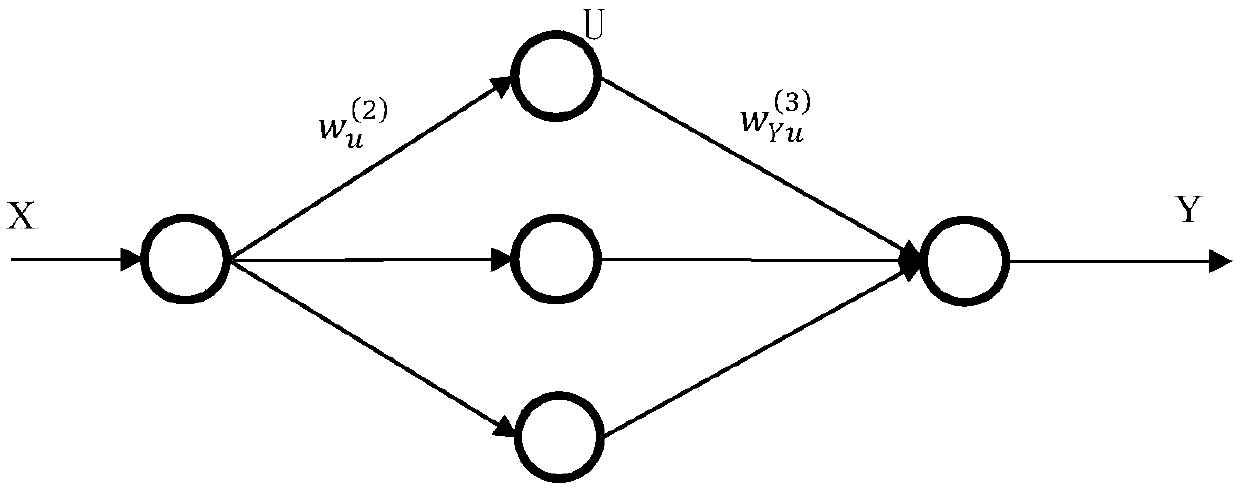

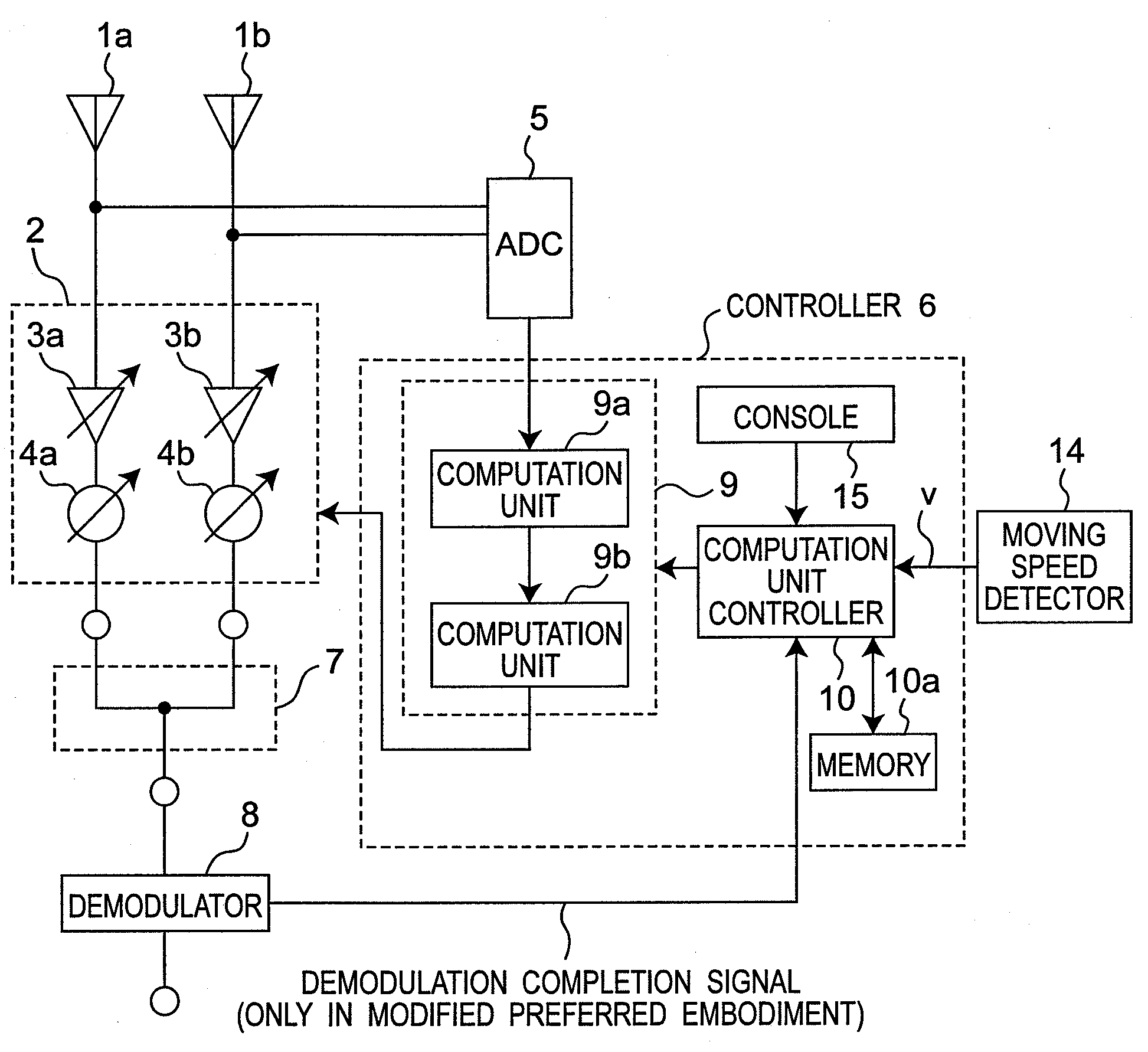

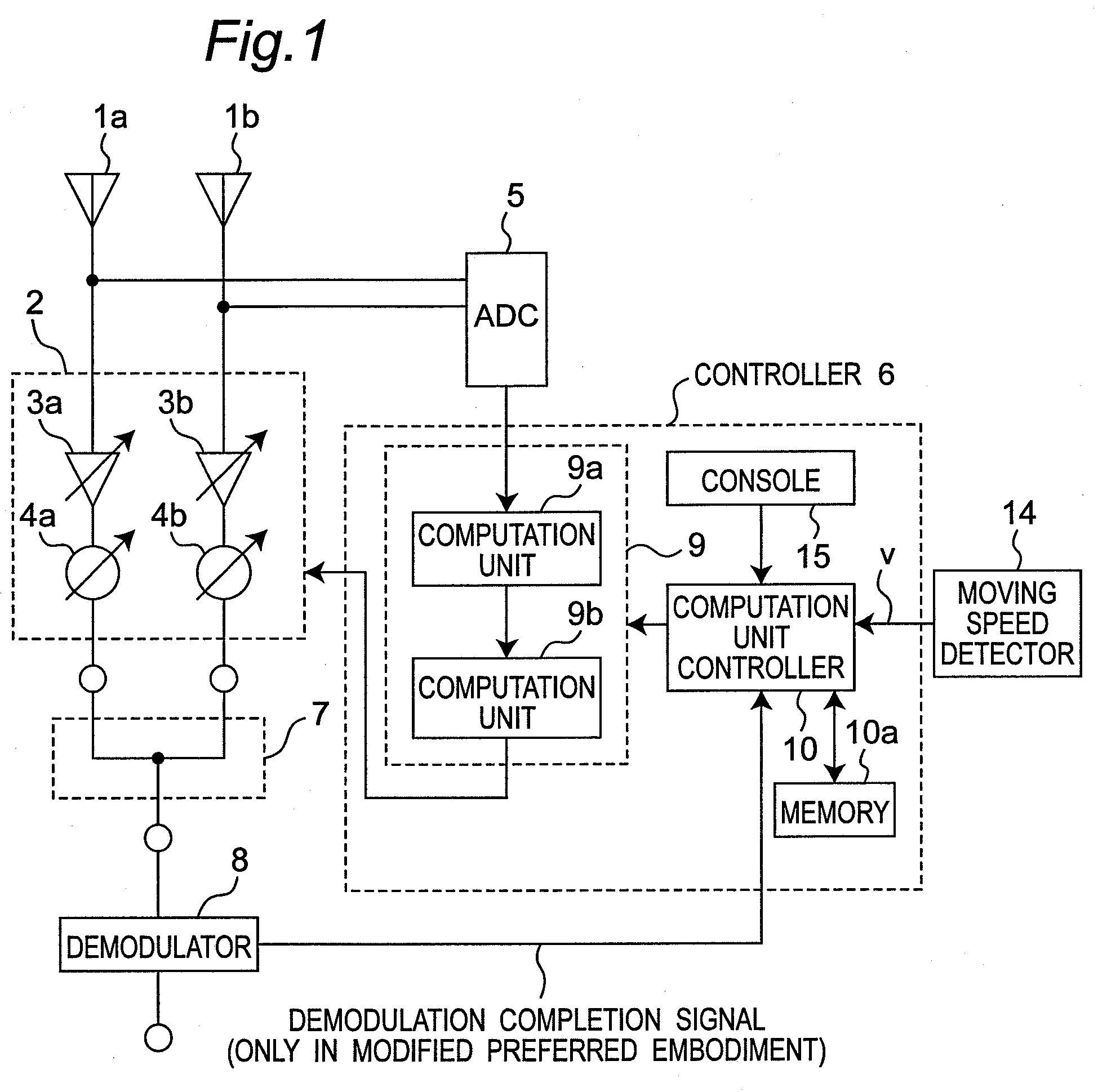

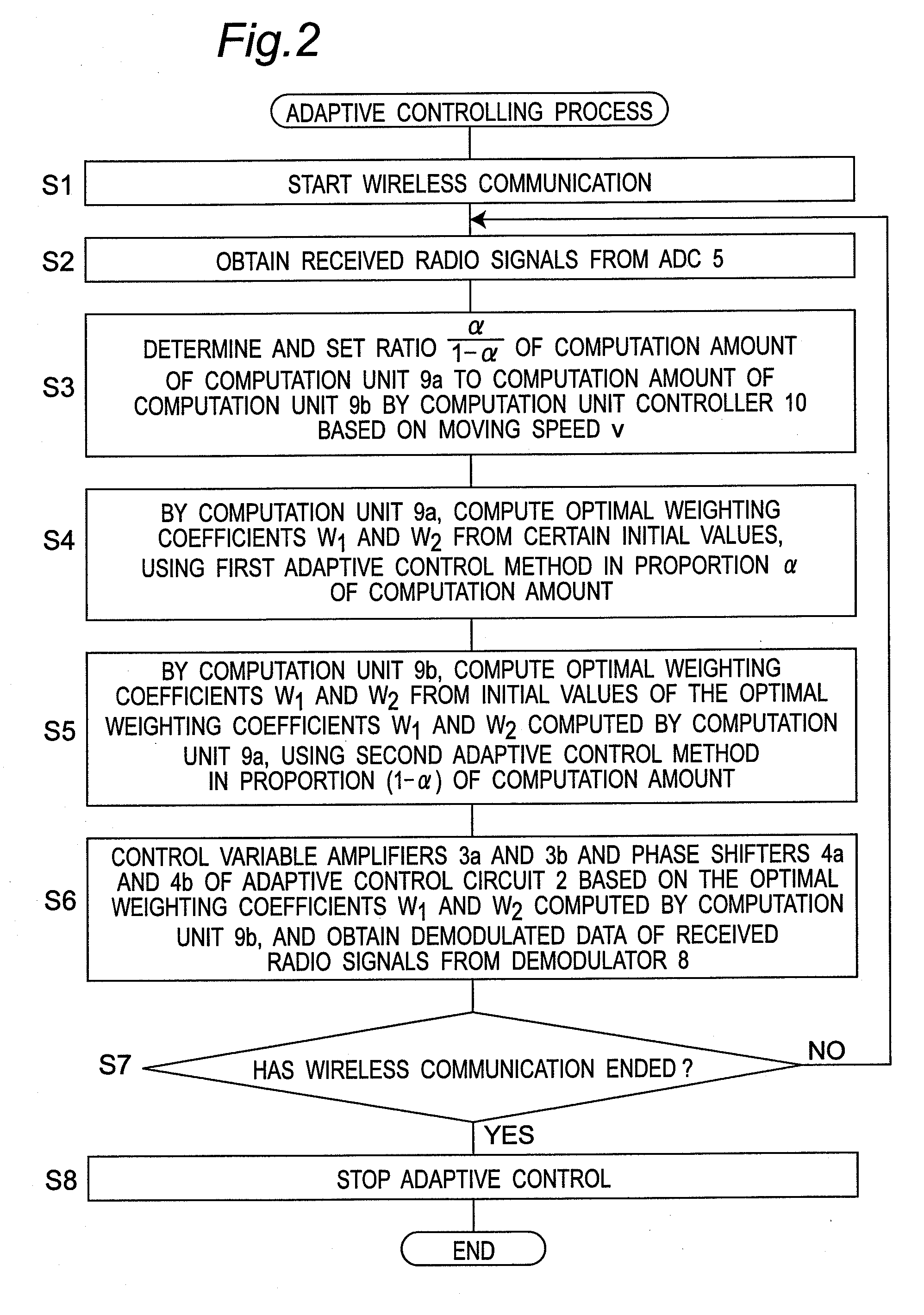

Adaptive control apparatus using multiple adaptive control methods

ActiveUS20090221253A1Improve signal qualitySmall convergence errorNoise figure or signal-to-noise ratio measurementDigital variable/waveform displayWeight coefficientSelf adaptive

In the adaptive control apparatus, a computation unit computes weighting coefficients, using a first adaptive control method in a proportion α of a first computation amount, where the first adaptive control method has a first convergence rate and a first convergence error. Further, a computation unit computes weighting coefficients from initial values of the weighting coefficients computed by the computation unit, using a second adaptive control method in a proportion (1−α) of a second computation amount, where the second adaptive control method has a second convergence rate slower than the first convergence rate and a second convergence error smaller than the first convergence error. A controller controls determination of a ratio α / (1-α) based on a moving speed of a mobile unit, and controls the computation units to perform computing processes.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

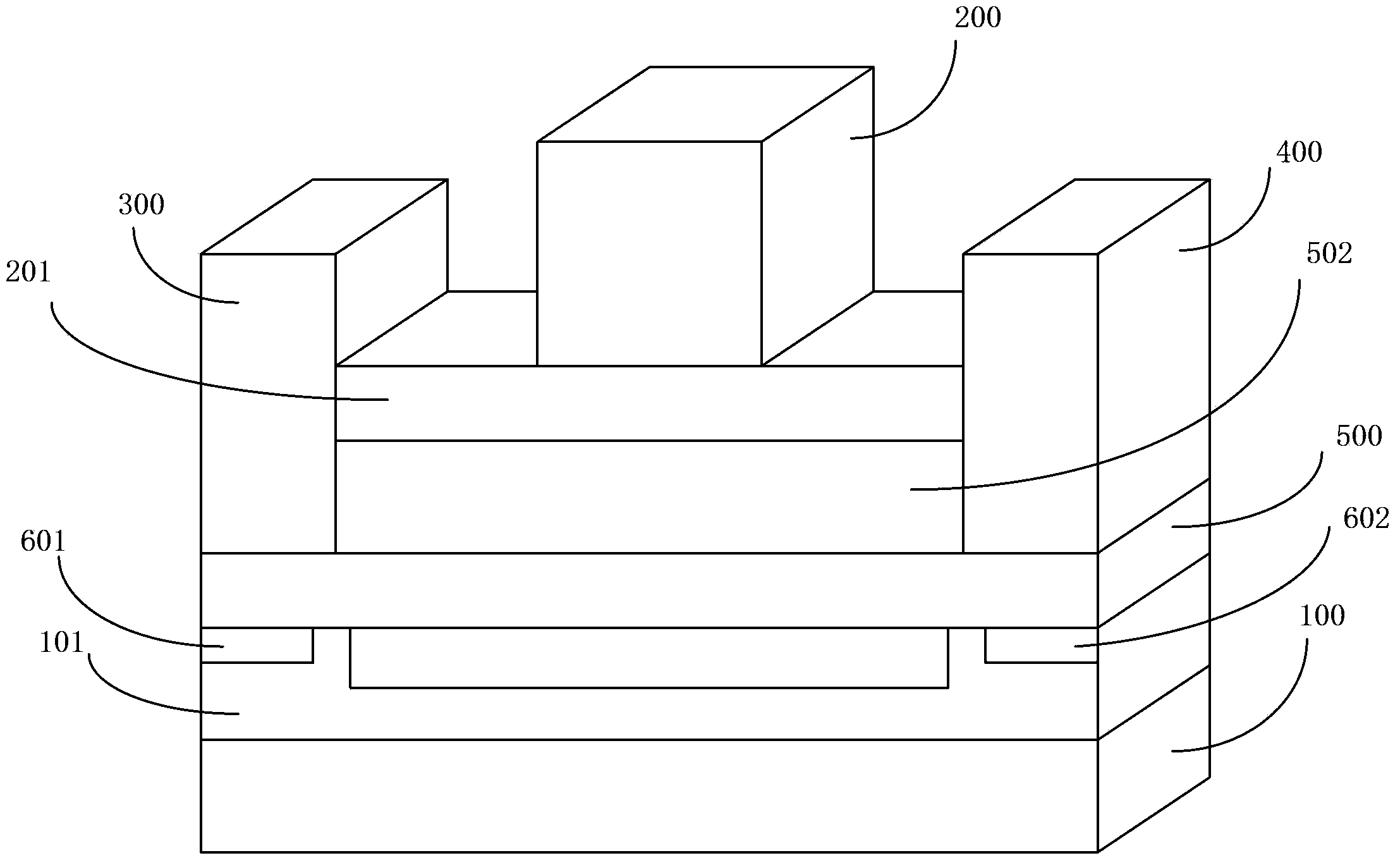

Double-gate fin-type field effect transistor and manufacturing method thereof

ActiveCN103531618AFast controlIncrease contact resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesShort-channel effectEngineering

The invention discloses a double-gate fin-type field effect transistor including a bottom gate, a first dielectric layer on the bottom gate, two bottom contacts at the top part of the first dielectric layer, a fin-type adjustable channel layer on the first dielectric layer and the bottom contacts, a source electrode and a drain electrode, which are formed at positions of the fin-type adjustable channel layer, corresponding to the two bottom contacts, an insulator formed on the fin-type adjustable channel layer and between the source electrode and the drain electrode, a second dielectric layer formed on the insulator and a top gate on the second dielectric layer and a manufacturing method thereof. The double-gate fin-type field effect transistor is provided with the adjustable channel layer, capable of carrying out switch conversion greatly, providing greater channel charge control capability and faster drive current, reducing a short-channel effect and improving performances of contact resistance of a device and the like.

Owner:SEMICON MFG INT (SHANGHAI) CORP

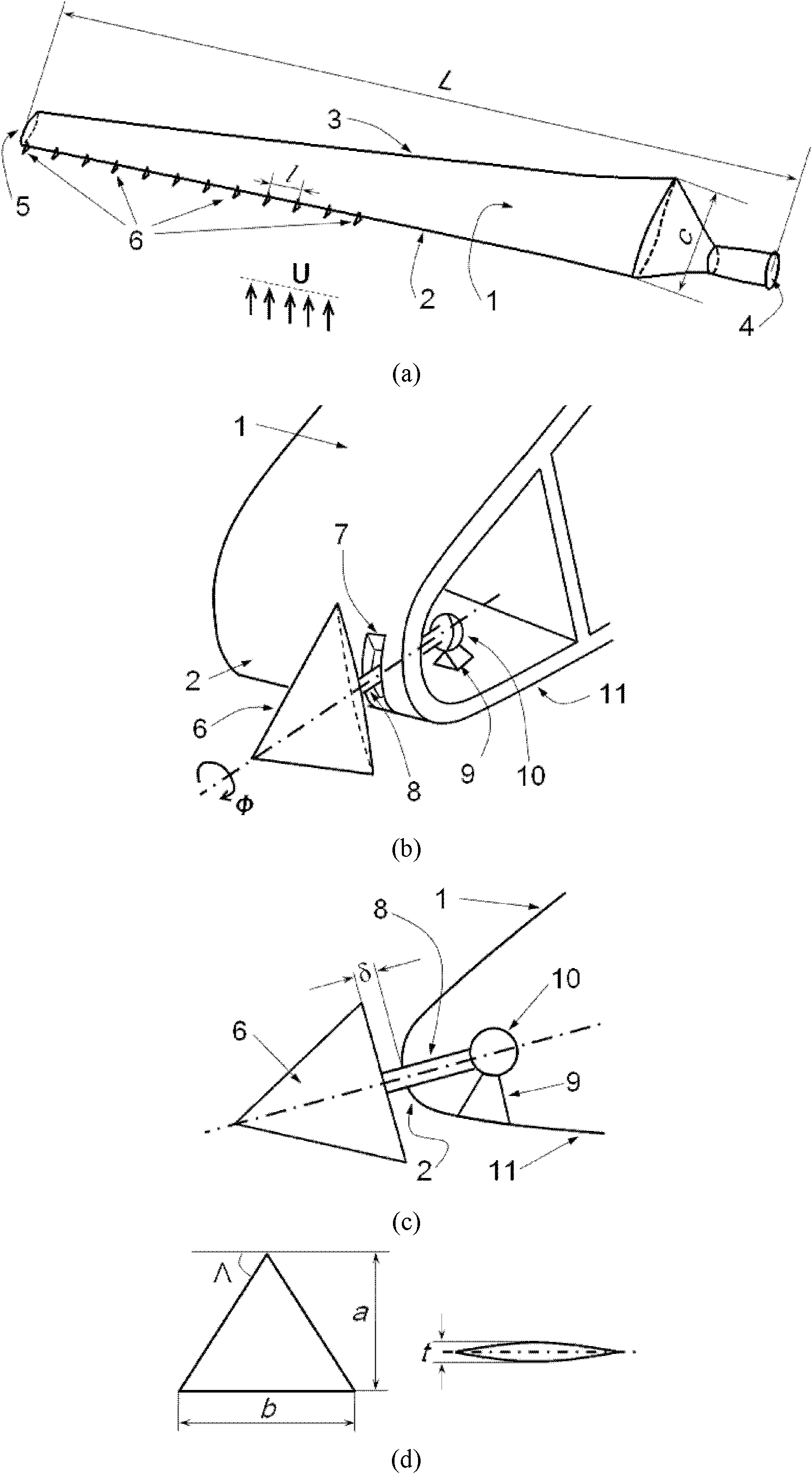

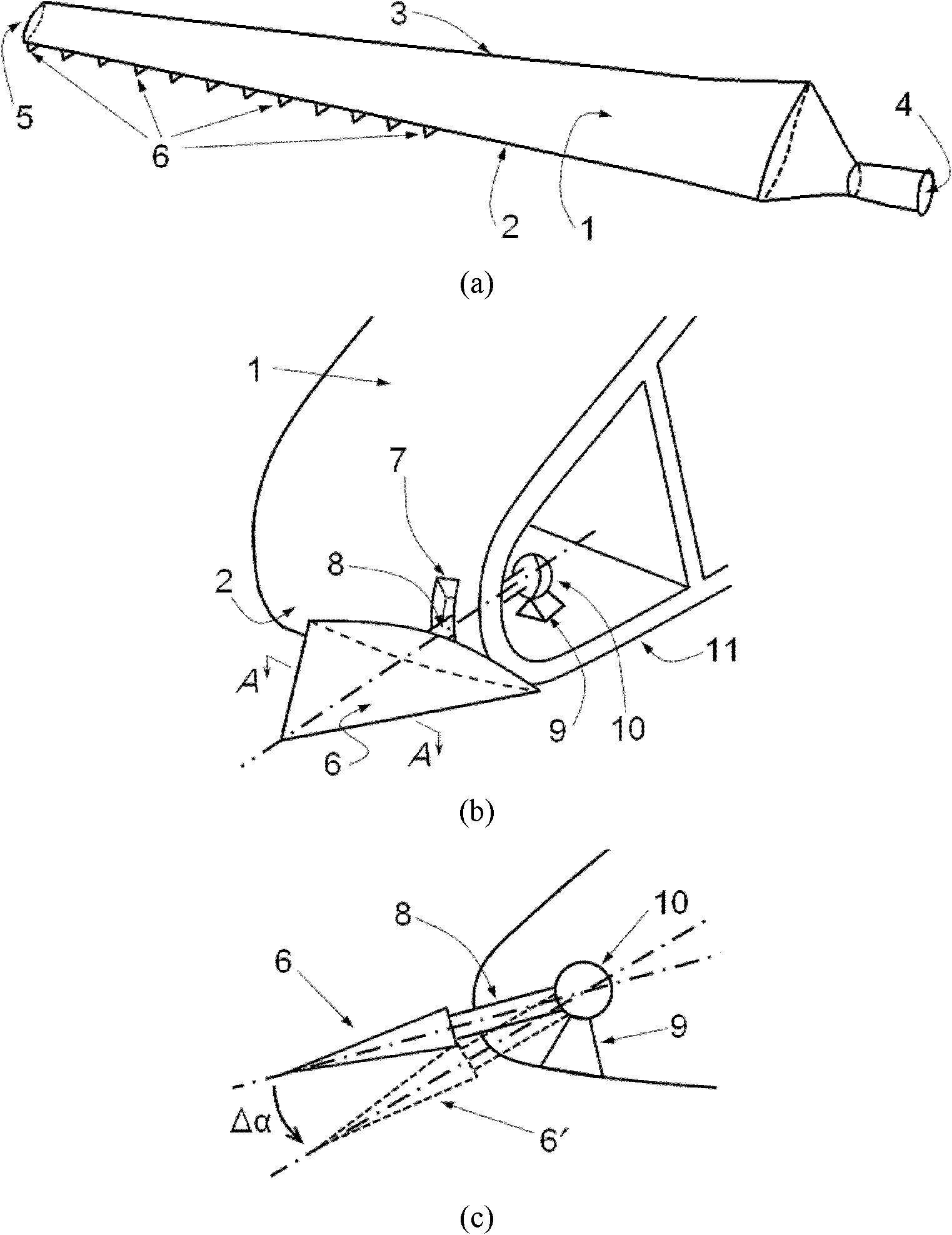

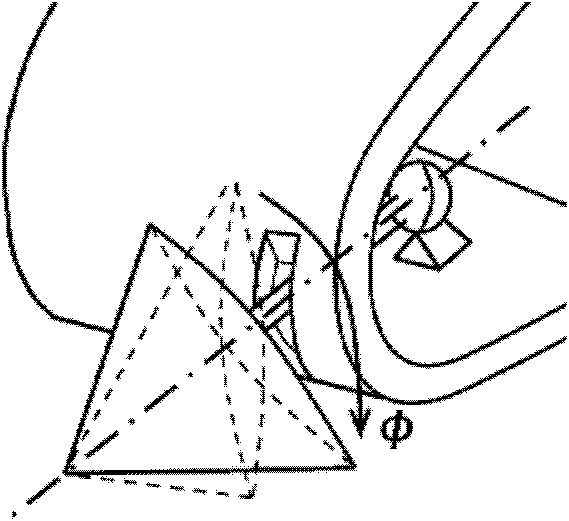

Device for utilizing front edge rudder pieces to adjust output power of rotating blade and method thereof

InactiveCN101865081AFast controlShort response timeWind motor controlMachines/enginesWind drivenWind force

The invention relates to a wind-driven generator, in particular to a device for utilizing front edge rudder pieces to adjust output power of a rotating blade and a method thereof. A certain quantity of rudder pieces are added at the front edge of the rotating blade, strong vortex flow generated by the rudder pieces under different attitude angles is utilized to carry out active intervention on a flow characteristic of the upper surface of the blade to change the original aerodynamic characteristic thereof and lead the blade to keep stable output power in larger range of operating conditions; and the rudder piece has two rotational degrees of freedom of rolling and pitching, not only can lead all the rudder pieces to keep a uniform attitude angle, but also can adjust the attitude angle of each rudder piece separately in the process of practical control. The device provided by the invention has simpler design and more flexible and finer control, can effectively improve the aerodynamic property of the rotating blade when in high-wind-velocity off-design working conditions, and improve operating efficiency of a wind-driven generator set.

Owner:PEKING UNIV

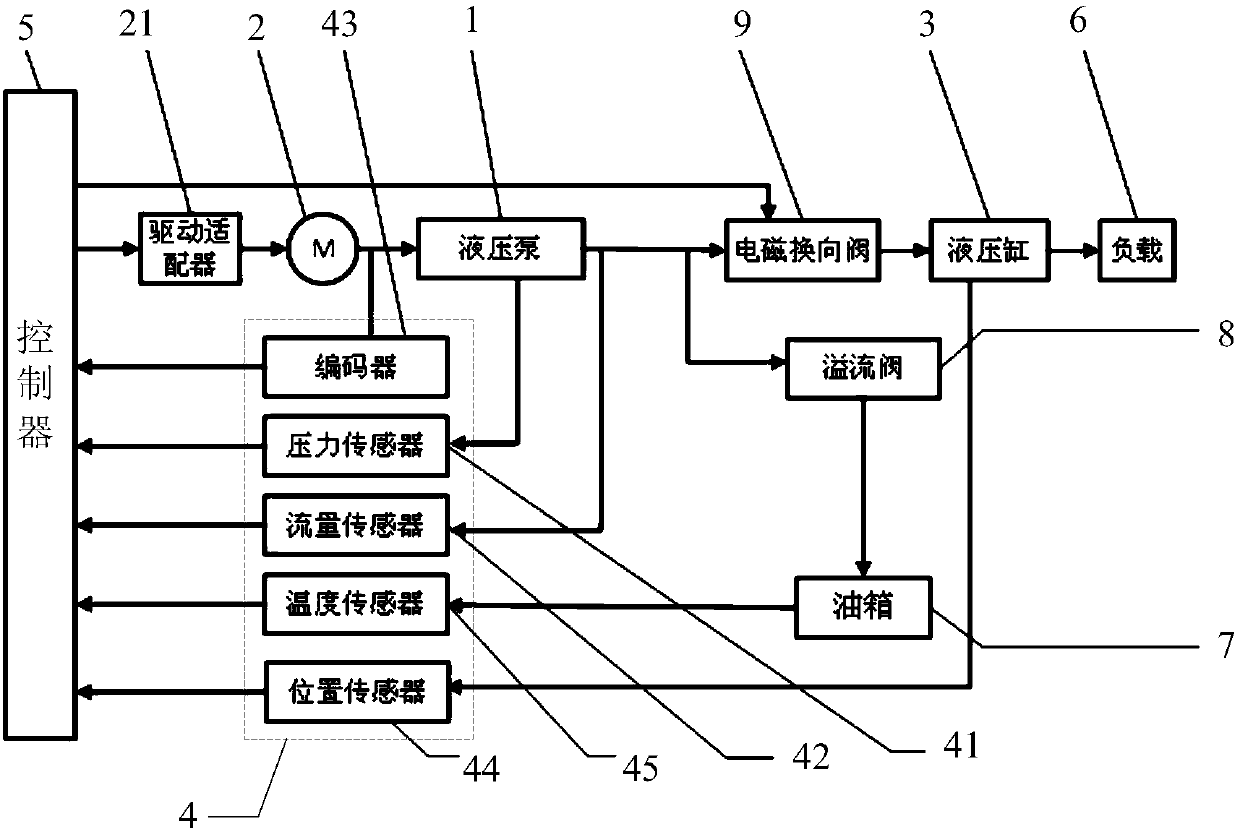

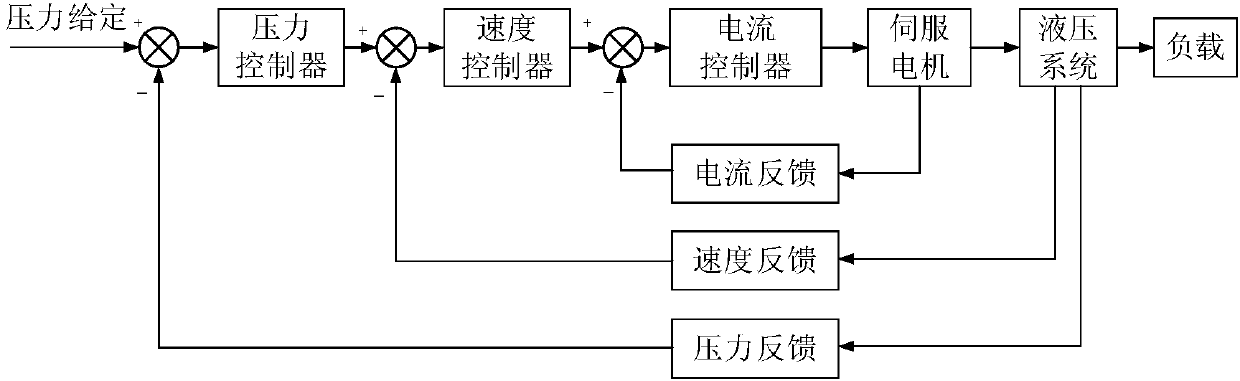

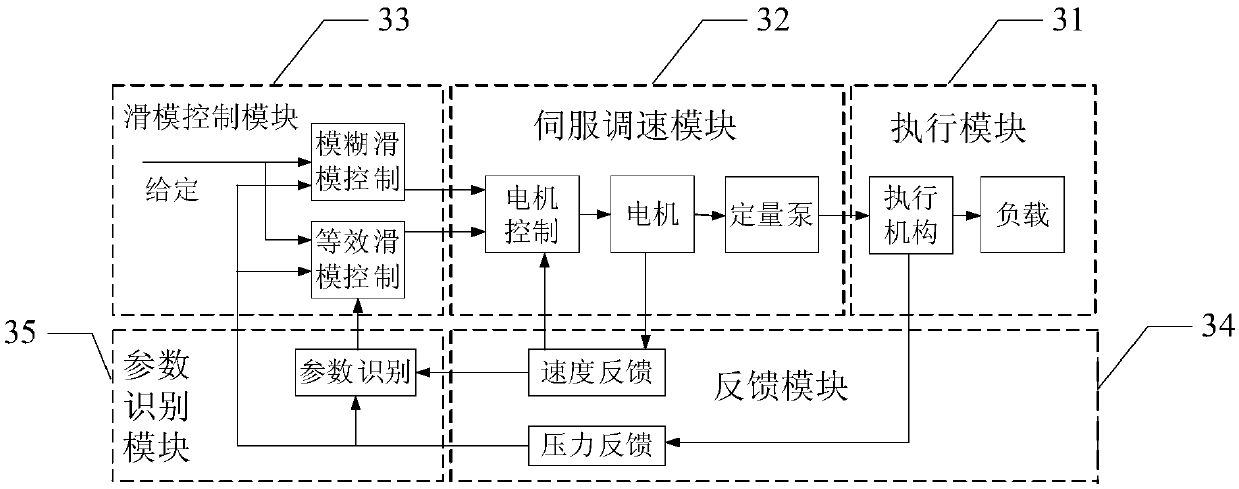

Direct drive type electro-hydraulic servo pressure control system

InactiveCN107218269AFast controlHigh control precisionFluid-pressure actuator testingServomotorsElectric driveElectro hydraulic

The invention relates to a direct drive type electro-hydraulic servo pressure control system. The direct drive type electro-hydraulic servo pressure control system comprises an execution module, a servo speed regulation module, a sliding mold control module and a feedback module, wherein the execution module is used for executing corresponding operation under pressure drive provided by hydraulic pressure; the servo speed regulation module is in rigid connection with the execution module and is used for regulating pressure provided for the execution module under corresponding electric drive signals; the sliding mold control module is used for outputting the electric drive signals to the servo speed regulation module under given signals; and the feedback module is used for feeding data collected from the execution module and the servo speed regulation module back to the sliding mold control module. Linear control can be achieved, and the control accuracy is then improved.

Owner:SHENZHEN POLYTECHNIC

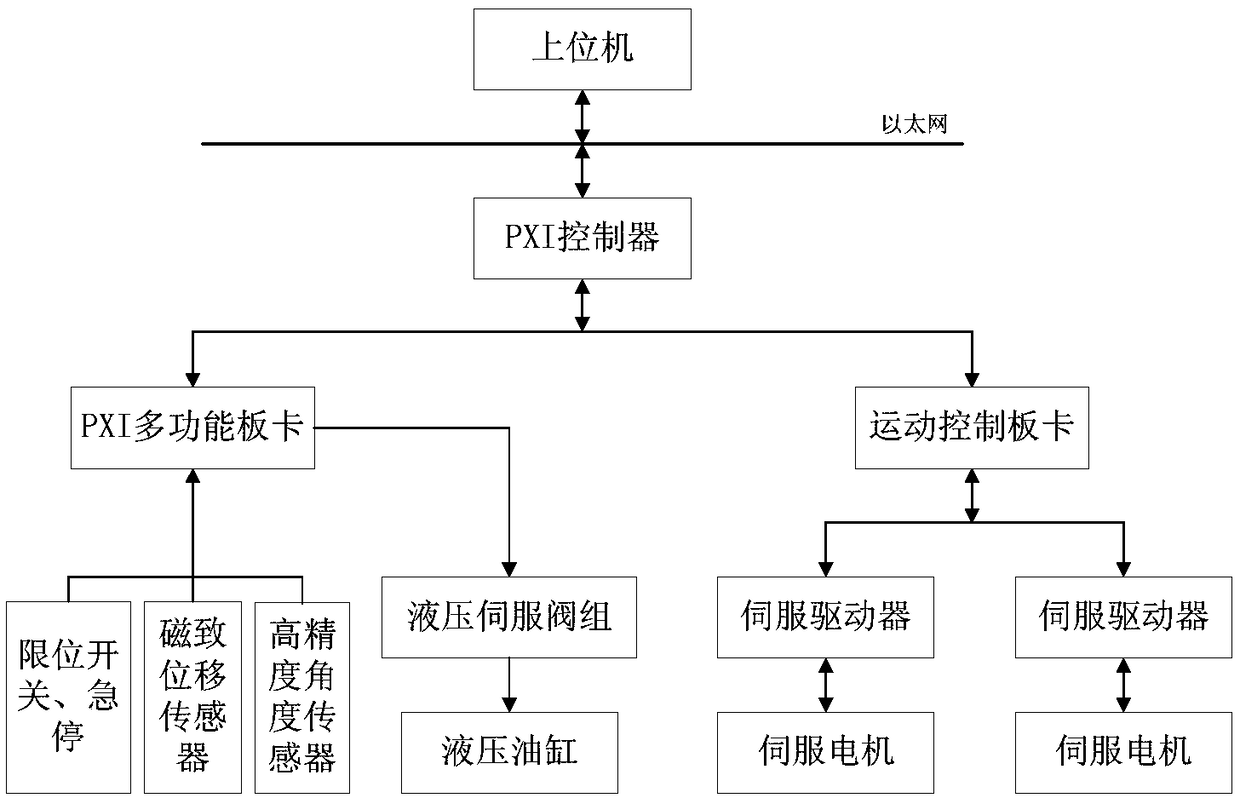

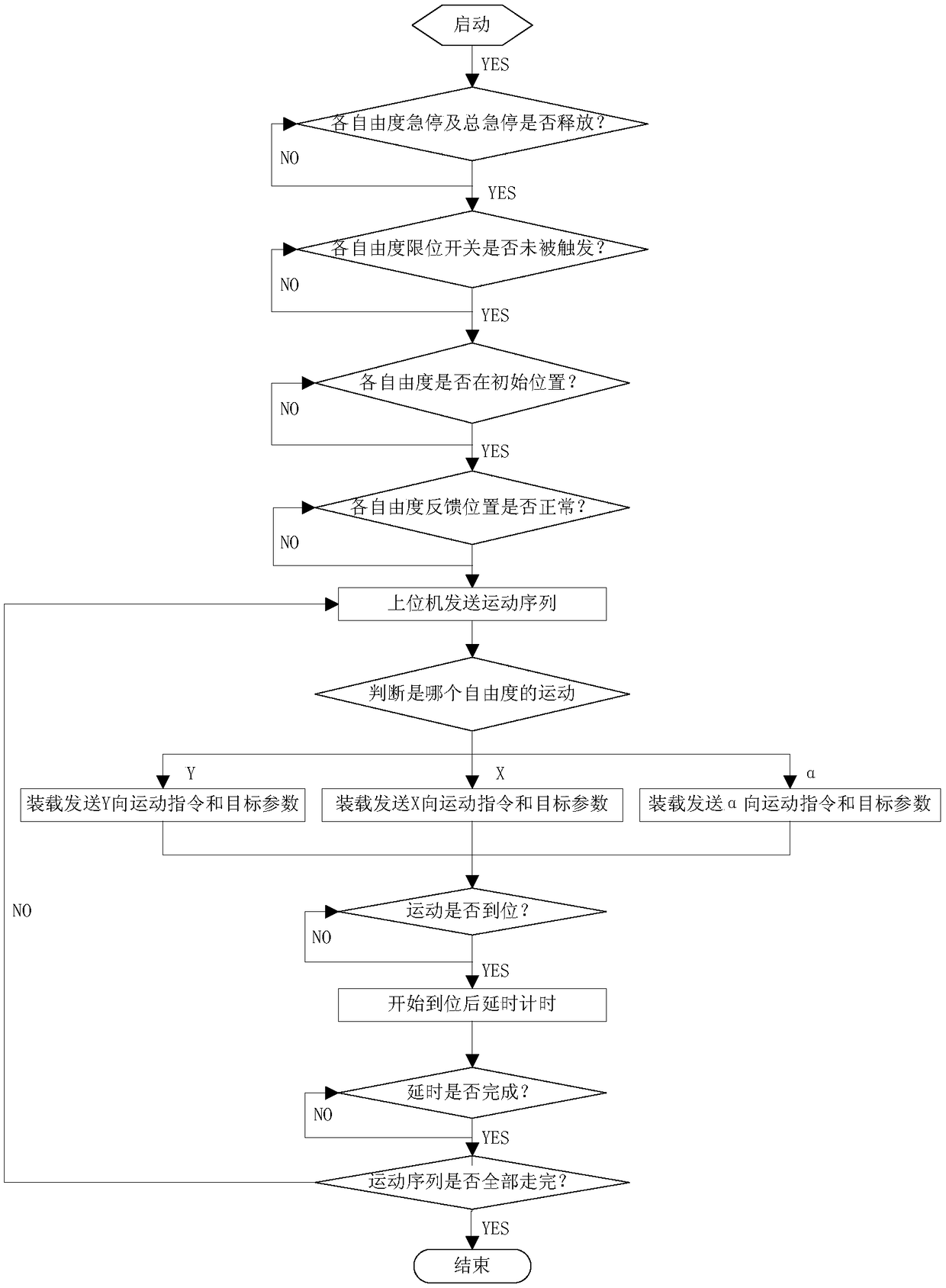

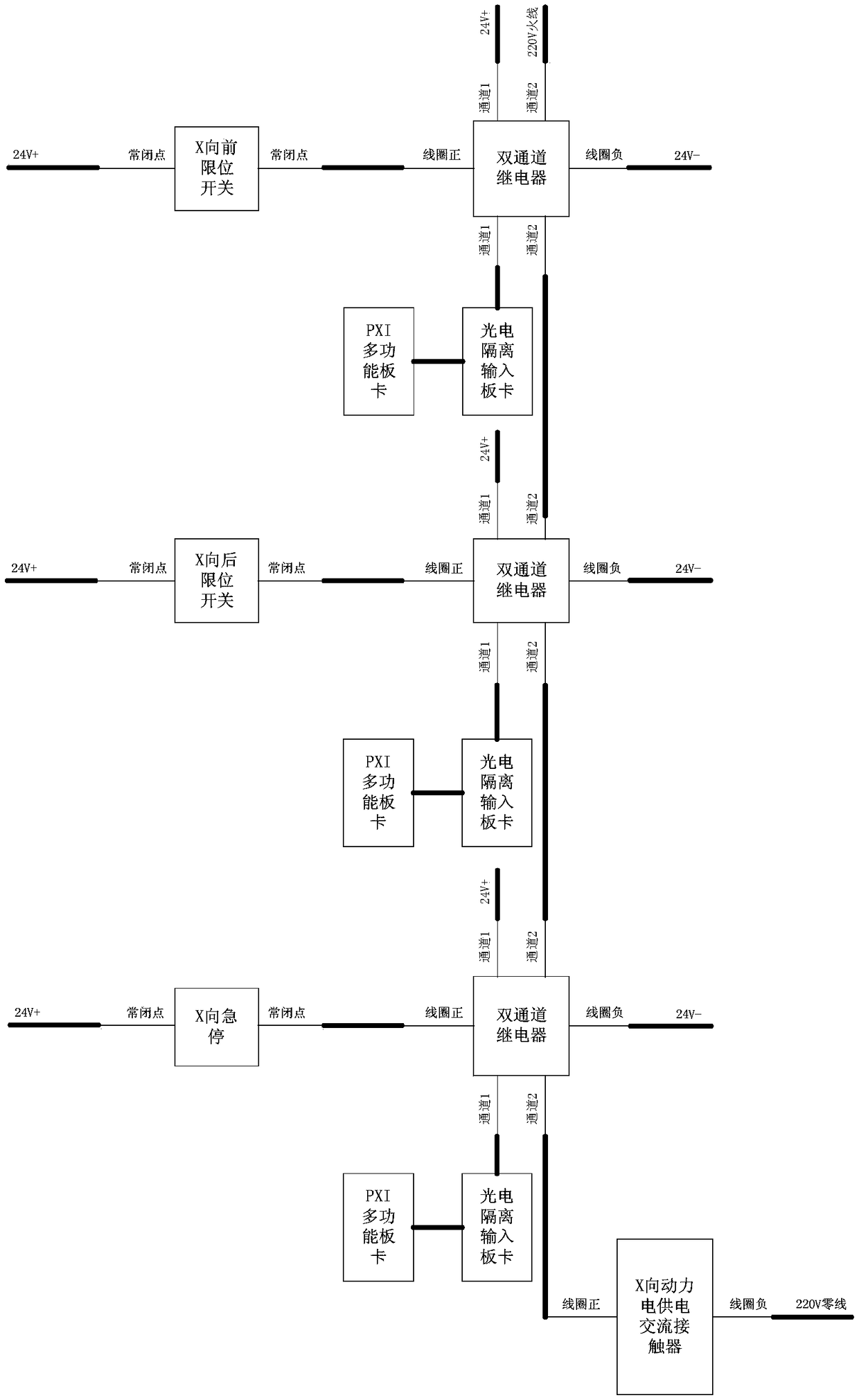

Wind tunnel three-degree-of-freedom model insertion mechanism control system and method

InactiveCN109269758AImprove ductilityImprove scalabilityAerodynamic testingThree degrees of freedomControl system

The invention provides a wind tunnel three-degree-of-freedom model insertion mechanism control system and a wind tunnel three-degree-of-freedom model insertion mechanism control method. The three degrees of freedom are a vertical Y direction, a horizontal X direction and a pitch alpha direction. Displacement sensors are installed in the Y direction and the X direction of a test model, and an anglesensor is installed in the alpha direction; actuators are installed on three degrees of freedom, and driving elements drive the actuators to implement corresponding motions; the degrees of freedom ofthe test model insertion mechanism in the X direction and the alpha direction and the actuators are placed on a horizontal working platform, and are supported by means of Y-direction degree of freedom; an upper computer sequentially packages normal motion sequences of a current test item by item in a form of a motion sequence, processes the normal motion sequences into a form of instructions which can be identified by a PXI controller, and transmits the instructions to the PXI controller; the PXI controller receives and parses the instructions, forms control instructions corresponding to thedriving elements and transmits the control instructions to the corresponding driving elements, receives feedback information of a PXI multifunctional acquisition board card, and feeds back motion in-place information to the upper computer when the execution of the actuators is in place; and the upper computer and the PXI controller enter a standby state after all the motion sequences are completed.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

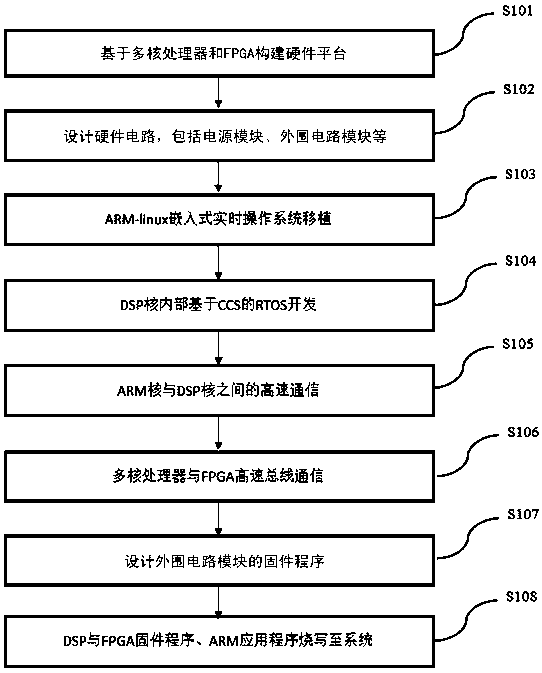

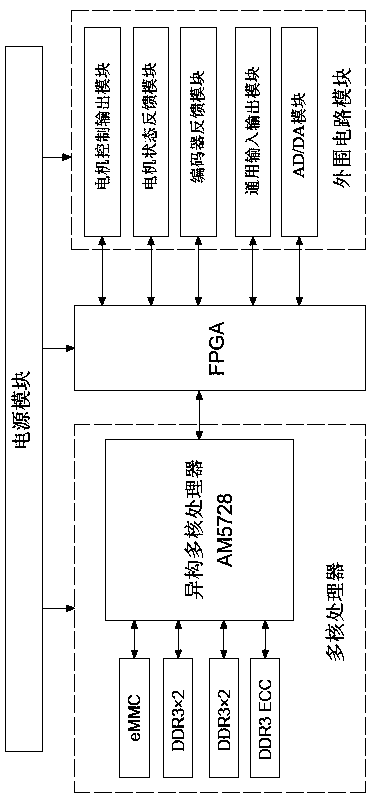

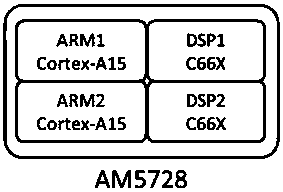

Multi-axis linkage embedded type digital control system and development method thereof

The invention provides a multi-axis linkage embedded type digital control system and a development method thereof. The method comprises steps of constructing a hardware platform; designing a hardwarecircuit; transplanting an ARM-linux embedded real-time operation system, carrying out RTOS development on a multi-core processor; establishing communication between inner cores of the multi-core processor, establishing communication between the multi-core processor and an FPGA, developing firmware programs of a periphery circuit module and solidifying DSP, the FPGA firmware programs and the ARM application programs to the system. The digital control system comprises the multi-core process, the FPGA, a power supply module and the periphery circuit module based on FPGA expansion. The power supply module is connected with the multi-core processor, the FPGA and the periphery circuit module. The multi-core processor is connected with the FPGA. According to the invention, design difficulty levelof the system can be effectively reduced; development period is greatly shortened; and the system and the method help users to concentrate on solving specific application problems.

Owner:HUNAN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com