Multi-axis linkage embedded type digital control system and development method thereof

An embedded numerical control, multi-axis linkage technology, applied in general control system, control/regulation system, digital control and other directions, can solve the problem of long cycle, insufficient platform reconfigurability to realize equipment interchange, and insufficient human-computer interaction issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

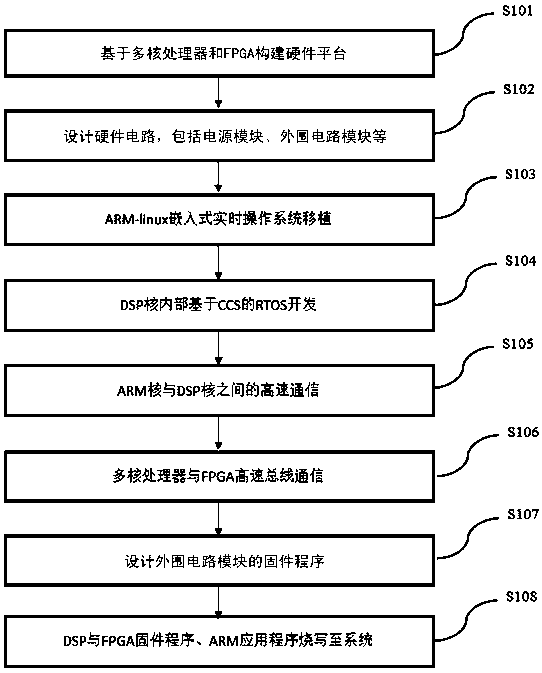

[0038] figure 1 A work flow chart of a development method of a multi-axis linkage embedded numerical control system is shown. Specifically, the development method includes the following steps:

[0039] S101. Building a hardware platform based on multi-core processors and FPGAs

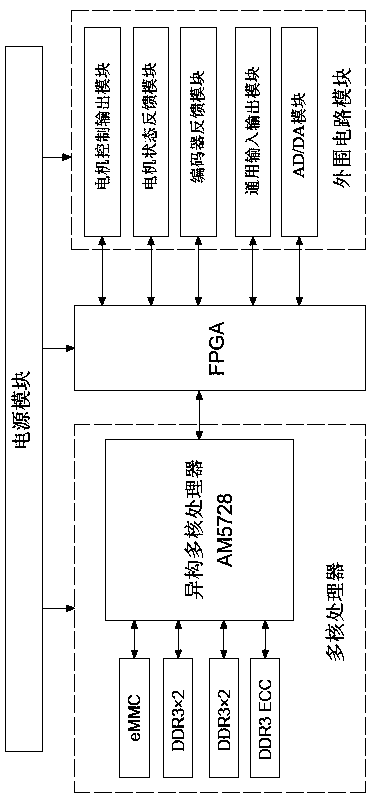

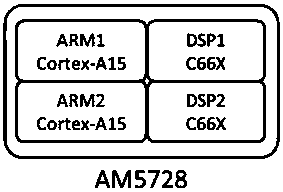

[0040] The heterogeneous multi-core processor AM5728 is used as the computing unit of the numerical control system, and the Intel Cyclone10 series FPGA chip is used as the control core of the numerical control system. Among them, the heterogeneous multi-core processor AM5728 has two ARM Cortex-A15 RISC CPU cores and two TI C66x VLIW floating-point DSP core, developers can separate multi-thread control and motion con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com