Process for preparing 3,4-dimethylpyrazole phosphate

A technology of dimethylpyrazole phosphate and dimethylpyrazole, which is applied in 3 fields, can solve the problems of long reaction time and achieve the effects of short reaction time, less by-products and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

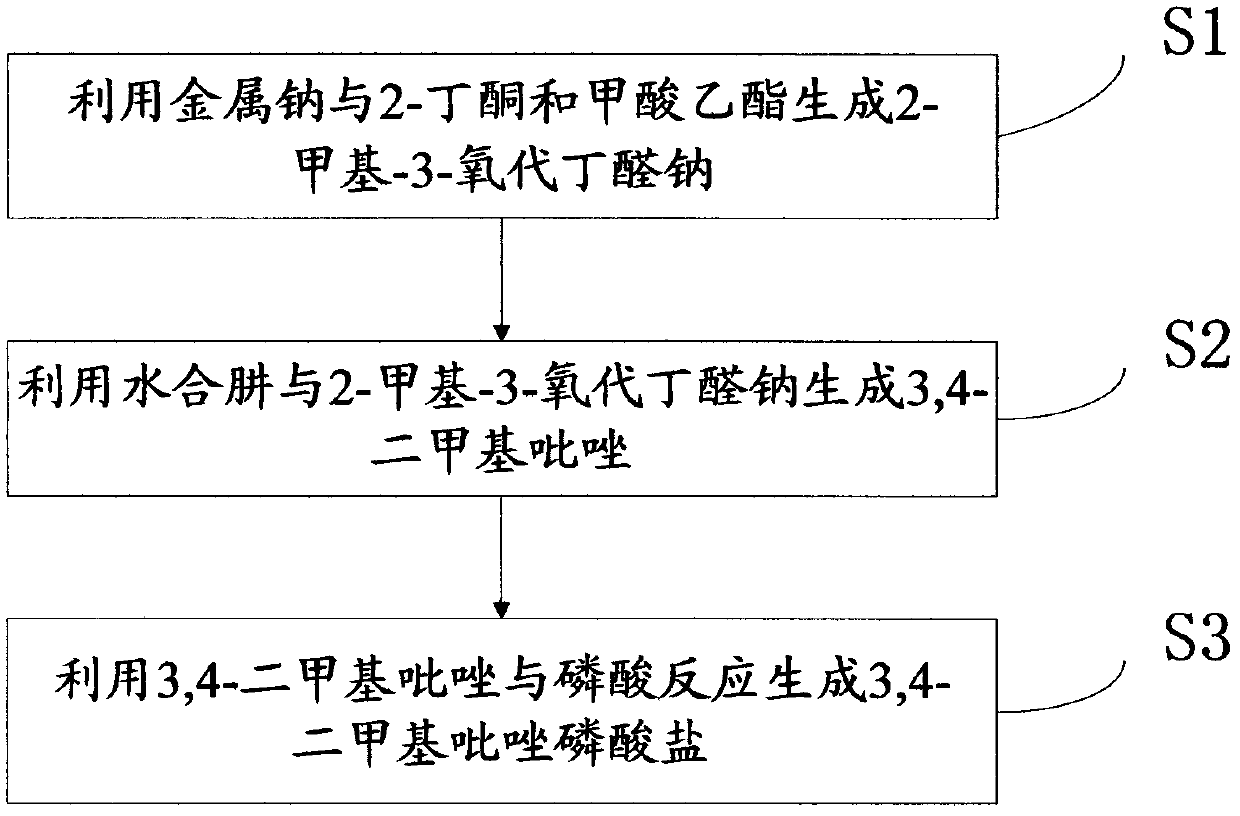

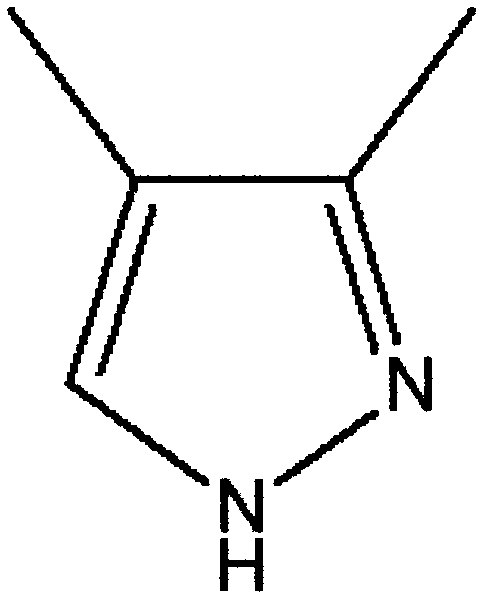

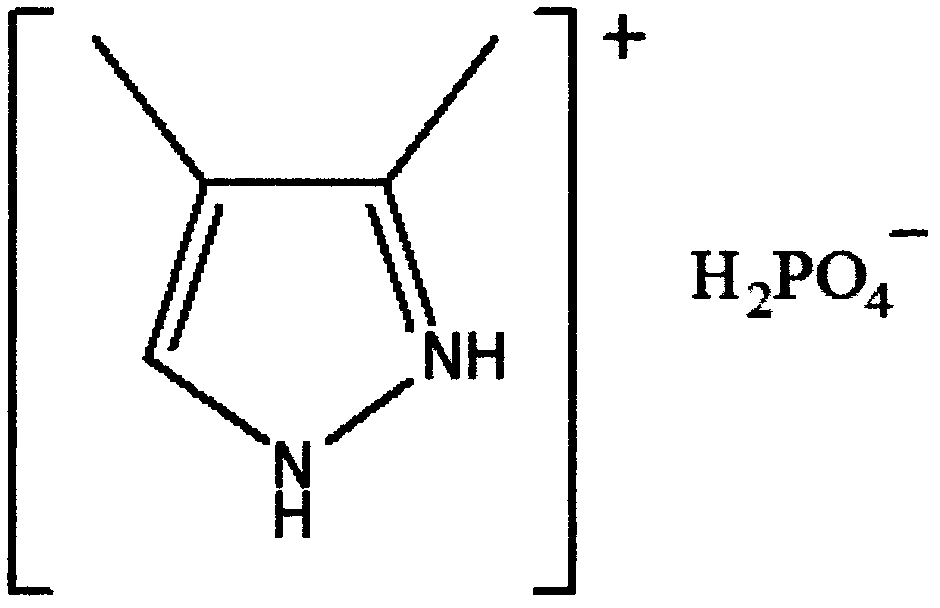

[0025] The invention provides a method for preparing 3,4-dimethylpyrazole phosphate. In the method, an organic solvent of sodium metal is used to replace a strong base, so that 2-butanone and ethyl formate undergo a condensation reaction to generate 2- Sodium methyl-3-oxobutyraldehyde, so as to synthesize 3,4-dimethylpyrazole with high selectivity. The reaction of 3,4-dimethylpyrazole with phosphoric acid gives 3,4-dimethylpyrazole phosphate.

[0026] The invention provides a method for effectively synthesizing 3,4-dimethylpyrazole phosphate with readily available raw materials, mild reaction conditions, short reaction time and few by-products.

[0027] see figure 1 , figure 1 It is a flowchart of the preparation method of 3,4-dimethylpyrazole phosphate of the present invention, and the preparation method of 3,4-dimethylpyrazole phosphate comprises: step S1, mixing metal sodium with 2-butanone and formic acid The mixed solution of ethyl ester generates sodium 2-methyl-3-oxo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com