Patents

Literature

20315results about How to "Short reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

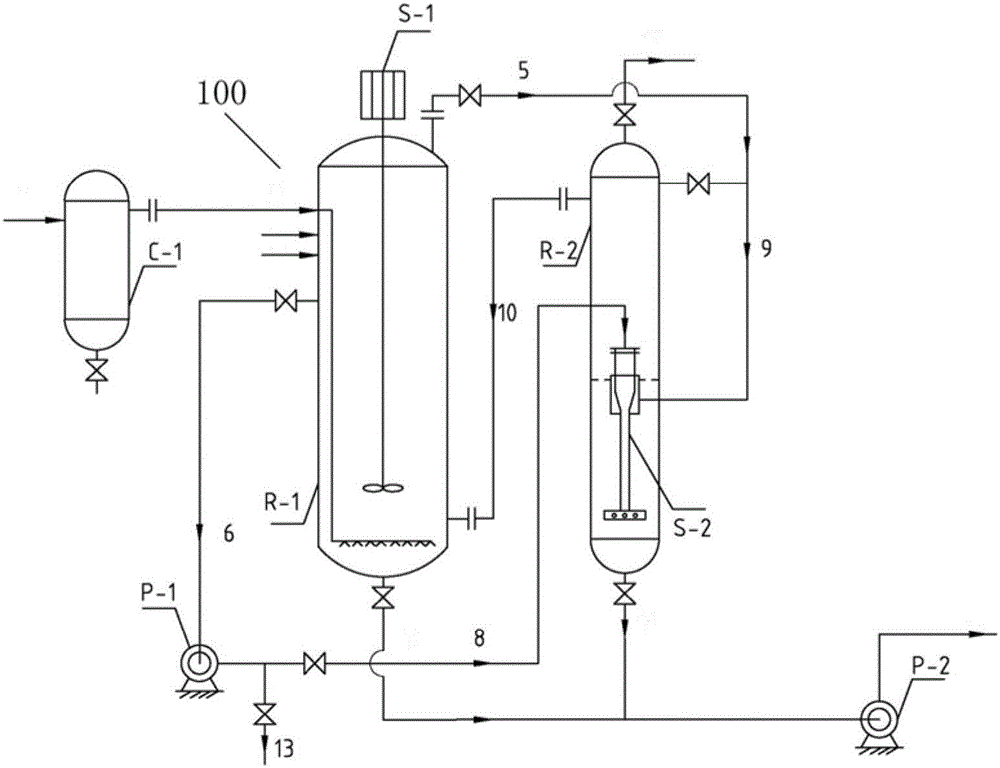

Device and technique for producing cyclohexane by benzene hydrogenation

ActiveCN106187660AImprove mass transfer efficiencyIncrease reaction rateHydrocarbon by hydrogenationBenzeneGas phase

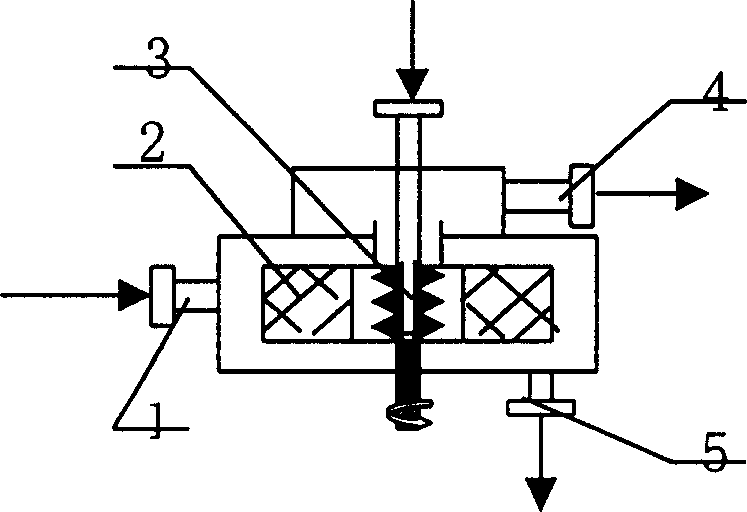

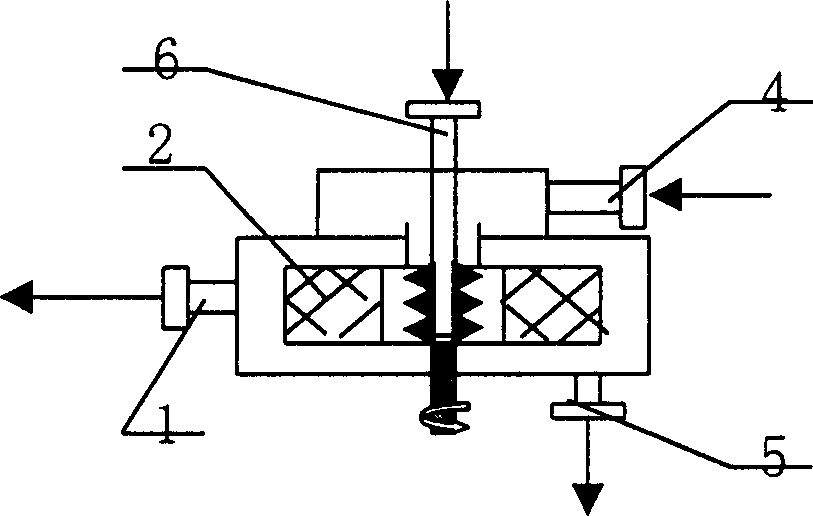

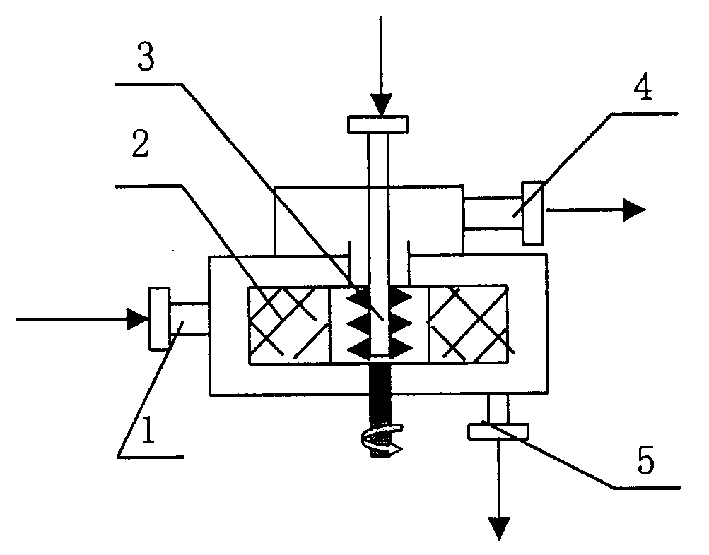

The invention discloses a device and technique for producing cyclohexane by benzene hydrogenation. The device for producing cyclohexane by benzene hydrogenation comprises a reactor, a superfine bubble generator and a bubble breaker, wherein the reactor is provided with a first containing cavity; the wall of the first containing cavity is provided with a feed port, a circulation discharge port, a circulation return port and a gas phase outlet; the superfine bubble generator is provided with a second containing cavity; the wall of the second containing cavity is provided with a return port and a gas phase outlet; the return port of the superfine bubble generator communicates with the circulation return port of the reactor; the bubble breaker is arranged in the second containing cavity; the bubble breaker is provided with a gas phase inlet and a liquid phase inlet which communicates with the circulation discharge port of the reactor; and the gas phase inlet of the bubble breaker communicates with the gas phase outlet of the reactor. The device disclosed by the embodiment of the invention has the advantages of high mass transfer efficiency, high reaction rate, short reaction time, low material consumption and energy consumption, simple structure, low manufacturing cost and low maintenance cost.

Owner:NANJING UNIV

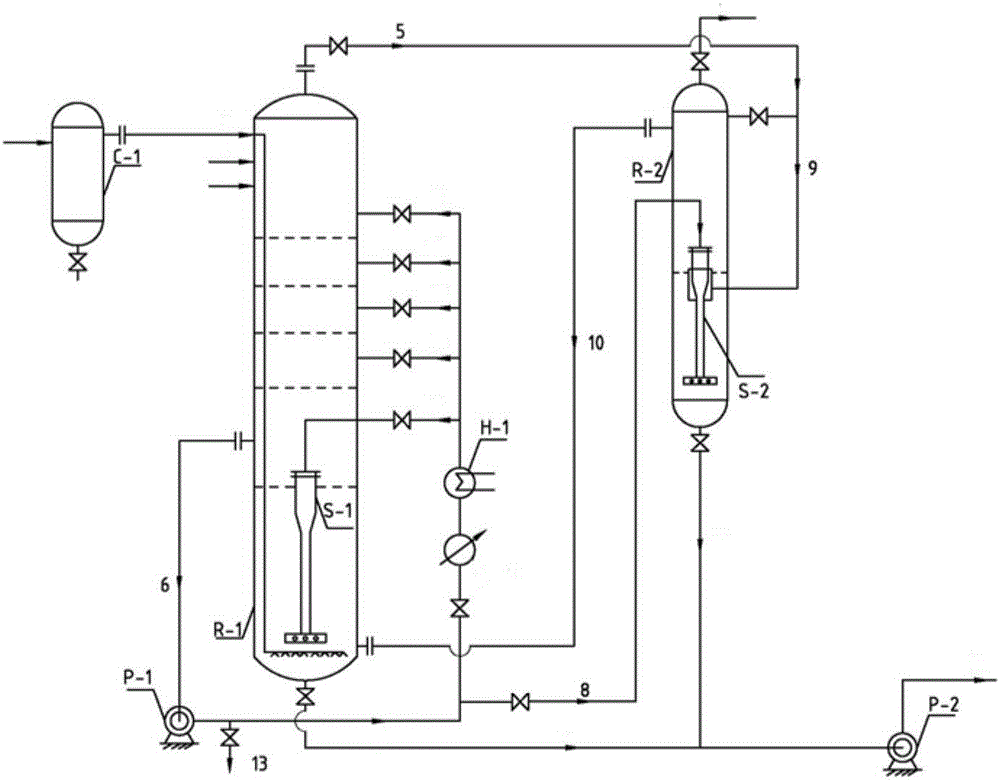

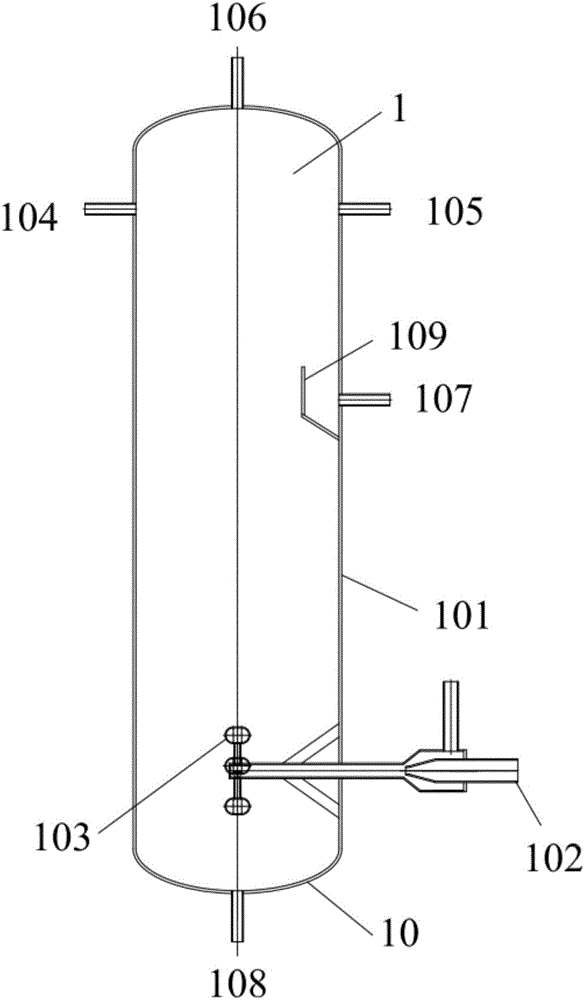

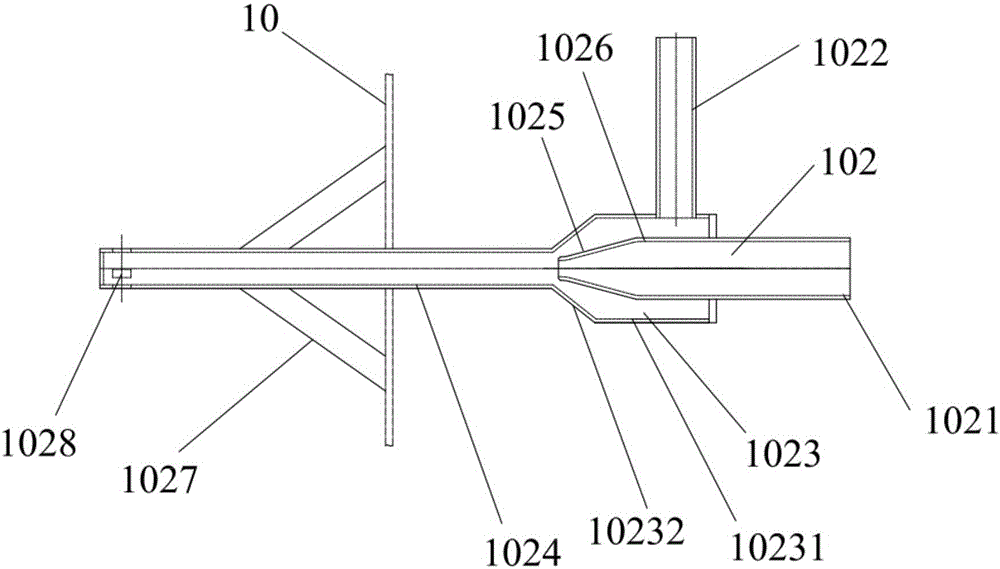

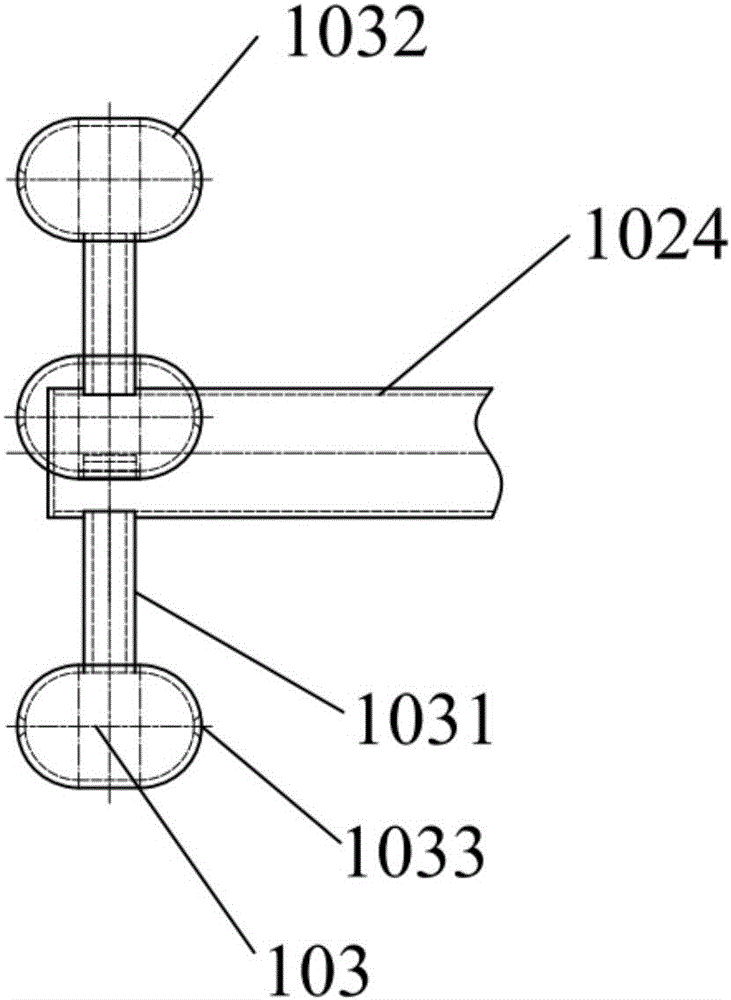

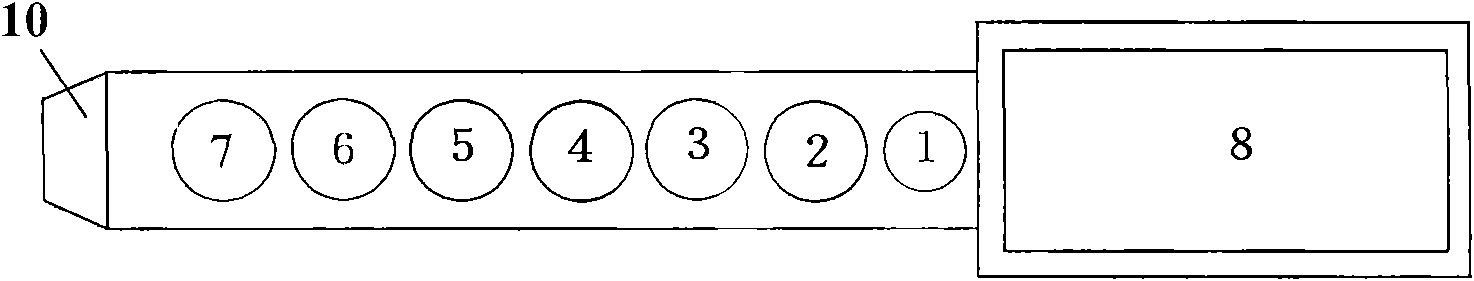

Tower-type super fine bubble reactor

ActiveCN106268544AImprove mass transfer efficiencyIncrease reaction rateLiquid-gas reaction processesReaction rateEngineering

The invention discloses a tower-type super fine bubble reactor. The tower-type super fine bubble reactor comprises a body, a primary bubble breaker and a secondary bubble breaker, wherein a reaction cavity is formed in the body, a through hole, a liquid inlet, a circulating liquid outlet, an air inlet and a circulating air outlet are formed in the wall of the reaction cavity, one part of the primary bubble breaker penetrates through the through hole and extends into the reaction cavity, the primary bubble breaker is provided with a circulating liquid inlet, a circulating air inlet and an air-liquid mixture outlet, the circulating liquid inlet is communicated with the circulating liquid outlet, and the circulating air inlet is communicated with the circulating air outlet. The secondary bubble breaker is provided with a feeding port and a discharging port, and the feeding port is communicated with the air-liquid mixture outlet. The tower-type super fine bubble reactor has the advantages of being high in mass transfer efficiency, high in reaction rate, low in energy consumption and the like, the reaction time can be remarkably shortened, and reactor size can be decreased.

Owner:NANJING UNIV

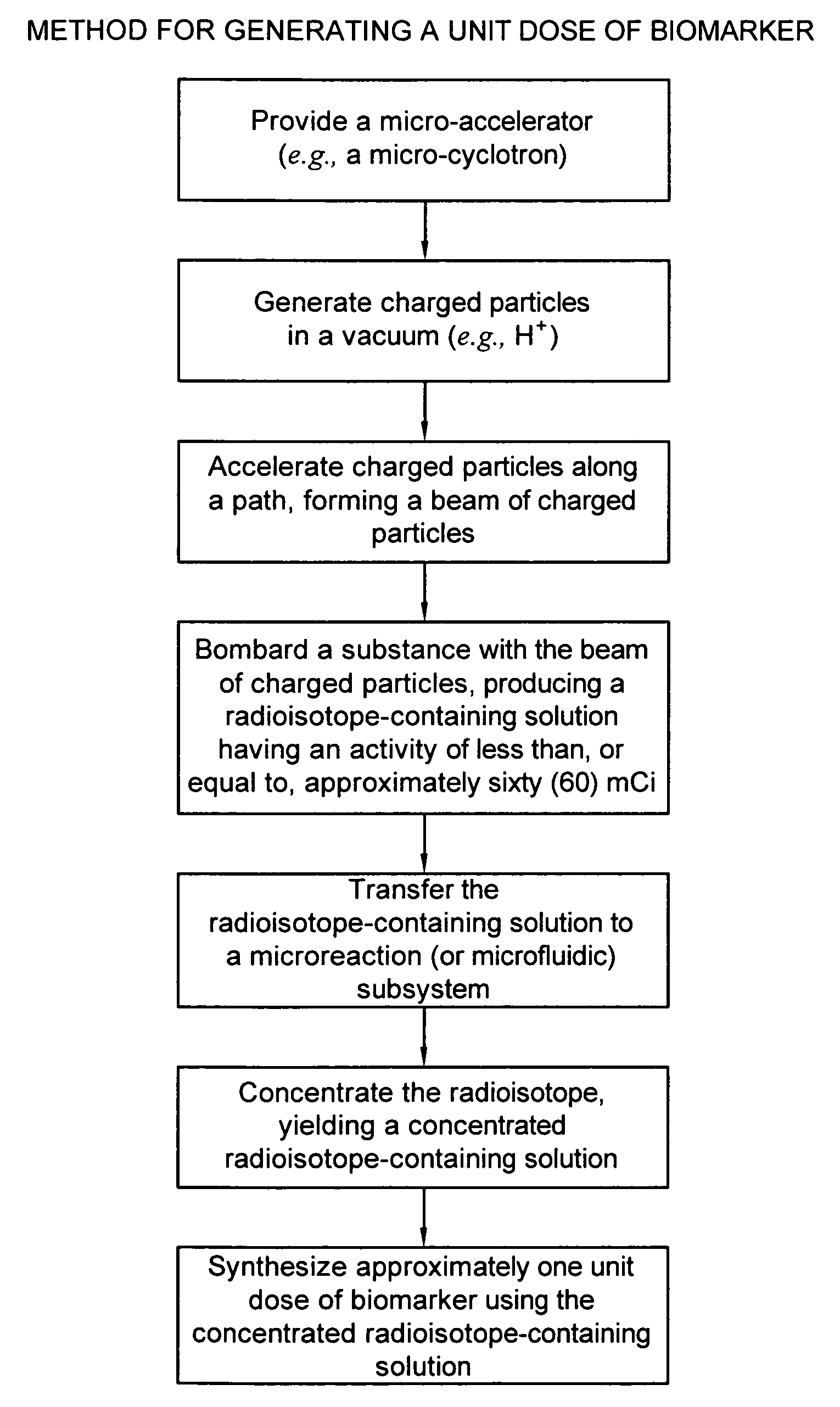

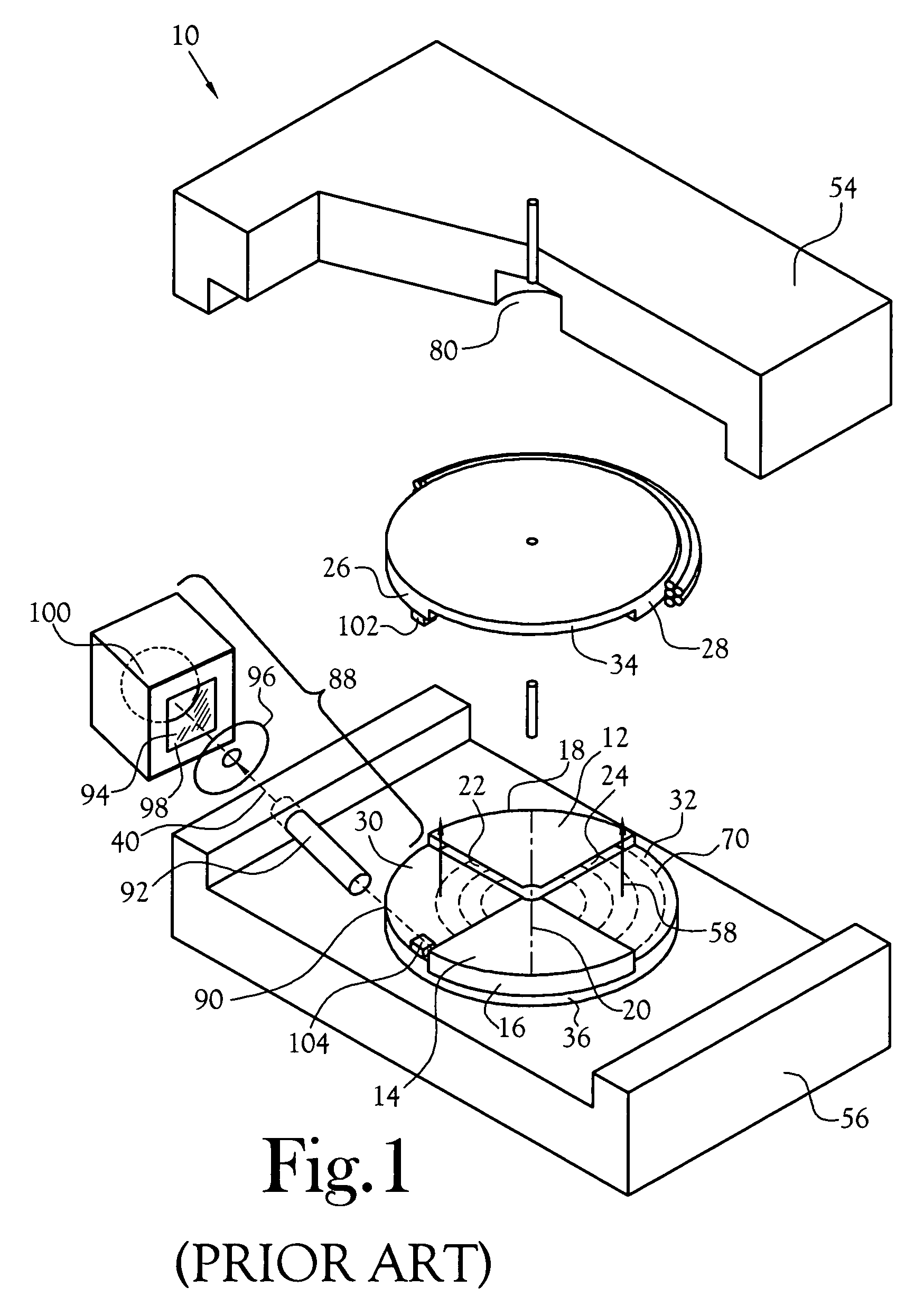

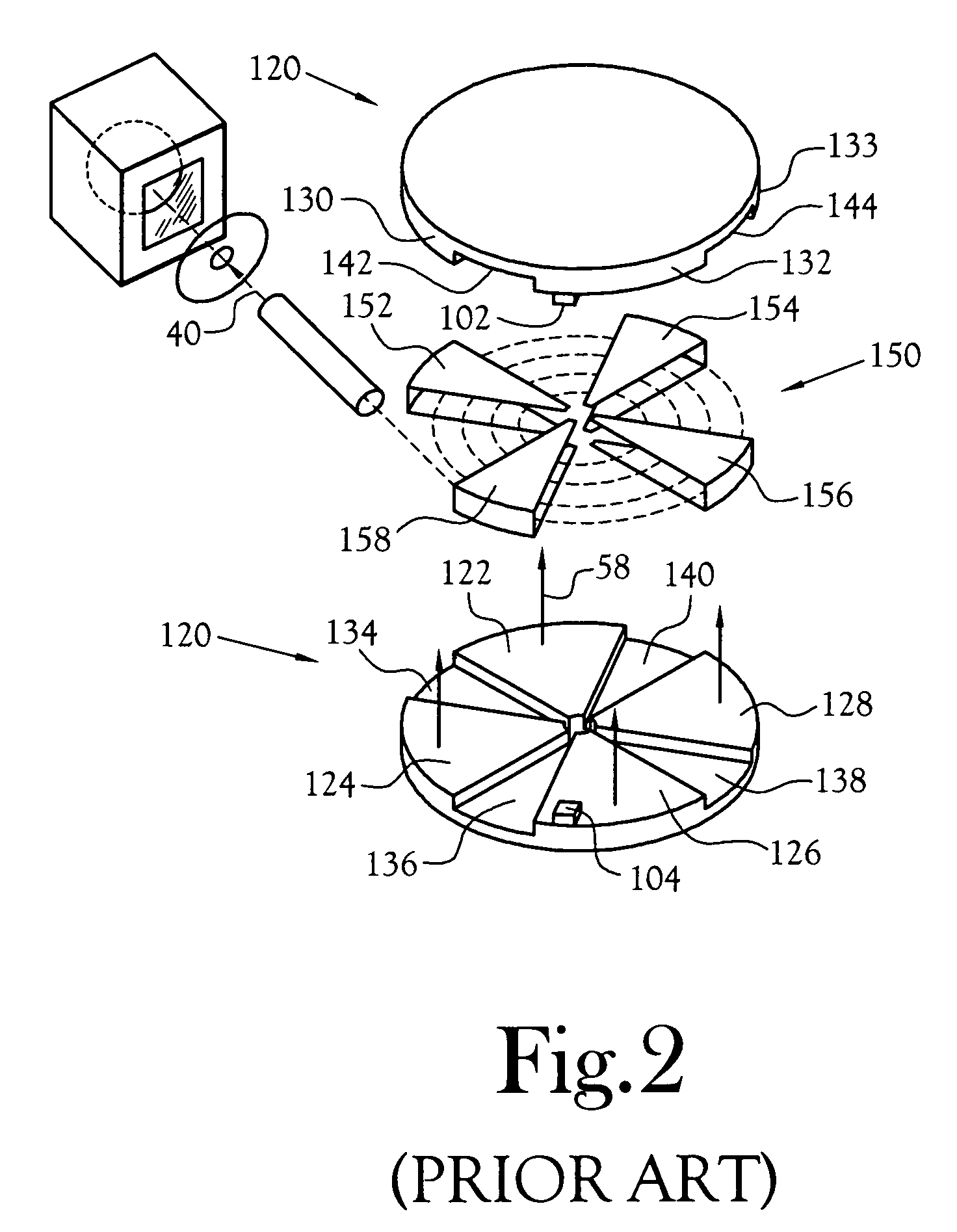

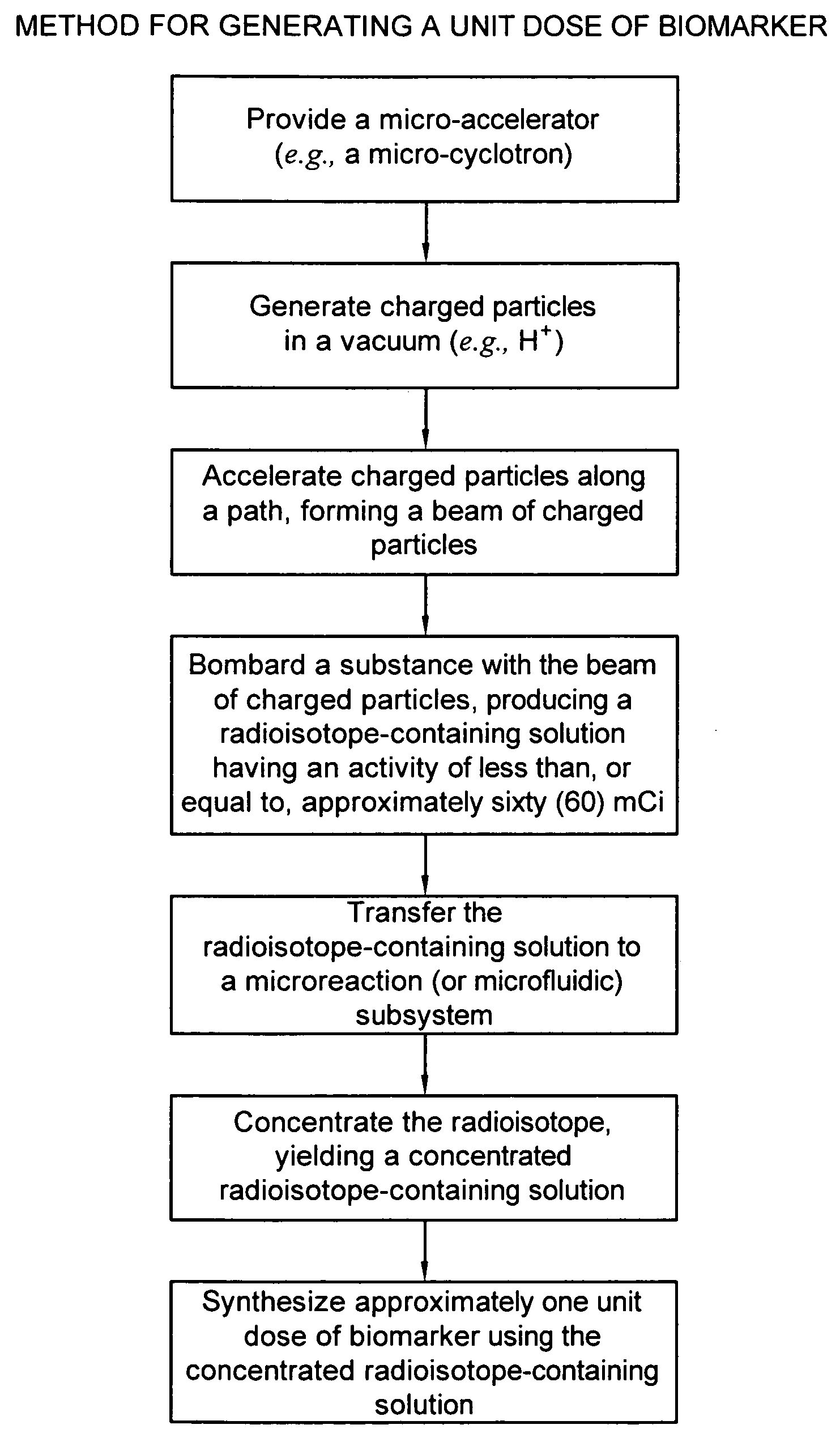

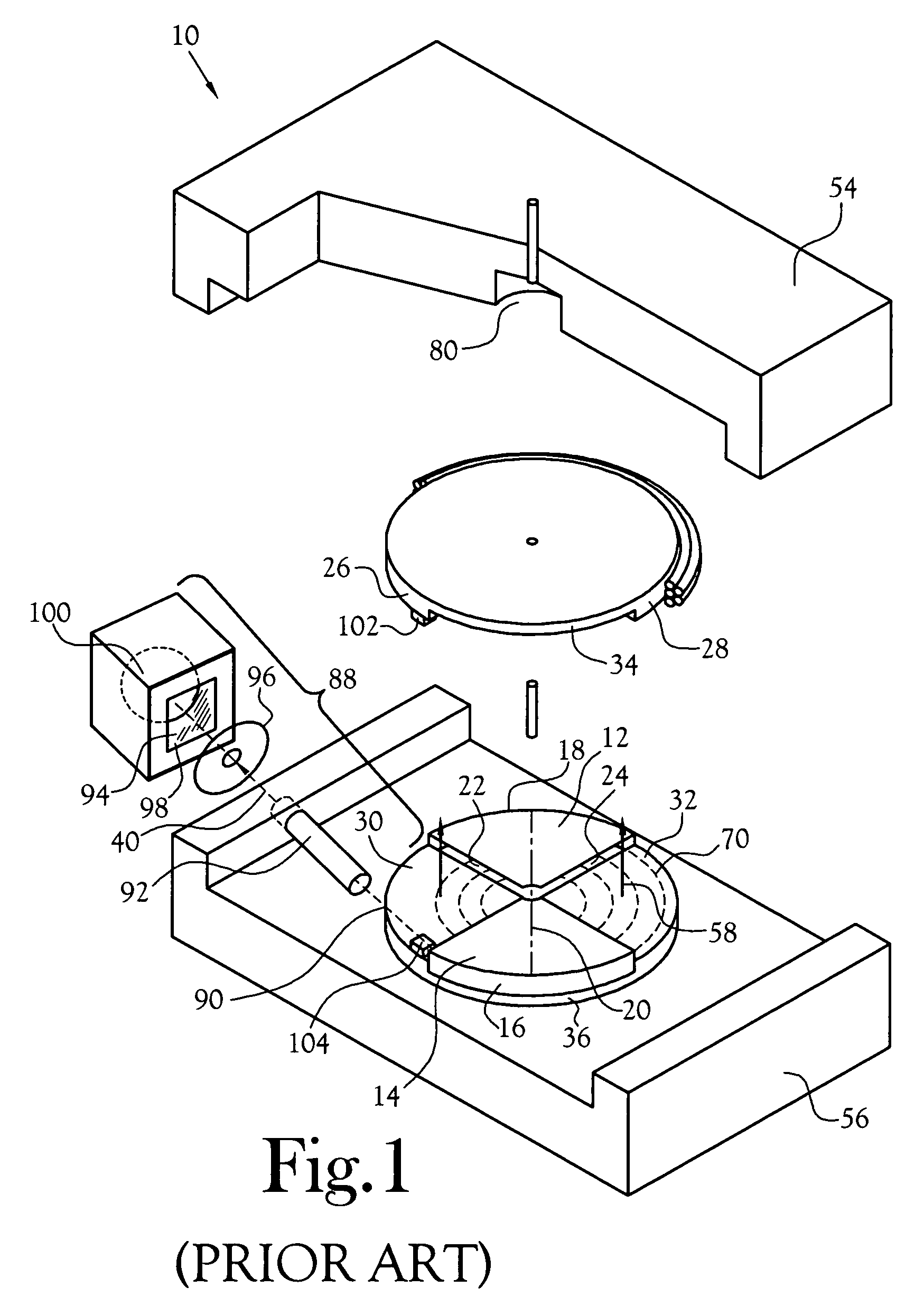

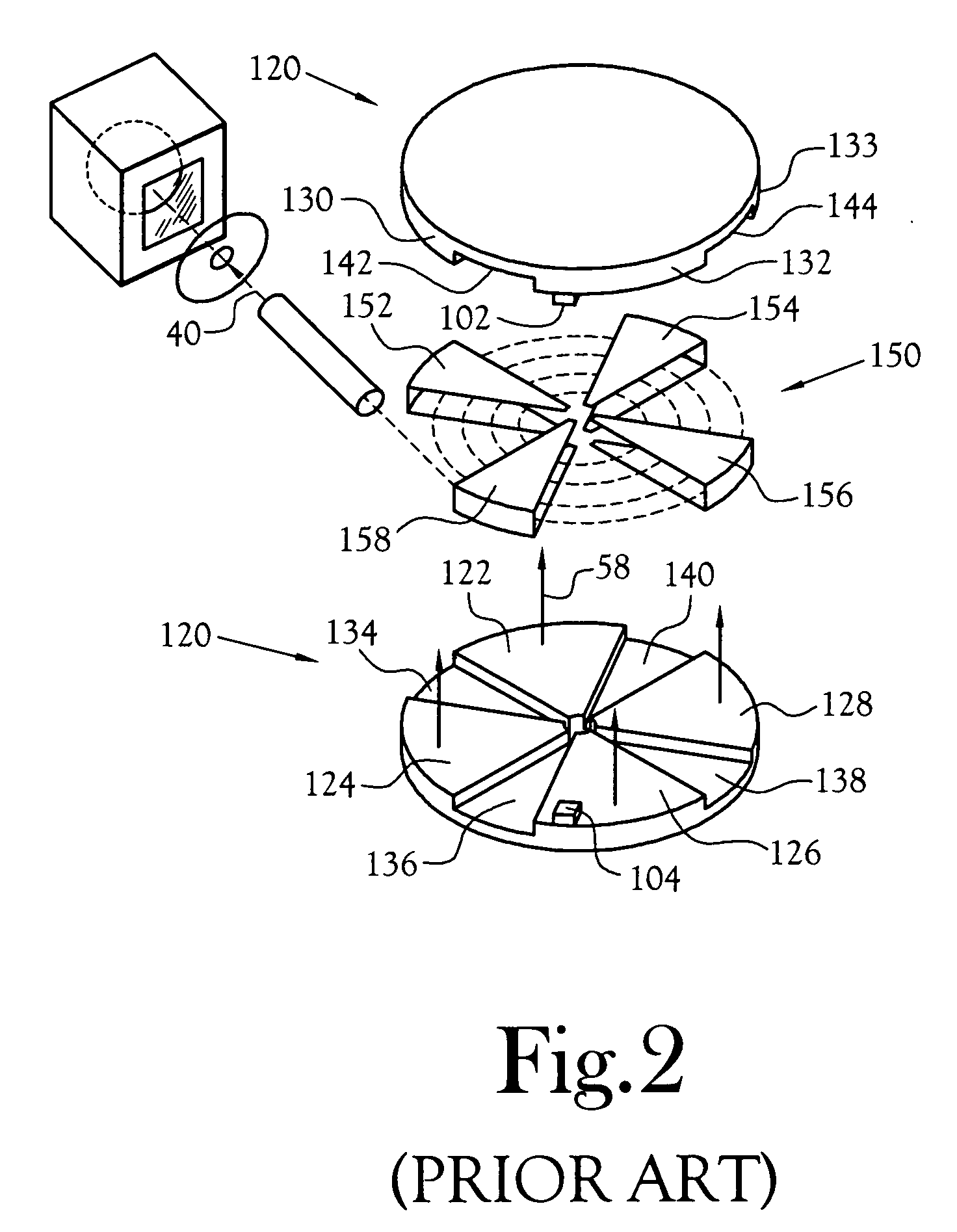

Biomarker generator system

ActiveUS7476883B2Efficient dosingEfficient productionMaterial analysis using wave/particle radiationIsotope delivery systemsChemical synthesisMicroreactor

A biomarker generator system for producing approximately one (1) unit dose of a biomarker. The biomarker generator system includes a small, low-power particle accelerator (“micro-accelerator”) and a radiochemical synthesis subsystem having at least one microreactor and / or microfluidic chip. The micro-accelerator is provided for producing approximately one (1) unit dose of a radioactive substance, such as a substance that emits positrons. The radiochemical synthesis subsystem is provided for receiving the radioactive substance, for receiving at least one reagent, and for synthesizing the approximately one (1) unit dose of a biomarker.

Owner:BEST ABT INC

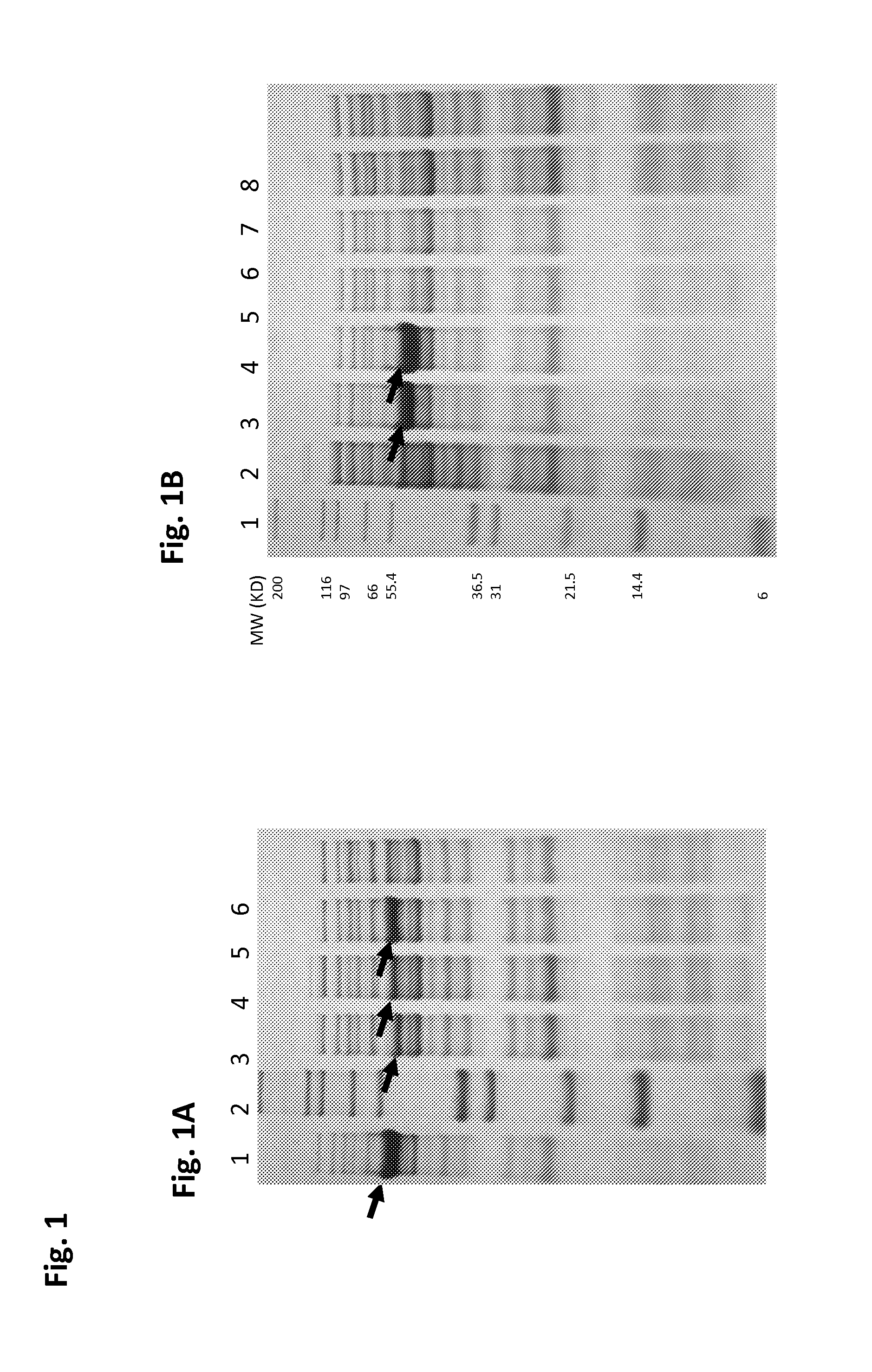

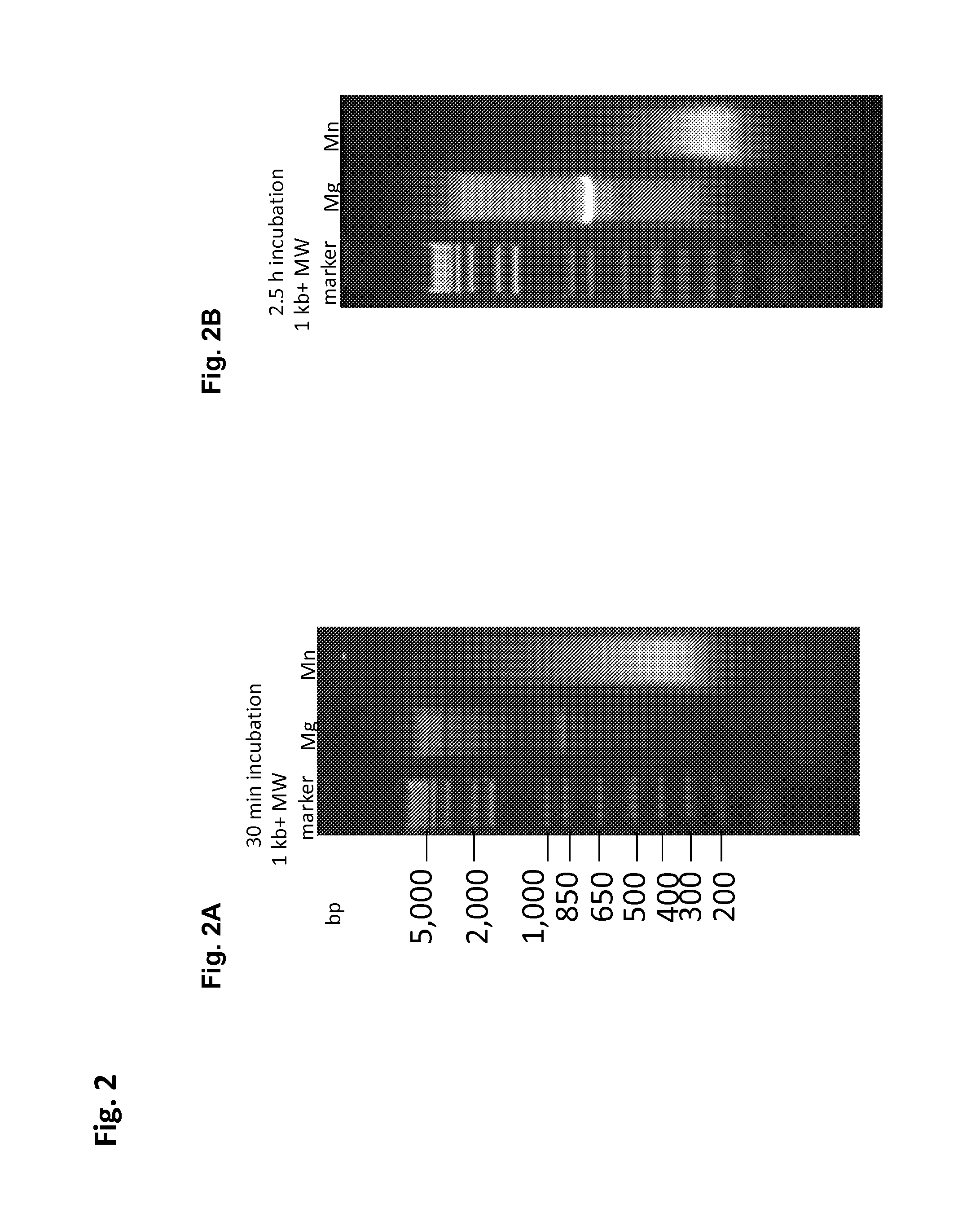

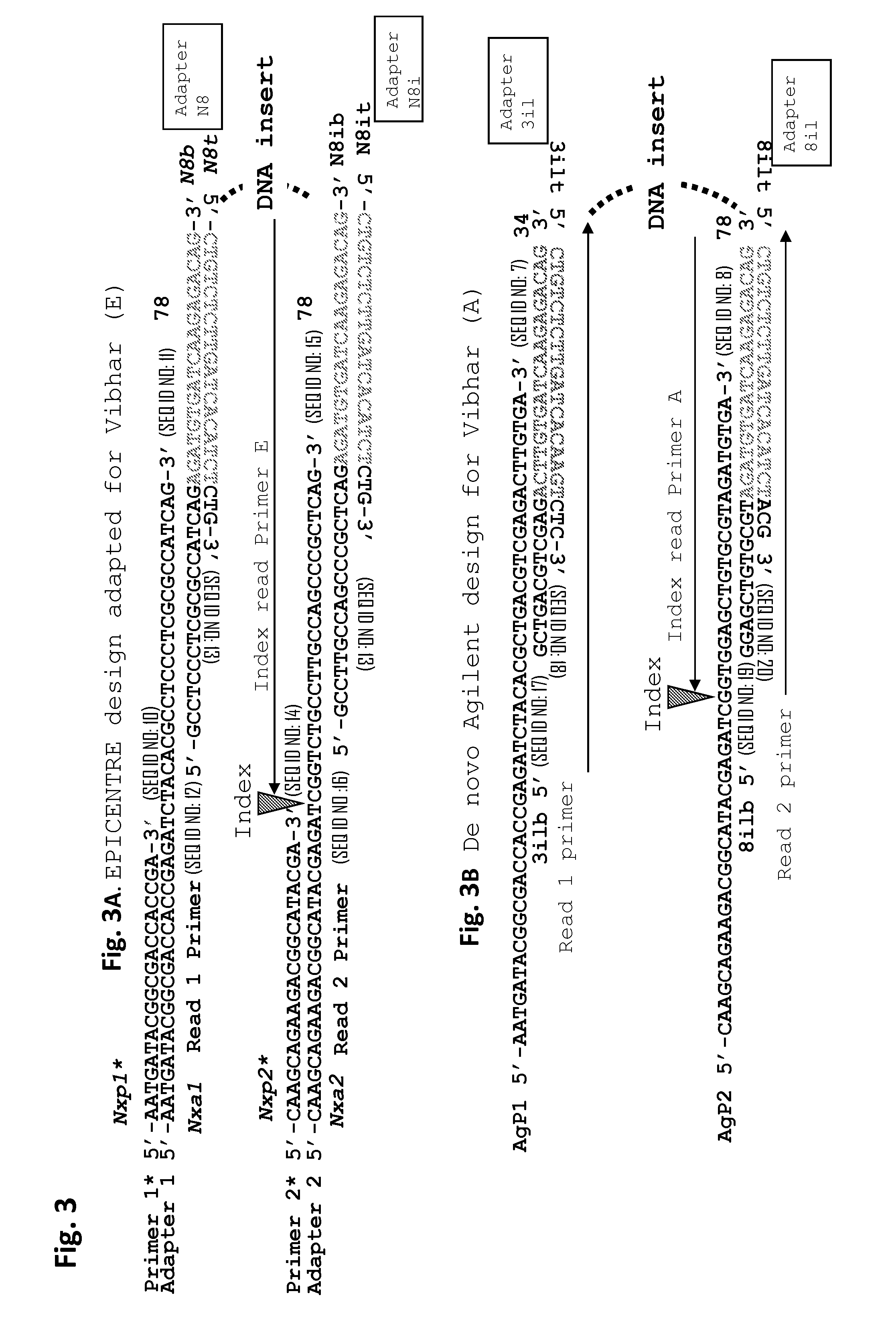

Methods and compositions for DNA fragmentation and tagging by transposases

ActiveUS9005935B2Broadens transposase reaction conditionsReduce concentrationSugar derivativesTransferasesDNA fragmentationWild type

The present invention provides new compositions for transposase-mediated fragmenting and tagging DNA targets. The invention relates to the surprising discovery that use of manganese ions (Mn2+) in transposase reactions improves the transposase reaction. It also relates to the surprising discovery that Mg2+ ions can be used in a transposase reaction with wild-type and / or engineered transposases at levels much higher than previously thought. The invention provides for the use of naturally-occurring transposases in in vitro reactions, as well as improved schemes for cleaving, tagging, and amplifying target DNA.

Owner:AGILENT TECH INC

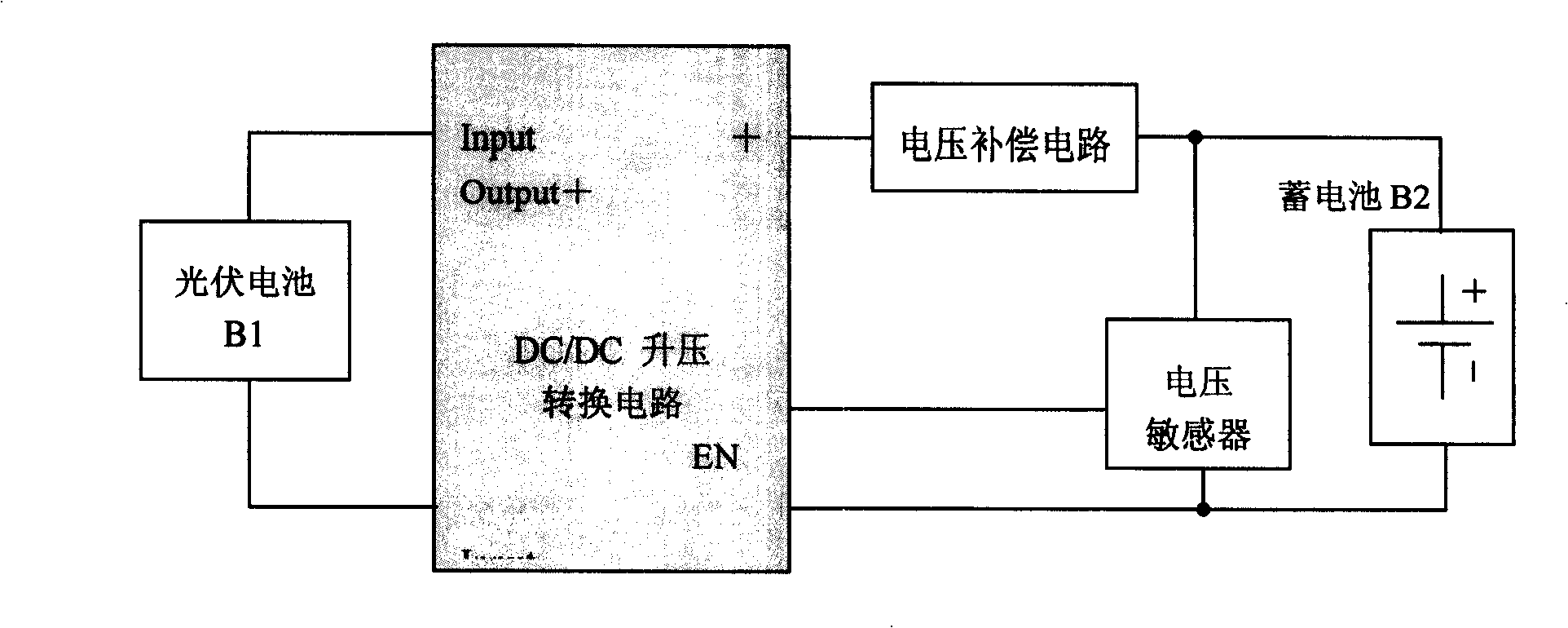

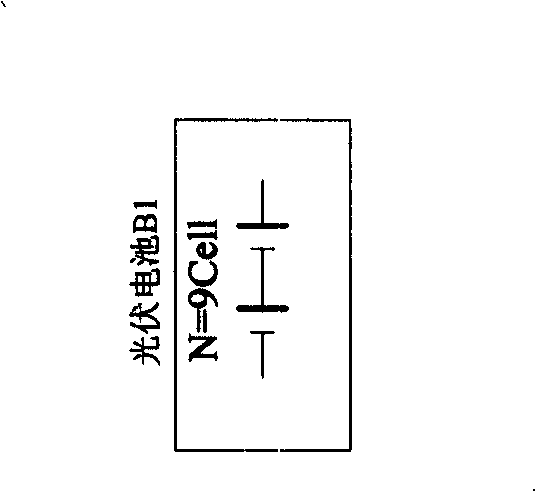

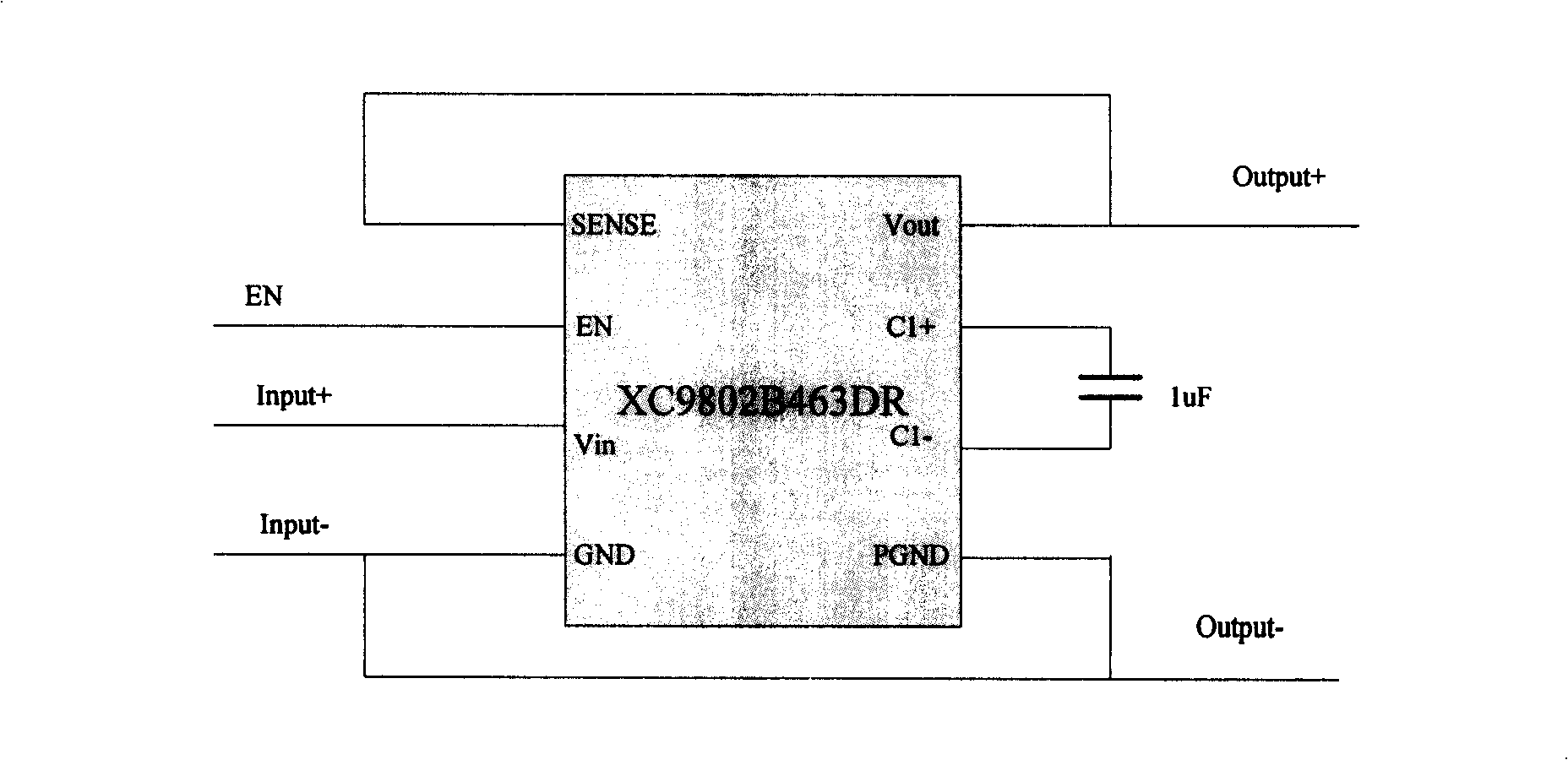

Photovoltaic battery- DC / DC voltage boosting convert charging method

InactiveCN101257221AAvoid overchargingRealize chargingBatteries circuit arrangementsElectric powerOvervoltageElectricity

The invention relates to a photovoltaic cell -DC / DC boost conversion charge method which belongs to battery technique field. The method includes: 1) a portable equipment accumulator voltage is detected by a voltage sensor, when lows to full charge capacity, the voltage sensor makes DC / DC boost converter starting DC / DC conversion, and electricity quantity flows from photovoltaic current to lithium battery for charging; 2) when the portable equipment accumulator is in full charge capacity state, accumulator need not charge again, the voltage sensor makes DC / DC boost converter forbidding DC / DC conversion, thereby, the portable equipment accumulator is protected and over charge phenomena is prevented. The method can be realized simply, and has short reaction time, high efficiency, overvoltage protection and anti-counterblast protection.

Owner:BEIJING HI TECH WEALTH INVESTMENT DEV

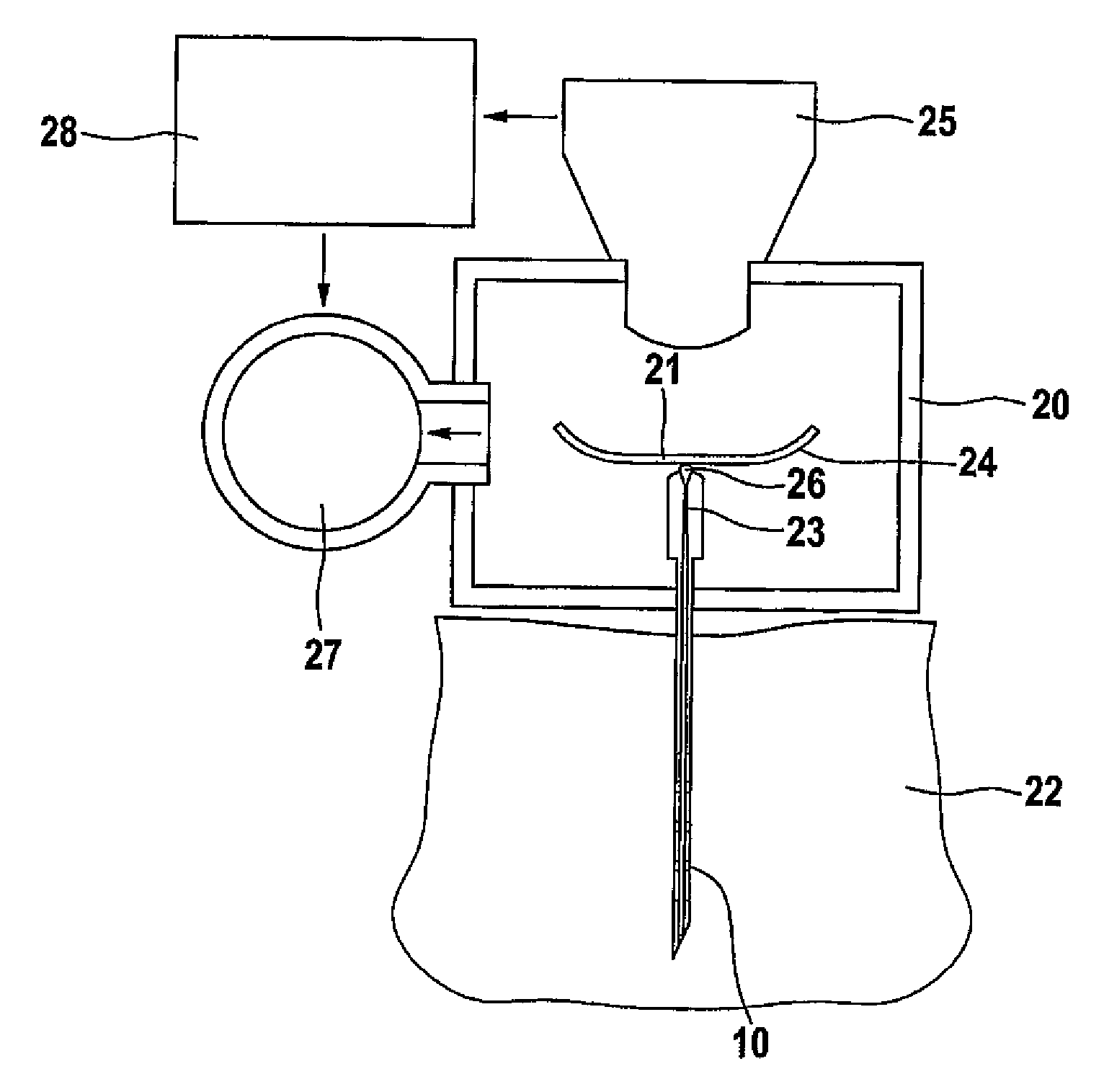

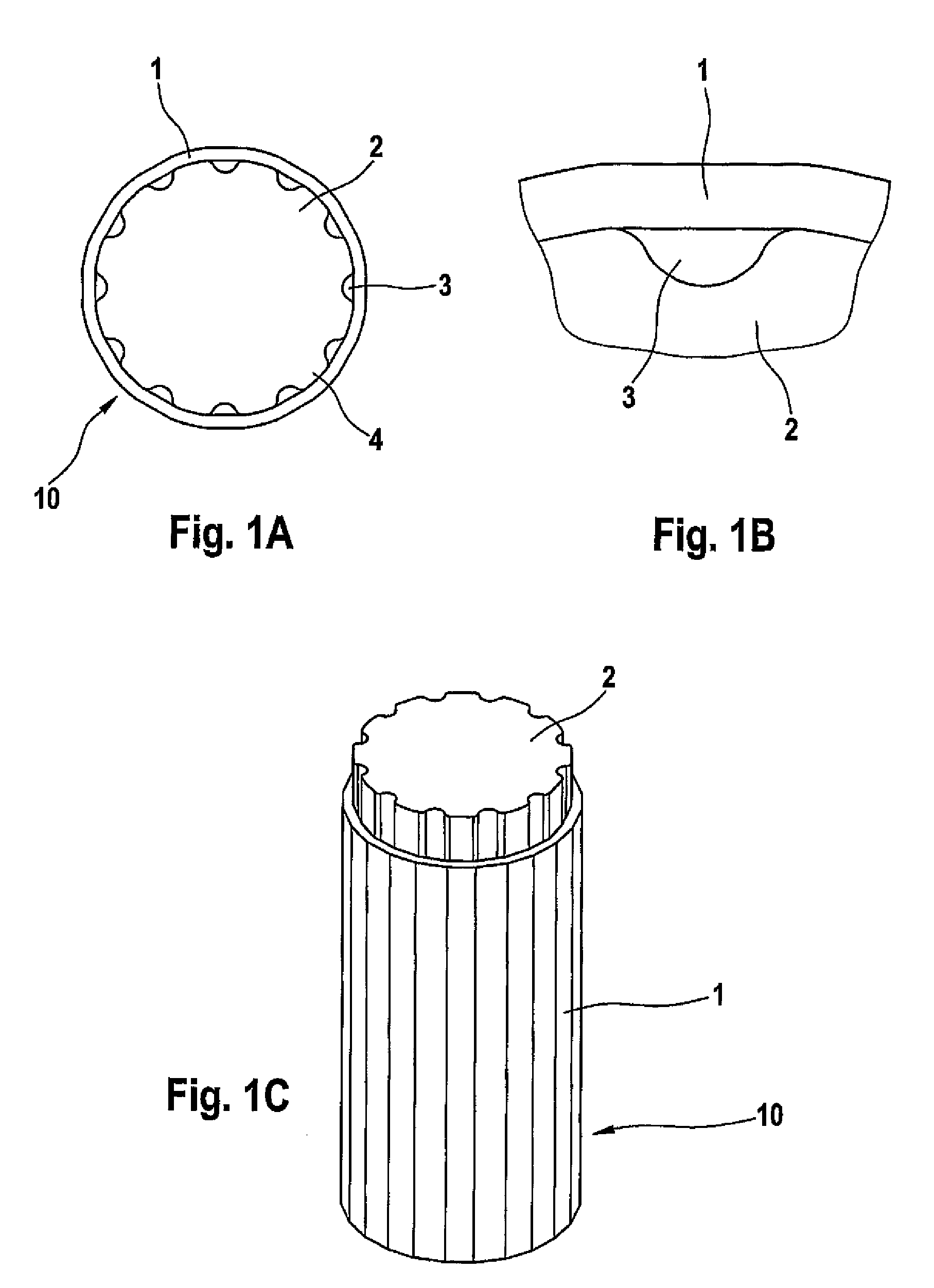

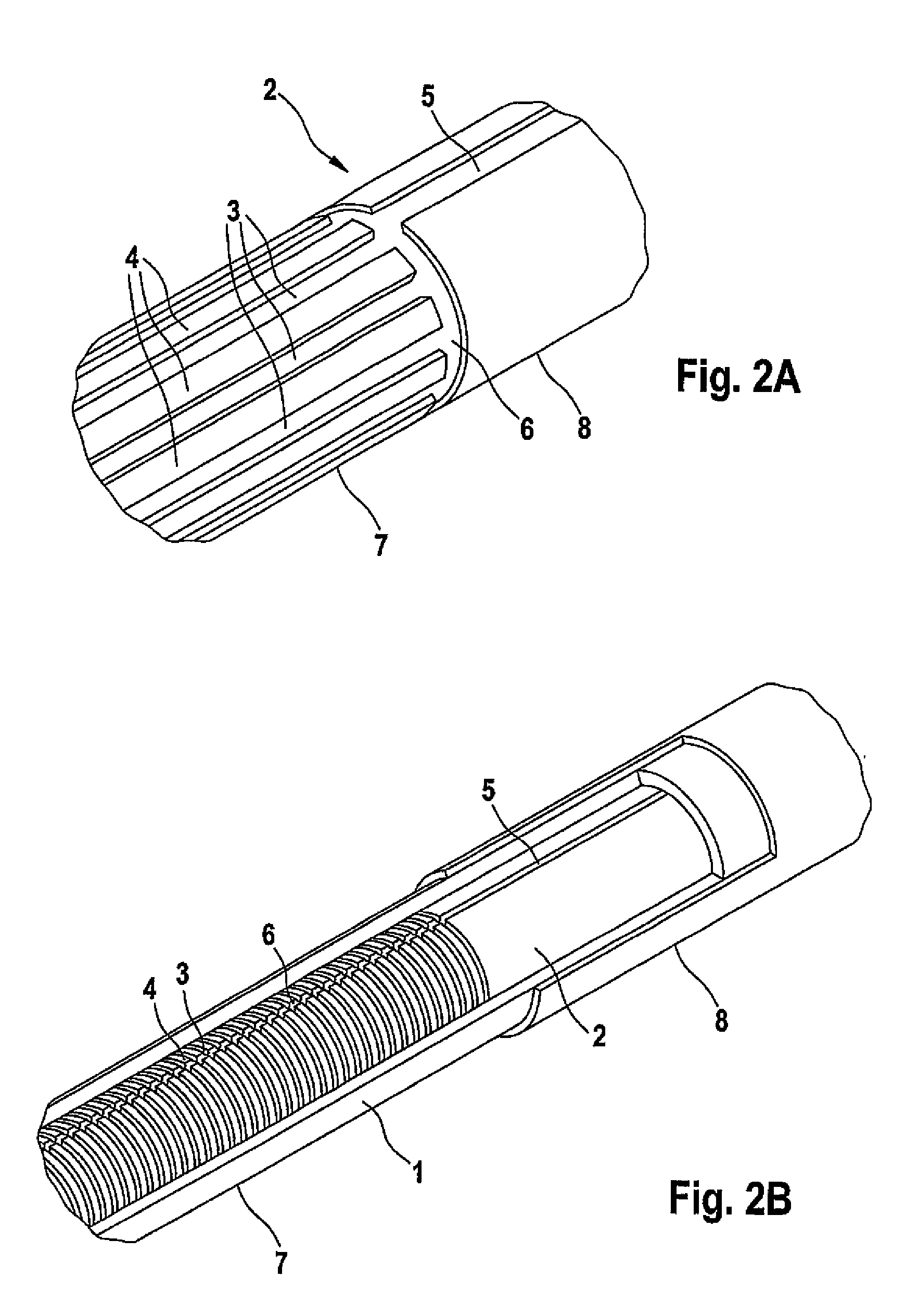

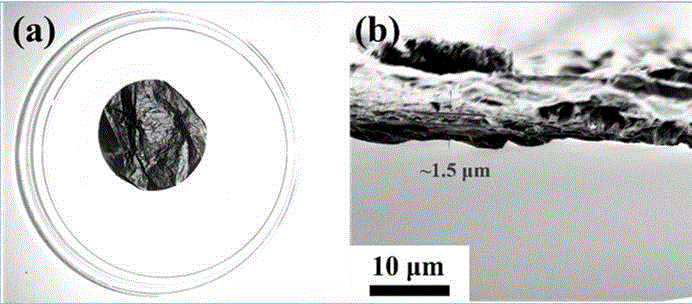

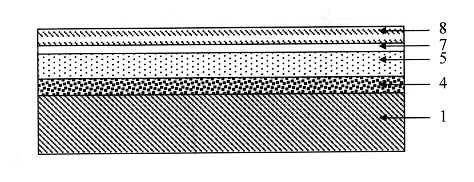

Catheter With Microchannels For Monitoring The Concentration Of An Analyte In A Bodily Fluid

InactiveUS20080214909A1Reduce dead volumeShort reaction timeVaccination/ovulation diagnosticsAnimal teeth treatmentAnalyteBody fluid

Catheter for monitoring the concentration of an analyte in a body fluid having an implantable distal area (7) for the uptake of body fluids and a proximal area (8) with an outlet opening (14), wherein the catheter comprises a catheter casing (1) having microopenings which are permeable to at least part of the body fluid and at least partially hold back corpuscular components, and a catheter core (2) which is located in the catheter casing (1). The catheter core preferably has a microstructure on its peripheral surface and / or the catheter casing has a microstructure on its inner wall which form a hollow space between the catheter core and catheter casing. Moreover the invention concerns a method for the manufacture of such a catheter.

Owner:ROCHE DIABETES CARE INC

Process for the production of esters from alcohols using acetic acid as acetylating and clays as catalysts

InactiveUS6472555B2Easy to adaptLow reaction temperatureOrganic compound preparationOrganic chemistry methodsAcetic acidAlcohol

The present invention relates to a process for the preparation of esters from alcohols using acetic acid as acetylating agent and clays as catalysts, which comprises the preparation of esters in a single step from the reaction of aliphatic, acyclic, cyclic, heterocyclic, alpha,beta-unsaturated and aromatic alcohols with carbon atoms in the range of C1 to C10 with acetic acid in a molar ratio of 1:3 to 11 using reusable natural montmorillonite / metal ion-exchanged clay catalysts in the solvent medium of aliphatic, aromatic, or chlorinated hydrocarbons at 30-140° C. for a period in the range of 0.02 to 3.0 hrs, and recovering the corresponding esters by simple work-up procedure.

Owner:COUNCIL OF SCI & IND RES

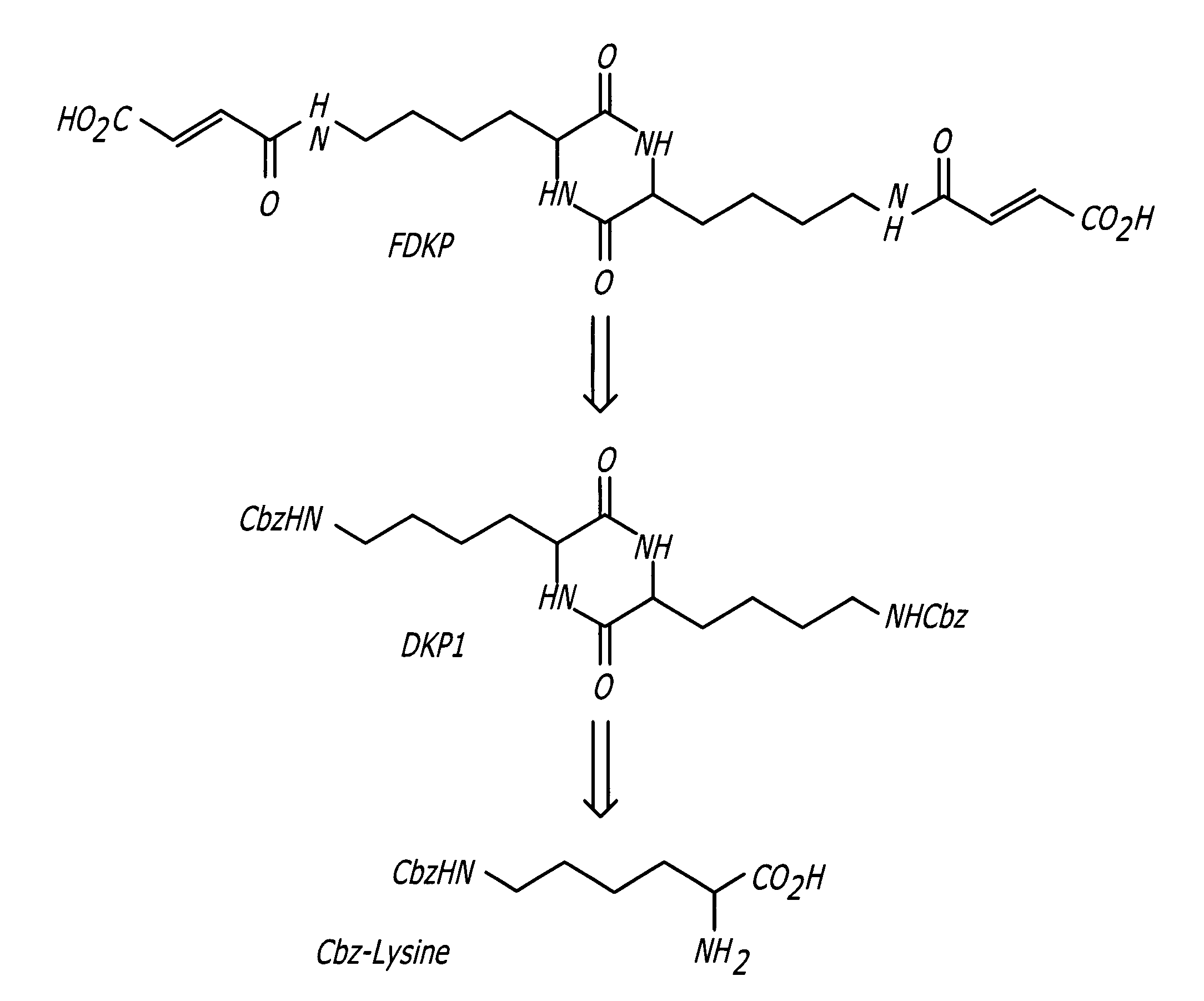

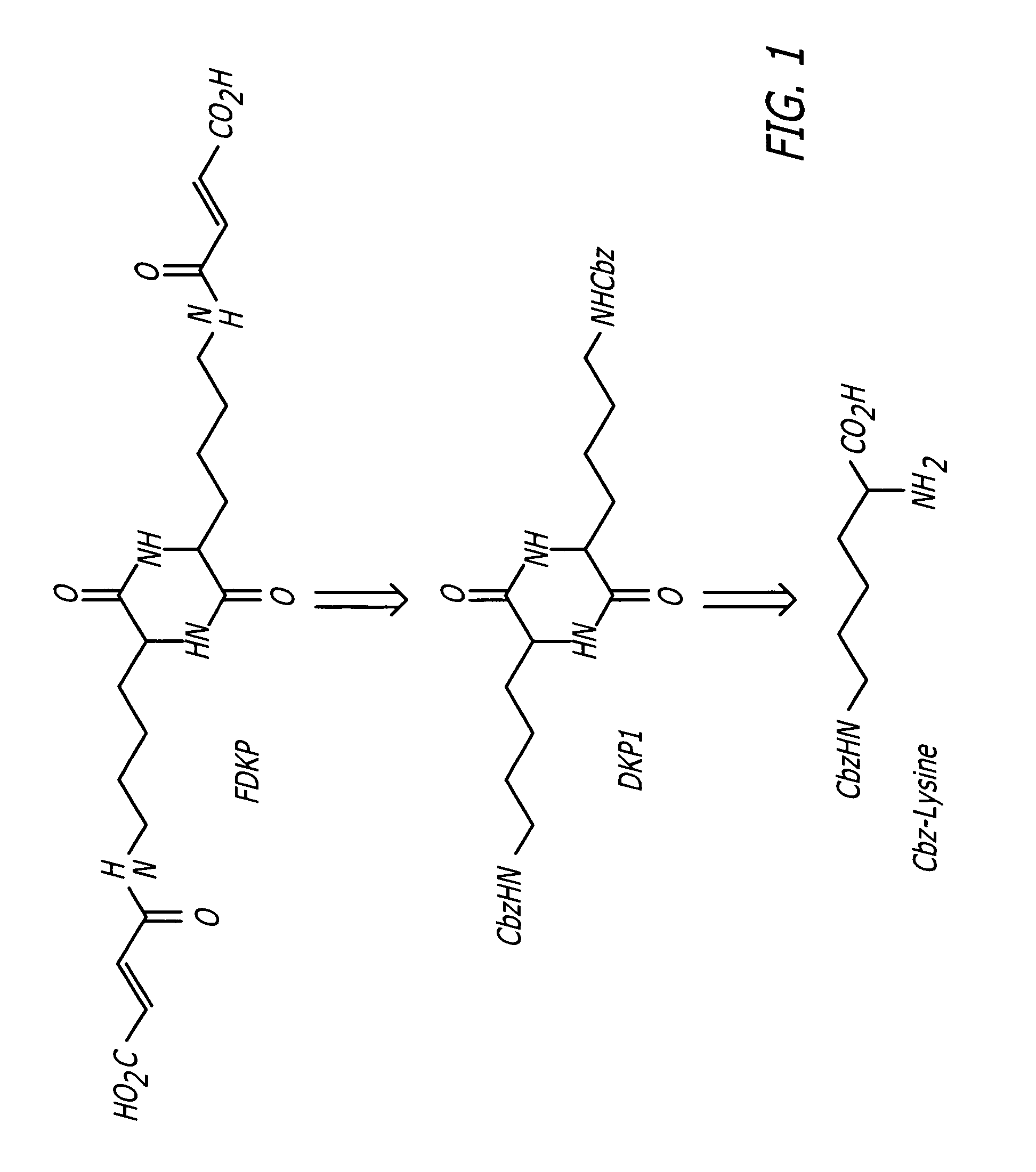

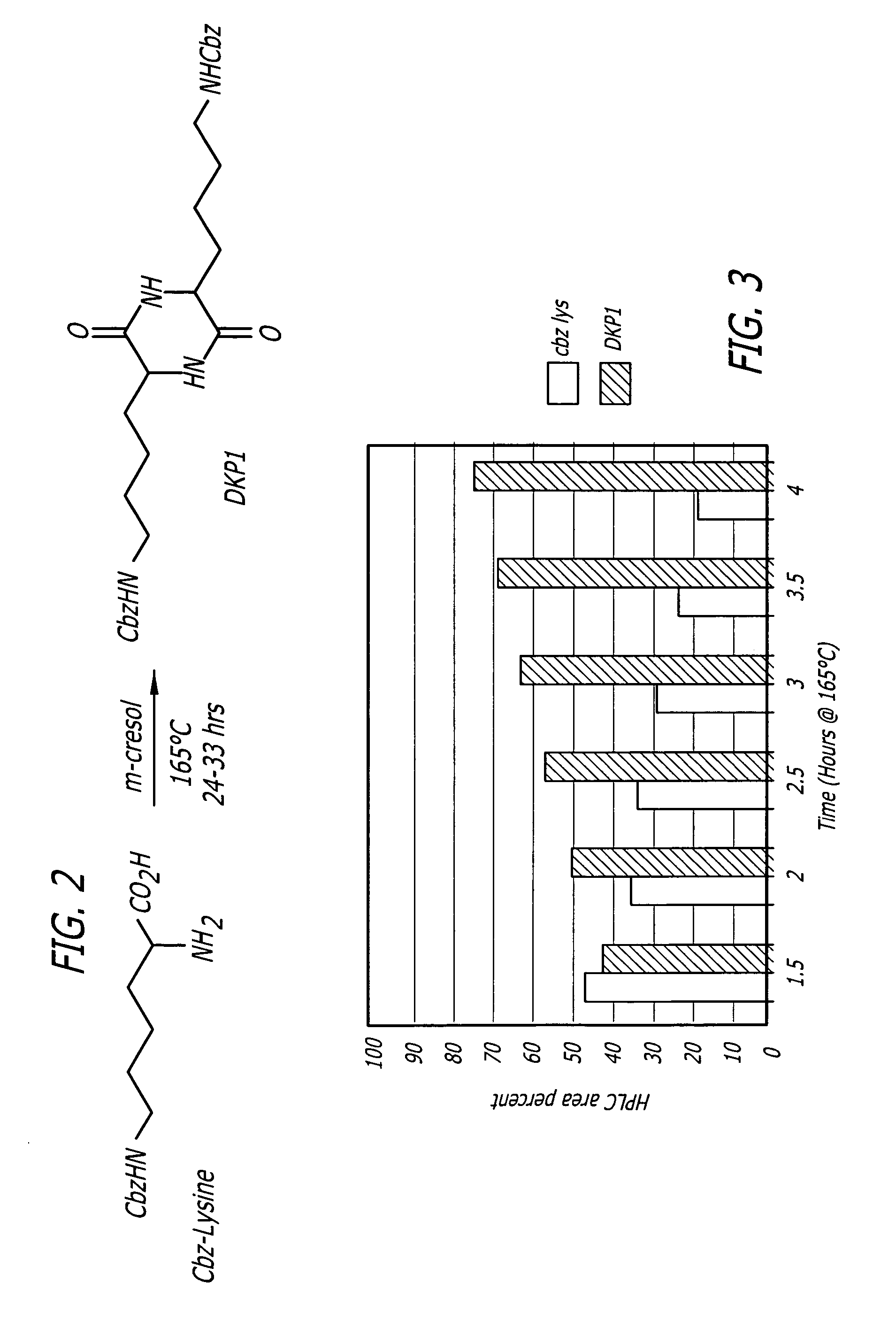

Catalysis of diketopiperazine synthesis

ActiveUS20060041133A1Fast reaction timeHigh yieldOrganic chemistryPhysical/chemical process catalystsPhosphoric acidDiketopiperazines

Provided is a method for the synthesis of N-protected bis-3,6-[4-aminobutyl]-2,5-diketopiperazine including the step of heating a solution of c-amino protected lysine in the presence of a catalyst selected from the group consisting of sulfuric acid, phosphoric acid, and phosphorus pentoxide.

Owner:MANNKIND CORP

Catalytic reaction method

InactiveCN1507940AReduce dosageIncrease profitChemical/physical/physico-chemical moving reactorsPorous catalystMulti phase

The present invention discloses a catalytic reaction method. Said method can make the catalytic reaction be implemented in the supergravitational field. Said method utilizes the rotary bed supergravitational field equipment as reactor, on the rotor of said rotary bed supergravitational field equipment a porous catalyst layer and / or a porous filler layer are fixed, and the described catalytic reaction is homogeneous reaction or heterogeneous reaction. Said invention cal reduce catalyst consumption, raise utilization rate of catalyst, raise stability of catalyst and can reduce denergy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +2

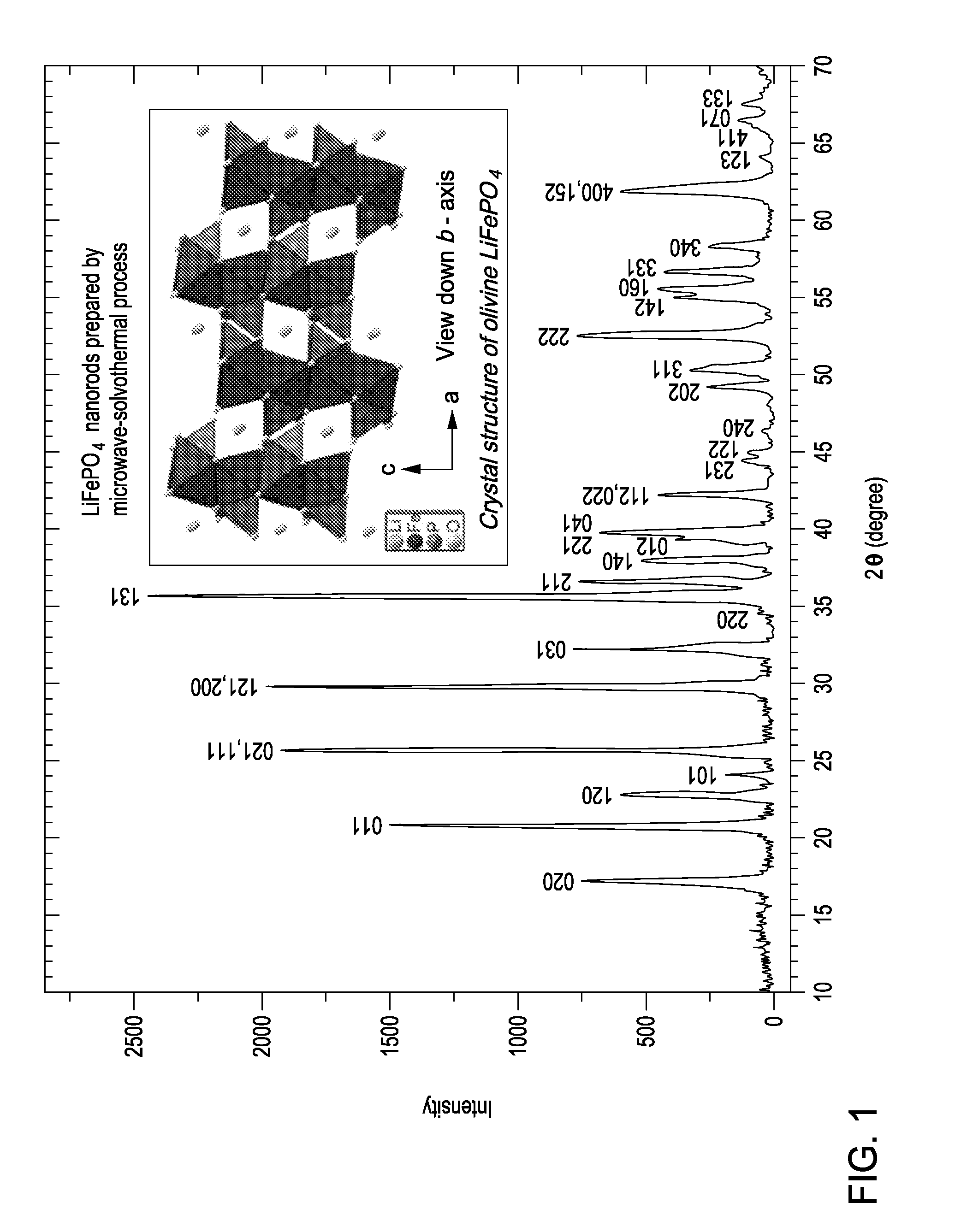

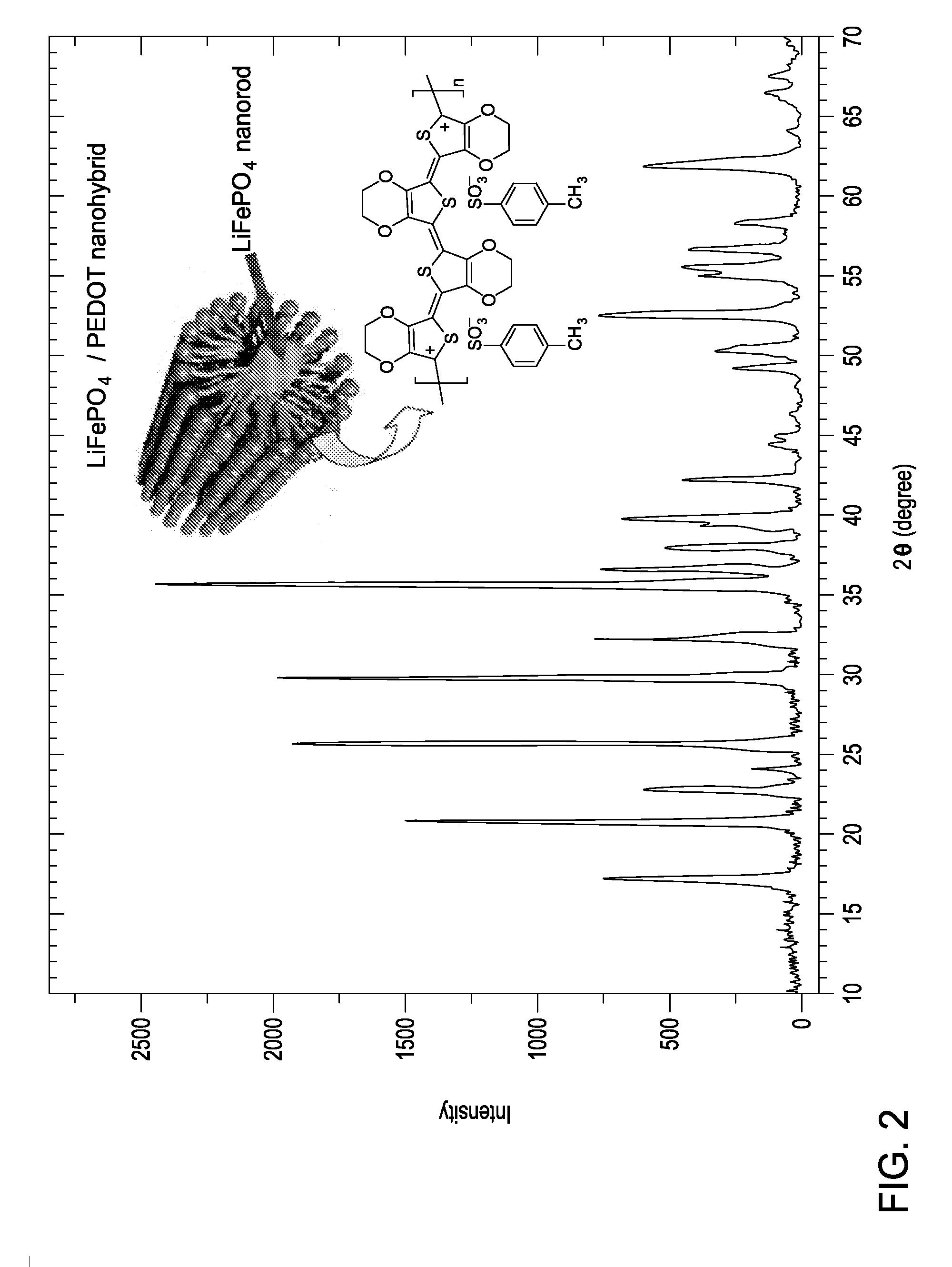

Rapid microwave-solvothermal synthesis and surface modification of nanostructured phospho-olivine cathodes for lithium ion batteries

InactiveUS20090117020A1Simple preparation procedureShort reaction timePhosphatesCell electrodesSurface modificationOlivine

The present invention includes methods, coatings, and a nanostructured phospho-olivine composition LixMyPO4, capable of being formed hydrothermally or solvothermally in aqueous solutions and non-aqueous solutions M is one or more elements selected from the group consisting of Fe, Mn, Co, Ti, Ni, Cu, V, Mo, Zn, Mg, Cr, Al, Ga, B, Zr, Nb or combination thereof and x is between 0 and 1 and y is between 0.8 and 1.2. The phospho-olivine may also have the compositions like LixFe1-yMyPO4, wherein x is between 0 and 1, and y is between 0 and 1.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

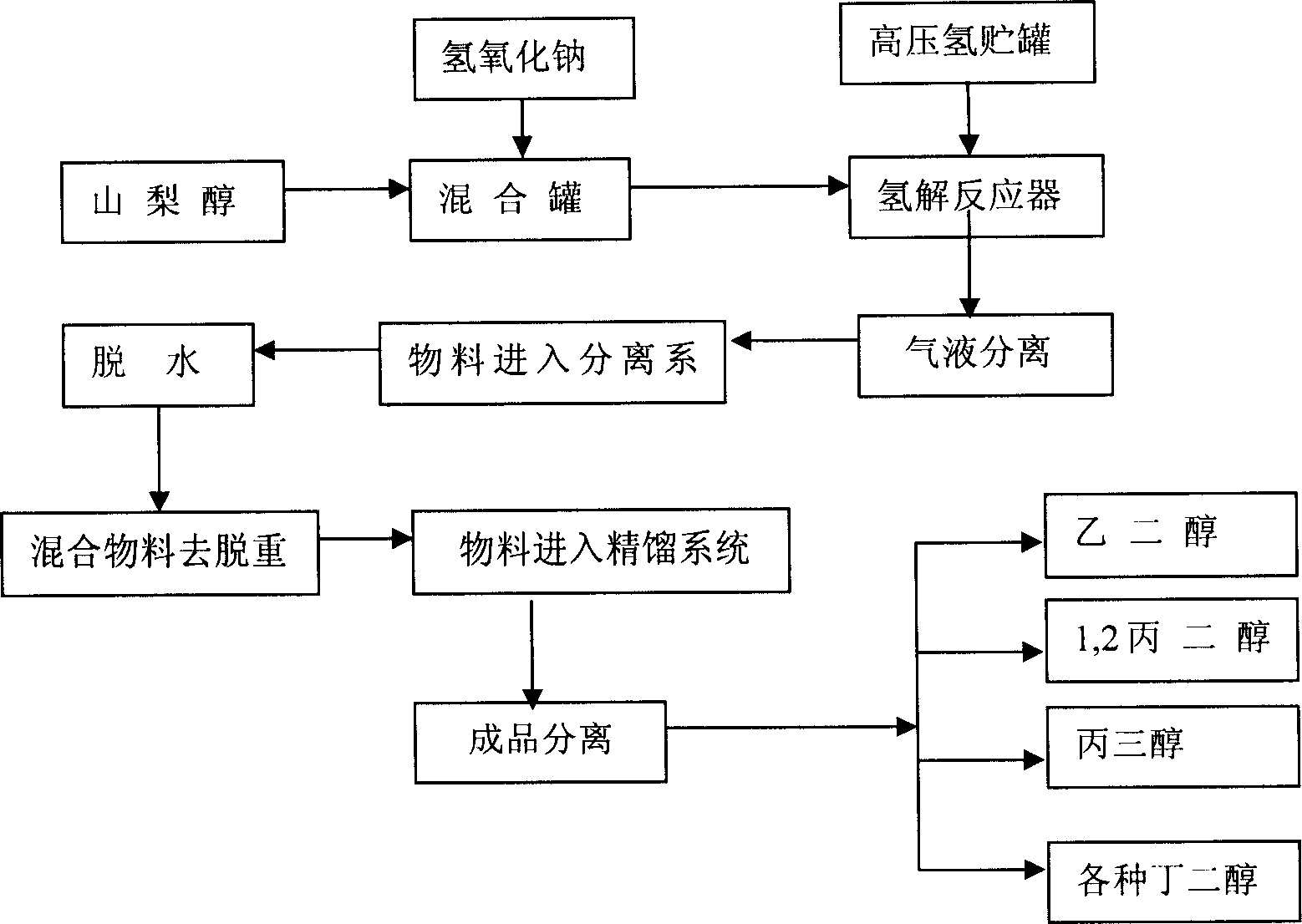

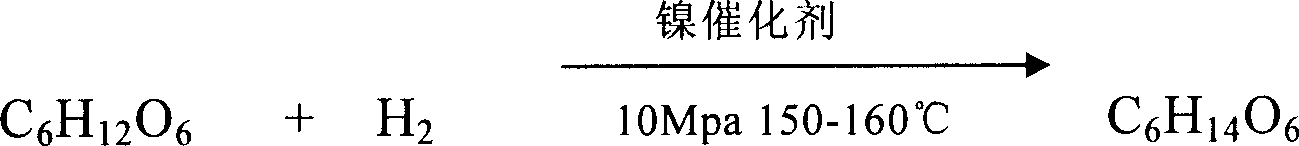

Process for producing diatomic alcohol and polyol from cracking sorbierite

InactiveCN1683293AQuality improvementIncreased production flexibilityOrganic compound preparationOrganic chemistry methodsPolyolAlcohol

The present invention relates to sorbierite cracking process to prepare C2-C4 diatomic alcohol and polyol, and is especially the process of preparing sorbierite with corn material and hydrocracking sorbierite to prepare C2-C4 diatomic alcohol and polyol. The process includes hydrocracking sorbierite to prepare the mixture of C2-C4 diatomic alcohol and polyol at high temperature and high pressure in the presence of cracking sodium hydroxide and nickel / ruthenium catalyst, separation and refining to obtain single product. The production process of the present invention has the advantages of novel production path, unique technological condition, simultaneous production of several kinds of alcohol and high product quality. In addition, using grains, such as corn, as material to replace non-regenerable resource is significant.

Owner:王宗国

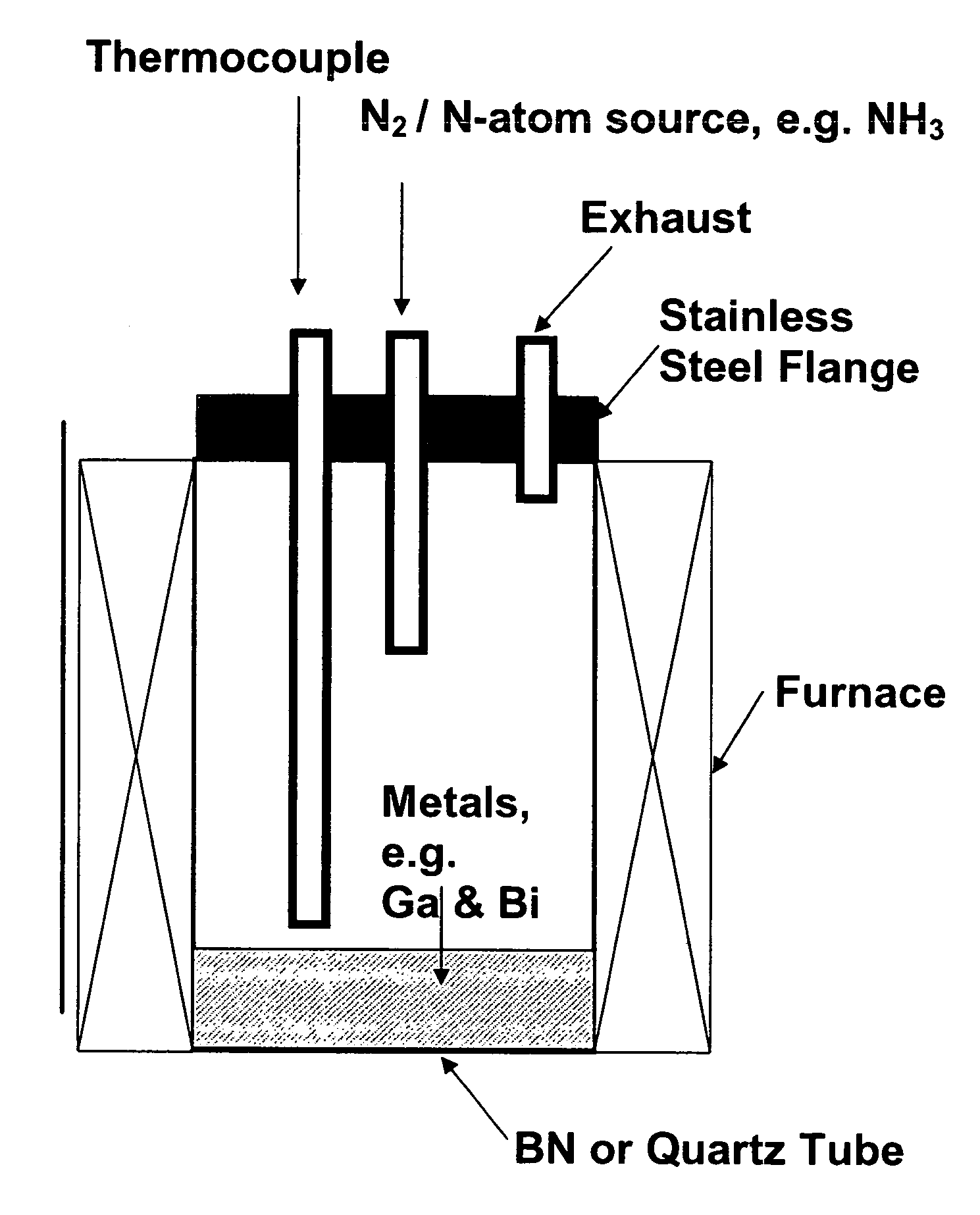

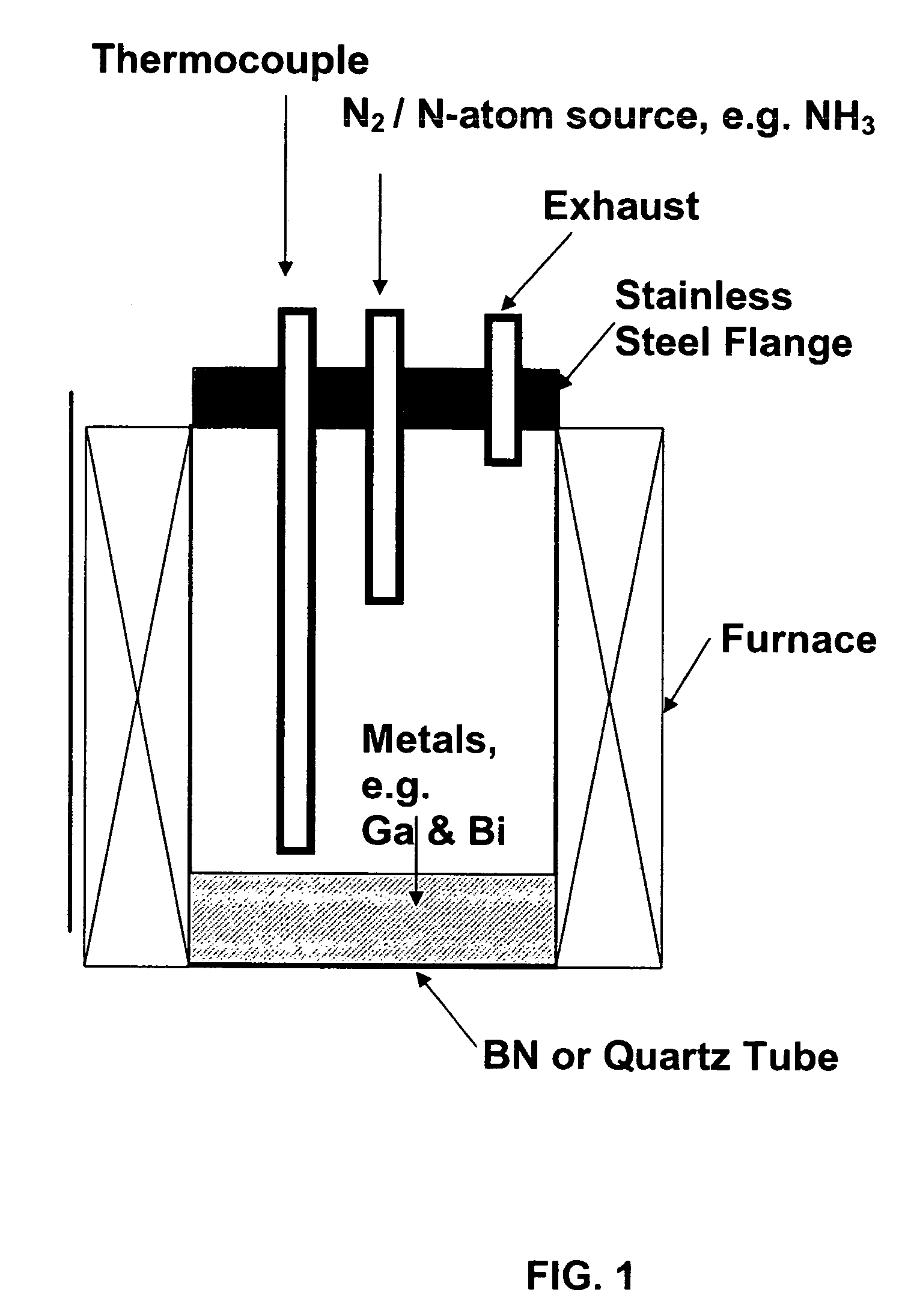

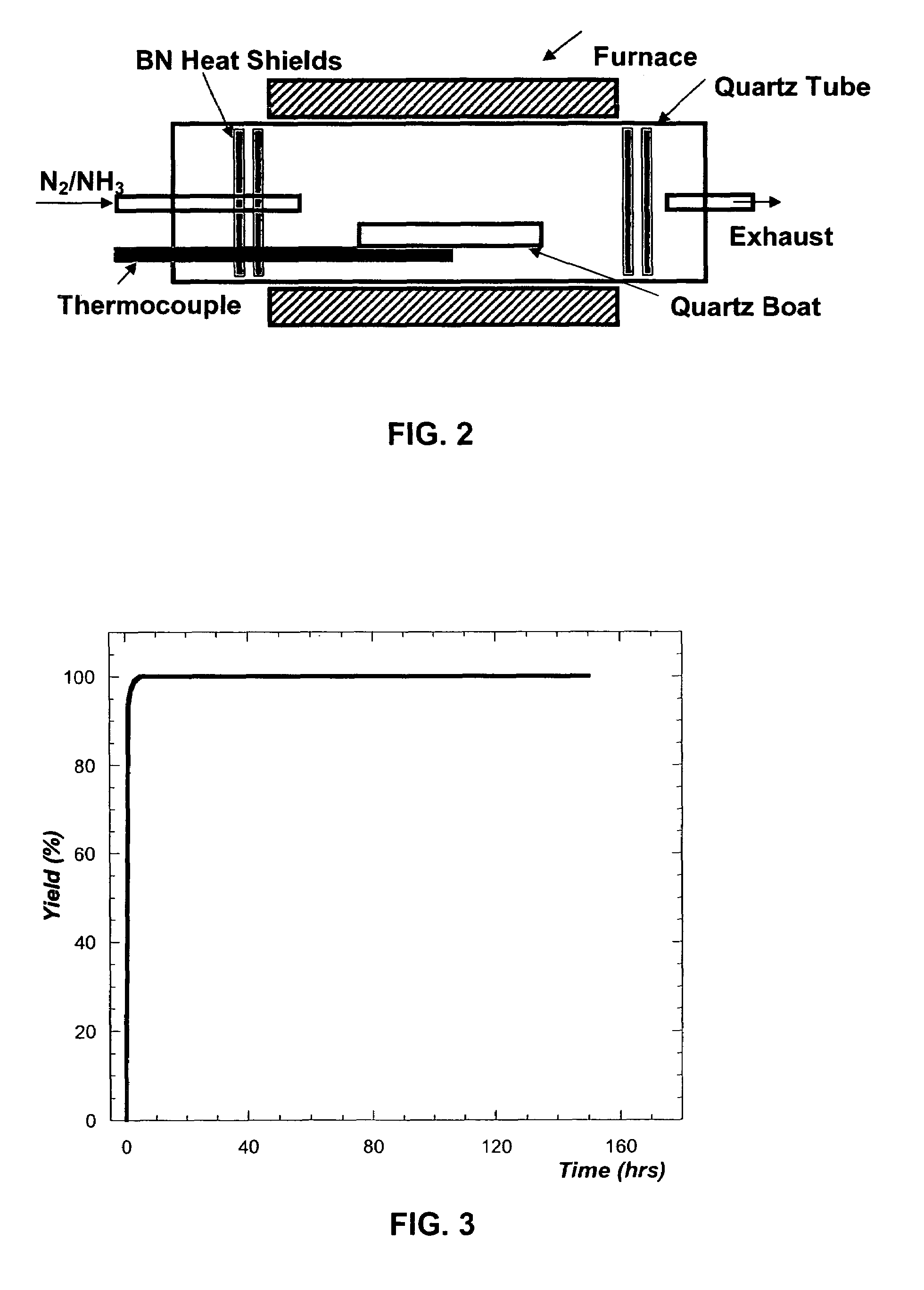

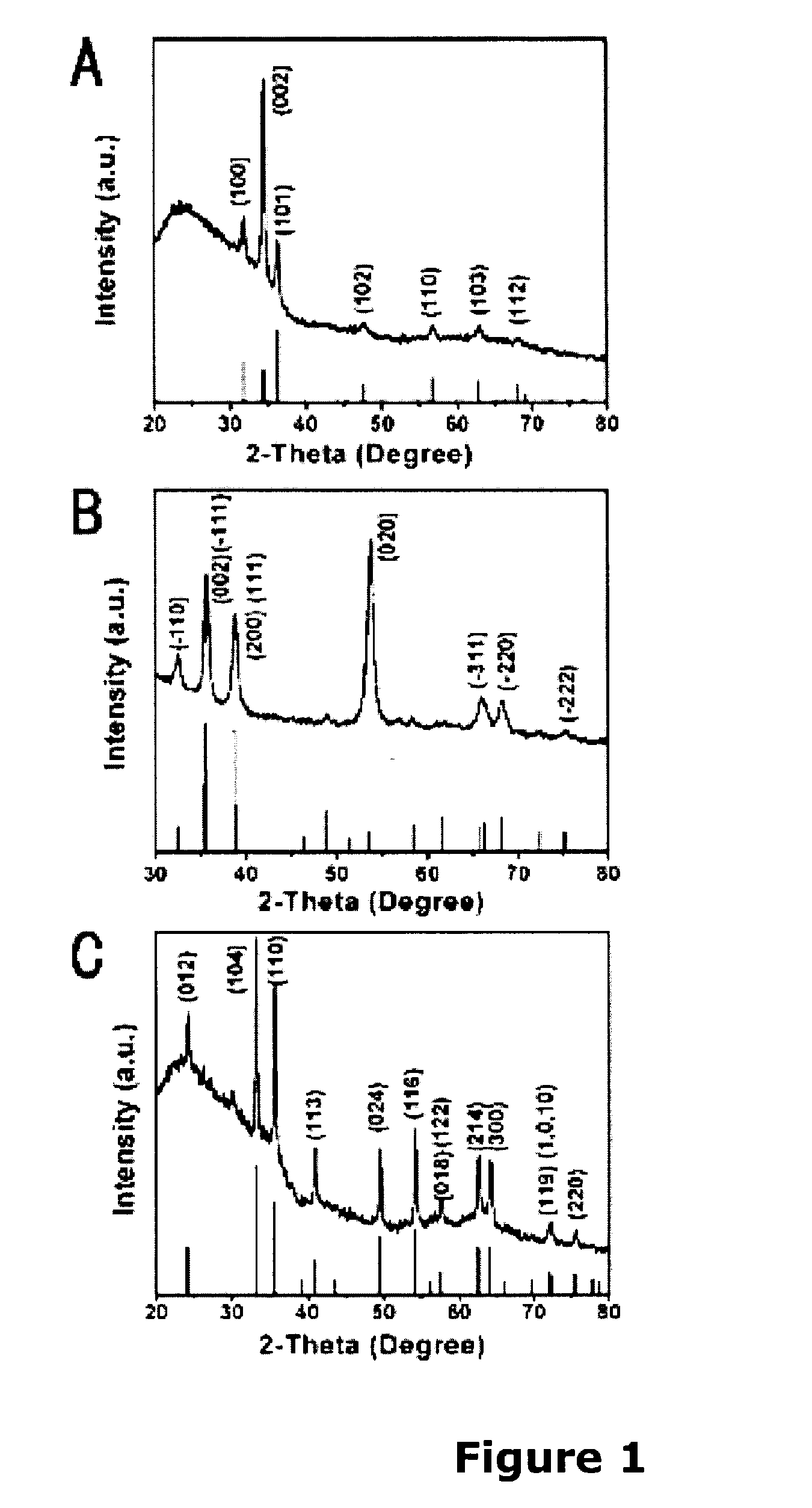

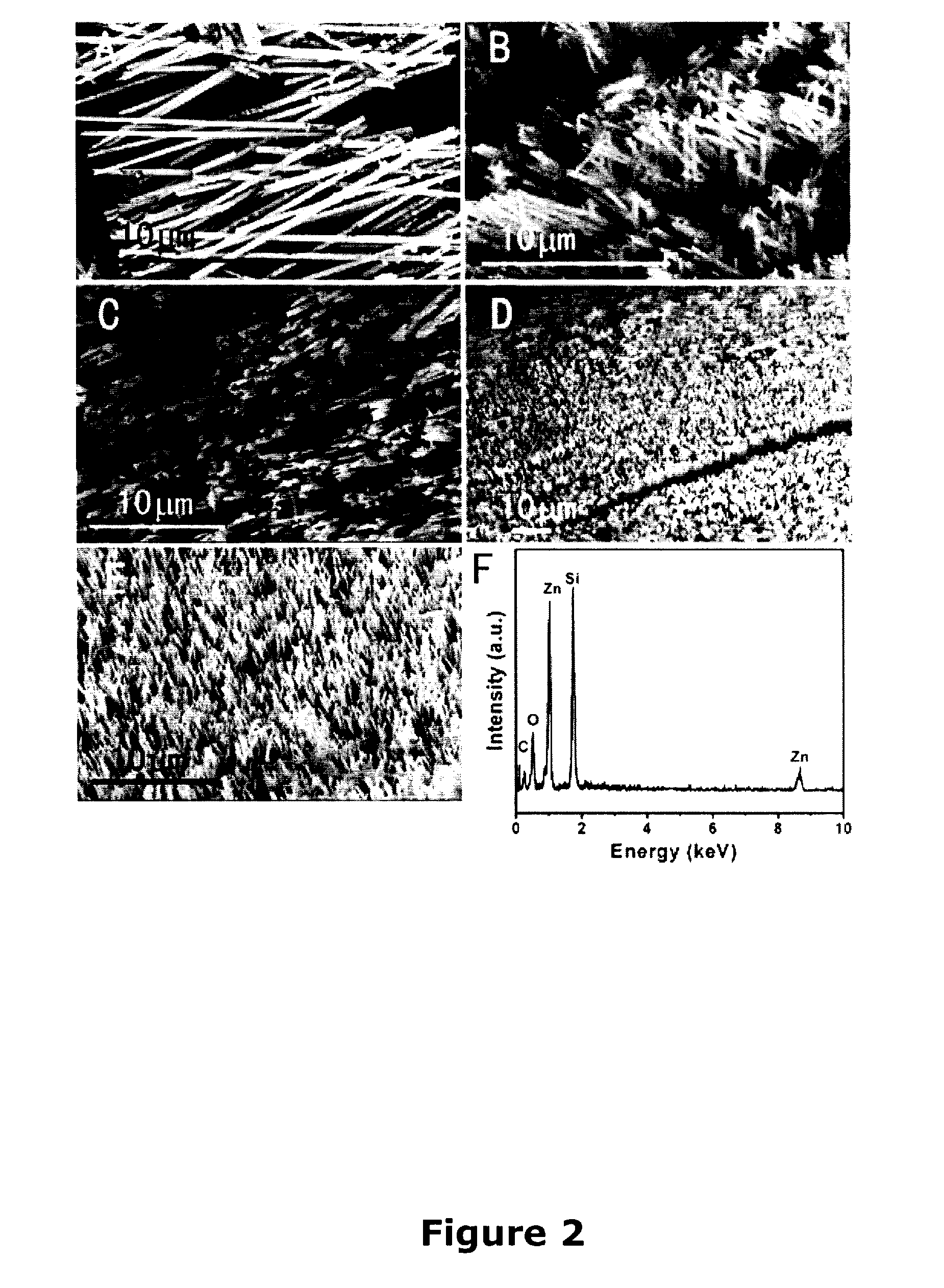

Method of making Group III nitrides

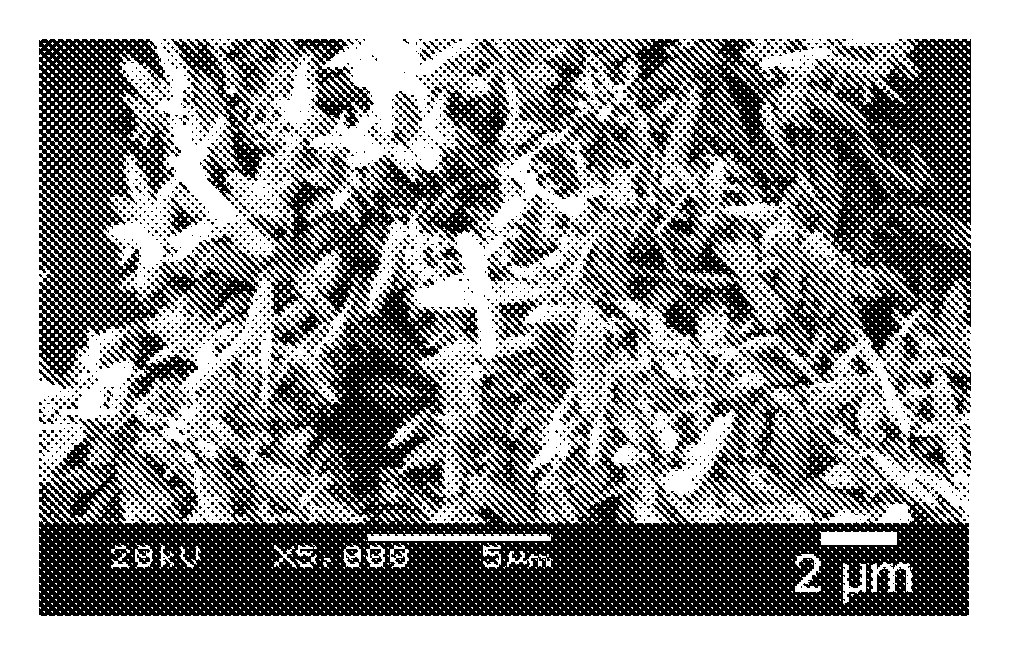

InactiveUS7381391B2High purityShort reaction timePolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsOptical propertyGlow Discharge Mass Spectrometry

The present invention provides compositions and a novel high-yielding process for preparing high purity Group III nitrides. The process involves heating a Group III metal and a catalytic amount of a metal wetting agent in the presence of a nitrogen source. Group III metals can be stoichiometrically converted into high purity Group III nitride powders in a short period of time. The process can provide multi-gram quantities of high purity Group III nitrides in relatively short reaction times. Detailed characterizations of GaN powder were preformed and are reported herein, including morphology and structure by SEM and XRD, optical properties by cathodoluminescence (CL), and Raman spectra to determine the quality of the GaN particles. The purity of GaN powder was found to be greater than 99.9% pure, as analyzed by Glow Discharge Mass Spectrometry (GDMS). Green, yellow, and red light emission can be obtained from doped GaN powders.

Owner:CORNELL RES FOUNDATION INC

Chemical/ionic/physical compounding cross linking hydrogel and preparation method thereof

The invention relates to chemical / ionic / physical compounding cross linking hydrogel and a preparation method thereof. The hydrogel is polymerized in a way that olefin monomer M1, a chemical cross-linking agent M2, multivalent ion biomacromolecule M3, an ionic cross-linking agent M4 and a physical cross-linking agent M5 are dissolved in water. The method comprises the following steps: preparing chemical / physical cross linked gel prepolymerization liquid, preparing chemical / ionic / physical cross linked gel prepolymerization liquid and preparing and purifying chemical / ionic / physical compounding cross linked gel. According to the invention, the characteristics and properties of the chemical cross-linking agent, the physical cross-linking agent and the ionic cross-linking agents are taken into consideration comprehensively, the compounding cross linking of molecular chains is realized; the prepared hydrogel is optically transparent and has higher mechanical ductility and rebound elasticity; the mechanic, optical and thermal performances and other performances can be regulated conveniently by controlling technology parameters and conditions; and the prepared hydrogel can be used in the fields such as tissue engineering, food industry, agricultural irrigation, daily chemical engineering, oil production, dye adsorption and biological medicine.

Owner:TIANJIN POLYTECHNIC UNIV

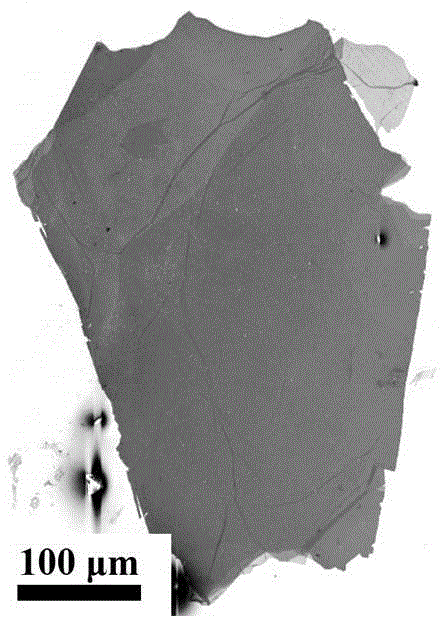

Preparation method of large-size graphene oxide or graphene

ActiveCN105293476ASmall sizeQuality improvementMaterial nanotechnologySingle layer grapheneHigh energyReducing agent

The invention discloses a preparation method of large-size graphene oxide or graphene. The preparation method mainly utilizes graphite as a raw material and comprises that 1, under the action of an intercalator and an expanding agent, graphite fully releases interlayer spaces so that interlayer interaction is reduced and a graphene aggregate is obtained, 2, the graphene aggregate is oxidized by an oxidizing agent, and then the oxidized graphene aggregate is peeled in water under gentle mechanical action so that a large area of a dispersion liquid of graphene oxide is obtained, and 3, the peeled graphene oxide is reduced by a reducer or heat treatment so that high conductivity graphene is obtained. The preparation method utilizes cheap raw materials, has a simple process, can be controlled easily, realizes fast and high efficiency solid-liquid separation, is convenient for industrial large scale production, prevents graphene crystal structure destroy caused by high energy supersonic wave, high speed shearing or fluid crushing. The obtained graphene has a large size and high conductivity and can be popularized and used in fields of high efficiency heat management, flexible display, energy conversion and storage.

Owner:FUDAN UNIV

Enzyme-linked immune analysis method and fully-automatic enzyme-linked immune analyzer

ActiveCN102116771AUnique structural shapeNo wasteMaterial analysis by optical meansBiological testingTemperature controlControl system

The invention relates to an enzyme-linked immune analysis method and a fully-automatic enzyme-linked immune analyzer. The analyzer comprises a rack component, a washing component, a sample adding / reagent adding component, a heating and temperature control component, a fluid path system, an input and output device, an optical measurement component and a control system, wherein the rack component comprises a rack soleplate; a pillar is arranged on the rack soleplate; a lower fixed plate and an upper fixed plate are arranged on the pillar from bottom to top in sequence; a circular reaction plate is arranged between the lower fixed plate and the upper fixed plate; the circular reaction plate is connected with the upper fixed plate and the lower fixed plate through a central shaft; a first motor is fixedly arranged at the lower part of the lower fixed plate; and the first motor is used for driving the circular reaction plate to rotate through a first transmission mechanism. When in use, the enzyme-linked immune analysis method and the fully-automatic enzyme-linked immune analyzer can carry out the detection of corresponding projects without wasting reagent through only one sample; and detection reagents need not to be respectively contained in different reagent bottles, so that the operation is very convenient, and the operation error is not easily caused, thereby ensuring the accuracy of the detection results.

Owner:SHENZHEN YHLO BIOTECH

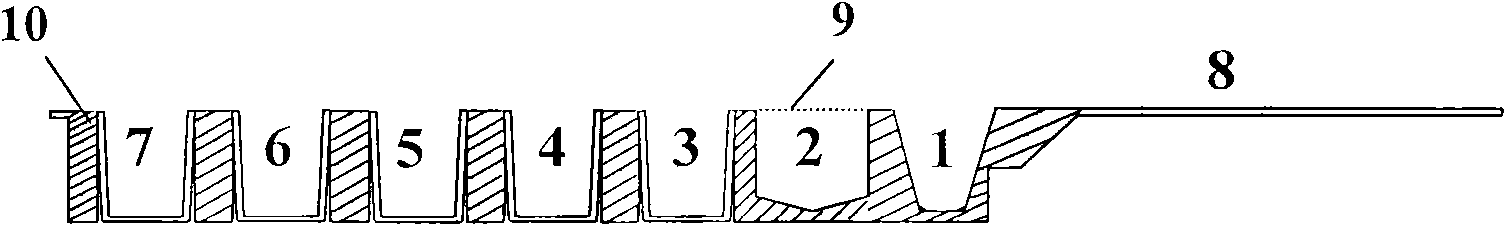

Thin-film solar cells on the basis of IB-IIIA-VIA compound semiconductors and method for manufacturing same

InactiveUS6429369B1Improve adhesionReduce capacityFinal product manufactureSolid-state devicesSulfurEngineering

The invention relates to a thin-film solar cell on the basis of IB-IIIA-VIA compound semiconductors and a method for producing such a solar cell. Between the polycrystalline IB-IIIA-VIA absorber layer of the p-type conductivity and the carrier film serving as a substrate, a back electrode of intermetallic phases of the same IB- and IIIA-metals are located which are deposited for the generation of the absorber layer. The absorber layer and the back electrode are produced in such a way that the precursor consisting of IB-IIIA-metals is vertically only incompletely converted into the photovoltaicly active absorber material from the side opposite to the carrier film by reaction with chalcogen such that intermetallic phases of the IB- and IIIA-metals are directly located on the carrier film, which metals serve as back electrode of the solar cell structure.

Owner:ODERSUN

Biomass refining by selective chemical reactions

InactiveUS20110071306A1High substrate loadingShort reaction timeSugar derivativesSugar derivatives preparationChemical reactionPropanoic acid

A method is disclosed for the acid hydrolysis of carbohydrates in or from biomass, using a solvent system including an aqueous ether, where the ether form a majority of the system, which affords high yields to the platform chemicals such as 2-furfural and 5-hydroxymethylfurfural (5-HMF). The later can also undergo a domino reaction to chemicals including levulinic acid, particularly with oxygenated anions and greater water content. A total dissolution and reaction of biomass occurs under a range of relatively mild conditions (combined Severity range ˜2.2-2.6). Lignin and lignin derived products can be easily separated by precipitation.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

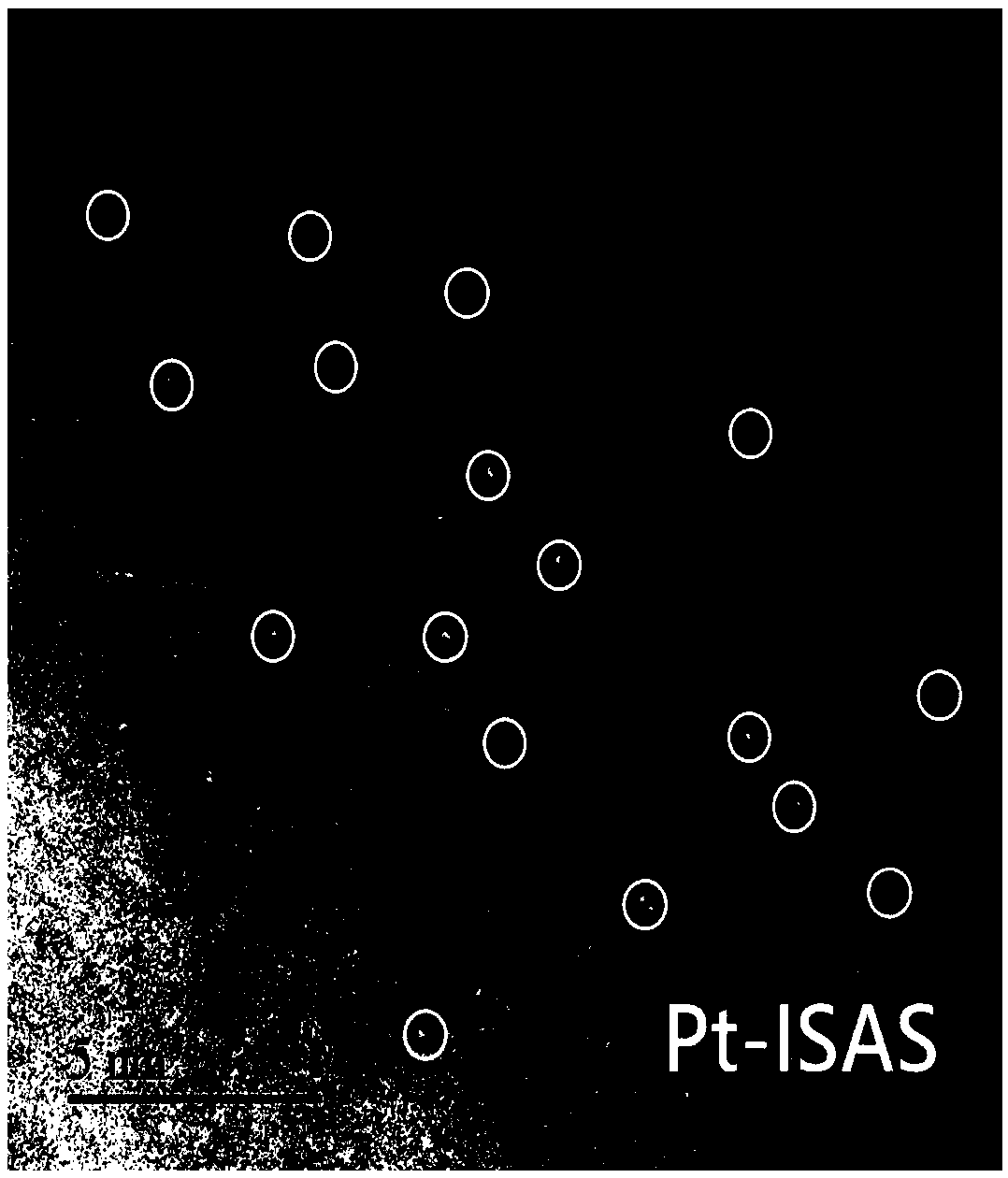

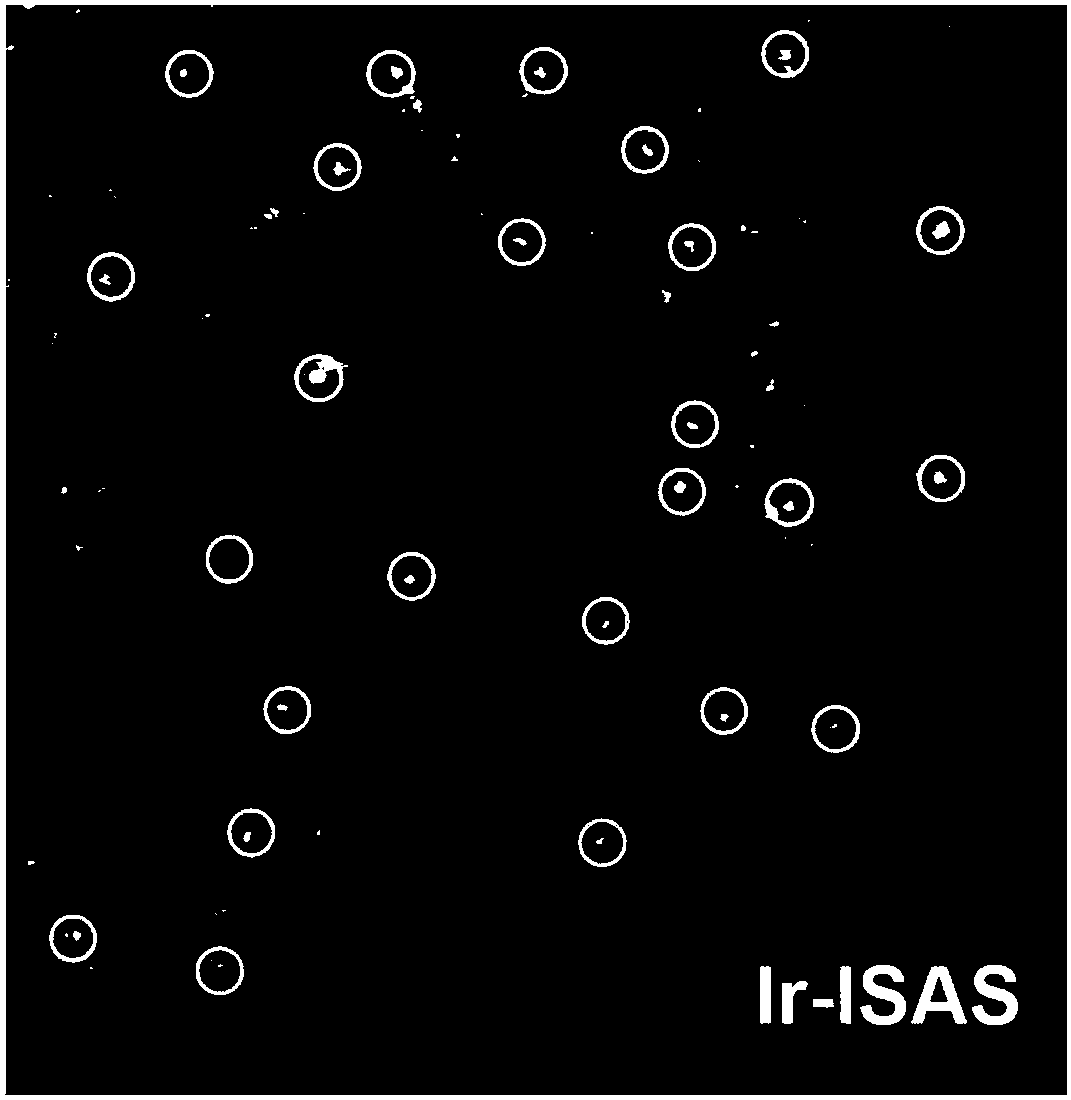

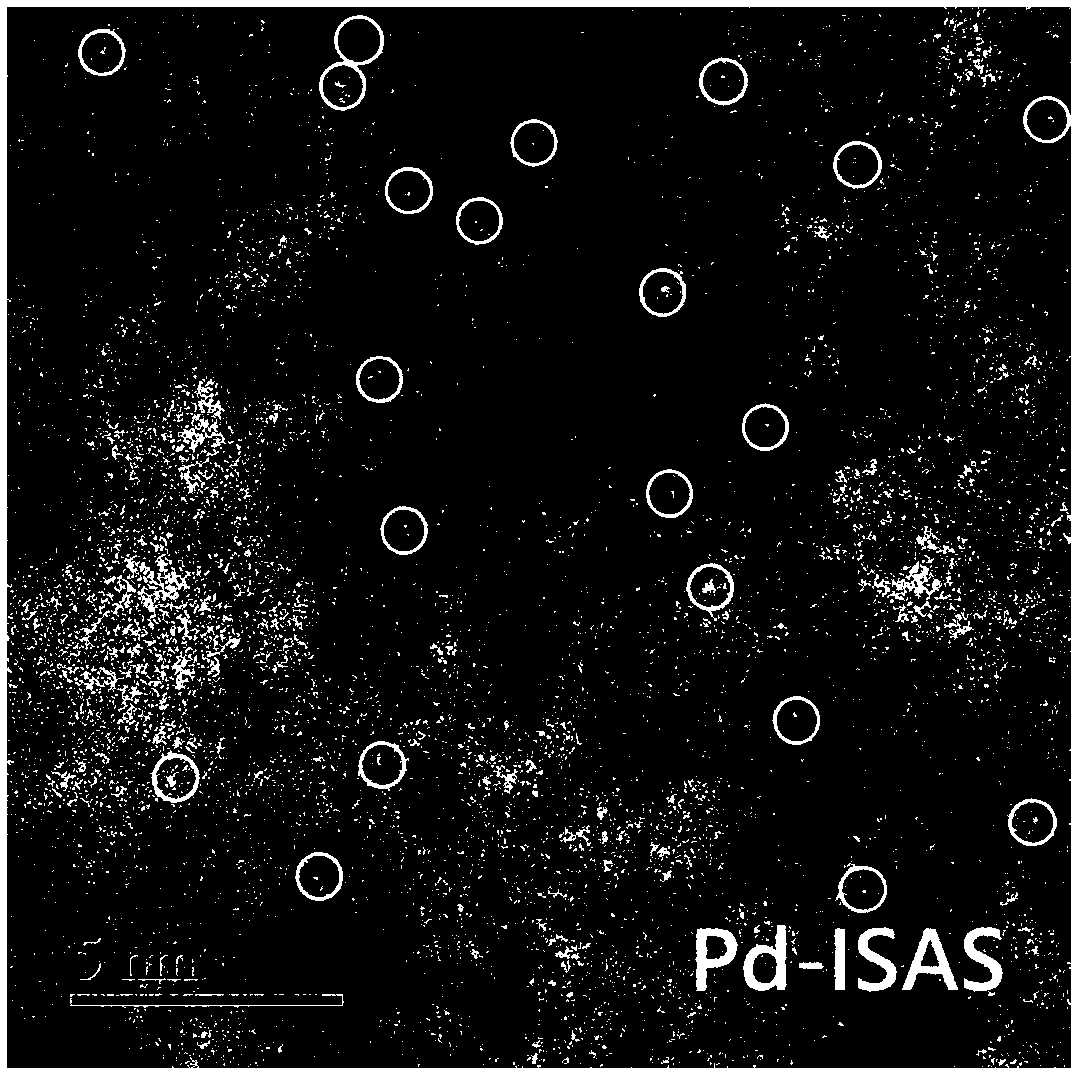

Preparation method of metal monatomic site catalyst

ActiveCN107626294ASmall particlesUniform particle size distributionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsZinc compoundsPorous carbon

The invention provides a preparation method of a metal monatomic site catalyst. According to the synthetic strategy, a porous complex composite material coated with an acetylacetone metal salt is formed from a zinc compound and an imidazole organic ligand through coordination in a methanol solution of the acetylacetone metal salt, and then a porous carbon support doped with nonmetal heteroatomic nitrogen is formed from the imidazole organic ligand through a high-temperature pyrolytic reaction in an inert gas atmosphere, wherein metal atoms interact with surrounding nonmetal heteroatomic nitrogen and exist in the form of single atoms. The method is simple, safe, low in cost and applicable to synthesis of various noble metal and non-noble metal monatomic site catalysts, and the obtained metal monatomic site catalyst is high in metal concentration and good in heat stability, can be applied to the fields of energy, catalysis, medicine, biology and the like and has quite broad market prospect.

Owner:TSINGHUA UNIV

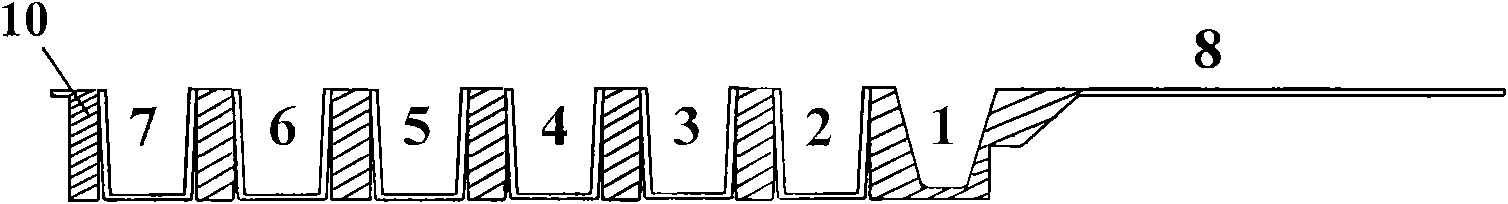

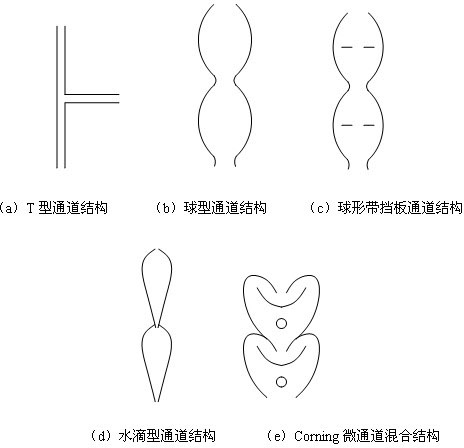

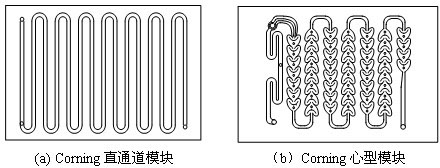

Method for undergoing chlorobenzene nitration reaction by using micro-channel reactor

ActiveCN102432471APrevent leakageAvoid dangerNitro compound preparationTemperature controlChlorobenzene

The invention relates to a method for undergoing a chlorobenzene nitration reaction by using a micro-channel reactor, belonging to the technical field of application of organic synthesis. In the method, nitric acid, sulfuric acid, water and chlorobenzene are taken as initial reaction raw materials, and processes such as mixed acid preparation, mixed acid and chlorobenzene preheating, mixed acid and chlorobenzene reacting and the like are completed in a micro-channel reactor system. In the reaction, nitro-sulfuric mixed acid is taken as a nitrating agent, the effective concentration of sulfuric acid in the mixed acid is 50-90 percent, the molar ratio of the nitric acid to the sulfuric acid in the mixed acid is 1:1-1:10, the molar ratio of the chlorobenzene to the nitric acid is 1:1.0-1:2.0, the reaction temperature is 50-100 DEG C, and the reaction time is 30-120 seconds. The chlorobenzene transformation ratio is up to 97 percent, the selectivity of nitrochlorobenzene serving as a product is over 96.5 percent, and the ratio of ortho-para nitrochlorobenzene is over 0.6. A strengthened mixed micro-channel reactor adopted in the invention is particularly suitable for undergoing a continuous nitration reaction, and has the characteristics of stable temperature control and safe process.

Owner:CHANGZHOU UNIV

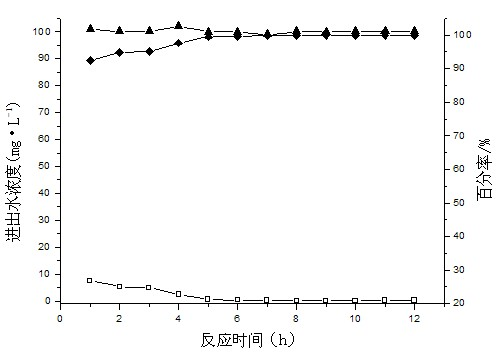

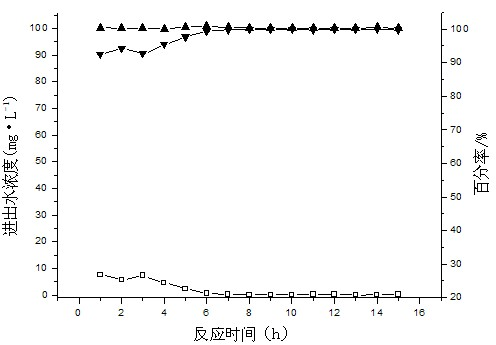

Sphingomonas strain and application thereof in water treatment

InactiveCN102168054APromote degradationReduce concentrationBacteriaMicroorganism based processesIndustrial waste waterWater source

The invention belongs to the technical fields of environmental engineering and bioengineering and particularly relates to a sphingomonas strain and applications thereof in the aspects of shortcut nitrification-denitrification of nitrogen-containing industrial waste water and domestic sewage and treatment of a polluted water source. The sphingomonas strain is separated from a Taihu water in China,is a local strain and has high safety; and the strain can be grown in a basic medium, wherein in the basic medium, CO2 is used as a carbon source and energy or CO2 and an organism are used as a mixedcarbon source and energy, and ammonia nitrogen or nitrate nitrogen is used as a nitrogen source. The bacterium liquid, the dormancy cell and the immobilized strain of the sphingomonas can decompose ammonia nitrogen into nitrite nitrogen and simultaneously can decompose the ammonia nitrogen into nitrogen, can be used as denitrification microorganism for converting the ammonia nitrogen into the nitrite nitrogen and the nitrogen, thereby achieving the shortcut nitrification-denitrification. The strain can rapidly decompose the ammonia nitrogen and is suitable for treating the nitrogen-containingindustrial waste water and domestic sewage as well as polluted water source.

Owner:NANJING UNIV

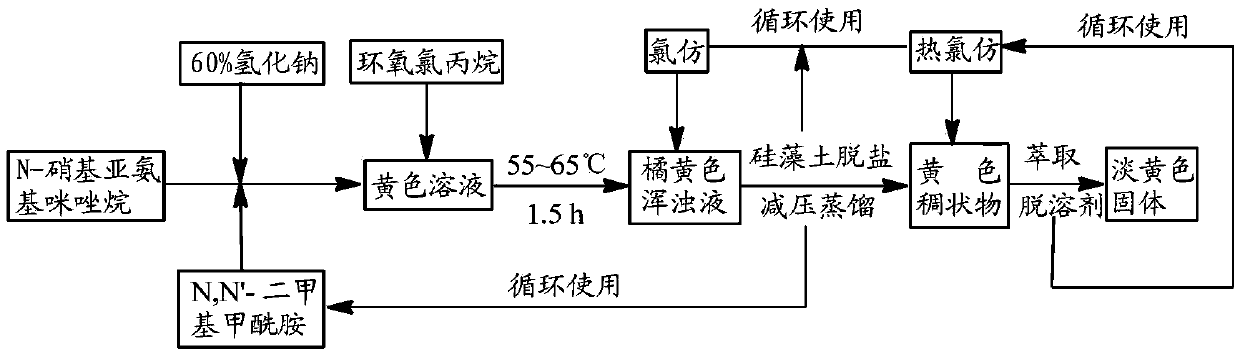

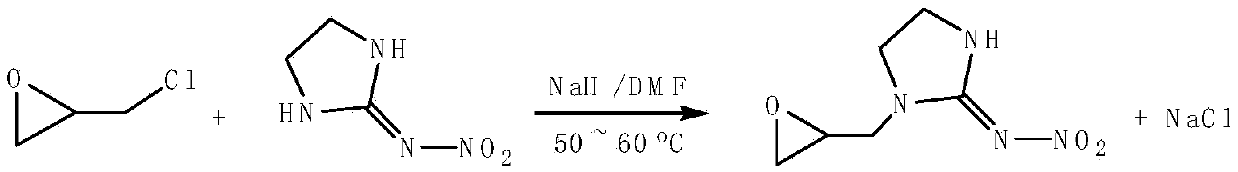

Method for preparing cycloxylidin

The invention discloses a method for preparing cycloxylidin, which belongs to the technical field of pesticides preparation. The method comprises the following steps: under nitrogen protection, N-nitroiminoimidazolidine and an organic solvent are added in a reactor, then sodium hydride is added in batches, and the material is heated to the temperature of 50-60 DEG C, chloropropylene oxide is added drop by drop in the reactor, after the reaction product is cooled, chloroform is added, and the product is filtered by diatomite, then evaporative crystallization is carried out, and the crystals can be precipitated, vacuum distillation is carried out on a processed filtrate to obtain a light yellow dense solid, then heat chloroform is used for extraction, and finally heat ethanol or acetone is used for recrystallization to obtain cycloxylidin: 1-(2,3-glycidyl)-N-nitroimidazoline-2-ylamine, wherein the yield is about 83%. The method has the advantages of short reaction time, high yield and green environmental protection, and is more suitable for large-scale industrial production.

Owner:山东聚强绿洲生物科技有限公司

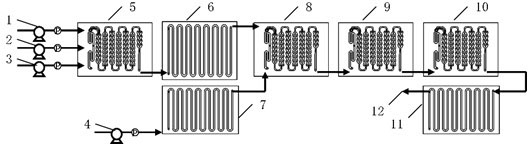

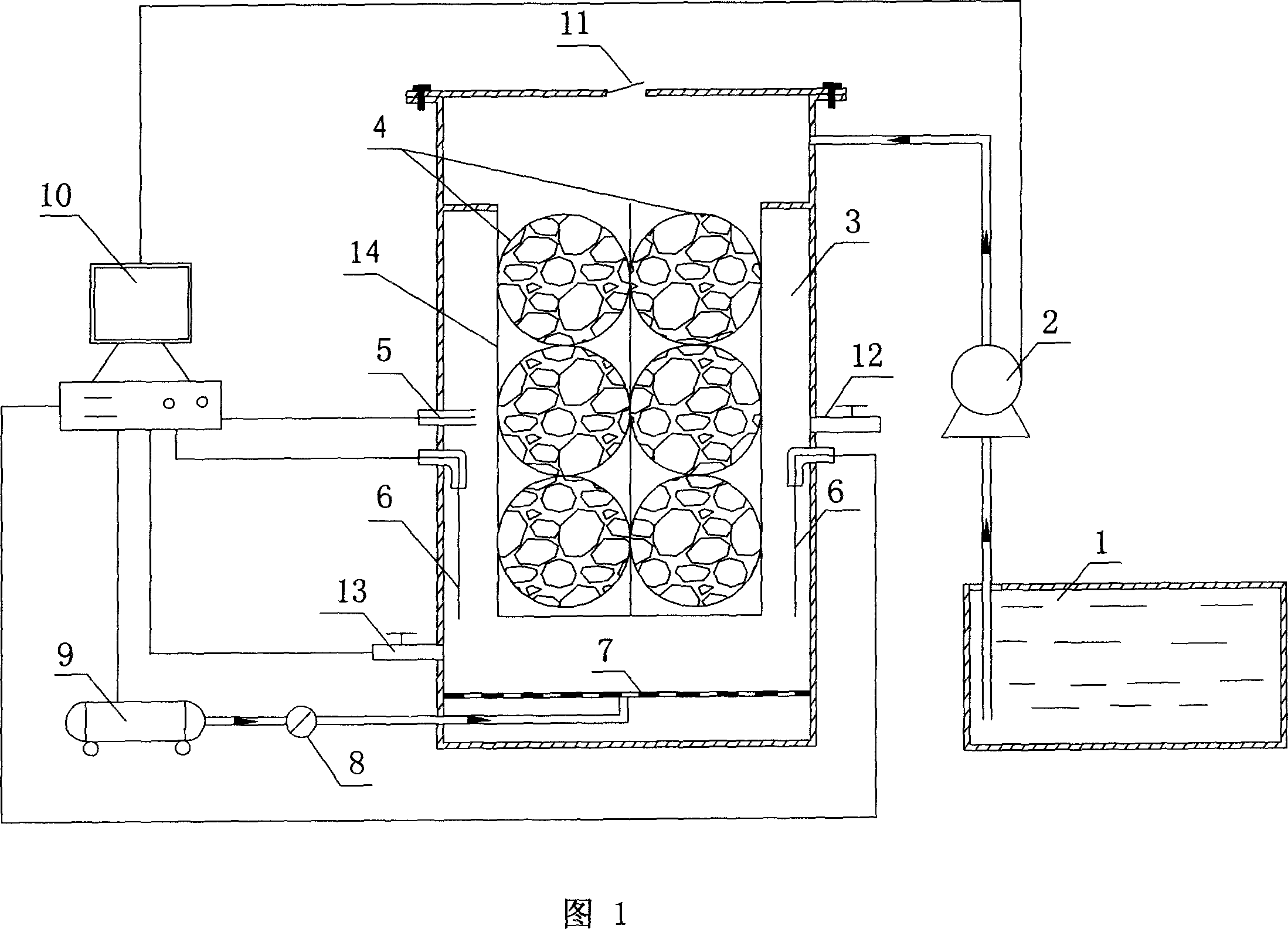

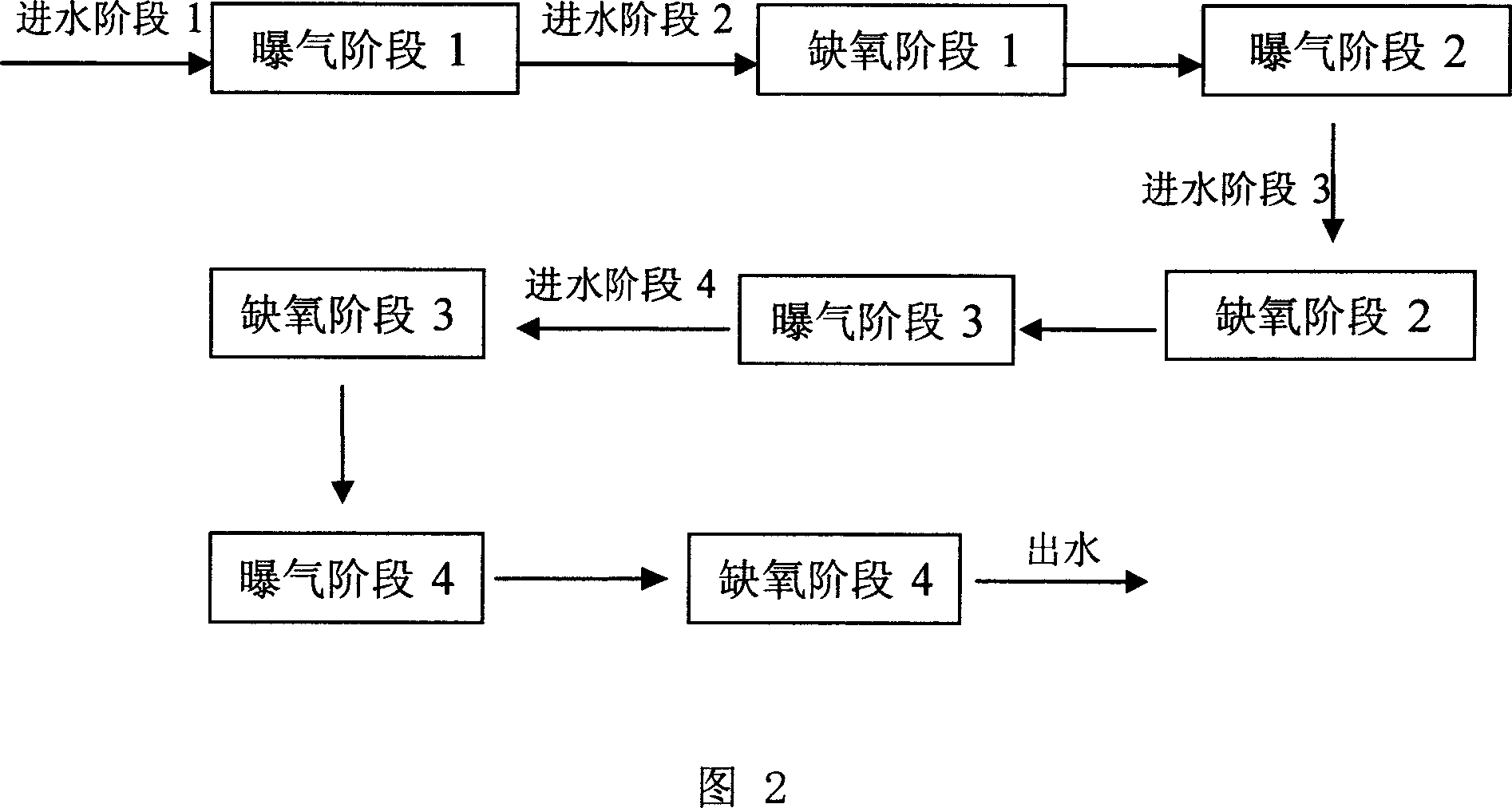

Operation mode and apparatus of short distance nitration-anaerobic ammoxidation batched biomembrane denitrogenation

InactiveCN1927739AToxic reductionControl the maximum cumulative concentrationTreatment with aerobic and anaerobic processesSludgeElectron donor

One kind of short range nitrifying-anaerobic aminoxidizing sequencing batch type denitrifying biomembrane mode and plant is disclosed. The limited aerating mode with real-time control of the sewage temperature inside the reactor and high frequency alternation between aeration and anaeration can inhibit the growth of nitrite oxidizing bacteria and denitrifying bacteria so that the aminoxidizing bacteria and the anaerobic aminoxidizing bacteria become the dominant bacteria in the nitrifying and denitrifying stages. In the nitrifying stage, nitrification is stopped in the nitrite step; and in the denitrifying stage, ammonia nitrogen acts as the direct electron donor to reduce nitrite. The plant is provided with fixed spherical composite stuffing with spherical shell of polypropylene and filled inside biological composite material. Sectional discrete water feeding mode is adopted to feed the sewage to be treated in four stages into the reactor.

Owner:HUNAN UNIV

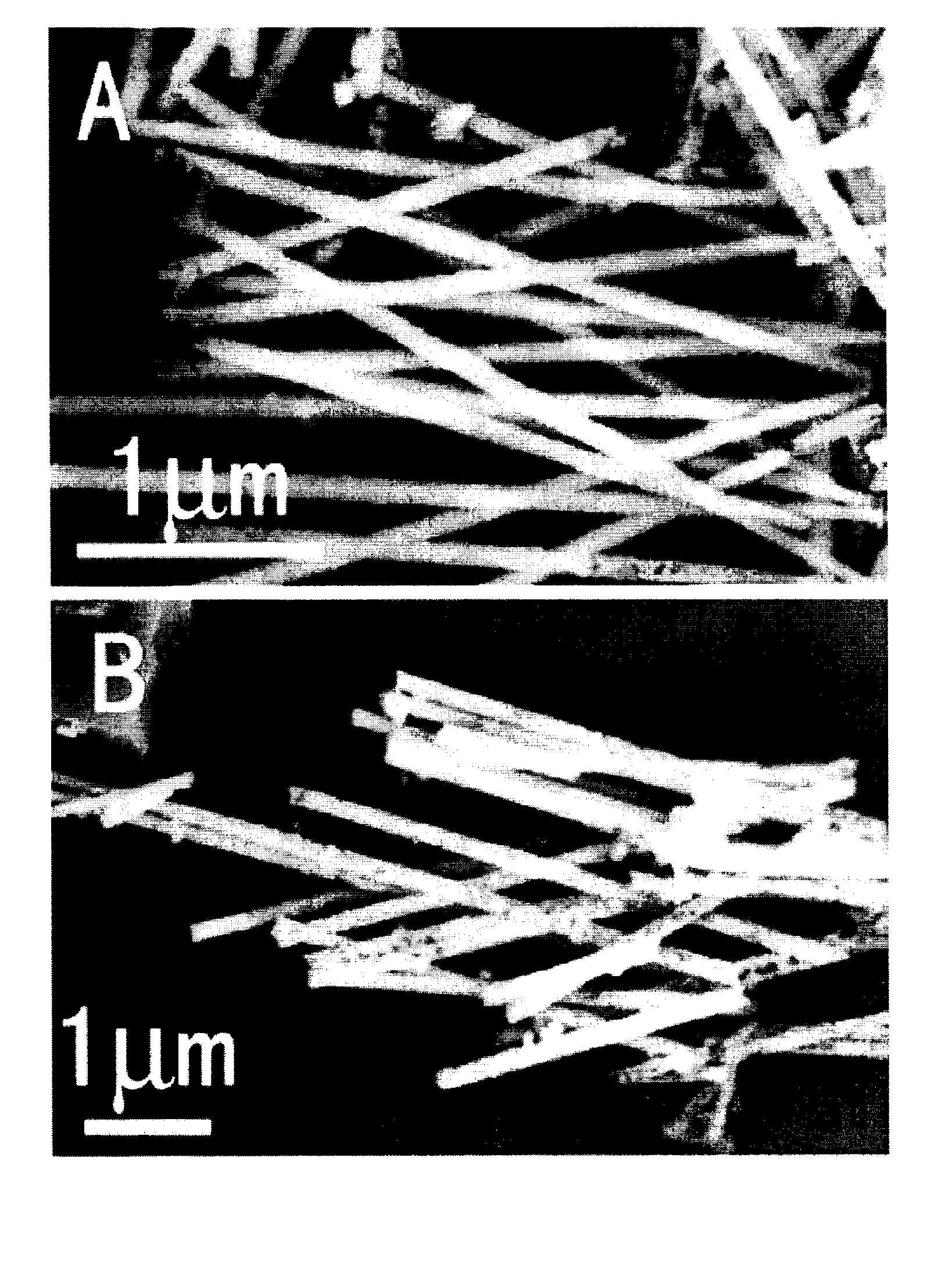

Methods of Making Binary Metal Oxide Nanostructures and Methods of Controlling Morphology of Same

ActiveUS20100278720A1Reduce crystallinityControl dimensionalityCopper oxides/halidesManganese oxides/hydroxidesPorous membraneNanostructure

The present invention includes a method of producing a crystalline metal oxide nanostructure. The method comprises providing a metal salt solution and providing a basic solution; placing a porous membrane between the metal salt solution and the basic solution, wherein metal cations of the metal salt solution and hydroxide ions of the basic solution react, thereby producing a crystalline metal oxide nanostructure.

Owner:WONG STANISLAUS S +1

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

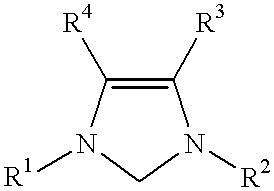

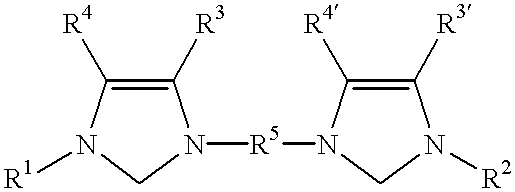

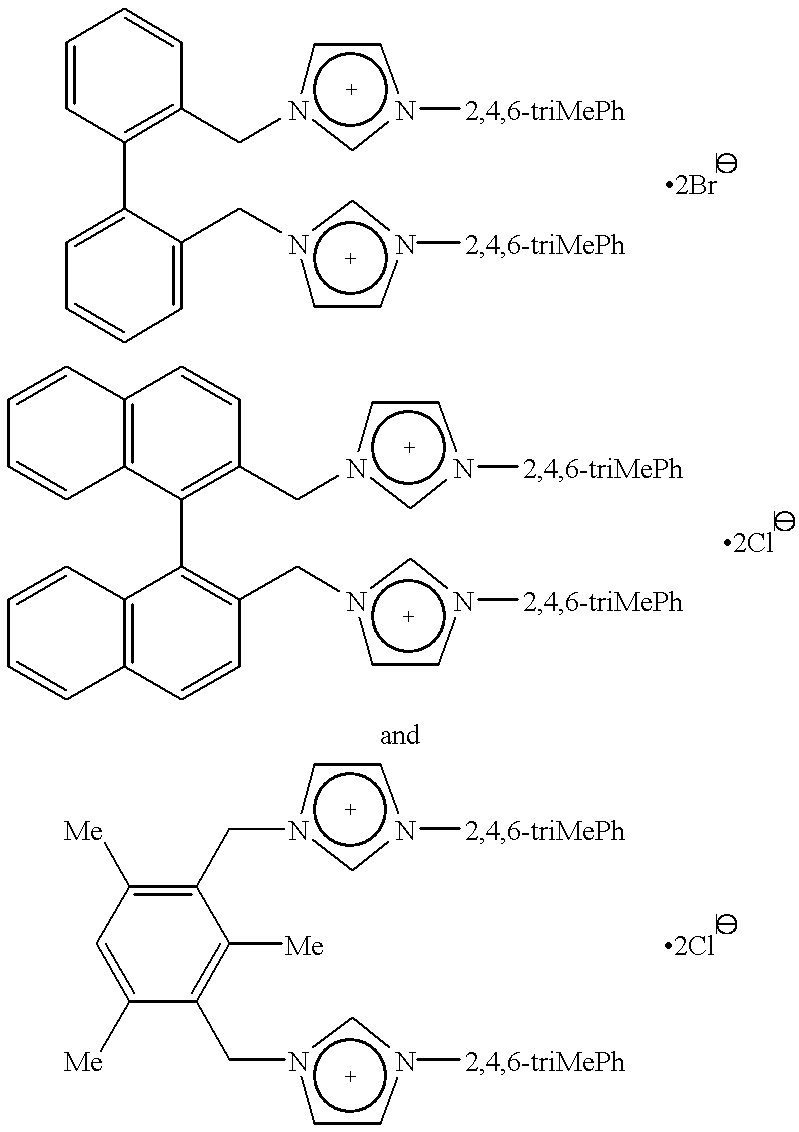

Catalyst system comprising transition metal and imidazoline-2-ylidene or imidazolidine-2-ylidene

InactiveUS6316380B1Inexpensive and readily synthesizedHigh yieldCarboxylic acid esters preparationOrganic grignard reactionsCarbeneImidazolidines

This invention provides a catalyst system useful in many coupling reactions, such as Suzuki, Kumada, Heck, and amination reactions. The catalyst system of the present invention makes use of N-heterocyclic carbenes or their protonated salts. The composition of the catalyst system comprises at least one transition metal compound and at least one N-heterocyclic carbene or its protonated salt. This invention further provides novel N-heterocyclic carbenes and their protonated salts. One type of N-heterocyclic carbene used in this invention is an imidazolinc-2-ylidene wherein the 1 and 3 positions are each, independently, substituted by an aromatic group in which each ortho position is, independently, substituted by a secondary or tertiary group which has at least three atoms.

Owner:NEW ORLEANS RES & TECH FOUND UNIV OF +1

Preparation method of graphene inorganic nanocomposite

InactiveCN101774574AEvenly dispersedIncrease surface areaNanostructure manufactureZinc oxides/hydroxidesStored energyInorganic salts

The invention discloses a preparation method of a graphene inorganic nanocomposite, which comprises the following steps: firstly, adding grapheme into the aqueous solution of soluble inorganic salt, and scattering the grapheme by ultrasound; then adding precipitant under the mixing condition, centrifuging at a high speed and heat treating the obtained mixed liquor, and finally obtaining the graphene inorganic nanocomposite. The composite has high surface area, adjustable diameter of nano particles, and important application value on catalysis, stored energy, drug delivery and the like.

Owner:XIANGTAN UNIV

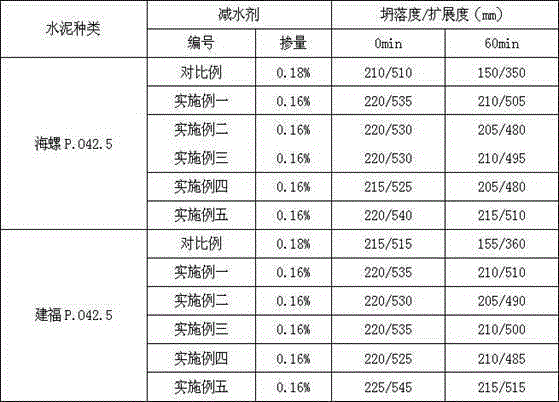

Mud resisting and slump retaining type polycarboxylic acids water reducer and preparation method thereof

ActiveCN105110687ASimple preparation processNo pollution in the processFunctional monomerCross linker

The invention discloses a mud resisting and slump retaining type polycarboxylic acids water reducer and a preparation method thereof. The mud resisting and slump retaining type polycarboxylic acids water reducer comprises, by weight, unsaturated polyoxyethylene ether 32.5% to 33.6%, unsaturated carboxylic acid 1.7% to 2.5%, functional monomer 3.25% to 3.36%, cross-linking agent 0.08% to 0.13%, oxidizing agent 0.12% to 0.32%, reducing agent 0.09% to 0.17%, chain transferring agent 0.03% to 0.06%, alkalinity modifier 0.86% to 1.22%, and water 60%. The water reducer in the invention has quite strong adaptability for sandstone with high silt content, good effect on mud resisting, large initial dispersibility, low cost and good slump retaining performance. Moreover, the preparation method in the invention reacts at normal temperature; has short reaction time, low energy consumption, low cost, high security coefficient, and no need to control the temperature in the whole production process; and is simple, without pollution, and suitable for commercial production.

Owner:厦门路桥翔通建材科技有限公司

Biomarker generator system

ActiveUS20080067413A1Efficient dosingEfficient productionIsotope delivery systemsMaterial analysis using wave/particle radiationMicroreactorParticle accelerator

A biomarker generator system for producing approximately one (1) unit dose of a biomarker. The biomarker generator system includes a small, low-power particle accelerator (“micro-accelerator”) and a radiochemical synthesis subsystem having at least one microreactor and / or microfluidic chip. The micro-accelerator is provided for producing approximately one (1) unit dose of a radioactive substance, such as a substance that emits positrons. The radiochemical synthesis subsystem is provided for receiving the radioactive substance, for receiving at least one reagent, and for synthesizing the approximately one (1) unit dose of a biomarker.

Owner:BEST ABT INC

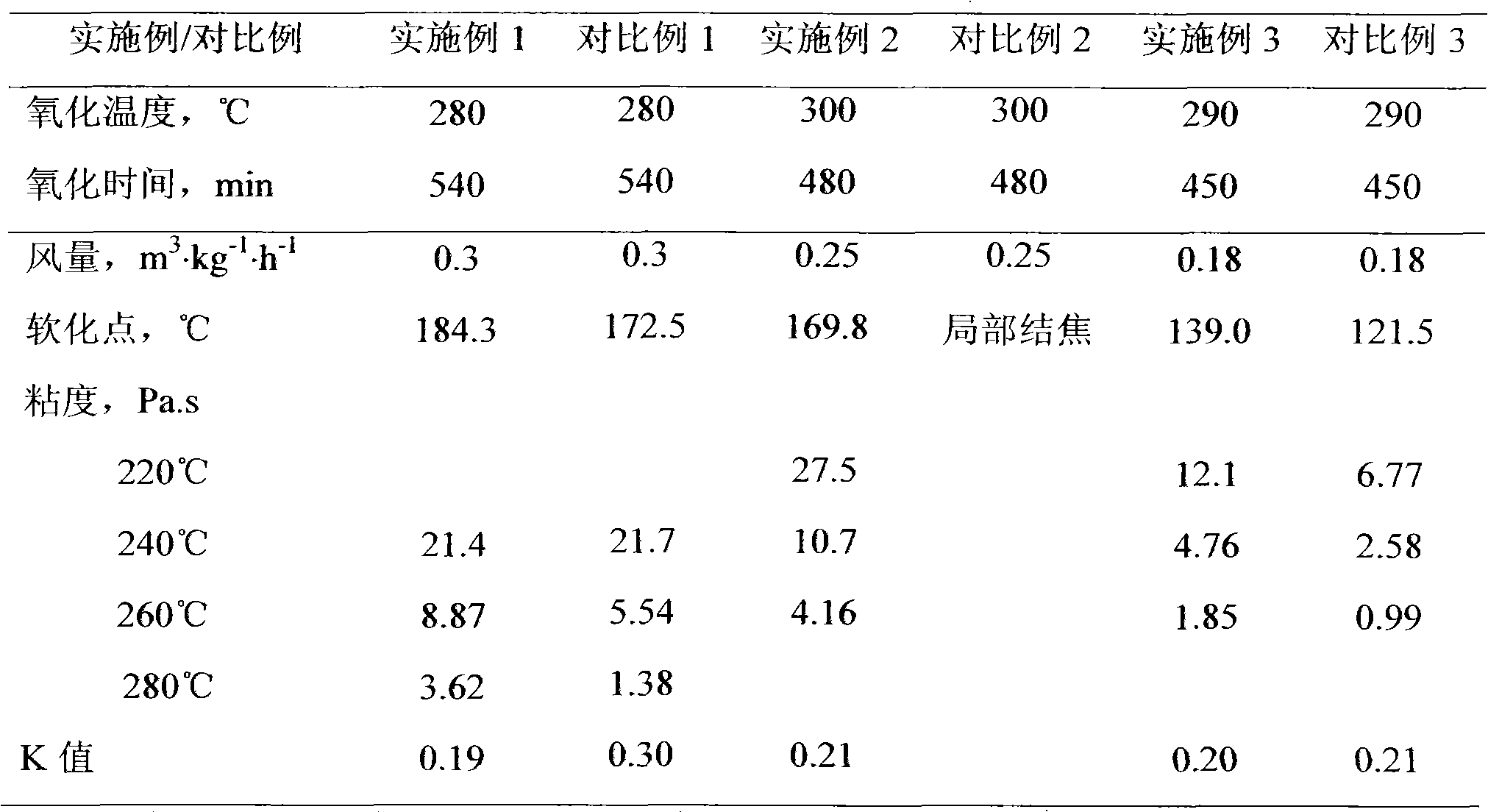

Preparation method of high softening point asphalt

ActiveCN102464989AIncrease profitQuality improvementWorking-up pitch/asphalt/bitumen by chemical meansMolten stateTemperature control

The invention provides a preparation method of high softening point asphalt, and the method comprises: heating an asphalt raw material to a molten state, subjecting the asphalt raw material, reaction additives accounting for 0.01%-5% of the total mass of the asphalt raw material, as well as air to full premixing reaction, with the mixing temperature controlled at 80-180DEG C and the mixing time controlled at 1min-40min; then introducing the mixture to an oxidation reactor for air blowing oxidation at a temperature of 200-340DEG C for 3-10h, with the air blowing rate of an oxidation tower maintained at 0.05-0.5m<3>.kg<-1>.h<-1>, thus obtaining a high softening point asphalt product with excellent high temperature performance and temperature susceptibility resistance. The method of the invention solves the problems of overlong reaction time, nonuniform air distribution, easy coking, short oxidation tower operation cycle, and poor product performance, etc. existing in current high softening point asphalt production processes by oxidation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

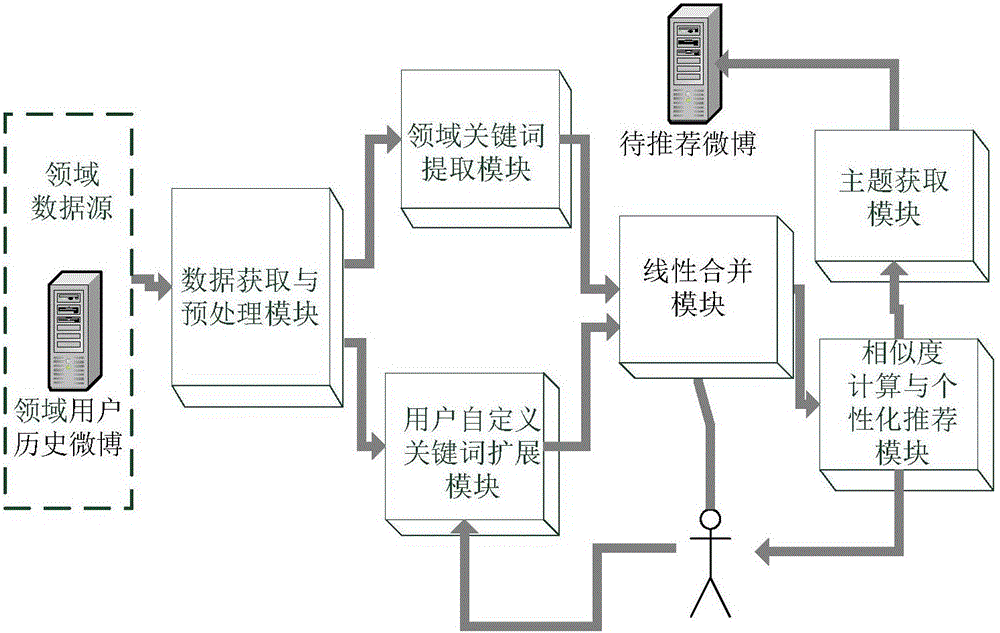

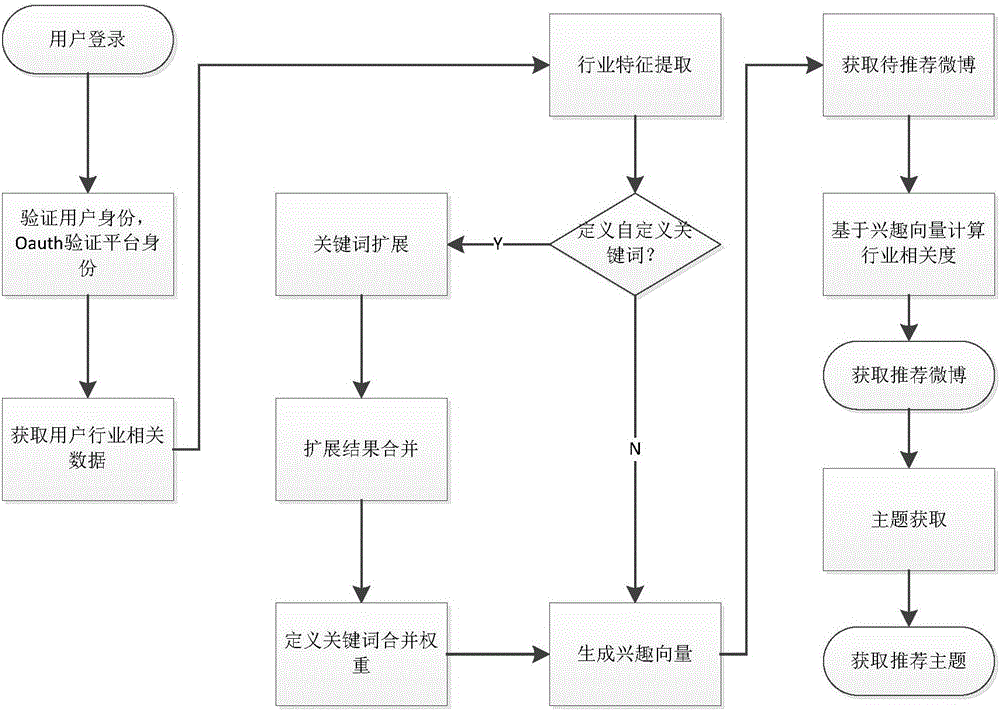

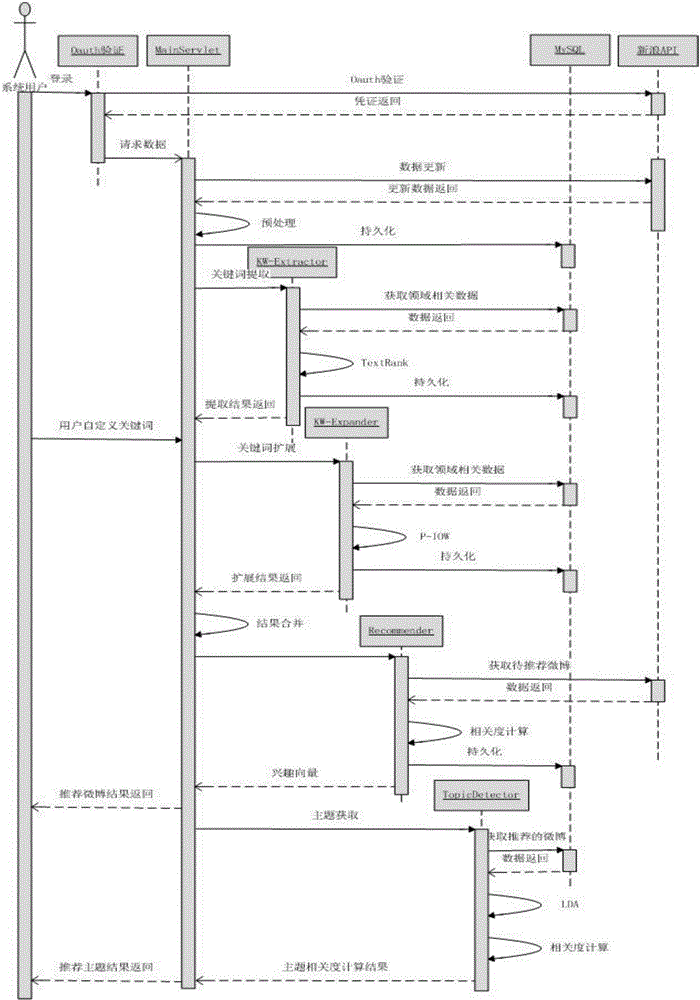

System and method for recommending domain information based on microblog platform

InactiveCN106776881AImprove presentation skillsDynamic interest needs fulfillmentSpecial data processing applicationsPersonalizationMicroblogging

The invention discloses a system and method for recommending domain information based on a microblog platform. The system comprises a data obtaining and preprocessing module, a domain key word extracting module, a user defined key word extending module, a linear combining module, a similarity calculating and personality recommending module and a subject obtaining module; the method for recommending the domain information is designed and achieved aimed at the character of the microblog platform. According to the method, seamless combination is conducted between key word extracting and key word expanding, thus the extracting of domain character is guaranteed, the dynamism of a recommending result is also guaranteed, and through the experiment of the corresponding system based on Sina microblog, the effectiveness of the method is verified; the method can assist enterprises in microblog marketing, and thus the efficiency in microblog marketing of the enterprises can be effectively improved.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com