Operation mode and apparatus of short distance nitration-anaerobic ammoxidation batched biomembrane denitrogenation

A sequencing batch biofilm and anaerobic ammonium oxidation technology, which is applied in the fields of environmental protection and sewage treatment, can solve the problems of carcinogenicity, infrastructure investment, increased land occupation, and high energy consumption, so as to reduce poisoning and avoid poisoning effect, the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0040] Implementation case: denitrification treatment of landfill leachate in a small landfill.

[0041] The average daily water volume of the leachate treatment system of a small landfill is 50m 3 / day, the effective volume of the reaction vessel 3 of the selected device is 150m 3 , the volume of preheating tank 1 is 50m 3 .

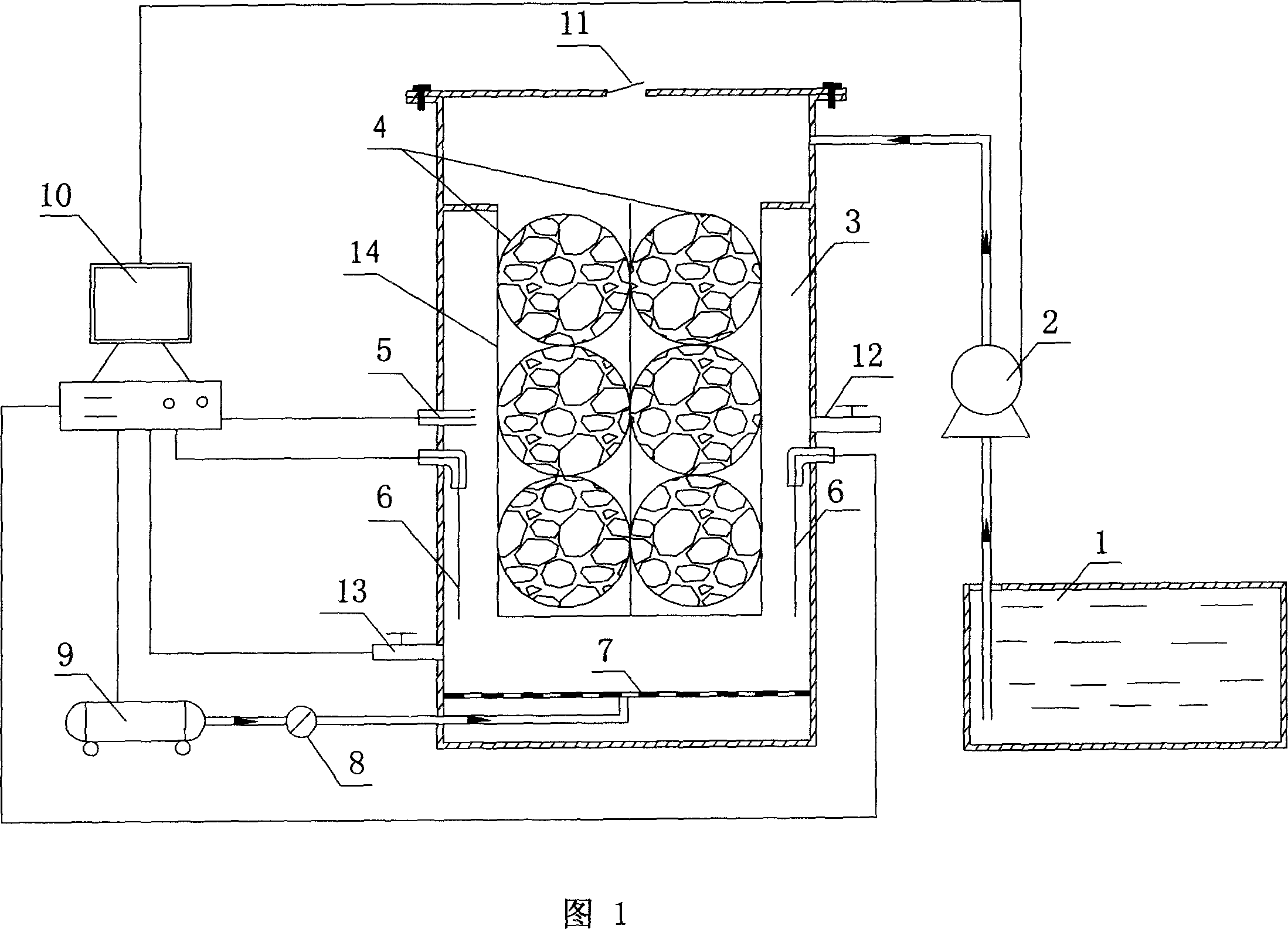

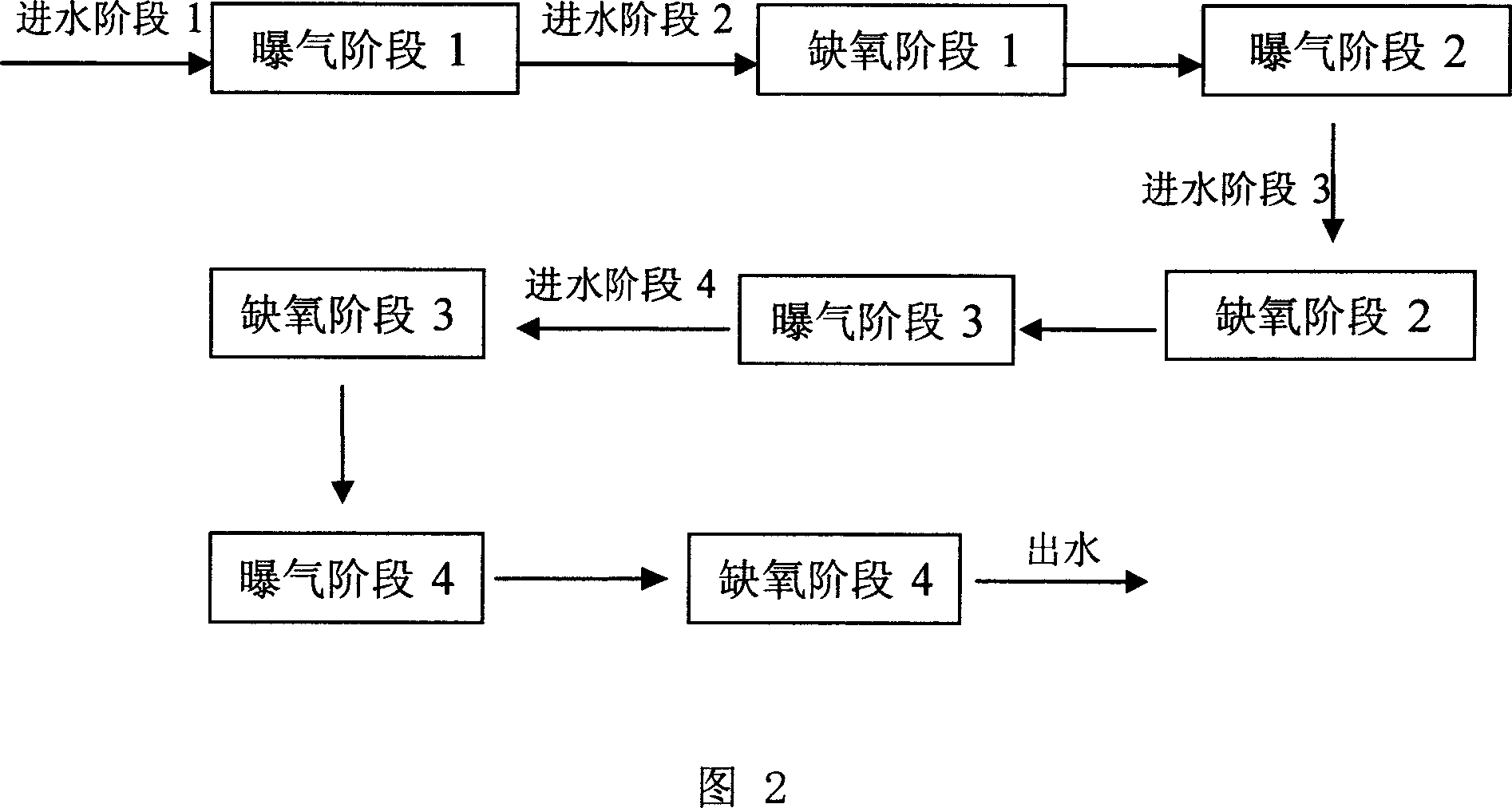

[0042] The device structure of the present embodiment is shown in Figure 1, and it comprises the preheated water tank 1 that can heat sewage, reaction container 3, aerator 9 and aeration head 7, and preheated water tank 1 is connected with reaction vessel 3 by pipeline. The water inlet set at the upper end is connected, and the preheating tank 1 can preheat the incoming water to 26°C-33°C. An electromagnetic metering pump 2 is installed between the preheating tank 1 and the reaction vessel 3, which can be controlled in 10 directions through the automatic control part. The reaction vessel 3 implements real-time quantitative water addition. The reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com