Patents

Literature

600 results about "Effective volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

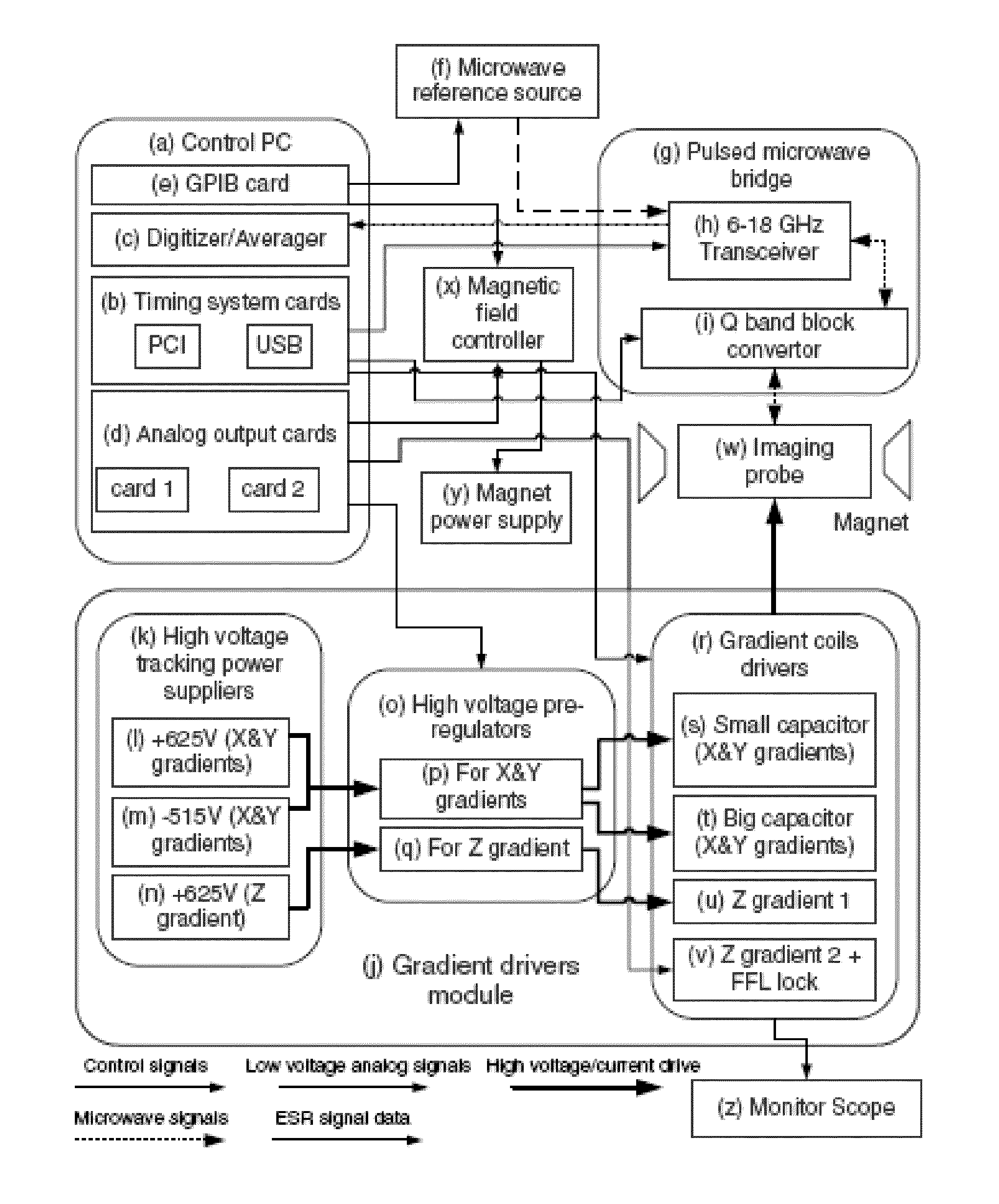

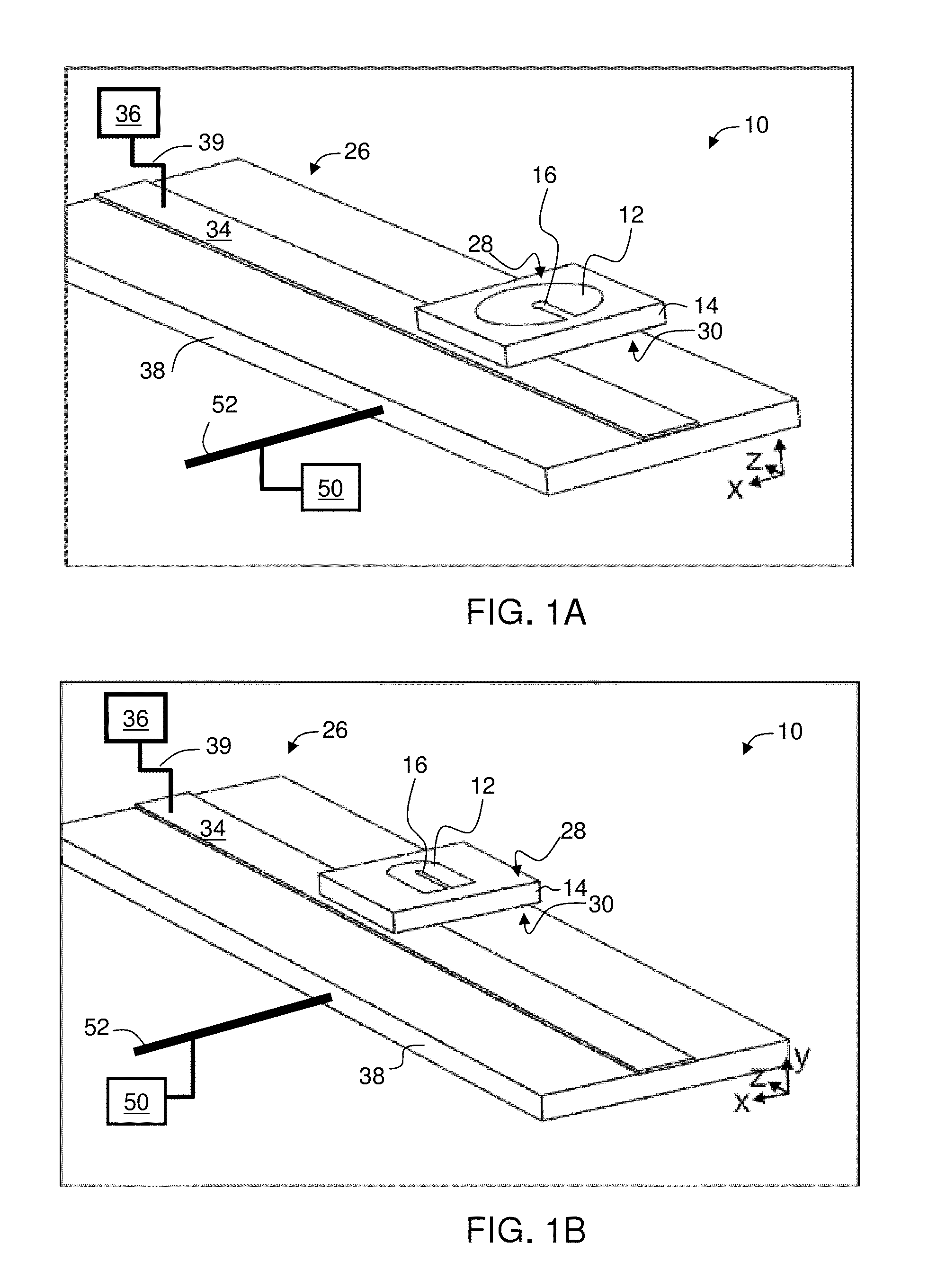

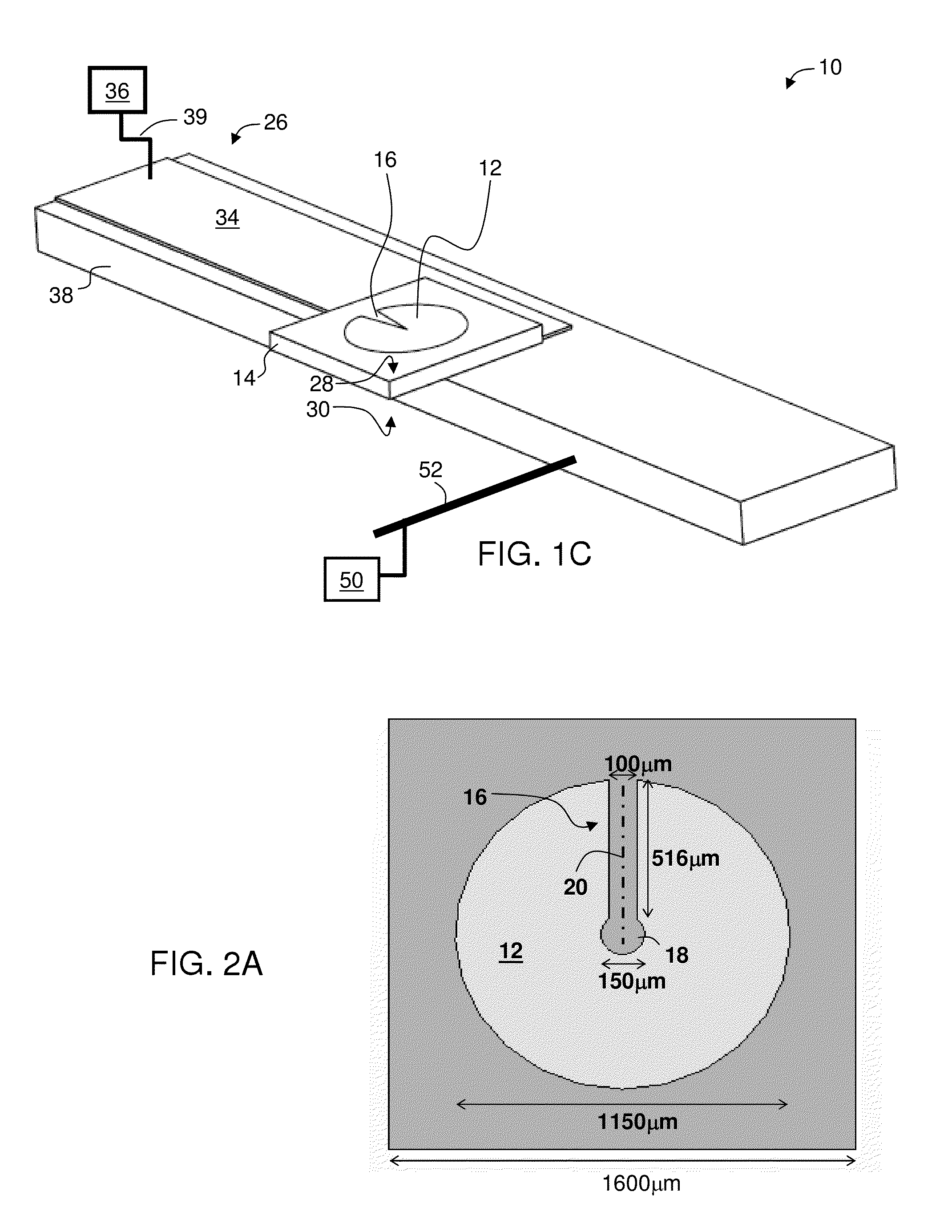

System and method for electron spin resonance

ActiveUS20130093424A1Measurements using electron paramagnetic resonanceElectric/magnetic detectionMicrowaveResonance

A resonator system for electron spin resonance (ESR) is disclosed. The resonator system comprises: a generally planar resonator layer defining an open-loop gapped by a non-conductive gap in the layer, and a microwave feed, positioned configured for transmitting microwave to the resonator layer such as to concentrate, with a quality factor of at least 100, a magnetic field within an effective volume of less than 1 nL above the layer.

Owner:TECHNION RES & DEV FOUND LTD

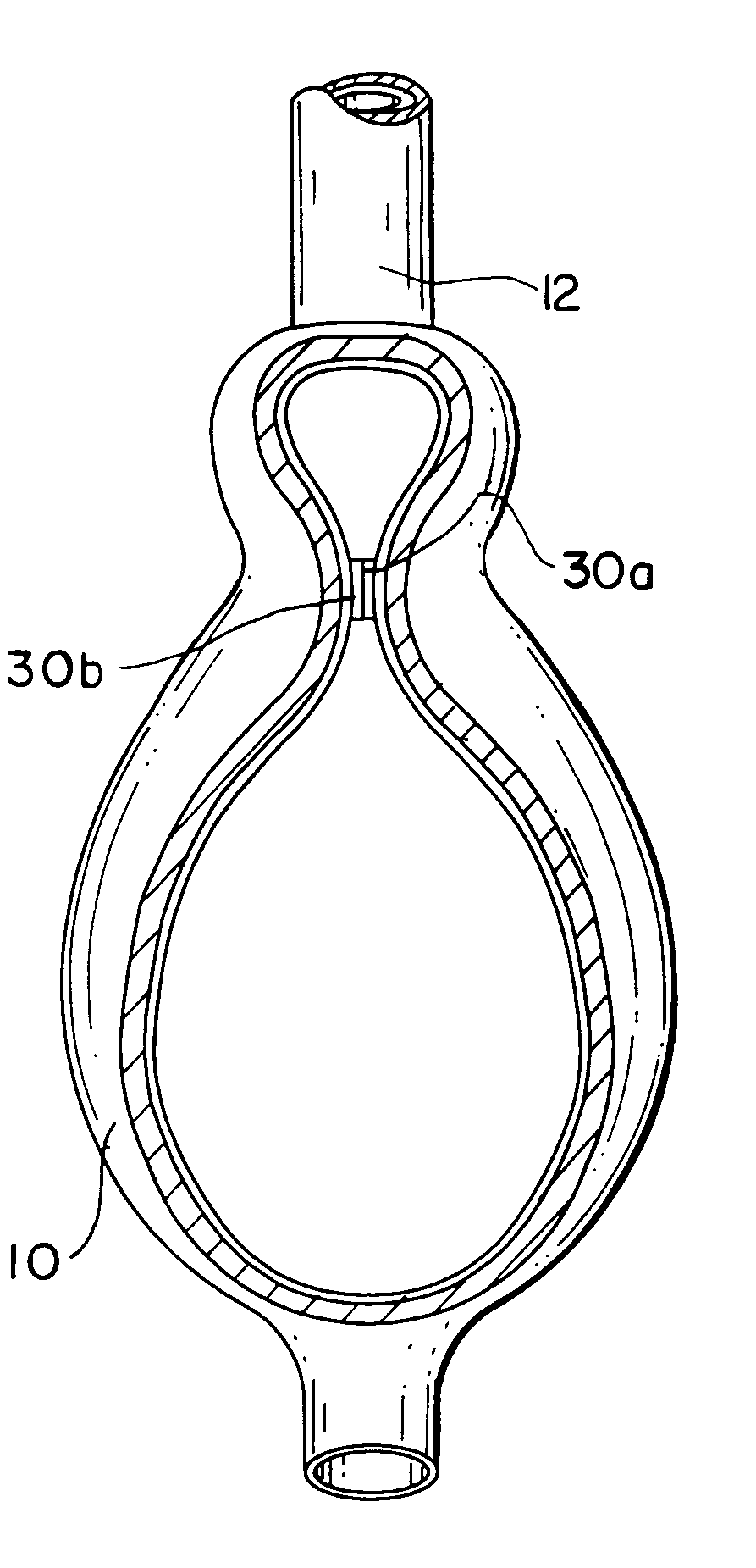

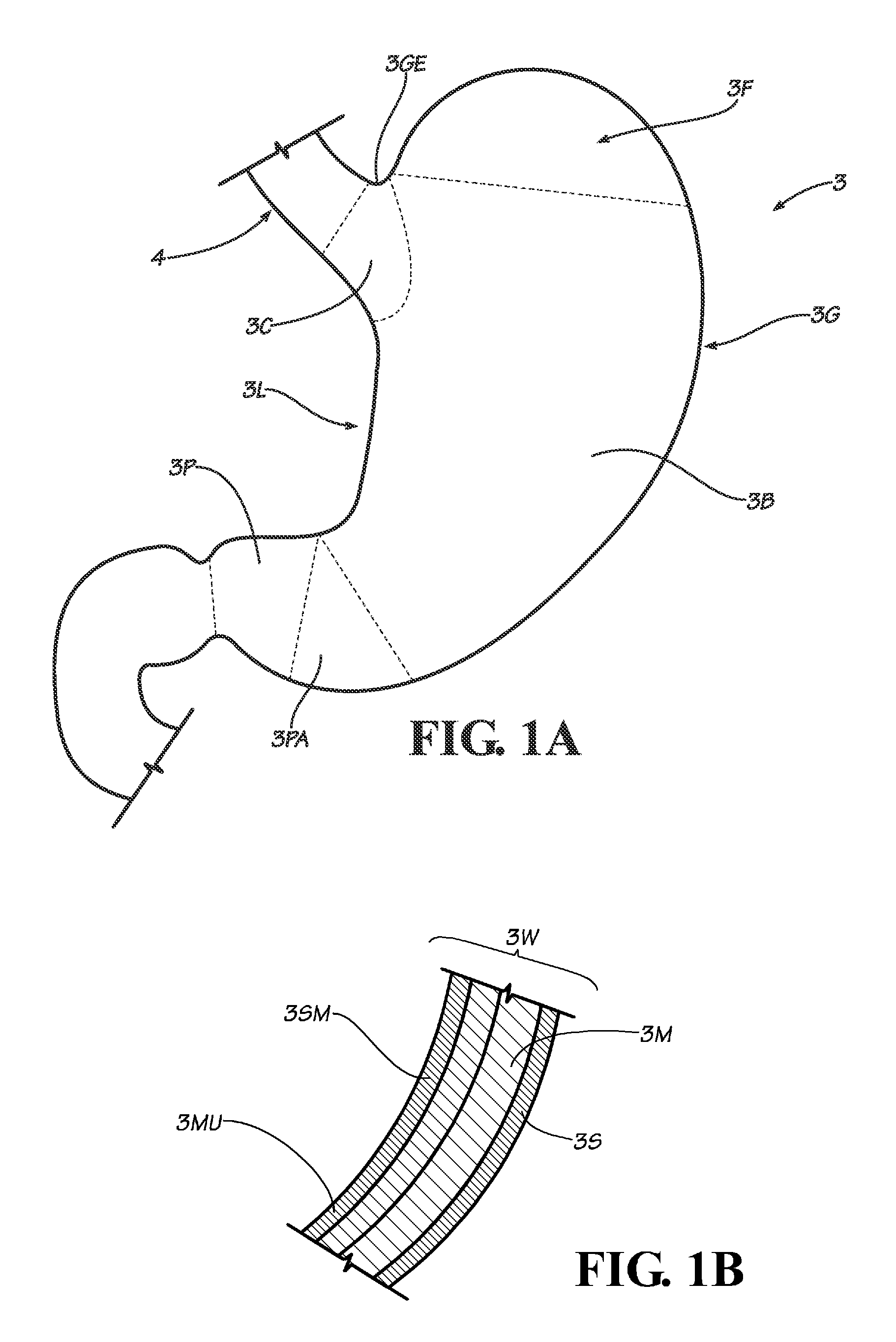

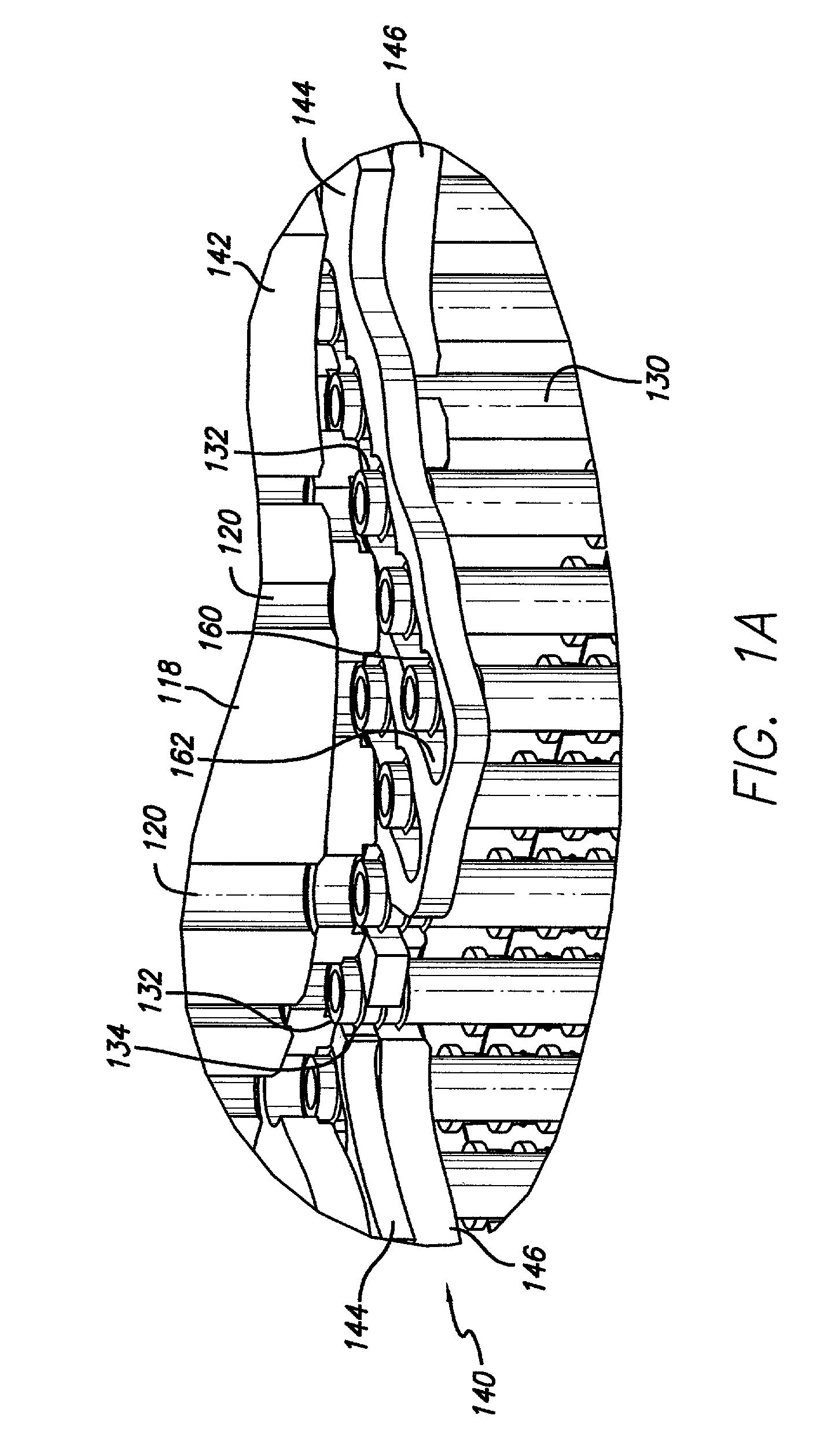

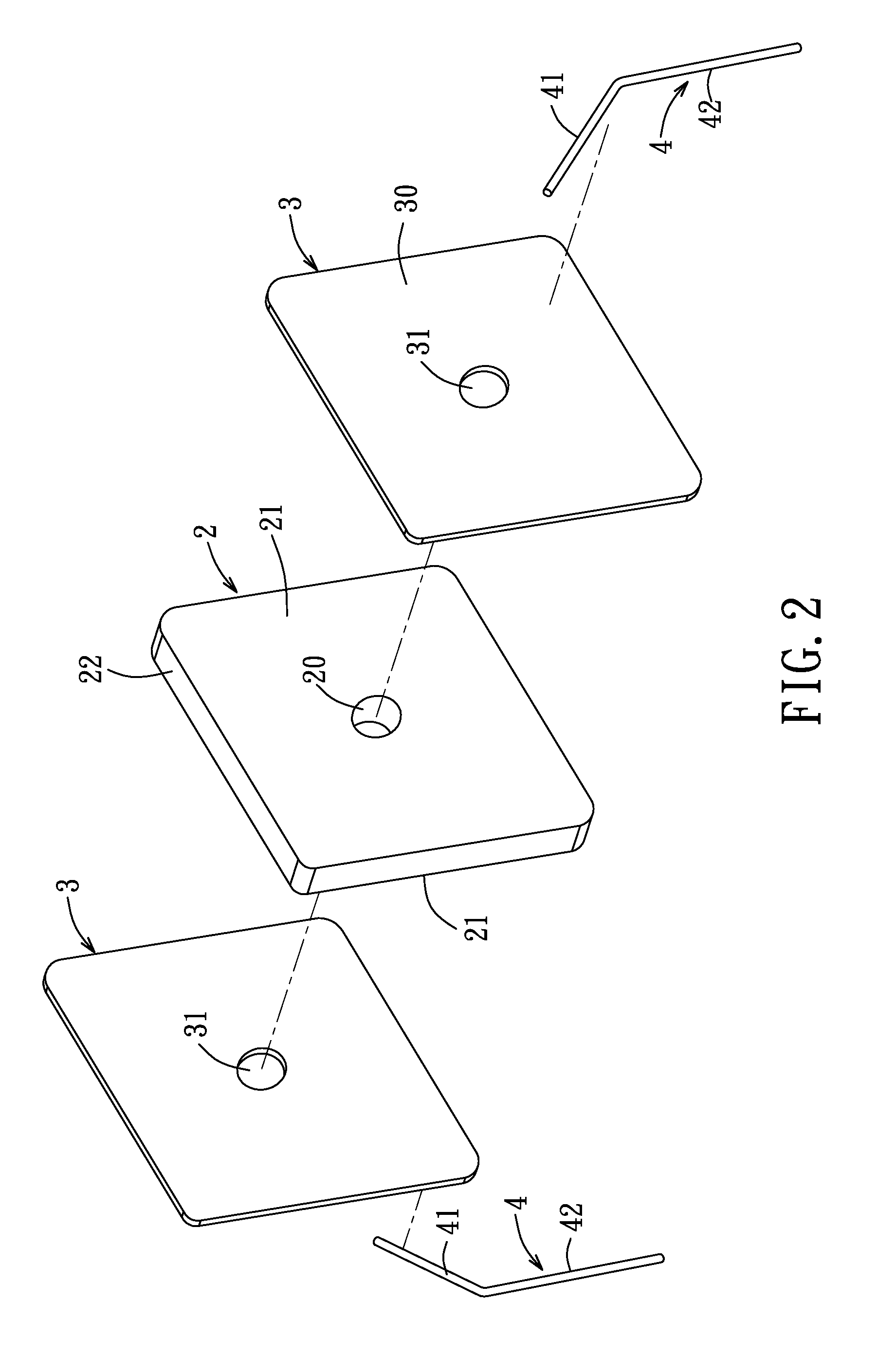

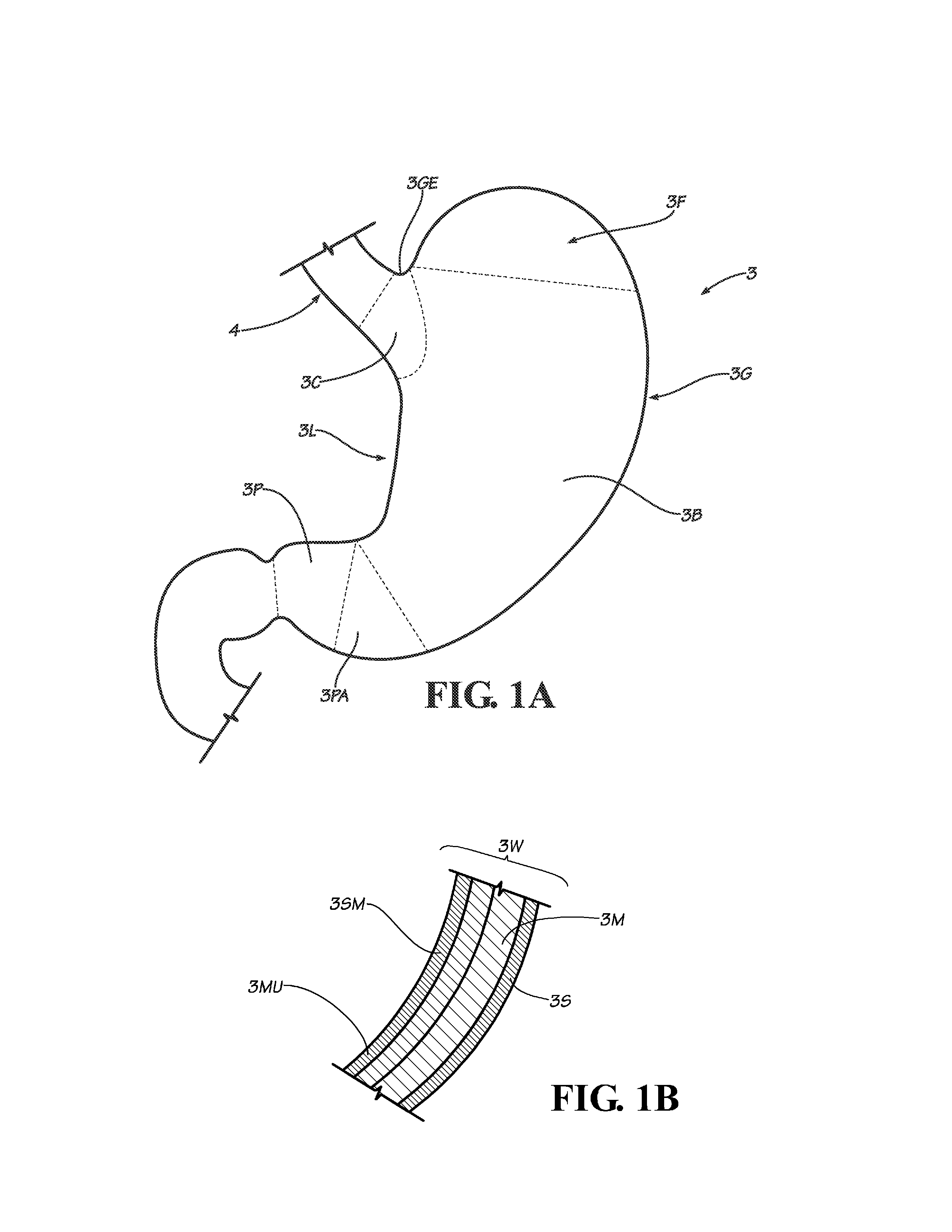

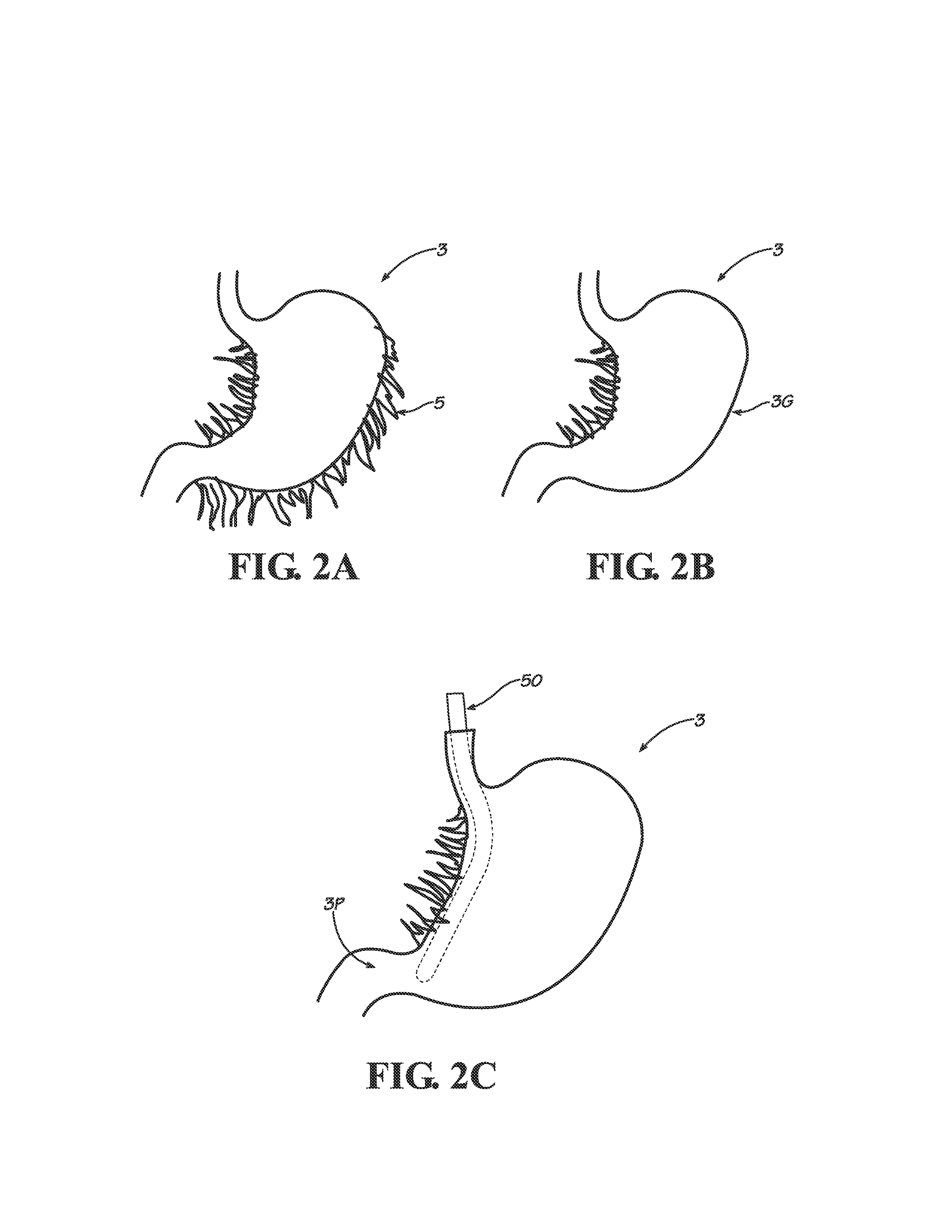

Stomach reduction methods and apparatus

ActiveUS7497822B1Lower the volumeReduces the patient's desire to eatOesophagiObesity treatmentStomach wallsEffective volume

The effective volume of a patient's stomach cavity can be reduced by implanting at least two magnetic devices in the stomach at different locations on the stomach wall. The magnets cooperate with one another magnetically to change the effective volume of the stomach. For example, the magnets may magnetically attract one another to pull in portions of opposite side walls of the stomach. The magnetic devices may be implanted non-surgically (e.g., via one or more catheters introduced into the stomach cavity via the patient's mouth and esophagus). The magnets may be removable to reverse the treatment. Removal may be non-surgical.

Owner:TORAX MEDICAL

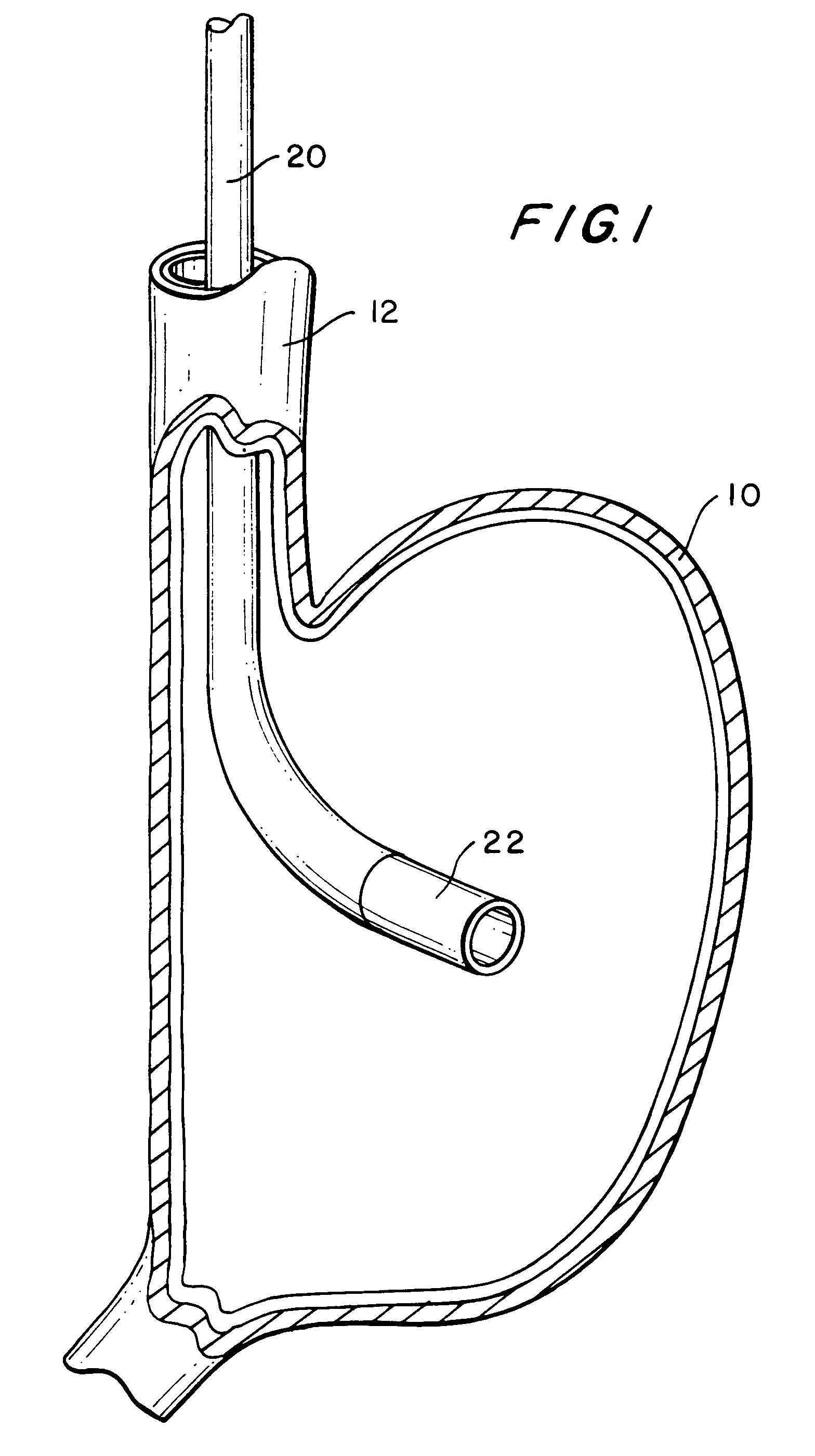

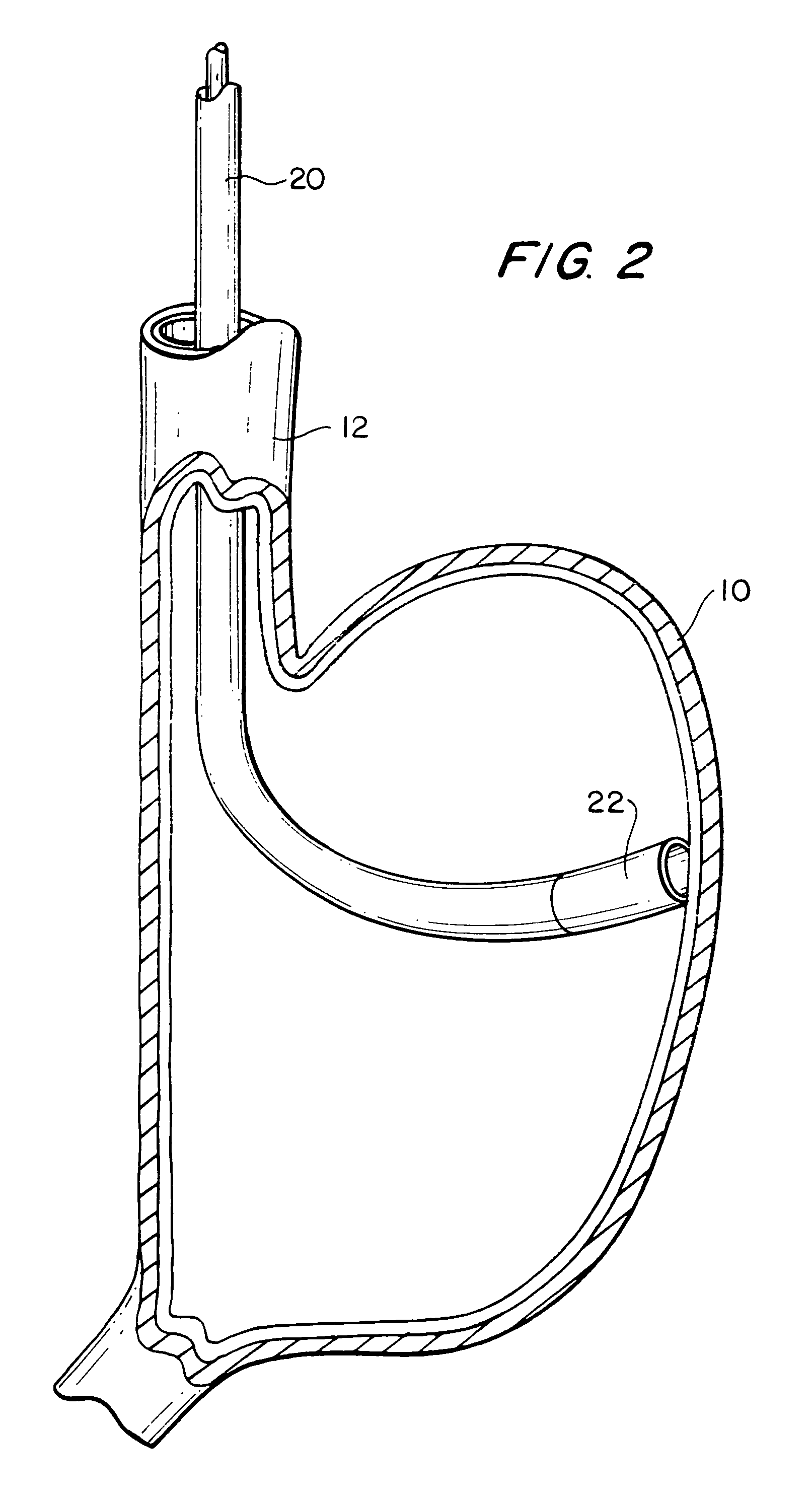

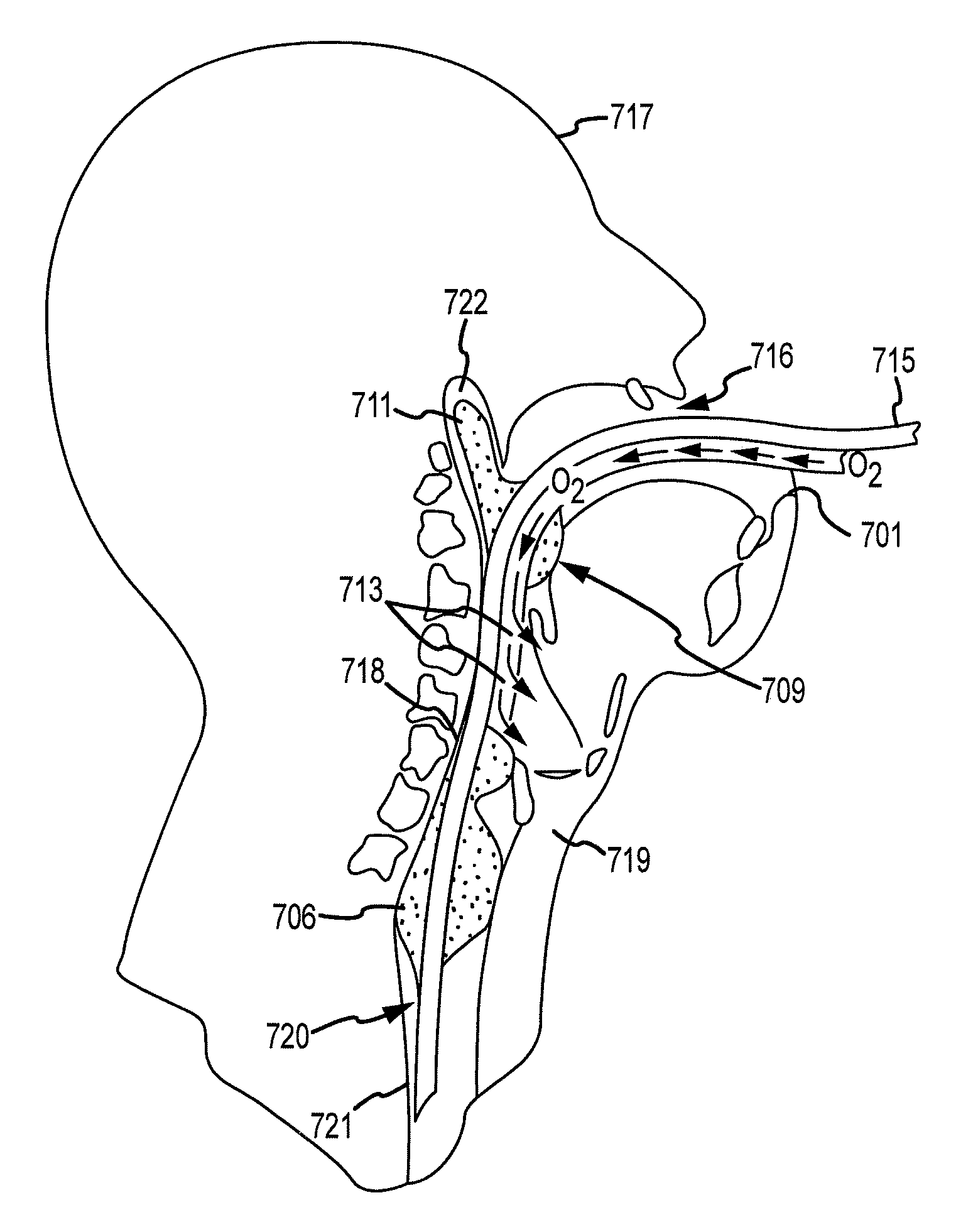

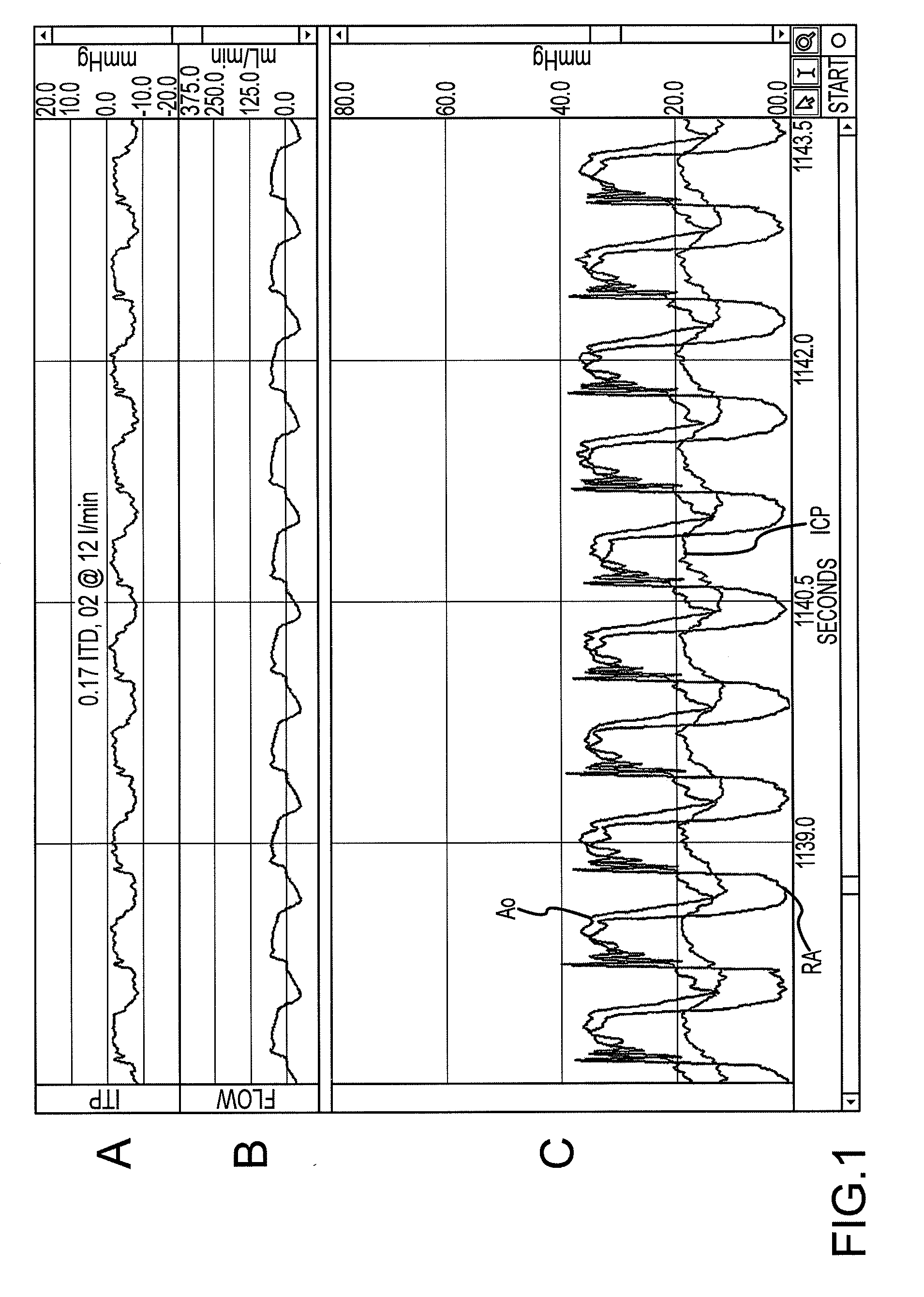

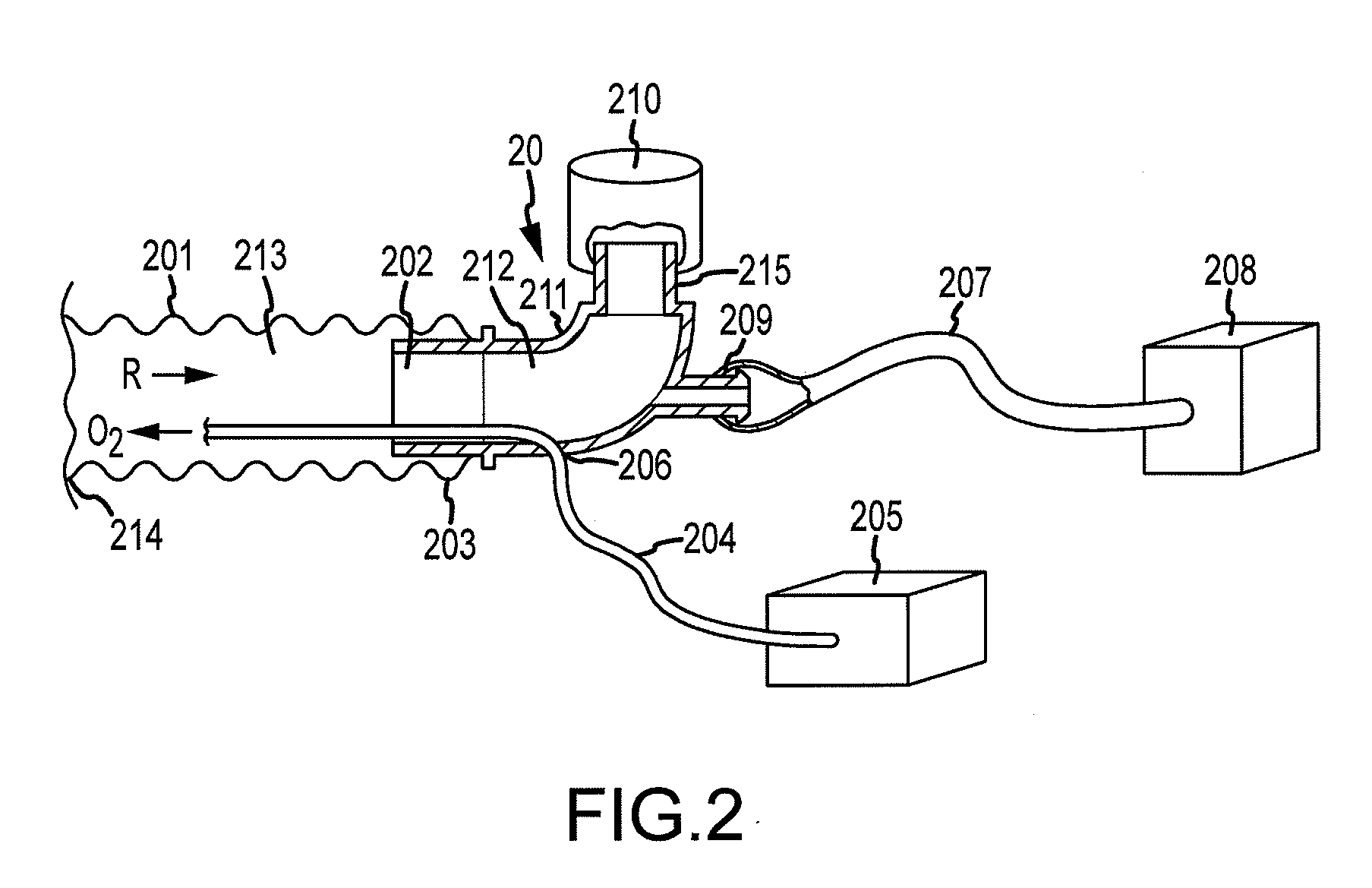

System, method, and device to increase circulation during cpr without requiring positive pressure ventilation

InactiveUS20090277447A1Speed up the flowRespiratorsElectrotherapyEmergency medicineIntermittent positive pressure ventilation

In one embodiment, the invention provides a method for performing cardiopulmonary resuscitation which comprises: 1) interfacing an airway system with a patient's airway, wherein the airway system includes at least a first lumen and a second lumen; 2) repeatedly performing CPR chest compressions on the patient; and simultaneously with the CPR chest compressions; 3) applying a continuous vacuum to the first lumen for a period of time ranging from 10 seconds to the end of the CPR chest compressions; and 4) injecting an effective volume of oxygen gas into the person's lungs at high velocity through the second lumen.In other embodiments, the invention provides a cardiopulmonary resuscitation system for use during the performance of CPR chest compressions on a patient, a novel locking supraglottic airway device, and a valve device for applying vacuum to a patient's airway.

Owner:ADVANCED CIRCULATORY SYST

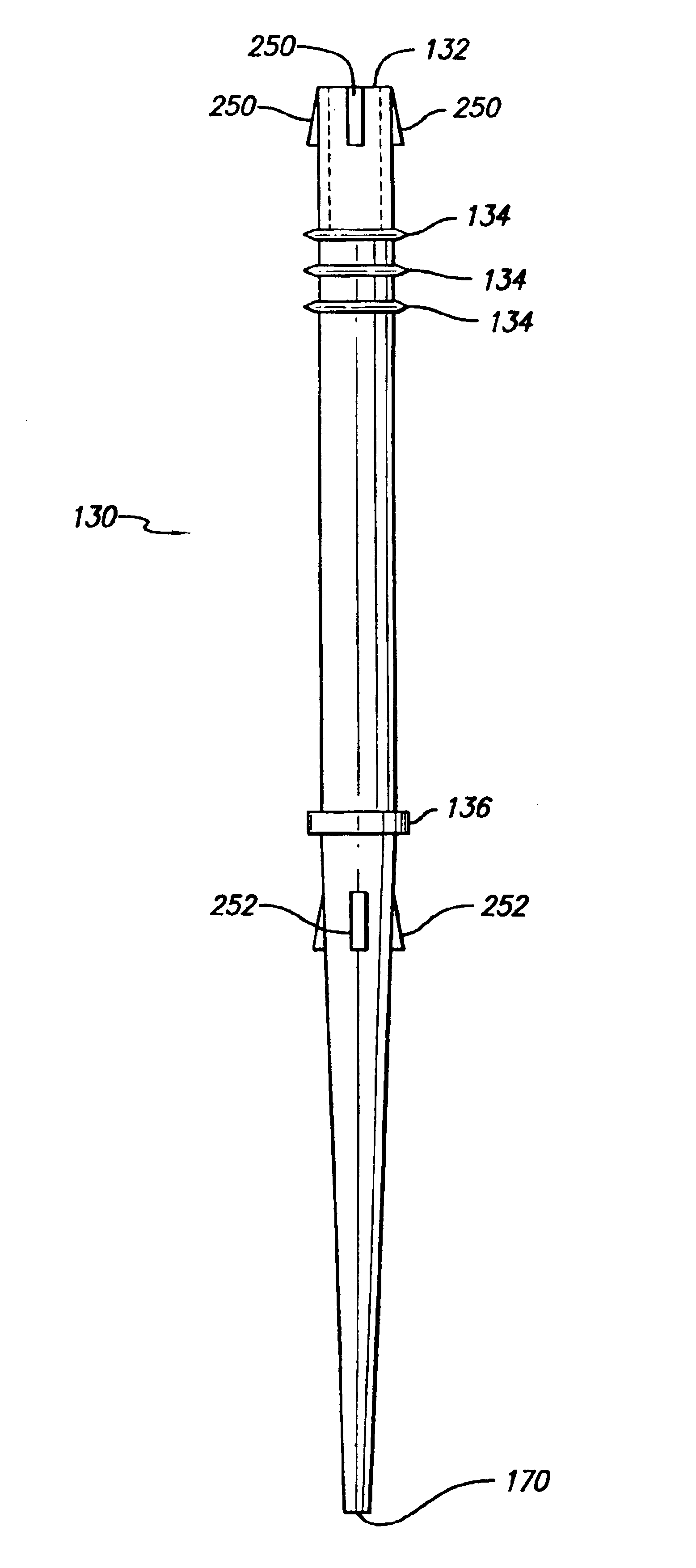

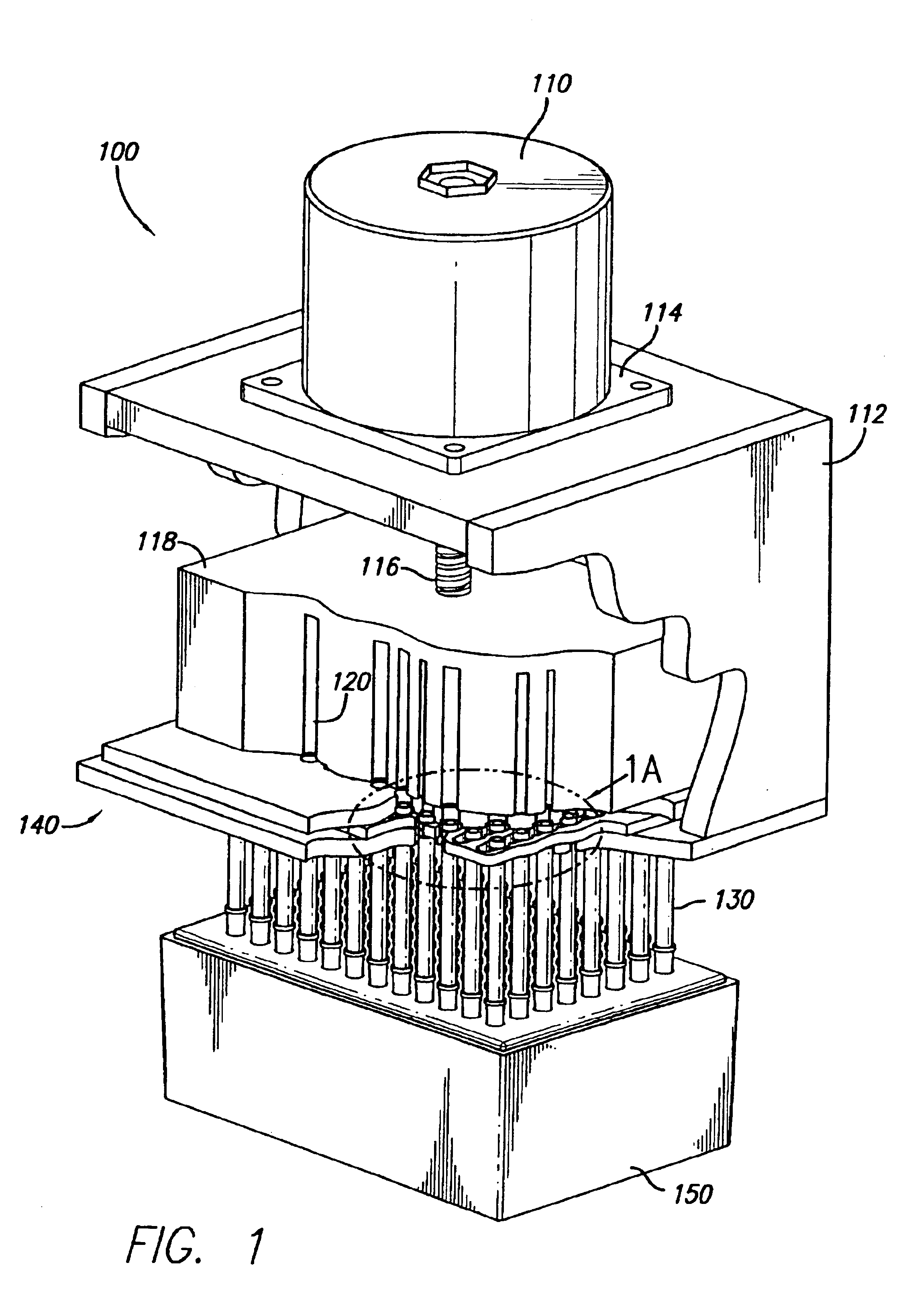

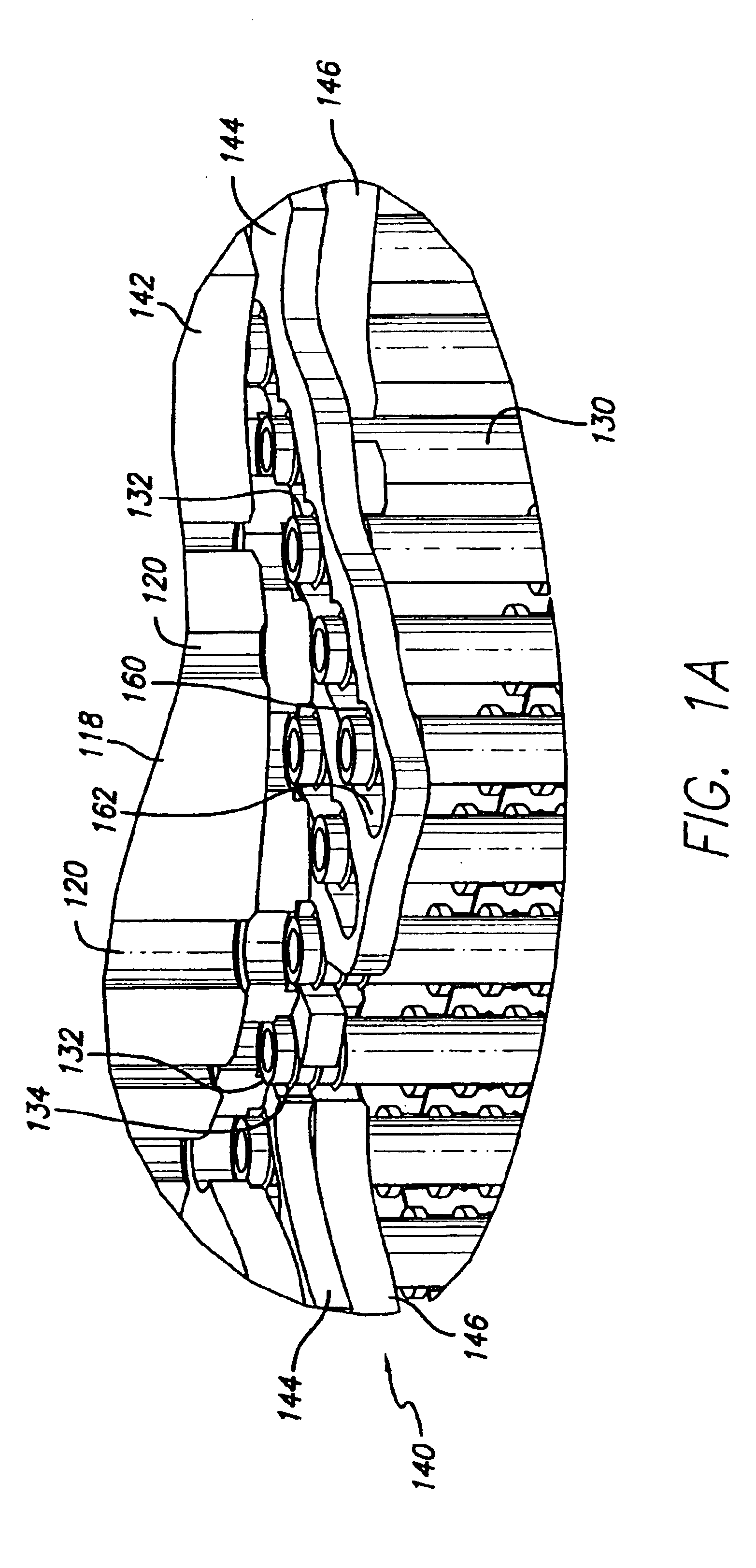

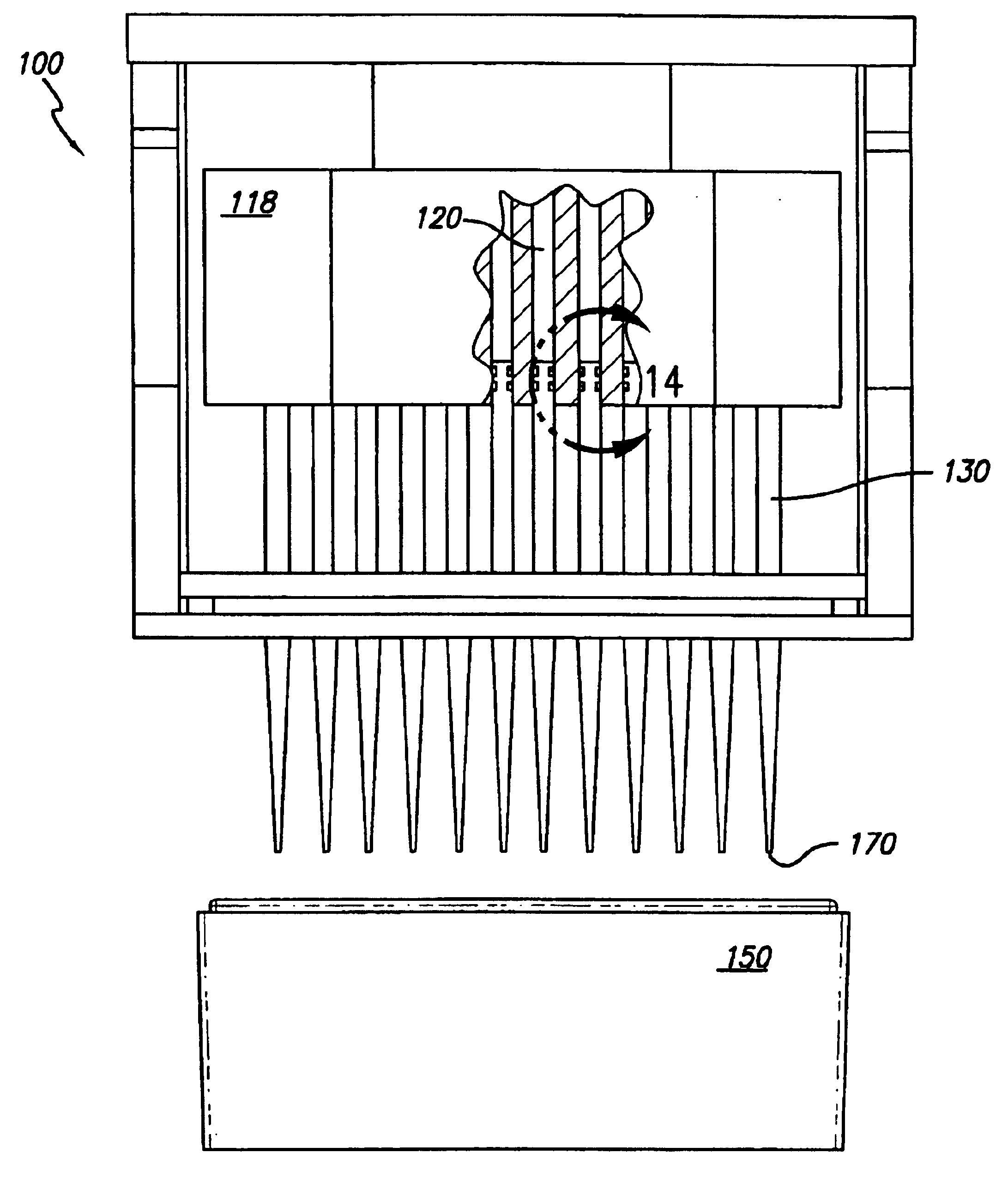

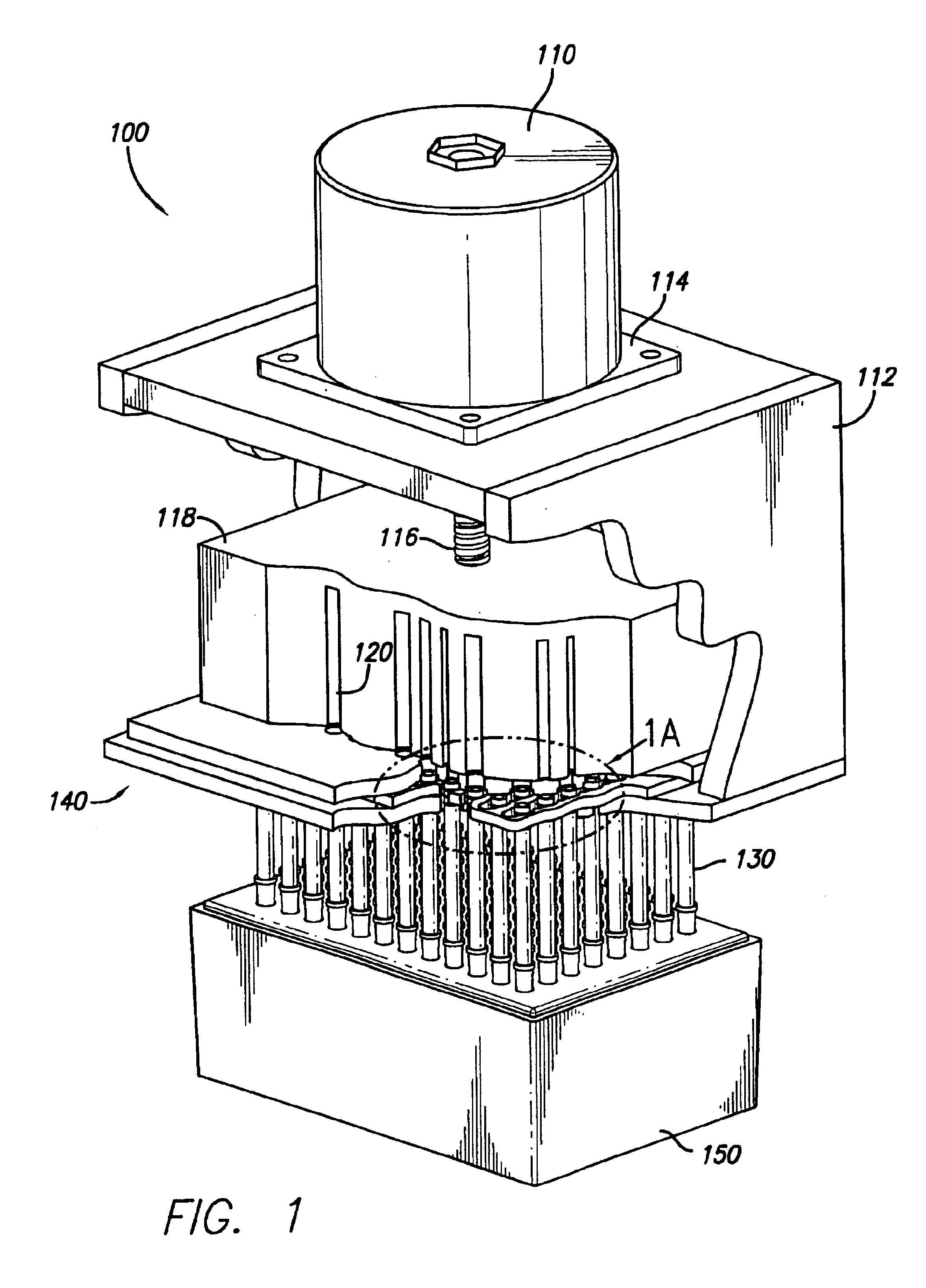

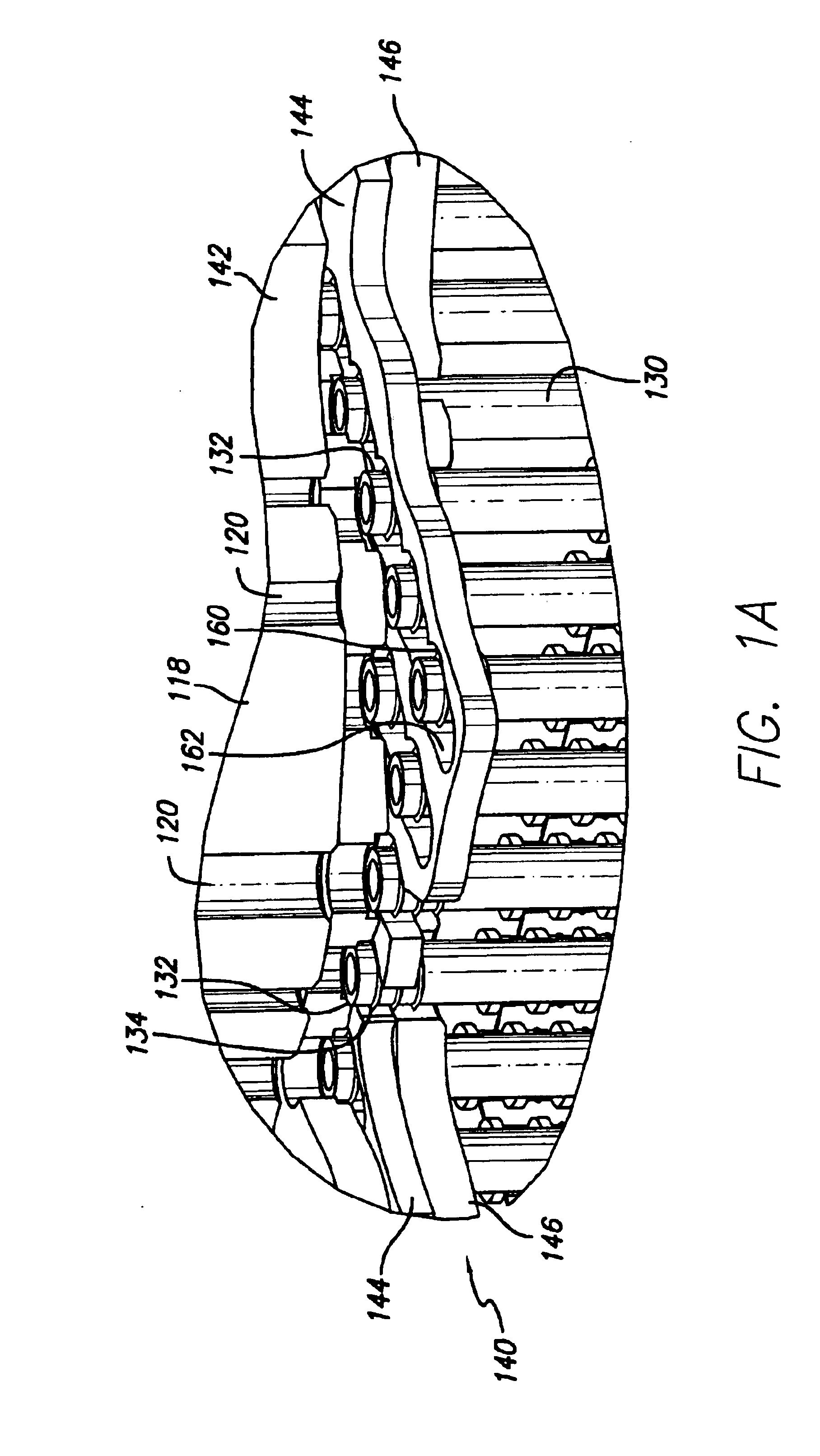

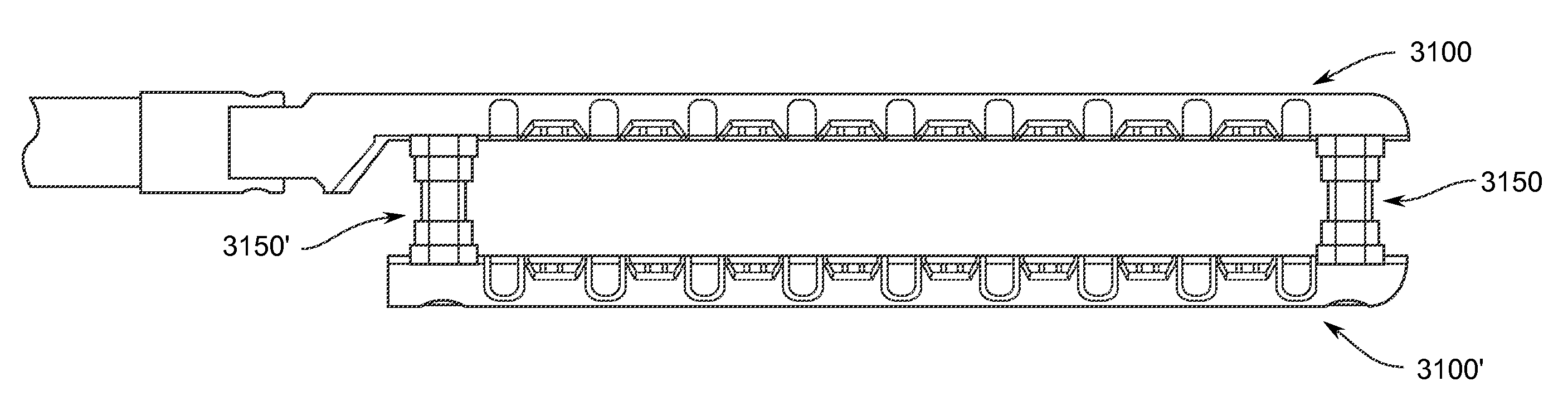

Pipettor and externally sealed pipette tip

InactiveUS6780381B2Reduce maintenancePrecise and accurate amountWithdrawing sample devicesBurettes/pipettesPipetteEffective volume

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way.

Owner:YIU FELIX H

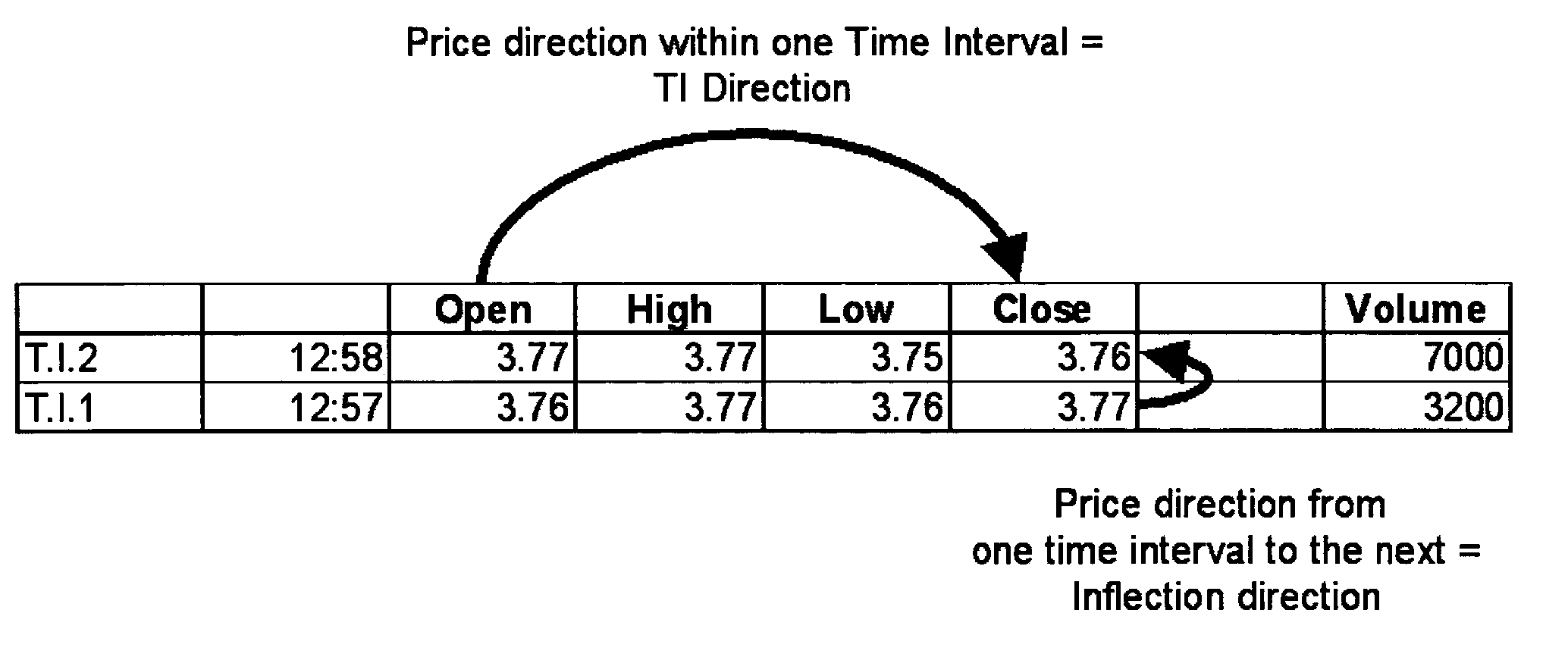

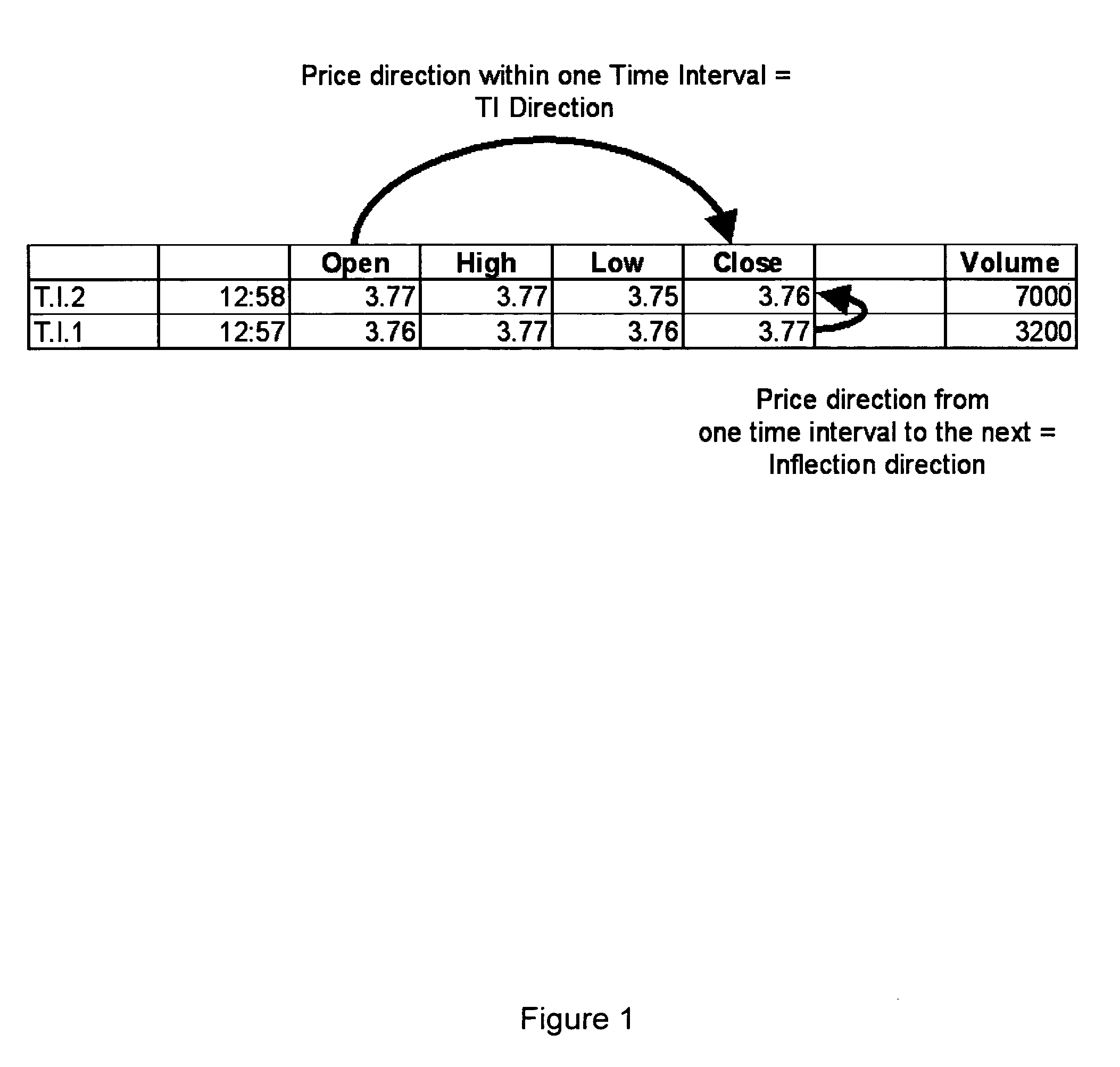

Method to determine price inflections of securities

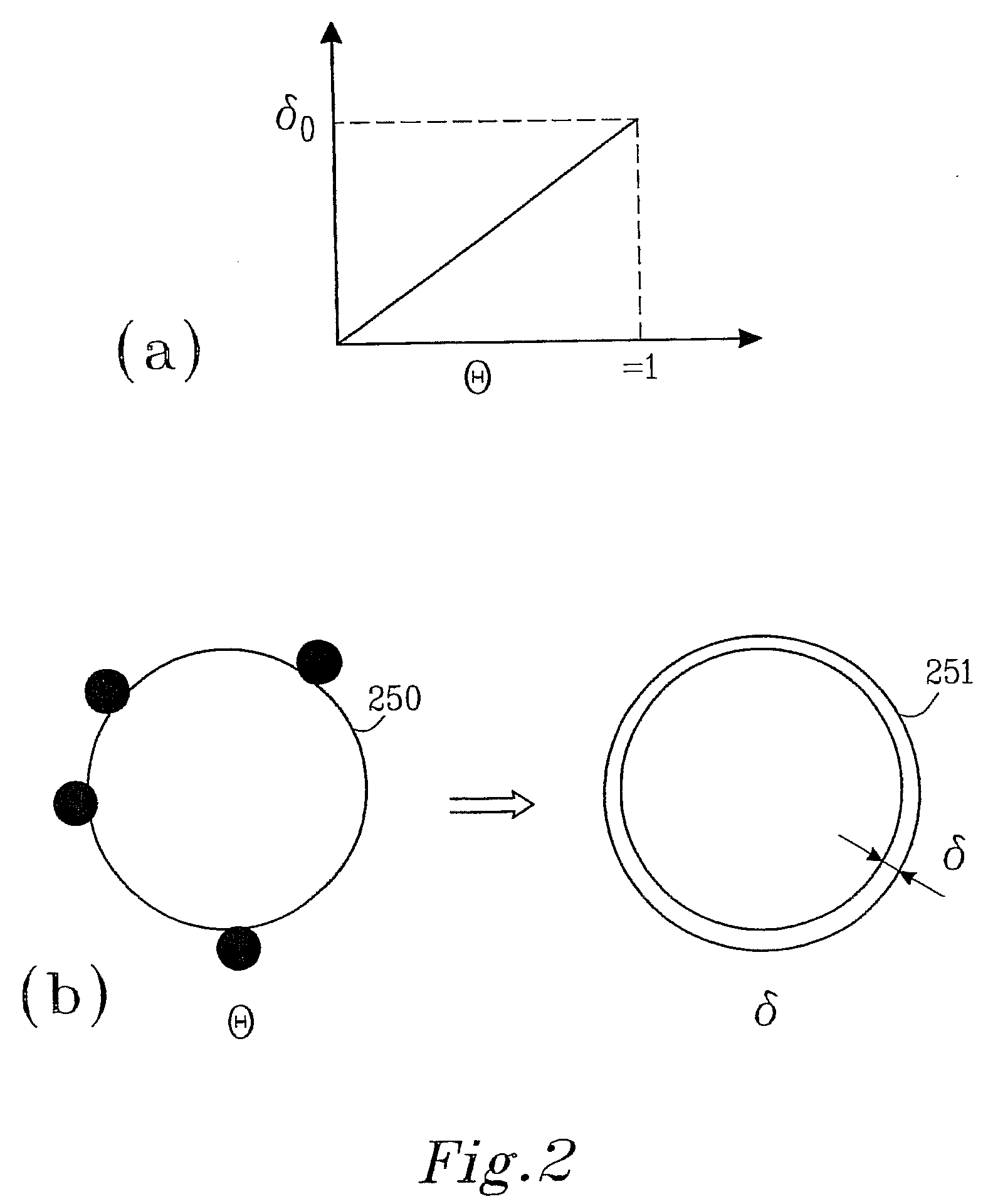

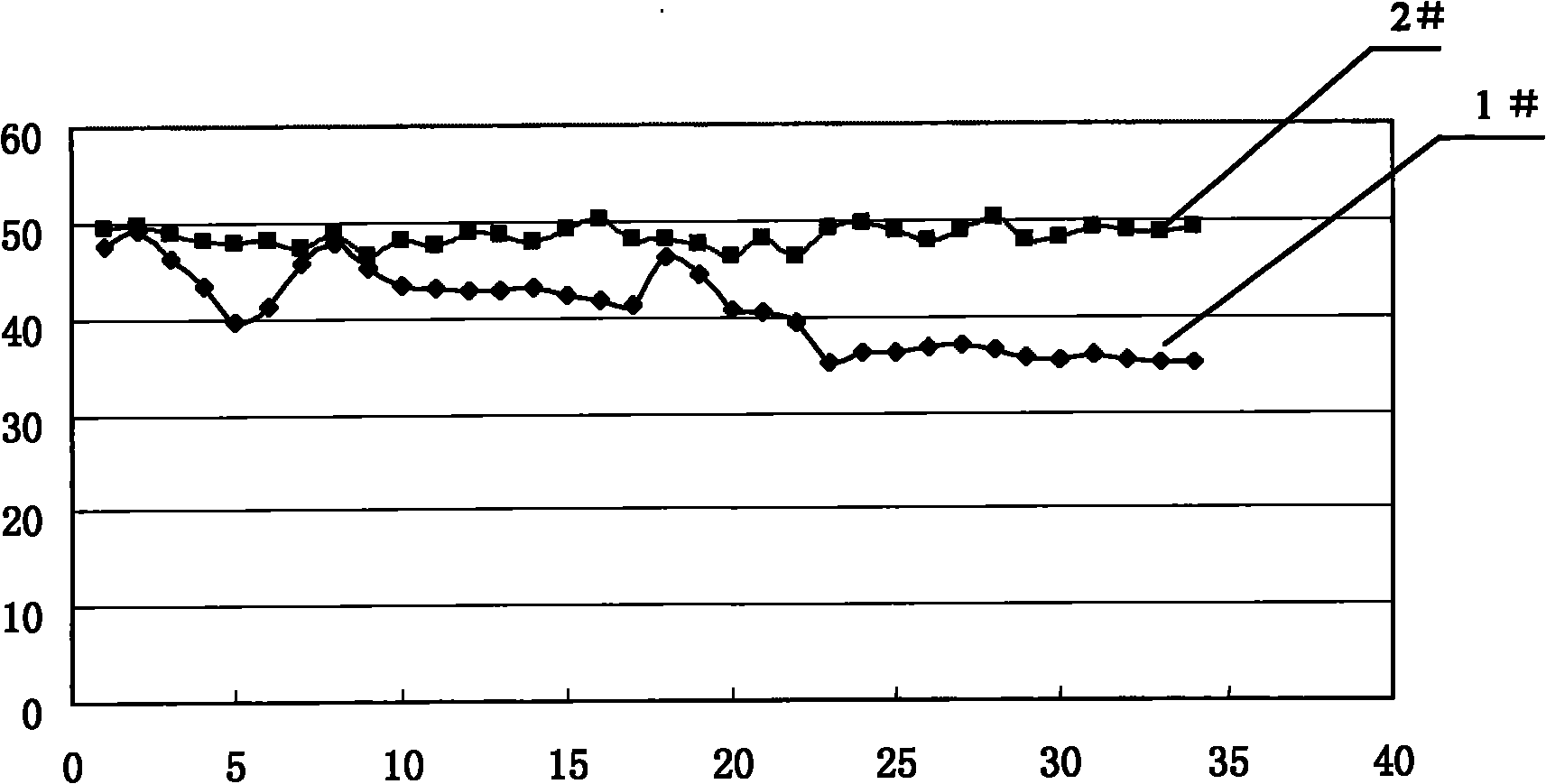

The present invention provides a method to detect buying or selling activities of large market players of a given equity, compared to the activity of smaller players. For a set of consecutive trading sessions, the method analyses only trading data (open / high / low / close / volume) aggregated into regular intervals such as one-minute, two-minutes or five-minute trading data. The method considers only time intervals corresponding to price inflections, i.e. for which the closing price was different from the previous time interval. The method further analyses the volume of said time intervals and calculates the effective volume that was responsible for a price inflection. The method then separates the effective trading volumes related to the said time interval into large and small size volumes and plots the evolution of the said volume sizes on a graph. Analysis of trend divergence between large and small size volume flow trends allows detection of the said buying and selling activity by large or small market players.

Owner:WILLAIN PASCAL

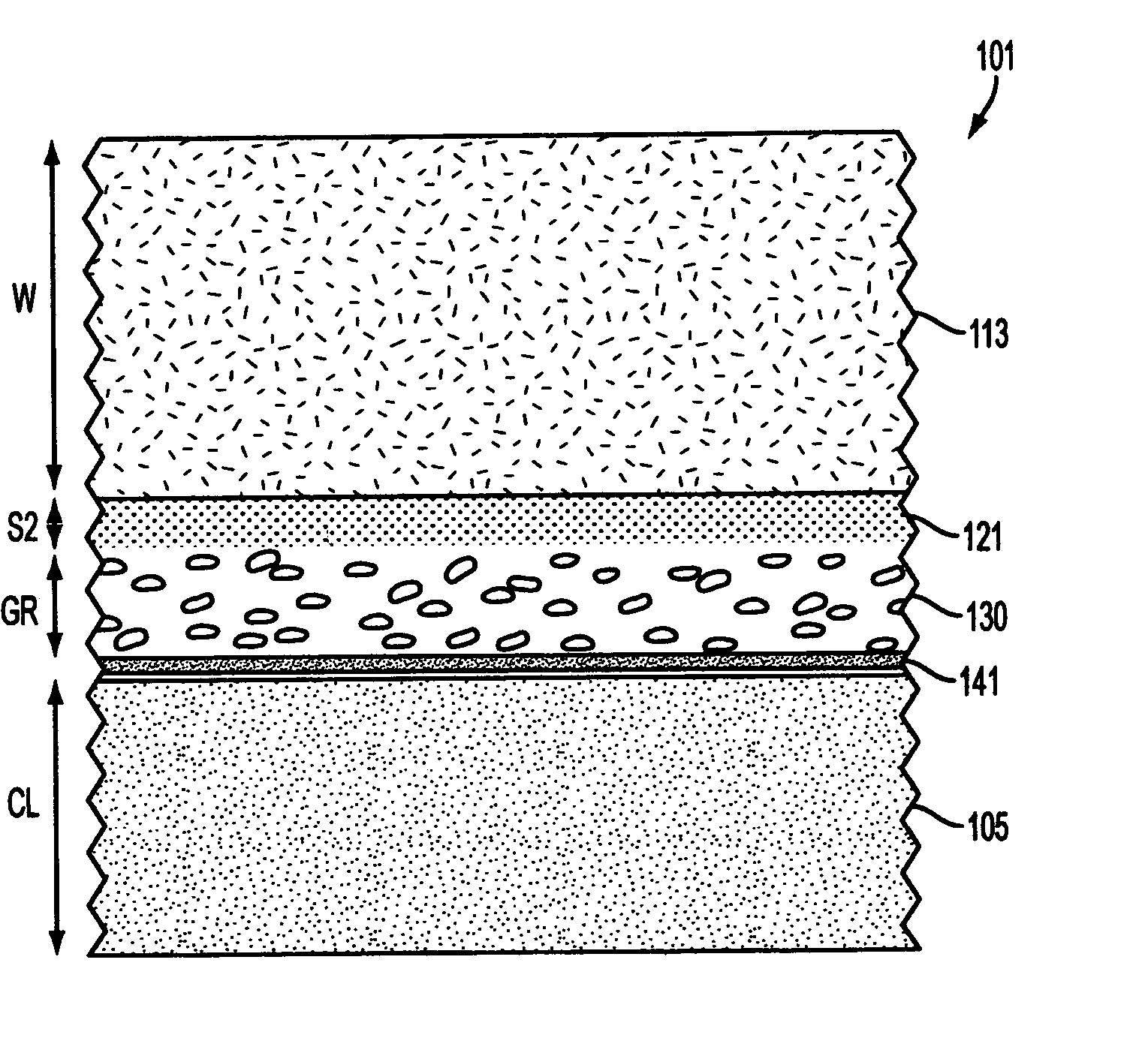

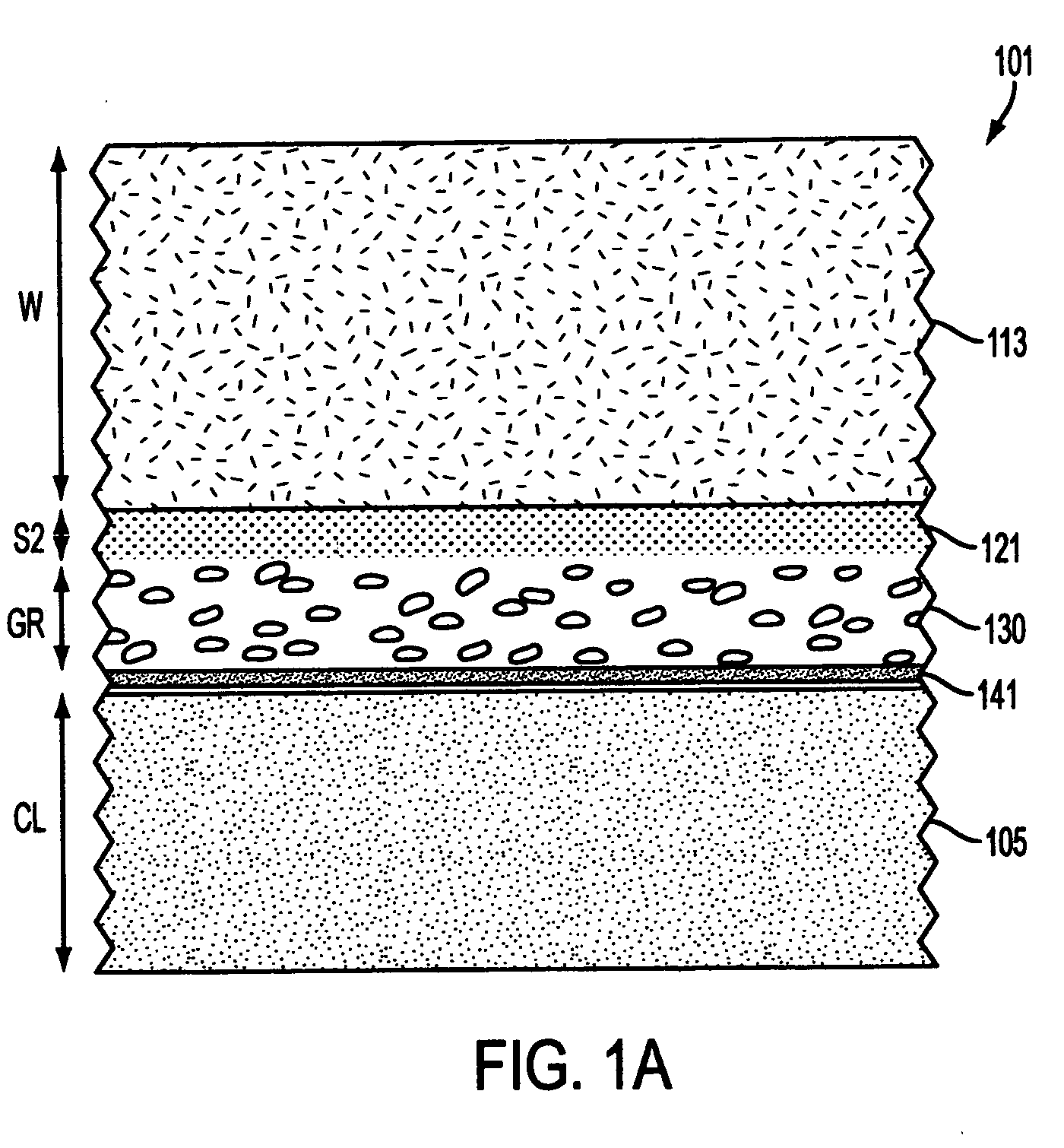

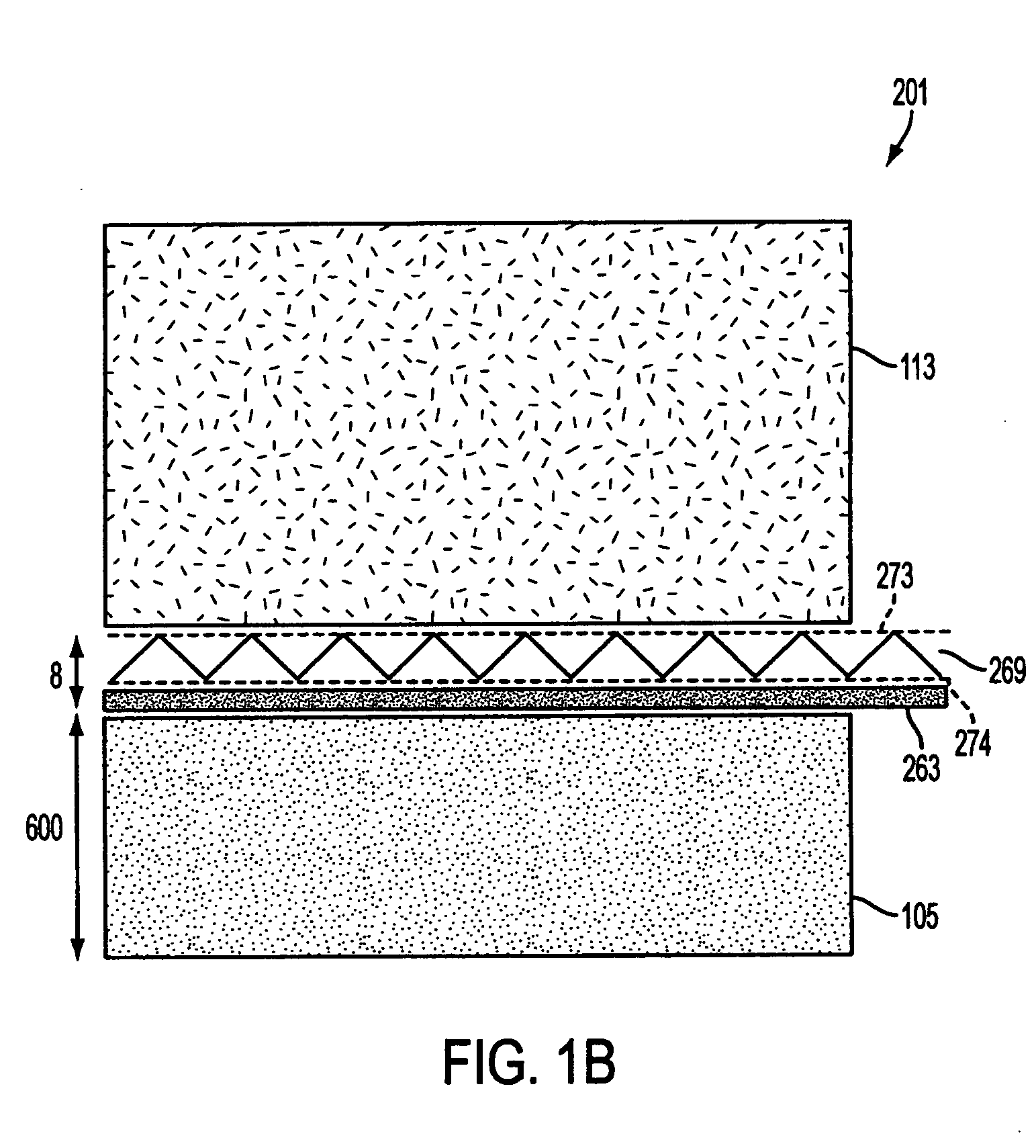

Void-maintaining synthetic drainable base courses in landfills and other large structures, and methods for controlling the flow and evacuation of fluids from landifills

Numerous embodiments of one or more layers of void-maintaining synthetic drainable base courses (“VMSDBC's”) are provided as incorporated into landfills and other waste containment facilities. Key advantages of landfills and methods according to the invention include a substantial decrease in the necessity for conventional gravel and sand layers, and an increase in the effective volume of a landfill or similar facility. Moreover, the invention decreases the cost attendant to locating, transporting, and forming conventional rock, sand and gravel materials into discreet layers.

Owner:ADVANCED GEOTECH SYST

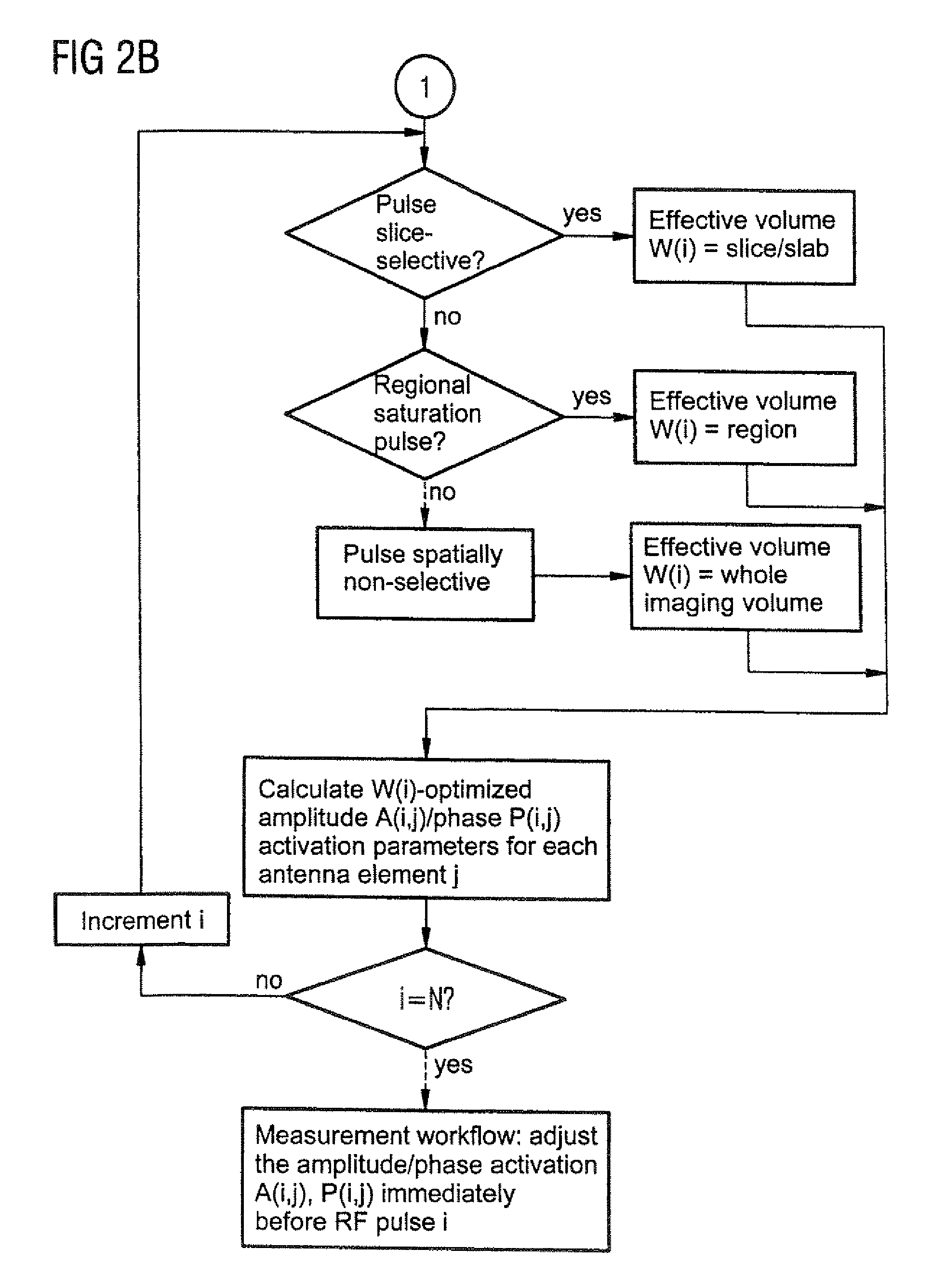

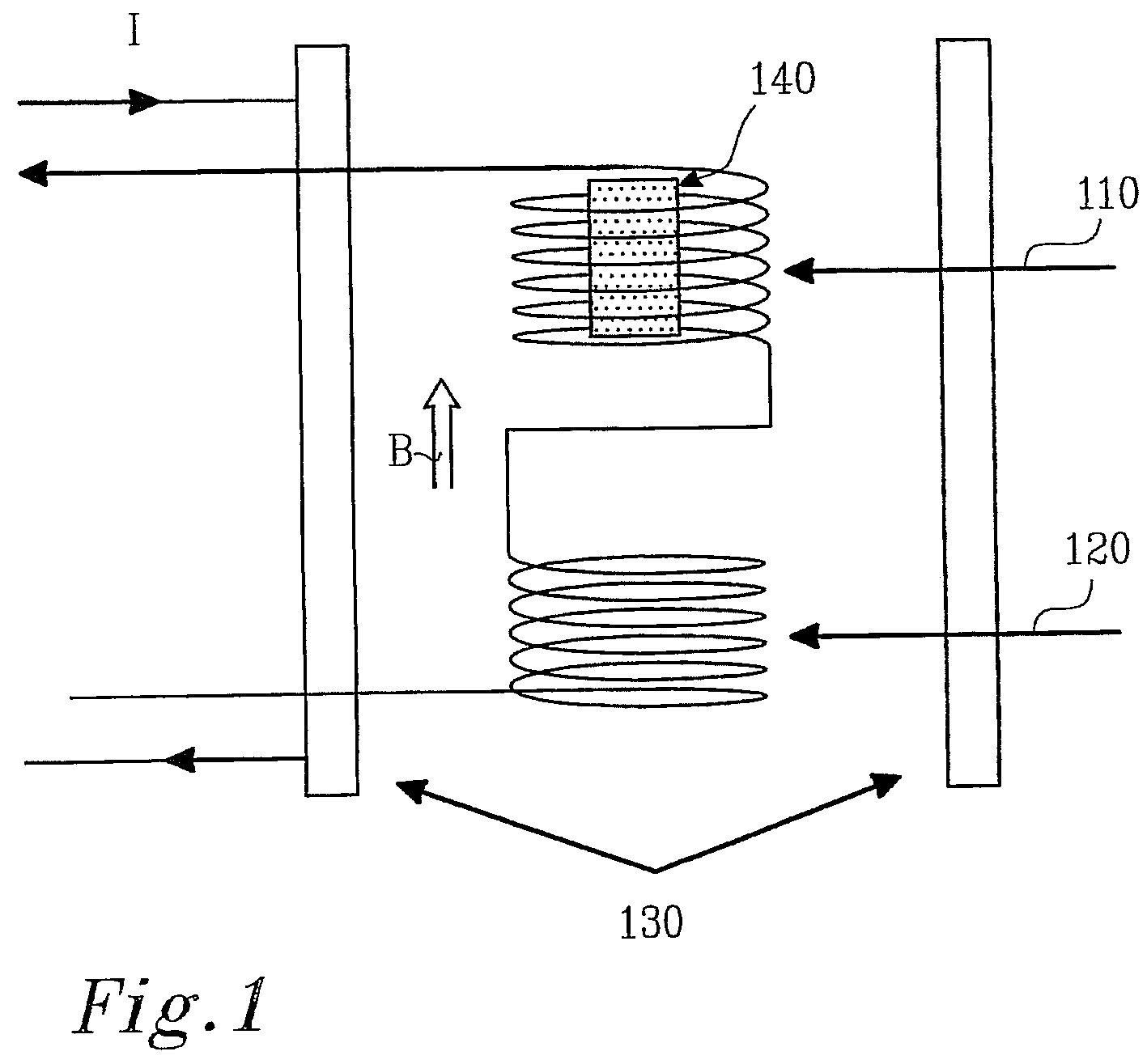

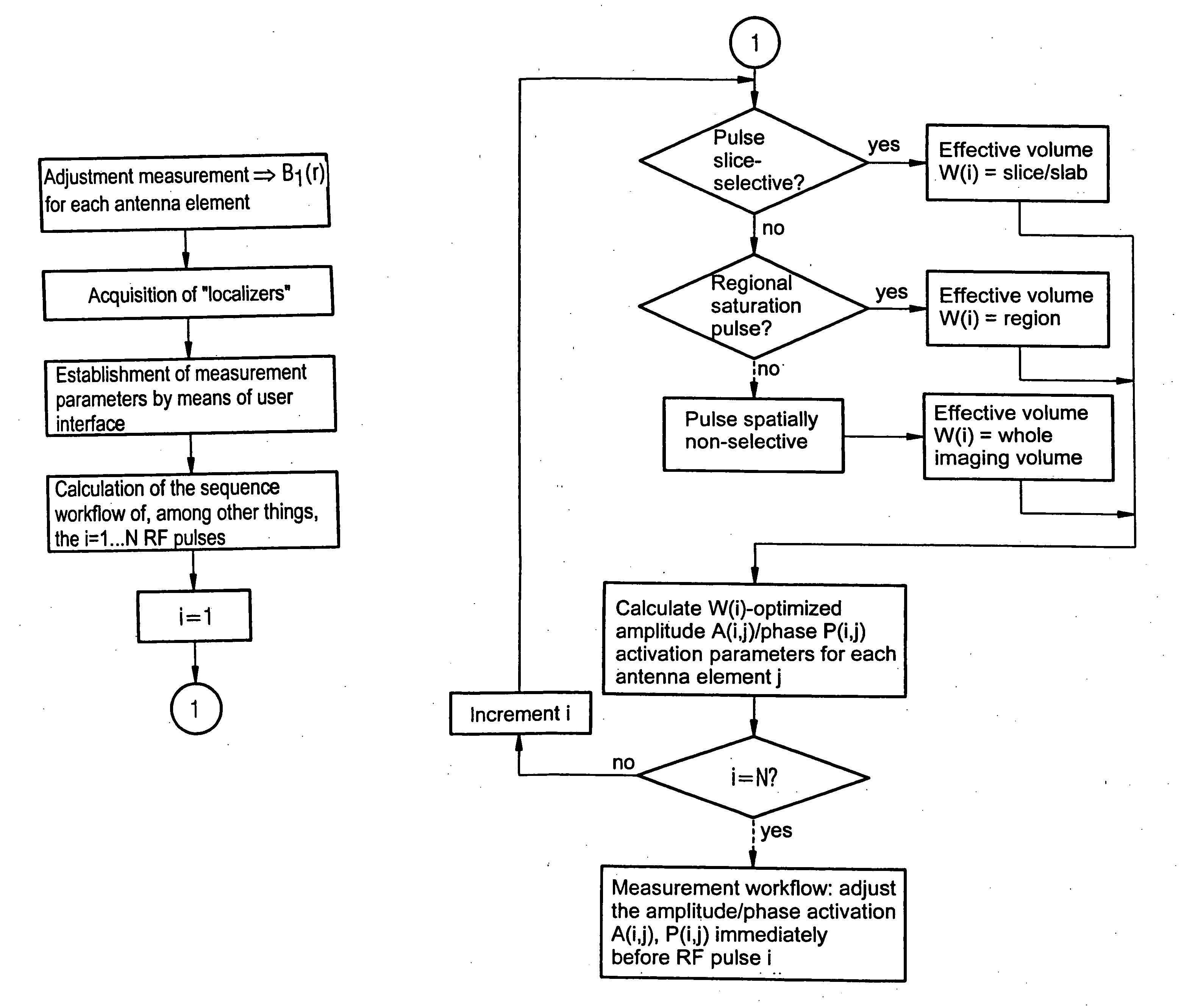

Magnetic resonance system and operating method for RF pulse optimization

In a magnetic resonance system and an operating method therefor, a B1 field distribution of a radio-frequency antenna is measured in at least one part of a examination volume of the magnetic resonance system, and then the RF pulses emitted by the radio-frequency antenna are optimized, based on the determined B1 field distribution, for homogenization in a specific volume. An effective volume within the examination volume is determined beforehand for each applied RF pulse and, based on the determined B1 field distribution, the appertaining RF pulse is individually adjusted such that the B1 field is homogenized within the effective volume of the RF pulse.

Owner:SIEMENS HEALTHCARE GMBH

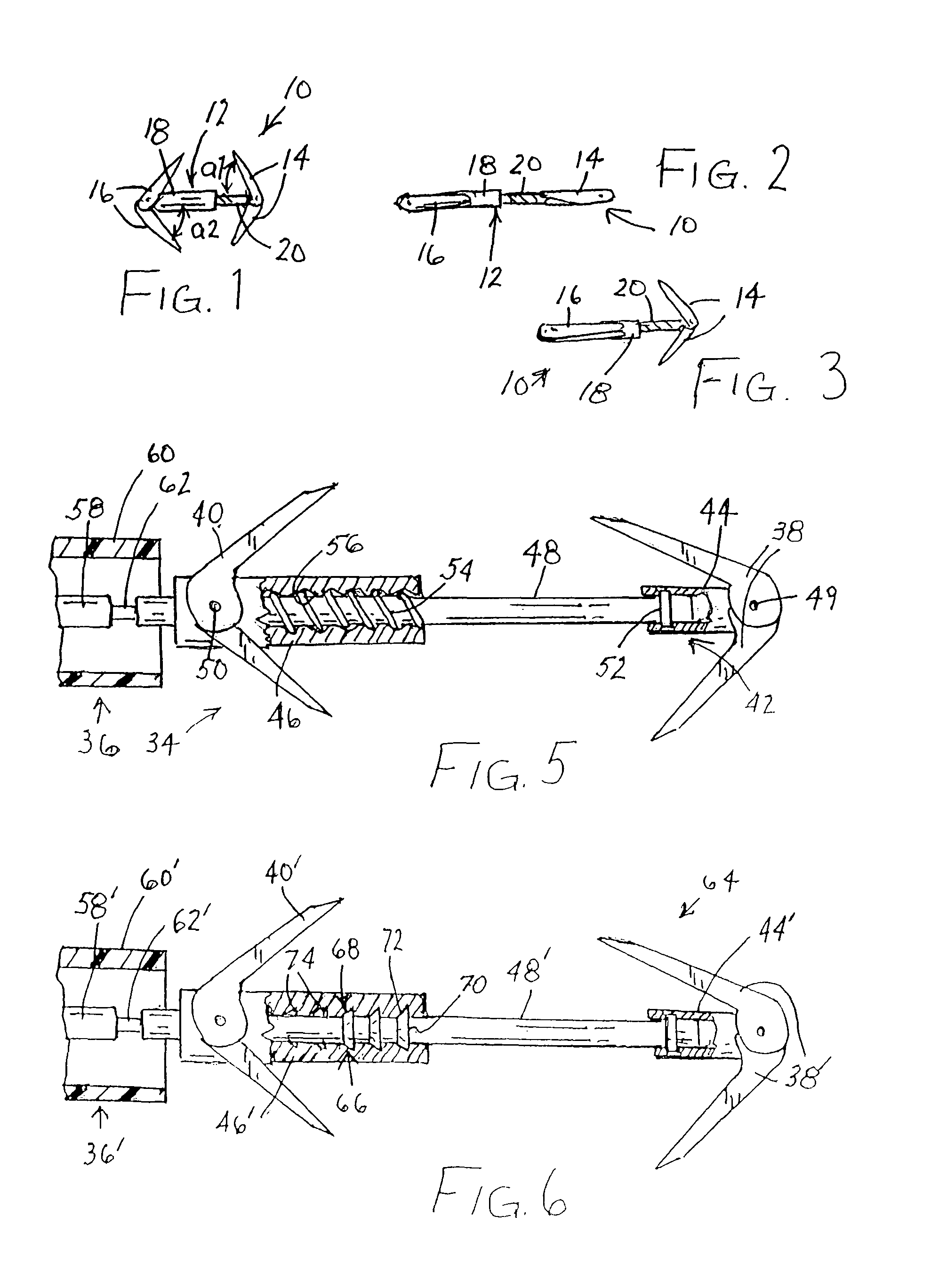

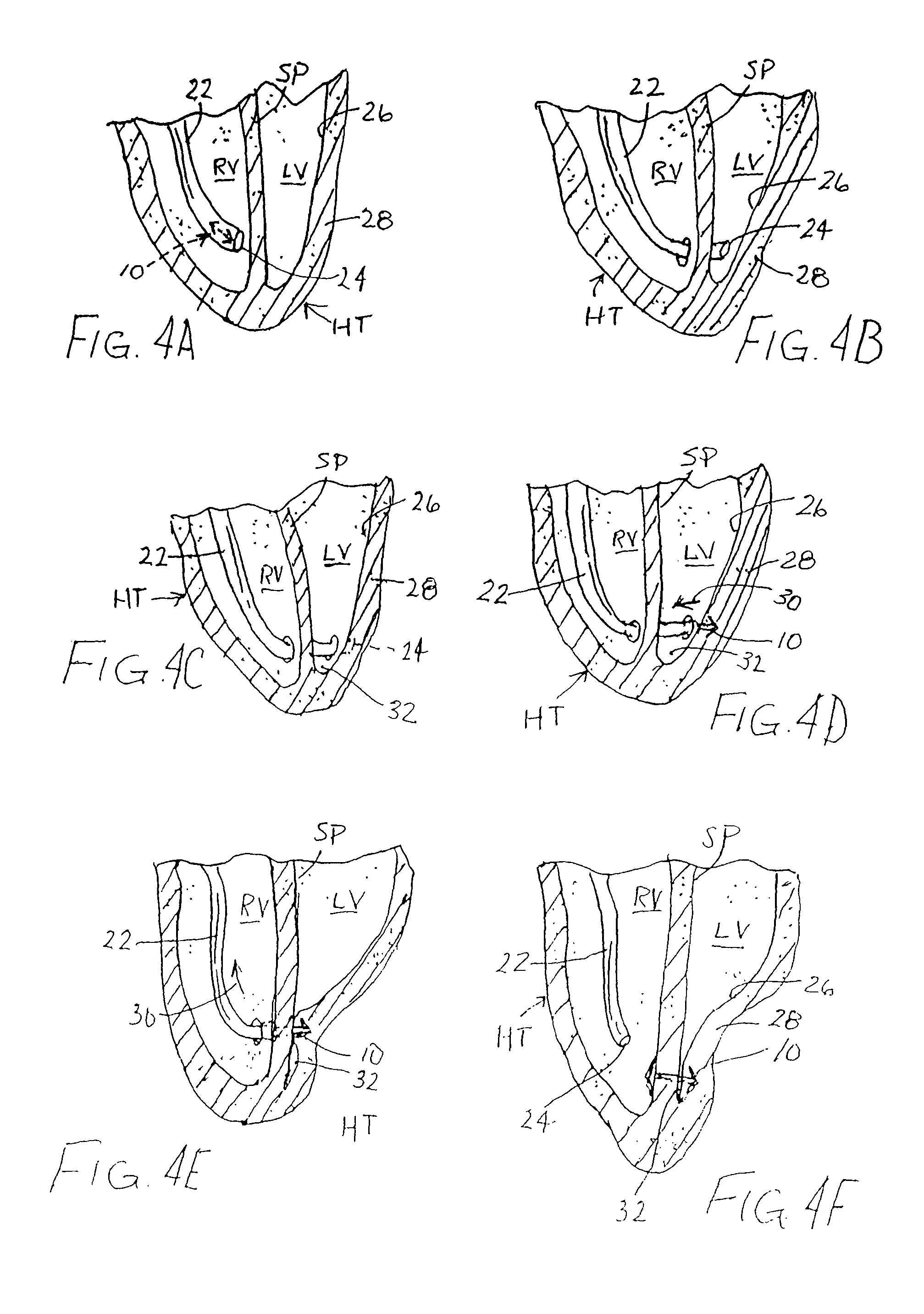

Method and device for improving cardiac function

InactiveUS7798953B1Facilitate invasive procedureImprove heart functionDiagnosticsSurgeryVeinEffective volume

In a method for improving cardiac performance, a compressive cardiac implant is passed through an anterior intraventricular vein of a patient's heart to a position proximate an apex or lower end of a left ventricle of the patient's heart. A distal end portion of the compressive cardiac implant is moved from the anterior intraventricular vein into the patient's left ventricle and thereafter passed through a septum of the patient's heart and into a right ventricle thereof. The distal end portion of the compressive cardiac implant is then engaged with the septum, and the compressive cardiac implant is operated to compress the apex or lower end of the patient's left ventricle so as to reduce the effective volume of the left ventricle.

Owner:WILK PATENT

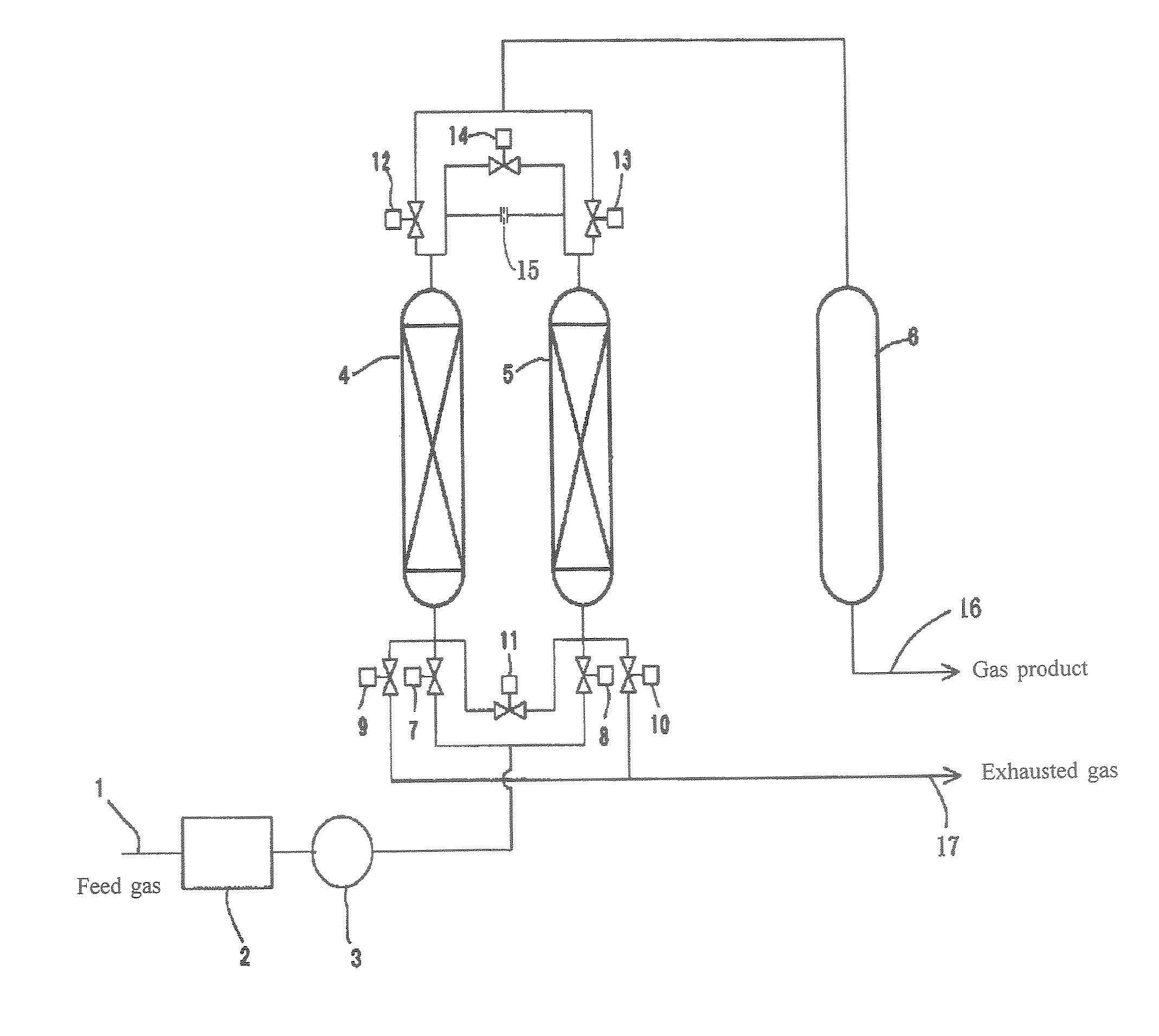

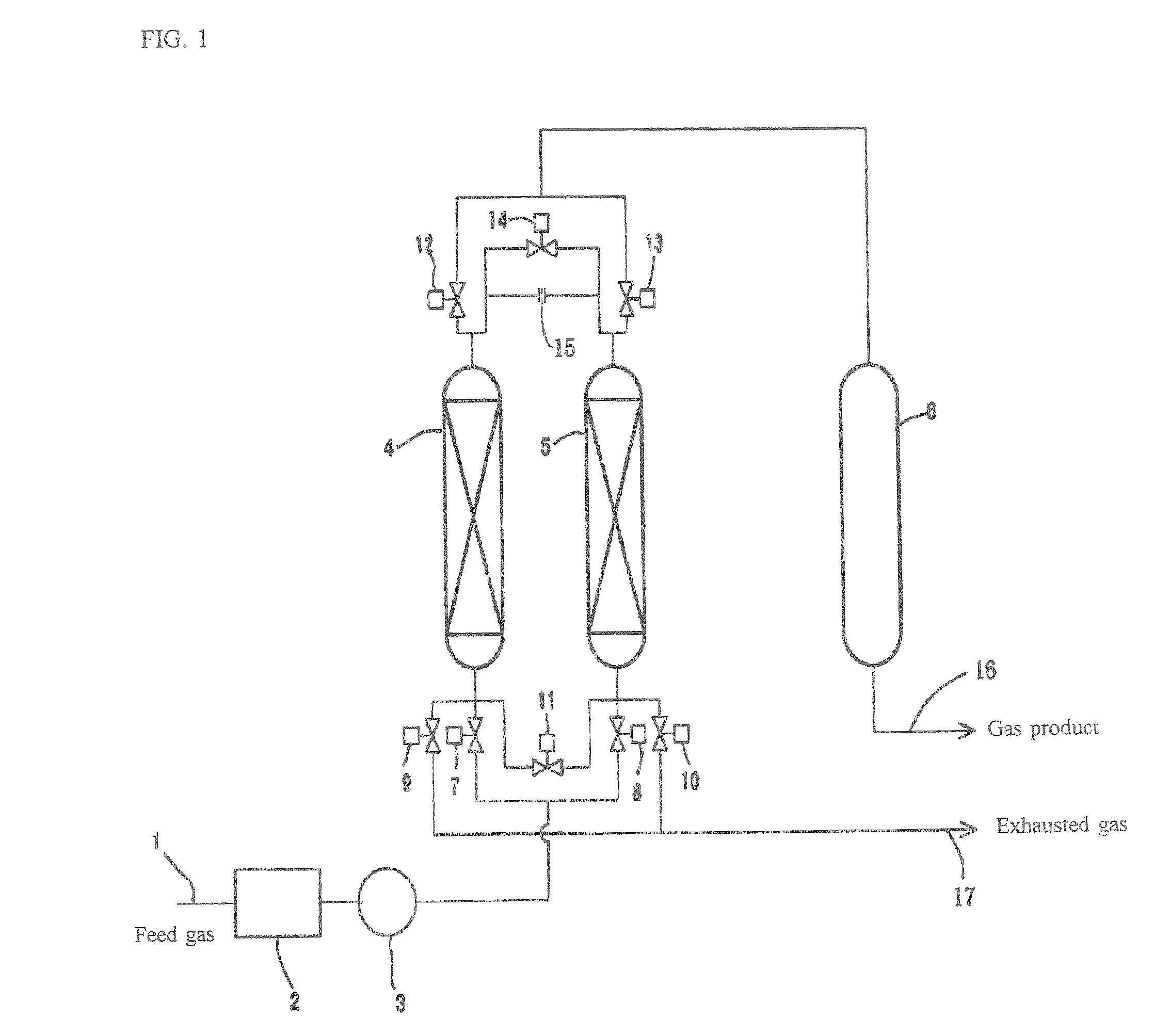

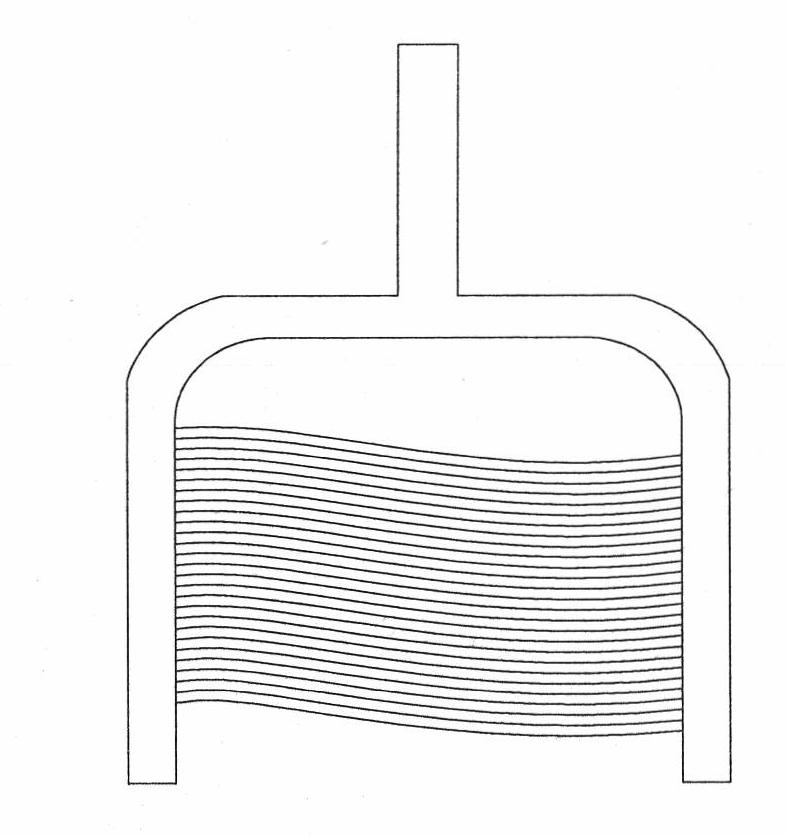

Method of Separating Nitrogen Gas and Molecular Sieve Carbon

ActiveUS20070261550A1Lower the volumeCost-effectiveGas treatmentNitrogen compoundsMolecular sieveNitrogen gas

Owner:KURARAY CO LTD

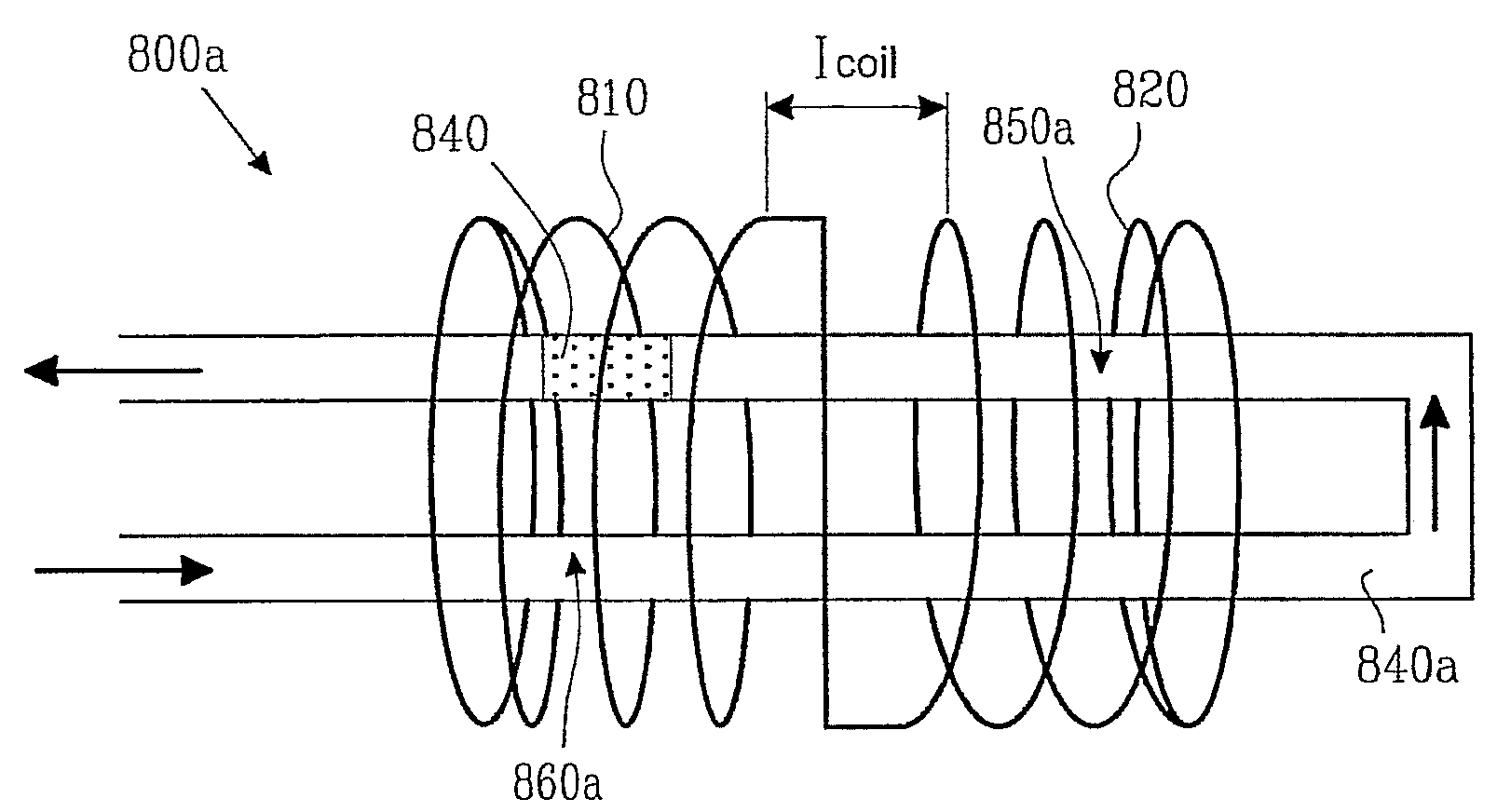

Detection device and method

ActiveUS20090085557A1High magnetizationDecrease of magnetisationElectrical measurementsSusceptibility measurementsCarrier fluidMagnetic response

The present invention relates to method and device for detecting changes of a magnetic response of at least one magnetic particle in a carrier fluid. The method comprises: using a measuring procedure comprising measuring the characteristic rotation time of said magnetic particle, said measuring procedure further involving measuring Brownian relaxation in said carrier fluid under influence of an external pulsed excitation magnetic field, and based on said influence of said external pulsed excitation magnetic field measuring a hydrodynamic volume of a particle or a change in a hydrodynamic volume of the particle change upon modification of an effective volume of the particle or its interaction with said carrier fluid by detecting change of magnetization of the particle with time by monitoring change of an output signal in detection coil.

Owner:ACREO SWEDISH ICT

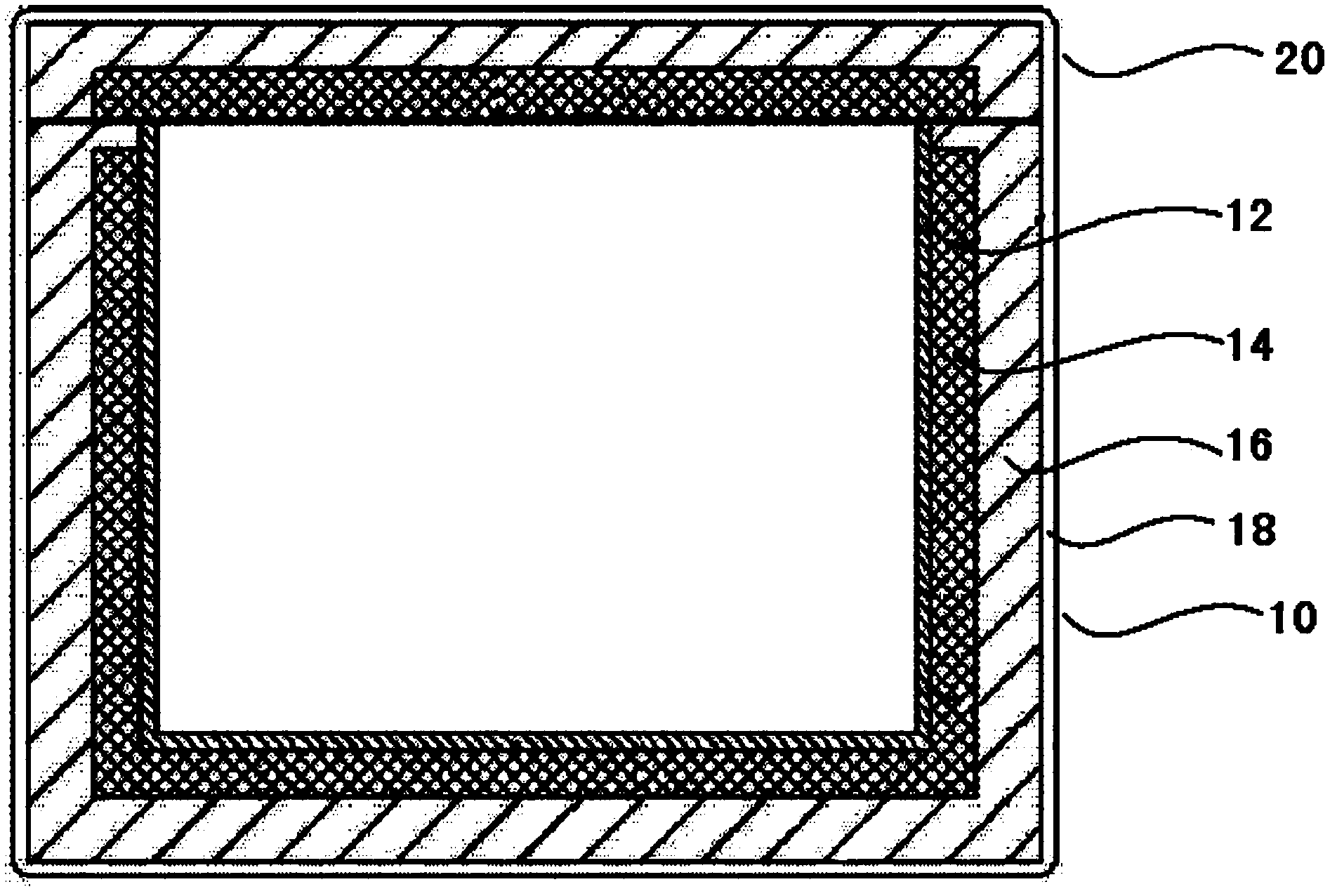

Heat insulation cold closet for medical supplies

ActiveCN103723379AReduce thicknessIncrease effective volumeLighting and heating apparatusInsulation for cooling apparatusEngineeringEffective volume

The invention discloses a heat insulation cold closet. According to the heat insulation cold closet, due to the fact that a vacuum heat insulation panel layer and a rigid polyurethane layer are arranged in a polyurethane foamed plastic layer to form a composite head insulation structure, the thickness of the heat insulation cold closet is reduced so that the effective volume of a heat insulation closet in the same shape can be greatly increased; furthermore, the coefficient of heat insulation of the heat insulation cold closet is smaller than or equal to 0.004W / mK, heat radiation, heat conduction and heat convection between the interior of the closet body and the outside environment can be effectively prevented, and the heat insulation closet can guarantee that the interior temperature is controlled below 2-8 DEG C for more than 120 hours. The heat insulation cold closet is mainly used for cold storage and refrigeration during transportation and storage of medicine such as vaccine, insulin, blood products, biological products and reagents.

Owner:SUZHOU ANTEK INDAL

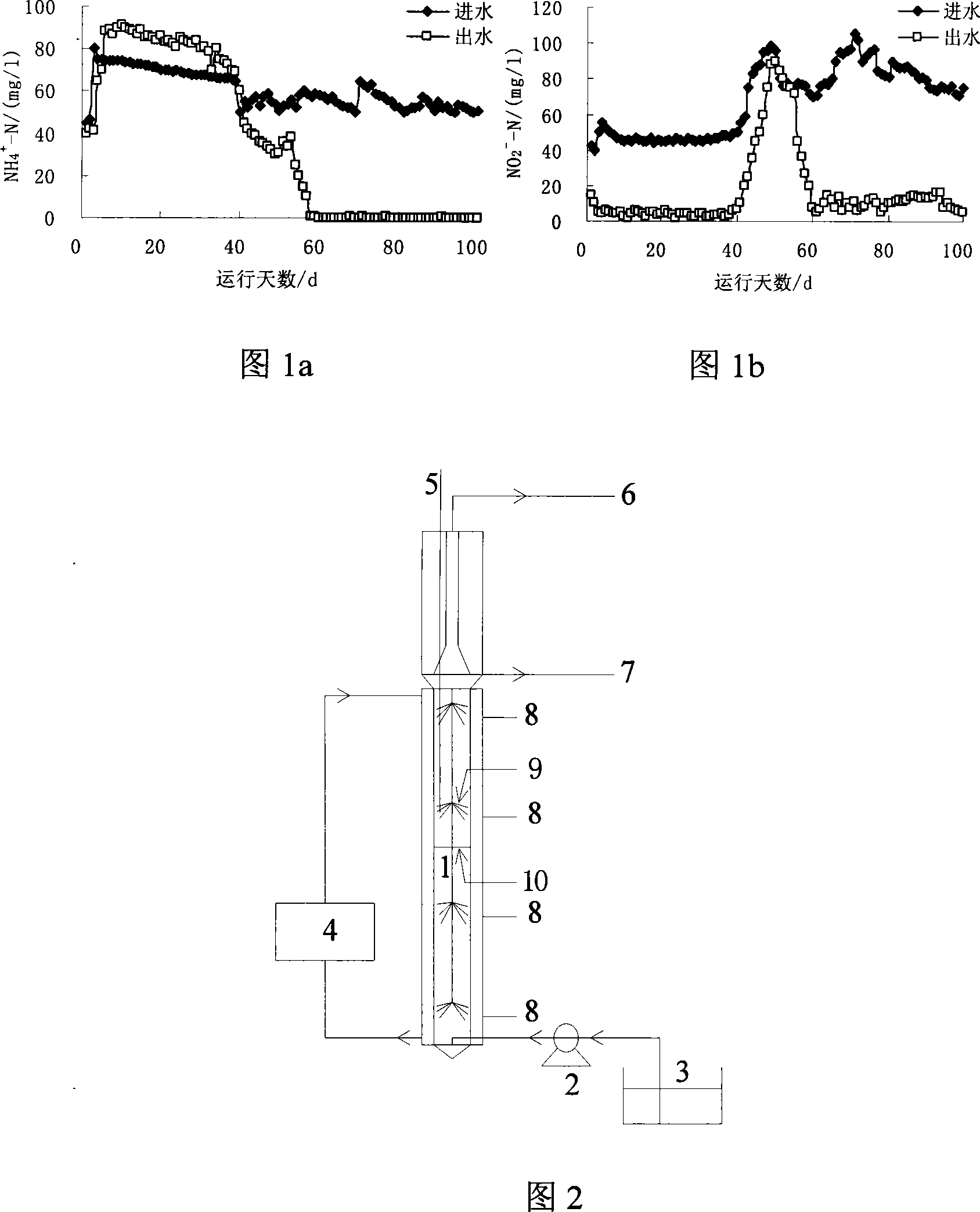

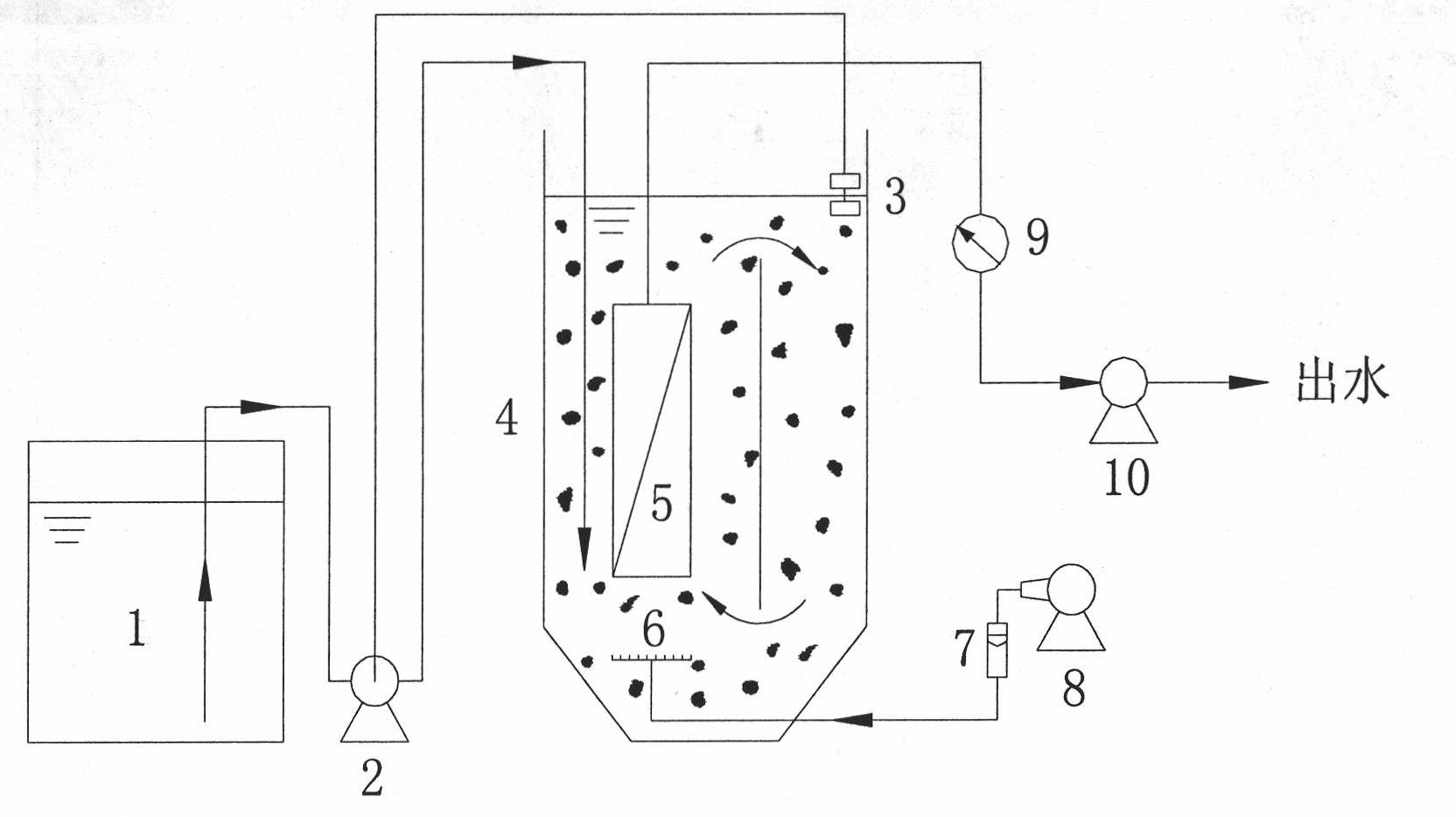

Method for rapidly culturing anaerobic ammonium oxidation bacteria by up-flow type anaerobic sludge bed reactor

InactiveCN101205526AHigh removal rateGuaranteed uptimeBioreactor/fermenter combinationsBiological substance pretreatmentsActivated sludgeWater baths

The invention discloses a method by using an up-flow anaerobic sludge blanket - biomemebrane reactor to quickly cultivate anaerobic ammonium oxidation bacteria, comprising the following steps: enriched microorganisms are preserved in an internal membrane of a UASB reactor; garbage landfill is selected for treating activated sludge during the leachate SBR process as seed sludge, and seeded sludge quantity is 45 to 65 percent of effective volume of the reactor; a constant temperature circulating water bath is adopted to maintain temperature of a reaction zone to be 1 DEG C higher or lower than 32 DEG C; waste water is synthesized by adoption of manpower, and waste water components comprise NH4Cl, NaNO2, MgSO4, KH2PO4, CaCl2, NaHCO3, a microelement I and a microelement II; mass ratio of NH4<+>-N and NO2<->-N during the process of water distribution is controlled to be ranged from 1 to 1.0 to 1 to 1.6; PH value of influent is adjusted to be 7.4 to 7.8. The invention has the advantages of simple technology, stable system operation, high nitrogen removal rate, short acclimation concentration time and so on.

Owner:SOUTH CHINA UNIV OF TECH

Pipettor and externally sealed pipette tip

InactiveUS6793891B2Reduce maintenancePrecise and accurate amountWithdrawing sample devicesBurettes/pipettesPipetteEngineering

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way. Additionally, seals may be seated in grooves engraved in either the pipette tip or the pipette block to provide a sliding seal between the pipette block and pipette tip.

Owner:YIU FELXI

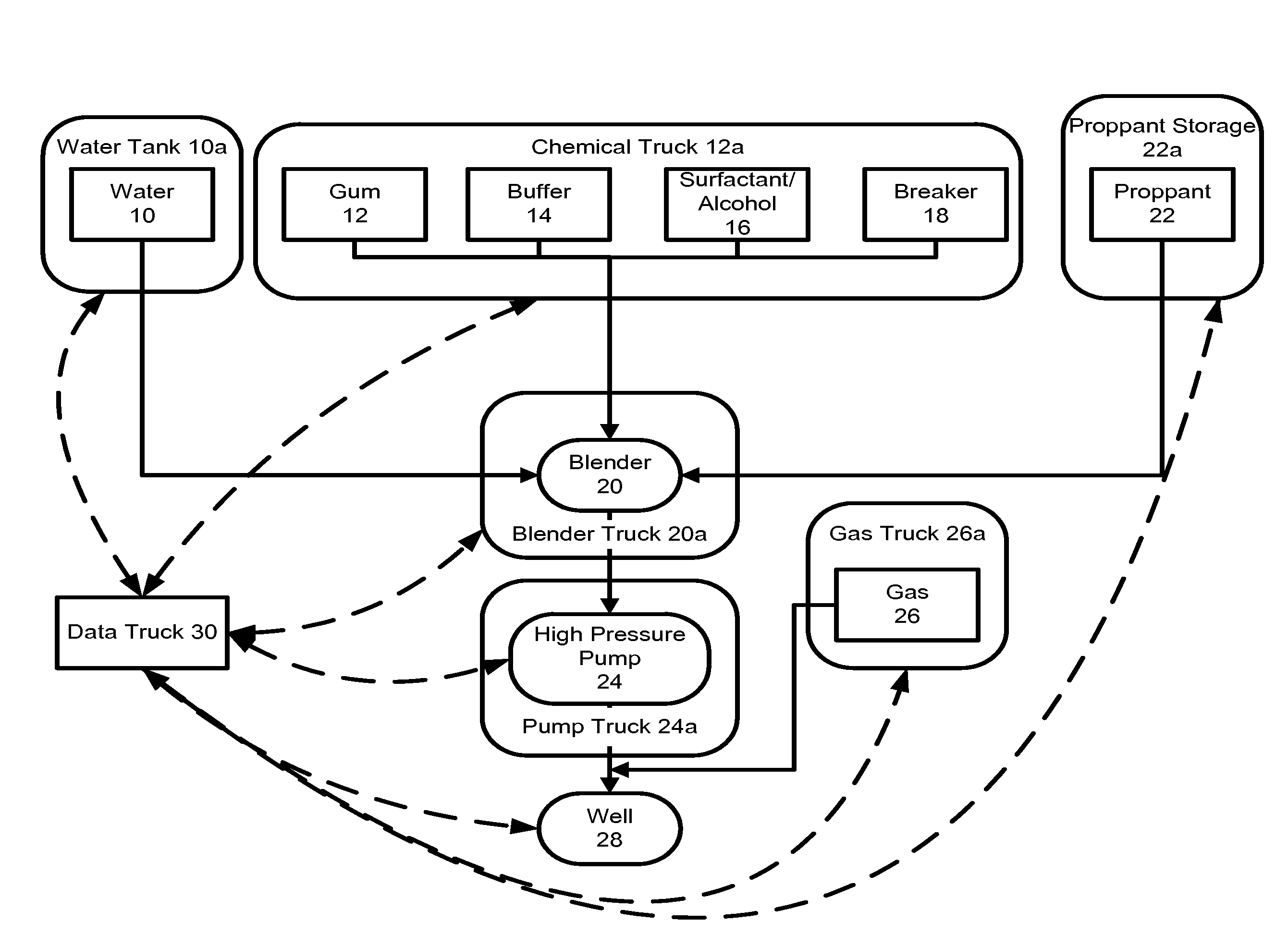

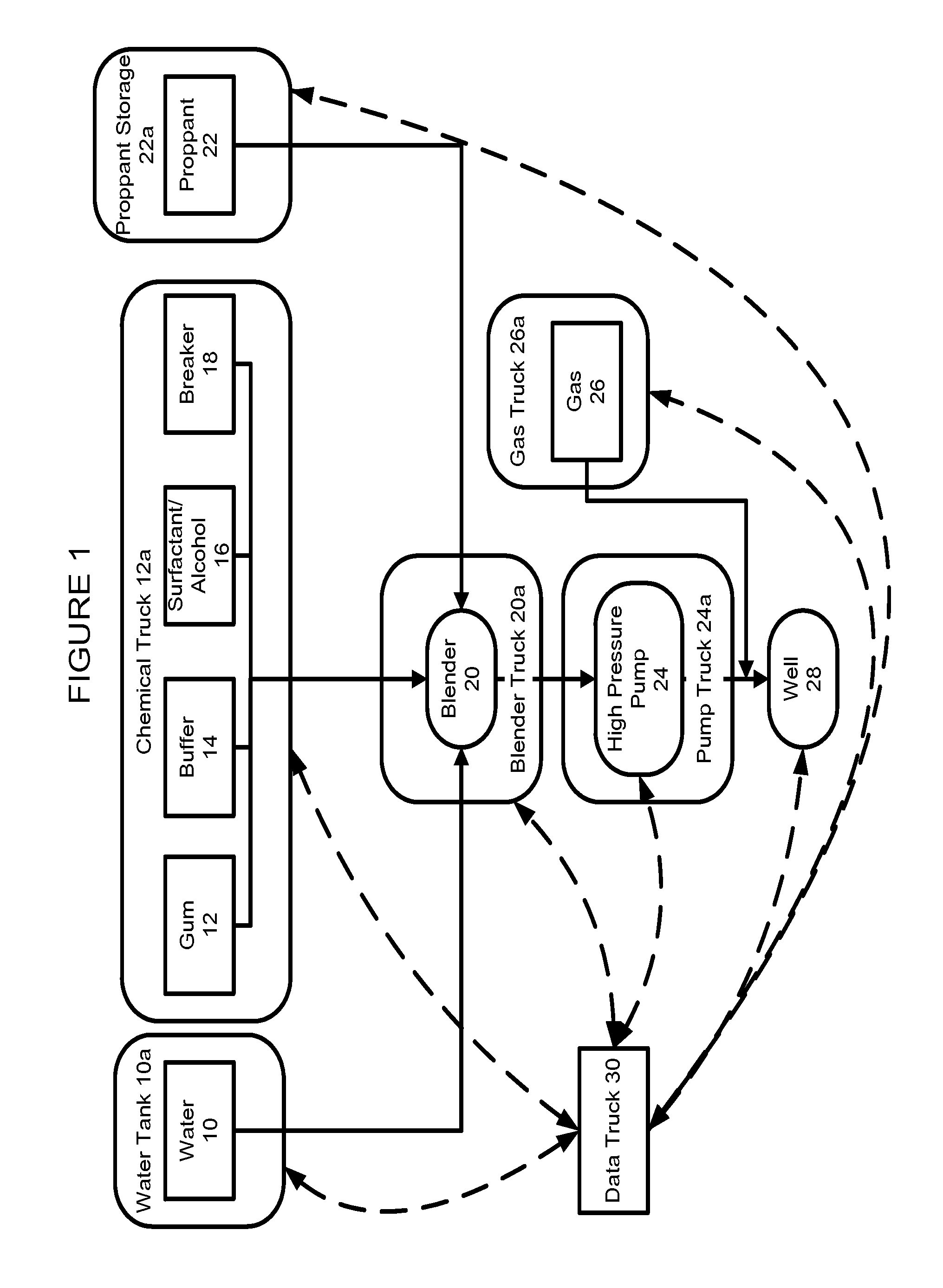

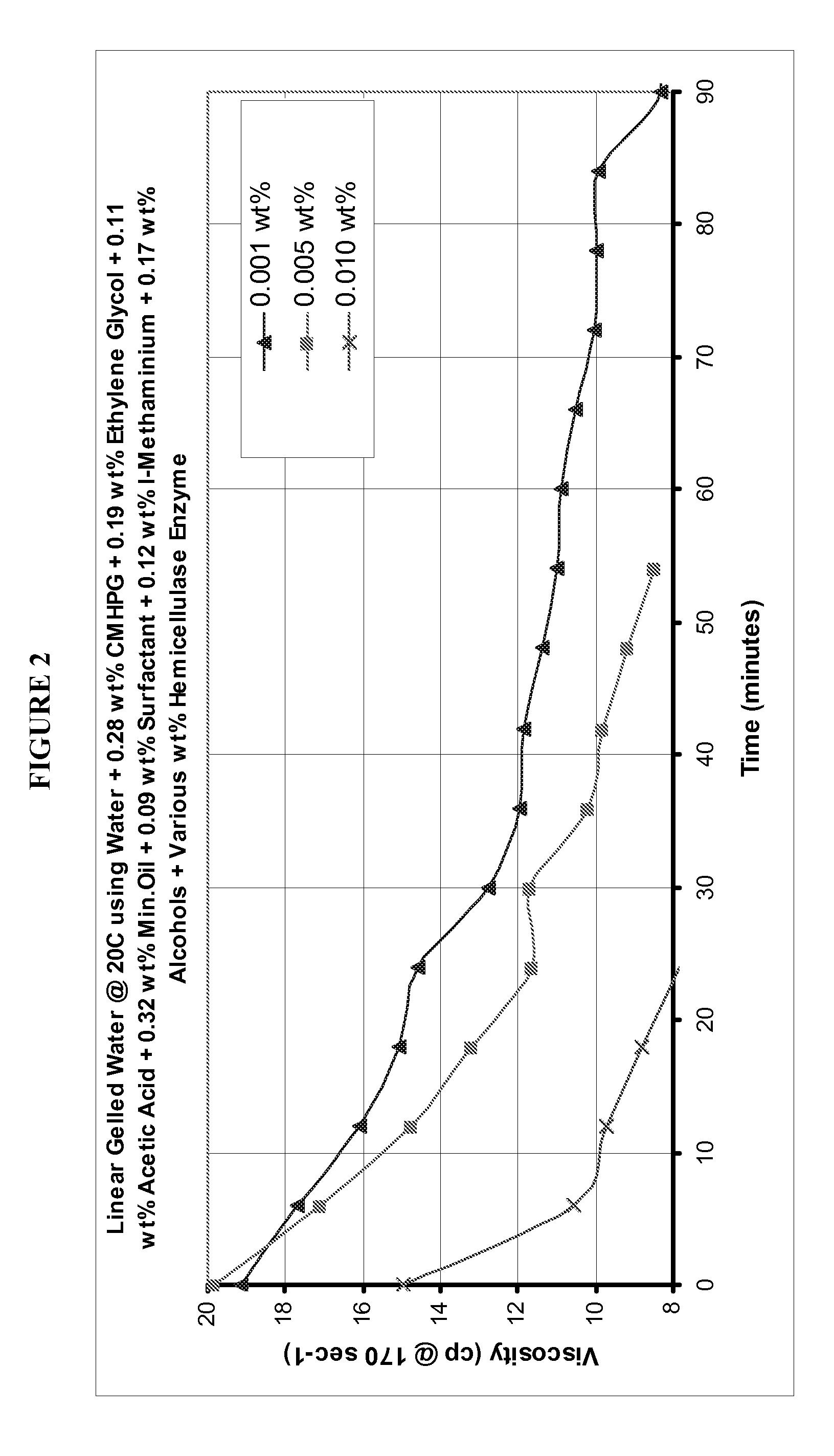

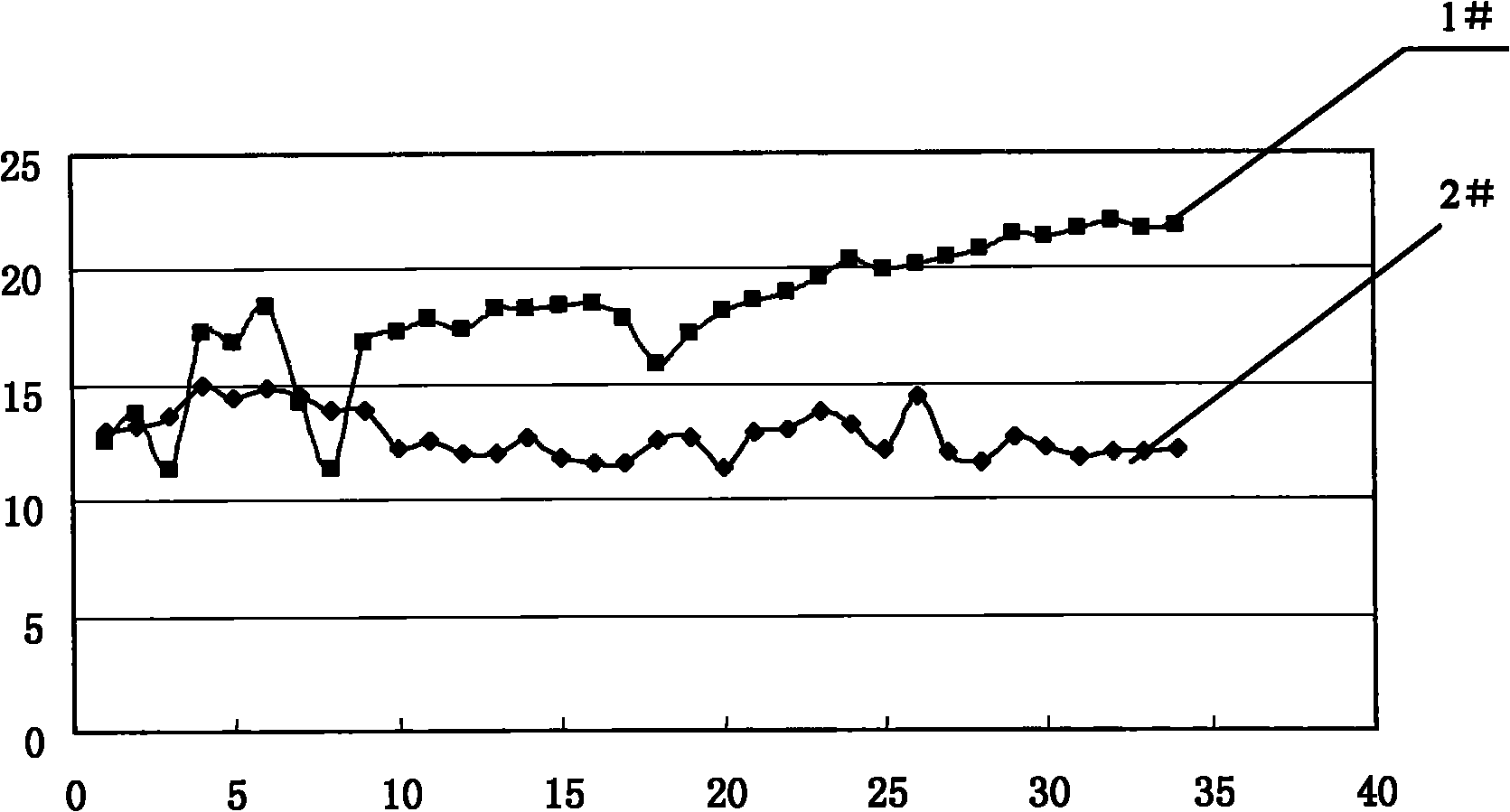

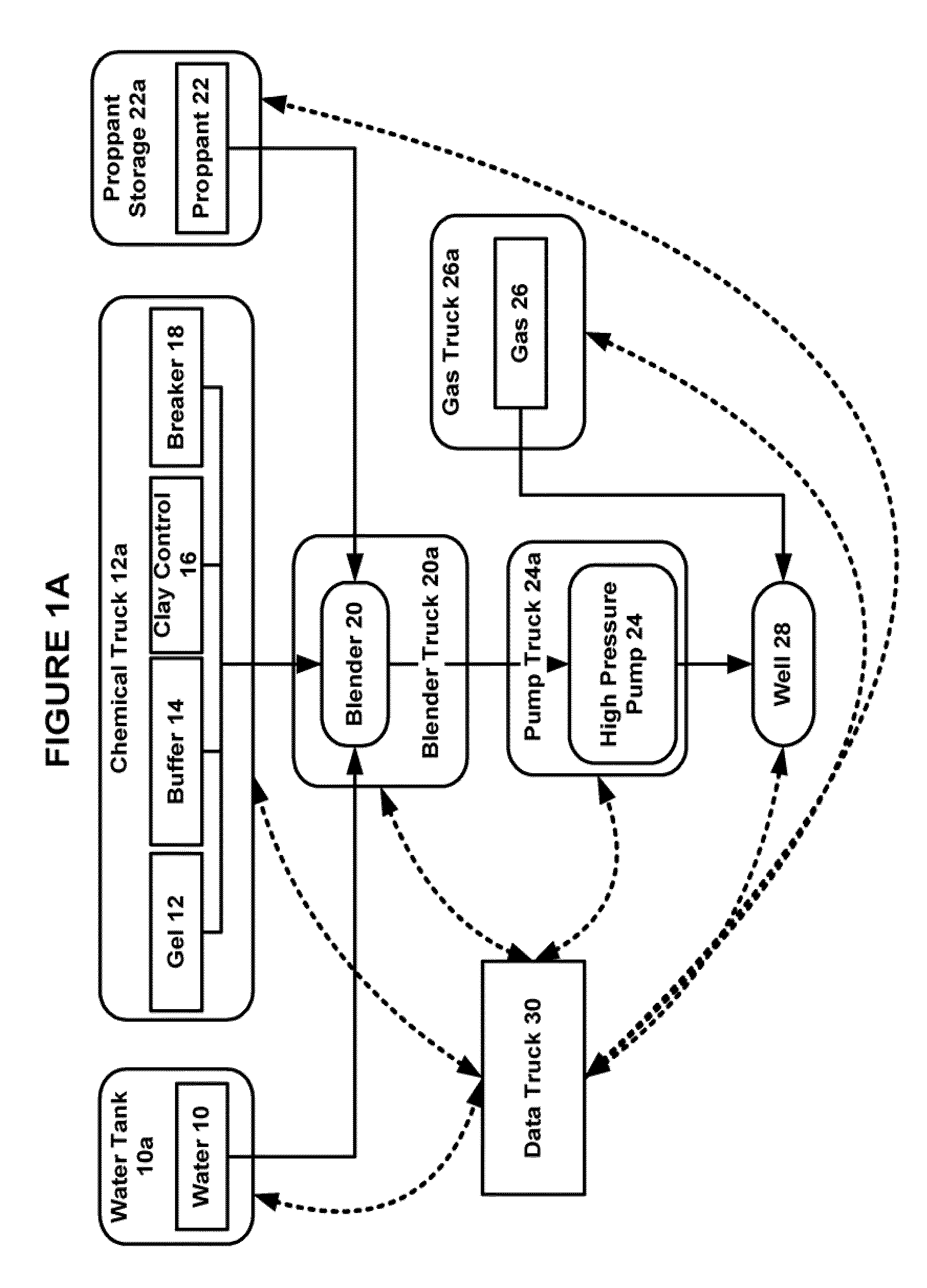

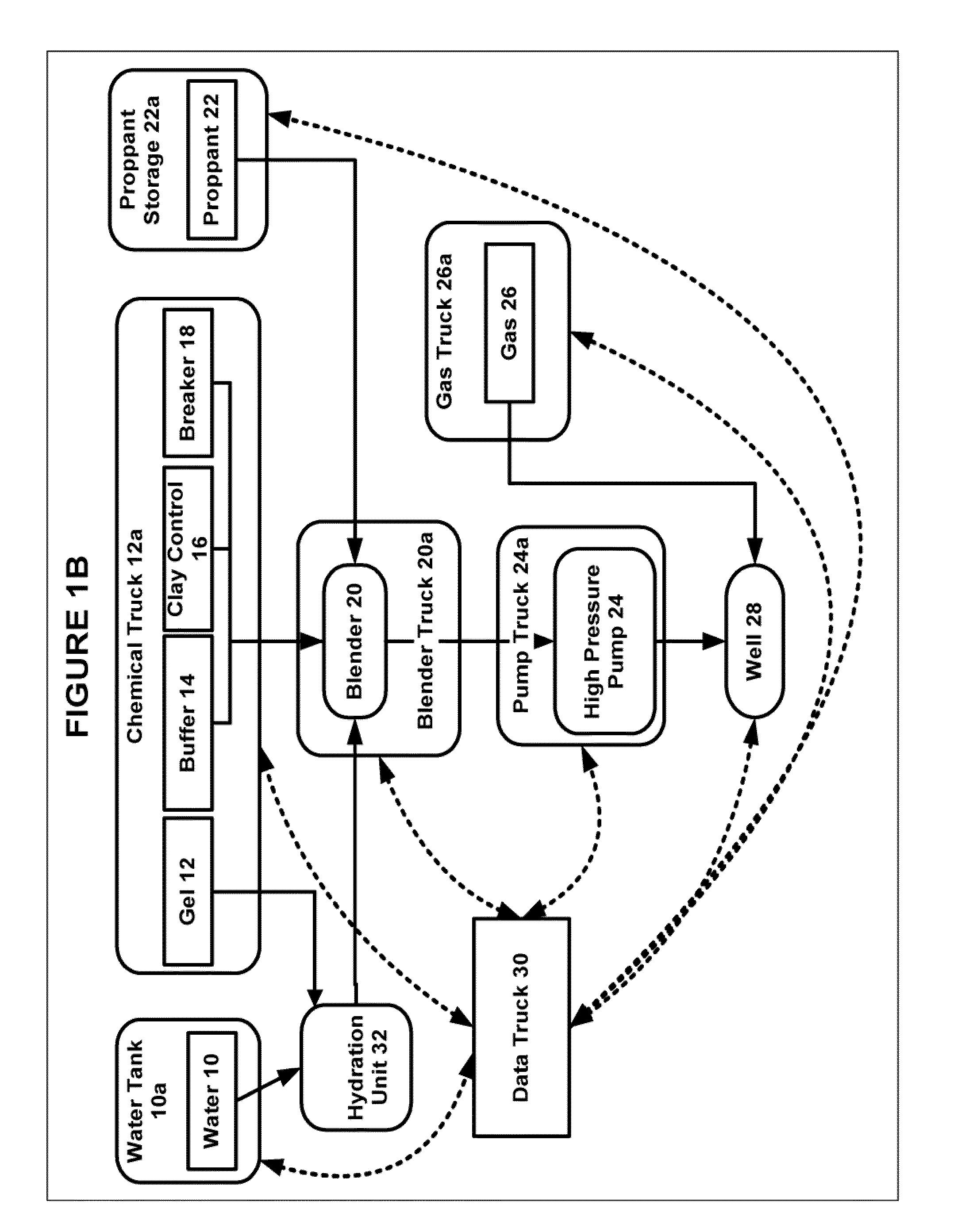

Fracturing fluid compositions, methods of preparation and methods of use

The invention describes improved fracturing compositions, methods of preparing fracturing compositions and methods of use. Importantly, the subject invention overcomes problems in the use of mists as an effective fracturing composition particularly having regard to the ability of a mist to transport an effective volume of proppant into a formation. As a result, the subject technologies provide an effective economic solution to using high ratio gas fracturing compositions that can be produced in a continuous (i.e. non-batch) process without the attendant capital and operating costs of current pure gas fracturing equipment.

Owner:CENTURY OILFIELD SERVICES

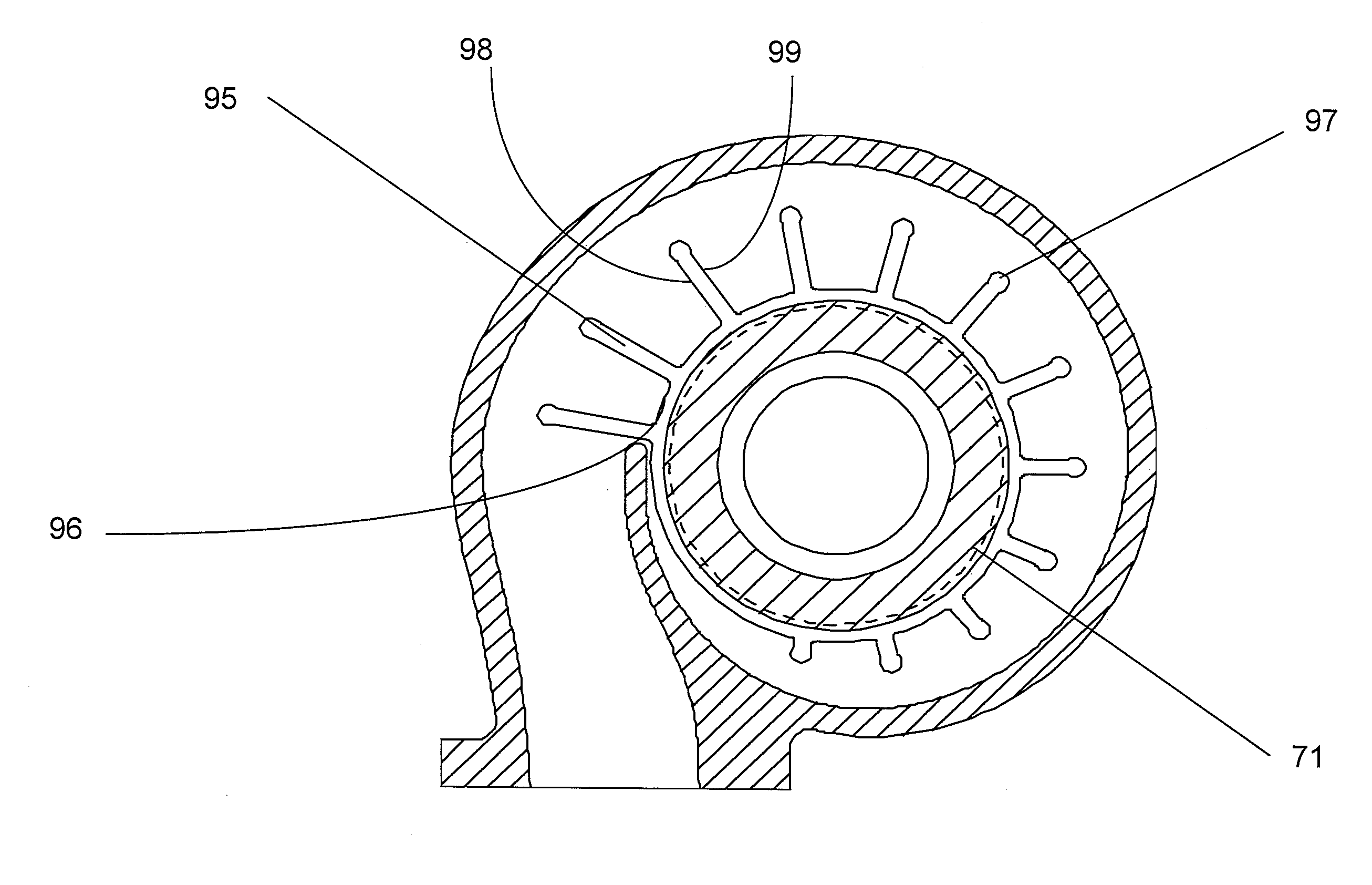

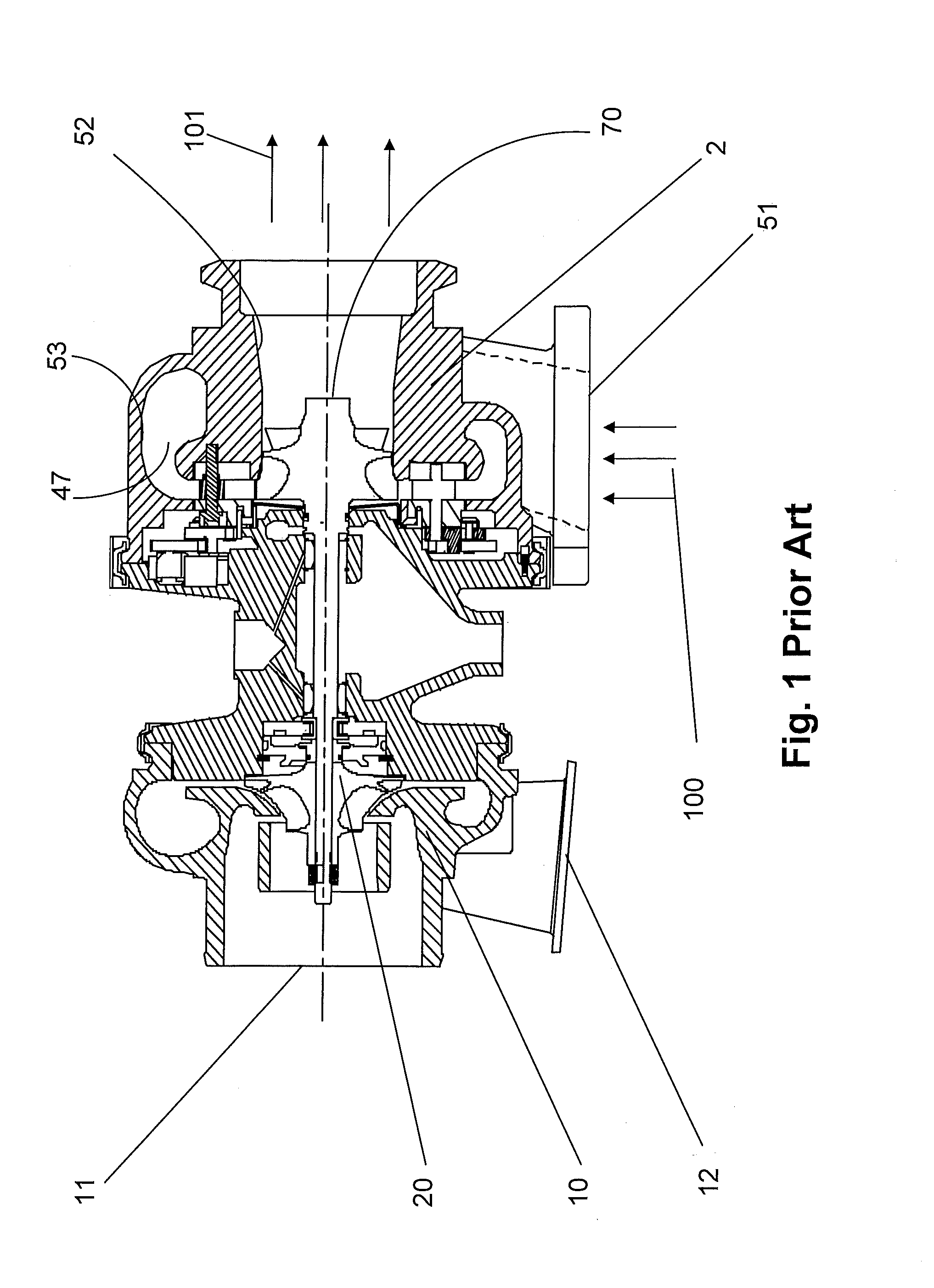

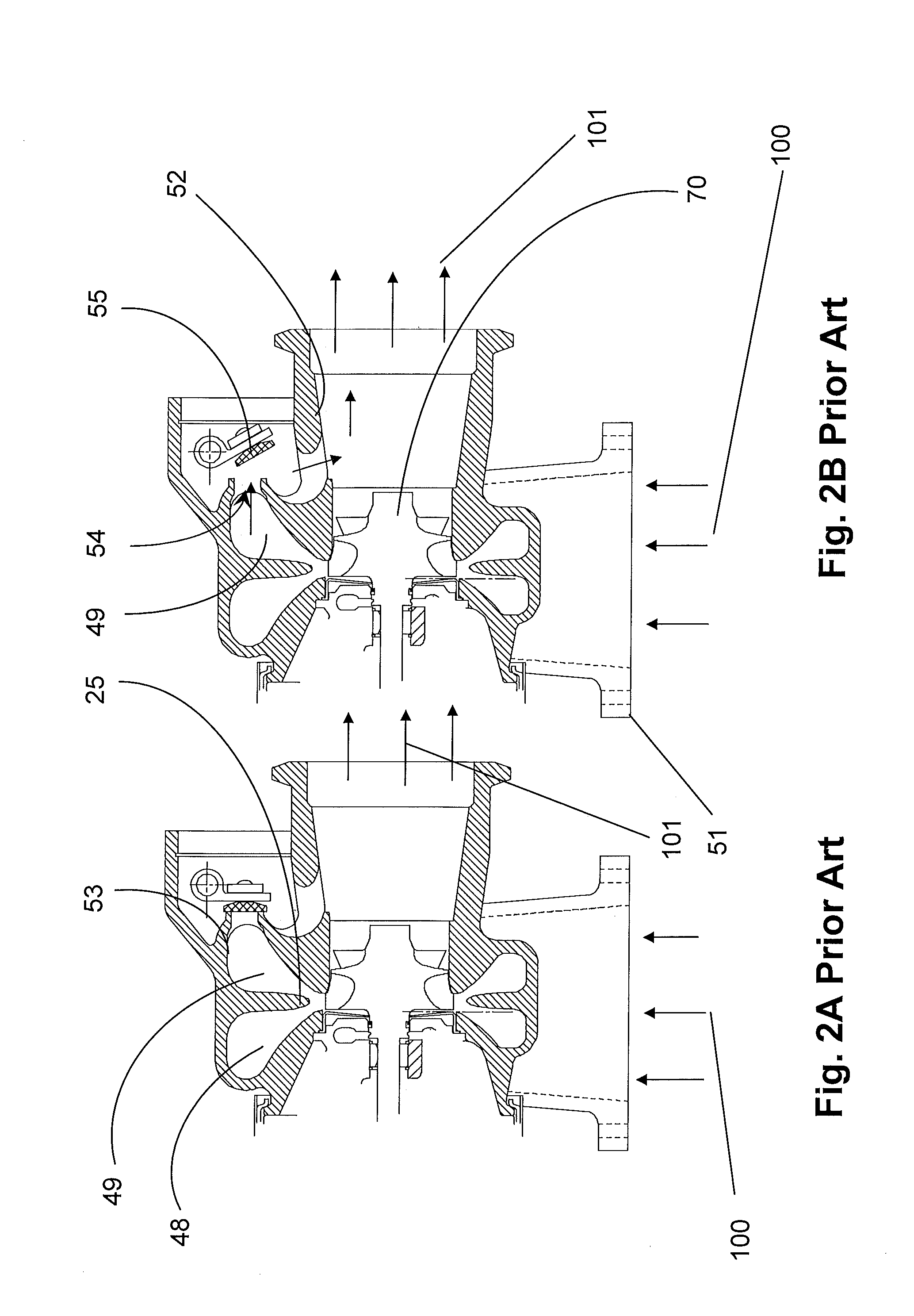

Simplified variable geometry turbocharger with increased flow range

InactiveUS20130219885A1Low costExpand flow rangeInternal combustion piston enginesPump componentsImpellerTurbine wheel

A variable geometry turbocharger is simplified yet able to maintain pulse energy. In a first embodiment, a turbine housing is provided with a pivoting flow control valve which pivots about a point near the entry to the turbine housing. By moving the valve about the pivot point, the effective volume of the turbine housing volute is varied, thus effectively reducing the volume of exhaust gas in the volute, allowing control of exhaust gas flowing to the turbine wheel. In the second embodiment of the invention, a rotating wedge segment within the volute is rotated from a first position to a second position, changing the effective volume of the volute and allowing control of exhaust gas flowing to the turbine wheel.

Owner:BORGWARNER INC

Method for fast starting up procedure for nitrifying wastewater of containing ammonia in short range

InactiveCN1562799AReduce difficultyGuaranteed uptimeTreatment using aerobic processesTreatment with aerobic and anaerobic processesNitrogenVolumetric Mass Density

The steps of the method are followings: 1) first to put inoculum and aerobic active mud in biologic reactor, inoculum quantity is 70 percent of biologic reactor effective volume; 2) to dilute ammonia containing waste water to that ammonia and nitrogen density is 5-6 mmol / L to be used as reactor water, waterpower stay time that waste water in the biologic reactor is 16-18 hours, temp. is controlled from 25 deg.C to 28 deg.C, pH value is controlled from 7.2 to 7.5, dissolved oxygen density is controlled from 2.5 mg / L to 3.0 mg / L, 3) to value is controlled from 7.2 to 7.5, dissolved oxygen density is controlled from 2.5 mg / L to 3.0 mg / L; 3) to reduce diluting times of ammonia containing waste water progressively to increase ammonia and nitrogen density of the water until it reaches 30 mmol / L or to use raw waste water to be reactor used water directly. When ammonia and nitrogen disloging ratio reaches 97-99 percent, pH value is controlled from 32 deg.C to 35 deg.C, dissolved oxygen density is controlled from 1.0 mg / L to 1.5 mg / L.

Owner:ZHEJIANG UNIV

Multiple frequency Helmholtz resonator

InactiveUS7055484B2Small sectionIncrease in sizeInternal combustion piston enginesAir intakes for fuelHelmholtz resonatorEngineering

The tunable resonator is coupled to the engine speed control such that the resonator is set to a different frequency range when the engine speed is changed. The frequency range is changed by opening and closing necks and / or changing the effective volume of the resonator.

Owner:CARRIER CORP

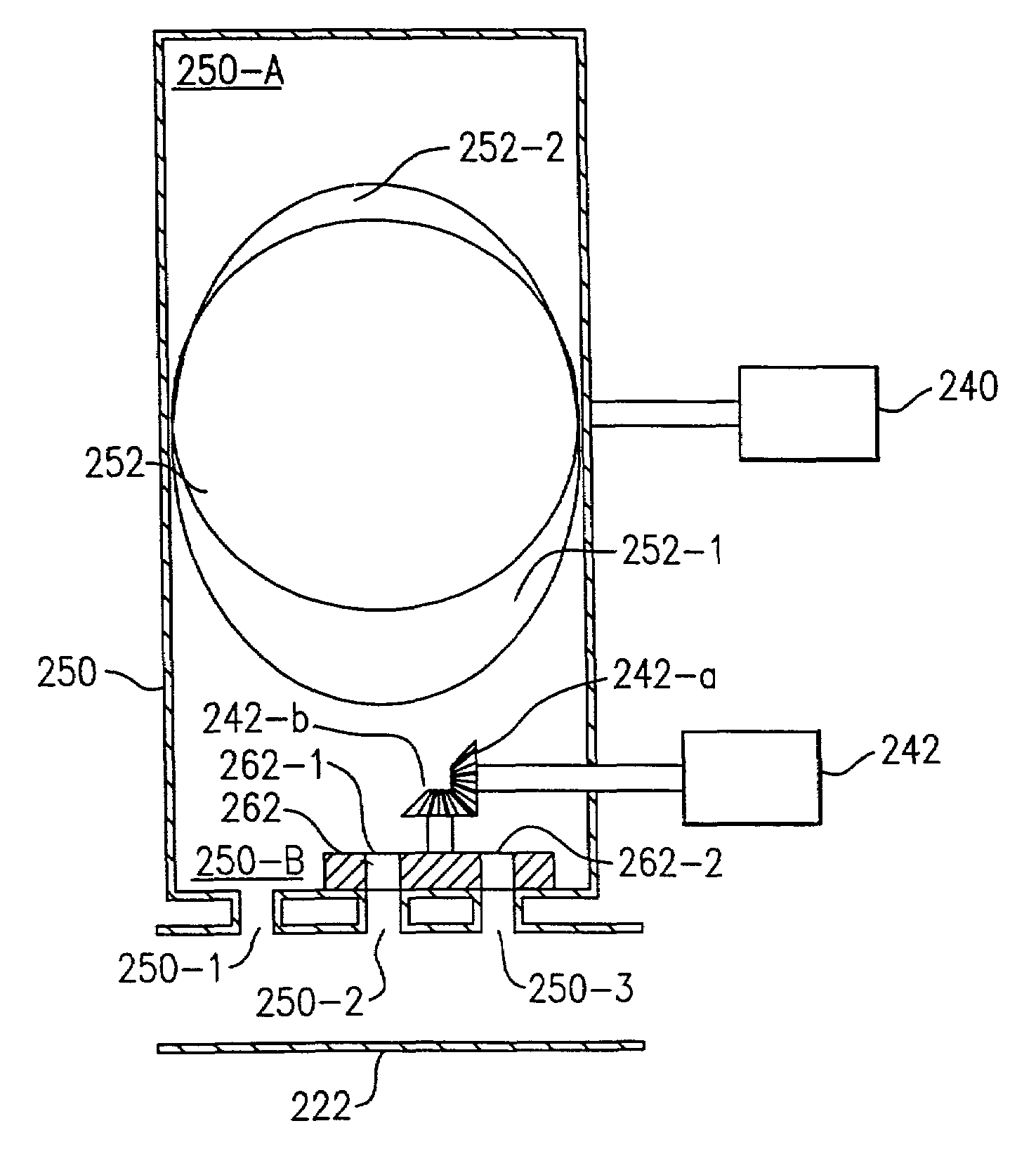

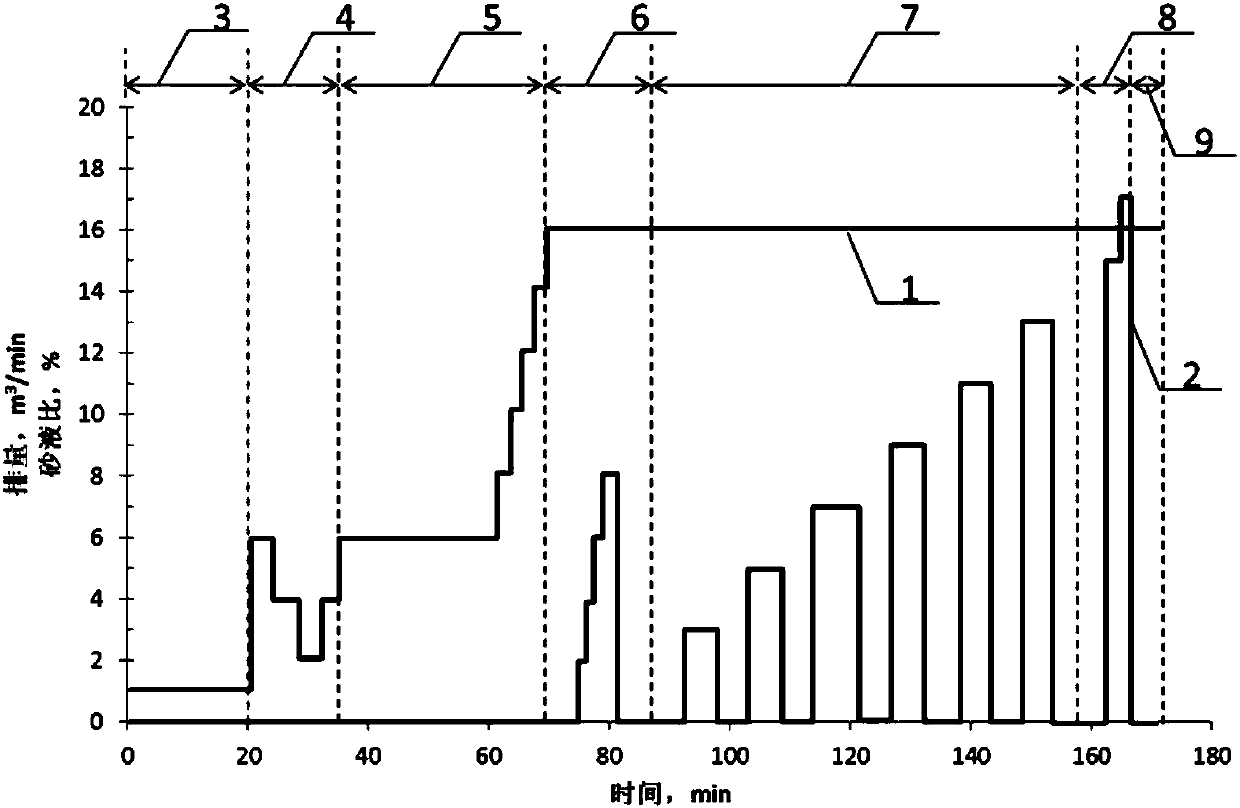

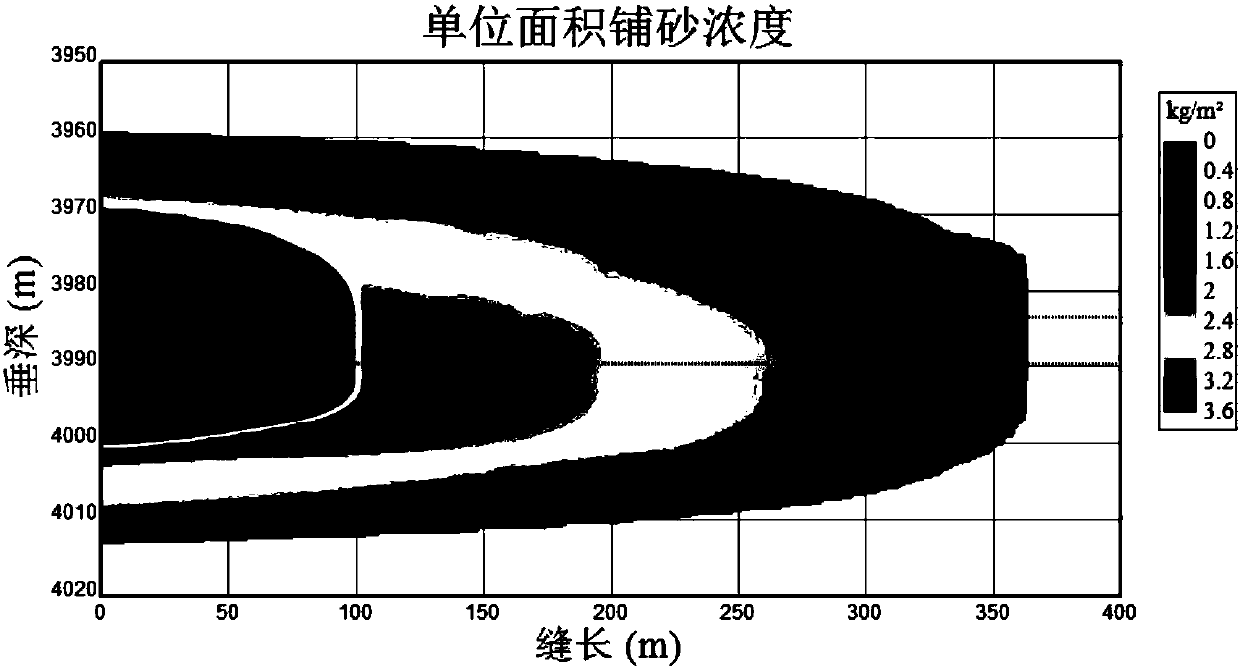

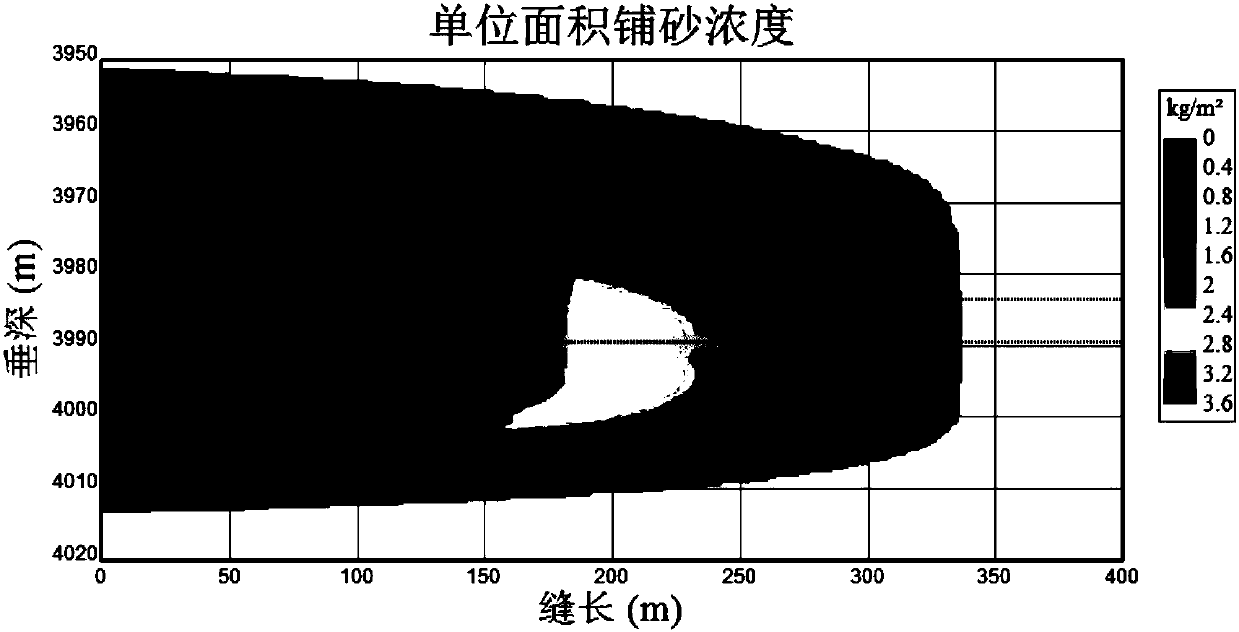

Volume fracturing method of deep shale gas multi-scale proppant packing

The invention discloses a volume fracturing method of deep shale gas multi-scale proppant packing. The volume fracturing method of deep shale gas multi-scale proppant packing comprises the following steps: (1) evaluating key engineering parameters of shale gas; (2) determining a fracturing fluid system and a proppant; (3) optimizing fracture parameters and fracturing construction parameters; (4) determining the position of a fracturing section shower hole and perforating parameters; (5) carrying out acid pretreatment; (6) carrying out low viscosity quick water low-displacement fracture heightcontrolling fracturing; (7) carrying out ultra low density proppant screen-out fracturing; (8) carrying out multi-scale fracture fracturing packing; and (9) according to a hole volume of each fracturing section, carrying out over-displacing operation according to 110-120%. The volume fracturing method of deep shale gas multi-scale proppant packing, disclosed by the invention, has the advantages that the net pressure is effectively increased by combining processes of optimizing acid treatment to reduce a fracture pressure, carrying out low viscosity quick water low-displacement injection fracture height controlling, screening out in a mixed ultra low density proppant fracture and so on, and through full-process small particle size proppant injection construction, the filling degree of the deep shale gas fracture system of small and micro fracture development is enhanced. Therefore, the effective volume of the fracture is further increased, and the long-time fracture flow conductivity isfurther improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

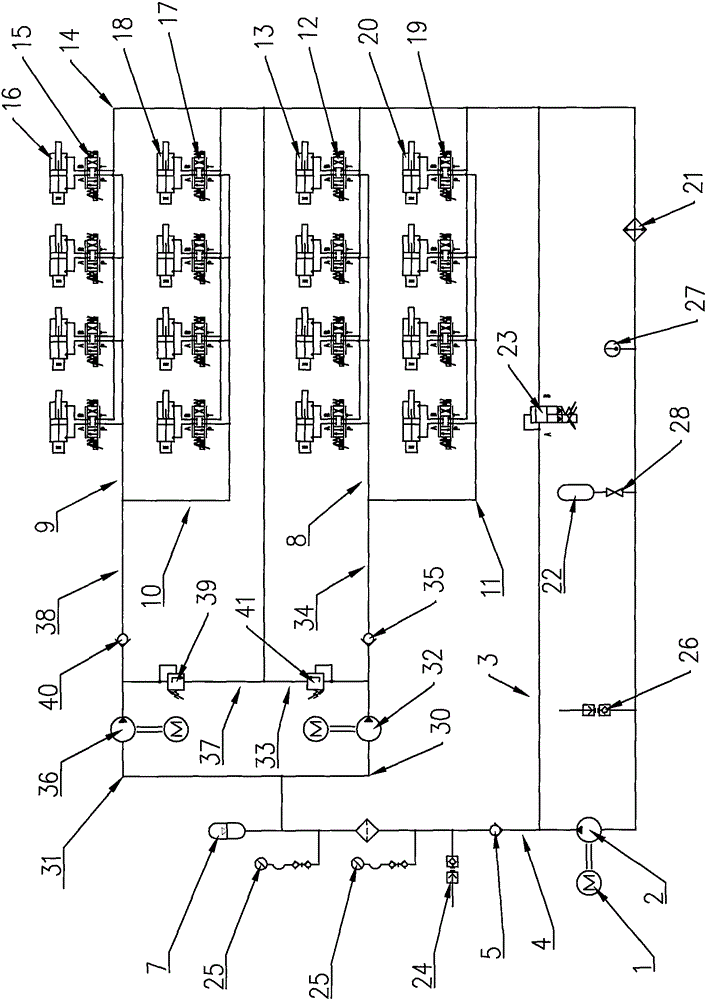

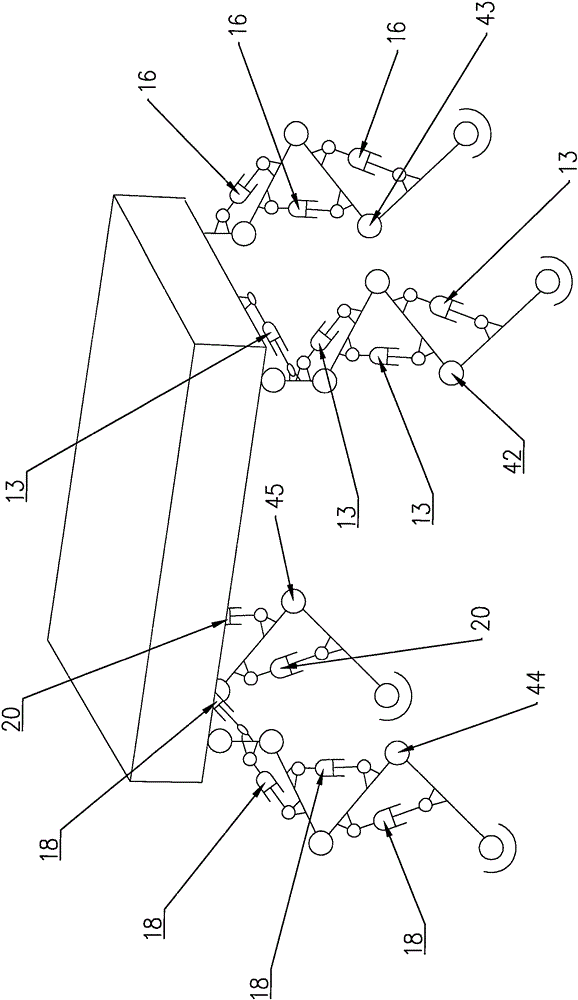

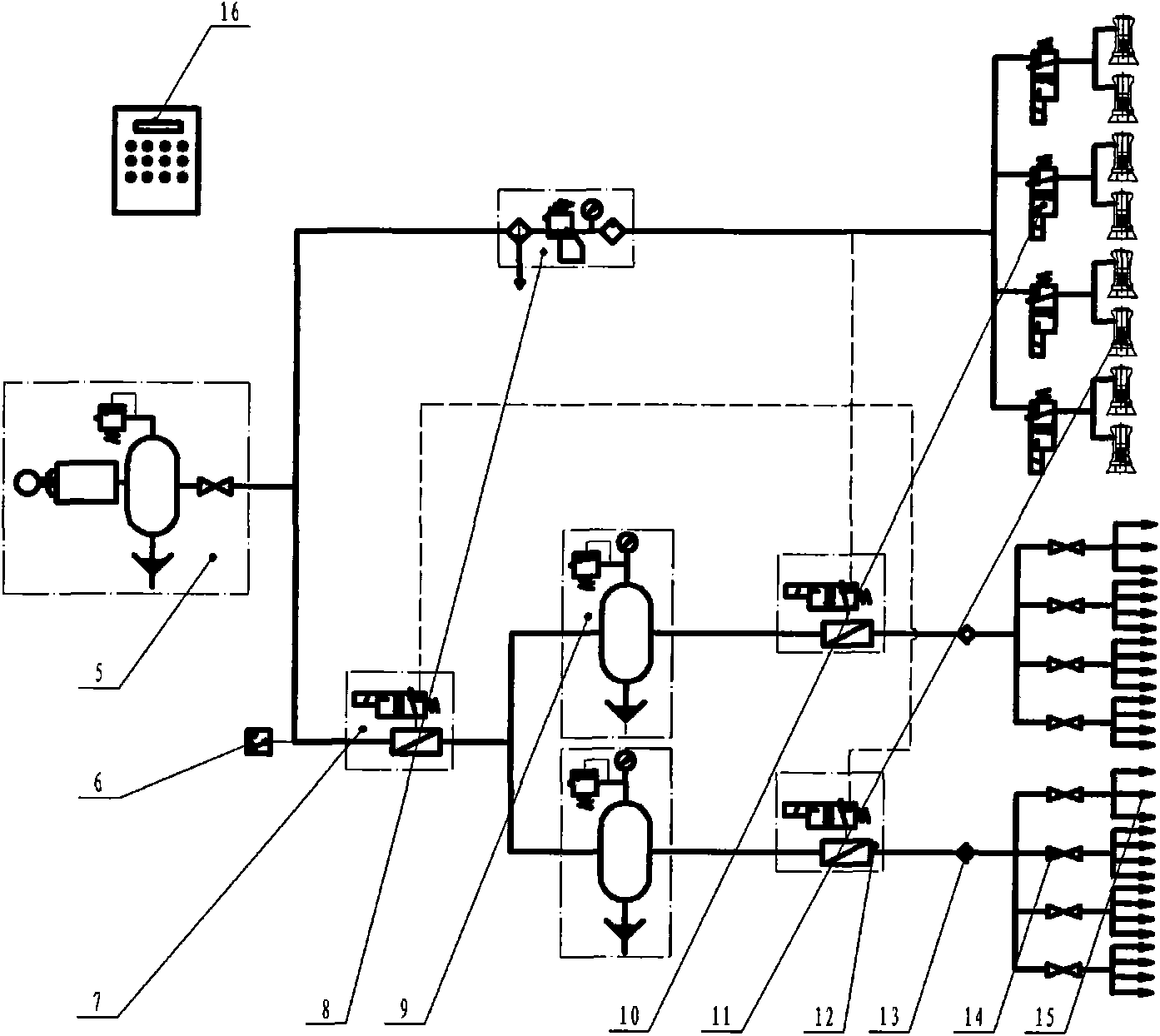

Electric servo hydraulic power source drive system of four-foot robot

ActiveCN105156382APlay a role in maintaining pressureEasy to check for faultsProgramme-controlled manipulatorServomotor componentsHydraulic pumpHigh pressure

An electric servo hydraulic power source drive system of a four-foot robot comprises a quantitative gear pump. The oil outlet of the quantitative gear pump is connected with the inlet of a high-pressure oil pipe. The outlet of the high-pressure oil pipe is connected with the inlet of a left oil supply pipe and the inlet of a right oil supply pipe. The left oil supply pipe is connected with a left hydraulic pump in series. The outlet of the left oil supply pipe is connected with the inlet of a left overflow pipe and the inlet of a left supercharging oil pipe. The middle of the left overflow pipe is connected with a left overflow valve in series. The outlet of the left supercharging oil pipe is connected with the oil inlet of a left front leg oil supply pipe and the oil inlet of a right rear leg oil supply pipe. The right oil supply pipe is connected with a right hydraulic pump in series, and the outlet of the right oil supply pipe is connected with the inlet of a right overflow pipe and the inlet of a right supercharging oil pipe. The middle of the right overflow pipe is connected with a right overflow valve in series. The outlet of the right supercharging oil pipe is connected with the oil inlet of a right front leg oil supply pipe and the oil inlet of a left rear leg oil supply pipe. According to the purpose, the electric servo hydraulic power source drive system of the four-foot robot is light, large in effective volume, constant in oil supplementing pressure, long in driving mileage, low in noise, long in service life, and stable and reliable in performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

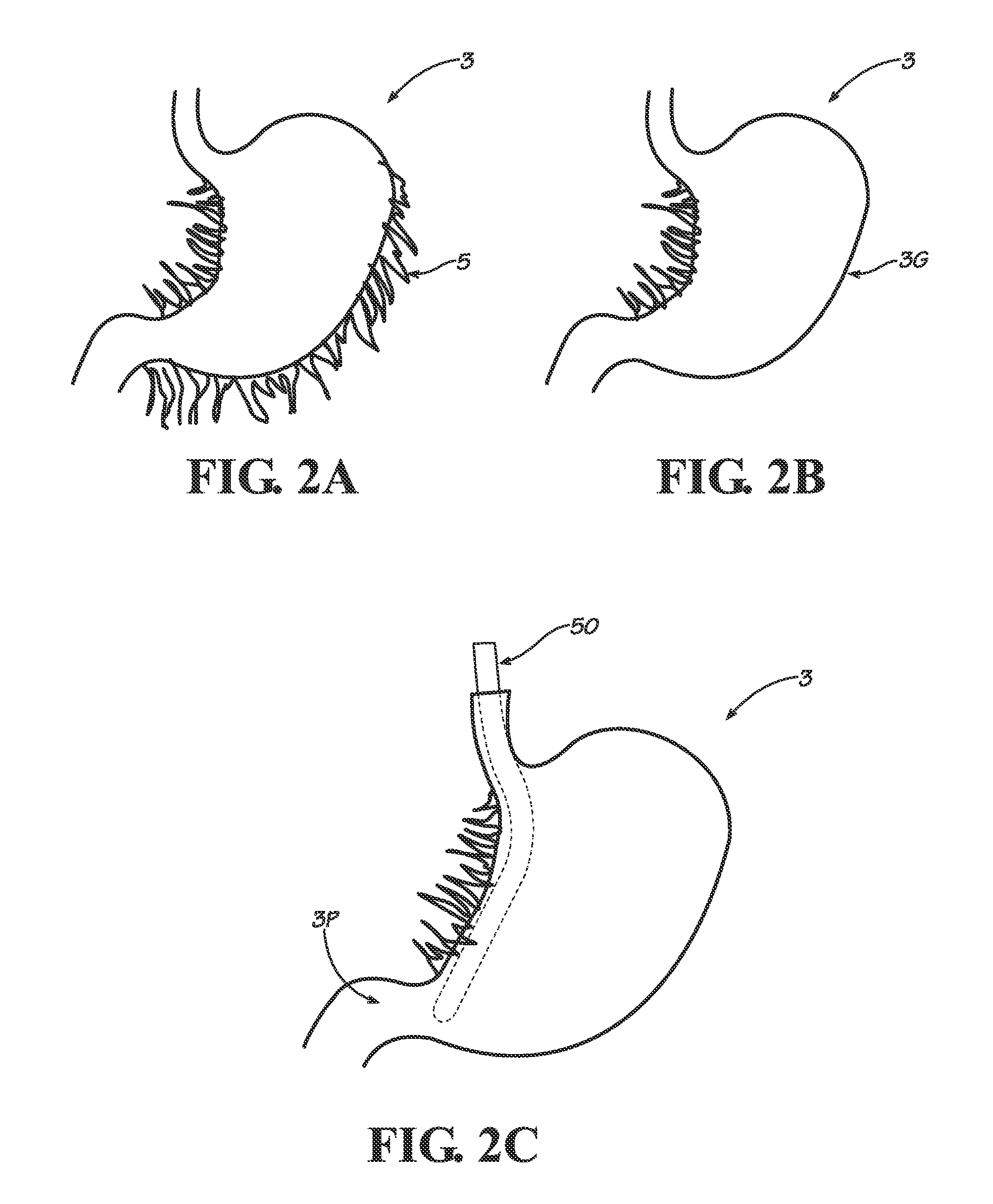

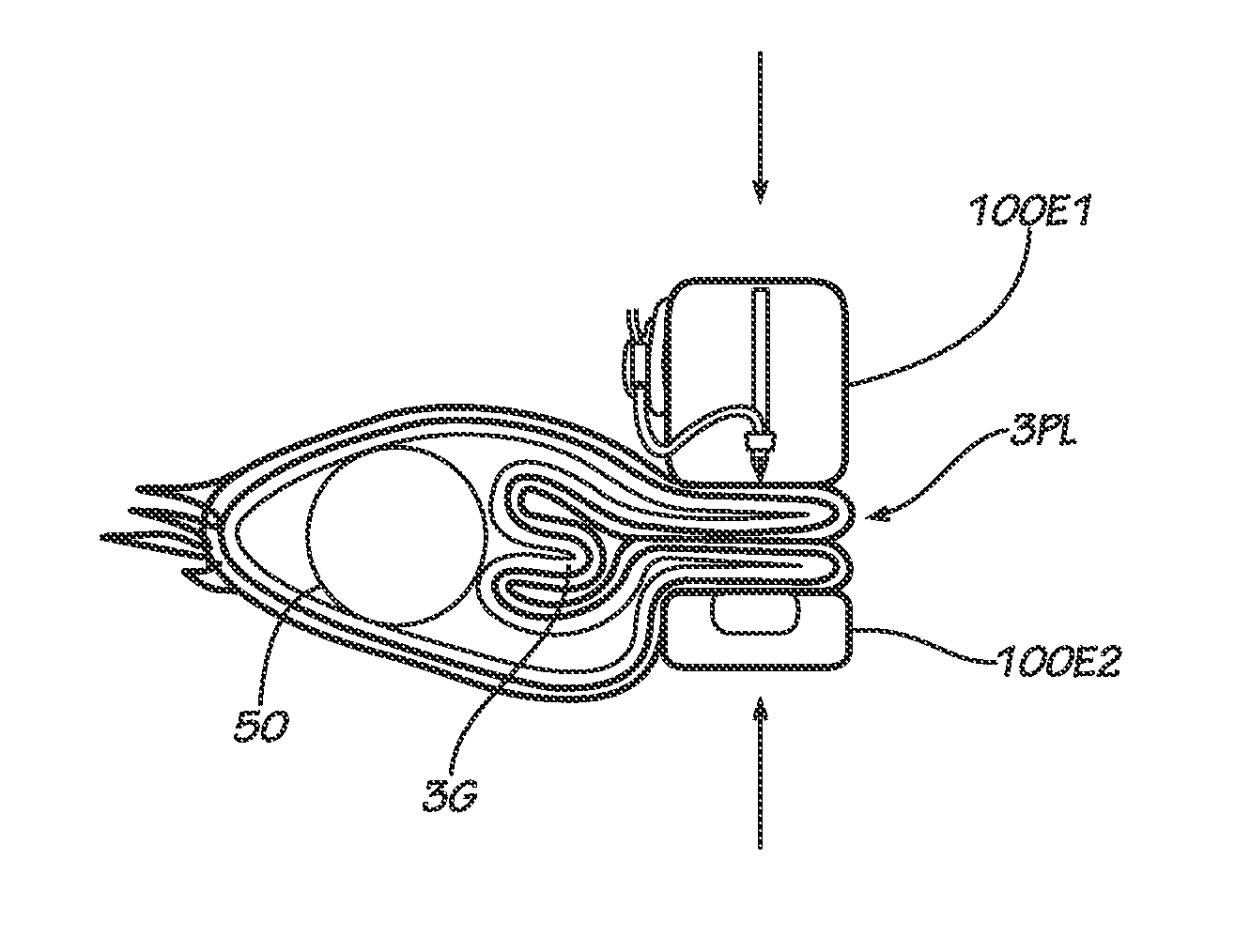

Methods, instruments and devices for extragastric reduction of stomach volume

Methods, instruments and systems are provided for separating opposite walls of the stomach by extragastric application of suction. Plication of the stomach can be performed between the separated walls after which the separate walls are brought back toward one another. In another aspect, methods, instruments, devices and systems are provided for reducing the effective volume of a stomach by performing one or more extragastric plications of the stomach.

Owner:VIBRYNT

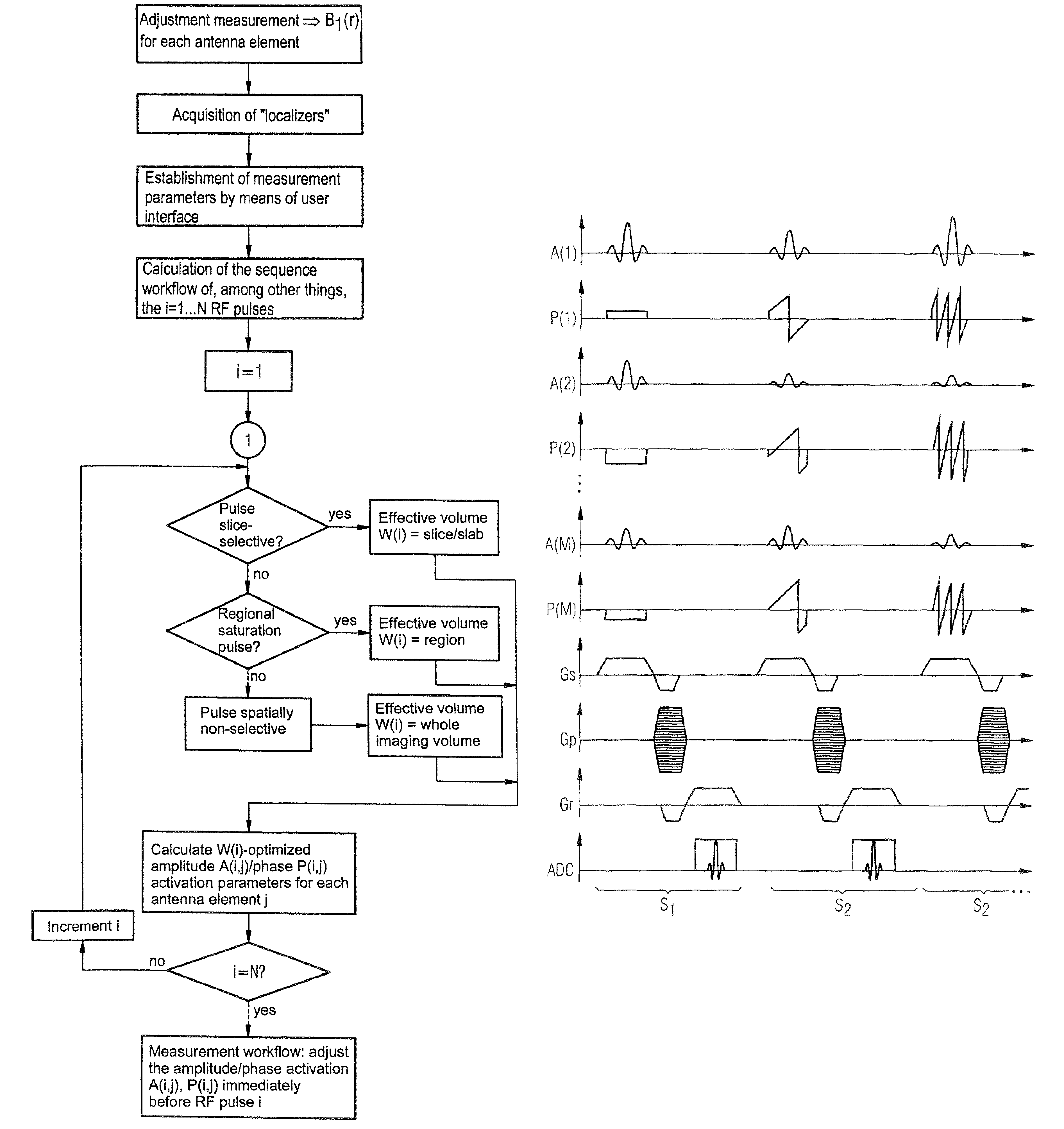

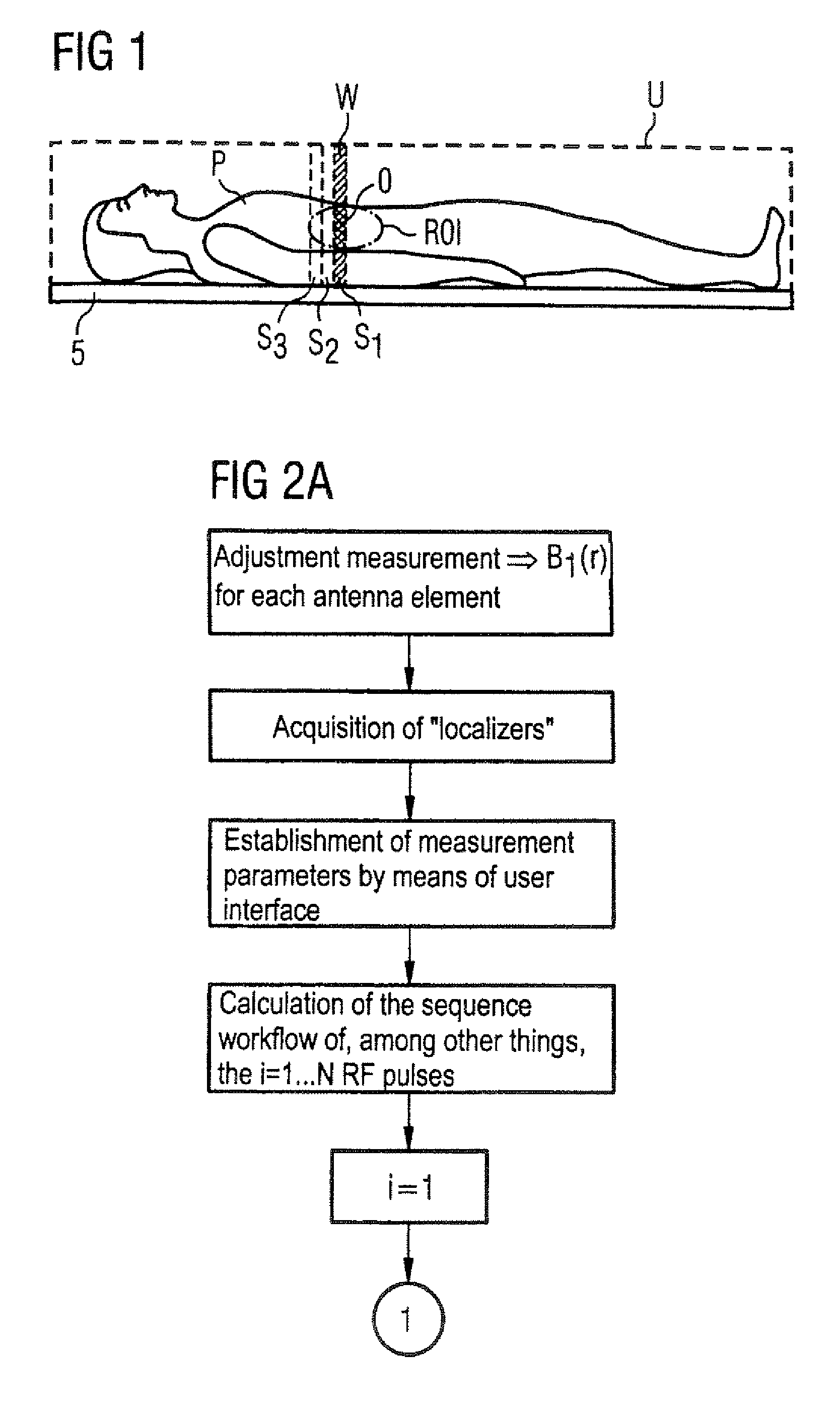

Magnetic resonance system and operating method for RF pulse optimization

ActiveUS20050189940A1Easy to optimizeBetter optimizedDiagnostic recording/measuringSensorsResonanceSpecific volume

In a magnetic resonance system and an operating method therefor, a B1 field distribution of a radio-frequency antenna is measured in at least one part of a examination volume of the magnetic resonance system, and then the RF pulses emitted by the radio-frequency antenna are optimized, based on the determined B1 field distribution, for homogenization in a specific volume. An effective volume within the examination volume is determined beforehand for each applied RF pulse and, based on the determined B1 field distribution, the appertaining RF pulse is individually adjusted such that the B1 field is homogenized within the effective volume of the RF pulse.

Owner:SIEMENS HEALTHCARE GMBH

Pipettor and externally sealed pipette tip

InactiveUS20030190263A1Reduce manufacturing costReduce maintenanceWithdrawing sample devicesBurettes/pipettesPipetteEffective volume

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way.

Owner:YIU FELIX H

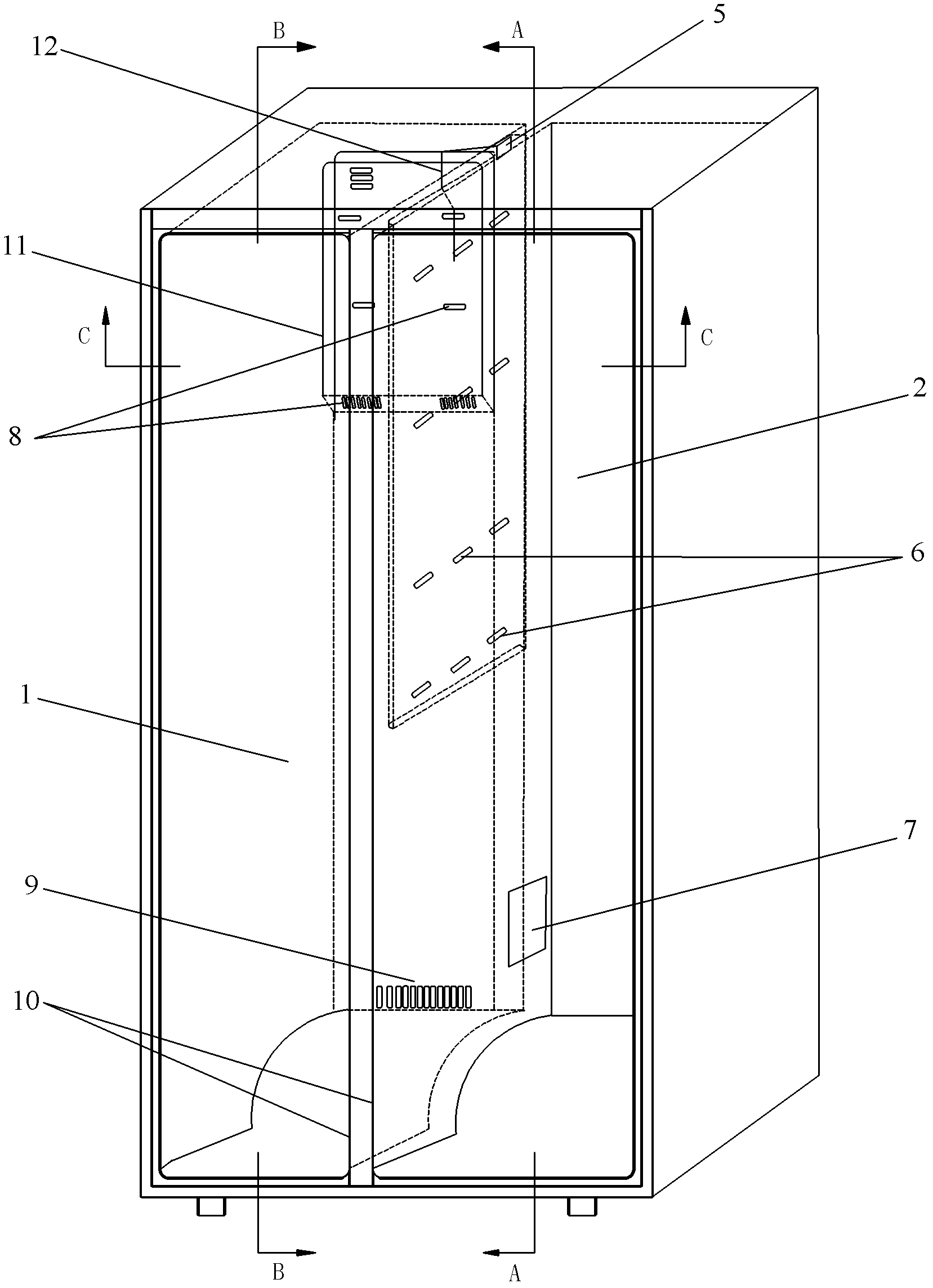

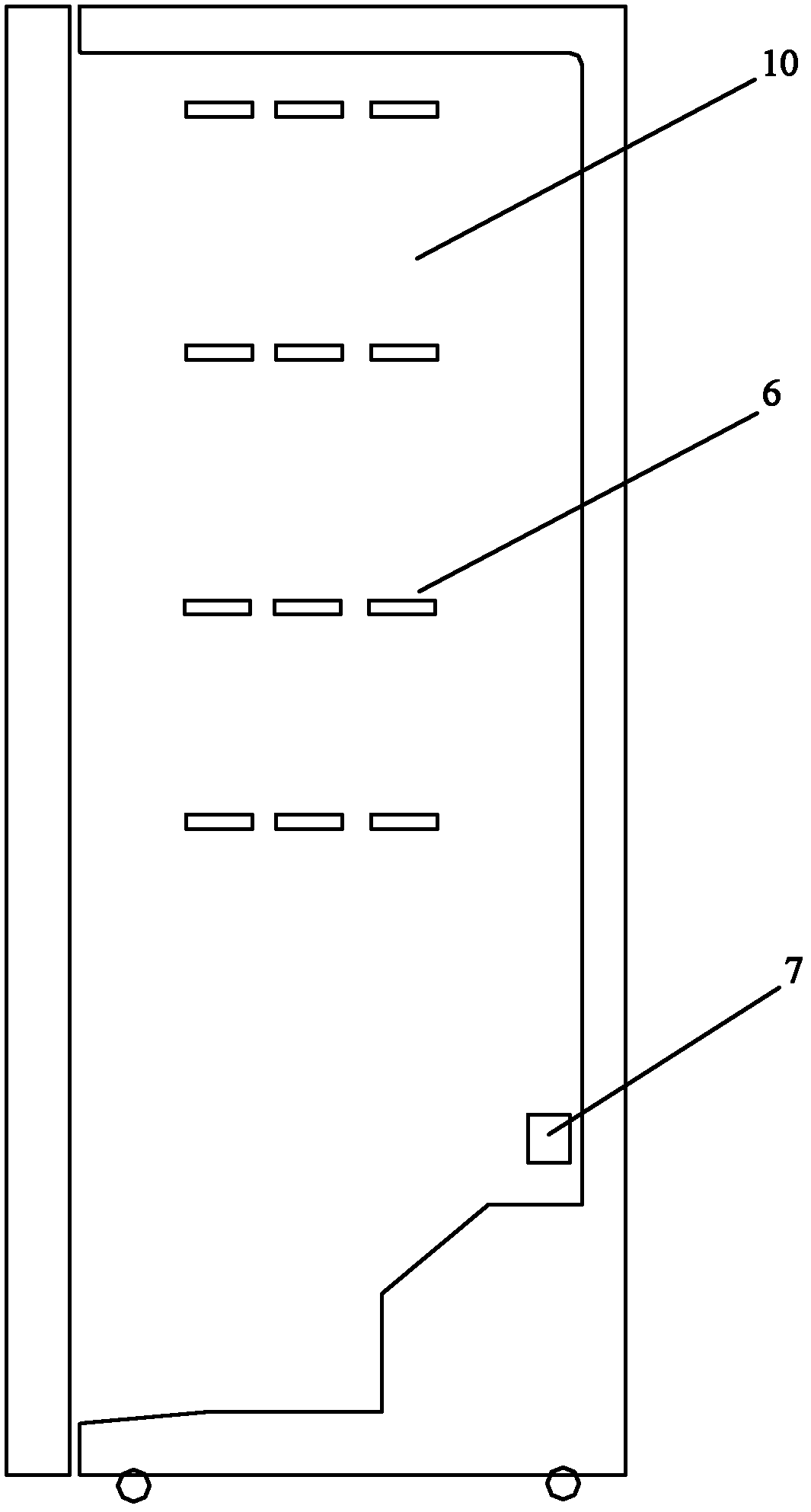

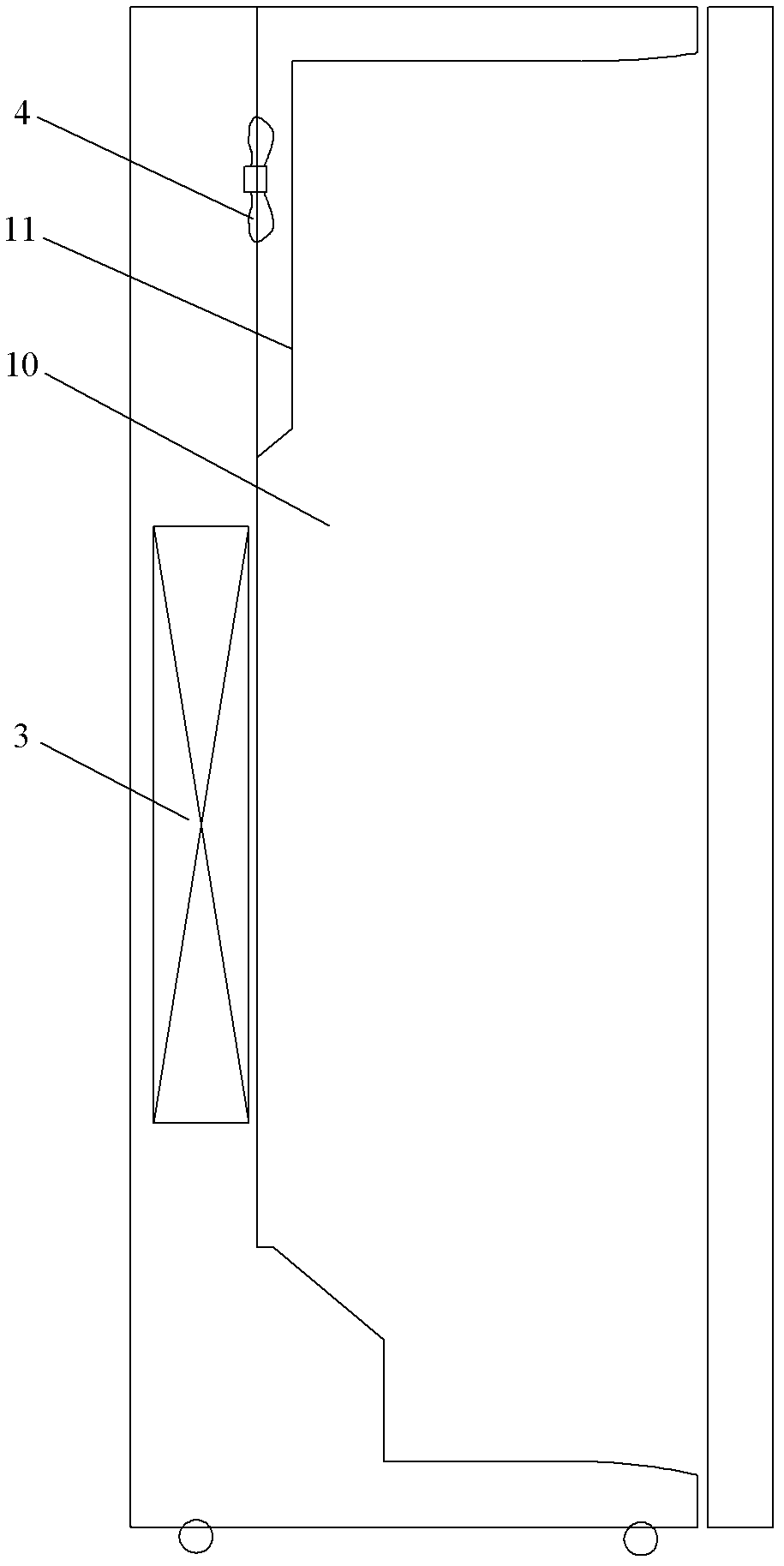

Refrigerator

InactiveCN102494460AImprove uniformityLighting and heating apparatusDomestic refrigeratorsEffective volumeRefrigerated temperature

The invention provides a refrigerator. The refrigerator comprises a freezing chamber and a refrigerating chamber, wherein the freezing chamber and the refrigerating chamber are arranged side by side; an evaporator is arranged in the freezing chamber; clapboards are arranged between the freezing chamber and the refrigerating chamber; a refrigerating chamber duct is longitudinally formed in the clapboards and is communicated with the evaporator and the refrigerating chamber respectively; a plurality of refrigerating chamber air supply outlets are longitudinally arranged on the wall, on the side of the refrigerating chamber, of the clapboards; and the cool air generated by the evaporator enters the refrigerating chamber via the refrigerating chamber duct and the refrigerating chamber air supply outlets. The refrigerator has the following beneficial effects that: occupation of the volume in the refrigerating chamber can be avoided; and the effective volume of the refrigerating chamber can be enlarged.

Owner:HAIER GRP CORP +1

Novel method for proportioning ore grinding media

The invention relates to the technical field of ore grinding medium addition for large ball mills, in particular to a novel method for proportioning ore grinding media, which comprises the following steps of: (1) making regulations on composition of feed granularities for a ball mill; (2) adding two ore grinding media different in diameter at the same time according to the regulated composition of feed granularities; (3) keeping two ore grinding media different in diameter in proportion by weight of 1: (0.9-1.1); (4) keeping the filling ratio of the ore grinding media for the ball mill at 38-42%; and (5) determining the adding quantity and the adding cycle of the ore grinding media in each time according to the effective volume of the ball mill, wherein the ore grinding media are steel balls, the adding cycle of the ore grinding media respectively is 24h, 12h, 8h, 4h, or 2h, and the steel ball is 127mm, 120mm, 110mm, 100mm or 80mm in diameter. The method for proportioning the ore grinding media has the beneficial effects that the yield of coarse grade products is reduced, the yield of fine grade products is increased, the ore grinding efficiency of the ball mill is improved, and the composition of ore grinding granularities is improved at certain degree to satisfy the requirement of follow-up grading work.

Owner:ANSTEEL GRP MINING CO LTD

Green coal bed methane fracturing fluid compositions, methods of preparation and methods of use

The invention describes improved environmentally friendly, non-toxic, CBM friendly, green fracturing compositions, methods of preparing fracturing compositions and methods of use. Importantly, the subject invention overcomes problems in the use of water-based mists as an effective fracturing composition particularly having regard to the ability of a mist to transport an effective volume of proppant into a formation. As a result, the subject technologies provide an effective economic solution to using high ratio gas fracturing compositions that can be produced in a continuous (i.e. non-batch) process without the attendant capital and operating costs of current pure gas fracturing equipment.

Owner:CALFRAC WELL SERVICES

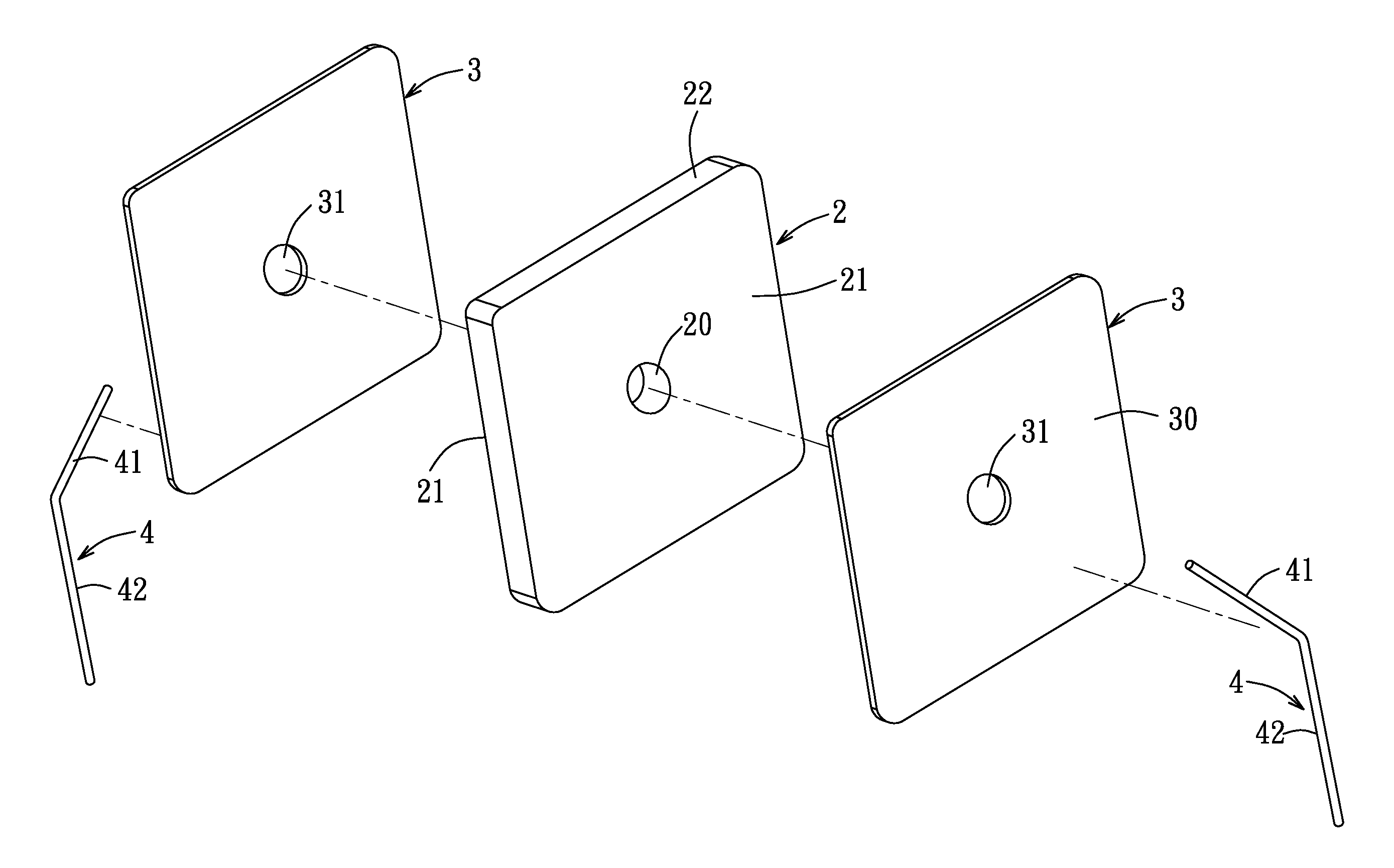

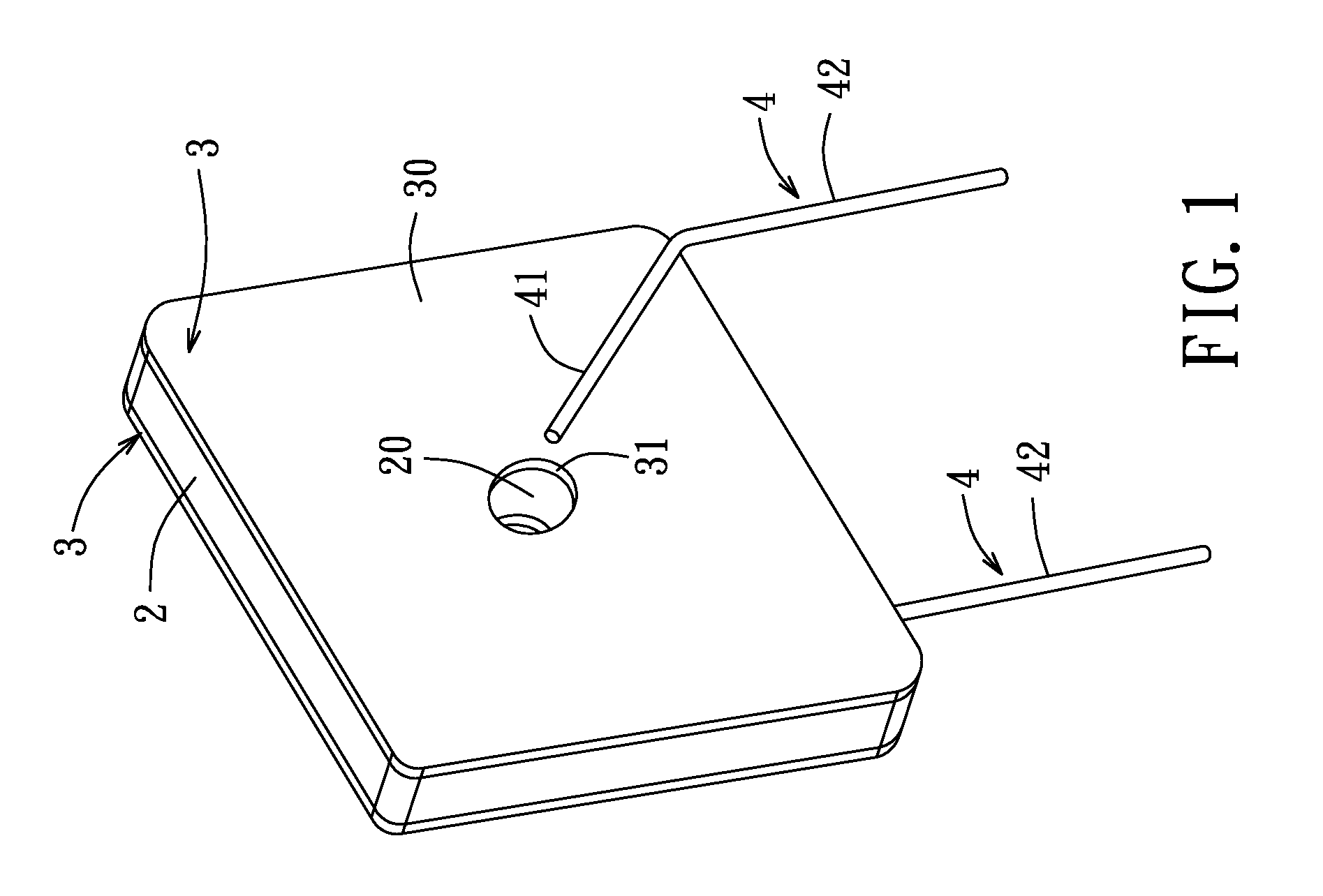

Insertable polymer PTC over-current protection device

ActiveUS8508328B1Overcomes drawbackCurrent responsive resistorsPositive temperature coefficient thermistorsEngineeringThermal expansion

An insertable PPTC over-current protection device includes: first and second electrodes; a solder material; conductive lead pins bonded to the first and second electrodes, respectively, each of the lead pins having a connecting segment extending along and bonded to an outer surface of the respective one of the first and second electrodes through the solder material, and a free segment extending outwardly from the connecting segment beyond a peripheral edge of the respective one of the first and second electrodes; and a PTC polymer matrix laminated between the first and second electrodes. The PTC polymer matrix is formed with at least one hole that has an effective volume to accommodate thermal expansion of the PTC polymer matrix.

Owner:FUZETEC TECHNOLOGY CO LTD

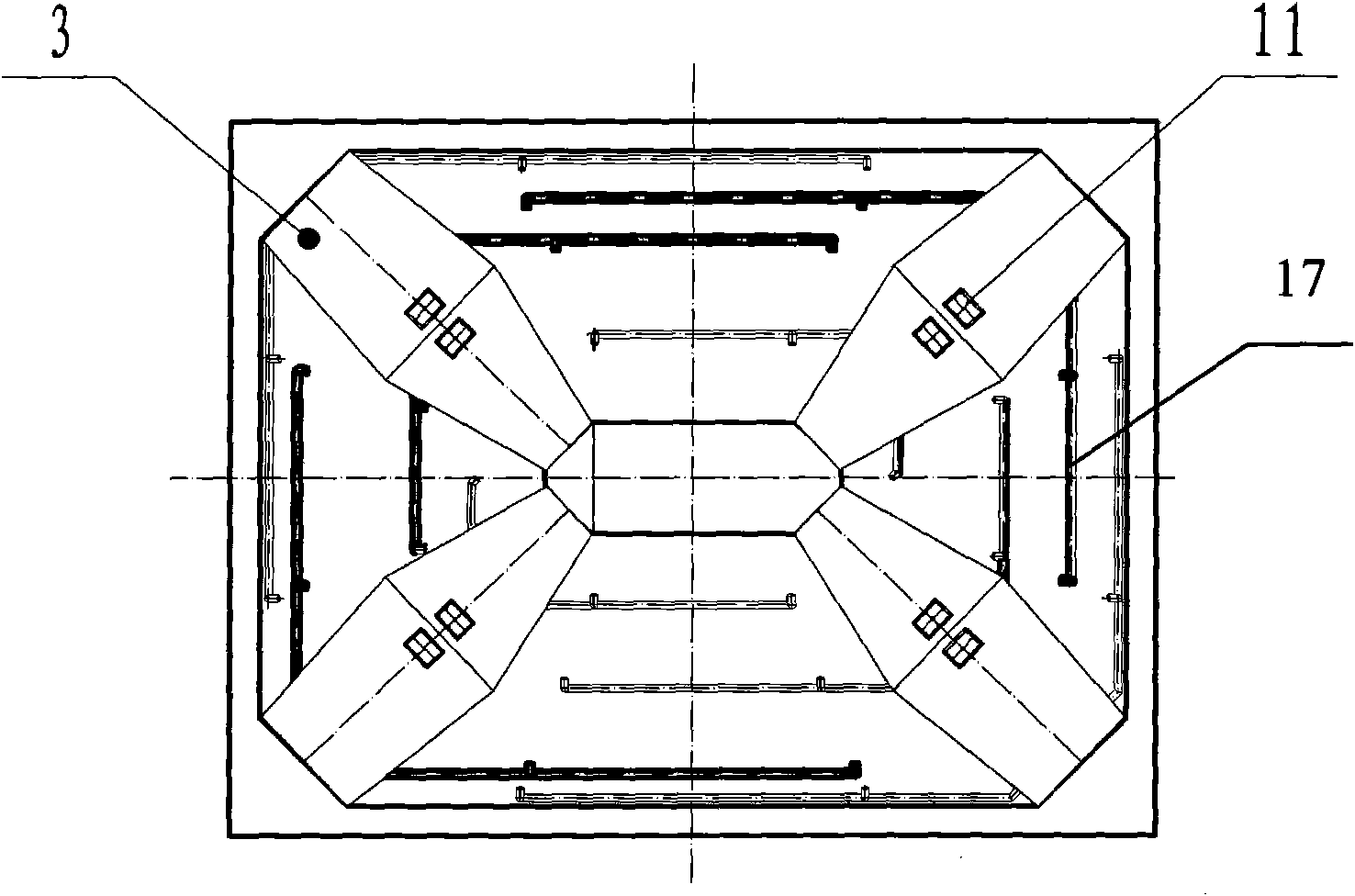

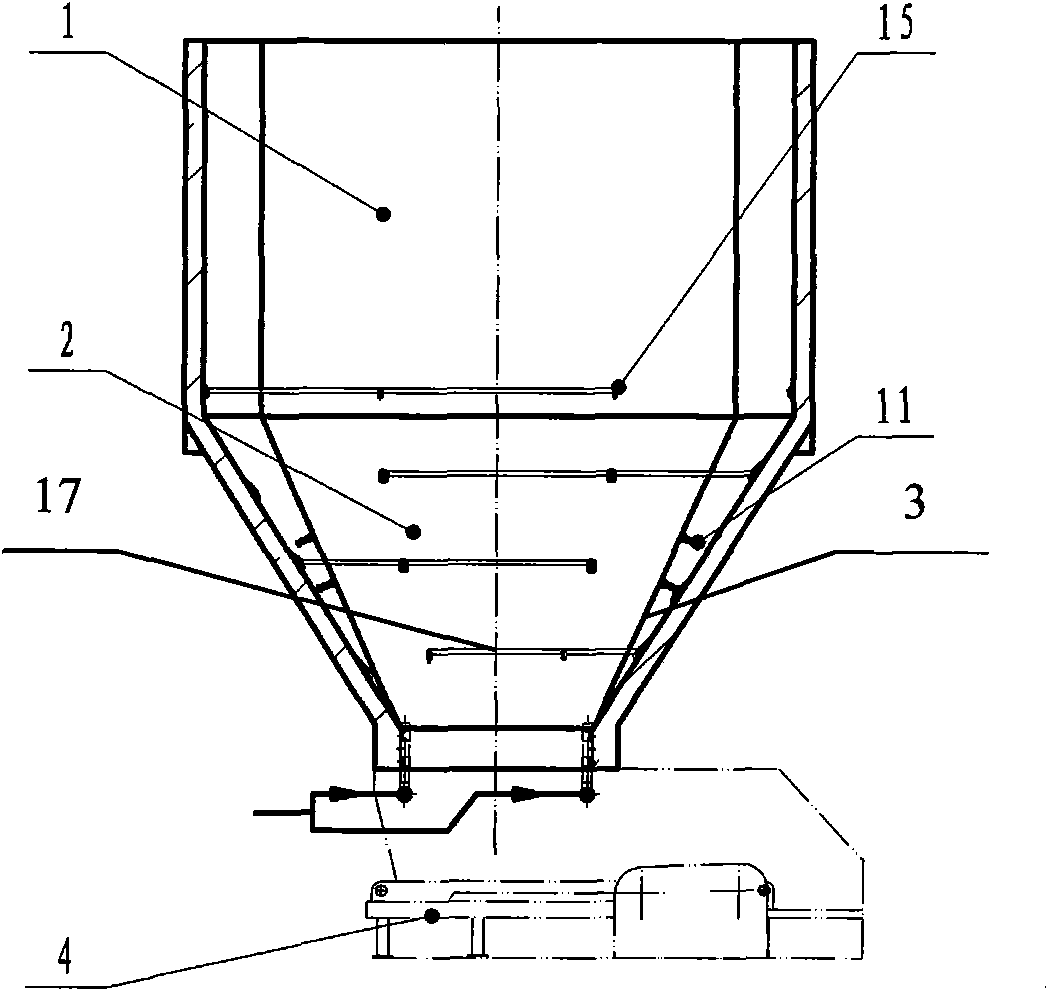

Device for eliminating blocking stocks from reinforced concrete ore bin and using method thereof

The invention discloses a device for eliminating blocking stocks from a reinforced concrete ore bin and a using method thereof. Multi-layer pneumatic flow-aiding air pipes (17) are additionally arranged on the bin wall of an ore bin cone (2), pneumatic flow-aiding nozzles (15) with different ejection directions are arranged on the pneumatic flow-aiding air pipe (17), and the pneumatic flow-aidingair pipe (17) is connected with an air compressor by a pipeline; carbon-manganese plates or steel plates (3) are paved at four pyramid angles in a rectangular funnel bin of the reinforced concrete orebin, and a pneumatic vibration hammer (11) is additionally arranged at the rear part of the carbon-manganese plate or the steel plate (3); and the pneumatic vibration hammer (11) is connected with apulse electromagnetic valve set, a pneumatic triplet piece and the air compressor in sequence by pipelines. In the using method, all groups of nozzles are controlled to ventilate according to the ejection sequence from the bottom layer to the top layer, the interval time can be adjusted within 1-9 seconds, the flow-aiding air pressure is set between 0.4MPa and 0.8MPa, and the air pressure of the pneumatic vibration hammer is controlled between 0.5MPa and 0.7MPa. The invention can eliminate the blocking stocks in the ore thoroughly, ensure smooth feeding in ore dressing production, simple structure, reliable working and convenient operation, and improve the effective volume utilization ratio of the ore bin by 1 / 4-1 / 3.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Fluidized bed film bioreactor for sewage treatment

InactiveCN102167469AReduce pollutionExtended service lifeMultistage water/sewage treatmentWaste rubberTotal nitrogen

The invention discloses a fluidized bed film bioreactor for sewage treatment, which belongs to the technical field of water and waste water treatment. The invention utilizes a process combining a biological fluidized bed with a film bioreactor, i.e. the reactor is filled with self-produced carrier granules with a diameter of about 5mm, wherein the carrier granules are made of waste rubber powder, activate carbon and adhesive, and the filling ratio is 10-30% of the effective volume of the reactor. By means of the synergistic effect of the carriers and sludge to finish the film forming process, microorganism is grown on the filler to reduce the concentration of the sludge in the reactor, change the environment running condition of the reactor and slow down the film pollution, thus further prolonging the service life of the film and improving the treatment capacity of the film. By filling the self-produced carrier granules in the film bioreactor and using the filler to change and regulate the interior microenvironment of the fluidized bed film bioreactor, such as dissolved oxygen (DO), the quantity of the filler and the water retention time, a local anoxic zone is formed, thus further realizing the synchronous nitration and denitrification function and improving the removal efficiency of total nitrogen as well as the denitrification efficiency. The fluidized bed film bioreactor for sewage treatment has a simple structure, does not feed the addition of chemical agent, is convenient and efficient to run and operate, can obtain high-quality outlet water, saves energy, can remove various pollutants such as organic matters, total nitrogen and the like, is suitable for treatment of organic waste water such as industrial and domestic waste water and the like, and can be hopefully applied in engineering practice.

Owner:BEIJING FORESTRY UNIVERSITY

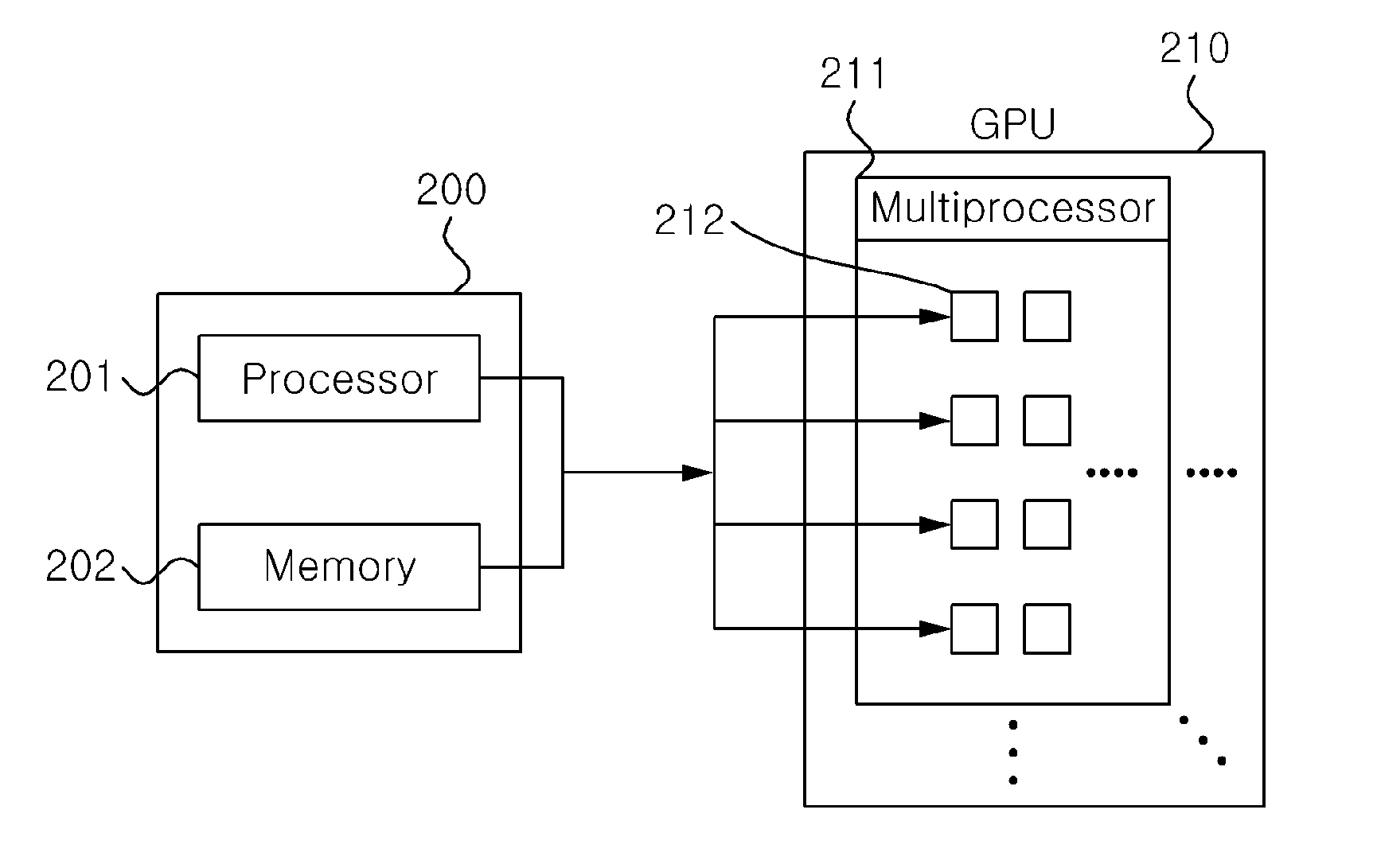

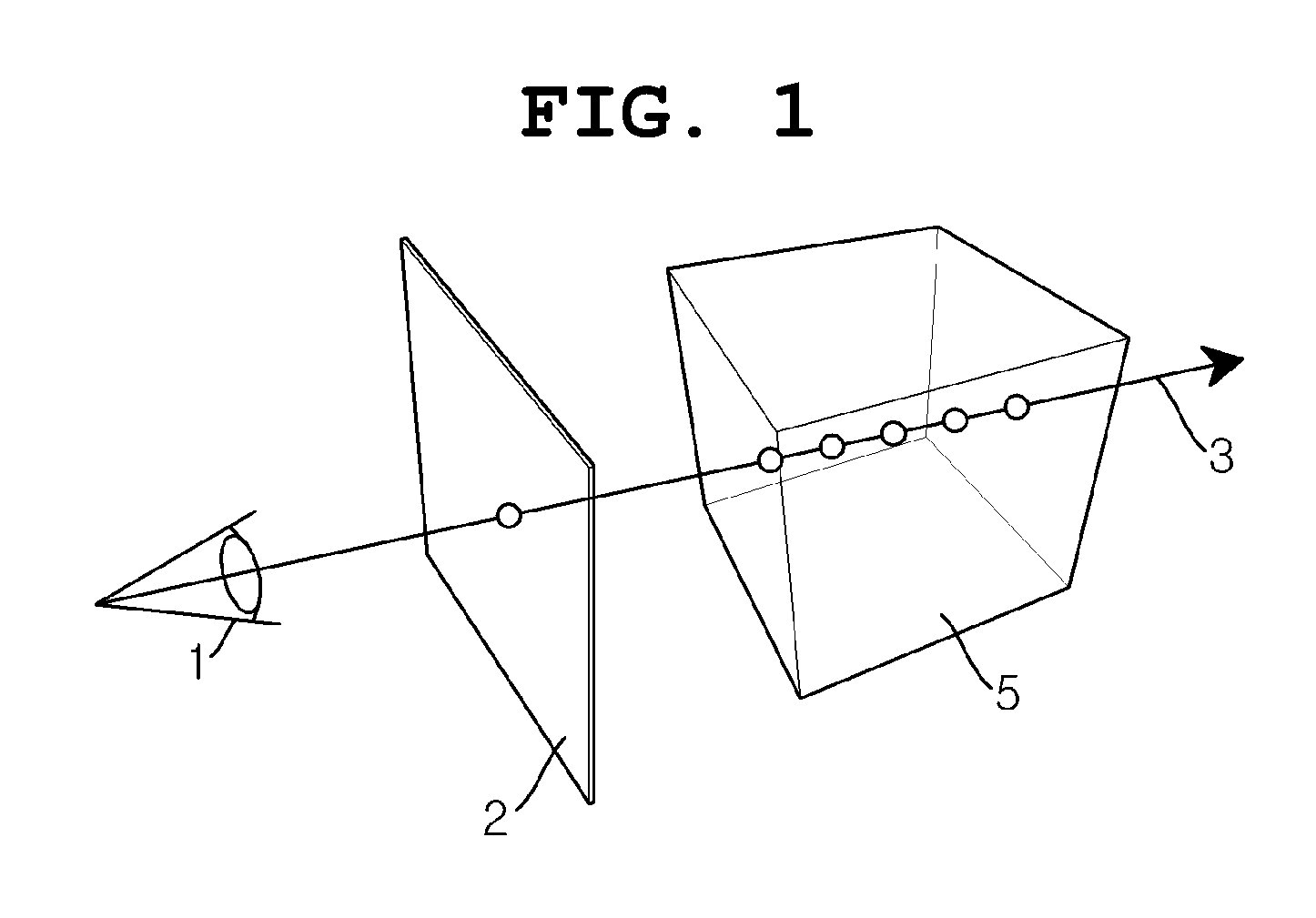

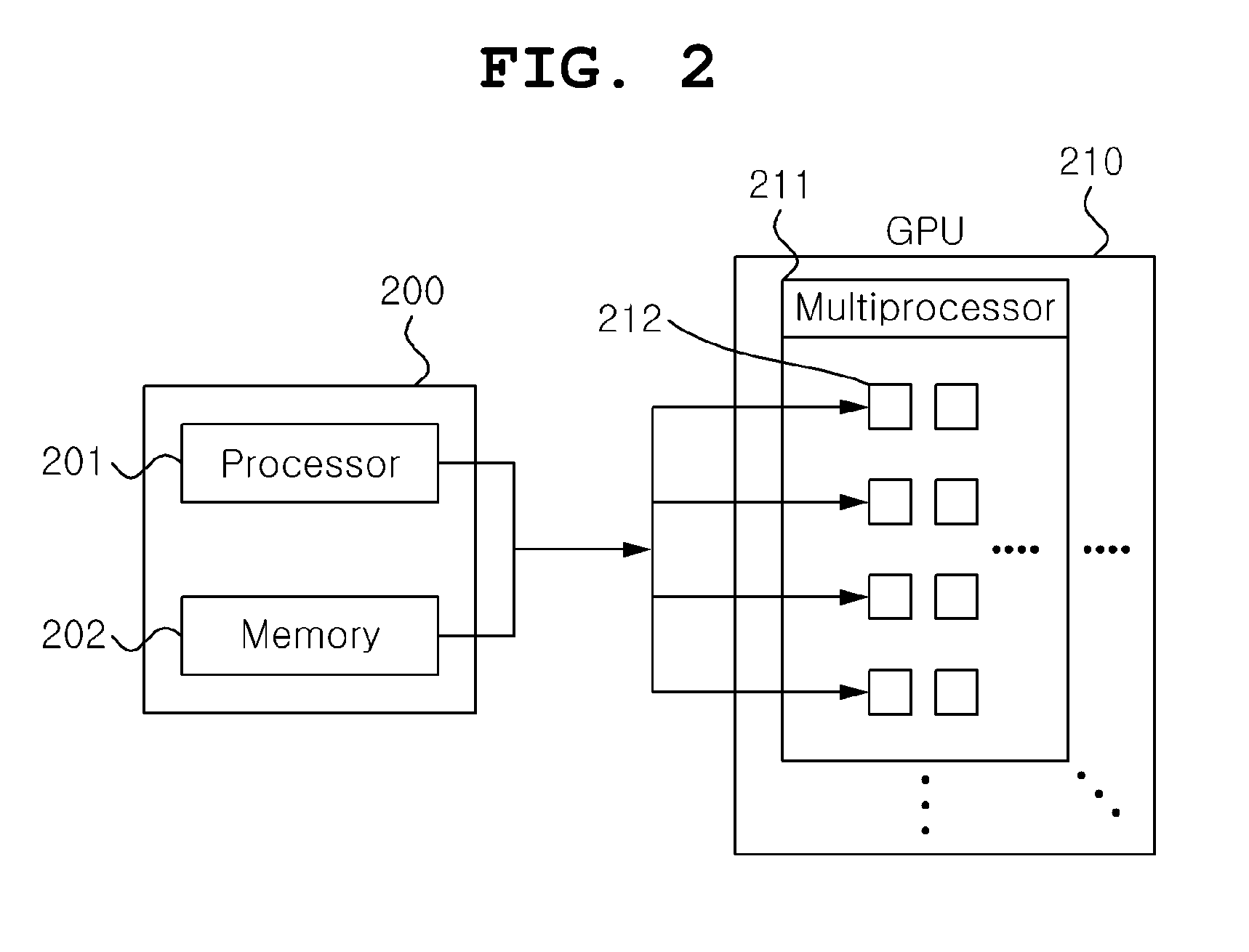

Processor and method for accelerating ray casting

ActiveUS20160350960A1Increase speedImage analysisImage generationViewpointsComputer graphics (images)

A processor and method for accelerating ray casting are disclosed herein. The processor for accelerating ray casting includes a computation unit, a sorting unit, an allocation unit, and an execution control unit. The computation unit calculates the length information of a section in which a ray corresponding to each of the pixels of a two-dimensional (2D) scene corresponding to a viewpoint intersects an effective volume in order to apply ray casting to the pixel. The sorting unit sorts the ray based on the length information of the section in which the ray intersects the effective volume. The allocation unit allocates the sorted rays to respective thread groups having a parallel multiprocessor structure in order of the sorting. The execution control unit transfers control instructions to the allocated thread groups so that the allocated thread groups execute ray casting for the sorted rays.

Owner:CORELINE SOFT

Methods, Instruments and Devices for Extragastric Reduction of Stomach Volume

Methods, instruments and systems are provided for separating opposite walls of the stomach by extragastric application of suction. Plication of the stomach can be performed between the separated walls after which the separate walls are brought back toward one another. In another aspect, methods, instruments, devices and systems are provided for reducing the effective volume of a stomach by performing one or more extragastric plications of the stomach.

Owner:VIBRYNT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com