Patents

Literature

85 results about "Temporary seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

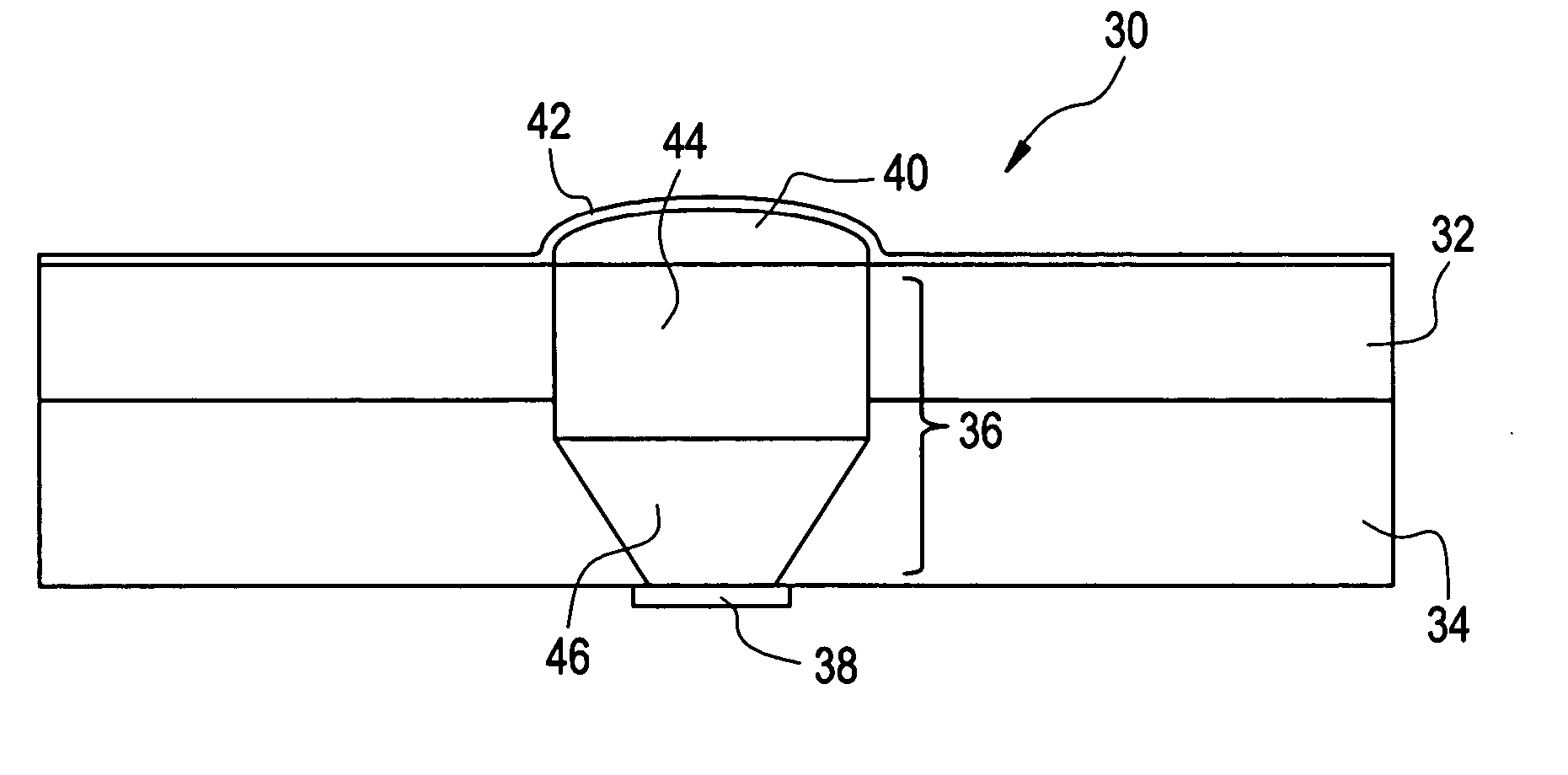

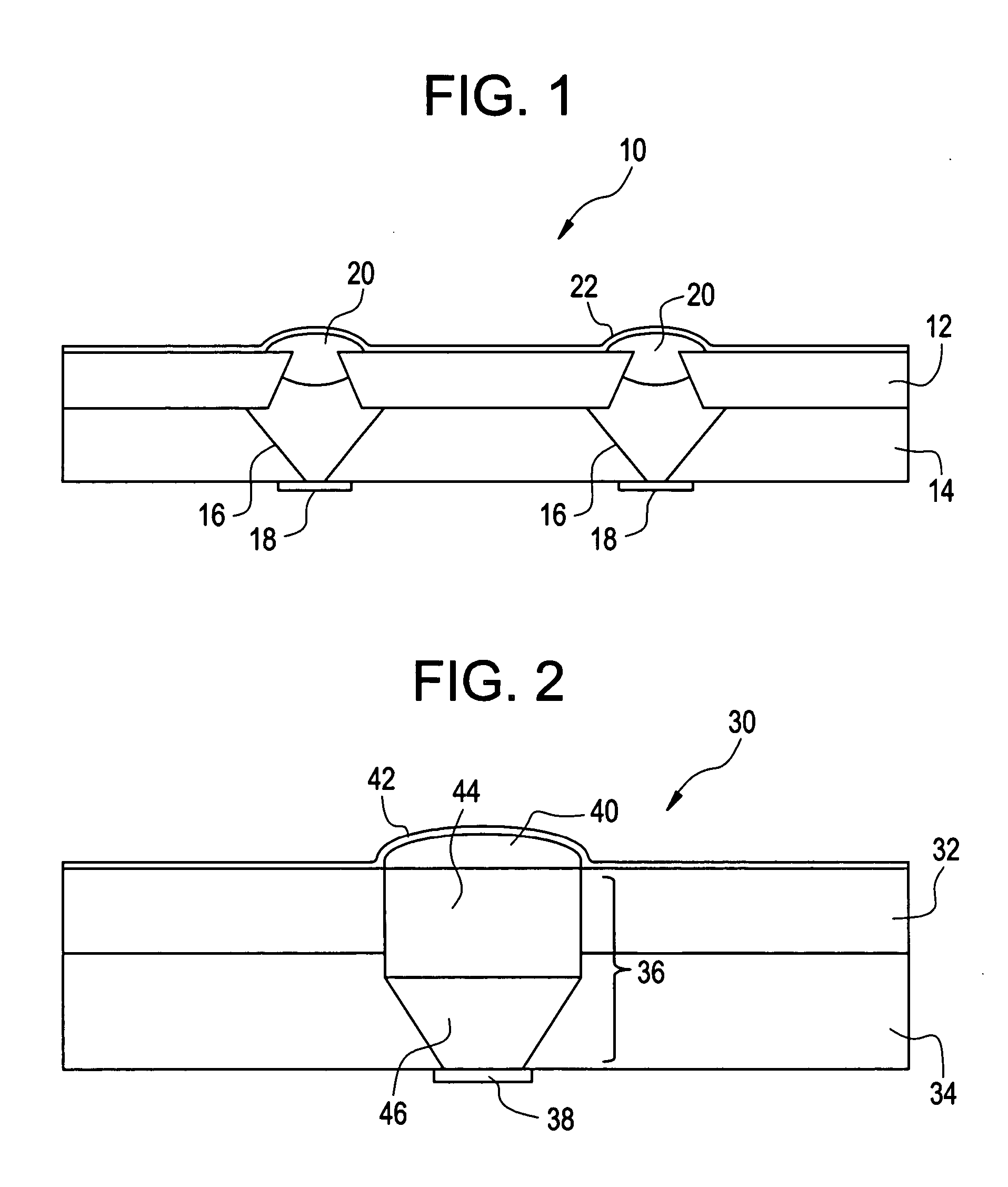

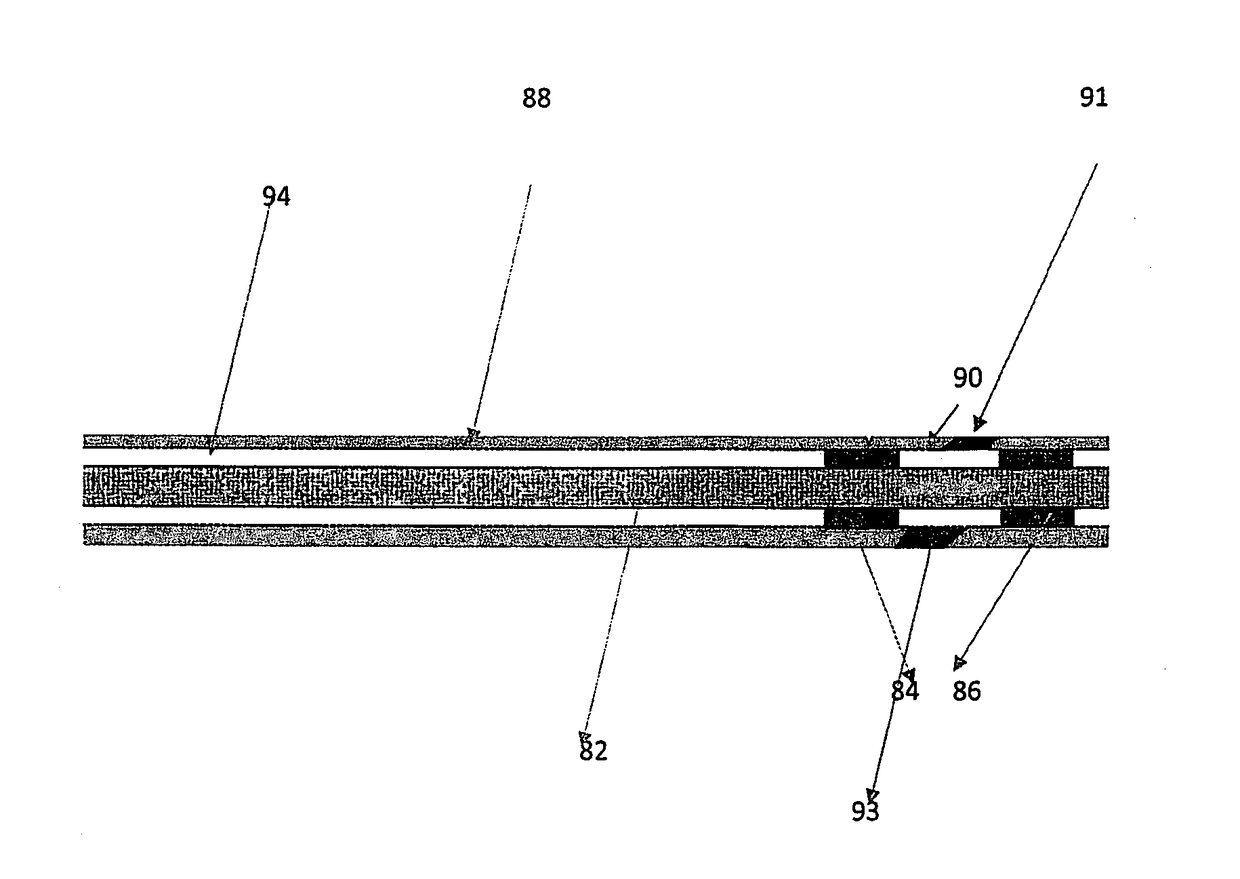

Low temperature methods for hermetically sealing reservoir devices

Methods are provided for hermetically sealing an opening in a reservoir of a containment device. The method comprises applying a polymeric material to an opening in a reservoir of a containment device, the reservoir comprising reservoir contents (such as a drug or a sensor) to be hermetically isolated within the reservoir, the applied polymeric material closing off the opening and forming a temporary seal; and adhering a hermetic sealing material onto the polymeric material to hermetically seal the opening. The reservoir can be a micro-reservoir. The containment device can comprises an array of two or more of reservoirs, and the method comprises hermetically sealing each of the two or more reservoirs.

Owner:MICROCHIPS BIOTECH INC

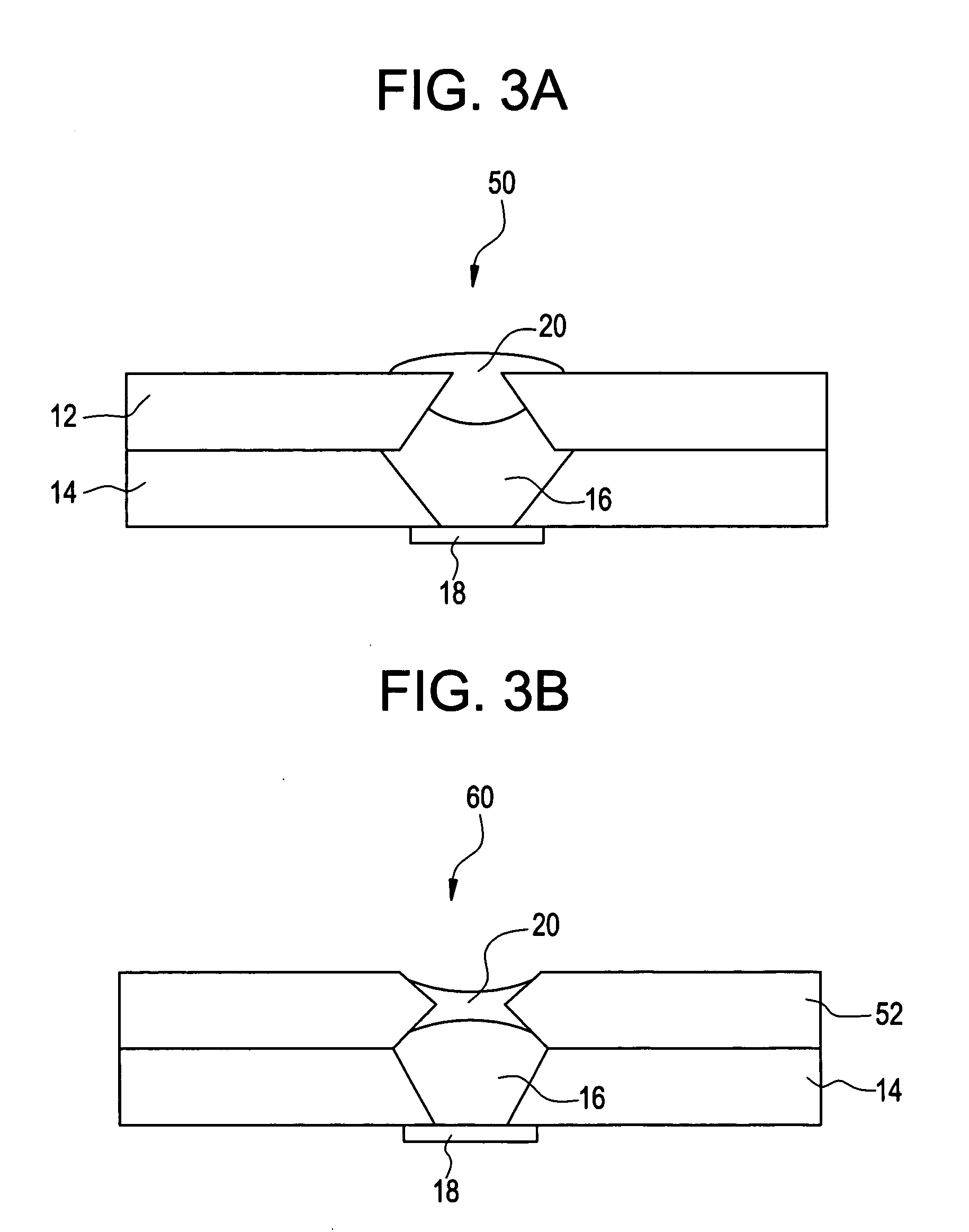

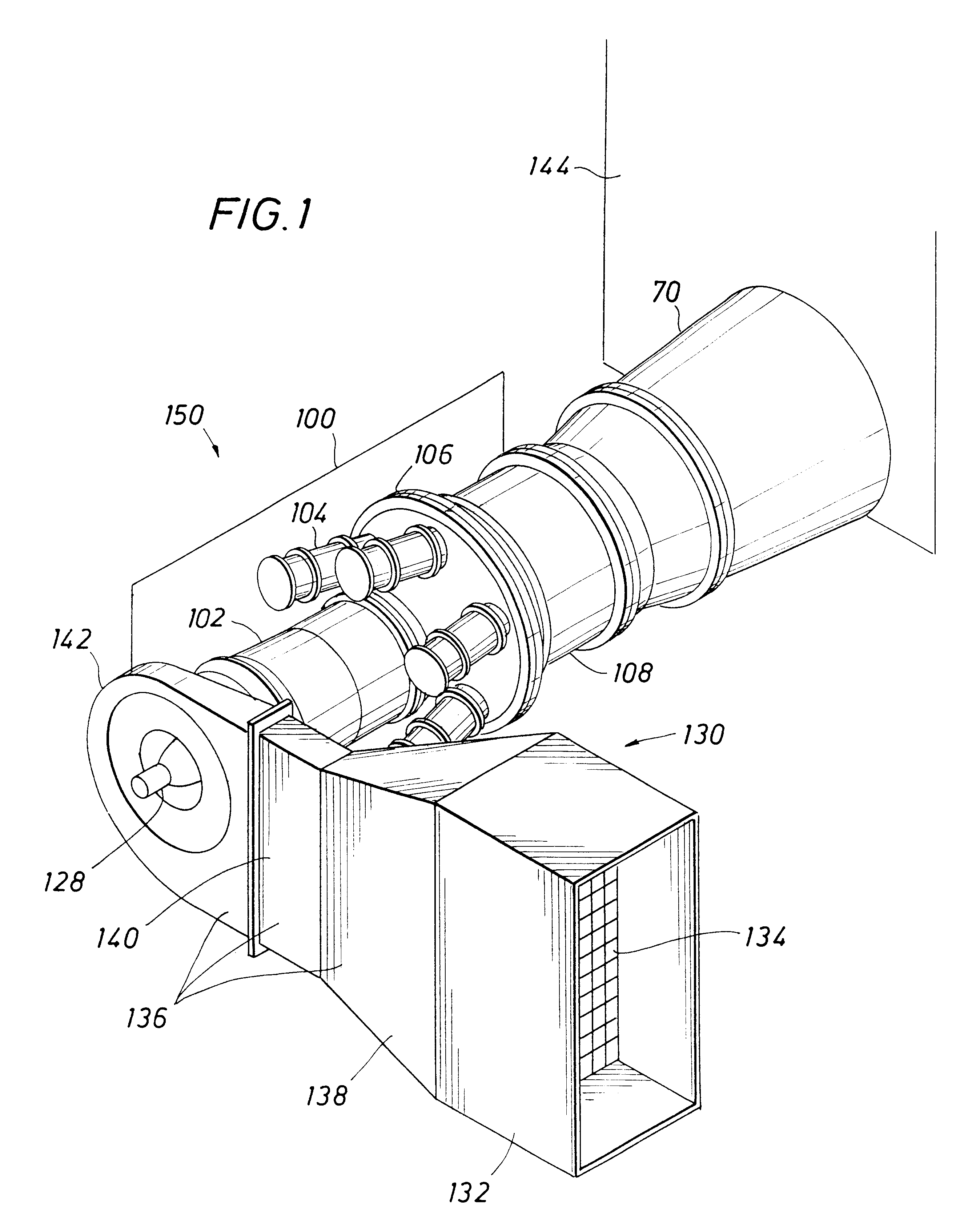

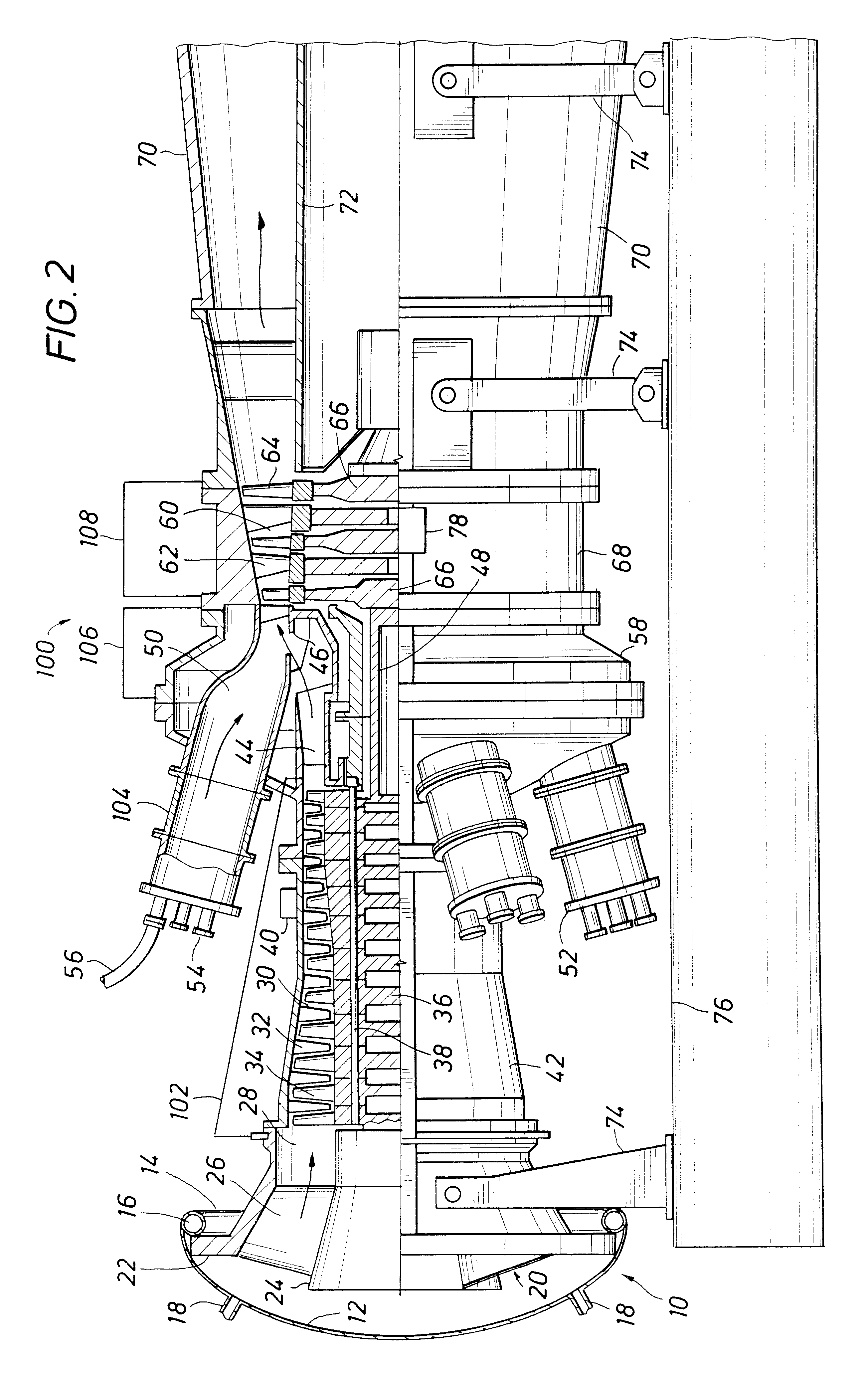

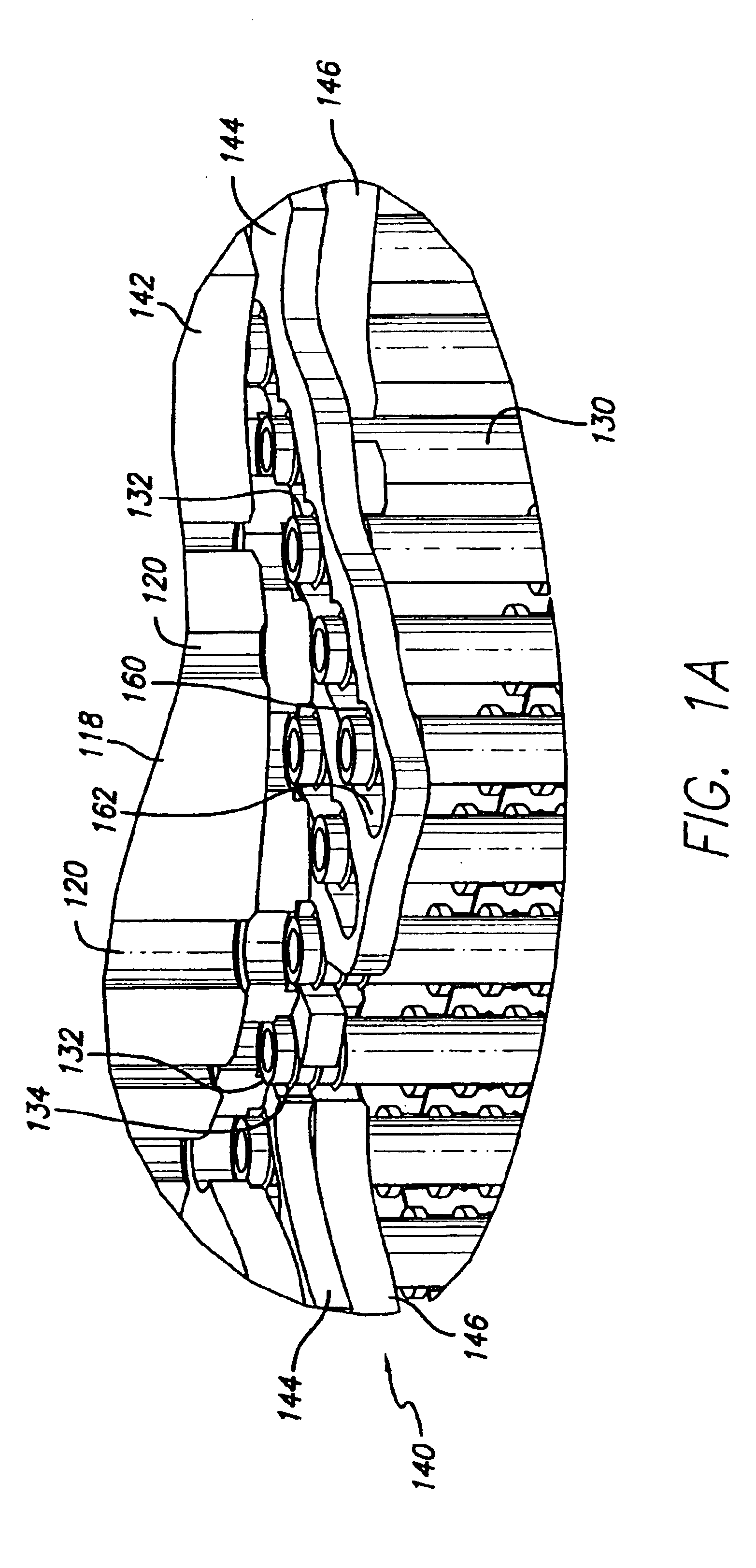

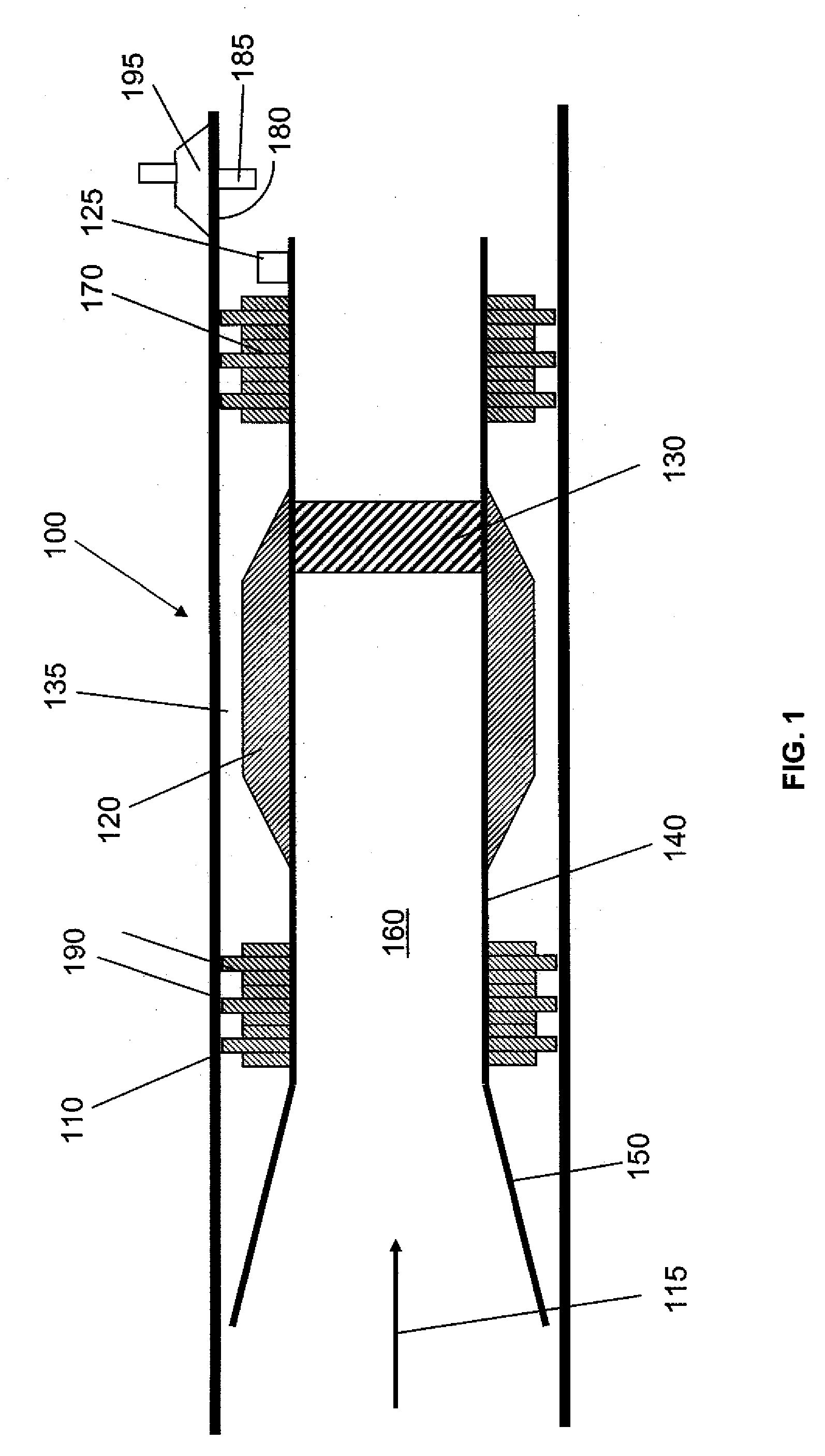

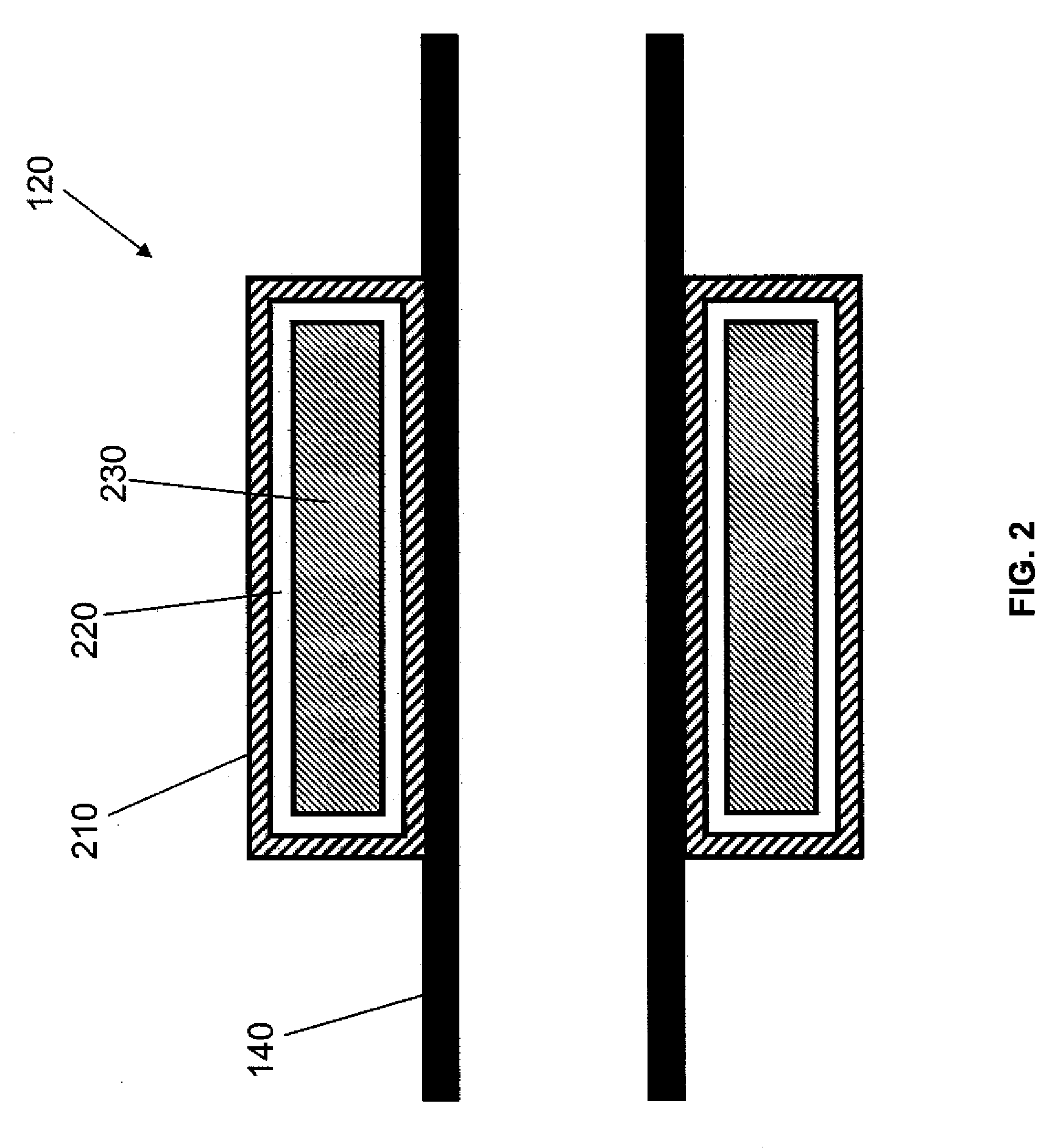

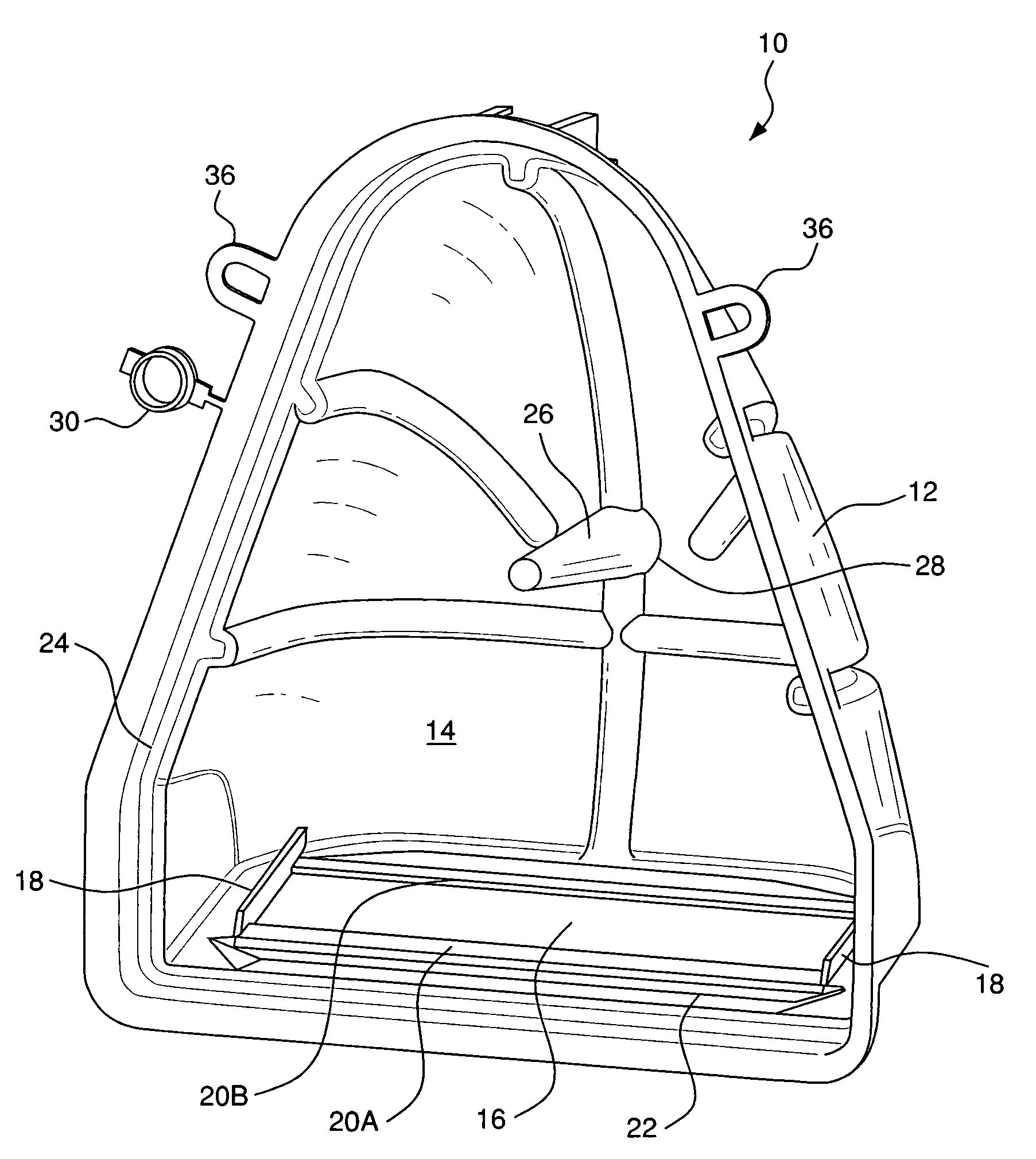

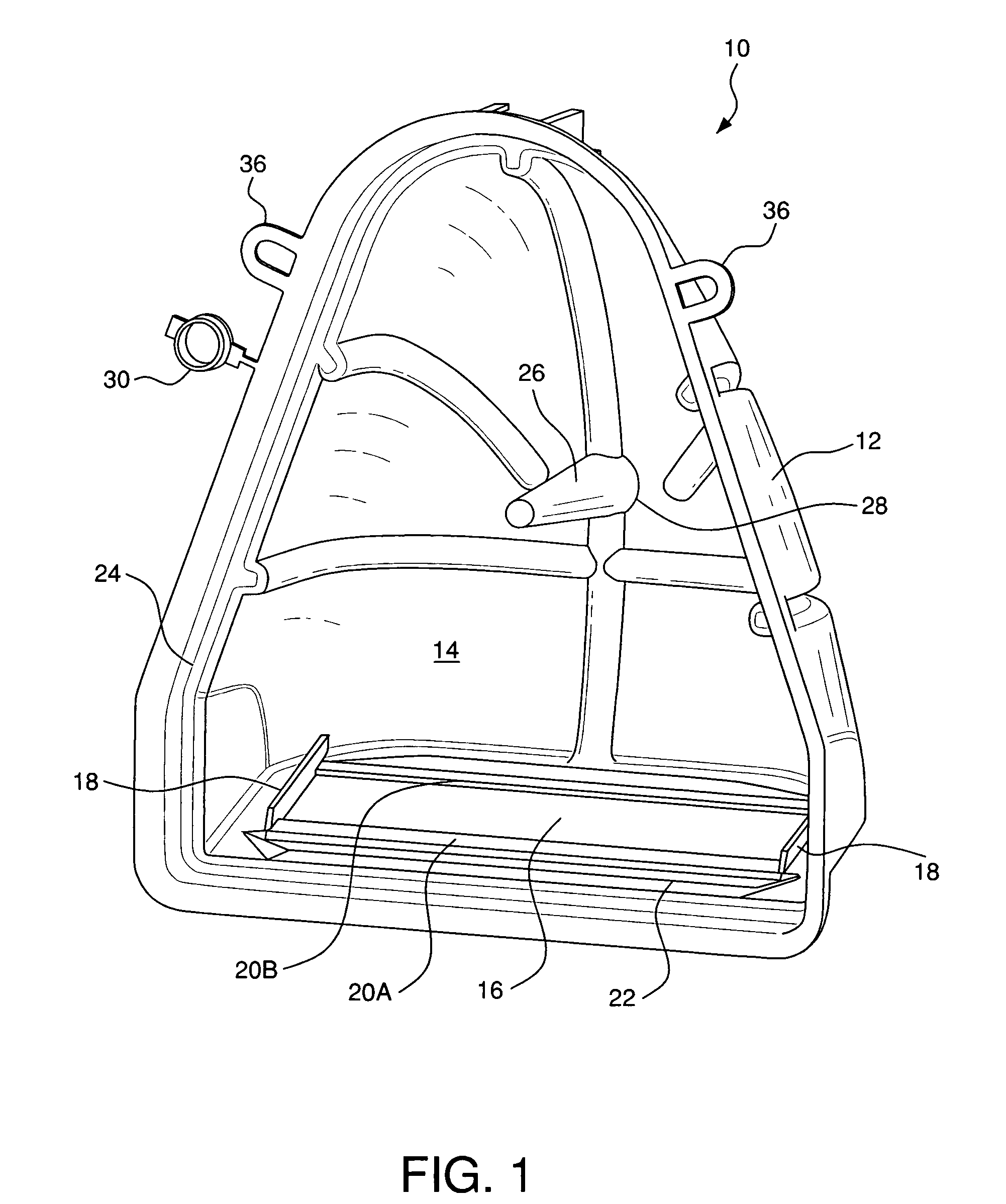

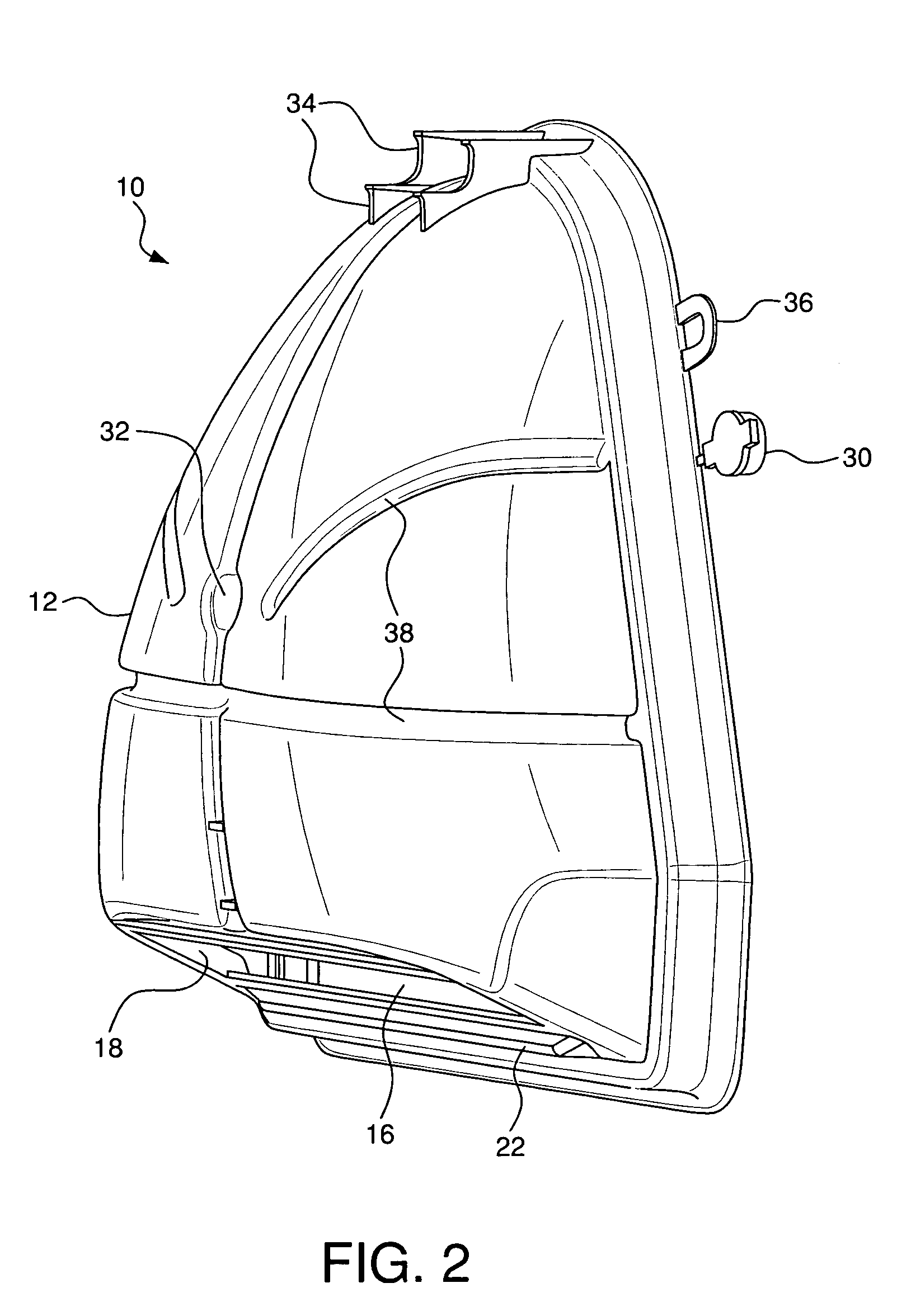

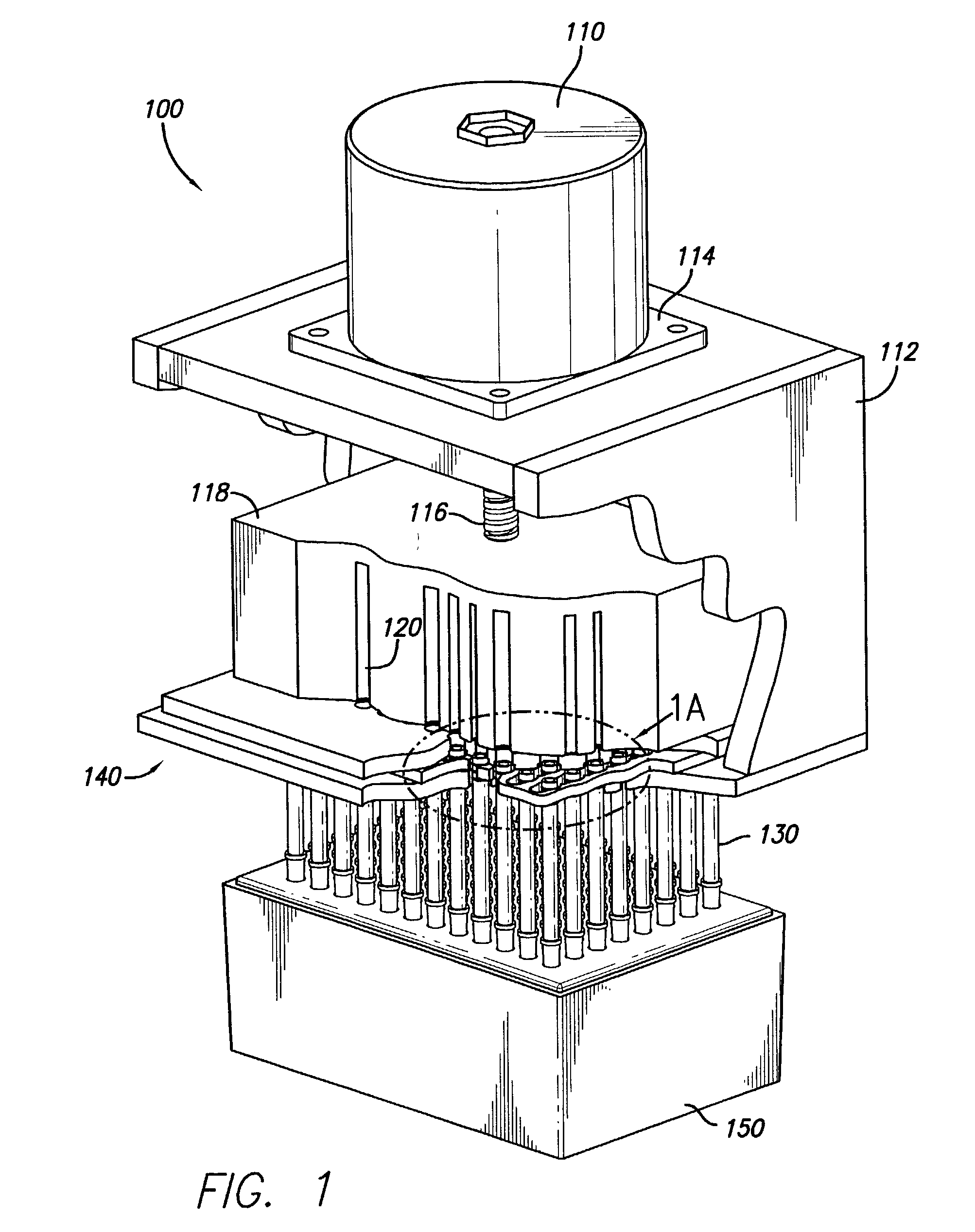

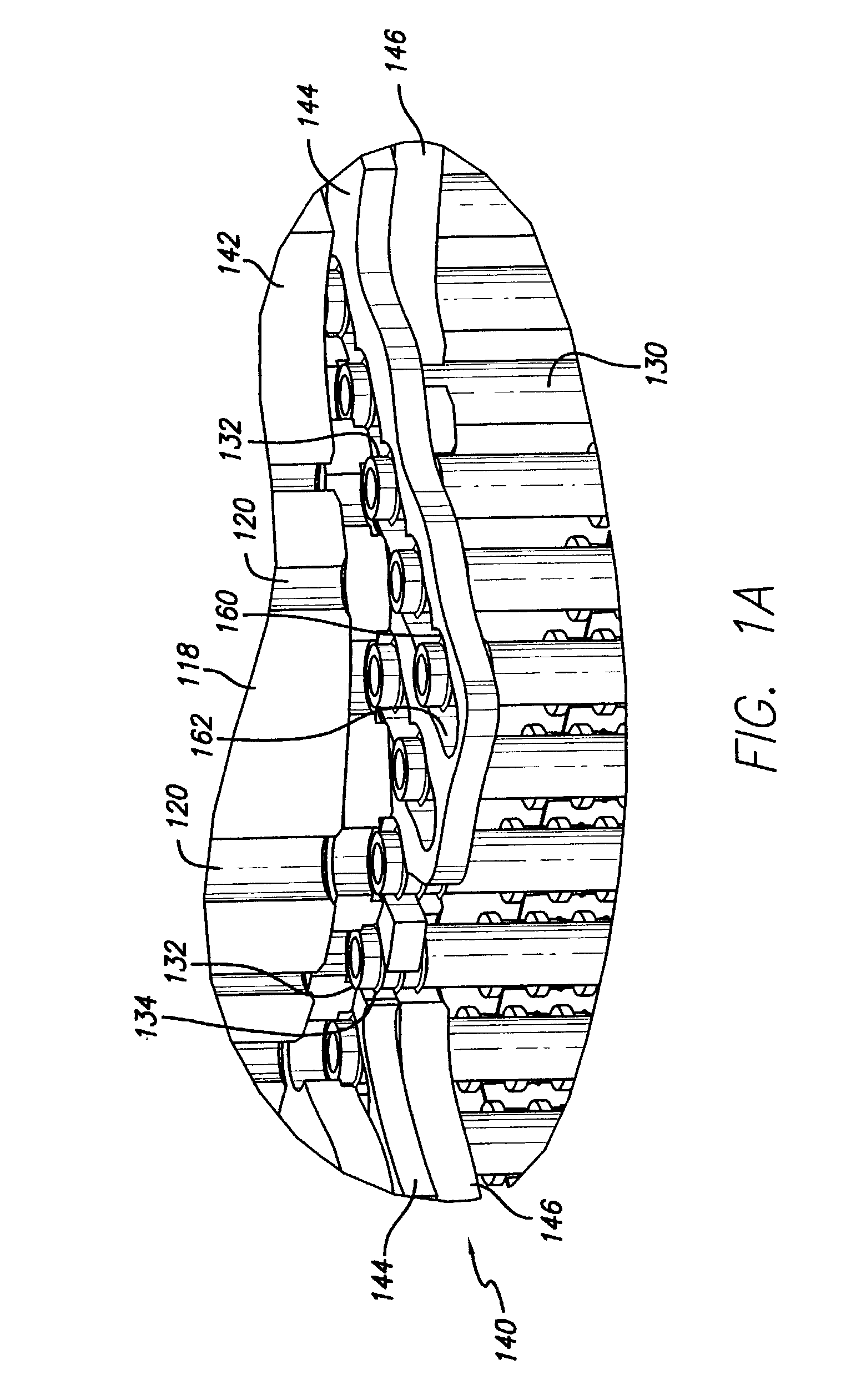

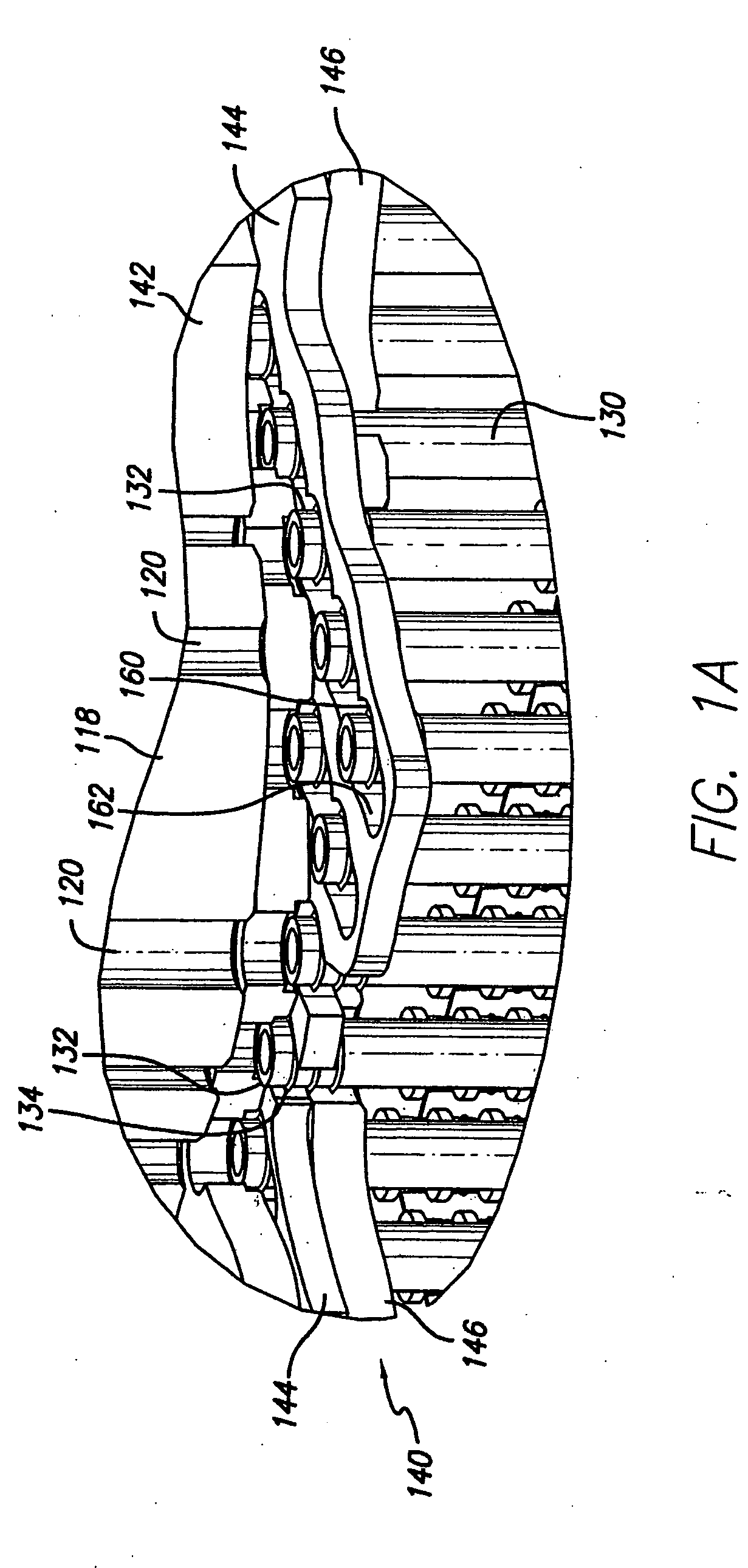

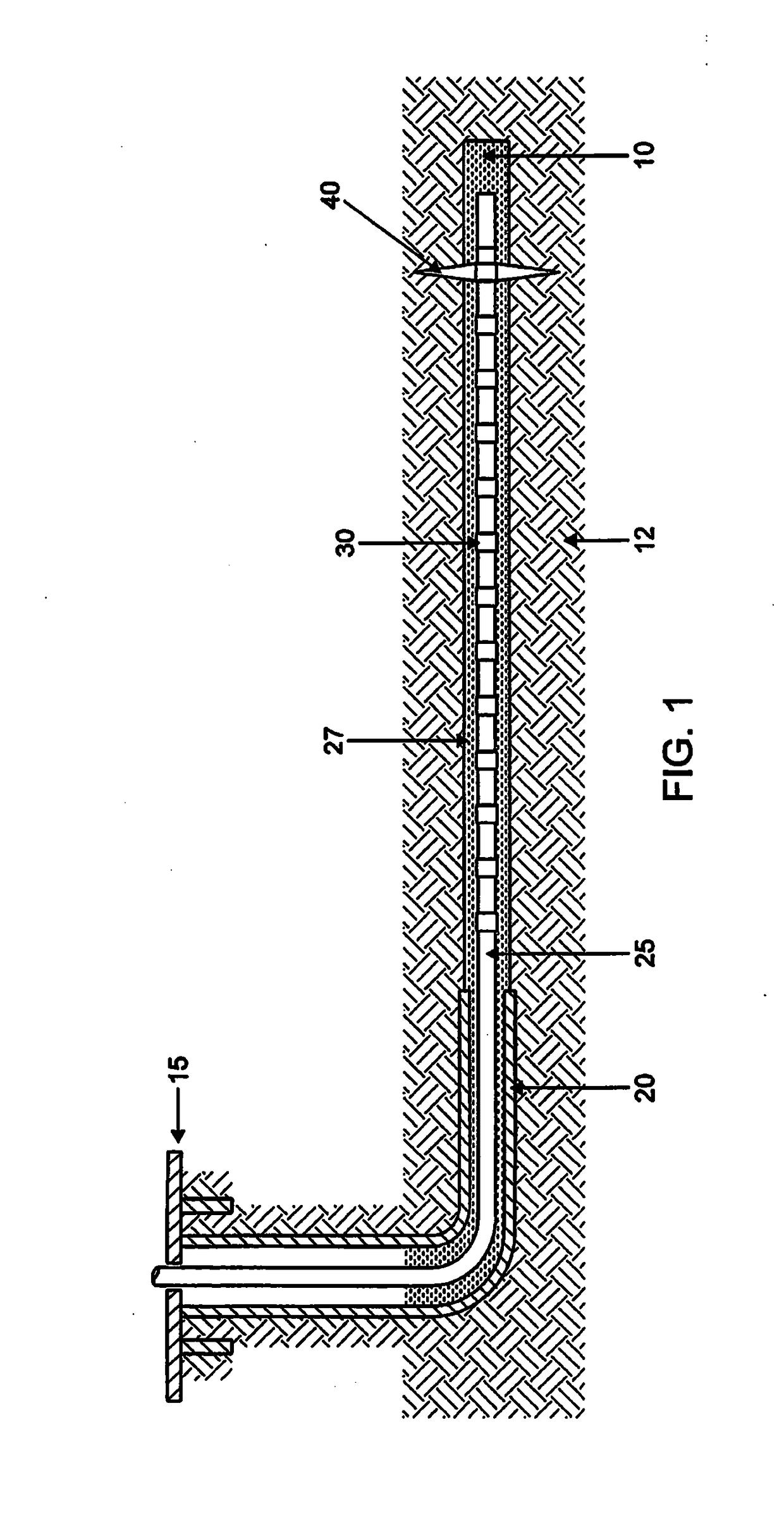

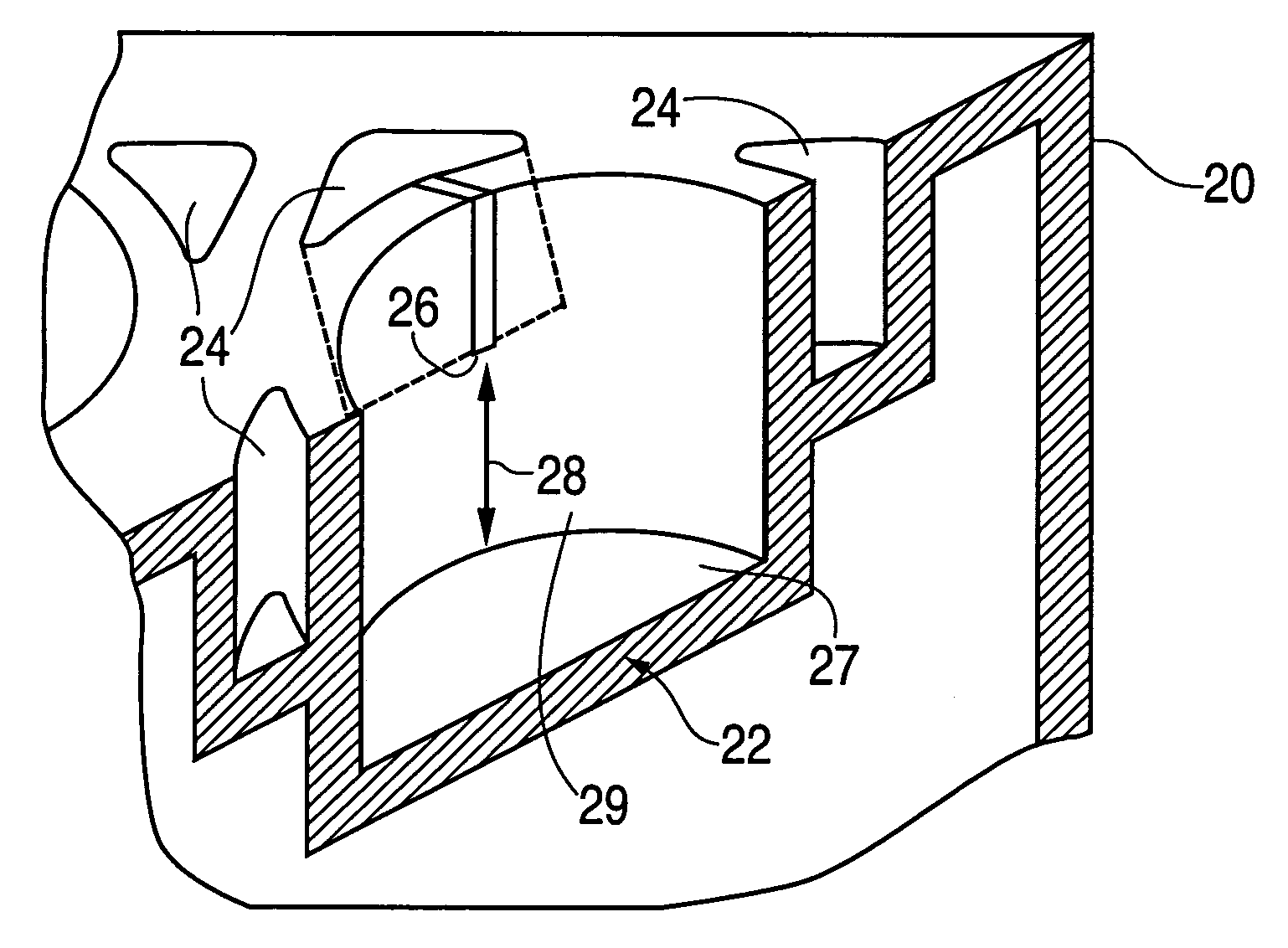

Manifold for use in cleaning combustion turbines

InactiveUS6491048B1Improve cleanlinessImprove effectivenessPump componentsElectrostatic cleaningParticulatesCombustion

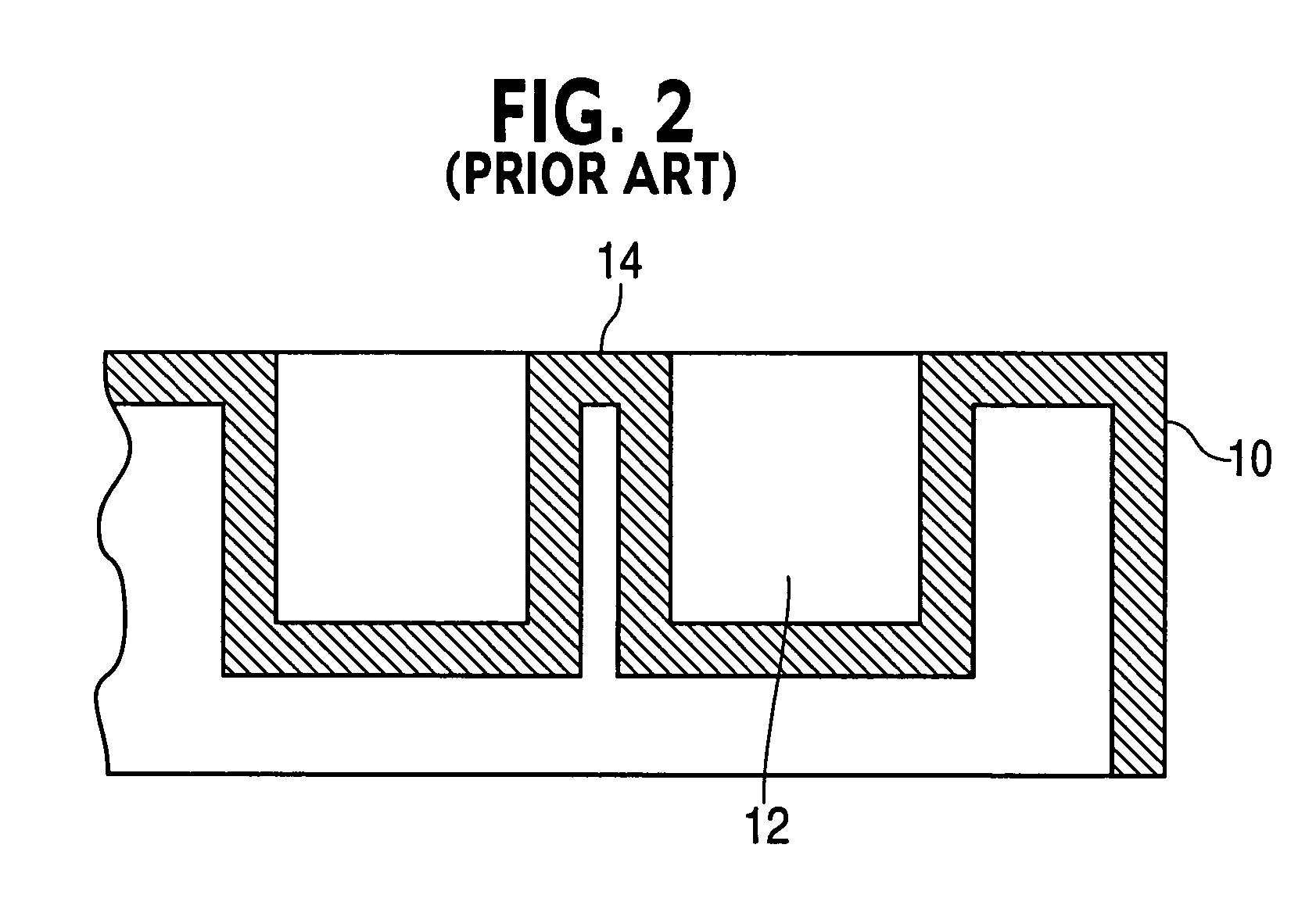

The present invention is directed to a manifold for temporarily blocking the air intake of the compressor section of a combustion turbine to facilitate cleaning. A manifold suitable for providing a temporary seal about the air intake of the compressor section and through which a foamed cleaning solution can be pumped is disclosed. The manifold is conveniently provided as a flexible manifold body having an inflatable tubular member along the periphery thereof for sealing with the air intake and a plurality of hose connections through which a foamed cleaning solution can be delivered to the compressor section of the combustion turbine. Particulate films and contaminants adhering to the internal components of the compressor section of a turbine are readily removed by pumping a foamed cleaning solution such as a foamed, aqueous surfactant solution through the manifold and into the compressor section. Contaminants resulting from fuel combustion and deposited in the combustion and turbine sections are removed by pumping a second, foamed cleaning solution through those sections. The second solution typically comprises a foamed, aqueous acid solution optionally including a corrosion inhibitor. The compressor section must be isolated from such acid solutions, e.g. by pumping the foamed surfactant solution through the manifold and compressor section prior to and simultaneously with pumping the foamed acid solution through the combustion section.

Owner:GENERAL ELECTRIC CAPITAL AS AGENT

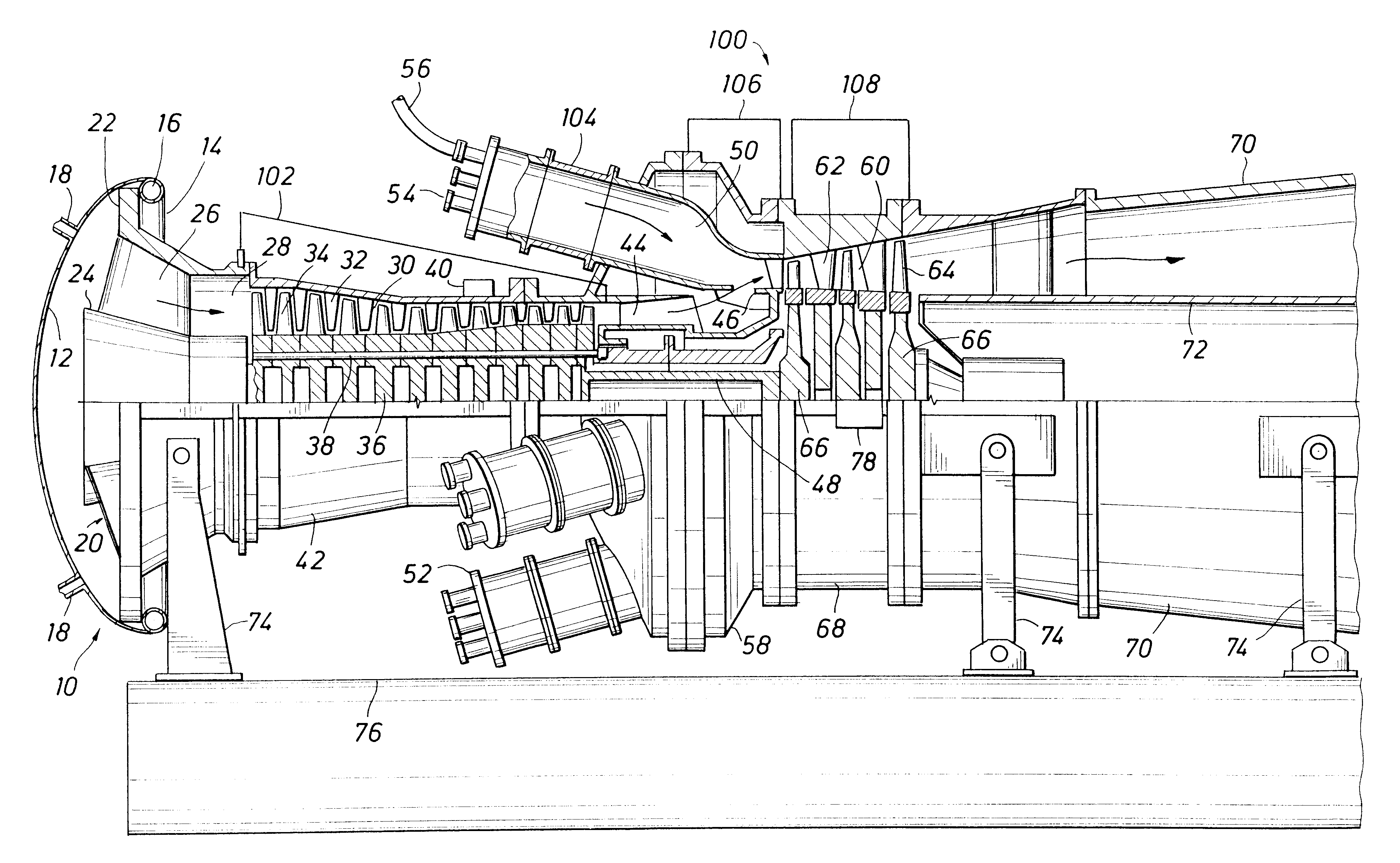

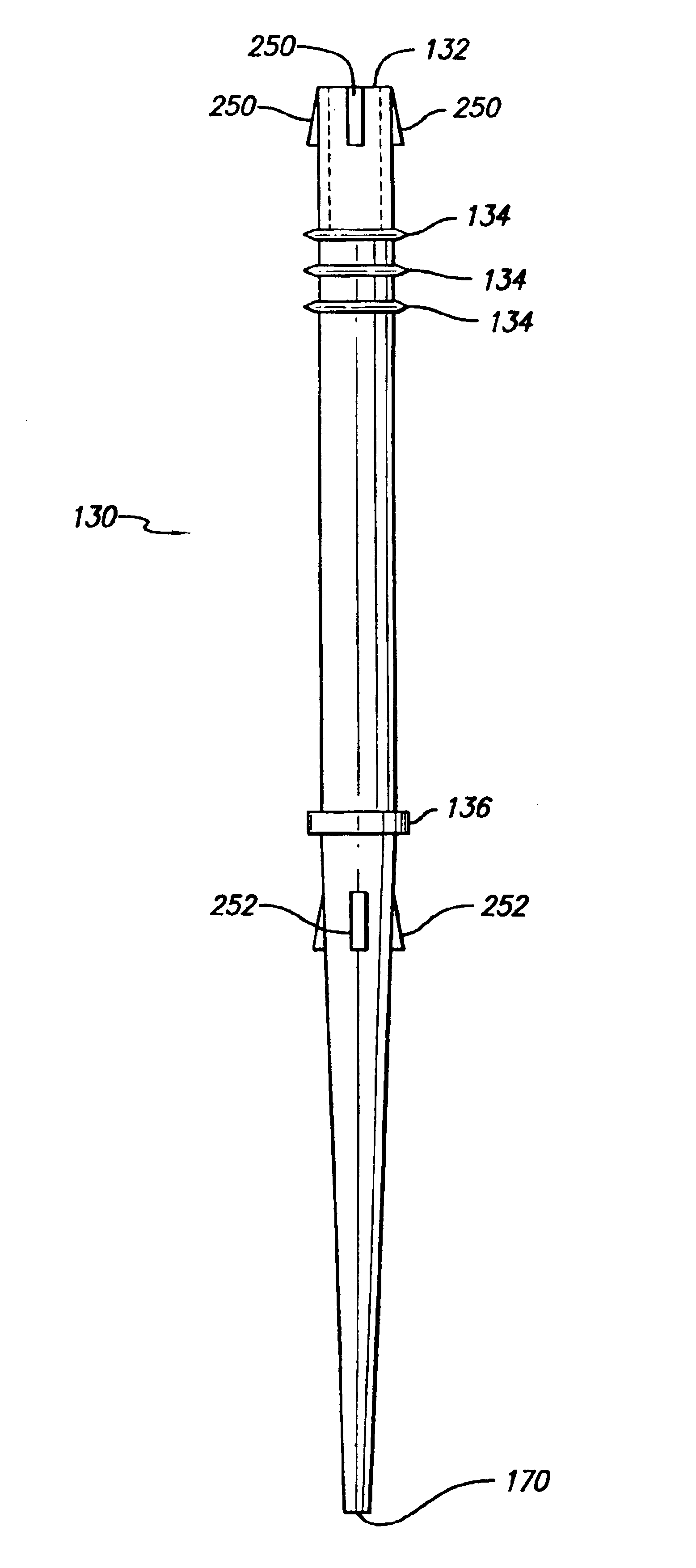

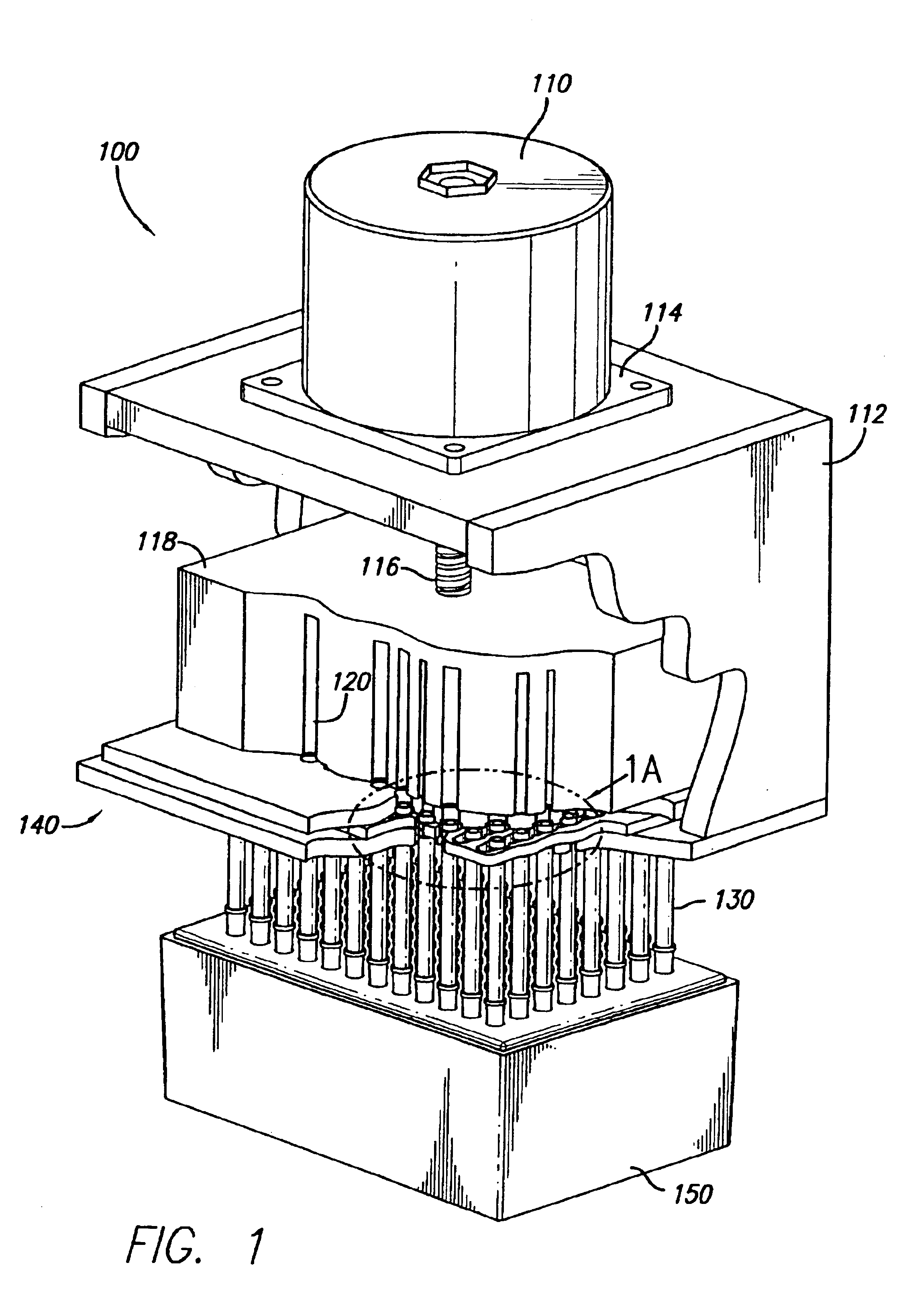

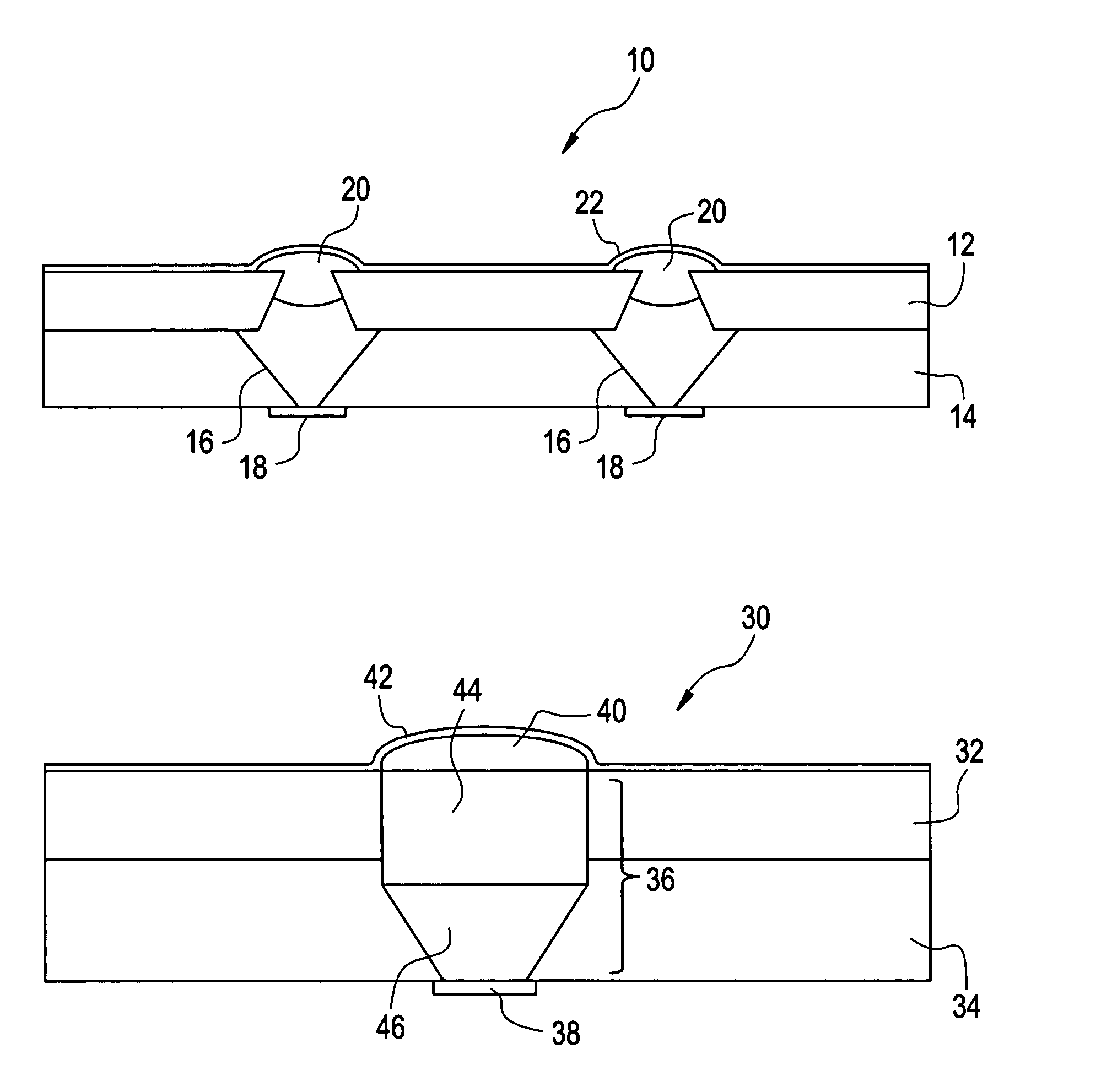

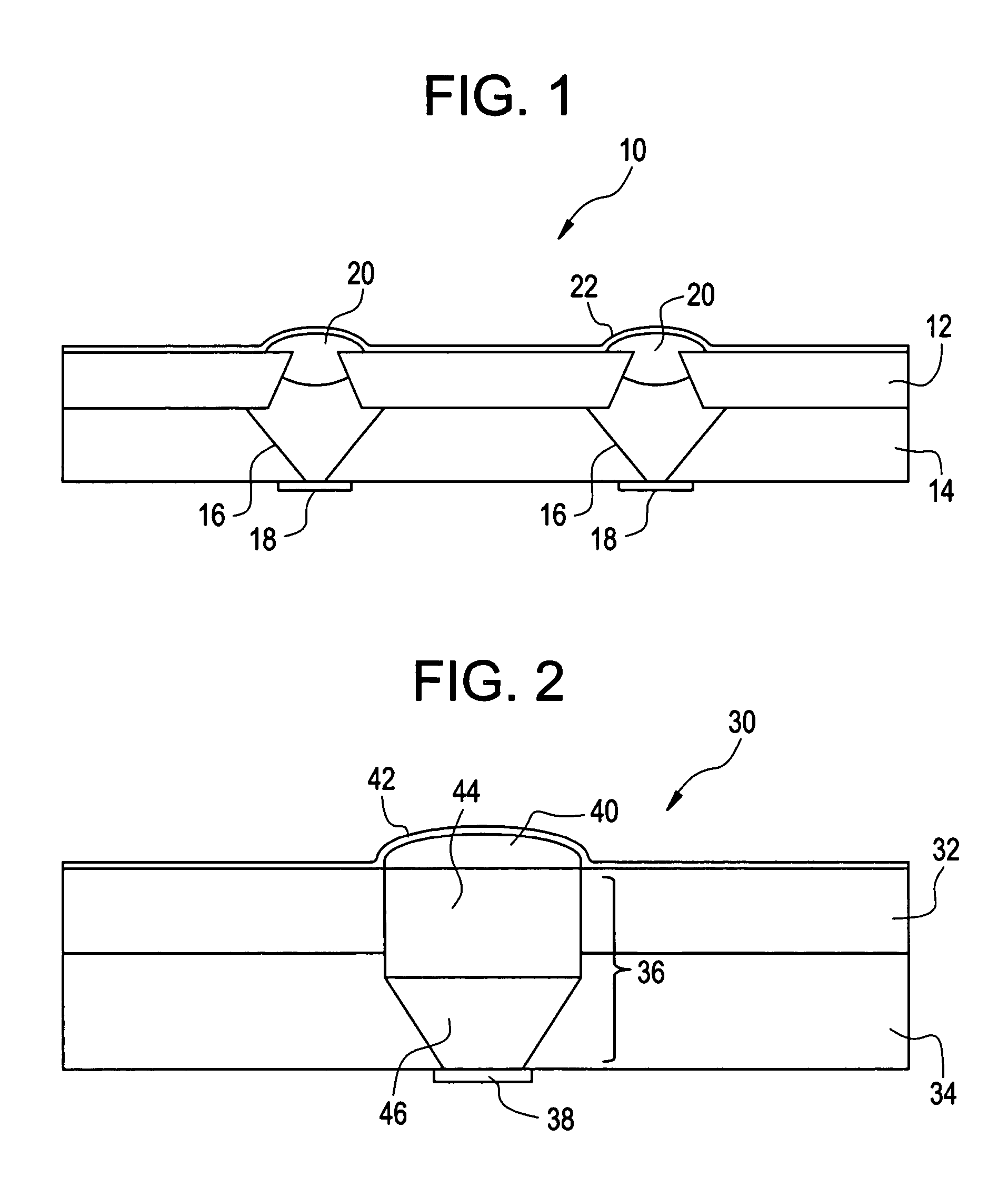

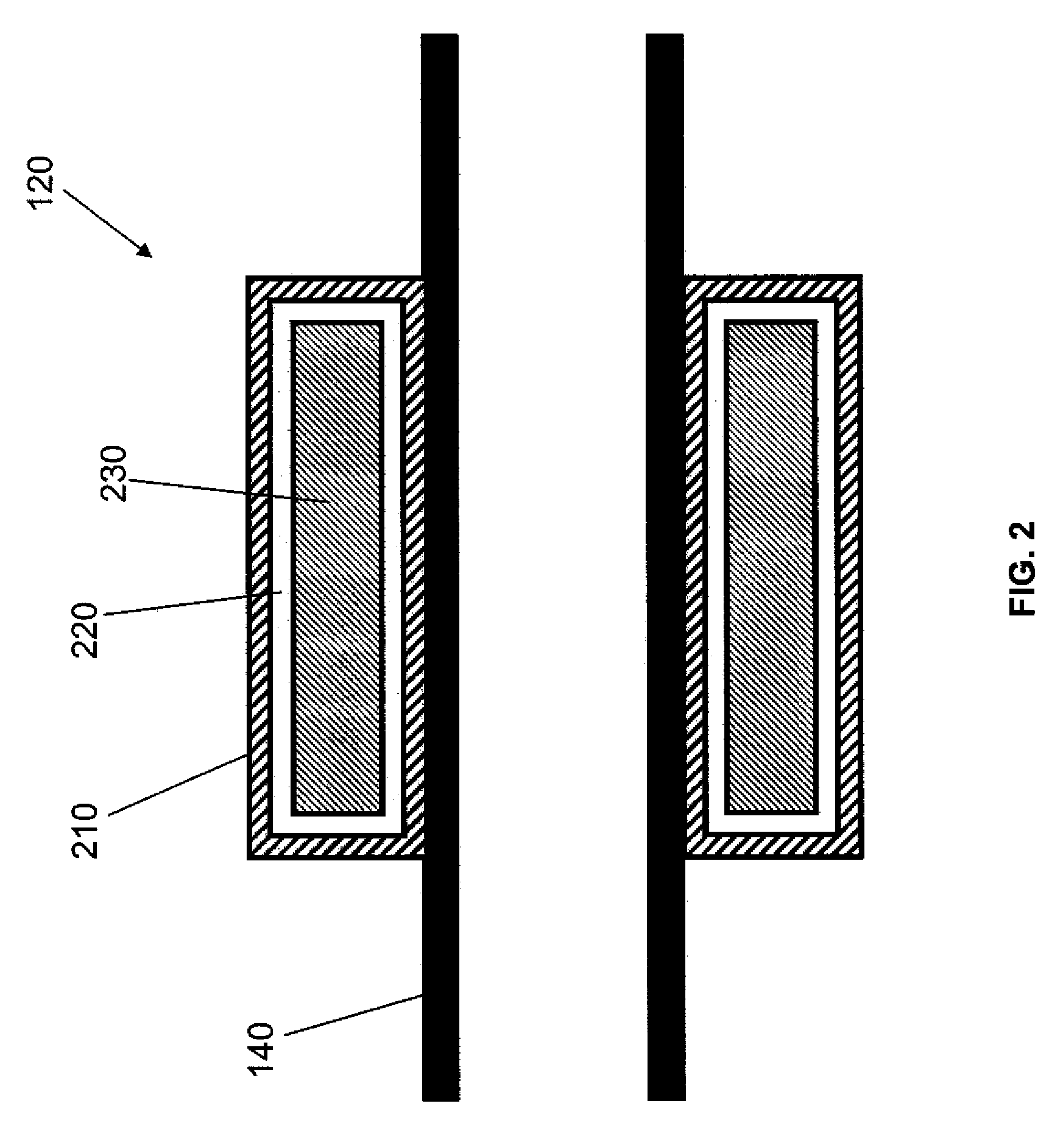

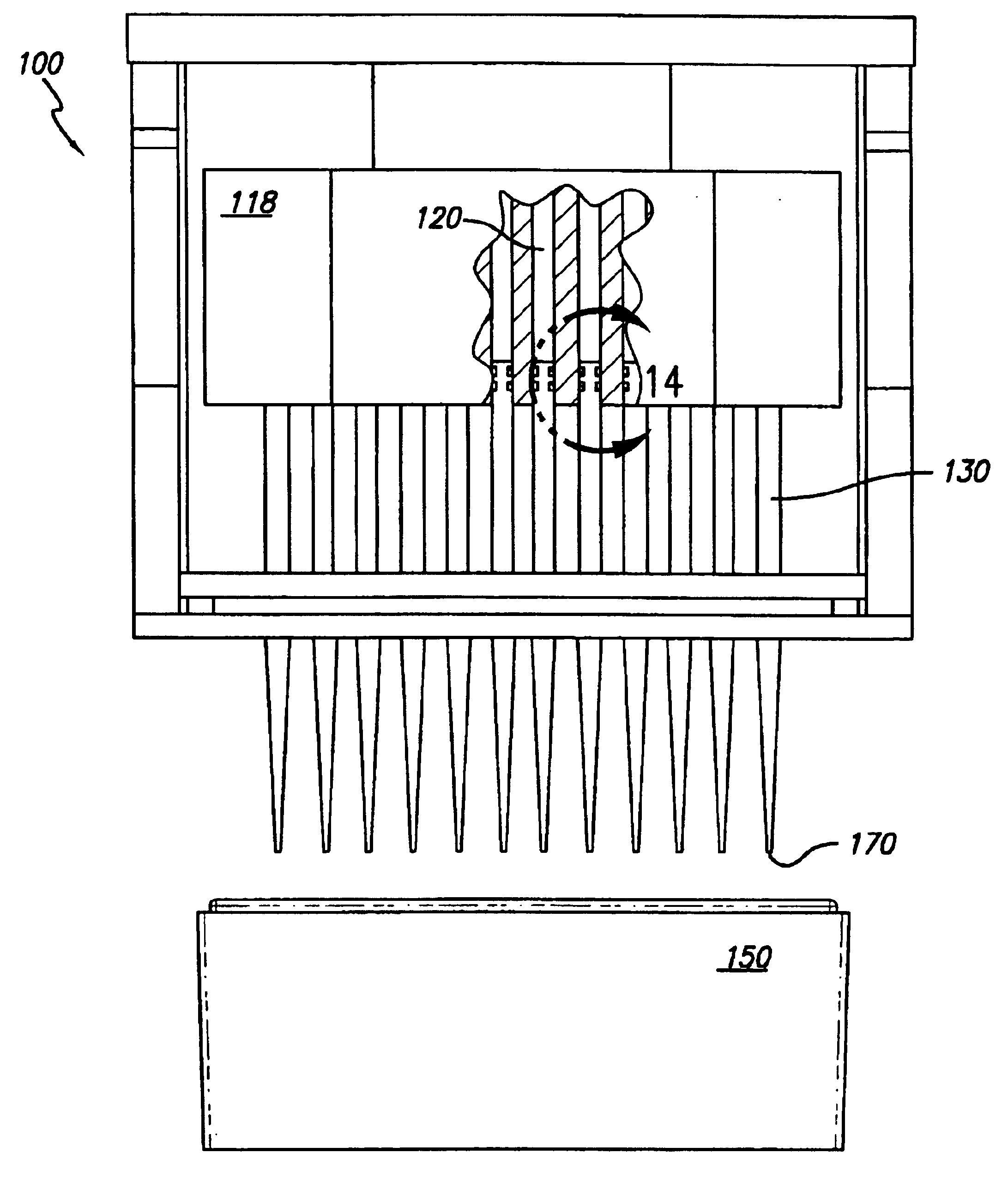

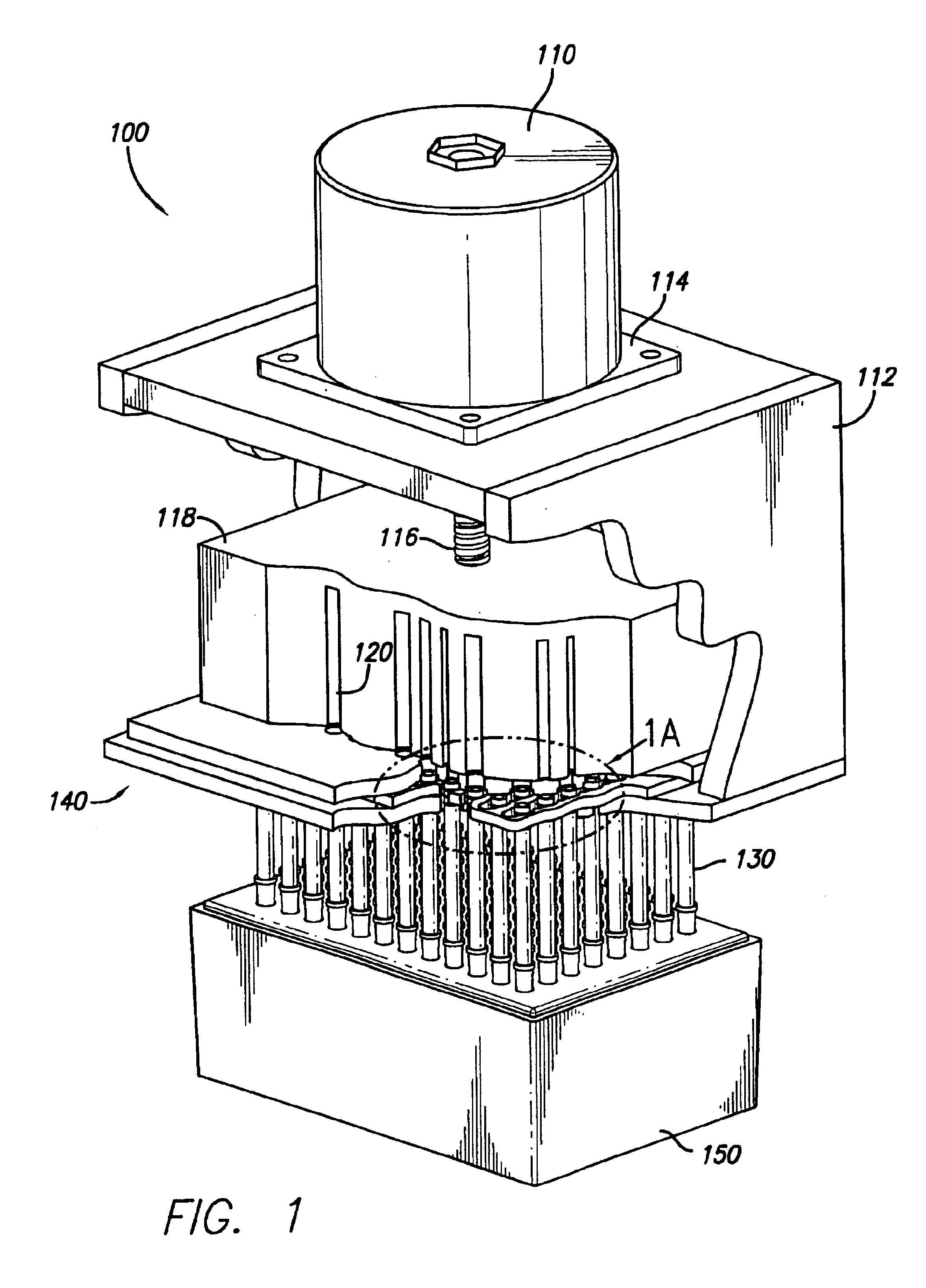

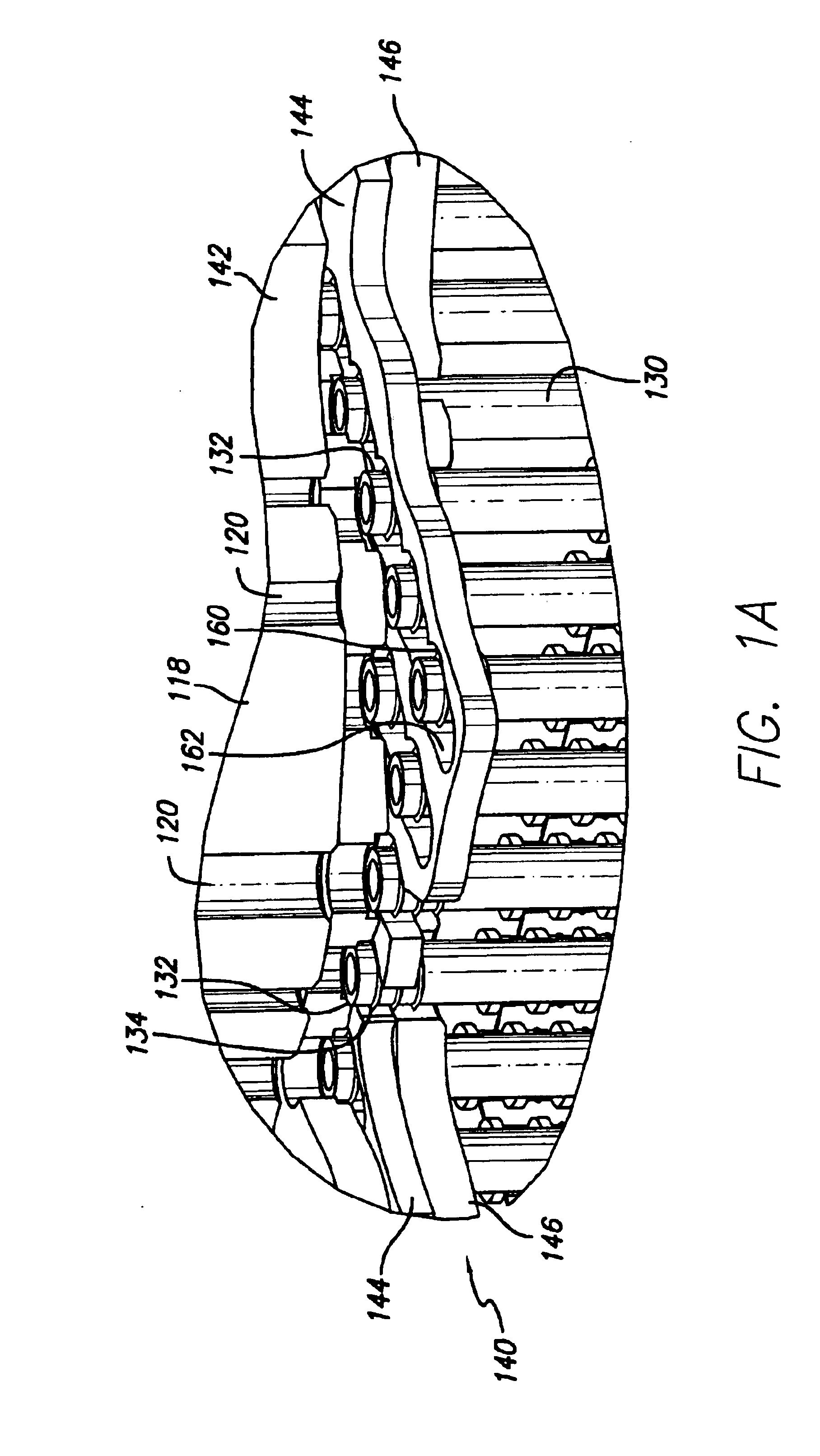

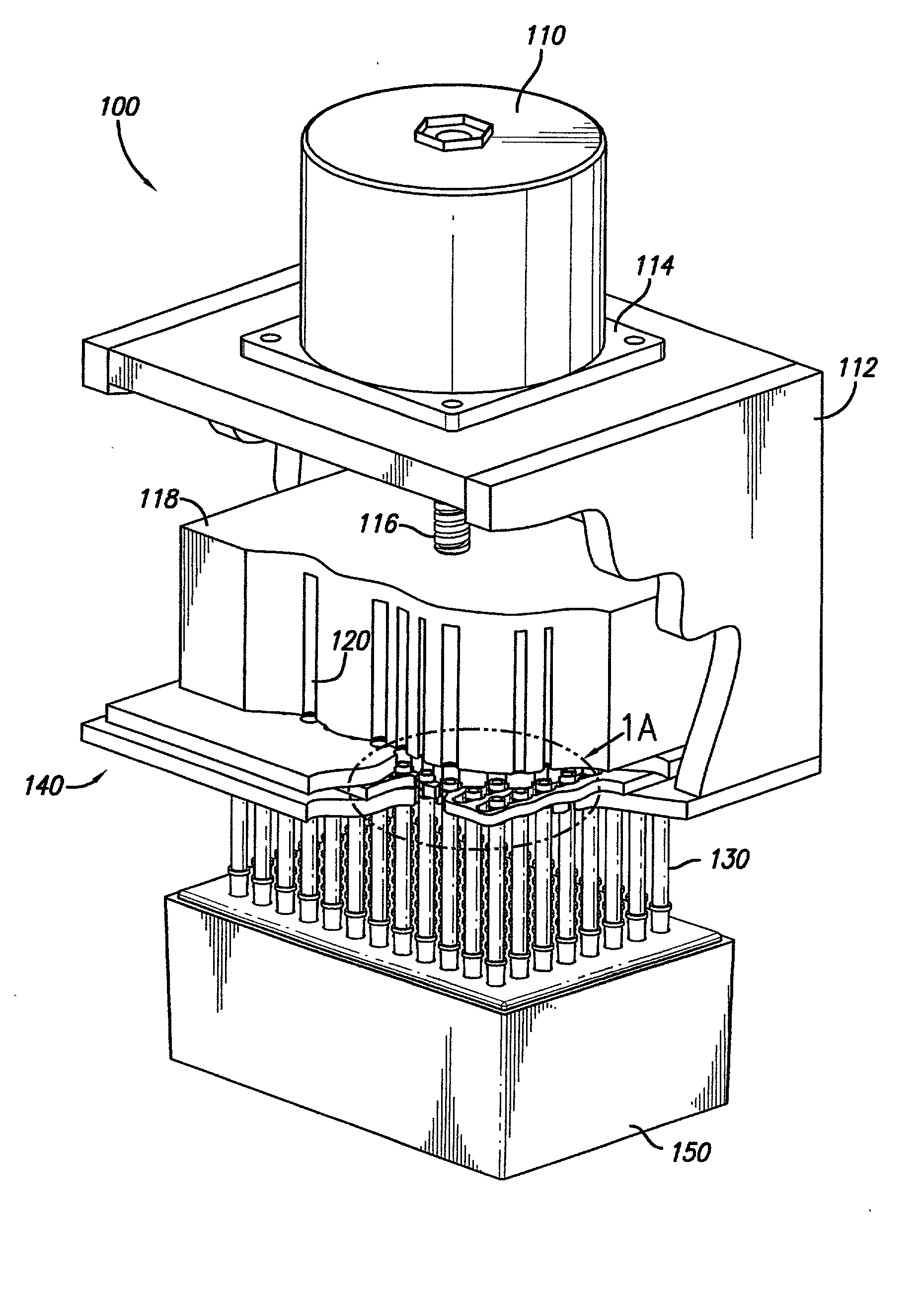

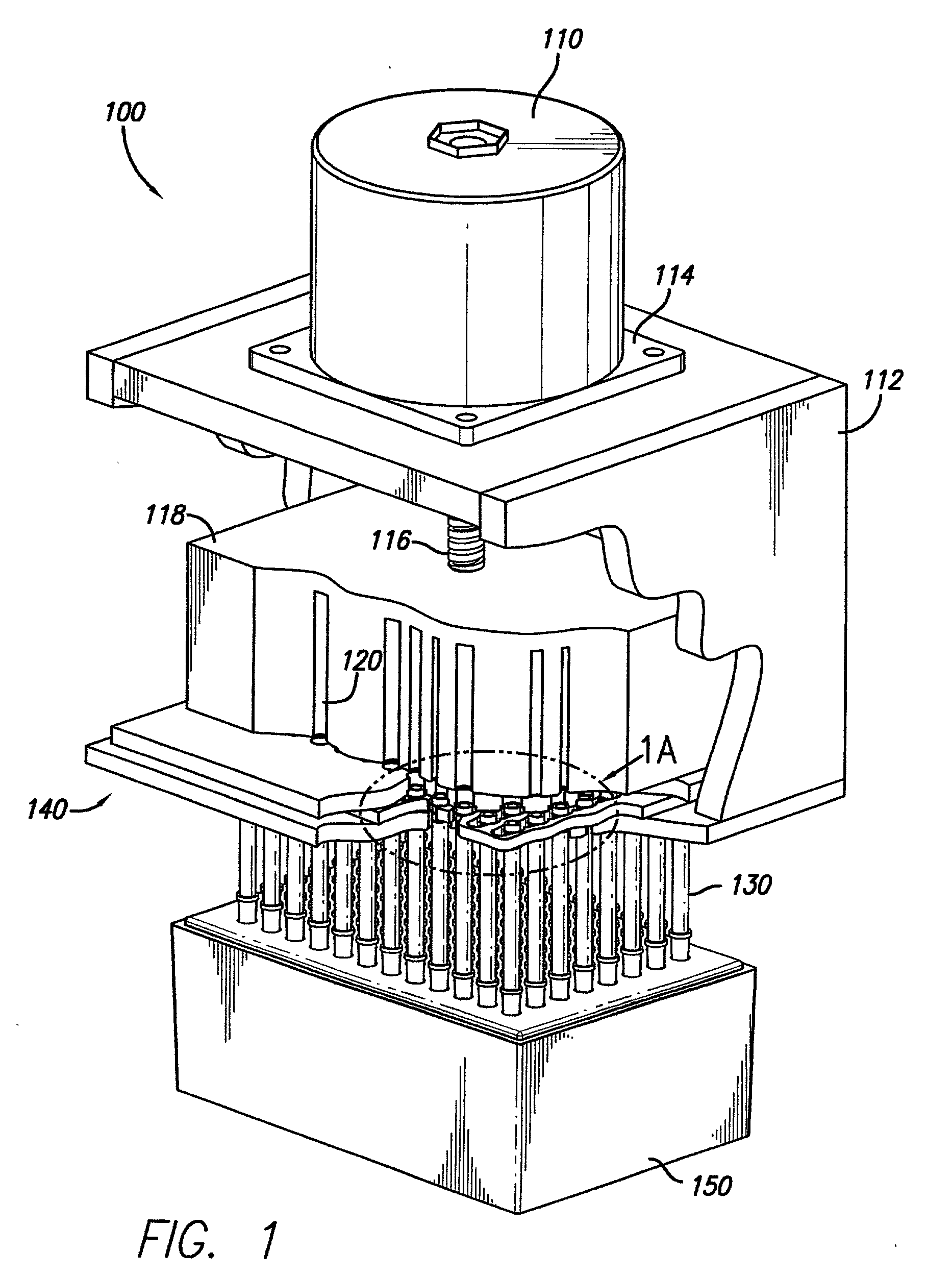

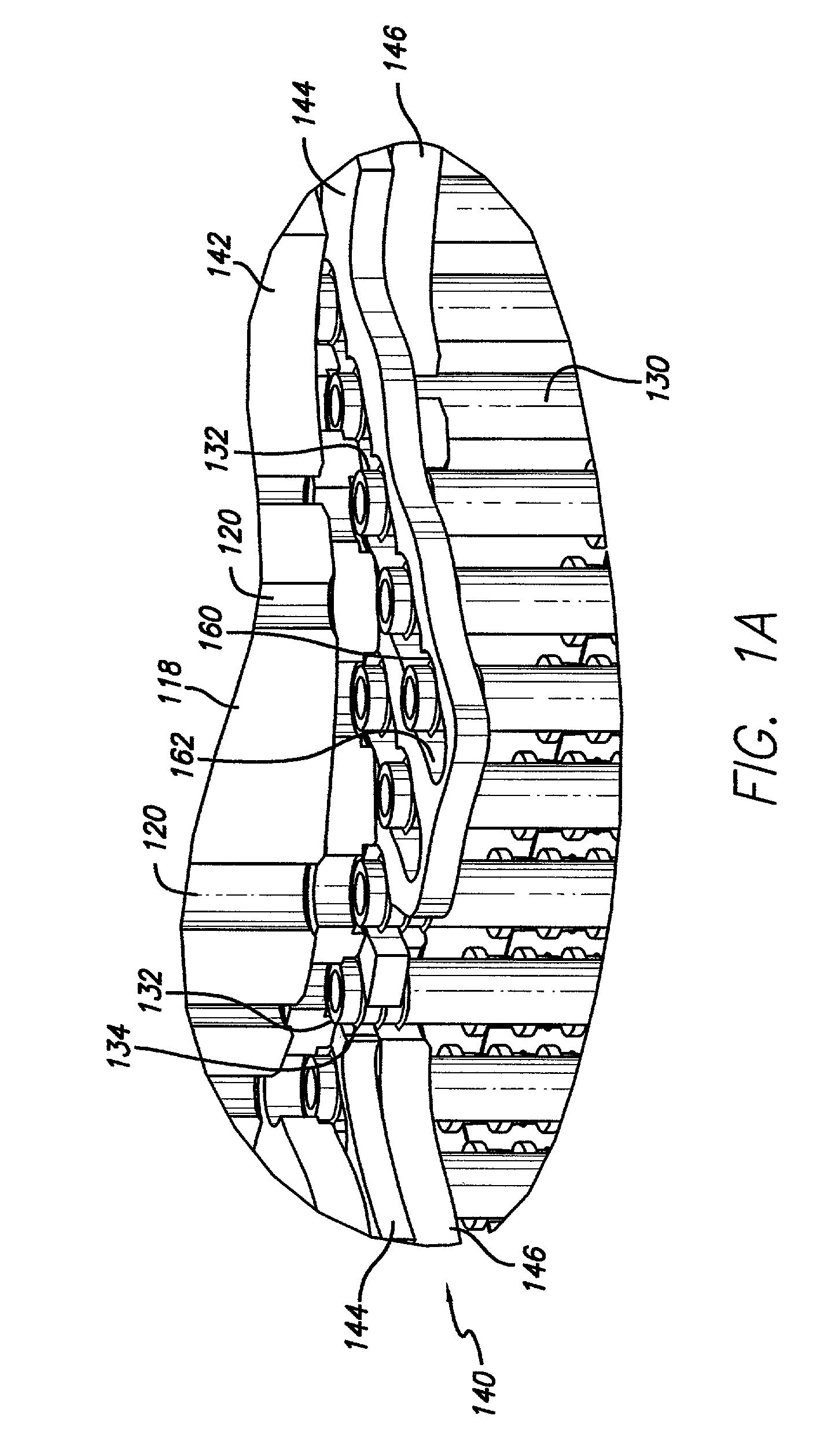

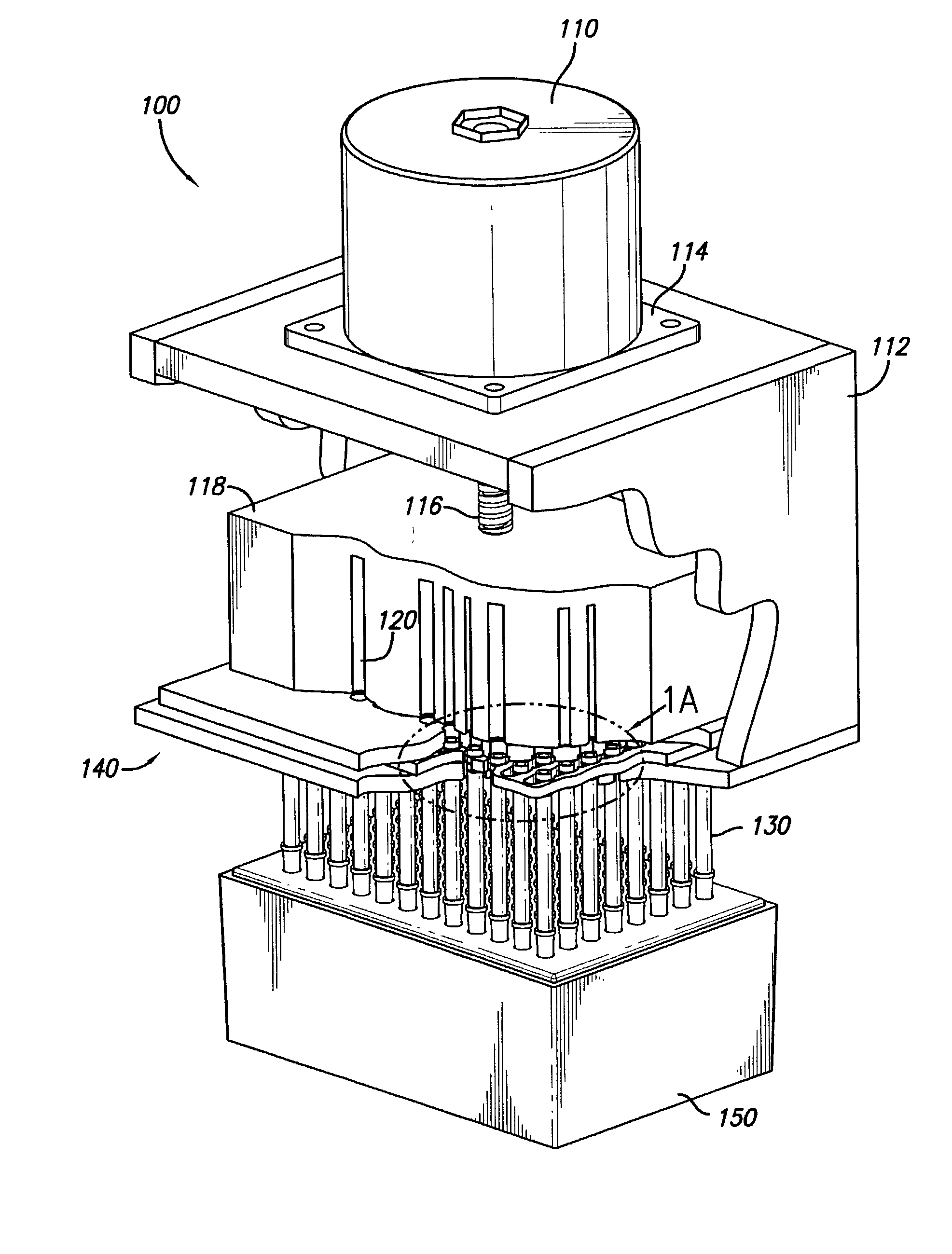

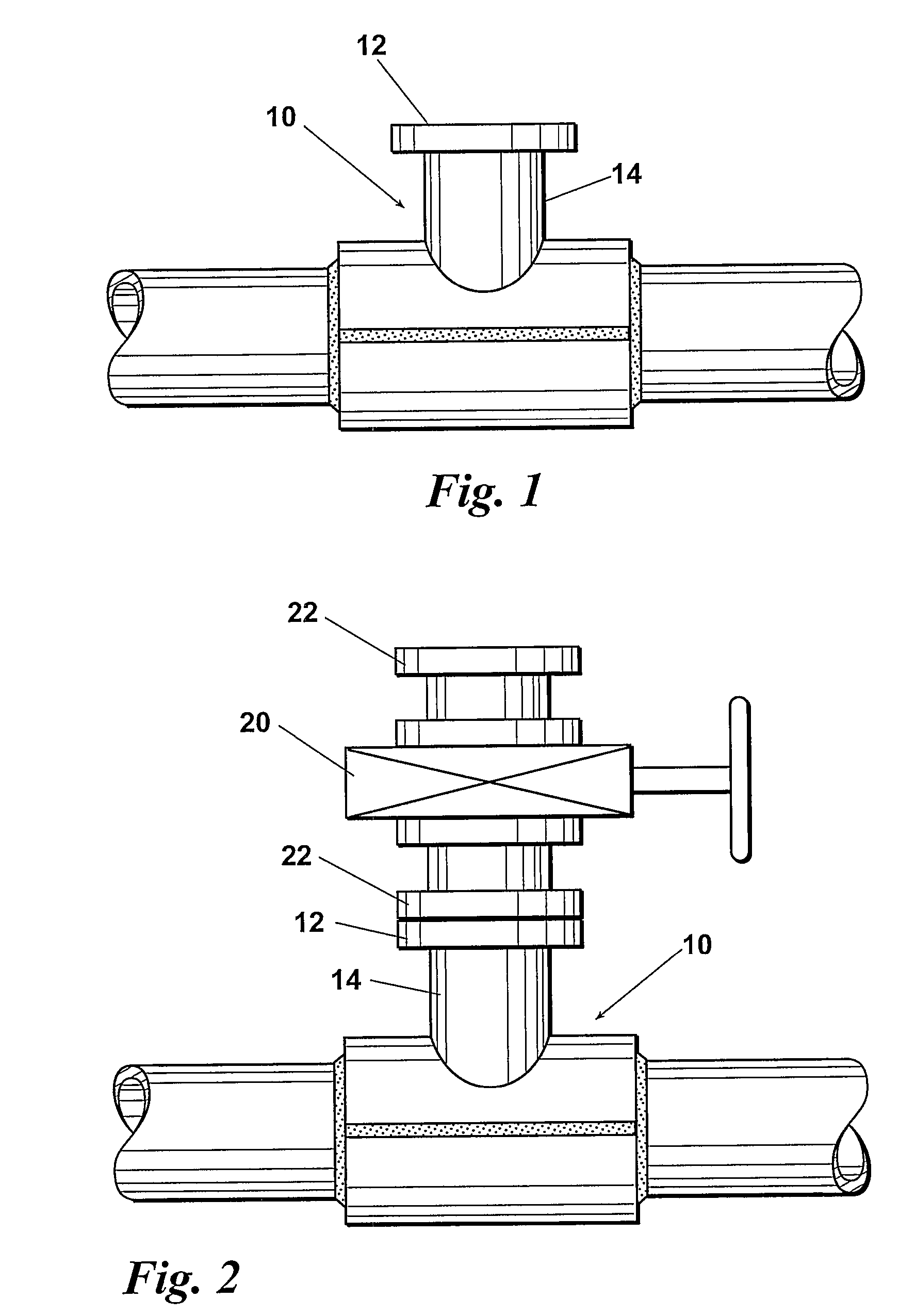

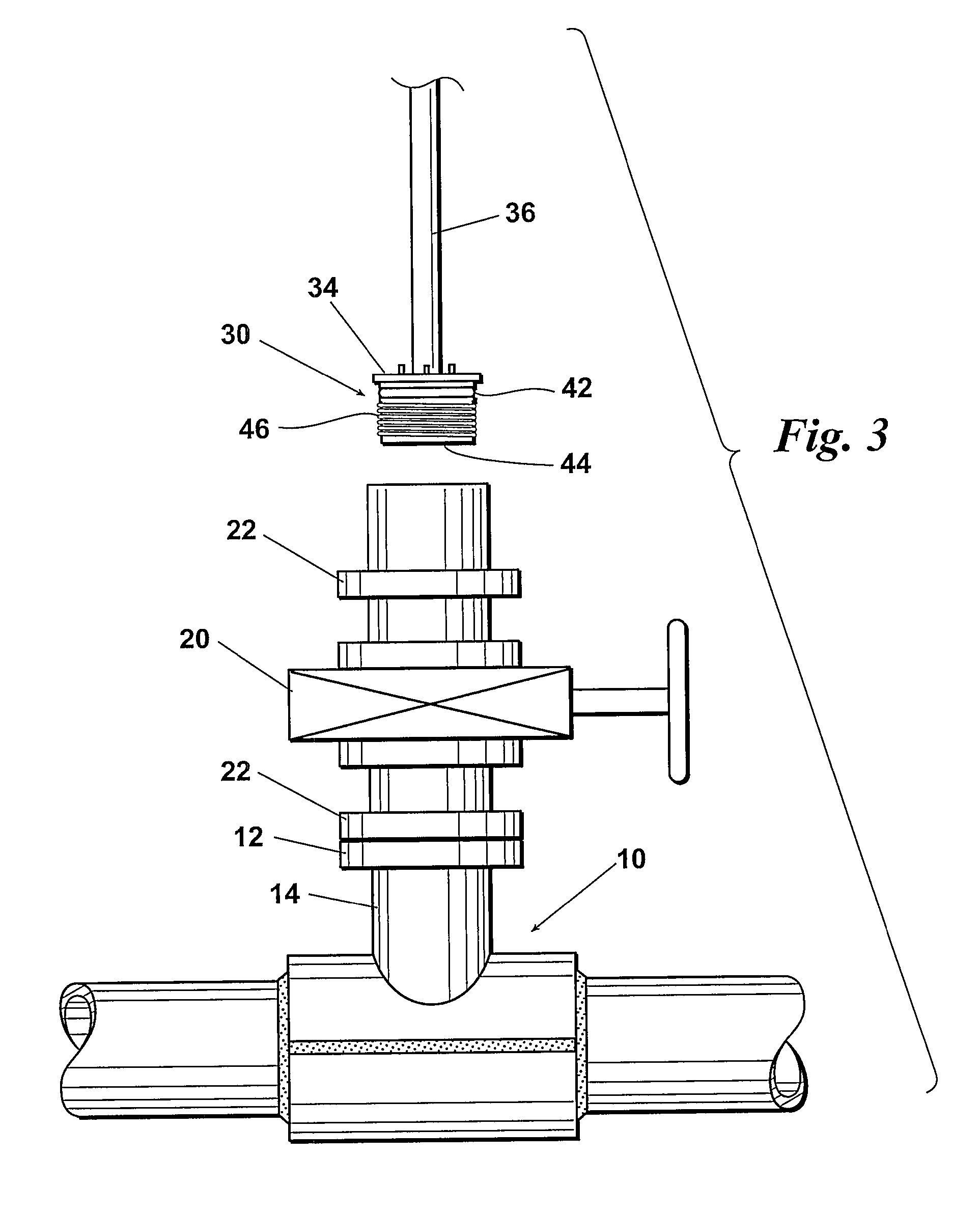

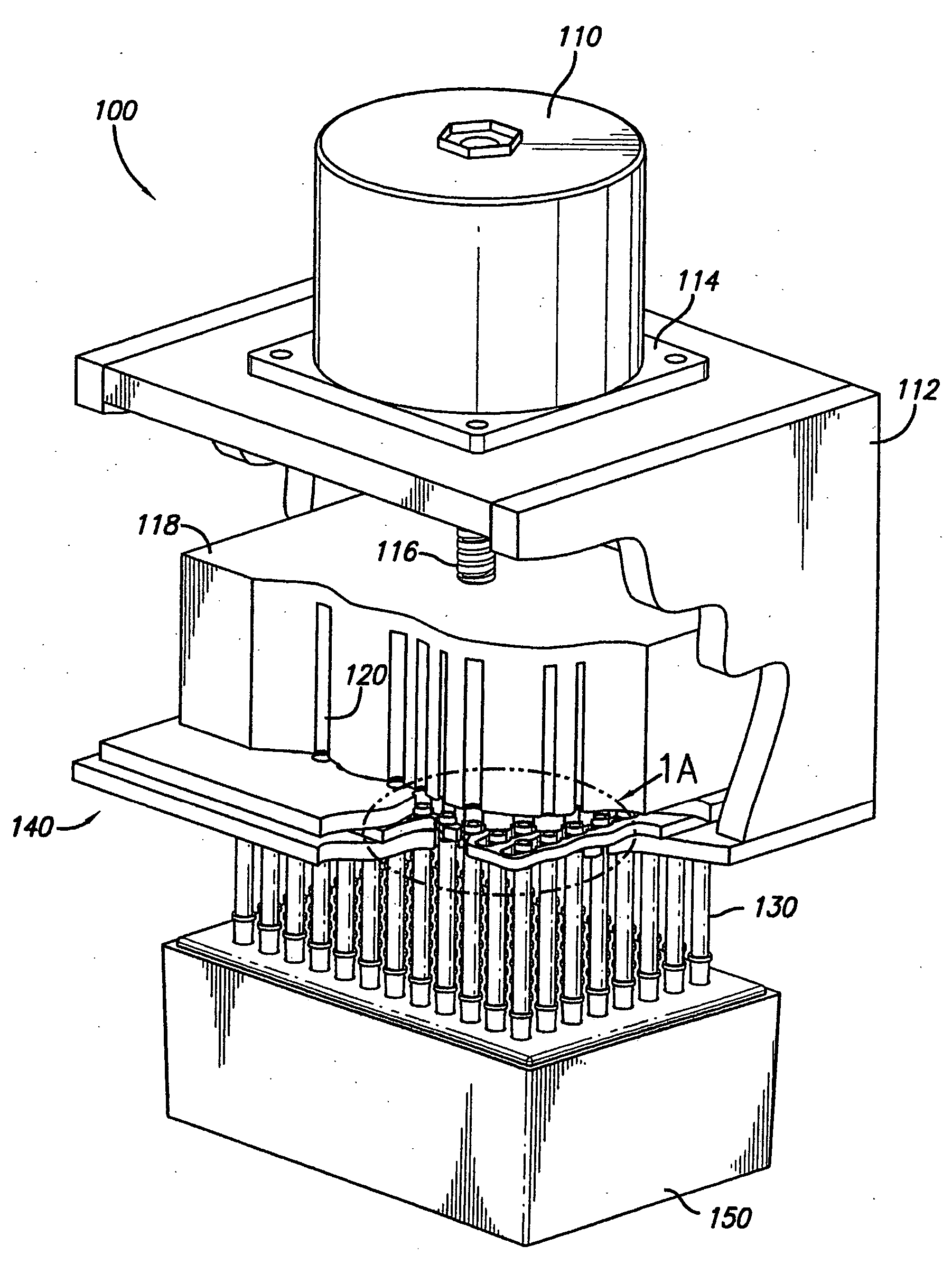

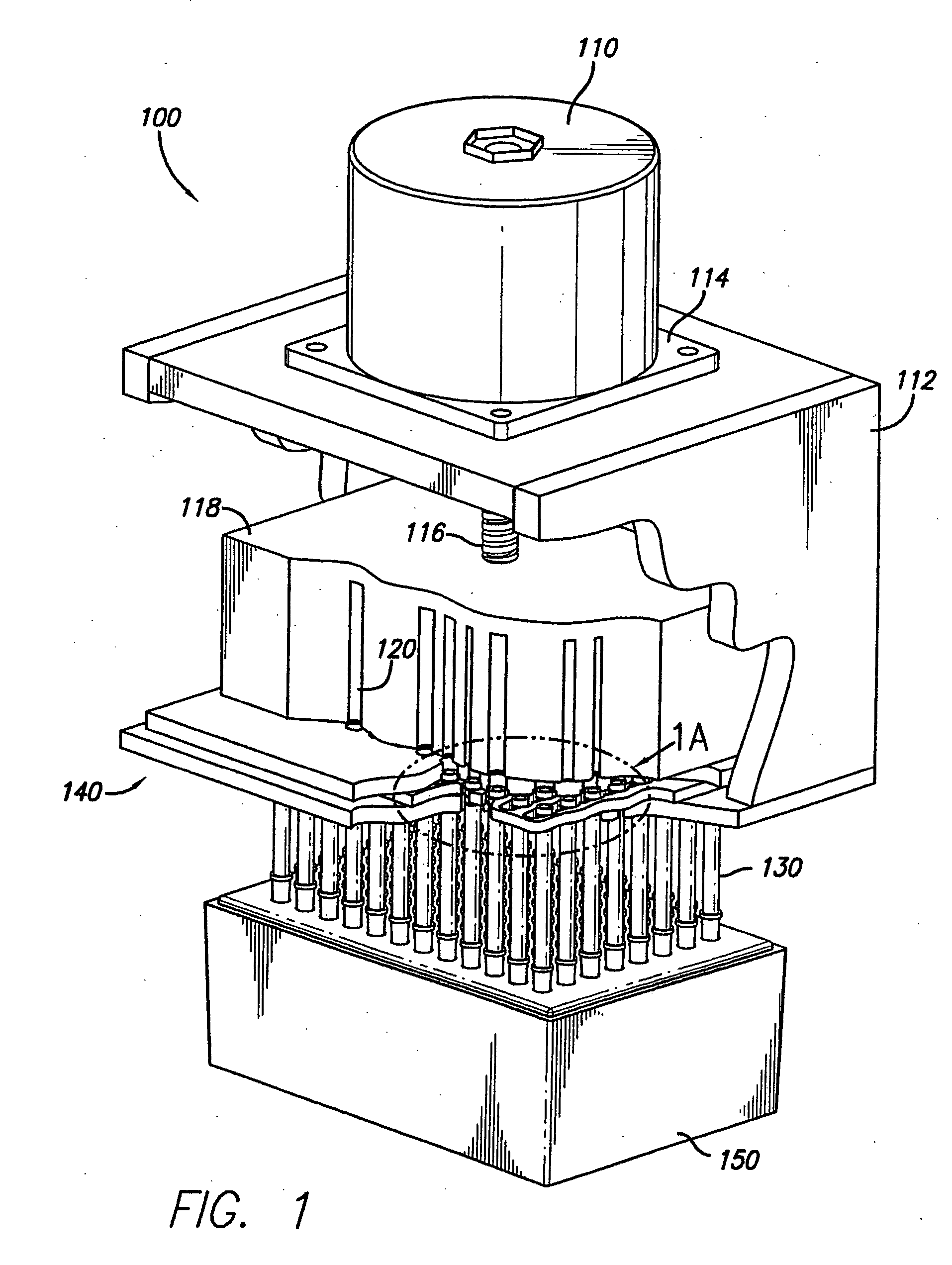

Pipettor and externally sealed pipette tip

InactiveUS6780381B2Reduce maintenancePrecise and accurate amountWithdrawing sample devicesBurettes/pipettesPipetteEffective volume

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way.

Owner:YIU FELIX H

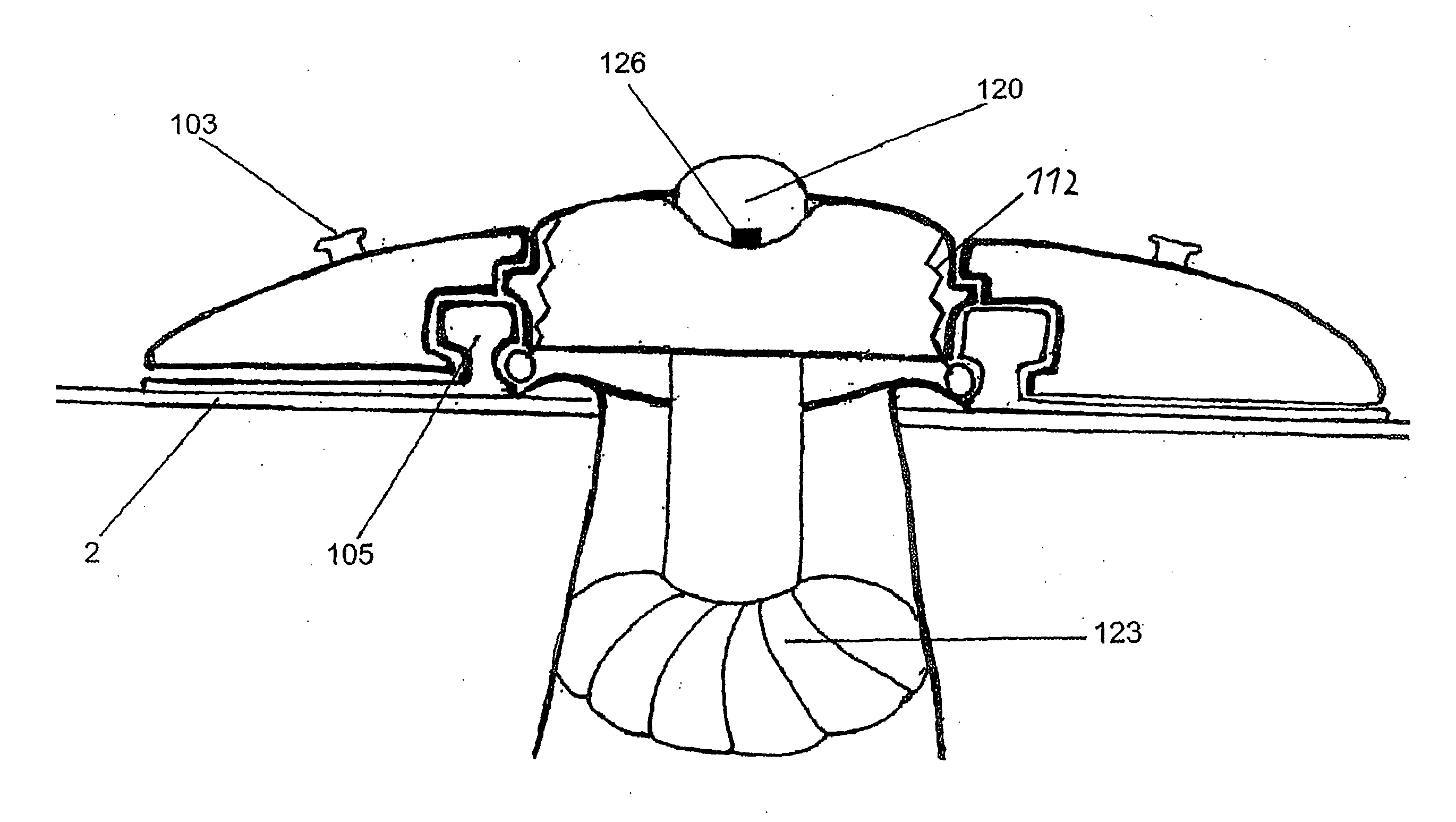

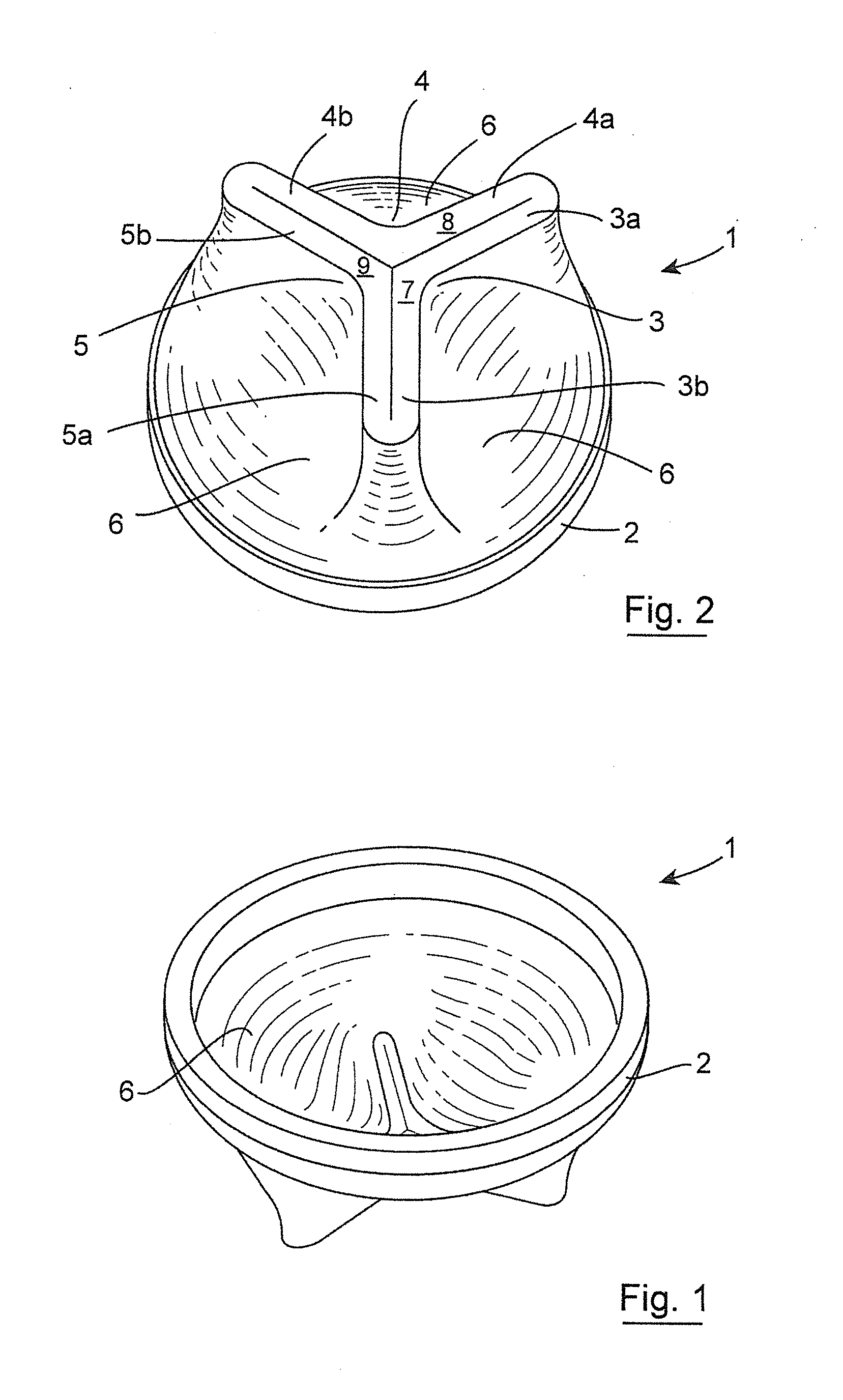

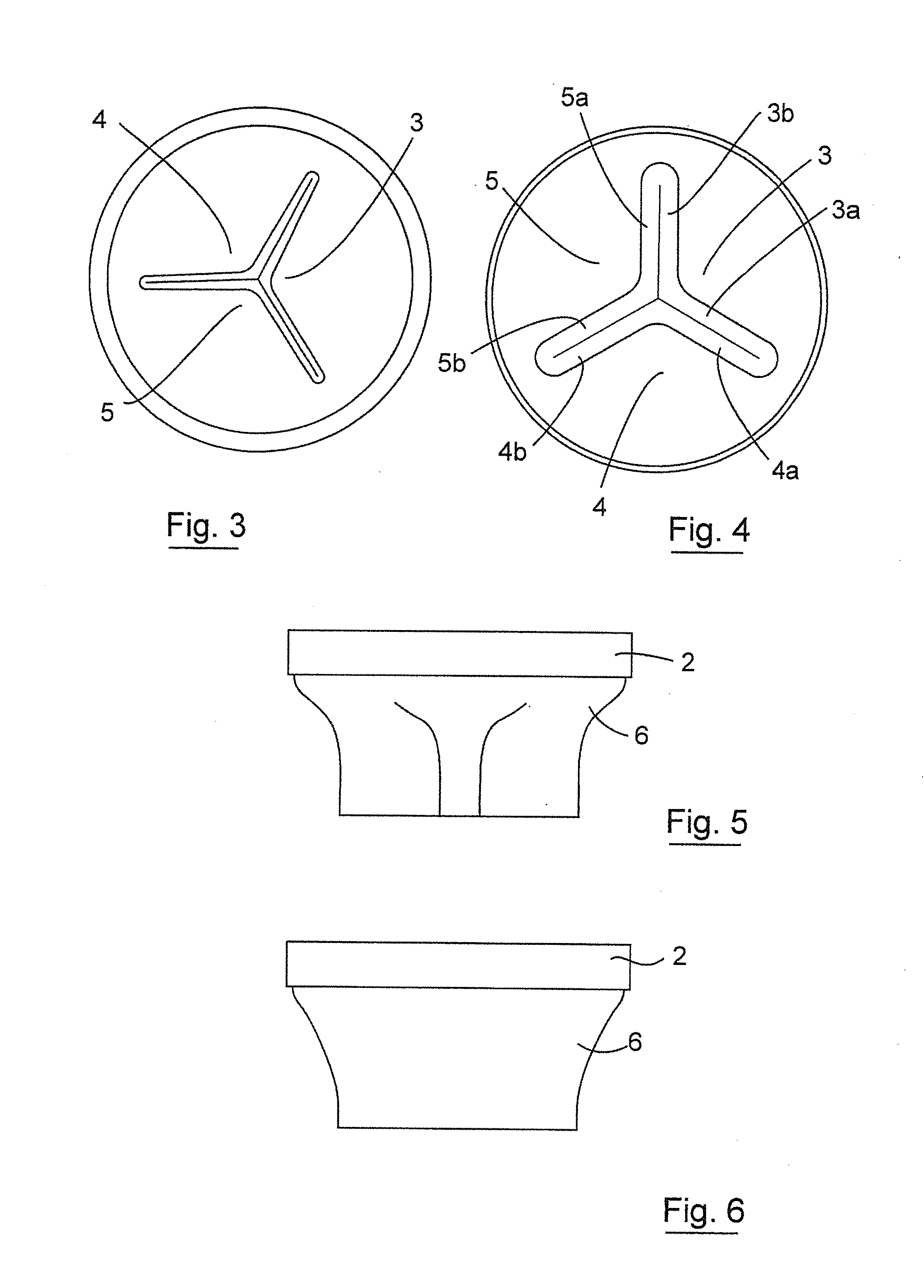

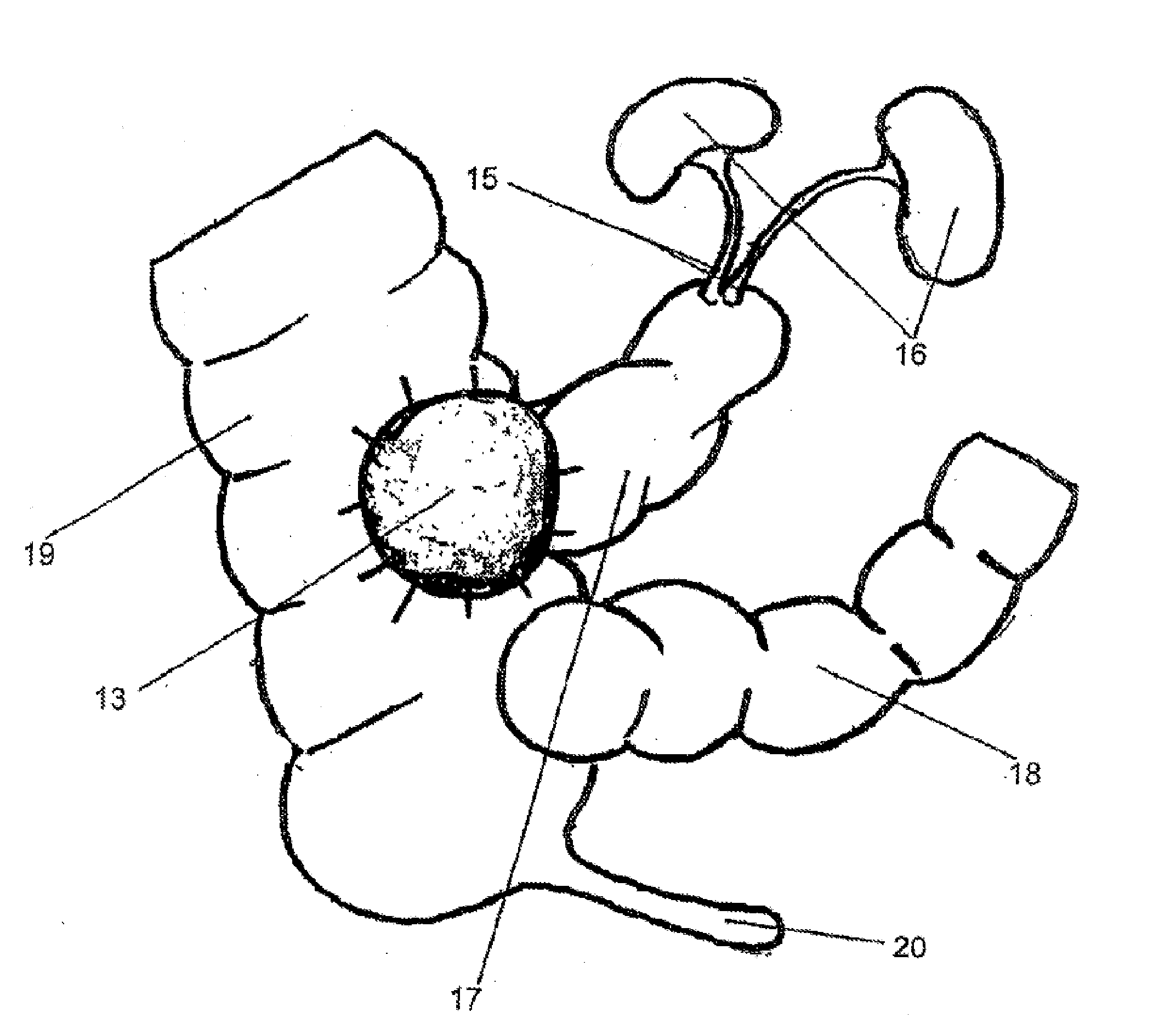

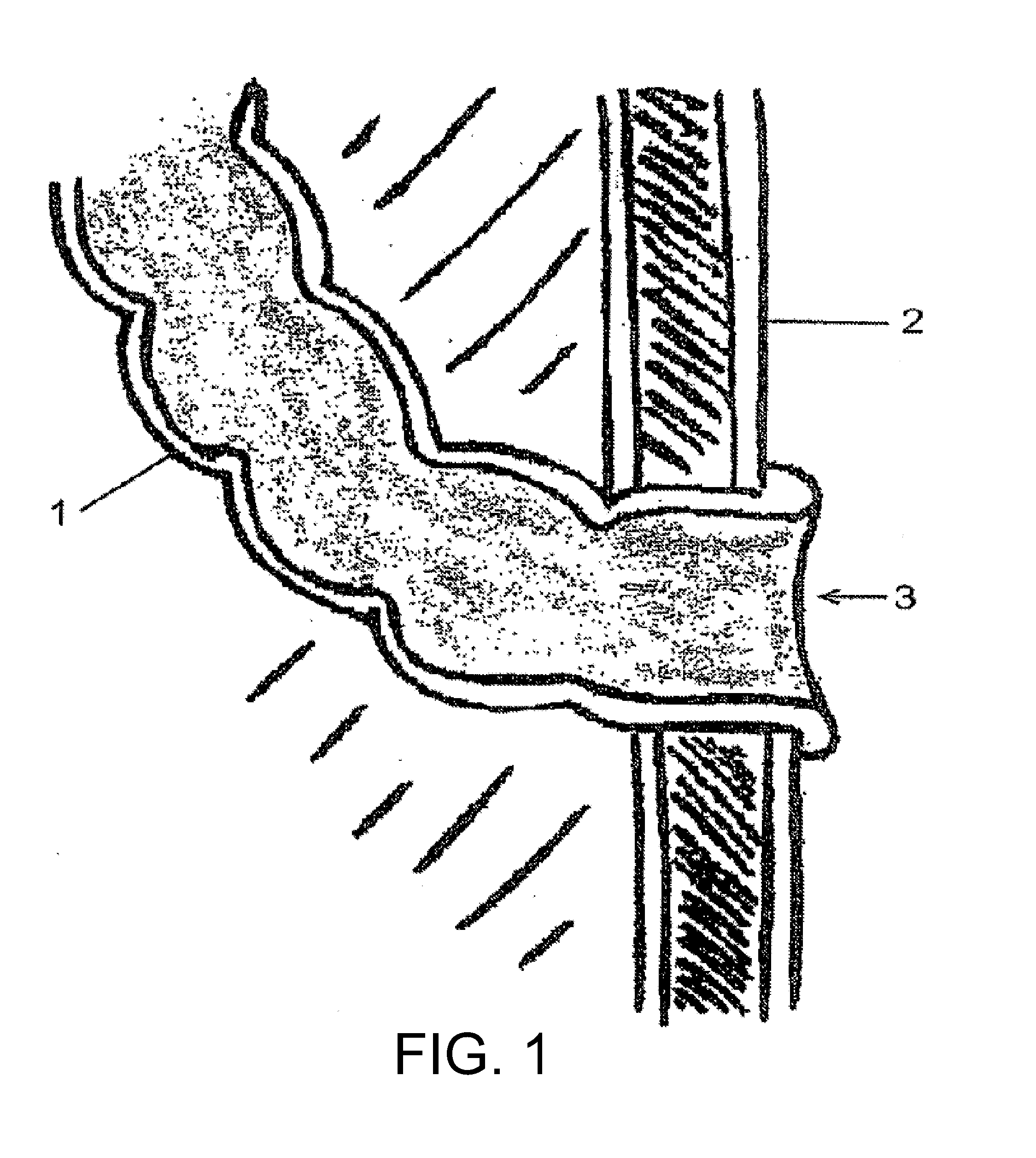

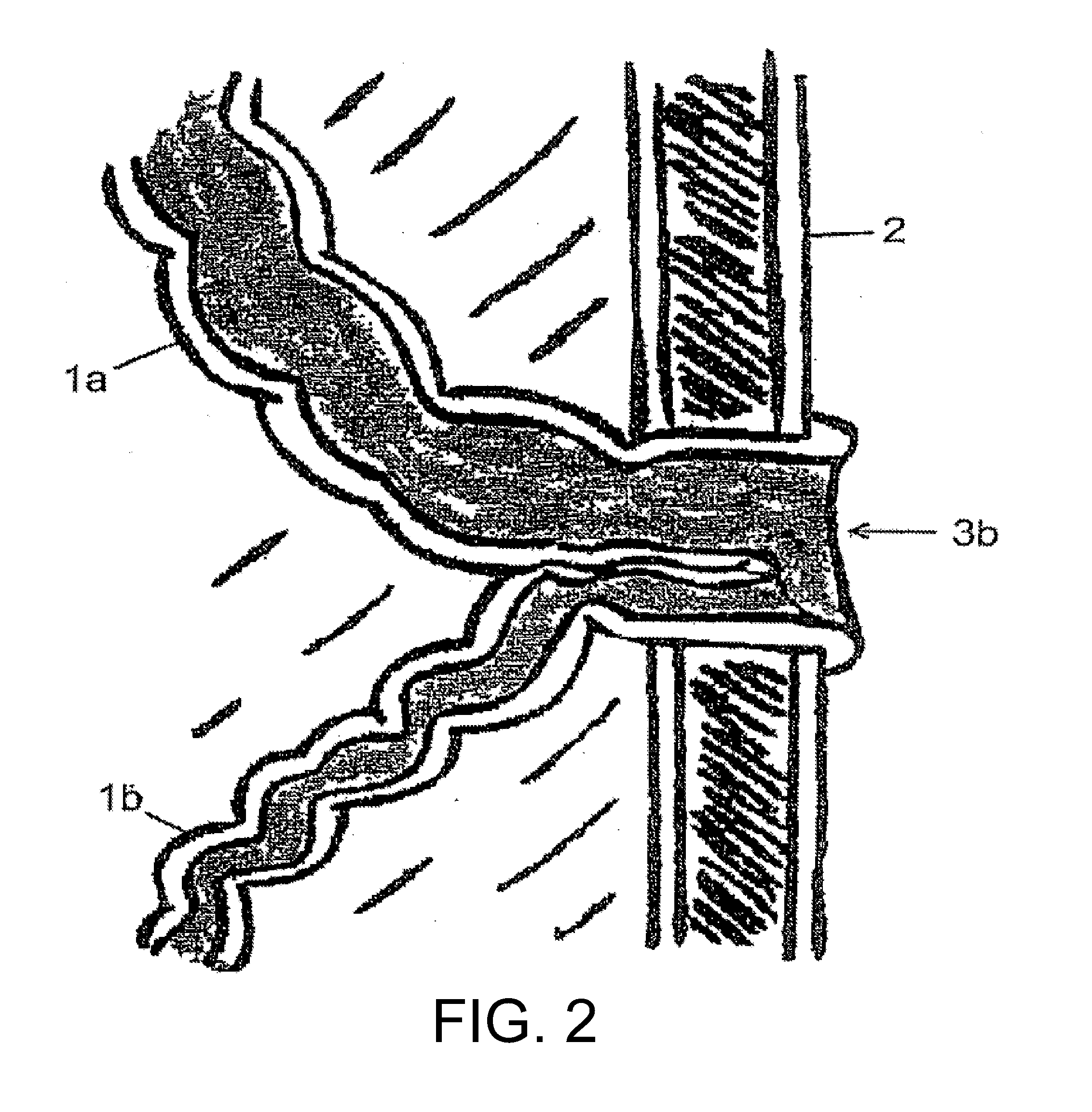

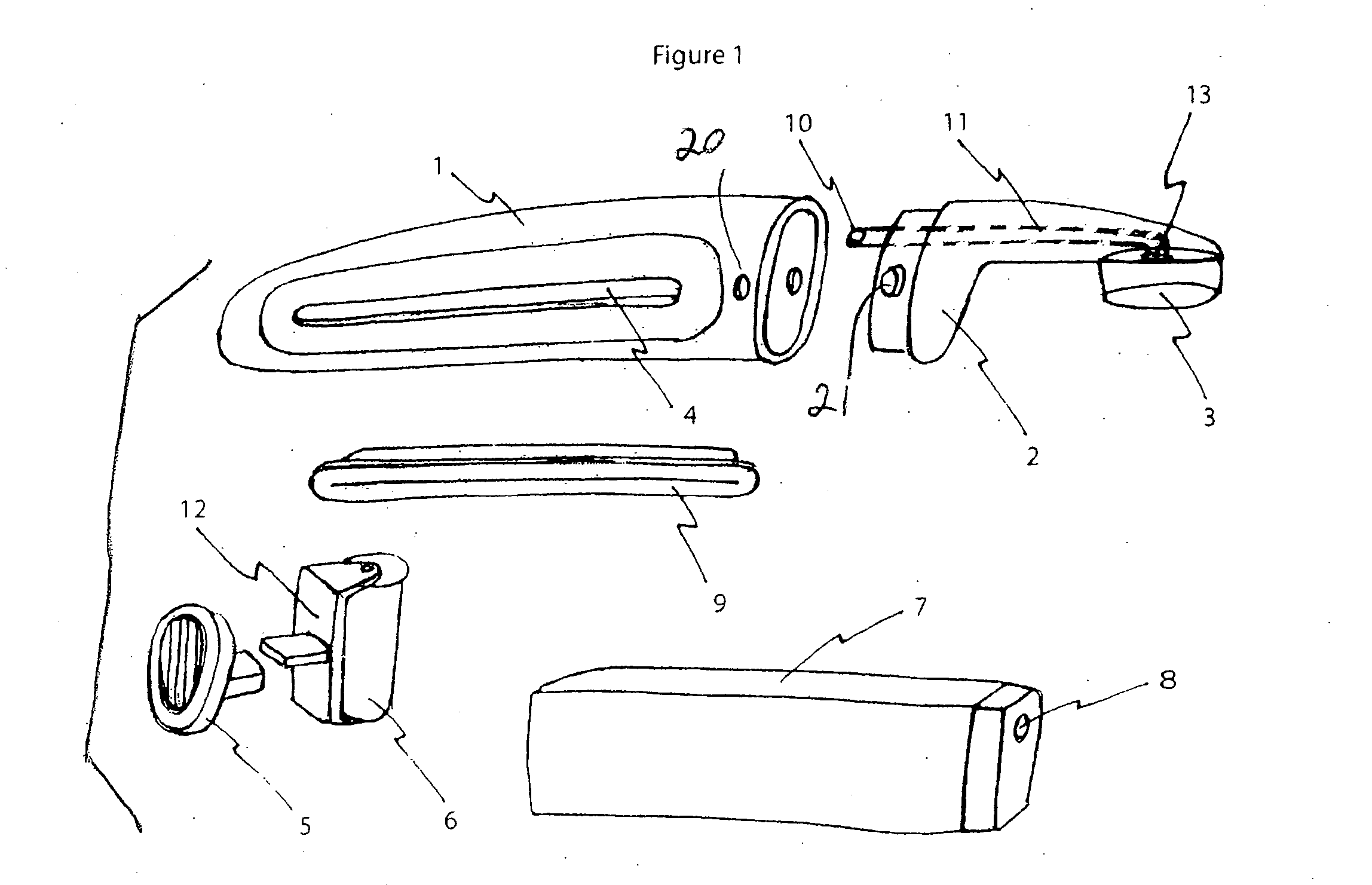

Device for a temporary ileostomy or urostomy closure

InactiveUS20110106032A1Cost-effectiveNon-surgical orthopedic devicesColostomyEngineeringAbdominal wall

The invention relates to a temporary seal for a stoma, which seal is designed in such way that fluid emerging during exchange of the seal is received in a receptacle or, when inserted into the intestinal lumen, already receives fluid there in a receptacle. The device for temporary closure of a stoma comprises a base plate 105 for permanent application in the periphery of a stoma on the outer face of an abdominal wall 2, and a seal which is connected releasably to the base plate 105 to form a temporary stoma closure and is configured in such a way that it forms a receiving volume for receiving at least on receptacle for fluid emerging from the stoma 3.

Owner:KETEK

Low temperature methods for hermetically sealing reservoir devices

Methods are provided for hermetically sealing an opening in a reservoir of a containment device. The method comprises applying a polymeric material to an opening in a reservoir of a containment device, the reservoir comprising reservoir contents (such as a drug or a sensor) to be hermetically isolated within the reservoir, the applied polymeric material closing off the opening and forming a temporary seal; and adhering a hermetic sealing material onto the polymeric material to hermetically seal the opening. The reservoir can be a micro-reservoir. The containment device can comprises an array of two or more of reservoirs, and the method comprises hermetically sealing each of the two or more reservoirs.

Owner:MICROCHIPS BIOTECH INC

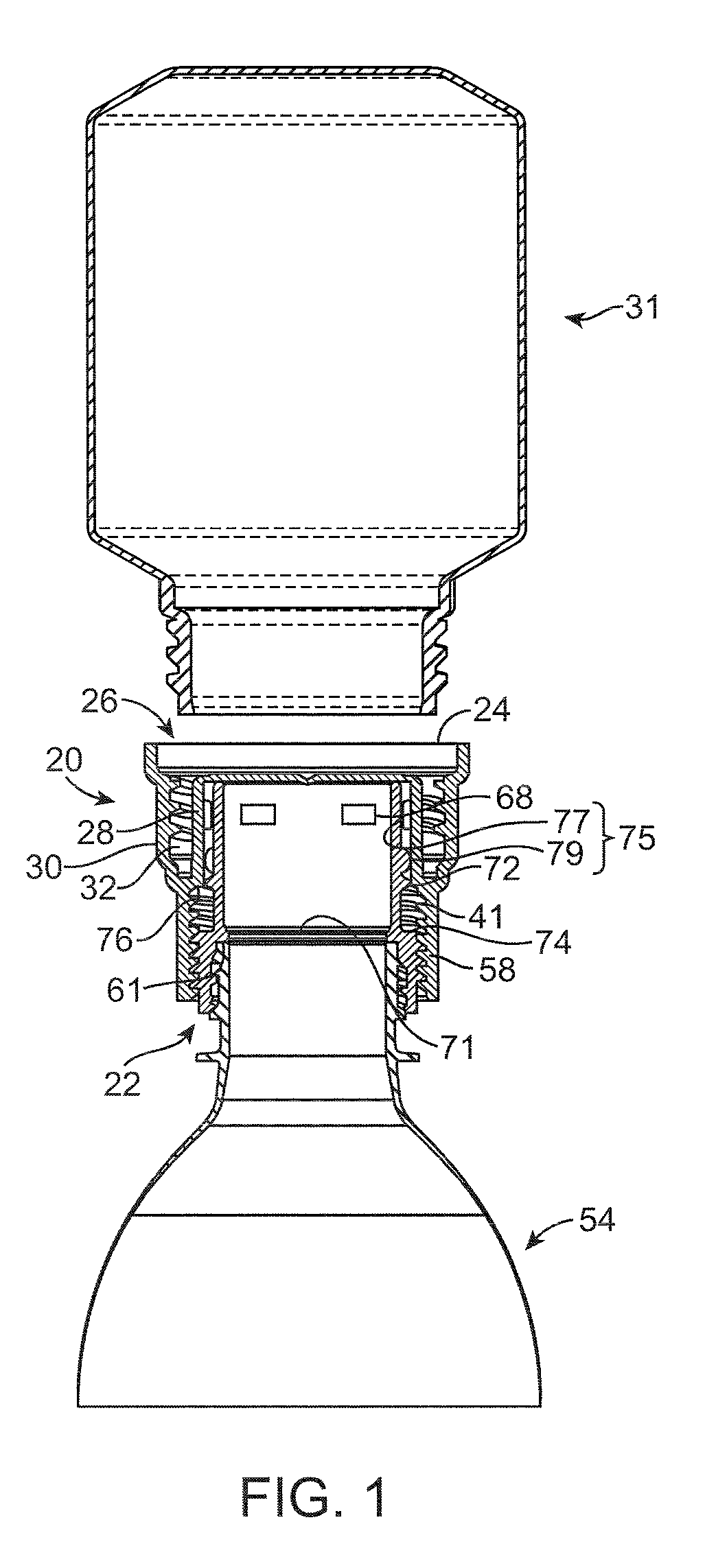

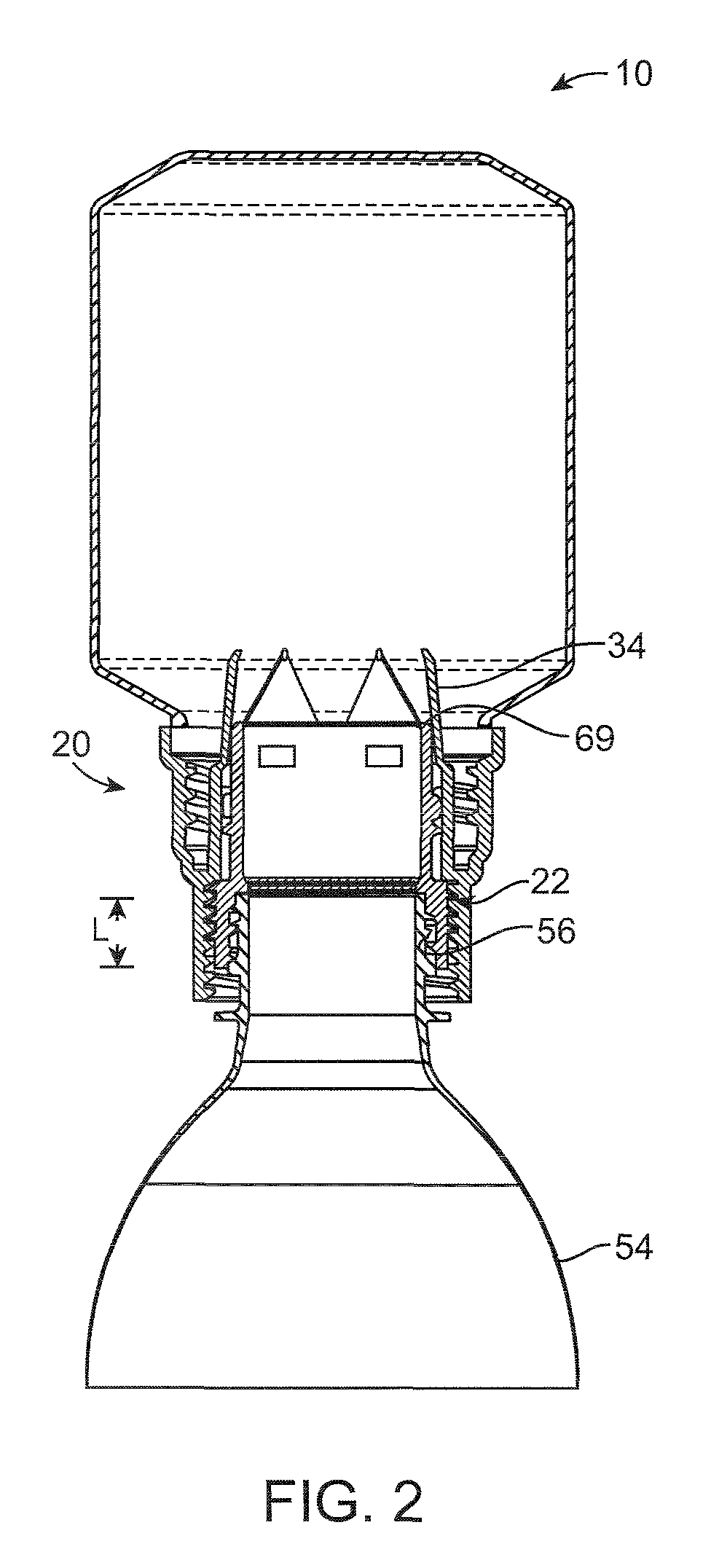

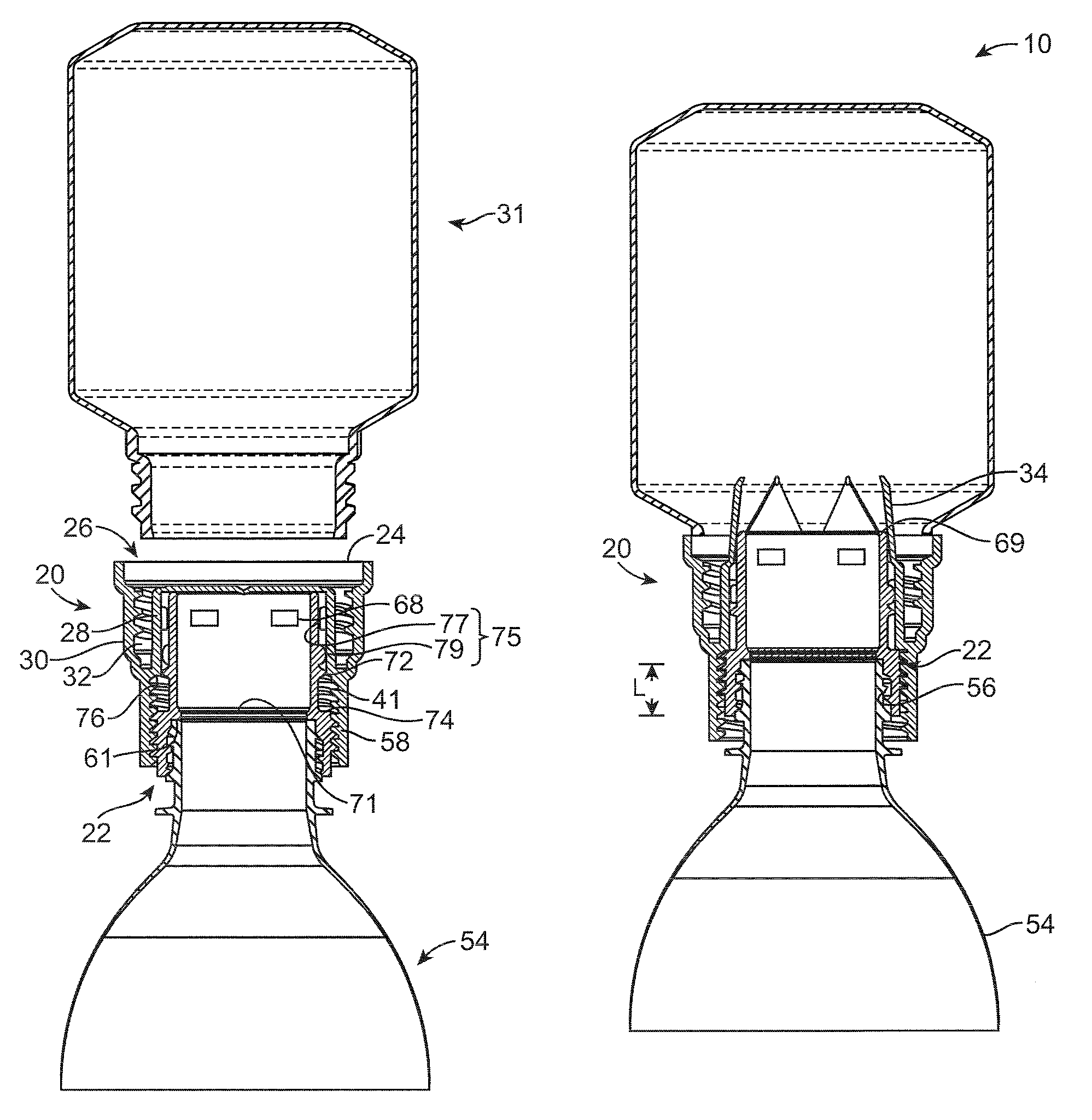

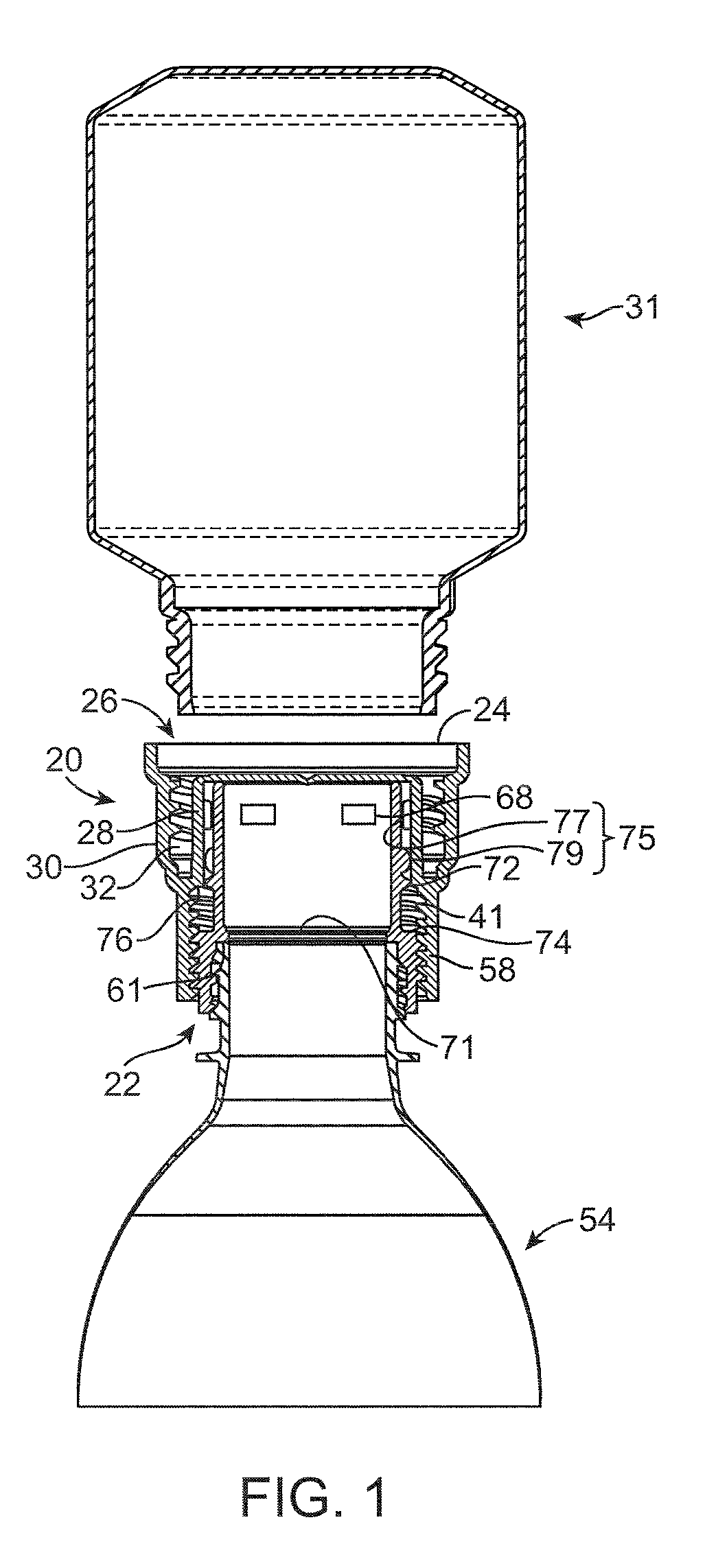

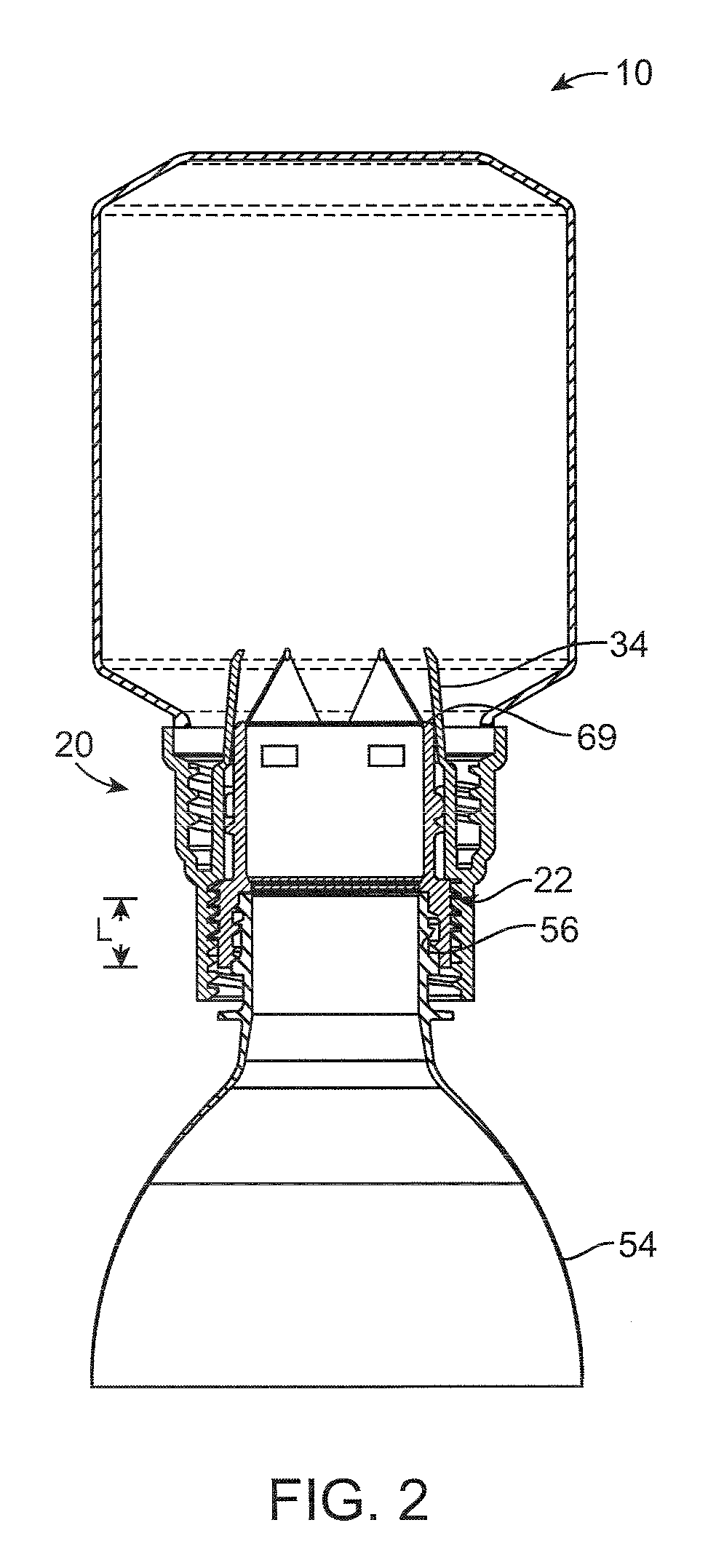

Bottle mixing assembly

A mixing assembly includes a coupler with a temporary seal that is connected to a first container containing mix ingredients. An internally and externally threaded insert is threadedly mated with the internally threaded coupler in an initial position short of breaching the temporary seal. A second container is screwed into the internally threaded insert. Sealing relationships are formed between the coupler and the insert, and between the insert and the received second container. Once the second container is secured to the insert, the coupler is screwed downwardly toward the insert to cause the insert to threadedly advance toward and eventually breach the temporary seal to enable contents of the first container to mix with that of the second container.

Owner:JPRO DAIRY INT

Apparatus for sealing and isolating pipelines

A pipeline tool for use within a pipeline comprises a tool body with an internal flow bore, a swellable component disposed about the tool body, and a temporary seal disposed internally of the flow bore. The pipeline tool may further comprise a tracking device attached to the tool body, wherein the tracking device comprises a mechanical fixture, or an emitter that emits a signal that can be tracked.

Owner:HALLIBURTON ENERGY SERVICES INC

Pipettor and externally sealed pipette tip

InactiveUS6793891B2Reduce maintenancePrecise and accurate amountWithdrawing sample devicesBurettes/pipettesPipetteEngineering

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way. Additionally, seals may be seated in grooves engraved in either the pipette tip or the pipette block to provide a sliding seal between the pipette block and pipette tip.

Owner:YIU FELXI

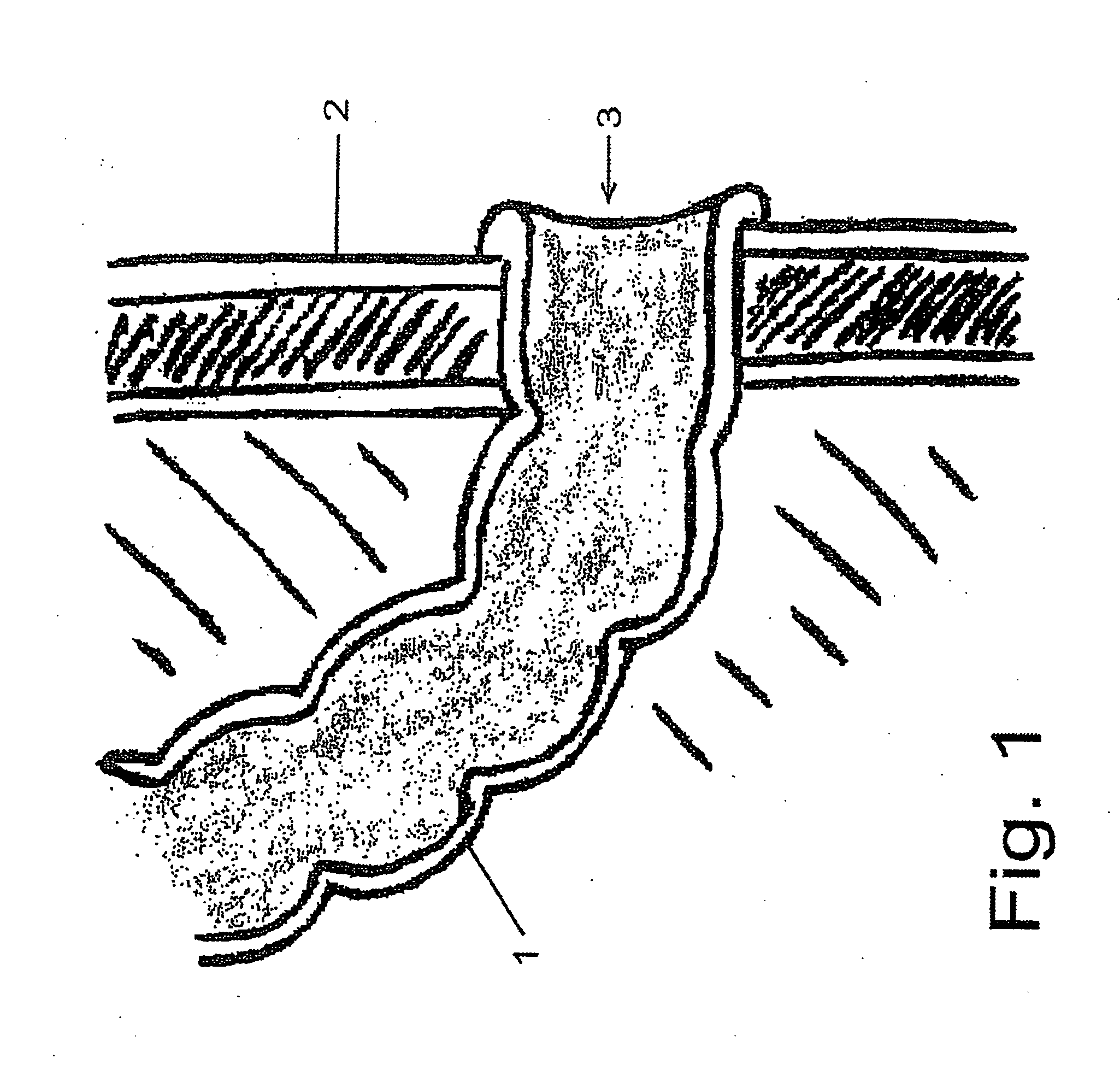

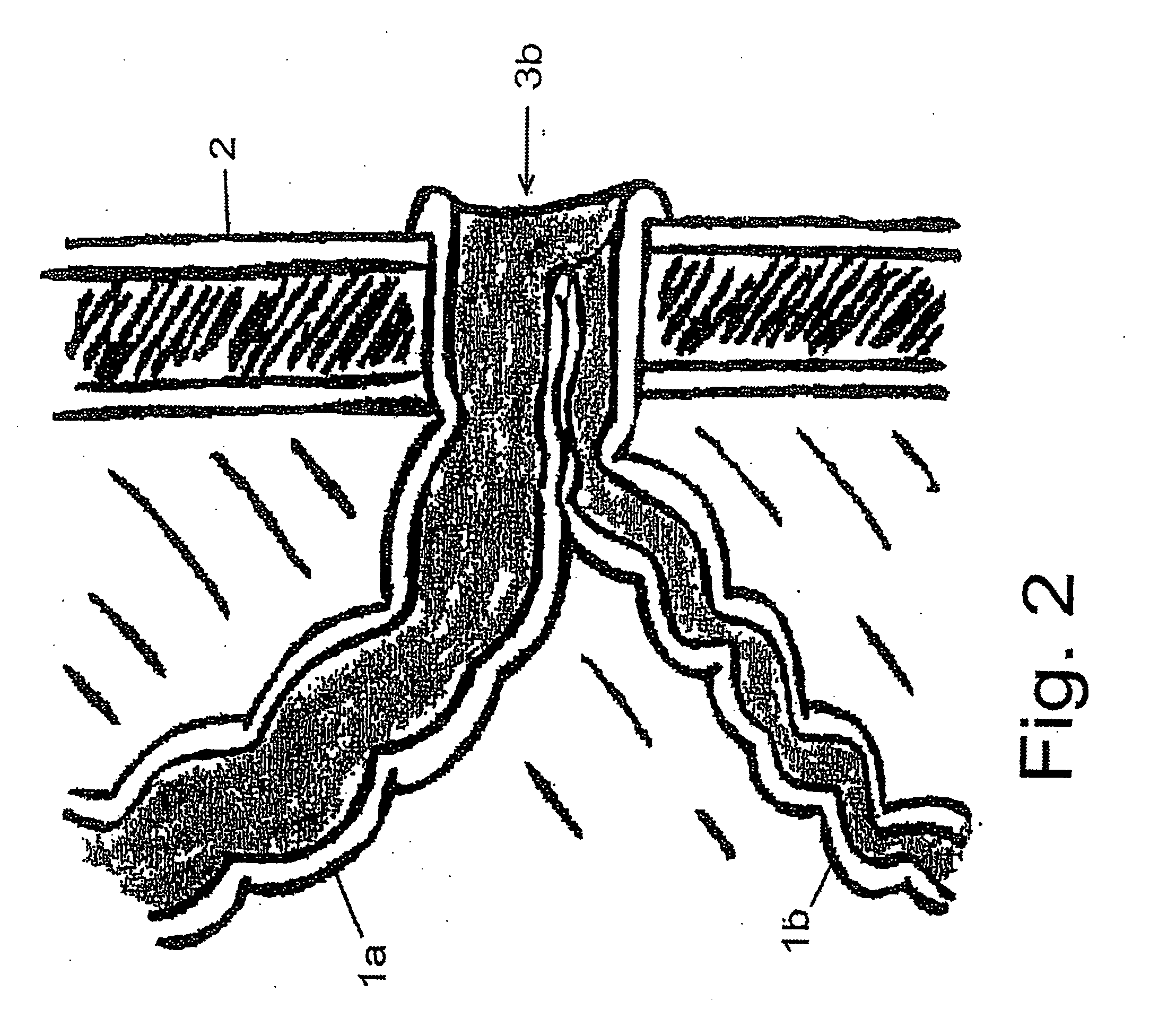

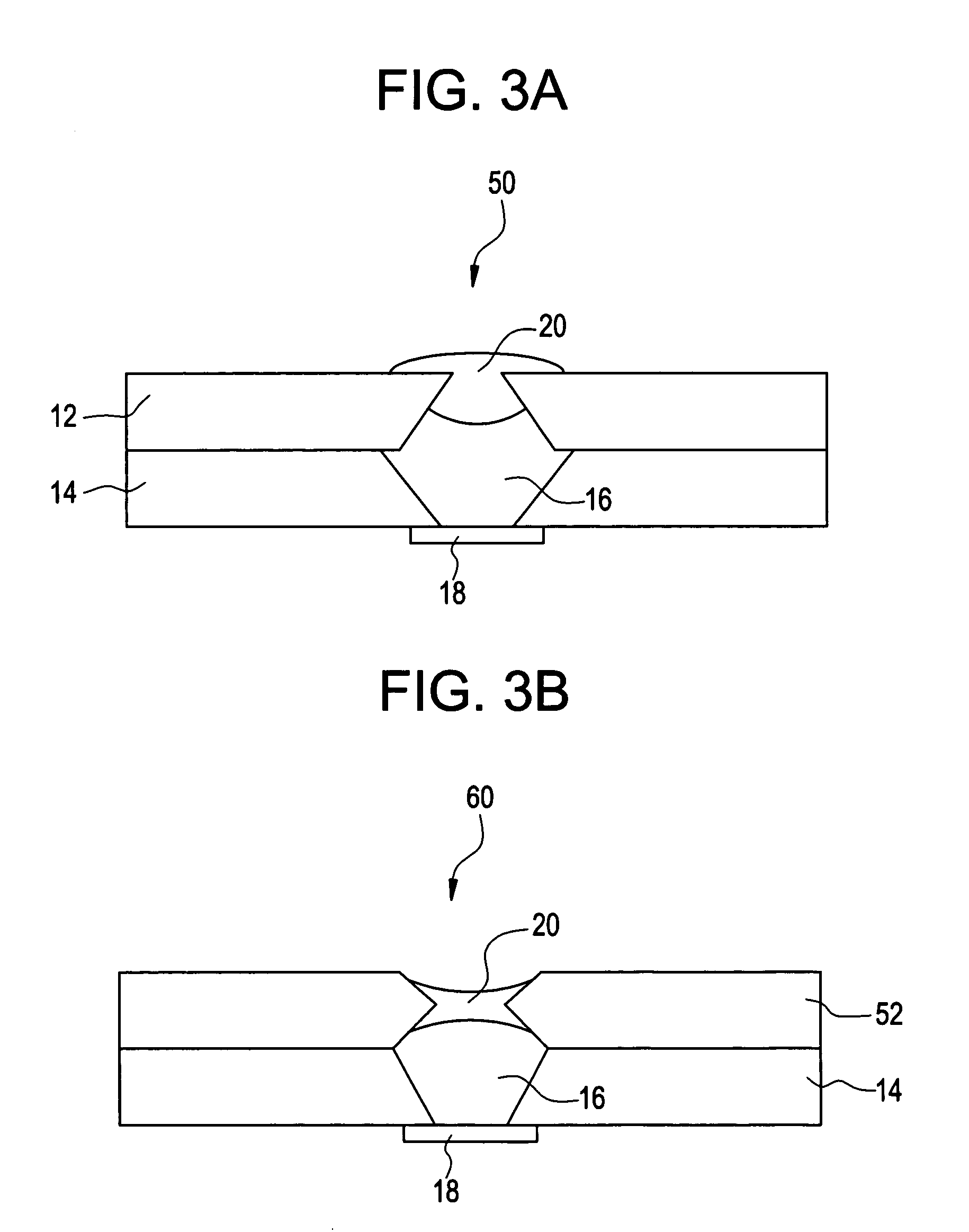

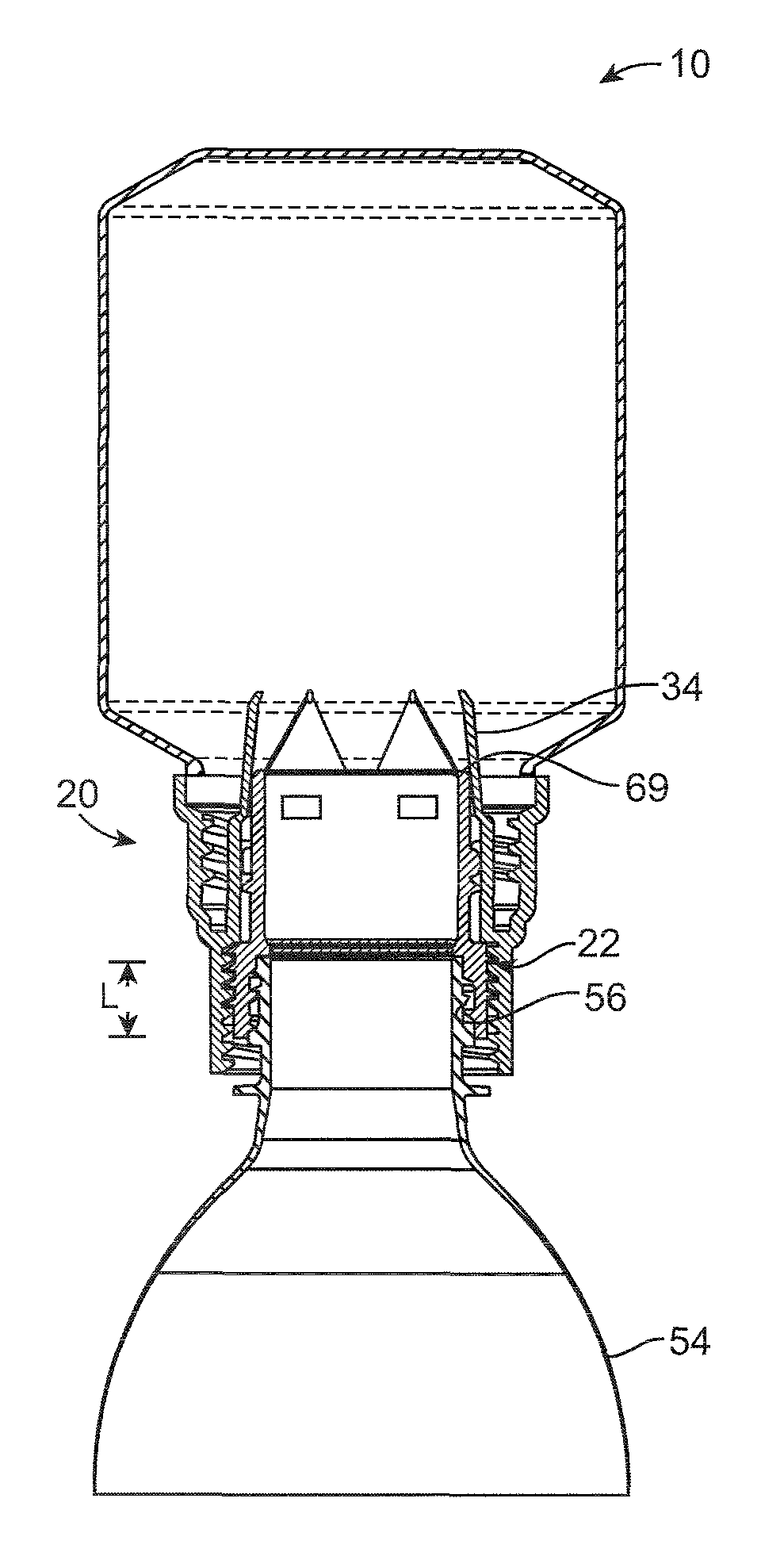

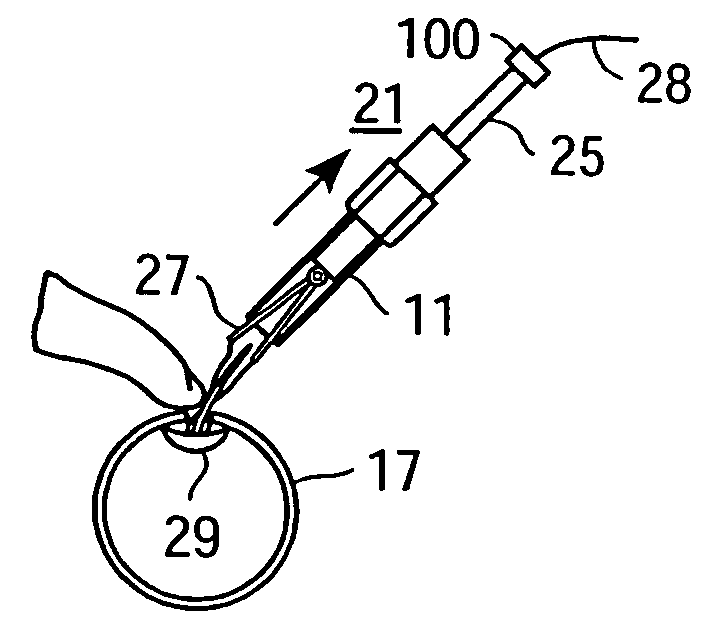

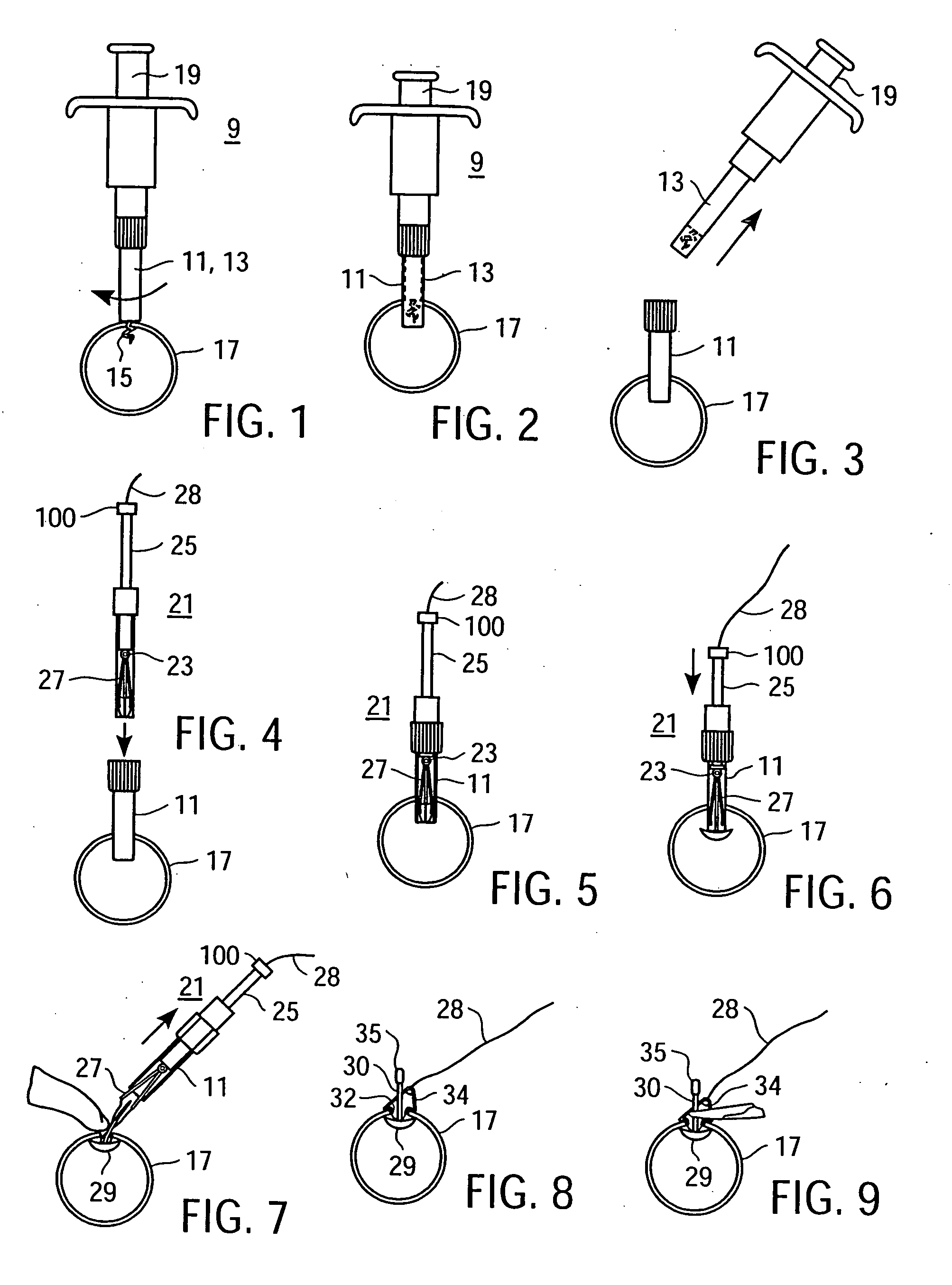

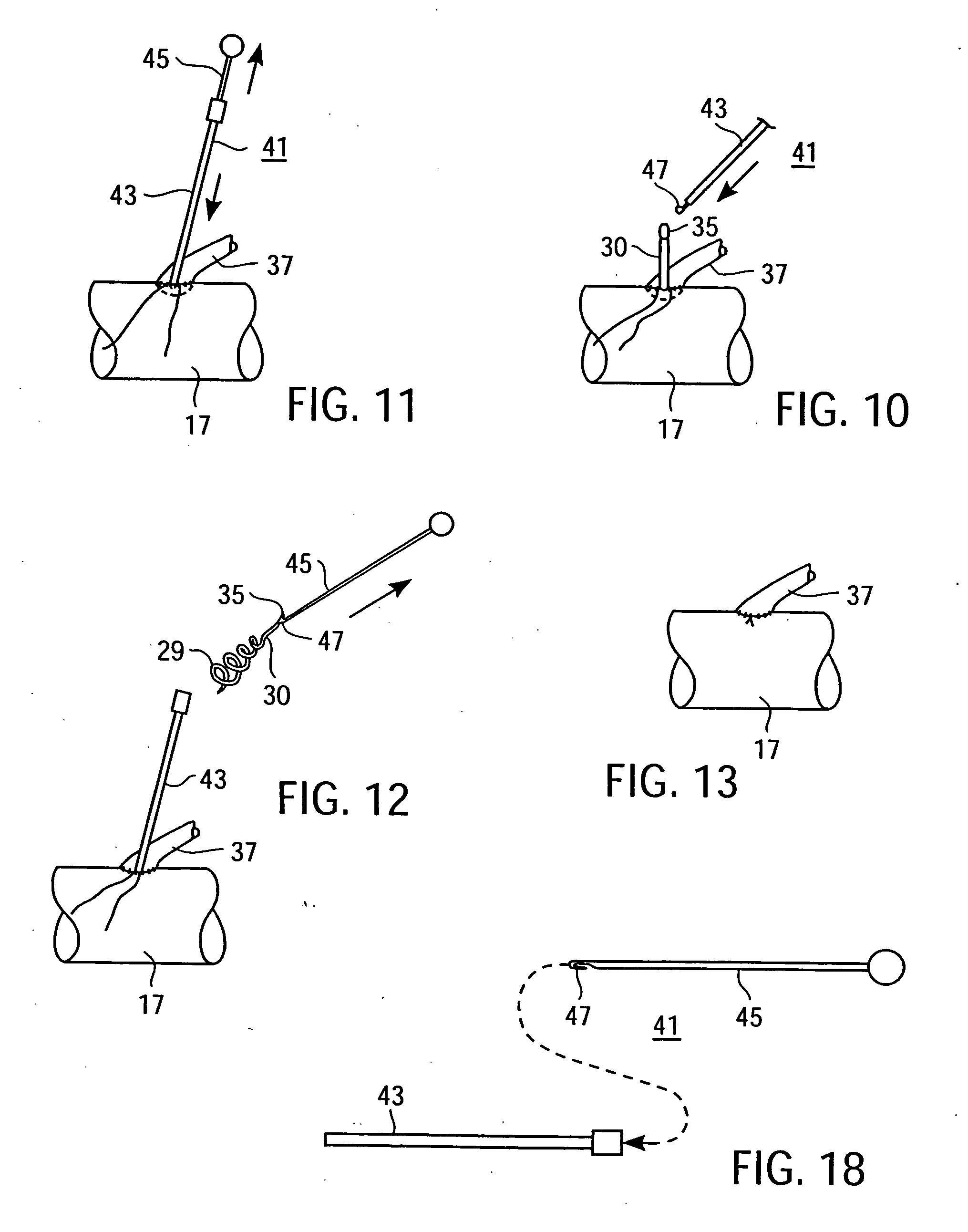

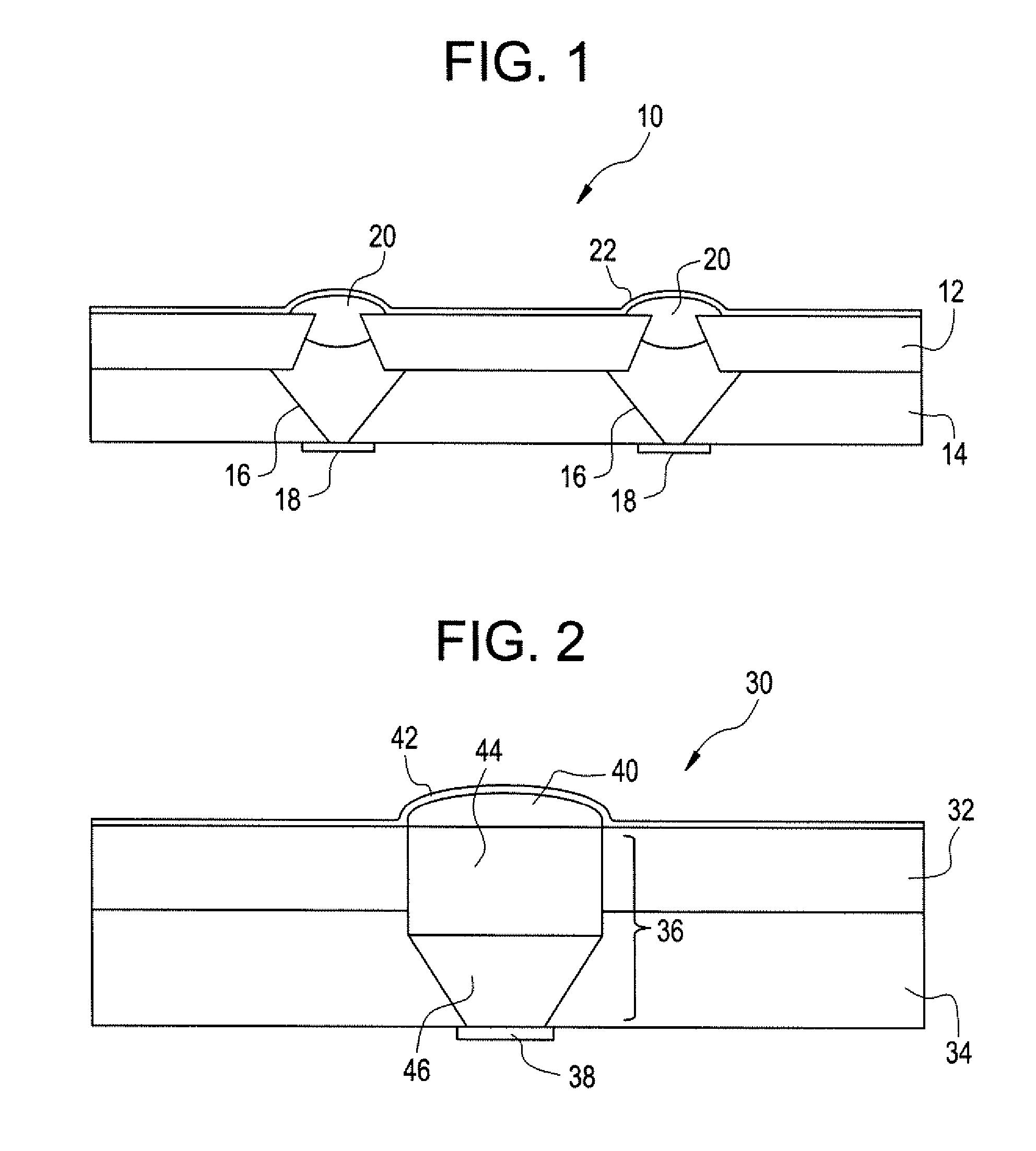

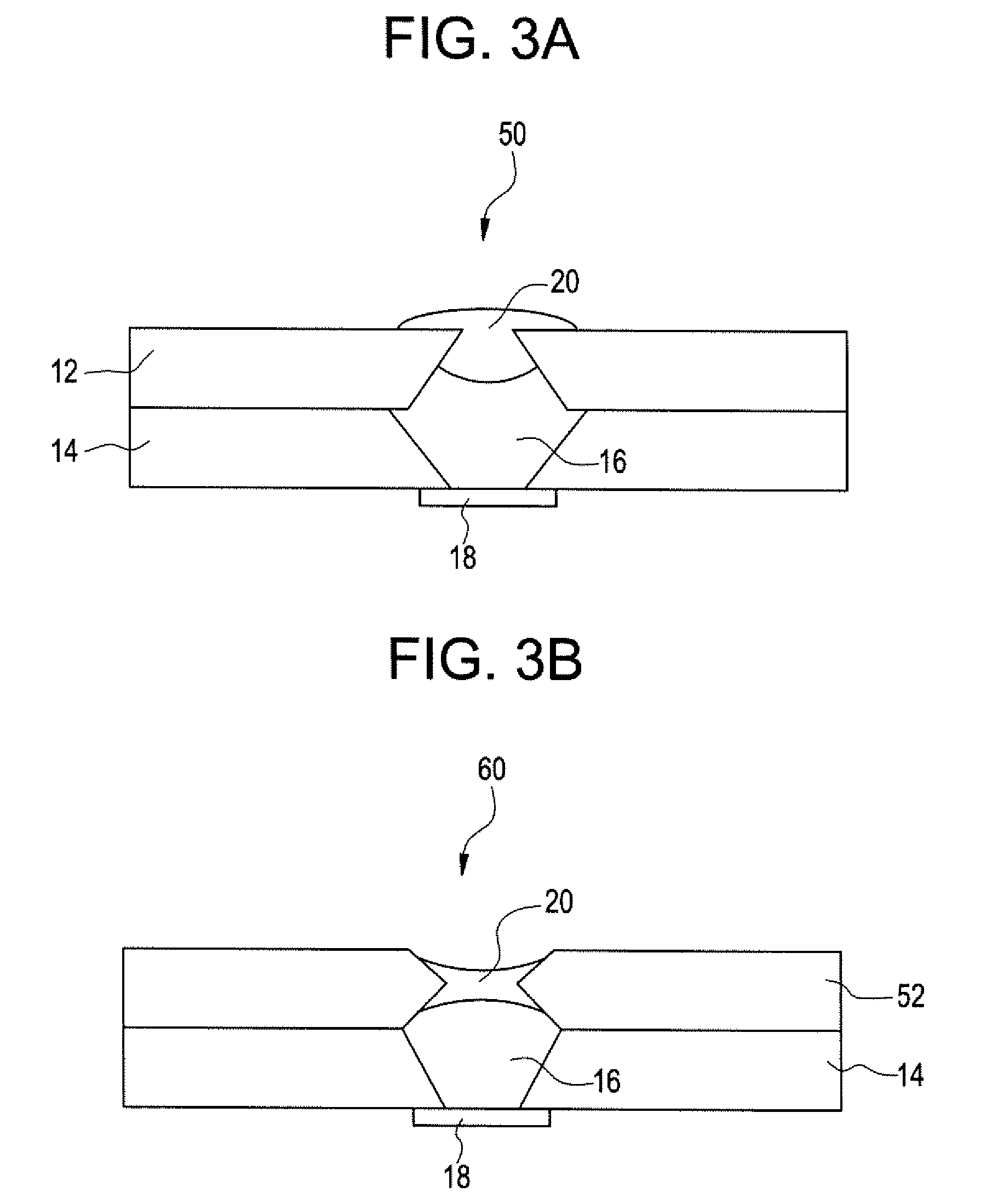

Temporary seal and method for facilitating anastomosis

Forming a proximal anastomosis on an aortic wall includes method and instrumentation and apparatus for forming an aortic puncture and inserting a fluid-impervious sealing element with a lateral flange and central stem into the vessel through the puncture. An anastomosis of a graft vessel over the puncture is partially completed with the central stem of the sealing element protruding through the partial anastomosis. A removal instrument attaches to the central stem and retrieves the sealing element that disassembles in helical disassociation of the flange and stem into a continuous strand that is withdrawn from the partial anastomosis prior to completion of the procedure.

Owner:MAQUET CARDIOVASCULAR LLC

Apparatus for sealing and isolating pipelines

A pipeline tool for use within a pipeline comprises a tool body with an internal flow bore, a swellable component disposed about the tool body, and a temporary seal disposed internally of the flow bore. The pipeline tool may further comprise a tracking device attached to the tool body, wherein the tracking device comprises a mechanical fixture, or an emitter that emits a signal that can be tracked.

Owner:HALLIBURTON ENERGY SERVICES INC

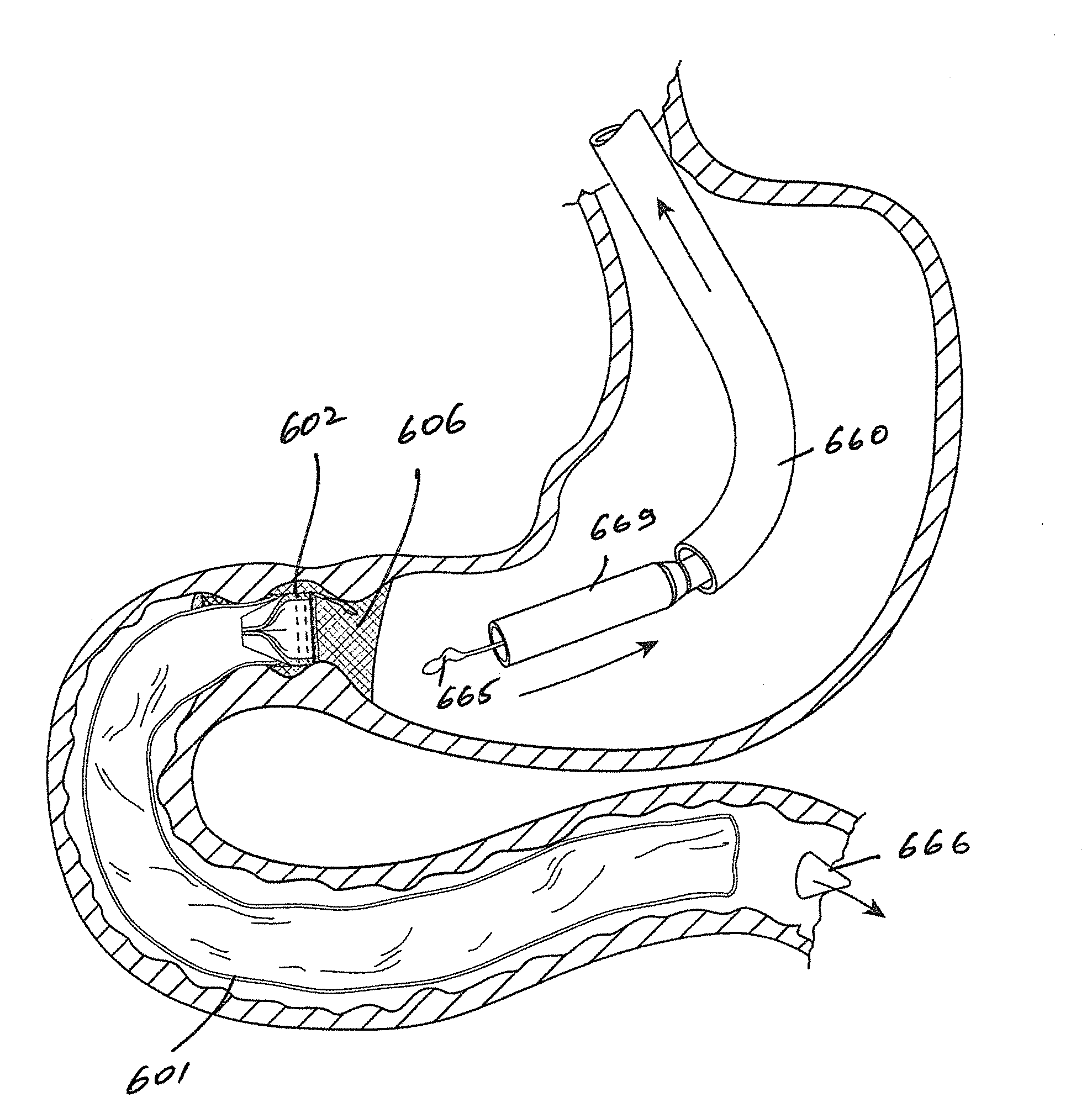

Gastrointestinal implant device and delivery system therefor

A delivery system comprises a delivery catheter with a distal capsule which contains a scaffold, a valve and a sleeve in the retracted configuration. The delivery system includes a proximal expandable element provided by an inflatable proximal balloon and a distal expandable element provided by a distal balloon. The proximal balloon provides a temporary seal at the proximal side of the valve. The distal balloon provides a temporary distal seal between a distal olive and a distal end of the sleeve. An inflation fluid is introduced into the sleeve between the proximal and distal balloons the fluid causes the sleeve to expand axially to the expanded deployed configuration. When the sleeve is in the extended deployed configuration the distal balloon is deflated, allowing the olive to detach and travel distally. The rest of the delivery system can then be withdrawn proximally, leaving the implant device in situ.

Owner:VYSERA BIOMEDICAL

Pipettor and externally sealed pipette tip

InactiveUS20030190263A1Reduce manufacturing costReduce maintenanceWithdrawing sample devicesBurettes/pipettesPipetteEffective volume

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way.

Owner:YIU FELIX H

Hermetically Sealed Devices for Controlled Release or Exposure of Reservoir Contents

InactiveUS20070036835A1Material nanotechnologyPharmaceutical delivery mechanismControlled releaseHermetic seal

Methods are provided for hermetically sealing an opening in a reservoir of a containment device. The method comprises applying a polymeric material to an opening in a reservoir of a containment device, the reservoir comprising reservoir contents (such as a drug or a sensor) to be hermetically isolated within the reservoir, the applied polymeric material closing off the opening and forming a temporary seal; and adhering a hermetic sealing material onto the polymeric material to hermetically seal the opening. The reservoir can be a micro-reservoir. The containment device can comprises an array of two or more of reservoirs, and the method comprises hermetically sealing each of the two or more reservoirs.

Owner:MICROCHIPS INC

Bottle mixing assembly

A mixing assembly comprises a coupler with a temporary seal that is connected to a first container containing mix ingredients. An internally and externally threaded insert is threadedly mated with the internally threaded coupler in an initial position short of breaching the temporary seal. A second container is screwed into the internally threaded insert. Sealing relationships are formed between the coupler and the insert, and between the insert and the received second container. Once the second container is secured to the insert, the coupler is screwed downwardly toward the insert to cause the insert to threadedly advance toward and eventually breach the temporary seal to enable contents of the first container to mix with that of the second container.

Owner:JPRO DAIRY INT

Plug for beverage container lid

A device and system for temporarily sealing an orifice in a beverage container lid, comprising a plug having an upper surface, a body portion and a lower surface, said body portion adapted to be inserted and releasably retained in the orifice to provide a temporary seal thereof, and an external member located on the upper surface of the plug configured to allow a user to grip the plug for ease of removal from the orifice.

Owner:BURNS THOMAS

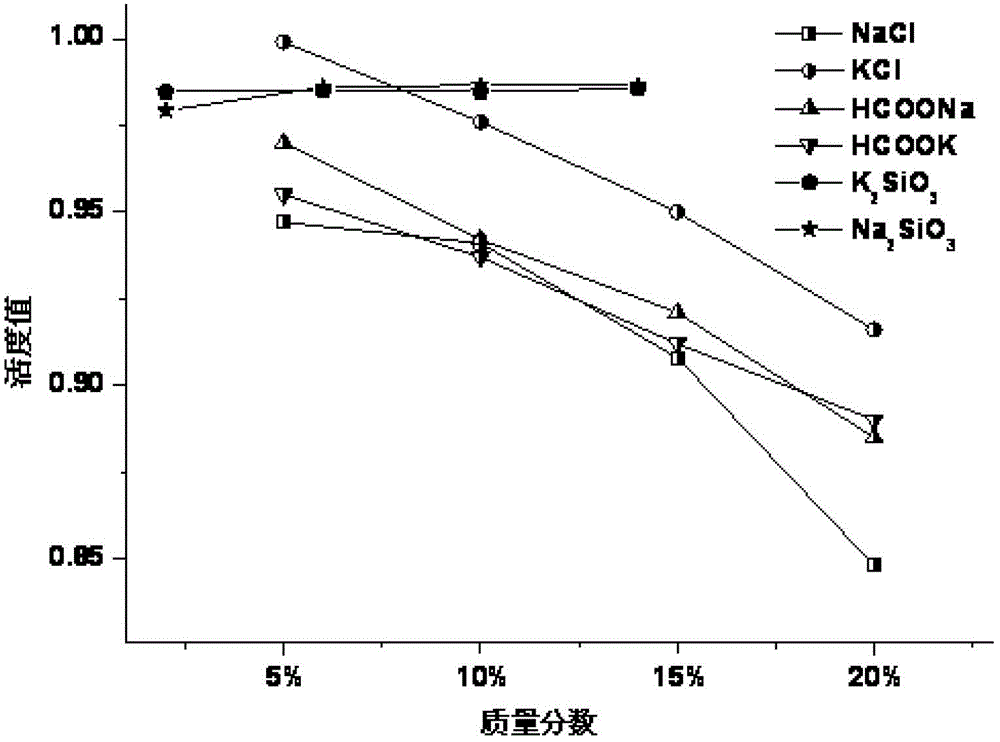

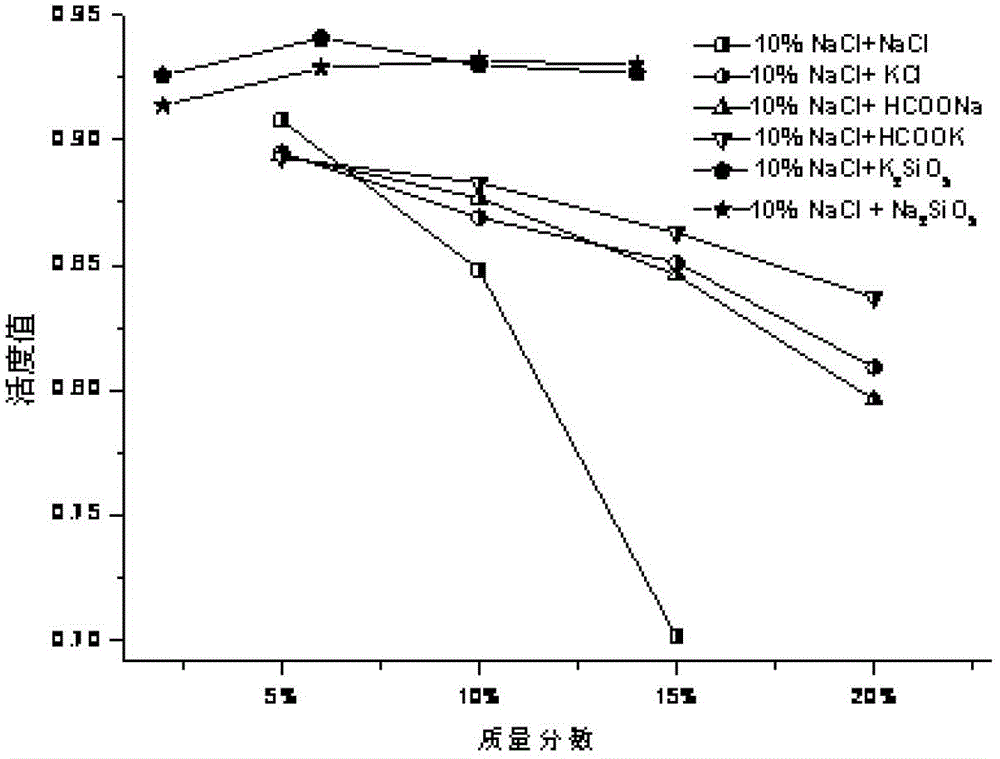

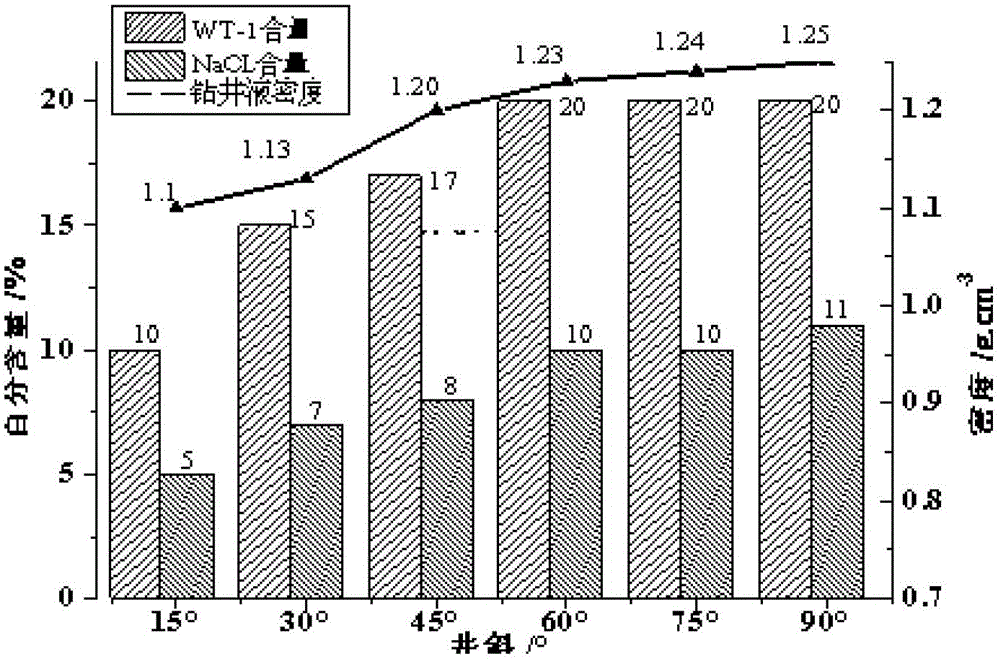

Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

InactiveCN103146363AAvoid differential pressure lossThe system has strong chemical inhibition and anti-collapse effectDrilling compositionSealing/packingFriction reductionMass ratio

The invention discloses a composite salt low-activity anti-sloughing drilling fluid and a construction method thereof. The composite salt low-activity anti-sloughing drilling fluid consists of the following raw materials in percentage by mass: 0.2-0.3% of drilling fluid viscosifier, 2-3% of carboxymethyl starch, 1.5-2% of aqueous dispersion cation emulsified asphalt, 0.2-0.3% of anti-salt anti-calcium filtrate reducer, 1% of sulfonated phenolic resin, 2% of acid-soluble temporary seal reservoir protective agent, 1% of superfine calcium, 0.1% of caustic soda and the balance of clean water. In construction, the composite salt accounting for 5-15% of the dosage of the composite slat low-activity anti-sloughing drilling fluid is added, and the composite salt is formed by mixing sodium formate and sodium chloride at a mass ratio of 2:1. By utilizing the composite salt, the function of chemically suppressing mudstone and preventing sloughing in the drilling fluid as well as the density of the drilling fluid are improved. With strong chemical suppression and low solid phase, the composite salt low-activity anti-sloughing drilling fluid completely meets the strict high-quality requirements of a long open-hole section for friction reduction and resistance reduction of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Pulling iron pocket, lid and shield

A pocket, lid and shield for casting a pulling iron in a concrete structure are described. The pocket includes a slot reinforced with stiffening members for receiving the pulling iron. The pocket also includes a frangible support post for supporting the pulling iron when it is received in the pocket. Also described are embodiments of a shield, which include clipping members adapted to engage the stiffening members, for covering the slot, and a lid having a lip for engaging a peripheral groove in the pocket. Methods of over-molding a pulling iron cable are also described. According to the methods, a temporary seal, which can be used in over-molding a subsequent pulling iron cable, can be formed simultaneously with each over-molded product. During molding, the cable can be held in the center of a channel in the mold tool using a retractable magnetic pin.

Owner:PENNSYLVANIA INSERT CORP

Pipettor and externally sealed pipette tip

InactiveUS20030190264A1Reduce manufacturing costReduce maintenanceWithdrawing sample devicesBurettes/pipettesPipetteEffective volume

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way. Additionally, seals may be seated in grooves engraved in either the pipette tip or the pipette block to provide a sliding seal between the pipette block and pipette tip.

Owner:YIU FELXI

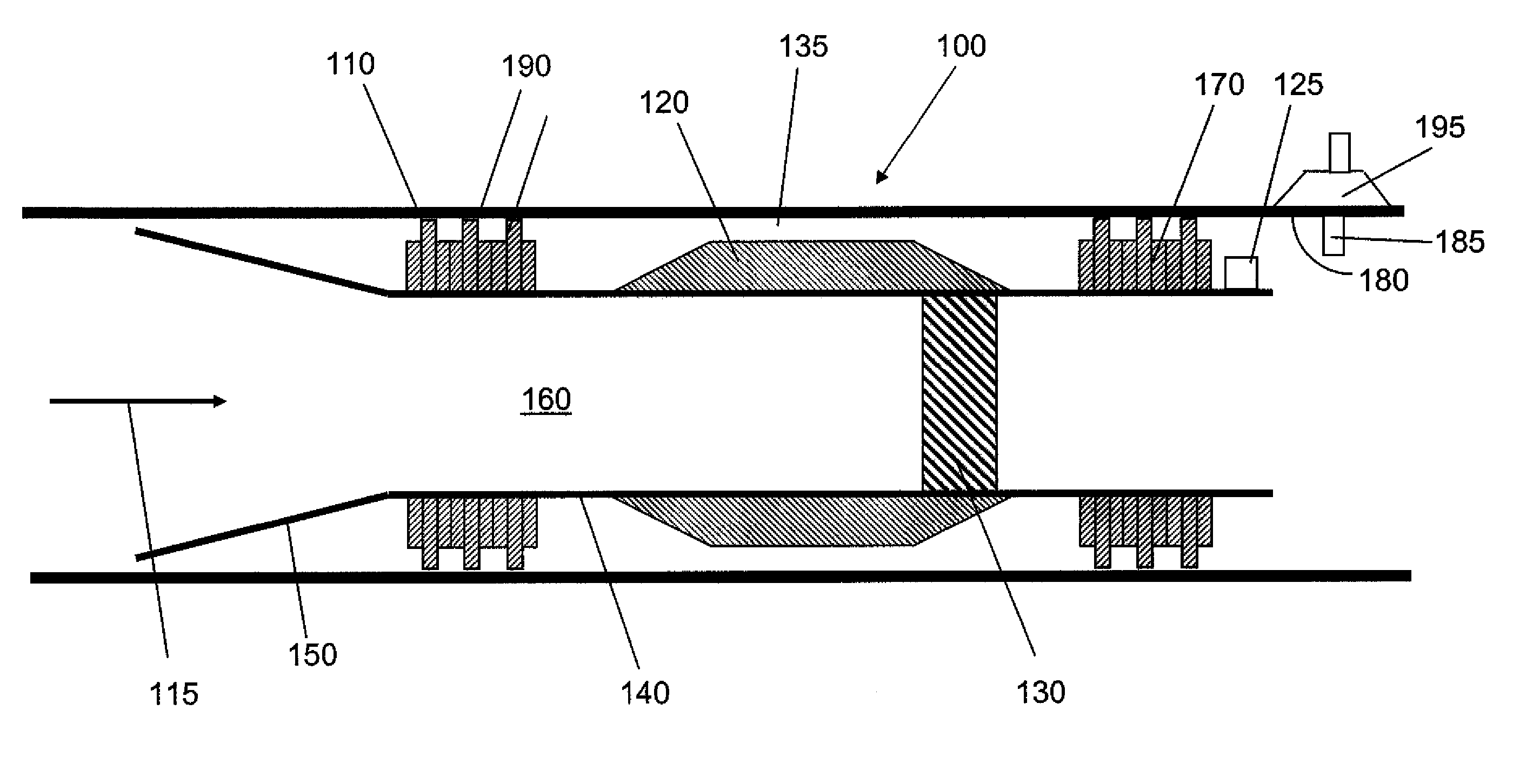

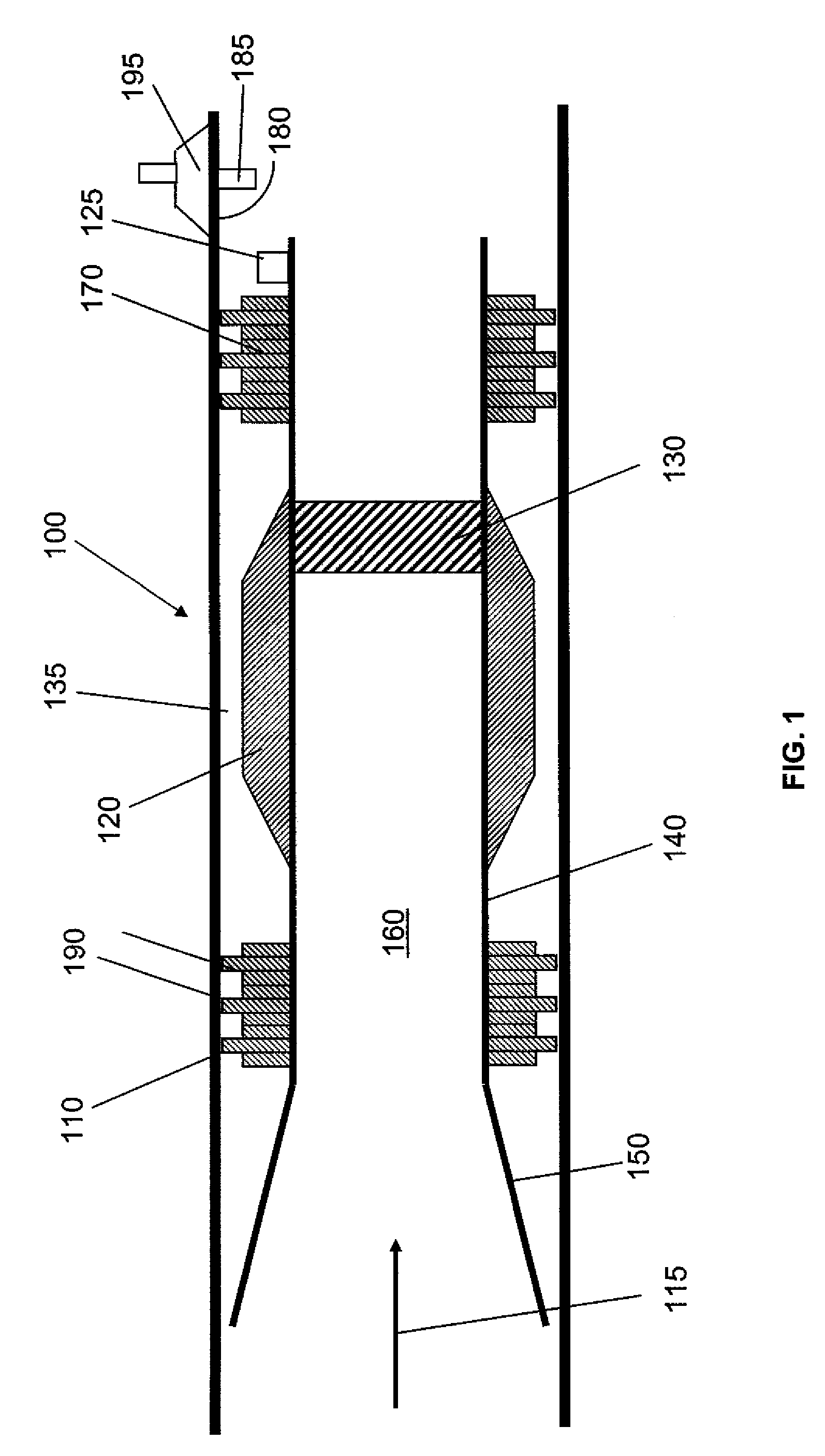

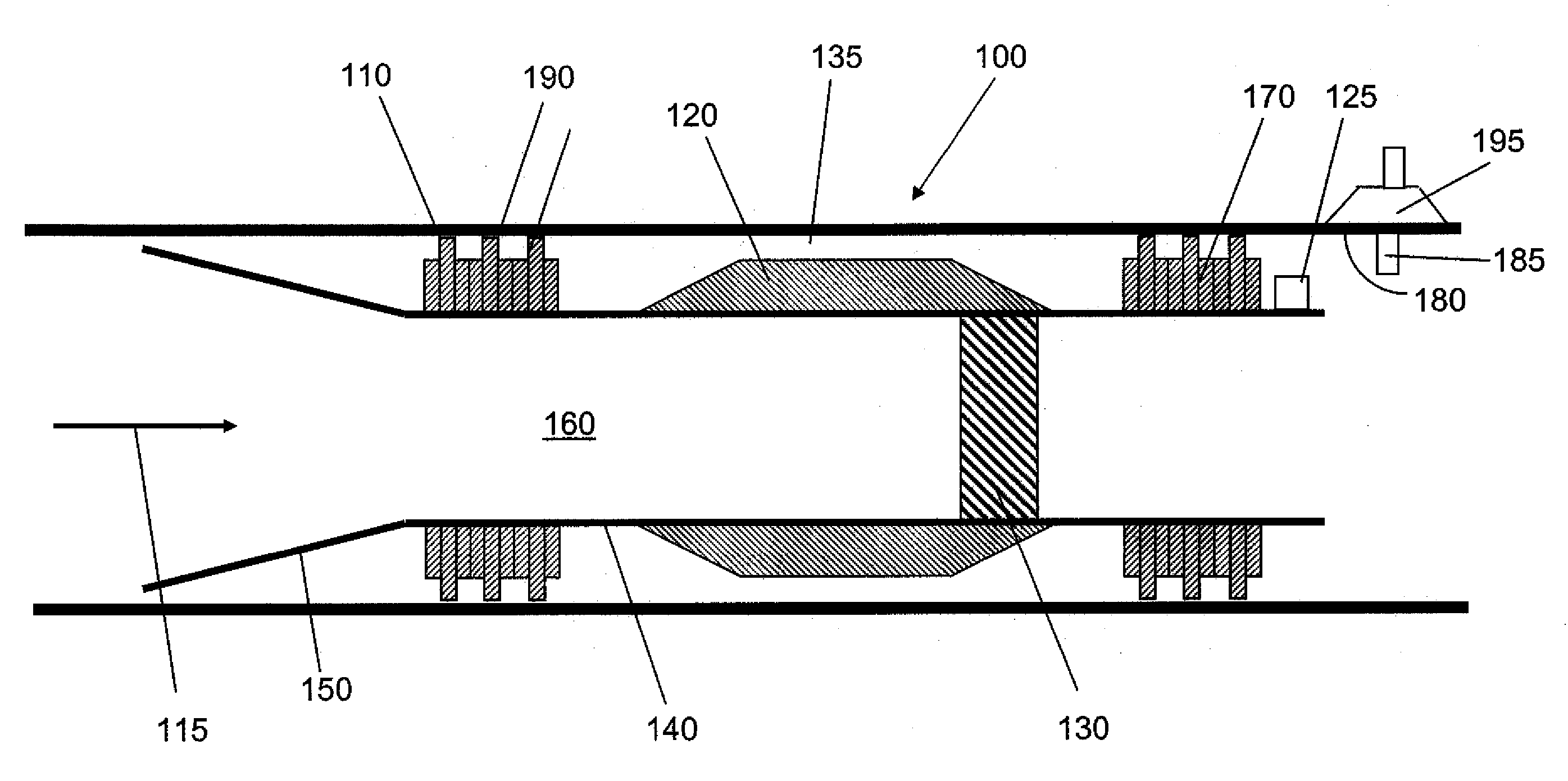

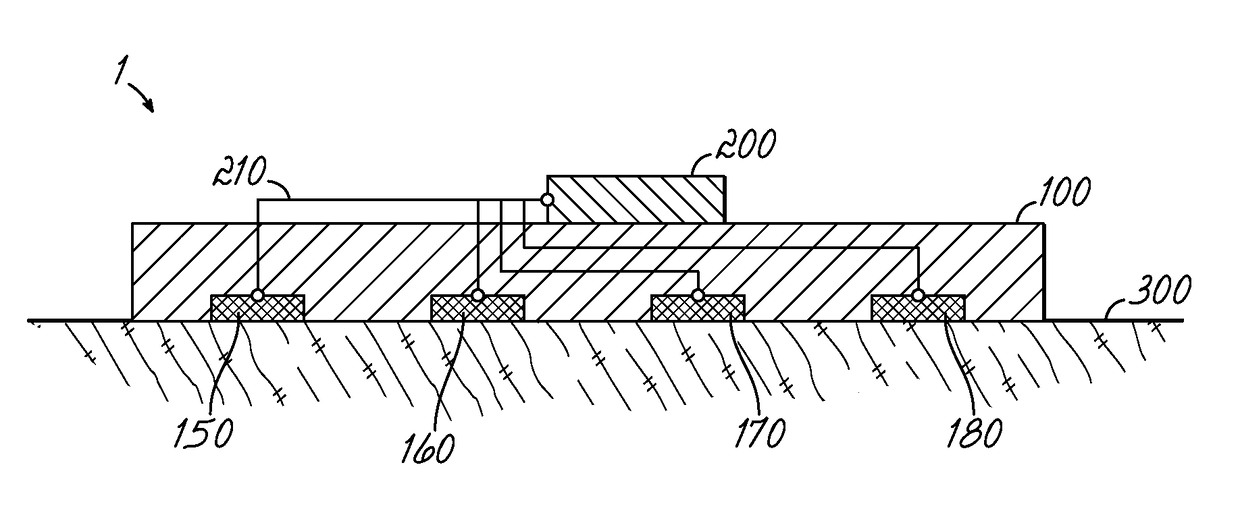

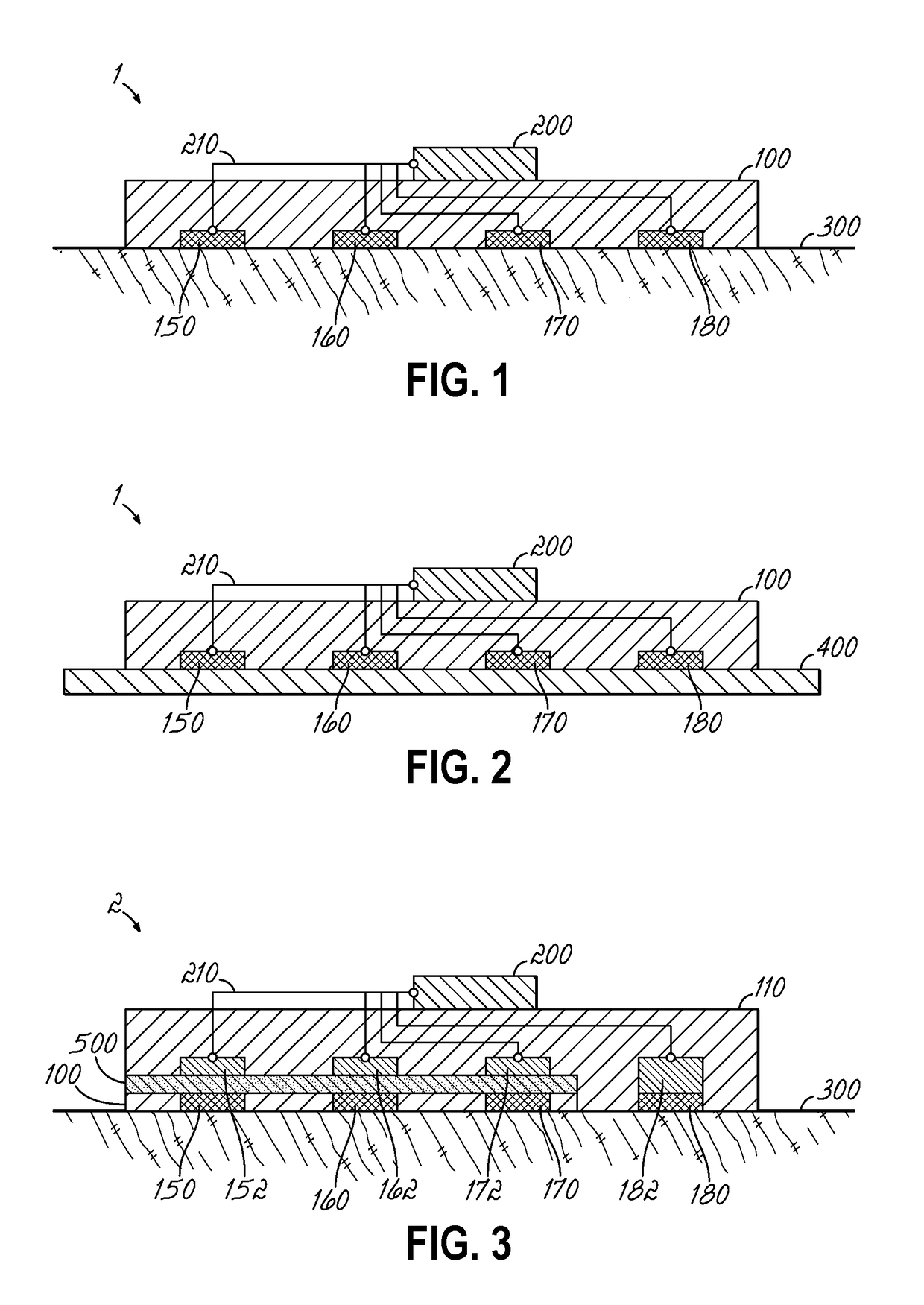

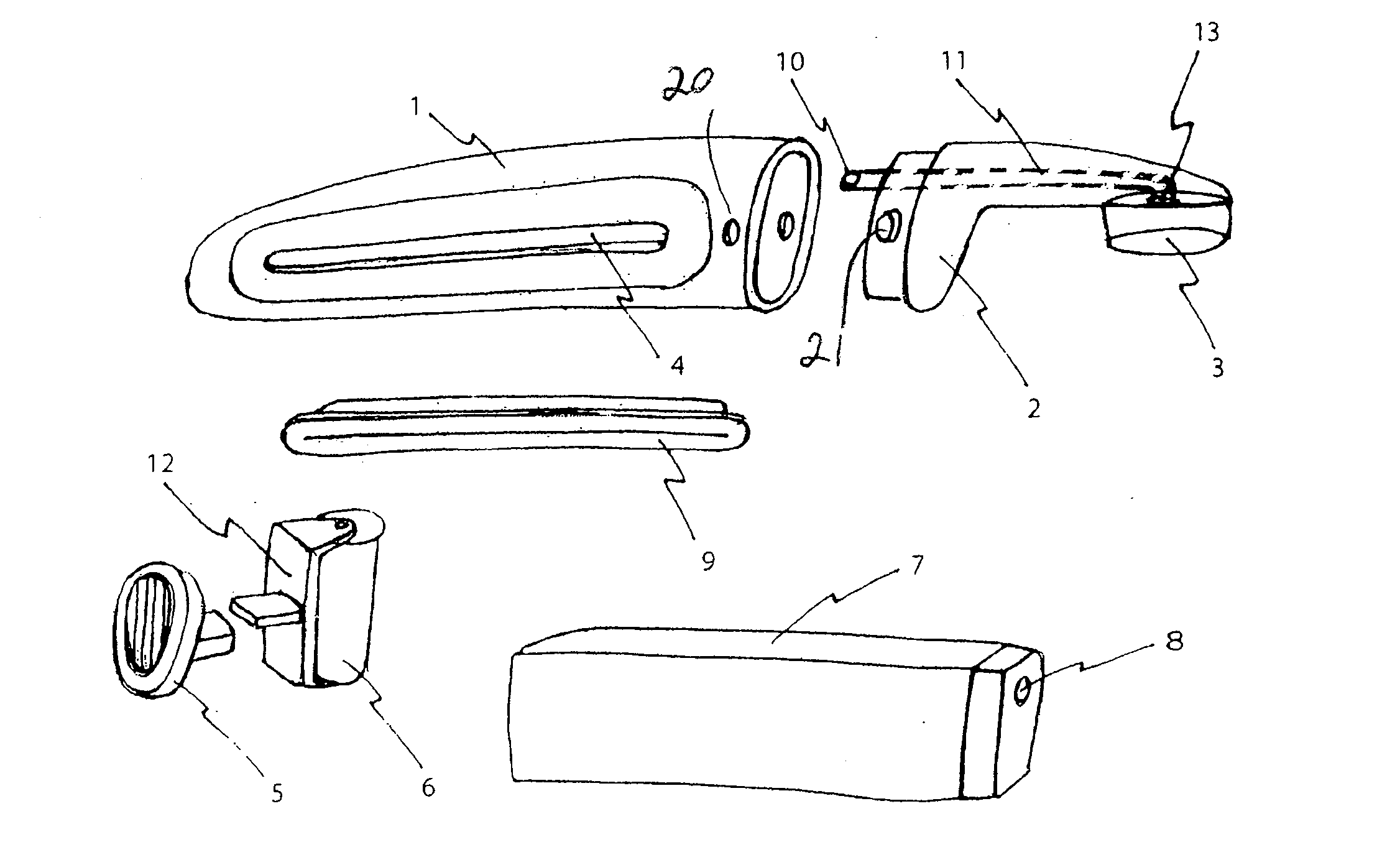

Combinatorial sensing of sweat biomarkers using potentiometric and impedance measurements

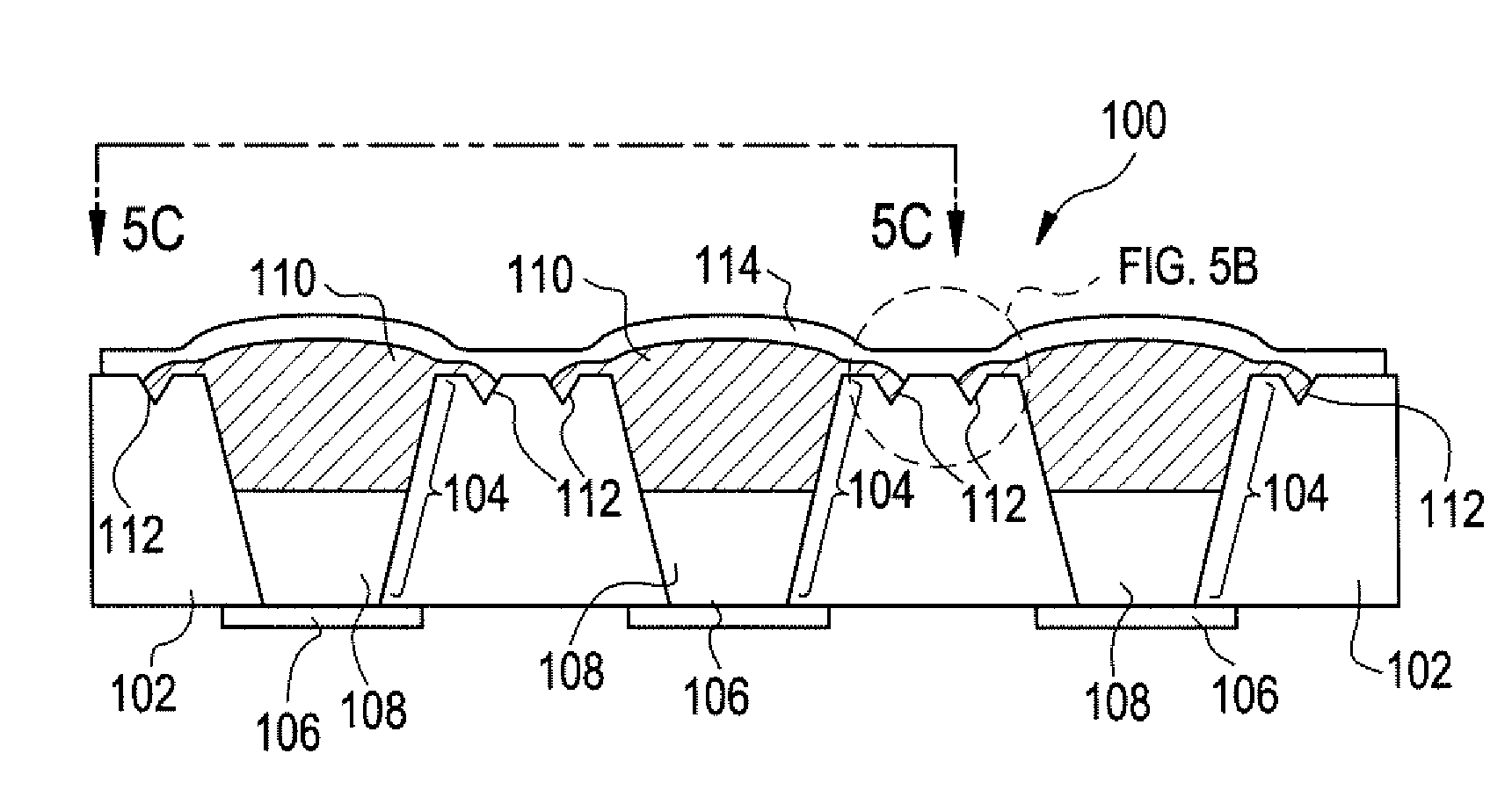

A wearable sweat sensor device (1) may include a plurality of sensors (150, 160, 170, 180) capable of measuring a plurality of ion-selective biomarker potentials and a mechanism that analyzes a combination of measurements as a proxy for one or more physiological conditions such as muscle activity, exertion, or tissue damage. A device may include a sensor capable of taking at least one skin impedance measurement along with a plurality of sensors (150, 160, 170, 180) and a mechanism that analyzes a combination of measurements as a proxy for one or more physiological conditions, such as hydration or sweat rate. Because several of said sensors (150, 160, 170, 180) may not be stable when stored if fully exposed to air, the device (1) may include a temporary seal (400) for said sensors (150, 160, 170, 180) that is removable prior to placement and use of said sensors (150, 160, 170, 180).

Owner:GOVERNMENT OF THE UNITED STATES AS REPRESENTED BY THE SEC OF THE AIR FORCE +1

Device for a Temporary Ileostomy or Urostomy Closure

A device for a temporary seal of a stoma coupled to an intestine having an intestinal lumen includes a base plate is configured to be applied permanently about a periphery of the stoma on an outside of a body. A cover is releasably connected to a base plate for forming a temporary stoma steal and that is configured in such a way that it forms a volume for receiving at least one receptacle for fluid emerging from the stoma. A tube-shaped container is detachably coupled with the base plate and disposed within the cover, but not attached to the cover so, the container configured to be separable from the base plate. The container opens to the stoma and configured to receive fluid emerging therefrom.

Owner:KRATKY PETER

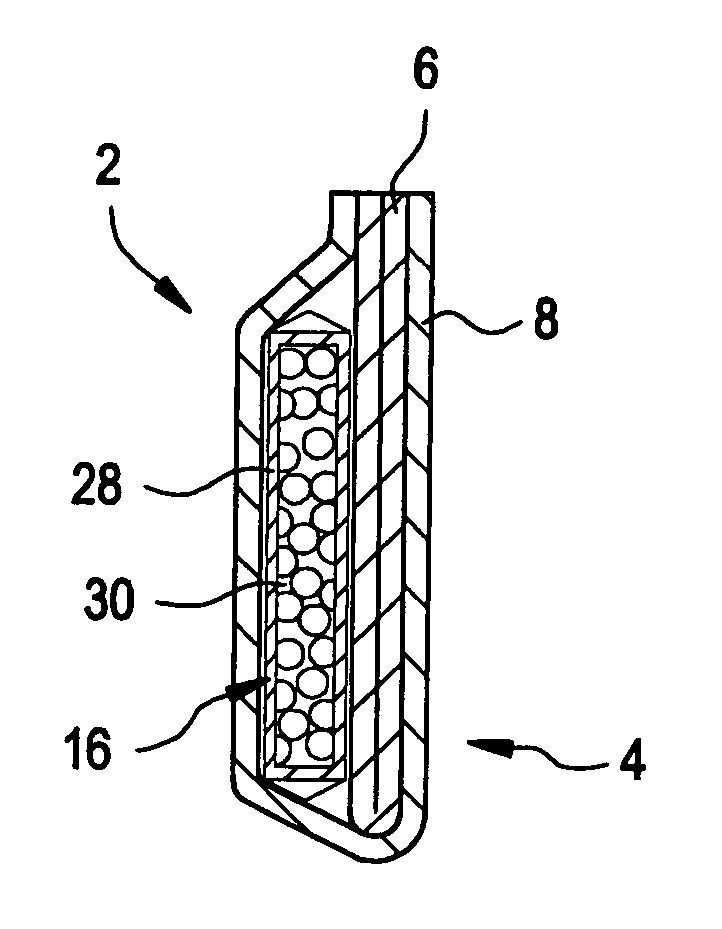

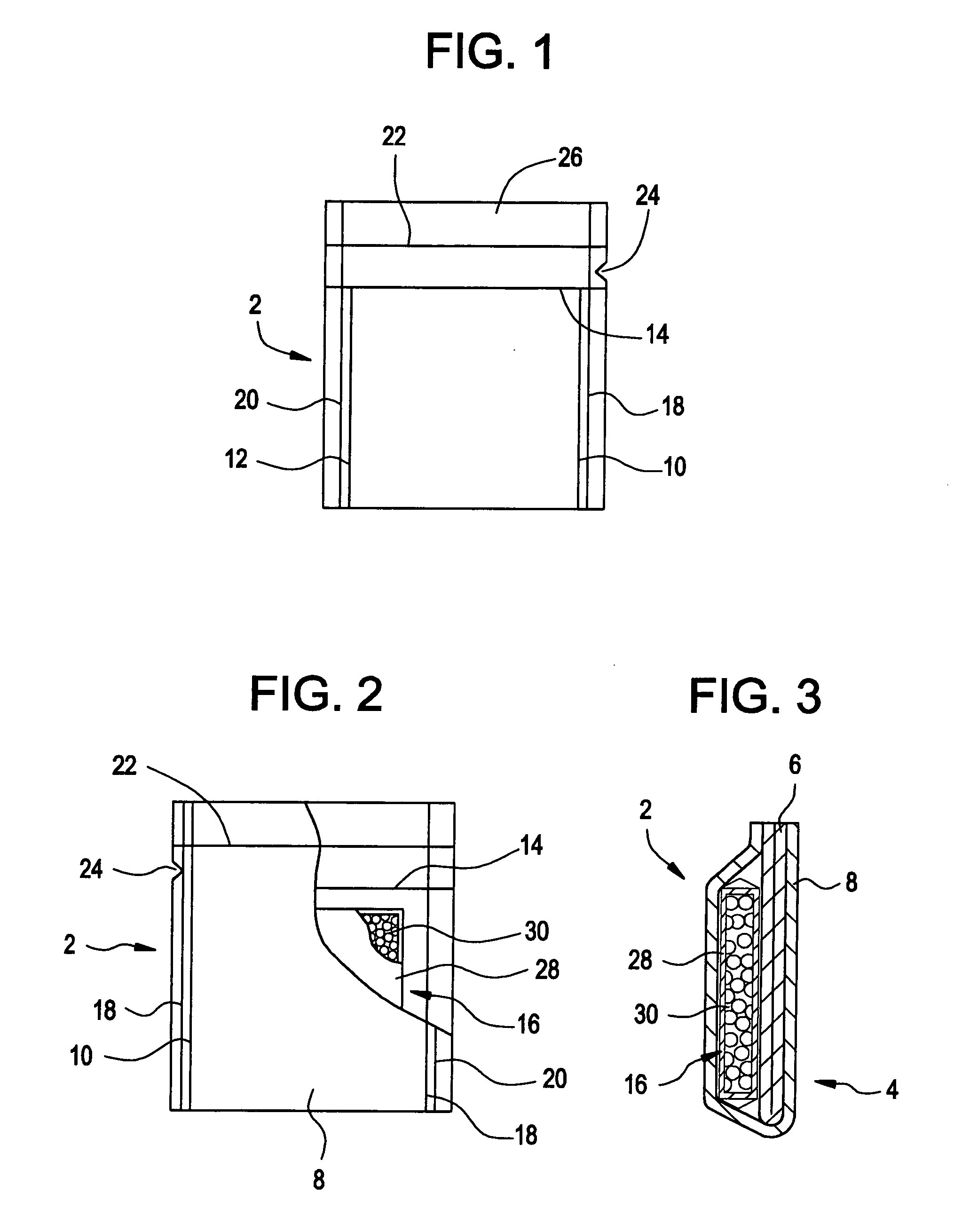

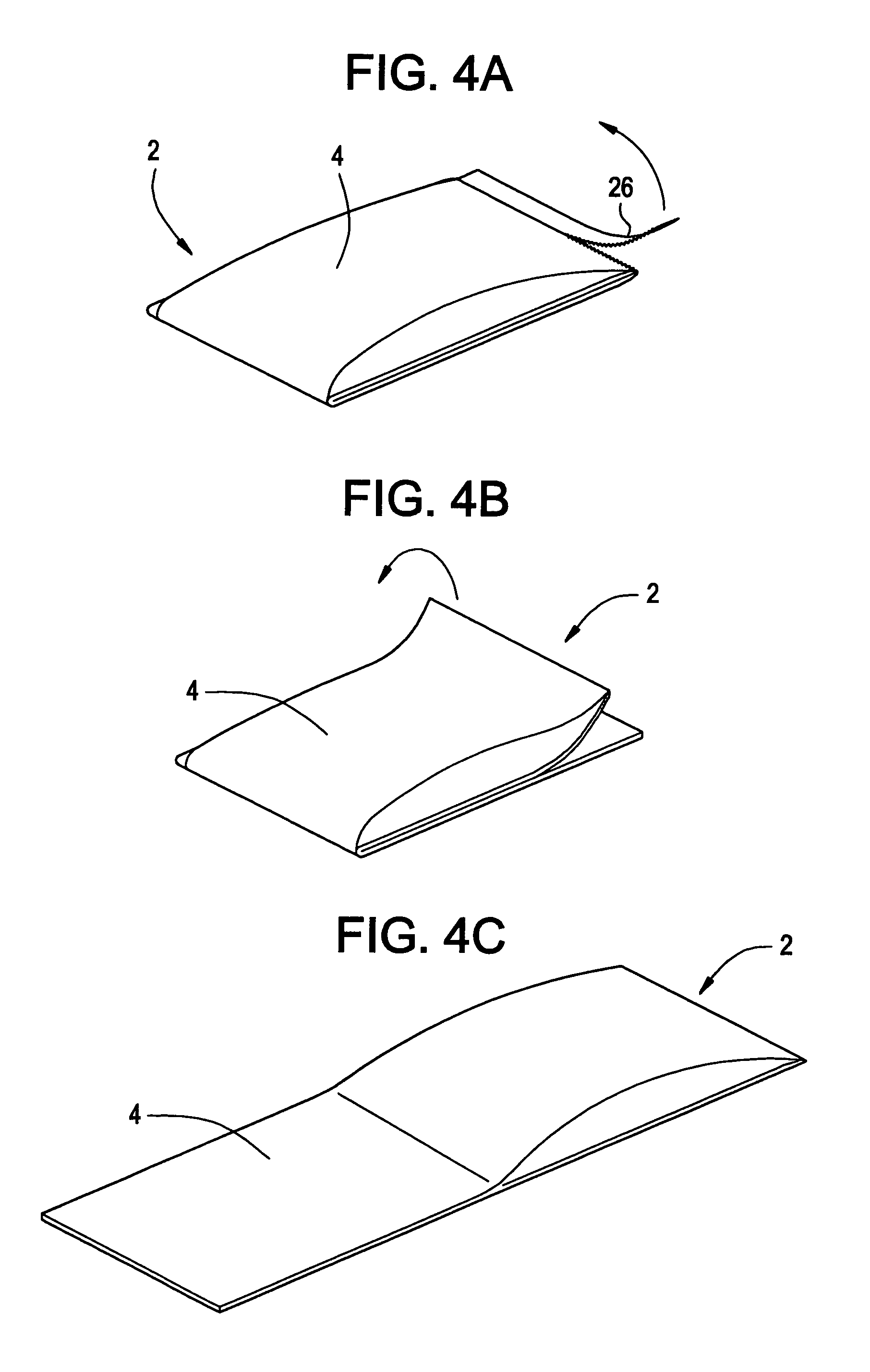

Heating apparatus

InactiveUS20130047974A1Ready-for-oven doughsExothermal chemical reaction heat productionEngineeringMoisture barrier

A heating apparatus includes an elongated flexible envelope (4) comprising two sheets (6), (8) that are attached to each other along permanent side seams (10), (12) and along a permanent bottom seam (14) and a moisture-activated chemical heater (16) disposed inside envelope (4), wherein envelope (4) is folded over on itself and secured by temporary side seams (18), (20) and a permanent top seam (22) to form a continuous moisture barrier surrounding the moisture activated chemical heater (16) and wherein heater (2) may be opened for use by removing top seam (22) and unfolding envelope (4) by unpeeling temporary seals (18), (20) to provide unfolded envelope (4), wherein sheets (6) and (8) remain sealed along permanent seams (10), (12) and (14), but wherein envelope (4) now has an open top end (30).

Owner:INNOPHOS INC

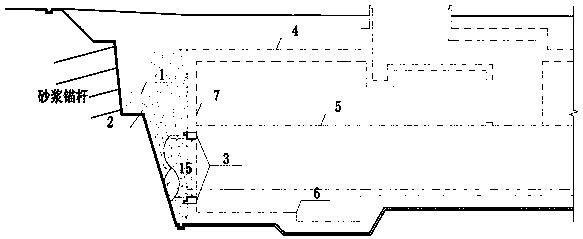

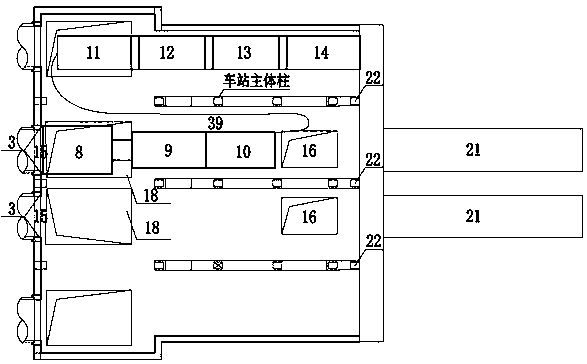

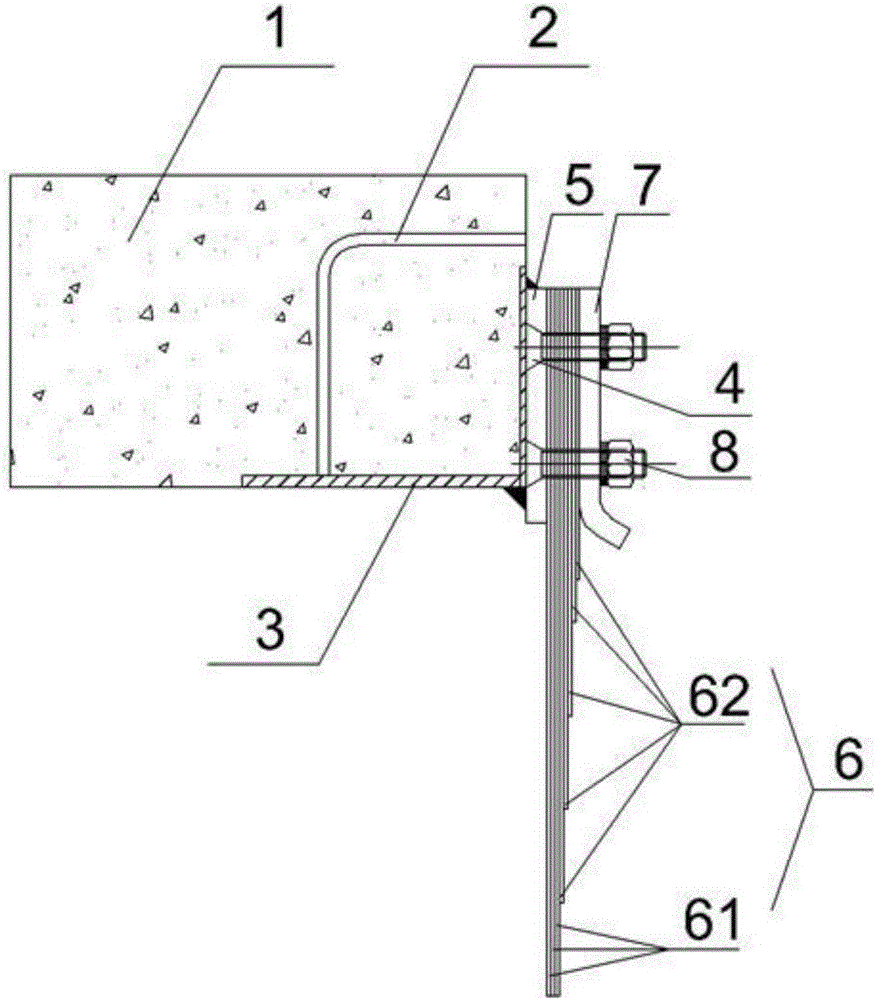

Double-split starting method of small-clearance double-line tunnel shield

PendingCN110748349ASmall construction cross-effectsRelieve schedule pressureMining devicesUnderground chambersArchitectural engineeringStructural engineering

The invention discloses a double-split starting method of a small-clearance double-line tunnel shield. The method comprises the following steps that arranging a starting station main body structure, backfilling and reinforcing a starting end, installing a temporary seal of a tunnel door, installing a starting frame, assembling and debugging a shield, installing a reaction frame, installing a negative ring segment, and performing starting trial tunneling of the shield. According to the method, the reasonable space layout is carried out on a starting station structure well, temporary reverse hidden excavation pilot tunnel is constructed to assist split starting, the shield starting frame, the reaction frame and the negative ring segment are sequentially installed, the split starting construction of the double-line small-clearance tunnel shield under the condition that the whole starting is difficult due to the insufficient space of a site is realized, and engineering practice verifies that the split starting method has the advantages of small construction cross influence, small influence on the surrounding environment, reduction of construction period pressure, safety, reliability and the like, and can be applicable to projects with insufficient length of the end well of the subway shield starting vehicle station.

Owner:中铁隧道集团一处有限公司 +1

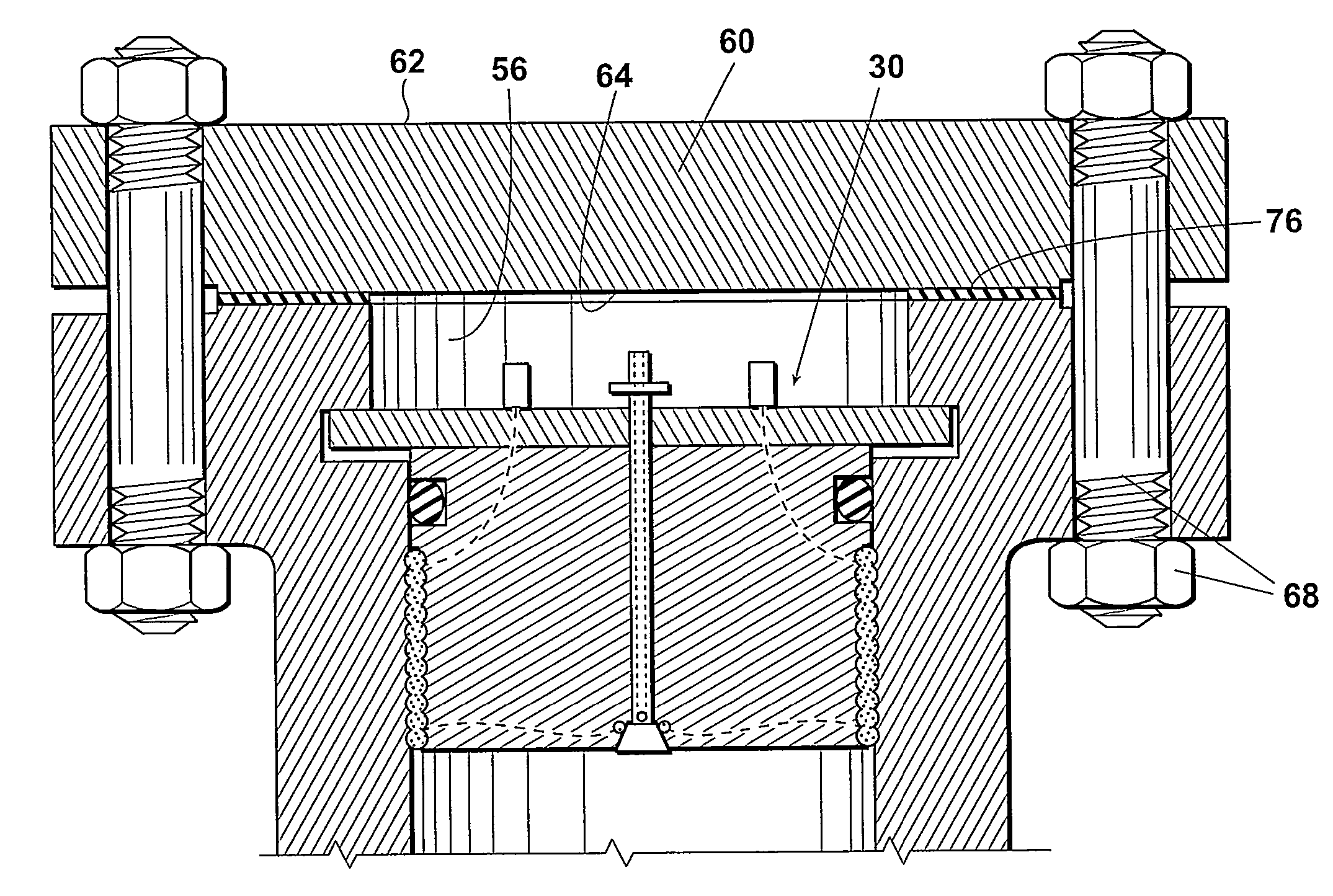

Fusible Completion Plug

A fusible completion plug and method for its use includes a cylindrical plug body having a lower portion that includes a fusible element in communication with an electric power supply. The completion plug also includes an elastomeric seal that provides for a temporary seal. A pressure balancing port and equalization valve are provided to relieve the differential pressure across the completion plug as the plug is positioned in place. The pressure equalization valve also includes a fusible element for fusing the valve within the port, thereby preventing a leak path through the plug body. A blind flange may be installed above the completion plug in case the plug fusion fails. The blind flange may be a traditional blind flange or may be a fusible blind flange.

Owner:TDW DELAWARE INC

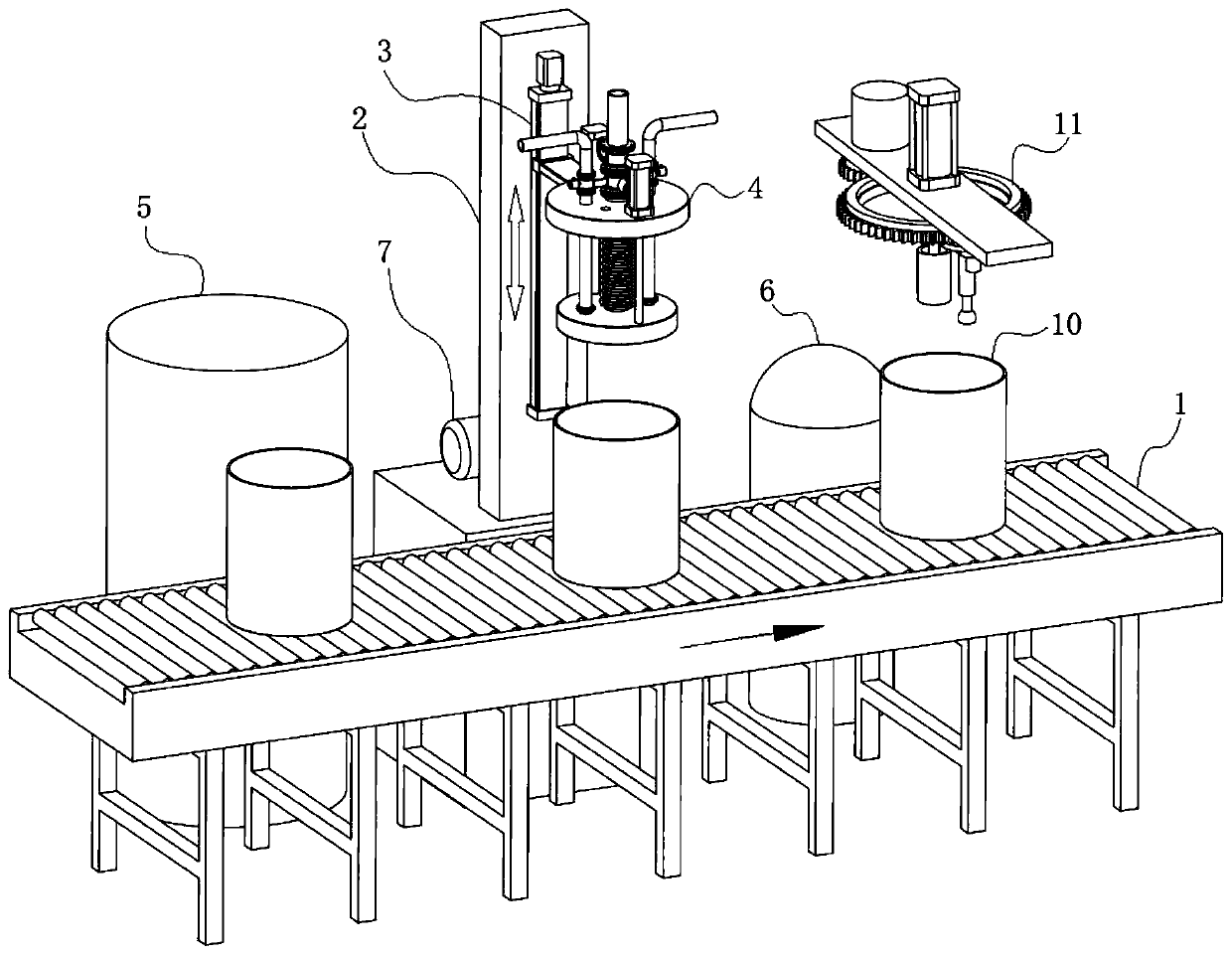

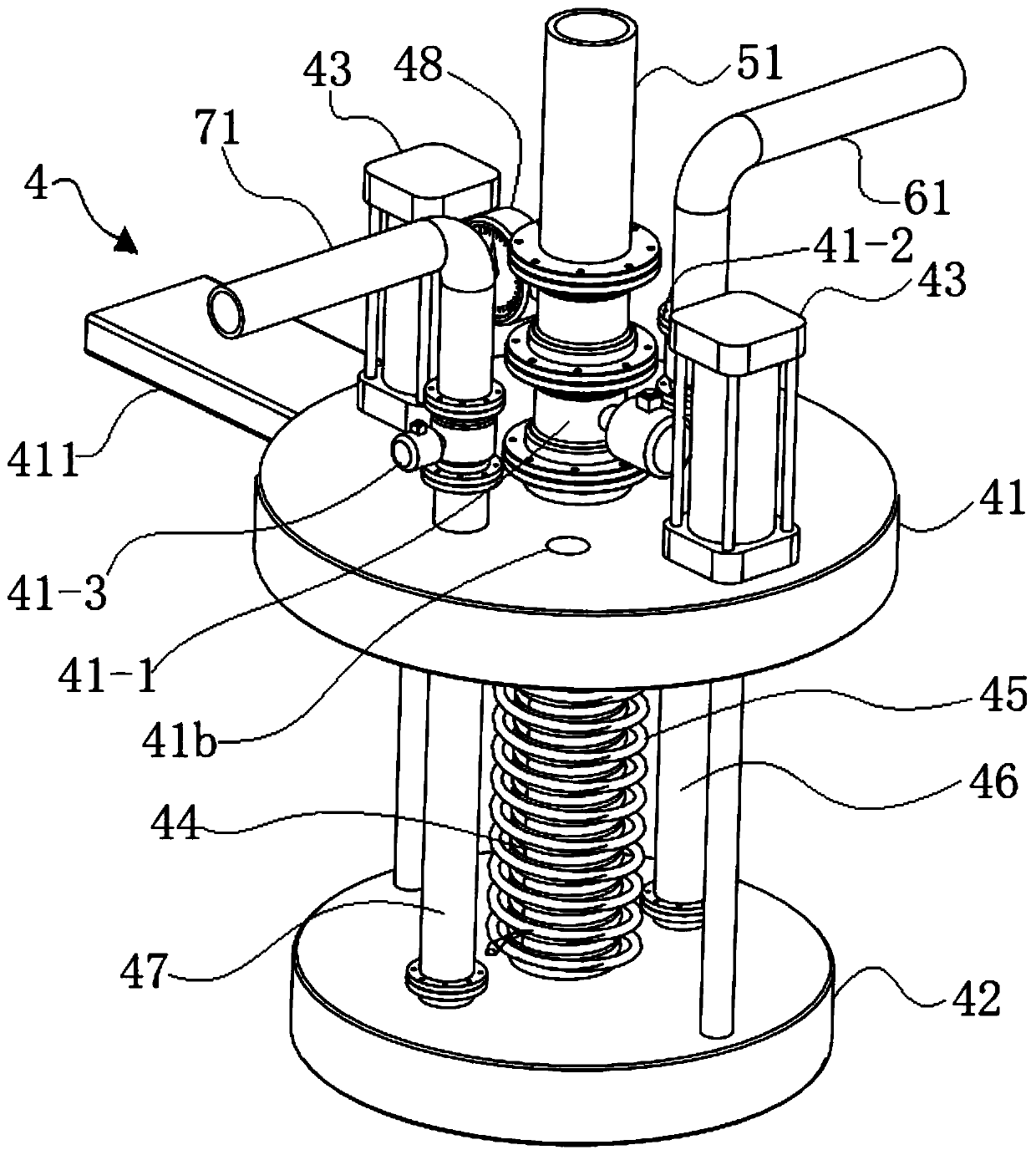

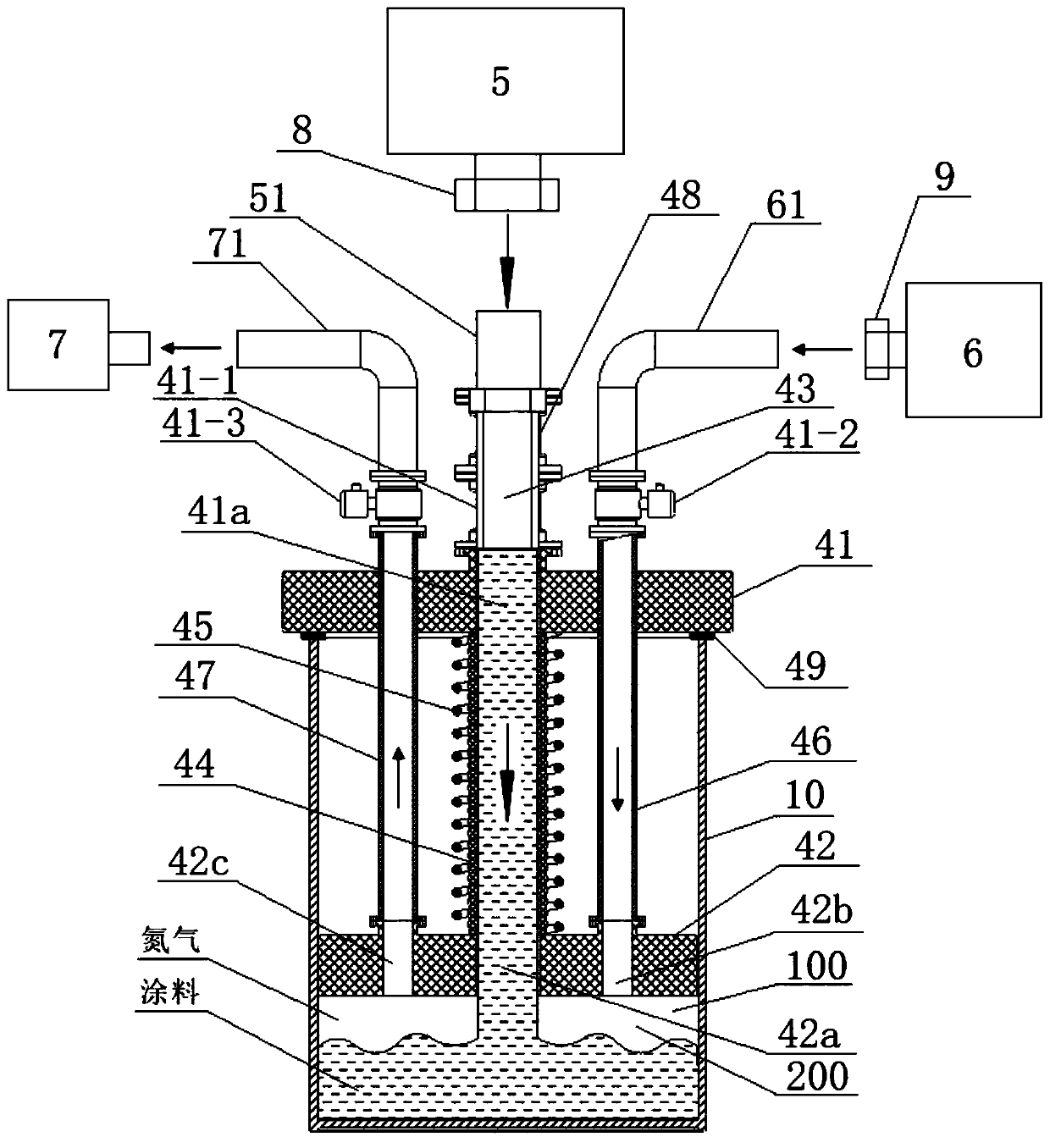

Anti-oxidation batch filling system for coating material production line and filling method thereof

ActiveCN111453681APrevent oxidationReduce exposureCapsSynchronising machinesProduction lineNitrogen gas

The invention discloses an anti-oxidation batch filling system for a coating material production line and a filling method thereof. The anti-oxidation batch filling system for the coating material production line comprises a conveying device, a piston type filling head, an air exhausting device, a nitrogen supplying source, a coating material supplying source and a barrel lid buckling mechanism. The piston type filling head partially extends into a coating material barrel, so that a variable coating material filling space is formed between the bottom of the piston type filling head and the inner bottom of the coating material barrel. The air exhausting device is used for exhausting air in the variable coating material filling space. The nitrogen supplying source is used for feeding nitrogen into the variable coating material filling space to enable the variable coating material filling space to form a nitrogen filling environment. The coating material supplying source is used for filling the variable coating material filling space in the nitrogen filling environment with the coating material. A temporary seal barrel lid is buckled to a mouth of the coating material barrel through the barrel lid buckling mechanism to seal the coating material barrel containing the coating material. By the adoption of the anti-oxidation batch filling system for the coating material production line, the manner that the air is exhausted and then the nitrogen is filled is adopted, so that the variable coating material filling space of the coating material barrel can form the nitrogen filling environment, and therefore the phenomenon that the coating material is in contact with the air and is oxidized in the filling process is avoided.

Owner:江苏金鼎建设集团有限公司

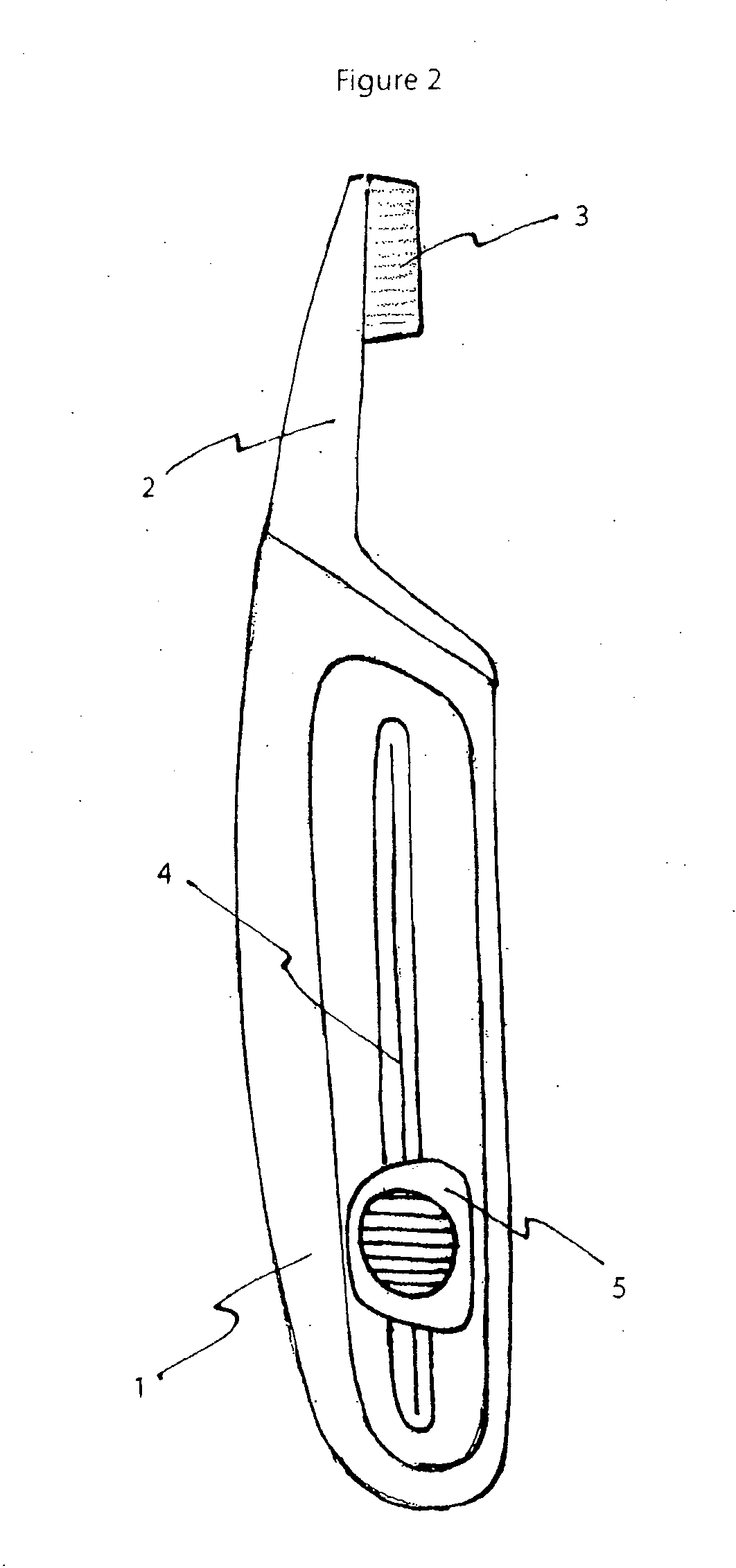

Dentifrice-Dispensing Toothbrush

InactiveUS20080003048A1Improved tooth brushing procedureQuick cleanCarpet cleanersFloor cleanersBristleToothpaste

A dentifrice-dispensing toothbrush having a handle defining a cavity that is at least partially open at one end of the handle, a dentifrice cartridge located in the cavity and defining an opening located proximate the cavity opening, the opening closed with a cap or temporary seal. There is a head carrying brushing bristles and adapted to be removably engaged with the handle at the cavity opening. The cartridge is fluidly connected to and so delivers dentifrice to the bristles. A roller located in the handle cavity is manually moved to compress the cartridge and so dispense dentifrice; the roller is moved through a roller actuator mechanism coupled to the roller and extending outwardly from the handle.

Owner:GLASSMAN KAREN +1

Pipettor and externally sealed pipette tips

InactiveUS20040234420A1Reduce maintenancePrecise and accurate amountAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipetteEngineering

A pipettor uses no pistons in order to provide highly automated, precise and accurate pipetting operations. Additionally, a self-aligning pipette tip enables better engagement of such pipette tips by the pipettor. The pipette tips may be automatically engaged and locked into place by the pipettor and may be automatically disengaged to enable highly-automated pipetting processes for industrial and laboratory purposes. Open proximal ends of the pipette tips are engaged by a pipette block, which then forms a temporary seal with the individual pipette tips. Displacement of the pipette block with respect to the pipette tips increased or decreases the effective volume of the pipette tip allowing it to aspirate or expel fluids in a precise, accurate, and predictable way.

Owner:APRICOT DESIGNS INC

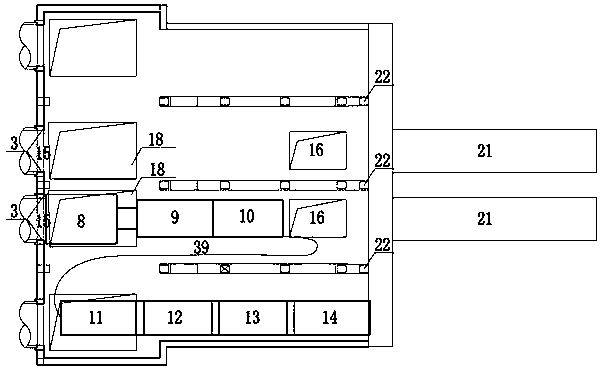

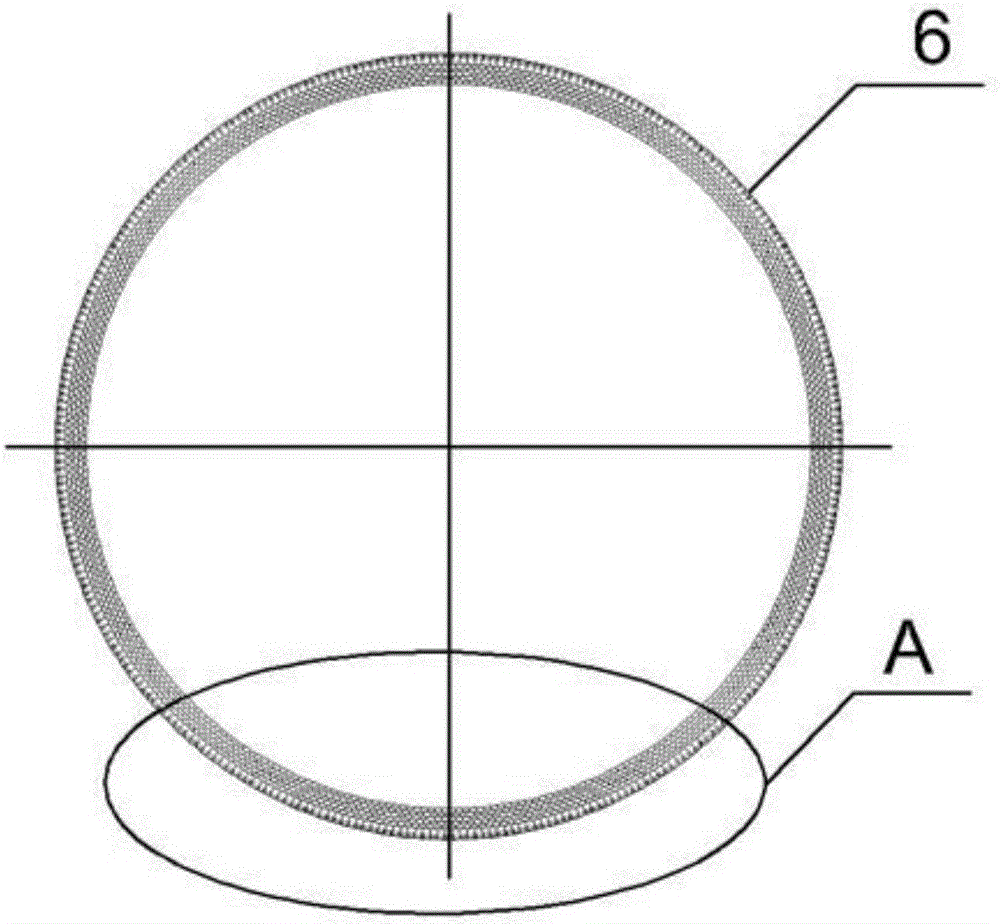

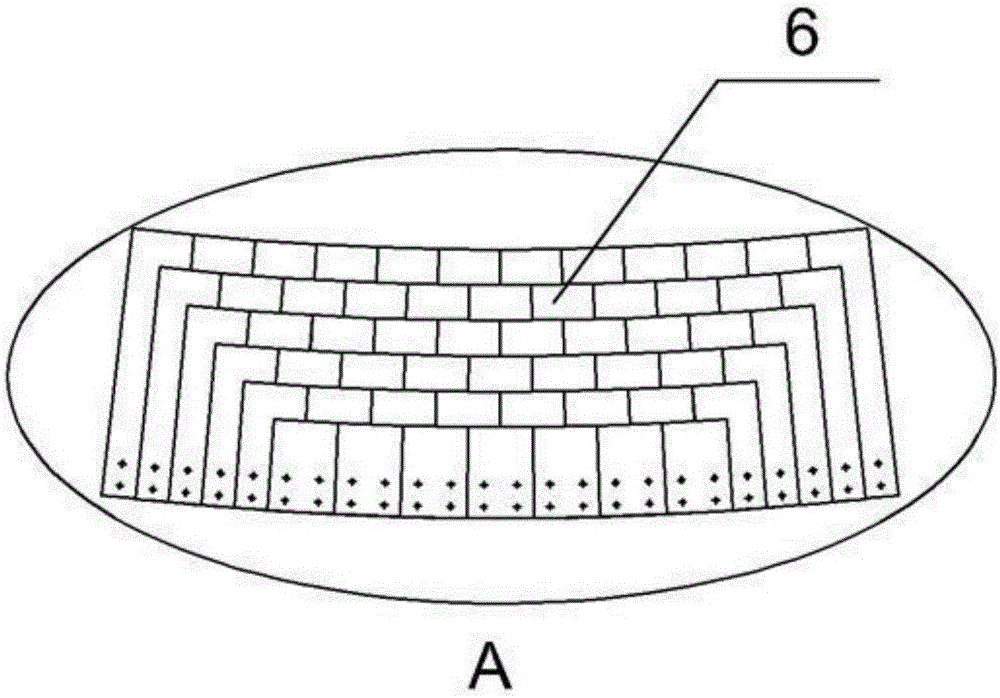

Shield with-water receiving tunnel hole temporary sealing device and shield with-water receiving tunnel hole temporary sealing method

ActiveCN105065010AImprove sealingHigh strengthUnderground chambersTunnel liningSheet steelEngineering

The invention discloses a shield with-water receiving tunnel hole temporary sealing device, which comprises a plurality of bases, a spring steel plate beam and a plurality of press plates, wherein the bases are uniformly distributed on the circumference of an embedded steel ring; the spring steel plate beam comprises one or a plurality of spring steel plate layers; a plurality of spring steel plates form an annular structure; the length of each spring steel plate is smaller than the radius of the embedded steel ring; the press plates are uniformly distributed on the spring steel plate beam and are in opposite arrangement to the plurality of bases; and one end of each press plate is bent at a certain radian in a direction towards a receiving well. The invention also discloses a shield with-water receiving tunnel hole temporary sealing method. The temporary sealing device achieves the goal of blocking the stratum water and soil loss through tightly attaching the spring steel plates onto the shield outer wall and the duct piece outer wall by the self rebounding force. The temporary sealing method solves the problem of tunnel hole sealing implementation difficulty under the with-water receiving condition, and has the advantages that the operation is simple; the labor is reduced; and the efficiency is improved, so that a good tunnel hole temporary sealing effect is achieved.

Owner:CCCC SECOND HARBOR ENG +1

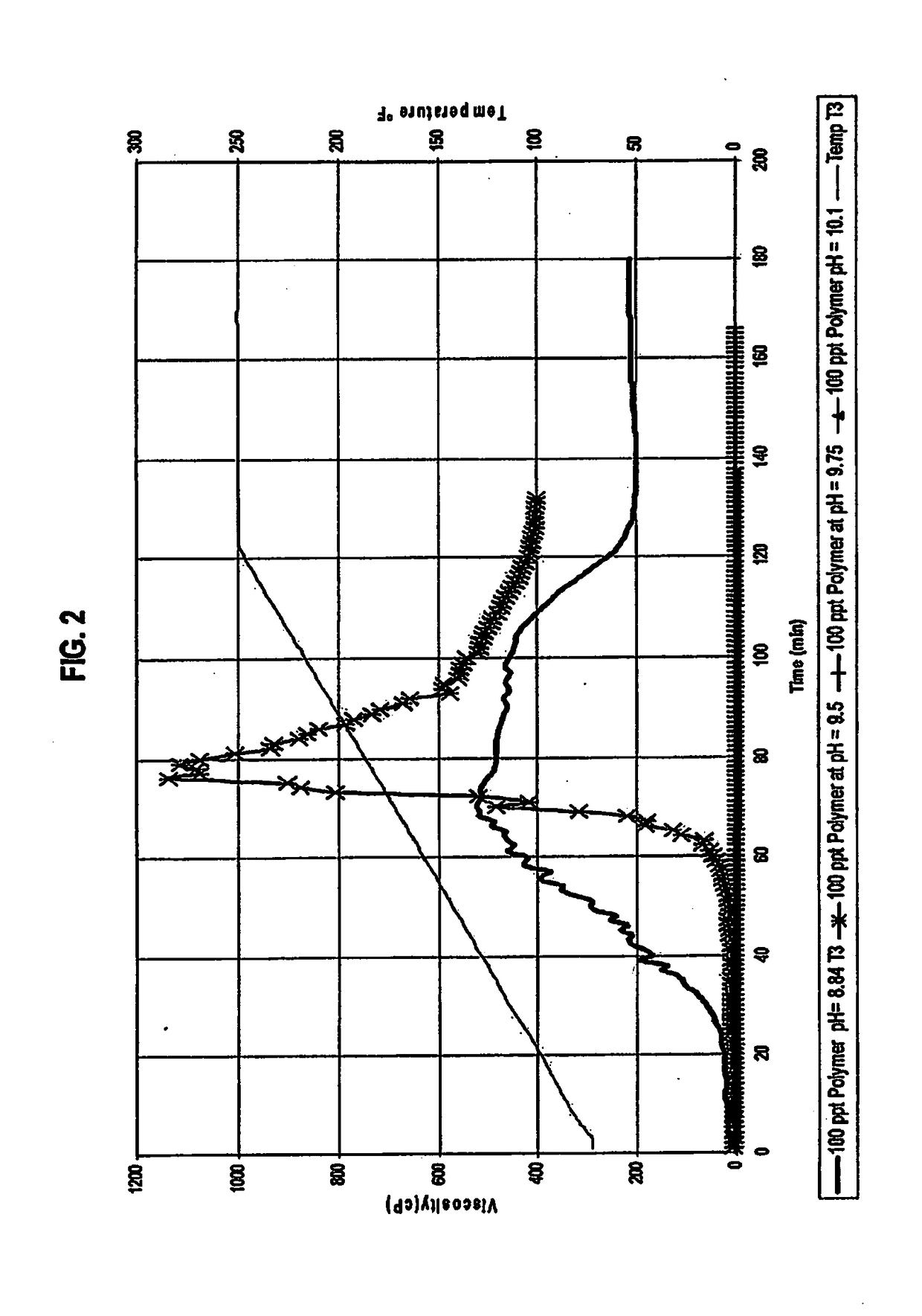

Well intervention method using a chemical barrier

ActiveUS20180209240A1Improve the level ofFacilitate cross-linkingFluid removalDrilling compositionCompound (substance)Oil well

A well treatment fluid containing borated galactomannan may be used to isolate a pre-determined productive zone in an oil or gas well. The fluid is pumped into the well in a substantially non-hydrated form and forms a temporary seal. The fluid may be used as a chemical packer in place of a mechanical packer. After the pre-determined productive zone is isolated, a well intervention operation may be performed within the isolated pre-determined zone.

Owner:BAKER HUGHES INC

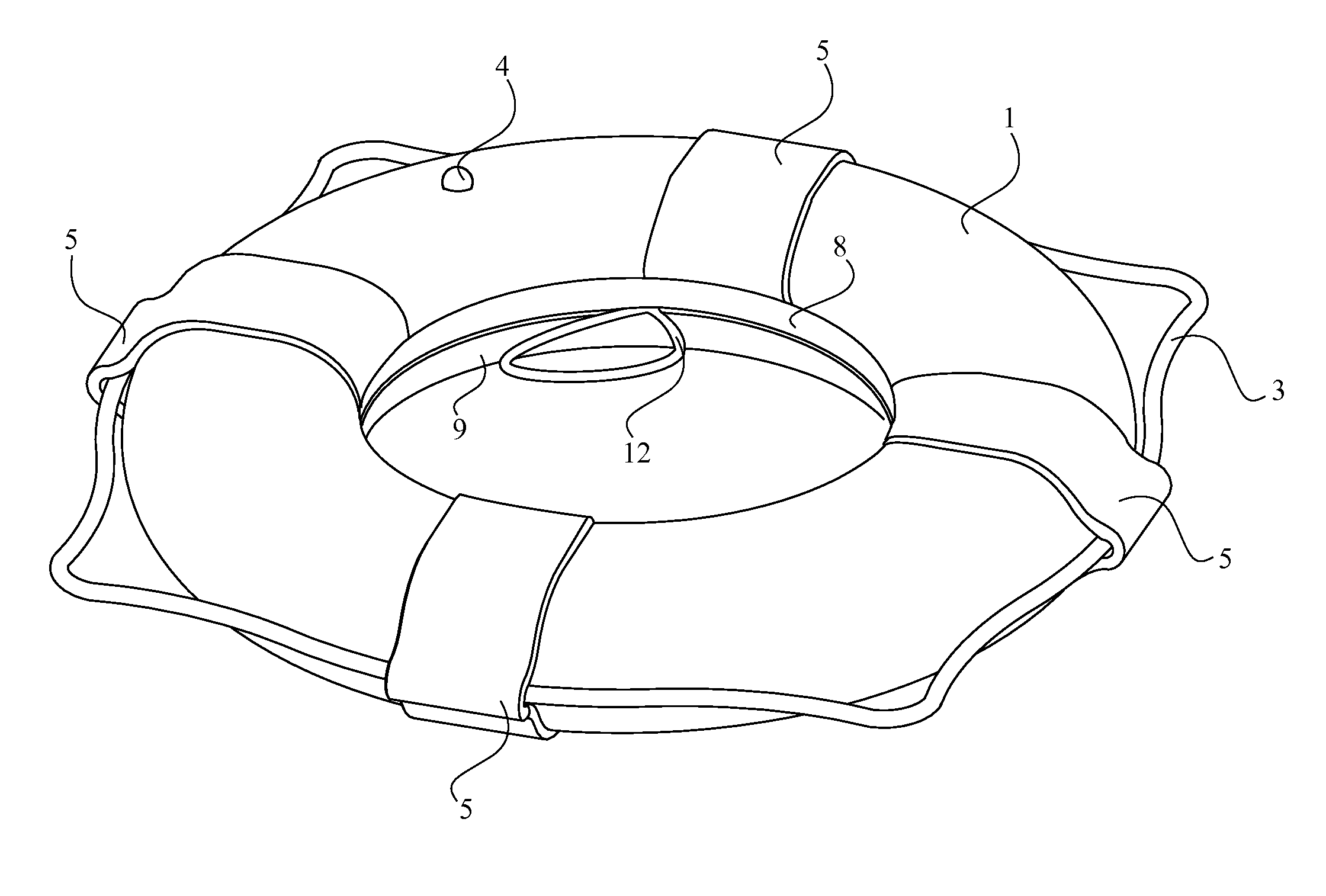

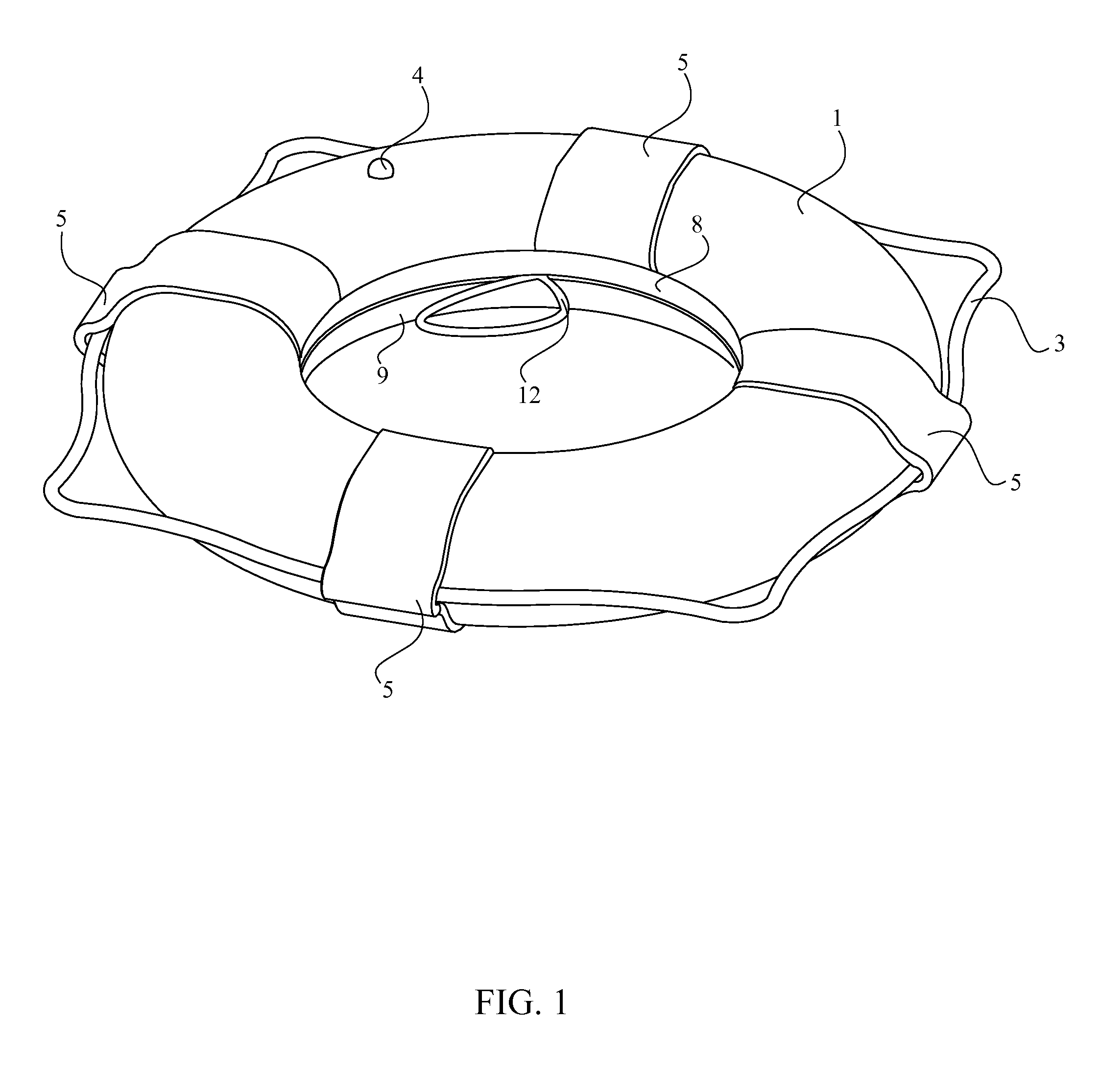

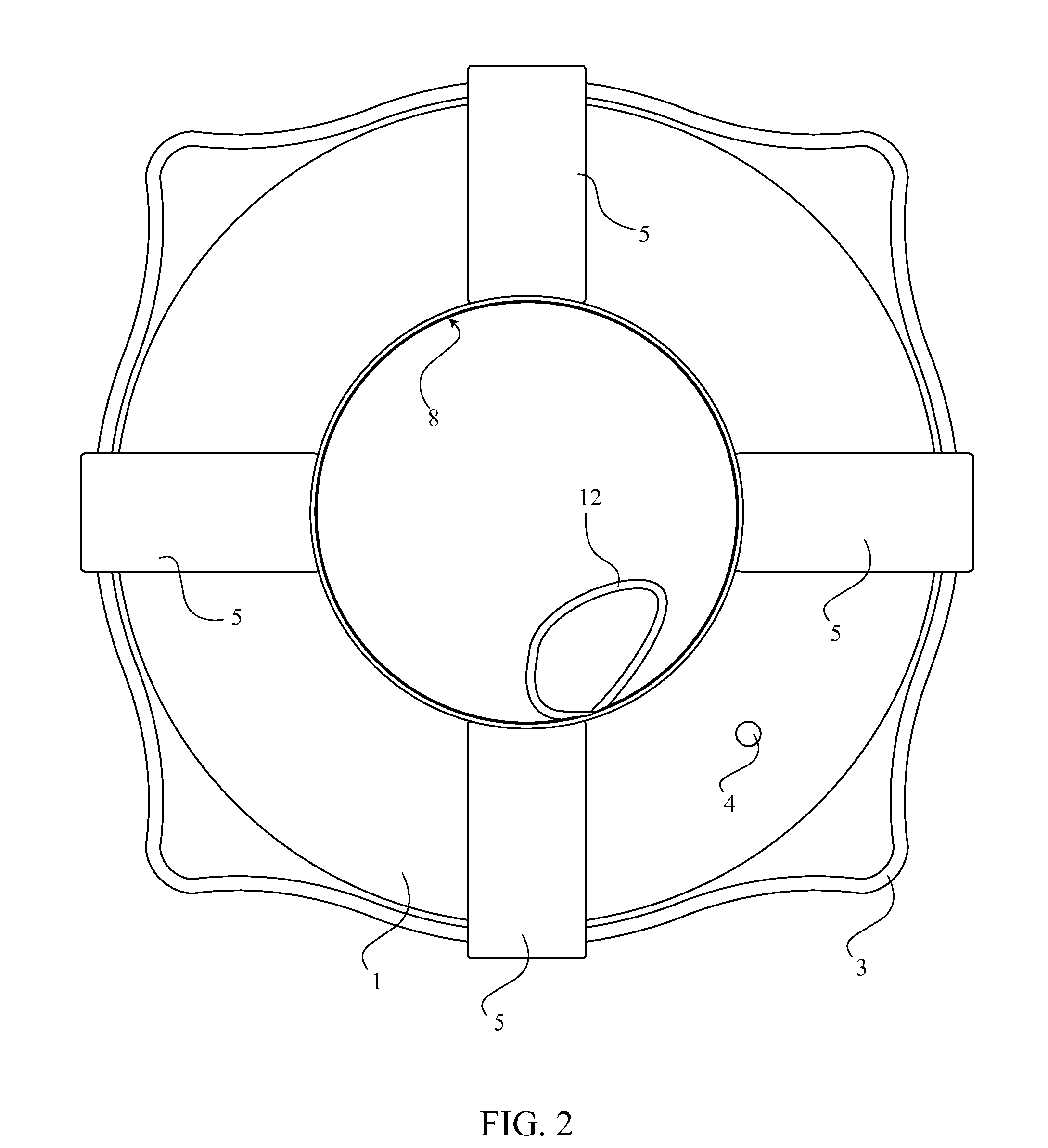

Life ring buoy and flotation cushion

The present invention is an improved life ring buoy and flotation cushion that has the ability to be deployed and retrieved to aide a distressed person from drowning. The present invention has the ability to emit light upon being deployed. The present invention combines a flotation device, a retrieval line and a plurality of illuminating sources. The retrieval line is stowed within a recessed cavity in the flotation device. The illuminating sources are switched on prior to deploying the flotation device. The retrieval line is protected from detrimental ultraviolent light because it is stowed within the flotation device. A temporary seal prevents the retrieval line from prematurely exiting the recessed cavity. The improved retrieval line has an eye spliced in the exposed end and wrapped in brightly colored protective tubing, eliminating direct exposure to sunlight. The exposed retrieval line eye is tethered to the mechanical switch for the integral lights.

Owner:GRANDINETTI THOMAS PAUL

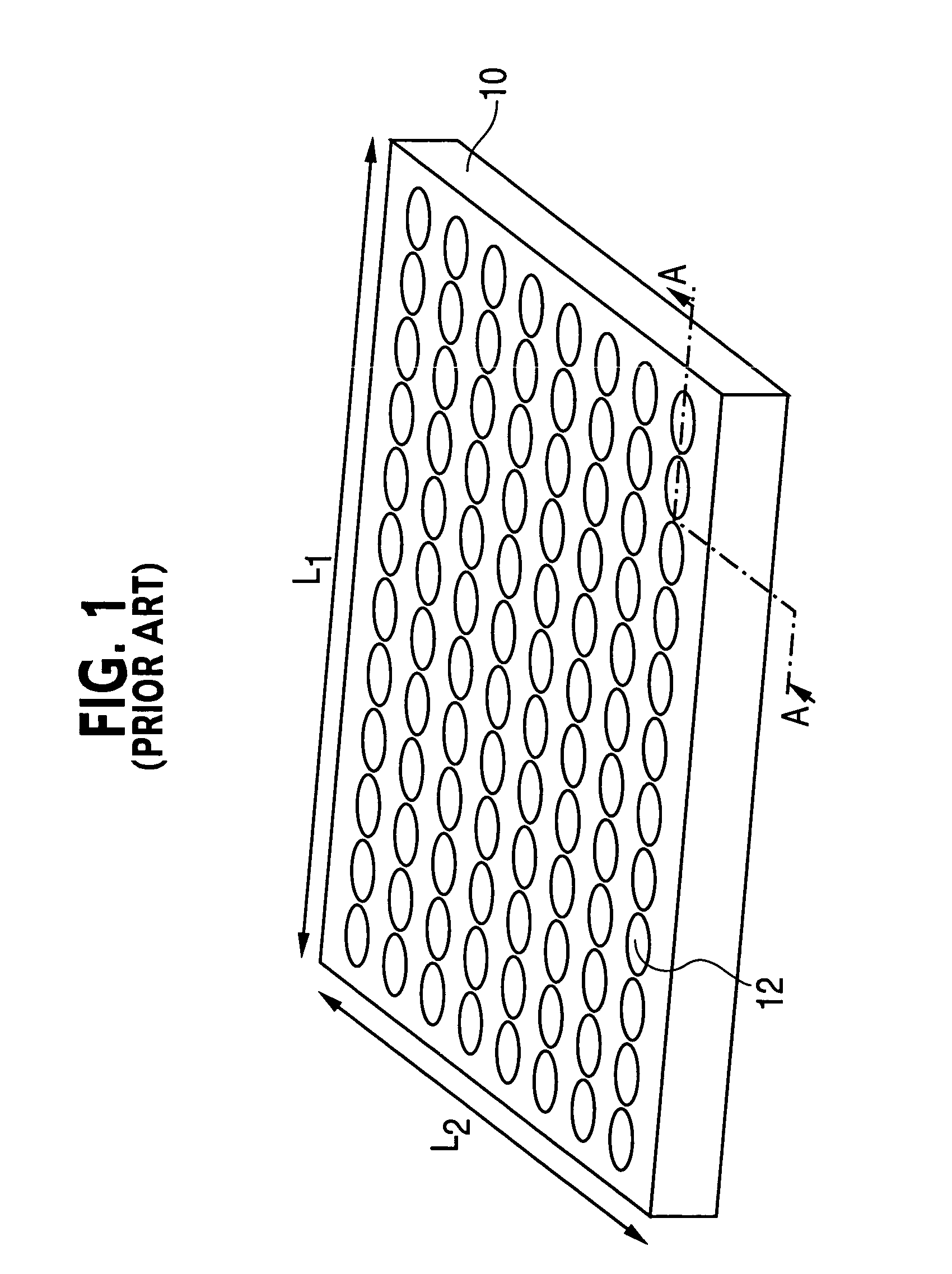

Kinetic microplate with temporary seals

Owner:THERMO FISHER SCI ASHEVILLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com