Anti-oxidation batch filling system for coating material production line and filling method thereof

An anti-oxidation, production line technology, applied in packaging, application, bottling machine, etc., can solve the problems of paint impact, affect paint quality, reduce product qualification rate, etc., and achieve the effect of avoiding oxidation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

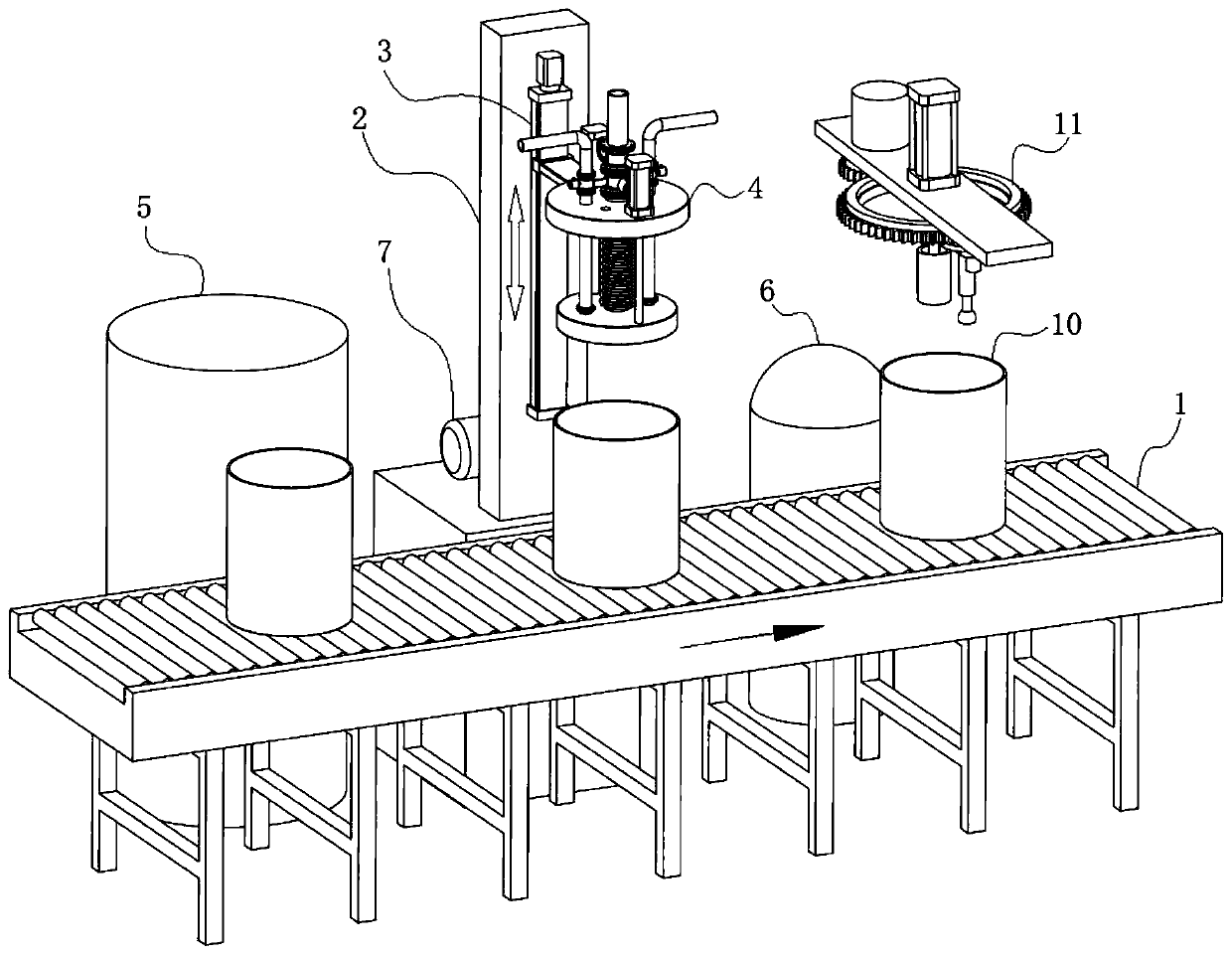

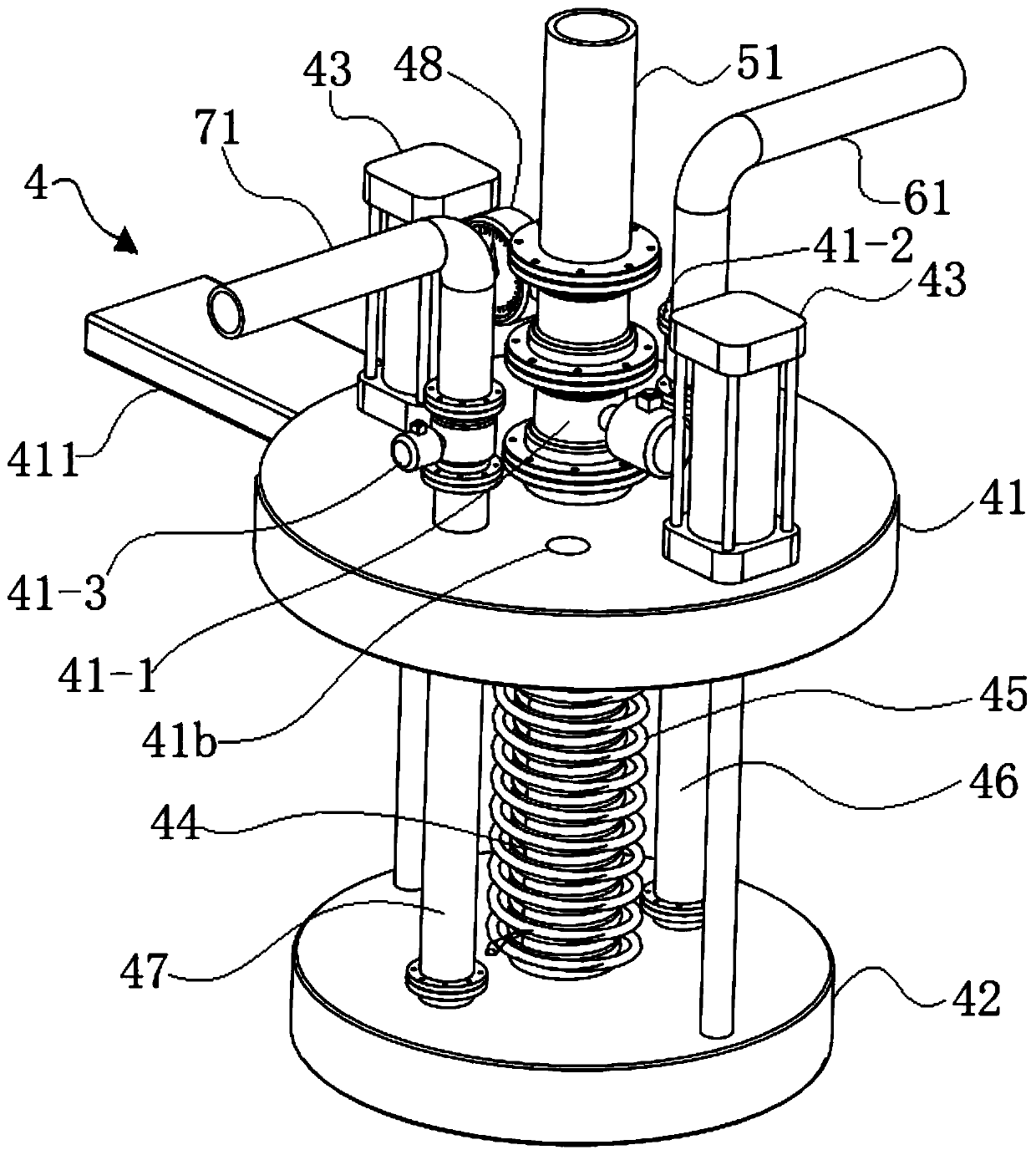

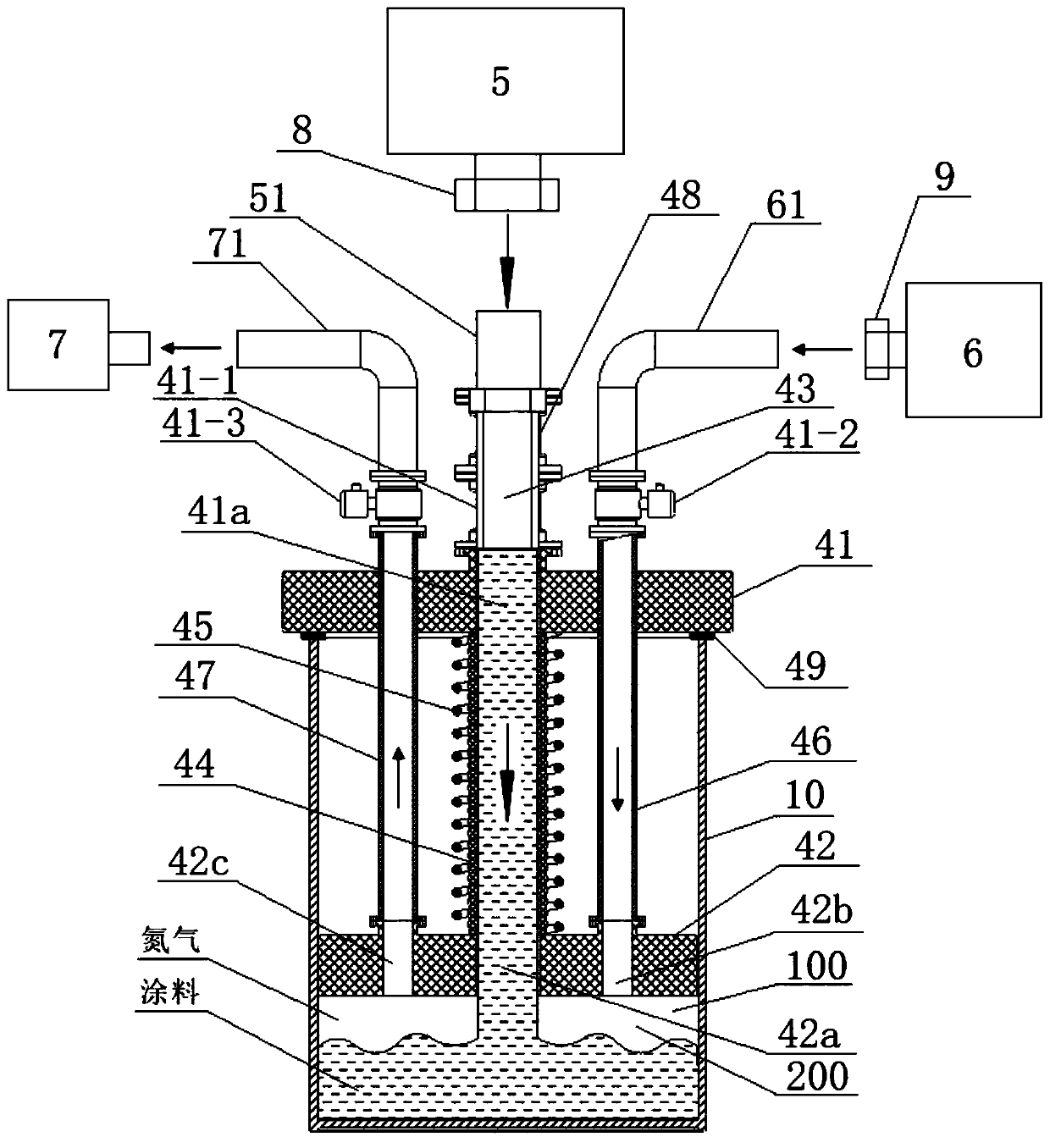

[0039] as attached figure 1As shown, an anti-oxidation batch filling system for a paint production line includes a conveying device 1 for conveying paint barrels 10; a piston-type filling head 4 installed on a frame 2 in a vertical posture On the servo linear slide module 3, the piston filling head 4 is displaced in the vertical direction by the servo linear slide module 3, and the piston filling head 4 is driven by the servo linear slide module 3 The moving part extends into the paint bucket 10, so that a variable paint filling space 100 is formed between the bottom of the piston filling head 4 and the inner bottom of the paint bucket 10; End docking, used to extract the air in the variable paint filling space 100; nitrogen supply source, its outlet end is docked with the inlet end of the piston filling head 4, used to fill the variable paint filling space 100 with n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com