Patents

Literature

5607results about How to "Strong impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1569774AStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Heavy polymer coated slow-release fertilizer with sulfide as bottom coat

InactiveCN1246265CStrong impact resistanceImprove wear resistanceFertiliser formsUrea compound fertilisersControl releaseCoated urea

The invention relates to an enveloped controlled release fertilizer and method for preparation which consists of, preheating the urea particles to a predetermined temperature, spraying the molten liquid state sulfur to the urea particles, forming a layer of smooth and compact sulfur-coated urea, charging hot-curing resin component on the sulfur-coated urea for even distribution onto the urea particle surface and fast formation.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

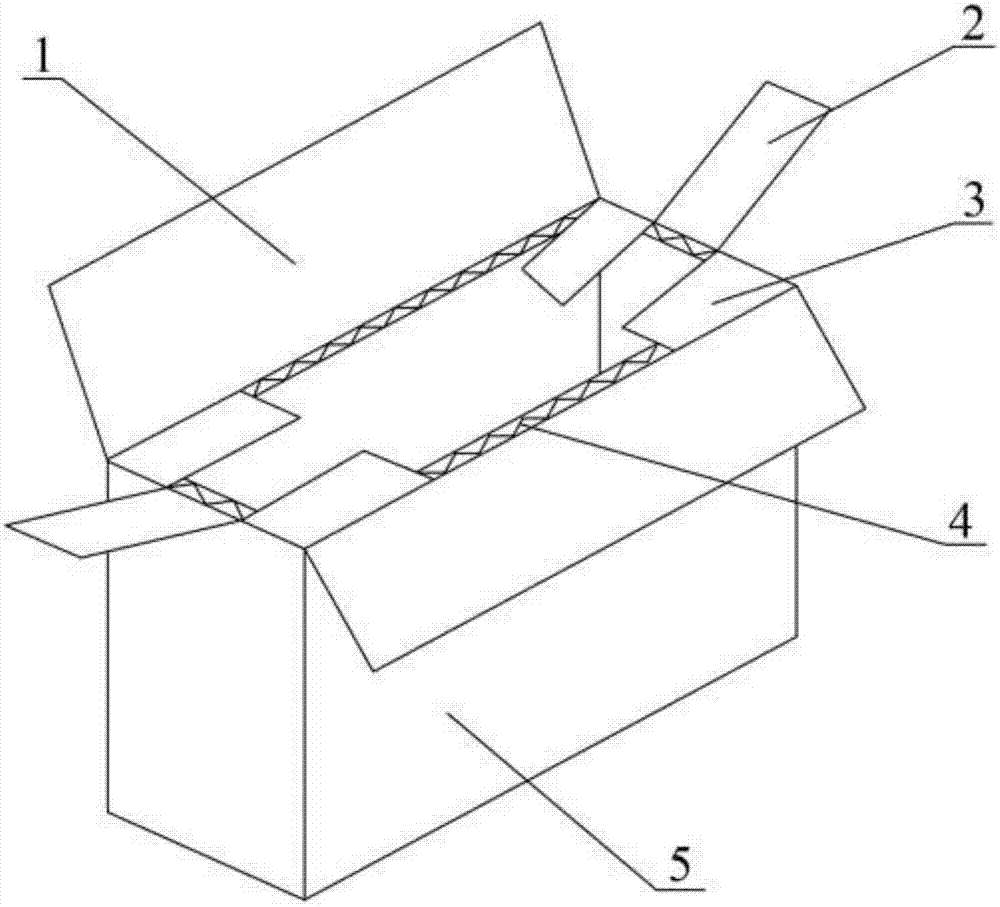

Double-layered packaging paper box

The invention relates to the technical field of paper boxes, and provides a double-layered packaging paper box. The double-layered packaging paper box comprises box covers, cover strips, flaps, reinforcing plates and a box body outer layer, wherein the reinforcing plates are arranged in the box body outer layer; the cover strips are arranged on the left surface and the right surface of the upper part of the box body outer layer; the flaps are arranged on the front surfaces and the rear surfaces of the cover strips; the box covers are arranged on the front surface and the rear surface of the upper part of the box body outer layer; and each reinforcing plate comprises a reinforcing plate main body, reinforcing ribs and connecting ribs. By arrangement of the cover strips and the flaps, good paper box packaging operation can be realized favorably, the box packaging speed is increased, the production efficiency is improved, and huge economic benefits can be brought for users; and by arrangement of the reinforcing ribs, impact resistance and compression resistance of the paper box are enhanced favorably, the using effect of the paper box is improved, the impact resistance and the compression resistance of the paper box are high, huge economic benefits are brought for the users, and characteristics of impact resistance and extrusion resistance are realized.

Owner:慈溪市奇超科技有限公司

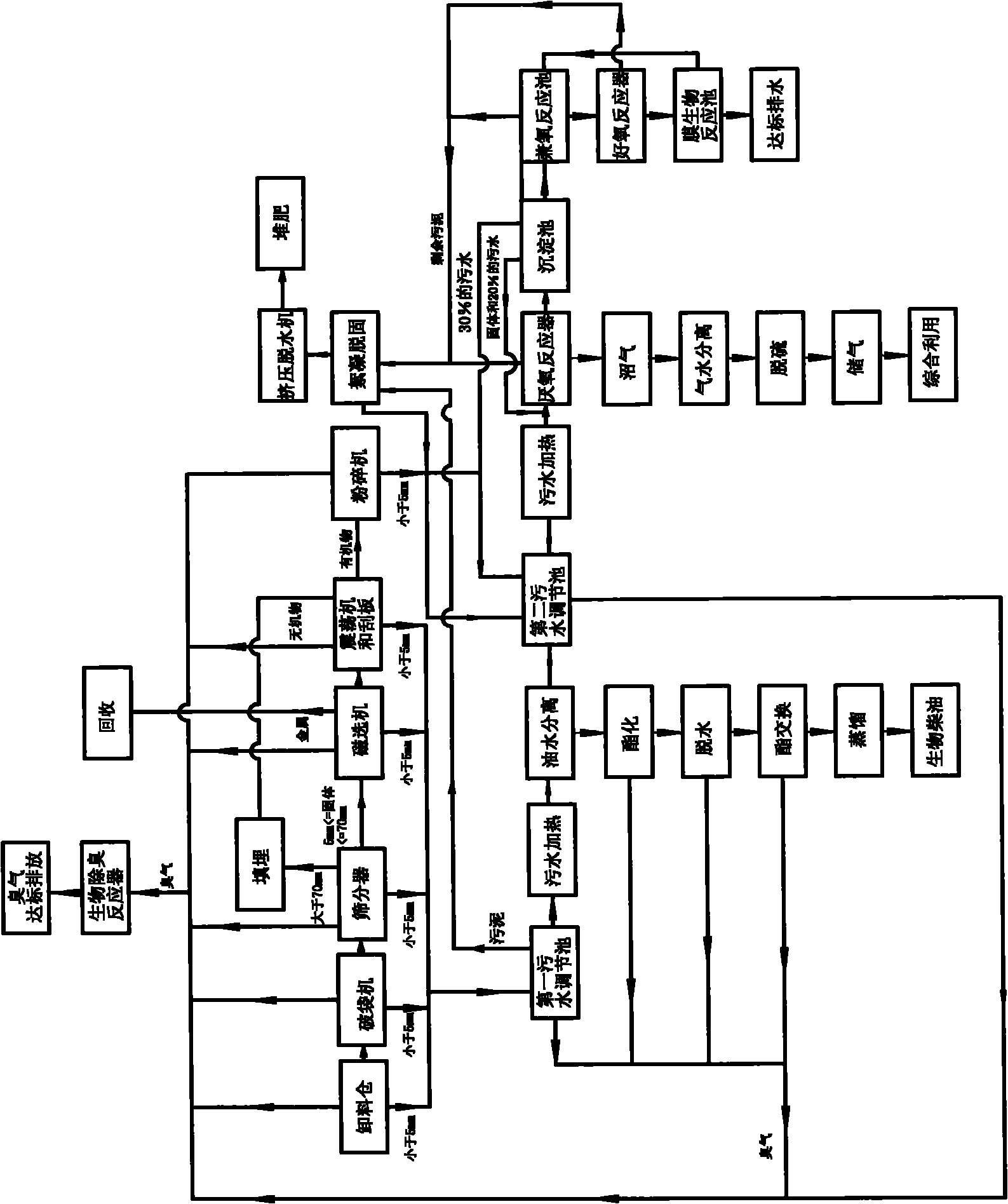

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

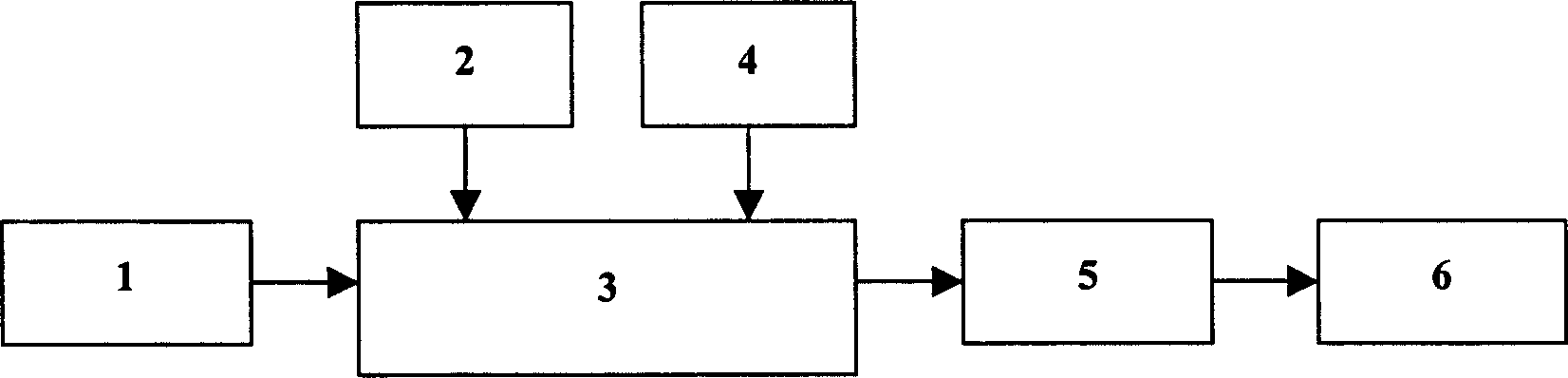

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

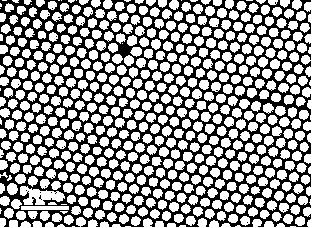

Three-dimensional ordered macroporous alumina and preparation method thereof

ActiveCN102838142AGood three-dimensional orderImprove uniformityAluminium oxides/hydroxidesMicrosphereCalcination

Owner:CHINA PETROLEUM & CHEM CORP +1

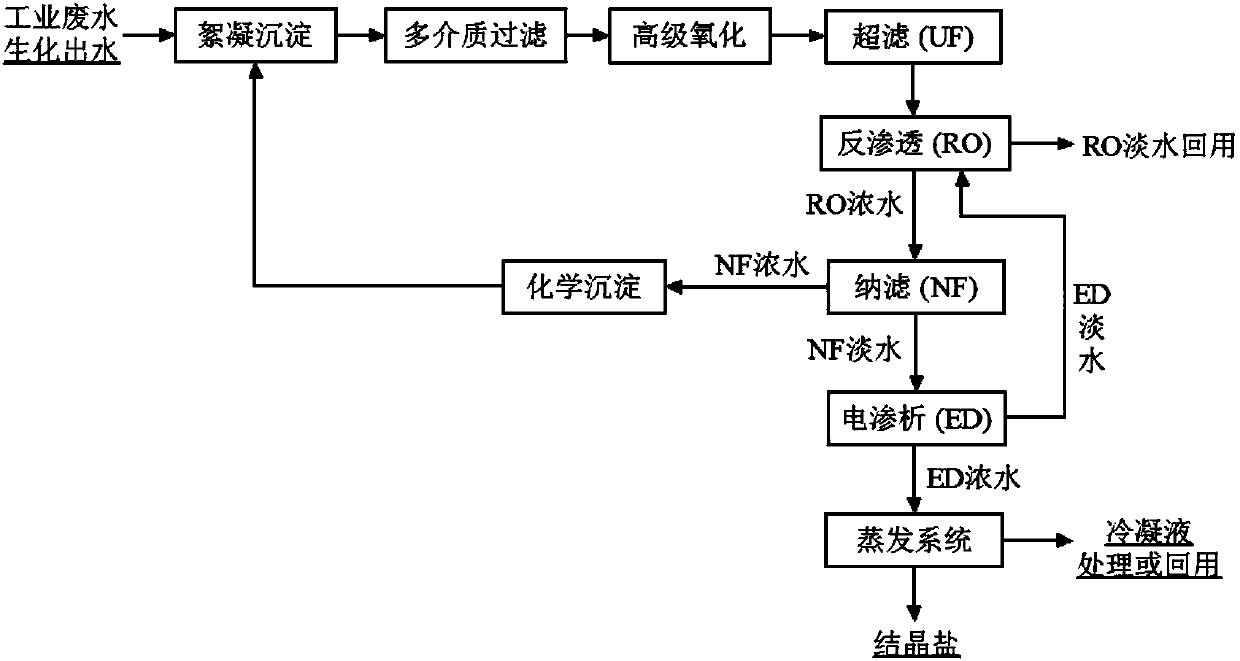

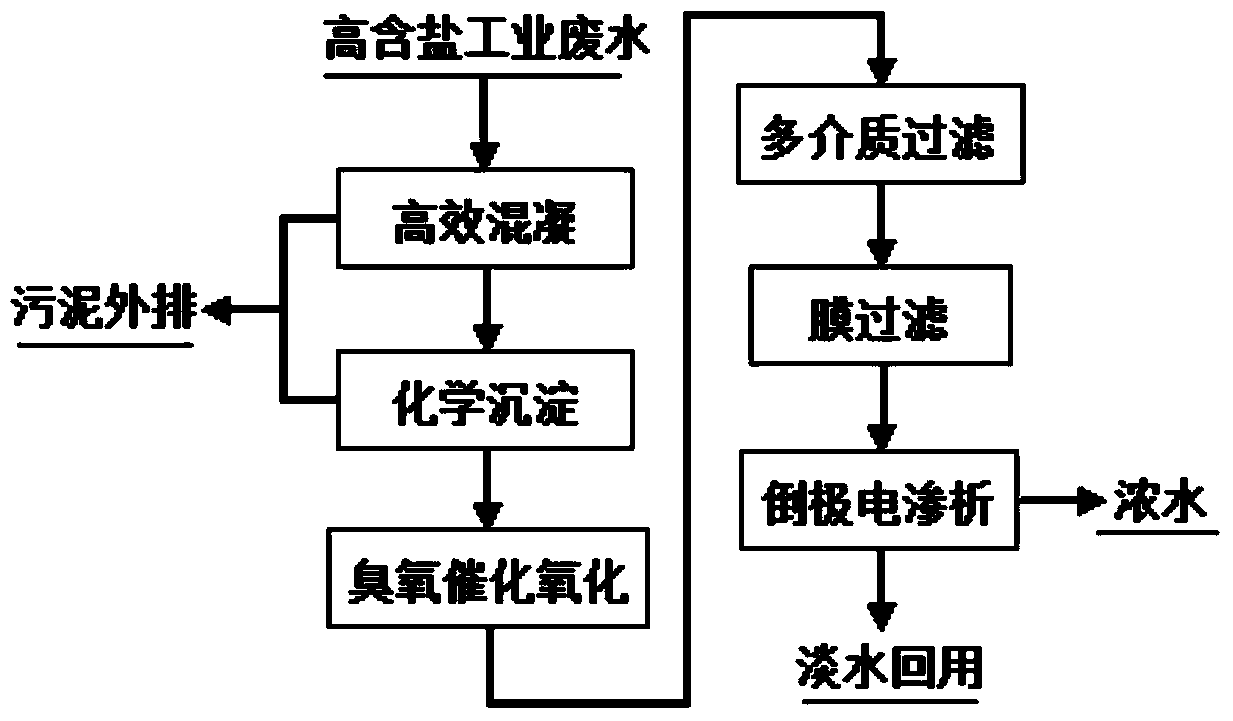

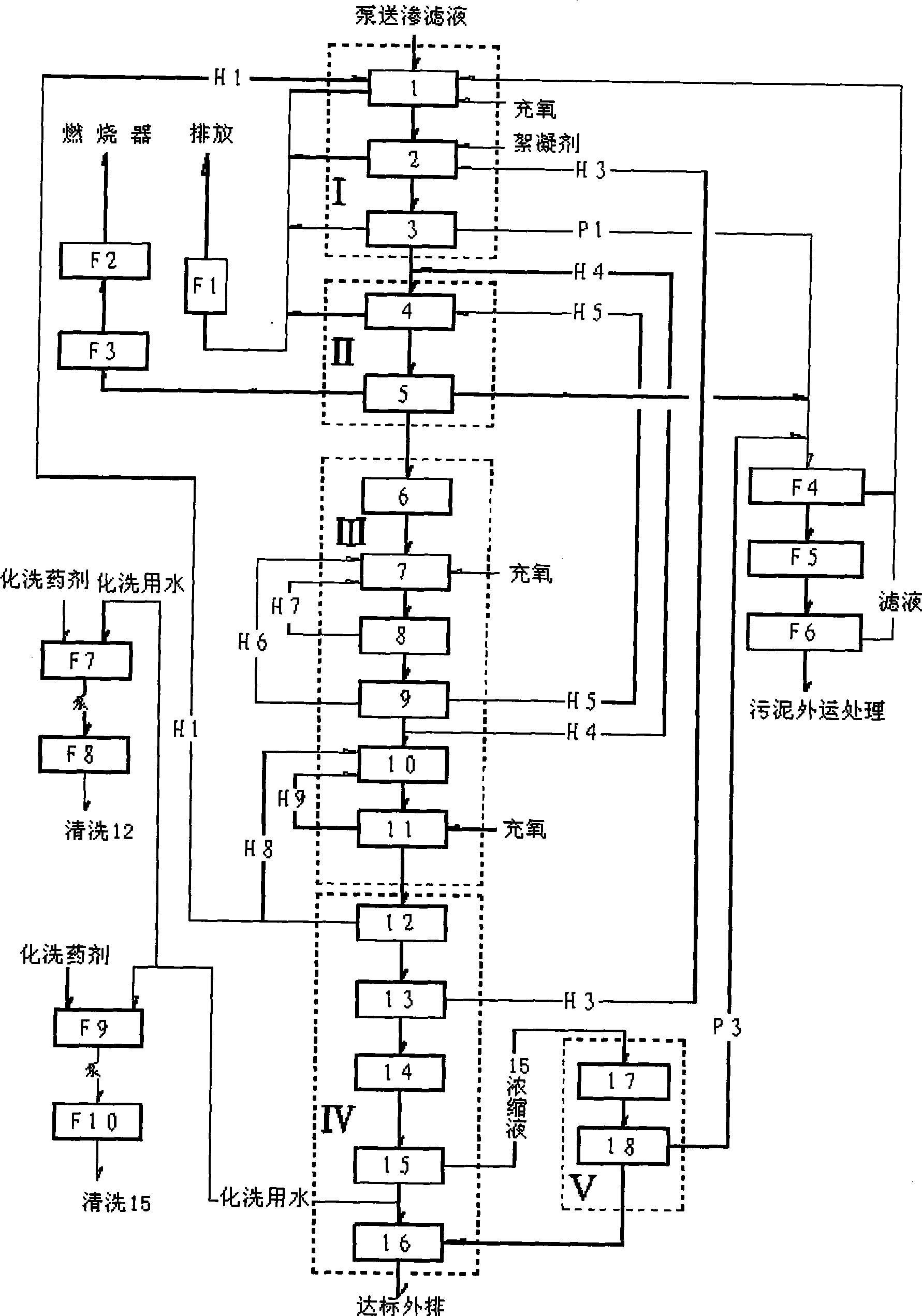

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

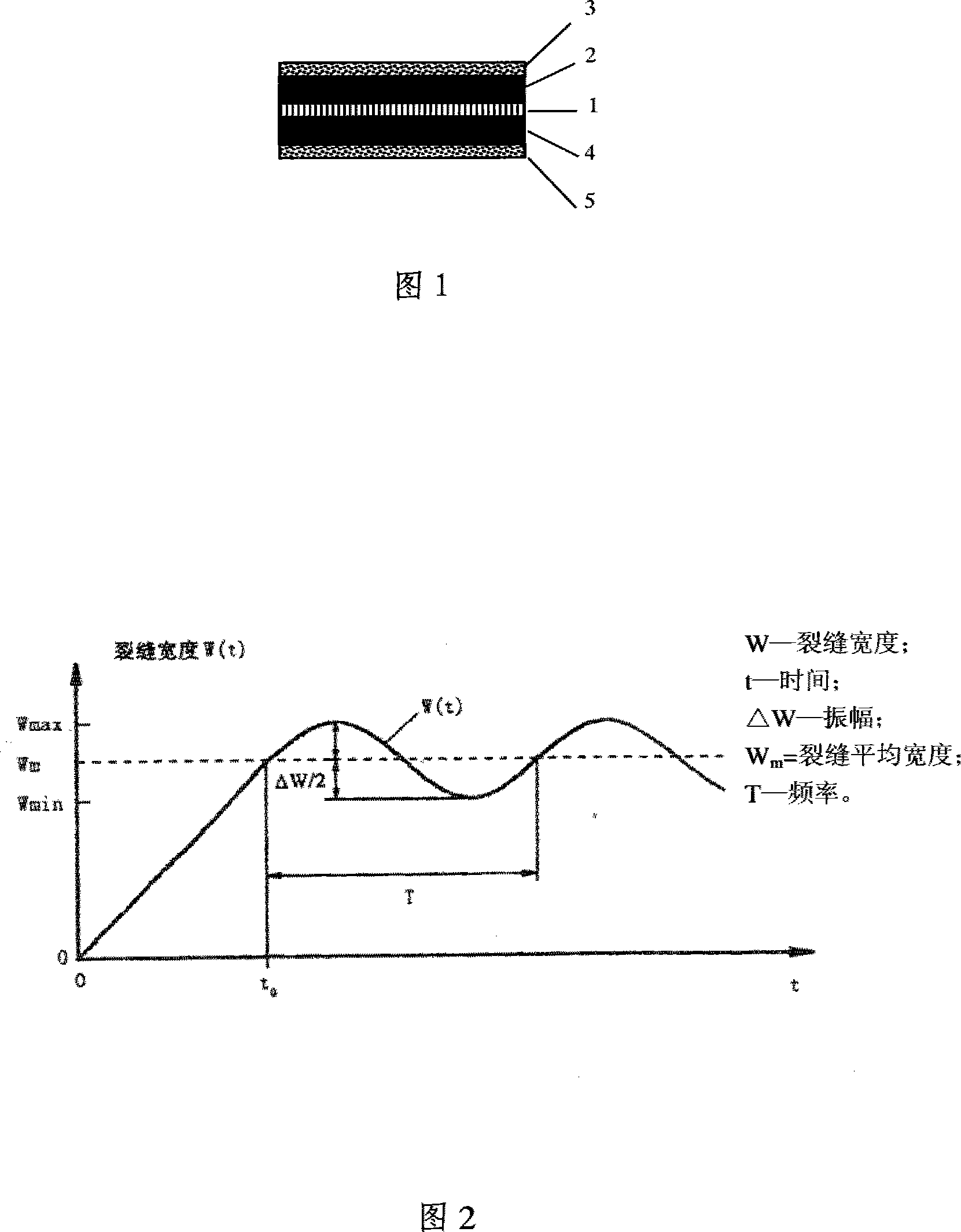

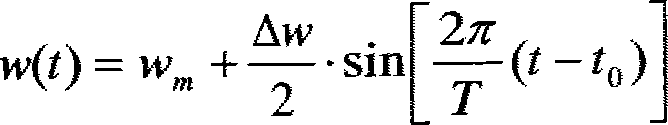

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

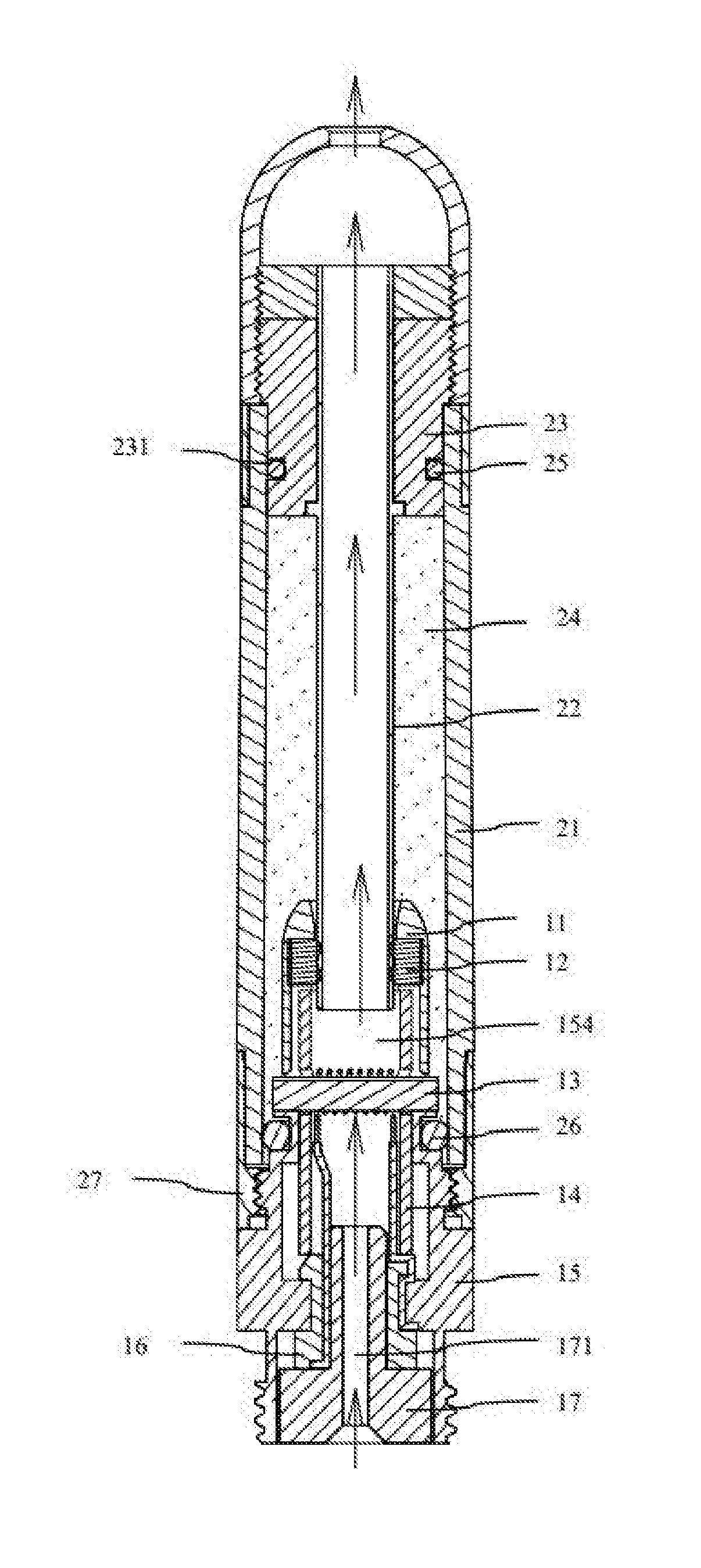

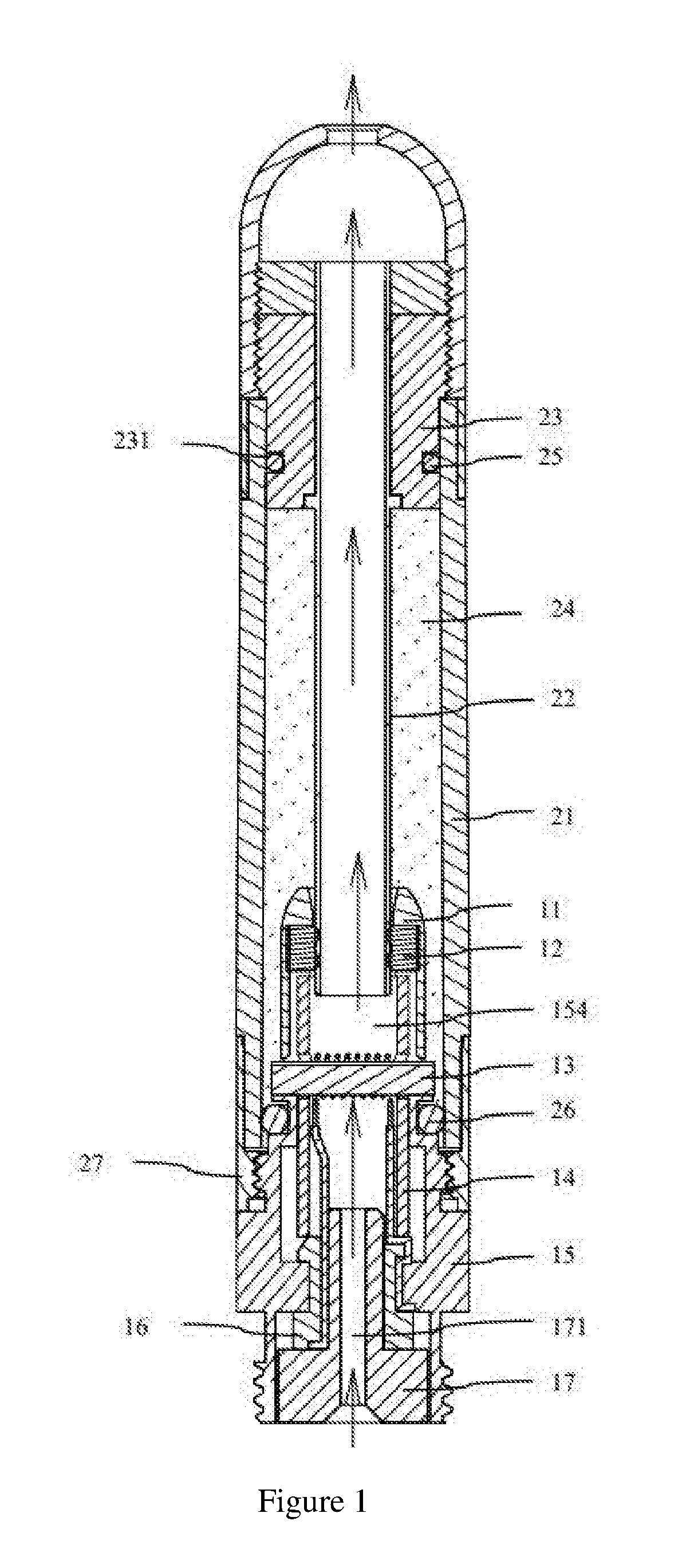

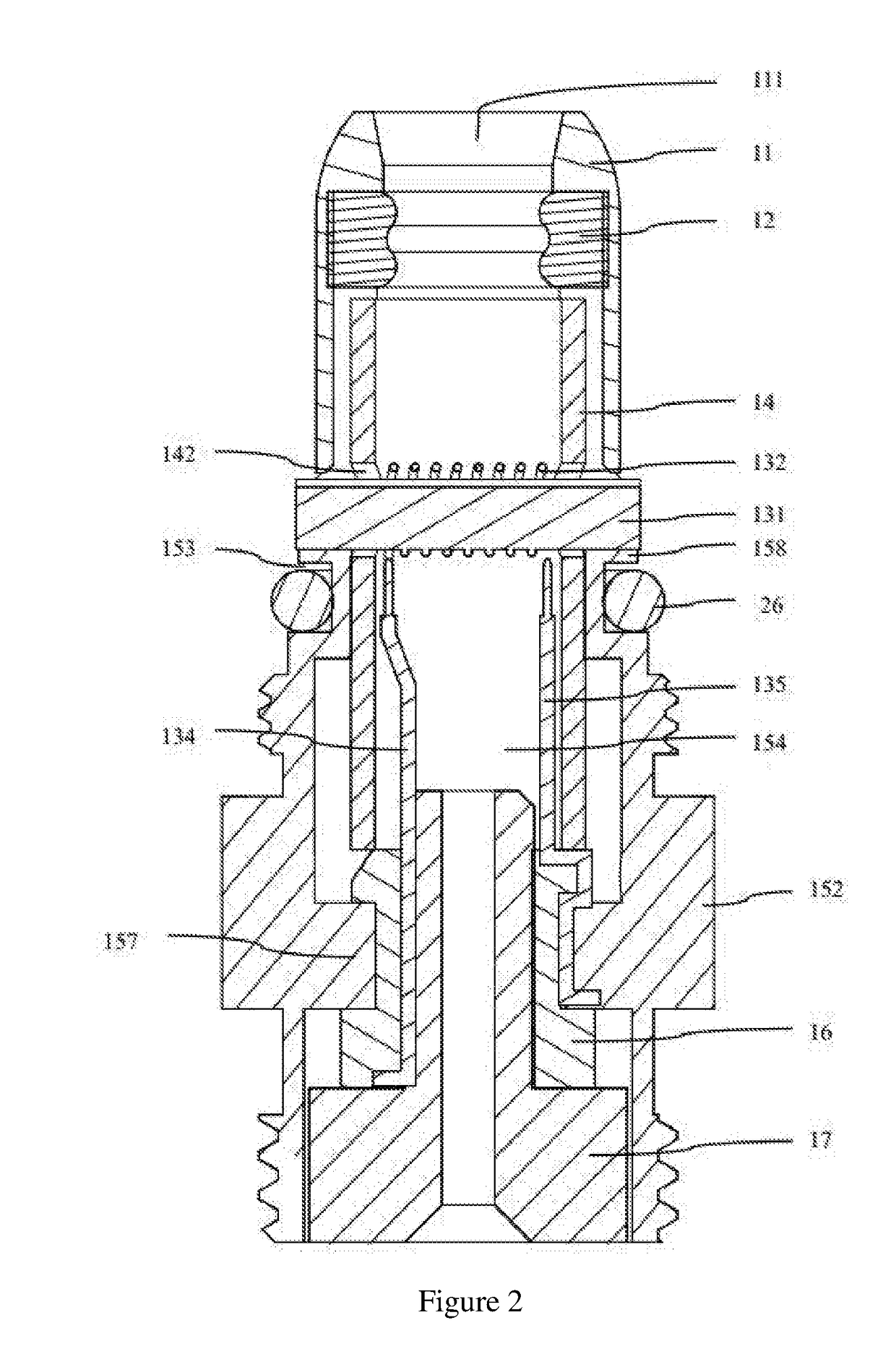

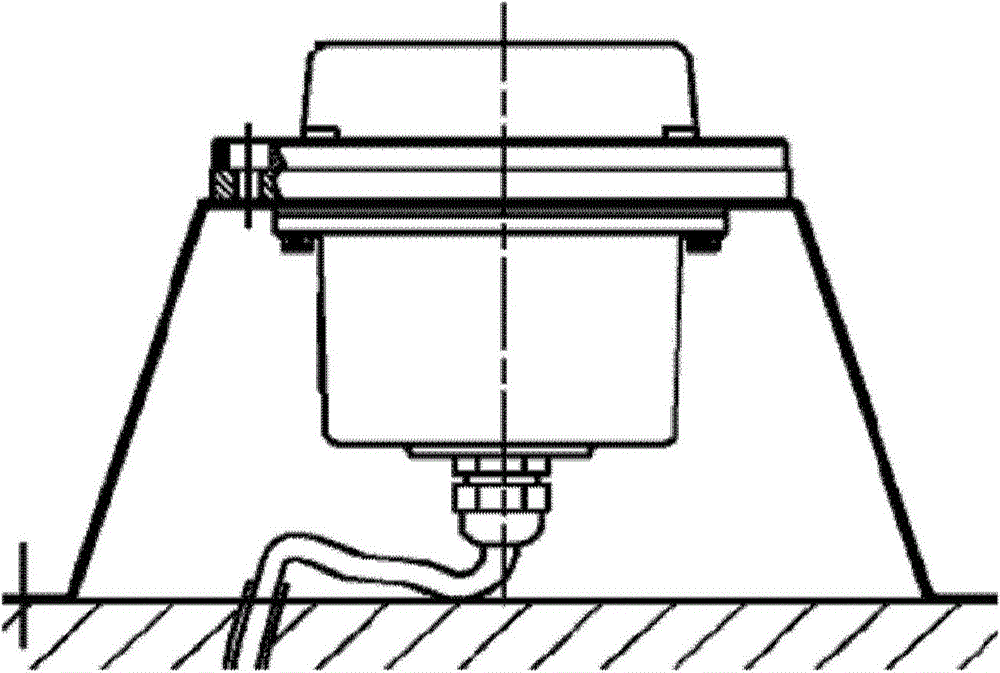

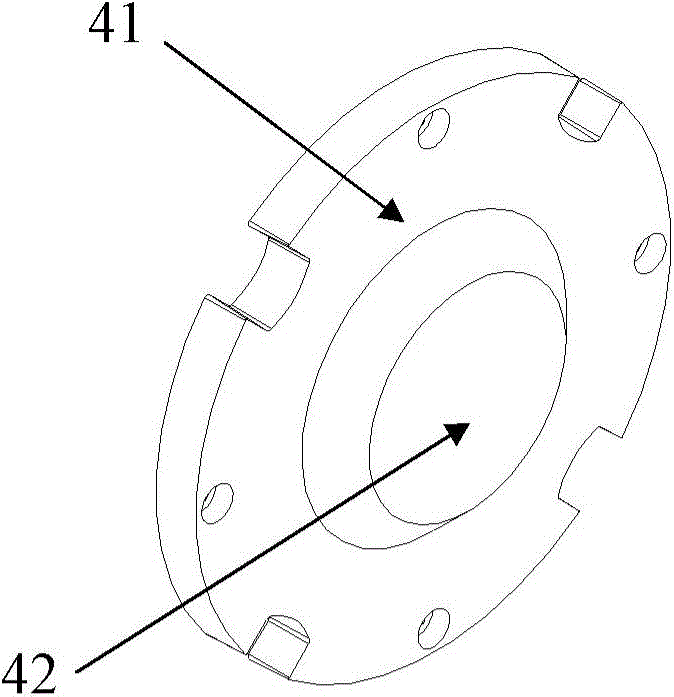

Vaporization assembly and electronic cigarette

InactiveUS20170295846A1Avoid heatingAvoid instabilitySteam generation heating methodsTobacco devicesEngineeringElectronic cigarette

The invention relates to a vaporization assembly and an electronic cigarette; the vaporization assembly comprises an e-liquid cup assembly and a vaporization core arranged in the e-liquid cup assembly; the e-liquid cup assembly has an e-liquid storage chamber used for accommodating e-liquid; the vaporization core comprises a vaporization base and an electric heating wire assembly; the vaporization base is internally provided with a smoke passageway used for providing passage to the smoke produced by vaporization; the electric heating wire assembly is arranged on the smoke passageway; the electric heating wire assembly comprises an electric heating wire used for heating and vaporizing the e-liquid; the vaporization core comprises an insulating tube used for isolating the vaporization base from the electric heating wire; the insulating tube is interposed in the vaporization base, and supports the electric heating wire along the length of the vaporization base.

Owner:HUIZHOU KIMREE TECH

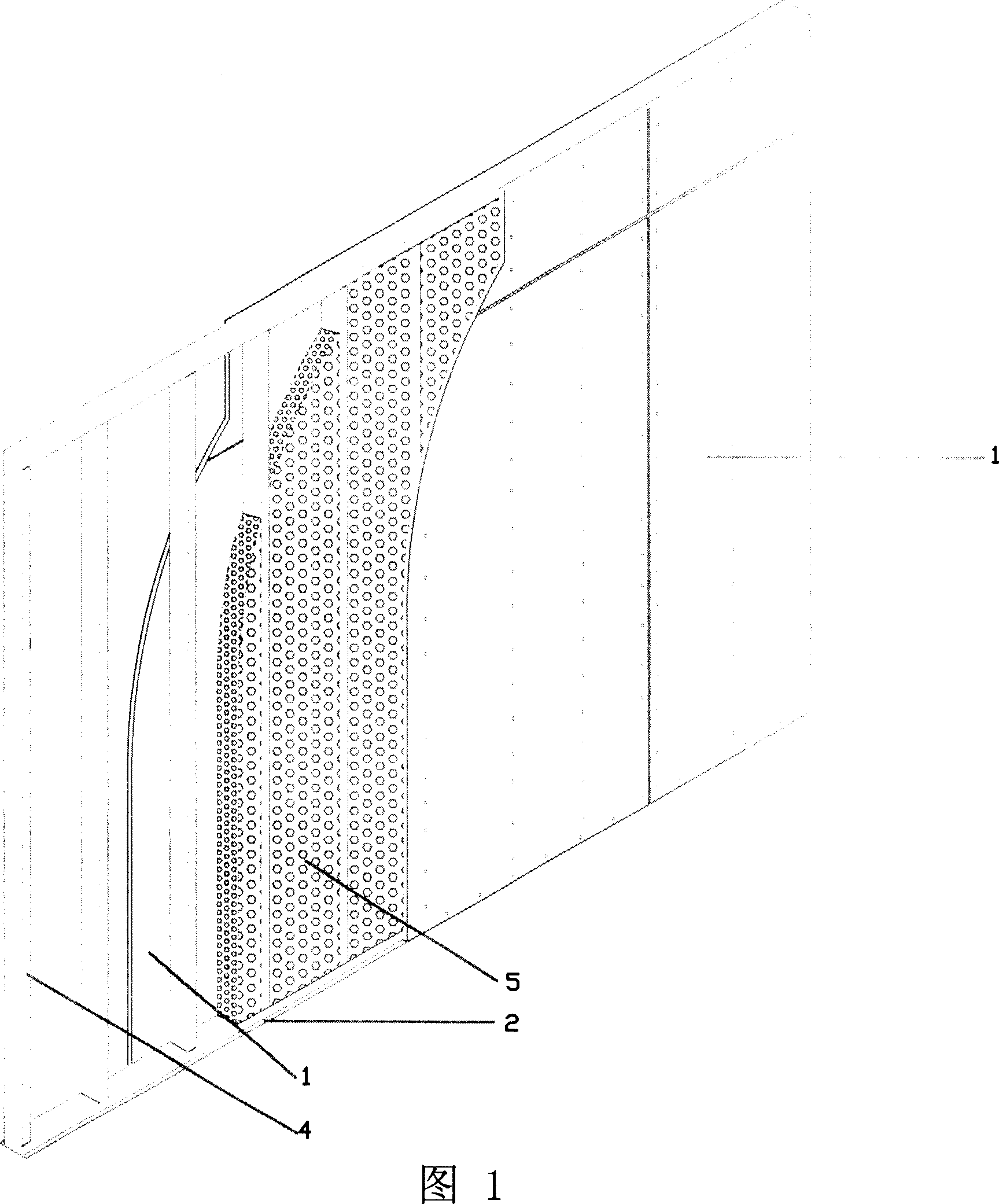

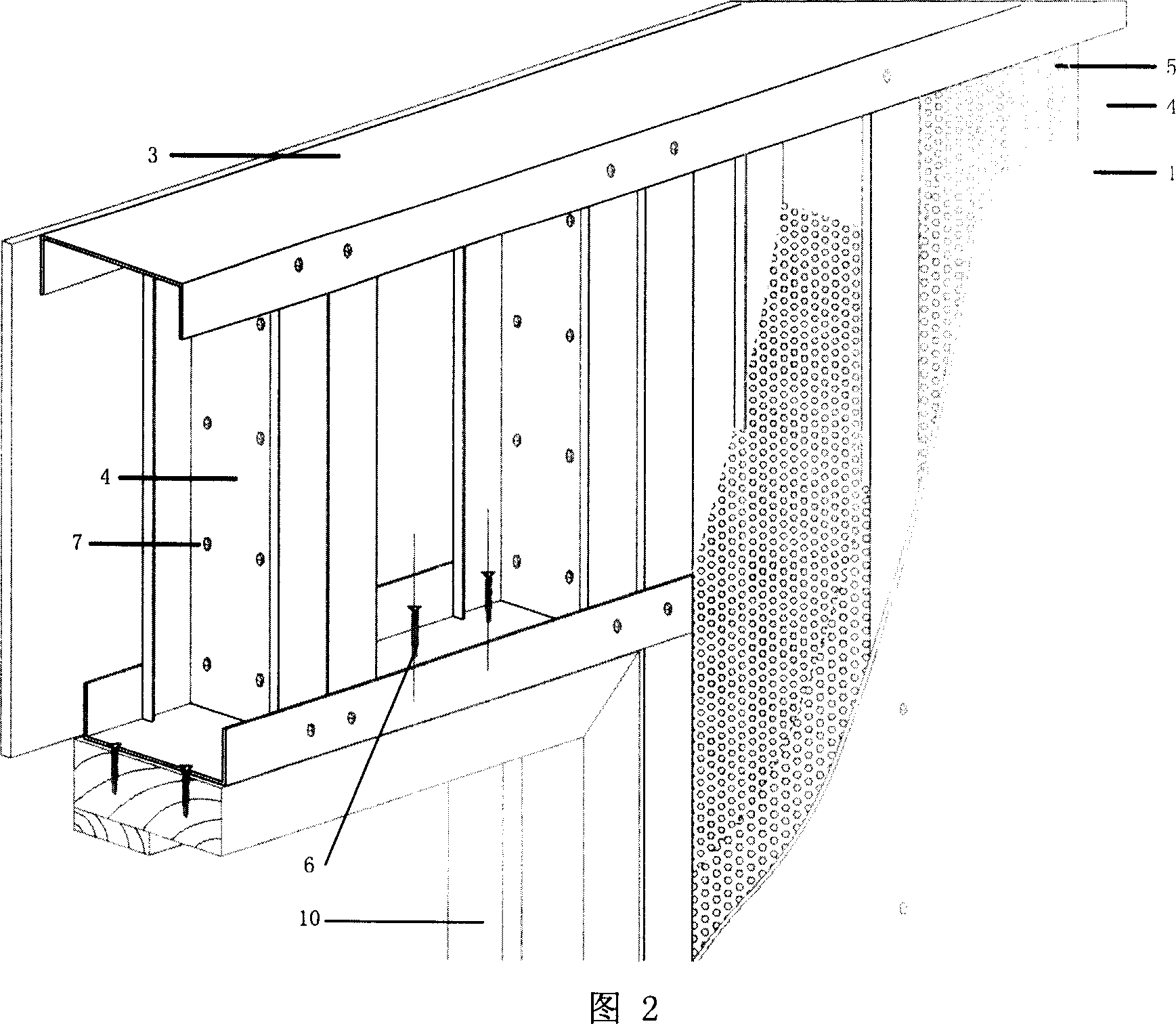

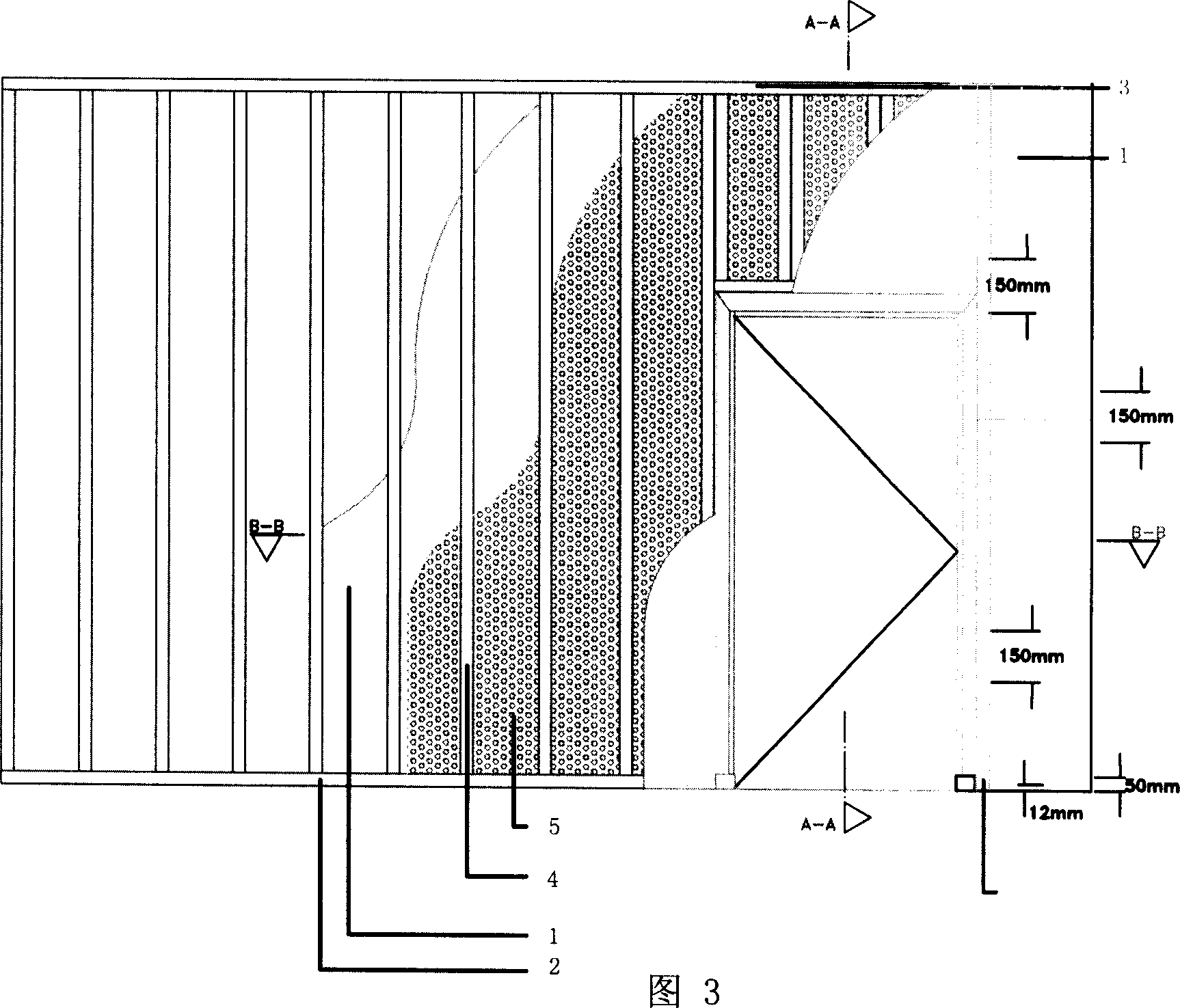

Fiver cement board grouting wall and construction method therefor

The invention discloses a lightweight nonbearing grouting wall and its construction method for inner walls of buildings, comprising a lightgage steel joist or C-shaped steel as a framework, two fiber cements covered on two sides, a hollow space within lightweight grouting materials by special equipment, and a skin layer decorated and dealt directly. The wall has a simple structure for easy construction and a light weight thereby reducing the cost of entire structure and improving the fireproof property up to 2.5 hours or more and the sound insulation property as 40dB, therefore the invention is an inner wall construction with higher utility and economic profit.

Owner:杨建平

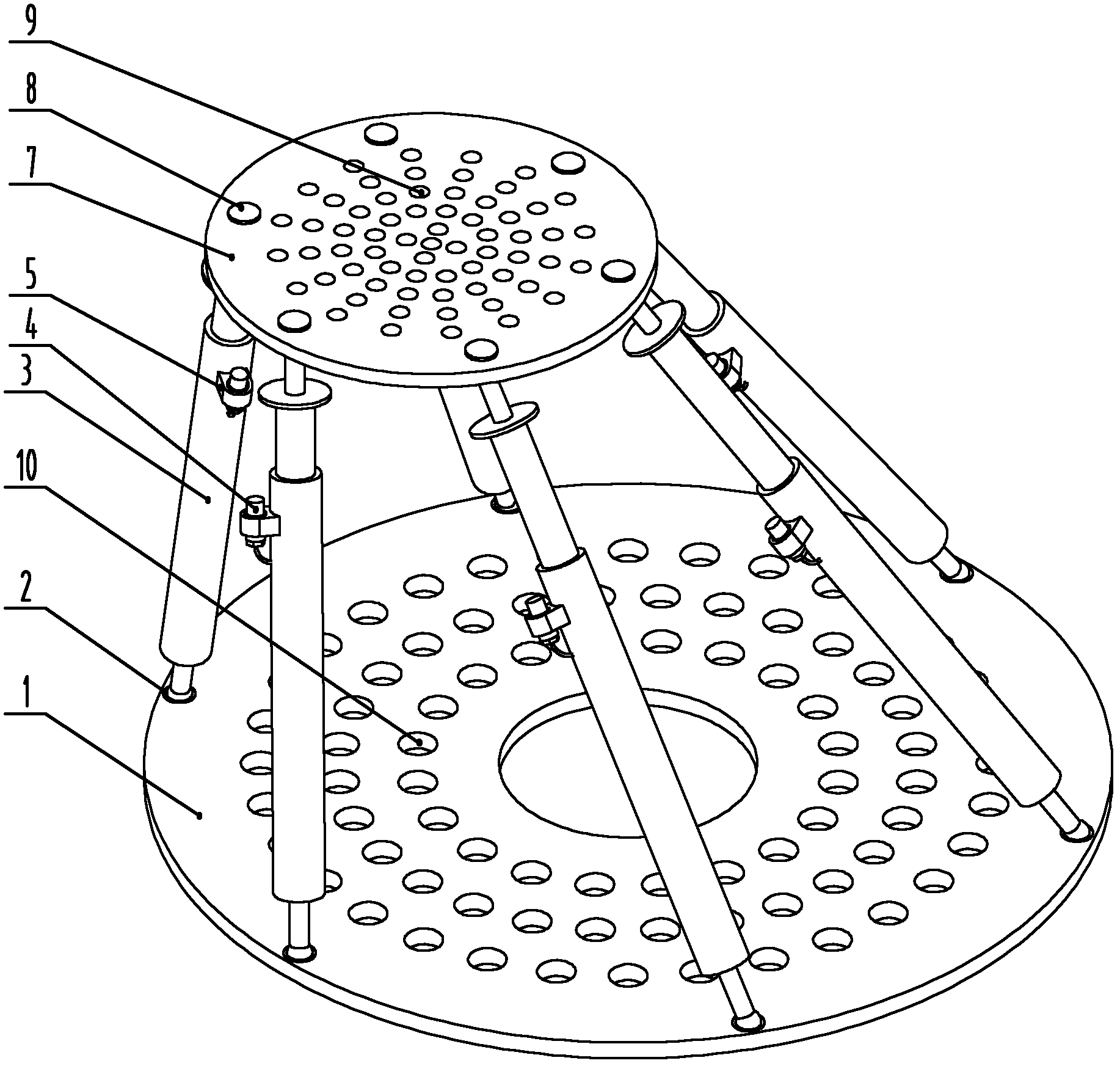

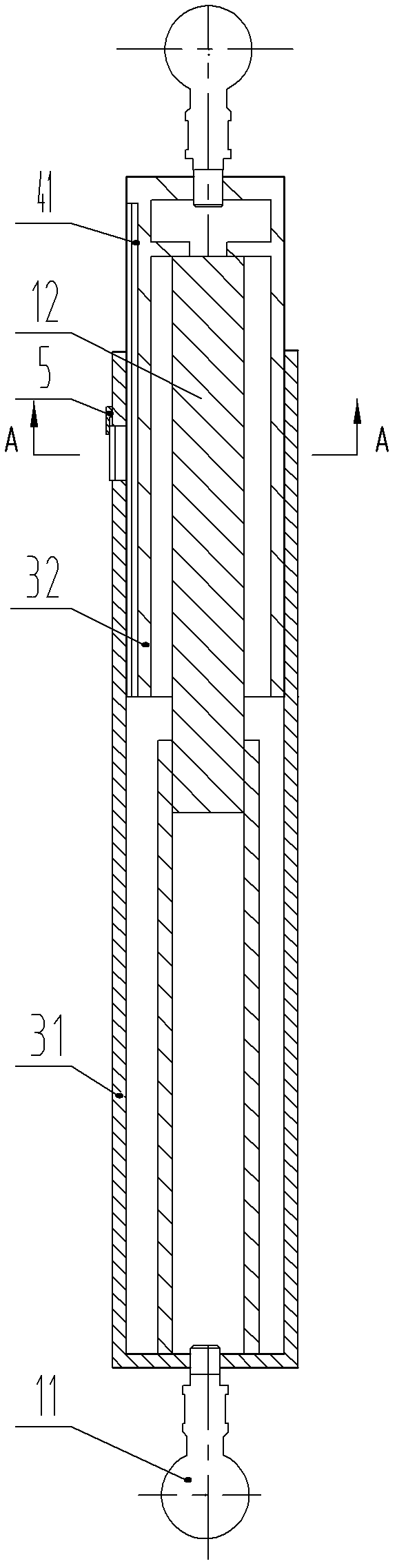

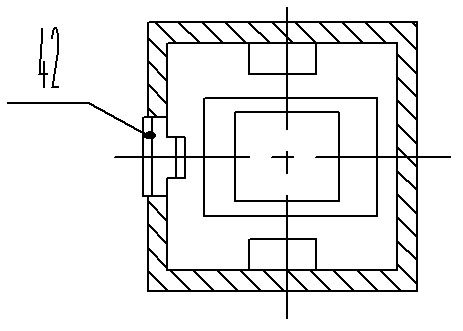

Spatial six-degree-of-freedom vibration measuring and damping vibration attenuating method

InactiveCN102628728AStrong impact resistanceSimple structureNon-rotating vibration suppressionVibration testingVibration controlMeasurement point

The invention discloses a spatial six-degree-of-freedom vibration measuring and damping vibration attenuating method. The method comprises the following steps of: 1) erecting six-displacement-sensor parallel measuring and damping vibration attenuating mechanism; 2) fixing a detected motion object and a fixed platform; 3) obtaining a motion variation rule by using an expansion variation displacement time of an expansion pull rod, and obtaining a vibration rule of the detected motion object by using a measurement algorithm with a positive solution; 4) obtaining a damping value of a six-degree-of-freedom controllable damper required by the vibration by using a damping vibration attenuating algorithm; and 5) adjusting the damping value of the six-degree-of-freedom controllable damper to a value obtained by the damping vibration attenuating algorithm. According to the invention, six-degree-of-freedom measurements of three vibration displacements and three vibration angles of the motion object at the same measurement point are achieved by using one set of mechanism; meanwhile, the vibration control of the motion object can be achieved; and the spatial six-degree-of-freedom vibration measuring and damping vibration attenuating method disclosed by the invention has the advantages of high accuracy, simple structure, good flexibility, strong adaptability, wide application range and the like.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

Method for deeply treating, desalting and recycling industrial wastewater with high salt content

ActiveCN104016530AImprove catalytic oxidation efficiencyGood removal effectMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to the field of industrial wastewater treatment processes and provides a method for deeply treating, desalting and recycling industrial wastewater with high salt content. The method comprises the following steps: 1) carrying out efficient coagulation treatment on the industrial wastewater with high salt content to obtain supernatant; 2) carrying out chemical precipitation on the supernatant obtained in the step 1) to remove high valence ions with valence higher than bivalence in the wastewater; 3) carrying out catalytic ozonation treatment on the supernatant subjected to chemical precipitation in the step 2); 4) carrying out multi-media filtration, precise filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 3) in sequence; and 5) carrying out electrodialysis reversal treatment on the effluent obtained after membrane filtration in the step 4). By adopting the method, organic matters, bacteria, colloids, suspended particles, Ca<2+>, Mg<2+> and high valence ions, other soluble inorganic salts and the like in the industrial wastewater with high salt content are removed by utilizing the coupling and synergistic effects of different unit technologies, thus achieving deep treatment, desalting and recycling of the industrial wastewater with high salt content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Electric locomotive pantograph copper-soaking carbon contact strip producing method

ActiveCN104774012AImprove conductivityHigh mechanical strengthPower current collectorsShock resistanceNitrogen gas

The invention discloses an electric locomotive pantograph copper-impregnated carbon contact strip producing method. The method comprises the steps that 1, pitch coke powder, graphite powder, siliconized graphite powder and high temperature pitch are mixed according to the proportion to be ground into powder; the mixed powder is prepressed into a stage stock column, and then the stage stock column is solidified and squeezed to be molded and roasted, so that a composite carbon contact strip is obtained; 2, the composite carbon contact strip is cleaned and dried, then is cooled and placed into a graphite crucible, and is placed in an electric furnace at temperature of 1300-1400 DEG C to be preheated; copper liquid is poured into the crucible to soak the composite carbon contact strip, then the crucible is placed in an oil press cover, nitrogen is led in, heat preservation is kept for 3-5 min under the specific intensity of pressure, and finally cooling is carried after pressure releasing. According to the electric locomotive pantograph copper-impregnated carbon contact strip producing method, the electroconductibility of the copper-impregnated carbon contact strip is improved, the electrical resistivity is lowered, the mechanical strength of the carbon contact strip and copper impregnated angle can be increased, then the carbon contact strip abrasive resistance and self-lubrication are improved, the copper-impregnated carbon contact strip is more resistant to abrasion, main line damage and block dropping are avoided, the shock resistance is high, and the service life of the copper-impregnated carbon contact strip is prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

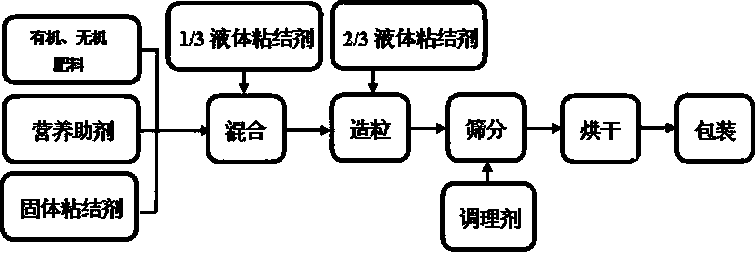

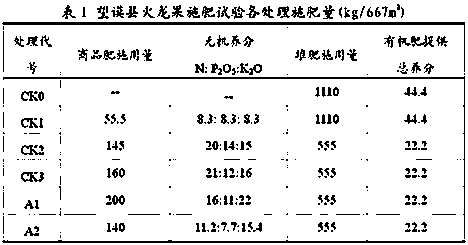

Compound fertilizer special for dragon fruit, and preparation method and application thereof

InactiveCN103819277AImproved physical and chemical propertiesIncrease organic matterFertilizer mixturesNutritionHorticulture

The invention discloses a compound fertilizer special for dragon fruit, and a preparation method and an application thereof, and belongs to the technical field of the fertilizers and the preparation methods thereof. The compound fertilizer special for the dragon fruit is prepared from the following components by weight percent: 40-90% of organic fertilizer, 40-49% of inorganic chemical fertilizer, 4-6% of humic acid, 0.5-1.5% of nutritional additives, 5-7% of composite binder and 0.4-0.7% of conditioner. Due to optimized combination of the organic fertilizer, the inorganic fertilizer, major elements and trace elements, the dragon fruit can be enabled to bloom and bear fruits early, the yield of the dragon fruit can be increased, and the quality of the dragon fruit also can be improved. Due to organic-inorganic combination, complete nutrition is provided for the growth of the dragon fruit, and the soil structure can also be modified easily, the utilization rate of the fertilizer is increased, and the yield and the quality of the dragon fruit can be improved remarkably; in the meantime, the compound fertilizer also has the advantages that the agricultural wastes are recycled and the preparation cost of the fertilizer is low, and therefore, the compound fertilizer is excellent in economic benefit and ecological environmental benefit.

Owner:GUIZHOU UNIV

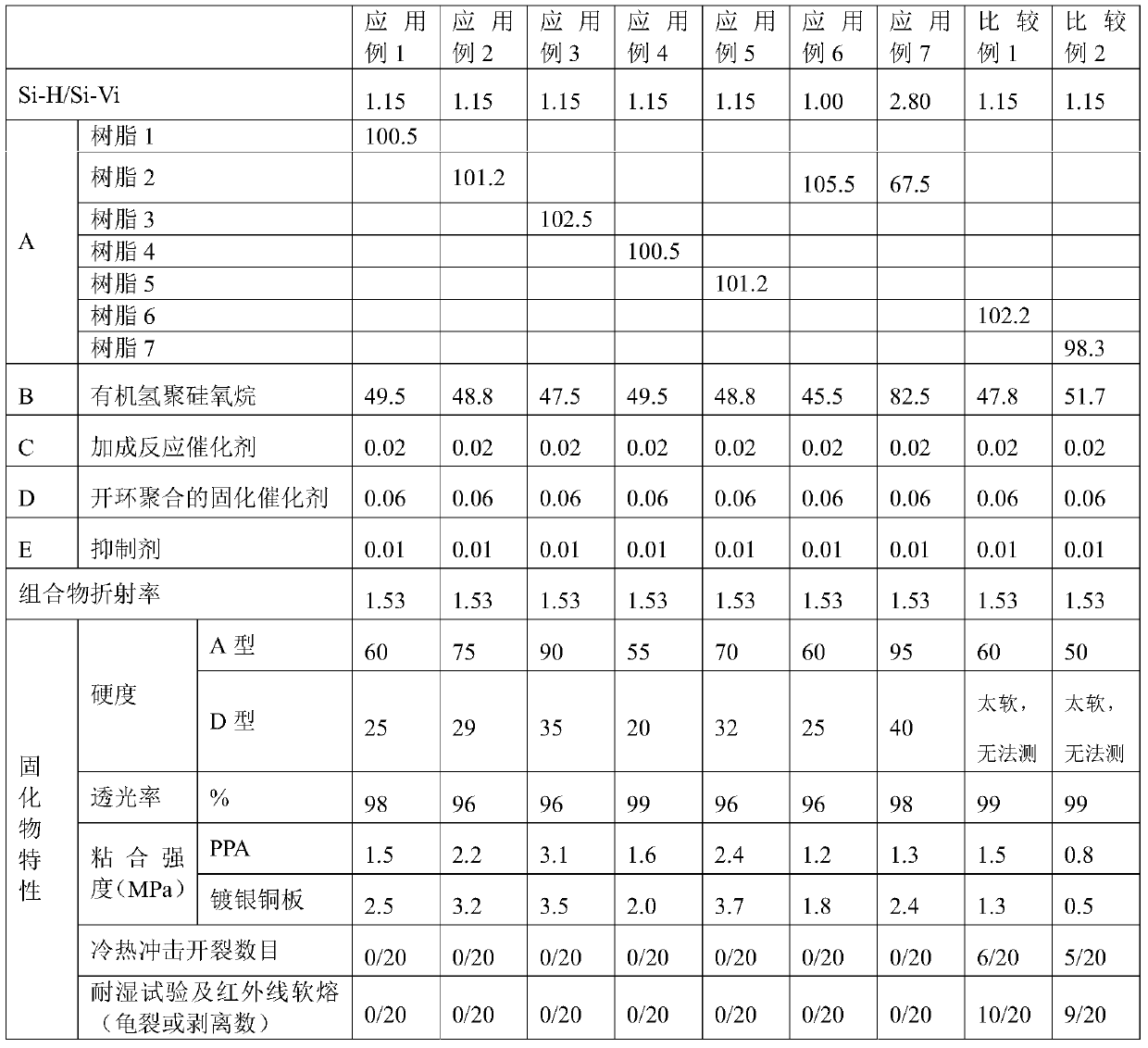

Organic silicone resin, curable organopolysiloxane composition and application

The invention discloses an organic silicone resin, a curable organopolysiloxane composition and an application. A structural formula of the organic silicone resin is shown as formula I. The curable organopolysiloxane composition is obtained by mixing the organic silicone resin with an organic silicone compound having at least two hydrogen atoms bonded with a silicone atom in one molecule. The curable organopolysiloxane composition can be applied on luminescent semiconductor package. The curable organopolysiloxane composition has the following advantages of excellent adhesive property, relatively strong hardness, excellent impact resistance, high transparency, little color change in a heat resistance test and high luminescent efficiency. Besides, the curable organopolysiloxane composition is not easy to peel off in a thermal shock test and presents excellent adhesive power in adhesive experiments with PPA and metal. The formula I is R1R22SiO(R3SiO3 / 2)a(SiO4 / 2)b(R42SiO)cOSiR22R1.

Owner:GUANGZHOU HUMAN CHEM

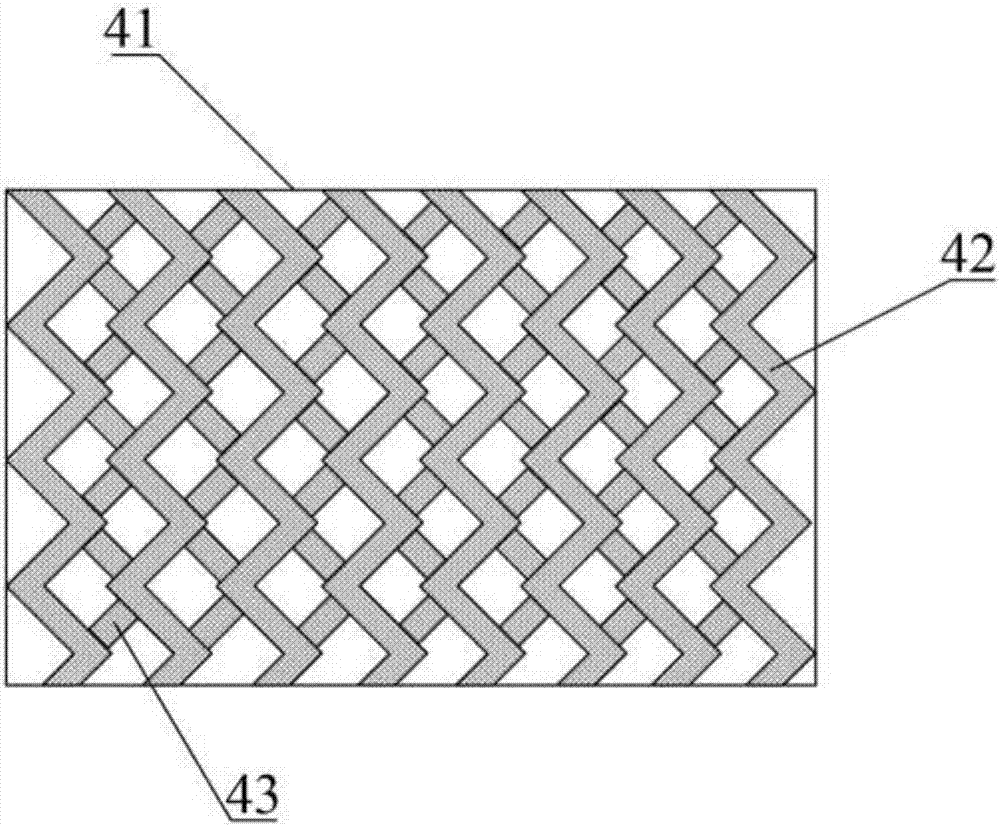

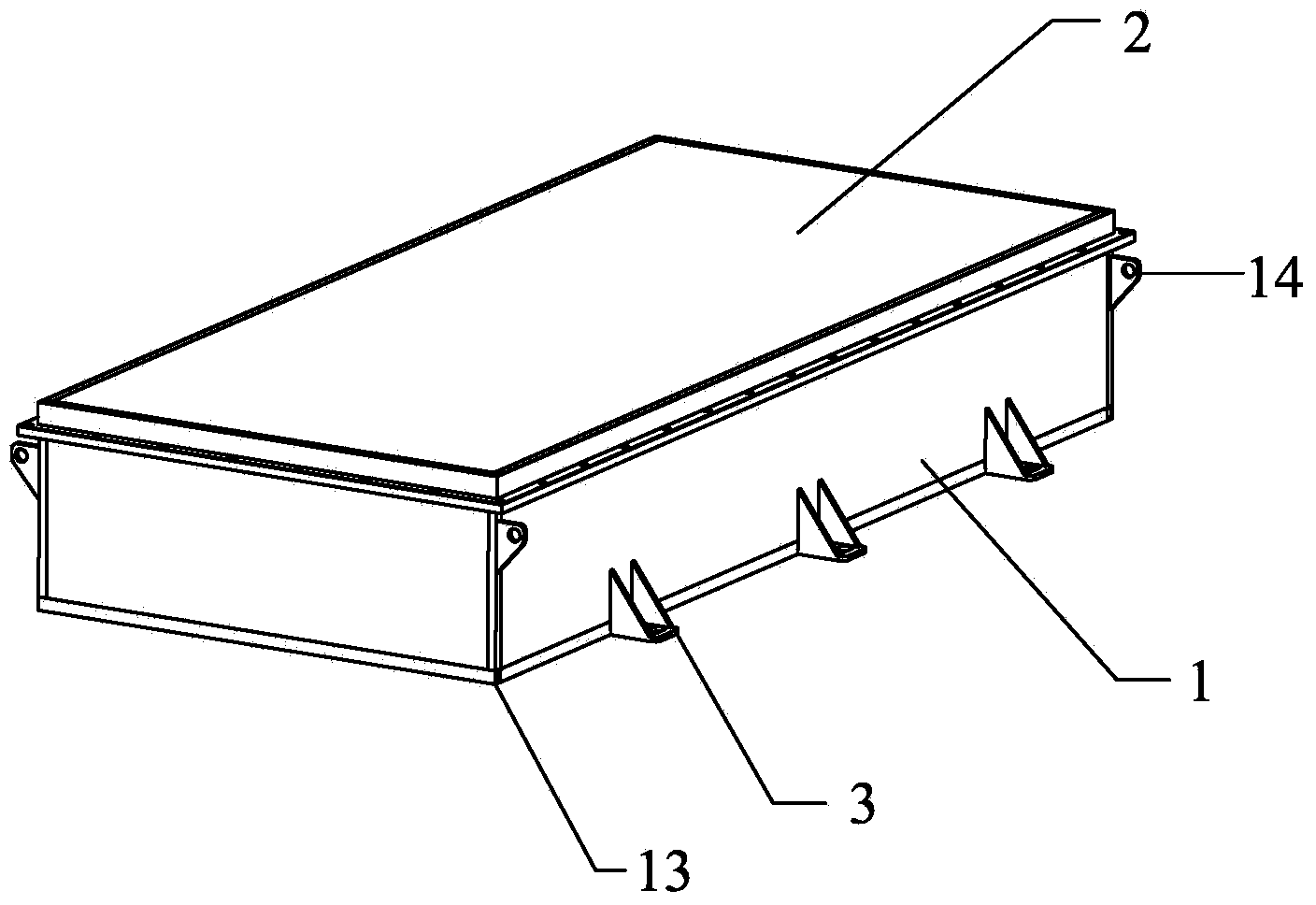

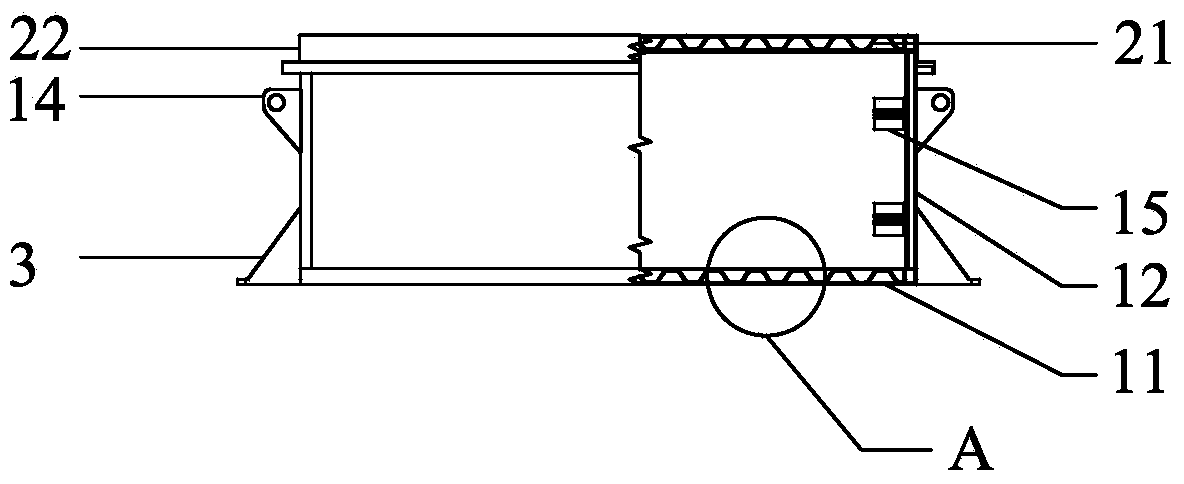

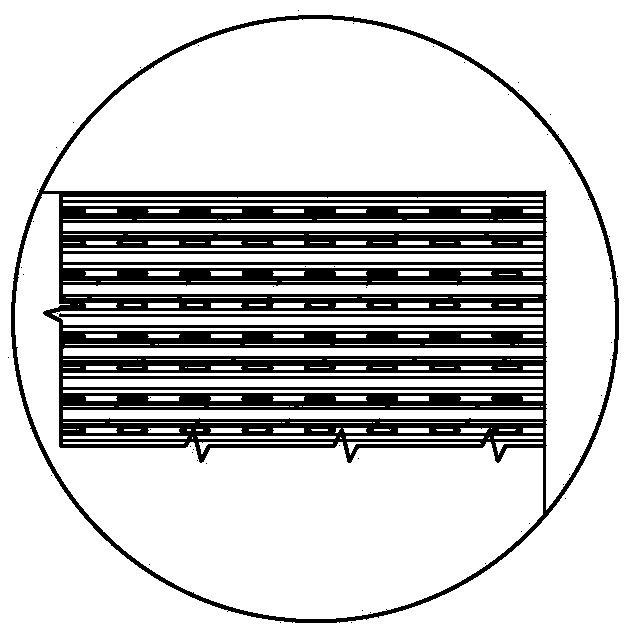

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

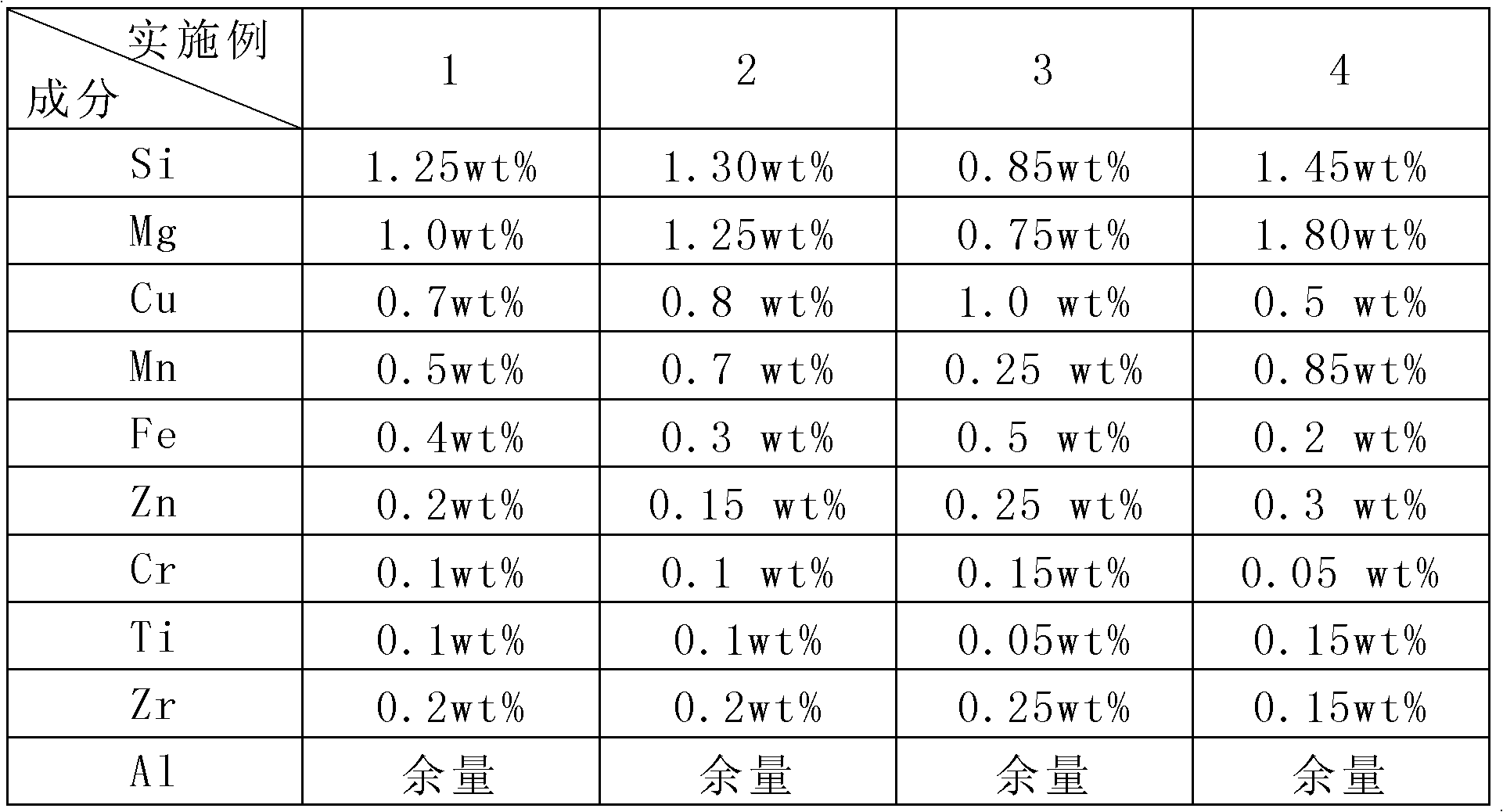

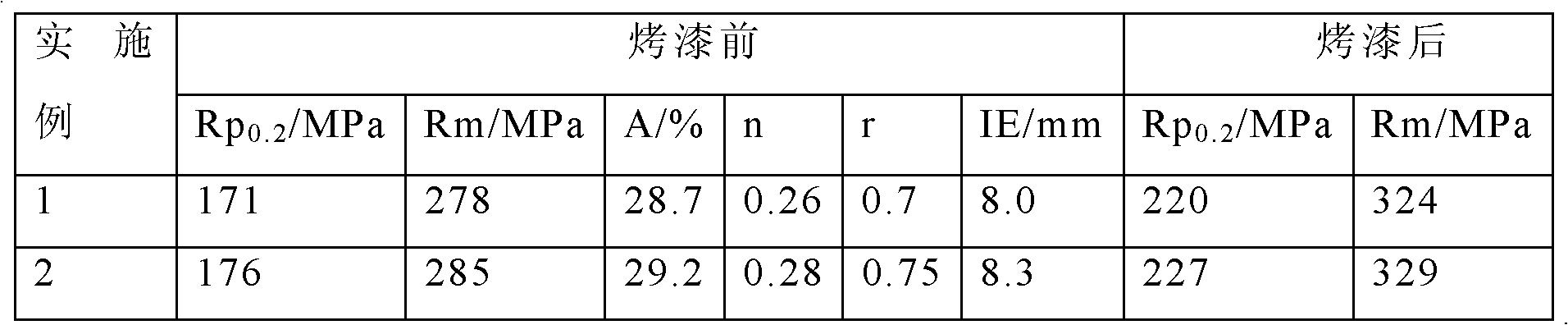

Al-Mg-Si alloys for automobile body sheets and manufacturing method thereof

ActiveCN101880805AStrong impact resistanceLower yield strengthCooking & bakingUltimate tensile strength

The invention provides Al-Mg-Si alloys for automobile body sheets and a manufacturing method thereof, belonging to the technical field of alloy materials. The invention solves the following problems: the existing 6000 series alloys have poor stamping forming performance and the strength of the alloys is possibly reduced through paint baking after stamping. The alloys comprise the following components in percentage by weight: 0.75-1.5% of Si, 0.2-0.5% of Fe, 0.2-1.0% of Cu, 0.25-1.0% of Mn, 0.75-1.85% of Mg; 0.15-0.3% of Zn, 0.05-0.15% of Cr, 0.05-0.15% of Ti, 0.05-0.35% of Zr and the balance Al. The alloys have the advantages of low yield strength, convenient stamping, high plasticity and good impact resistance and baking hardenability.

Owner:ZHEJIANG GKO IND CO LTD

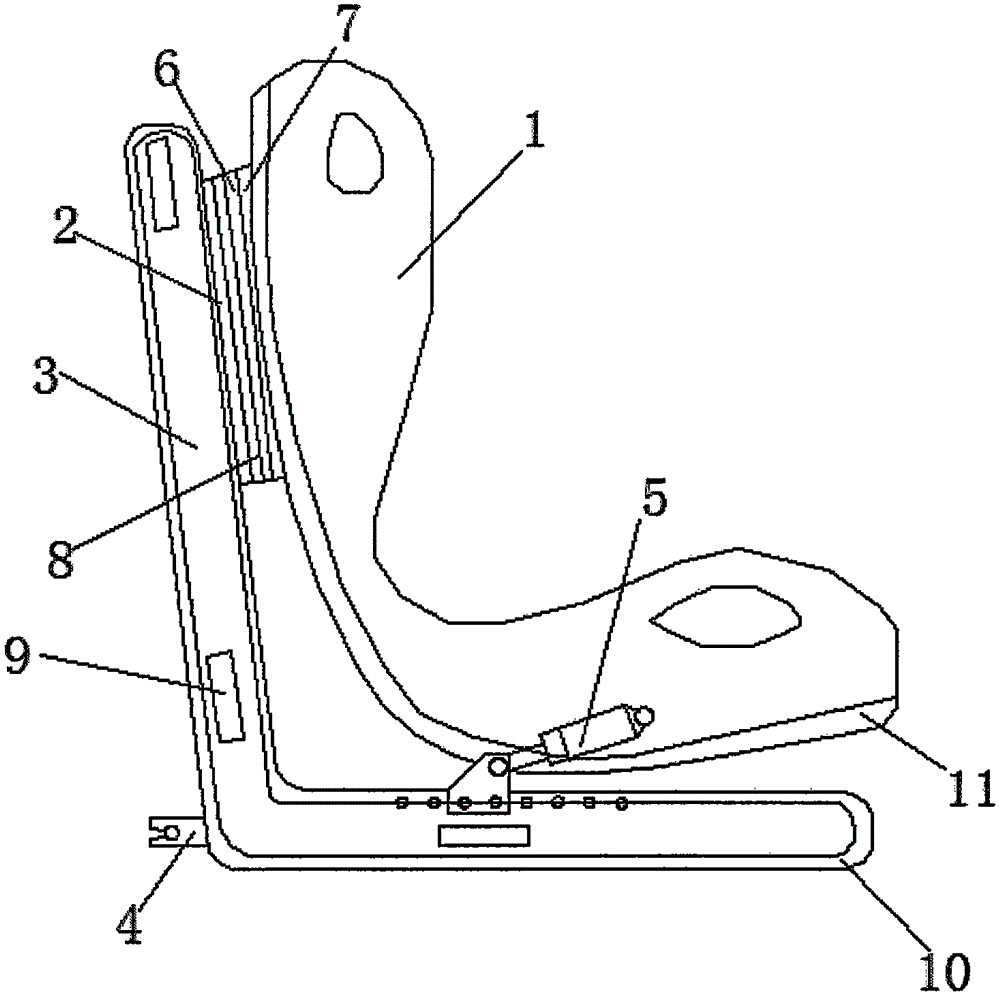

Anti-shock damping safety seat

InactiveCN105564278AImprove comfortGood shock absorptionKids chairsMovable seatsEnergy absorbingShock resistance

The invention discloses an anti-shock damping safety seat. The both sides at the bottom of a seat main body are connected with a supporting plate through damping rods; the back surface of the seat main body is in sliding connection with a back plate through a damping connecting piece; the damping connecting piece comprises a connecting block, a damping spring group, a silica gel layer and a sliding block; one side of the connecting block is fixedly connected with the back surface of the seat main body, while the other side of the connecting block is connected with the silica gel layer through the damping spring group; one side of the silica gel layer is connected with the sliding block; a sliding chute in fit with the sliding block is formed in the back plate; a fixing base is coated with a first anti-collision bag; the first anti-collision bag is filled with a buffer material; a buffer bag is arranged in the fixing base and filled with a buffer gas generating material; second anti-collision bags are arranged on the back surface and the bottom surface of the seat main body and are filled with an energy absorbing material; arc-shaped rubber layers are arranged on the outer sides of the second anti-collision bags. The anti-shock damping safety seat, disclosed by the invention, is better in shock resistance, good in buffering and damping effect, capable of automatically recovering within a certain range, and good for protecting human body.

Owner:CHONGQING TECH & BUSINESS INST

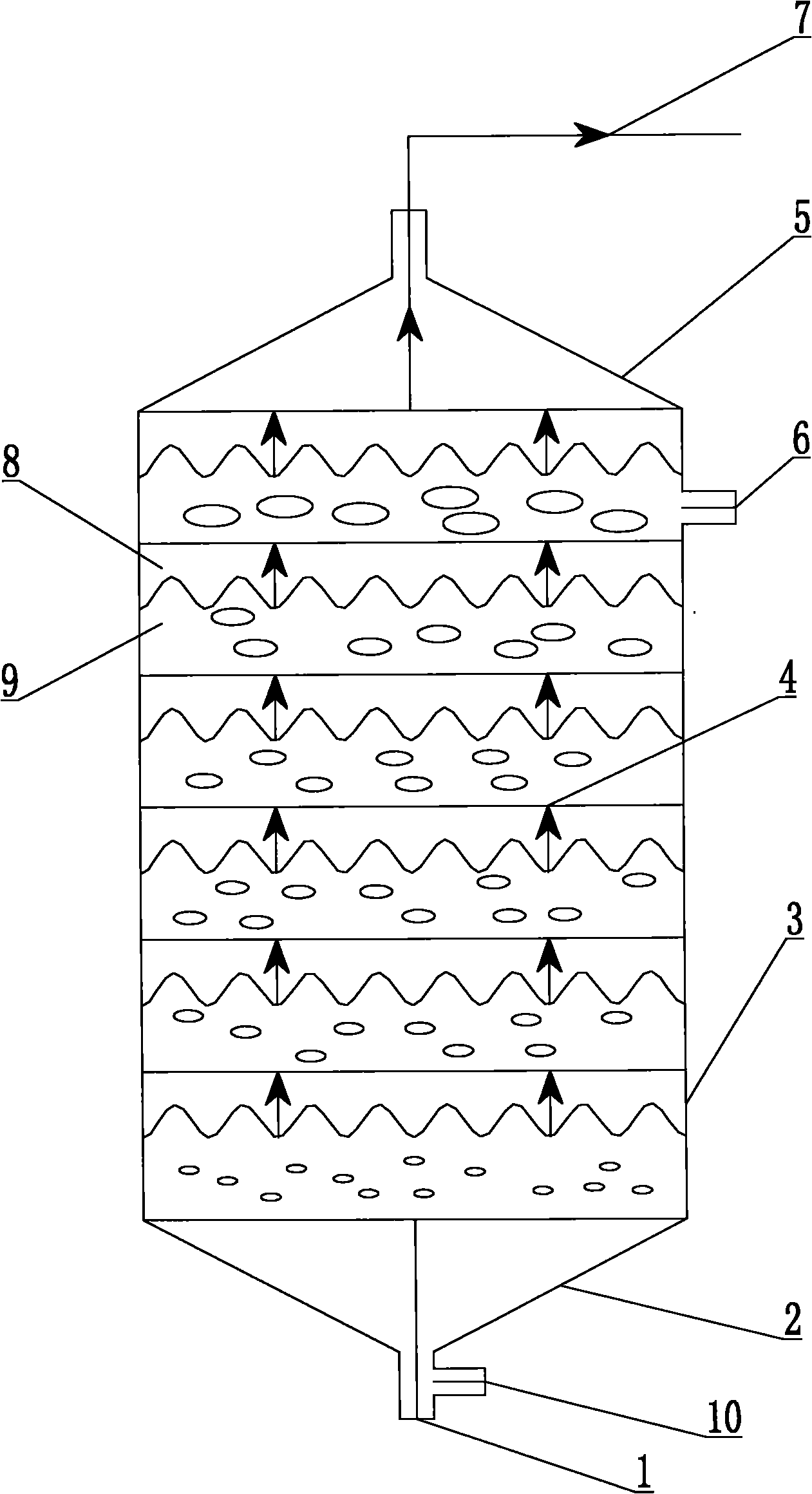

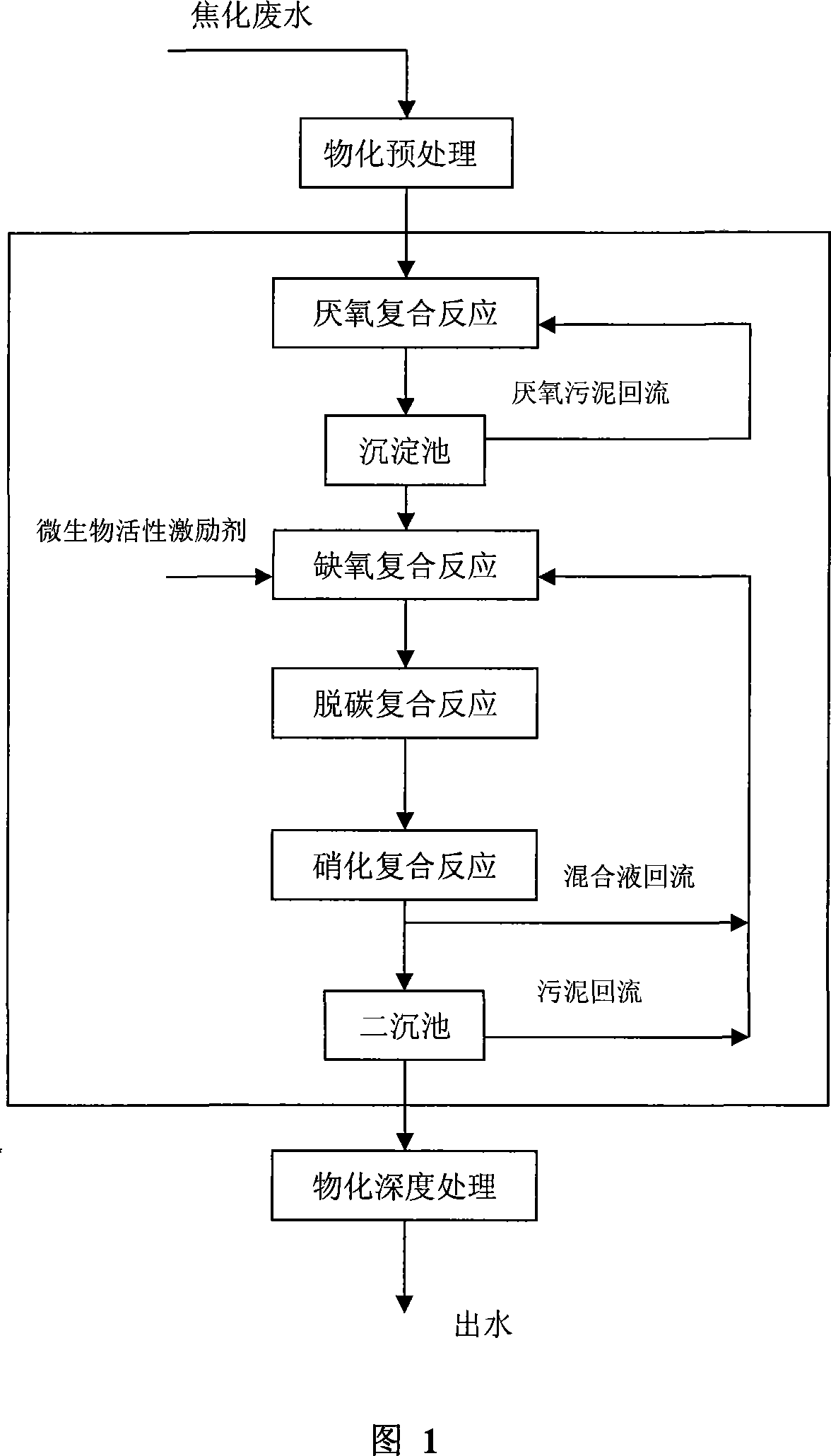

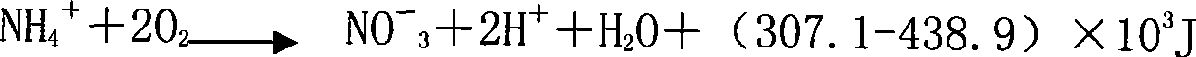

Impact-resistant multiplication combined type coking waste water treatment process

InactiveCN101113065AOptimize material compositionImprove biodegradabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater treatmentWater quality

An anti-impact multiplying combination coking wastewater treatment technique relates to a treatment method of coking wastewater. The coking wastewater is first qualified by a physical-chemical pretreatment to improve biodegradable property of wastewater; the composite technology of a biological carrier of active sludge is adopted to do anaerobic / hypoxia / aerobic decarbonization / aerobic nitrification biochemical combination treatment; suspended or floating folding ball-shaped fillings are arranged in biochemical reactors and when micro organism traits are abnormal or a great amount of foams existing in the reactor, micro organism active incentive agents are added to the reactor in interval to improve active sludge traits and organism film quantity; finally the water is treated by a physical-chemical advanced treatment to reach a top grade standard. The invention not only strengthens the removal of COD, ammonia-nitrogen, volatile phenol and other pollutants in the coking wastewater by biochemical treatment but also resists serious water quality impact and has the advantages of quick system startup, less foams in an aeration tank, small occupying space, low operation cost and stable and effective treatment to coking wastewater.

Owner:TONGJI UNIV +1

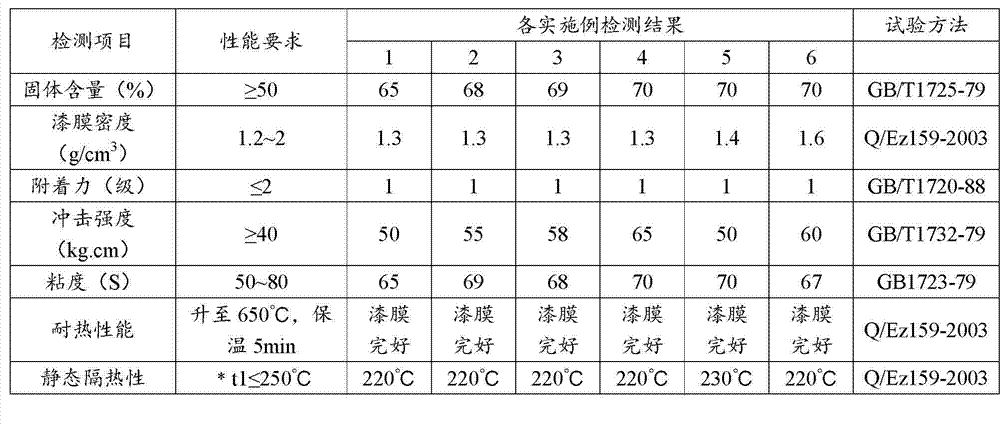

High-temperature-resistant heat-insulation paint and preparation method thereof

The invention relates to high-temperature-resistant heat-insulation paint and a preparation method thereof and belongs to the technical field of materials. The paint is used for heat-insulation protection of spacecrafts. The paint comprises, by weight, 25-35 parts of epoxide resin modified organic silicon resin containing nano particles, 10-20 parts of polybenzimidazole, 5-10 parts of high-temperature-resistant inorganic nonmetal compounds, 20-30 parts of high-temperature-resistant fillers, 1-3 parts of curing agents and 5-27 parts of solvents. The paint is high-temperature resistant, low in thermal conduction, high in shock resistance, low in density, good in bonding capacity, good in comprehensive performance index and capable of guaranteeing strength and rigidity of structural materials under the high temperature condition and meeting harsh requirements of aviation and space fields.

Owner:SHANDONG LIAOCHENG QILU SPECIAL PAINT

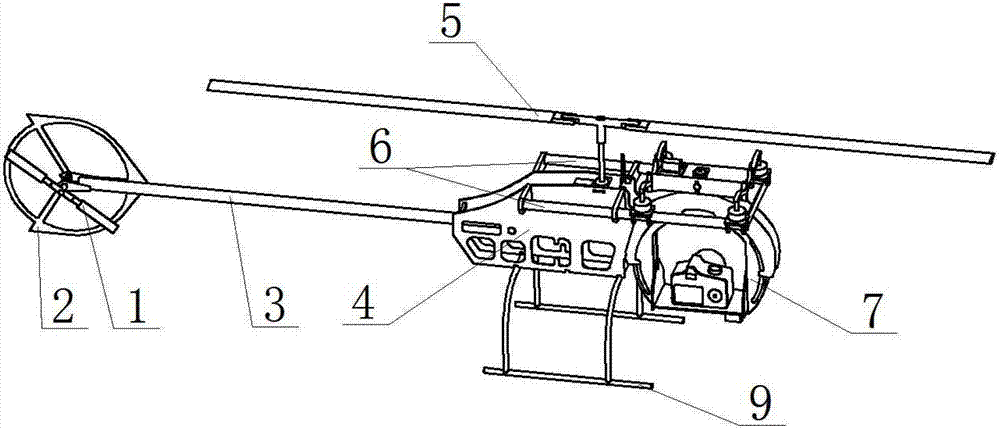

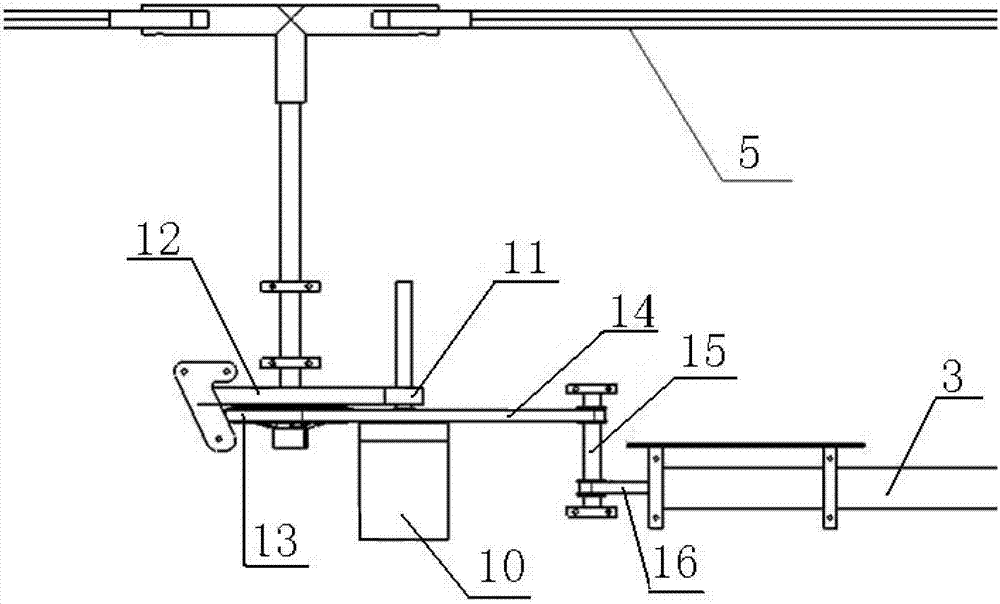

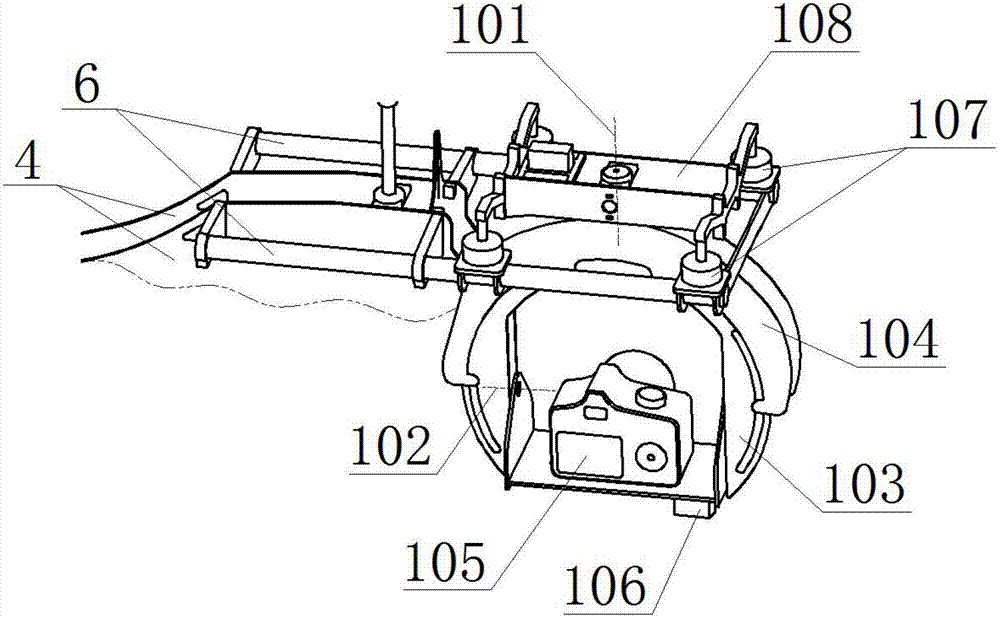

Small electric unmanned helicopter aerial photography system based on front-end triaxial-type pan-tilt

ActiveCN103029834AAgile captureLanding gear loweredAircraft componentsRotocraftAviationSystems design

The invention relates to a small electric unmanned helicopter aerial photography system based on a front-end triaxial-type pan-tilt. The small electric unmanned helicopter aerial photography system is a small unmanned helicopter aerial photography system design mainly comprising a front-end triaxial-type pan-tilt design, a small unmanned helicopter platform design, a ground station design, and a communication system design, and belongs to the technical field of aircraft designs. The aerial photography system is light and flexible, high in integration level, low in noise, small in vibration, good in use maneuverability, low in requirements on the conditions of use environments, site and the like, and capable of realizing the omnibearing photography. The aerial photography system has a high practical value and a wide application prospect in the field of unmanned aircrafts.

Owner:TIANXUN INNOVATION BEIJING TECH CO LTD

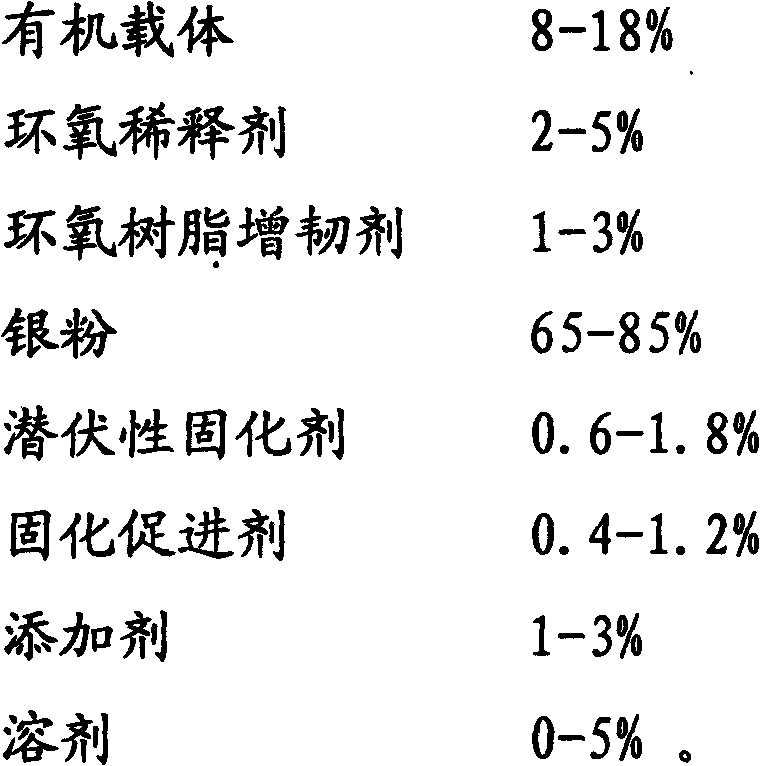

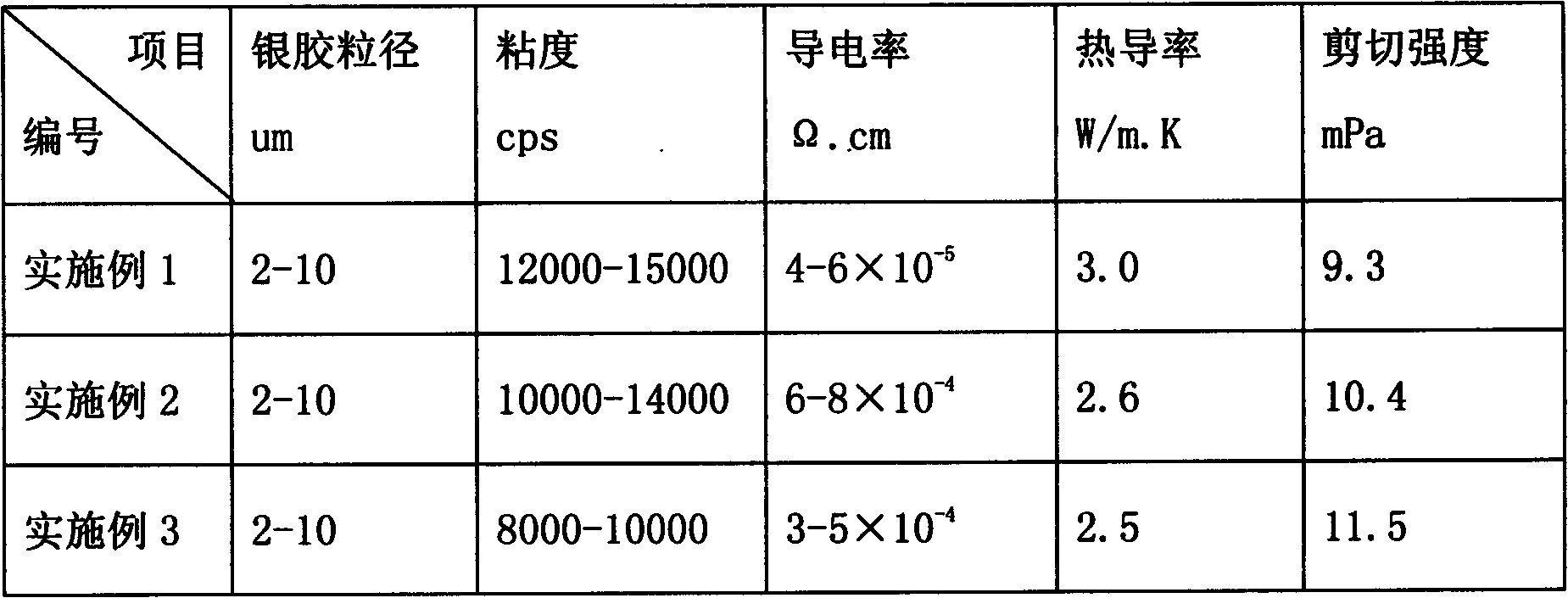

Epoxy conductive resin applicable to binding of LED (light-emitting diode) chips, and preparation method thereof

ActiveCN102634313ALow resistivityStrong impact resistanceEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyUltimate tensile strength

The invention discloses epoxy conductive resin applicable to binding of LED (light-emitting diode) chips. A preparation method comprises the steps of: adding 8-18% of an organic carrier and 2-5% of epoxy diluent, evenly stirring, conducting vacuum defoamation for 15-20 minutes, adding and evenly mixing 0.6%-1.8% of a latent curing agent, 0.4-1.2% of a curing accelerator, 1-3% of epoxy resin flexibilizer, and 1-3% of an additive into a reaction kettle, conducting vacuumizing for 30-60 minutes with the vacuum degree of minus 0.1MPa; and finally adding 65-85% of silver powder into a three-dimensional stirred tank, and fully stirring evenly and grinding in a three-roll machine for one to three times, thus obtaining the epoxy conductive resin. The epoxy conductive resin has low resistivity, strong impact resistance, high heat conducting coefficient, strong mechanical strength, and good heat-resistant and aging-resistant performances, and can meet the active technology demand of LED packaging industry.

Owner:GUANGZHOU BAIYUN CHEM IND

Epoxide resin pouring sealant with low density and high impact resistance and preparation method thereof

ActiveCN101580686ALow densityExcellent dielectric insulation propertiesNon-macromolecular adhesive additivesOther chemical processesWeather resistanceMiniaturization

The invention relates to a preparation method for epoxide resin pouring sealant with low density and high impact resistance. The epoxide resin pouring sealant in the invention comprises epoxide resin, curing agent and promoter thereof, reactive diluent, polyurethane prepolymer coating hollow glass microballoon, foam killer and the like. The encapsulating material has low toxicity, fine wetting quality, and condensate thereof has low density, high impact resistance, low linear expansibility and good weather resistance. The pouring sealant is applicable to encapsulation of electrical apparatus elements under the condition of miniaturization, light weight and impact resistance.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

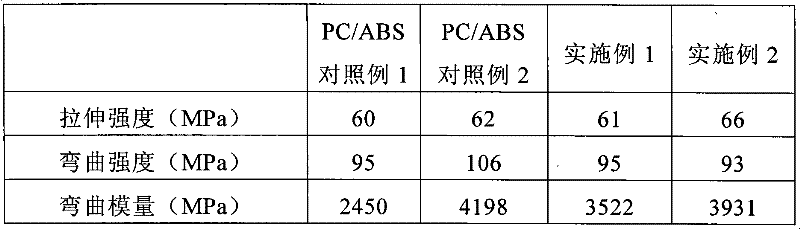

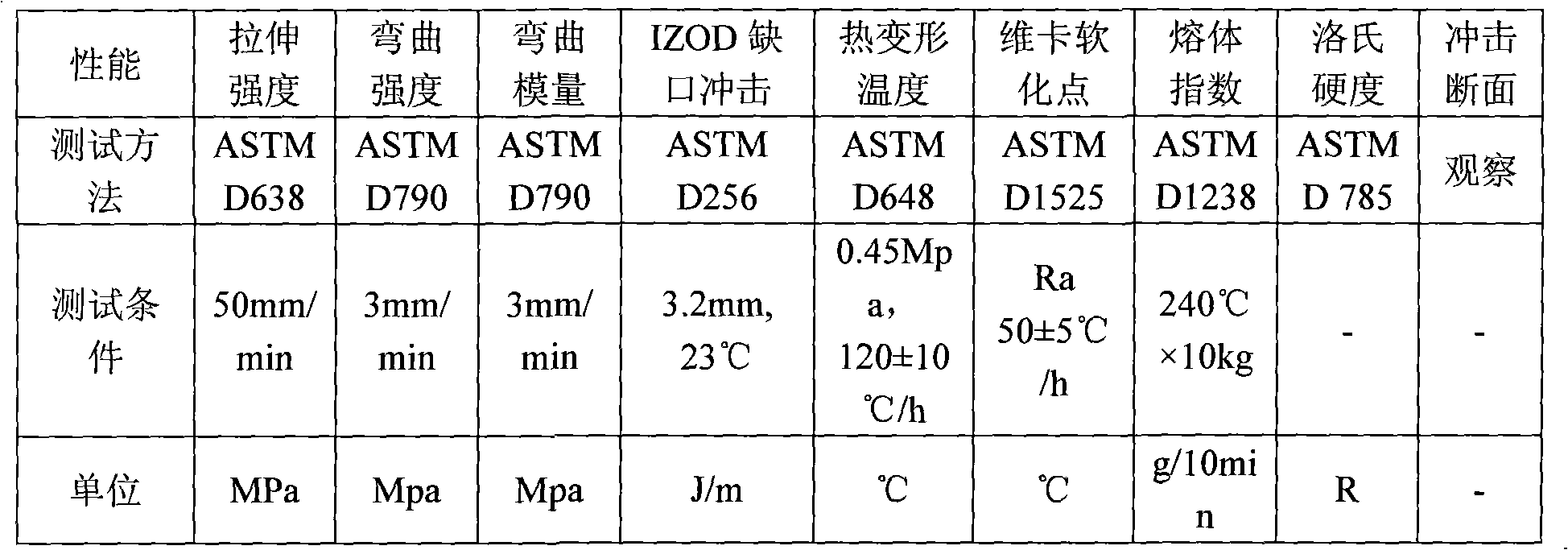

Thermoplastic resin composite material for laptop shells and manufacturing method thereof

The invention relates to a thermoplastic resin composite material for laptop shells and a manufacturing method thereof. The composite material comprises the following components in percentage by weight: 40 to 60 parts of thermoplastic resin, 10 to 20 parts of organic fibers, 0 to 20 parts of inorganic fibers, 0 to 10 parts of other aids, and 20 to 40 parts of halogen-free flame-retarding master batch. The manufacturing method comprises: melting thermoplastic resin to obtain melt, immersing fibers into the melt of the thermoplastic resin, adding other aids into the melt, cooling the melt, and making fiber reinforced thermoplastic resin granules; and mixing the granules and the halogen-free flame-retarding master batch in batch to obtain the composite material. Compared with the prior art, the composite material manufactured by the method has high toughness, high strength and high rigidity, and has the characteristics of environment-friendliness, flame retardance, high thermostability, and low-temperature toughness. The thermoplastic resin composite material is an ideal novel laptop shell material.

Owner:HEFEI GENIUS NEW MATERIALS

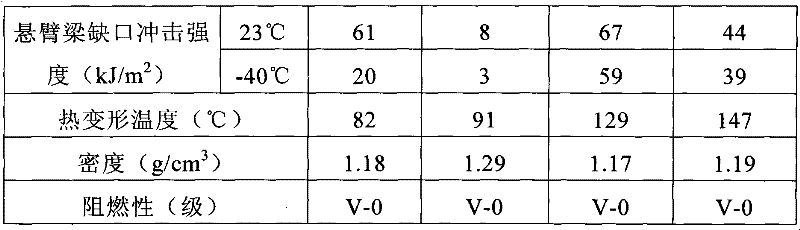

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

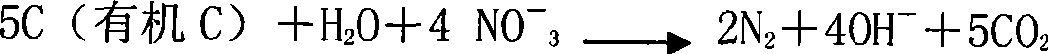

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

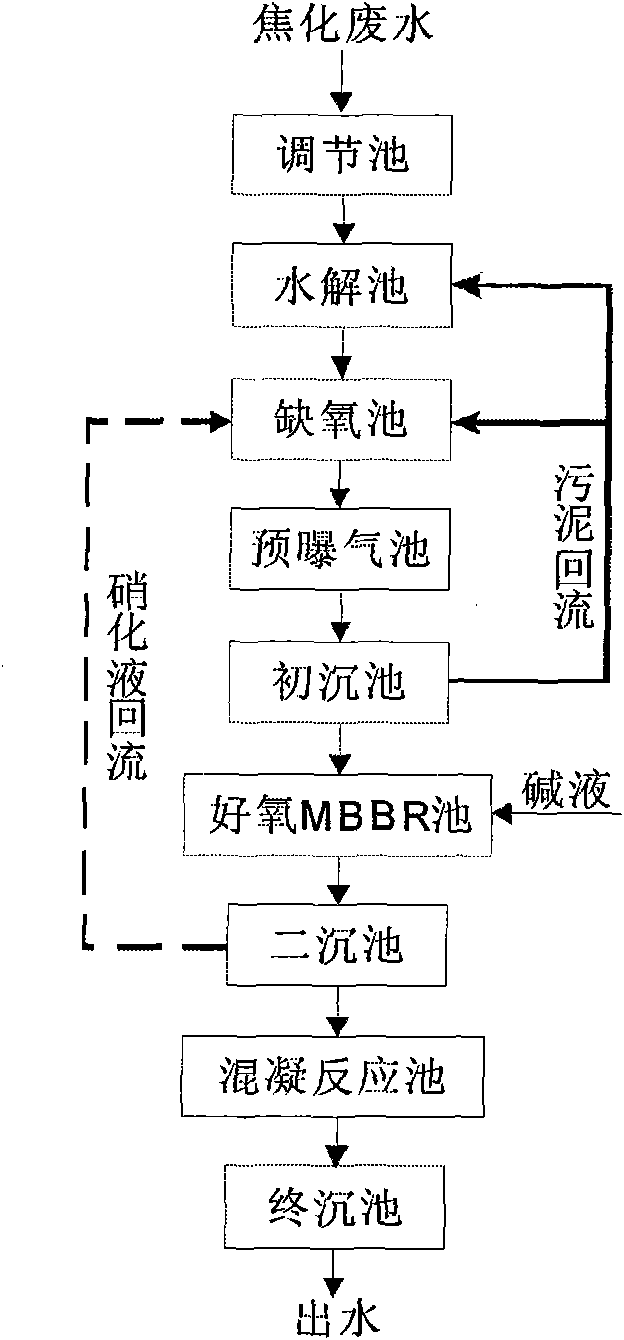

Polycarbonate/polyamide alloy and preparation method thereof

The invention relates to a polycarbonate / polyamide alloy and a preparation method thereof. The alloy contains the following components by weight percentage: 30-80 of polycarbonate, 20-70 of polyamide, 5-30 of toughening agent, 1.5-15 of compatibilizer and 0.2-3 of assistant; wherein the contents of the toughening agent, the compatibilizer and the assistant are based on the total weight of the polycarbonate and the polyamide. Compared with the prior art, due to the blending of the polycarbonate and the polyamide with the excellent compatibilizer in the preparation method, the preparation process is reasonable, the prepared polymer has good paint adhesion, solvent resistance and impact resistance and simultaneously combines the low moisture absorption, heat resistance, wear resistance and self-lubricity of the polycarbonate, and the polycarbonate / polyamide alloy can be widely applied in automobiles (front and rear baffles, column covers, wheel covers and instrument covers), electronic appliances (electric tool housings, wiring devices and relays) and other fields.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

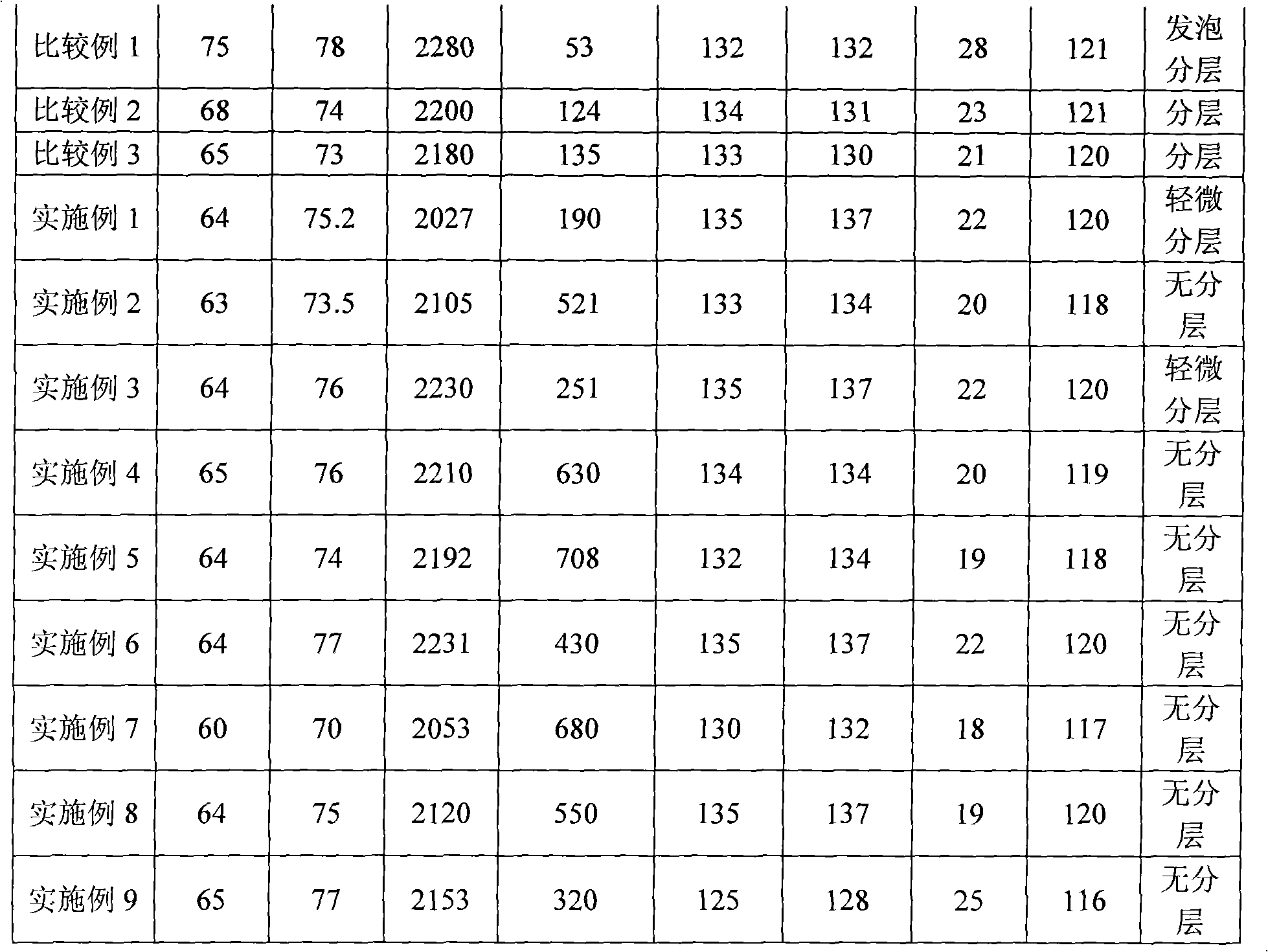

Recessed led airport boundary light

ActiveCN103712135BLower the altitudeDirect impactLighting applicationsPlanar light sourcesFree formTransmittance

The invention provides an embedded LED airport boundary lamp which comprises a lamp, an outer cover, an LED lamp panel, a lens module and a radiating plate. The lamp comprises a cylindrical body and an annular wing; the outer cover comprises a waterproof mounting portion and a light transmittance portion; the LED lamp panel comprises a base panel and a plurality of LED lamp beads fixed onto the base panel; the lens module is positioned above the LED lamp panel and comprises a lens fixing plate and a plurality of lenses, the lenses correspond to the LED lamp beads on the LED lamp panel, the LED lamp beads are embedded into the corresponding lenses, and the outer surface of each lens in the design is provided with double free-form surfaces; the lens module and the LED lamp panel are sequentially fixed to the radiating plate from top to bottom, the radiating plate is upwardly fixed to the bottom of the outer cover, the lens module and the LED lamp panel are positioned in an inner space of the hollow boss-shaped light transmittance portion of the outer cover, and the outer cover is downwardly fixed to the lamp. The embedded LED airport boundary lamp has the advantage that the height of a ground protruded part of the LED airport boundary lamp can be greatly reduced.

Owner:HAIFENG NAVIGATION TECH

Acrylic resin with high toughness

The invention discloses acrylic resin with high toughness, which comprises the following components according to the weight portion: 50-75 of acrylic resin, 5-35 of polyethylene resin, 5-35 of compatilizer, 0.2-1 of processing materials, 4-15 of filling agent and 0.3-1 of dispersing agent, wherein the acrylic resin is one or the composition of more than two of isotactic PP, syndiotactic PP, block co-polymerized polypropylene or random co-polymerized polypropylene, and melting flow index of the acrylic resin is (0.4-30)g / 10min. The invention aims at overcoming the defects of the prior art, and providing the acrylic resin with rich source, low price, high elongation at break, strong temperature toleration, high softening point, excellent impact property, fatigue and bending resisting properties and wide application.

Owner:广东智汇赛特新材料有限公司

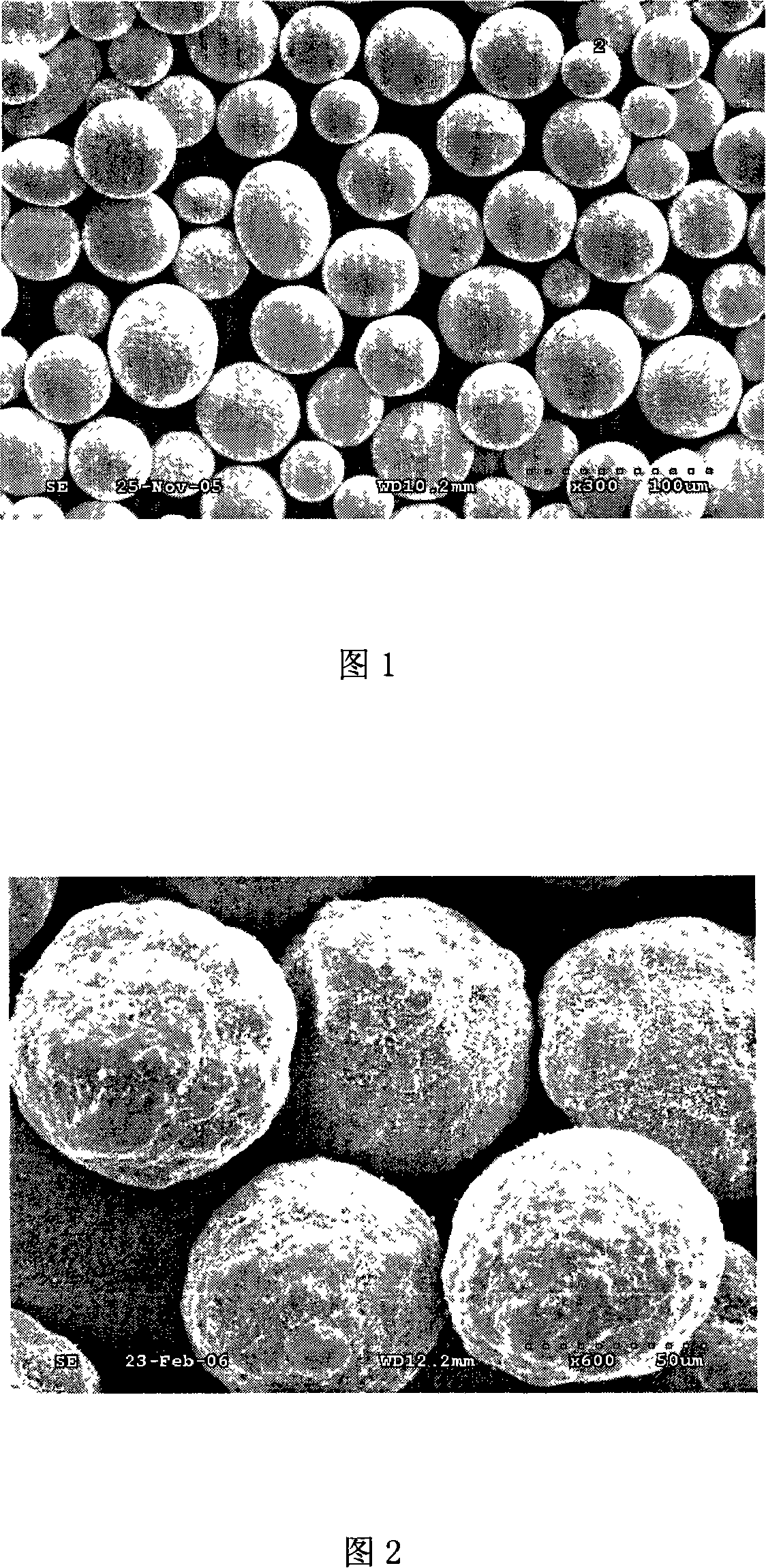

Wear-resistant carbon fiber modified polyether-ether-ketone composite material and preparation method thereof

The invention discloses a wear-resistant carbon fiber modified polyether-ether-ketone composite material, which is prepared from the following ingredients in parts by weight: 40 to 60 parts of polyether-ether-ketone resin, 10 to 30 parts of polyfluortetraethylene resin, 8 to 20 parts of polyimide resin, 2 to 5 parts of carbon fiber, 5 to 10 parts of vermiculite, 5 to 15 parts of parithenolide, 4 to 8 parts of orthoclase powder and 1 to 2 parts of compatilizers. The invention also discloses a preparation method of the composite material. The composite material has the advantages that the wear-resistant performance is good; the high-temperature-resistant performance is excellent; the processing is easy; the anti-impact performance is good; the intensity is high; the composite material can be widely applied to the field of mechanical part preparation; in addition, the preparation method is simple; the cost is low.

Owner:SUZHOU ZHENZHAN TECHCAL MATERIAL CO LTD

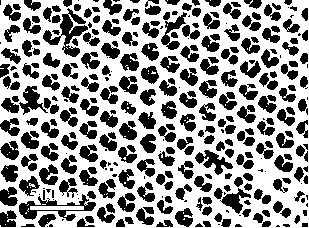

Hot spraying WC/Co powder and coat preparation

The present invention discloses one kind of hot sprayed WC / Co powder and its coating and their preparation. The hot sprayed WC / Co powder consists of Co 5-25 wt%, C 5-6 wt%, and W for the rest, and is in spherical granular structure of size below 150 micron. The powder is prepared through the following steps: 1. sieving, washing and stoving W powder; 2. spheroidizing W powder; 3. carbonizing spheroidized W powder; and 4. coating with Co to form the WC / Co powder. The hot sprayed WC / Co coating is prepared through spraying the WC / Co powder with ultrasonic flame. The WC / Co powder is compact, high in flowability and homogeneous in components; and the hot sprayed WC / Co coating is compact and homogeneous, and has close combination with the base, micro hardness up to 894HV0.2 and wide application.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com