Thermoplastic resin composite material for laptop shells and manufacturing method thereof

A notebook computer and thermoplastic resin technology, which is applied in the field of thermoplastic resin composite materials and its manufacturing, can solve the problems of unsatisfactory thickness and weight of the whole machine, unsatisfactory comprehensive mechanical properties, and difficulty in realizing ultra-thin design, etc. Impact performance, high specific strength and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Plasticize and melt 60kg of ABS resin at a temperature of 190-210°C to obtain an ABS resin melt; 10kg of continuous PA66 fibers are impregnated with the melt of ABS resin to completely infiltrate the PA66 fibers. Among them, the continuous PA66 fiber is drawn out from the creel, the tension is adjusted by the tension roller, and then enters the melt impregnation die, where the dispersion and infiltration of the fibers are realized in the die, the fiber content is controlled through the fiber outlet of the die, cooled and solidified, and passed through the die. The pelletizer cuts to a fixed length (eg 8mm, 12mm, etc.). The obtained pellets are batch-mixed with the halogen-free flame-retardant masterbatch at a ratio of 2:1 to obtain the product.

Embodiment 2

[0035] Plasticize and melt 40kg of PP resin at a temperature of 170-190°C to obtain a PP resin melt; 20kg of continuous PET fibers and 20kg of continuous glass fibers are simultaneously impregnated by the melt of PP resin, so that the PET fibers and glass fibers are completely infiltrated . Among them, the continuous PET fiber and glass fiber are drawn out from the creel, the tension is adjusted by the tension roller, and then enter the melt impregnation die, and the dispersion and infiltration of the fibers are realized in the die, and the fiber content is controlled through the fiber outlet of the die, and the cooling Solidified, cut into fixed length (such as 8mm, 12mm, etc.) by pelletizer. The obtained pellets are batch-mixed with the halogen-free flame-retardant masterbatch at a ratio of 5:2 to obtain the product.

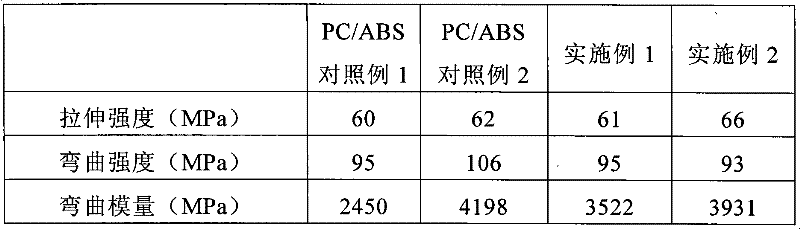

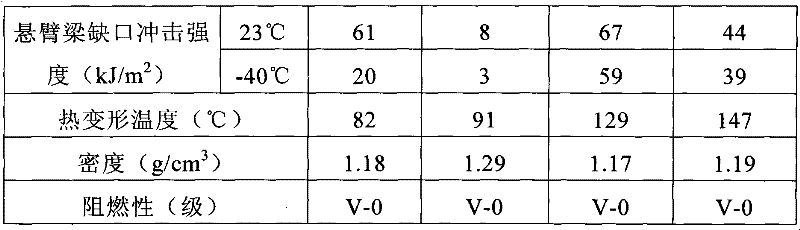

[0036] Table 1 shows the performance test results of the PC / ABS composite material and the examples.

[0037] Table 1 Injection molding process embodiment p...

Embodiment 3

[0041] A method for manufacturing a thermoplastic resin composite material for a notebook computer casing, comprising the following steps:

[0042] (1) Prepare materials according to the following components and contents: 50kg of thermoplastic resin, 10kg of organic fiber, 10kg of inorganic fiber, 5kg of other additives, 25kg of halogen-free flame retardant masterbatch, among which, the thermoplastic resin is ABS resin, and the organic fiber is nylon 9T fiber , its melting point is higher than that of ABS resin, the inorganic fiber is carbon fiber, and other additives are color masterbatch;

[0043] (2) Control the temperature to 210°C, melt the ABS resin to obtain a melt, and then lead out the nylon 9T fiber and carbon fiber from the creel, adjust the tension through the tension roller, enter the melt impregnation die, fully impregnate the ABS resin melt, and Add the color masterbatch to it, then cool and cut into pellets of fiber-reinforced thermoplastic resin, and finally m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com