Patents

Literature

7463 results about "Halogen free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

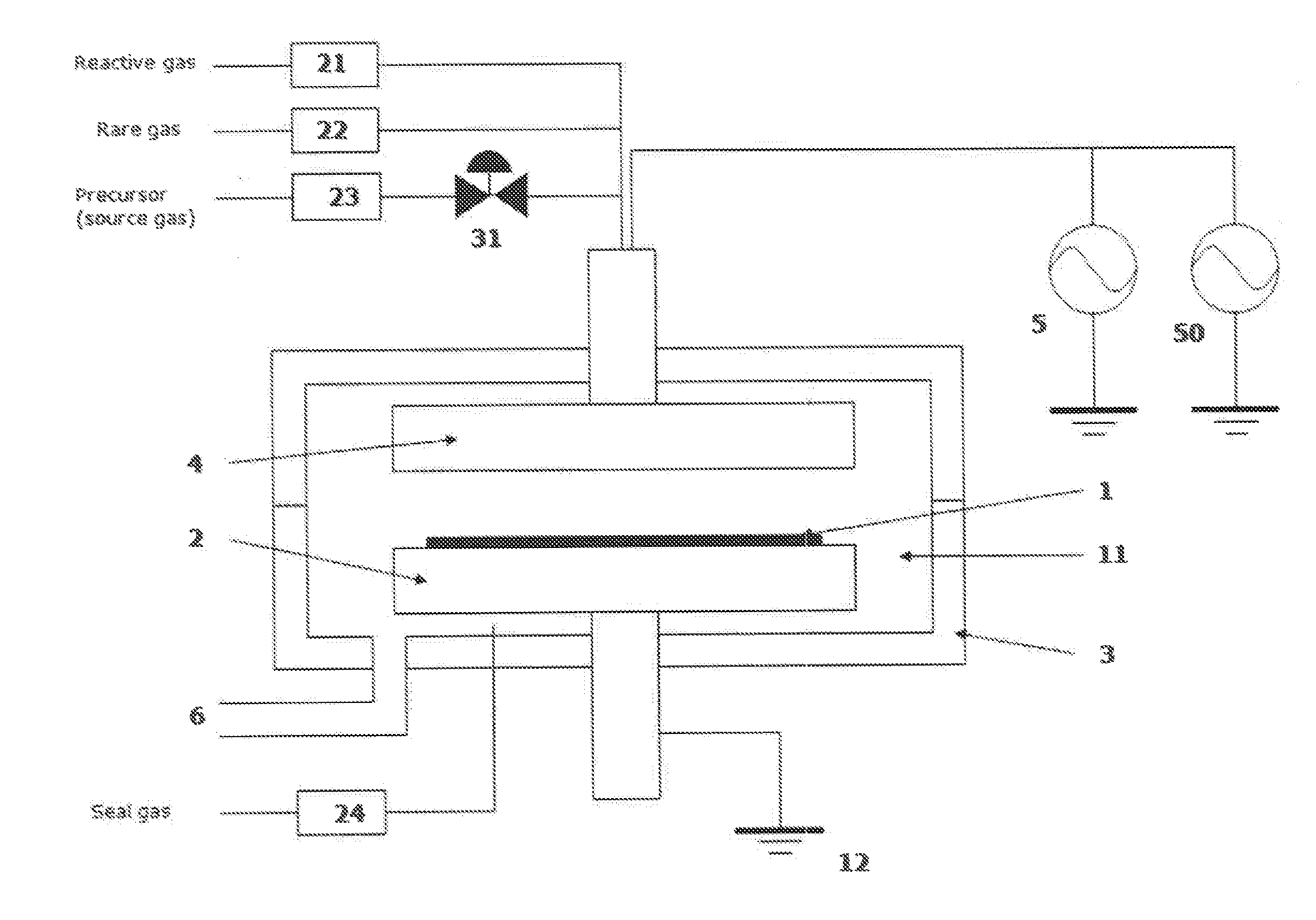

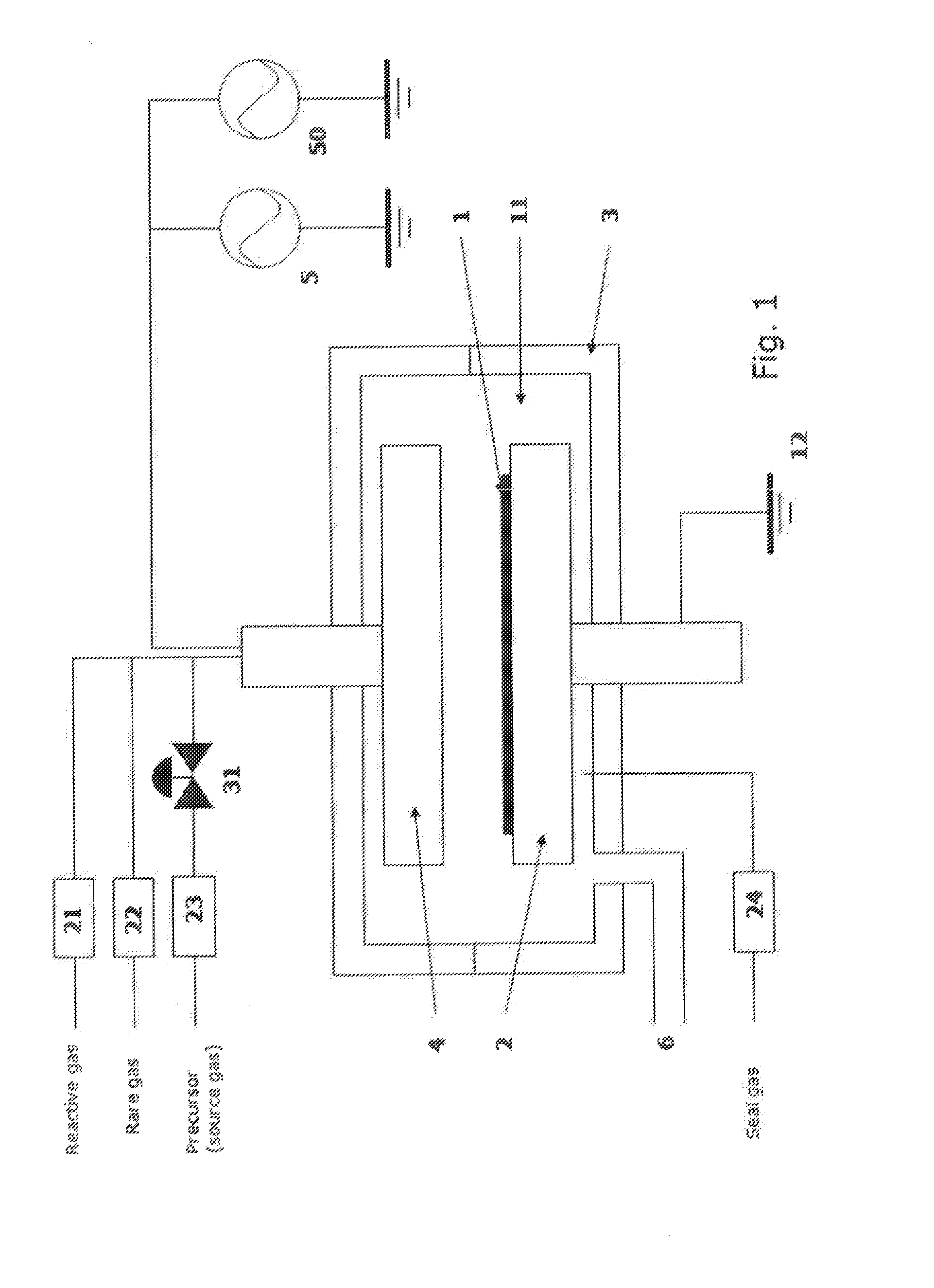

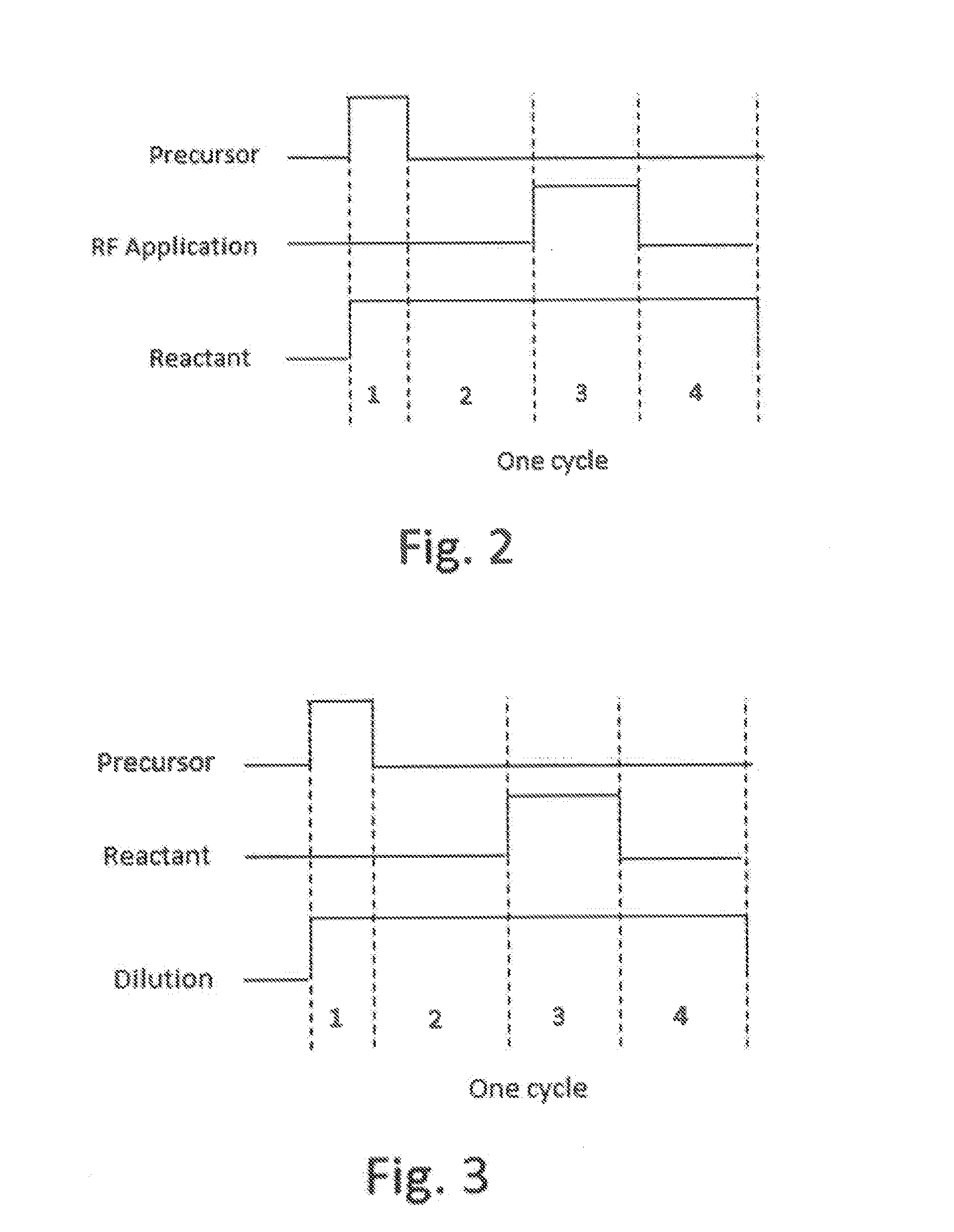

Method for Forming Dielectric Film Containing Si-C bonds by Atomic Layer Deposition Using Precursor Containing Si-C-Si bond

InactiveUS20130224964A1Good step coverageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNoble gasOxygen

A method of forming a dielectric film having Si—C bonds on a semiconductor substrate by atomic layer deposition (ALD), includes: (i) adsorbing a precursor on a surface of a substrate; (ii) reacting the adsorbed precursor and a reactant gas on the surface; and (iii) repeating steps (i) and (ii) to form a dielectric film having at least Si—C bonds on the substrate. The precursor has a Si—C—Si bond in its molecule, and the reactant gas is oxygen-free and halogen-free and is constituted by at least a rare gas.

Owner:ASM IP HLDG BV

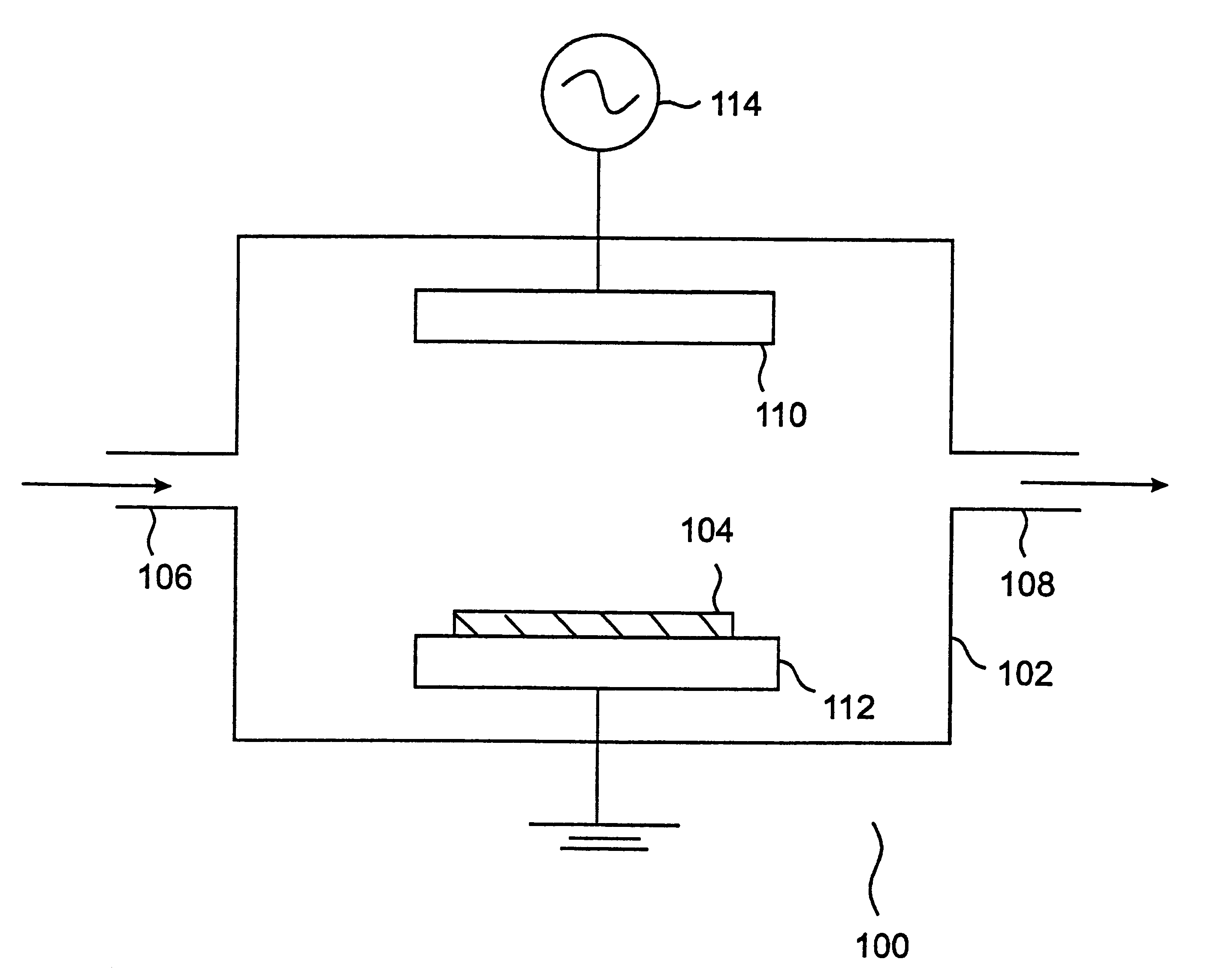

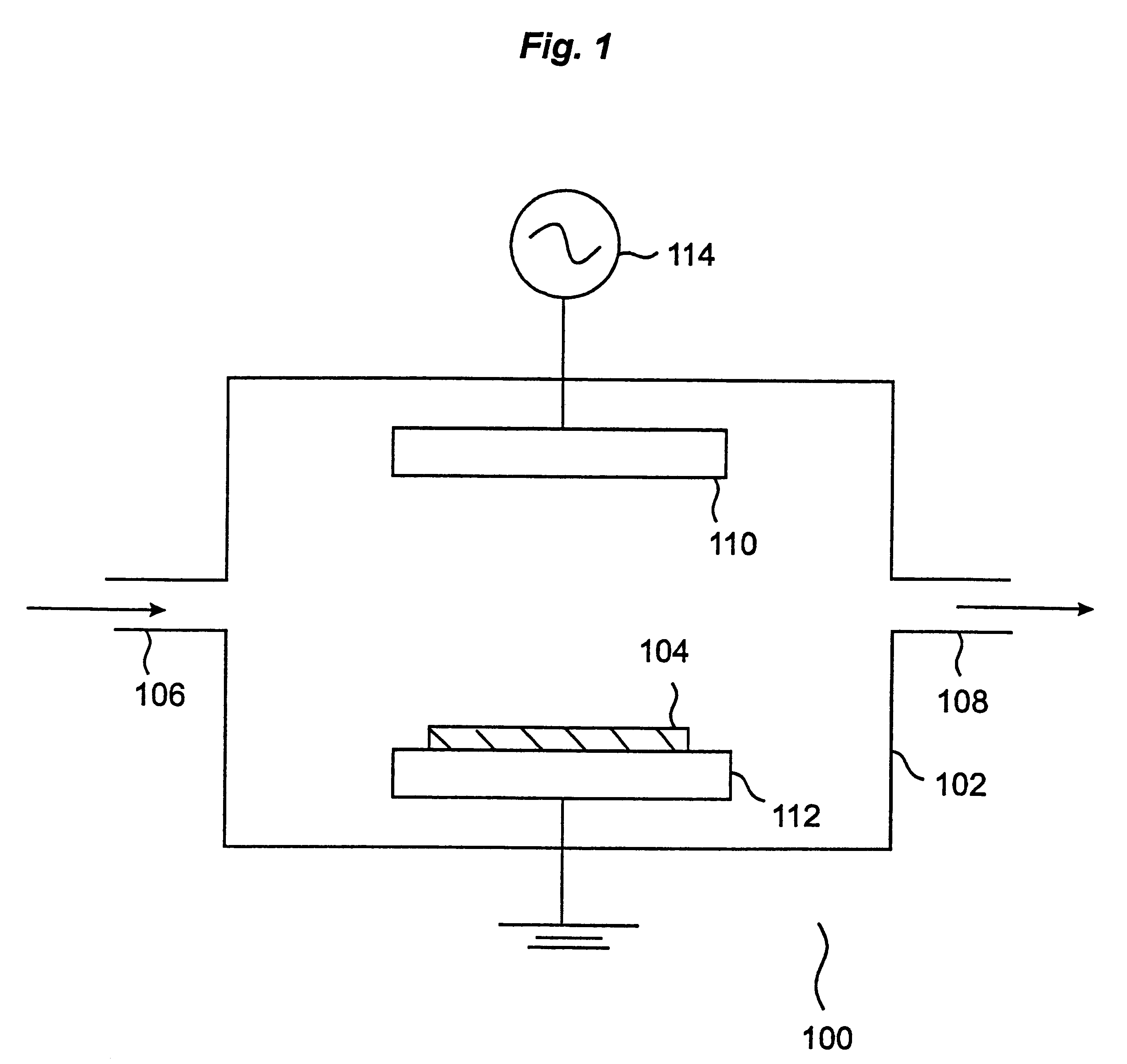

Plasma cleaning and etching methods using non-global-warming compounds

InactiveUS6242359B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrifluoroacetic anhydrideChemical vapor deposition

Provided is a novel method of cleaning a chemical vapor deposition processing chamber having deposits on an inner surface thereof is provided. The process involves forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound, and contacting active species generated in the plasma with the inner surface of the chamber, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. Also provided is a method of etching a layer on a silicon wafer. The method involves the steps of: (a) introducing a silicon wafer into a processing chamber, the silicon wafer comprising a layer to be etched; and (b) forming a plasma from one or more gases comprising a fluorine-containing but otherwise halogen-free non-global-warming compound. Active species generated in the plasma are contacted with the silicon wafer, thereby etching the layer, with the proviso that the non-global-warming compound is not trifluoroacetic anhydride. The chemistries in accordance with the invention provide environmentally benign alternatives to the conventionally used global-warming chemistries for chamber cleaning and semiconductor etching processes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

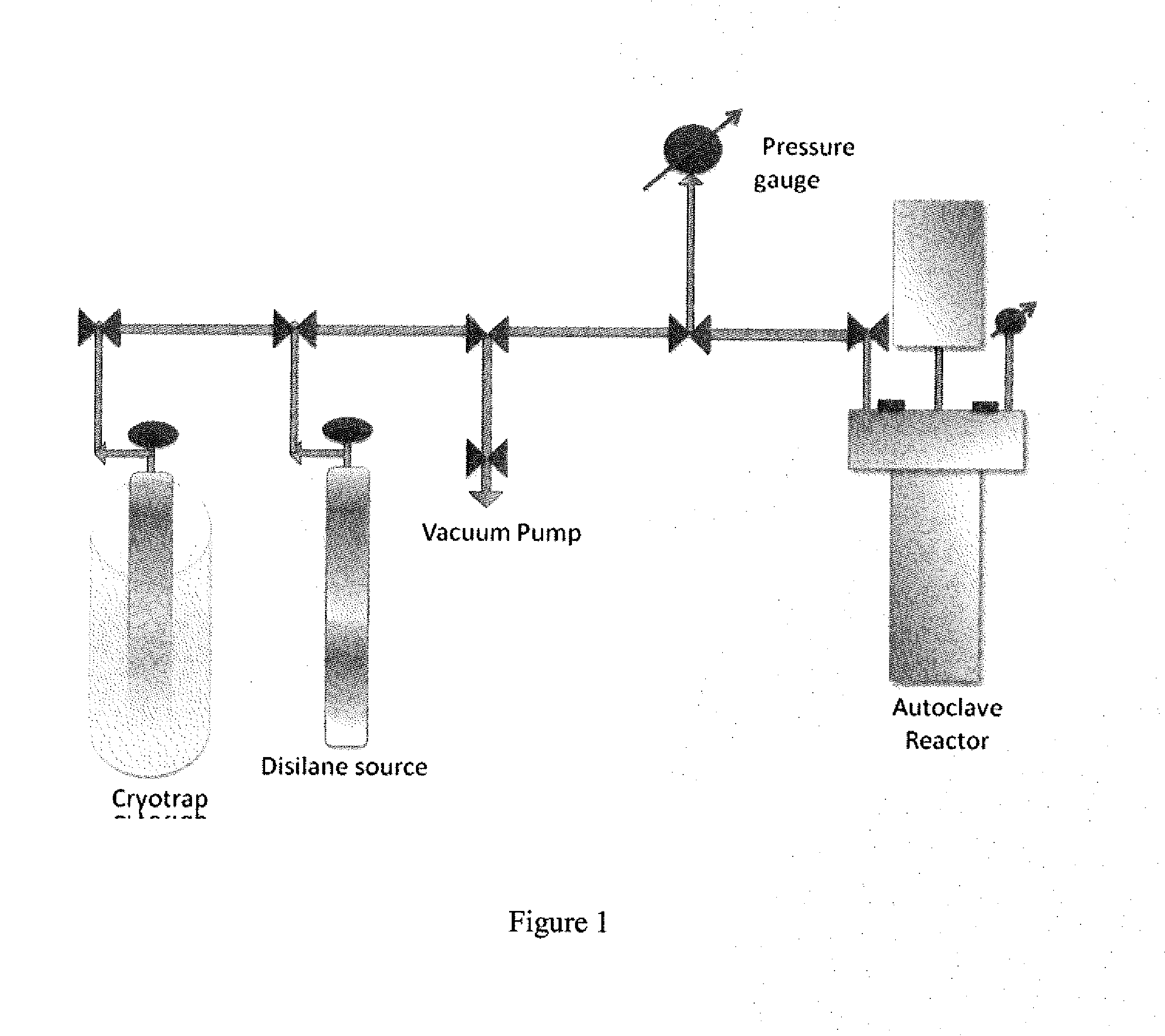

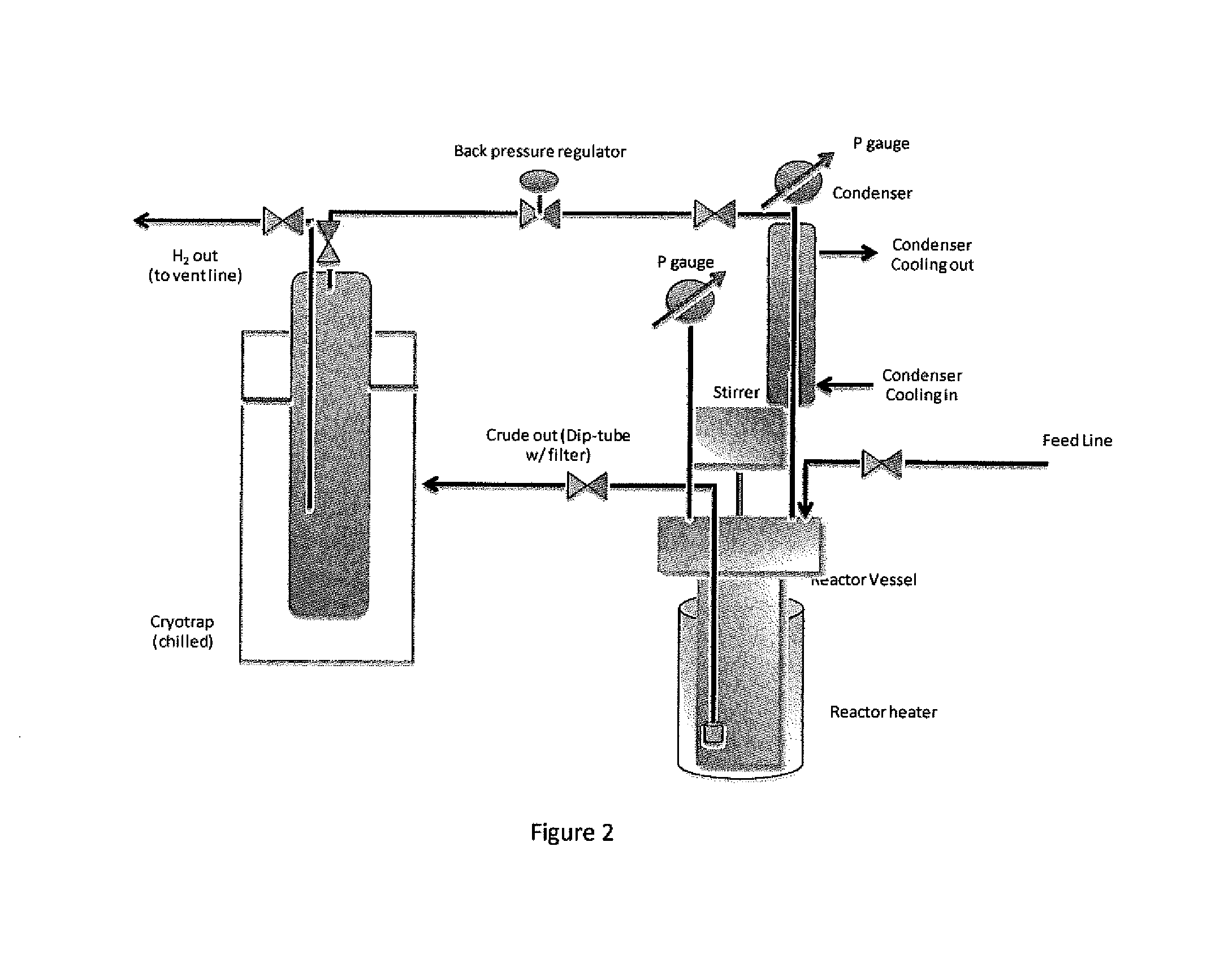

Halogen free syntheses of aminosilanes by catalytic dehydrogenative coupling

ActiveUS20150094470A1Silicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenGas phase

Compounds and method of preparation of Si—X and Ge—X compounds (X═N, P, As and Sb) via dehydrogenative coupling between the corresponding unsubstituted silanes and amines (including ammonia) or phosphines catalyzed by metallic catalysts is described. This new approach is based on the catalytic dehydrogenative coupling of a Si—H and a X—H moiety to form a Si—X containing compound and hydrogen gas (X═N, P, As and Sb). The process can be catalyzed by transition metal heterogenous catalysts such as Ru(0) on carbon, Pd(0) on MgO) as well as transition metal organometallic complexes that act as homogeneous catalysts. The —Si—X products produced by dehydrogenative coupling are inherently halogen free. Said compounds can be useful for the deposition of thin films by chemical vapor deposition or atomic layer deposition of Si-containing films.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method of producing morphologically uniform microcapsules and microcapsules produced by this method

InactiveUS6294204B1Readily water-miscibleSpeed up concentrationPowder deliveryBiocidePolymer dissolutionEmulsion

The invention relates to a process for the production of morphologically uniform microcapsules that contain peptides, proteins or other water-soluble biologically active substances as active ingredients as well as microcapsules that are produced according to this process with a degree of concentration of between 3 to 30% by weight and a diameter<=8 mum.According to the invention, biodegradable polymers are dissolved in a halogen-free solvent or solvent mixture, and the buffered active ingredient solution, which has a pH of between 6.0 to 8.0, is dispersed into this solution. Then, an aqueous solution that contains a surface-active substance (W / O / W-emulsion) is added to this W / O-emulsion, and the solvent is removed.The microcapsules that are produced with this process do not show any tendency toward agglomeration. The encapsulation efficiency of the process is approximately 90 to 95%.

Owner:ALRISE BIOSYST

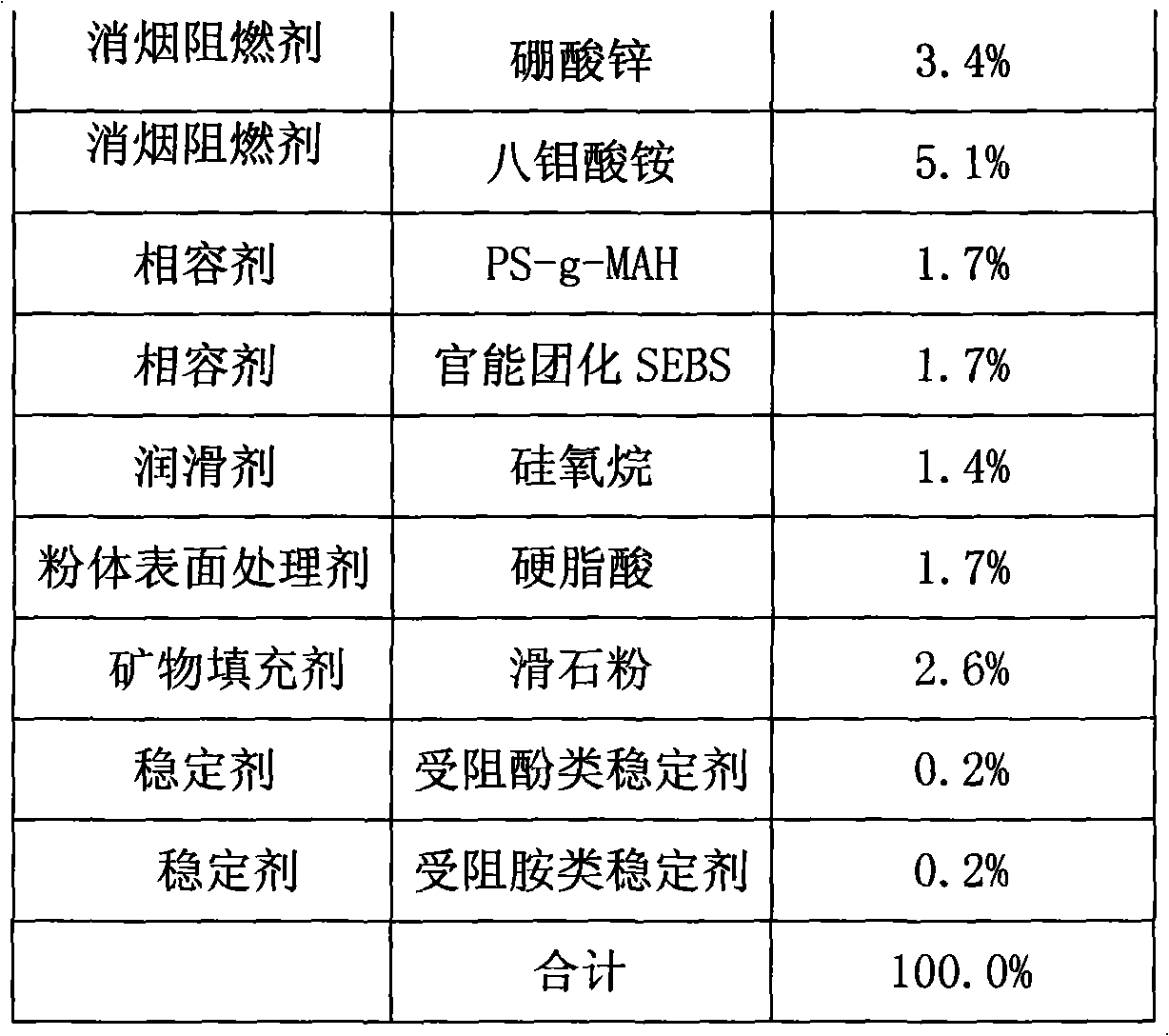

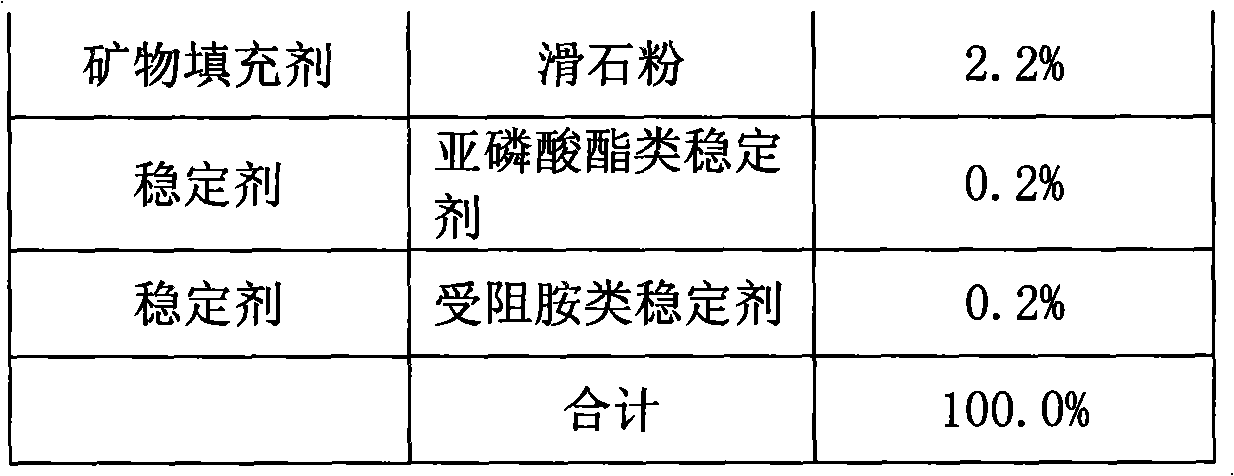

Halogen-free flame-retardant thermoplastic elastomer electrical cable material using polyphenylene ether as base material and preparation method thereof

InactiveCN101358028AGood compatibilityReduce stratificationInsulated cablesInsulated conductorsElastomerPolyphenylene oxide

The invention discloses a halogen-free flame-retardant thermoplastic elastomer cable material with polyphenylether as the base materials and a preparation method thereof. The raw material of the cable material contains the components with the following weight percentage: 10 to 35 percent of matrix resin A; 5 to 15 percent of matrix resin B; 10 to 25 percent of elastomer; 5 to 25 percent of softening plasticizer; 8 to 15 percent of flame-retardant plasticizer; 20 to 40 percent of smoke-suppression flame retardant; 3 to 10 percent of compatilizer; 1 to 5 percent of lubricant; 1 to 5 percent of powder surface conditioner; 0 to 10 percent of mineral filler; 0.1 to 1 percent of stabilizing agent. The invention adds matrix resin, polyphenylether of strong polarity and functional group of styrene-ethylene / butylene-styrene segmented copolymer, which effectively improves the compatibility of non-polar elastomer with polyphenylether; the invention also adds plasticizer, which reduces the hardness of the material and increases the flexibility; and through the optimization and interaction of the softening plasticizer and the flame-retardant plasticizer, the invention reduces the hardness and improves the tactility of the material, and the flame retardant performance is excellent.

Owner:NINGBO SHIP PLASTIC CO LTD

Halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and a preparation method thereof. The composite material consists of the following components in percentage by mass: 25 to 80 percent of polyolefin resin, 5 to 60 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of flame retardant and flame retardance synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood plastic composite material, the halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material has the characteristics of simple production flow, little using amount of the flame retardant, good halogen-free flame retardant effect, wide range of molding modes and the like and is applicable to various injection molding products, such as electric appliance shells, automobile parts, furniture, buildings and other parts.

Owner:GUANGDONG KINGFA TECH CO LTD

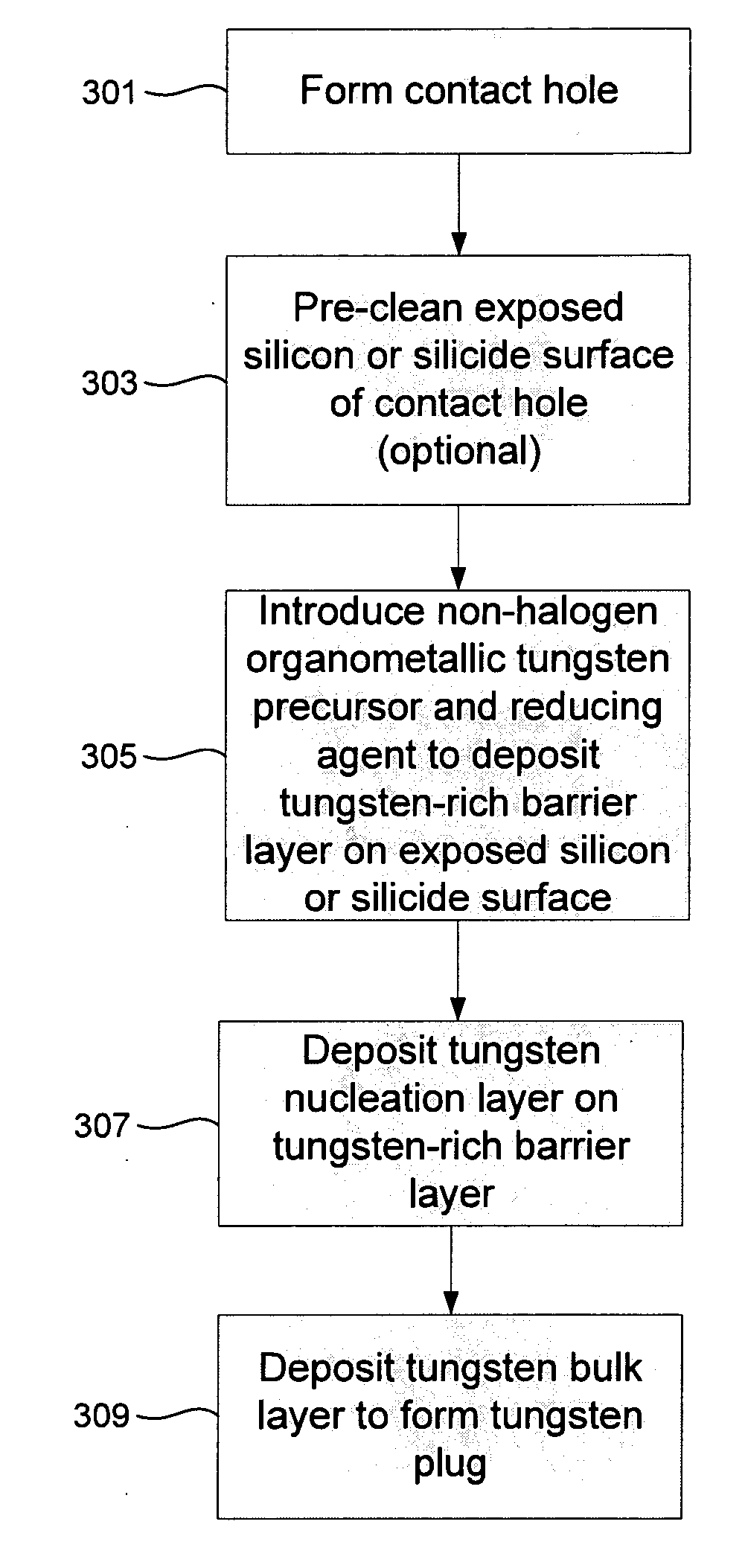

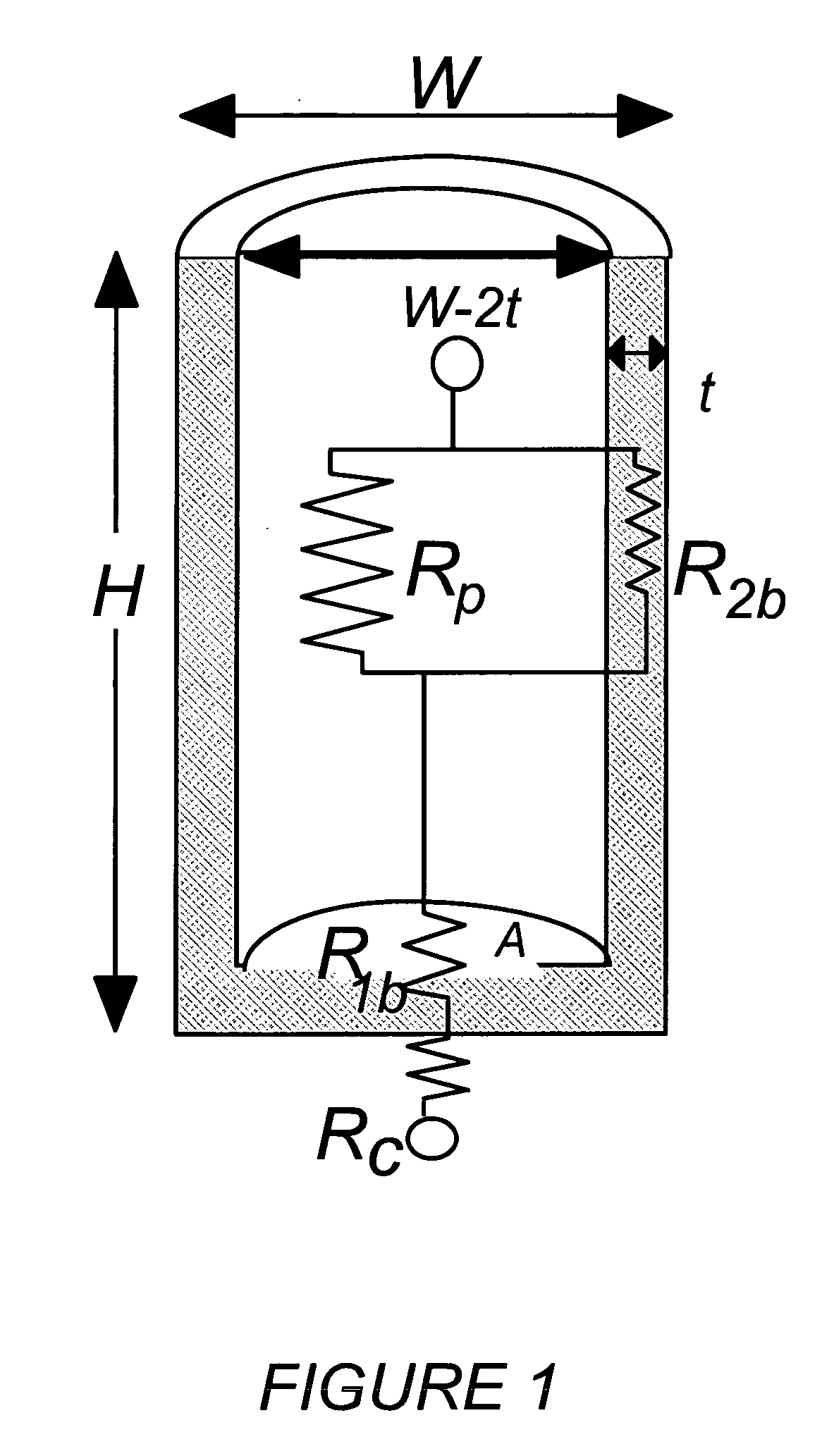

Methods for forming all tungsten contacts and lines

InactiveUS20090163025A1Improve adhesionGood baseSemiconductor/solid-state device detailsSolid-state devicesBit lineNucleation

Novel low-resistivity tungsten film stack schemes and methods for depositing them are provided. The film stacks include a mixed tungsten / tungsten-containing compound (e.g., WC) layer as a base for deposition of tungsten nucleation and / or bulk layers. According to various embodiments, these tungsten rich layers may be used as barrier and / or adhesion layers in tungsten contact metallization and bitlines. Deposition of the tungsten-rich layers involves exposing the substrate to a halogen-free organometallic tungsten precursor. The mixed tungsten / tungsten carbide layer is a thin, low resistivity film with excellent adhesion and a good base for subsequent tungsten plug or line formation.

Owner:NOVELLUS SYSTEMS

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

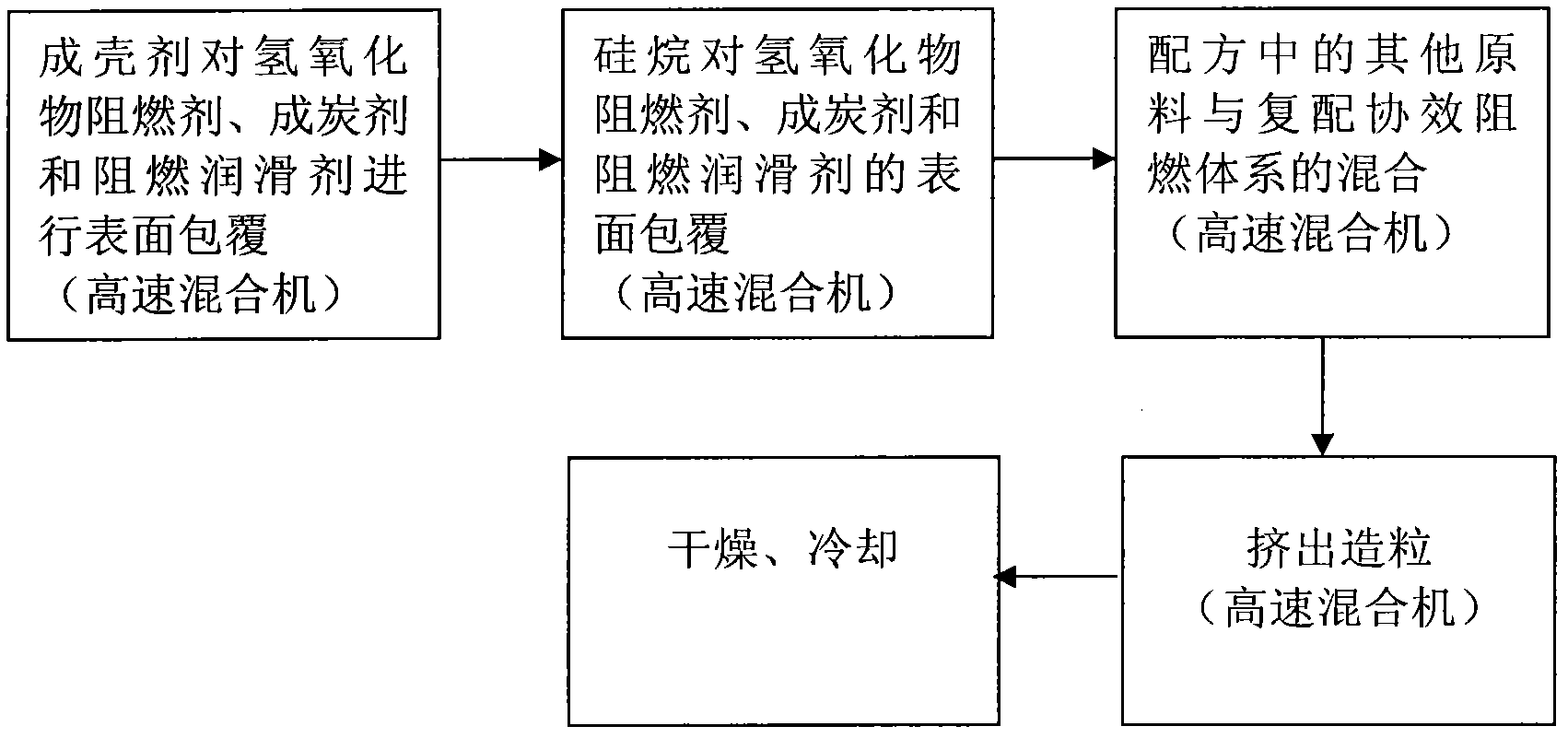

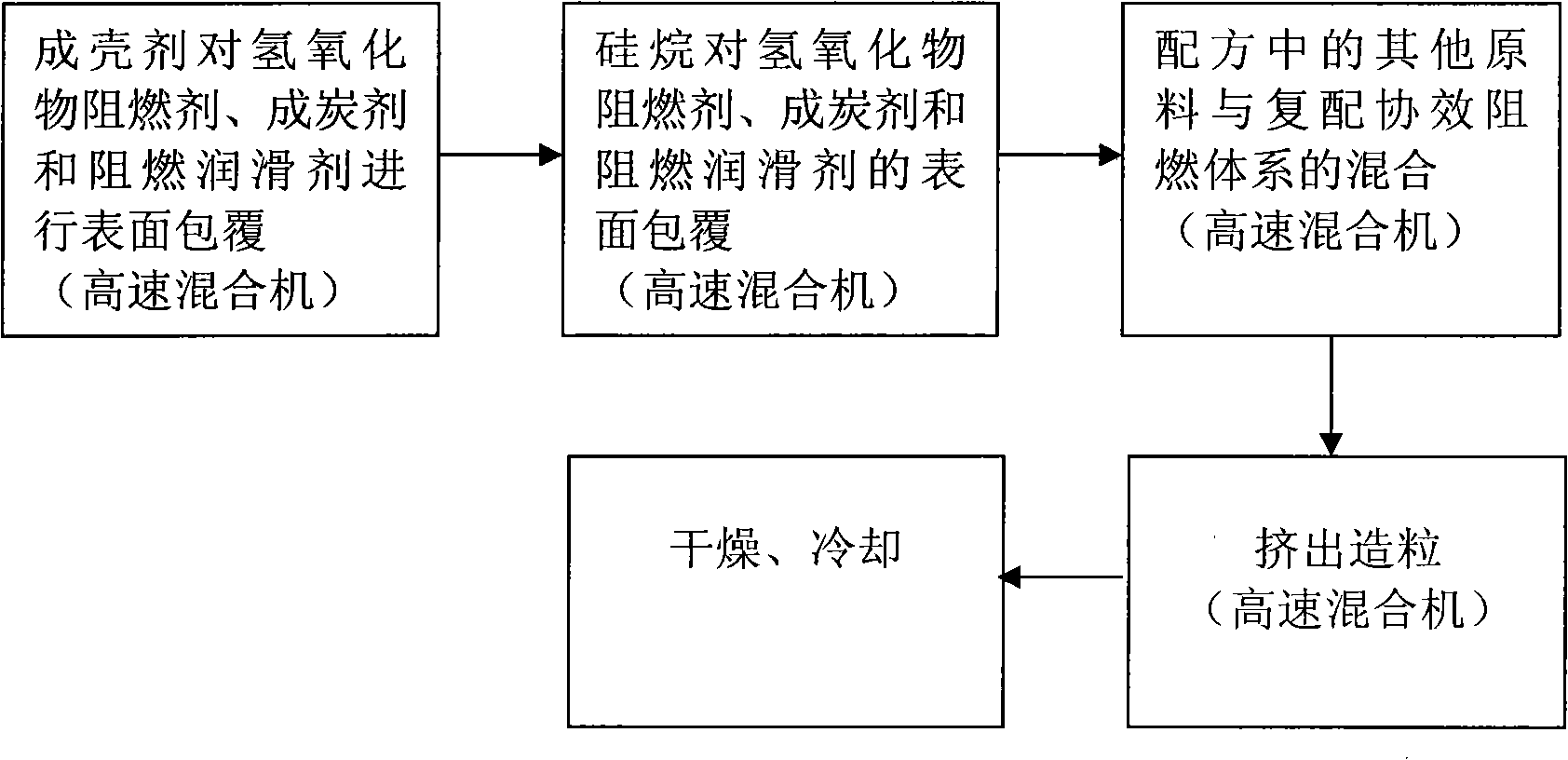

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

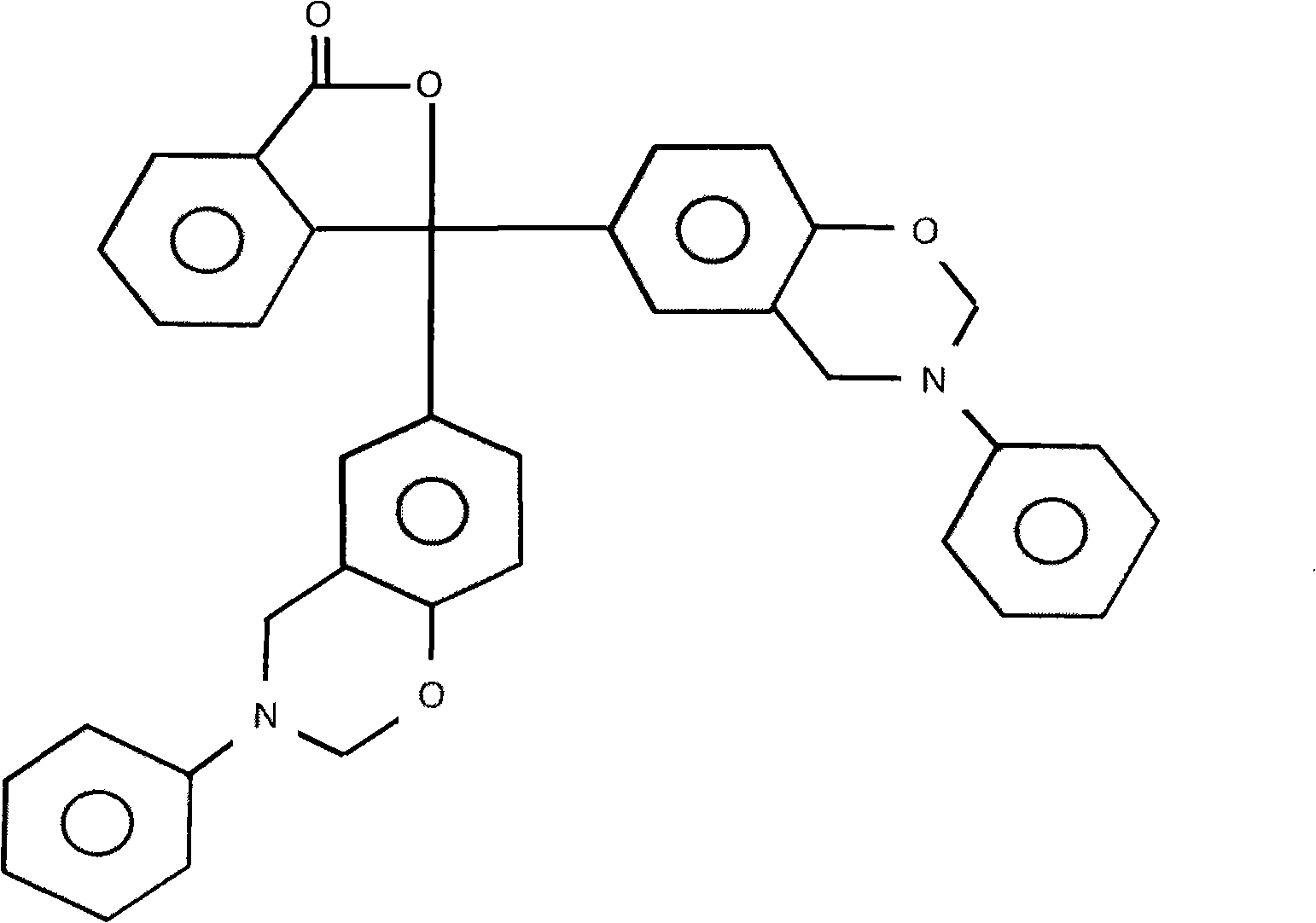

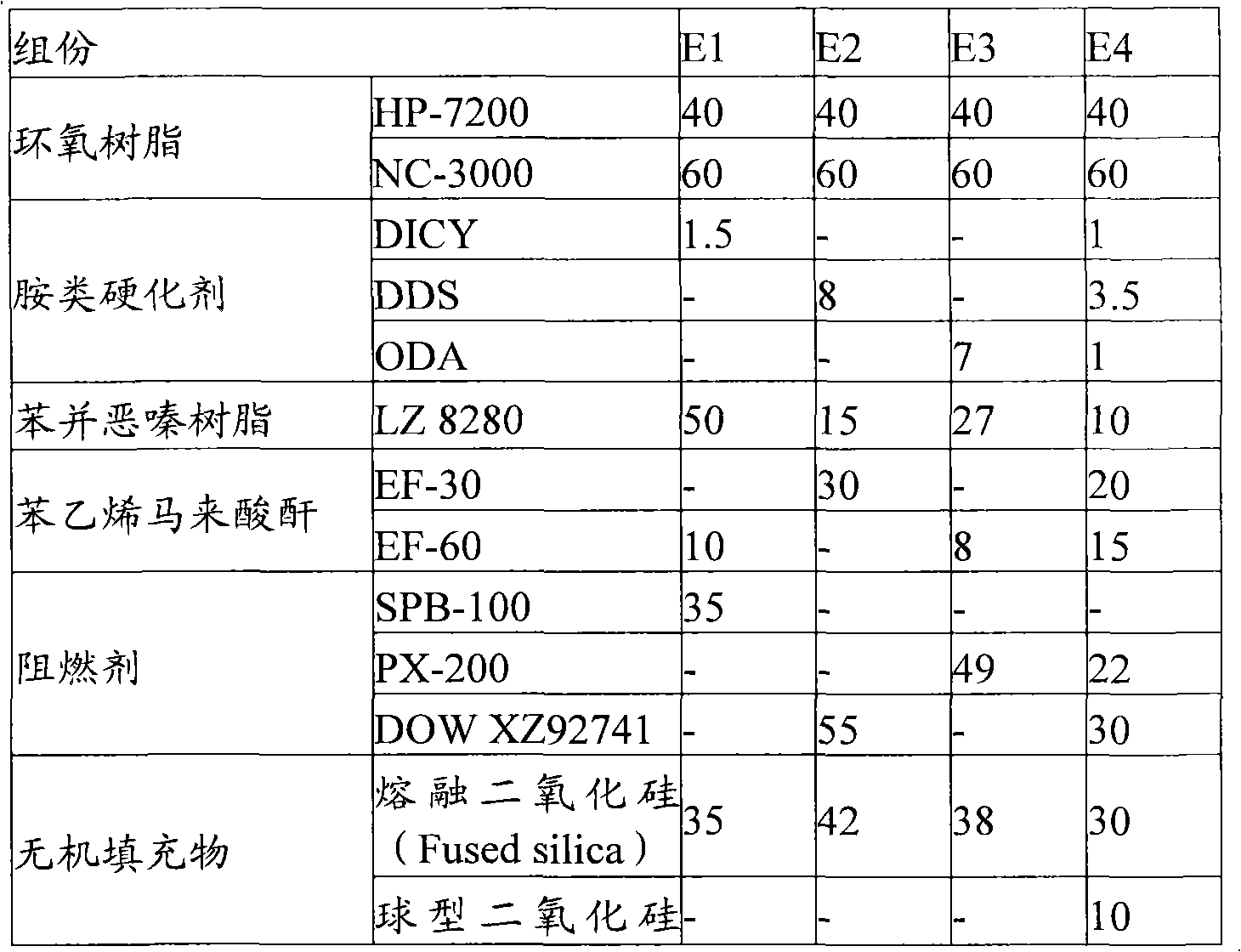

Halogen-free resin composition and its application for copper clad laminate and printed circuit board

ActiveUS20130161080A1Low dielectric constantImprove heat resistancePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsEpoxyLow dissipation

A halogen-free resin composition includes (A) 100 parts per hundred resin of epoxy resin; (B) 1 to 100 parts per hundred resin of benzoxazine resin; (C) 1 to 100 parts per hundred resin of styrene-maleic anhydride; (D) 0.5 to 30 parts per hundred resin of amine curing agent; and (E) 5 to 150 parts per hundred resin of halogen-free flame retardant. The composition obtains properties of low dielectric constant, low dissipation factor, high heat resistance and flame retardancy by specific composition and ratio. Thus, a prepreg or a resin film, which can be applied to a copper clad laminate and a printed circuit board, is formed.

Owner:ELITE MATERIAL

Halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive and preparation method thereof

ActiveCN101735619AExcellent electrical performanceImprove flame retardant performanceOther chemical processesCross-linkHydrogen

The invention discloses a halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive and a preparation method thereof. The preparation method comprises: adding vinyl dimethicone, a reinforcing material, a heat-conducting filling material and a halogen-free flame retardant in a vacuum kneader, dehydrating and blending for 30-120 minutes at 100-150 DEG C and vacuum degree of 0.06-0.1MPa to obtain a base material, adding a cross-linking agent containing hydrogen silicone oil and a cross-linking inhibitor to the base material at the normal temperature, adequately agitating for 10-30 minutes to prepare a component A; adding a platinum catalyst to the base material, adequately agitating for 10-30 minutes to prepare a component B; taking the component A and the component B of the same parts by weight, blending uniformly, and deaerating for 5-10 minutes at the vacuum degree of 0.06-0.1MPa to obtain the halogen-free flame-retarded heat-conducting organic silicon electronic potting adhesive. The potting adhesive has good flow properties and convenient use and can be cured at the normal temperature or a high temperature, condensate has excellent flame retardant property and heat-conducting property, and the potting adhesive can be widely applied to the fields of electronic electric appliance, chip encapsulation and LED encapsulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Low-smoke halogen-free flame retardant thermoplastic elastomer alloy for flexible wire rod and preparation method thereof

InactiveCN101225224AHigh tensile strengthHigh elongationInsulated cablesInsulated conductorsLow voltageAntioxidant

The invention discloses a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires and a preparation method of the alloy, which is characterized in that: the material comprises thermoplastic polyurethane elastomer, thermoplastic styrene elastomer, compatilizer, phosphorus-nitrogen compound flame retardant, flame-retarding potentiating agent, lubricant, antioxidant and colorant; the weight ratio of the thermoplastic polyurethane elastomer, the thermoplastic styrene elastomer, the compatilizer, the phosphor-nitrogen compound flame retardant, the flame-retarding potentiating agent, the lubricant, the antioxidant and the colorant is 40 to 55 : 5 to 25 : 5 to 10 : 20 to 25 : 3 to 10 : 1.5 : 0.25 : 0.25; the preparation method is that the all components are evenly mixed in a high-speed mixer, and then extruded, drew and granulated at 170 to 210 degree centigrade, and then a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires is obtained. The low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires has the advantages of achieving distinct flame-retarding effect at a small quantity of flame retardant dosage, satisfying the flame-retarding requirement of low-voltage wires, adjusting the Shore durometer number of the material between 80 to 95, good pliability, high physical mechanical property and according with the halogen-free and environment-friendly requirement.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

Halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and preparation method thereof

The invention discloses a halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and a preparation method thereof. The halogen-free flame-retardant polyolefin injection-grade wood-plastic composite comprises the following components in percentage by mass: 25 to 70 percent of polyolefin resin, 5 to 50 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of fire retardant and synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood-plastic composite, the halogen-free flame-retardant polyolefin injection-grade wood-plastic composite prepared by the invention has the characteristics of simple production flow, less fire retardant dosage, good halogen-free flame-retardant effect, wide molding mode range and the like, and is suitable for various injection-molded products such as shells of electrical appliance products, furniture, materials for automobiles, artworks, building products with complex construction and the like.

Owner:KINGFA SCI & TECH CO LTD +1

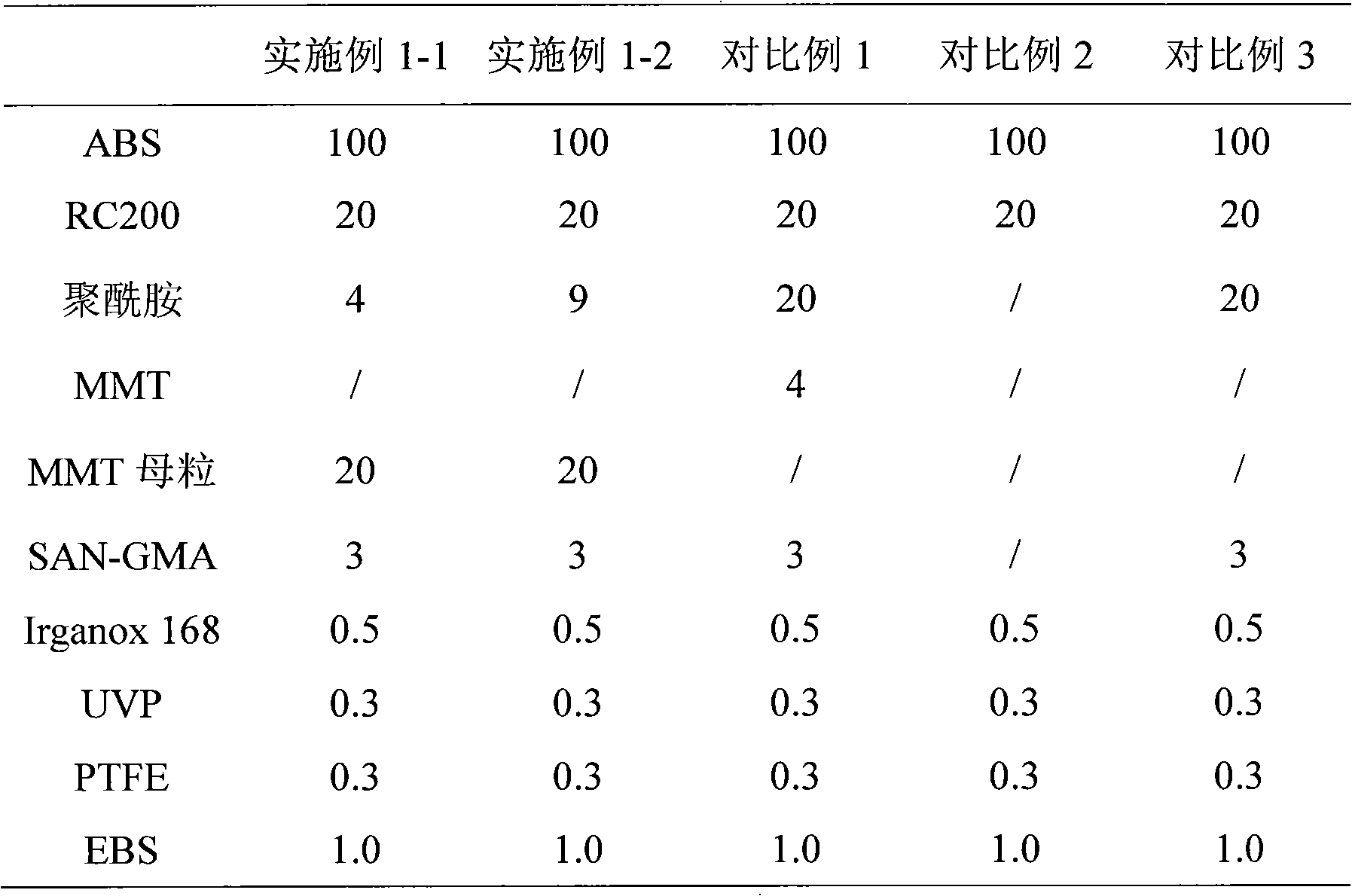

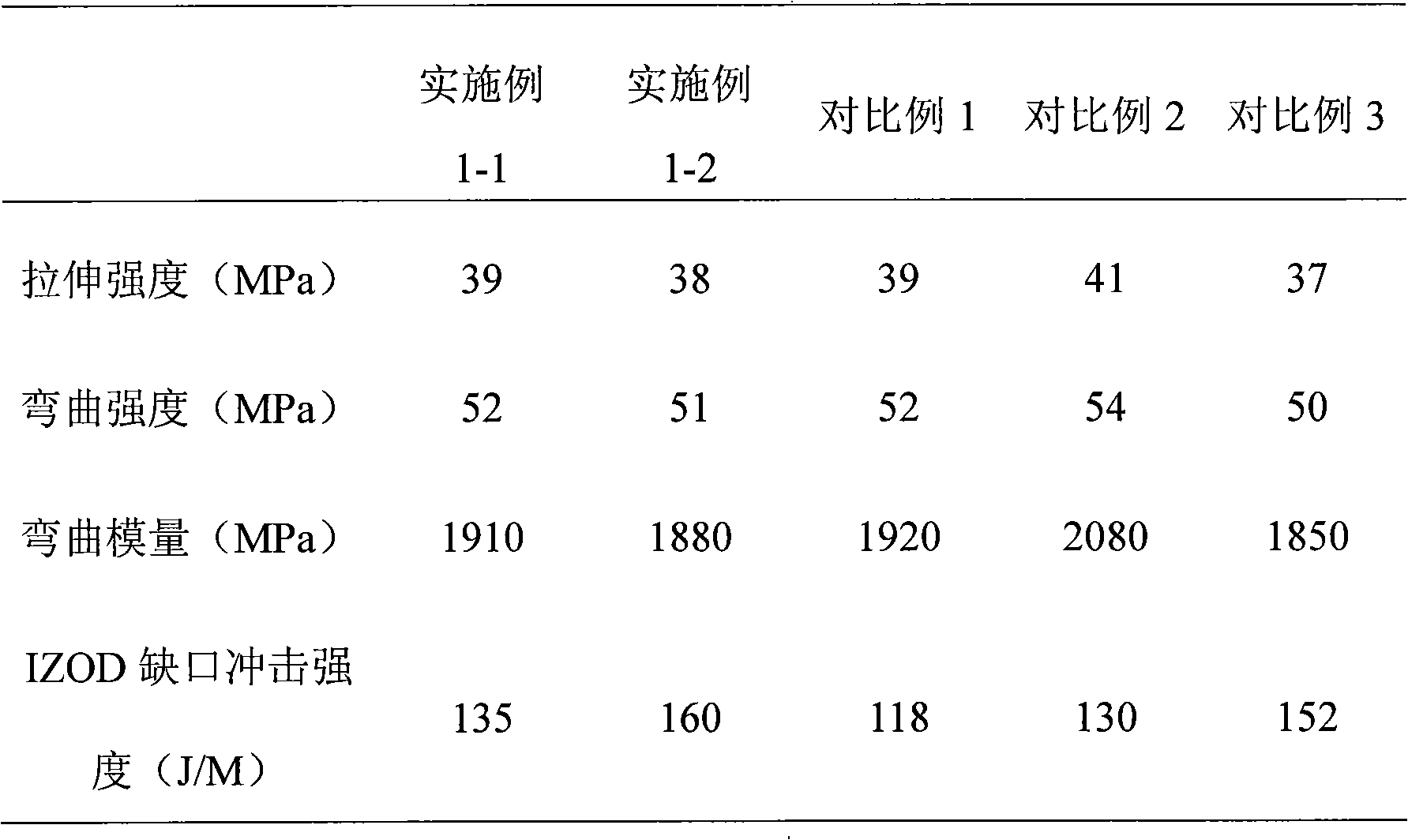

High-performance halogen-free flame retardant ABS modified resin and preparation method thereof

The invention relates to a high-performance halogen-free flame retardant ABS modified resin and a preparation method thereof. The resin comprises the following components with the content (in parts by weight): 100 ABS resin, 4-30 polyamide, 5-25 phosphate fire retardant, 0.1-0.5 anti-drippage agent, 5-10 toughening agent, 1-5 nano filler, 1-5 compatilizer, 0.2-1 antioxidant, 0.1-0.5 light stabilizer and 1-5 processing agent. Compared with the prior art, the invention has reasonable technique, and overcomes the defects of poor flame retardant property and low impact strength of the existing halogen-free flame retardant ABS; and the invention adopts a novel high-efficiency halogen-free flame retardant compounding synergism technology, a novel polyamide coal-forming agent, the high-efficiency synergism between organic and inorganic fire retardants, and the master batch method processing technique, thus endowing the resin with high fire resistance on the basis of improving the original good performances (especially the impact performance) of the ABS resin, and having wide application prospect.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

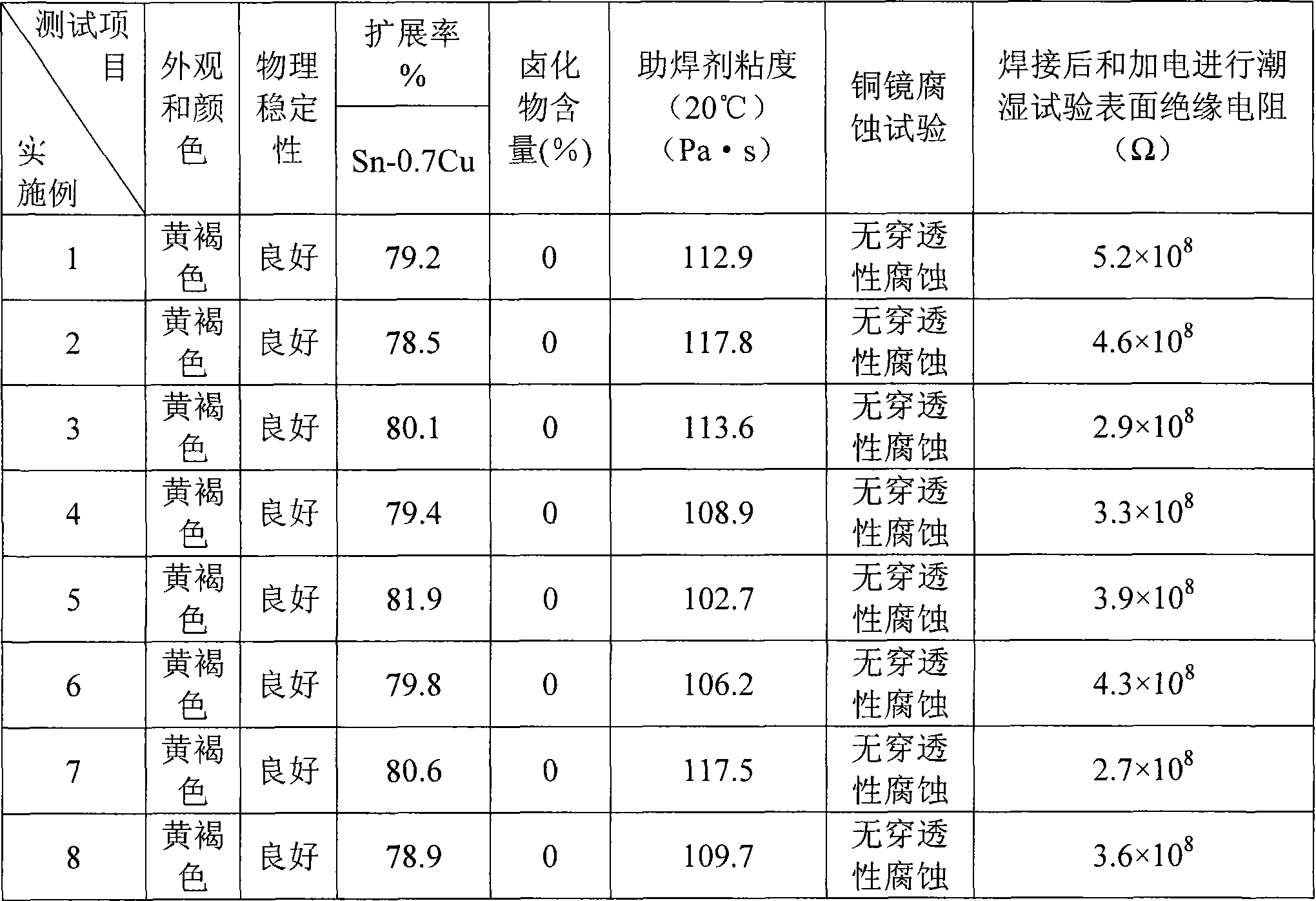

Low-rosin and cleaning-free welding accessory without halogen for lead-free welding grease

InactiveCN101073862AGood print shapeNo viscosity requirementWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention is concerned with low rosin type halogen-free and cleaning-free flux using for lead-free solder paste, belonging to flux field. About the existing rosin type flux, the leftover after welding is high and the leavings with halogen has cauterization. The matter of this invention is 5 to 20 wt percent of organic acid activator, 10 to 29 wt percent of modified rosin, 1 to 10 wt percent of binder, 0.5 to 6 wt percent of stabilizer, 1 to 6 wt percent of surfactant, 1 to 8 wt percent of corrosion inhibitor, 1 to 10 wt percent of thickener, and the rest is solvent with high boiling point. The copper mirror after welding is not penetration, and this invention without halogen has high insulation resistance and good assistant jointing capability. The viscosity of matched solder paste is advisable to solve the high content of rosin in the flux and great smoke. The leftover after welding is colorless and transparent film and it dose not absorb water with the normal temperature without clearing to fit for the welding demand of common production.

Owner:BEIJING UNIV OF TECH

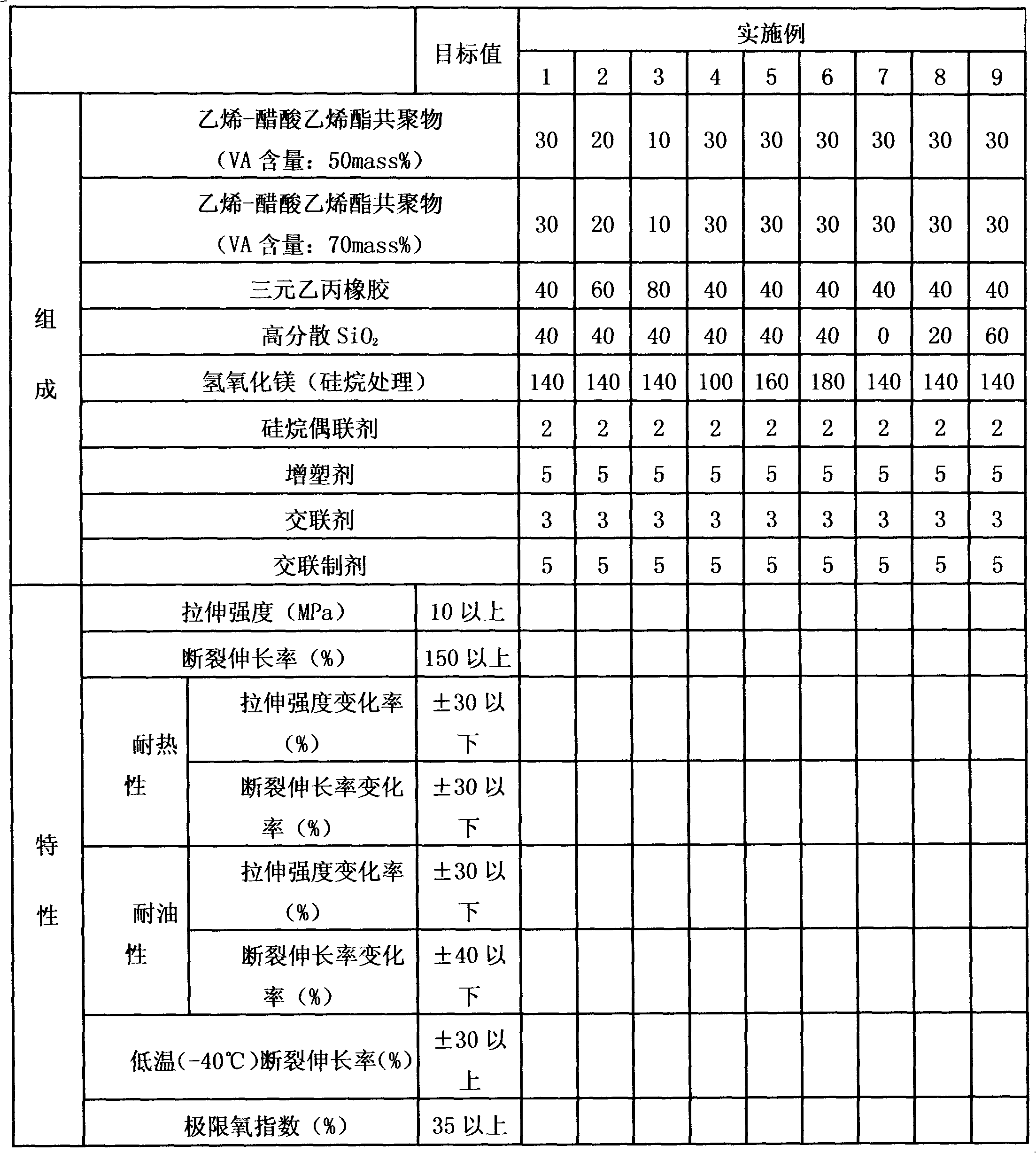

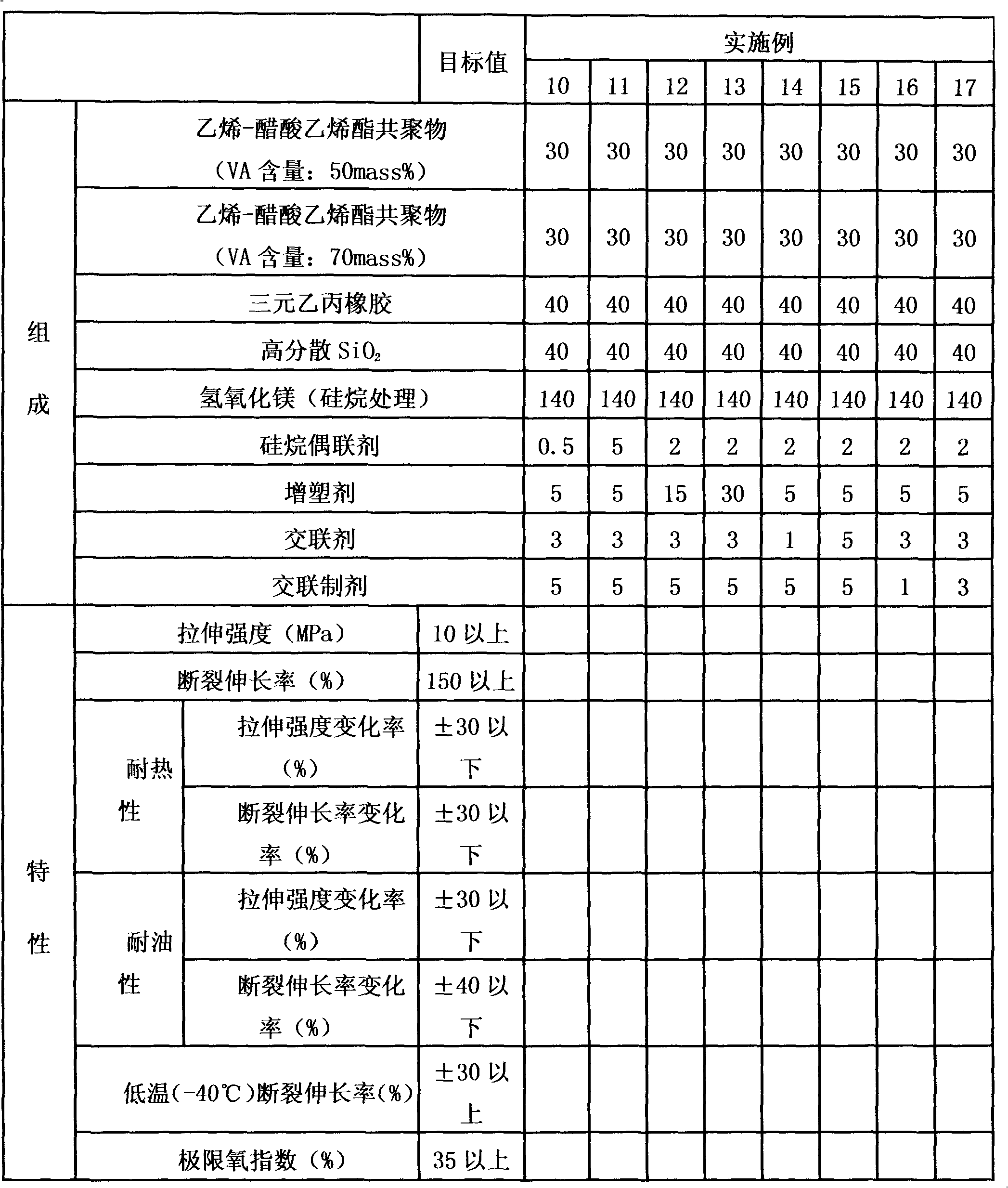

Halogen-free flame-retardant cable sheath material for railway locomotive and manufacturing method for halogen-free flame-retardant cable sheath material

InactiveCN102382358AImprove toleranceImprove low temperature resistanceInsulated cablesInsulated conductorsPlasticizerEngineering

The invention discloses a halogen-free flame-retardant cable sheath material for a railway locomotive and a manufacturing method for the halogen-free flame-retardant cable sheath material. The halogen-free flame-retardant cable sheath material comprises 100 weight parts of rubber, 100 to 180 weight parts of metal hydroxide serving as a flame retardant, 0 to 60 weight parts of carbon black or white carbon black serving as a reinforcing agent, 0.5 to 5 weight parts of silane coupling agent, 5 to 30 weight parts of plasticizer, 1 to 5 weight parts of crosslinking agent and 1 to 5 weight parts of crosslinking aid. The halogen-free flame-retardant cable sheath material is prepared by a blending technology. The sheath material has excellent flame retardancy, oil resistance and low-temperature resistance, is suitable for cable sheaths of railway locomotives, and can meet the requirement of halogen-free flame-retardant cables for locomotives.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Natural fiber reinforcement halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN101418099AImprove flame retardant performanceImprove mechanical propertiesGlass fiberHeat deflection temperature

The invention provides a natural fiber reinforced halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing assistant, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of compatilizer, and 5 to 30 portions of natural fiber. The invention also provides a method for preparing the material. The composite material has the advantages that the composite material has excellent flame-retardant effect and excellent comprehensive mechanical property; the flame-retardant property of the composite material can reach 1.6mm V0; the tensile strength is more than or equal to 60MPa; the bending modulus is more than or equal to 4,000MPa; the gap impact strength is more than or equal to 10KJ / m<2>; the shrinkage ratio is between 4 and 6 per thousand; the heat distortion temperature is more than or equal to 140 DEG C; and the composite material is a novel environment-friendly material, and has no safety and health problems of glass fibers.

Owner:SHANGHAI KINGFA SCI & TECH +1

Halogen-free expansion type flame-retardant and preparation thereof

The invention relates to a halogen-free intumescent flame-retardant polypropylene composite and a preparation method thereof. Calculated by weight percentage, the composite comprises 35 to 80 percent of polypropylene, 5 to 30 percent of coated poly-ammonium phosphate, 1 to 20 percent of melamine and the derivatives, 1 to 15 percent of halogen-free macromolecular char forming flame retardant, 0.1 to 5 percent of flame retardant synergist, 1 to 20 percent of rigid inorganic particle, 0.05 to 5 percent of coupling agent, 0.1 to 10 percent of compatilizer, 1 to 20 percent of toughening agent and 0.01 to 4 percent of antioxidant. Compared with the prior art, the material of the invention has good toughness, high strength and environment-protecting flame retardance, and the composite can be widely applied in the fields such as automobile and electronic appliances.

Owner:SHANGHAI RES INST OF CHEM IND +1

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

Halogen-free resin composition and copper clad laminate and printed circuit board using same

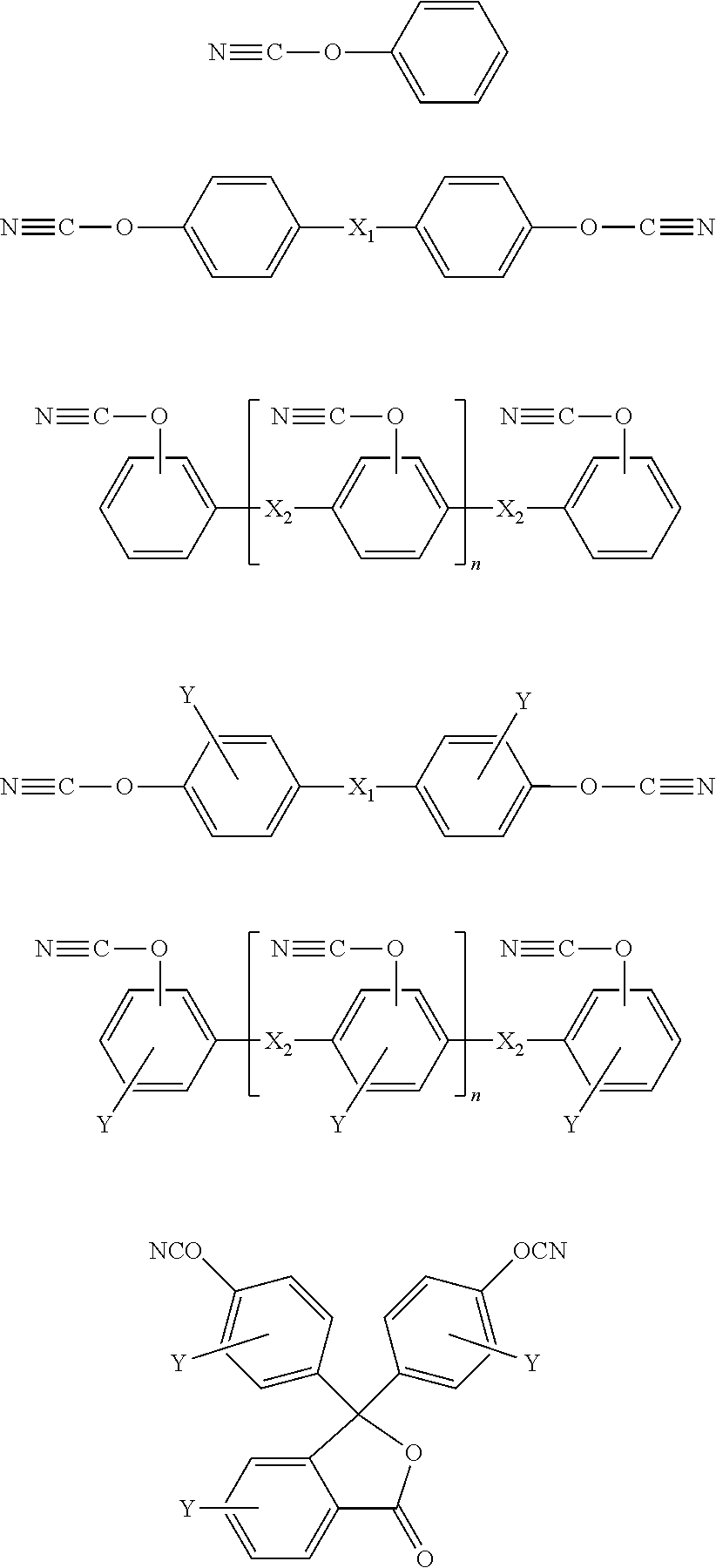

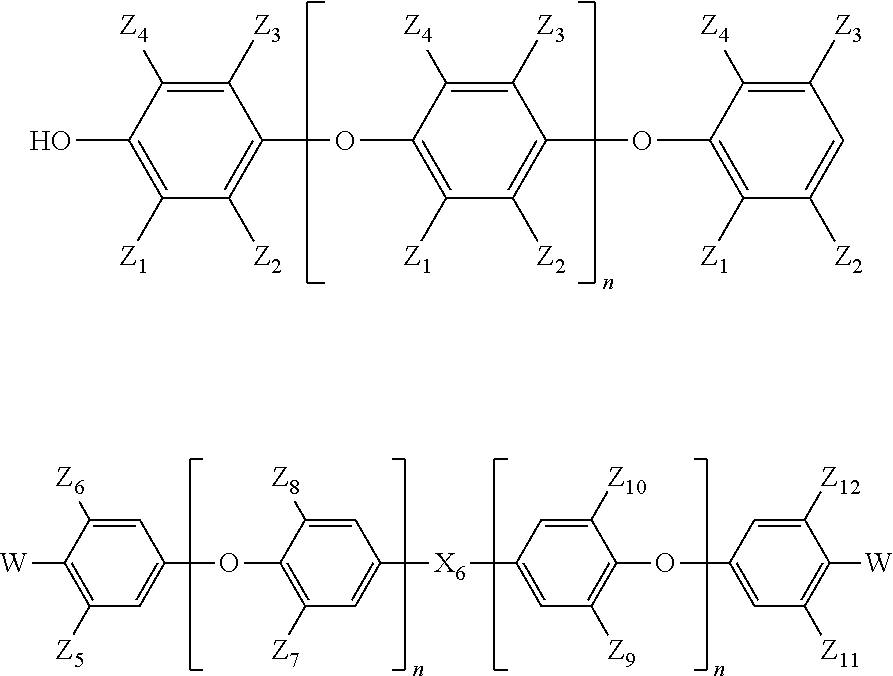

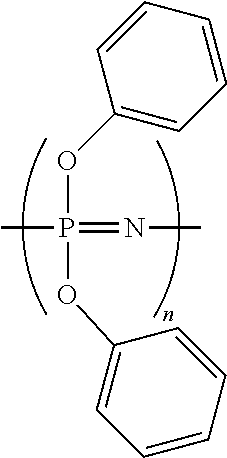

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

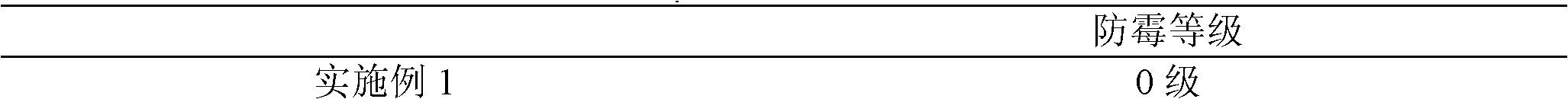

Anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material and preparation method thereof

The invention discloses an anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material, which comprises the following components in parts by mass: 25-70 parts of plastic resin, 10-50 parts of plant fiber powder, 5-10 parts of camphor wood powder, 0.5-20 parts of a compatibilizer, 0-15 parts of a toughening agent, 10-35 parts of a flame retardant and a synergist, 2-5 parts of a thermal stabilizer, 0-1 part of an antioxidant and 1-4 parts of a lubricating agent. According to a method for preparing the wood-plastic composite material with a two-step fusion method disclosed by the invention, the interfacial compatibility can be improved effectively, and the flame retardance of the wood-plastic composite material is enhanced on the premise of keeping high mechanical property; and moreover, the using amount of ammonium polyphosphate serving as a major flame retardant is reduced. Compared with the conventional wood-plastic composite material, the wood-plastic composite material disclosed by the invention has a simple production flow, has the technical effects of flame retardance, smoke suppression and mildew resistance, and is widely applied to occasions such as indoor and outdoor architectural decoration, and the like.

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE +1

Ceramic bovine flame retardant polymer composite material and application thereof

InactiveCN104650441AImprove high temperature strengthImprove flame retardant performanceInsulatorsPolyolefinPlasticizer

The invention provides a ceramic bovine flame retardant polymer composite material based on polyolefin or a thermoplastic polyurethane elastomer. The ceramic bovine flame retardant polymer composite material is prepared from the following components in parts by weight: 30-40 parts of polyolefin resin or the thermoplastic polyurethane elastomer, 25-45 parts of a ceramic forming filler, 20-30 parts of a halogen-free flame retardant, 1-5 parts of a flame-retardant synergist, 1-3 parts of a plasticizer, 0.5-2 parts of an antioxidant and 0.02-0.15 part of a crosslinking agent, wherein the ceramic forming filler is prepared from the following components including low softening point glass powder and a silicate mineral filler. The invention also provides application of the ceramic bovine flame retardant polymer composite material in the field of cables. According to the ceramic bovine flame retardant polymer composite material disclosed by the invention, a dense ceramic bovine product can be formed within a range from 600 DEG C to 1000 DEG C, and the formed ceramic bovine product is good in high-temperature strength and flame retardancy and is also good in mechanical properties under room temperature.

Owner:SICHUAN UNIV

Non-crosslinking halogen-free flame-retardant cable insulating material or sheath material and preparation method thereof

ActiveCN103012941ACause damageReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerHalogen

The invention discloses a non-crosslinking halogen-free flame-retardant cable insulating material or sheath material, comprising the following components in part by weight: 100 parts of ethylene and ethylene copolymer and / or ethylene propylene diene monomer, 0-20parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0-40 parts of polymeric elastomer, 0-3 parts of coupling agent, and 0-20parts of color master batch, wherein the ethylene and ethylene copolymer are selected from one or more of the following materials: ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate copolymer and the like. According to the halogen-free flame-retardant cable insulating material or sheath material, the insulating layer or the sheath layer prepared by the uncrosslinked halogen-free flame-retardant cable insulating material or sheath material can be adaptive to the environment at -40 to 80 DEG C, and the material can not generate poisonous gases such as halogen hydride in case of fire, so that harm to lives and property loss can not be caused by the poisonous gases such as halogen hydride; and besides, the production cost of the material is low.

Owner:SHENZHEN WOER NEW ENERGY ELECTRICAL TECH CO LTD

Flameproof polymer composition

InactiveUS6750282B1Improve mechanical propertiesIncrease spacingPigmenting treatmentGreenhouse cultivationElastomerCross-link

The invention relates to a flameproof, essentially halogen-free polymer composition, containing the following: a) 100 parts by weight of a thermoplastic, cross-linkable or cross-linked, elastomeric and / or duroplastic polymer; b) 10 to 200 parts by weight of magnesium, calcium, zink and / or aluminiumhydroxide and / or their double hydroxides; c) 1 to 50 parts by weight of an organic intercalated sheet silicate.

Owner:BYK ADDITIVES

Ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and method for preparing ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from same

ActiveCN102153802AEnhanced cross-linking efficiencyIncreased uniform photocrosslinking depthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention relates to ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable material and a method for preparing an ultraviolet-light deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer from the same. The method comprises the following steps: adding a metal hydroxide flame retardant, a cationic photoinitiator, a free radical photoinitiator, a multi-functional cross-linking agent, a compound antioxidant, a flame-retardant synergist, a synergistic smoke suppressant and a processing aid to polyethylene or grafted and modified polyethylene and / or ethylene vinyl acetate or grafted and modified copolymer thereof which are used as base materials, compounding, mixing the materials uniformly according to the proportion, granulating, extruding to prepare the ultraviolet-light cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer, and immediately irradiating with a specific ultraviolet-light source to obtain the deeply cross-linked halogen-free flame-retardant polyolefin cable insulating or sheathing layer. The cross-linking equipment used for preparing the novel material by using anovel technology has low investment, and the process is simple and environmental friendly, saves energy, ensures high production efficiency and low cost and good quality of product and can be widely used for producing high-performance special wire and cable products and the like.

Owner:HEILONGJIANG MINGXIANG TECH

High temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material and method for preparing high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material

ActiveCN103012940AReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention discloses a high temperature self-crosslinking halogen-free flame retardant cable insulation material or sheath material. The cable insulation material or sheath material comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-20 parts of compatilizer, 20-250 parts of halogen-free flame retardant, 0-5 parts of antioxidant, 0-5 parts of lubricating agent, 0.01-5 parts of peroxide crosslinking agent, 0-40 parts of polymer elastomer, 0-3 parts of coupling agent and 0-20 parts of color masterbatch; and the ethylene and the copolymer thereof are selected from one or a plurality of the following materials of ethylene-vinyl acetate copolymer, ethylene-methyl acrylate copolymer, ethylene-ethyl acrylate and the like. The high temperature peroxide crosslinking agent crosslinks under the temperature condition of above 150 DEG C only, during a cable material mixing extrusion and insulating layer or sheath layer formation process, chemical crosslinking or micro-crosslinking cannot be caused, but the high temperature peroxide crosslinking agent generates a crosslinking function when the temperature is higher than 150 DEG C in the case of fire, so that the production cost is lowered.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

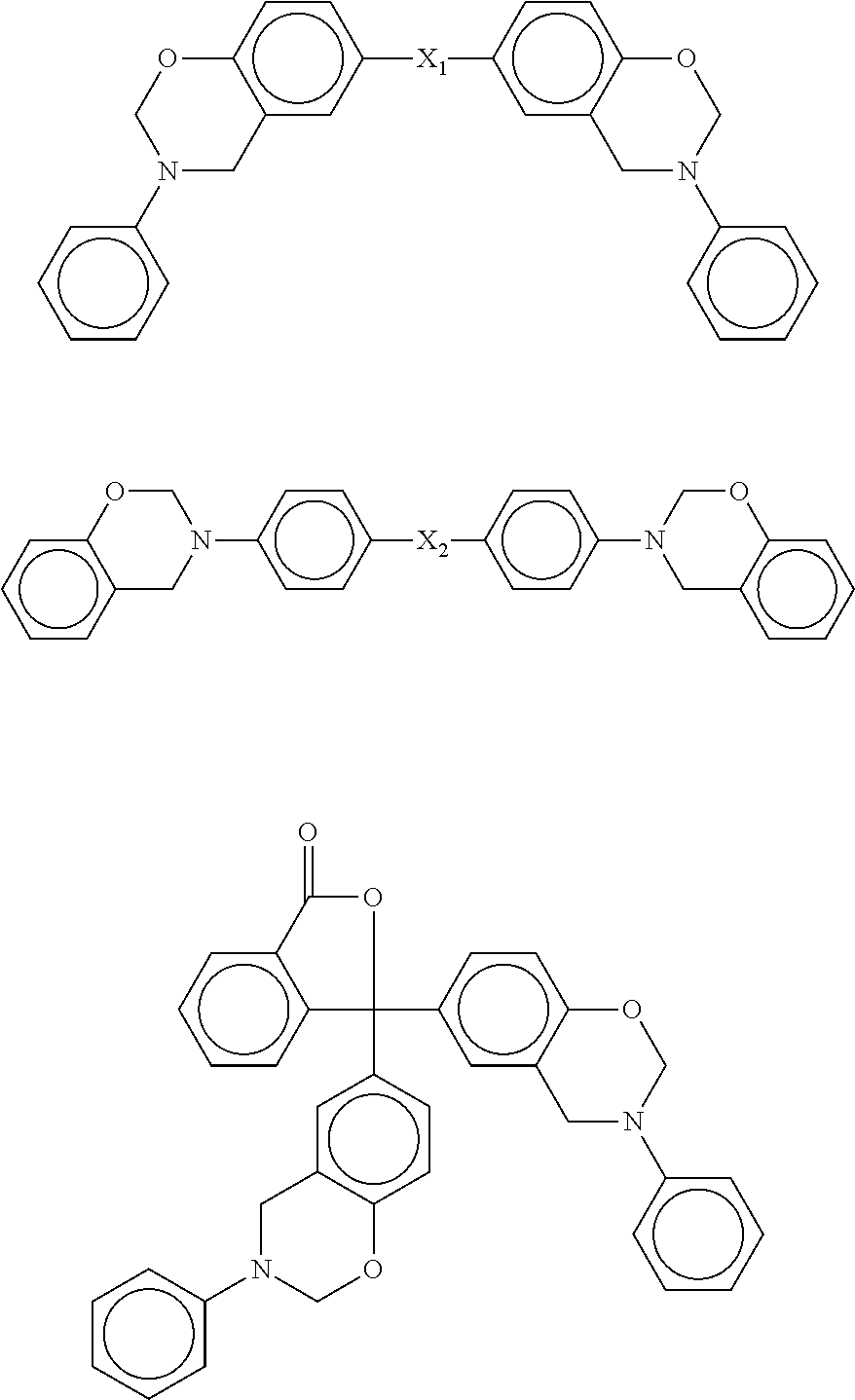

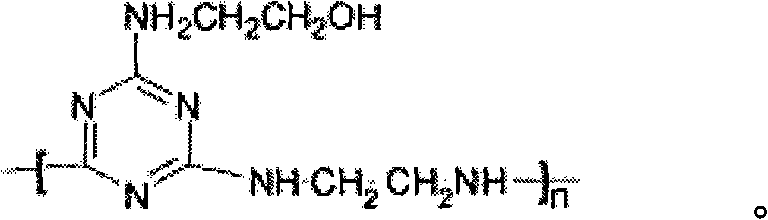

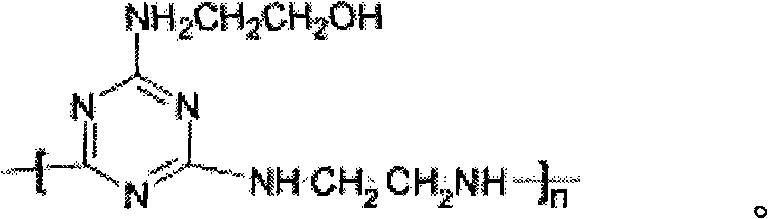

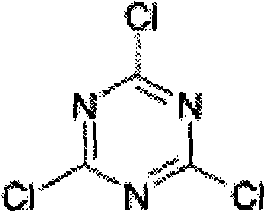

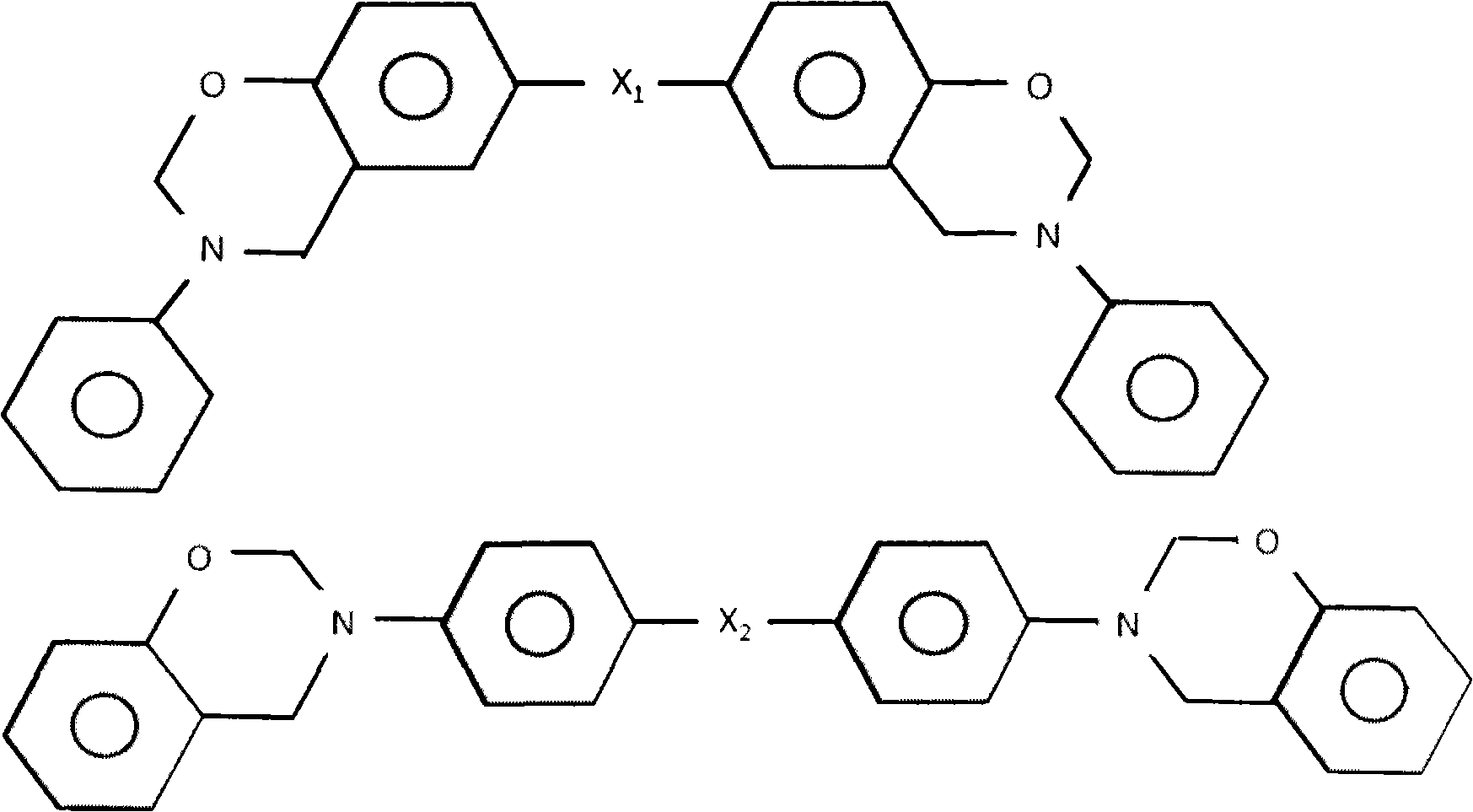

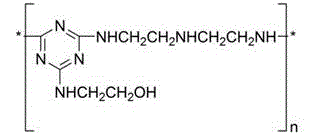

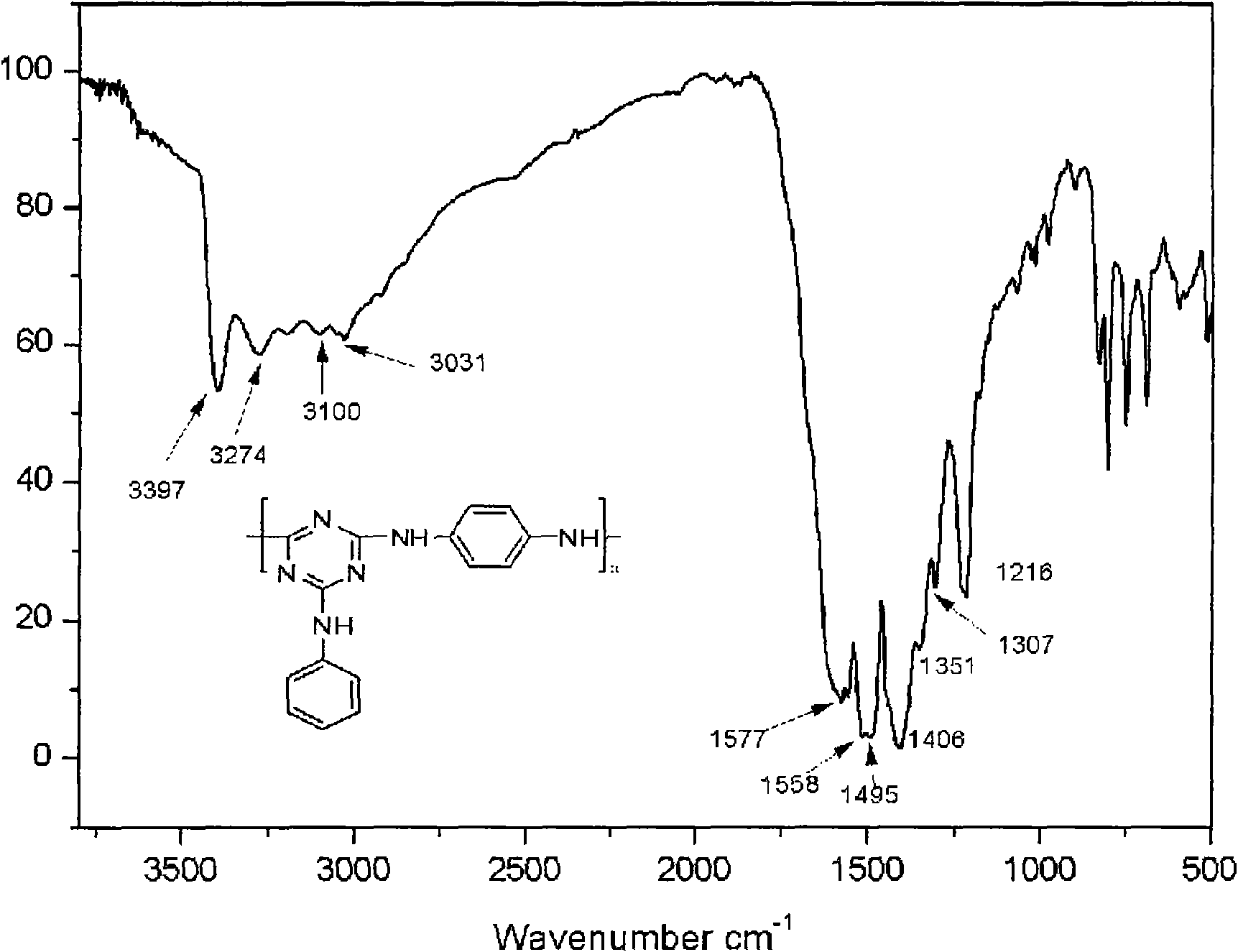

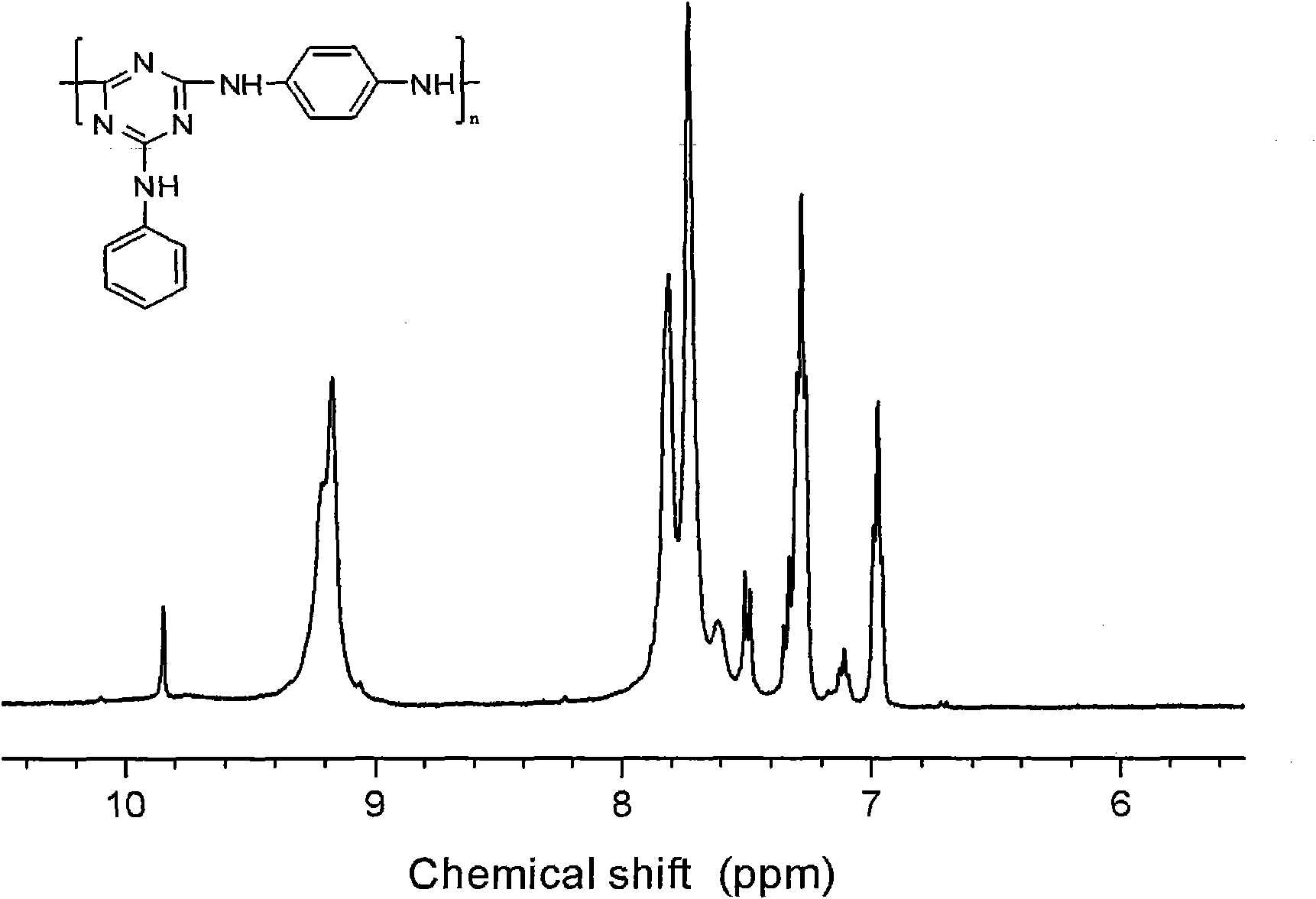

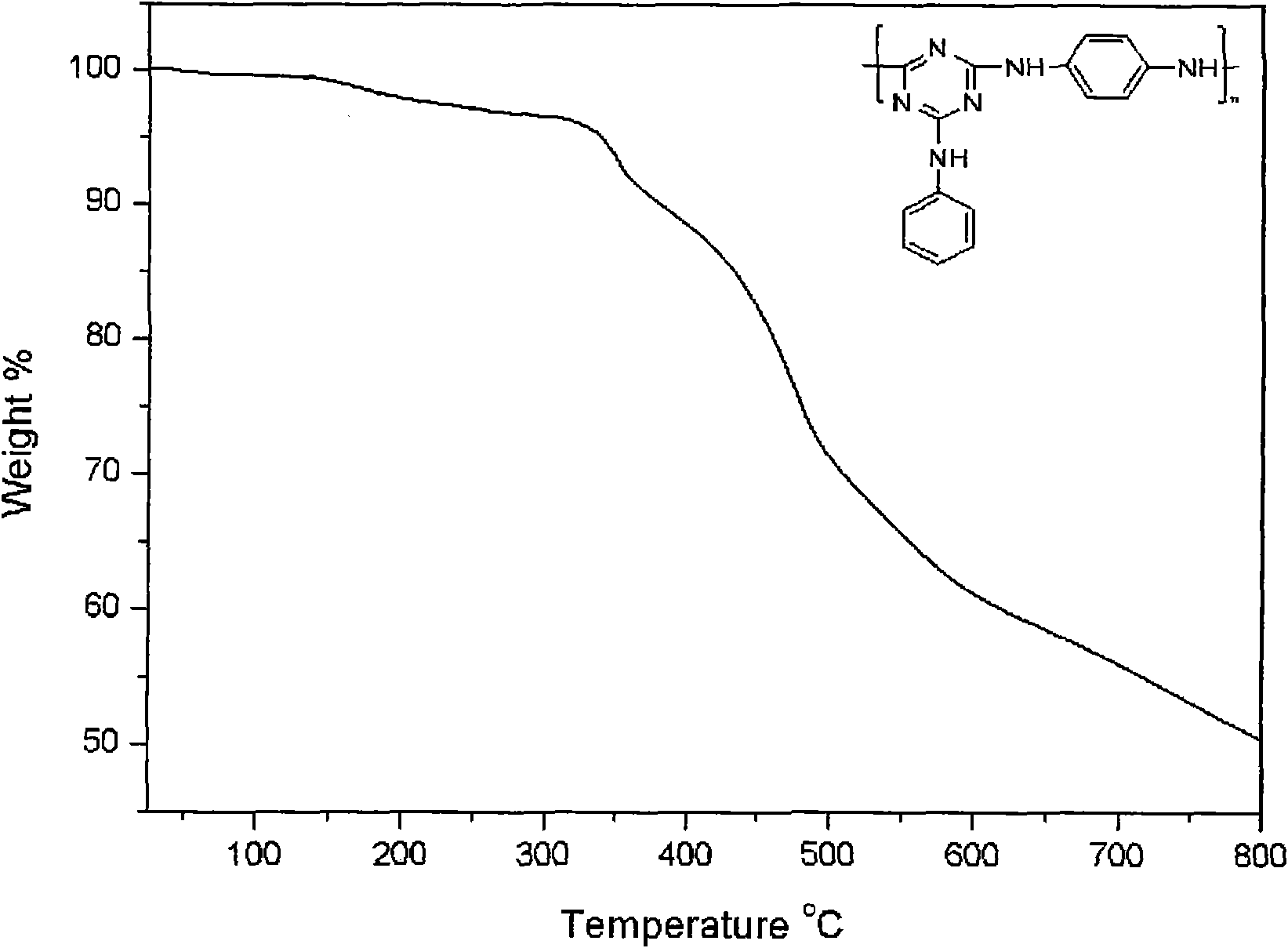

Triazine carbonific containing aromatic chain structure and preparation method

InactiveCN101586033AImprove the defects of poor mechanical behaviorGood foaming effectFireproof paintsChain structureThermal stability

A triazine carbonific containing aromatic chain structure, the carbonific is obtained by aromatic binary compound and monosubstituted cyanuric chloride with structural general formula being NH2-Ar-NH2, HO-Ar-OH or HS-Ar-SH under catalyst action. The invention further claims a method of preparing the triazine carbonific containing aromatic chain structure. Compared with the prior art, the invention has the advantages that: the triazine halogen-free flame retardant obtained by the invention has high thermal stability, high char rate under high temperature; the reaction process is one kettle way continuous reaction, and the preparation process is simple, the intermediate does not need to be processed; the post process method is simple, and the reaction time is short, the yield is high; the invention can effectively save energy consumption, improve the production efficiency and reduce the production cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Halogen-free flame retardant antistatic PC/ABS alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant antistatic PC / ABS (Poly Carbonate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof, belonging to the technical field of alloy materials. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention comprises the following components in parts by weight: 1-30 parts of ABS resin, 40-90 parts of PC resin, 8-20 parts of fire retardant, 1-10 parts of flexibilizer, 0.02-0.5 part of antistatic agent, 0.1-1 part of photo-thermal stabilizing agent and 0.1-1 part of processing agent. The invention also discloses a preparation method of the halogen-free flame retardant antistatic PC / ABS alloy material, which comprises the following steps of: mixing the 1-30 parts of ABS resin, the 40-90 parts of PC resin, the 8-20 parts of fire retardant, the 1-10 parts of flexibilizer, the 0.02-0.5 part of antistatic agent, the 0.1-1 part of photo-thermal stabilizing agent and the 0.1-1 part of processing agent, and then sending to a dual-screw extruder, mixing, extruding, staying, cooling, sized-dicing and obtaining a finished product of the halogen-free flame retardant antistatic PC / ABS alloy material. The halogen-free flame retardant antistatic PC / ABS alloy material provided by the invention has the advantages of simple process, continuity, high production efficiency and stable quality.

Owner:HEFEI GENIUS NEW MATERIALS

Low smoke halogen-free flame retardant ethylene-propylene-diene rubber and preparation method by extrusion molding thereof

ActiveCN101704976AGood mechanical propertiesEasy extrusionEngine sealsVehicle sealing arrangementsPolymer scienceMechanical property

The invention relates to a low smoke halogen-free flame retardant ethylene-propylene-diene rubber and a preparation method by extrusion molding thereof; the preparation method comprises the following steps: firstly, raw rubber matrix is evenly mixed at 80-100 DEG C by an open mill or a banbury mixer, and then cooled down to the room temperature; carbon black, modified nanometer / micrometer hydroxide, plasticizer, flame retardant synergist, vulcanization accelerator and vulcanizing agent are added in sequence according to the proportion and evenly mixed. Mixed rubber is added into a single screw extrusion machine; the temperature of a machine body, a screw and a machine head is controlled to be 50-90 DEG C; the rotating speed of the screw is within 15-40 r / min to cause that glue stock is continuously squeezed out; and hot air (175-200 DEG C) or microwave (915-2450 MHz) is adopted to cause that the glue stock is continuously vulcanized and molded. The flame retardant ethylene-propylene-diene rubber has excellent mechanical property, low smoke halogen-free flame retardant performance and good extrusion performance, and is applicable to manufacturing of flame retardant gland strips used in doors and windows for building and vehicles.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com