Halogen-free expansion type flame-retardant and preparation thereof

A flame-retardant polypropylene composition technology, applied in the field of halogen-free intumescent flame-retardant polypropylene composition and its preparation, can solve the problems of dioxin, trouble, a large amount of smoke and corrosive gas, etc., and achieve flame retardancy Good, good toughness, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

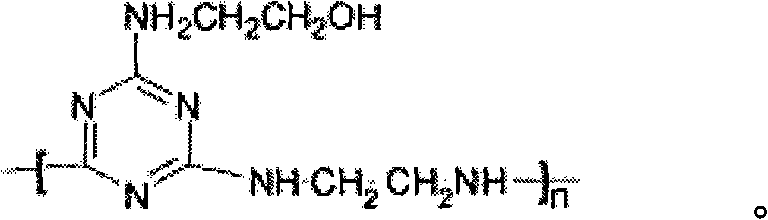

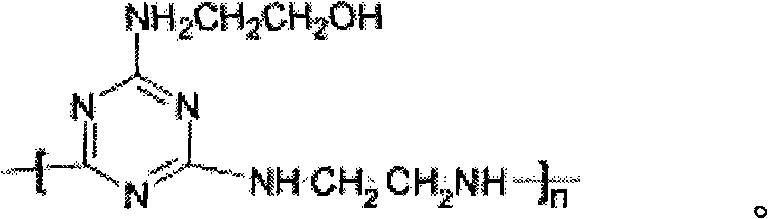

[0029] This example is a preparation example of a halogen-free macromolecular char-forming flame retardant.

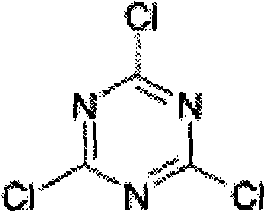

[0030] Add 46.1g of cyanuric chloride in the 500ml reaction flask equipped with reflux condenser, constant pressure dropping funnel, stirrer and thermometer, then add 10ml acetone and 10ml distilled water, fully stir, cyanuric chloride is dispersed evenly, Then, under the condition of -5~5℃, 15.3g of ethanolamine and NaOH solution (10gNaOH dissolved in 25ml of distilled water) were evenly added dropwise while stirring. Hour. Then raise the temperature to room temperature, then evenly add 9.25g1,3-propanediamine and NaOH solution dropwise in the reaction flask (10gNaOH is dissolved in 25ml distilled water), raise the reaction temperature to 40~65°C after the dropwise addition, Under these conditions, the reaction was stirred for 4 to 6 hours. Then, under the condition of 40-65°C, continue to evenly add 9.25g of 1,3-propylenediamine and NaOH solution (10gNaOH dissolved...

Embodiment 2-14 and comparative example 1-3

[0032] This group of examples is a preparation example of the halogen-free intumescent flame-retardant polypropylene composition of the present invention.

[0033] According to the data listed in Table 1 (1) the inorganic rigid particles, coupling agent, and compatibilizer are first subjected to high-speed stirring; (2) the coated ammonium polyphosphate, melamine and its derivatives, and halogen-free macromolecules are formed Charcoal flame retardant is carried out jet pulverization, carries out high-speed agitation and mixing again; (3) then polypropylene, flame retardant synergist, toughening agent, antioxidant, step (1) and (2) processed inorganic rigidity The particles and the obtained halogen-free intumescent flame retardant are mixed at high speed, and then subjected to twin-screw extrusion and granulation to obtain the halogen-free intumescent flame-retardant polypropylene composition. Injection molding sample preparation, test performance, the results are also shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com