Patents

Literature

1005 results about "Granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material. It is applied in several technological processes in the chemical and pharmaceutical industries. Typically, granulation involves agglomeration of fine particles into larger granules, typically of size range between 0.2 and 4.0 mm depending on their subsequent use. Less commonly, it involves shredding or grinding solid material into finer granules or pellets.

Granules, tablets and granulation

ActiveUS20080111269A1Quick cureEasy to assemblePowder deliveryElectrostatic separationMaterials scienceAirflow

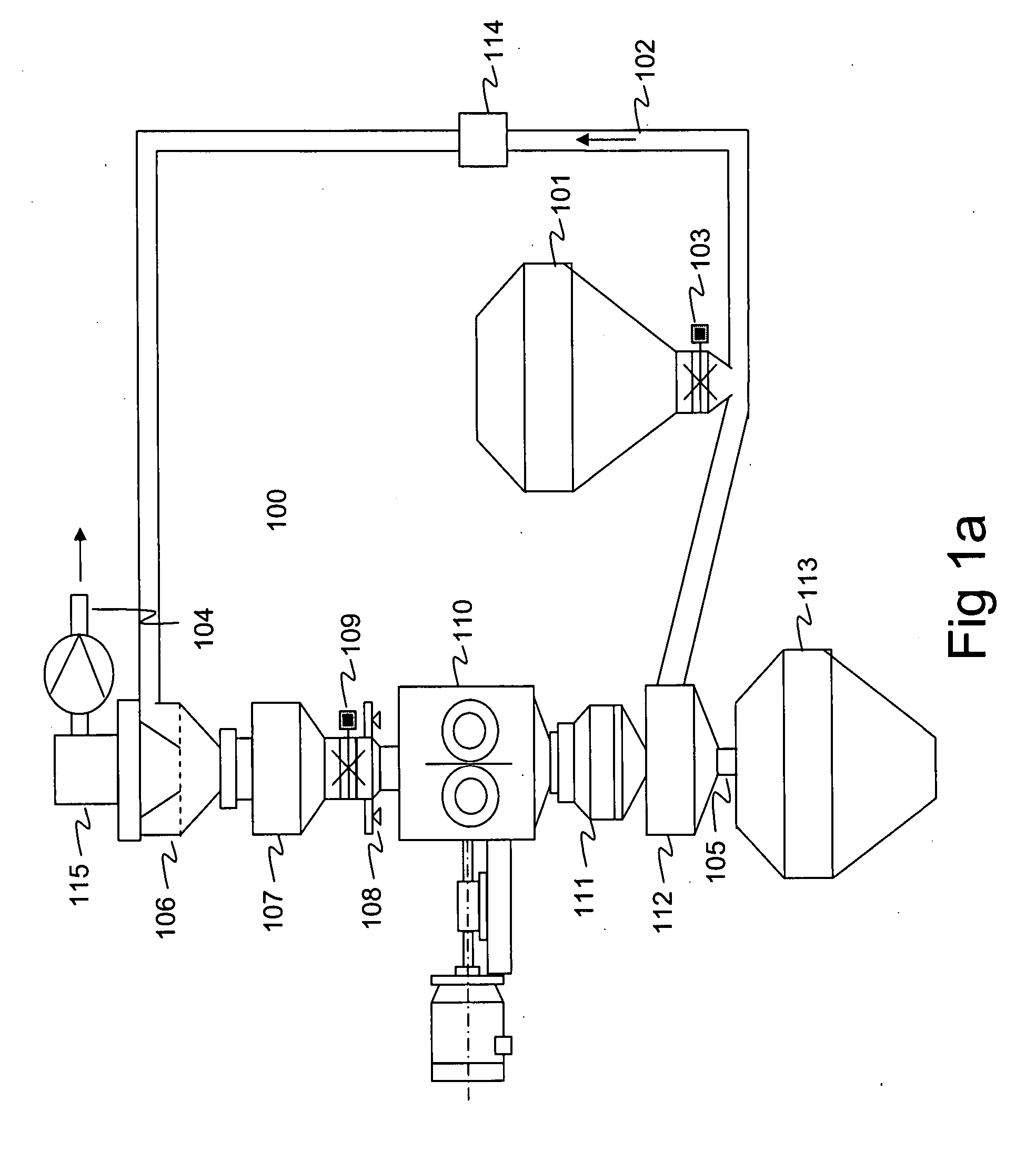

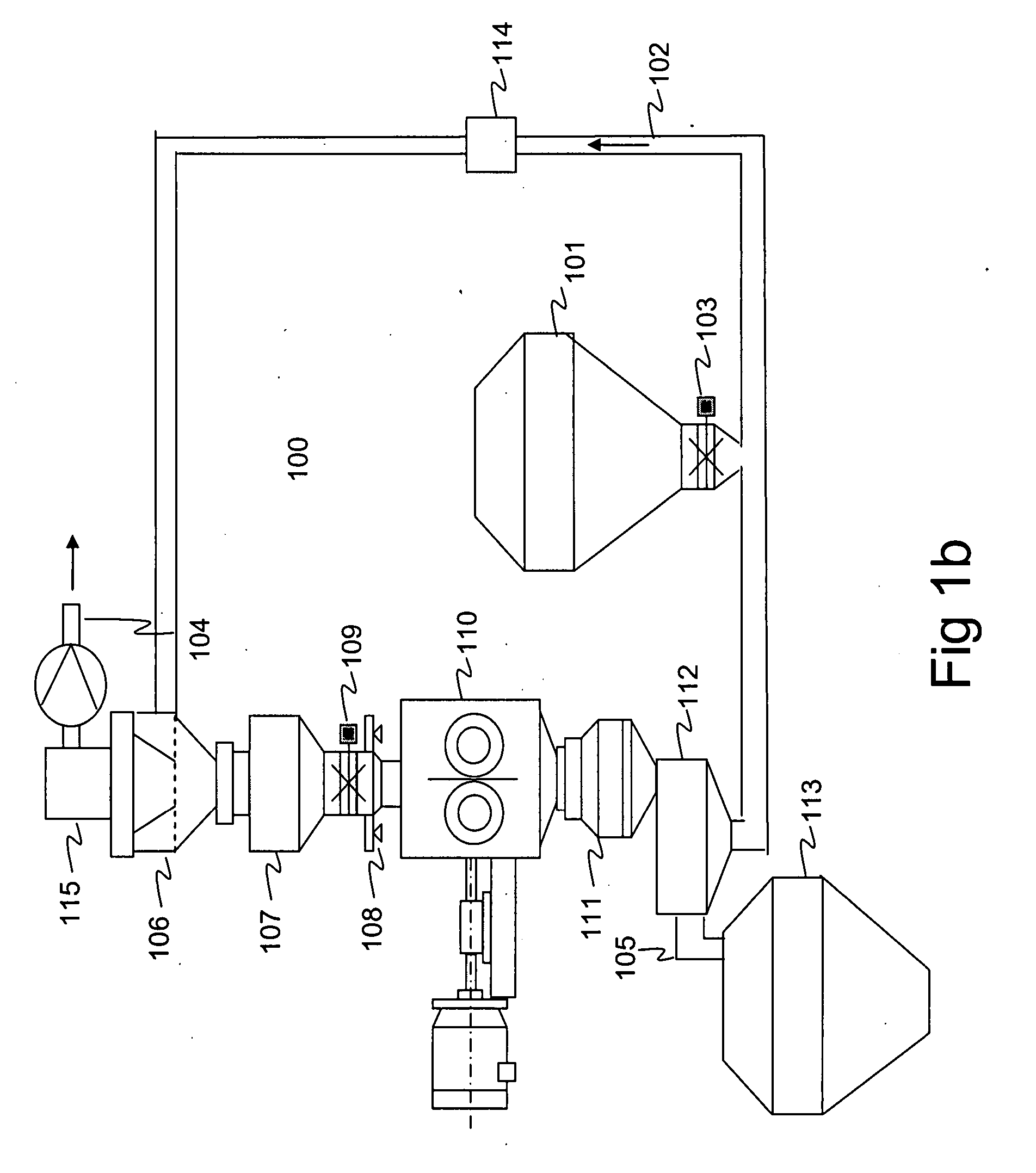

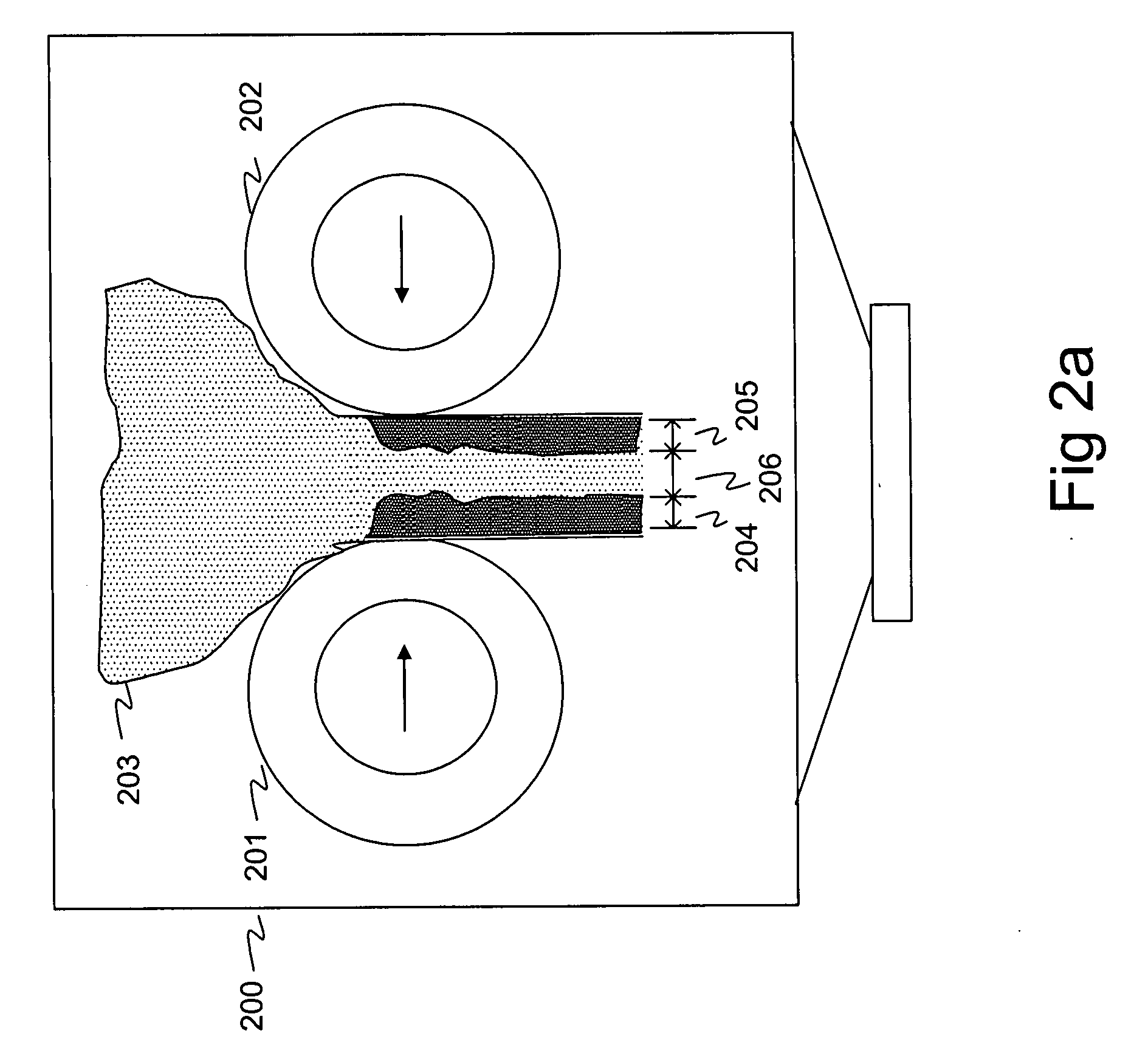

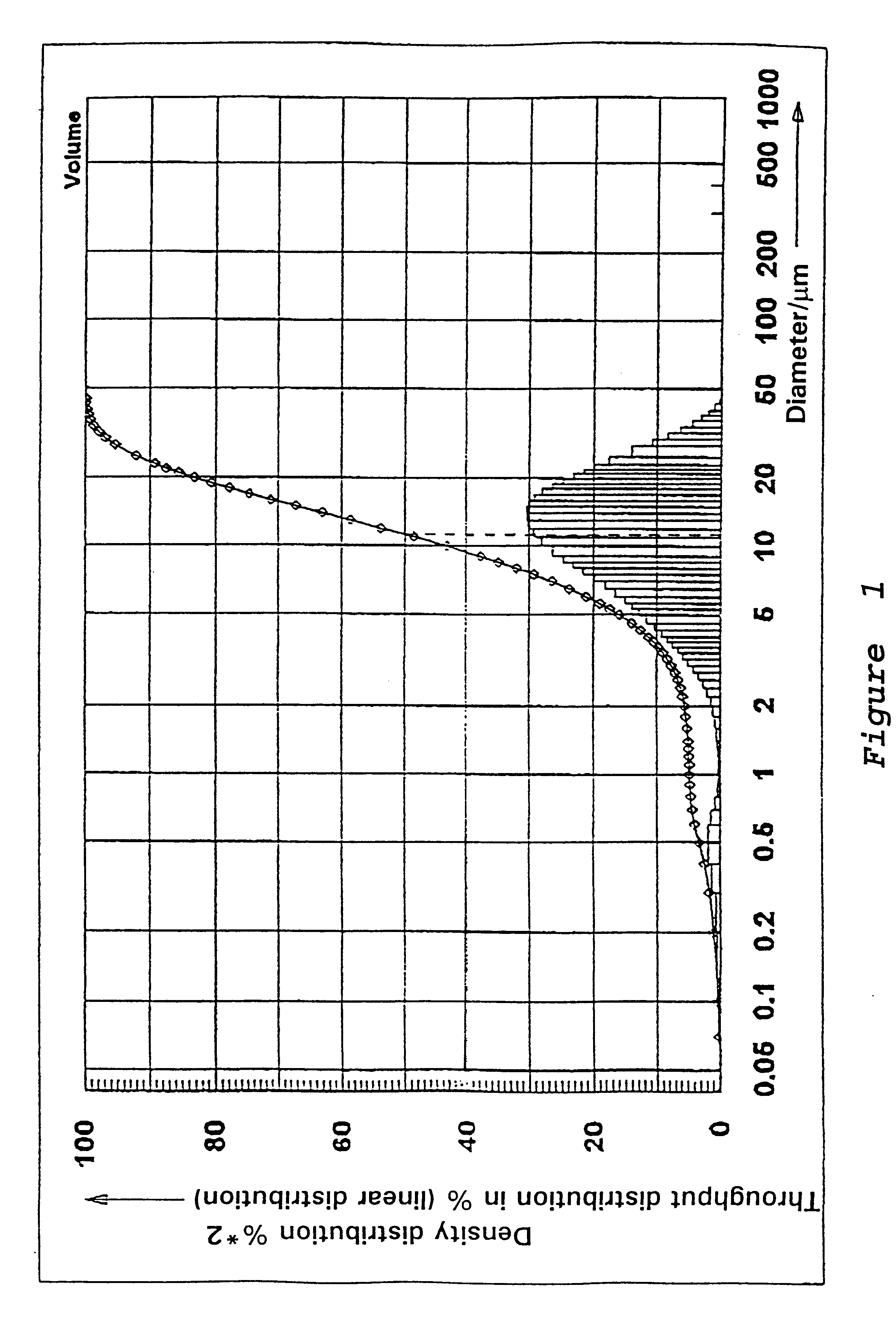

The invention provides, inter alia, a method for producing granules from a powder, characterized in that a low compaction force is applied to the powder to produce a compacted mass comprising a mixture of fine particles and granules and separating fine particles from the granules by entraining the fine particles in a gas stream. Also provided are apparatus for use in the process and tablets formed by compression of the resultant granules.

Owner:ATACAMA LABS OY

Precipitated silicic acid

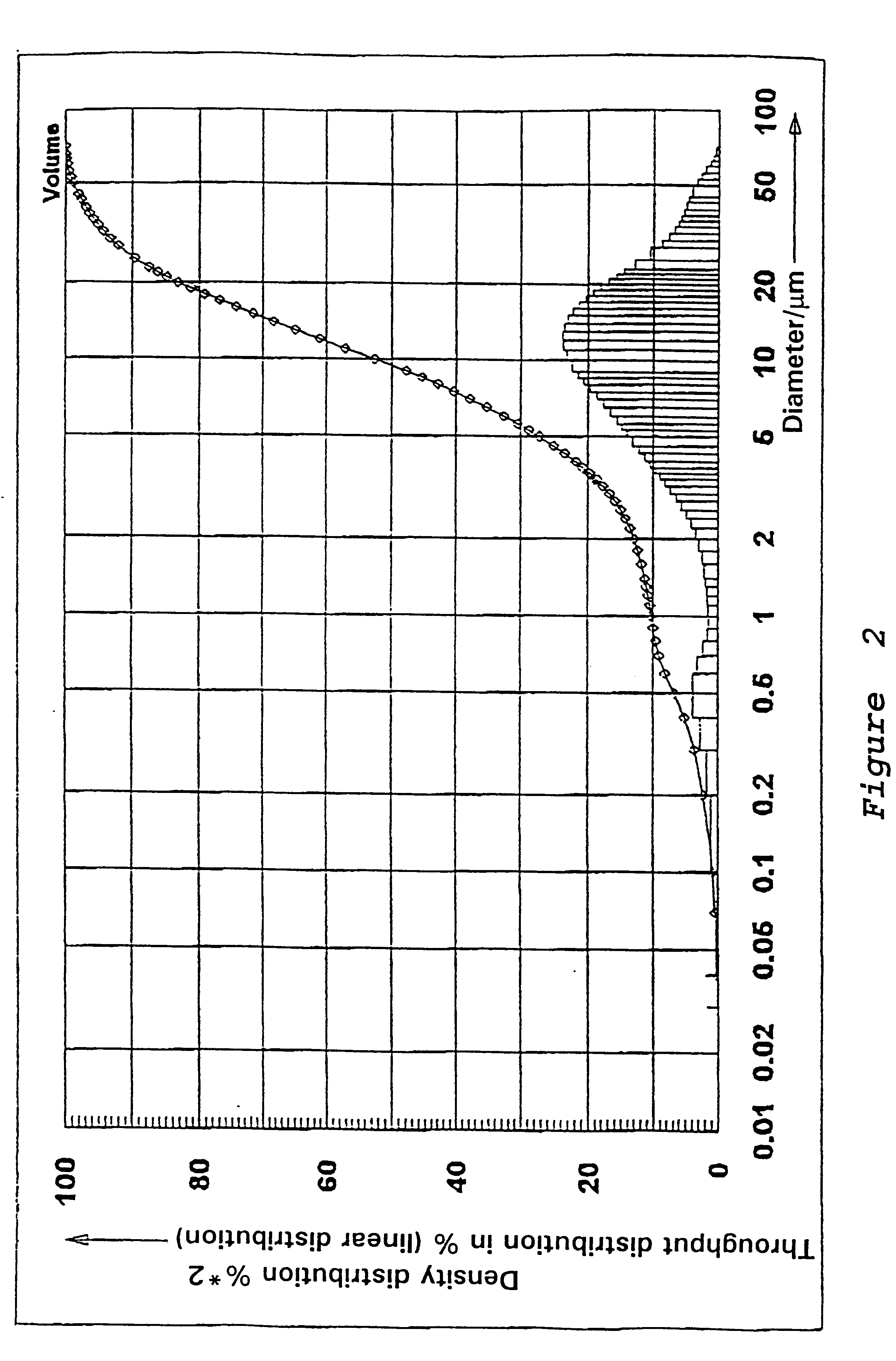

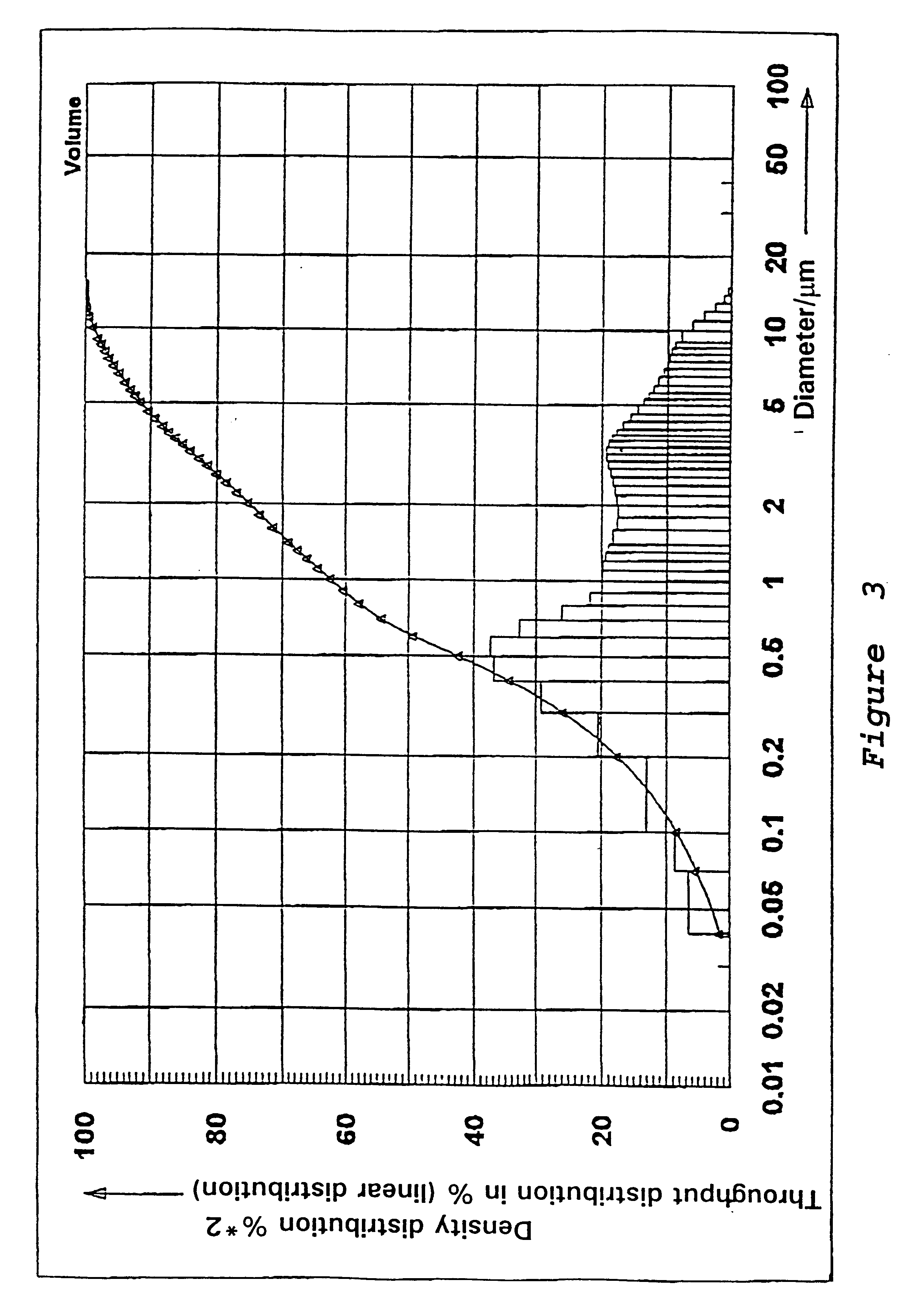

InactiveUS6268424B1Easily dispersible in tire carcassExtended service lifePigmenting treatmentSilicaSilicic acidPhysical chemistry

Precipitated silica having the following parameters:is prepared by reacting alkali silicate with mineral acids and aluminum sulfate solution at temperatures of 60-95° C. at a pH of 7.0-10.0 while stirring constantly, wherein the reaction is continued to a solids concentration of 40-110 g / l, the pH is adjusted to a value between 3 and 5, and the precipitated silica is filtered off, washed and then dried, and optionally ground or granulated.

Owner:EVONIK DEGUSSA GMBH

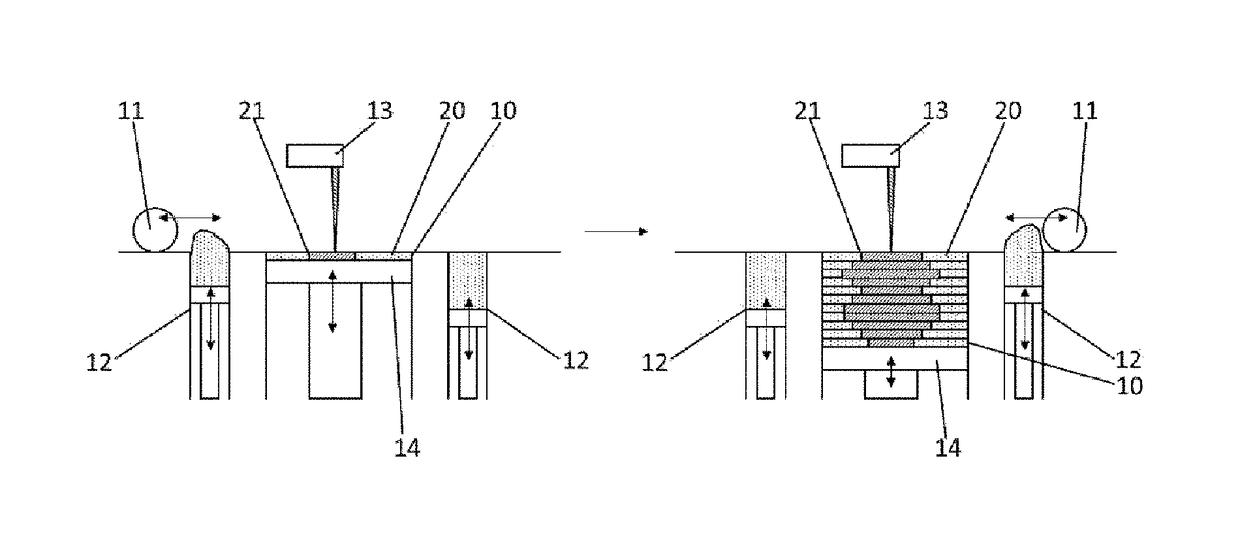

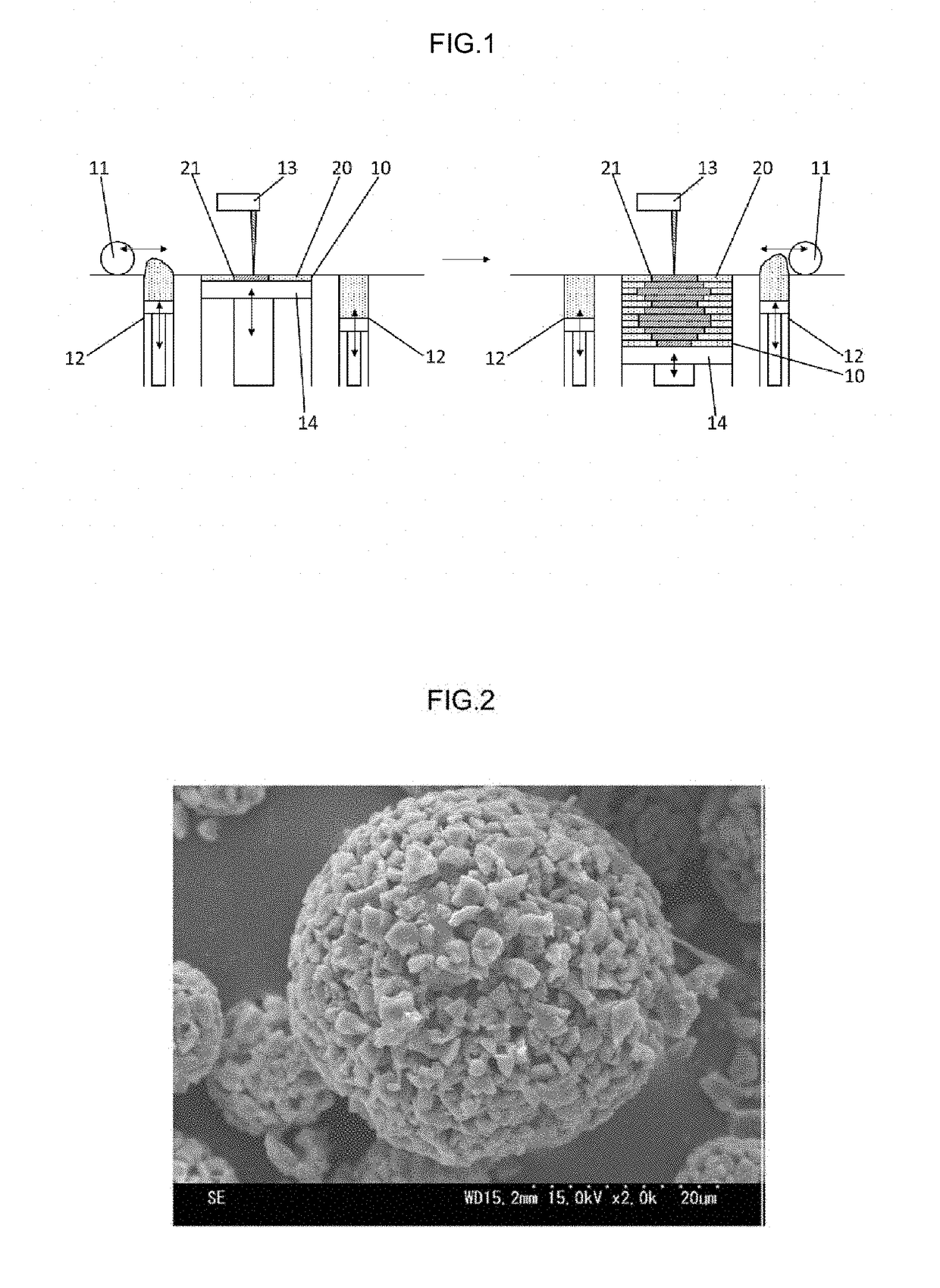

Powder material for powder additive manufacturing and powder additive manufacturing method using same

InactiveUS20170189960A1Additive manufacturing apparatusTransportation and packagingMetallurgyMaterials science

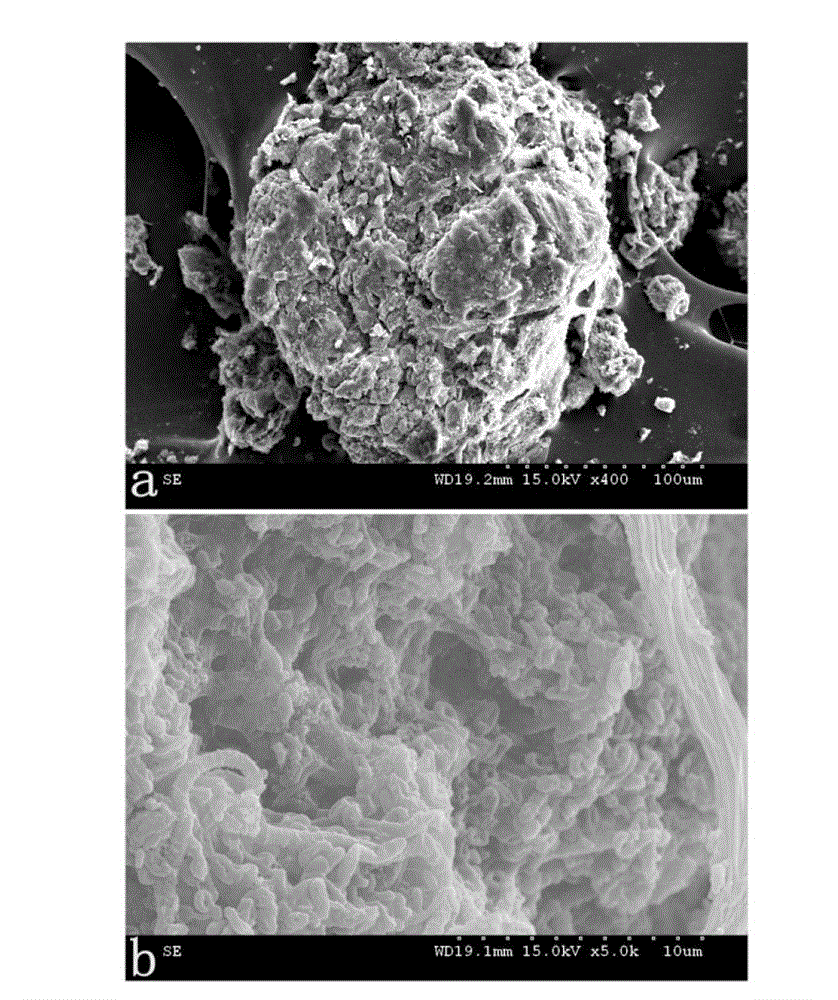

[Problem] To provide a powder material that has good fluidity and is used for powder additive manufacturing.[Solution] The powder material of this invention is used in powder additive manufacturing. The powder material is formed of particles having a form of secondary particles that are formed with primary particles bound three-dimensionally with interspaces. The secondary particles forming the powder material preferably have an average particle diameter of 1 μm or larger, but 100 μm or smaller. The secondary particles forming the powder material are preferably granulated particles. The powder additive manufacturing method of this invention is carried out, using the powder material.

Owner:FUJIMI INCORPORATED

Ta powder, production method therefor, and ta granulated powder

InactiveUS20160104580A1Improved characteristicHigh electrostatic capacitySolid electrolytic capacitorsTransportation and packagingTACLSingle phase

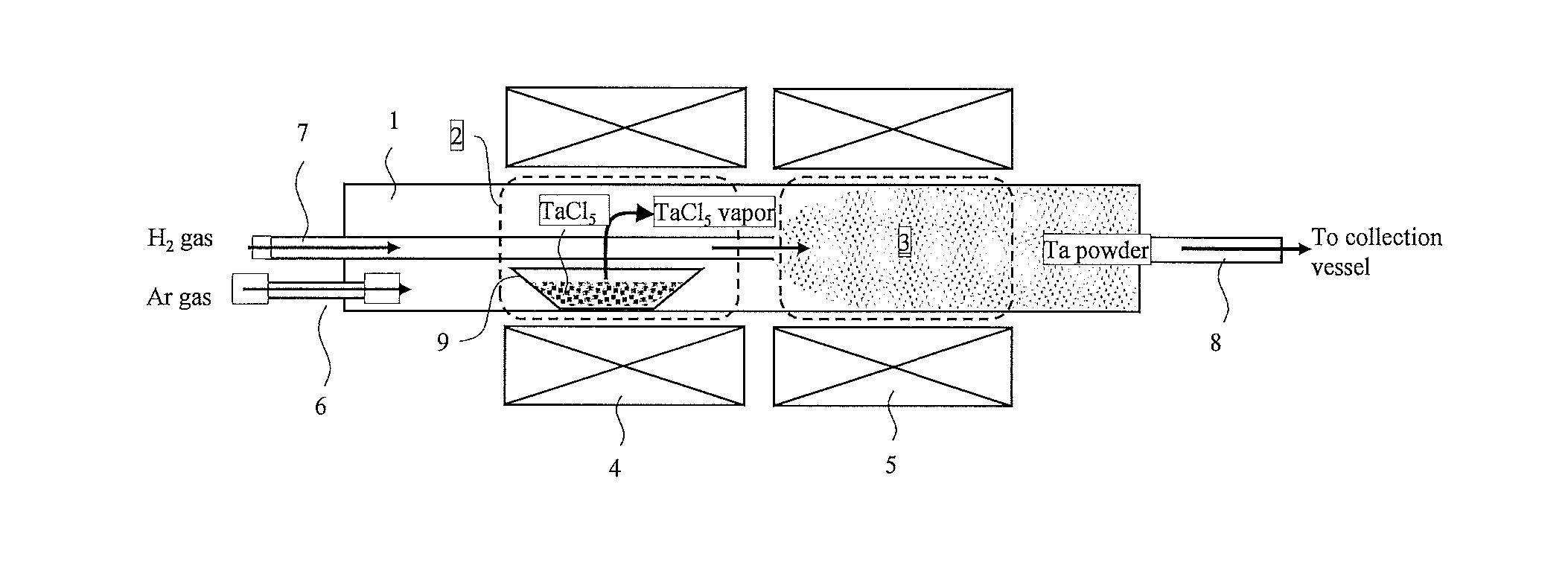

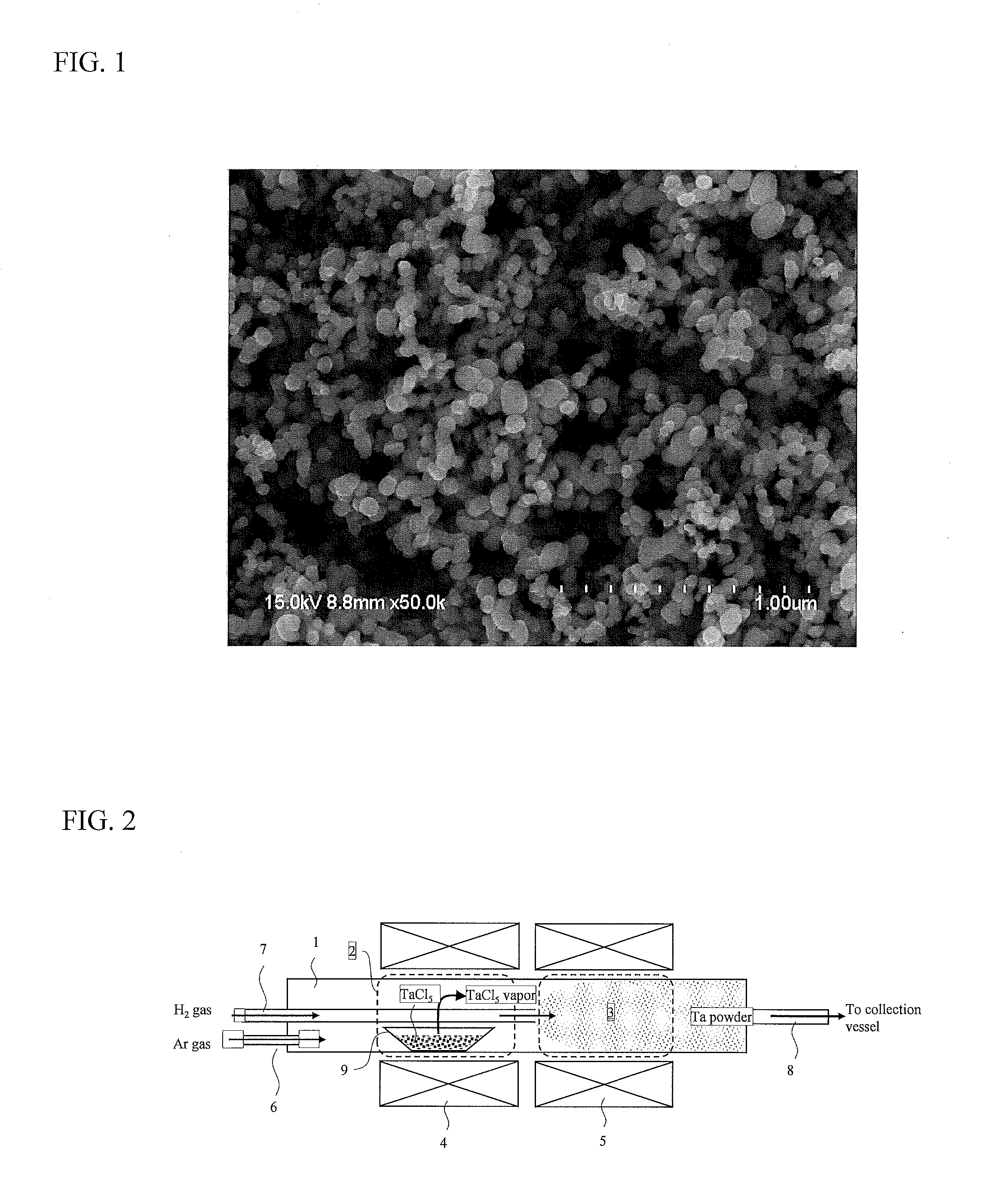

Method of producing Ta powder for tantalum solid electrolytic capacitor capable of stably providing CV value of more than 220 k and to provide the Ta powder and its Ta granulated powder. In method of producing Ta powder by vaporizing TaCl5 through heating and reducing with H2 gas, the reduction is performed under conditions that feeding rate of TaCl5 vapor passing through section area of reaction field of 1 cm2 for 1 minute is 0.05˜5.0 g / cm2·min and residence time of TaCl5 vapor in the reduction reaction field is 0.1˜5 seconds and reduction temperature of TaCl5 is 1100˜1600° C., whereby Ta powder including a single phase of β-Ta of tetragonal system or mixed phase of β-Ta and α-Ta of cubic system and having average particle size of 30˜150 nm is obtained. Further, Ta granulated powder is obtained by granulating the Ta powder.

Owner:ISHIHARA CHEM

Covering material for immobilized in-situ remediation of nitrogen in bottom sediment and preparation method thereof

ActiveCN102701552AMeet industrial requirementsReduce ammonia nitrogen contentSludge treatmentWater/sewage treatment by ion-exchangeIon exchangeAmmonium adsorption

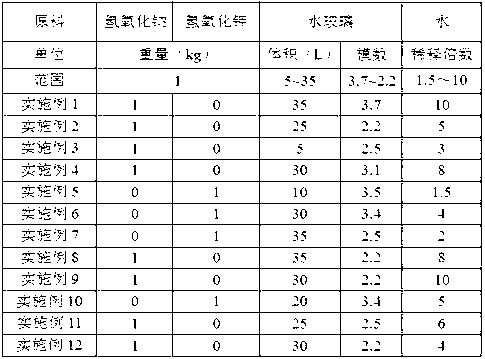

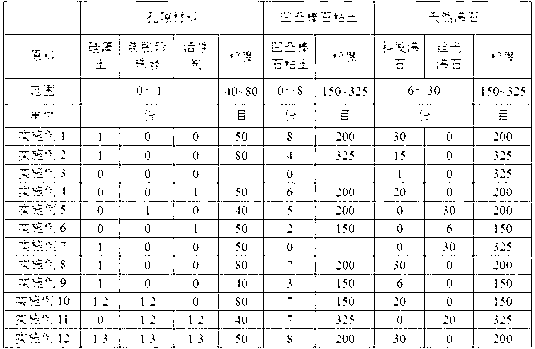

The invention discloses a covering material for immobilized in-situ remediation of nitrogen in bottom sediment and a preparation method of the covering material, belonging to the technical field of bottom sediment covering of surface water body. The covering material is the mixture of a powdery raw material and a binding agent, wherein relative to 1L of the binding agent constituting the covering material, the content of the powdery raw material is 1-2kg; the powdery raw material comprises the following components in parts by weight: 0-1 part of porous material, 0-8 parts of attapulgite clay and 6-30 parts of natural zeolite; the binding agent consists of an active material and an excitant; and relative to 1kg of the active material constituting the binding agent, the content of the excitant is 1-3L. According to the preparation method, the powdery raw material consists of natural materials such as zeolite, the binding agent consists of inorganic polymers, and the covering material is granulated and formed by an extruder and cured at room temperature. The covering material is a medium material with strong ion exchange capability and excellent biological load property and does not need to be sintered; and moreover, the covering material provided by the invention has the advantages of higher ammonium adsorption capability and lower cost as compared with the traditional materials.

Owner:NANJING UNIV

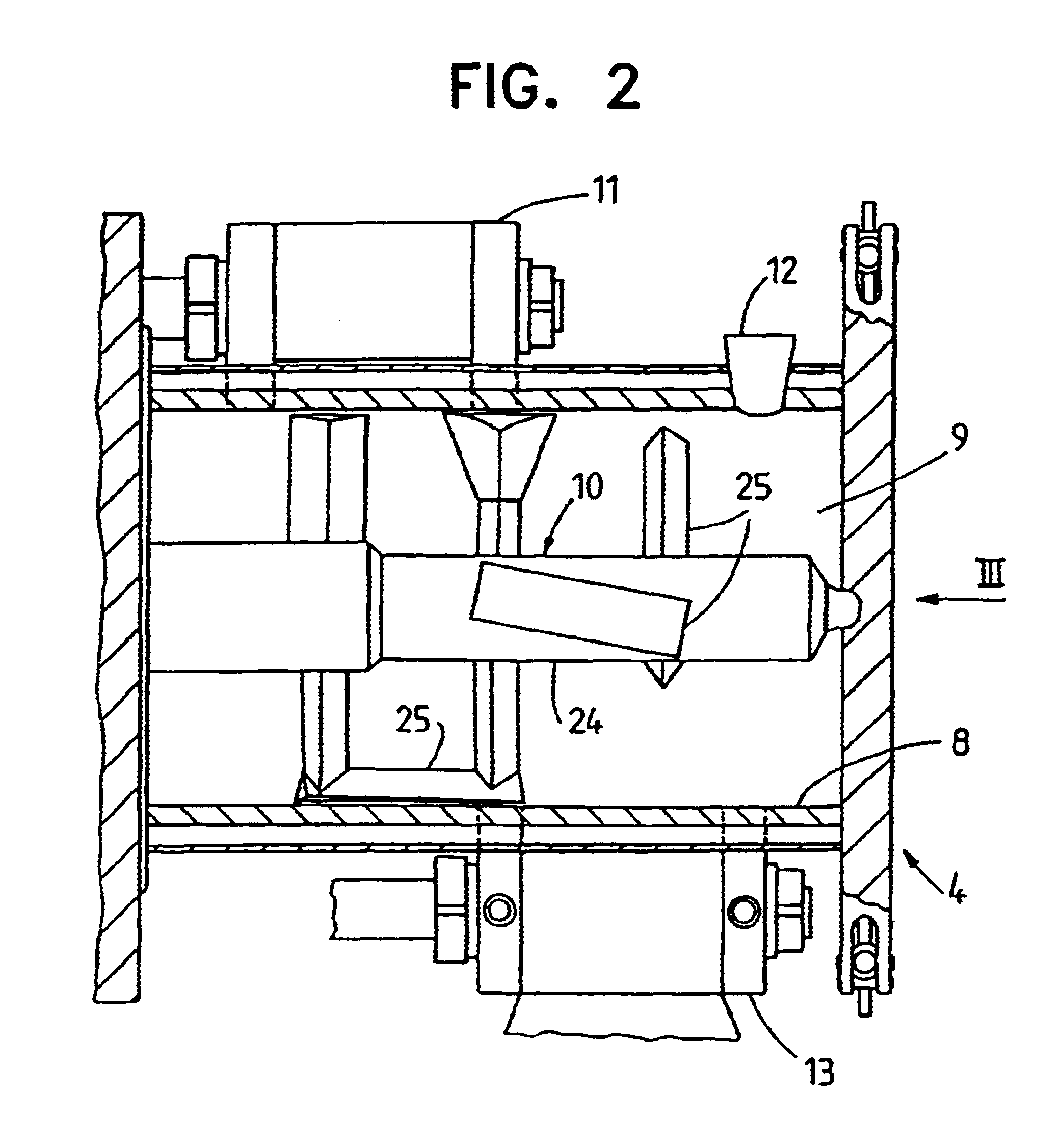

Process and apparatus for continuous wet granulation of powder material

ActiveUS7910030B2Simple processQuantity minimizationRotary stirring mixersFrozen sweetsEngineeringActive ingredient

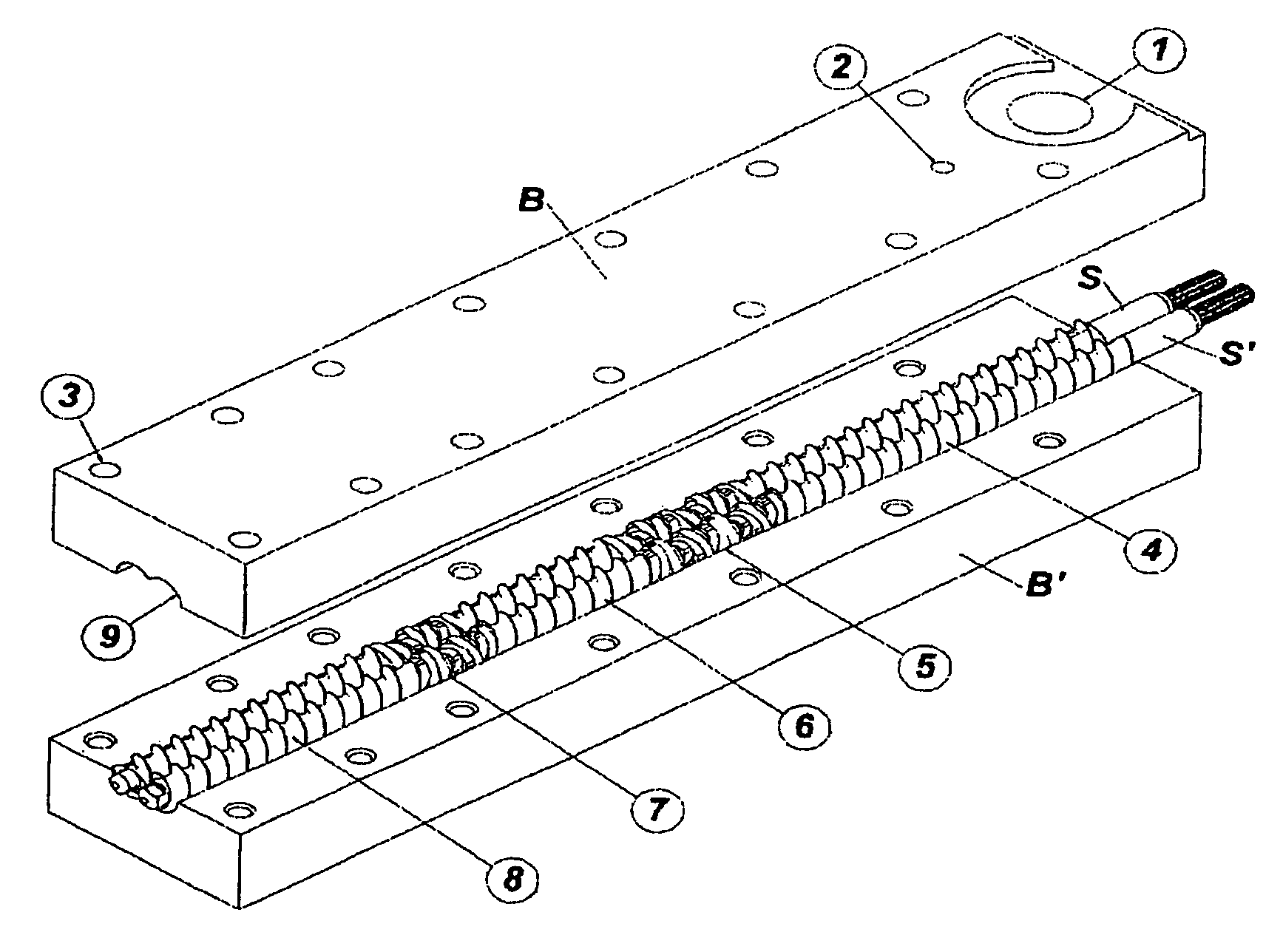

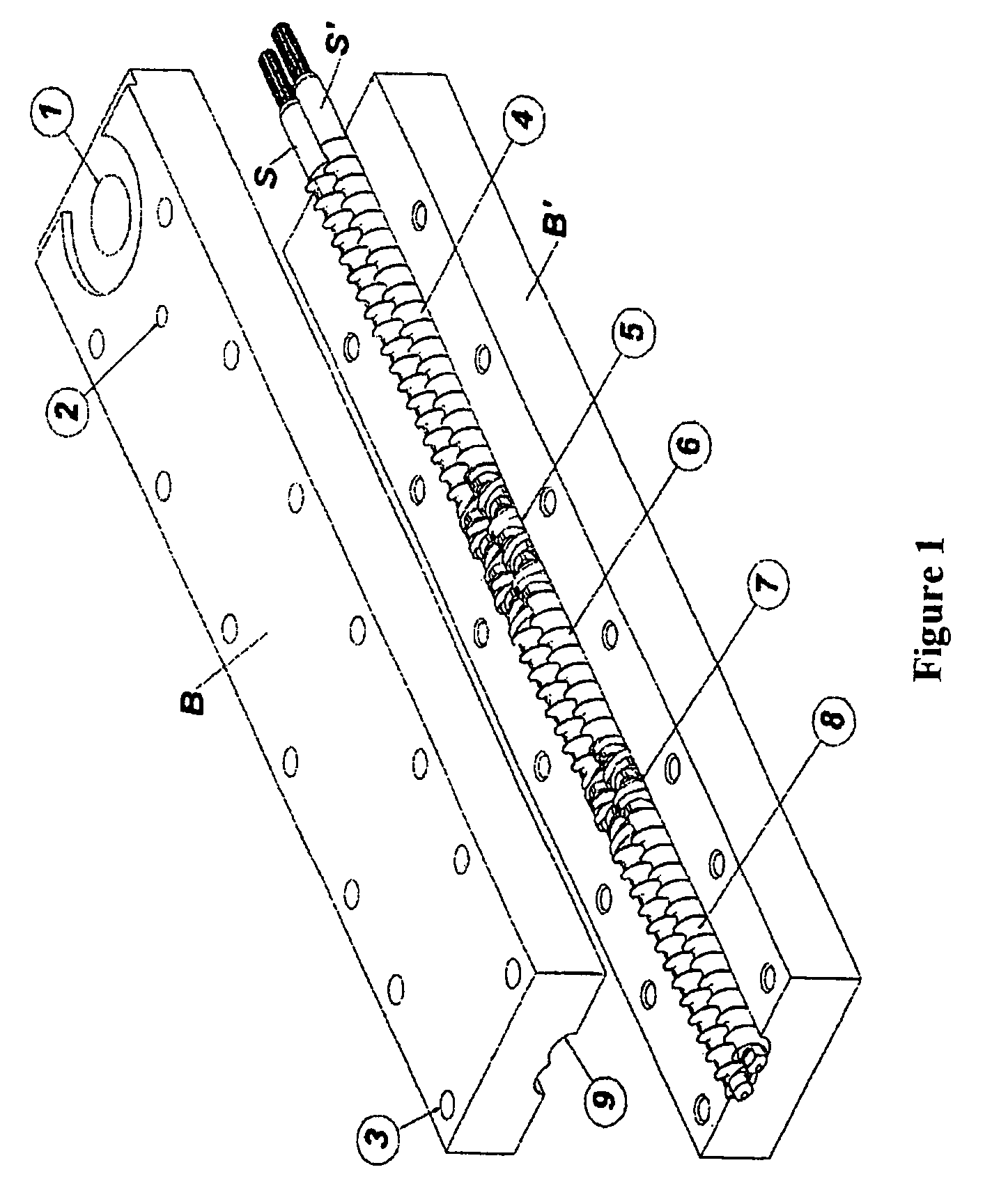

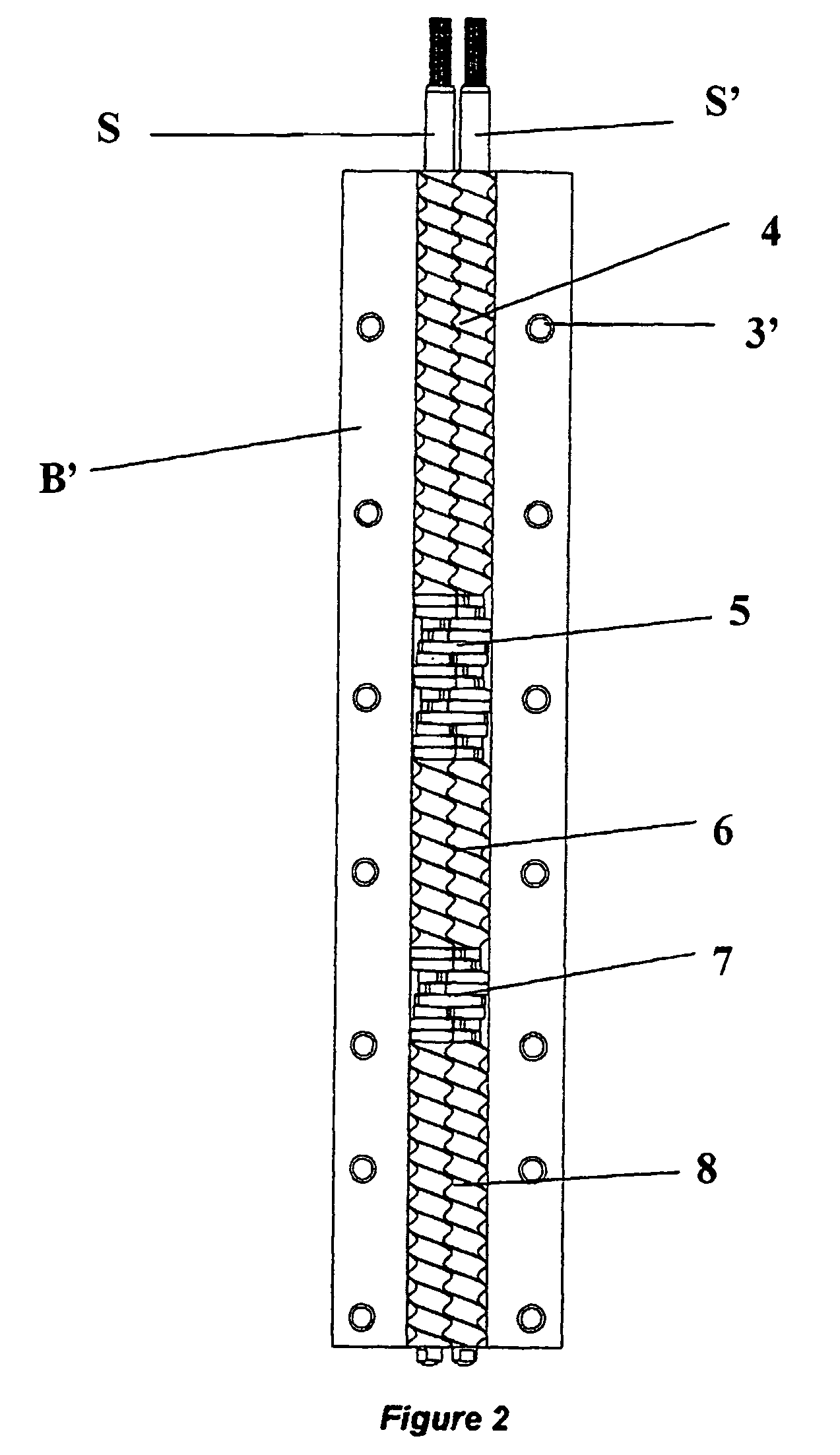

An apparatus for wet granulating a powder material comprises: —a barrel having a granulation chamber and being provided with a first inlet (1) for receiving said powder material and for supplying it to said granulation chamber and with a second inlet (2) for receiving a granulating liquid and for supplying it to said granulation chamber, said granulation having an aperture (9) for discharge of granules from said barrel, and —a transporting means (S) for advancing said powder material toward the end of said granulation chamber while granulating it with the aid of said granulating liquid, said transporting means (S) comprising a first transport zone (4) at its rear end, an agglomeration zone (5) downstream from the first transport zone (4) and a second transport zone (8) at its front end, said first inlet (1) and said second inlet (2) being positioned above the first transport zone (4), wherein said aperture (9) has a shape tightly fitting the terminal portion of the transporting means (S) for directly discharging said granules from the granulation chamber. The apparatus is useful for continuously wet granulating biologically-active ingredient formulations, chemicals, detergents and foodstuffs.

Owner:UNIV GENT

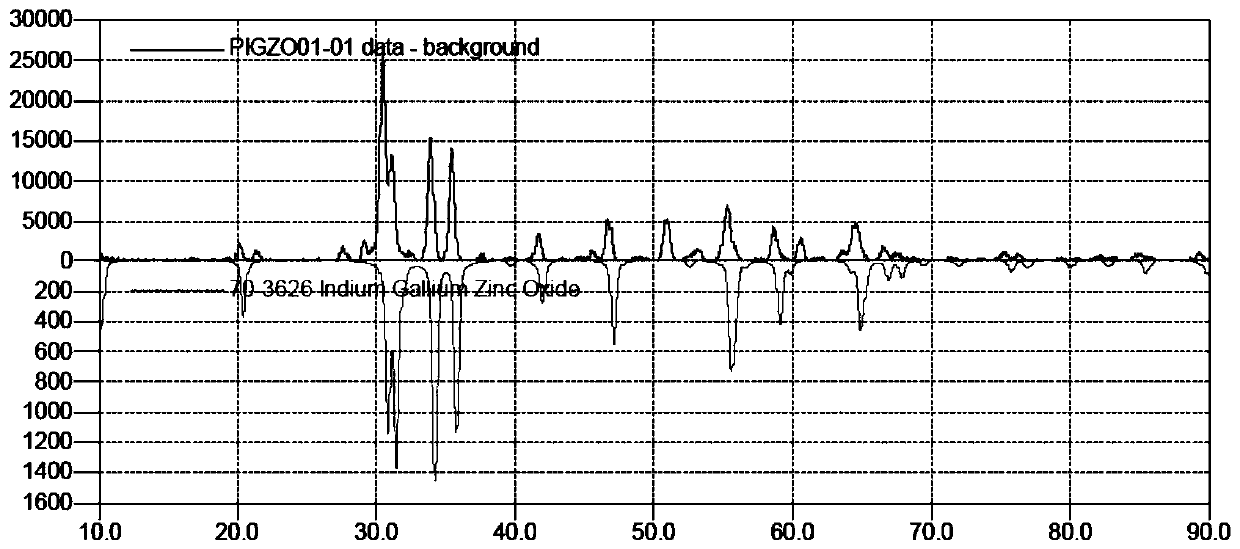

Oxide sintered body, sputtering target, transparent conductive thin film and manufacturing method therefor

InactiveCN1690011ALower specific resistanceImprove permeabilityConductive layers on insulating-supportsElectroluminescent light sourcesElectrical resistance and conductanceThin membrane

There is provided an amorphous transparent conductive thin film with a low resistivity, a low absolute value for the internal stress of the film, and a high transmittance in the visible light range, an oxide sintered body for manufacturing the amorphous transparent conductive thin film, and a sputtering target obtained therefrom. An oxide sintered body is obtained by: preparing In2O3 powder, WO3 powder, and ZnO powder with an average grain size of less than 1 mum so that tungsten is at a W / In atomic number ratio of 0.004 to 0.023, and zinc is at a Zn / In atomic number ratio of 0.004 to 0.100; mixing the prepared powder for 10 to 30 hours; granulating the obtained mixed powder until the average grain size is 20 to 150 mum; molding the obtained granulated powder by a cold isostatic press with a pressure of 2 to 5 ton / cm2, and sintering the obtained compact at 1200 to 1500 degree.C. for 10 to 40 hours in an atmosphere where oxygen is introduced into the atmosphere of the sinter furnace at a rate of 50 to 250 liters / min per 0.1 m3 furnace volume.

Owner:SUMITOMO METAL MINING CO LTD

Method for manufacturing photocatalyst multifunctional dust-free active carbon color ball

InactiveUS20120083403A1Single functionImprove adsorption capacityGas treatmentCatalyst protectionMordeniteFar infrared

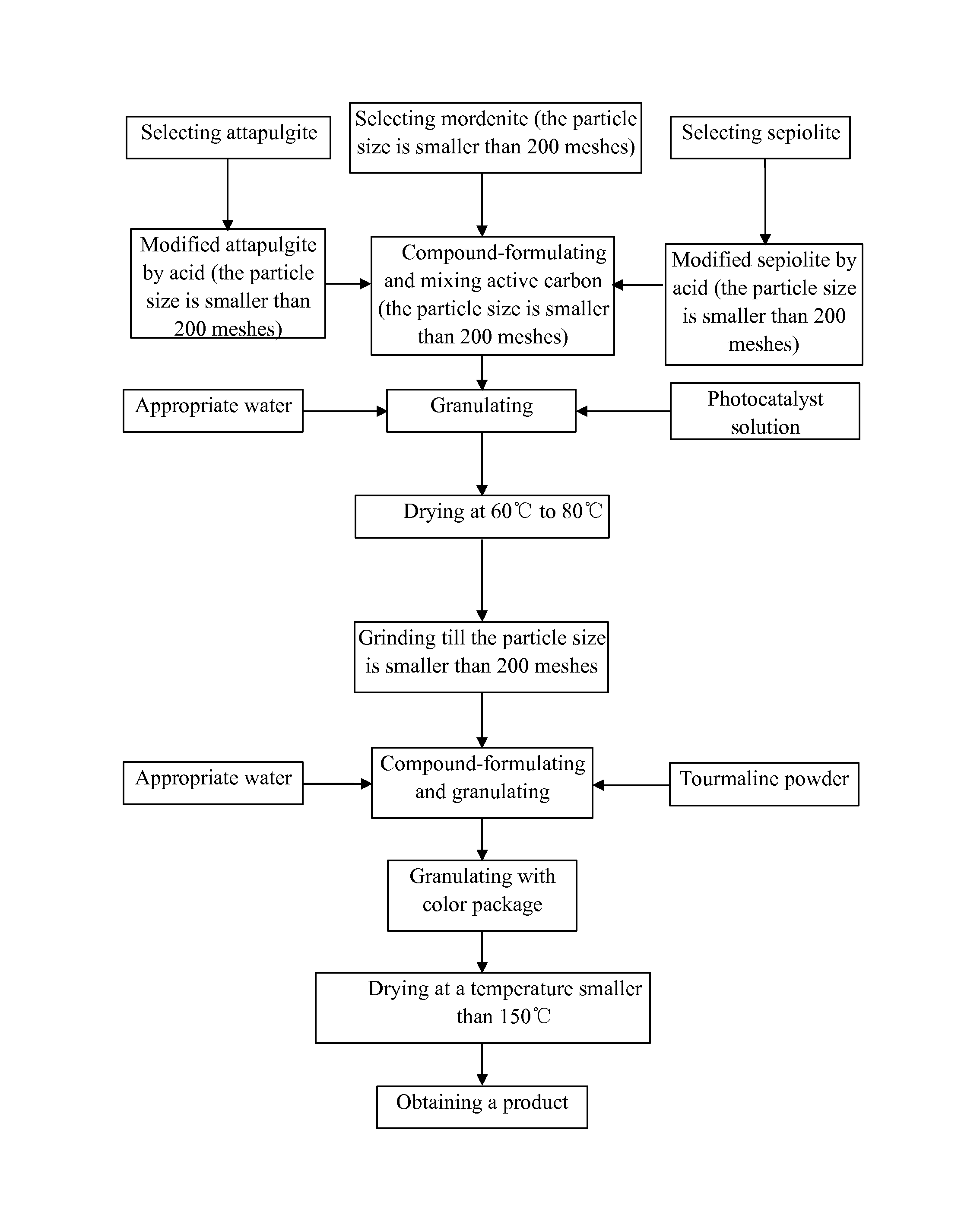

A method for manufacturing photocatalyst multifunctional dust-free active carbon color ball includes the steps of (1) compound-formulating and mixing 8%-15% attapulgite, 8%-15% sepiolite, 5%-10% mordenite and 50%-65% active carbon; (2) after step (1), granulating by adding 5%-10% photocatalyst and appropriate water and mixing; (3) after step (2), drying at 60° C.-80° C. and then grinding till the particle size is smaller than 200 meshes; (4) after step (3), compound-formulating and granulating by adding 5%-10% tourmaline powder and appropriate water; and (5) after step (4), drying at 150° C. and obtaining a product, wherein the percentage of every raw material is expressed by weight. The photocatalyst multifunctional dust-free active carbon color ball can strongly adsorb formaldehyde, benzene, ammonia, sulfur dioxide, carbon monoxide and other harmful toxic polar molecules, and has multiple functions of adsorption, decomposition, releasing negative ions, emitting far infrared, instead of the originally single adsorption function of active carbon.

Owner:NINGBO CANGHAI NEW MATERIALS DEV

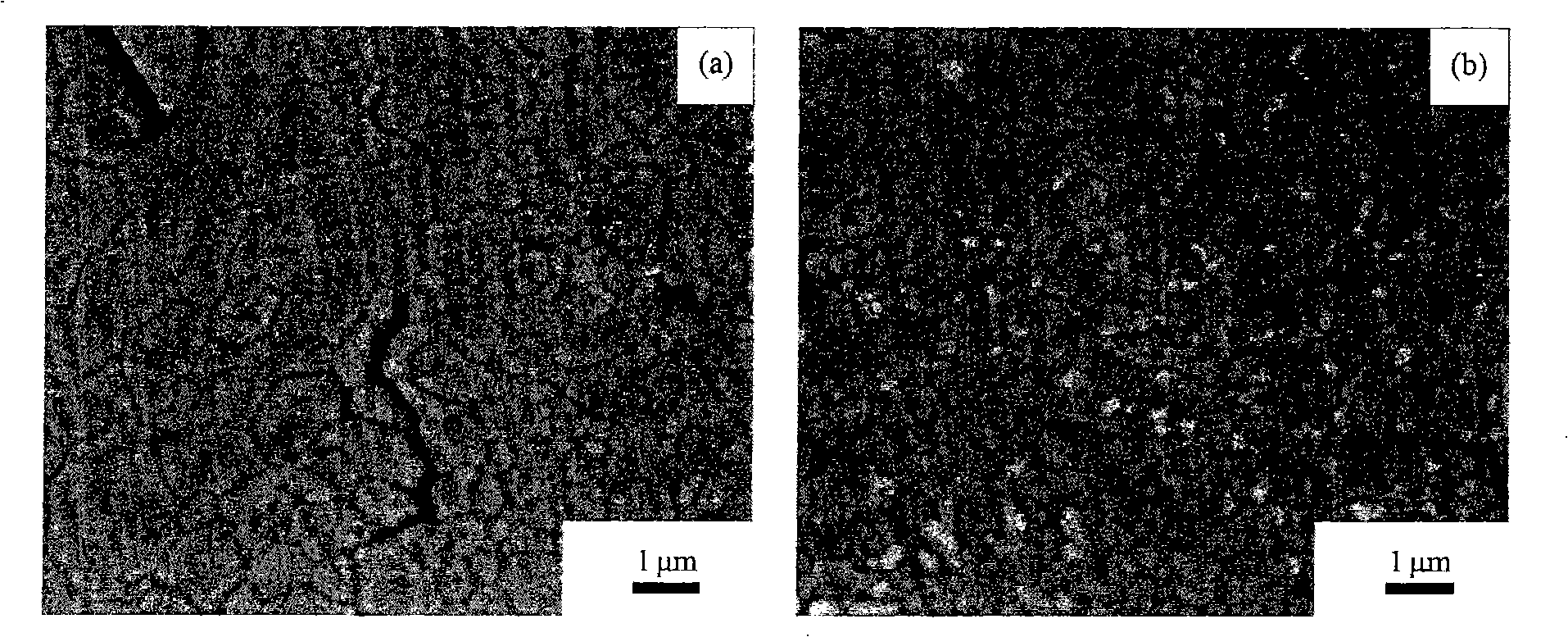

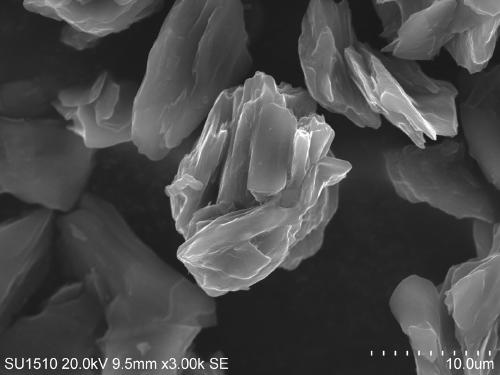

Silicon-carbon cathode material with artificial SEI layers, high specific volumetric capacity and cycle performance

ActiveCN106207177AImprove cycle performanceIncrease capacityMaterial nanotechnologyCell electrodesCarbon compositesLithium-ion battery

The invention relates to a silicon-carbon cathode material with artificial SEI layers, high specific volumetric capacity and cycle performance and application of the silicon-carbon cathode material. The silicon-carbon cathode material is of an intermediate-phase graphite structure which is secondarily granulated, outer shell layers of the intermediate-phase graphite structure are amorphous carbon coating layers, inner shell layers of the intermediate-phase graphite structure are dense LiF membranes, and nanometer silicon is uniformly dispersed to form cores of the intermediate-phase graphite structure. A method for preparing the silicon-carbon cathode material includes steps of 1, crushing and shaping intermediate-phase graphite balls with large particle diameters to obtain intermediate-phase graphite micro-powder with median particle diameters of approximately 7 micrometers; 2, carrying out ball-milling dispersion on the nanometer silicon and the micro-powder obtained at the step 1; 3, uniformly mixing lithium acetate solution and materials obtained at the step 2 with one another; 4, carrying out dropwise addition reaction on NH4F solution and materials obtained at the step 3; 5, carrying out spray-drying on materials obtained at the step 4; 6, mixing PVDF (polyvinylidene fluoride) and materials obtained at the step 5 with one another to obtain mixtures and granulating and coating the mixtures; 7, immobilizing and carbonizing materials obtained at the step 6; 8, sieving materials obtained at the step 7. The silicon-carbon cathode material and the application have the advantages that the silicon-carbon composite cathode material is stable in cycle performance, high in specific volumetric capacity and easy to industrially produce; a lithium ion battery with a cathode which is processed from the silicon-carbon cathode material is high in specific volumetric capacity and excellent in cycle performance.

Owner:天津爱敏特电池材料有限公司

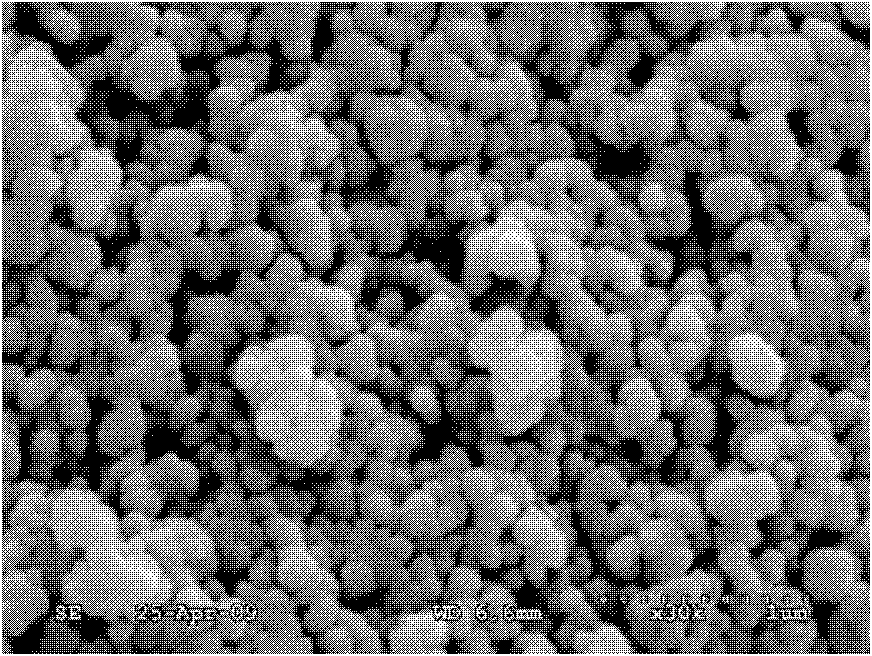

Microballons of laminar dual hydroxy composite metal oxide and preparation method

This invention relates to a method for preparing lamellar dihydroxyl composite metal oxide microspheres. The method comprises: preparing lamellar dihydroxyl composite metal oxide (hydrotalcite) nano- or submicro-particles by co-precipitation, nucleation / crystallization / isolation, nonequilibrium crystallization or hydrothermal synthesis, preparing into slurry with a certain solid content, adding bonding agent, spin-spraying for granulation, and drying to obtain microspheres with diameters of 5-100 mu.m. The bulk density, specific surface area, pore volume and most probable pore diameters of the microspheres are 0.4-0.8 g / cm3, 40-150 m2 / g, 0.1-0.8 cm3 / g and 2-40 nm, respectively. The microspheres can be directly used for catalysis or separation after activated, and the mass transfer resistance and carbon accumulation are minimized.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing magnetic charcoal material, device adopting method and application

ActiveCN109621897AAvoid resistanceIncrease the active siteOther chemical processesNature of treatment waterSludgeEconomic benefits

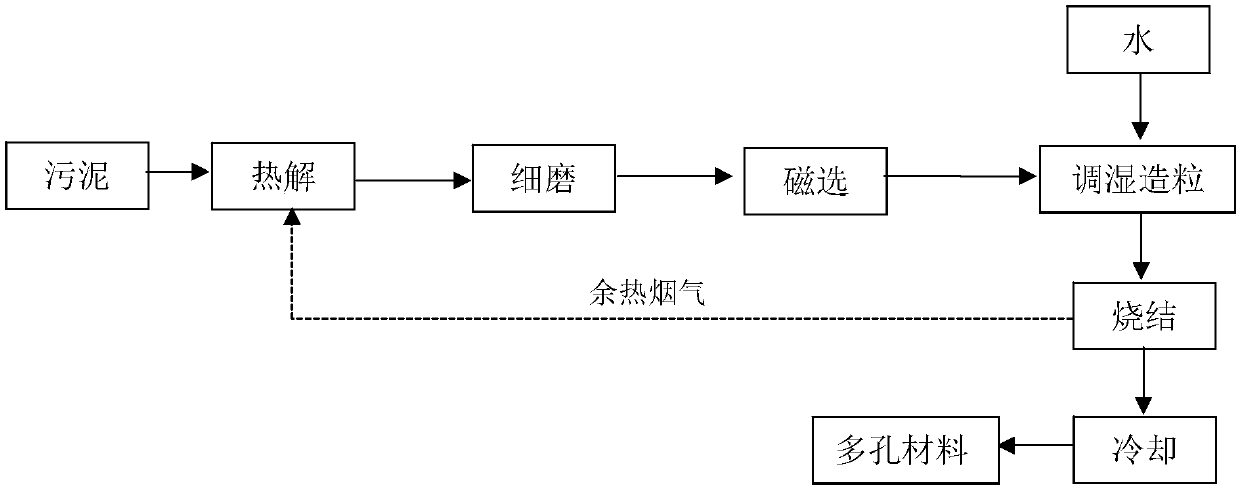

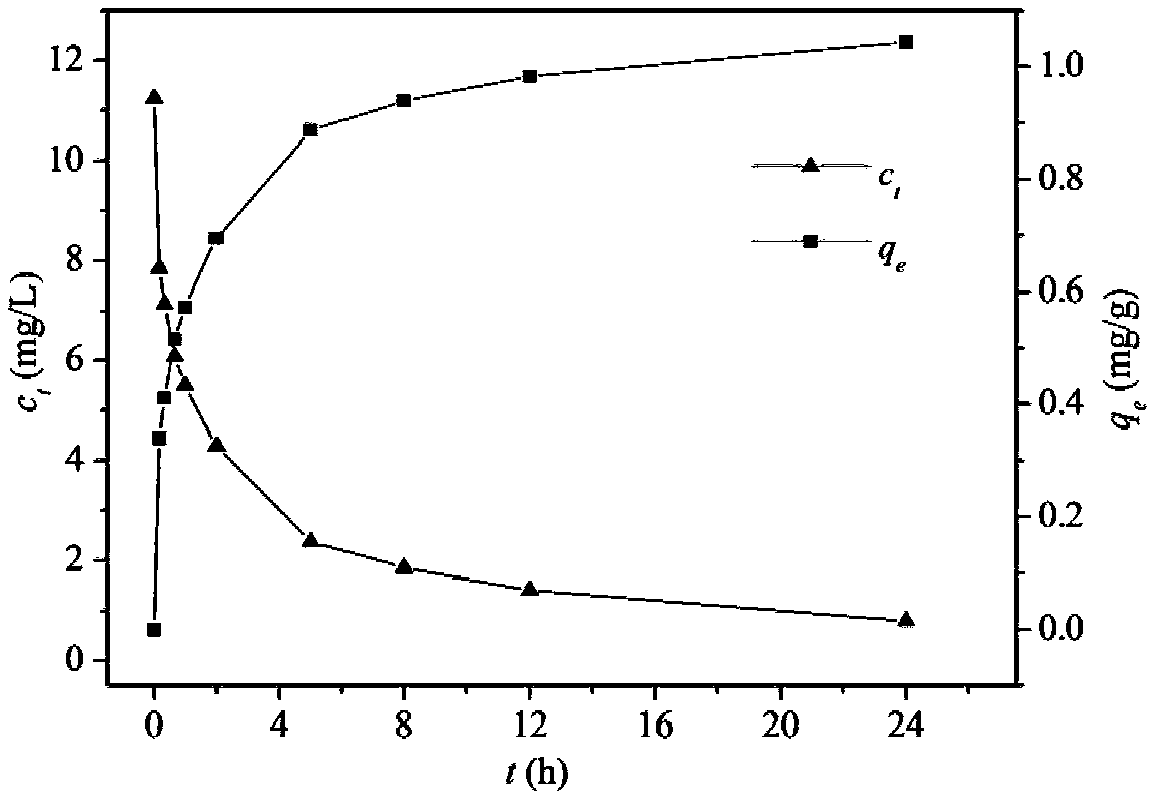

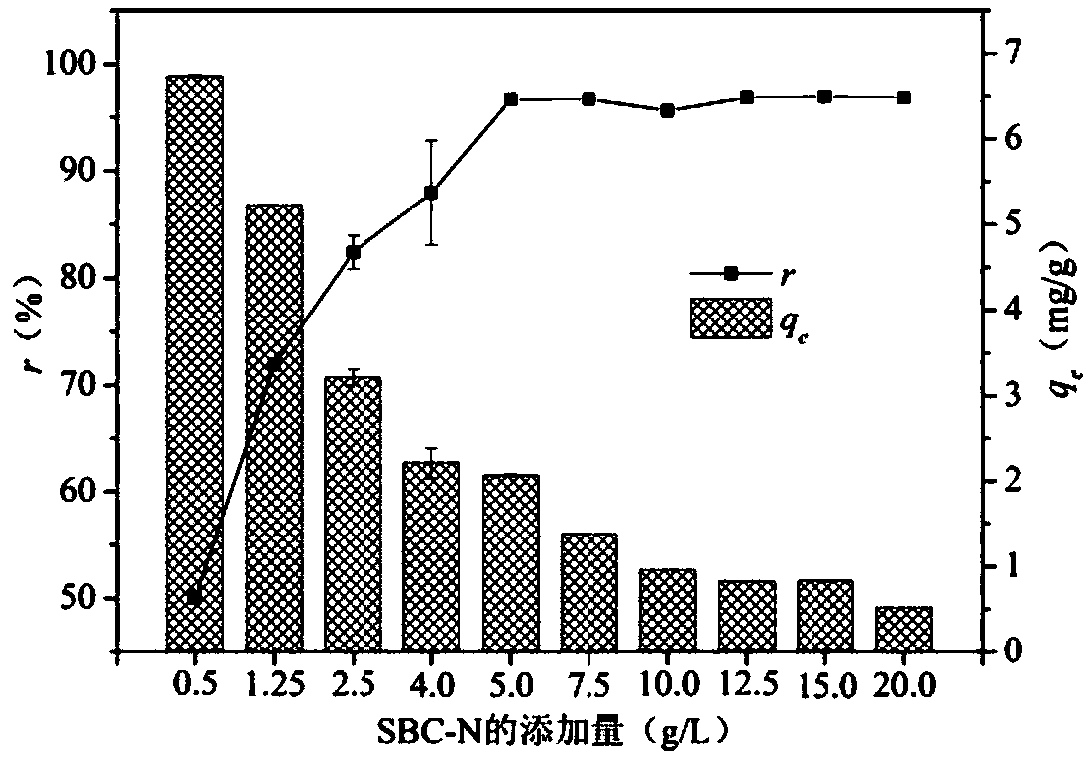

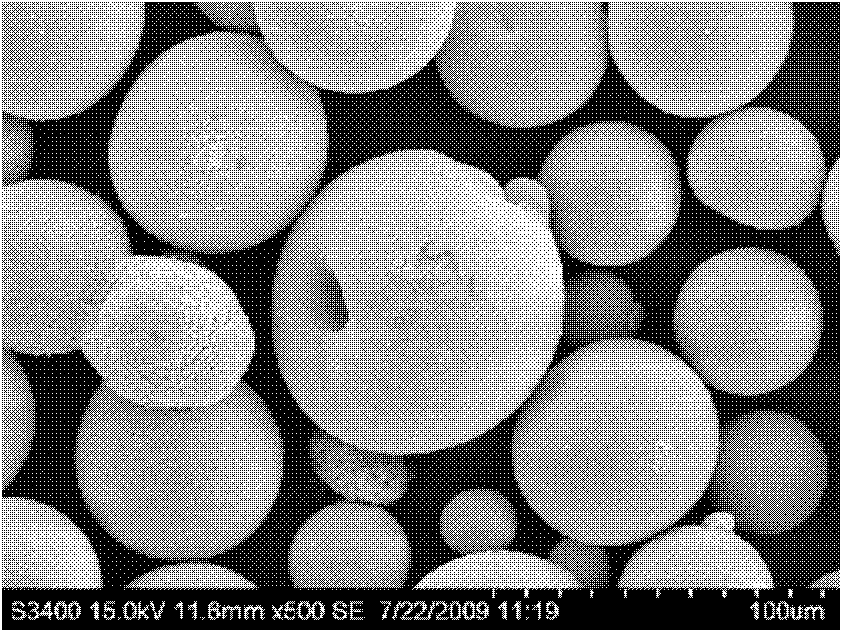

The invention relates to a method for preparing a magnetic charcoal material, a device adopting the method and application. The method comprises the following steps that sewage treatment plant sludgeis subjected to high-temperature anaerobic pyrolysis, and sludge charcoal is obtained; then dry fine grinding is carried out, and charcoal powder is obtained; the sludge charcoal powder is subjected to dry magnetic separation, a magnetic material is obtained, granules obtained after humidifying and pelleting are subjected to high-temperature sintering in protective atmosphere, and sintered materials are obtained; furnace cooling is carried out, and the magnetic charcoal material of a porous structure is obtained. According to the method, the magnetic material is separated out of the sludge pyrolysis product charcoal and is used for preparing the magnetic charcoal material, the magnetic charcoal material is used for efficiently adsorbing and removing quinolone antibiotics such as ciprofloxacin, recycling utilization of the sludge charcoal is achieved, the preparation cost of the adsorption materials is reduced, the process is simple, high practicality is achieved, and good economic benefits and environmental benefits are achieved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

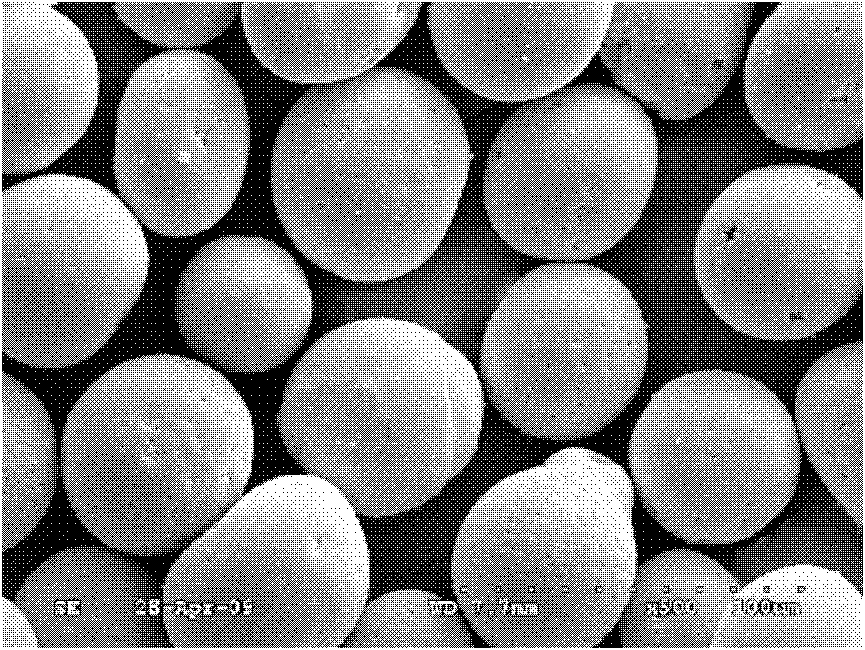

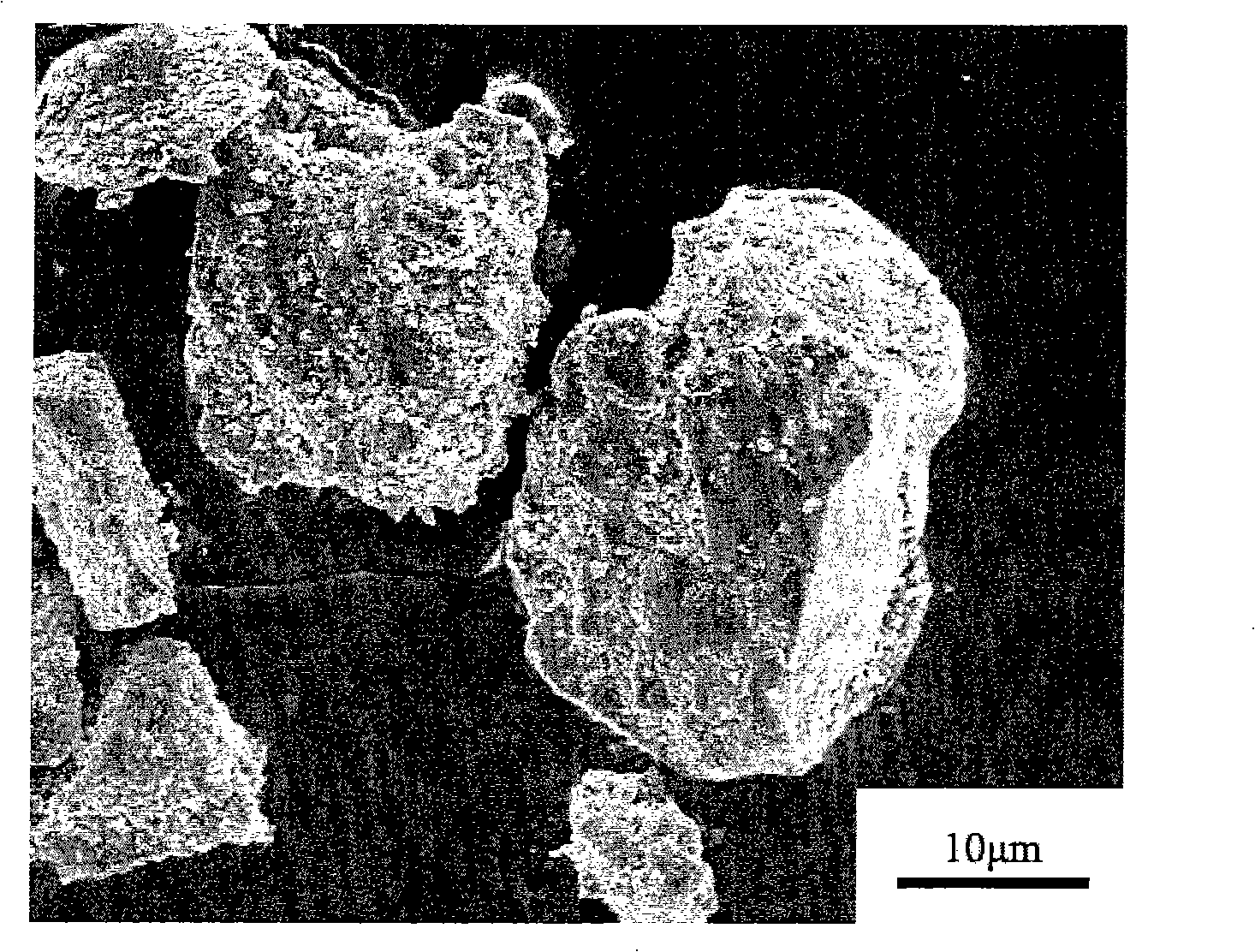

Yttria stabilized zirconia powder, its preparation method and formed coating

The invention discloses a yttria stabilized zirconia powder with low impurity content and a preparation method thereof. The yttria stabilized zirconia powder is a composite powder with a nanostructured shell cladding nanometer particles. The preparation method comprises the following steps of: carrying out low temperature drying by the use of a nanometer YPSZ amorphous powder synthesized by a continuous coprecipitation method; carrying out ball milling dispersion on parts of the nanometer YPSZ powder which has undergone crystalline conversion, and carrying out spray drying granulation, screening and calcining on dispersed slurry; and carrying out plasma densification treatment, drying and screening on the calcined powder so as to finally obtain the spherical powder with the nanostructured shell cladding nanometer particles. The YPSZ powder for thermal spraying has very low impurity content, and the content of a single impurity is lower than 100 ppm. A compact shell is formed outside the nanometer YPSZ agglomerate particles, thus raising apparent density and fluidity of the agglomerate powder and increasing the melting effect of the powder in plasma.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

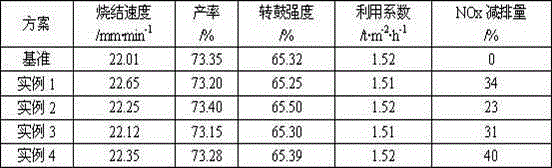

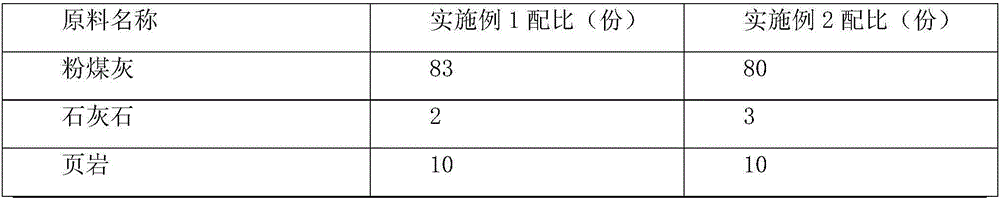

Method for reducing NOx emission in iron ore sintering process

ActiveCN105087906AReduce generationEmission reductionFuel additivesIron ore sinteringMixed materials

The invention discloses a method for reducing NOx emission in the iron ore sintering process. Firstly, conventional sintering fuel coke powder or anthracite is screened into three grain sizes of -1 mm, 1-3 mm and +3 mm; the coke powder or anthracite with the grain size being -1 mm and high-reaction-activity fossil fuel or biomass fuel with the grain size being -1 mm are pressed into fuel particles with the grain size being 1-3 mm; the fuel particles obtained through pressing with the grain size being 1-3 mm and the coke powder or anthracite obtained through screening with the grain size being 1-3 mm are added into fine particle iron ore, part of coarse particle iron ore, flux and return mines to be subjected to granulation in a rotary drum mixer; and the granulated mixed material, modified coke powder or anthracite with the particle size being +3 mm and the remaining coarse particle iron ore are subjected to secondary mixing granulation, and the obtained mixed material is distributed and then ignited and sintered. Generation of fossil fuel NOx in each grain size is controlled specifically according to the features of NOx generated by the fossil fuel in different grain sizes, so that generation of NOx is reduced to a greater extent to reduce NOx emission, and NOx emission is reduced by 20%-40%.

Owner:CENT SOUTH UNIV

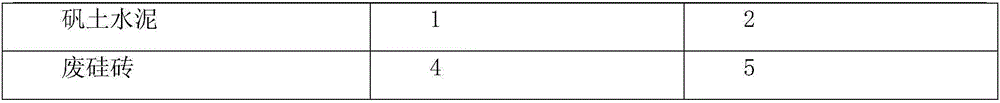

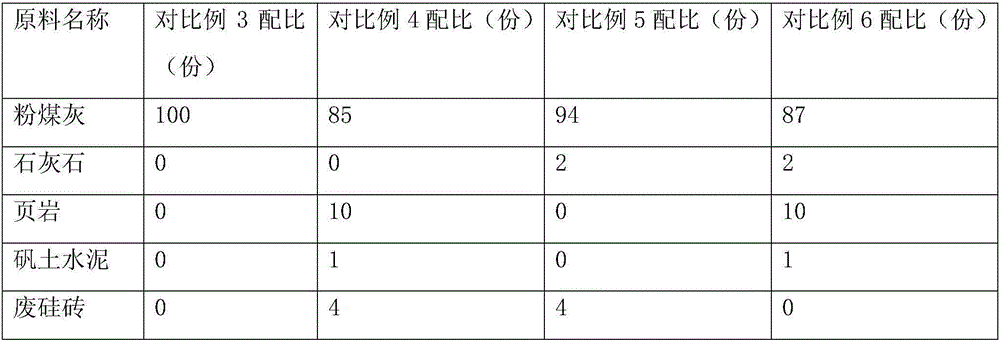

Preparation method of light-weight and high-intensity coal ash ceramsites

ActiveCN106396634AHigh strengthHigh ball rateCeramic materials productionCeramicwarePorosityEconomic benefits

Owner:PANZHIHUA UNIV

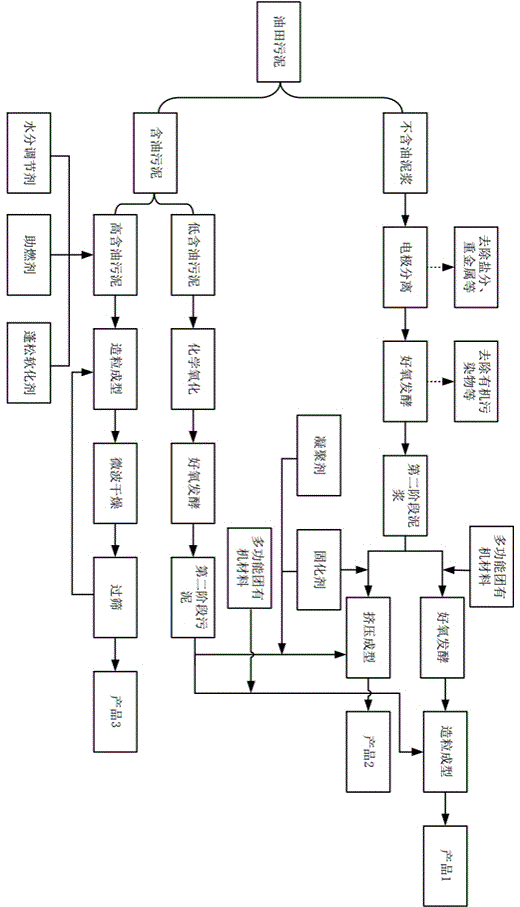

Comprehensive utilization method of oil field drilling sludge

The invention relates to the technical field of resource development, in particular to a comprehensive utilization method of oil field drilling sludge. Sludge which does not contain oil is subjected to electrode separation, aerobic fermentation and granulation to form a product 1 or is subjected to extrusion forming to form a product 2; sludge which contains low content of oil is subjected to oxidation, aerobic fermentation and extrusion forming to form the product 2 or is subjected to granulation to form the product 1; sludge containing high content of oil is added with a moisture modifier, a combustion improver and a bulking and softening agent and is subjected to granulation forming and microwave drying, dried granules are screened, undersize materials are subjected to granulation forming again, and oversize materials form a product 3. Compared with the prior art, oil field drilling sludge, oily sludge and oil sludge and sand with different oil content are treated from the perspective of comprehensive utilization of resources, and the ultimate products can be effectively used as different resources.

Owner:韩京龙

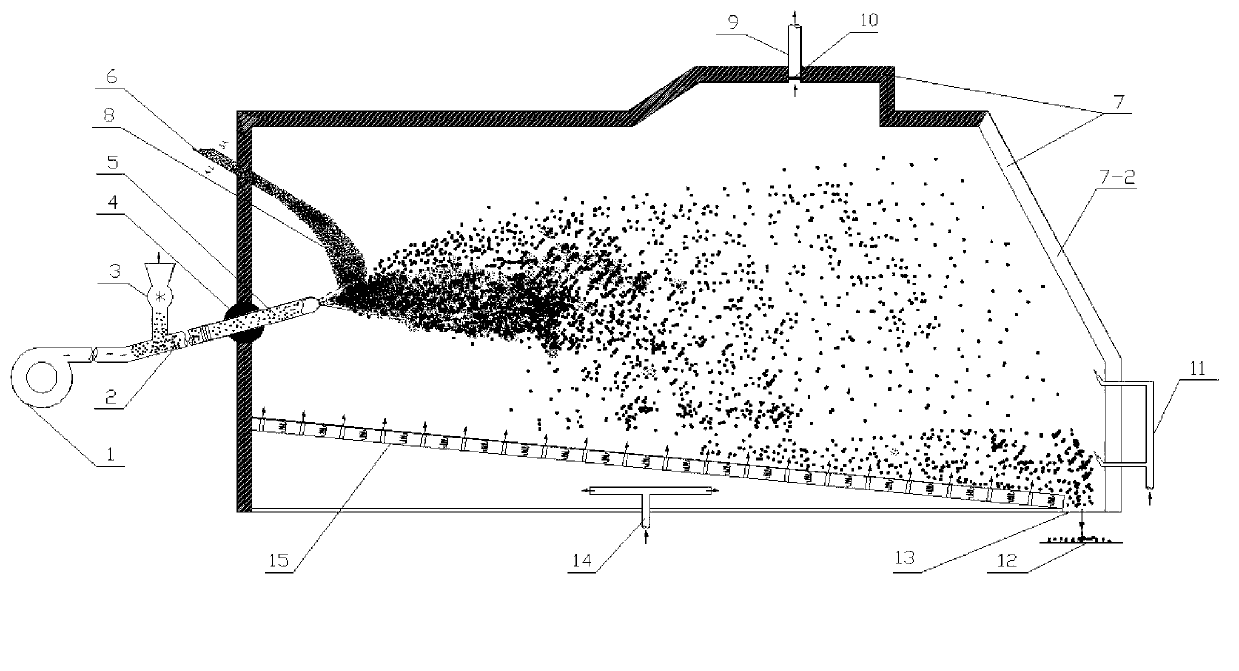

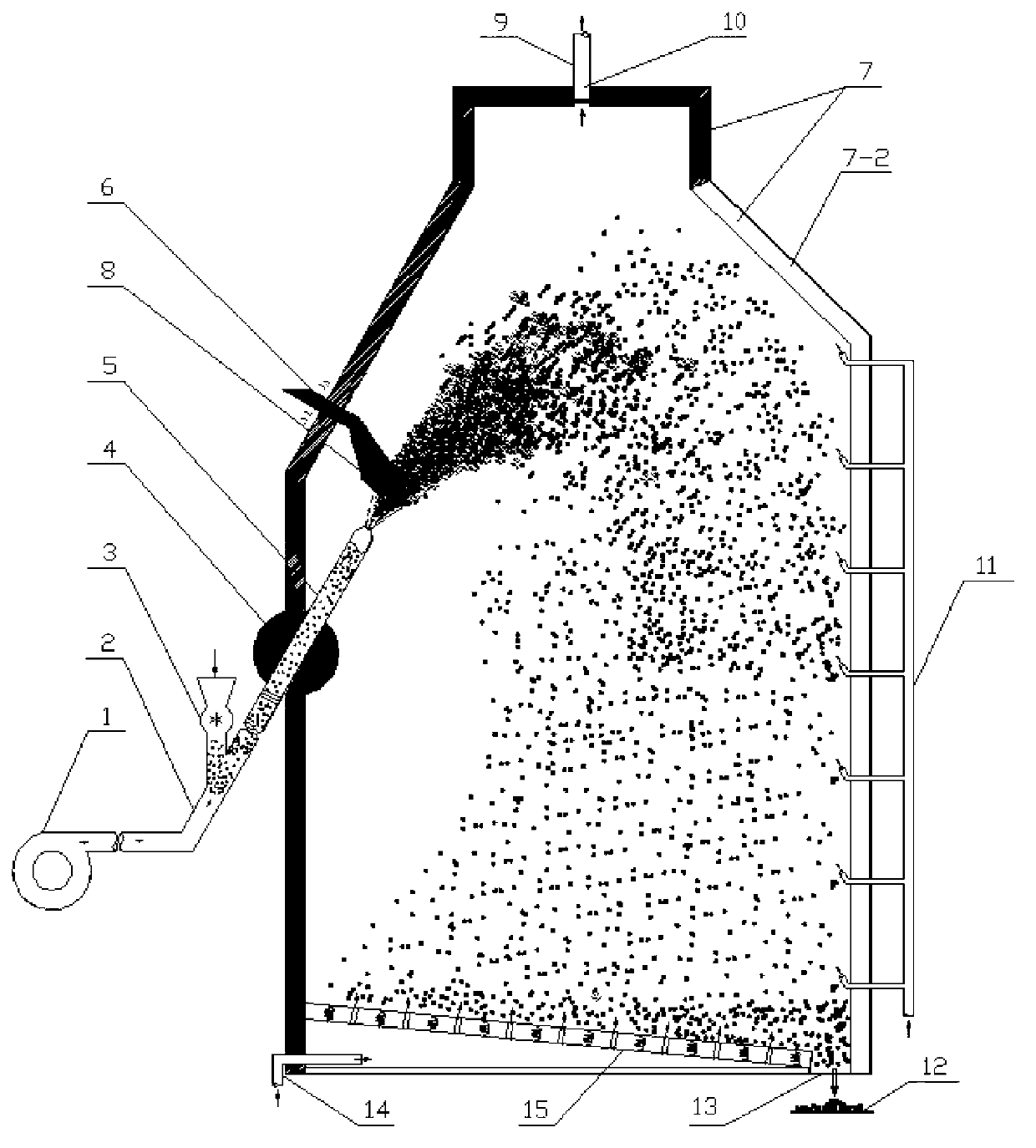

Device and method for gas-solid ejection and granulation of molten blast furnace slags

InactiveCN103014201AUniform grainEasy to control distanceRecycling and recovery technologiesGas solidMolten slag

The invention relates to a device and a method for gas-solid ejection and granulation of molten blast furnace slags. The device comprises a molten slag lead-in unit, an ejection agent supply unit, a device wall cooling and anti-sticking unit, a rapid cooling discharge unit and a high-temperature-air discharge unit. The method includes: using a mixture of high-pressure gas and solid granules as ejection and granulation agents, performing blowing and granulation for high-temperature molten blast furnace slag liquid flow at a high speed, and breaking the flow into molten slag granules; and then, during flying of the slag granules, rapidly cooling the slag granules by fluidified cooling gas sprayed into the lower portion and anti-sticking cooling gas ejected into via the side wall in an attaching manner so that the slag granules are rapidly solidified to solid granules, and the problem of sticking of the molten slag granules is solved effectively. The method is capable of greatly promoting kinetic energy of the ejection agents to be converted into granule surface energy, ejection agent energy use ratio is increased, the small uniform slag granules are obtained, granulation and rapid cooling are achieved, the slag granules with high vitreous body rate are obtained, and usability of molten blast furnace slag material resources is guaranteed while waste heat in the slags is recovered efficiently.

Owner:UNIV OF SCI & TECH BEIJING

Cross-linked polyethylene composition powder and its prepn

ActiveCN1974650AGuaranteed degree of cross-linkingCross-linking smoothlyLow-density polyethyleneLinear low-density polyethylene

The present invention discloses peroxide cross-linked polyethylene composition powder and its production process. The peroxide cross-linked polyethylene composition powder consists of: low density polyethylene of density 0.910-0.925 g / cu cm and MI 2-30 g / 10min in 70-90 weight portions, linear low density polyethylene graft of density 0.910-0.930 g / cu cm and MI 5-20 / 10min in 5-16 weight portions, high density polyethylene of density 0.940-0.960 g / cu cm and MI 0.5-10 g / 10 min in 1-10 weight portions, antioxidant in 0.1-1 weight portion, and cross-linking agent and assistant in 0.1-3 weight portions. Its production process includes extruding polyethylene composition in a double screw extruder to obtain granular composition, mixing the granular composition with cross-linking agent assistant, milling, and mixing with cross-linking agent. The cross-linked polyethylene composition powder may be cross-linking formed at low temperature.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Environment friendly composite material for controlling loss of nitrogen fertilizer and applications

This invention discloses a method for preparing environmentally friendly composite for controlling nitrogen fertilizer loss. The method comprises: (1) mixing attapulgite, chitosan, polyacrylamide, etc.; (2) irradiating at 500-1300 Gy to form the composite. The composite can be mixed with nitrogen fertilizer and granulated to form controlled-release nitrogen fertilizer granules (with diameters of 1.5-3 mm). The composite can cooperatively adsorb and fix nitrogen and decrease fertilizer requirement, thus can prevent nitrogen entry into water and air and efficiently control water eutrophication and greenhouse gas N2O emission. The composite has such advantages as low cost and high efficiency in fixing nitrogen.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

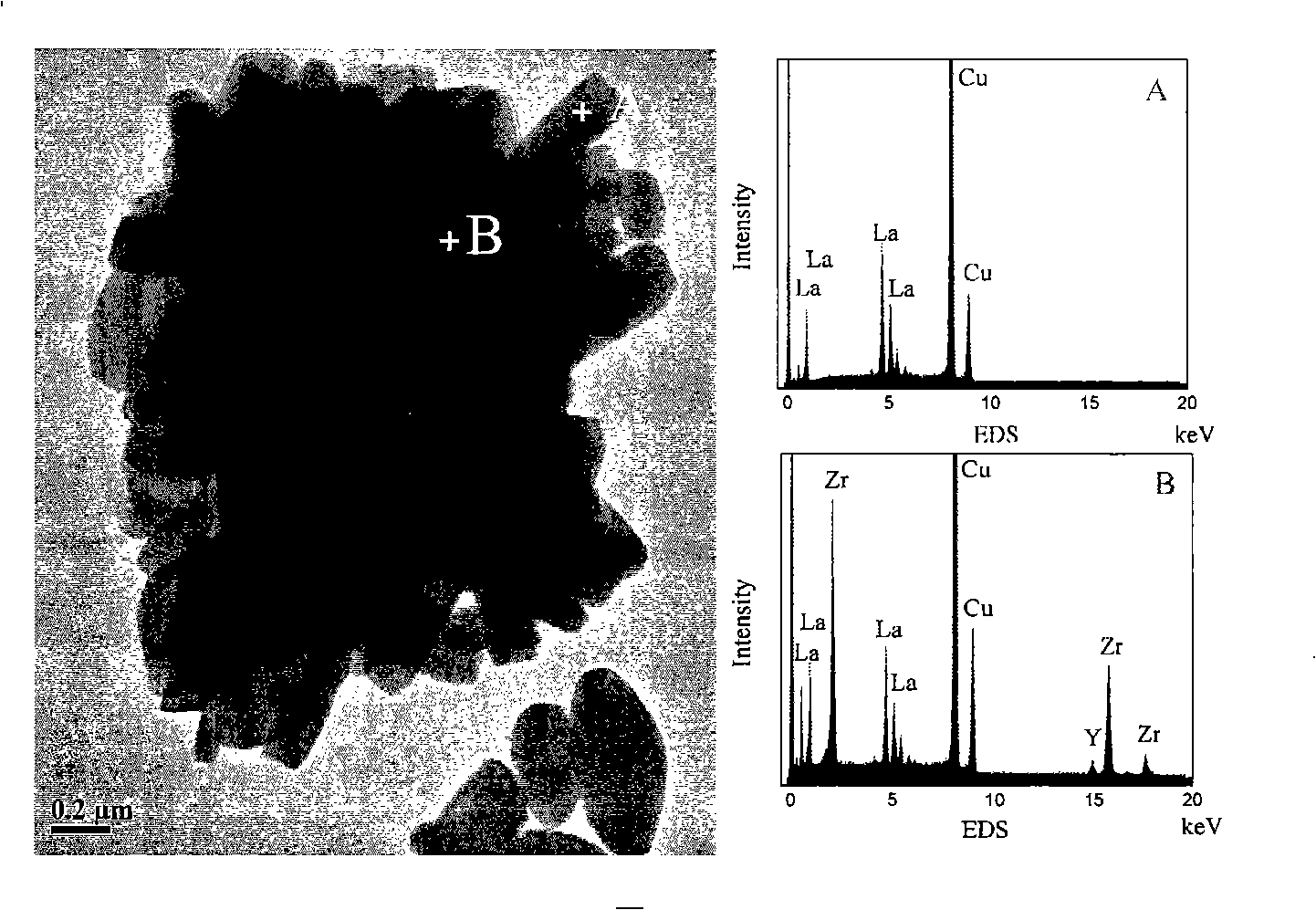

Yttrium coated stable zirconium oxide powder, preparation and application thereof

ActiveCN101318824AGood anti-sinteringImprove anti-sintering performanceReaction temperatureThermal barrier coating

The invention relates to a modified yttrium coating stable zirconia powder body and a preparation method and an application thereof, which belong to the coating preparation field. The invention takes a YSZ powder body as a raw material, adopts a non-homogeneous phase precipitation method to prepare an outphase coating YSZ powder body, and obtains a coating YSZ powder body with good effects through controlling conditions such as solution concentration, reaction temperature and time, etc. A thermal barrier coating with anti-sintering performance, a slow grain growth at a high temperature and good thermal insulating performance can be obtained after the powder body undergoes granulation and plasma spraying.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Cemented carbide for composite matrix and preparation method of cemented carbide

The invention discloses cemented carbide for a composite matrix and a preparation method of the cemented carbide. According to a formula, a WC (wolfram carbide) powder mixture is a mixture of conventional WC powder and cast WC powder whose mass ratio is (33-40) : (60-67); the mass ratio of cobalt powder and the WC powder mixture is (8-17) : (83-92); the preparation process comprises steps as follows: material preparation, wet grinding, dry granulation, press forming and low-pressure vacuum integrated sintering. The average WC grain size of the cemented carbide prepared with the preparation method according to the formula is 2.0-3.2 microns, the bending strength is 3,200-3,400 MPa, and the hardness is HRA 85.0-90.8.

Owner:HUNAN CENTURY SPECIAL ALLOY

Production method for modified artificial graphite negative electrode material

ActiveCN105428615ALow costChange structureCell electrodesSecondary cellsCarbon nanotubeCarbonization

The invention provides a production method for a modified artificial graphite negative electrode material. The method comprises: taking powder obtained by grinding petroleum coke as a main raw material and performing shaping treatment; adding a certain proportion of petroleum asphalt into the shaped petroleum coke material, and performing secondary granulation treatment in an extrusion fusion way; adding the granulated material into a mixture of petroleum asphalt and coal asphalt or coal tar, and performing coating modification treatment; putting the material into a graphitization furnace in bulk to perform high-temperature graphitization treatment, or performing carbonization and graphitization treatment in sequence; performing dispersion and grading treatment after the material is cooled to the room temperature; and finally adding few carbon nanotubes to perform mixing and screening. The method has the advantages that the main raw material is ground petroleum coke powder, and the powder is recycled, so that the cost can be reduced; secondary granulation of small granules can increase the capacity of the material and improve the cycle performance of the material; and due to the adoption of a graphite plate loading mode, the graphitization degree of the material can be increased, namely, the capacity can be increased, and the energy consumption cost can be reduced.

Owner:大连宏光锂业有限责任公司

Friction grain and watering prilling process therefor

The invention discloses a friction granule and the granulation technology thereof. Firstly, resin, toughener, rubber, antifriction, fiber, molding agent, filling, and friction material waste machining material are weight according to a certain proportion, mixed and added into a mixing plant to be stirred by adding water, so a wet mixture is obtained; granulation is carried out on the wet mixture on a granulation device to obtain a granular matter; the granular matter is roasted for many hours under the temperature of 100-200 DEG C to obtain a dried granular material; and at last, the dried granular material is screened according to the requirement to obtain the granular material with needed grit number. The invention utilizes waste materials, reduces the production cost and facilitates the environment protection; in addition, the wearable performance, the vibration resistance and the anti-attenuation of the obtained friction granule are all improved; the brake is sensitive and stable with little noise; and the damage caused for a braking disc drum is little.

Owner:NINGGUO FEIYING AUTO SPARE PARTS +2

Method for extracting paeonol by use of CO2 supercritical extraction technology

InactiveCN103787859AFacilitated releaseFacilitated DiffusionCarbonyl compound separation/purificationBulk chemical productionPhysical chemistryCyclodextrin

The invention discloses a method for extracting paeonol by use of the CO2 supercritical extraction technology. The method comprises the following steps: washing cortex moutan, drying, grinding, seiving and performing ultrasonic treatment; adding an appropriate amount of beta-cyclodextrin, granulating and drying; uniformly mixing emu oil serving as an entrainer with the raw material powder; feeding the granulated particles into a supercritical extraction kettle for CO2 supercritical extraction; refrigerating the paeonol extract liquid in the supercritical extraction kettle and taking out to obtain an automatic-layering extract, wherein the upper layer is light yellow liquid, and the lower layer is light red brown solid; and separating the liquid to obtain high-purity active monomer paeonol. The method disclosed by the invention has the advantages of simple extraction process, high extraction rate, low extraction temperature, short extraction time and the like; the yield of paeonol can exceed 1.4%; and moreover, CO2 is non-toxic and residue-free, the energy consumption is reduced, cyclic use can be realized, the shortcomings of the traditional extraction method that the paeonol is easily volatilized and the yield is low are overcome, and the application prospect is broad.

Owner:XUANCHENG BAICAO PLANT IND & TRADE CO LTD

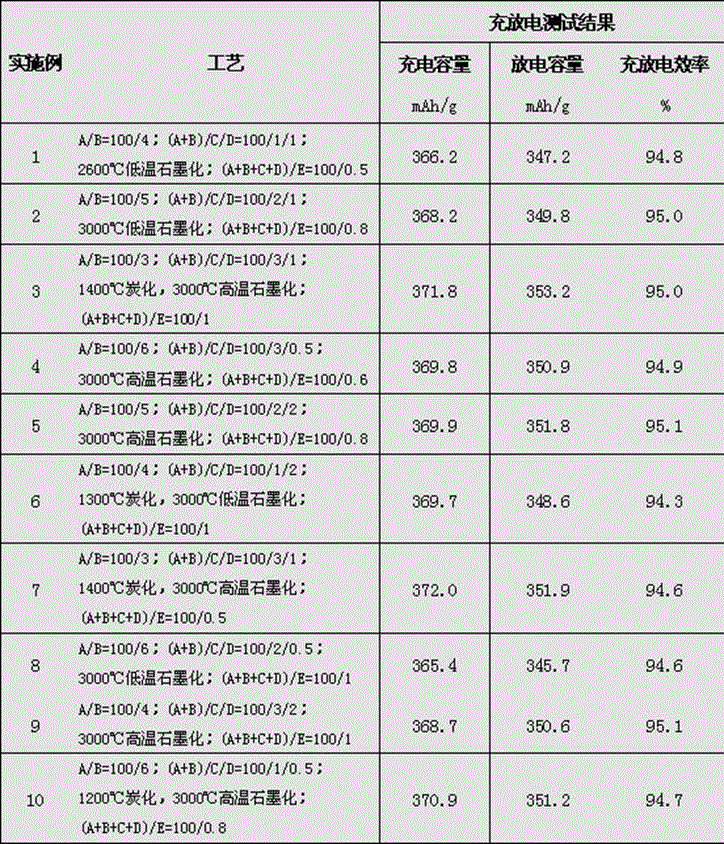

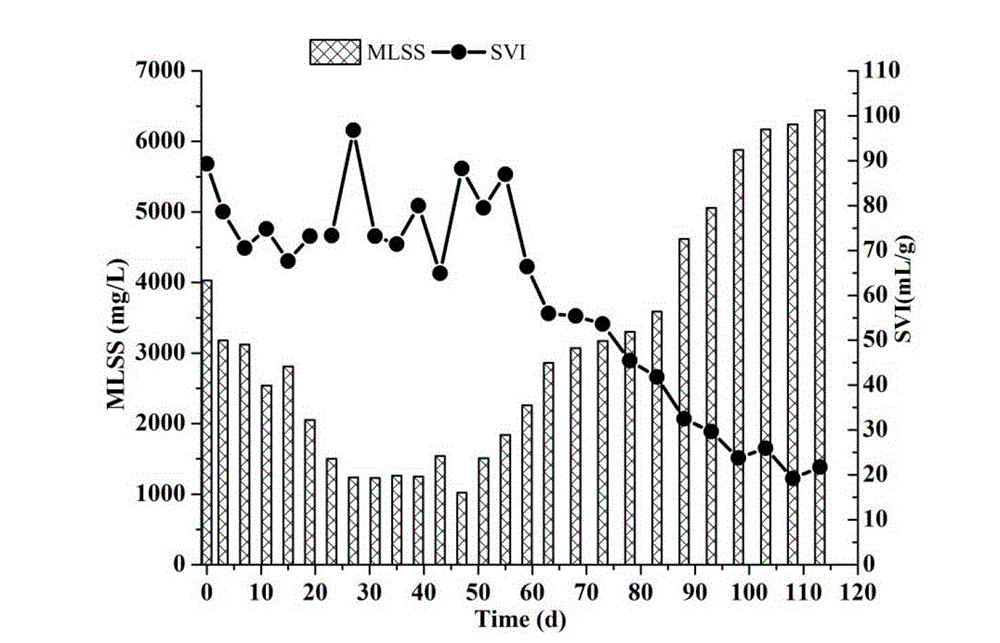

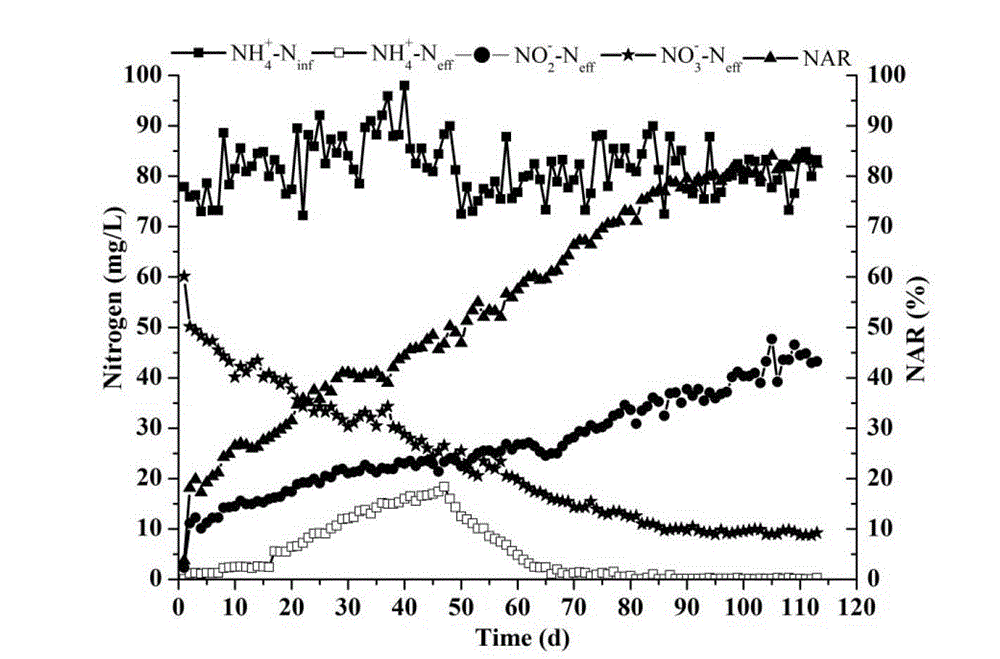

Method for achieving fast cultivation of shortcut nitrifying granule sludge

ActiveCN103145233AGranularizeImprove sedimentation performanceTreatment using aerobic processesSustainable biological treatmentSequencing batch reactorChemical oxygen demand

The invention belongs to the fields of treatment and regeneration of municipal sewage, and particularly relates to a method for rapidly cultivating aerobic granular sludge with good shortcut nitrifying performance. A sequencing batch reactor (SBR) is operated by fixed aeration time and aeration rate by gradually shortening the settling time; and the shortcut nitrifying granule sludge is rapidly cultivated. The granulation of common floc sludge is successfully achieved within 20 days via three stages of overdue cultivation, granule forming and granule maturation; the nitrite accumulation rate (NAR) achieves 80% within 80 days; the mean grain size is greater than 800 microns; the removal rate of the NH4<+>-N is close to 100%; and the removal rate of the chemical oxygen demand (COD) is 94%.

Owner:BEIJING UNIV OF TECH

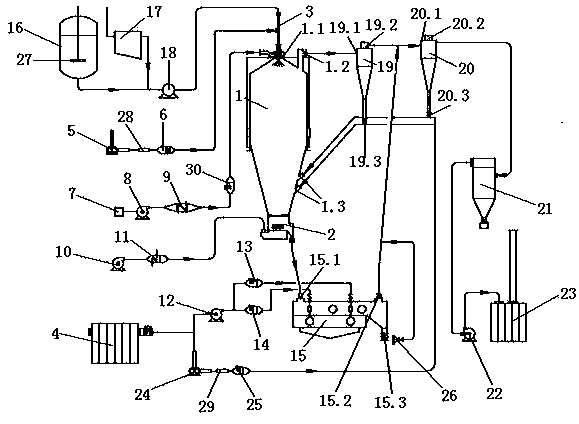

Drying flow granulation technology and device for paraquat water soluble granule spray

ActiveCN103816836APrevent leakageAvoid direct inhalationBiocideGranulation by liquid drop formationMaterials preparationWater soluble

The invention discloses a drying flow granulation technology and a device for a paraquat water soluble granule spray. The technology comprises the following steps: raw materials preparation; spray drying granulating; primary dust removing and tower returning for continuous granulation; tower bottom granulating; fluidized bed granulating and drying outside the tower; secondary dust removing and tower returning for continuous granulation; and dust removing for a third time. The device comprises a feeding mechanism, an atomizing mechanism, an air intake mechanism, a drying granulation mechanism, a vibration fluidization dry cooling mechanism, and an exhausting mechanism. According to the technology for the paraquat water soluble granule spray provided by the invention, the granulation yield is improved; the granulation intensity is enhanced; moreover, sealed production is achieved; the dust leakage is avoided; the production security is greatly improved; according to the device, the full automatic, dust-free, clean and continuous production of the paraquat water soluble granule is achieved; moreover, the environmental pollution is reduced; the intoxication of people caused by direct inhaling is prevented; the production security is improved.

Owner:NANJING GAOZHENG AGROCHEM

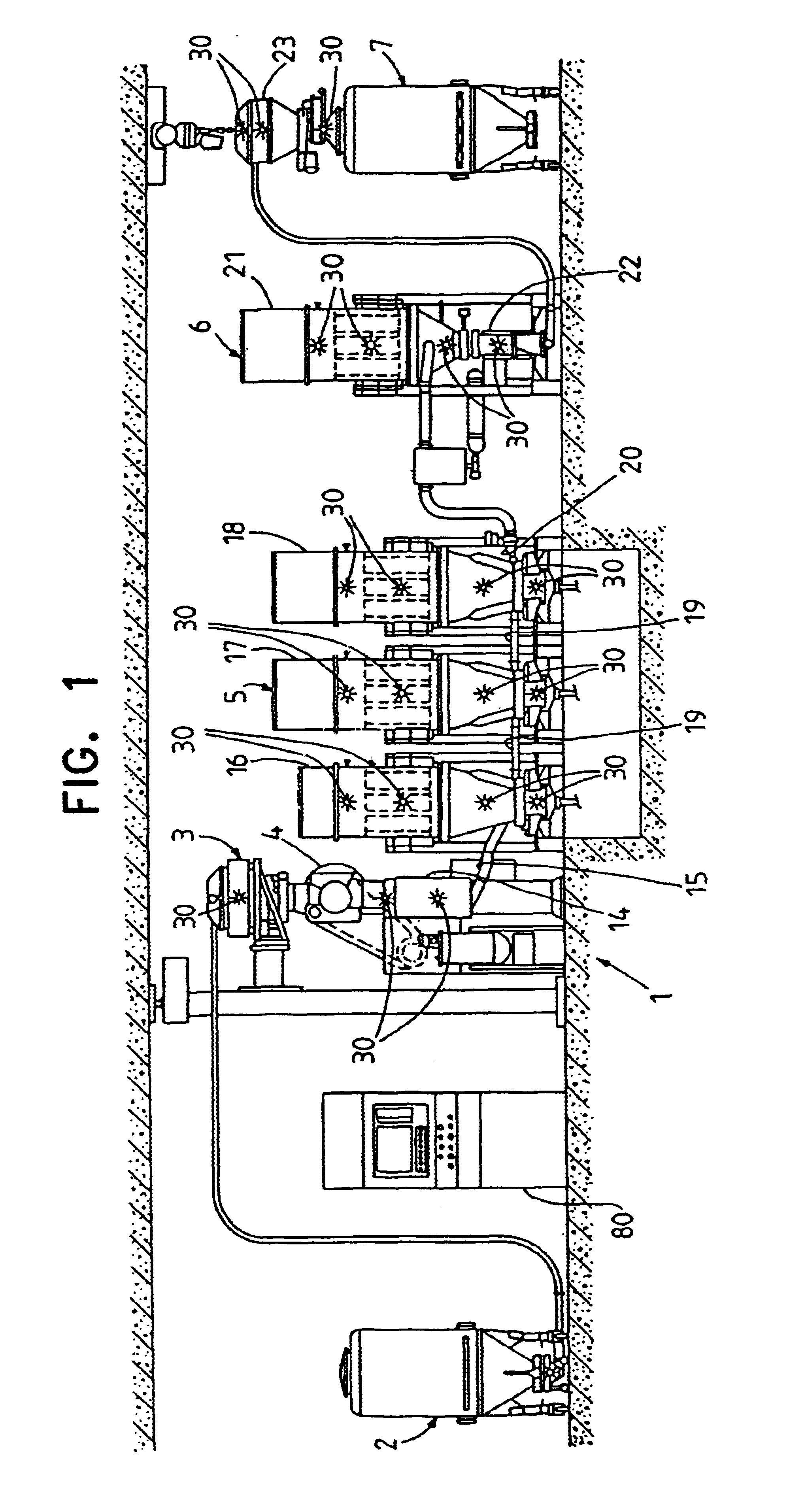

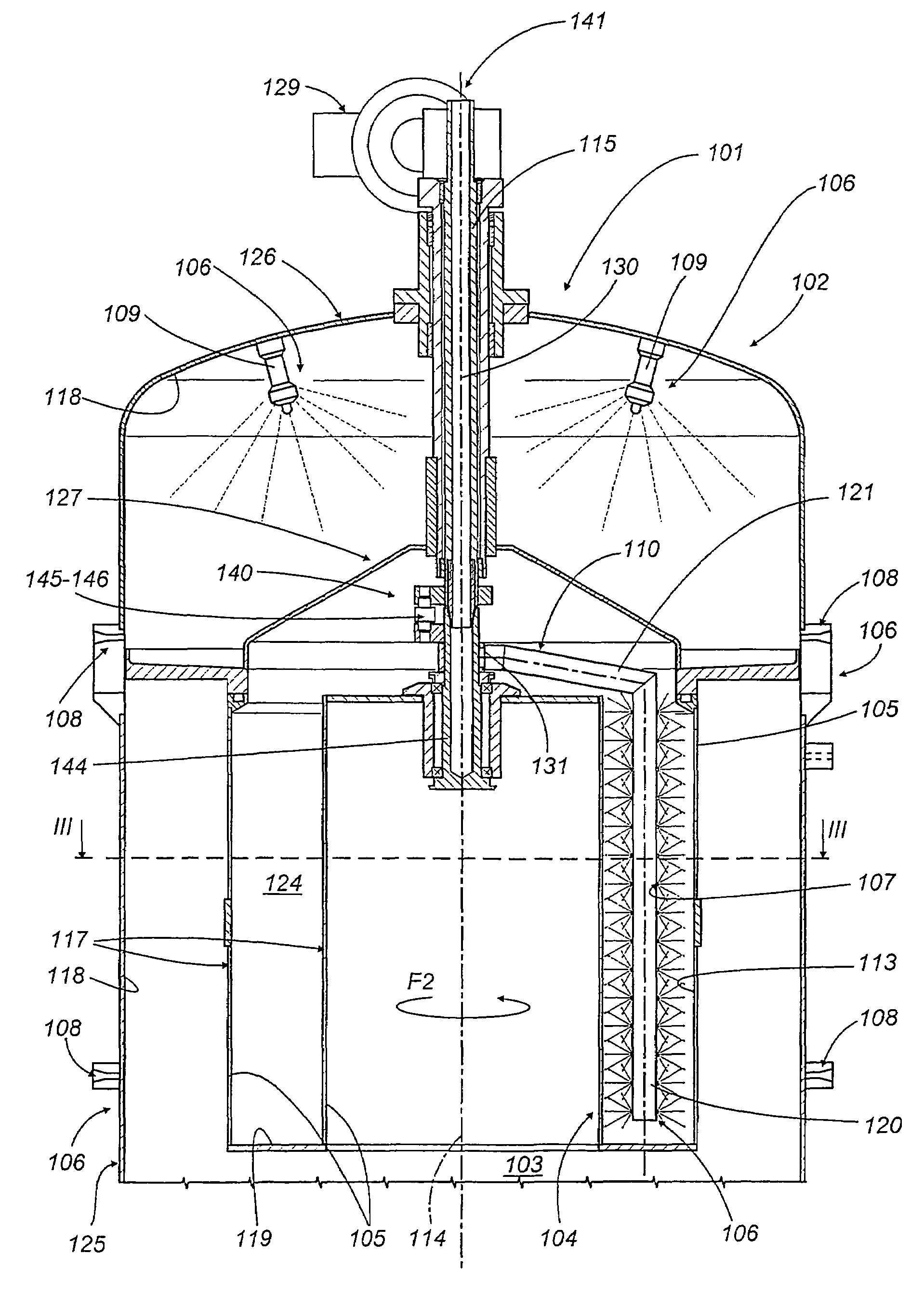

Quasi-continuous treatment of particulate materials with cleansing nozzle system

The multicell apparatus according to the invention is suitable for batchwise and in particular quasi-continuous operation, i.e. for the continuous processing of batches in rapid succession, for example for the preparation of readily free-flowing granules which are suitable for filling in capsules or sachets. The apparatus is in particular a multifunctional system which combines the process steps of batch introduction, metering, mixing / granulation, drying, product cooling and product collection with one another in a very compact design. The individual batches are conveyed inside the apparatus through a product path which is hermetically sealed from the outside and in which an internal pressure lower than the ambient pressure may additionally prevail at least in sections. This, together with the cleaning nozzles connected to a central cleaning system, permits contamination-free operation both with aqueous and with organic starting materials.

Owner:GLATT MASCHINEN UND APPARATEBAU AG

Sub-micro grain hard alloy anvil and preparation method thereof

ActiveCN103572136AEffective control of flexural strengthAdjust the flexural strengthTemperingVitamin C

The invention discloses a sub-micro grain hard alloy anvil and a preparation method thereof. The sub-micro grain hard alloy anvil comprises the following alloy components: WC (Wolfram Carbide), 10% of Co, 0.4-0.6% of Cr3C2 and 0.2-0.3% of VC (Vitamin C); the particle size of an alloy crystal is 0.8-0.9mum; the porosity of an alloy is A00B00C00; the hardness of the alloy is 90.5-91.5HRA; the coercive force of the alloy is 205-245Oe. The preparation method comprises the steps: with WC powder with the Fisher particle size of 1.0-1.2mum and Co powder with the Fisher particle size of 0.8-1.0mum as raw materials, adding Cr and V additives in the alloy in the preparation process of the WC powder; preparing an alloy mixture by using a rolling wet grinding process, wherein the wet grinding time is 55-60h, and the mass ratio of a ball material is 4:1; drying and granulating the wet ground mixture by using a spray drying granulation method; and sintering a pressed anvil blank at the temperature of 1400-1410 DEG C by using a pressure sintering process, wherein the pressed anvil blank is obtained through cold isostatic compaction; and carrying out copious cooling treatment on the sintered pressed anvil blank by using liquid nitrogen with the temperature of 180 DEG C below zero to 190 DEG C below zero, and then, carrying out subsequent reinforcement treatment on a refined anvil by using a 350-400 DEG C medium-temperature tempering treatment process.

Owner:DALIAN FAR EASTERN CARBIDE

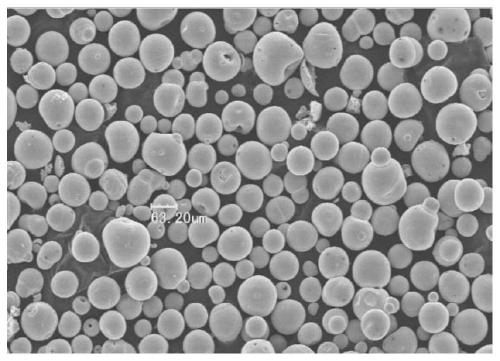

Rare earth doped indium gallium zinc oxide powder as well as preparation method and application thereof

InactiveCN111574217AHigh densityUniform tissueVacuum evaporation coatingSputtering coatingRare-earth elementIndium

The invention relates to a preparation method of rare earth doped indium gallium zinc oxide powder. The method comprises the following steps of: sequentially adding water, a dispersing agent, galliumoxide powder and rare earth oxide powder into a first mixing barrel to perform pre-dispersion on the added raw materials, and grinding an obtained pre-dispersed solution to obtain first mixed slurry;sequentially adding water, a dispersing agent and zinc oxide powder into a second mixing barrel to perform pre-dispersion on the added raw materials, adding an obtained pre-dispersed solution into thefirst mixed slurry to perform grinding so as to obtain second mixed slurry; sequentially adding water, a dispersing agent and indium oxide powder into a third mixing barrel for pre-dispersing, and adding an obtained pre-dispersed solution into the second mixed slurry so as to perform grinding to obtain third mixed slurry; adding an adhesive into the third mixed slurry, and performing grinding toobtain fourth mixed slurry; and granulating, mixing and screening the fourth mixed slurry to finally obtain the rare earth doped indium gallium zinc oxide powder. According to the preparation method of the invention, the problem of non-uniform components caused by doping of large-particle-size rare earth elements into IGZO powder can be solved.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

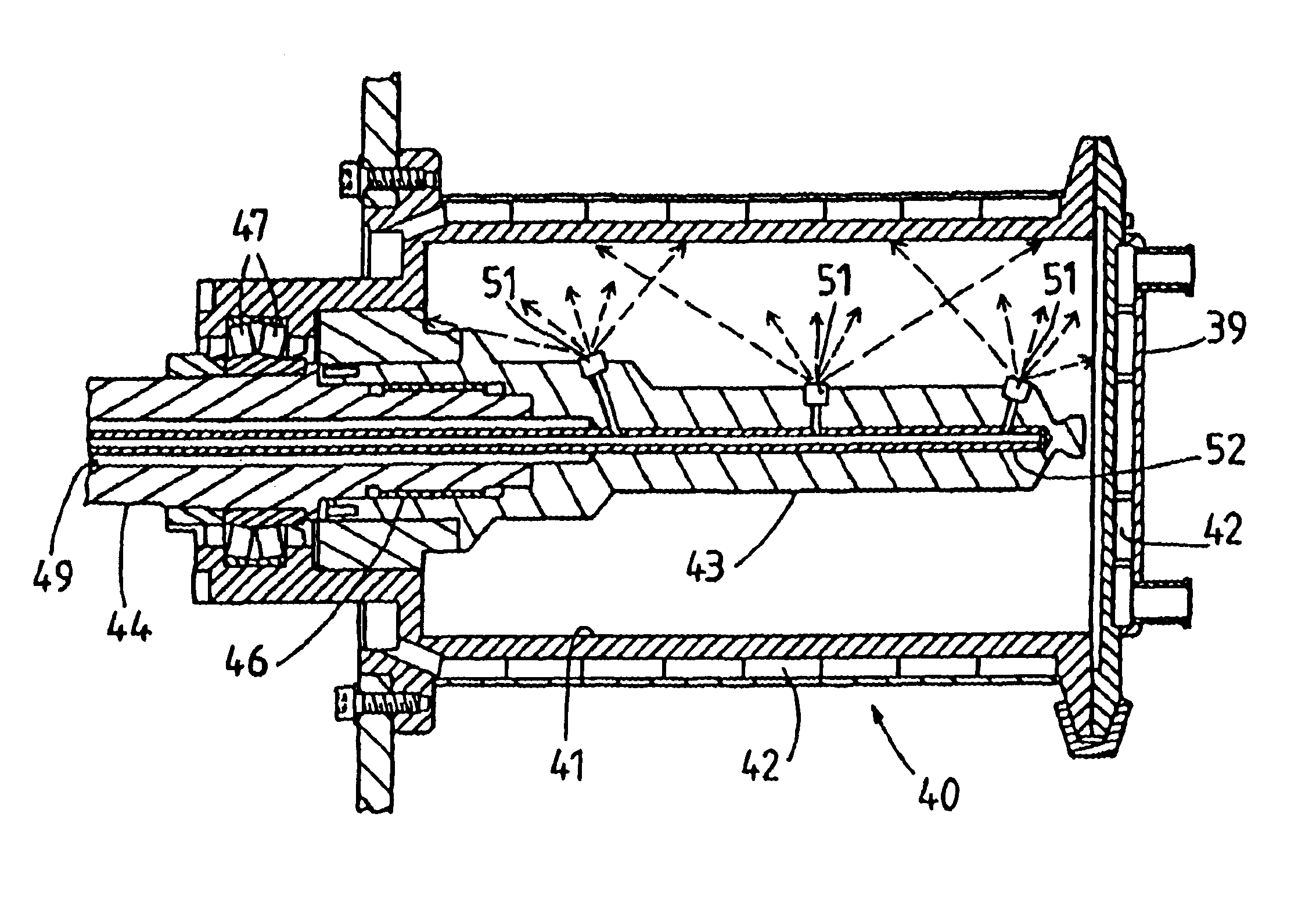

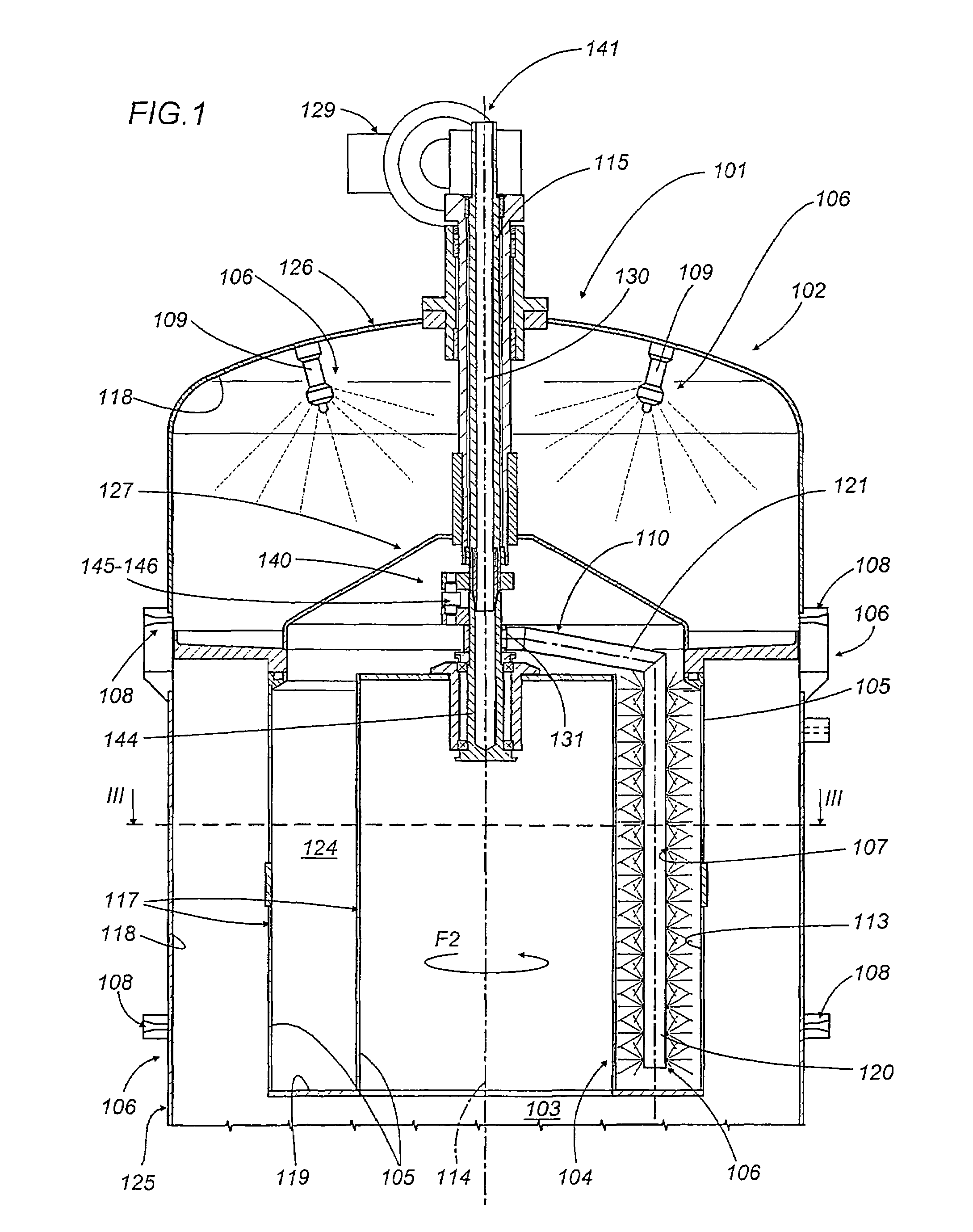

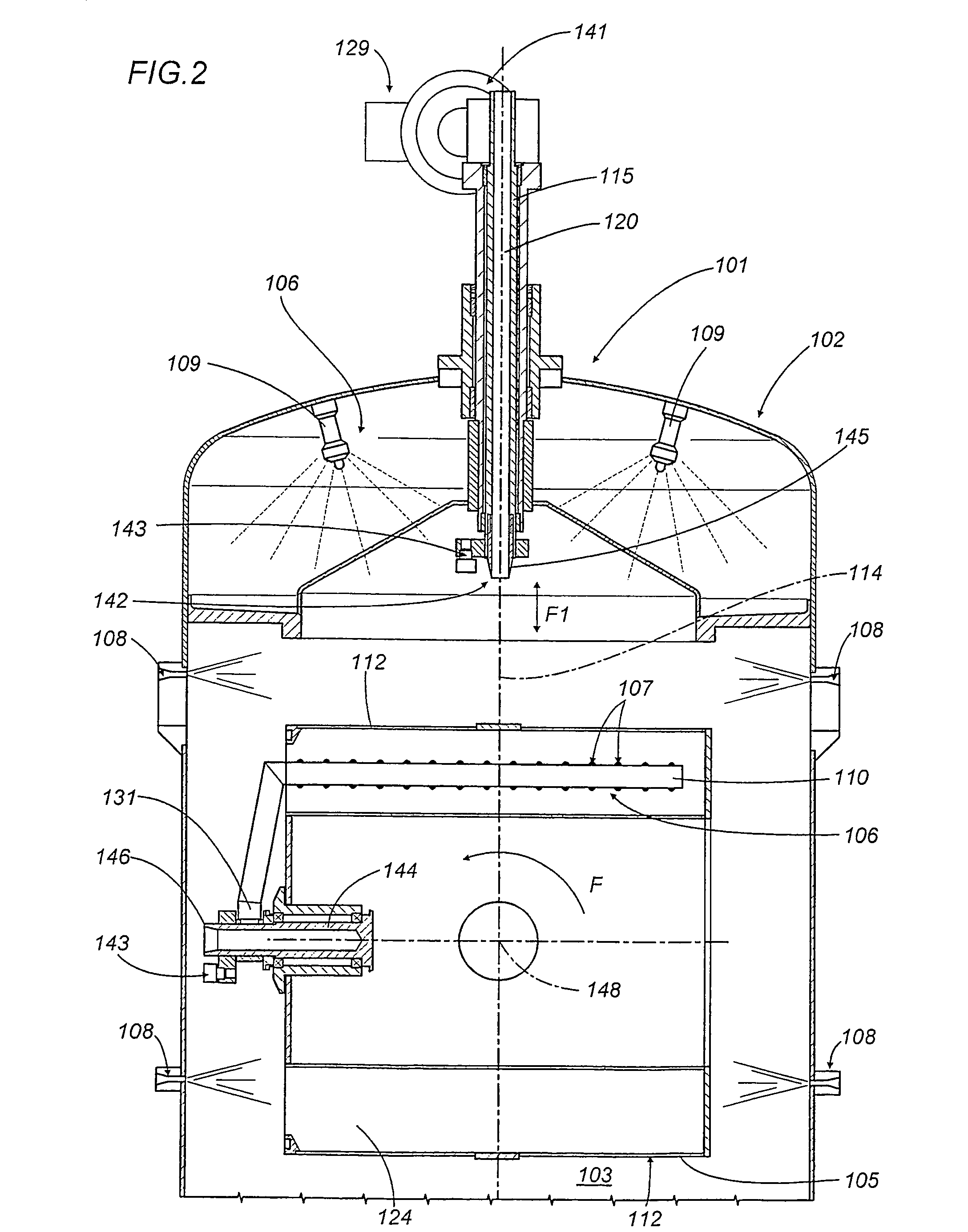

Granulator device for the treatment of powdered products

InactiveUS7534278B2Easy constructionImprove efficiencyDispersed particle filtrationTransportation and packagingWorking fluidEngineering

A granulator device (101) for the treatment of powdered products comprises a closed container (102) forming a chamber (103) for treatment of the products, filter elements (104, 105) projecting into the treatment chamber (103), the filter elements comprising a multi-layer filtering wall (105) through which a fluid current can pass, and powder removing parts (106; 107, 108, 109, 110) designed to diffuse at least one service fluid directed towards at least the filtering wall (105); the powder removing parts (106; 107, 108, 109, 110) having at least first diffuser nozzles (107) and at least second diffuser nozzles (108) to diffuse the service fluid so as to free the filtering wall (105) of the powders trapped in it; there also being parts (140, 142, 147) for supporting and driving the filter elements (104, 105) which can change the angle of the filter elements (104, 105) from a first operating position, in which at least the first nozzles (107) act on the filtering wall (105), to a second operating position in which the filter elements (104) are set at an angle to the first operating position to allow the second diffuser nozzles (108) to operate on the filtering wall (105).

Owner:IMA IND MASCH AUTOMATICHE SPA

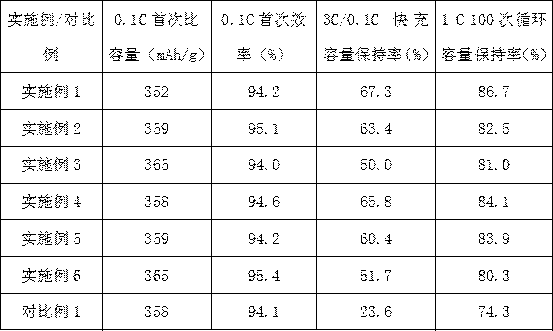

Quick-charging graphite negative electrode material and preparation method thereof

ActiveCN111204756AHigh degree of isotropyReduce dosageCarbon compoundsCell electrodesGraphite particleAsphalt

The invention discloses a preparation method of a quick-charging graphite negative electrode material. The method comprises the following steps: (1) composite granulation: adding a graphite precursor,a binder and tackifying resin into a mechanical fusion machine according to a certain ratio, and performing treating for 5-20 minutes to obtain a quick-charging graphite precursor; and (2) putting the quick-charging graphite precursor prepared in the step (1) into a graphitization furnace, and carrying out high-temperature graphitization treatment for 20-50 hours to obtain the quick-charging graphite negative electrode material. According to the method, the asphalt coats the surface of the graphite with a layer of uniform amorphous carbon, the secondary particles formed by strong adhesion under high-speed stirring are different from the secondary particles prepared by common low-temperature low-speed stirring heat treatment, and the graphite particles are smooth and flat in surface, freeof burrs, more stable in structure, higher in isotropy and better in rate capability and cycle performance. The method is simple in technological process, high in operability, low in cost and suitablefor large-batch preparation.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com