Comprehensive utilization method of oil field drilling sludge

An oilfield drilling and sludge technology, applied in the direction of sludge treatment, drilling composition, chemical instruments and methods, etc., can solve the problems of resource consumption, high cost, secondary environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

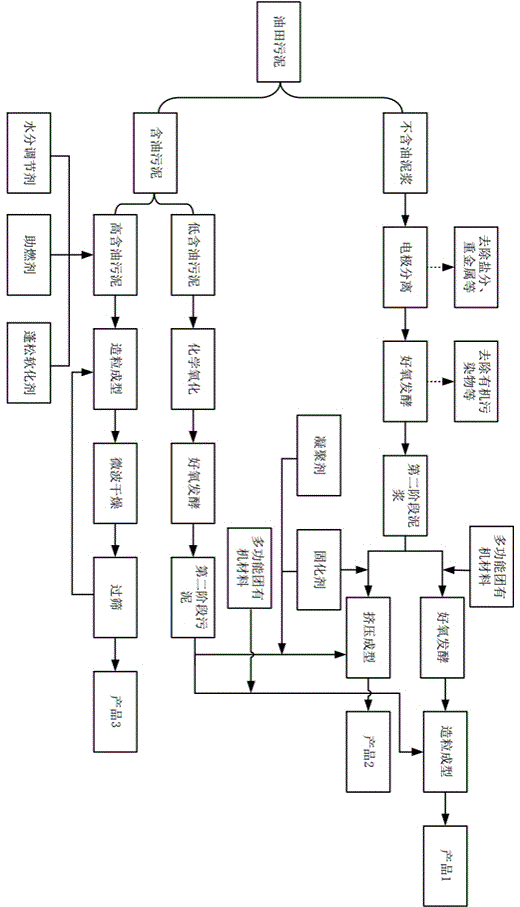

Image

Examples

Embodiment 1

[0035] Embodiment 1, the by-product of this oilfield is the mud that does not contain oil substantially, according to the following steps:

[0036] ⑴Use the electrode separation method to remove soluble cations from the mud; the size of the anode and cathode electrodes used is 1000cm in length and 500cm in width; the distance between the cathode and anode electrodes is 2000cm; the current is 1A; the voltage is 220V; the pole separation time is 10 days; the number of electrodes 10; the electrodes are arranged side by side.

[0037] (2) The mud treated in step (1) is aerobically fermented with local oil-degrading bacteria to remove organic pollutants. The specific steps are as follows:

[0038] a) Screening of local oil-degrading bacteria: put fresh rice in a paper box without a cover, the height is 2 / 3 of the height of the carton, and a wire mesh of the same size is placed in the upper part to prevent mice and other animals from eating it, and then spread on the wire mesh Gauz...

Embodiment 2

[0042] Embodiment 2, other are with embodiment 1, and difference is:

[0043] (4) Precipitating the mud treated in step (2), adding a curing agent to the sediment and then extruding to form a product 2; the product 2 is used as a building material and a municipal facility material.

Embodiment 3

[0044] Embodiment 3, the by-product of this oil field is low oily sludge, according to the following steps:

[0045] (5) Chlorine dioxide, hydrogen peroxide, permanganate, ozone or Fenton are added as oxidizing agents to low oily sludge, and the ratio of added parts by weight is low oily sludge: oxidizing agent = 2000:1, mixing and stirring, stirring time 10 hours to remove most of the oil and organic pollutants in low oily sludge;

[0046] (6) The sludge treated in step (5) is aerobically fermented by local oil-degrading bacteria to remove the remaining oil and organic pollutants; the specific steps are as follows:

[0047] a) Screening of local oil-degrading bacteria: put fresh boiled sweet potatoes in a wide-mouth plastic jar without a lid, the height is 2 / 3 of the height of the plastic jar, and a wire mesh of the same size is placed in the upper part to prevent rats and other animals from eating them. Cover the barbed wire with gauze to prevent soil particles from falling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com