Patents

Literature

4191results about "Compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions comprising fluoroolefins and uses thereof

The present invention relates to fluoroolefin compositions. The fluoroolefin compositions of the present invention are useful as refrigerants or heat transfer fluids and in processes for producing cooling or heat. Additionally, the fluoroolefin compositions of the present invention may be used to replace currently used refrigerant or heat transfer fluid compositions that have higher global warming potential.

Owner:EI DU PONT DE NEMOURS & CO

Tetrafluoropropene compositions and uses thereof

InactiveUS20100122545A1Lower global warming potentialCompressorHeat pumpsAir conditioningHeat transfer fluid

The present invention relates to compositions for use in refrigeration, air-conditioning, and heat pump systems wherein the composition comprises a tetrafluoropropene and at least one other component. The compositions of the present invention are useful in processes for producing cooling or heat, as heat transfer fluids, foam blowing agents, aerosol propellants, and fire suppression and fire extinguishing agents.

Owner:EI DU PONT DE NEMOURS & CO

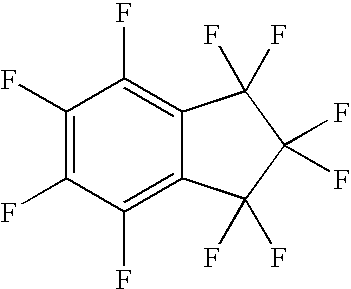

Solvent compositions containing chlorofluoroolefins or fluoroolefins

Compositions and methods based on the use of fluoroalkene containing from 3 to 4 carbon atoms and at least one carbon-carbon double bond, such as HFO-1214, HFO-HFO-1233, or HFO-1354, having properties highly beneficial in solvent cleaning applications.

Owner:HONEYWELL INT INC

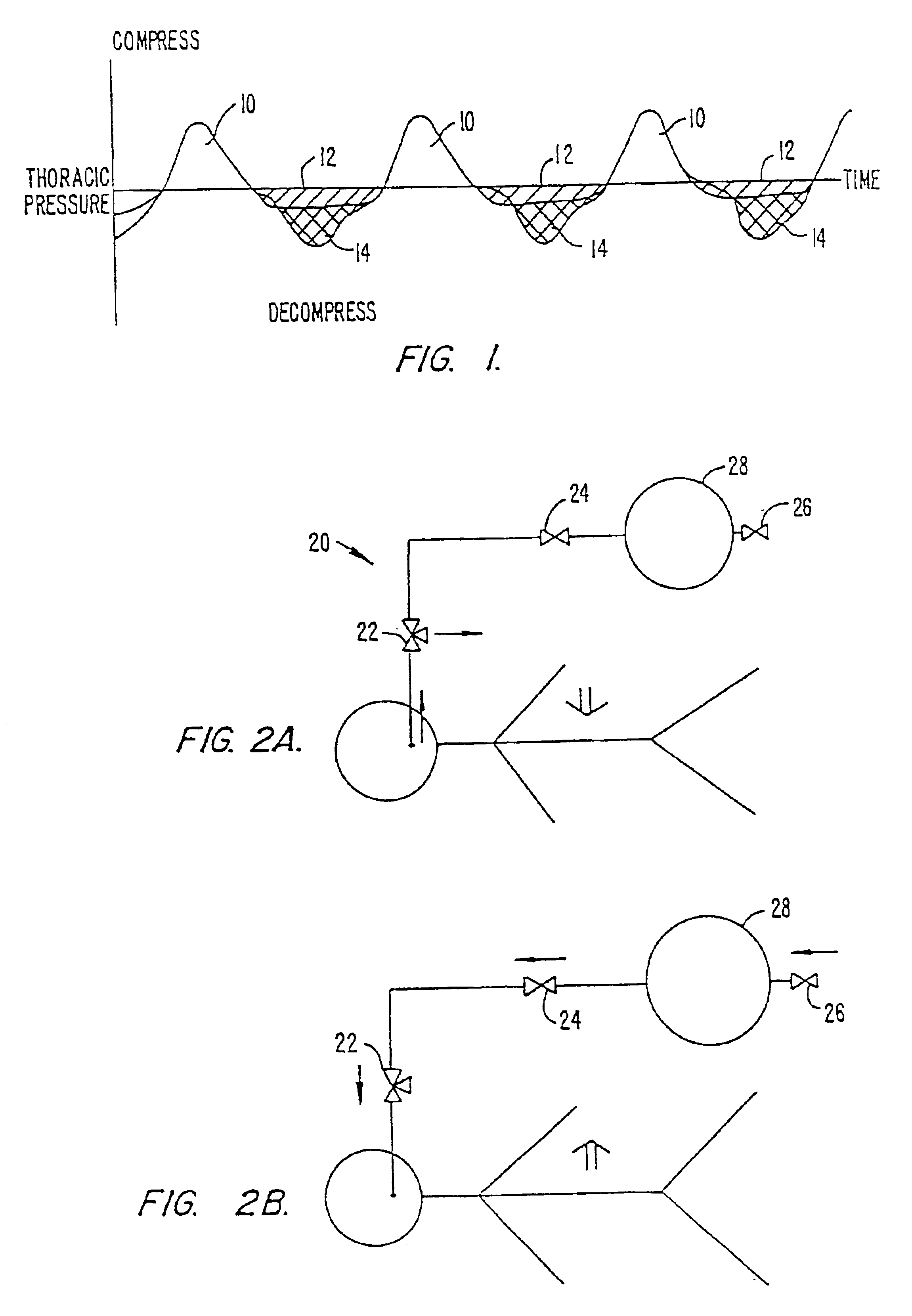

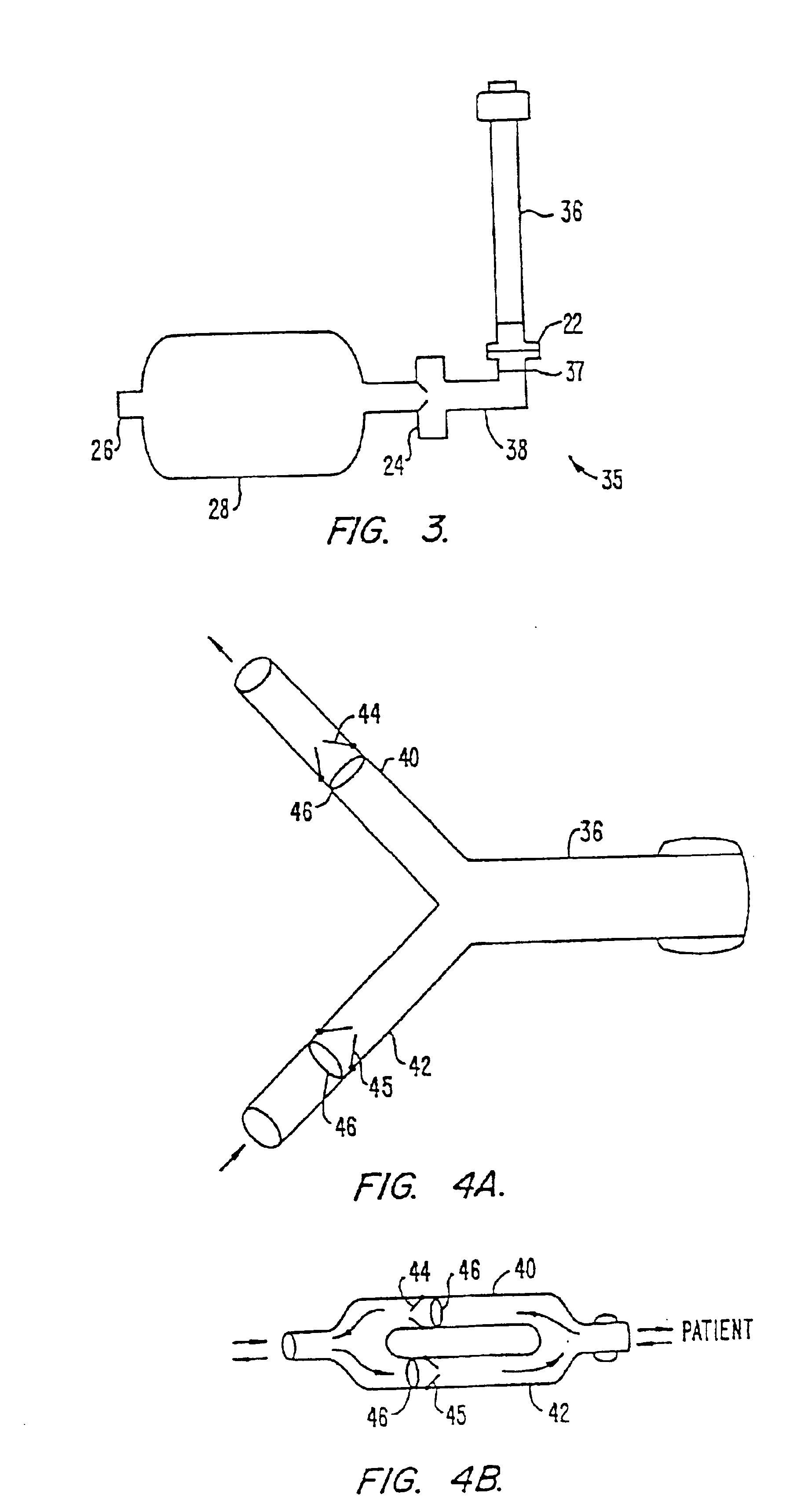

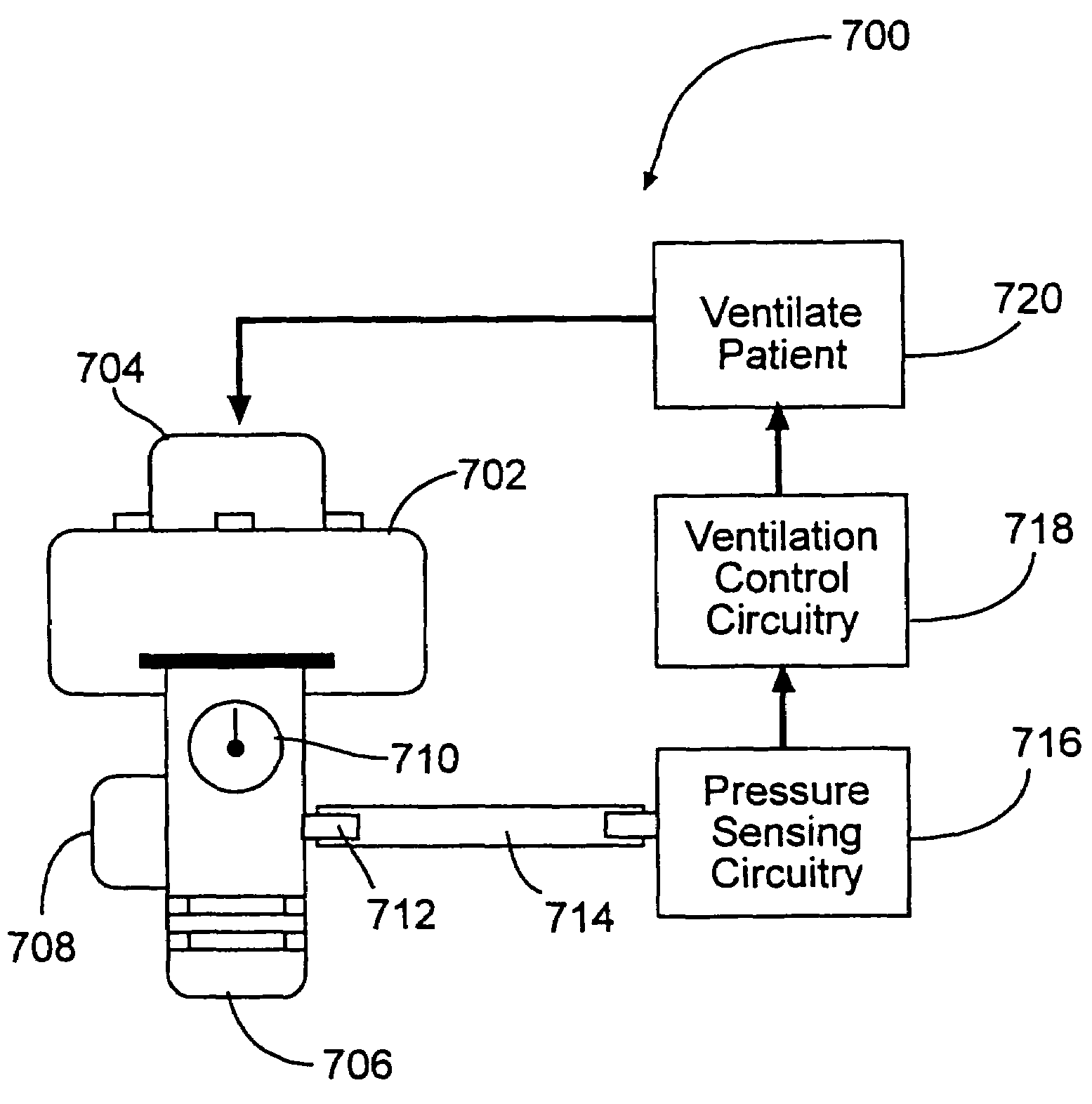

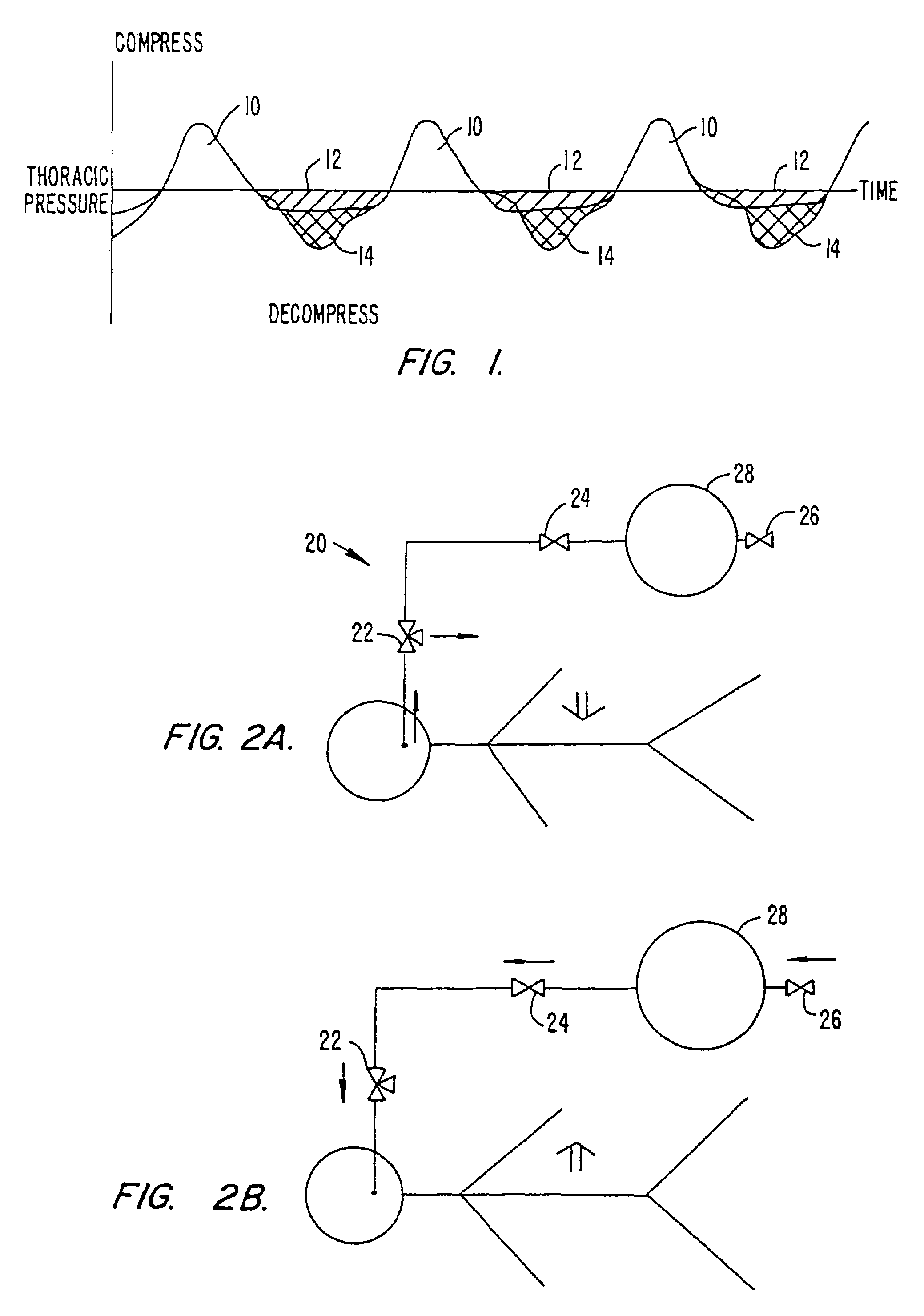

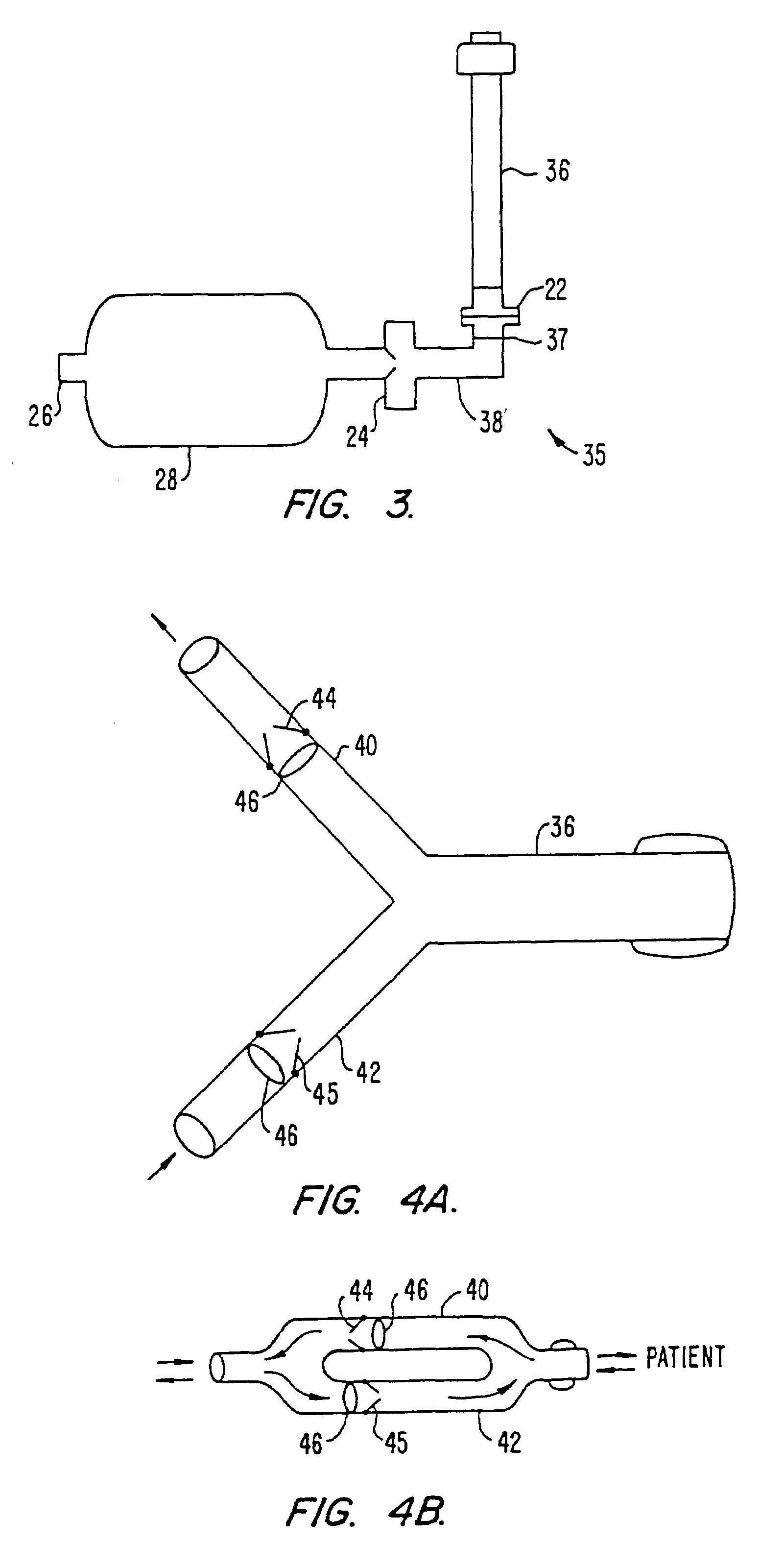

Systems and methods for enhancing blood circulation

InactiveUS6986349B2Increase loopDecrease and prevent flowCompressorElectrotherapyHeart rightInhalation

A method for increasing circulation in a breathing person utilizes a valve system that is interfaced to the person's airway and is configured to decrease or prevent respiratory gas flow to the person's lungs during at least a portion of an inhalation event. The person is permitted to inhale and exhale through the valve system. During inhalation, the valve system functions to produce a vacuum within the thorax to increase blood flow back to the right heart of the person, thereby increasing cardiac output and blood circulation.

Owner:ZOLL MEDICAL CORPORATION

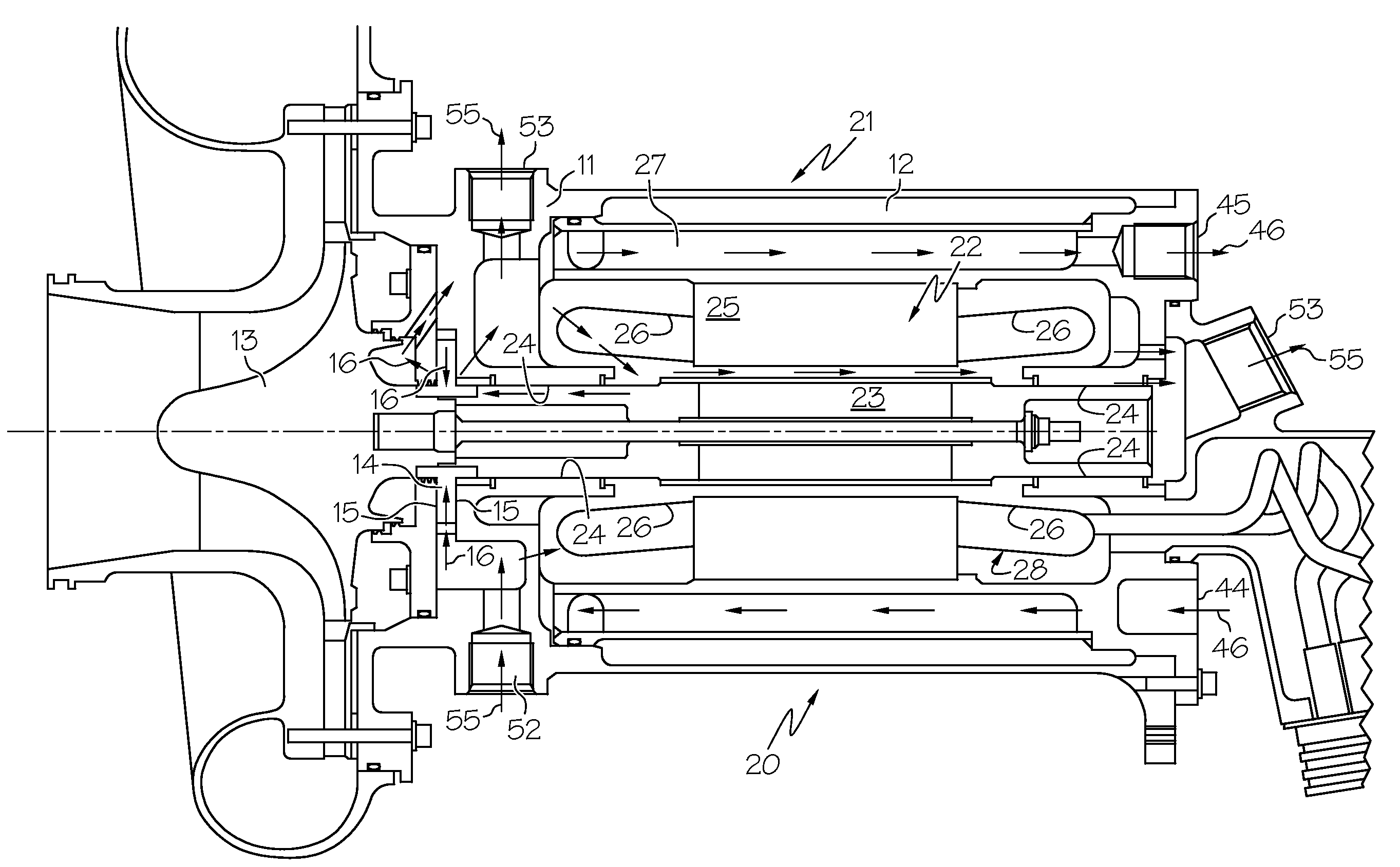

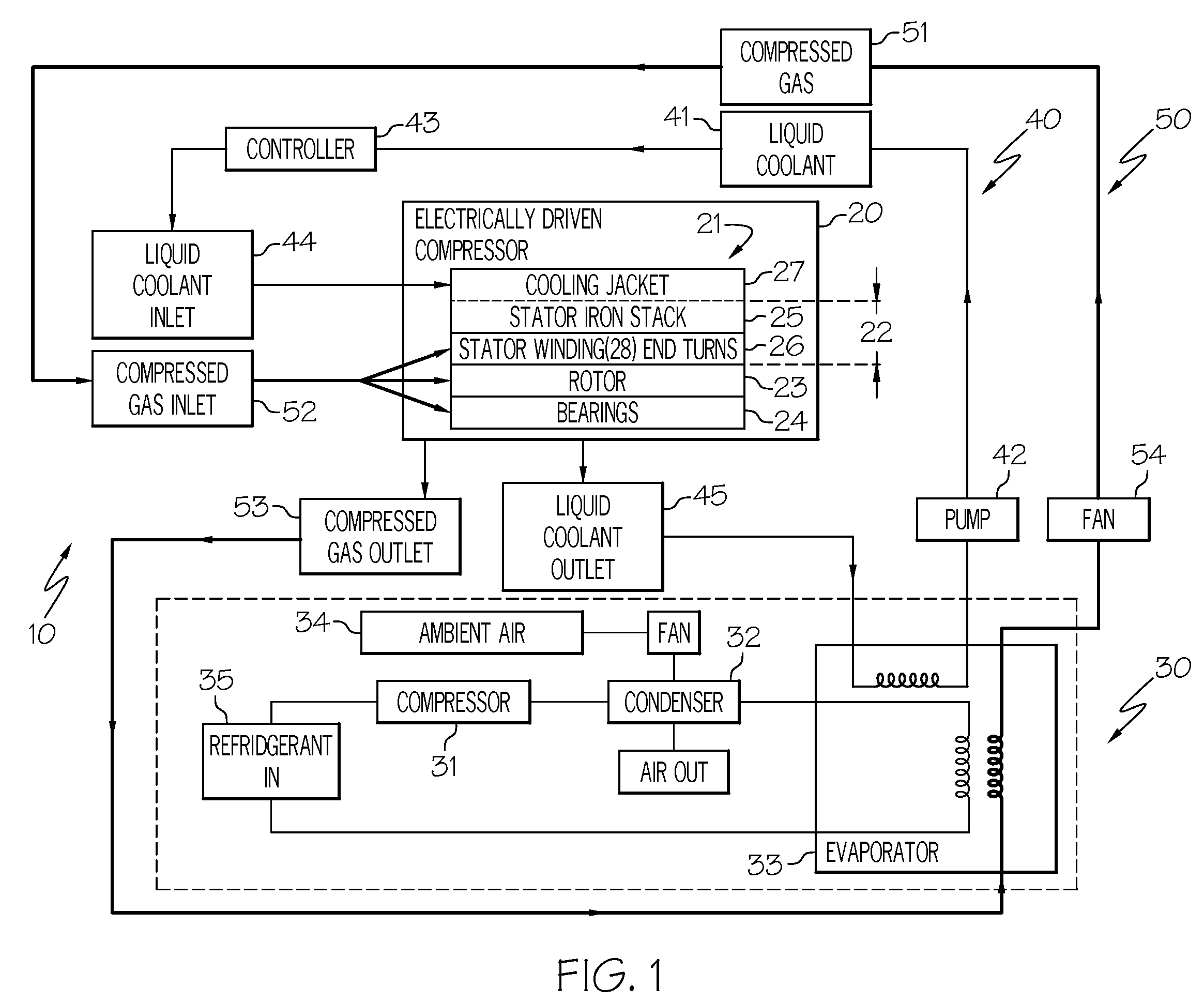

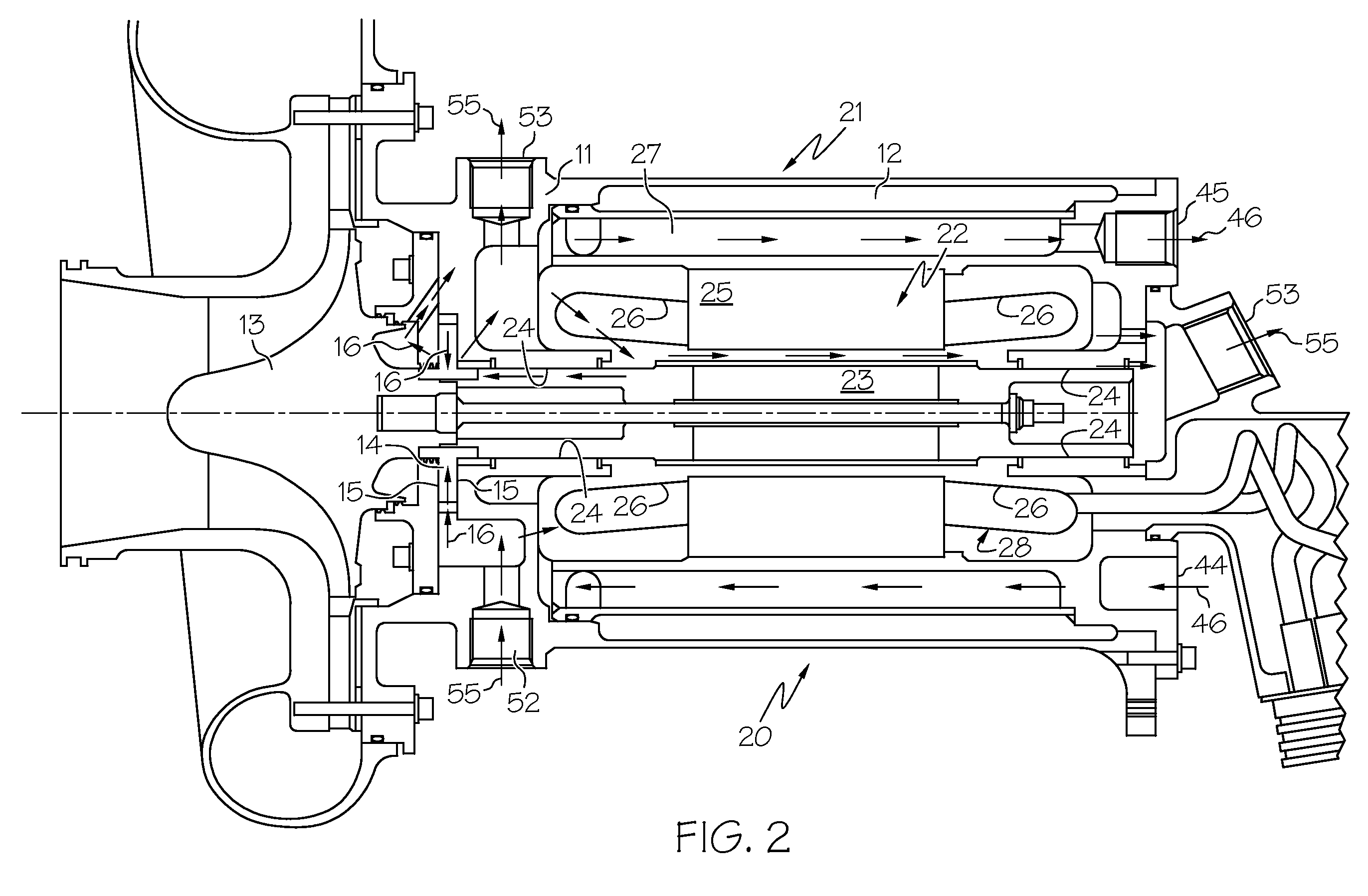

Thermal and secondary flow management of electrically driven compressors

Owner:HONEYWELL INT INC

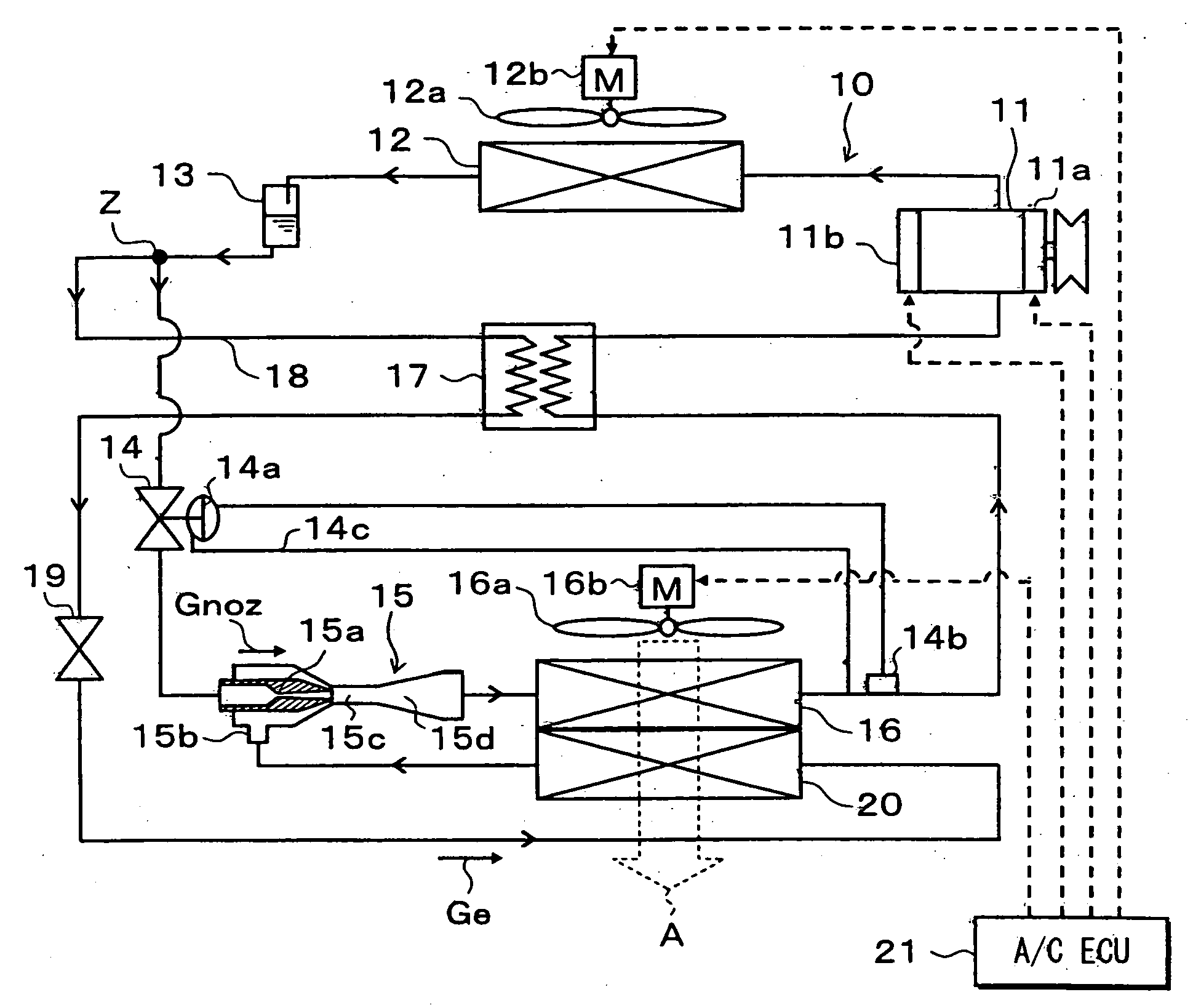

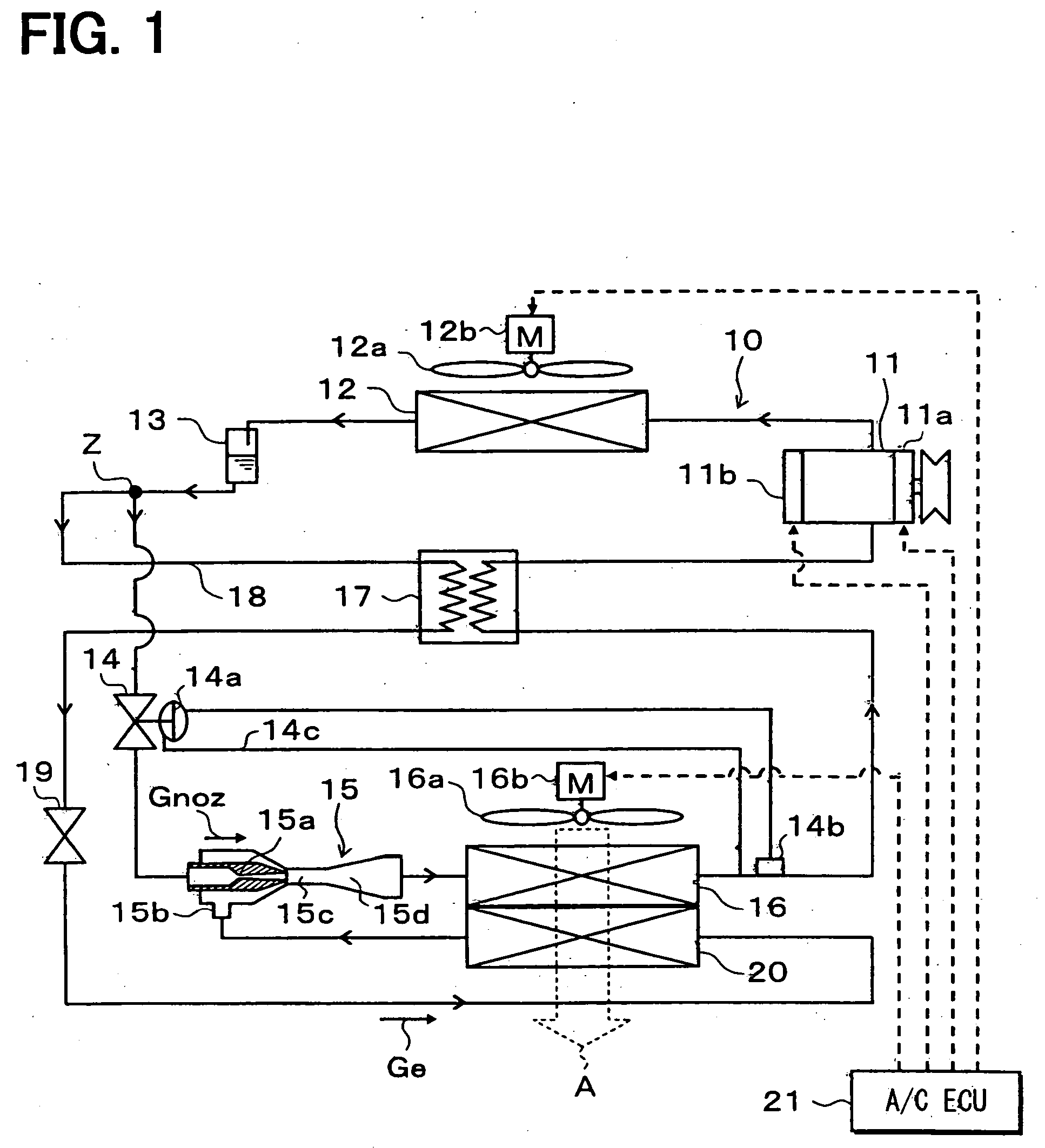

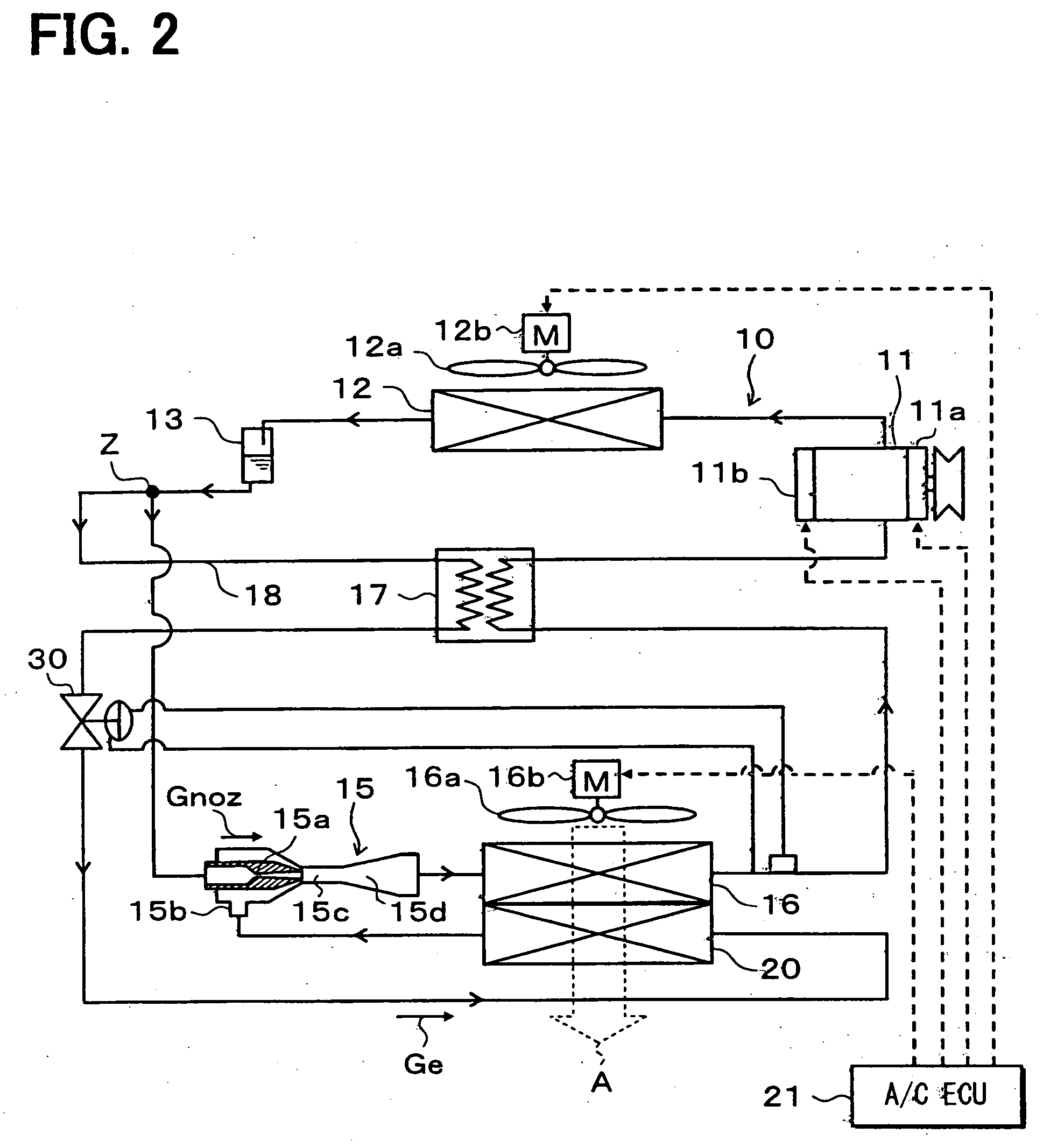

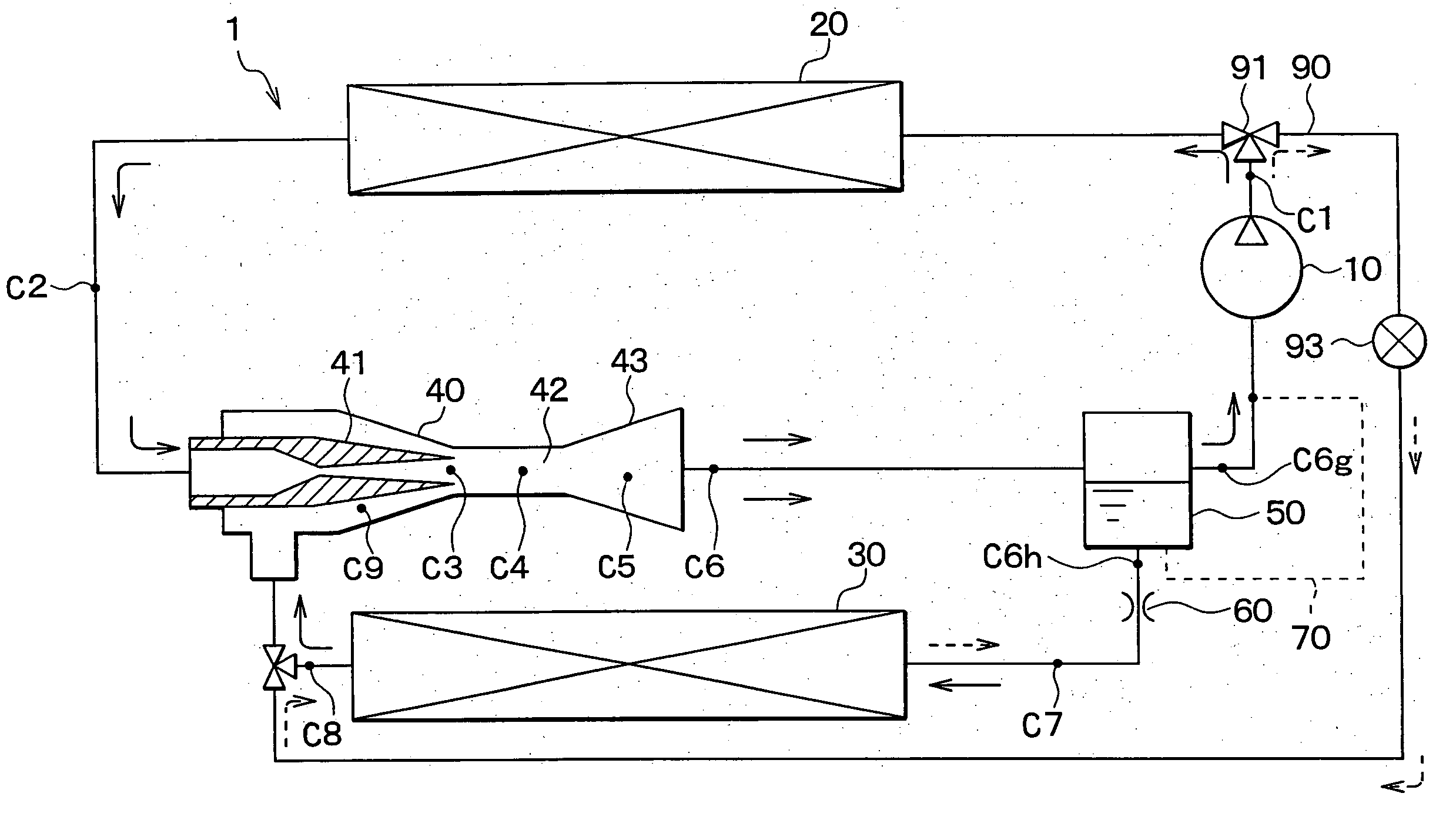

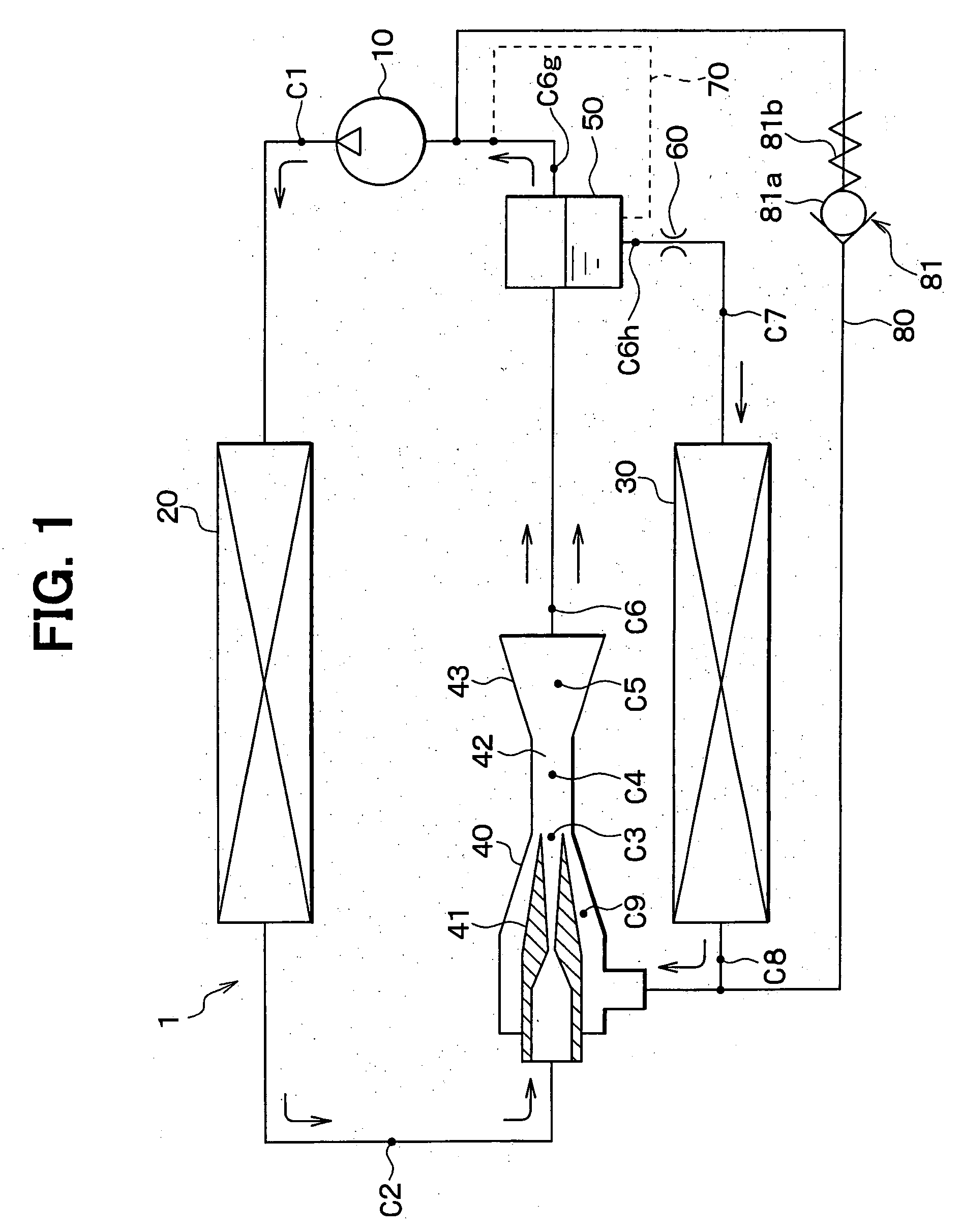

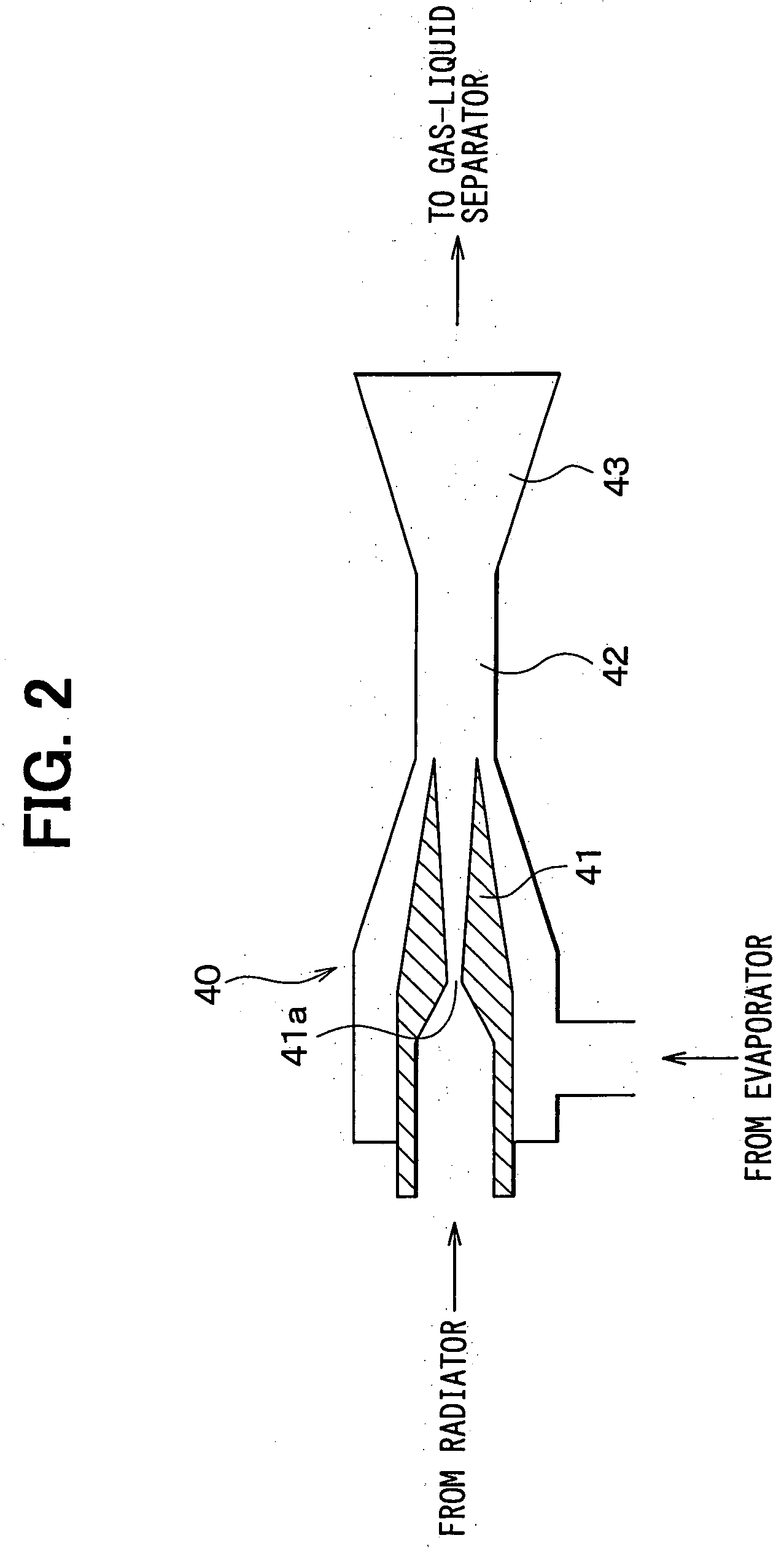

Ejector cycle system

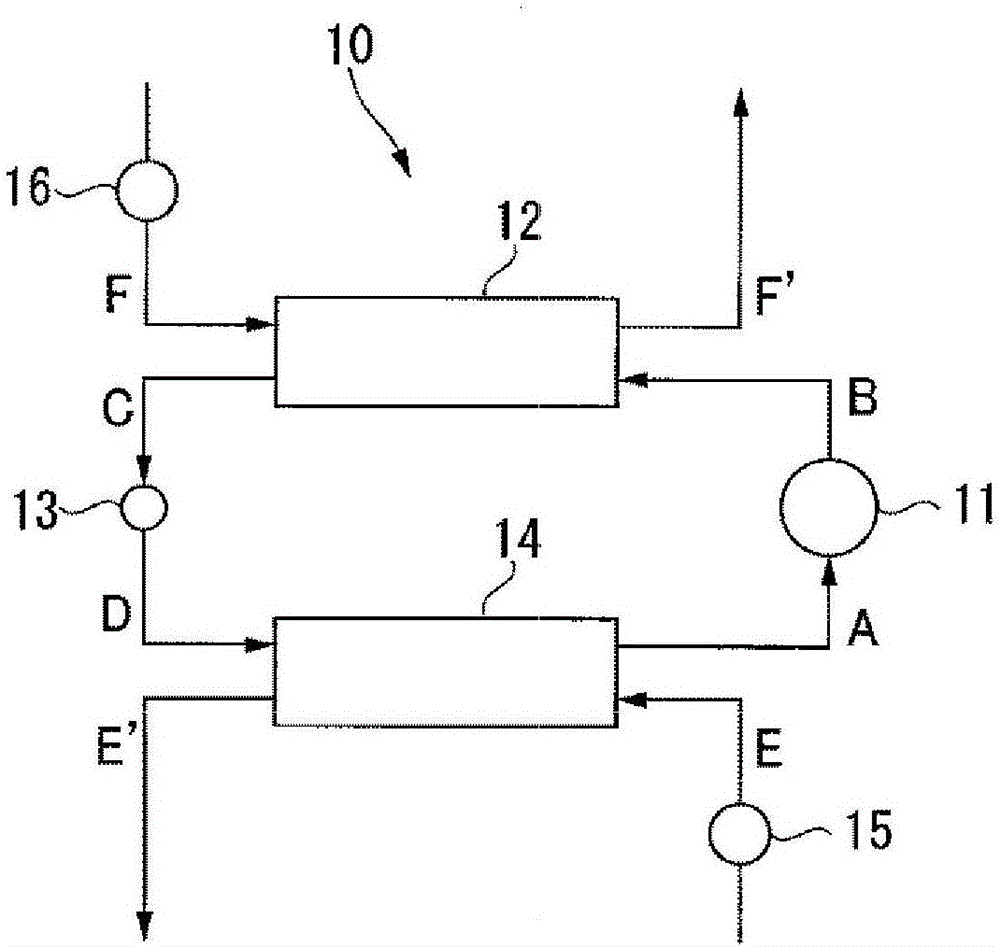

InactiveUS20070000262A1Efficiently returnedCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

An ejector cycle system with a refrigerant cycle through which refrigerant flows includes an ejector disposed downstream of a radiator, a first evaporator that evaporates refrigerant flowing out of the ejector, a throttling unit located in a branch passage and depressurizes refrigerant to adjust a flow rate of refrigerant, and a second evaporator located downstream of the throttling unit. In the ejector cycle system, a flow ratio adjusting means adjusts a flow ratio between a first refrigerant flow amount depressurized and expanded in a nozzle portion of the ejector and a second refrigerant flow amount drawn into a refrigerant suction port of the ejector, based on a physical quantity related to at least one of a state of refrigerant in the refrigerant cycle, a temperature of a space to be cooled by the first and second evaporators, and an ambient temperature of the space.

Owner:DENSO CORP

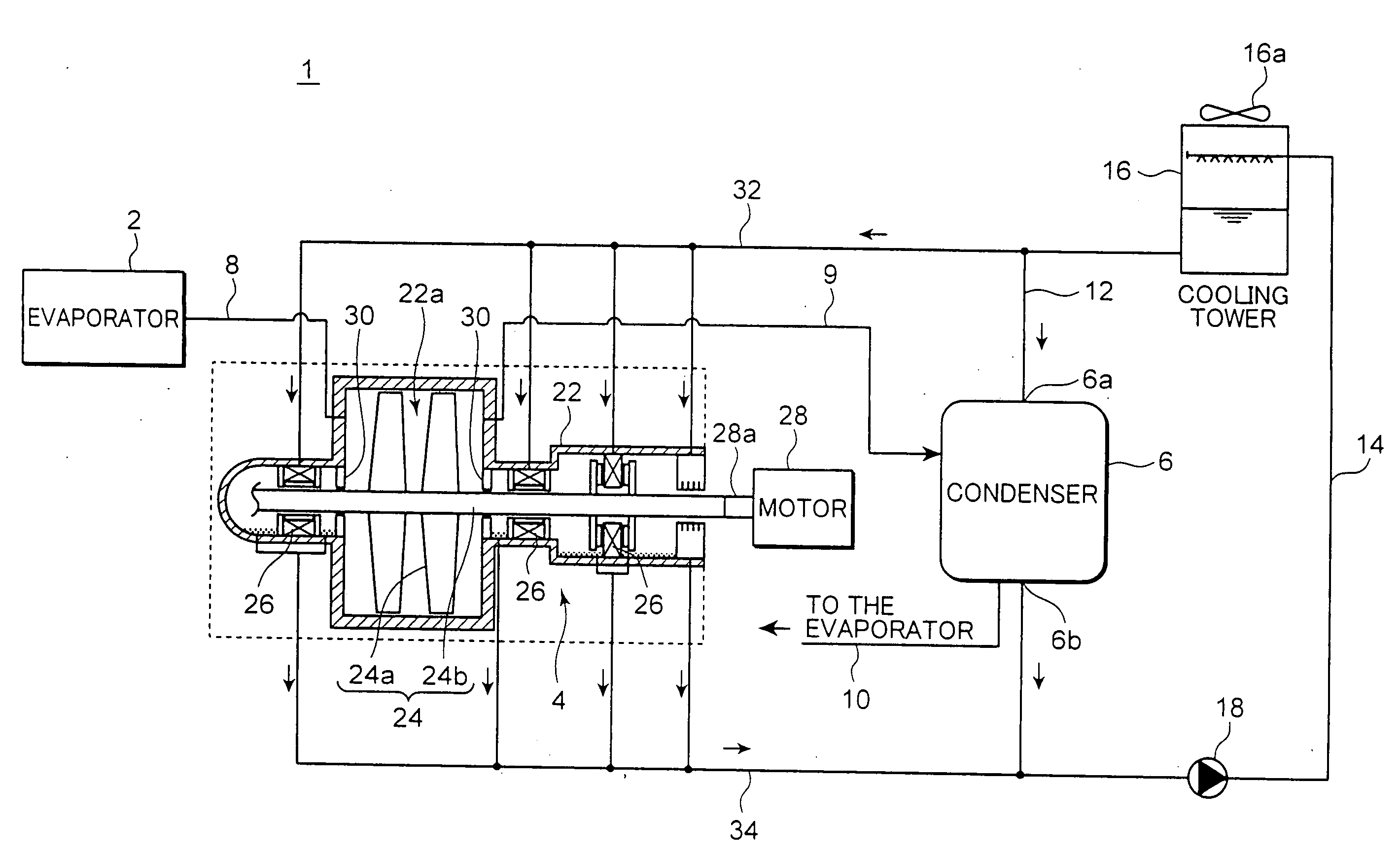

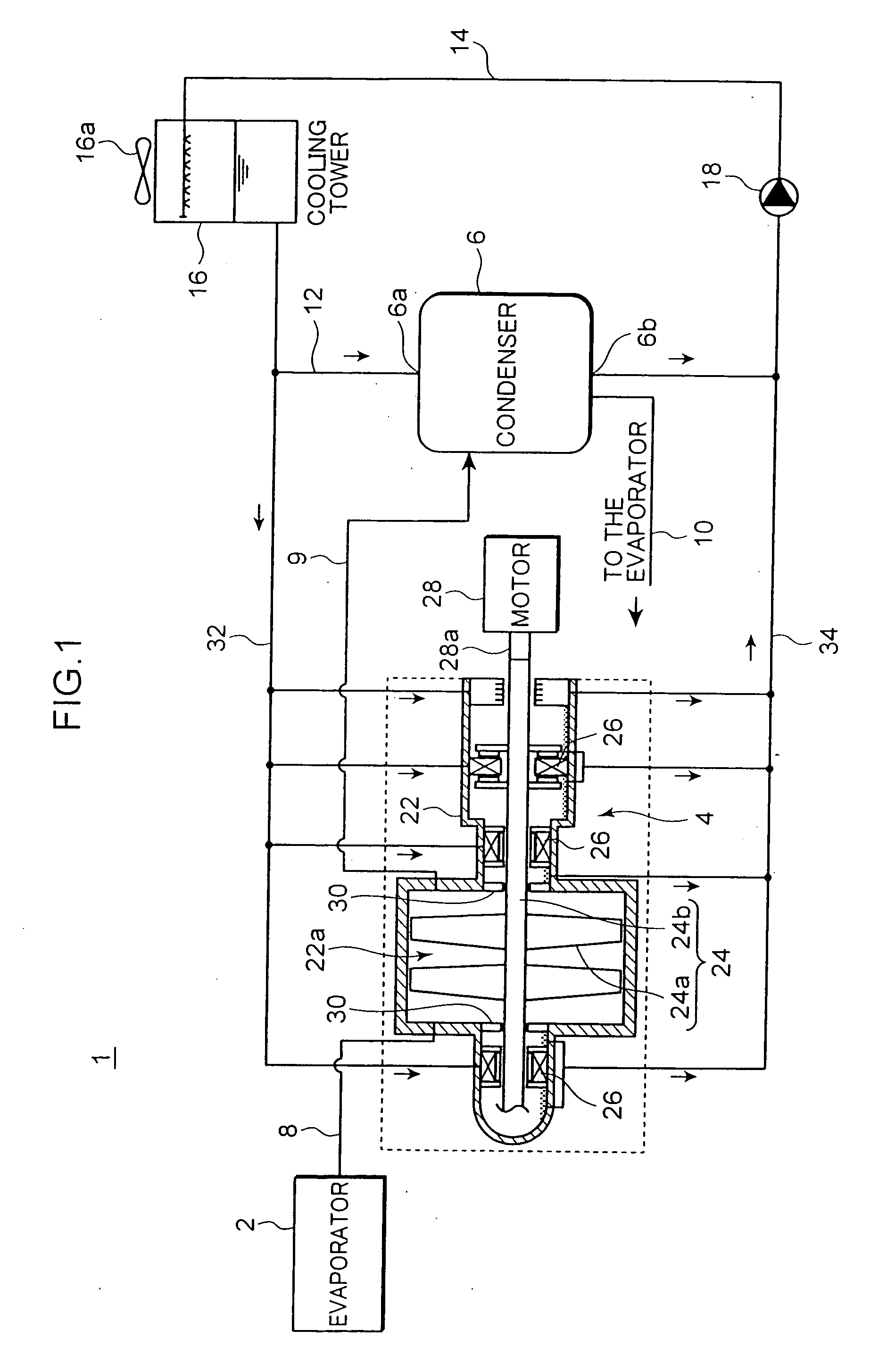

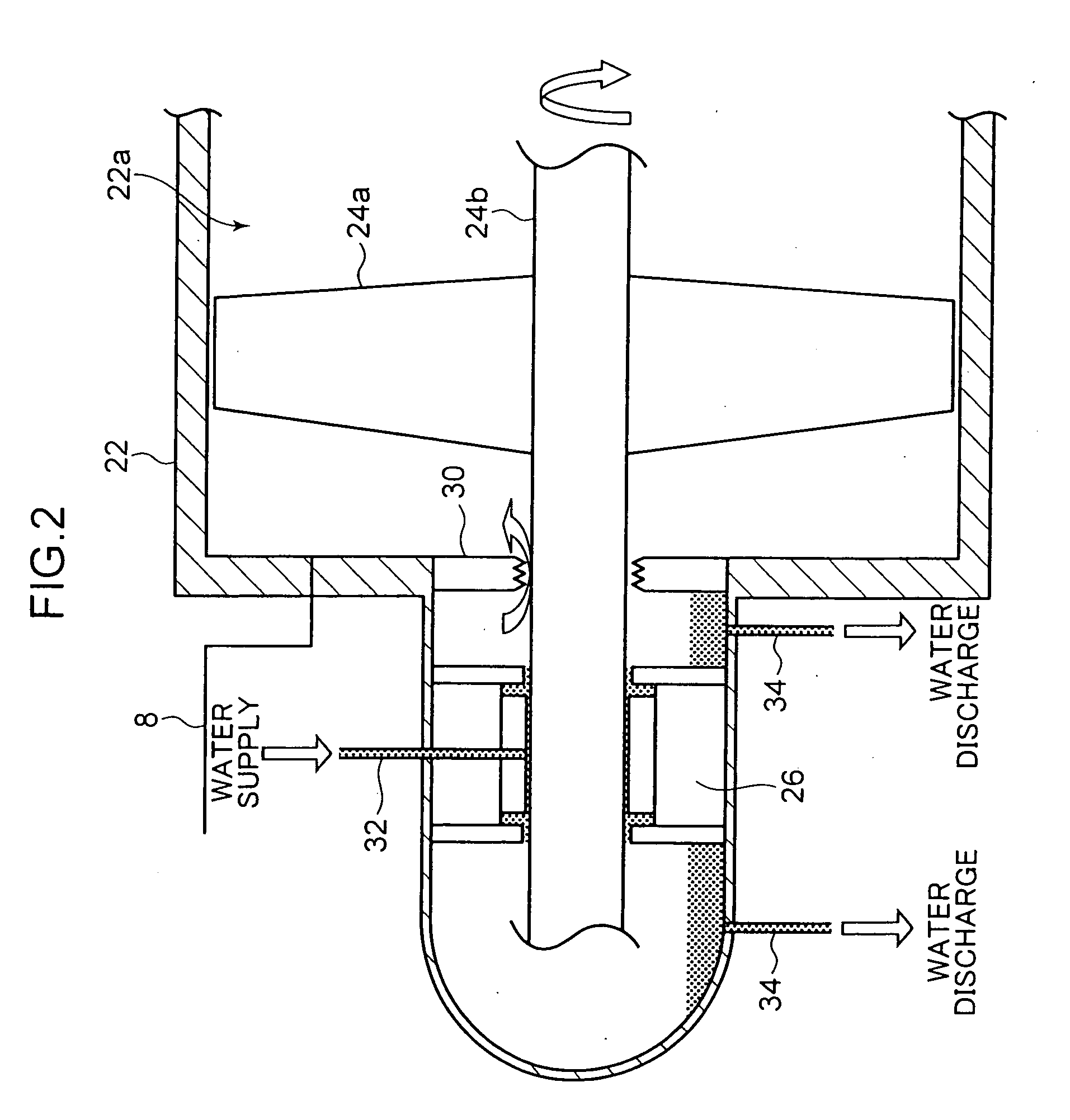

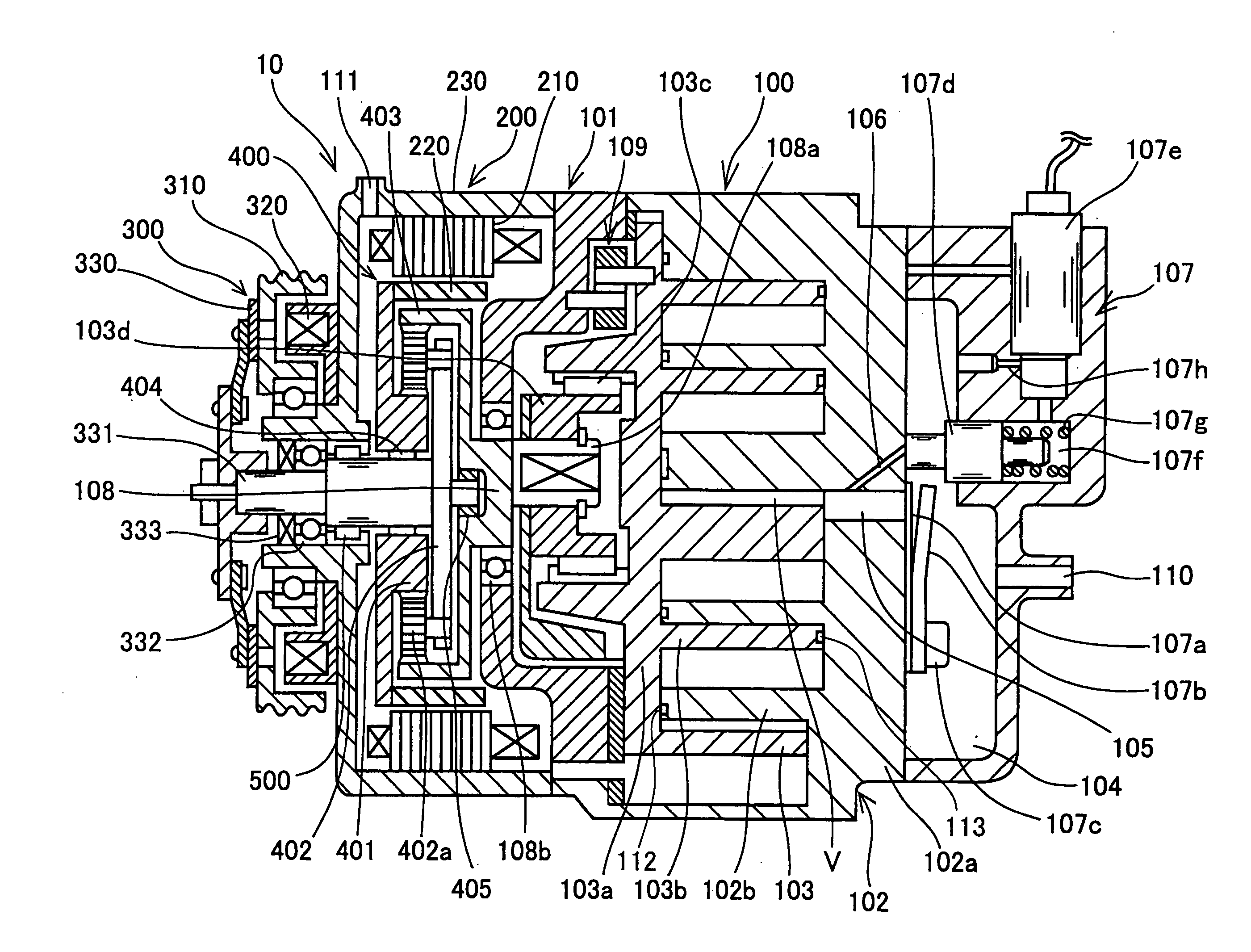

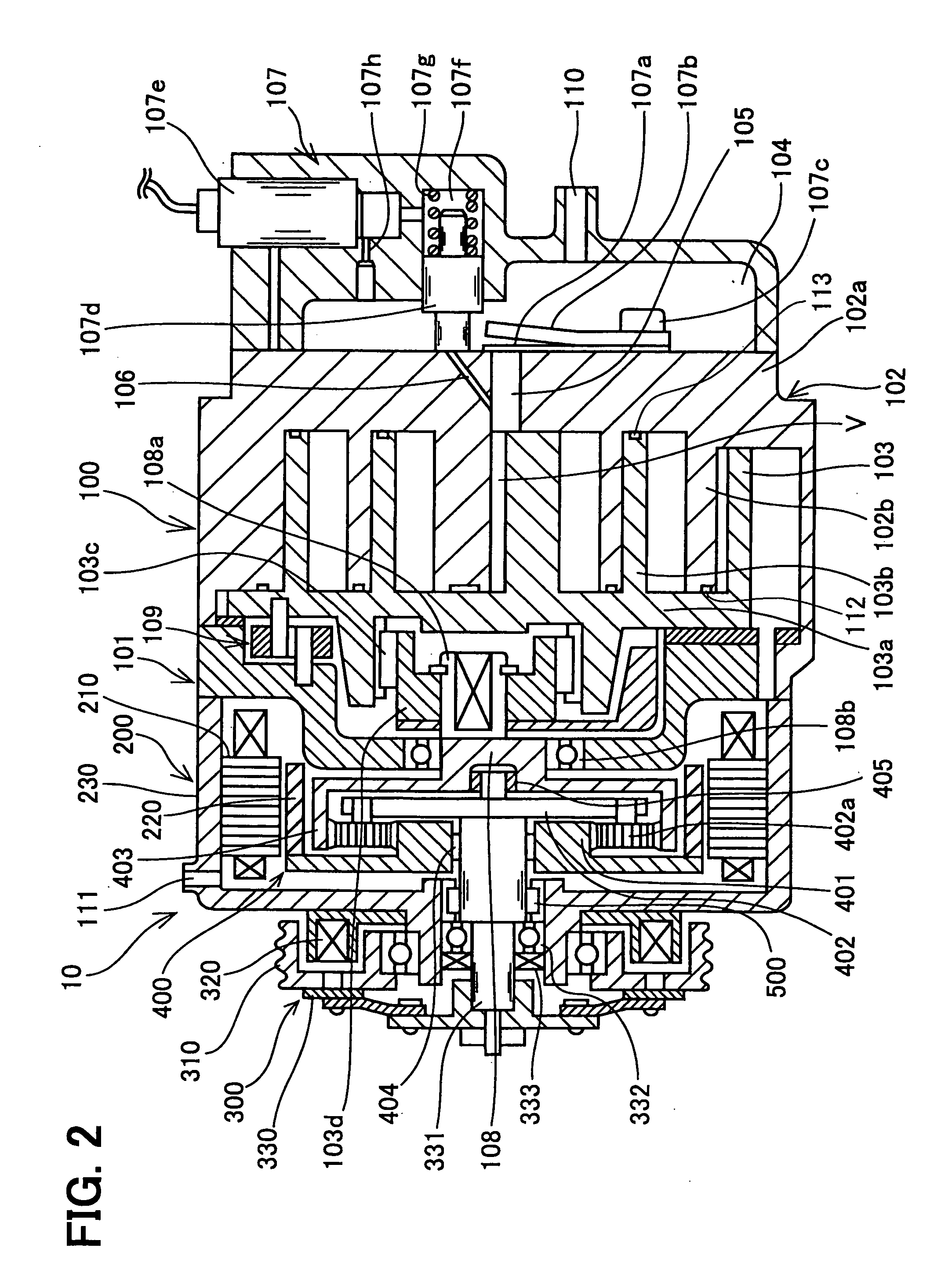

Compressor and refrigerating machine

ActiveUS20110174009A1Easy disposalSimple configurationCompressorPump componentsRotational axisWater vapor

A compressor and a refrigerating machine which enable an easy disposal of a lubricant, are friendly to the natural environment, and have simple configurations, are provided.The compressor which is used in a refrigerating machine including an evaporator and a condenser and adapted for compressing refrigerant gas evaporated in the evaporator to convey the compressed refrigerant gas to the condenser, includes: a motor; a housing having a compression chamber inside; a rotary member which has a rotating shaft and is rotated by a driving force of the motor so as to compress water vapor serving as the refrigerant gas in the compression chamber; a bearing for supporting the rotating shaft of the rotary member in the housing; and a lubricant supplier for supplying water serving as a lubricant to the bearing.

Owner:THE TOKYO ELECTRIC POWER CO INC +3

Diabetes treatment systems and methods

InactiveUS7204251B2Increase loopDecrease and prevent flowCompressorElectrotherapyHeart rightInhalation

Owner:ZOLL MEDICAL CORPORATION

Fluid machine

InactiveUS20050214148A1Improve sealingSmall sizeCompressorEngine of arcuate-engagement typeEngineeringSliding contact

An outer end of a seal element for a fixed scroll is extended to a position close to an end of an inside spiral wall of the fixed scroll, and an outwardly extended portion is formed at an outer periphery of a disc-shaped base plate of a movable scroll, so that a bottom surface of the movable scroll is always kept in a sliding contact entirely with the seal element during the orbital movement of the movable scroll. A thickness of the outwardly extended portion formed at the outer periphery of the disc-shaped base plate is made smaller than that of the disc-shaped base plate, so that the weight of the fluid machine can be smaller.

Owner:NIPPON SOKEN +1

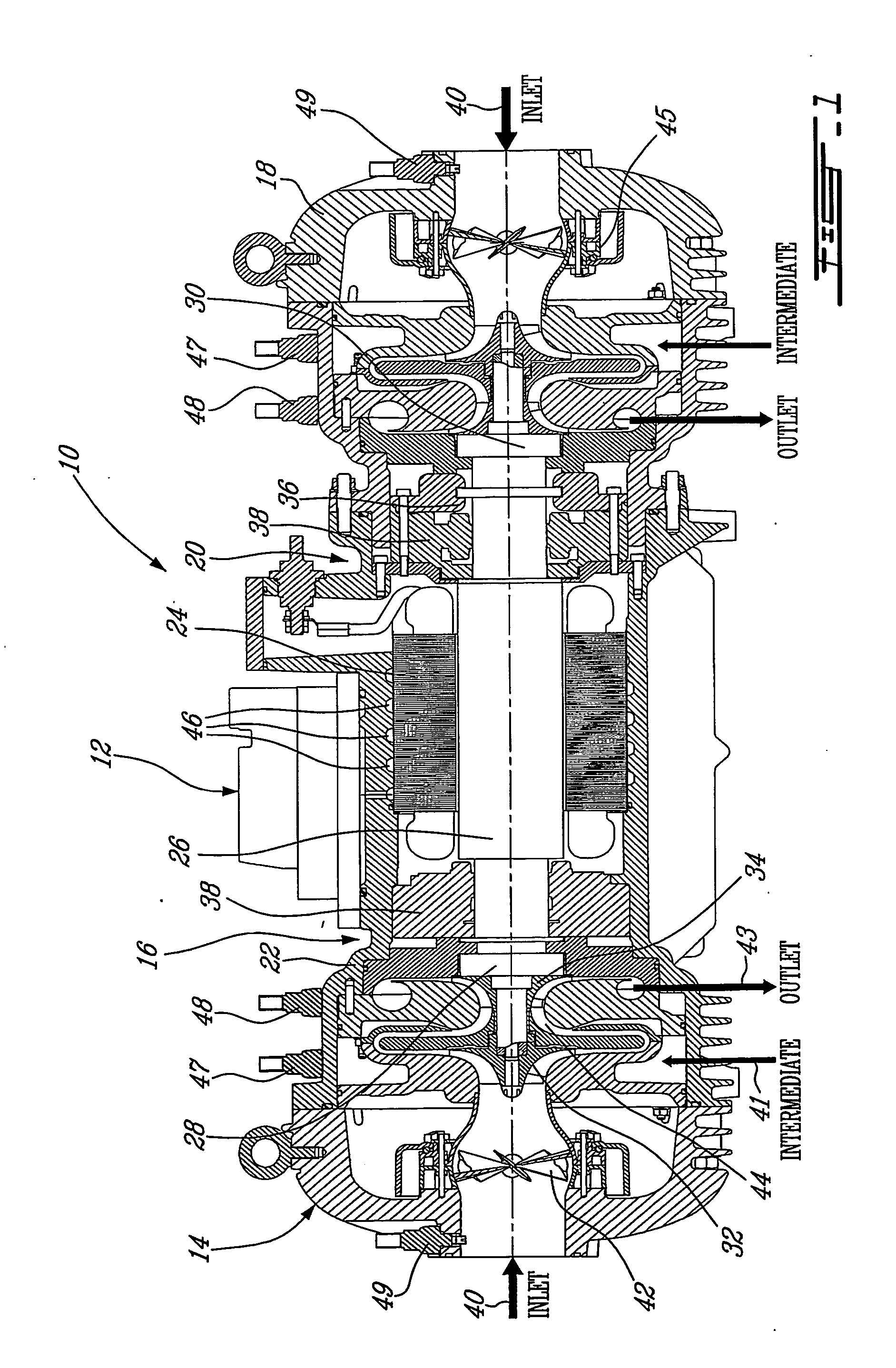

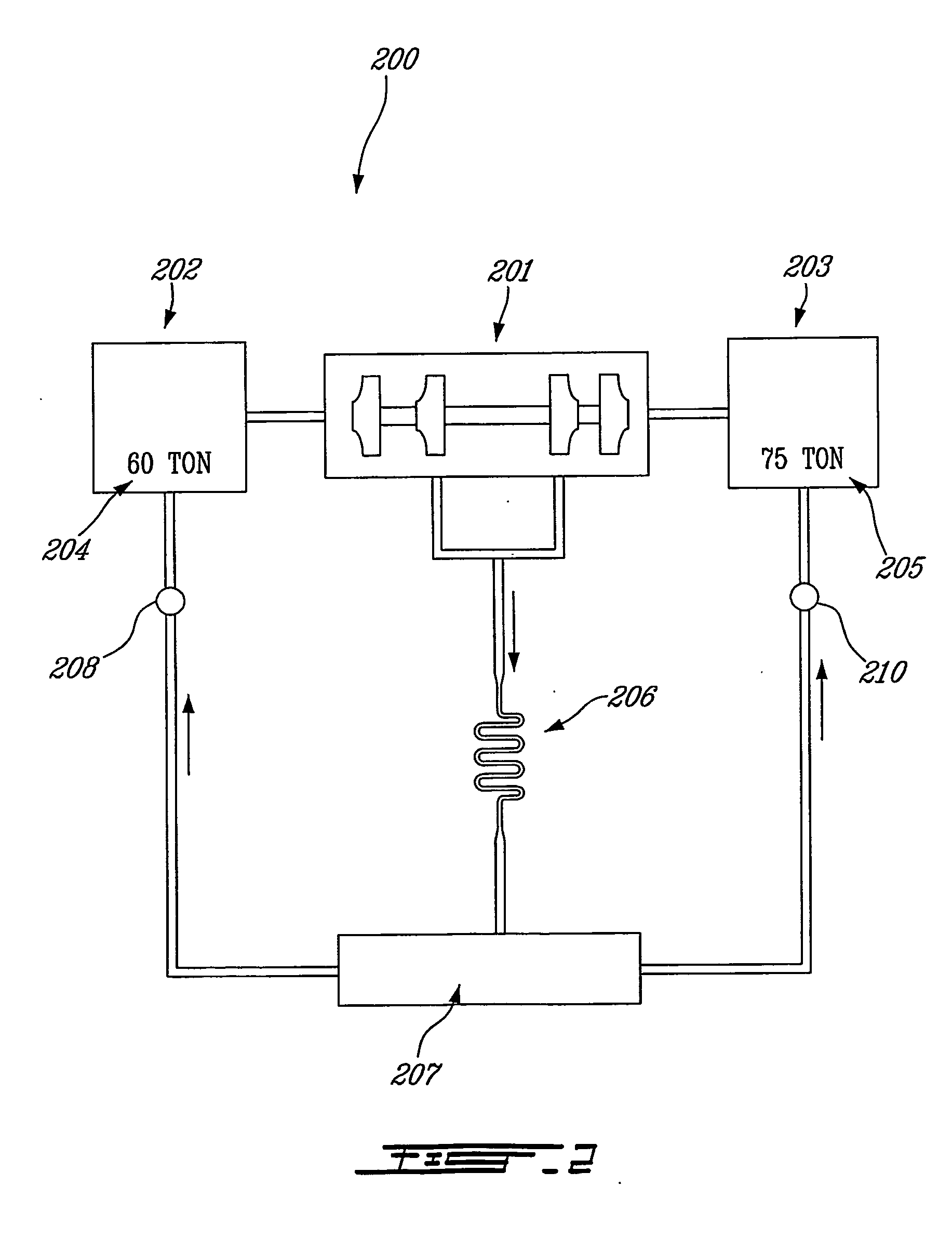

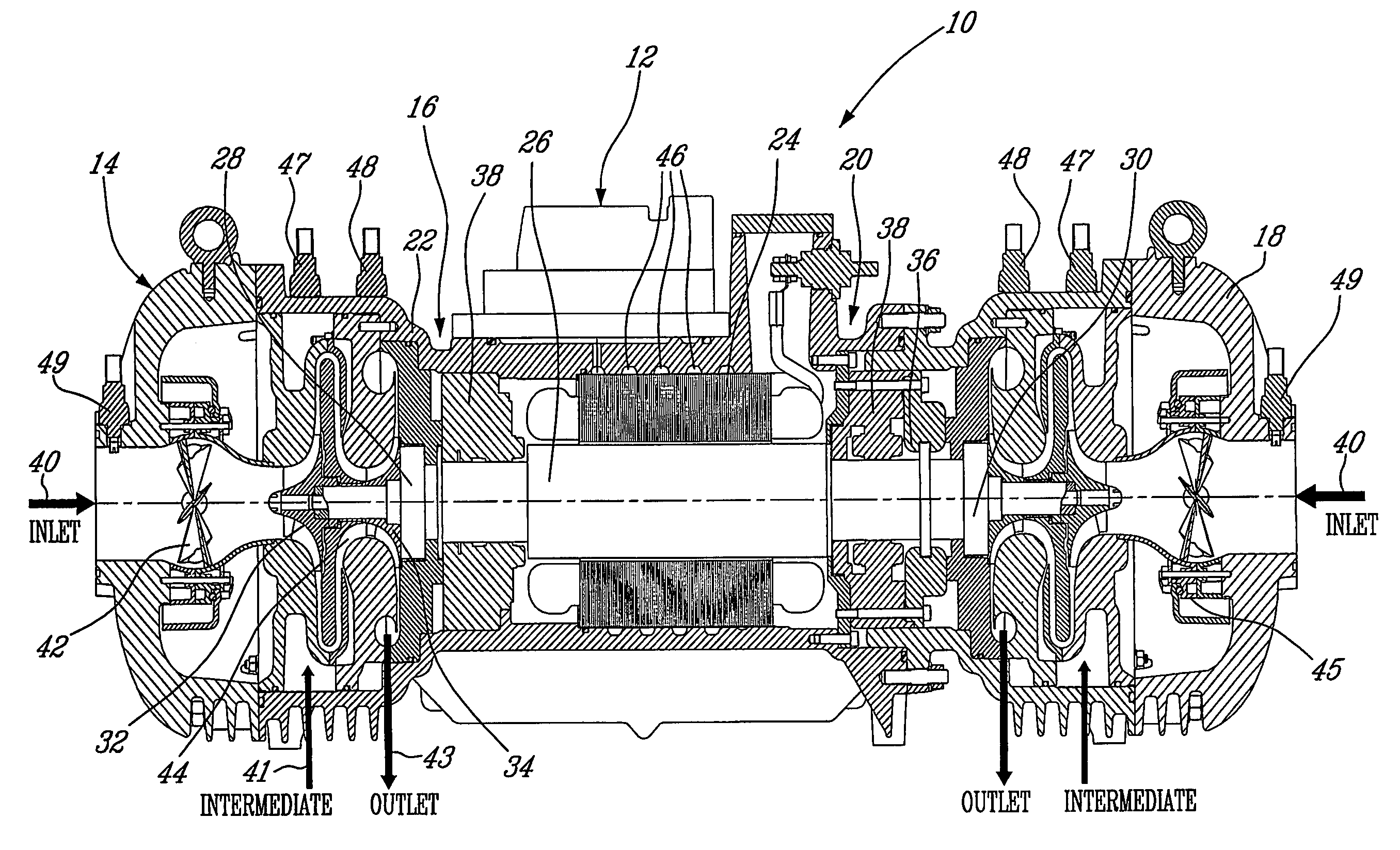

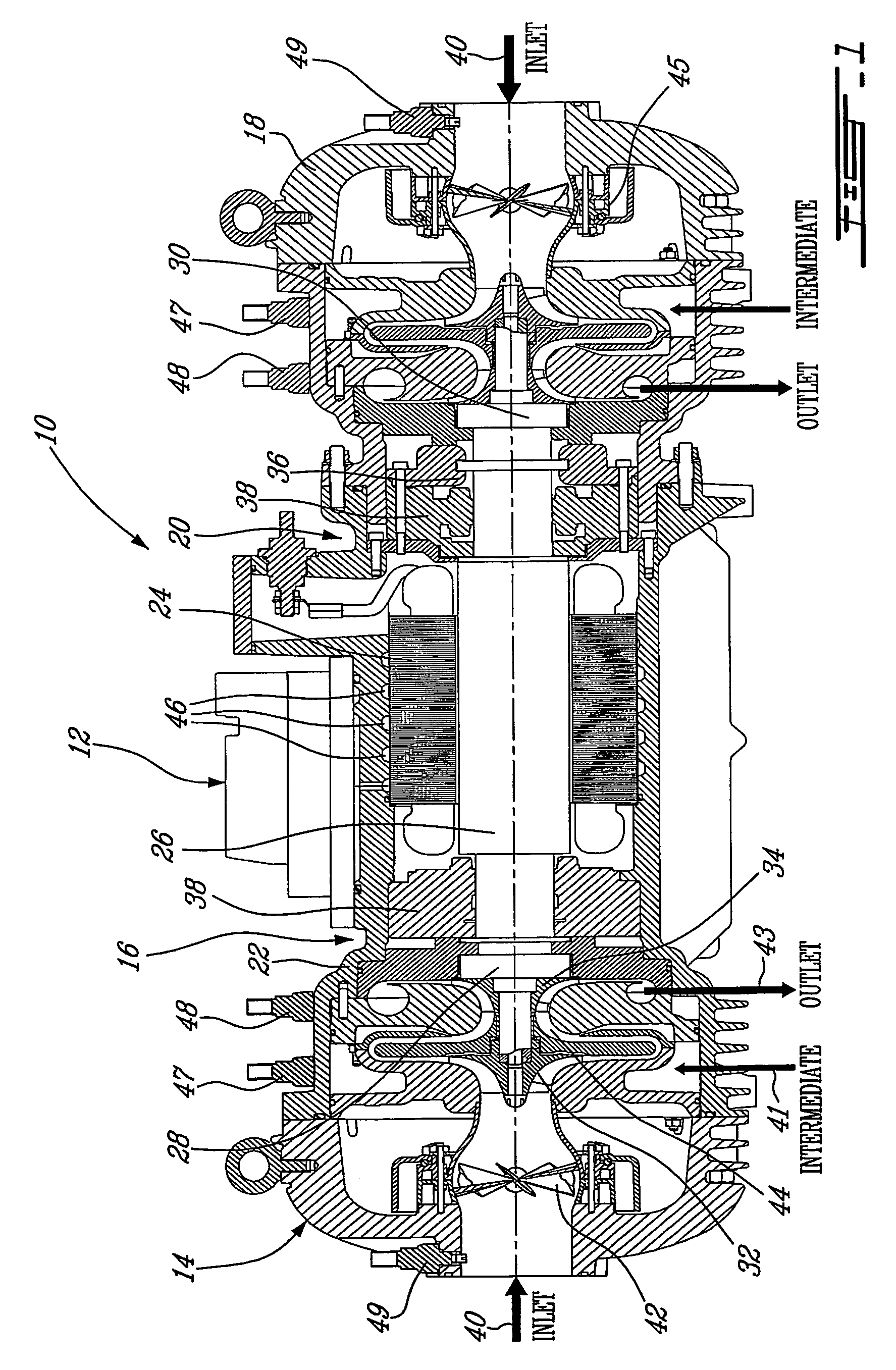

Centrifugal compressor

ActiveUS20050223737A1Improved centrifugal compressorCompressorPump componentsMagnetic bearingControl system

A compact and efficient compressor is provided, based on using magnetic bearing technology, which can operate at high speed and comprises a reliable control system. The compressor of the present invention makes use of two separate compressors mounted on a single common motor, thus sharing a single drive. The balancing of the thrust at high RPM is improved by using a pair of electromagnetic bearings.

Owner:DANFOSS AS

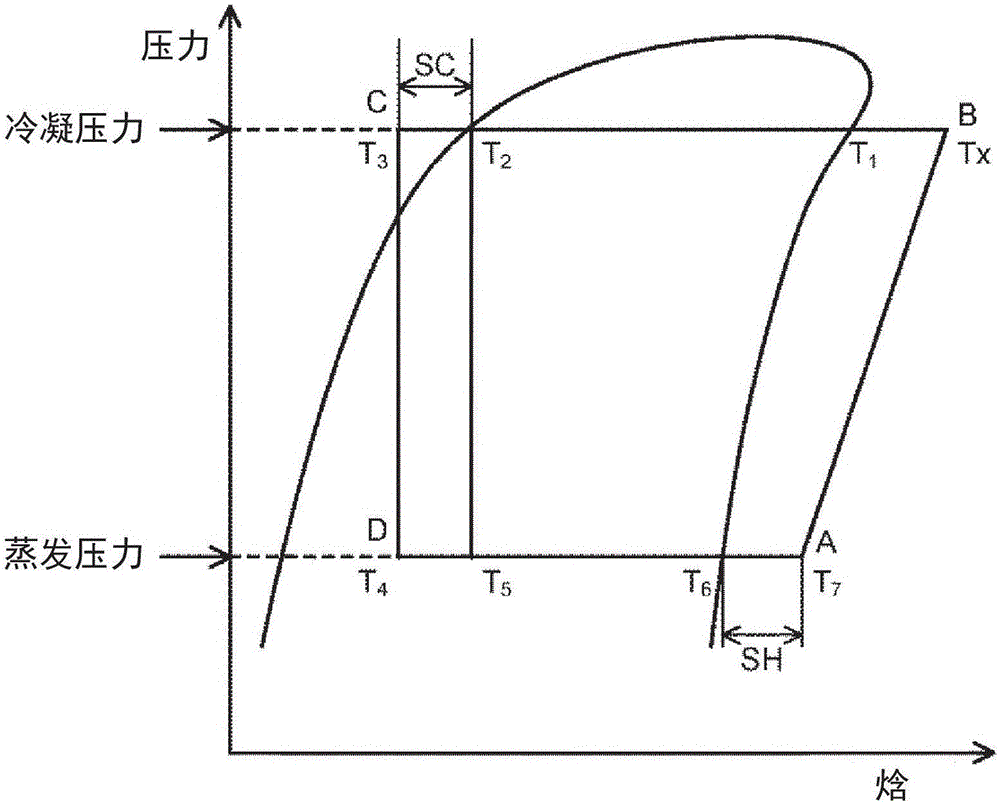

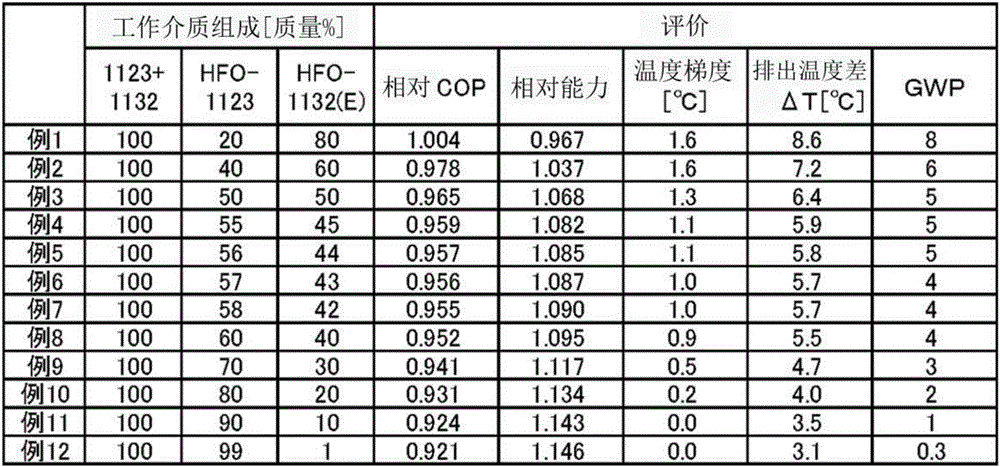

Working medium for heat cycles, composition for heat-cycle systems, and heat-cycle system

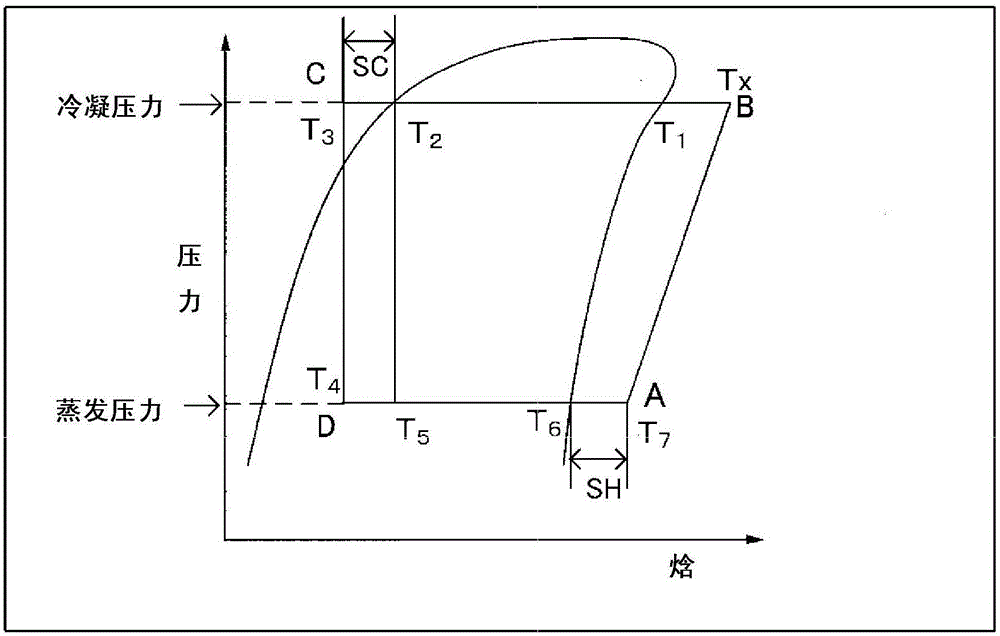

ActiveCN106133110AReduce temperature gradientLower discharge temperatureCompressorCompression machines with non-reversible cycleEngineeringRefrigeration

Provided are: a working medium for heat cycles which has a low impact on global warming, a low temperature gradient, and a sufficiently low discharge temperature, and which exhibits excellent cycle performance (i.e. refrigeration capacity and coefficient of performance); a composition for heat-cycle systems; and a heat-cycle system. The working medium for heat cycles includes trifluoroethylene and 1, 2-difluoroethylene. Also provided are: a composition for heat-cycle systems; and a heat-cycle system which uses the working medium and the composition. It is prefereable that, in the working medium for heat cycles, the ratio of the total amount of trifluoroethylene and 1, 2-difluoroethylene be at least 20 mass%, and equal to or less than 100 mass%.

Owner:AGC INC

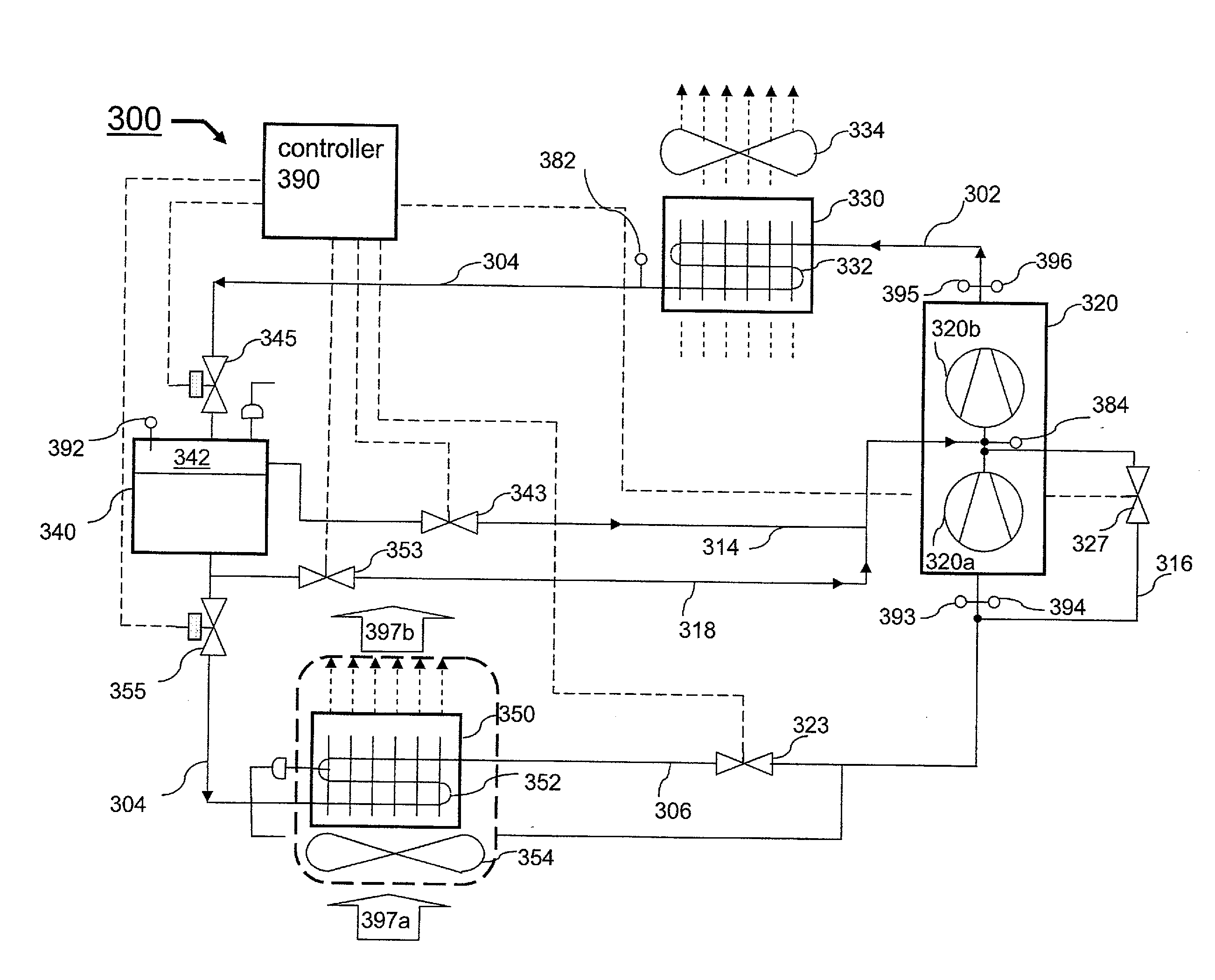

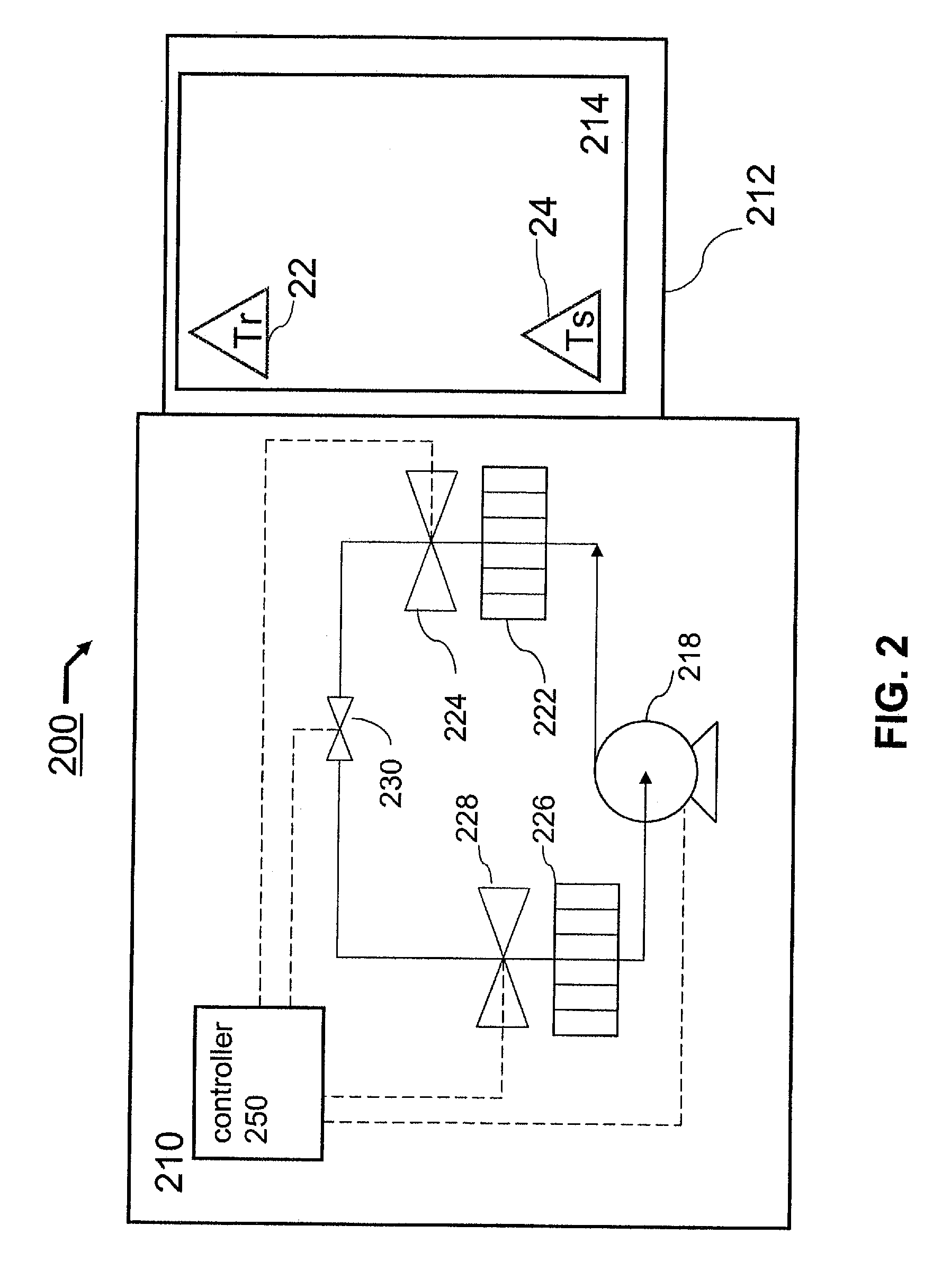

Parameter control in transport refrigeration system and methods for same

InactiveUS20120227427A1Maintain cargo qualityCompressorMechanical apparatusProcess engineeringEngineering

Embodiments of transport refrigeration systems, apparatus, and / or methods for the same can provide exemplary verification for operating characteristics thereof. In one embodiment, a calculated compressor mid stage pressure can be verified using a prescribed relationship to other transport refrigeration system characteristics.

Owner:CARRIER CORP

CPR mask with compression timing metronome and methods

InactiveUS7174891B2Improve performanceEnsure correct executionCompressorElectrotherapyAnesthesiaMetronome

A facial mask includes a mask body that is adapted to be coupled to a patient's face. A valve system is coupled to the mask body to permit the inflow of respiratory gasses into the mask body and to permit the outflow of respiratory gasses from the mask body. A metronome is coupled to the mask body to produce a repeating chest compression signal to facilitate the performance of regular chest compressions when performing cardio pulmonary resuscitation. The metronome may also produce a ventilation signal to facilitate the proper ventilation of the patient.

Owner:ZOLL MEDICAL CORPORATION

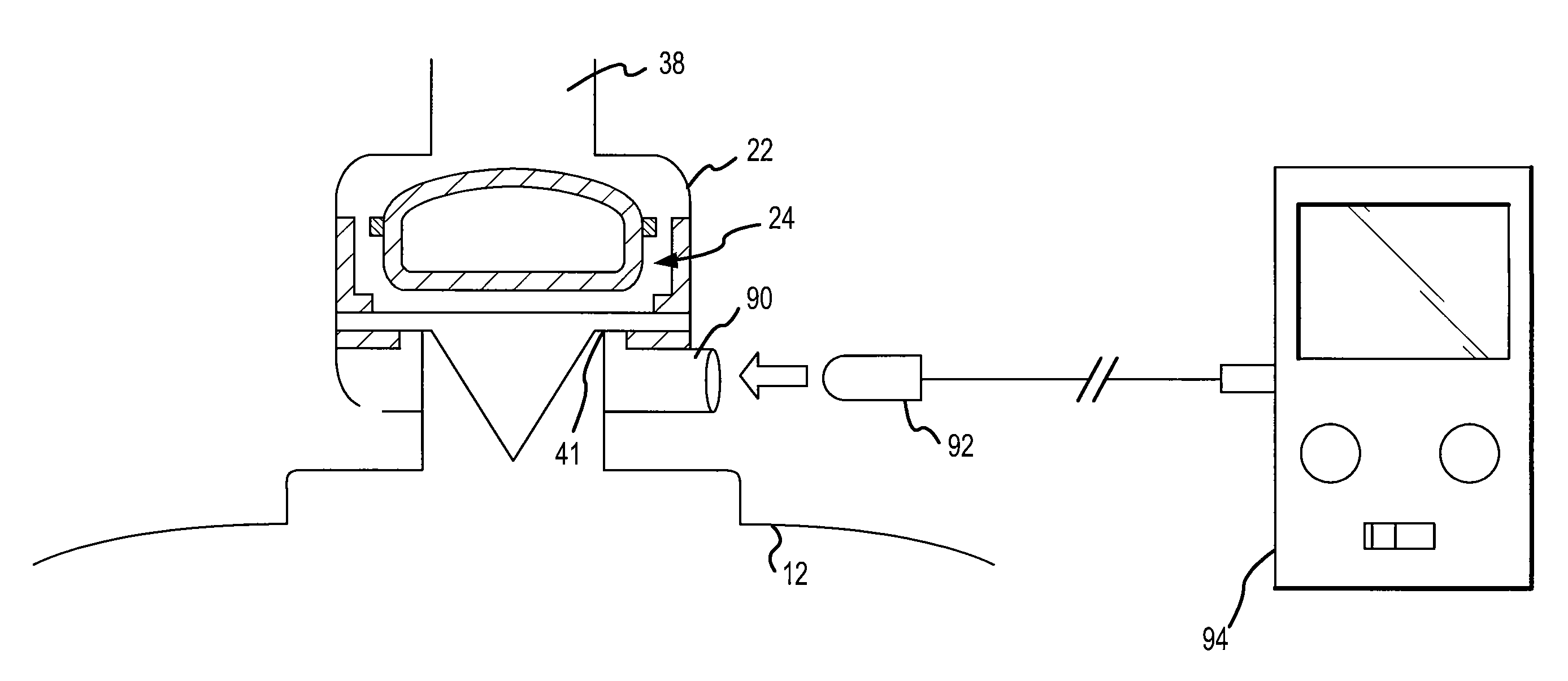

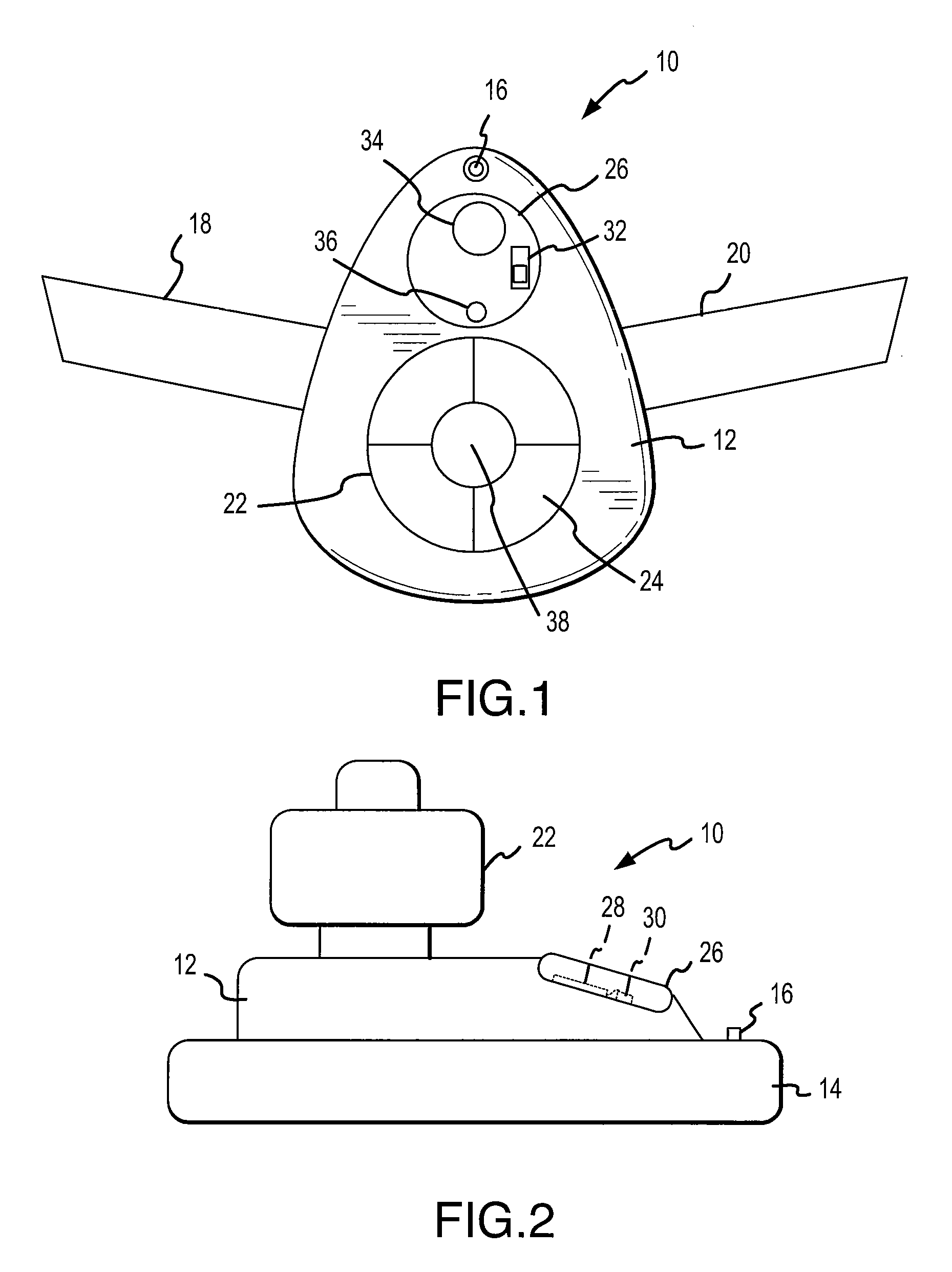

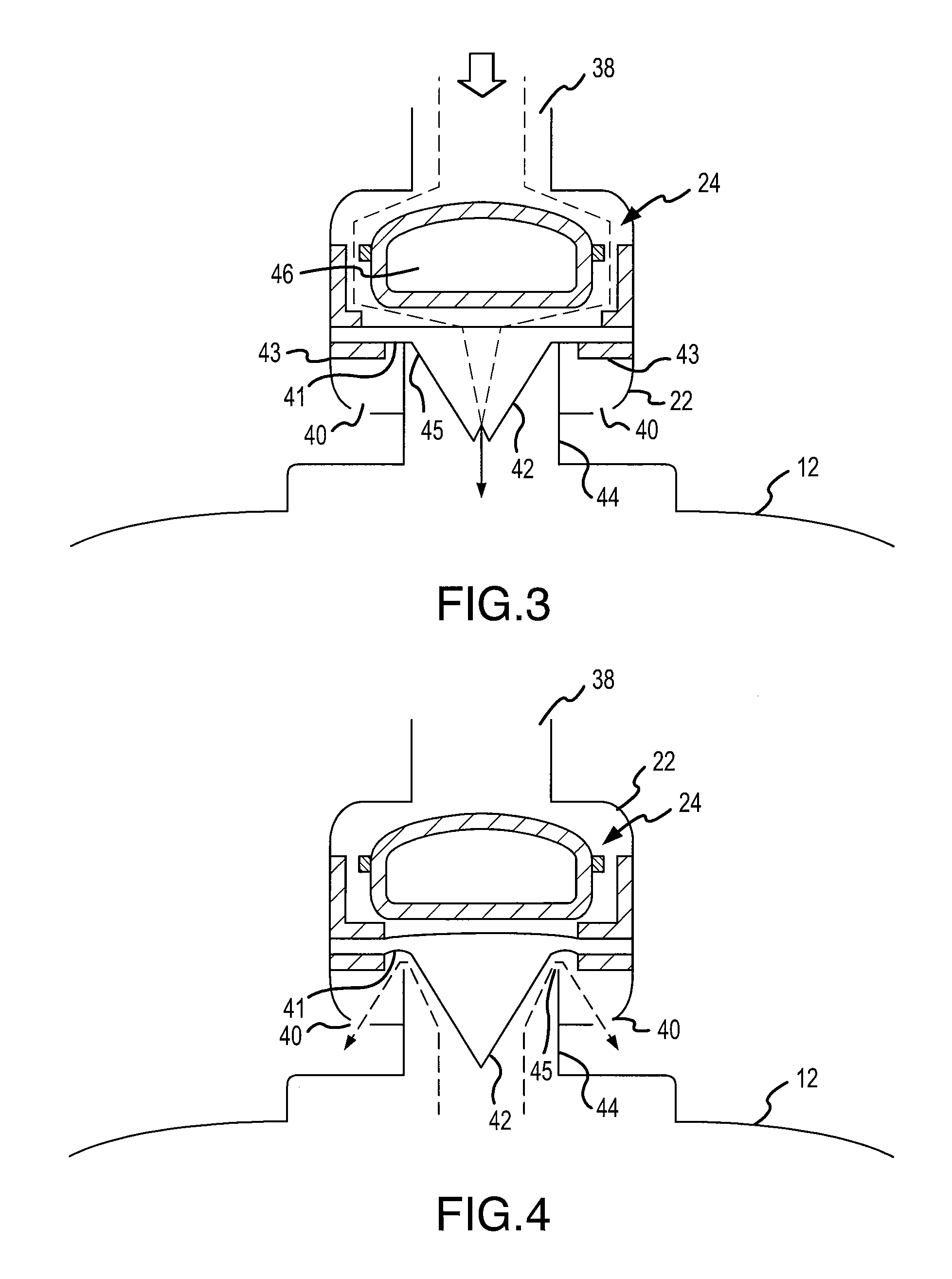

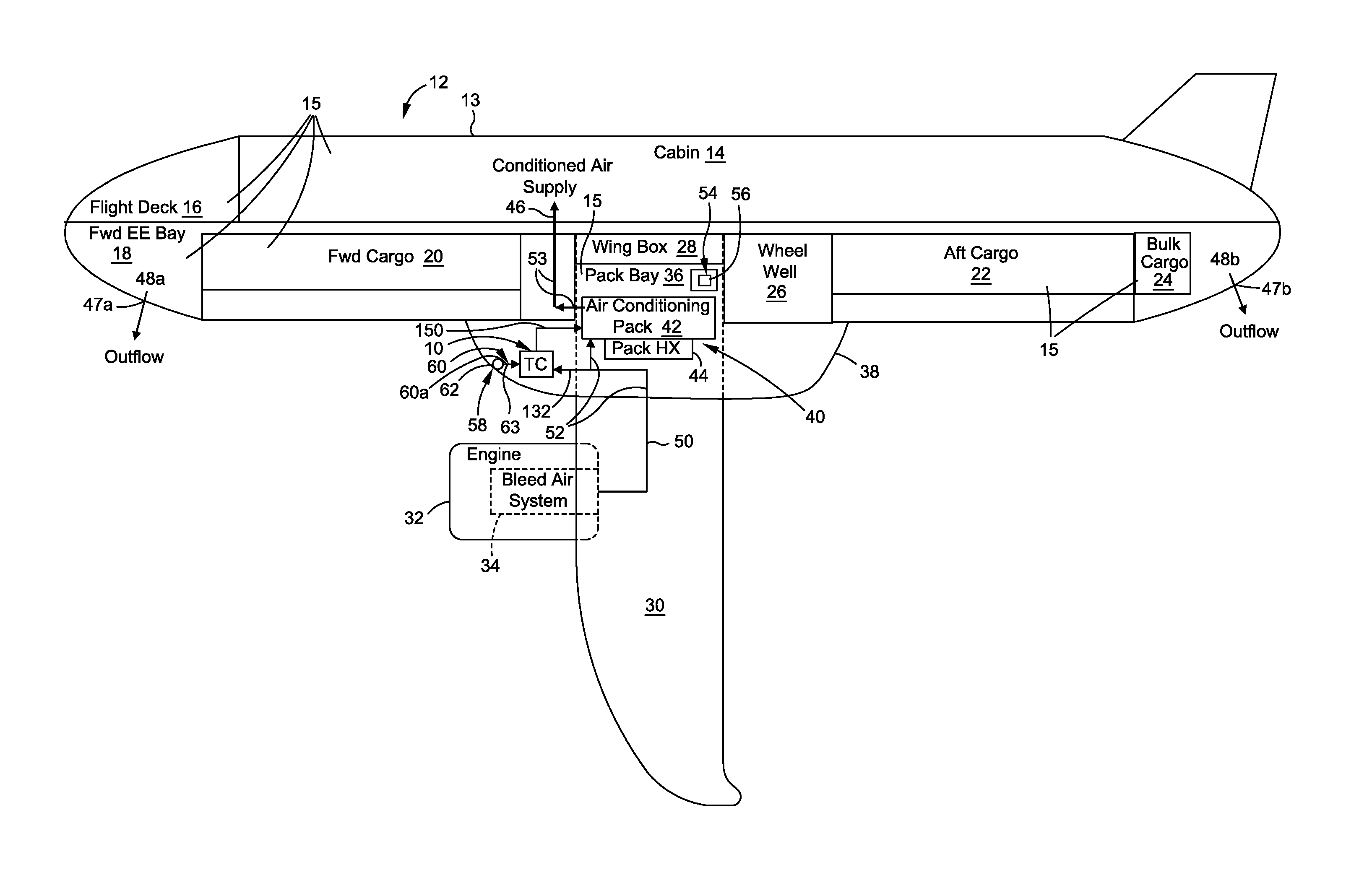

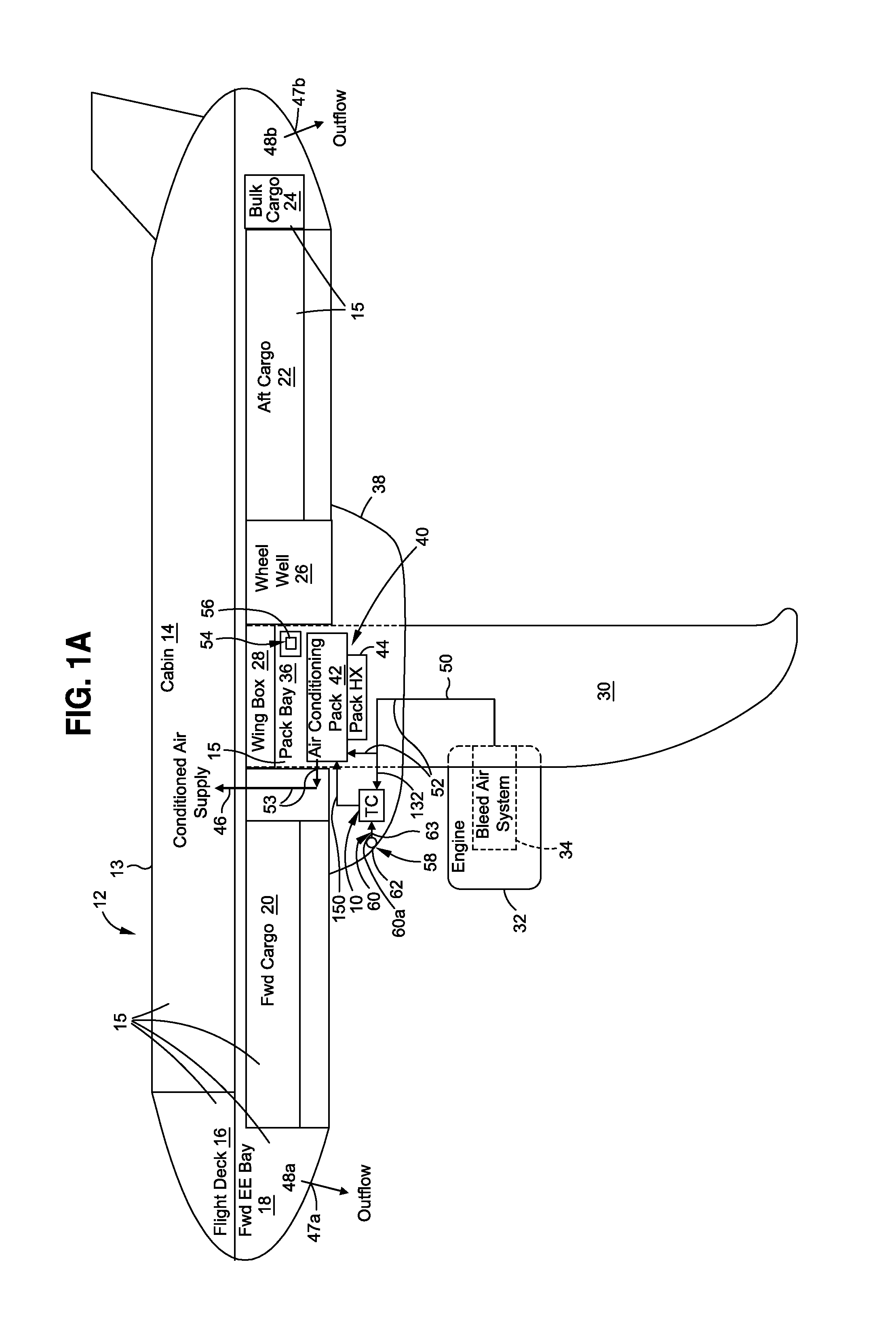

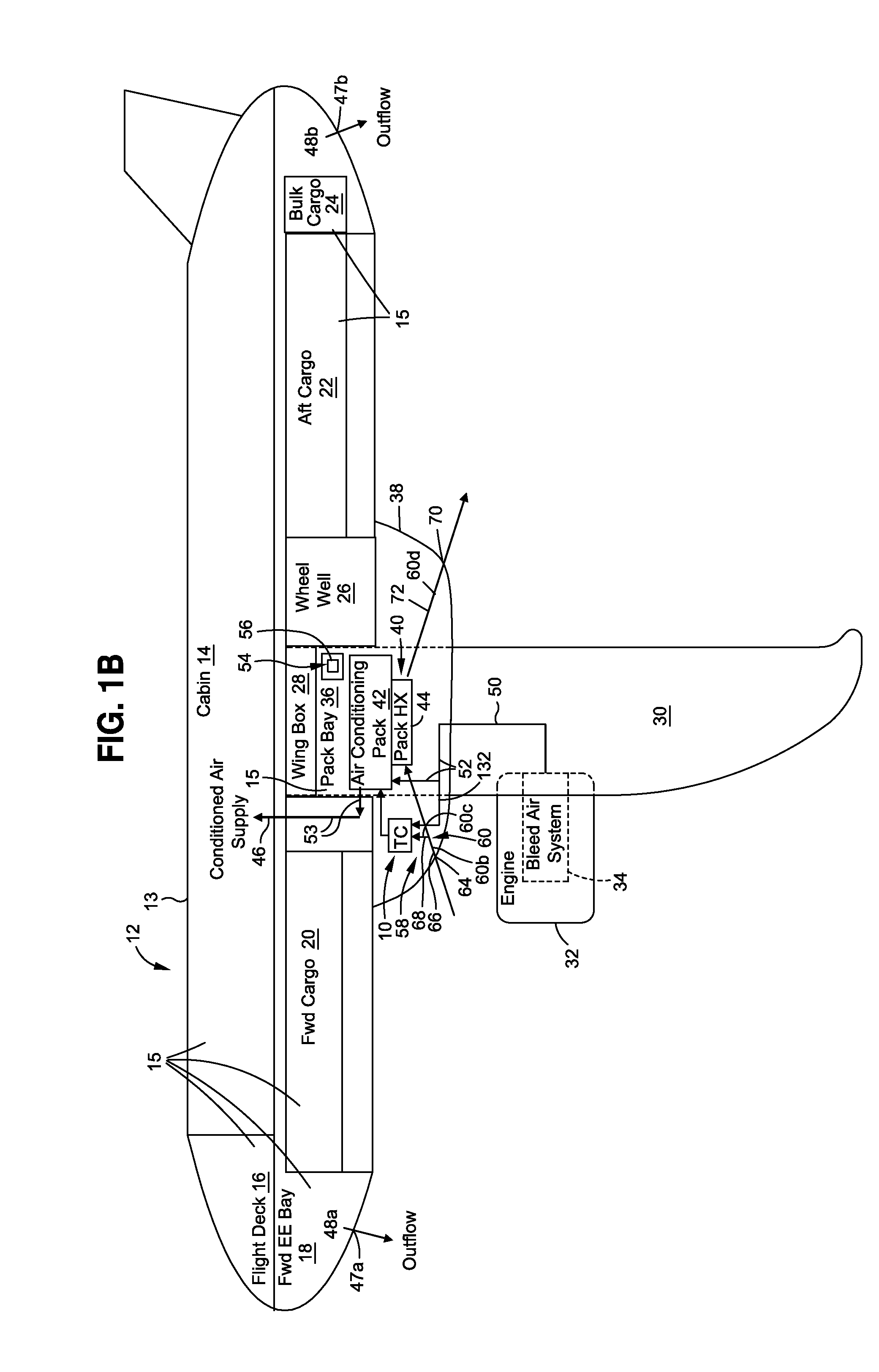

Turbo-Compressor System and Method for Extracting Energy from an Aircraft Engine

ActiveUS20150251766A1Easy to optimizeSatisfies needCompressorAir-treating devicesBleed airControl valves

A turbo-compressor (TC) system for extracting energy from an aircraft engine. The TC system has a TC assembly with a turbine mechanically coupled to at least one compressor. The TC system has a TC inlet in fluid communication with a bleed air system in the aircraft engine and a TC outlet in fluid communication with an air conditioning (AC) pack of an aircraft air conditioning system and configured to extract reduced temperature pack inlet air from the TC assembly into the air conditioning pack. The TC system has a ram air inlet coupled to the at least one compressor. The TC system has a TC control valve, and a TC check valve or a TC shutoff valve, both coupled to the TC assembly via a plurality of connective ducts. The TC system extracts energy from the bleed air to reduce bleed air flow and AC pack ram air usage.

Owner:THE BOEING CO

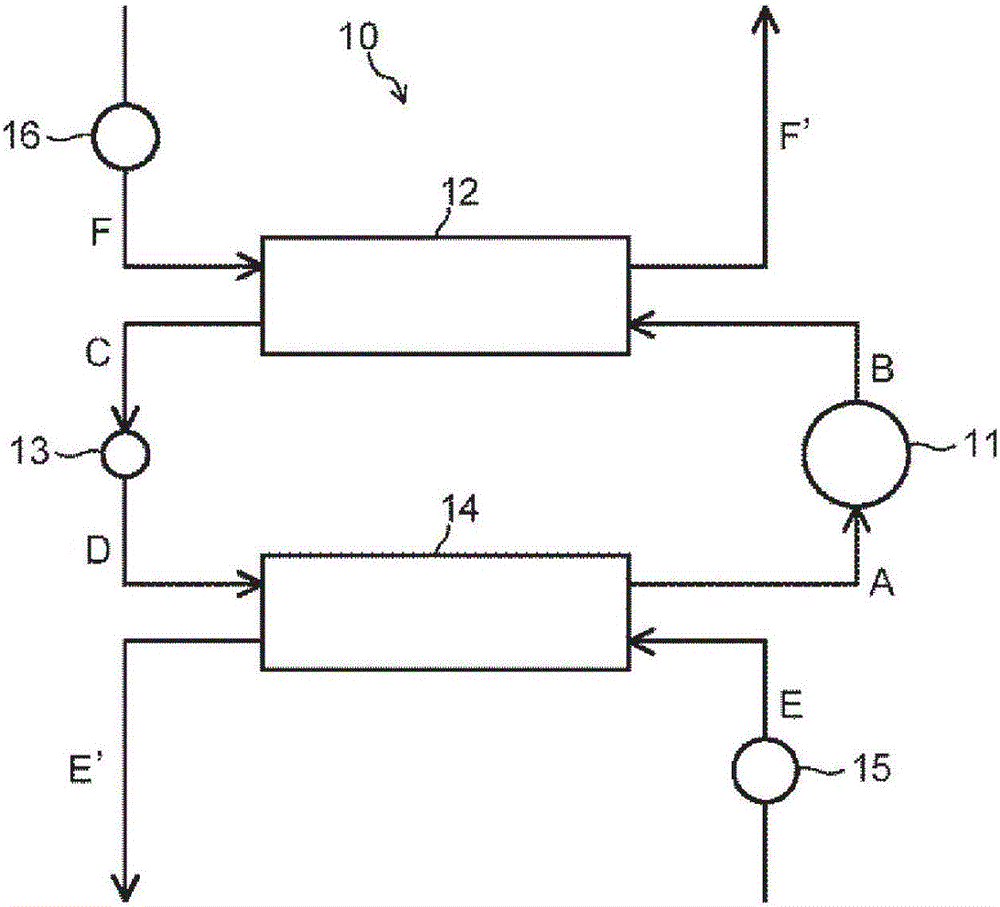

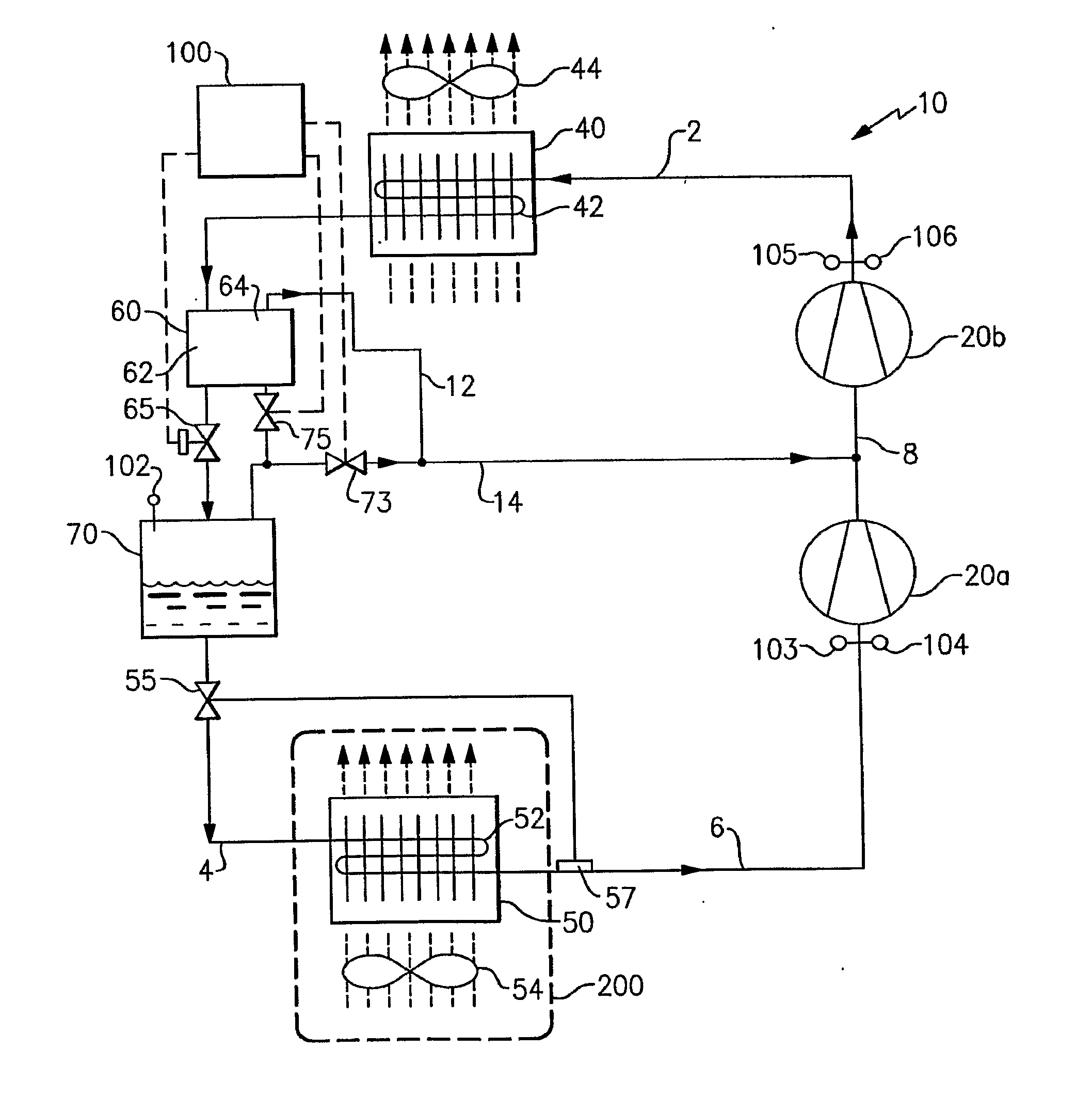

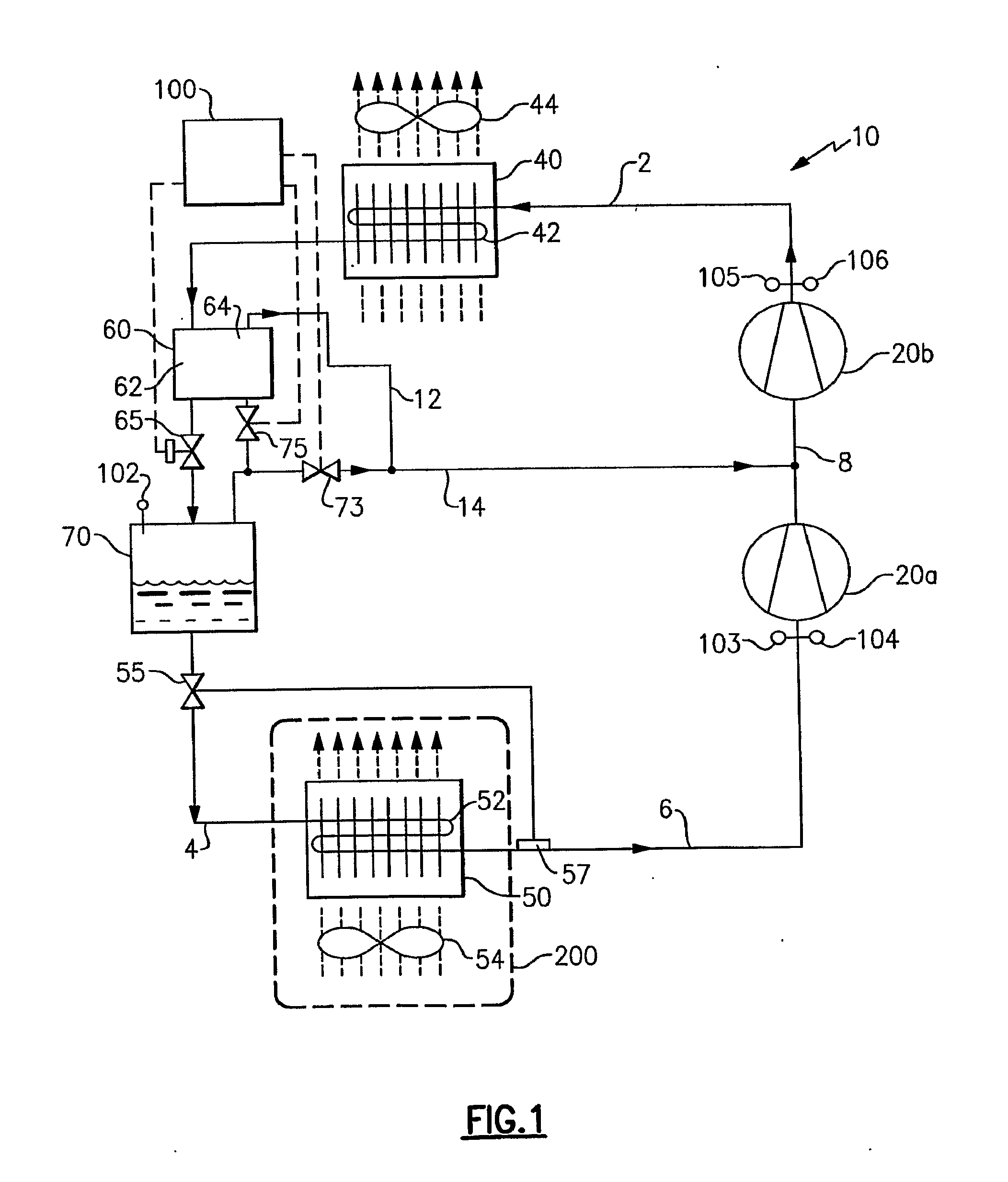

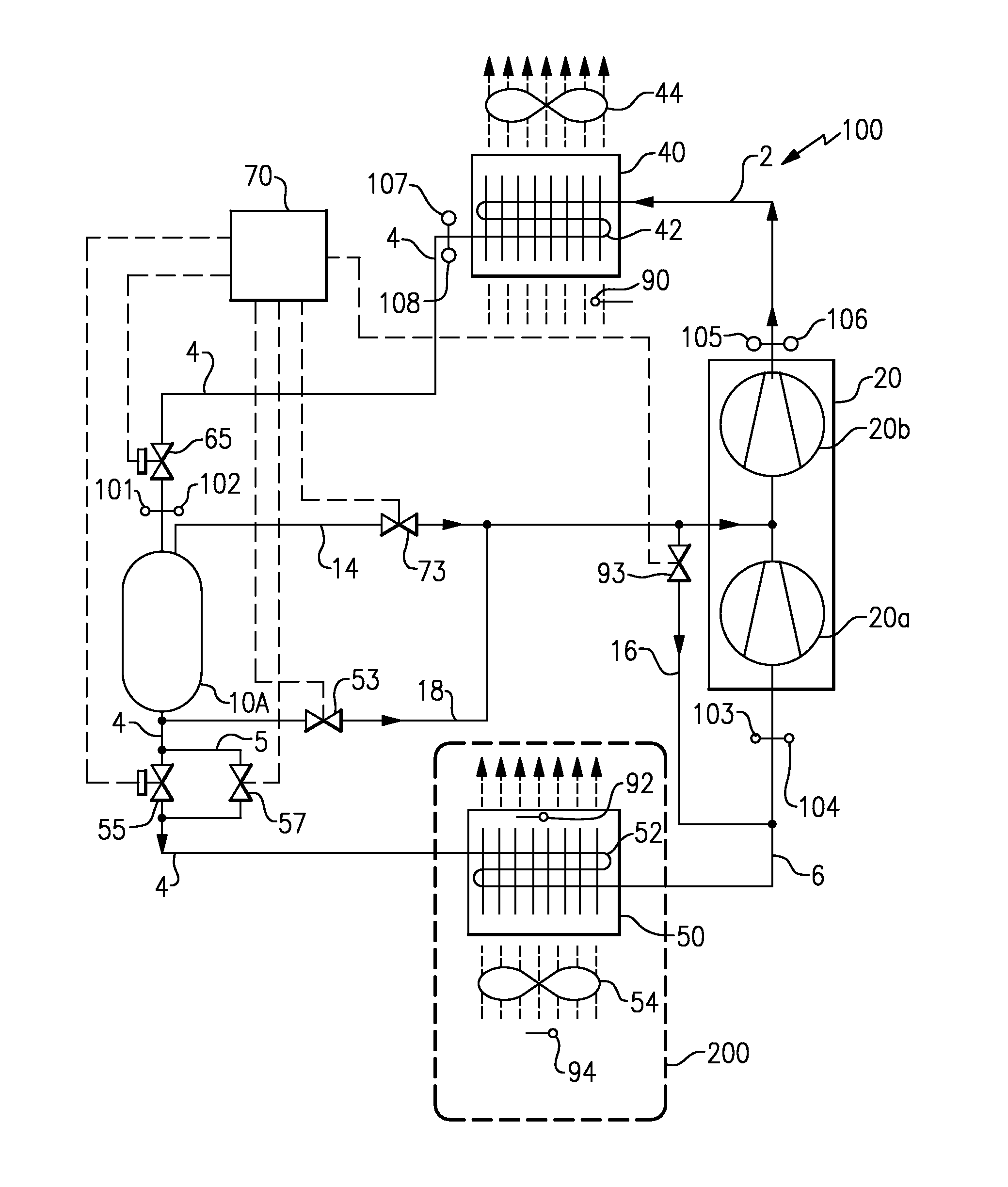

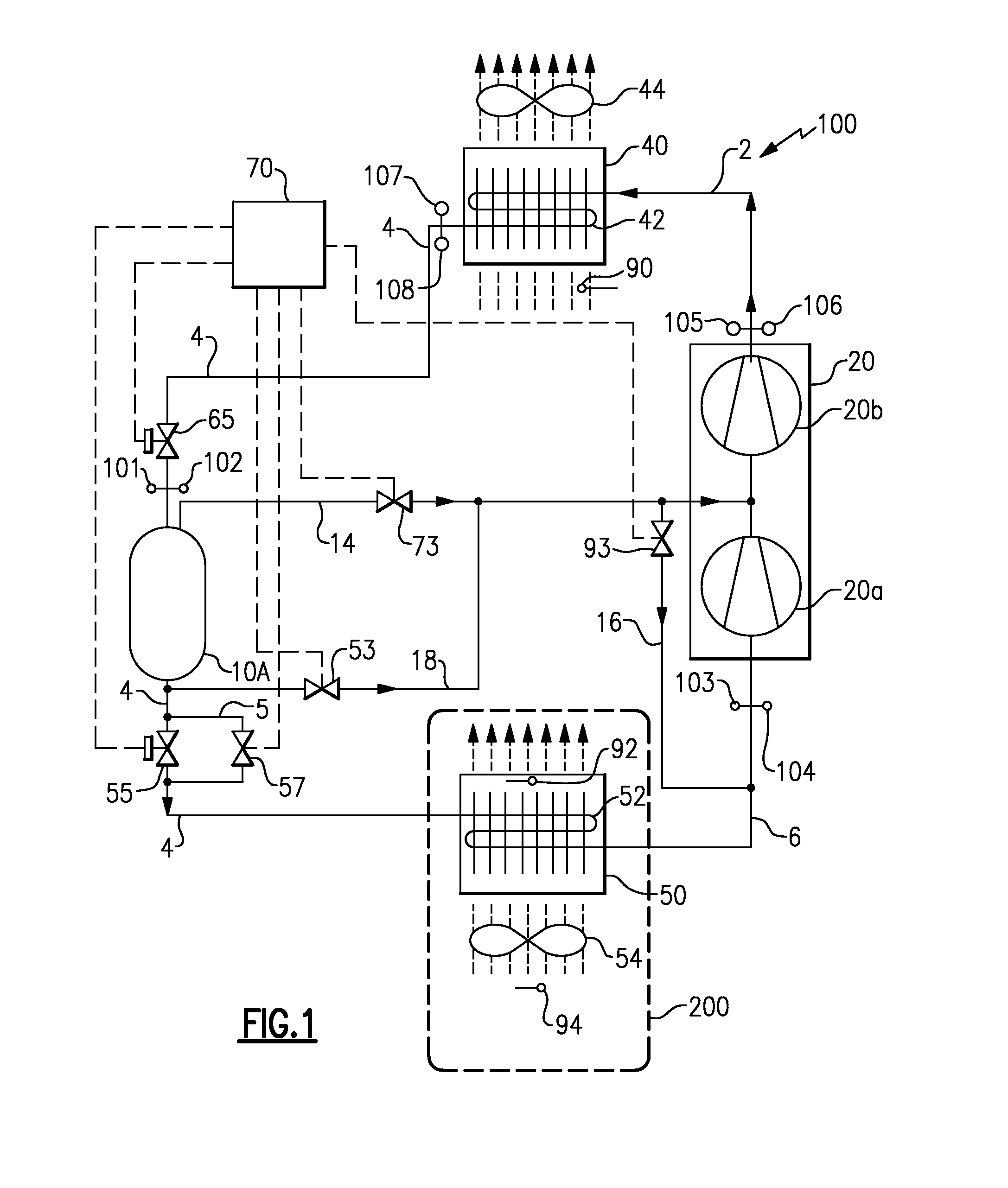

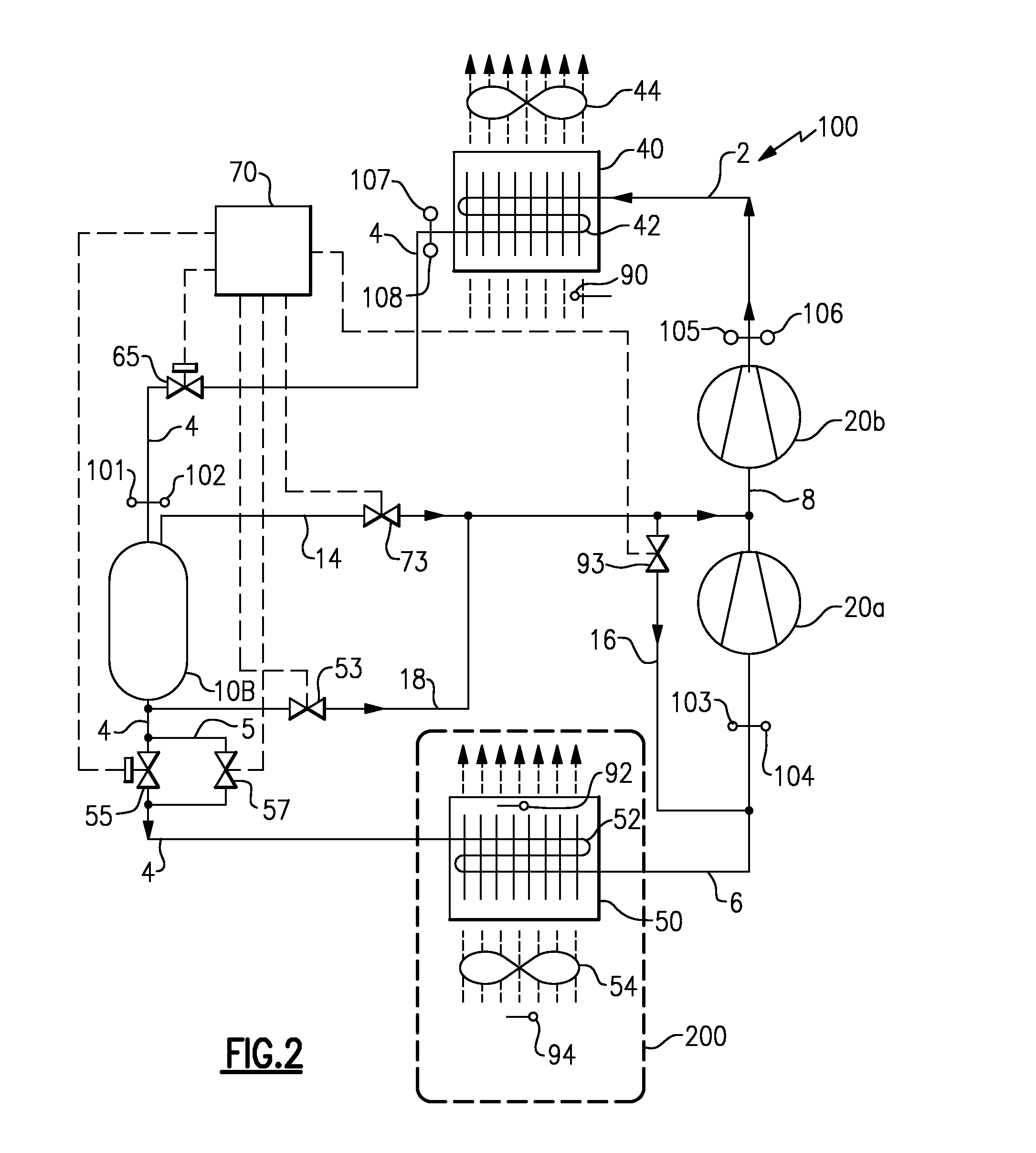

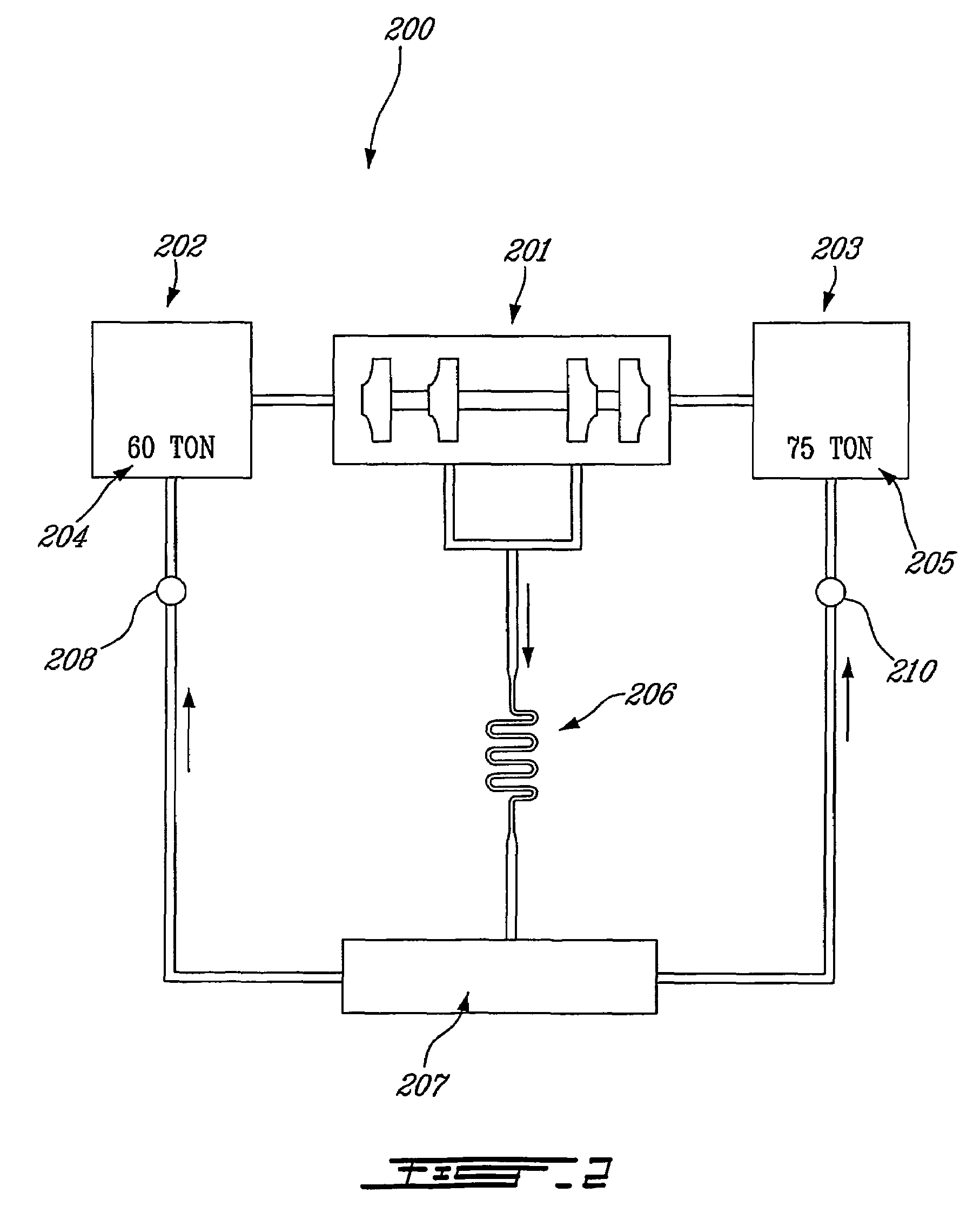

Refrigerant vapor compression system with flash tank economizer

A refrigerant vapor compression system includes a flash tank disposed in series refrigerant flow relationship in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit upstream of the flash tank. A refrigerant vapor line is provided to direct refrigerant vapor from the flash tank to an intermediate pressure stage of the compression process. A refrigerant-to-refrigerant heat exchanger operates to transfer heat from refrigerant flowing through the primary refrigerant circuit to refrigerant flowing through the refrigerant vapor line.

Owner:CARRIER CORP

Refrigerant vapor compression system operation

ActiveUS20120192579A1Relieving refrigerant pressureRelieve pressureCompressorMechanical apparatusThermodynamicsCharge detection

A method is provided for protecting a refrigerant vapor compression system during a standstill period following shutdown of the refrigerant vapor compression system. A method is provided for detecting a low refrigerant charge level in a refrigerant vapor compression system operating in a transcritical mode. A refrigerant vapor compression system is provided that includes a controller operative to perform a refrigerant charge detection method.

Owner:CARRIER CORP

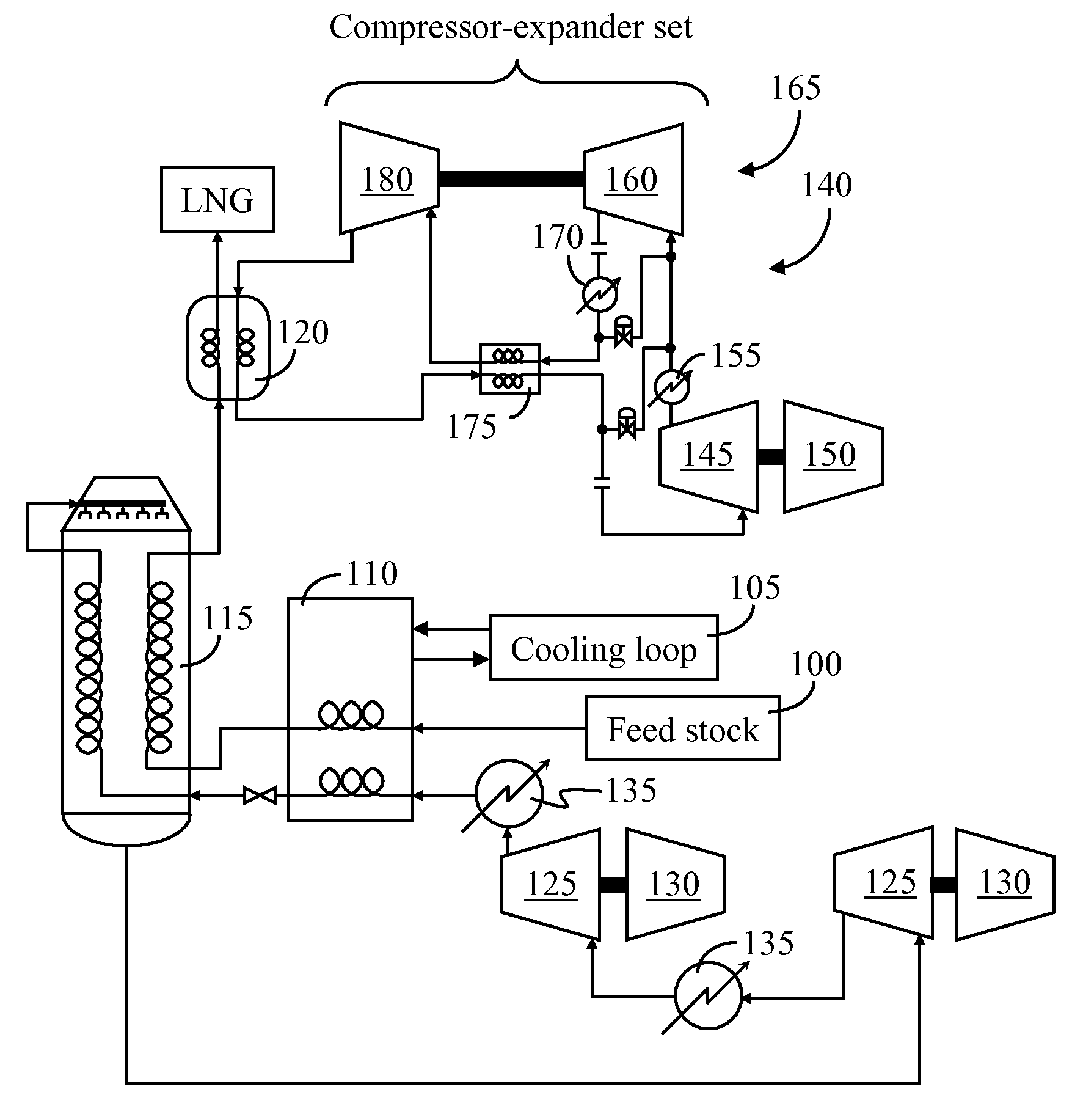

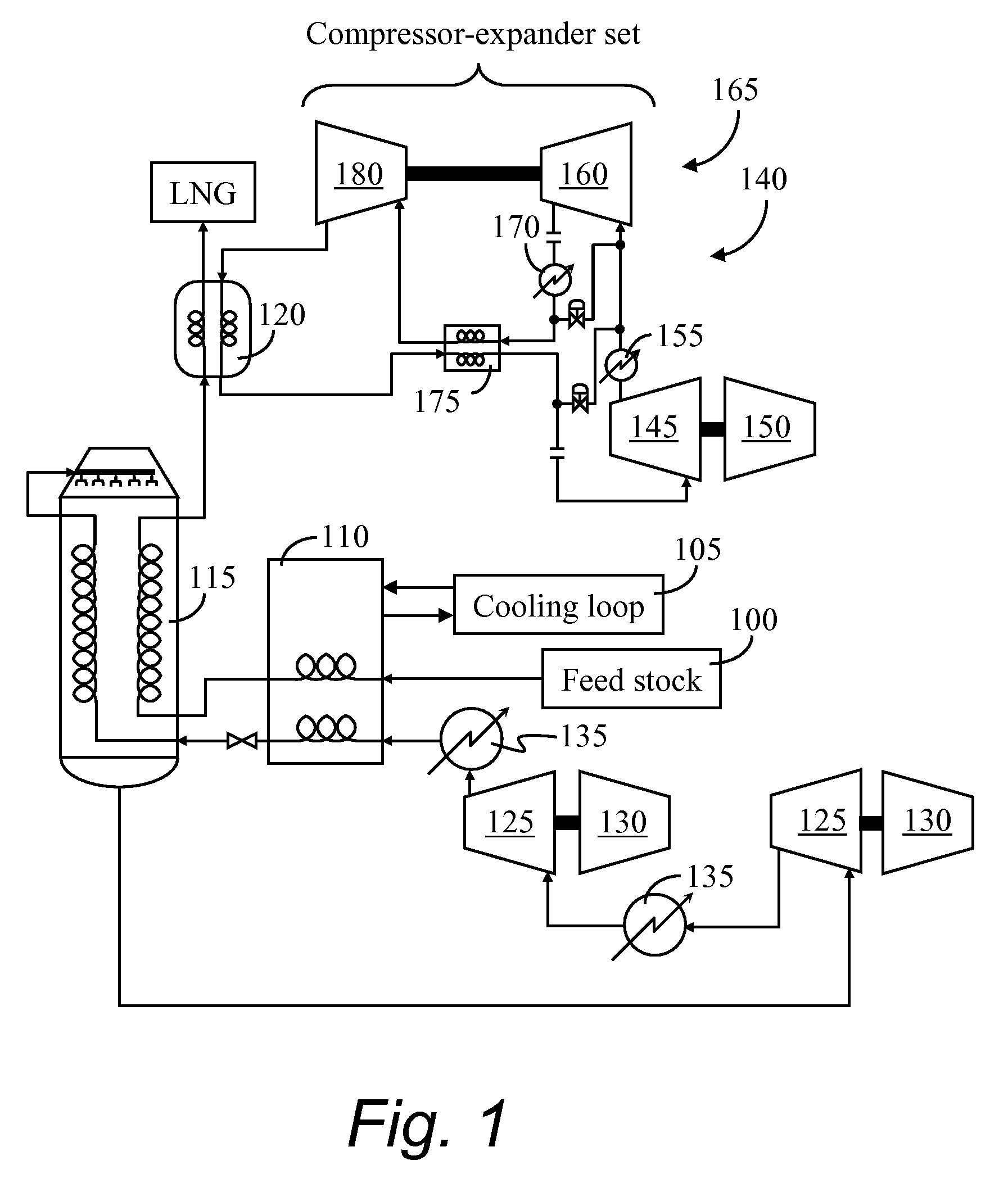

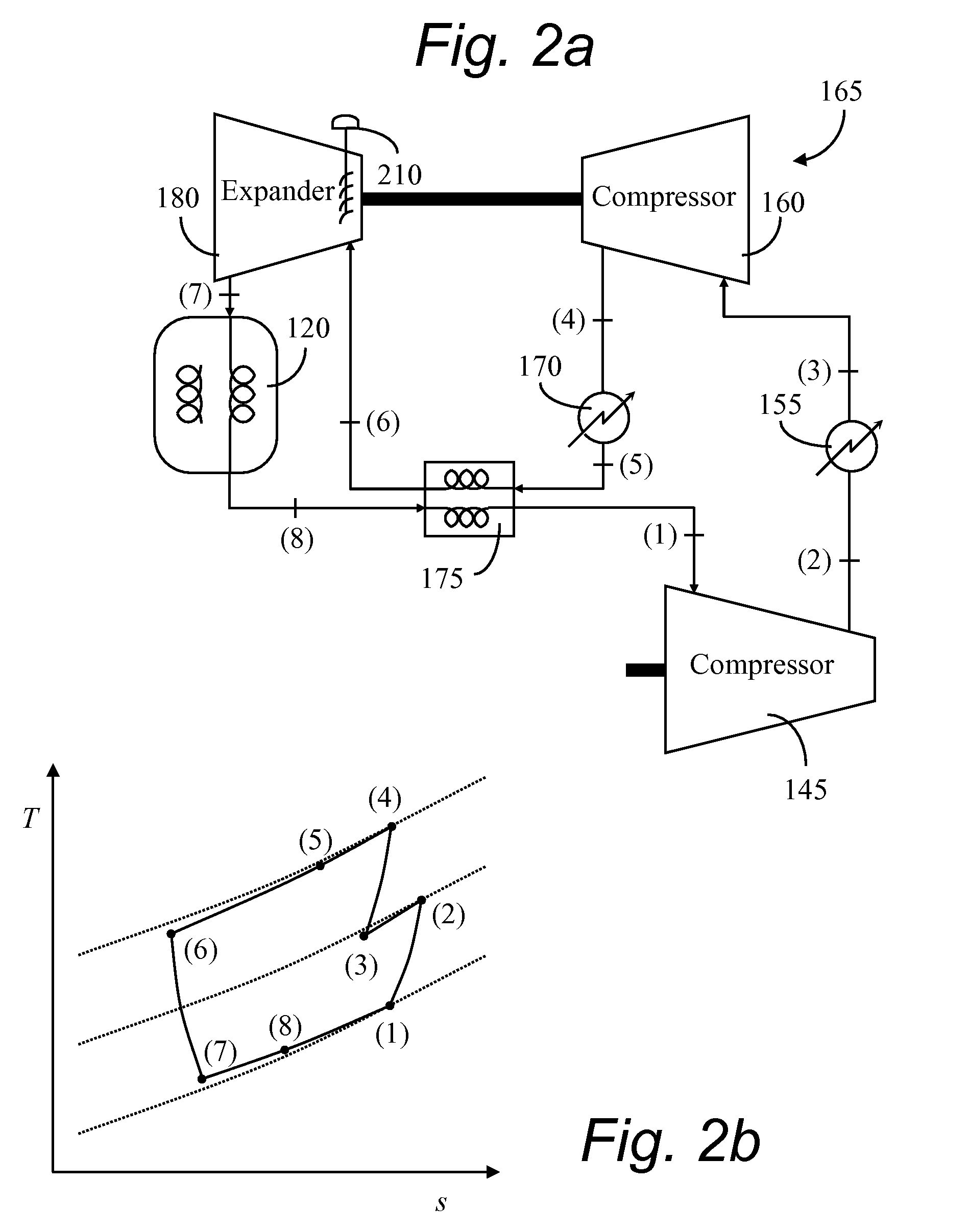

Compressor-Expander Set Critical Speed Avoidance

ActiveUS20090232663A1Reduce stepsIncrease flow rateCompressorSolidificationControl systemRotation velocity

A control method and apparatus for critical rotational speed avoidance in a compressor-expander set in a gas refrigeration system. By varying an opening of an antisurge or recycle valve, a shaft power used by the compressor in the compressor-expander set may be varied, thereby varying the rotational speed of the compressor-expander set to move it away from its critical speed zone. Additionally, a feedforward signal may be provided by a compressor-expander set control system to cause an antisurge valve for a recycle compressor to open upon a trip or shutdown of one compressor-expander set.

Owner:COMPRESSOR CONTROLS LLC

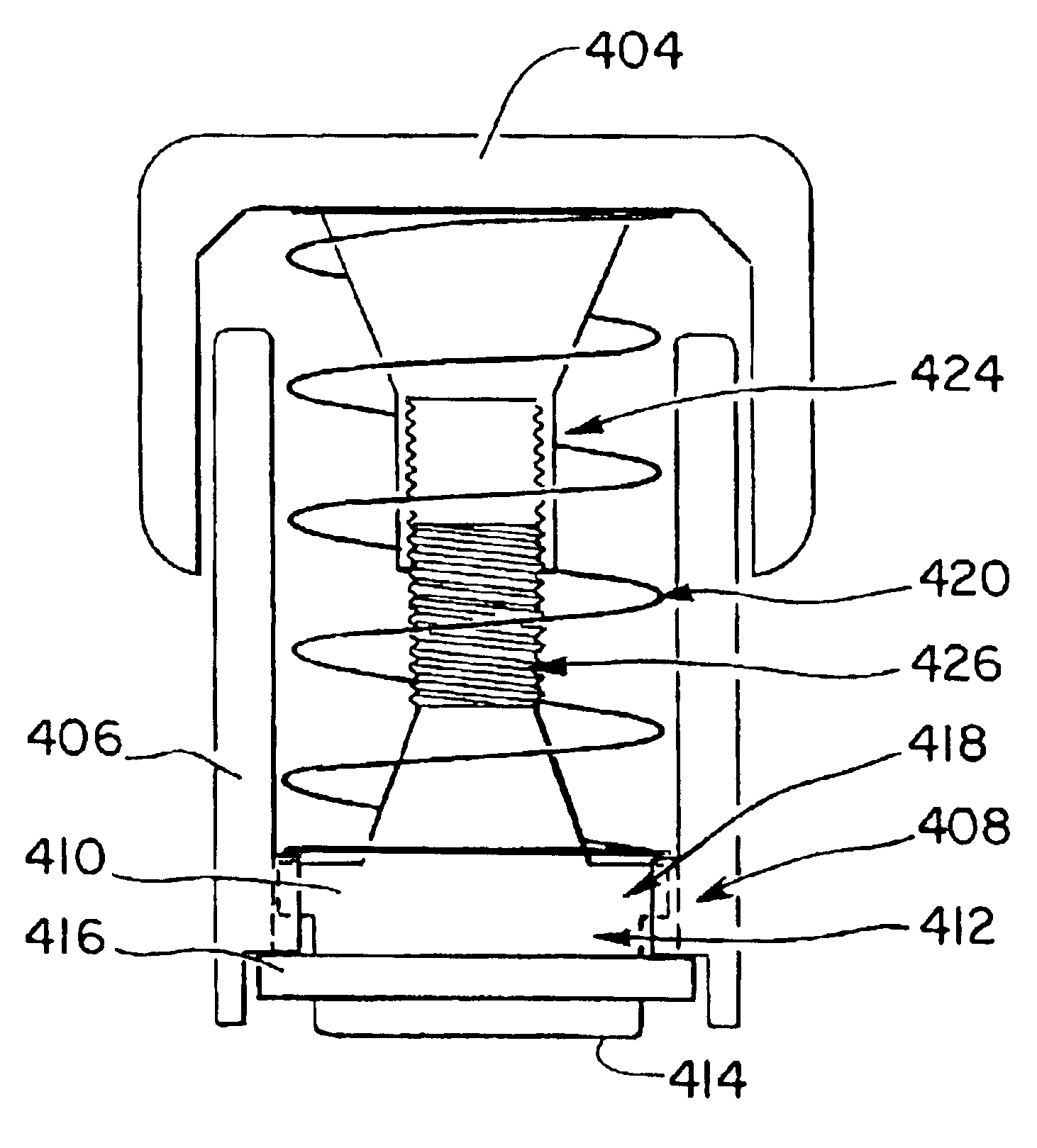

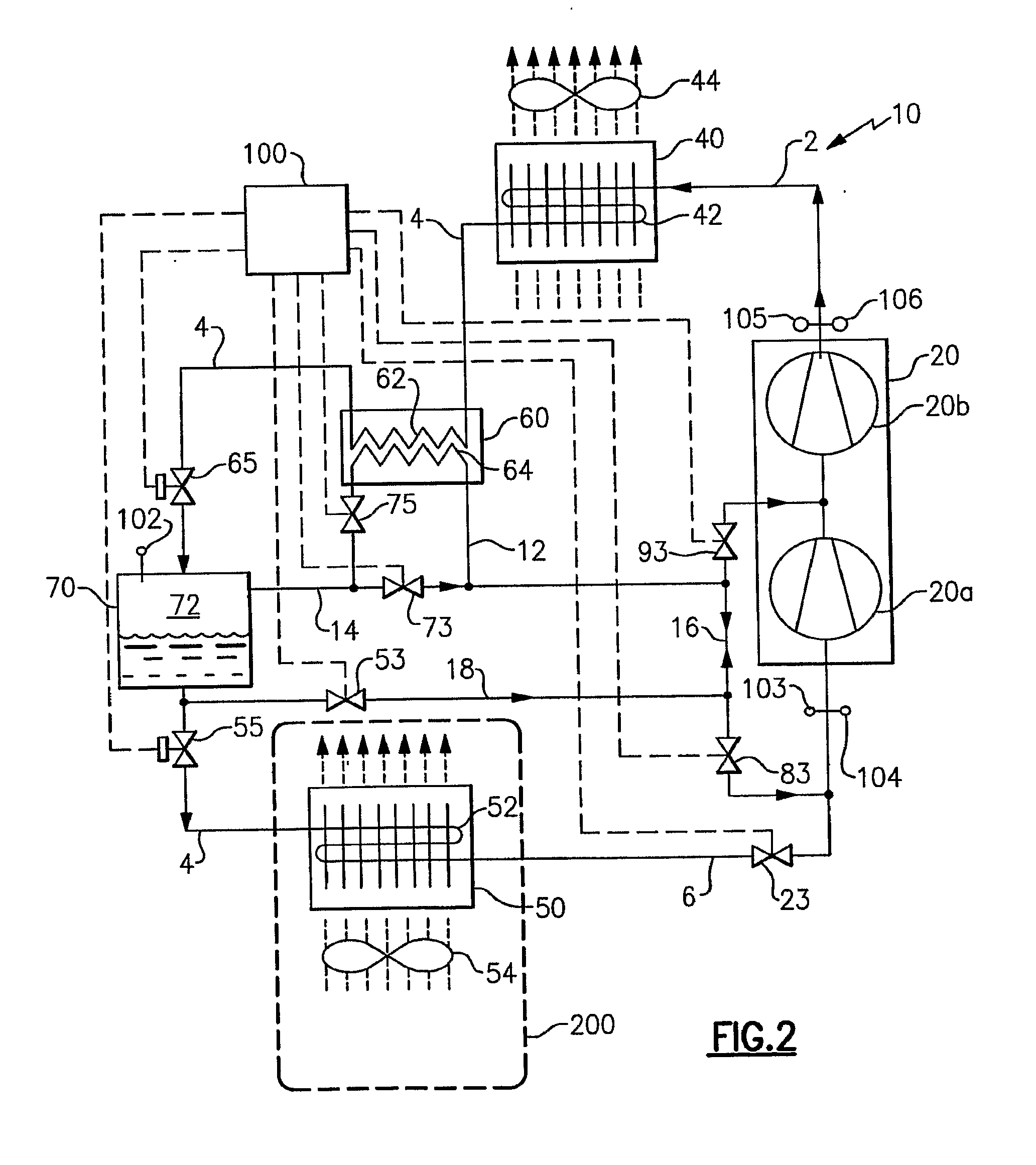

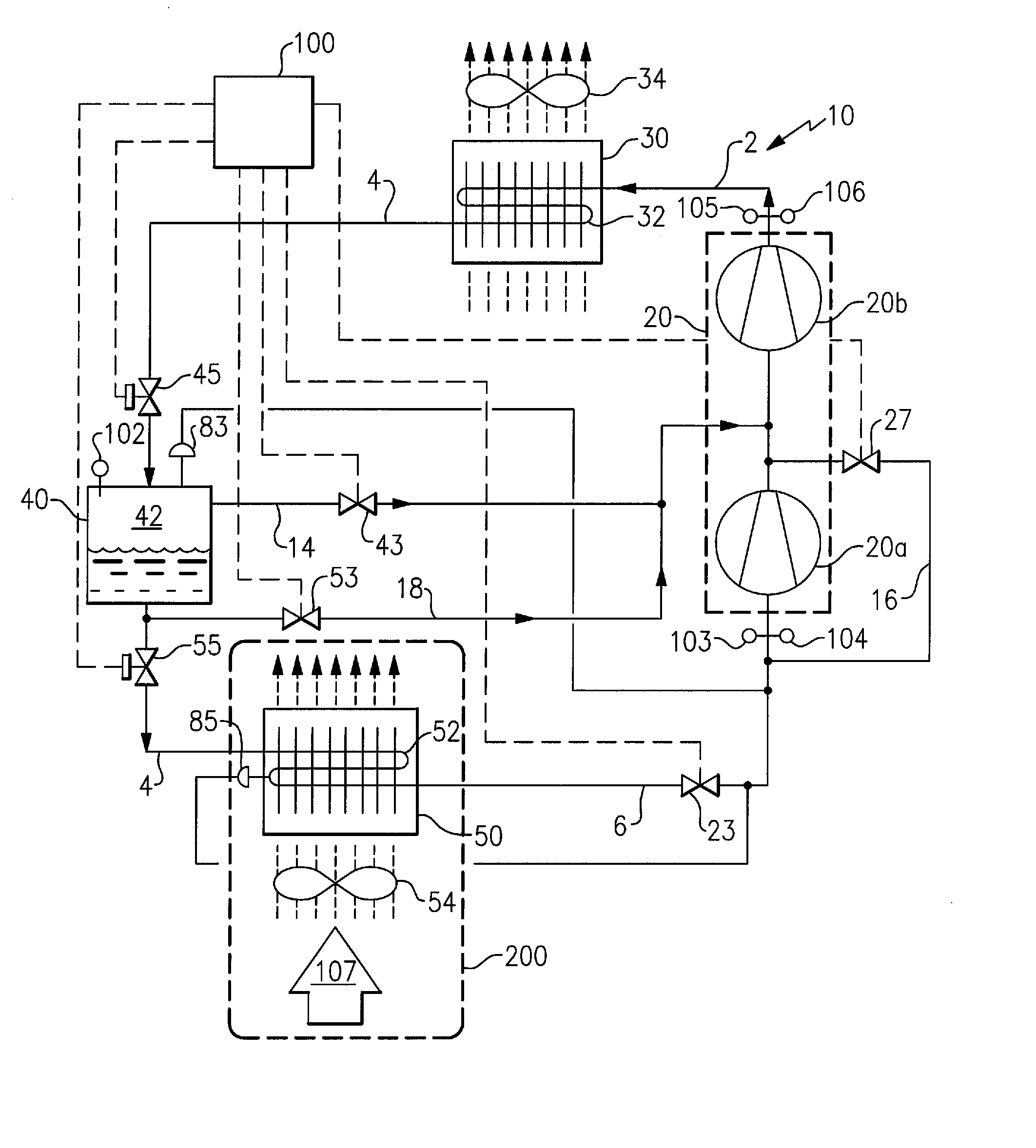

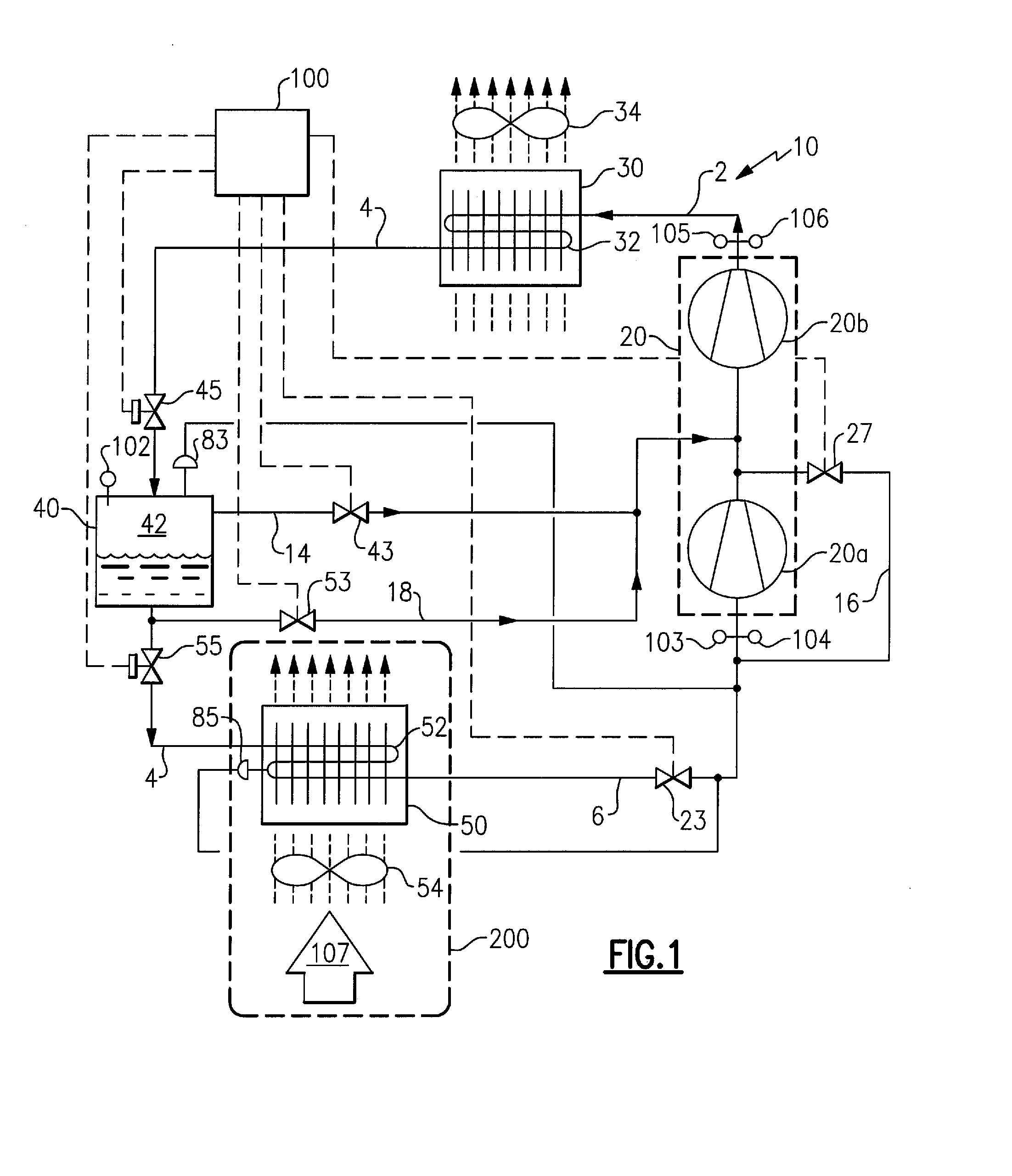

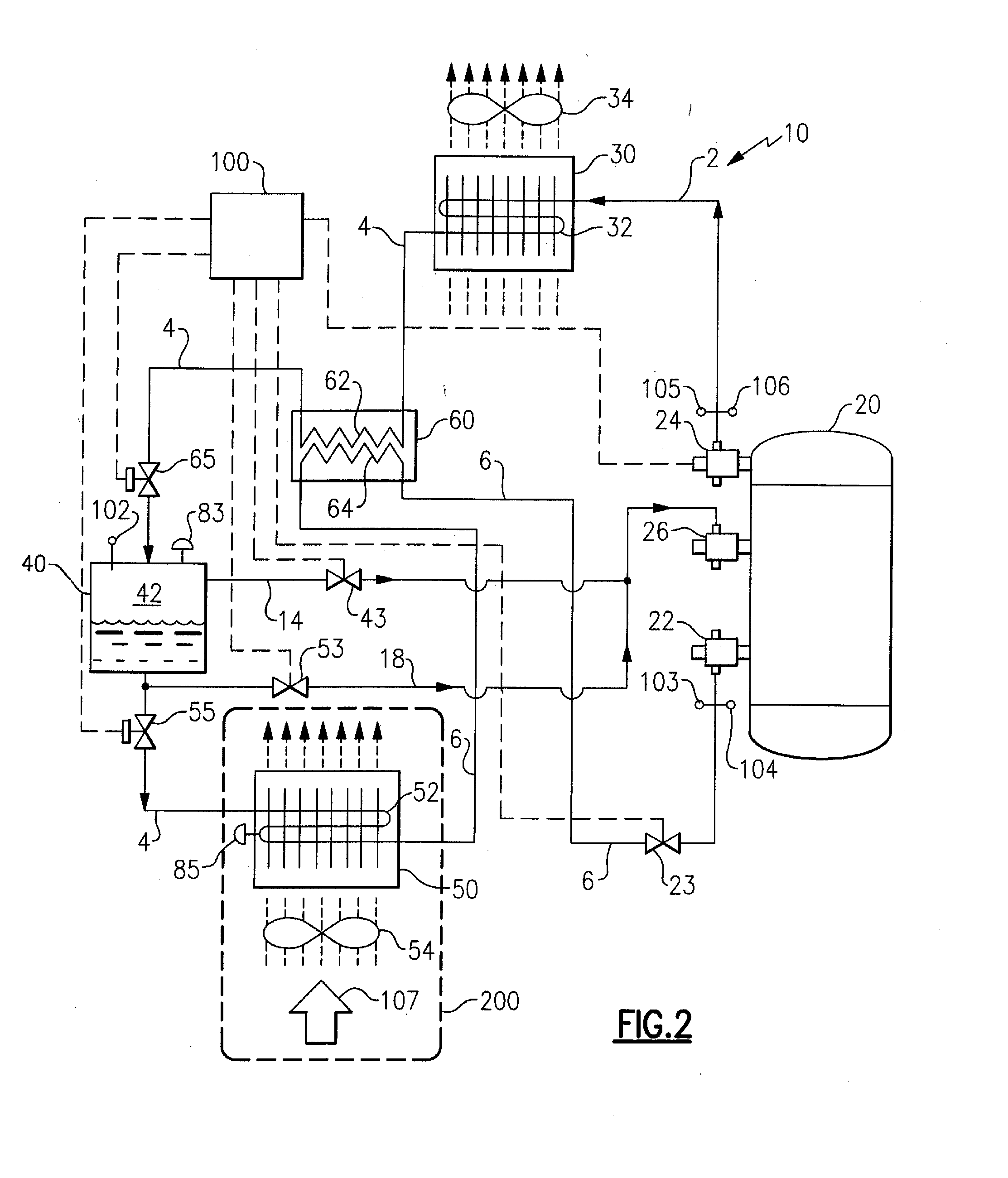

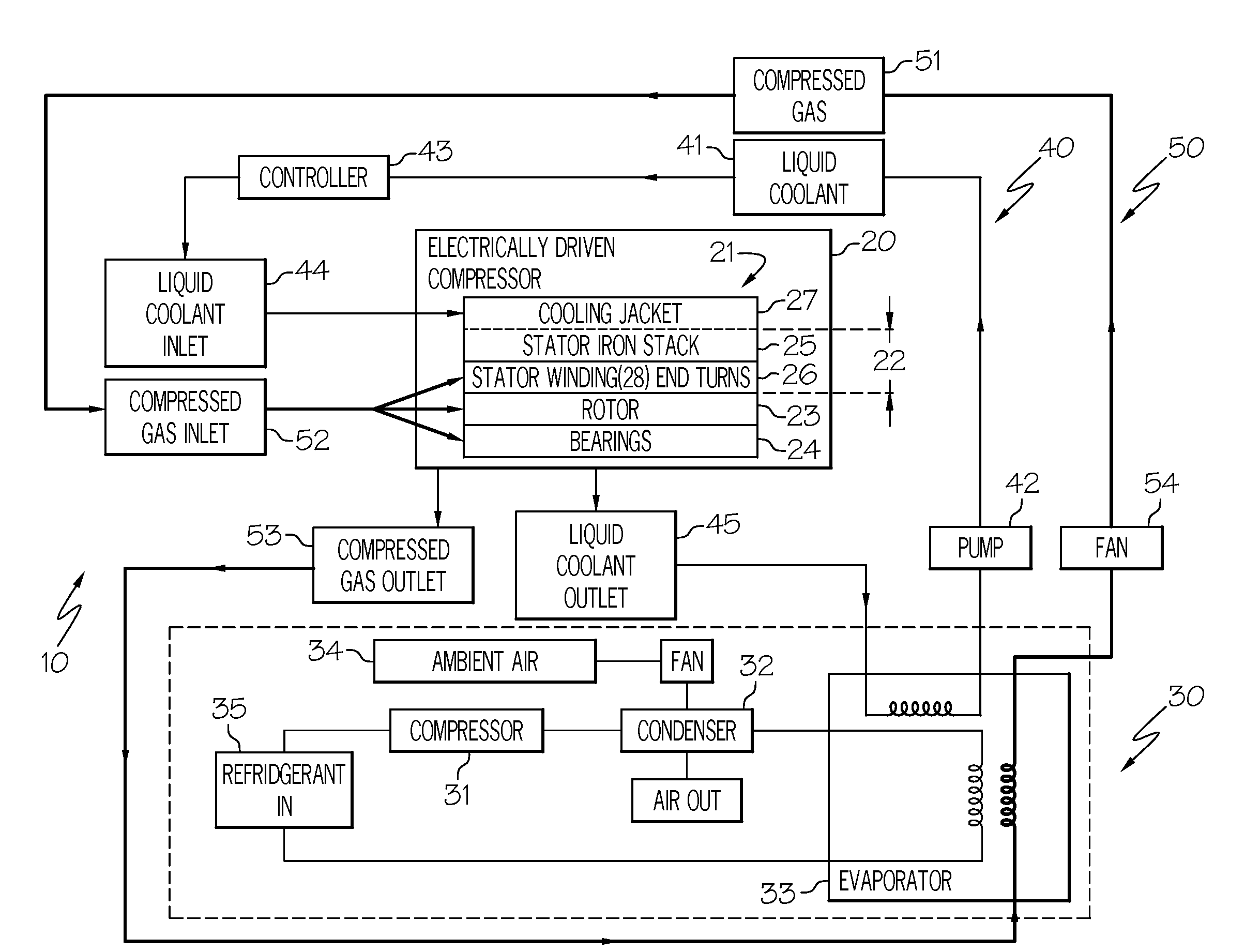

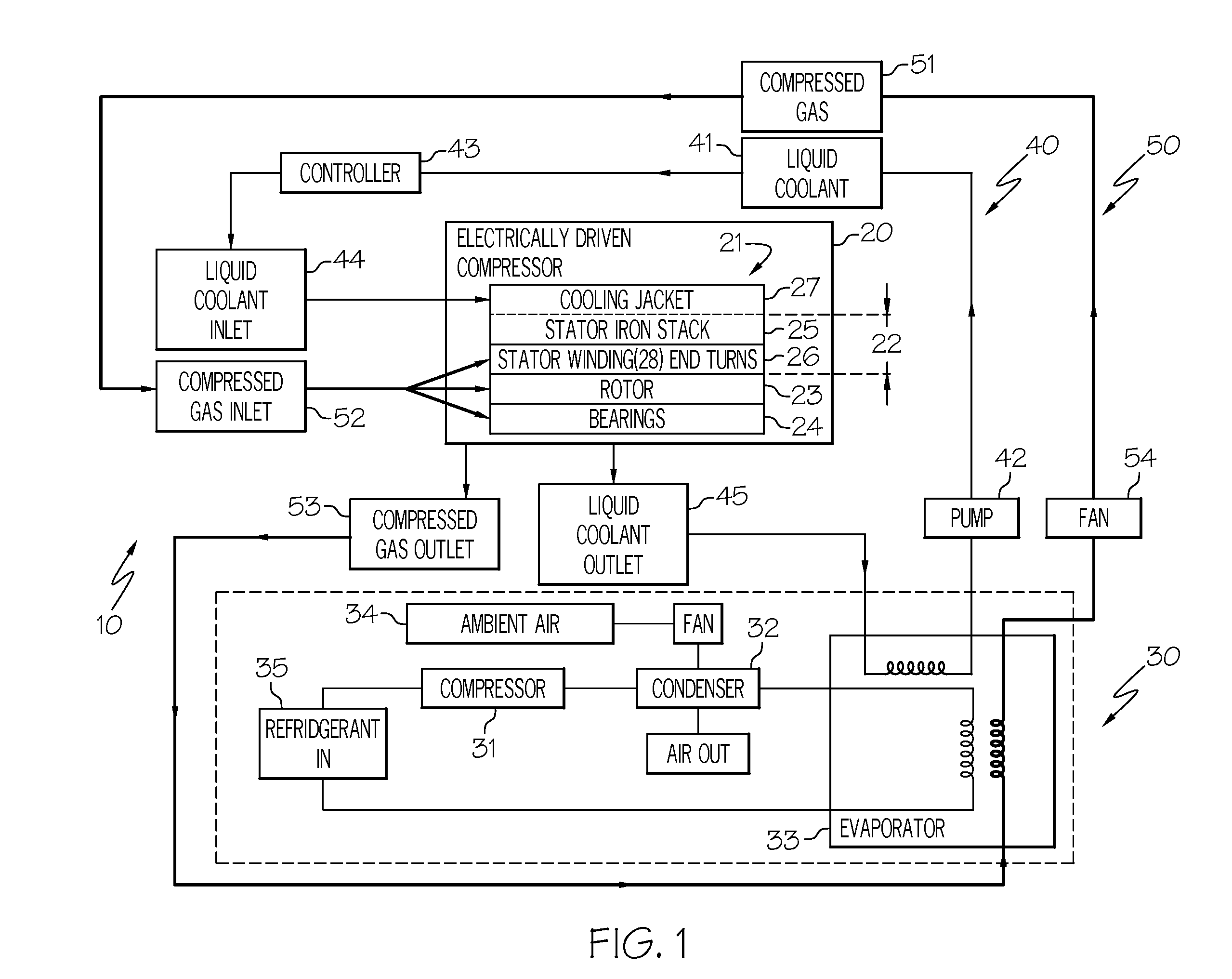

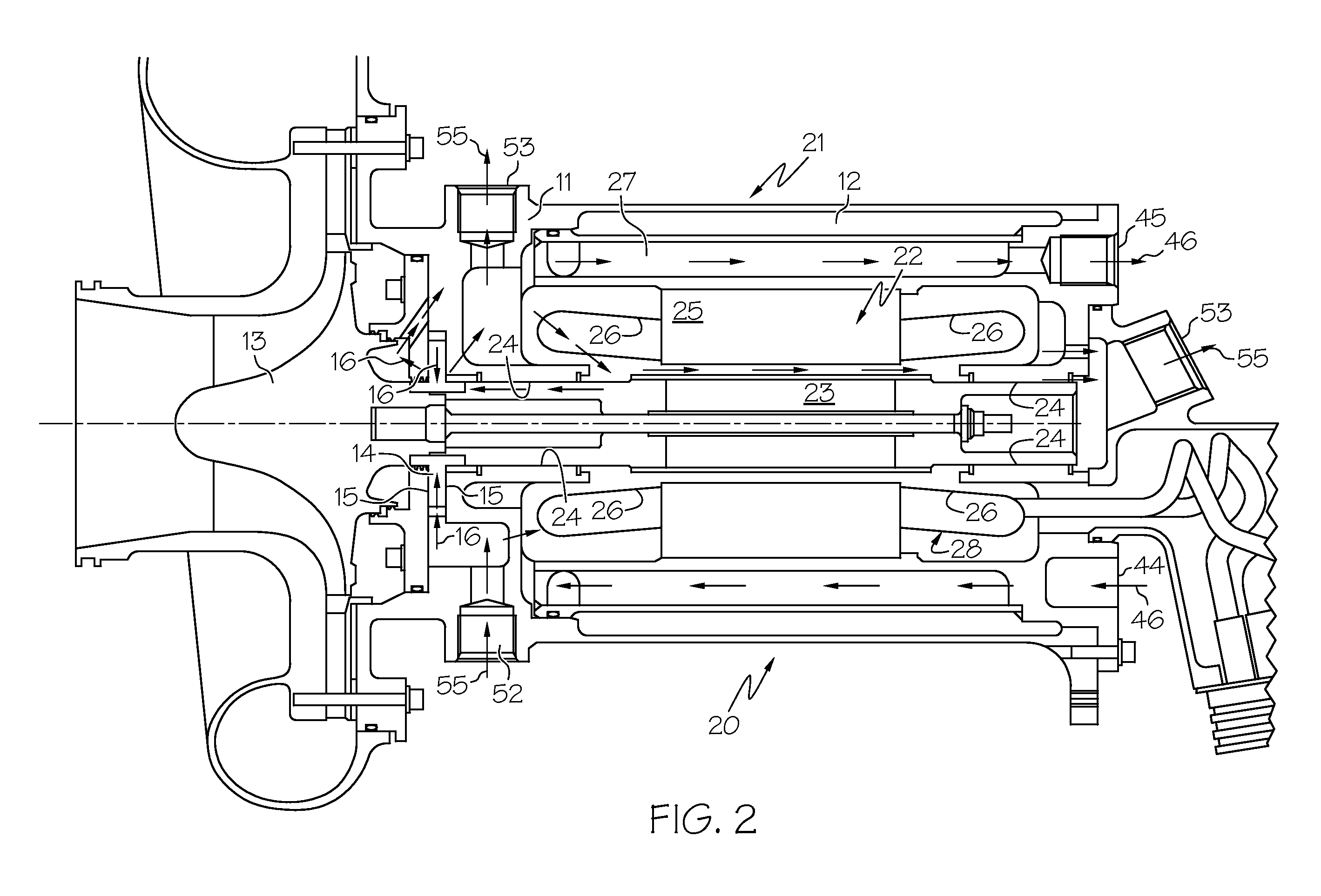

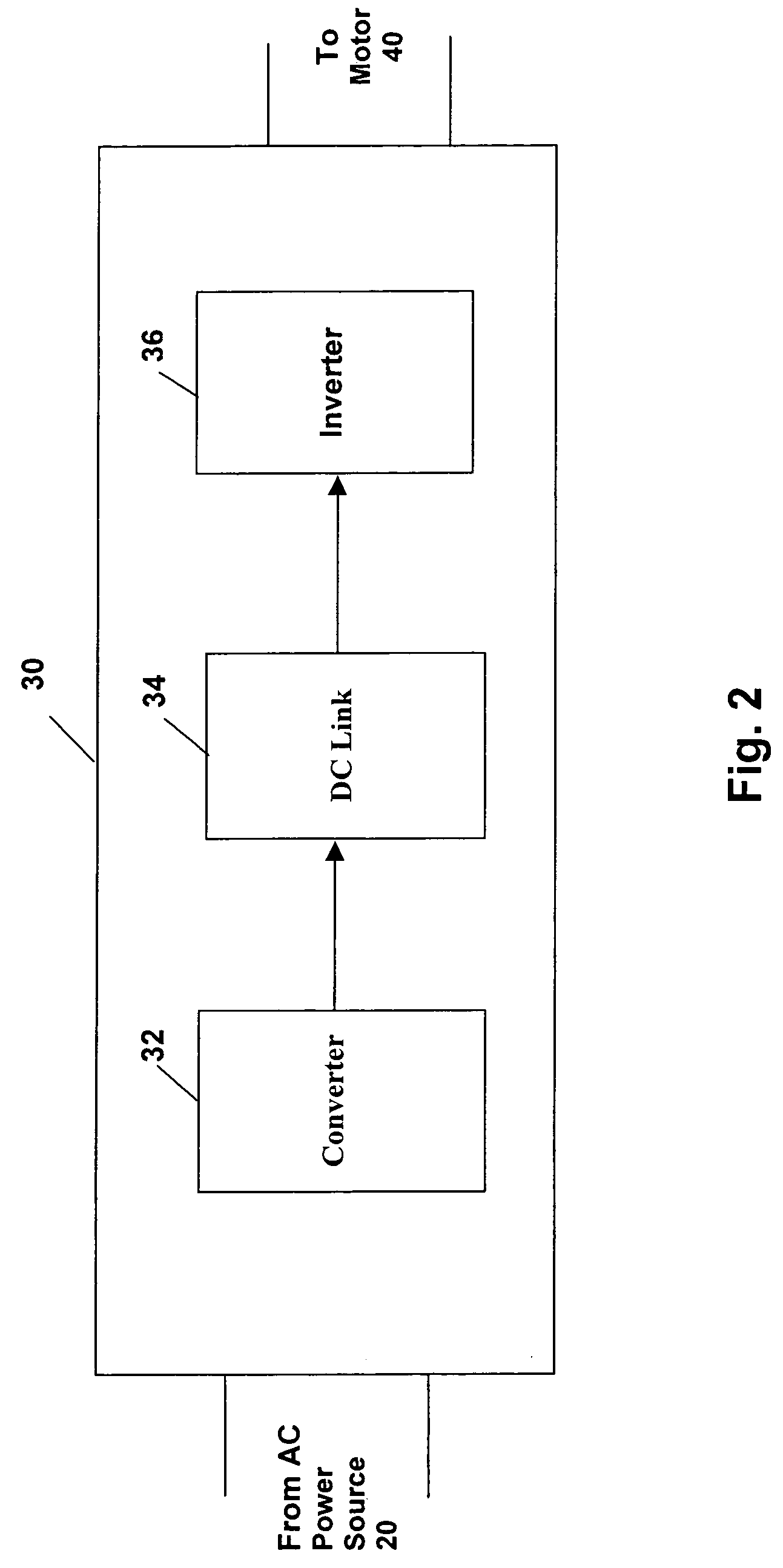

Thermal and secondary flow management of electrically driven compressors

A cooling system for an electrical motor or generator includes a first cooling loop, a second cooling loop, and a heat exchange system. The first cooling loop may extract heat from an iron stack and winding of the electrical motor or generator. The second cooling loop may extract heat from end turns of the stator winding, the rotor, and the bearings independently from and simultaneously to the first cooling loop. At least the first cooling loop may pass through the heat exchange system. A liquid coolant may circulate in the first cooling loop and a compressed gas, such as compressed air or compressed refrigerant in vapor form, may circulate in the second cooling loop. The cooling system and method for an electrical motor or generator may be suitable for, but not limited to, applications in the aircraft and aerospace industries, such as driving a cabin air compressor of an aircraft.

Owner:HONEYWELL INT INC

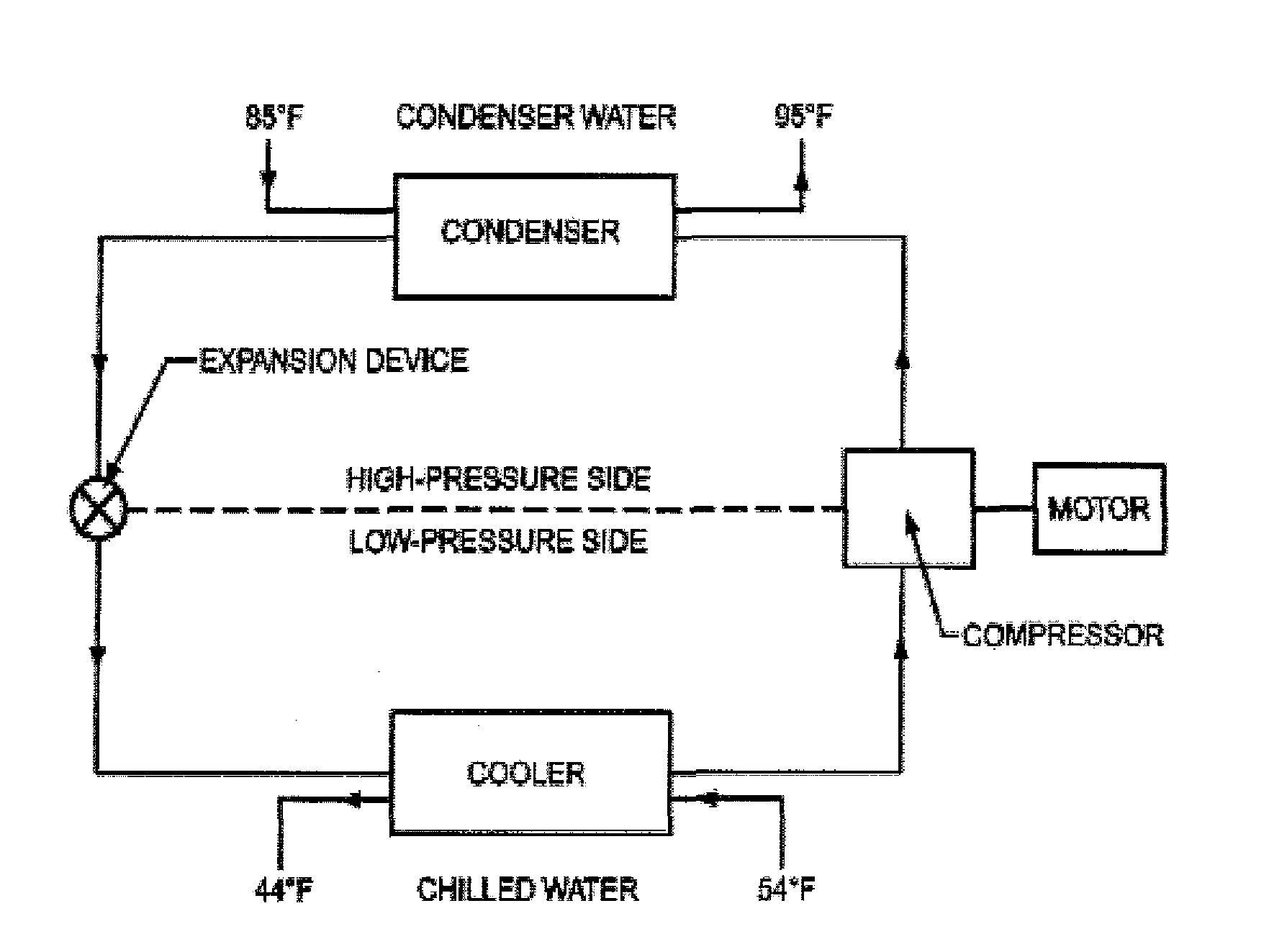

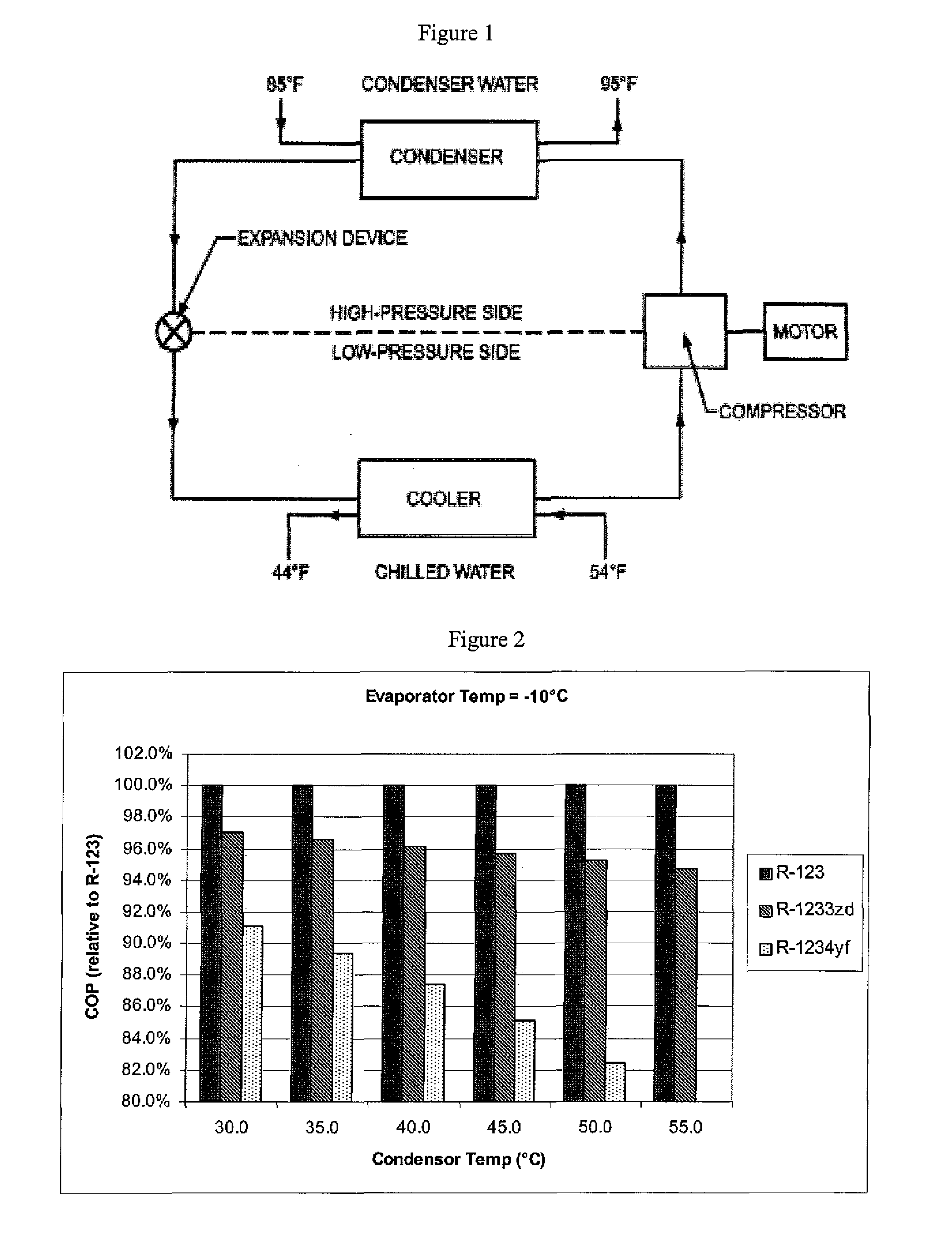

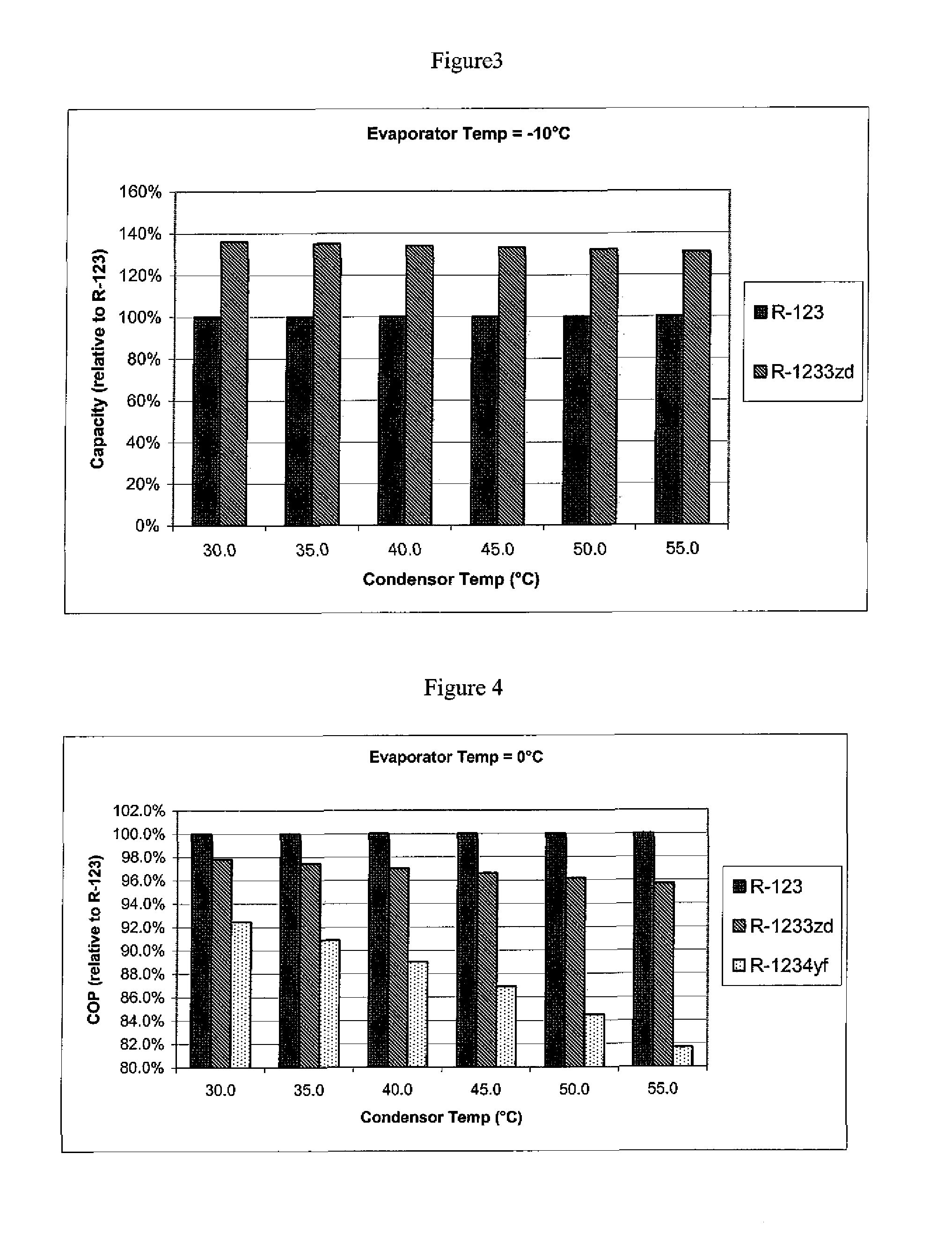

Use of r-1233 in liquid chillers

ActiveUS20100326095A1High global warming potentialLower ozone depleting and global warming potentialsCompressorOther chemical processesRefrigerantChiller

This invention relates to the use of chloro-trifluoropropenes as refrigerants in negative-pressure liquid chillers and methods of replacing an existing refrigerant in a chiller with chloro-trifluoropropenes. The chloro-trifluoropropenes, particularly 1-chloro-3,3,3-trifluoropropene, have high efficiency and unexpectedly high capacity in liquid chiller applications and are useful as more environmentally sustainable refrigerants for such applications, including the replacement of R-123 and R-11.

Owner:ARKEMA INC

Ejector cycle

ActiveUS20040003608A1Small sizeReduce lubricationCompressorAir-treating devicesOperation modeCheck valve

In an ejector cycle having an ejector for decompressing refrigerant, a check valve is disposed in an oil return passage through which refrigerant including a lubrication oil is introduced from a refrigerant outlet side of an evaporator to a refrigerant suction side of a compressor while bypassing the ejector. When the lubrication oil amount staying in the evaporator reduces, the check valve is automatically closed, and a normal operation mode of the ejector cycle is automatically set. On the contrary, when a large amount of lubrication oil stays in the evaporator, the check valve is automatically opened, and an oil return mode is automatically set. Therefore, the lubrication oil staying in the evaporator can be controlled equal to or lower than a predetermined amount, thereby effectively returning the lubrication oil to the compressor.

Owner:DENSO CORP

Liquid vapor separation in transcritical refrigerant cycle

A refrigerant vapor compression system includes a flash tank disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. The flash tank has a shell defining an interior volume having an upper chamber, a lower chamber and a middle chamber. A first fluid passage establishes fluid communication between the middle chamber and the upper chamber and a second fluid passage establishing fluid communication between the middle chamber and the lower chamber. An inlet port opens to the middle chamber. A first outlet port opens to the upper chamber and a second outlet port opens to the lower chamber.

Owner:CARRIER CORP

Centrifugal compressor

ActiveUS7240515B2Improved centrifugal compressorCompressorPump componentsMagnetic bearingControl system

A compact and efficient compressor is provided, based on using magnetic bearing technology, which can operate at high speed and comprises a reliable control system. The compressor of the present invention makes use of two separate compressors mounted on a single common motor, thus sharing a single drive. The balancing of the thrust at high RPM is improved by using a pair of electromagnetic bearings.

Owner:DANFOSS AS

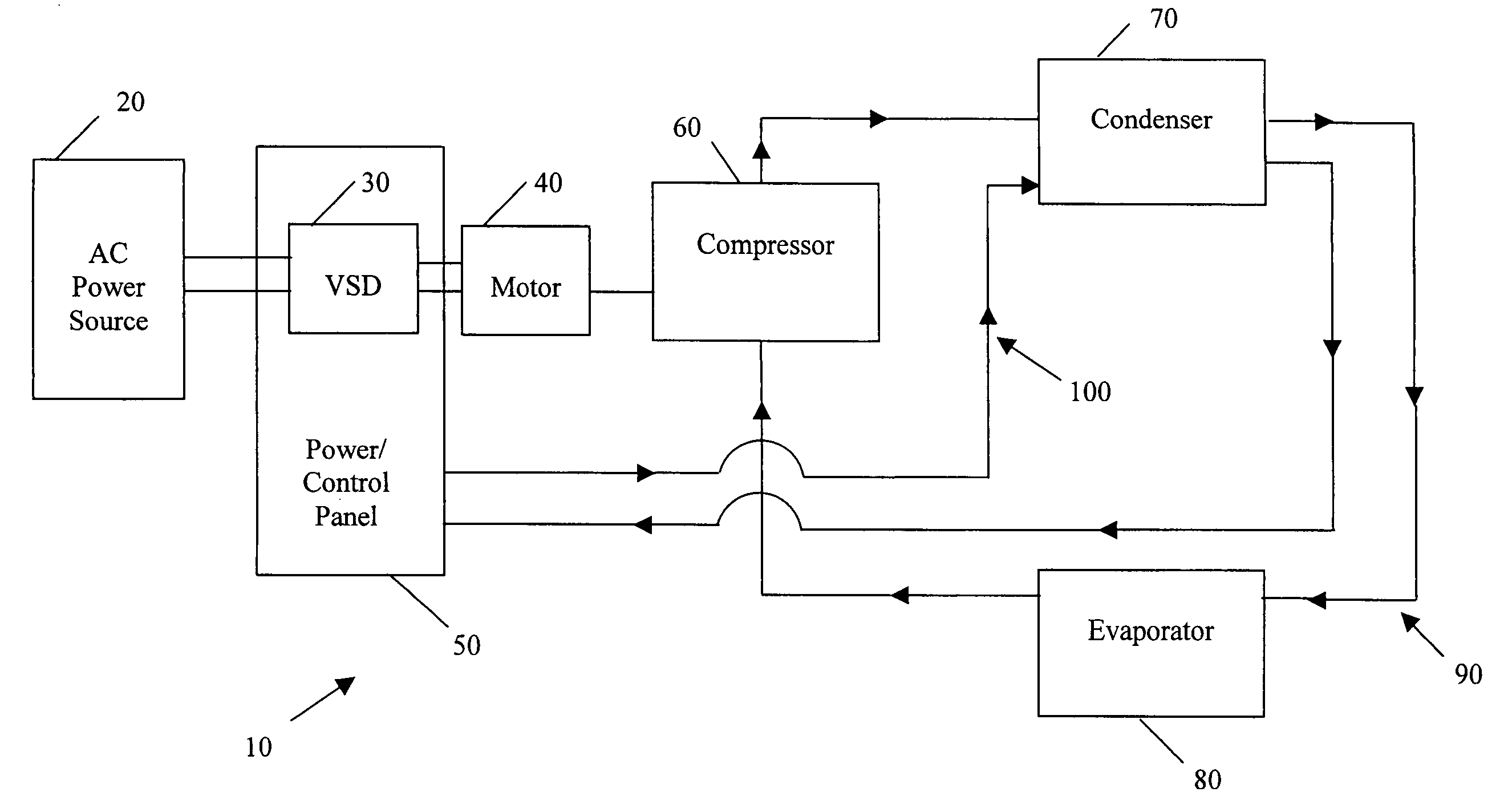

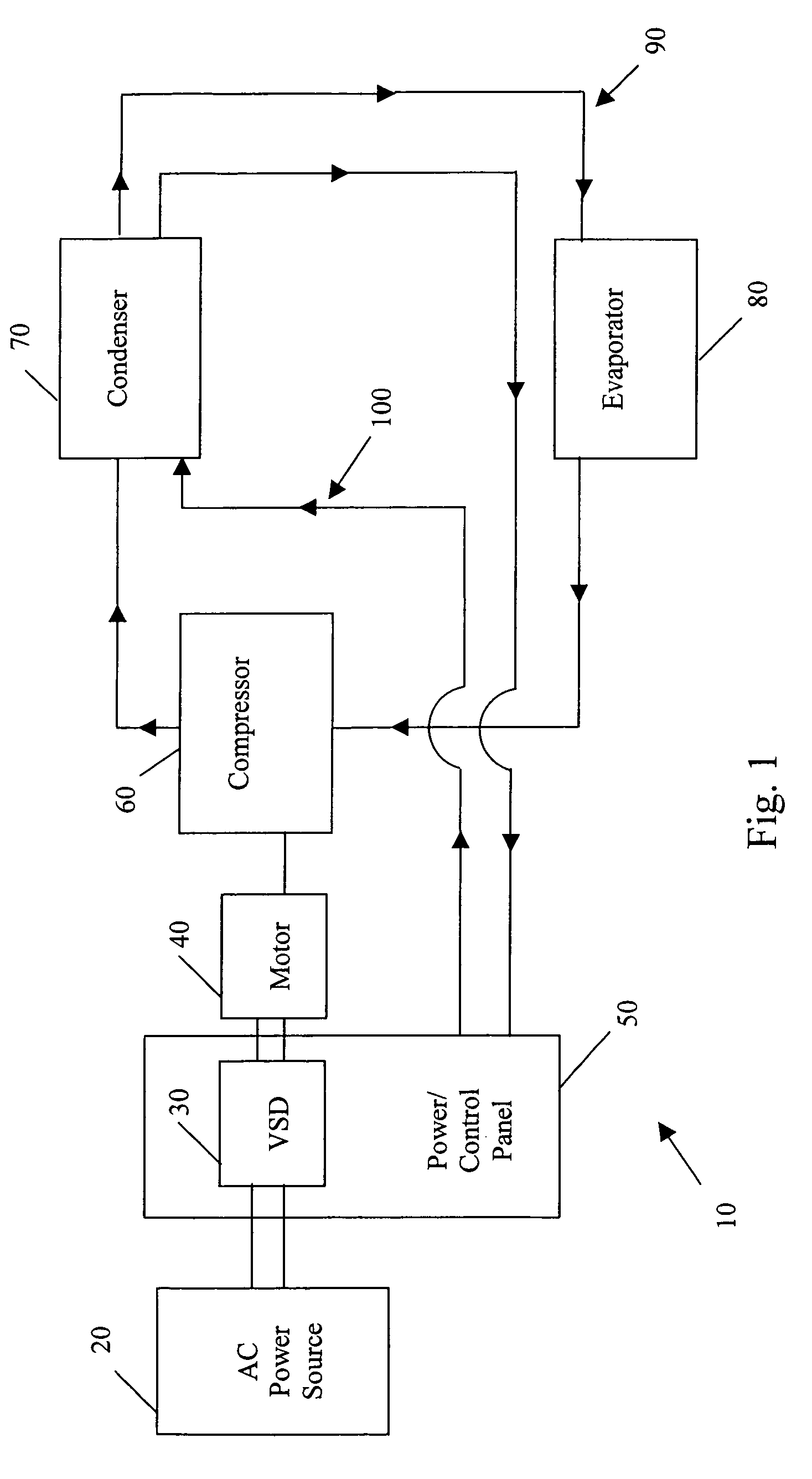

Electronic component cooling system for an air-cooled chiller

ActiveUS7003971B2Reduce in quantityInhibition formationCompressorEvaporators/condensersElectronic componentRefrigerant

A chiller system includes a refrigerant loop, the refrigerant loop further including a compressor, an air-cooled condenser arrangement and an evaporator arrangement connected in a first closed refrigerant loop. A motor is connected to the compressor to drive the compressor, a drive is connected to the motor to power the motor and a power / control panel controls the refrigerant loop. The power / control panel and the condenser arrangement are connected in a second closed coolant loop. The second closed coolant loop provides cooling to the enclosure and / or components within the enclosure disposed on a chill plate. Condensation is substantially prevented from forming inside the enclosure, despite the enclosure lacking a humidity control device.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

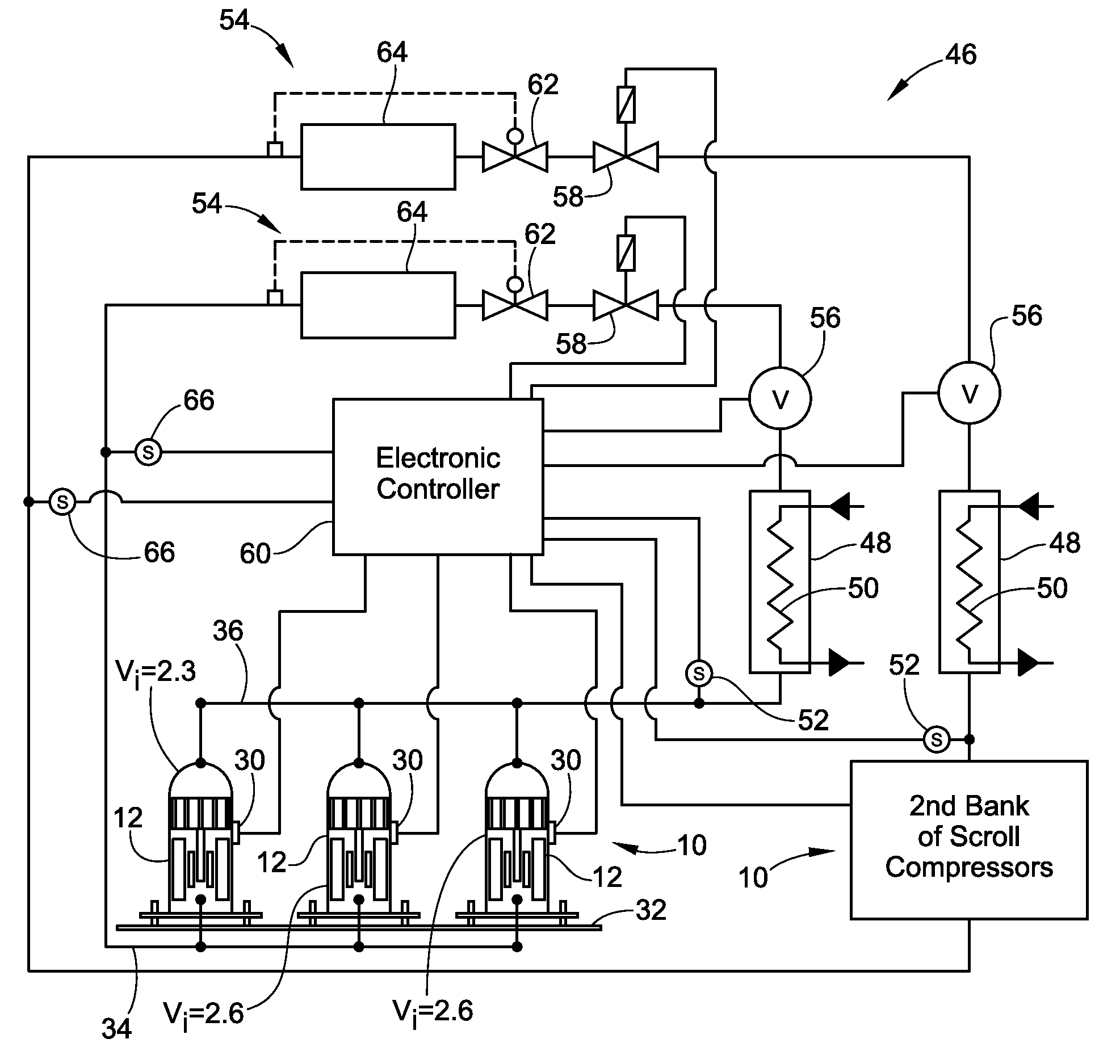

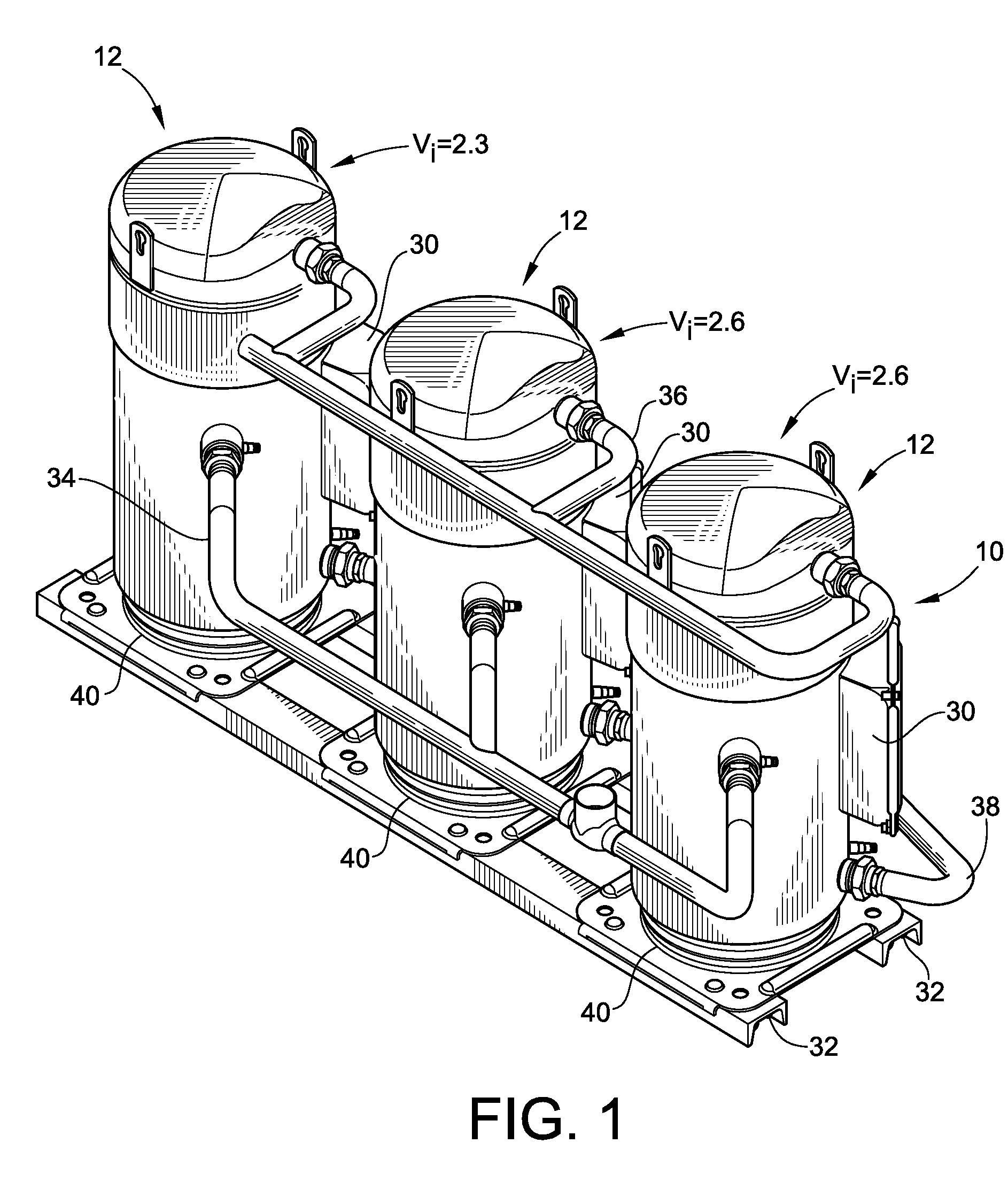

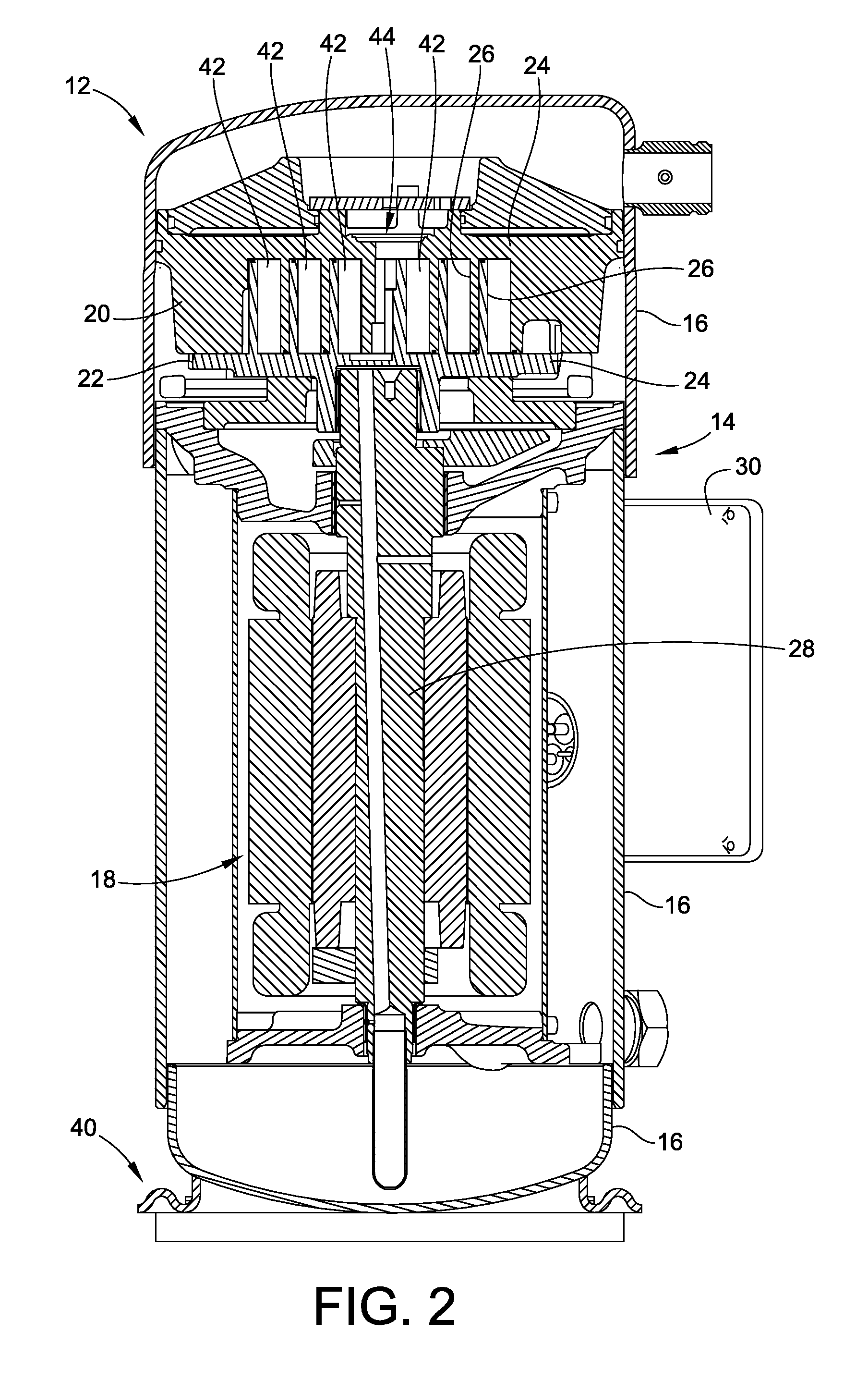

Scroll Compressors with Different Volume Indexes and Systems and Methods for Same

InactiveUS20100186433A1Improve efficiencyRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringScroll compressor

Owner:BITZER KUEHLMASCHINENBAU GMBH

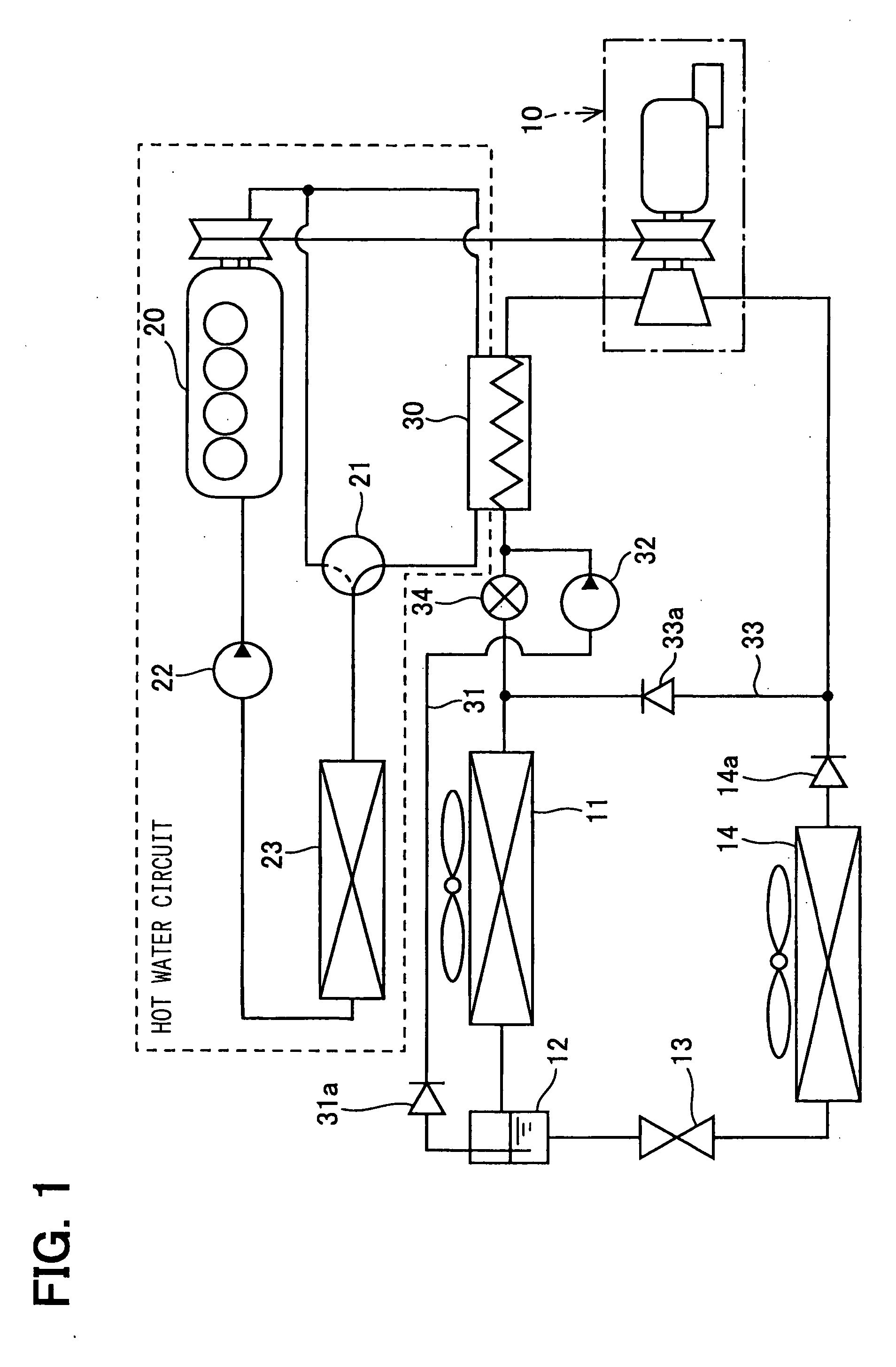

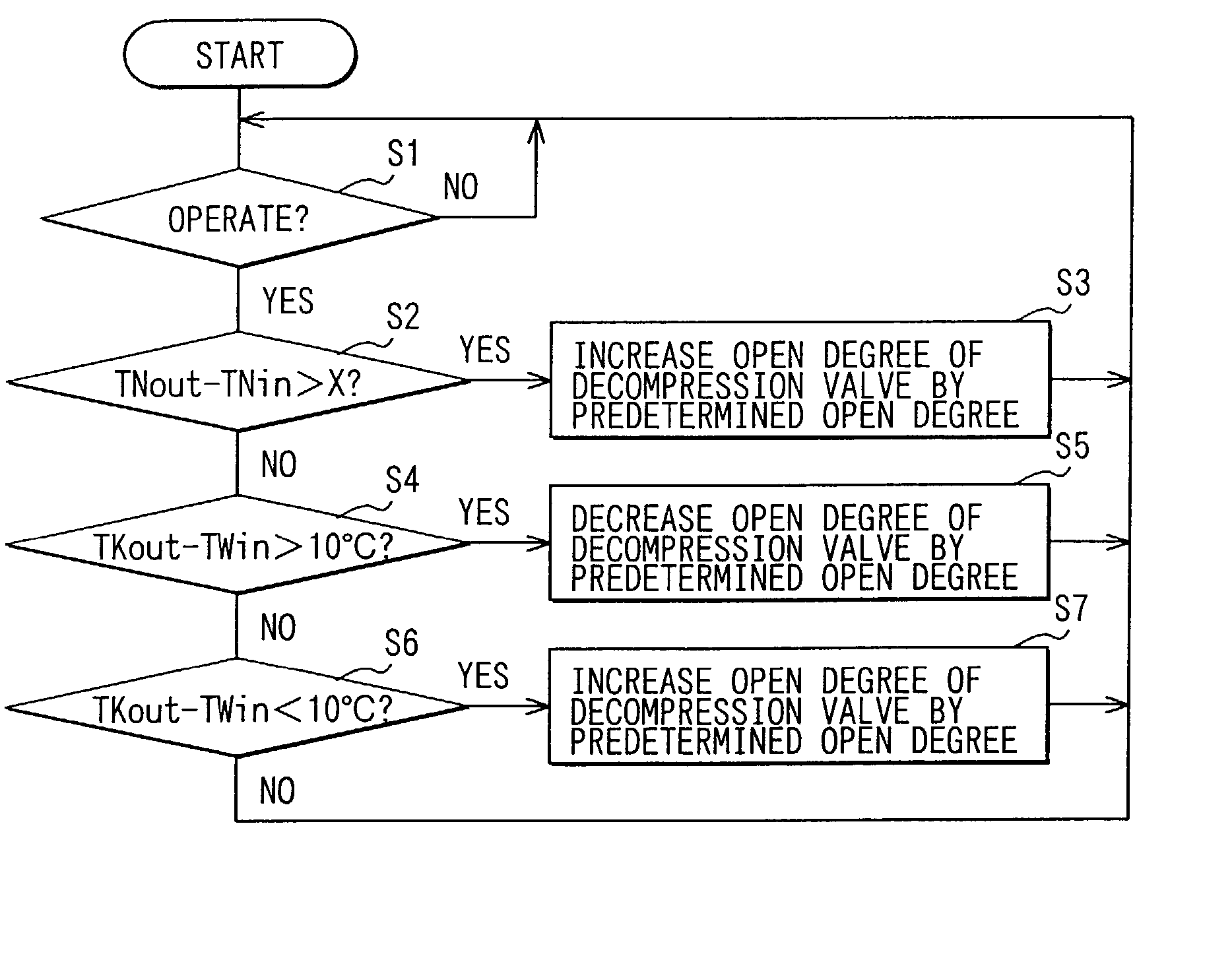

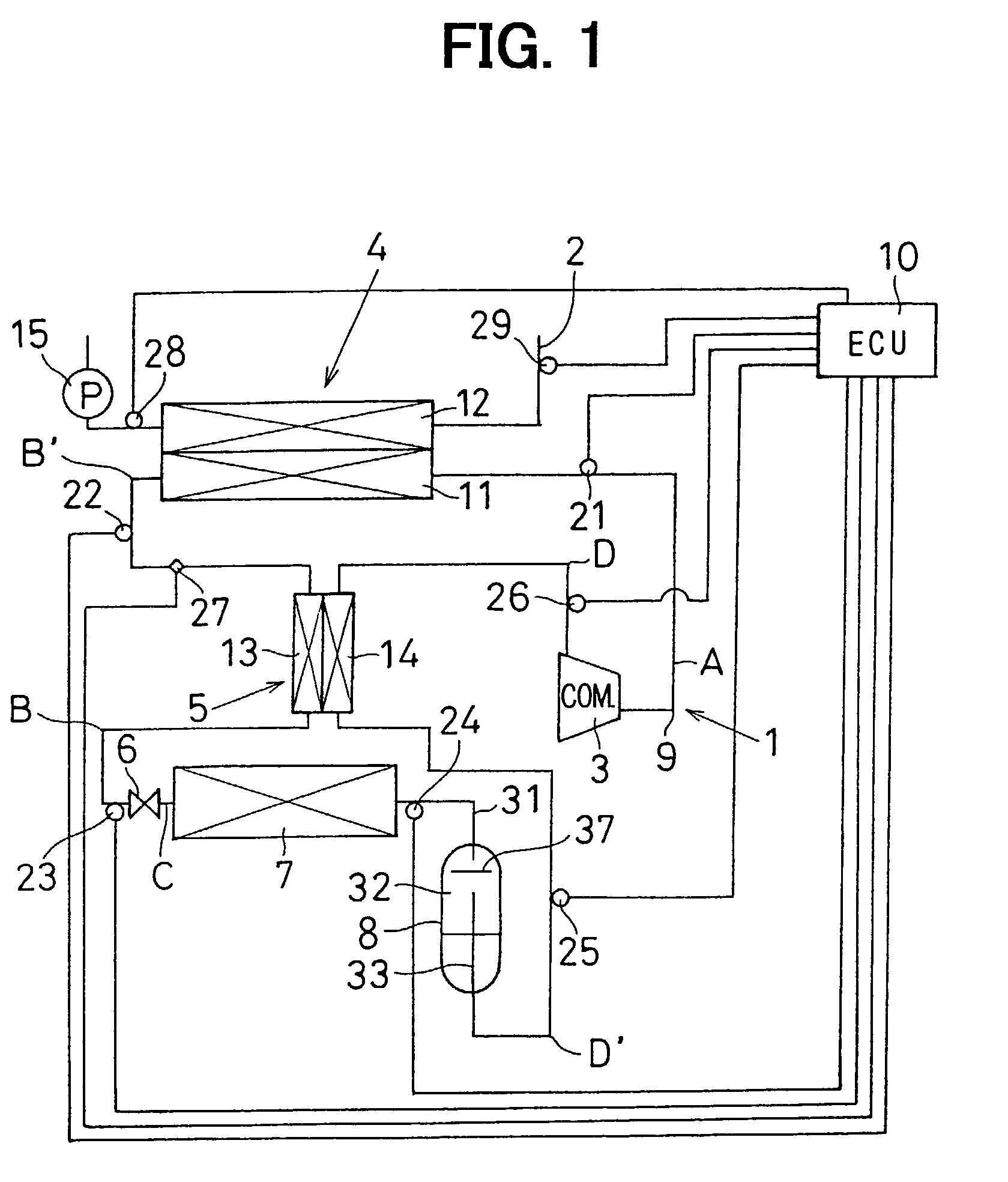

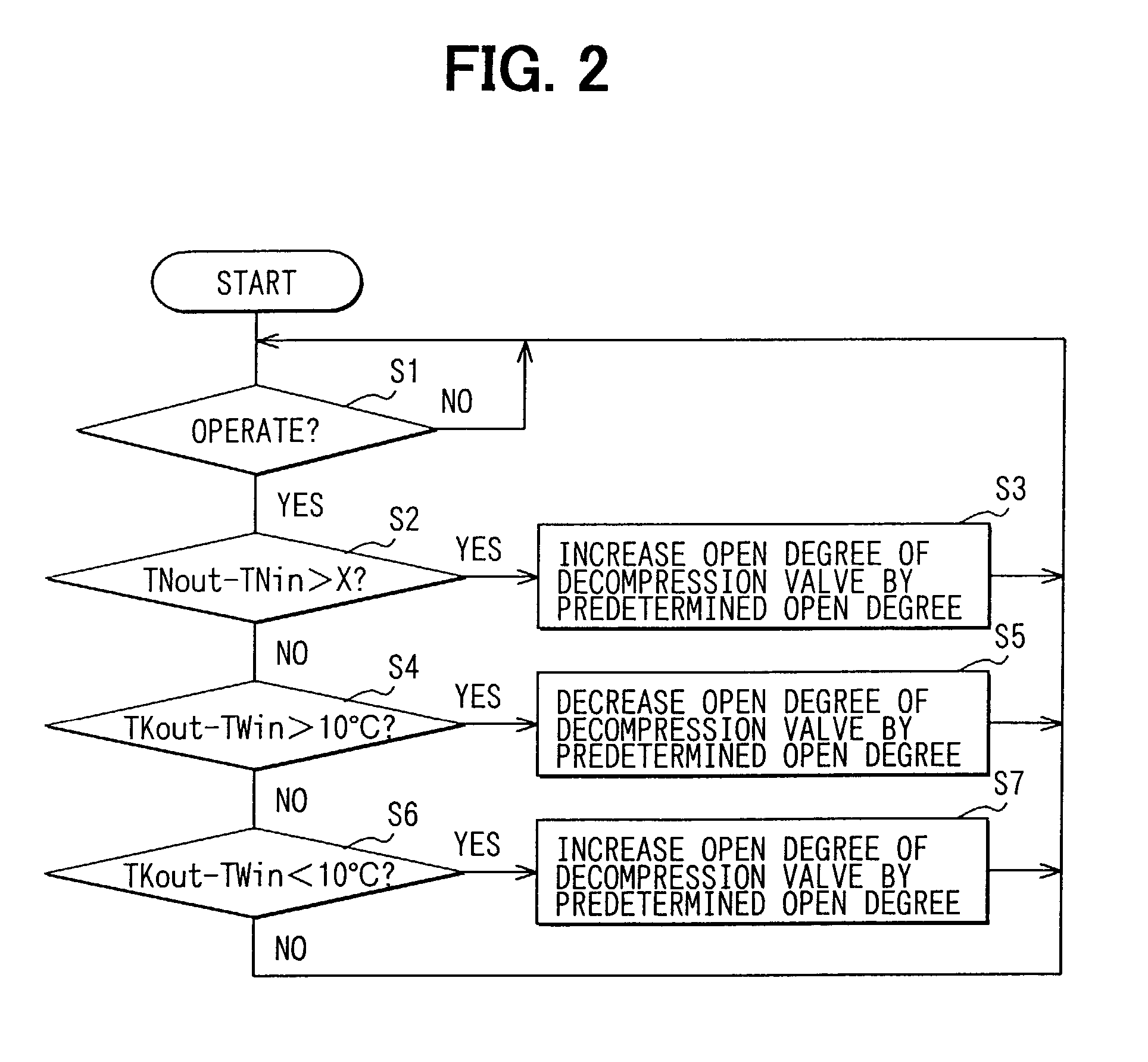

Super-critical refrigerant cycle system and water heater using the same

InactiveUS20030061827A1Speed up heat exchangeIncrease heightCompressorHeat pumpsWater flowEngineering

In a heat-pump water heater with a super-critical refrigerant cycle, a valve open degree of a decompression valve is controlled to control a pressure of high-pressure side refrigerant so that a temperature difference between refrigerant flowing out from the water-refrigerant heat exchanger and water flowing into a water-refrigerant heat exchanger is set in a predetermined temperature range. Thus, the pressure of high-pressure side refrigerant in the super-critical refrigerant cycle can be controlled, thereby suitably adjusting heat-exchange performance of an internal heat exchanger, and restricting the temperature of refrigerant discharged from the refrigerant compressor from being uselessly increased.

Owner:DENSO CORP

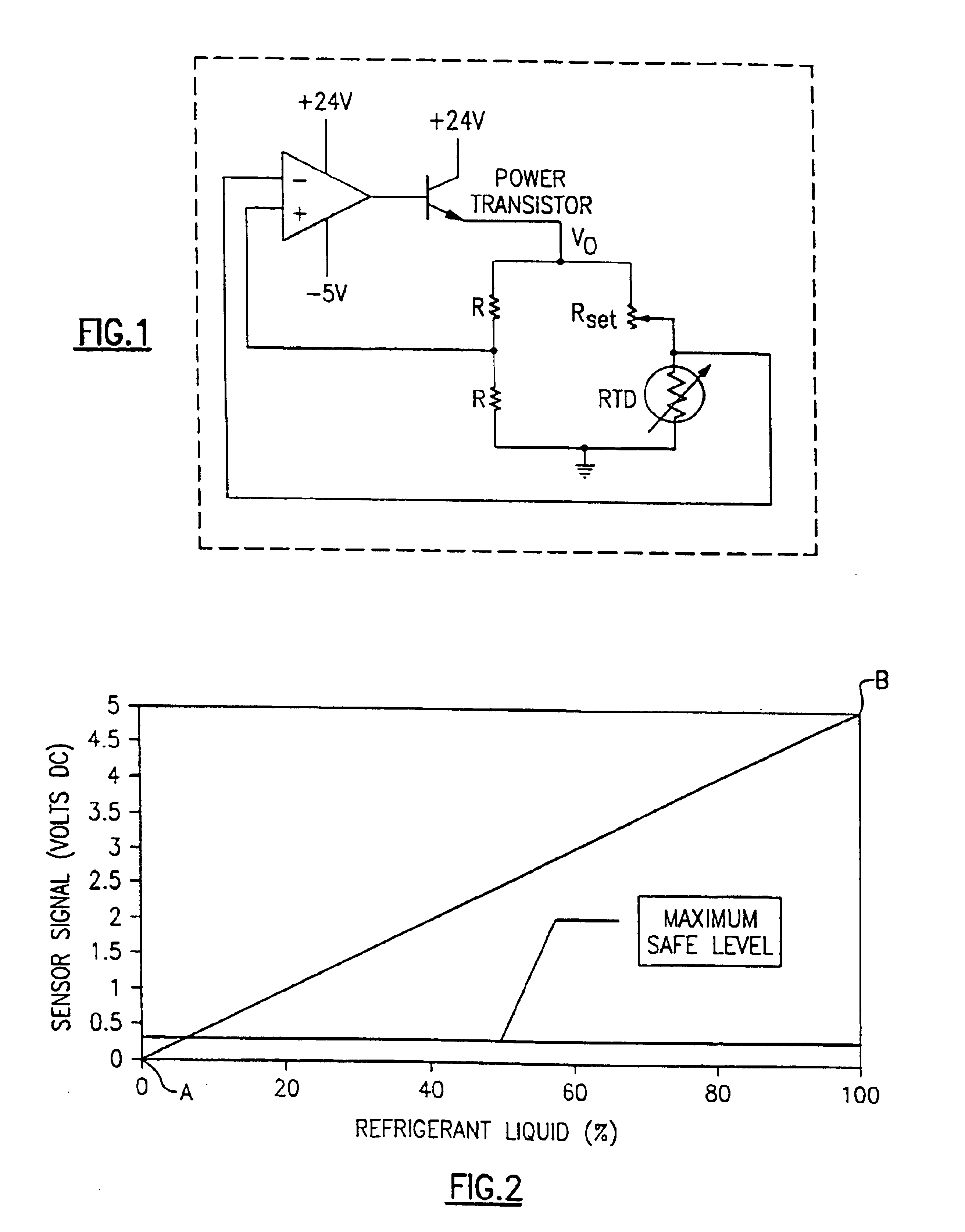

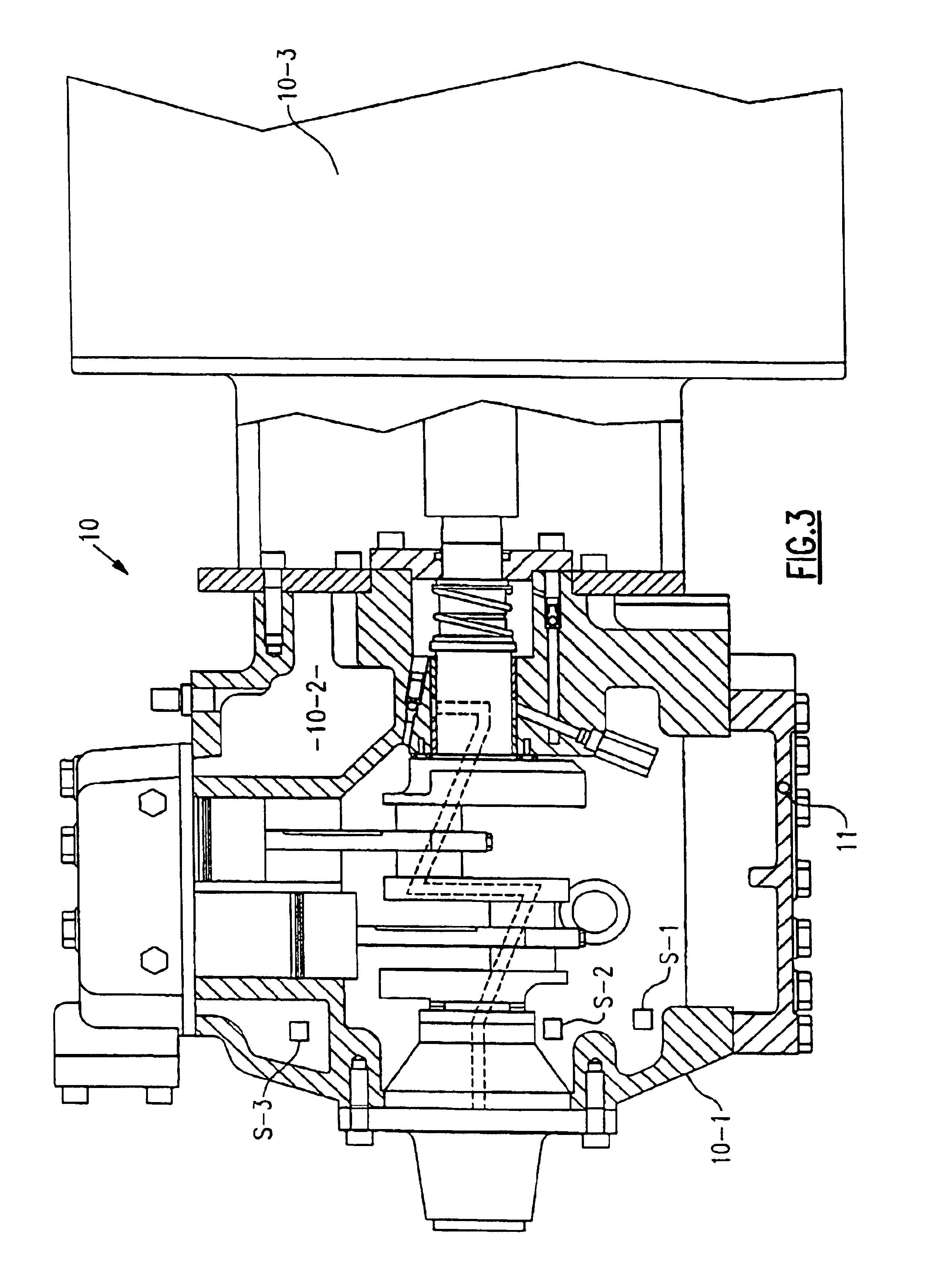

Compressor protection from liquid hazards

InactiveUS6886354B2Minimize liquid hazardMinimize liquid hazardsCompressorPositive displacement pump componentsEngineeringRefrigerant

Two liquid levels are sensed in the oil sump of a compressor to determine if sufficient oil and excess refrigerant are present prior to starting the compressor and appropriate steps taken, if necessary. At start-up, and during operation, the presence or flow of liquid refrigerant in the suction of the compressor is sensed and appropriate steps taken, if necessary.

Owner:CARRIER CORP

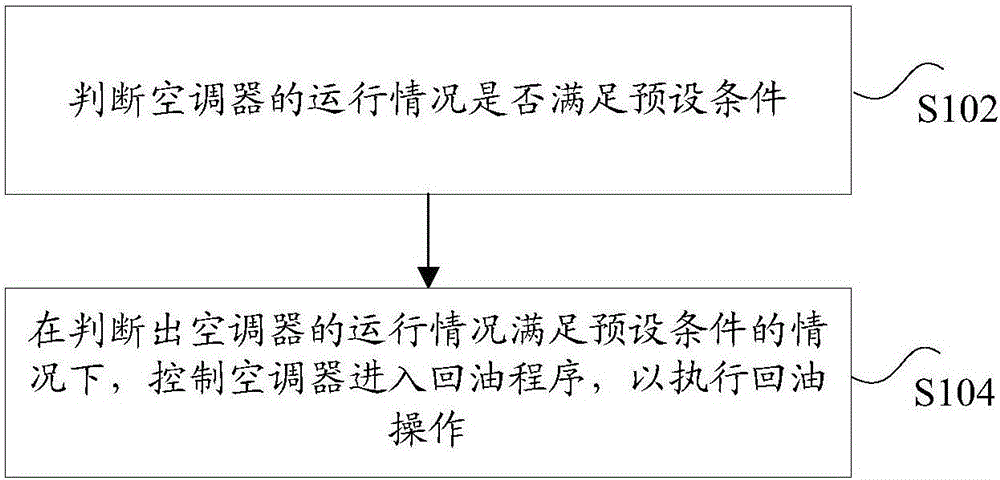

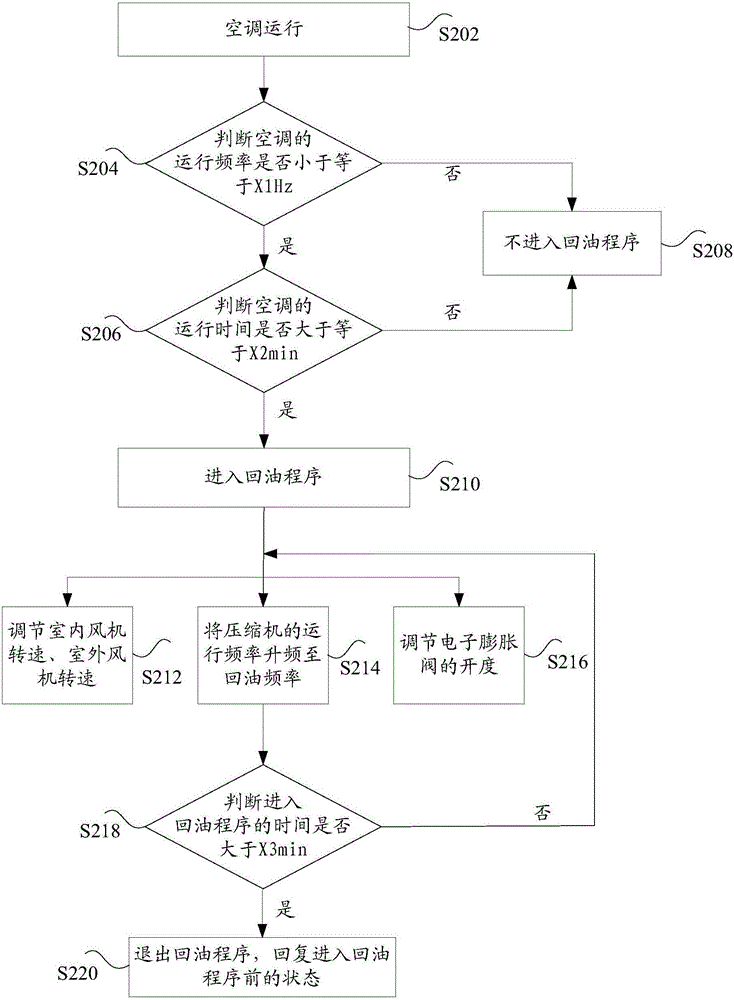

Air conditioner and oil return control method and device thereof

ActiveCN106091479AIncrease operating frequencyIncrease output powerCompressorRefrigeration safety arrangementIndustrial engineering

Owner:GREE ELECTRIC APPLIANCES INC

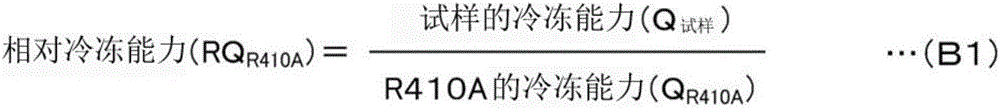

Working medium for heat cycle, composition for heat cycle system, and heat cycle system

InactiveCN106414654AImprove stabilityInhibition of the effects of global warmingCompressorCompression machines with non-reversible cycleEngineeringDouble bond

Provided are: a working medium for a heat cycle, said working medium containing 1,2-difluoroethylene and exhibiting high stability, reduced environmental impact, and cycle performance that can replace that of R410A (a pseudo-azeotropic mixed refrigerant including difluoromethane and pentafluoroethane at a mass ratio of 1:1) and 1,1,1,2-tetrafluoroethane; a composition for heat cycle system, said composition using the medium; and a heat cycle system using the composition. The working medium for a heat cycle is characterized by the inclusion of 1,2-difluoroethylene and at least two types of hydrofluorocarbon selected from the group of hydrofluorocarbons that include a carbon-carbon double bond other than a saturated hydrofluorocarbon and 1,2-difluoroethylene.

Owner:ASAHI GLASS CO LTD

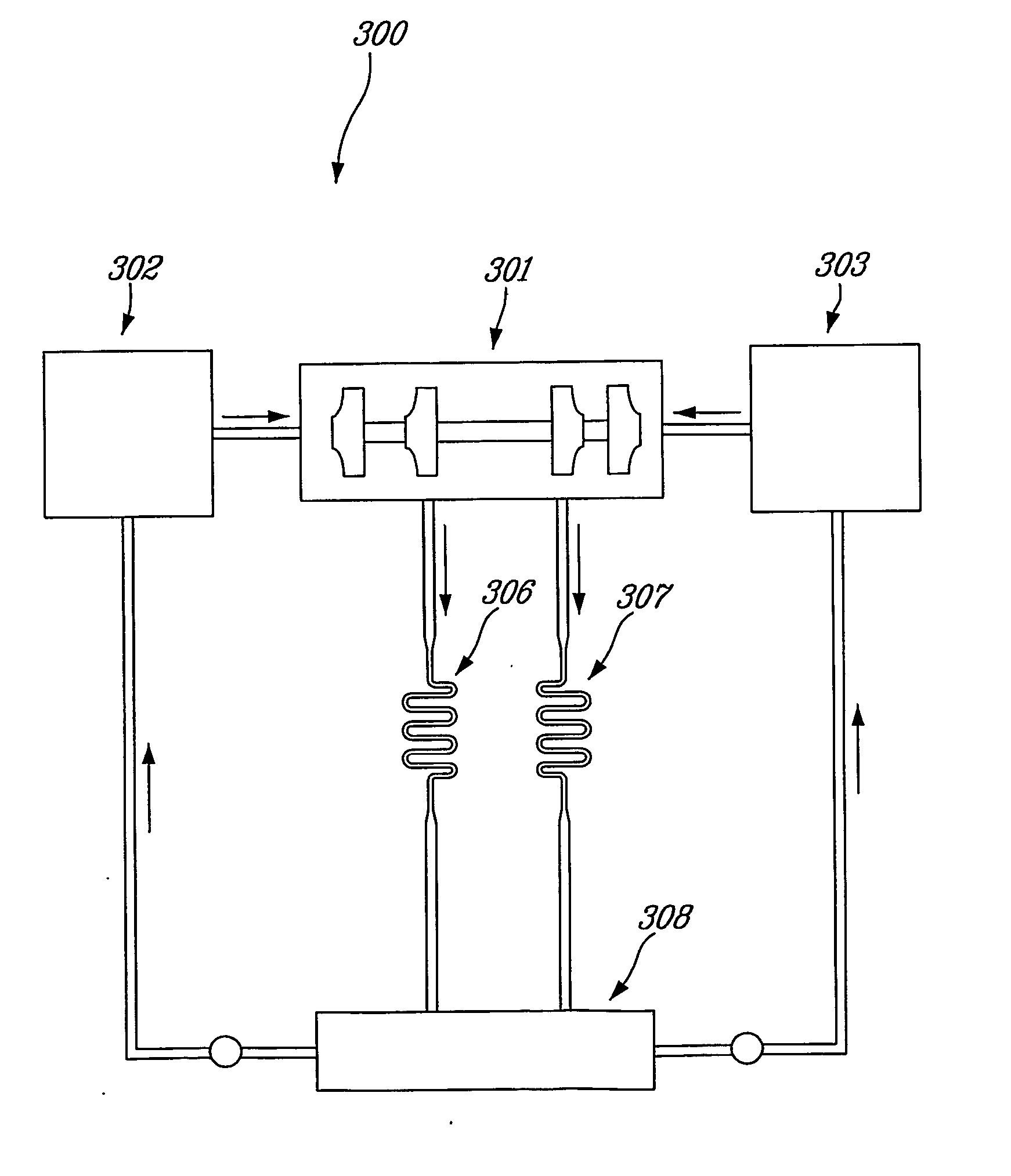

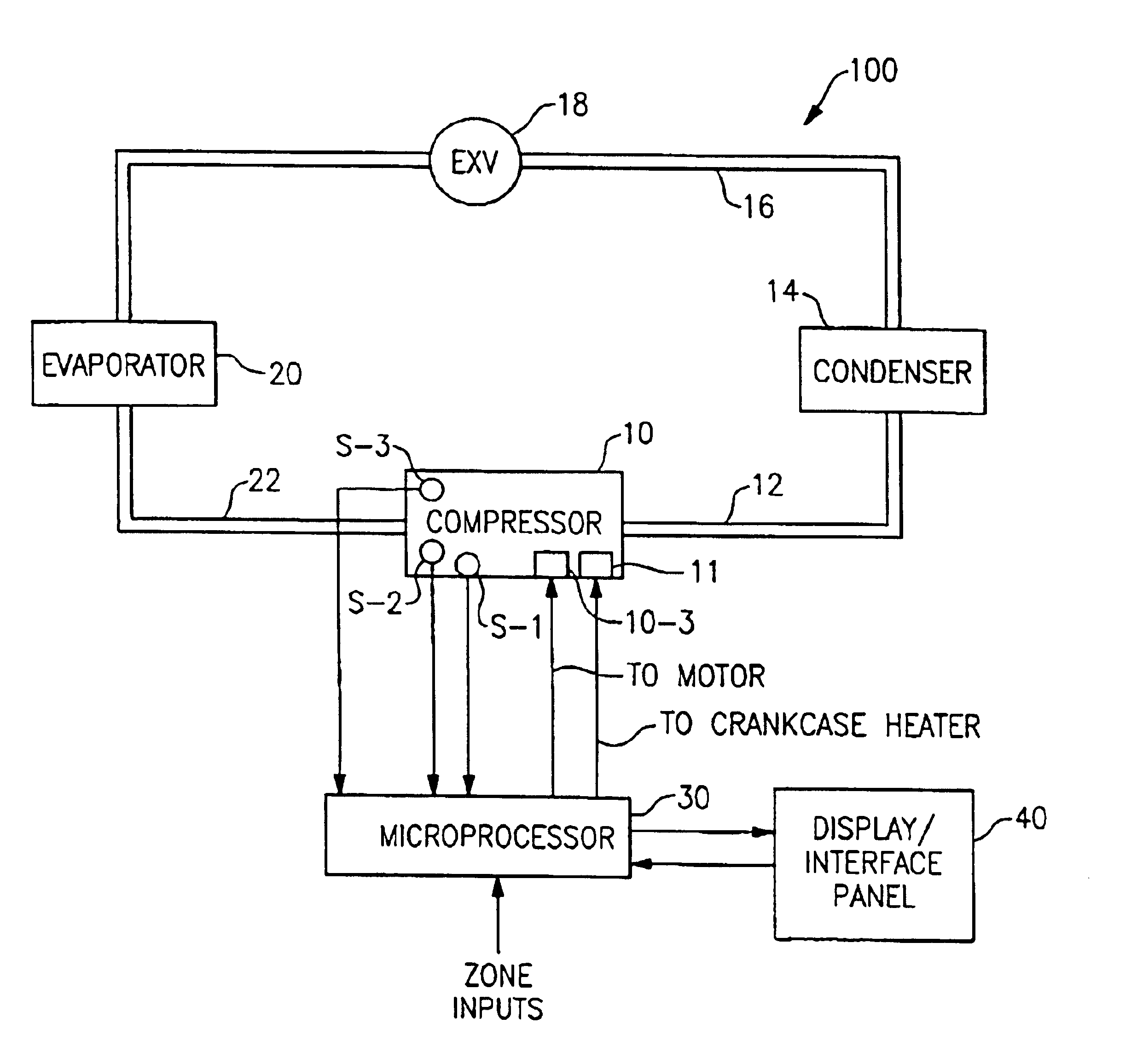

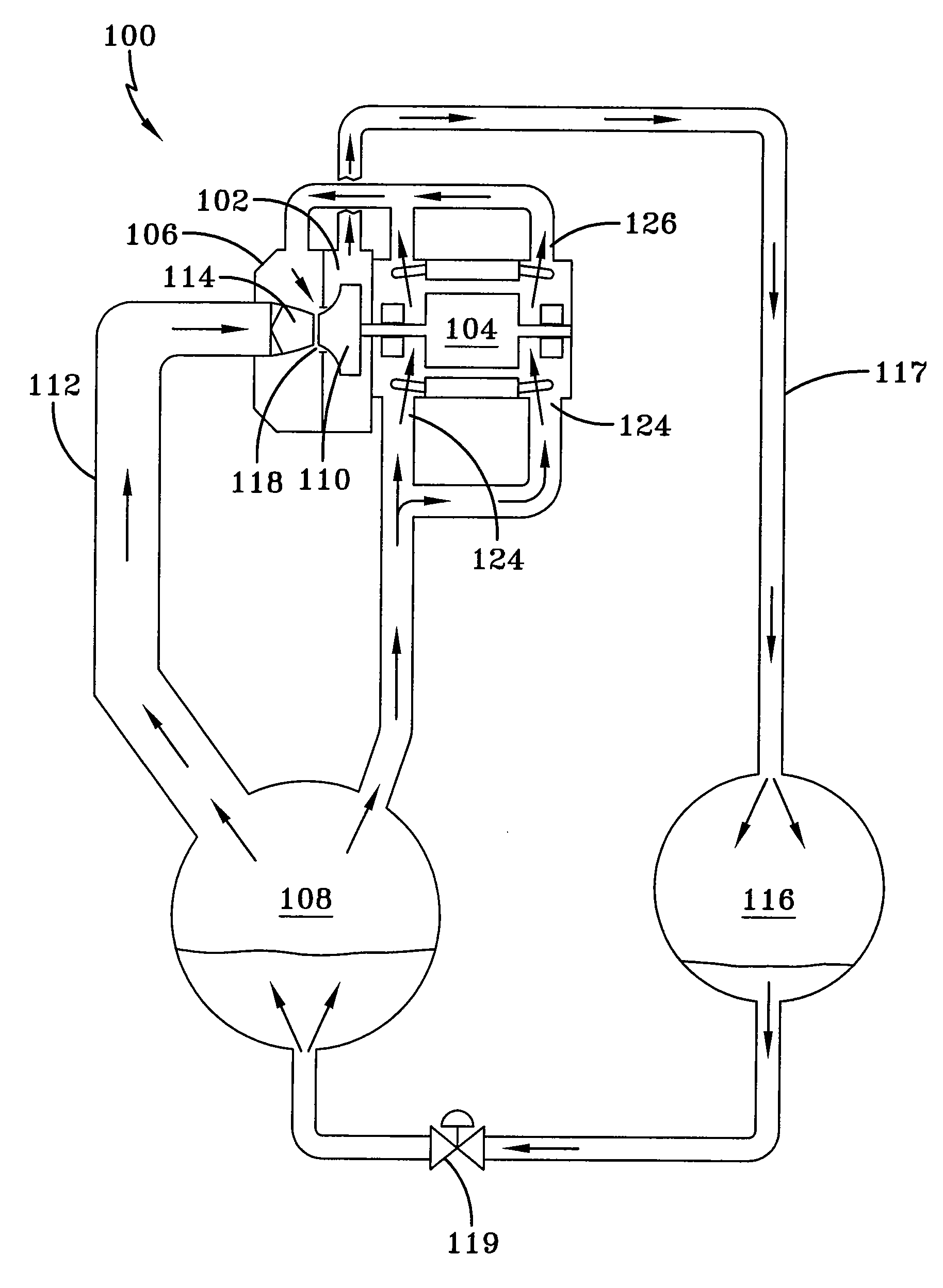

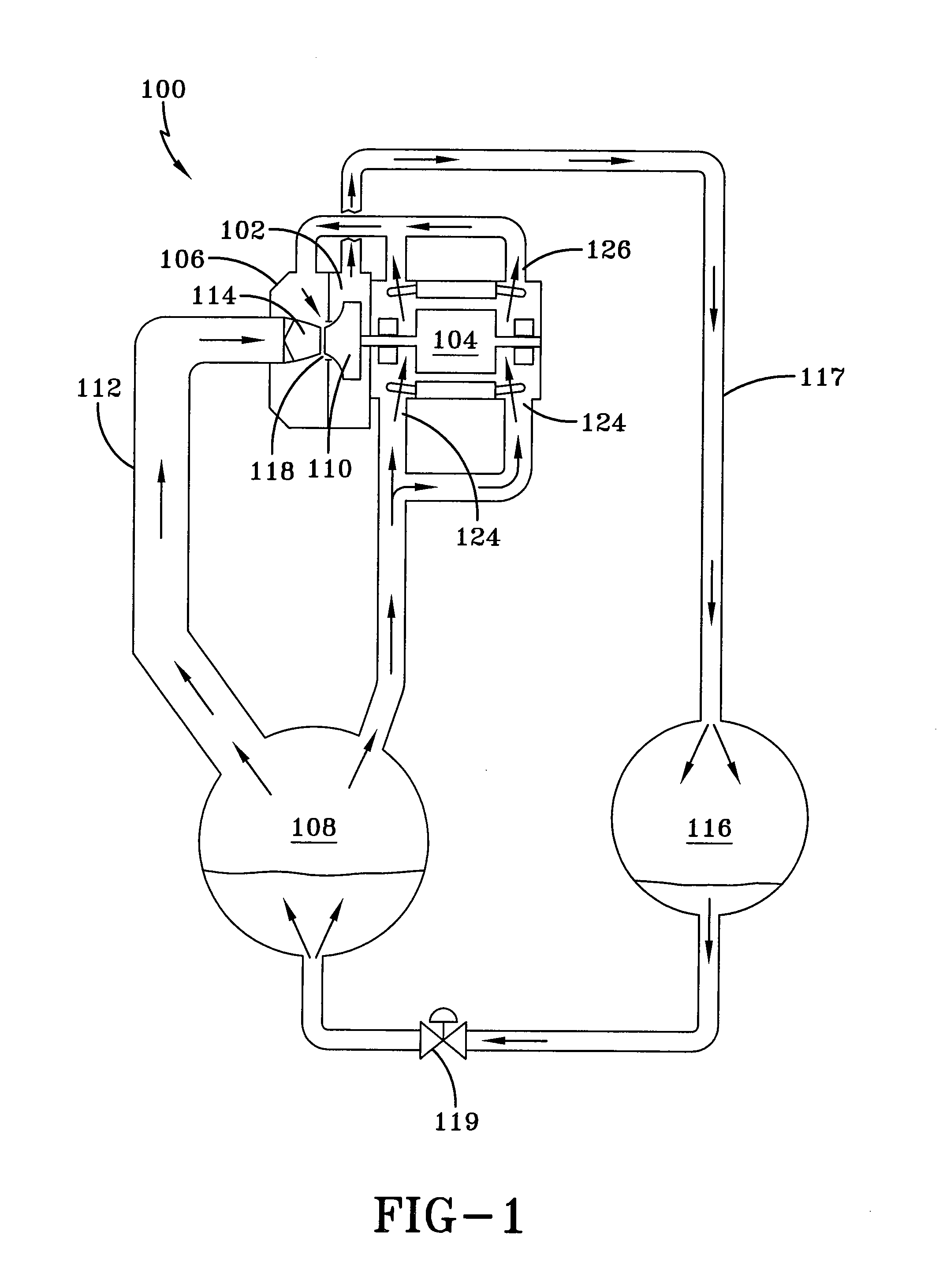

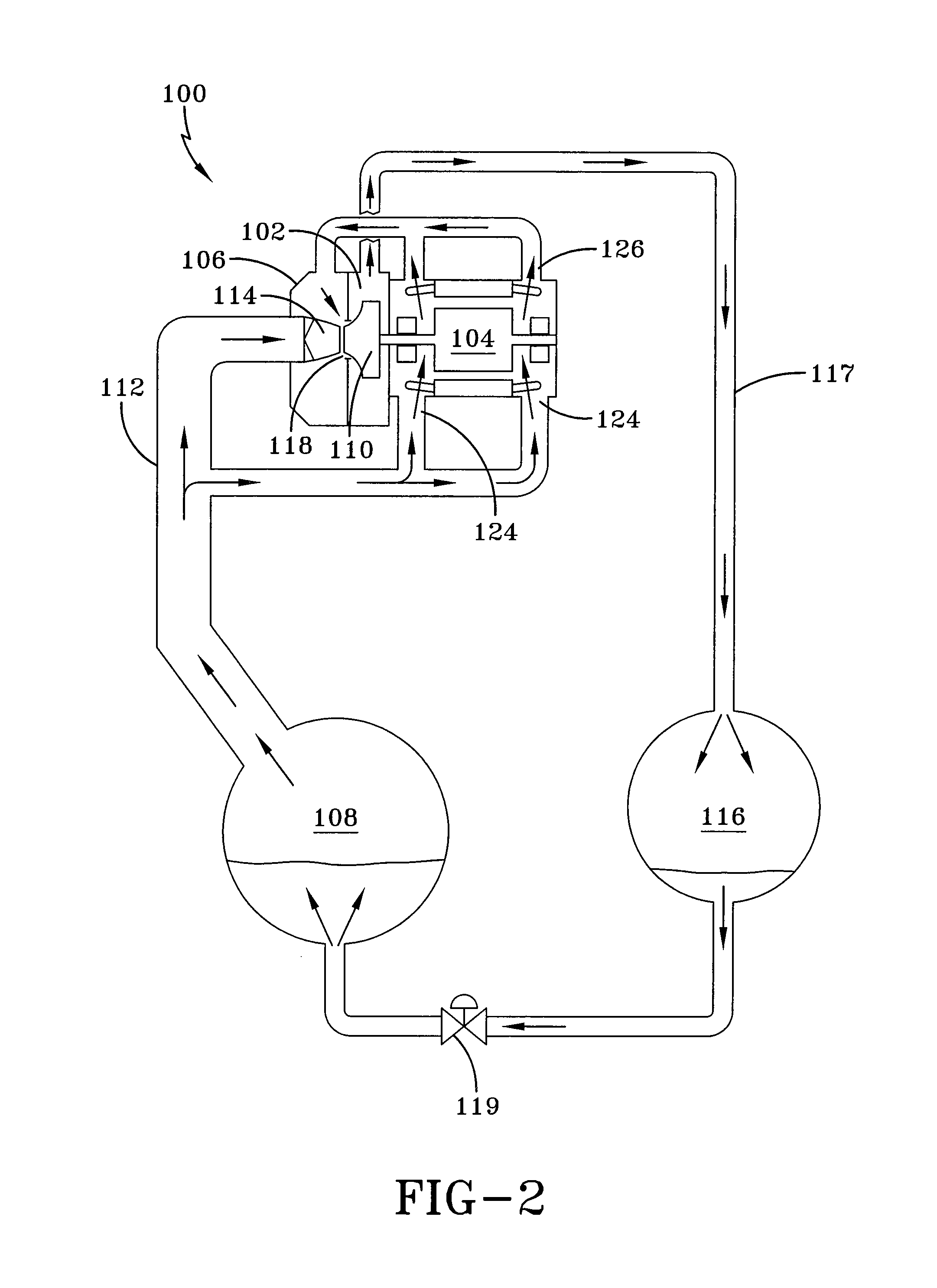

System and method for cooling a compressor motor

ActiveUS7181928B2Unacceptable compromises to system efficiencyImprovement in motor coolingCompressorPump componentsEngineeringAir compressor

Apparatus and methods are provided for cooling motors used to drive gas and air compressors. In particular, the cooling of hermetic and semi-hermetic motors is accomplished by a gas sweep using a gas source located in the low-pressure side of a gas compression circuit. The gas sweep is provided by the creation of a pressure reduction at the compressor inlet sufficient to draw uncompressed gas through a motor housing, across the motor, and out of the housing for return to the suction assembly. The pressure reduction is created by means provided in the suction assembly, such as a nozzle and gap assembly, or alternatively a venturi, located upstream of the compressor inlet. Additional motor cooling can be provided by circulating liquid or another cooling fluid through a cooling jacket in the motor housing portion adjacent the motor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

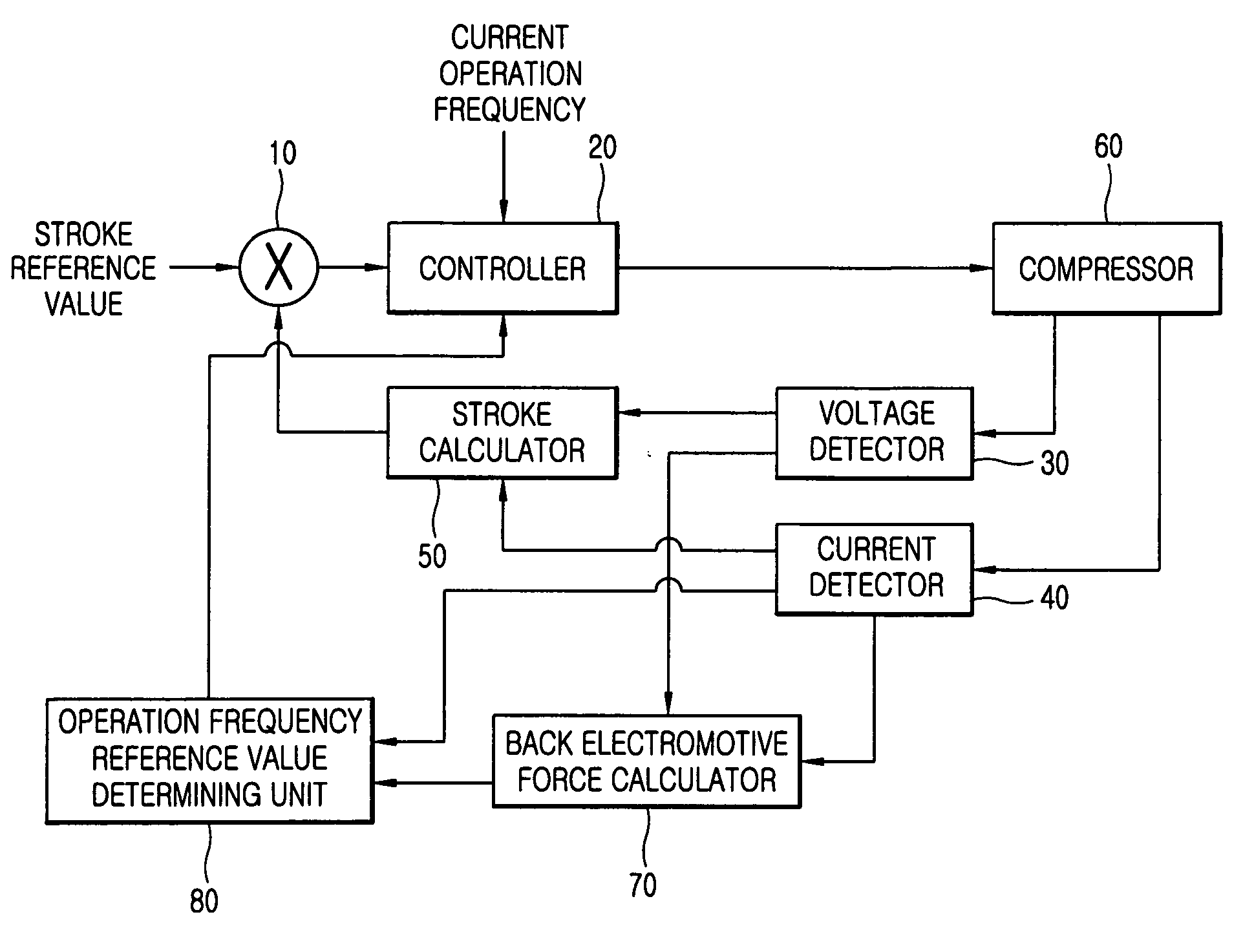

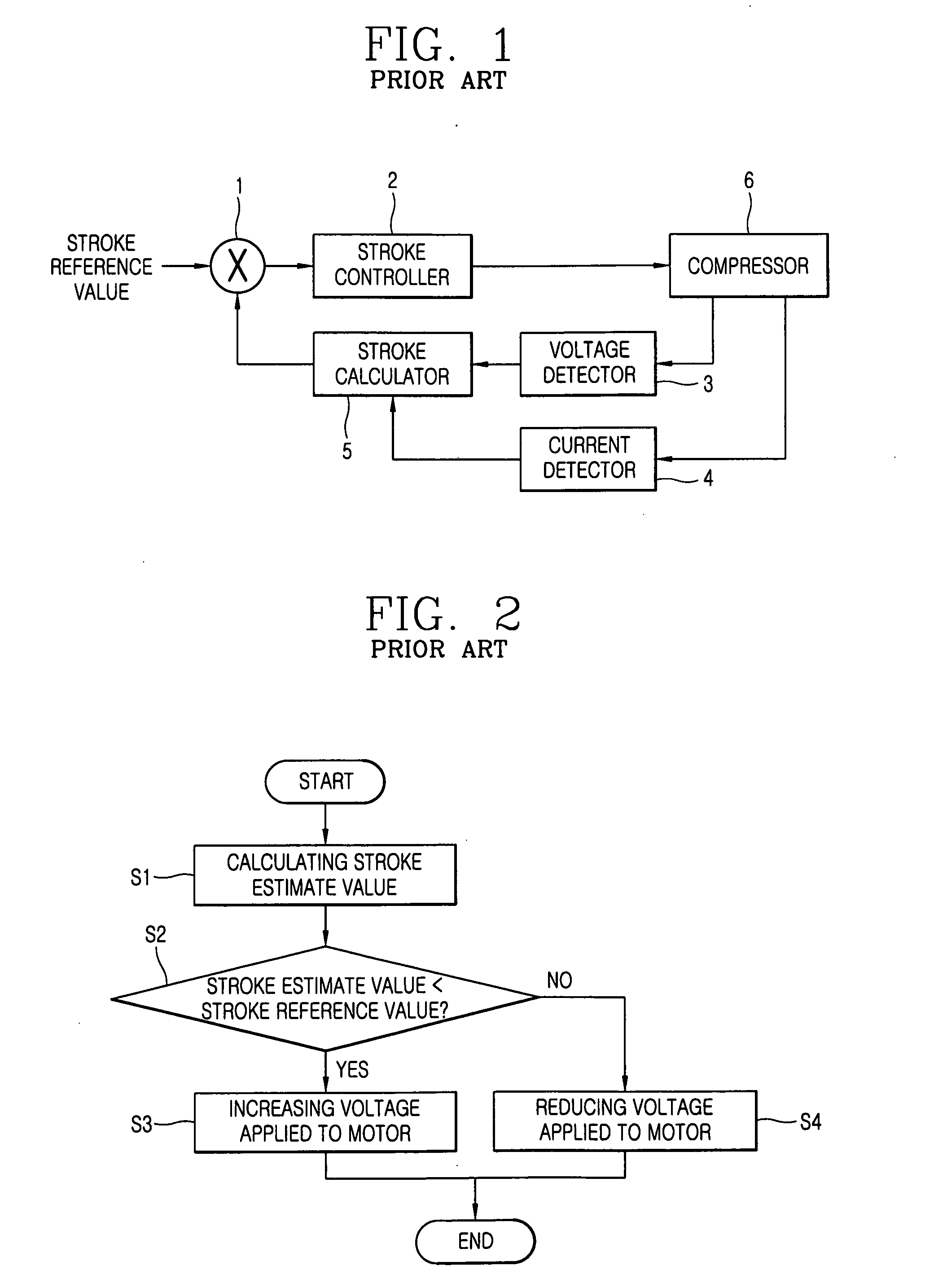

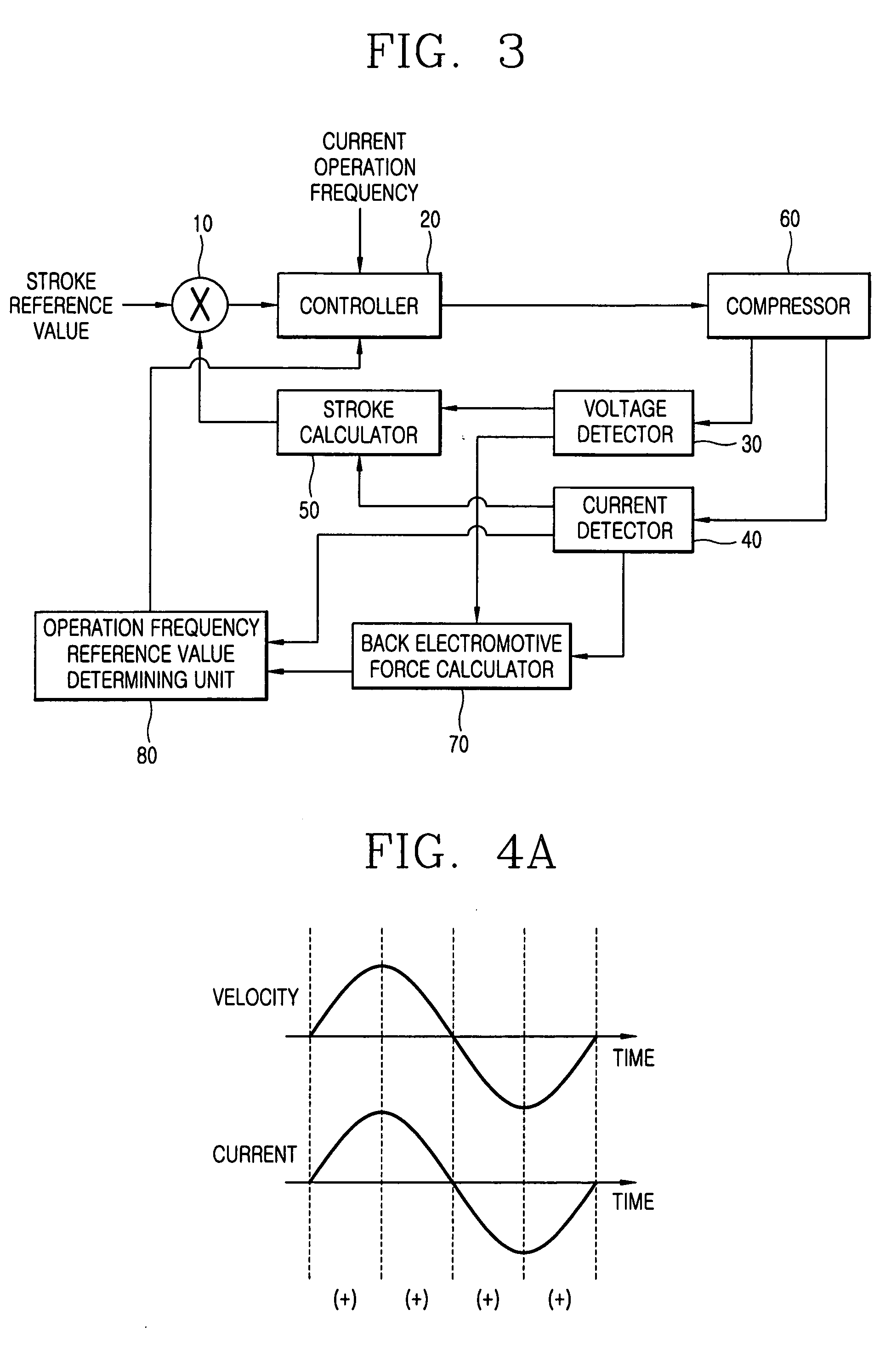

Apparatus and method for controlling operation of compressor

ActiveUS20060056980A1Easy to operateCompressorDC motor speed/torque controlMechanical resonanceElectromotive force

An apparatus for controlling an operation of a compressor includes: a back electromotive force calculator for calculating a back electromotive force of a compressor based on a value of a current applied to a motor of the compressor and a value of a voltage applied to the motor of the compressor; an operation frequency reference value determining unit for detecting a mechanical resonance frequency of the compressor based on the back electromotive force value and the current value and determining the detected mechanical resonance frequency as an operation frequency reference value; and a controller for varying an operation frequency of the compressor according to the determined operation frequency reference value.

Owner:LG ELECTRONICS INC

Popular searches

Organic chemistry Heat-exchange elements Heat storage plants Direct contact heat exchangers Compression machines with reversible cycle Base-materials Detergent mixture composition preparation Semiconductor/solid-state device manufacturing Detergent solvents Perfluorocarbons/hydrofluorocarbons capture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com