Liquid vapor separation in transcritical refrigerant cycle

a technology of liquid vapor separation and refrigerant cycle, which is applied in the direction of refrigeration components, mechanical equipment, lighting and heating equipment, etc., can solve the problems of transport refrigeration equipment and other problems, and the refrigerant vapor compression system used in connection with the transport refrigeration system is generally subject to stringent operating conditions, vibration and movement, and size restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

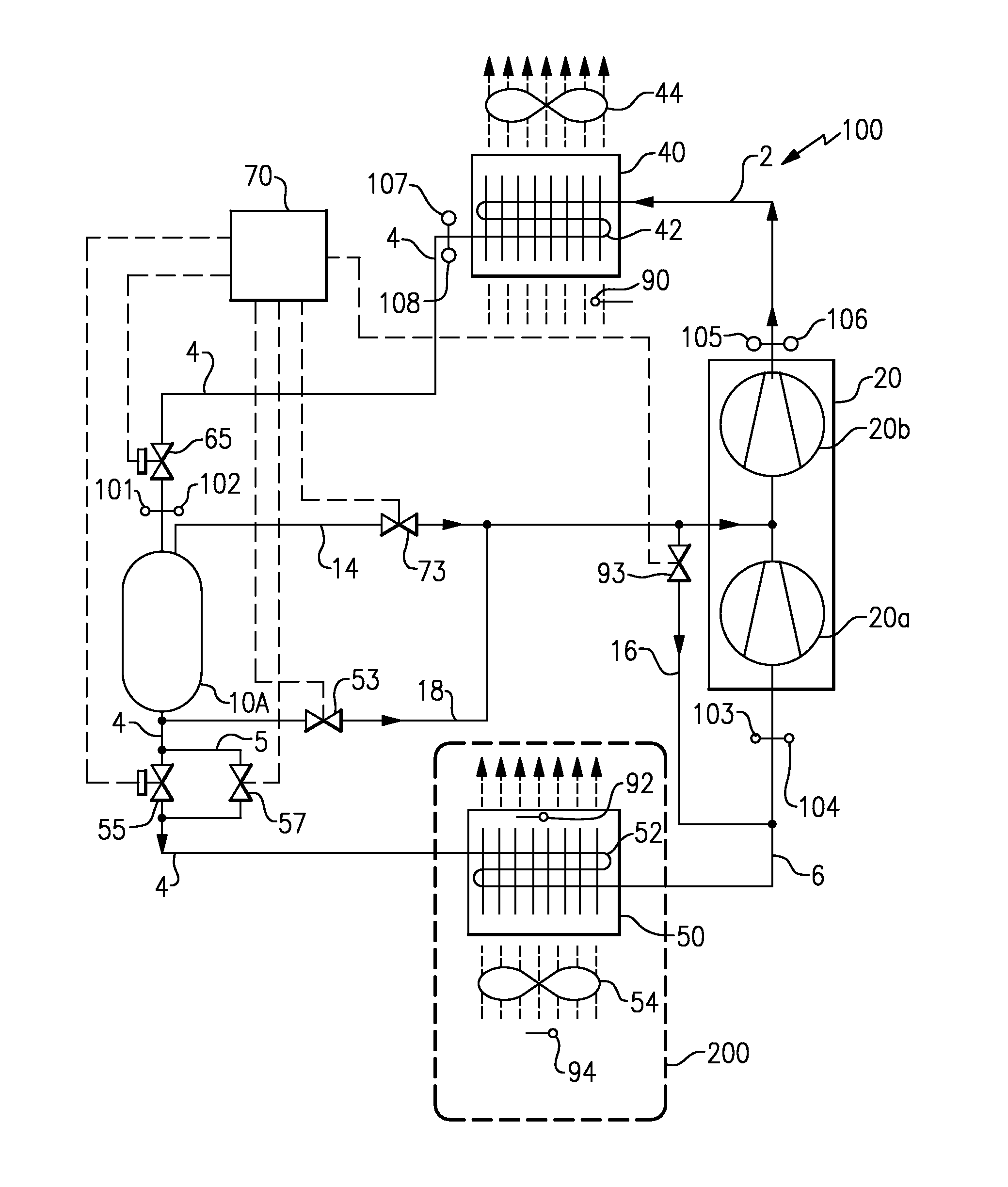

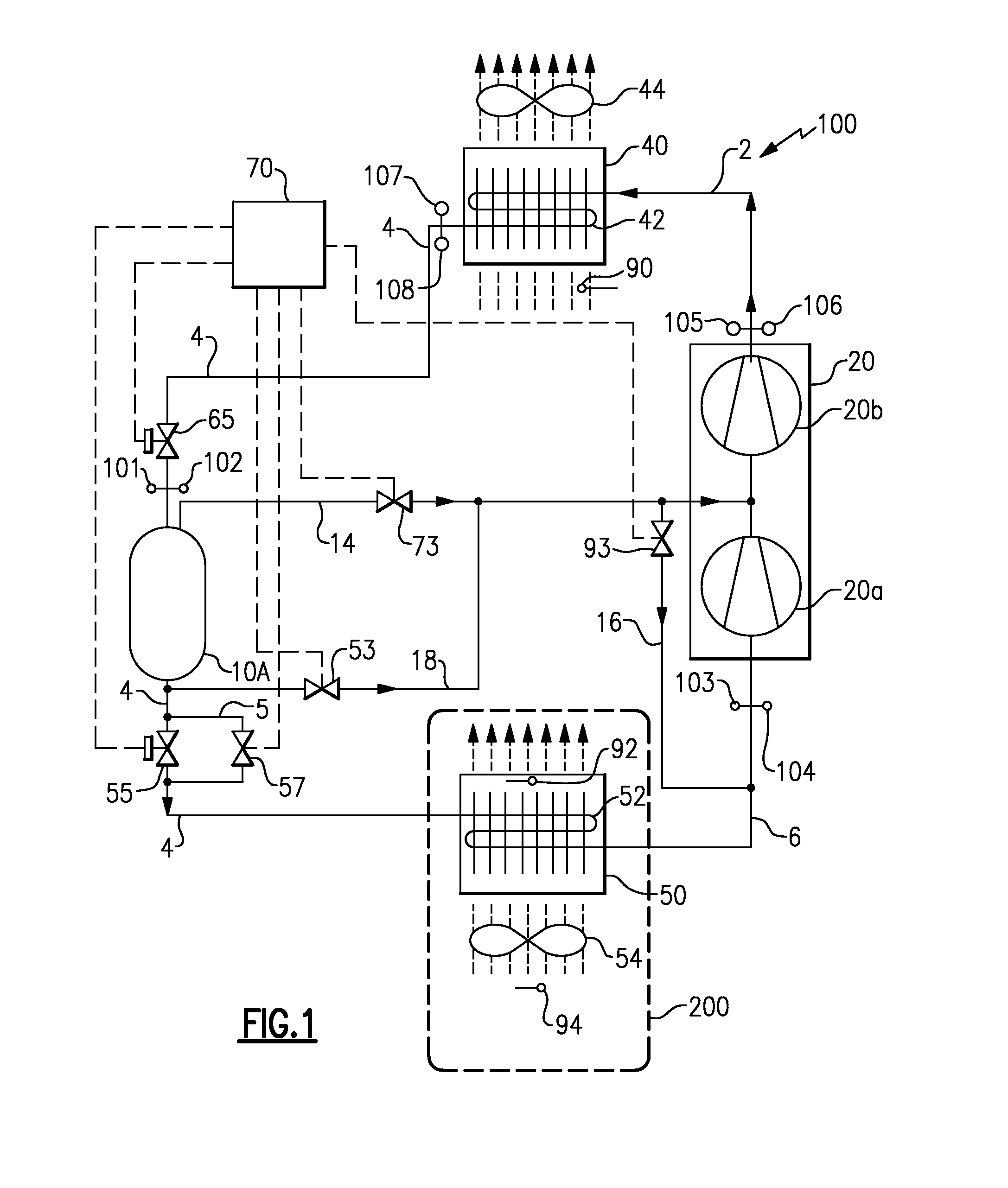

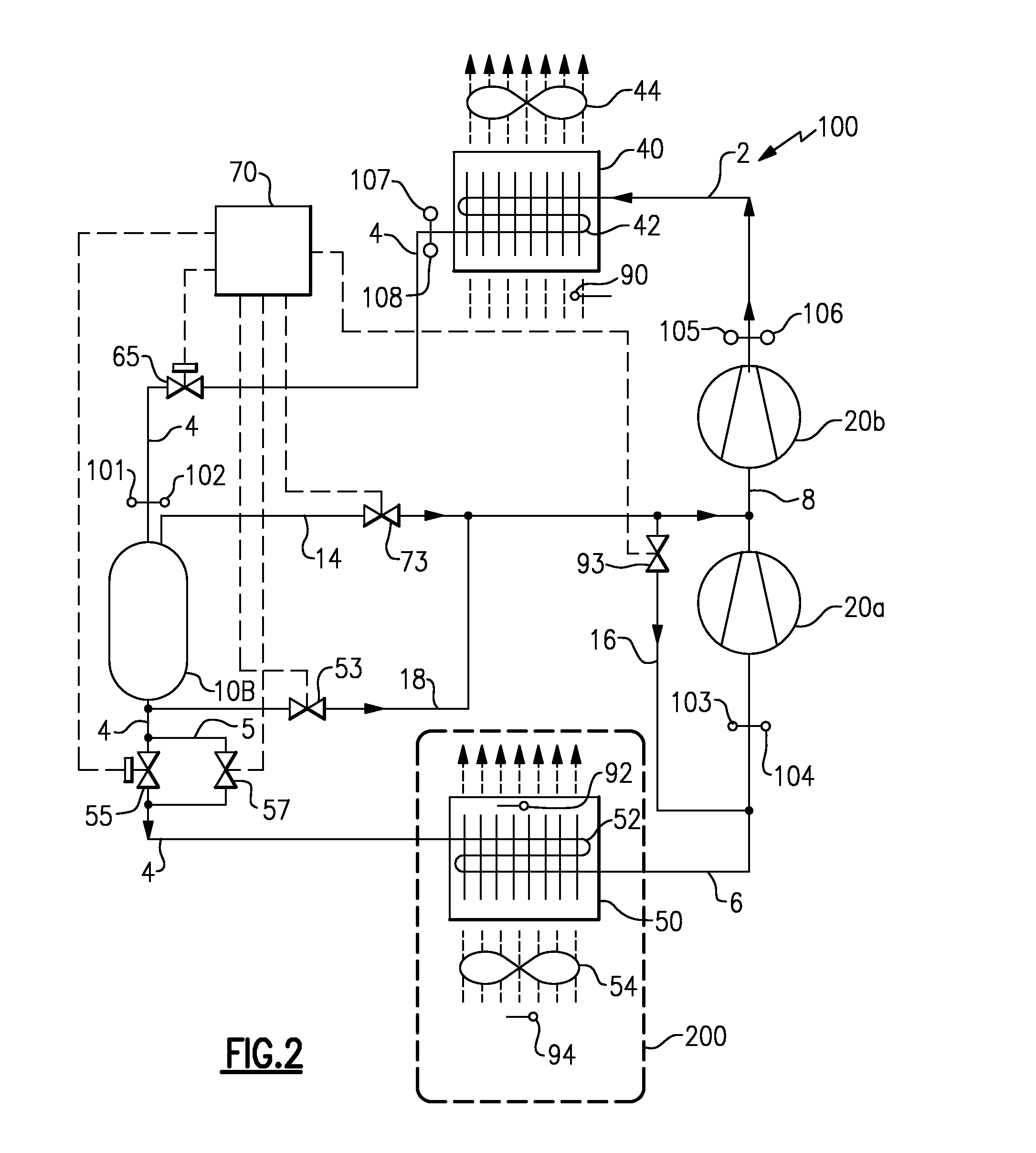

[0015]Referring now to FIGS. 1 and 2, there are depicted therein exemplary embodiments of a refrigerant vapor compression system 100 suitable for use in a transport refrigeration system for refrigerating the air or other gaseous atmosphere within the temperature controlled cargo space 200 of a truck, trailer, container or the like for transporting perishable / frozen goods. The refrigerant vapor compression system 100 is particularly adapted for operation in a transcritical cycle with a low critical temperature refrigerant, such as for example, but not limited to, carbon dioxide. The refrigerant vapor compression system 100 includes a multi-step compression device 20, a refrigerant heat rejecting heat exchanger 40 and a refrigerant heat absorbing heat exchanger 50, also referred to herein as an evaporator, with refrigerant lines 2, 4 and 6 connecting the aforementioned components in refrigerant flow communication in a refrigerant circuit. A primary expansion device 55, such as for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com