Patents

Literature

4318 results about "Valve stem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A valve stem is a self-contained valve which opens to admit gas to a chamber (such as air to inflate a tire), and is then automatically closed and kept sealed by the pressure in the chamber, or a spring, or both, to prevent the gas from escaping. They are most commonly used on automobile, motorcycle, and bicycle tires, but also for many other applications.

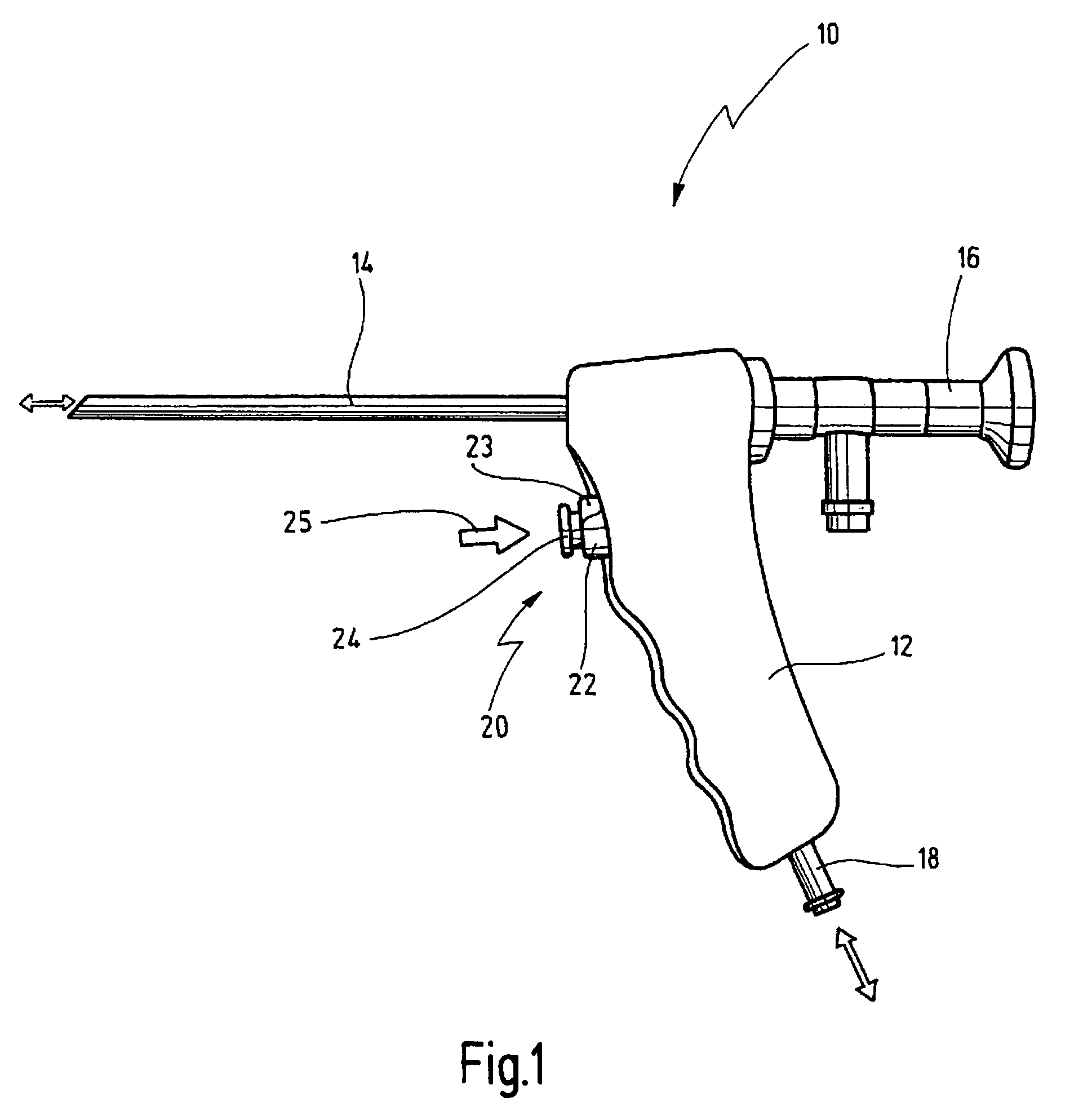

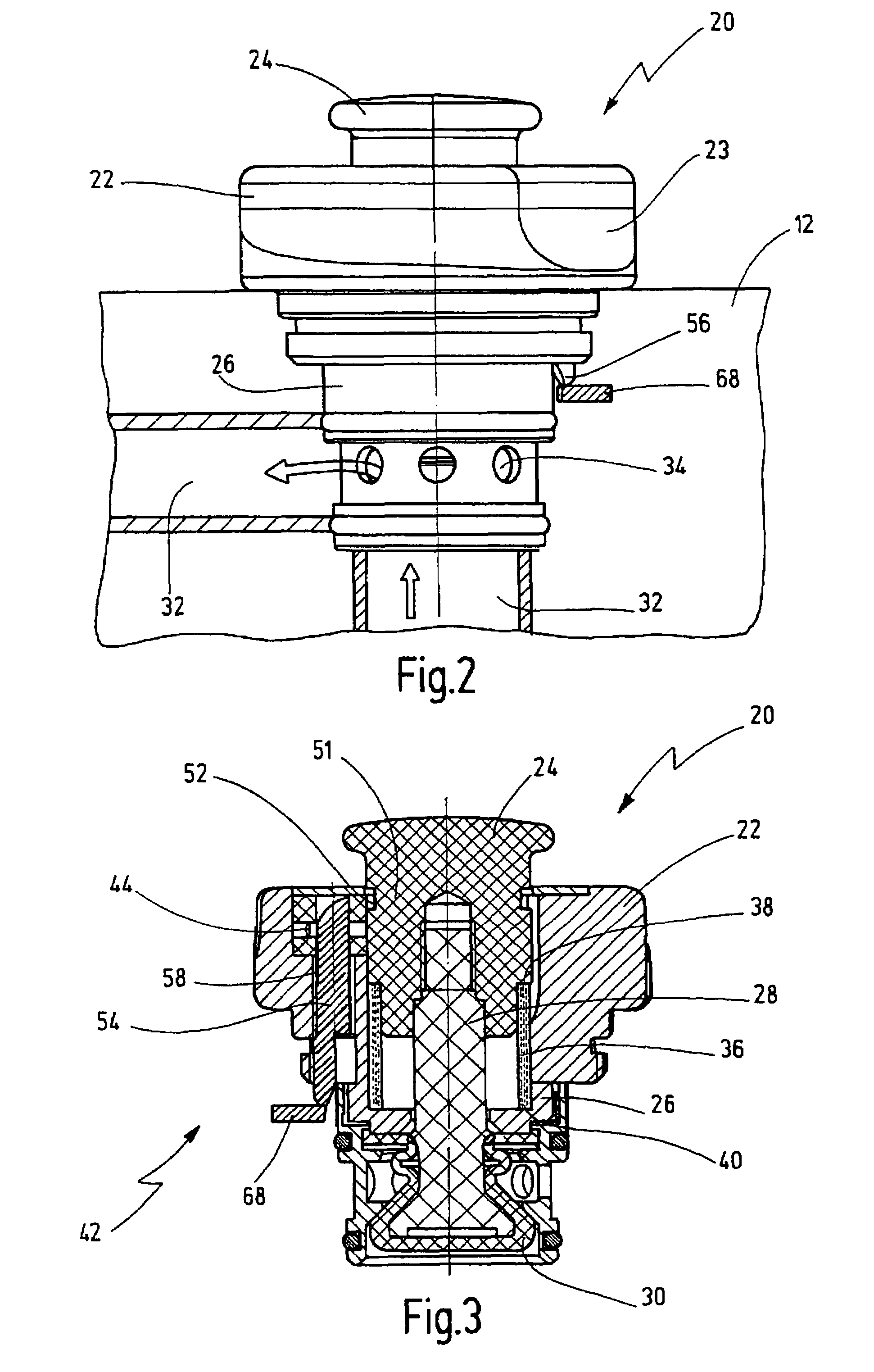

Four function surgical instrument

Owner:INASURGICA

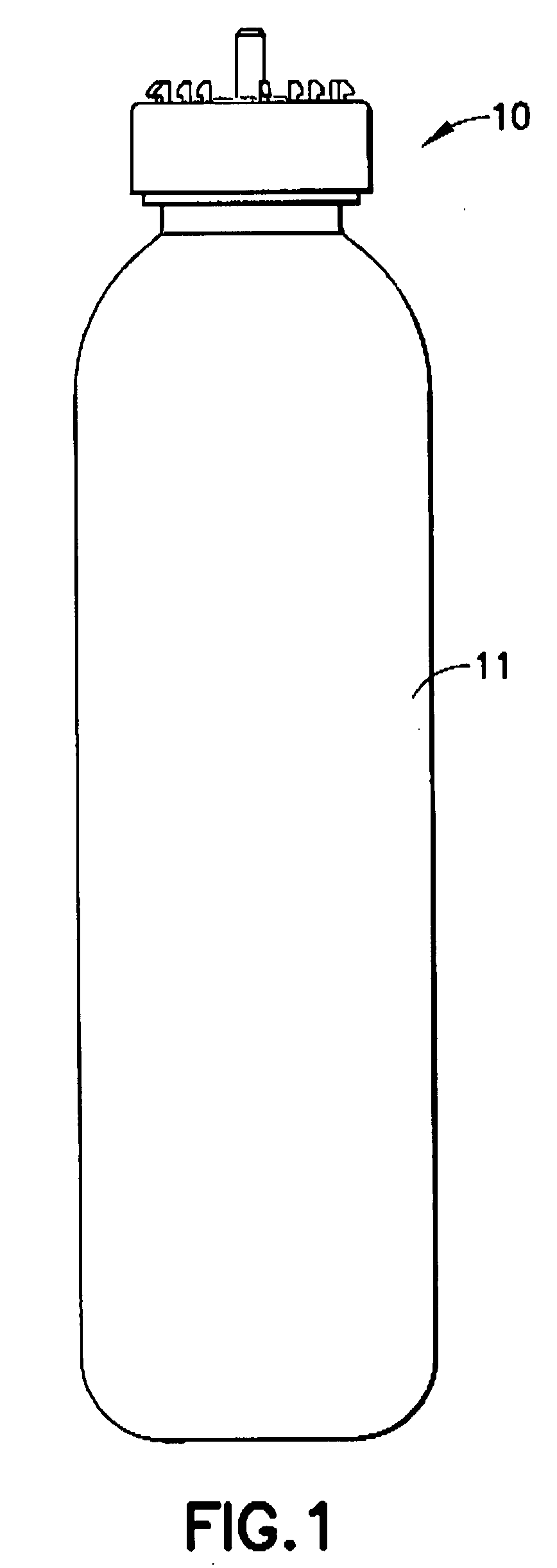

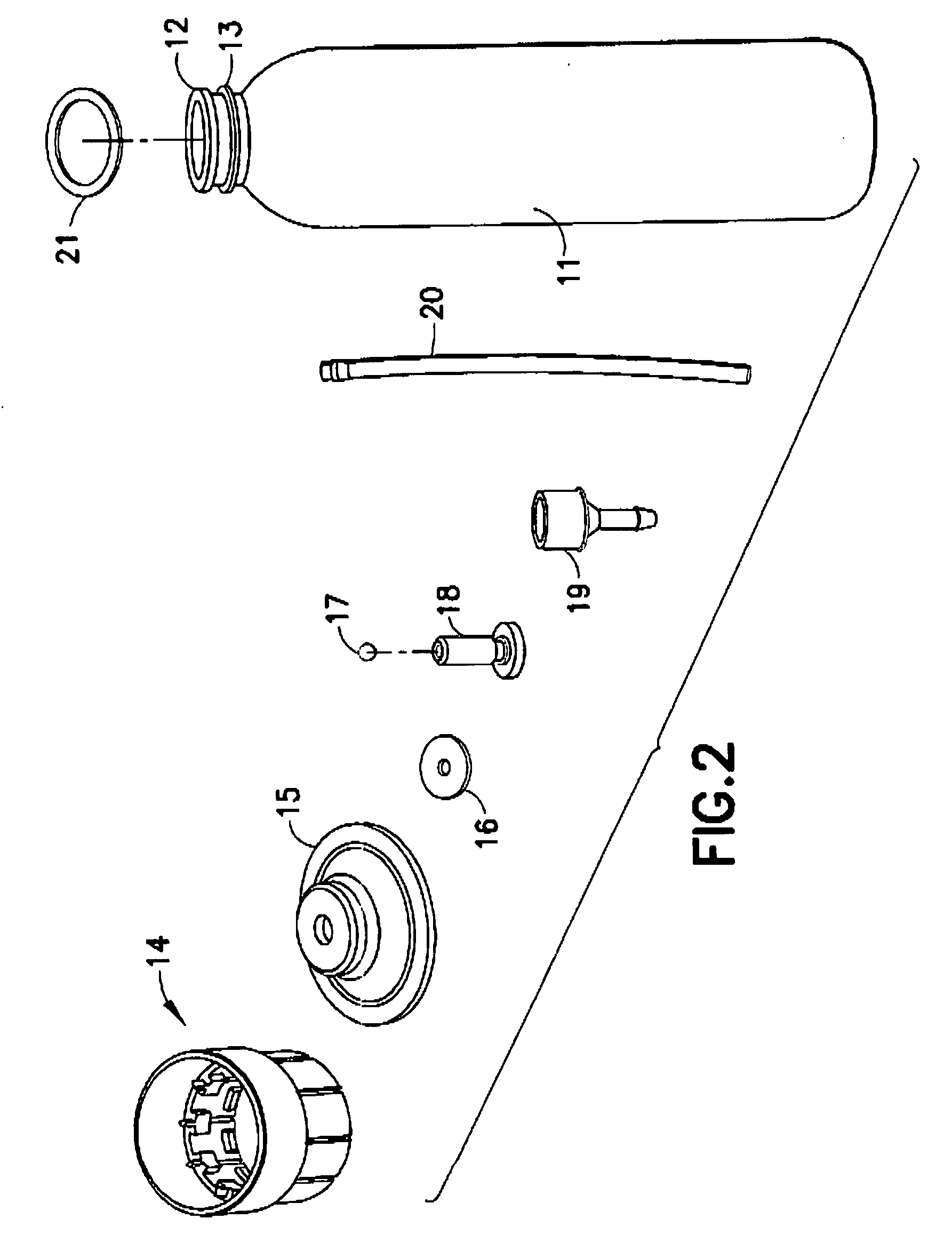

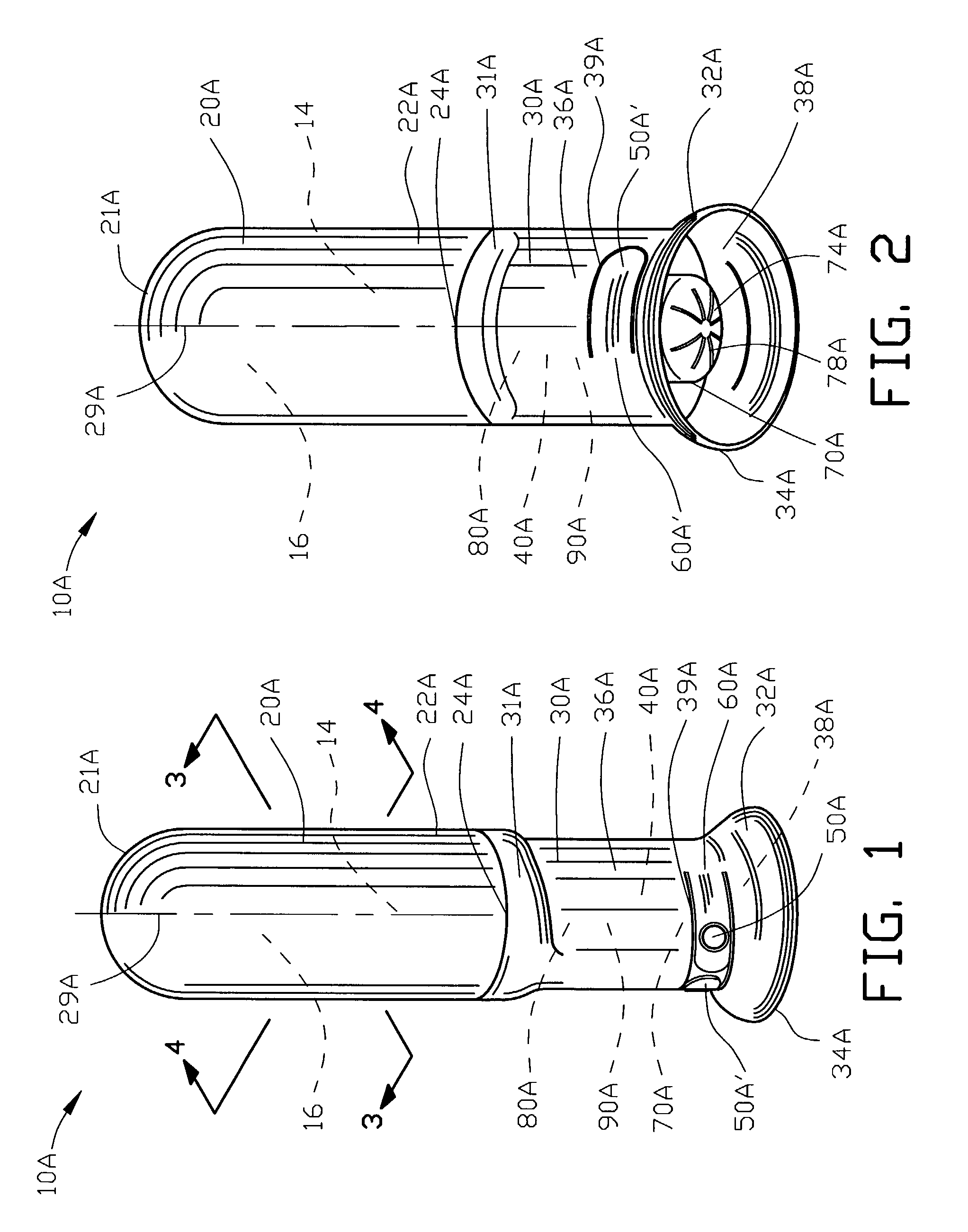

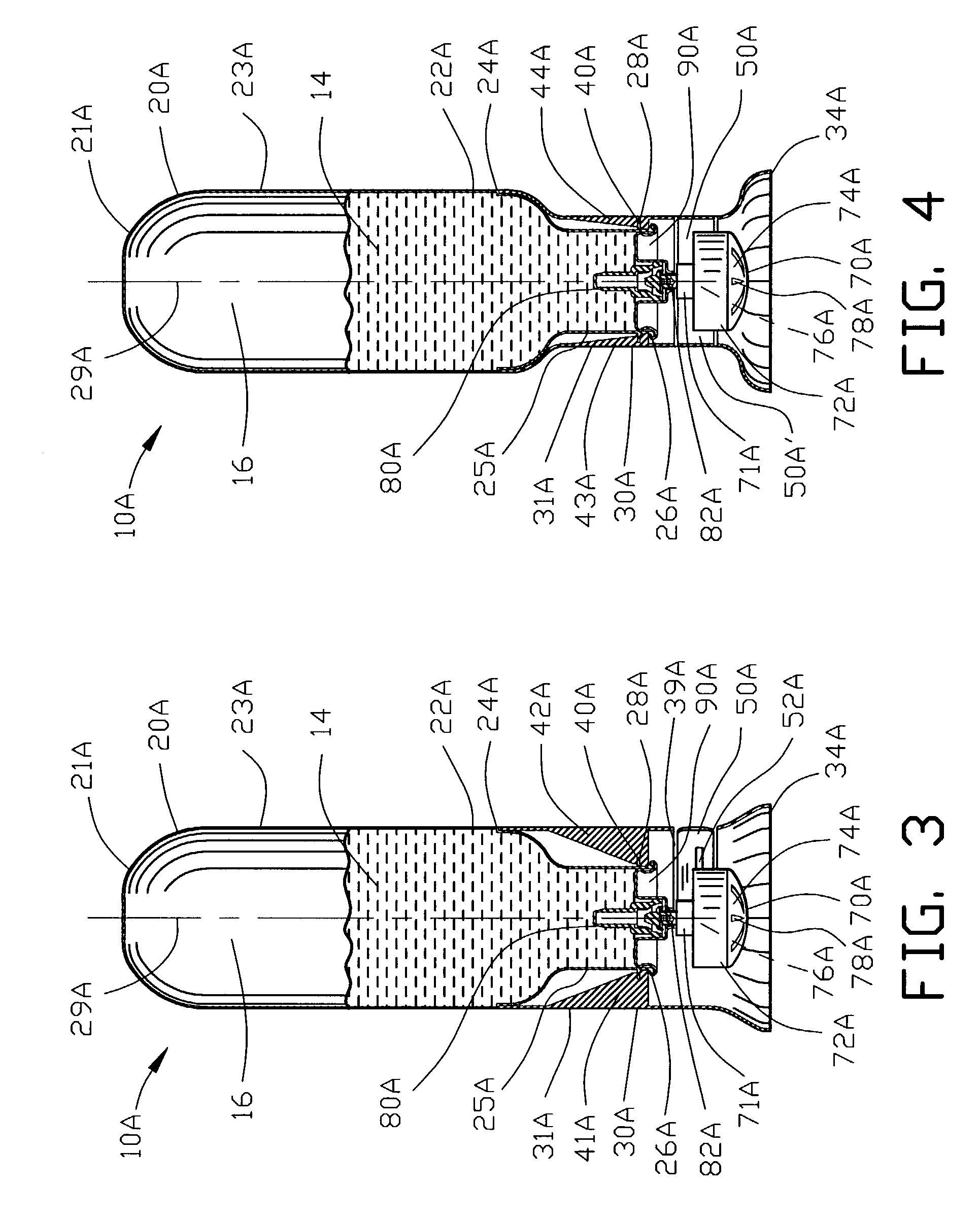

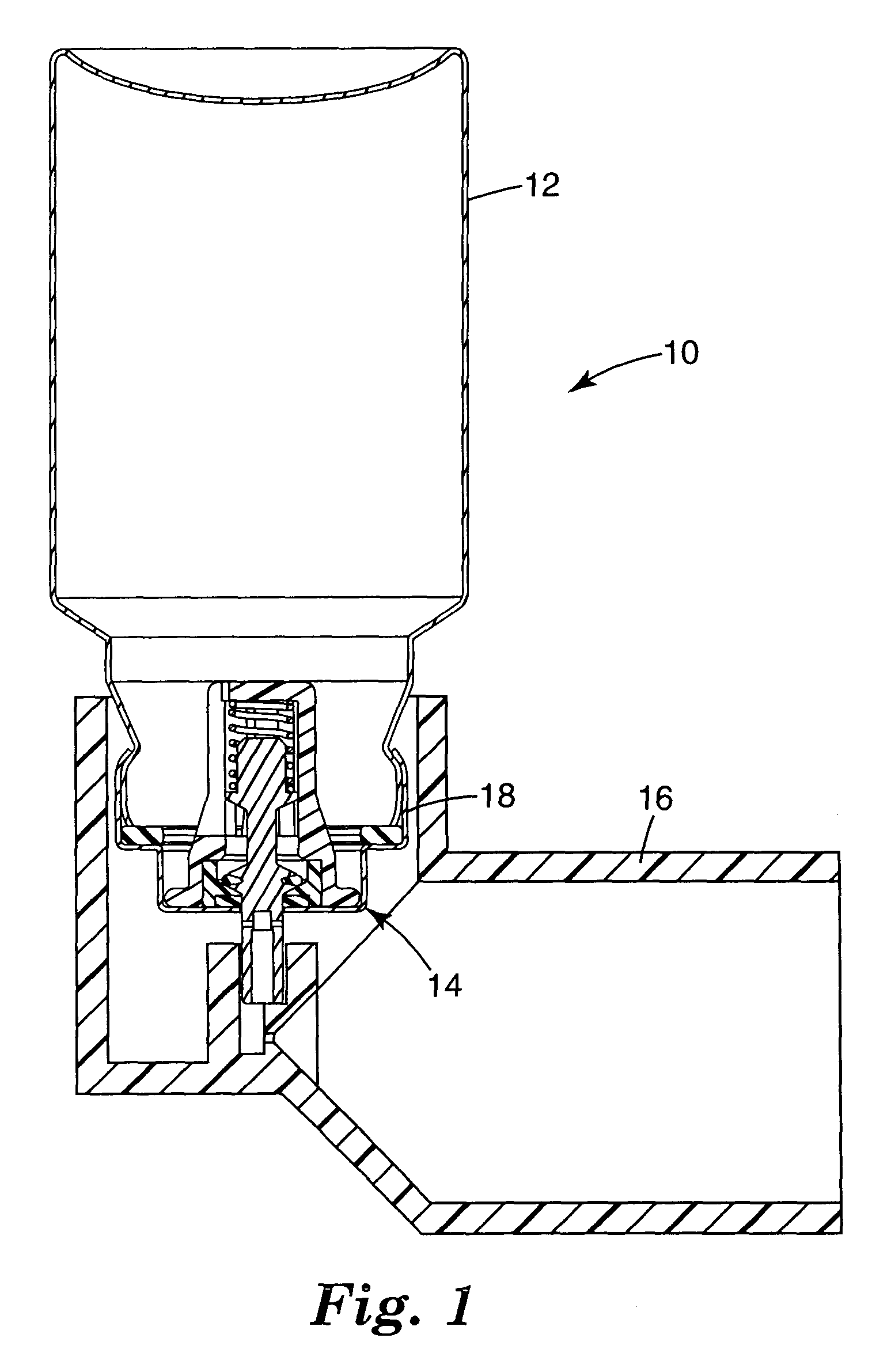

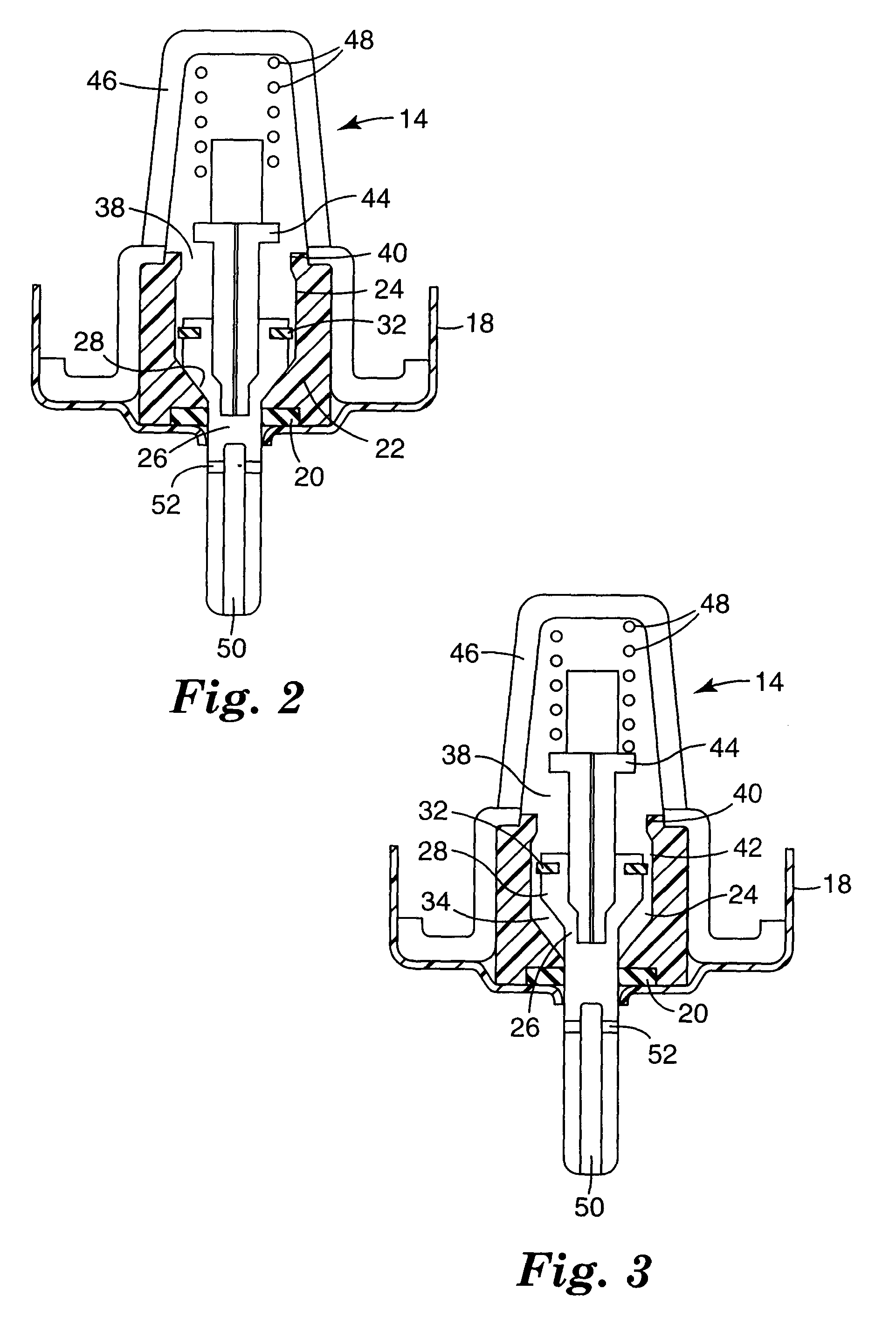

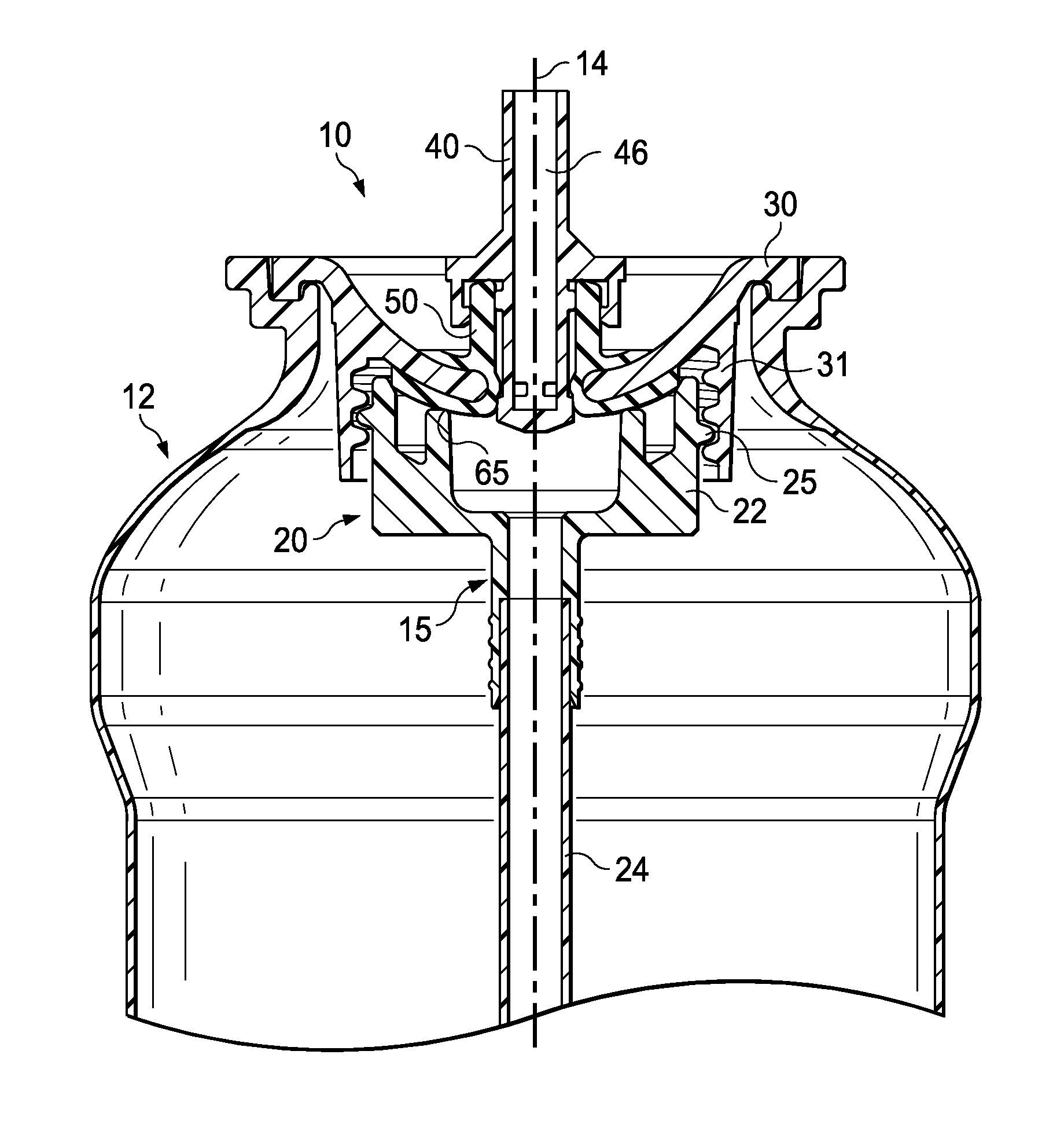

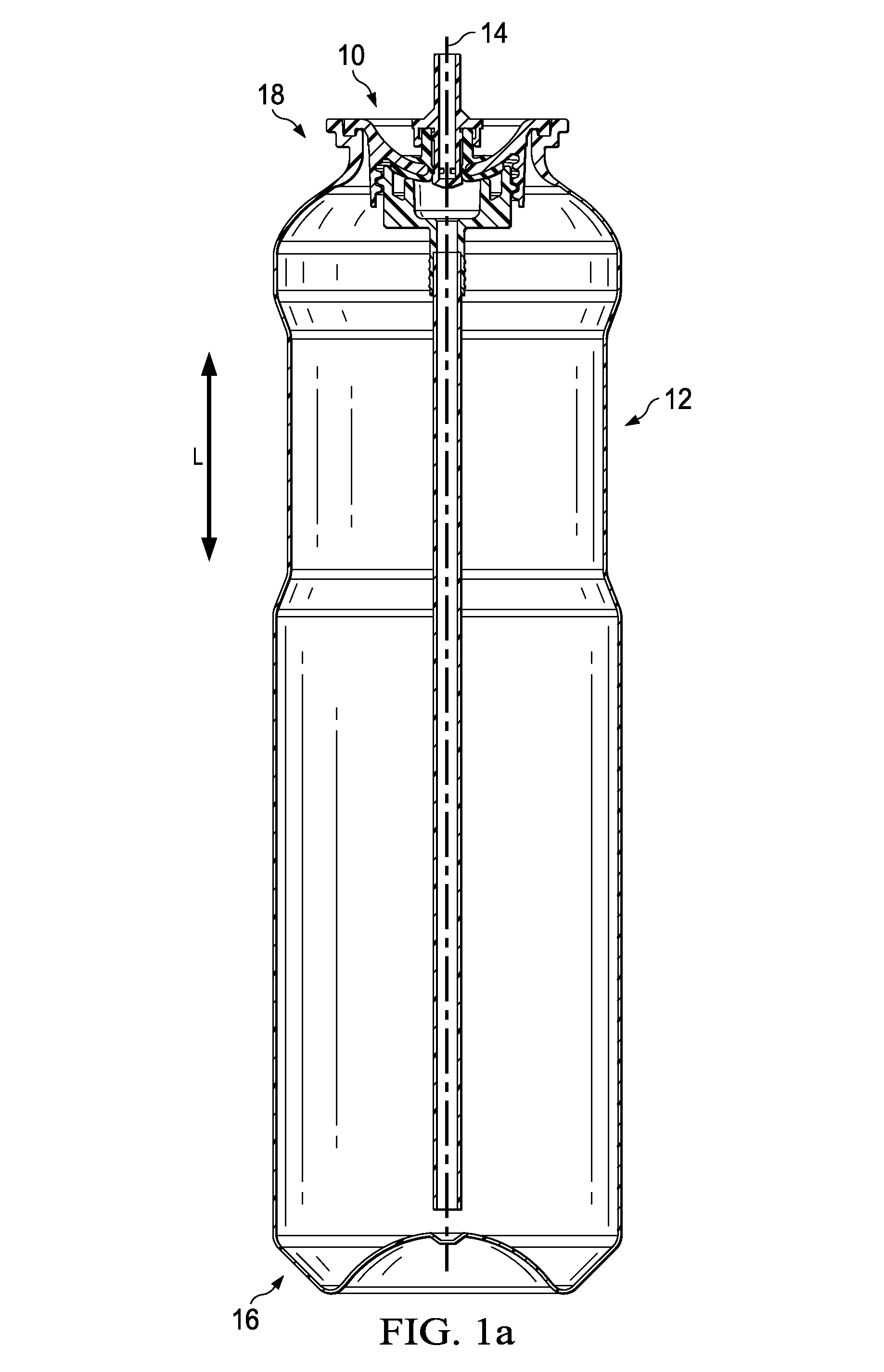

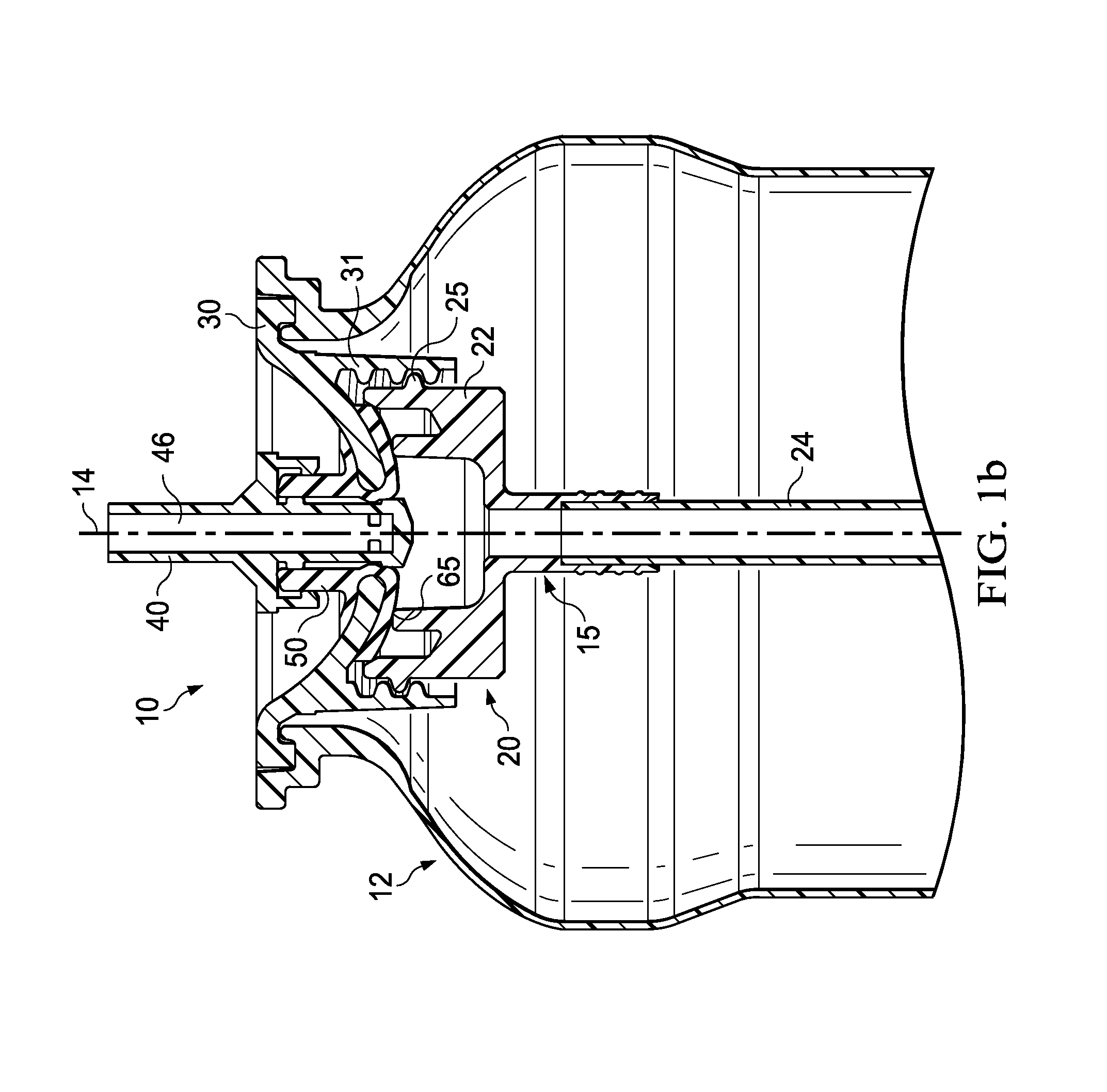

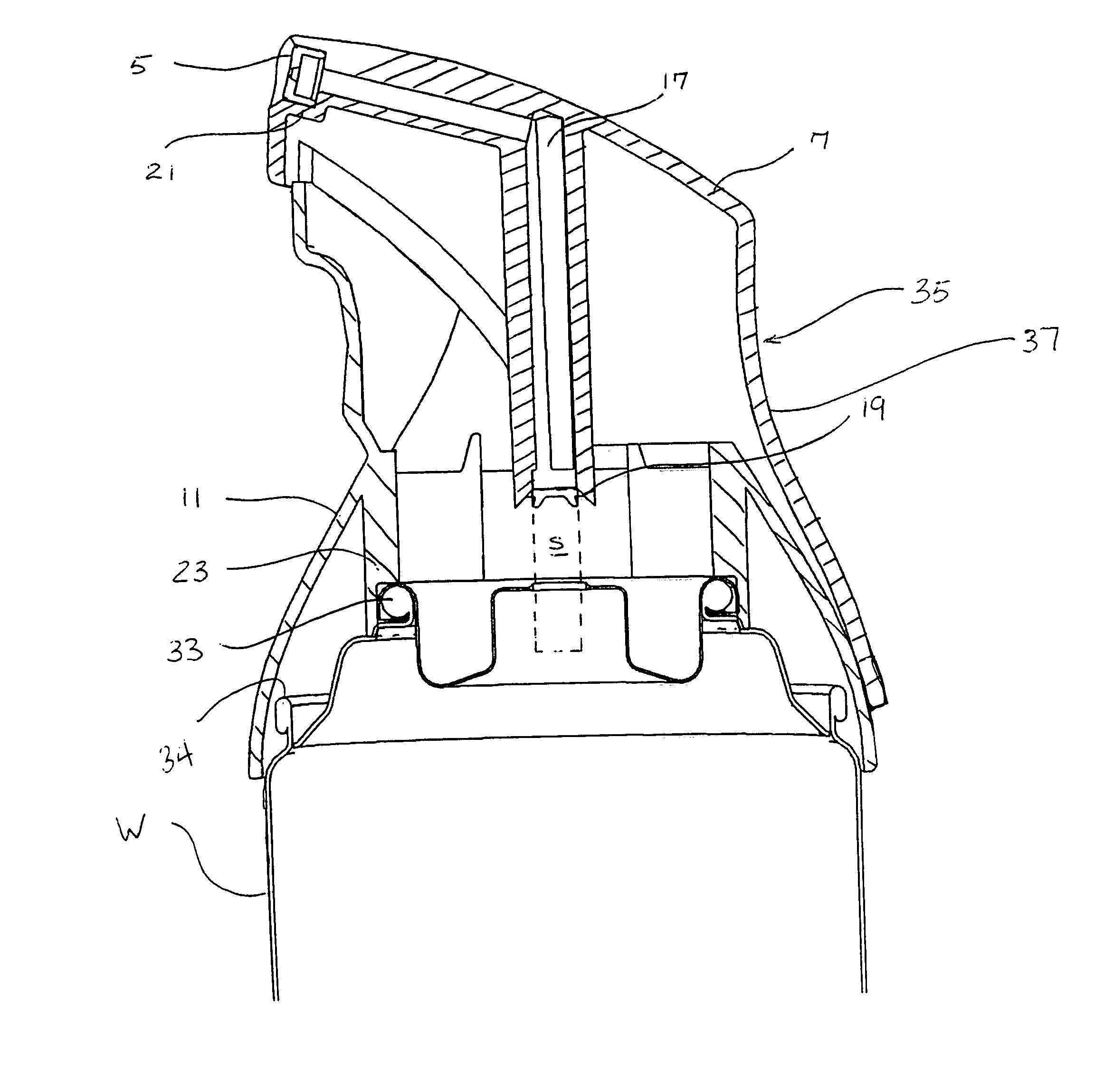

Plastic aerosol valve and method of assembly, mounting and retention

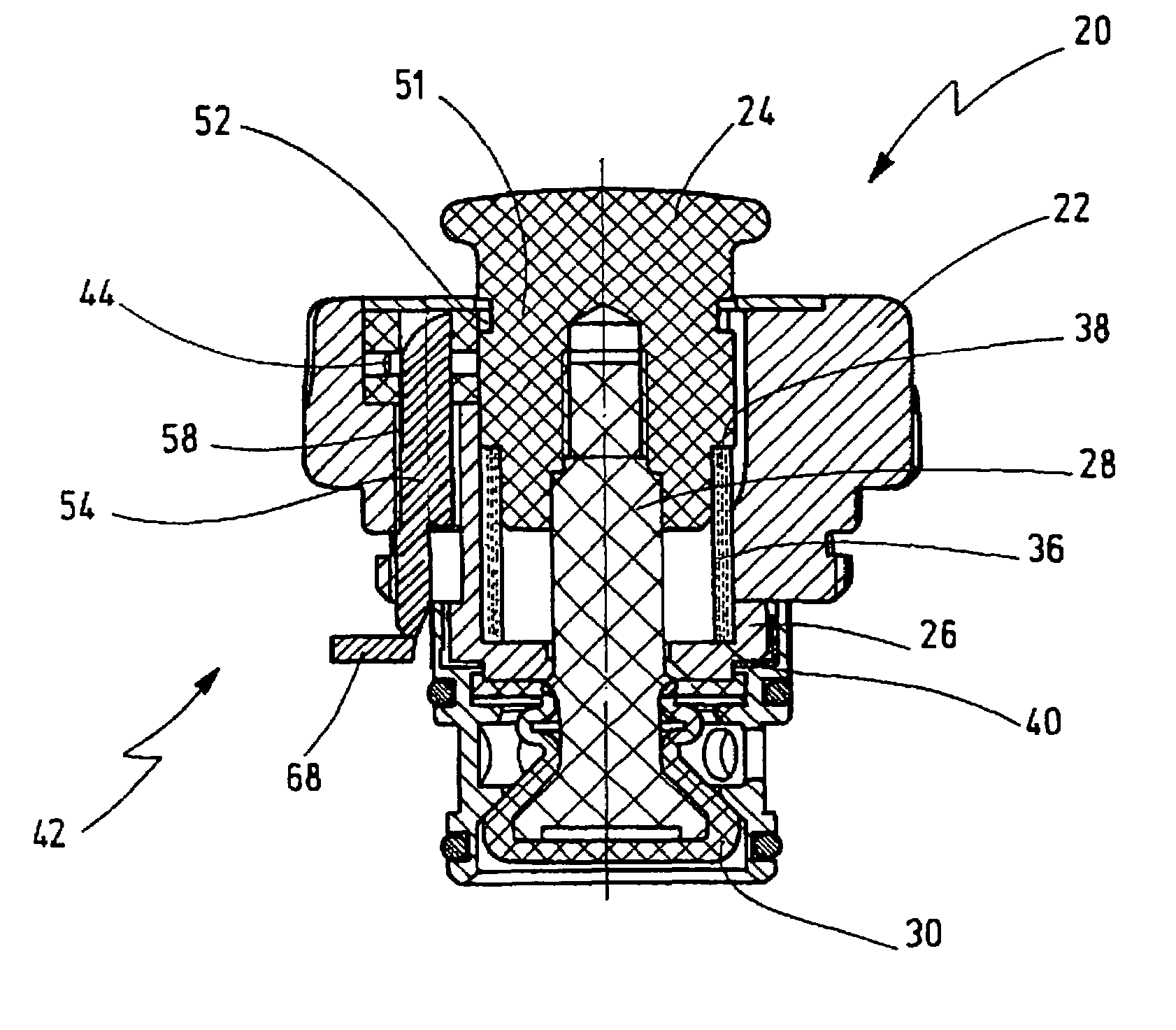

InactiveUS20090014679A1Guaranteed ease of operationShorten speedSingle-unit apparatusLiquid dispensingEngineeringBottle

A plastic aerosol valve with a plastic valve stem, plastic housing, plastic mounting cup, and plastic locking ring. The plastic valve is assembled into the mounting cup. The plastic housing is assembled into the plastic mounting cup by snap fittings. The plastic mounting cup has a peripheral portion that snap fits up into the plastic locking ring. The plastic locking ring has frangibly-connected upper and lower portions. The lower portion snap fits with the top of a plastic product bottle to mount the aerosol valve assembly on the bottle. The upper ring portion thereafter is telescoped downwardly over the lower ring portion to lock and retain the aerosol valve assembly on the pressurized bottle. The plastic mounting cup can be molded separately, or integrally with the plastic locking ring. A check valve may be contained in the valve stem.

Owner:PRECISION VALVE CORP

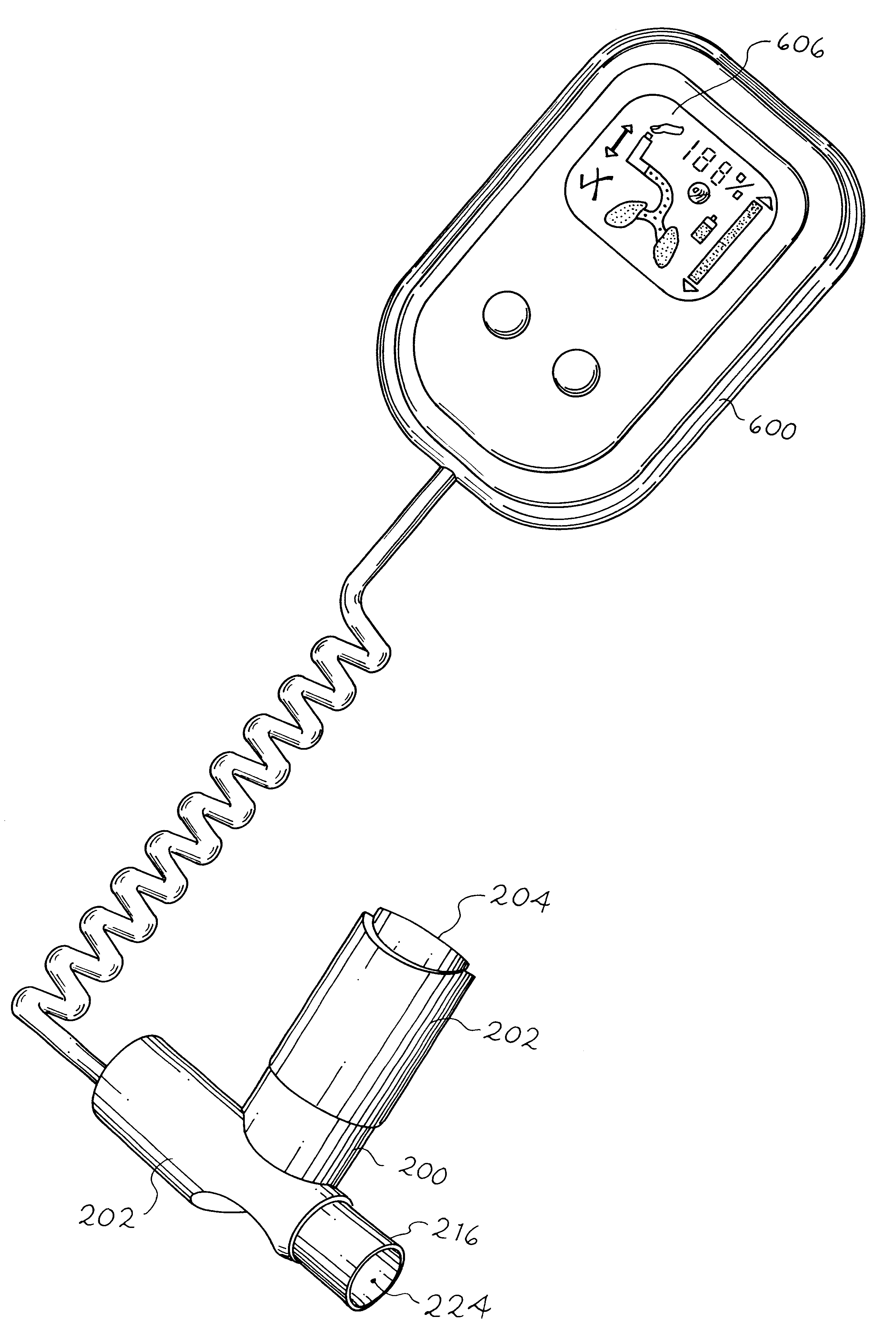

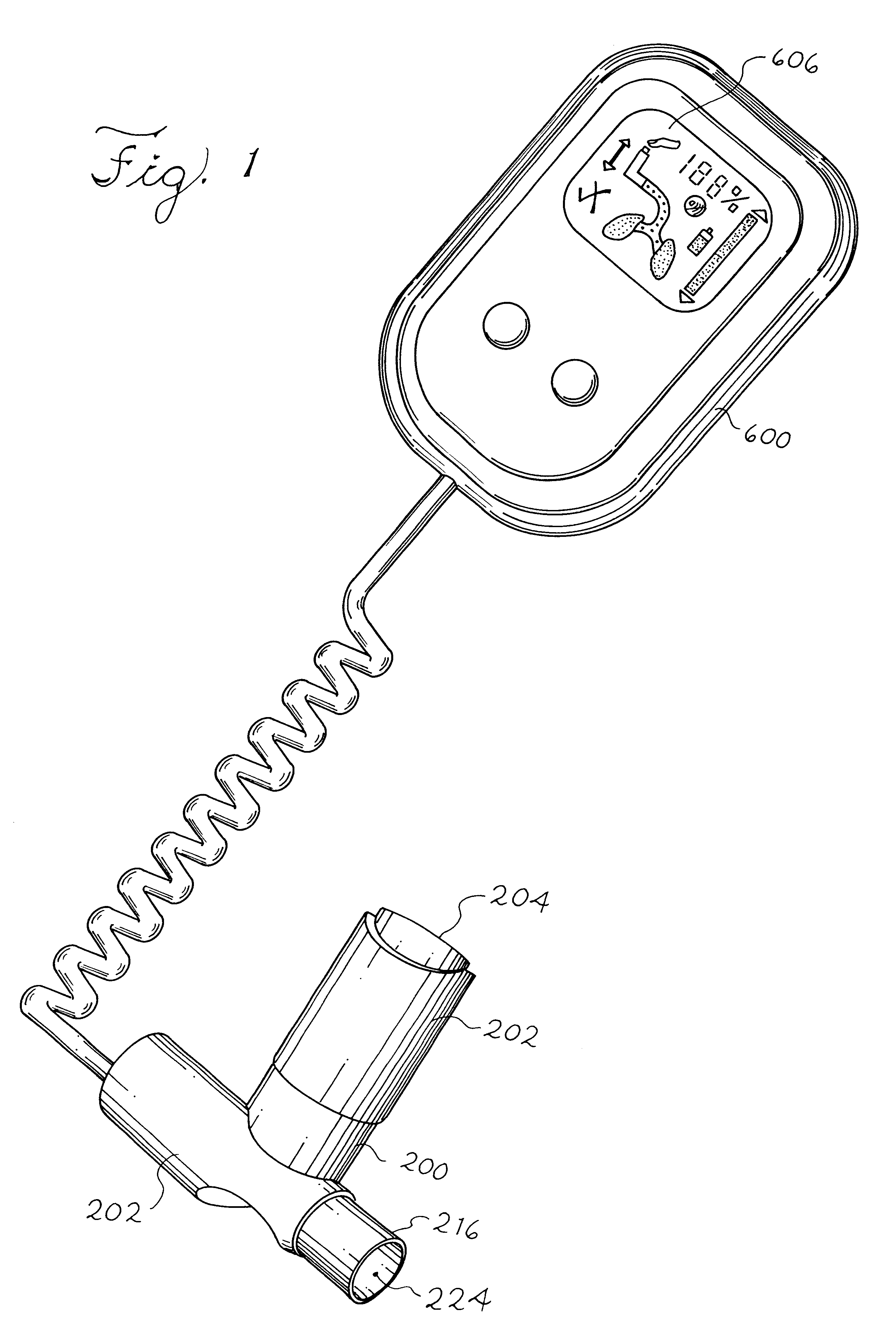

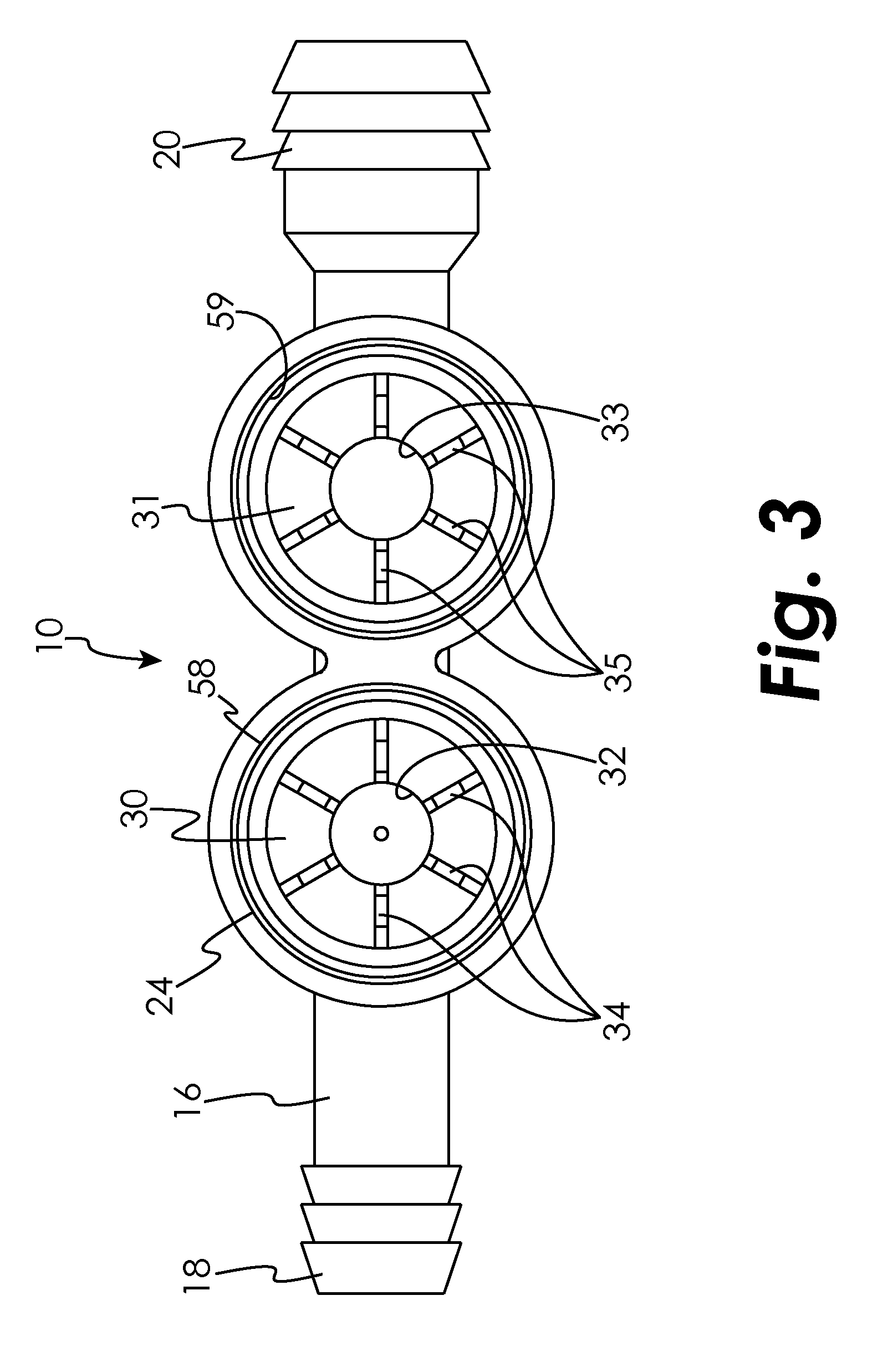

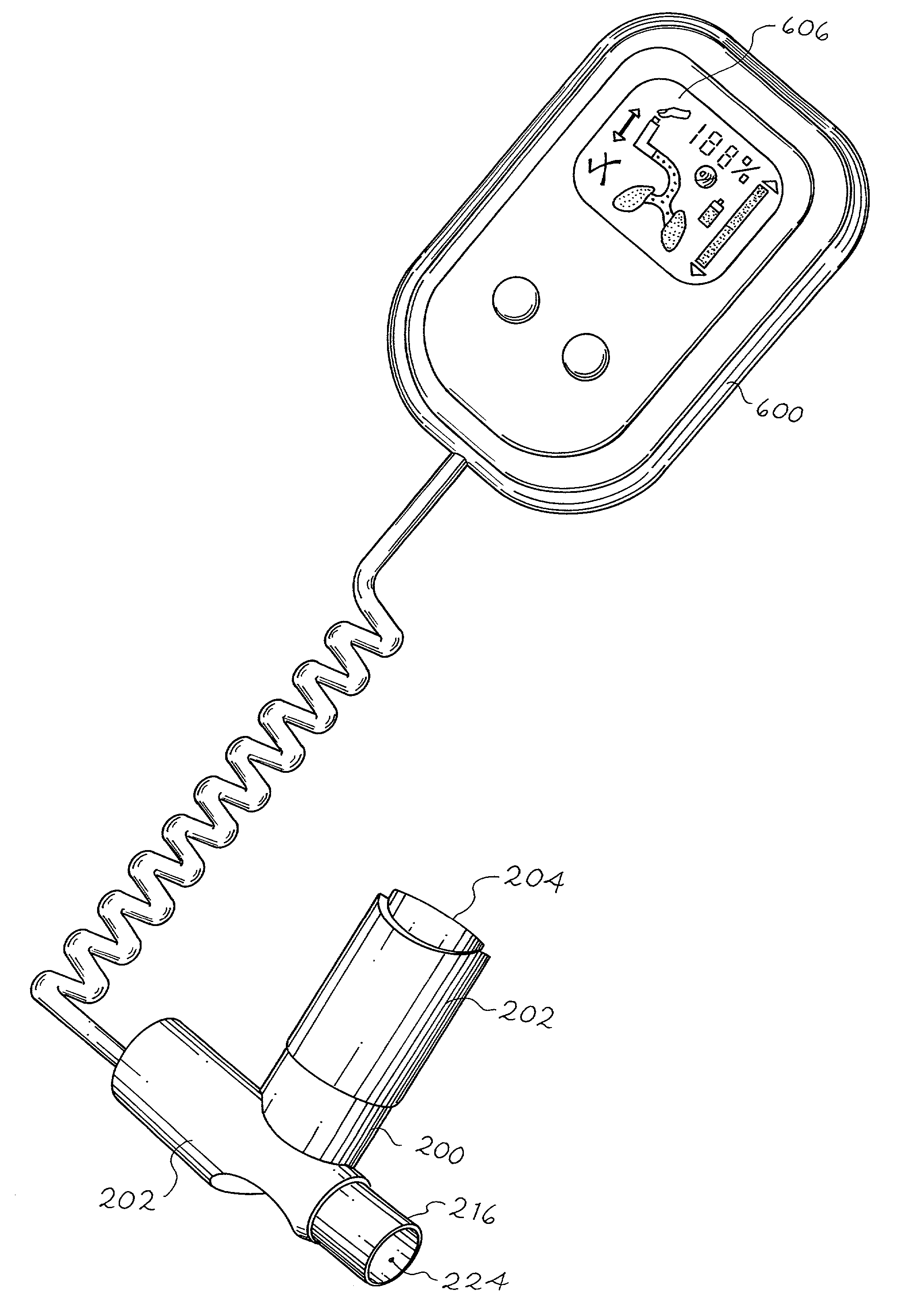

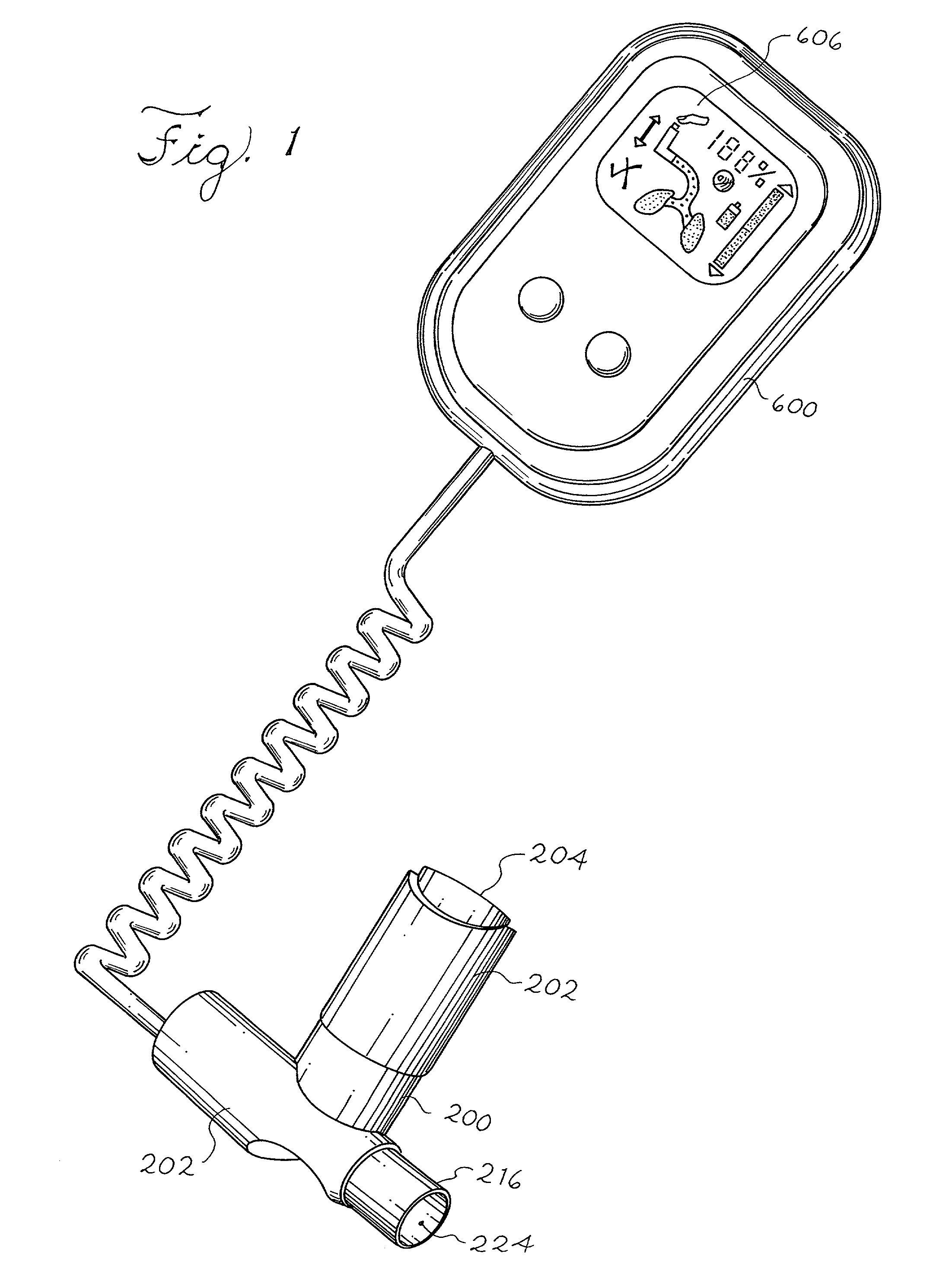

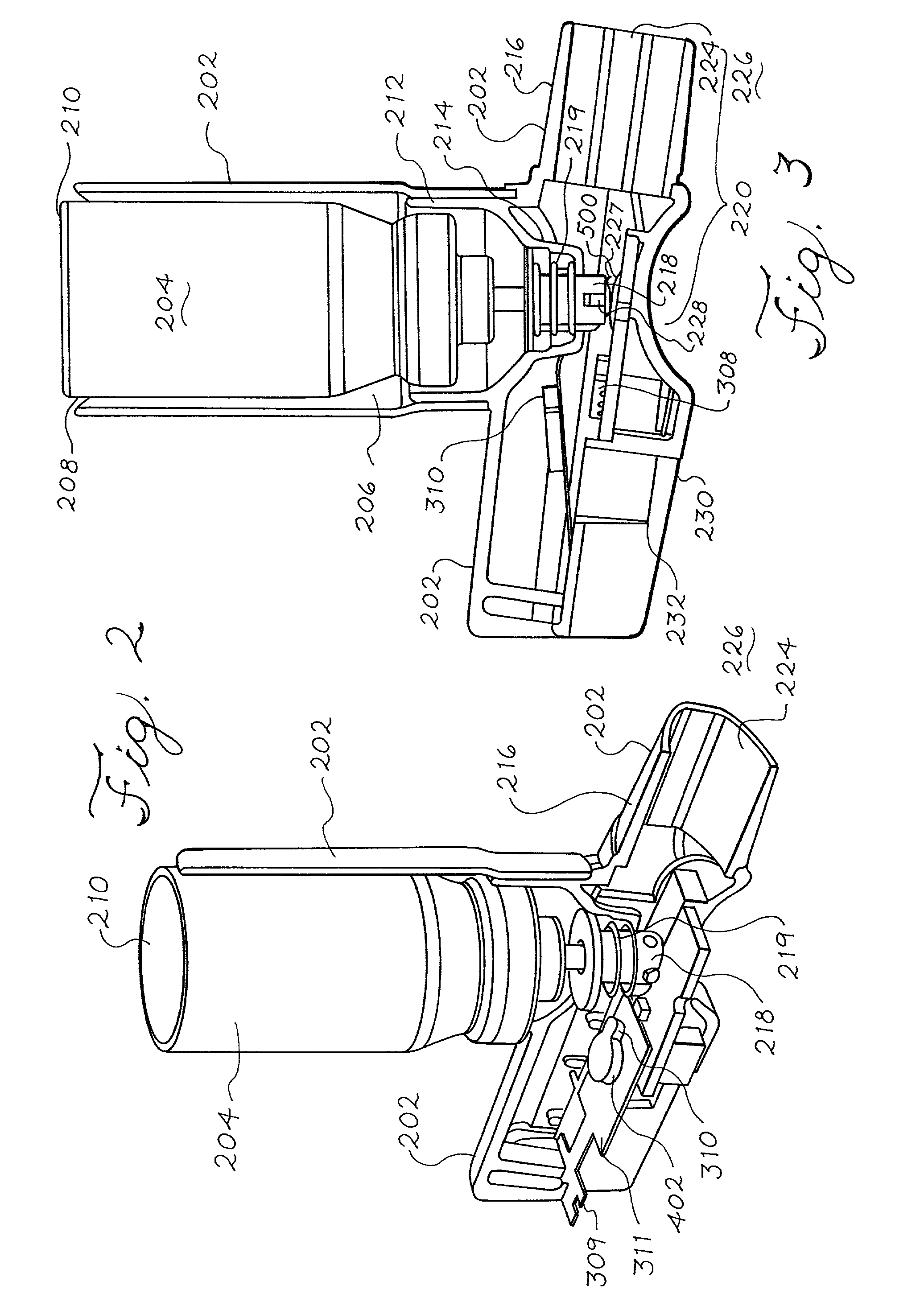

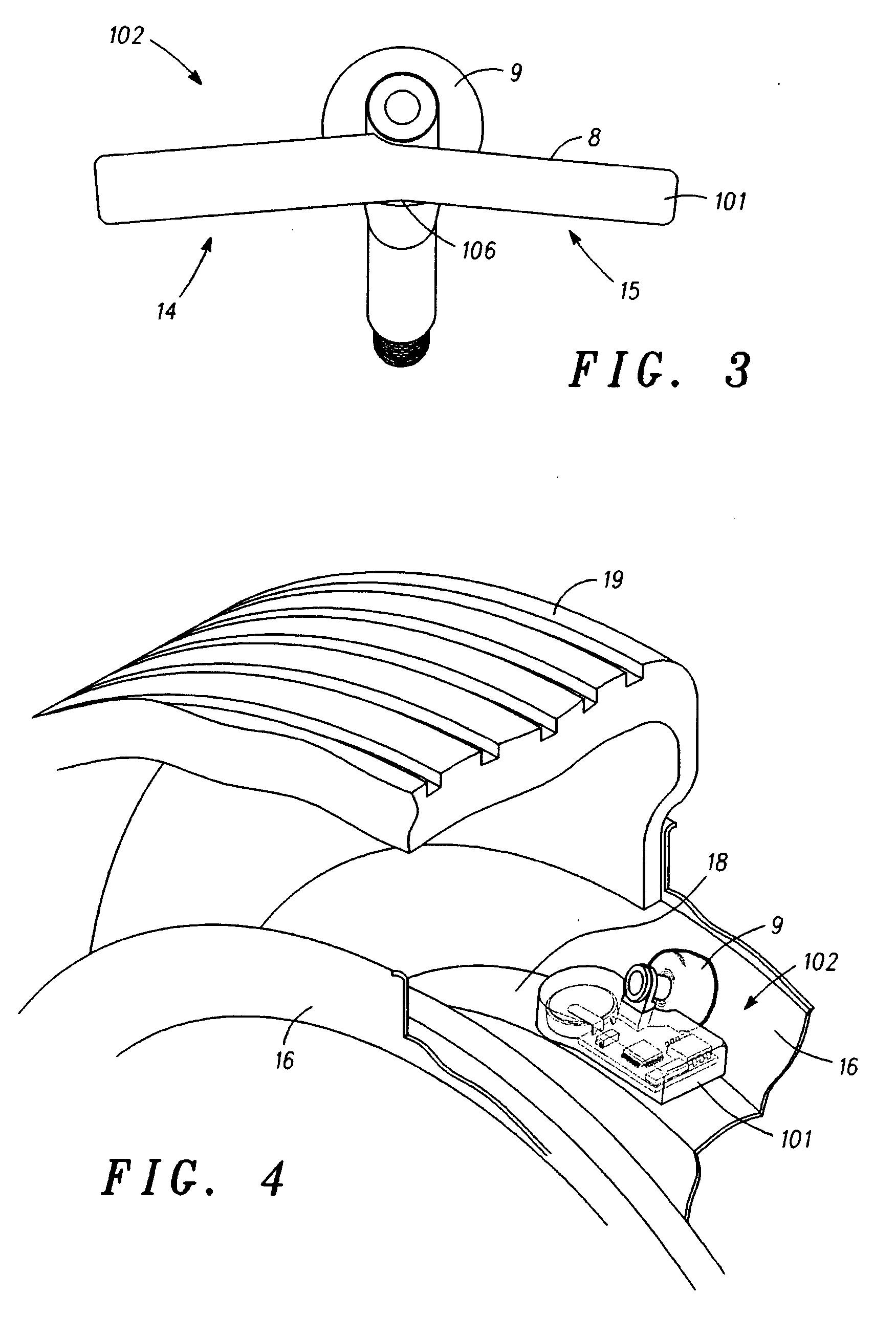

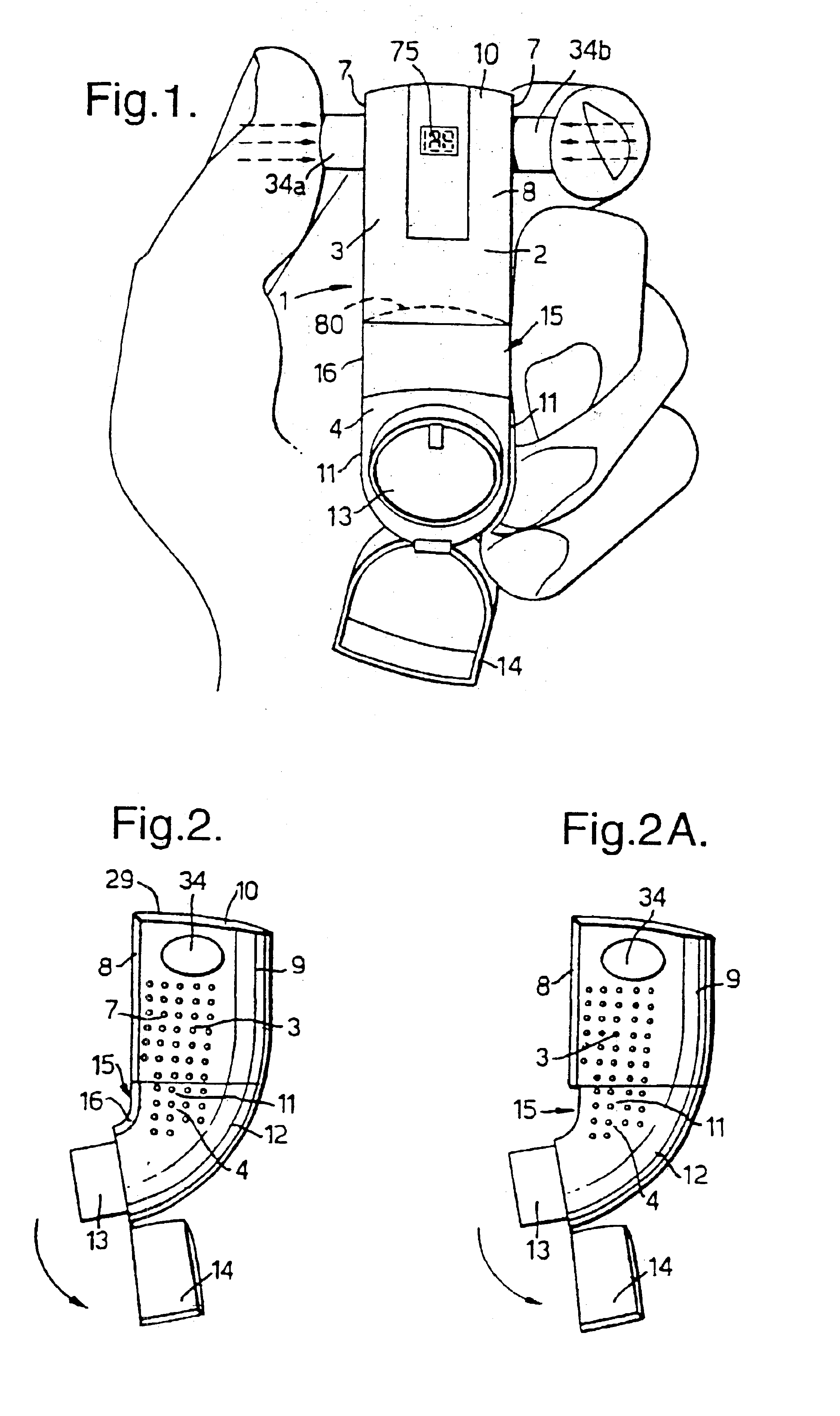

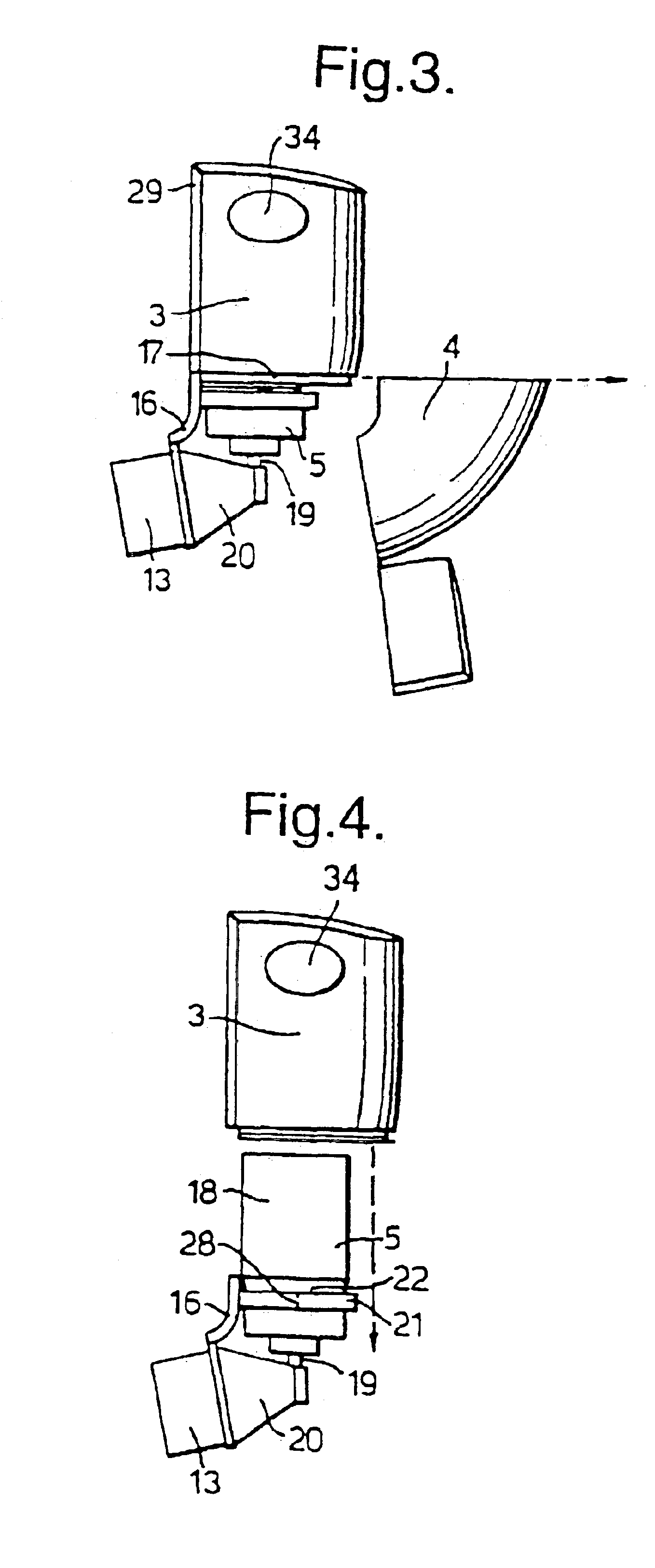

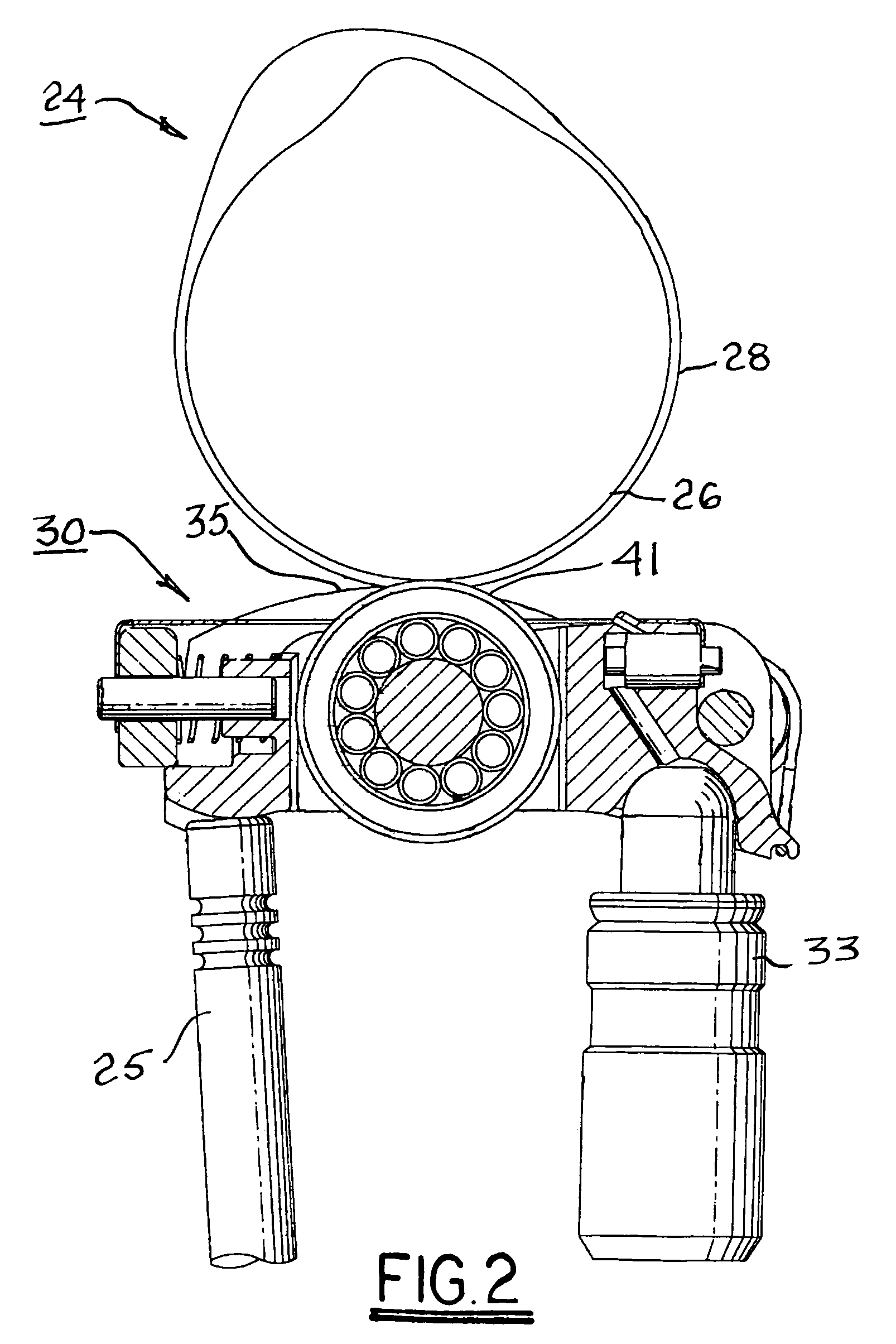

Aerosol dispensing inhaler training device

An aerosol dispensing inhaler training device for determining whether a user is properly operating an aerosol dispensing device. The training device includes an aerosol dispensing device having a container with a valve stem extending longitudinally therefrom and movable between a closed position and an open position. The container dispenses a portion of the contents within the container when the valve stem is moved to the open position. The aerosol dispensing device includes a housing adapted to support the container reciprocally moveable within the housing along a longitudinal axis from a first position, the housing comprising a well adapted to receive the valve stem and an exhaust port comprising one end in fluid communication with the well and a second end in fluid communication with the ambient atmosphere, wherein the portion of the contents within the container is dispensed from the first end of the exhaust port to the second end of the exhaust port when the housing moves to an actuation position where the valve stem is actuated so that a portion of the contents within the container is dispensed through the second end of the exhaust port when the valve stem is moved to the open position. An actuation sensor generates a signal that indicates when the housing is moved to the actuation position and the valve stem is actuated. A shake sensor determines whether the contents within the container have been properly agitated for consumption by a user.

Owner:1263152 ONTARIO

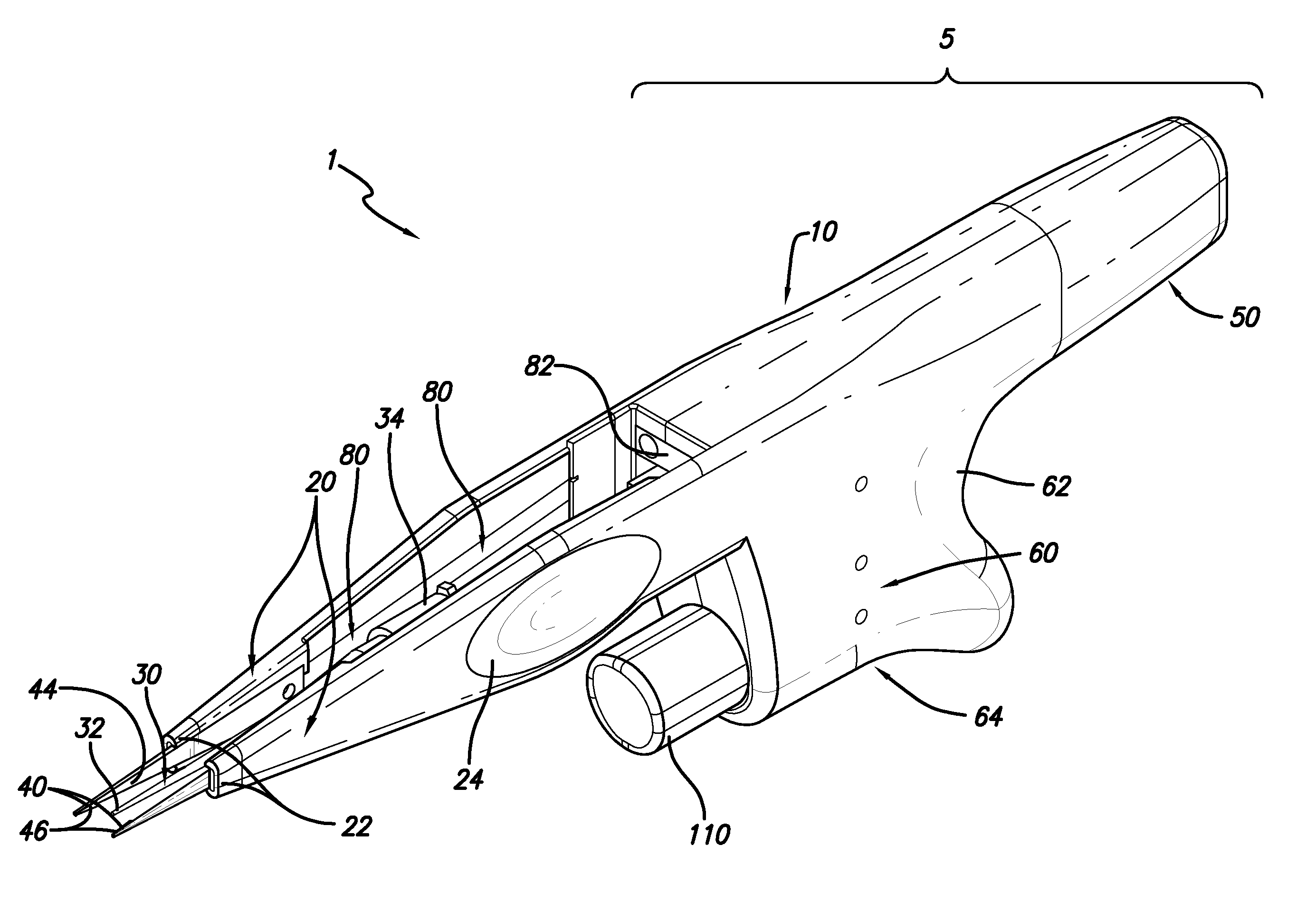

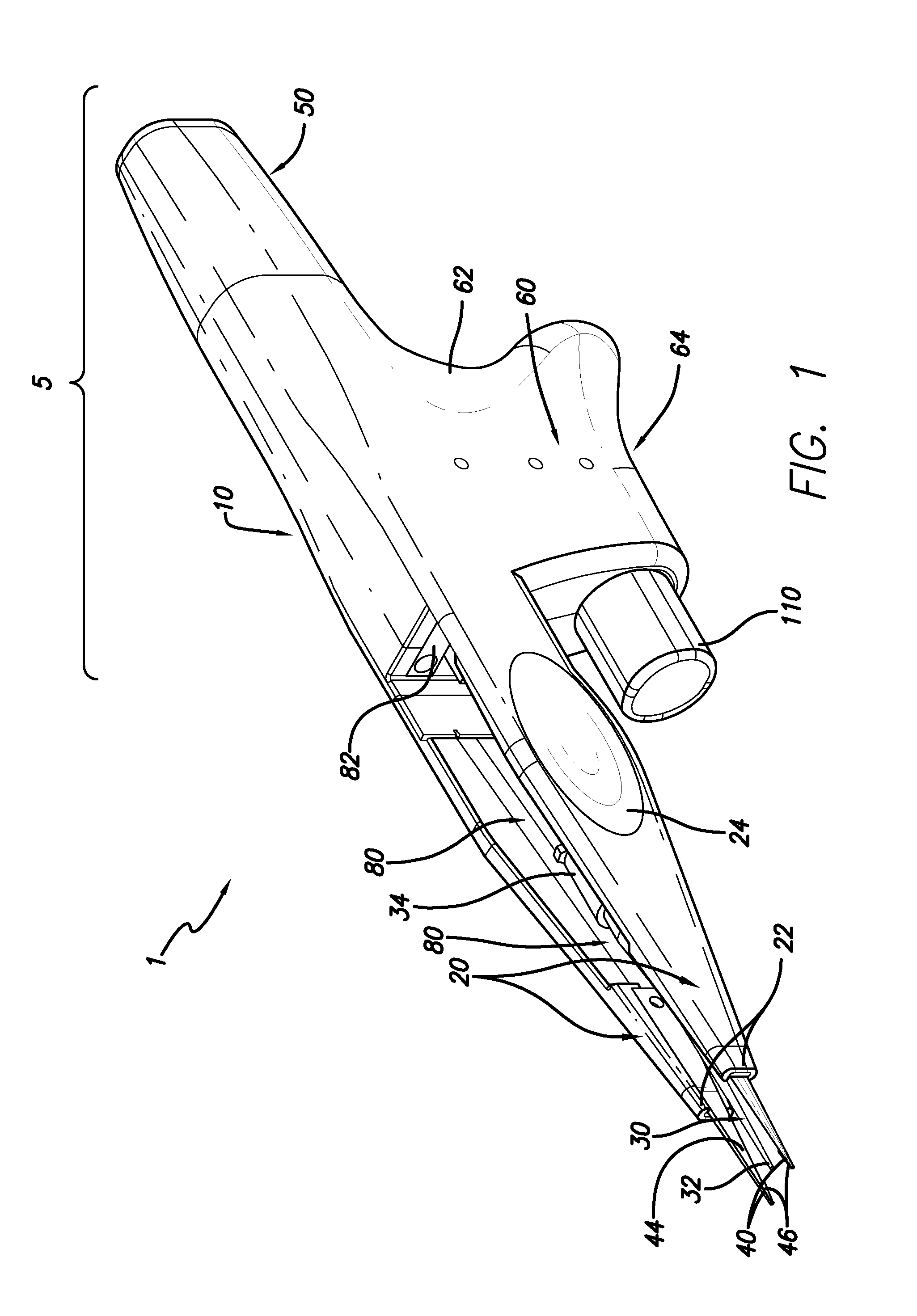

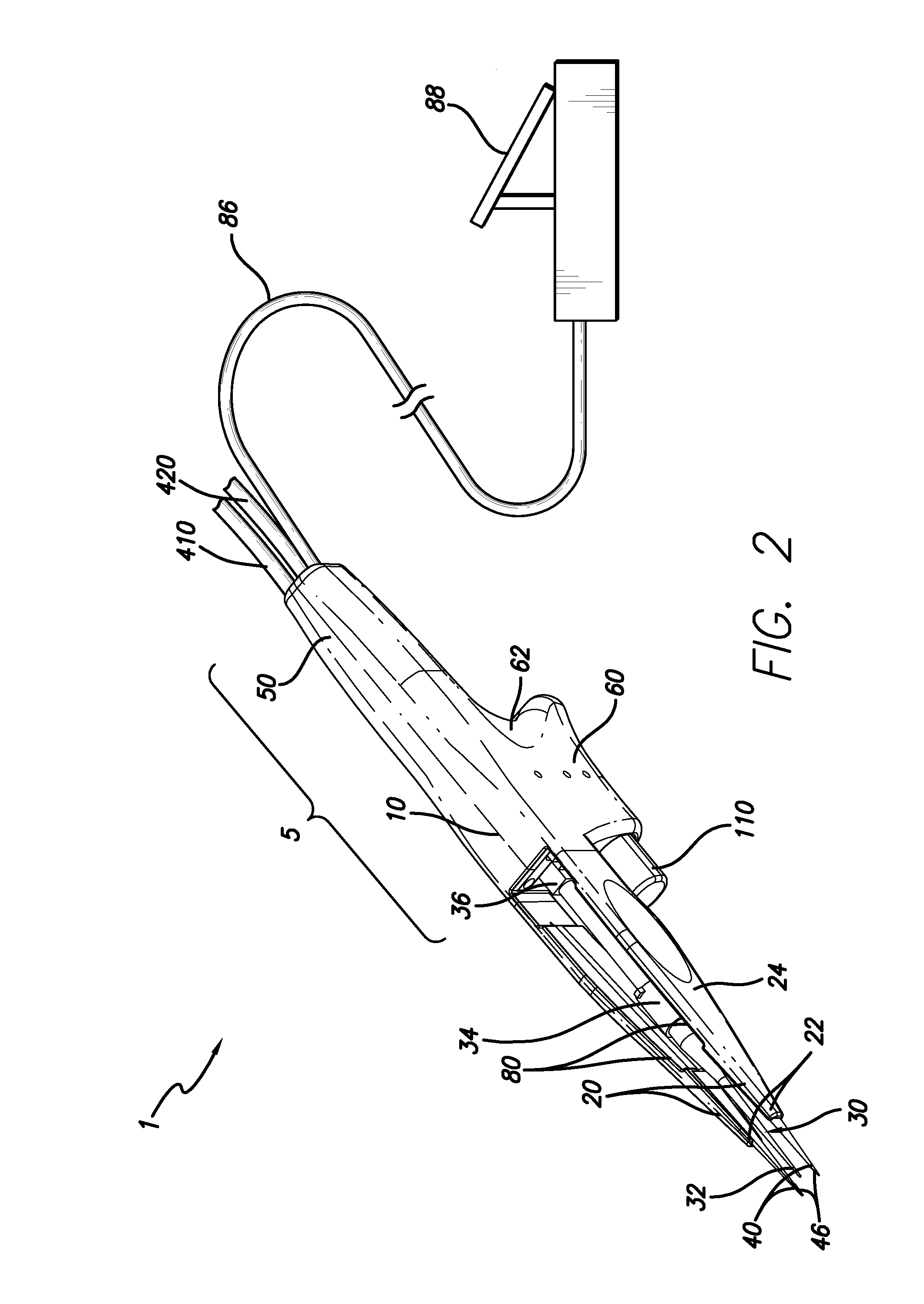

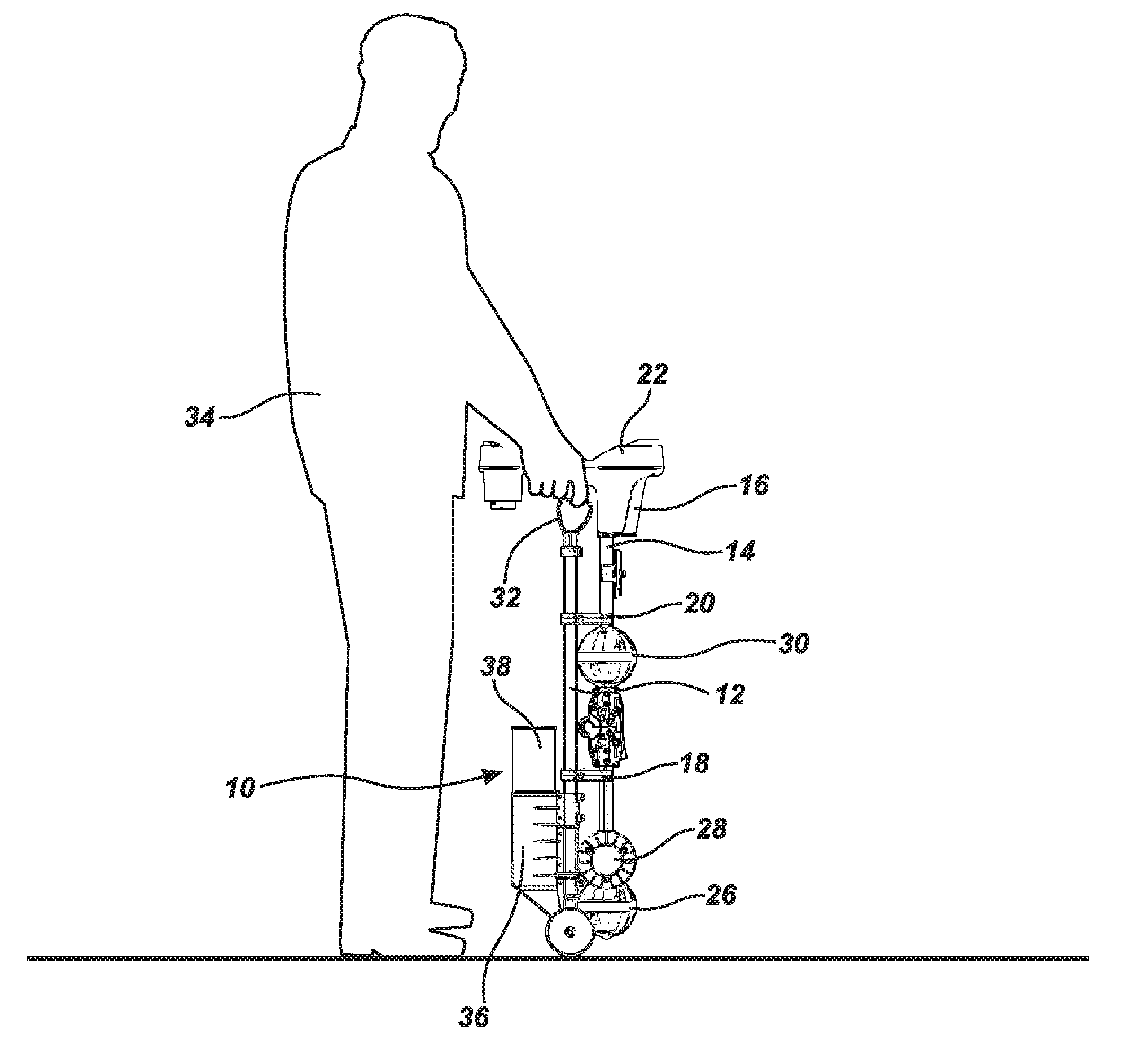

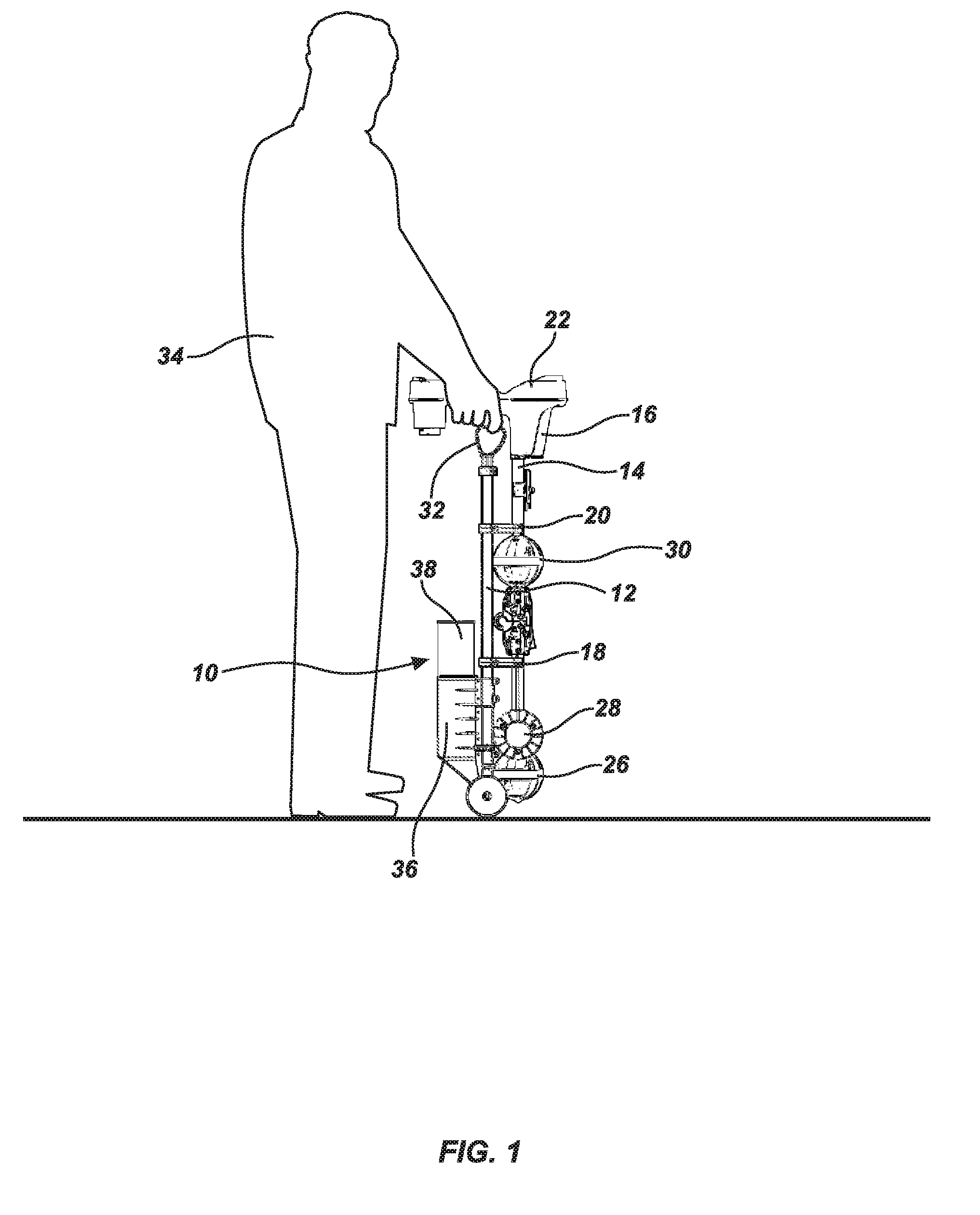

Marking Paint Applicator for Portable Locator

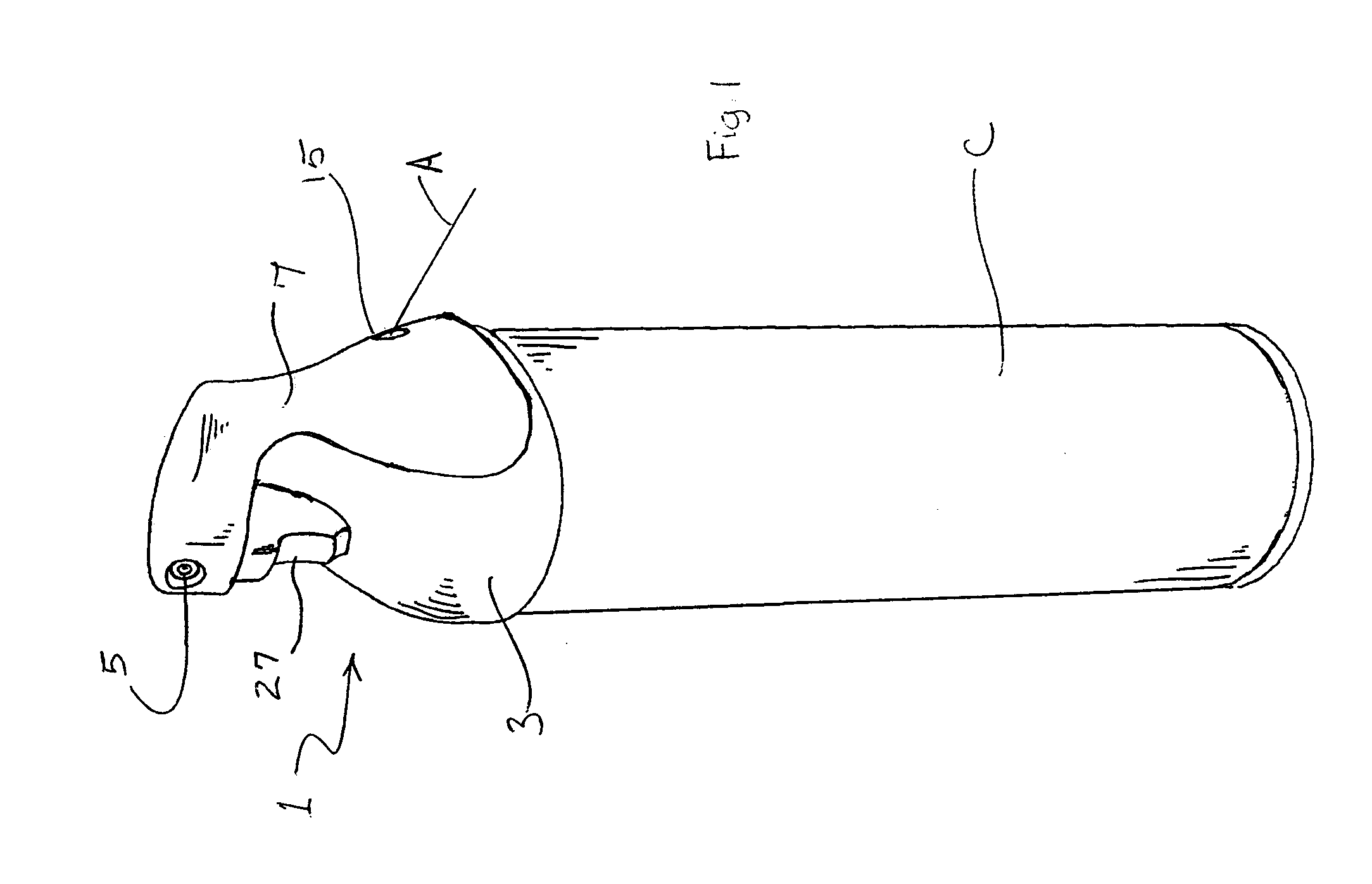

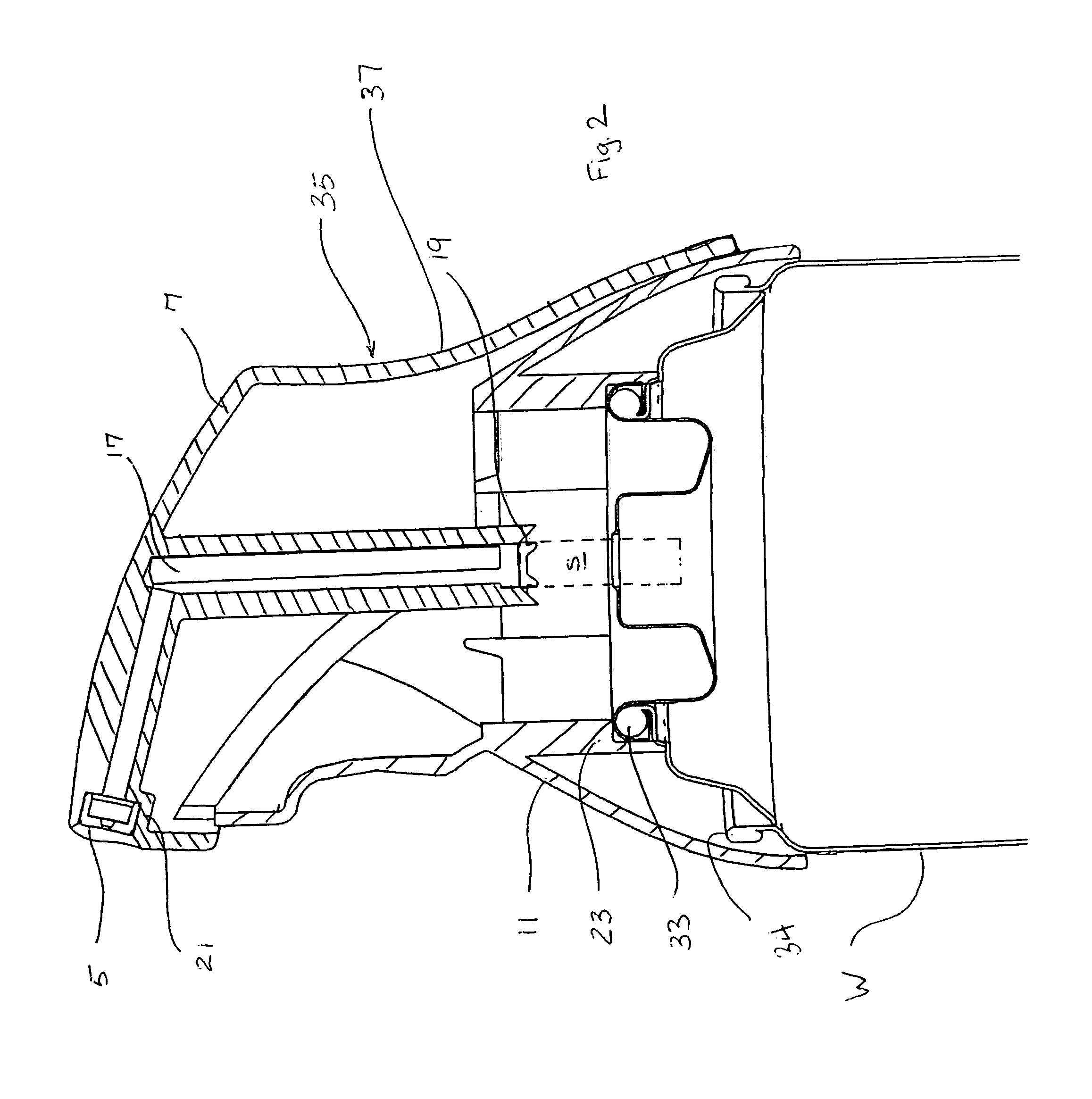

A marking paint applicator for a portable electronic locator that locates buried cables and pipes via electromagnetic emissions includes an elongated support structure and a manually moveable trigger mechanism mounted adjacent an upper end of the support structure. At least one bracket assembly is provided for removably connecting the support structure to an antenna mast of the portable locator so that the trigger mechanism will be adjacent a handle of the locator and the trigger mechanism can be squeezed by a finger of an operator's hand while grasping the handle. A receptacle is mounted to the support structure for carrying an inverted aerosol paint can and positioning a valve stem of the aerosol paint can for spraying paint onto the ground to mark the location of a buried cable or pipe. An actuating mechanism is capable of selectively deflecting the valve stem to cause the aerosol paint can to spray paint onto the ground to mark the location of a buried cable or pipe. A linkage connects the trigger mechanism to the actuating mechanism for deflecting the valve stem when the trigger mechanism is squeezed.

Owner:SEEKTECH A CALIFORNIA CORP

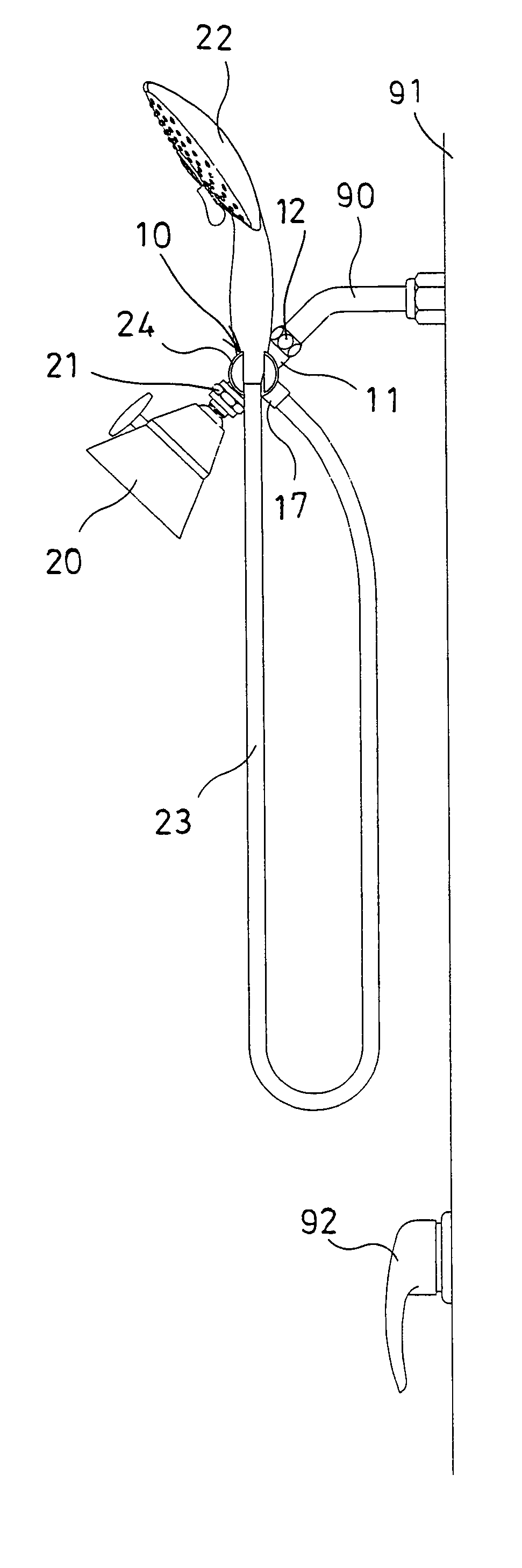

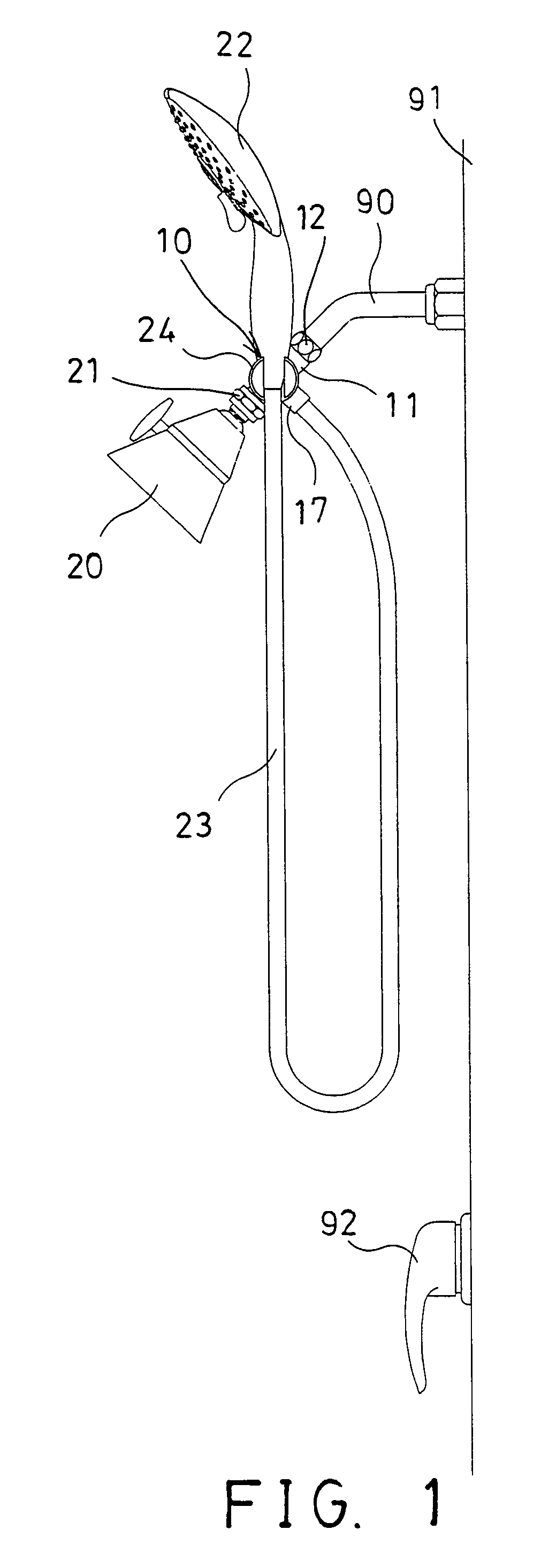

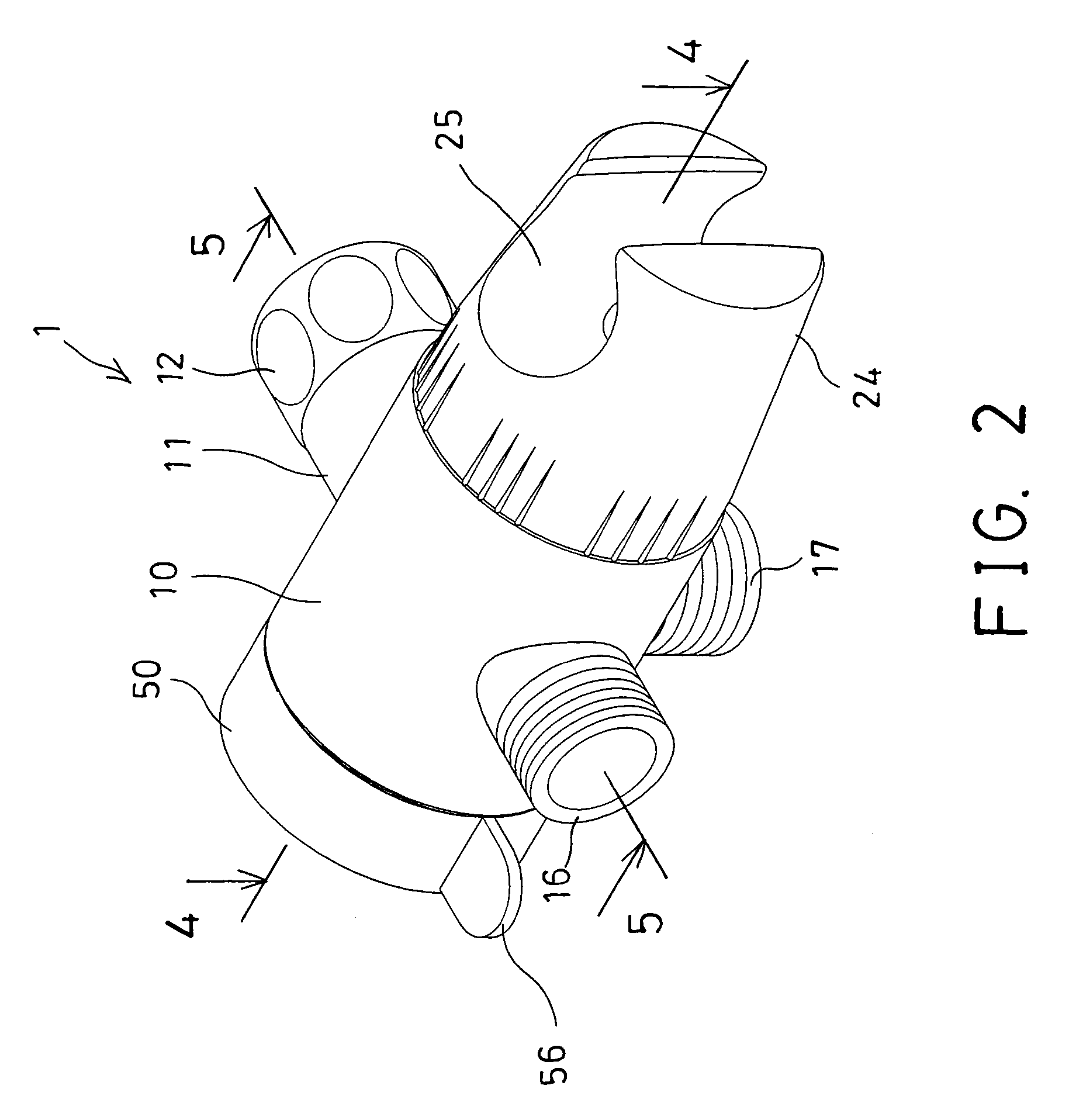

Holder device for shower head and nozzle

Owner:INTERLINK PROD INT INC

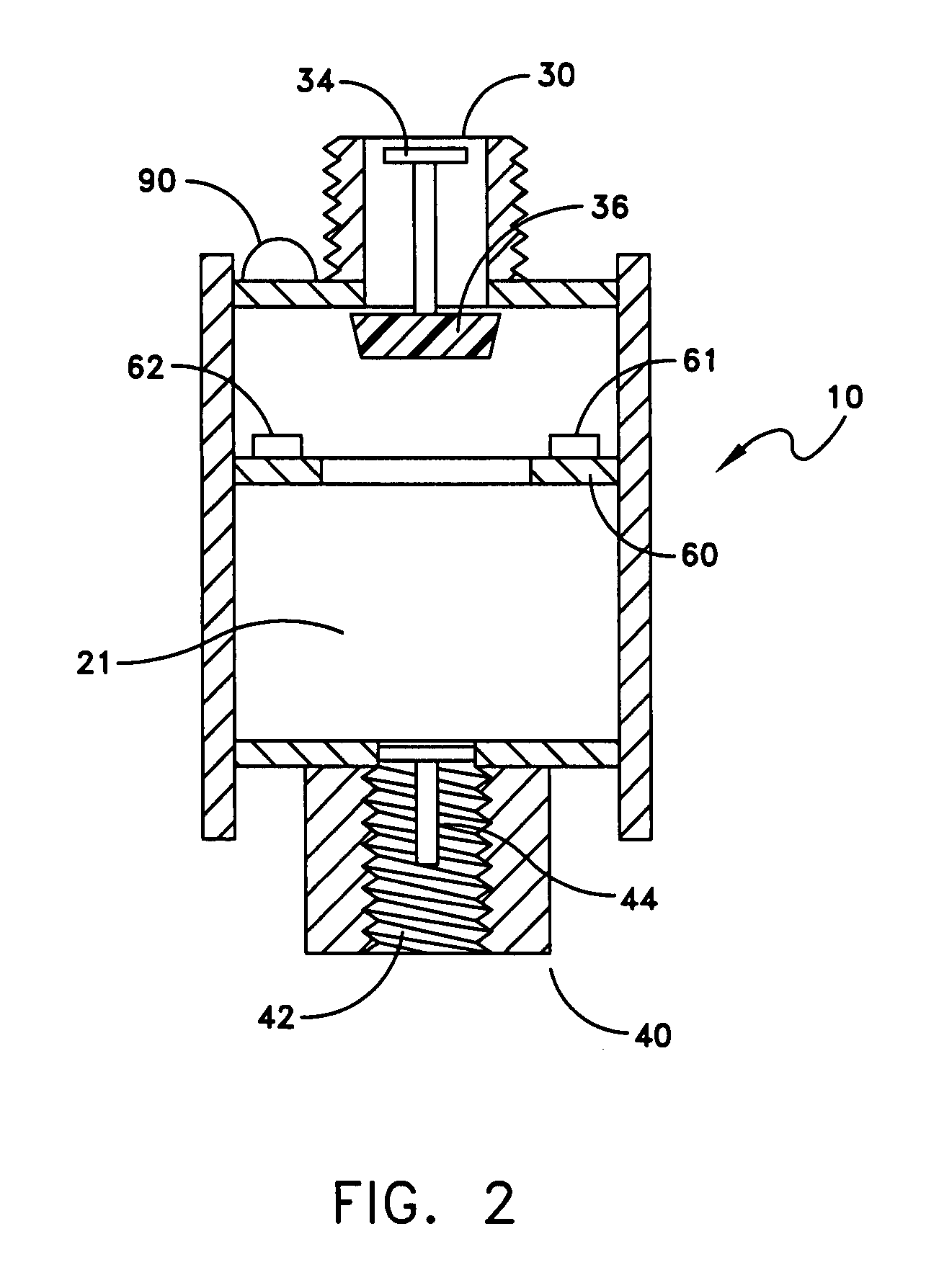

Check valve

InactiveUS20110186151A1Maximum vacuum boostIncrease airflowCheck valvesEqualizing valvesEngineeringInternal combustion engine

A check valve which is positioned in the vacuum air line of an internal combustion engine. The check valve includes a single-piece valve body having an outlet port and two or more inlet ports, with one outlet port located substantially in line with the inlet port and connected by a venturi tube. The second inlet port is separated from the main air flow line by the valve stem and a diaphragm which allows communication there between and prevents back pressure. The second inlet port communicates with the outlet port through the valve stem and a second venturi tube which provides a vacuum boost to a device, usually vehicle brakes, connected to the inlet. The use of seal diaphragms having a non-constant radius allows for faster recovery time for replenishment than prior art devices.

Owner:TECHNIPLAS US LLC

Inverted aerosol dispenser

An inverted aerosol dispensing device is disclosed having an undercap rotatably secured to the aerosol container with a bottom portion of the undercap supporting the aerosol container on a supporting surface to store the aerosol dispensing device in an inverted position. The undercap is rotatable into a first rotational position for enabling an actuator to discharge an aerosol product in a generally downwardly direction. The undercap is rotatable into a second rotational position for inhibiting the actuator from moving the valve stem.

Owner:SEAQUIST PERFECT DISPENSING FOREIGN INC

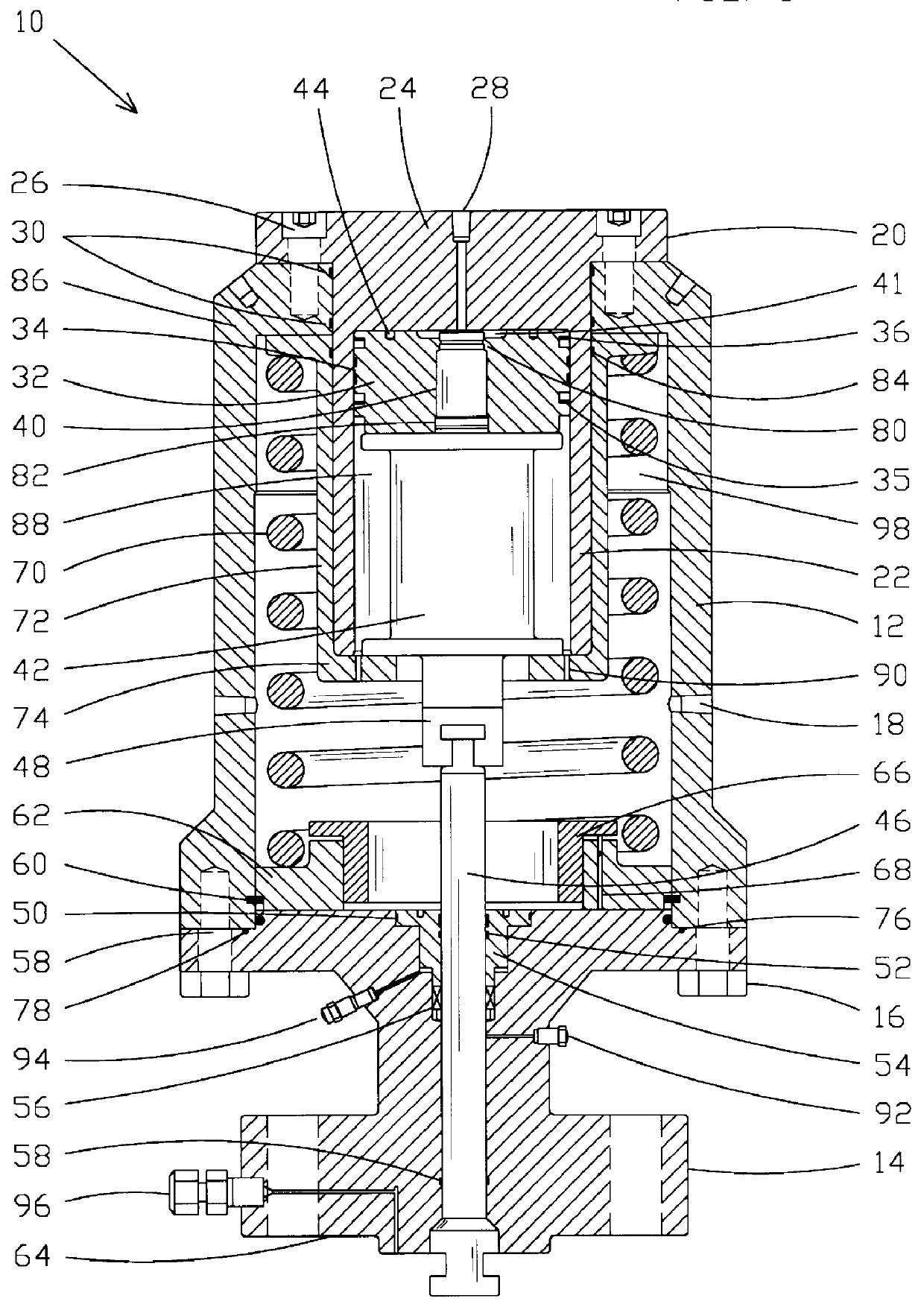

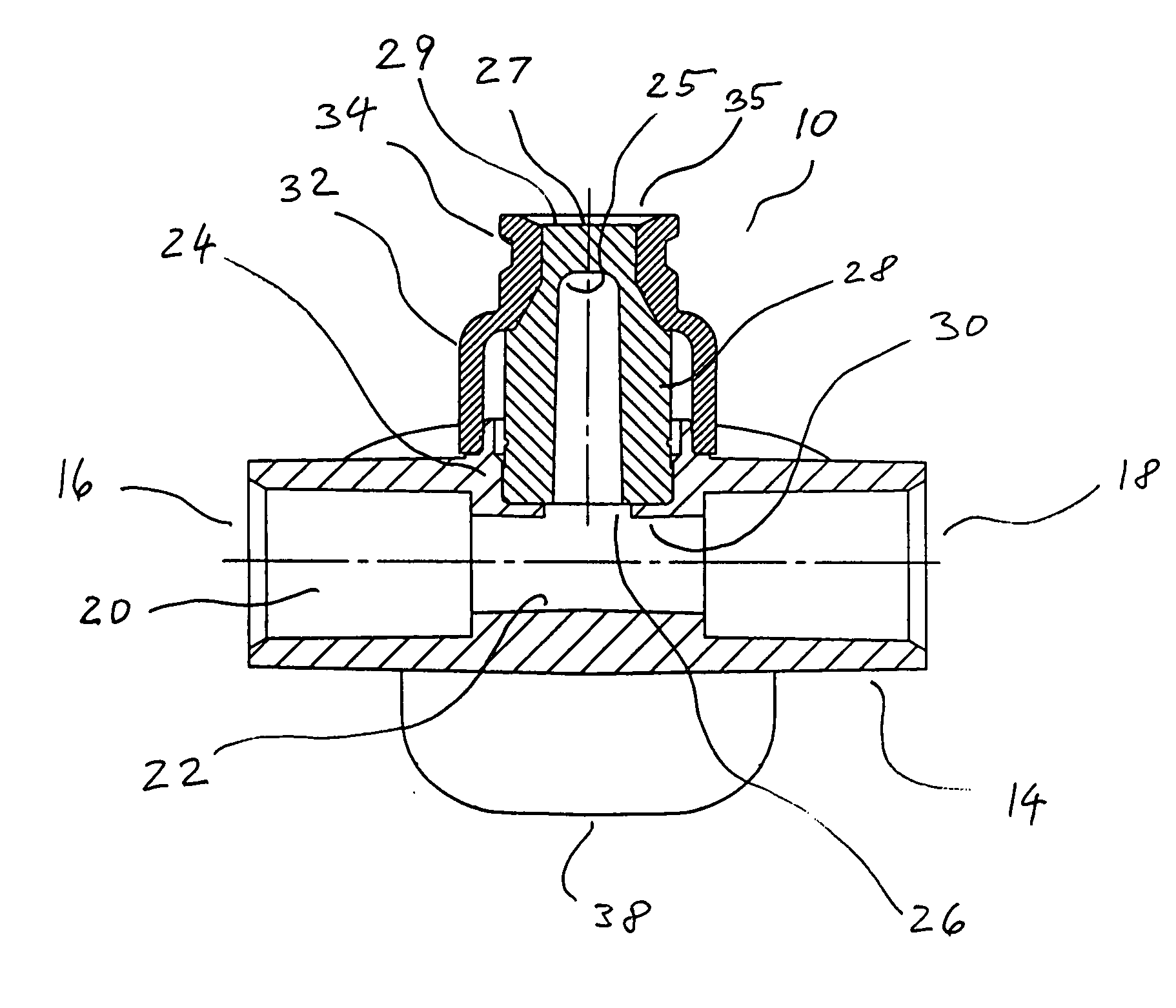

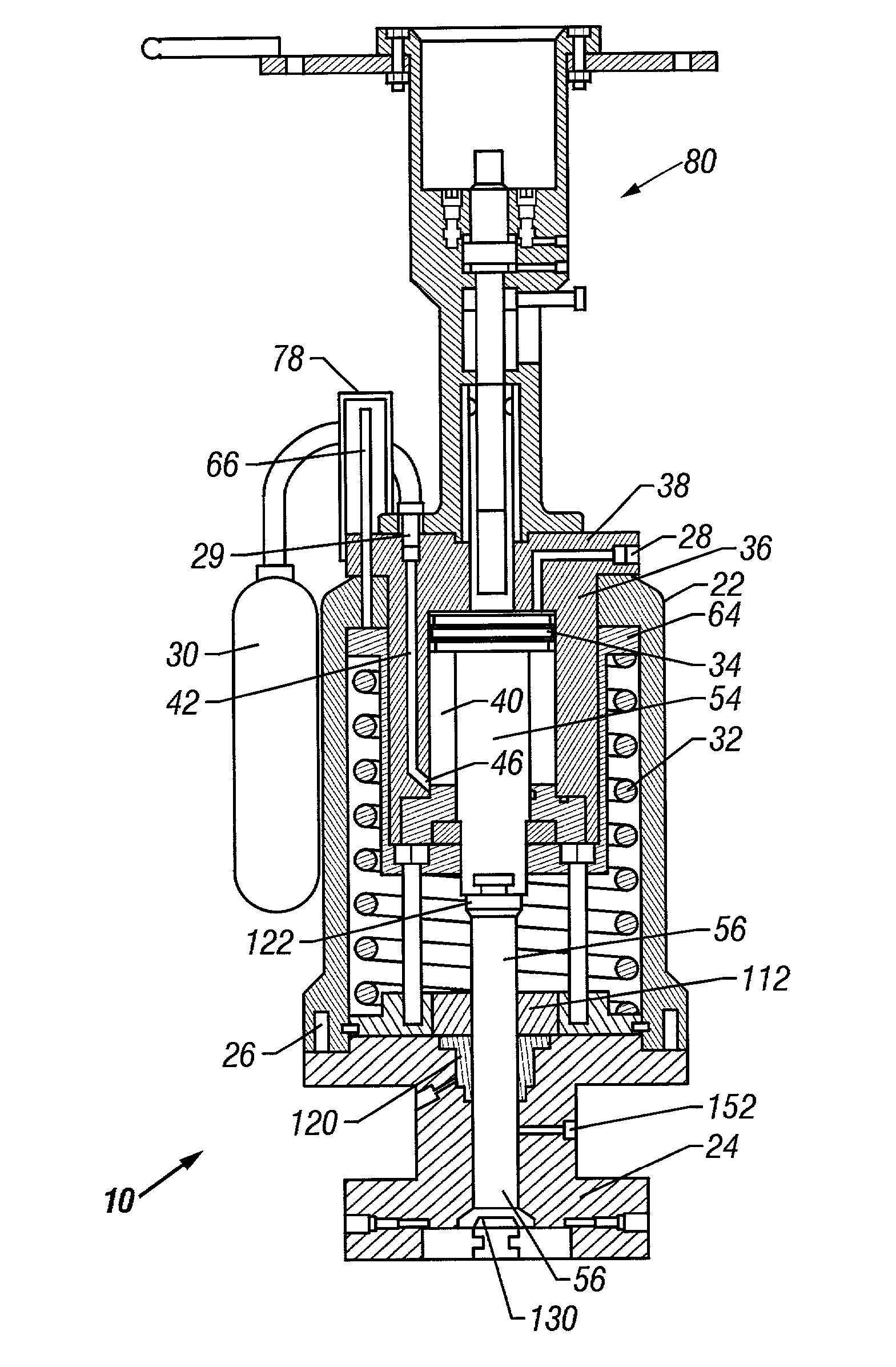

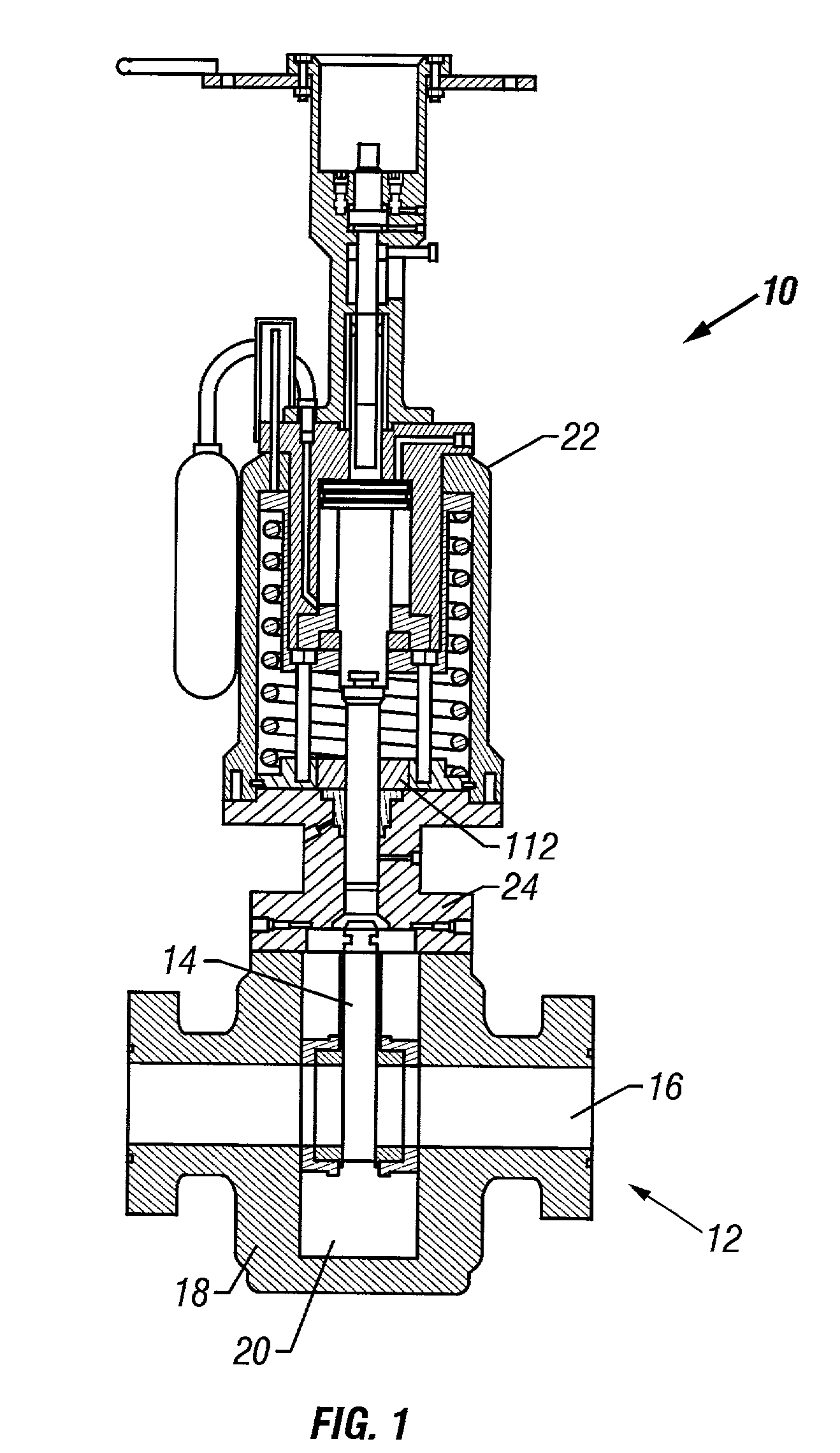

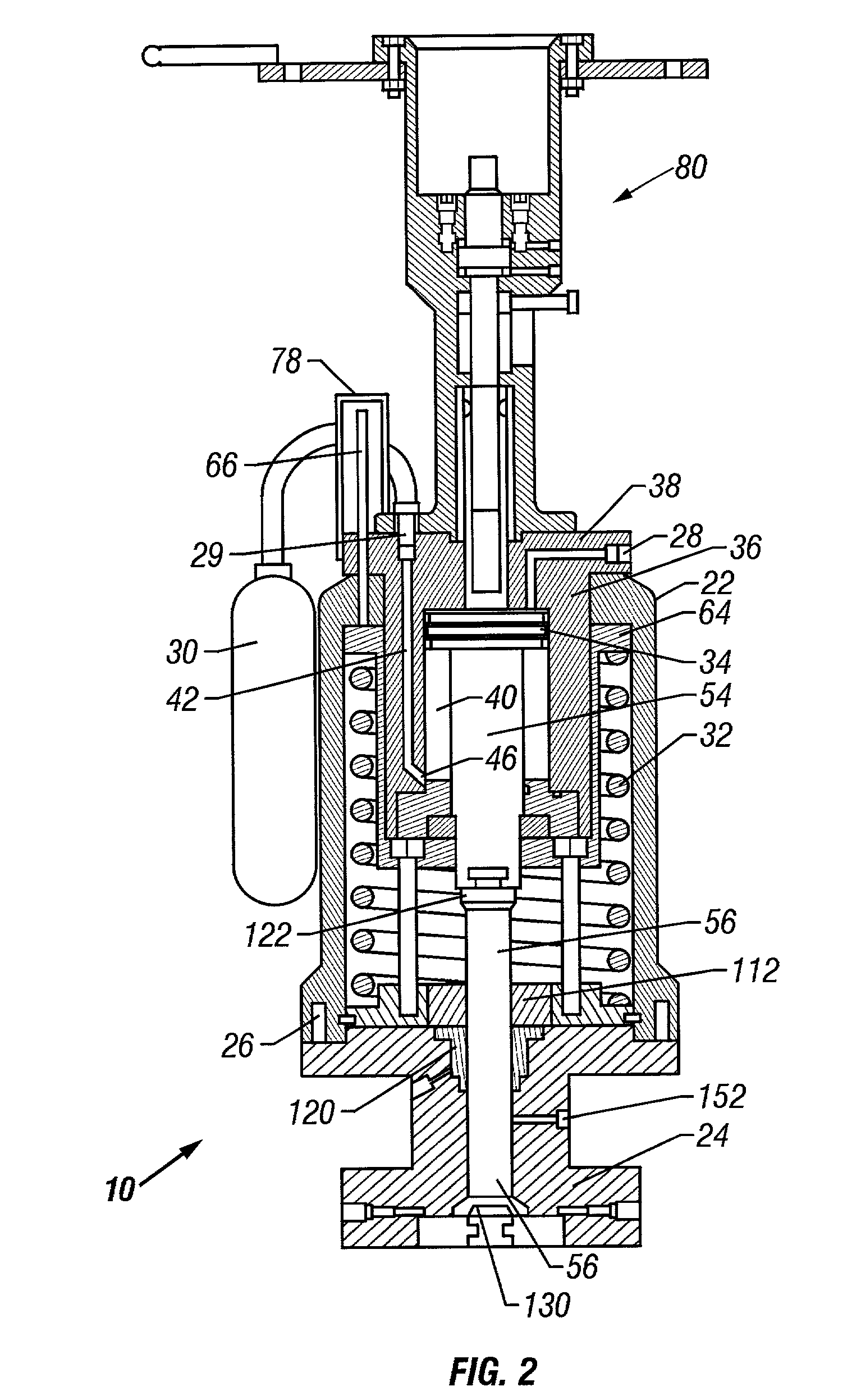

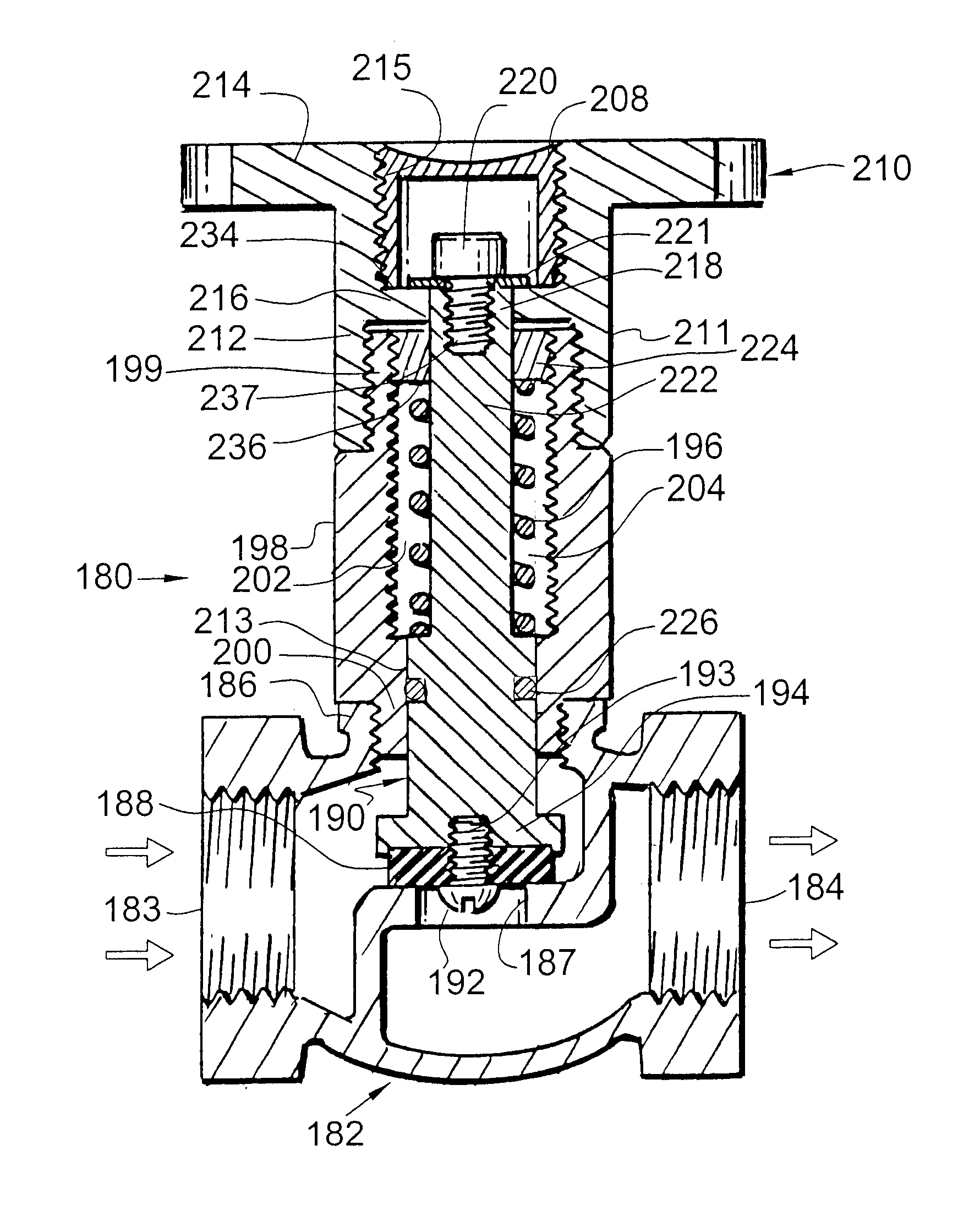

Subsea valve actuator and method

InactiveUS6041804AEasy to configureEasy to modifyPlug valvesOperating means/releasing devices for valvesValve stemControl line

A subsea actuator and method is disclosed that includes a removable monolithic cap / hydraulic chamber that seals the actuator housing top with seals placed around the monolithic cap, defines a straight hydraulic line and port for control line hydraulic fluid, and provides for fasteners to secure the top of the subsea actuator. The monolithic cap / hydraulic chamber is so limited in metal and machine time that it can be a throw-away maintenance item. A preferably cup-shaped spring lifter is provided in telescoping relationship to the hydraulic chamber. Several short hydraulic fluid passageways are provided in the bottom cup portion of the spring lifter to permit assist hydraulic control fluid into the hydraulic chamber below the piston. The driving stem provides a removable connection to the hydraulic piston from the top of the actuator housing and a quick disconnect permits disconnection of the driving stem from the valve stem. The high tension spring does not need to be removed to perform maintenance, and all wear items and seals are readily accessible. Change or replacement of the stem packing is made from the top of the bonnet to avoid dissasembling the bonnet to valve body connection. The spring chamber within the actuator housing may be increased in size to accommodate a larger spring as necessary for fail-safe operation without changing the size of the hydraulic chamber. All sliding components ride on wear rings to increase the lifetime of reliable subsea operation. The moving components are mounted in a compact, concentric configuration.

Owner:WORLDWIDE OILFIELD MACHINE

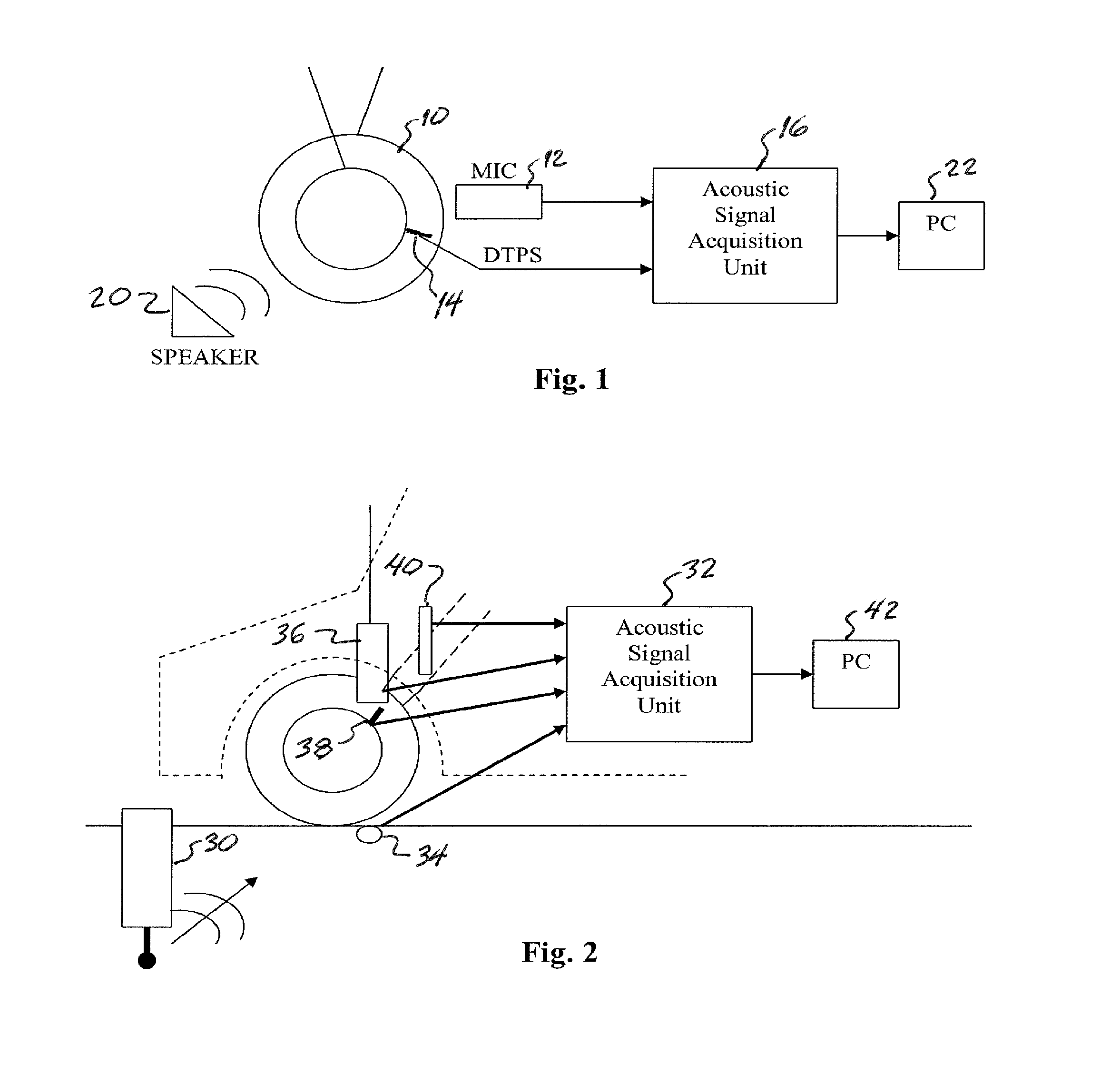

Aerosol dispensing inhaler training device

An aerosol dispensing inhaler training device for determining whether a user is properly operating an aerosol dispensing device. The training device includes an aerosol dispensing device having a container with a valve stem extending longitudinally therefrom and movable between a closed position and an open position. The container dispenses a portion of the contents within the container when the valve stem is moved to the open position. The aerosol dispensing device includes a housing adapted to support the container reciprocally moveable within the housing along a longitudinal axis from a first position, the housing comprising a well adapted to receive the valve stem and an exhaust port comprising one end in fluid communication with the well and a second end in fluid communication with the ambient atmosphere, wherein the portion of the contents within the container is dispensed from the first end of the exhaust port to the second end of the exhaust port when the housing moves to an actuation position where the valve stem is actuated so that a portion of the contents within the container is dispensed through the second end of the exhaust port when the valve stem is moved to the open position. An actuation sensor generates a signal that indicates when the housing is moved to the actuation position and the valve stem is actuated. A shake sensor determines whether the contents within the container have been properly agitated for consumption by a user.

Owner:1263152 ONTARIO

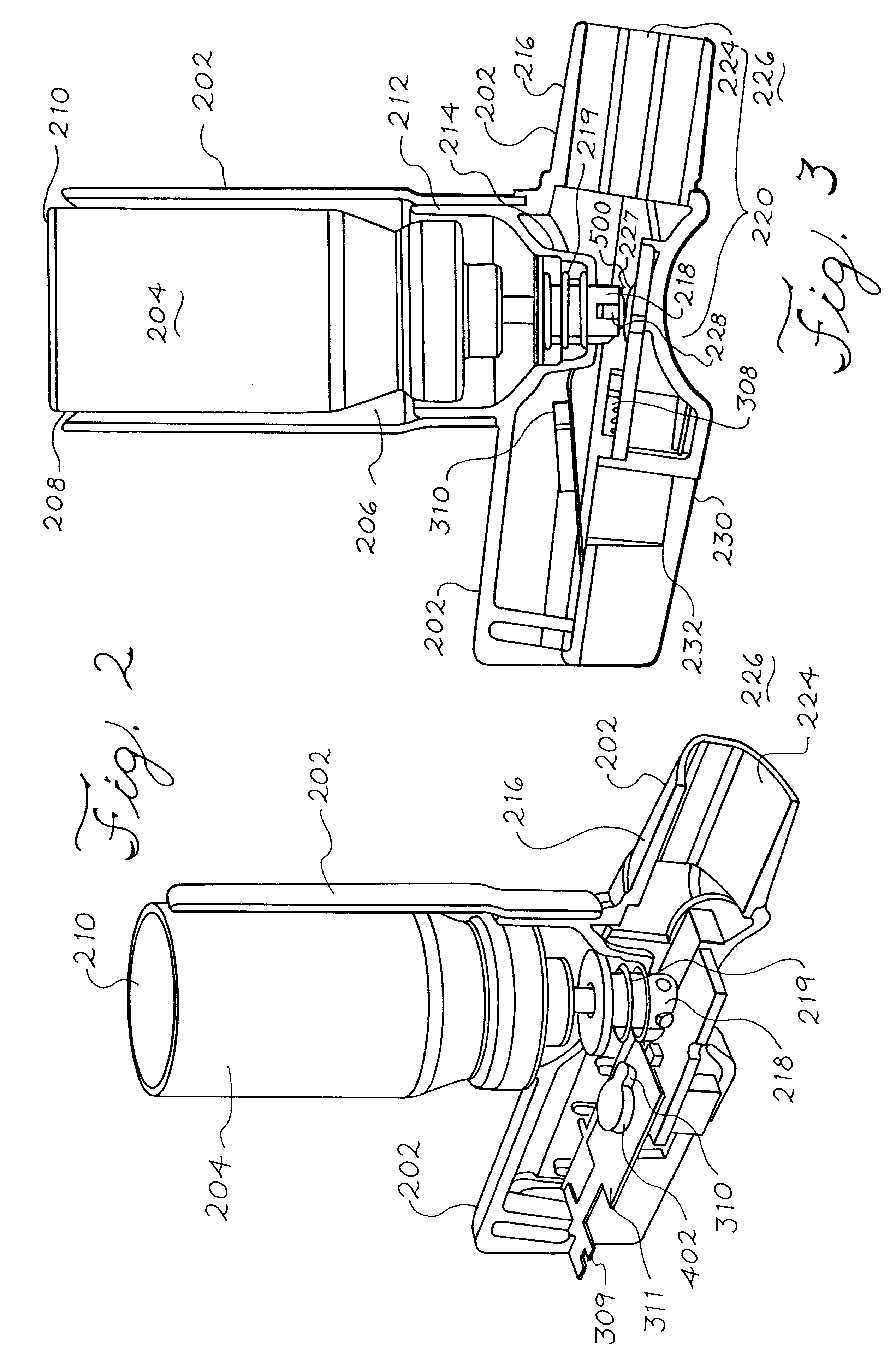

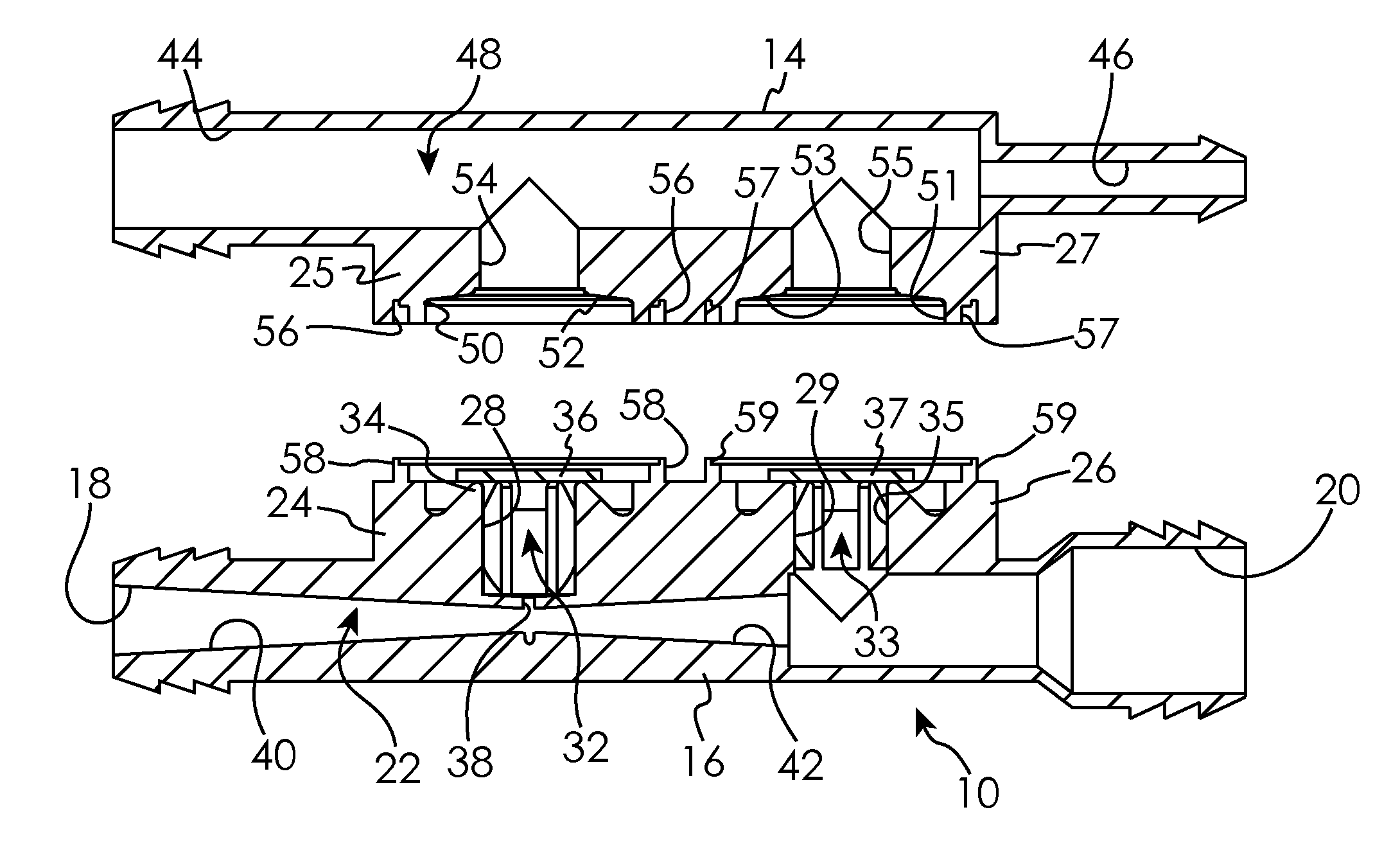

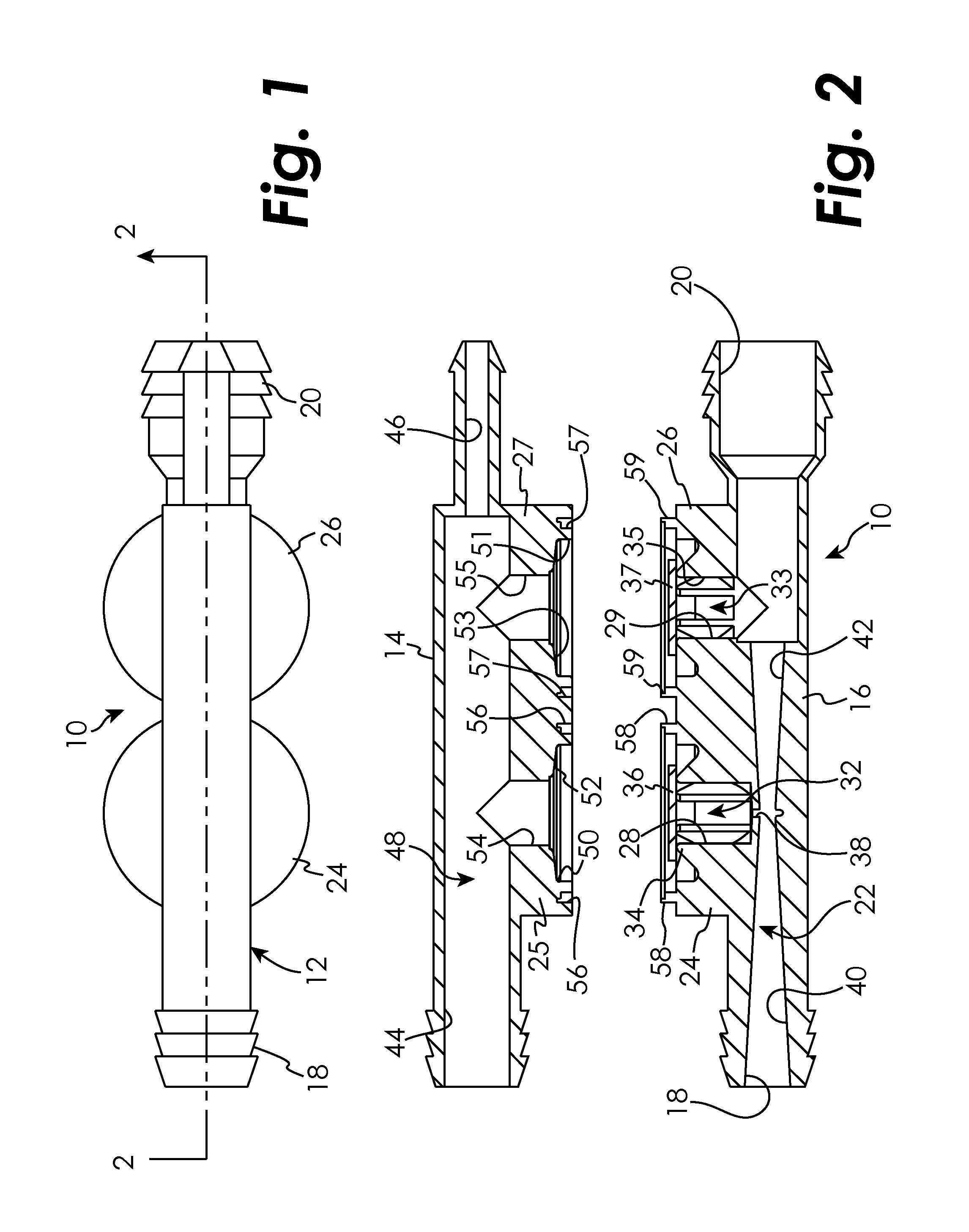

Method and apparatus for coupling and uncoupling an injection valve pin

An injection molding system comprising an actuator, a mounting plate, a mold and a manifold mounted between the mounting plate and the mold, the mounting plate being removably coupled to the mold, the actuator comprising an actuating member reciprocally drivable along an axial path of travel and a housing removably coupled to the mounting plate; a valve pin coupled to the shaft of the actuator for movement of the valve pin together with movement of the actuating member, the valve pin comprising a pin stem and a pin connector; the actuator having an actuator coupling adapted to reversibly couple to and decouple from the pin connector in a radial direction relative to the axial path of travel, the pin stem extending from the actuator into the manifold when the housing of the actuator is coupled to the mounting plate and the pin connector is received within the actuator coupling; the actuator housing being mounted on or within the mounting plate for radial movement upon decoupling of the actuator housing from the mounting plate such that the pin connector is decouplable from the actuator coupling upon said radial movement while the actuator housing is disposed on or within the mounting plate, the actuator being removable from on or within the mounting plate leaving the valve stem behind extending into the manifold.

Owner:SYNVENTIVE MOLDING SOLUTIONS INC

Metering valve for a metered dose inhaler providing consistent delivery

InactiveUS7234460B2Improve consistencyReduce the amount requiredSolid materialLiquid spraying apparatusEngineeringValve stem

The present invention relates to a novel design for a metering valve that provides improved consistency of formulation delivery. Generally, the metering valve includes (a) a valve stem that generally defines a longitudinal axis and includes a body portion having a metering surface, wherein the longitudinal axis and a plane tangential to at least a portion of the metering surface define an angle from about 2° to about 90°; and (b) a valve body having an internal chamber defined at least in part by the body wall and includes a metering portion configured to substantially conform to the metering surface of the valve stem.

Owner:3M INNOVATIVE PROPERTIES CO

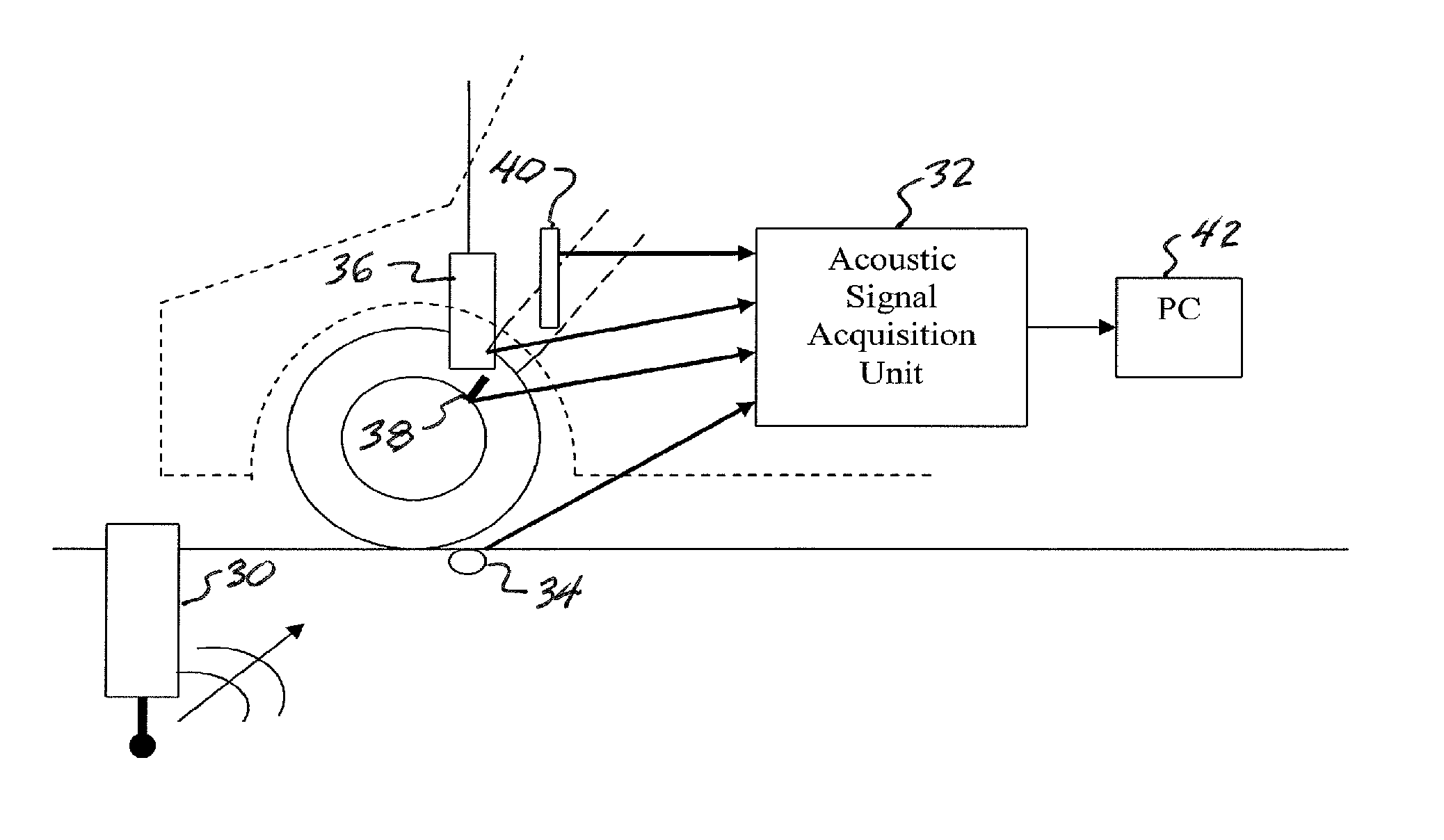

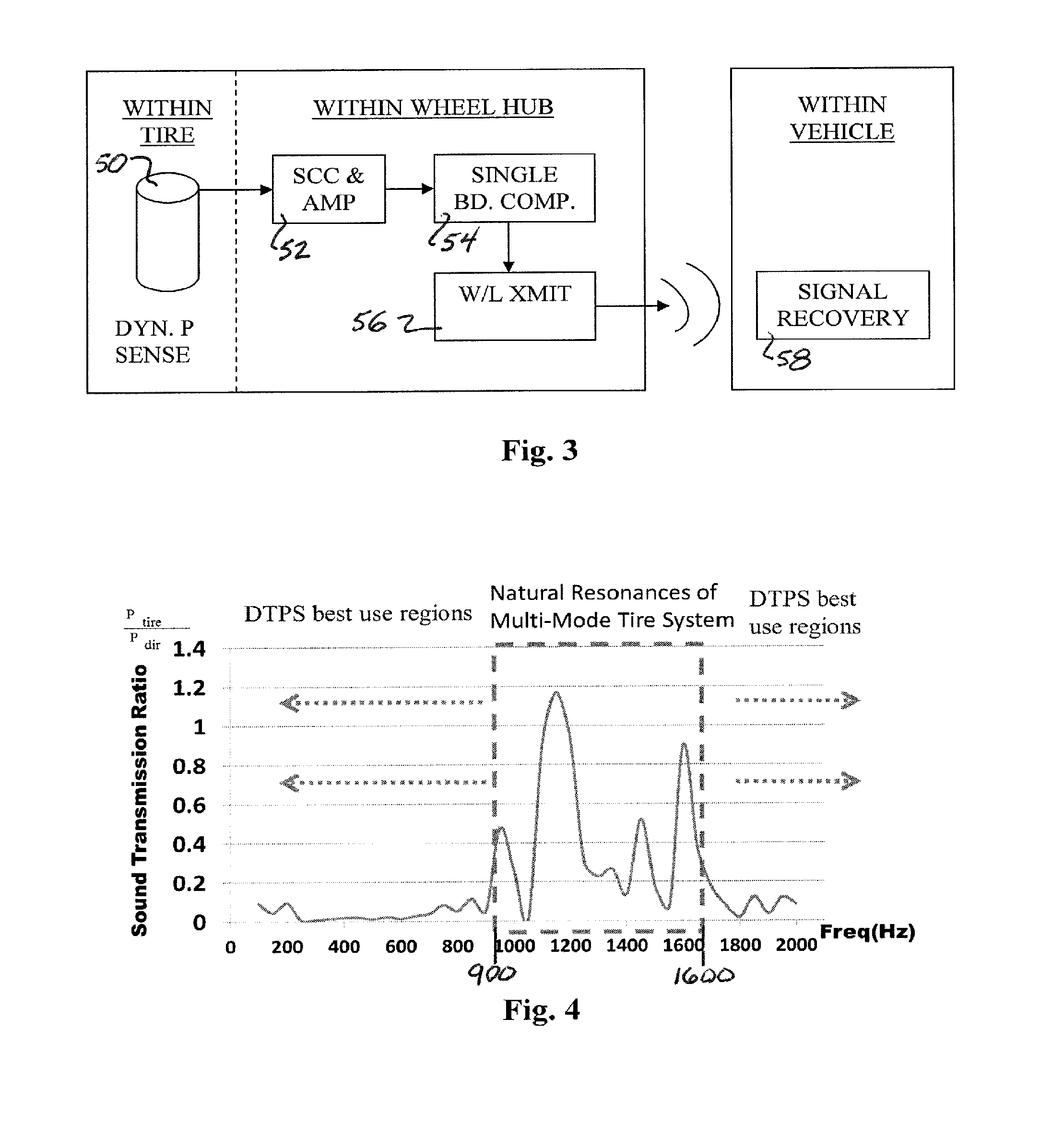

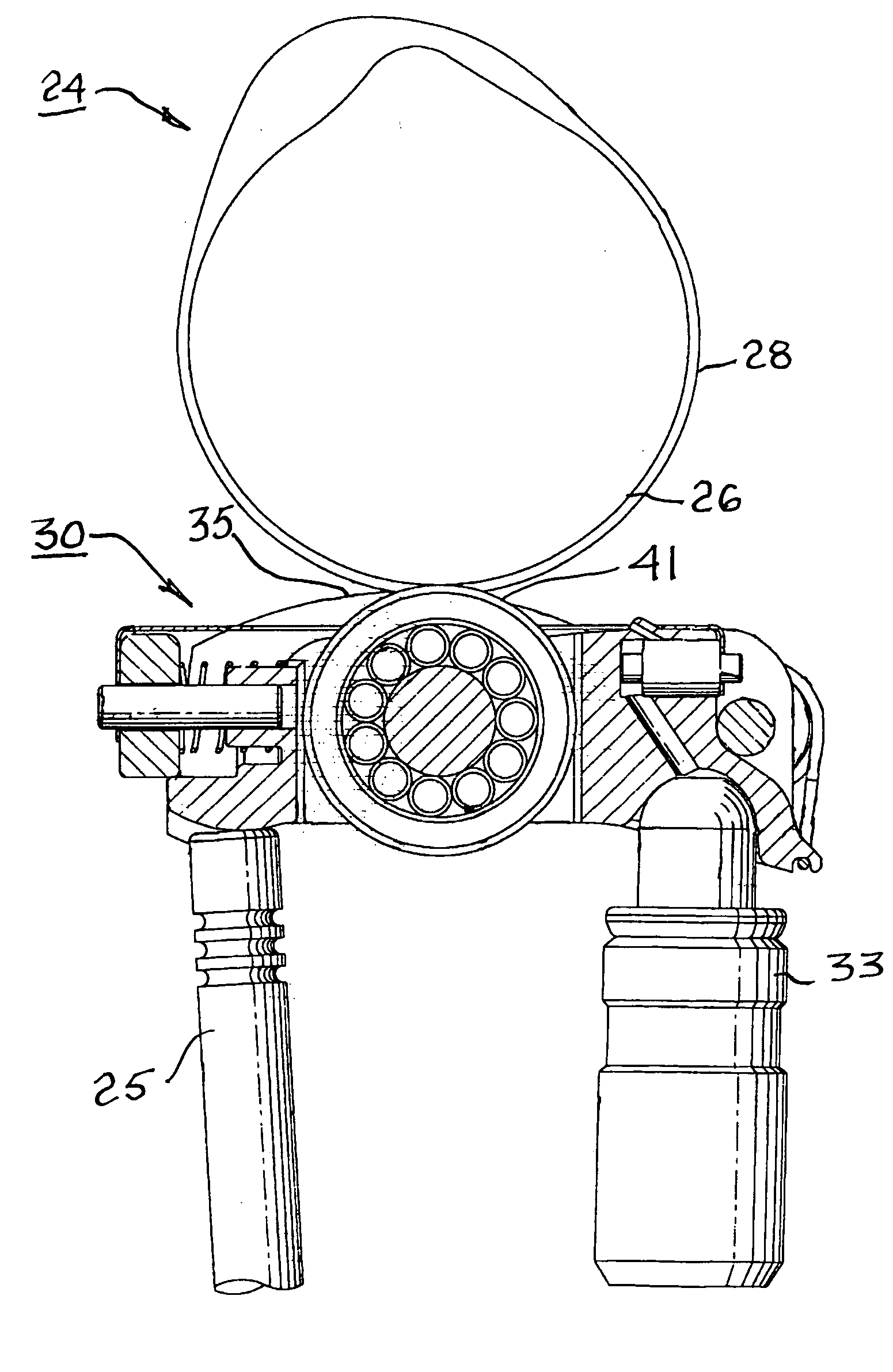

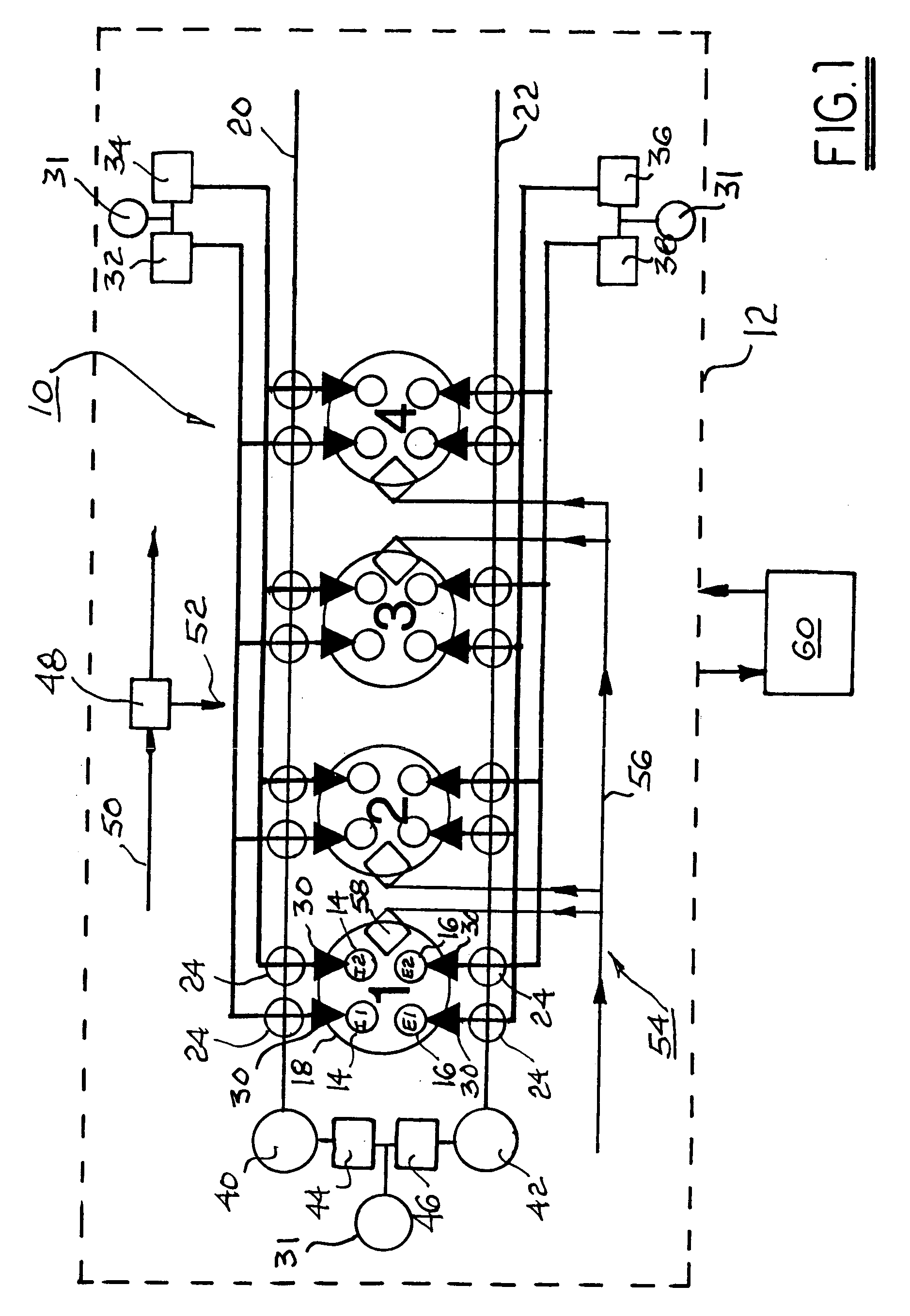

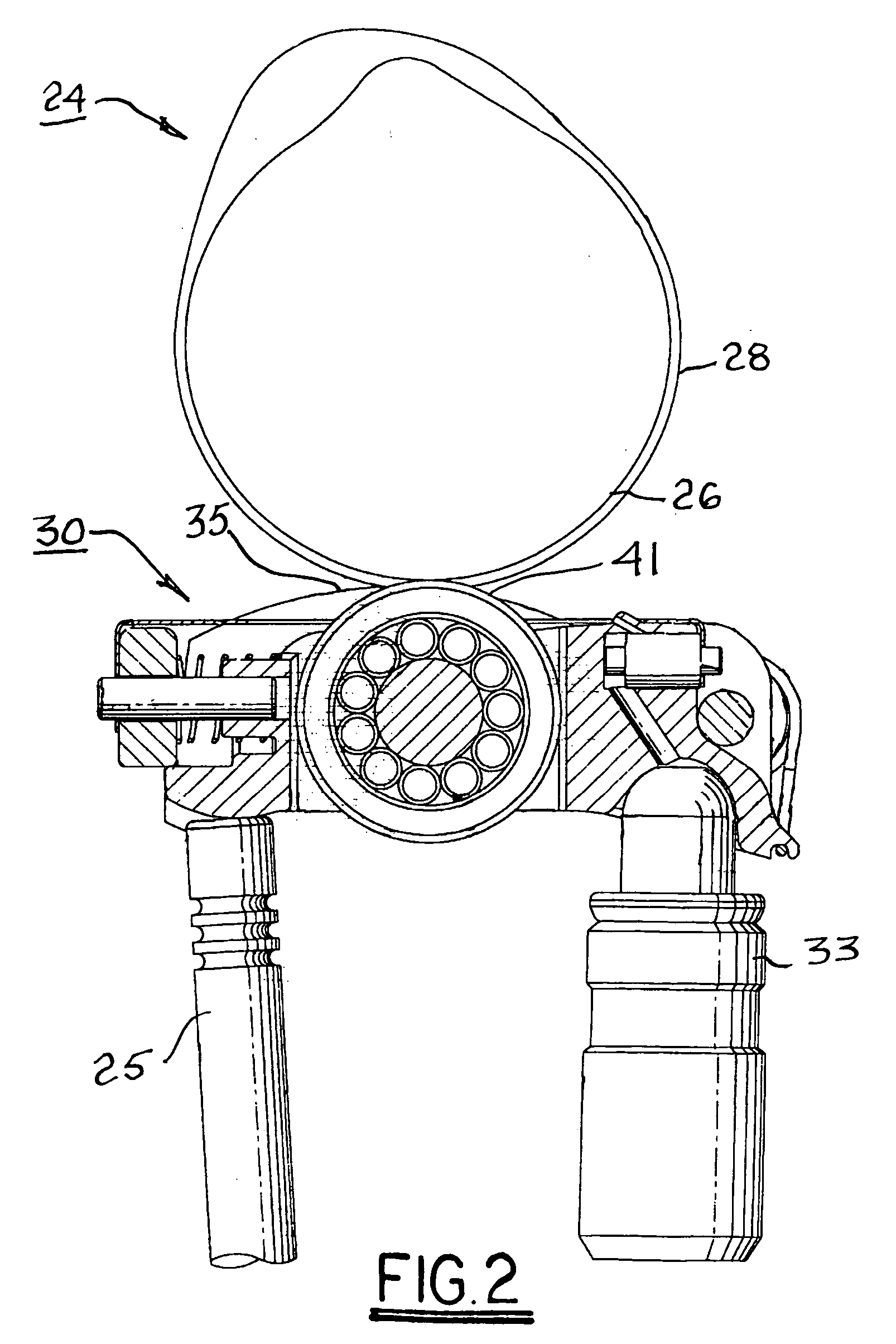

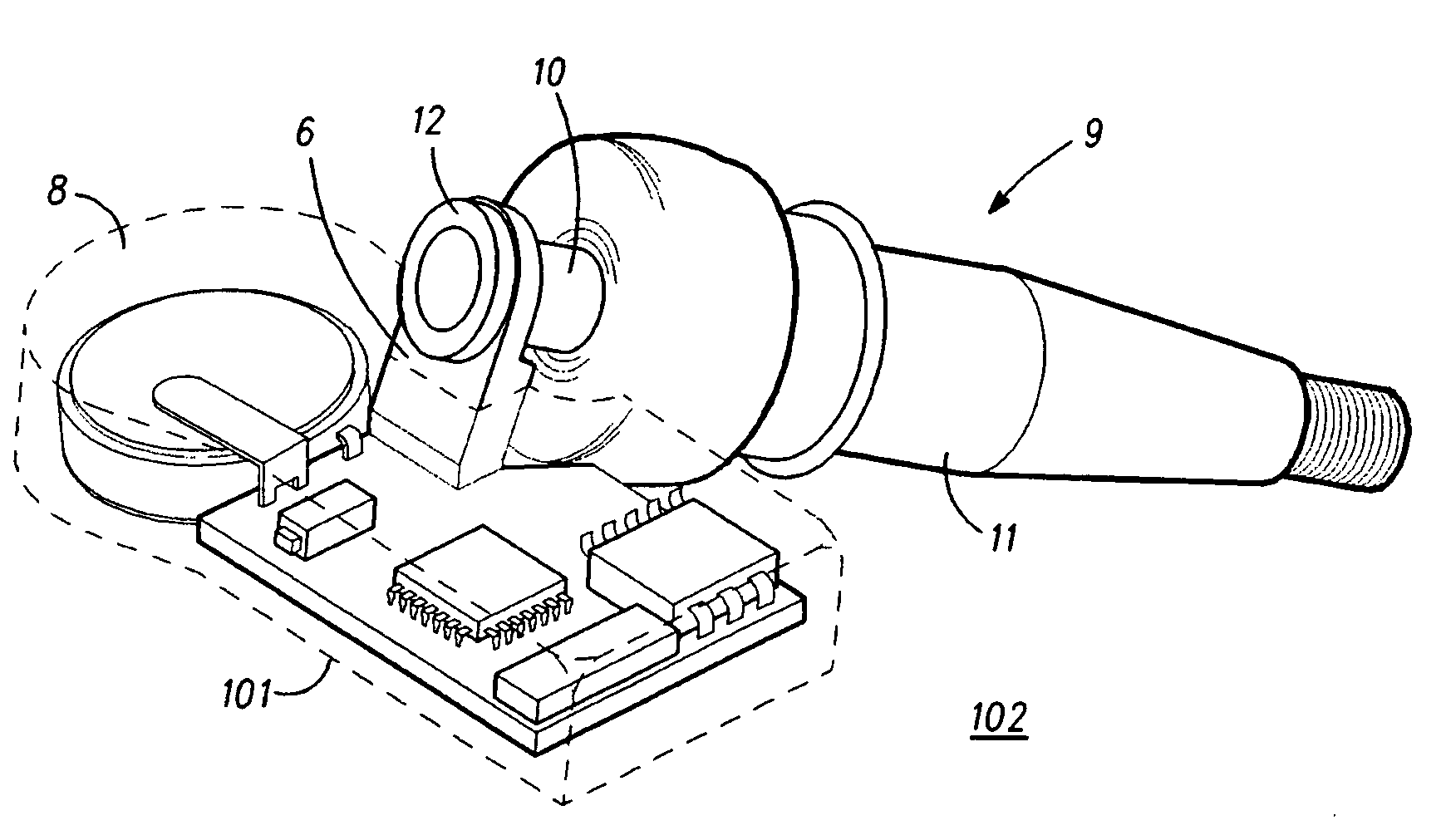

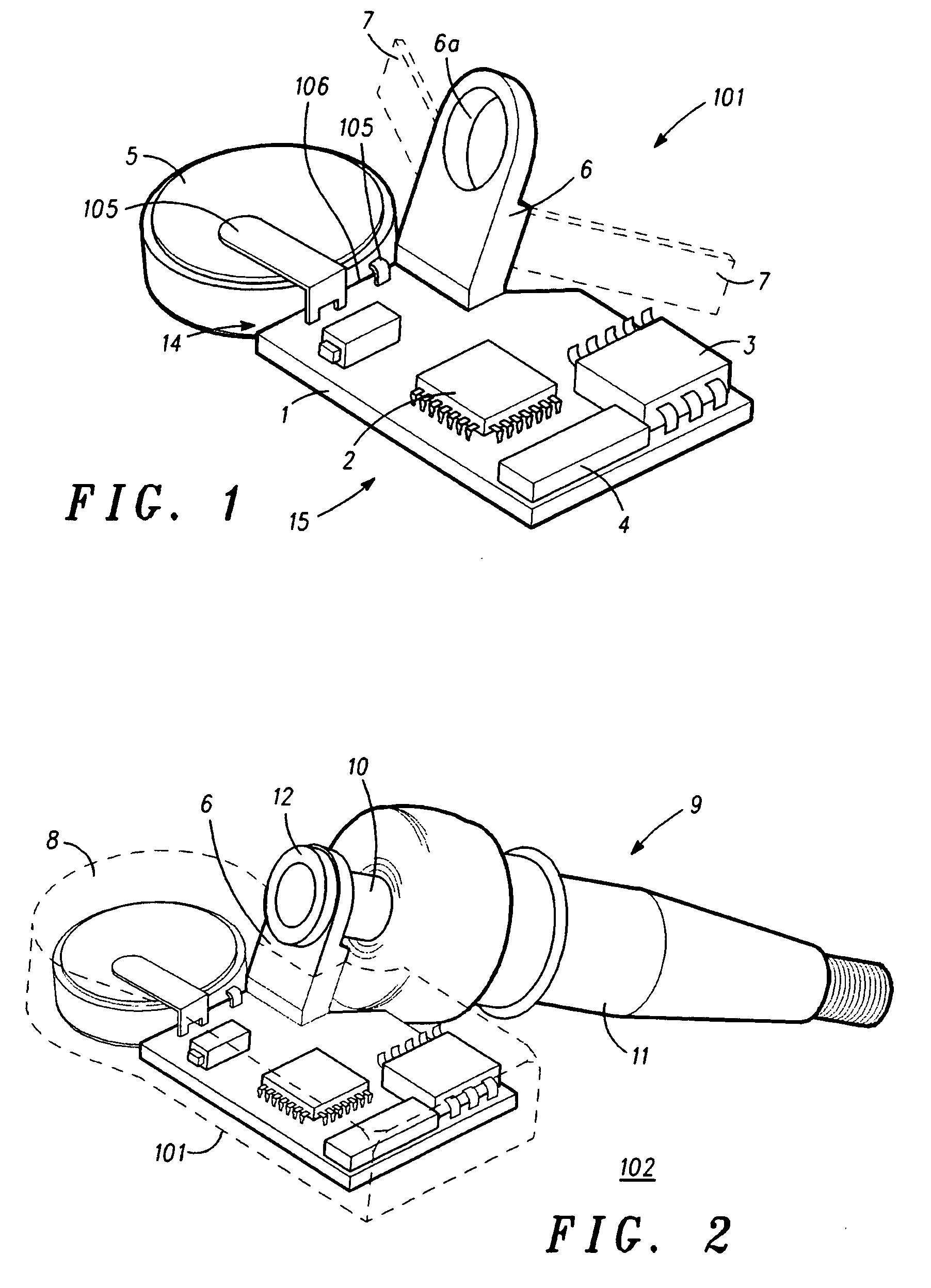

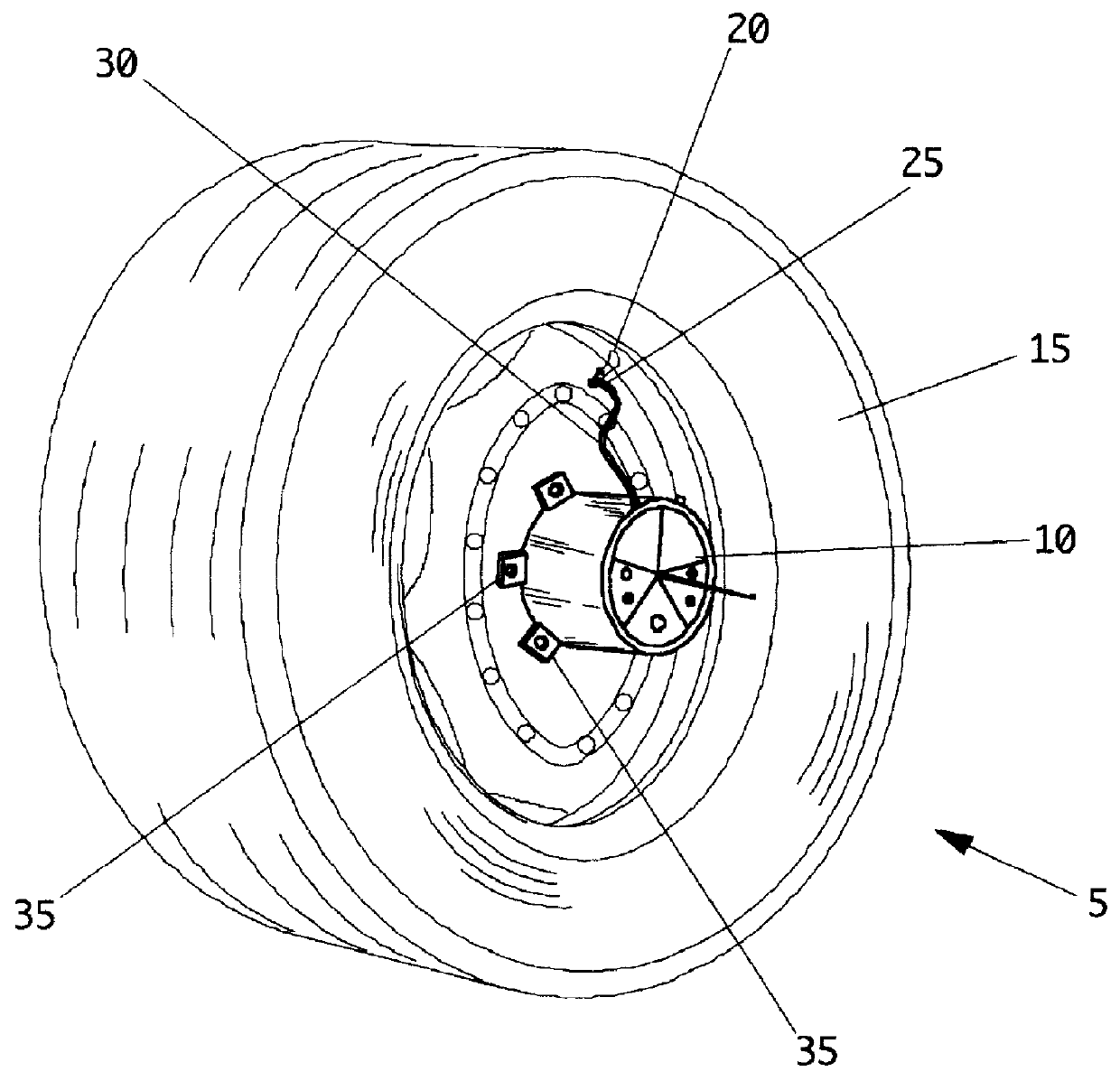

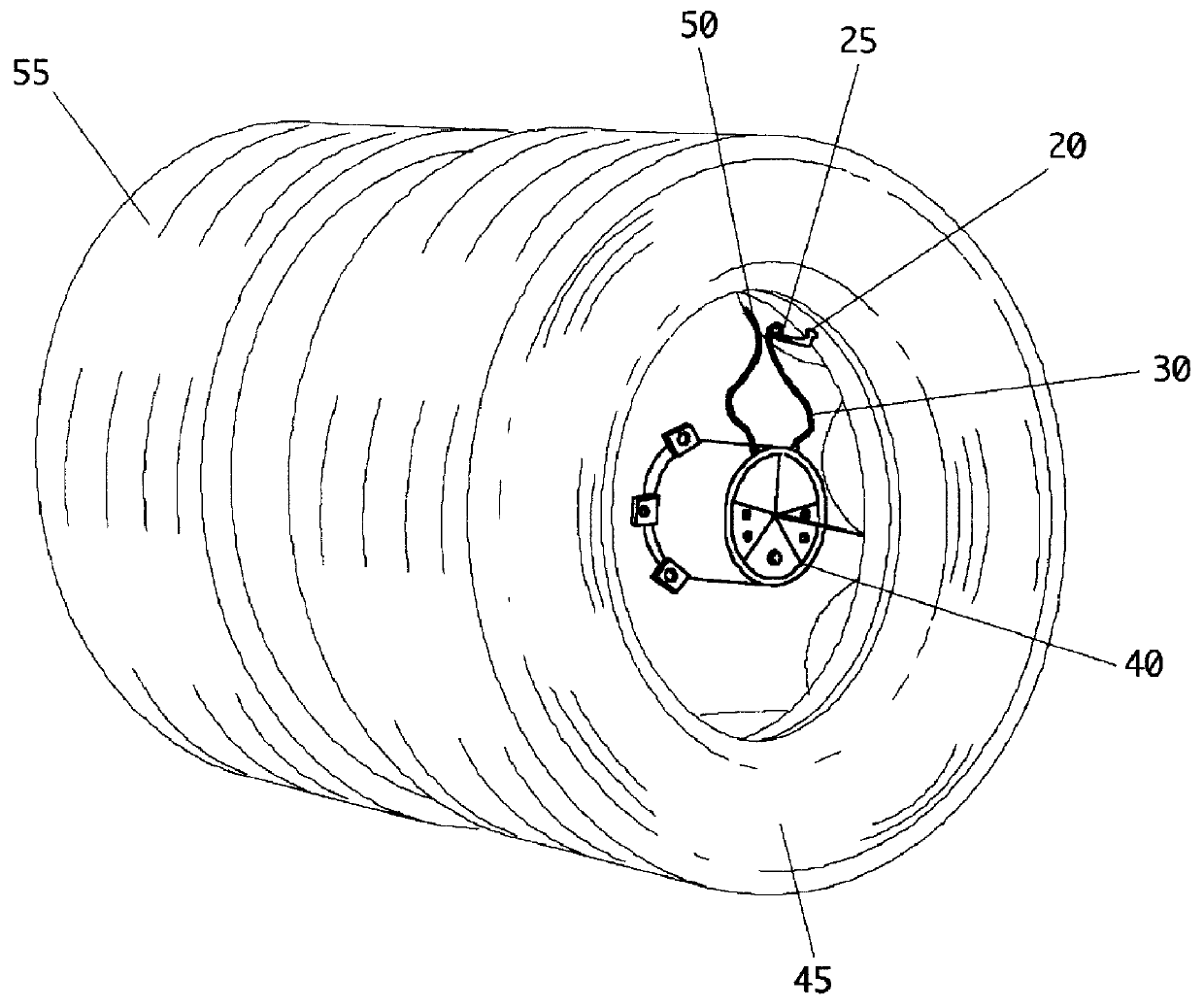

Real-time wireless dynamic tire pressure sensor and energy harvesting system

ActiveUS20140070935A1Quick testImprove detection accuracyBatteries circuit arrangementsMaterial analysis using sonic/ultrasonic/infrasonic wavesAuditory radiationEnergy harvester

An instantaneous / real-time wireless dynamic tire pressure sensor (DTPS) for characterizing pavement qualities and for detecting surface and subsurface pavement defects under normal driving conditions. Signal processing provides quantitative assessment of surface conditions. DTPS includes a vehicle tire valve stem-mounted pressure sensor and wheel hub-mounted signal conditioning, amplification, and transmitting circuitry. A signal processing computer within the vehicle is wirelessly coupled to the hub-mounted circuitry. Tire pressure changes caused by ground vibration excitation from the interaction between the tire and pavement at normal driving speeds are detected. When acoustic radiation from a surface wave is significantly stronger than acoustic noise, subsurface information can be extracted. An energy harvester based on strong magnetostatic coupling between a high permeability core solenoid, fixed proximate a vehicle wheel, and a bias magnet array, fixedly mounted in conjunction with a dust shield, can provide power the DIPS.

Owner:NORTHEASTERN UNIV

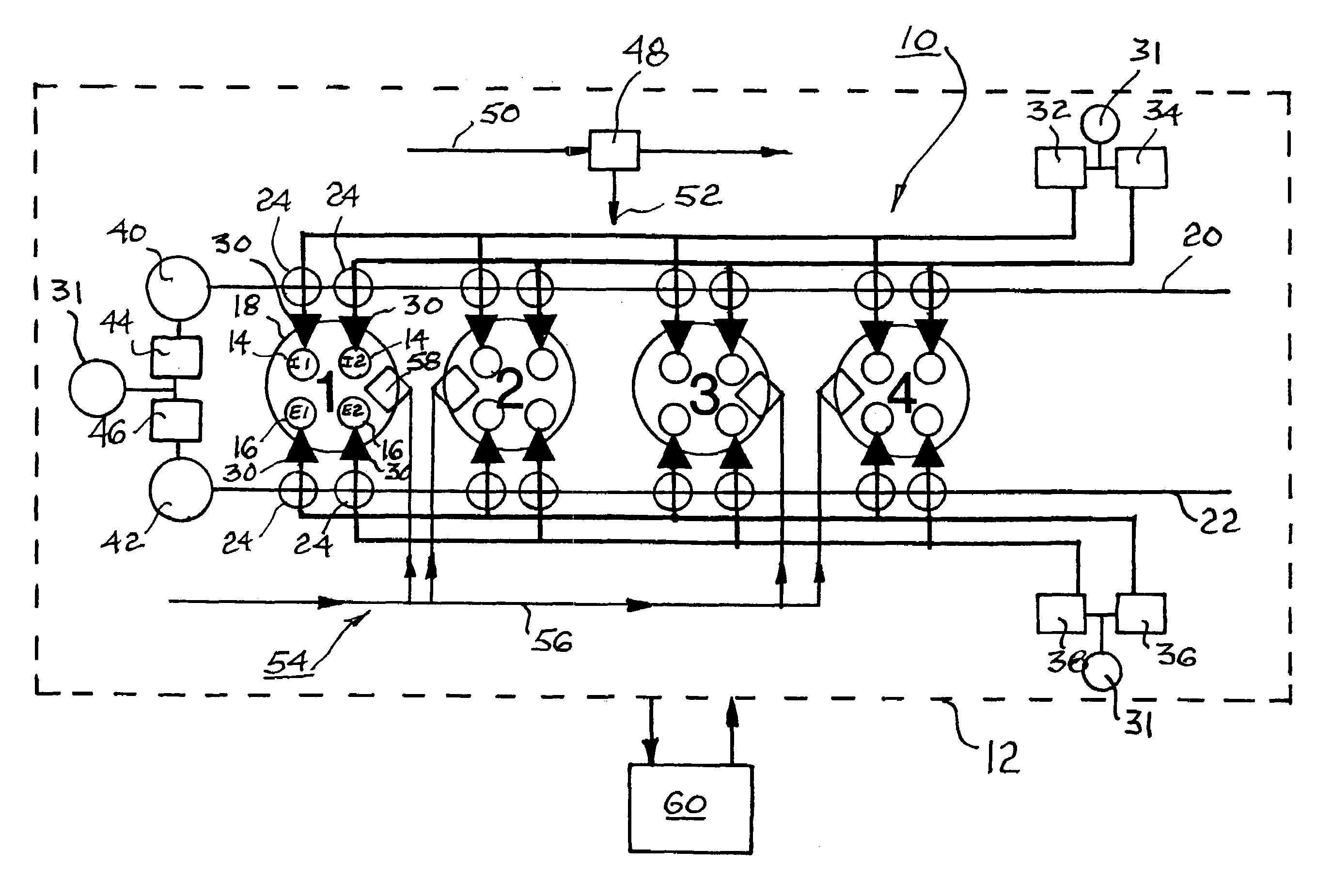

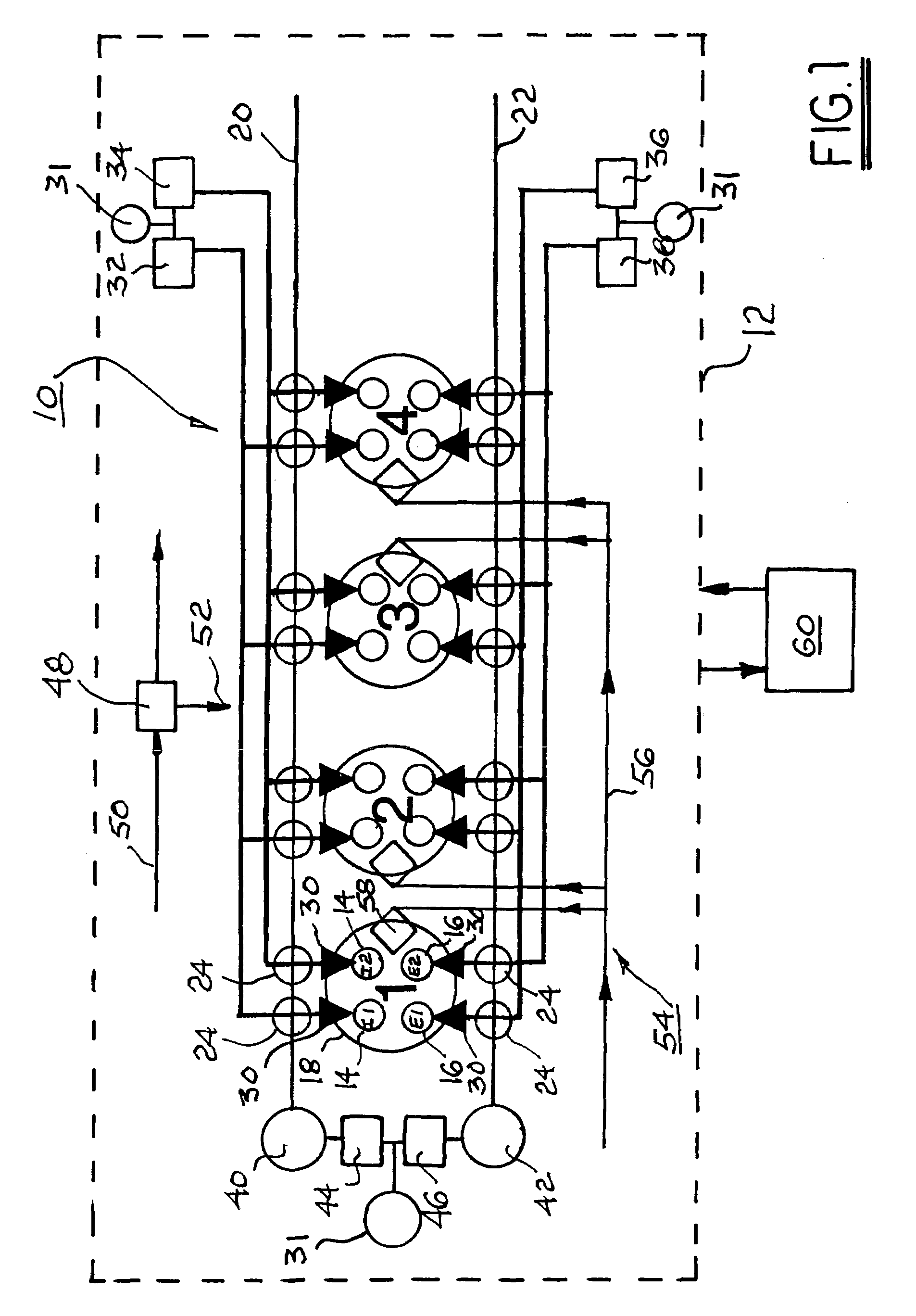

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS20060144356A1Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

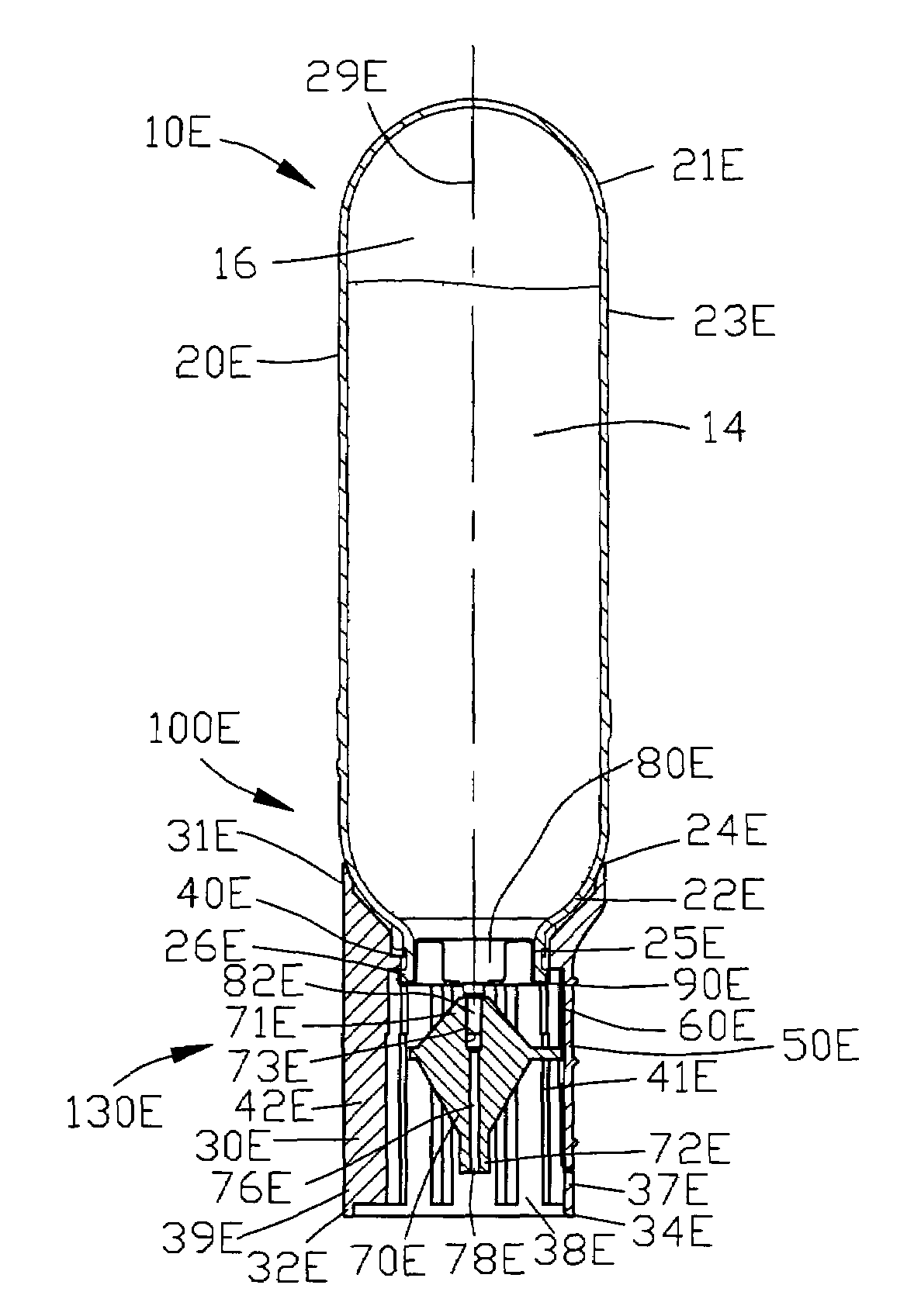

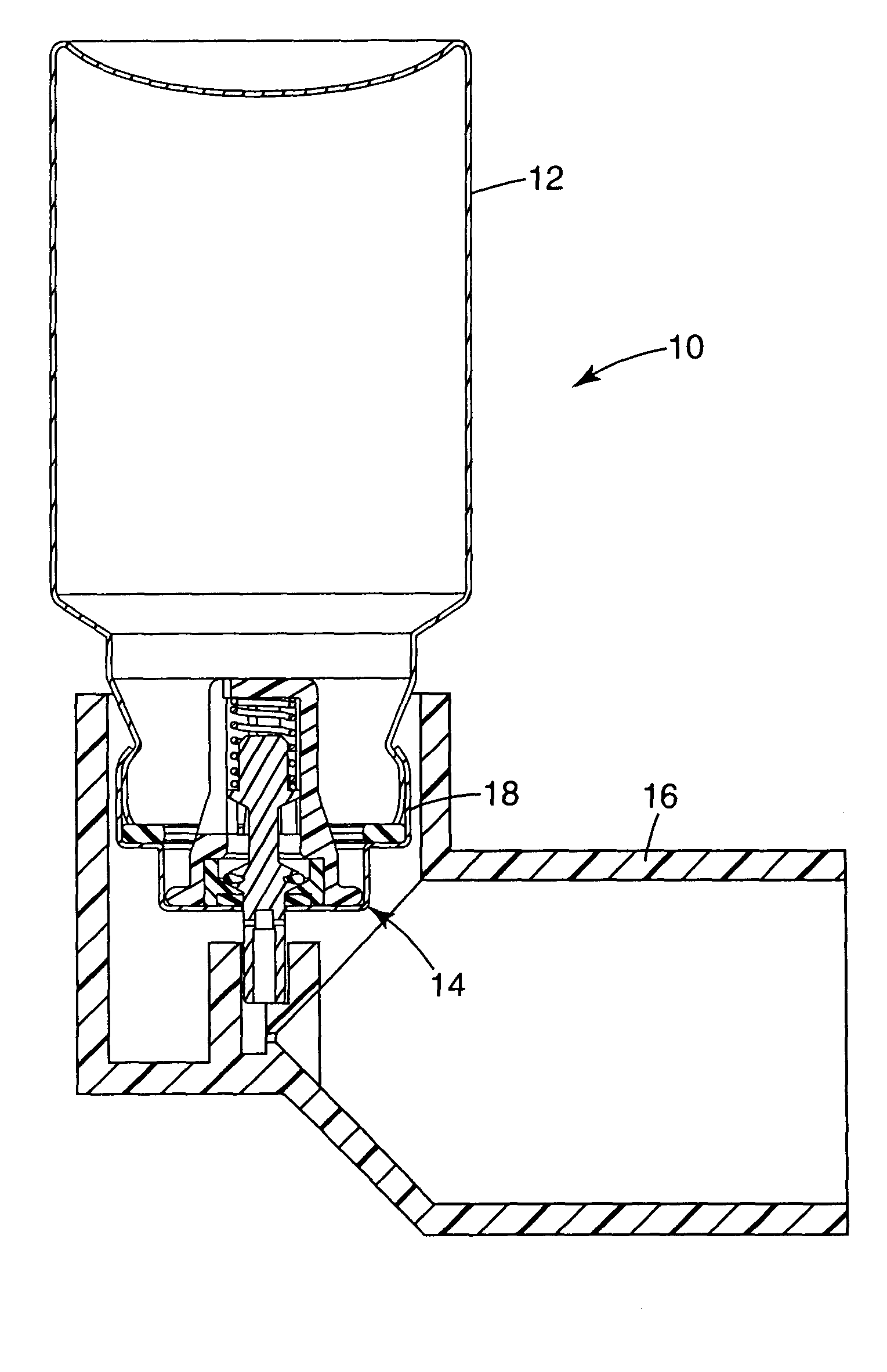

Compressible valve for a pressurized container

A compressible valve is used with a pressurized container for dispensing an aerosol product. The compressible valve includes a valve cup connected to a dispensing structure disposed inside an open top end of a bottle. A grommet is disposed in the valve cup and has an integral sealing portion and spring portion. A grommet longitudinal passageway passes through the spring portion and the sealing portion and is coaxial with a valve cup longitudinal passageway. An elongate valve stem is disposed in the grommet passageway. The grommet sealing portion provides a seal between the valve stem and the valve cup and between the dispensing structure and the valve cup.

Owner:PROCTER & GAMBLE CO

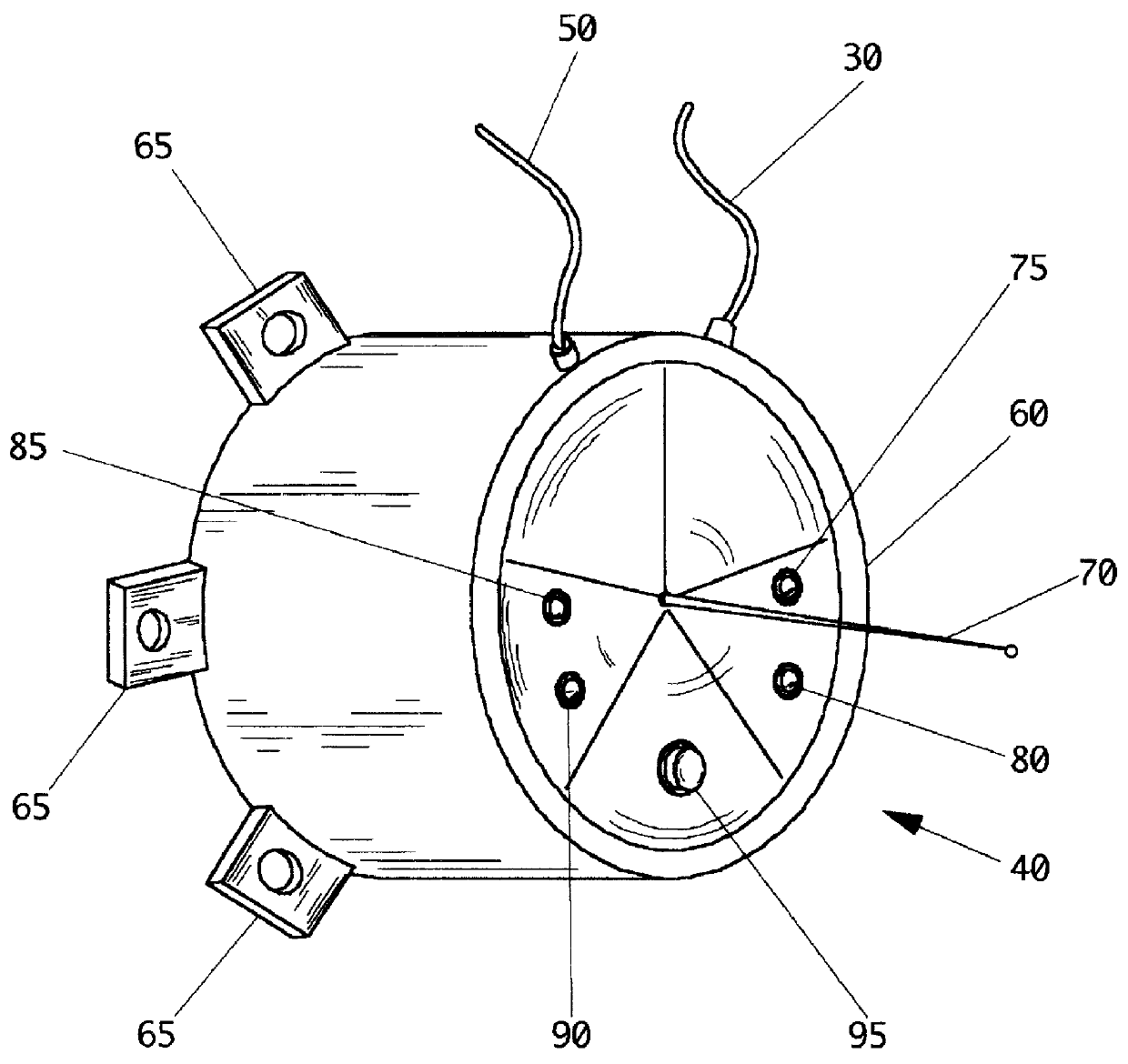

Tire pressure sensor assembly

The disclosure provides a tire pressure sensor assembly that includes a battery and a printed circuit board (PCB) configured with electronics to measure tire pressure and to transmit an electromagnetic signal related to the measured tire pressure. The PCB and battery are contained in a housing that allows the PCB and the battery to be angularly oriented with respect to each other. Such orientation permits the sensor to conform to the curved surface of the rim. An embodiment of the disclosed tire pressure sensor assembly is adapted to fasten to a valve stem via a metal terminal. The attachment configuration permits the valve stem assembly to deform as the valve stem is installed in a rim and also allows the valve stem to function as a portion of the antenna structure to facilitate transmitting the RF signal to a receiver.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

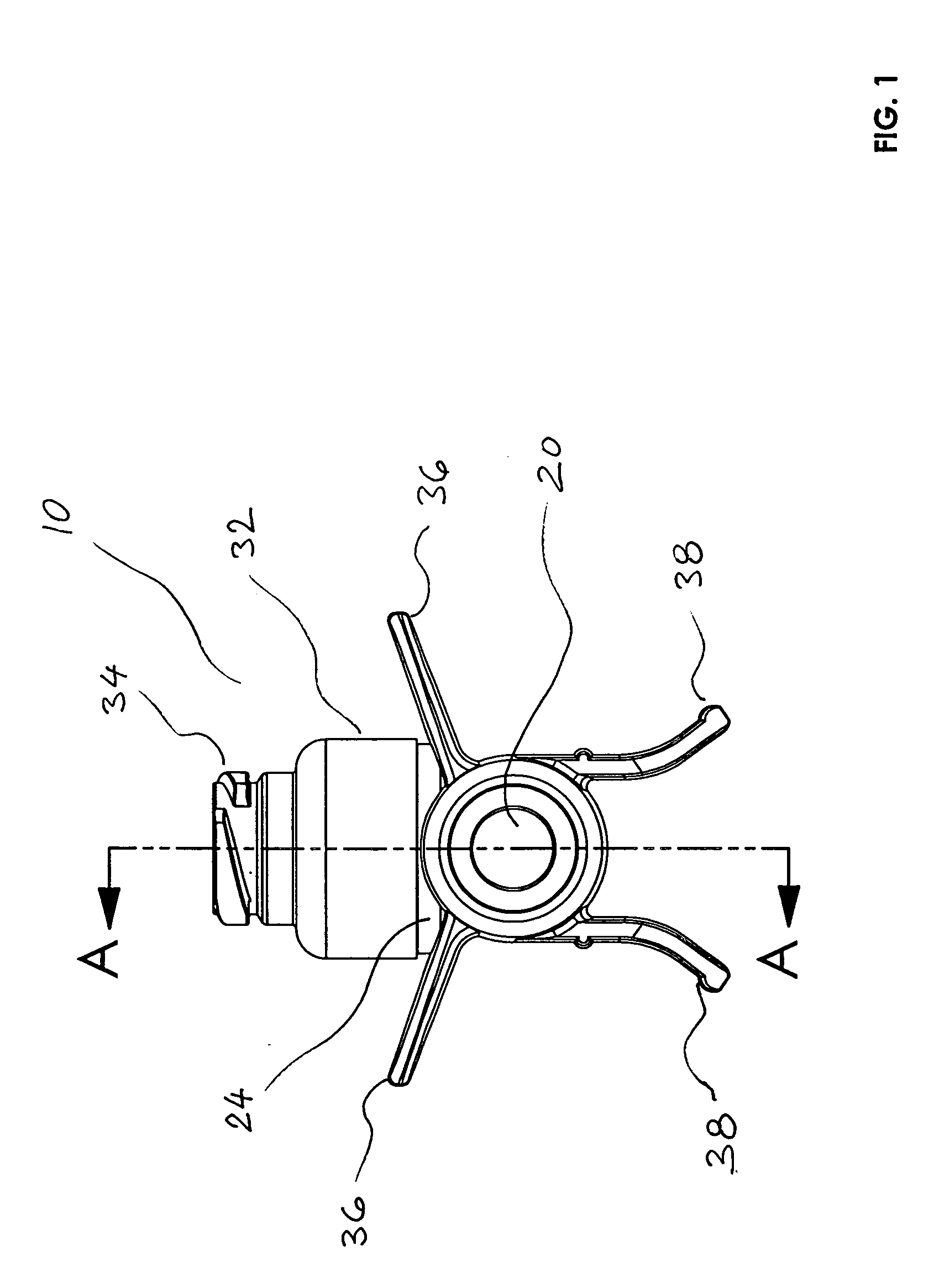

T-port with swabbable valve

InactiveUS20050261637A1Reduce riskEasy to wipeValve arrangementsInfusion devicesEngineeringPort site

A slit-type T-port site that includes a swabbable valve with a slit at an end thereof. The valve stem with a slit is located in a valve body and is deformable. When engaged by a tip of an instrument, the top portion of the stem folds inward and its slit opens to form a direct non-hemolytic flow pathway between the instrument and the main T-port site flow channel.

Owner:HALKEY ROBERTS CORP

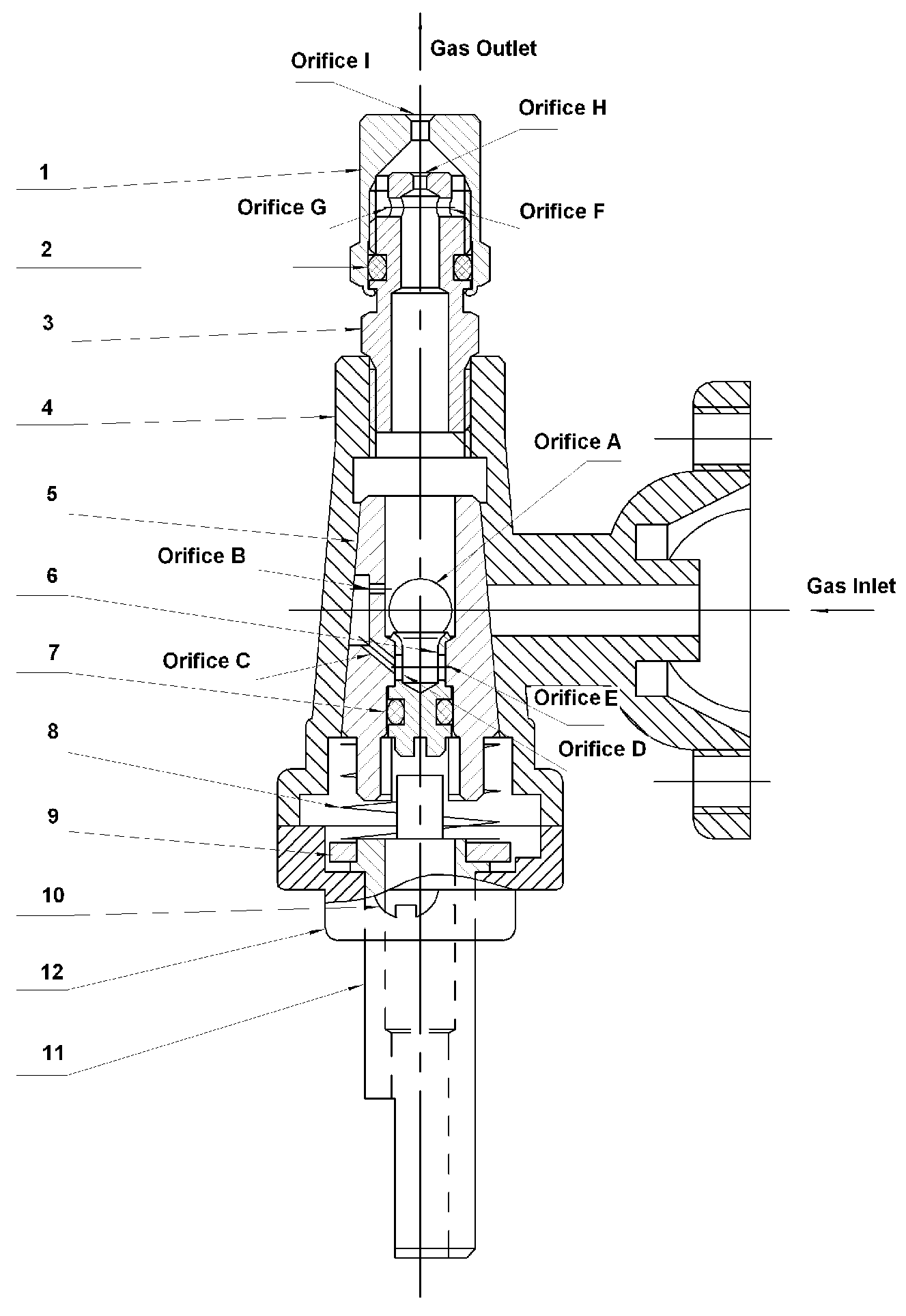

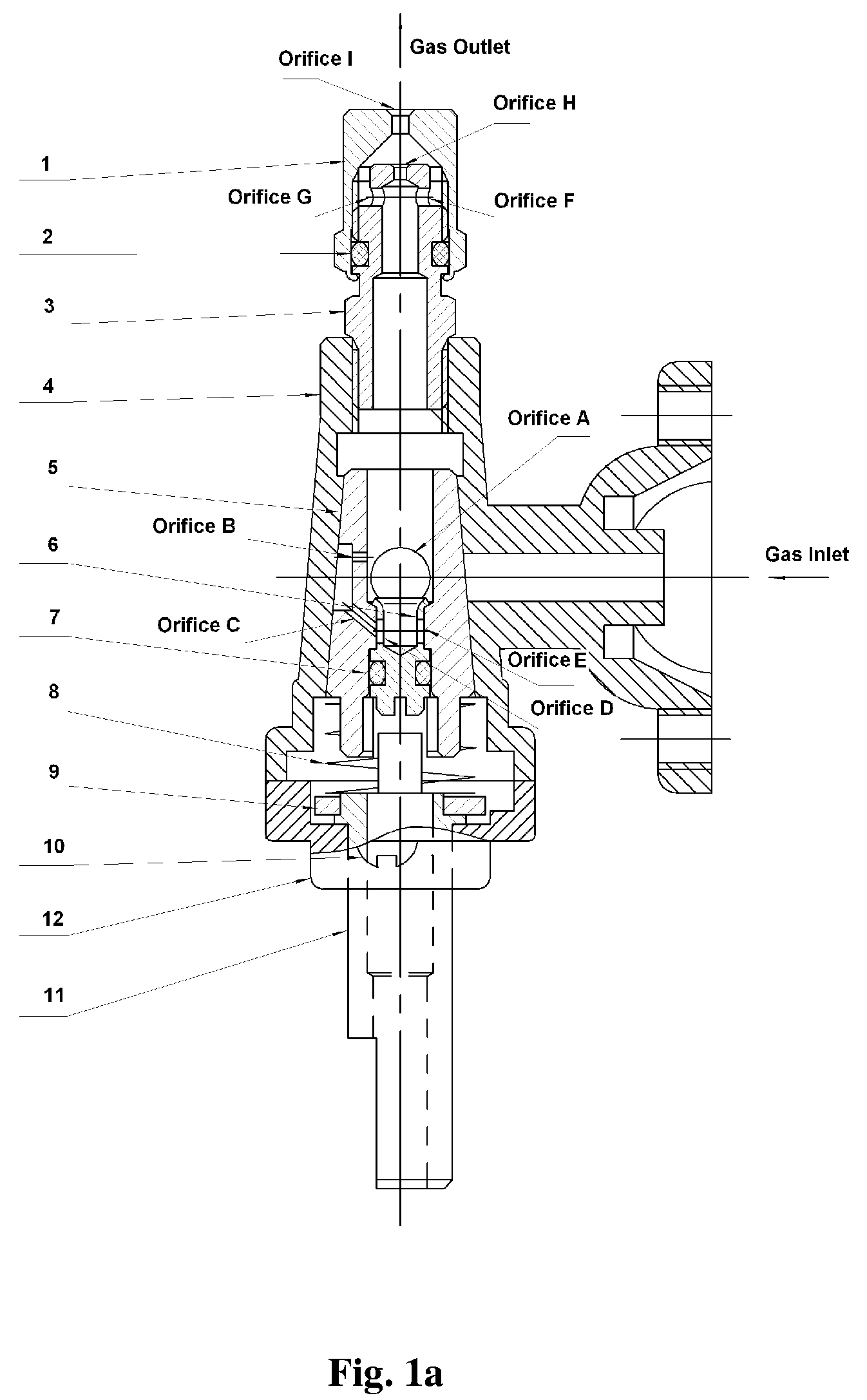

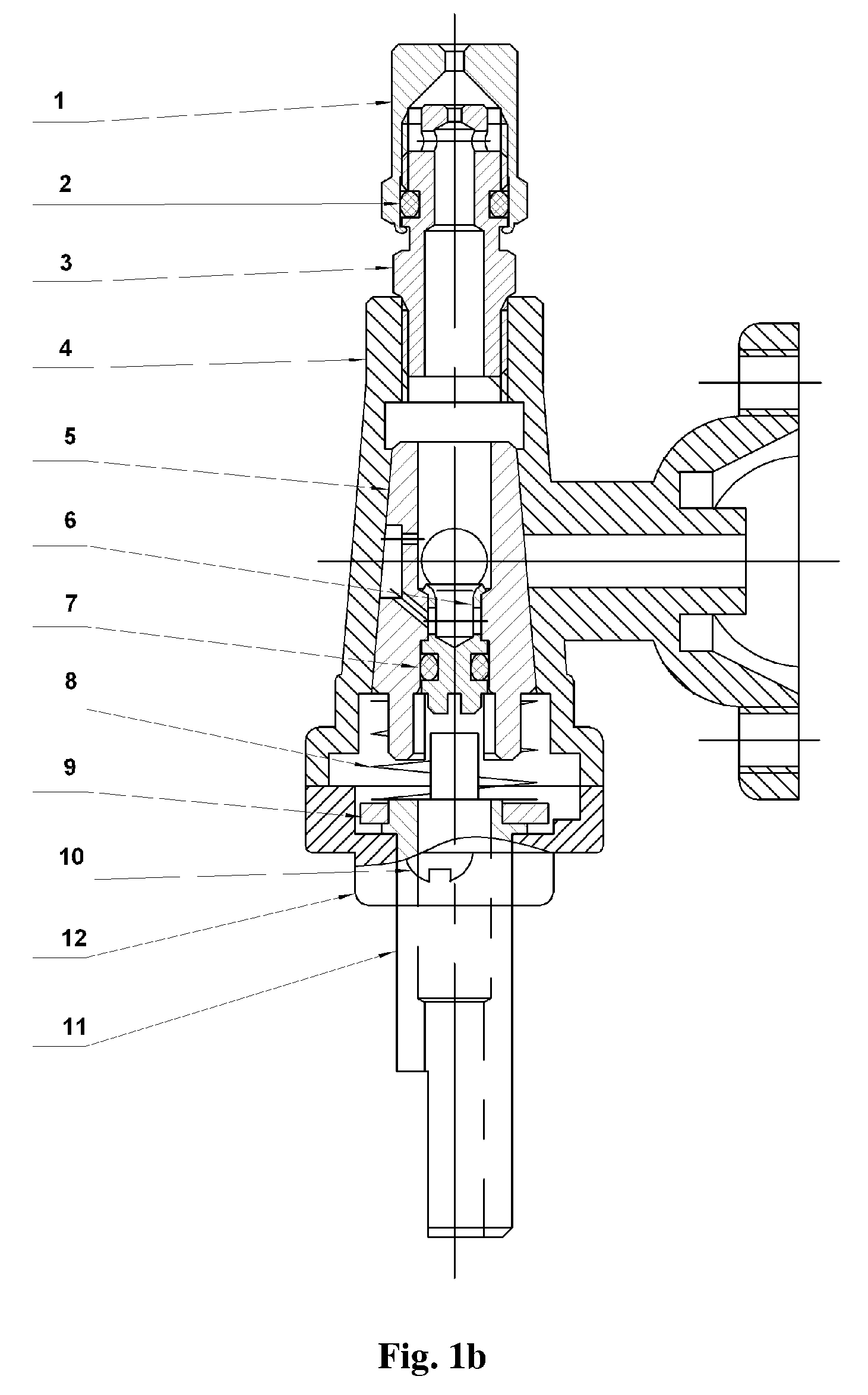

Manual gas valve with natural/LP gas conversion capability

ActiveUS7458386B2Reliable supplyEasy to operateVessel mounting detailsPlug valvesTester deviceProcess engineering

Owner:NINGBO WANAN

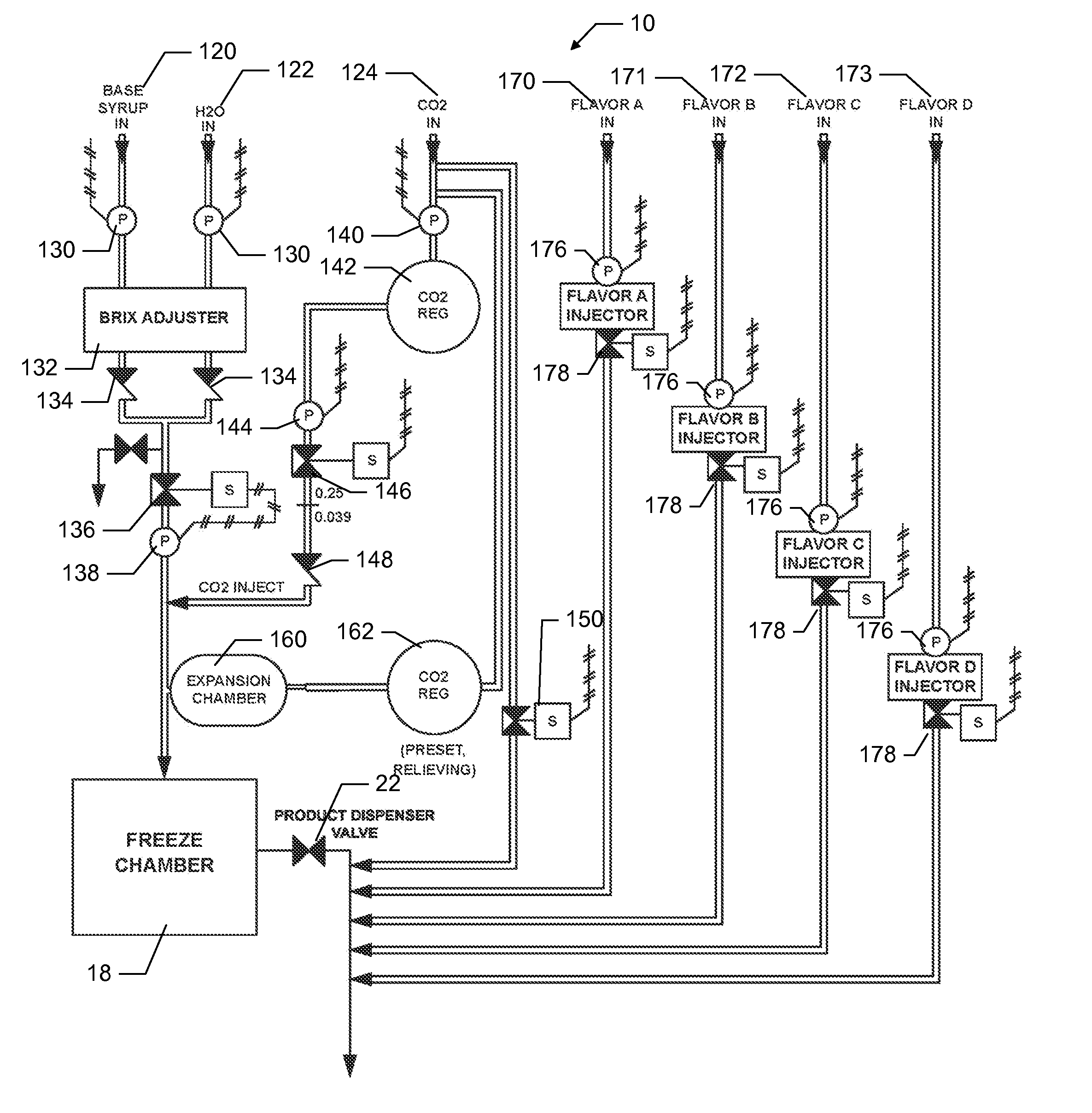

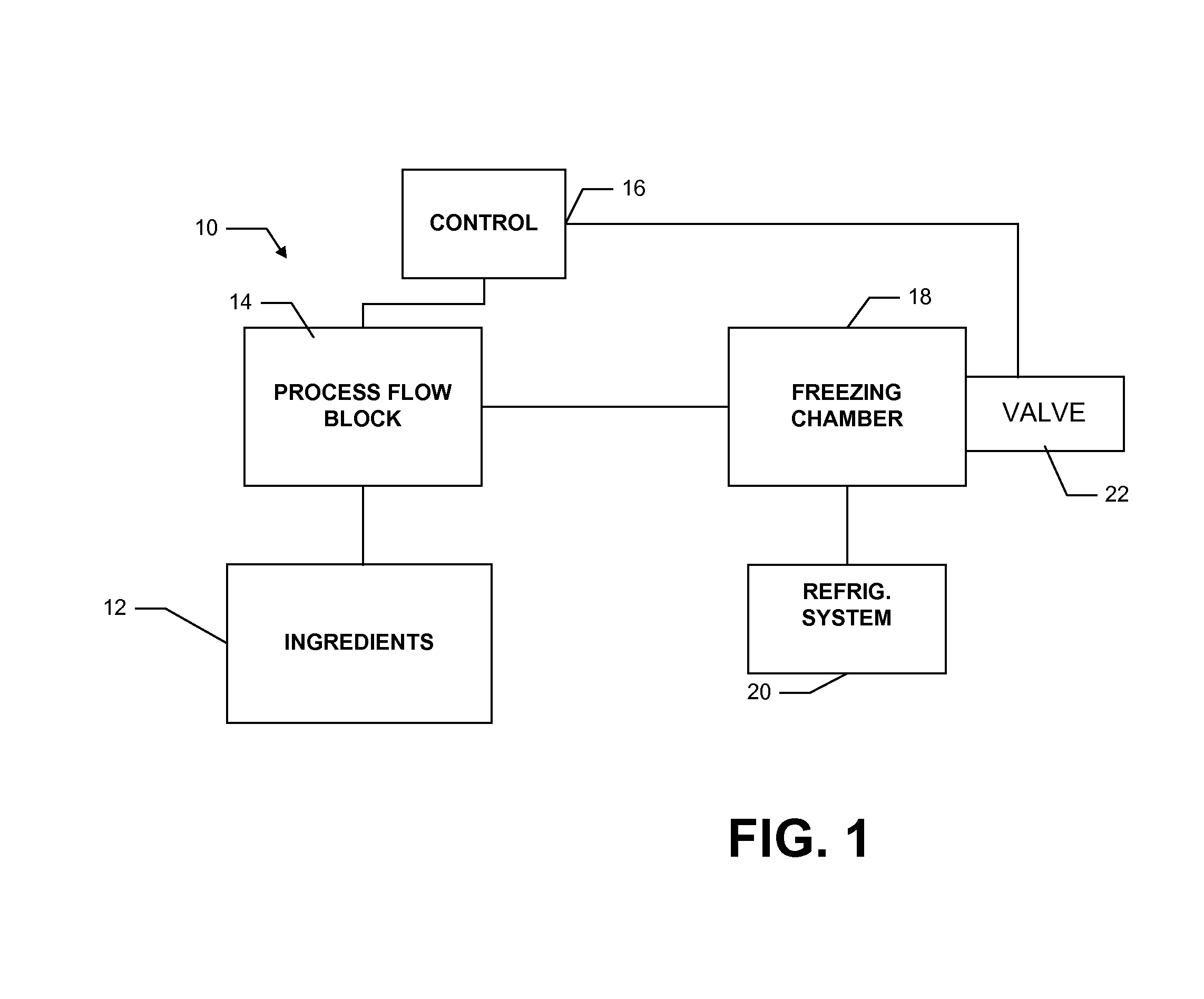

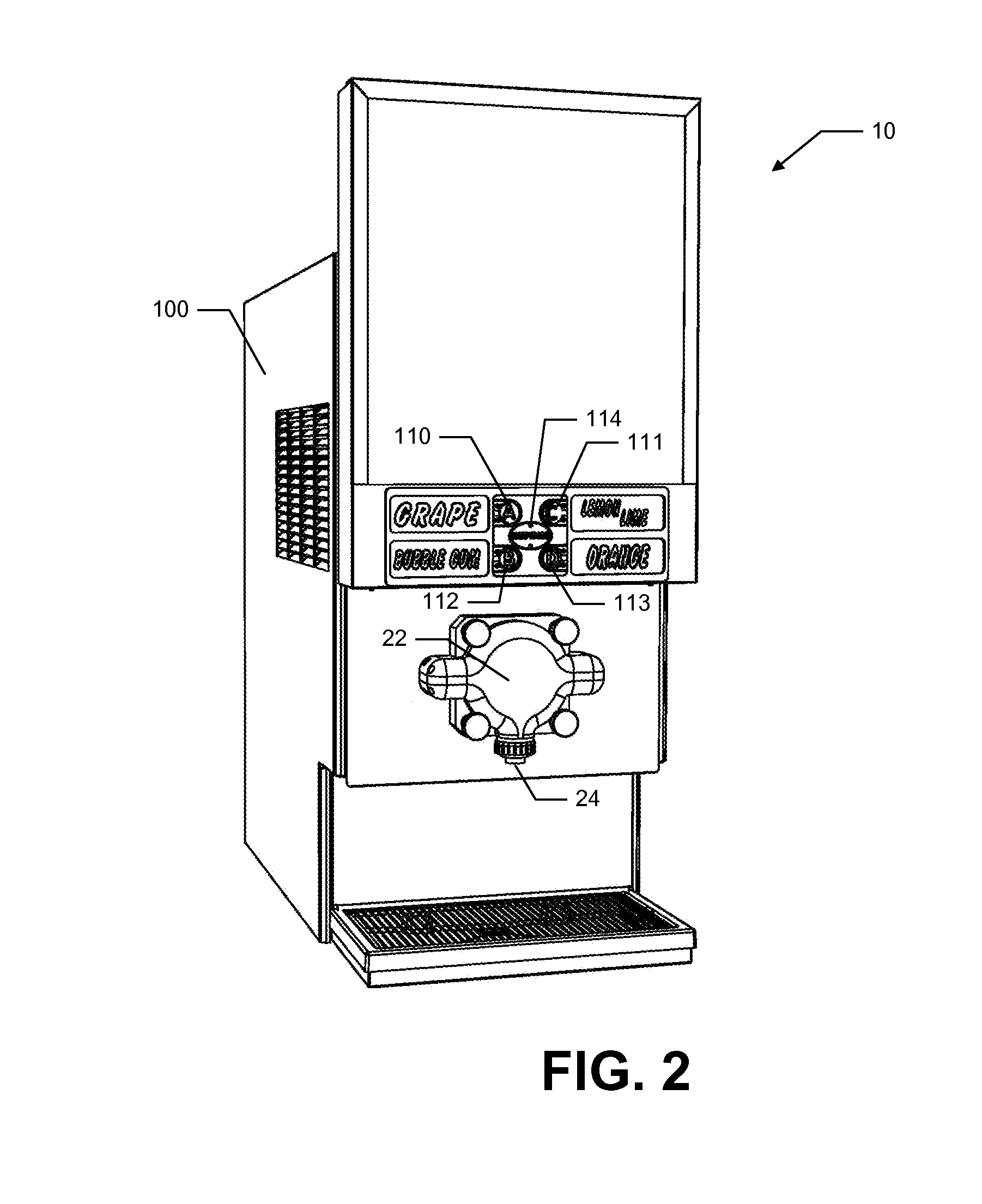

Multi-ingredient food dispensing machine

InactiveUS20080041876A1Reduce in quantityOpening closed containersBottle/container closureAdditive ingredientEngineering

The present disclosure provides an improved system and method that includes a food dispensing machine for dispensing a base food product through a dispensing valve and adding ingredients and other additives, such as flavors and the like, to the base food product when the product is dispensed from a product chamber. Multiple conduits coupled between additive sources and the dispensing valve can be selectively used to flow the various additives to the dispensing valve when the product is dispensed. The system and method may assist in reducing the number of product chambers generally required to deliver multiple products, allow various combinations of products, and even more combinations for those units having multiple product chambers with multiple dispensing valves. The disclosure further provides a unique valve that includes a movable nozzle assembly that unseats and seats on a fixed valve stem with attendant advantages in the above described dispensing valve.

Owner:FBD PARTNERSHIP

Spray actuating mechanism for a dispensing canister

ActiveUS7204393B2Economical and easy to manufacture and assembleFunction increaseLiquid dispensingEngineeringActuator

A spray actuator for a pressurized aerosol canister that simplifies the mechanical moving parts of a spray actuator to a body and a trigger and a third nozzle piece being inserted at the very end of the product dispensing passage either in the body or the trigger. The moveable trigger rotates about a pivot or hinge point on the body and is biased by engagement with the valve stem or an additional spring return into a neutral unactuated position where the product is not dispensed. When dispensing of the product is desired, the user grasps the actuator and pulls the trigger against the body and overcomes the bias of the valve stem and the valve is actuated as discussed above to dispense the pressurized aerosol product.

Owner:SUMMIT PACKAGING SYST INC

Tire pressure gauge

A tire pressure gauge for attachment to a valve stem includes a wall defining a chamber having a first port adapted to sealingly engage a valve stem, a probe being mounted in the first port so as to open a valve of a valve stem sealingly engaged by the first port, a pressure sensor in the chamber, a memory, a display physically supported on the device, a processor being operatively coupled to said display, pressure sensor and memory; and code being stored in the memory and operable by the processor to: retrieve at least one value indicative of a first threshold tire pressure from the memory, determine a pressure sensed by the pressure sensor, and, cause the display to present information indicative of a relative value of the sensed value to the first threshold tire pressure.

Owner:MEASUREMENT

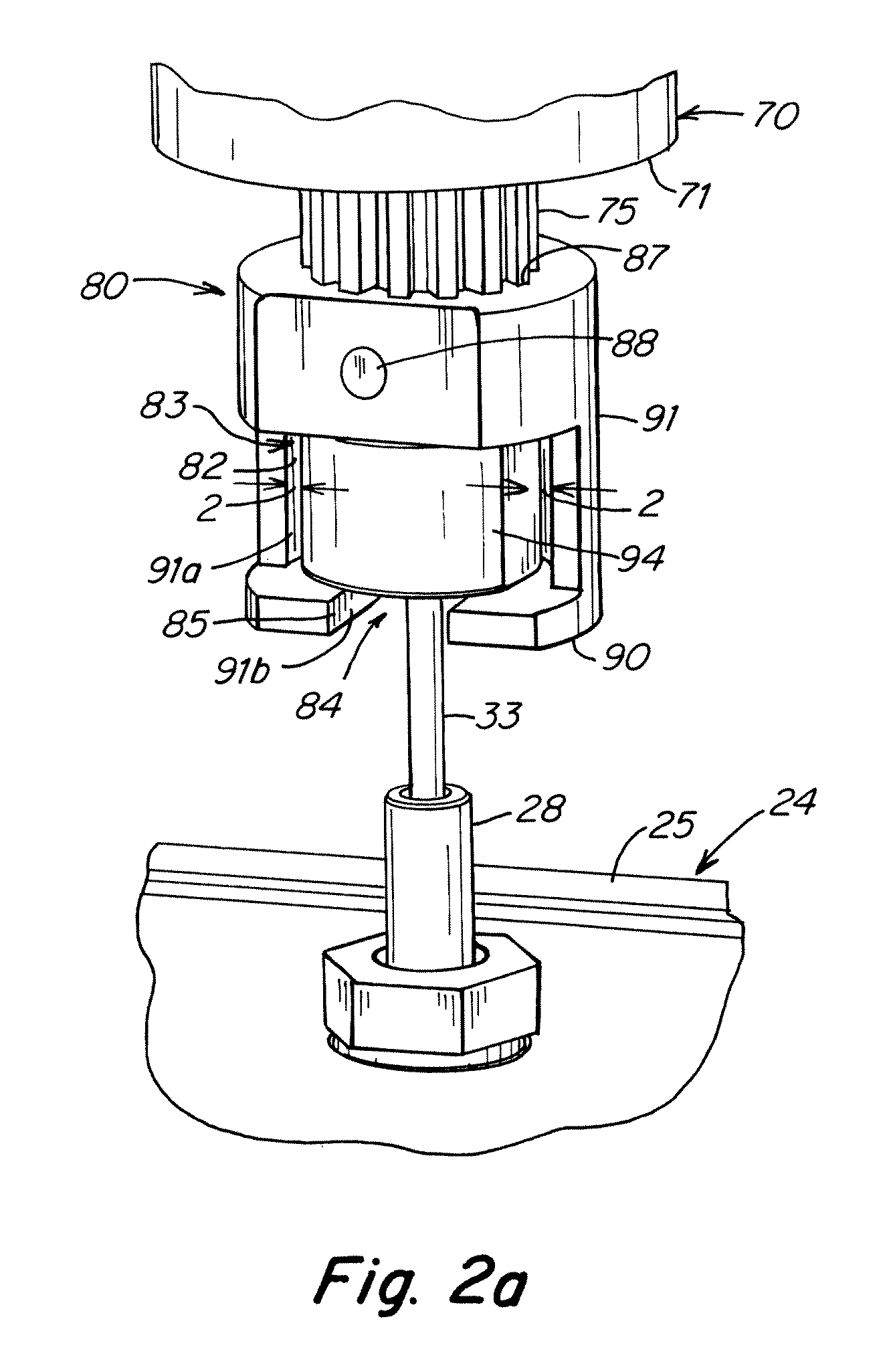

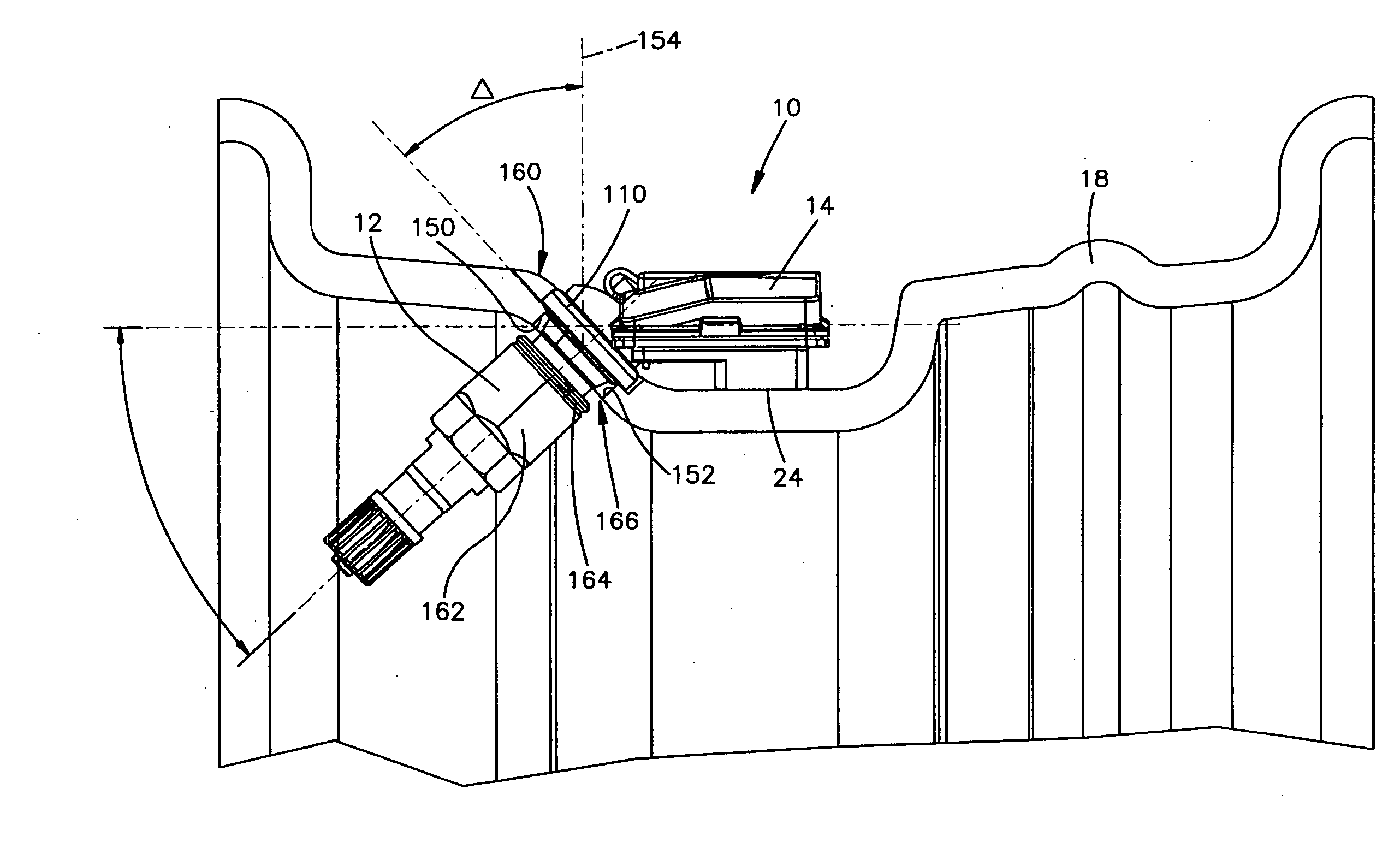

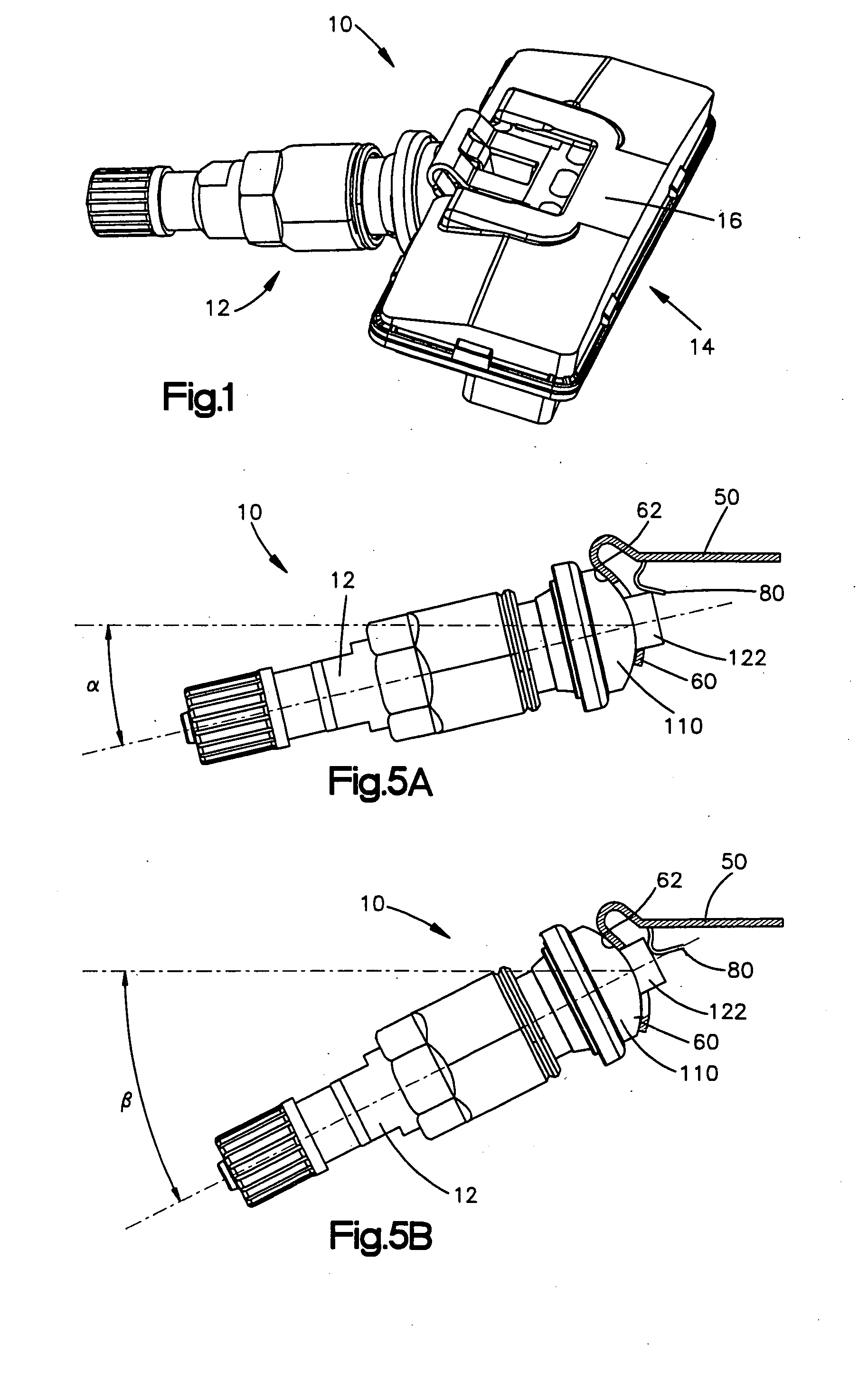

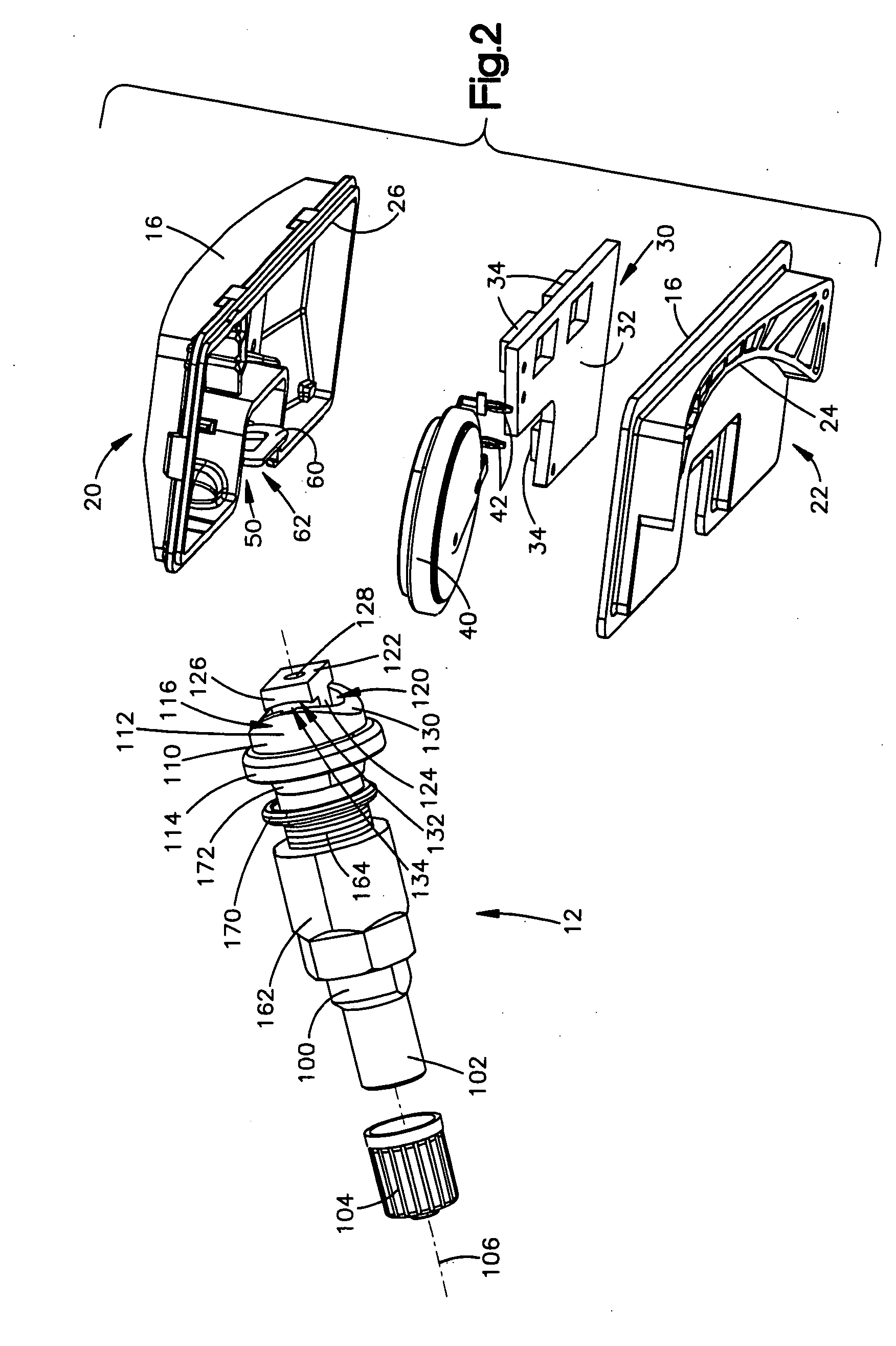

Tire pressure monitoring apparatus

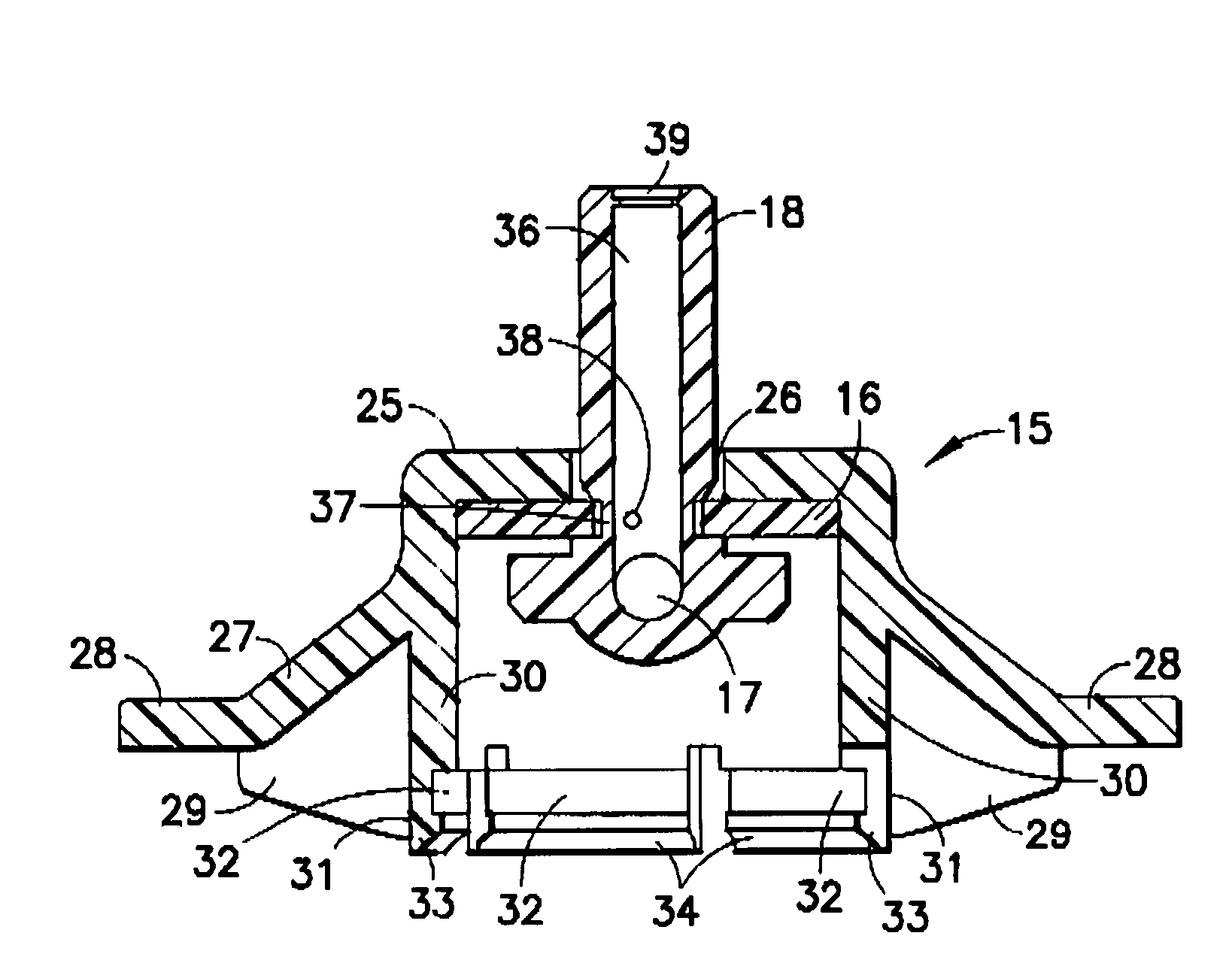

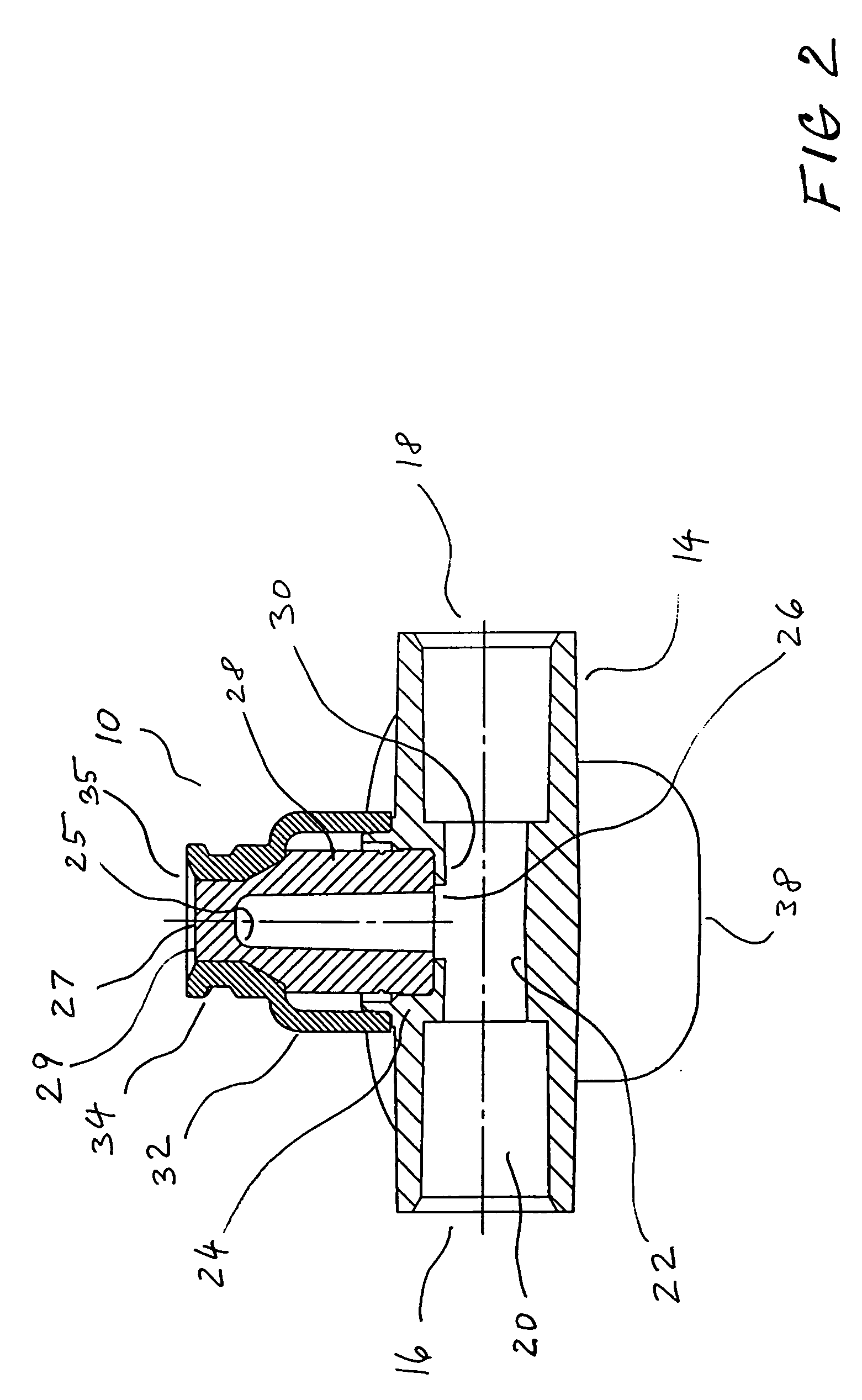

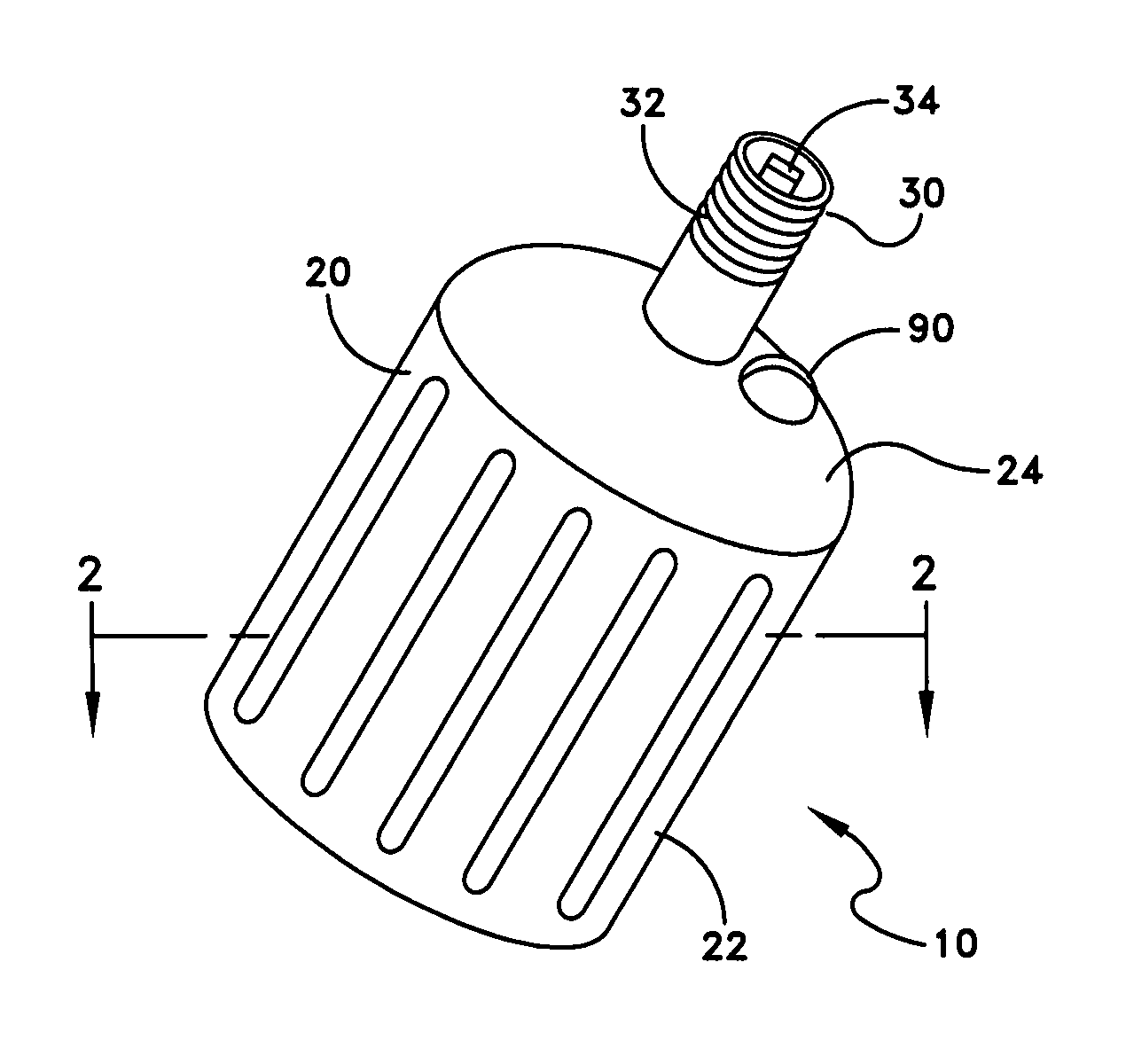

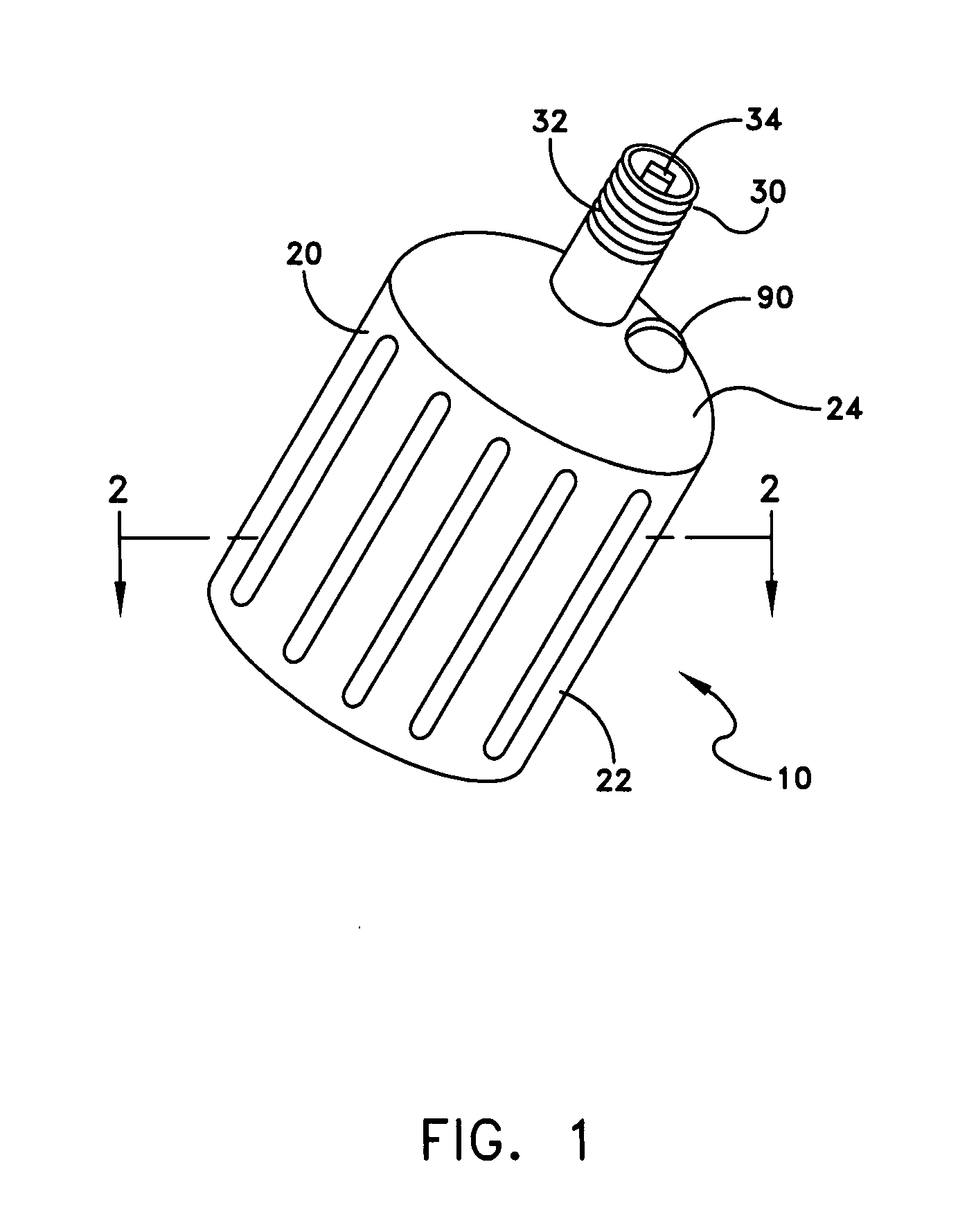

A tire pressure monitoring apparatus (10) includes a pressure transducer (14) and a valve stem (12). A support bracket (50) connects the valve stem (12) to the pressure transducer (14) and facilitates pivotal movement between the valve stem and the pressure transducer. The support bracket (50) includes a valve stem biasing member (80) that exerts a spring bias on the valve stem (12) to help maintain a selected angular position of the valve stem relative to the pressure transducer (14).

Owner:TRW AUTOMOTIVE US LLC +1

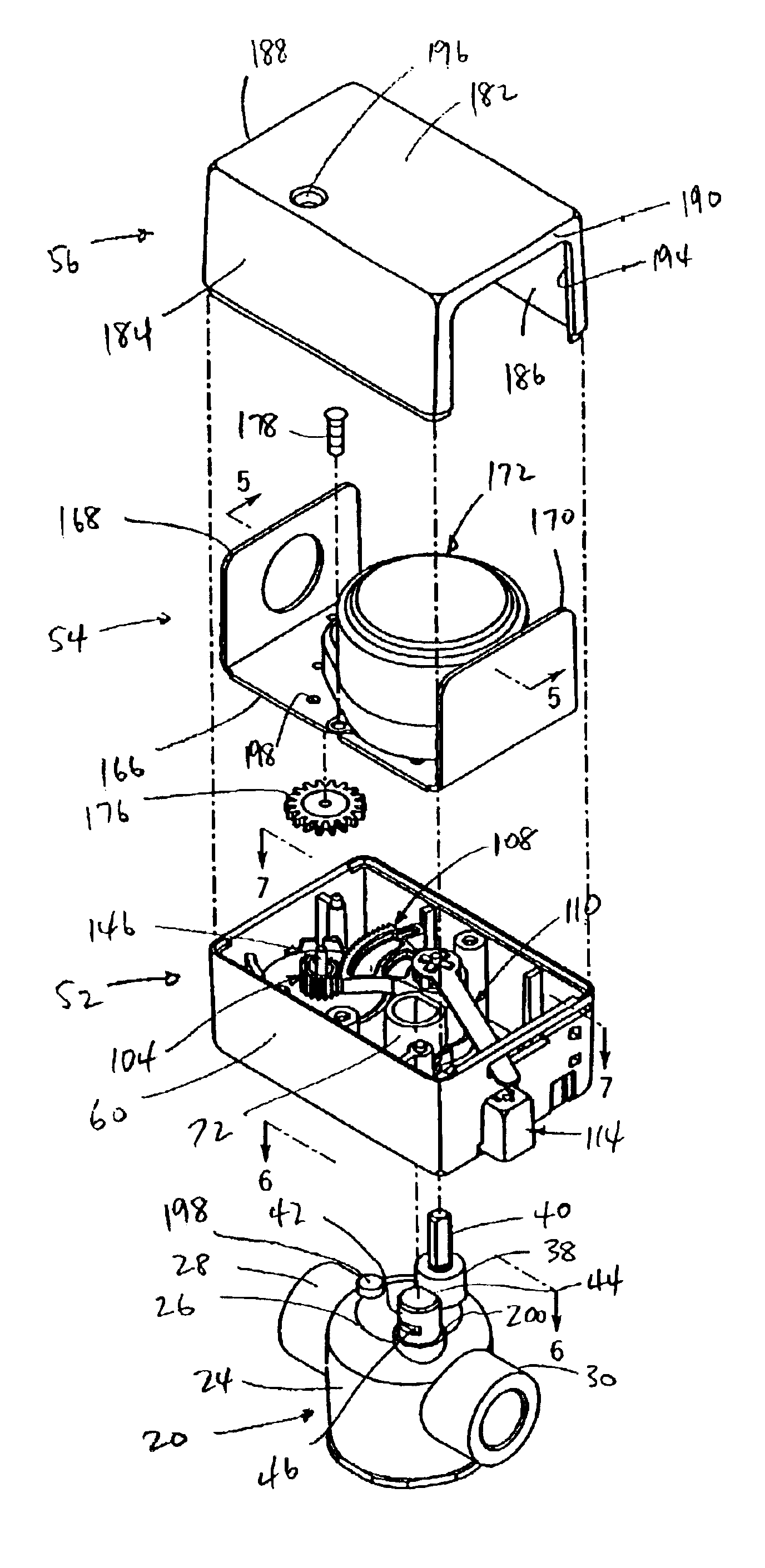

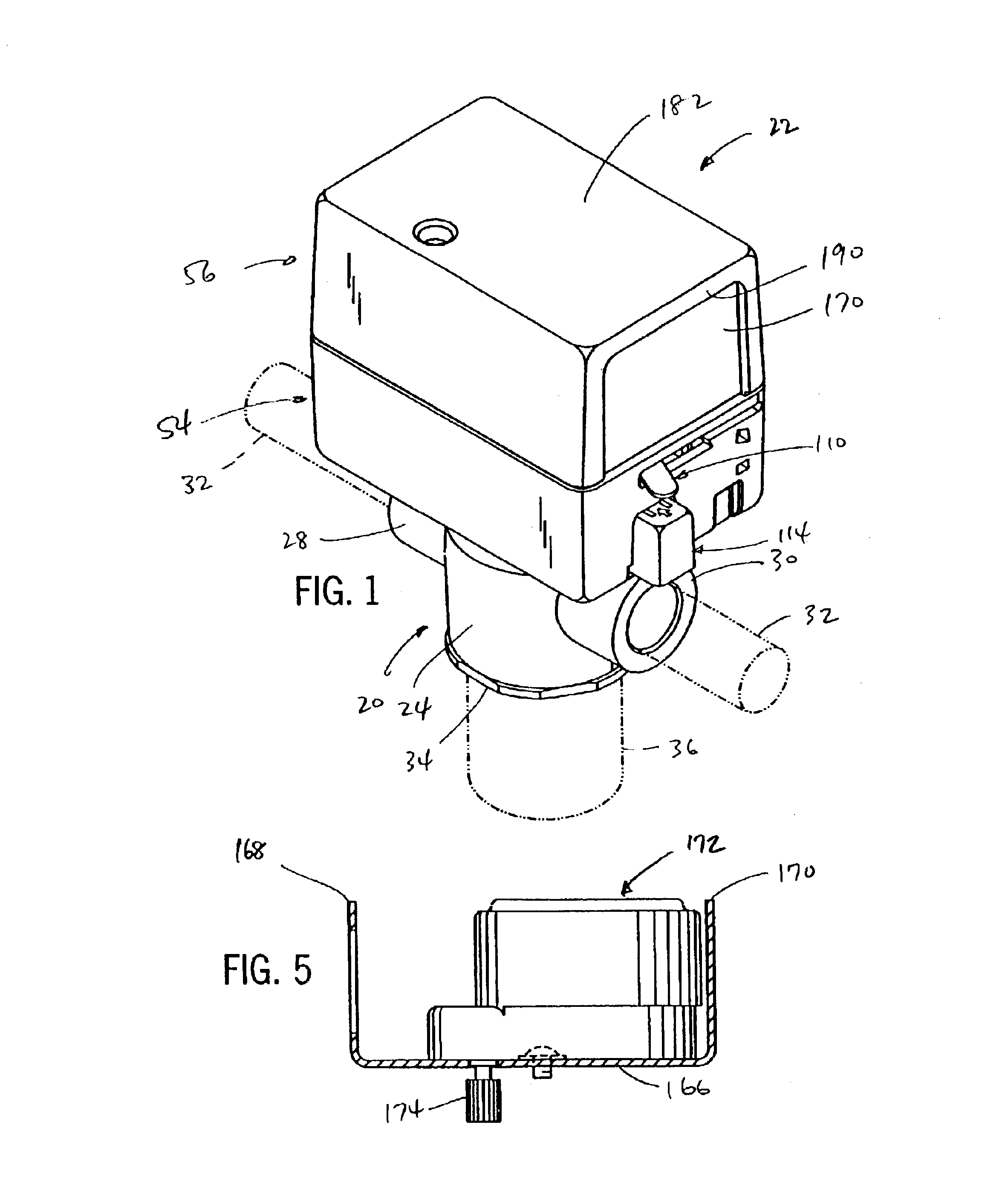

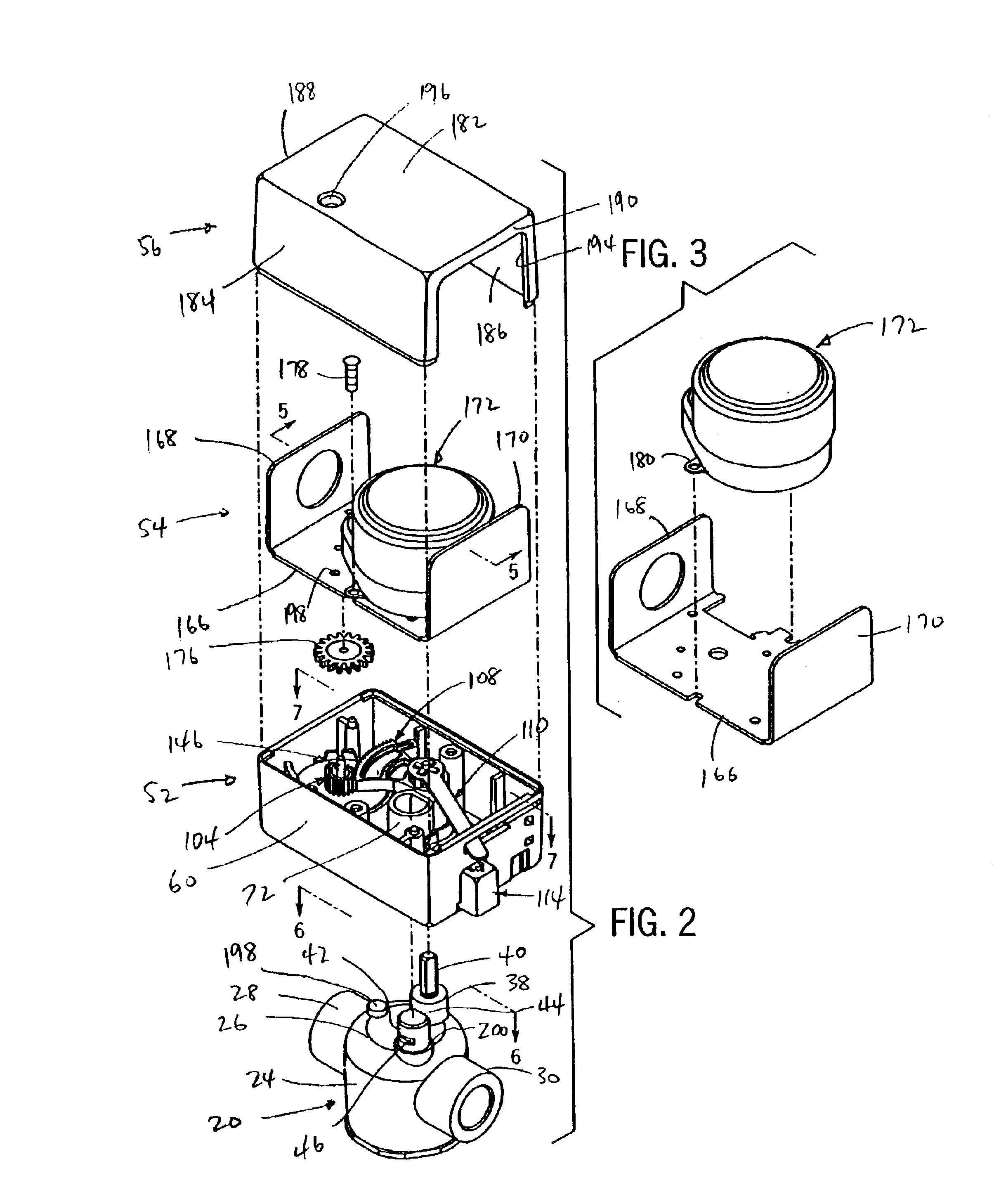

Valve with removable actuator

InactiveUS7048251B2Easy to disengageSimple componentsOperating means/releasing devices for valvesPreventing unauthorised/accidental actuationValve stemInternal cavity

A valve assembly includes a valve body and a valve actuator which is releasably engageable with the valve body. The valve body has an internal cavity within which a valve member is located, and a valve stem is interconnected with the valve body and is accessible from the exterior of the valve body. The valve body further includes a mounting member, and the valve actuator is selectively engageable with the mounting member. The valve actuator includes a latch member which is movable between a latching position and a release position. The mounting member includes a slot, and the latch member has a blocking member that is received within the slot when the latch member is in its latching position, to prevent removal of the valve actuator from the valve body. The latch member is manually movable to a release position, in which the blocking member is removed from the slot in the mounting member to enable the valve actuator to be disengaged from the mounting member. The valve actuator includes a motor which drives a gear assembly for selectively imparting rotation to the valve member. The motor is secured to a mounting member such as a mounting plate. The mounting plate includes one or more walls that are exposed to the exterior of the valve actuator, such that heat from operation of the motor is conducted via the mounting plate away from the motor to the one or more walls for dissipation into the surrounding environment.

Owner:CALEFFI

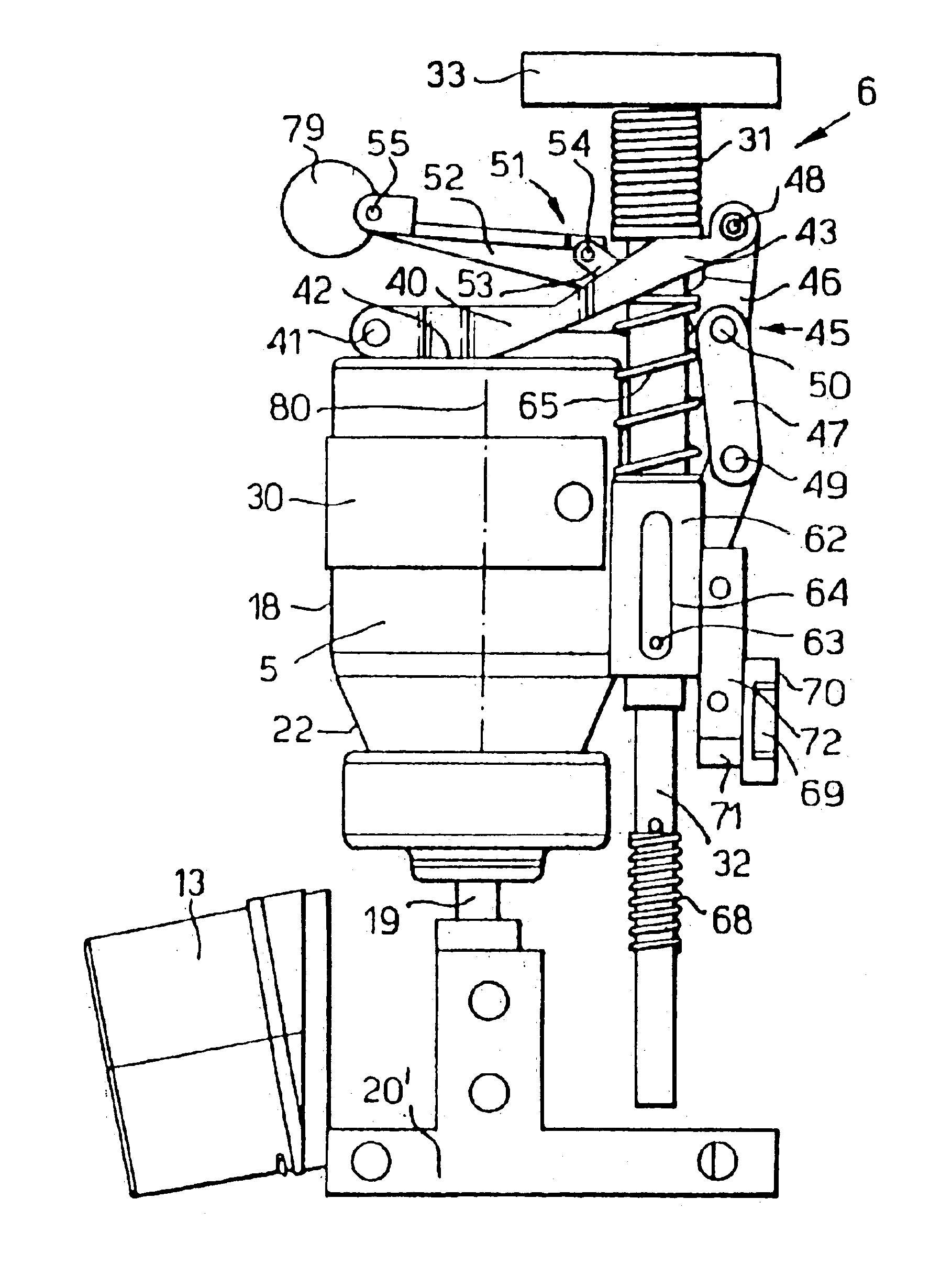

Inhaler

InactiveUS6860262B2Easy to controlNot lose timing accuracyMedical devicesMedical atomisersInhalationLocking mechanism

An inhaler for delivering medicament by inhalation, comprising a housing for holding a canister of medicament having a body and a valve stem compressible together to actuate the canister to deliver a dose of medicament from the valve stem, an actuation mechanism for compressing the canister, a cannister re-set mechanism comprising a locking element for locking the canister in a compressed state and a release member resiliently biassed by the actuation mechanism on compression of the canister to release the locking mechanism to allow reset of the canister. By provision of the locking element for locking the canister in a compressed state, it is possible to ensure re-set does not occur immediately. The release member subsequently releases the locking mechanism to allow re-set of the canister after a proper dose has been delivered. The cannister reset mechanism further comprises a damping element for damping movement of the release member to delay the action of the resilient biassing to release the locking element a predetermined period of time after actuation of the canister.

Owner:ASTRAZENECA AB

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS7308872B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

Valve actuator and method

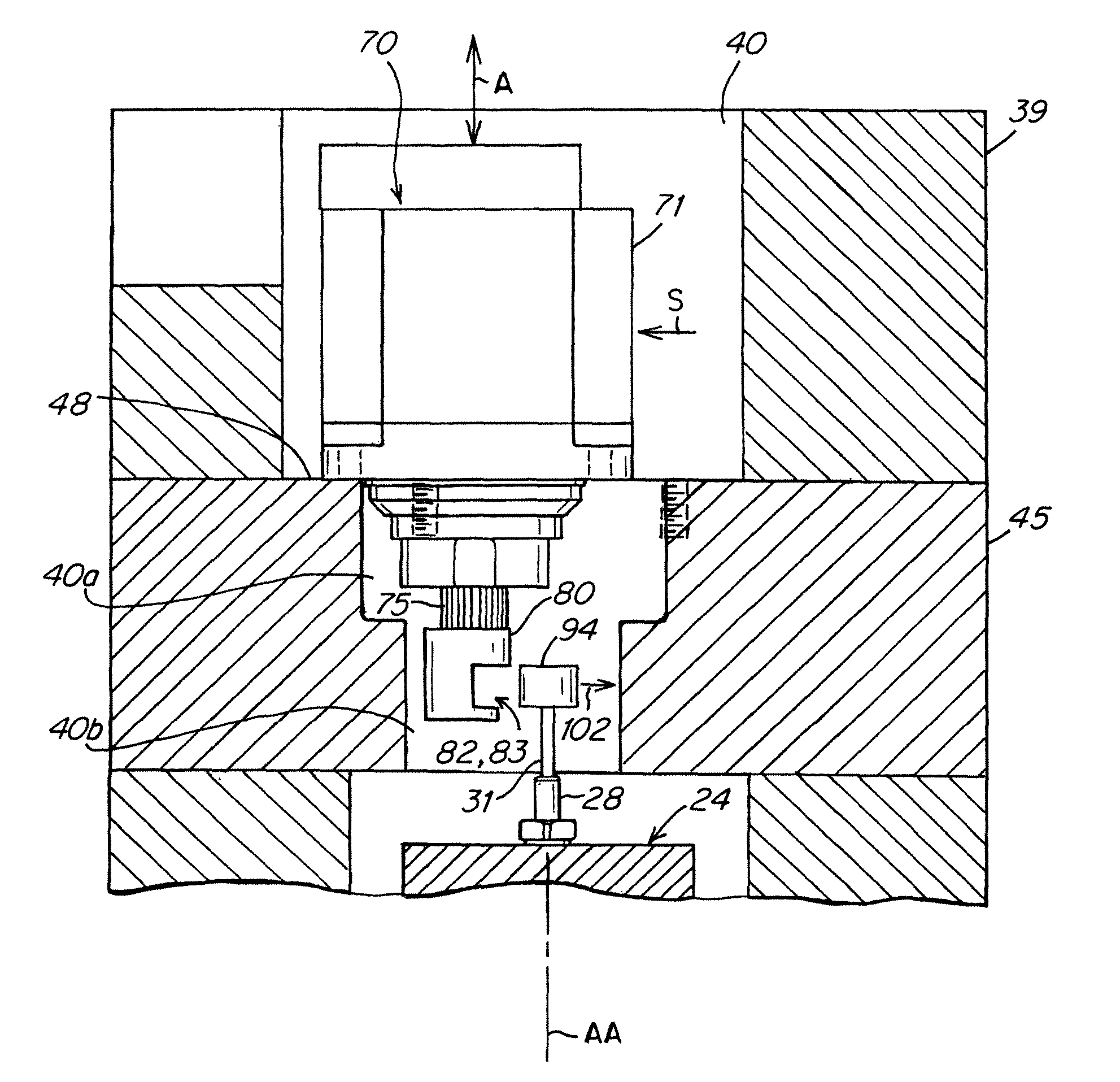

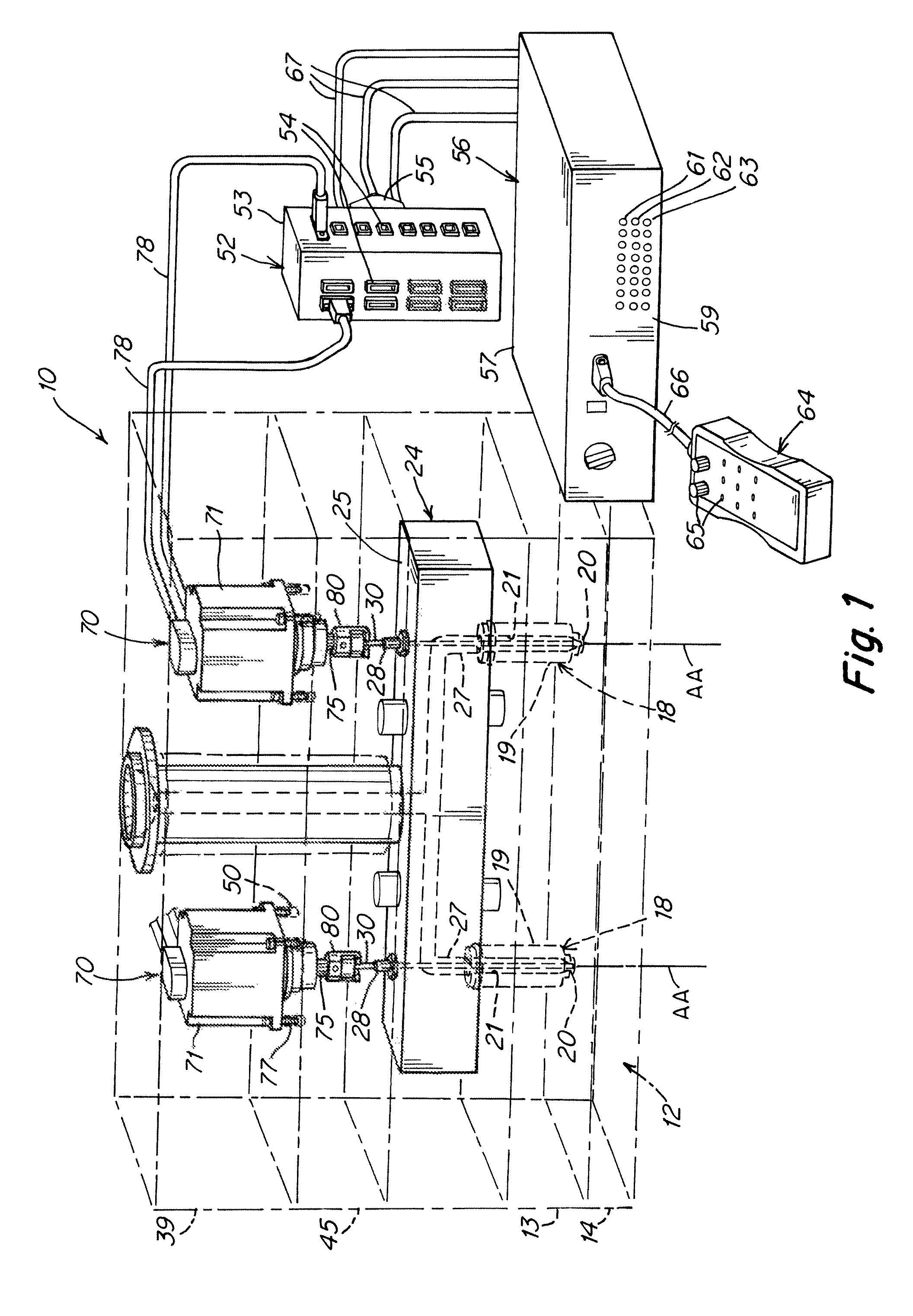

InactiveUS20020124889A1Easy to configureLow profileOperating means/releasing devices for valvesPipeline systemsValve actuatorValve stem

A subsea actuator and method is disclosed that includes all moving components mounted in a compact, concentric configuration. The subsea actuator is highly reliable and will operate at depth even with zero valve body cavity pressure. A preferably cup-shaped spring pusher is provided in telescoping relationship to the hydraulic chamber. A piston position indicator is provided which is connected externally to the hydraulic piston cylinder to avoid the possibility of hydraulic leaks due to the piston indicator. A manual override may be provided with a manual override indicator. The manual override indicator has a shorter travel length than the manual override operating stem to thereby reduce the overall length of the manual override assembly. The driving stem provides a removable connection to the hydraulic piston from the top of the actuator housing and a quick disconnect permits disconnection of the driving stem from the valve stem. In a preferred embodiment, upper and lower t-slot connections are utilized in the driving stem assembly. In a preferred embodiment, two back seat valves are removably secured to the driving stem to engage respective seats and provide additional sealing around the driving stem so as to prevent leakage between the valve chamber and actuator housing chamber. The high tension spring does not need to be removed to perform maintenance, and all wear items and seals are readily accessible. Change or replacement of the stem packing is made from the top of the bonnet to avoid dissasembling the bonnet to valve body connection. Pre-load bolts are used to adjustably preload the tension in the return spring. The height / weight of the actuator is significantly reduced as compared to prior art subsea valve actuators.

Owner:WORLDWIDE OILFIELD MACHINE INC

Press-down valve for medical instruments for suction and irrigation

Owner:KARL STORZ GMBH & CO KG

Universal, remote, continuous vehicle tire air pressure monitoring and reporting system

InactiveUS6011463AReduce inventory costsReduce manufacturing costTyre measurementsTyre-inflating valvesLow voltageRadio reception

This invention is a method and system for reporting the under or over pressure conditions on motor vehicle tires. The device is comprised of air hoses, pressure sensors, radio transmitters with antennas, a radio receiver, a display unit with lights, batteries, lights, and associated electrical components. An assembly mounted on the front of each wheel, over or in place of the hubcap, consists of an air pressure monitor utilizing air pressure inflation valves, a radio transmitter with battery cell, a radio transmitter antenna, and high / low indicator lights. Air hoses attached to each tire's valve stem are connected to the air pressure inflation valves of the air pressure monitors. The wheel mounted transmitters are powered by a low voltage battery that is normally powered off until activated by the changes of the pre-set air pressure of the tire air pressure monitoring sensor.

Owner:CORMIER SR LEVITE

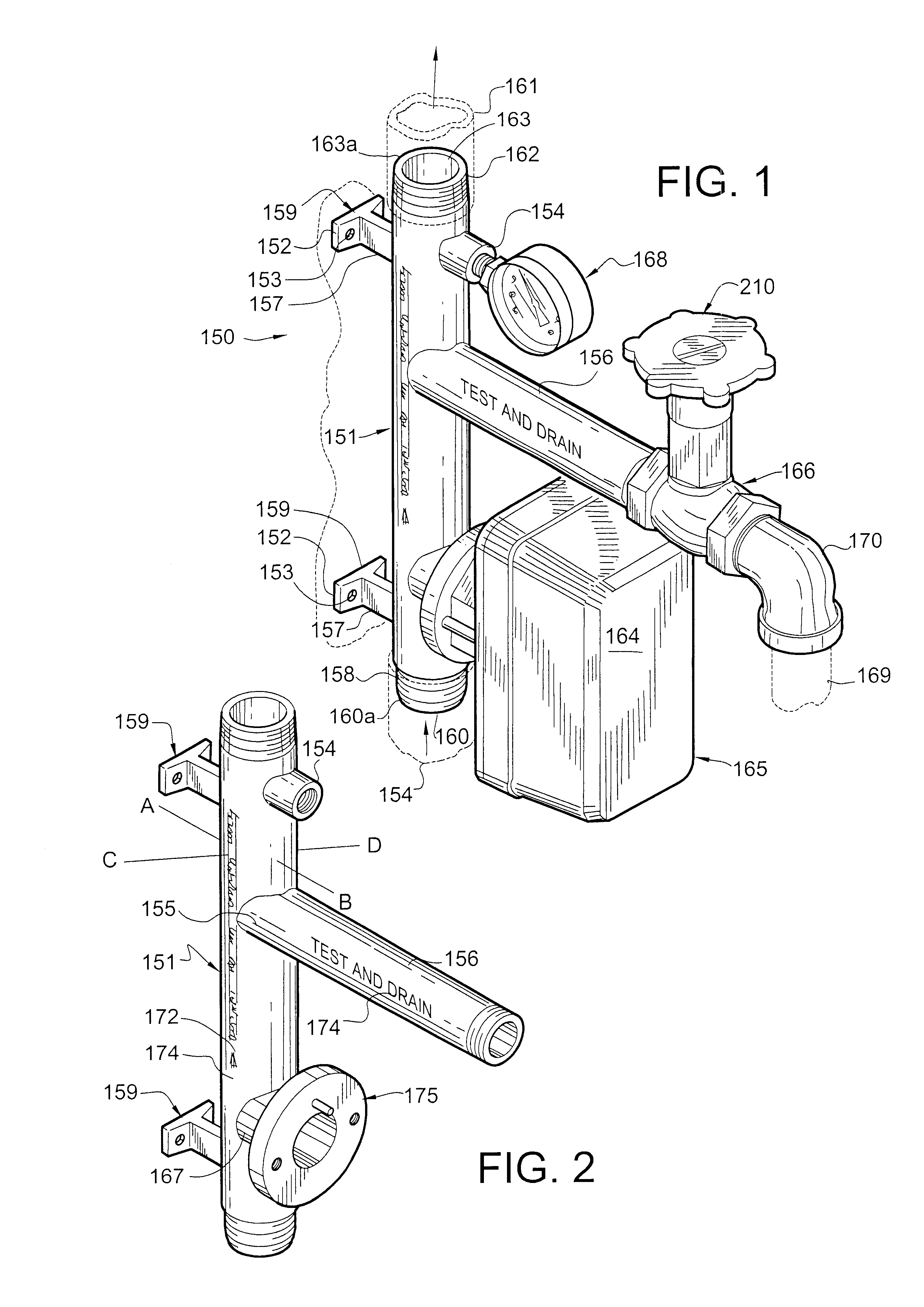

Fire-control sprinkler system

InactiveUS6601604B1Simple methodEasy to useOperating means/releasing devices for valvesServomotor componentsFire controlSprinkler system

This invention provides for a valve system for use in fire suppression systems that provides pressure relief, pressure testing, and drain / test fluid flow capability. The valve system consists of a valve body with an attached riser. Adjustably attached to the riser is a rotary handle for raising and lowering a spring loaded valve stem. A blocking plug is provided for attachment to the handle which operates to block the movement of the valve stem during pressure testing of the fire suppression system. A tension disk is adjustably attached to the inside of the riser to manually adjust the spring tension. In addition, a means is provided for preventing system fluid from contacting the spring.

Owner:FERGUSON FIRE & FAB INC

Low friction live-loaded packing

ActiveUS7963502B2Reduce packing friction and packing wearAvoid squeezingSpindle sealingsOperating means/releasing devices for valvesEngineeringControl valves

Owner:FISHER CONTROLS INT LLC

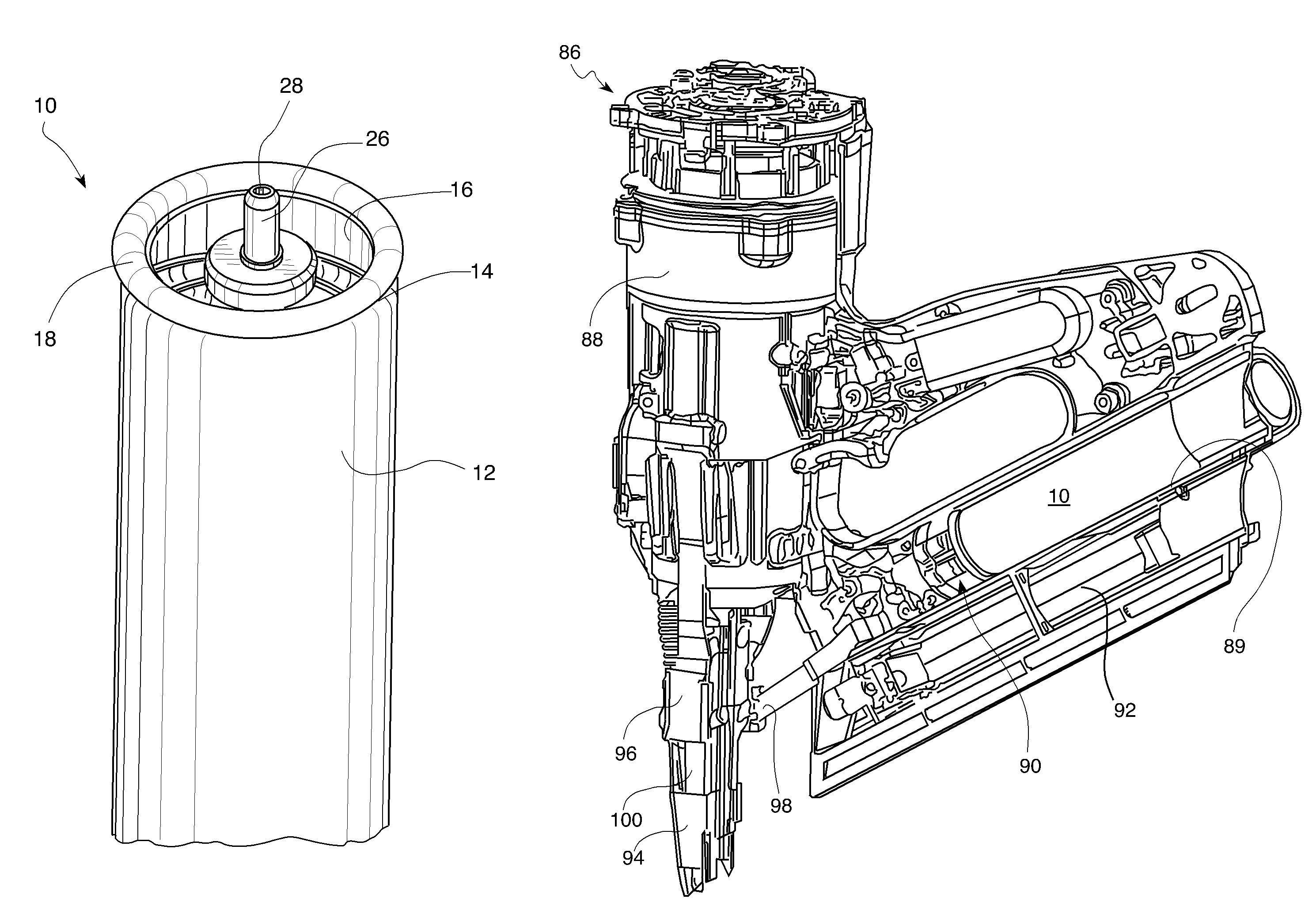

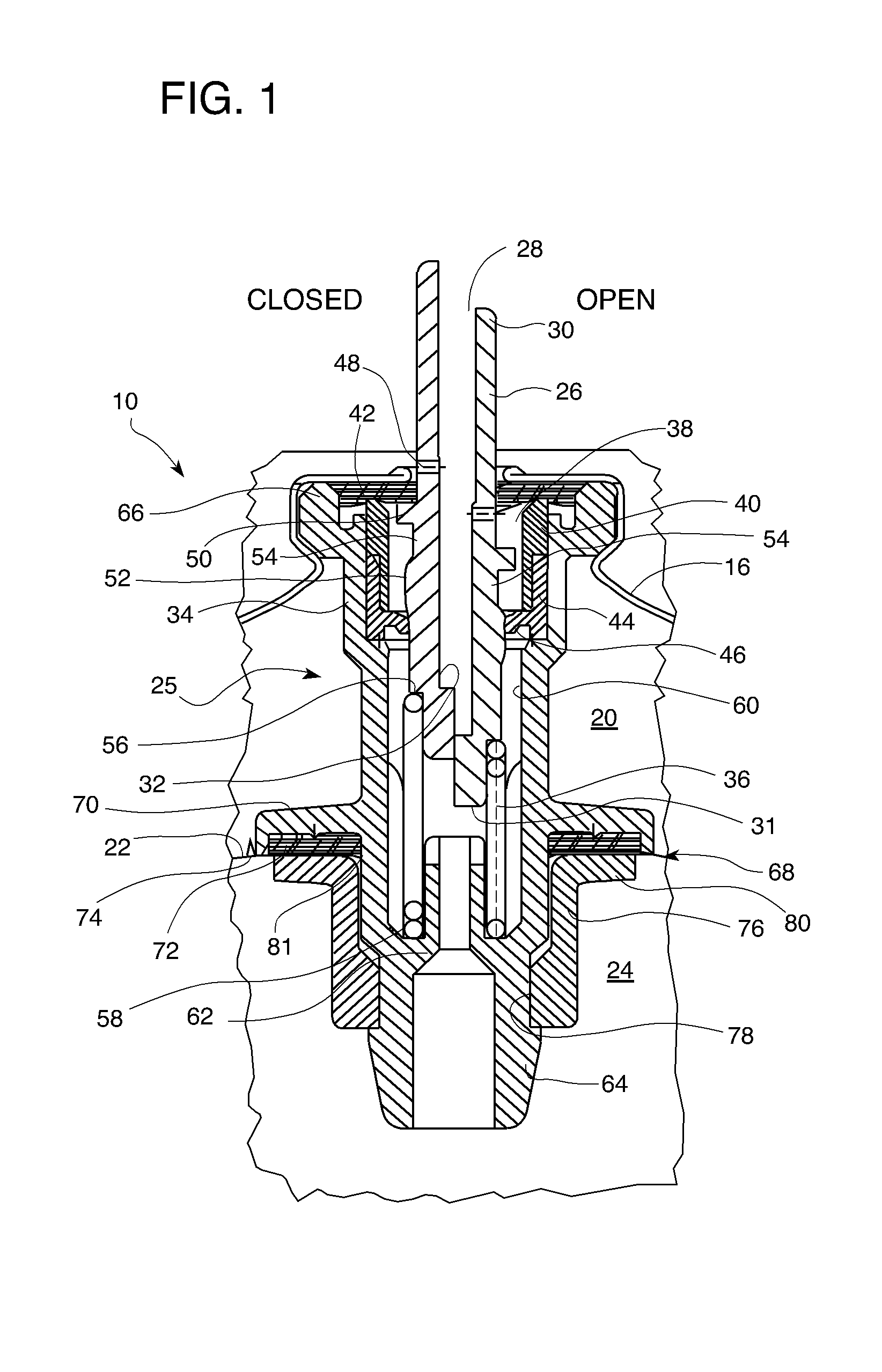

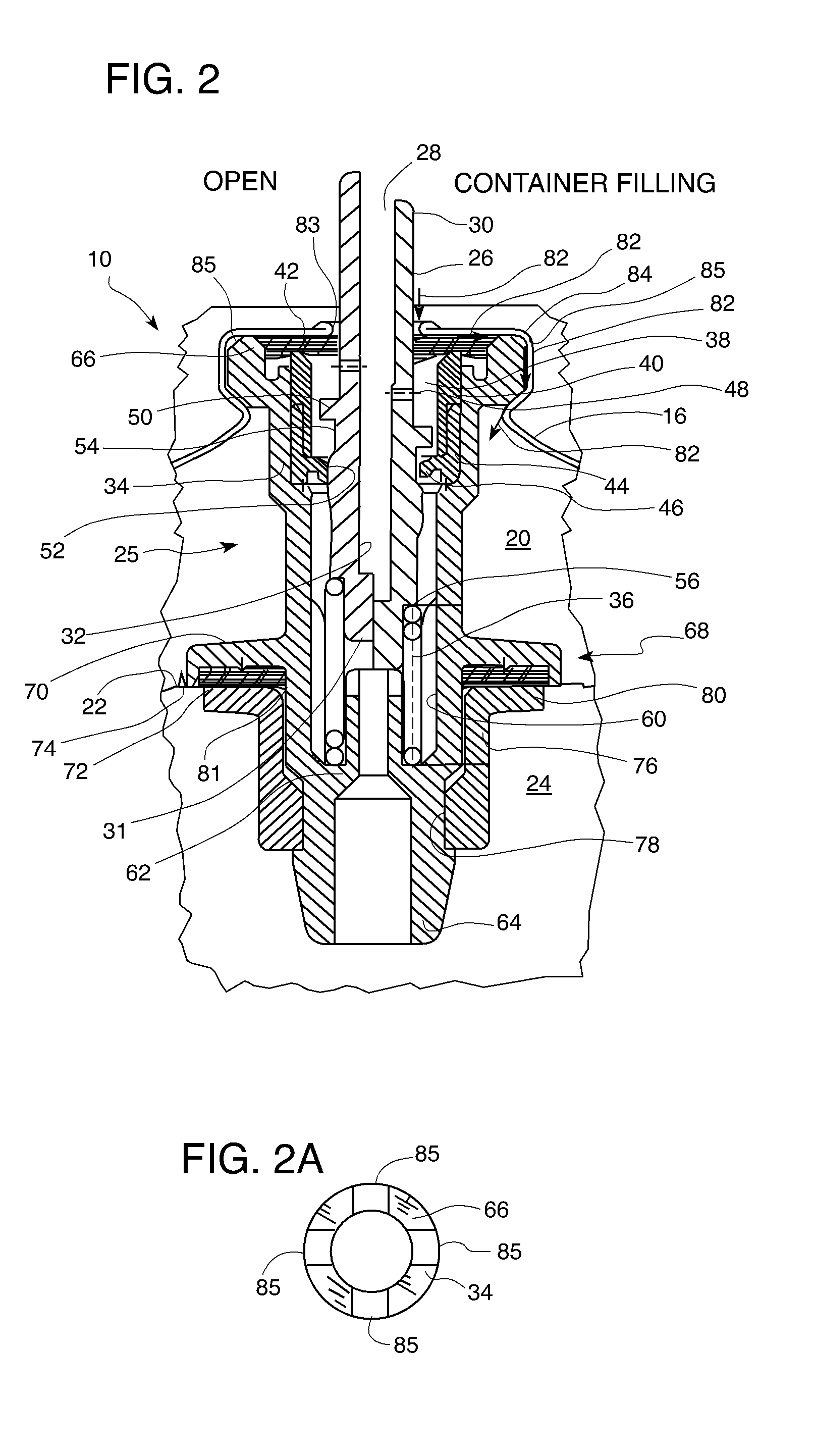

In-can fuel cell metering valve

ActiveUS7392922B2Extended service lifeReduce system costStapling toolsContainer filling methodsFuel cellsCombustion

A fuel cell for use with a combustion tool for delivery of a predetermined amount of fuel with each stem actuation is provided and includes a housing defining an open end enclosed by a closure. A main valve stem has an outlet, disposed in operational relationship to the open end and reciprocating relative to the housing at least between a closed position wherein the stem is relatively extended, and an open position wherein the stem is relatively retracted. A fuel metering valve is located within the housing, associated with the main valve stem, including a fuel metering chamber disposed in close proximity to the closure and configured so that when the stem is in the open position, only a measured amount of fuel is dispensed through the outlet. In a preferred embodiment, the fuel cell housing includes a separate fuel container, and the fuel metering valve includes a valve body having a second end opposite the fuel metering chamber located within the container.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com