Patents

Literature

907 results about "Surface conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

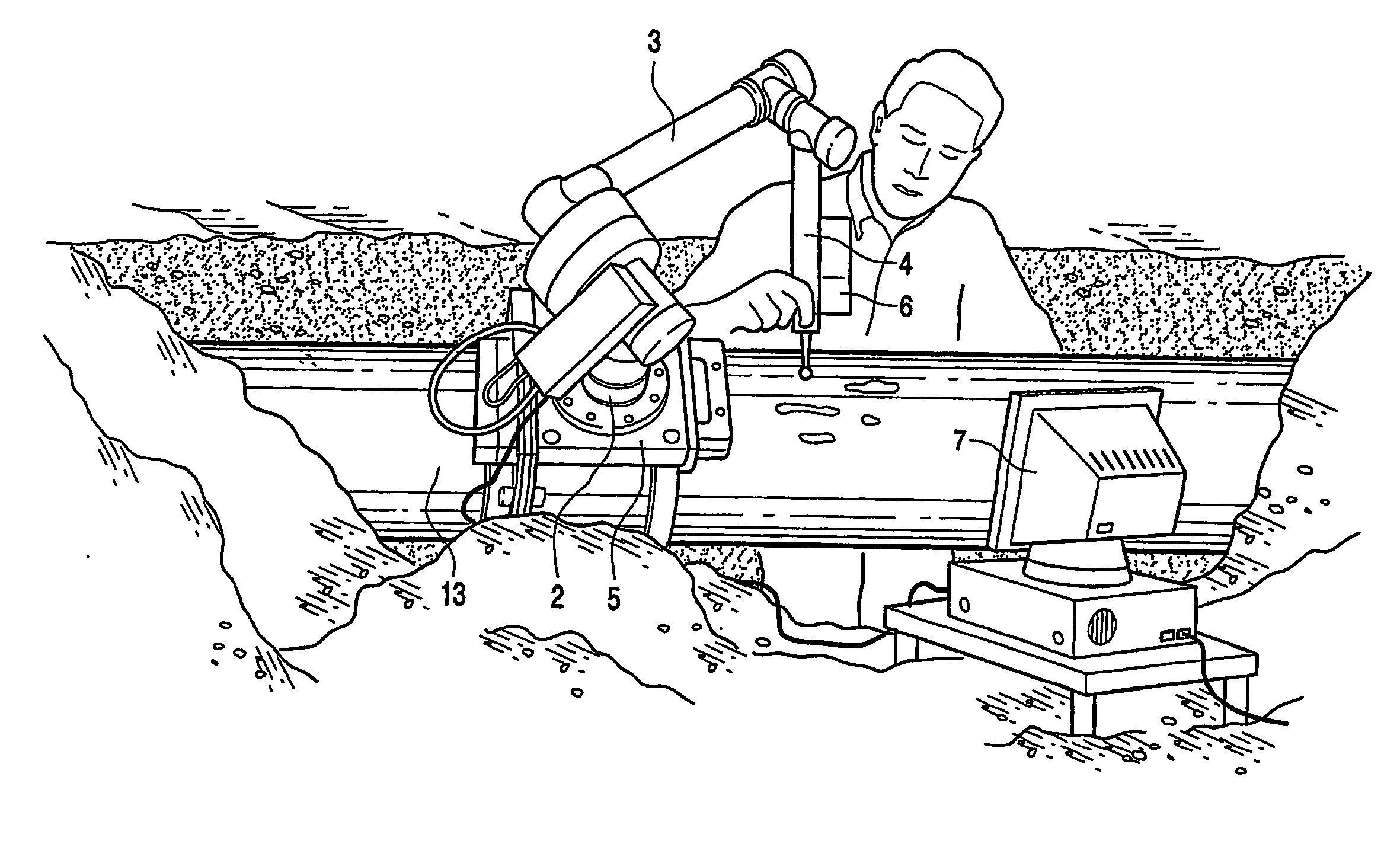

Method and apparatus for scanning corrosion and surface defects

InactiveUS20060288756A1Readily usable outputAccurately determineAnalysing solids using sonic/ultrasonic/infrasonic wavesWave based measurement systemsSurface conditionsPrediction system

The present invention relates to a method and an apparatus for determining the life span for secure use of a pipeline comprising the steps of a) defining an area for surface corrosion analysis on the pipeline, b) providing a corrosion scanning system for scanning the defined area on the pipeline, c) localizing and measuring the corrosion on the surface of the defined area by means of the corrosion scanning system, d) determining the remaining wall-thickness of the pipeline at the defined area by means of the corrosion scanning system, and e) processing the surface condition data related to corrosion at the defined area obtained in steps c) and d) to determine the life span for secure use of the pipeline. In another aspect the present invention relates to a corrosion scanning system for performing for performing the method according to the invention. In another aspect the invention relates to a prediction system for predicting the secure life span of a pipeline.

Owner:DE MEURECHY GUIDO D K

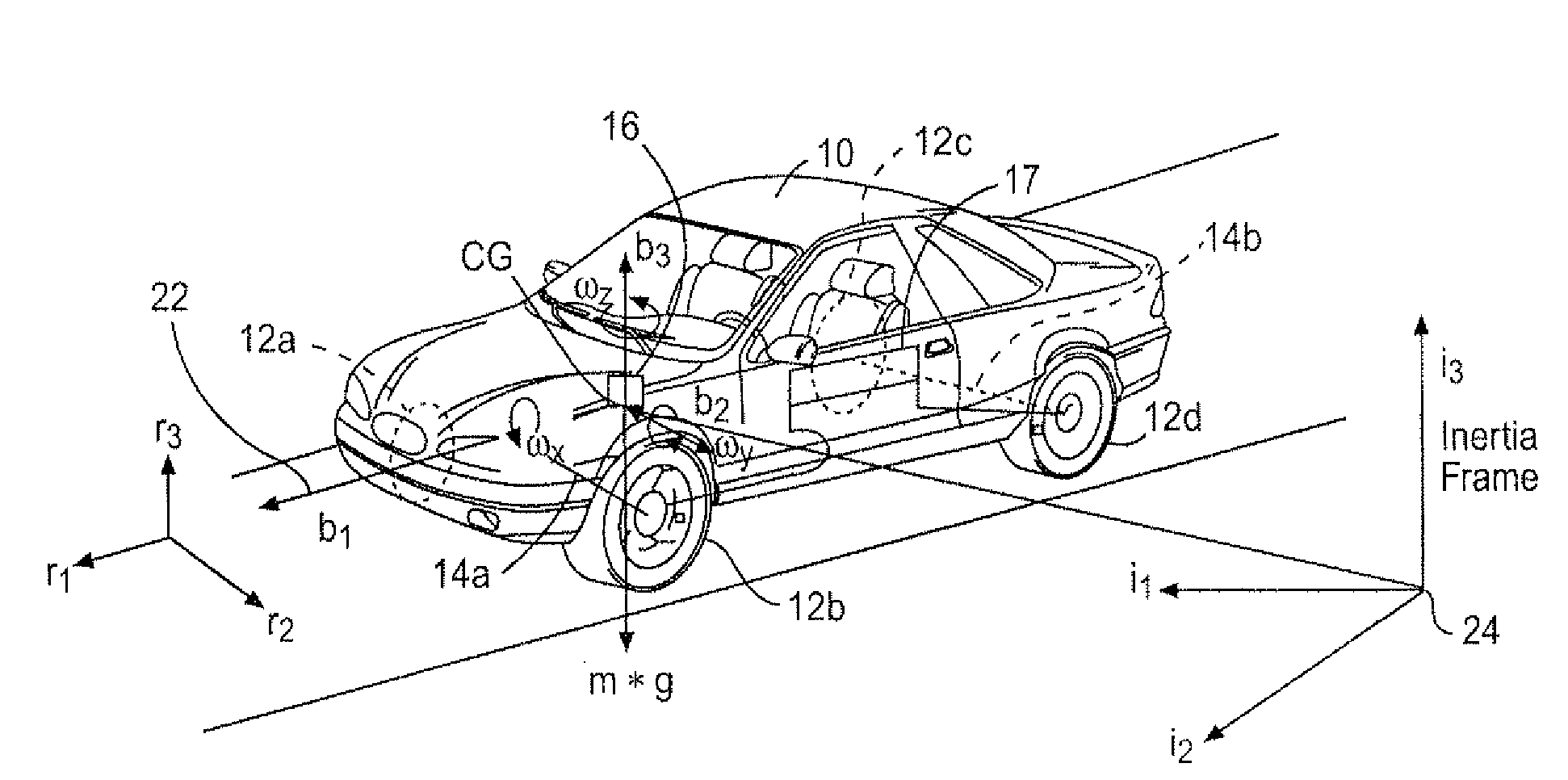

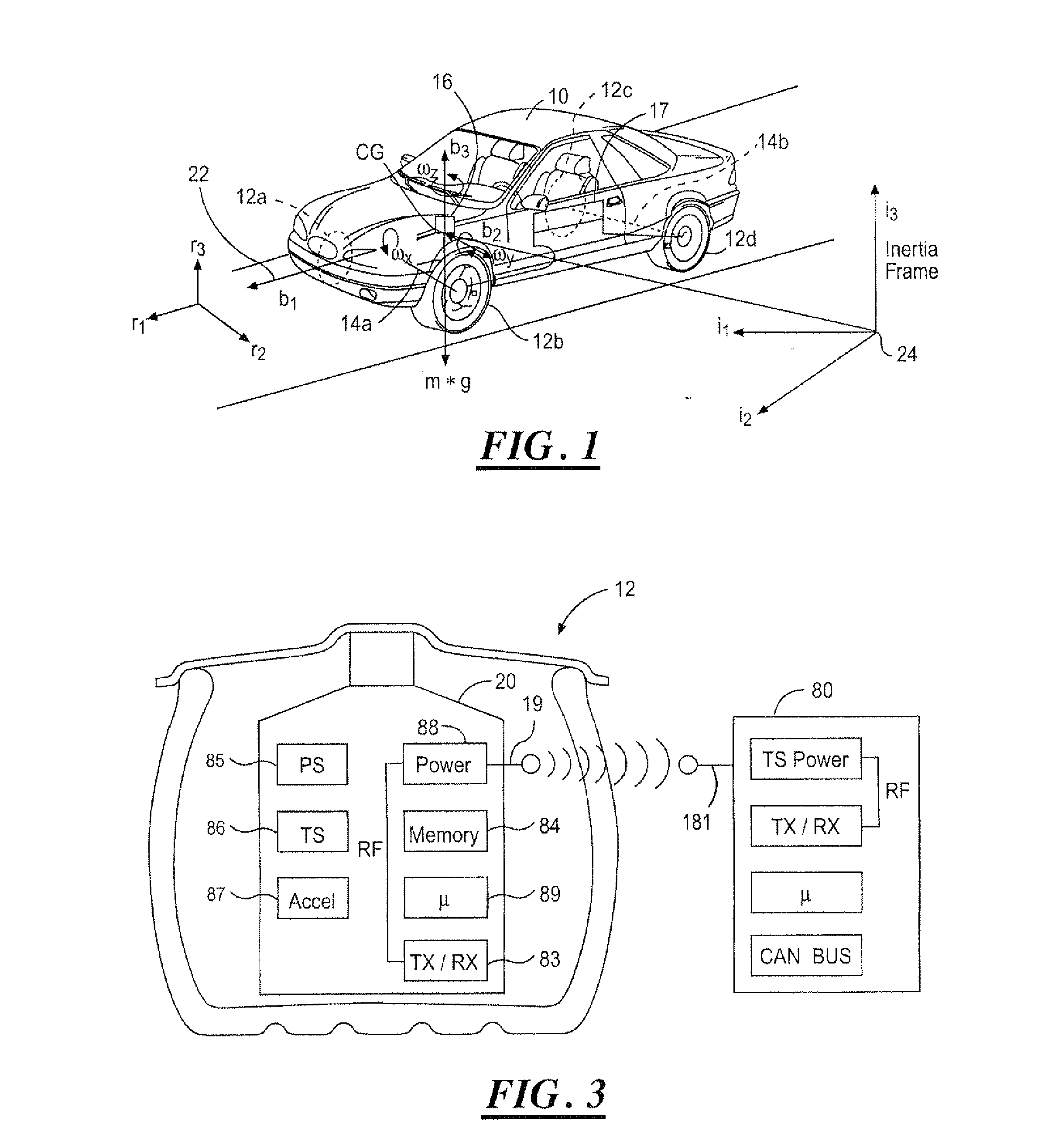

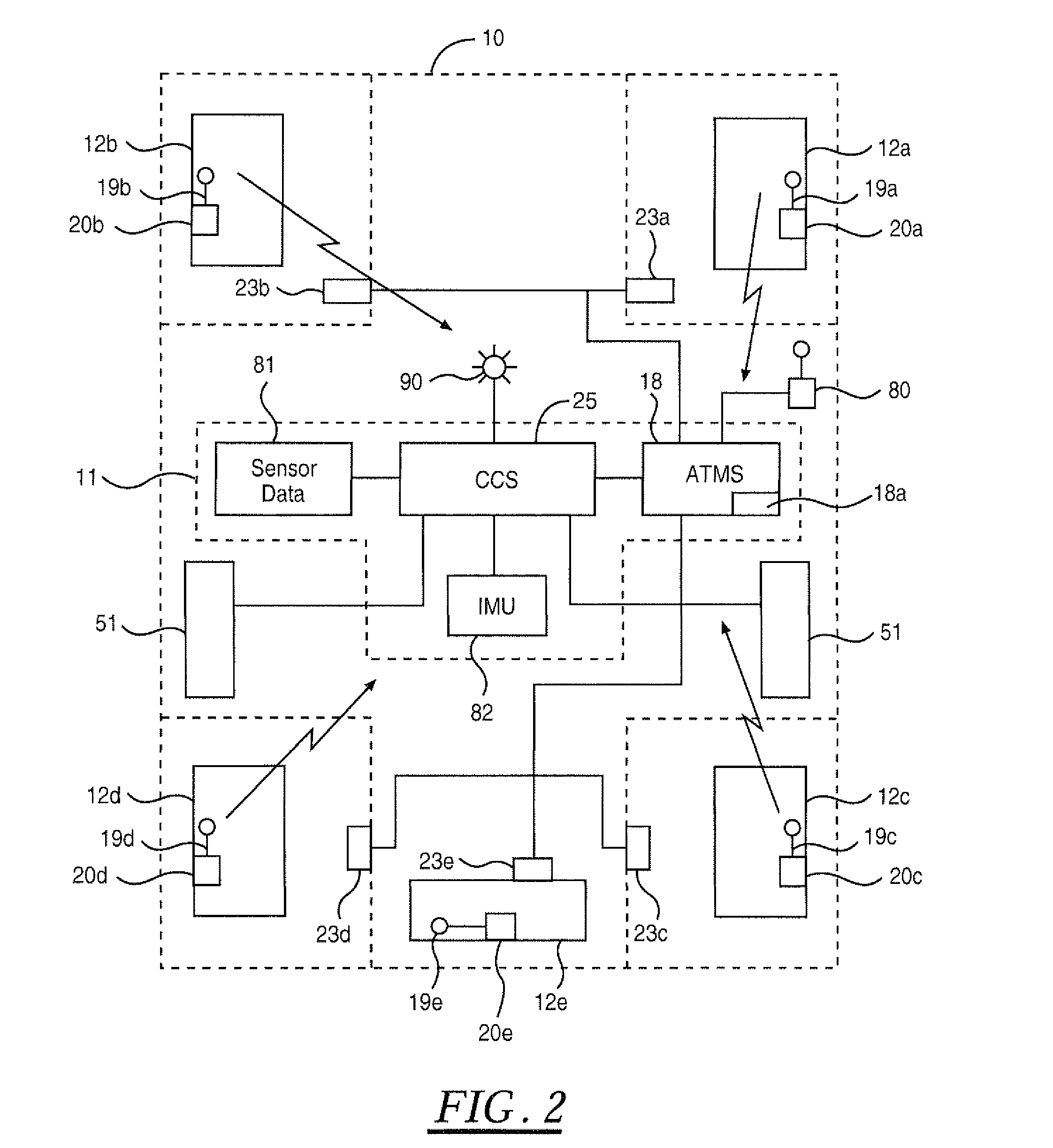

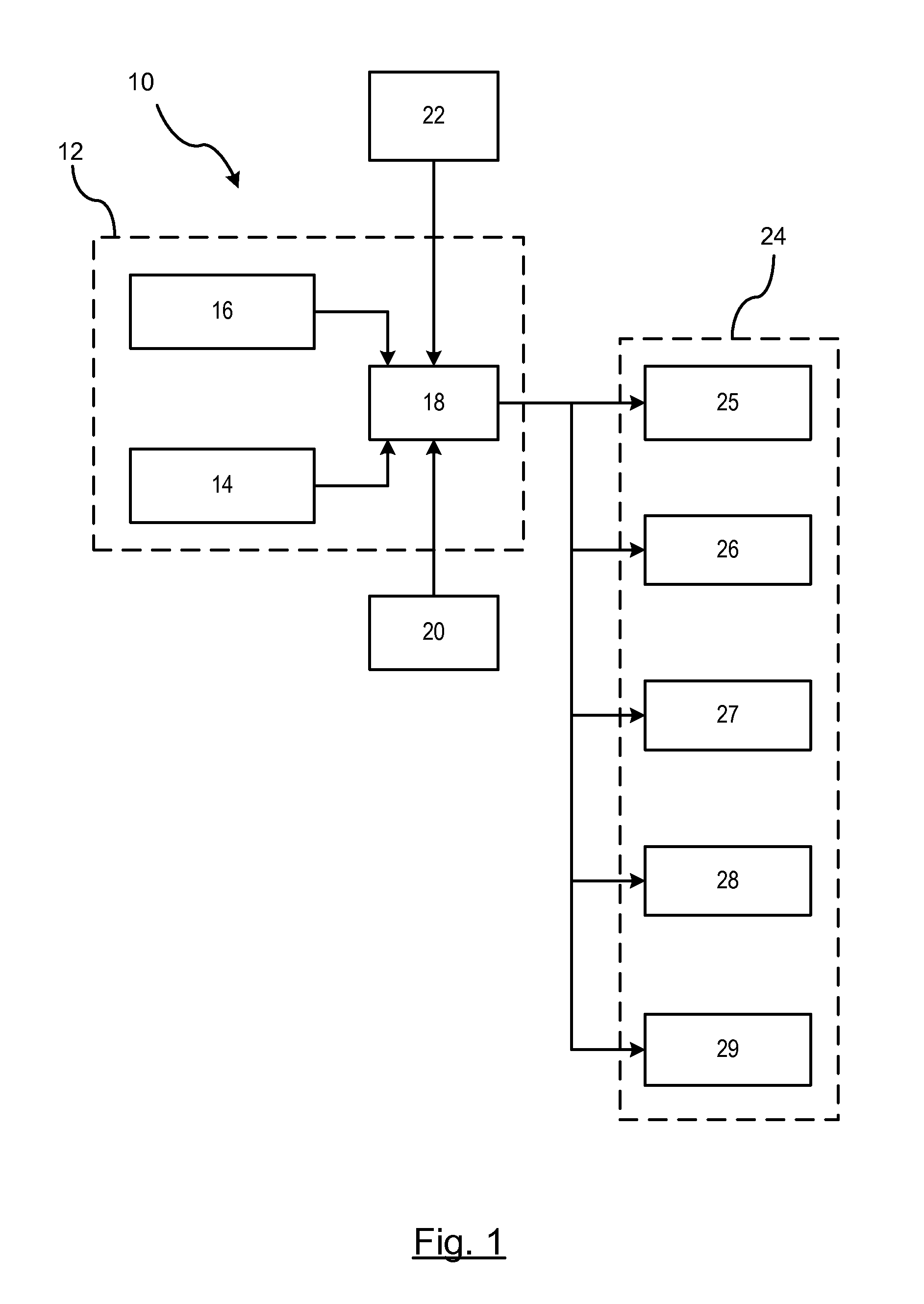

Vehicle Control System With Advanced Tire Monitoring

ActiveUS20080243334A1Improve vehicle rideImprove handlingDigital data processing detailsAnimal undercarriagesVehicle dynamicsControl system

A control system (11) for a vehicle (10) includes vehicle dynamics sensors (35-47) providing a vehicle dynamics signal. Tire monitoring system sensors (20) in each wheel generate tire signals including temperature, pressure and acceleration data. A controller (26) communicates with the tire monitoring system sensors (20) and at least one vehicle dynamics sensor, and generates a roadway surface condition estimation value as a function of the multi-axis acceleration data of the tire signals. The roadway surface condition estimation value is transmitted to a suspension control system (33) to adjust the vevhicle suspension characteristics in response to the roadway surface condition estimation value.

Owner:FORD GLOBAL TECH LLC

Method for chemical vapor deposition of silicon on to substrates for use in corrosive and vacuum environments

InactiveUS7070833B2Improve propertiesReduce outgassingPretreated surfacesSolid state diffusion coatingRoom temperatureSurface conditions

A method of passivating the surface of a substrate to protect the surface against corrosion, the surface effects on a vacuum environment, or both. The substrate surface is placed in a treatment environment and is first dehydrated and then the environment is evacuated. A silicon hydride gas is introduced into the treatment environment, which may be heated prior to the introduction of the gas. The substrate and silicon hydride gas contained therein are heated, if the treatment environment was not already heated prior to the introduction of the gas and pressurized to decompose the gas. A layer of silicon is deposited on the substrate surface. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the treatment environment. The substrate is then cooled and held at a cooled temperature to optimize surface conditions for subsequent depositions, and the treatment environment is purged with an inert gas to remove the silicon hydride gas. The substrate is cycled through the silicon depositing step until the surface of the substrate is covered with a layer of silicon. The treatment environment is then evacuated and the substrate cooled to room temperature.

Owner:SILCOTEK CORP

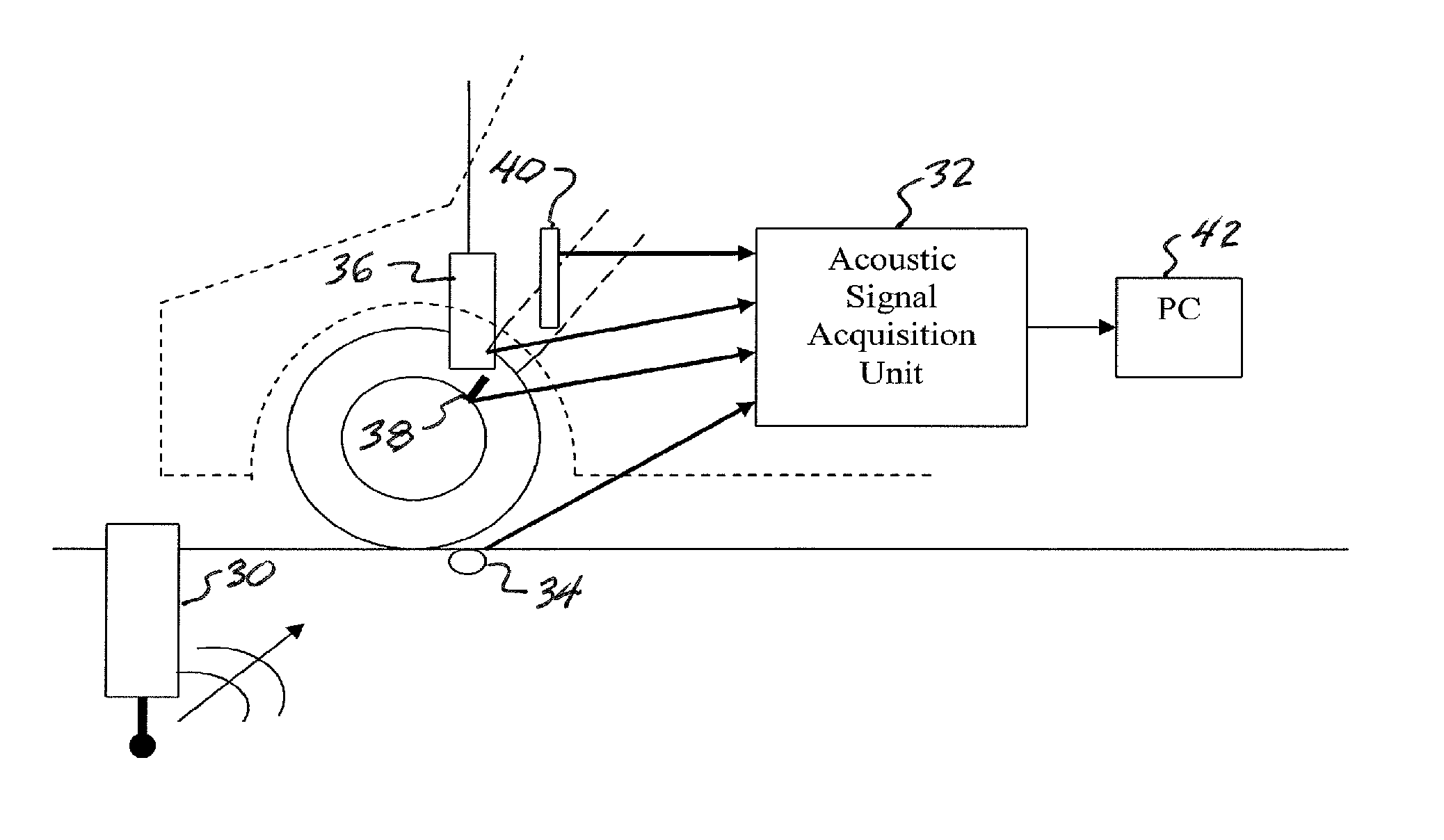

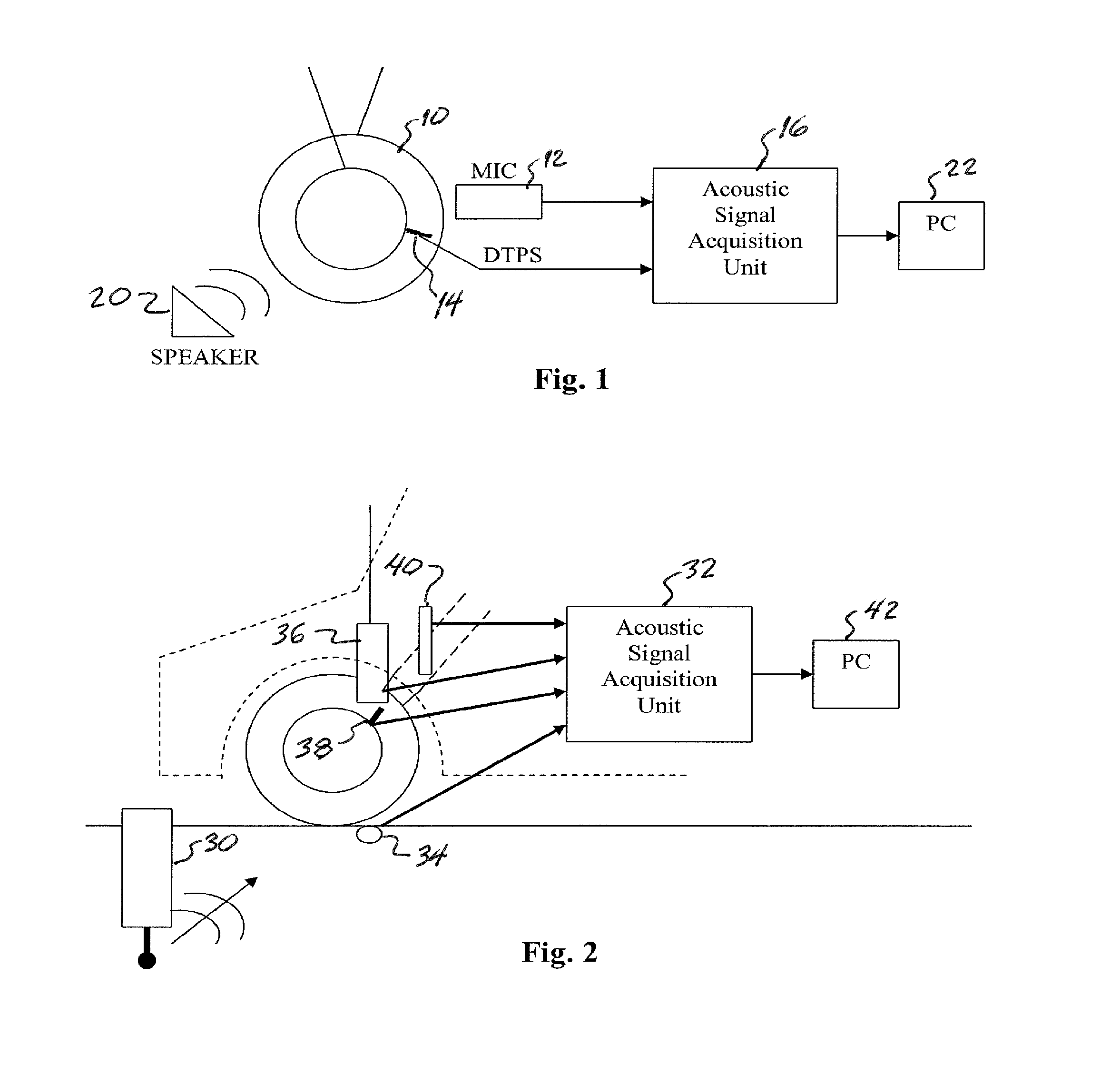

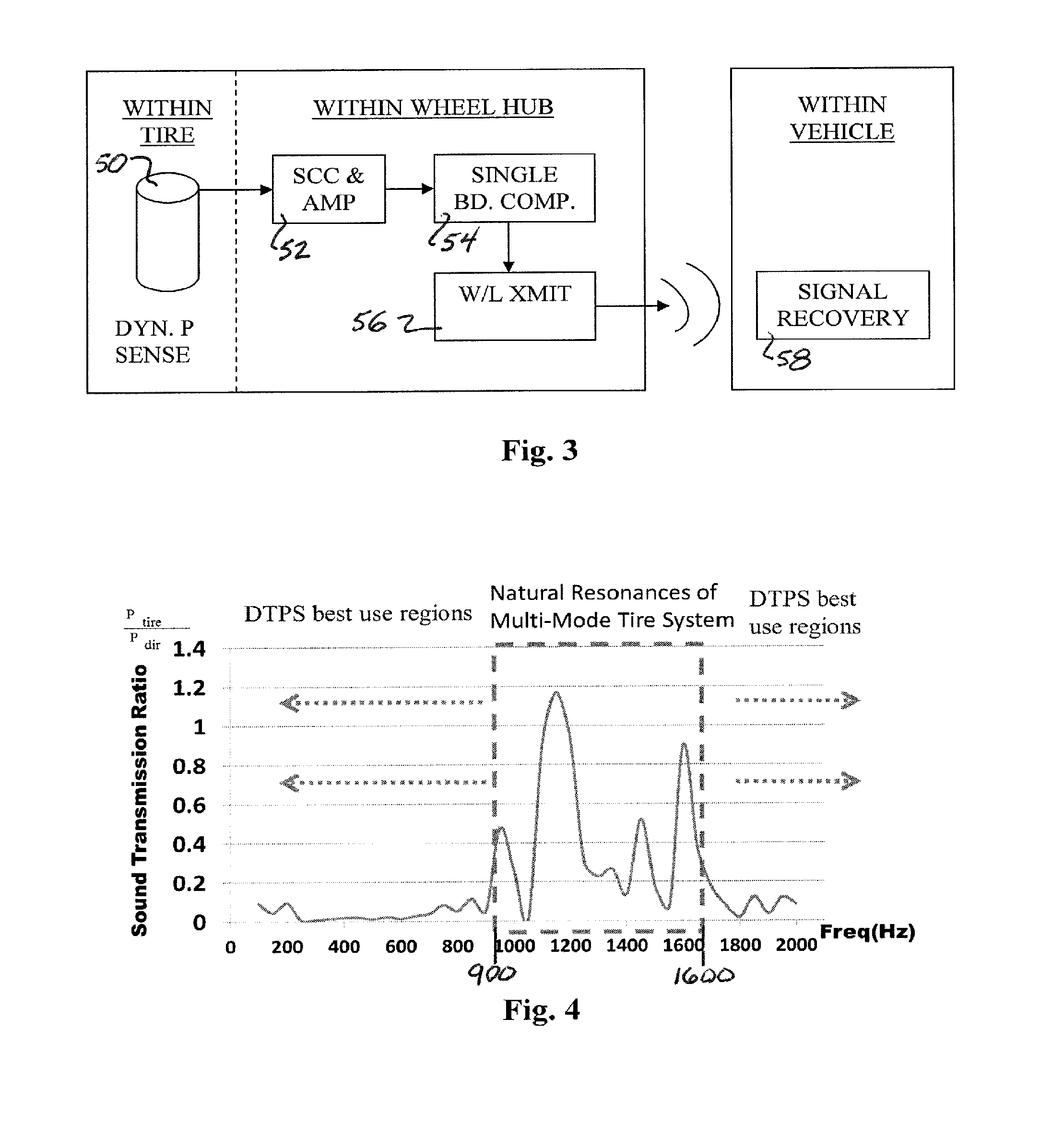

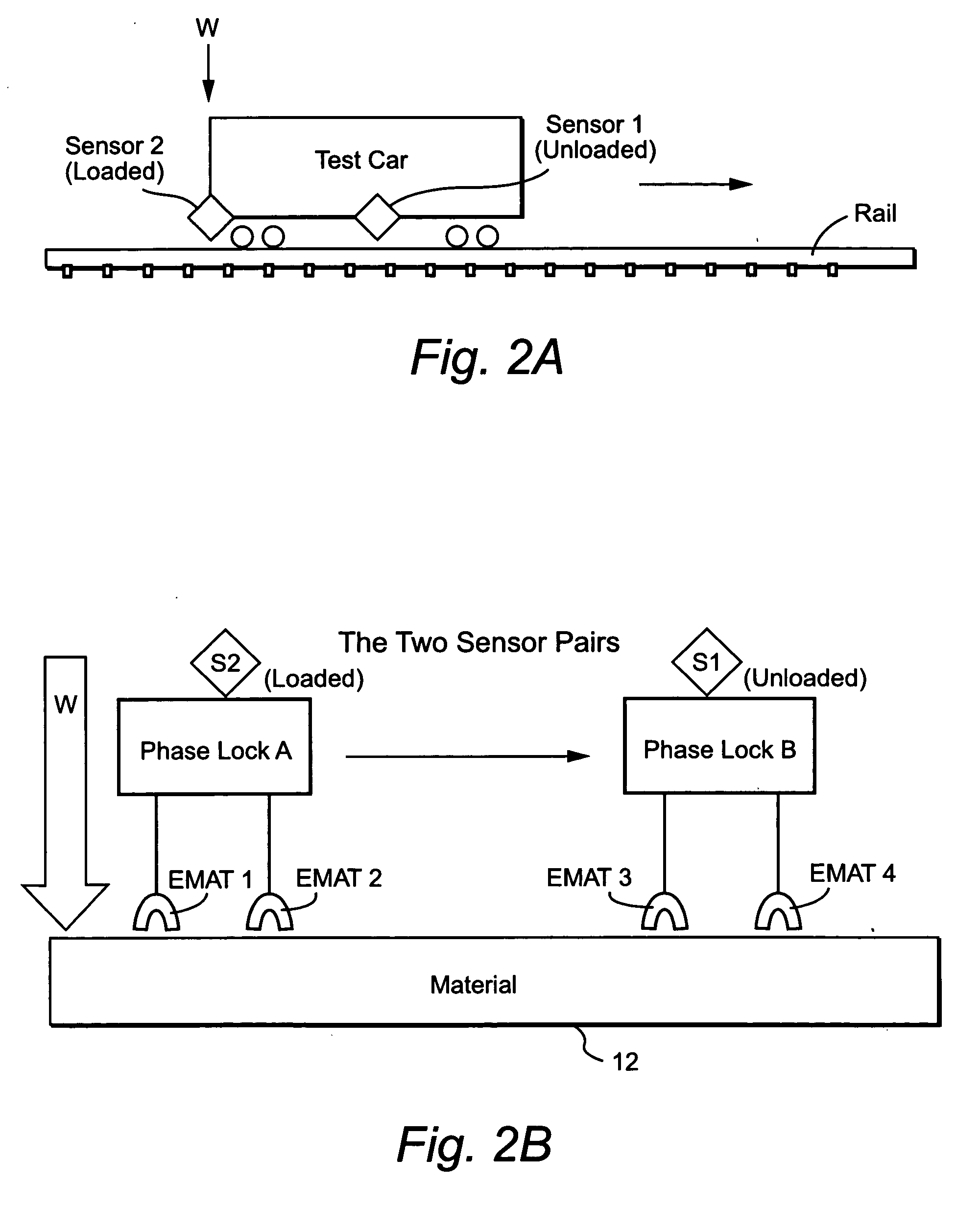

Real-time wireless dynamic tire pressure sensor and energy harvesting system

ActiveUS20140070935A1Quick testImprove detection accuracyBatteries circuit arrangementsMaterial analysis using sonic/ultrasonic/infrasonic wavesAuditory radiationEnergy harvester

An instantaneous / real-time wireless dynamic tire pressure sensor (DTPS) for characterizing pavement qualities and for detecting surface and subsurface pavement defects under normal driving conditions. Signal processing provides quantitative assessment of surface conditions. DTPS includes a vehicle tire valve stem-mounted pressure sensor and wheel hub-mounted signal conditioning, amplification, and transmitting circuitry. A signal processing computer within the vehicle is wirelessly coupled to the hub-mounted circuitry. Tire pressure changes caused by ground vibration excitation from the interaction between the tire and pavement at normal driving speeds are detected. When acoustic radiation from a surface wave is significantly stronger than acoustic noise, subsurface information can be extracted. An energy harvester based on strong magnetostatic coupling between a high permeability core solenoid, fixed proximate a vehicle wheel, and a bias magnet array, fixedly mounted in conjunction with a dust shield, can provide power the DIPS.

Owner:NORTHEASTERN UNIV

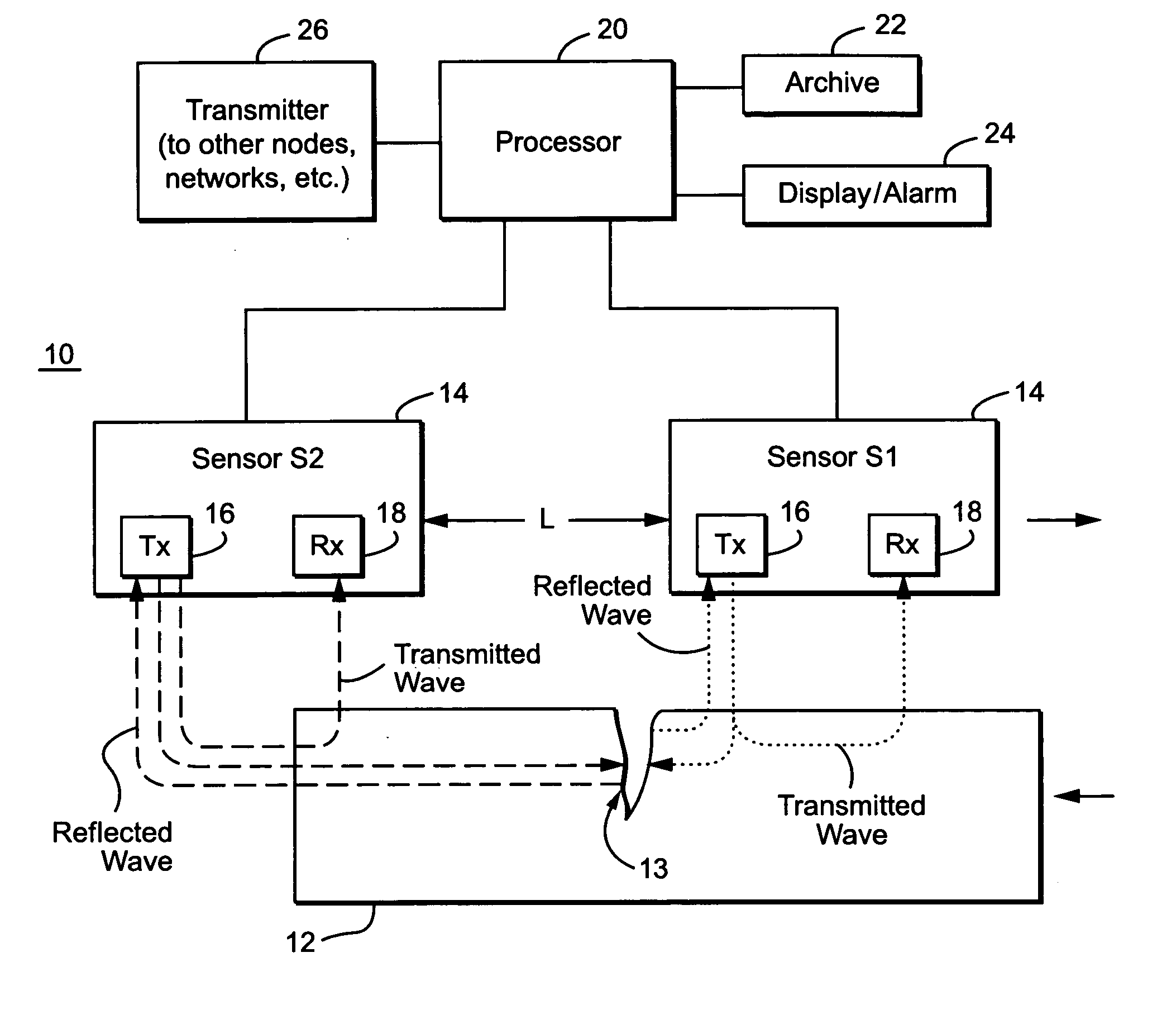

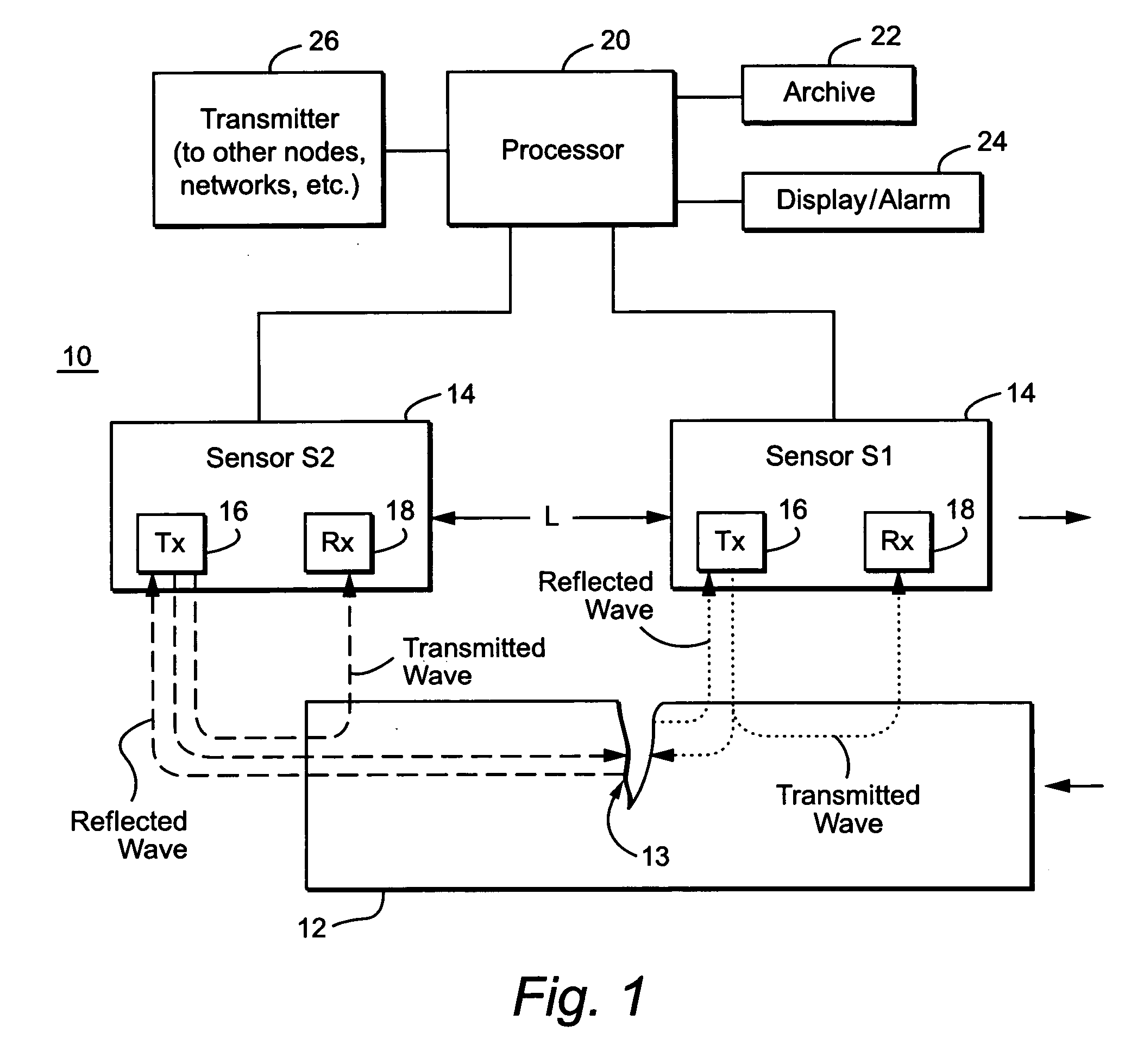

Method and apparatus for determining and assessing a characteristic of a material

InactiveUS20050072236A1Low costImprove accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesDifferential measurementCrazing

An acoustic energy-based, non-contact or contact testing approach provides low cost, highly accurate, and reliable information to (a) identify flaws and anomalies and (b) assess the integrity of a particular material. This approach is not hindered by surface conditions or impediments, and indeed, looks beneath the surface of the material by propagating an acoustic wave through the material using two differential transducers. A dynamic differential measurement is made of the material under a load condition and an unloaded condition that allows identification and assessment of various characteristics of the material. Multiple “windows” of information may be generated that permit (a) direct detection of flaws, defects, and anomalies using a scattering technique, (b) detection of crack closure and opening used to assess the stability of the material, (c) determination of strain on the material which relates to its performance, and (d) determination of defect dynamics linked to the defect size and stability.

Owner:LUNA INNOVATIONS

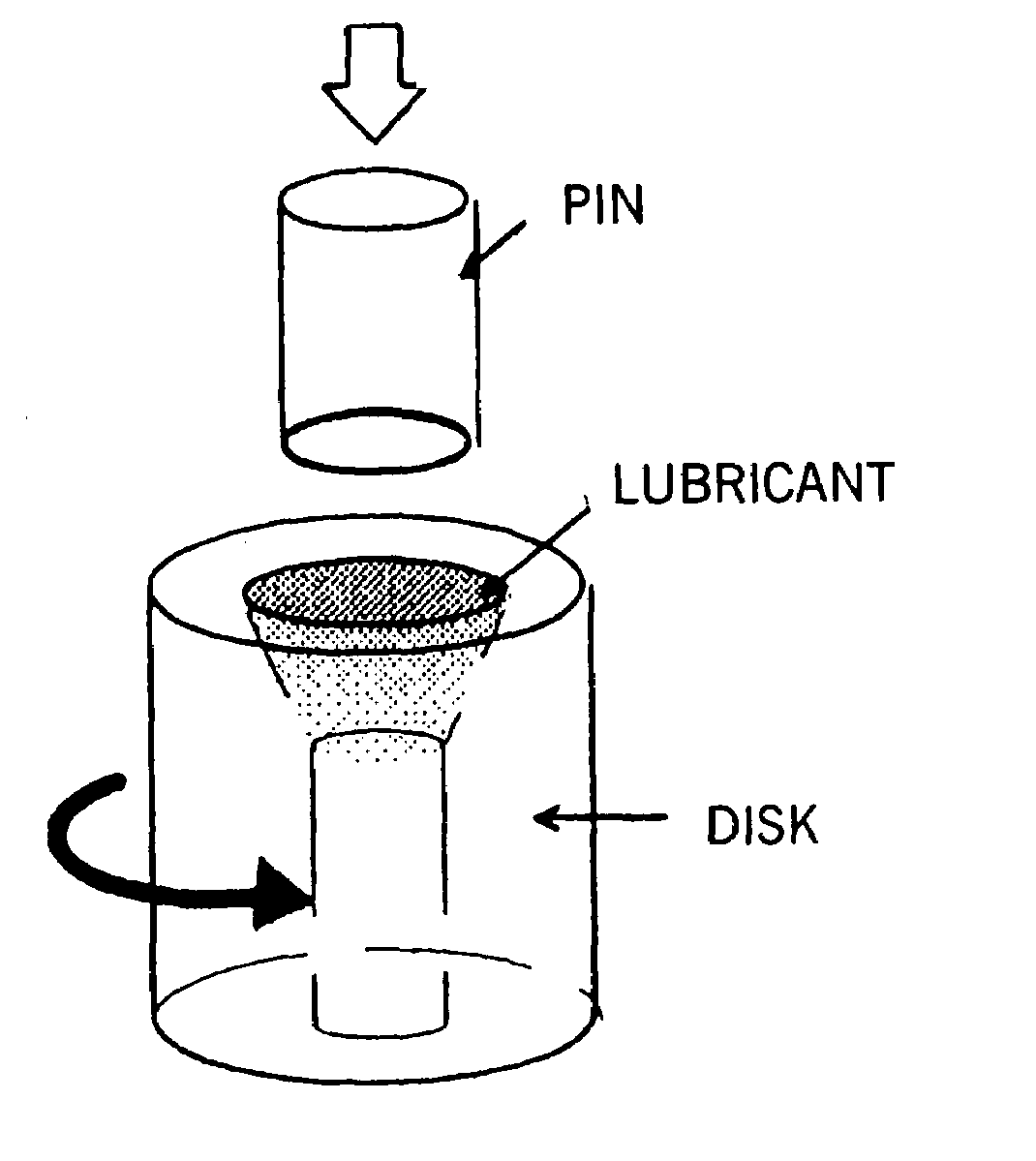

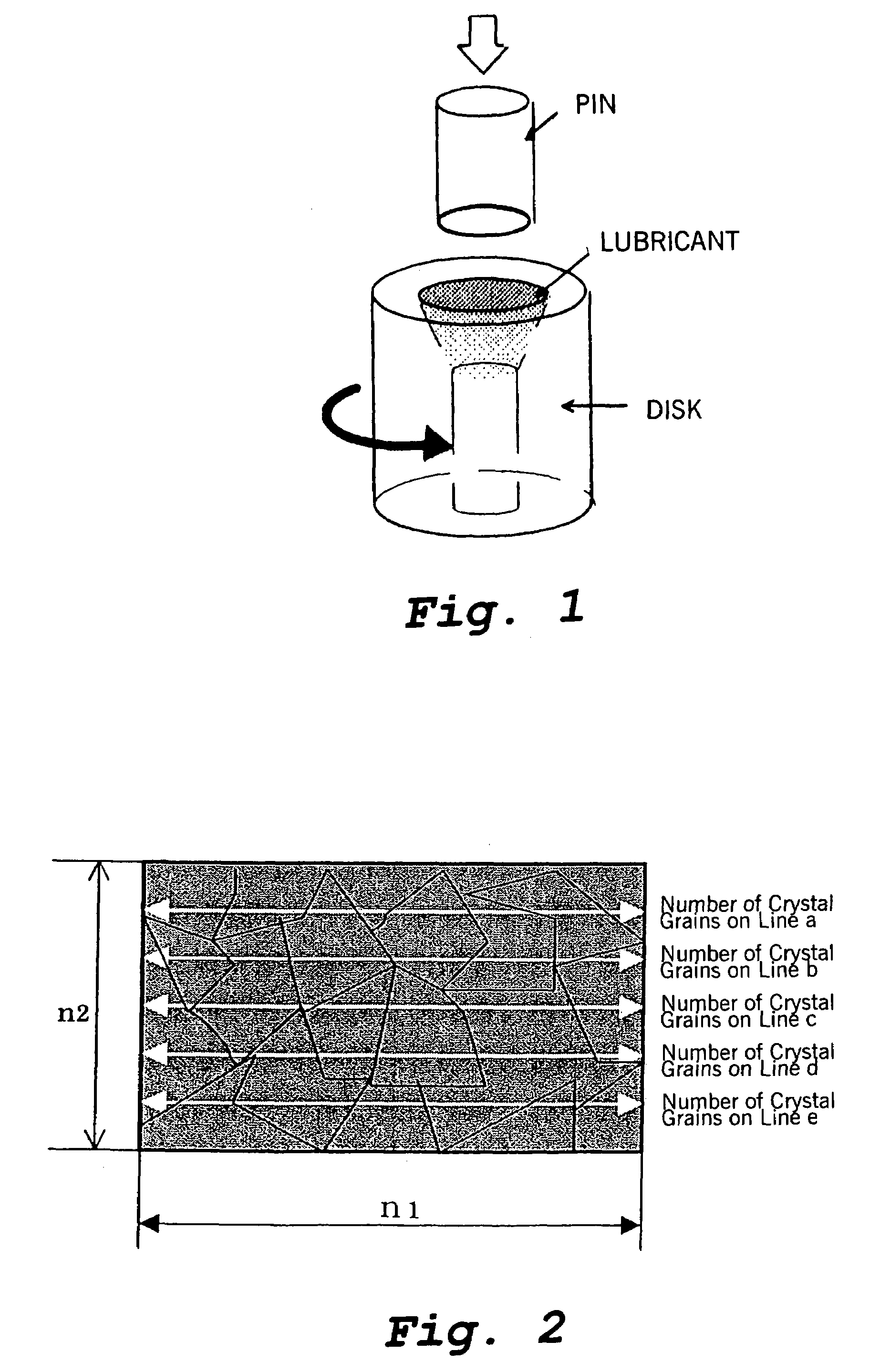

Surface conditioning prior to chemical conversion treatment of a steel member

ActiveUS7666266B2Optimized diameterShort timeOther chemical processesCorrosion preventionPotassiumMaterials science

By subjecting a threaded joint for OCTG (oil country tubular goods) to surface conditioning with an aqueous solution of potassium tetraborate or sodium tetraborate prior to manganese phosphate chemical conversion treatment, a manganese phosphate chemical conversion coating having coarse crystal grains with an average crystal grain diameter of 10-110 micrometers is formed on the surface of the steel member which may be any steel including a high Cr steel. This manganese phosphate chemical conversion coating can hold a large amount of a liquid lubricant, and it is effective at preventing the occurrence of galling at the time of makeup of a threaded joint for OCTG.

Owner:NIPPON STEEL CORP

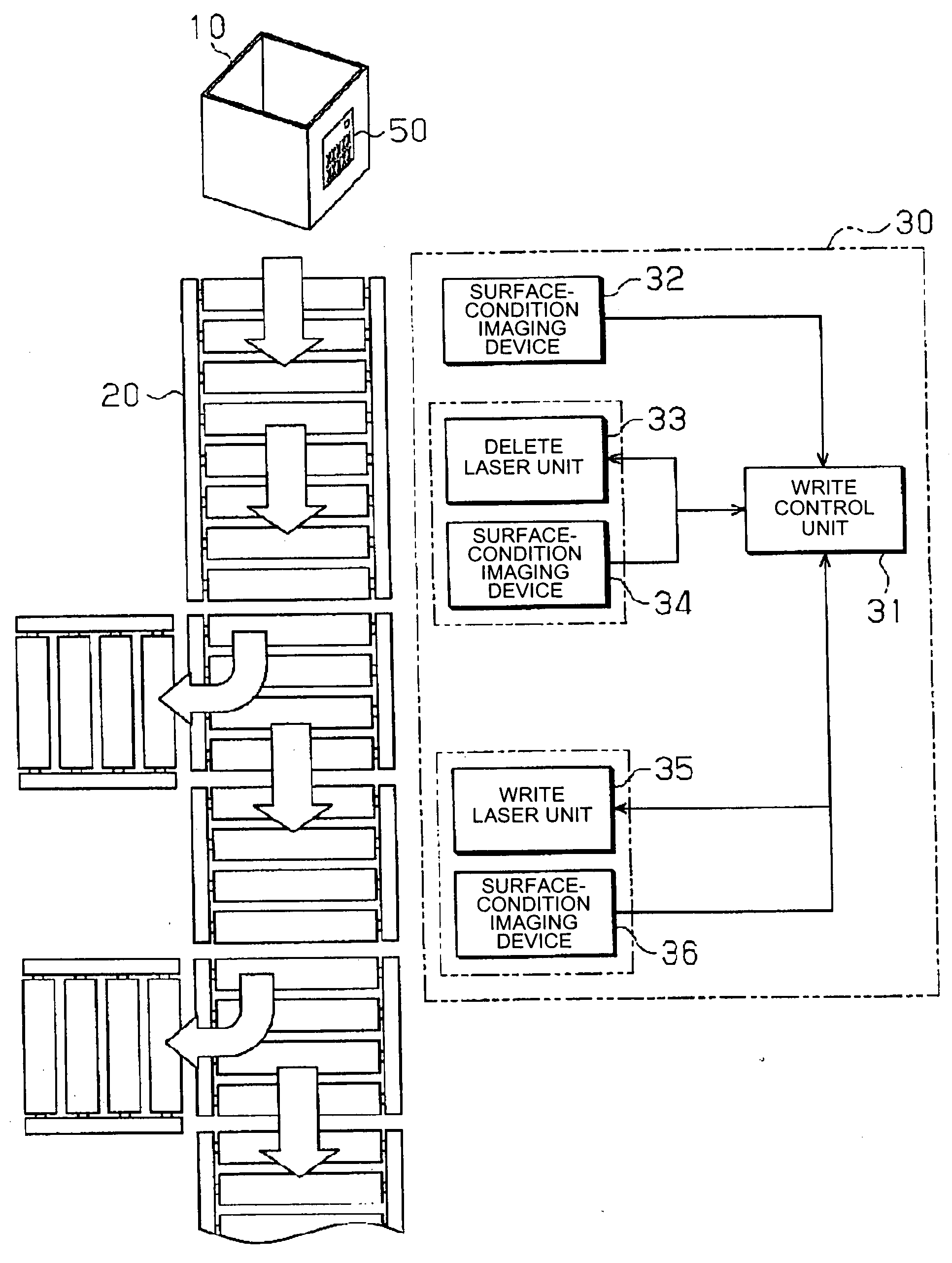

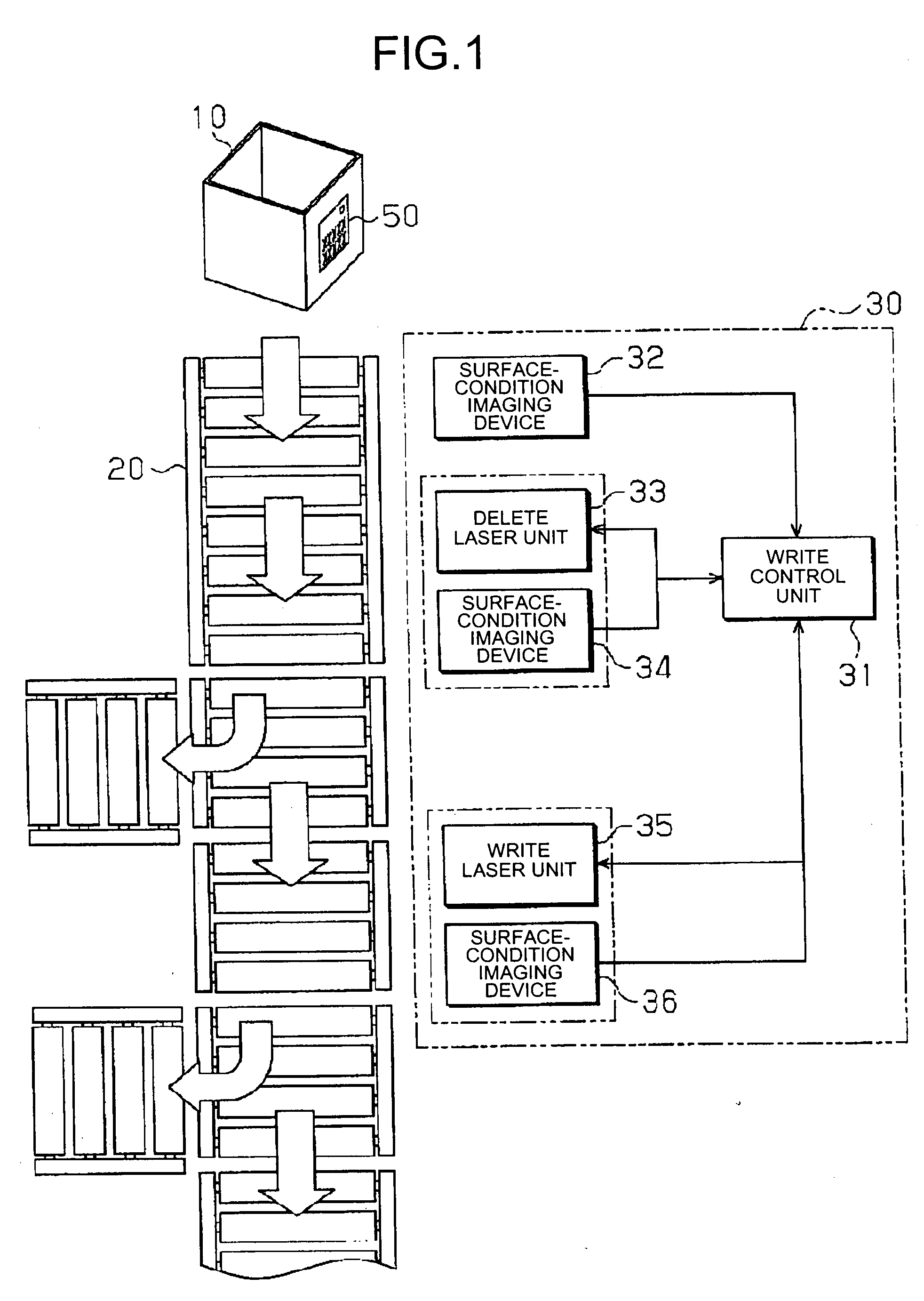

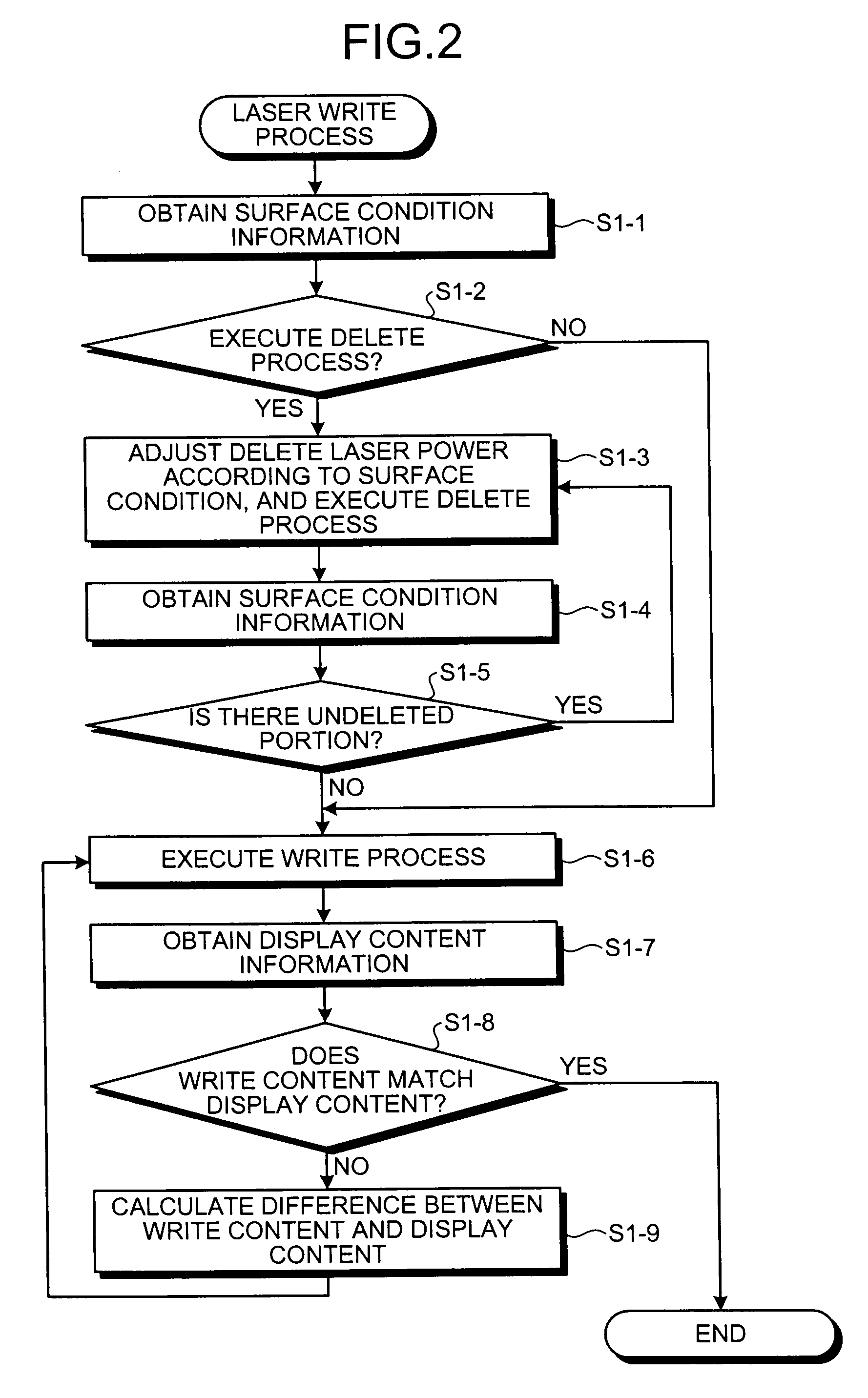

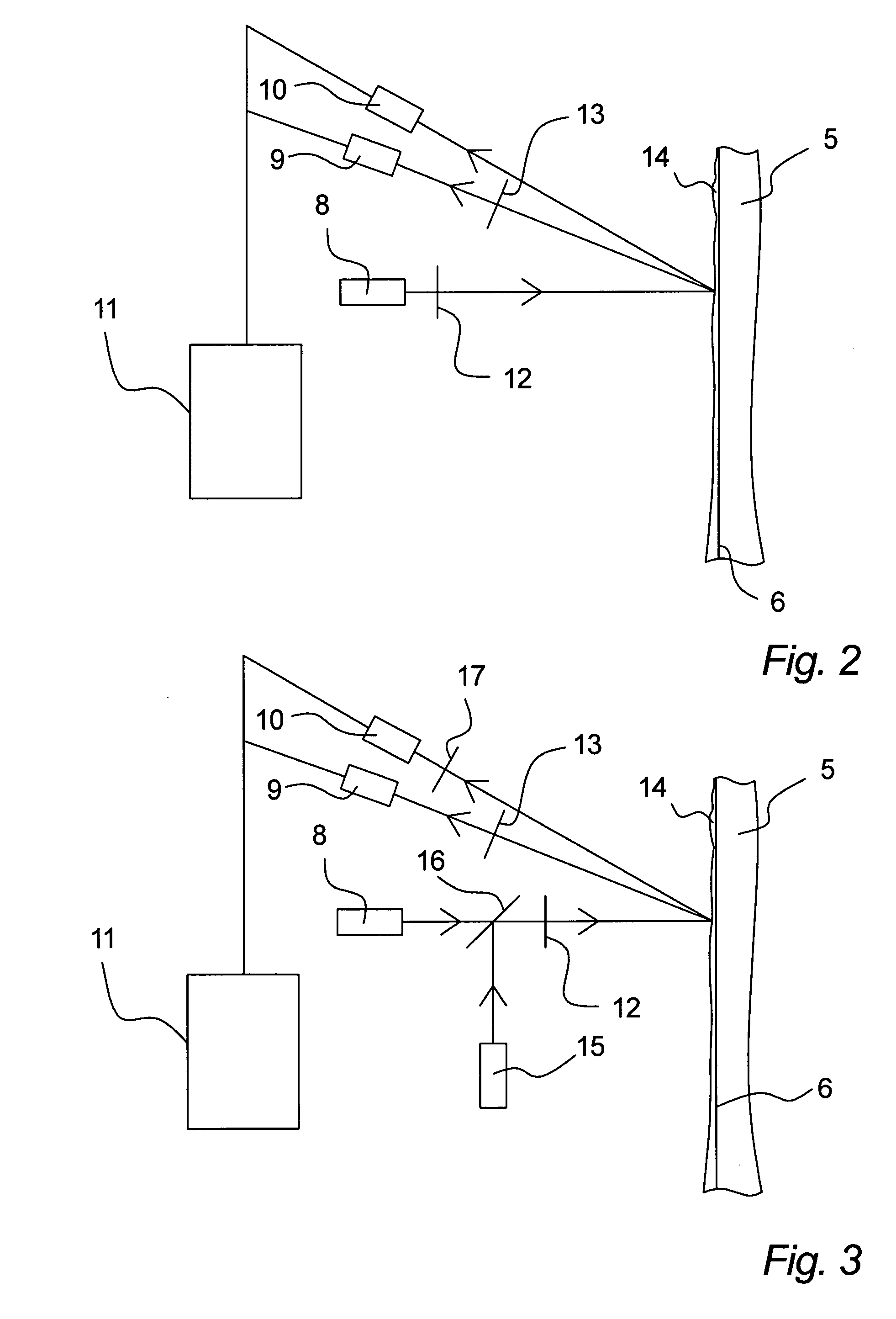

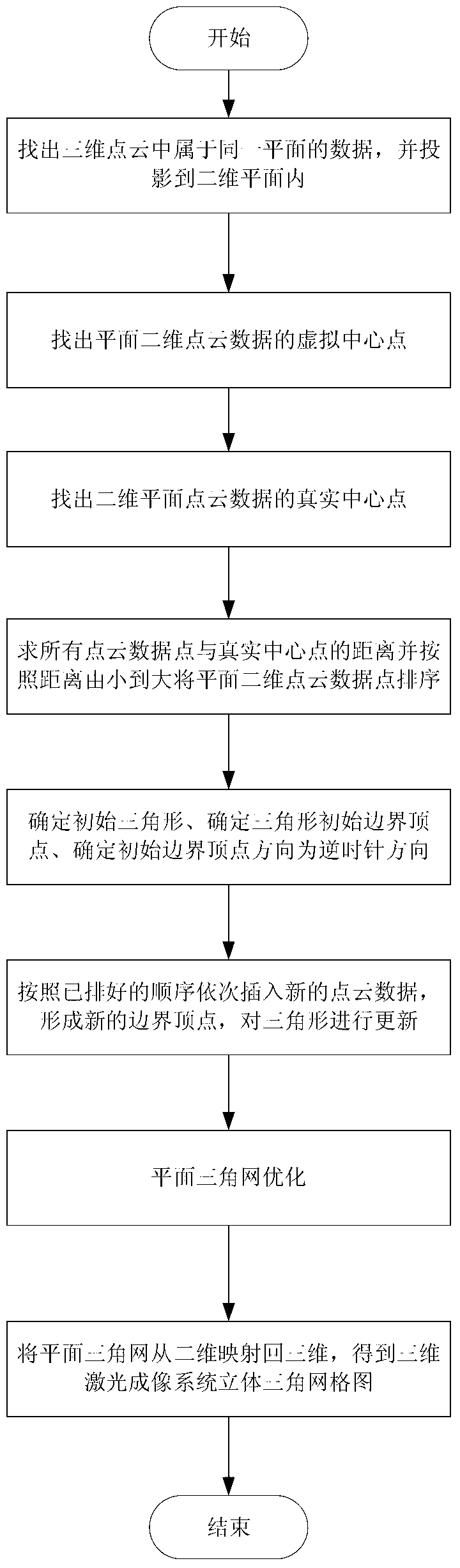

Laser rewriting system

InactiveUS20080192618A1Solve problemsCombination recordingRecording apparatusSurface conditionsComputer science

A surface-condition-information obtaining unit obtains information on a surface condition of a rewritable display medium on which information is reversely displayed visually. A write-laser output unit outputs a write laser to irradiate the rewritable display medium with the write laser, to perform a drawing on the rewritable display medium. A control unit performs a write process for displaying an image on the rewritable display medium by adjusting a laser output condition based on the information obtained by the surface-condition-information obtaining unit and controlling the write-laser output unit based on an adjustment of the laser output condition.

Owner:RICOH KK

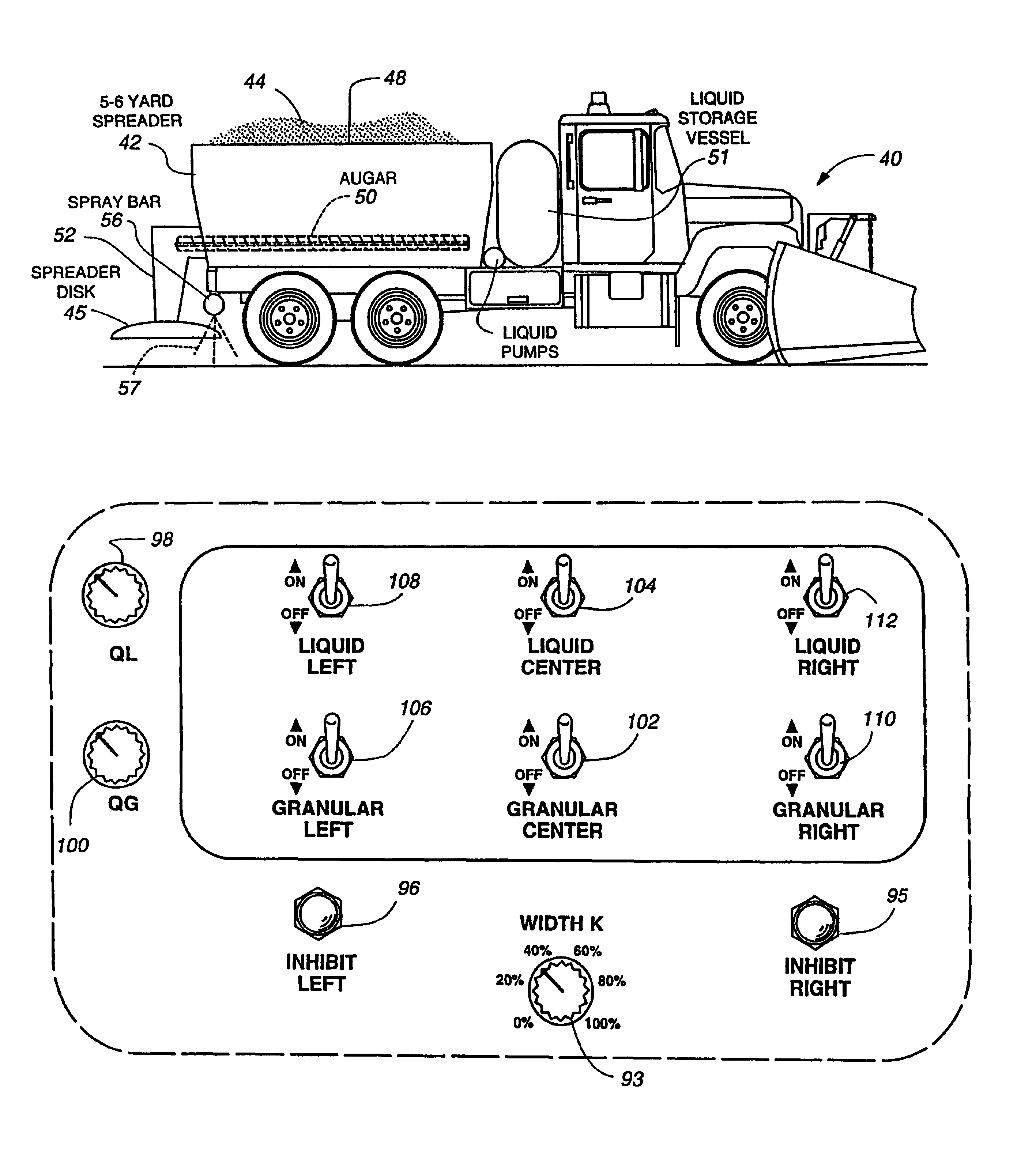

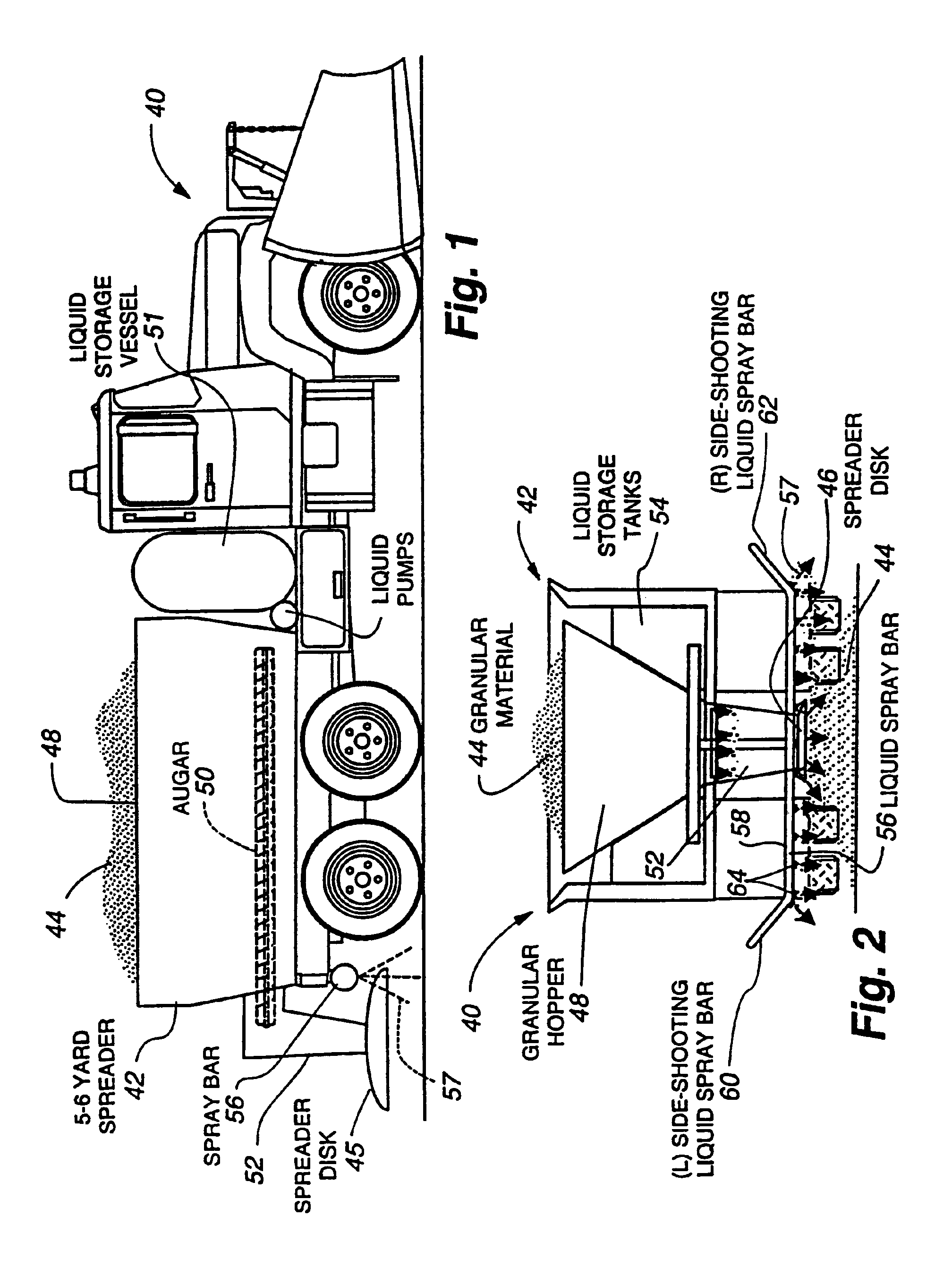

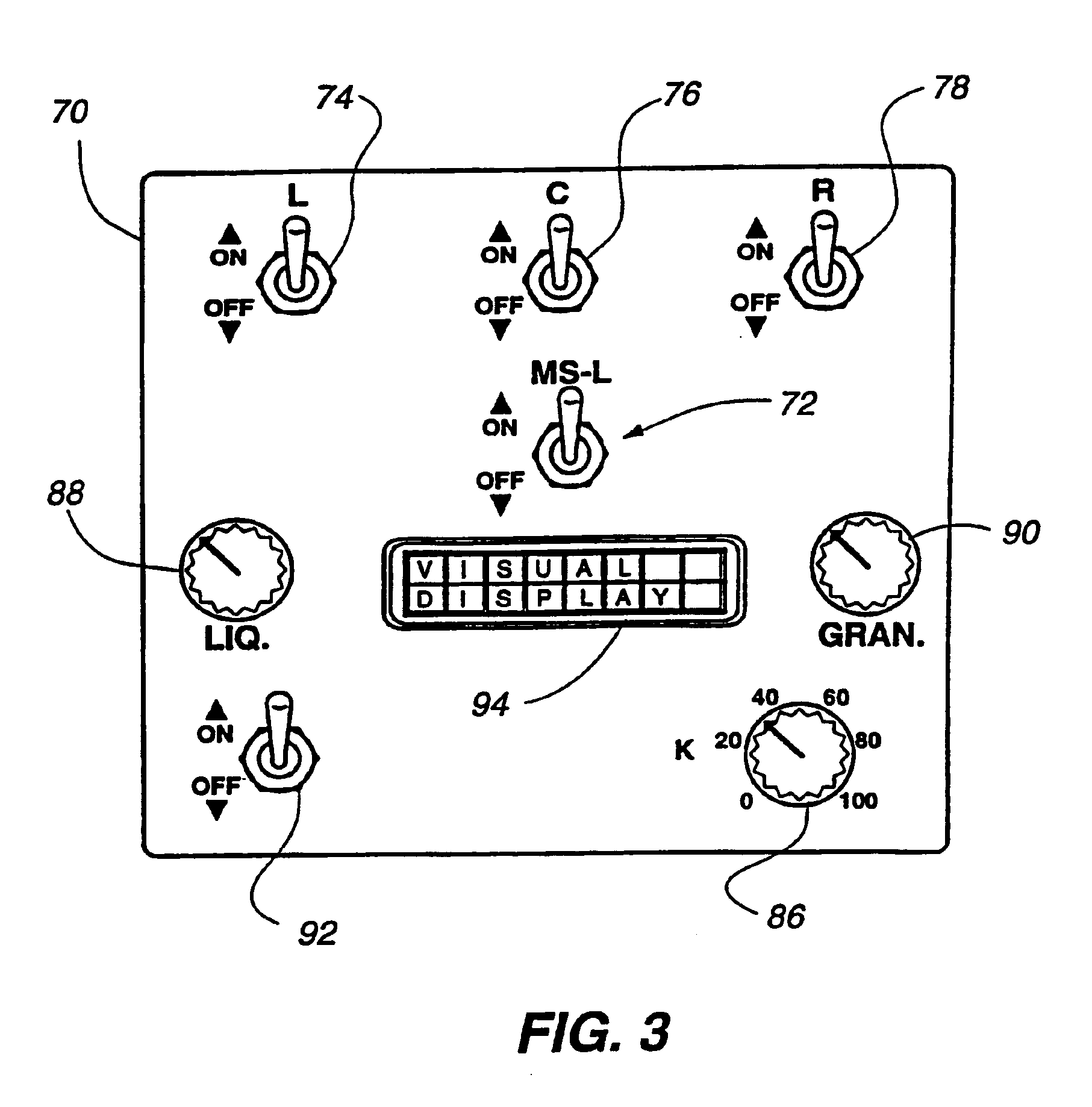

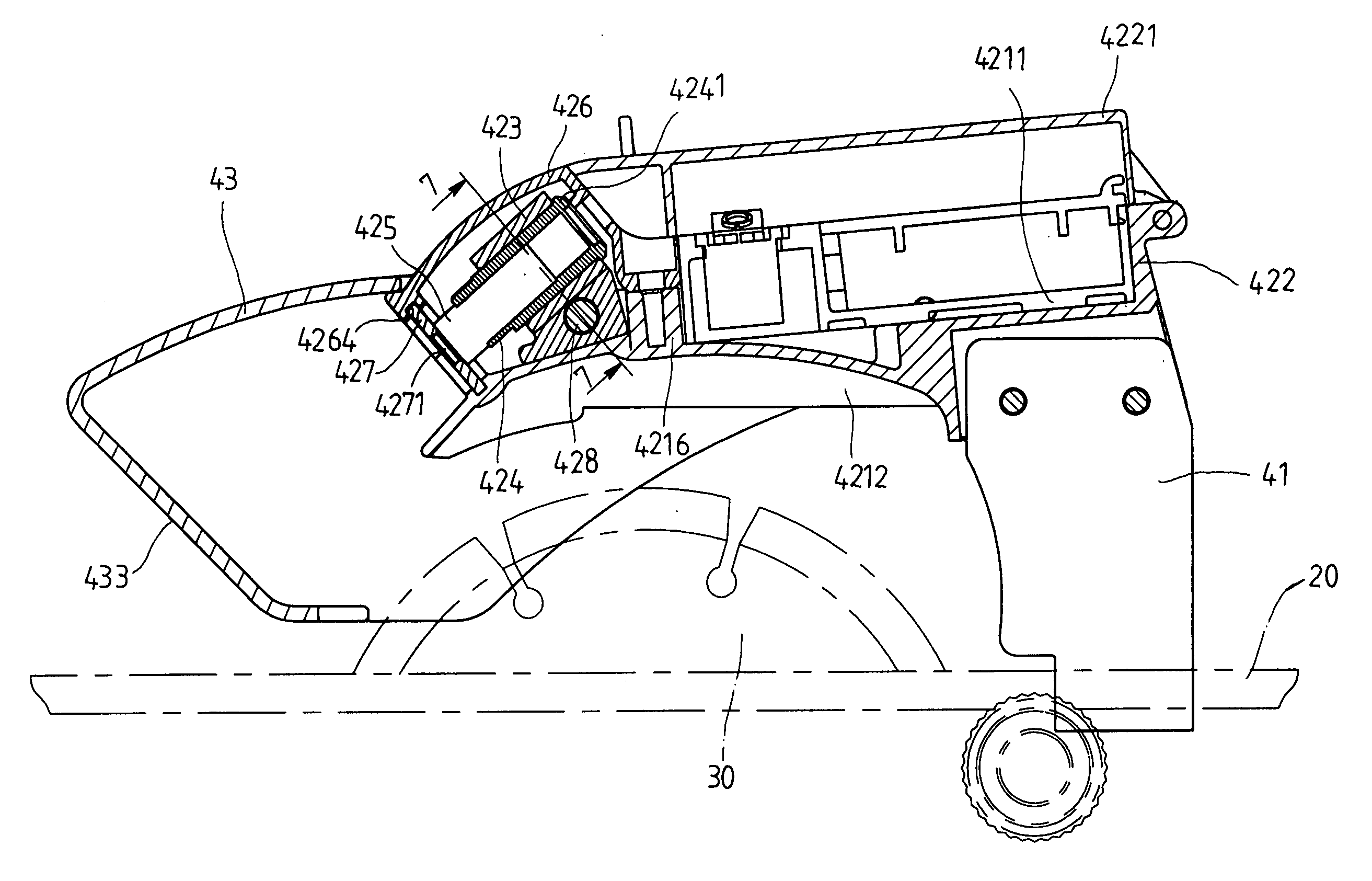

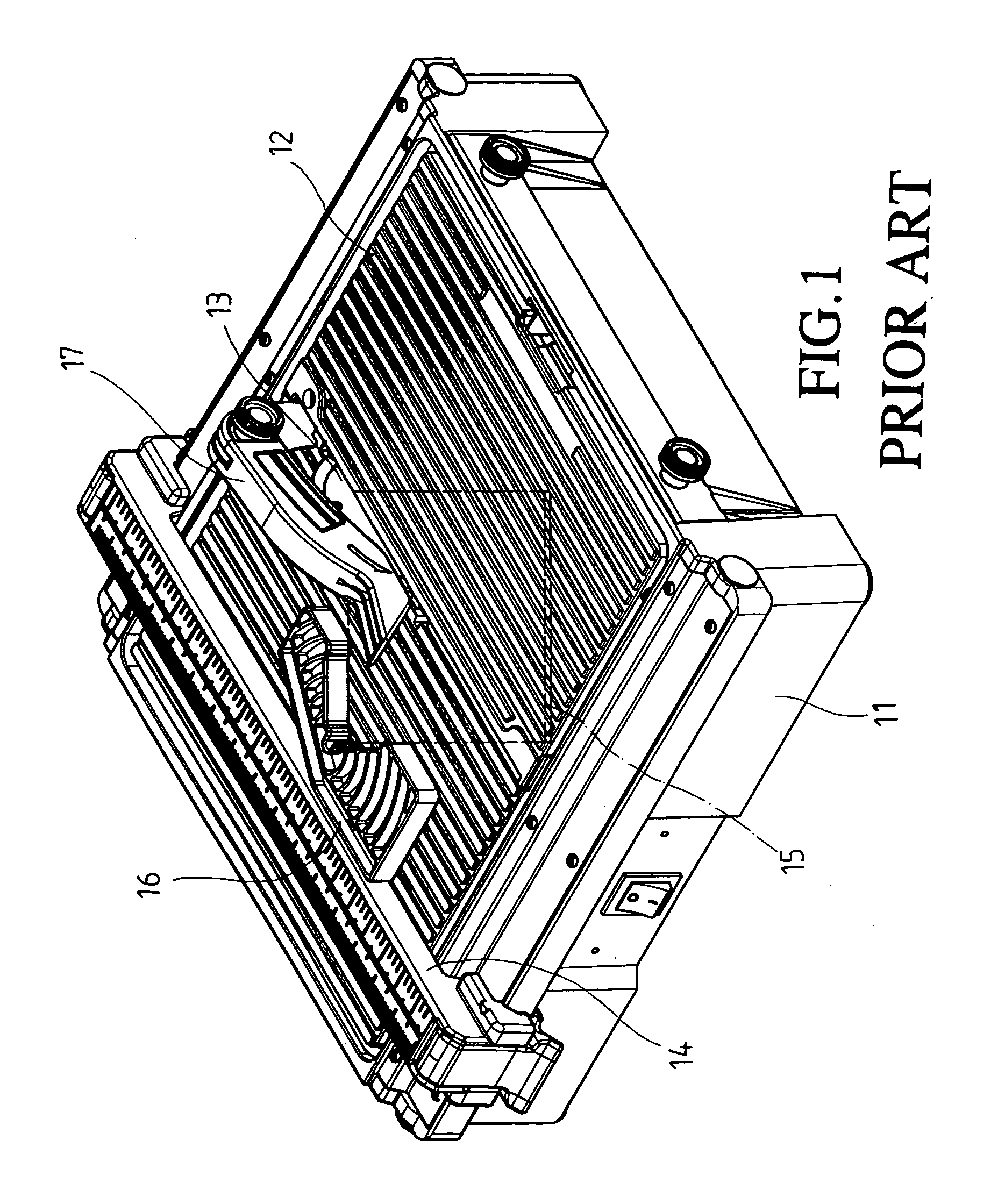

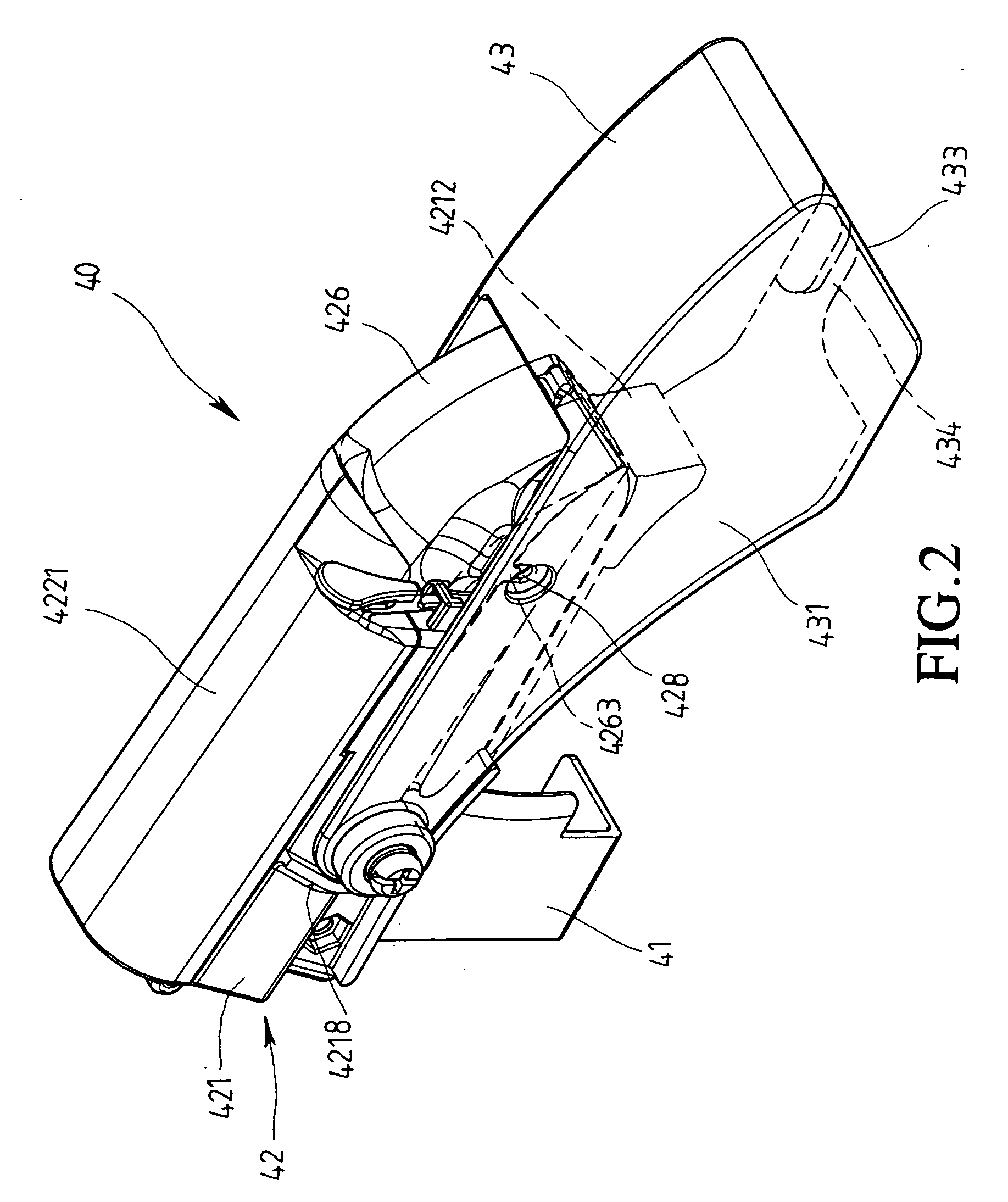

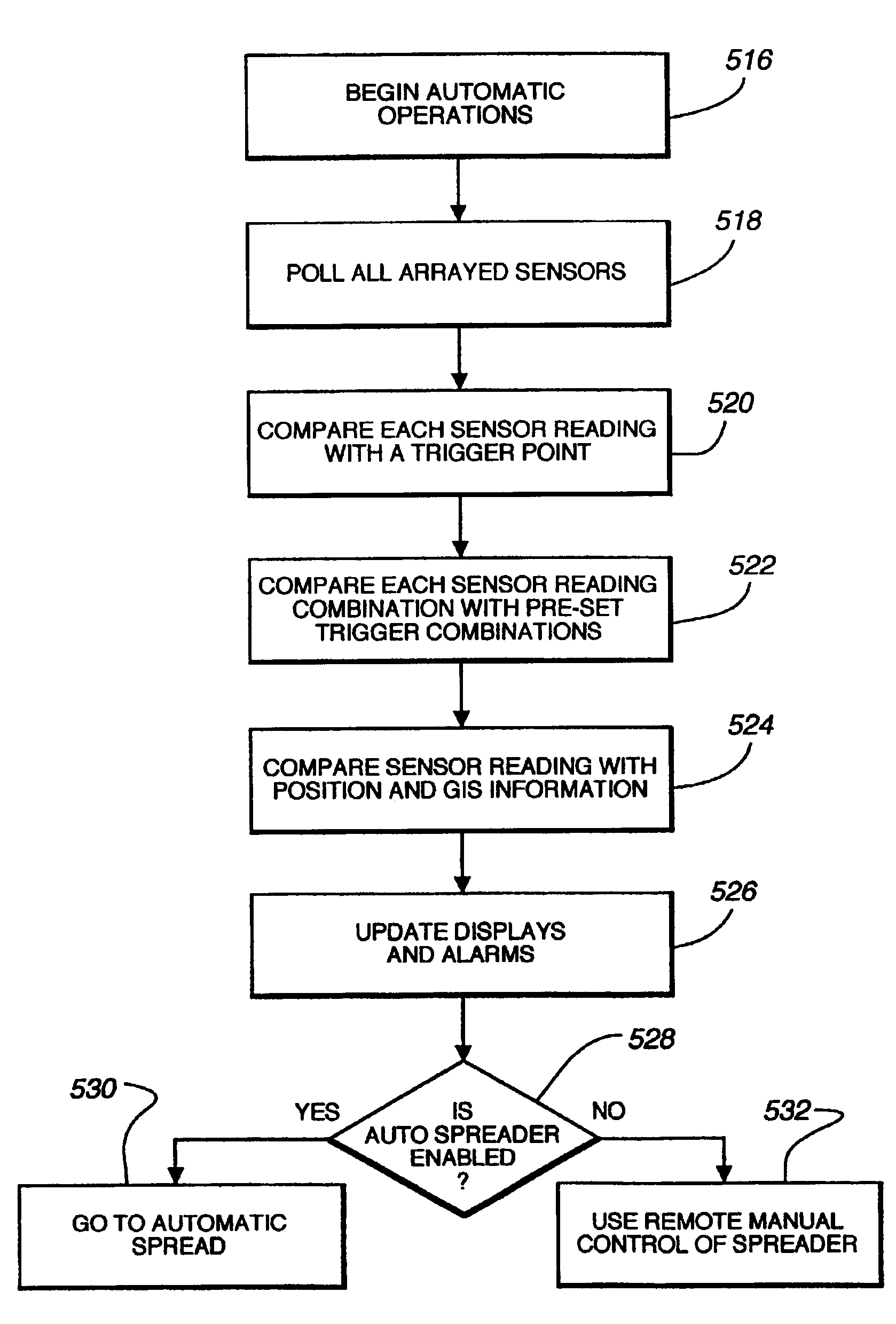

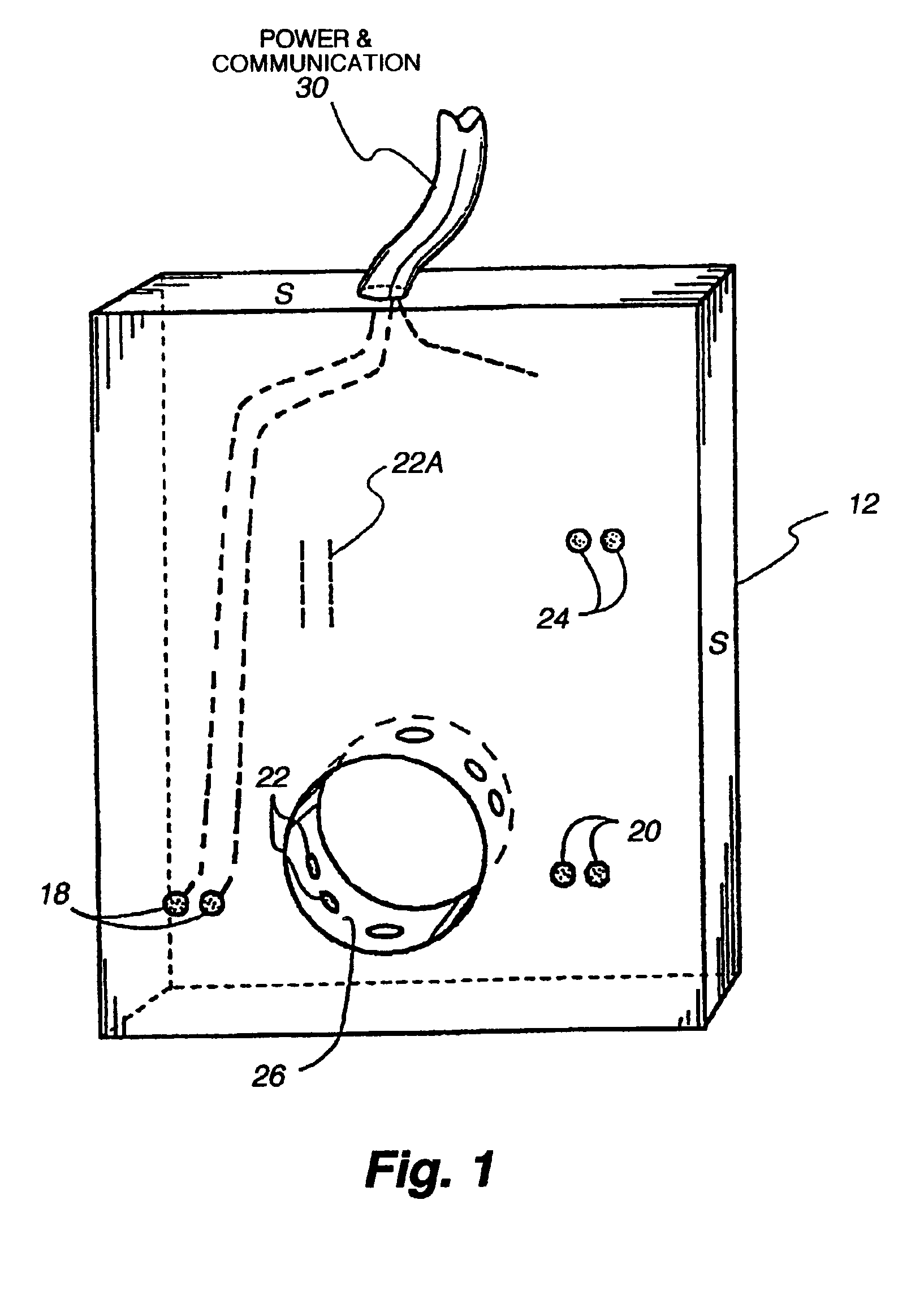

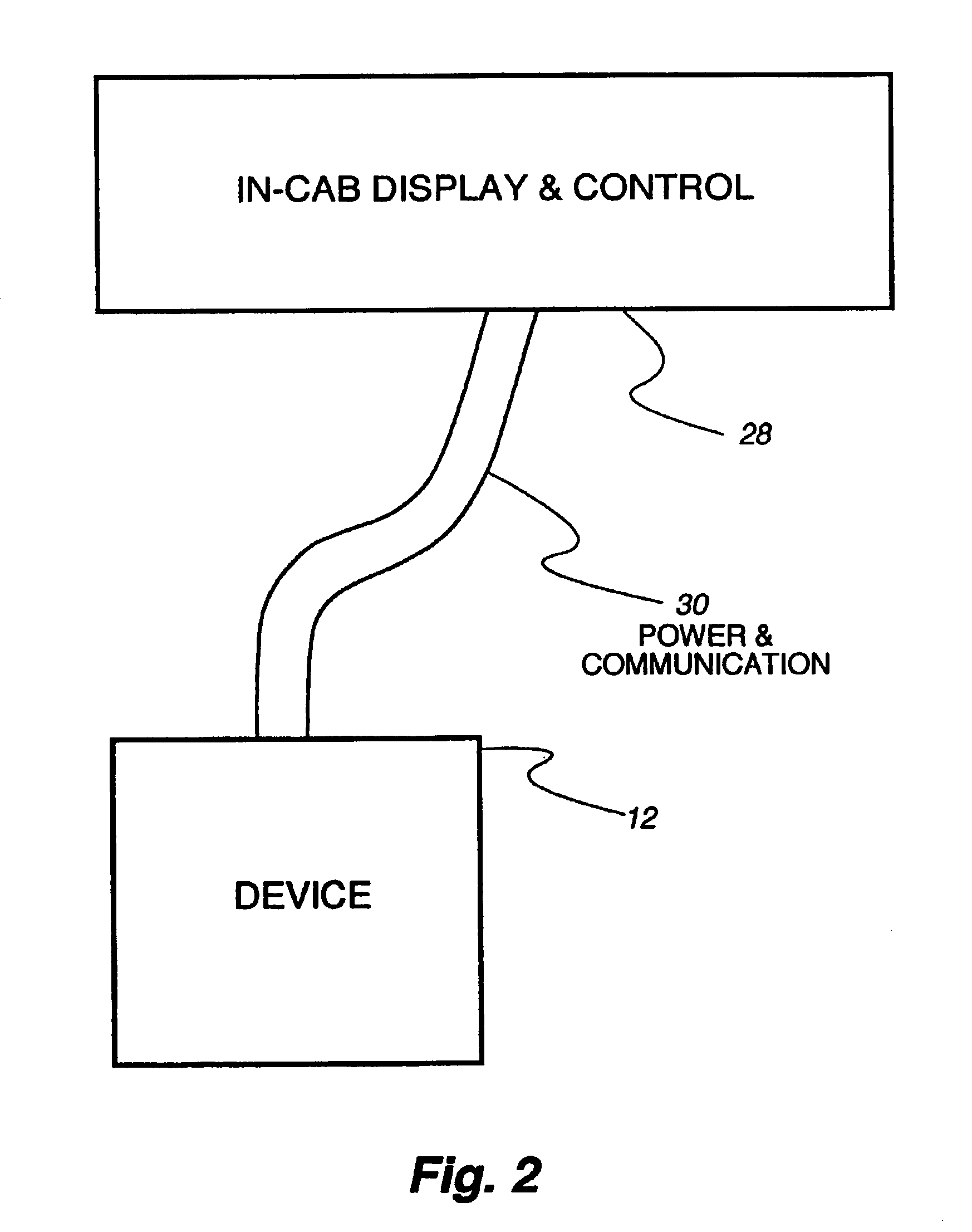

Apparatus and system for synchronized application of one or more materials to a surface from a vehicle and control of a vehicle mounted variable position snow removal device

InactiveUS6938829B2OptimizationDigital data processing detailsLiquid fertiliser distributionEngineeringSurface conditions

An apparatus and system, preferably mounted on a service vehicle, provides synchronized application of fluid materials, either solid or liquid, to a vehicle travel surface in proportional amounts or spatially distributed proportions in response to user defined requirements and / or operation of a vehicle mounted component in response to conditions encountered in real time. A first embodiment is a vehicle mounted apparatus and system for coordinated application of a plurality of materials to a surface simultaneously and in desired proportions and / or widths automatically and / or selectively. A second embodiment includes a granular material distribution device and includes a plurality of liquid spray headers and pumping means. A third embodiment of the present invention is a vehicle mounted apparatus and system for automated coordinated application of a plurality of materials to a surface as well as automated component control such as blade blocking plate control based on sensed current surface condition information and current accurate location information as well as past operating history and predicted near term weather conditions.

Owner:WEATHER INSIGHTS

In situ methanogenesis modeling and risk analysis

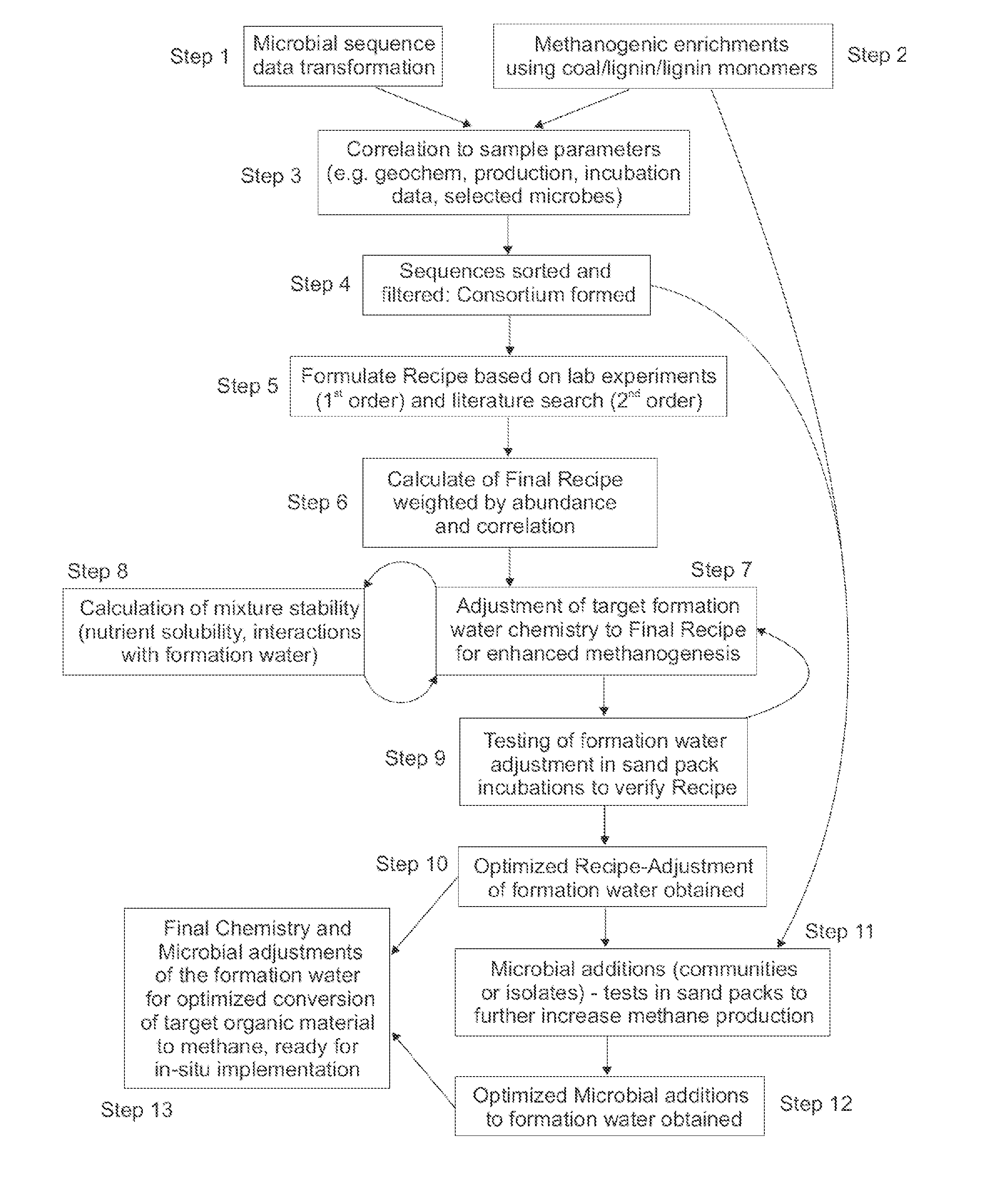

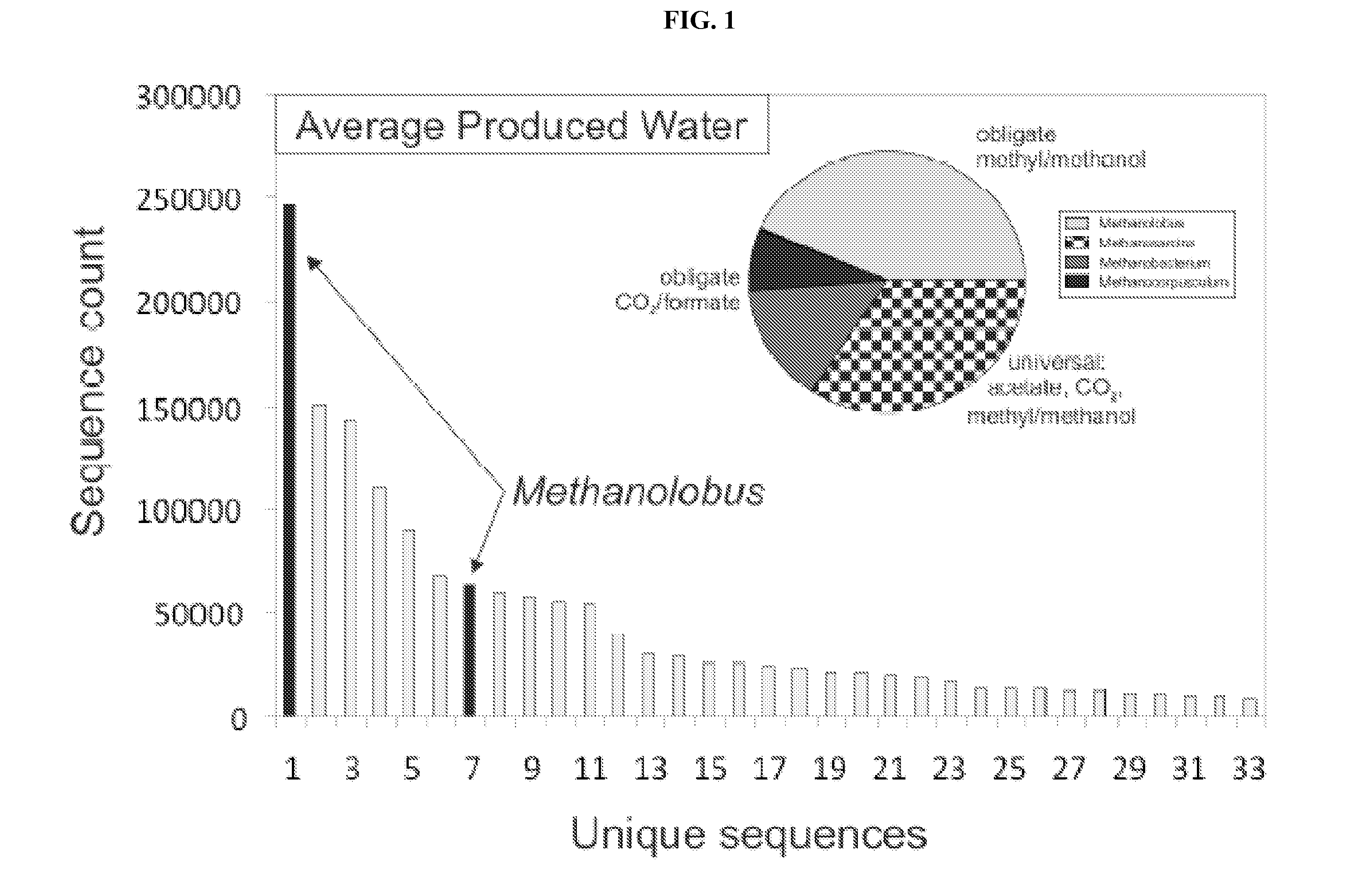

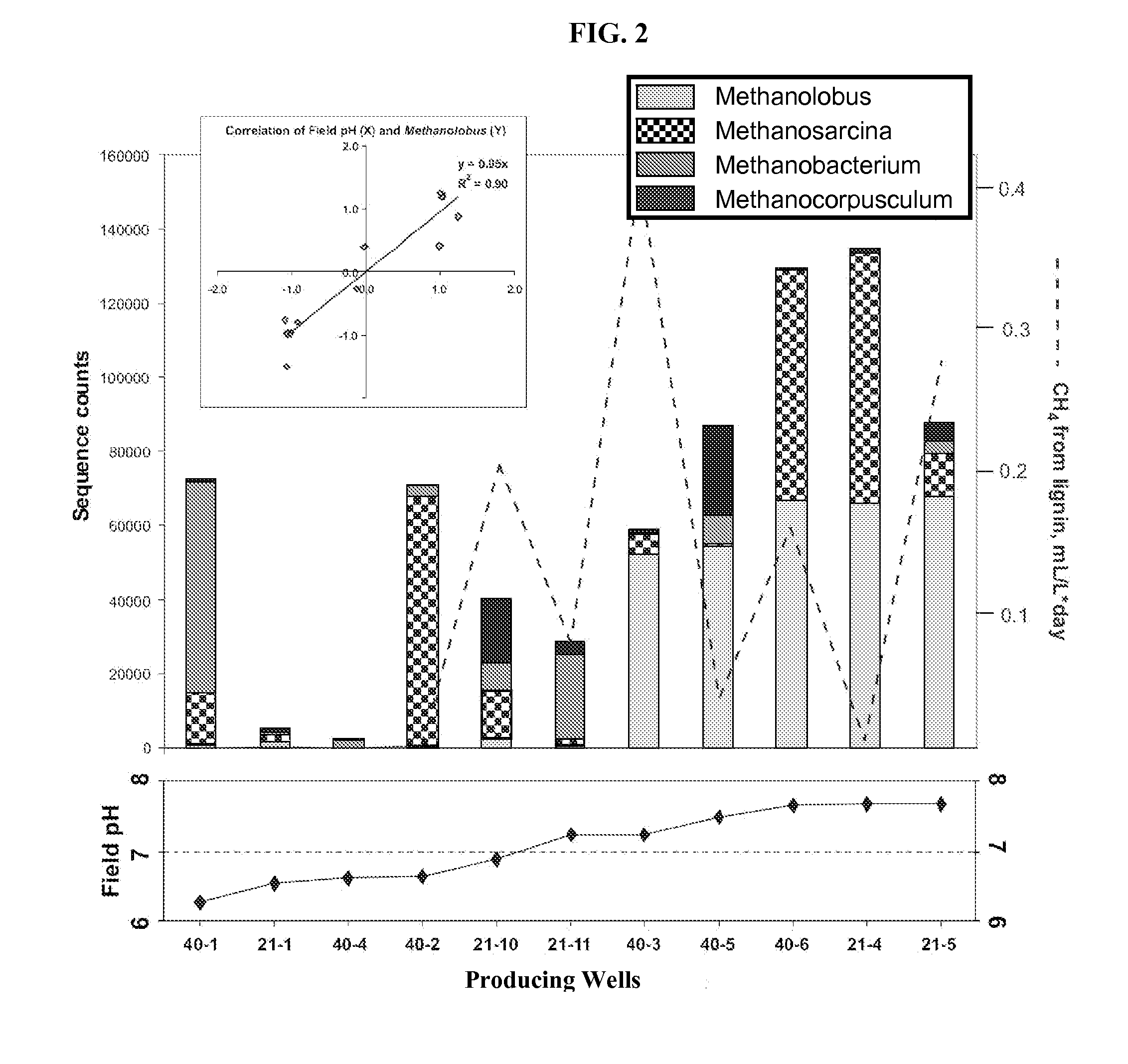

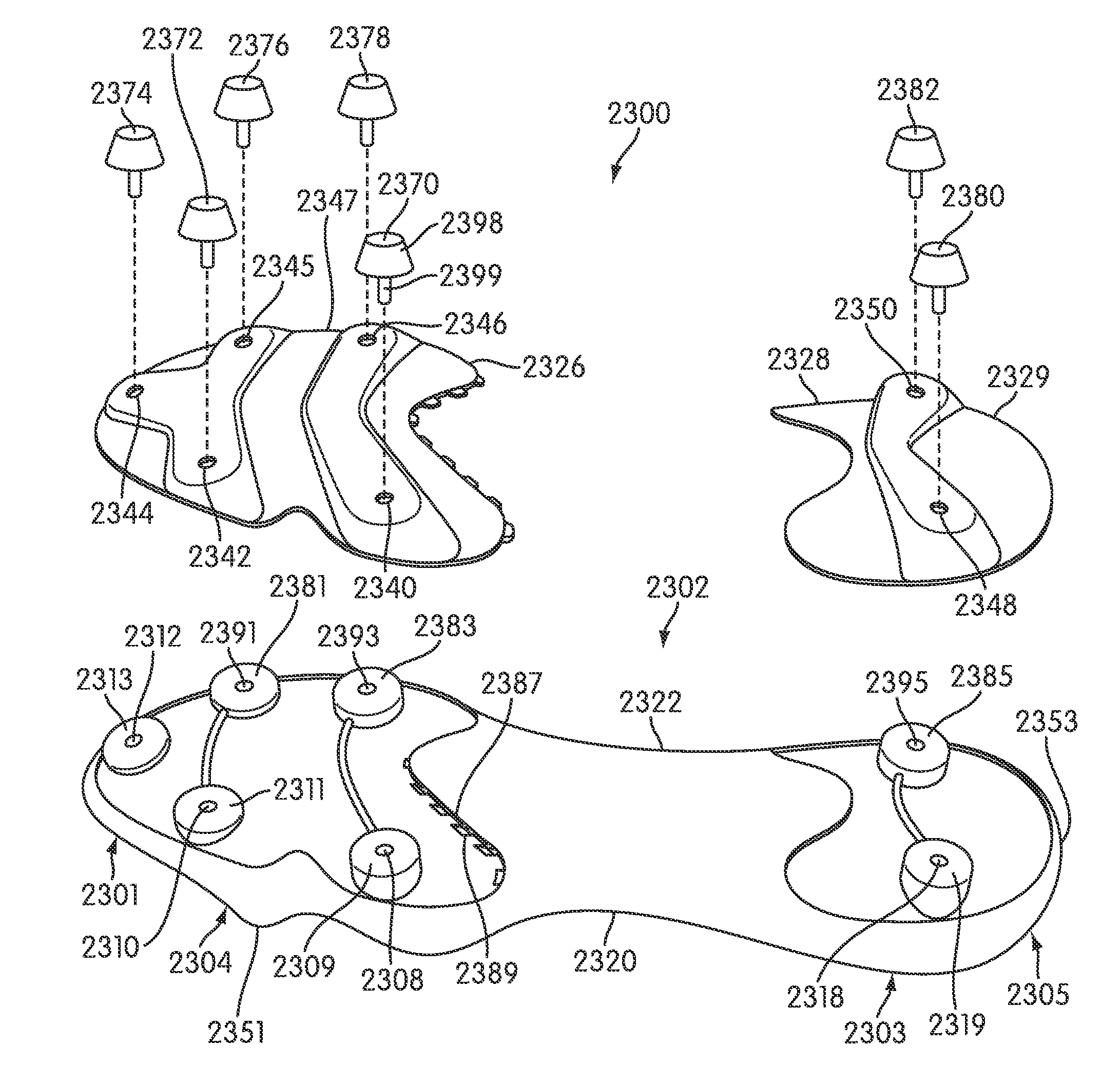

ActiveUS20110308790A1Enhancing methanogenic rateEnhance methanogenic degradationSurveyBacteriaComputational modelMicrobiome

This invention generally relates to natural gas and methylotrophic energy generation, bio-generated fuels and microbiology. In alternative embodiments, the invention provides nutrient amendments and microbial compositions that are both specifically optimized to stimulate methanogenesis, or “methylotrophic” conversion. Additionally, the invention provides methods to develop nutrient amendments and microbial compositions that are both specifically optimized to stimulate methanogenesis in a given reservoir. The invention also provides methods for the evaluation of potentially damaging biomass formation and scale precipitation resulting from the addition of nutrient amendments. In another embodiment, the invention provides methods for simulating biogas in sub-surface conditions using a computational model.

Owner:CONOCOPHILLIPS CO

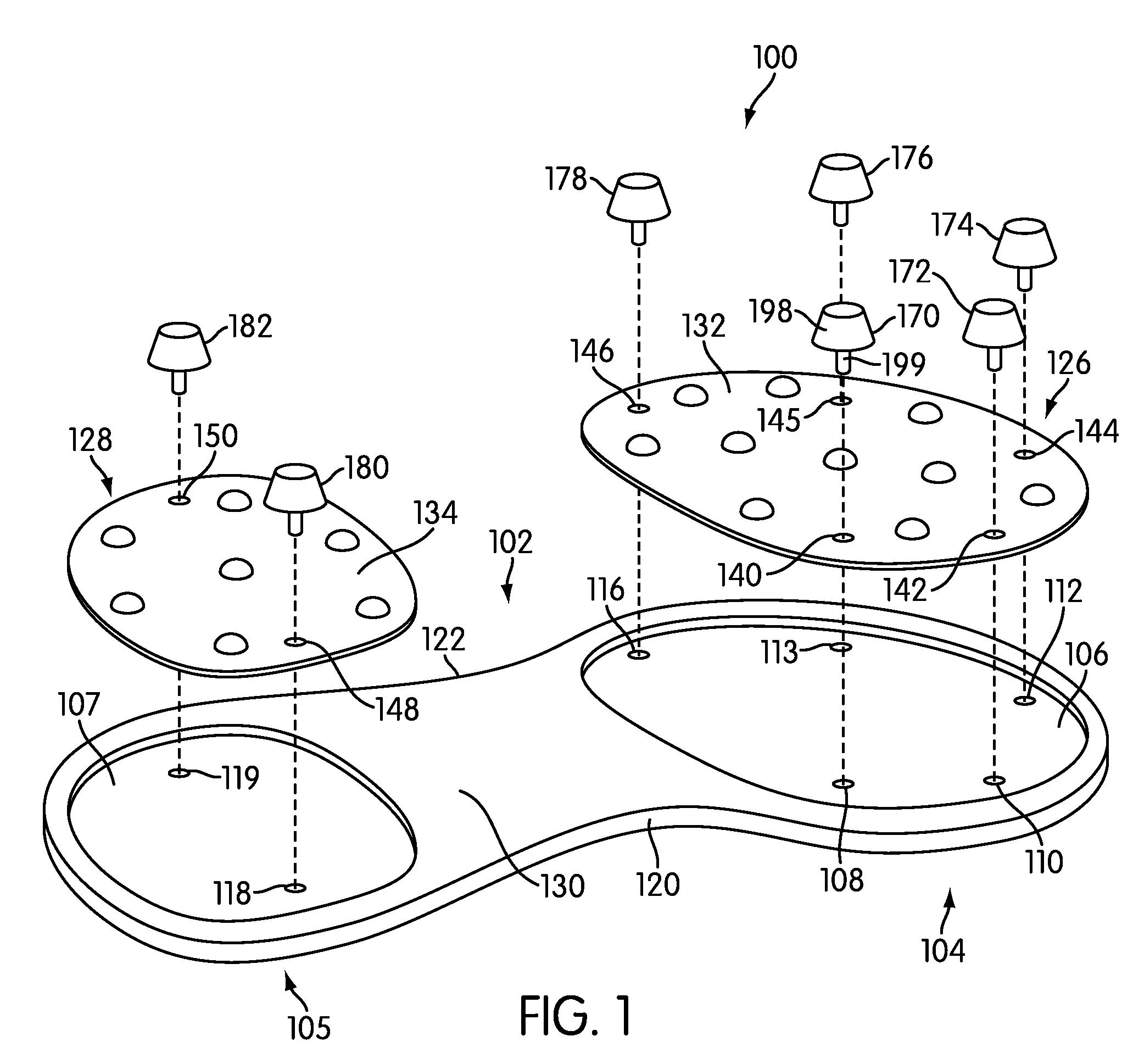

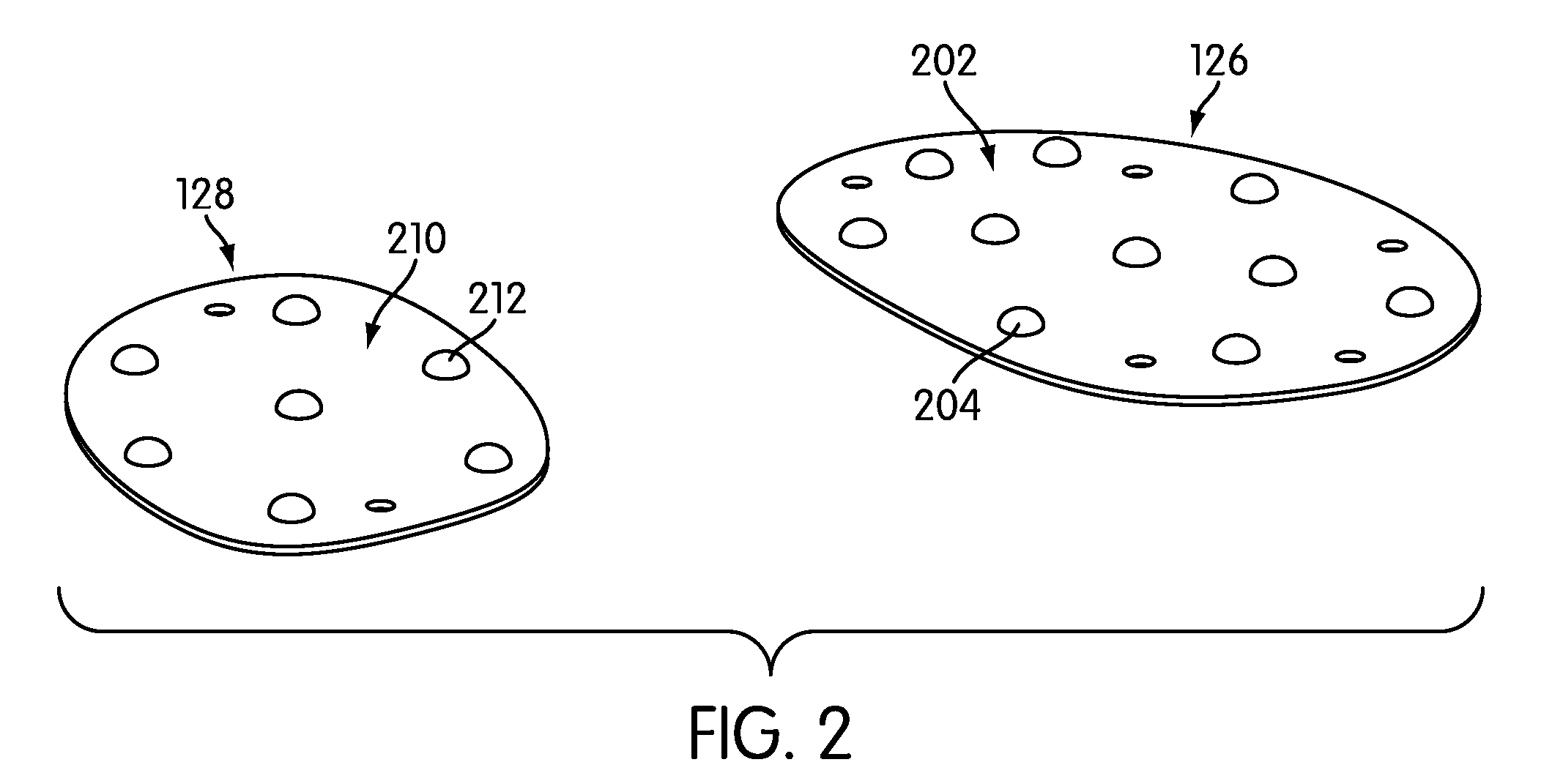

Interchangeable pod system

An article of footwear with an interchangeable pod system is disclosed. The interchangeable pod system includes an outsole, a pod set, and a cleat set. The pods are attached to the outsole by means of the members of the cleat set. Variations in the types of pods and cleats used allow a wearer to reconfigure the article of footwear in order to maximize performance on a given surface in a given set of surface conditions as well as other parameters.

Owner:NIKE INC

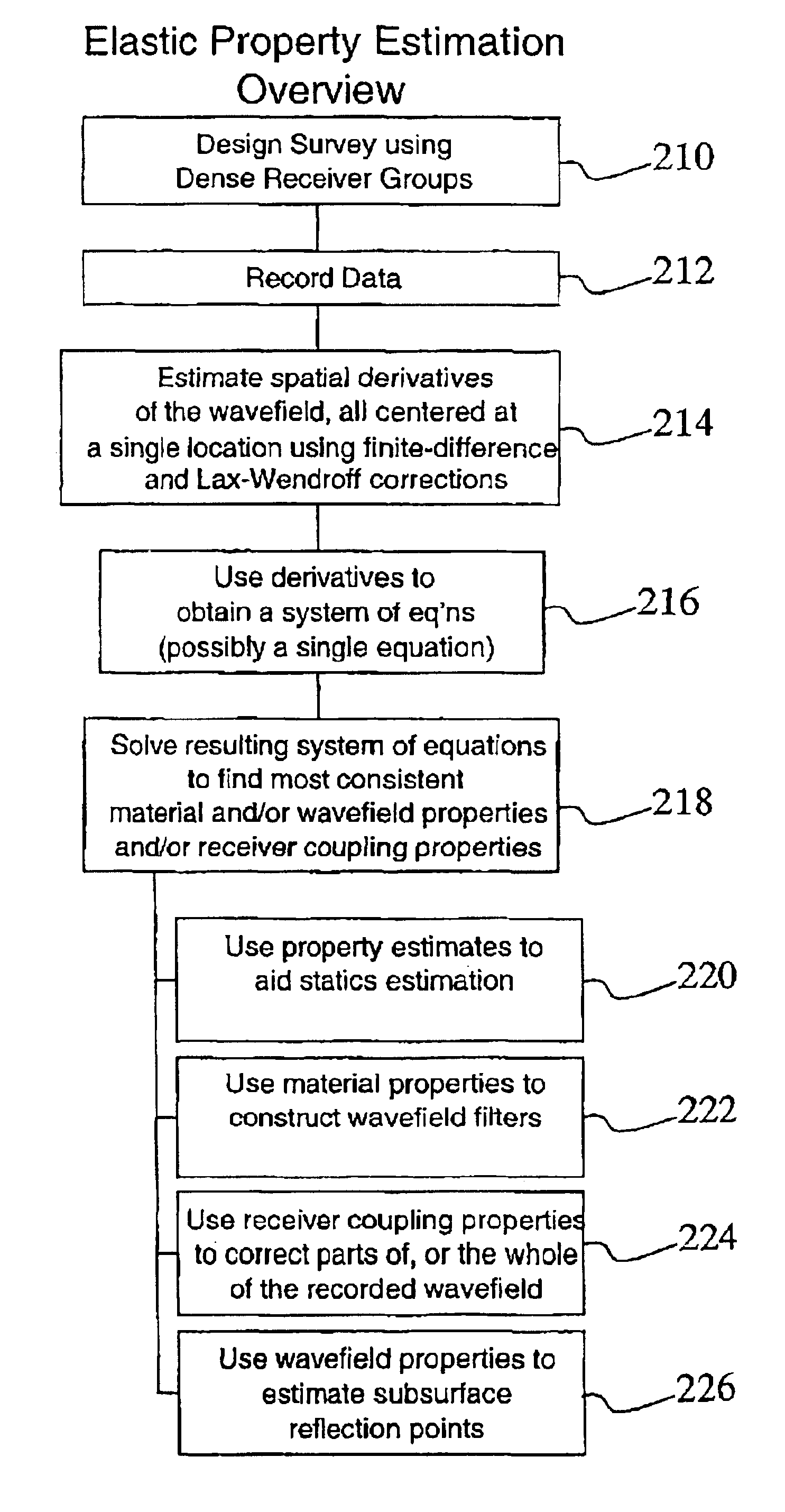

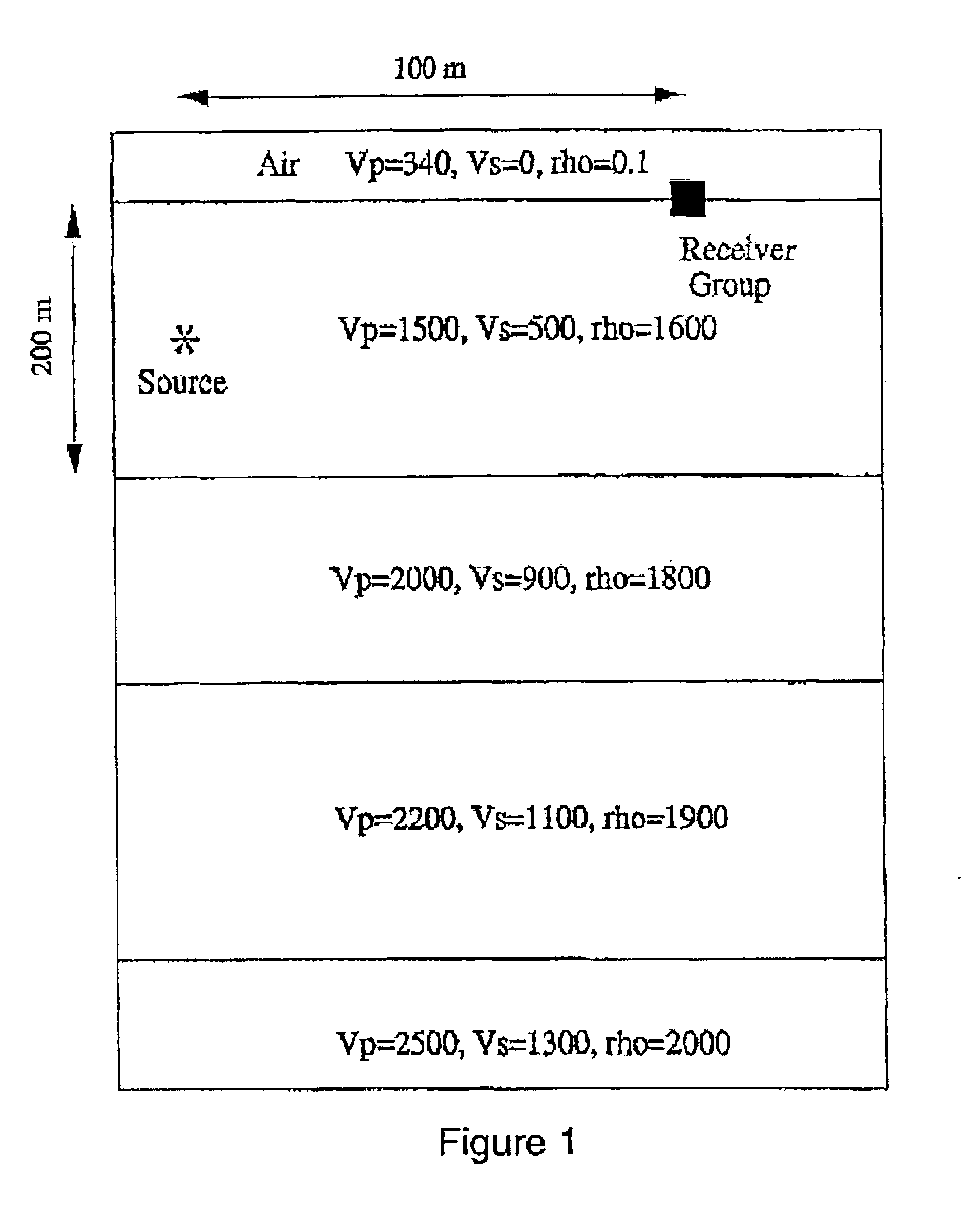

System and method for estimating seismic material properties

InactiveUS6903999B2Electric/magnetic detection for well-loggingSeismic signal receiversWave equationWave field

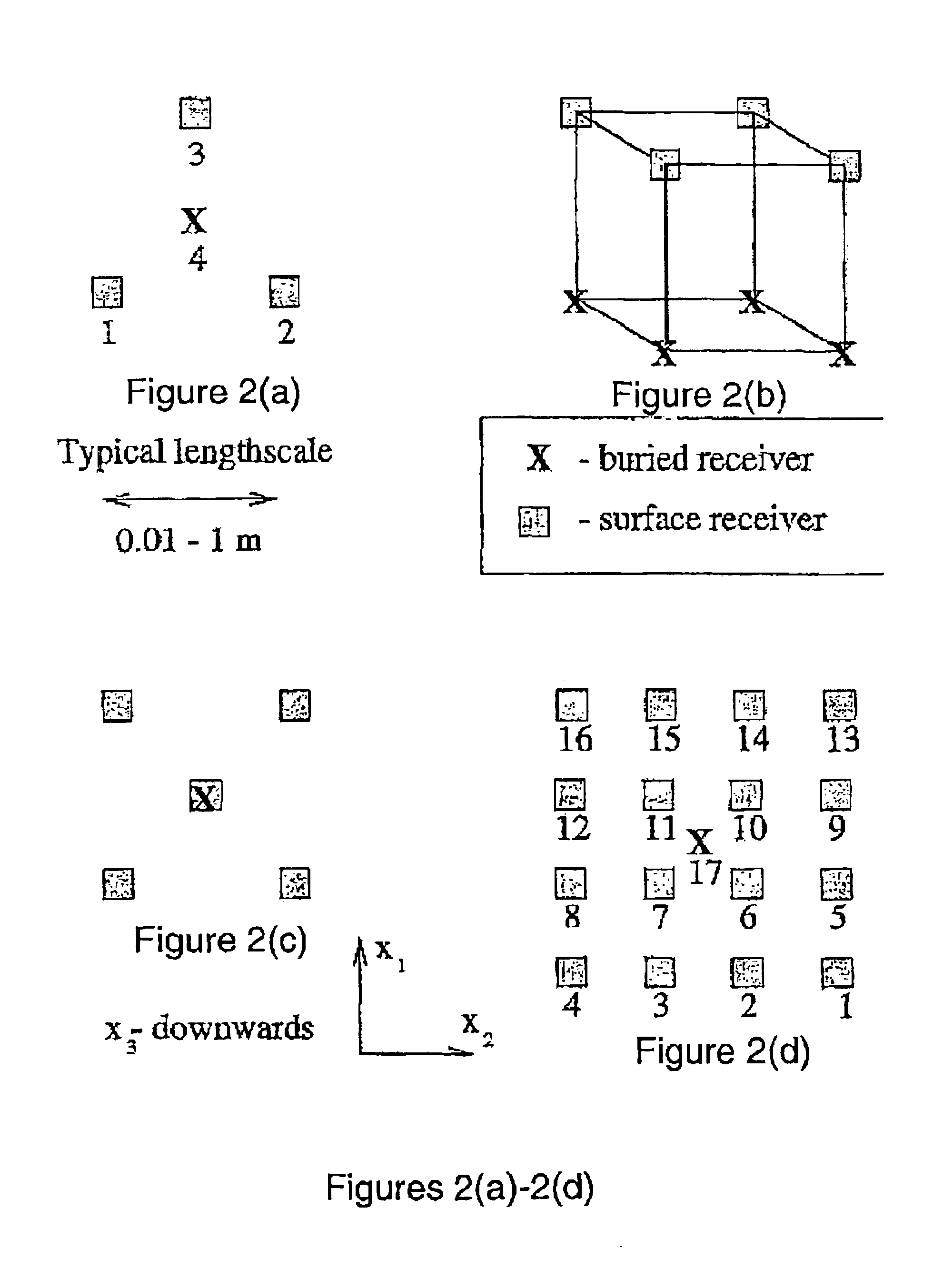

A method for estimating near-surface material properties in the vicinity of a locally dense group of seismic receivers is disclosed. The method includes receiving seismic data that has been measured by a locally dense group of seismic receivers. Local derivatives of the wavefield are estimated such that the derivatives are centered at a single location preferably using the Lax-Wendroff correction. Physical relationships between the estimated derivatives including the free surface condition and wave equations are used to estimate near-surface material properties in the vicinity of the receiver group. Another embodiment of the invention is disclosed wherein the physical relationships used to estimate material properties are derived from the physics of plane waves arriving at the receiver group, and the group of receivers does not include any buried receivers.

Owner:SCHLUMBERGER TECH CORP

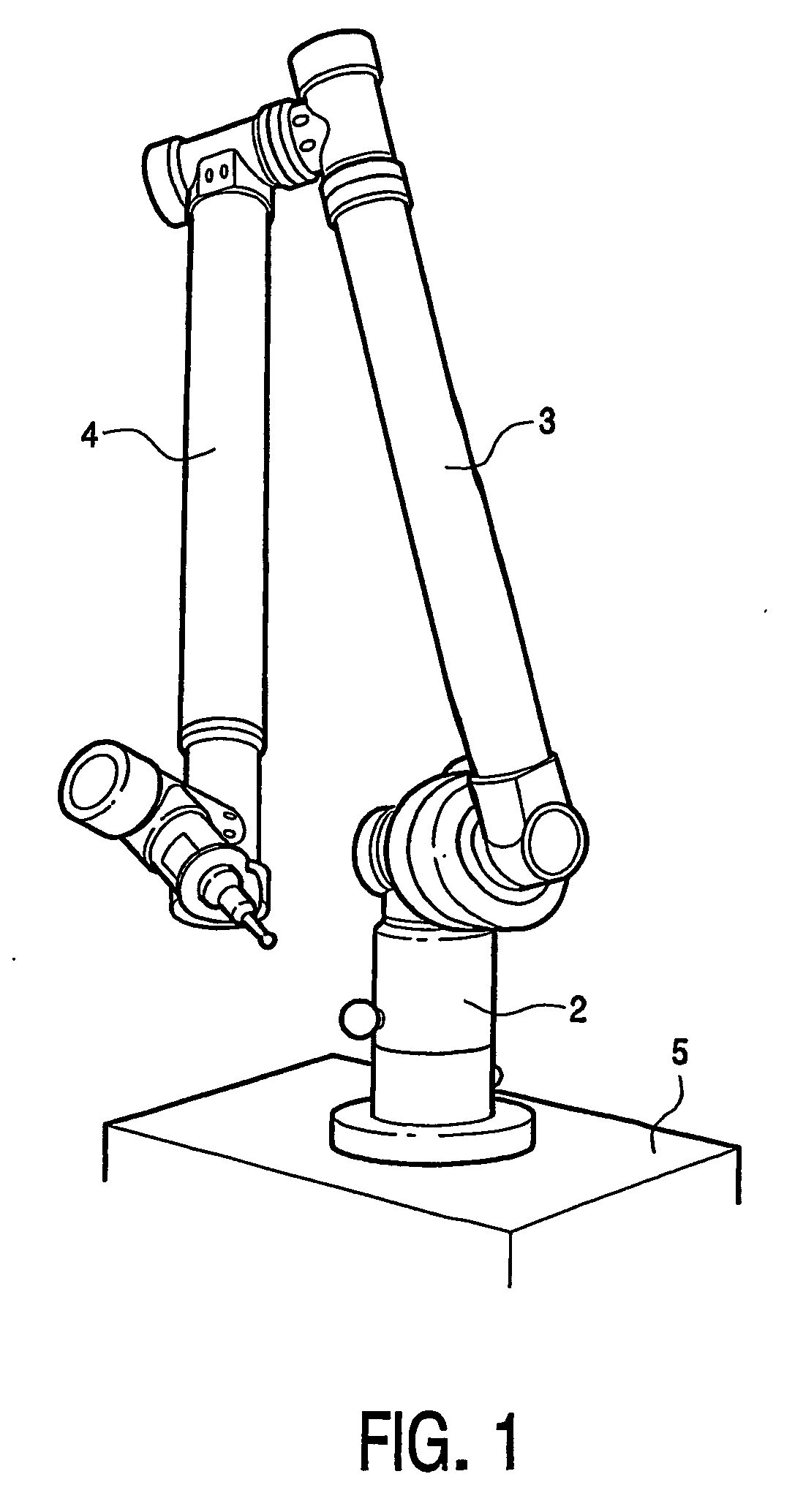

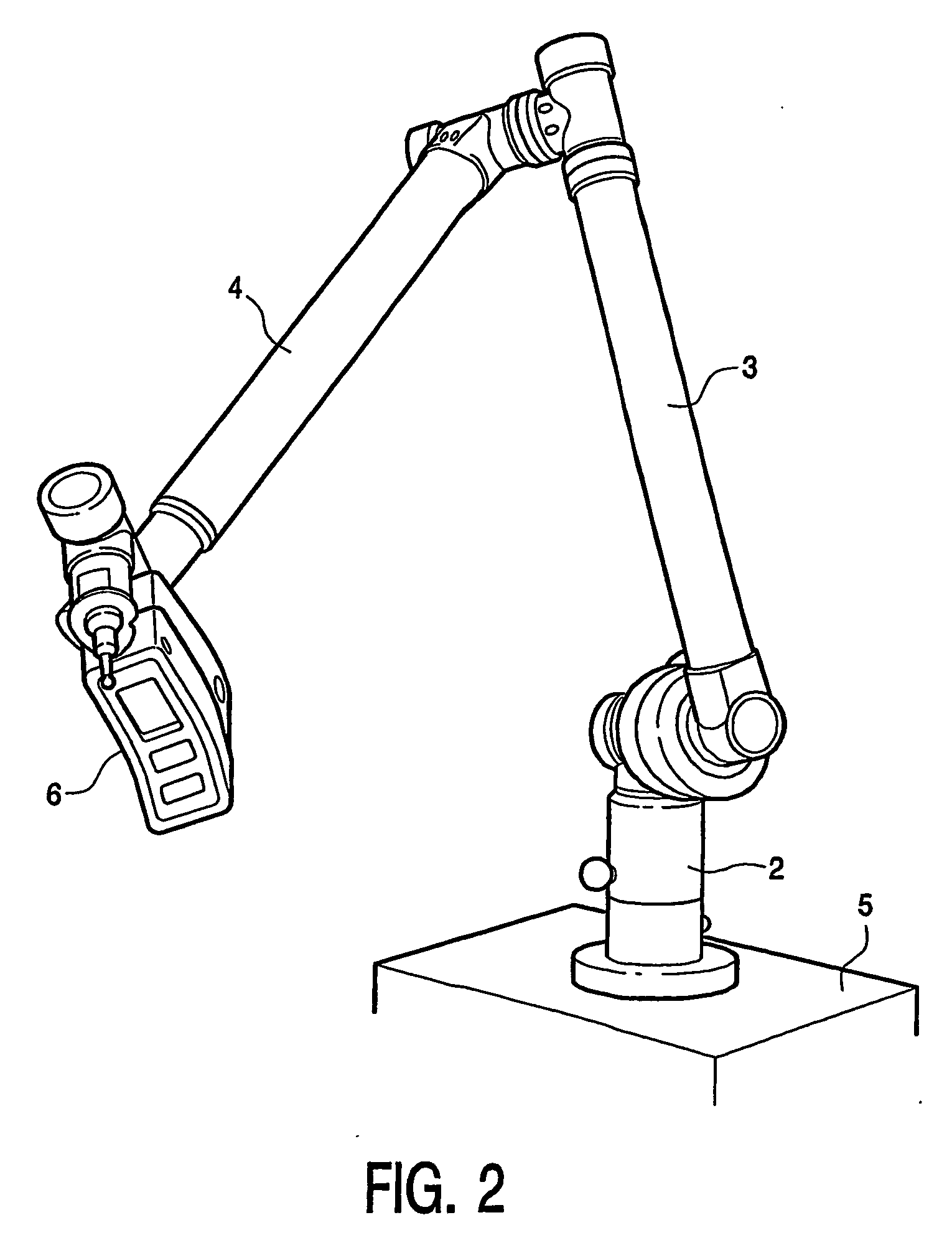

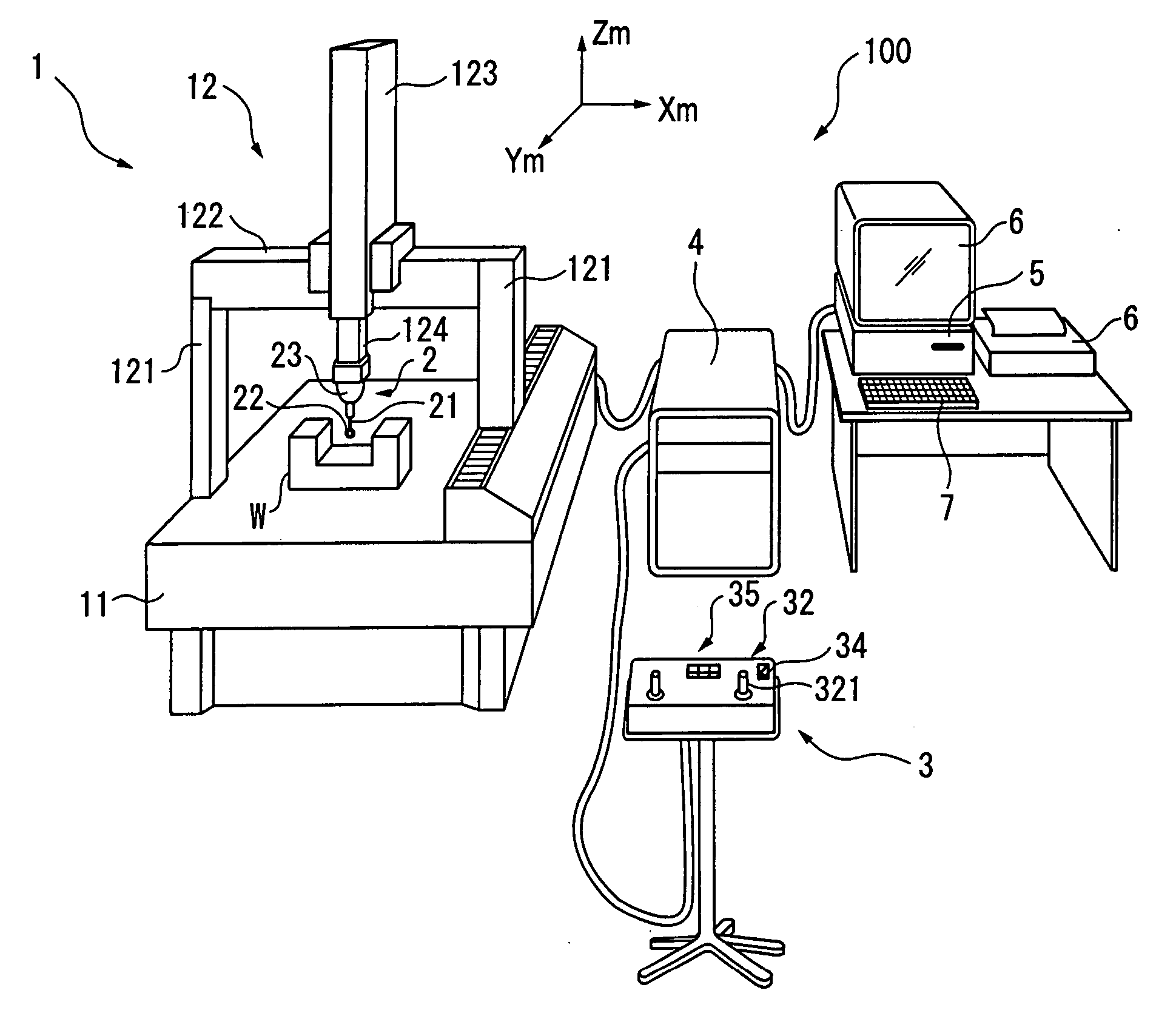

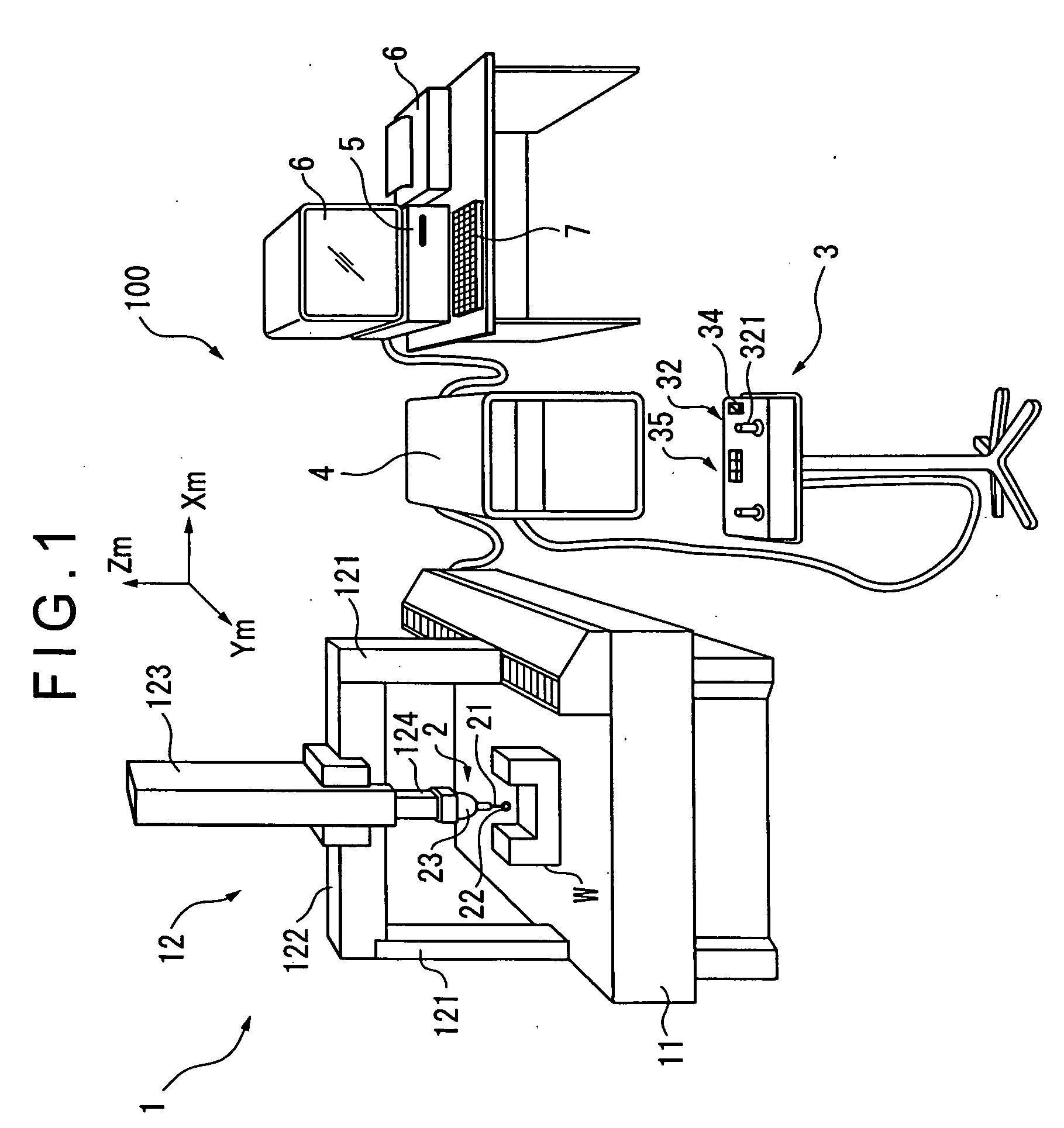

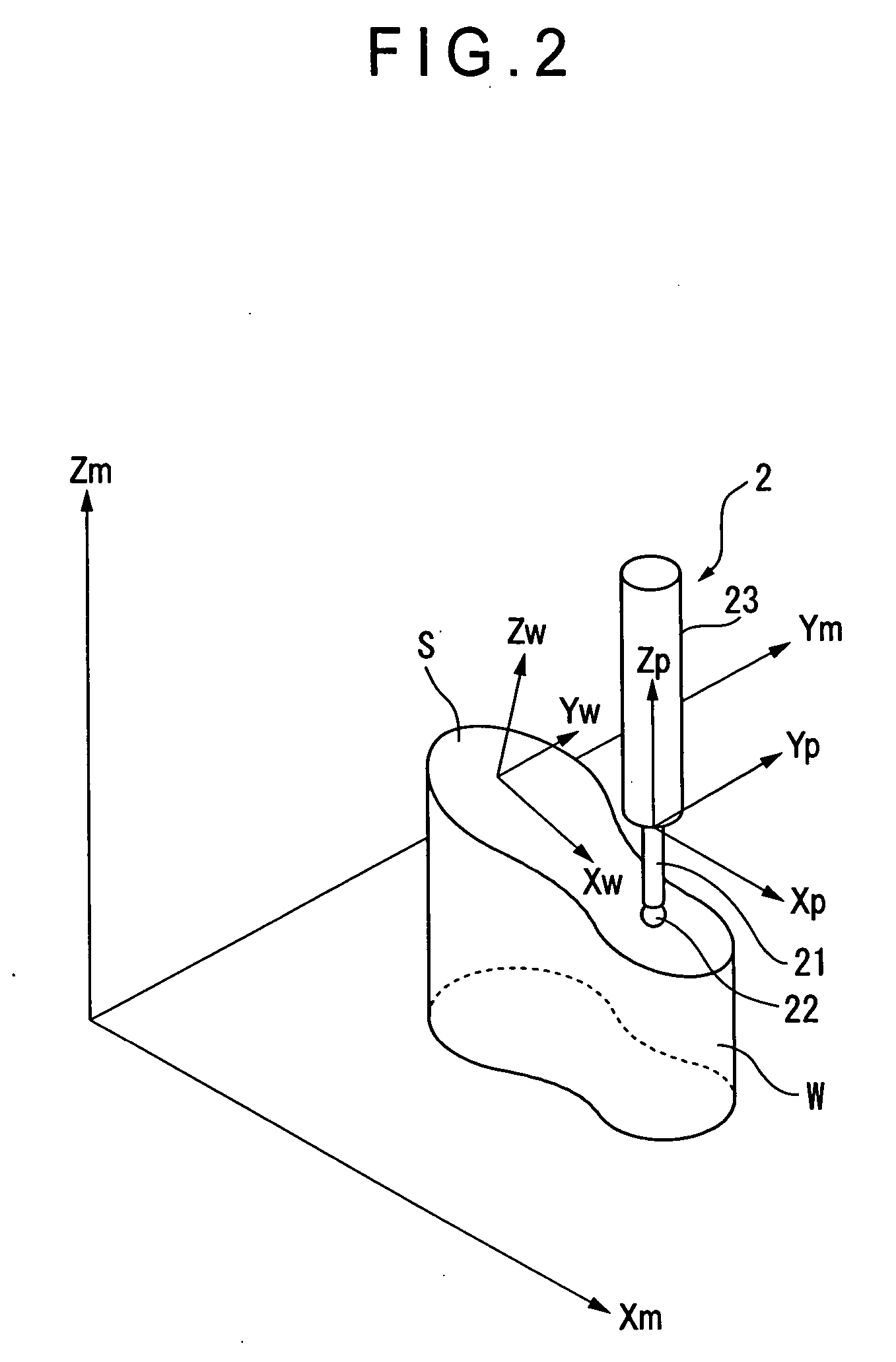

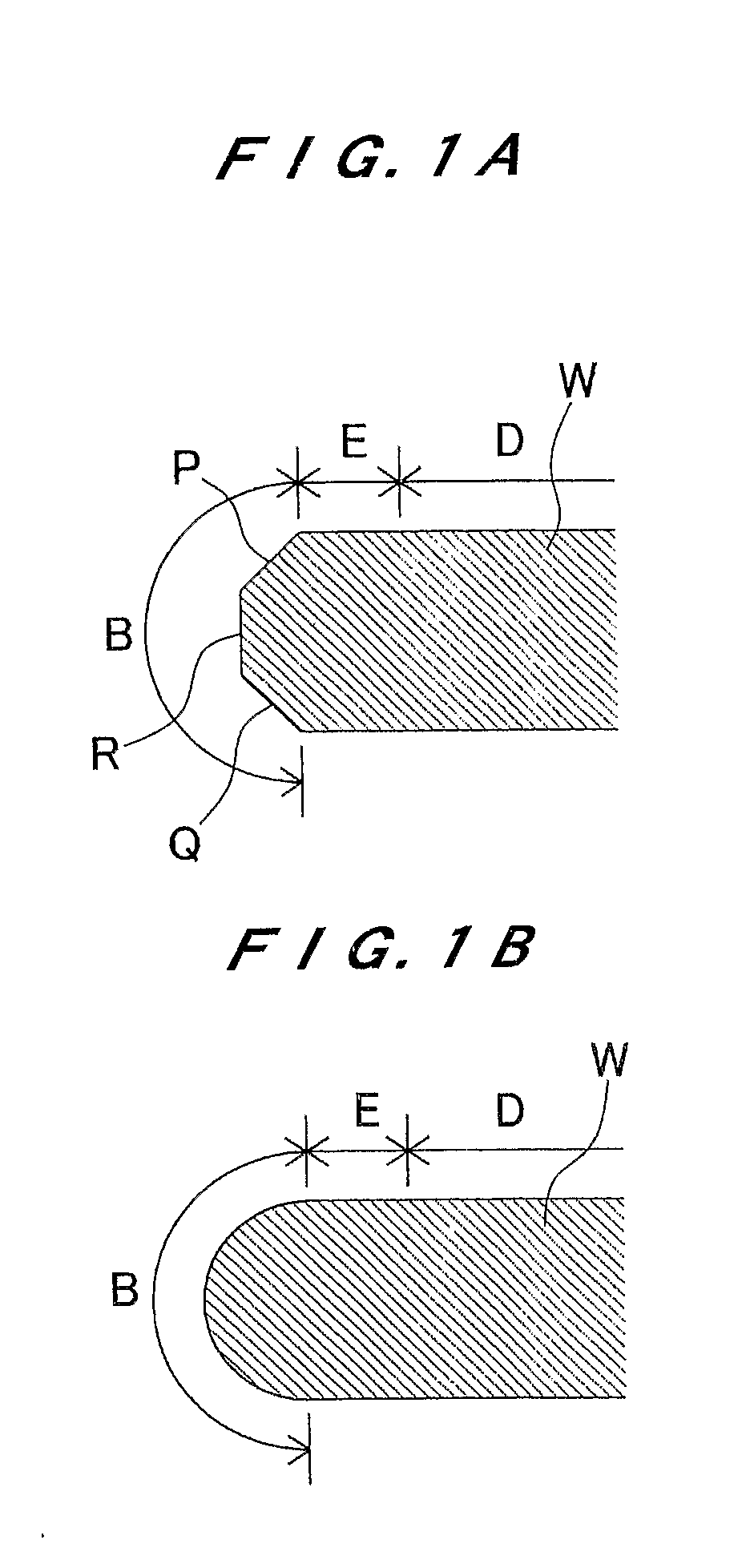

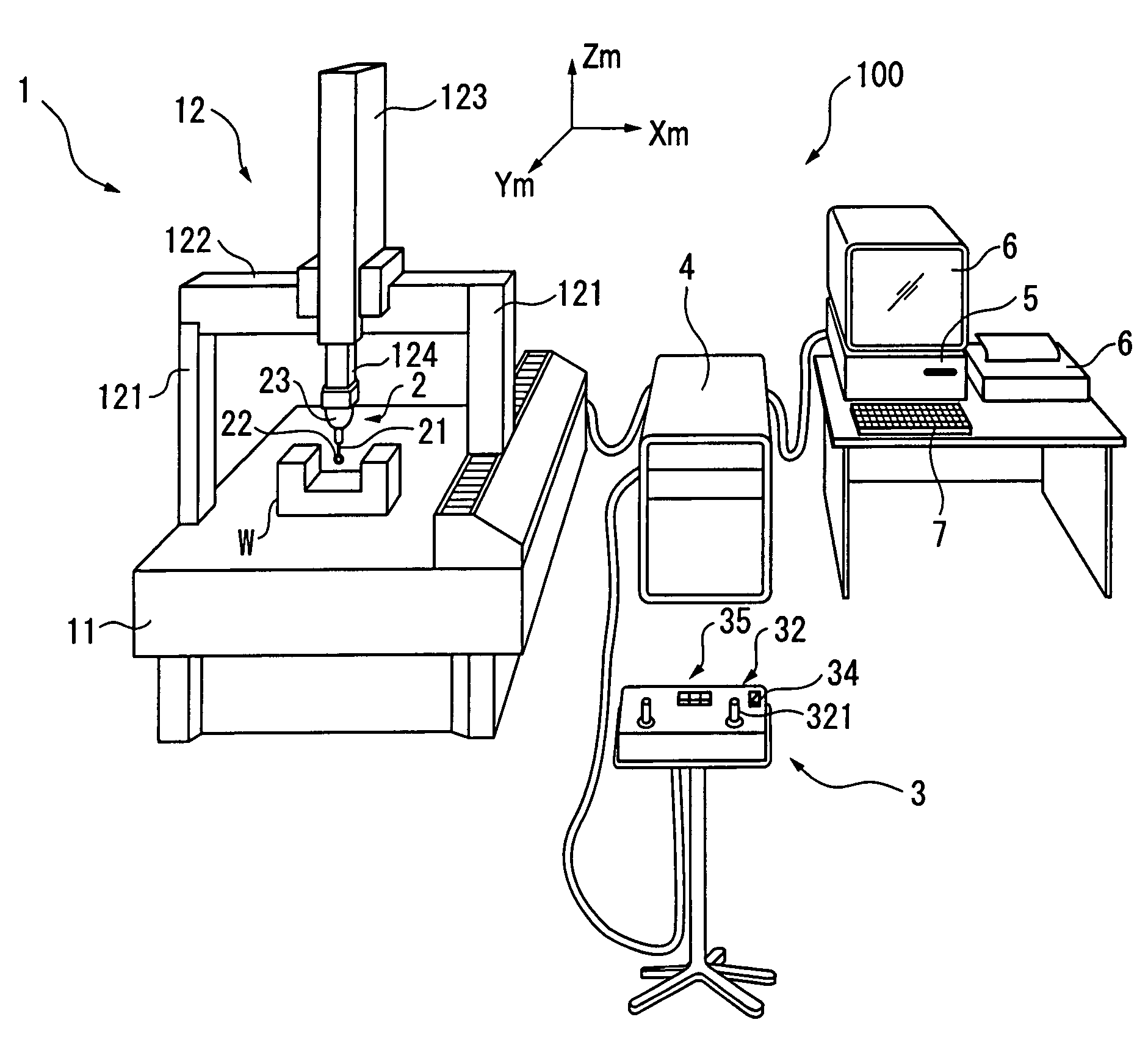

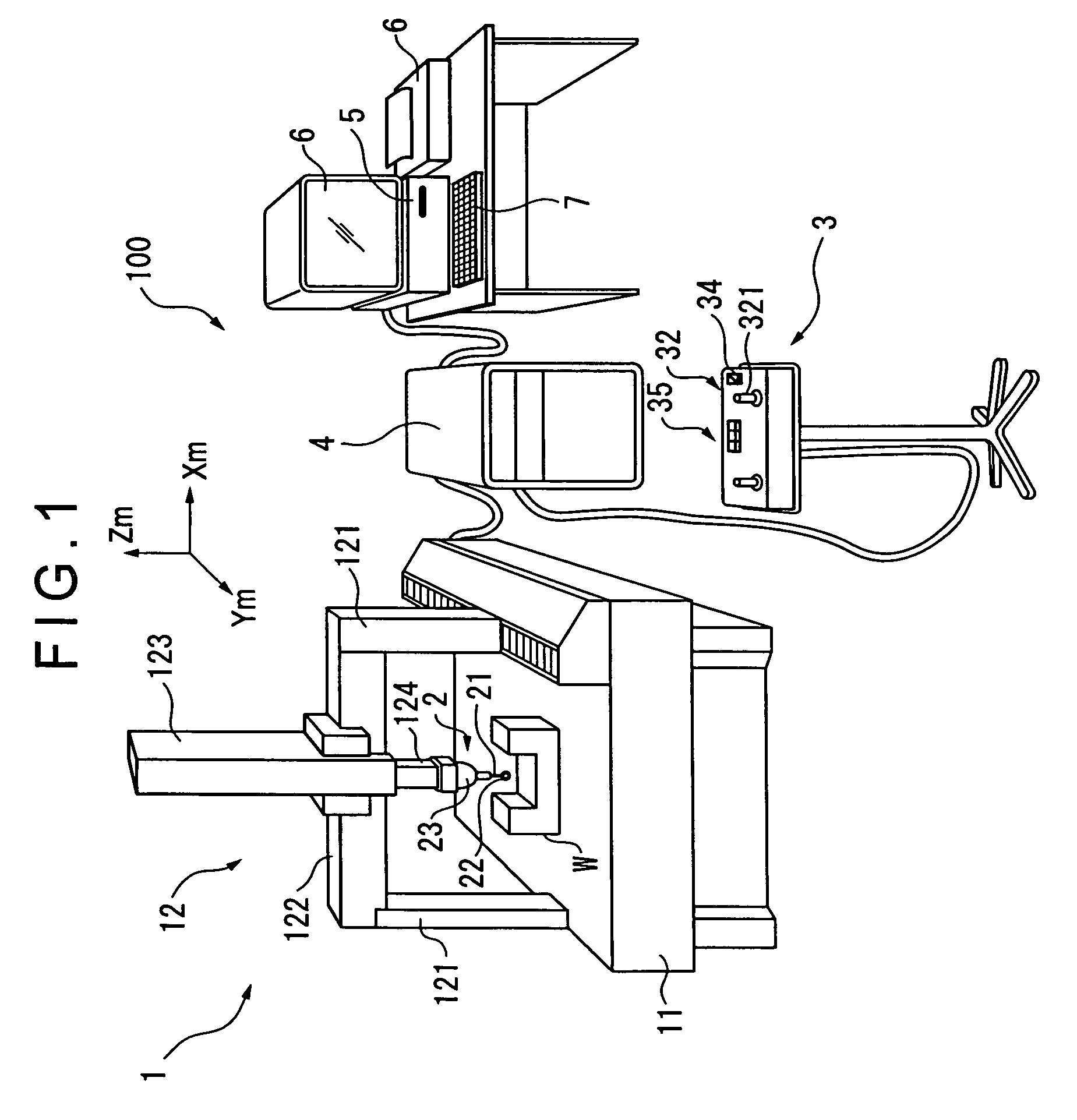

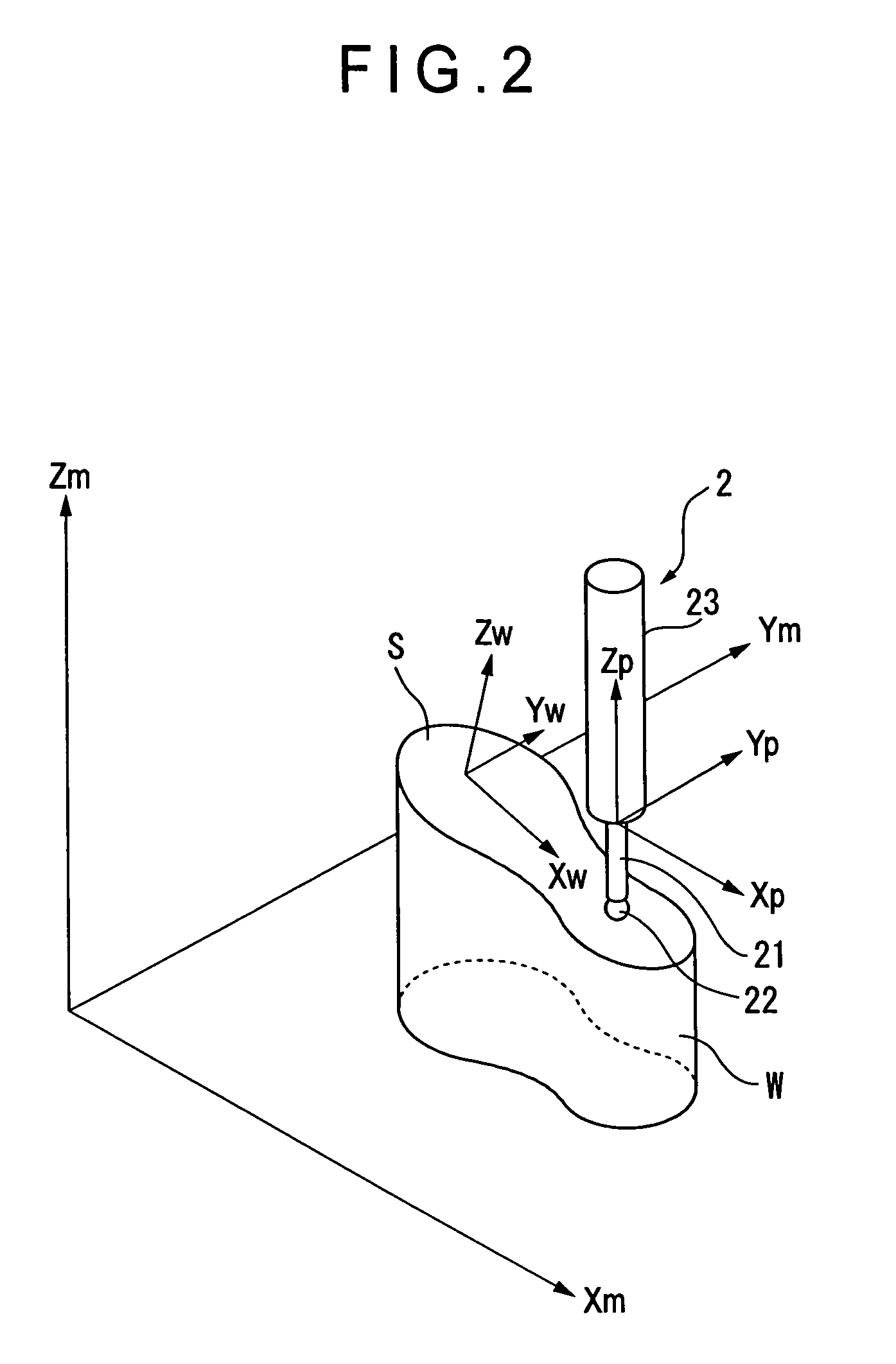

Surface scan measuring device, surface scan measuring method, surface scan measuring program and recording medium

ActiveUS20050263727A1Reduce necessary measuring timeImprove accuracyMechanical counters/curvatures measurementsInvestigating moving sheetsMeasurement deviceSurface conditions

A surface scan measuring device, a surface scan measuring method, a surface scan measuring program and a recording medium storing such a program which can appropriately adjust the scanning speed, the sampling pitch and other measurement parameters according to the surface condition of a workpiece are provided. The surface scan measuring device includes a radius of curvature computing section (543) for computing the radius of curvature of the scanning point from the measurement data acquired during the ongoing scanning operation, a moving speed deciding section (544) for deciding the moving speed of the scanning probe according to the computed radius of curvature and a sampling pitch deciding section (546) for deciding the sampling pitch according to the computed radius of curvature.

Owner:MITUTOYO CORP

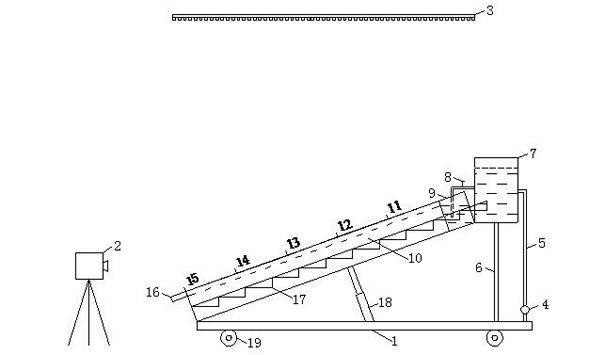

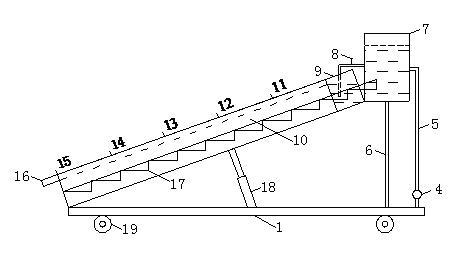

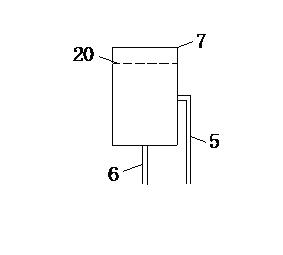

Fine simulation test device and fine simulation test method for slope water erosion

The invention discloses a fine simulation test device and a fine simulation test method for slope water erosion. The fine simulation test device comprises an underframe provided with trundles and a test soil groove connected with the underframe, the test soil groove is arranged above the underframe, one end of the test soil groove is hinged to one end of the underframe, and a water tank matched with the test soil groove is arranged at the other end of the test soil groove. A hydraulic rod is arranged between the test soil groove and the underframe, an equalization pond is arranged between thetest soil groove and the water tank, the equalization pond is communicated with the water tank through a water conveying pipe, the water conveying pipe and a water pump are arranged on one side of the water tank, a water discharging pipe is communicated with the lower portion of the water tank, a three-dimensional laser scanner is arranged in front of the test soil groove, a railfall device is arranged right above the test soil groove, and a flow collecting opening connected with the test soil groove is arranged at the end of the test soil groove hinged to the underframe. The fine simulation test device and the fine simulation test method for the slope water erosion have the advantages of being capable of controlling slope soil bulk density, vegetation types and cover degree manually, simulating soil water erosion conditions under different site conditions, and studying influences and response theories of all factors on soil water erosion under different underlying surface conditions.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

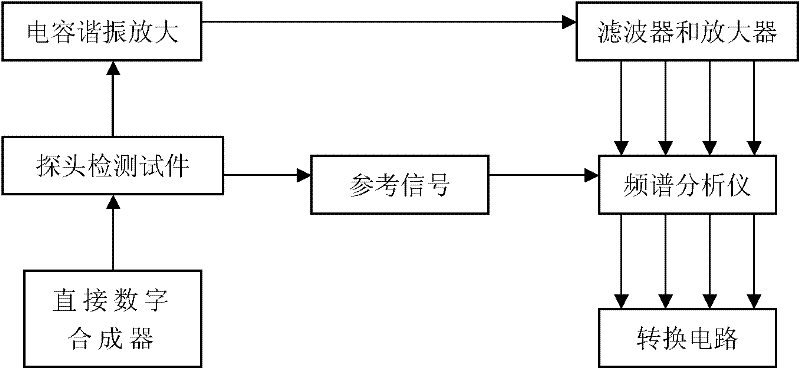

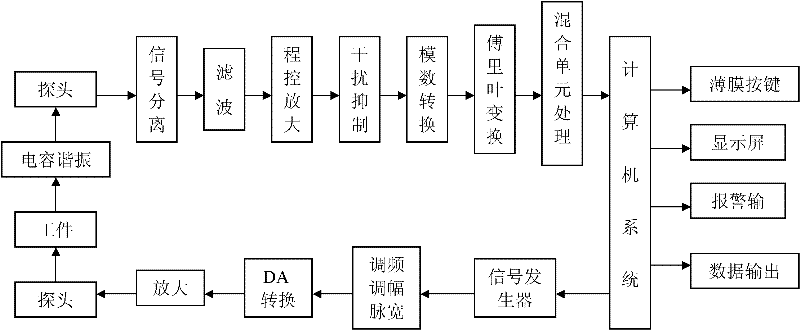

Electromagnetic resonance-based nondestructive testing method for metal material

InactiveCN102230914AFacilitates non-destructive testingRealize detectionMaterial magnetic variablesCapacitanceMetallic materials

The invention discloses an electromagnetic resonance-based nondestructive testing method for metal materials. According to the method, responding resonance signals of eddy current testing are obtained through multipled resonant capacitors in testing coils, comparative analysis of the responding resonance signals is carried out, and the relationships between a defect size and a signal amplitude and between defect depth and a signal phase are calibrated in advance, thereby enabling convenient nondestructive testing of metal materials. The electromagnetic resonance-based nondestructive testing method not only can produce same defect detection effects as a plurality of conventional electromagnetic testing methods like single-frequency eddy current and pulsed eddy current do, but also can effectively detect internal defects in a workpiece and detect workpieces with complicated surface conditions such as a casting surface, an unsmooth surface, a surface with oil stains, a rust-resisting paint, a corrosion layer or other pollutants, etc., without contact under the condition of a high liftoff value; according to the method, no cleaning is needed for test pieces, and particularly, no cumbersome processes like magnetization and demagnetization of magnetic metal materials are needed.

Owner:XIAMEN ANRUI JIE ELECTRONICS TECH

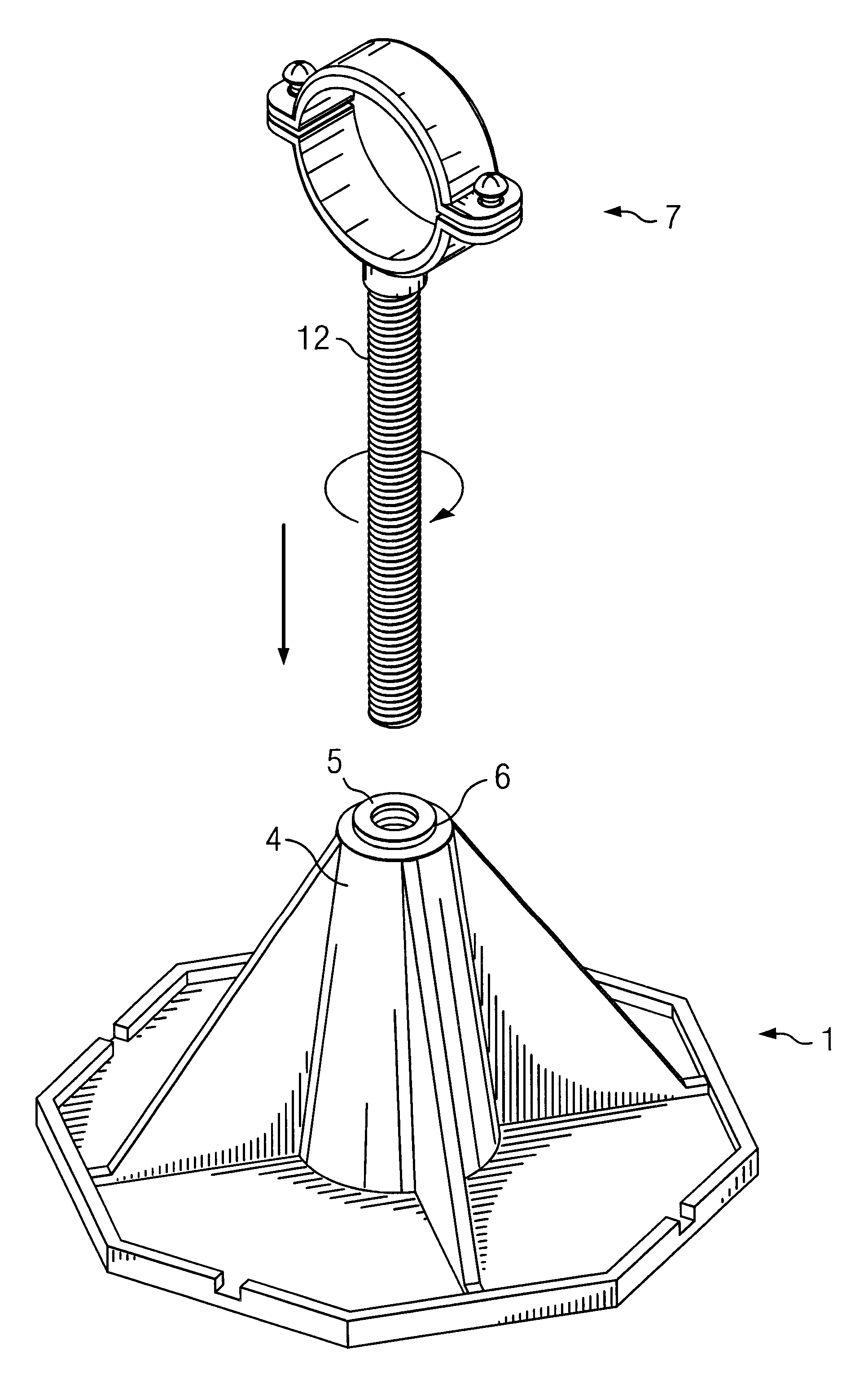

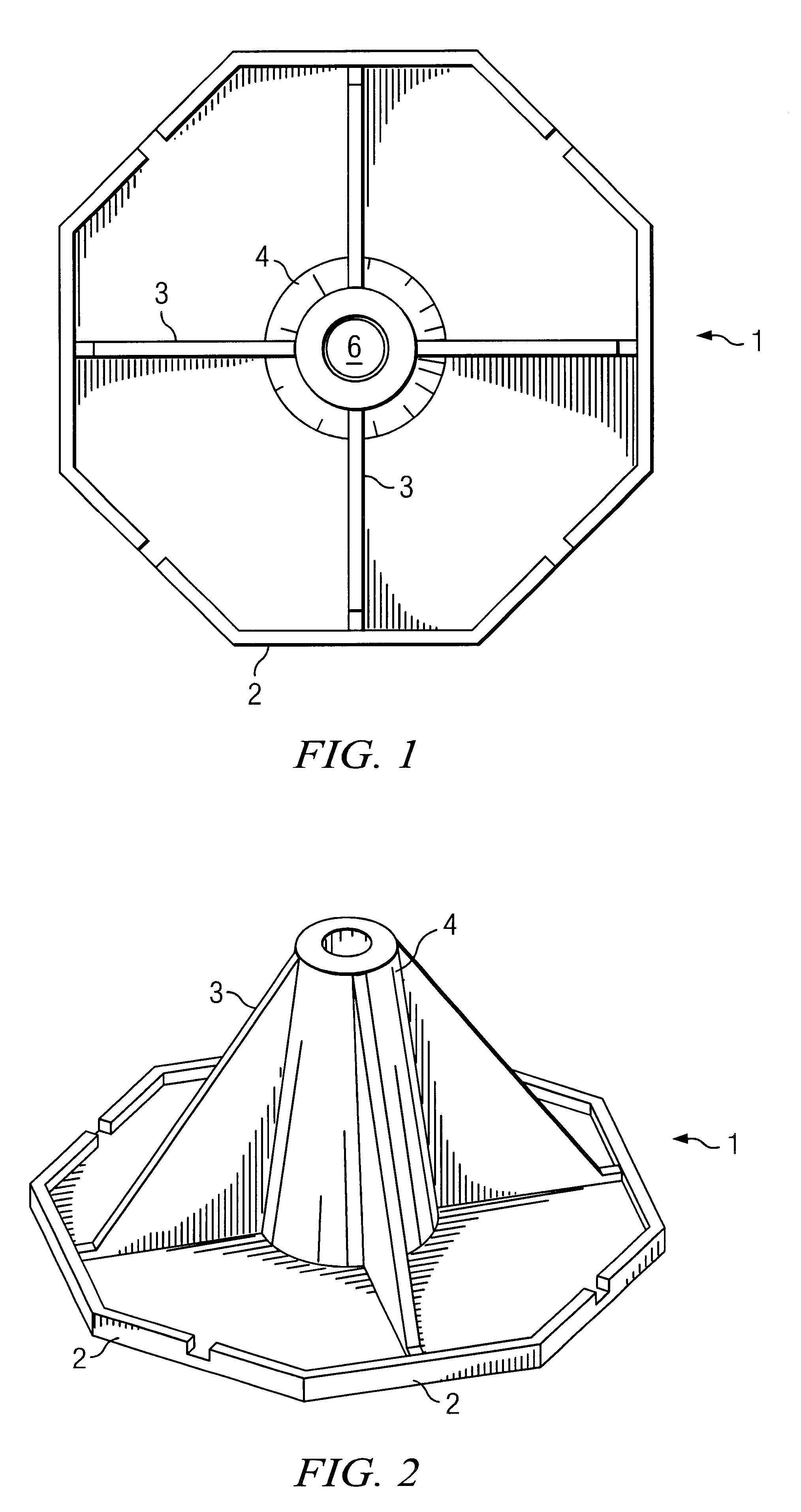

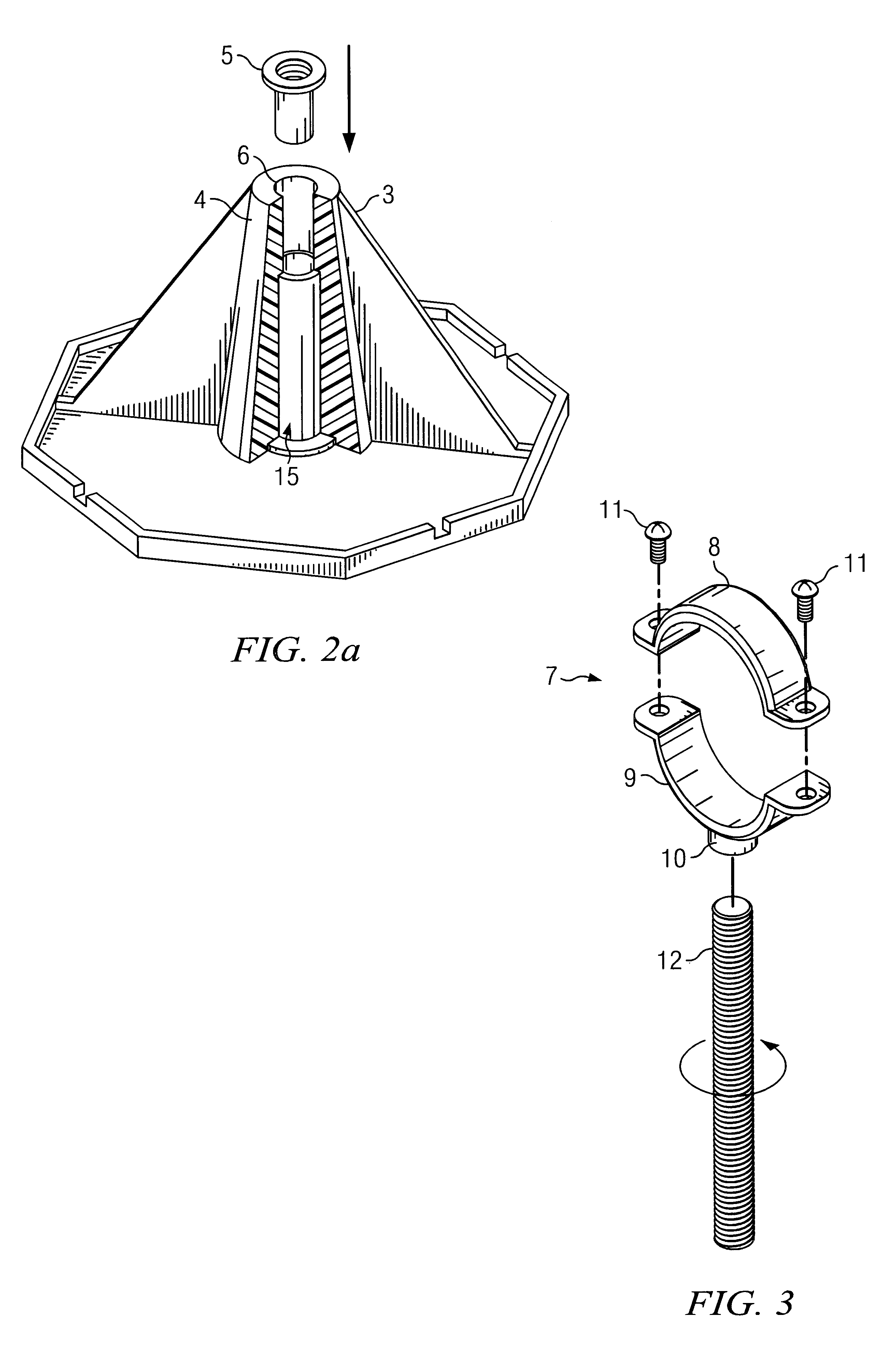

Single post support

A single post adjustable support device to provide interval support to a drain piping system where the piping is required to be suspended above a roof surface at continually changing elevations due to the need to have the piping system maintain a continual and gradual slope, compensating for un-regular surface conditions of the roof surface.

Owner:ISIMET MAPA

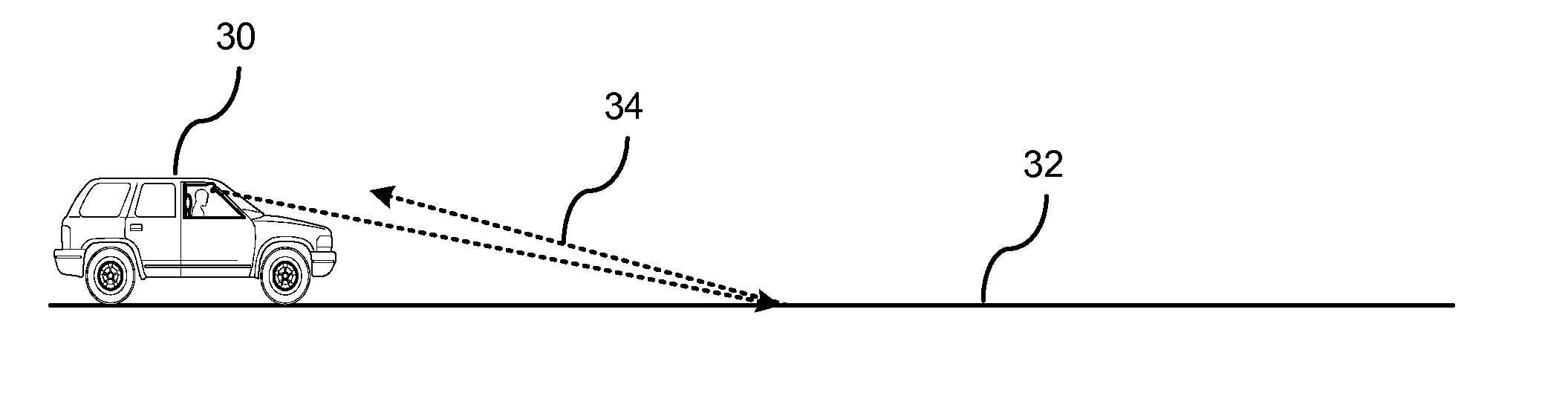

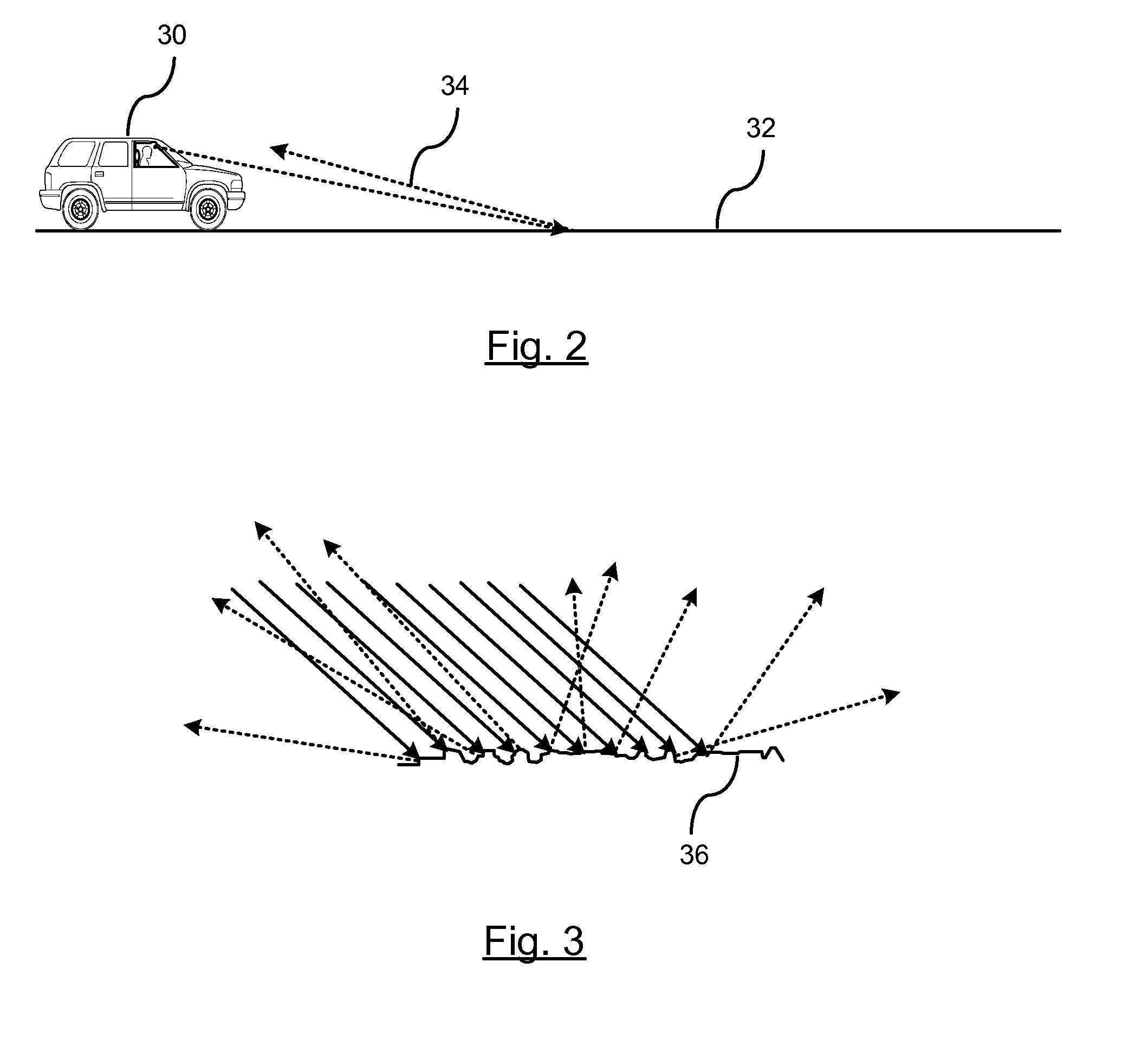

Road surface reflectivity detection by lidar sensor

ActiveUS20160178802A1Mitigate water/snow/iceIncreased scattered beamWeather condition predictionScattering properties measurementsPhotovoltaic detectorsRadar

A method of determining a surface condition of a road of travel. A light beam directed at a surface in the road of travel is transmitted utilizing a lidar system. A response is analyzed at a photodetector of the lidar system after transmitting the light beam. A determination is made whether a form of precipitation is present on the road of travel in response to analyzing the response at the photodetector. A precipitation indicating signal is generated in response to the determination that the ground surface includes a form of precipitation on the road of travel.

Owner:GM GLOBAL TECH OPERATIONS LLC

Laser guiding device for tile cutting machine

A laser guiding device is adjustably connected to a support frame on a top of the tile cutting machine and includes a frame in which a laser generating piece is received. An adjusting screw threadedly and transversely extends through the frame and is rotatably connected between two side walls of the support member such that the laser generating piece is moved in the direction of the adjusting screw to generate a laser beam on the tile to be cut. The laser beam is visible regardless of the surface condition of the tile and the debris during cutting.

Owner:MOTOMAX ELECTRIC

Vehicle mounted travel surface and weather condition monitoring system

InactiveUS6977597B2Show reliableReduce developmentArrangements for variable traffic instructionsWithdrawing sample devicesMonitoring systemVehicle detection

A system and apparatus for detecting and evaluating surface conditions on a road surface and atmospheric conditions simultaneously from a vehicle is disclosed. The system comprises a sensor for detecting the presence of deposited material on a road surface, a detector for determining one or more characteristics of the deposited material such as freezing temperature, process means for converting a detected signal and display means for displaying the condition of the road surface, and a sensor for detecting falling precipitation. An embodiment of the present invention includes a remote sensing apparatus which utilizes electromagnetic radiation to sense actual surface material conditions, temperatures, and composition and local atmospheric conditions at the vehicle as it is moving over a travel surface. This information is then processed through a computer in order to determine those additional steps necessary to apply additional materials to the road surface in order to minimize hazardous driving conditions.

Owner:WEATHER INSIGHTS

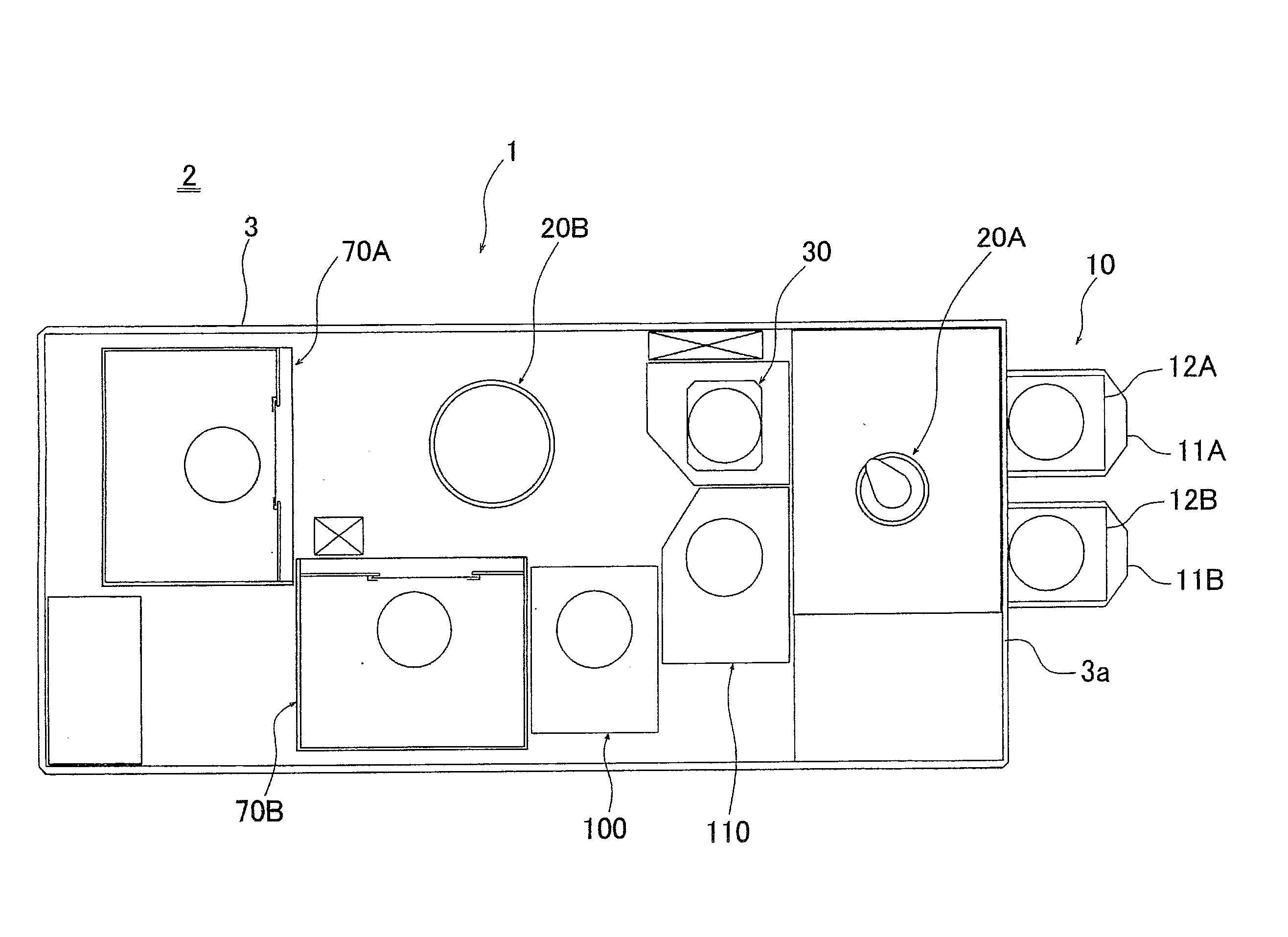

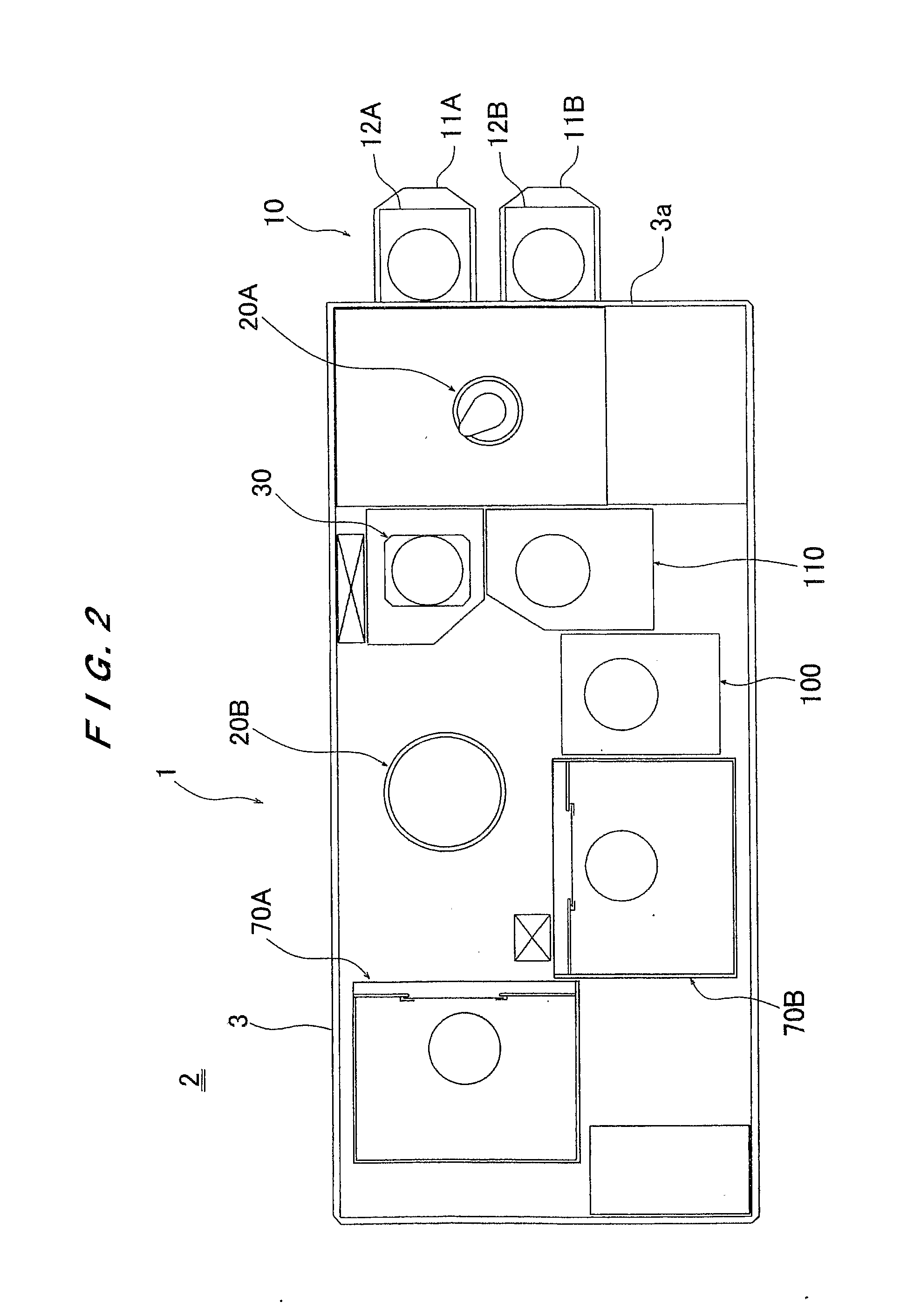

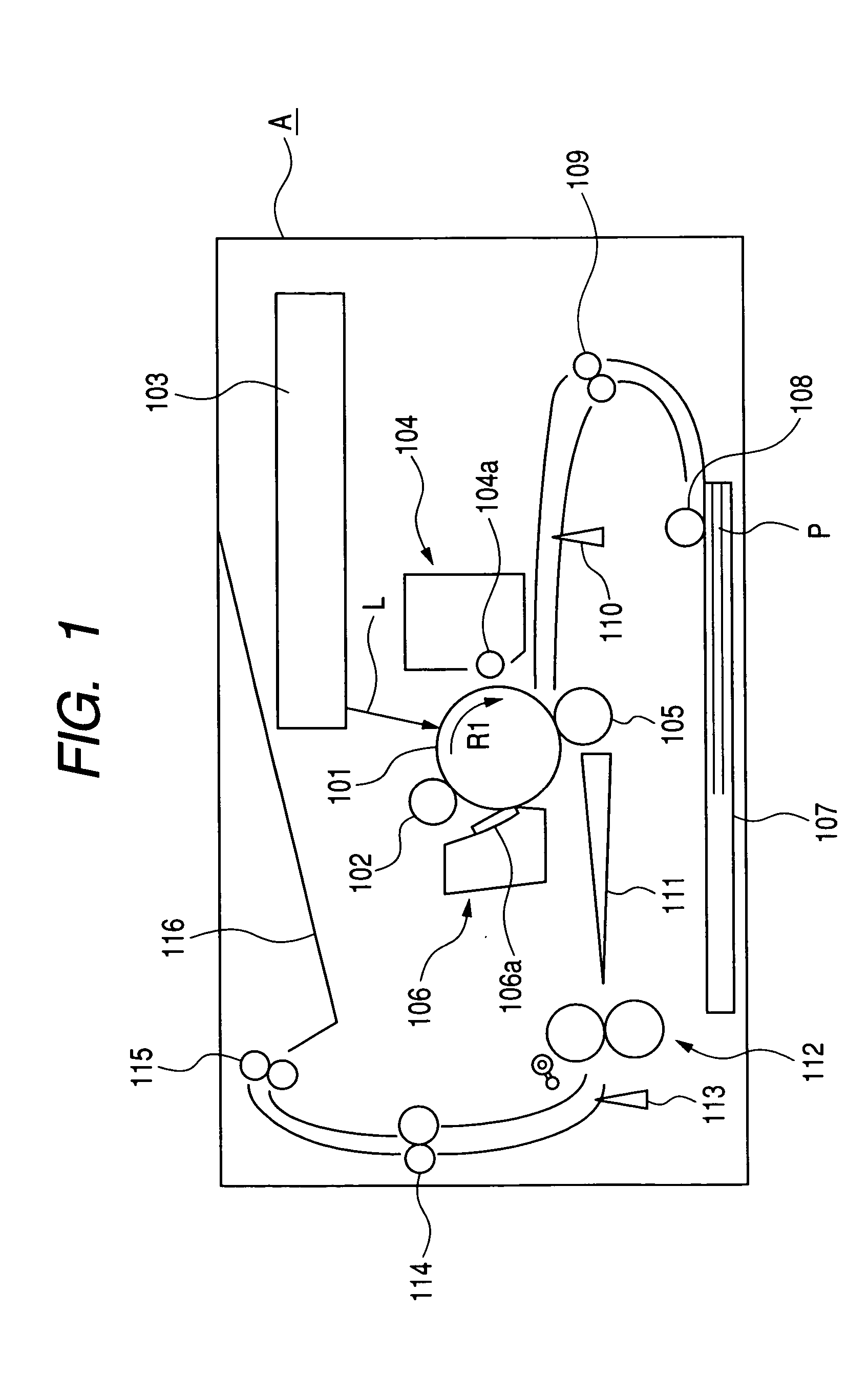

Substrate Processing Apparatus

ActiveUS20080200100A1Easy to polishEdge grinding machinesPolishing machinesSurface conditionsDiameter measurement

A substrate processing apparatus (1) includes first and second polishing units (70A, 70B) for polishing a peripheral portion of a substrate (W), a primary cleaning unit (100) for cleaning the substrate (W), a secondary cleaning and drying unit (110) for drying the substrate (W) cleaned in the primary cleaning unit (100), and a measurement unit (30) for measuring the peripheral portion of the substrate (W). The measurement unit (30) includes a mechanism for measurement required for polishing in the first and second polishing units (70A and 70B), such as a diameter measurement mechanism, a cross-sectional shape measurement mechanism, or a surface condition measurement mechanism.

Owner:EBARA CORP

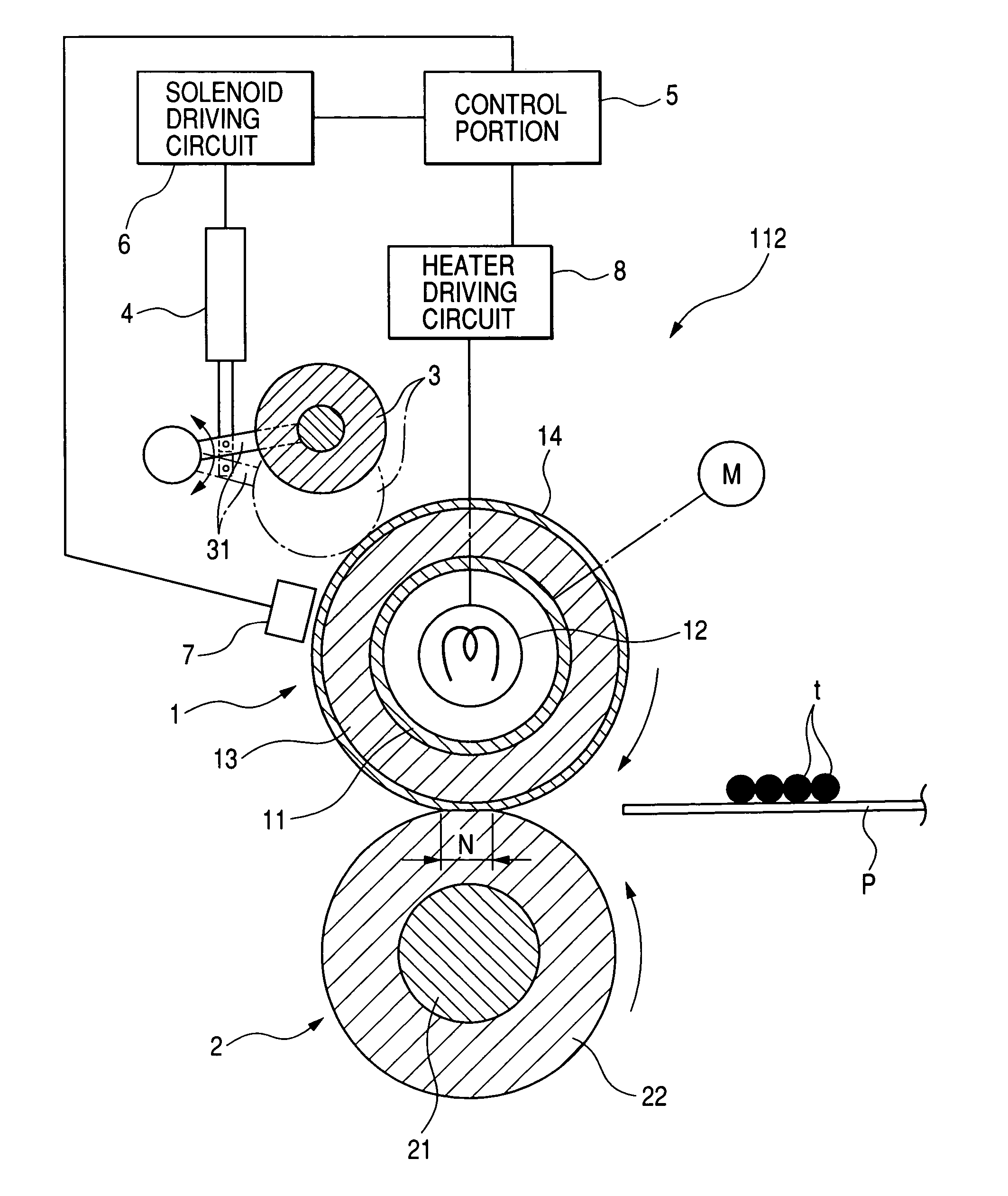

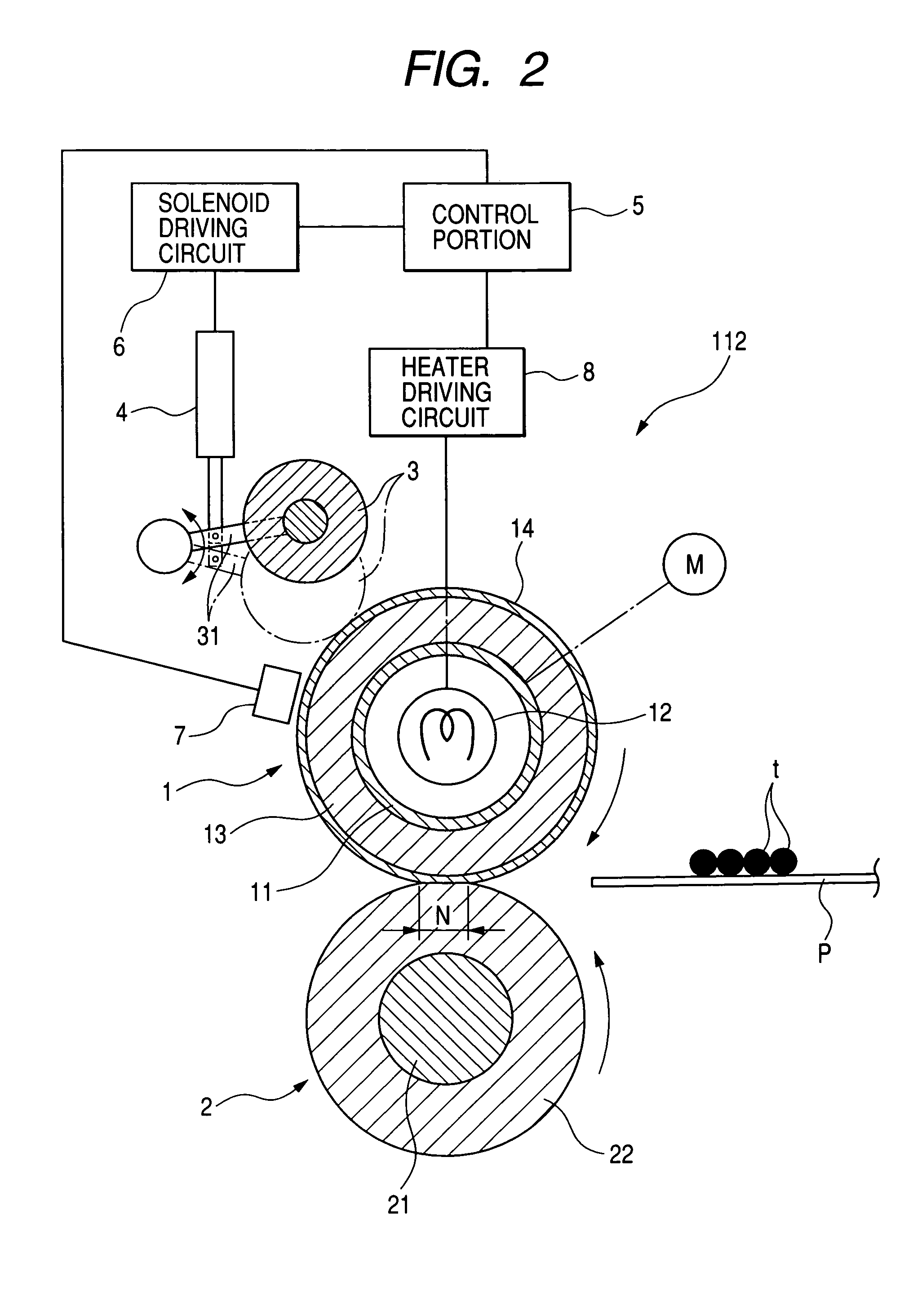

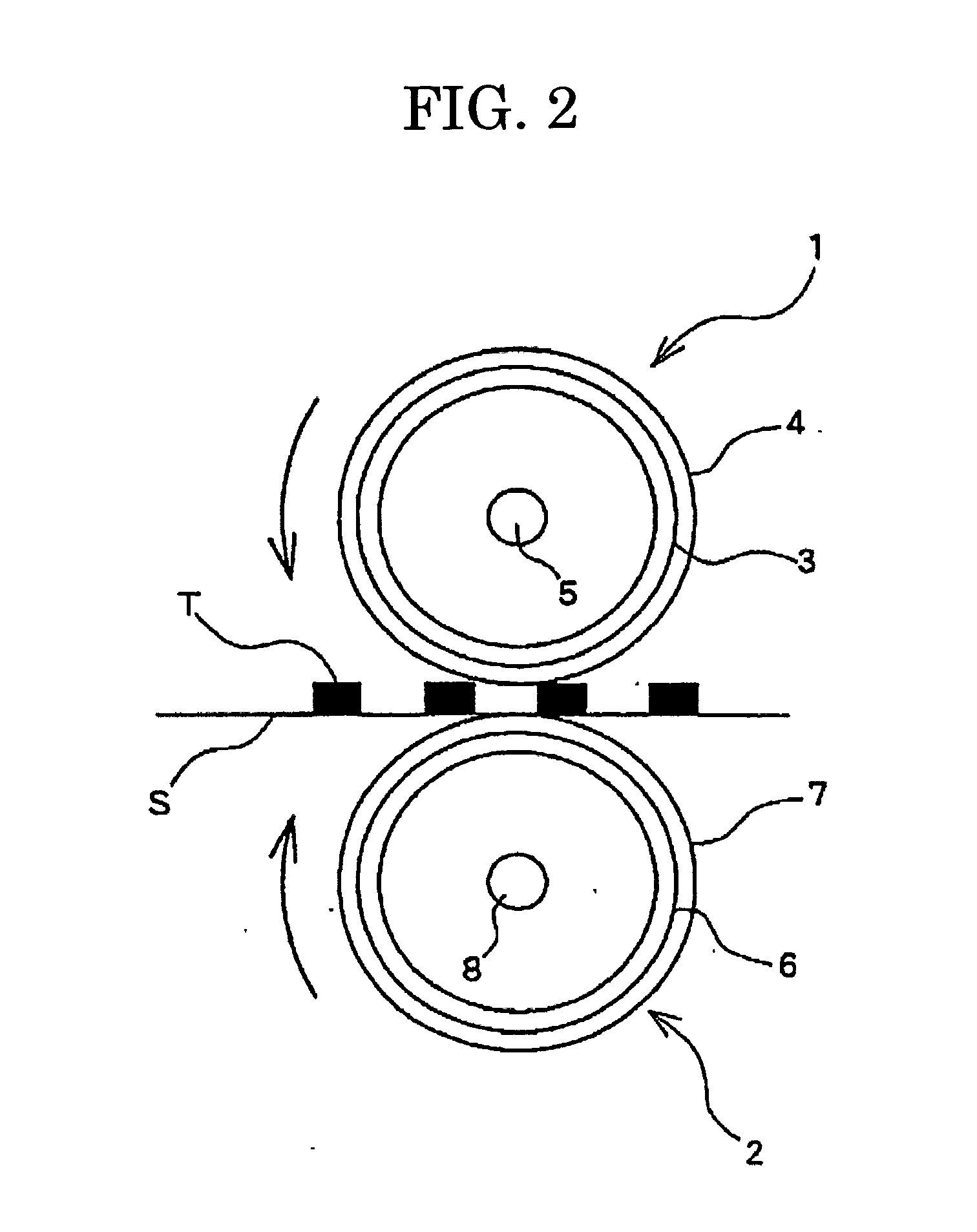

Image fixing apparatus capable of changing surface condition of fixing rotary member and fixing rotary member for use therein

The present invention provides a fixing apparatus including a rotatable member, a heater for heating the rotatable member, and control means which controls a heat generation of the heater, wherein a toner image on a recording material is heated by the rotatable member, the apparatus has a surface condition changing mode for changing a surface condition of the rotatable member, and, when the surface condition changing mode is selected, the control means controls the heat generation of the heater in such a manner that a surface temperature of the rotatable member becomes equal to or higher than a melting temperature of a surface layer of the rotatable member.

Owner:CANON KK

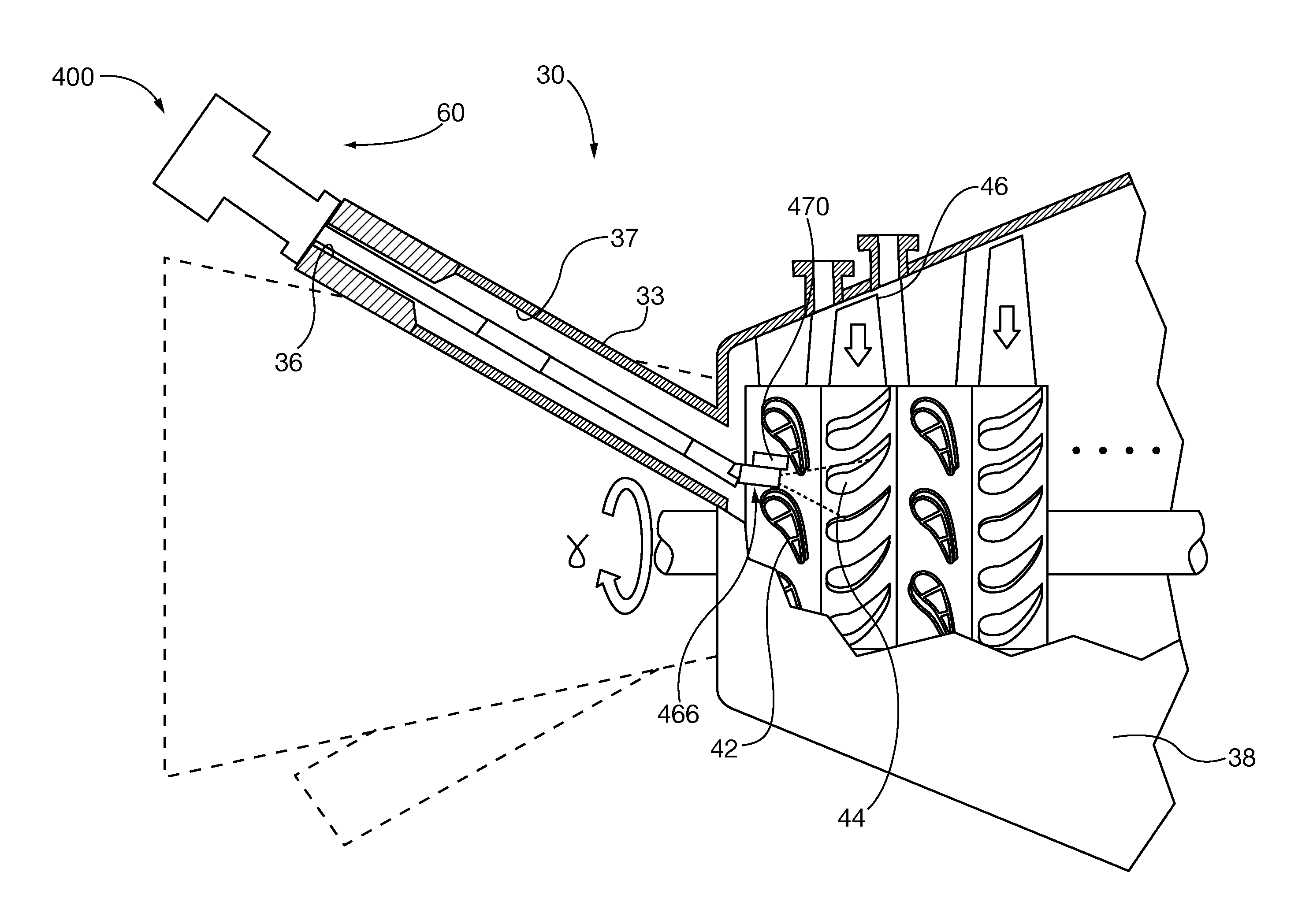

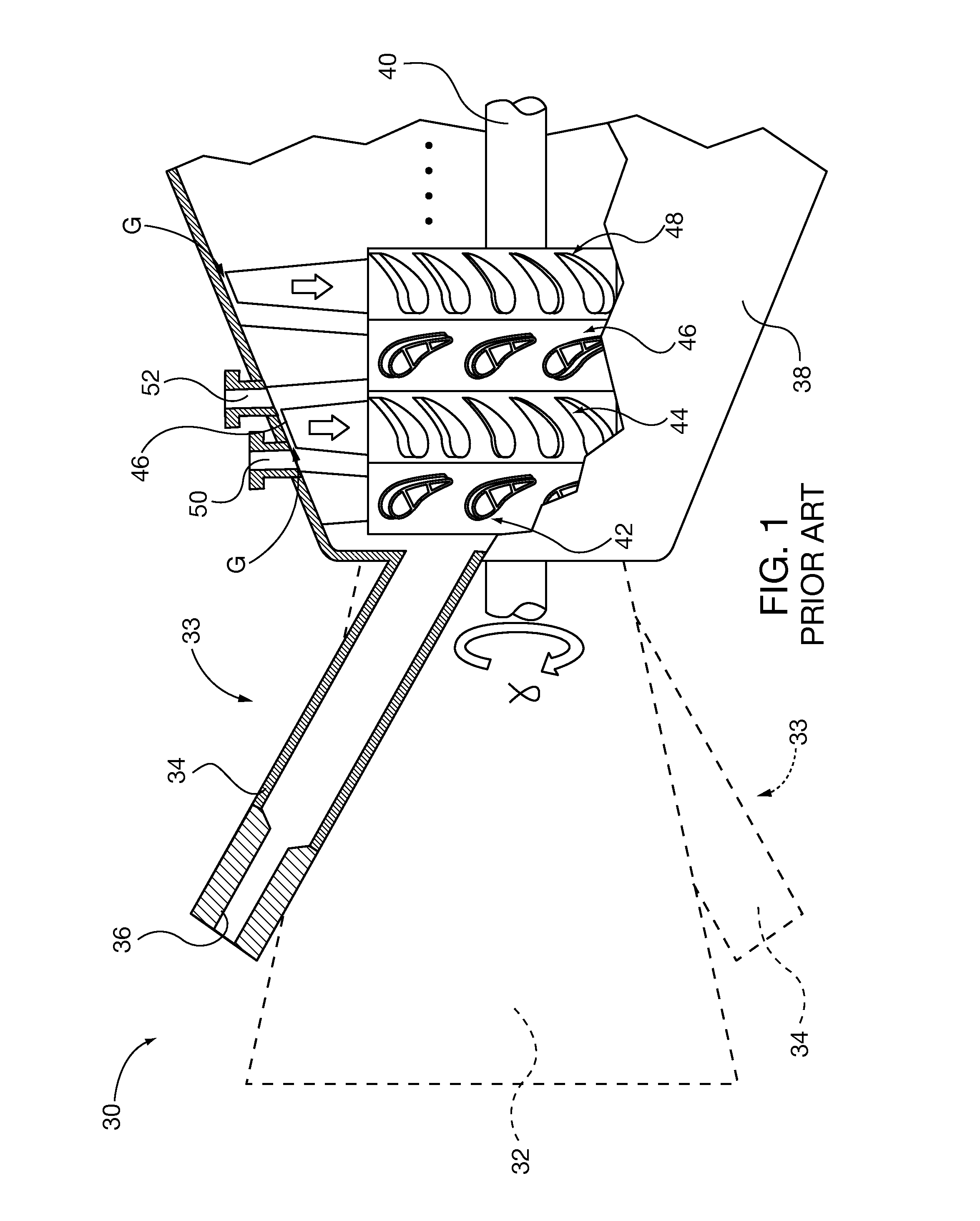

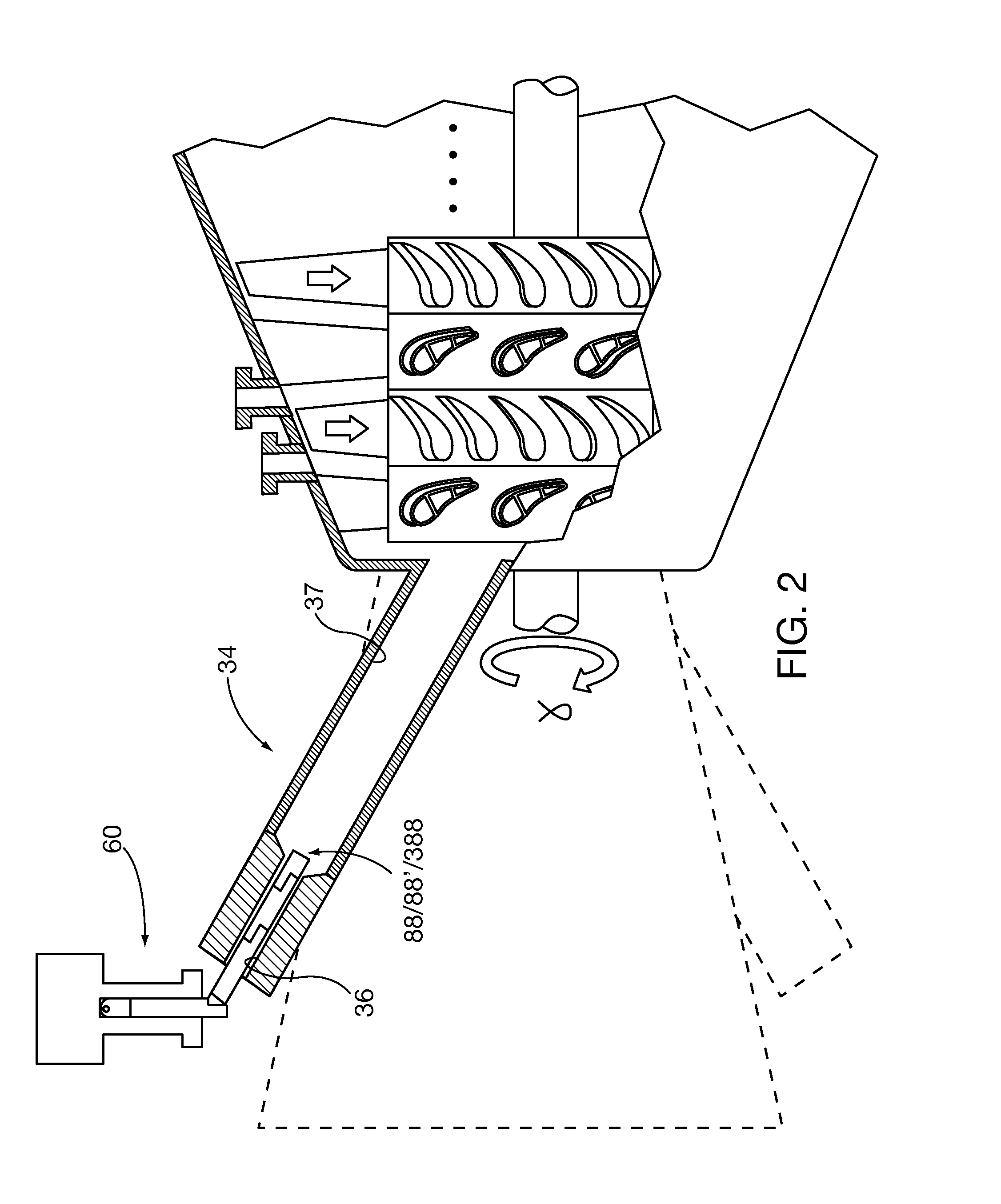

Method and system for surface profile inspection of off-line industrial gas turbines and other power generation machinery

ActiveUS20150300920A1Facilitates of dimensionalGathering informationGas-turbine engine testingMaterial analysis by optical meansIndustrial gasTime profile

Internal components of power generation machines, such as gas or steam turbines, are inspected with a laser profilometer inspection system that is inserted and positioned within the turbine, for example through an inspection port that is in communication with an open inter-row spacing volume between an opposing turbine vane and turbine blade row. Component surface profile scans are performed to determine relative profile heights along a two-dimensional scan line generated by the profilometer. Three-dimensional profile information is obtained by translating the scan line across the surface. Real time profile information is gathered without physical contact, which is helpful for extracting off-line engineering information about component surface conditions, including surface spallation, perforation, and gaps between components. The system is capable of determining blade tip gap between a turbine blade tip and its opposing abradable surface in the turbine casing.

Owner:SIEMENS ENERGY INC

Surface scan measuring device, surface scan measuring method, surface scan measuring program and recording medium

ActiveUS7392692B2Improve accuracyNecessary measuring timeMechanical counters/curvatures measurementsInvestigating moving sheetsSurface conditionsComputer science

A surface scan measuring device, a surface scan measuring method, a surface scan measuring program and a recording medium storing such a program which can appropriately adjust the scanning speed, the sampling pitch and other measurement parameters according to the surface condition of a workpiece are provided. The surface scan measuring device includes a radius of curvature computing section (543) for computing the radius of curvature of the scanning point from the measurement data acquired during the ongoing scanning operation, a moving speed deciding section (544) for deciding the moving speed of the scanning probe according to the computed radius of curvature and a sampling pitch deciding section (546) for deciding the sampling pitch according to the computed radius of curvature.

Owner:MITUTOYO CORP

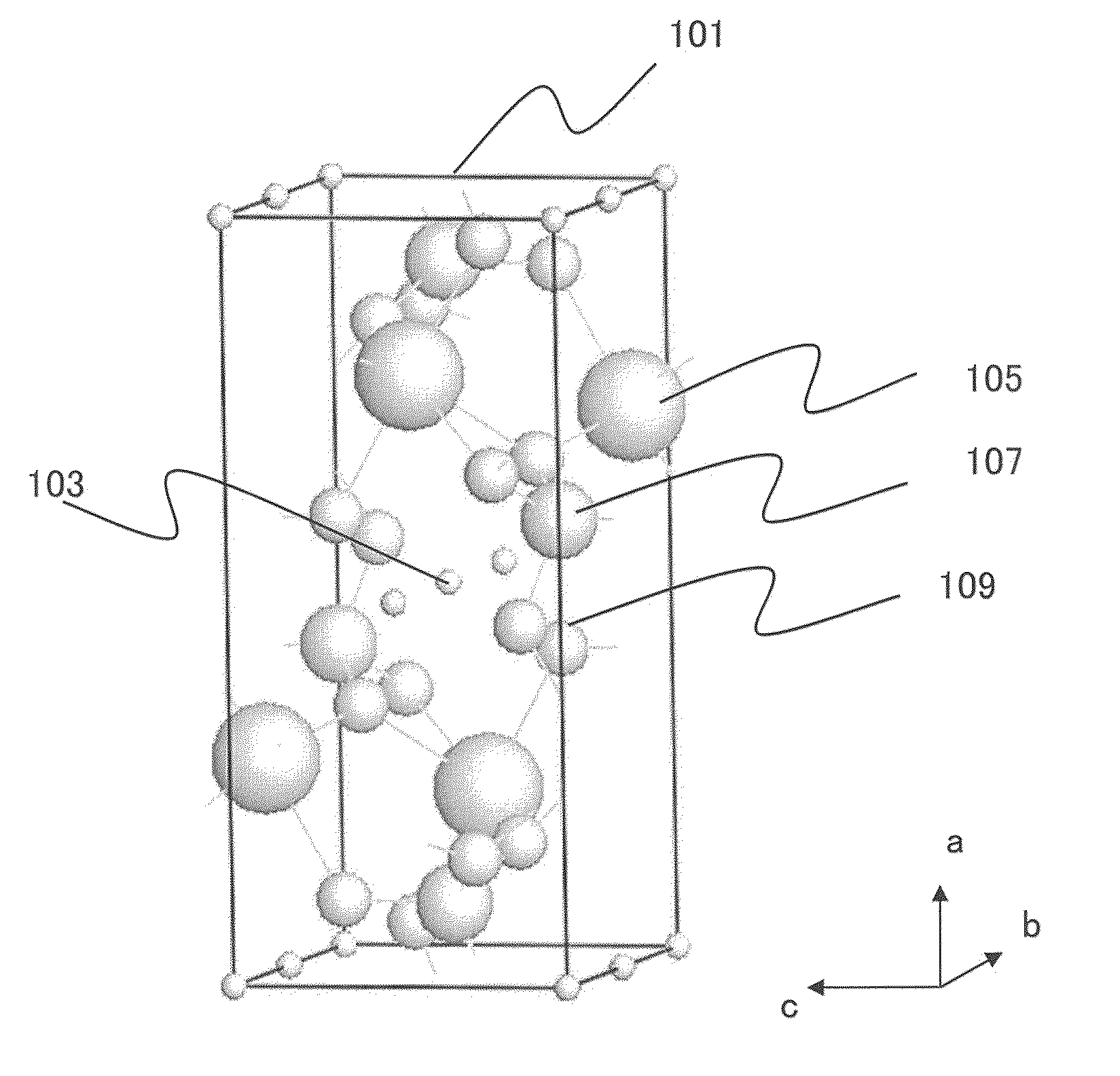

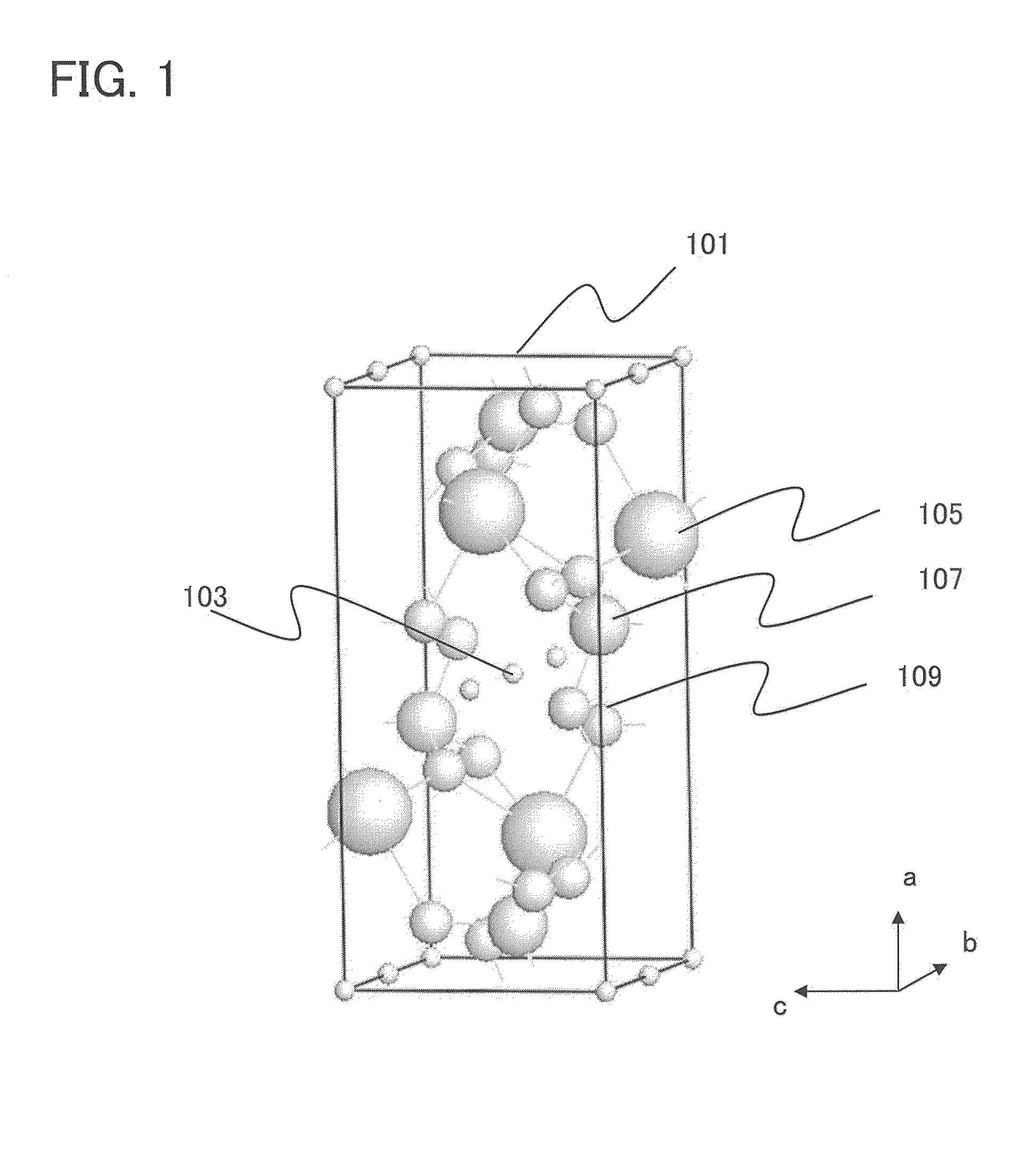

Manufacturing method for positive electrode active material

ActiveUS20110031105A1Highly uniform surface conditionImprove performanceCell electrodesFinal product manufactureMicrowaveSource material

It is an object to provide a manufacturing method for a large amount of positive electrode active material with few variations, having a highly uniform surface condition, micro-size, and high performance. An aqueous solution of a compound, which becomes the source material for the positive electrode active material, is put in an airtight container and irradiated with microwaves, thus heating while water in the airtight container is evaporated and a high pressure is formed in the air tight container. A large amount of micro-sized positive electrode active material having a highly uniform surface condition can be formed. A compound, which becomes the source material for the positive electrode active material, is put in an airtight container and irradiated with microwaves, thus heating while water in the airtight container is evaporated and a high pressure is formed in the air tight container.

Owner:SEMICON ENERGY LAB CO LTD

Peelable pouch containing a single film dosage and process of making same

InactiveUS20070205127A1Easy accessImprove usabilityPharmaceutical containersMedical packagingSurface conditionsEngineering

A peelable pouch for containing a single dosage product having a top layer joined to a bottom layer by a containment seal and a distributing seal formed with a stress riser separating a primary compartment from a secondary compartment. The primary compartment houses the product, sealed from the exterior environment. The secondary compartment includes a fold-over line. When the pouch is folded about the fold-over line the tear promoting surface condition permits a user to easily tear off a portion of the pouch and expose a portion of the secondary compartment. The product is accessed by peeling apart the secondary compartment, the distributing seal, and then peeling open the primary compartment. Preferred embodiments incorporate variation in the primary and secondary containment seal thicknesses.

Owner:R P SCHERER TECH INC

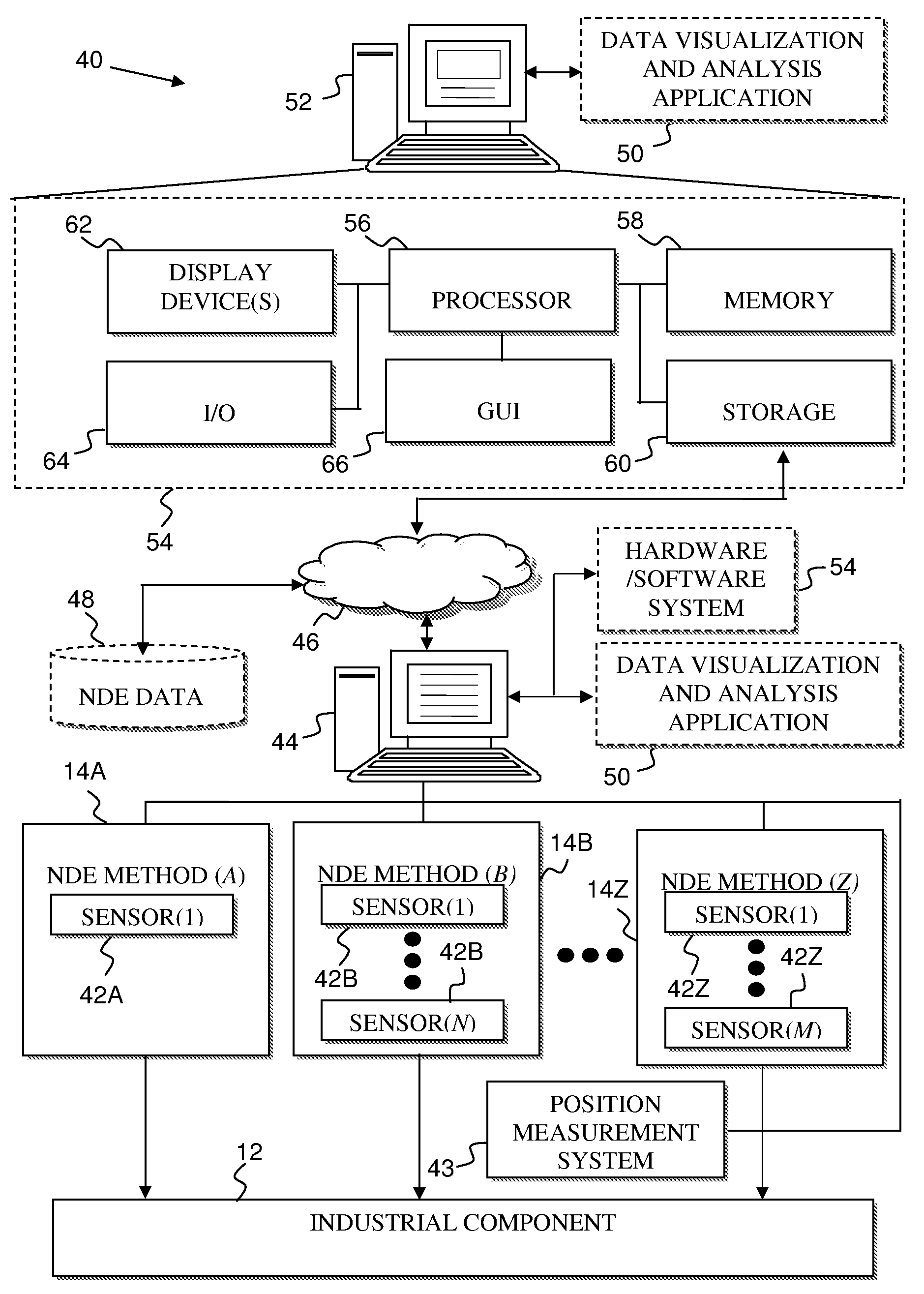

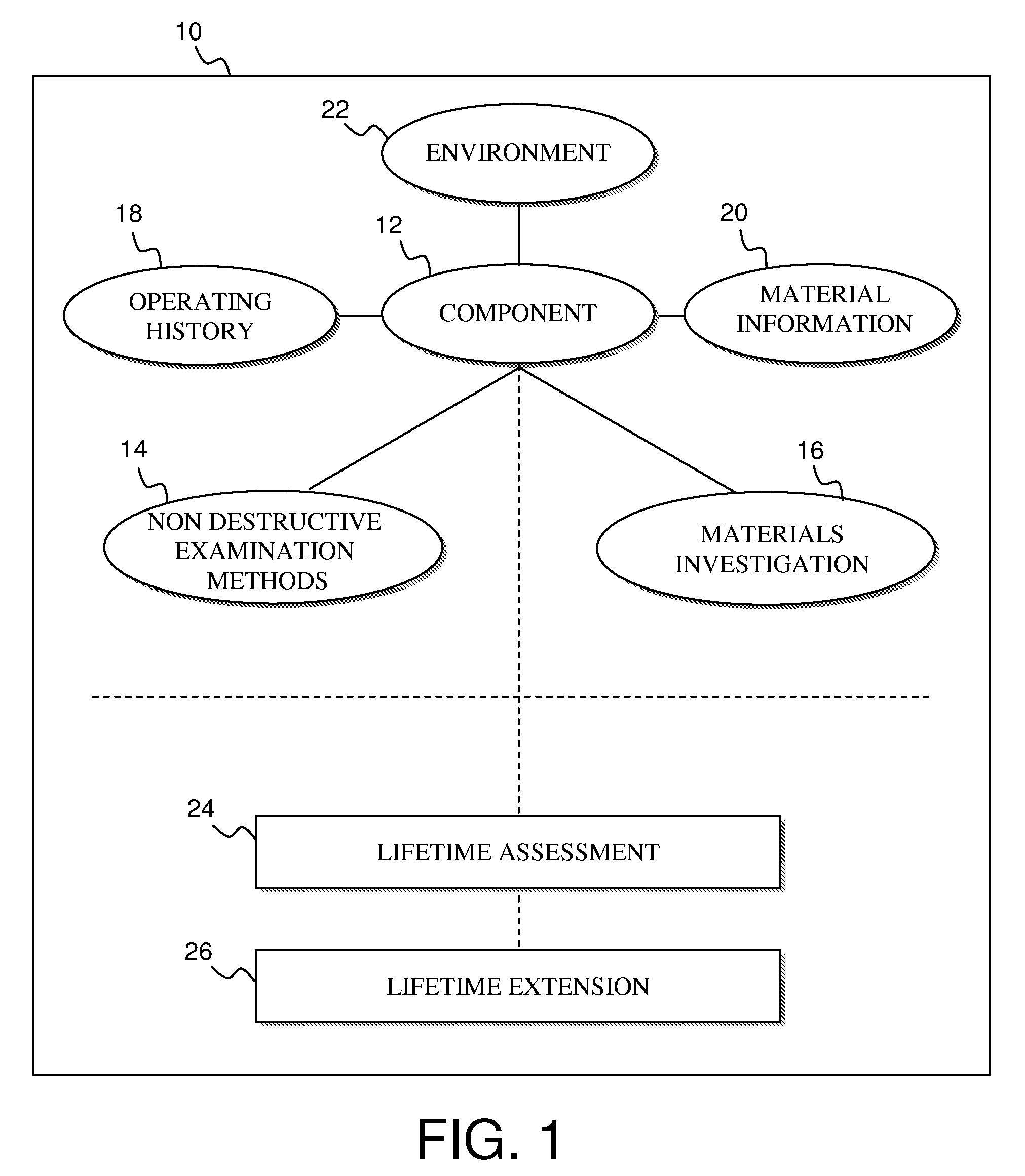

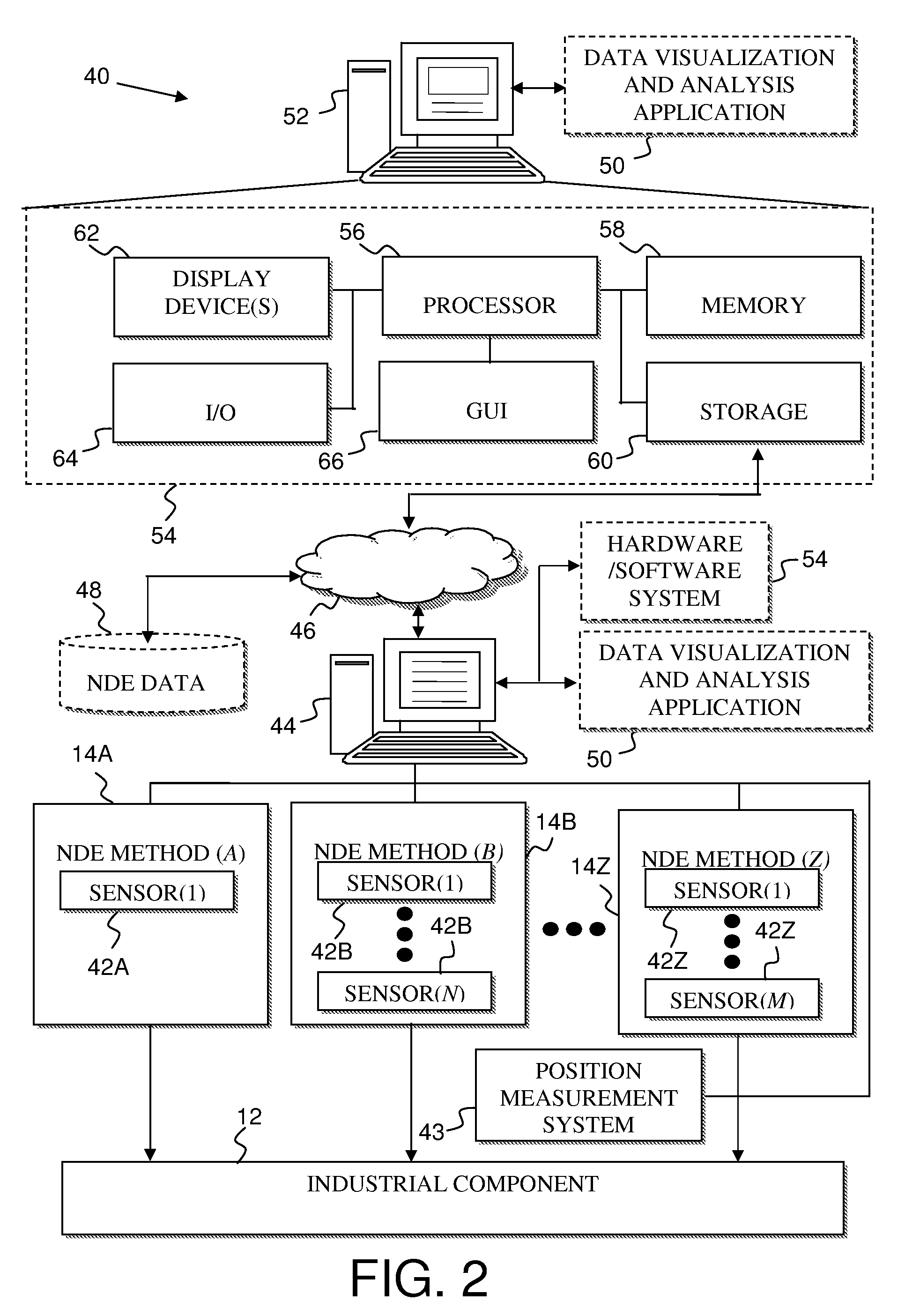

Non-Destructive Examination Data Visualization and Analysis

Interactive virtual inspection of modeled objects is provided. A graphic user interface facilitates interaction between a Data Visualization and Analysis application and the inspector. The Data Visualization and Analysis application acquires non-destructive examination data that is collected with reference to an industrial component under evaluation. The acquired non-destructive examination data is transformed into a visualization defined by a volumetric representation that is rendered on at least one display device as at least one view representative of the component under evaluation. The inspector may navigate the volumetric representation to investigate the integrity of the industrial component including non-surface conditions thereof.

Owner:SIEMENS ENERGY INC

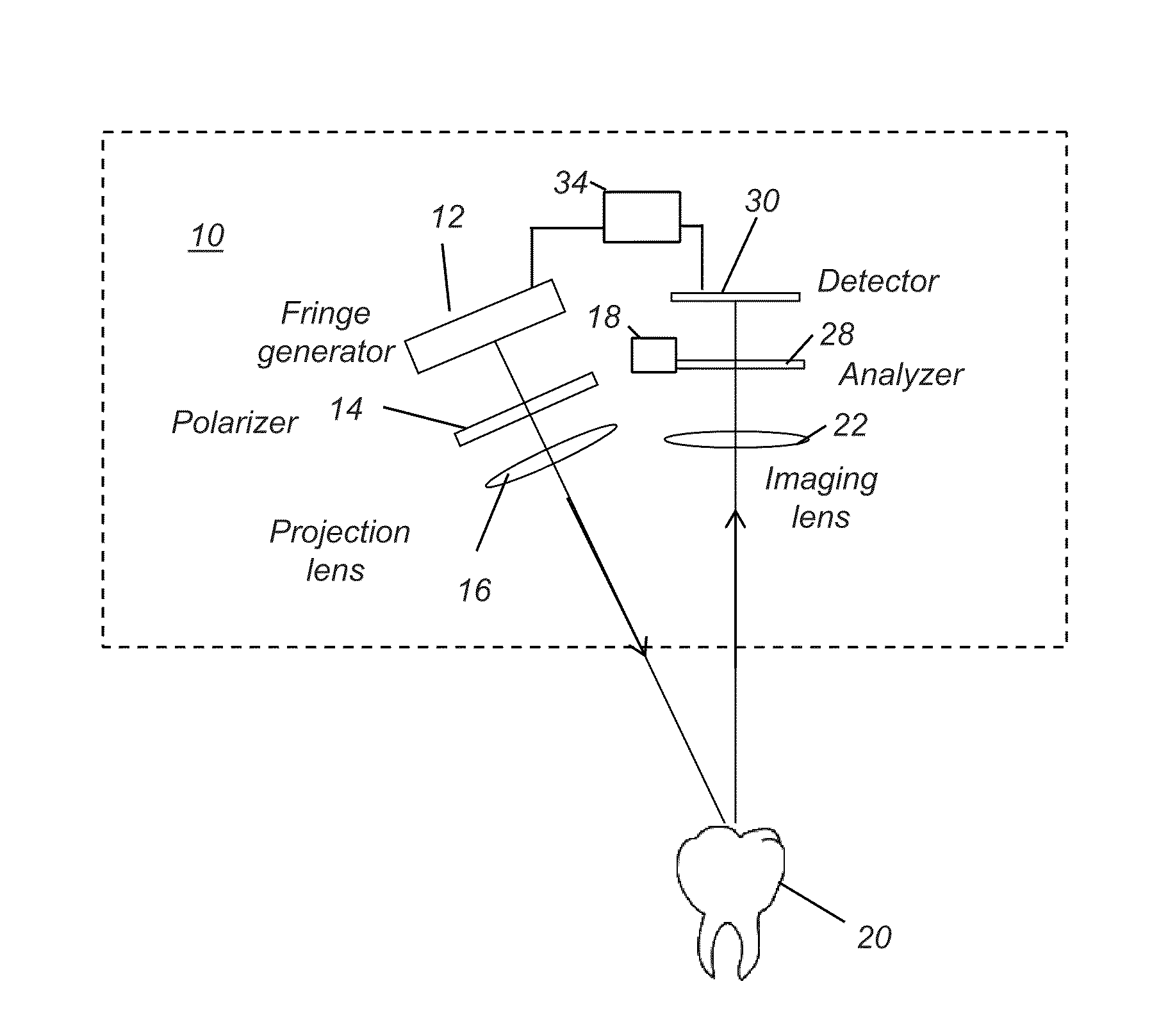

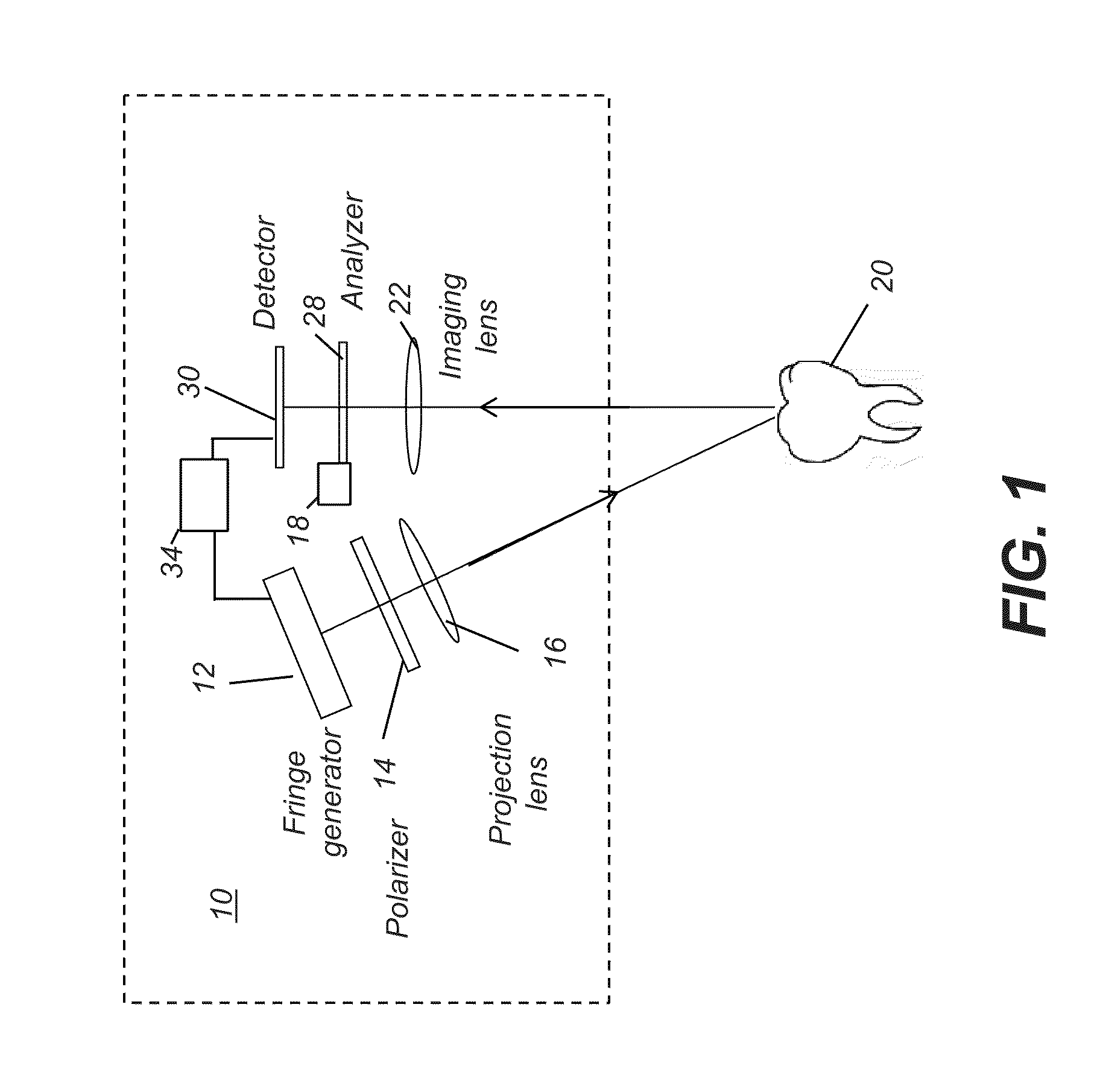

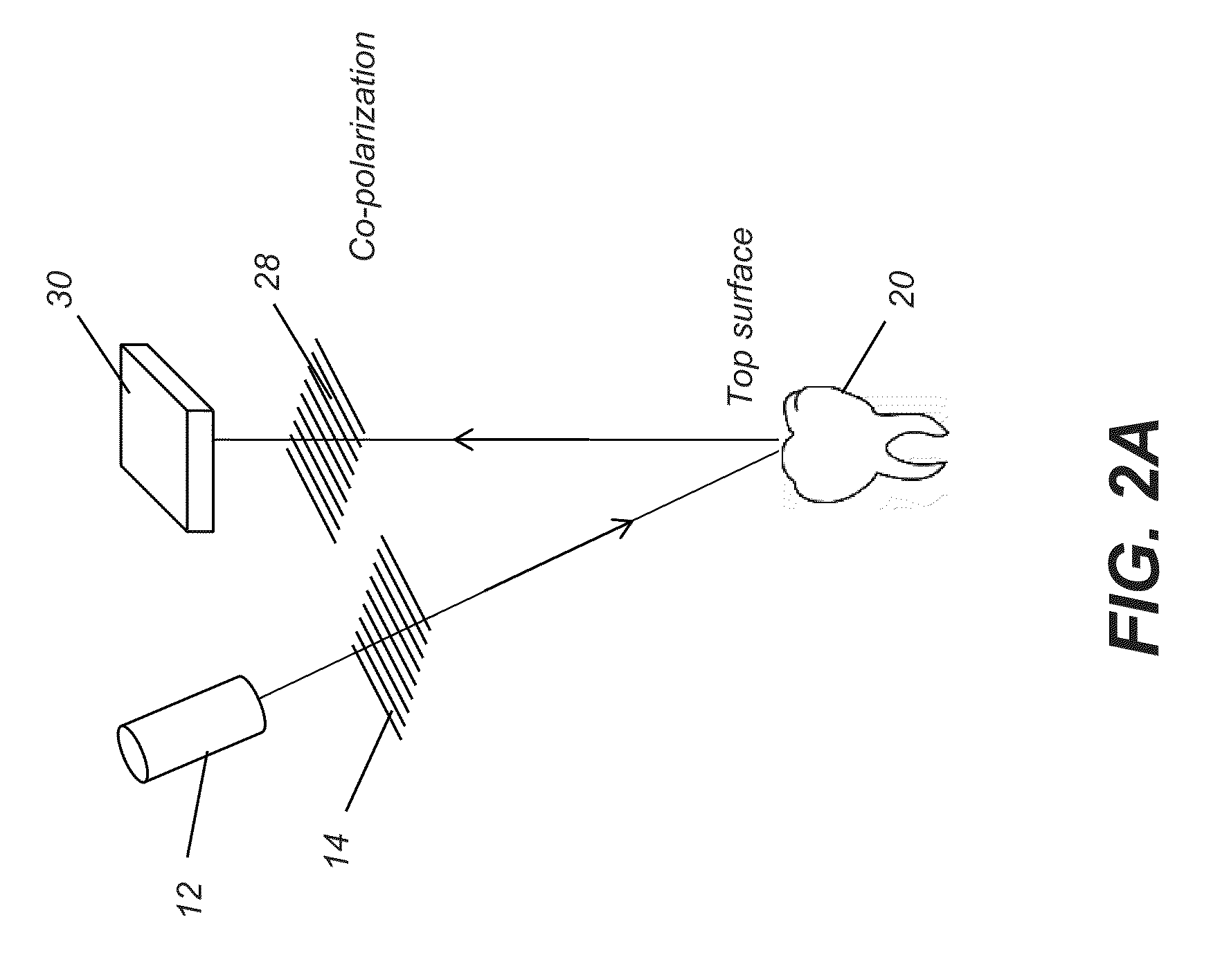

System and method for detecting tooth cracks

ActiveUS20110287387A1Convenient registrationImprove visualizationImage enhancementImpression capsTooth crackSurface conditions

A method for imaging the surface of a tooth, the method executed at least in part on a computer records a first set of images of the tooth, wherein each image in the first set of images is illuminated according to a pattern oriented in a first direction. A second set of images of the tooth are recorded, wherein each image in the second set of images is illuminated according to a pattern oriented in a second direction that is shifted more than 10 degrees with respect to the first direction. A first contour image is reconstructed according to the recorded first set of images and a second contour image according to the recorded second set of images. A residual image is formed as a combination of the first and second contour images. The residual image is analyzed and surface conditions of the tooth reported.

Owner:DENTAL IMAGING TECH

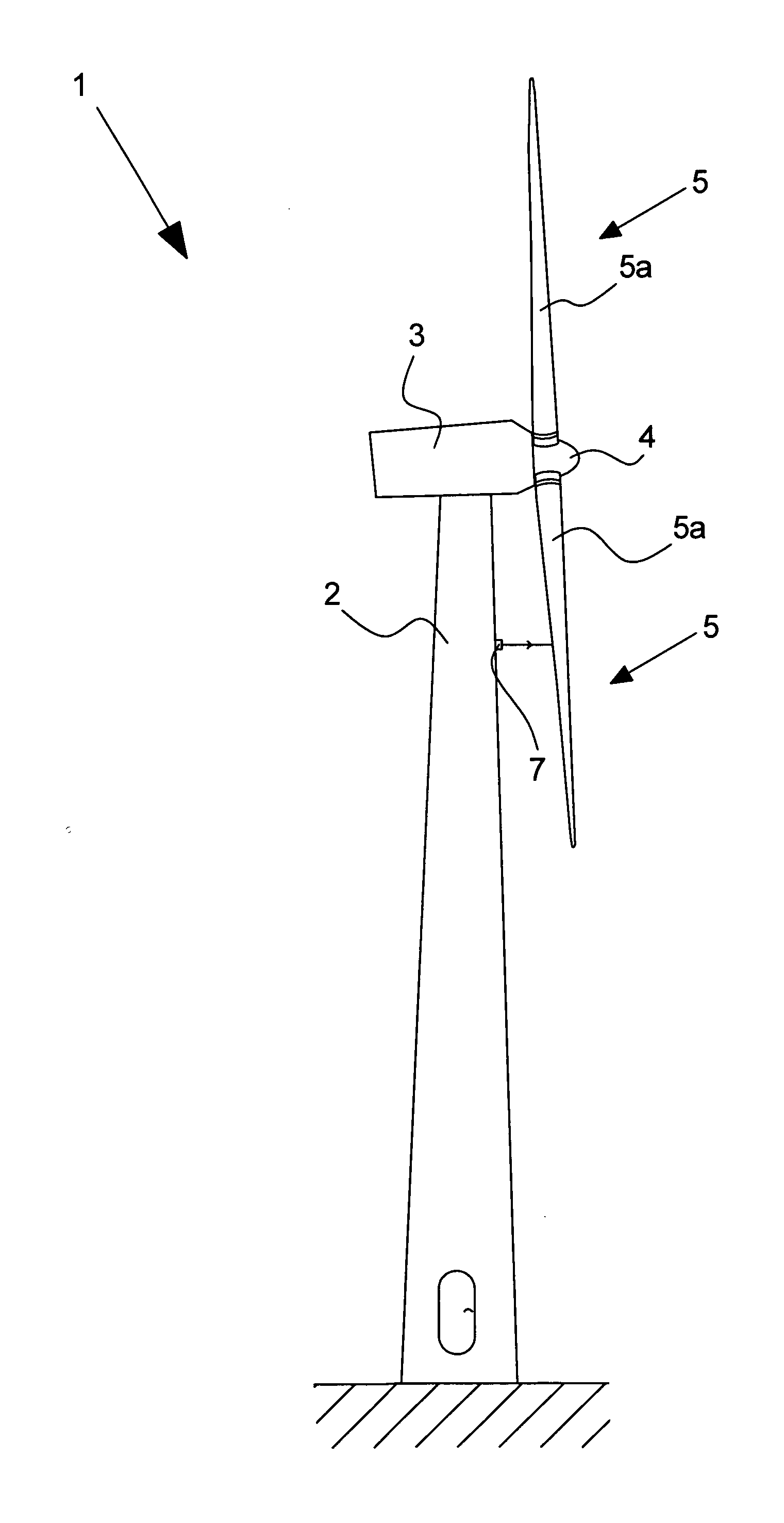

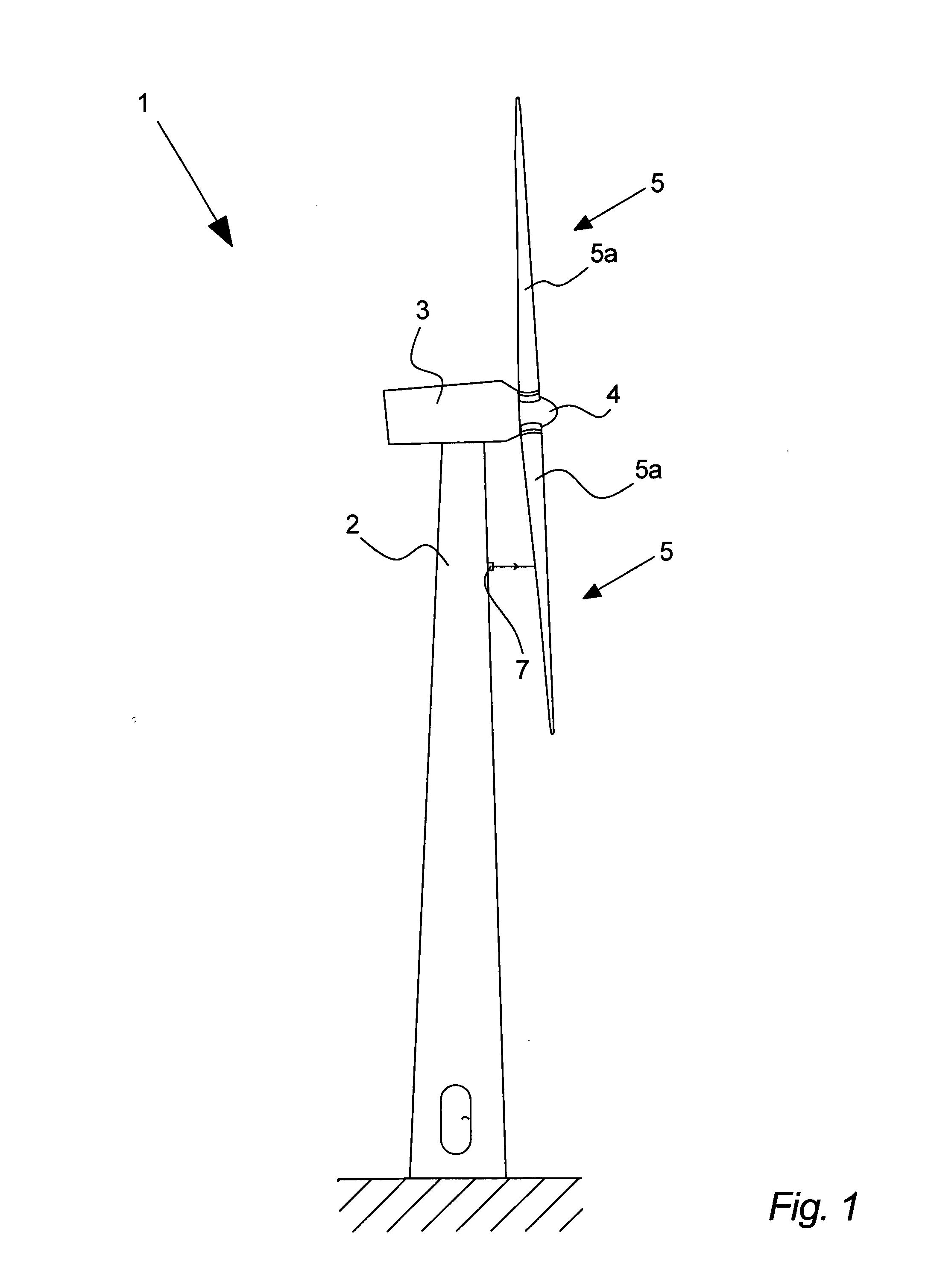

Detection of ice on airfoils

InactiveUS20120207589A1Increase in sizeImprove efficiencyWind motor controlScattering properties measurementsSurface conditionsSpecular reflection

A structure including at least one airfoil, at least one device for detecting surface conditions on a surface of the at least one airfoil, and at least one sensor device, the sensor device including at least one radiation emitter adapted to emit radiation directed towards at least one surface of the airfoil, at least one first detector arranged for receiving a portion of the emitted radiation when reflected from the at least one surface and producing a first output according to an intensity thereof, at least one second detector arranged for receiving a portion of the emitted radiation when reflected from the at least one surface and producing a second output according to an intensity thereof, and control means adapted to receive and evaluate the output from the detectors based on an amount of diffuse reflected and mirror reflected radiation reflected from the at least one surface, and producing an output according thereto.

Owner:LIWAS

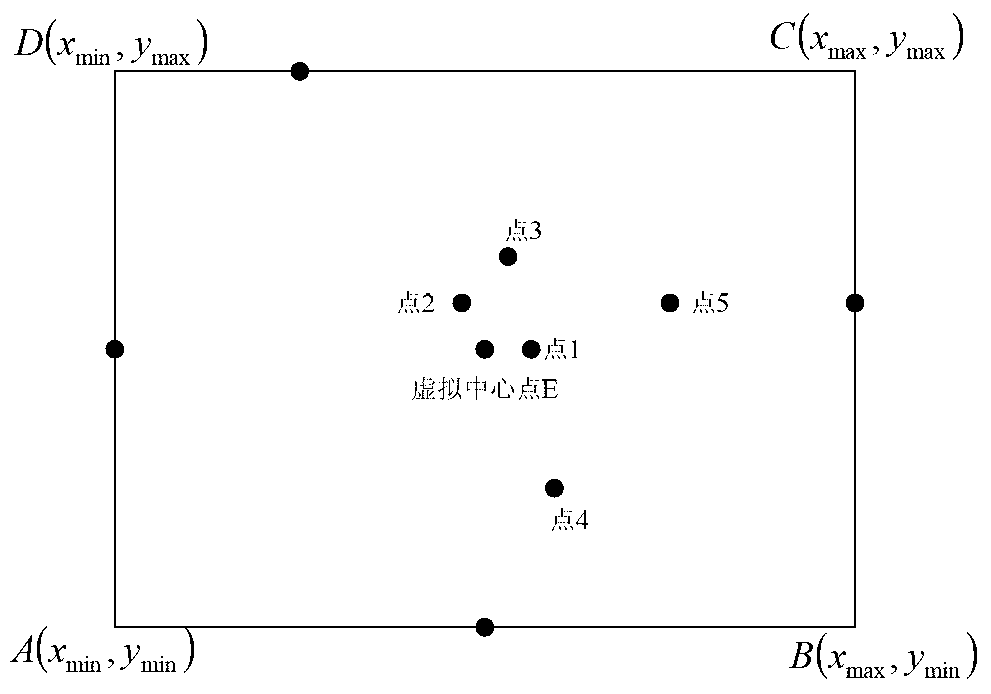

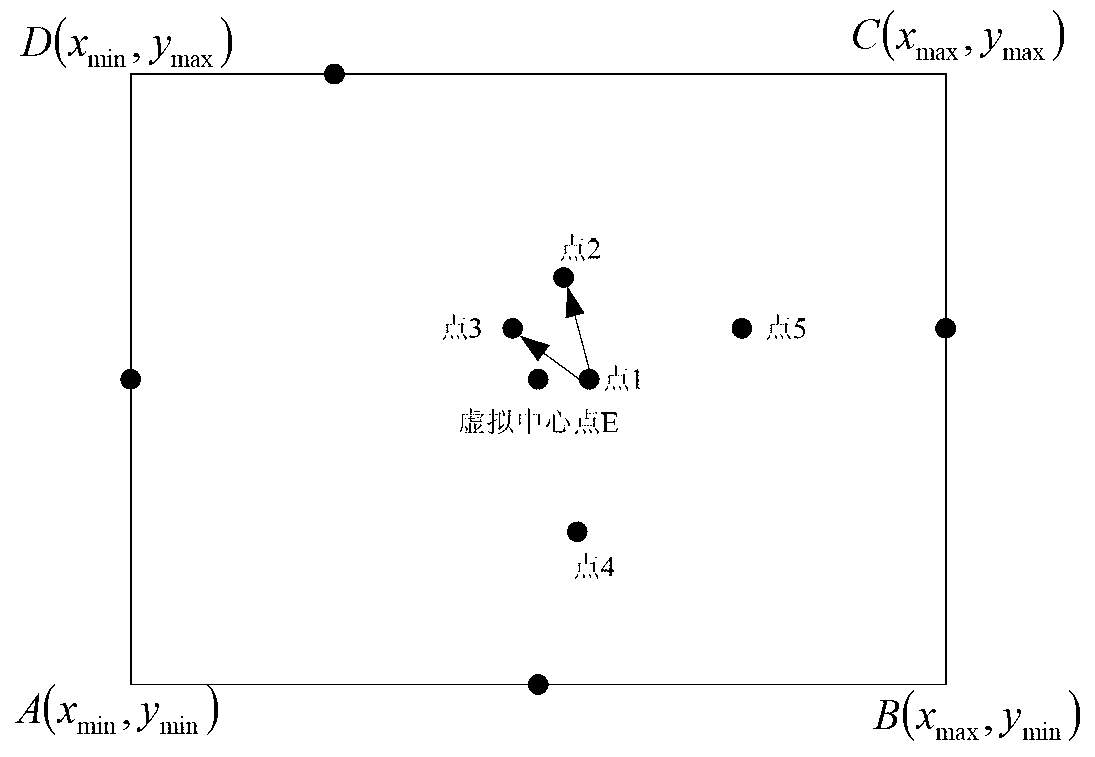

Three-dimensional laser imaging system planar point cloud data triangularization processing method

The invention discloses a three-dimensional laser imaging system planar point cloud data triangularization processing method. According to the three-dimensional laser imaging system planar point cloud data triangularization processing method, firstly, three-dimensional point cloud data which are on the same plane are obtained from three-dimensional point cloud data, the three-dimensional point cloud data which are on the same plane are projected to a two-dimensional plane to form plane two-dimensional point cloud data, a virtual central point of the two-dimensional point cloud data is calculated, a point which is closest to the virtual central point is used as an actual central point of scattered data, distances between discrete points and the actual central point are compared, the two-dimensional point cloud data are presorted to find an initial triangle and initial boundary vertexes, the initial boundary vertexes are sorted anticlockwise, all the two-dimensional point cloud data are inserted into according to the arrayed sequence, boundary vertex update and triangle update are conducted, and planar point cloud data of a plane triangulation network are mapped back to a three-dimensional coordinate to generate three-dimensional triangular network model of an article to be scanned. Compared with the prior method, the three-dimensional laser imaging system planar point cloud data triangularization processing method has the advantages that the train of thought is simple and clear, programming is easy to achieve, and planes with holes or concave surfaces or other complex surface conditions can be processed.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

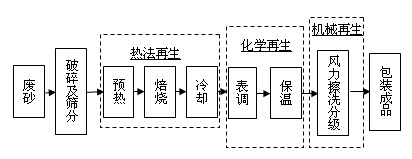

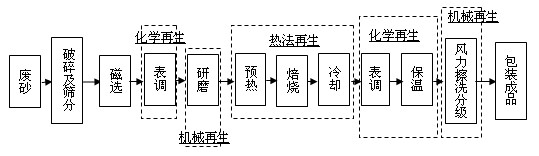

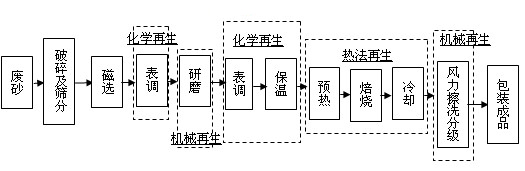

Chemical regeneration method in casting waste sand disposing process

InactiveCN102000764AGood regeneration performanceSolve sinteringMould handling/dressing devicesChemical treatmentDie casting

The invention provides a chemical regeneration method in the casting waste sand disposing process, relating to a process for performing surface chemical processing on various impurities which are attached on the surface of waste sand and are better not be reused in casting-form sand materials. During the chemical regeneration, chemical surface conditioning liquid I or / and chemical surface conditioning liquid II is or are used, and the disposing sand temperature is not more than 400 DEG C. The chemical regeneration method in the invention is carried out before or after the hot-method regeneration disposing or mechanical regeneration disposing of the casting waste sand disposing processing, and the chemical disposing technique is combined with the traditional hot-method regeneration and mechanical friction regeneration. The regeneration new sand formed in the method has better quality of the new sand, can better meet the application requirement on multi-form sand producing technique (hot core box, warm core box and cold core box) for recycling different casting waste sands (hot core box resin casting waste sand, warm core box resin casting waste sand, gas or / and organic fat hardening cold core box resin casting waste sand and profile damp die casting sand), and has better economical efficiency.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Toner for developing electrostatic image

InactiveUS20050164114A1High abundanceDevelopersElectrographic process apparatusSurface conditionsEngineering

A toner for developing an electrostatic image which has a small particle size essential for attaining a high-quality image, and can output a high-quality image excellent in frictional charging property and free from scumming. The toner for developing an electrostatic image has the volume average particle diameter of 2.0 μm to 7.1 μm and the surface condition of the toner is in scab form.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com