Patents

Literature

1225 results about "Surface chemical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of surface chemistry. : a branch of chemistry that deals with the properties of surfaces or phase boundaries and with the chemical changes occurring at a surface or interface.

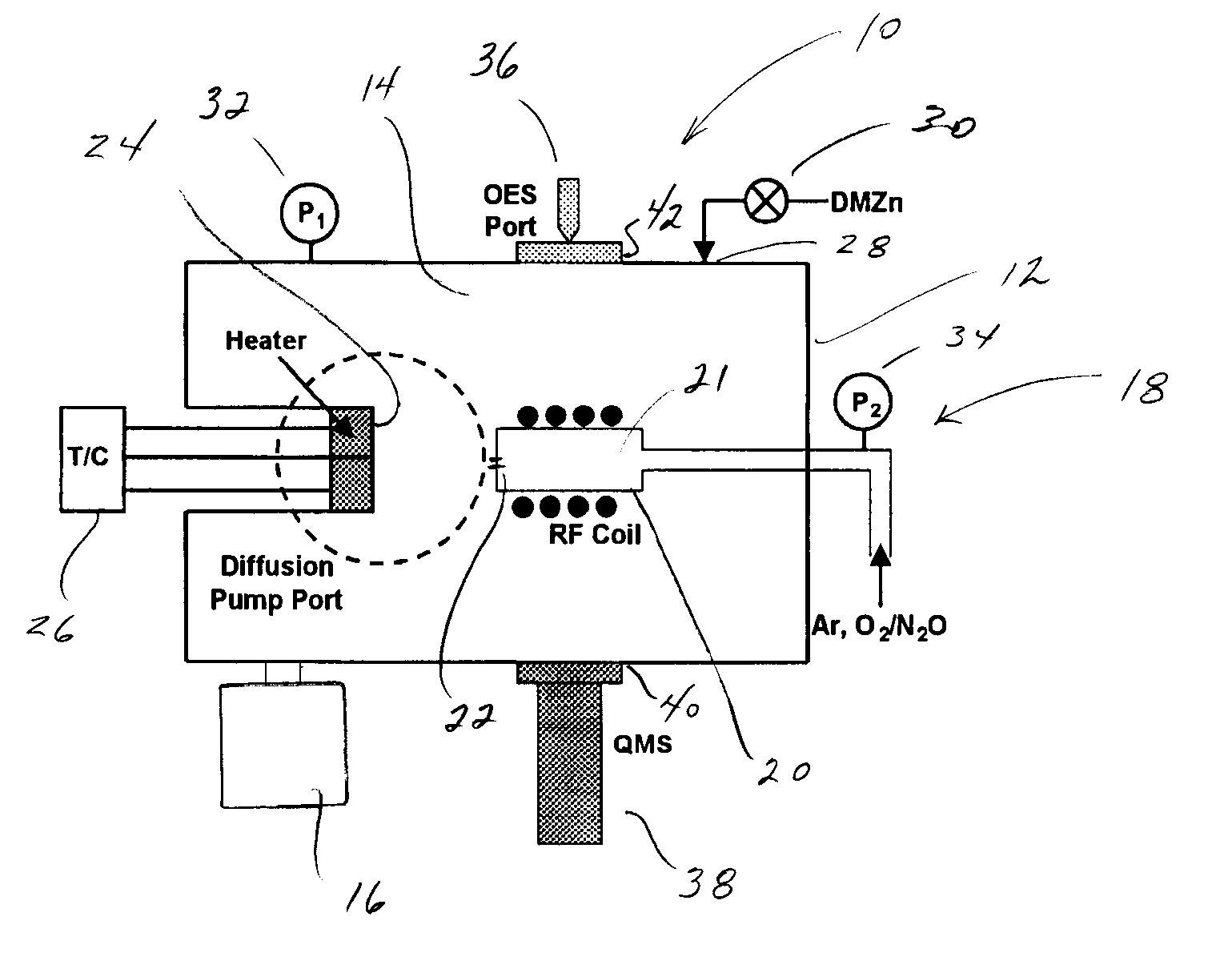

High Vacuum Plasma-Assisted Chemical Vapor Deposition System

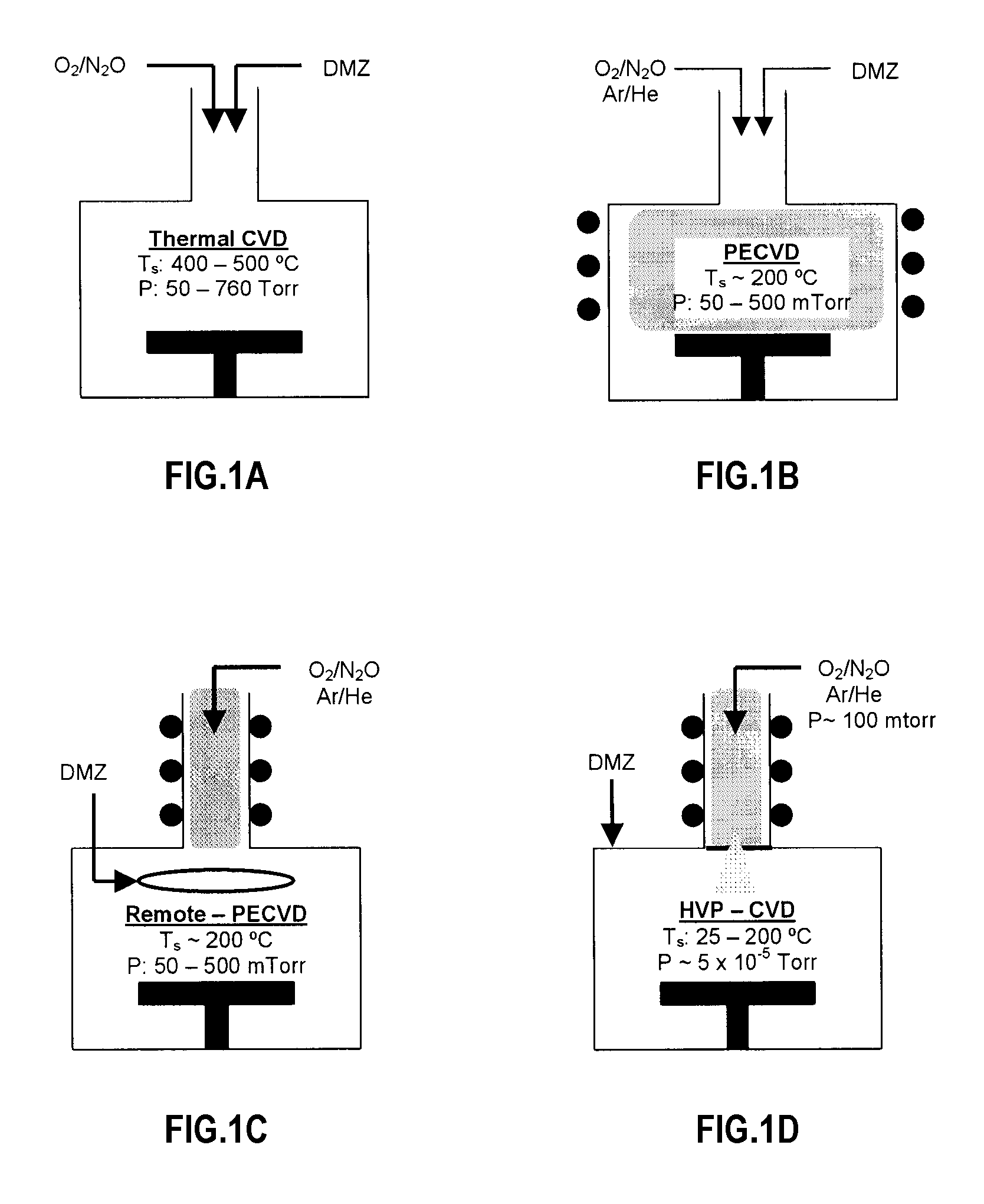

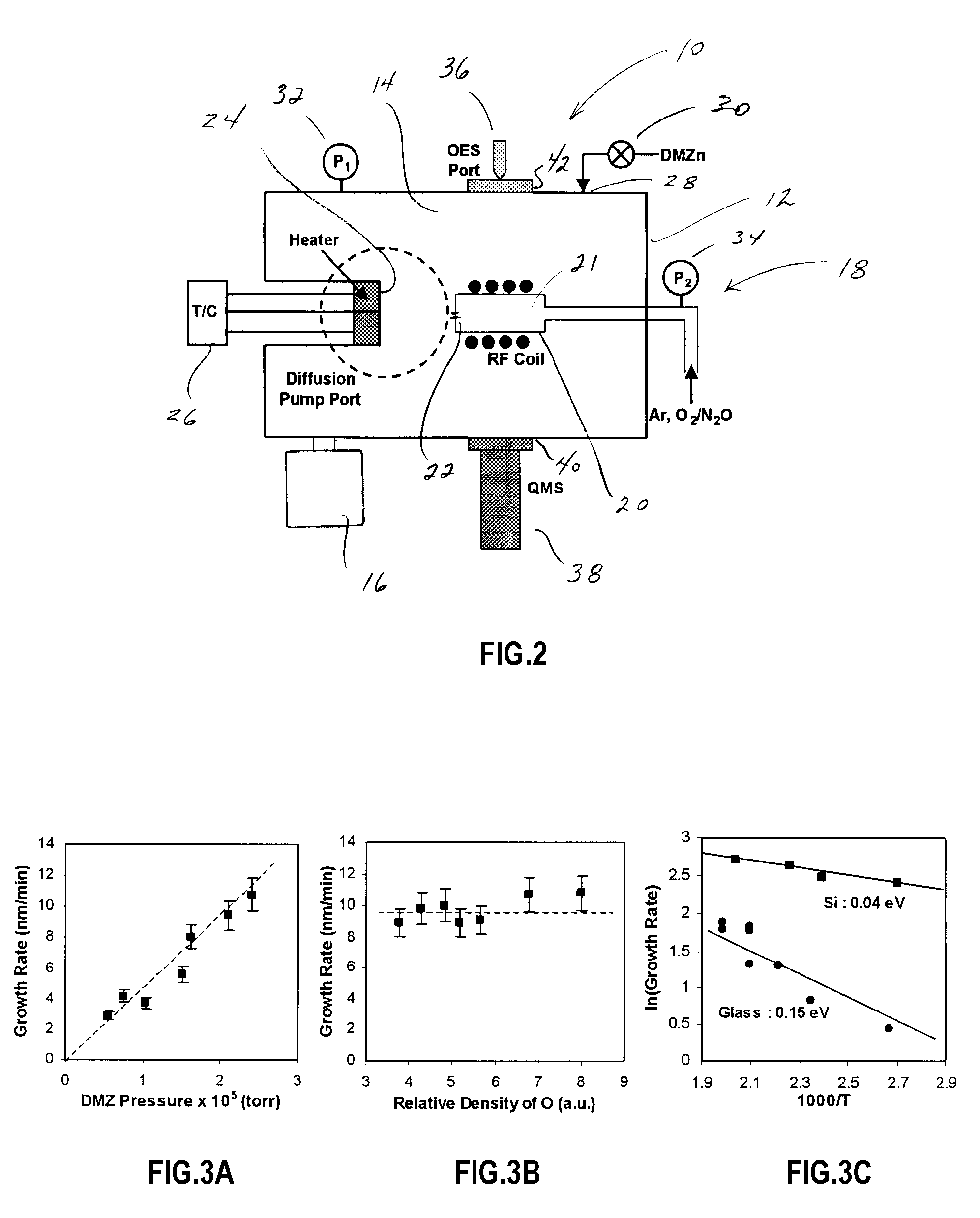

The invention is directed to a novel approach to thin film synthesis that is described as high vacuum plasma-assisted chemical vapor deposition (HVP-CVD). In one application of HVP-CVD, atomic oxygen and organometallic precursors are simultaneously introduced into a high vacuum chamber. Gas-phase chemistry is eliminated or substantially eliminated in the collisionless or substantially collisionless environment, allowing the surface chemistry between atomic oxygen and the precursor(s) to be interrogated directly. In preliminary work it has been observed that the presence of atomic oxygen greatly accelerates the desorption of organic ligands, facilitating oxide formation. The prominent advantages of the HVP-CVD include reduced substrate temperature, significant rates, inherent uniformity, facilitated doping, and the ability to directly study these processes in-situ with high vacuum diagnostics that are not compatible with conventional CVD technologies.

Owner:COLORADO SCHOOL OF MINES

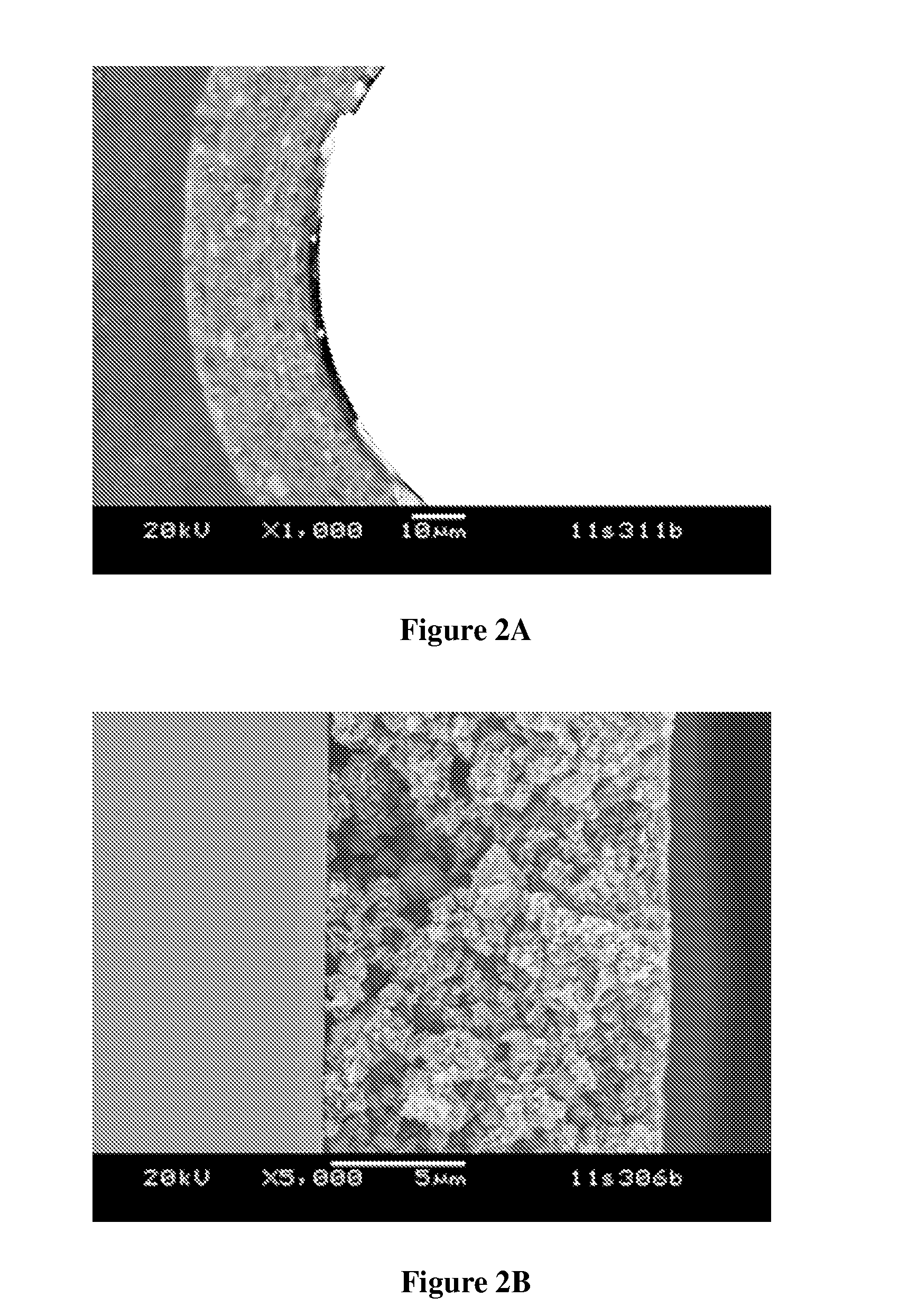

Process for preparing nanostructured materials of controlled surface chemistry

InactiveUS6669823B1Good dispersionReduce hydrolysis rateMaterial nanotechnologyMolten spray coatingCharge carrierNanostructured materials

A process to prepare stoichiometric-nanostructured materials comprising generating a plasma, forming an "active volume" through introduction of an oxidizing gas into the plasma, before the plasma is expanded into a field-free zone, either (1) in a region in close proximity to a zone of charge carrier generation, or (2) in a region of current conduction between field generating elements, including the surface of the field generation elements, and transferring energy from the plasma to a precursor material to form in the "active volume" at least one stoichiometric-nanostructured material and a vapor that may be condensed to form a stoichiometric-nanostructured material. The surface chemistry of the resulting nanostructured materials is substantially enhanced to yield dispersion stable materials with large zeta-potentials.

Owner:NANOPHASE TECH CORP

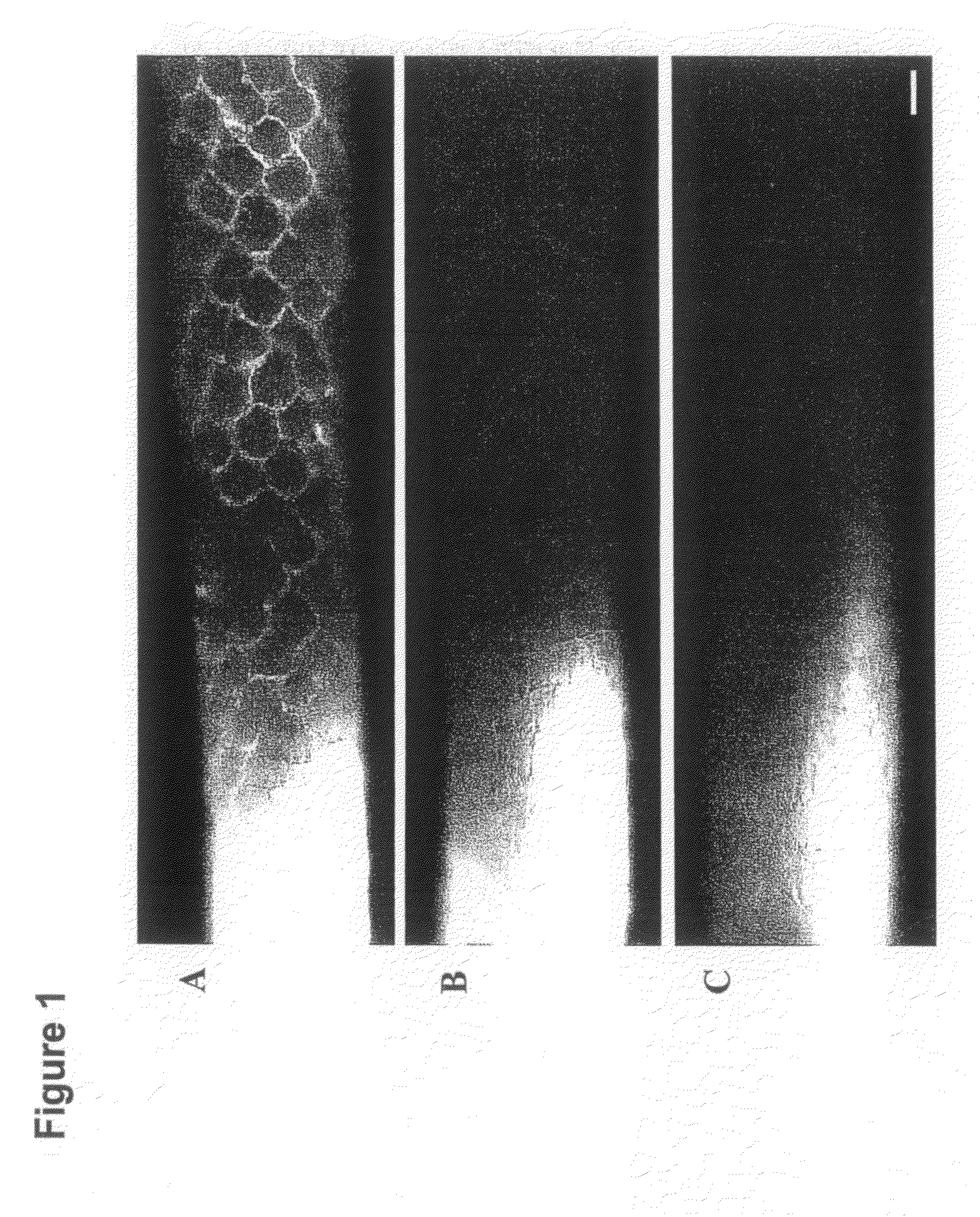

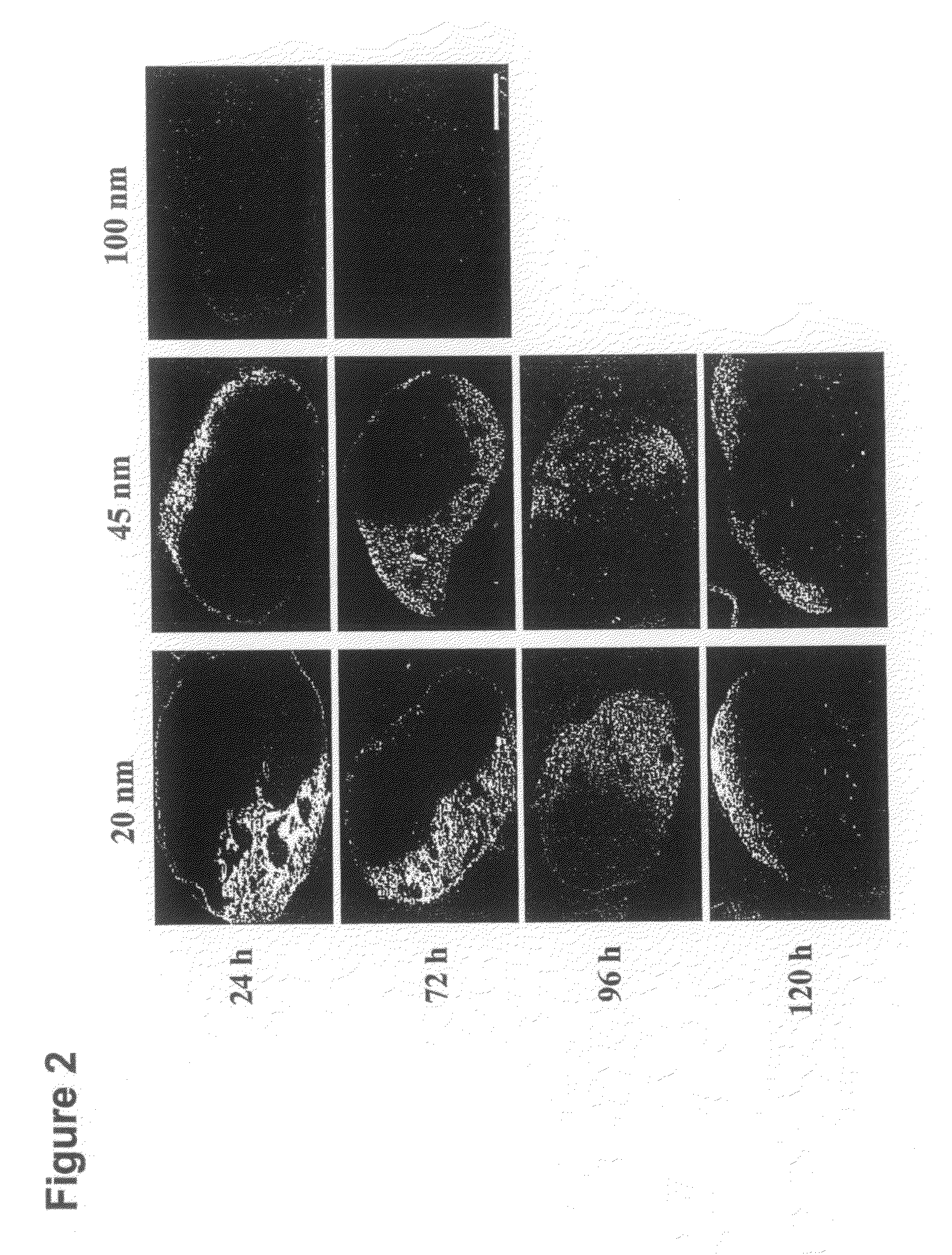

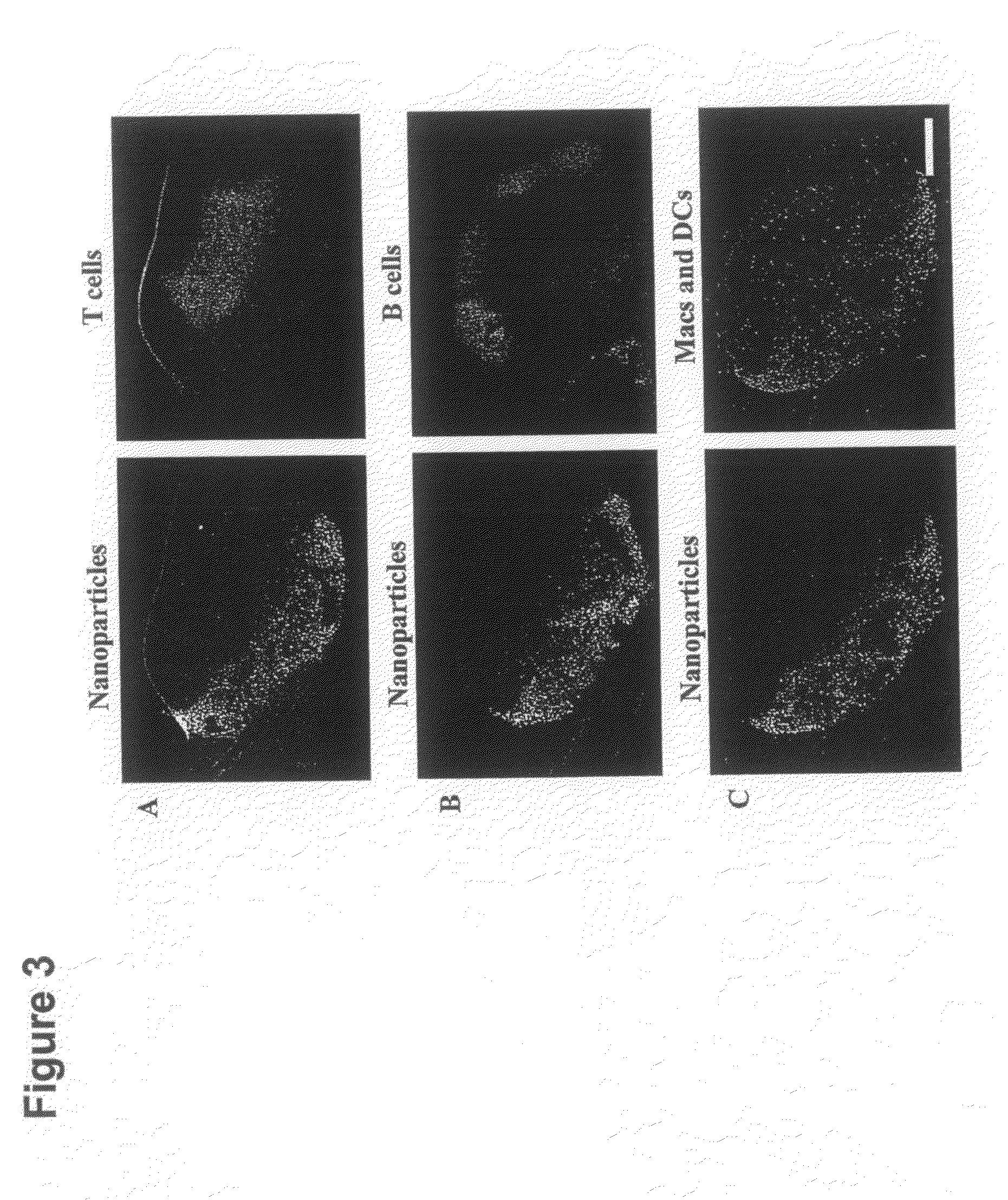

Nanoparticles for immunotherapy

Nanoparticles that activate complement in the absence of biological molecules are described. The nanoparticles are shown to specifically target antigen presenting cells in specifically in lymph nodes, without the use of a biological molecule for targeting. These particles are useful vehicles for delivering immunotherapeutics. Surface chemistries and chemical formulations for the nanoparticles are described.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

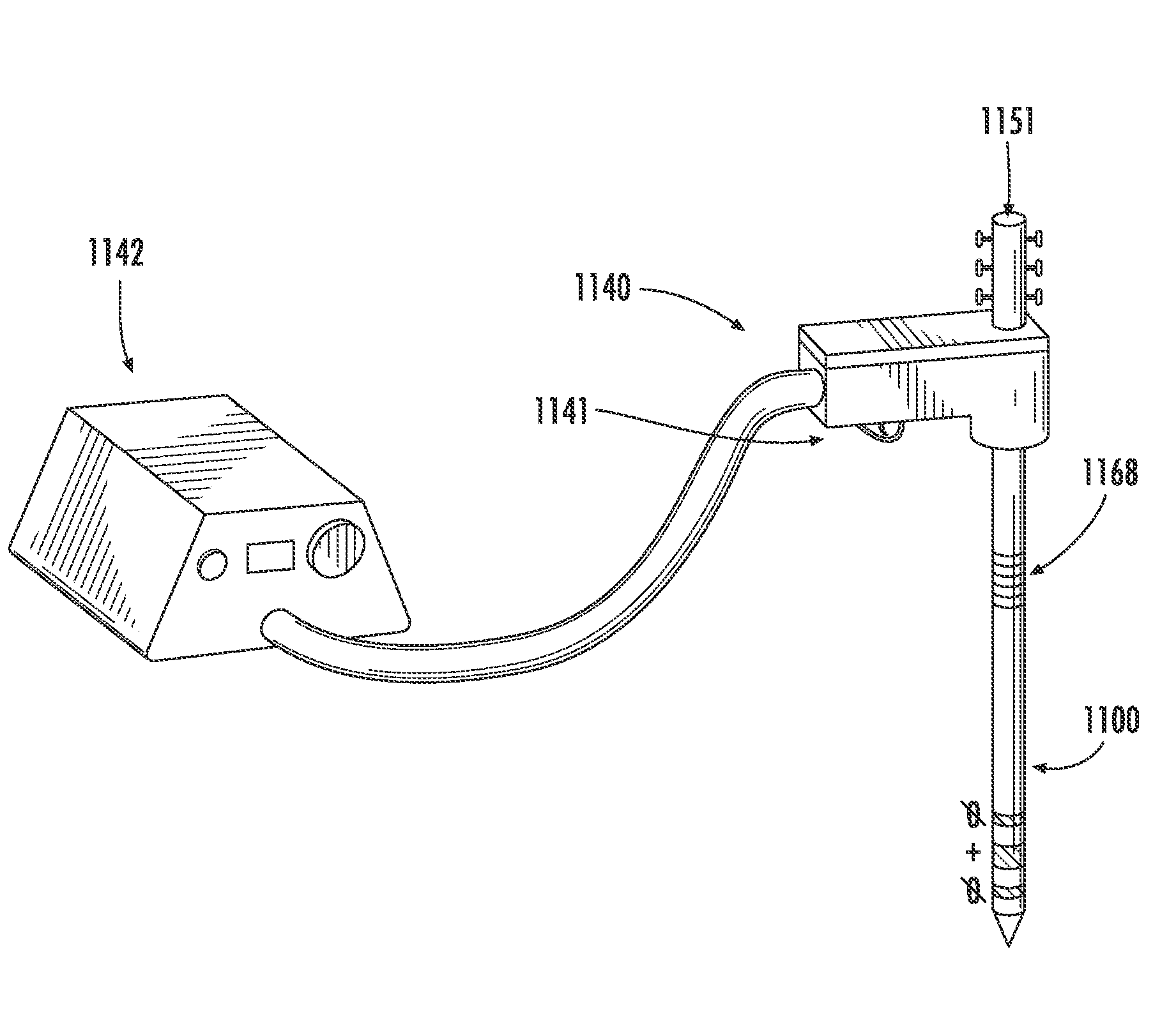

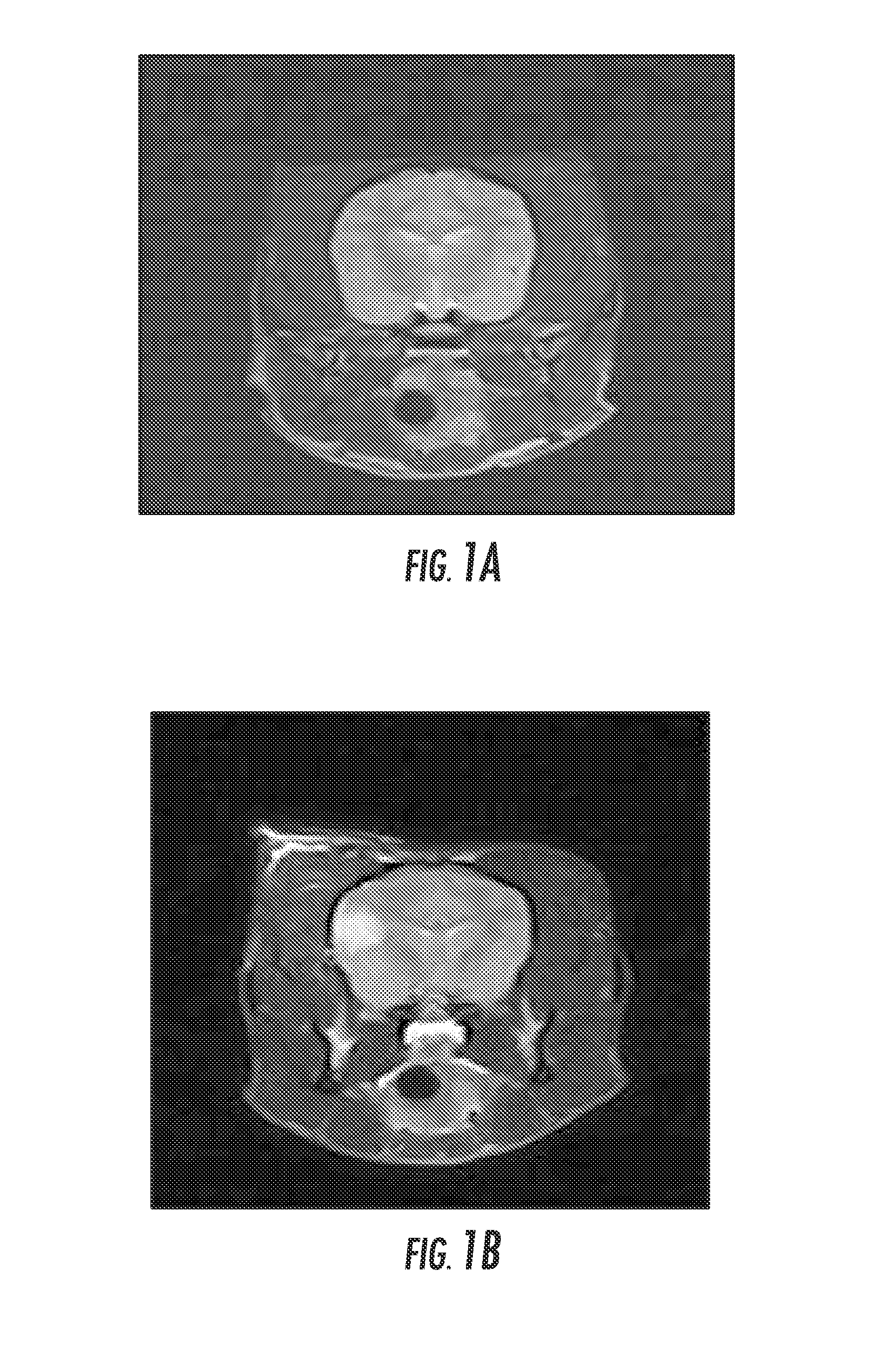

Irreversible electroporation using nanoparticles

The present invention provides methods, devices, and systems for in vivo treatment of cell proliferative disorders. The invention can be used to treat solid tumors, such as brain tumors. The methods rely on non-thermal irreversible electroporation (IRE) to cause cell death in treated tumors. In embodiments, the methods comprise the use of high aspect ratio nanoparticles with or without modified surface chemistry.

Owner:VIRGINIA TECH INTPROP INC

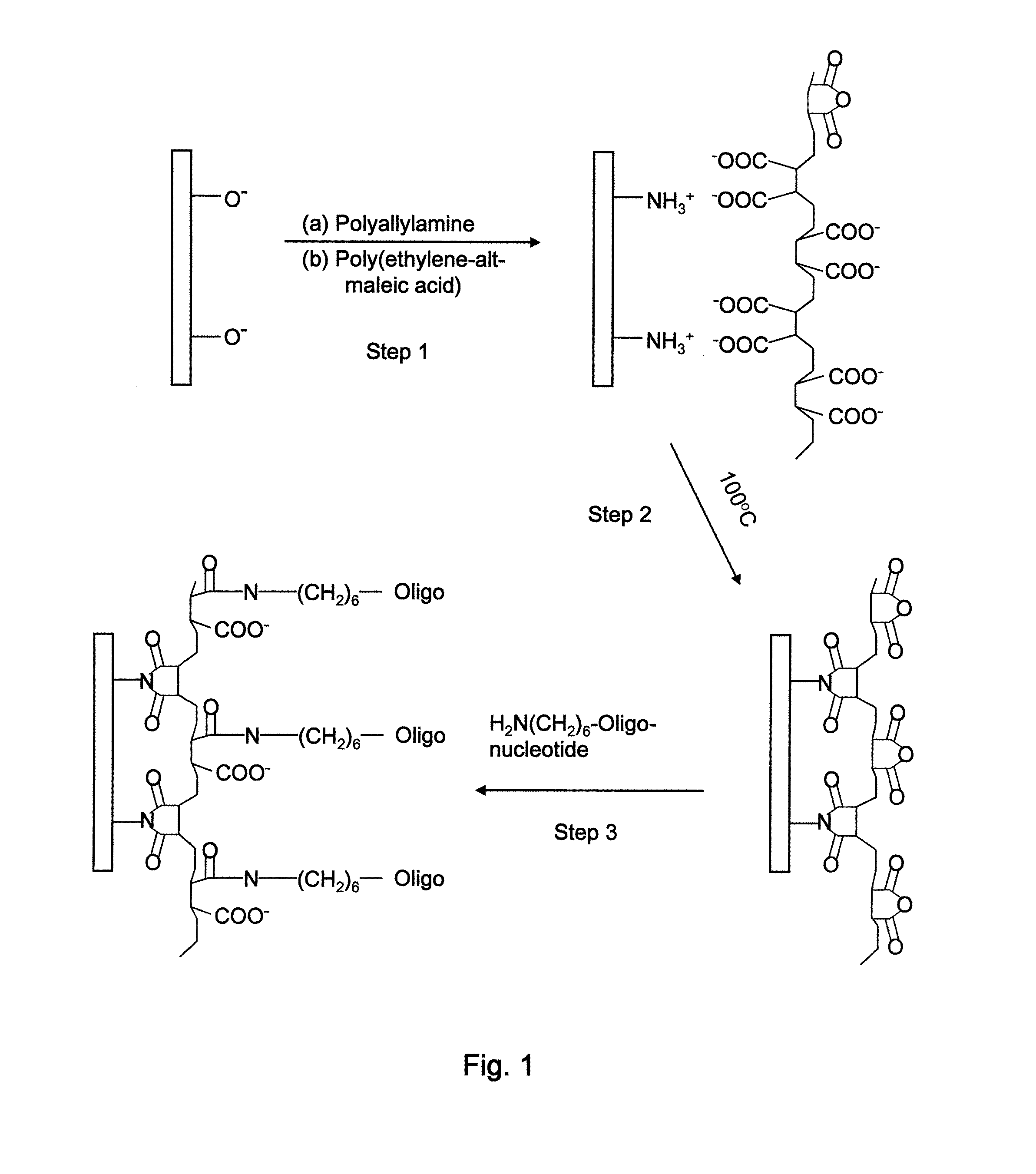

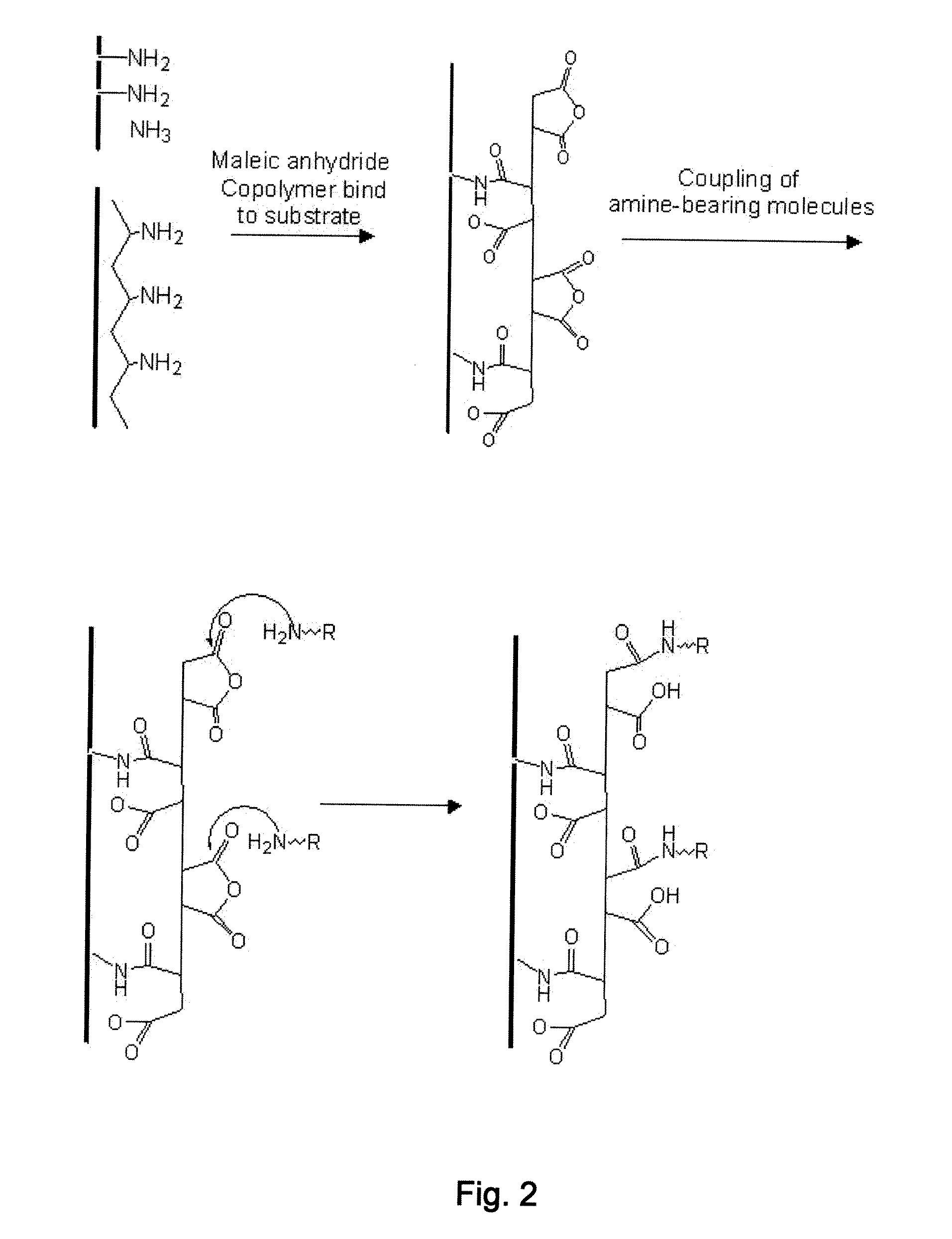

Biomolecule Immobilization on Biosensors

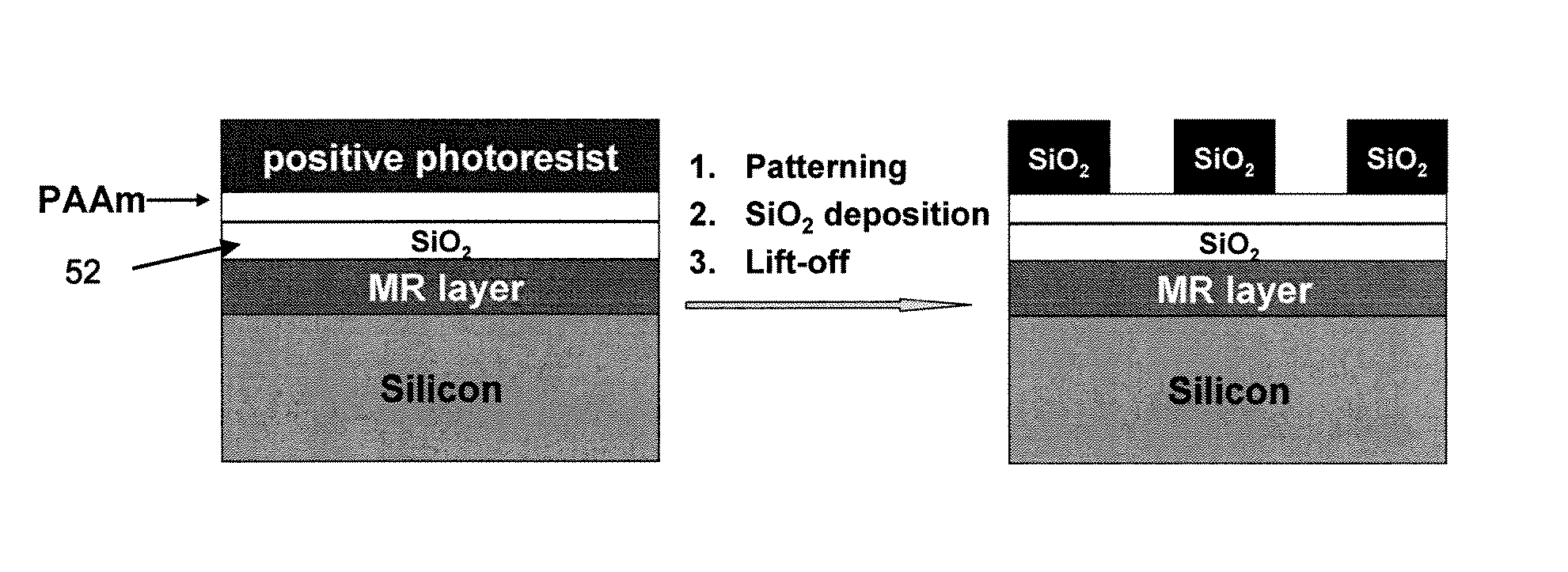

A highly specific and versatile surface chemistry for immobilization of amine-terminated probes is disclosed. A bi-layered polymer thin film serves as the platform for coupling the probes, which are preferably oligonucleotides. The process involves sequentially coating a substrate with polyamine and polyacid anhydride. Hydrolyzed polyacid anhydride groups may be converted to non-hydrolyzed groups at about 100° C. prior to probe attachment. The process of coating the substrate requires no harsh chemical pretreatment of substrates such as RCA or Piranha cleaning. In addition, simple thermal activation of the anhydride groups has a low requirement for storage, leading to a long shelf life of modified surfaces. The disclosed surface chemistry is especially compatible with microfabrication processes, and its effective application to magnetic biosensors is demonstrated.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

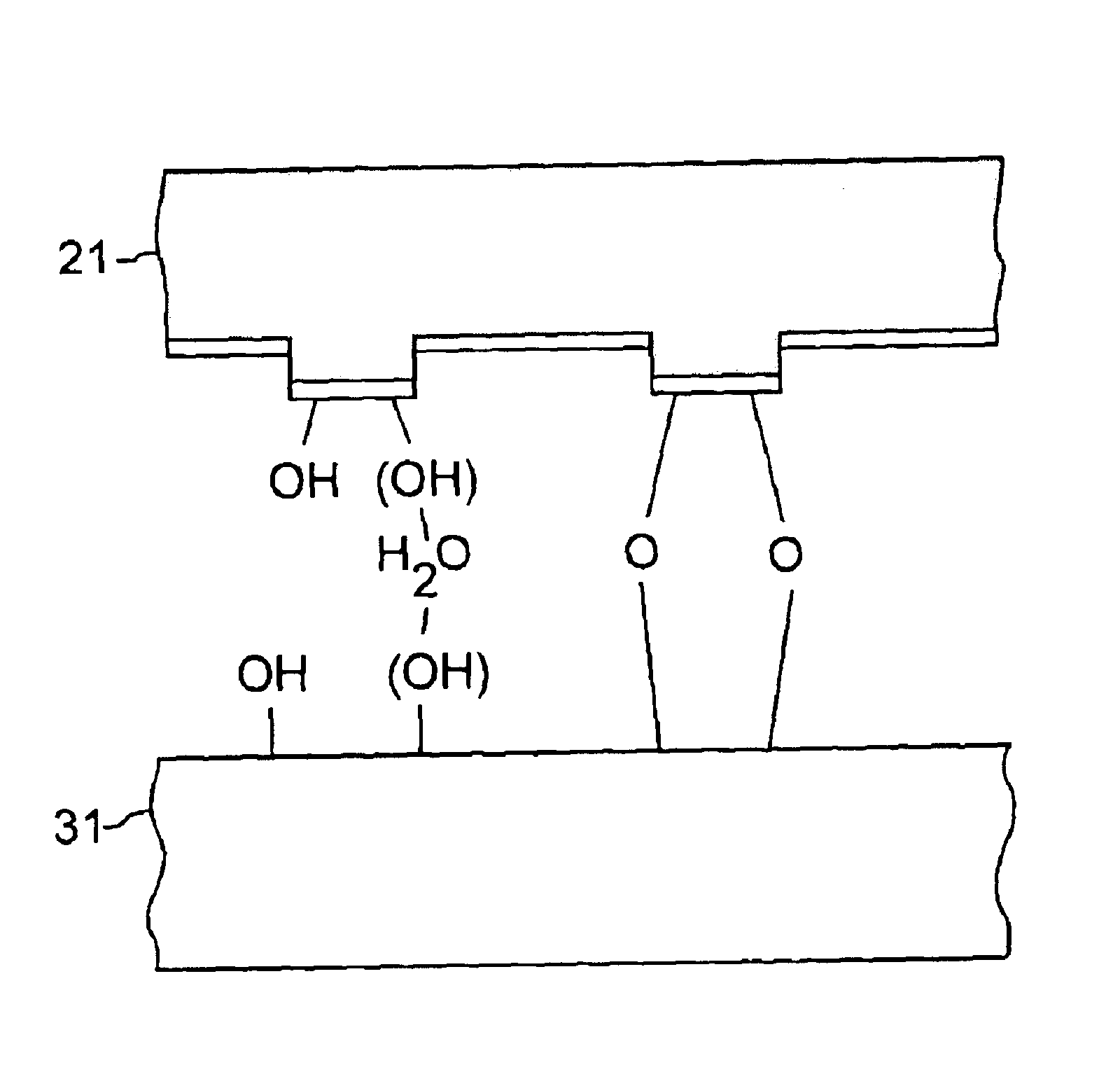

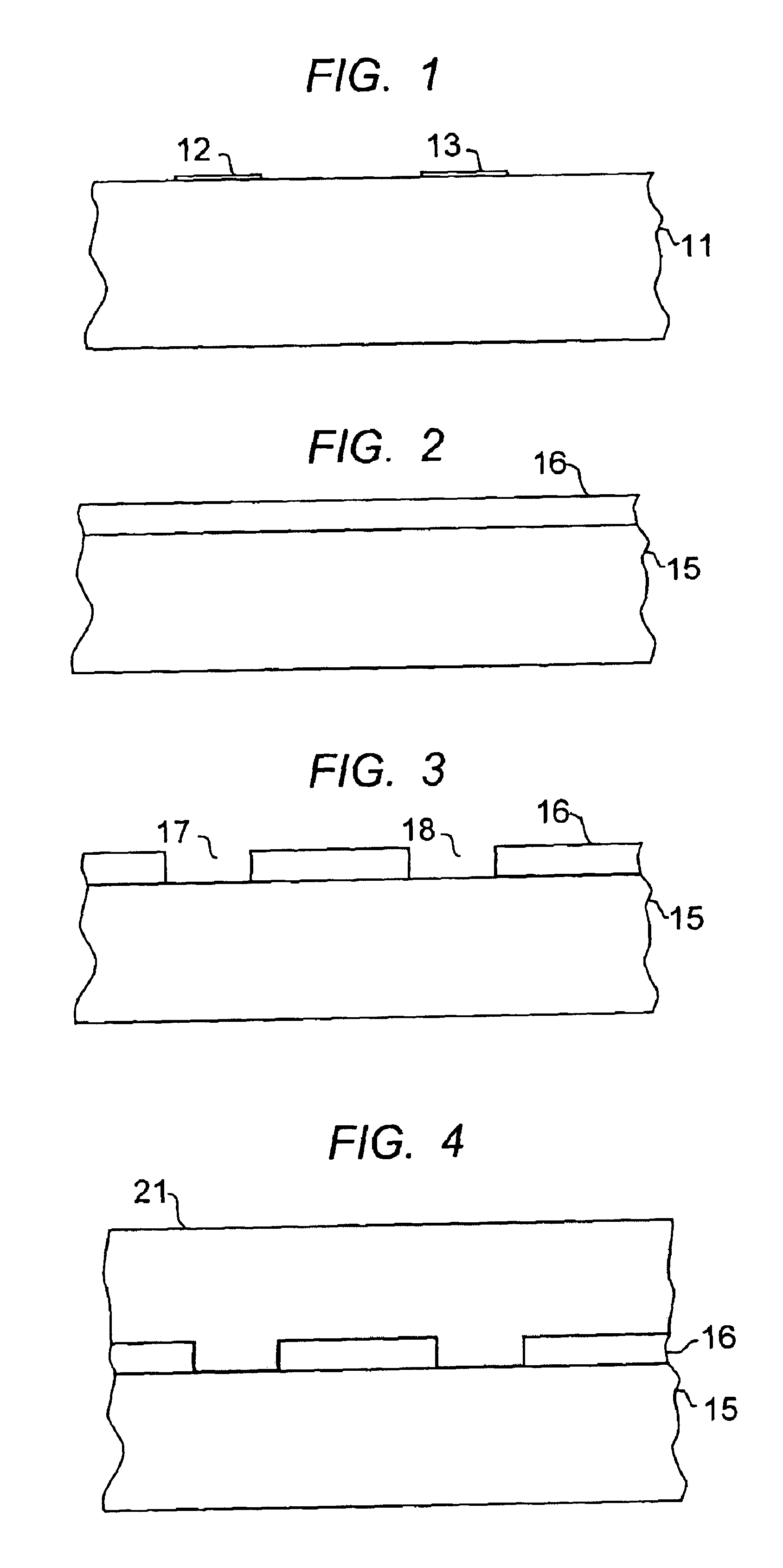

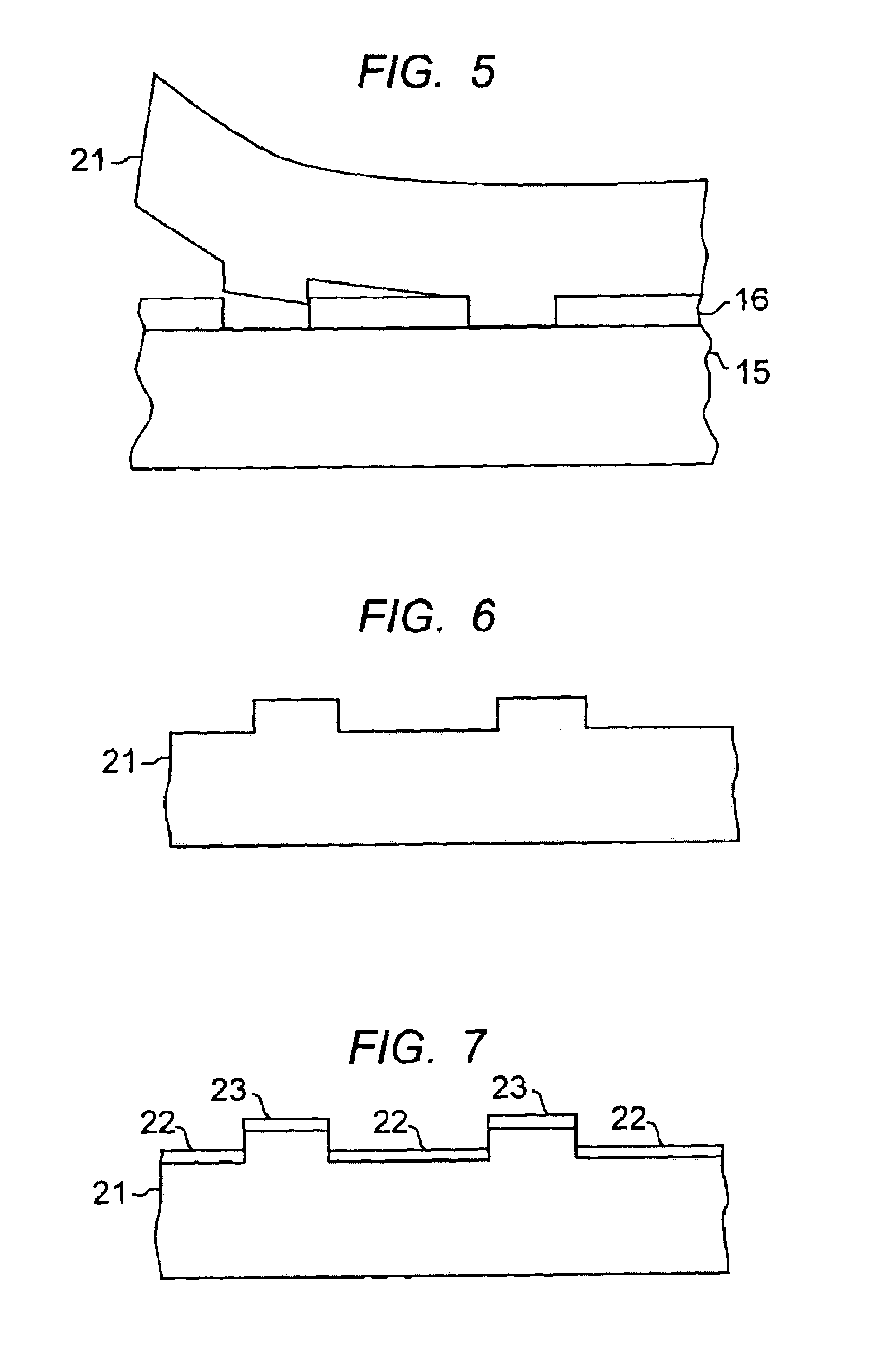

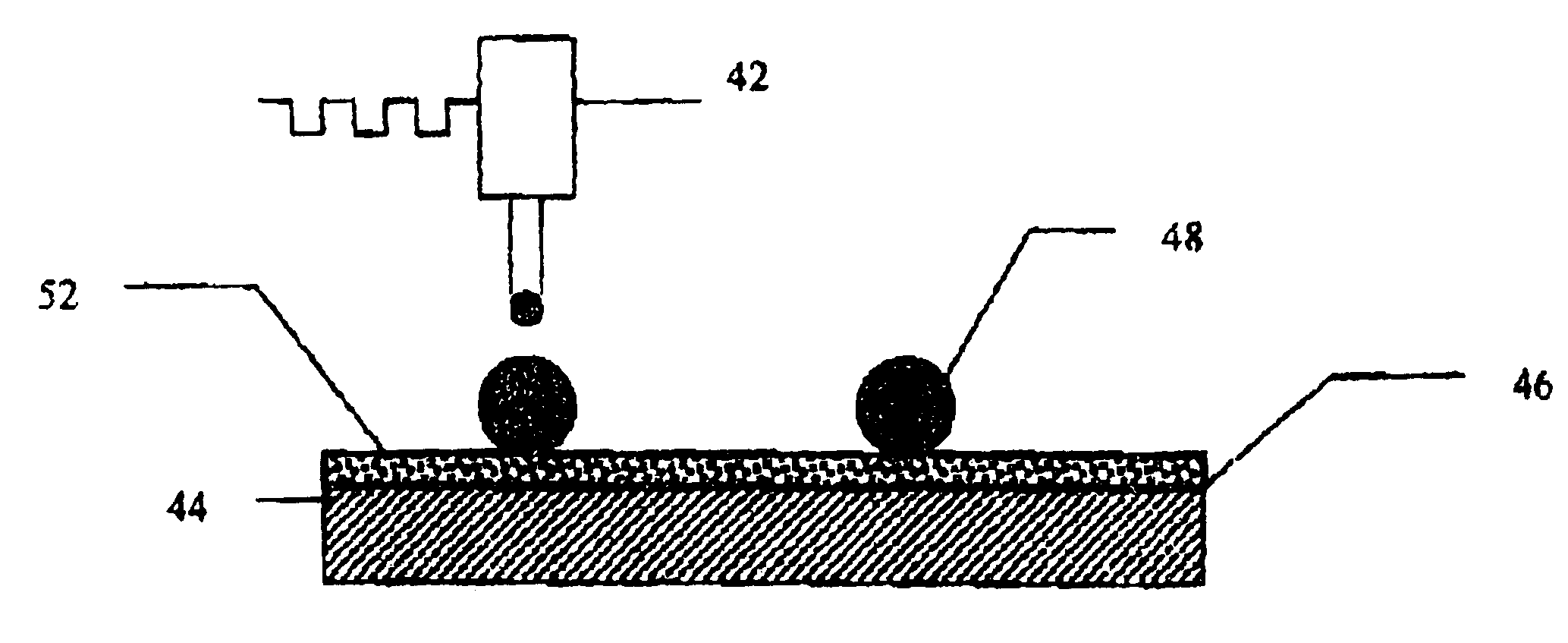

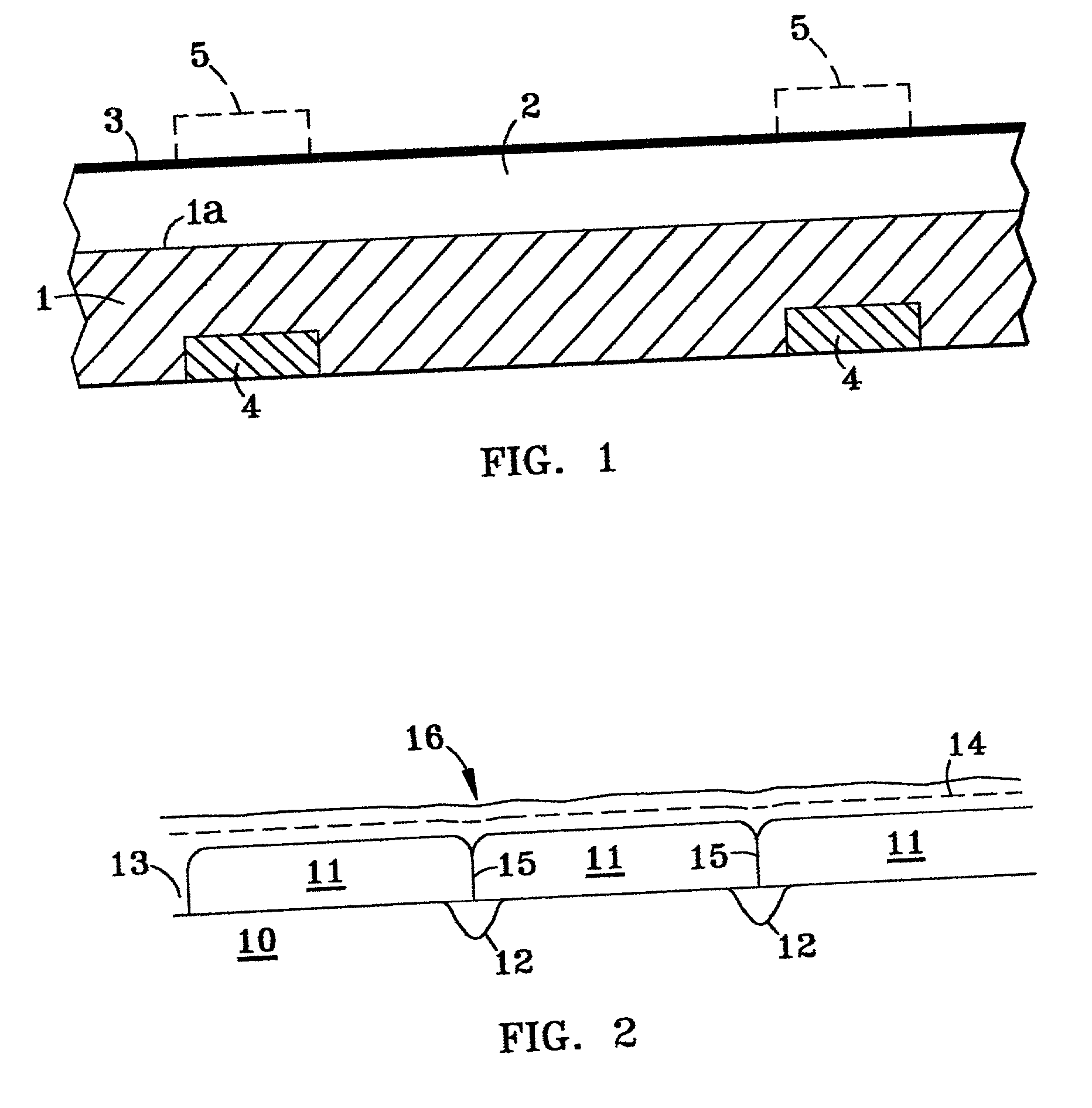

Forming nanoscale patterned thin film metal layers

The specification describes a contact printing technique for forming patterns of thin films with nanometer resolution over large areas. The procedure, termed here “nanotransfer printing (nTP)”, relies on tailored surface chemistries for transferring thin films, typically metal films, from the raised regions of a stamp to a substrate when these two elements are brought into intimate physical contact. This technique is purely additive, it is fast (<15 s contact times), and the printing occurs in a single processing step at room temperature in open air. nTP is capable of producing patterns with a wide range of features with sizes down to ˜100 nm, and edge resolution better than 25 nm. Electrical contacts and interconnects have been fabricated for high performance organic thin film transistors (TFTs) and complementary inverter circuits, to demonstrate one of the many potential applications for nTP.

Owner:ALCATEL-LUCENT USA INC +1

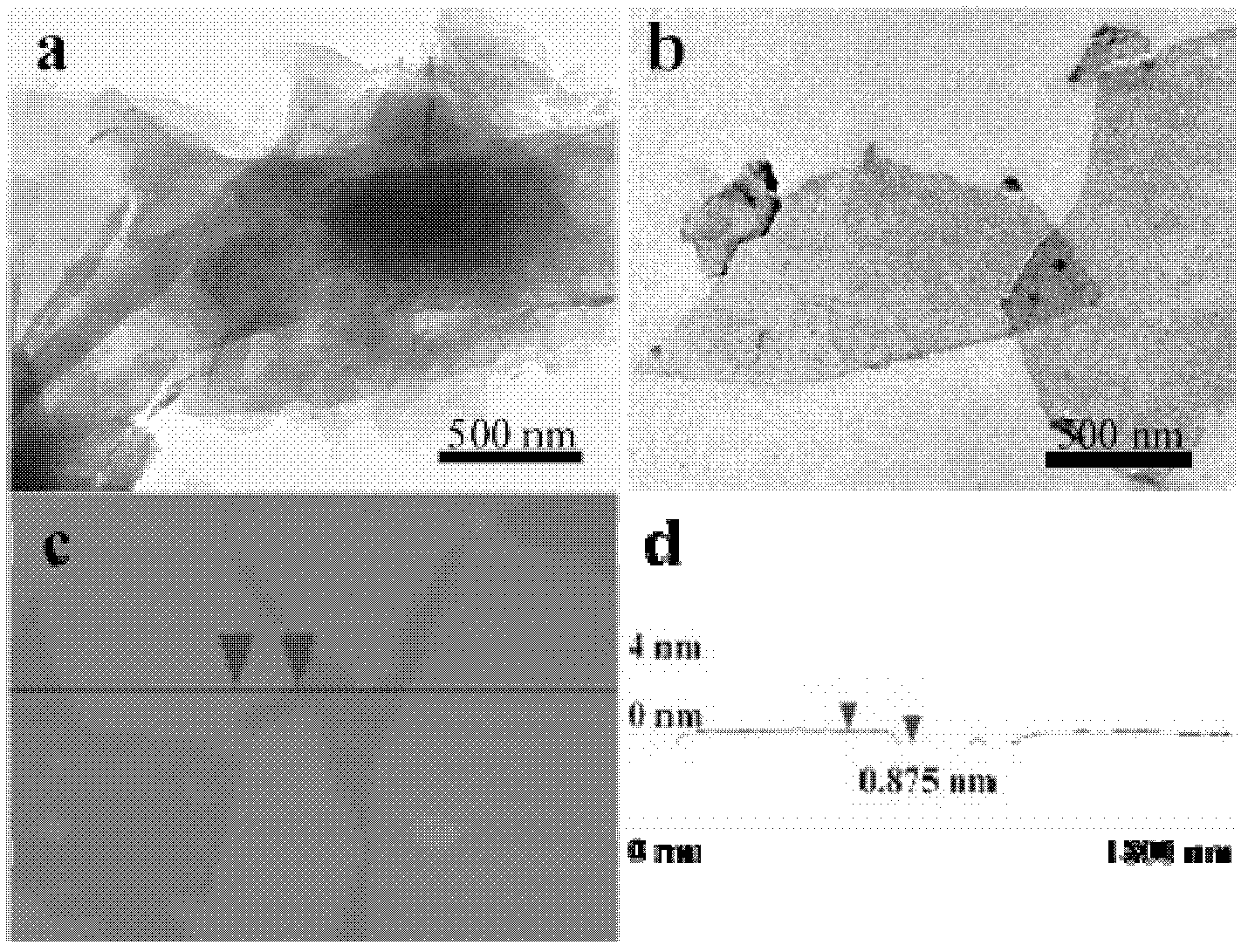

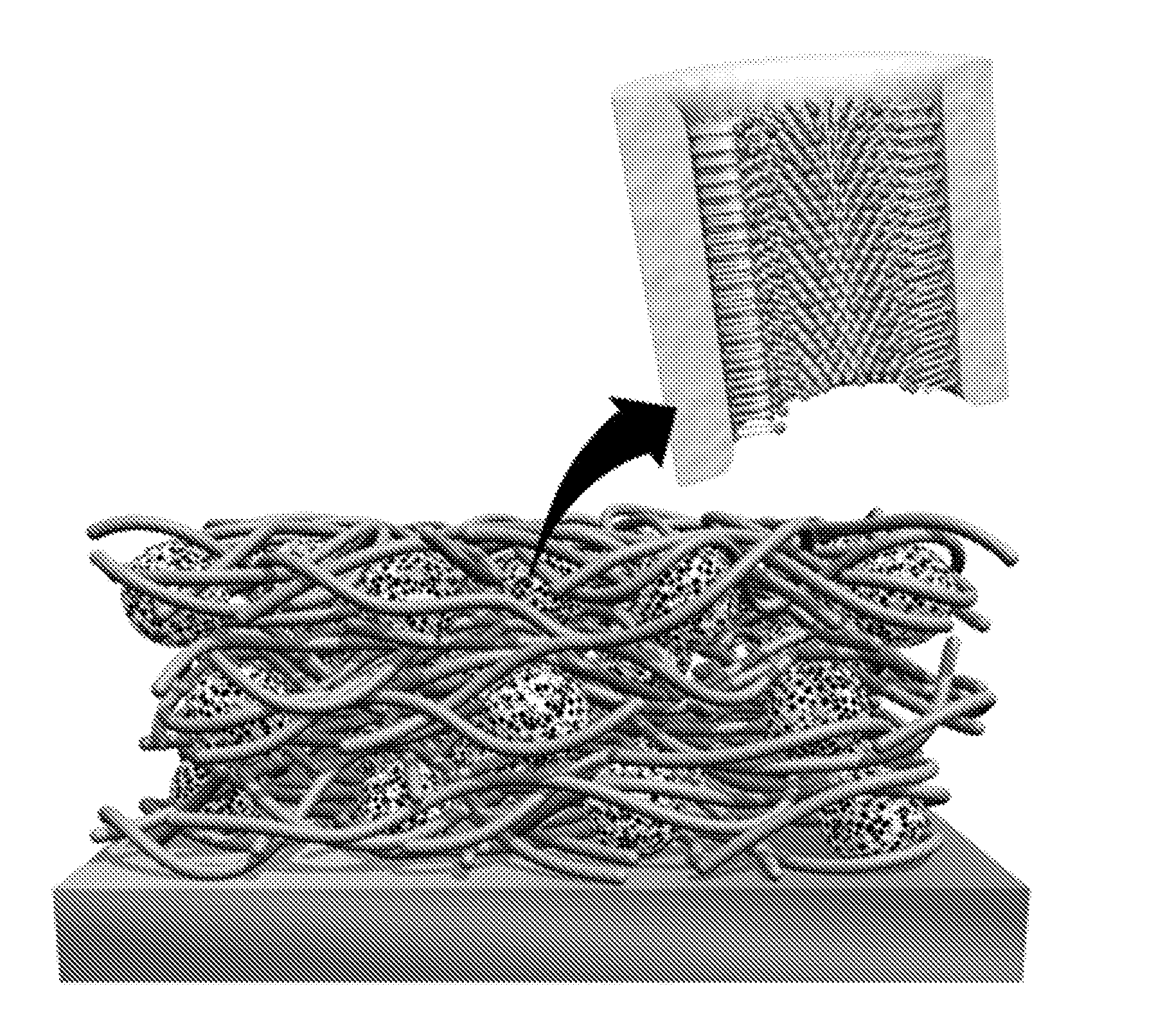

Large-area ultra-thin carbon nanotube film and its preparation process

The large-area untrathin nano carbon tube film with well feature in microcosmic level comprises nano carbon tubes with centimeter-level length and more then 90wt% purity. Wherein, the least thickness of single-layer film can achieve 20nm with near transparent color and more then 10cm2 film area; there are multiple functional groups on tube surface. It also discloses the opposite preparation technique: with the macroscopic body of nano carbon tube, oxidating the macroscopic body in air; then, dipping into hydroperoxide; adding strong acid to poach till the liquid shows neutrality; finally, adding alcohol or acetone into the liquid to float the tube and form the film.

Owner:TSINGHUA UNIV +1

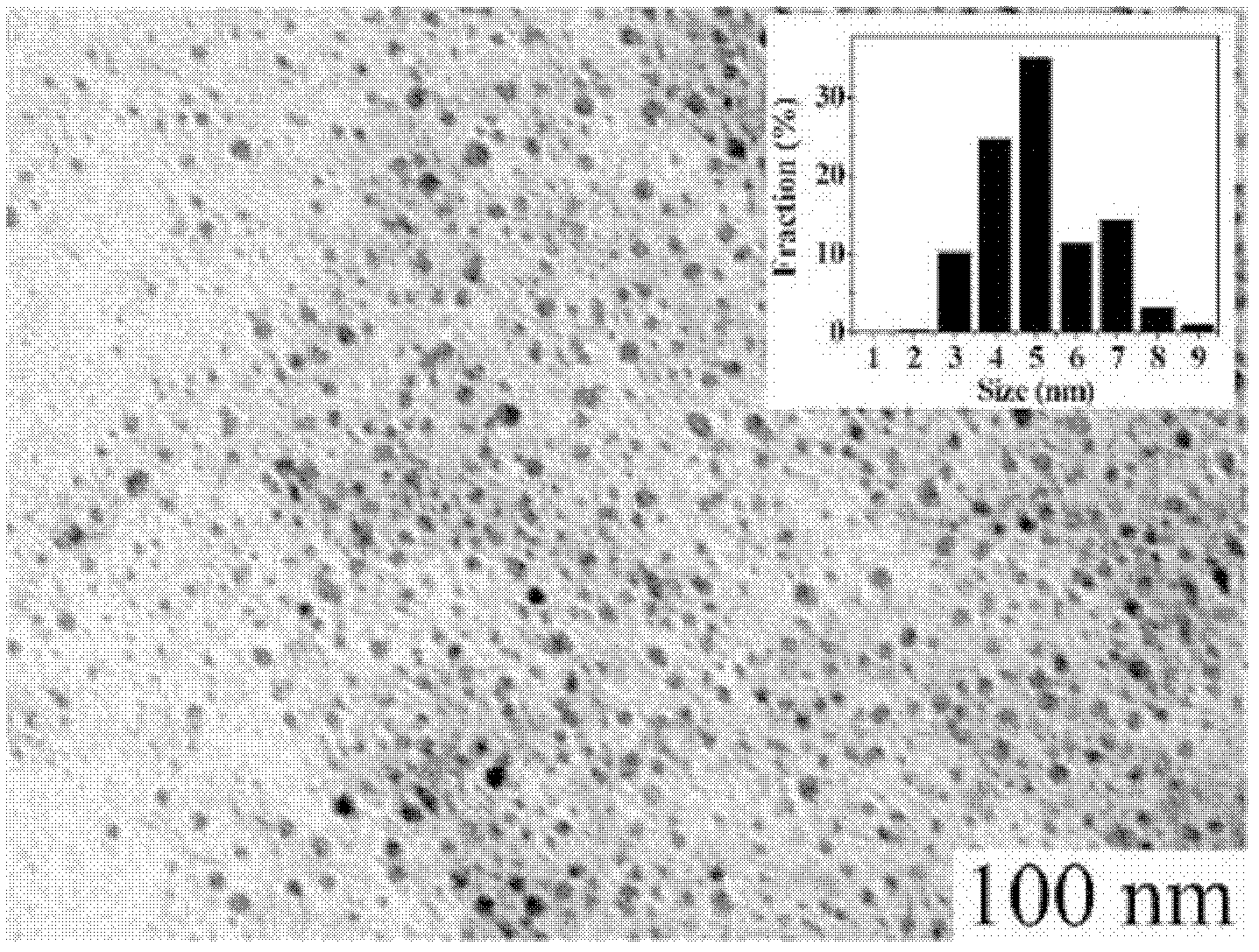

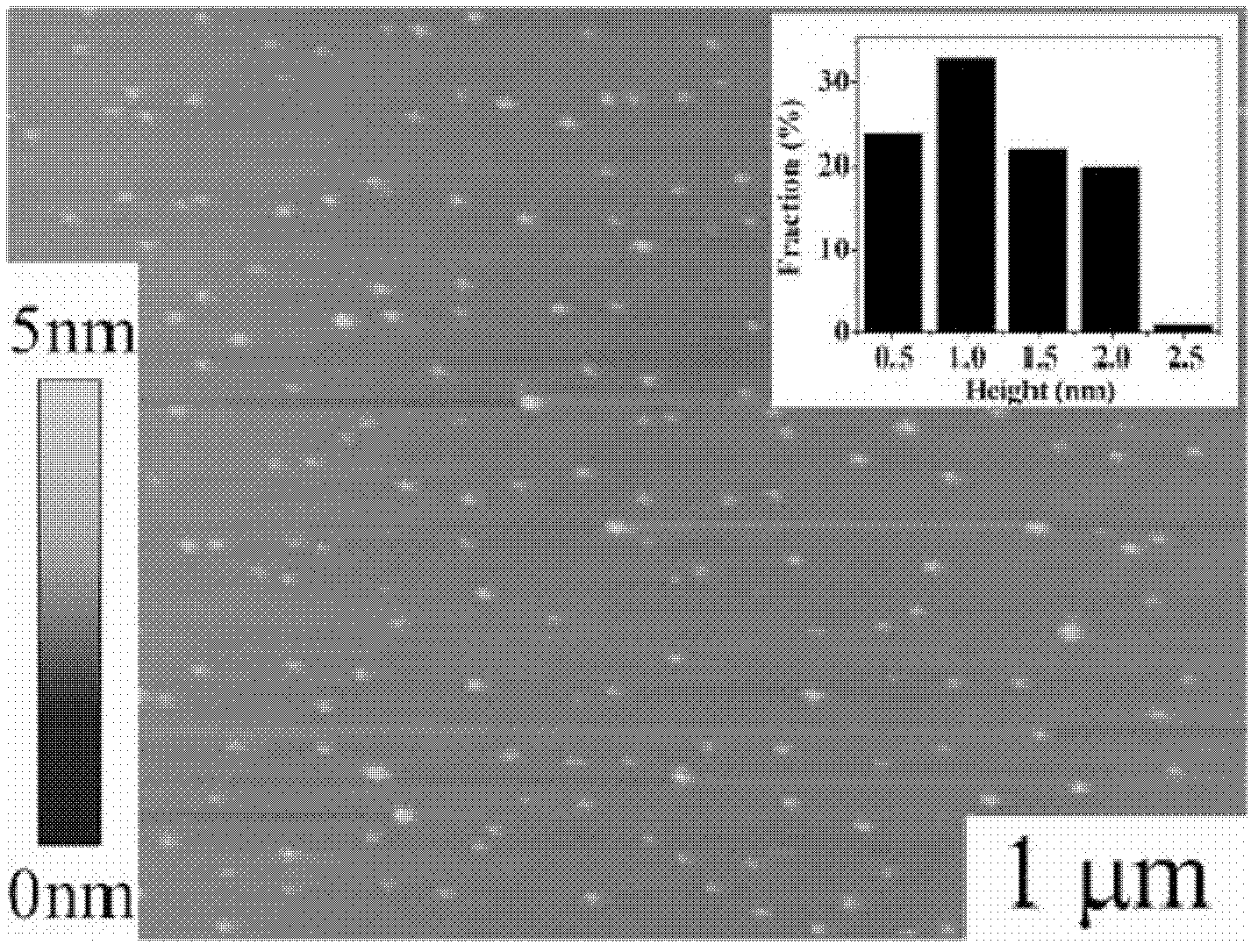

Method for preparing fluorescent graphene quantum dots by solvothermal method

InactiveCN102660270AHigh degree of oxidationLuminescent compositionsChromatographic separationSurface oxidation

The invention belongs to the technical field of the preparation of graphene quantum dots (GQDs), and particularly relates to a method for preparing fluorescent graphene quantum dots with controllable oxidation degree and fluorescence by a solvothermal method. According to the technical scheme, the method comprises the following steps of: 1, preparing graphene oxide; 2, preparing green fluorescent graphene quantum dots by a single-step method starting from the graphene oxide; and 3, preparing the fluorescent graphene quantum dots with the controllable oxidation degree by a column chromatographic separation method. According to the method, the sizes and surface oxidation degree of the graphene quantum dots can be controlled under the synthetic condition, so that the fluorescent properties and surface chemical characteristics of the graphene quantum dots are controlled. The prepared graphene quantum dots are high in chemical stability and biocompatibility, low in biotoxicity, and high in property of applicable upconversion fluorescence, matt and the like and bleaching performance. By the excellent properties, the graphene quantum dots have a wide application range in aspects of biological imaging, photovoltaic devices and sensors, and are novel promising fluorescent nano materials.

Owner:JILIN UNIV

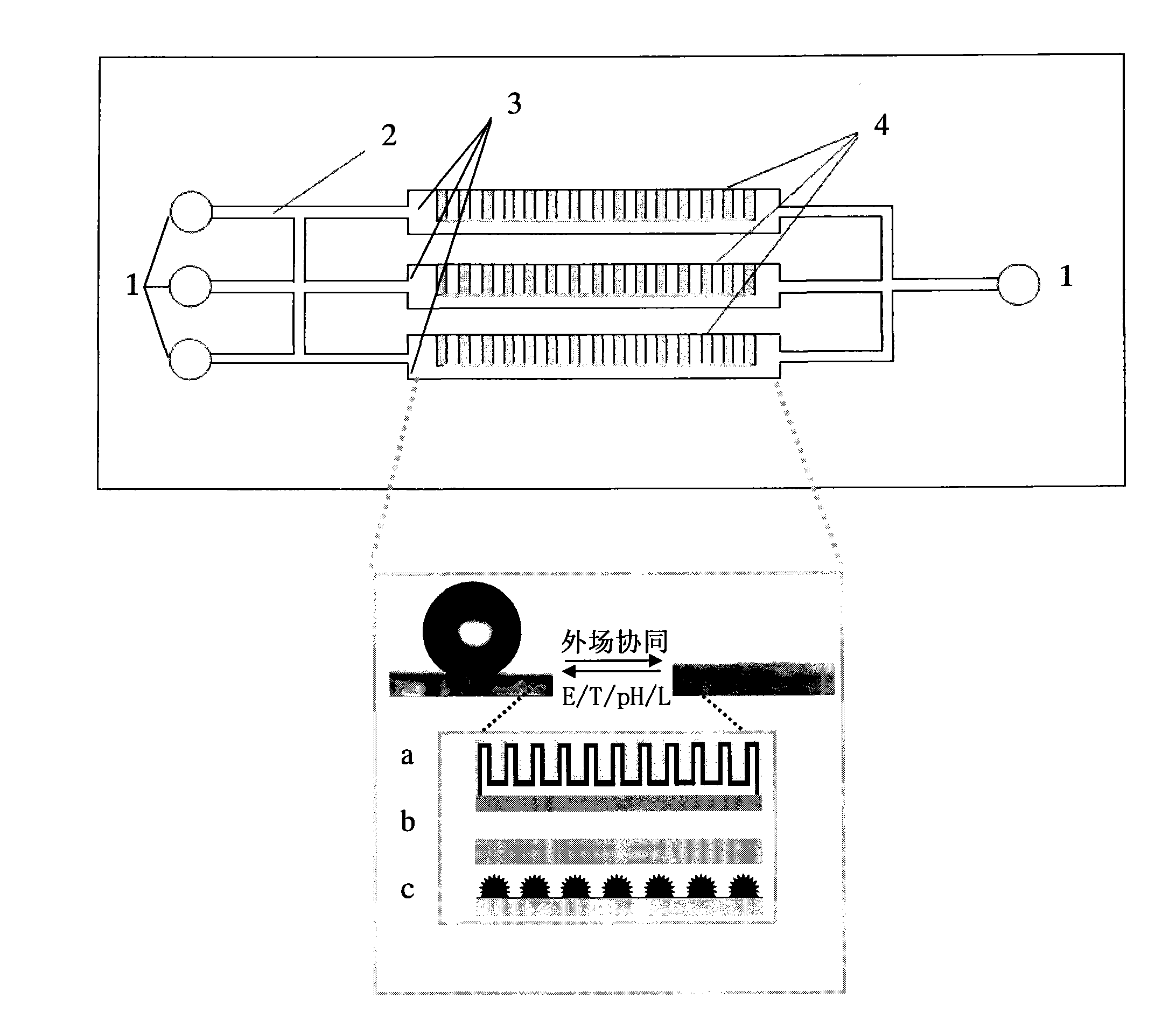

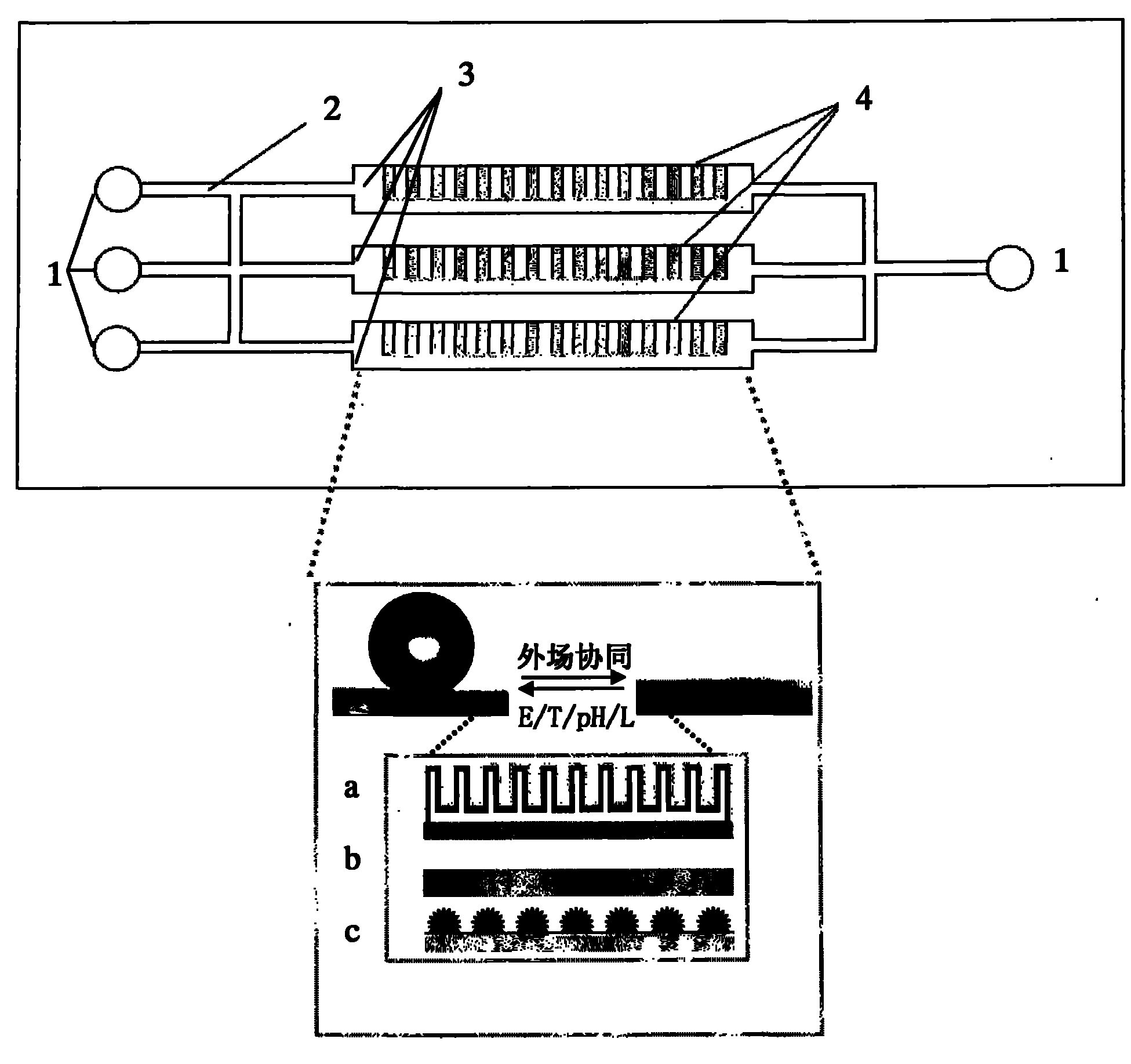

Microfluidic chip and manufacturing method thereof

InactiveCN102059161AIntelligent control of flow stateRapid reversible transitionLaboratory glasswaresChemical/physical/physico-chemical processesChemical compositionMicrometer

The invention relates to a microfluidic chip and a manufacturing method thereof. The microfluidic chip comprises an upper chip unit and a lower chip unit; the surfaces of the chip units are respectively provided with a liquid storing hole, a liquid channel communicated with the liquid storing holes and a microchannel communicated with the liquid channel; the upper chip unit and the lower chip unit are attached to each other and the microchannel is sealed between the two chip units; the microfluidic chip also comprises a micro valve, wherein the micro-valve main body is one of the following structures: a three-dimensional micrometer and three-dimensional nanometer hierarchical structure of polymers formed on the microchannel in array arrangement, a three-dimensional micrometer structure ofpolymers formed on the microchannel in array arrangement or a three-dimensional nanometer structure of polymers formed on the microchannel in array arrangement; the polymers can generate specific responses to an external field under the action of the external field; and the specific responses are reversibility transformation of one or more of surface chemical compositions of the polymers, the above structures and surface properties, thus realizing controllable operations for the flow state of a microfluid in the microchannel. The micro valve in the microfluidic chip is manufactured in situ and miniaturized on the microfluidic chip, thus realizing switch gradient control for the flow of the microfluid and fast switch reversibility transformation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

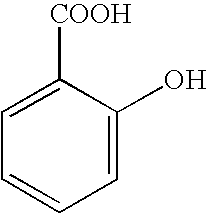

Composition and method of effecting superficial chemical skin peels

InactiveUS6869611B1Useful in treatmentSalicyclic acid active ingredientsCosmetic preparationsSalicylic acidSolvent

A method for effecting a superficial chemical skin peel is provided wherein a concentrated solution of salicylic acid in a dermatologically acceptable solvent is applied to be treated. The concentrated salicylic acid solution contains at least 15 wt % salicylic acid and preferably at least about 20 wt % salicylic acid, The composition and method are useful in the treatment of skin disorders such as photodamaged skin, hyperpigmentation, acne vulgaris, and the like.

Owner:KLIGMAN DOUGLAS E +1

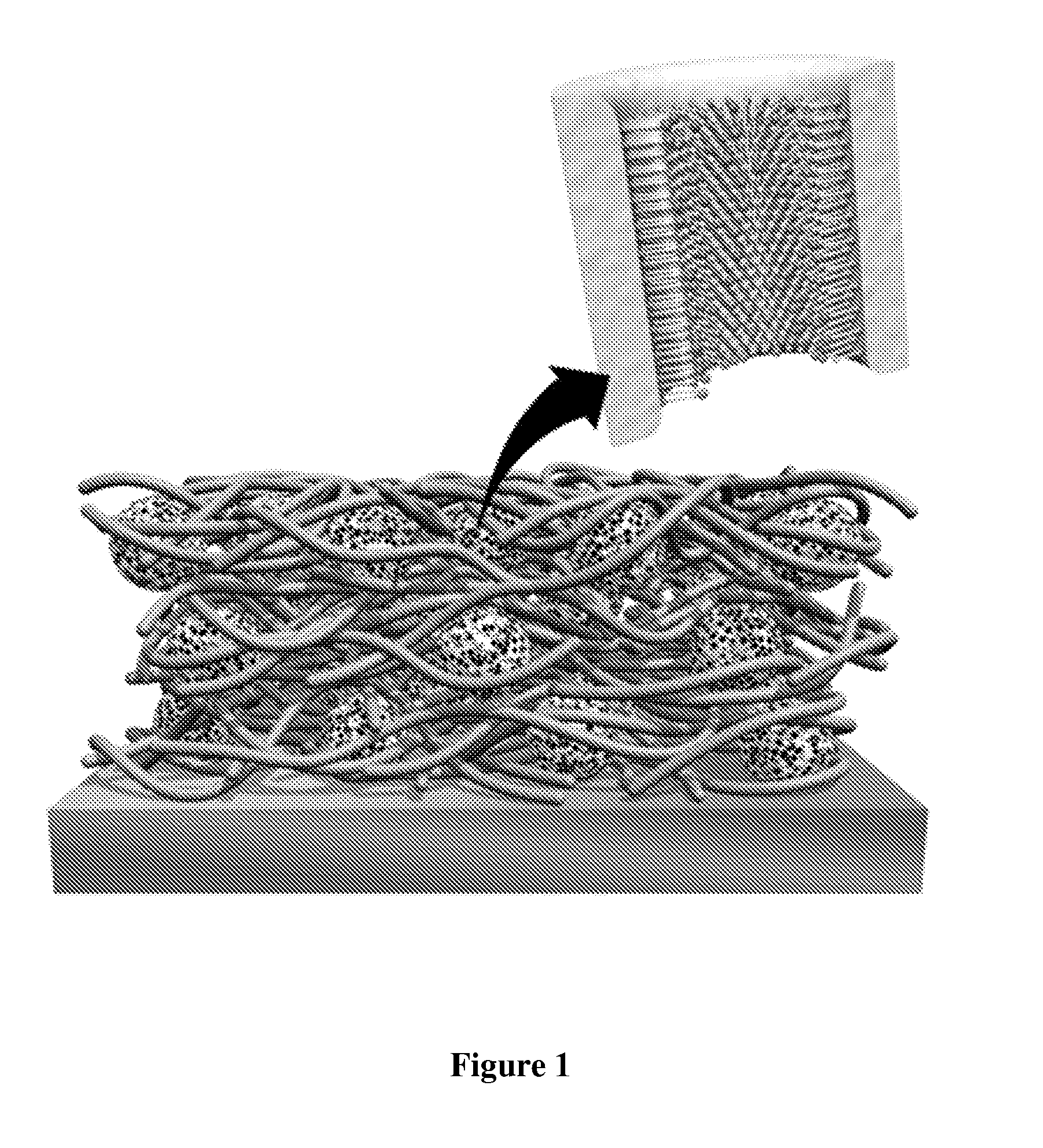

Porous multi-component material for the capture and separation of species of interest

A method and porous multi-component material for the capture, separation or chemical reaction of a species of interest is disclosed. The porous multi-component material includes a substrate and a composite thin film. The composite thin film is formed by combining a porous polymer with a nanostructured material. The nanostructured material may include a surface chemistry for the capture of chemicals or particles. The composite thin film is coupled to the support or device surface. The method and material provides a simple, fast, and chemically and physically benign way to integrate nanostructured materials into devices while preserving their chemical activity.

Owner:BATTELLE MEMORIAL INST

Inorganic powder organic surface modifying method

ActiveCN101134852AImprove performanceAchieve chemical modification of organic surfacesPigment treatment with organosilicon compoundsOrganic solventOil water

The present invention provides process of organizing the surface to modify inorganic powder, and during the process, inorganic superfine particles are dispersed homogeneously in non-polar organic solvent and have the surfaces well organization modified. The process includes preparing water solution for dispersing inorganic powder, dissolving organic surface modifier, organic surface modifying, solid-liquid separating and washing, and post-treatment. The process features that oil-water interface and phase transfer are utilized for organic surface modification of inorganic superfine powder in non-polar organic solvent.

Owner:江苏河海纳米科技股份有限公司 +1

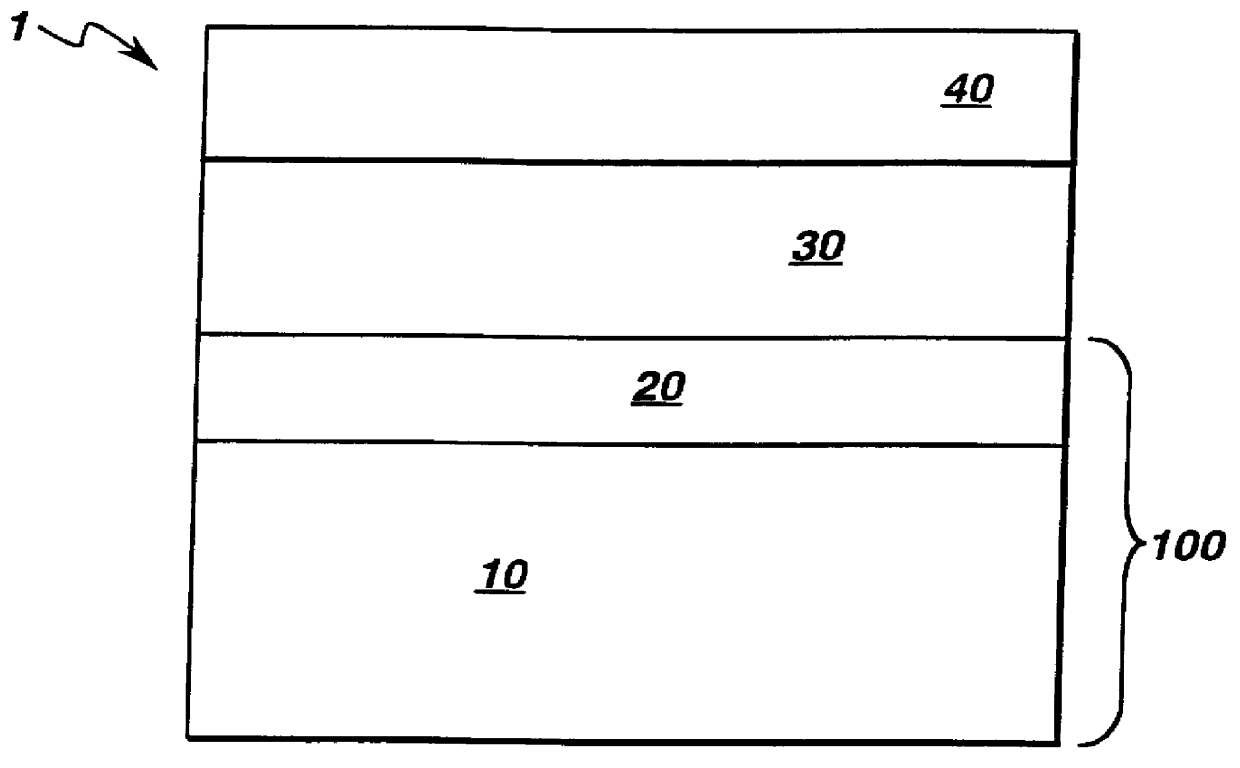

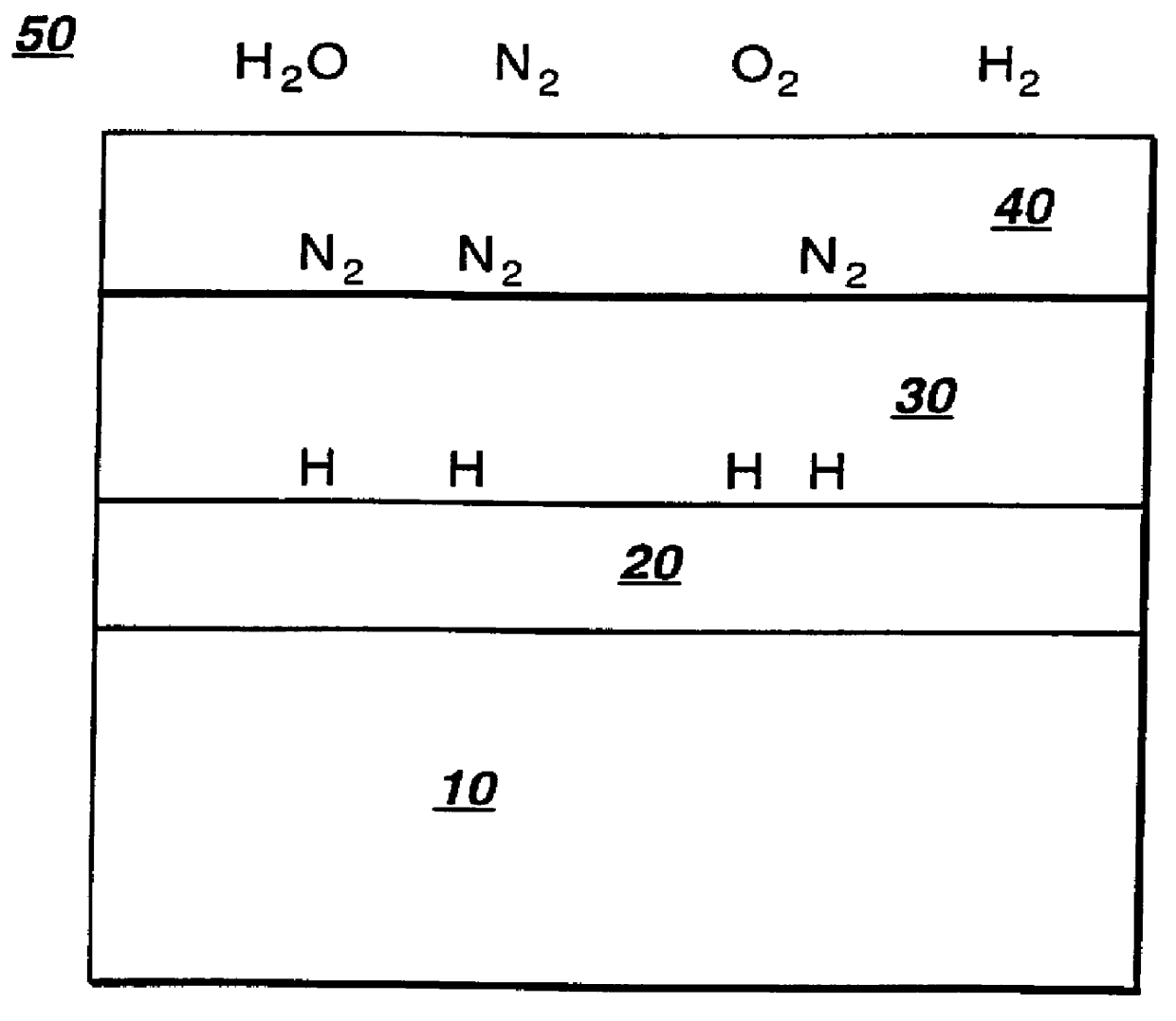

Gas sensor with protective gate, method of forming the sensor, and method of sensing

InactiveUS6041643AMaterial testing goodsGas analyser construction detailsForeign matterCatalytic metal

A gas sensor determines the presence of at least one designated gas in a gaseous environment. The gas sensor comprises a semiconductor substrate; a thin insulator layer disposed on the semiconductor substrate; a catalytic metallic gate disposed on the thin insulator layer; and a chemically modified layer disposed on the catalytic metal gate. The chemically modified layer comprises a material that protects the sensor from corrosive gases and interference from at least one foreign matter and water, alters at least one of surface chemical properties and surface physical properties of the sensor, and passes only the designated gas therethrough.

Owner:GENERAL ELECTRIC CO

Method for conducting surface chemical copper plating on inorganic particles through dopamine

ActiveCN105112894AReduce pollutionShort processLiquid/solution decomposition chemical coatingCopper platingElectromagnetic shielding

The invention discloses a method for conducting surface chemical copper plating on inorganic particles through dopamine. The method comprises the steps that poly-dopamine layers are made to subside on the surfaces of the inorganic particles in an alkaline solution through the oxidative polymerization effect of the dopamine, then by utilizing functional groups of the poly-dopamine layers, and meanwhile under the effect of an additional auxiliary reducing agent of dimethylamine broane (DMAB), copper ions are reduced to pure copper on the surfaces of the inorganic particles, and a continuous and compact metal copper layer is formed. The method is simple to operate, low in equipment requirement and low in cost; the prepared copper-plated inorganic particles have the characteristics of being low in density, good in conductivity and the like; the method can be used for preparing electricity and thermal conductive coatings, electromagnetic shielding paint, wave-absorbing materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing light metal super-hydrophobic surface

InactiveCN101423945AExcellent superhydrophobic propertiesWear-resistantAnodisationOther chemical processesLow temperature plasmaWear resistance

The invention relates to a preparation method for a light metal superhydrophobic surface, in particular to a light metal surface with a superhydrophobic property and corrosion and wear resistance. The preparation method comprises the following steps: a layer of porous oxidation film is formed on the surface through anodic oxidation of the light metal surface first; the surface is modified by a low-temperature plasma treatment technique; and at last, the superhydrophobic surface is formed on the surface of the oxidation film through chemical modification. The method does not require complex and expense equipment and has a simple process, good repetitiveness, a contact angle of the surface and water up to 153 to 170 degrees as well as good corrosion and wear resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

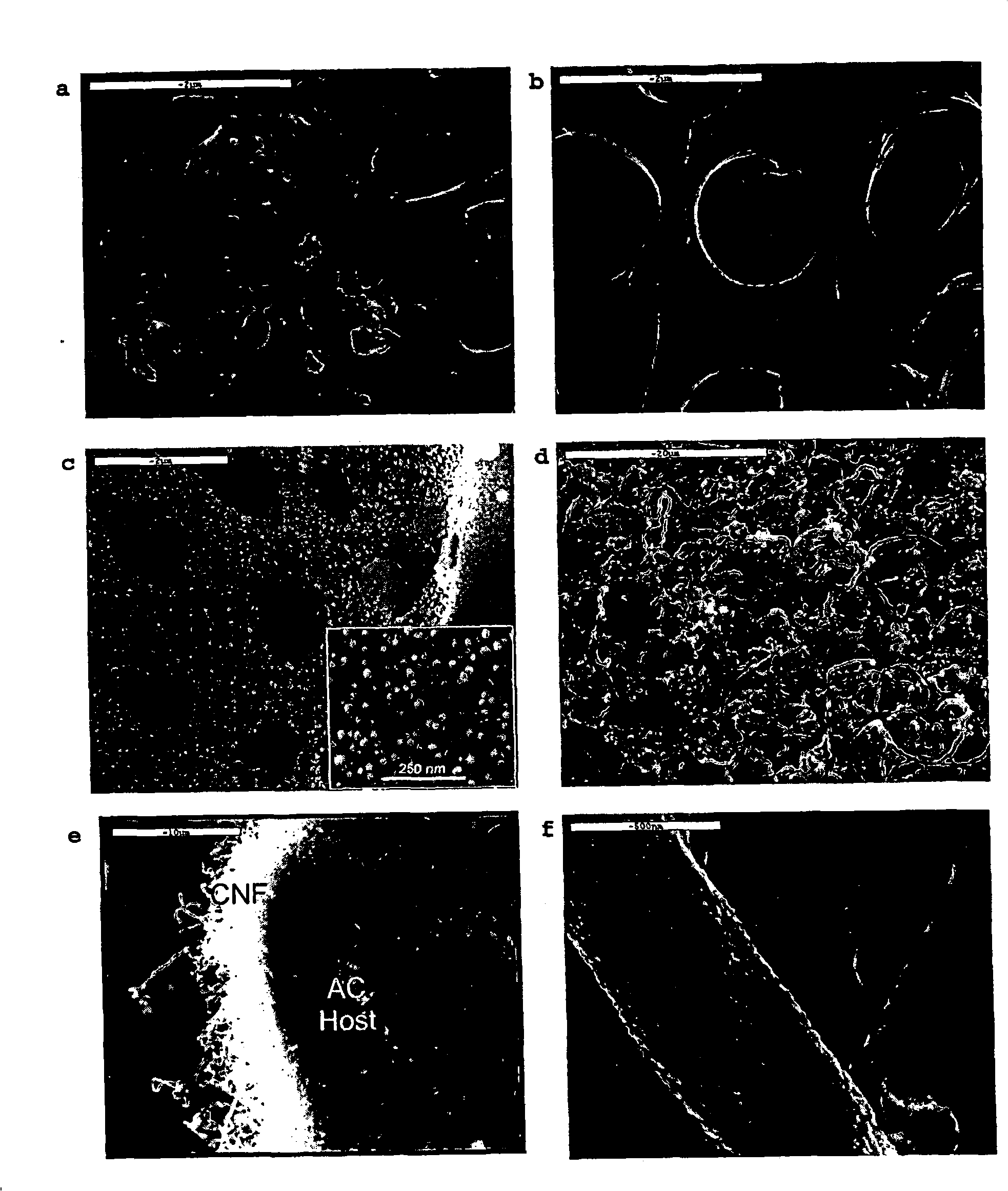

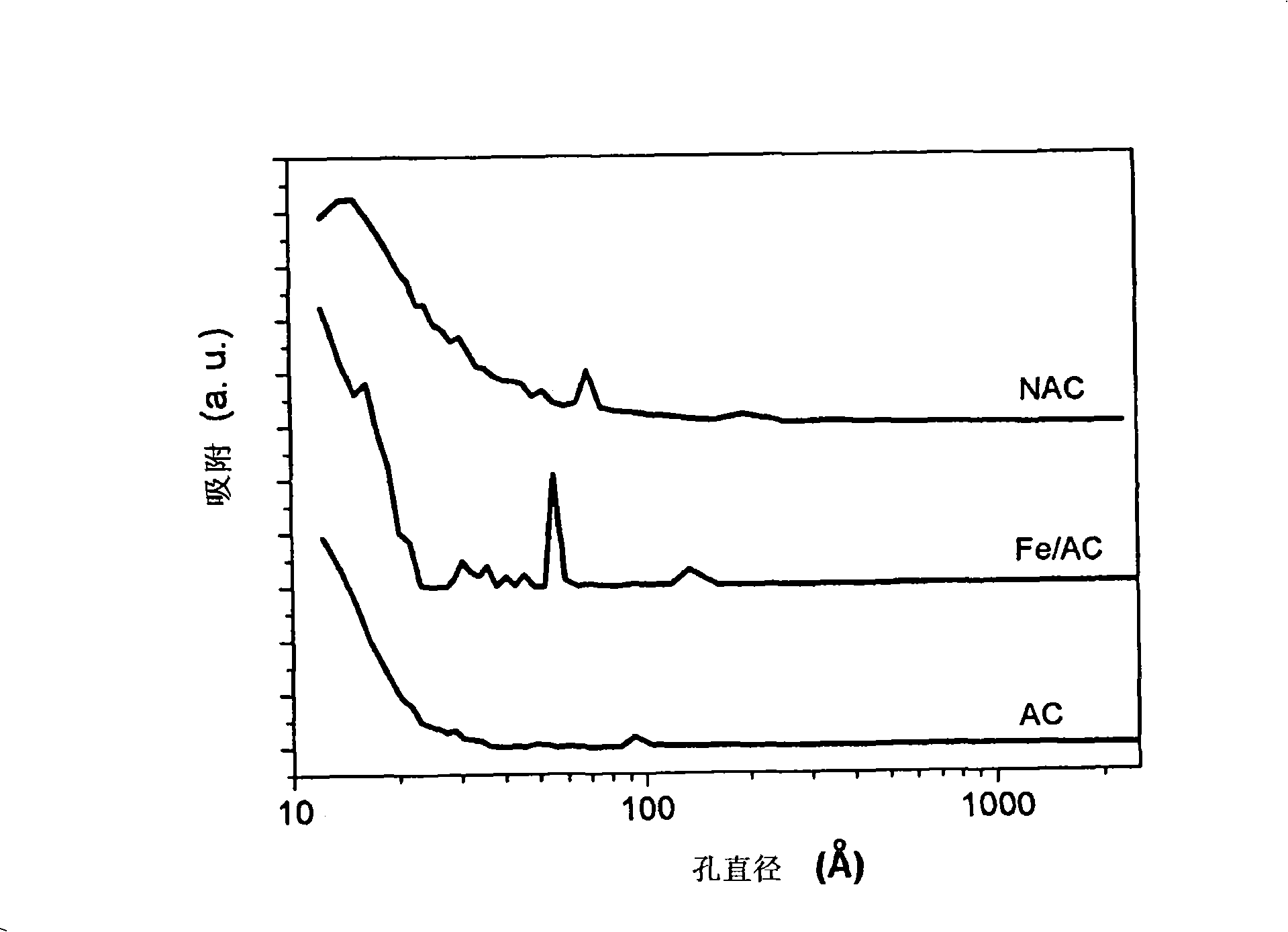

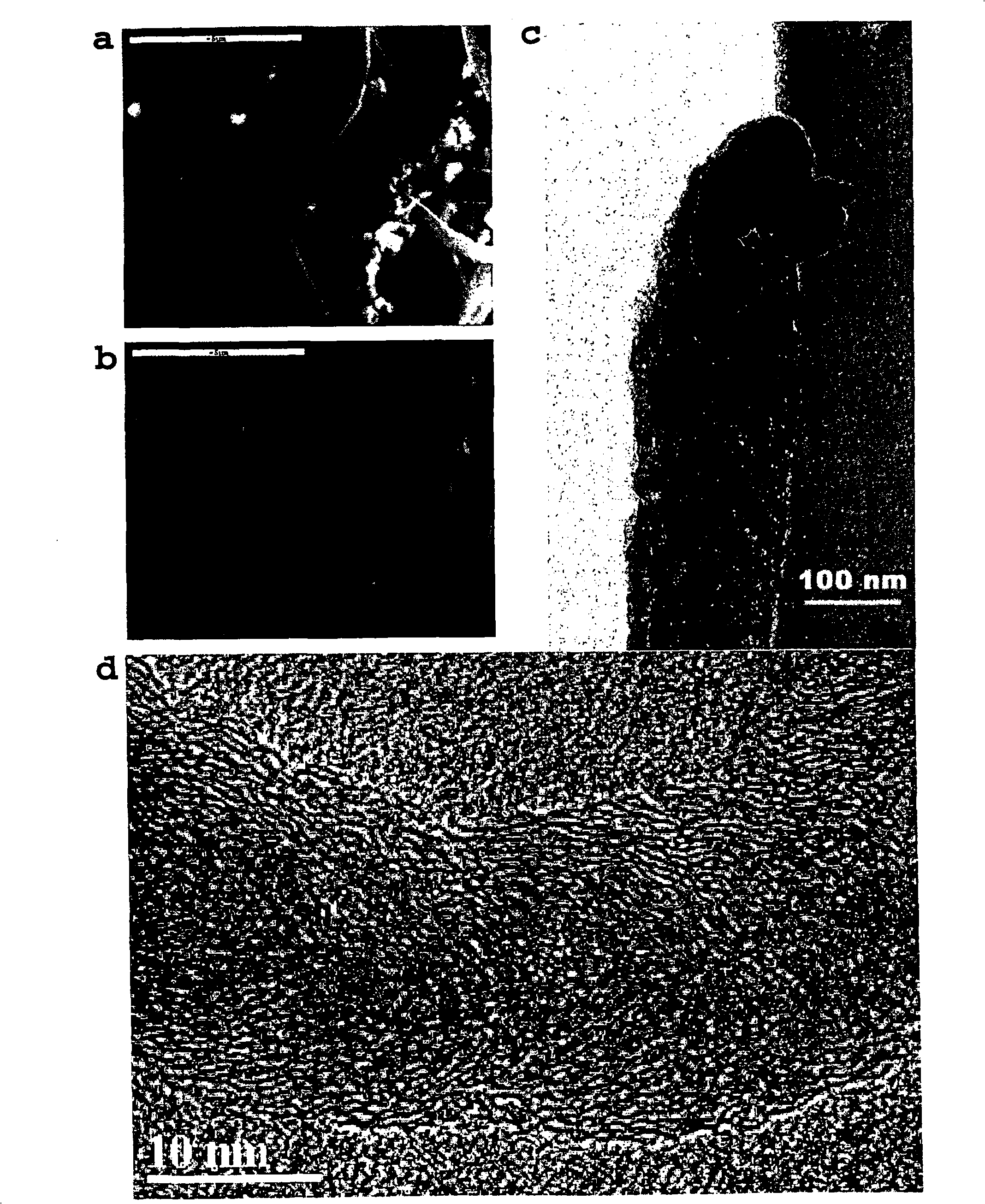

Nanosized carbon material-activated carbon composite

InactiveCN101304945AAvoid disadvantagesMaterial nanotechnologyCarbon compoundsCarbon compositesActivated carbon

The present invention relates to carbon-carbon composite material comprising a carbonaceous carrier and nanosize carbon structures (e.g. CNT or CNF), wherein the nanosize carbon structures are grown on the carbonaceous carrier. The carrier may be porous, as in activated carbon or consists of carbon black particles. In accordance with the invention, nanocarbon growth in the pores of porous carriers can be realized. The process for the manufacture of a this carbon-carbon- composite material comprises the steps of treating a carbonaceous carrier material with a metal -containing catalyst material, said metal being capable of forming nanosize carbon structures, and growing nanosize carbon structures by means of a CVD (chemical vapour deposition) method on the treated carrier in a gas atmosphere comprising a carbon-containing gas, followed by an optional surface modification step. This process allows optimising porosity, hydrodynamical properties and surface chemistry independently from each other, which is particularly beneficial in respect of the use of the composite for water purification. Carbon black-based composites are particularly useful for filler applications.

Owner:SUD CHEM IP GMBH & CO KG

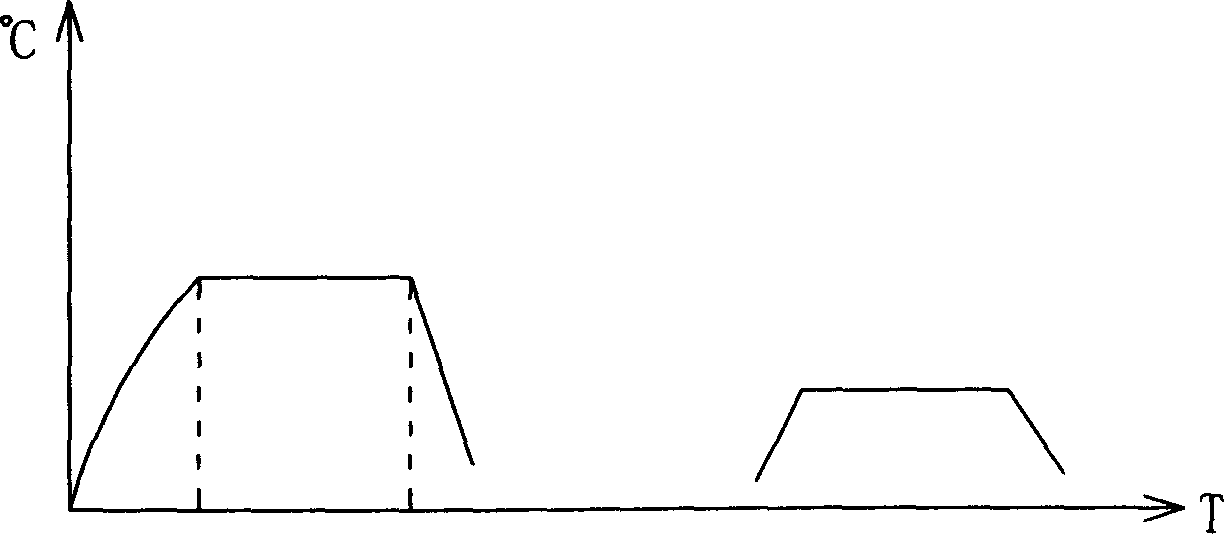

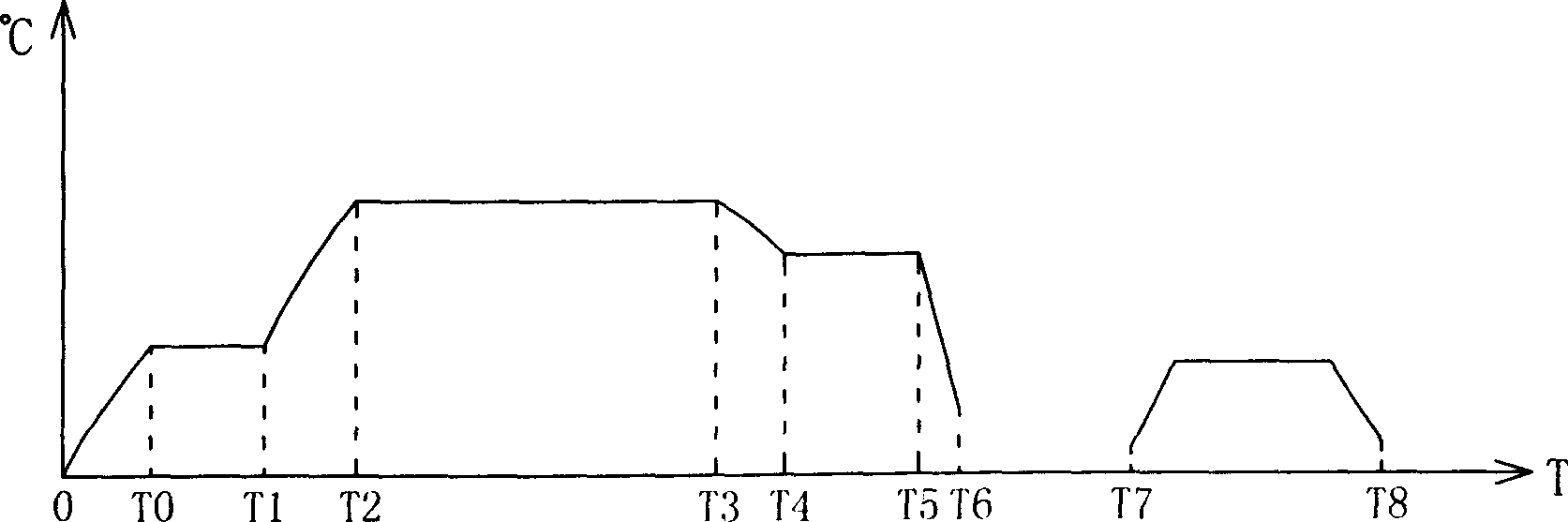

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

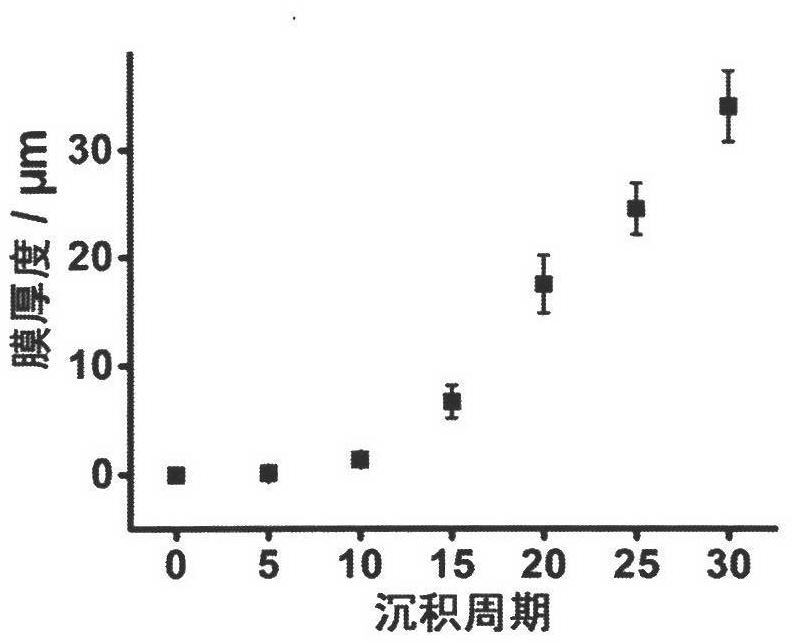

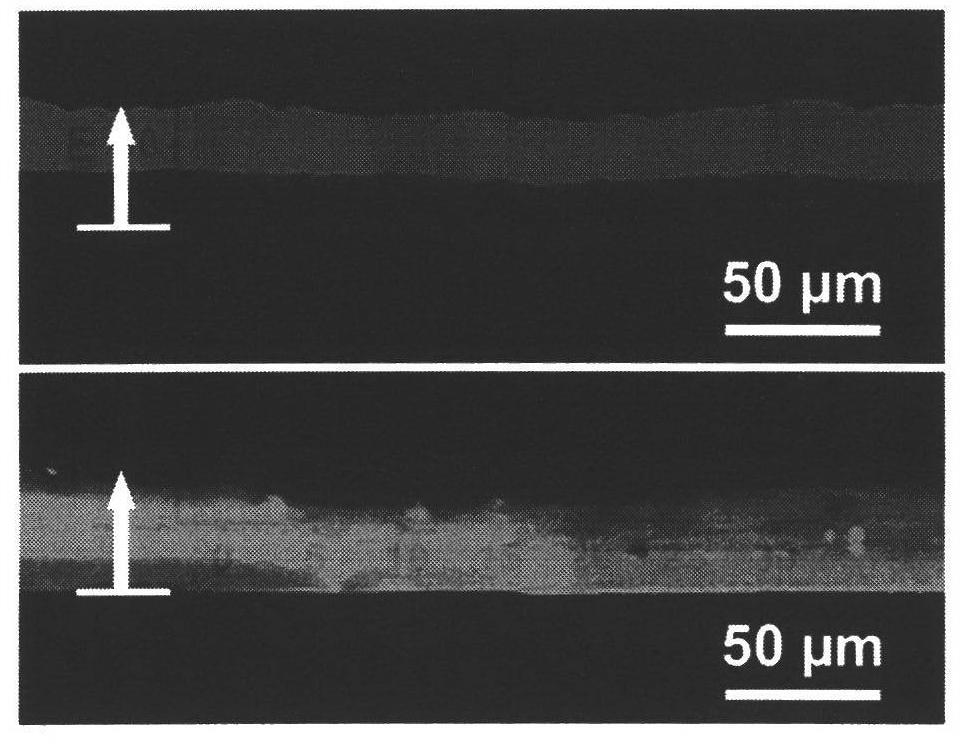

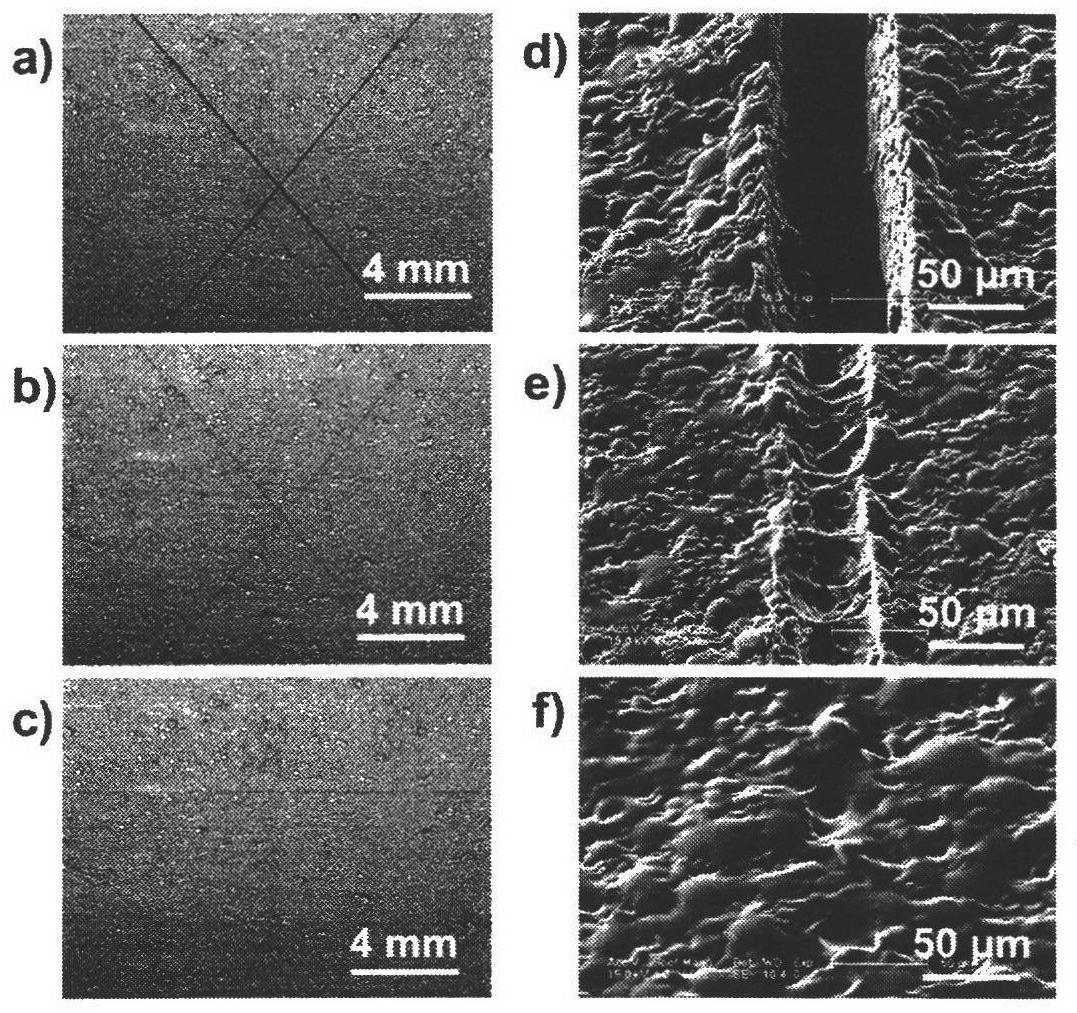

Method for preparing self-repairing polyelectrolyte coating based on layer-by-layer assembly technology

InactiveCN102319662AImprove liquidityPromote repairSpecial surfacesAlginic acid coatingsPolyelectrolytePolymer science

The invention belongs to the technical field of preparation of self-repairing coatings, and relates to a method for preparing a polyelectrolyte coating having self-repairing capability based on a layer-by-layer assembly technology. The prepared polyelectrolyte coating has high strength in the air and high mobility when the coating is immersed in water or the water is sprayed on the coating, so huge scratches caused by mechanical damage on the coating can be spontaneously repaired. The self-repairing polyelectrolyte coating has the advantages that: a repair means is easy to implement, the sameposition can be repeatedly and spontaneously repaired, and the preparation of the coating is free from the limitation of a substrate. Moreover, the method for preparing the self-repairing polyelectrolyte coating is simple, and the used raw materials are non-toxic and harmless. The method for preparing the self-repairing coating is believed to contribute to research of aspects comprising material science, surface chemistry, polymer science and the like, and the self-repairing polyelectrolyte coating is expected to be widely applied in aspects of preparation of protective coatings, biological material coatings, display equipment and the like.

Owner:JILIN UNIV

Pre-treatment liquid for use in preparation of an offset printing plate using direct inkjet CTP

InactiveUS6906019B2Improve image qualityFast plating speedSurface-active detergent compositionsDuplicating/marking methodsPre treatmentSurface chemical

A method of making a printing plate in which the uncoated surface of a substrate is treated with a pre-treatment solution prior to the deposition of ink on the surface. The pre-treatment liquid comprises a polyvalent metal salt, and at least one of an organic swelling reagent and / or a coalescence reagent. The pre-treatment liquid is applied to form a thin, homogenous layer of approximately 4 μm to the entire upper surface of the recording plate. The swelling reagent and / or the coalescence reagent and the polyvalent metal cations are physically well localized in the porous structure of the plate's surface. After partial drying of the pretreated anodized aluminum plate, CTP liquid is deposited onto the surface to form an image. The CTP liquid solids react with the pre-treatment liquid and are, therefore, chemically bound to the surface. This allows all data to be deposited in a single pass of the inkjet head without the problem of clustering.

Owner:HEWLETT PACKARD IND PRINTING LTD

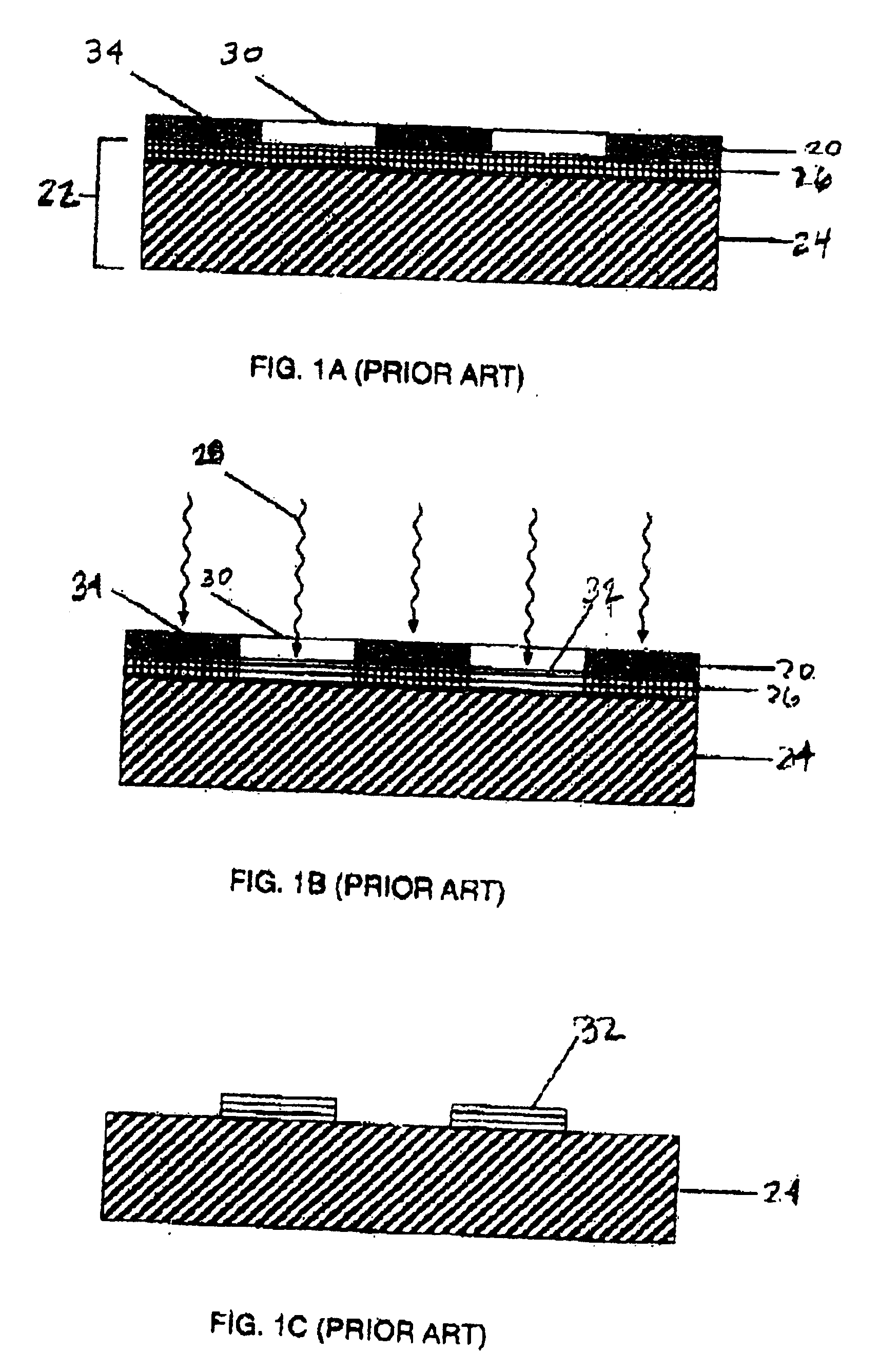

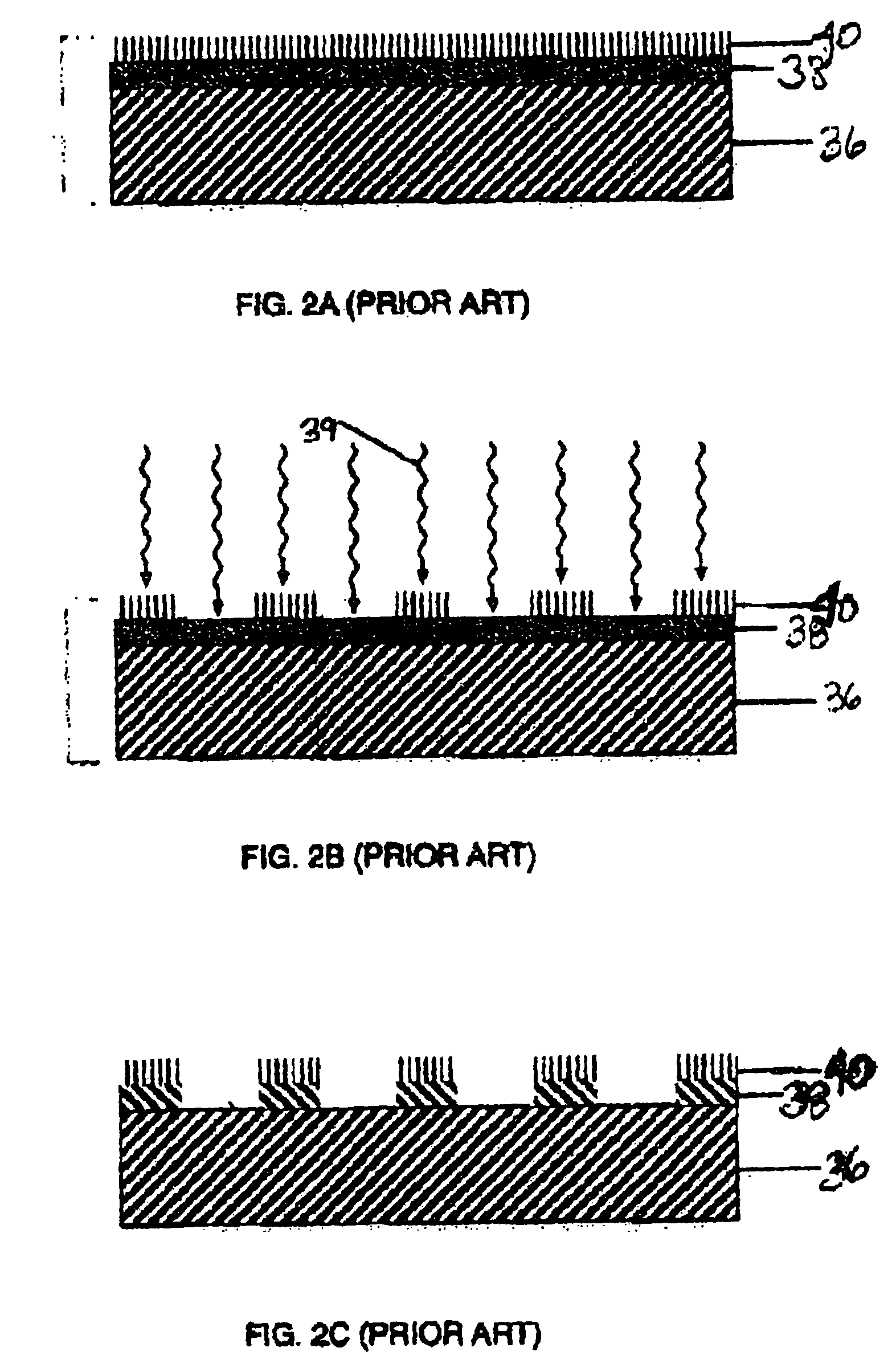

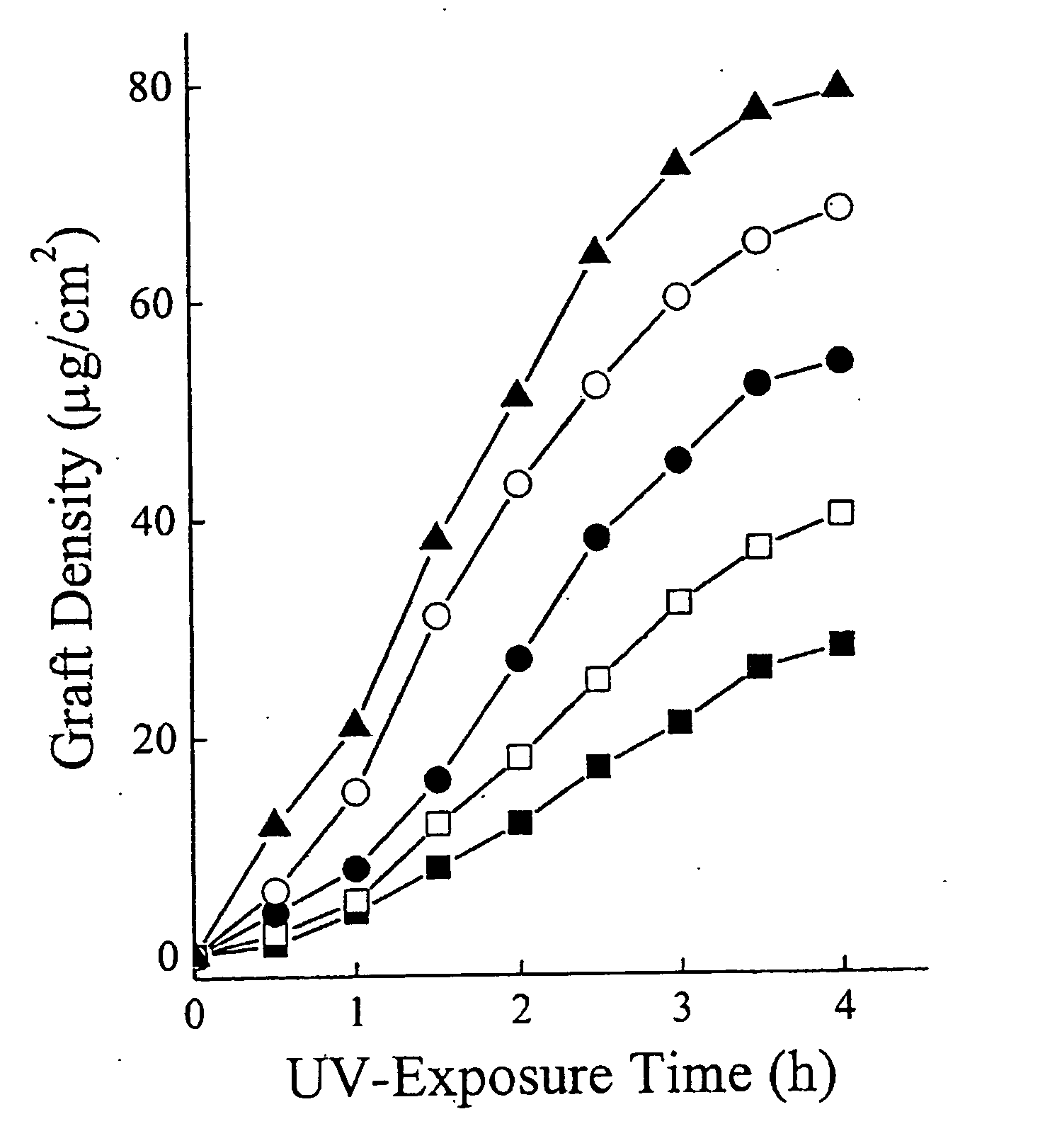

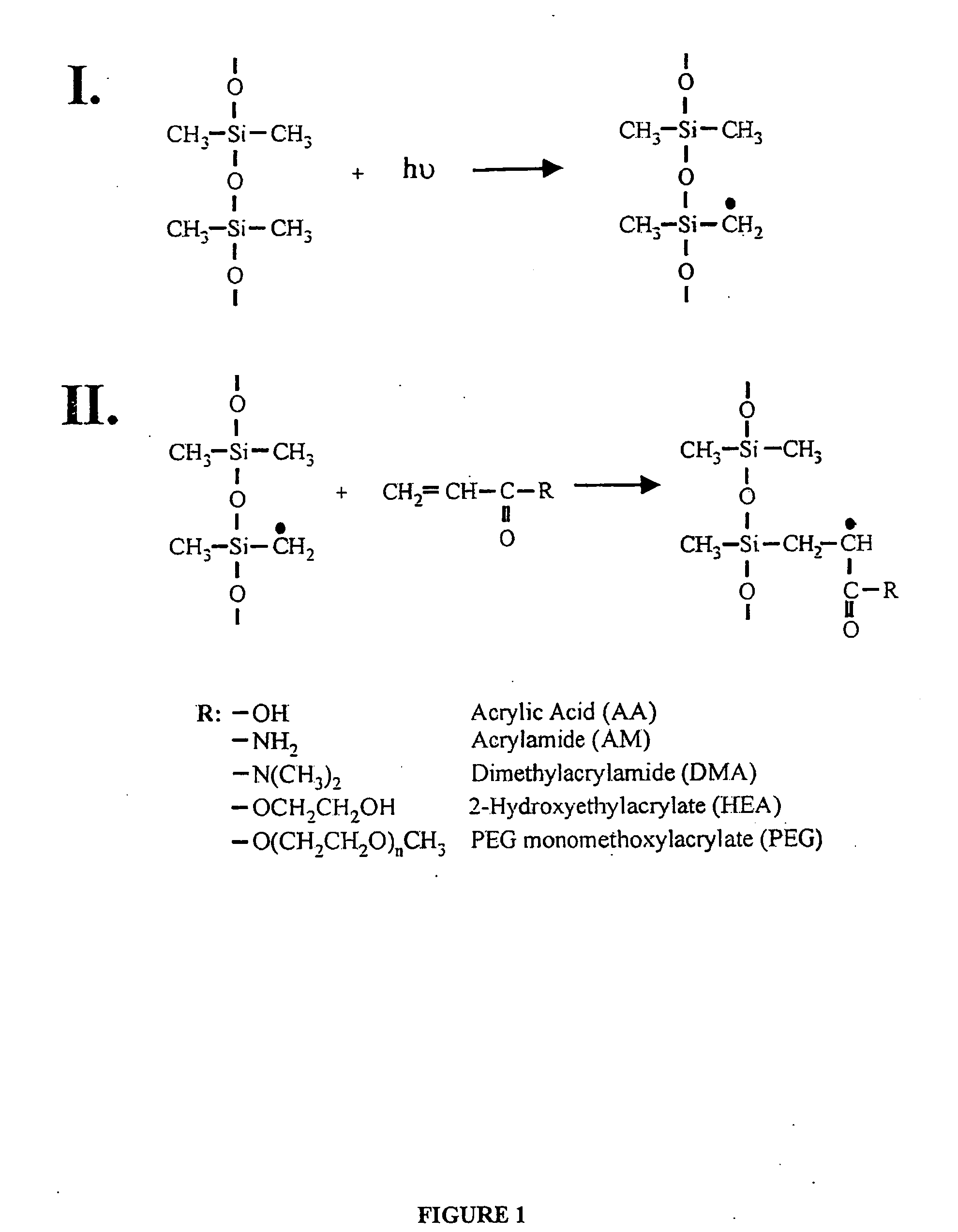

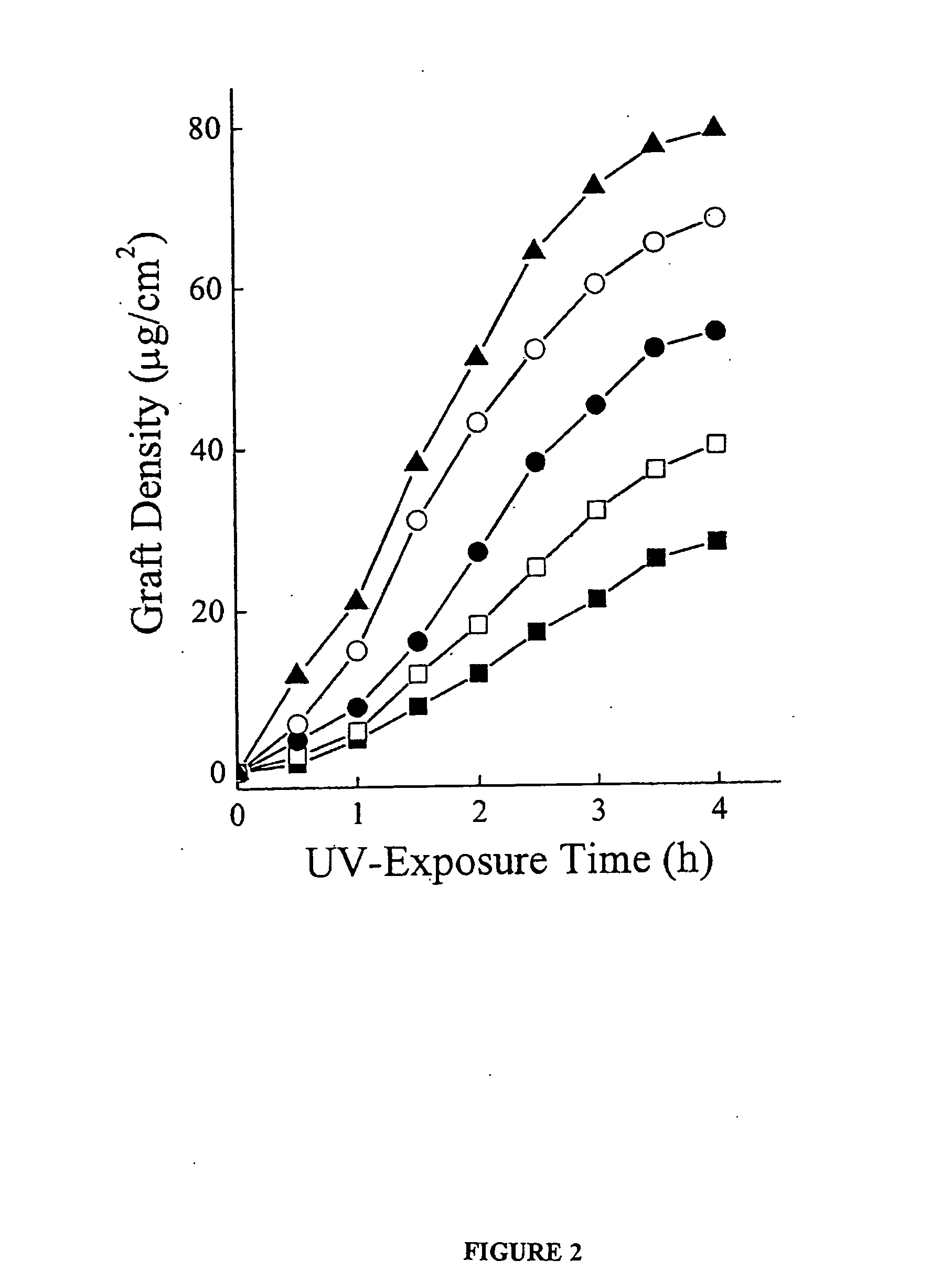

Chemical modifications to polymer surfaces and the application of polymer grafting to biomaterials

InactiveUS20050237480A1Numerous polymerizationQuality improvementMaterial analysis by electric/magnetic meansOptical partsPolymeric surfacePolymer science

Polymer-based biomaterials are popular due to ease of fabrication and low costs. However, many polymer substrates have undesirable surface properties. The invention provides a procedure to covalently apply a graft polymer to the surface of a polymer substrate by ultraviolet graft polymerization. The graft polymer is formed from monomers such as PEG, AA, monomethoxy acrylate PEG, HEMA, or DMA. Also, mixed monomers may be used to create the graft and the surface properties of the graft may be tailored for different properties, including hydrophobicity, friction coefficient, electroosmotic mobilities and electrophoretic separations. The invention has particular utility in tailoring surface chemistries in ocular lenses and polymer microdevices. I.II.R:—OHAcrylic Acid(AA)—NH2Acrylamide (AM)—N(CH3)2Dimethylacrylamide (DMA)—OCH2CH2OH2-Hydroxyethylacrylate (HEA)—O(CH2CH2O)nCH3PEG monomethyoxylacrylate (PEG)

Owner:RGT UNIV OF CALIFORNIA

Chemical method for silver coating on copper powder surface

The invention relates to a method for copper powder surface chemical plating silver, belonging to field of chemical silver plating. Said method comprises following steps: putting copper powder into diluted acid of 5-10% to remove oxide on surface of copper powder; adding disperser of 1-30% of copper powder by weight, stabilizer of 10-60% of copper powder by weight into deionized water to form reducing liquid, adding copper powder and stirring; adding silver nitrate into deionized water, adding ammonia, stirring and adding sodium-hydroxide and getting silver amine solvent; adding silver amine solvent into reducing liquid under stirring, finishing chemical silver plating of copper surface 10-50 minutes later; filtering, separating and washing, vacuum drying and getting silver-coated copper powder. The process is characterized by simple preparation and raw material, reduced silver-plated layer on container wall by adding silver amine solvent into reducing liquid, high silver converting rate. The electrical resistance of got copper powder is smaller than 2*10-4 omegacm.

Owner:TSINGHUA UNIV

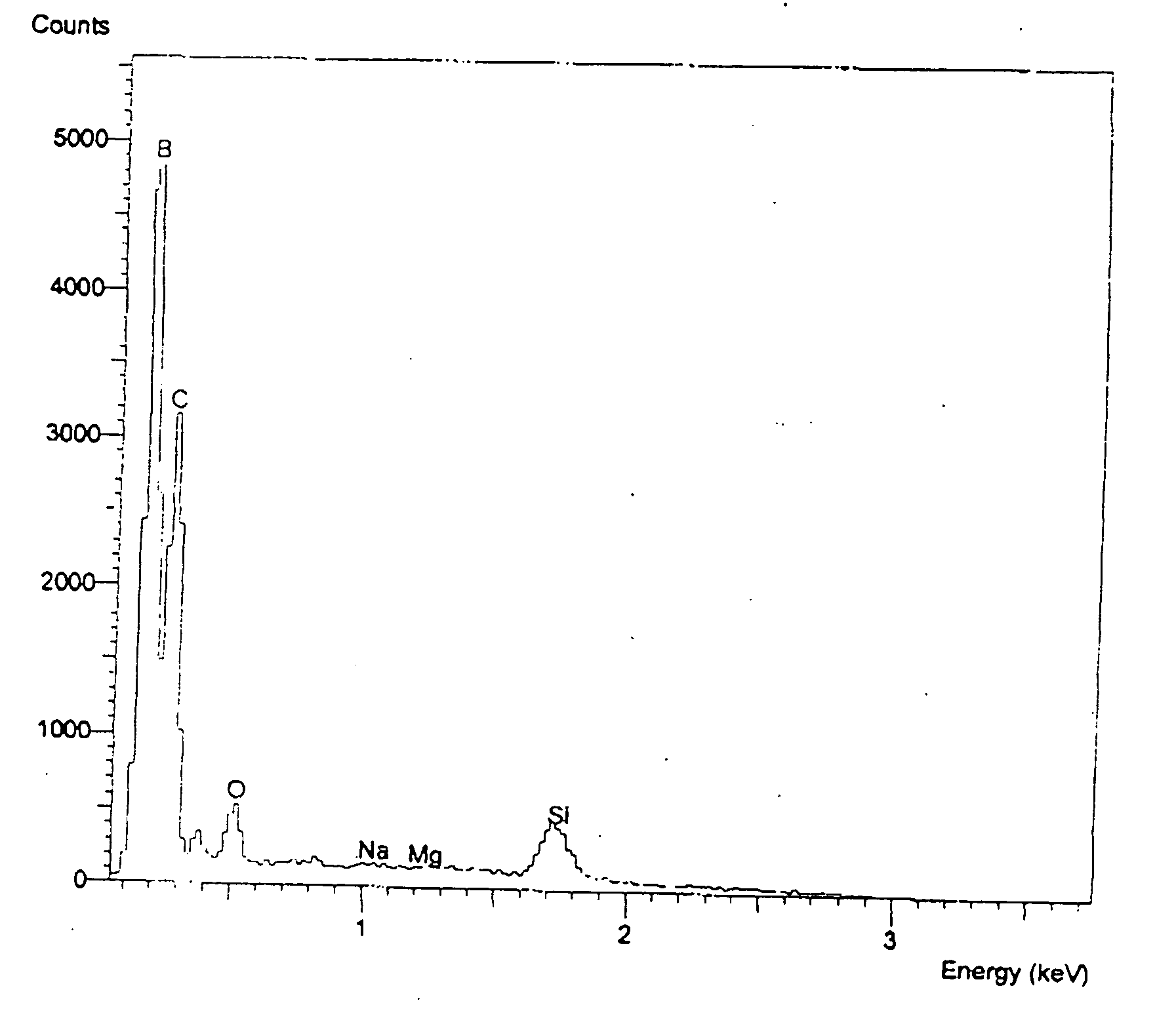

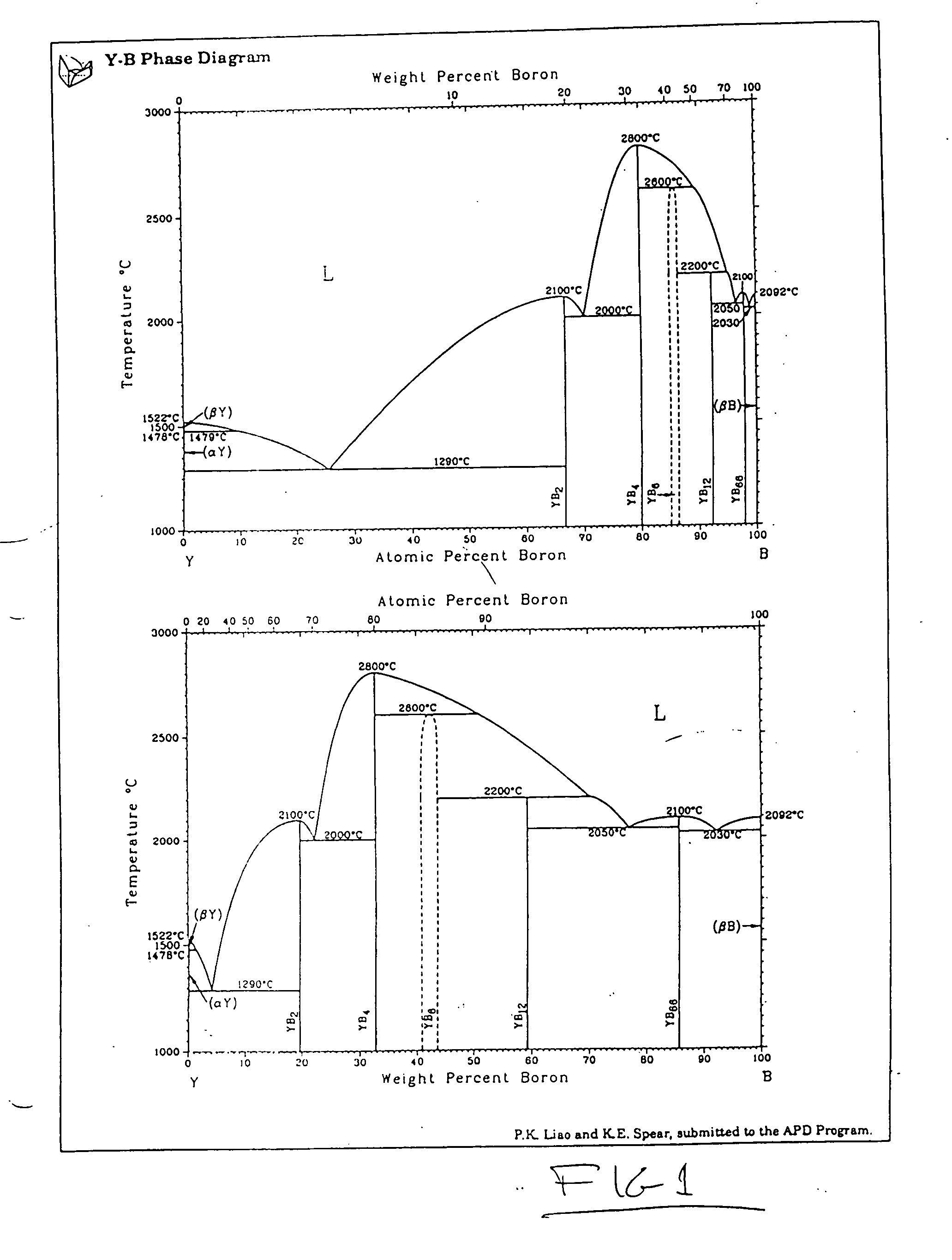

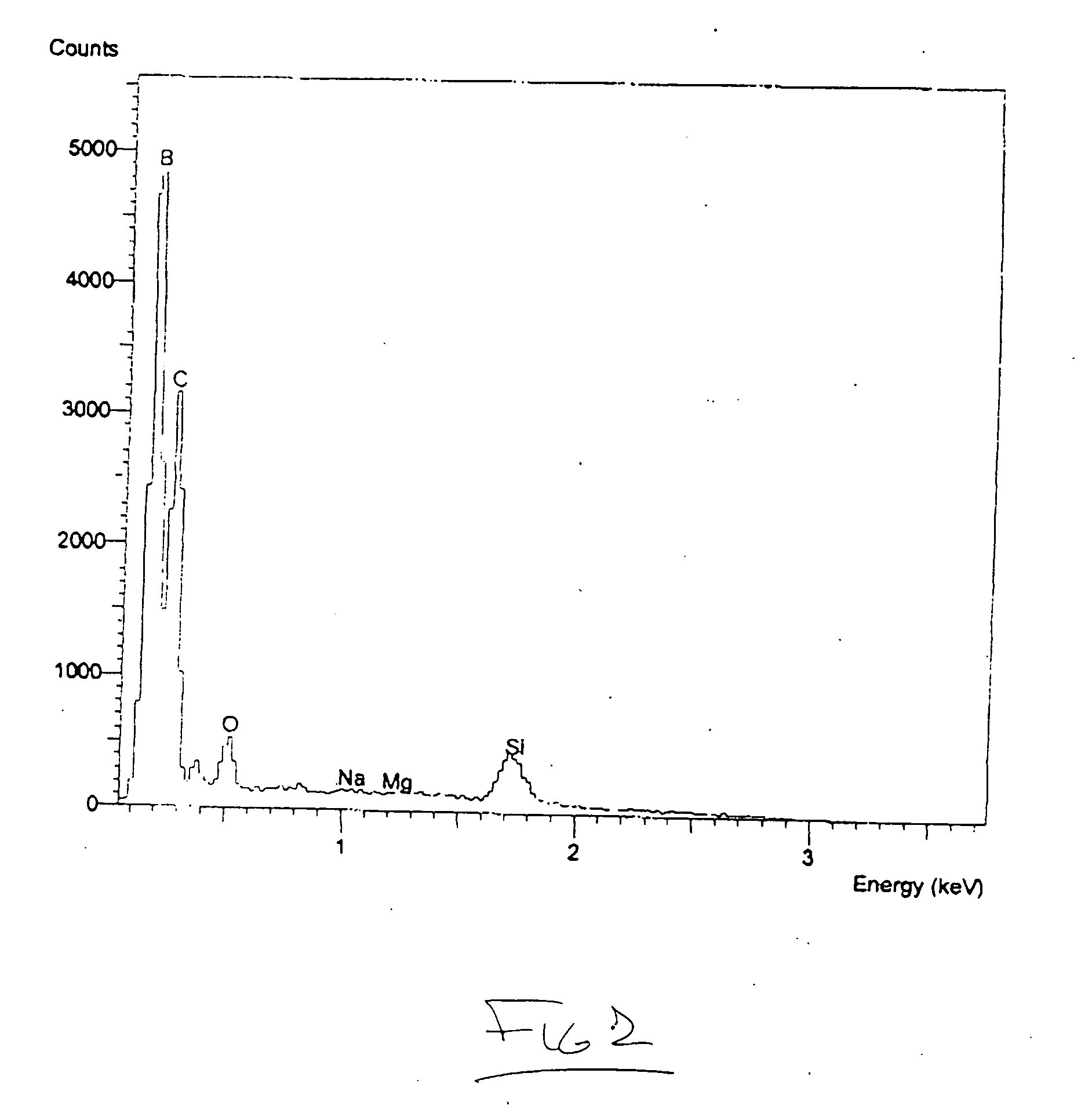

Method for depositing boron-rich coatings

InactiveUS20050208218A1Not readyReduce usageSpark gapsLiquid surface applicatorsLutetiumControl manner

A method is disclosed for coating substantially pure boron or highly boron-rich borides in a controlled manner. Such a method of coating of boron has a variety of applications, including surface chemical and wear protection, neutron absorption, prevention of impurity emission from heated filaments and ion beams, elimination of metal dust from vacuum systems, boridizing, boron cluster emission, and reactive chemistry. Borides with a boron-to-metal ratio of 20 or more are known to exist and may be used as a feedstock for substantially pure boron coatings for deposition processes requiring feedstock electrical conductivity, and / or enhanced reactivity. While most metal borides coincidentally produce significant metal vapor as a by-product, certain borides of yttrium, holmium, erbium, thulium, terbium, gadolinium, and lutetium have been identified as capable of producing substantially pure boron vapor.

Owner:IBADEX

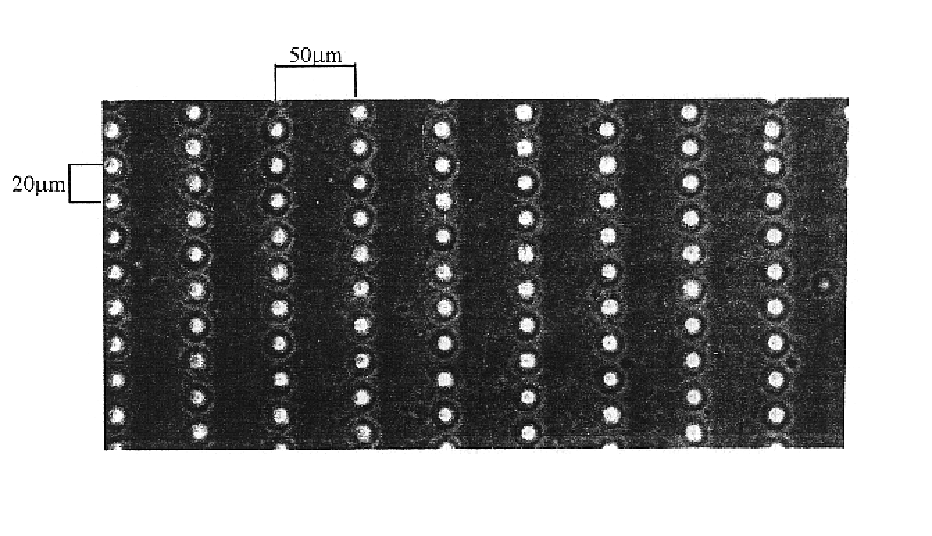

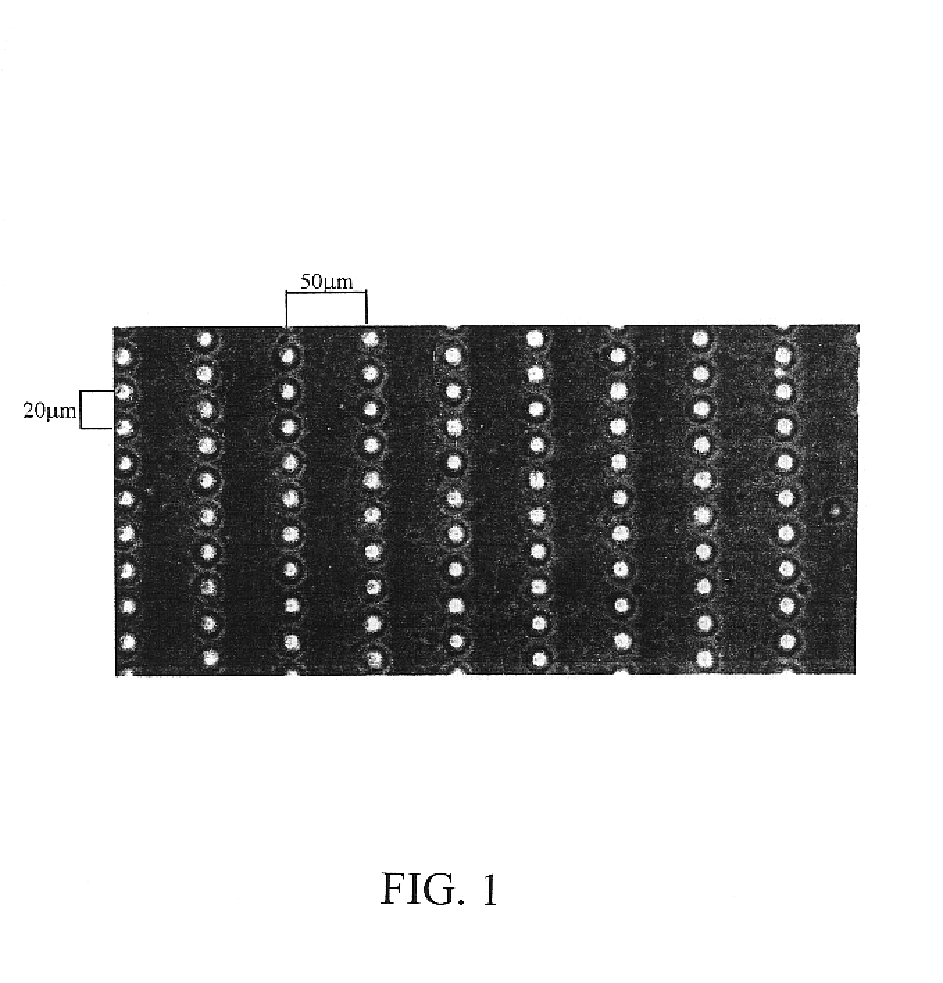

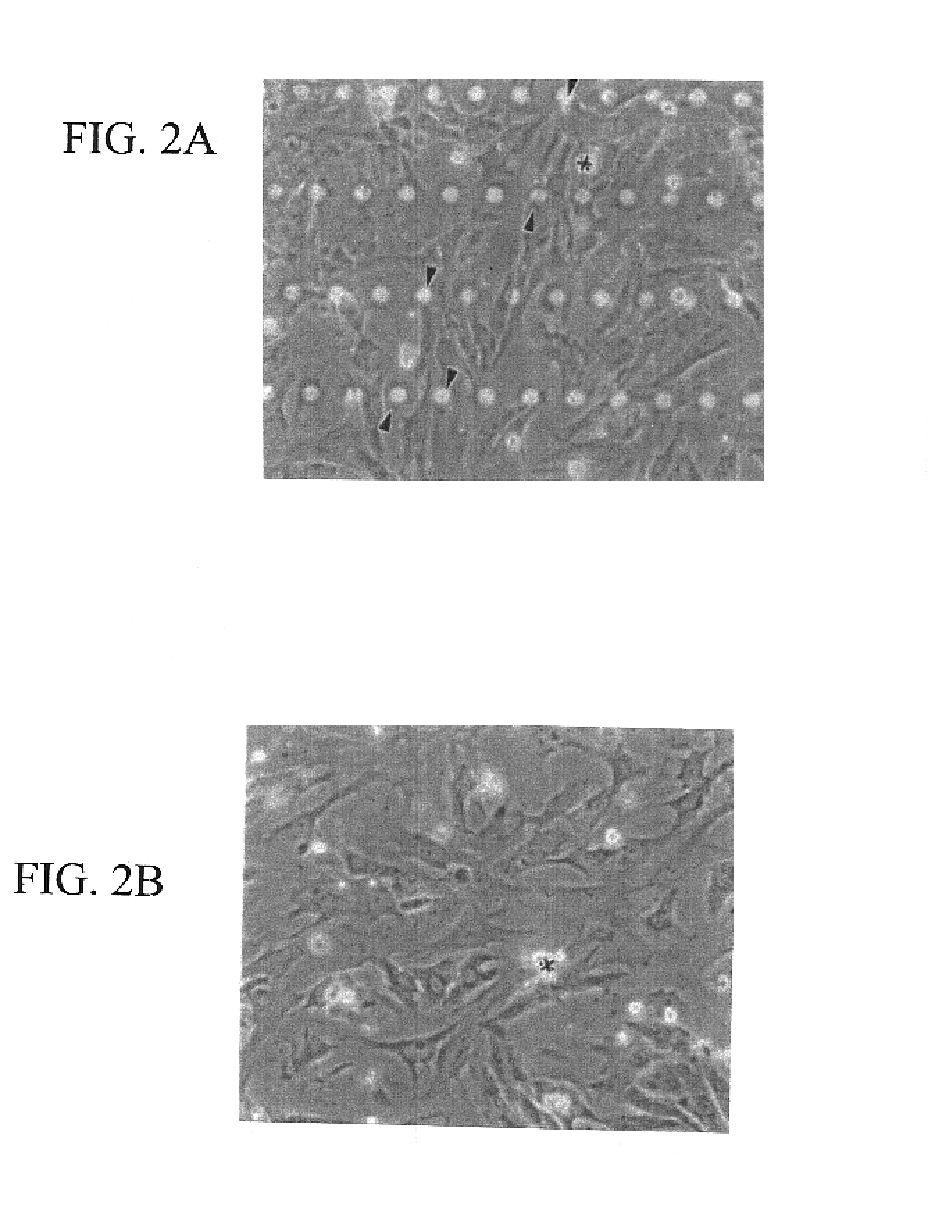

Microfabrication of membranes containing projections and grooves for growing cells

InactiveUS6942873B2Promote cell differentiationImprove adhesionBioreactor/fermenter combinationsBiocideCulture cellMechanobiology

The present invention provides a novel substrate for use in growing cells and for the study of mechanobiology. The membrane of the present invention comprises appropriate microtopography and surface chemical modifications to facilitate the production of adherent and oriented cells that phenotypically resemble cells in vivo.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

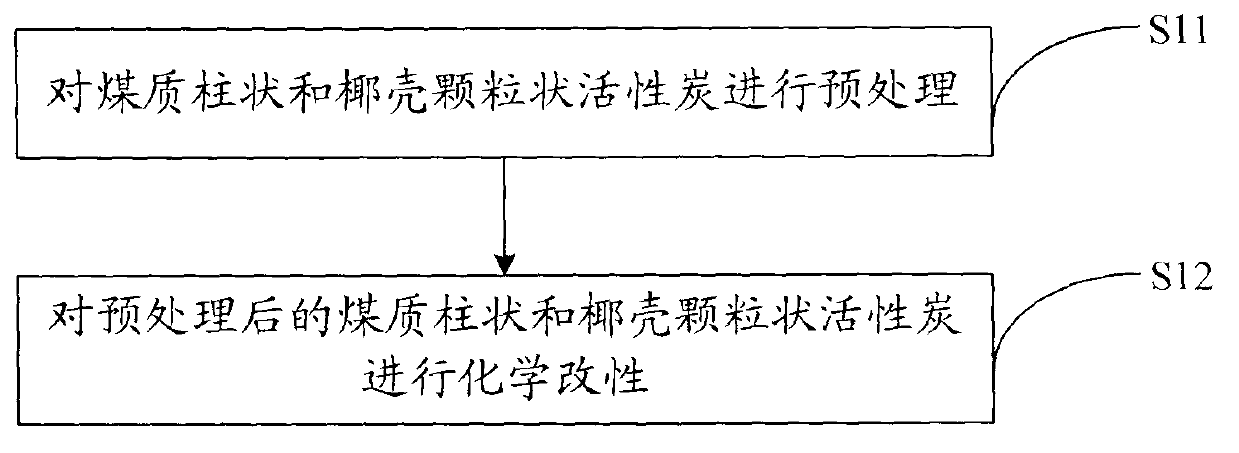

Preparation method of super-hydrophobic active carbon modified material

InactiveCN102989414ALarge hole volumeEasy to makeOther chemical processesAbsorption capacityLiquid water

The invention discloses a preparation method of a super-hydrophobic active carbon modified material. The material is prepared by applying a chemical liquid phase impregnation method, using trimethylchlorosilane as a modifier, using absolute methanol as a solvent, respectively using pre-processed coal columnar active carbon and coconut shell granulated active carbon as carriers, impregnating via liquid phase, drying in vacuum, and commonly blowing air and drying. The hydrophobic performance is respectively detected through a contact angle test and a liquid water adsorption experiment; and the adsorption is checked by using benzene adsorption experiment and an iodine value test. The invention has the advantages of simple preparation process, less material consumption and wild preparation condition; and the preparation method is carried out at room temperature. The prepared active carbon modified material has super-hydrophobic surface chemical performance and great pore volume, which makes up the shortcomings of easy absorption of moisture in the multi-pore carbon material with high humidity and small absorption capacity of the target organic matters; and the prepared active carbon modified material is easy to recycle and can be repeatedly recycled, so that the industrial cost is reduced and a foundation is further laid for the industrialized application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing the surface of a dielectric

InactiveUS20010016226A1Maximize capacitanceMinimize dangerPretreated surfacesSemiconductor/solid-state device manufacturingSurface reactionElectrical performance

This invention relates to a method for improving the chemical and electrical performance characteristics of a dielectric material especially one with high dielectric constant. The method comprises the steps of first obtaining a high dielectric constant material, the material having a degraded upper surface reduced dielectric constant and then modifying the surface chemistry of said upper surface by reacting said upper surface with a reactant. The reaction enables removal of the degraded layer. In a variant of the method, the gas reactant preferentially reacting with upper surface as compared to the bulk.

Owner:IBM CORP

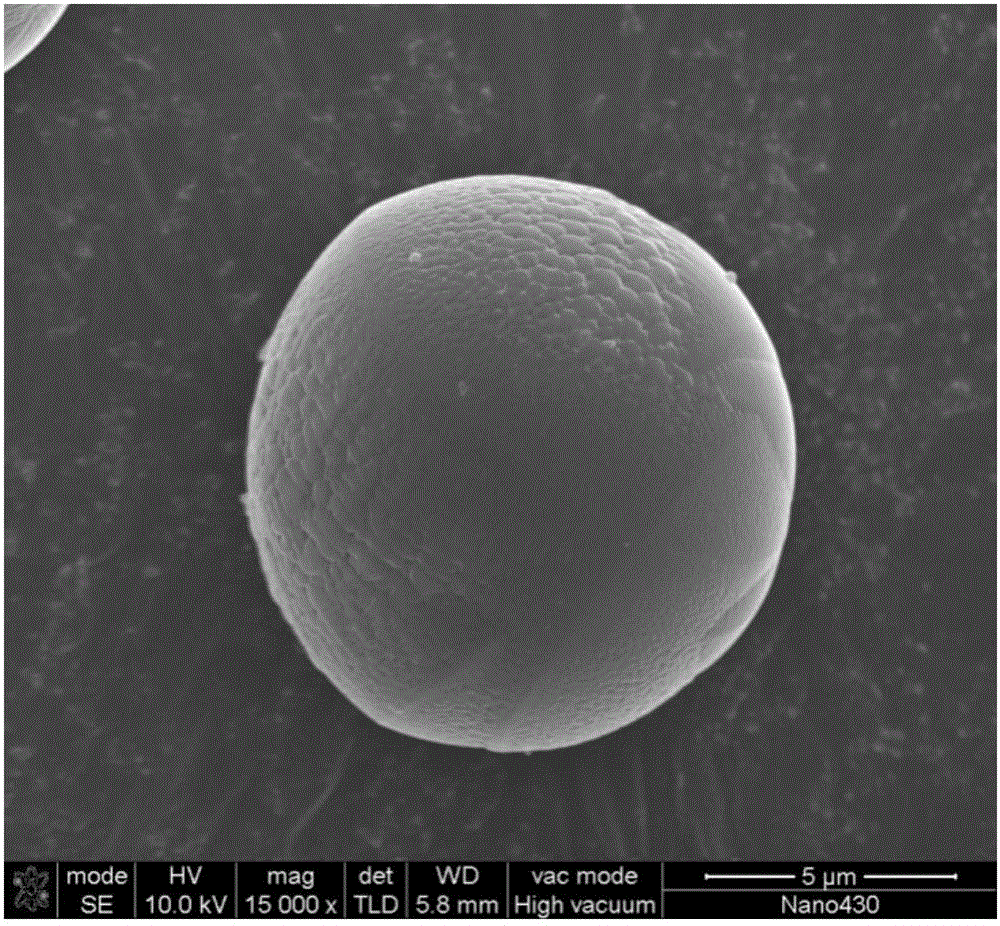

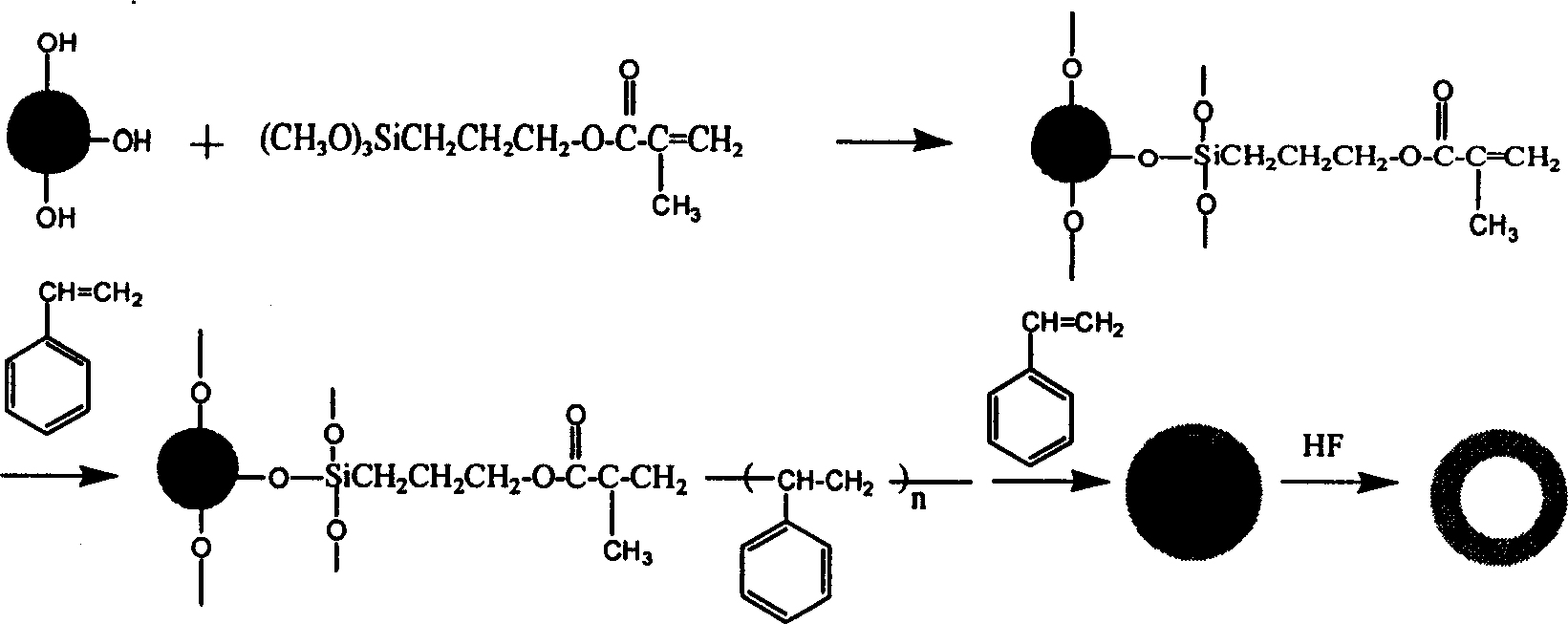

Hollow polymer microsphere and method for preparing same

InactiveCN1631951AImprove thermal stabilityUnique physical and chemical propertiesPolymer scienceMicrosphere

The invention belongs to high molecular material technological field, concretely relates to a polymer shallow micro ball and its preparing method. The high molecular shallow micro ball links the surface chemical bond of the organic nm micro ball with a layer of polymer by micro latex synthesizing method, forming the micro ball with polymer inorganic nm compound core shell structure, then wash the inorganic material by strong acid to acquire the product, whose size is mm~nn. The invention has simple operation, high efficiency, average size of micro ball, and the shallow micro ball in the polymer made has outstanding heat stability and chemical stability, with bright future of application.

Owner:TONGJI UNIV

Preparation method of continuous high quality soldering powder

The invention discloses a method for preparing alloy powder, more particularly relates to a method for continuously preparing high-quality tin alloy welding powder. The invention is characterized in that an atomizing chamber is vacuumed, then inert protection gas is filled into the atomizing chamber; the tin alloy material is melted in a melting furnace, and then is controlled to be atomized in the atomizing chamber; after being cooled, the tin alloy material is solidified into tin alloy powder grain; by the sieving of the equipment, the needed product is obtained; products not meeting the requirements is melted and prepared again. The invention has the advantage that the quality of tin alloy powder is greatly improved by optimizing producing condition; the surface chemical property is improved; the productive labor cost can be greatly lowered; high priority is given to environmental protection in the process of realizing a circular production process. Products prepared by the method can be widely applied to encapsulation and circuit board welding material in electronic industry.

Owner:HUIJIN ATOMIZING SCI

Method for preparing titanium dioxide product for high-specific surface area denitrating catalyst

InactiveCN101318697AImprove performanceWill not polluteCatalyst carriersDispersed particle separationFiltrationHigh surface

The invention relates to a method for preparing titania raw materials with high specific surface area used by denitration catalyst, which relates to the chemical product preparation technical field. The method comprises the following steps that: a metatitanic acid produced by adoption of the sulfuric acid method is processed by an organic surfactant and then modified so as to reduce the viscosity of the metatitanic acid; and loose titania products with high specific surface area and high surface chemical activity used by the denitration catalyst are prepared through filtration and calcination of the processed metatitanic acid. The method has a simple technique for processing the metatitanic acid and has low cost; and added organic substances are fully decomposed during the calcining stage, thereby impurities can not be brought into the final products and the environmental pollution can not be caused.

Owner:四川华铁钒钛科技股份有限公司

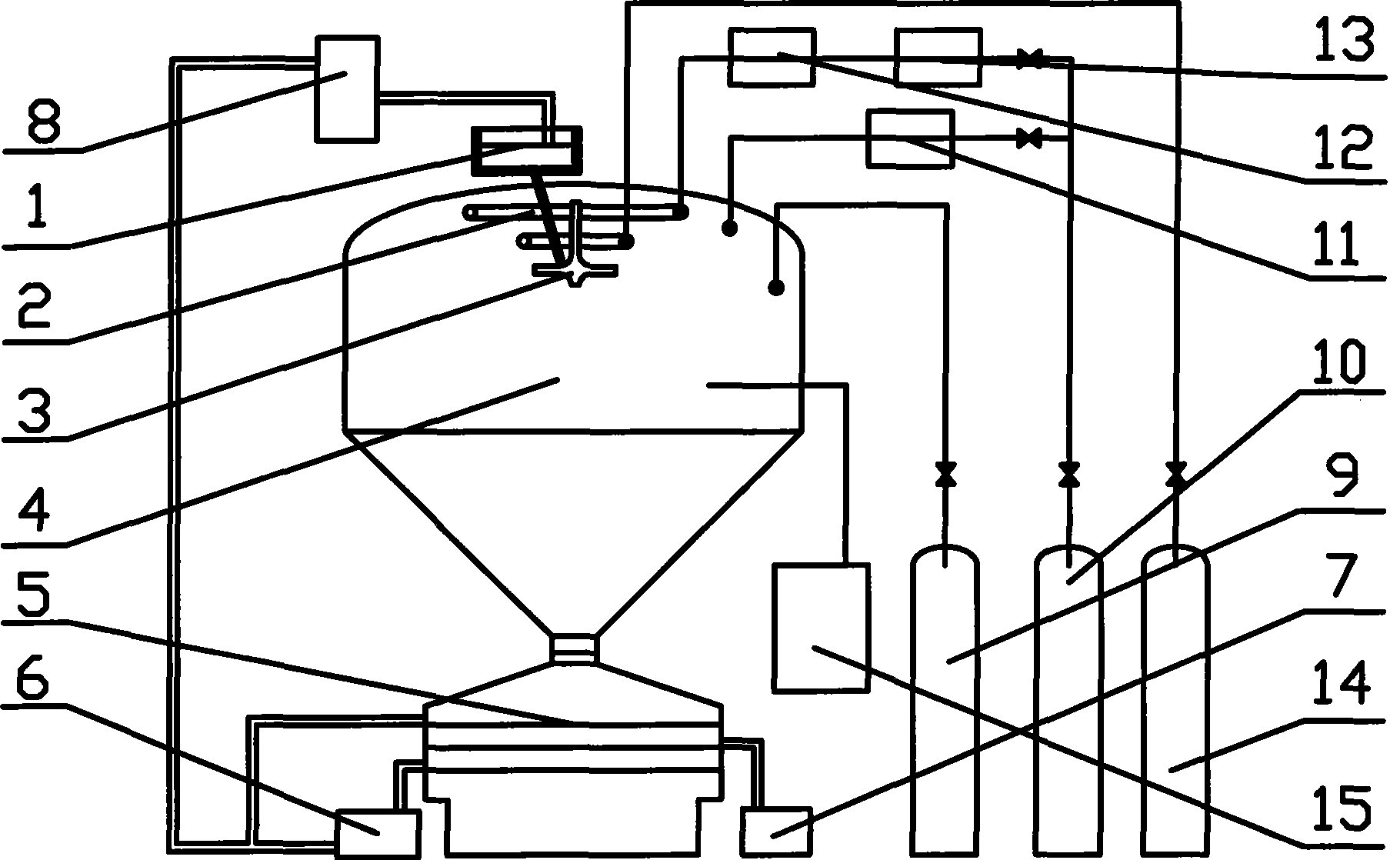

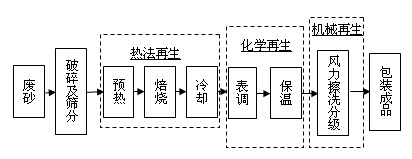

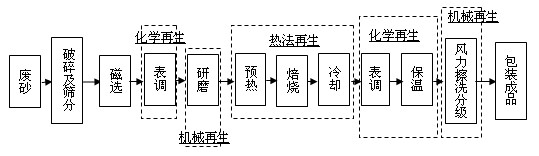

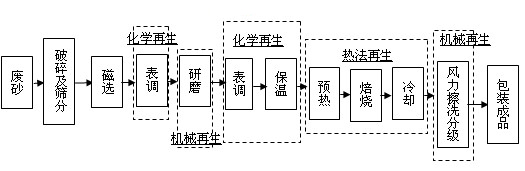

Chemical regeneration method in casting waste sand disposing process

InactiveCN102000764AGood regeneration performanceSolve sinteringMould handling/dressing devicesChemical treatmentDie casting

The invention provides a chemical regeneration method in the casting waste sand disposing process, relating to a process for performing surface chemical processing on various impurities which are attached on the surface of waste sand and are better not be reused in casting-form sand materials. During the chemical regeneration, chemical surface conditioning liquid I or / and chemical surface conditioning liquid II is or are used, and the disposing sand temperature is not more than 400 DEG C. The chemical regeneration method in the invention is carried out before or after the hot-method regeneration disposing or mechanical regeneration disposing of the casting waste sand disposing processing, and the chemical disposing technique is combined with the traditional hot-method regeneration and mechanical friction regeneration. The regeneration new sand formed in the method has better quality of the new sand, can better meet the application requirement on multi-form sand producing technique (hot core box, warm core box and cold core box) for recycling different casting waste sands (hot core box resin casting waste sand, warm core box resin casting waste sand, gas or / and organic fat hardening cold core box resin casting waste sand and profile damp die casting sand), and has better economical efficiency.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Stone paper and manufacturing method thereof

The invention provides stone paper and a manufacturing method thereof. The stone paper comprises the following components in part by weight: 6 to 12 parts of low-density polyethylene, 6 to 12 parts of linear low-density polyethylene, 3 to 6 parts of hot melt adhesive, 5 to 10 parts of titanium dioxide, 65 to 75 parts of heavy calcium carbonate, 3 to 5 parts of silane coupling agent, 0.5 to 1.5 parts of stearic acid, 0.5 to 1.5 parts of epoxy plasticizer, and 0.2 to 0.6 part of polyethylene wax. In the method, high polymer is used as a base material, the calcium carbonate is subjected to compound modification, other additives are added, the characteristics of the surface chemical principle and modification of the high polymer are used and a special process is adopted; and the stone paper is prepared by mixing the polymer, performing composite modification on the filler, plasticizing the filler and polymer, extruding and casting, and performing calendaring molding. The stone paper and the method have great significance for saving energy, protecting natural resources and improving environment.

Owner:山东高旭新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com